Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5109 results about "Wire wrap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wire wrap was invented to wire telephone crossbar switches, and later adapted to construct electronic circuit boards. Electronic components mounted on an insulating board are interconnected by lengths of insulated wire run between their terminals, with the connections made by wrapping several turns of uninsulated sections of the wire around a component lead or a socket pin.

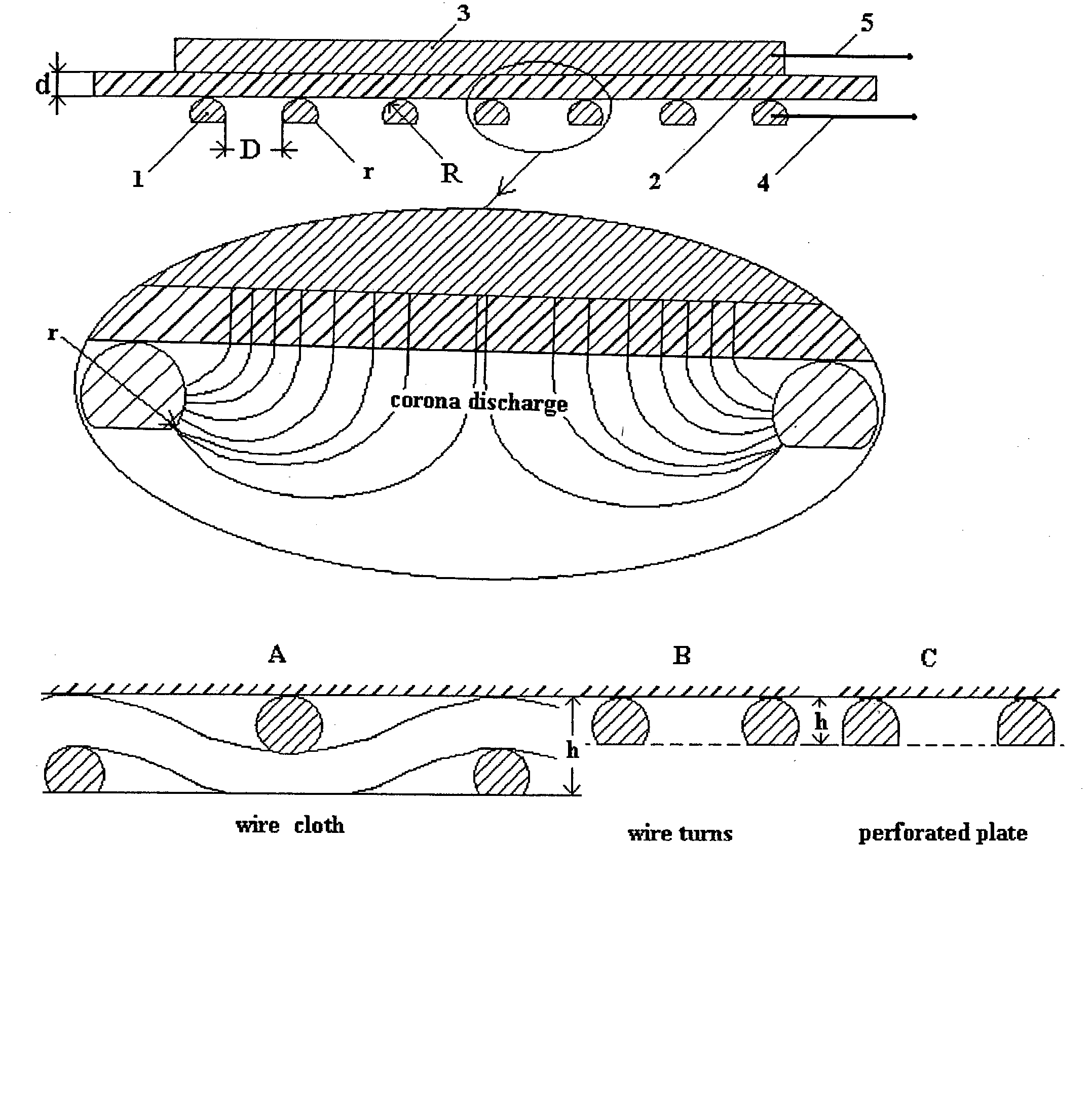

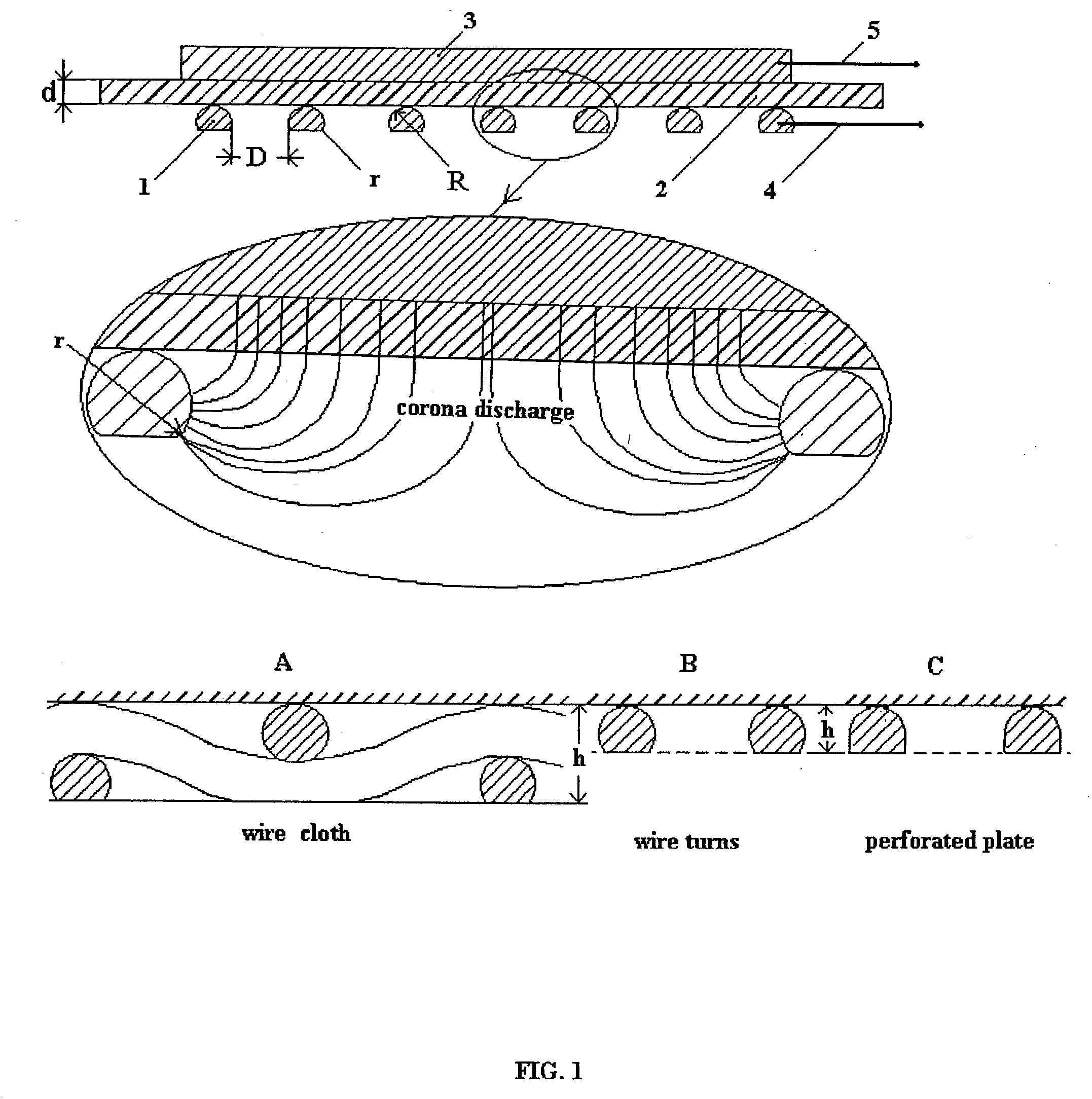

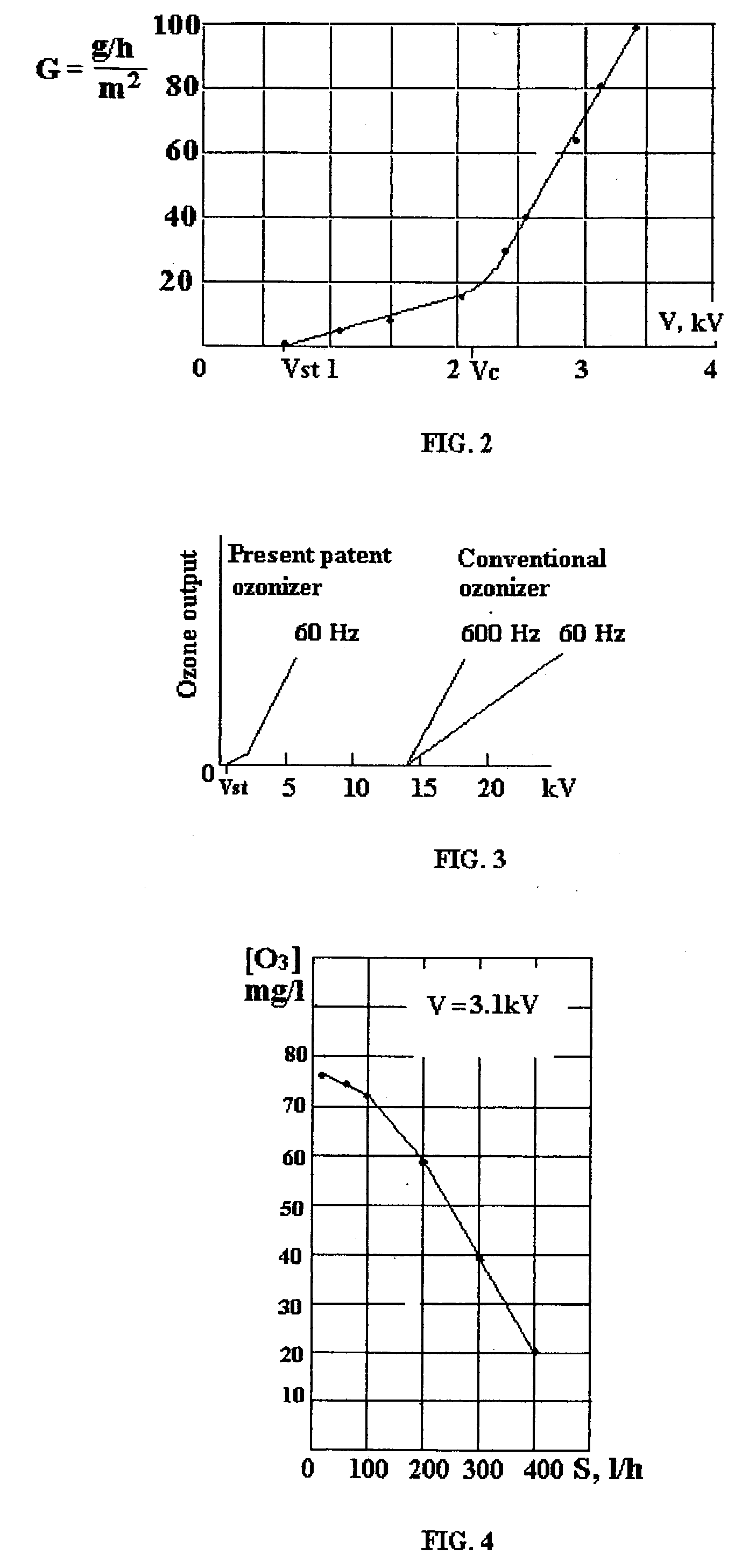

Method for surface corona/ozone making, devices utilizing the same and methods for corona and ozone applications

A method for making surface corona discharge, which produces ozone gas and apparatus for producing the same are disclosed, in which a dielectric spacer / film having a specific capacity C' equal to or more than 200 nanofarad per square meter positioned between the base electrode and the net electrode. Said net electrode is a wire net or a perforated metal or a wire winding having an open area not less than about 70%, and a size of hole D equals to or less than about 0.7V / P, where V is a voltage in kilovolts and P is pressure of an ambient air or an oxygen in atmospheres. Net electrode has radius R of wire or radius of an edge of openings in the perforated metal equal to or more than about 1.6d, where d is the thickness of the said dielectric spacer / film, which is determined by a fundamental formula d=9k / C', where d is in millimeters, C' is in nF / m2, and k is dimensionless dielectric constant k of given material. Under disclosed parameters said surface corona is safe for human contact if said net electrode is grounded. Start voltage Vst of ozone production is determined by experimental formula Vst=0.7+60 / C', kV, here C' in nF / m2. The even and high intensity corona surface and high ozone output takes place if the operating voltage is more than about 3Vst. AC power supply is applied to produce ozone gas at "home" voltage 0.7-1.0 kV and produces ozone gas more effectively at 2,5-3.6 kV. A method for disinfection and decontamination of objects by using the direct corona contact and apparatus for making the same is disclosed, in which safe corona surface is placed on said object and is acting by ozone, ultraviolet and ion bombing simultaneously in the unique environment, which takes place inside of the safe corona. A method for ozone disinfection and decontamination and devices for making the same is disclosed, in which said ozone generating element is placed in a closed container / room with or without treated objects and produce a high ozone concentration due to effective ozone dispersion from corona surface without blowing of air / oxygen through said container / room.

Owner:ANDREEV SERGEY I +1

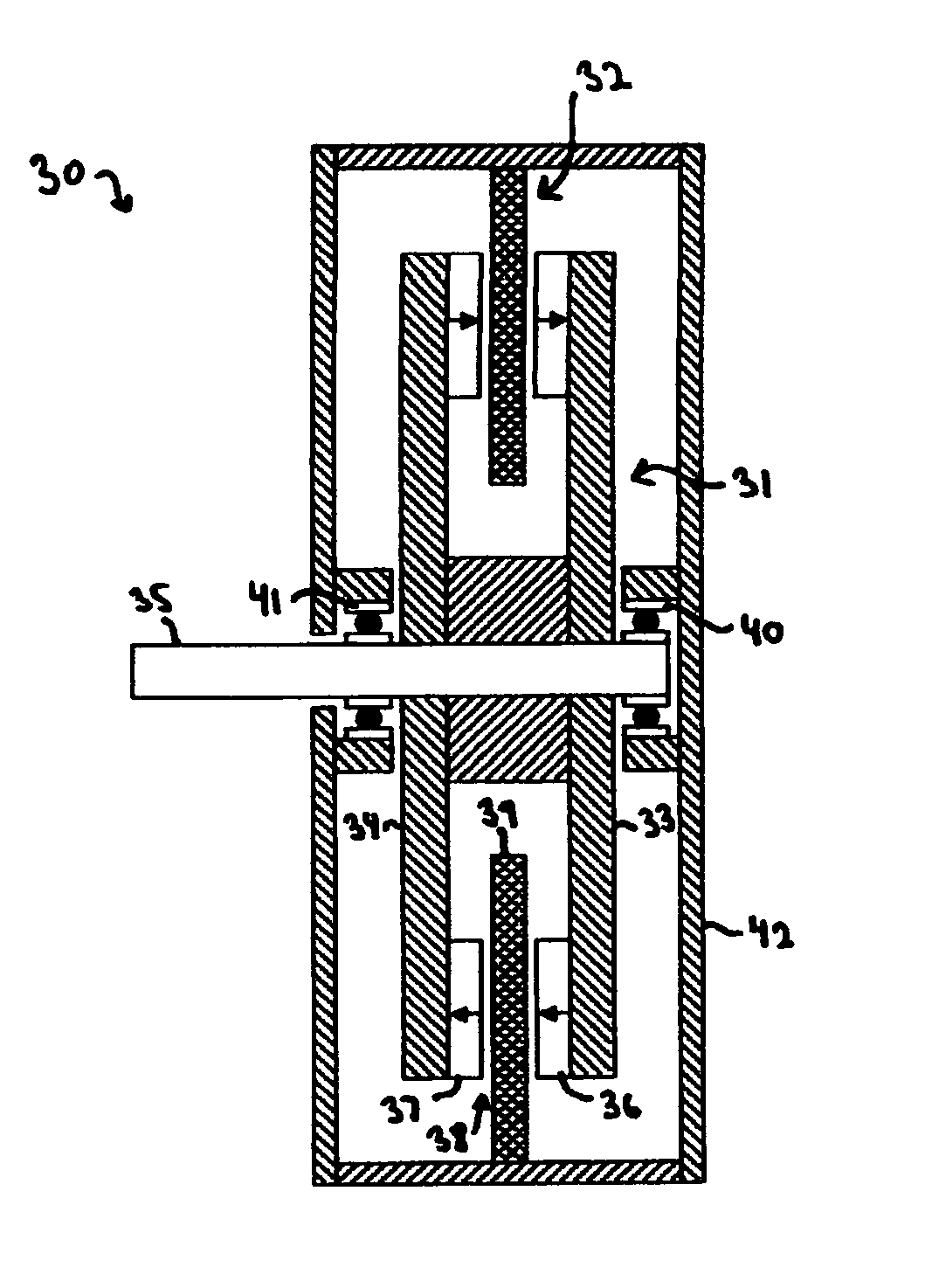

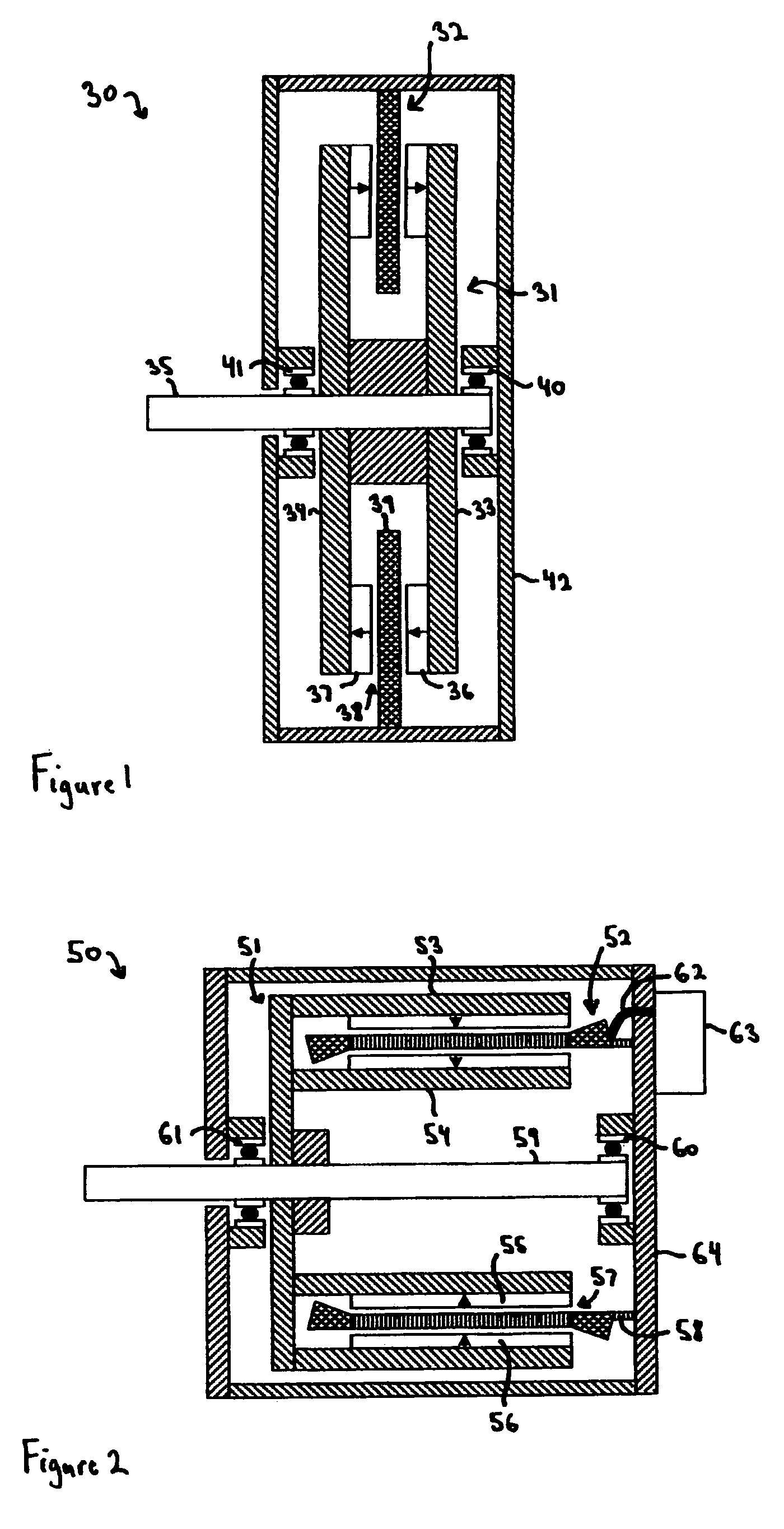

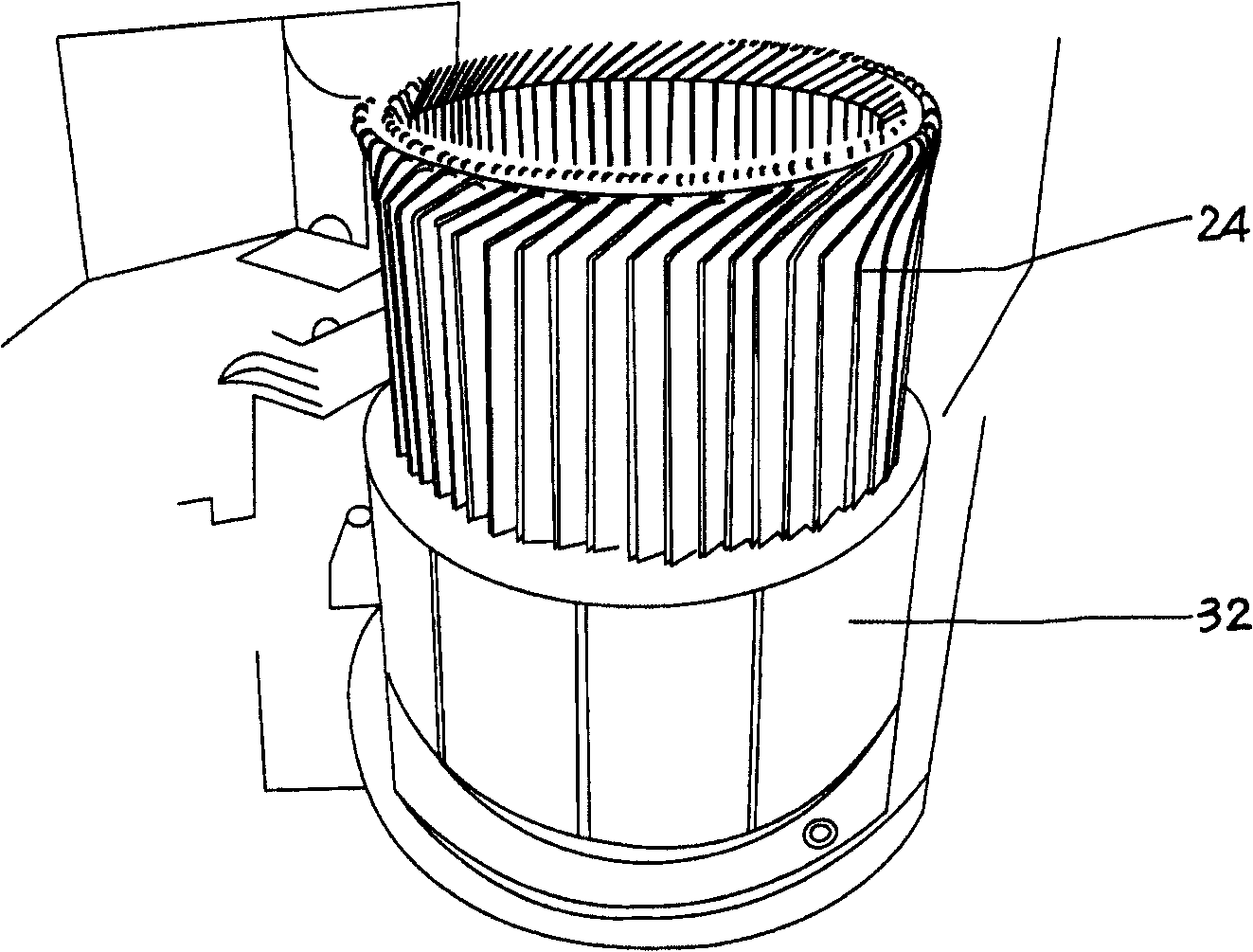

High performance air core motor-generator winding

InactiveUS7402934B1Long and reliable operating lifeIncrease winding densitySynchronous generatorsWindingsMagnetic polesRotational energy

A motor-generator for converting between electrical and rotational energy includes a rotor mounted for rotation about an axis of rotation relative to a stationary a stator that magnetically interacts with the rotor. The rotor has two spaced apart rotor portions that define therebetween an armature airgap. Magnetic poles on the rotor portions drive magnetic flux across the airgap. An air core armature is located in the airgap, such that opposite sides of the air core armature face the two opposed rotating surfaces of the rotor. The air core armature has windings in which AC voltage is induced as the rotor rotates. The windings are wound with multiple individually insulated strand conductor wire wrapped with a wrapping of a thin dielectric tape film over the multiple individually insulated strand conductor wire.

Owner:REVOLUTION ELECTRIC MOTOR

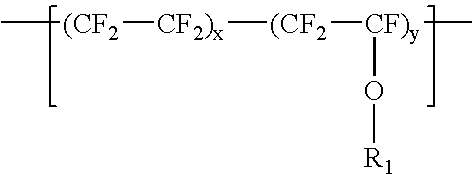

Polyimide based compositions useful as electronic substrates, derived in part from (micro-powder) fluoropolymer, and methods and compositions relating thereto

InactiveUS7026032B2Well as to enableLiquid crystal compositionsSubstation/switching arrangement detailsPolymer scienceFluoropolymer

The present invention is a polymeric composite comprising a polyimide component and a fluoropolymer component derived from a micro powder. The fluoropolymer micro powder has a melt point between 250 and 375° C. The fluoropolymer micro powder has an average particle size between 20 and 5000 nanometers (5.0 microns).The polyimide component and the fluoropolymer component are inter-mixed at a high dispersion level where the fluoropolymer component is present in a weight ratio from 10 to 60 percent. The polymeric composite of these two components is particularly useful in the form of a thin film used in high-speed digital circuitry or high signal integrity for low loss of a digital signal. The film can also be used as a wire wrap, or as a coverlay or base film substrate for flexible circuitry laminates.

