Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32153results about How to "Simple production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing humic acid and salt thereof by oxidation and degradation of brown coal

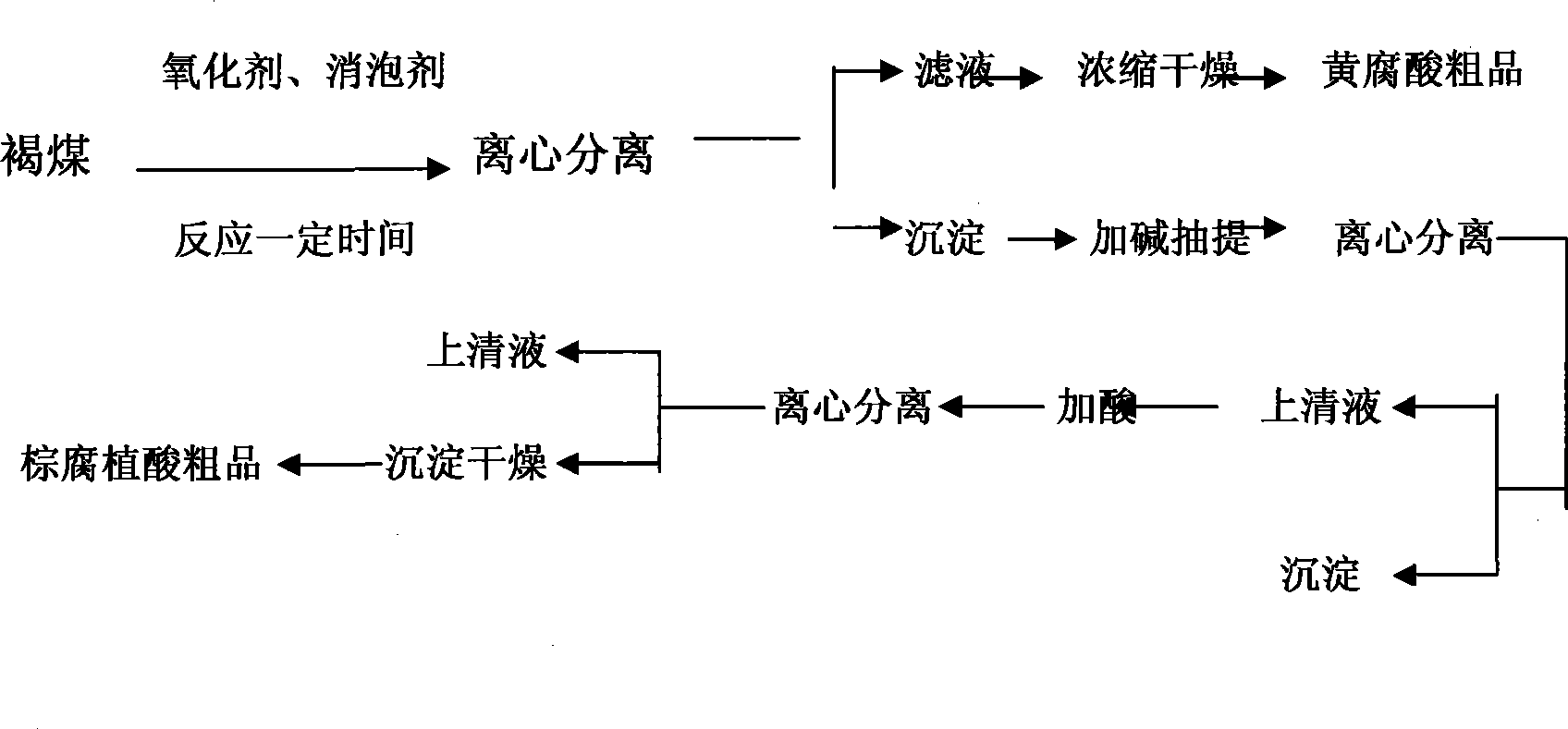

The invention discloses a method for producing humic acid and salt thereof through the oxidative degradation of young lignite. The method comprises the following steps: carrying out the oxidation reaction of the lignite containing the humic acid and aqueous hydrogen peroxide solution; after the reaction, obtaining water soluble fulvic acid through centrifugal separation, supernatant filtration, concentration and drying; adding alkali into the fulvic acid to prepare a fulvic acid salt product; carrying out the alkaline extraction and centrifugal separation of the residue deposit of the production of the fulvic acid, adding acid into the supernatant till the pH value is 1 to 2, carrying out a reaction at an increased temperature or room temperature, carrying out centrifugal separation after the reaction is finished, and obtaining purified ulmic acid after precipitation and drying; and directly concentrating and drying the supernatant in the previous step to obtain the humate. The method can improve the yield of the fulvic acid and total humic acid in the young lignite, and simultaneously increase the active group in the humic acid. The method can be used for producing fulvic acid, fulvic acid salt, ulmic acid and ulmic acid salt products. In particular, the method puts an end to the environmental pollution caused by the nitric acid which is taken as an oxidation degradation agent. In addition, the method has a short technological line, low cost, simple requirements on equipment, and moderate conditions. The method which can be applied to the industrialized production has good application prospect.

Owner:KUNMING UNIV OF SCI & TECH +4

Formula of pure binary super low interface tension composite oil-displacement agent of surfactant and pdymer for triple oil production

The composite oil-displacement agent consists of polymer 0-0.3 wt.%, surfactant 0.05-0.6 wt% and water 99.1-99.95 wt%, and is produced in kettle reactor with coagulated petroleum fraction from raw oil. It has surfactant concentration not higher than available systems, high interface tension reducing effect and stable performance. The ternary composite oil-displacement agent has no alkali and saltwhile reaching superlow interface tension and thus no alkali scale formed, no loss in polymer viscosity and viscolerasticity. In the compounding of the composite oil-displacement agent, common sewagemay be used and this produces certain environment protection effect.

Owner:PETROCHINA CO LTD

Video-assisted margin marking for dental models

InactiveUS20100281370A1Simple production processSpeed up the processInput/output for user-computer interactionImpression capsInteractive modelingAmbiguity

