Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

350results about "Bobbin-winding devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device for sewing or knitting machines for changing the spool for the looper thread

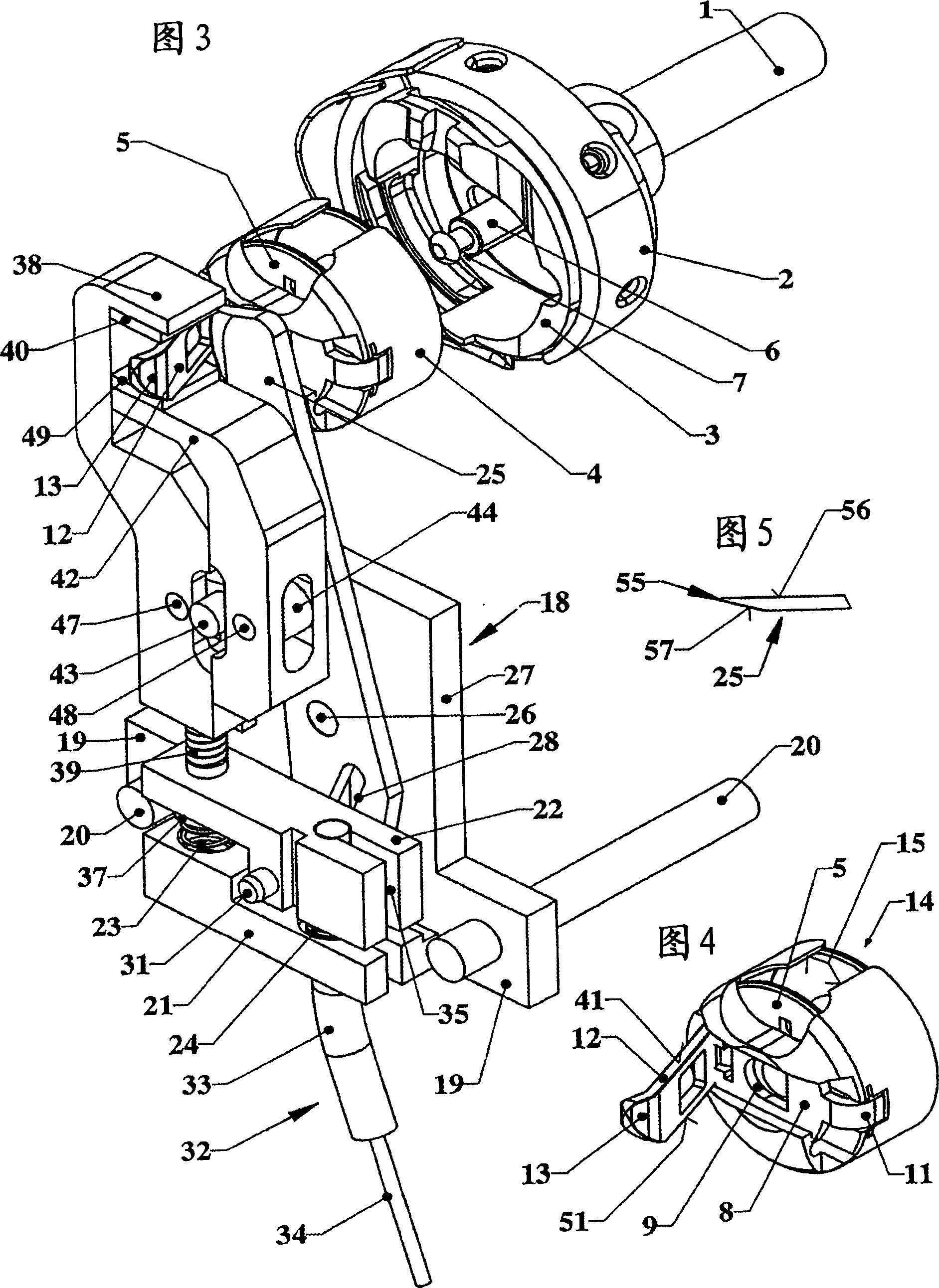

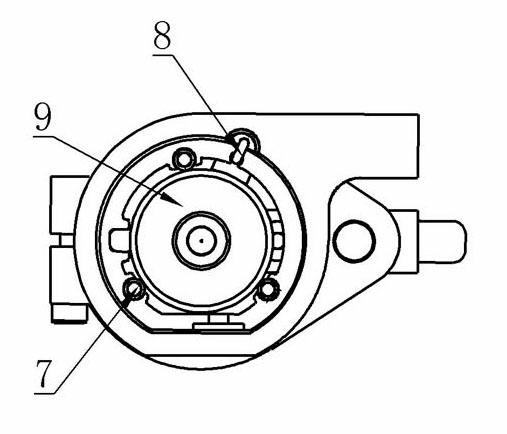

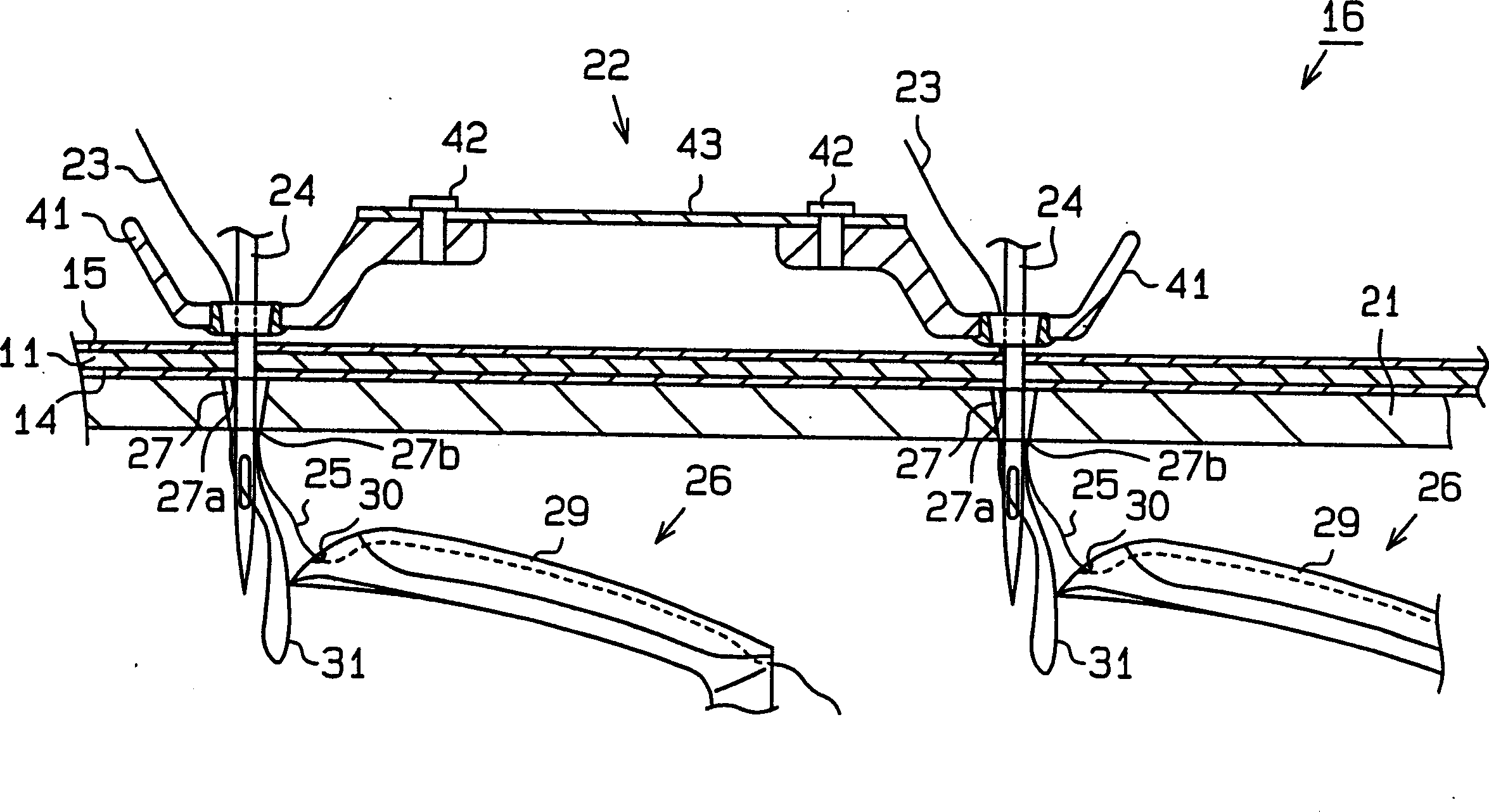

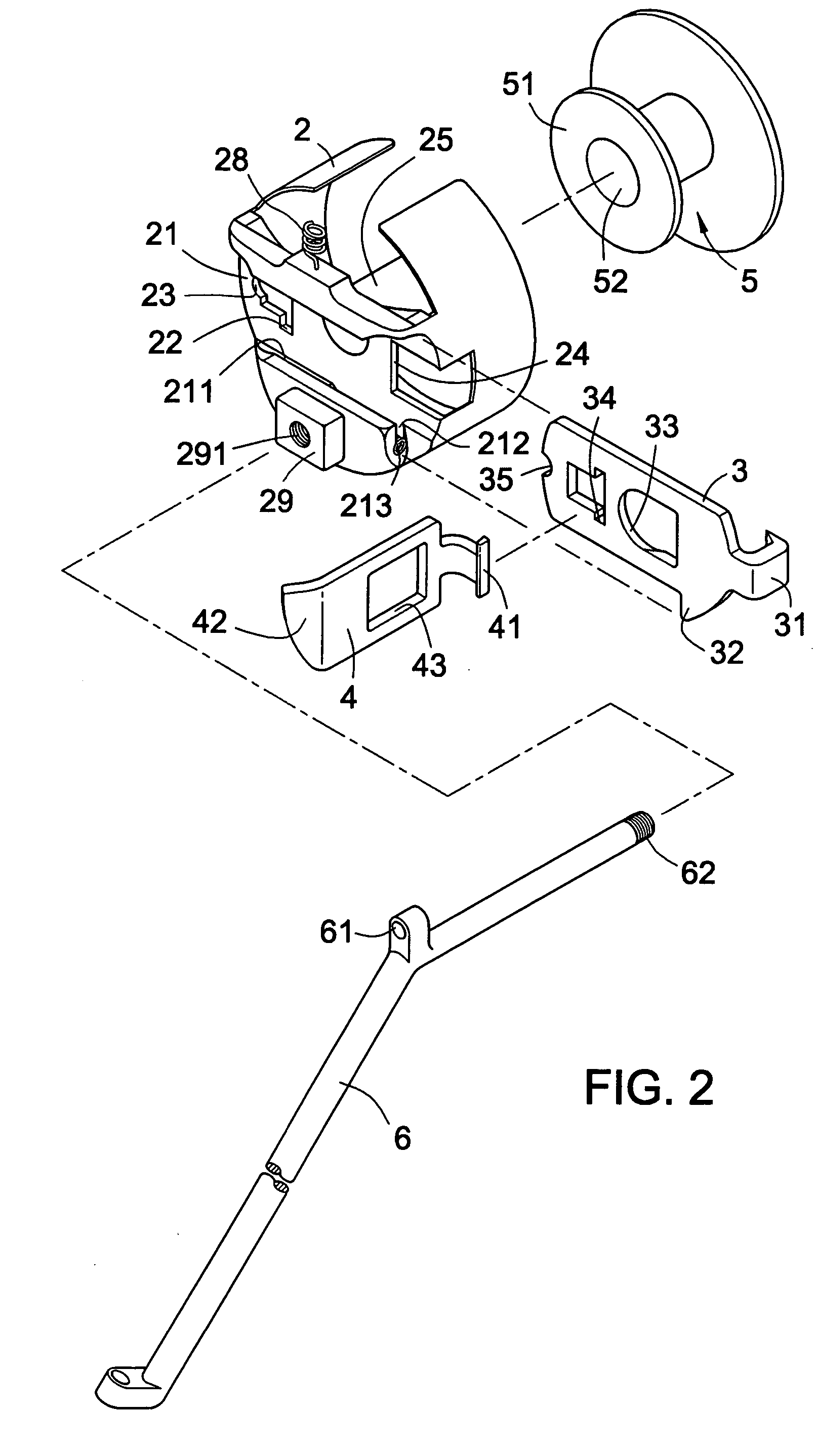

The invention relates to a device for double-thread lockstitch sewing or knitting machines, for exchanging the spool capsule housing the spool, housed in a sub-capsule in the shuttle and locked thereto by means of a locking element on a pin on the sub-capsule operated by a spool capsule lid, whereby, in order to open the spool capsule lid (12), an opening finger (25), displaceable between the above and the front face on the spool capsule (4) and a catcher device (50) are provided, comprising clamp jaws (38,42) engaging with the longitudinal edge surfaces (41,51) of the opened spool capsule lid (12), which together with the opening finger (25) may be displaced along a track, running parallel to the axis of the shuttle (2).

Owner:ZOJE SEWING MASCH CO LTD

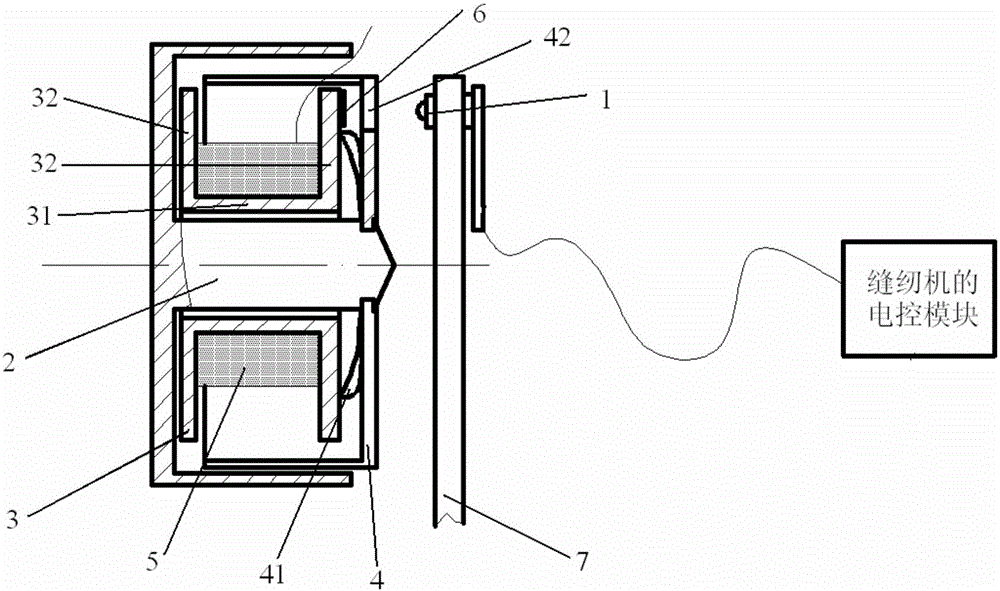

Base thread monitoring device for sewing machine

The invention provides a base thread monitoring device for a sewing machine. The sewing machine comprises a base plate, a bobbin case and a bobbin core which is filled with base thread in a winding mode, wherein the bobbin core is completely contained in the bobbin case, a thread winding column of the bobbin core is provided with a light reflecting surface, a light transmitting hole is formed in the side wall of the bobbin case, a photoelectric sensor is installed on the base plate, the photoelectric sensor is arranged on the outer side of the bobbin case, and is arranged opposite to the light transmitting hole, and the photoelectric sensor is composed of a receiver and a emitter. When the base thread on the thread winding column is large in amount, the base thread can shield the light reflecting surface. When the base thread is almost used out, the light reflecting surface is gradually exposed, the light reflecting surface can receive a signal which is given out by the emitter and enters through the light transmitting hole, and can reflect the signal to the receiver, the receiver gives out a signal after receiving the signal to have control over the sewing machine, and achieves the objective that the sewing machine cannot carry out sewing of the next time after finishing the current sewing, and therefore the phenomenon that the quality of a sewing product is influenced by lack of the base thread can be avoided.