Owner:EI DU PONT DE NEMOURS & CO

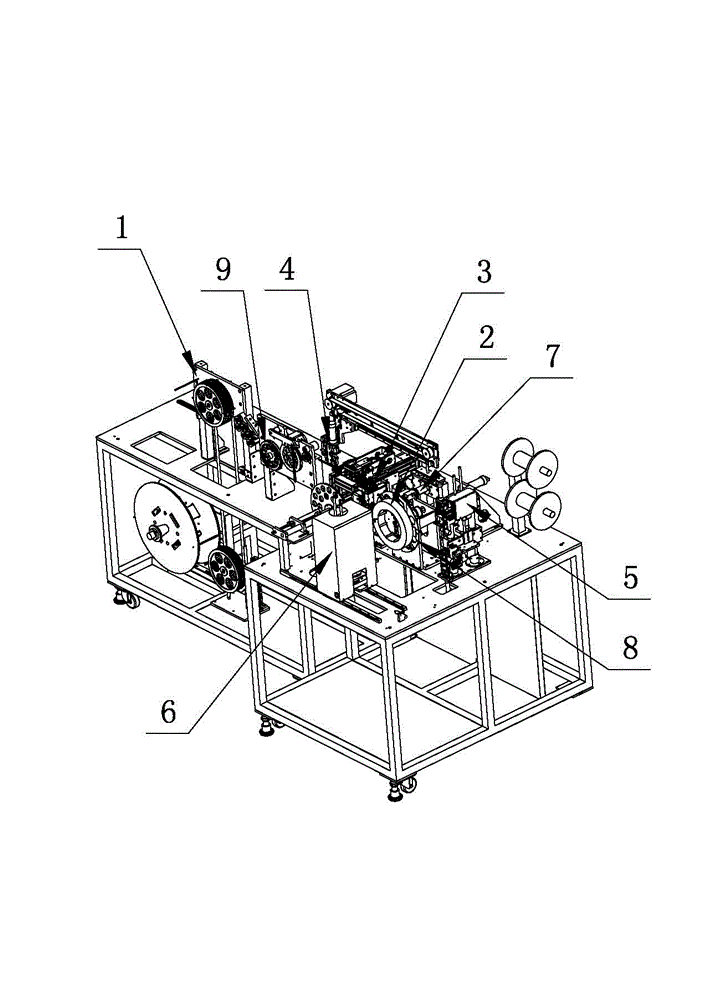

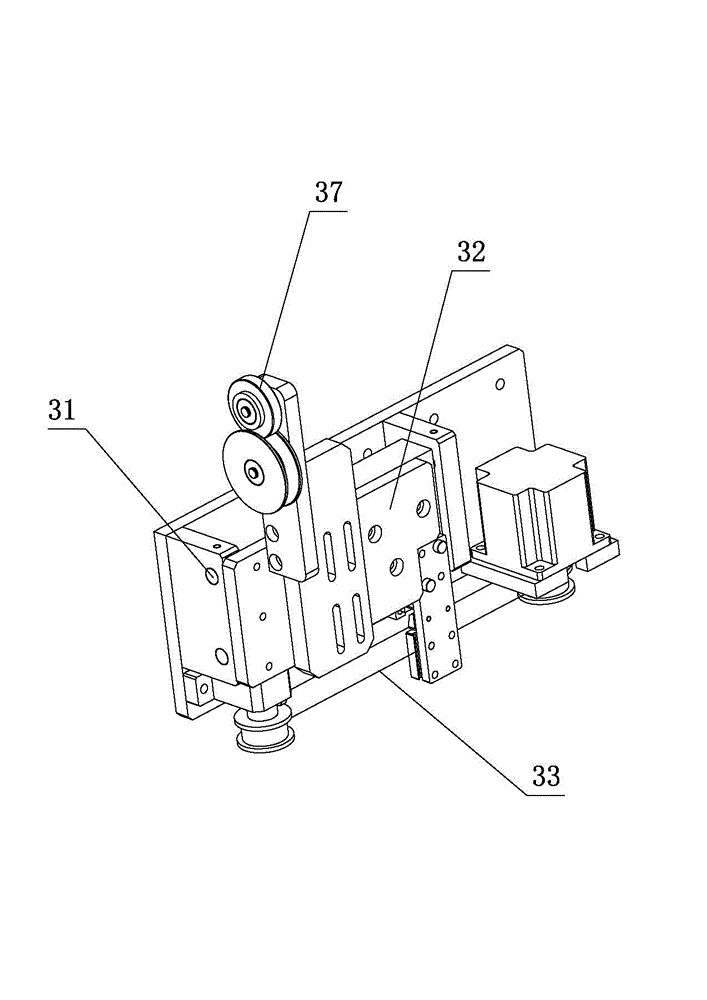

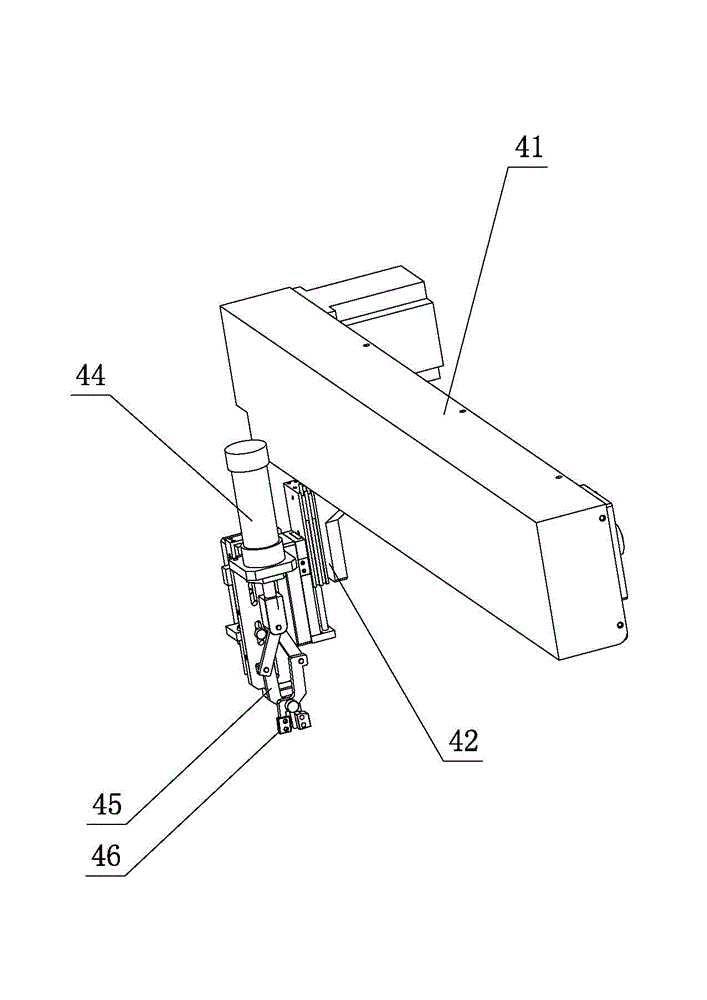

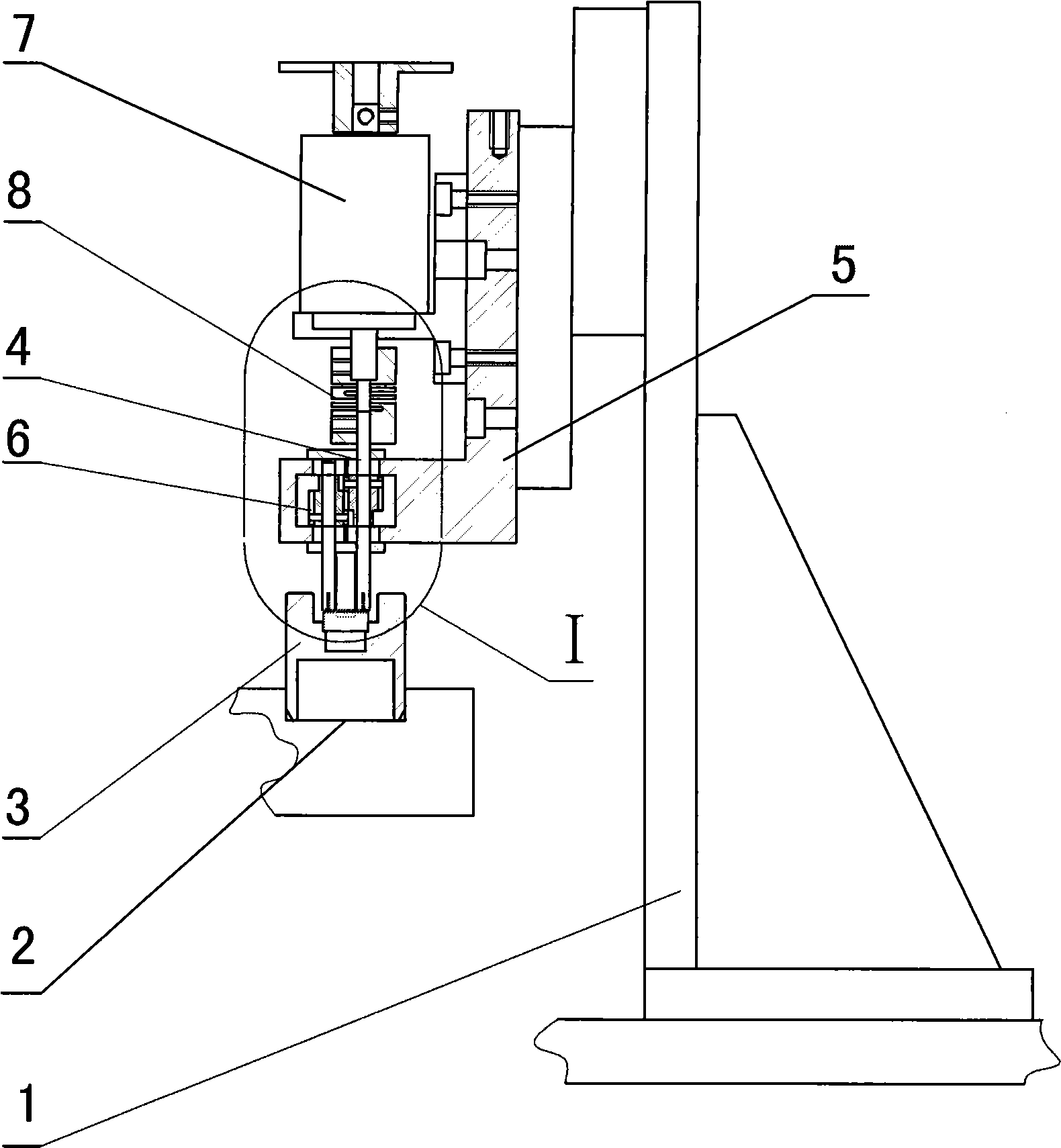

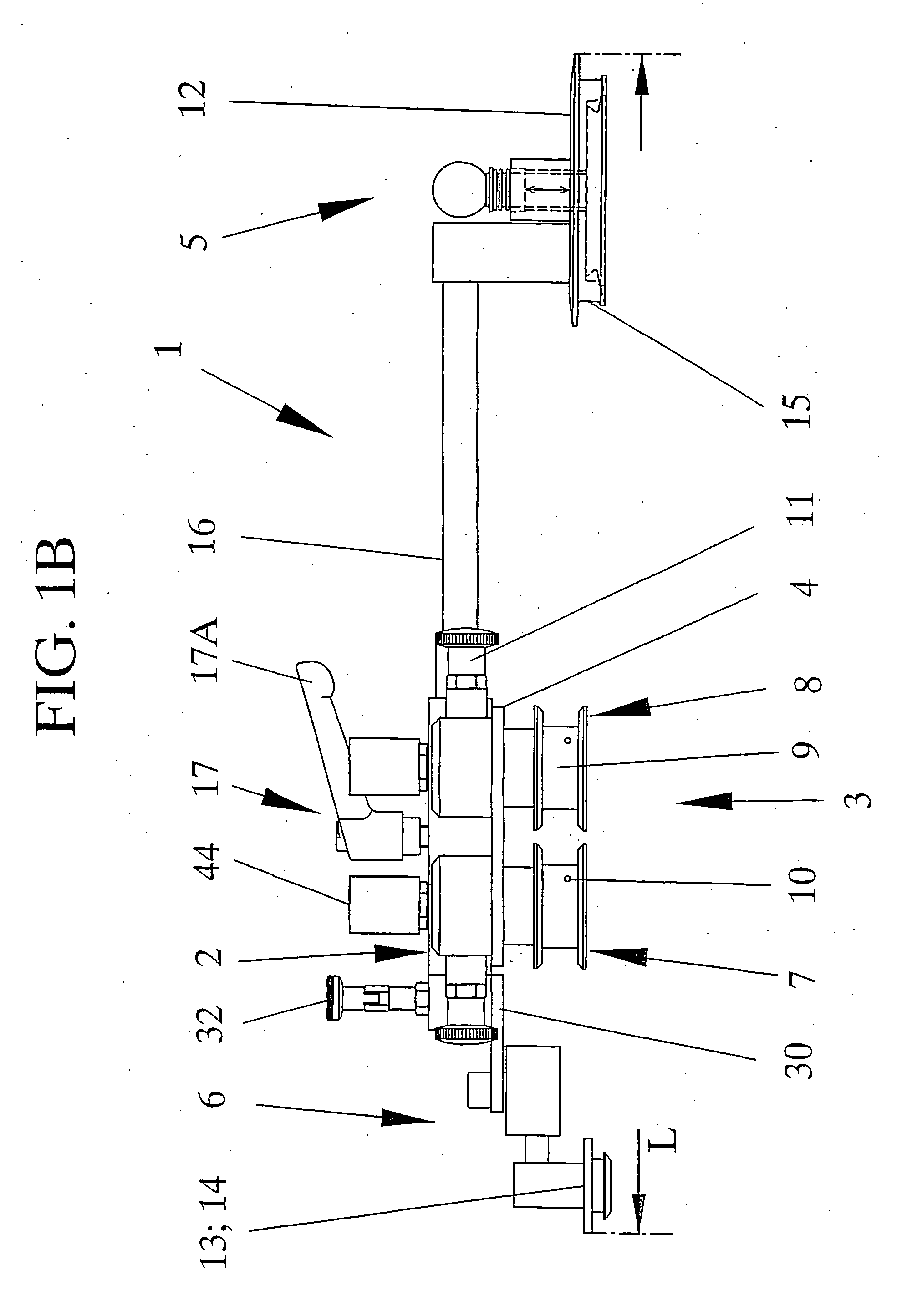

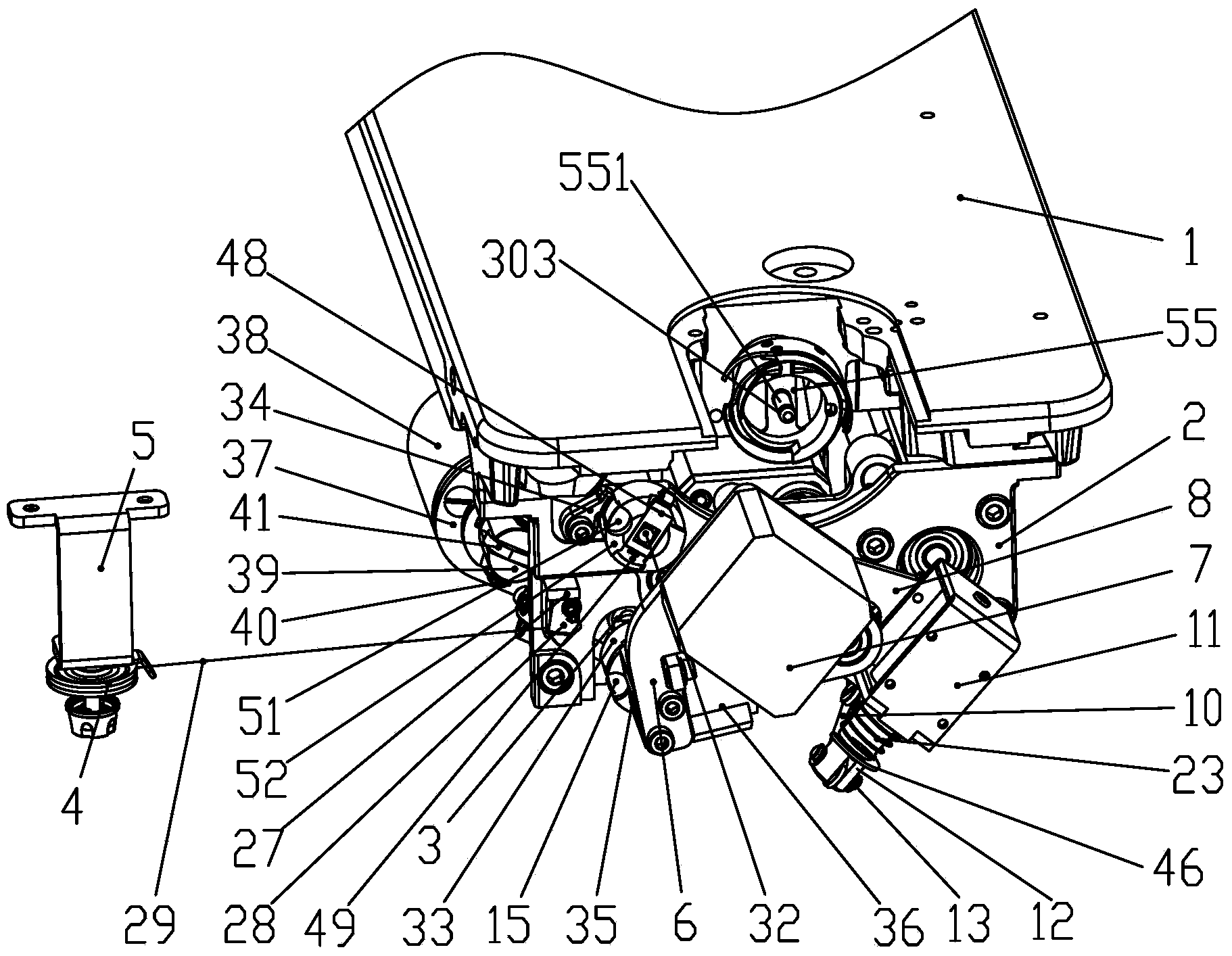

Automatic wire winding, binding and cutting integrated machine and automatic winding, binding and cutting method thereof

InactiveCN102941936AReduce manufacturing costFilament handlingBundling machine detailsWire rodWire cutting

The invention relates to the technical field of mechanical automation production devices, in particular to an automatic wire winding, binding and cutting integrated machine and automatic winding, binding and cutting method thereof. The integrated machine comprises a frame, a wire releasing device, a wire feeding device, a wire winding device, a ribbon tightening device, a ribbon contour device and a ribbon cutting device are arranged on the frame, a wire is pulled to the wire winding device through the wire feeding device and is automatically clamped, fixed and wound by the wire winding device, an annular wire coil is formed after the wire is wound, a ribbon cut off by the ribbon cutting device is conveyed to the wire coil by the ribbon contour device and is further tightened onto the wire coil by the ribbon tightening device, the wire is cut off by the wire feeding device, the wire coil is automatically unloaded by a wire clamping and coil unloading device, the winding, binding and cutting process of the whole wire coil is finished, the wire can be peeled and accuracy of the length of the wire coil can be controlled according to requirements of a customer, fully automatic unmanned operation of wire winding / length counting, wire binding, compensation, wire cutting, peeling and coil unloading is realized, and the manufacturing cost of an enterprise is reduced.

Owner:温增璟

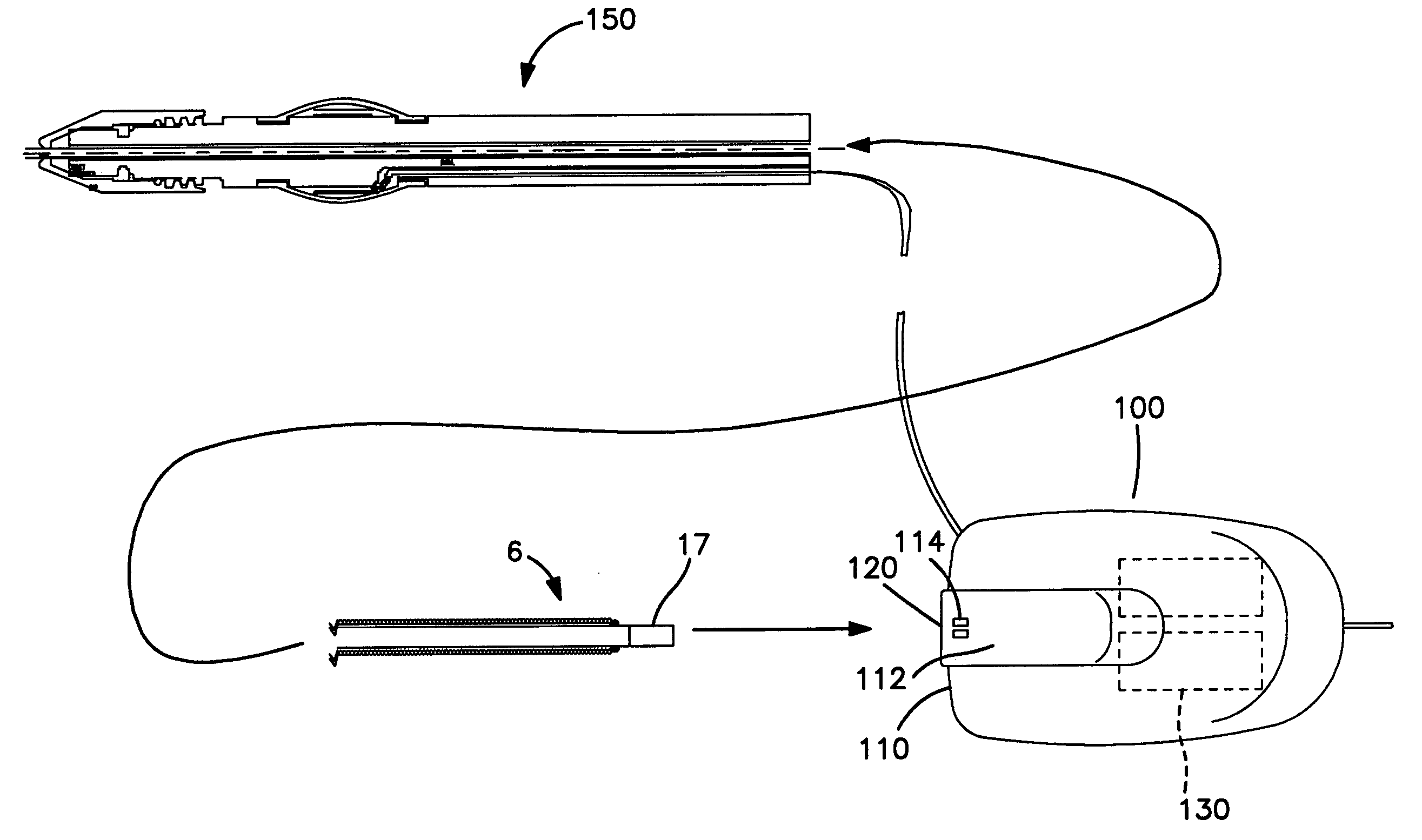

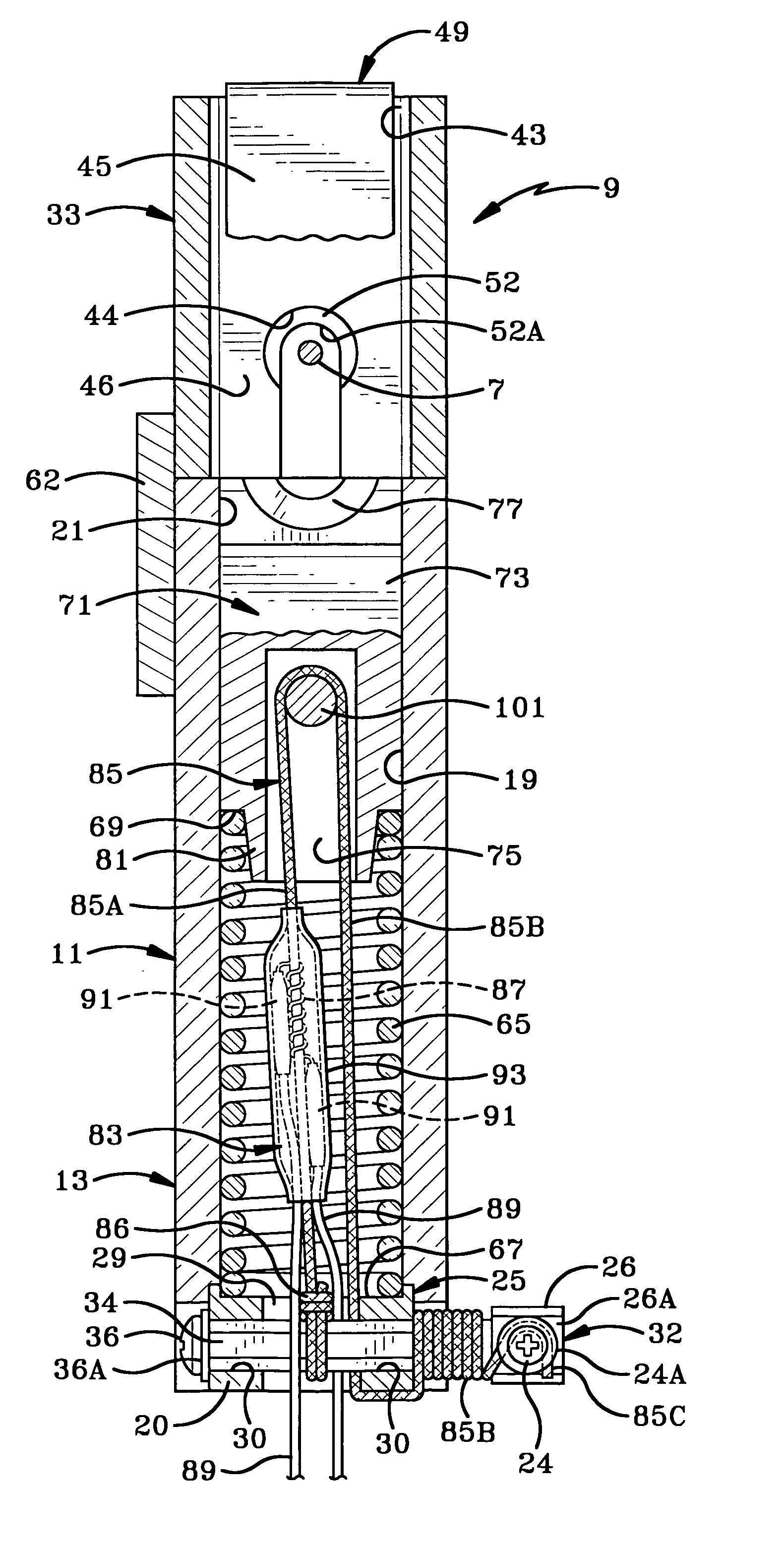

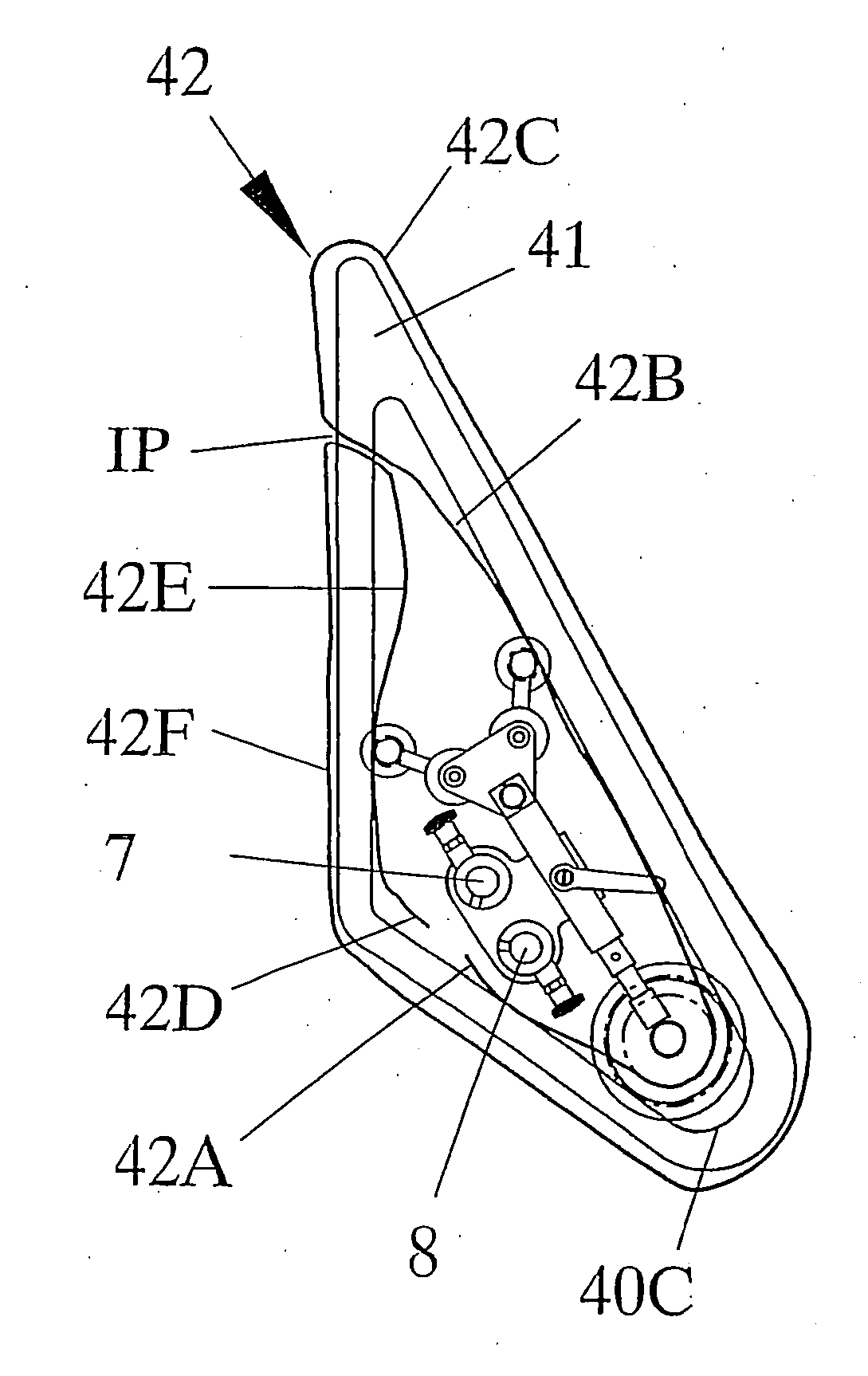

Vascular guidewire system

InactiveUS20050273020A1Shorten the timeSaving of other resourceElectrotherapyGuide wiresShape-memory alloyEngineering

A vascular guidewire in an embodiment of the present invention, having such features as uniform diameter, low-profile cross section over its length and a distal tip capable of deflection and variable configurations, provides a range of advantages. A variable distal tip of shape-memory alloy deflects into varied configurations when remotely actuated. Such actuation, according to an aspect of the present invention, can be by way of a side entry, easily repositioned, single-handed controller that allows both rotational control of the guidewire and control of the variable tip. In another aspect, a longitudinal element in the guidewire, such as an exterior wire wrap, can provide dual functionality, including structural support as well as an electrical path for use in energizing, and thus deflecting, the distal tip. In yet another aspect, the overall guidewire geometry having constant circumference and low profile, as well as side-access controllability, permits advantageous coaxial mounting and removal of catheters over the proximal guidewire end and facilitates insertion and removal of guidewires through catheters in vivo.

Owner:WINDCREST

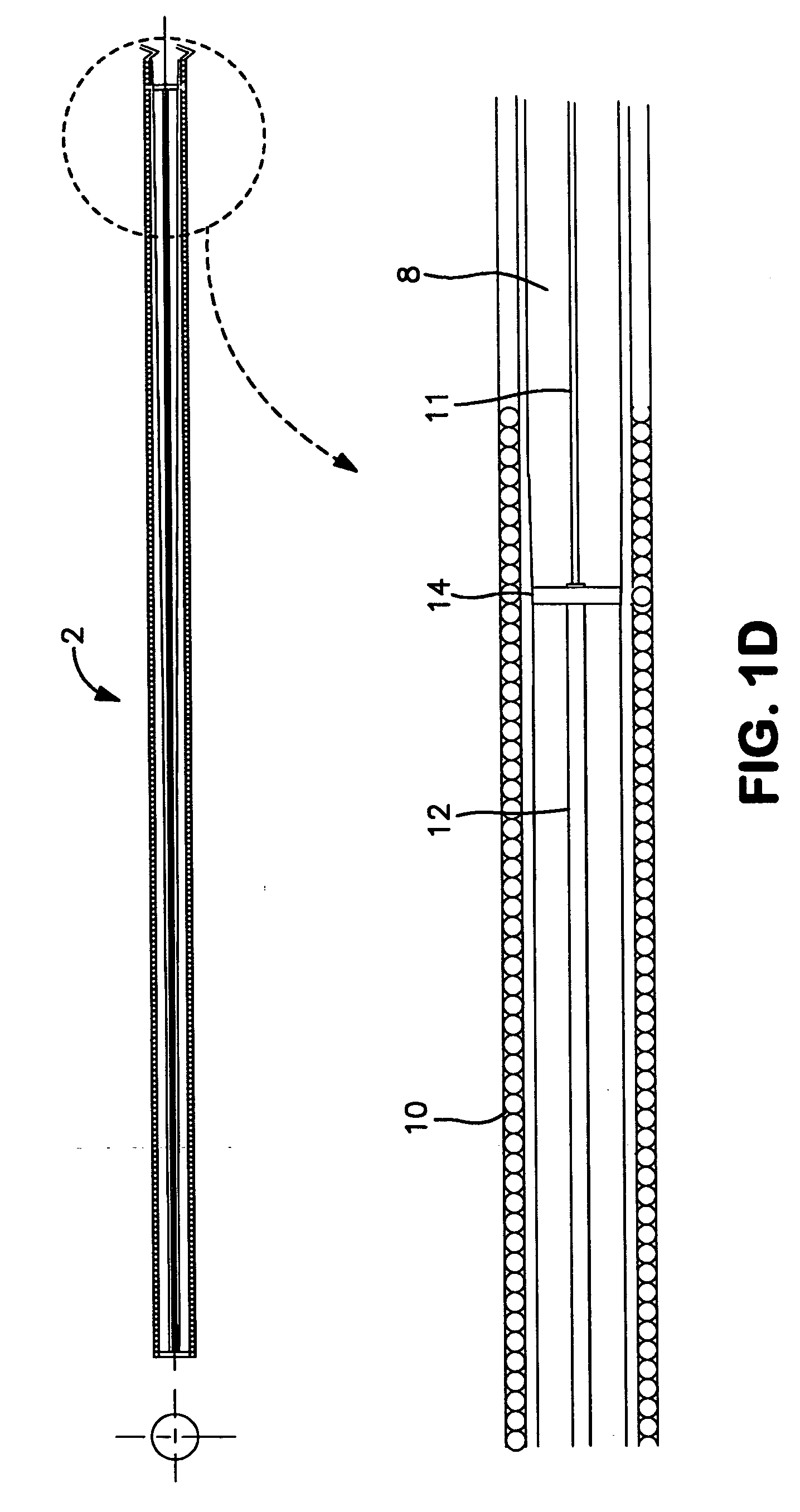

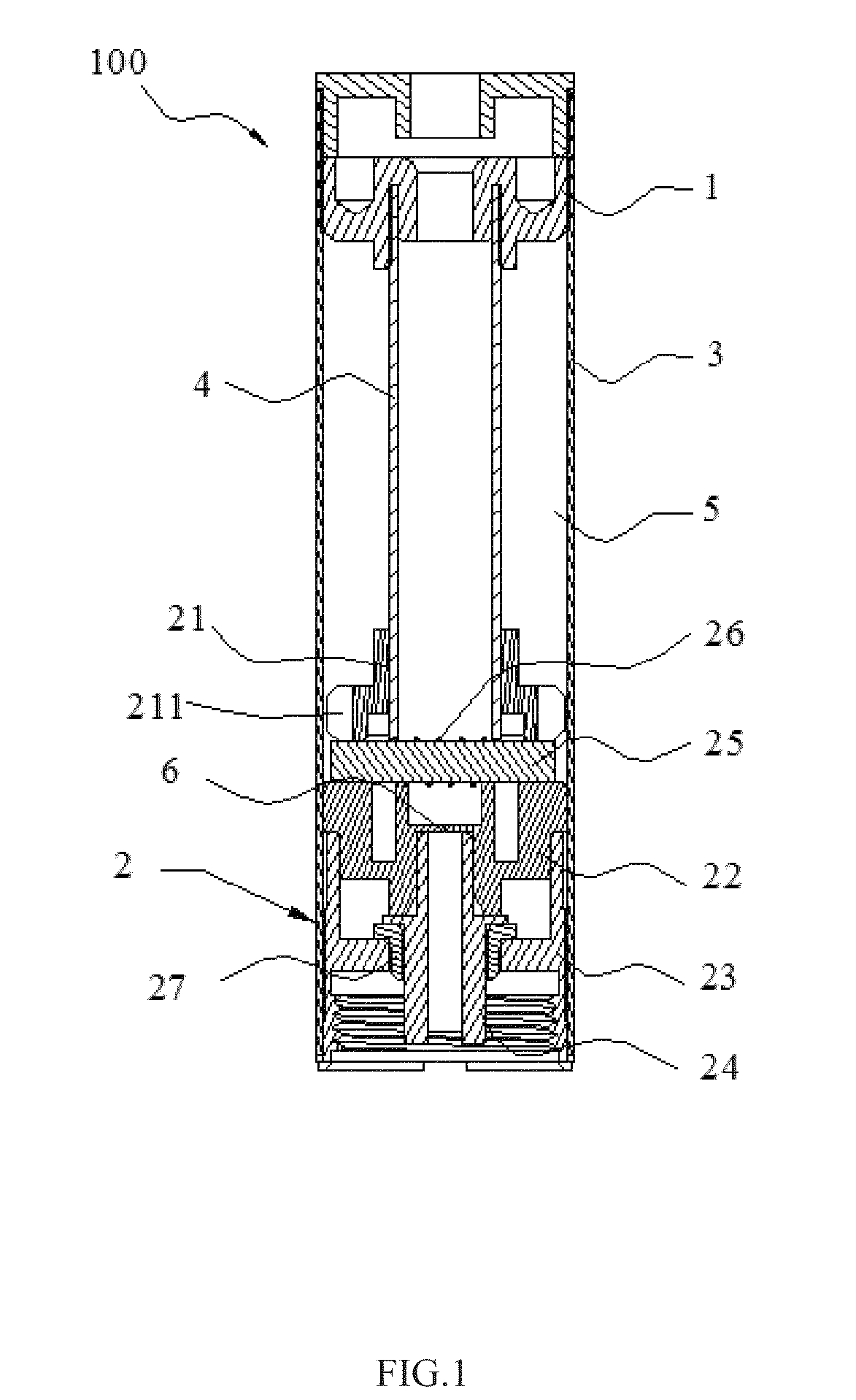

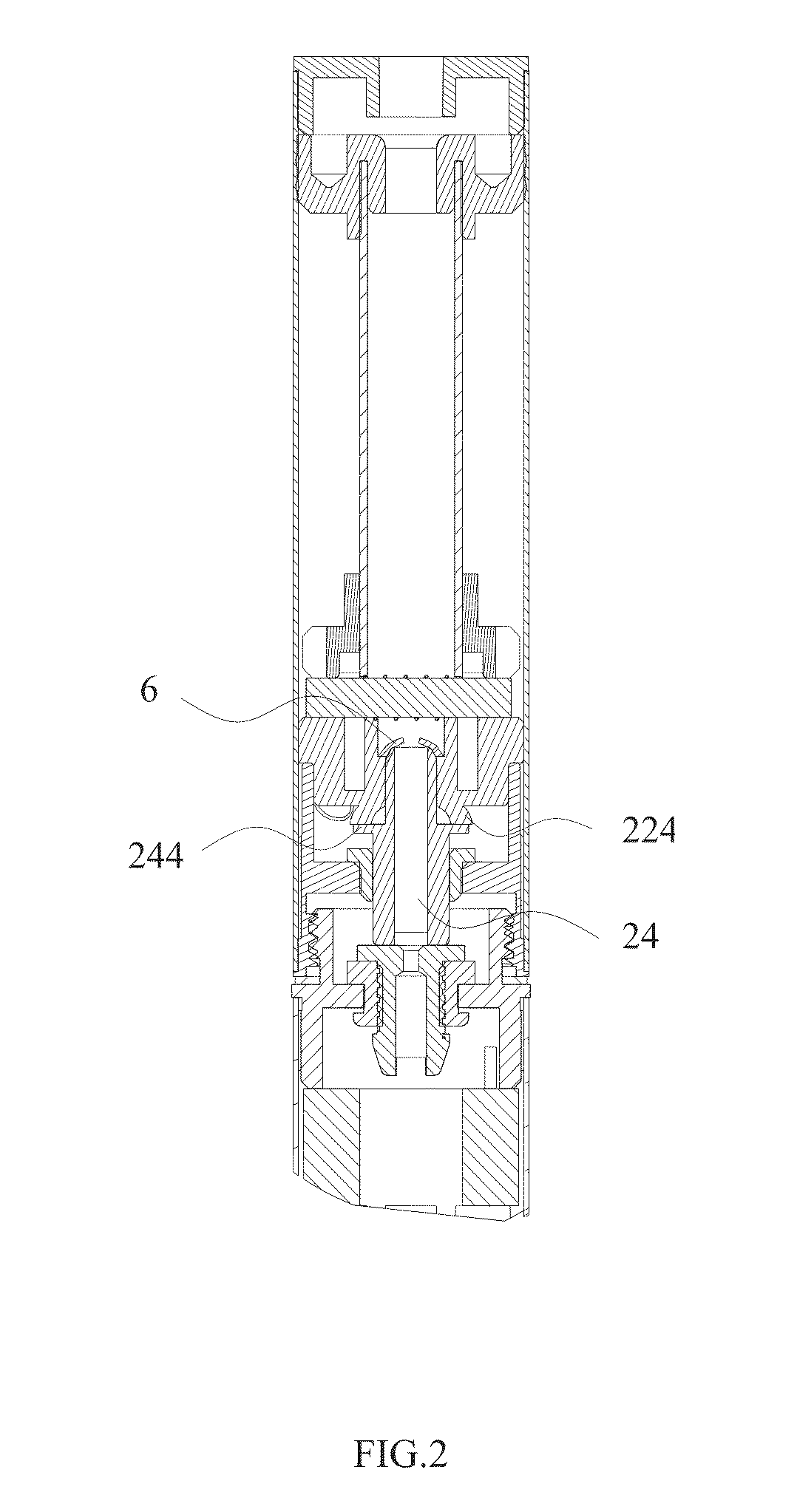

Atomizing device and electronic cigarette having same

ActiveUS9078475B2Less-harmful to humanEasy to useOhmic-resistance electrodesMedical devicesEngineeringWire wrap

