Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

401 results about "Industrial sewing machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

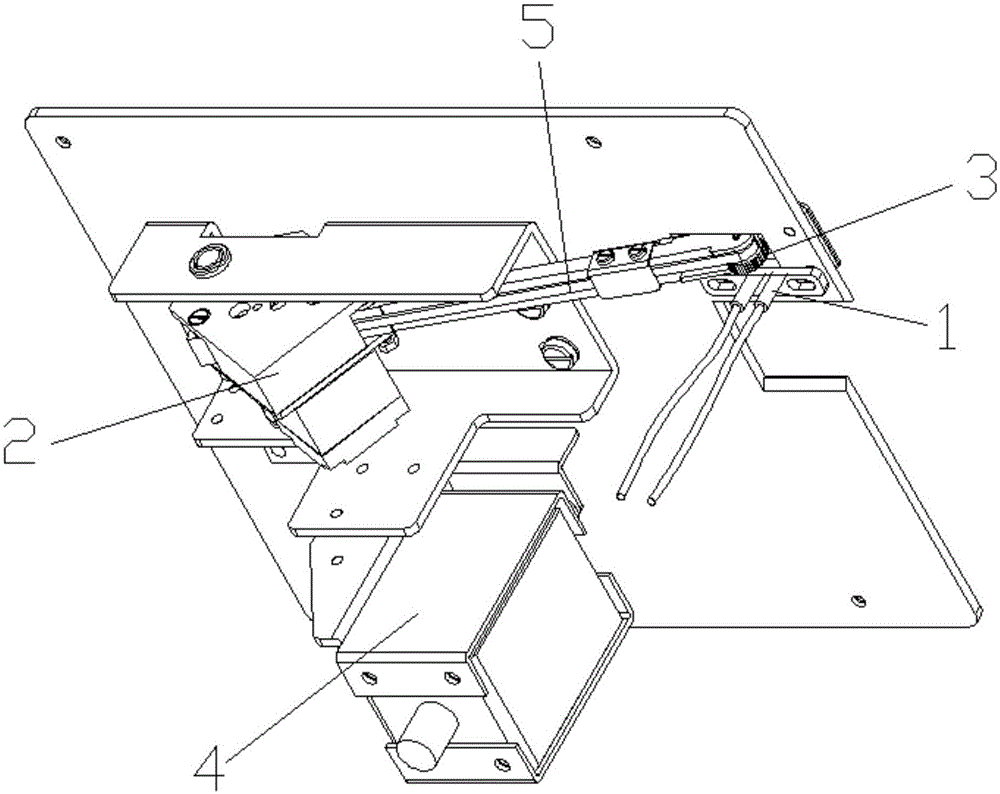

Intelligent sewing device and system

ActiveCN104018297ASewing precisionImprove work efficiencyProgramme-controlled sewing machinesSewing-machine control devicesHuman–computer interactionManipulator

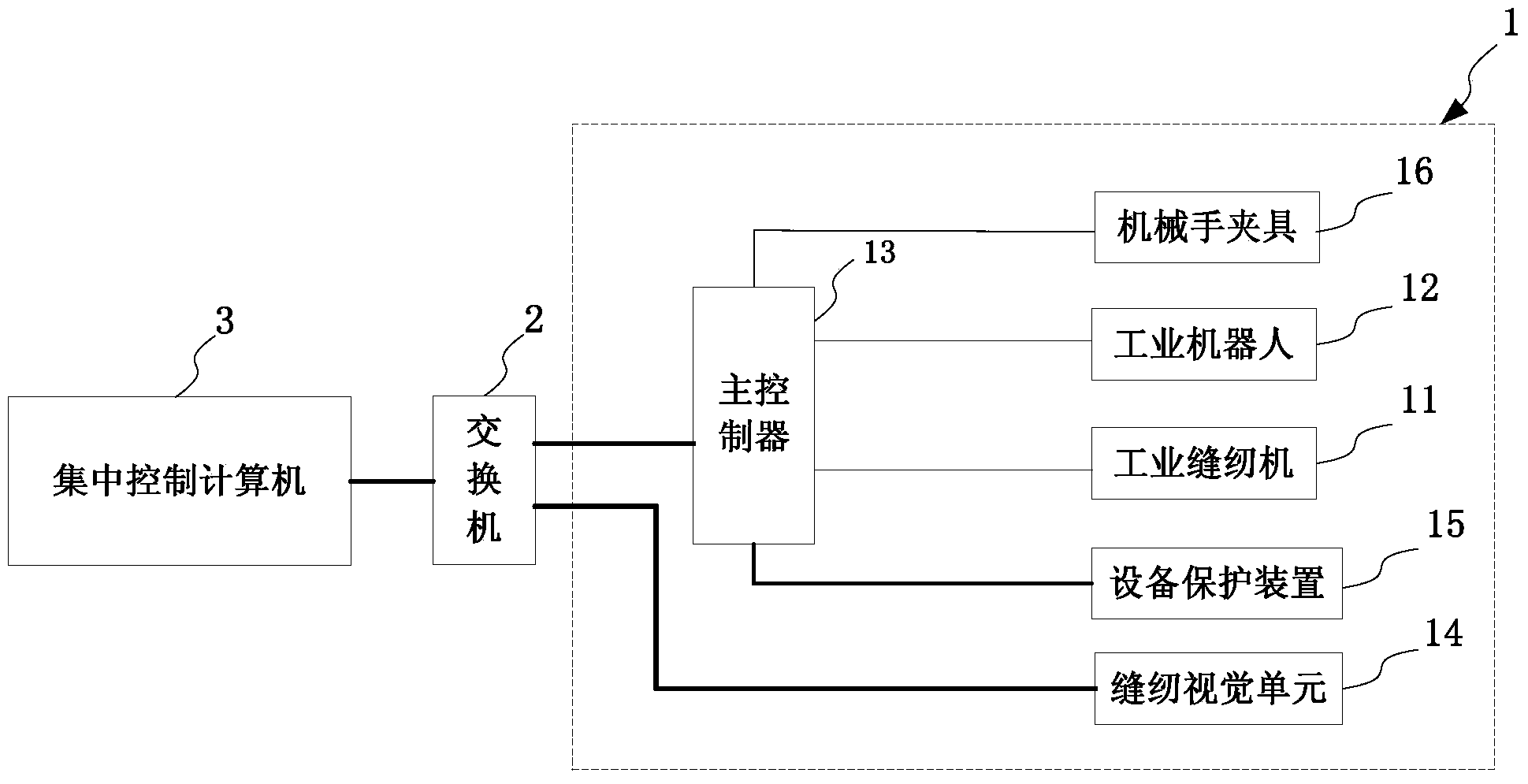

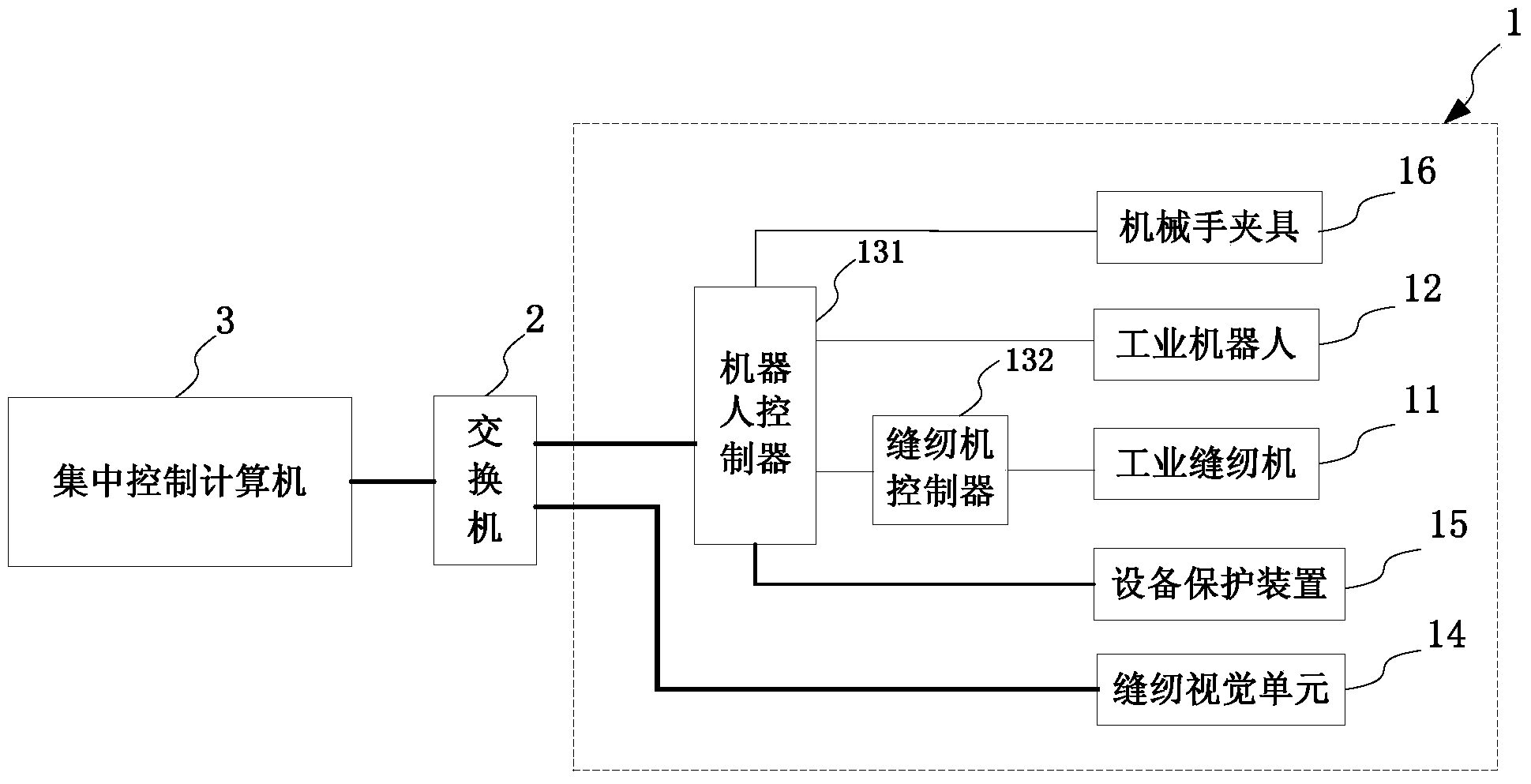

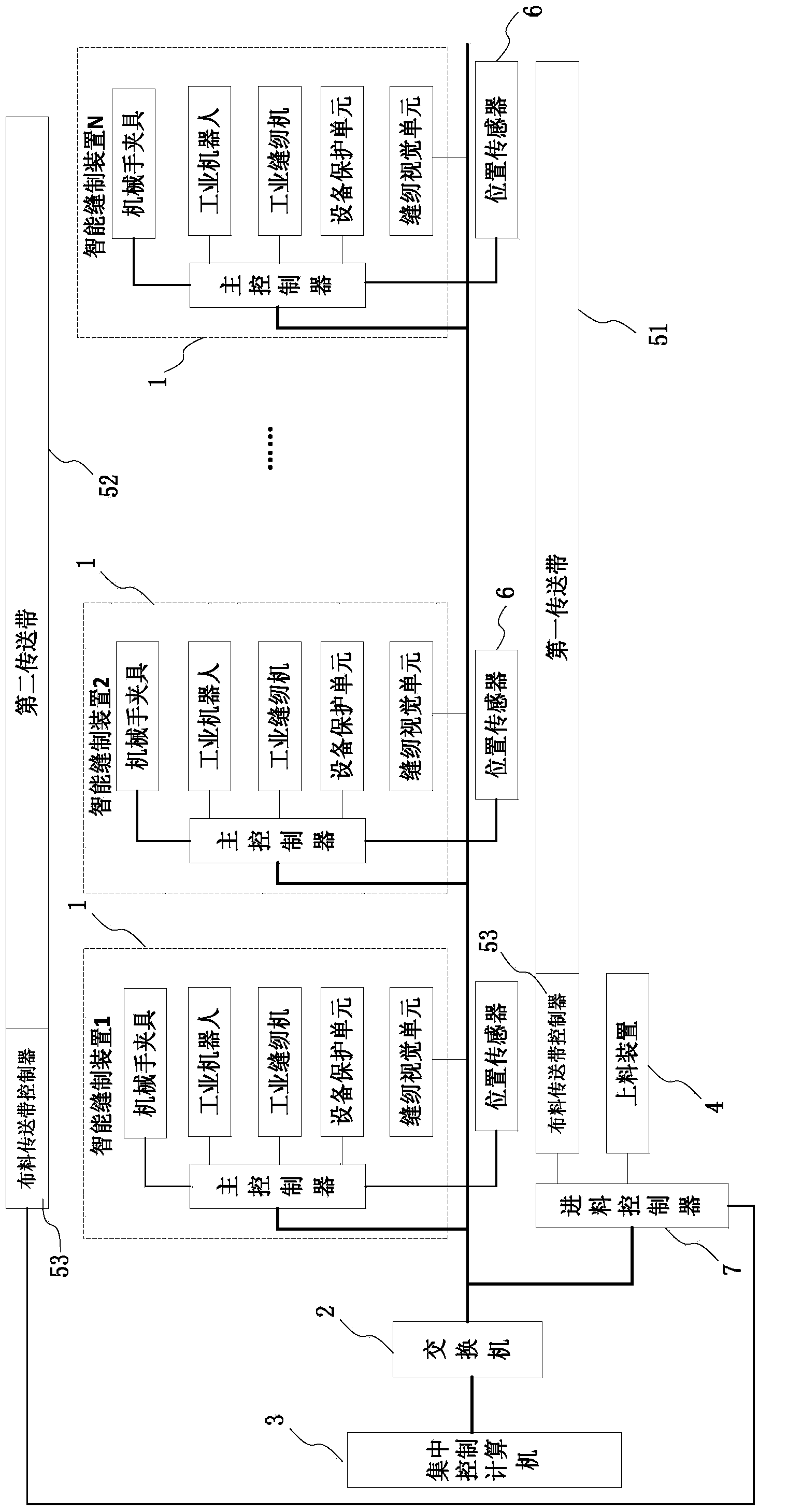

The invention provides an intelligent sewing device and system. The device comprises an industrial sewing machine for sewing cloth, a mechanical arm clamp, an industrial robot, a main controller and a sewing vision unit. The industrial robot operates the mechanical arm clamp for sewing matching. The industrial sewing machine, the mechanical arm clamp, an equipment protecting device and the industrial robot are connected through the main controller which then carries out control. The sewing vision unit is used for shooting sewing workbench images and obtaining cloth images. The system comprises a plurality of intelligent sewing devices, main controllers, exchangers, feeding controllers, loading devices, feeding devices and centralized control computers. The main controllers and the exchangers are in communication connection with the intelligent sewing devices. The feeding controllers are in communication connection to the exchangers. The loading devices are connected with the feeding controllers. The feeding devices are used for placing of cloth by the loading devices and conveying the cloth to the intelligent sewing devices. The centralized control computers are in communication connection with operation man-machine interaction platforms of the exchangers. Through the system, automatic loading, feeding and sewing are achieved, during a sewing process, the cloth can be used for locating or correcting an algorithm, sewing is accurate, and working efficiency and product yield are greatly improved.

