Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1023 results about "Polyvinyl butyral" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyvinyl butyral (or PVB) is a resin mostly used for applications that require strong binding, optical clarity, adhesion to many surfaces, toughness and flexibility. It is prepared from polyvinyl alcohol by reaction with butyraldehyde. The major application is laminated safety glass for automobile windshields. Trade names for PVB-films include KB PVB, Saflex, GlasNovations, Butacite, WINLITE, S-Lec, Trosifol and EVERLAM.

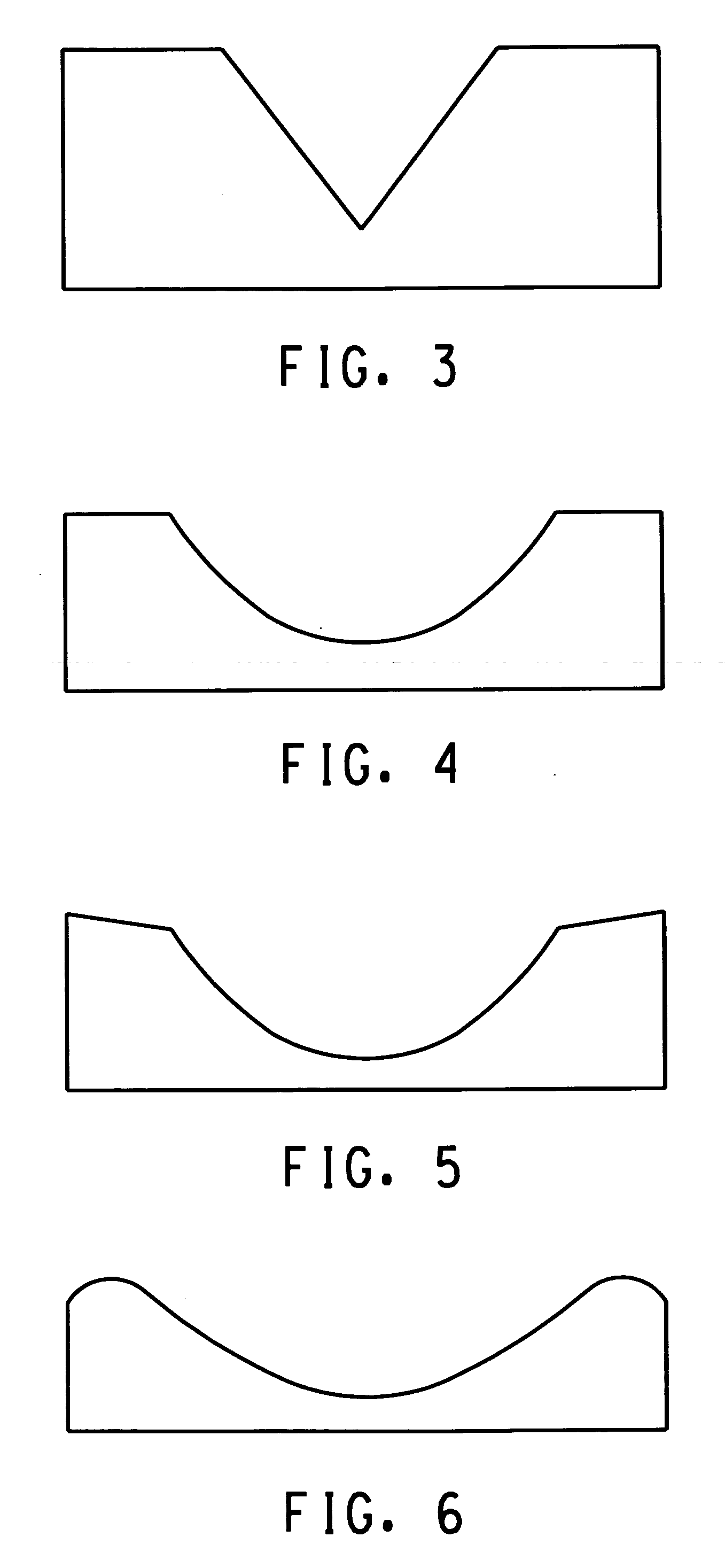

Polymeric interlayers having a wedge profile

InactiveUS20070009714A1Glass/slag layered productsThin material handlingPolyvinyl butyralPolymer chemistry

Continuous webs of self supporting adhesive sheet incorporating at least one layer of a polymeric composition such as polyvinyl butyral and comprising at least one area of a non-uniform thickness profile are provided. These webs are useful in the production of barrier windshields for heads-up display systems. The windshields may also optionally have acoustic barrier properties.

Owner:EI DU PONT DE NEMOURS & CO

Special-purpose energy-saving environment-friendly type nano coating for aluminum alloy sections (door and window) and preparing method thereof

InactiveCN101012350AStrong UV resistanceImprove insulation efficiencyLiquid surface applicatorsEpoxy resin coatingsEpoxyPolyvinyl butyral

The invention discloses a specific nanometer paint of energy-saving environment-protective typed aluminium alloy section bar (door and window), which comprises the following parts: 90-100% filming agent, 0.1-10% hardener, 0.5-8% levelling agent, 0.5-10% nanometer material, 20-50% fill and 10% hollow microball, wherein the filming agent is one or more of epoxy resin, polyester resin, acrylic acid resin, amino resin, phenol resin or alkide resin; the hardener is one or more of dicyandiamide, imidazole, dihydrazide, polybasic carboxylic acid, beta-hydroxyalkyl amide or triglycidol isocyanuric ester hardener; the levelling agent is one or more of polyacrylic resin, siliceous acryl resin, polyvinyl butyral, benzoin, hydrocastor oil, cellulose acetate butyrate or epoxy soy oil; the nanometer material is nanometer zinc oxide; the hollow micro-ball is hollow ceramic microball.

Owner:苏州裕丰装饰门窗有限公司

Intrusion resistant safety glazings and solar cell modules

ActiveUS20080210287A1Lamination ancillary operationsPV power plantsPolyvinyl butyralPhysical chemistry

Described certain plasticized poly(vinyl butyral) (PVB) interlayer sheets that may be used to produce safety glass and solar cell laminates having enhanced penetration resistance and adequate adhesion levels. In particular, the stress value of these interlayer sheets at an elongation of 120% is preferably in the range of from about 8 to about 15 N / mm2.

Owner:DOW GLOBAL TECH LLC

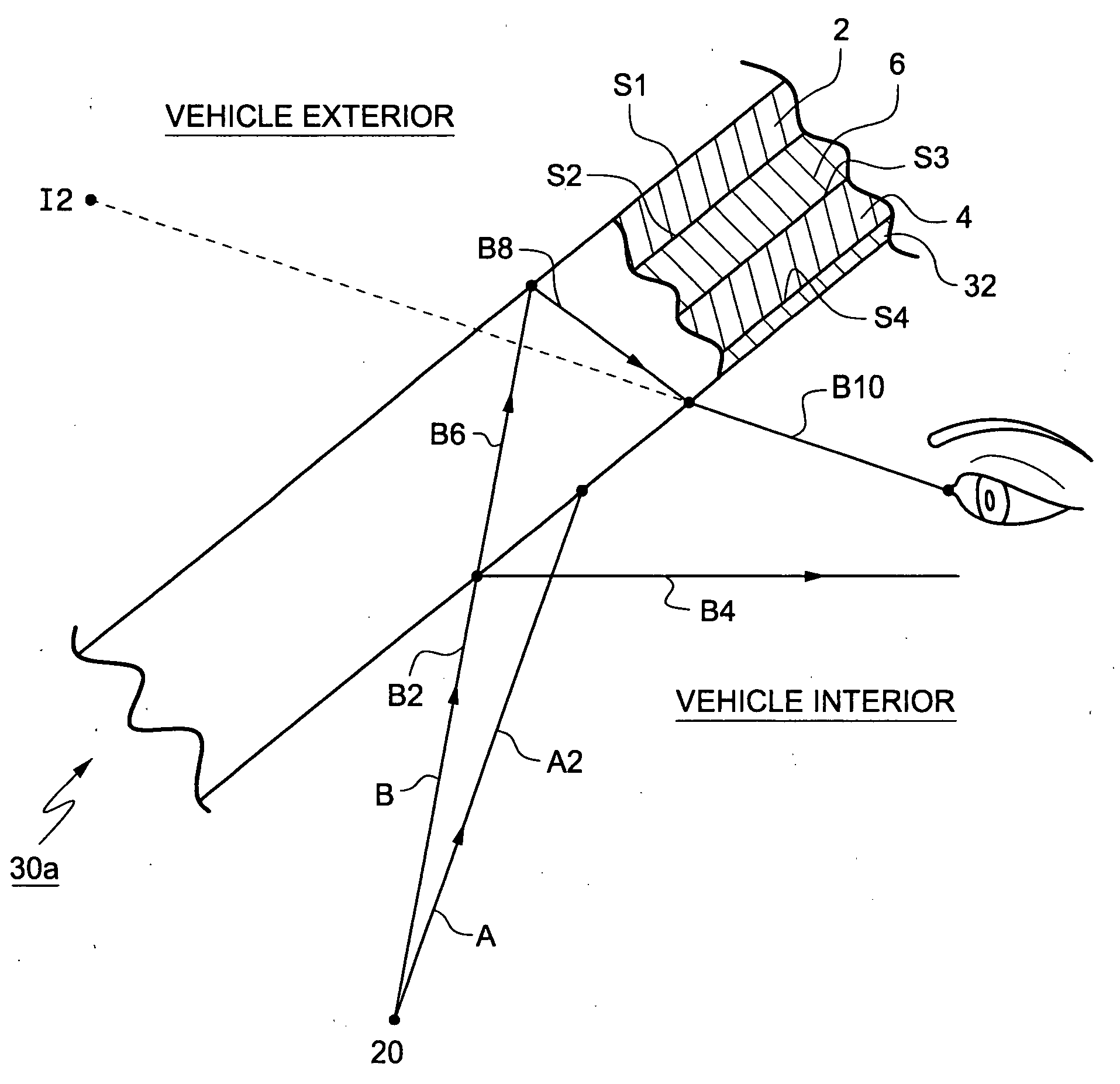

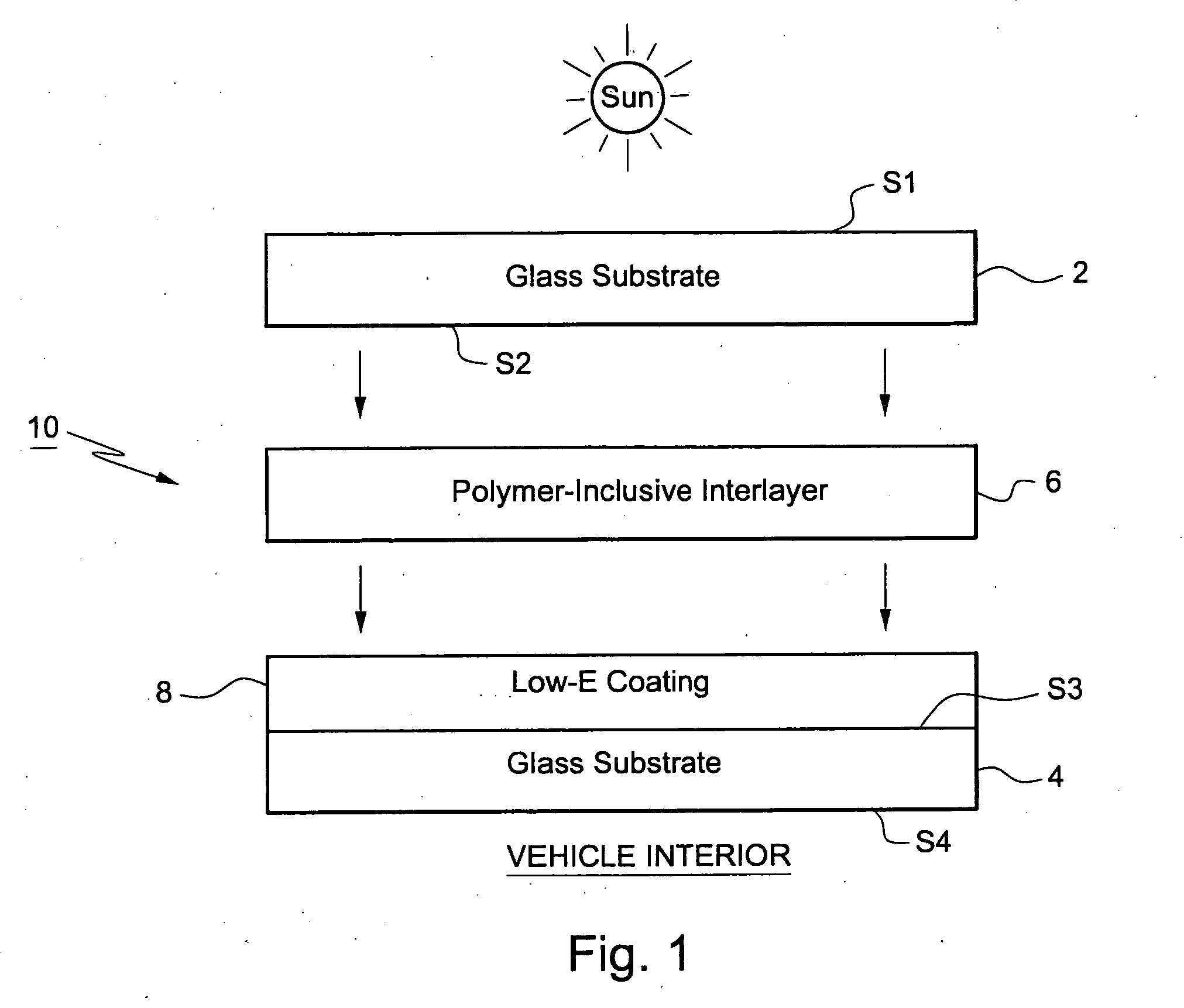

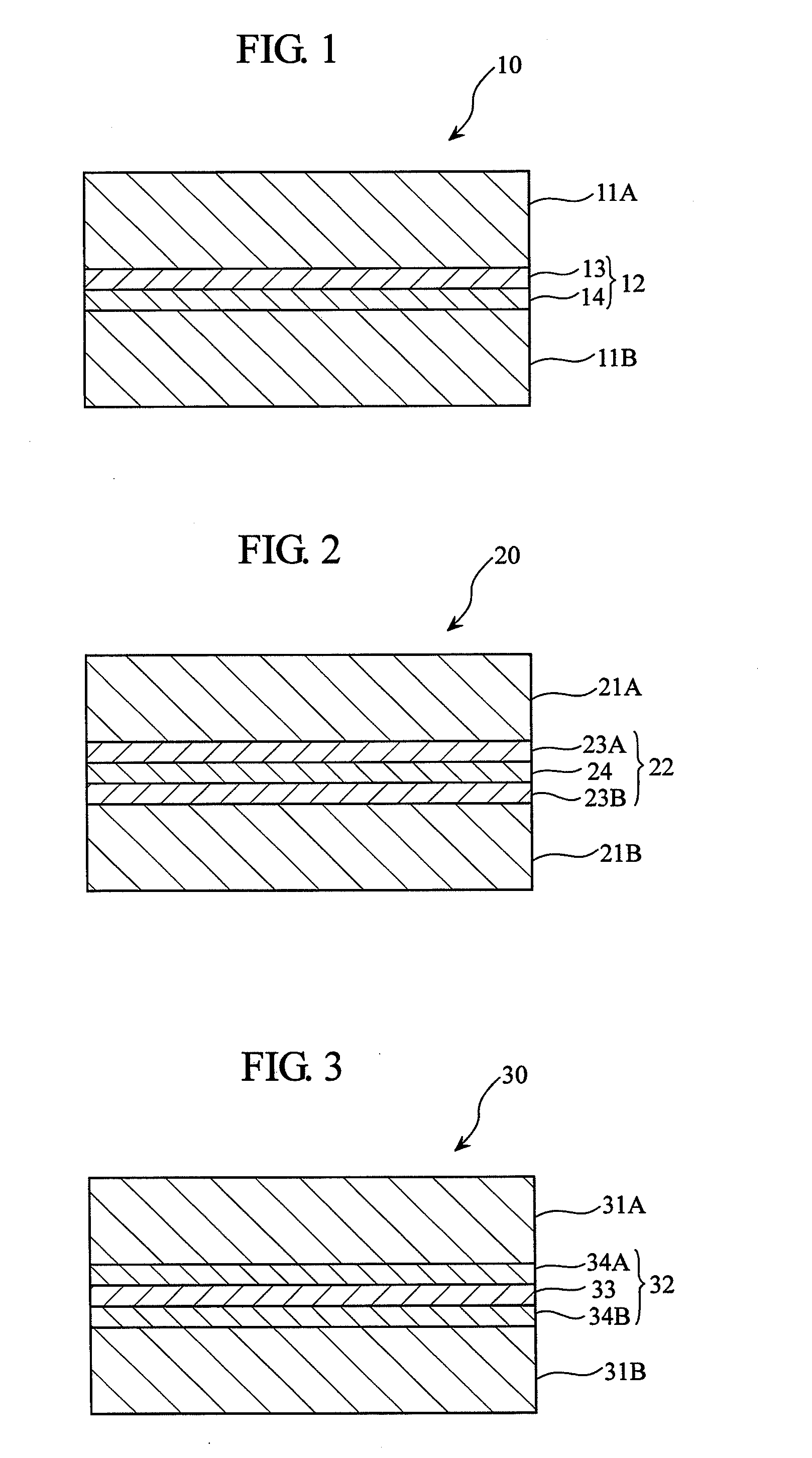

Windshield for use with head-up display and/or method of making the same

ActiveUS20090303604A1Reduce needReduce reflectionGlass/slag layered productsCoatingsPolyvinyl butyralHead-up display

Certain example embodiments relate to a head-up display system for a vehicle having a windshield. First and second substantially parallel spaced-apart substrates sandwich a polymer-inclusive interlayer. An anti-reflective coating is provided on a surface of one of the first and second substrates. The anti-reflective coating is arranged so as to optically remove or block at least some of light rays produced by an image source of the head-up display system so as to reduce the occurrence of multiple images being produced by the image source. The anti-reflective coating is provided on a surface of the first or second substrate opposite the polymer-inclusive interlayer. In certain example embodiments, the polymer-inclusive interlayer may include polyvinyl butyral and / or may have a substantially uniform thickness.

