Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1577 results about "Hydrophilic monomer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

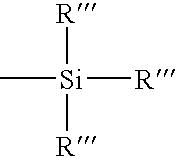

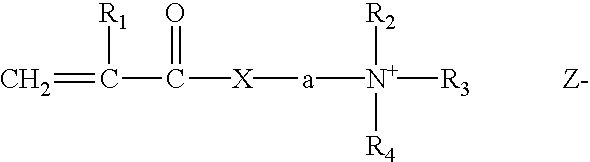

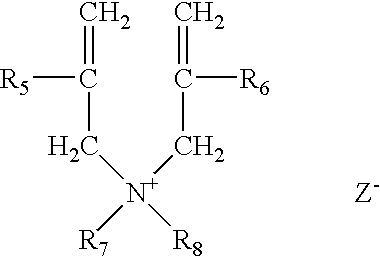

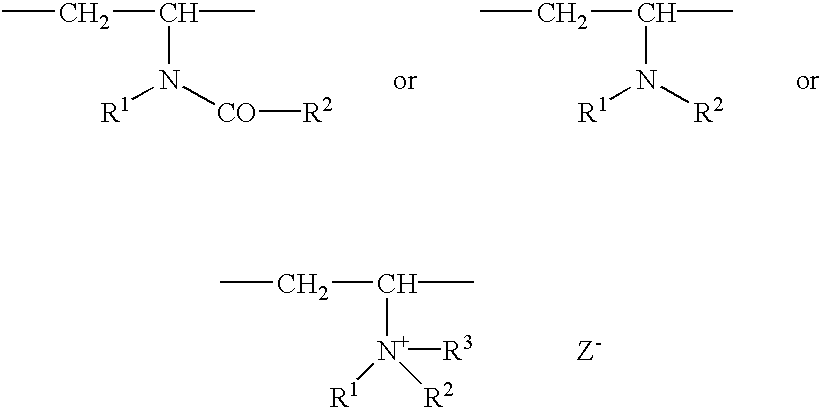

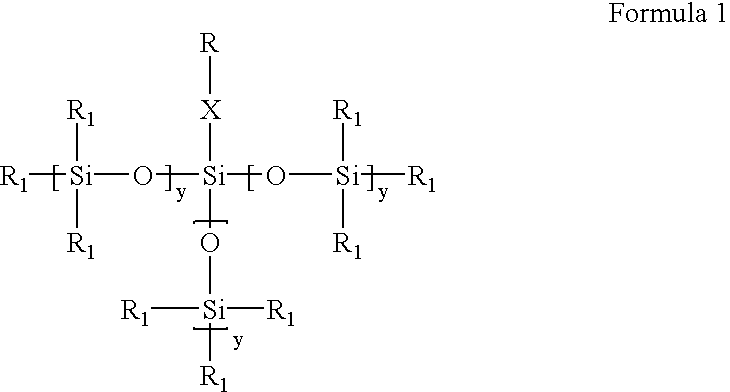

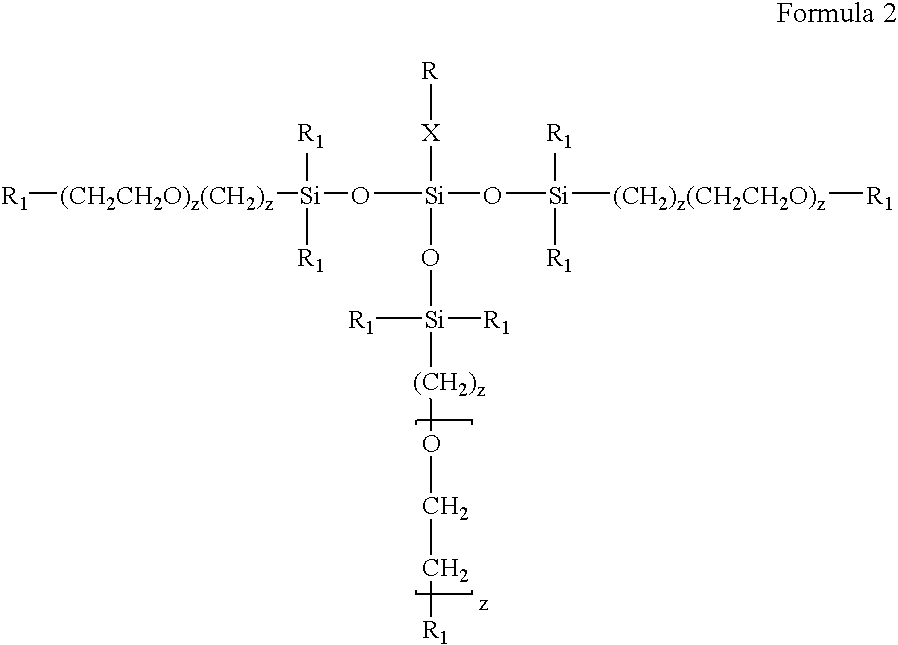

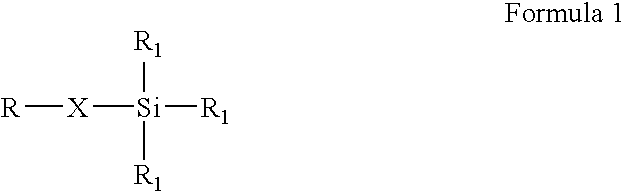

Hydrophilic modifier monomers of the formula (X-div) zHy are disclosed wherein X is a reactive group, Hy is a hydrophilic group and div is a divalent linking group, z being a number up to the available valence of Hy, excess Hy valences being taken up by hydrogen.

Novel Polymers

ActiveUS20080015315A1Sufficient amountReduce the amount requiredOrganic compound preparationCarboxylic acid esters preparationHydrophilic monomerPolymer science

The invention relates to novel crosslinkable copolymers which are obtainable by (a) copolymerizing at least two different hydrophilic monomers selected from the group consisting of N,N-dimethyl acrylamide (DMA), 2-hydroxyethyl acrylate (HEA), glycidyl methacrylate (GMA), N-vinylpyrrolidone (NVP), acrylic acid (AA) and a C1-C4-alkoxy polyethylene glycol (meth)acrylate having a weight average molecular weight of from 200 to 1500, and at least one crosslinker comprising two or more ethylenically unsaturated double bonds in the presence of a chain transfer agent having a functional group; and (b) reacting one or more functional groups of the resulting copolymer with an organic compound having an ethylenically unsaturated group.

Owner:ALCON INC

Methacrylate copolymers for medical devices

A polymer of hydrophobic monomers and hydrophilic monomers is provided. It is also provided a polymer blend that contains the polymer and another biocompatible polymer. The polymer or polymer blend and optionally a biobeneficial material and / or a bioactive agent can form a coating on an implantable device such as a drug delivery stent. The implantable device can be used for treating or preventing a disorder such as atherosclerosis, thrombosis, restenosis, hemorrhage, vascular dissection or perforation, vascular aneurysm, vulnerable plaque, chronic total occlusion, patent foramen ovale, claudication, anastomotic proliferation for vein and artificial grafts, bile duct obstruction, ureter obstruction, tumor obstruction, or combinations thereof.

Owner:ABBOTT CARDIOVASCULAR

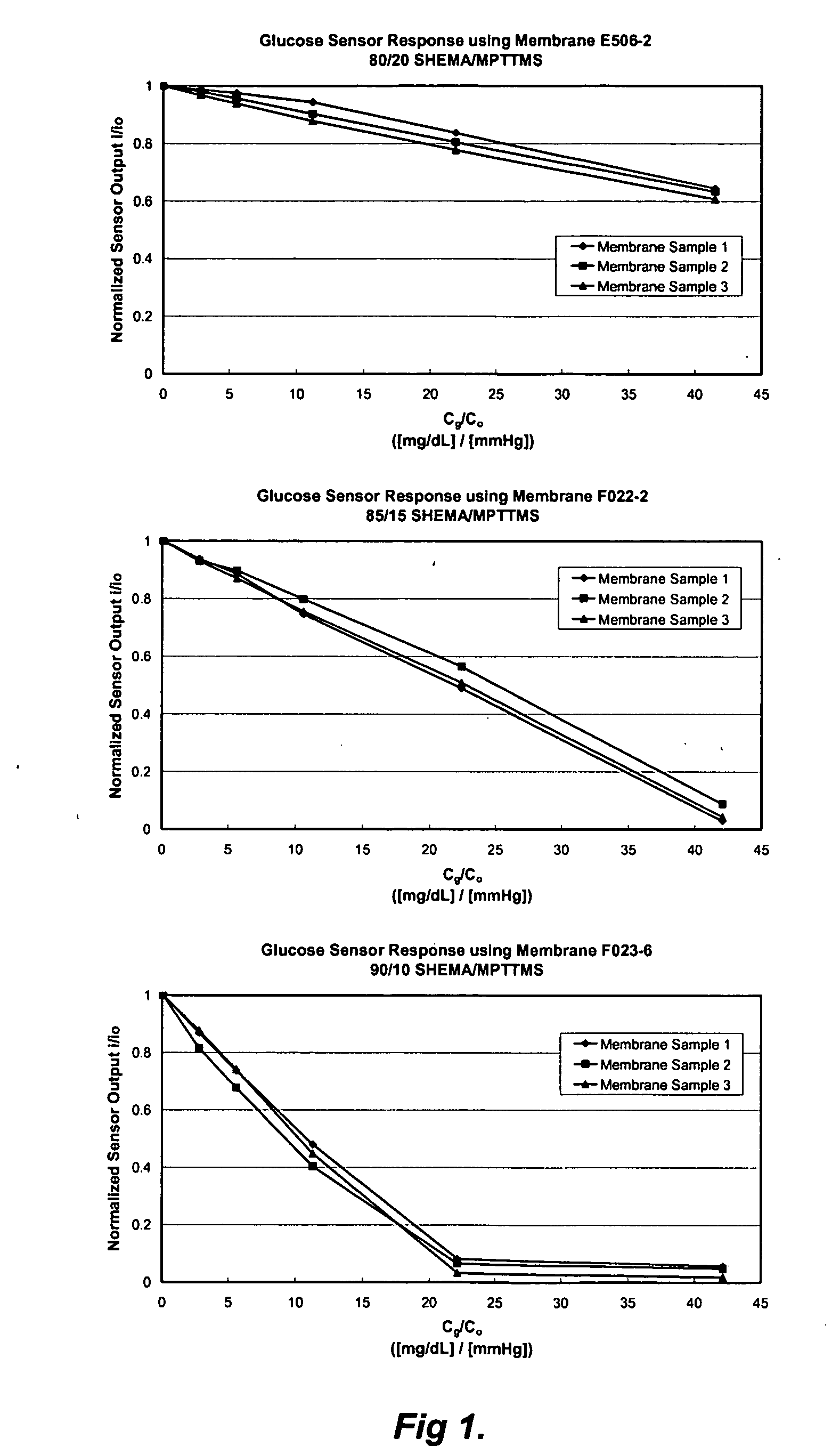

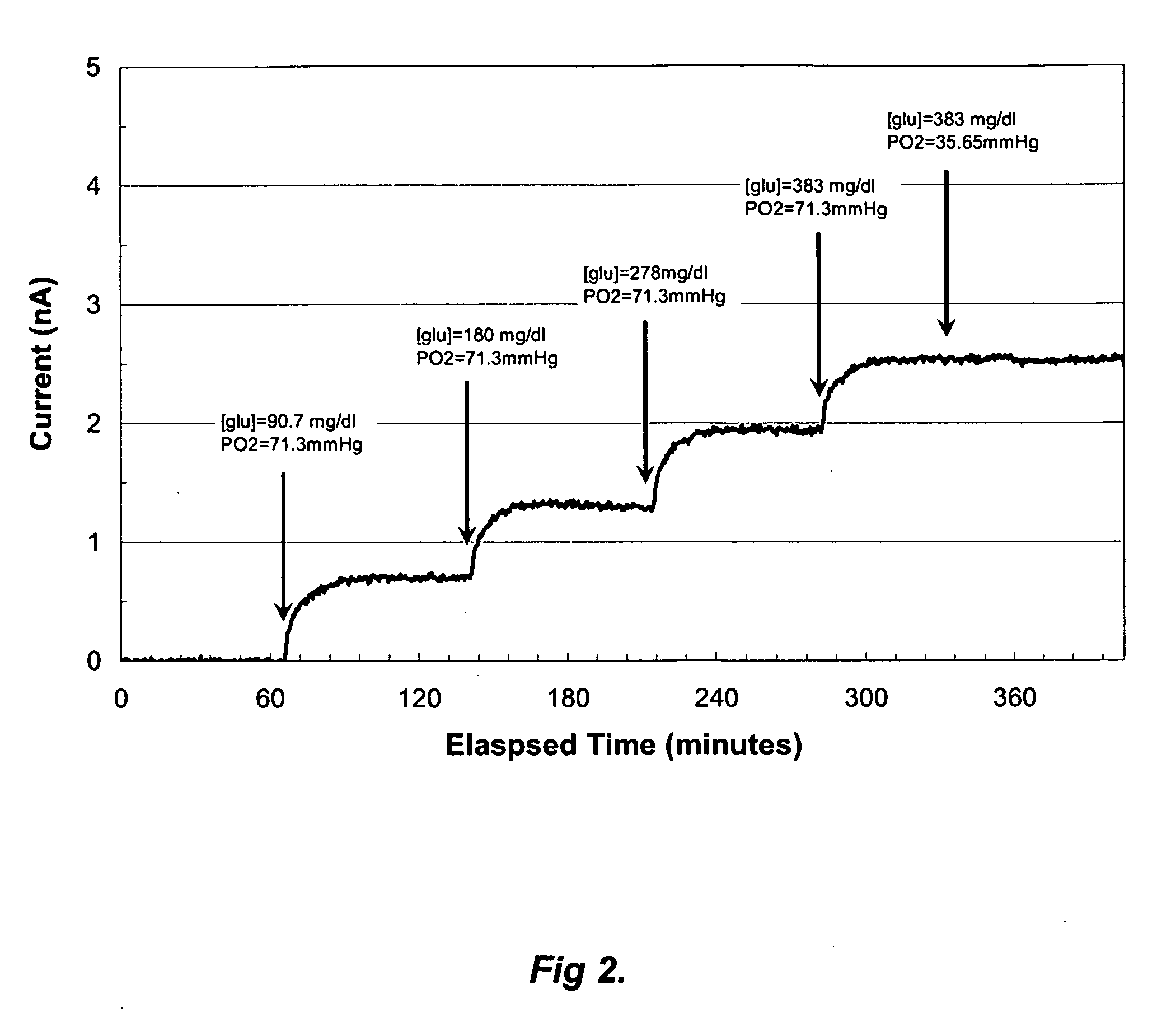

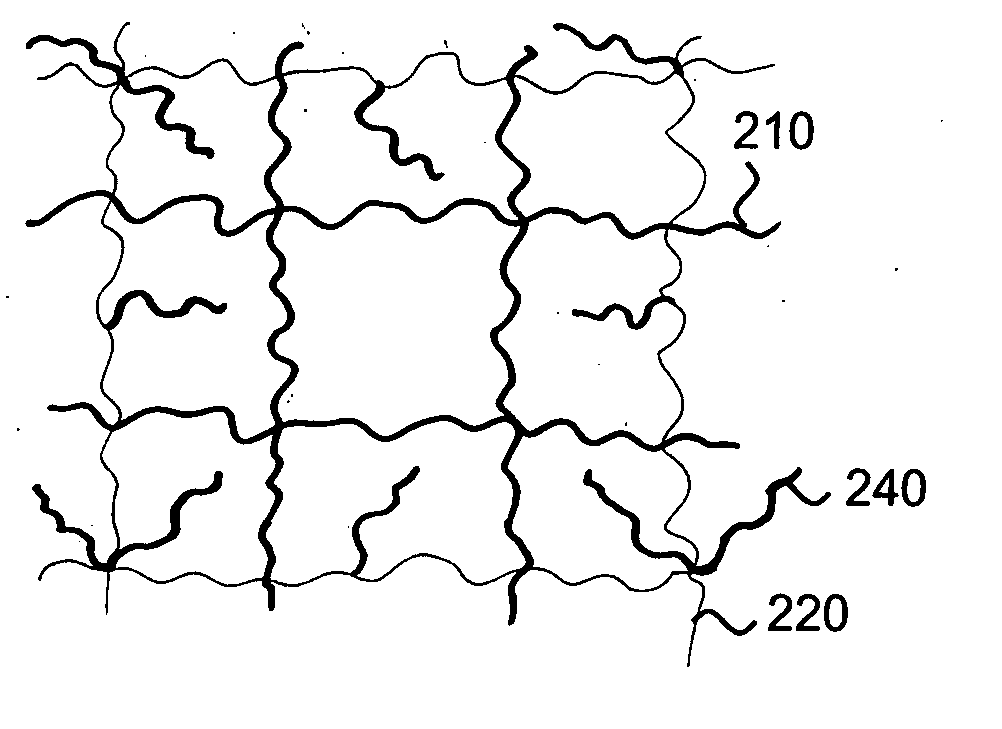

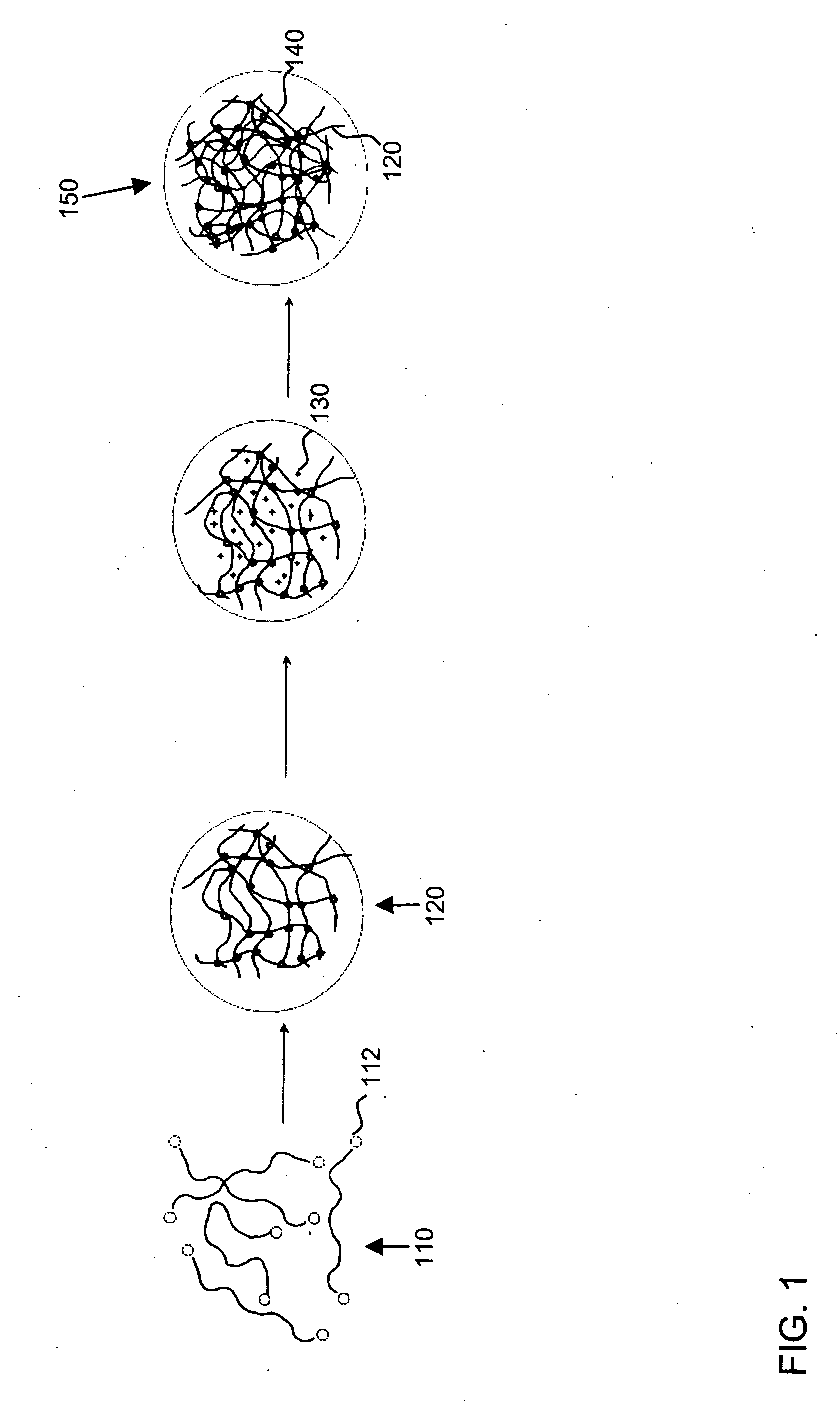

Membranes with controlled permeability to polar and apolar molecules in solution and methods of making same