An atomizing device includes an atomizing sleeve; a mouthpiece assembly and an atomizing assembly received in the atomizing sleeve. The atomizing assembly includes an oil obstructing ring, a supporting sleeve, a porous body being fixed between the oil obstructing ring and the supporting sleeve, a heating wire wrapping around the porous body, a screw sleeve located at an end of the atomizing sleeve, an insulated ring and an tubular electrode received between the screw sleeve and the insulated ring. An oil valve is formed between the supporting sleeve and the tubular electrode, or between the tubular electrode and the insulated ring; the oil valve is opened or closed by a movement of the tubular electrode, and the oil valve is configured as an air passage in communication with the air pipe when the oil valve is opened. An electronic cigarette using the atomizing device is also provided.

Owner:SHENZHEN FIRST UNION TECH CO LTD

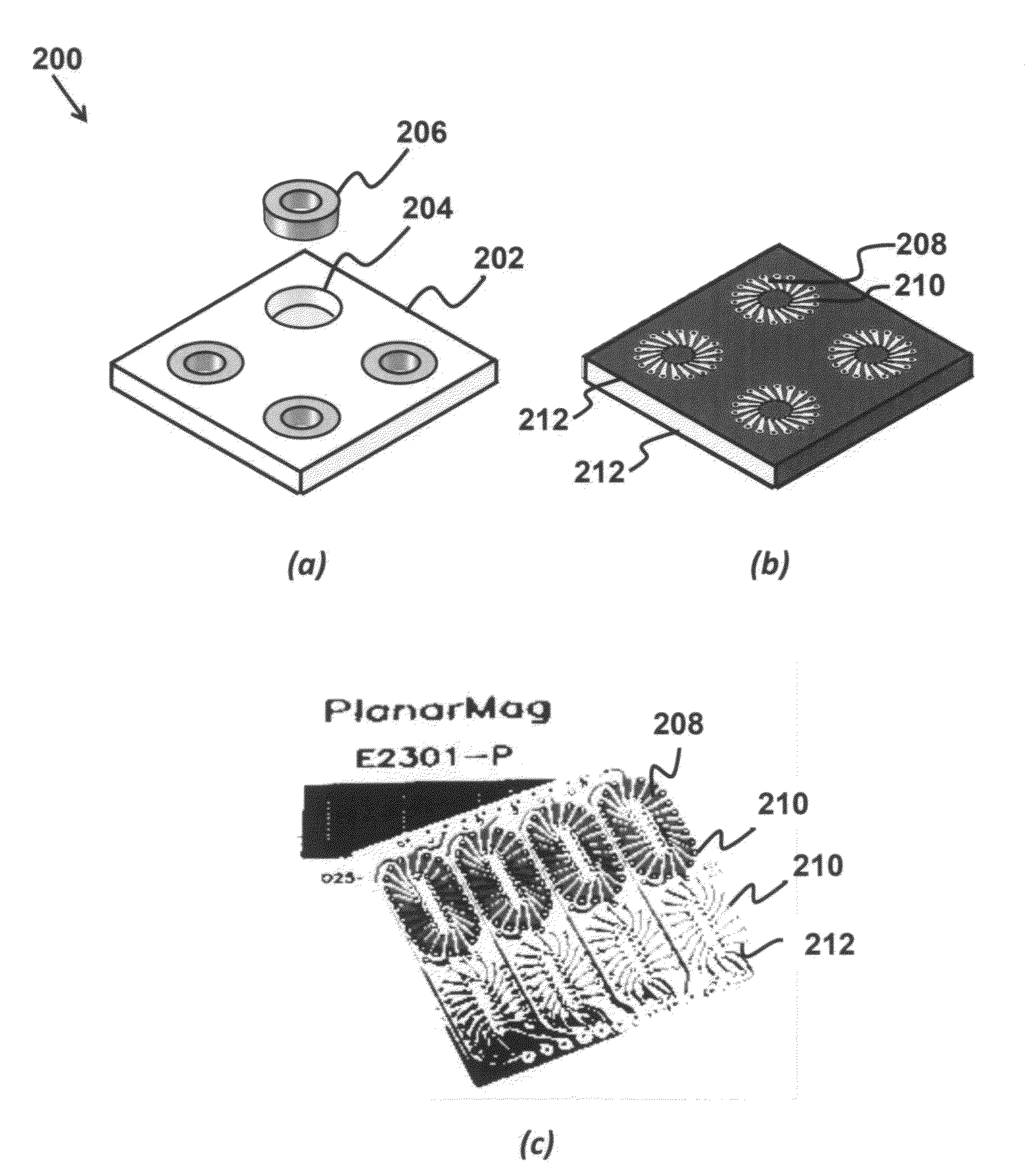

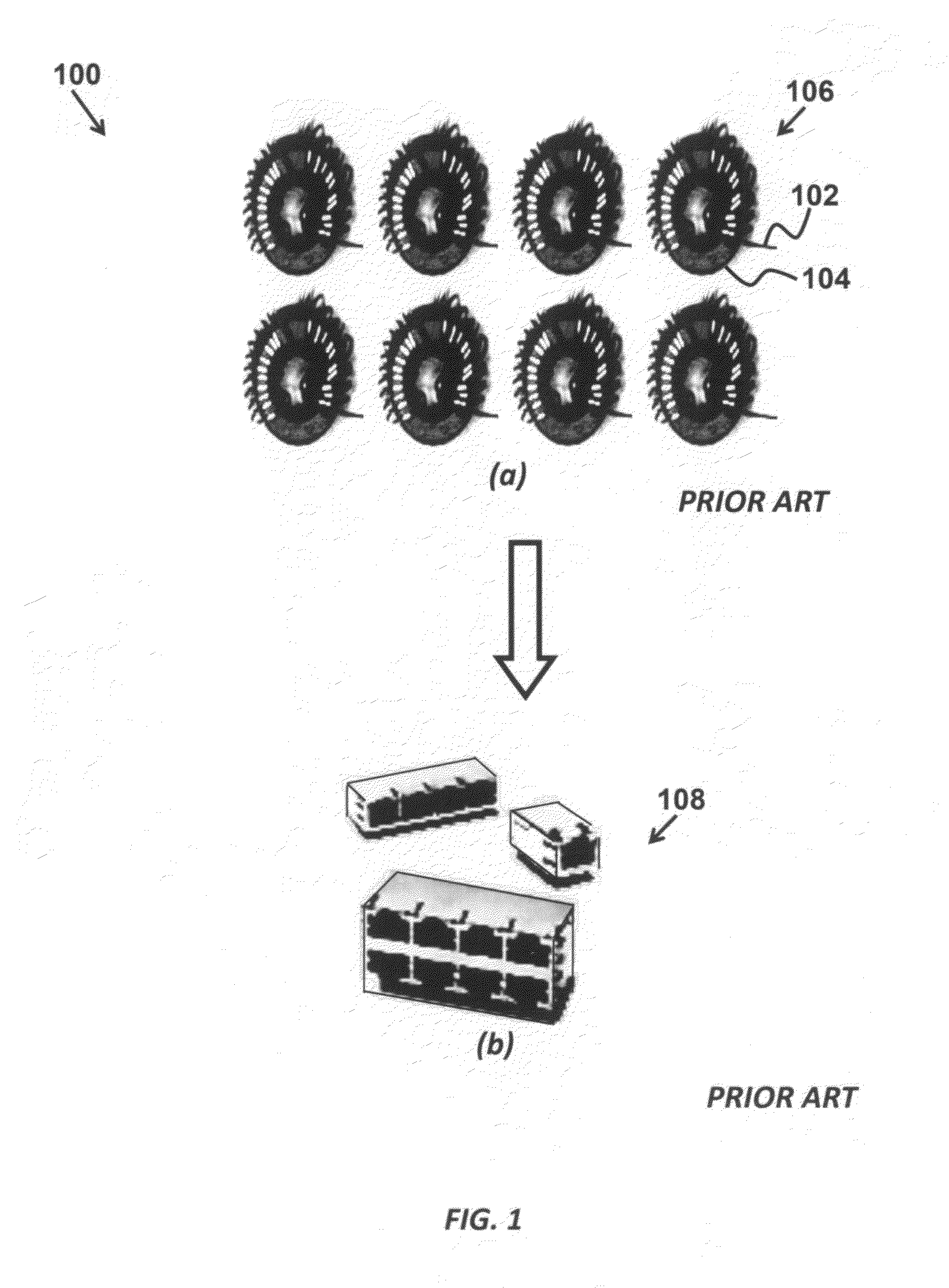

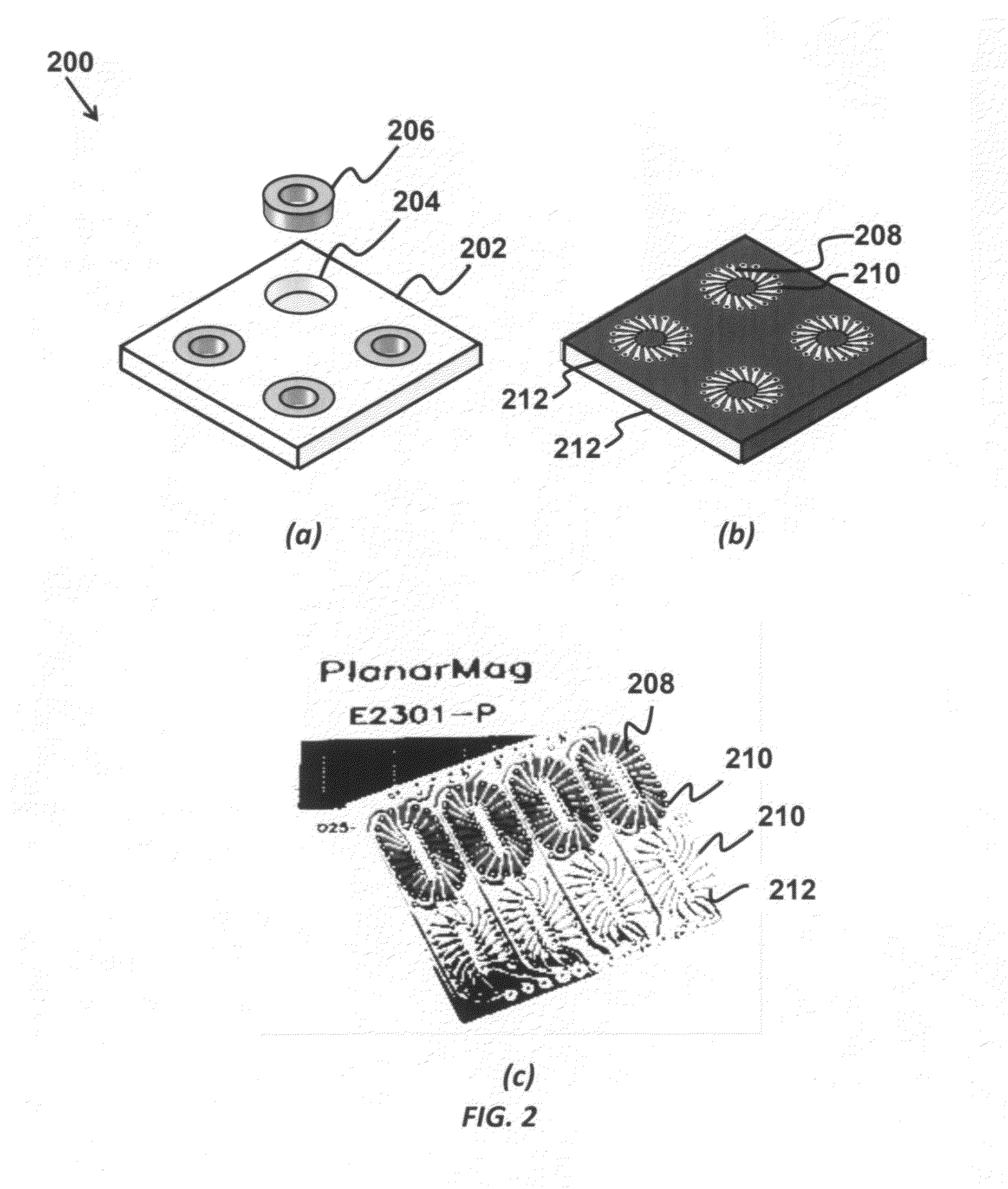

Manufacture and use of planar embedded magnetics as discrete components and in integrated connectors

ActiveUS20100295646A1Coupling for high frequencyCross-talk/noise/interference reductionEngineeringConductive materials

The current invention provides an integrated planar transformer and electronic component that includes at least one wideband planar transformer disposed in a planar substrate, where each wideband planar transformer includes a planar substrate in a fully-cured and rigid state, a ferrite material embedded in the planar substrate, where the ferrite material is enveloped in an elastic and non-conductive material, inter-wound conductors disposed around the embedded ferrite material, where top and bottom conductors are bonded by an insulating adhesive. The top and bottom conductors are connected in an inter-connected pattern by conductive vias disposed on each side of the ferrite material and span through the layers to the conductors. The planar transformer further includes at least one center tap connected to at least one inter-wound conductor. The integrated planar transformer and electronic component further includes at least one electronic component connected to at least one terminal of the wide-band planar transformer.