Owner:JACK SEWING MASCH CO LTD

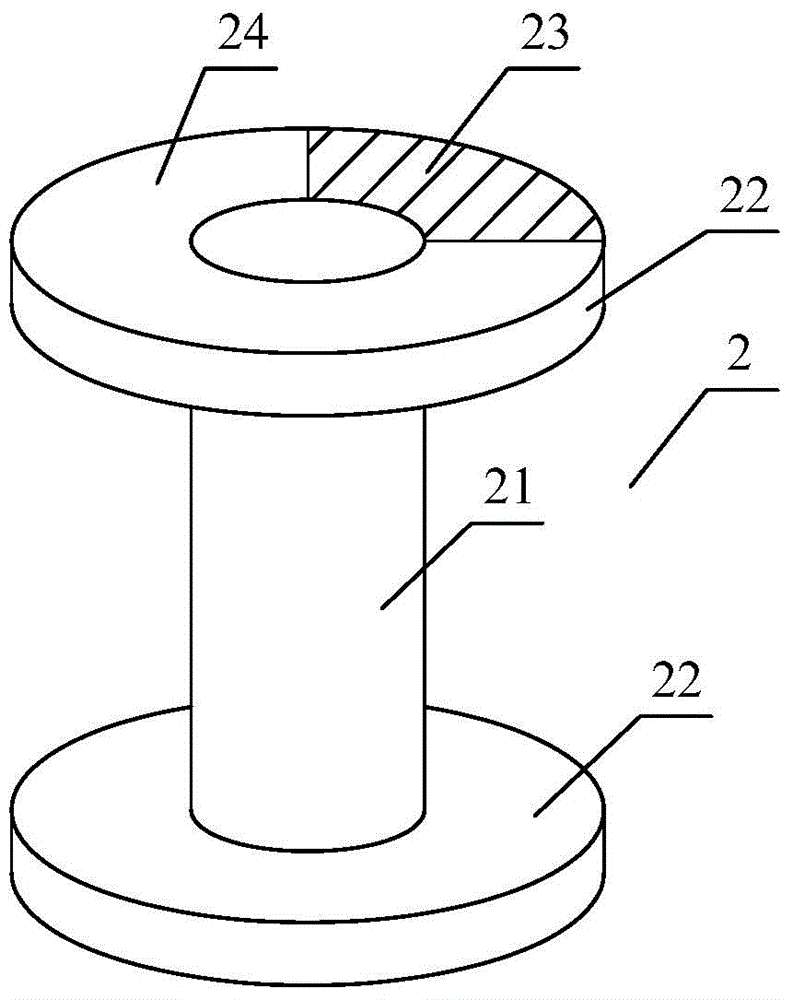

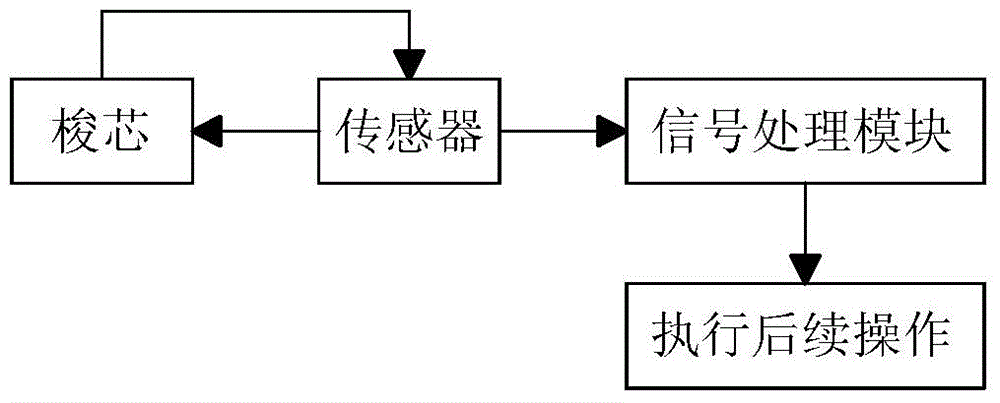

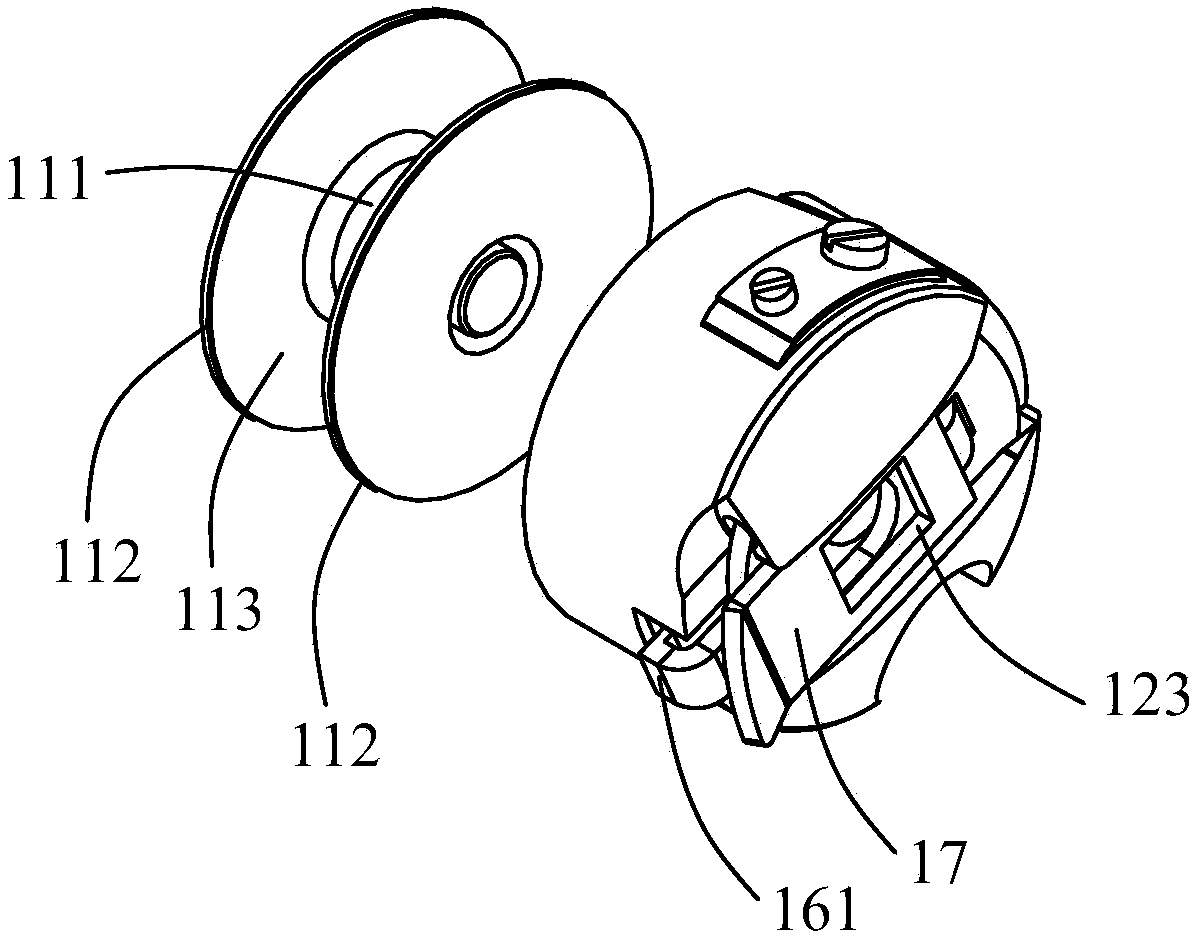

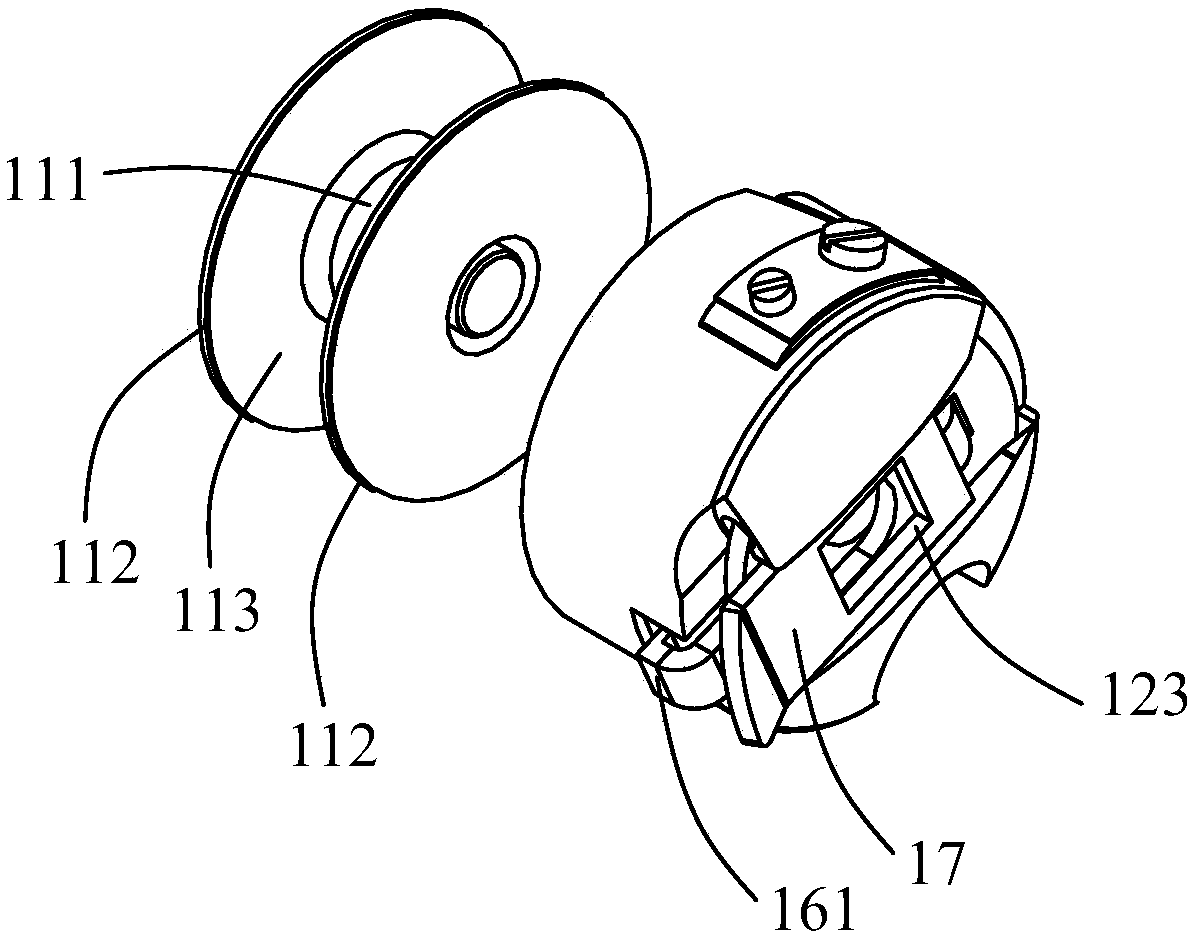

Device and method for detecting amount of bottom thread of sewing machine

The invention provides a device for detecting the amount of bottom thread of a sewing machine. The sewing machine comprises a bottom plate, a rotating shuttle and an electronic control module, wherein the rotating shuttle comprises a shuttle shell and a shuttle core; the shuttle core comprises a winding post and two flanges; at least one flange in the two flanges is provided with a first surface part and a second surface part on the outer surface; a light hole is formed on the outer wall of the shuttle shell; the first surface part or the second surface part is exposed outside from the light hole; the sewing machine also comprises a sensor fixed in the bottom plate; the sensor comprises a transmitter used for transmitting light, and a receiver used for receiving light; the receiver and the transmitter of the sensor just face to the first surface part or the second surface part exposed outside from the light hole, and the light reflection capabilities of the first surface part and the second surface part are different from each other; the sensor is connected with a signal processing module; the signal processing module is connected with the electronic control module. The device for detecting the amount of the bottom thread of the sewing machine is capable of timely detecting whether the bottom thread is used up or not in real time.