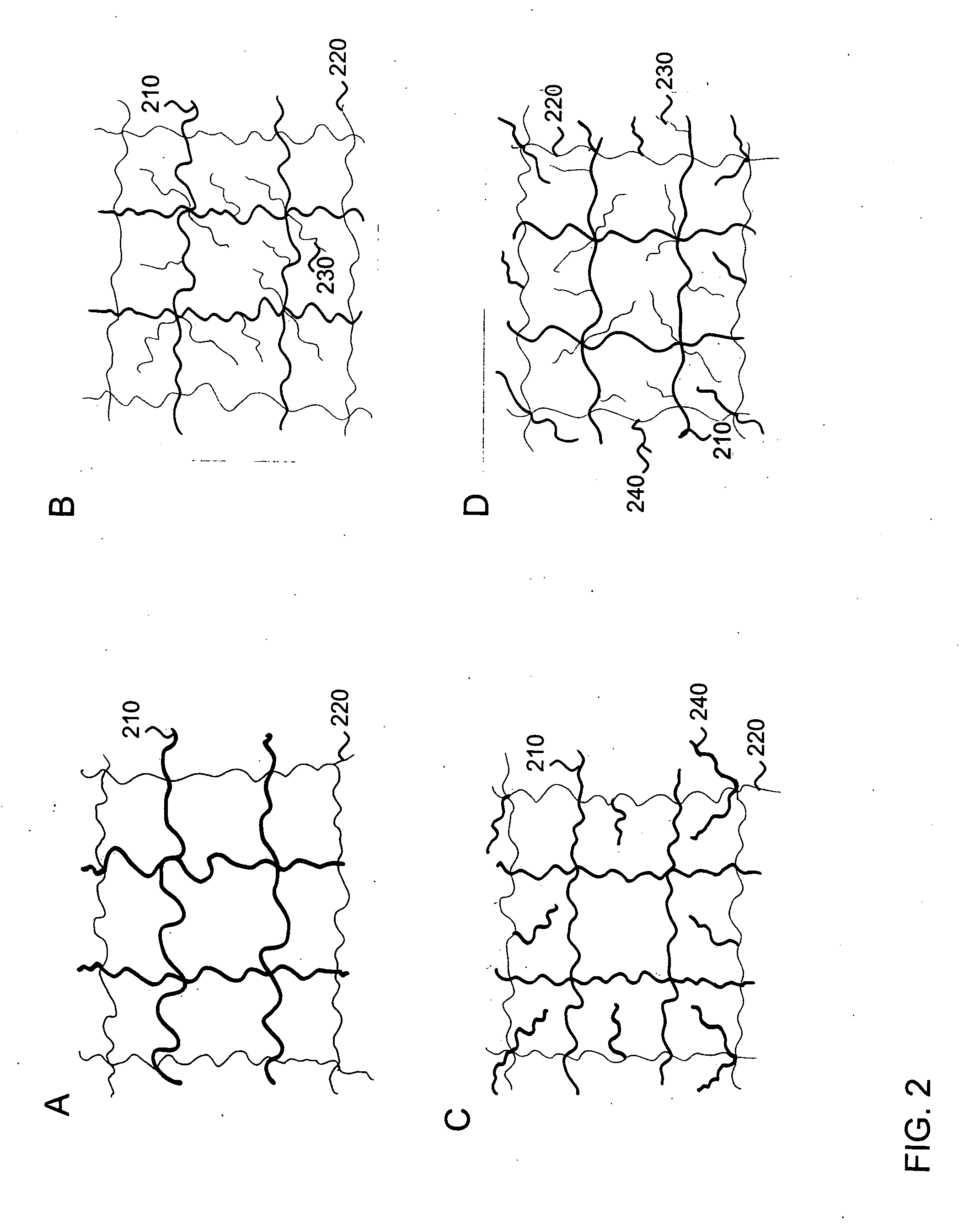

A membrane for use in an implantable glucose sensor including at least one crosslinked substantially hydrophobic polymer and at least one crosslinked substantially hydrophilic polymer; wherein the first and second polymers are different polymers and substantially form an interpenetrating polymer network, semi- interpenetrating polymer network, polymer blend, or copolymer. The membranes are generally characterized by providing a permeability ratio of oxygen to glucose of about 1 to about 1000 in units of (mg / dl glucose) per (mmHg oxygen). Three methods of making membranes from hydrophobic and hydrophilic monomers formed into polymer networks are provided, wherein according to at least two of the methods, the monomers may be substantially immiscible with one another.

Owner:RGT UNIV OF CALIFORNIA

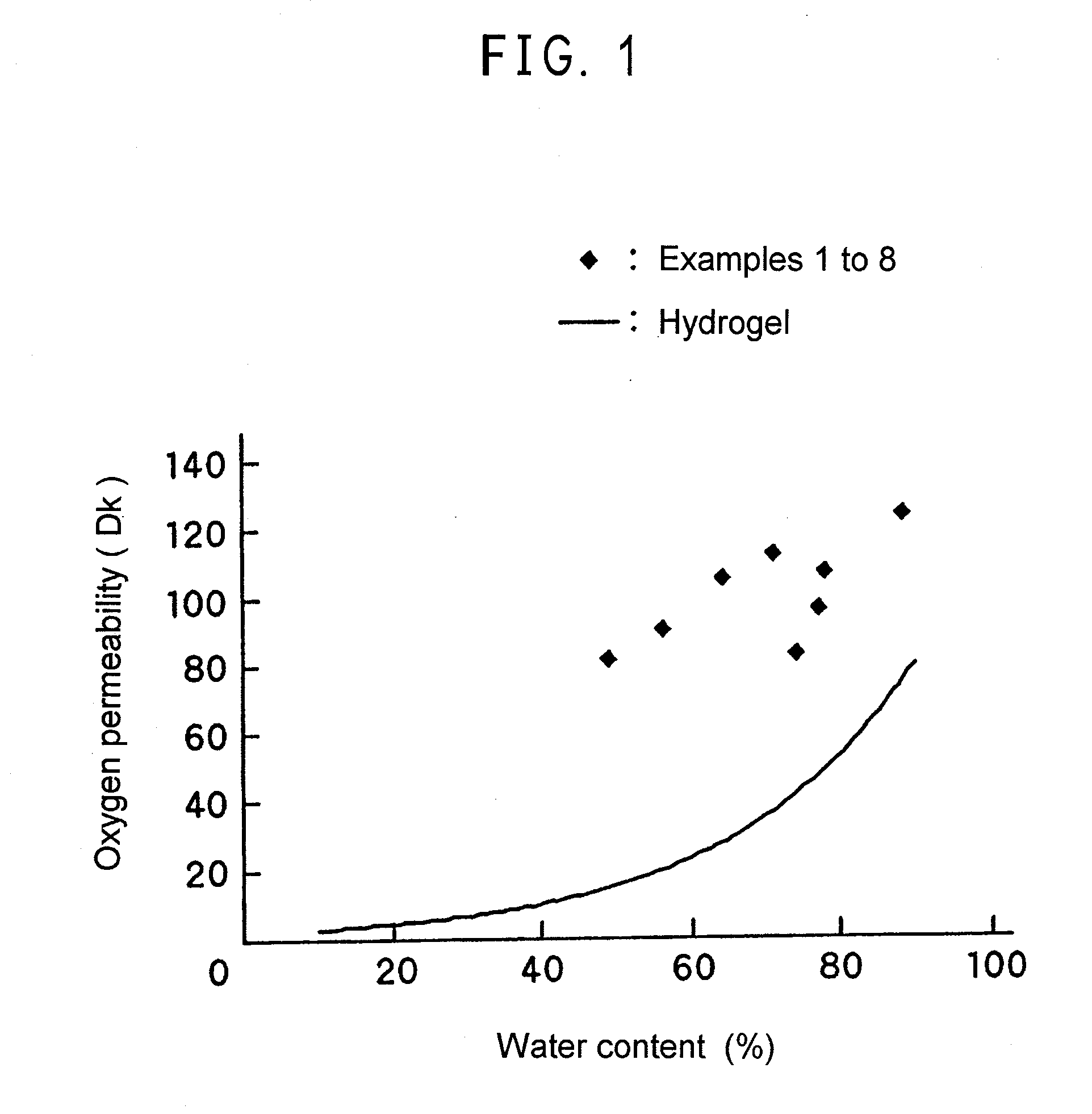

High water content silicone hydrogels

ActiveUS7934830B2Increase moisture contentSuitable oxygen permeability propertyLayered productsThin material handlingHydration reactionHydrophilic monomer

Owner:BAUSCH & LOMB INC

Ionic silicone hydrogels

Owner:JOHNSON & JOHNSON VISION CARE INC

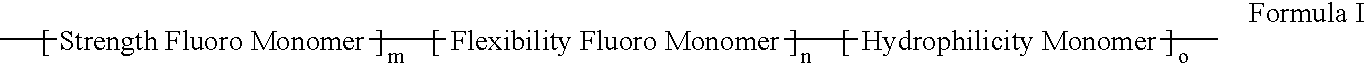

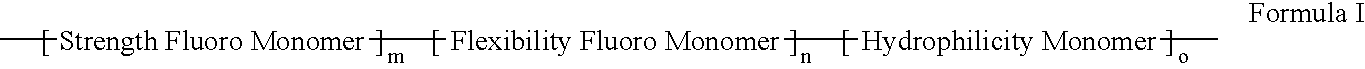

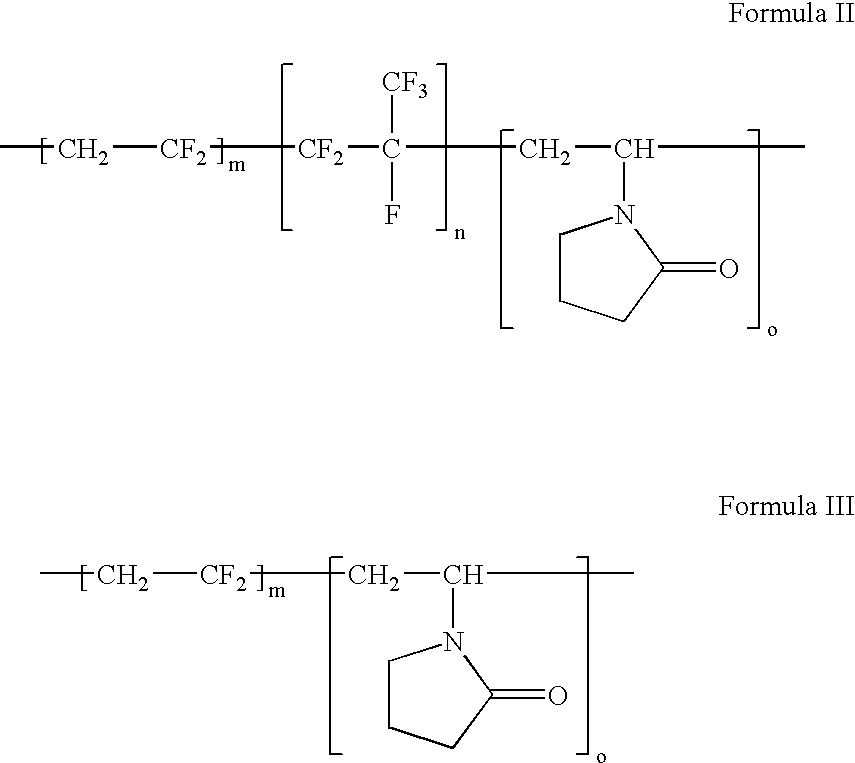

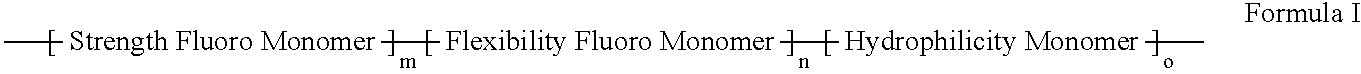

Polymers of fluorinated monomers and hydrophilic monomers

ActiveUS20060047095A1Improve propertiesProvide flexibilityFibre treatmentSurgeryDiseasePolymer science

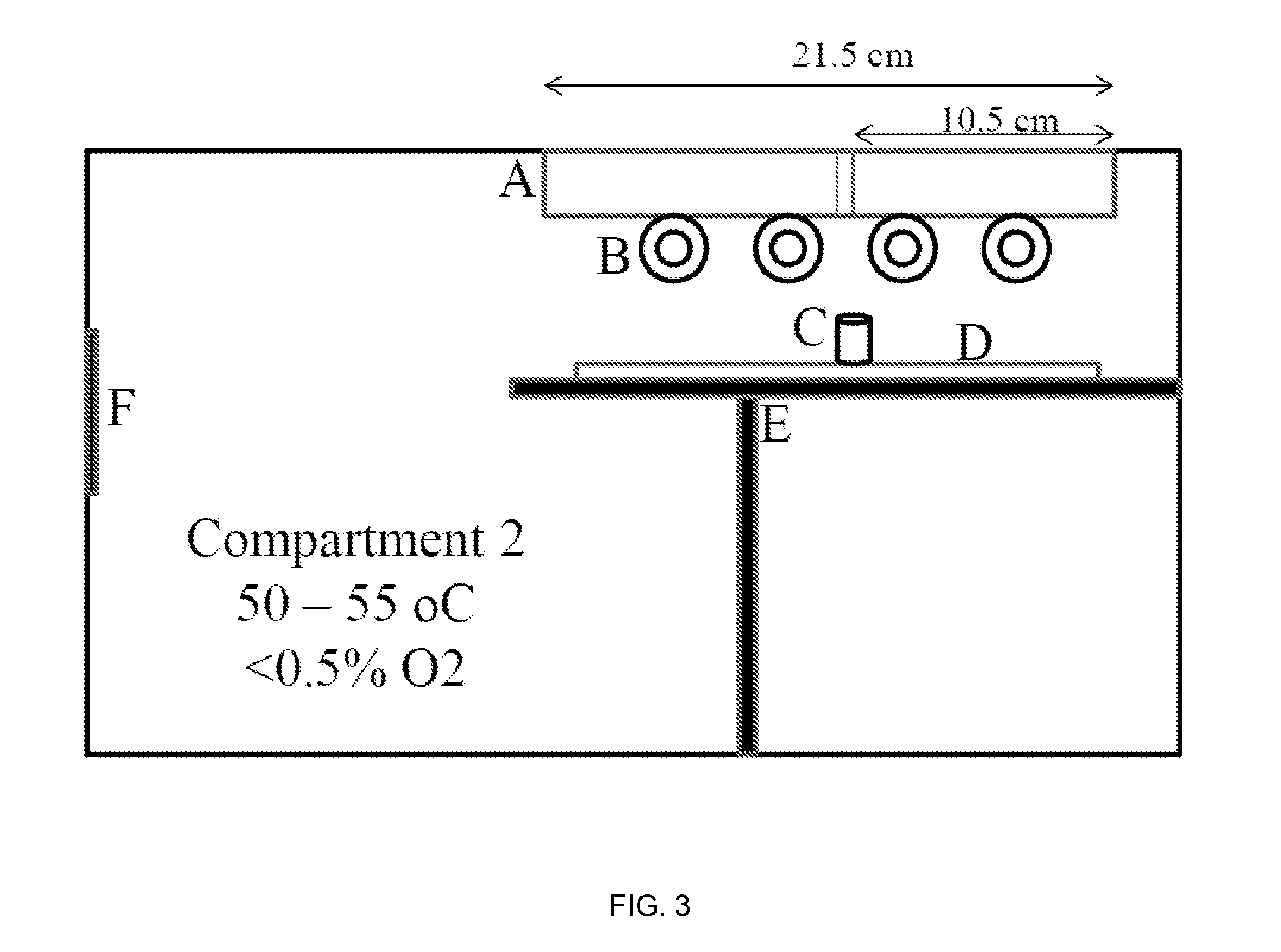

A polymer of fluorinated monomers and hydrophilic monomers is provided. It is also provided a polymer blend that contains a polymer of fluorinated monomers and another biocompatible polymer. The polymer of fluorinated monomers or polymer blend described herein and optionally a bioactive agent can form a coating on an implantable device such as a drug-delivery stent. The implantable device can be used for treating or preventing a disorder such as atherosclerosis, thrombosis, restenosis, hemorrhage, vascular dissection or perforation, vascular aneurysm, vulnerable plaque, chronic total occlusion, patent foramen ovale, claudication, anastomotic proliferation for vein and artificial grafts, bile duct obstruction, ureter obstruction, tumor obstruction, or combinations thereof.