Owner:PLANARMAG

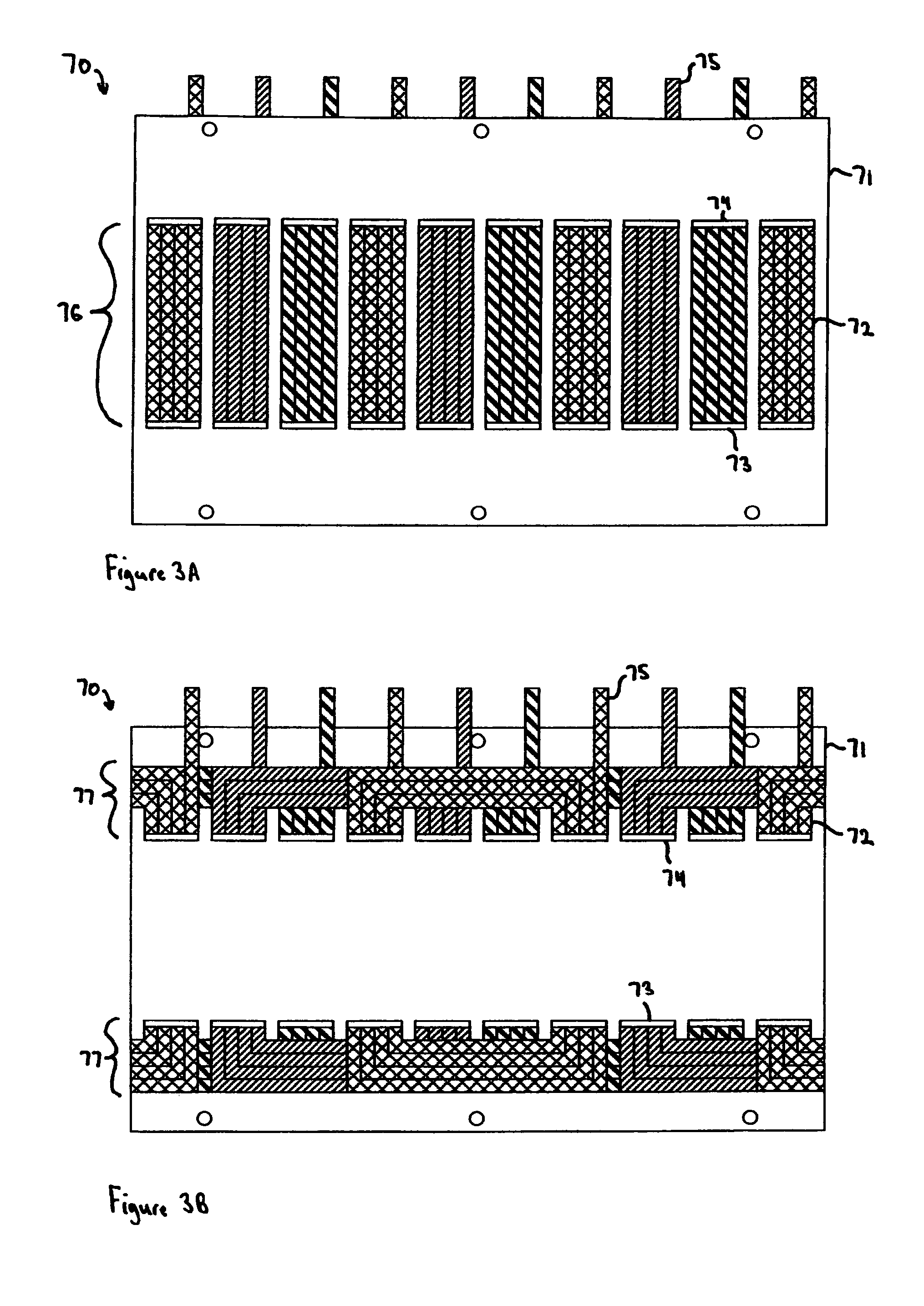

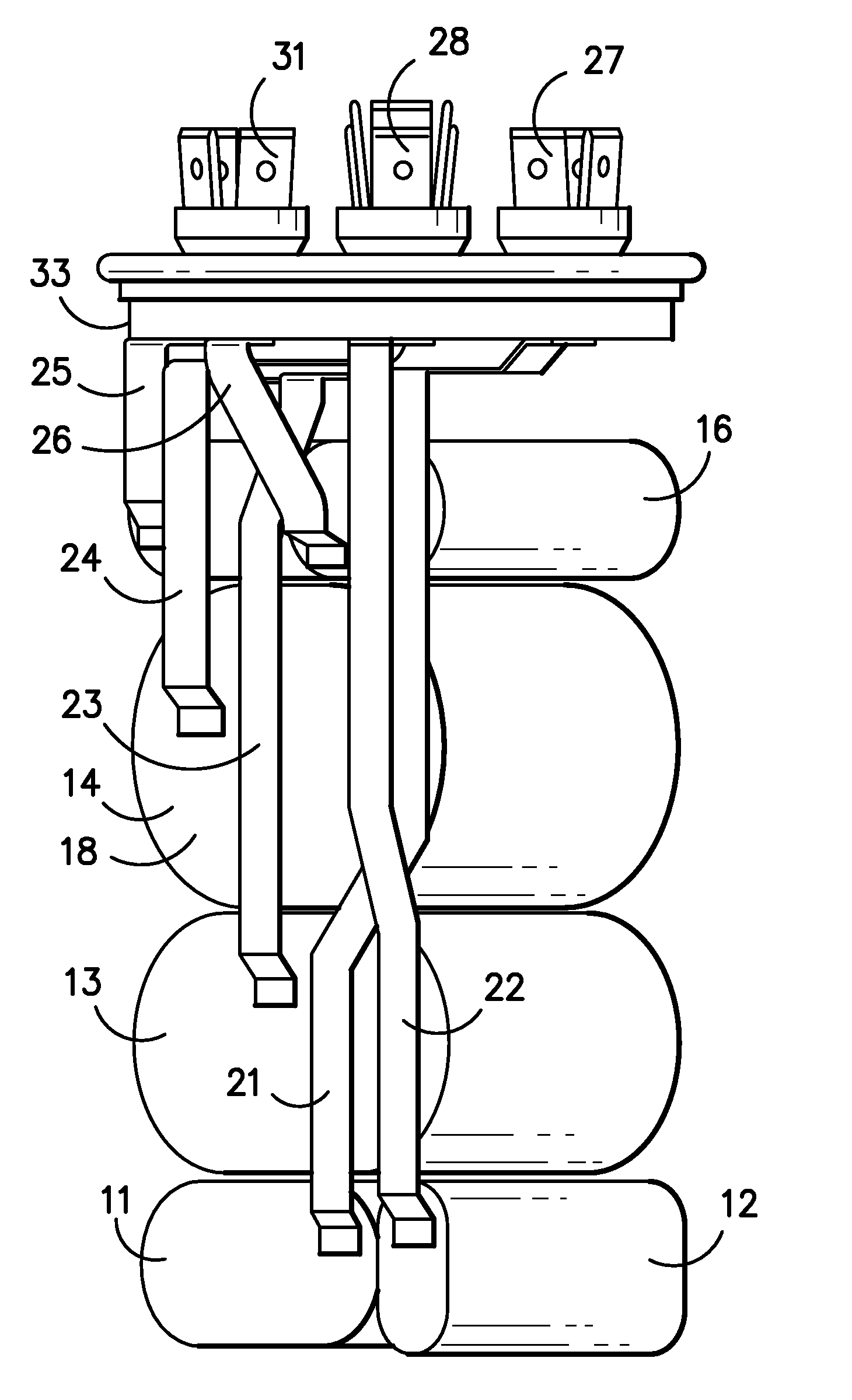

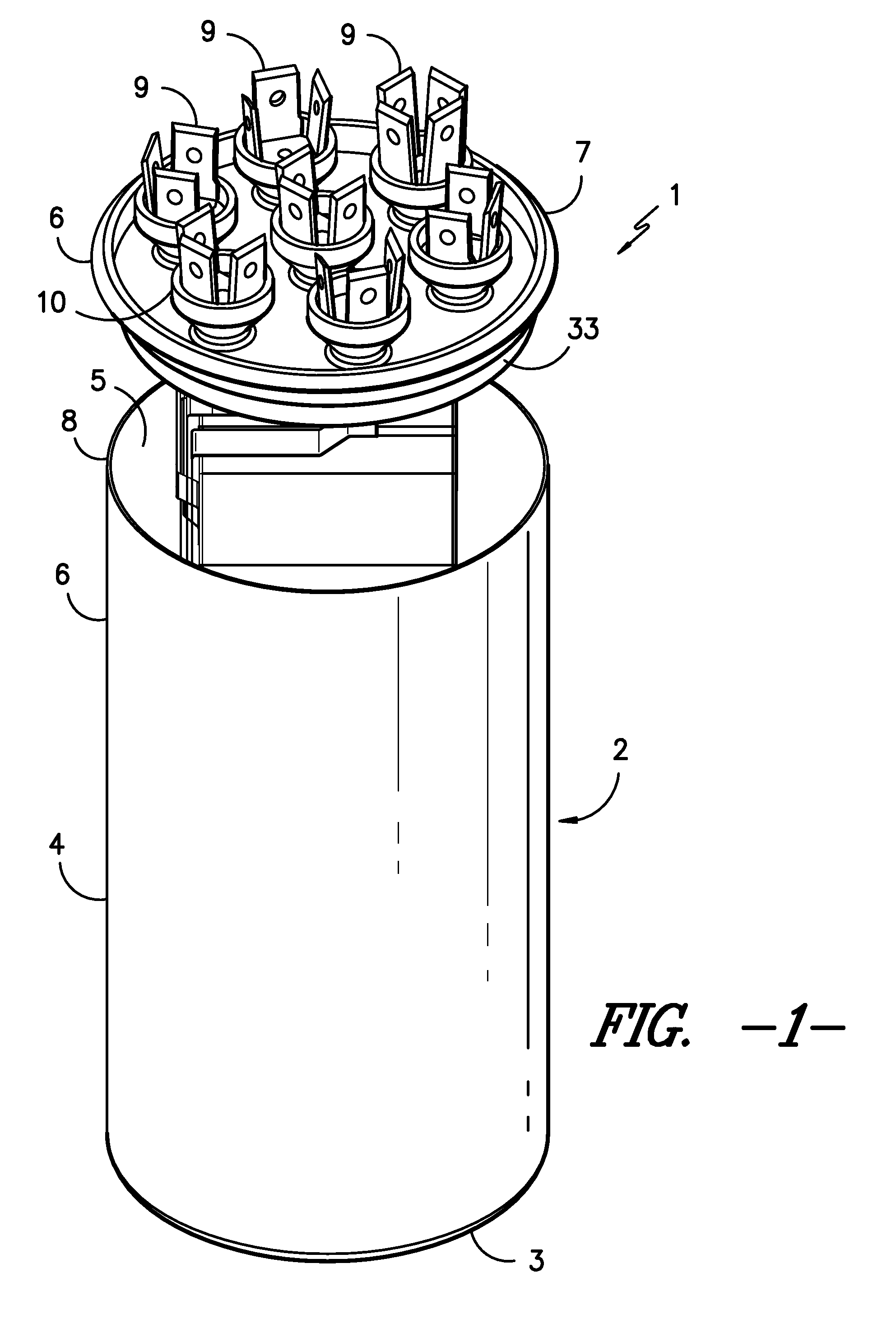

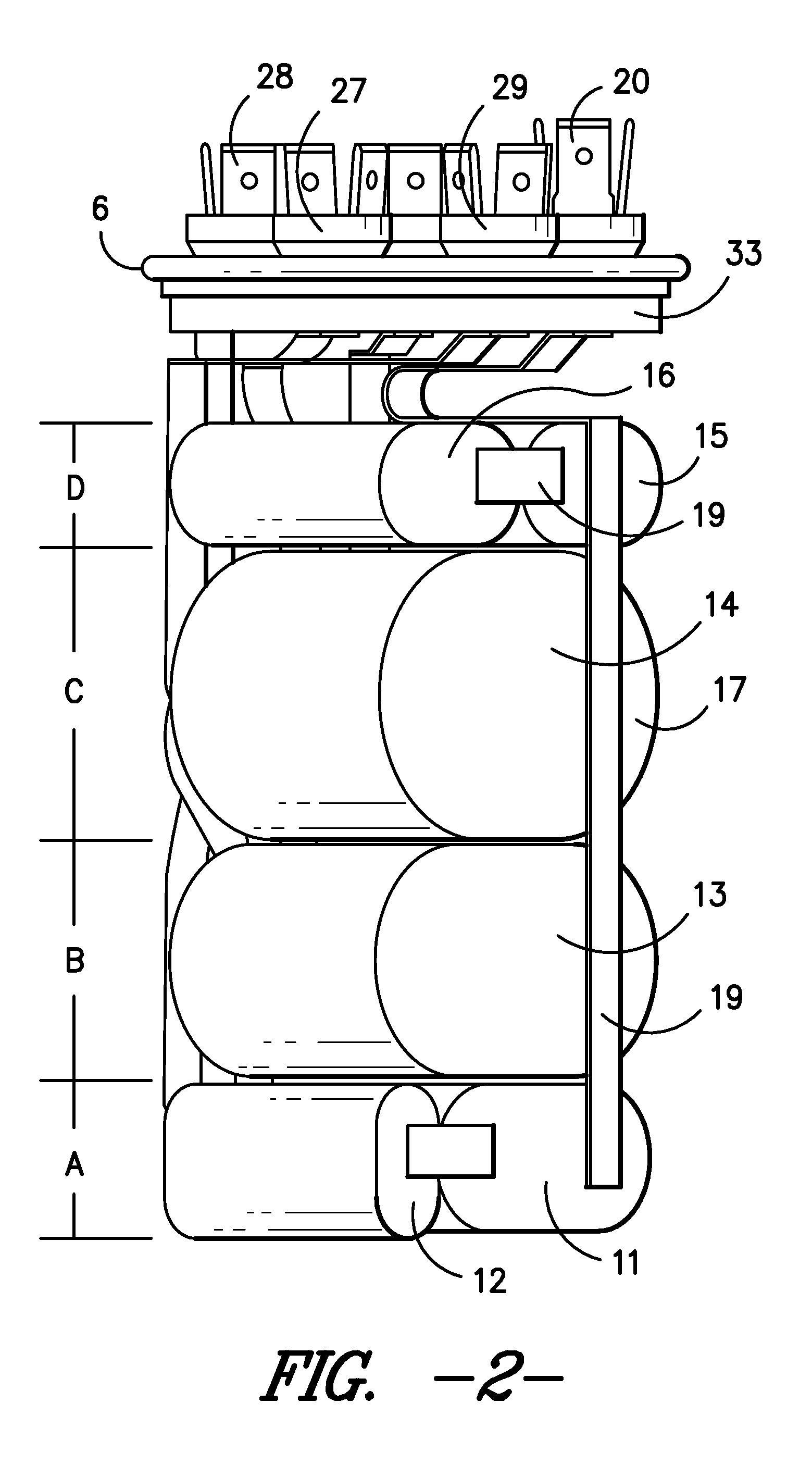

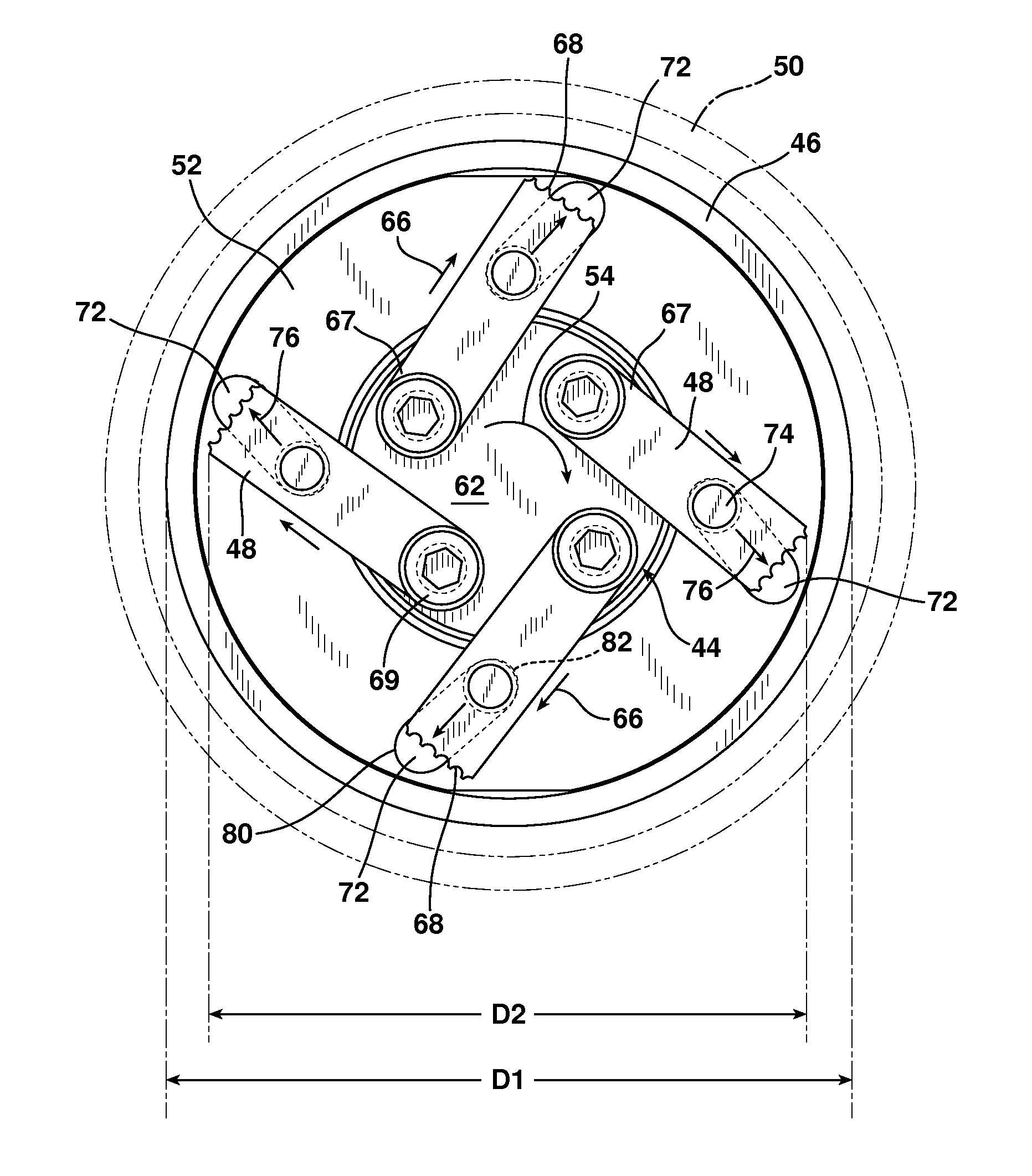

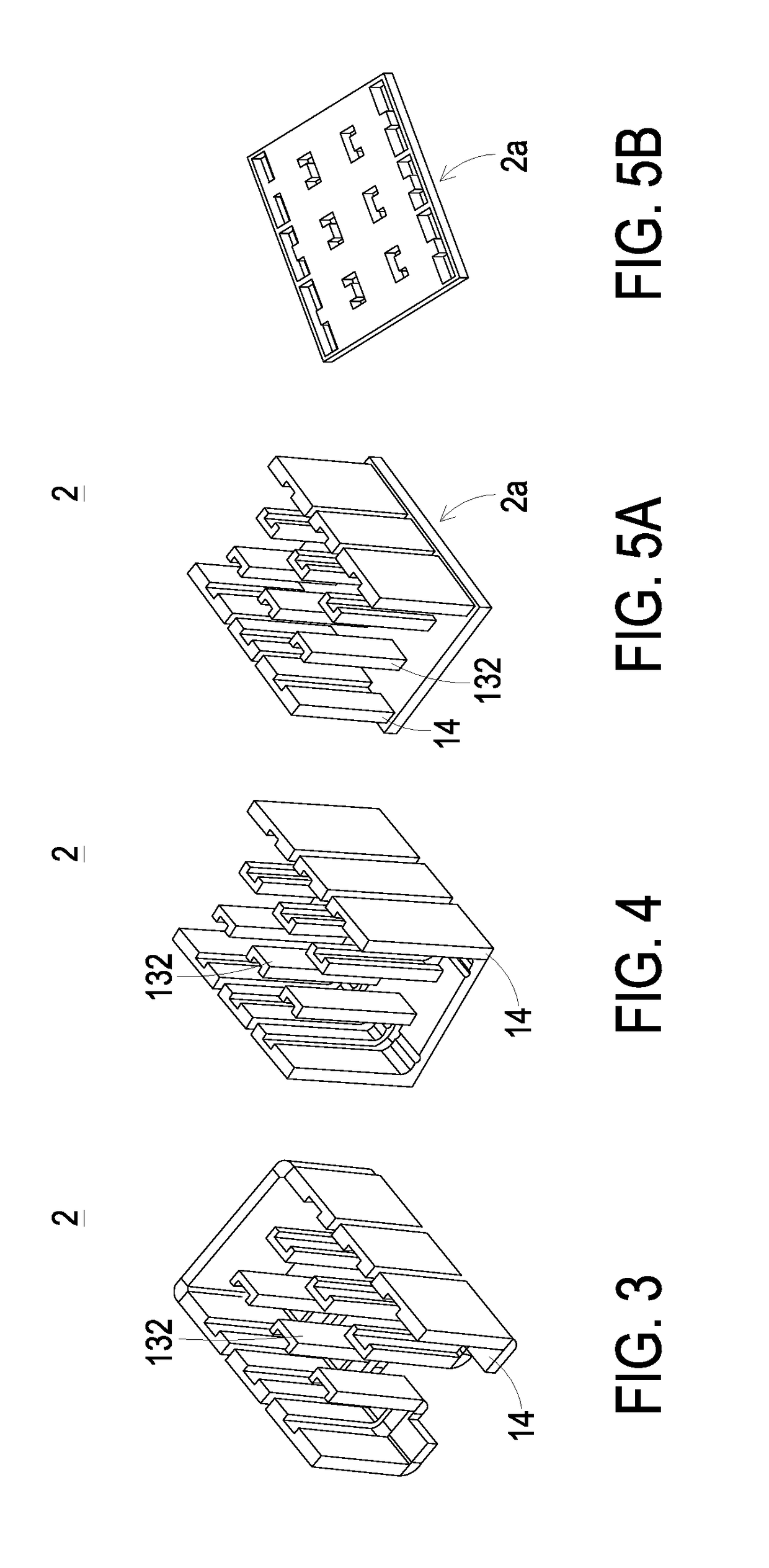

Configurable multi-capacitor assembly

ActiveUS9466429B1Improve volumetric efficiencyMultiple fixed capacitorsFixed capacitor housing/encapsulationCapacitanceEngineering

A capacitor assembly is provided with a plurality of wound capacitor elements aligned horizontally in a longitudinally extended housing, whereby the largest capacitor element solely occupies a tier in the housing, another tier in the housing is solely occupied by two of the capacitor elements, and wherein the capacitor elements are configurable to provide various capacitance values.

Owner:CORNELL DUBILIER MARKETING

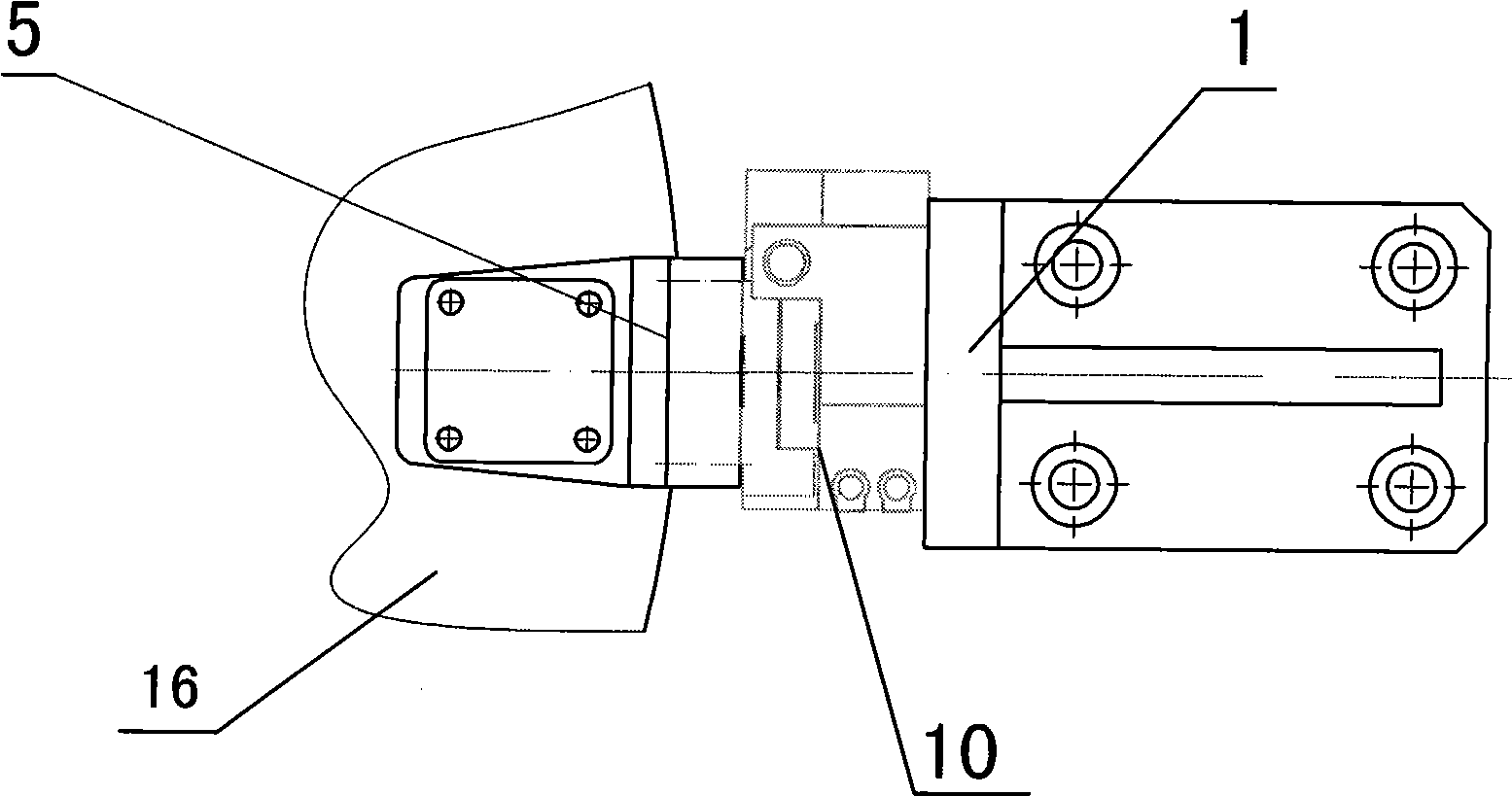

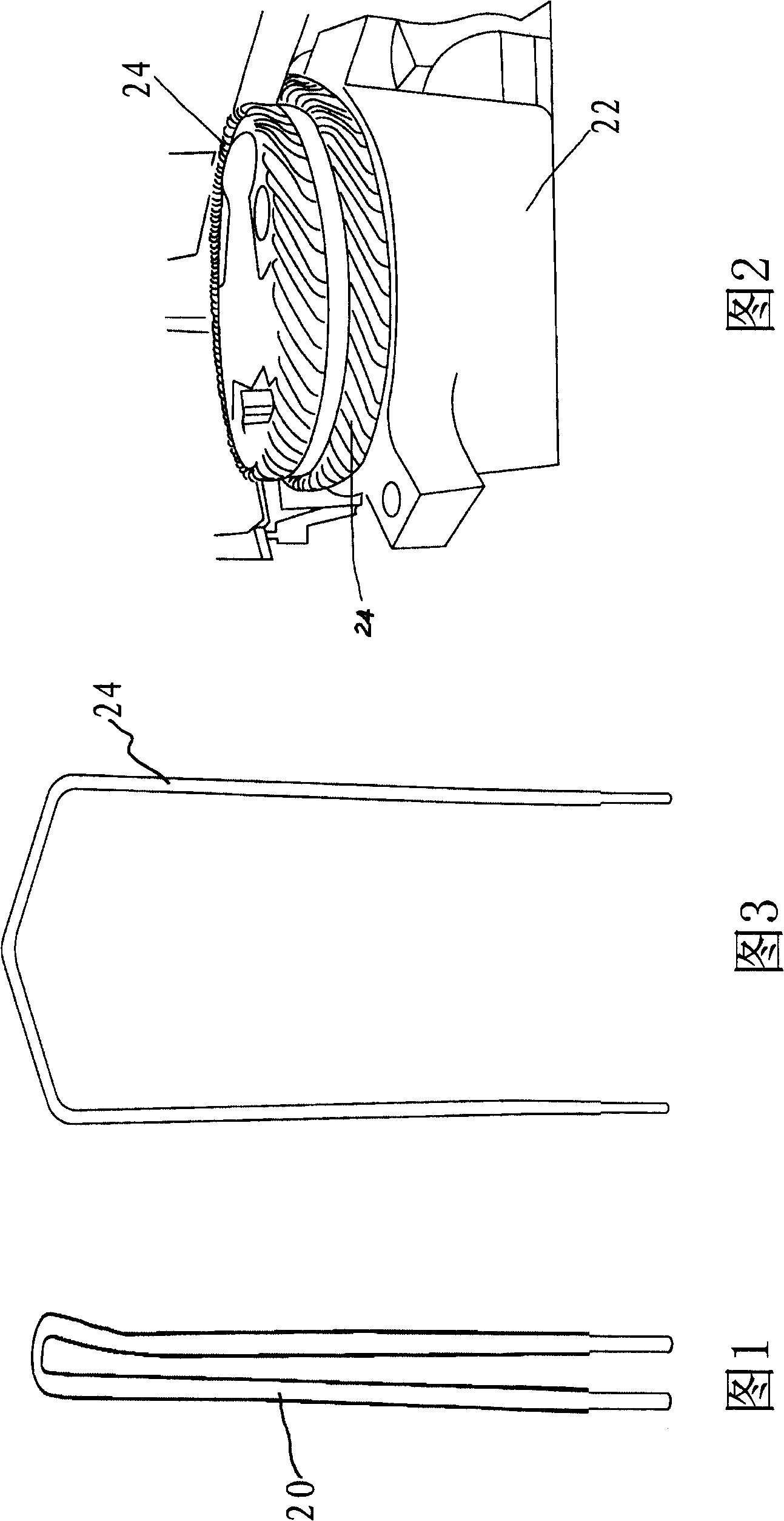

Winding device and winding machine

ActiveCN101533698AImprove efficiencyUniform number of turnsWinding capacitor machinesCoils manufactureAutomatic controlInductor

The invention discloses a high-efficiency winding device for winding stubs of electronic elements such as resistors, capacitors, inductors and the like, and a full automatic integrated winding machine. The winding machine comprises a rack (24) and a worktable (13). The worktable (13) is provided with a working turntable (16), the winding device, an upper fixture manipulator (21), a lower fixture manipulator (18), a charging conveyer belt (17), a cutting device (19), a clamping device (20), a discharging device (22) and the like. The winding device adopts a winding shaft (4) that has a kinking body (12) with the section being semicircle at the tail end to wind the stubs of workpieces. The winding machine realizes the full automatic control over the following process of: charging, cutting off thread ends, clamping by the fixture, installing the fixture, automatic winding, discharging and removing the fixture. The winding device and winding machine are suitable for the batch production of large-scale enterprises and have good market prospect.

Owner:东电化电子(珠海)有限公司

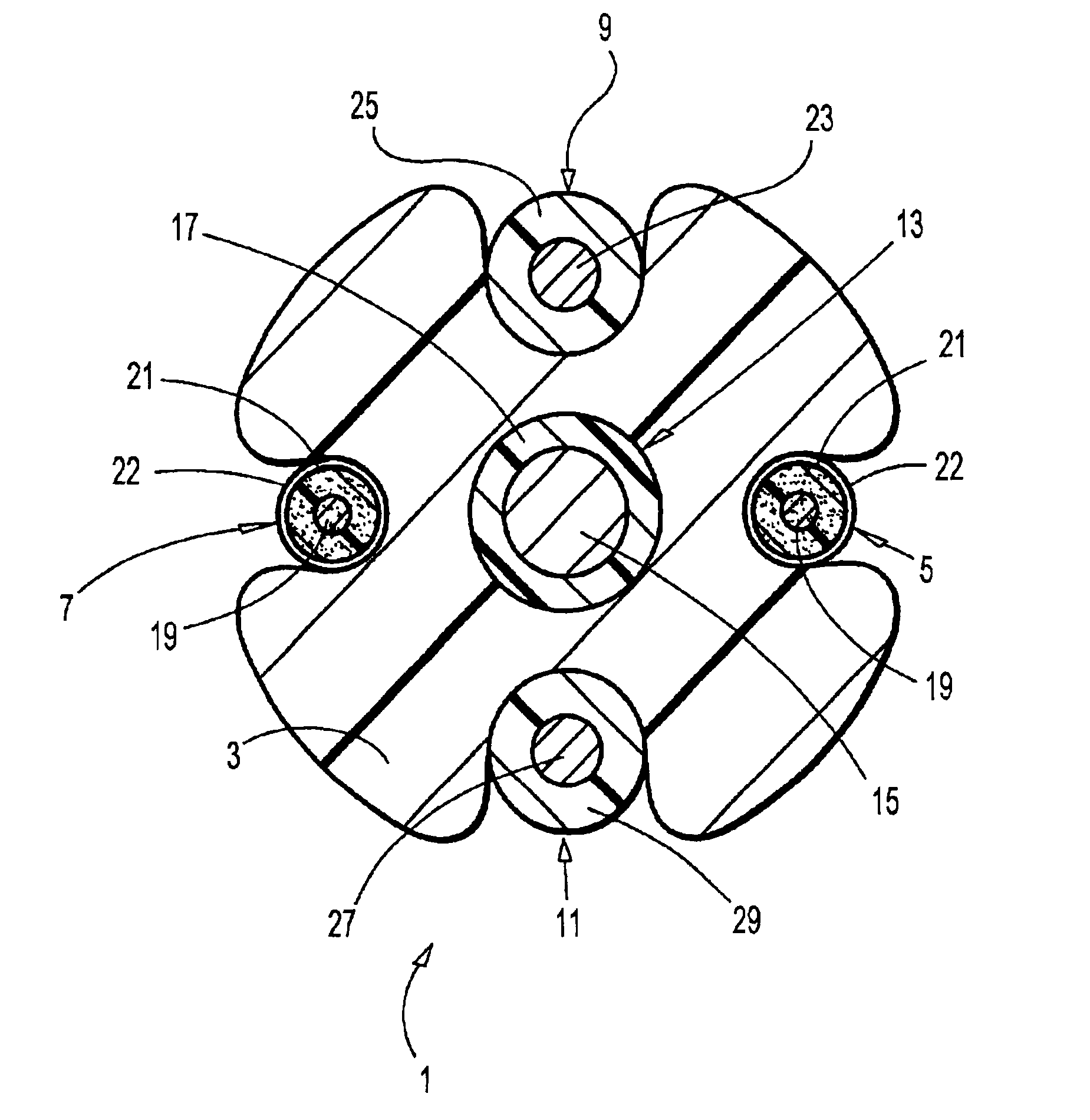

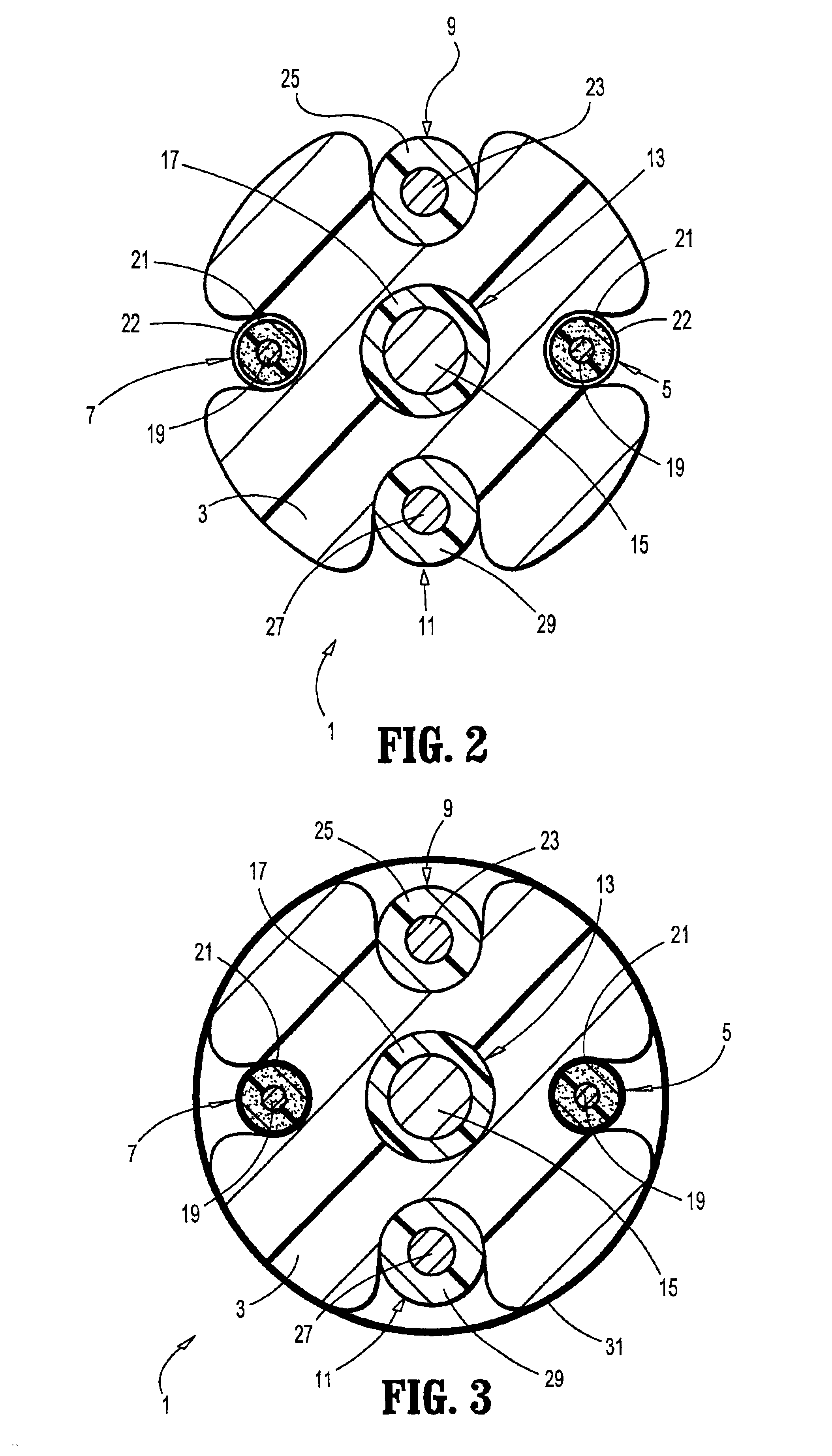

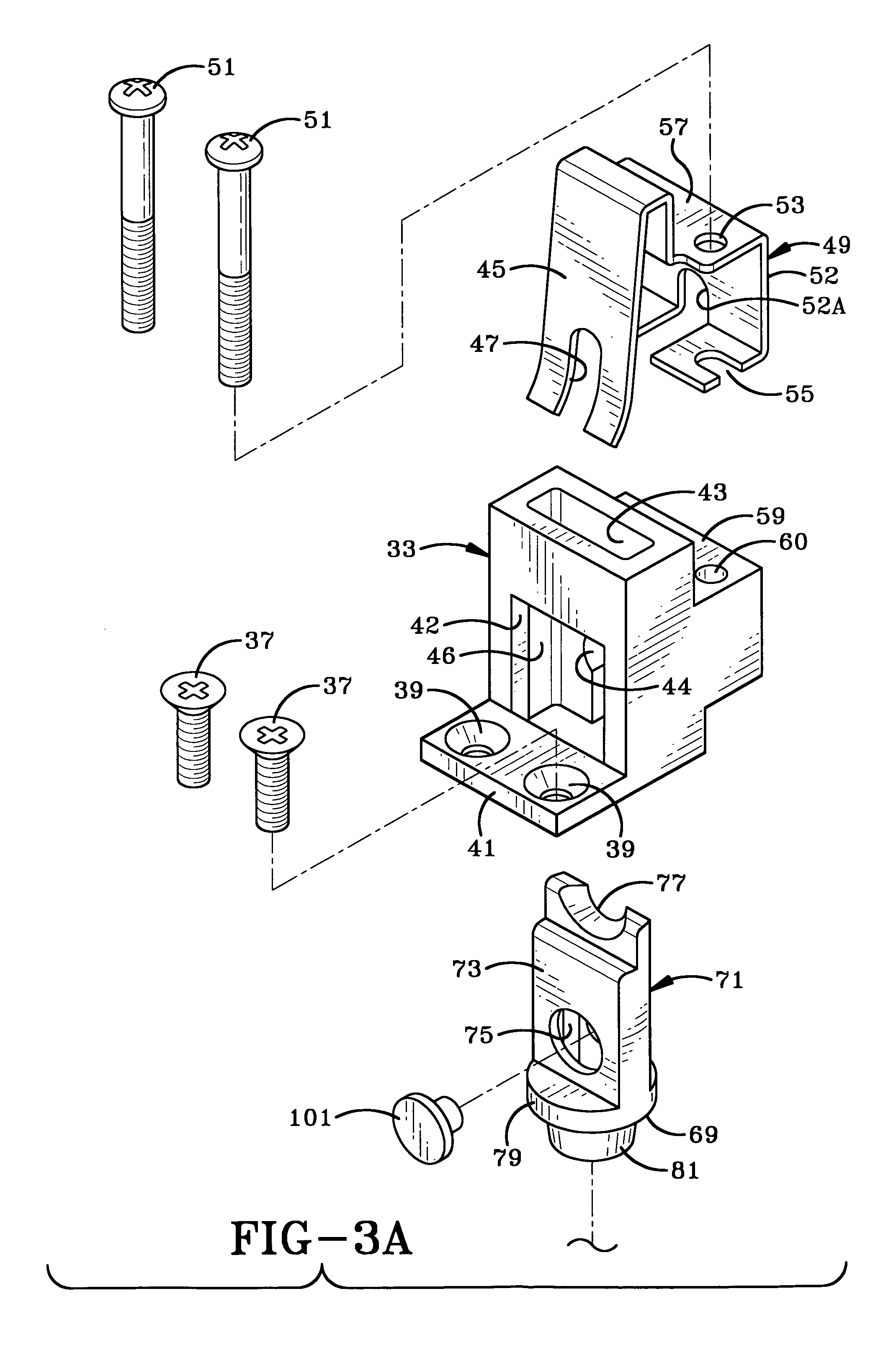

Contact assembly for land grid array interposer or electrical connector

InactiveUS6659778B2Improve conductivityCurrent-carrying capability can be increasedElectrical measurement instrument detailsSemiconductor/solid-state device detailsHelical lineElectrical conductor

The present invention provides an electrical contact comprising a first member having spring properties and a second member wrapped around at least a portion of the first member wherein the second member has a greater electrical conductivity than the first member. In one embodiment, a conductor is wrapped around at least a portion of a spring. In another embodiment, the spring is formed into a coil or helix with a wire wrapped around at least a portion of the helical spring. In one form of this embodiment, the spring has a plurality of turns and the wire is wrapped around at least two of the turns. In another form of this embodiment, the spring has a plurality of turns and the wire is wrapped around all of the turns. An interposer connector is also provided having a frame including a top surface and a bottom surface and a plurality of apertures arranged in a pattern and opening onto the top and bottom surfaces of the frame. A plurality of springs are provided with each spring having a conductor wrapped around at least a portion of the spring where the conductor has a greater electrical conductivity than the spring. One of the springs is positioned within each of the apertures so that at least a portion of each of the conductors is exposed above the top and bottom surfaces of the frame.

Owner:HIGH CONNECTION DENSITY INC

Sensor cable

InactiveUS6777947B2Leakage is detectedDetection of fluid at leakage pointMeasurement of fluid loss/gain rateElectricitySurface layer

A cable suitable for detecting the presence of corrosive liquids is disclosed. In an embodiment the cable includes two sensing wires wrapped around a core member, at least one of the sensing wires being surrounded by a non-conductive surface layer. In an alternate embodiment the cable includes two sensing wires wrapped around a core member, the sensing wires and core member being encapsulated by a non-conductive surface layer. Preferably, the cable includes insulating wires for detecting the location of a leak. When a corrosive liquid contacts the sensing wires of the cable an electrical connection is created between them.