Owner:JACK SEWING MASCH CO LTD

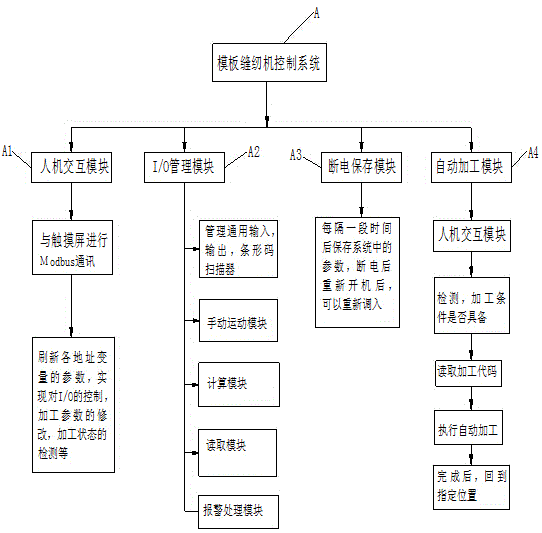

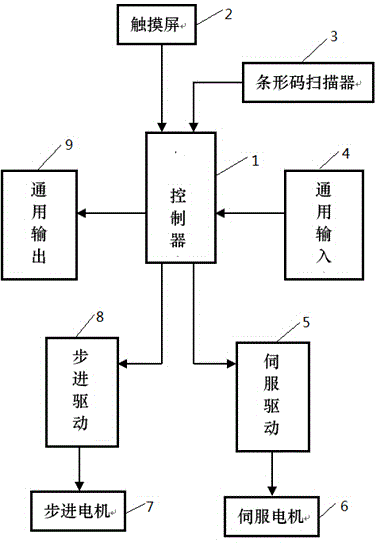

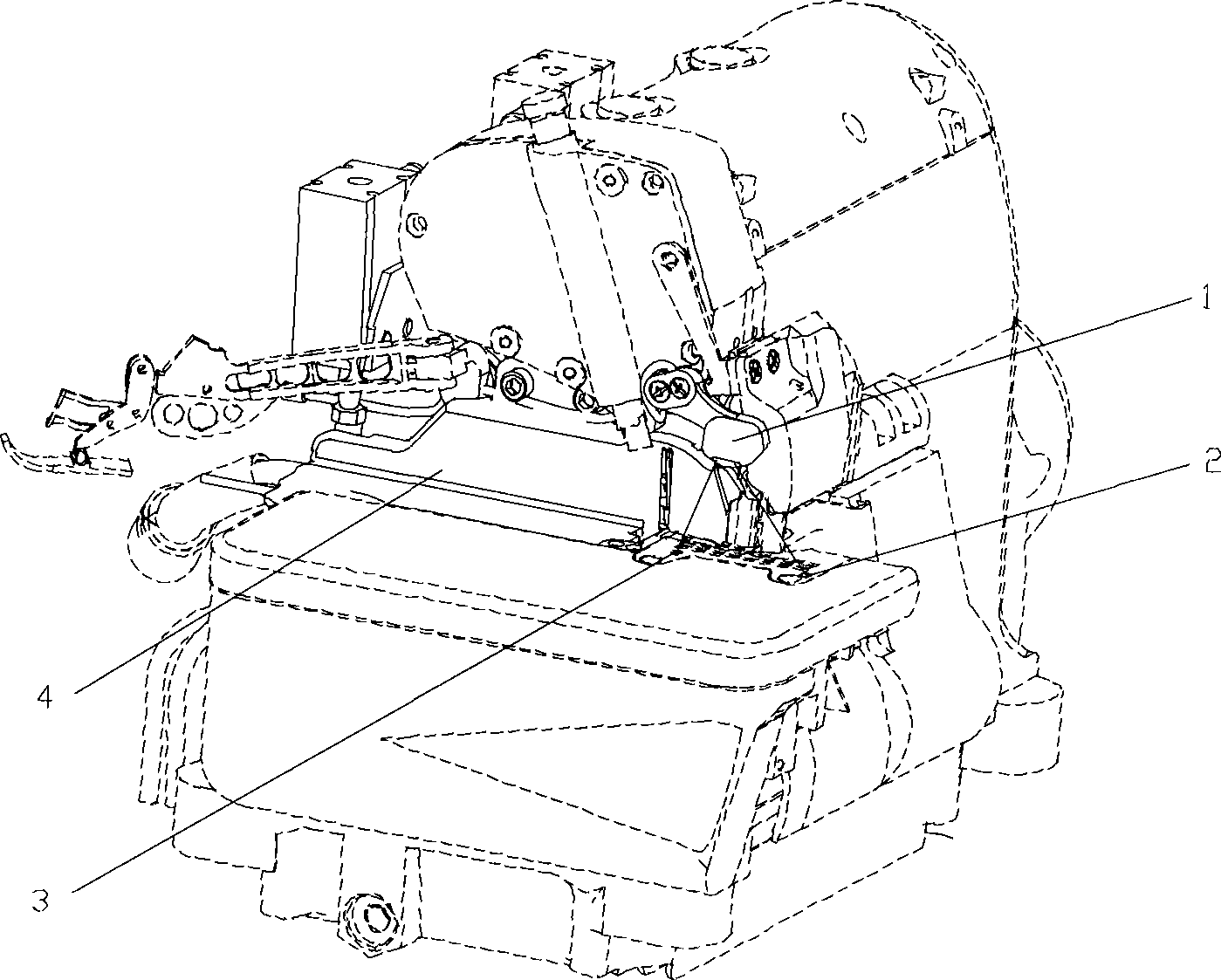

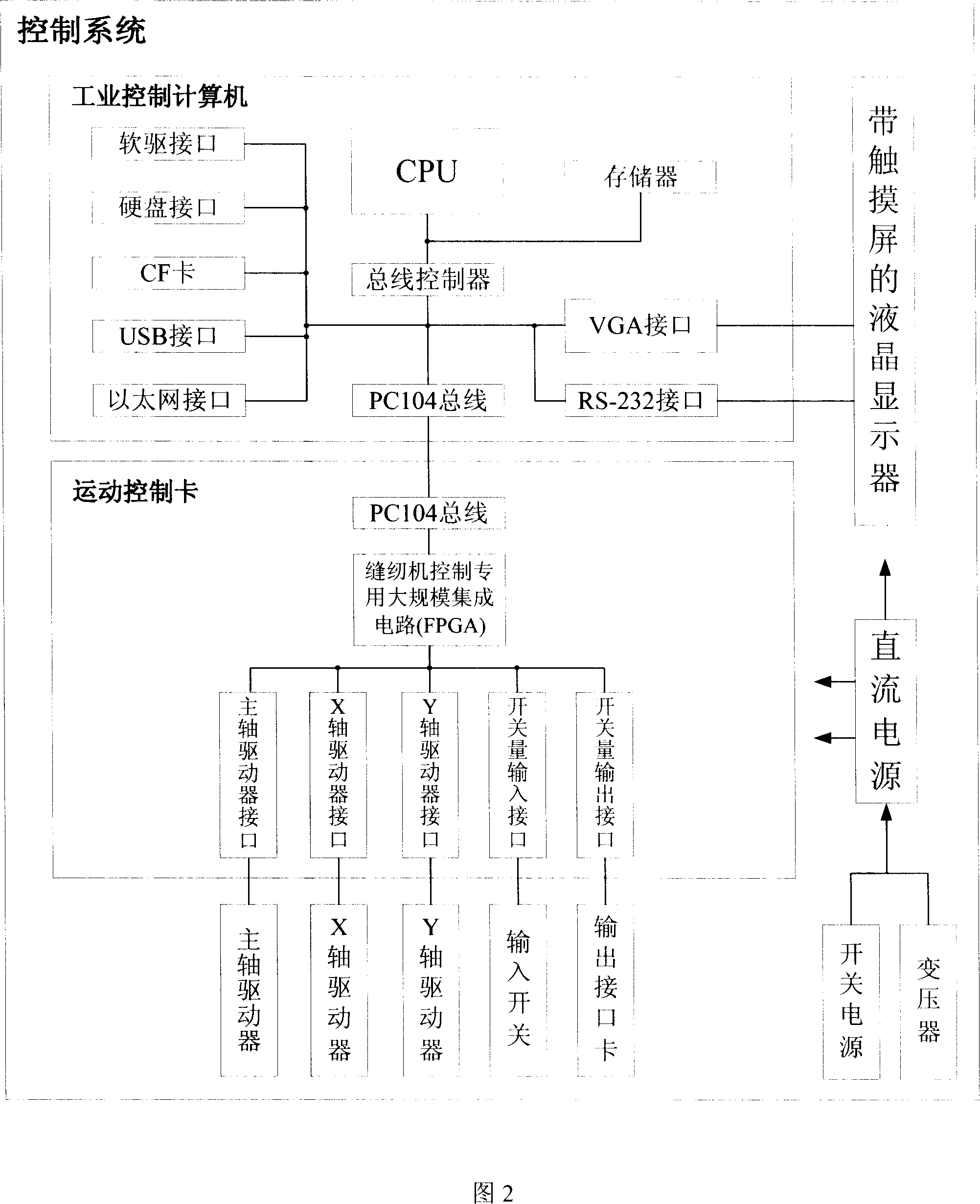

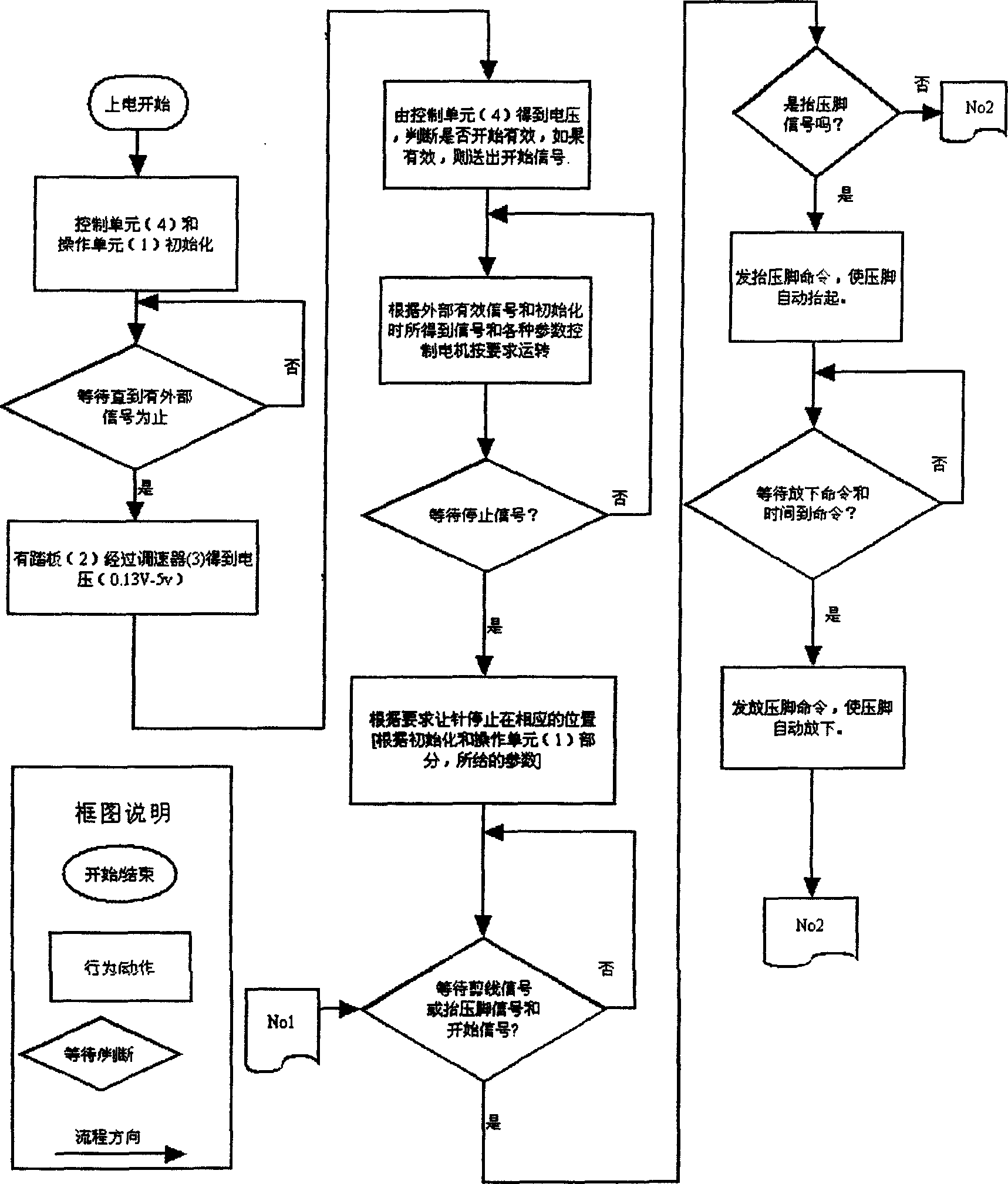

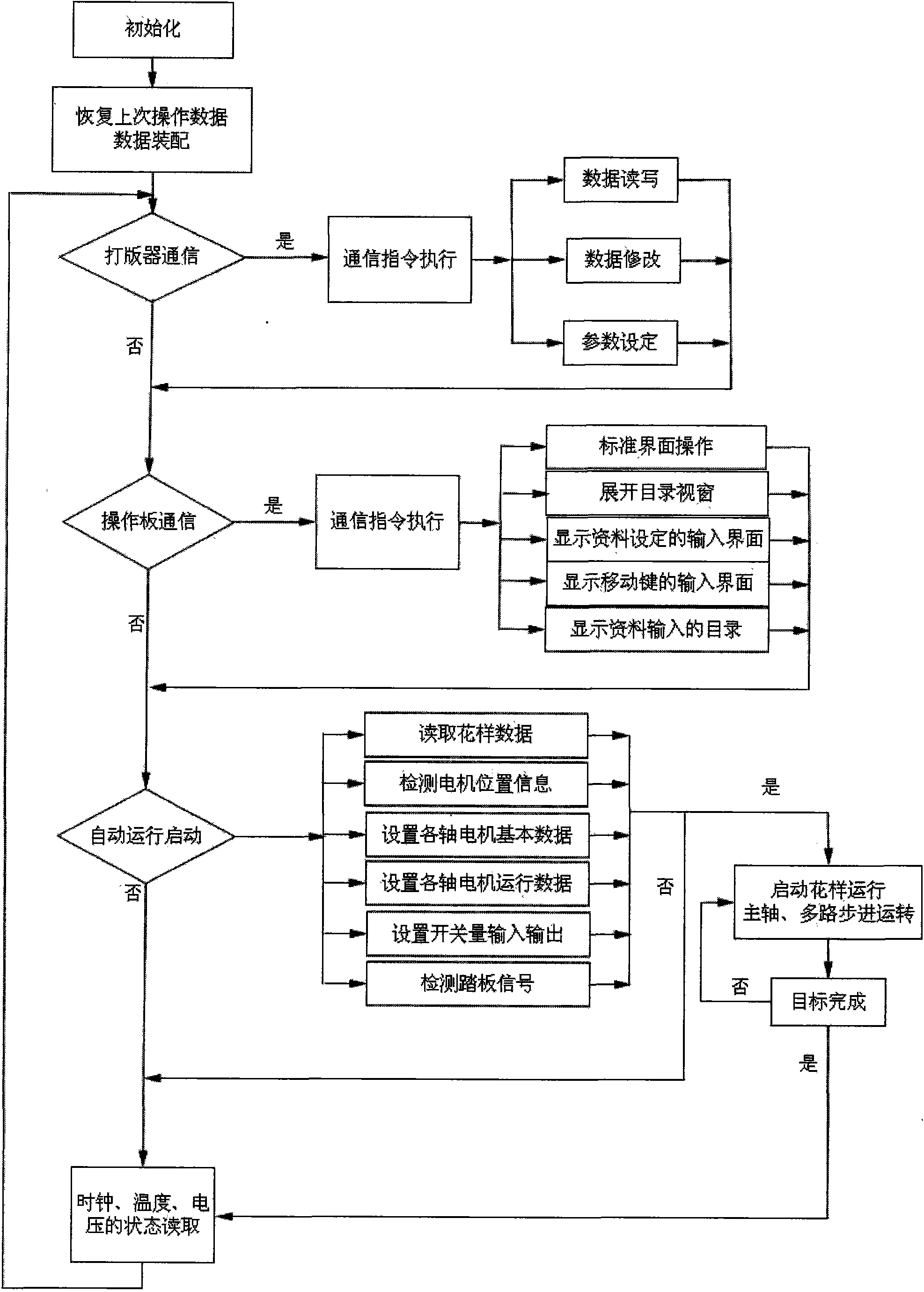

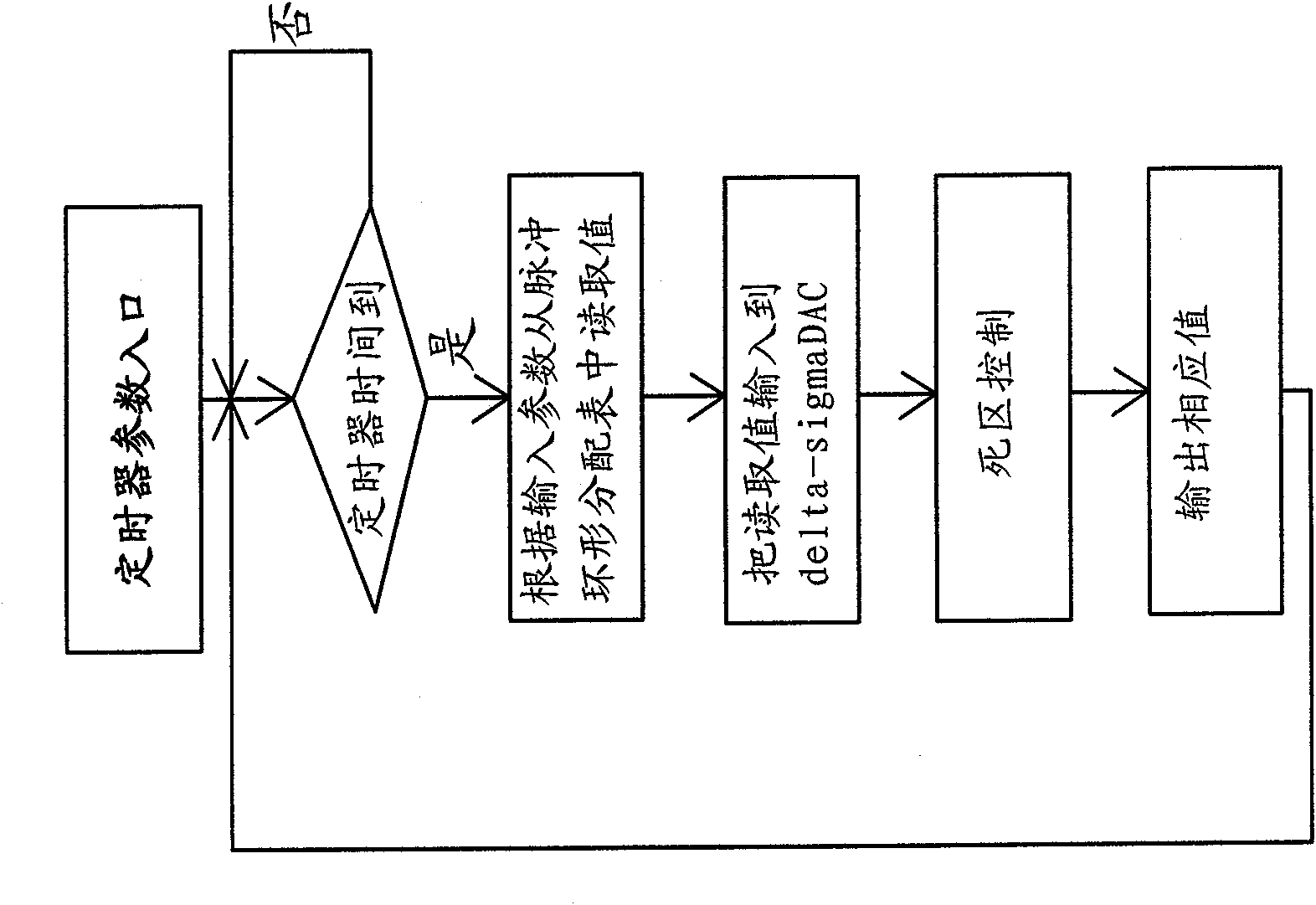

Control system and method for template sewing machine

ActiveCN104562455AGuaranteed machining accuracyGuaranteed motion reliabilitySewing apparatusInterference resistanceControl system

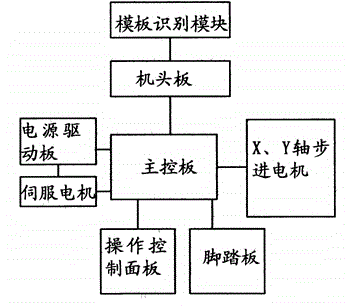

The invention discloses control system and method for a template sewing machine, and belongs to the field of control of industrial sewing machines. The system comprises a human-computer exchange module, an I / O management module, a power-off storage module and an automatic processing module. According to the system, the program of a main shaft encoder is read up to 1ms per cycle; the program can be cycled at 20 times when a main shaft rotates at the top speed; therefore, the processing precision and movement reliability are greatly improved; meanwhile, a controller is high in interference resistance and generality and supports most of servo motors, stepping drives and touch screens in the market.

Owner:FOSHAN GOOGOL AUTOMATION TECH

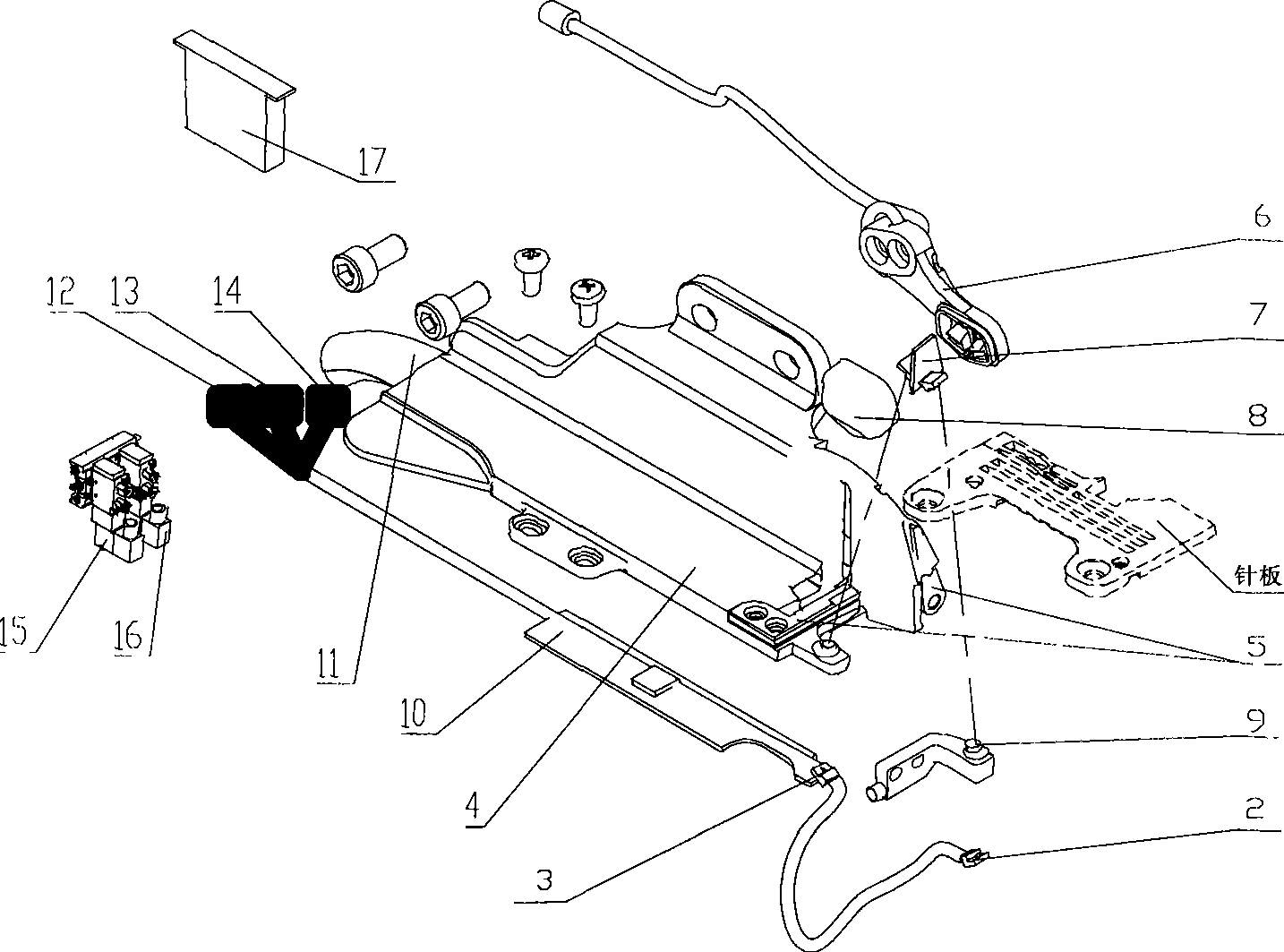

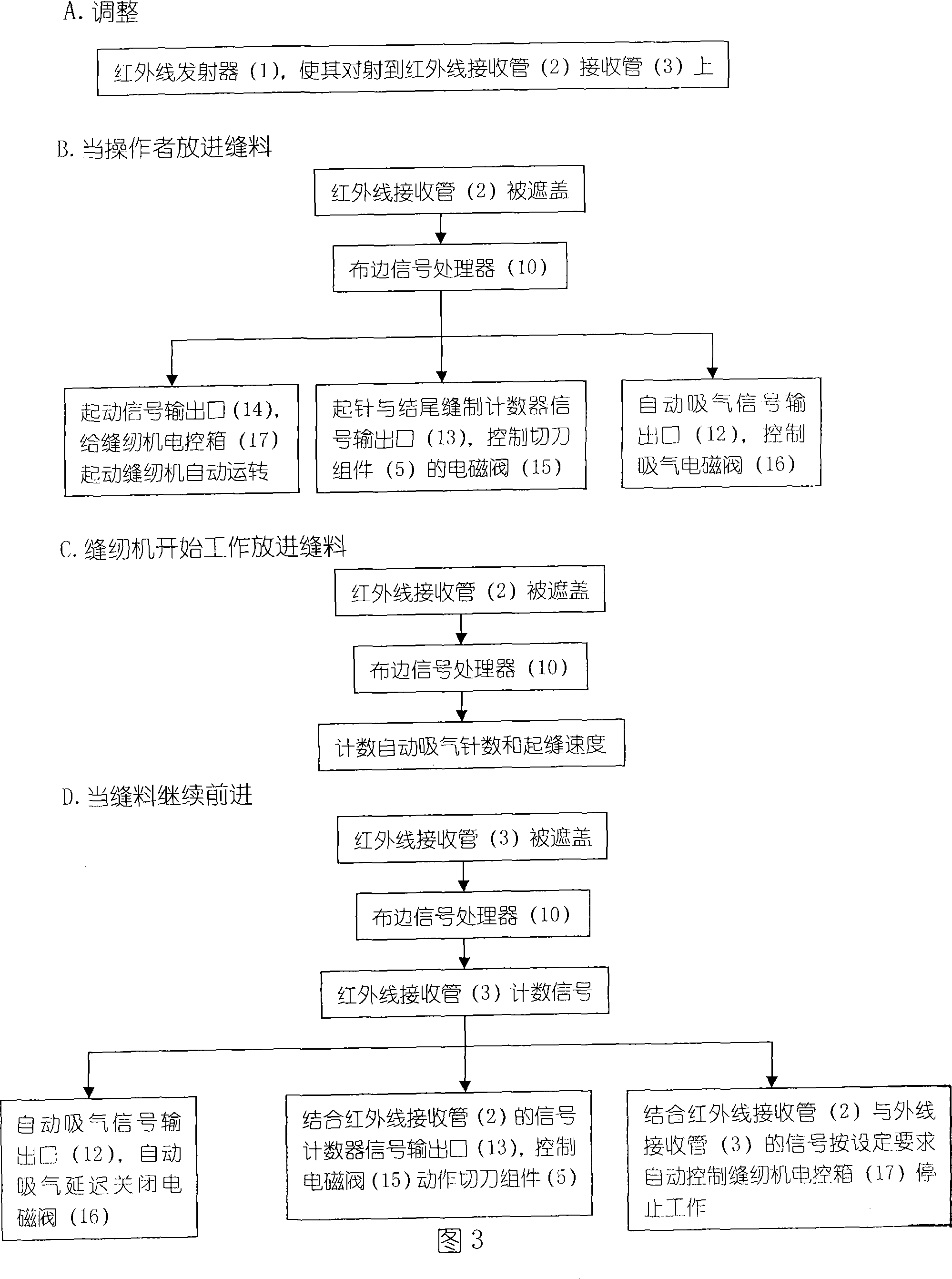

Photoelectronic control system for industrial sewing machine

ActiveCN101429712ARealize automatic start-up operationHigh control precisionSewing-machine control devicesOptical detectionControl systemWire cutting

The invention discloses a photoelectric control system for an industrial sewing machine, and relates to the technical field of photoelectric control, in particular to an infrared control system capable of detecting fabric edge length of materials sewn and whether sewing materials exist by an industrial sewing machine. The control system comprises two infrared emitters (1) independently forming a relative included angle (phi), an infrared receiver tube (2) and an infrared receiver tube (3) positioned in a front circular hole and a back circular hole of a needle plate holder, a cutter assembly (5), a fabric edge signal processor (10), an air suction pipe (11) and a sewing machine electric cabinet (17), and comprises steps of a to d. Two groups of signals about having or no fabric edges are provided to the fabric edge signal processor to be processed through judging whether the fabric edges are existed on a sewing machine needle plate; and starting, stopping, accounting, speed raising, speed reducing, wire cutting and air sucking and the like of the sewing machine are controlled automatically according to positions of the fabric edges supplied to a system controller. The control system has the characteristics of accurate output signals, good anti-interference property, easy processing and high performance cost ratio, is suitable for various industrial sewing machines, and the like.

Owner:上海富山精密机械科技有限公司

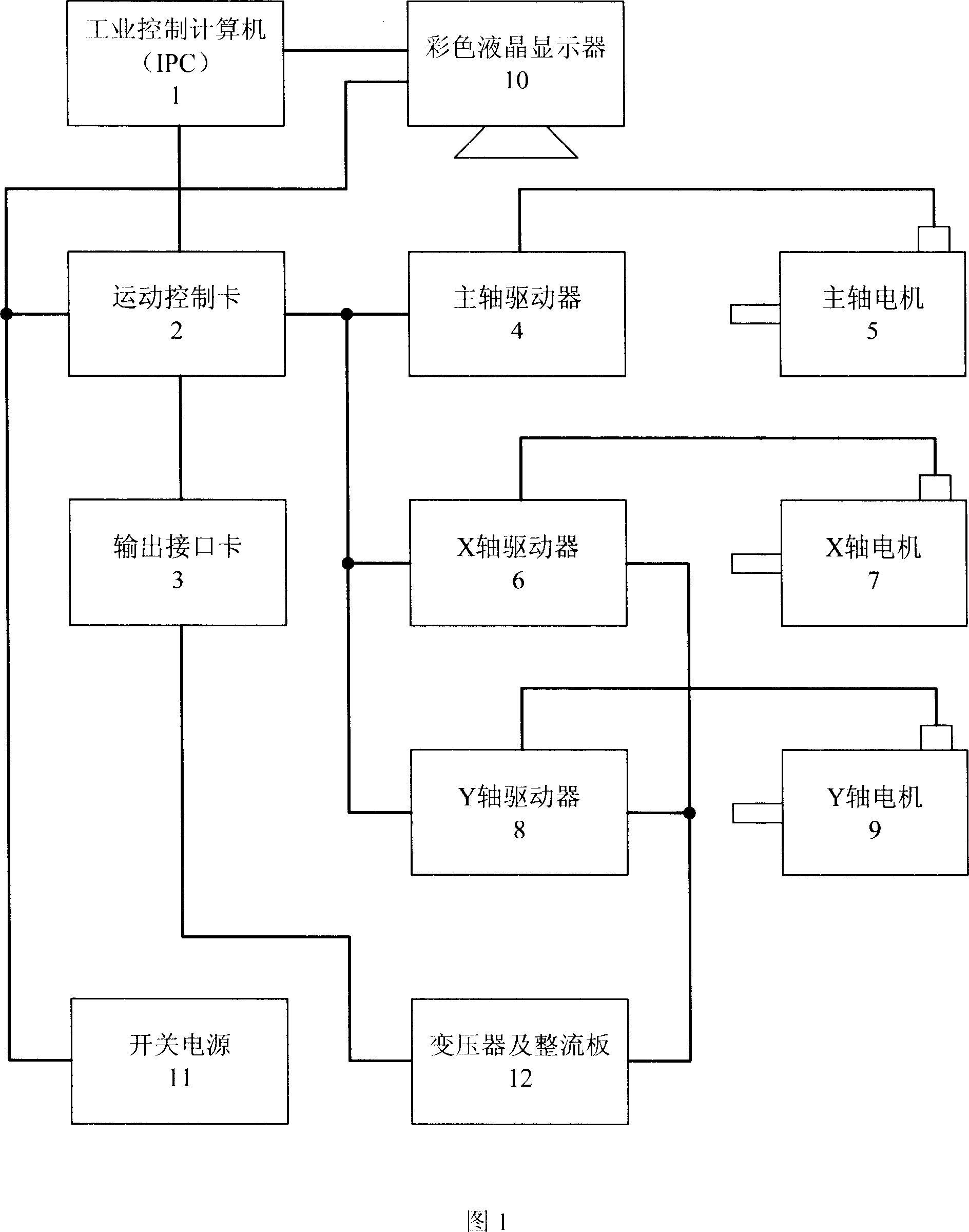

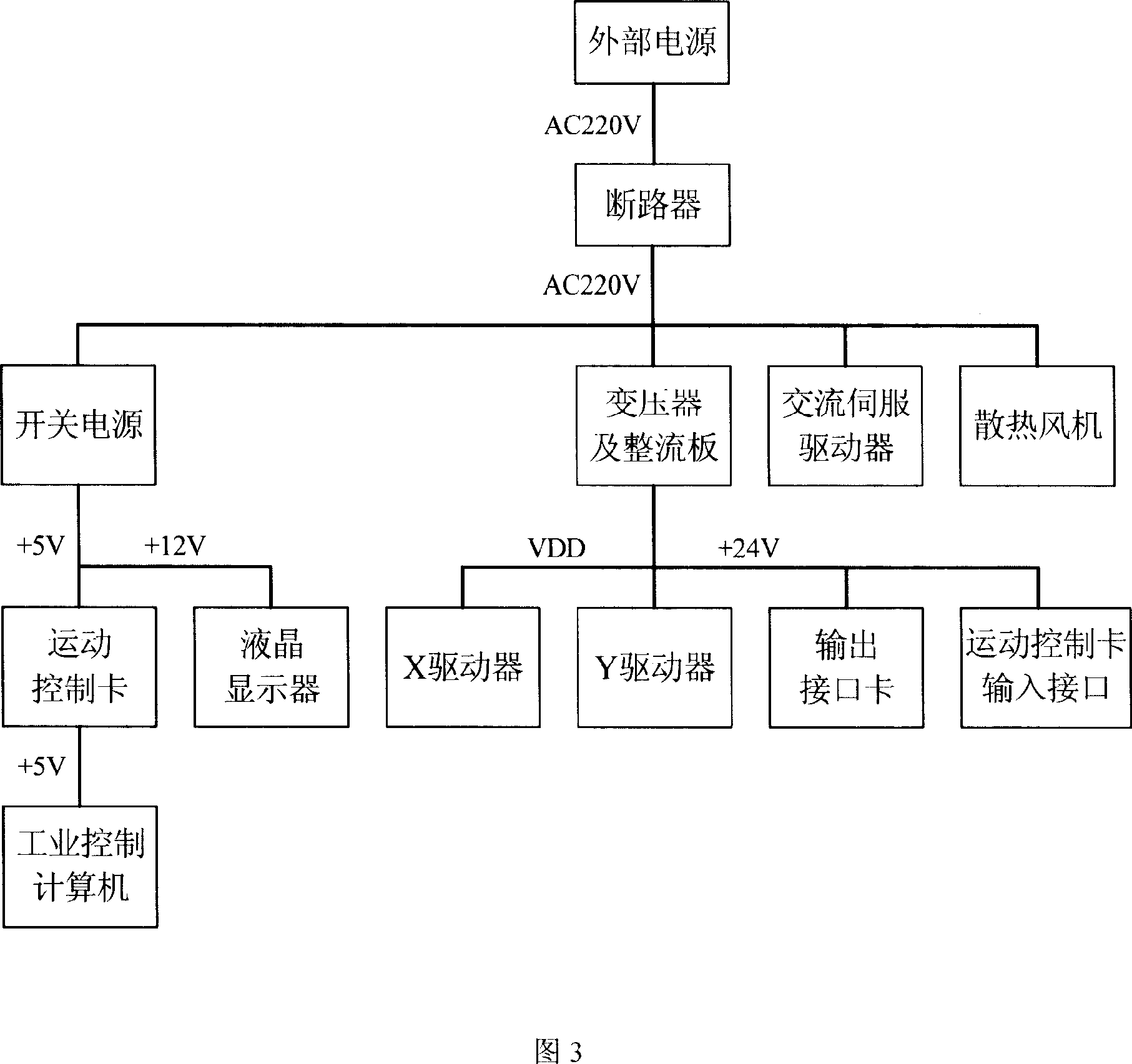

Computer control system of industrial sewing machine

InactiveCN101012604AFunction increaseIncrease the spindle speedProgramme-controlled sewing machinesSewing-machine control devicesHuman–machine interfaceTransformer

The invention provides a computer control system for industrial sewing machines, comprising a computer control cell containing an industrial control computer, a motion control card and an output interface card, a servo driving cell containing AC servo motor or step motor, a man-machine interface cell containing color liquid crystal display with touch screen performance, and a power supply cell for system containing switching power supply, transformer and rectifying plate. The invention adopts the module cell structure. The inside of each cell is relatively independent, self-contained and high integrated degree. It can configure relative parts flexibly to constitute the system according to the difference of host of industrial sewing machine. By the system software program, sewing every designs, lines or schemes automatically in high speed is accomplished. It is provided with convenient operation, simple plate-marking program, improved speed and low labor intensity.