Owner:JACK SEWING MASCH CO LTD

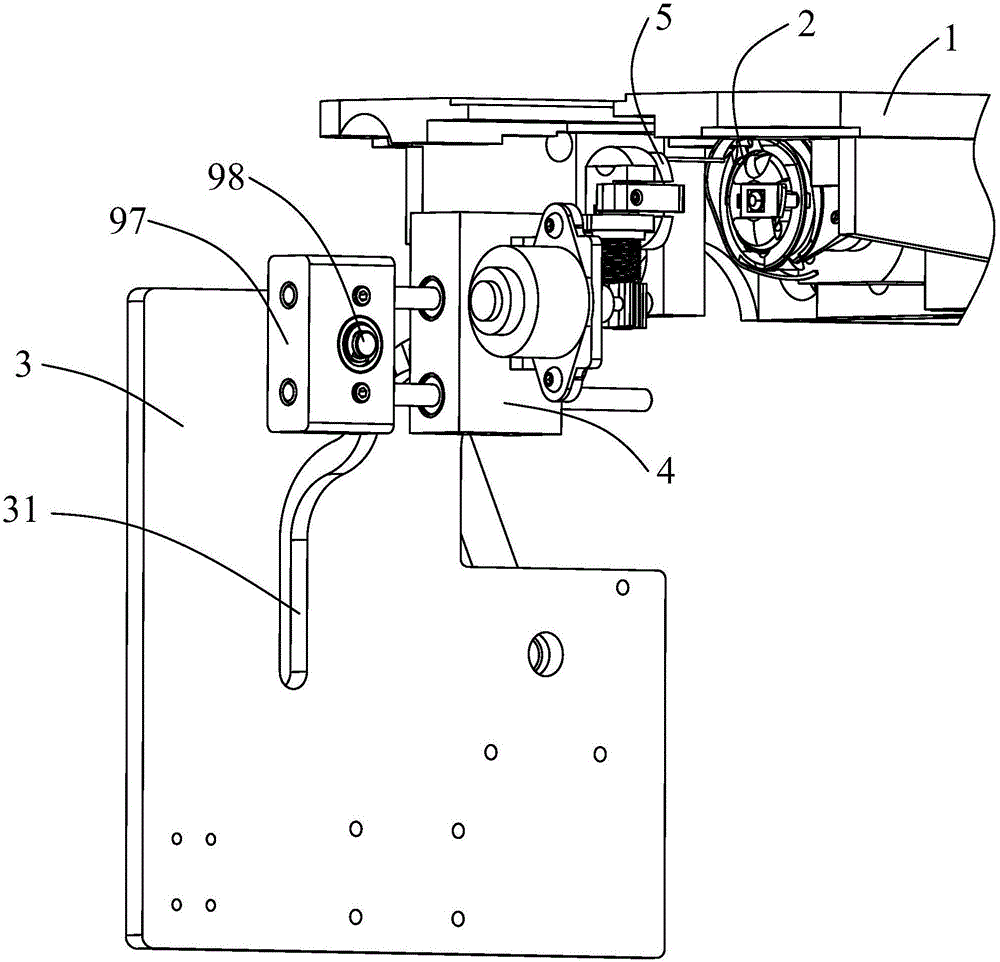

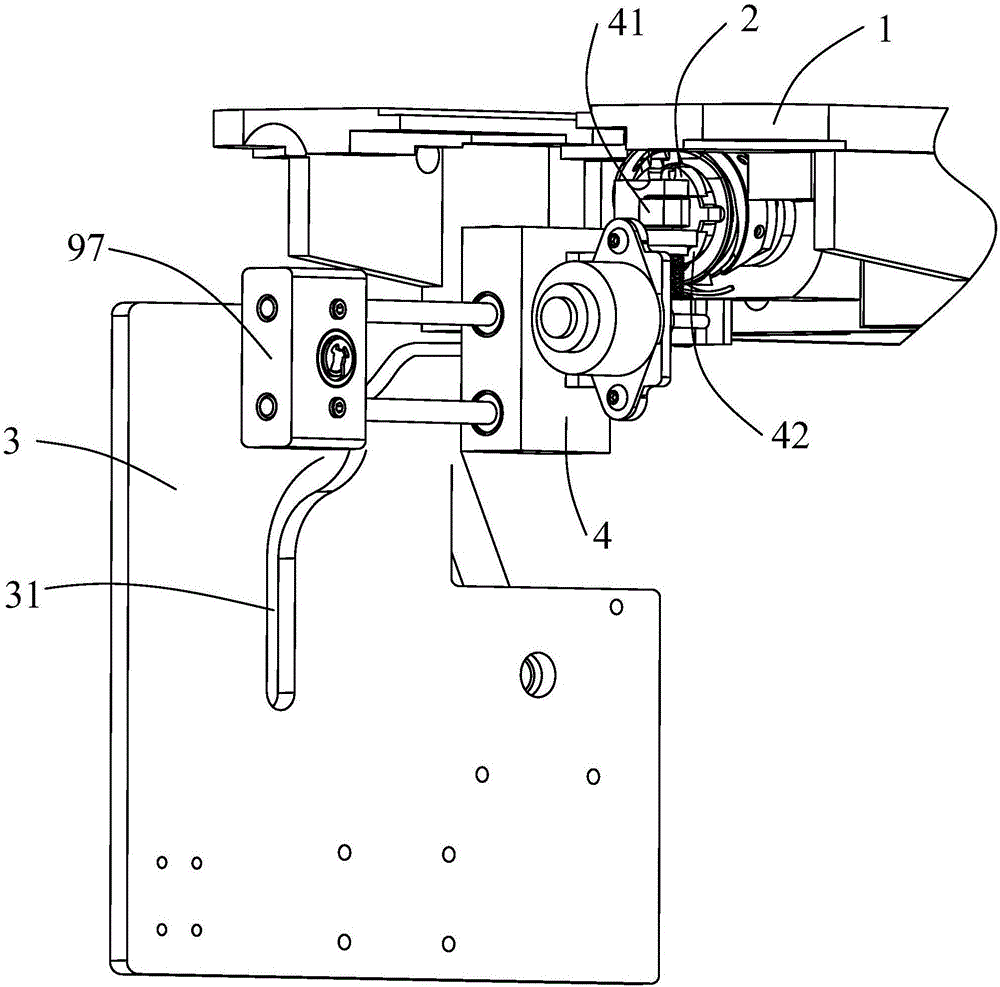

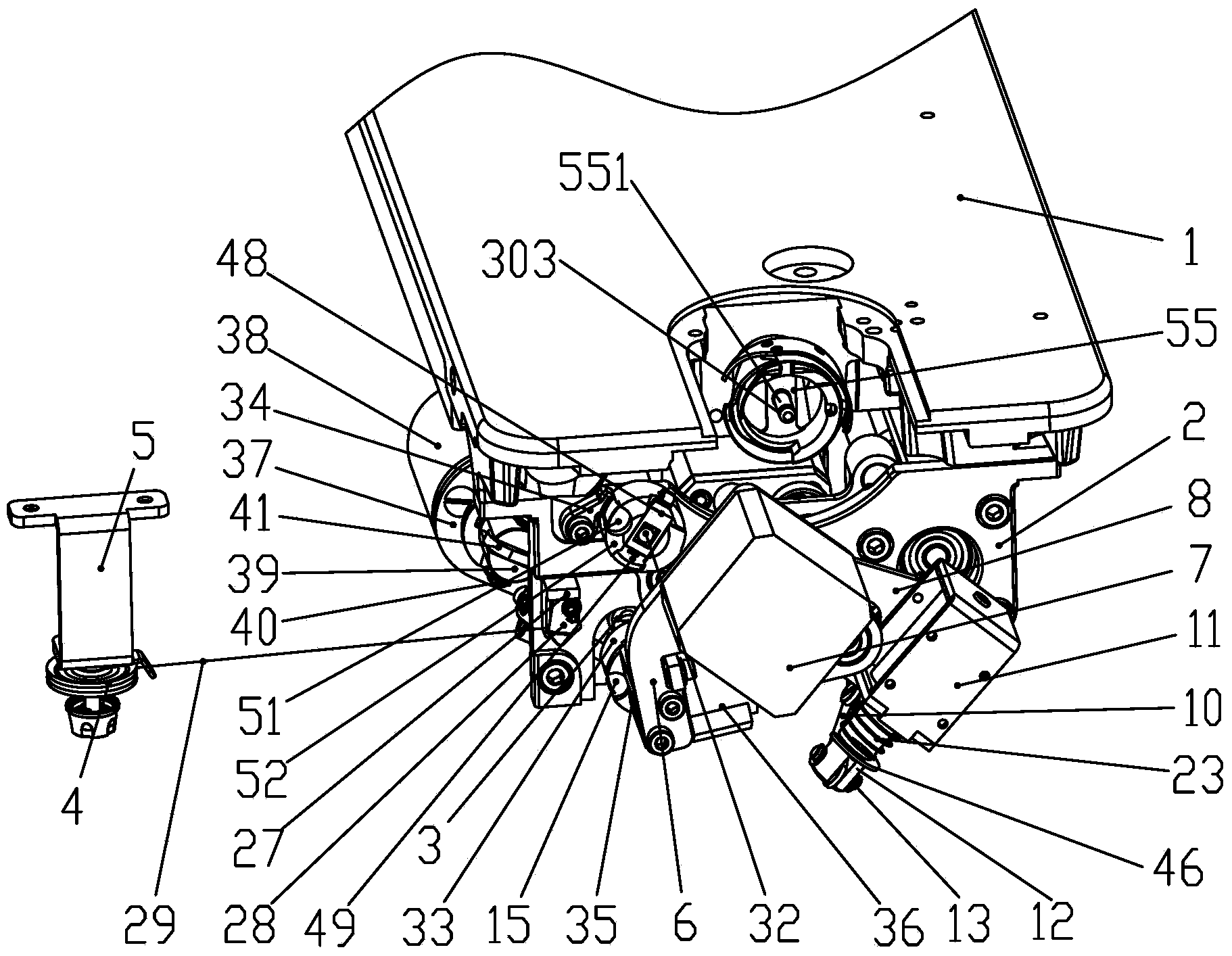

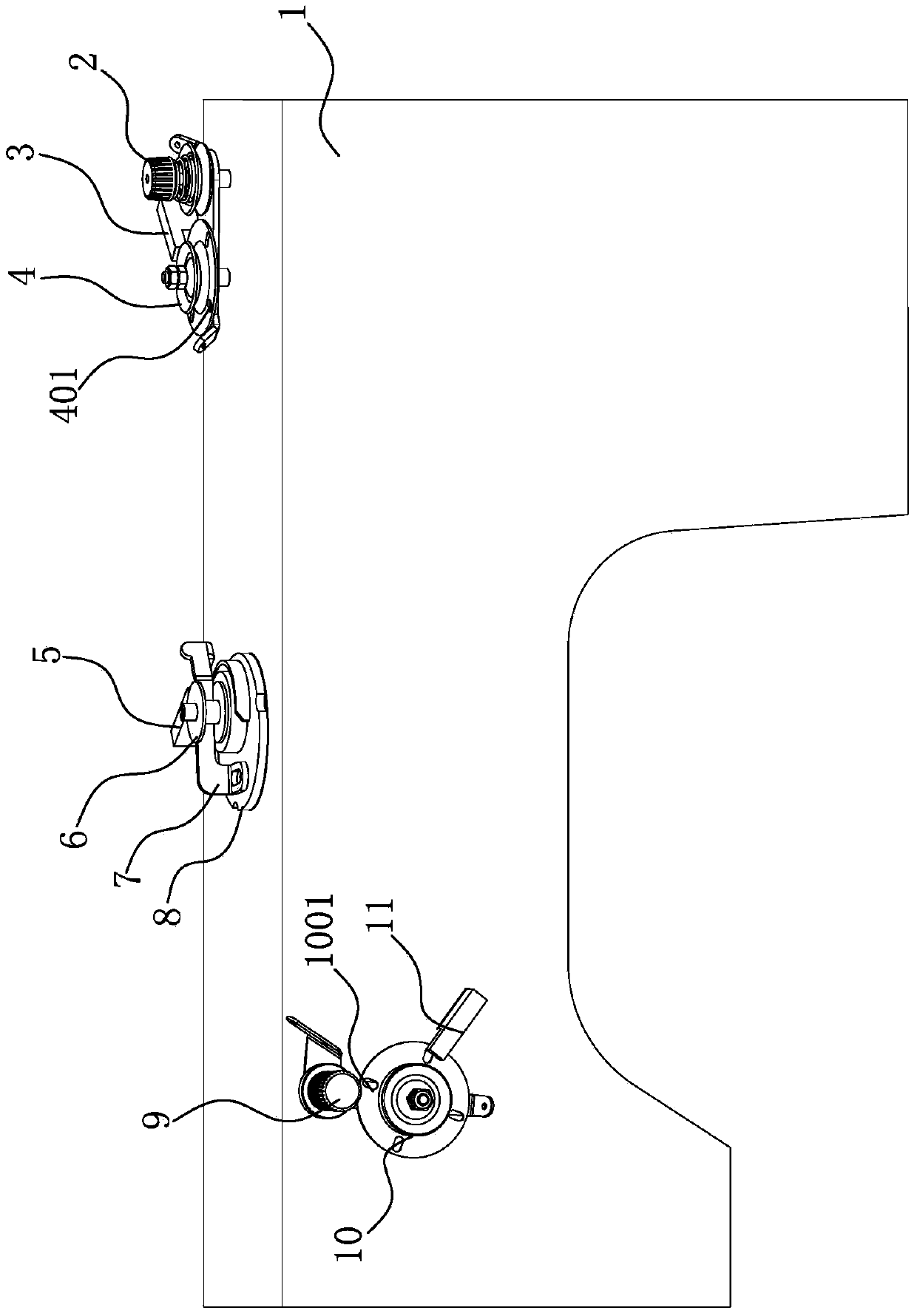

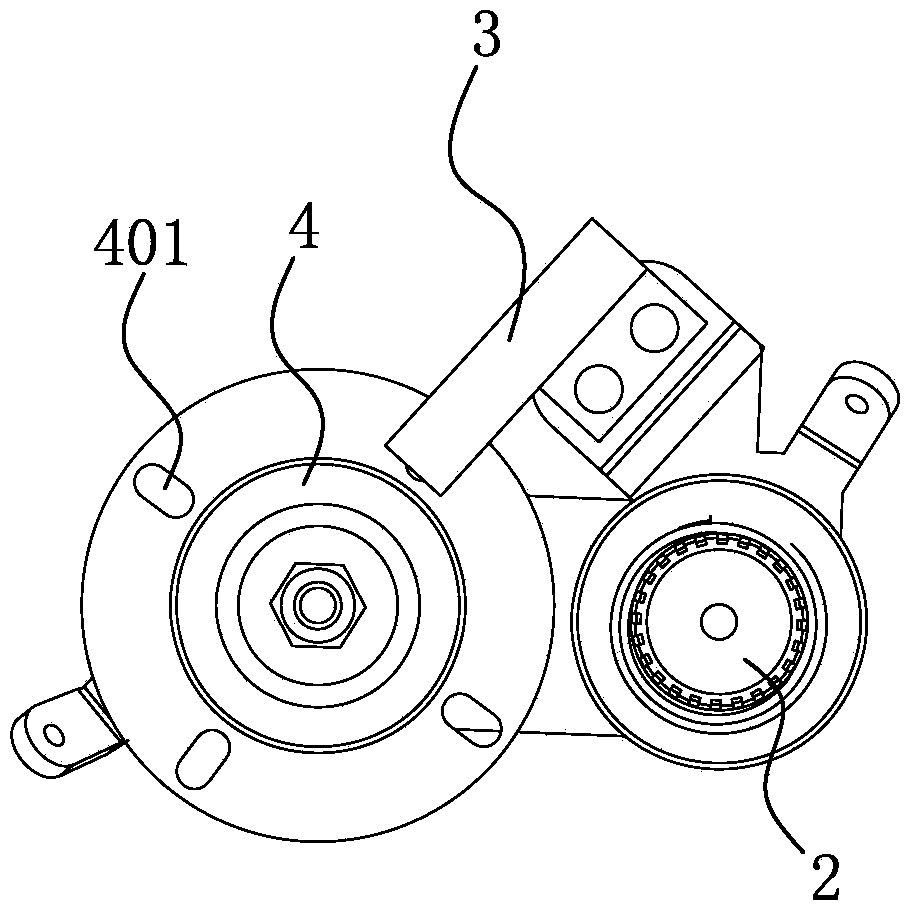

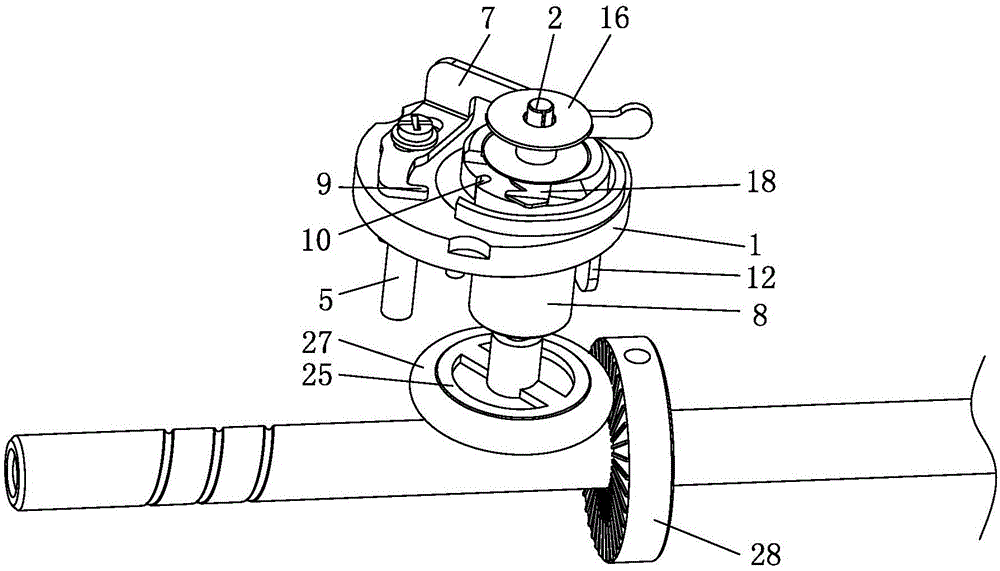

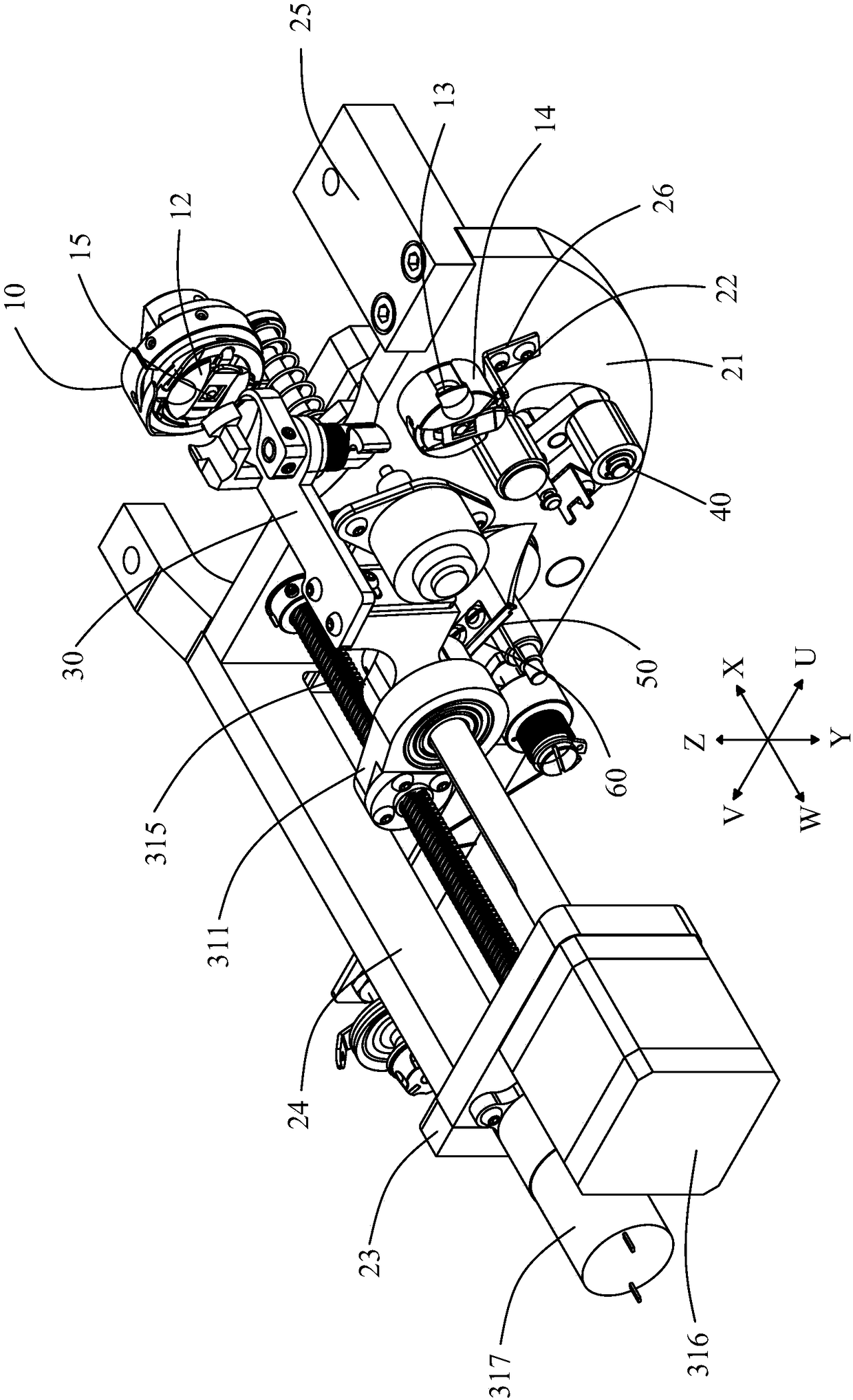

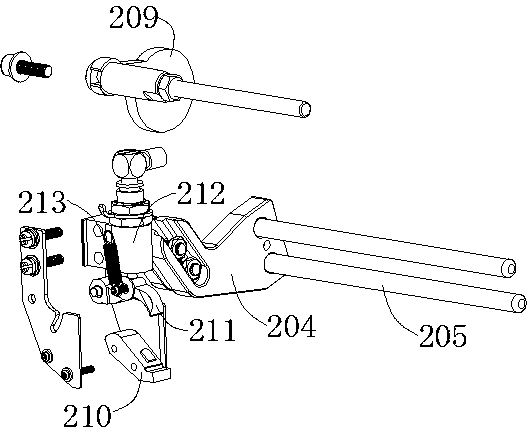

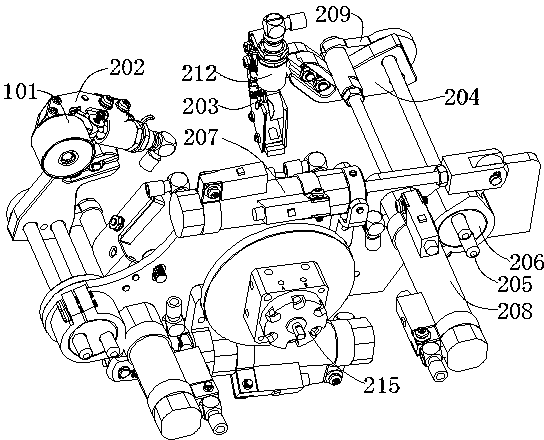

Automatic shuttle changing device and method

ActiveCN106222901APrevent empty walkImprove sewing efficiencyBobbin-winding devicesBobbinEngineering

The invention provides an automatic shuttle changing device which comprises a rotating shuttle, wherein a first shuttle shell and a first shuttle core are arranged on a rotating shuttle spindle of the rotating shuttle in a sleeving manner. The device also comprises a fixed base plate with a bottom line allowance detection station, a grabbing station and a replacement station, a movable shuttle shell claw, a bottom line allowance detection sensor mounted on the shuttle shell claw, and a movable storage device, wherein an empty station and a storage station are formed in the storage device; a hollow rotating shaft is arranged at the empty station; a second shuttle shell and a second shuttle core are arranged at the storage station; bottom lines are fully wound on a winding post of the second shuttle core; the shuttle shell claw is used for grabbing and moving the first shuttle shell and the first shuttle core or the second shuttle shell and the second shuttle core. According to the automatic shuttle changing device disclosed by the invention, the bottom line allowance on the winding post of the first shuttle core can be detected and monitored in real time; and when the bottom lines on the first shuttle core run short, the sewing machine automatically stops, the first shuttle core with insufficient bottom line is automatically taken down from the rotating shuttle, and the second shuttle core full of wound bottom lines is automatically replaced into the rotating shuttle, so that the sewing efficiency and sewing quality are improved.

Owner:JACK SEWING MASCH CO LTD

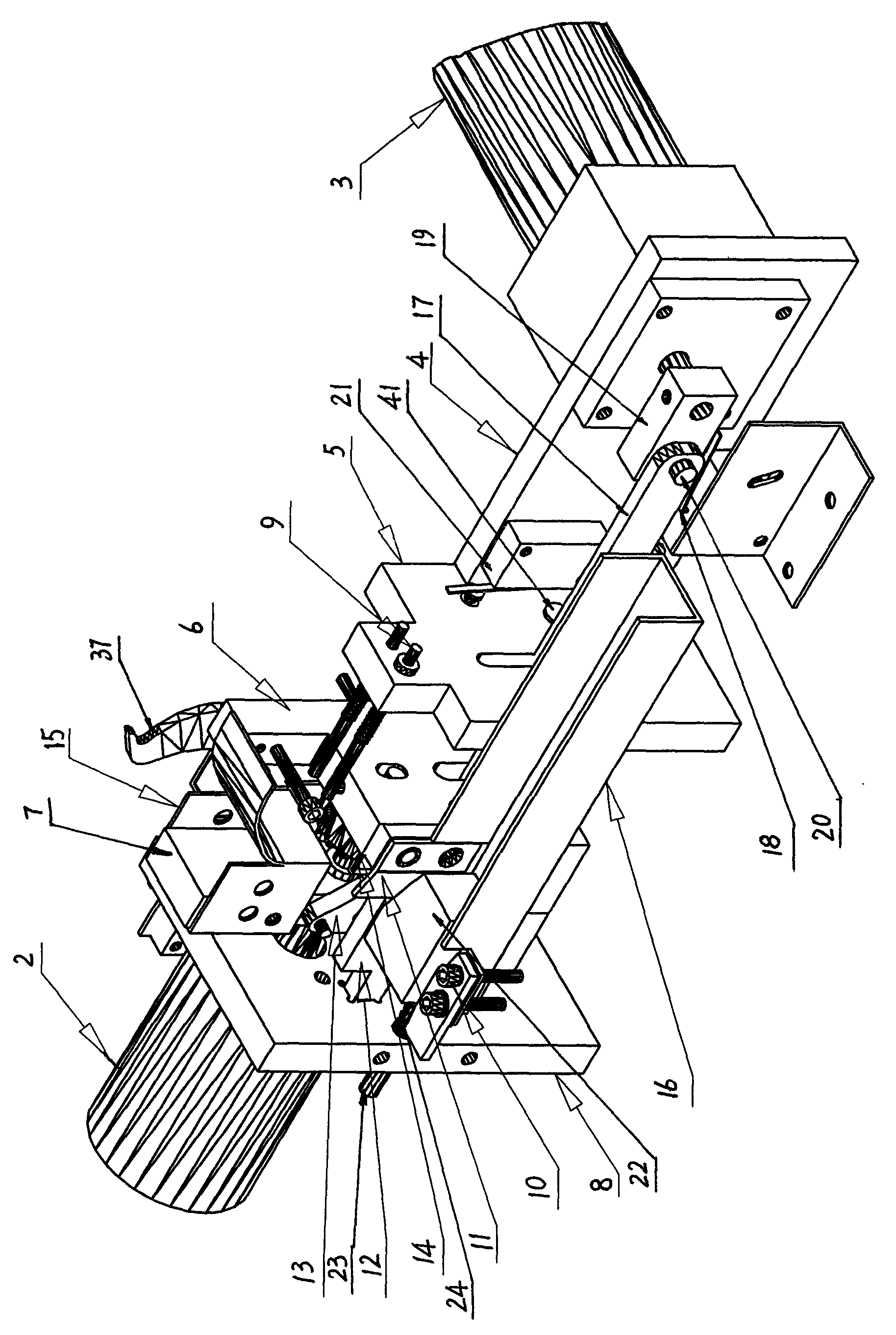

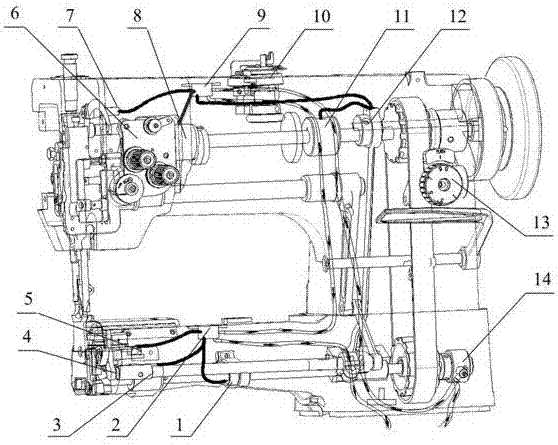

Automatic bobbin changing and winding device and method

ActiveCN104264386AImprove work efficiencyHigh degree of automationBobbin-winding devicesBobbinWire wrap

The invention discloses an automatic bobbin changing and winding device and method. The automatic bobbin changing and winding device comprises a bottom plate, a shuttle cabin and a rotating shuttle, a shuttle shell and a bobbin are arranged on the spindle of the rotating shuttle, a bracket is arranged at the front side of the bottom plate, a rotating shaft is arranged on the front lateral surface of the bracket, the rotating shaft is provided with a first shuttle shell and a first bobbin, and bottom lines fully wind a winding post of the first bobbin; the automatic bobbin changing and winding device further comprises a rotary winding shaft, a push plate capable of rotating and moving horizontally in the axial direction, a shell grasping seat, a bobbin push rod and a line clamping mechanism, a first shaft part and a second shaft part are arranged at the front end of the winding shaft, the shell grasping seat is used for grasping and moving the shuttle shell and bobbin, the shuttle shell or the first shuttle shell and first bobbin, the bobbin push rod is used for backward pushing the bobbin from the shuttle shell, the line clamping mechanism is used for clamping the bottom lines on a line barrel, and the push plate is used for forwardly pushing the bobbin into the shuttle shell. The automatic bobbin changing and winding device and method are capable of automatically changing the bobbin and winding the bobbin, the automatic degree is very high, both time and labor are saved, and the working efficiency of a sewing machine is greatly improved.