Owner:GUARDIAN EURO S A R L

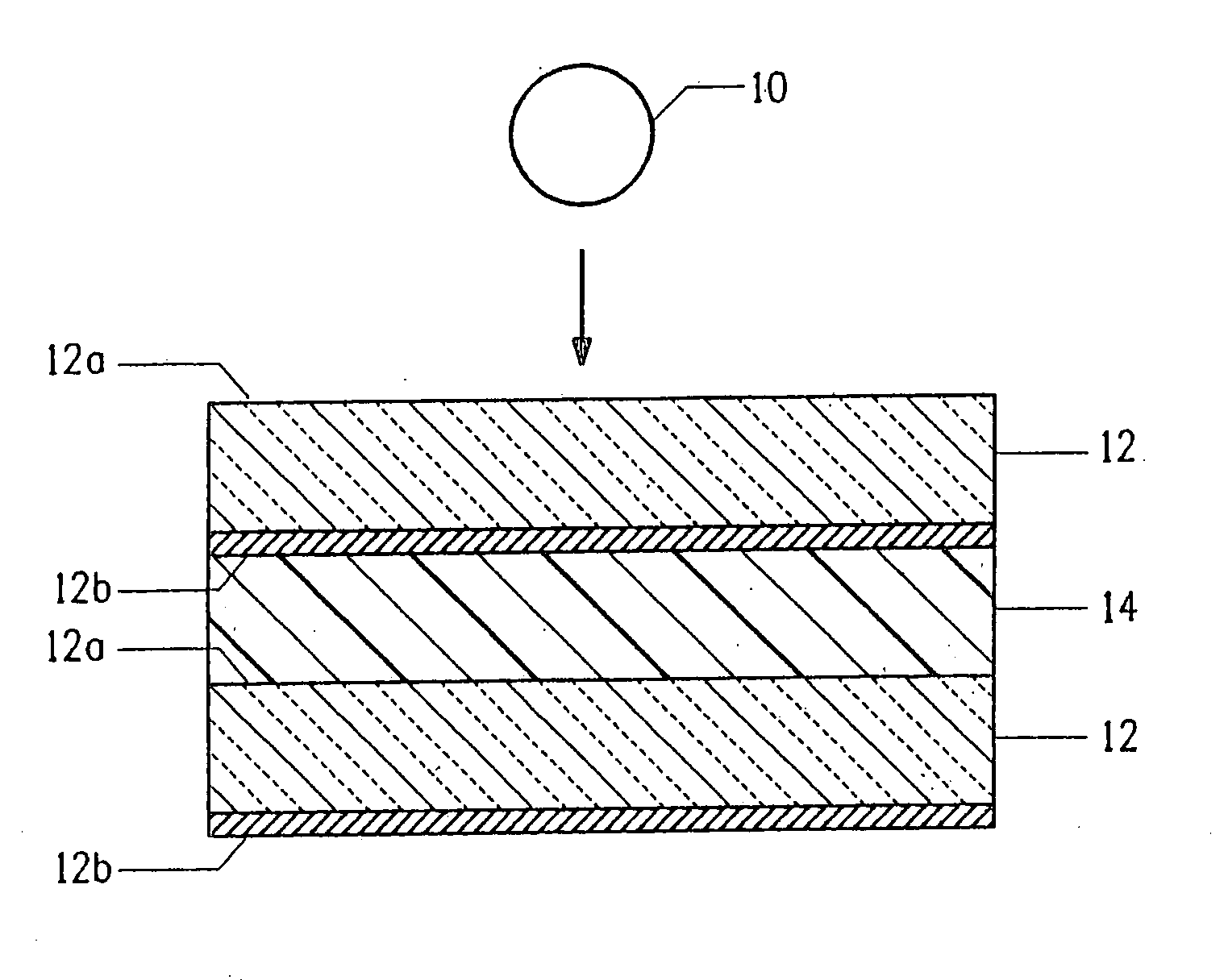

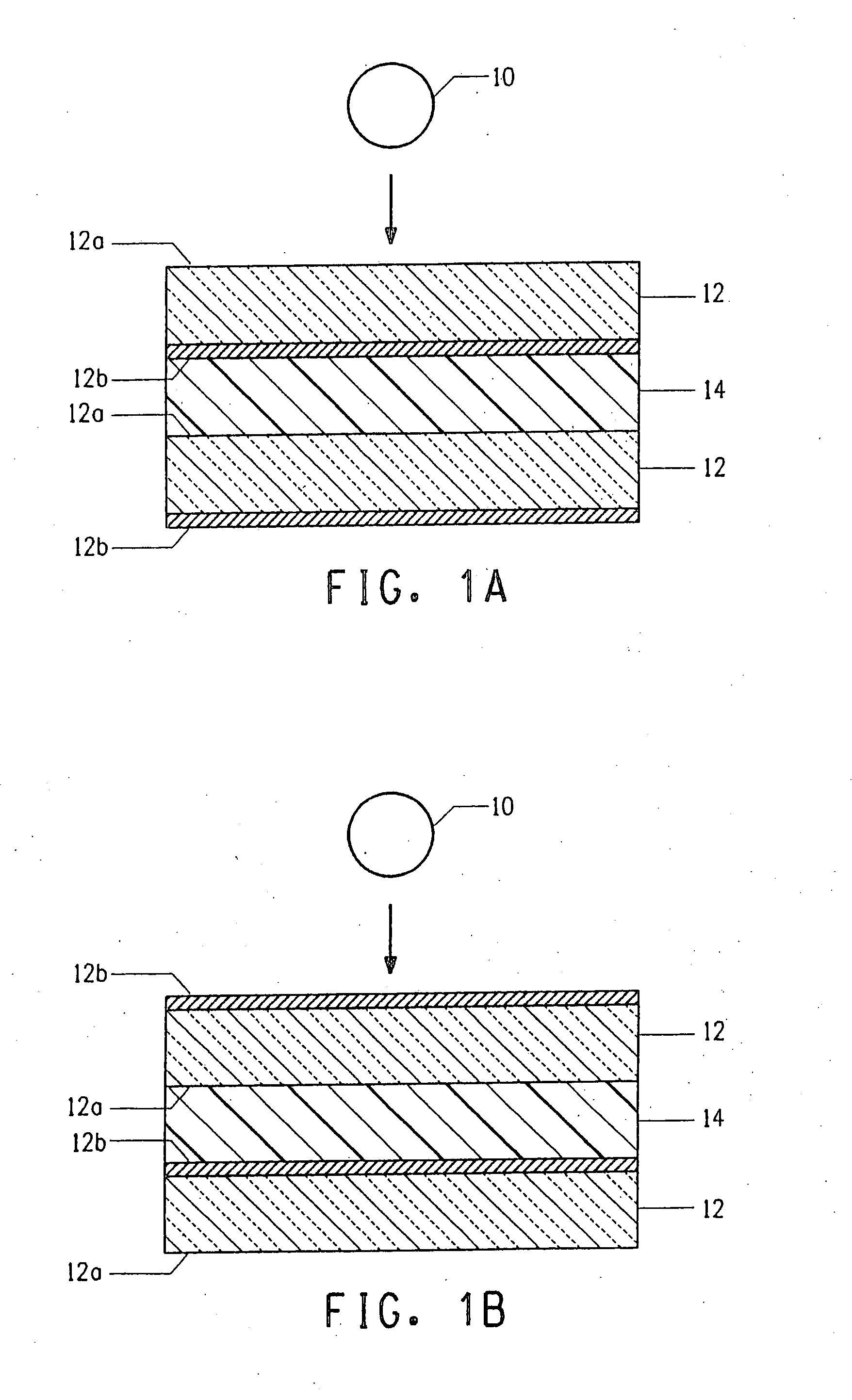

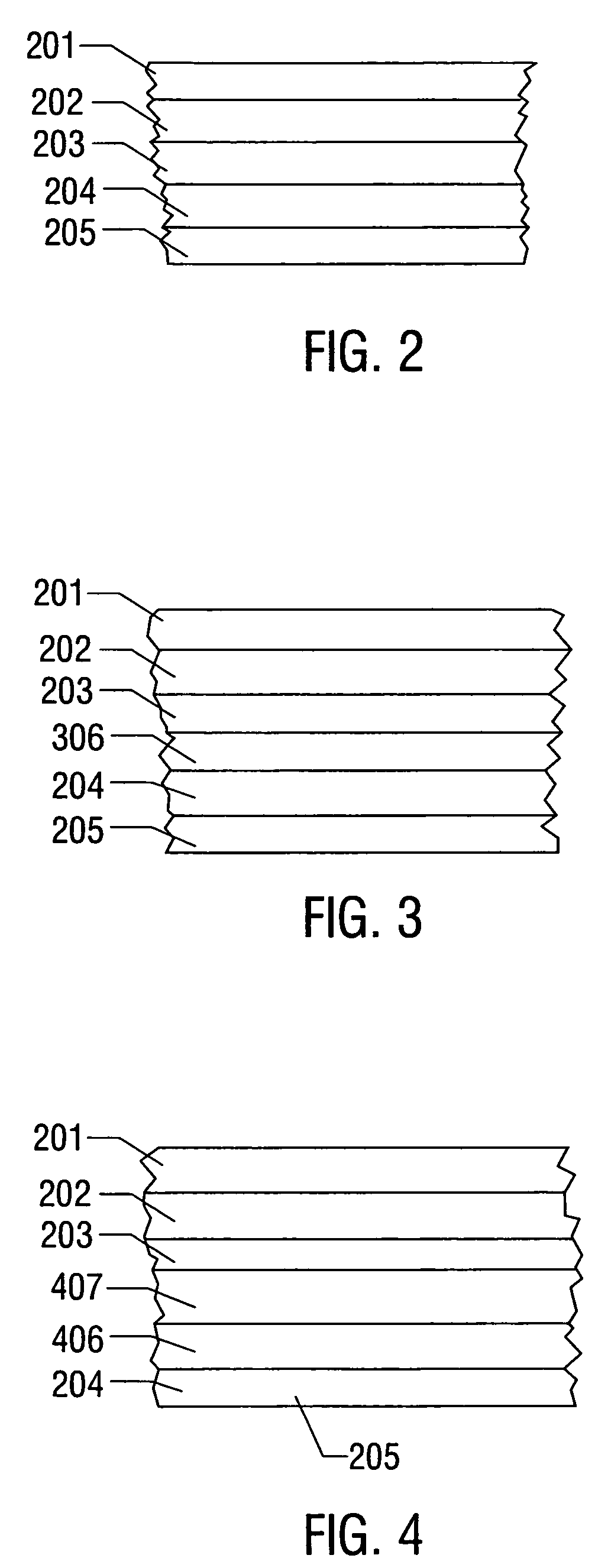

Intrusion resistant glass laminates

InactiveUS20050170160A1Increase stiffnessHigh stiffnessFilm/foil adhesivesSynthetic resin layered productsPolyvinyl butyralPolyethylene terephthalate

Composite laminate interlayers for adhering a glass laminate comprising a sheet of polyethylene terephthalate (PET) between layers of plasticized polyvinyl butyral (PVB) adhesive layers, wherein at least one of the PVB adhesive layers is stiffened, e.g. by reduction in the amount of plasticizer, and has a glass transition temperature greater than 35° C. The PET is preferably 0.075 to 0.25 mm (3-10 mils) thick and can have a functional coating for reducing radiation, e.g. UV or IR or visible light, transmission through the glass laminate. The laminate can also comprise at least one elastomeric layer adapted to reducing sound transmission through the glass laminate. The laminates exhibit enhanced maximum flexural modulus of greater than about 350 Newtons / centimeter.

Owner:SOLUTIA INC

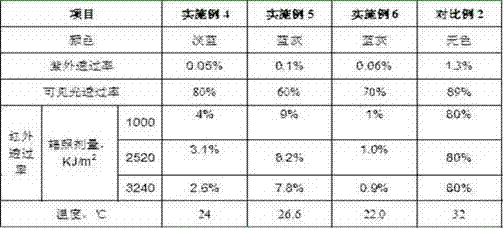

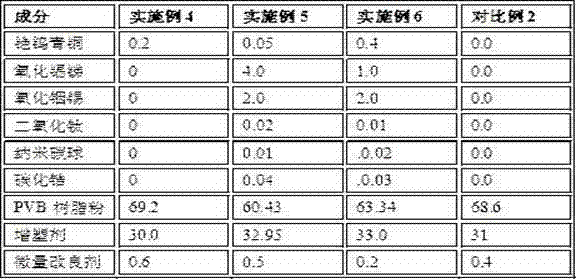

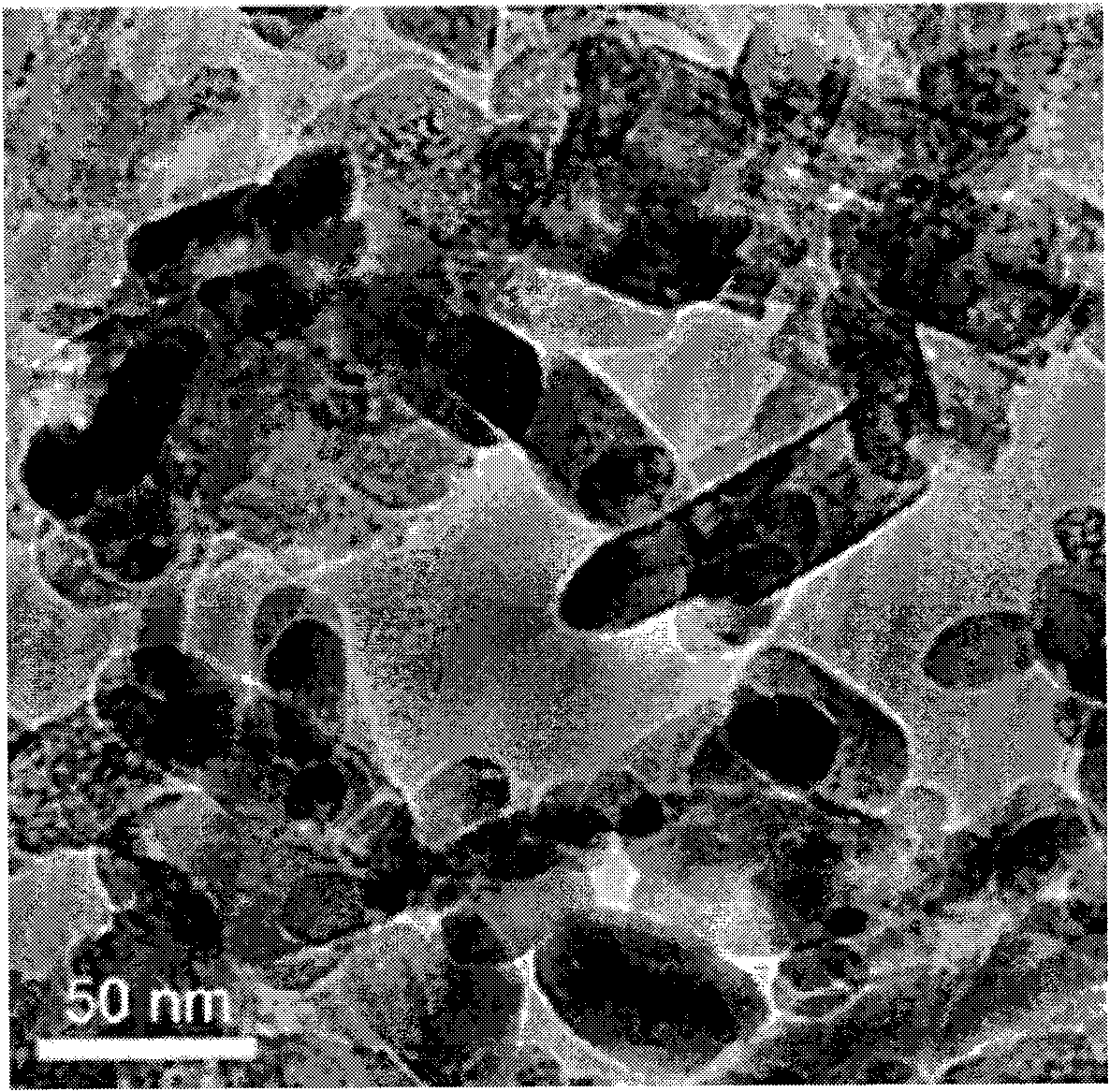

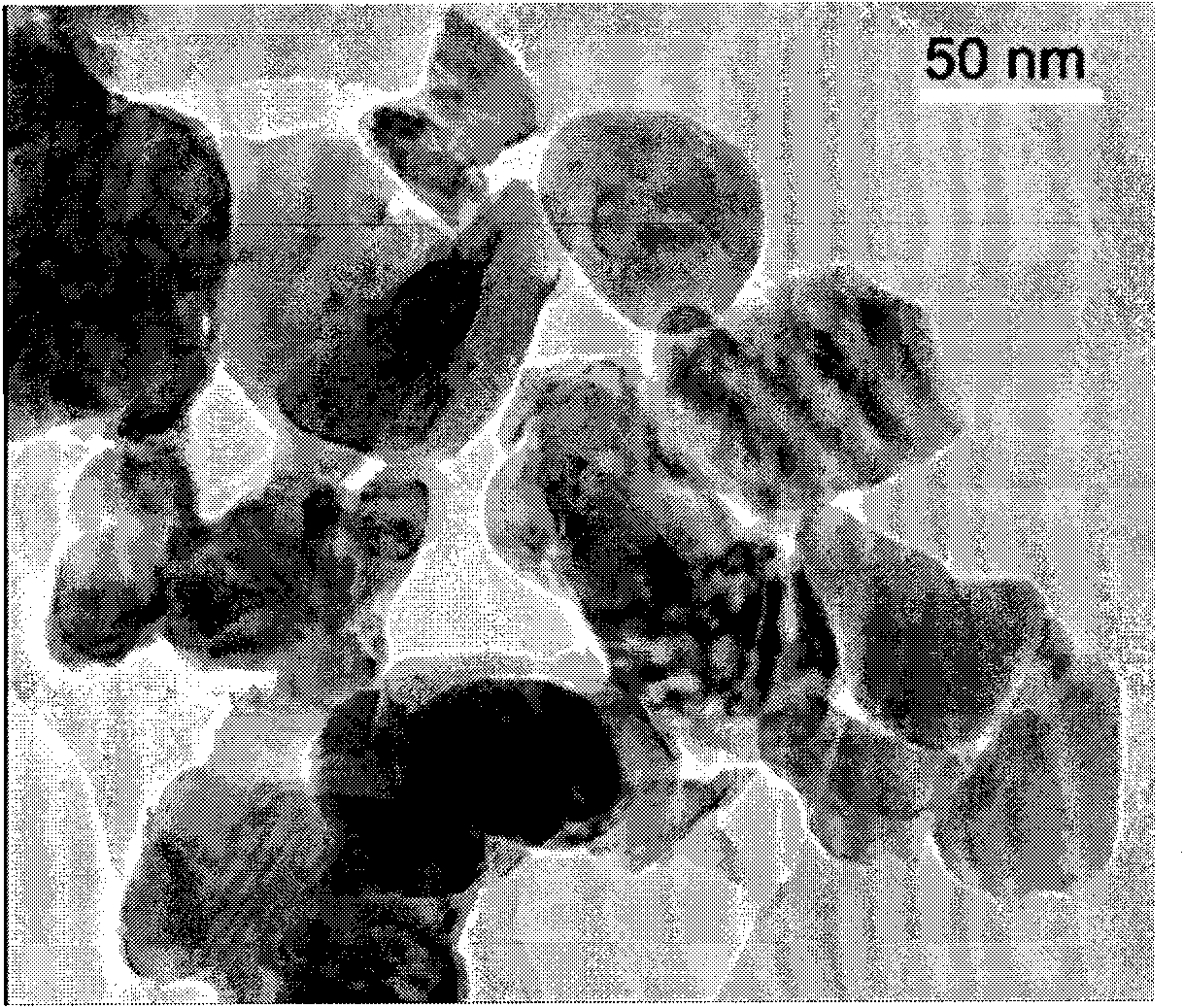

PVB (polyvinyl butyral) film for dynamically rejecting infrared rays and resisting ultraviolet rays and preparation method thereof

ActiveCN104262874AHas the effect of heat insulation and UV protectionPlay the effect of energy saving and environmental protectionPolyvinyl butyralInfrared

The invention discloses a PVB (polyvinyl butyral) film for dynamically rejecting infrared rays and resisting ultraviolet rays and a preparation method thereof. The functional PVB film comprises cesium tungsten bronze, antimony indium oxide, indium tin oxide, titanium dioxide, nano carbon spheres, zirconium carbide, PVB resin powder, a plasticizer, a trace improver and the like. The preparation method comprises the following steps: dispersing the cesium tungsten bronze composite nanoparticles with a solvent, adding the plasticizer, stirring uniformly, adding the PVB resin powder and trace improver, thoroughly mixing, and carrying out film formation on the mixture by running to obtain the heat-insulation ultraviolet-resistant PVB film. The ultraviolet rejection ratio of the PVB film is greater than 99.0%, the visible light transmittance is adjustable within the range of 60-85%, and the infrared rejection ratio is up to 80-99%; and the PVB film can be directly used for producing heat-insulation infrared / ultraviolet-resistant safety laminated glass, can be widely used in architectural curtain walls, doors / windows, zeniths, automobile windshields and the like, and is a novel energy-saving film material.

