Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1175 results about "Monomethyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spin-on adhesive for temporary wafer coating and mounting to support wafer thinning and backside processing

InactiveUS6869894B2Semiconductor/solid-state device testing/measurementSynthetic resin layered productsAdhesiveFluorescence

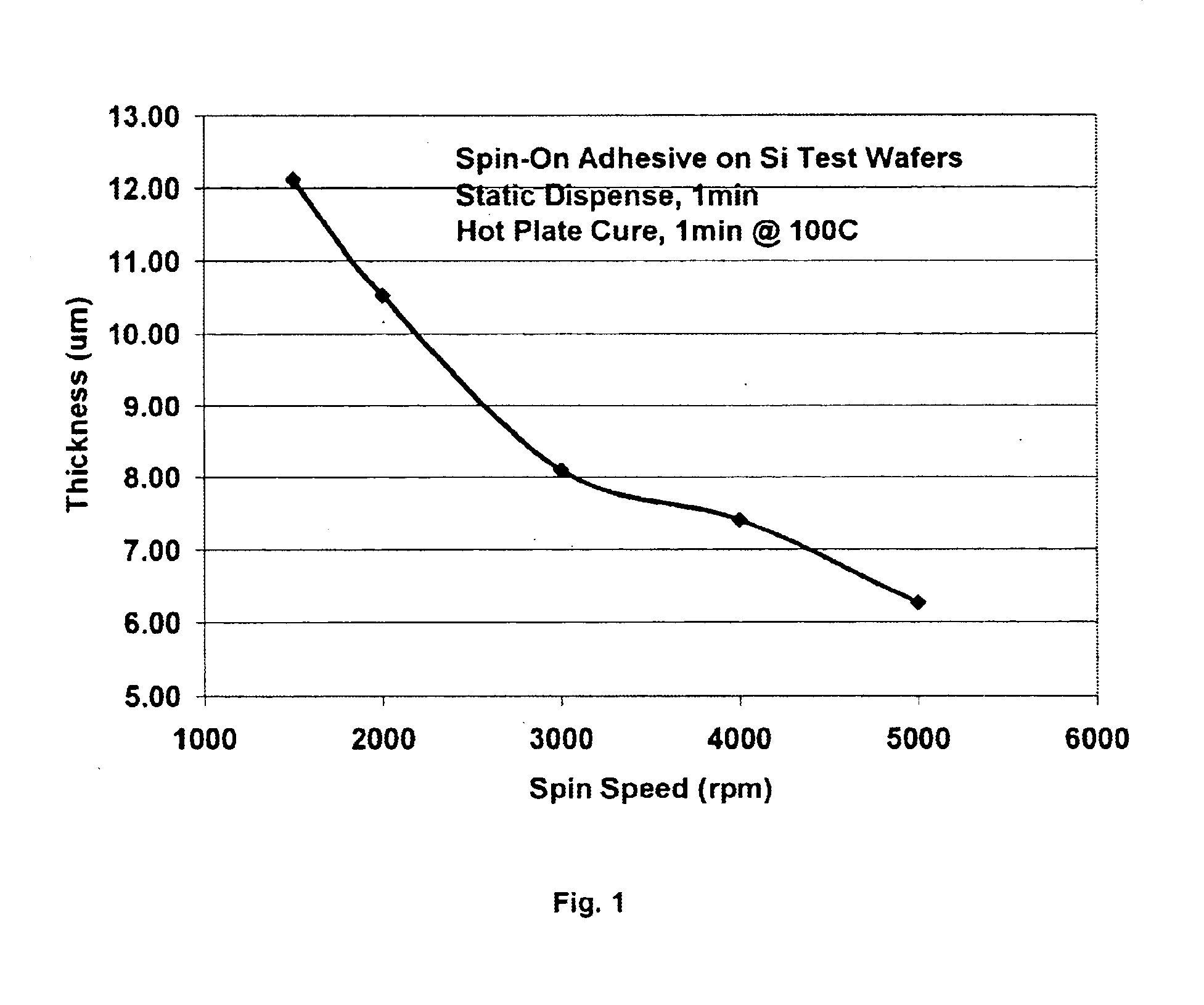

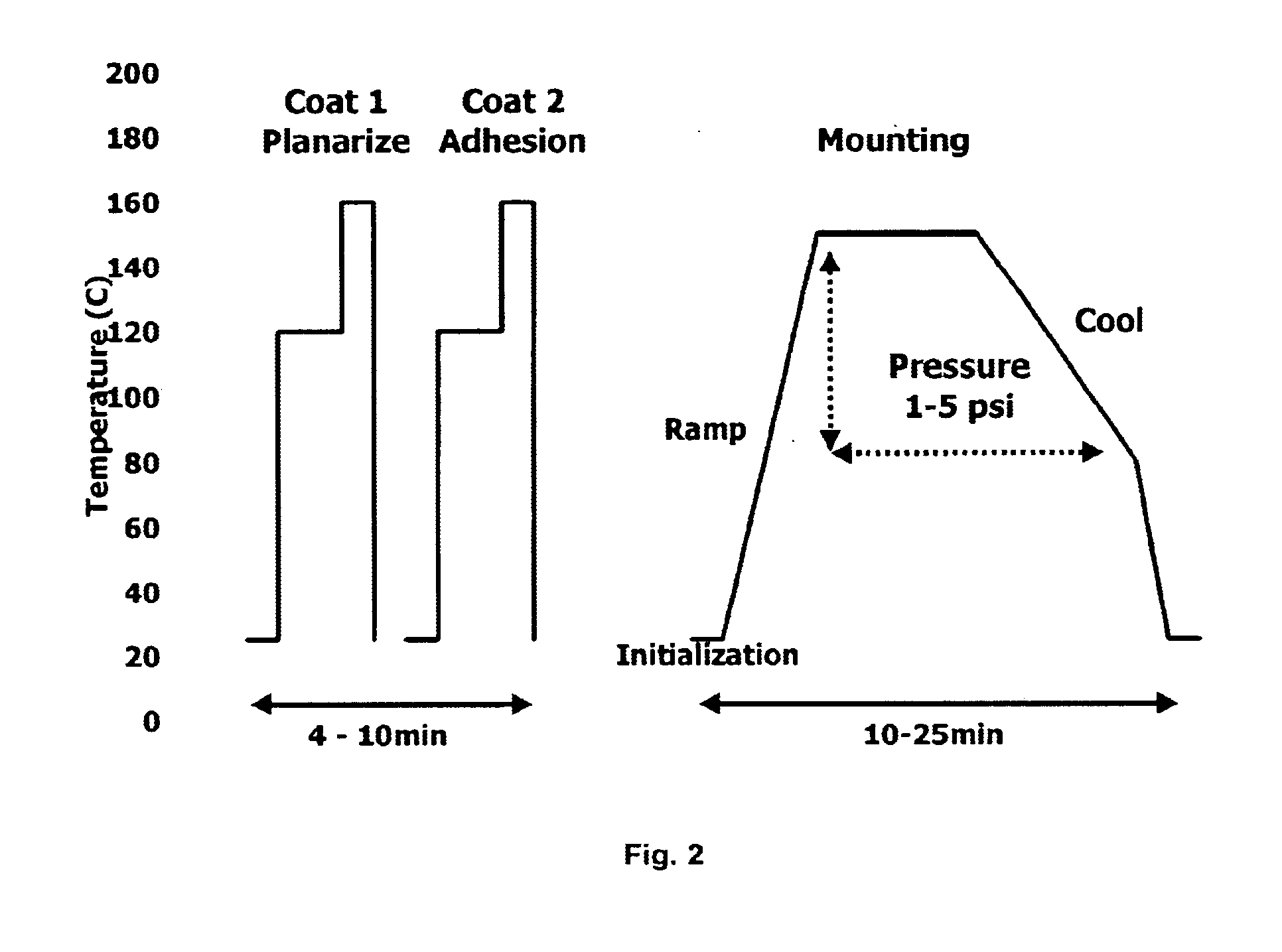

A liquid form adhesive system is provided for spin-coating on wafers and mounting to rigid carrier substrates to support thinning and backside processing. The liquid adhesive comprises about 30-35% of a rosin, between 5-10% of a thermoplastic urethane, a nonionic surfactant present between 1-3%, and a trace of an ultraviolet fluorescing dye. The entire system is dissolved in 50-65%, by weight, of a dual solvent mixture composed of dimethylacetamide and propylene glycol monomethyl ether. When the mixture is made to a specific viscosity, filtered, applied by a spin-coating method to the wafer frontside surface, and cured, the result is a uniform and smooth surface of defined thickness. When the coated wafer is mounted to a rigid substrate, it may be mechanically thinned to thicknesses down to and beyond 25 um, depending upon the wafer composition, diameter, and process. Once thinned, the adhesive is safe for backside processing and is dissolved away at completion to provide a thinned wafer that is clean and ready for final dicing or chipping operations.

Owner:GENERAL CHEM CORP +1

Method for modifying polyvinylidene fluoride ultrafiltration membrane by amphiphilic co-polymer