Owner:NVENT SERVICES GMBH

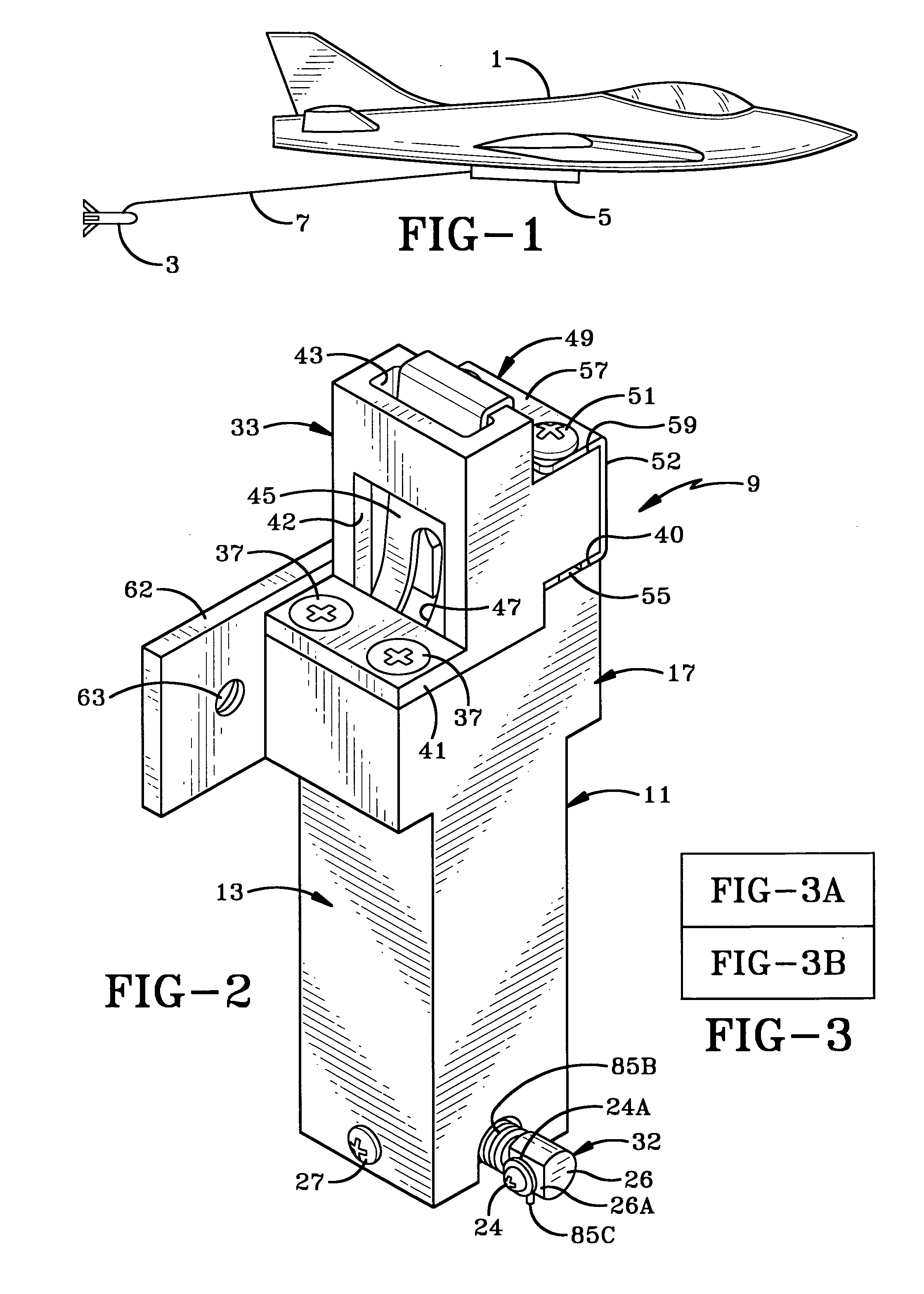

Method and apparatus for rapid severance of a decoy towline

ActiveUS20100257983A1Rapid severanceEasy to identifyParachutesHeating/cooling contact switchesDecoyEngineering

A method and apparatus for rapidly severing a decoy towline extending from an aircraft by a mechanical spring actuated cutting blade and a thermal fuse type of release mechanism eliminating a pyrotechnic actuation device. The cutting blade is biased toward cutting engagement with the towline by a preloaded coil compression spring retained in the loaded position by a length of a polymer cord. The polymer cord has a heater wire wrapped about a portion of the cord which is connected to a DC voltage supply. The heater wire melts the cords when electrically connected to the DC power supply which releases the restraint on the spring which then drives the cutting blade into severing engagement with the towline.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

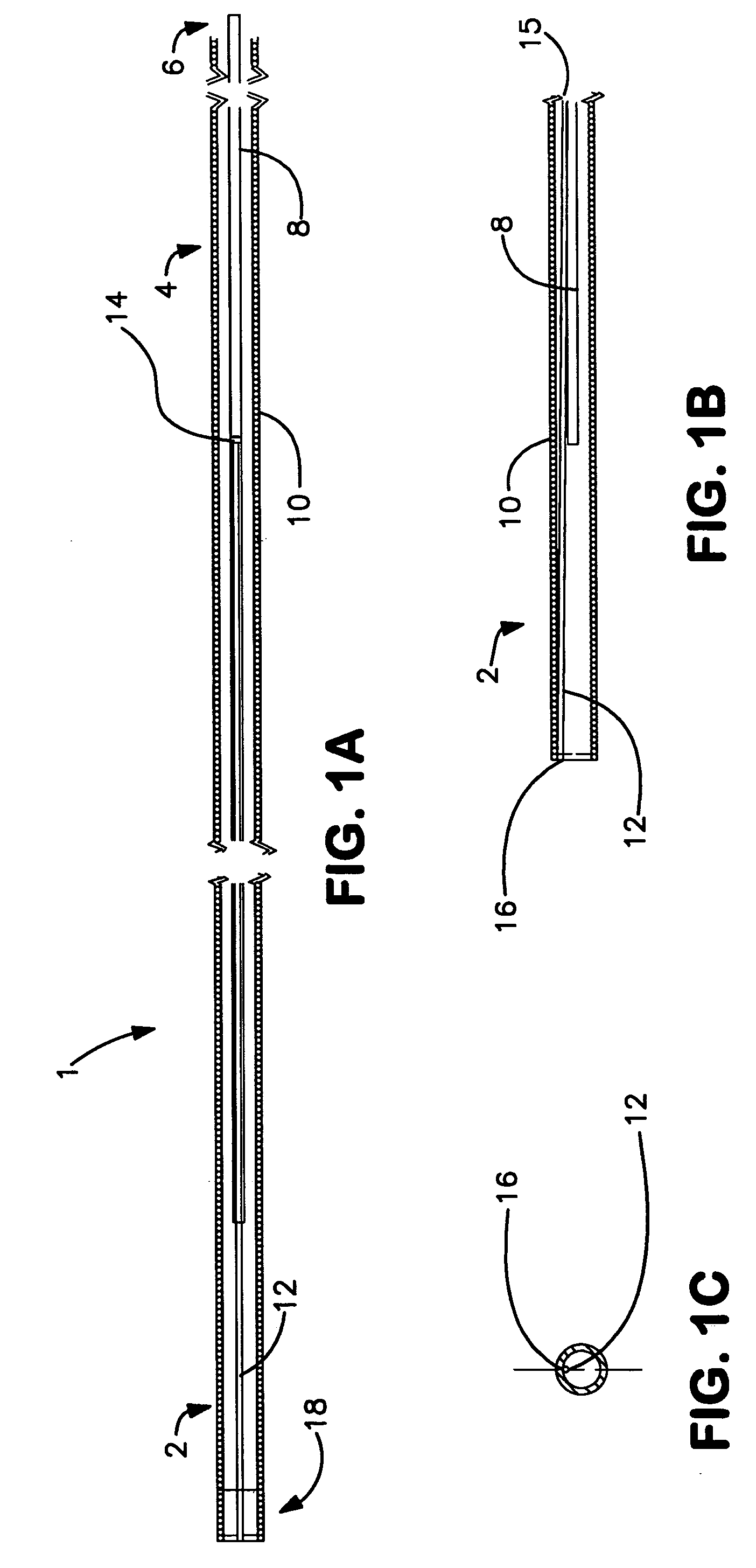

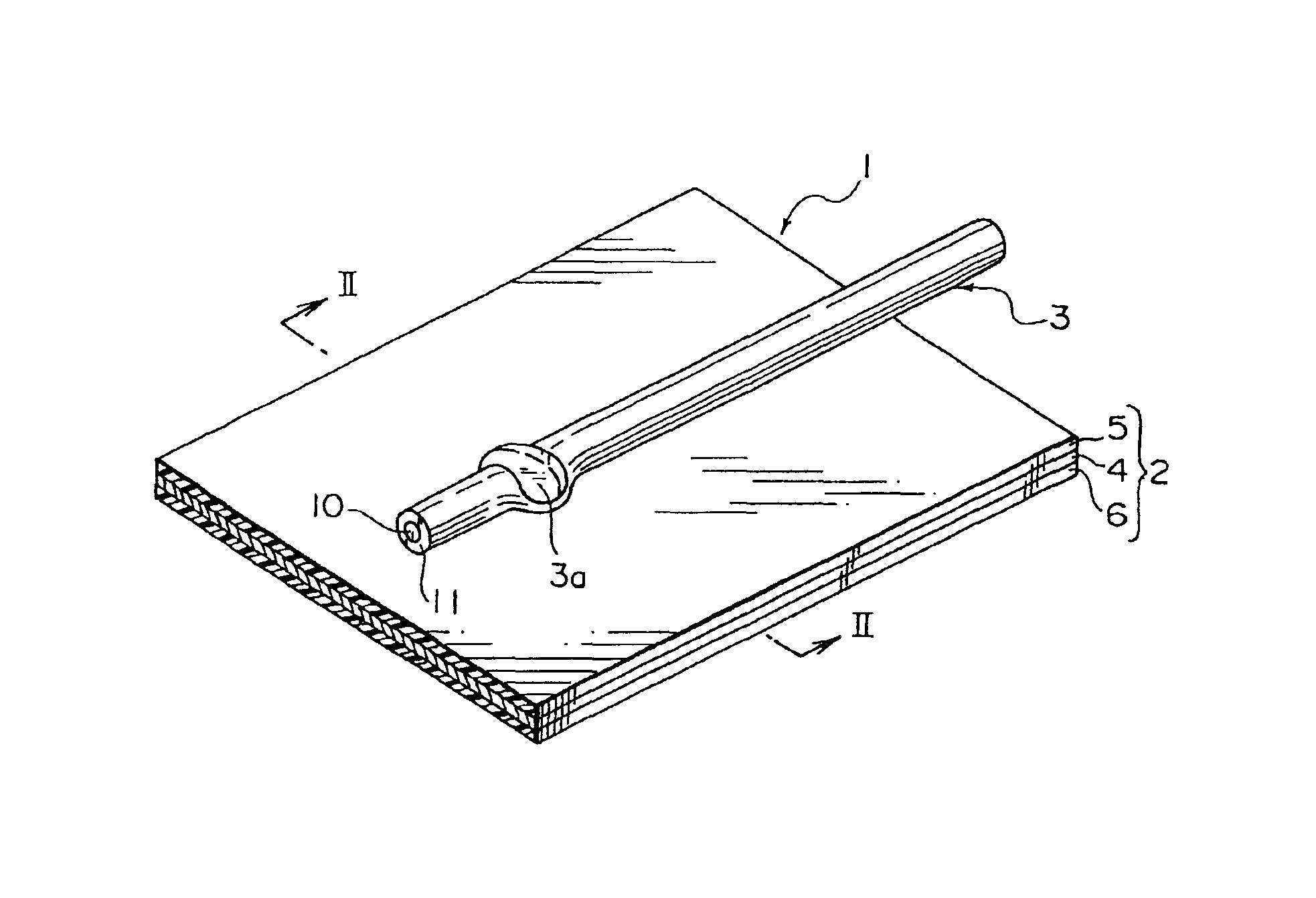

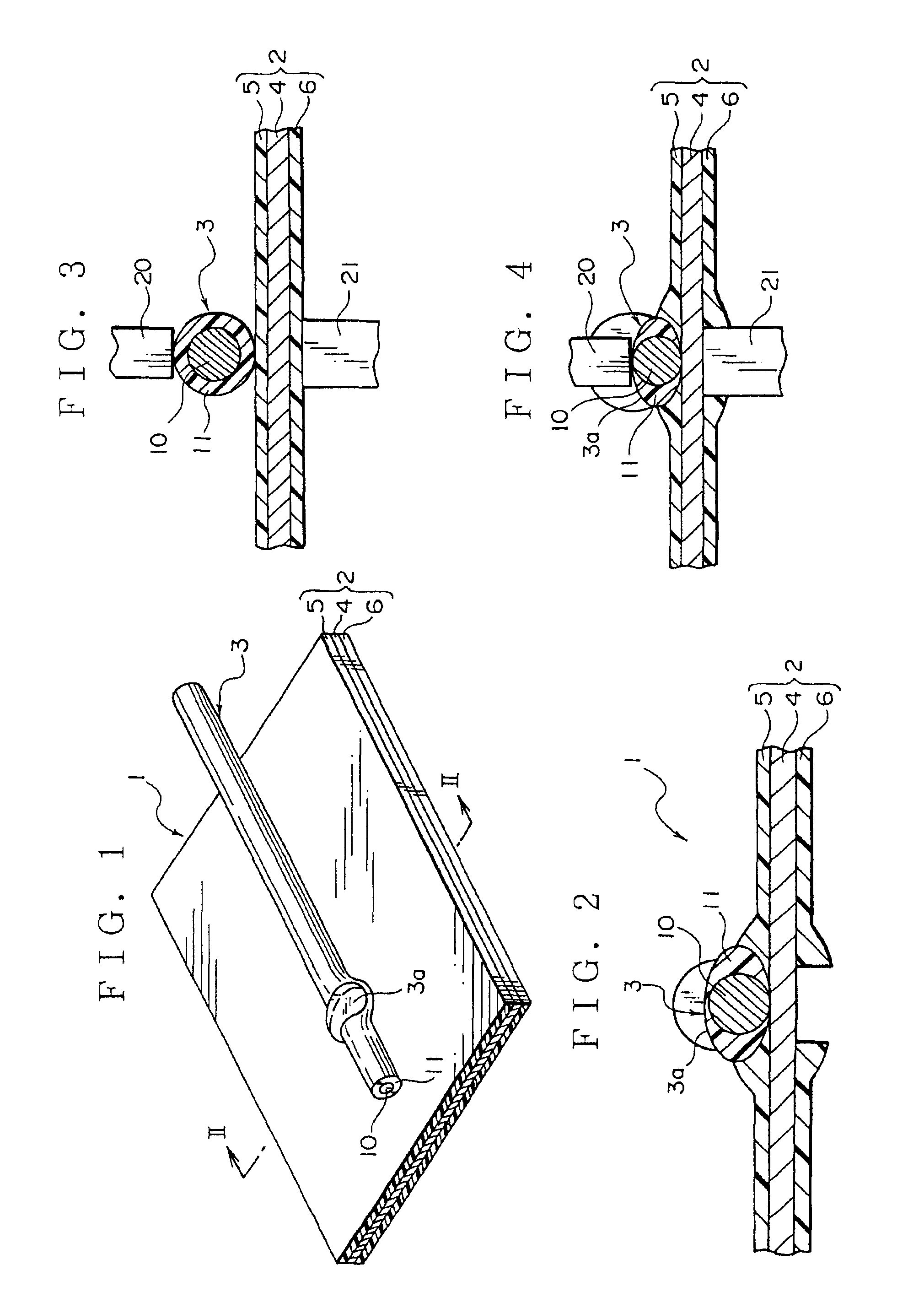

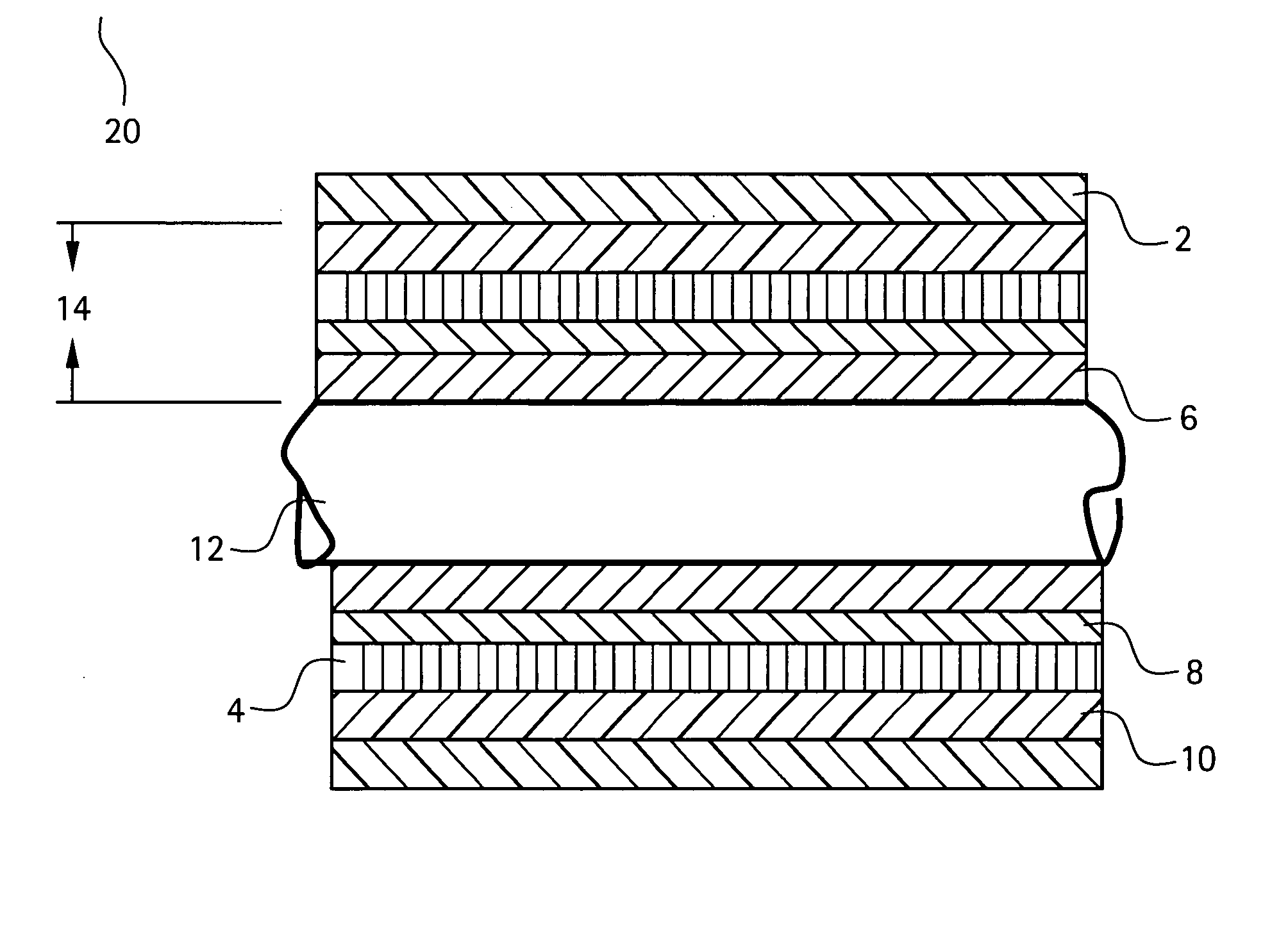

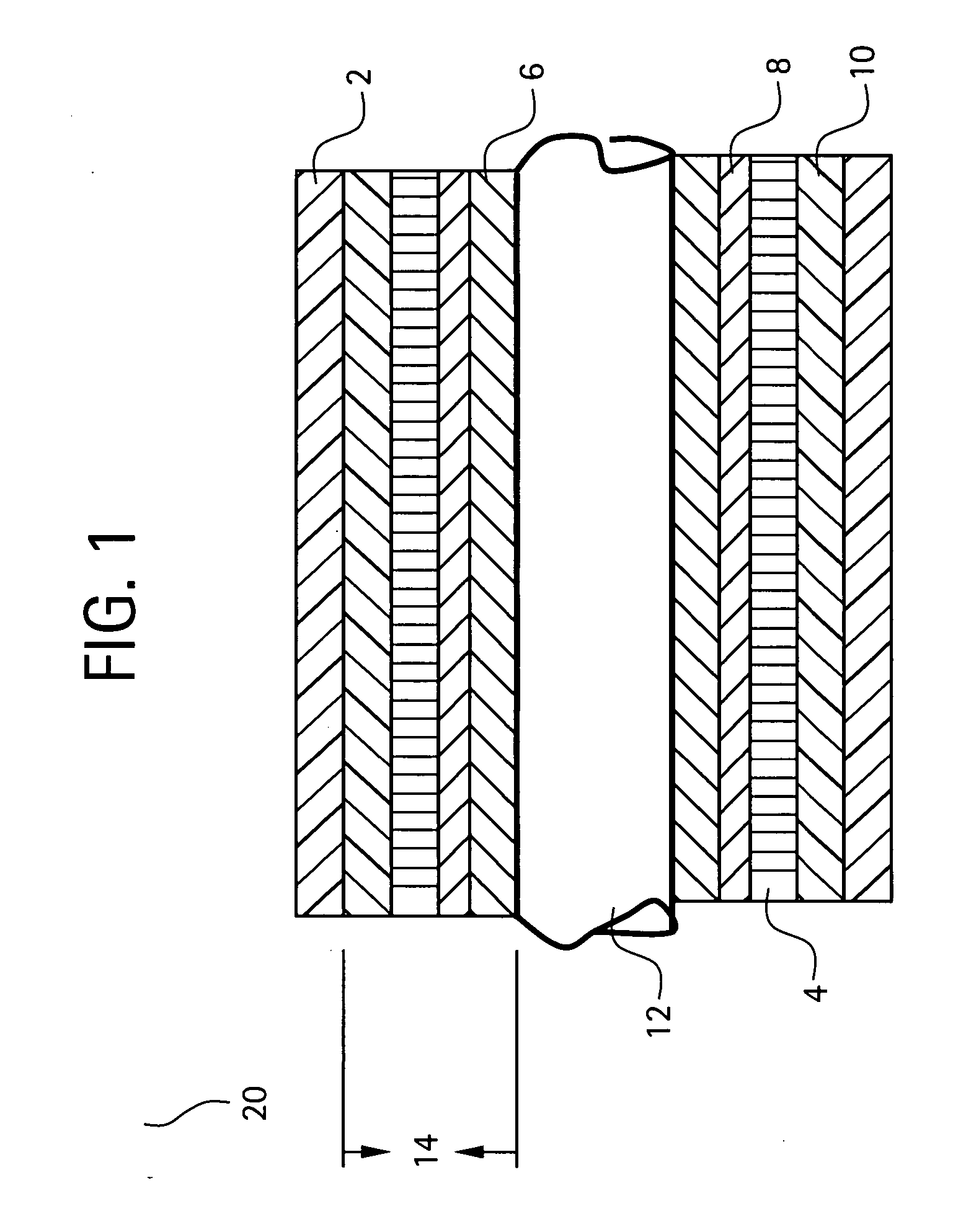

Cable-enrolling conductive thin-film sheet and manufacturing method thereof

InactiveUS6858804B2Lower assembly costsLow costPrinted circuit assemblingNon-insulated conductorsElectrical conductorUltrasonic welding

The cable-enrolling conductive thin-film sheet 1 consists of a conductive thin film 2 and an insulated cable 3. The conductive thin film 2 has a conductor layer 4 and first and second insulating layers 5, 6. The first insulating layer 5 is laminated on one face of the conductor layer 4, while the second insulating layer 6 is laminated on the other face of the conductor layer 4. The insulated cable 3 has an electrically conductive core wire 10 and an insulating sheath 11 covering the core wire 10. The insulated cable 3 laid on the first insulating layer 5 is partially welded to the sheet 2 by ultrasonic welding to obtain the cable-enrolling conductive thin-film sheet 1. The first insulating layer 5 is welded to be secured to the sheath 11, and the conductor layer 4 is mechanically connected to the core wire 10 by the ultrasonic welding.

Owner:YAZAKI CORP

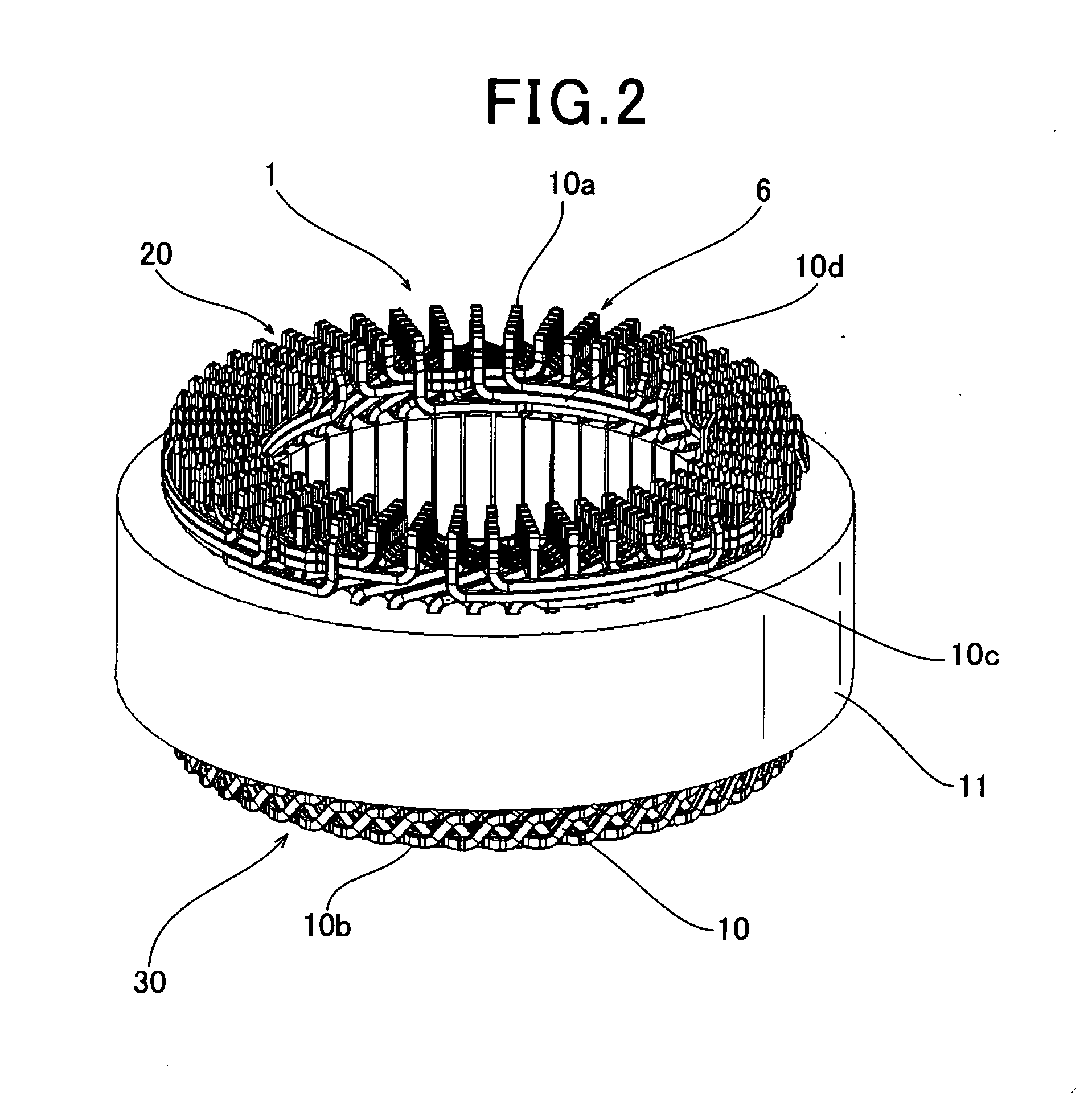

Electric rotating machine

ActiveUS20120161569A1Improve vibration resistanceSynchronous machinesAsynchronous induction motorsElectric machineMagnetic poles

The stator of the electric rotating machine includes a stator winding constituted of a plurality of U-shaped conductor segments each including a turn portion and two straight portions, the U-shaped conductor segments being connected in series by welding at welded portions formed in ends of the straight portions, and a stator core formed with slots, the straight portions of each U-shaped conductor segment being accommodated in corresponding two of the slots. The welded side slot pitch as an interval of the corresponding two of the slots on the side opposite to the turn portions is narrower than the N-S magnetic pole pitch of the rotor. The stator winding includes overlapped wire wrapping sections each constituted of the U-shaped conductor segments accommodated in the corresponding two of the slots, and crossover wires disposed on the side of the welded portions for connecting the overlapped wire wrapping sections.

Owner:DENSO CORP

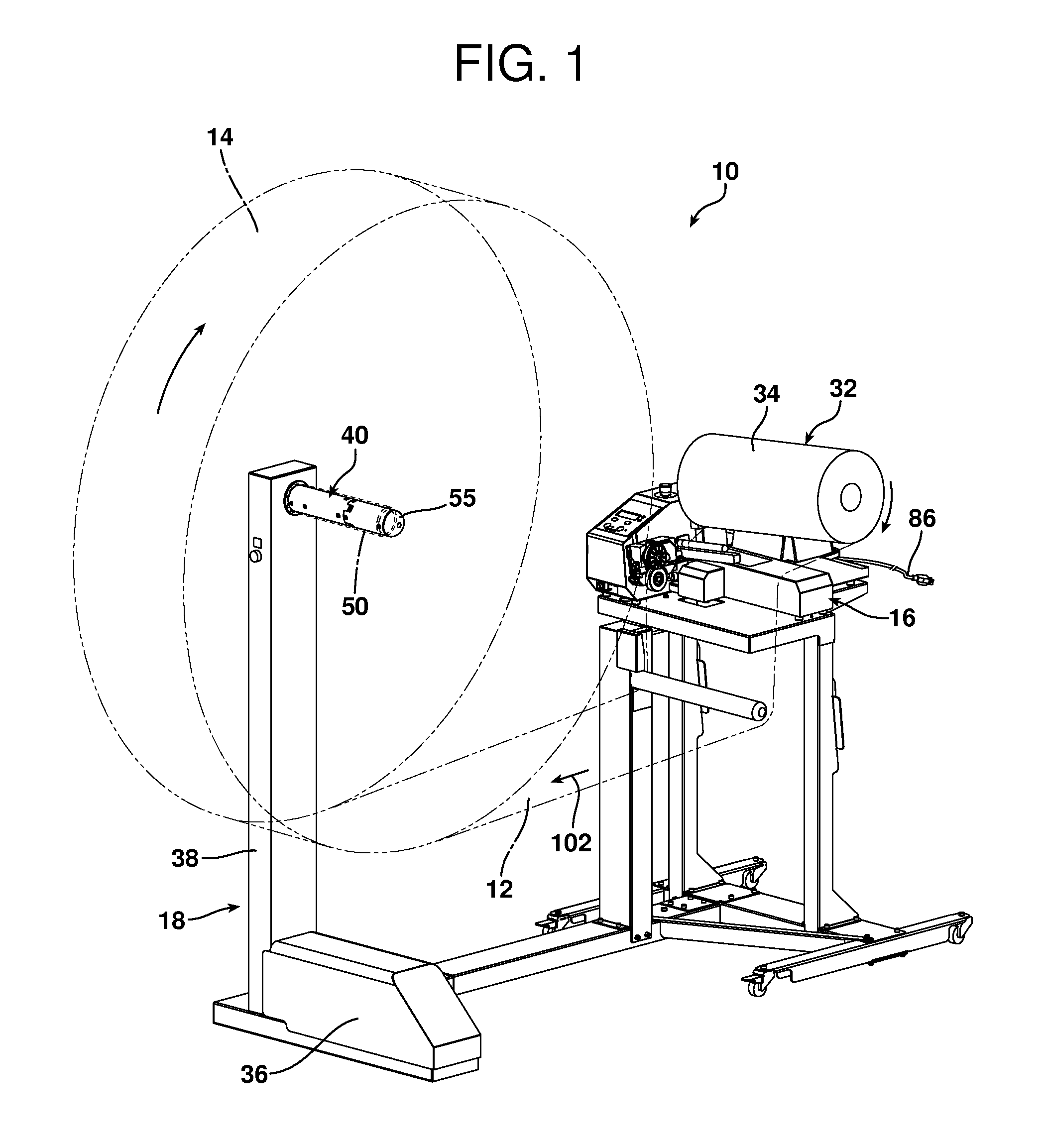

Method for Horizontally Winding and Unwinding a Parallel Wire Strand

InactiveUS20130248638A1Avoid damageAvoid injuryFilament handlingBridge structural detailsMechanical engineeringRotational axis

Owner:SHANGHAI PUJIANG CABLE +1

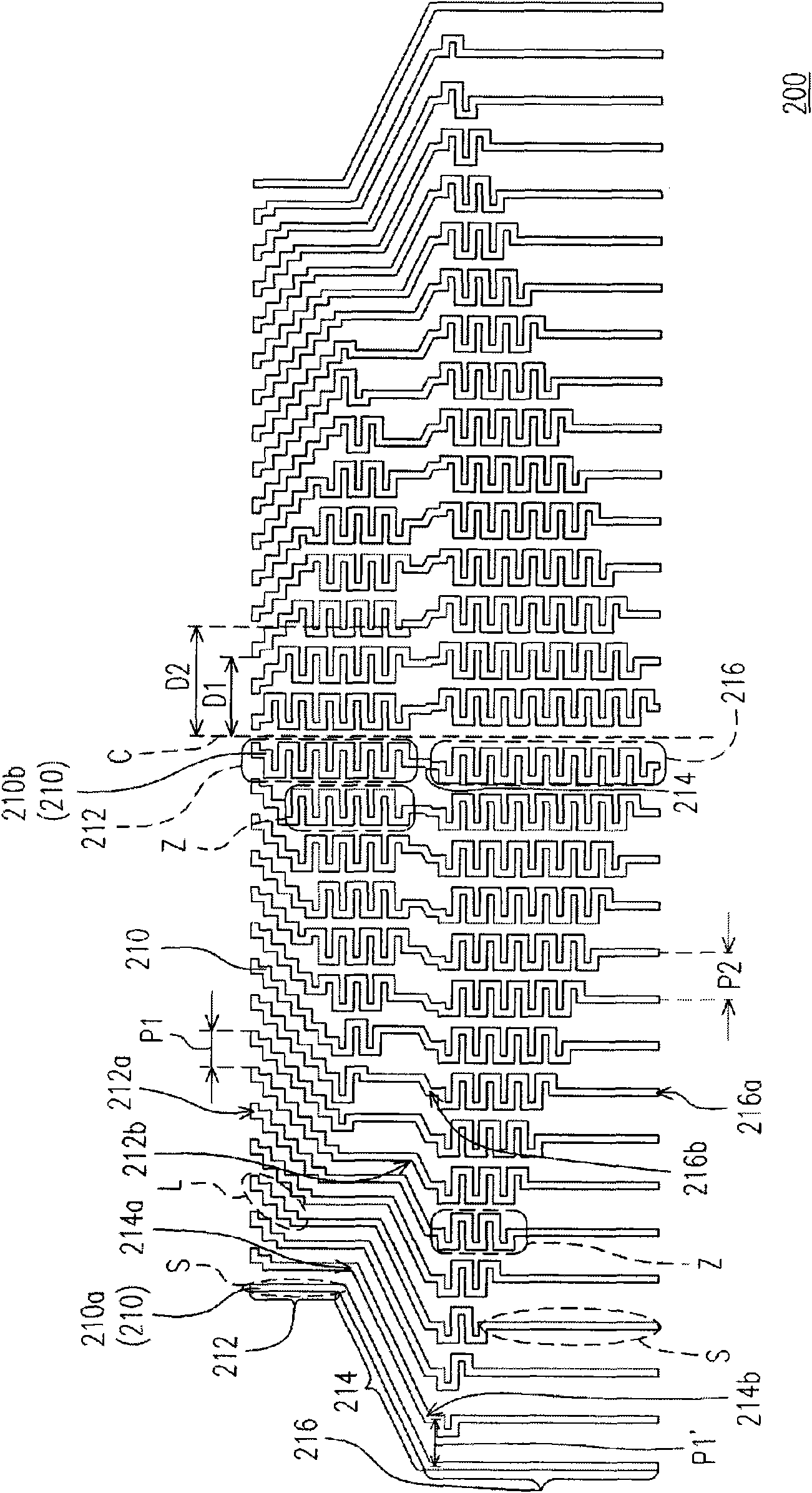

Fan-out circuit and display panel

ActiveCN101673003AImprove qualityUniform signal transmission qualityStatic indicating devicesNon-linear opticsWire wrap

The invention discloses a fan-out circuit comprising a plurality of fan-out wires which are mutually electrically insulated, wherein each fan-out wire comprises a first winding part, an extension partand a second winding part; the first winding part is provided with a chip abutting end and a first connecting end, and the space between every two adjacent chip abutting ends is P1; the second winding part is provided with a second connecting end and a signal wire connecting end, and the second connecting end is connected with the first connecting end through the extension part; in addition, thespace between every two adjacent signal wire connecting ends is P2, and P2 is greater than P1; and in the fan-out wires, some of the first winding parts are provided with a staircase-shaped pattern. The invention also discloses a display panel containing the fan-out circuit.