Owner:JACK SEWING MASCH CO LTD

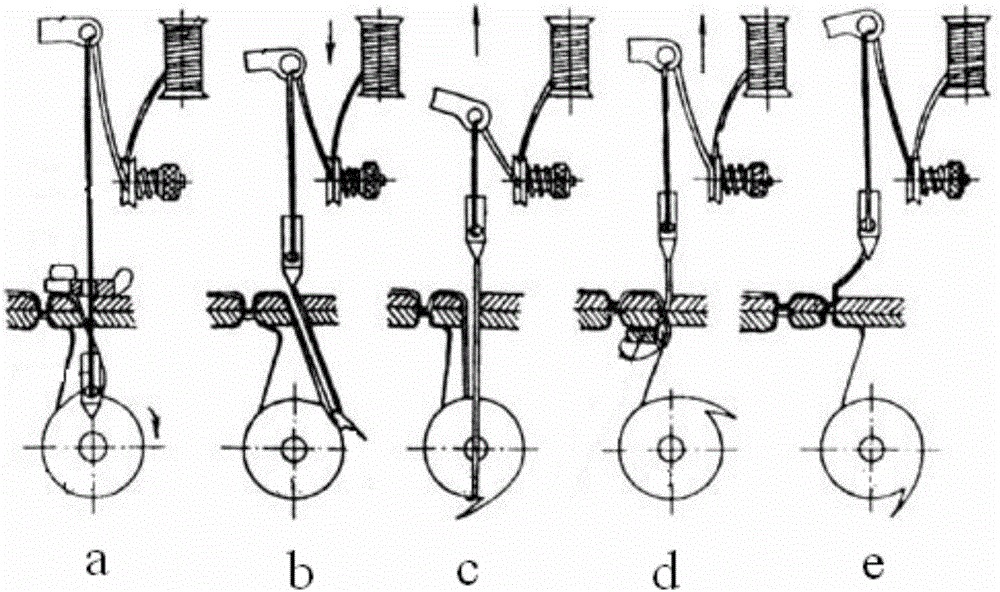

Sewing machine bottom shuttle replacing method

ActiveCN103643413ASimplify the shuttle changing stepsImprove shuttle changing efficiencyBobbin-winding devicesBobbinSewing machine

The invention discloses a sewing machine bottom shuttle replacing method. The sewing machine bottom shuttle replacing method is characterized by comprising the steps of taking out a first shuttle casing from a shuttle table of a sewing machine base and installing a standby second shuttle casing in the shuttle table; taking out a first shuttle peg from the replaced first shuttle casing, cutting off a bottom line connected between the first shuttle peg and the first shuttle casing and clamping a remaining line of the first shuttle casing through a remaining line clamping device; removing the bottom line left on the first shuttle peg, winding a new bottom line fully and connecting the newly-wound bottom line to the remaining line on the first shuttle casing; installing the first shuttle peg into the first shuttle casing for standby. The whole shuttle replacing steps are simplified, the shuttle replacing efficiency is improved, automatic operation is facilitated through various mechanisms, the steps of taking the shuttle casings and the shuttle peg of a bottom shuttle of the sewing machine, winding the line on the shuttle peg, installing the shuttle peg into the shuttle casing, installing the shuttle casing into the shuttle table and the like can be automatically achieved, accordingly automatic bottom line replacement of the sewing machine is achieved, the trouble that a specially-assigned person monitors the operation is avoided, and the labor cost is reduced.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

Automatic bottom line changing device of computer embroidery machine

InactiveCN101979747ASimplify spare parts requirementsHigh degree of automationBobbin-winding devicesEmbroidering machines apparatusReciprocating motionEngineering

The invention discloses an automatic bottom line changing device of a computer embroidery machine, which can automatically change a shuttle peg of a bottom line rotating shuttle in a mechanical mode so as to further improve the production efficiency and the automation degree of the computer embroidery machine and lighten the labor intensity of workers. Therefore, a mounting plate is fixedly arranged on a machine frame; one end of the mounting plate is close to a rotating shuttle box, while the other end of the mounting plate is fixedly provided with a shuttle peg bin; two right angle type guide plates, which have the same shape and are opposite to each other, are arranged in the mounting plate; the outer side of the lower lateral surface of a horizontal section of the guide plate is provided with a sliding block; the upper part of the sliding block is provided with a rotary block and a positioning rotary block; the upper end face of the positioning rotary block is a semicircle surface, two lateral surfaces of the positioning rotary block are planes parallel to each other, and the positioning rotary block contact a limit track formed by the lower lateral surfaces of the horizontal sections of the two guide plates; a cylinder and a shuttle peg paw are vertically arranged on the left lower part of the rotary block; and the sliding block performs horizontal linear reciprocating motions with the help of a guide rod and a belt driving structure, thereby making the shuttle peg paw perform circular track motions between the shuttle peg box and the shuttle peg bin to realize the bottom line automatic changing.

Owner:FOSHAN QICHUANG TECH DEV

Base line allowance detection device for lock stitch sewing machine and detection method thereof

ActiveCN103741393ASimple structure and principleLow retrofit costBobbin-winding devicesLine sensorBobbin

The invention relates to a base line allowance detection device for a lock stitch sewing machine and a detection method thereof. The base line allowance detection device for the lock stitch sewing machine comprises a base line quantity detection part, a facial line use quantity detection part and a controller. The base line quantity detection part comprises a base line counting disc, a cop latch winder, a base line sensor for sensing the turning number of turns of the base line counting disc and a winding sensor for sensing the starting and stopping of the cop latch winder. The facial line use quantity detection part comprises a facial line counting disc and a facial line sensor for sensing the turning number of turns of the facial line counting disc. The controller is provided with a control module which controls the cop latch winder and the lock stitch sewing machine to work and receives and processes signals of the base line sensor, the winding sensor and the facial line sensor. According to fact that the base line winding quantity minus the facial line use quantity is the base line allowance, base line allowance detection is achieved. The base line allowance detection device is simple in structure, convenient to operate and use and high in intelligence degree and has accuracy in detection.

Owner:NINGBO SANHEXIN AUTOMATION

Automatic shuttle peg feeder for automatic ground thread replacing device of computerized embroidery machine

ActiveCN102086576ARealize automatic replenishment functionReplenish spare bobbins one by one when solvingBobbin-winding devicesEmbroidering machines apparatusBobbinAutomotive engineering

The invention discloses an automatic shuttle peg feeder for an automatic ground thread replacing device of a computerized embroidery machine. Shuttle pegs which are stored in batch and are filled with ground threads are sent out one by one according to the requirement on the ground thread replacing device, and manual replacement of a rotating shuttle or replenishment of a standby shuttle peg is not required, so that the production efficiency and the automatic degree of the computerized embroidery machine are improved. The automatic shuttle peg feeder in the automatic ground thread replacing device consists of a shuttle peg cabin for storing standby shuttle pegs and an automatic propelling mechanism for conveying the standby shuttle pegs, wherein the shuttle peg cabin is fixedly connected with an installation plate which is fixedly arranged on the automatic ground thread replacing device through an installation frame; and the automatic propelling mechanism is fixedly arranged on the installation plate and corresponds to the shuttle peg cabin.

Owner:FOSHAN QICHUANG TECH DEV

Automatic thread winding and cutting integrated winder

InactiveCN105734850AUser-friendly thread volume adjustmentEasy to operateBobbin-winding devicesBobbinEngineering

Owner:JACK SEWING MASCH CO LTD

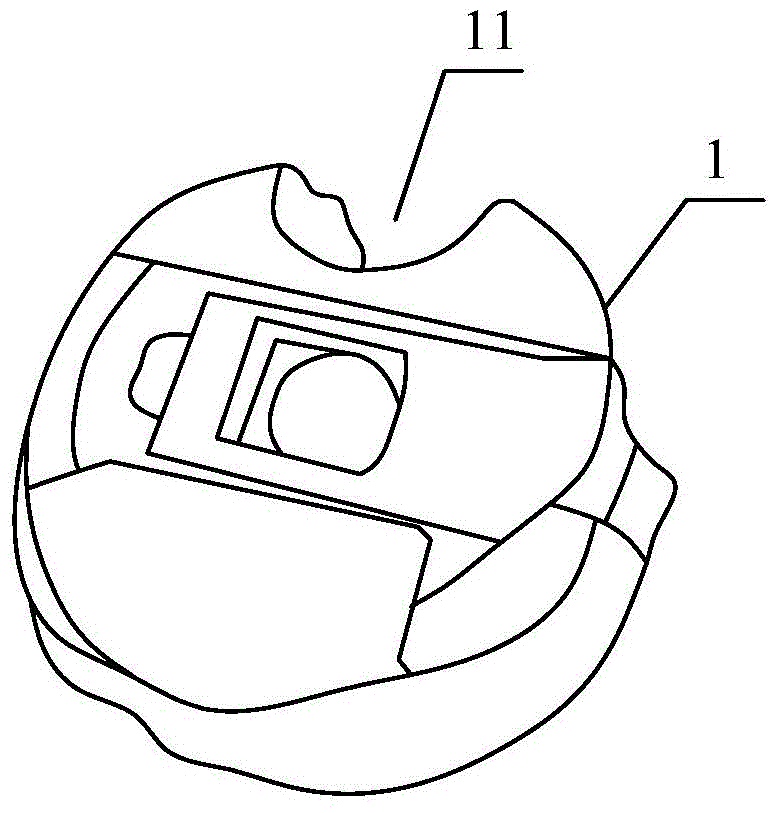

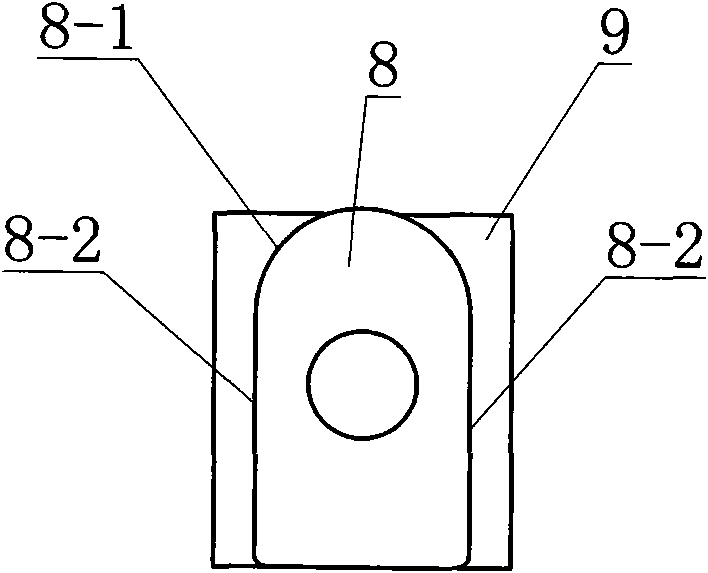

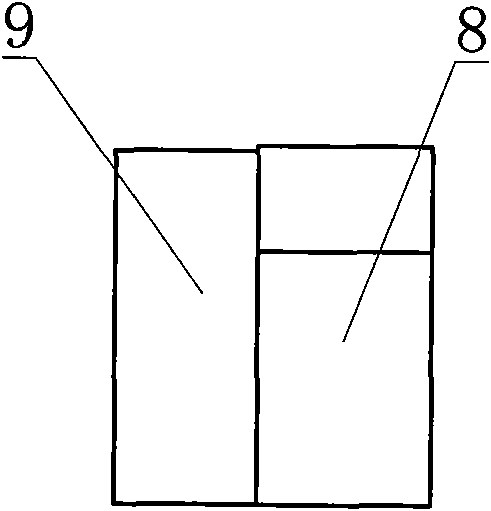

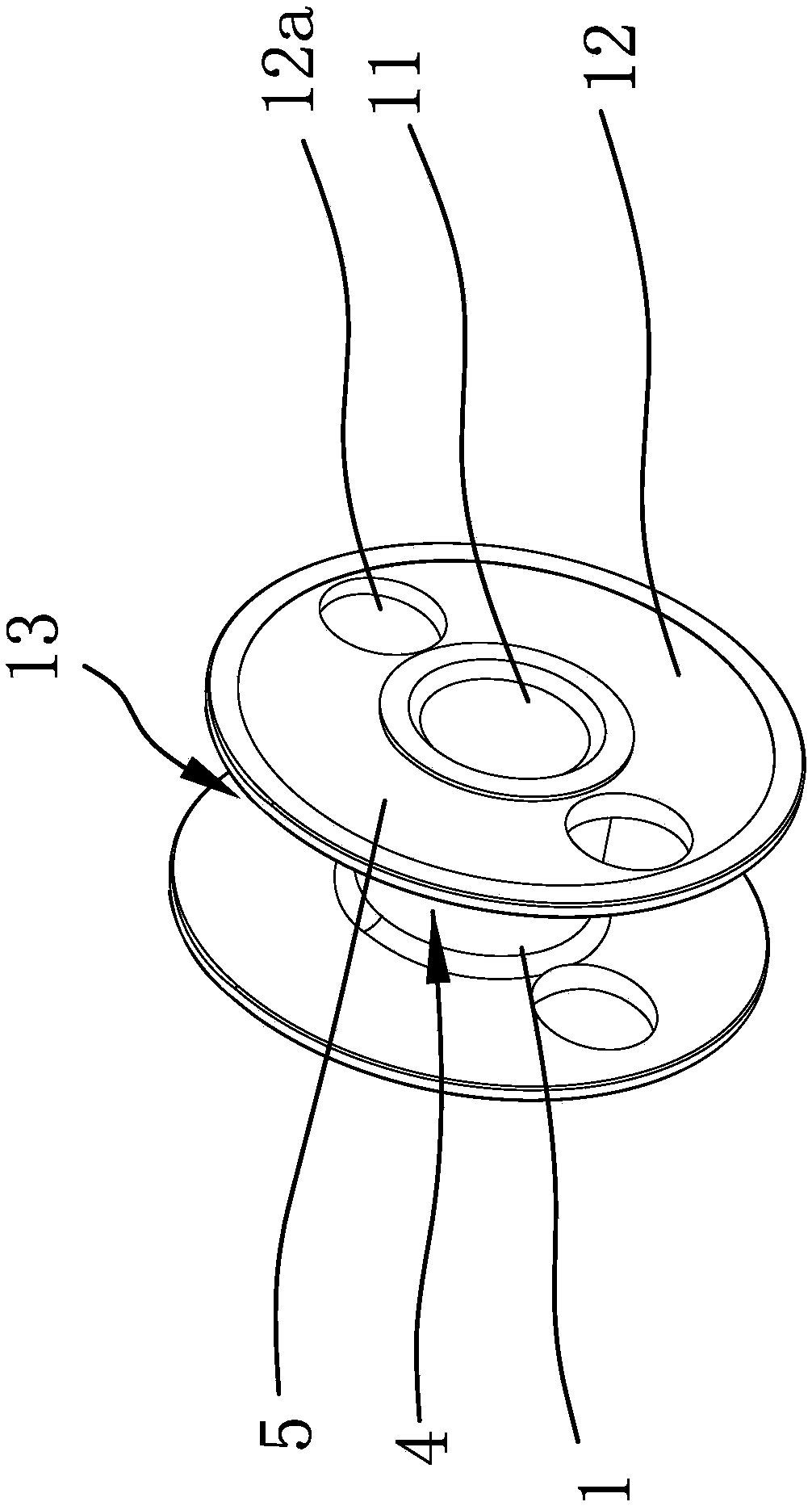

Detection structure of shuttle peg upper base line of sewing machine

The invention provides a detection structure of a shuttle peg upper base line of a sewing machine, and belongs to the technical field of sewing devices, which can solve the technical problem that theconventional detection structures of the shuttle peg upper base line is low in detection precision. A shuttle peg includes a cylinder having a through hole; the through hole is arranged along the axisof the cylinder; two ends of the cylinder have baffle plates extending outward radially, and a line winding groove is formed between the two baffle plates. The detection structure includes an electrical control module and a photoelectric sensor; a first reflective layer is arranged on the bottom of the line winding groove; light holes are formed in the baffle plates; and the photoelectric sensorcan emit a light beam to the first reflective layer. The detection structure is practical and simple, is low in cost, and is high in recognition precision.

Owner:JACK SEWING MASCH CO LTD

Method and device for controlling residual thread length of bobbin of sewing machine

InactiveCN105970505AAvoid influenceHigh degree of automationBobbin-winding devicesBobbinControl theory

The invention belongs to the technical field of sewing machines, and particularly refers to a method and device for controlling the remaining thread amount of a sewing machine bobbin. Codes are arranged on one side or both sides of the bobbin, and an automatic winding amount control device measures the code on the bobbin according to the code. The returned signal obtains the winding number of the bobbin, and the unwinding number detecting device obtains the unwinding number of the bobbin in the sewing process according to the signal returned by measuring the code on the bobbin, and the number of unwinding coils of the bobbin is obtained by the controller according to the number of unwinding coils and In the sewing process, the difference in the number of unwinding coils of the bobbin judges whether the length of the line segment required by the next sewing process is met; the present invention measures the number of winding coils and the number of unwinding coils of the bobbin in the sewing process respectively by two sensors, Then the controller judges whether the remaining thread meets the length of the thread segment required by the next sewing process through calculation. The operator does not need to worry about the remaining length of the bottom thread, and avoids empty needles or needle stoppages due to failure to replace the bobbin in time. The effect on the fabric caused by continuing to sew after changing the bobbin.