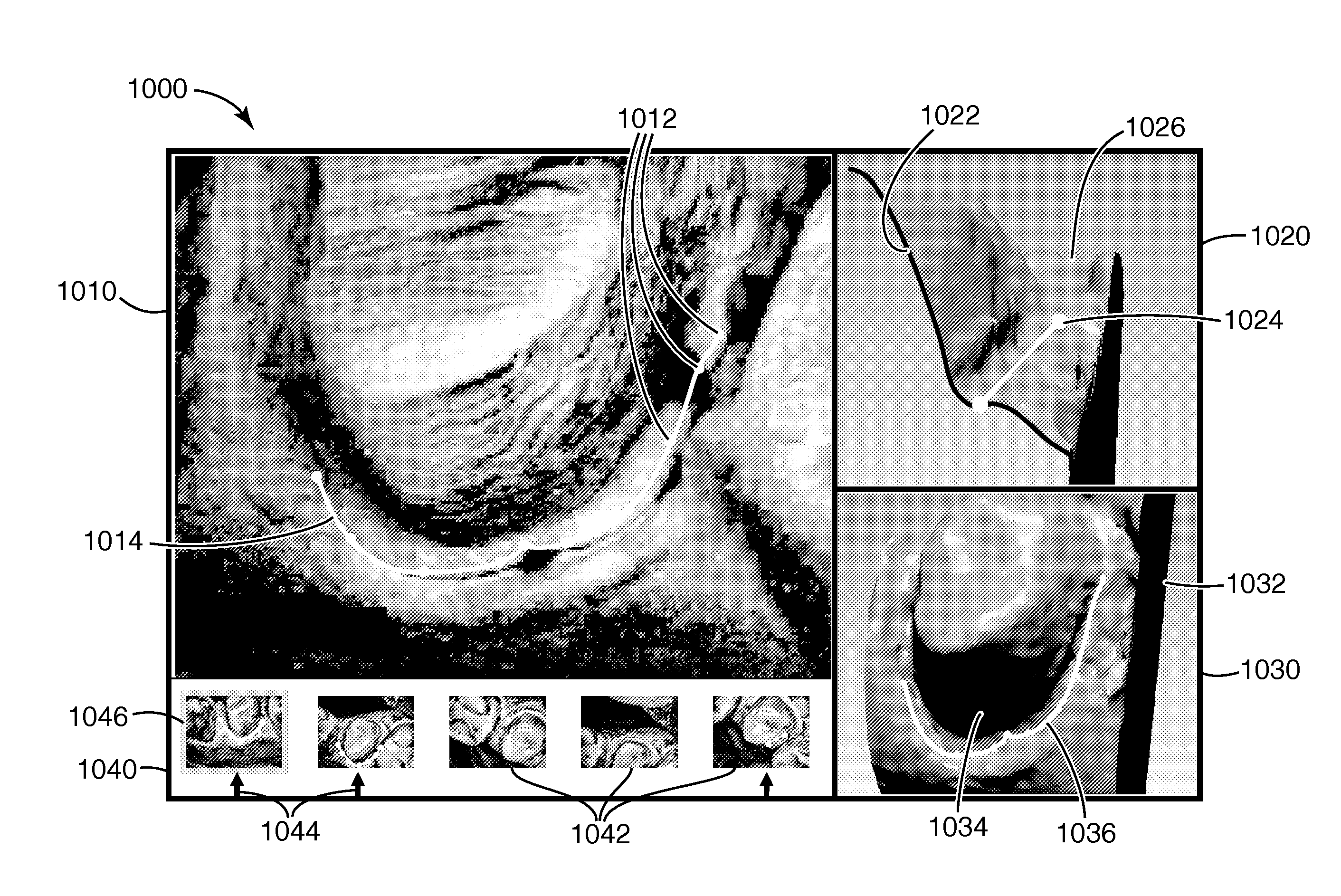

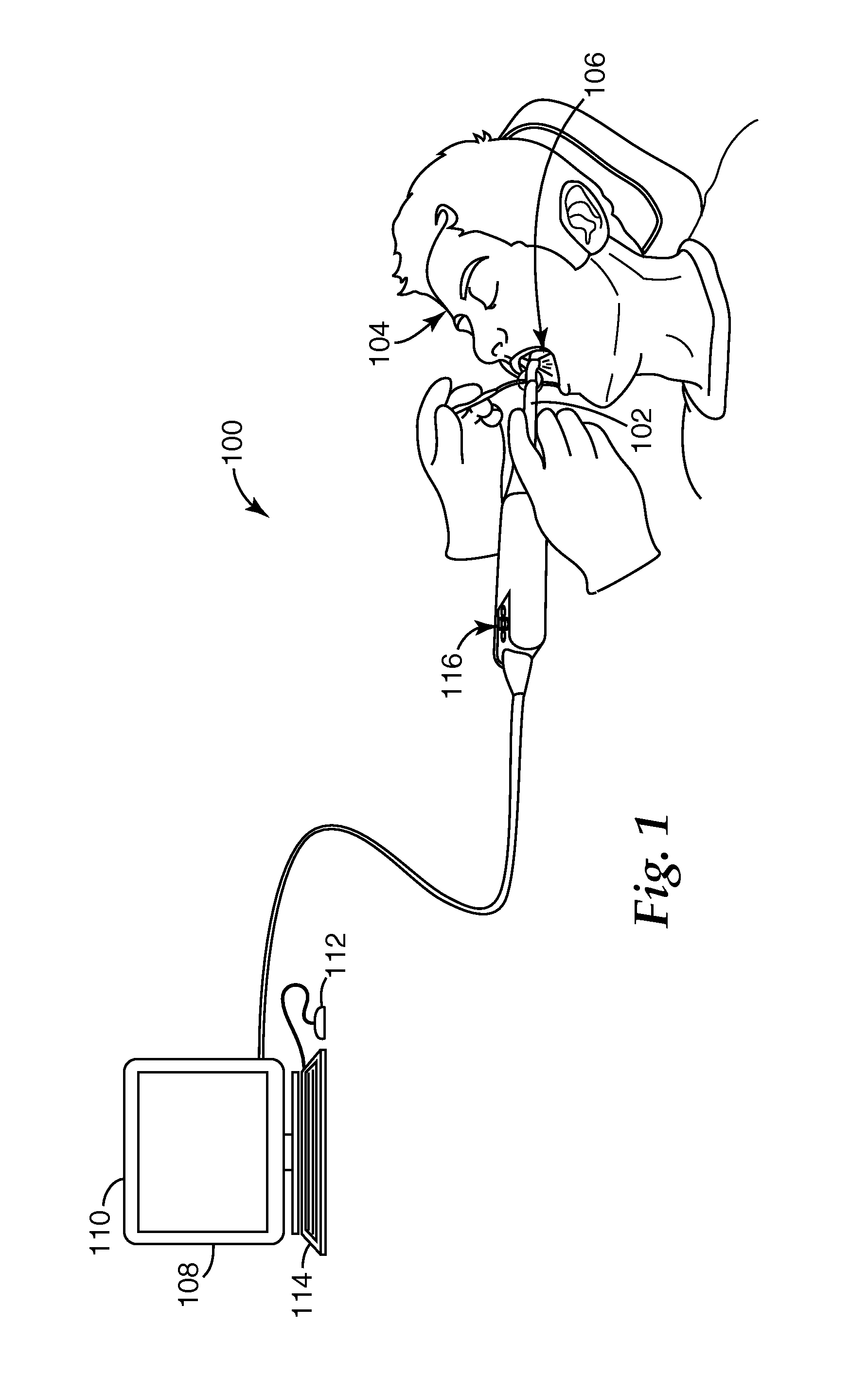

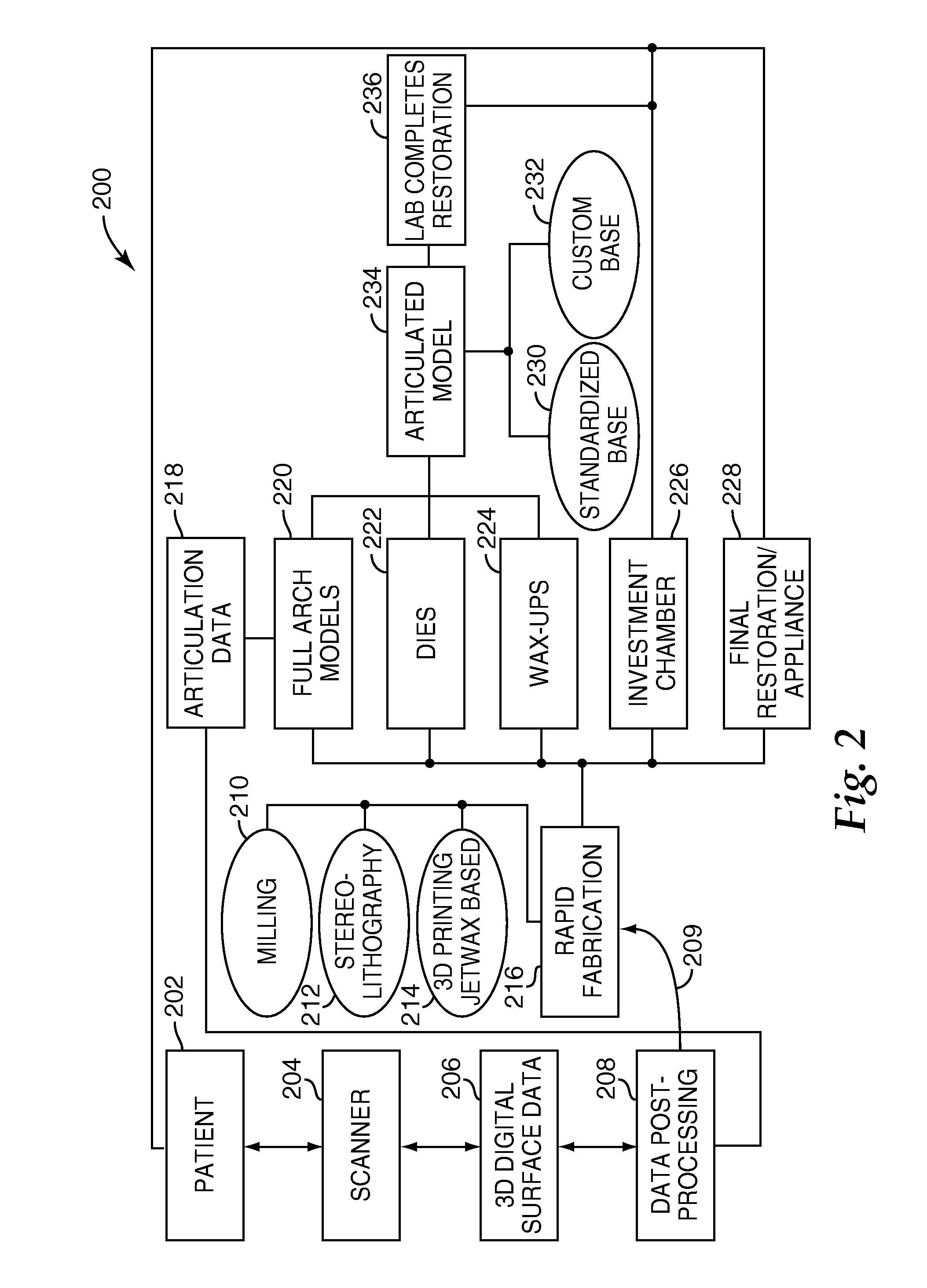

Tools are described for preparing digital dental models for use in dental restoration production processes, along with associated systems and methods. Dental modeling is improved by supplementing views of three-dimensional models with still images of the modeled subject matter. Video data acquired during a scan of the model provides a source of still images that can be displayed alongside a rendered three-dimensional model, and the two views (model and still image) may be synchronized to provide a common perspective of the model's subject matter. This approach provides useful visual information for disambiguating surface features of the model during processing steps such as marking a margin of a prepared tooth surface for a restoration. Interactive modeling tools may be similarly enhanced. For example, tools for margin marking may synchronize display of margin lines between the still image and the model so that a user can interact with either or both of the visual representations, with changes to a margin reflected in both displays.

Owner:3M INNOVATIVE PROPERTIES CO

Method for depositing paint-coat of metal surface, especially for gradient paint-coat

InactiveCN1405355ASimple production processLow costMetallic material coating processesAlloyIonization

The invention refers to a method of melting-covering coating of metal surface, especially a method of gradient coating. The steps: 1, pre-smear the mixing pwoder of Fe-, Co- or Ni-group alloying powder and ceramic powder; 2, use plasm produced by ionizing non-oxidizing gas in plasm moment to scan metal surface in order to produce melting-covering layer or gradient cost. It has positive effects.