Owner:MIANYANG WEIBO ELECTRONICS

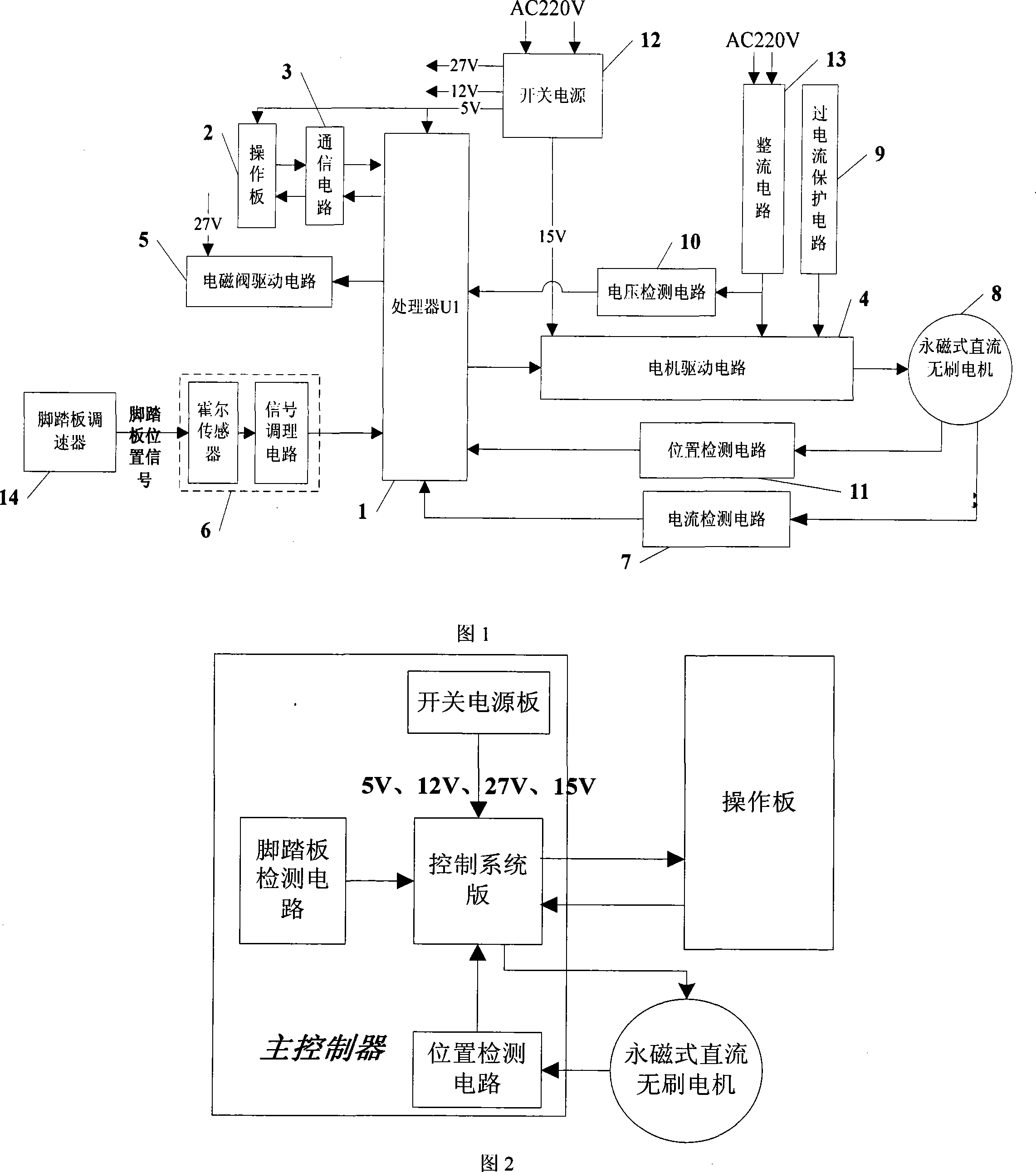

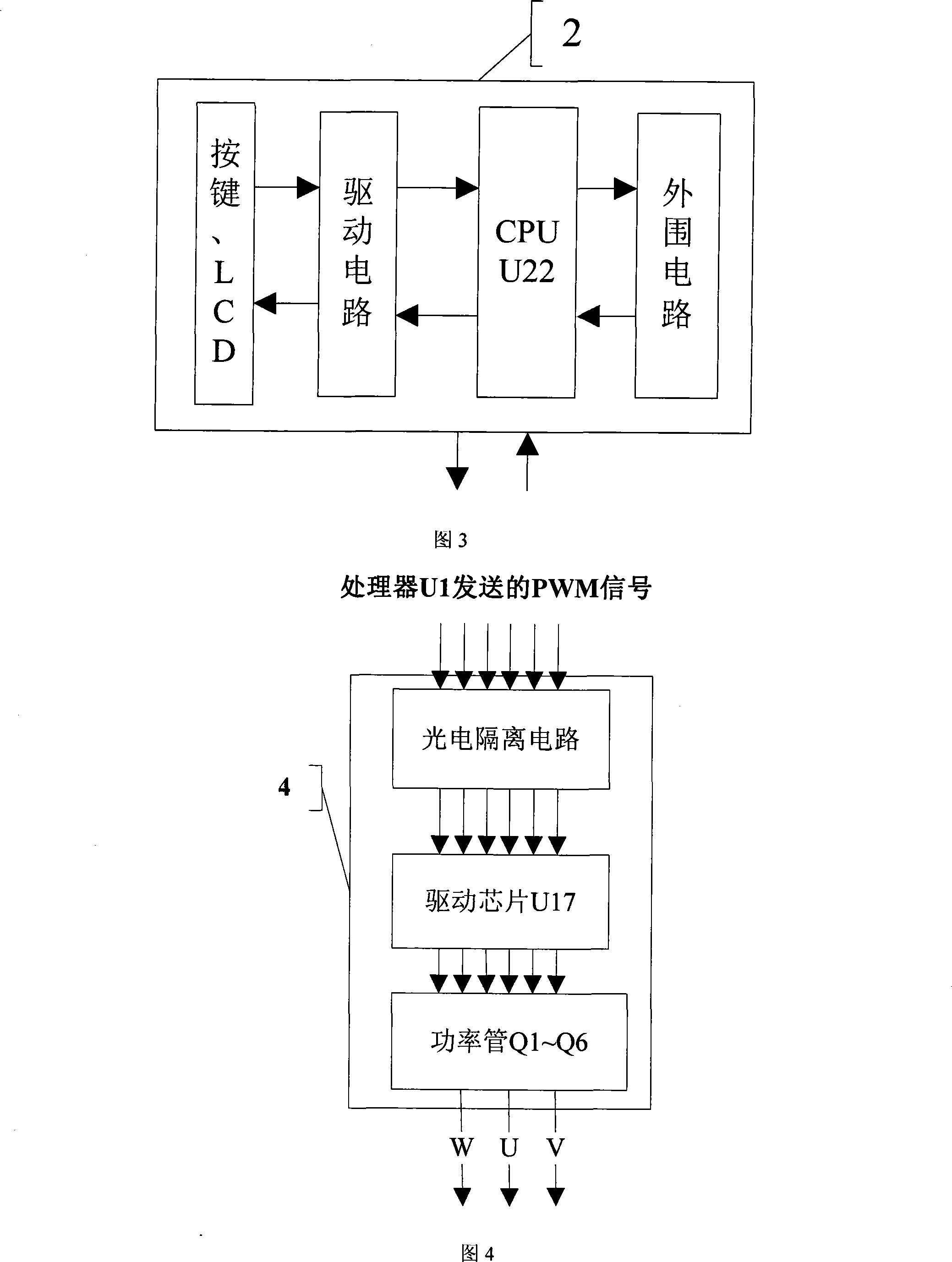

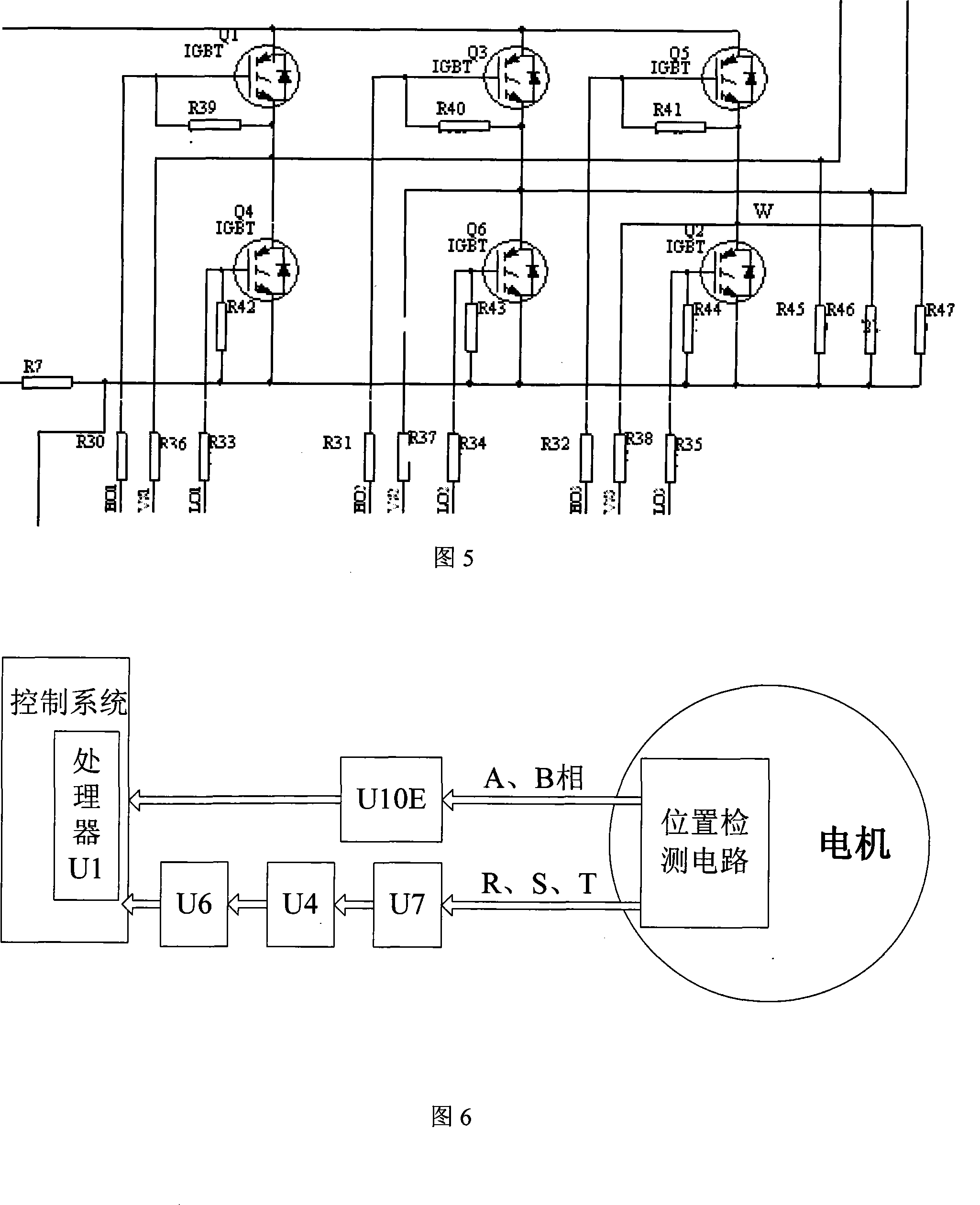

Direct-driving single needle industrial sewing machine control system

InactiveCN101177848AReduce economic costsImprove anti-interference abilitySewing-machine control devicesProgramme control in sequence/logic controllersHuman–machine interfaceEngineering

The invention discloses a direct-drive control system of a single-needle industrial flat bed sewing machine. The system consists of a processor, an operation board, a communication circuit, a motor drive circuit, an electromagnetic valve drive circuit, a footrest detecting circuit, a position detecting circuit, a motor, an over-current protection circuit, a voltage detecting circuit, a current detecting circuit, a switch power, a rectification circuit and a footrest speed regulator; the design of a hardware circuit and software of the system is modularized; thread stop motion is relatively rapid, accurate and free of lagged thread; the overlap ratio of stitch is high, stitching is accurately numbered and sewing process is relatively stable; a human and machine operation interface is more humanized and exercisable, and Chinese characters are also displayed, thereby overcoming the disadvantages of the traditional human and machine interfaces that only English and numerical information is available.

Owner:XI AN JIAOTONG UNIV

Crimping powder coating

InactiveCN102321421ADoes not cause uneven texturePowdery paintsEpoxy resin coatingsPolyvinyl butyralEpoxy

The invention relates to crimping powder coating which is applied to the surface painting of electrical control cabinets, industrial sewing machines and other mechanical and electrical products. The invention aims to provide the crimping powder coating which can not be affected by thickness of the metal plate and rise speed of baking temperature to overcome the defects of the existing crimping powder coating that nonuniform texture is caused by the over slow baking temperature rise when thicker and thinner plates are painted. The crimping powder coating provided by the invention consists of base powder and a strip agent, and the base powder components of the crimping powder coating comprise epoxy resin, carboxyl resin, barium sulfate, calcium carbonate, a curing agent, quaternary ammonium bromide, polyvinyl butyral, and pigments. The preparation of the crimping powder coating provided by the invention comprises the following steps: weighing the base powder components and the strop agent; mixing the base powder components uniformly, and fusing and extruding through an extruder; cooling and smashing the extrudate into powders, thus the base powder is obtained; and adding the strip agent in the base powder, and mixing uniformly, thus the crimping powder coating is obtained.

Owner:ZHEJIANG CHAOLANG ADVANCED MATERIALS

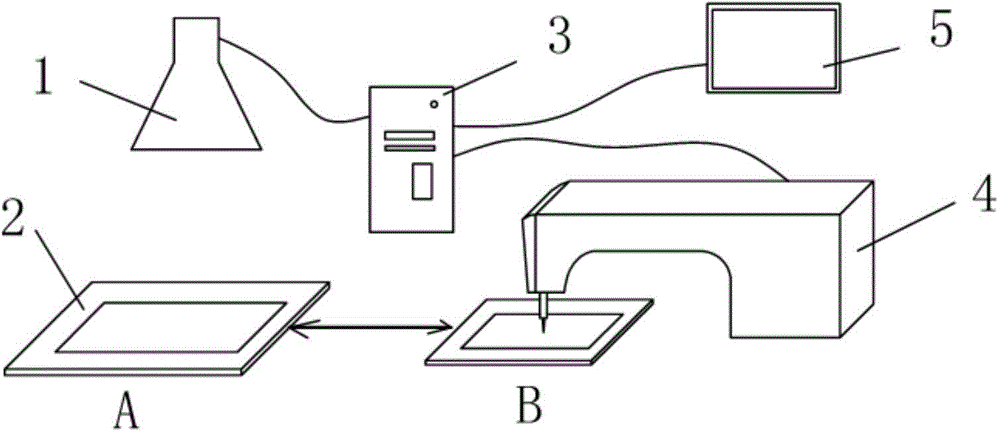

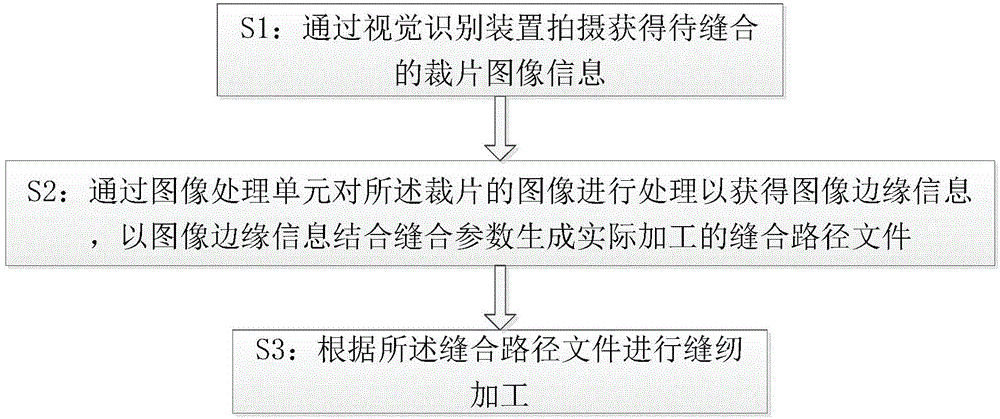

Industrial sewing machine system and cut part sewing processing method by same

InactiveCN104695139ASolve flexible production needsLower performance requirementsProgramme-controlled sewing machinesWork-feeding meansEngineeringVisual recognition

The invention discloses an industrial sewing machine system and a cut part sewing processing method by the same and belongs to the field of industrial sewing machines. The industrial sewing machine system comprises a visual recognition device, an input and output device (5), a sewing machine body (4) and a control unit (3), wherein the visual recognition device is used for photographing to-be-sewn cut parts to obtain images thereof, the input and output device (5) is used for inputting control parameters during sewing and displaying actual sewing process parameters, the sewing machine body (4) comprises a driving motor for performing sewing operation, and the control unit (3) is used for processing the cut part images to obtain cut part edge information, combining the cut part edge information with the control parameters inputted by the input and output device, and controlling a sewing process according to sewing paths. The invention further discloses the processing method of the industrial sewing machine system. By the aid of the system and the method, high-quality, high-efficiency and high-flexibility production can be achieved, so that both production efficiency and product quality of clothing and shoe manufacturing industries are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