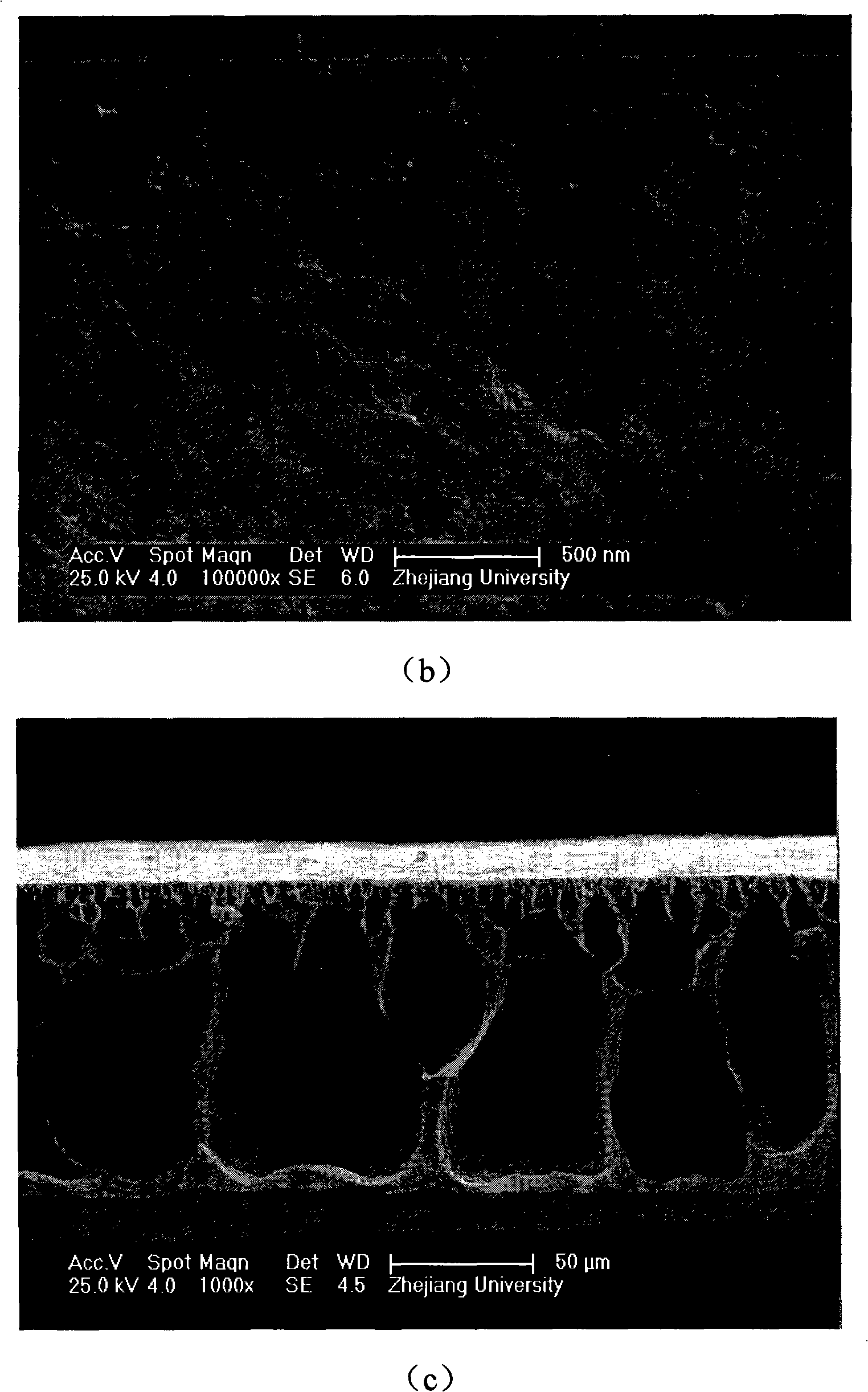

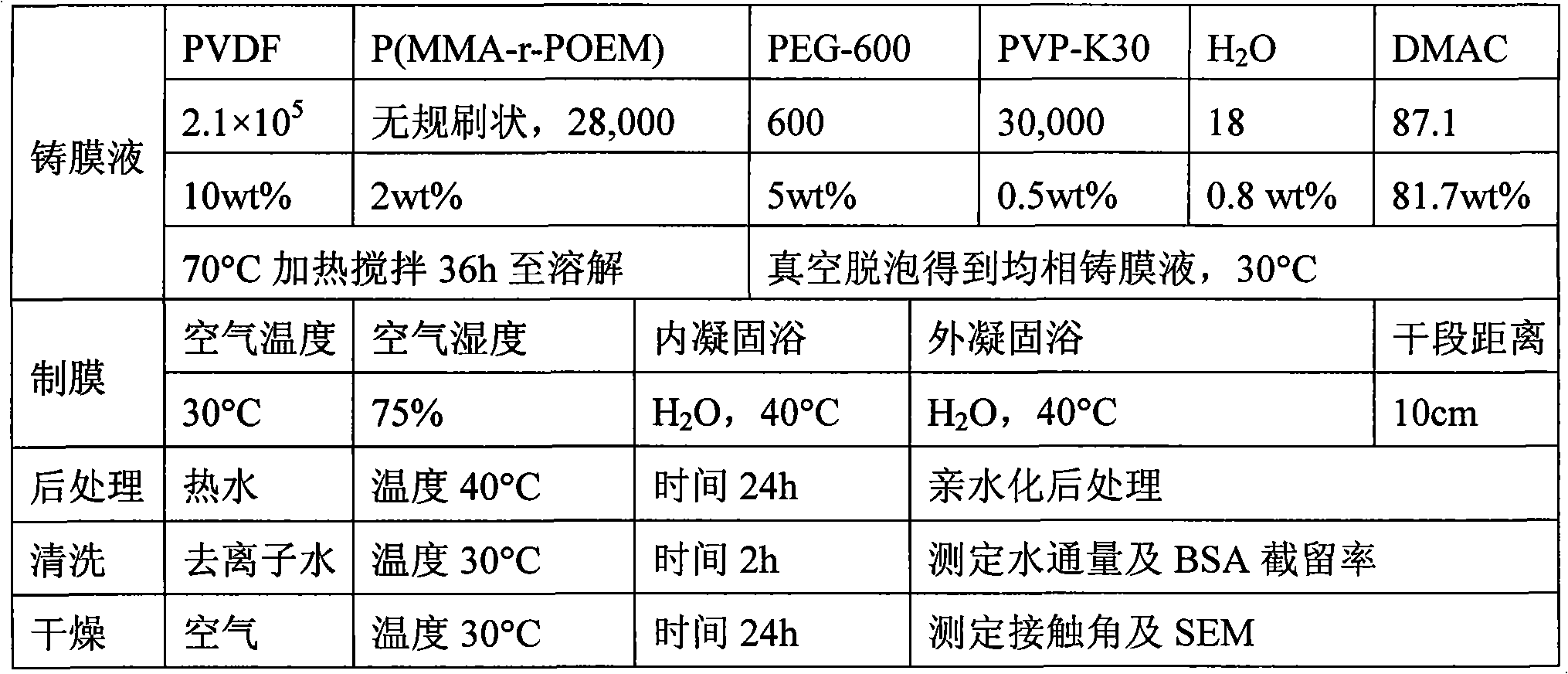

InactiveCN101264428AImprove hydrophilicityReduce energy consumptionSemi-permeable membranesUltrafiltrationDumbbell shaped

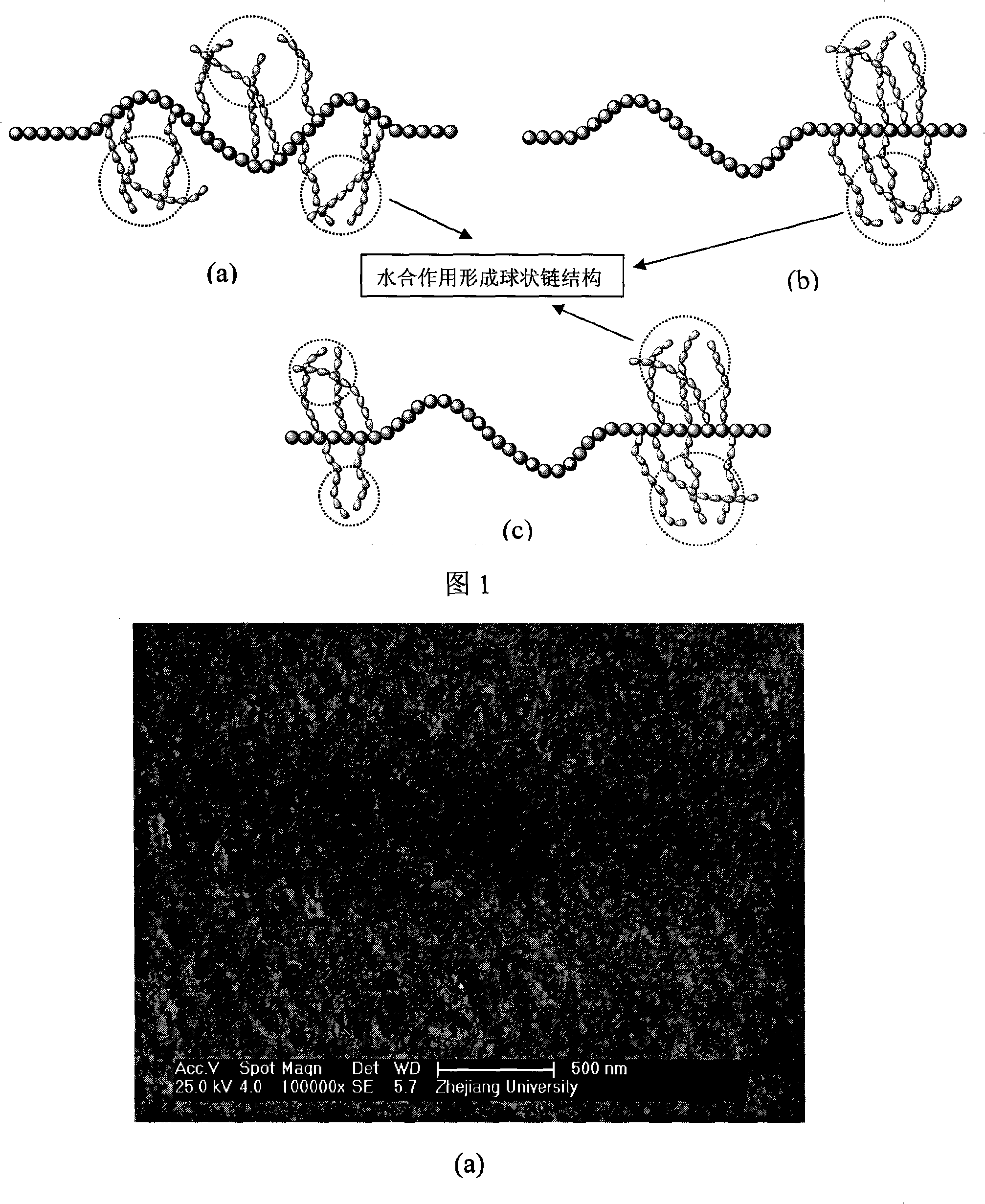

The invention discloses a method of producing the hyperfiltration membrane of amphiphilic copolymer modified polyvinylidene fluoride, comprising the following steps: 1) mixing polyvinylidene fluoride, poly (methyl methacrylate - monomethyl ether polyoxyethylene methyl methacrylate), additives, non-solvent and solvent to form the casting film solution; 2) making the casting film solution into the polyvinylidene fluoride membrane by using the film forming machine and then soaking in the coagulation bath; 3) conducting the posttreatment of hydrophilicity; 4)obtaining the hydrophilic polyvinylidene fluoride ultrafiltration membrane after cleaning and drying. The method is characterized in that the brush shape, chain ball shape or dumbbell shape amphiphilic copolymer are mixed with the polyvinylidene fluoride to produce the polyvinylidene fluoride hyperfiltration membrane with hydrophilicity, anti-pollution, large flux and high retention rate by adopting the solution phase conversion method. The method has the advantages that the obtained membrane is provided with dozens to hundreds nanometer of particular densified hydrogel surface layers, the contact angle of the membrane surface can be reduced below 60 degrees and can be lowered to 0 degree within tens of seconds, the water flux can reach 1000L / m<2> / h (0.1Mpa) or above, the retention rate of BSA can reach 90% or more and the recovery rate of water cleaning flux can reach 90% or higher.

Owner:ZHEJIANG UNIV

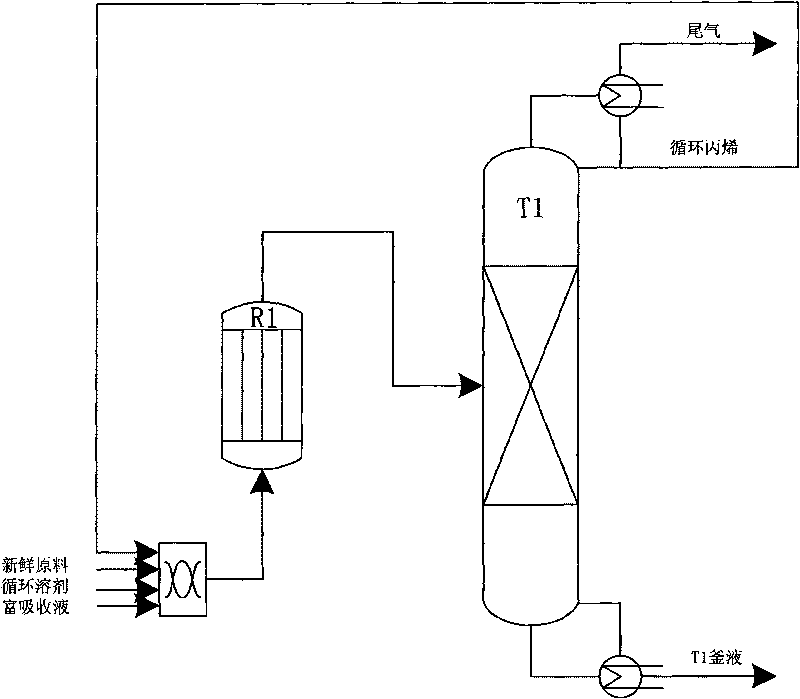

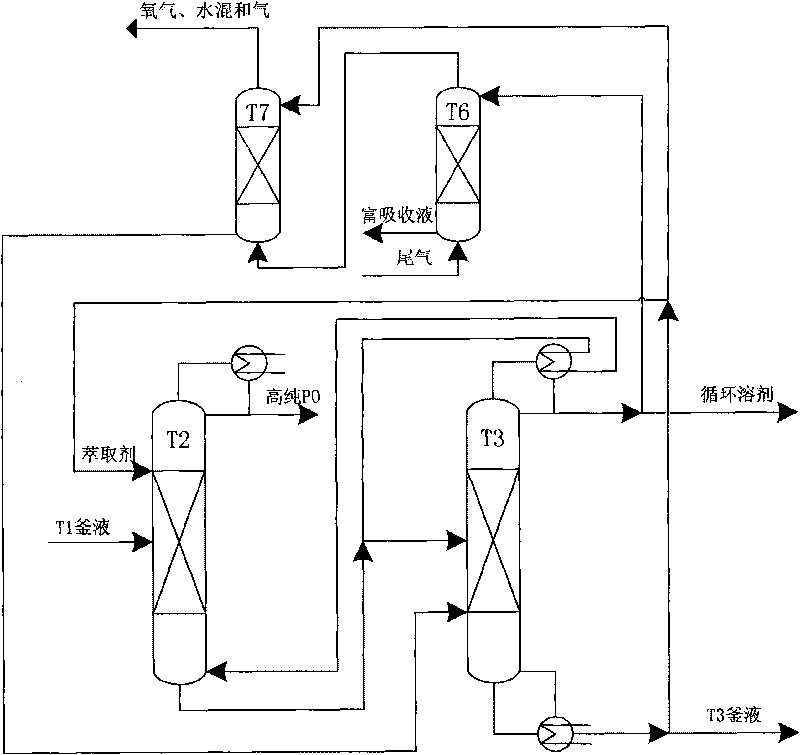

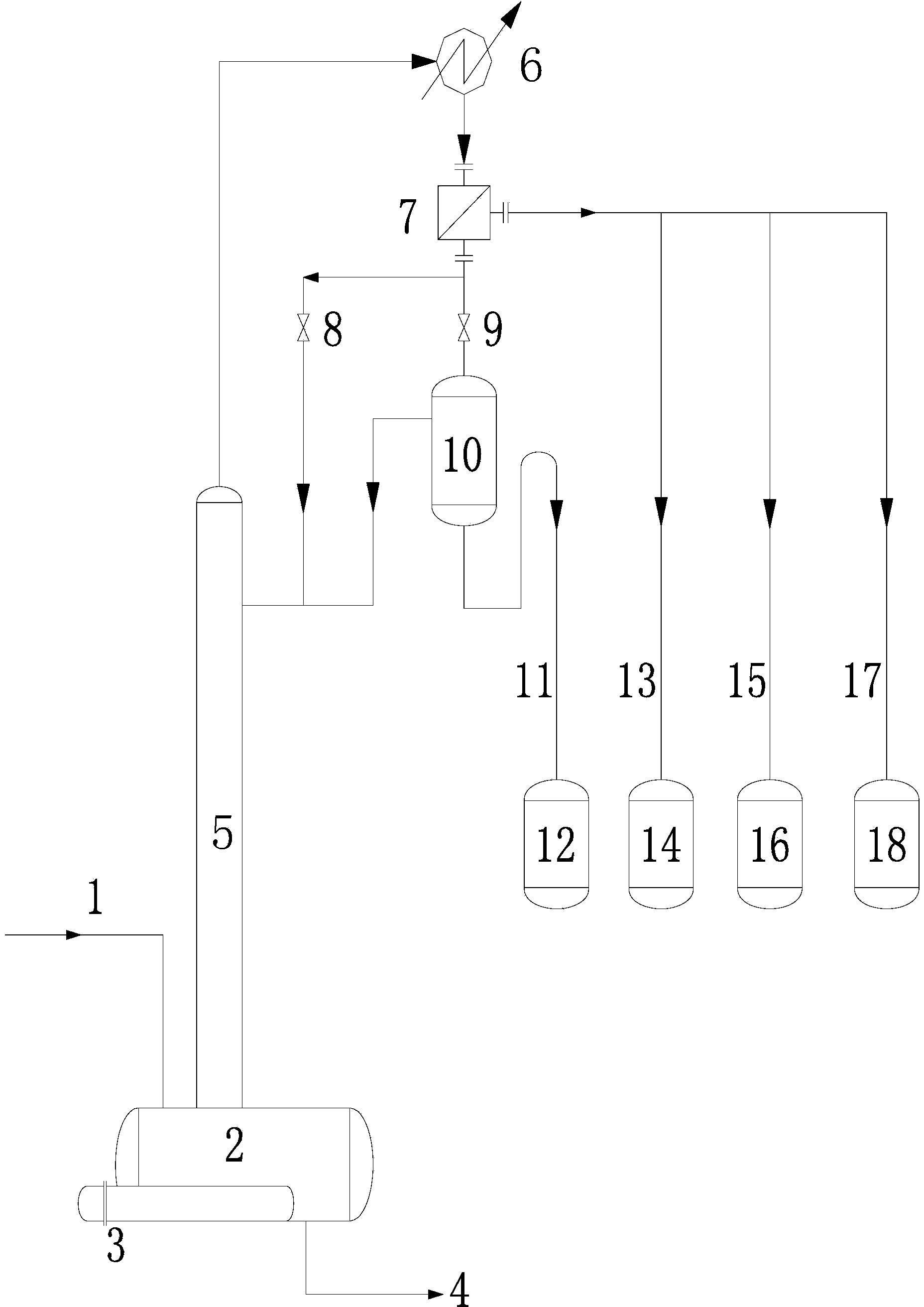

Energy-saving and emission-reducing technique for producing propane epoxide by using hydrogen peroxide epoxidation propylene