Owner:ABBOTT CARDIOVASCULAR

Method for making hydrophobically associative polymers, methods of use and compositions

InactiveUS6417268B1Cosmetic preparationsSludge treatment by de-watering/drying/thickeningHydrophilic monomerSludge

Method for producing an hydrophobically associative polymer is provided which is characterized by forming a monomer solution comprising a surfactant, at least one hydrophobic ethylenically unsaturated monomer, at least one hydrophilic monomer selected from nonionic ethylenically monomers, cationic ethylenically unsaturated monomers, anionic ethylenically unsaturated monomers or mixtures thereof, and water; forming a salt solution comprising a multivalent salt and water; mixing the monomer solution and salt solution to form a mixed solution; and charging the mixed solution with an initiator, thereby polymerizing the monomers to form the hydrophobically associative polymer in a dispersion. Aqueous dispersion containing the hydrophobically associative polymer formed by the method. The aqueous dispersion containing the hydrophobically associative polymer may be used in a paint formulation, in a mobility control fluid useful in enhanced oil recovery, in a secondary or tertiary oil recovery system, in an enhanced oil recovery method, in a cementious composition, in an oil well drilling mud formulation, in a fracturing fluid formulation, in a wastewater treatment system, or in a dewatering sludge system.

Owner:SOLENIS TECH CAYMAN

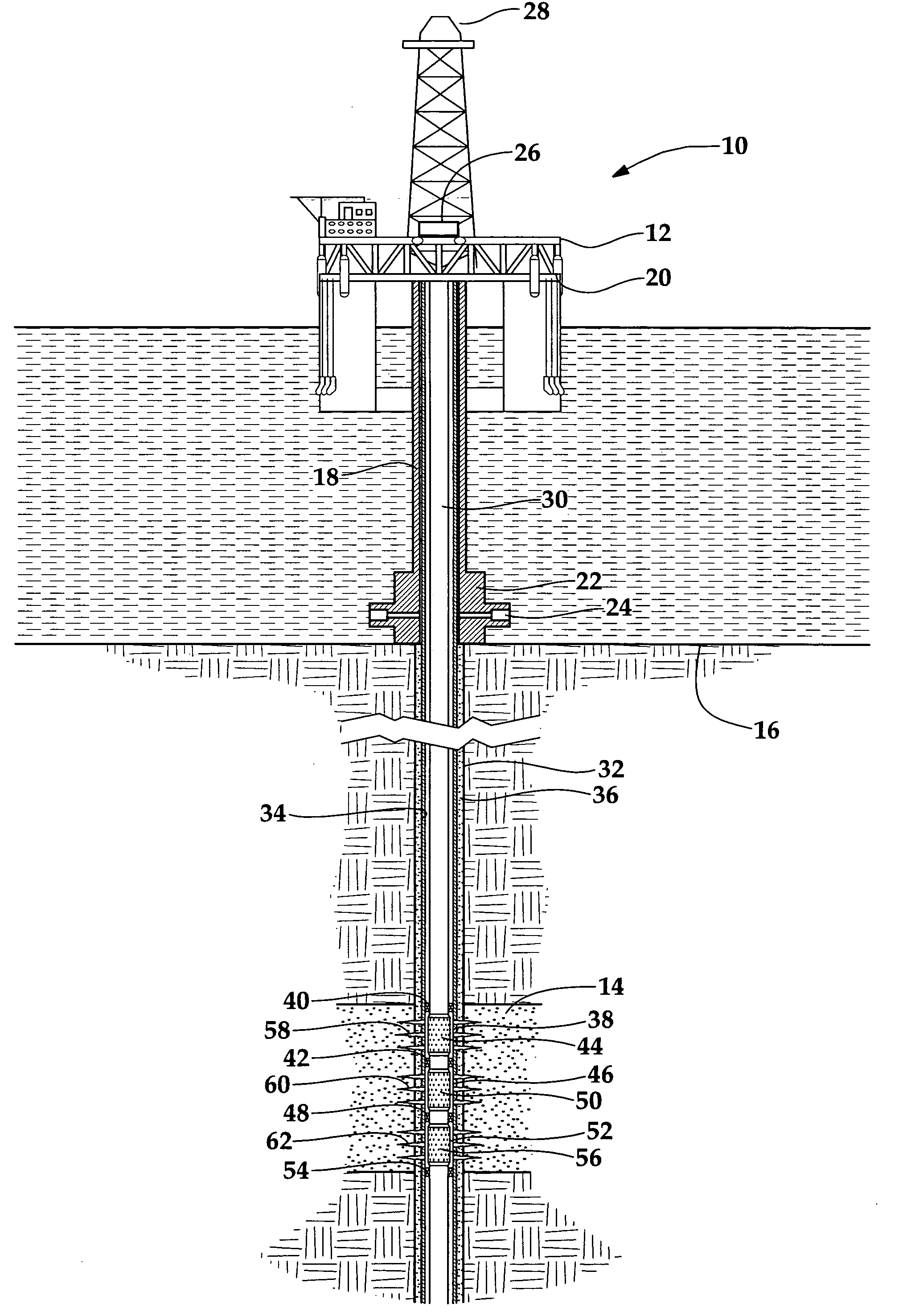

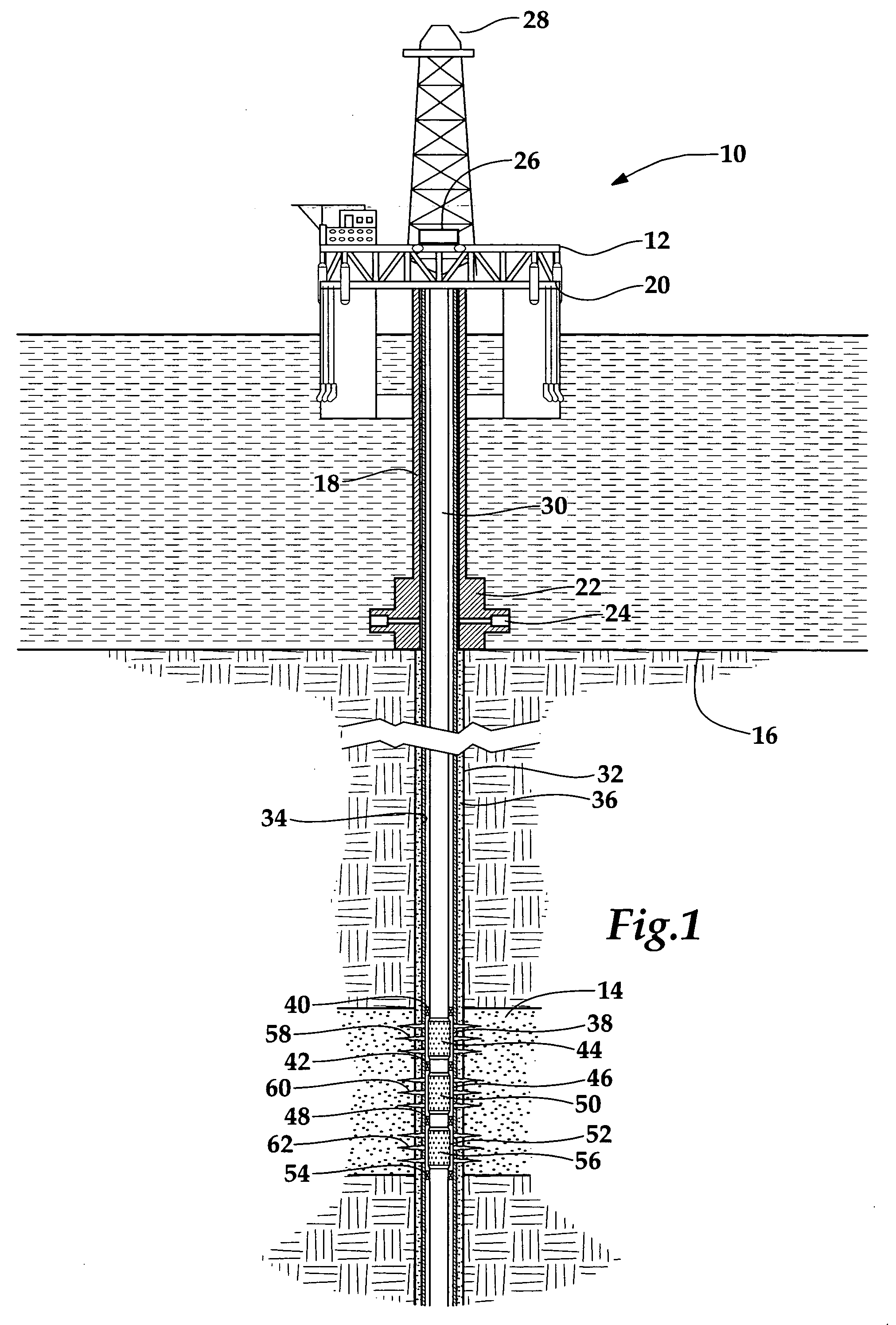

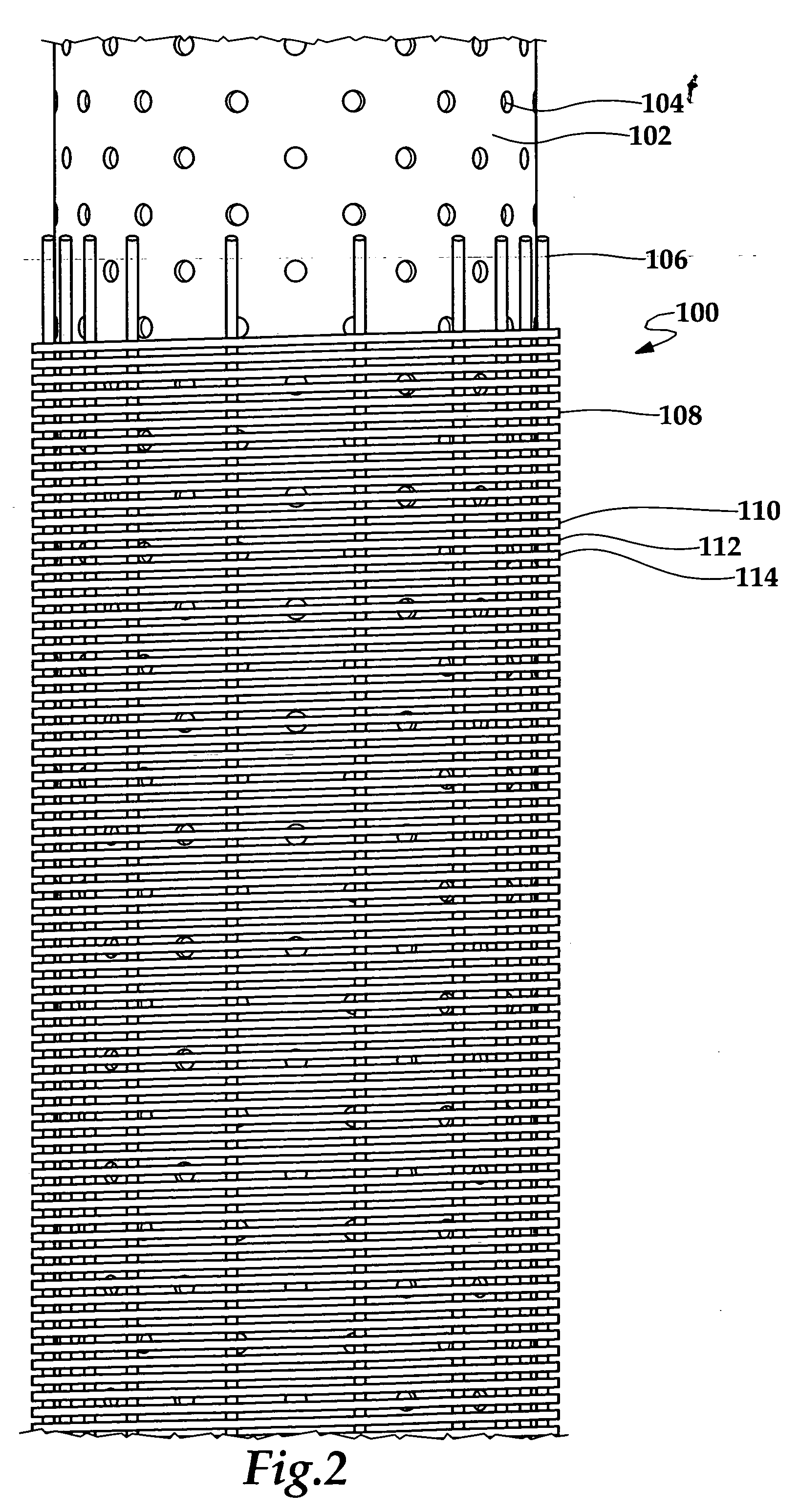

Apparatus and method for reducing water production from a hydrocarbon producing well

InactiveUS20070012444A1Reduce water productionReduce penetrationFluid removalSealing/packingHydrophilic monomerWater production

A filtering apparatus for use in a hydrocarbon producing well for reducing water production therein includes a filtering medium treated with a relative permeability modifier such that the relative permeability modifier reduces the permeability of the filtering medium if the relative permeability modifier contacts water production. The relative permeability modifier may be used to treat a metal portion of the filtering medium in the case of a wire wrap screen or a wire mesh screen or may be use treat a metal portion or the prepacked component of a prepacked screen. The relative permeability modifier may be a polymer of at least one hydrophilic monomer and at least one hydrophobically modified hydrophilic monomer, a hydrophobically modified polymer, a hydrophobically modified water-soluble polymer, hydrophobically modified copolymers thereof or the like.

Owner:HALLIBURTON ENERGY SERVICES INC

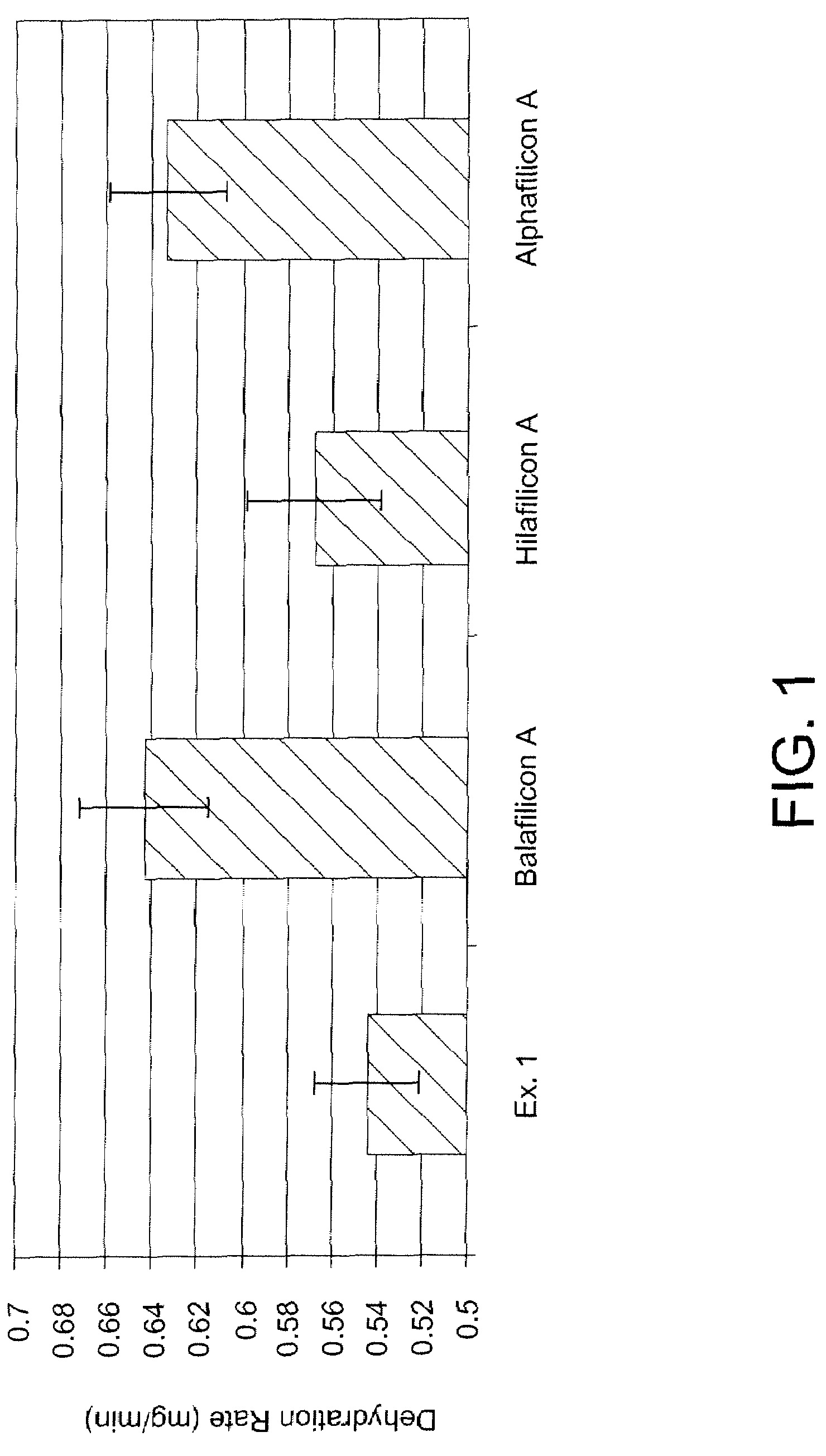

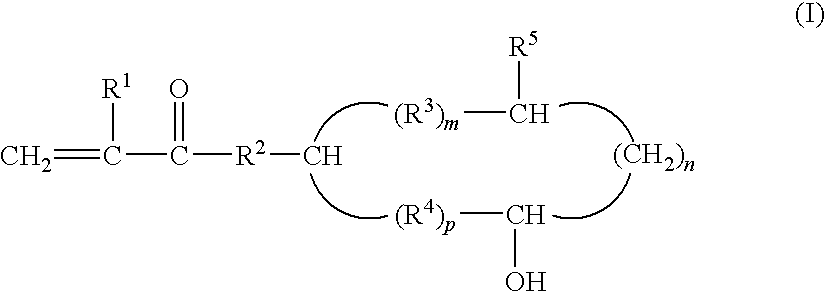

High water content ophthalmic devices

ActiveUS8138290B2Reduce dehydrationAvoid problemsSenses disorderPharmaceutical delivery mechanismHydrophilic monomerHigh water content

An ophthalmic device is disclosed that is a polymerization product of a monomeric mixture comprising (a) a major amount of a non-silicone-containing hydrophilic monomer; (b) a hydrophobic monomer; and (c) a crosslinking agent, wherein the ophthalmic device has an equilibrium water content of at least about 70 weight percent and further wherein the ophthalmic device has an evaporative dehydration barrier layer on the surface thereof. A method for the mitigation of evaporative corneal dehydration employing the high water content ophthalmic device is also disclosed.