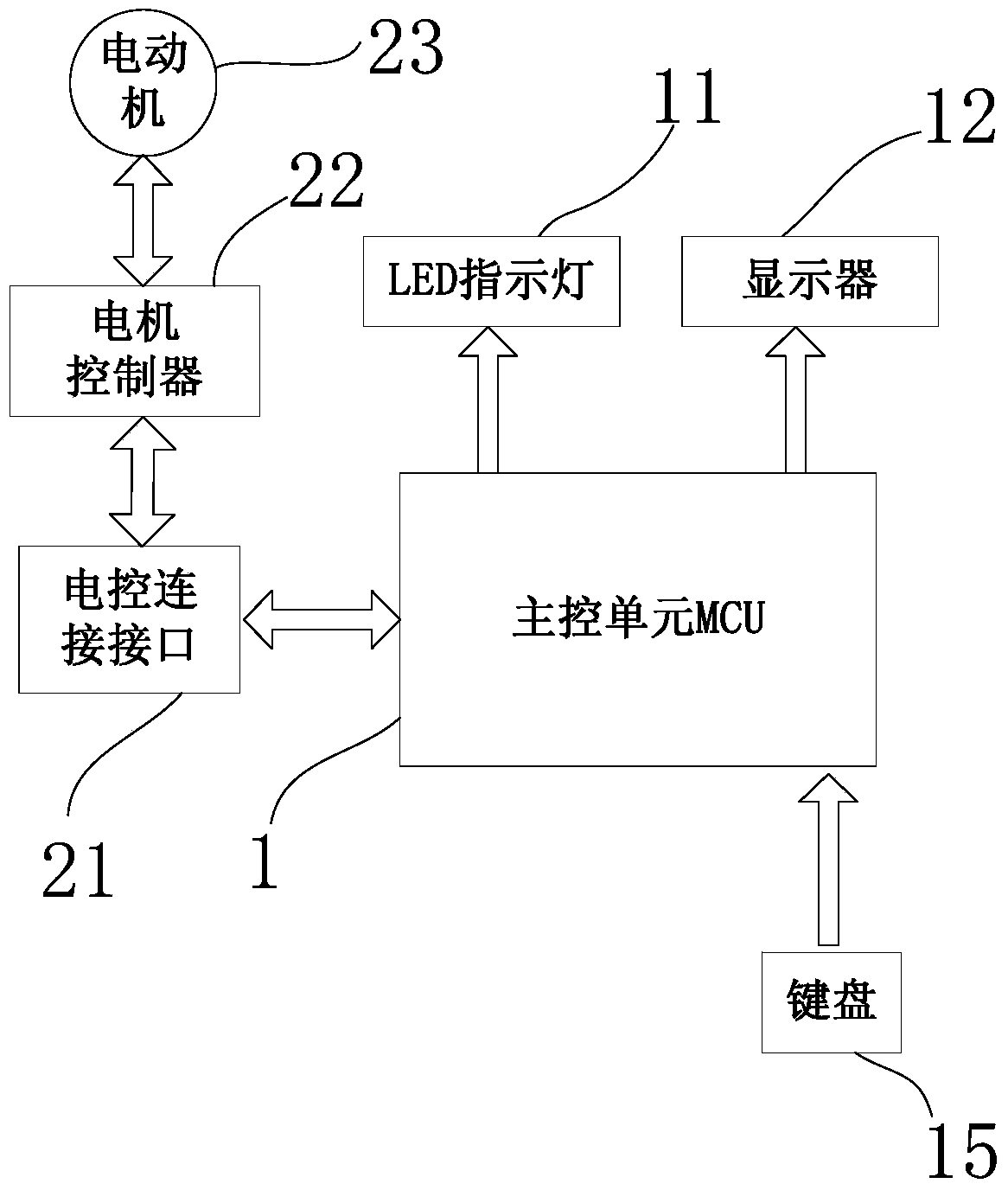

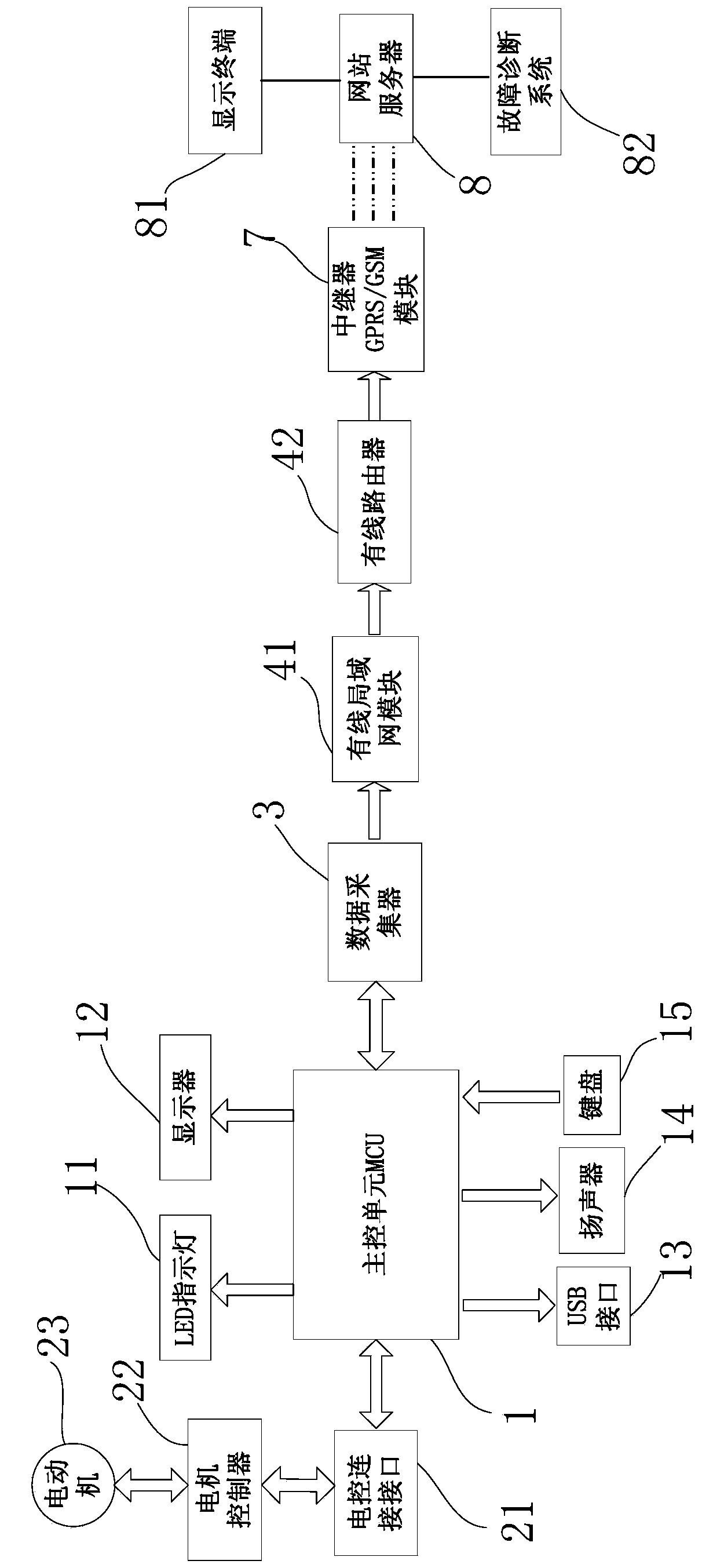

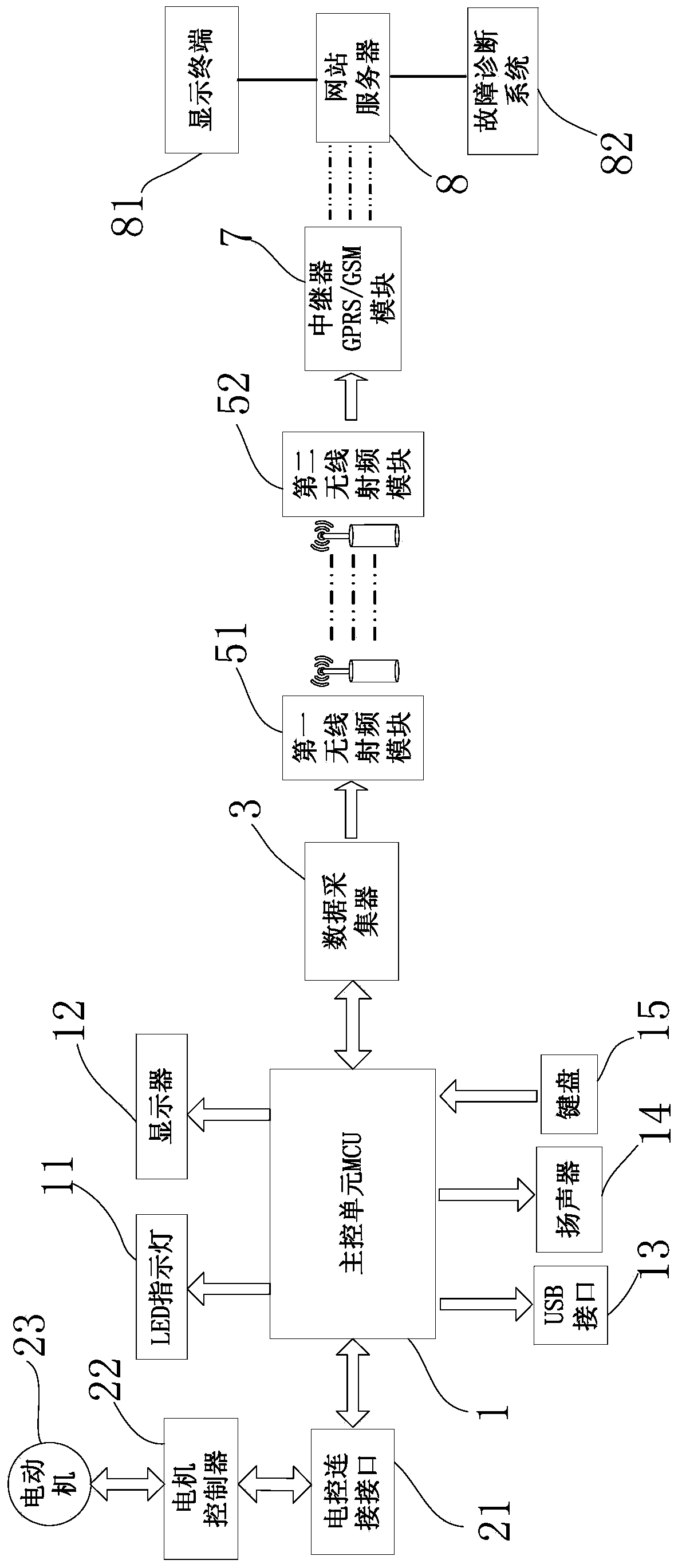

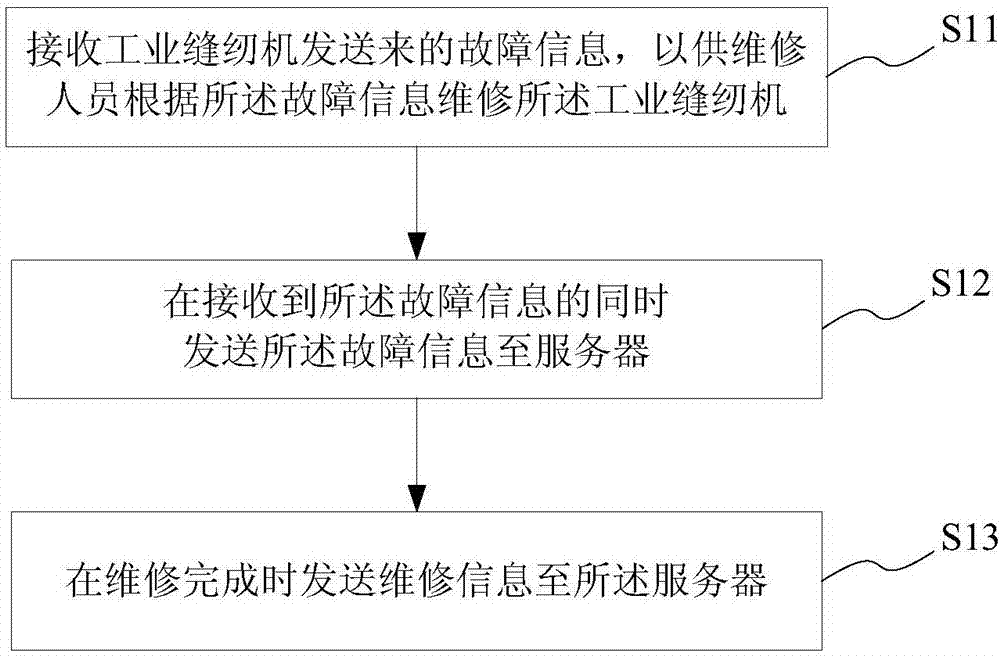

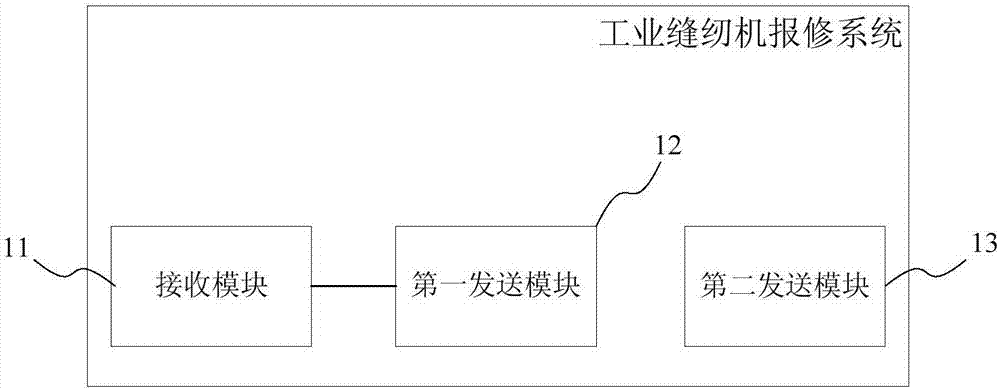

Remote monitoring and fault diagnosis system of industrial sewing machine

The invention provides a remote monitoring and fault diagnosis system of an industrial sewing machine. The remote monitoring and fault diagnosis system comprises a motor, a motor controller, an electrical control connecting interface, a main control unit and a data acquisition device which are arranged on the industrial sewing machine and are connected in sequence, wherein the data acquisition device is connected with the main control unit and is in communication connection with a relay through a data transmission device; a GPRS (General Packet Radio Service) / GSM (Global System for Mobile communication) module is arranged in the relay; the relay is in communication connection with a network server; the network server is connected with a display terminal and a fault diagnosis system respectively. The information such as machine setting parameters of the motor is transmitted to the relay by the data acquisition device through the data transmission device; the received information is transmitted to a customer service website server by the relay through the built-in GPRS / GSM module; customer service staff remotely monitors the working state of the industrial sewing machine through the display terminal and the fault diagnosis system which areconnected with the website server, so that a user can be helped timely to solve the problem.

Owner:JACK SEWING MASCH CO LTD

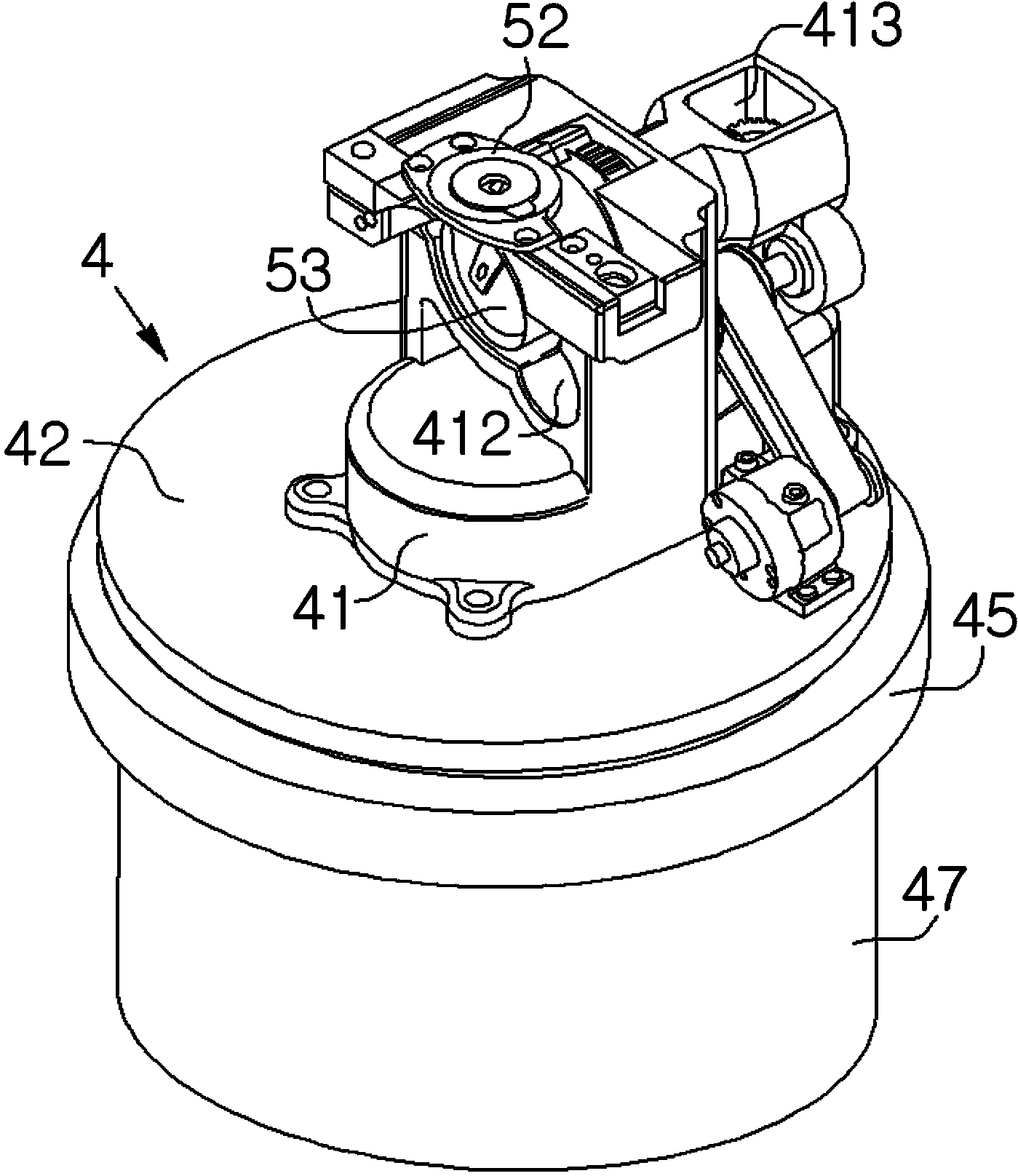

Industrial sewing machine

ActiveCN104141201ASuitable for sewingThe stitches are strong and beautifulProgramme-controlled sewing machinesNeedle severing devicesProgrammable logic controllerReciprocating motion

The invention belongs to the technical field of machinery and discloses an industrial sewing machine. A needle holder is driven to do vertical reciprocation by a swing rod and is driven to rotate around the needle holder axis by a needle holder rotation motor. A rotary hook and a hook carrier are mounted on a hook carrier assembly which comprises a shell, a rotary disc, a circular rotary seat, a belt pulley ring, a rotary hook motor, an assembly bearing and a slip ring. The rotary hook assembly is driven to do horizontal rotation by a rotary hook motor. Cloth to be sewn is clamped by a cloth feeding mechanism to do plane moving between the needle holder and the rotary hook. The needle holder rotation motor, the rotary hook carrier motor and the rotary hook motor are connected to a programmable logic controller on a table through the slip ring. The programmable logic controller drives the needle holder and the rotary hook carrier assembly to do rotation with same phase and same angular velocity. Products sewn by the industrial sewing machine have stable and firm stitches, and the industrial sewing machine is particularly suitable for sewing leather / cloth products in variable curved shapes.

Owner:广州明志电脑花样缝纫机械有限公司

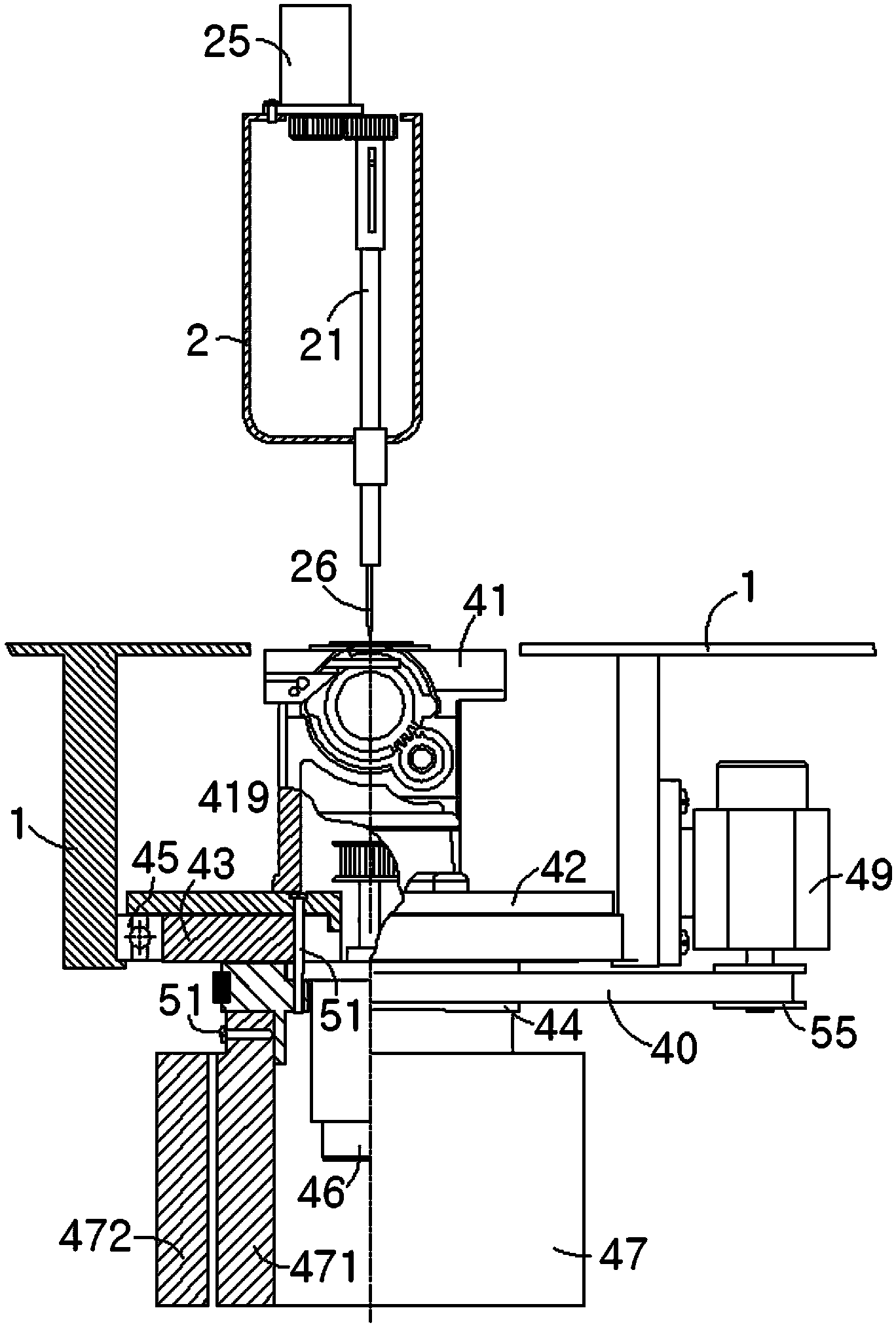

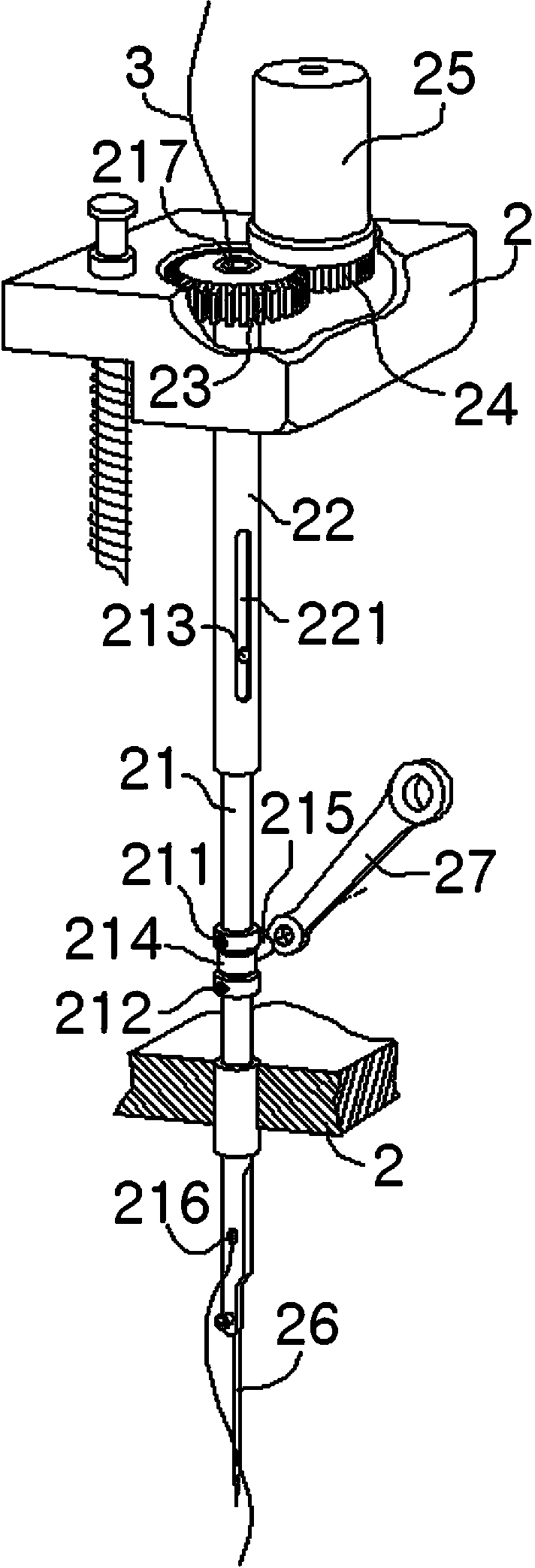

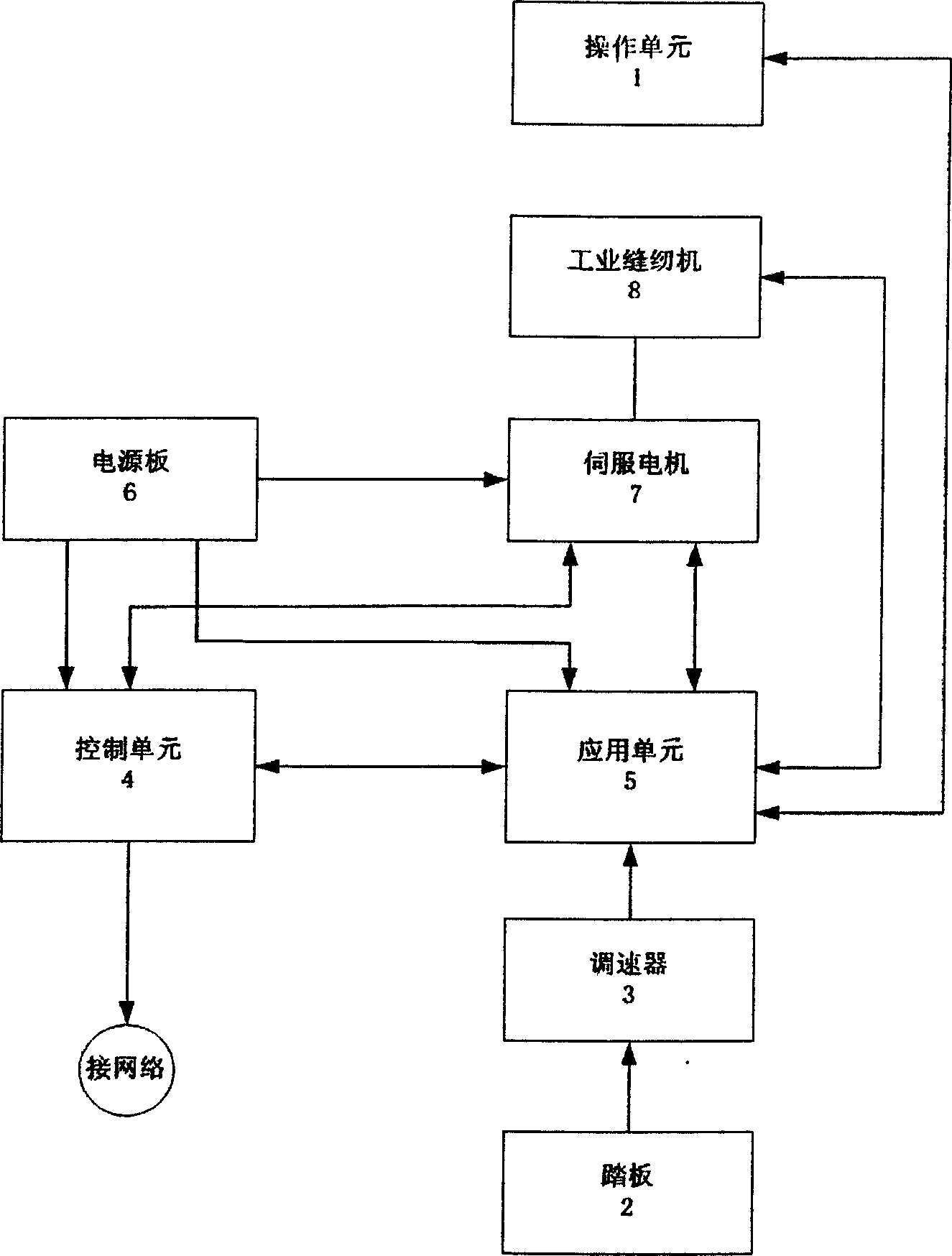

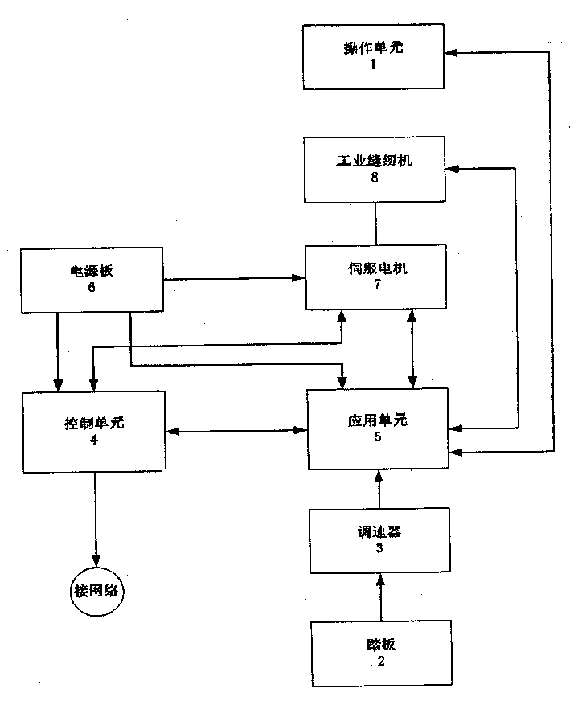

Computerized controller for industrial sewing machine

InactiveCN1548601AReduce volumeReduce system power consumptionProgramme-controlled sewing machinesRemote controlHall element

The computerized controller for industrial sewing machine includes operation unit, pedal, speed regulator, control unit, application unit board, power supply board and servo motor. The present invention has mainly DSP chip in the control unit for the software control of servo motor and various sewing program and Hall element-optoelectronic coder combination for the sewing machine needle positioning control. The present invention may be also connected to computer network for remote control and monitoring. The present invention may be used in the control of computerized flat sewing machine, embroidery machine, overseam sewing machine, etc.

Owner:徐章松

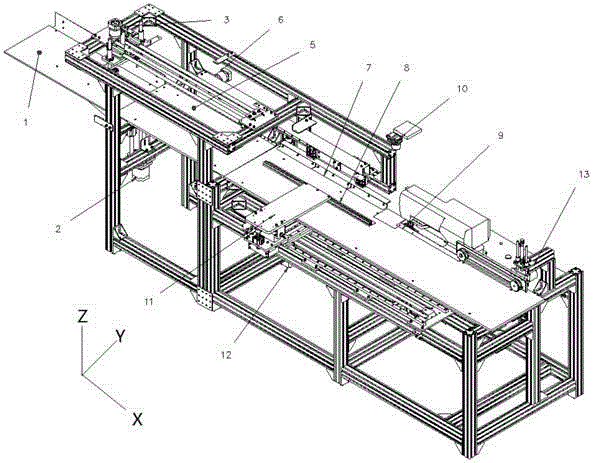

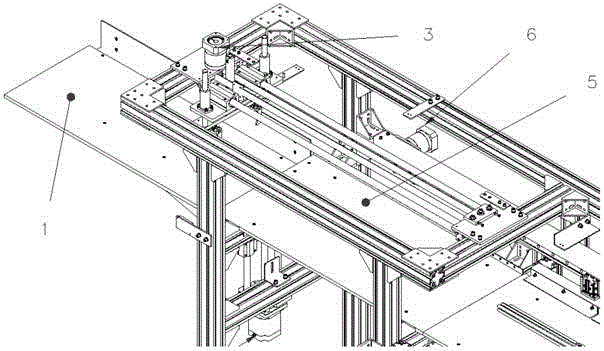

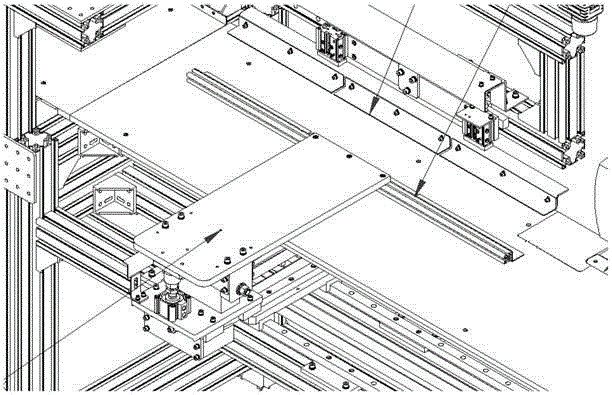

Two-step aligning adjusting-type full-automatic industrial sewing machine

ActiveCN105133203AReduce adjustmentShorten adjustment timeWork-feeding meansEngineeringMechanical engineering

The invention relates to a two-step aligning adjusting-type full-automatic industrial sewing machine. The two-step aligning adjusting-type full-automatic industrial sewing machine comprises a feeding mechanism, a preliminary adjustment mechanism, a visual adjusting mechanism and a headpiece assembly, all of which are sequentially connected and arranged along an X direction. A chuck gripper absorbs cloth and can transversely move above a feeding rack. A sensor group is arranged on a working surface in a pre-set material region and used for inducting the front-end edge position of cloth and feeding a signal back to a pre-regulating power mechanism. The pre-regulating power mechanism is used for adjusting parallelism between cloth and an X direction. The visual adjusting mechanism comprises a visual adjusting region, the upper portion of which is provided with a vision device. A preliminary material-conveying mechanism enables cloth in the pre-set material region to be conveyed to a setting position in an adjusting region by force under drive of a second motor. Cloth is pressed by a working pressing plate so that cloth can move along an X direction to a region corresponding to the vision device. According to a photographing position of the vision device, adjustments in peripheral directions including an X direction and a Y direction are made on cloth or adjustments are made in an X direction and a Y direction and in a peripheral direction with a Z shaft as the center.