Owner:山东科技大学机械电子工程学院

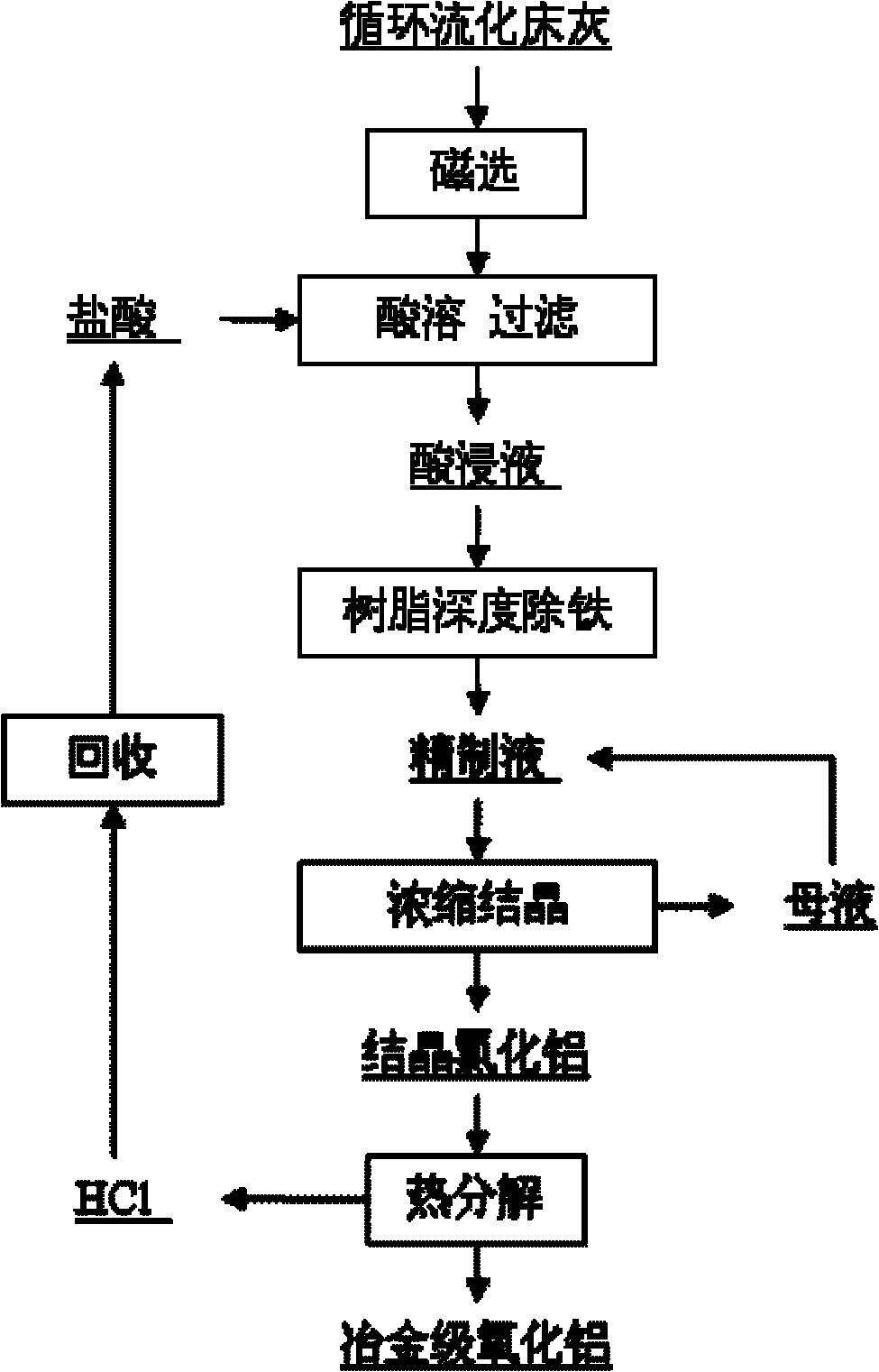

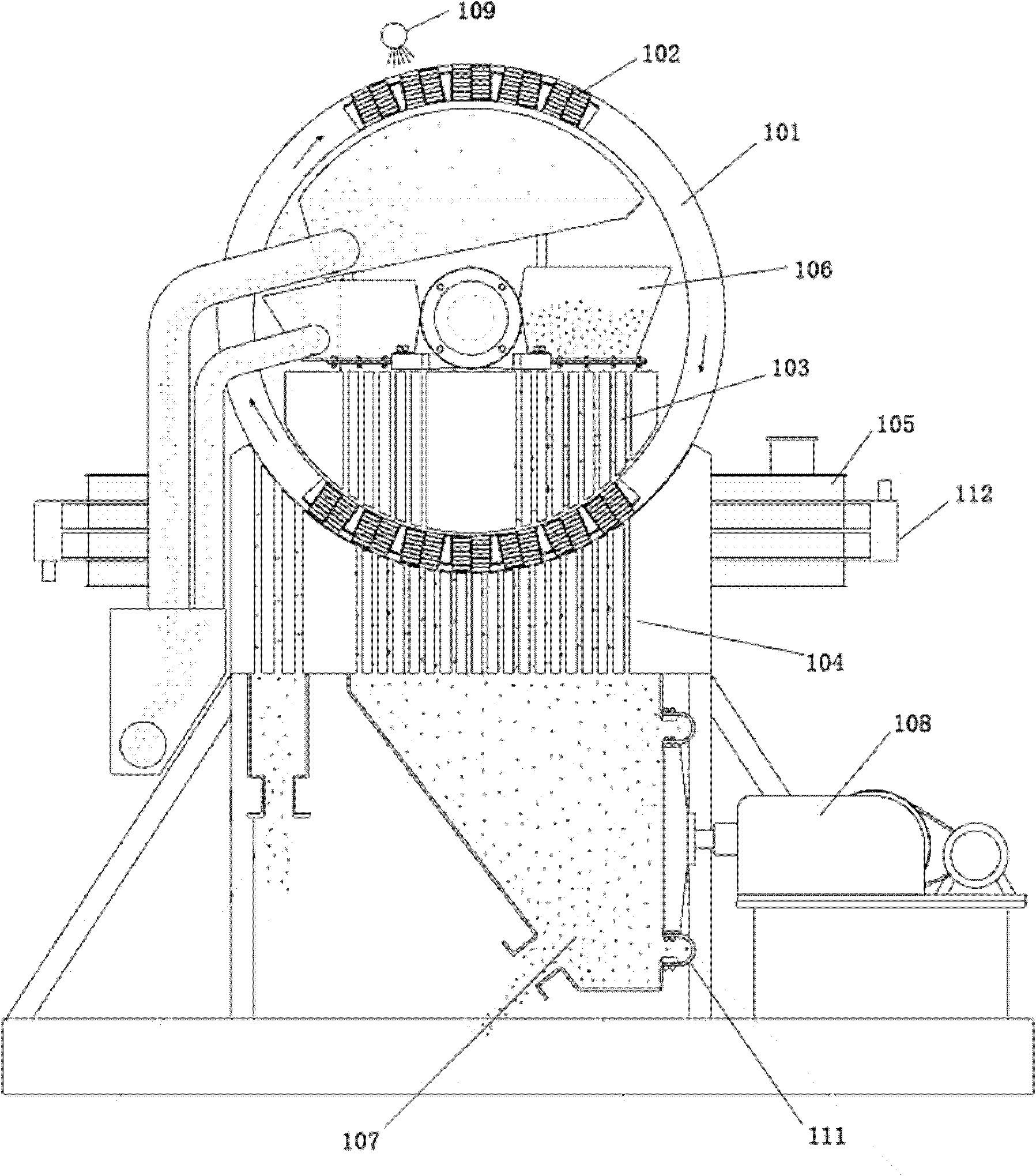

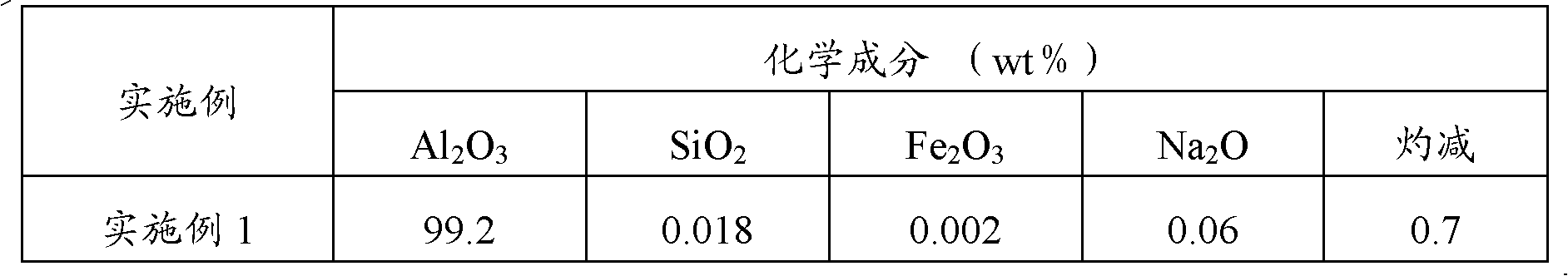

Method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash

ActiveCN102145905AHigh extraction rateReduce manufacturing costSolid waste disposalTransportation and packagingAluminium chloridePulverized fuel ash

The invention discloses a method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash as a raw material. The method comprises the following steps of: a) grinding the pulverized fuel ash, and removing iron by a wet magnetic separation method; b) reacting the pulverized fuel ash subjected to magnetic separation with hydrochloric acid to obtain hydrochloric acid immersion liquid; c) allowing the hydrochloric acid immersion liquid to pass through a large pore type cation resin column for further iron removal to obtain refined aluminum chloride solution; d) concentrating the refined aluminum chloride solution, and crystallizing to obtain an aluminum chloride crystal; and e) calcining the aluminum chloride crystal and decomposing to obtain the metallurgy-level aluminum oxide. The method has a simple process and an easily-controlled production process, and is high in aluminum oxide extraction efficiency, low in production cost and stable in product quality.