InactiveCN101693703ASuitable for industrial productionEther separation/purificationChemical industryThermal energyExtractive distillation

The invention relates to an energy-saving and emission-reducing technique for producing propane epoxide by using hydrogen peroxide epoxidation propylene, belonging to the field of petrochemical technology. The technique comprises a reaction part, a separation part and a tail gas treatment part, and is characterized in that propylene and hydrogen peroxide have an epoxidation reaction through a Ti-Si molecular sieve at medium pressure and low temperature; the propylene and solvent have higher recovery rate, the propane epoxide meeting the requirement of commercial-grade purity can be obtained by extractive distillation, and the joint product of propylene glycol monomethyl ether can be prepared by azeotropic distillation and purification; after part of tail gas is condensed and absorbed and the propylene is recovered, the tail gas reaches the standard and is discharged; extracting agent, absorbing agent and entrainer which are needed by the technique are in closed cycle in the process flow; and medium-pressure operation is adopted by a propylene tower to ensure water-cooling on the top of the tower, and thermal energy can be recovered by multiple-effect rectification and matching of streams. The technique has the effect and the advantage that the new energy-saving and environment-friendly technique for producing the propane epoxide can generate remarkable economic and social benefits.

Owner:DALIAN UNIV OF TECH

Leadless electronic slurry composition for solar silicon photovoltaic cell and preparation method thereof

InactiveCN101345263AHigh electrical conductivityRefined nanocrystalline structureFinal product manufactureSemiconductor devicesAdhesiveSlurry

The invention discloses a compounding and a preparation method for lead-free electronic slurry used for a solar silicon photocell; according to the mass percentage, the slurry is obtained by preparing 70 to 75 percent of aluminium powders, 20 to 25 percent of organic adhesive, 1 to 5 percent of inorganic glass powders and 1 to 5 percent of additives; the aluminium powder is ball-shaped aluminium powder with the surface covered by an aluminium nitride protection layer, with the purity not less than 99.9 percent and the average grain size of 2 to 6 microns; simultaneously, organic adhesives consisting of ethyl cellulose, resin, hexadecanol, diethyleneglycol monomethyl ether, diethyleneglycol monobutyl ether, terpineol and n-butyl alcohol are added into the aluminium powder; the inorganic glass powder is silicon dioxide, boracic acid, alumina, antimony oxide and zirconia; the additive consists of Span and pump oil. The product prepared by the method of the invention has no dust generation or aluminium peeling phenomenon and achieves the requirement of no lead and environmental protection.

Owner:NANTONG UNIVERSITY

Dehydrochlorination stabilization of polychlorinated alkanes

InactiveUS6534688B2Suppression problemReduces and preventsHalogenated hydrocarbon separation/purificationAlkaneMonomethyl ether

Owner:OCCIDENTAL CHEM CORP

Electroconductive cellulose-based film, a method of producing the same, an anti-reflection film, an optical element, and an image display

InactiveUS20050003081A1High uniformity and transparencyGood optical performanceCathode ray tubes/electron beam tubesPhotosensitive materialsCellulosePolymer science

The present invention relates to a method of producing an electroconductive cellulose-based film having high uniformity and transparency and excellent in optical properties while preventing a bleaching phenomenon at the time of forming an electroconductive layer. The method of producing an electroconductive cellulose-based film according to the present invention is a method of producing an electroconductive cellulose-based film by coating a cellulose-based film with a coating solution containing a binder, superfine particles and a solvent to form an electroconductive layer thereon, wherein the coating solution comprises at least one kind of glycol monoalkyl ether-based solvent selected from the group consisting of ethylene glycol monomethyl ether, ethylene glycol monoethyl ether, propylene glycol monomethyl ether, and propylene glycol monoethyl ether in an amount of 20 to 40% by weight based on the total solvent, and a ketone-based solvent in an amount of 20 to 50% by weight based on the total solvent.

Owner:NITTO DENKO CORP

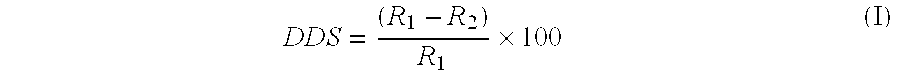

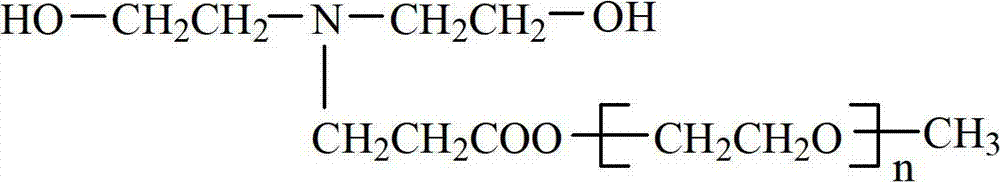

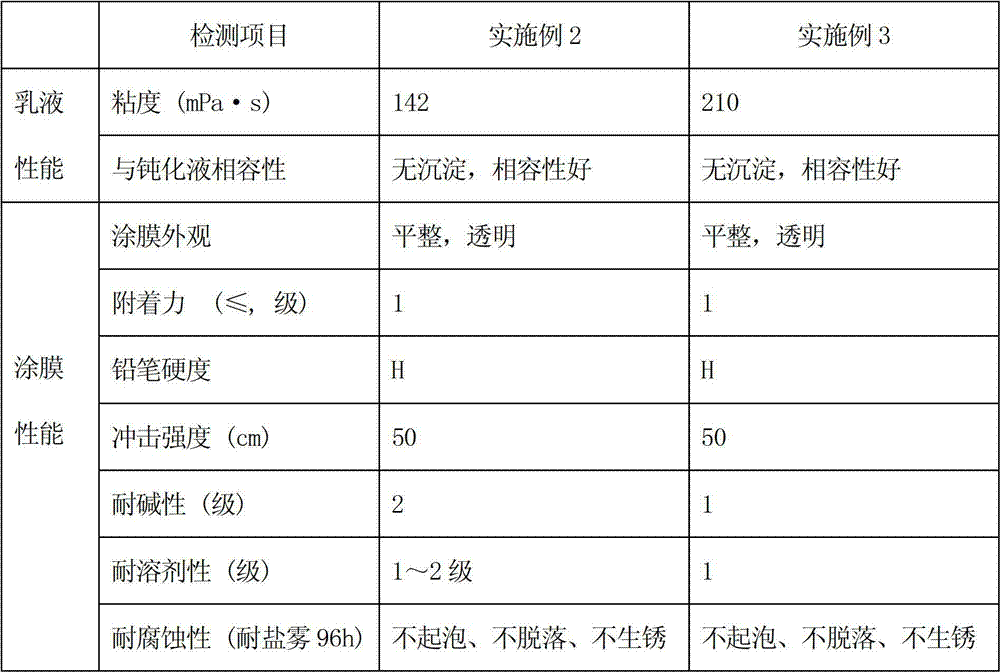

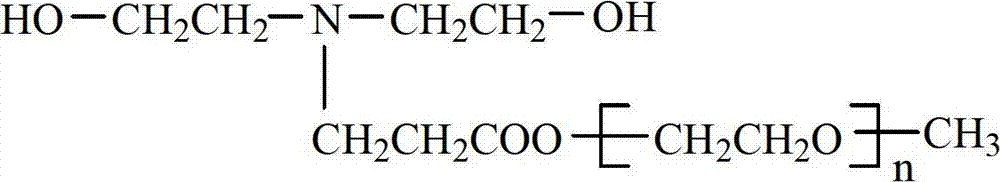

Cation-nonionic mixed aqueous polyurethane emulsion and preparation method thereof

ActiveCN102775578AGood chemical resistanceImprove corrosion resistancePolyurea/polyurethane coatingsChromium freePropanoic acid

The invention relates to a cation-nonionic mixed aqueous polyurethane emulsion and a preparation method thereof. The emulsion is aqueous polyurethane which has a cation hydrophilic group and a nonionic hydrophilic side chain. The preparation method comprises the steps of firstly introducing the nonionic hydrophilic side chain by using a specific nonionic hydrophilic chain extender; and introducing the cation hydrophilic group by using a cation hydrophilic chain extender, wherein the amounts of the nonionic hydrophilic chain extender and the cation hydrophilic chain extender respectively account for 1-10 percent and 1-8 percent according to the total weight of the raw materials, and the specific nonionic hydrophilic chain extender is 3-(N,N-dihydroxyethyl) amino-propionic acid polyethyleneglycol monomethyl ether ester which is prepared by heating and reacting methoxy polyethylene glycol single methyl acrylate and diethanol amine in a molar ratio of 1:1. By using the emulsion, the defect of the existing emulsion is overcome, and the requirement of zinc-plating steel plate chromium-free passivation pretreatment on aqueous polyurethane resins are met, so that the cost is reduced.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Essence with moss faint scent and applications thereof

ActiveCN103333743AKeep natural propertiesThe aroma is calm and richTobacco preparationEssential-oils/perfumesAdditive ingredientCarboxylic acid

The invention discloses an essence with moss faint scent and applications thereof. The essence with moss faint scent comprises following ingredients: orcinol monomethyl ether, divarinol monomethyl ether, ethyl everninate, methyl divaricatinate, beta-orcinol carboxylic acid methyl ester, orcinol carboxylic acid ethyl ester, ethyl divaricatinate, pinocarveol, bata-elemene, propylene glycol, and the like. Inherent aroma compounds of natural plant essences with moss faint scent are applied in the preparation of the essence of the invention, and the essence with moss faint scent is prepared by such steps: dissolving the ingredients, and allowing the mixture to stand. Technologies are simple and are easy to operate; ingredients are easy to obtain; cost is low; operability is high; scent lasting time is long; scent quality is high; the moss faint scent is true to nature; the essence of the invention can be used as a substitute of natural moss faint scent essences so as to reduce the demand for natural essences, and possesses promising application prospect in the fields of daily use essences and cigarette essences.

Owner:CHINA TOBACCO JIANGSU INDAL

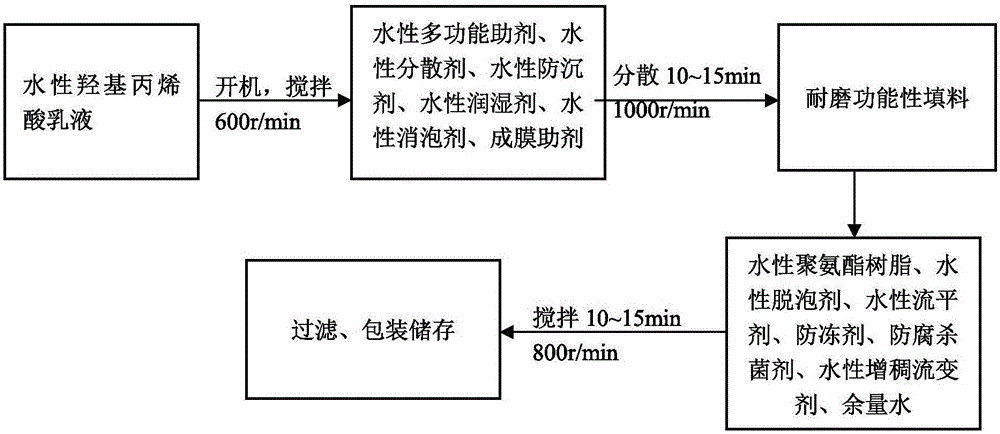

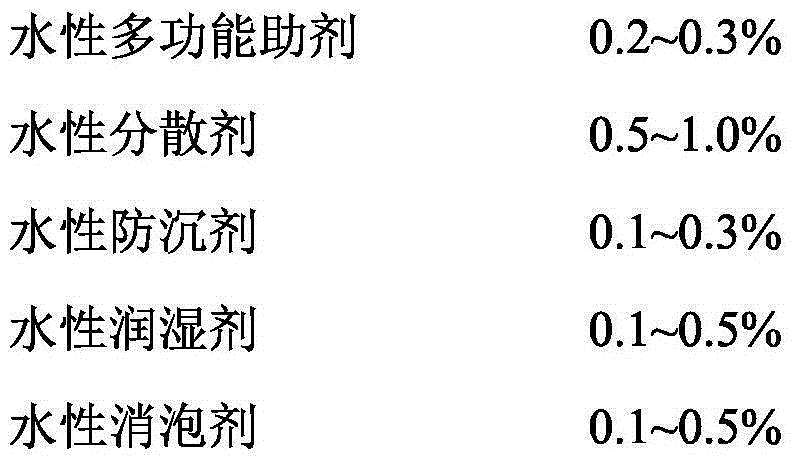

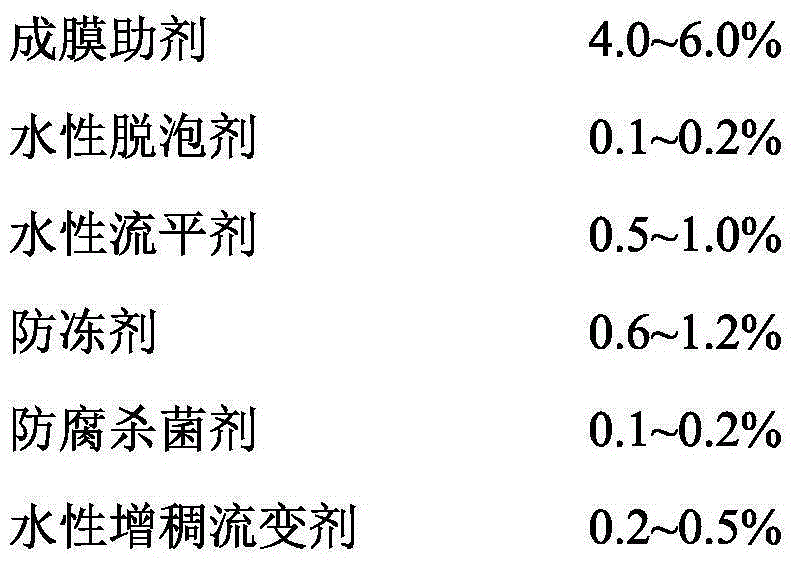

High-hardness water-borne double-component wood-ware varnish with high wear resistance and preparing method thereof