Owner:SUZHOU POLIMA MACROMOLECULE MATERIAL CO LTD

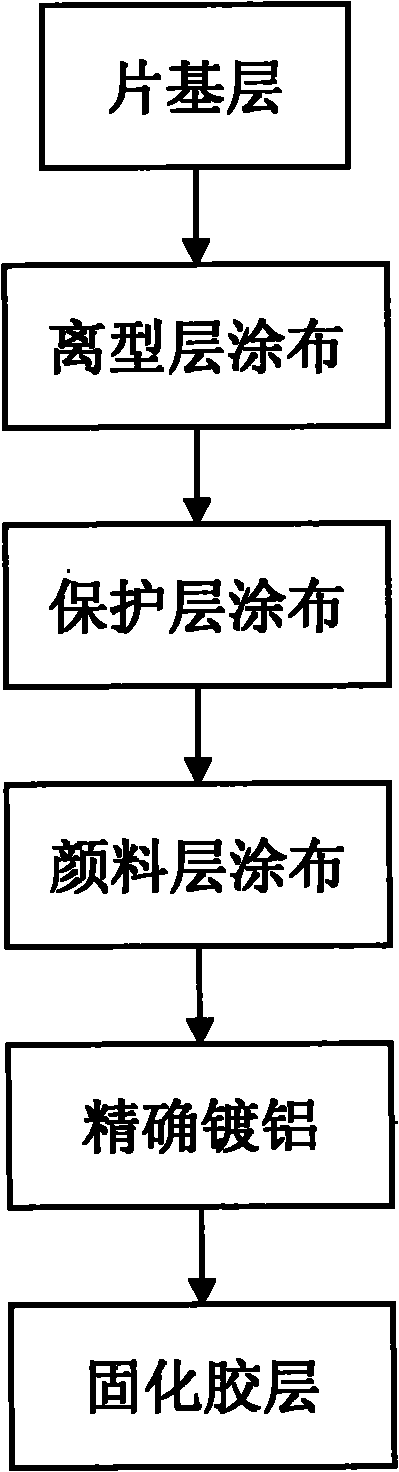

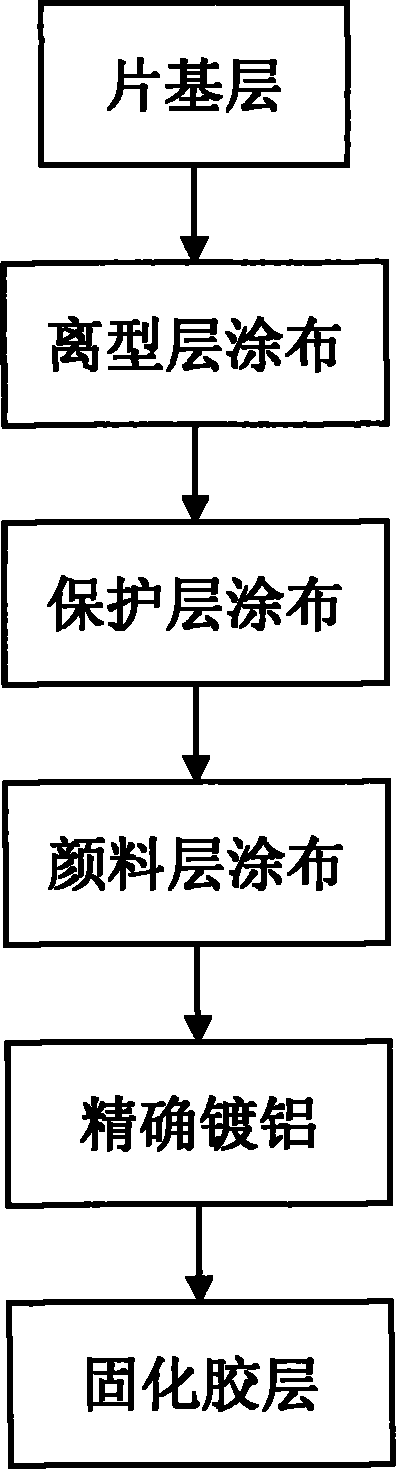

Production method of hot stamping foil

ActiveCN101879819ASolving Hot Stamping RequirementsEvenly paintedCoatingsThermographyPolyvinyl butyralHot stamping

The invention discloses a production method of hot stamping foil, which adopts six production process flows: release coating, protective layer coating, color layer coating, accurate aluminizing and curing glue layer coating. In the whole production process, water soluble glue, water soluble ink and water soluble gloss oil are used to realize the integrated production of the hot stamping foil, methacrylates and monomers which are emulsified and polymerized are mixed in a certain ratio, a dye leveler, thickener and the like are added in the mixture, the resulting product is coated and dried, polyvinyl butyral-based glue is coated, and the whole production of the hot stamping foil is finished. The hot stamping foil produced by the process has the characteristics of energy conservation, environmental protection and sanitation.

Owner:江苏卫星新材料股份有限公司

Production method of environment-friendly water-soluble gum electrochemical aluminothermic transfer printing film

InactiveCN101570090APromote environmental protectionThermographyInk transfer from master sheetPolyvinyl butyralAcrylic resin

The invention relates to a production method of an environment-friendly water-soluble gum electrochemical aluminothermic transfer printing film. The production method comprises the following steps: a PET film of 6 to 15 micron is adopted as a carrier film; the carrier film is sequentially provided with four coatings such as a releasing layer, a color layer, an aluminum layer and an adhesive layer; wherein the releasing layer, the color layer and the adhesive layer coat the coating materials on a PET basal membrane substrate by a smooth roll or an anilox roll in a forward coating mode or backward coating mode; the aluminum layer is spray-plated in a vacuum spray-plating mode; the invention adopts the environment-friendly material and the production technique to produce the aluminothermic transfer printing film product, and the key points are as follows: solvent based acrylic resin, ethylene-vinyl acetate resin, ketone resin and cellulosic resin hot melt adhesive are changed into cellulose acetate and products made by cellulose acetate; and vinyl cellulose, polyvinyl butyral and powdery silicon dioxide are synthesized by water and a mixed solvent in a mode of wetting and dispersing. The production method has the characteristics of having no solvent residue harmful to human body and being beneficial to environmental protection and the like.

Owner:莫国平

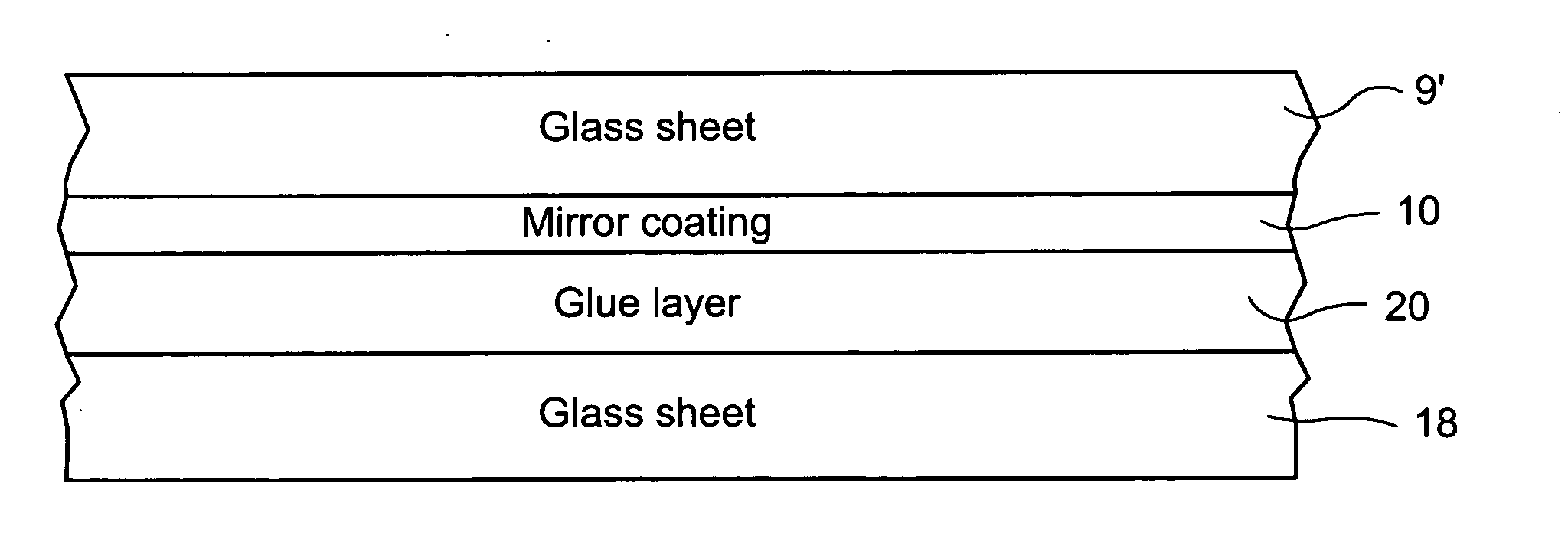

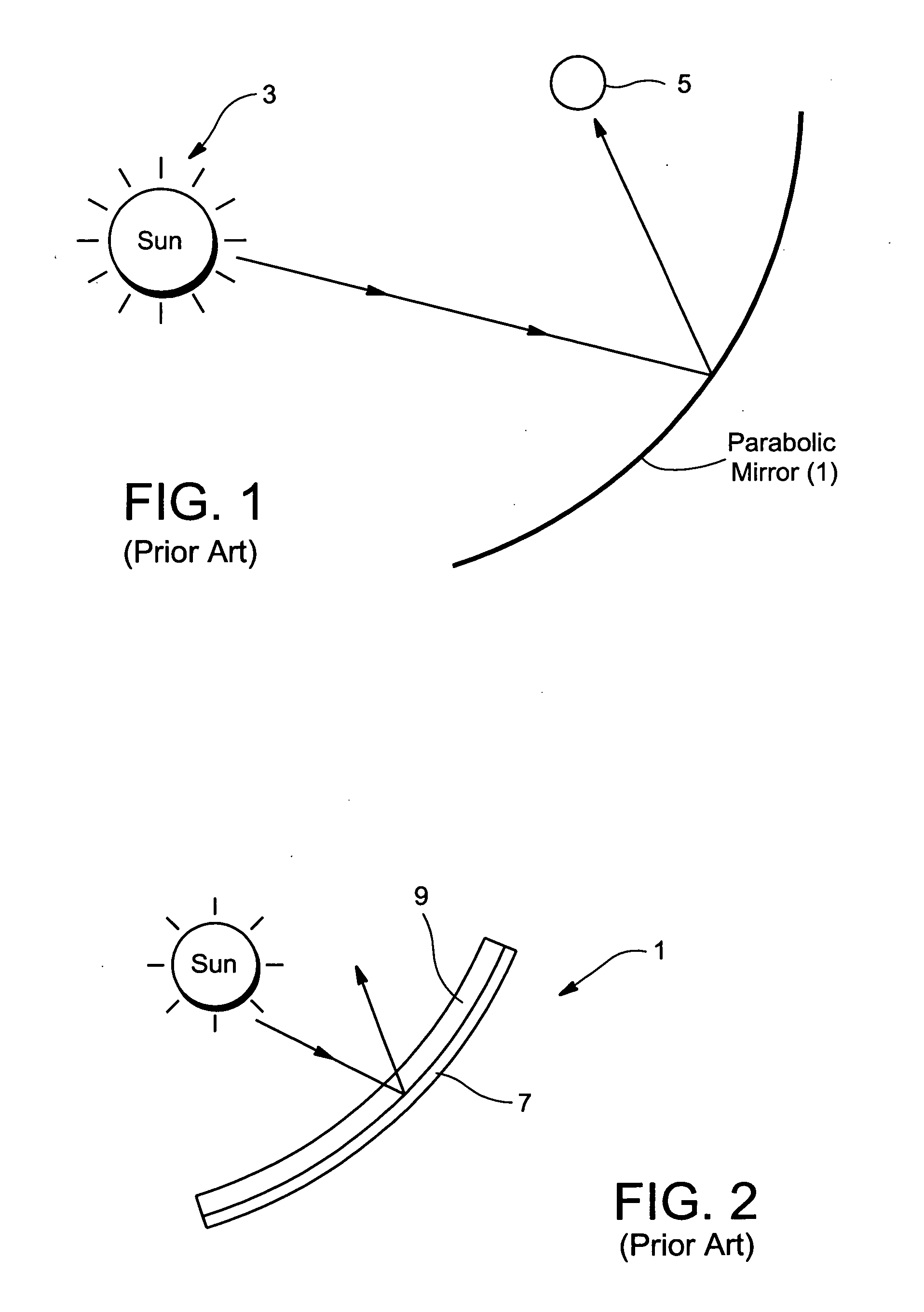

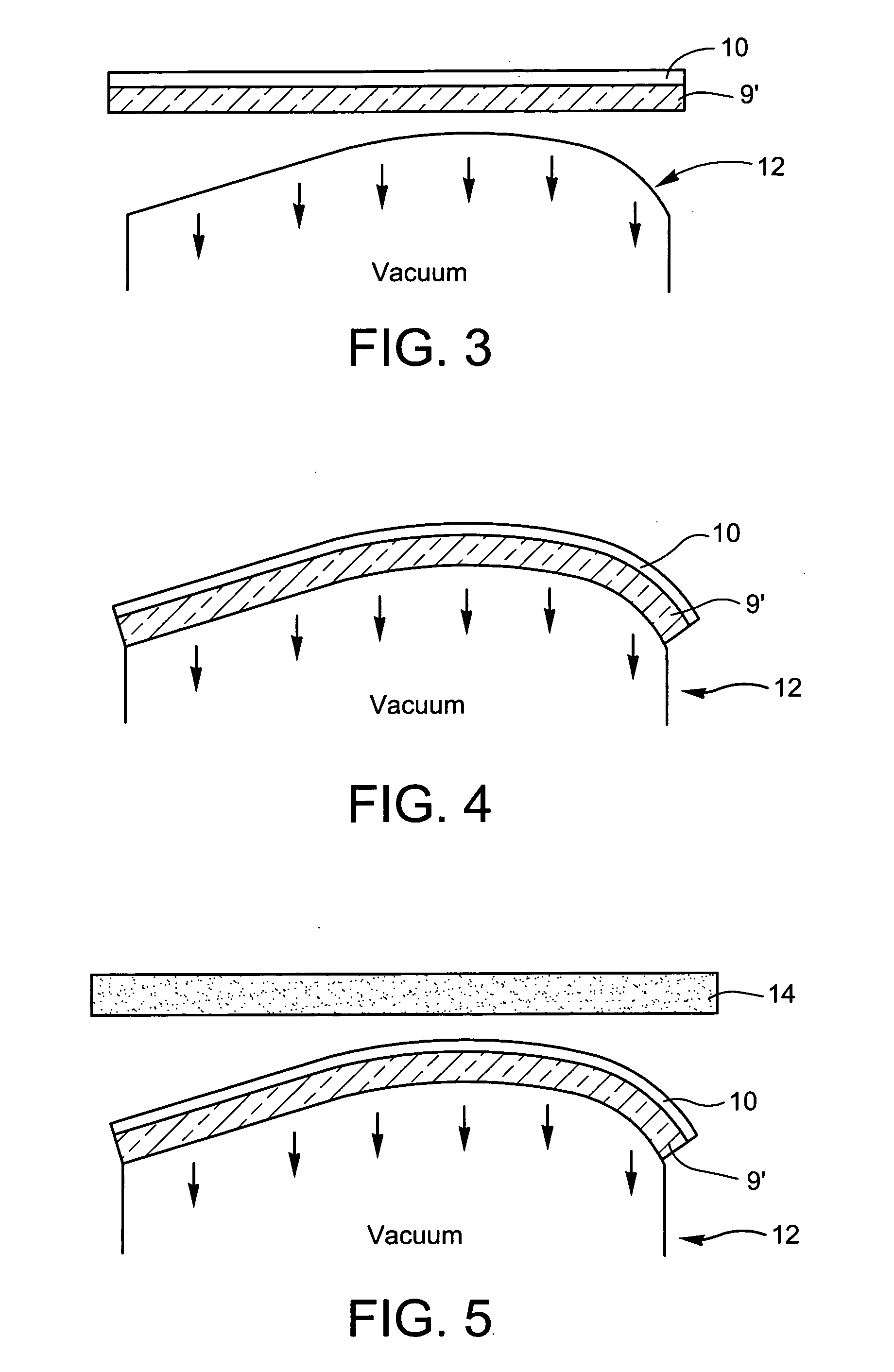

Method of making reflector for solar collector or the like, and corresponding product, including reflective coating designed for improved adherence to laminating layer

A reflector (e.g., mirror) for use in a solar collector or the like is provided. In certain example embodiments of this invention, a reflector is made performing at least the following steps: (a) forming a reflective coating on a flat glass substrate, (b) cold-bending the glass substrate with the reflective coating thereon; and (c) applying a plate or frame member (e.g., another glass sheet / substrate, or alternatively a thermoplastic member) to the cold-bent glass substrate, the plate or frame member for maintaining the coated glass substrate in a desired bent orientation. In certain example embodiments, the reflective coating is a mirror coating and includes a passivating film including tin oxide and / or silane(s) for better adhering to the polymer based glue / adhesive / laminating layer which may be made of polyvinyl butyral (PVB) or the like.