Owner:JACK SEWING MASCH CO LTD

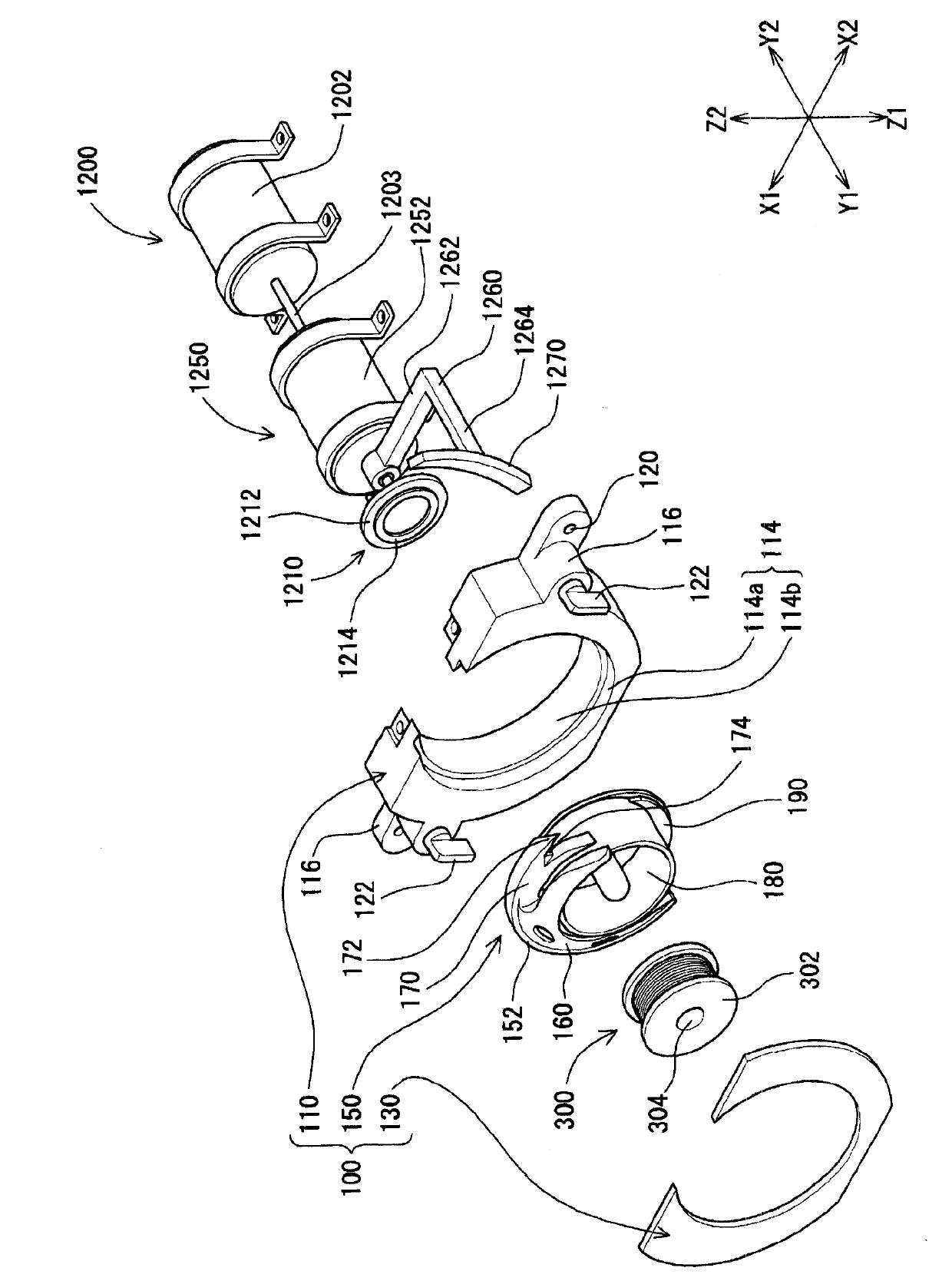

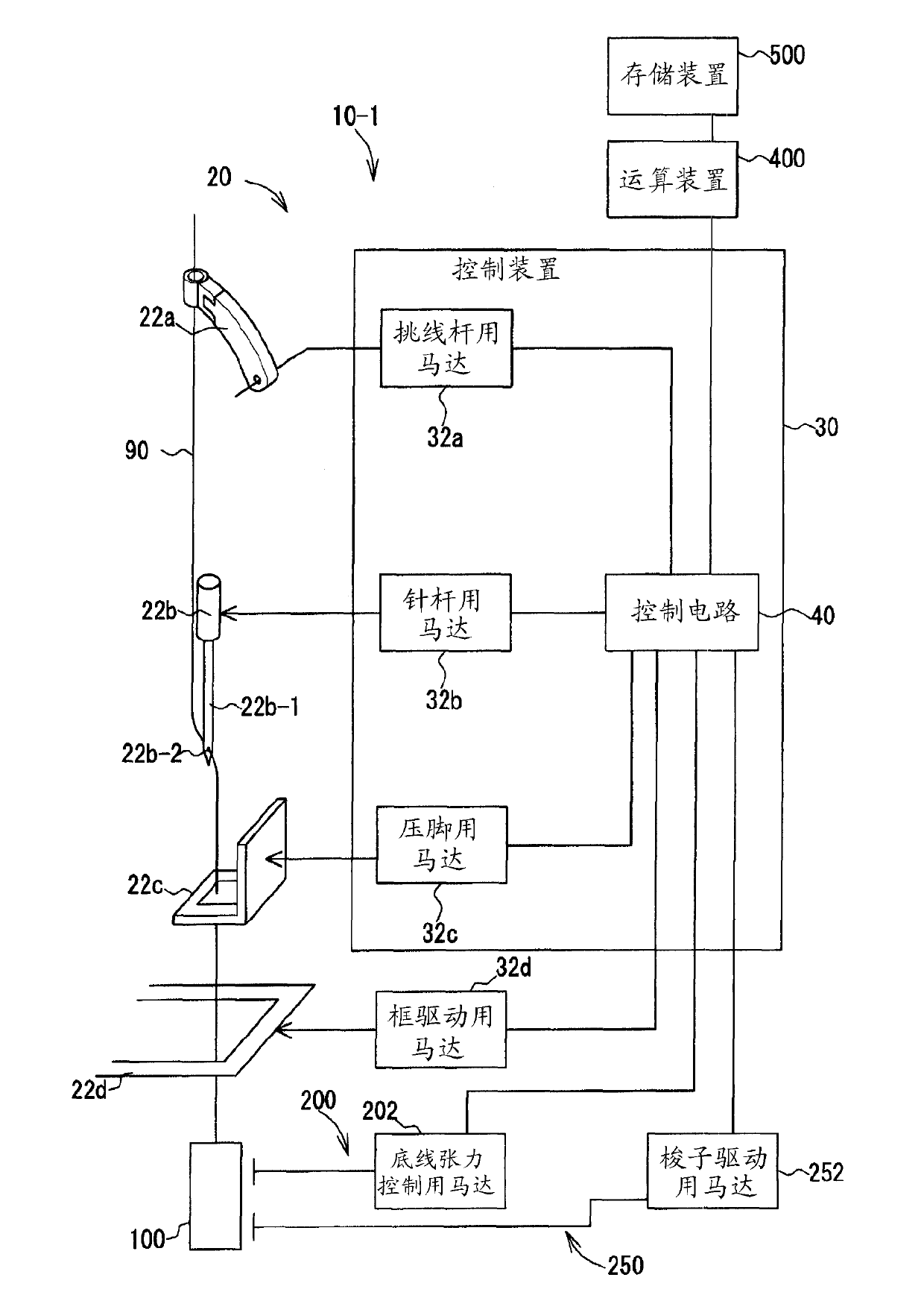

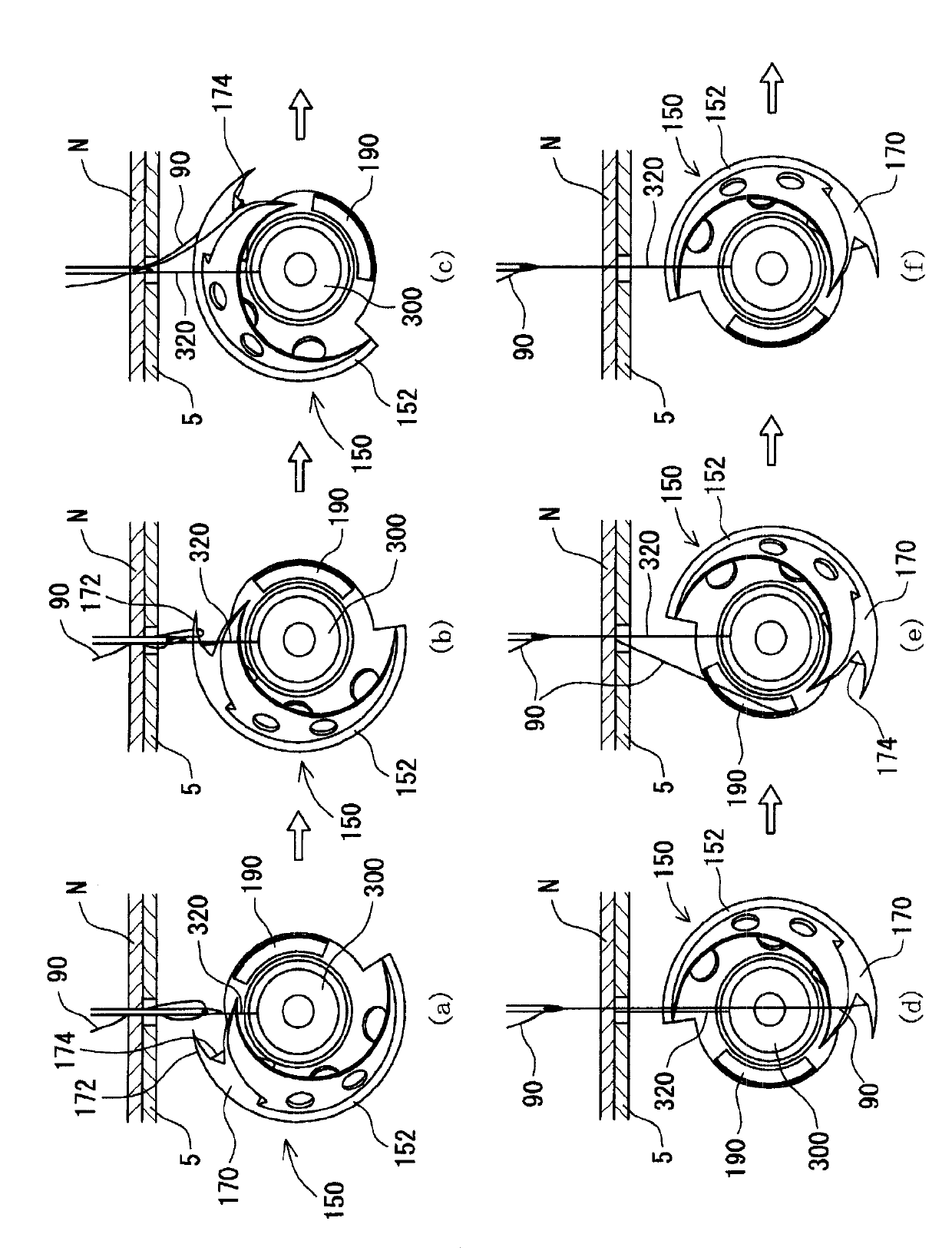

Lower-thread tension control device for sewing machine, and sewing machine

A lower-thread tension control device for a sewing machine, capable of finely and accurately controlling the tension of a lower thread without relying on frictional force. A lower-thread tension control device for a sewing machine comprises an outer shuttle (110), a middle-shuttle presser (130), a middle shuttle (150), a lower-thread tension control mechanism (200), a shuttle driving section (250), and a bobbin (300). A magnet section (190) is provided to the middle shuttle (150). A magnet section (270) is provided close to the magnet section (190), to an arm (260) provided to the rotating shaft of a shuttle driving motor (252) of the shuttle driving section (250). The middle shuttle (150) is rotated by rotating the magnet section (270) by means of the motor (252). Also, a magnet section (214) is provided to a rotating disc (210) which is provided to the rotating shaft of a lower-thread tension controlling motor (202) of the lower-thread tension control mechanism (200) so as to be close to the middle shuttle (150). A magnet section is provided to a portion of the bobbin (300), said portion being located on the rotating disc (210) side, and the bobbin (300) is rotated by the motor (202).

Owner:NSD

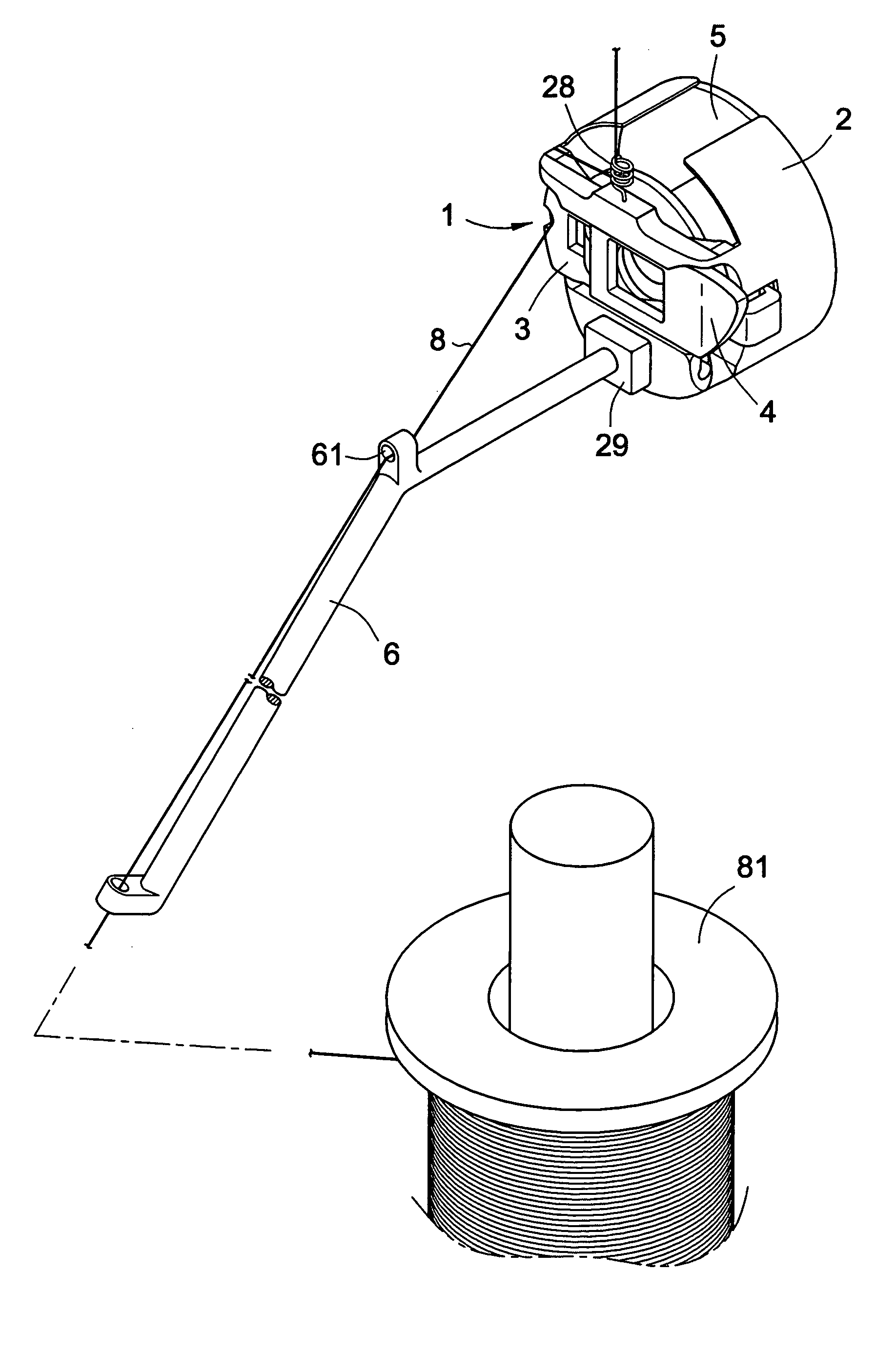

Automatic bottom shuttle replacing device

The invention discloses an automatic bottom shuttle replacing device which comprises a bobbin case taking mechanism and a bobbin taking mechanism, wherein the bobbin case taking mechanism is used for grabbing a bobbin case, and the bobbin taking mechanism is used for taking out a bobbin from the bobbin case and winding a new bottom line on the bobbin. When the bobbin taking mechanism takes out the bobbin from the bobbin case, a connecting line between the bobbin case and the bobbin is cut off by the aid of a line cutting mechanism, a residual line on the bobbin case is reserved, the new bottom line is connected with the residual line on the bobbin case by the aid of a connecting mechanism after the new bottom line is completely wound on the bobbin, and the bobbin is placed into the bobbin case by the bobbin taking mechanism to serve as a spare part.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

Sewing machine bottom line early warning device and early warning method thereof

InactiveCN103498302AReduce labor intensityEasy to transformBobbin-winding devicesBobbinUltimate tensile strength

The invention relates to an early warning method of a sewing machine bottom line early warning device. The sewing machine bottom line early warning device is designed for solving the technical problem that an existing similar product is inconvenient in bottom line early warning, poor in effect and higher in manufacturing cost. The early warning device comprises sensors, an audible-visual alarm and a controller. The key design points of the early warning device are that the sensors comprise the first sensor for monitoring the rotation speed of a main machine in a sewing machine and the second sensor for monitoring the angular speed of a bobbin in the sewing machine, and the controller is used for receiving signals acquired by the first sensor and the second sensor, controlling the main machine in the sewing machine to rotate and controlling the audible-visual alarm to warn early. The angular speed of the bobbin can be sensed by the second sensor to reach the safe angular speed in early warning and achieve early warning operation. The sewing machine bottom line early warning device is little in change on an existing sewing machine and low in manufacturing cost, uses intelligent control to reduce product reject rate, effectively reduces labor intensity of operators, reduces labor and is suitable for sewing machine bottom line early warning operation or improving structures of similar products.

Owner:胡贤郎

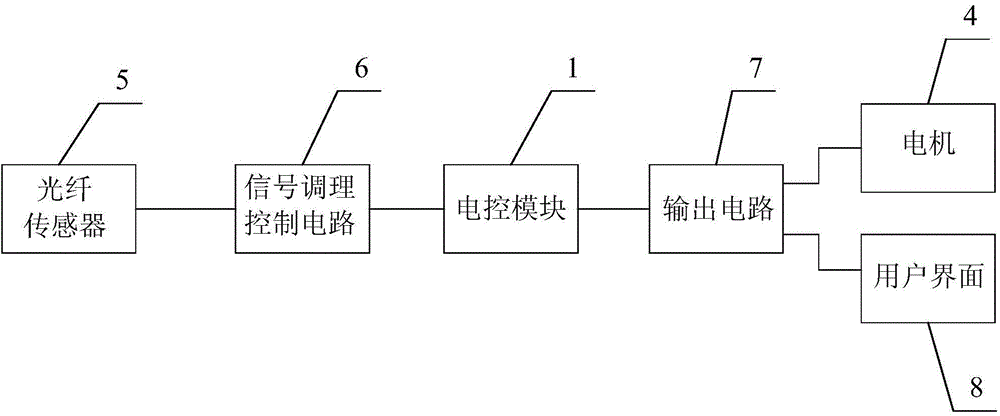

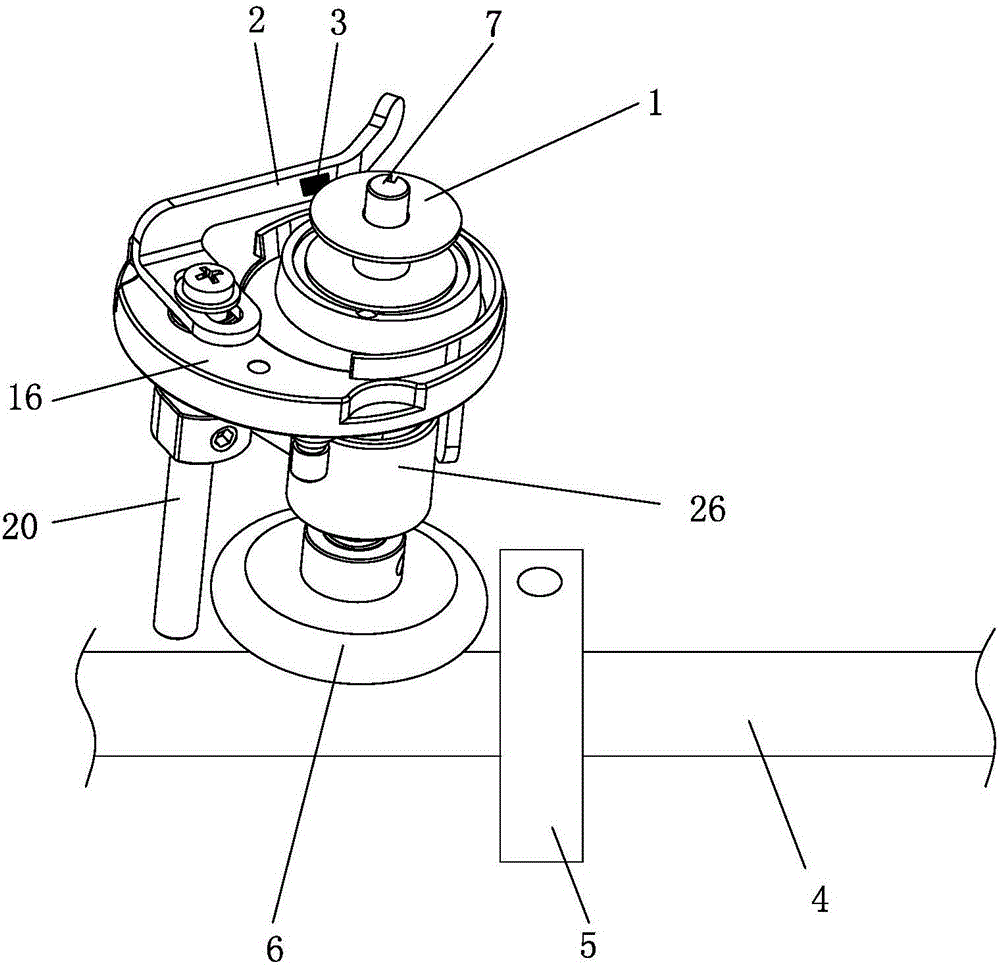

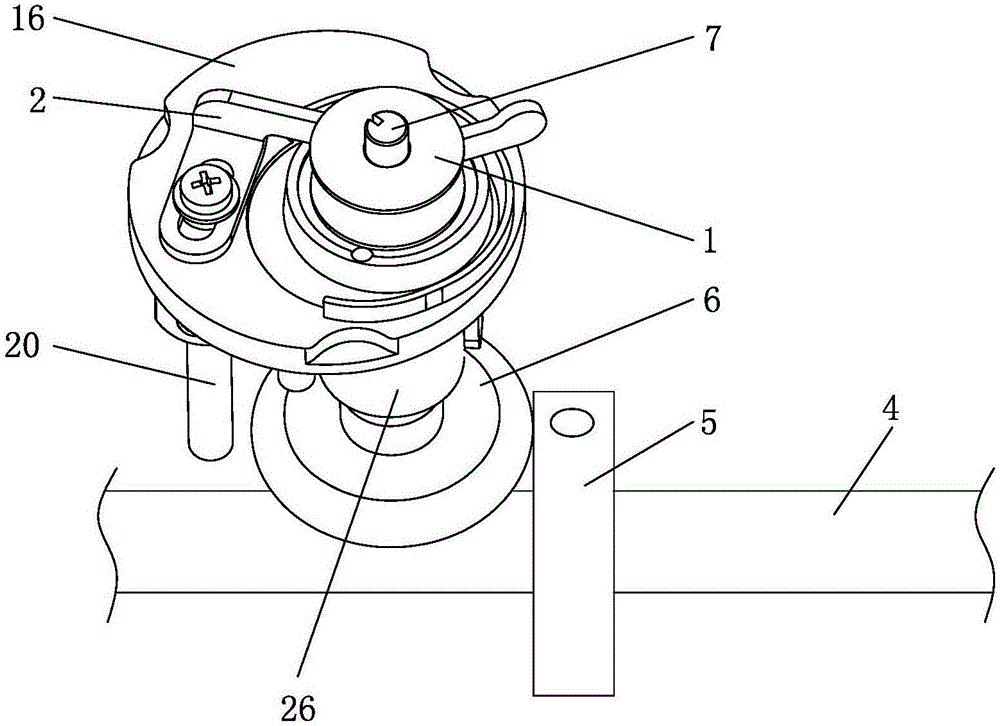

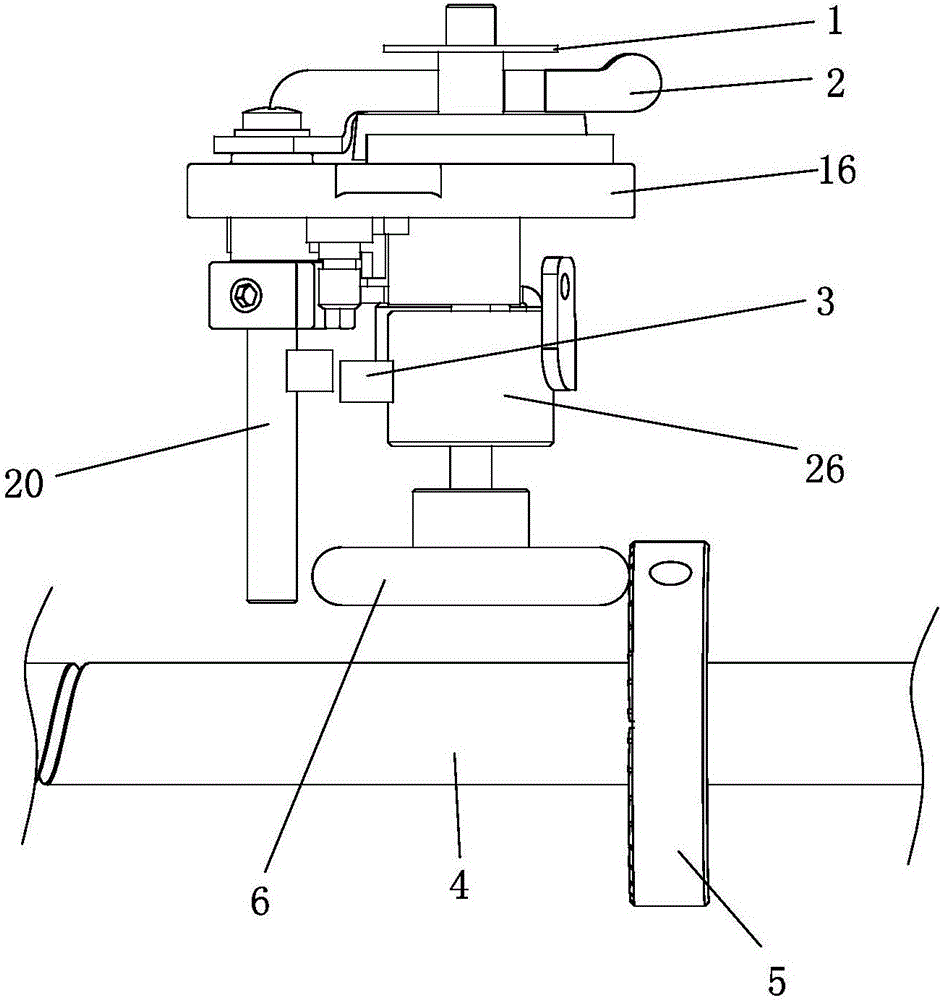

Bottom wire detection control system and method based on optical fiber sensor and applied to industrial sewing machine