Owner:SHANGHAI WEISHI MACHINERY

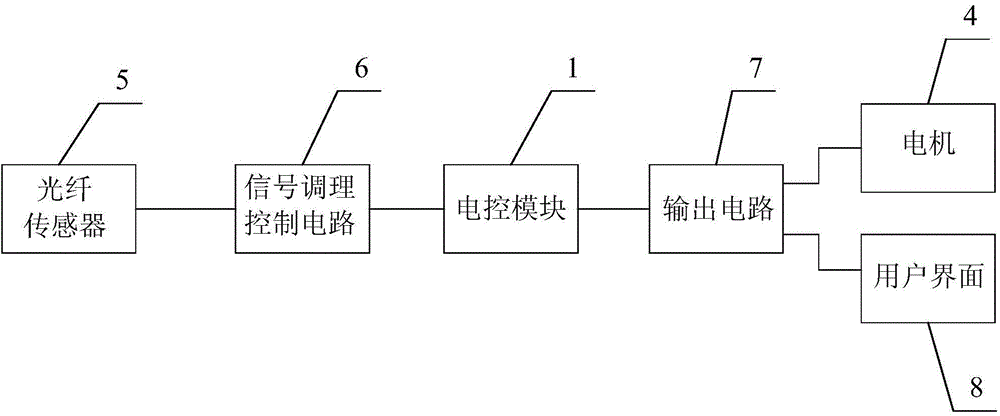

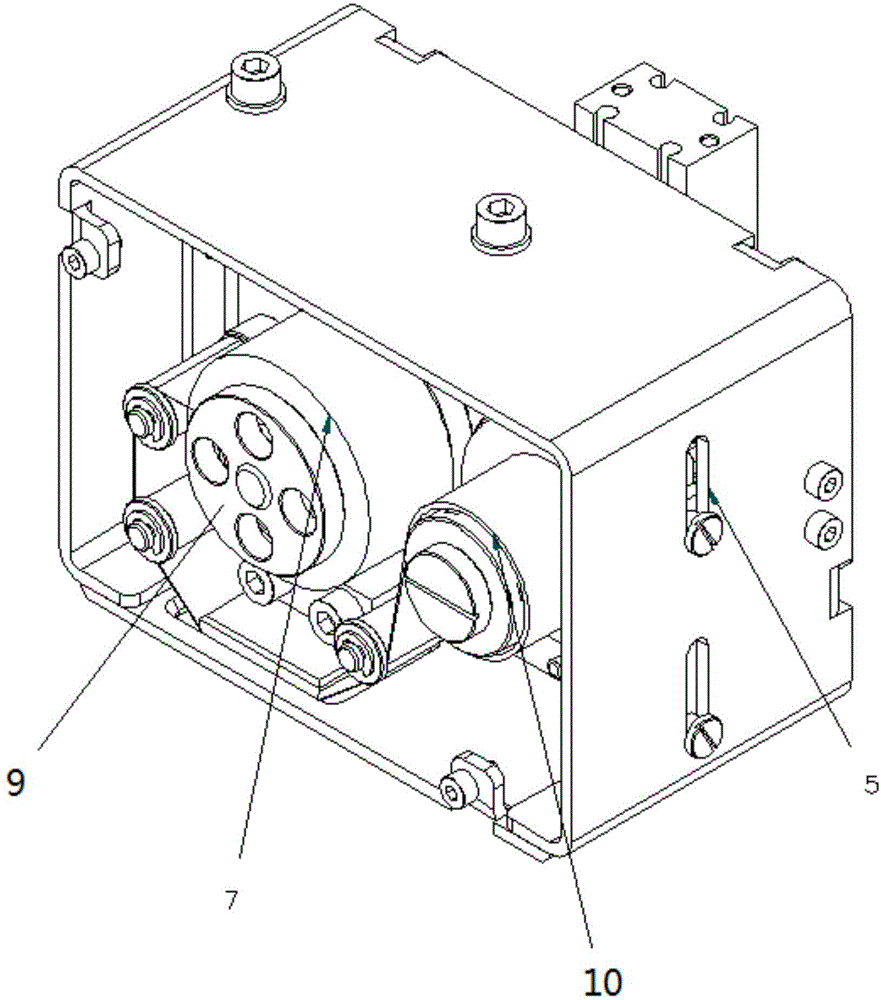

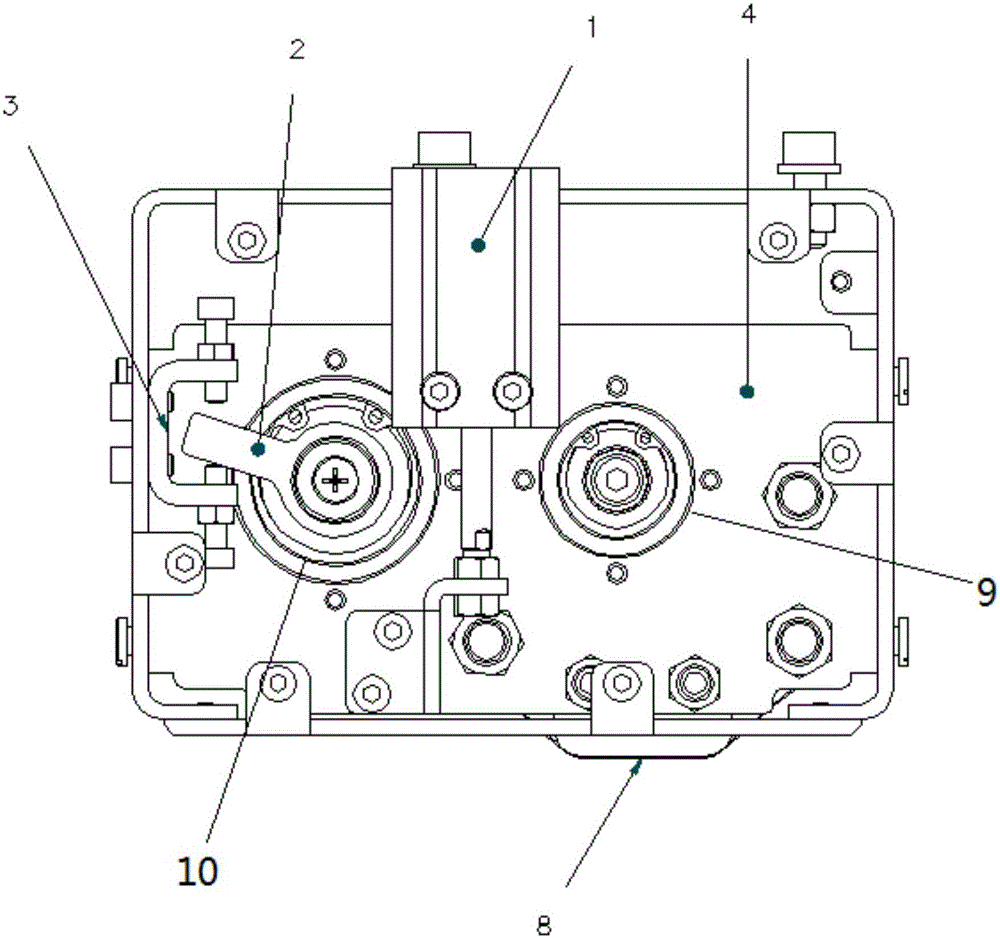

Bottom wire detection control system and method based on optical fiber sensor and applied to industrial sewing machine

ActiveCN104372538AImprove detection accuracyGuaranteed reliabilityBobbin-winding devicesLoop takersBobbinEngineering

The invention provides a bottom wire detection control system based on an optical fiber sensor and applied to an industrial sewing machine. The system comprises an electric control module, a rotating shuttle and a motor. The rotating shuttle comprises a shuttle case and a shuttle core. The shuttle core comprises a winding post and flanges arranged at the two ends of the winding post. A reflective sheet is fixed to the outer circumferential face of the winding post, and bottom wires are wound around the winding post. The optical fiber sensor is fixed to a shuttle support. The shuttle case is provided with an optical fiber emitter inlet and a gap, wherein the optical fiber emitter inlet and the gap are communicated with each other. The optical fiber sensor is connected with the electric control module through a signal conditioning control circuit. The electric control module is also connected with the motor through an output circuit. The bottom wire detection control system applied to the industrial sewing machine can judge whether the shuttle core is not installed in the shuttle case and whether the bottom wires on the shuttle core are enough according to optical signals of reflected light detected by the optical fiber sensor; meanwhile, the optical fiber sensor is adopted as a detection element, so that the system is high in sensitivity, higher and more reliable in detection performance and higher in anti-electromagnetic-interference capability.

Owner:BULLMER ELECTROMECHANICAL TECH

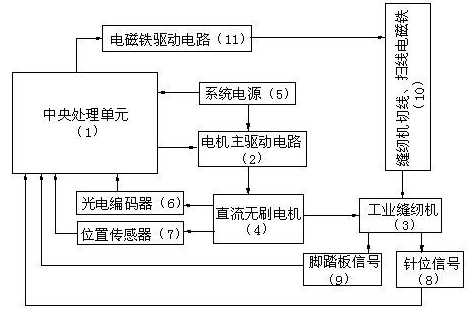

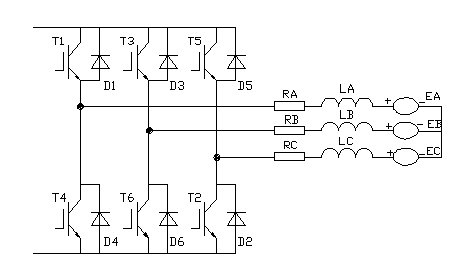

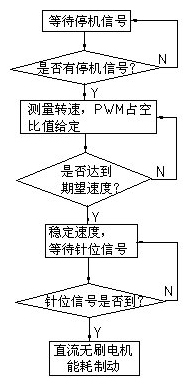

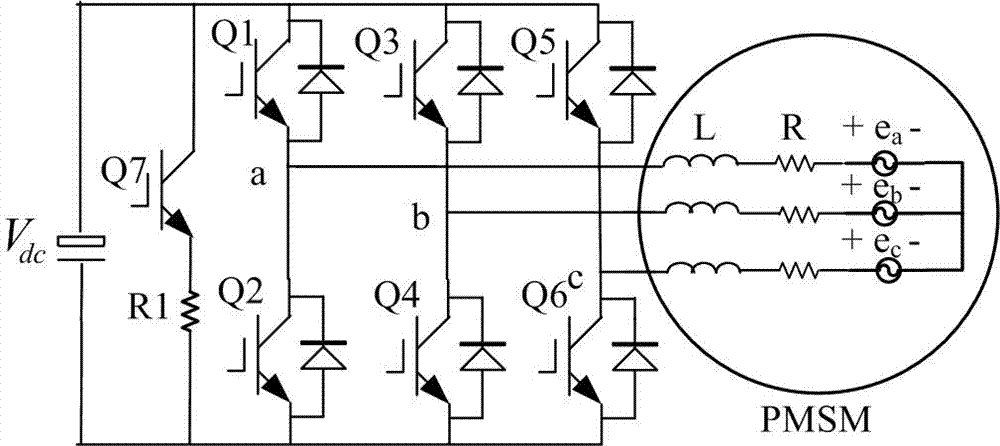

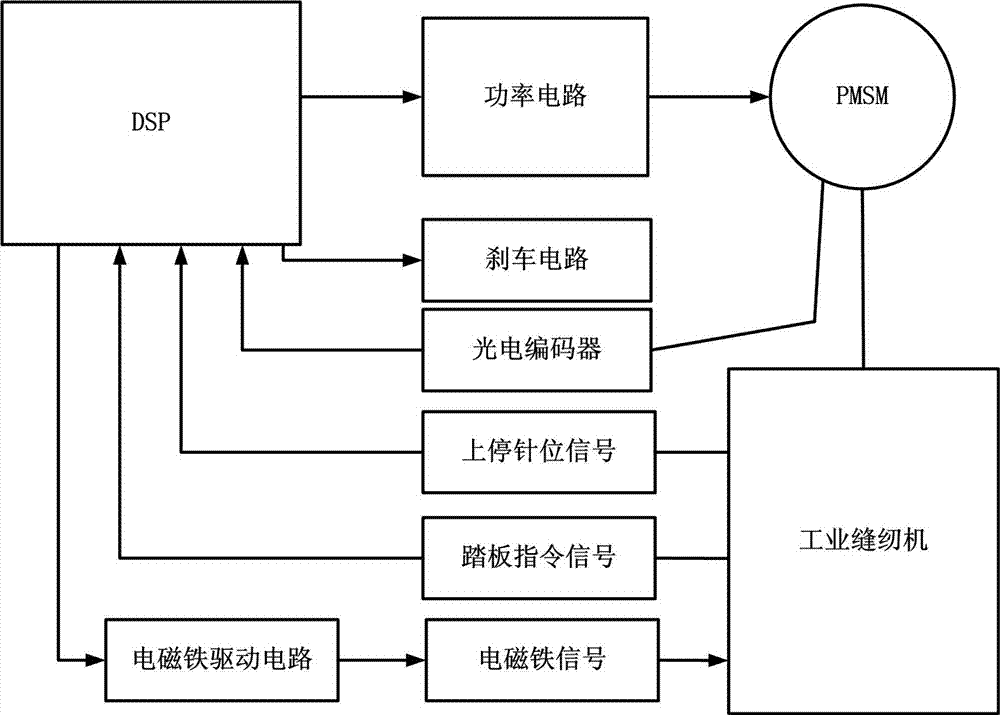

Quick shutdown system and method of industrial sewing machine

The invention relates to a quick shutdown system and method of an industrial sewing machine. The system comprises a central processing unit, a bridge rectifier circuit composed of six switching tubes and a DC brushless electric machine used for controlling the operation of the industrial sewing machine, wherein the input end of the bridge rectifier circuit is connected with a system power supply; the triple outputs of the bridge rectifier circuit are connected with the three-phase winding of the DC brushless electric machine in turn; the control ends of the switching tubes are separately connected with the six-way PWM control signals of the central processing unit; an optical-electricity encoder and a position sensor which are arranged on the DC brushless electric machine and the pin signal and pedal signal of the industrial sewing machine are separately connected with the central processing unit; and the central processing unit continuously collects the motor speed, calculates the PWM duty ratio of six-way drive waveform and controls the on / off state of the three switching tubes of the middle and lower bridge arms of the bridge rectifier circuit, thus realizing quick shutdown. By using the system of the invention, the shutdown time of the industrial sewing machine can be greatly shortened, the production efficiency can be increased, the shutdown process is stable without causing motor vibration, and the reliability is good.

Owner:YIWU HUACHEN ELECTROMECHANICAL CO LTD

Intelligent safety bus monitoring system

InactiveCN107360038ARepair in timeFull storageSewing-machine control devicesData switching networksData informationMonitoring system

The invention discloses an intelligent safety bus monitoring system comprising a vehicle data server, a remote monitoring terminal and a plurality of vehicle detection terminals. The vehicle detection terminals are used for detecting environmental parameters in buses, the number personnel in buses, and equipment safety situations of the buses and sending the detected data information to the vehicle data server; the vehicle data server receives data information sent by the plurality of vehicle detection terminals; and the management staff obtains information in the vehicle data server by the remote monitoring terminal connected to the vehicle data server. The vehicle detection terminals consist of temperature and humidity detection modules, speed detection modules, positioning modules, electrical equipment detection modules, personnel number statistics modules, control modules and wireless communication modules. According to the invention, the system has functions of vehicle detection and monitoring and is capable of detecting safety of vehicles, so that the vehicle fault occurrence probability is reduced, and the personnel safety is improved; and the vehicle management efficiency by the management staff is increased.

Owner:JACK SEWING MASCH CO LTD

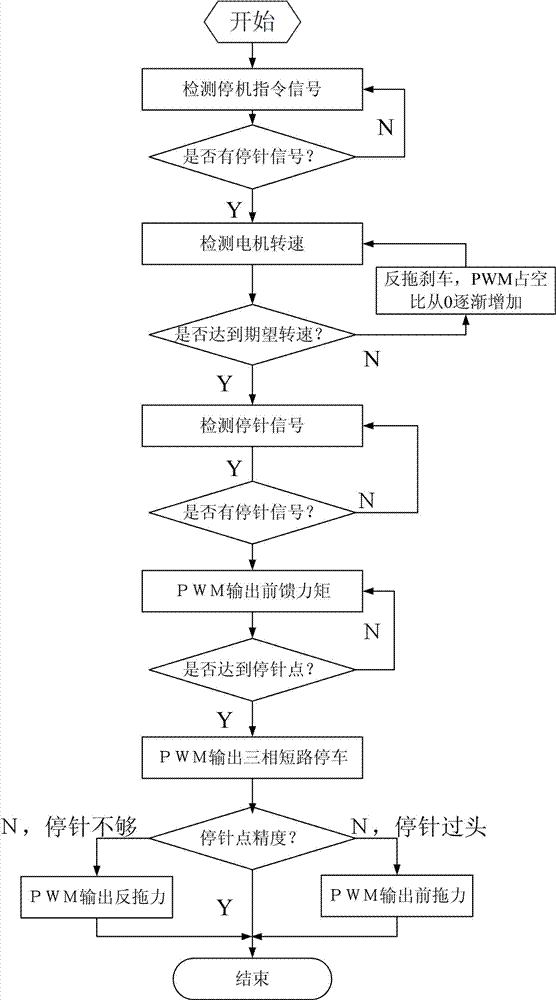

Precise positioning system of industrial sewing machine and working method of precise positioning system

InactiveCN103572514AImprove accuracyEnsure safetySewing-machine control devicesNeedle barsClosed loopComputer module

The invention discloses a precise positioning system of an industrial sewing machine and a working method of the precise positioning system and relates to a positioning system of a sewing machine and a working method of the positioning system. The general phenomena of low stop precision, reversal, shaking, poor stability and the like are caused by a reason that the conventional industrial normal sewing machine positioning method generally adopts an adjustment system with a closed-loop position. The precise positioning system is characterized in that a controller comprises a quick reverse-dragging braking module, a speed adjustment module, a torque feedforward module and a three-phase short-circuit controllable stopping module. According to the technical scheme provided by the invention, the quick reverse-dragging braking module is adopted to enable a servo motor to be deaccelerated quickly, and the speed adjustment module is used for stabilizing the speed within a range; when the sewing machine starts to be positioned near to a trimming point, the sudden load change is maximum, and the torque feedforward module supplies a forward dragging torque in advance to counteract the sudden load change during trimming; when a head of the sewing machine is positioned near to a needle stopping point, the three-phase short-circuit controllable stopping module brakes a three-phase short circuit, so that the problems of inaccurate needle stopping and needle stopping shake, which are caused by reverse-dragging braking, can be solved.