Owner:BAUSCH & LOMB INC

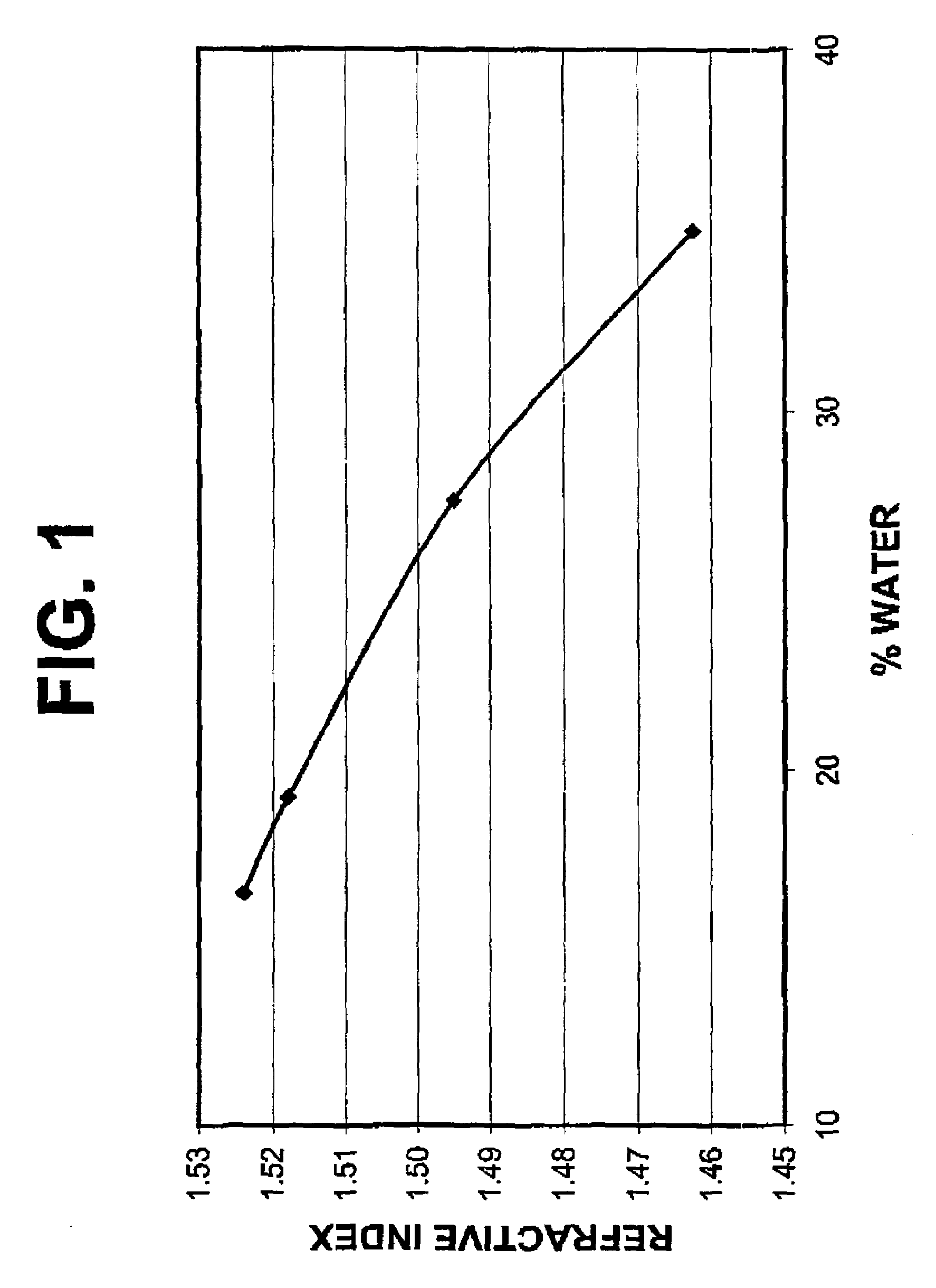

Low water content, high refractive index, flexible, polymeric compositions

InactiveUS6852793B2Ideal physical propertyHigh refractive indexOrganic dyesIntraocular lensHydrophilic monomerRefractive index

Optically transparent, relatively high refractive index polymeric compositions and ophthalmic devices such as intraocular lenses and corneal inlays made therefrom are described herein. The preferred polymeric compositions are produced through the polymerization of one or more copolymers with one or more hydrophilic monomers and optionally one or more aromatic-based monomers, hydrophobic monomers or a combination thereof.

Owner:BAUSCH & LOMB INC

Surface treatment of medical devices

InactiveUS20080142038A1Improve wettabilityElectrostatic cleaningCoatingsHydrophilic monomerCarboxylic acid

A method for improving the wettability of a medical device is provided, the method comprising the steps of (a) providing a medical device formed from a monomer mixture comprising a hydrophilic monomer and a siloxy-containing monomer, (b) subjecting a surface of the medical device to a surface treatment, and (c) contacting the treated surface of the medical device with a wetting agent solution comprising a carboxylic acid-containing polymer or copolymer to form a carboxylic acid-containing polymeric or copolymeric layer on the treated surface of the medical device.

Owner:BAUSCH & LOMB INC

Polymers of fluorinated monomers and hydrophilic monomers

ActiveUS20060269586A1Provide flexibilityProvide strengthStentsAntifouling/underwater paintsHydrophilic monomerPolymer science

A polymer blend that contains a polymer of fluorinated monomers and another biocompatible polymer. The polymer blend can form a coating on a medical device. The medical device can be used for treat, prevent or ameliorate a medical condition.

Owner:ABBOTT CARDIOVASCULAR

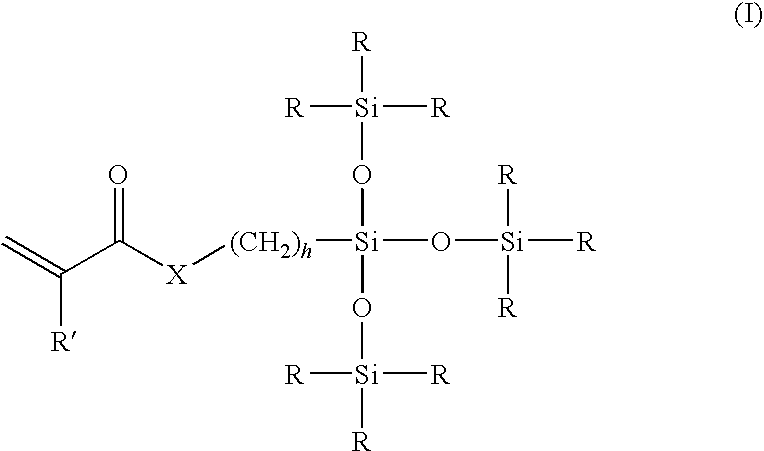

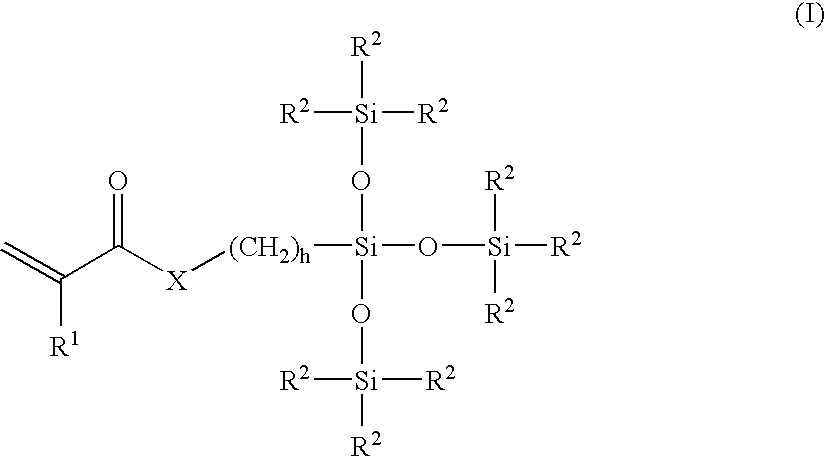

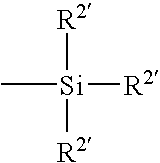

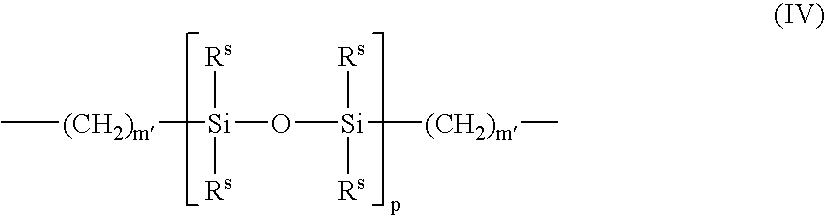

High refractive index polymeric siloxysilane compositions

InactiveUS7169874B2Improve clarityEasy to produceSilicon organic compoundsProsthesisHydrophilic monomerHydrophilic polymers

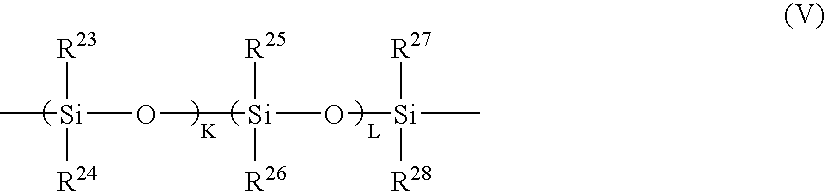

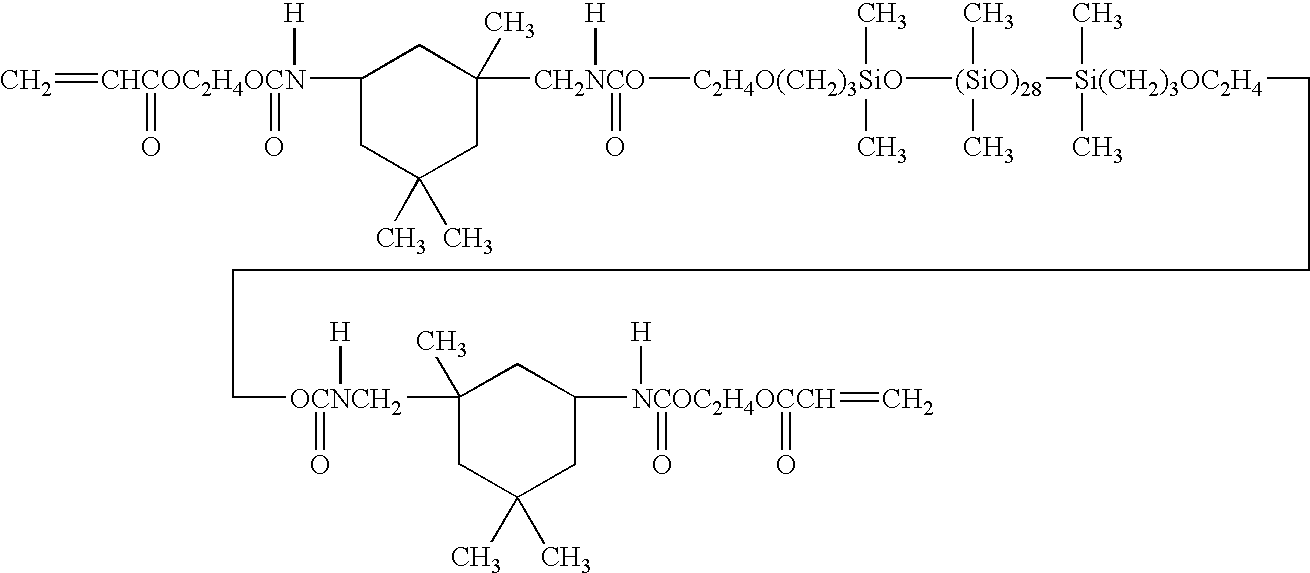

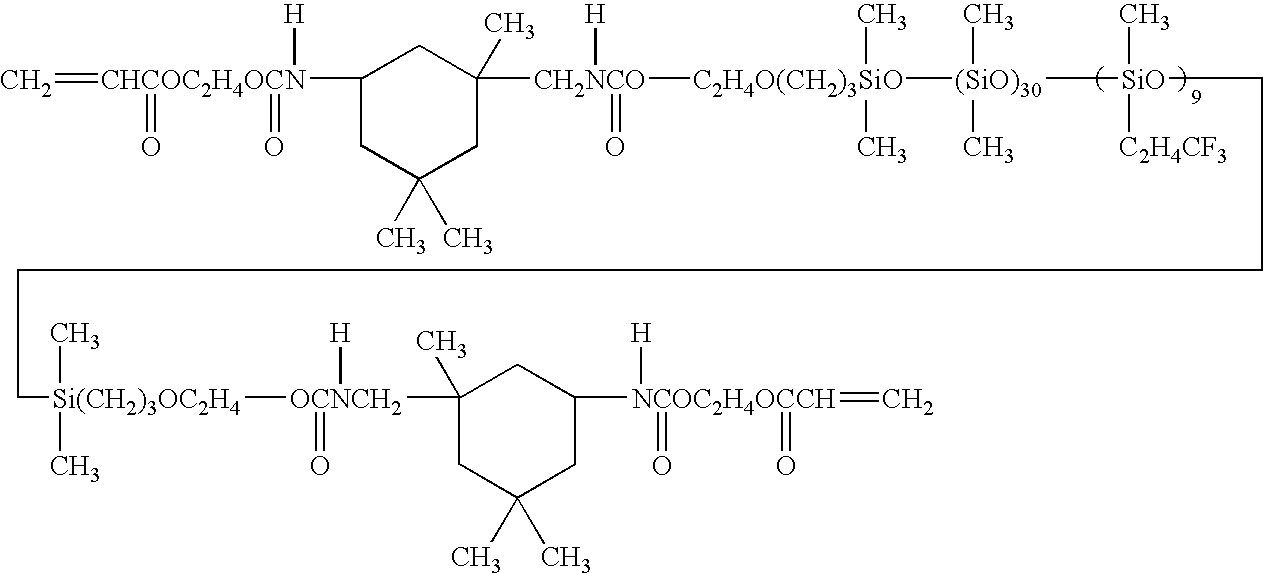

Optically transparent, relatively high refractive index polymeric compositions and ophthalmic devices such as intraocular lenses, contact lenses and corneal inlays made therefrom are described herein. The preferred polymeric compositions are produced through the polymerization of one or more siloxysilane monomers or the copolymerization of one or more siloxysilane monomers with one or more aromatic or non-aromatic non-siloxy monomers, hydrophobic monomers or hydrophilic monomers.

Owner:BAUSCH & LOMB INC

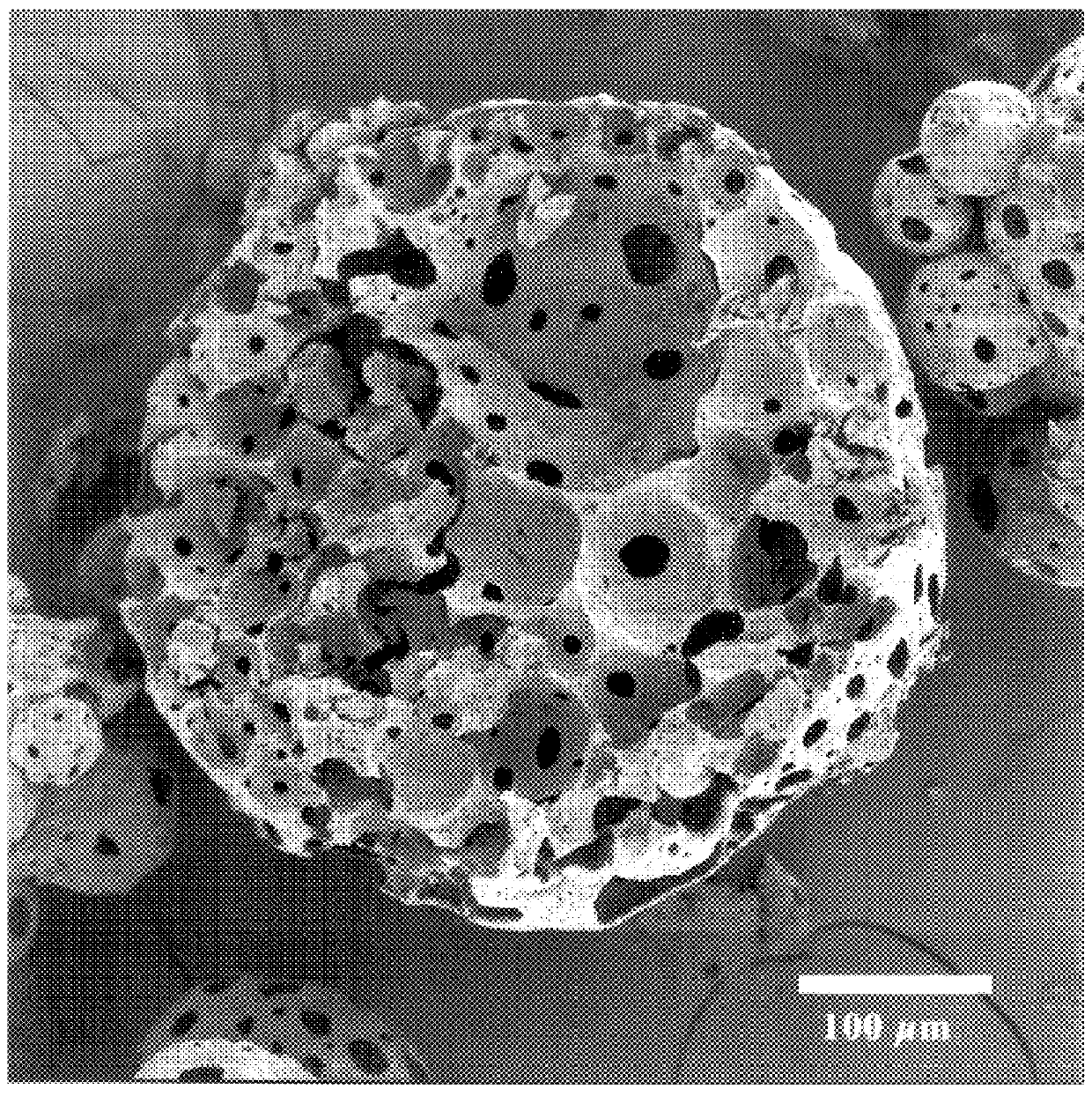

Hydrophilic polymeric material and method of preparation

InactiveUS6218440B1Allows preparationStable maintenanceOther chemical processesPharmaceutical non-active ingredientsHydrophilic monomerPolymer science

The present invention relates to a porous crosslinked hydrophilic polymeric material having cavities joined by interconnecting pores wherein at least some of the cavities at the interior of the material communicate with the surface of the material. The present invention also relates to a process for producing the polymeric material. This process involves combining a hydrophilic monomer phase with an oil discontinuous phase to form an emulsion, and polymerizing the emulsion. The emulsion can be a high internal phase emulsion (i.e., a "HIPE"). The polymeric material can be produced in a variety of forms. In one embodiment the emulsion is suspended in an oil suspension medium, and emulsion droplets are polymerized to produce polymeric microbeads.