Owner:GUARDIAN GLASS LLC

Alcohol zircon flour coating for heavy castings and its production method

The invention relates to a paint used in large casting element and relative production, wherein said paint is alcohol-base zircon powder casting paint, which contains zircon at 62-75%, lithium-base at alta-mud 1-3%, deionized water at 1-3%, modified almasilate at 1-3%, nanometer clay at 0.15-0.8%, alumind at 0.020-0.08%, soluble polyester resin at 0.2-1.2%, polyvinyl butyral (PVB) at 0.1-0.8%, abietyl at 0.6-3%, industrial alcohol at 15-25%, alcohol isopropylicum at 1-5%, and aromatic solvent oil at 150#1-5%. The inventive product has high fire resistance, etc.

Owner:德阳立达化工有限公司

Solvent soluble poly(urethane/urea) resins

InactiveUS6723820B1Non-fibrous pulp additionLamination ancillary operationsPolyvinyl butyralNitrocellulose

Solvent based poly(urethane / urea) resins suitable for formulating flexographic and gravure laminating printing ink and coating compositions formed from a poly(urethane) prepolymer solution made from a blend of polymeric diols and diols reacted with diisocyanates and then with diamine in an organic solvent. The resin is prepared by adding the poly(urethane) prepolymer solution at a controlled rate to the diamine in a organic solvent which allows a resin solution to be formed, which may be used in the formulation of laminating printing ink and coating compositions without the need for adjuvants, grinding in polyvinyl butyral or blending with nitrocellulose base.

Owner:SUN CHEM CORP

Composite comprising cellulose and thermoplastic polymer

Disclosed are composite compositions and articles prepared from such composites. The composition comprises or is produced from cellulose material, thermoplastic polymer, and a compatibilizing agent which is the reaction product of polyvinyl butyral, having hydroxyl functionality, and a second polymer which comprises or is produced from polyvinyl butyral and a second polymer wherein the polyvinyl butyral comprises a hydroxyl functionality and the second polymer reacts with at least a portion of the hydroxyl functionality.

Owner:DOW GLOBAL TECH LLC

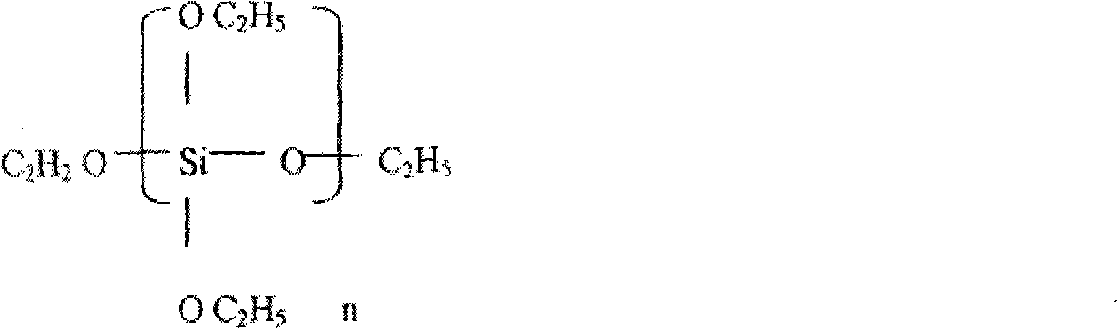

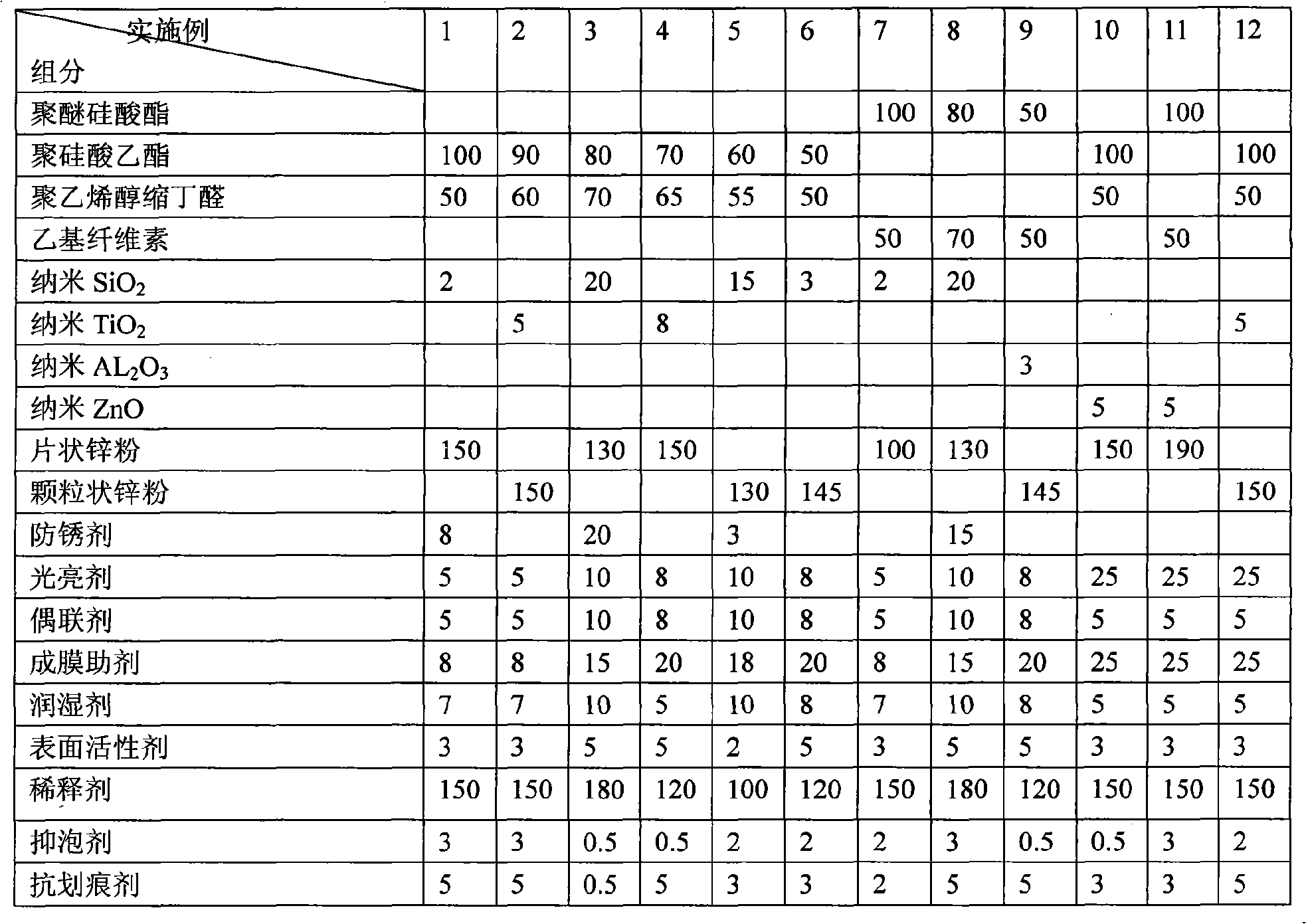

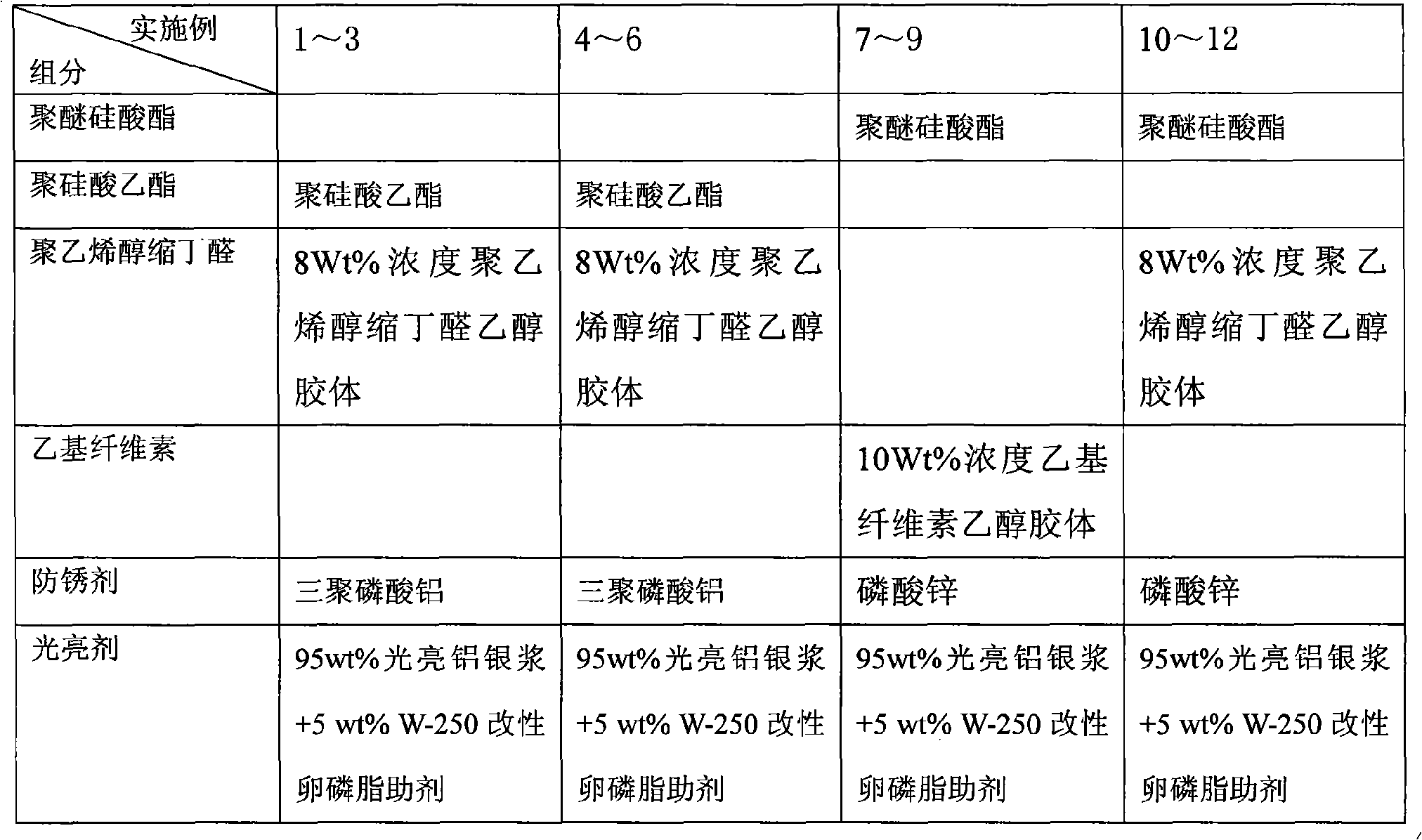

Zinc metallic coating

The invention discloses a zinc metal coating layer, the zinc metal coating is characterized in that when being calculated according to the parts by weight, the components of the the zinc metal coating are as follows: 50 parts to 100 parts of polyether silicate ester or polymerized silica acid ester, 50 parts to 100 parts of polyvinyl butyral or ethyl cellulose, 1 part to 20parts of one or a plurality of component (s) among nanometer silicon dioxide, nanometer titanium dioxide, nanometer molybdenum dioxide, or nanometer zinc oxide, 80 parts to 200 parts of zinc powder, 0 to 20 parts of rust preventing agent,, 5 parts to 100 parts of coupling agent, 5 parts to 25 parts of brightening agent, 8 parts to 250 parts of film forming auxiliary agent, 5 parts to 10 parts of wettinh agent, 1 part to 5 parts of surface activating agent, 100 parts to 200 parts of thinning agent, 0.5 part to 3 parts of anti-foaming agent and 0.5 part to 5 parts of anti-scratching agent. The bright metal zinc coating layer related by the invention can be taken as the anti-corrosive oxidation resistant zinc metal coating layer of metal product, particularly the black metal product, which can replace the commonly adopted galvanizing technology. The bright zinc metal coating layer of the invention can very conveniently and effectively paint a zinc metal coating layer the binding of which is firm on the metal product, particularly the black metal product.

Owner:胡仲寅

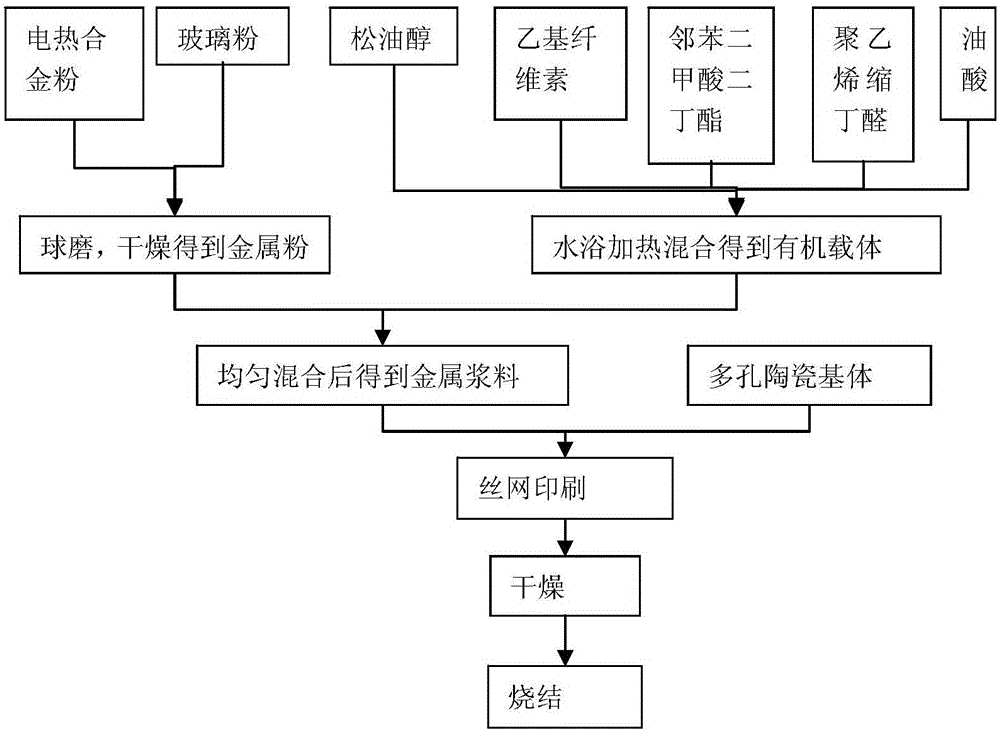

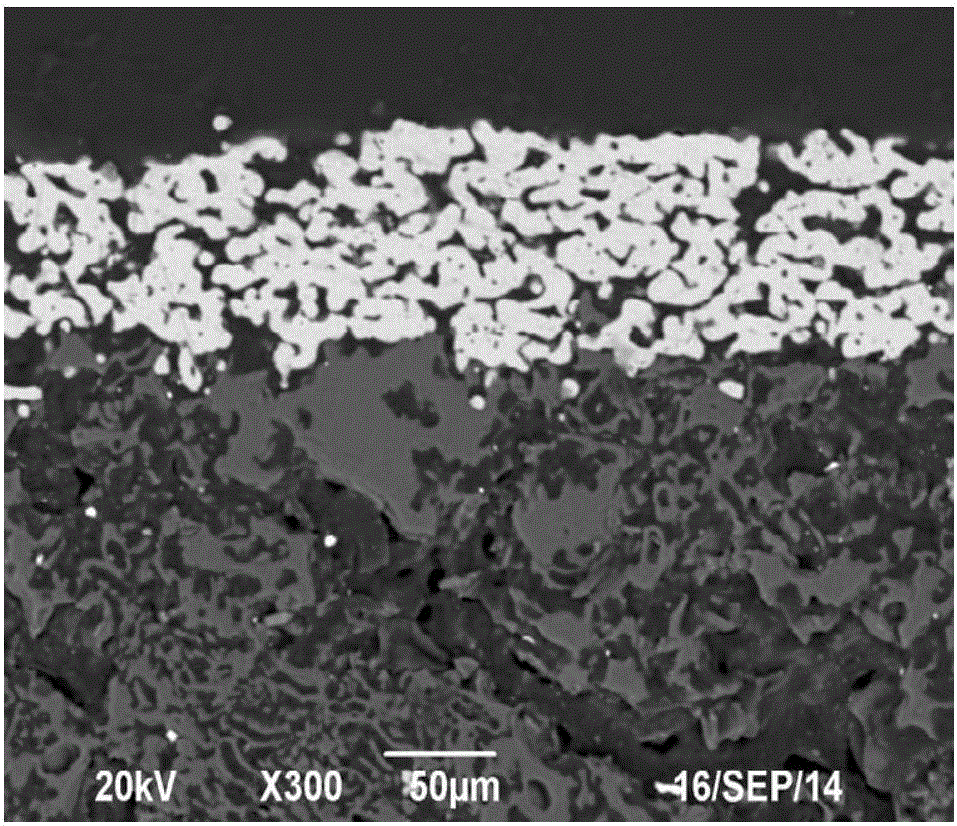

Metal-film porous ceramic heating element and application thereof

ActiveCN107182139AHigh bonding strengthSolve the problem of residual carbon prone to appear on the interfaceTobacco devicesHeating element materialsPolyvinyl butyralScreen printing

The invention relates to a metal-film porous ceramic heating element and application thereof, more particularly to a metal-film porous ceramic heating element and application thereof in an electronic cigarette atomizer. A preparation method of a metal-film porous ceramic heating element comprises: electrothermal alloy powder and glass powder are mixed uniformly to obtain a metal powder mixture; terpineol, ethyecellulose, dibutyl phthalate, polyvinyl butyral and oleic acid are mixed uniformly to obtain an organic carrier; the metal powder mixture and the organic carrier are mixed uniformly to obtain a metal paste; and the metal paste is coated on a porous ceramic substrate by screen printing, and sintering is carried out to obtain a metal-film porous ceramic heating element. The process is simple and is easy to control; and large-scale industrial application can be realized conveniently. And the prepared metal-film porous ceramic heating element is especially suitable for an electronic cigarette atomizer.