Owner:WOLONG ELECTRIC GRP CO LTD

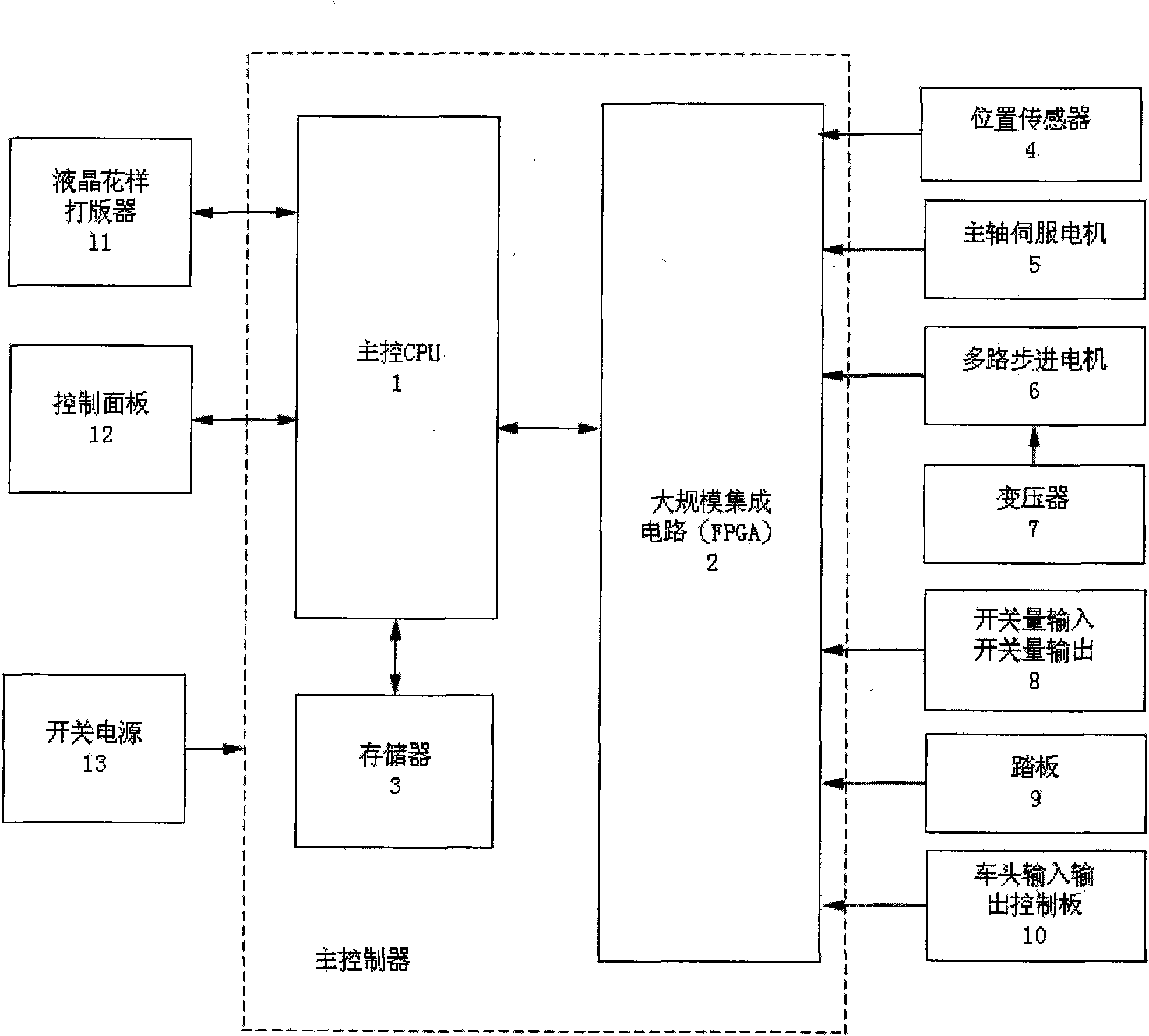

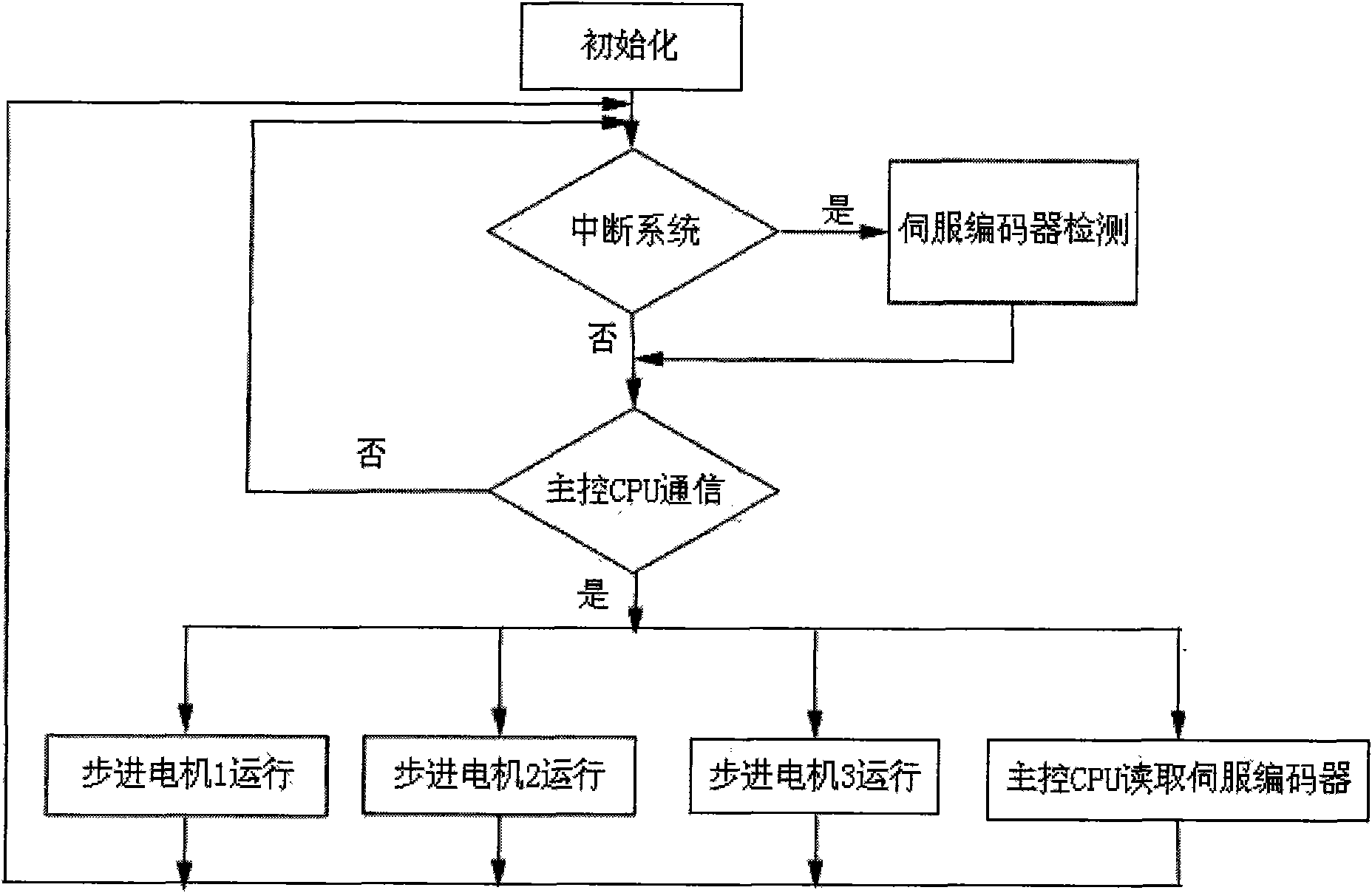

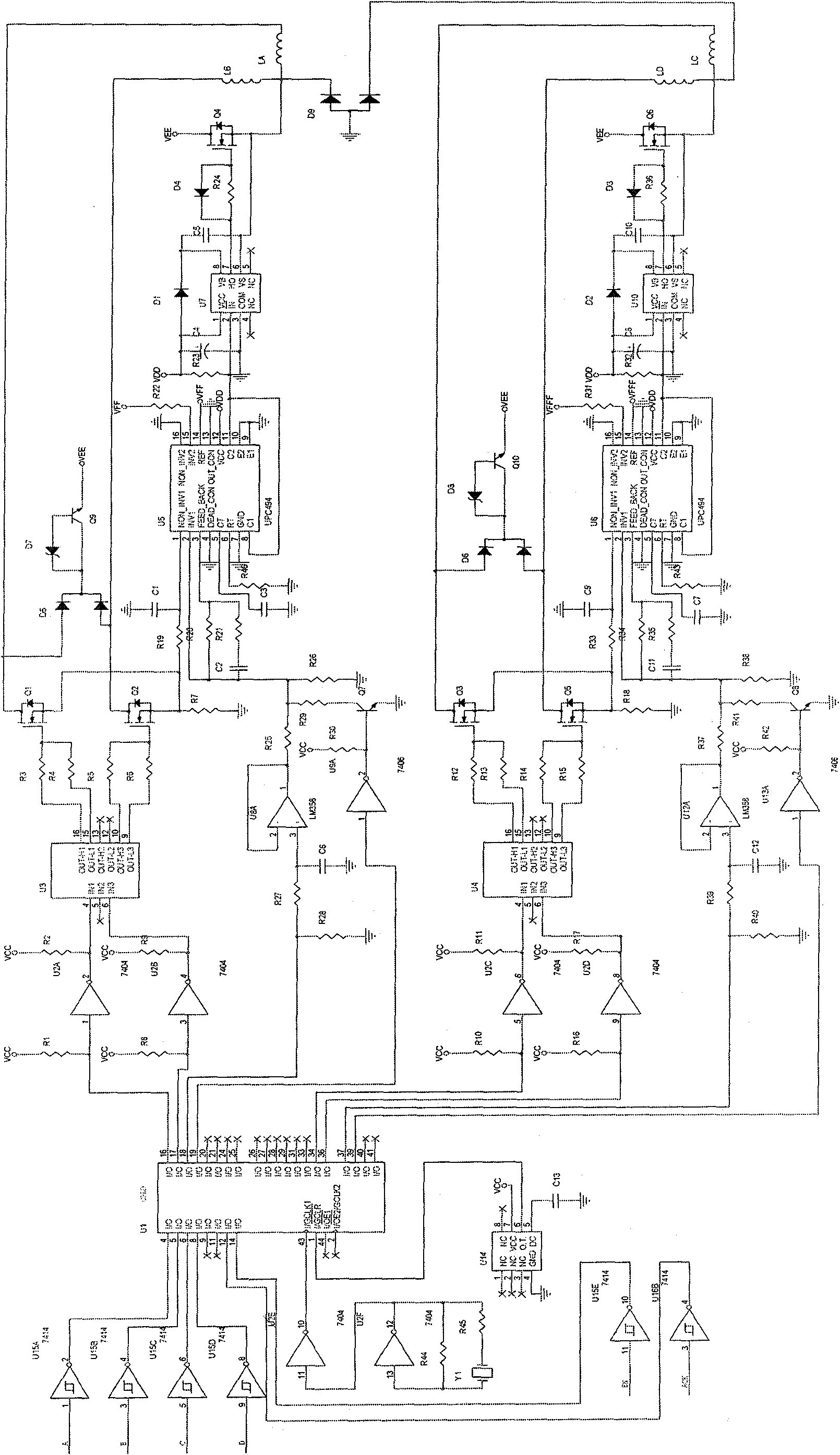

High-speed industrial sewing machine control system based on CPU and FPGA structures

InactiveCN101603246AOverloadReduce loadProgramme-controlled sewing machinesSewing-machine control devicesData accessData file

The invention relates to a high-speed industrial sewing machine control system based on CPU and FPGA structures, comprising a control unit, a memory, a position sensor, an motion unit, an operation display unit, a power supply unit, a auxiliary action unit adopting switching value of input and output and a pedal as a system; wherein the control unit of the invention comprises a master control CPU, FPGA, a front-wheel input and output control panel and a liquid crystal version display device; the memory is used to store system software and data files generated during the operation of the system; the position sensor fixes the position of a machine needle; the motion unit of the invention comprises a spindle servo motor and a multi-way stepping motor; the operation display unit of the invention comprises a control panel; the power supply unit of the invention comprises a switch power supply. The invention mainly uses the CPU and FPGA structures in the control unit; the communication and data access among each unit and the control of the spindle servo motor are completed by the master control CPU; the parts with requirement on fast reaction speed and more calculation workload is completed by FPGA, thereby reducing the load of the main control CPU and improving the operation speed of the speed of industrial sewing machines.

Owner:广州壹体电机科技有限公司

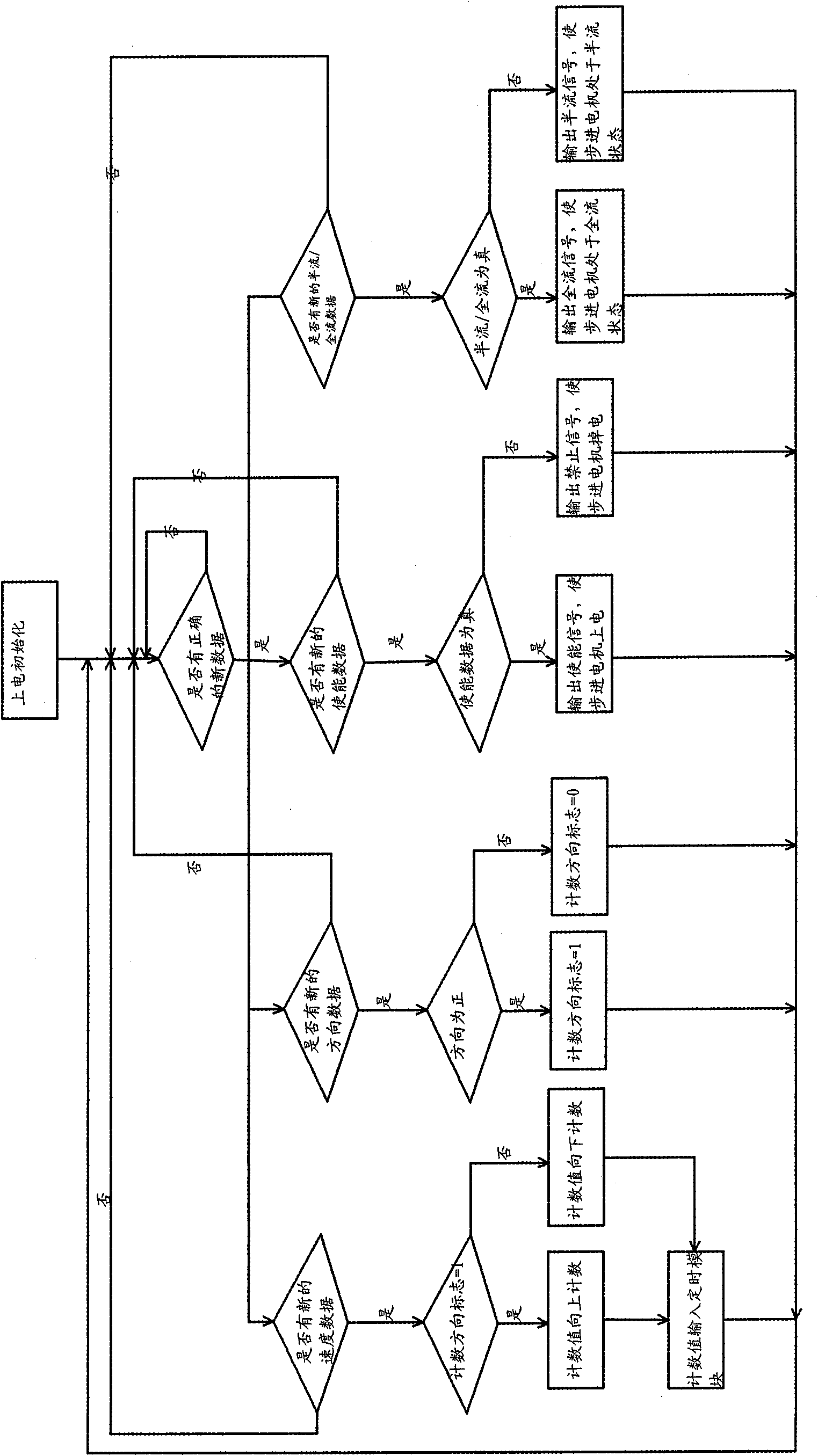

Step motor controller

InactiveCN101594111ASmooth rotationLarge driving torqueProgramme controlComputer controlMicrocontrollerMotor controller

The invention belongs to the technical field of electronics, relates to a hybrid four-phase six-line step motor controller on an industrial sewing machine, and solves the problems that a step motor loses steps, is out of control and the like when the prior step motor controller controls the step motor to run. The step motor controller comprises a controller and a driving circuit of the step motor connected with the controller; the controller comprises a CPLD; the interior of the CPLD is provided with a counter, a timer, a DAC and a dead zone controller respectively, wherein the counter is used for counting positive and negative steering input pulses, the timer is used for providing subdivided time constants, the DAC is used for realizing analog quantity output of an I / O port of the CPLD, and the dead zone controller is used for avoiding short circuit due to synchronous starting of upper and lower bridges in the driving circuit; and a signal input end of the CPLD is connected with an external singlechip, and an output end of the CPLD is connected with the driving circuit. The step motor controller has the advantages that the step motor does not lose the steps, is not out of control during operation and the like.

Owner:ZHEJIANG NEW FEIYUE CO LTD

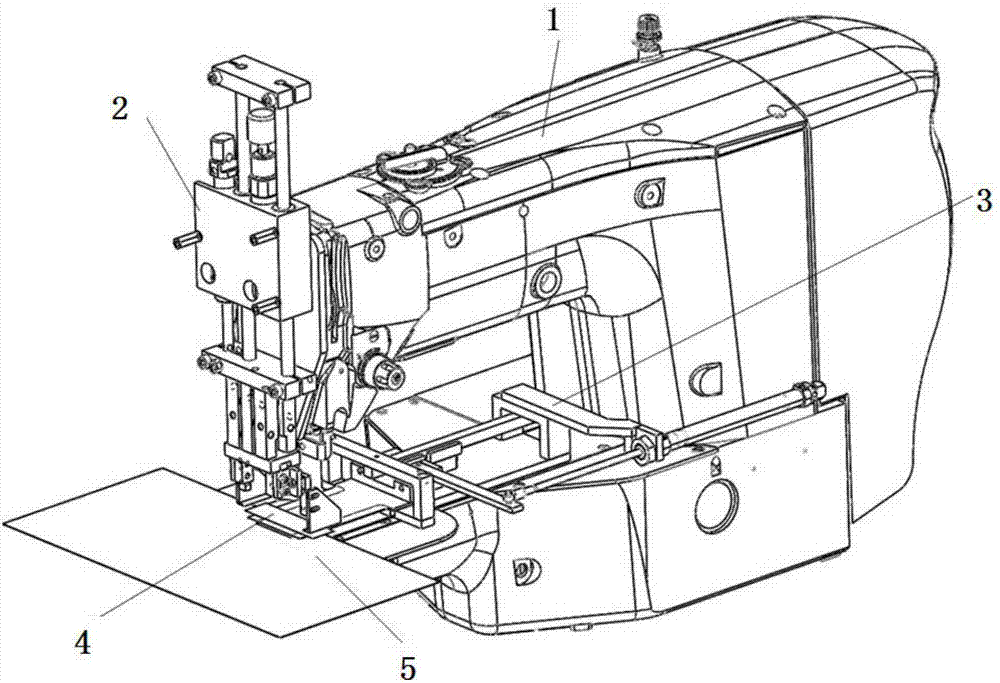

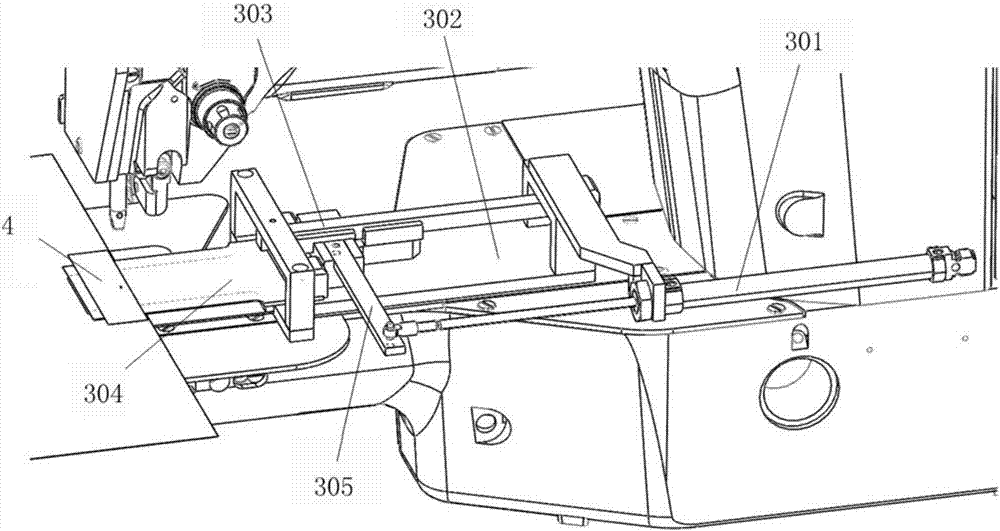

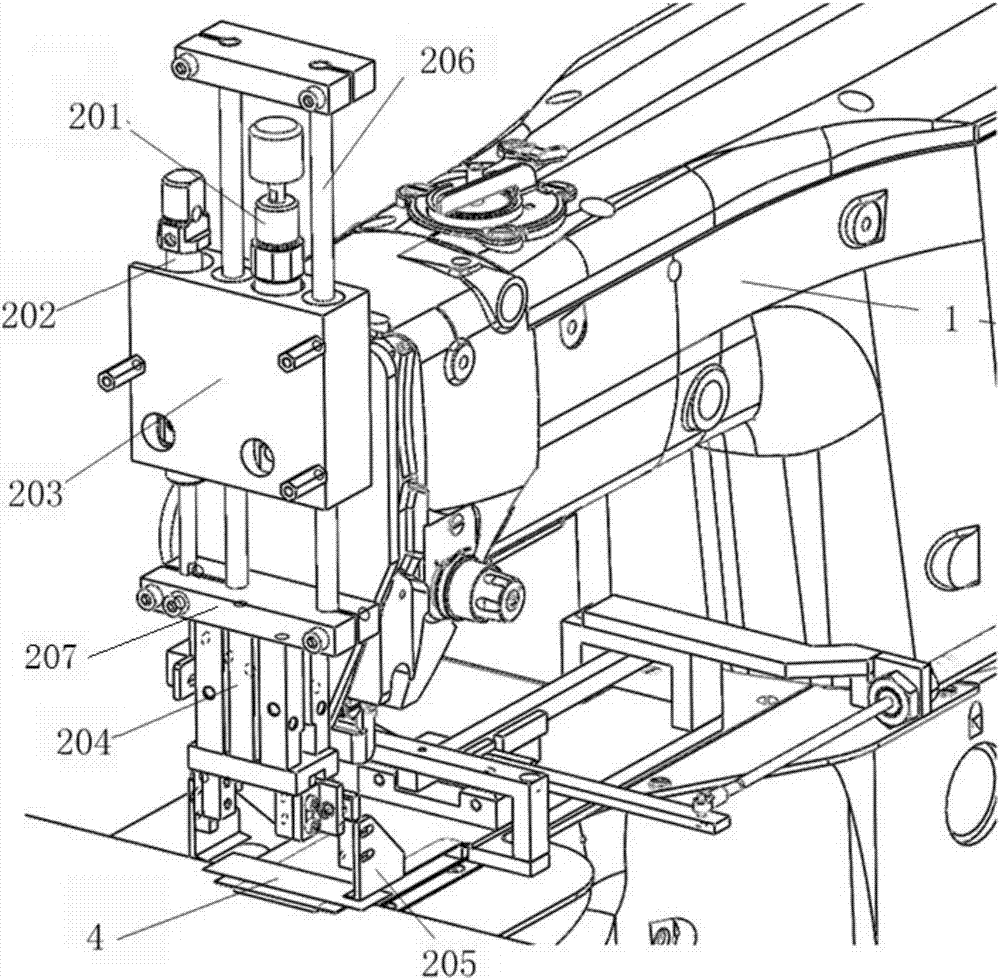

Automatic folding and sewing equipment of labels

PendingCN107401001ARealize fully automatic foldingImprove folding efficiencyWork-feeding meansEngineeringIndustrial sewing machine

The invention provides automatic folding and sewing equipment of labels. The automatic folding and sewing equipment of labels comprises an industrial sewing machine, a folding mechanism and a material supporting mechanism, wherein the folding mechanism is arranged on a machine head of the industrial sewing machine; the material supporting mechanism is arranged at the lower part of the industrial sewing machine; the labels are folded by the folding mechanism after being sent below the folding mechanism by the material supporting mechanism, then the folded labels are sewn onto a piece of fabric by the industrial sewing machine; the material supporting mechanism consists of a label supporting plate and a supporting plate driving device; the supporting plate driving device pushes the label supporting plate to a sewing position and retracts the label supporting plate after completion of folding; the folding mechanism consists of a material folding clamping jaw and a clamping jaw driving device; the clamping jaw driving device drives the material folding clamping jaw to move up and down; material folding clamping devices are arranged at both ends of the bottom of the material folding clamping jaw; the material folding clamping devices are driven to retract inward when the material folding clamping jaw is lowered onto the label supporting plate, so that both ends of each label placed on the label supporting plate are folded inward. Through the adoption of the automatic folding and sewing equipment of labels disclosed by the invention, automatic folding of the labels can be achieved, and the sewing efficiency and the sewing quality of the labels are improved.

Owner:JACK SEWING MASCH CO LTD

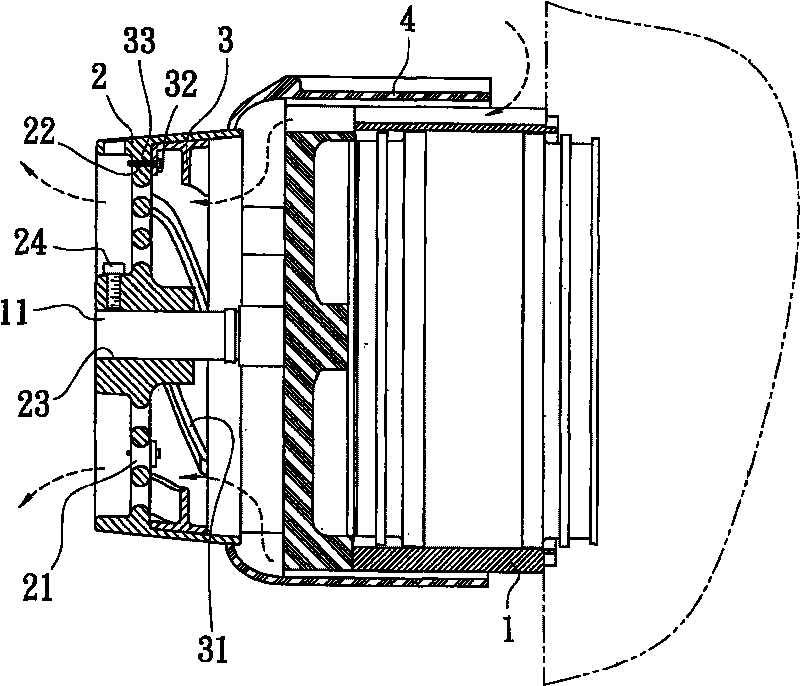

Direct-drive motor heat sink of industrial sewing machine

InactiveCN101705587AGuaranteed service lifeImprove cooling effectLubrication/cooling devicesSewing-machine control devicesDrive motorHeat sink

The invention relates to a direct-drive motor heat sink of an industrial sewing machine, wherein a hand wheel is assembled correspondingly at the back end of a main shaft of a direct-drive motor for supplying power to a sewing machine stand, a radiator fan is assembled at a part corresponding to the direct-drive motor in the interior of the hand wheel, and an outer shell is sleeved at the outside of the direct-drive motor to the hand wheel to form a diversion channel. Compared with the prior art, the invention disperses the high temperature generated by the operation of the direct-drive motor by the radiator fan through vents of the hand wheel, simultaneously ensures the diversion channel to form a cross-ventilated pipeline so as to realize the excellent heat radiating effect and ensure the service life of the direct-drive motor.

Owner:顾飞龙

Adhesive tape type fabric sucker for industrial sewing machine

ActiveCN105063903APrecise lateral delivery toModerate adsorptionWork-feeding meansDrive wheelEngineering

The invention relates to an adhesive tape type fabric sucker for an industrial sewing machine. The sucker comprises a shell, wherein a cylinder is vertically installed in the shell, a telescopic ejector rod of the cylinder is fixedly connected with an adhesive tape rotation mechanism, and the adhesive tape rotation mechanism moves up and down along guiding grooves in the two sides of the shell under the driving of the cylinder; a one-way wheel and a driven wheel are fixed to the adhesive tape rotation mechanism, the one-way wheel is provided with a rocker arm, a limiting component is arranged on the shell, and the rocker arm is located in the vertical space of the limiting component; adhesive tape is wound around the one-way wheel and the driven wheel, the inner side of the adhesive tape is attached to a sucker body in a sliding mode, and the sucker body is connected to the lower portion of the adhesive tape rotation mechanism; when the rotation mechanism 4 is lifted up, fabric disengages from the adhesive tape to fall into a required area under the relatively outward action force of the shell, so that disengagement is achieved; meanwhile, the rocker arm rotates in the forward direction under the action of the limiting component, and the one-way wheel rotates in the forward direction to drive the adhesive tape to advance by the length of one sucker body; when the rotation mechanism is pressed downwards, the rocker arm rotates in the reverse direction freely under the action of the limiting component to conduct adsorption, and the one-way wheel restores freely in the reverse direction.