The invention provides high-hardness water-borne double-component wood-ware varnish with high wear resistance. The varnish is composed of main agent A and a curing agent B. The main agent A is composed of, by weight, 50-70% of water-borne hydroxyl acrylic emulsion, 10-30% of water-borne polyurethane resin, 4.0-8.0% of water-borne wear-resisting functionality filler, 6.5-11.7% of adjuvant and the balance water; the curing agent B is composed of, by weight, 80% of water dispersing modified polyisocyanate and 20% of propylene glycol monomethyl ether acetate. According to a coating method for the high-hardness water-borne double-component wood-ware varnish with the high wear resistance, the main agent A, the curing agent and the water are mixed according to the weight ratio of 100:20:20-30. The varnish has the advantages of being high in hardness and wear resistance, drying fast, resisting scratching, being good in water resistance and excellent in alcohol resistance, and resisting adhesion, and can be widely applied.

Owner:中山吕邦新材料科技有限公司

Alcohol-free printing fountain solution and preparation method thereof

The invention discloses an alcohol-free printing fountain solution and a preparation method of the alcohol-free printing fountain solution. The alcohol-free printing fountain solution comprises, by weight, 10-15% of propylene glycol monomethyl ether, 2-4% of ethylene glycol, 4-8% of a citric acid, 0.5-1.5% of sodium hydroxide, 15-25% of glycerinum, 0.1-0.3% of sodium carboxymethyl cellulose, 0.05-0.1% of lauroyl diethanol amine, 0.4-0.6% of liquid tea saponin, 0.3-0.6% of dodecyl dimethyl benzyl ammonium chloride, 0.5-1% of dodecyl glucoside, 0.05-0.1% of 2-ethyl hexanol and 50-55% of water. The alcohol-free printing fountain solution does not contain isopropyl alcohol and is low in toxicity, safe, environmentally friendly, good in printing effect and low in cost, thereby having huge economic benefit and social benefit.

Owner:安徽唯宝印刷科技有限公司

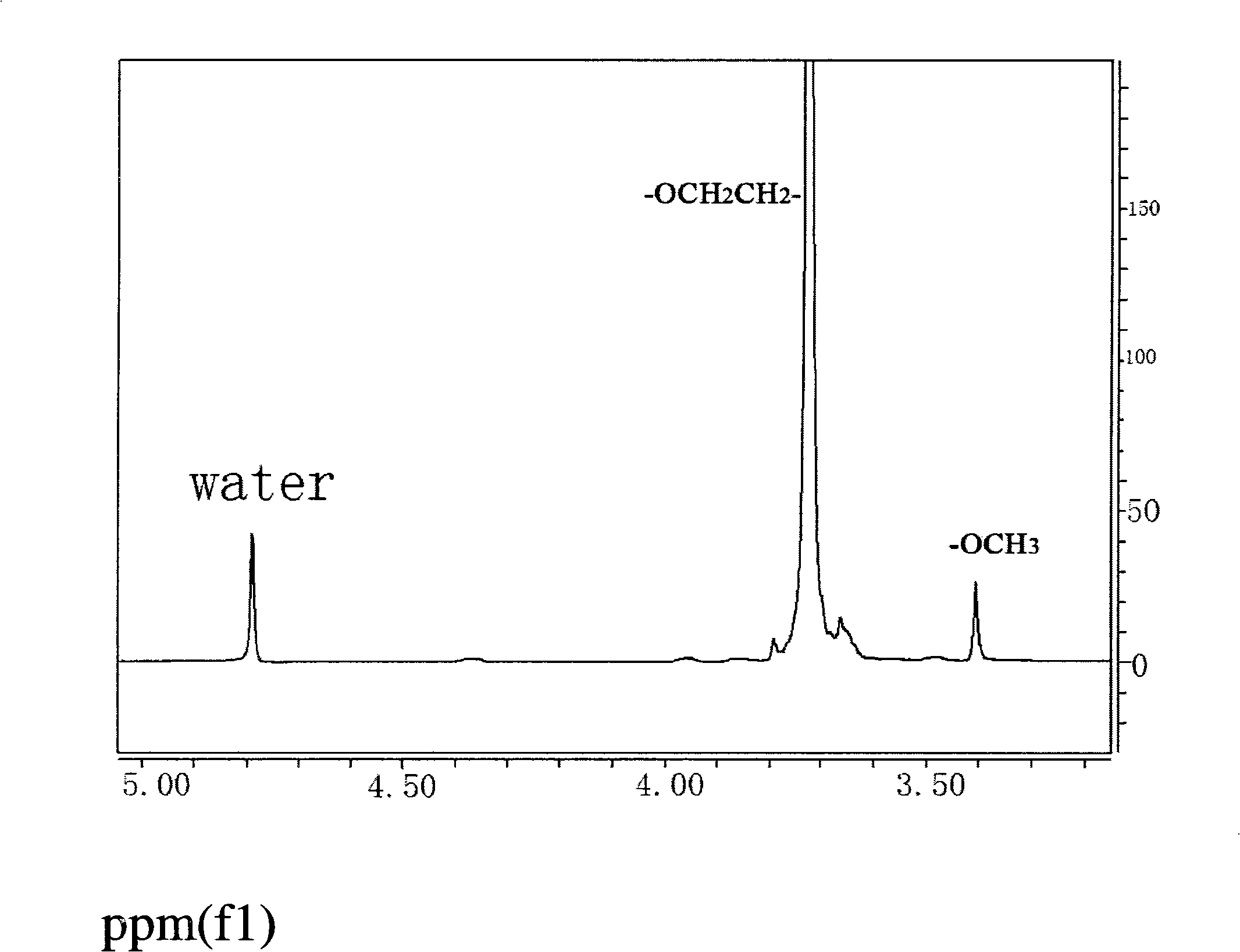

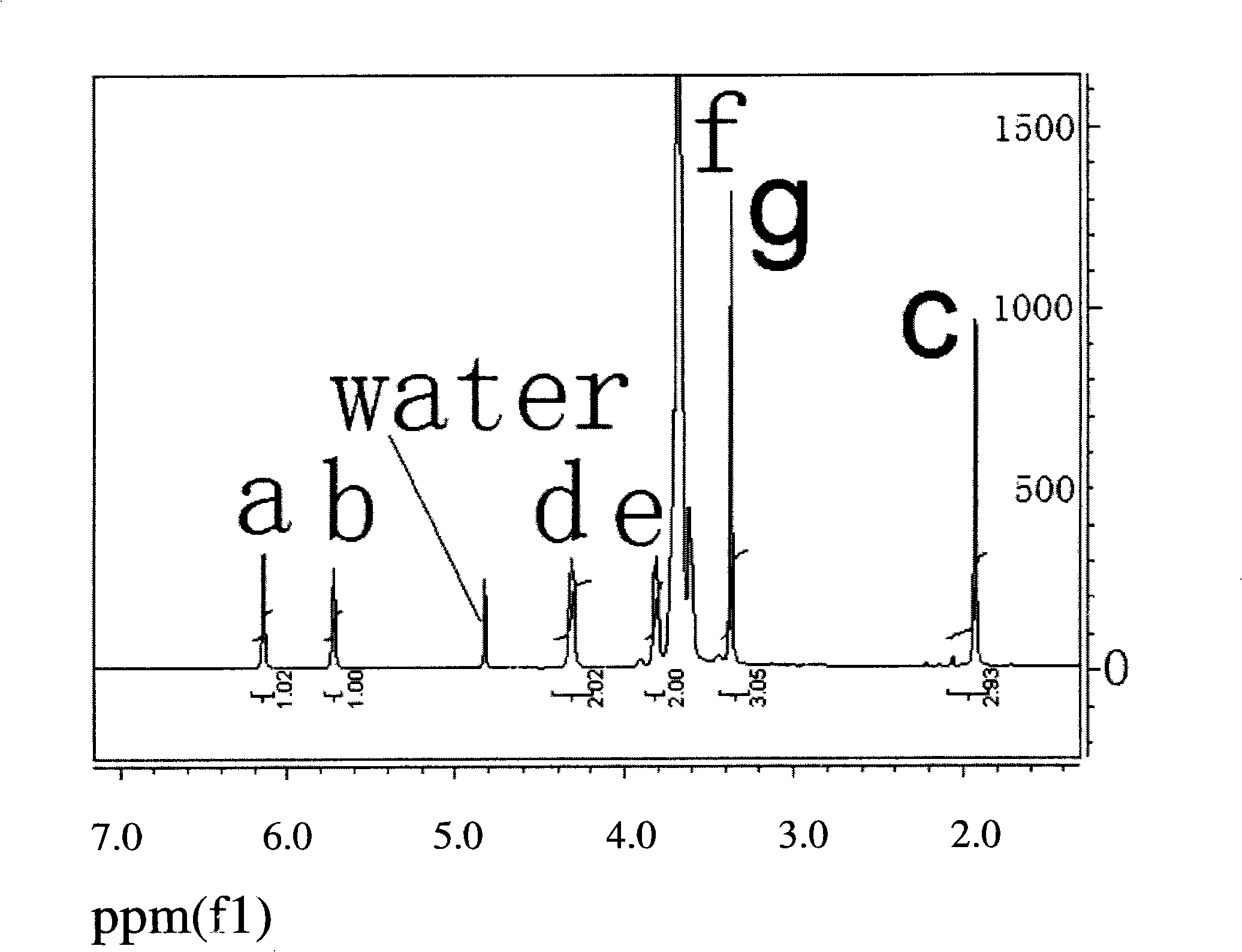

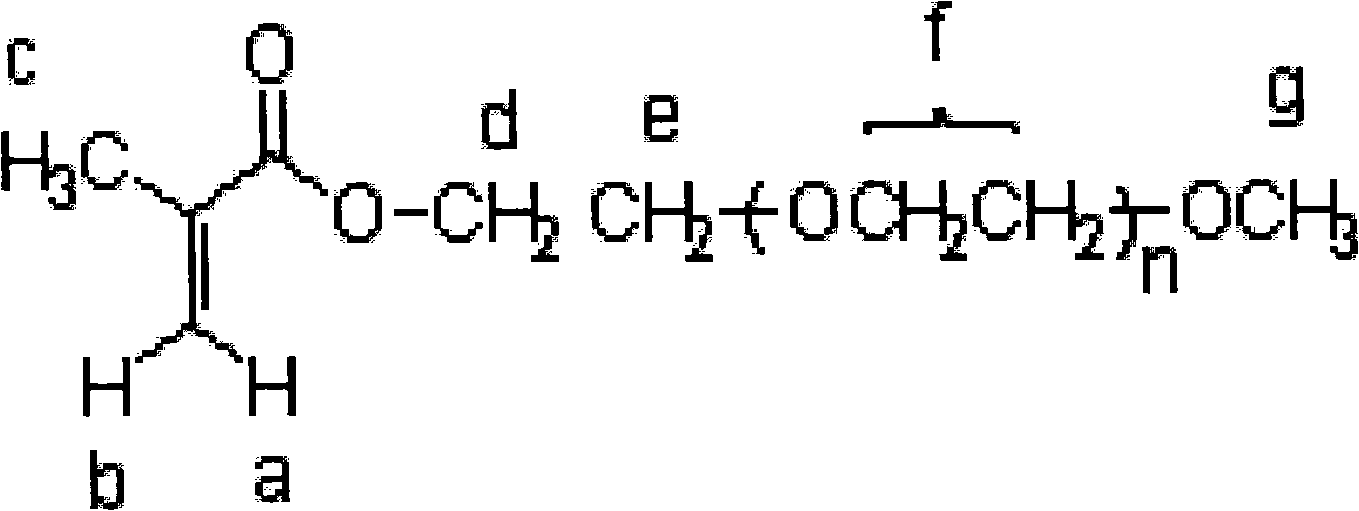

Method for synthesizing polyethyleneglycol monomethyl ether metacrylic acid ester

The invention discloses a method for synthesizing poly (ethylene glycol) methyl ether methacrylate. Methyl methacrylate and PGME are synthesized to generate the poly (ethylene glycol) methyl ether methacrylateby through the ester exchange reaction. The catalyst used in the ester exchange reaction is a base catalyst and has high catalytic activity; an inhibitive substance is added in the reaction system to avoid the polyreaction in the process of reaction and air is put into the reaction system; the reaction temperature is moderate and is between 80 and 85 DEG C; the reaction side product of methanol and a reaction medium form an azeotrope which is taken out of the reaction system, thereby ensuring that the reaction is done completely. The method quantificationally converts the PGME into the poly (ethylene glycol) methyl ether methacrylate, has esterification rate close to 100 percent, avoids the polyreaction and other side reactions, has simple steps and is suitable for the industrial production.