Owner:周宏明

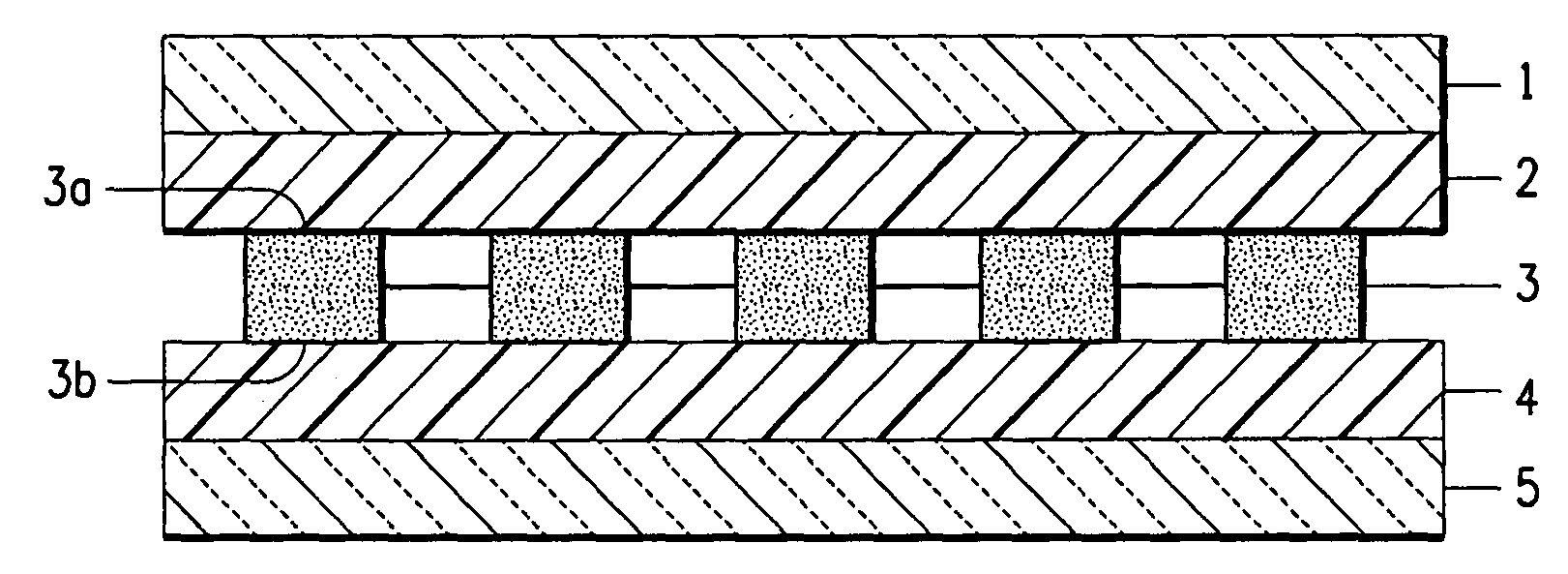

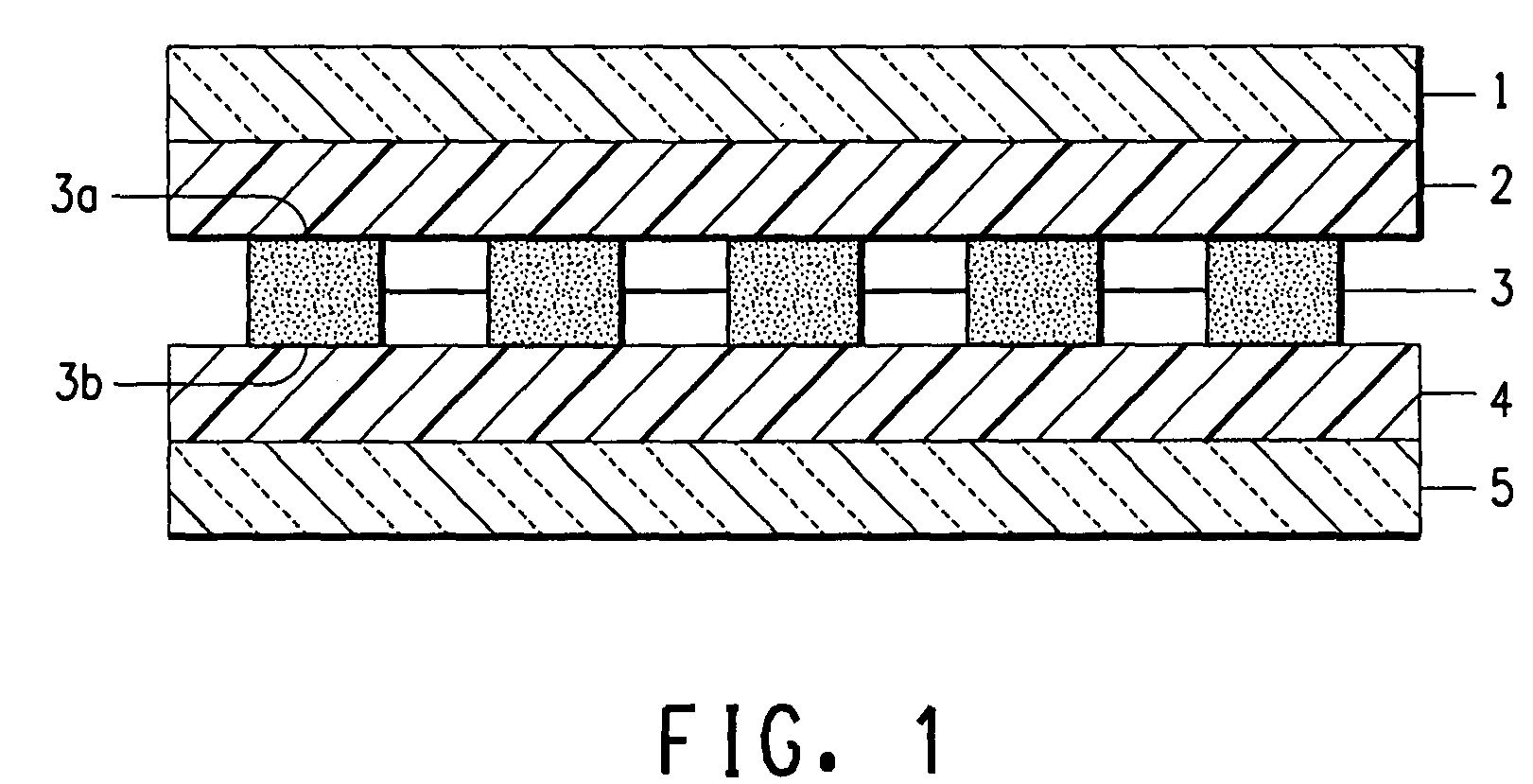

Composite interlayer for laminated glass

A composite interlayer suitable for using laminated glass includes a layer of plasticized polyvinyl butyral sandwiched between second and third polymeric layers. In a preferred embodiment, at least one and preferably both of the second and third layers are less than 5 mils thick and formed of polyurethane.

Owner:SOLUTIA INC

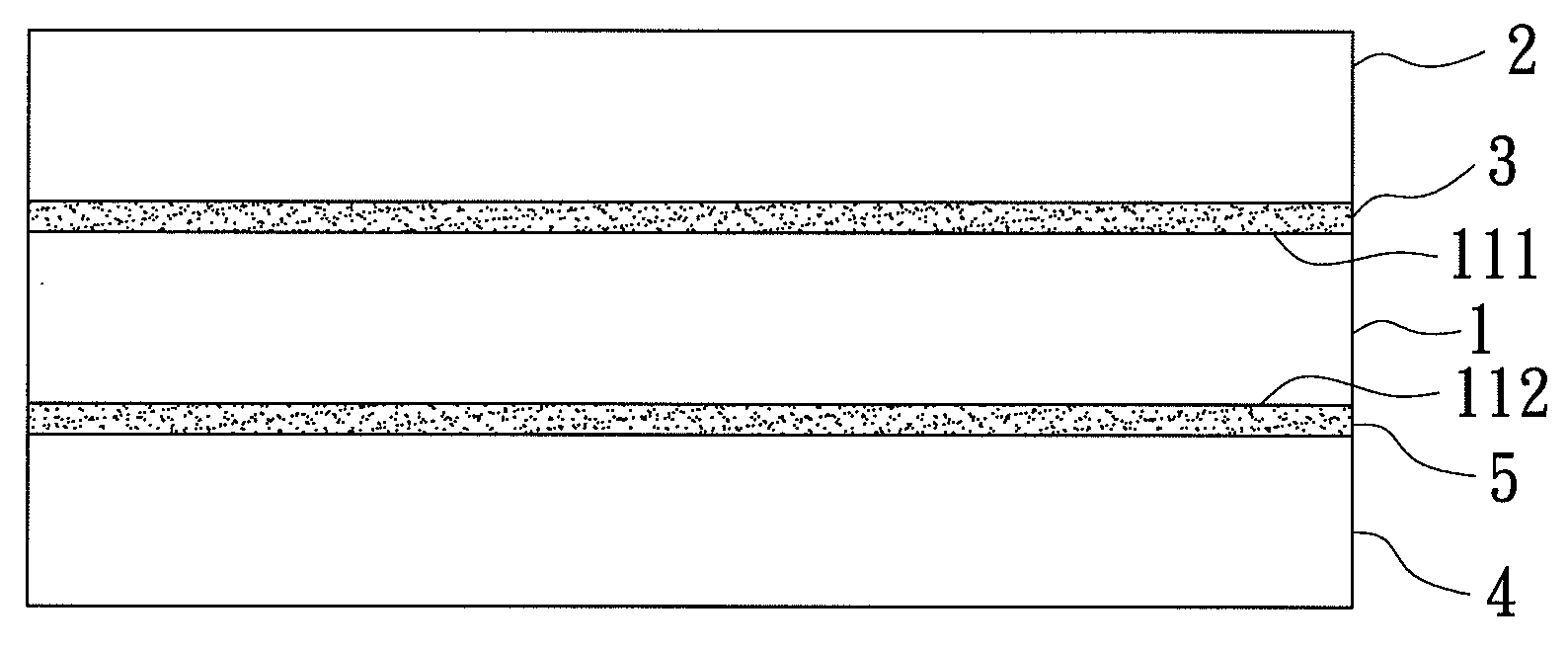

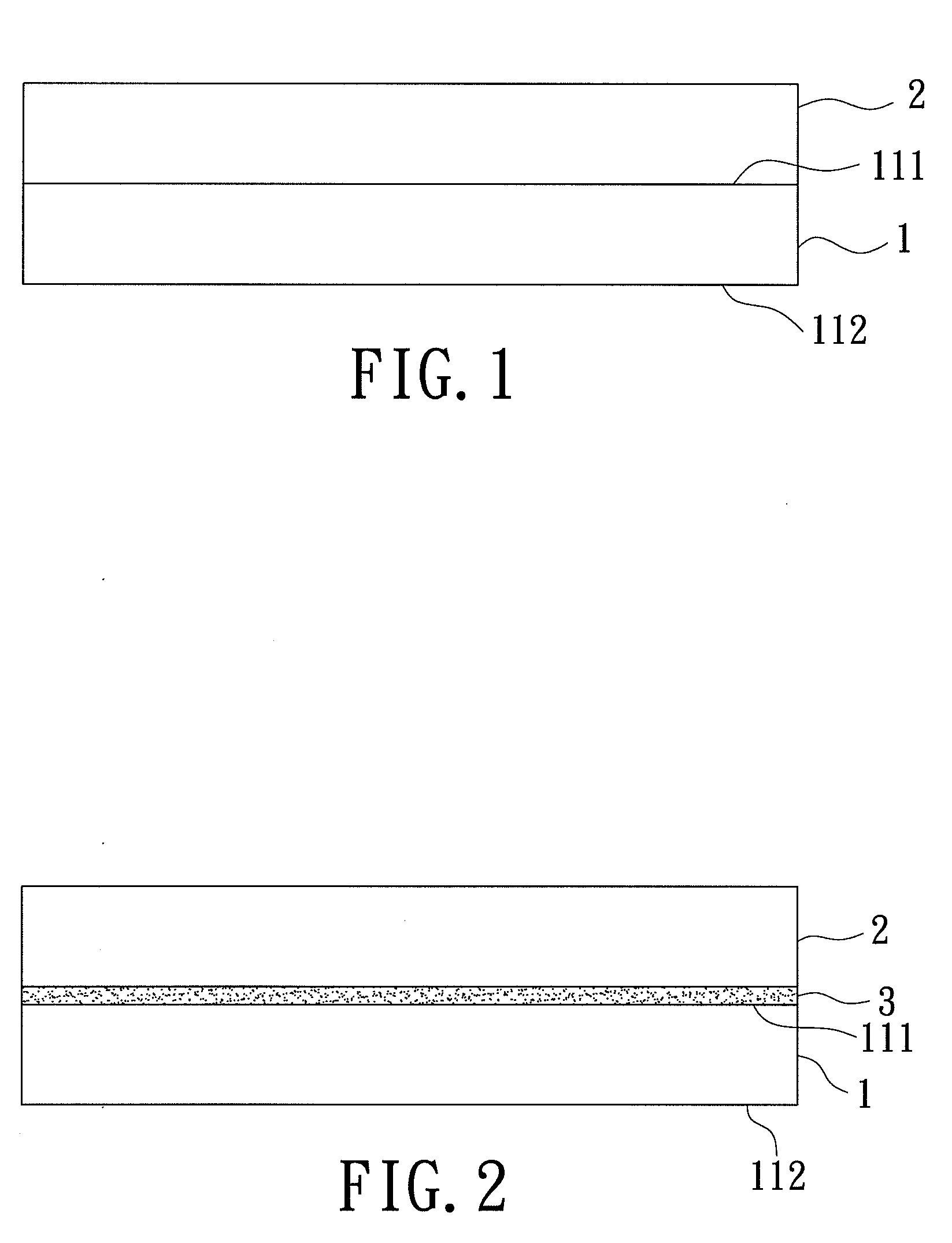

Laminate and article for daily use

ActiveUS20090297794A1High strengthExcellent touch feelingLayered product treatmentDecorative surface effectsWoven fabricPolyvinyl butyral

A laminate includes a base layer being made from one of woven fabrics, knitted fabrics, and non-woven fabrics, and having two surfaces, and a thin film layer made of a polyvinyl butyral-based composition and covering one of the two surfaces of the base layer. An article for daily use, at least one part of which is made of the laminate, is also disclosed.

Owner:LIN CHUN WEI

Method for preparing electrolyte ceramic membrane of lithium ion battery

The invention relates to a method for preparing an electrolyte ceramic membrane of a lithium ion battery, in particular to a tape casting method for preparing the electrolyte ceramic membrane of the lithium ion battery, and belongs to the field of ion conductive ceramic materials. The invention adopts the tape casting method; ceramic powder with a chemical formula of Li1.4Al0.4(Gel-xTix)1.6(PO4)3(wherein x is equal to 0-1.0) is selected as raw material powder; triethanolamine or phosphate are selected as a dispersing agent; ethanol, propyl alcohol, butanone, triclene, or azeotropic solution prepared from any two of the ethanol, propyl alcohol, butanone and triclene is selected as a solvent; polyvinyl butyral (PVB) is selected as an adhesive; polyethylene glycol or dibutyl phthalate is selected as a plasticizer; the range of solid content of slurry is controlled between 18 and 30vol percent; the uniform slurry is prepared through ball milling, and then is prepared into a green belt bythe tape casting method, and the green belt is subjected to heat treatment to form the electrolyte ceramic membrane; and the electrolyte ceramic membrane has good strength and toughness, and can be applied to actual production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

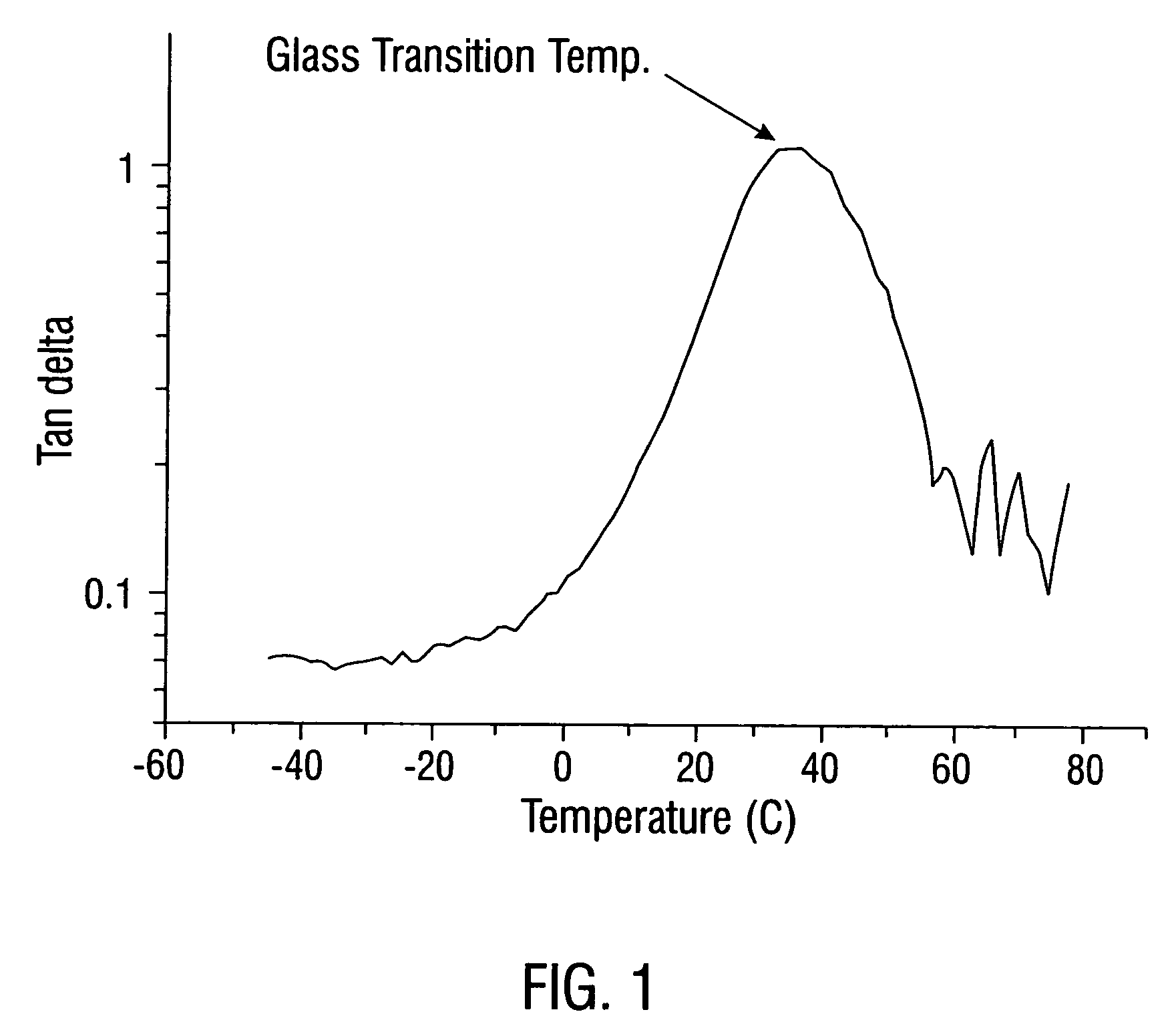

Solar cells encapsulated with poly(vinyl butyral)

ActiveUS7943845B2Plastic/resin/waxes insulatorsOrganic compound preparationPolyvinyl butyralPlasticizer

A solar cell pre-laminate assembly comprising (i) a solar cell component comprising one or a plurality of solar cells and having a light-receiving side and a back side, and (ii) stiff poly(vinyl butyral) sheet as an encapsulant layer, wherein the stiff poly(vinyl butyral) sheet is positioned next to the light-receiving or the back side of the solar cell component and comprises a poly(vinyl butyral) composition containing about 10 to about 23 wt % of a plasticizer based on the total weight of the composition.A process of preparing solar cell assembly comprising (i) providing a solar cell component and a stiff poly(vinyl butyral) sheet comprising a poly(vinyl butyral) composition containing about 10 to about 23 wt % of a plasticizer based on the total weight of the poly(vinyl butyral) composition, and (ii) encapsulating the solar cell component in a polymer matrix comprising the poly(vinyl butyral) composition.