Owner:SHANGHAI WEISHI MACHINERY

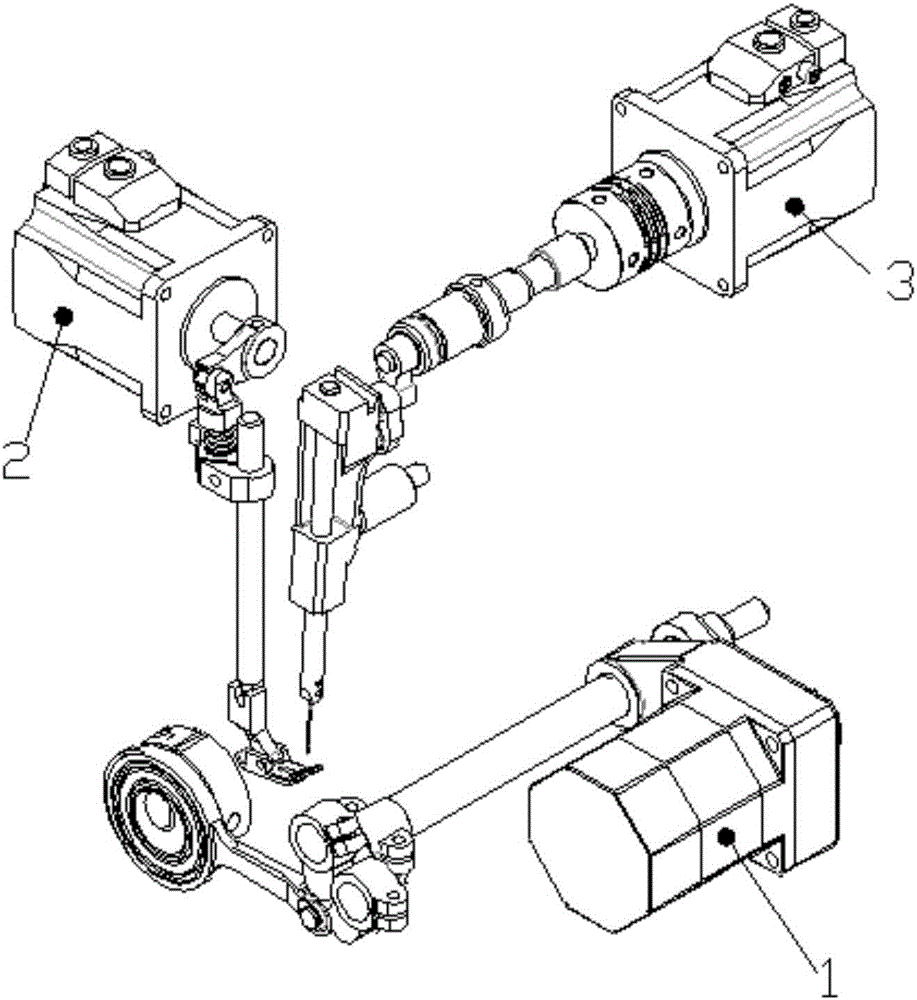

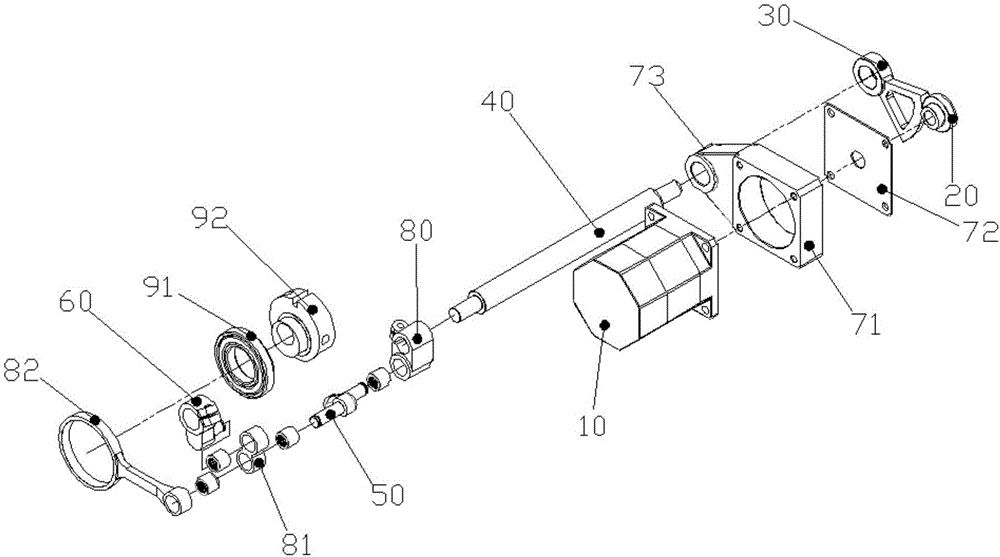

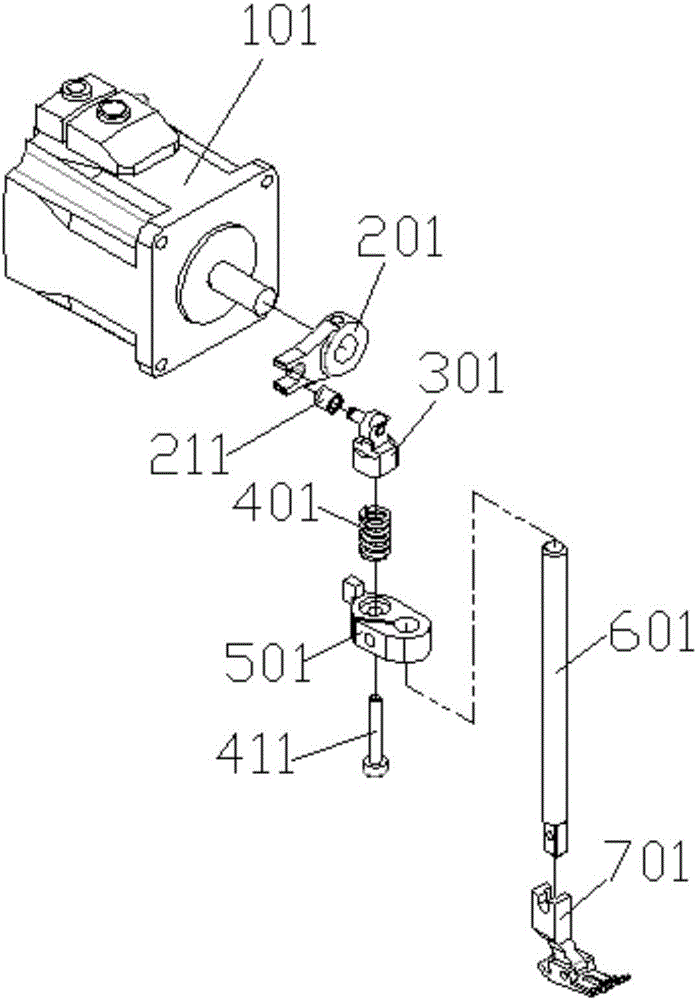

Industrial sewing machine

ActiveCN106637701APrecise stitch settingReal-time track changeProgramme-controlled sewing machinesSewing-machine control devicesEngineeringIndustrial sewing machine

The invention provides an industrial sewing machine which comprises a control device, an electronic stitch length control device, a self-adaption presser foot device and a needle rod swing device. The industrial sewing machine has the advantages of being precise in stitch setting and capable of achieving rail changing in real time, and the problems that a high-speed parallel sewing machine is single in function and cannot achieve decorative sewing and pattern sewing are solved. The industrial sewing machine can provide adaptive pressure according to sewing speed and the thickness of cloth, therefore, the sewing stitch meets requirements, the quality of a sewn product is improved, and an automatic pressure foot lifting function is integrated. The industrial sewing machine synchronizes with a feeding mechanism through swinging, then the sewing precision and quality of the stitch are improved, the problem of layer staggering of feeding and discharging commonly existing in the sewing process is solved, and the quality of the sewn product is improved.

Owner:苏州沃瑞豪兹自动化设备有限公司

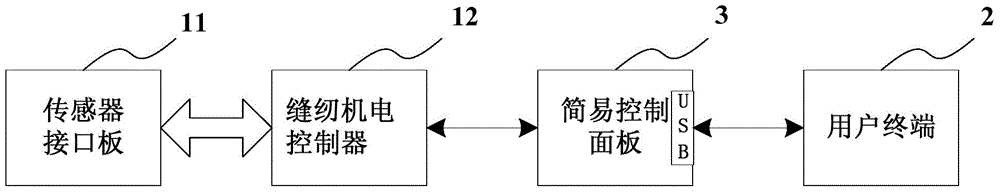

Simple control system of sewing machine

ActiveCN104018299AStructure optimization and streamliningLow costSewing-machine control devicesControl systemExecution control

The invention provides a simple control system of a sewing machine. A simple control panel with a USB interface is connected to an electric controller of an industrial sewing machine, so that the electric controller is connected to the simple control panel through a mobile phone or a panel personal computer or a user-defined mobile device or other user mobile terminals, and then an operator can input an action execution instruction to the electric controller of the sewing machine on the simple control panel; a mechanical worker can achieve parameter setting, action execution control and the like for the electric controller of the sewing machine through an APP at the user mobile terminal. An existing complex operating panel is omitted, the structure is simplified and optimized, the cost is saved, operation is more convenient and automatic, and the working efficiency and quality of the sewing machine are improved.

Owner:JACK SEWING MASCH CO LTD

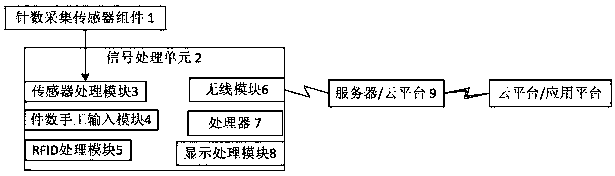

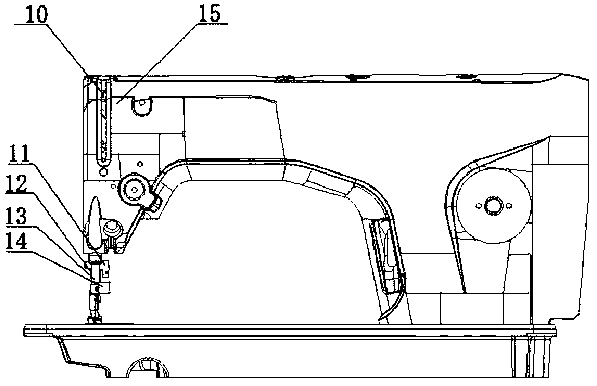

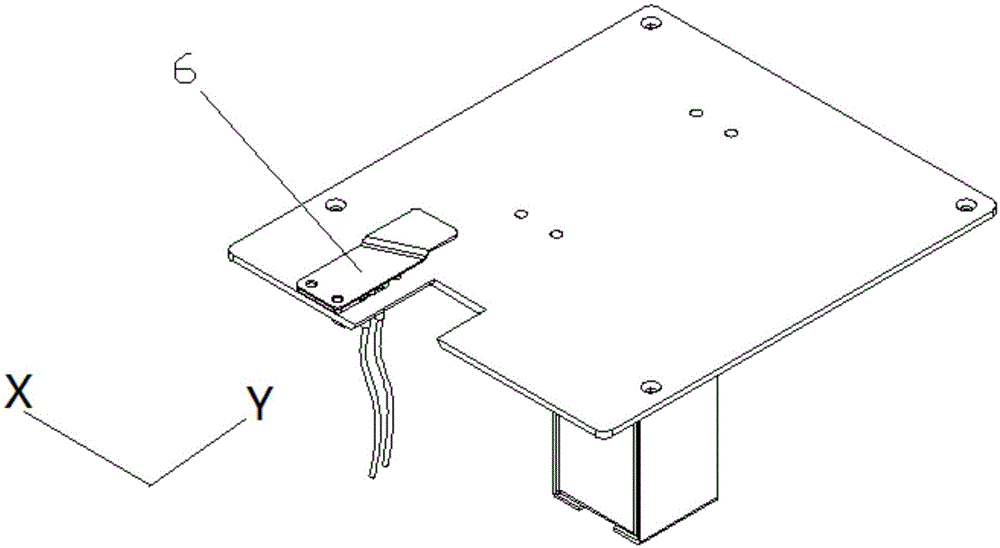

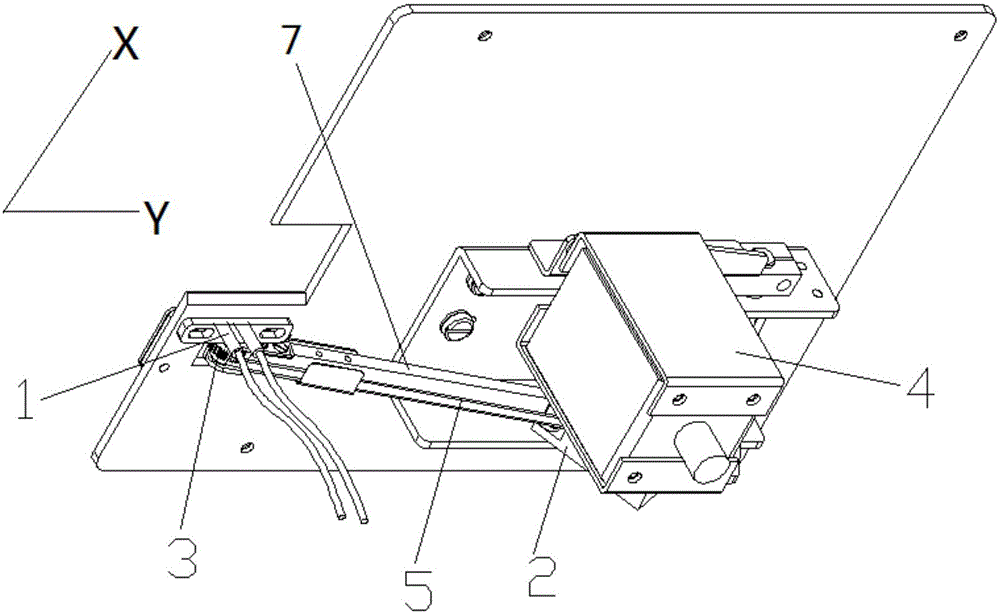

Device for collecting needle number of industrial sewing machine and piece counting method

InactiveCN109554833AEasy to adjustKnow the running status in real timeProgramme-controlled sewing machinesSewing-machine control devicesProcess efficiencyManufacturing enterprises

The invention discloses a device for collecting needle number of an industrial sewing machine and a piece counting method and belongs to the technical field of garment producing and sewing. The devicecomprises a sewing machine relative movement mechanism, a needle number collection sensor component (1), a signal processing unit (2) and a server / cloud platform (9), and the needle number collectionsensor component (1) is mounted on the sewing mechanism relative movement mechanism and connected with the signal processing unit (2) which collects data of a needle number collection sensor (1) andsends the same to the server / cloud platform (9). The device is simple and convenient to mount, real-time state of sewing equipment is collected in real time and uploaded to a corresponding applicationplatform for data analysis and display, and circumstances like on-site order and environment are combined to know running state of each machine, personnel working condition and production processingprogress in real time, timely find unbalance of process and yield and timely solve the unbalance, so that processing efficiency of manufacturing enterprises and accuracy of delivery time are improved.

Owner:杭州衡朗科技有限公司

Automatic edge control device of industrial sewing machine

ActiveCN105063907ARealize automatic edge controlQuality improvementWork-feeding meansStopped workMotor drive

The invention relates to an automatic edge control device of an industrial sewing machine. The automatic edge control device comprises a platform, and a pressing plate is fixedly arranged on the platform. The feeding direction of sewing material is the X direction, and the direction perpendicular to the horizontal direction is the Y direction. A motor and an electromagnet are fixedly arranged on the lower portion of the platform, the motor drives a synchronous belt to rotate, the synchronous belt is installed on a rigid rocker arm, an ejector rod of the electromagnet ejects the rigid rocker arm up, the upper end of a ratchet presses cloth on the lower end face of the pressing plate, and friction force between the sewing material and the pressing plate is much smaller than that between the ratchet and the cloth. A pair of photoelectric switches are arranged at the parts, close to the sewing portion, of the platform in the Y direction; when the photoelectric switch on the inner side can not detect the sewing material, the motor works in the forward direction, and the synchronous belt drives the ratchet to rotate in the forward direction so that the sewing material can move outwards. When the photoelectric switch on the outer side senses the sewing material, the motor works in the backward direction, the synchronous belt drives the ratchet to rotate in the reverse direction until the photoelectric switch on the outer side can not sense the sewing material, and then the motor stops working.

Owner:SHANGHAI WEISHI MACHINERY

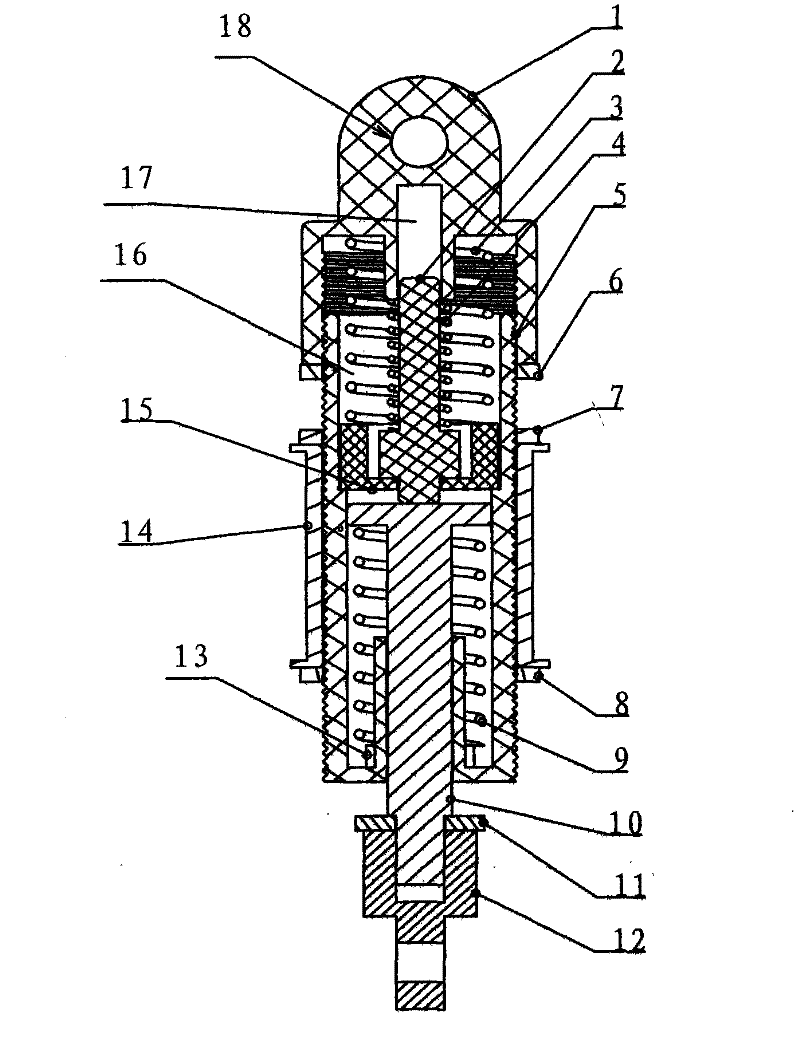

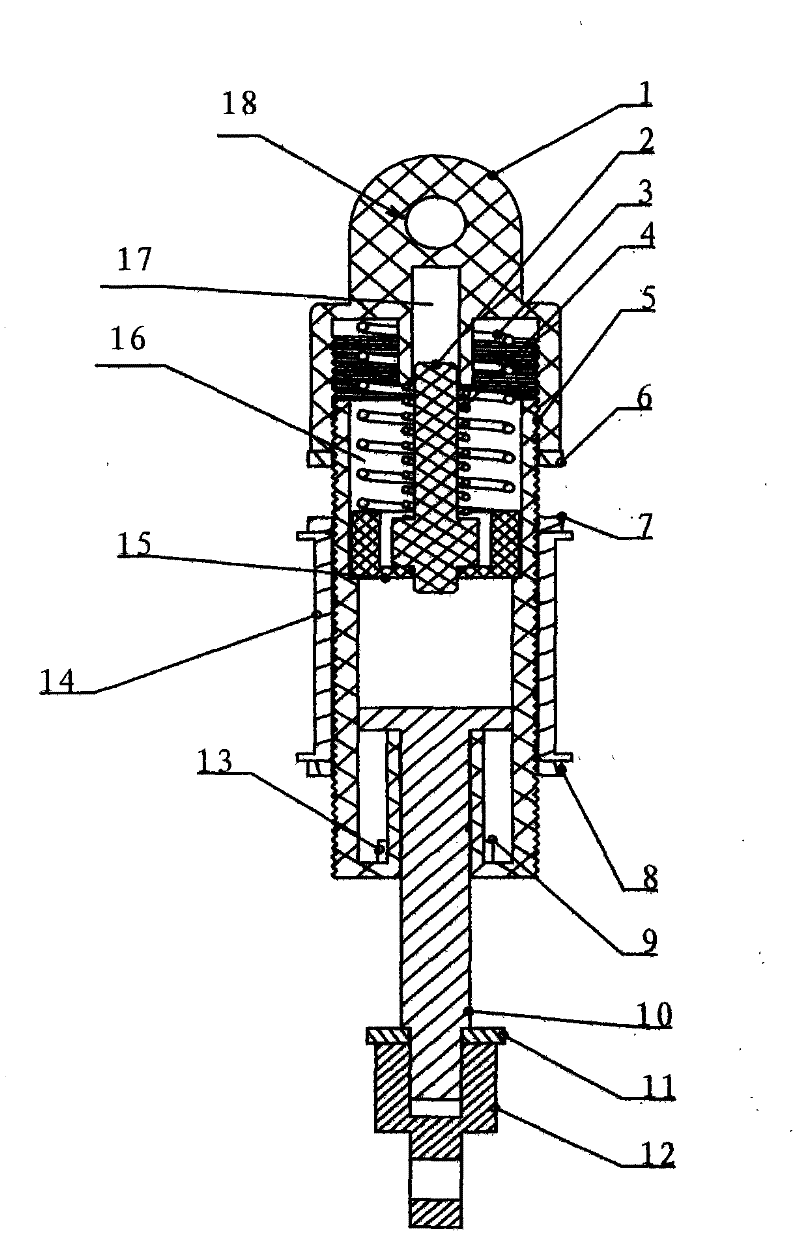

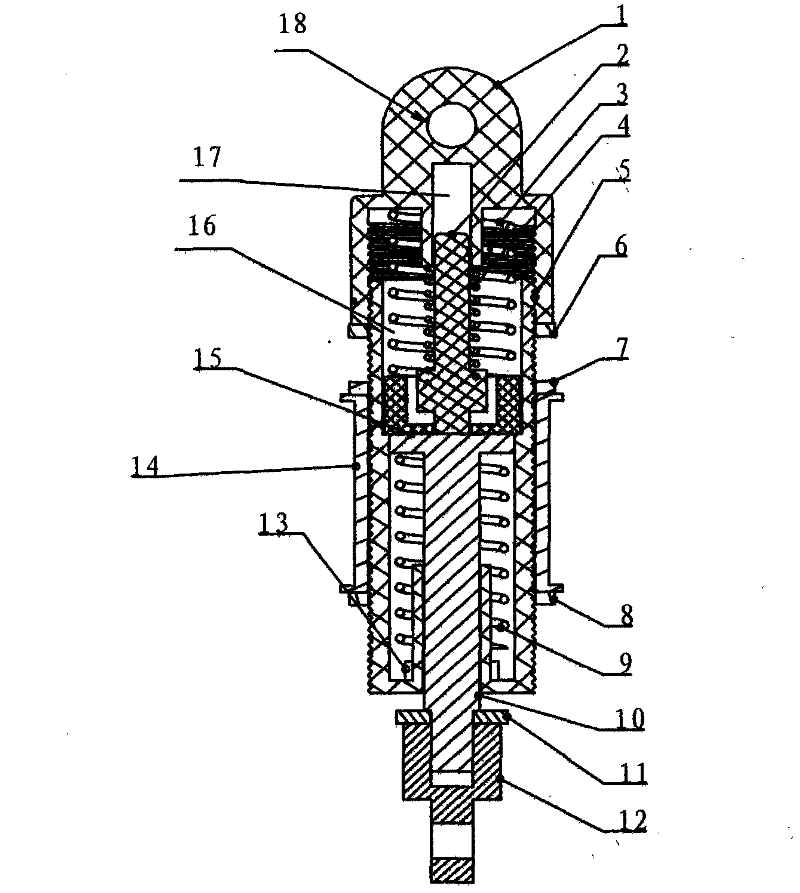

Integrated Inductive Pedal for Industrial Sewing Machines

ActiveCN102268789ARealize functionReduce distractionsSewing-machine control devicesBiochemical engineeringInductor

The invention discloses an integrated inductor pedal for an industrial sewing machine. The integrated inductor pedal comprises a sleeve shaped pedal shell, wherein the exterior of the pedal shell is sleeved with an inductor; one end of the pedal shell is provided with a pedal cover; a step shaped inner hole is arranged in the pedal shell; an iron core which is slidable up and down along the innerhole and is used for interacting with the inductor is arranged in the inner hole of the pedal shell; a running spring is arranged between the iron core and the pedal shell; and one end of the iron core stretches out from the other end of the pedal shell to be connected with a joint, and an elastic jacking device is arranged between the other end of the iron core and the pedal cover. The integrated inductor pedal for the industrial sewing machine has the advantages of higher stability and precision, small interference, smaller volume and little occupation space.

Owner:ZHEJIANG HMC

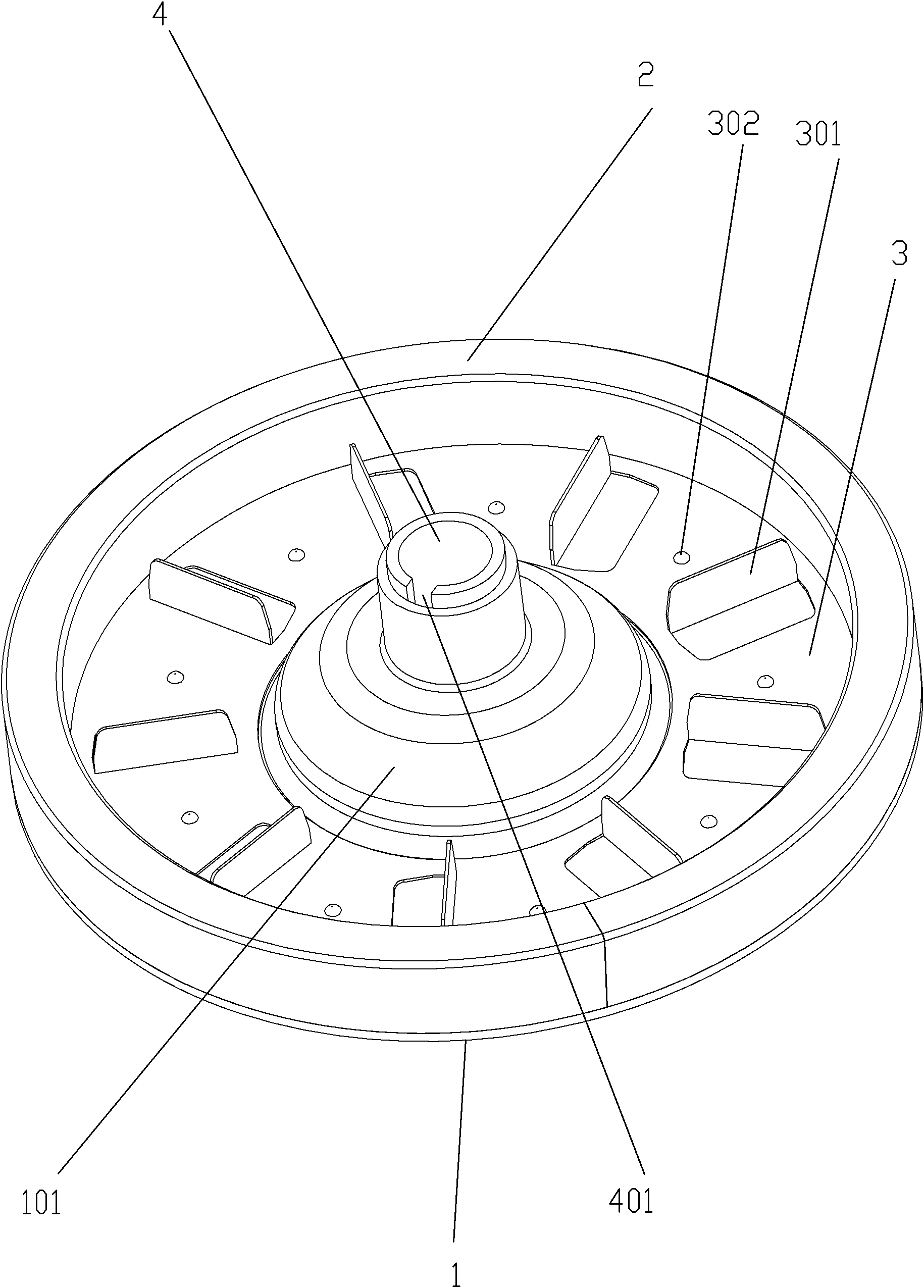

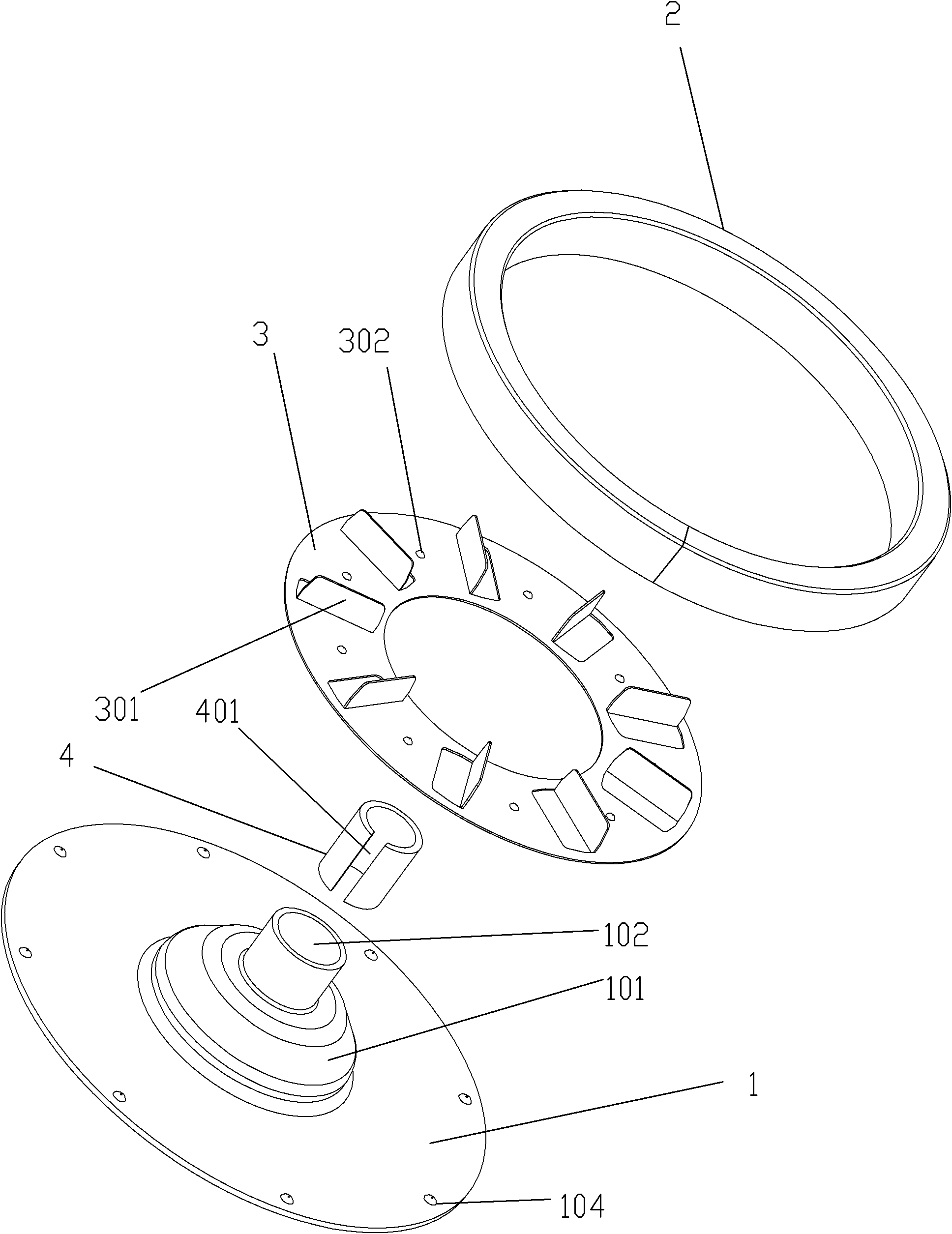

Motor clutching flywheel of industrial sewing machine and manufacturing method thereof

The invention discloses a motor clutching flywheel of an industrial sewing machine. The key point of the technical scheme is that: the flywheel comprises a flywheel flat plate manufactured by stamping, wherein a coupling part which is bulged backwards is arranged on the flywheel flat plate; the rear side of the flywheel flat plate is fixedly connected with a flywheel ring; and an impeller which is connected with the flywheel flat plate in a tight attaching way is arranged in the flywheel ring. In order to overcome the defects in the prior art, the motor clutching flywheel of the industrial sewing machine, which has a simple structure and low manufacturing cost and is stably operated, is provided; and the invention also provides a manufacturing method of the flywheel.