ActiveCN104372538AImprove detection accuracyGuaranteed reliabilityBobbin-winding devicesLoop takersBobbinEngineering

The invention provides a bottom wire detection control system based on an optical fiber sensor and applied to an industrial sewing machine. The system comprises an electric control module, a rotating shuttle and a motor. The rotating shuttle comprises a shuttle case and a shuttle core. The shuttle core comprises a winding post and flanges arranged at the two ends of the winding post. A reflective sheet is fixed to the outer circumferential face of the winding post, and bottom wires are wound around the winding post. The optical fiber sensor is fixed to a shuttle support. The shuttle case is provided with an optical fiber emitter inlet and a gap, wherein the optical fiber emitter inlet and the gap are communicated with each other. The optical fiber sensor is connected with the electric control module through a signal conditioning control circuit. The electric control module is also connected with the motor through an output circuit. The bottom wire detection control system applied to the industrial sewing machine can judge whether the shuttle core is not installed in the shuttle case and whether the bottom wires on the shuttle core are enough according to optical signals of reflected light detected by the optical fiber sensor; meanwhile, the optical fiber sensor is adopted as a detection element, so that the system is high in sensitivity, higher and more reliable in detection performance and higher in anti-electromagnetic-interference capability.

Owner:BULLMER ELECTROMECHANICAL TECH

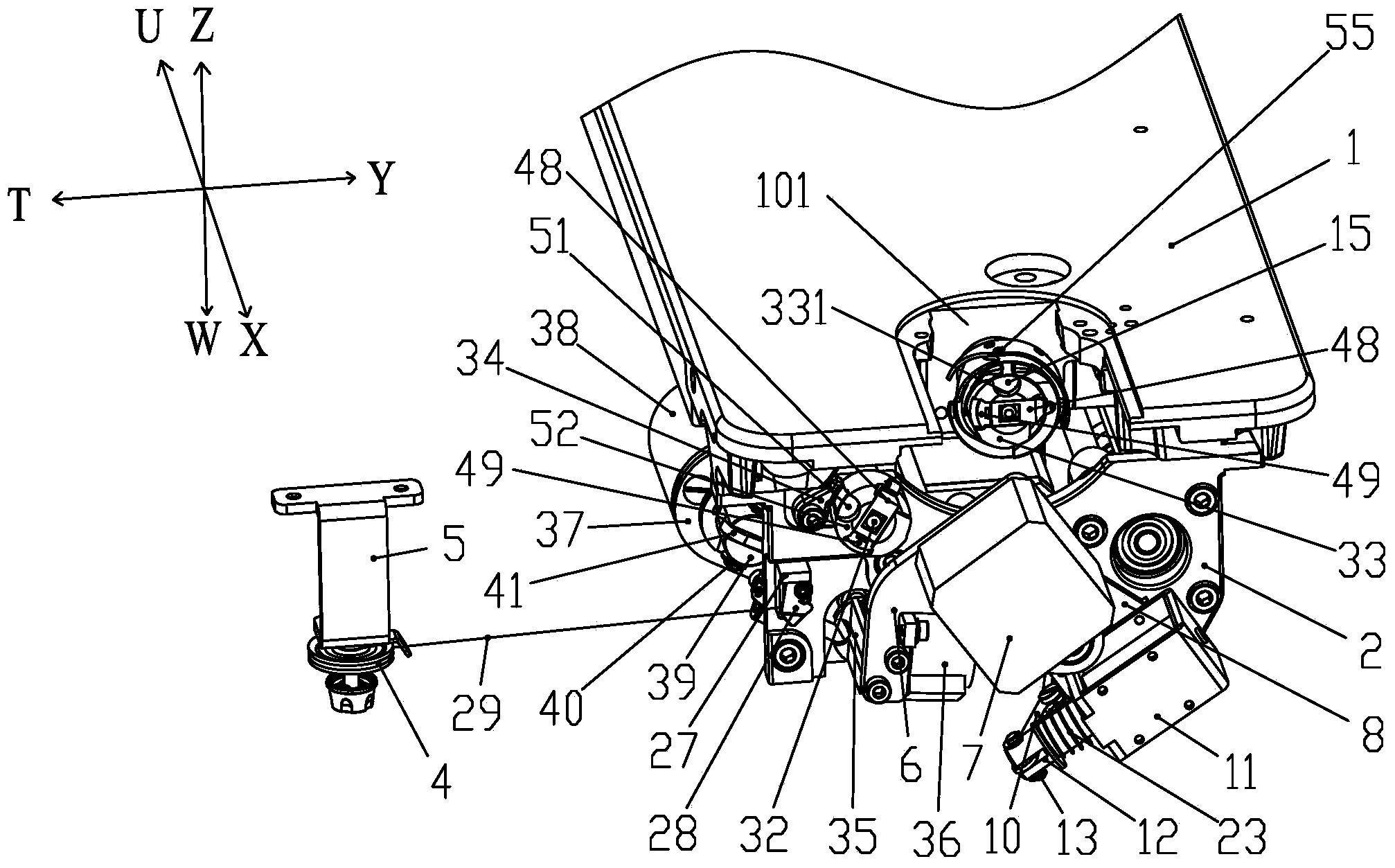

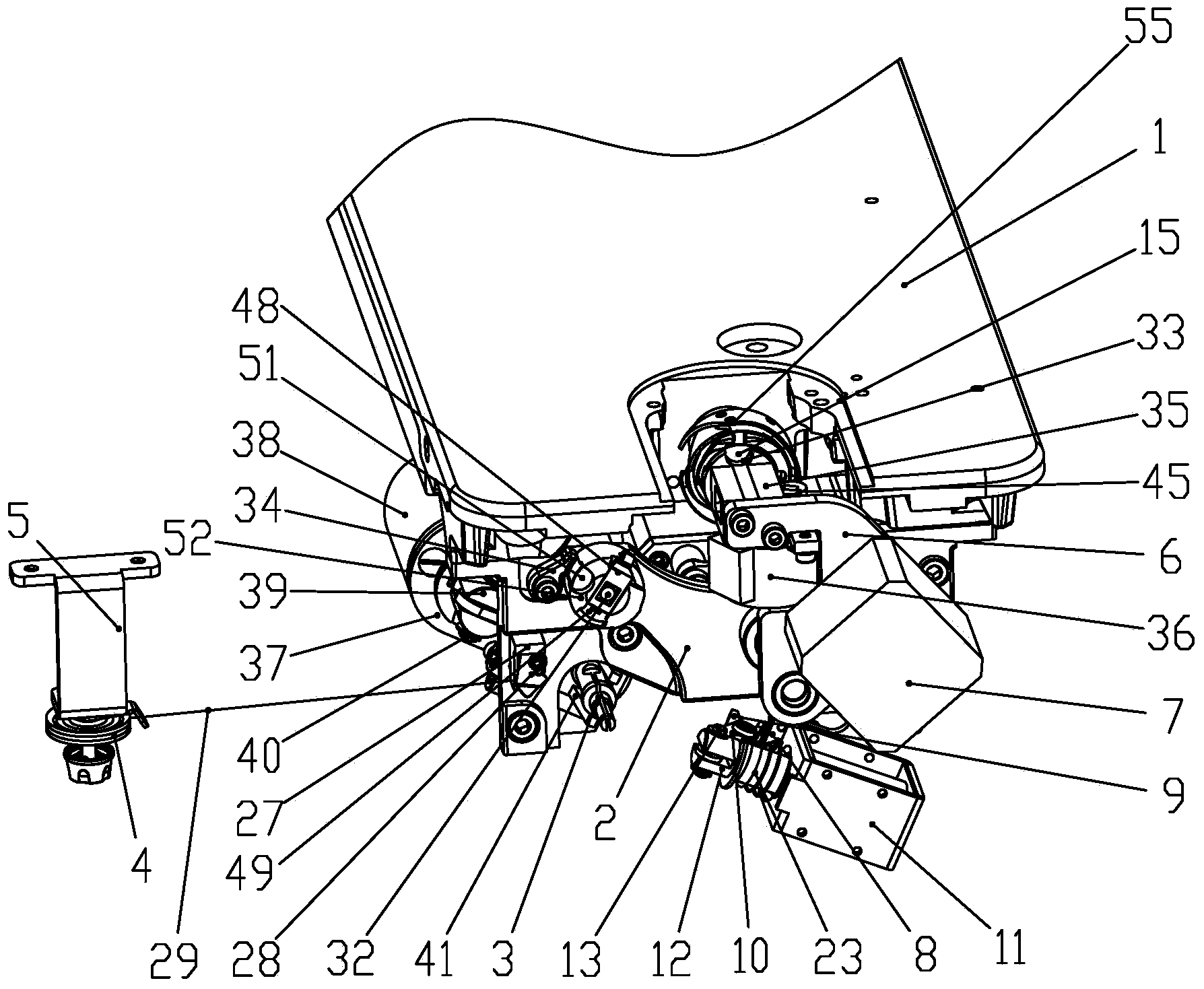

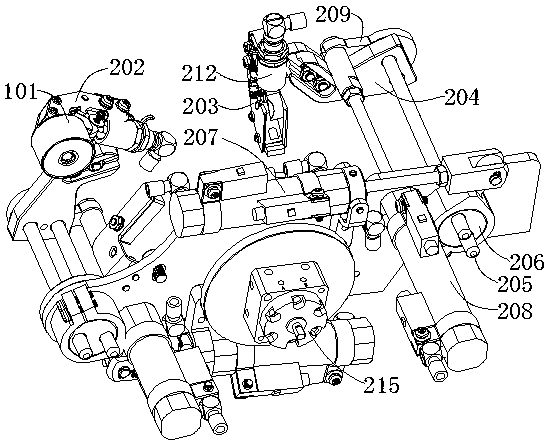

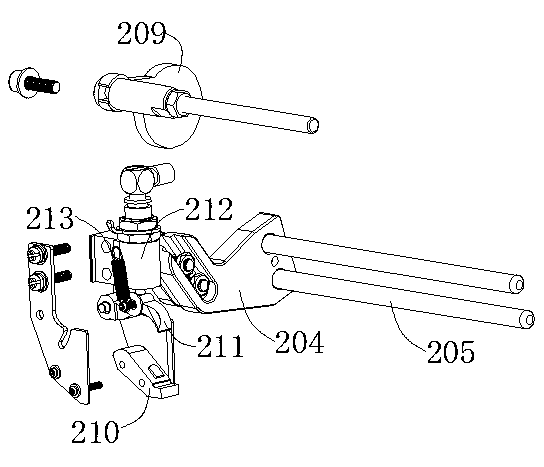

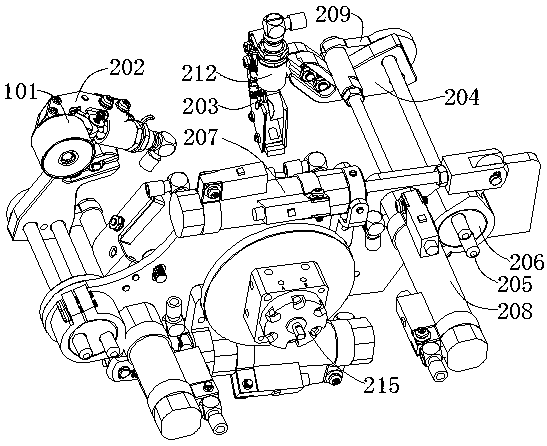

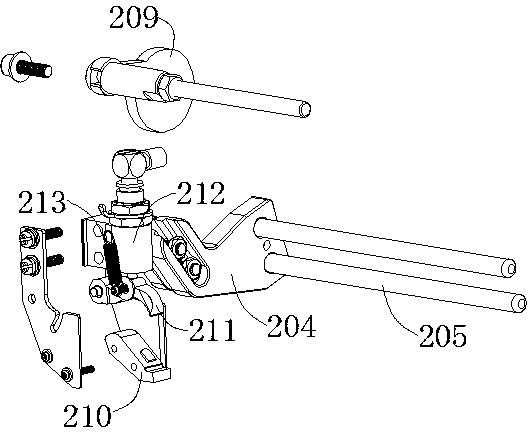

Automatic shuttle replacement device and method and sewing machine

ActiveCN108221203AHigh degree of automationImprove sewing efficiencyBobbin-winding devicesBobbinDrive wheel

The invention provides an automatic shuttle replacement device for replacing a first shuttle with the insufficient allowance of threads and a first shuttle case. The automatic shuttle replacement device comprises a main board, a shuttle case limiting shaft, a shuttle grabbing mechanism, a shuttle remaining thread removal mechanism, a shuttle winding and threading mechanism and a thread cutting mechanism, wherein the shuttle case limiting shaft is sleeved with a second shuttle wound by threads sufficiently and a second shuttle case; the shuttle grabbing mechanism comprises a hook claw base, a shuttle grabbing driving source and a shuttle grabbing hook claw, the shuttle grabbing hook claw is used for hooking a shuttle case plate on the first shuttle case or the second shuttle case; the shuttle remaining thread removal mechanism comprises a fixing shaft, a driving wheel unit and a driven wheel unit which are installed on the main board, and a thread clamping space; the shuttle and windingthreading mechanism comprises a winding shaft and a clamping base, a clamping interval and an interval inlet are formed in the clamping base; the cutting mechanism comprises a thread cutting edge arranged on the clamping base. The second shuttle wound by threads sufficiently and the second shuttle case can be replaced in a rotating shuttle, and automatic remaining thread removal, winding, threading and cutting can be performed on the replaced first shuttle and the second shuttle case, so that the automatic degree is quite high, and then the sewing efficiency is greatly improved.

Owner:JACK SEWING MASCH CO LTD

Sewing machine

InactiveCN1485488ASewing-machine casingsNeedle severing devicesTop dead centerBiomedical engineering

A sewing machine includes a supporting plate portion and a needle. The supporting plate portion contacts sewing fabric that is moved in a predetermined direction during a sewing operation. The needle is vertically moved between a top dead center above the supporting plate portion and a bottom dead center below the supporting plate portion. The supporting plate portion has a needle hole through which the needle passes. The lower end opening of the needle hole is larger than the upper end opening.

Owner:HASHIMA

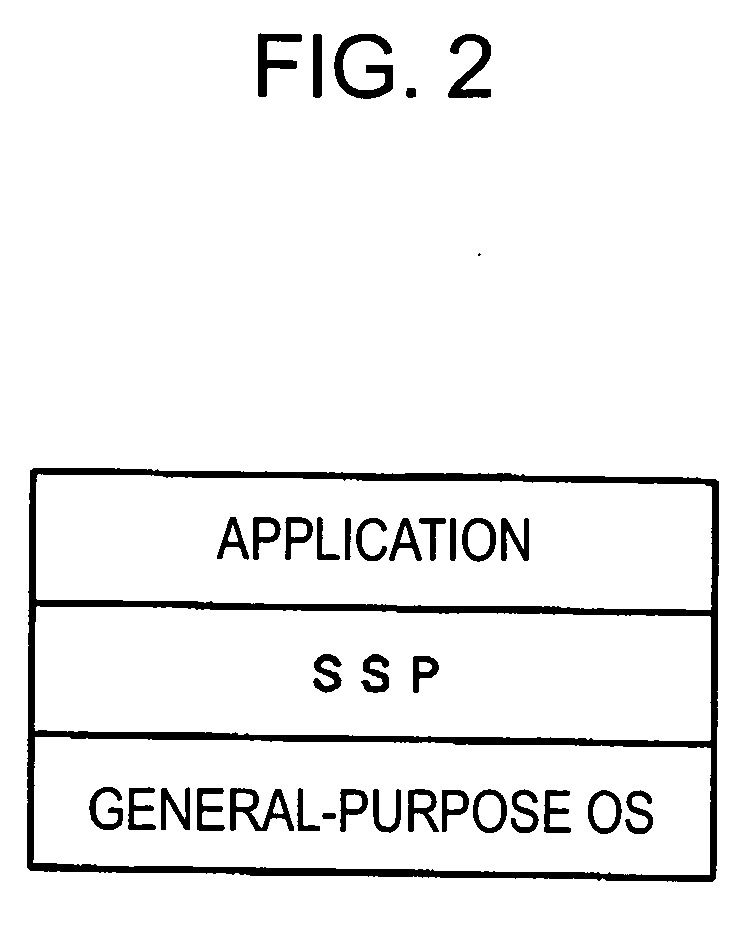

Signal processing apparatus

InactiveUS20060218525A1No increase in signal processing delayAvoid problemsInterprogram communicationSpeech analysisComputer hardwareManagement unit

A signal processing apparatus for performing signal processing including a plurality of steps in data units by means of software signal processing includes signal processing modules performing the steps, a circuit configuration information storing and managing unit storing the signal processing modules and circuit configuration information, a signal processing order determining unit determining a signal processing order by performing path routing, a signal processing executing unit executing the signal processing in the determined order, and a circuit configuration changing unit changing circuit configuration information and causing the signal processing order determining unit to re-execute path routing to determine a signal processing order for the changed circuit configuration information during a period from the end of the software signal processing in the data unit to the beginning of the subsequent data unit. Software signal processing from the beginning of the subsequent data unit is performed with the changed circuit configuration.

Owner:SONY CORP

Intelligent full-automatic bobbin line winding machine

ActiveCN103320993ASimple structureReduce manufacturing costBobbin-winding devicesEmbroidering machines apparatusWinding machineBobbin

The invention relates to an intelligent full-automatic bobbin line winding machine which comprises a base, a hollow bobbin conveying mechanism, a line winding motor, a driving motor, a line leading frame, a bobbin mounting and demounting mechanism, a line shearing mechanism, an intelligent control mechanism and a discharging disc. A tensioning device is arranged on the end portion of a rotary shaft of the line winding motor. The intelligent full-automatic bobbin line winding machine is mainly characterized in that the bobbin mounting and demounting mechanism comprises a sliding plate, a mounting plate, a line hanging gear and a bunker port, the sliding plate and the mounting plate are movably mounted on a sliding rail, the back of the sliding plate is connected with a rotary shaft of the driving motor through a push-pull rod, the line hanging gear is mounted on the sliding plate, the bunker port is fixed on the mounting plate, a driving motor sensing switch is arranged in the bunker port, a line winding motor control switch is mounted on one side of the bunker port, the other side of the bunker port is communicated with a discharging sensing switch mounted at the outer edge of the discharging disc in a passage direction, line winding motor shaft holes are formed in the mounting plate, and the line hanging gear is provided with an in-place delayed returning device. The intelligent full-automatic bobbin line winding machine has the advantages of simple structure, low manufacturing cost and the like and is suitable for textile equipment like sewing machines and embroiderers.