Owner:DOW GLOBAL TECH LLC

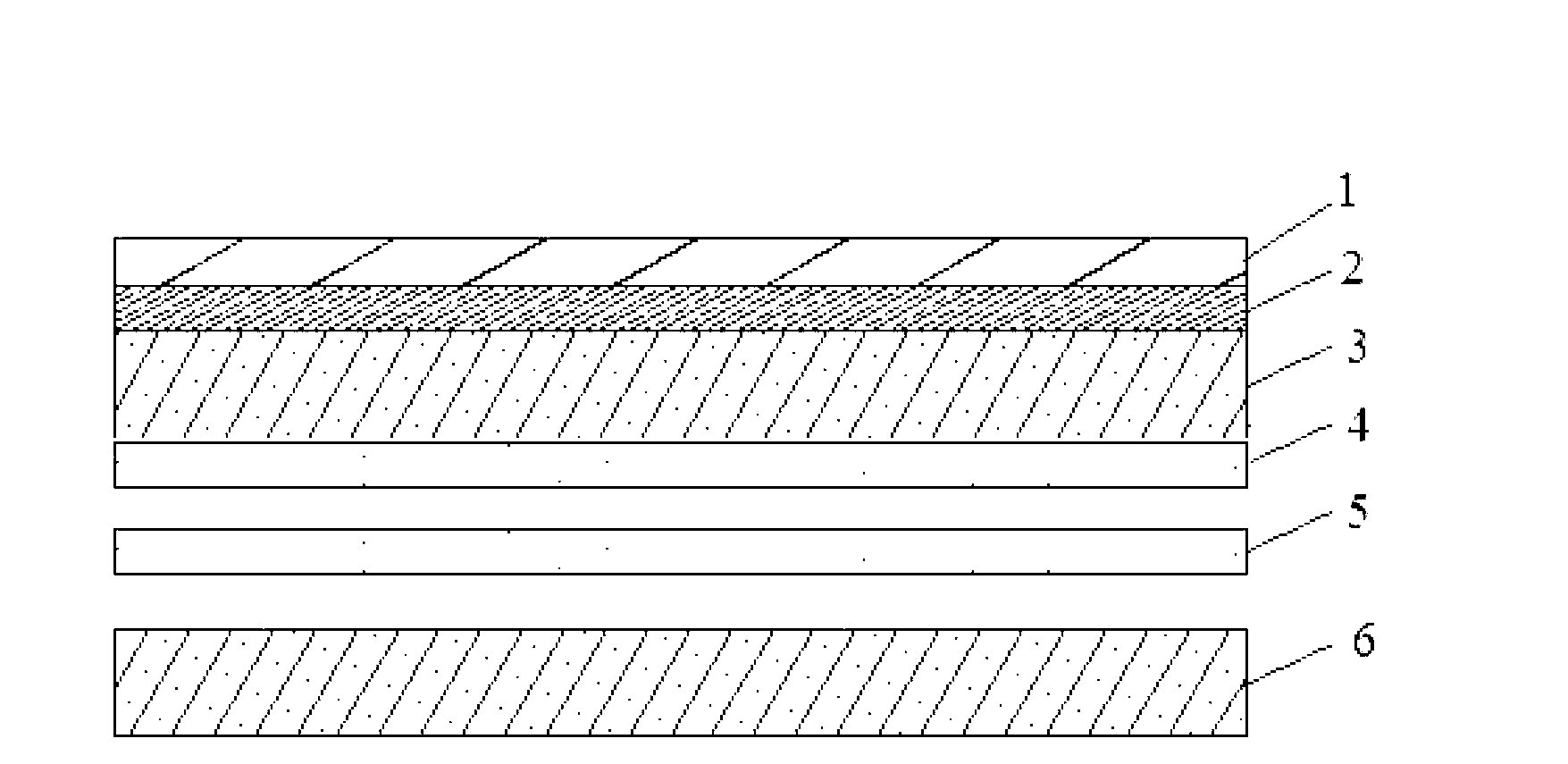

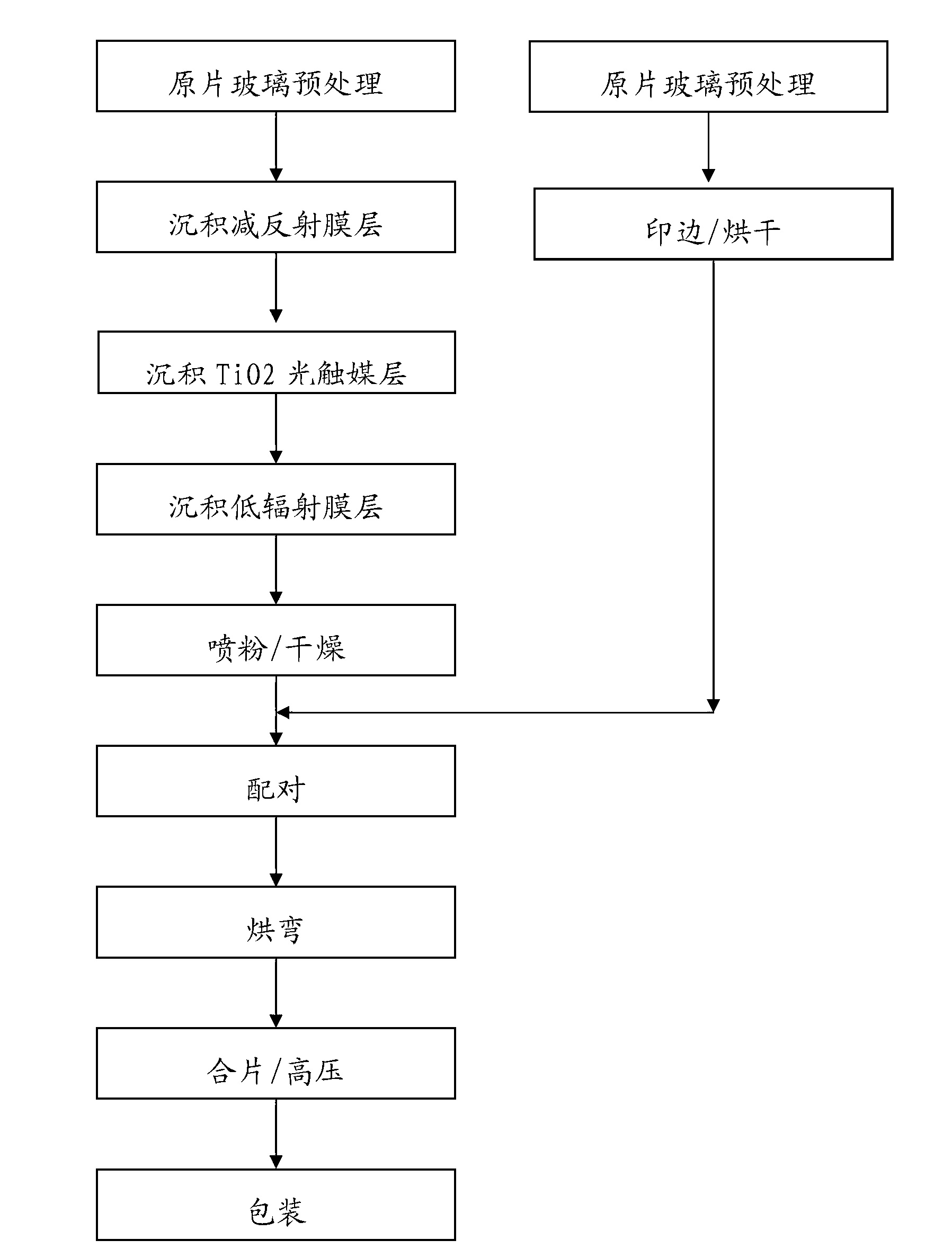

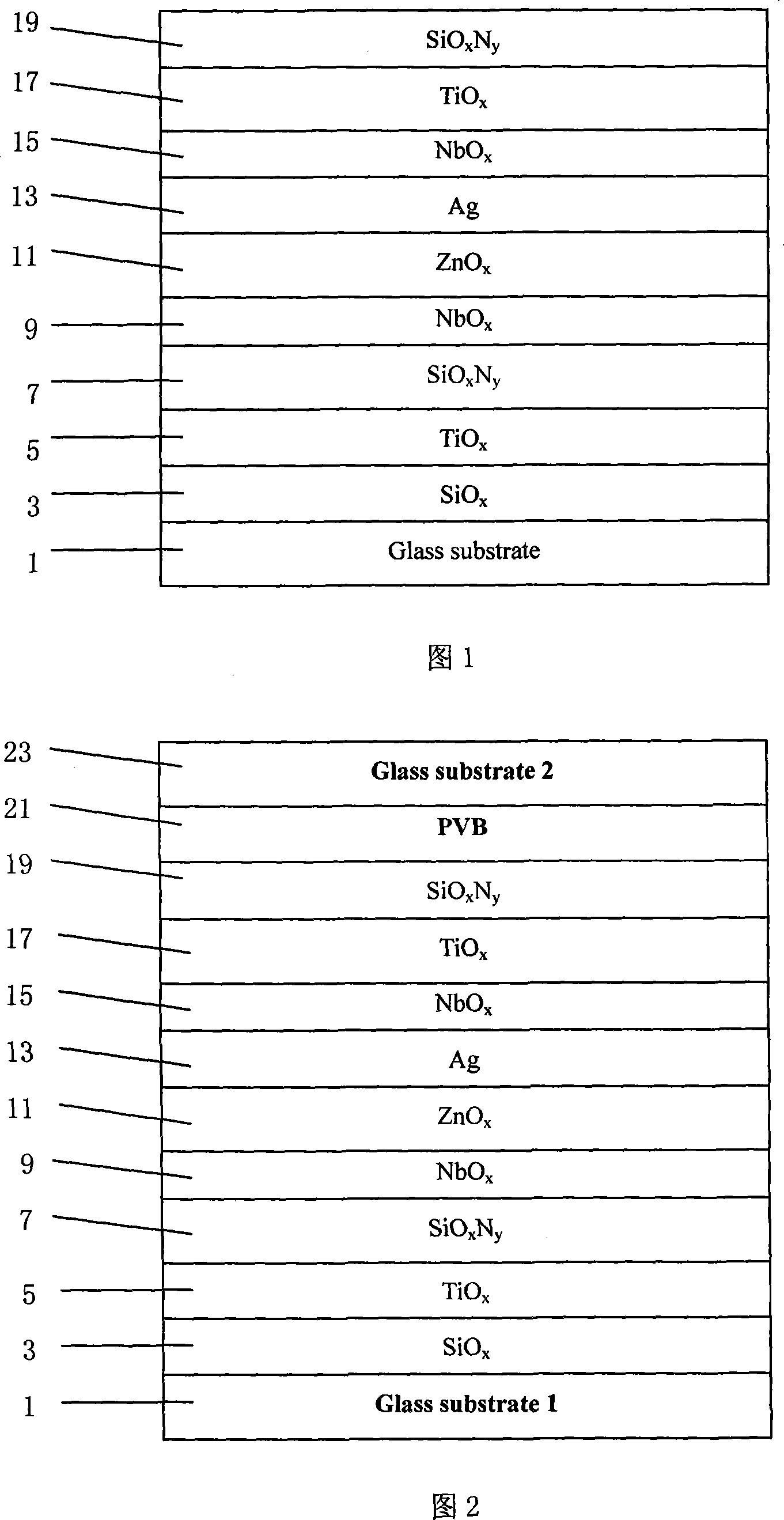

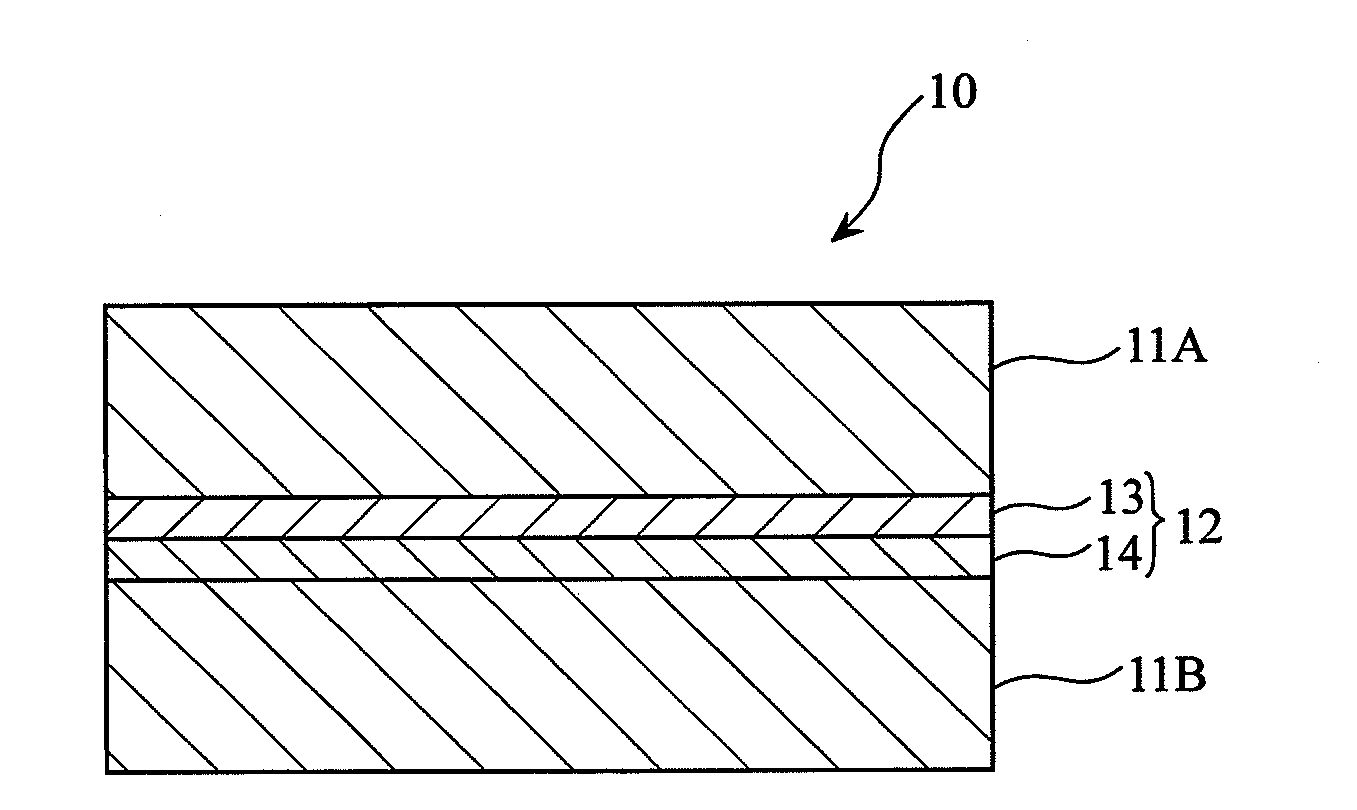

Anti-reflection, low-radiation and easy-cleaning coated glass capable of roasting and bending and manufacture method thereof