Owner:AU OPTRONICS CORP

Composite coatings for ground wall insulation in motors, method of manufacture thereof and articles derived therefrom

InactiveUS20050016658A1Windings insulation materialWindings insulation shape/form/constructionBobbinSilicone coating

An article comprises a bobbin wire; an electrically insulating backing disposed upon the bobbin wire; a mica paper disposed upon the electrically insulating backing and wound around the backing; and a silicone coating disposed upon the electrically insulating backing. A method of manufacturing an article comprises disposing an electrically insulating backing upon a bobbin wire; disposing mica paper upon the electrically insulating backing; and coating the mica paper with a silicone coating.

Owner:GENERAL ELECTRIC CO

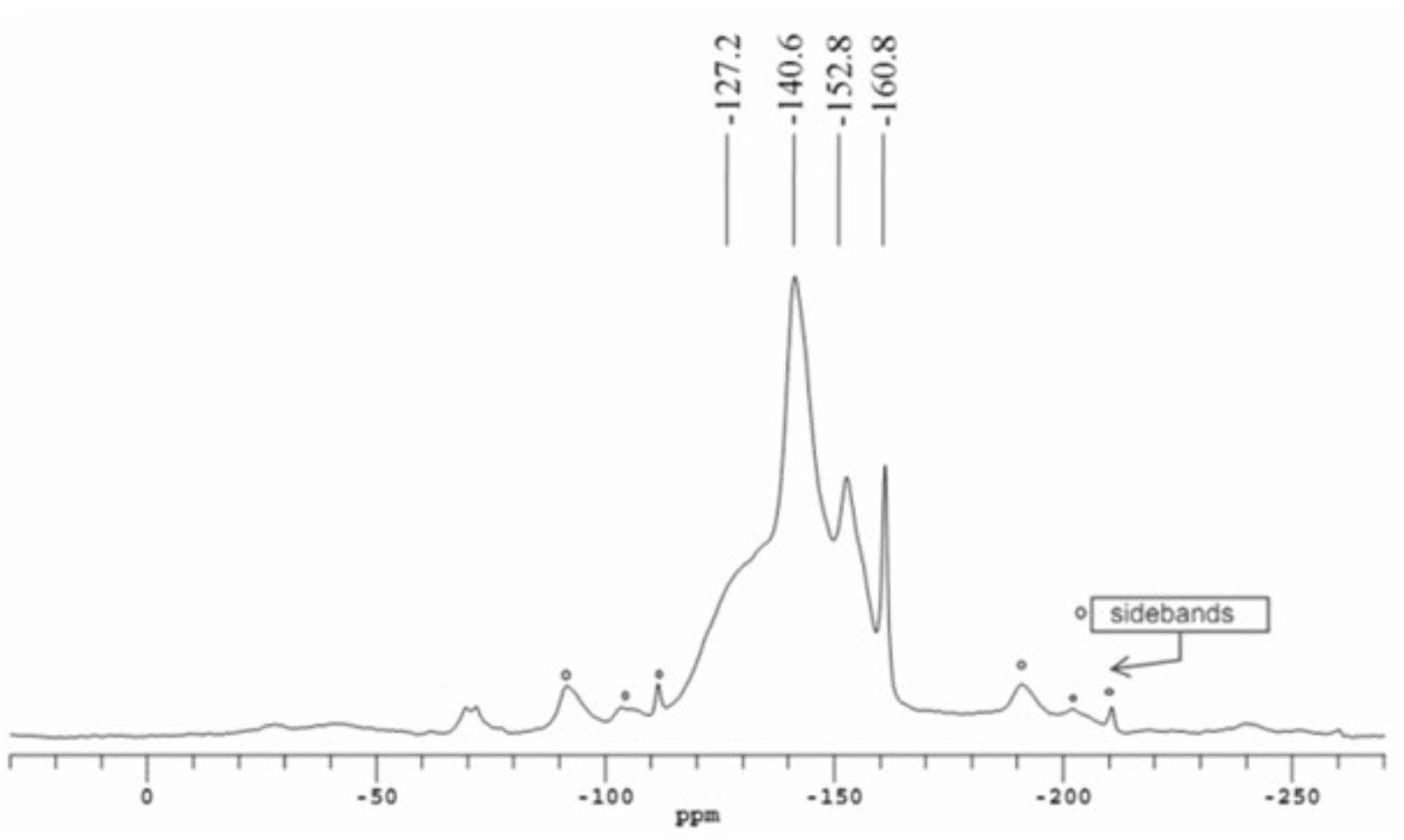

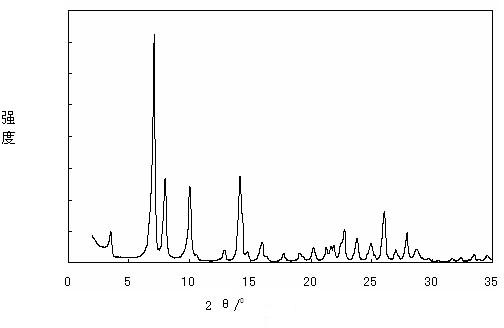

Fluorine-containing titanium-silicon molecular sieve with MWW (Manual Wire Wrap) structure and preparation method and application thereof

ActiveCN102627291AComplete crystalline structureImprove catalytic oxidation performanceMolecular sieve catalystsEther/acetal/ketal group formation/introductionX-rayCatalytic oxidation

The invention discloses a fluorine-containing titanium-silicon molecular sieve with a MWW (Manual Wire Wrap) structure and a preparation method and an application thereof. In the molecular sieve, a fluorine atom is connected with a framework silicon atom in the form of a chemical bond, an XRD (X-Ray Diffraction) spectrogram contains a characteristic spectral line of the molecular sieve with the MWW structure, and characteristic peaks of -150+ / -5ppm and -143+ / -5ppm appear in a 19FMAS-NMR (19 File Management Assistant For Server-Nuclear Magnetic Resonance) spectrogram; the preparation method comprises the following steps of: synthesizing a boron-containing parent body, post-treating, baking and the like; and the molecular sieve serving as a catalyst is applied to catalytic oxidation reactions of compounds containing carbon-carbon double bonds and at least one other functional group as well as reactions for catalytically synthesizing oxime. The molecular sieve has a complete crystalline state structure; according to the electronic effect of framework fluorine, the molecular sieve and higher catalytic oxidation capability; a preparation process is simple, and is easy for industrial production; synthesis of corresponding epoxides or catalytic synthesis of oxime from compounds containing carbon-carbon double bonds and at least one other functional group can be catalyzed at higher activity and high selectivity; and a reaction process is environmentally-friendly.

Owner:EAST CHINA NORMAL UNIV

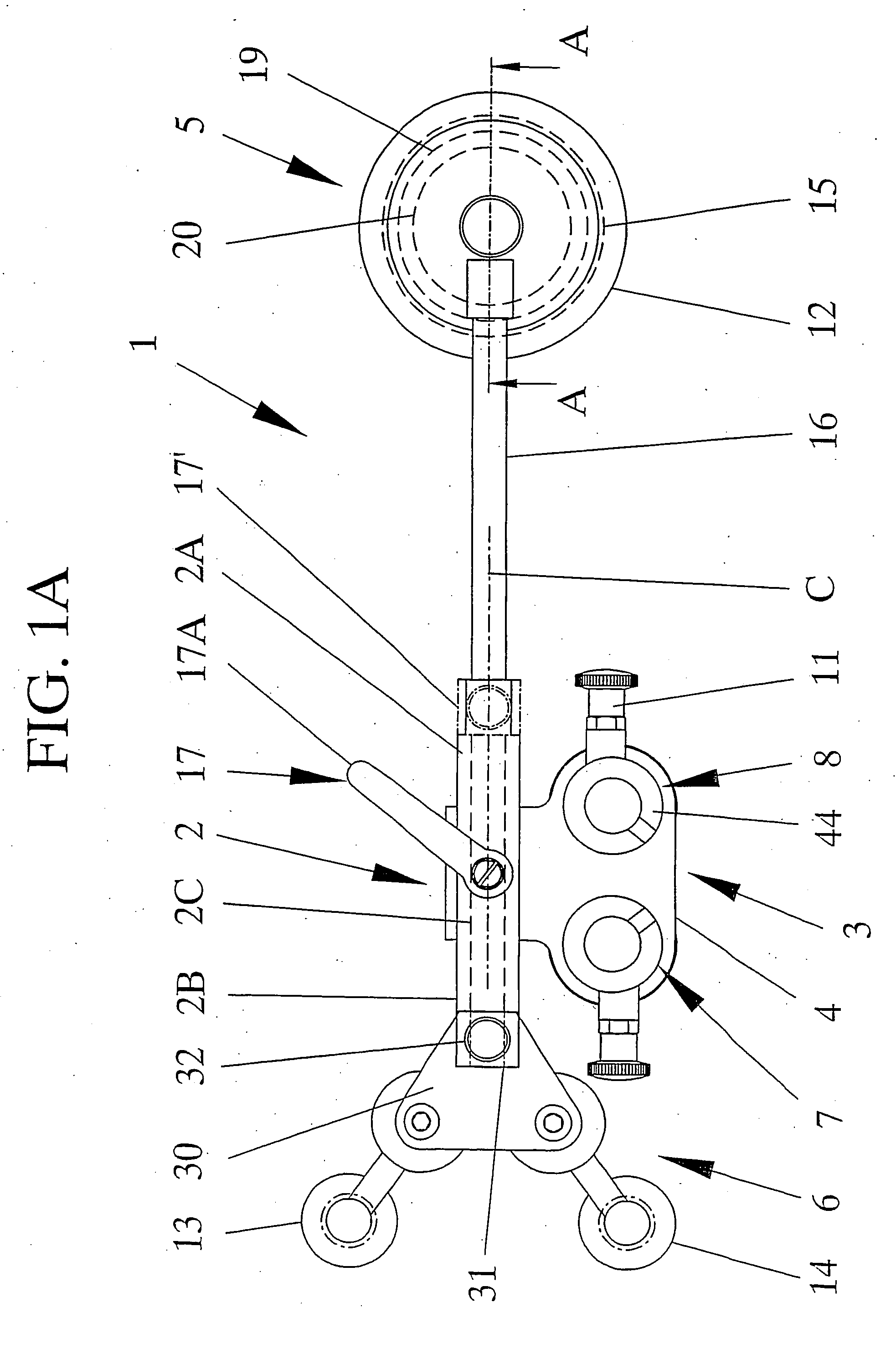

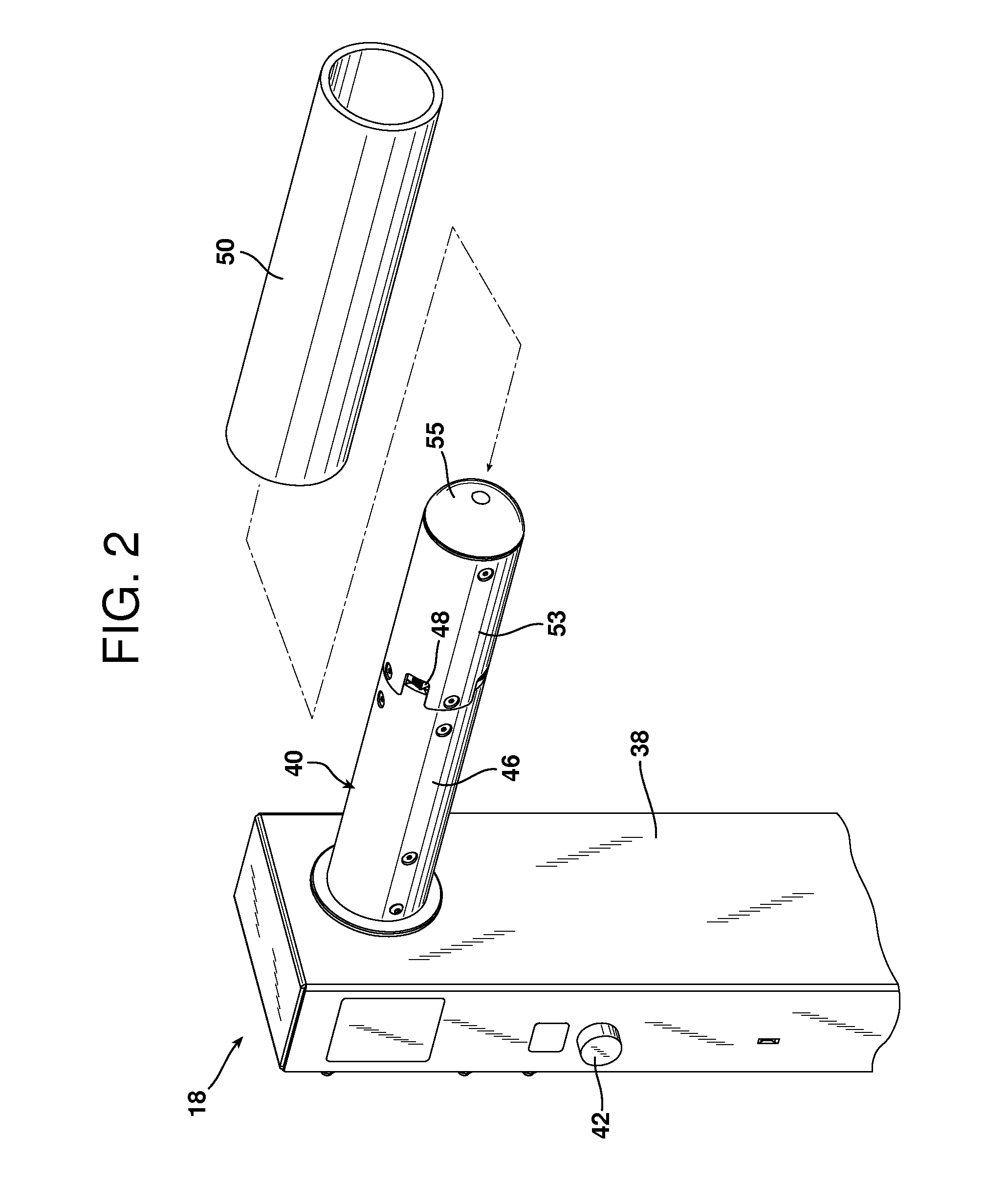

Method and a device for removing vehicle windows

InactiveUS20070000361A1Secure and effective non-destructiveEffective non-destructive removalWorkpiece holdersVehicle dissasembly recoveryNon destructiveEngineering

A method for the non-destructive removal of very small fixed window elements (40) from vehicles uses a cutting wire that is threaded through the adhesive bonding a window element to a vehicle, that is placed in a loop around the perimeter of the window element and that is pulled by wire wind-up elements (3) of a window element removal device. The device (1) is fitted to a window element frame (41), is expanded into firm clamping engagement with the window element frame (41) and is locked in the position firmly engaging the window element frame (41). The wire wind-up elements (3) are then operated until the wire cuts through the adhesive at the edge of the side window element around the entire perimeter thereof.

Owner:RAMHUSET DALA SPEGLAR

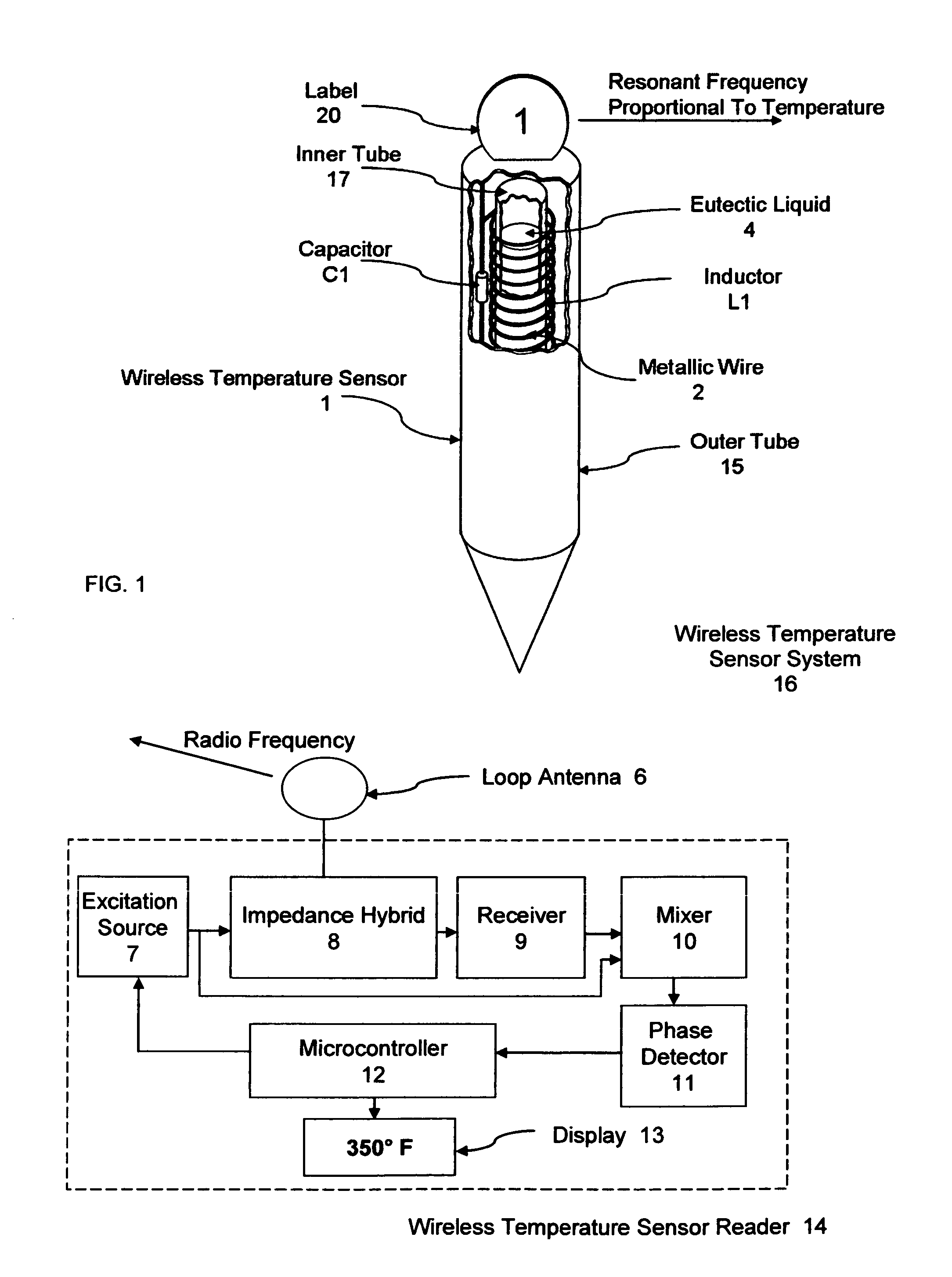

Wireless remote passive temperature sensor for monitoring food

InactiveUS20090147824A1Increase inductanceTemperature measurement in household appliancesThermometers using material expansion/contactionAir coreInductor

Owner:WT SYST

Preparation method of bonded gold-silver alloy wire

ActiveCN102776405AImprove conductivityStable chemical propertiesSemiconductor/solid-state device detailsSolid-state devicesCeriumTechnical design

The invention relates to a preparation method of a bonded gold-silver alloy wire, and belongs to the technical field of bonded wire processing processes. The bonded gold-silver alloy wire comprises the following metal materials by weight: 20-30% of silver, 5-1000 ppm of palladium, 5-1000 ppm of calcium, 5-1000 ppm of beryllium, 5-1000 ppm of cerium and the balance of gold; the preparation method comprises the following steps: 1), preparing materials; 2) smelting an alloy ingot; 3) pulling and casting an alloy rod; 4) wire-drawing; 5) annealing; 6) coiling; and 7) packaging. The preparation method of the bonded gold-silver alloy wire, provided by the invention, has the advantages of reasonable and standard technical design, and simple operation, the produced bonded gold-silver alloy wire has the advantages of strong conductivity, stable chemical performance, good oxidation resistance, flowability and plasticity, higher breaking force and better elongation, and moderate cost, and requirements of semiconductor package industry and LED (Light Emitting Diode) illumination technology on the performances of the bonded gold-silver alloy wire can be completely satisfied.

Owner:烟台招金励福贵金属股份有限公司

Winding Device

Owner:SEALED AIR U S

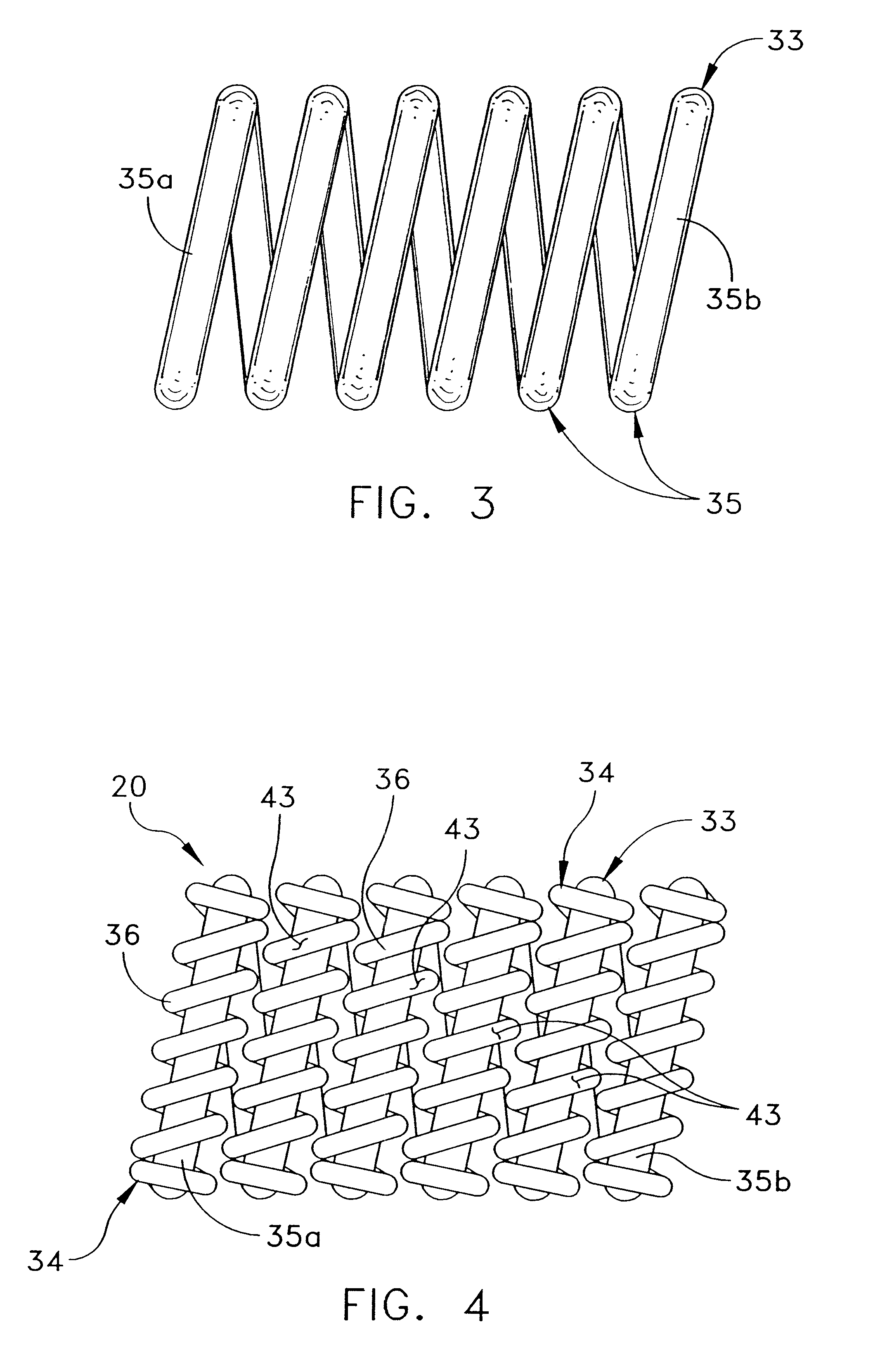

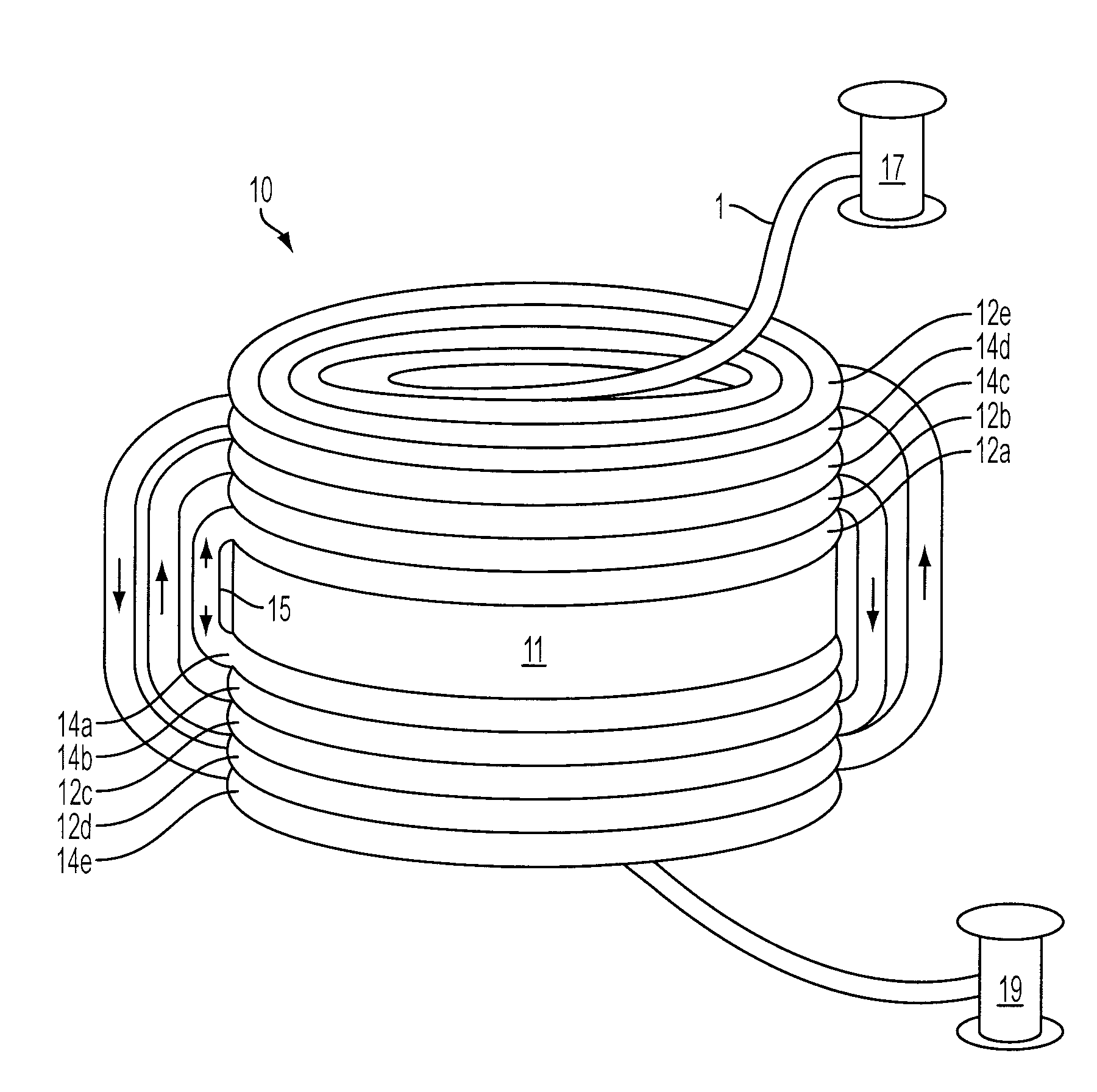

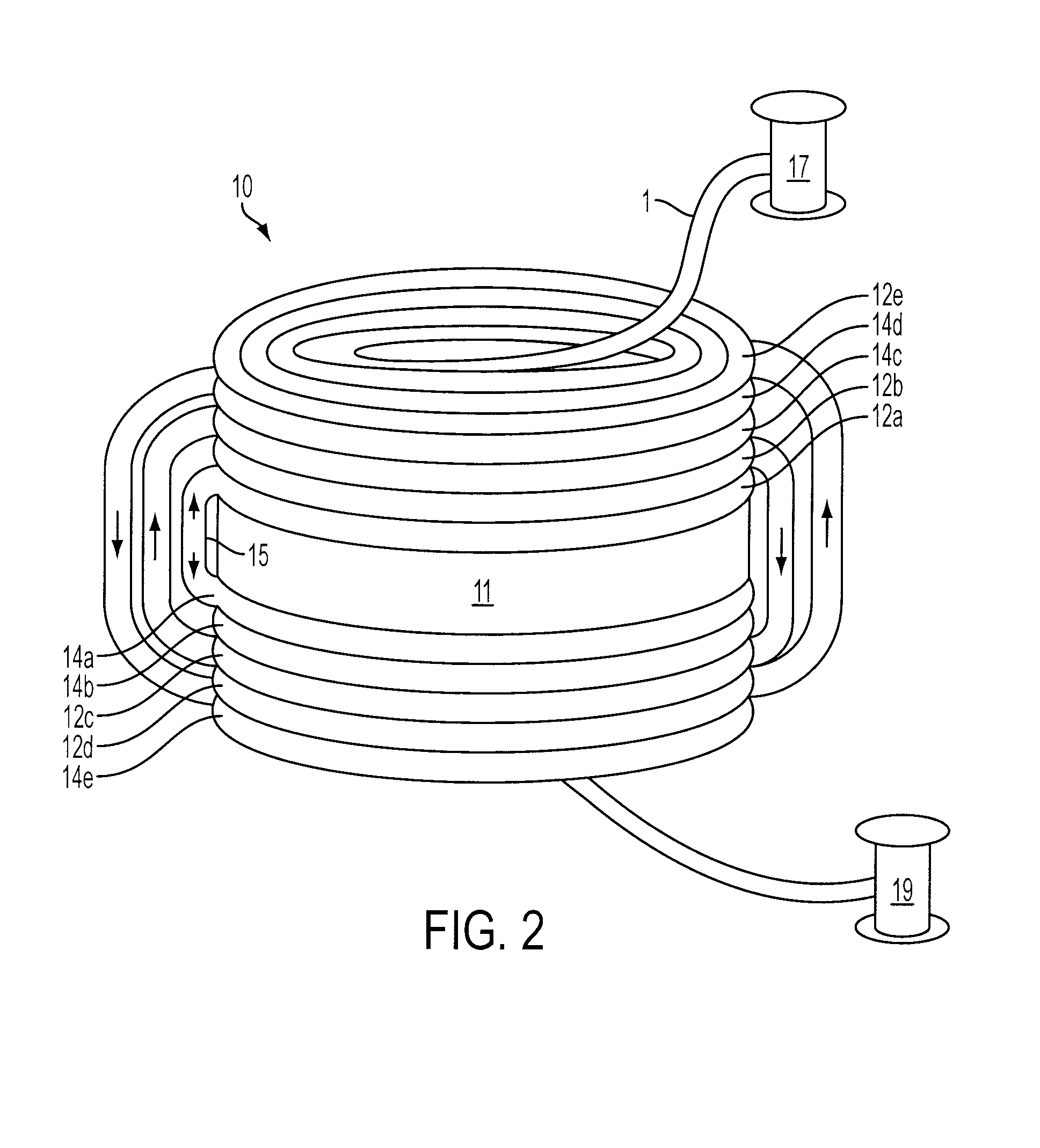

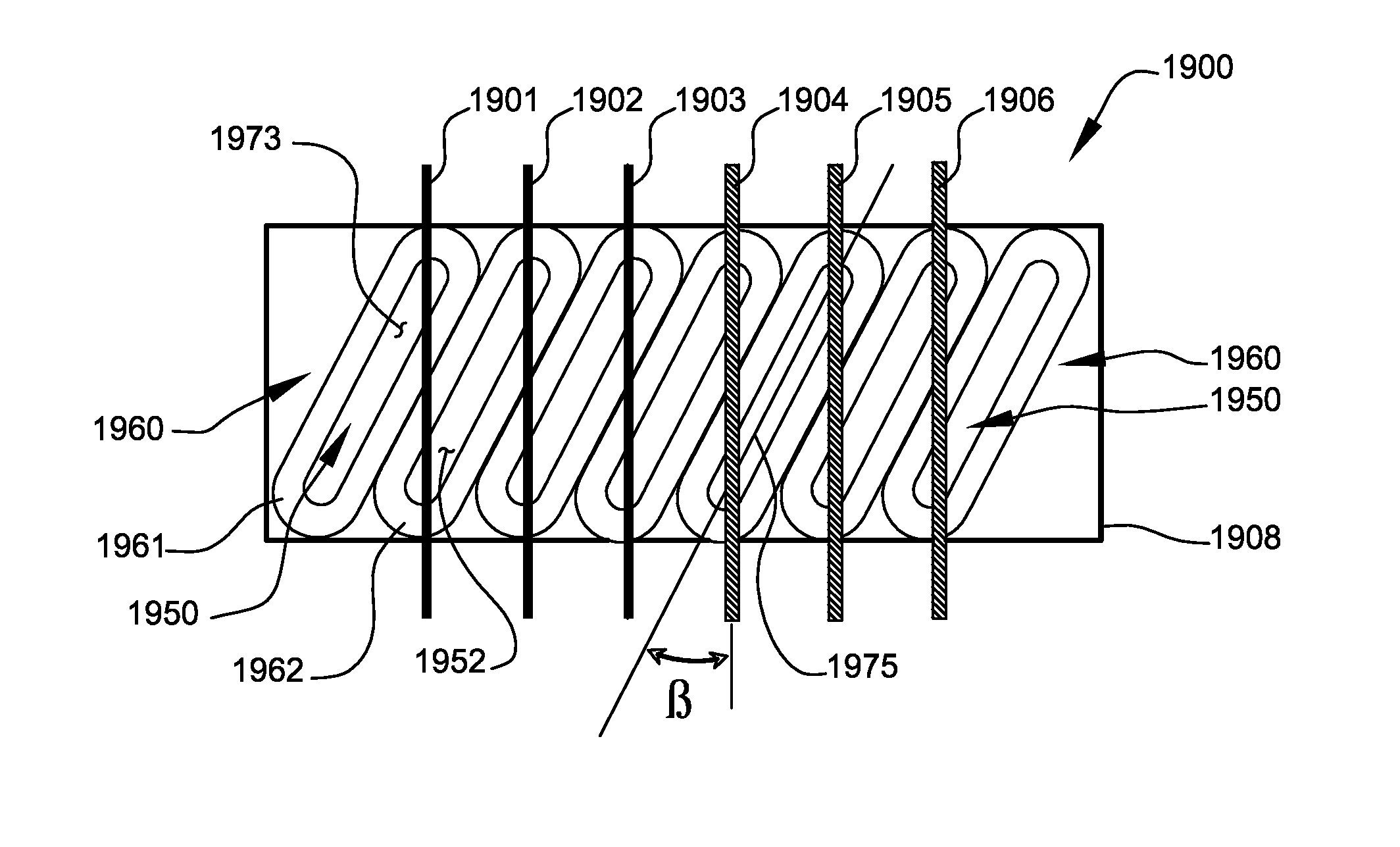

Crossover-Free Fiber Optic Coil Sensor and Winding Method

ActiveUS20080130010A1Easy to manufactureEliminates crossover siteMechanical working/deformationPaper/cardboard wound articlesFiberEngineering