Owner:SUNSTORM RES CORP

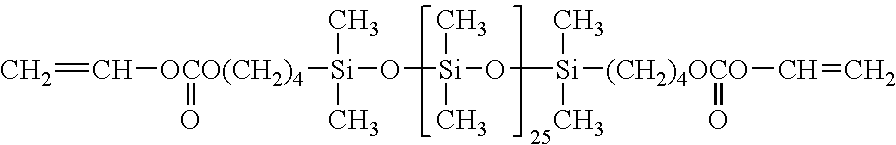

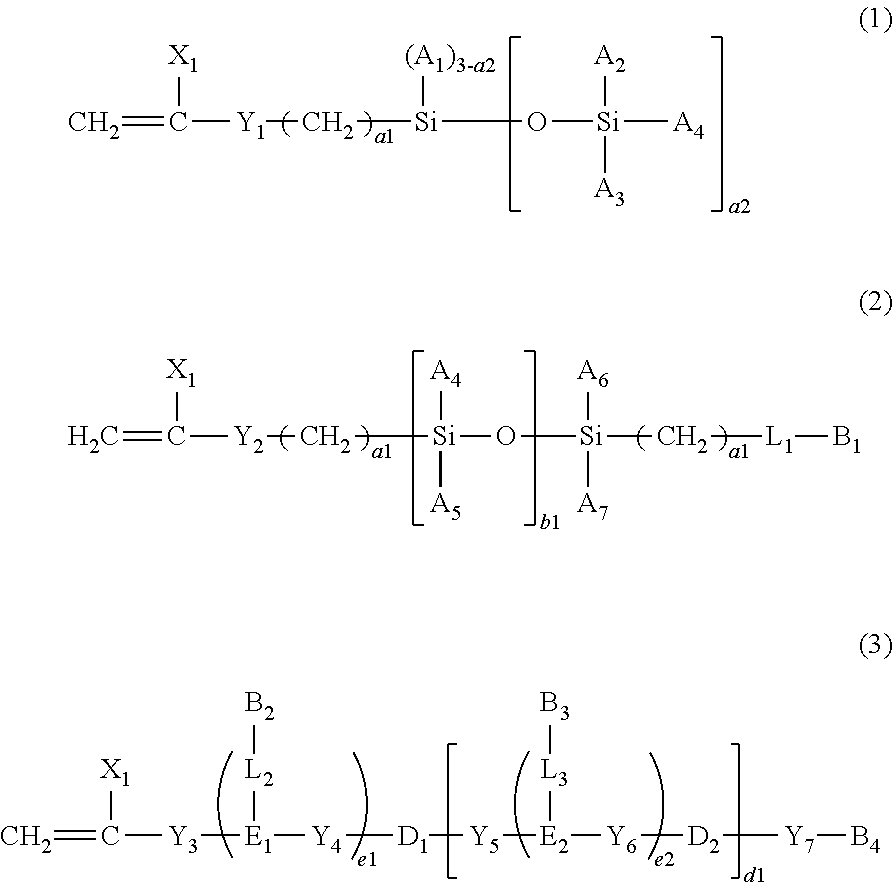

Water-processable silicone-containing prepolymers and uses thereof

The invention provide a class of water-processable polymerizable prepolymers which comprises (1) siloxane-containing monomeric units derived at least one siloxane containing monomer having one hydrophilic group or chain and / or polysiloxane-containing crosslinking units derived from at least one hydrophilized polysiloxane or chain-extended polysiloxane crosslinker; (2) hydrophilic monomeric units derived from one or more hydrophilic vinylic monomers; and (3) from about 0.05% to about 5% by weight of polymerizable units each having a pendant or terminal, ethylenically-unsaturated group and free of any polysiloxane segment. The prepolymer comprises from about 20% to about 50% by weight of silicone relative to the total weight of the prepolymer and has a high water solubility or dispersibility of at least about 5% by weight in water and suitable for making silicone hydrogel contact lenses.

Owner:ALCON INC

Aqueous based surfactant compositions

InactiveUS6177396B1Low viscosityUnstable structureInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsFlocculationHydrophilic monomer

The use of a stabiliser comprising a hydrophilic polymeric chain of more than four hydrophilic monomer groups and / or having a mass greater than 300 amu, linked at one end to a hydrocarbon-soluble hydrophobic group to reduce or prevent the flocculation of systems comprising a flocculable surfactant and a liquid medium which is capable of flocculating the surfactant and in which the stabiliser is capable of existing as a micellar solution at a concentration of at least 1% by weight.

Owner:HUNTSMAN INT LLC

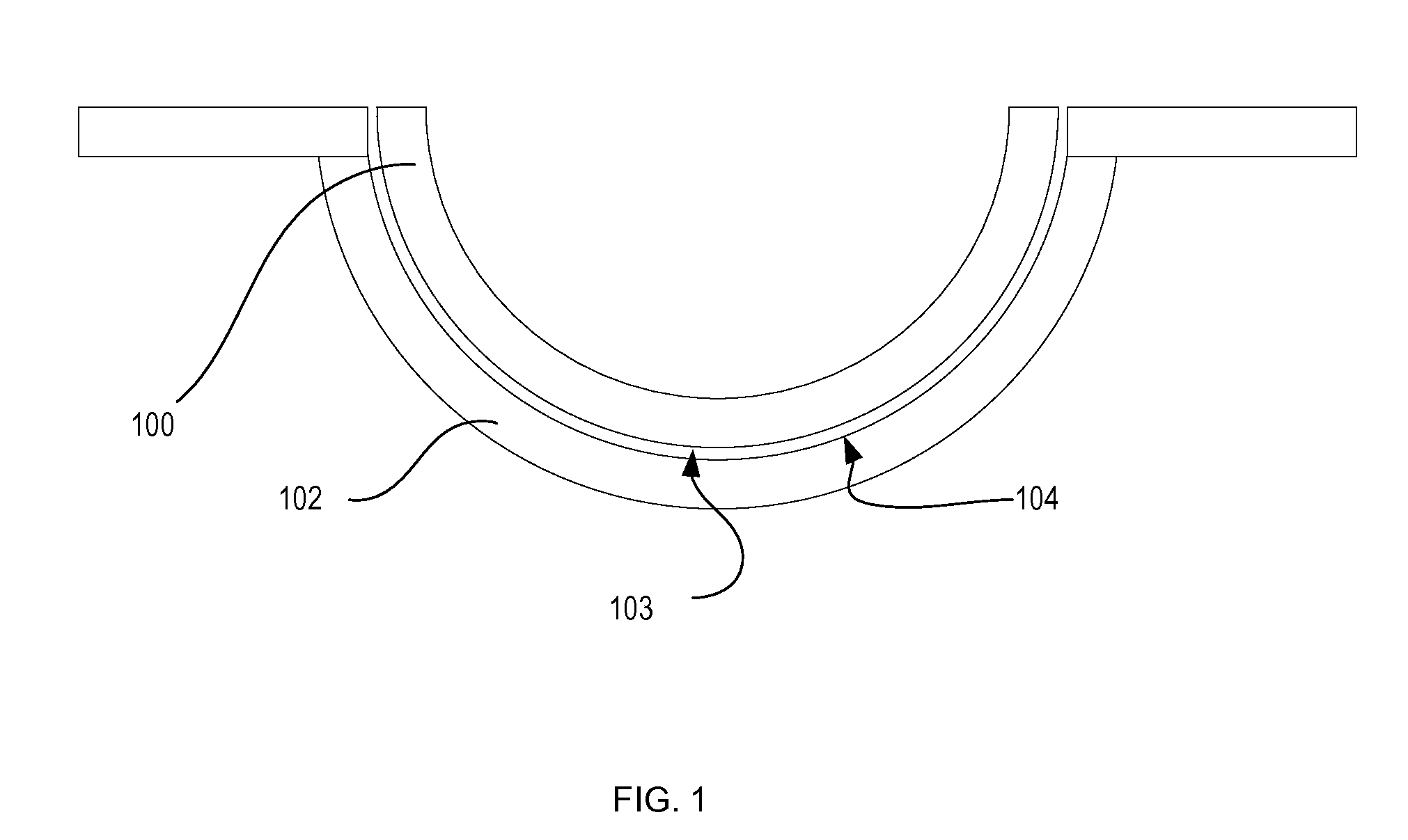

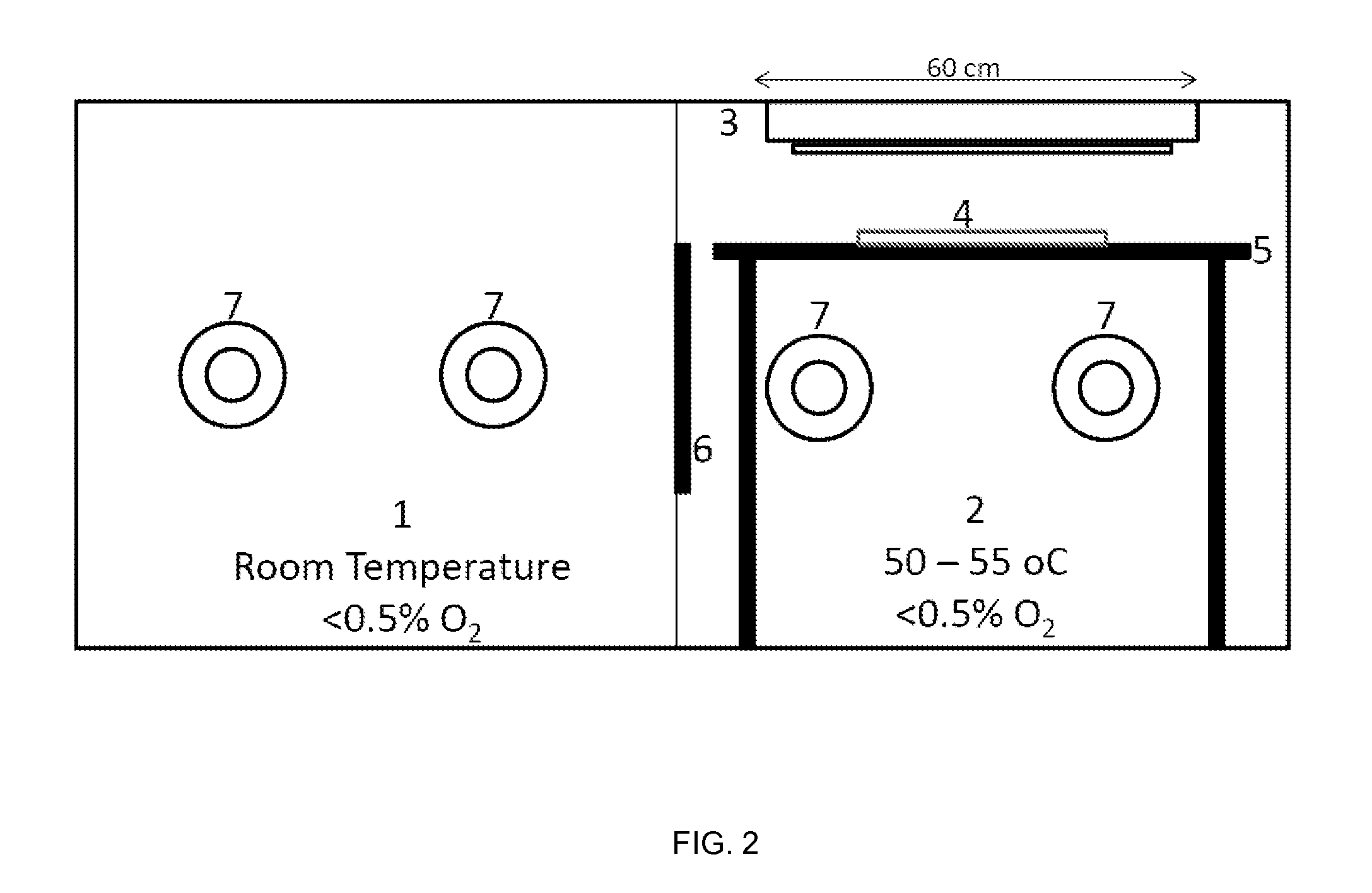

Conformable bandage and coating material

ActiveUS20070129474A1Relief the painCreating damageAntibacterial agentsPowder deliveryHydrophilic monomerNitrogen

The liquid, polymer-containing coating materials of this invention comprise a polymer of a polymerizable, nitrogen-containing, hydrophilic monomer, which may give thermoresponsive properties, and which is copolymerized with a hydrophobic, polymerizable siloxy-containing monomer, in a solvent system of a volatile hydrophobic (non-polar) liquid that is non-stinging to a user. The material forms a coating or bandage in the form of a film when applied to a surface or the skin of a user.