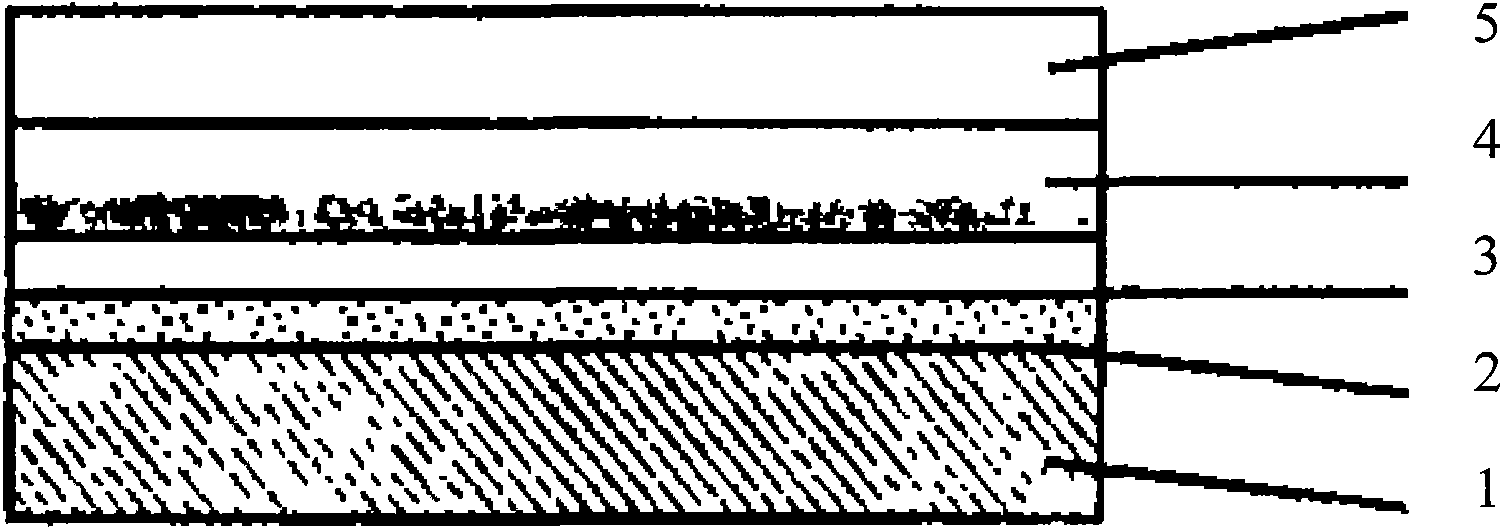

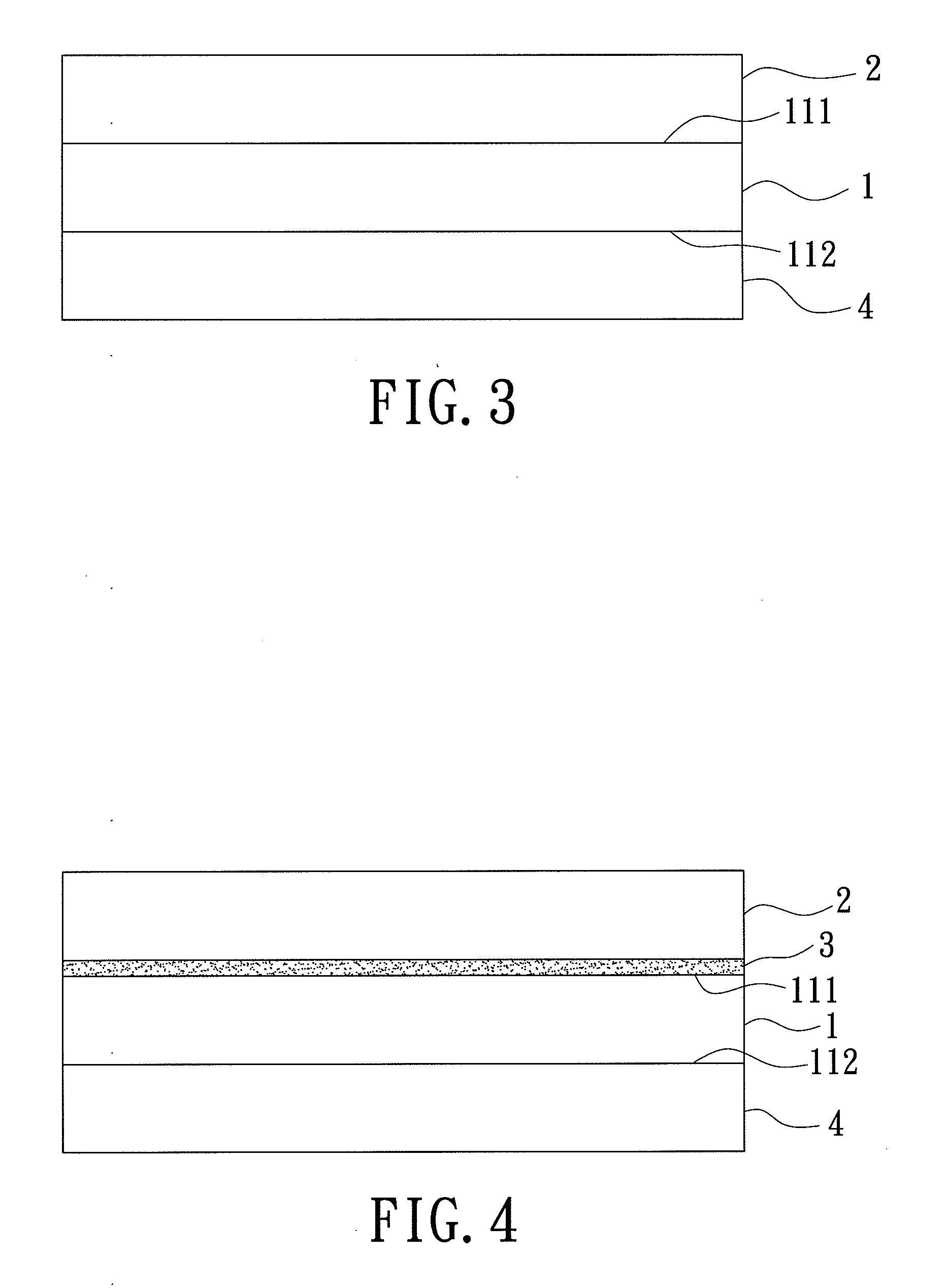

InactiveCN103241961AKeep it clean and shinyImprove transmittanceGlass/slag layered productsPolyvinyl butyralTransmittance

The invention relates to an anti-reflection, low-radiation and easy-cleaning coated glass capable of roasting and bending and a manufacture method of the coated glass. The glass is an anti-reflection, low-radiation and easy-cleaning coated laminated glass capable of roasting and bending, and the anti-reflection, low-radiation and easy-cleaning coated laminated glass capable of roasting and bending is formed by sequentially overlapping anti-reflection and low-radiation coated glass with polyvinyl butyral and a glass plate B, wherein the anti-reflection and low-radiation coated glass is structured by comprising a TiO2 photocatalyst layer, an anti-reflection film layer, a glass plate A and a low-radiation film layer which are overlapped from top to bottom in sequence. Compared with the prior art, the laminated glass manufactured from the anti-reflection, low-radiation and easy-cleaning coated glass has an easy-cleaning characteristic, also has the effects of increasing the visible light transmittance by 3 to 4% and reducing the visible light reflectance from 12 to 15% to 3 to 4%, can prevent the sight from being interfered by a projection of a matter in a car on the glass during driving, and has the visible light transmittance not less than 70% and sun light transmittance not greater than 50%; and the anti-reflection, low-radiation and easy-cleaning coated glass capable of roasting and bending is particularly suitable for a front windshield of the car.

Owner:FUYAO GRP SHANGHAI AUTOMOBILE GLASS CO LTD

Low radiation coated glass capable of being bended by baking

ActiveCN101168476AUnique heat insulation effectStructurally intactPolyvinyl butyralThermal insulation

A bake-bent low-radiation coated glass relates to coated glass, in particular to low-radiation coated glass. The invention provides a low-radiation coated glass and an interlayer thermal-insulation glass composed of the low-radiation coated glass, wherein the film structure of the low-radiation coated glass comprises a glass plate, a first dielectric layer, a low-radiation layer, a second dielectric layer, and a protective layer, wherein the film structure of one embodiment comprises a glass substrate SiOx / SiOxNy / SnOx / NiCrOx / ZnSnOx / Ag / NiCrOx / SnOx / SiOxNy film from inner to outer at the glass plate, the low-radiation coated glass, PVB (polyvinyl butyral) and another glass plate are layered to form an interlayer thermal-insulation glass which visible light transmission is more than 76% and solar energy transmission is lower than 53%, therefore, the interlayer thermal-insulation glass is particularly applied on vehicle front shield glass.

Owner:FUYAO GLASS IND GROUP CO LTD

Self-fixing zinc-rich primer in petroleum storage tank for resisting corrosion and preparation method thereof

InactiveCN101191028AImprove corrosion resistanceGood solvent resistanceAnti-corrosive paintsPolyvinyl butyralDibasic ester

The invention relates to a self-fixed zinc-rich primer using for anticorrosion inside an oil tank and a preparation method thereof. The self-fixed zinc-rich primer comprises A solution which consists of tetraethyl orthosilicate, butanol, ethanol, butyl acetate, dibasic ester, 36-38 percent of hydrochloride and distilled water, and B solution which consists of polyvinyl butyral (PVB), butanol, ethanol, zinc powder, ultrafine ferrophosphorus powder, mica powder, fly ash, alkoxy ammonium salt with acidic group and block copolymers, and polysiloxane-polyether copolymer, when in use, the A solution and the B solution are mixed and solidified to form a paint film which is characterized by self-repairing, corrosion resistance, solvent resistance, static conducting, rapid drying and good construction adaptability, etc. The self-fixed zinc-rich primer can be used for surface anticorrosion treatment of steel structures used in inner walls and outer walls of various storage tanks and offshore drilling platforms, etc.

Owner:CNPC RES INST OF ENG TECH +1

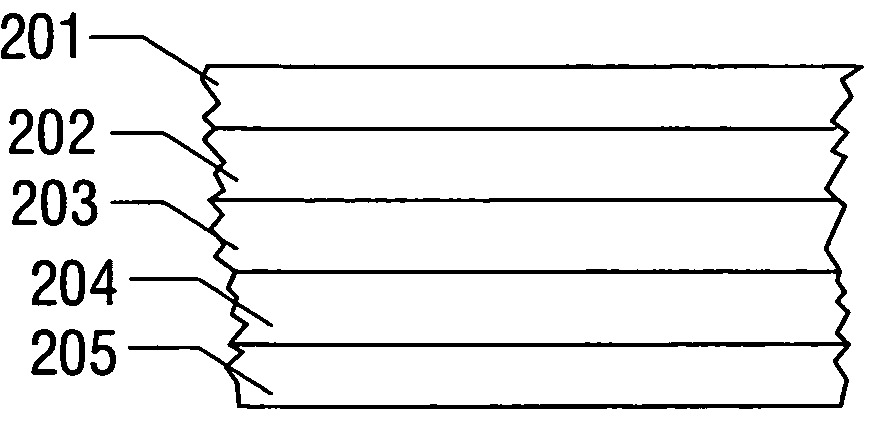

Laminated structures with superior impact resistance and process for making same

InactiveUS20050118445A1Synthetic resin layered productsConstructions elementsPolyvinyl butyralPolyvinyl alcohol

The present invention is a laminate article comprising at least three layers of plasticized polyvinylbutyral (PVB) sheet, wherein at least one layer of the laminate is a stiff PVB sheet and at least two layers are soft PVB sheets. A laminate article of the present invention is useful for providing increased protection from damages occurring to automobiles, buildings, and windows by virtue of exposure of same to, for example, hurricane force winds, impact from debris propelled by high-force winds, or by intentional impact against windows comprising the laminates of the present invention.

Owner:KURARAY AMERICA INC

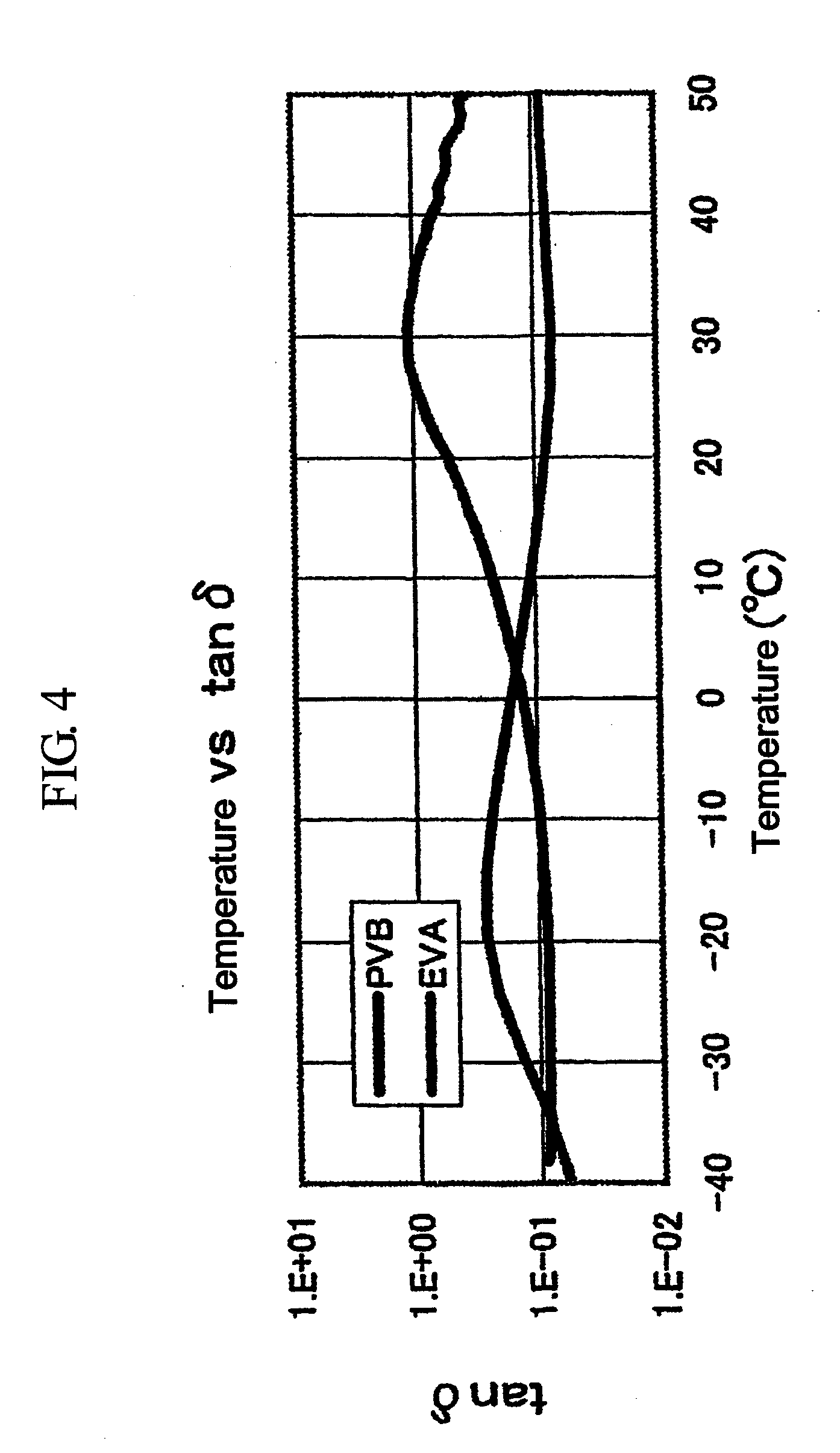

Intermediate film for laminated glass, laminated glass using the intermediate film, and process for the preparation of the laminated glass

InactiveUS20100233453A1High transparencyImprove penetration resistanceSynthetic resin layered productsLaminationPolyvinyl butyralWeather resistance

[Problem to be Solved]The object of the present invention is to provide an intermediate film for a laminated glass having excellent transparency, adhesion, impact resistance and penetration resistance as well as excellent light resistance and weather resistance, and scarcely turning yellow in a heating treatment during its preparation.[Means for Solving Problem]An intermediate film for a laminated glass comprising a laminate consisting of a layer (PVB layer) of a composition comprising polyvinyl butyral and a layer (EVA layer) of a composition comprising ethylene / vinyl acetate copolymer containing an organic peroxide, wherein the composition comprising polyvinyl butyral contains a benzophenone compound as an ultraviolet absorber; a laminated glass; and a process for the preparation of the same.

Owner:BRIDGESTONE CORP

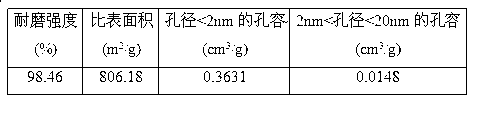

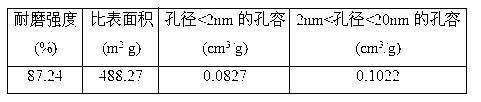

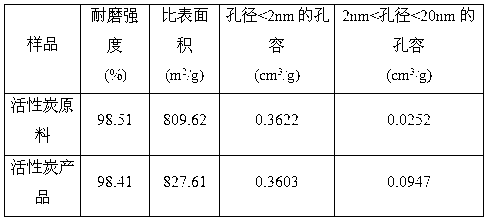

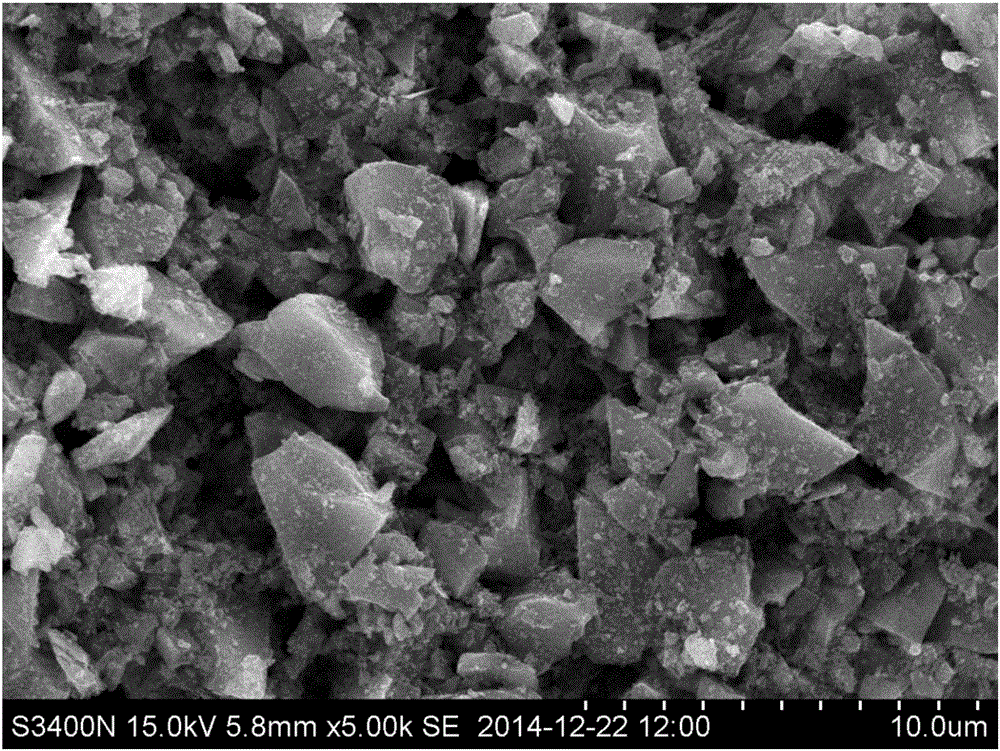

Method for preparing activated carbon

ActiveCN103253664AImprove wear resistanceIncrease microporosityCarbon compoundsPorosityPolyvinyl butyral

The invention relates to a method for preparing activated carbon. The method comprises the following steps of: weighing one of soluble phenolic resin, furfuryl alcohol resin, polyacrylonitrile and soluble starch, a carbon precursor polymer and one pore-forming agent of polyethylene glycol, polyvinyl alcohol and polyvinyl butyral, mixing, and adding one of methanol, ethanol and deionized water as a solvent for dissolution; and weighing the activated carbon raw material, adding into the solution for dipping, then drying, and carbonizing in a microwave high-temperature sintering furnace at the temperature of 500-1100 DEG C in a nitrogen atmosphere for 0.5-24h. According to the method for preparing activated carbon, provided by the invention, an activated carbon product prepared by the method has abrasion resistance and micropore porosity which are equivalent to those of the raw material activated carbon; and furthermore, the mesopore porosity is further increased in comparison with the raw material activated carbon, and the activated carbon has the advantages of double aperture distribution, large specific surface area and high abrasion resistance, and can meet the application requirements under specific conditions.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Method for preparing silicon-nitride ceramic substrate through silicon-powder tape casting

ActiveCN105884376AHigh thermal conductivityGood mechanical propertiesPolyvinyl butyralCeramic substrate

The invention discloses a method for preparing a silicon-nitride ceramic substrate through silicon-powder tape casting, and belongs to the technical field of insulation substrates. The method includes the steps that silicon powder and an inorganic burning-assisting additive serve as raw materials, castor oil serves as a dispersing agent, and polyvinyl butyral serves as a binding agent; according to the chemical state and the particle size of the surface of the silicon powder, a plasticizer capable of allowing the silicon powder to be subjected to tape casting is added, and a large-area green blank which is adjustable in thickness, smooth in surface and free of crack and pore is prepared; the green blank is subjected to rubber discharging to be sintered at the high temperature, and the silicon-nitride ceramic substrate with the heat conductivity larger than 50 W.m<-1>.K<-1>, the bending strength larger than 600 MPa and the fracture toughness larger than 8 MPa.m<1 / 2>is prepared.