Owner:JINAN SUNRISE CNC MACHINE

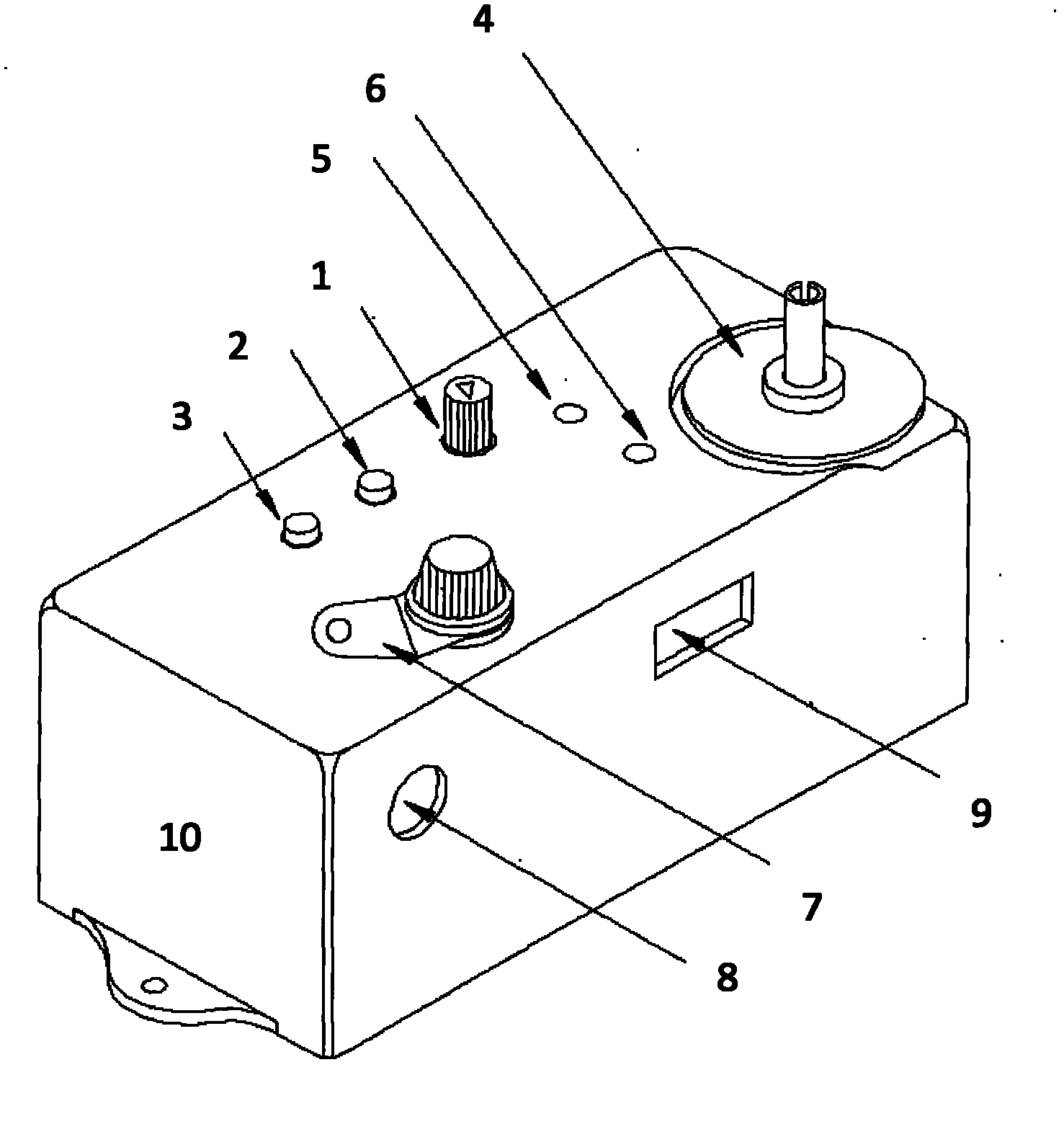

Intelligent industrial sewing electronic bobbin winder

The invention relates to a bobbin winder, in particular to an intelligent industrial sewing electronic bobbin winder which is controlled by a single chip microcomputer and can be start and pause in real time. The invention adopts the technical scheme that the intelligent industrial sewing electronic bobbin winder comprises a shell, a winder and a yarn trapper. The winder and the yarn trapper are located at two sides of the shell. The intelligent industrial sewing electronic bobbin winder is characterized in that the intelligent industrial sewing electronic bobbin winder further comprises the single chip microcomputer, a switching power supply, a minitype DC (Direct Current) motor, a circuit board, a power interface, an indicator lamp, a switch button and an adjustable potentiometer; the single chip microcomputer, the circuit board, the switching power supply and the minitype DC motor are arranged inside the shell; the power interface, the indicator lamp, the switch button and the adjustable potentiometer are arranged at the outer part of the shell; the single chip microcomputer, the power interface, the indicator lamp, the switch button, the adjustable potentiometer and the switching power supply are respectively electrically connected with the circuit board; and the switching power supply is electrically connected with the minitype DC motor which is connected with the winder and drives the winder to rotate.

Owner:宁波宇杰电子科技有限公司

Novel barrel type sewing machine

ActiveCN107043999ASolve the problem of instability and affecting the quality of sewingStable stitchLubrication/cooling devicesWork-feeding meansLocking mechanismEconomic benefits

The invention relates to the technical field of sewing devices, in particular to a novel barrel type sewing machine. The novel barrel type sewing machine includes a sewing machine body, an oil tan, and a fabric feeding mechanism, a stitch length locking mechanism, a pre-winding device, a dual-clamping machine, and an automatic lubrication system which are arranged on the sewing machine body; the fabric feeding mechanism includes a lower shaft, a tooth lifting cam, a tooth lifting fork, a tooth lifting shaft, a fabric feeding tooth guide rack, a fabric feeding tooth guide rack slide block, a fabric feeding tooth support, a fabric feeding tooth support shaft, a fabric feeding support slide block, and a fabric feeding tooth support positioning plate; the stitch length locking mechanism includes a stitch length button, a locking pin and a locking pin spring; and the pre-winding device includes a base, a winding shuttle core, a shuttle core shaft, a cutter, a shuttle core seat, a winding positioning wheel, a friction wheel, a winding positioning hook, and a limiting adjustment wrench which are fixed on the sewing machine body. The mechanical structure of the conventional sewing machine is changed, the automatic lubrication system is added, the performance of the sewing machine is fully improved, and the novel barrel type sewing machine has good application prospect and economic benefits.

Owner:TYPICAL SEWING MACHINE WANPING MACHINERY

Wire-guiding structure of a shuttle of a sewing machine

InactiveUS20050279265A1Increase supplyEasily woundBobbin-winding devicesCoils manufactureEngineeringConductor Coil

A wire-guiding structure of a shuttle of a sewing machine is disclosed. One end surface of the shuttle is formed with a wire-receiving hole for supplying wire continuously. A wire for seaming is supplied to an interior of the shuttle from an external larger scale wire-winding and the wire is wound around the wire-winding wheel for outputting. It is unnecessary to update the shuttle so as to increase the finishing efficiency. Furthermore, the end surface of the shuttle is installed with a wire-guiding rod for guiding wire successfully so that the wire can run along a predetermined path efficiently. Thus wire can be supplied successfully. Moreover, a wire-winding wheel is installed in the shuttle so that wire will be easily wound around the wire-winding wheel smoothly. Thus wire is supplied to the sewing machine successfully.

Owner:CHIEN CHIH I

Method for detecting baseline margin of sewing machine

ActiveCN105821596AImprove detection accuracyImprove reliabilityBobbin-winding devicesBobbinComputer module

The invention provides a method for detecting a baseline margin of a sewing machine. The method successively comprises the steps that a residual baseline wound on a wrapping pillar drives a bobbin to rotate, and the bobbin drives multiple sensed parts on a flange to rotate synchronously; a sensor senses the sensed part exposed from a through hole of a bobbin sleeve and then outputs a pulse signal, wherein the pulse signal is formed by high levels and low levels which are distributed at intervals; an electric control module of the sewing machine receives the pulse signal from the sensor and detects a level frequency of the pulse signal; when the level frequency of the pulse signal increases, the electric control module can determine that the baseline margin on the wrapping pillar is enough and can control a main motor of the sewing machine to continue rotating; and when the level frequency of the pulse signal decreases, the electric control module determines that the baseline margin on the wrapping pillar is insufficient and controls the main motor of the sewing machine to stop rotation. According to the application, whether the baseline margin on the bobbin is enough is determined according to rotation speed changes of the bobbin. The method has the advantages of very high detection accuracy and high reliability.

Owner:JACK SEWING MASCH CO LTD

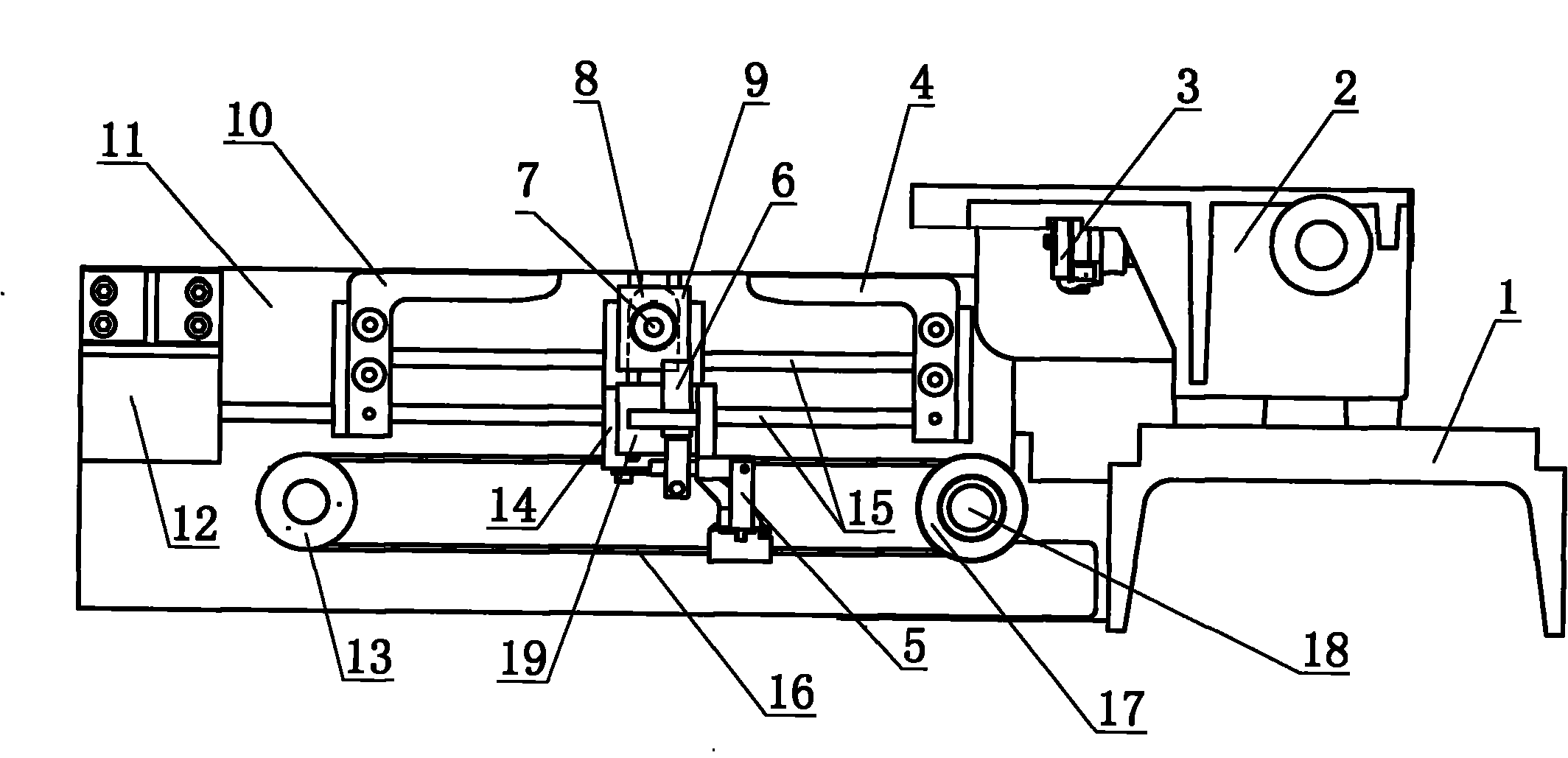

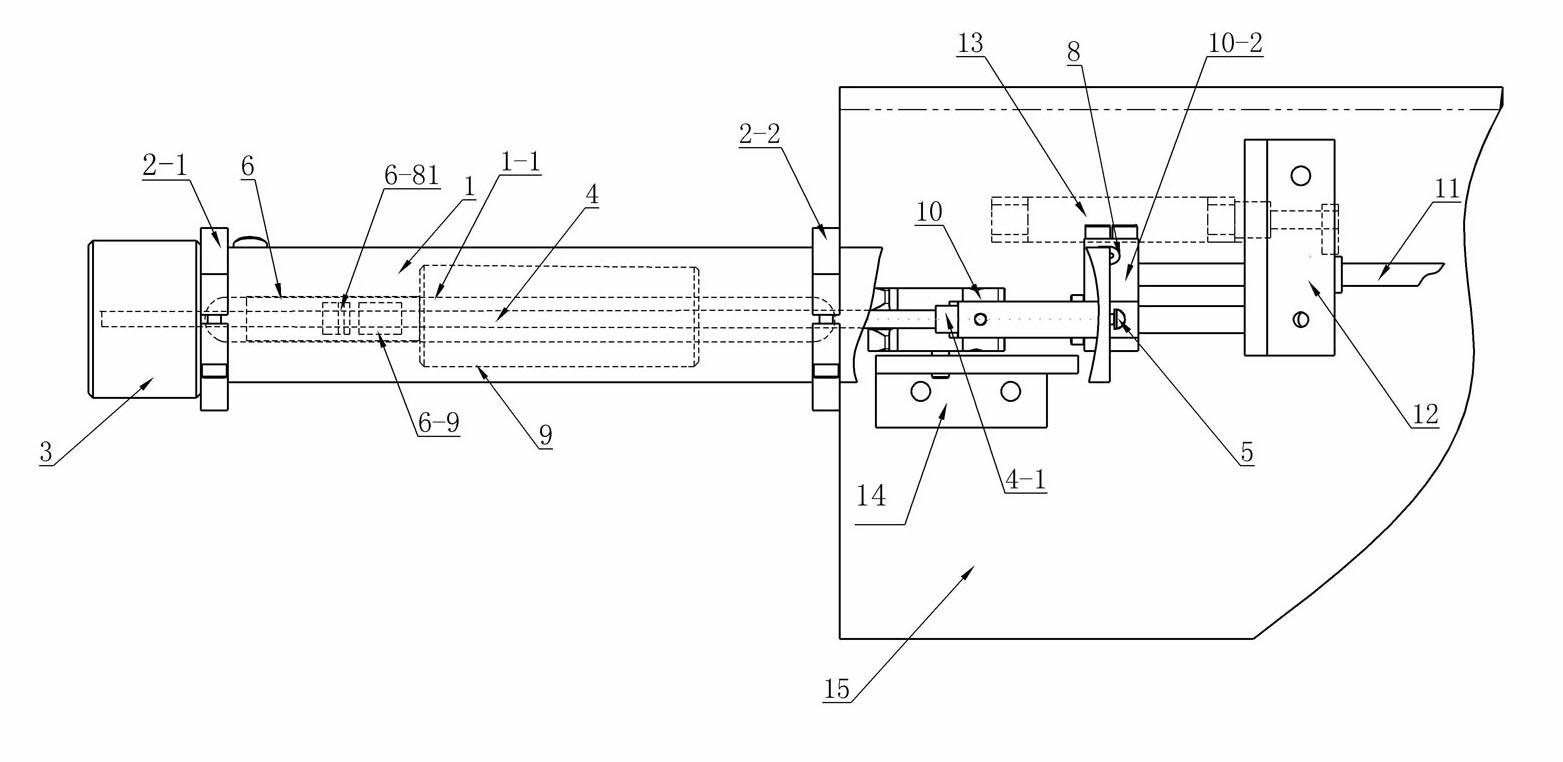

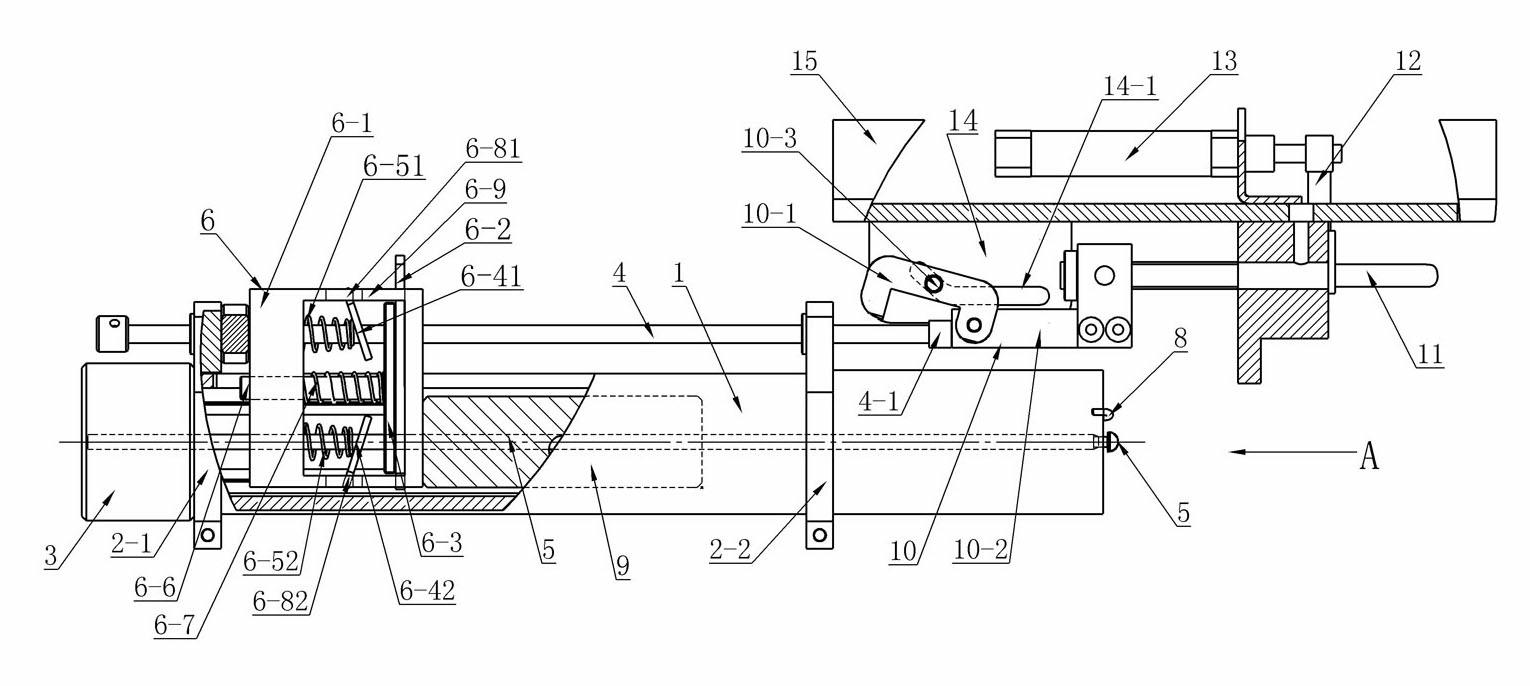

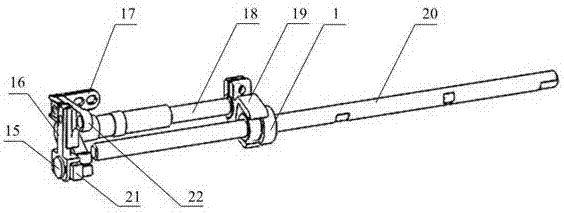

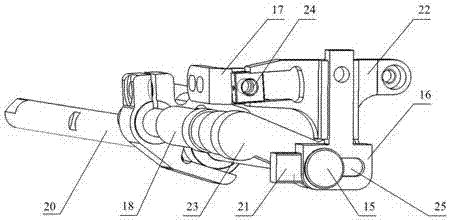

Thread winding and threading mechanism and method for cop latches and sewing machine

The invention provides a thread winding and threading mechanism for cop latches. The mechanism comprises a main plate with the fixed position, a winding shaft which is driven by a winding driving source to rotate and used for fixing the first cop latch, a thread clamping base which is driven by a thread clamping driving source to rotate and a shuttle grabbing hook claw which is driven by a shuttlegrabbing driving source to rotate and used for grabbing a first shuttle shell. The shuttle grabbing hook claw and the shuttle grabbing driving source are arranged on a hook claw base, the hook claw base can move in the axial direction of the first cop latch and is provided with a thread clamping gap and a gap inlet which is formed in one end of the thread clamping gap, the winding shaft and / or the thread clamping base can move in the axial direction of the first cop latch, and the winding shaft, the thread clamping base and the hook claw base can be supported by the main plate. According to the thread winding and threading mechanism for the cop latches, winding is achieved through cooperation of the winding shaft, the thread clamping base and the hook claw base, then threading is achievedaccording to a simplified manual threading track, winding and threading can be accurately conducted accordingly, and the mechanism does not need a mechanical arm and is simple in structure and easy to control.