Owner:ROCHAL TECH LLC

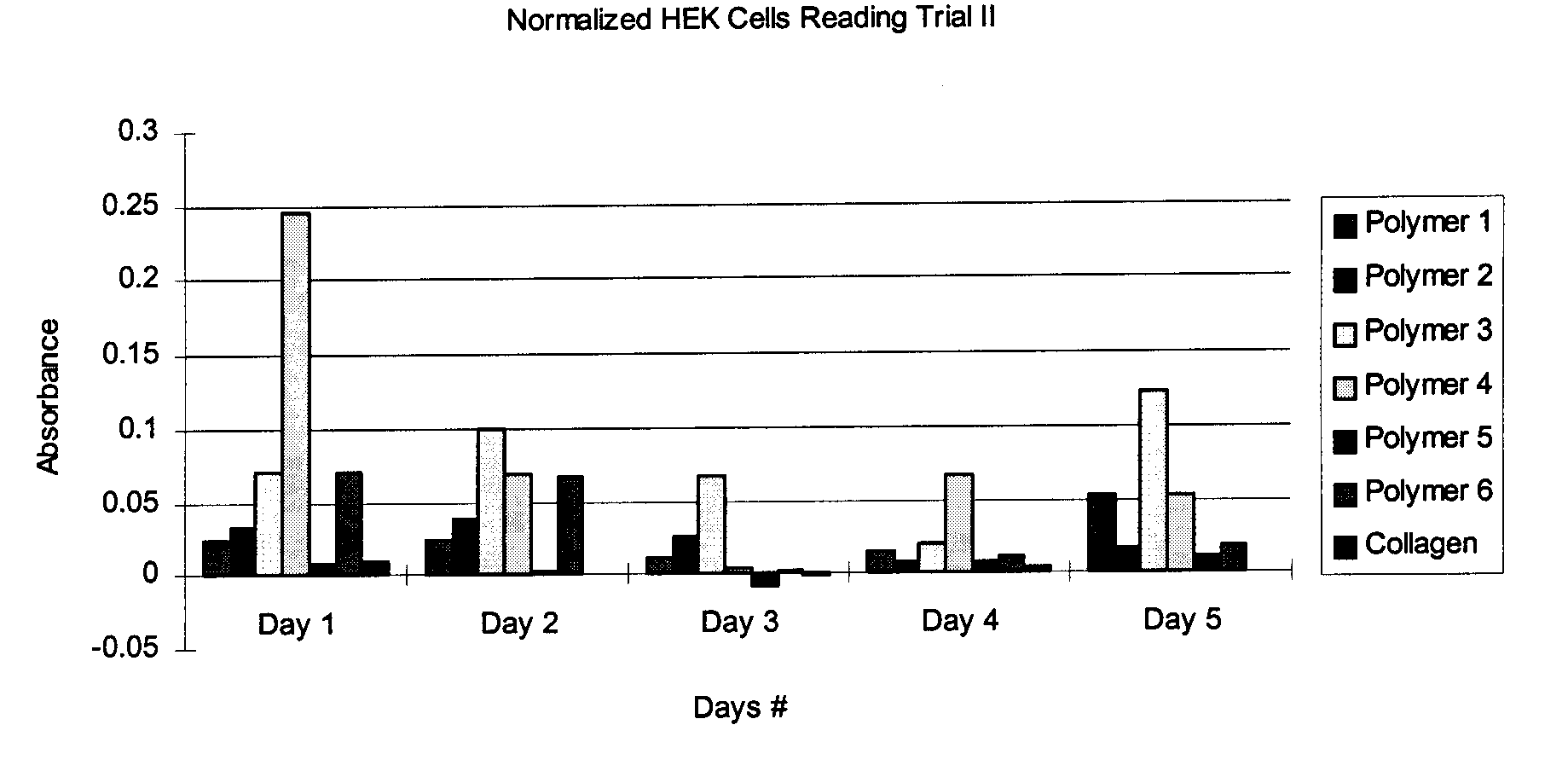

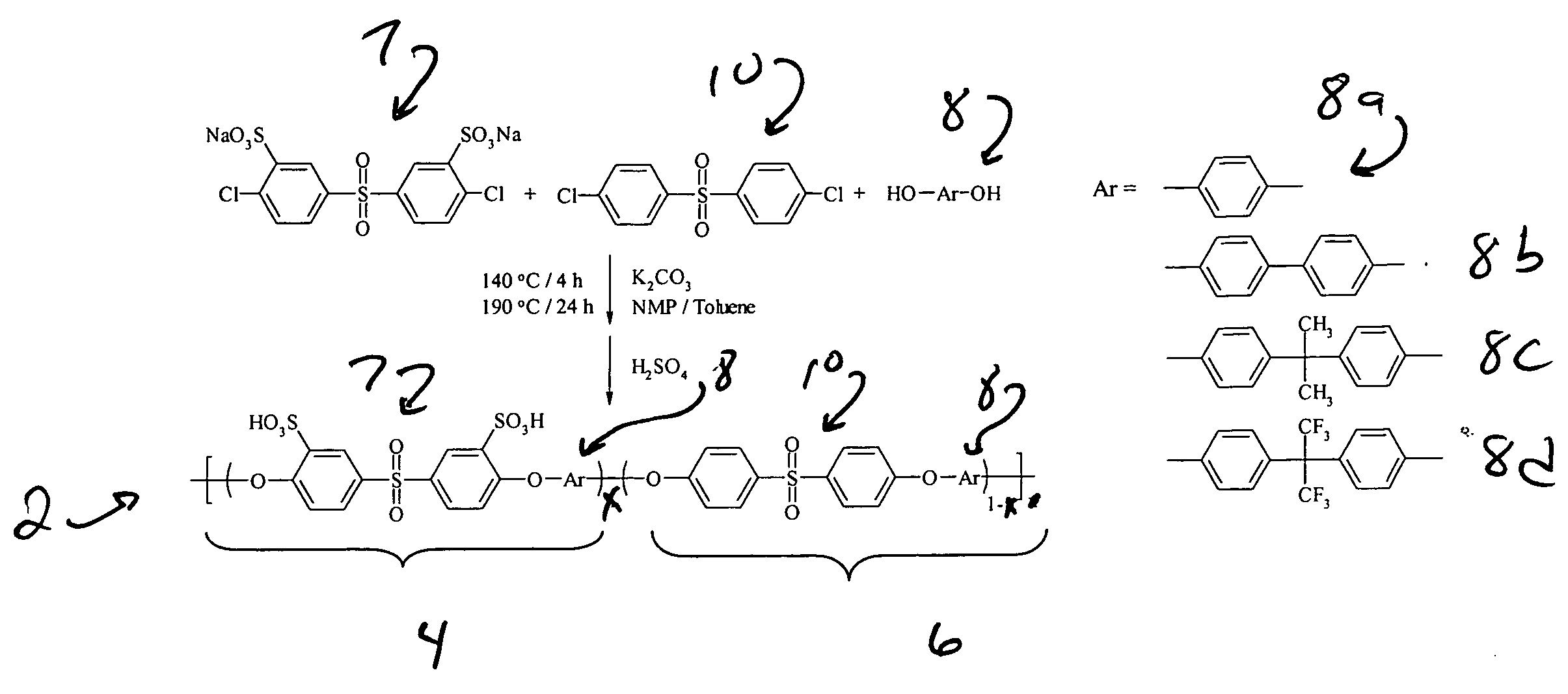

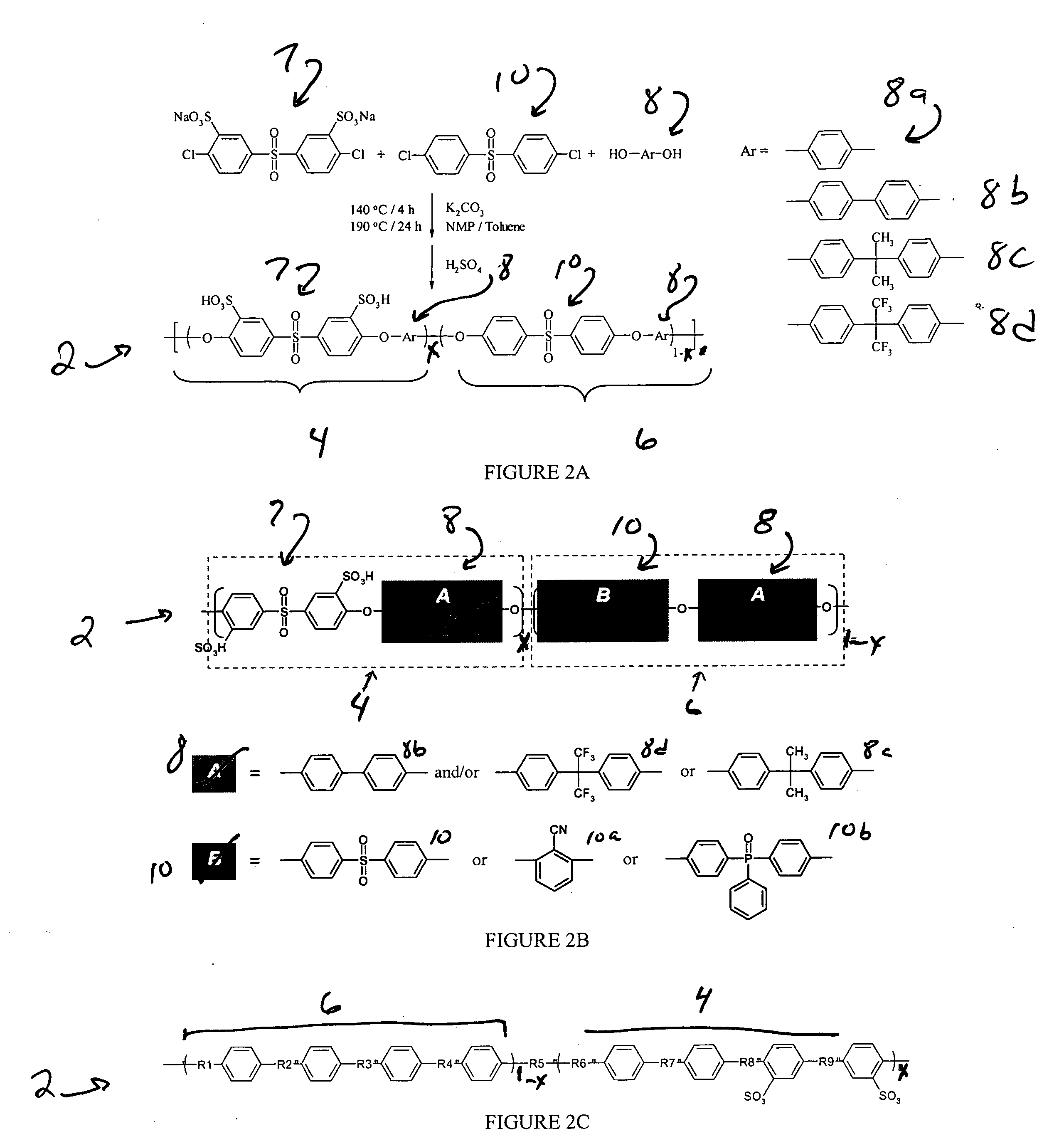

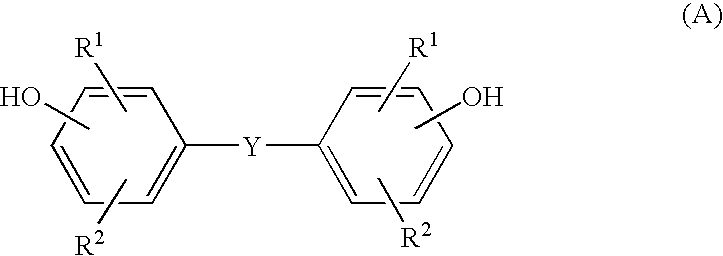

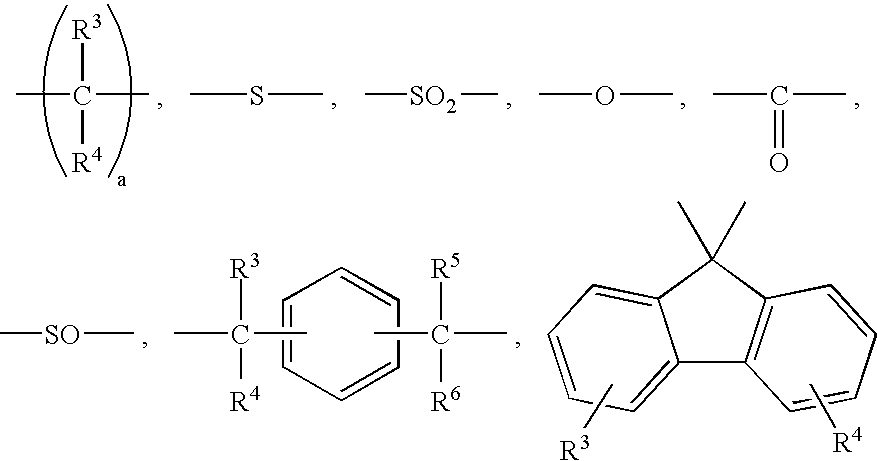

Chlorine resistant desalination membranes based on directly sulfonated poly(Arylene Ether Sulfone) copolymers

ActiveUS20070163951A1Improve pressure resistanceExemption stepsSemi-permeable membranesMembranesHydrophilic monomerSulfonate

The present invention provides a membrane, kit, and method of making a hydrophilic-hydrophobic random copolymer membrane. The hydrophilic-hydrophobic random copolymer membrane includes a hydrophilic-hydrophobic random copolymer. The hydrophilic-hydrophobic random copolymer includes one or more hydrophilic monomers having a sulfonated polyarylsulfone monomer and a second monomer and one or more hydrophobic monomers having a non-sulfonated third monomer and a fourth monomer. The sulfonated polyarylsulfone monomer introduces a sulfonate into the hydrophilic-hydrophobic random copolymer prior to polymerization.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

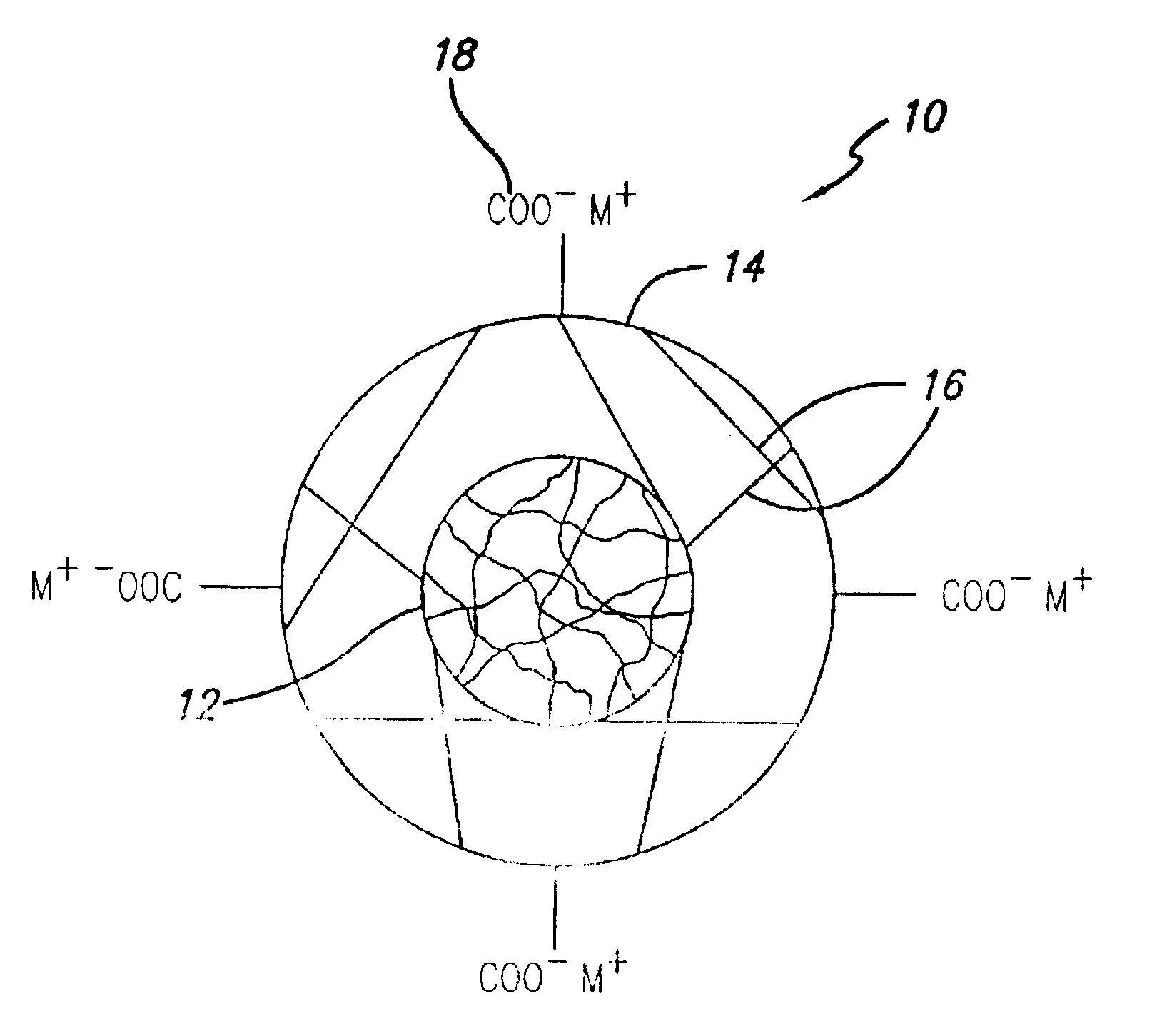

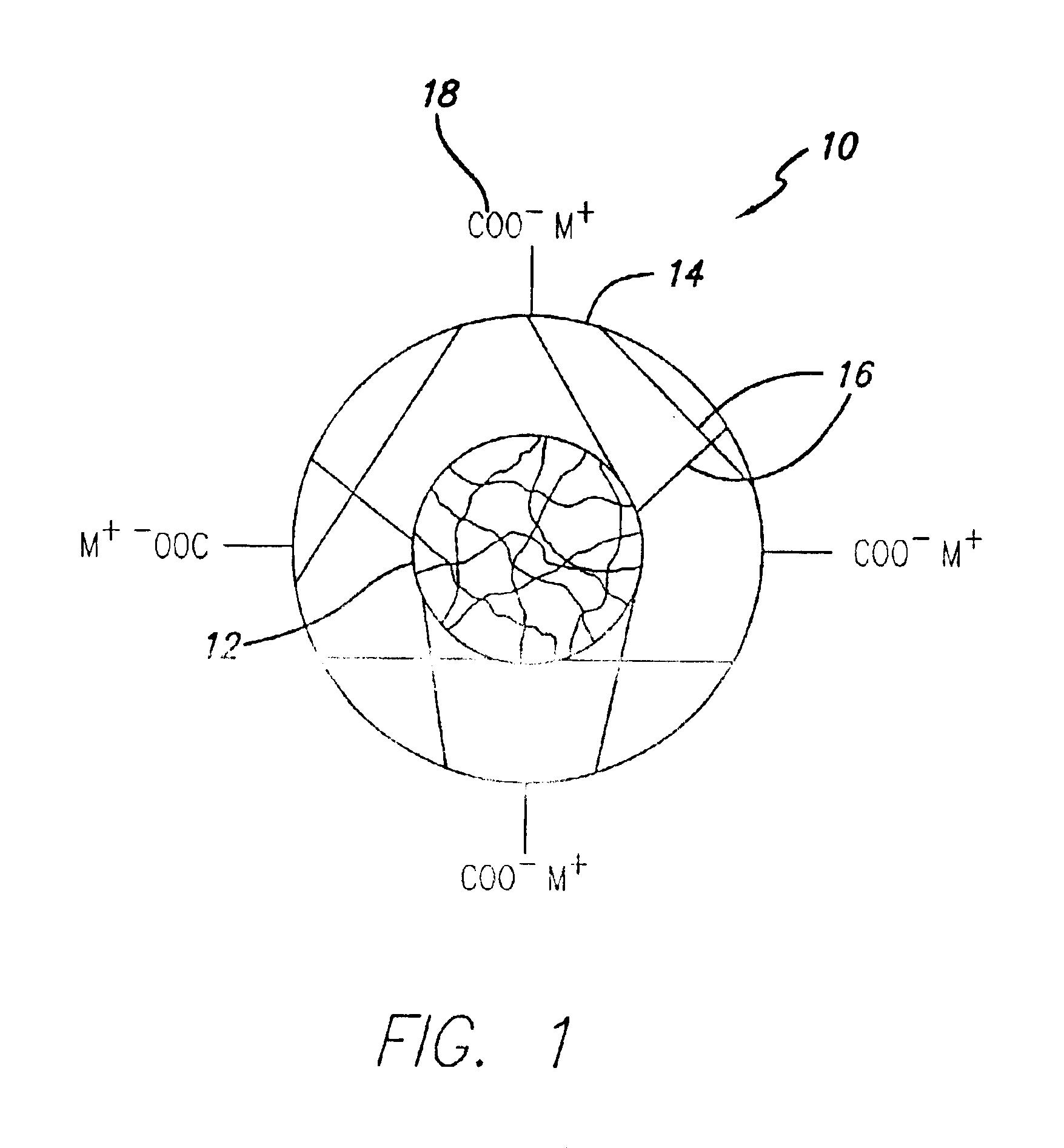

Specific core-shell polymer additive for ink-jet inks to improve durability

InactiveUS6858301B2Improve propertiesGood shear stabilityPhotosensitive materialsDuplicating/marking methodsHydrophilic monomerVitrification

Polymer particles are provided having (1) a core with a glass transition temperature within a range of −50° to +110° C. and (2) a shell surrounding the core. The core comprises at least one layer, with the layer(s) comprising at least one polymerized hydrophobic monomer and, optionally, a first cross-linker. The shell comprises a copolymerized mixture of least one hydrophobic monomer and at least one hydrophilic monomer and a second cross-linker for increasing thermal shear stability by forming cross-linkages. Use of these polymer particles in aqueous-based ink-jet inks provide laser print quality without any secondary treatment.