Owner:吉林长玉特陶新材料技术股份有限公司

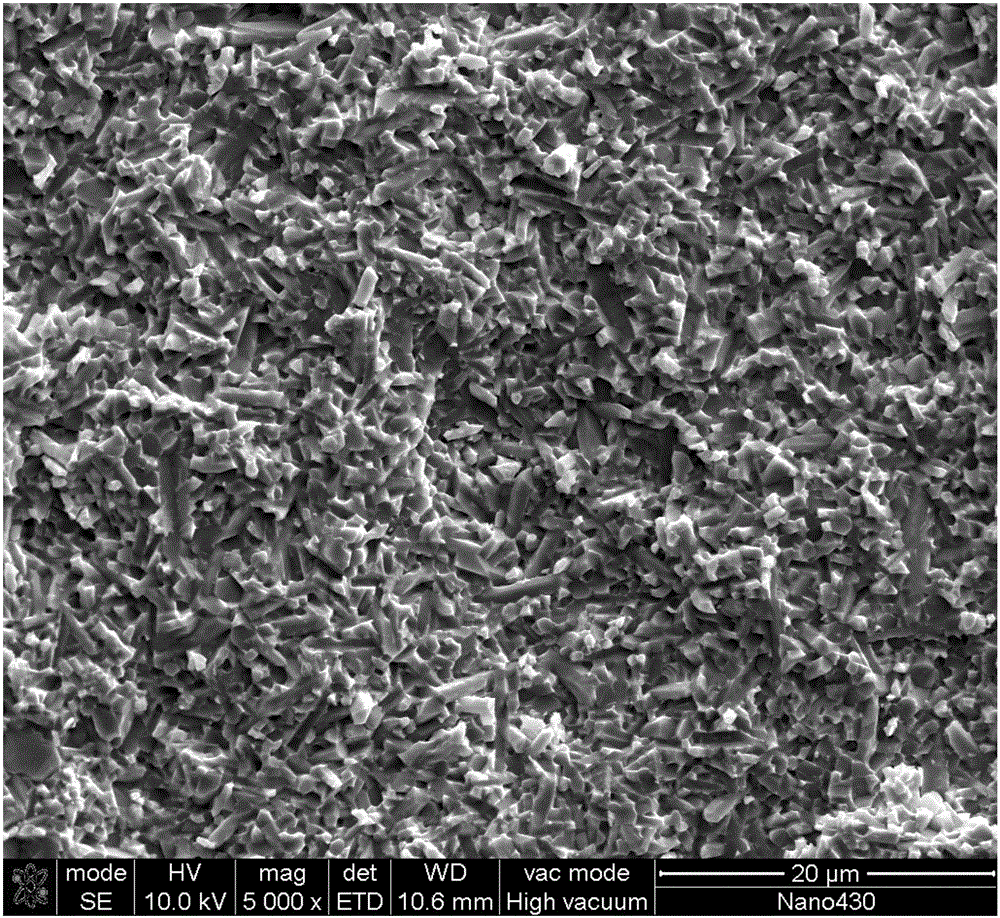

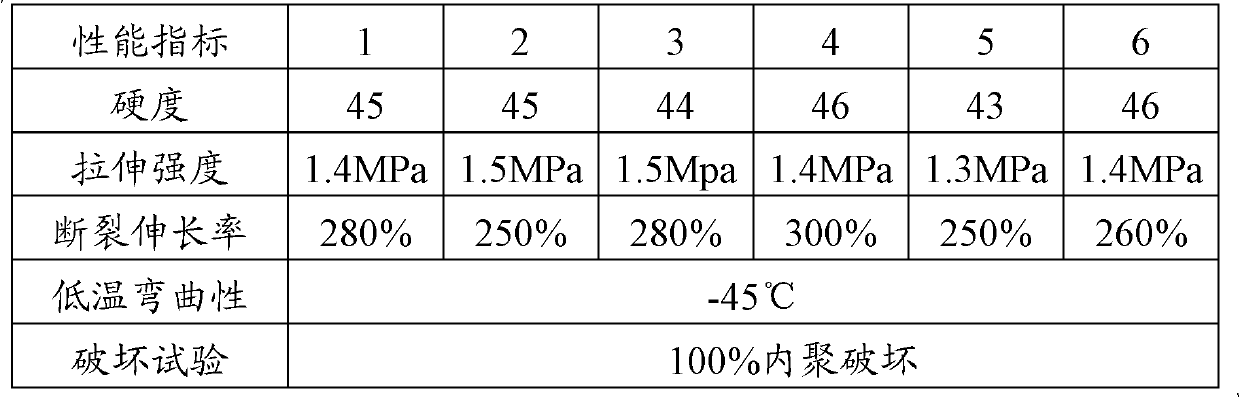

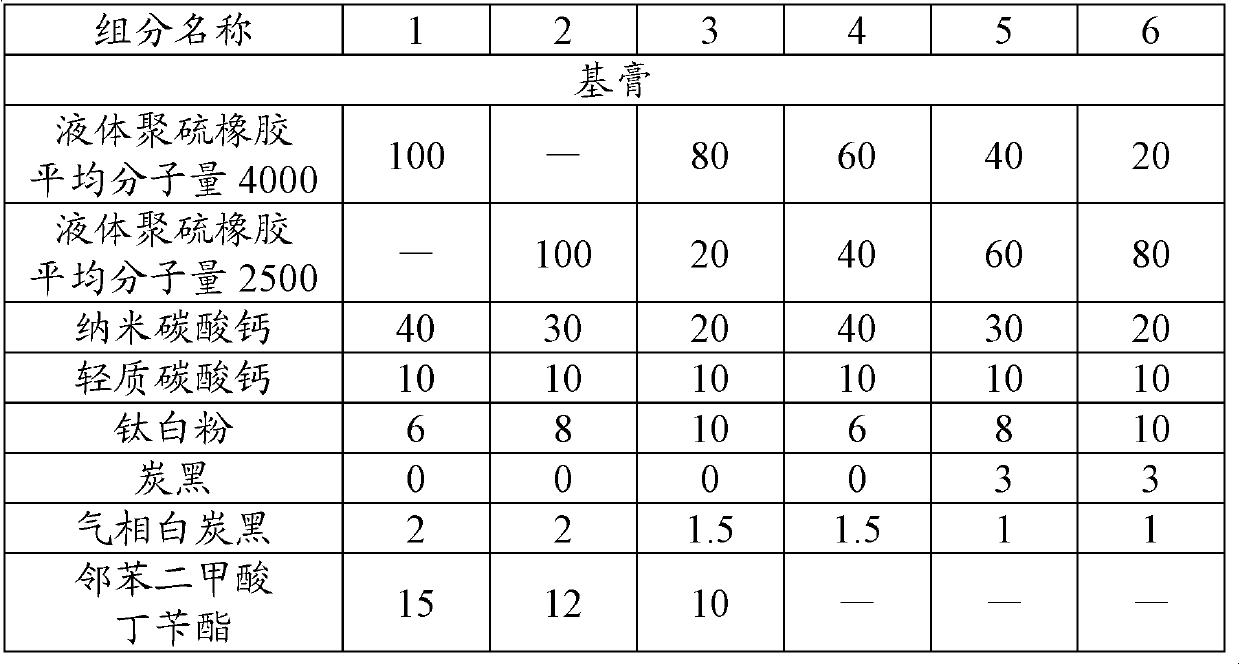

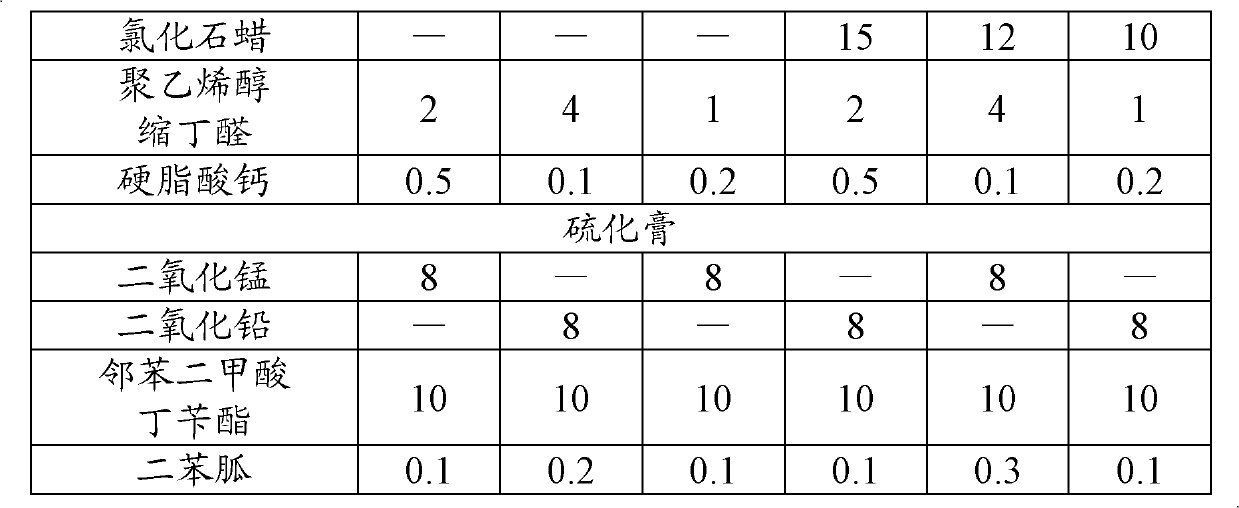

High-adhesion polysulfide sealant

InactiveCN101906285AOther chemical processesMacromolecular adhesive additivesPolyvinyl butyralPolysulfide rubber

The invention discloses a high-adhesion polysulfide sealant, which comprises base paste and vulcanizing paste. The base paste comprises 30 to 70 percent of liquid polysulfide rubber, 20 to 60 percent of filler, 0.5 to 10 percent of thickener, 5 to 20 percent of plasticizer and 0 to 5 percent of assistant, wherein the thickener polyvinyl butyral and adjusting the adhesive property of the sealant. The vulcanizing paste comprises 25 to 70 percent of vulcanizing agent, 25 to 70 percent of plasticizer and 0.5 to 5 percent of vulcanization accelerator. The mixing weight ratio of the base paste to the vulcanizing paste is 100:6-14. The invention also discloses a method for preparing the polysulfide sealant. The sealant and the method are characterized in that: the polyvinyl butyral is used as the thickener; the adhesive strength of the polysulfide sealant is improved; the use cost of the materials is low; the process is stable; and the repeatability is high. The material of the invention can be used for adhering sealing parts of airplanes, rapid trains, automobiles and the like. Therefore, the sealant has a high industrial application value.

Owner:ZHEJIANG UNIV

Production method of casting alcohol based paints using resin bonded sand

InactiveCN101288898AEasy to useImprove stabilityFoundry mouldsFoundry coresPolyvinyl butyralSodium Bentonite

The invention provides a production method for casting alcohol-based coating with a resin sand, comprising the compositions as follows: high bauxite powders, graphite powders, dextrin powders, bentonite powders, polyvinyl butyral, ferric oxide powders, colophony and 665 phenolic resin; the proportion of the composition is as follows: 60% of high bauxite powders, 20% of graphite powders, 5%-7% of dextrin powders, 5%-7% of bentonite powders, 0.5%-1% of polyvinyl butyral, 2%-3% of ferric oxide, 2%-3% of colophony and 2%-3% of 665 phenolic resin. The method of the invention solves the problems of the current clay sand dry-typed casting coating such as high cost, coarse surface after coating and easy cracking and is suitable for the application in the casting production.

Owner:QINGDAO HAILONG MACHINERY GRP

Polymer solid electrolyte film and preparation method thereof

The invention relates to a polymer solid electrolyte film and a preparation method thereof, which belong to the field of solid electrolyte. The solid electrolyte consists of polyvinyl butyral (PVB), lithium-bearing inorganic salt and a plasticizer, namely low molecular polyethylene glycol. The compositions in weight percentage of the polymer solid electrolyte film are 30 to 75 percent of the polyvinyl butyral, 10 to 85 percent of the lithium-bearing inorganic salt and 5 to 70 percent of the plasticizer. The preparation method comprises the following steps: the lithium-bearing inorganic salt is uniformly mixed with an organic solvent; the polyvinyl butyral powder is slowly added into the mixture and continuously stirred for 30 to 50 minutes; and finally the plasticizer is added. The invention increases the motion of polyvinyl butyral (PVB) segmers and improves the ionic conductivity of the solid electrolyte through the addition of the plasticizer; the room-temperature conductivity of the macromolecular solid electrolyte film prepared is about 10<-5>Scm<-1>, and the conductivity at the temperature of below 60 DEG C is about 10<-3>Scm<-1>; and the film-forming property and the mechanical property are good.

Owner:UNIV OF SCI & TECH BEIJING

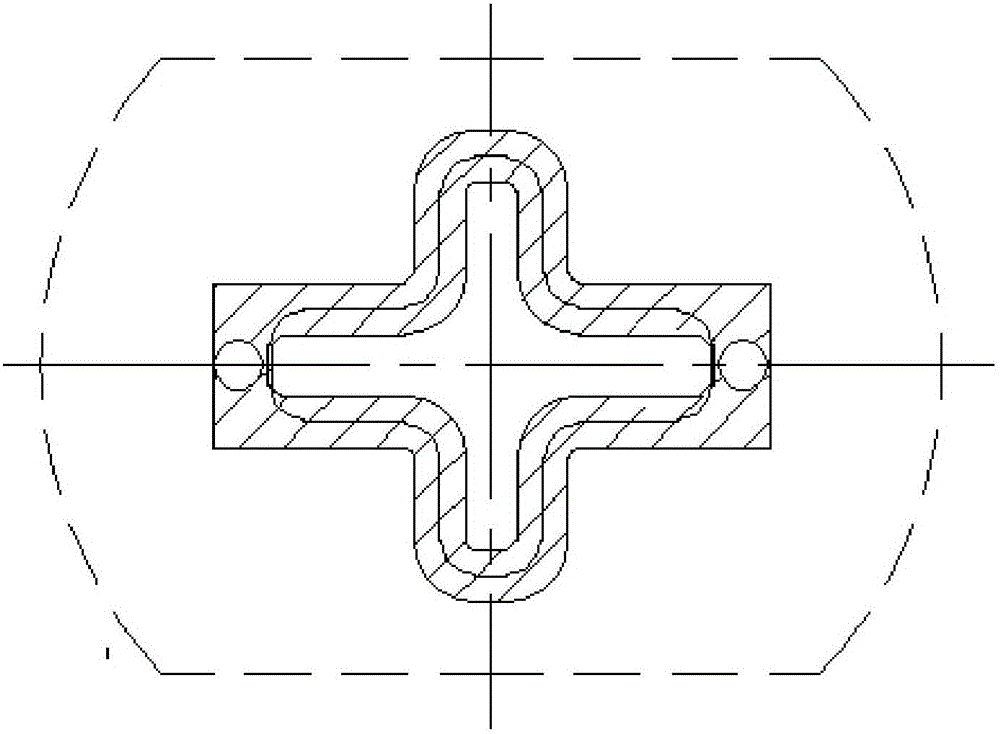

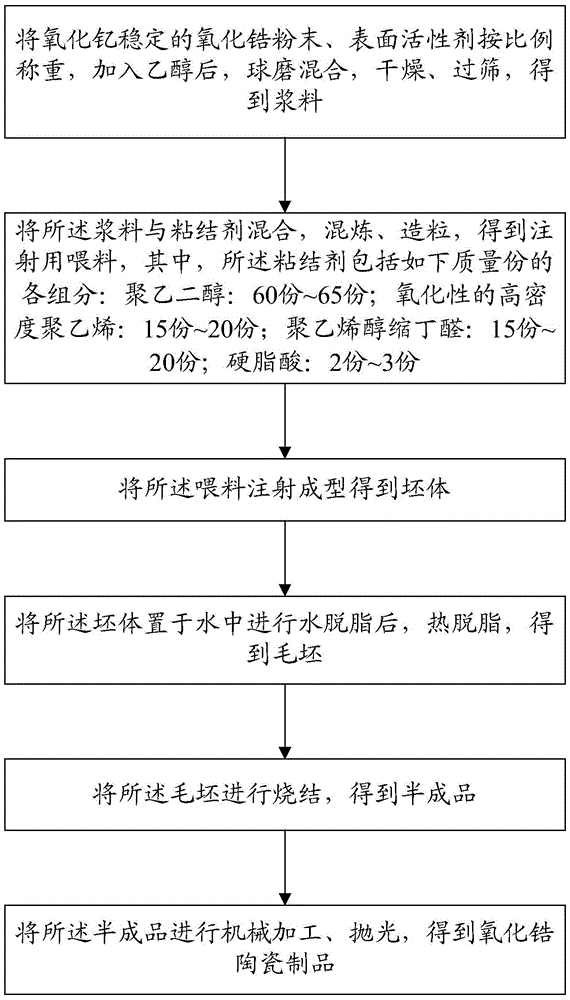

Forming method for zirconia ceramic products

The invention discloses a forming method for zirconia ceramic products. The forming method comprises the following steps: weighing yttria-stabilized zirconia powder and a surfactant in a ratio, adding ethanol, carrying out ball-milling mixing, drying, and sieving to obtain a slurry; mixing the slurry with a binder, mixing, and granulating to obtain a feedstock for injection, wherein the binder comprises the following components in parts by mass: 60-65 parts of polyethylene glycol, 15-20 parts of oxidizing high-density polyethylene, 15-20 parts of polyvinyl butyral, and 2-3 parts of stearic acid; carrying out injection forming on the feedstock to obtain green bodies; placing the green bodies in water and carrying out water debinding, and carrying out thermal debinding to obtain blanks; sintering the blanks to obtain semi-finished products; and machining and polishing the semi-finished products to obtain the zirconia ceramic products. The forming method for the zirconia ceramic products, which is disclosed by the invention, is capable of guaranteeing that the obtained ceramic products are high in strength, not liable to break, high in compactness, and uniform in porosity.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

Production process of laminated glass

The invention discloses a production process of laminated glass. The production process comprises the following steps of (1) selection and storage of polyvinyl butyral (PVB) adhesive sheets; (2) glass wiping, (3) sheet combination operation; (4) pre-pressing exhaust; and (5) high-pressure molding. Under the control action of a standard process, bubbles can be prevented from being formed at the edge of the laminated glass; meanwhile, the phenomena of explosion, glass radian out-of-tolerance, edge bubble adhesive failure, edge adhesive shrinkage, interlayer inclusion and the like are effectively controlled.

Owner:芜湖市兴业特种玻璃有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com