A method for winding a crossover-free fiber optic coil sensor comprising: attaching a fiber optic cable to an outer edge of a coil form, wherein the coil form comprises a first side and a second side; forming a first outside-in coil layer on the first side of the coil form using a first winding head; attaching a first inside-out separator on top of the first outside-in coil layer; forming a first inside-out coil layer on top of the first inside-out separator using the first winding head; forming a second outside-in coil on the second side of the coil form using a second winding head; attaching a second inside-out separator on top of the second outside-in coil layer; and forming a second inside-out coil layer on top of the second inside-out separator using the second winding head.

Owner:MORGAN RES CORP

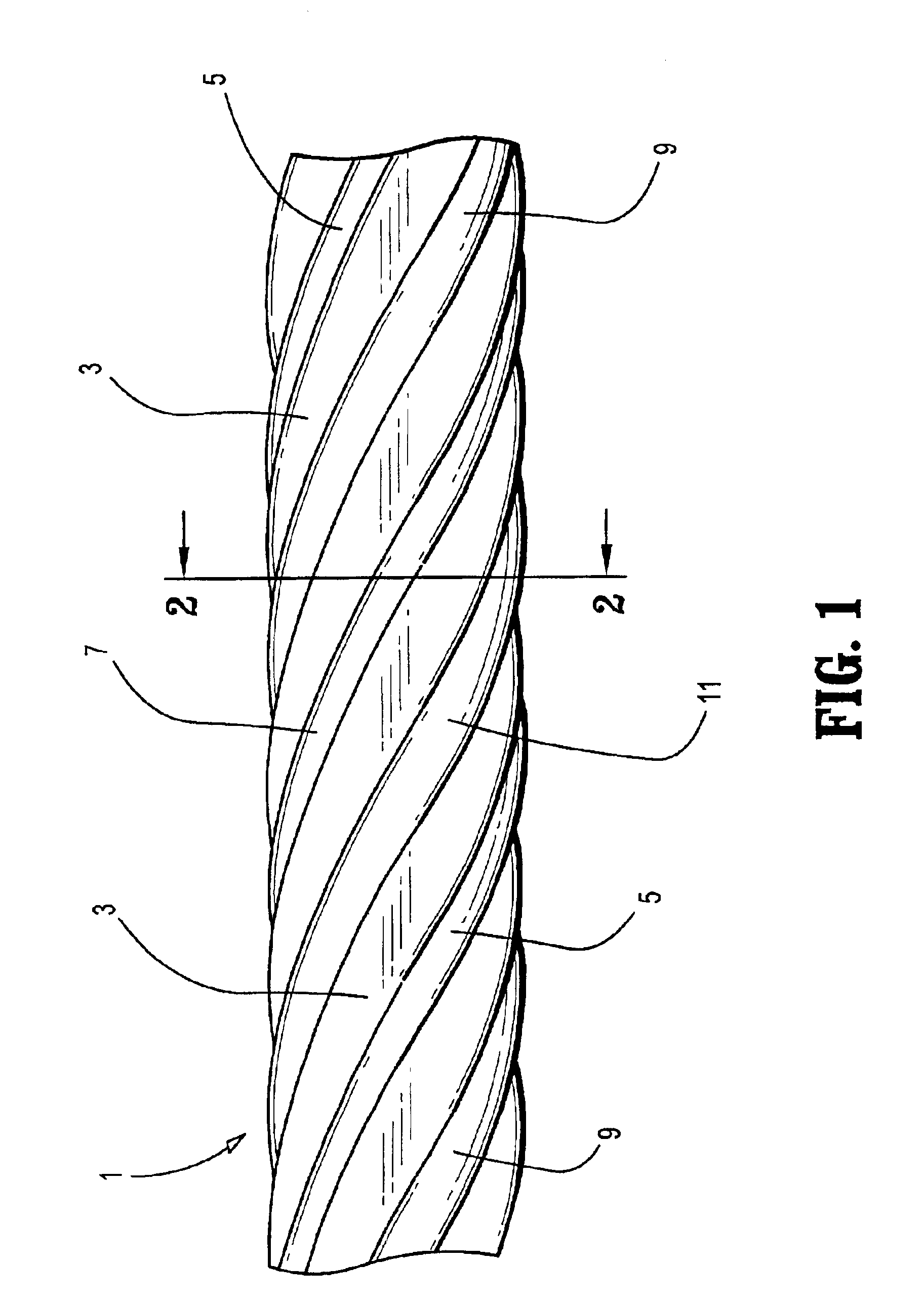

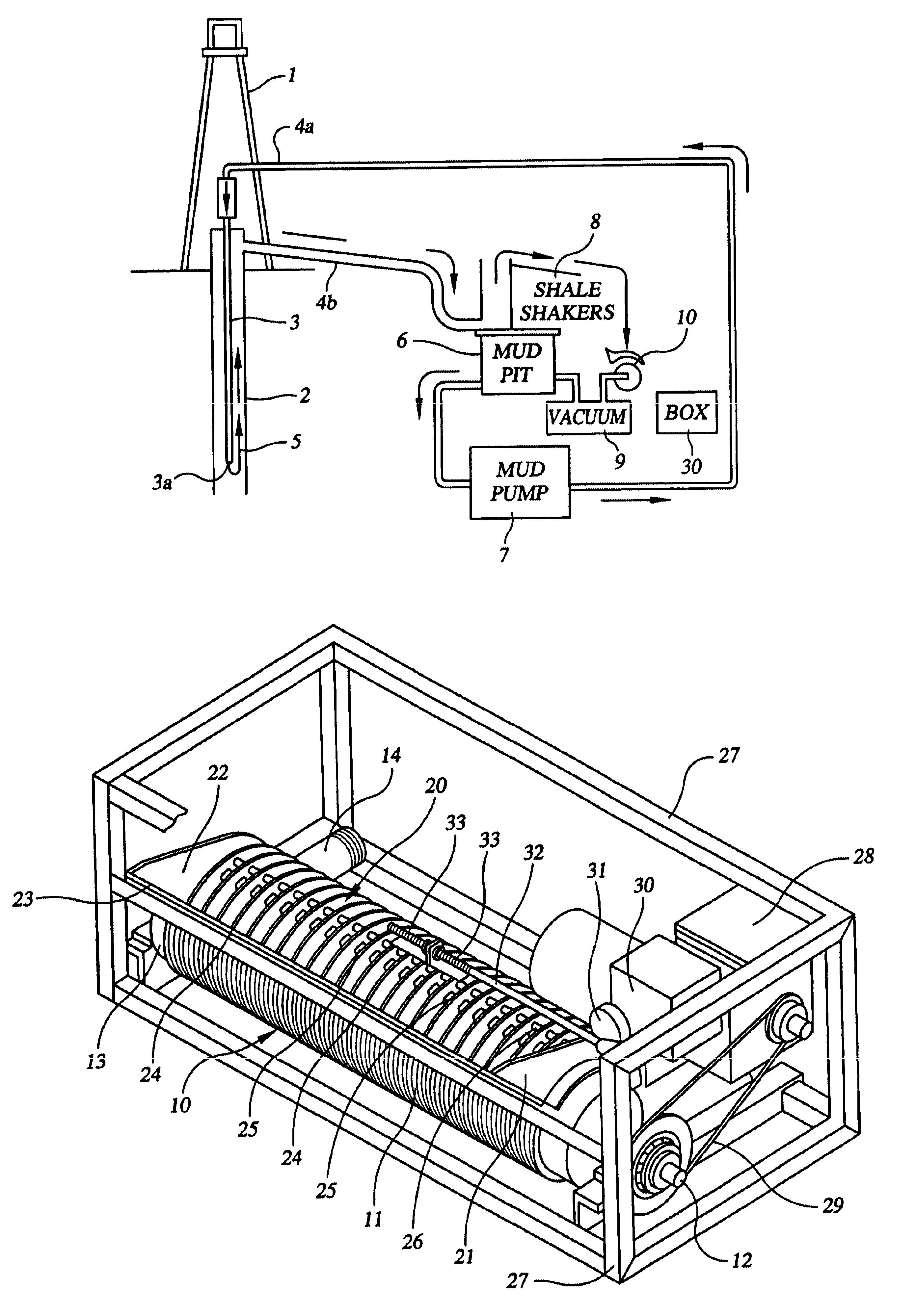

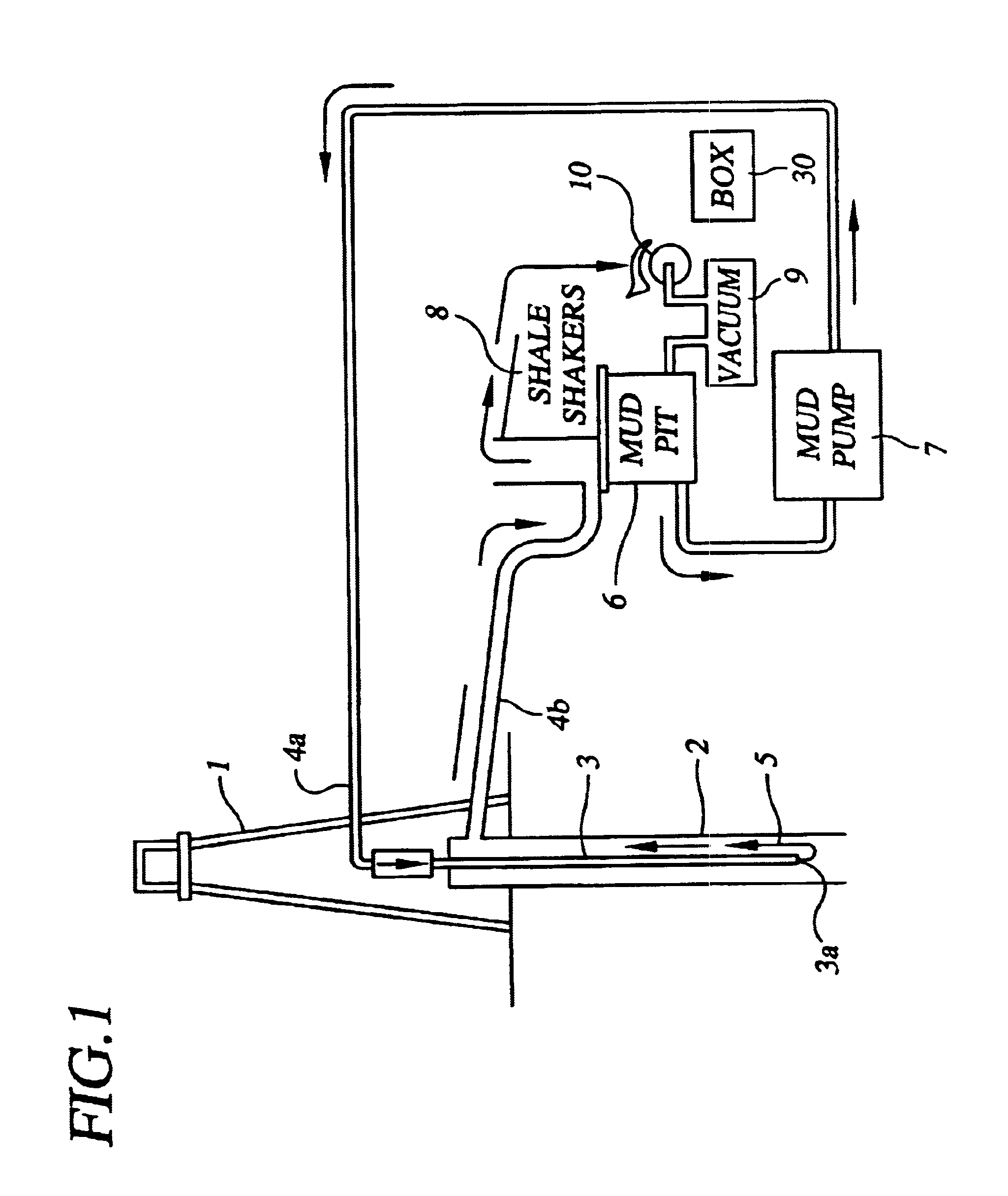

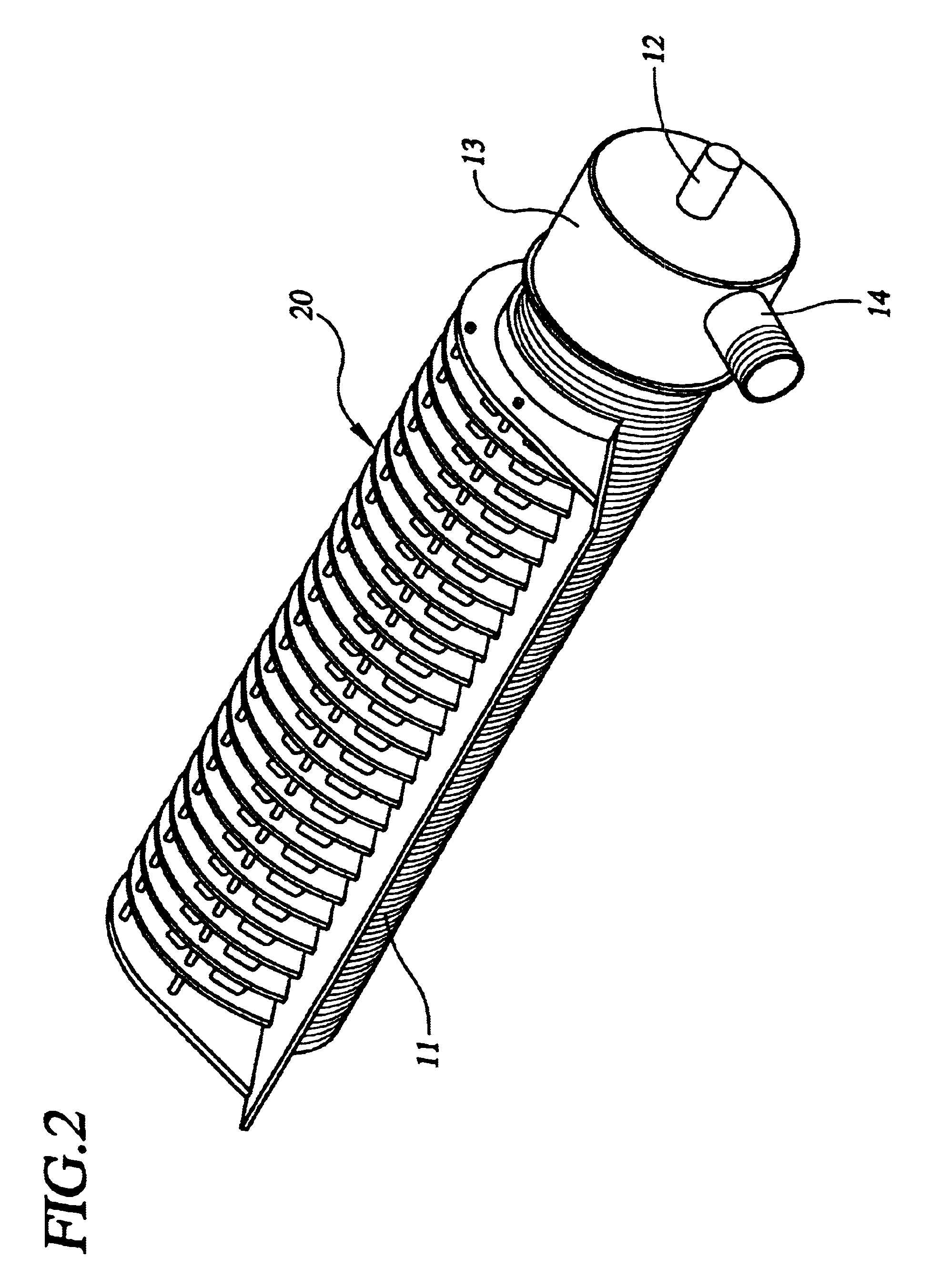

Method and apparatus for removing fluids from drill cuttings

InactiveUS6681874B2Minimal space requirementImprove efficiencyWater/sewage treatmentFlushingSolid componentWell drilling

A method and apparatus is provided for removing fluids, particularly entrained and / or adherent fluids, from drill cuttings generated during the well drilling process. A generally cylindrical wire-wrapped screen having a bore therethrough rotates about its longitudinal axis. Suction pressure is applied through the inner bore of the cylindrical wire-wrapped screen. As fluid-laden drill cuttings are deposited on the outer surface of the cylindrical wire-wrapped screen, fluids are drawn off of the cuttings and evacuated from the inner bore of the cylindrical wire-wrapped screen. Solid components of the cuttings remain on the outer surface of the cylindrical wire-wrapped screen and eventually roll off the screen. A scraping member is provided to agitate cuttings deposited on the outer surface of the cylindrical wire-wrapped screen.

Owner:HALLIBURTON ENERGY SERVICES INC

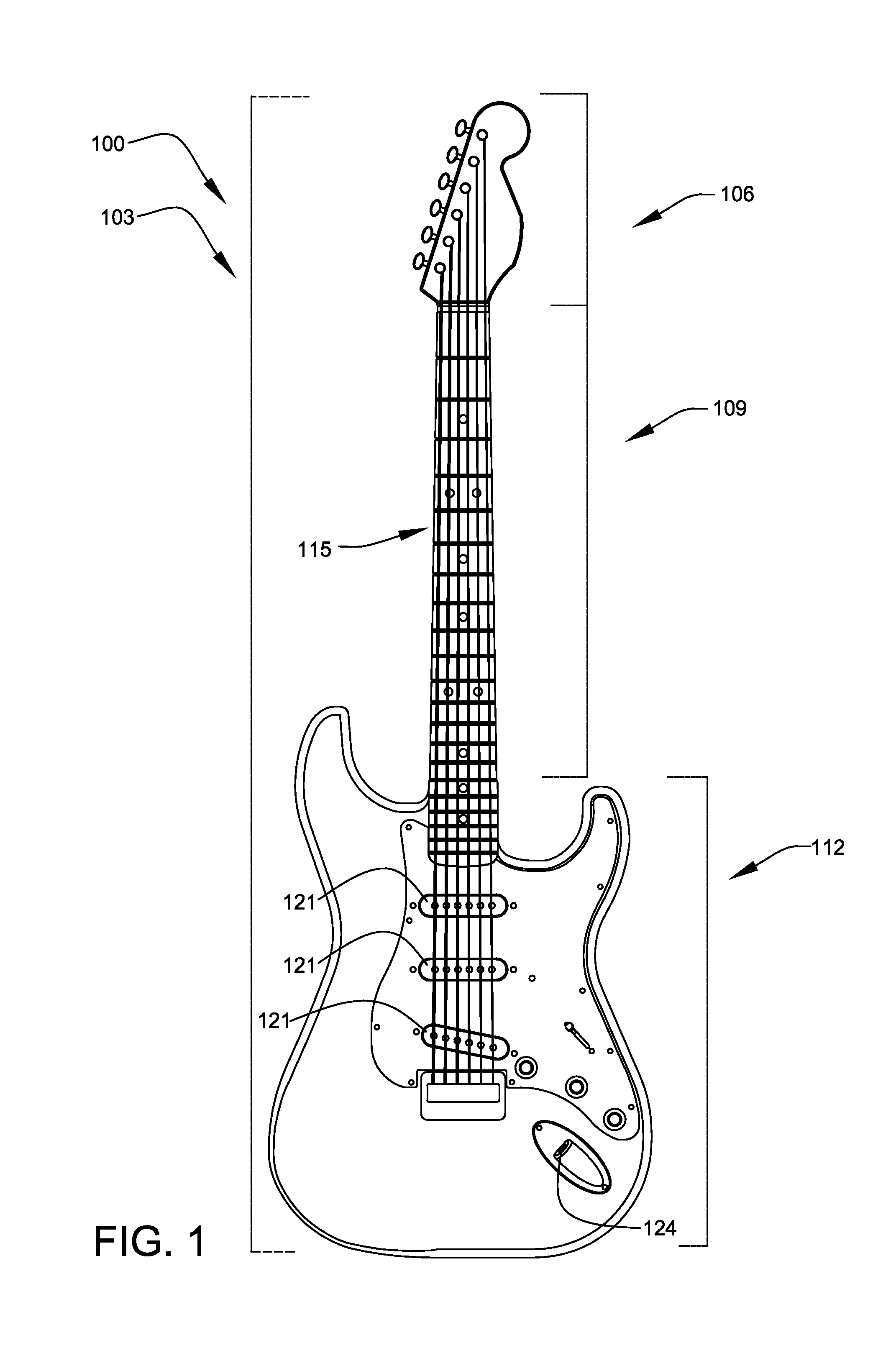

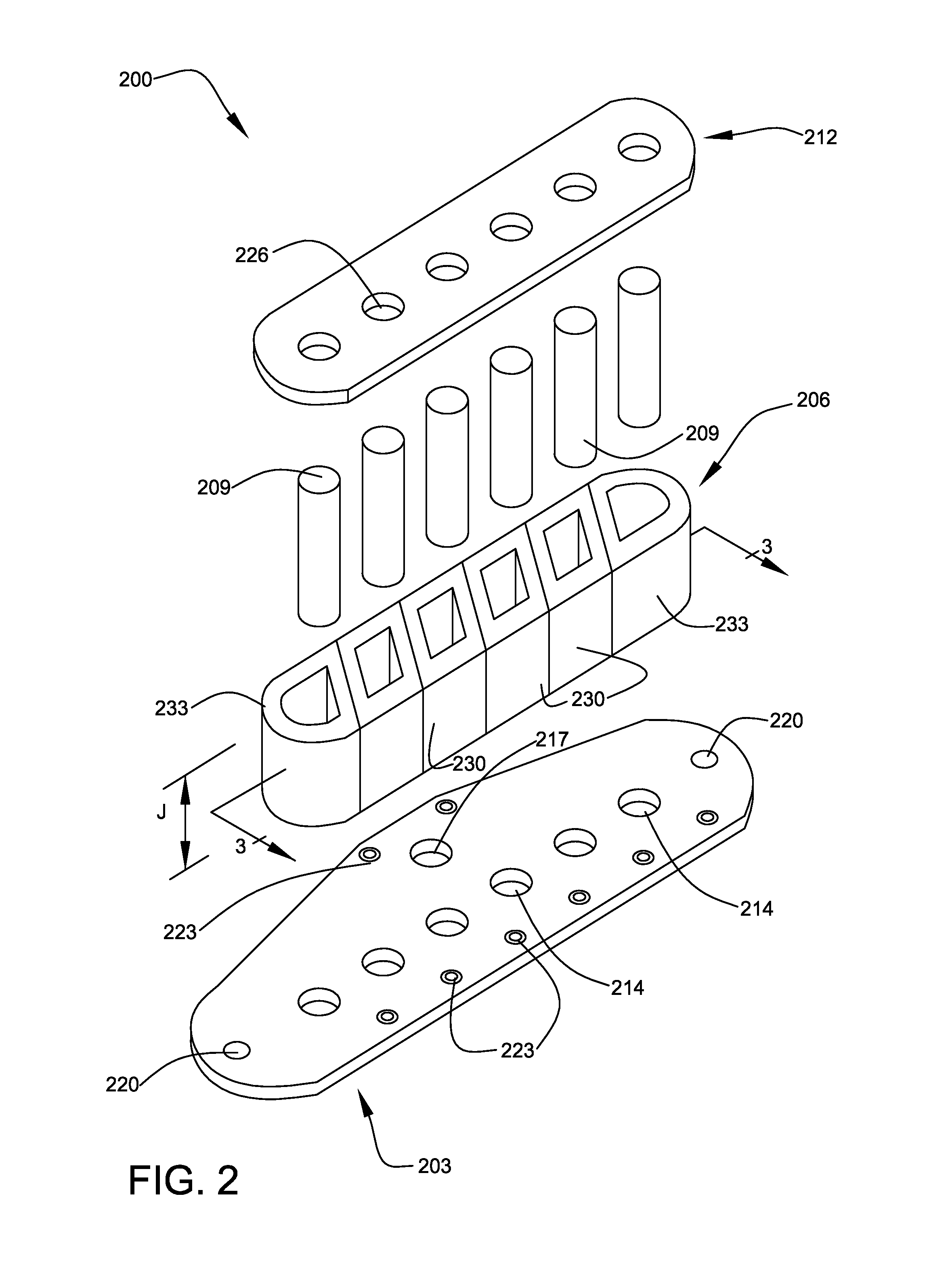

Musical instrument pickup systems

ActiveUS7989690B1Improved pickup sensitivityMaximize pickup outputElectrophonic musical instrumentsEngineeringWire wrap

Musical instrument pickups comprising a plurality of coil-wire wrappings, each coil-wire wrapping having a particular geometric cross-section. Related embodiments exhibiting noise cancellation features are also disclosed.

Owner:LAWING ANDREW SCOTT

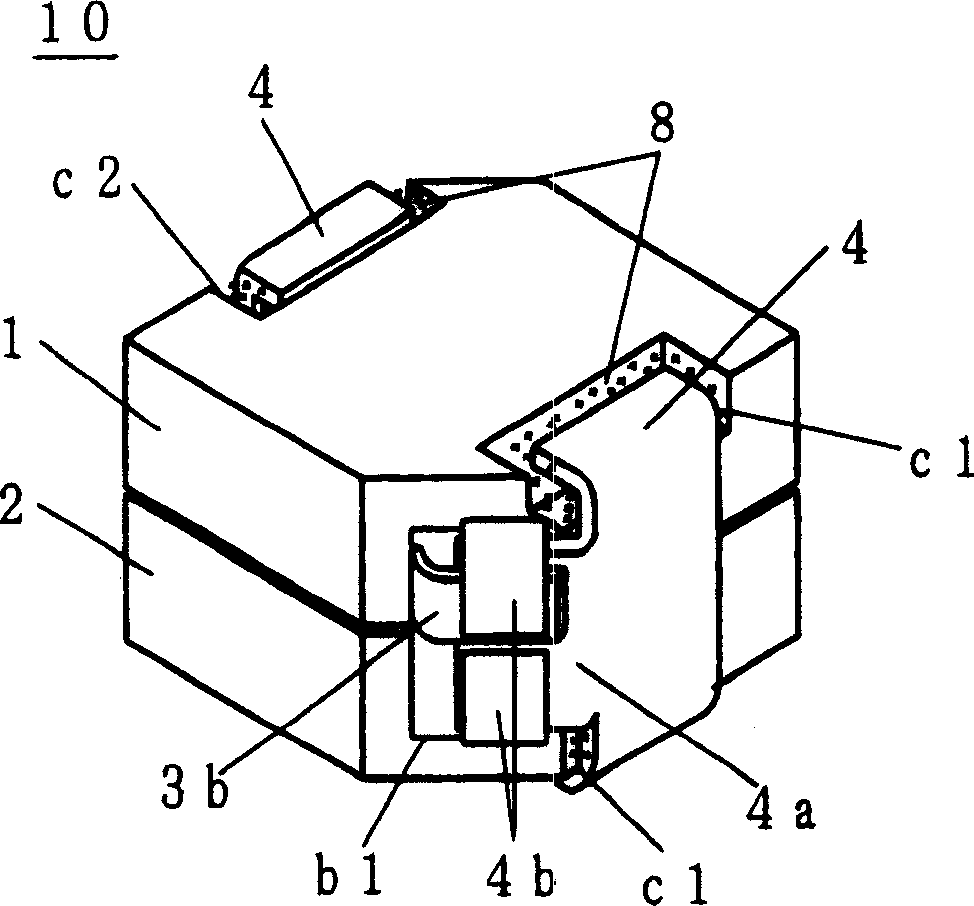

Automatic bobbin changing and winding device and method

ActiveCN104264386AImprove work efficiencyHigh degree of automationBobbin-winding devicesBobbinWire wrap

The invention discloses an automatic bobbin changing and winding device and method. The automatic bobbin changing and winding device comprises a bottom plate, a shuttle cabin and a rotating shuttle, a shuttle shell and a bobbin are arranged on the spindle of the rotating shuttle, a bracket is arranged at the front side of the bottom plate, a rotating shaft is arranged on the front lateral surface of the bracket, the rotating shaft is provided with a first shuttle shell and a first bobbin, and bottom lines fully wind a winding post of the first bobbin; the automatic bobbin changing and winding device further comprises a rotary winding shaft, a push plate capable of rotating and moving horizontally in the axial direction, a shell grasping seat, a bobbin push rod and a line clamping mechanism, a first shaft part and a second shaft part are arranged at the front end of the winding shaft, the shell grasping seat is used for grasping and moving the shuttle shell and bobbin, the shuttle shell or the first shuttle shell and first bobbin, the bobbin push rod is used for backward pushing the bobbin from the shuttle shell, the line clamping mechanism is used for clamping the bottom lines on a line barrel, and the push plate is used for forwardly pushing the bobbin into the shuttle shell. The automatic bobbin changing and winding device and method are capable of automatically changing the bobbin and winding the bobbin, the automatic degree is very high, both time and labor are saved, and the working efficiency of a sewing machine is greatly improved.