Owner:HEWLETT PACKARD DEV CO LP

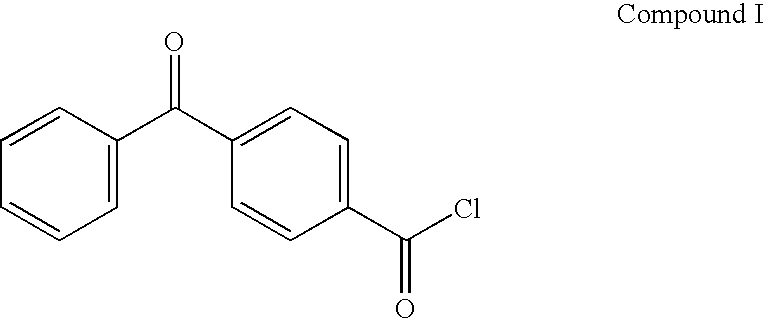

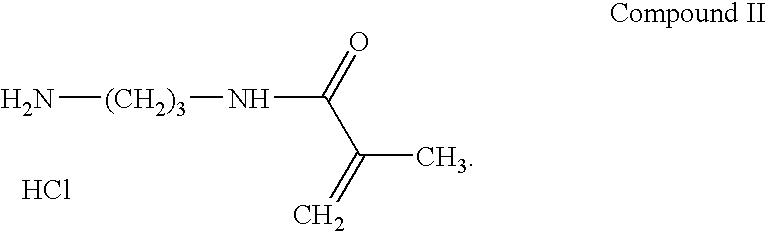

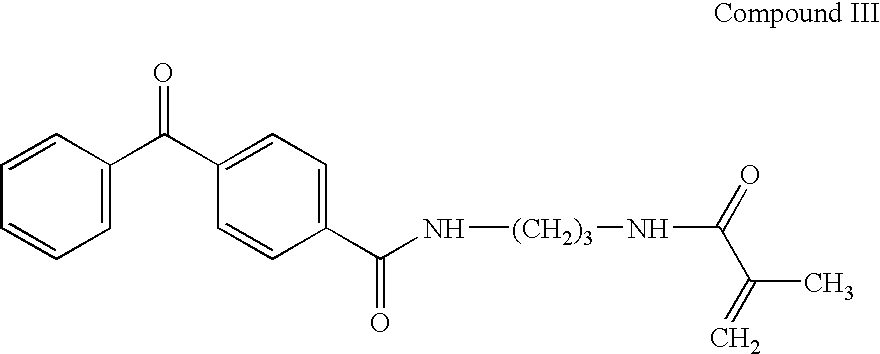

Medicament incorporation matrix

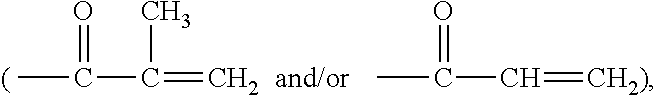

ActiveUS20060165751A1Increased durabilityIncrease tenacityImpression capsOther blood circulation devicesHydrophilic monomerMeth-

A coating composition, in both its uncrosslinked and crosslinked forms, for use in delivering a medicament from the surface of a medical device positioned in vivo. Once crosslinked, the coating composition provides a gel matrix adapted to contain the medicament in a form that permits the medicament to be released from the matrix in a prolonged, controlled, predictable and effective manner in vivo. A composition includes a polyether monomer, such as an alkoxy poly(alkylene glycol), a carboxylic acid-containing monomer, such as (meth)acrylic acid, a photoderivatized monomer, and a hydrophilic monomer such as acrylamide.

Owner:SURMODICS INC

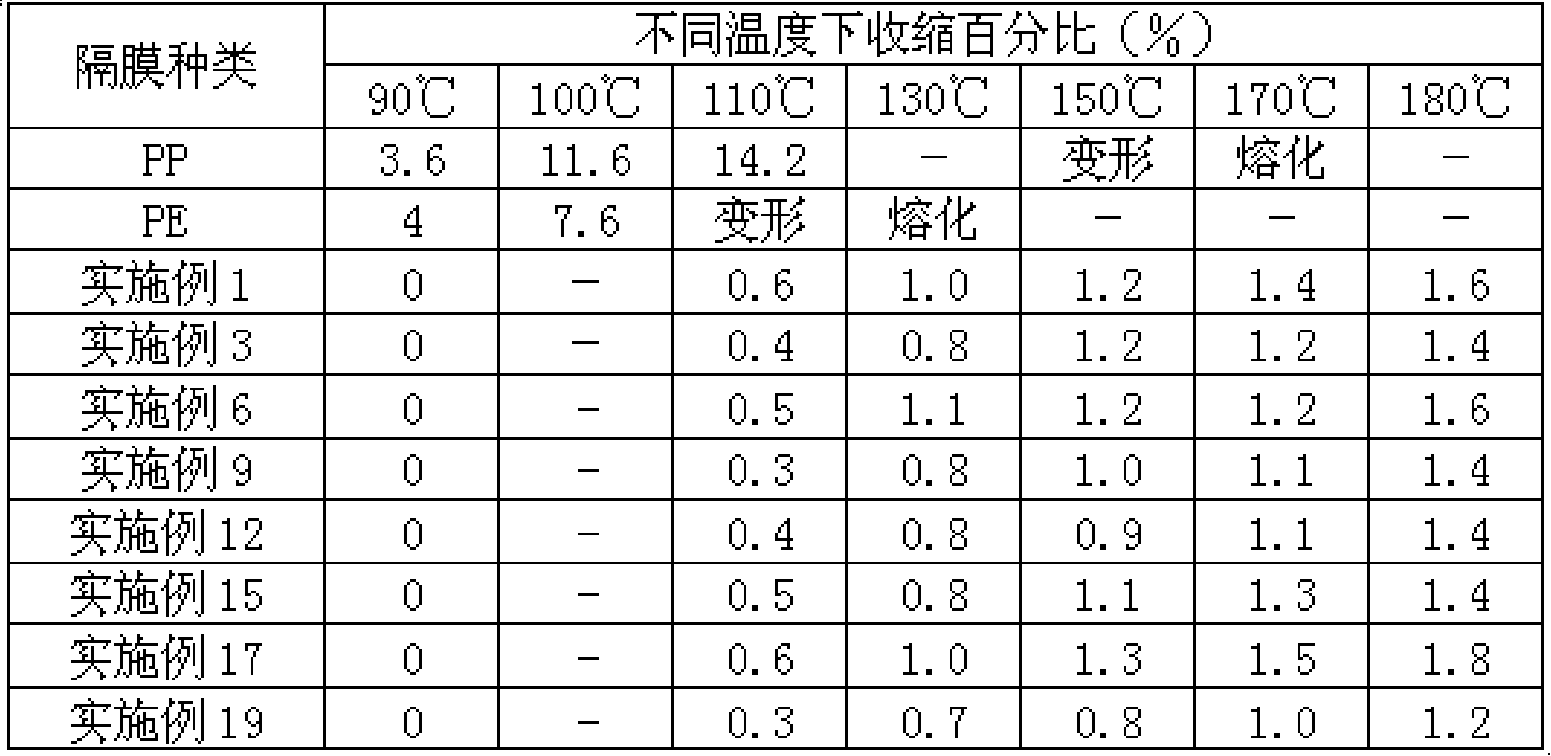

Non-woven cloth increasing micropore polymer diaphragm and usage as well as preparation method thereof

ActiveCN101226994AGood wet stateGood compatibilityElectrolytic capacitorsCell component detailsHydrophilic monomerSlurry

The invention relates to a non-woven fabric enhanced micropore polymer diaphragm material for a non aqueous electrolyte battery energy accumulator and method for preparation, which belongs to the manufacturing field of non aqueous electrolyte energy accumulators which are a battery and a capacitor. The non-woven fabric enhanced micropore polymer diaphragm is characterized in that the diaphragm comprises polymeric colloid emulsion which are copolymerized by 100 parts of water-soluble polymer, 30-500 parts of hydrophobic monomer, 0-200 parts of hydrophilic monomer and 1-5 parts of initiator. According to the 100 percent of the content of solids in polymer colloid emulsion, 0-100 percent of inorganic filler and 20-100 percent of plasticizer are added, obtained slurry is coated on the two surfaces of the non-woven fabric, and the non-woven fabric enhanced micropore polymer film is dried and obtained. The diaphragm has excellent heat resistance, excellent mechanical strength and low produce cost, is applied for a maintaining power, has higher safety and long cycle service life, and is friendly to the environment.

Owner:SICHUAN INDIGO TECH CO LTD

Aqueous based surfactant compositions

InactiveUS6090762ALow viscosityUnstable structureInorganic/elemental detergent compounding agentsCosmetic preparationsFlocculationHydrophilic monomer

The use of a stabiliser comprising a hydrophilic polymeric chain of more than four hydrophilic monomer groups and / or having a mass greater than 300 amu, linked at one end to a hydrocarbon-soluble hydrophobic group to reduce or prevent the flocculation of systems comprising a flocculable surfactant and a liquid medium which is capable of flocculating the surfactant and in which the stabiliser is capable of existing as a micellar solution at a concentration of at least 1% by weight.