Owner:SUN YAT SEN UNIV

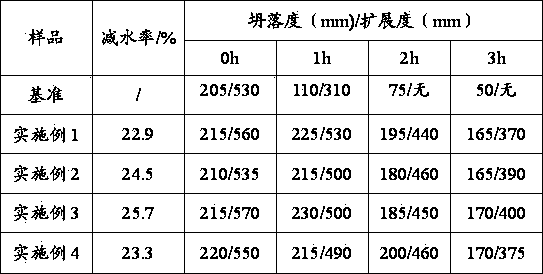

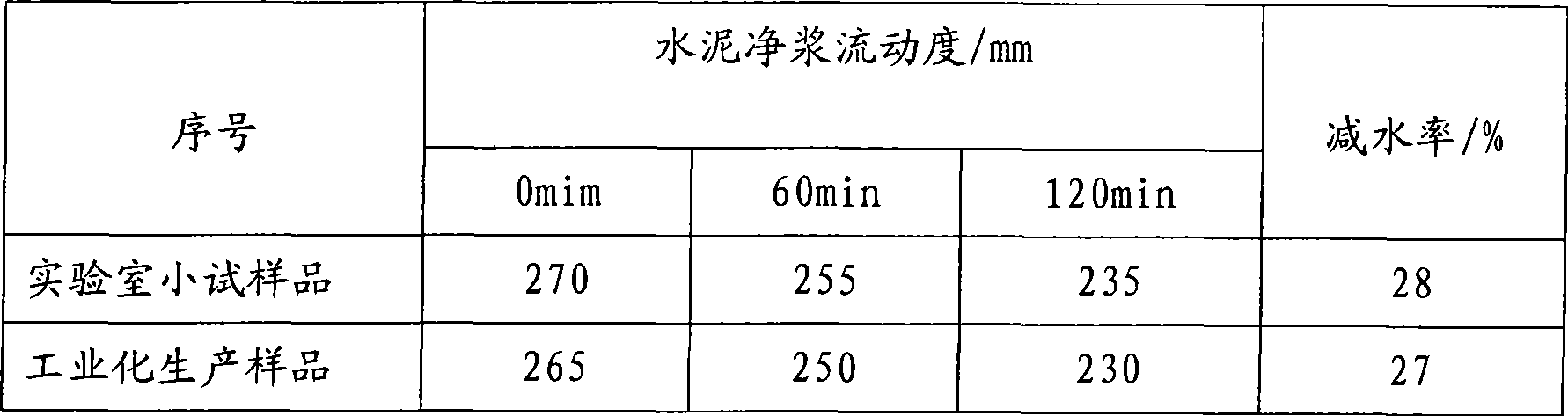

Preparation method for high-slump-retention polycarboxylate water reducer

InactiveCN103450411AIncreased steric hindranceSolve problems such as difficult pumpingMeth-Ptru catalyst

The invention discloses a preparation method for a high-slump-retention polycarboxylate water reducer. The preparation method comprises the following steps of: esterifying methoxylpolyethylene glycol monomethyl ethers with different molecular weights with methacrylic acid and a mixed polymerization inhibitor for a period of time under the action of a catalyst and at a certain temperature, then adding allyl alcohol in one time, further esterifying in the same conditions to obtain an esterified macromonomer MP containing crosslinking monomer allyl methacrylate; then performing aqueous solution polymerization on the MP, unsaturated sulfonate, (meth)acrylate unsaturated monomers and a chain transfer agent in a low-temperature condition and within a redox initiation system; and finally adding caustic soda liquid to neutralize, so as to obtain the polycarboxylate water reducer with a certain concentration. The high-slump-retention polycarboxylate water reducer prepared by the preparation method disclosed by the invention is a high-performance water reducer which is prepared at a low temperature by virtue of a molecular structure design, as well as is high in slump retention, excellent in dispersing performance, good in adaptability, simple in process, pollution-free, low in energy consumption, and easy to realize industrialized production.

Owner:KZJ NEW MATERIALS GROUP CO LTD

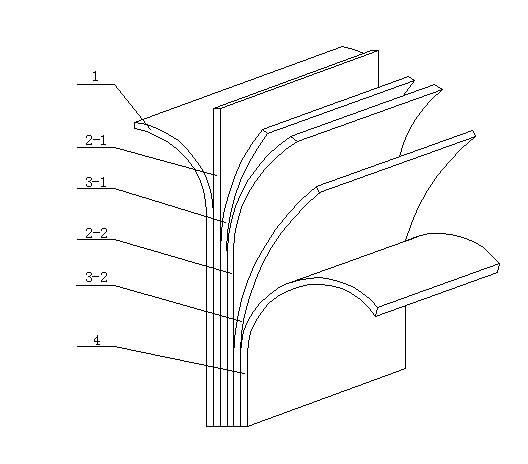

Anti-fogging agent composition and anti-fogging insulation window film formed thereby

InactiveCN102604460AGood anti-fog durabilityEasy to prepareFilm/foil adhesivesSynthetic resin layered productsPolyesterMonomethyl ether

The invention relates to an anti-fogging agent composition and an anti-fogging insulation window film formed thereby, wherein the anti-fogging agent composition comprises 9 to 14 wt% of hydrophilic resin, 55 to 76 wt% of propylene glycol monomethyl ether, 3 to 10 wt% of dimethyl methylamine, 1 to 5 wt% of triethylene diamine, 1 to 5 wt% of leveling agent, 5 to 26wt% of isopropanol and 5 to 24wt% of ethanol; the anti-fogging insulation window film comprises a first transparent polyester film or transparent polyethylene film substrate (2-1), a heat insulation acrylic adhesive layer (3-1), a second transparent polyester film or transparent polyethylene film substrate (2-2), an acrylic adhesive layer (3-2) and a release film (4), which are composited as a whole, wherein the anti-fogging coating (1) is formed by the anti-fogging agent composition; and the heat insulation acrylic adhesive layer (3-1) contains a specific insulation material. According to the invention, the anti-fogging insulation window film is anti-fogging, insulating and safe.

Owner:西安航天三沃化学有限公司

Modified aqueous alkyd resin coating

The invention discloses modified aqueous alkyd resin coating, which comprises the following raw materials in parts by weight: 70-85 parts of acrylic-modified aqueous alkyd resin, 10-25 parts of aqueous epoxide resin, 10-25 parts of nano silica sol, 2-5 parts of amino resin, 2-5 parts of rutile-type titanium dioxide, 2-6 parts of nano calcium carbonate, 1-4 parts of nano titanium dioxide, 2-5 parts of aluminum oxide, 2-6 parts of nano ferric oxide, 0.1-0.5 part of nano silver, 0.3-1 part of polyethylene glycol, 0.1-0.5 part of proprylene glycol monomethyl ether, 0.2-1 part of ethylene glycol butyl ether, 0.5-1.5 parts of triethanolamine, 0.1-0.5 part of benzotriazole, 0.05-0.5 part of a dispersant, 0.1-0.8 part of a defoaming agent, 1-4 part of a dryer, 1-3 parts of a silane coupling agent and 20-50 parts of water. The modified aqueous alkyd resin, coating is high in hardness and excellent in impact resistance, water resistance, corrosion resistance and bacterium resistance.

Owner:GUANGDE JIADIAN CHEM CO LTD

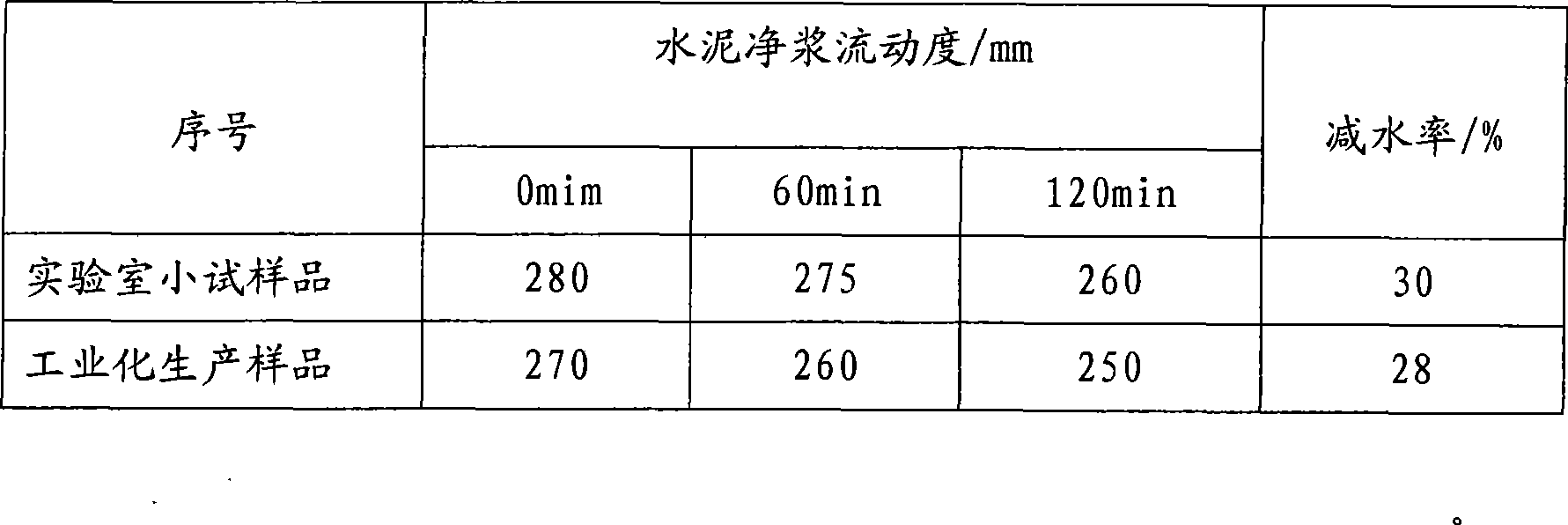

Preparation method of polycarboxylic acids high efficiency water reducer

InactiveCN101531747AReduce damage rateHigh effective contentHydroquinone monomethyl etherMonomethyl ether

The invention discloses a preparation method of polycarboxylic acids high efficiency water reducer, which includes steps of firstly synthesizing methoxypoly(ethylene glycol) monomethyl ether acrylate large monomer from methoxypoly(ethylene glycol) monomethyl ether and crylic acid which are used as raw materials, then copolymerizing the esterified large monomer and the acrylic acid to prepare the polycarboxylic acids high efficiency water reducer. In the synthesis of the esterified large monomer, hydroquinones and hydroquinone monomethyl ether are employed to coordinatedly blocking polymerization, thereby reducing failure ratio of unsaturated double bond, increasing effective content of the synthesized water reducer, increasing concrete water reducing ratio, and increasing slump retaining performance.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD

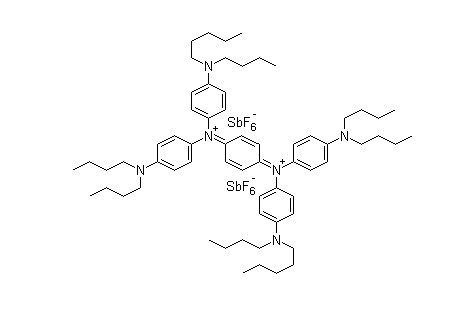

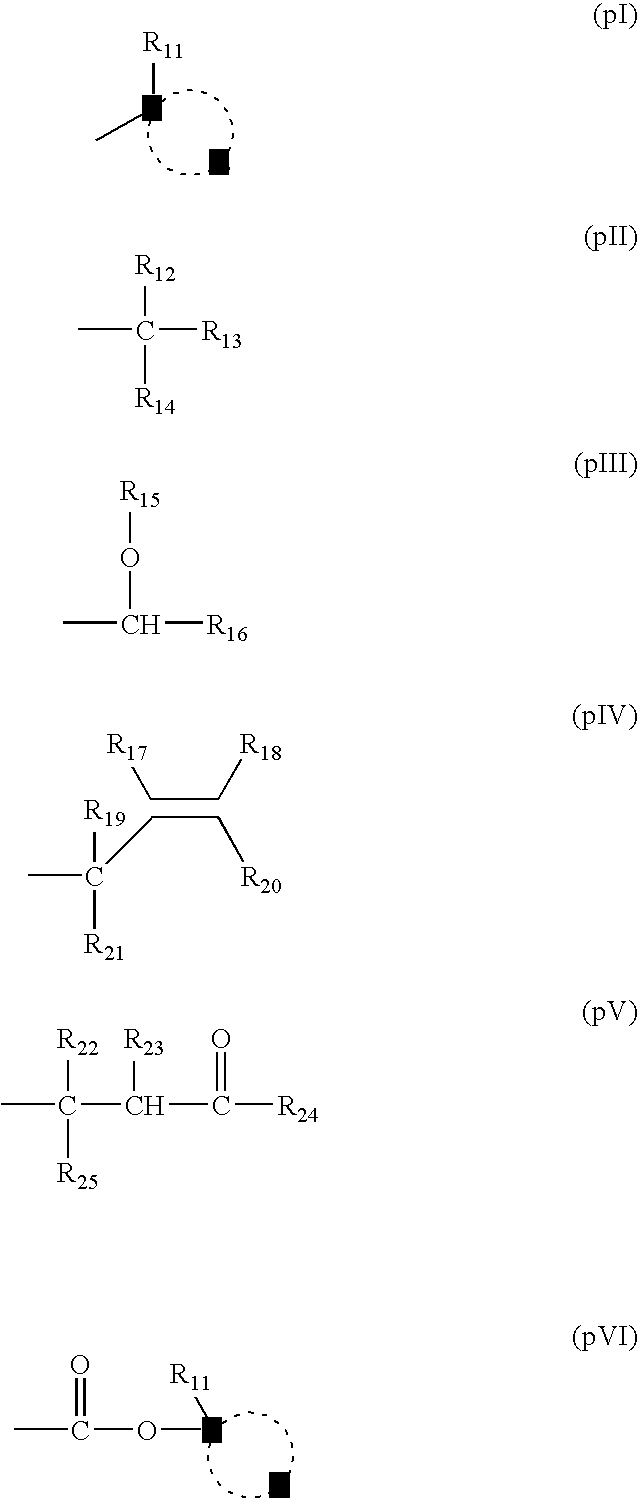

Radiation-sensitive resin composition

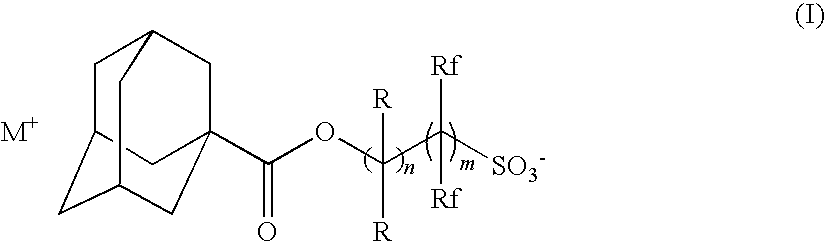

ActiveUS20100285405A1Photosensitive materialsPhotomechanical exposure apparatusHydrogen atomMonomethyl ether

A radiation-sensitive resin composition includes a resin, a radiation-sensitive acid generator, an acid diffusion controller, and a mixed solvent. The radiation-sensitive acid generator includes a compound (I) shown by a following general formula (I). The mixed solvent includes about 50 mass % to about 90 mass % of propylene glycol monomethyl ether acetate,wherein M+ represents a sulfonium cation or an iodonium cation, R represents a hydrogen atom or a hydrocarbon group having 1 to 8 carbon atoms, Rf represents a fluorine atom or a perfluoroalkyl group having 1 to 4 carbon atoms, n represents an integer from 1 to 10, and m represents an integer from 1 to 4.