Owner:中山市天虹电机制造有限公司

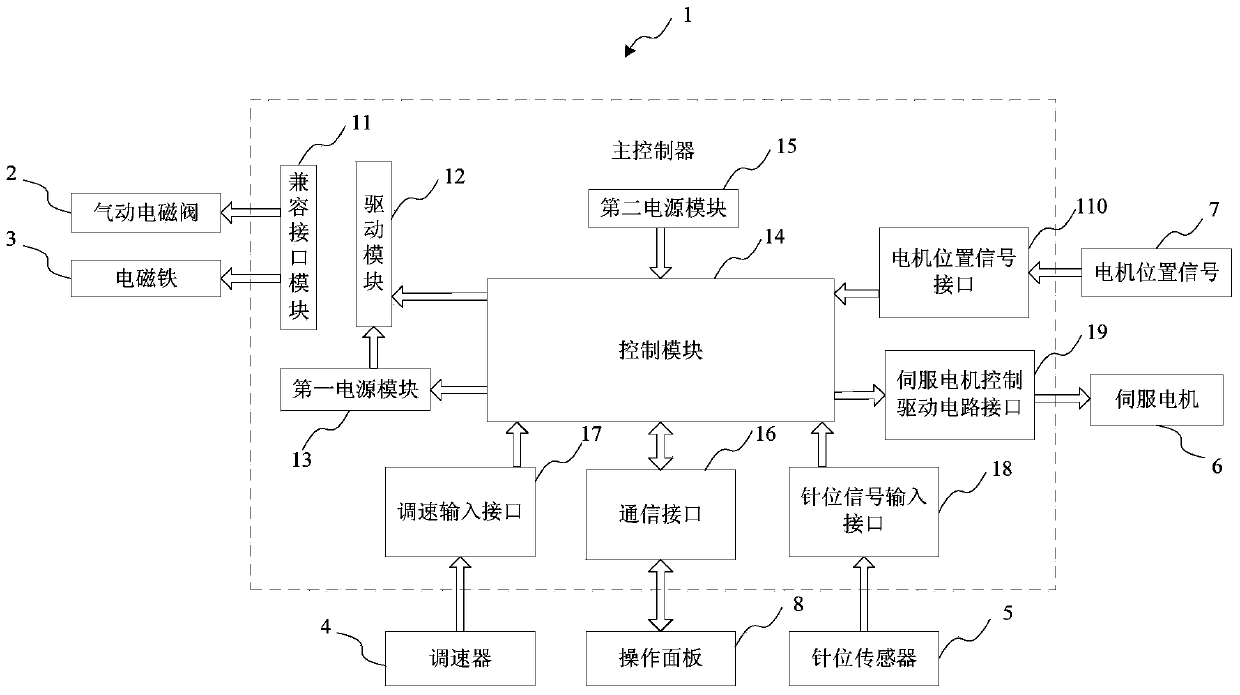

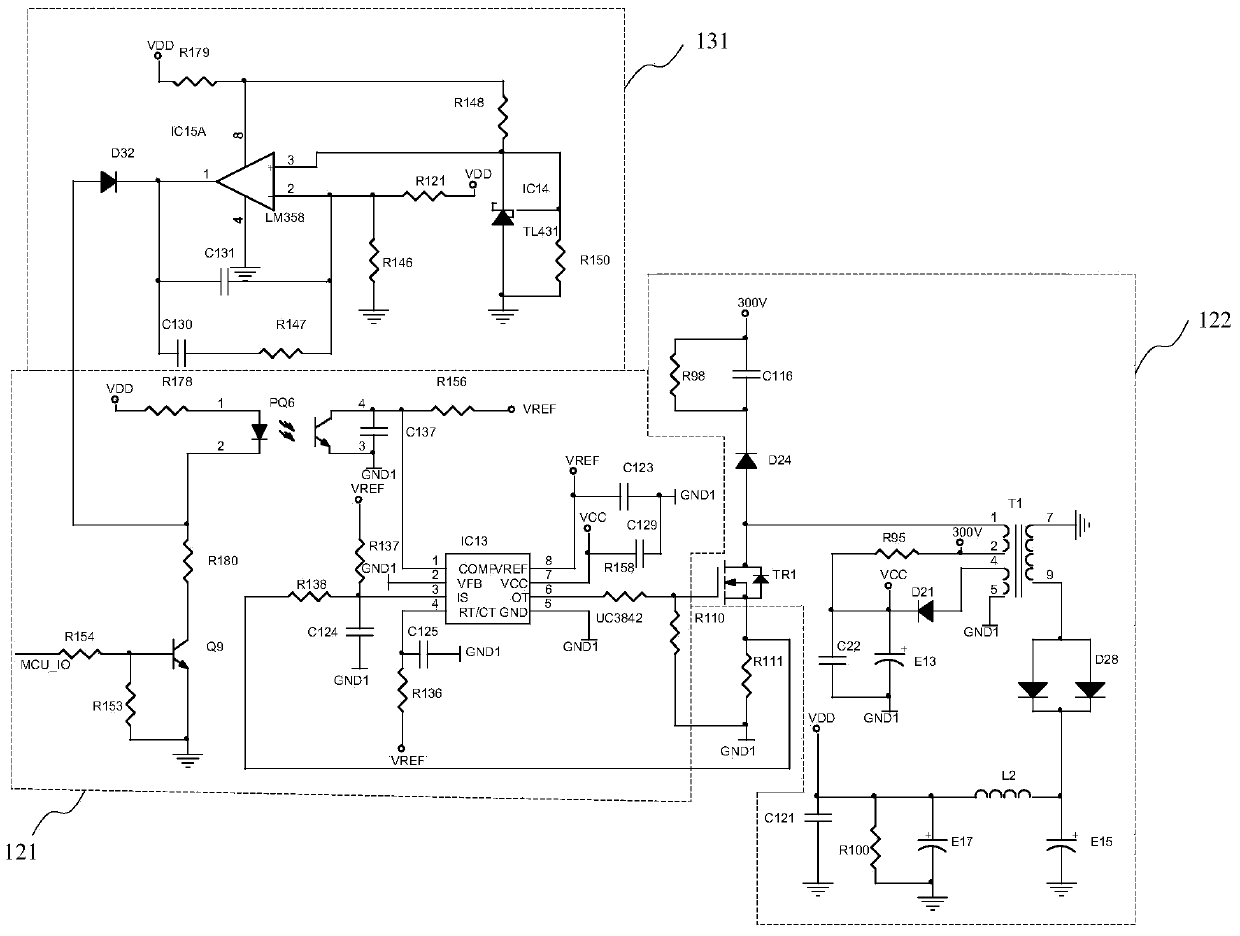

Control device for industrial sewing machines

ActiveCN103696167ASolve the problem of incompatibility controlLow costSewing-machine control devicesCommunication interfaceOperating point

The invention provides a control device for industrial sewing machines. The control device comprises a compatible interface module, a drive module, a first power module, a control module, a second power module, and a peripheral interface. The compatible interface module is used for providing an interface which can be connected with both a pneumatic electromagnetic valve and an electromagnet. The drive module generates different drive voltages to drive the pneumatic electromagnetic valve and the electromagnet according to different control signals. The first power module is used for providing the drive module with operating power and controlling and regulating the operating power. The control module is used for outputting different control signals to the drive module. The second power module is used for providing the control module with operating power. The peripheral interface is used for connecting the control module and a peripheral device. The control module is connected with an operating panel through a communication interface. The operating panel is operated to drive the control module to generate the different control signals. Through the application of the control device, the problem that the pneumatic electromagnetic valve and the electric electromagnet in the existing industrial sewing machines cannot be compatibly controlled is effectively solved.

Owner:ZHEJIANG ZOBOW MECHANICAL & ELECTRICAL TECH

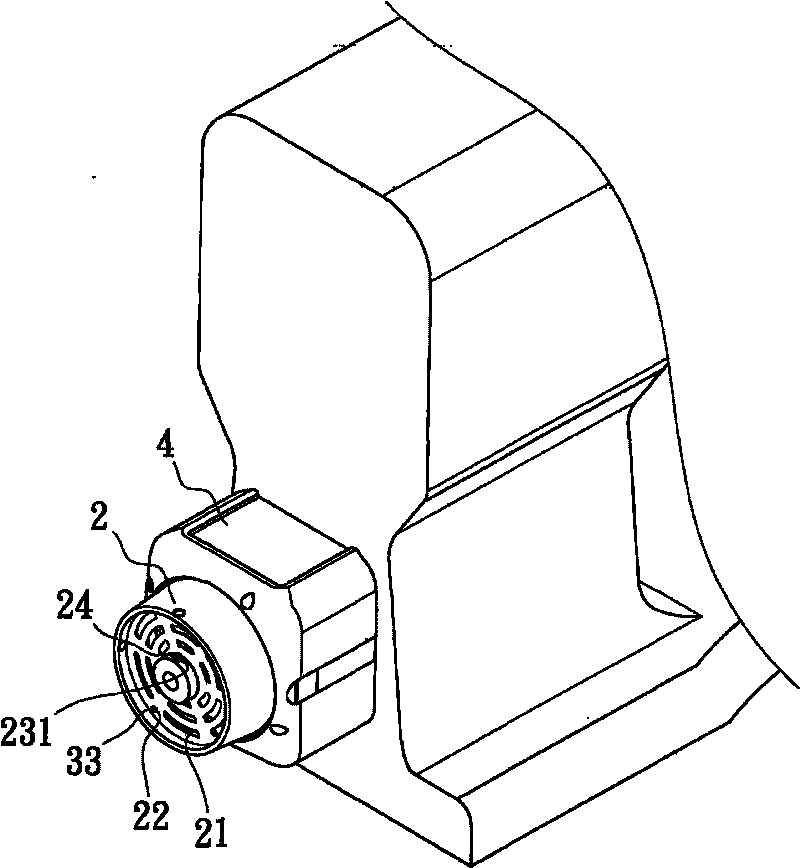

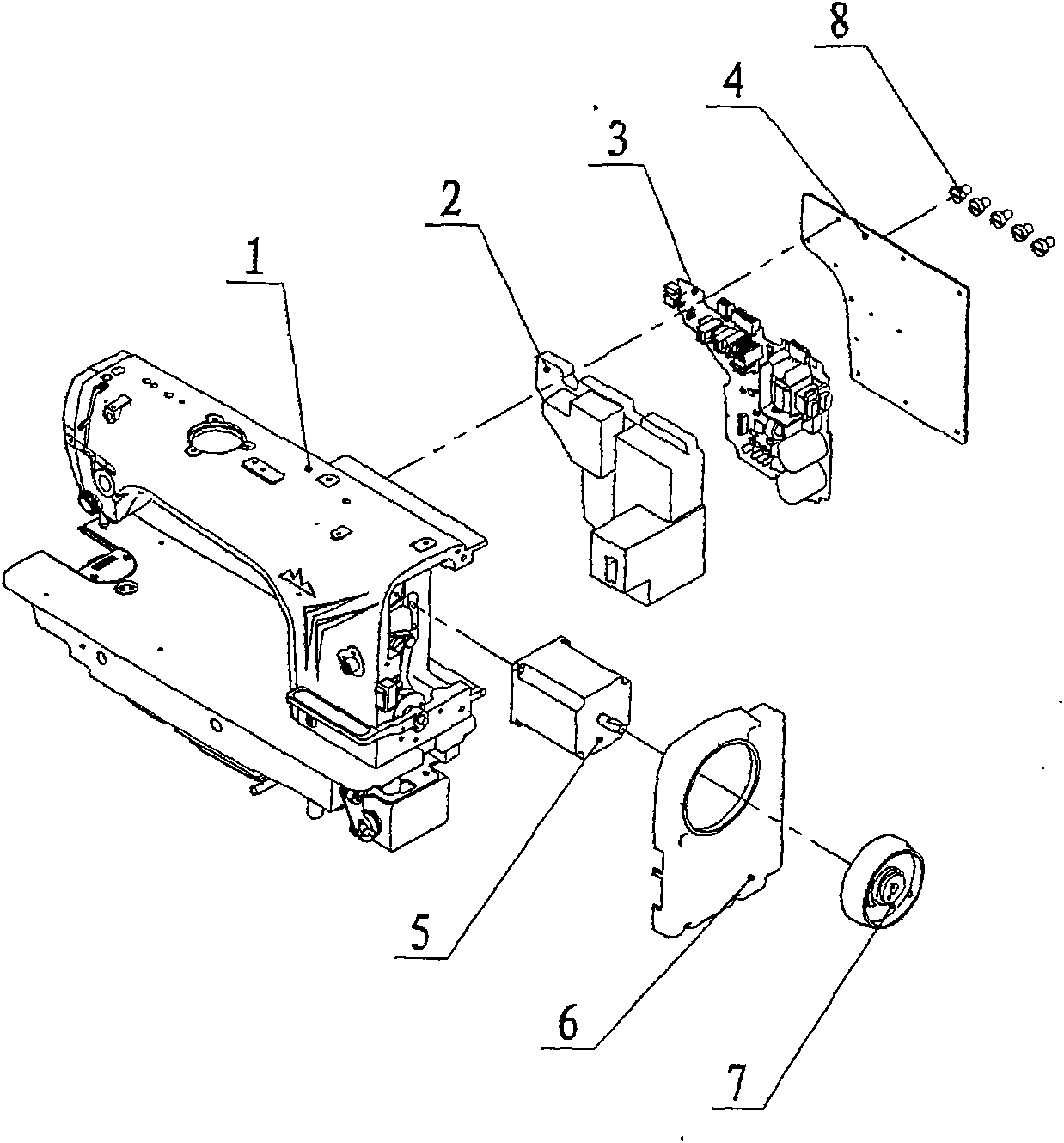

Electromechanically integrated industrial sewing machine

InactiveCN101575776AReduce volumeHigh degree of integrationSewing-machine control devicesServo actuatorElectric machinery

The invention relates to industrial sewing machine technology, in particular to an electromechanically integrated industrial sewing machine and aims at overcoming the defects of the existing direct-drive industrial sewing machine that the integration level is low; the number of exposed socket connectors is large; the packing cost is high; and transportation is inconvenient and the using effect is unstable. The electromechanically integrated industrial sewing machine provided by the invention adopts the following technical proposal: a servo-actuator (5) is arranged on a main shaft of a sewing machine head (1); a servo-actuator cover (6) and a servo-actuator hand-wheel (7) are arranged outside the servo-actuator (5); a controller box (2) is arranged on the back window of the sewing machine head (1); an electronic controller (3) is arranged inside the controller box (2); and an aluminium alloy back cover board (4) is adhered at the back of the electronic controller (3) so as to be fixed on the controller box (2). The invention has the advantages of small volume, high integration, non-exposed socket connector, low packing cost, convenient conveying process, easy mounting and usage process and stable using effect.

Owner:上海富山精密机械科技有限公司

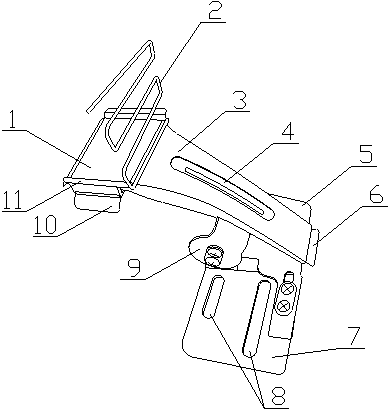

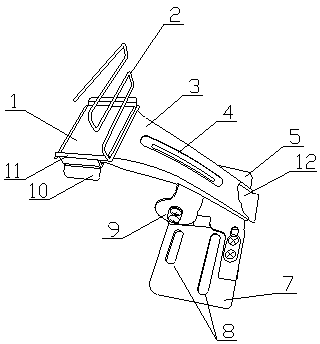

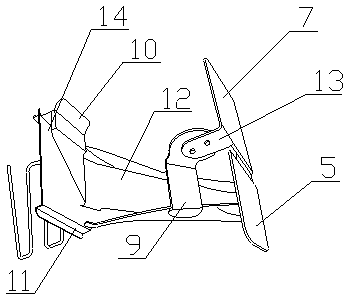

Novel front fly sewing hemmer

InactiveCN103451862APlay the role of leveling cloth stripsImprove work efficiencyWork-feeding meansEngineeringIndustrial sewing machine

The invention discloses a novel front fly sewing hemmer. The novel front fly sewing hemmer comprises a pedestal and a hemmer, wherein the hemmer comprises a housing, a cloth guide sheet, a cloth guide table and a cloth guide supporting frame; the cloth guide sheet is arranged in the housing; the cloth guide table is arranged behind the housing; an upper cloth feeding inlet is formed above the cloth guide table, and a lower cloth feeding inlet is formed below the cloth guide table; the cloth guide supporting frame is zigzag; the lower end of the cloth guide supporting frame is welded above the tail part of the housing and close to the upper cloth feeding inlet; the housing stretches in a trumpet shape towards the cloth guide table from the front end; a gap is reserved between the housing and the cloth guide sheet; the front end of the cloth guide sheet is provided with a cloth guide outlet which extends out of the front end of the housing. The sewing hemmer is matched with an industrial sewing machine, so that the working efficiency is high, and a cloth strip leveling effect can also be achieved when the cloth strip passes through the cloth guide supporting frame to facilitate machining.

Owner:JIAXING YONGCHENG GARMENTS

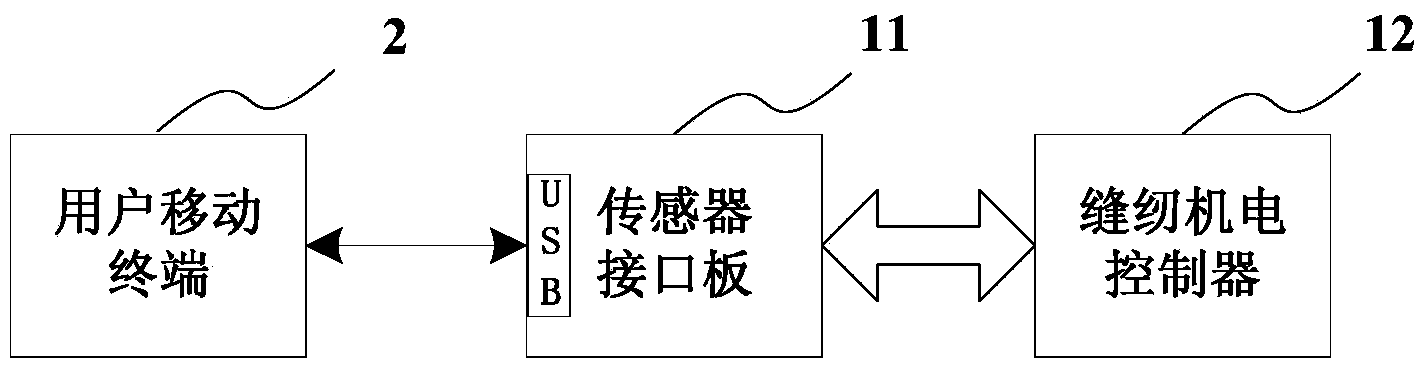

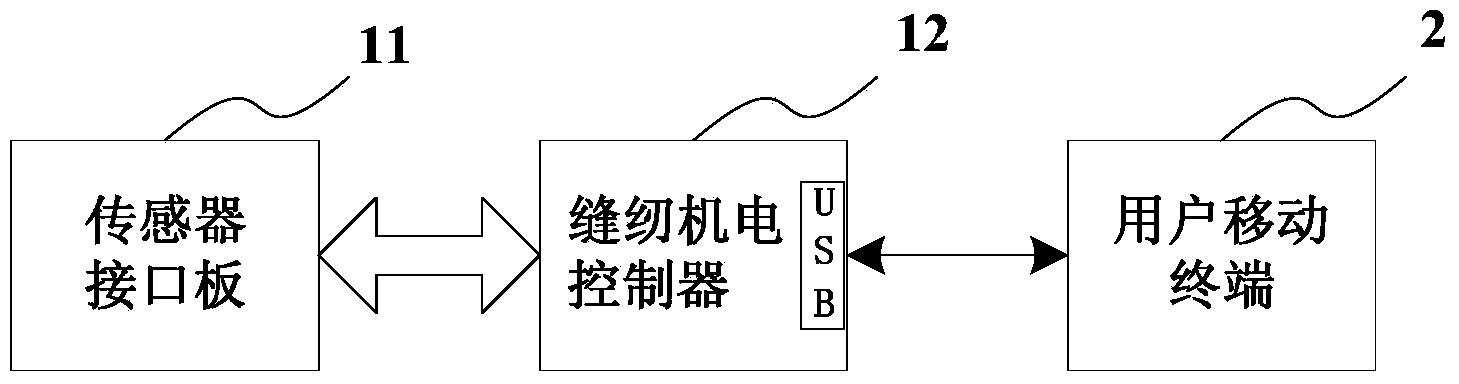

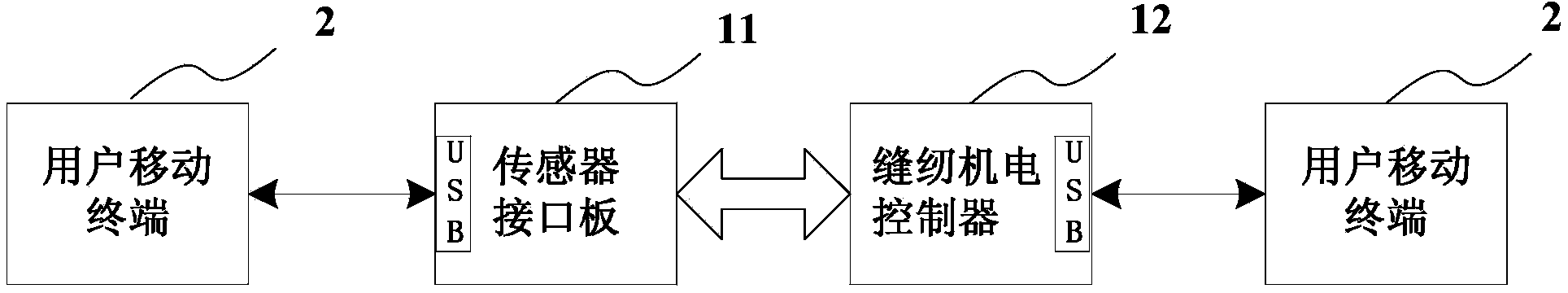

Sewing machine control system with USB (universal serial bus) interface

InactiveCN104035353AStructure optimization and streamliningLow costProgramme control in sequence/logic controllersTablet computerControl system

The invention provides a sewing machine control system with a (universal serial bus) interface. By adding the USB interface on a sensor interface board of an industrial sewing machine and / or an electric controller of the sewing machine, a mechanist or an operator is enabled to finish parameter setting, action execution controlling, searching work parameters and the like for the electric controller of the sewing machine by mounting an App (application) of a corresponding mobile terminal on a mobile phone, or a tablet computer or a user-defined mobile device like the tablet computer. The sewing machine control system with the USB interface has the advantages that a current complex operation panel is omitted, a structure is simplified and optimized, cost is lowered, operation is facilitated and automated, and sewing work efficiency and quality are improved.

Owner:JACK SEWING MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com