Owner:HUNTSMAN INT LLC

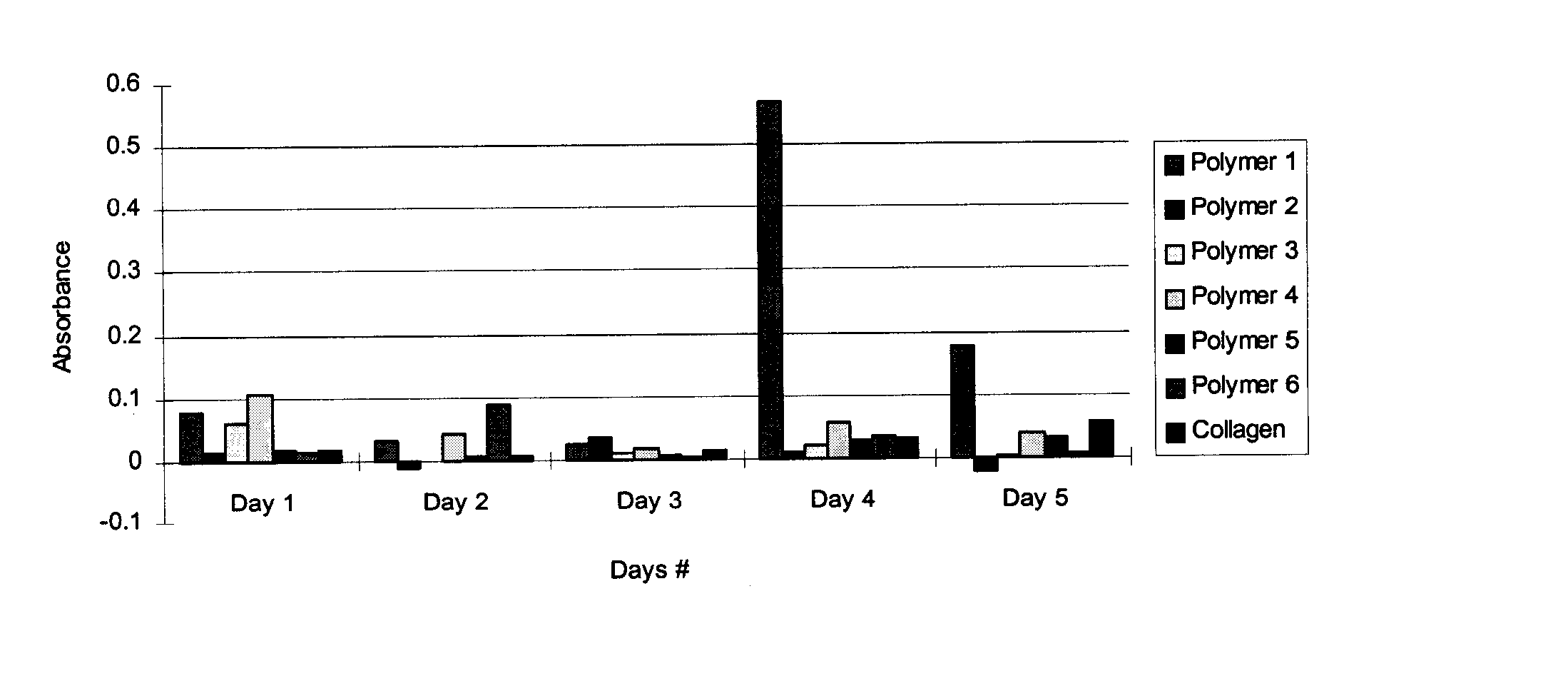

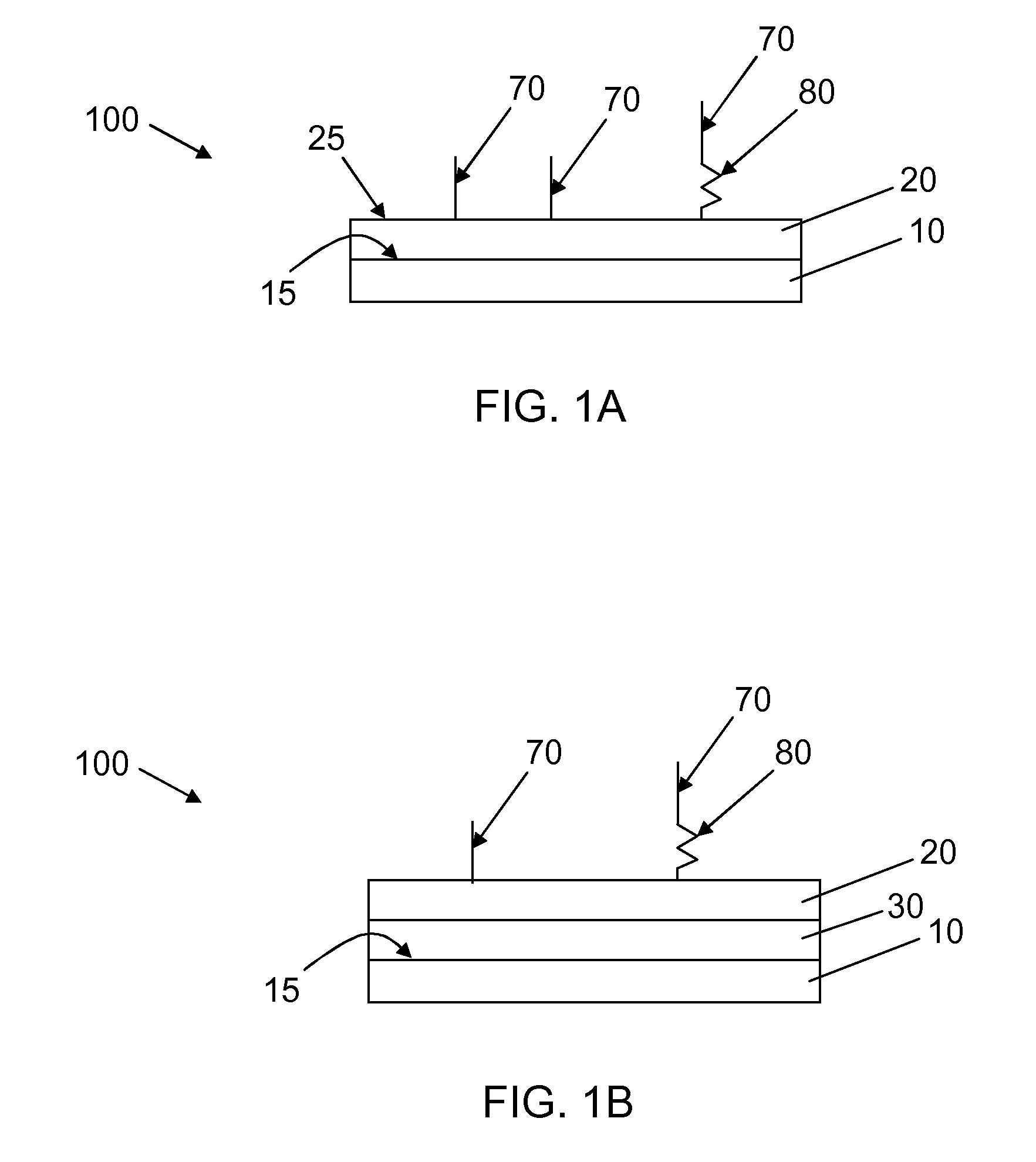

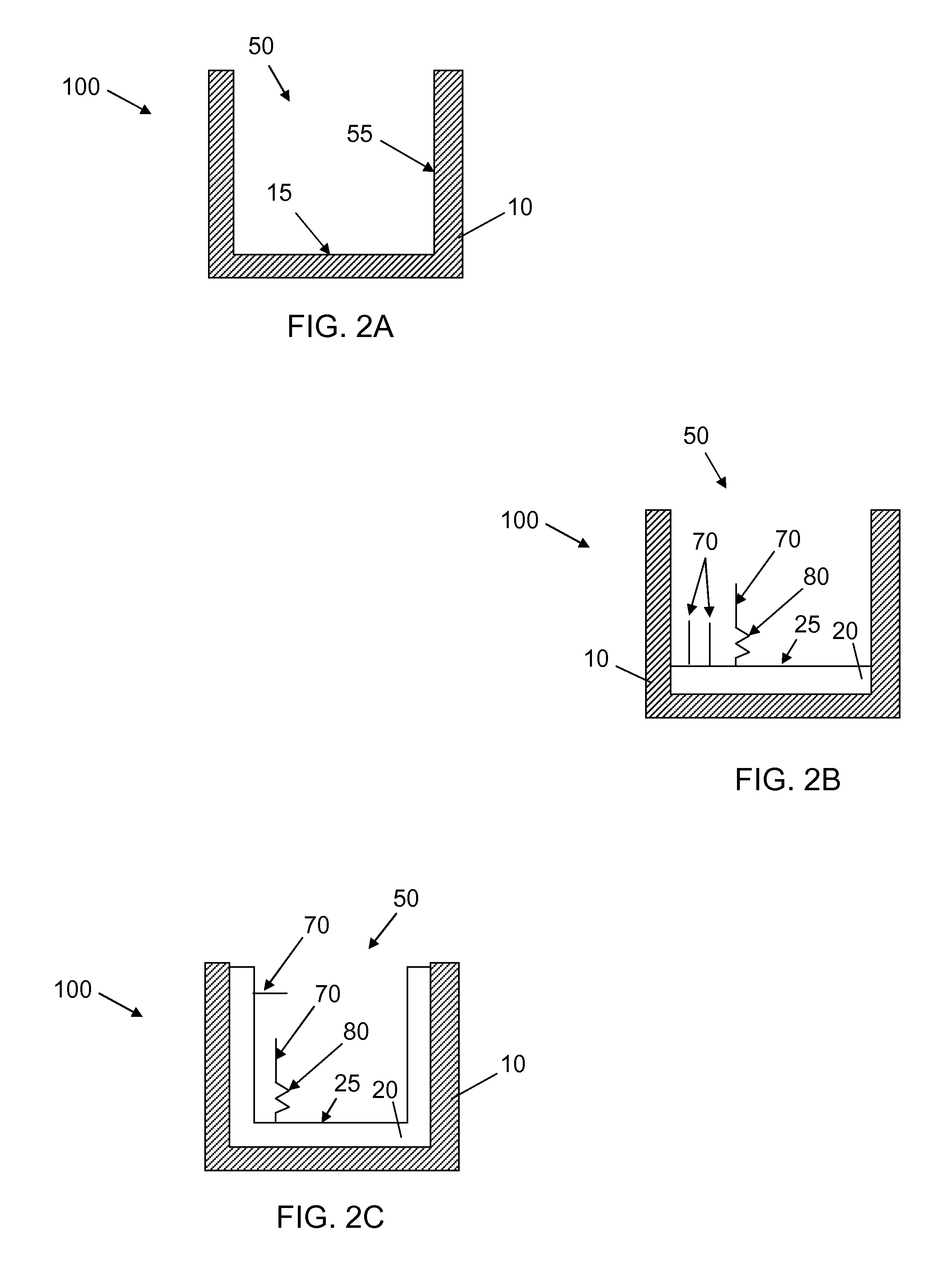

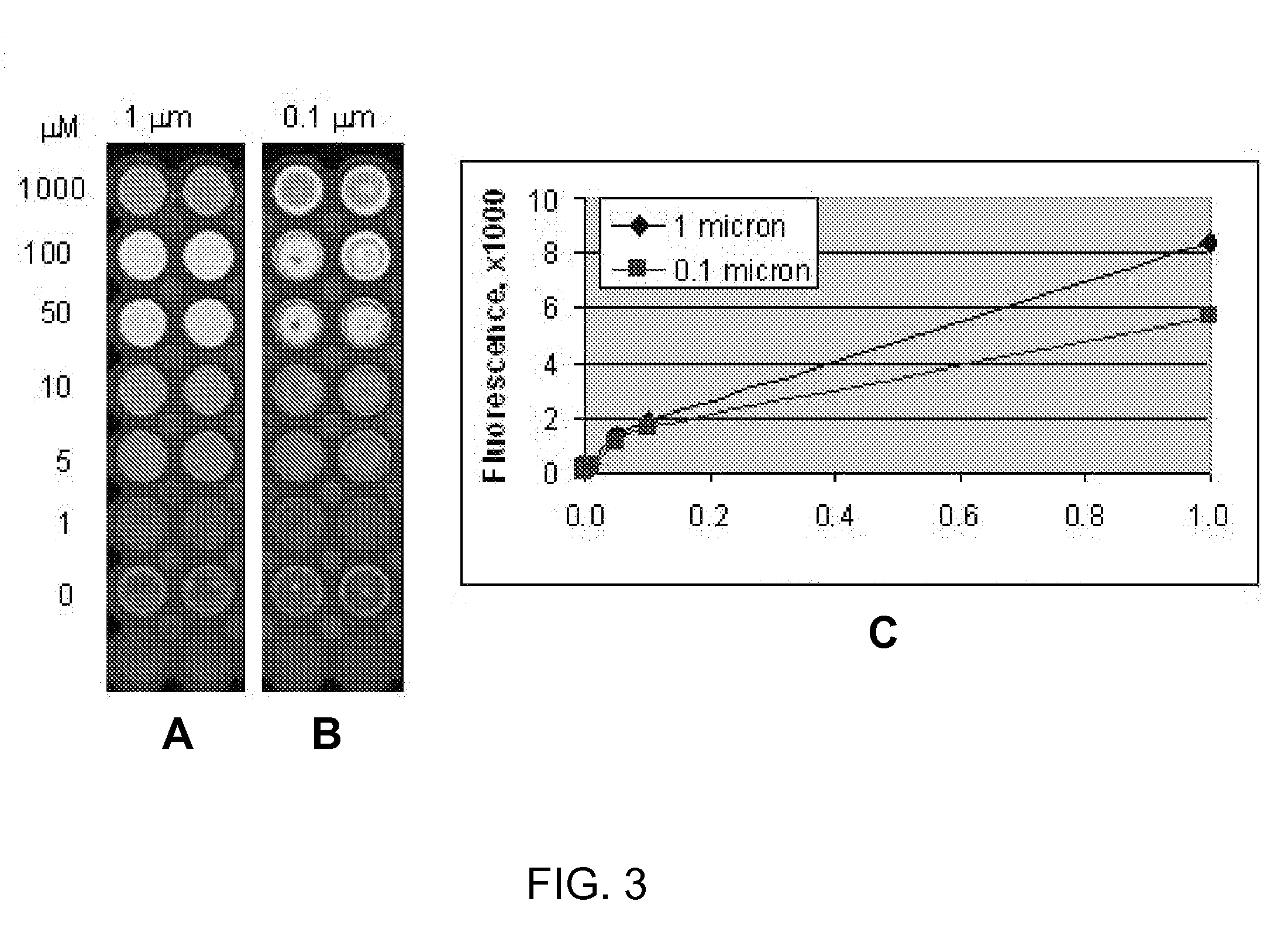

Synthetic surfaces for culturing cells in chemically defined media

InactiveUS20090191627A1Reduce Potential ContaminationExtended shelf lifeArtificial cell constructsCell culture supports/coatingSerum free mediaCross-link

Synthetic surfaces capable of supporting culture of eukaryotic cells including stem cells and undifferentiated human embryonic stem cells in a chemically defined medium include a swellable (meth)acrylate layer and a polypeptide conjugated to the swellable (meth)acrylate layer. The swellable (meth)acrylate layer may be formed by polymerizing monomers in a composition that includes a carboxyl group-containing (meth)acrylate monomer, a cross-linking (di- or higher-functional) (meth)acrylate monomer, and a hydrophilic monomer capable of polymerizing with the carboxyl group-containing (meth)acrylate monomer and the cross-linking (meth)acrylate monomer. The swellable (meth)acrylate layer has an equilibrium water content in water of between about 5% and about 70%. The conjugated peptide may include an RGD amino acid sequence.

Owner:GERON CORPORATION

Method for preparing the reactive tinting compound and the tinted contact lens

A method for preparing the tinted contact lens with the covalently bonded novel reactive tinting compound is disclosed. The reactive tinting compound with mono vinyl functionality is prepared by reacting the reactive dye with a hydrophilic monomer containing both pendent hydroxyl and vinyl groups under an alkaline condition. The water soluble reactive dyes containing either difluoro-chloropyrimidine or β-sulphatoethylsulphone reactive groups are used for synthesis of the reactive tinting dye. The lens forming materials are photo-polymerized in the presence of the reactive tinting compound to prepare a tinted contact lens. The reactive tinting compound is copolymerized with the lens forming monomers in a single photo-polymerization step that requires no subsequently alkaline soaking or developing step as used in the prior art. In addition, the covalently bonded dye is stable and durable in the lens and does not fade or leach out after multiple high-pressure thermal sterilizations.

Owner:SMART PERFORMER

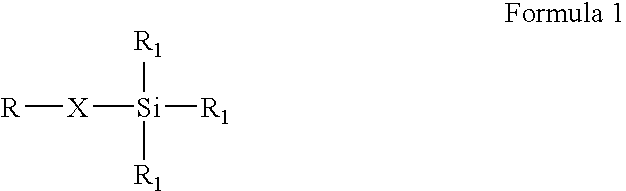

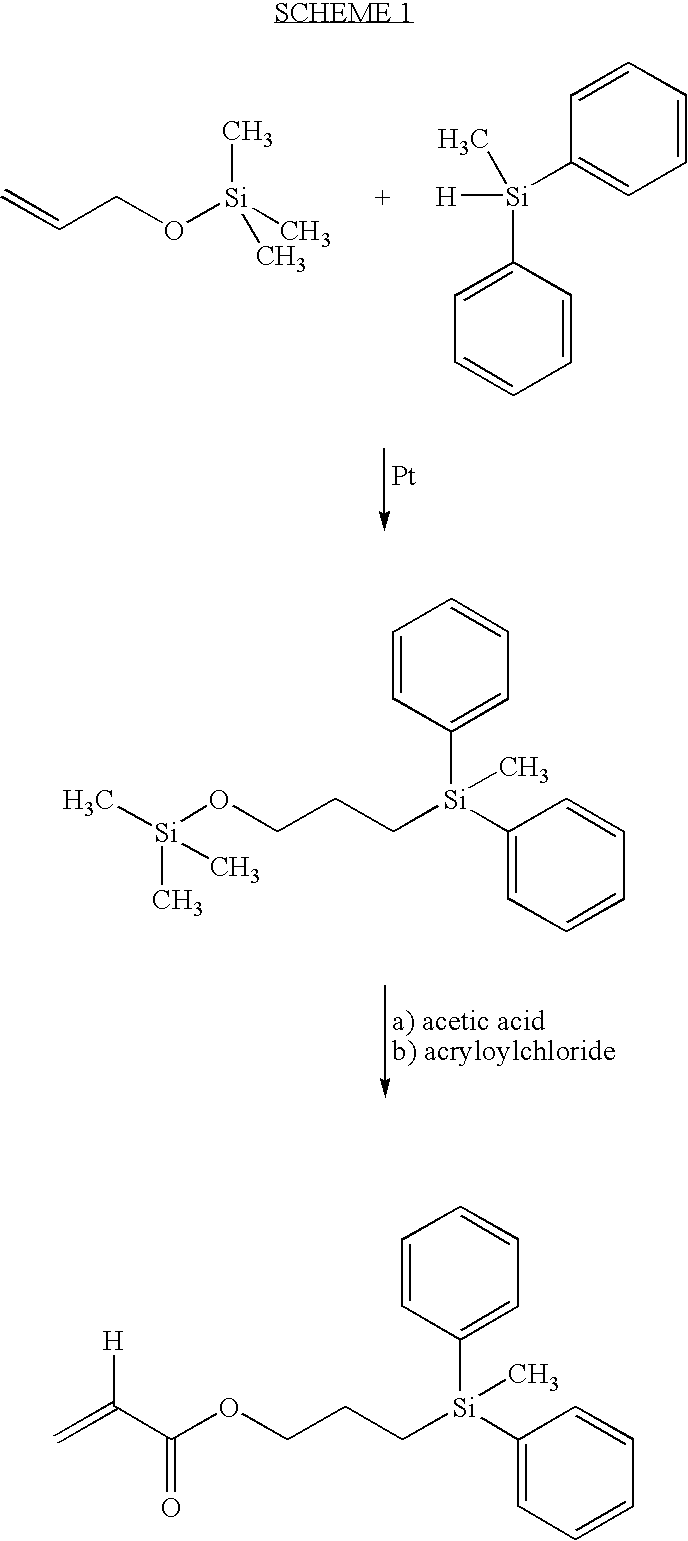

High refractive index aromatic-based silyl monomers

InactiveUS6846897B2Low production costIdeal physical propertySilicon organic compoundsOrganic chemistry methodsHydrophilic monomerSilylene

Optically transparent, relatively high refractive index polymeric compositions and ophthalmic devices such as intraocular lenses, contact lenses and corneal inlays made therefrom are described herein. The preferred polymeric compositions are produced through the polymerization of one or more aromatic-based silyl monomers or the copolymerization of one or more aromatic-based silyl monomers with one or more aromatic or non-aromatic non-siloxy-based monomers, hydrophobic monomers or hydrophilic monomers.

Owner:BAUSCH & LOMB INC

Transparent gel and contact lense from the same

InactiveUS20090012205A1Easily purifiableEasily synthesizableOptical articlesOptical elementsHydrophilic monomerPolymer science

A transparent gel is disclosed which has an interpenetrating polymer network of a copolymer containing a polysiloxane structure and a polycarbonate structure and a hydrophilic polymer obtained by polymerizing a hydrophilic monomer. The transparent gel is useful as a cultivation substrate, a container for storage and an ophthalmic material, comprising an easily synthesizable and purifiable silicon-containing resin, wherein a gel strength, transparency, oxygen permeability, birefringence and other characteristics are excellent.

Owner:MITSUBISHI GAS CHEM CO INC +1

Organic-inorganic hybrid super-hydrophilic coating as well as preparation method and application thereof

InactiveCN102241939AEasy to prepareMild reaction conditionsPretreated surfacesCoatingsHydrophilic monomerPtru catalyst

The invention discloses an organic-inorganic hybrid super-hydrophilic coating as well as a preparation method and an application thereof. The preparation method comprises: firstly carrying out hydrolysis condensation polymerization by a sol-gel method with ethyl orthosilicate used as a precursor, hydrochloric acid used as a catalyst, ethanol used as a solvent, a silane coupling agent used as a modifier and a proper amount of water to obtain a modified silica sol, then carrying out free radical polymerization on the modified silica sol and reactive hydrophilic monomers to obtain an organic-inorganic hybrid material, and carrying out solvent replacement to obtain an aqueous organic-inorganic hybrid super-hydrophilic coating. The coating is coated on plastics, glass or metal substrates through dipping or brushing to form a coating layer, the coating layer has a contact angle with water less than 5 degrees, the adhesion force with the substrates of level-0 and the hardness greater than 6H, and water drops can spread out quickly on the coating layer.

Owner:SOUTH CHINA UNIV OF TECH

Interpenetrating polymer network hydrogel corneal prosthesis

InactiveUS20070179605A1High tensile strengthHigh nutrient permeabilityNervous system cellsArtificial cell constructsCross-linkHydrophilic monomer

The present invention provides materials that have high glucose and oxygen permeability, strength, water content, and resistance to protein adsorption. The materials include an interpenetrating polymer network (IPN) hydrogel that is coated with biomolecules. The IPN hydrogels include two interpenetrating polymer networks. The first polymer network is based on a hydrophilic telechelic macromonomer. The second polymer network is based on a hydrophilic monomer. The hydrophilic monomer is polymerized and cross-linked to form the second polymer network in the presence of the first polymer network. In a preferred embodiment, the hydrophilic telechelic macromonomer is PEG-diacrylate or PEG-dimethacrylate and the hydrophilic monomer is an acrylic-based monomer. Any biomolecules may be linked to the IPN hydrogels, but are preferably biomolecules that support the growth of cornea-derived cells. The material is designed to serve as a corneal prosthesis.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

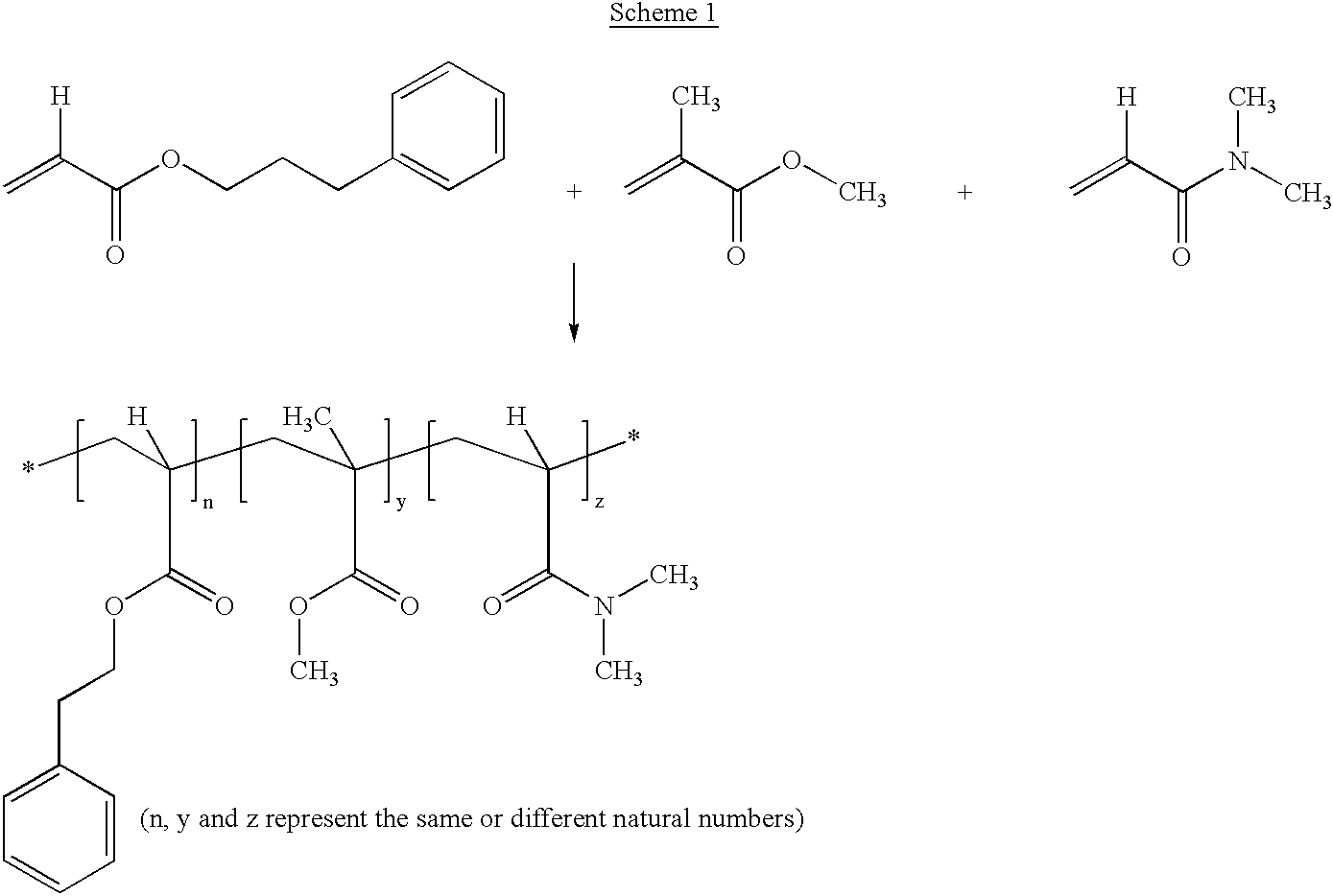

Pigment dispersion with polymeric dispersant

InactiveUS20060014855A1High optical densityGreat particle stabilityInksCoatingsHydrophilic monomerPolymer chemistry

The invention relates to a pigment dispersion for an ink jet ink composition, the pigment dispersion comprising pigment particles having a median particle size of 200 nm or less, and a polymeric dispersant comprising a random addition copolymer comprising at least one hydrophobic monomer type and at least one hydrophilic monomer type, wherein the polymeric dispersant comprises from 50 weight percent to 80 weight percent of hydrophobic monomers relative to the total weight of the polymeric dispersant, and wherein, when the polymer comprises more than one hydrophobic monomer type, at least 50 weight percent of the hydrophobic monomers relative to the total weight of the hydrophobic monomers is an acrylate comprising an aromatic group. The invention also provides an ink composition and ink jet printing method using the pigment dispersion.

Owner:EASTMAN KODAK CO

Ocular lens material

InactiveUS20040039077A1High oxygen permeabilityHigh mechanical strengthTissue regenerationProsthesisHydrophilic monomerPolymer science

An ocular lens material comprising a copolymer prepared by polymerization with heating of a monomer mixture and / or with irradiating a monomer mixture with ultraviolet ray by means of a molding method, the monomer mixture containing a polysiloxane macromonomer A, a Si-containing alkyl methacrylate B, a hydrophilic monomer C comprising NVP as C-1 and another hydrophilic monomer C-2, another monomer D and a crosslinkable monomer E comprising a crosslinkable monomer E-1 containing at least one group selected from acryloyl group, vinyl group and allyl group, and methacryloyl group, and a crosslinkable monomer E-2 containing at least two methacryloyl groups as main components, wherein (A+B) / C (weight ratio) is 30 / 70 to 70 / 30, A / B is 25 / 75 to 75 / 25, C-1 / C-2 is 50 / 50 to 100 / 0, the amount of D is 0 to 20% by weight in the monomer mixture, which has high oxygen permeability, high mechanical strength, excellent surface wettability and low surface frictional property.

Owner:MENICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com