Owner:JSR CORPORATIOON

A pesticide composition for preventing and treating plant disease and application thereof

ActiveCN1961667AHigh antibacterial activitySignificantly synergistic antibacterial activityBiocideFungicidesMetaboliteSuspending Agents

The invention relates to a pesticide compound for preventing plant disease, wherein said compound comprises emodin monomethyl ether and chrysophanol at 1:1-1:9 mass percentages; the compound can be obtained from Polygonaceae and soybean plant Chinese drug or made from manual purification or manual composition. Said compound added with other carrier and agent can be made into liquid, powder, emulsion, etc, whose effective component is 0.1-30%. The invention can generate sub metabolite with significant bacterial resistance.

Owner:INST OF PLANT PROTECTION & SOIL FERTILIZER HUBEI ACAD OF AGRI SCI

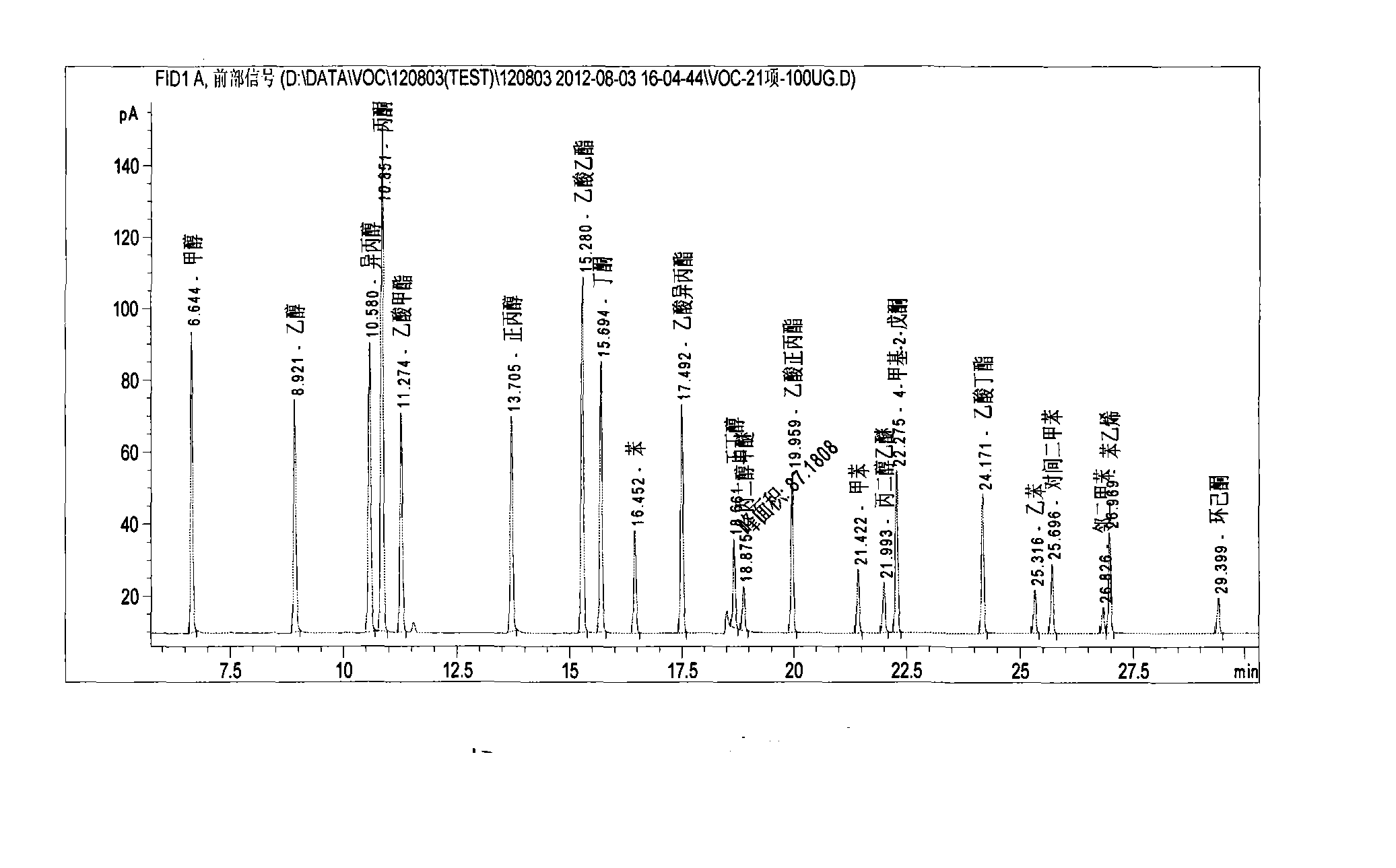

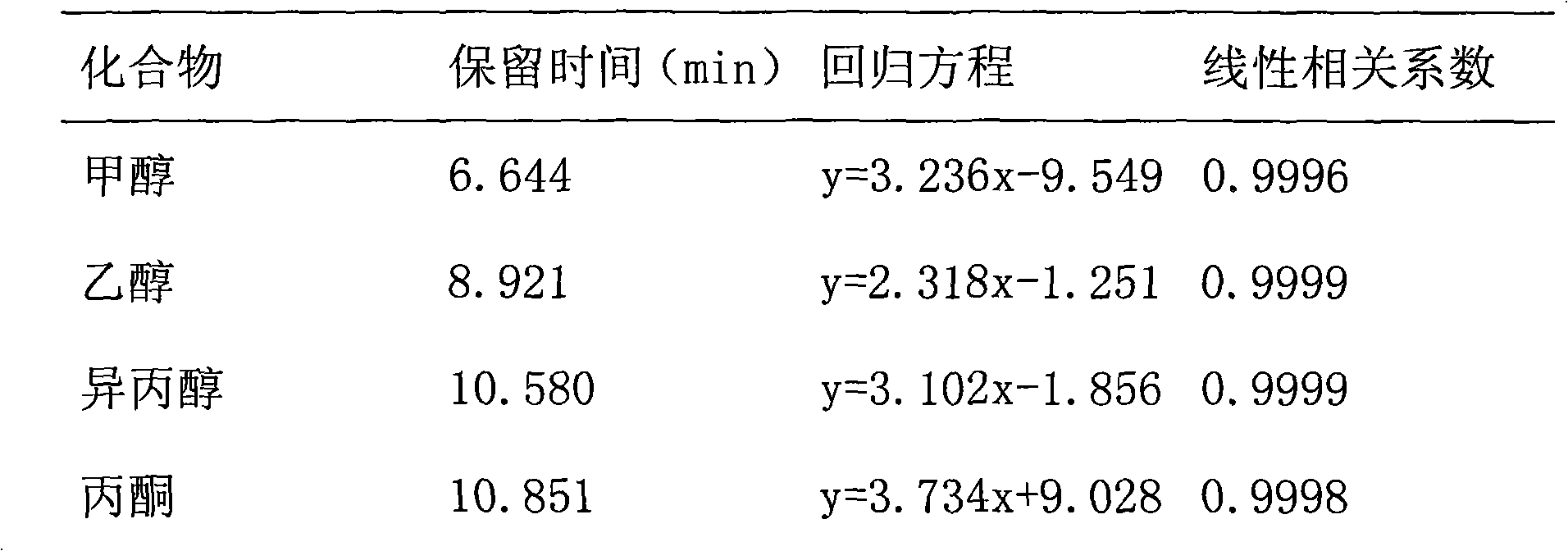

Method for detecting 21 volatile organic compounds (VOC) in tobacco packing box

The invention belongs to the technical field of tobacco packing box, and in particular relates to a method for detecting contents of 21 volatile organic compounds (VOC), including benzene, methyl benzene, p-xylene, m-xylene, o-xylene, styrene, methanol, ethanol, acetone, isopropyl alcohol, methyl acetate, normal propyl alcohol, ethyl acetate, butanone, acetic acid isopropyl ester, n-butyl alcohol, propylene glycol monomethyl ether, n-propyl acetate, propylene glycol monoethyl ether, 4-methyl-2-pentanone, butyl acetate, cyclohexanone in a tobacco packing box. The method for detecting 21 volatile organic compounds in the tobacco packing box disclosed by the invention comprises the following steps of: sample pretreatment: preparing a piece of hard box packing paper; cutting and reserving a main packing surface by an area of 22.0cm*5.5cm; rolling the printing surface of the sample inwards to obtain a barrel-shaped part; putting the barrel-shaped part in a headspace bottle; adding 1000mu l of glycerol triacetate; sealing, and implementing a headspace-gas chromatography detection. The method disclosed by the invention is high in sensitivity, high in recovery rate, and excellent in precision of detecting result.

Owner:GUANGZHOU PONY TESTING TECH

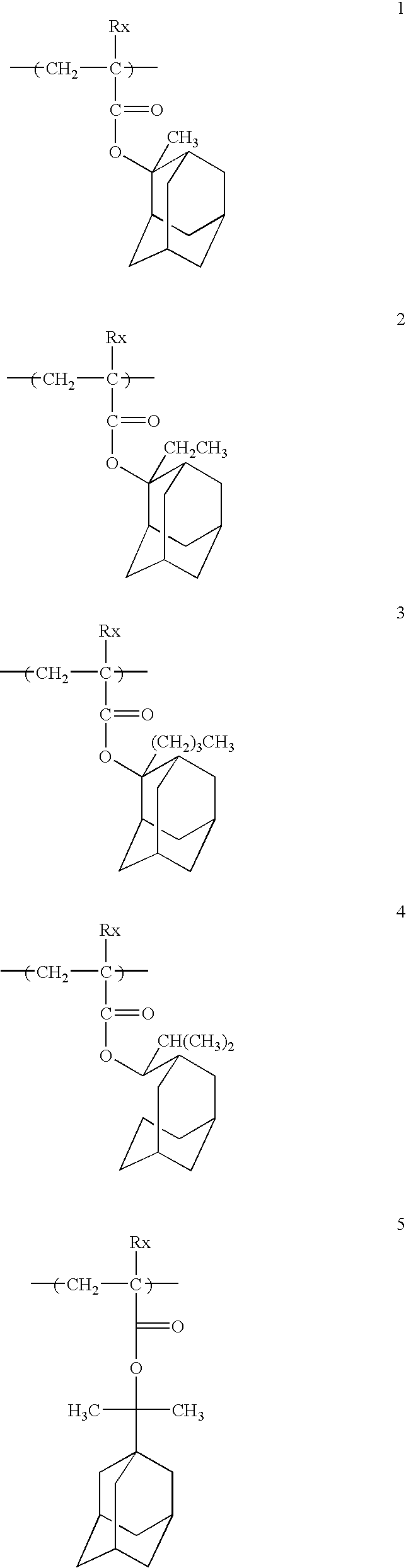

Copolymer for immersion lithography and compositions

ActiveUS20100047710A1Easy to integrateHigh yieldPhotosensitive materialsRadiation applicationsMonomethyl etherRadiation sensitivity

The present invention provides a copolymer which can prevent problems associated with immersion lithography (including occurrence of a pattern defect such as water mark, and variation in sensitivity or abnormal patterning due to elution of an additive such as a radiation-sensitive acid-generator) and which provides surface characteristics suitable for immersion lithography, and a composition containing the copolymer.The copolymer for immersion lithography has, at least, a repeating unit (A) that generates an alkali-soluble group by removing protecting group through action of an acid, and a repeating unit (B) having a lactone structure, wherein, when a solution of the copolymer in propylene glycol monomethyl ether acetate (hereinafter may be abbreviated as “PGMEA”) is applied to a wafer and then heated to form a thin film, and a 15-μL droplet of pure water is added onto the thin film, the inclination of the wafer at the time when the water droplet starts to move is 35° or less, or the contact angle of the top edge of the water droplet at the time when the water droplet starts to move is 64° or more.