Owner:JACK SEWING MASCH CO LTD

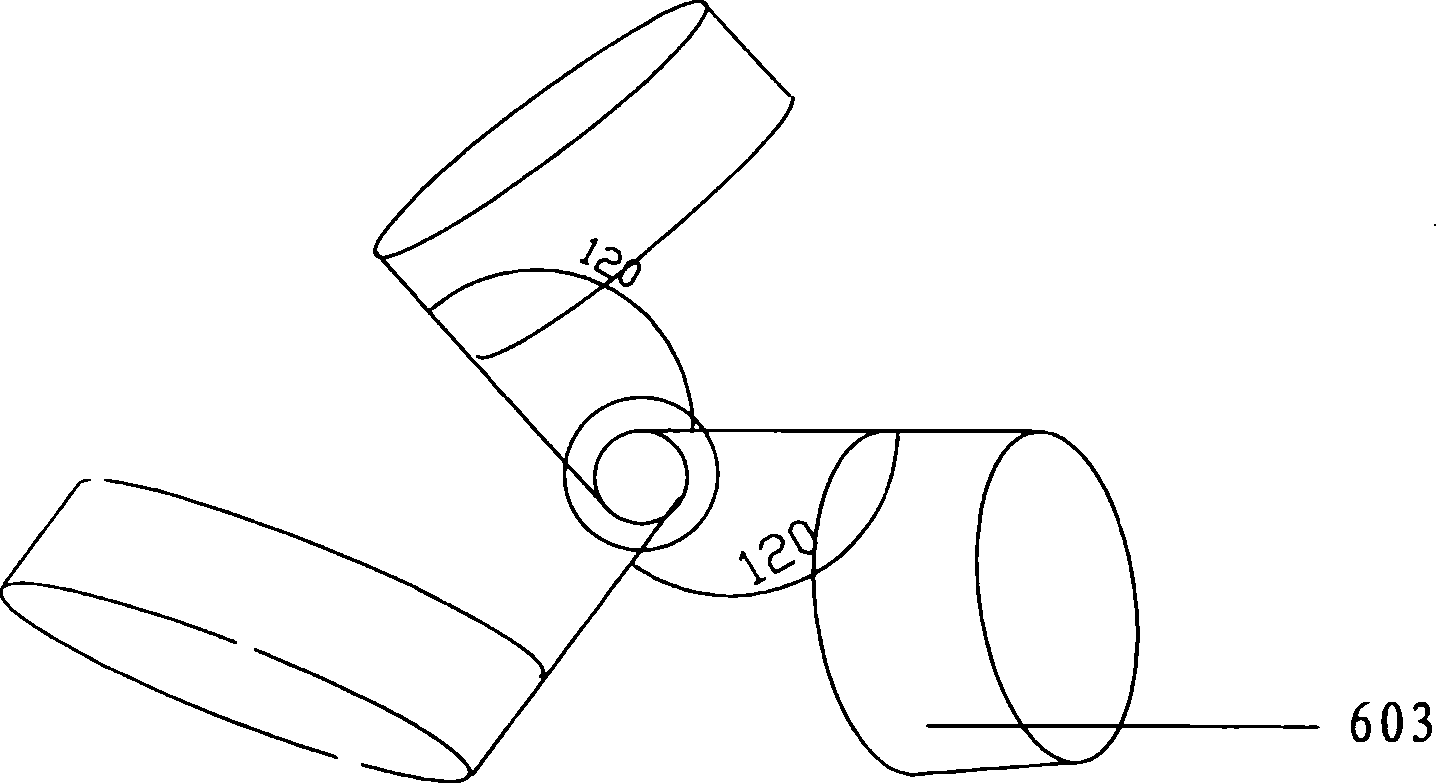

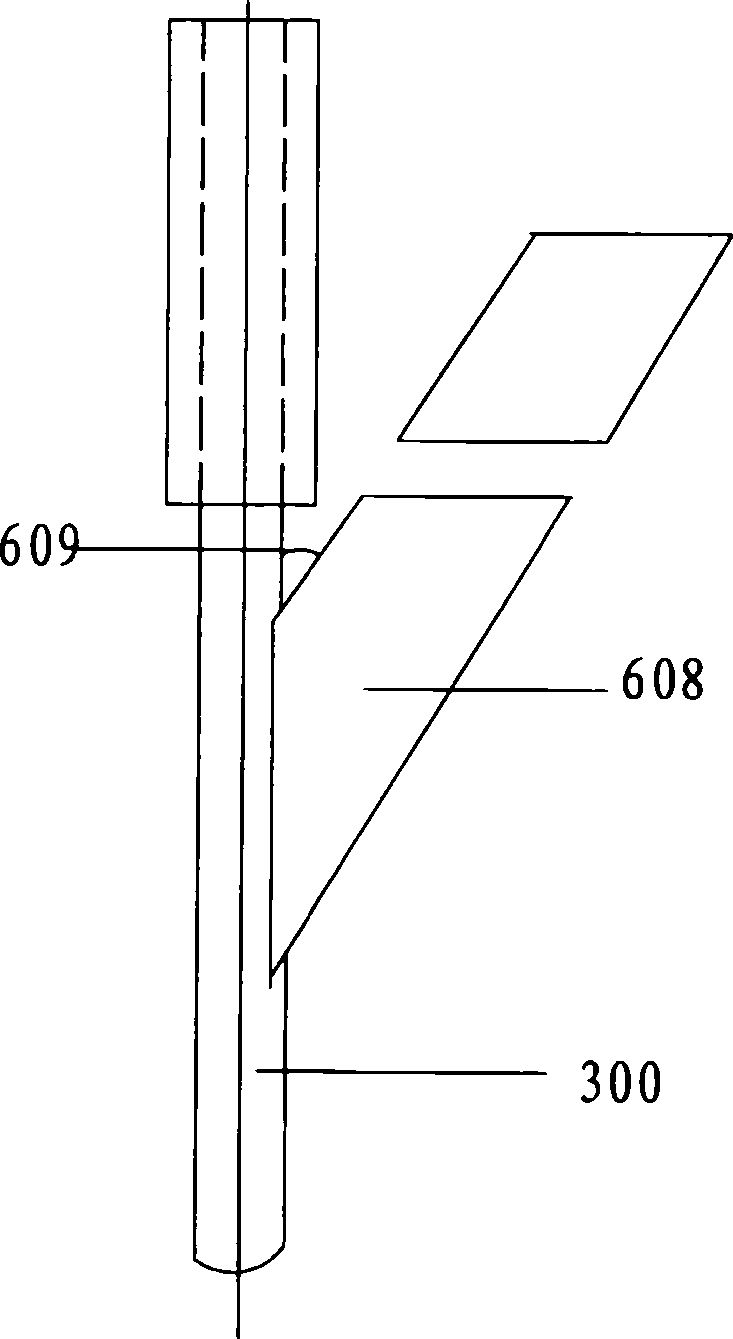

High-temperature superconducting cable coiling machine and cable coiling method

InactiveCN1881484ANo torsionImprove performanceSuperconductors/hyperconductorsFilament handlingHigh temperature superconductingSuperconductivity

The invention relates to a high-temperature superconductive cable coiler, which comprises track (500), back support (200) for fixing the ball lead screw (400) and superconductive cable, front back support (800) for fixing cable, insulated band lapping machine (700), and superconductive coiling machine (600), wherein the invention also provides a relative method which comprises: lapping the coiled high-temperature superconductive band material on one adjustable leg, and drawing out all the band of feeding disc, according to adjusted angle, to be lapped on the surface of cable skeleton (300) and adhered; the coiling plane (608) formed by band material forms angle (609) with cable skeleton (300), while it is tangent with the plane of cable skeleton (300); the coiling lapping head (603) rotates one time around the axle; and the superconductive band coiling machine is linked to move one length of cable coiling step; and the band material will be packed on the cable skeleton, without torsion angle, to avoid hurting band material caused by over large torsion angle, to damage the superconductivity.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Surface mounted sensor

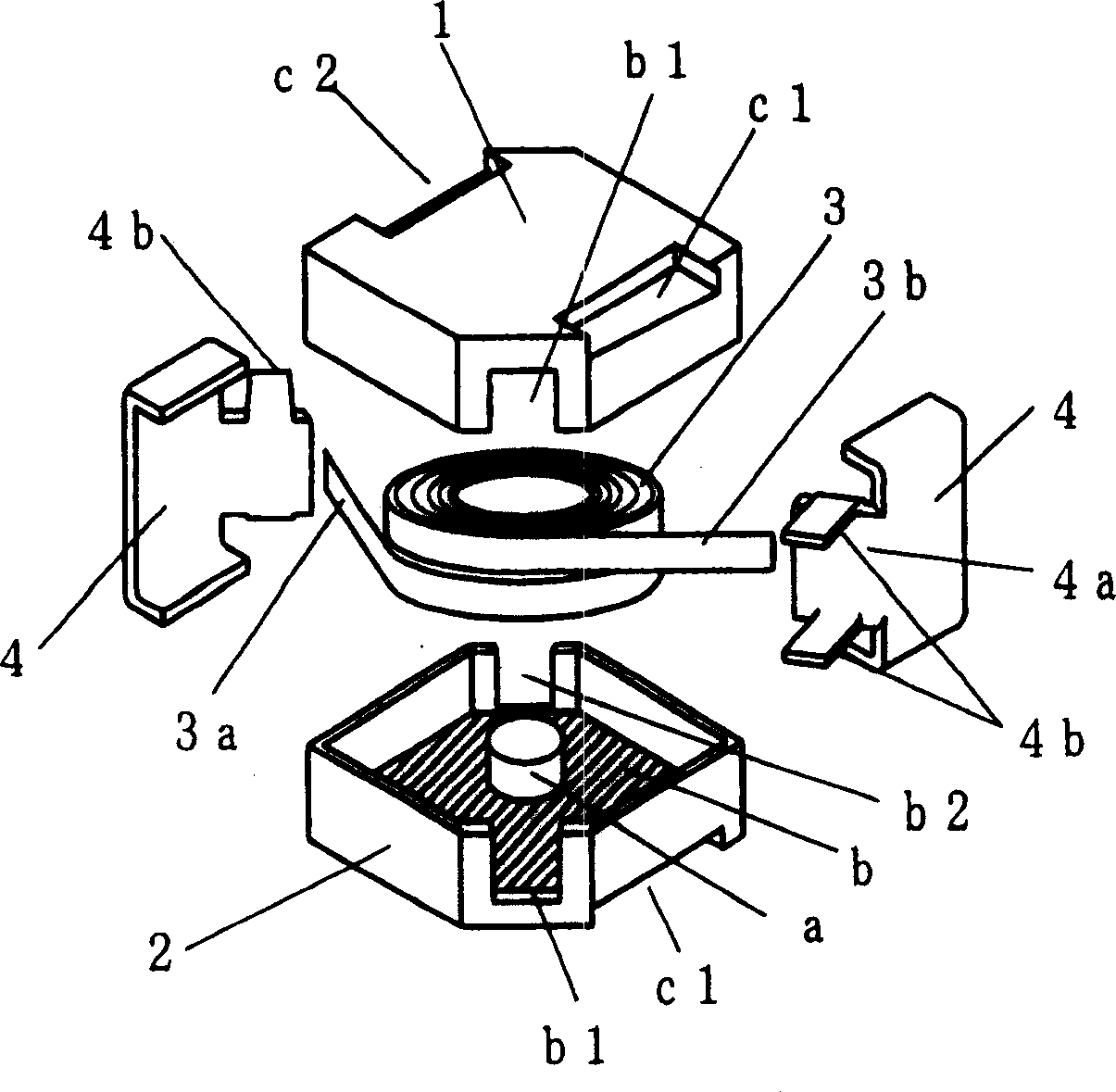

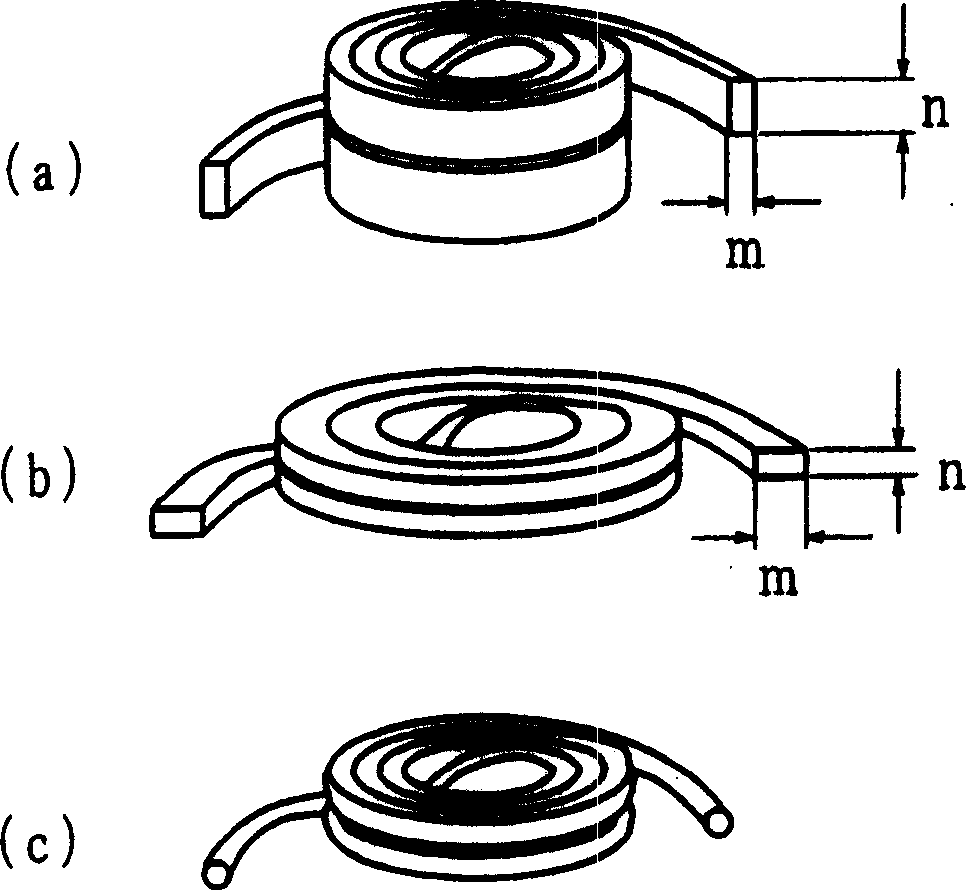

InactiveCN1619723ANo damageHigh drop impact resistanceTransformers/inductances coils/windings/connectionsInductance with magnetic coreBobbinSurface mounting

It is an object of the present invention to provide a surface mount type inductor in which a winding end can be joined to a connection electrode without bending, and the reliability of fixing the magnetic core can be improved. In a surface mount type inductor that accommodates two dimpled pot cores and an air core coil inside, the dimpled pot core has a core as a winding core inside, and the upper A pair of opposite end faces are provided with terminal engagement recesses, and a pair of opposite cutouts are provided at lower ends of the side faces. The air-core coil is wound by an insulated coated wire with a thermal adhesive layer on the surface. The winding initial end and the winding end end of the winding are drawn out to the outer circumference of the winding, which is a so-called α-coil coil. A connection terminal having a U-shaped cross-section and a terminal engaging recess that is configured to sandwich two pot-shaped magnetic cores with dimples combined together, and further has a terminal extending from the center of one end of the connection terminal. the connection part.

Owner:TOKO KABUSHIKI KAISHA

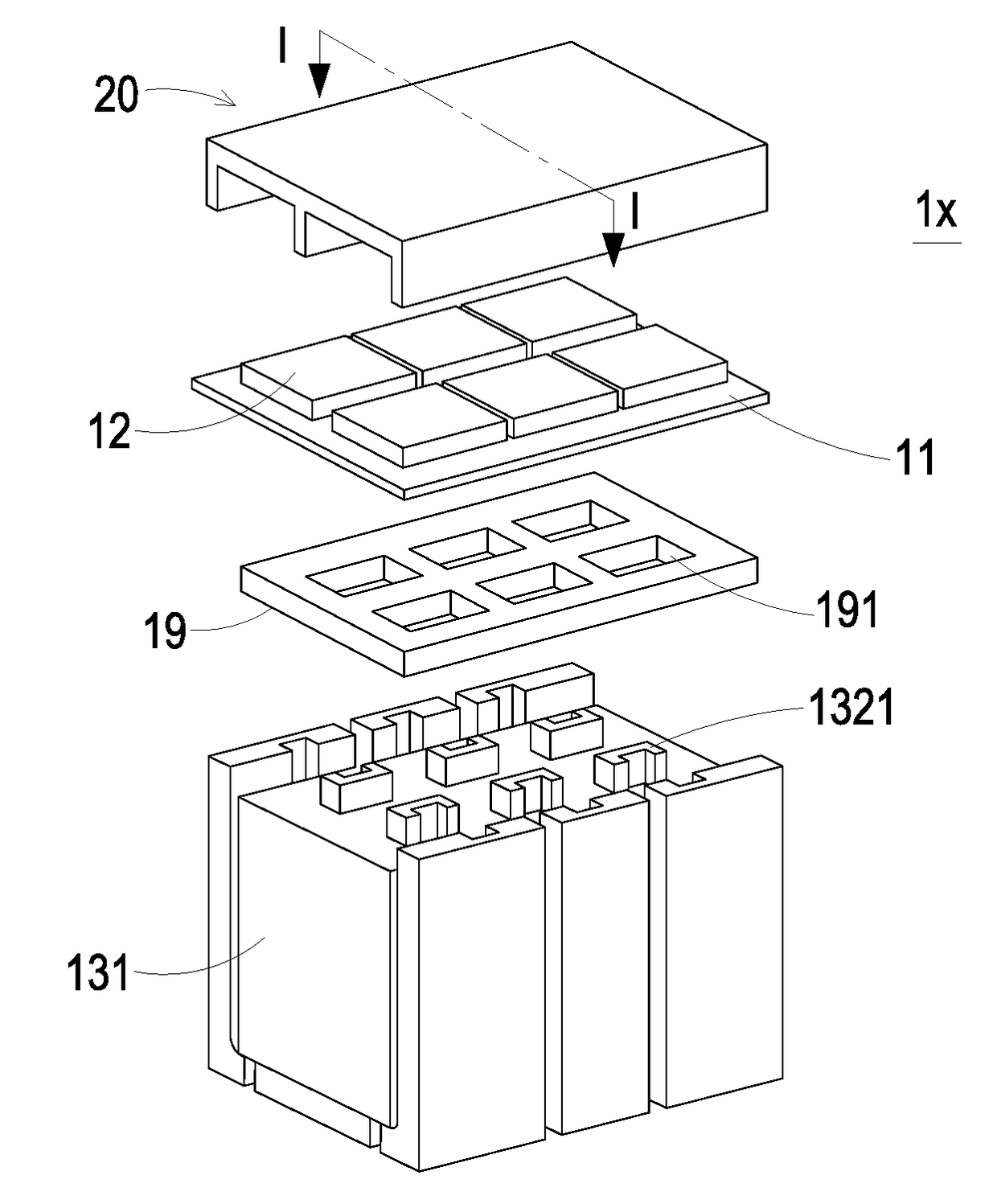

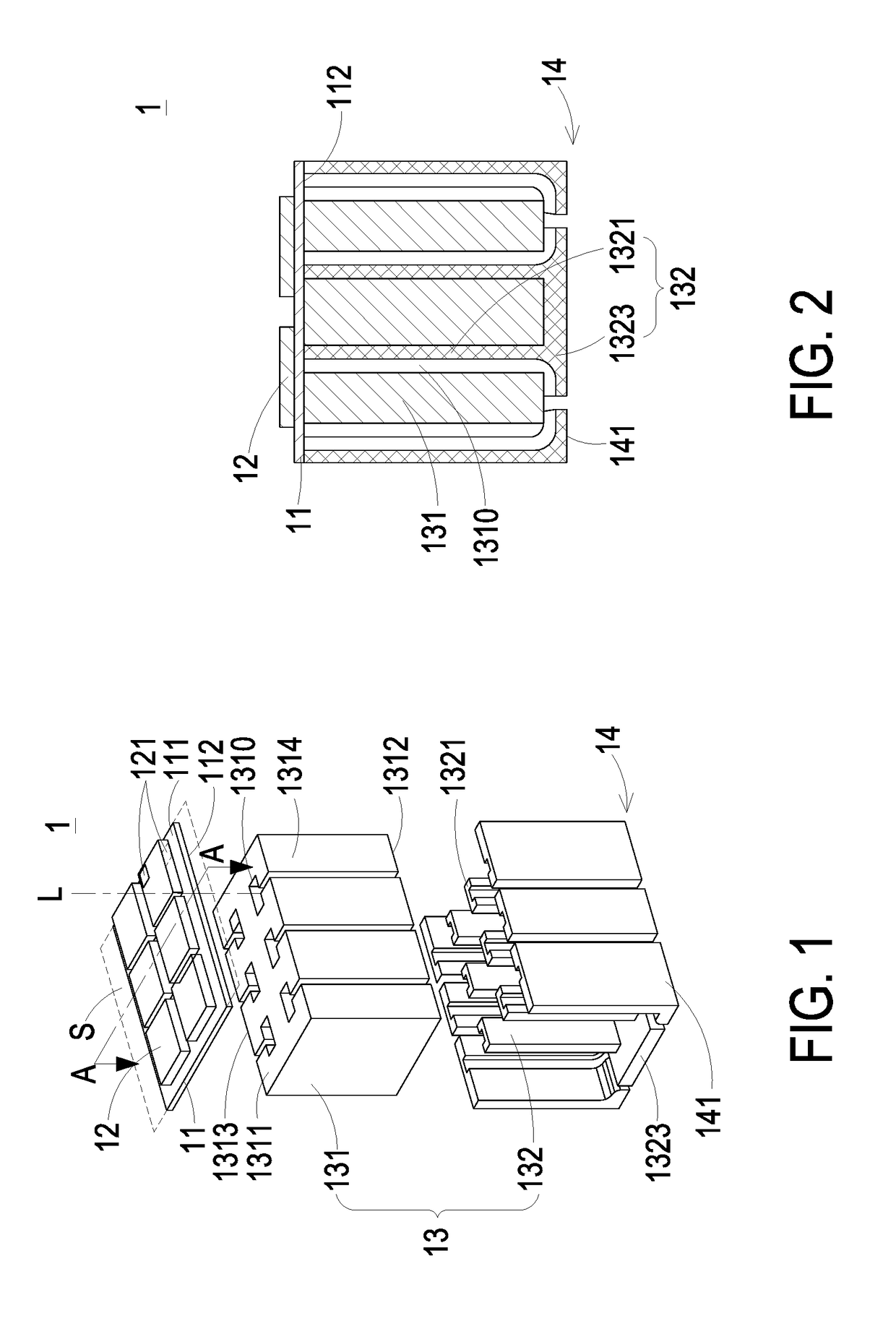

Power module and magnetic component thereof

ActiveUS20180122562A1Lower the volumeImprove power densityTransformers/inductances coils/windings/connectionsPrinted circuit aspectsVertical projectionInductor

A power module including a power device and a magnetic component is provided. The magnetic component is stacked with the power device and a vertical projection of the magnetic component is at least partially overlapping with the power device. The magnetic component includes a magnetic core and a winding set. The magnetic core includes a first surface, a second surface and at least one window. The window is located between the first surface and the second surface, and includes a passing-through axis vertical to a surface of the power device, where at least one leading pin or pad is disposed on the surface of the power device. The winding set includes at least one winding portion. The winding portion passes through the window and electrically connected to the power device. Each winding set and the magnetic core are configured to form an inductor, and the winding set is preformed.

Owner:DELTA ELECTRONICS INC

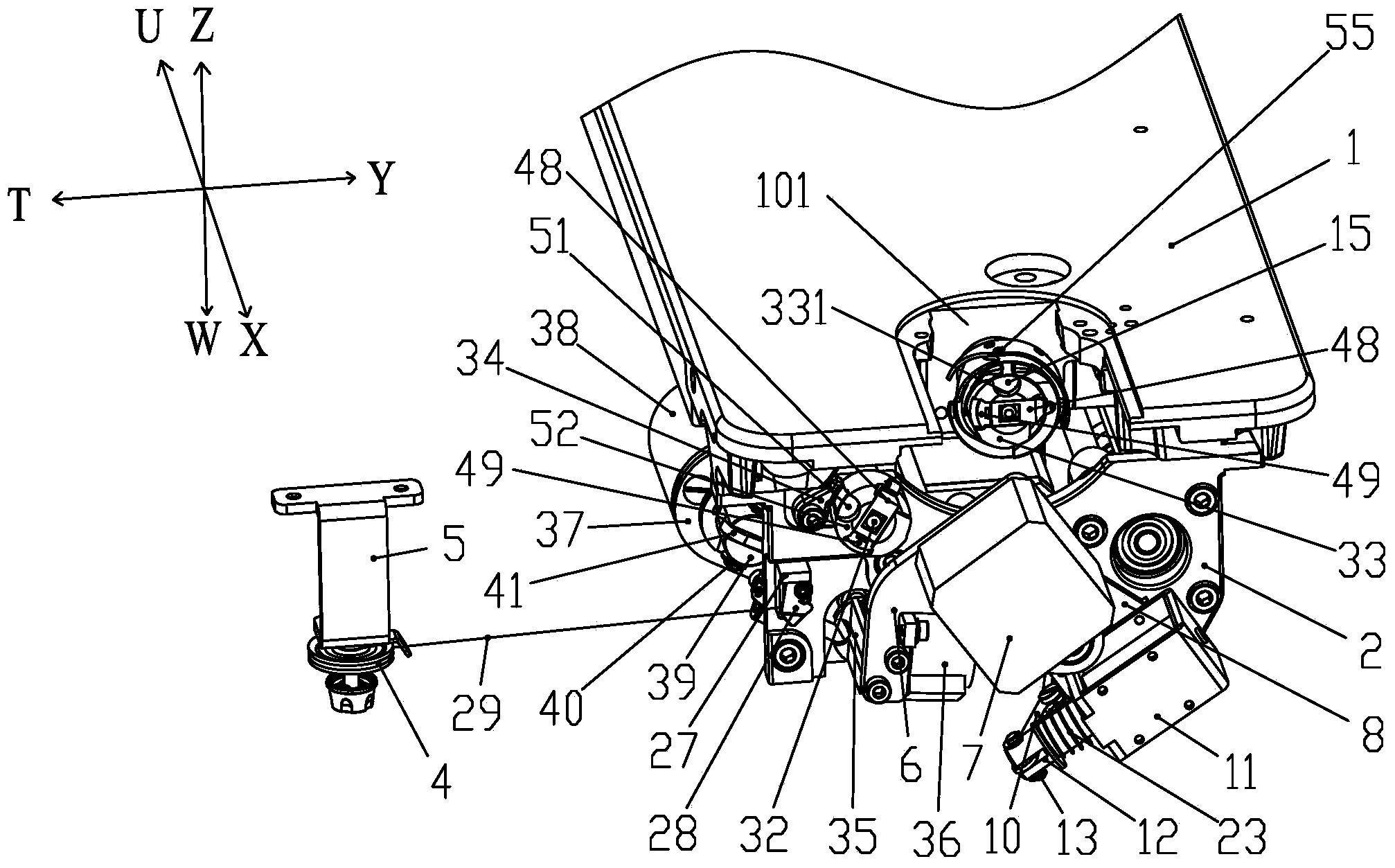

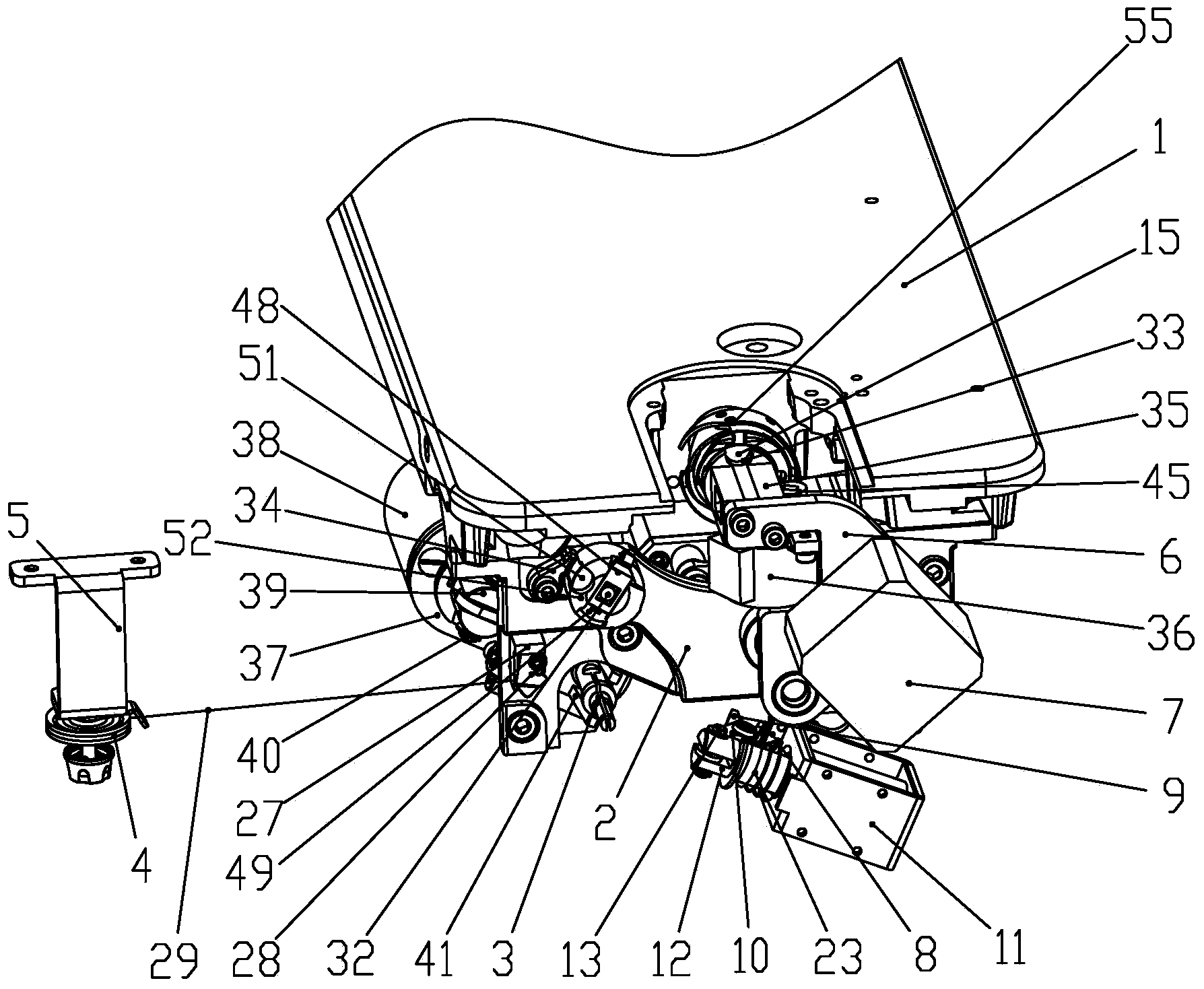

Method and device for removing leads from the twist machine and placing into stator and rotor groups

The invention discloses a method for removing winding wires in a twister and placing in a rotor or a stator group and a device thereof. The method comprises: removing a plurality of rectangle winding wires from a twisting clamp and inserting thereof into the rotor and the stator, wherein each of the plurality of rectangle winding wires has a pair of support leg, the spaced distance of which is equal to that between the stator and the rotor with scheduled number, and the support leg is inserted into a slot and connected integratively on one end; removing finger like pieces of a plurality of clamping modules between the support leg of the plurality of winding wires of the twisting clamp; removing the clamping module in a direction away from the twisting clamp, to extract the winding wires from the twisting clamp; providing the relative movement of the clamping module and the stator or the rotor, to causing free ends of the winding wires to be inserted into the rotor or the stator; and removing the finger like pieces between the support legs of the plurality of winding wires.

Owner:TECNOMATIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com