Owner:JACK SEWING MASCH CO LTD

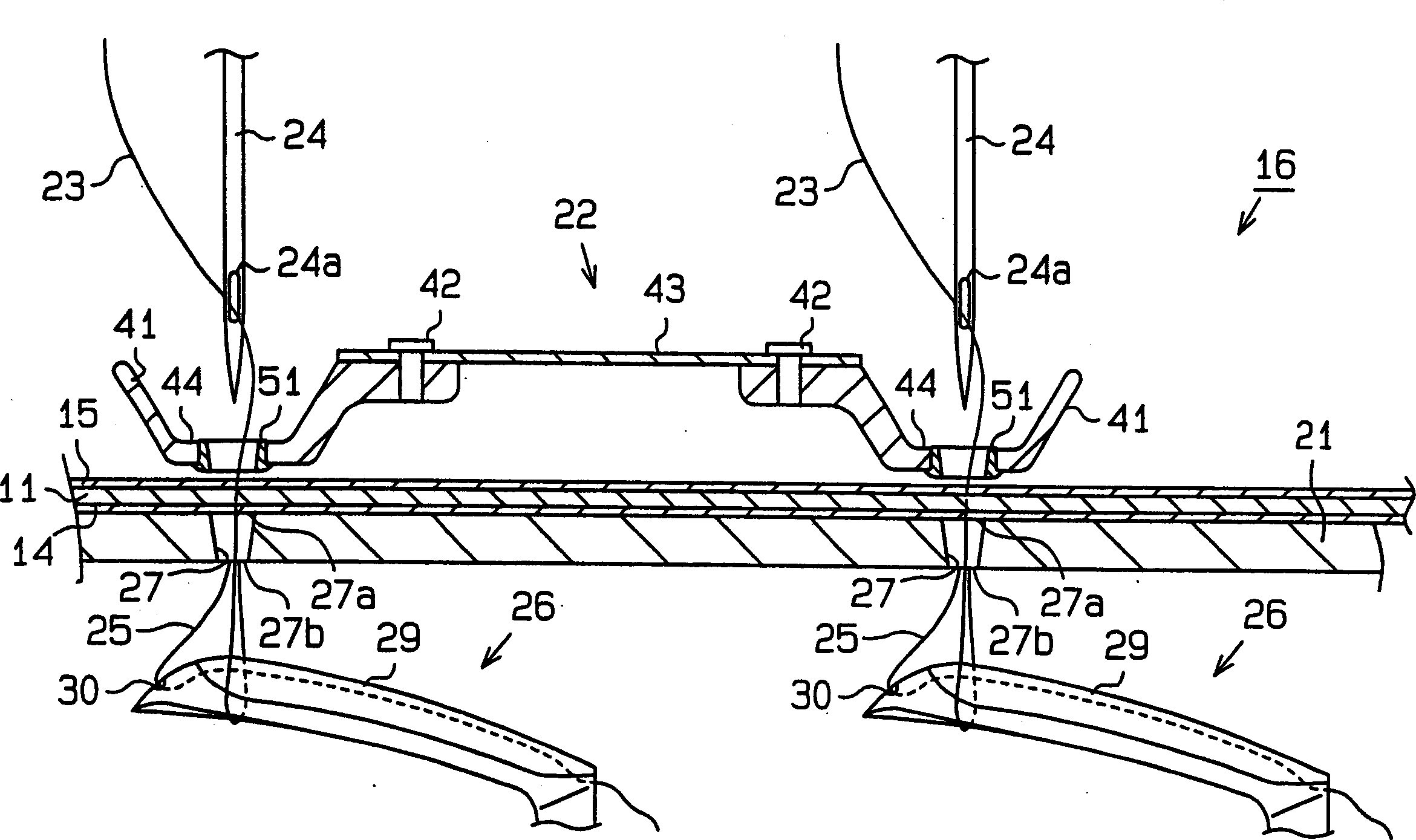

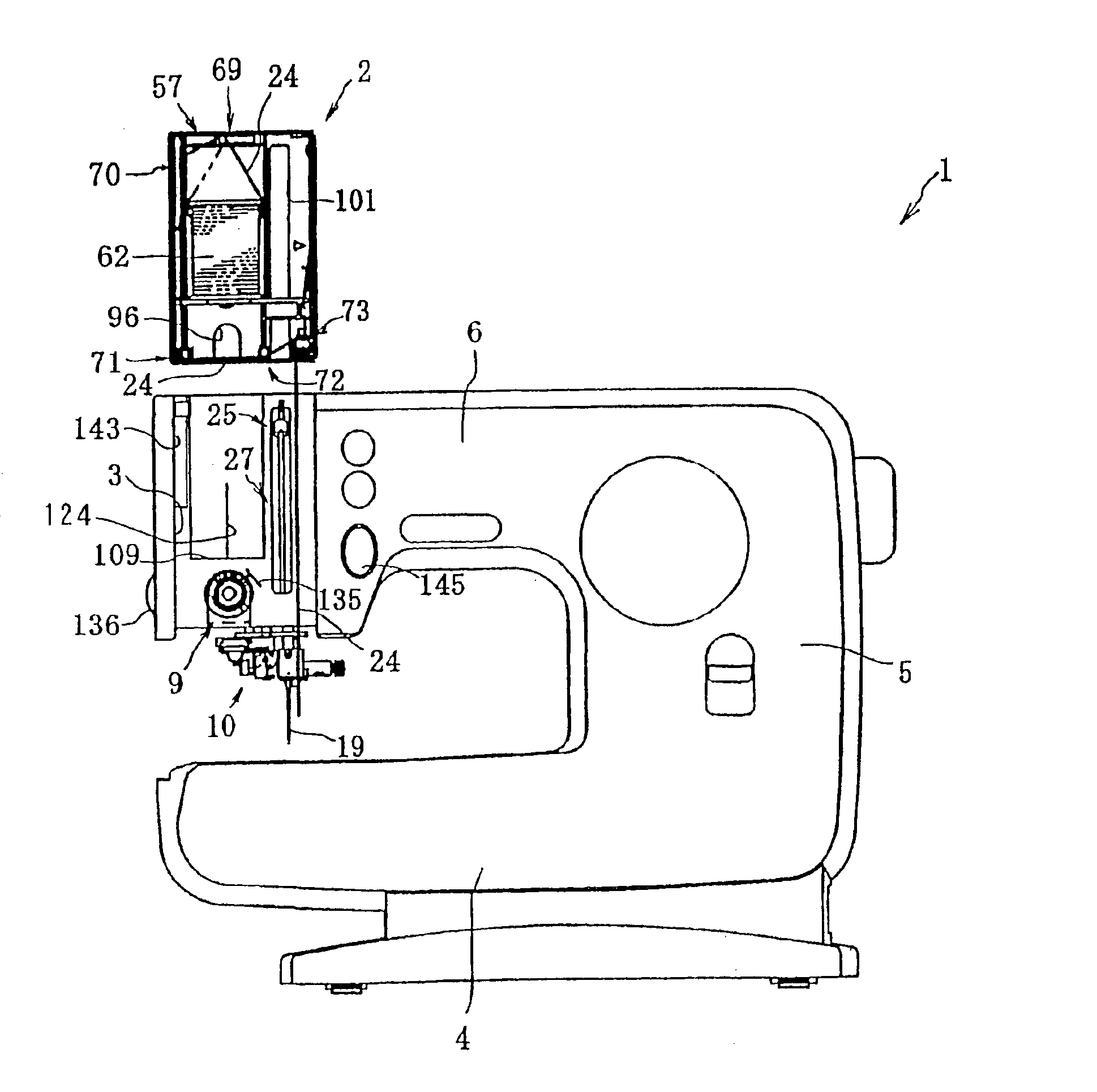

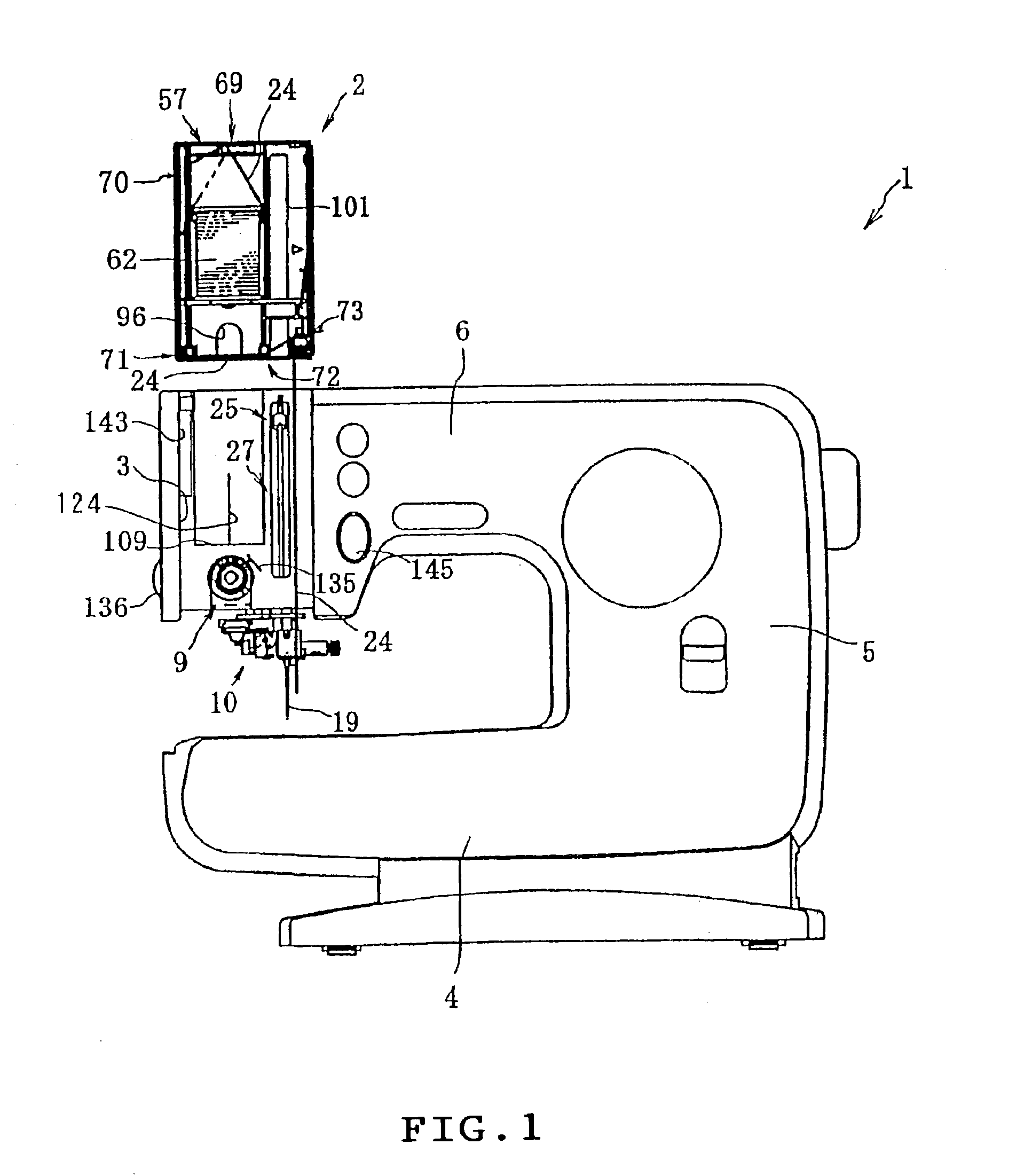

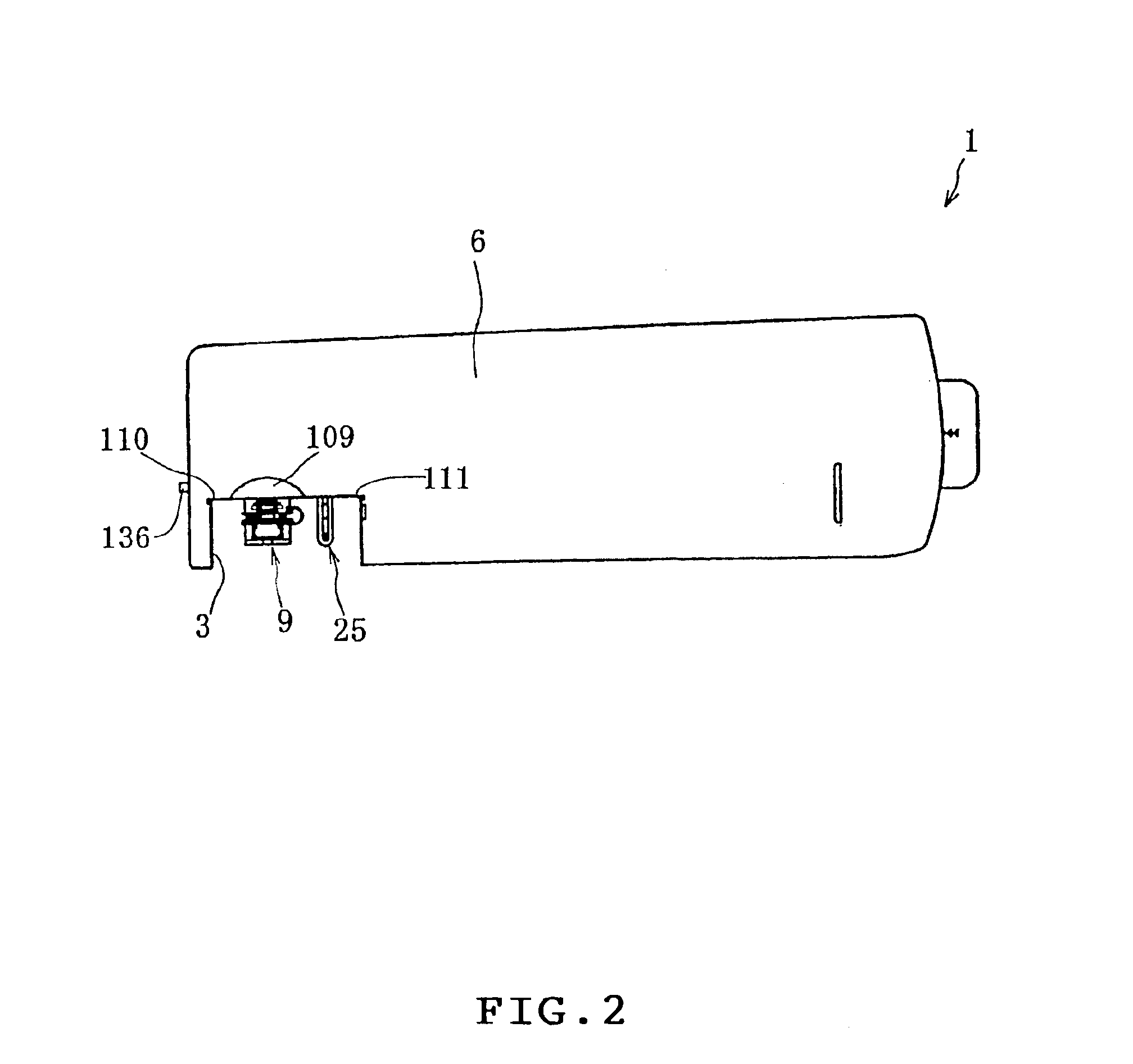

Sewing machine with needle thread cassette and needle thread cassette

InactiveUS6883447B1Improve handlingEasy to operateSewing-machine casingsFilament handlingBobbinEngineering

A sewing machine with a needle thread cassette, wherein a cassette mount (3) is reduced in size. The cassette mount (3) including a thread take-up lever travel region is formed in the form of a vertical groove in the arm head of the sewing machine. A needle thread cassette (2) having a thread bobbin (62) vertically received therein is removably mounted on the cassette mount (3) vertically from above. With a thread take-up lever (25) stopped in a position corresponding to a needle top stop position, the needle thread cassette (2) is mounted on the cassette mount (3), whereby the thread is engaged with the thread guard of the thread take-up lever (25) and a thread tension regulator (9).

Owner:BROTHER KOGYO KK

Method for automatically winding bottom line of bobbin

ActiveCN103643410ARealize the operationRaise the replacement bobbinBobbin-winding devicesBobbinElectric machinery

The invention discloses a method for automatically winding a bottom line of a bobbin. A bobbin case is provided with the bobbin. The method includes the steps: arranging a new bottom line to be wound outside a shaft hole of the bobbin, enabling the new bottom line to penetrate the shaft hole of the bobbin through a winding shaft, and fixing the new bottom wire into the shaft hole of the bobbin; taking out the bobbin from the bobbin case by moving the winding shaft, pulling the new bottom wire to be wound to a line winding surface of the bobbin through a line pulling hook, driving the winding shaft to rotate through a winding motor, and winding the new bottom line on the bobbin. The winding motor on a base is matched with the winding shaft, the bobbin can be automatically taken out, the line can be automatically wound, and the efficiency of replacing the bobbin and the bottom line is improved.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

Sewing machine bobbin thread residue detection device

InactiveCN106245247ARealize the alarmRealize early warningSewing-machine control devicesBobbin-winding devicesBobbinEngineering

Owner:JACK SEWING MASCH CO LTD

Shuttle peg replacing method

ActiveCN103643416ASave on caretaker operationsSolve the problem of manual threading on the bobbin caseBobbin-winding devicesBobbinEngineering

The invention discloses a shuttle peg replacing method. The shuttle peg replacing method comprises the steps of taking out a shuttle peg from a shuttle casing, pulling a connecting line between the shuttle casing and the shuttle peg to the position of a cutter blade to be cut off, reserving a remaining line on the shuttle casing, clamping the end of the remaining line on an elastic line clamping piece, removing the waste line on the shuttle peg and winding a new bottom line on the shuttle peg, connecting the end of the new bottom line to the end of the remaining line, and then installing the shuttle peg into the shuttle casing for standby. By adopting the shuttle peg replacing method, the shuttle peg taking, winding of the new bottom line, bottom line and remaining line connection and other operations are achieved automatically, accordingly the trouble that a specially-assigned person monitors the operation is avoided, and the labor cost is reduced.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

Bobbin taking mechanism of automatic shuttle replacing device

The invention discloses a bobbin taking mechanism of an automatic shuttle replacing device. The bobbin taking mechanism comprises a base capable of sliding forward and backward, a rotatable winding shaft and a winding motor connected with the winding shaft are arranged on the base, and a pneumatic sucker for adsorbing a bobbin is arranged on the winding shaft. The bobbin taking mechanism can automatically take out the bobbin from a bobbin case or place the bobbin with a wound new bottom line into the bobbin case under driving of the base, and a mounting plate is arranged on the base and driven by a first telescopic cylinder. When the bobbin is taken out, the pneumatic sucker can be driven to be close to the bobbin and suck the side wall of the bobbin, and bobbin clamping jaws can be driven to lock the side wall of the bobbin. When the bobbin is placed into the bobbin case, the bobbin clamping jaws are driven to open, and the pneumatic sucker is driven to eject the bobbin into the bobbin case.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com