Owner:MARUZEN PETROCHEMICAL CO LTD

Wood grain transfer printing water paint, aluminum alloy wood grain transfer printing section and manufacturing method thereof

ActiveCN103289551AStrong adhesionStrong weather resistanceSynthetic resin layered productsPretreated surfacesAcrylic resinUltraviolet lights

The invention discloses a wood grain transfer printing water paint, an aluminum alloy wood grain transfer printing section and a manufacturing method thereof. The aluminum alloy wood grain transfer printing section respectively comprises an aluminum base material, a silane polymer protection layer, a priming paint layer, a finish paint layer and a wood grain transfer printing film from underside to surface thereof; the priming paint layer and the finish paint layer both are formed by the wood grain transfer printing water paint by means of electrostatic spraying, wherein the wood grain transfer printing water paint is prepared with water-base organic silicon modified acrylic resin, isocyanate curing agent, propylene glycol monomethyl ether, n-butyl alcohol, isobutyl alcohol, adhesion promoter, ultraviolet light absorber, flatting agent, thickening agent, antioxidant, defoaming agent and the balance of deionized water. According to the invention, the water paint is uniformly sprayed on the aluminum alloy base material by the electrostatic spraying method, after hot setting, an even, flat and smooth paint film is formed, and the high-quality aluminum alloy wood grain transfer printing section with the advantages, such as strong adhesive force, excellent covering power, strong resistance to corrosion, excellent weather fastness, difficult pulverization and color fading, is provided.

Owner:FOSHAN KINNO METAL TECH

Polyurethane pigment dispersing agent and method for preparing same

InactiveCN106674463ALow viscosityImprove stabilityPigment pastesDispersion stabilityHydrophilic monomer

The invention provides a method for preparing a polyurethane pigment dispersing agent. The method includes A), carrying out reaction on diisocyanate and dihydric alcohol to obtain polyurethane prepolymers; B), carrying out reaction on the polyurethane prepolymers, anionic hydrophilic monomers and non-ionic hydrophilic monomers to obtain intermediates; C), neutralizing the intermediates and carrying out reaction on the intermediates, end capping agents or chain extenders to obtain the polyurethane pigment dispersing agent. The non-ionic hydrophilic monomers are selected from a type or a plurality of types of trimethylolpropane polyethylene glycol monoethylether and trimethylolpropane polyethylene glycol propylene glycol monomethyl ether; the anionic hydrophilic monomers are selected from a type or a plurality of types of methylol carboxylic acid, amino acid, sulfamic acid and sulfamate. The method has the advantages that amphiphilic macromolecular polymers with comb structures are the specific non-ionic hydrophilic monomers, accordingly, the steric hindrance stability of molecular spaces can be improved, and the viscosity of the prepolymers can be lowered; the charge stability can be improved by the specific anionic hydrophilic monomers, and accordingly the polyurethane pigment dispersing agent is good in dispersion stability.

Owner:SHANGHAI GOLD LION CHEM CO LTD

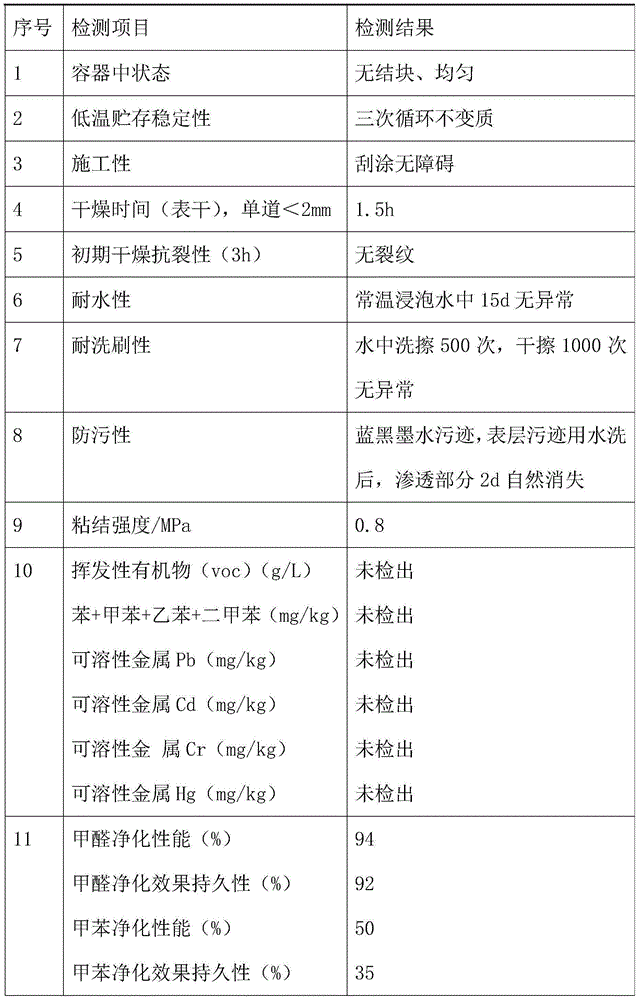

Multifunctional inner wall paint

InactiveCN105131774AGood scrub resistanceImprove rheologyCoatingsAcrylic resinHydroxyethyl cellulose

The invention discloses a multifunctional inner wall paint. The multifunctional inner wall paint comprises raw materials: modified acrylic resin emulsion, pure acrylic emulsion, light calcium carbonate, diatomite, lithopone, ultrafine talcum powder, water absorption composite materials, negative ion-anti-microbial additives, hydroxyethyl cellulose, a dispersant SN-5040, a wetting agent AP-680, 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate, propylene glycol monomethyl ether, an antifoaming agent TSP-01, sodium hexametaphosphate, a leveling agent L-150, a stain-resistant agent JZM-1, glycol, a multifunctional auxiliary agent AMP-95, mildew inhibitors and deionized water. The multifunctional inner wall paint has good scrubbing resistance, rheological property and brushing performance, can absorb harmful components in air indoors, adsorbs moisture, releases moisture, refreshes air, releases negative ions and is environmentally friendly and is helpful for health.

Owner:TIANCHANG YINHU PAINT

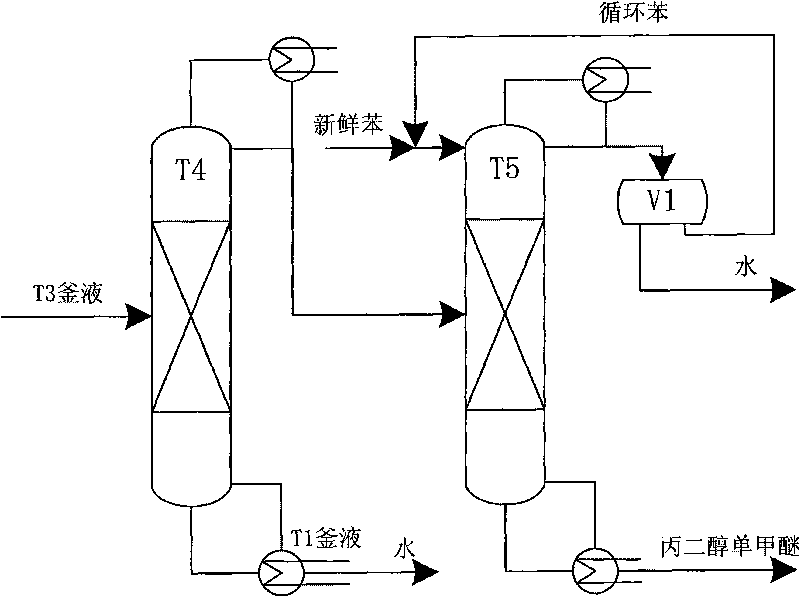

Process for separating ethandiol, mono methyl ether, isopropyl alcohol and water combined by extracting and axeotropy

The invention is a method of combining extraction and azeotropism to separate glycol monomethyl ether, isopropyl alcohol and water, and its steps: using glycerol and benzene as extractant and azeotropic agent, respectively, adopting a rectifying device to separate a mixed solution with isopropyl alcohol plus water plus glycol monomethyl ether, after separating, the isopropyl alcohol plus water is on the tower top and the water plus glycol monomethyl ether is in the tower bottom; separating the distillate from the tower top by extract-rectification process with the glycerol as extractant; after extraction separation, feeding the water plus glycol monomethyl ether in the bottom to an azeotropic distilling device and adopting the benzene as azeotropic agent, where the benzene is recycled. The contents of glycol monomethyl ether and sopropyl alcohol can both reach 99.5% above; those in the water are both lower than below 0.23% and it can primarily obtain glycol monomethyl ether acetate, after separating, the isopropyl alcohol is recycled, the glycol monomethyl ether is returned as raw material.

Owner:NANJING NORMAL UNIVERSITY

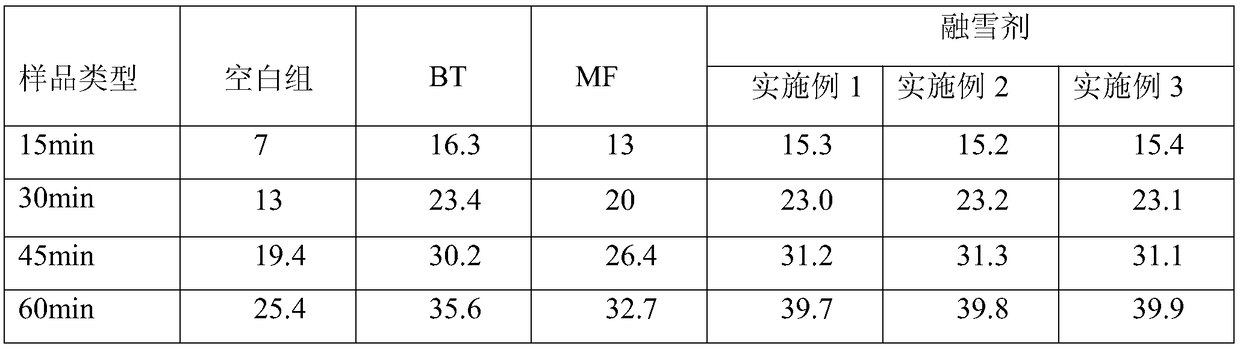

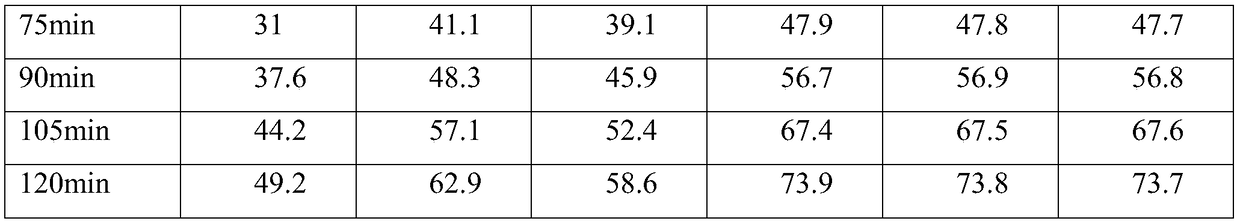

Salt-storage sustained-release snow-melt deicer and preparation method thereof

ActiveCN108949109AAvoid contactGood ice melting effectOther chemical processesRelease timeSnow melting

The invention provides a salt-storage sustained-release snow-melt deicer and a preparation method thereof. The method comprises the following steps: firstly, respectively preparing an anticoagulationchloride saturated solution and a nano-silicon dioxide modified diatomite suspension; then, adding the anticoagulation chloride saturated solution into the nano-silicon dioxide modified diatomite suspension, stirring, filtering in vacuum, drying and grinding to obtain sustained-release inorganic salt; preparing a polymer monomer solution, sequentially adding the sustained-release inorganic salt, isopropyl alcohol or propylene glycol monomethyl ether solution into a flask, putting the flask in an oil bath, and uniformly stirring, adding the polymer monomer solution and a mixed solution of KH570and gAIBN, keeping on stirring, reducing the temperature, adding triethylamine into the flask, stirring, and adding water to obtain the salt-storage sustained-release snow-melt deicer. According to the salt-storage sustained-release snow-melt deicer, snow-melt substances are not limited by temperature-control molecules, and have long release time and relatively high ice melting capacity.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

Resist composition for immersion exposure and pattern formation method using the same

ActiveUS20050186503A1Semiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersResistSolubility

A resist composition for immersion, comprises: (A) a resin of which solubility in an alkali developer increases under an action of an acid; (B) a photoacid generator; and (C) a mixed solvent containing an alkylene glycol alkyl ether carboxylate and a propylene glycol monomethyl ether.

Owner:FUJIFILM CORP +1

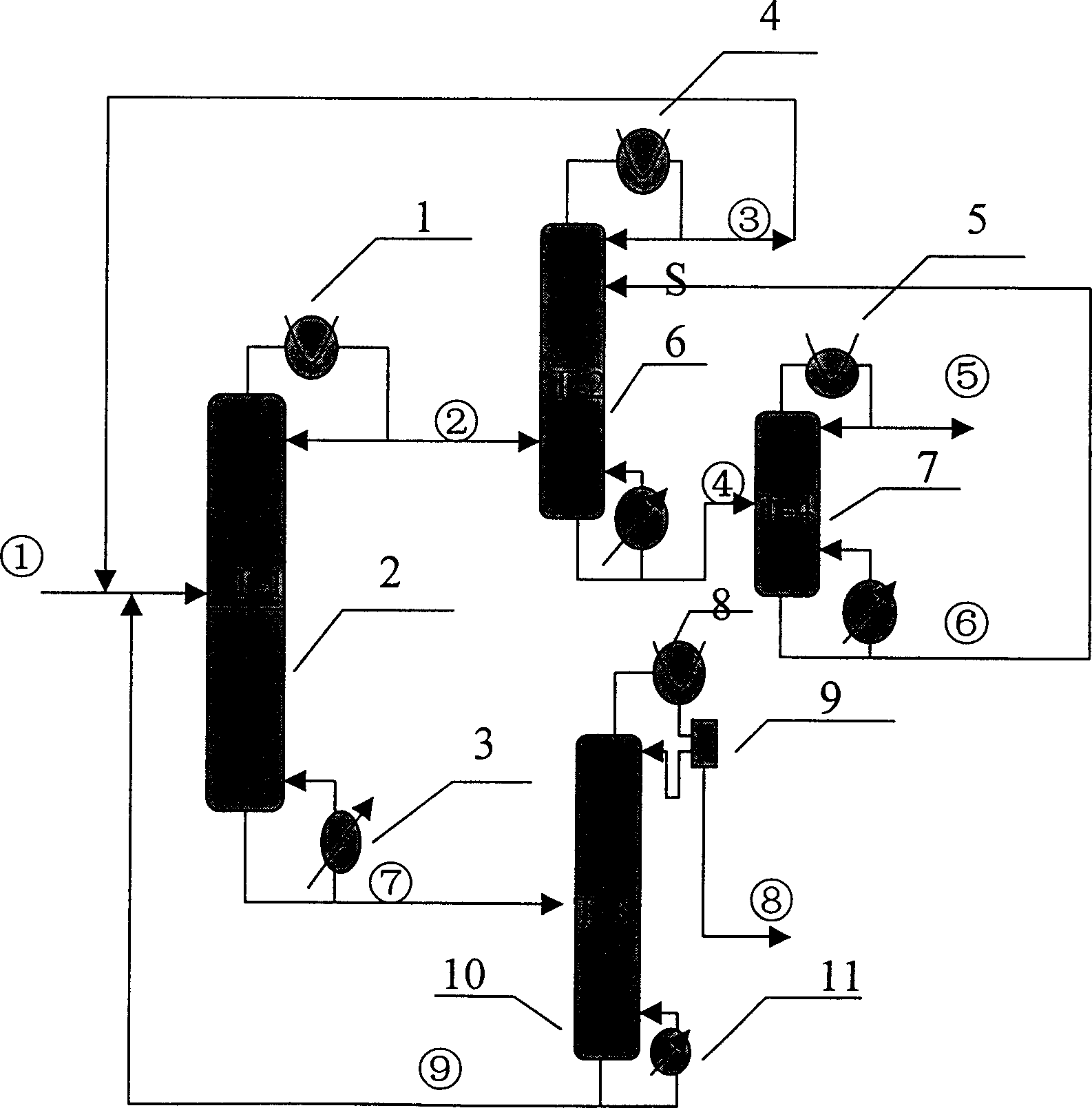

Azeotropic rectification device and method for separating propylene glycol monomethyl ether and water

ActiveCN103449981AEfficient recyclingReduce dosageEther separation/purificationAzeotropic distillationRefluxMonomethyl ether

The invention discloses an azeotropic rectification device and method for separating propylene glycol monomethyl ether and water. The azeotropic rectification device and method are characterized in that cyclohexane is adopted as an entrainer; waste liquor containing propylene glycol monomethyl ether, water and cyclohexane is added to a rectification kettle once; a rectification column is directly connected with the rectification kettle; a kettle-type reboiler is arranged on the rectification kettle; the waste liquor is heated into steam through the kettle-type reboiler and then enters the rectification column; the material at the top of the column is condensed and then transferred into the a reflux ratio controller; if the material at the top of the column is an azeotrope of cyclohexane and water, the material is fed into a phase splitting tank for phase splitting, a water phase is extracted, and cyclohexane reflows; if the material at the top of the column is cyclohexane, recovered cyclohexane is obtained; if the material at the top of the column is a transition fraction of cyclohexane and propylene glycol monomethyl ether, the material is extracted into a transition fraction storage tank; if the material at the top of the column is propylene glycol monomethyl ether, a propylene glycol monomethyl ether product can be obtained; once materials in the kettle of the column are basically the heavy components of the waste liquor, the extracting at the top of the column is stopped, and the residual materials in the kettle are discharged from the bottom part of the rectification kettle. The device and method for separating propylene glycol monomethyl ether and water are efficient and environment-friendly.

Owner:WUXI ZHONGTIAN SOLID WASTE DISPOSAL CO LTD

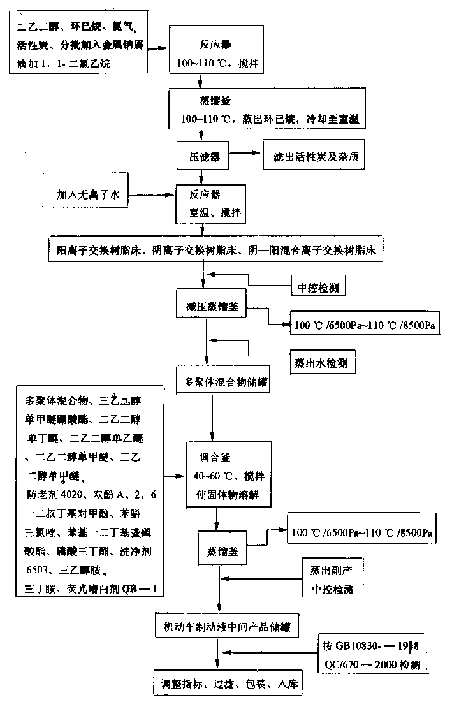

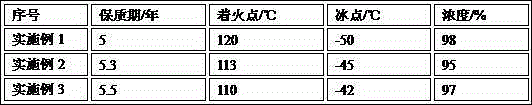

Brake fluid for motor vehicles and its production methods

A brake liquid for the hydraulic brake system of motor-driven vehicle is prepared through preparing polymer mixture by catalytic reaction between biethanediol and 1,1-dichlorethane, adding triethanediol monoethylether borate, triethanediol monomethyl ether, diethanediol monobutylether, diethanediol monoethylether, diethanediol monomethylether and additive, stirring, dissolving, vacuum processing and filtering. It features high properties.

Owner:LIAONING SANTE PETROCHEM

Method for preparing glycol methyl ether acetate

InactiveCN101239907AHigh yieldReduce dosageOrganic compound preparationPreparation by ester-hydroxy reactionAcetic acidMonomethyl ether

The invention discloses a method for preparing glycol monomethyl ether acetate, comprising using ethyl acetate and glycol methyl ether as materials, performing ester changing reaction in the presence of a solid alkali catalyst, distilling by-product ethanol fro a reaction tank through fractionation, filtering and recoverying the catalyst after reaction, fractionating the reaction liquid to obtain glycol monomethyl ether acetate. The invention has the advantages of: (1) high yield of 95.5-99.6%, (2) cheap catalyst and small usage which is 0.1-1.5% of the total weight of reaction materials; (3) gentle reaction condition, reaction under atmosphere pressure; (4) repeatedly-usable catalyst; (5) samll corrosion on the device and no environmental contamination.

Owner:EAST CHINA NORMAL UNIV

Anticorrosive environment-friendly spray paint formula

InactiveCN105199580ABright colorGood light fastnessAnti-corrosive paintsPolyurea/polyurethane coatingsDiacetone alcoholChemical industry

The invention discloses an anticorrosive environment-friendly spray paint formula, and relates to the field of chemical industries. The anticorrosive environment-friendly spray paint formula comprises the following components in parts by weight: 28 to 35 parts of glacial acetic acid, 3 to 7 parts of organic fluorine epoxy resin, 7 to 12 parts of epoxy modified organic silicon resin, 2 to 6 parts of glycol monomethyl ether, 6 to 9 parts of dimethyl sulfoxide, 8 to 13 parts of zinc phosphate, 8 to 13 parts of barium chromate, 1 to 4 parts of ethanol, 2 to 7 parts of polyacrylate, 1 to 4 parts of alcohol soluble resin, 7 to 13 parts of diacetone alcohol, 6 to 9 parts of zinc oxide, 8 to 13 parts of toluene diisocynate, 3 to 7 parts of n-butyl acetate, 12 to 16 parts of benzophenone, 9 to 13 parts of triethanolamine and 3 to 7 parts of diphenyl polysiloxane. The paint is bright in color and good in air-curing resisting effect, can substitute medium chrome yellow in inorganic pigment, is applicable to the outer wall paint, and has no harm of heavy metals, no harmful substances, good environment protection effect, little odor, no peculiar smell after being smeared on the wall, good mechanical performance, excellent electric insulation performance, dampness and water resistance, rust and cold resistance and ozone aging resistance.

Owner:王海平

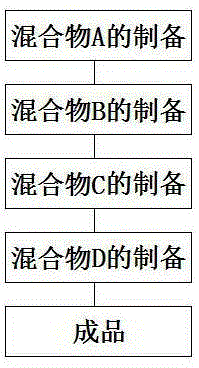

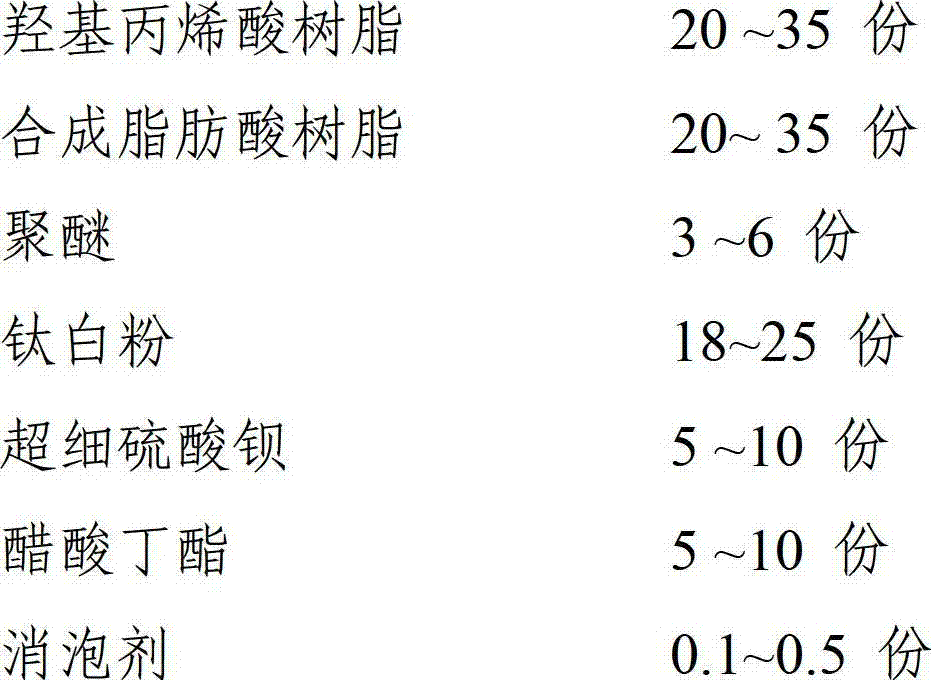

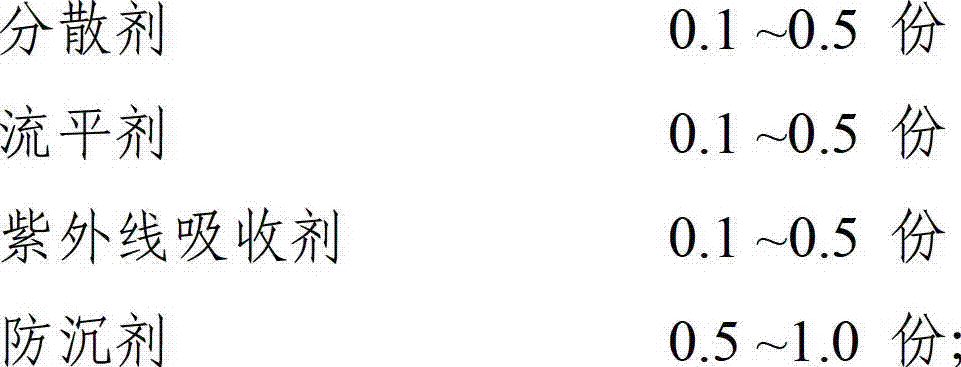

Highlight-dark-bubble-resistance white wood lacquer and preparation method and application thereof

ActiveCN102964953AStrong UV Absorbing PropertiesGood storage stabilityPolyester coatingsCyclohexanoneAcrylic resin

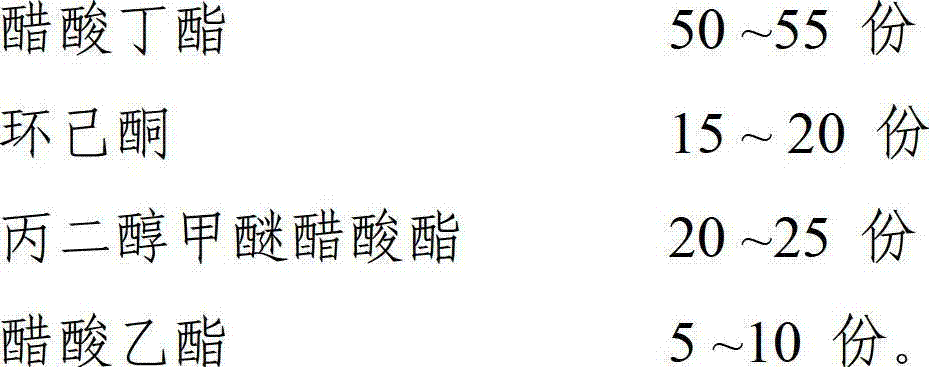

The invention provides a high-dark-bubble-resistance white wood lacquer which comprises a component A, a component B and a component C, wherein the weight ratio of the component A to the component B to the component C is 100:(80-100):(30-50), the component A comprises the following ingredients in parts by weight: 20-35 parts of hydroxy acrylic resin, 20-35 parts of synthetic fatty acid, 3-6 parts of polyether, 18-25 parts of titanium dioxide, 5-10 parts of superfine barium sulfate, 5-10 parts of n-butyl acetate, 0.1-0.5 part of defoaming agent, 0.1-0.5 part of dispersing agent, 0.1-0.5 part of flatting agent, 0.1-0.5 part of ultraviolet absorbing agent and 0.5-1.0 part of anti-settling agent; the component B comprises the following ingredients in parts by weight: 10-20 parts of polyisocyanate, 40-60 parts of co-polymer and 20-30 parts of n-butyl acetate; and the component C comprises the following ingredients in parts by weight: 50-55 parts of n-butyl acetate, 15-20 parts of cyclohexanone, 2-25 parts of propylene glycol monomethyl ether acetate and 5-10 parts of acetic ether. The invention also provides a preparation method of the wood lacquer. The high-dark-bubble-resistance white wood lacquer provided by the invention is high in gloss, strong in sand mark covering capacity, and good in dark bubble resistance.

Owner:濮阳展辰新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com