Owner:CHINA SHENHUA ENERGY CO LTD

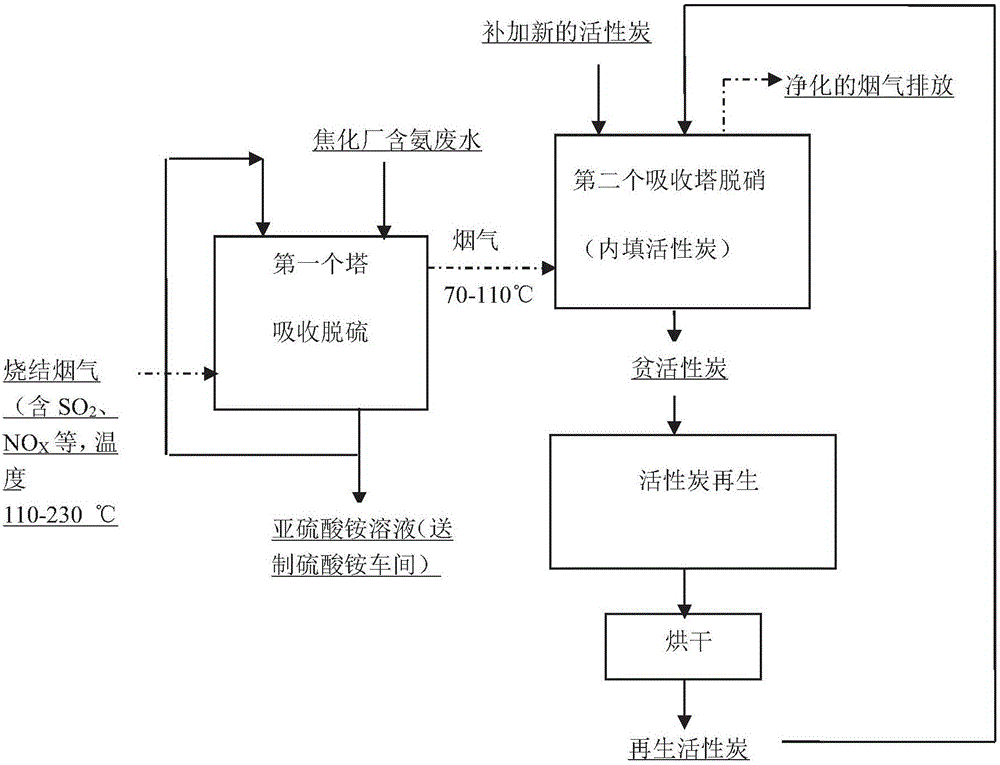

Ammonia-carbon combined desulfurization and denitration method for sintering flue gas

ActiveCN106621773AHigh mechanical strengthImprove recycling ratesGas treatmentOther chemical processesActivated carbonFlue gas

The invention discloses an ammonia-carbon combined desulfurization and denitration method for sintering flue gas. The sintering flue gas is desulfurized through ammonia-containing absorption liquid and then is adsorbed through activated carbon; the activated carbon is obtained by roasting carbonaceous materials and metallic oxide sources at a mass ratio of 2: 1 to 5: 1 at 850-1100 DEG C; the carbonaceous materials refer to semicoke or a mixture of coal and biomass. In the method, ammonia is cooperated with the activated carbon prepared through the method in use, desulfurization and denitration can be effectively achieved, secondary pollution is reduced, the process is cut short, and the treatment cost is reduced.

Owner:CENT SOUTH UNIV

PVC foaming wood plastic composite material

The invention discloses a PVC foaming wood plastic composite material which is produced by processing the raw materials based on the parts by weight: 100 parts of polyvinyl chloride (PVC), 40-50 parts of lignified plant fiber, 10-20 parts of active light calcium, 3-6 parts of calcium zinc complex stabilizer, 1-3 parts of compound-type foaming agent, 0.5-1.5 parts of lubricating agent OPE wax, 0.5-1 part of compound lubricating agent and 3-8 parts of foaming conditioning agent; the raw materials are evenly mixed by a mixing machine and then are directly put into a screw extruder to be extruded and molded at the temperature of 160-170 DEG C. The PVC foaming wood plastic composite material is added with full dose of heat stabilizer in the process of blending and processing, so that the degradation temperature of plastics can be increased, thermal degradation of the plastics and carbonization of wood powder in the process of mixing and forming can be prevented, and the operation of extruding and molding can be completed in one step, thus greatly simplifying the production technique and reducing the production cost.

Owner:石河子市森力新材料科技有限公司

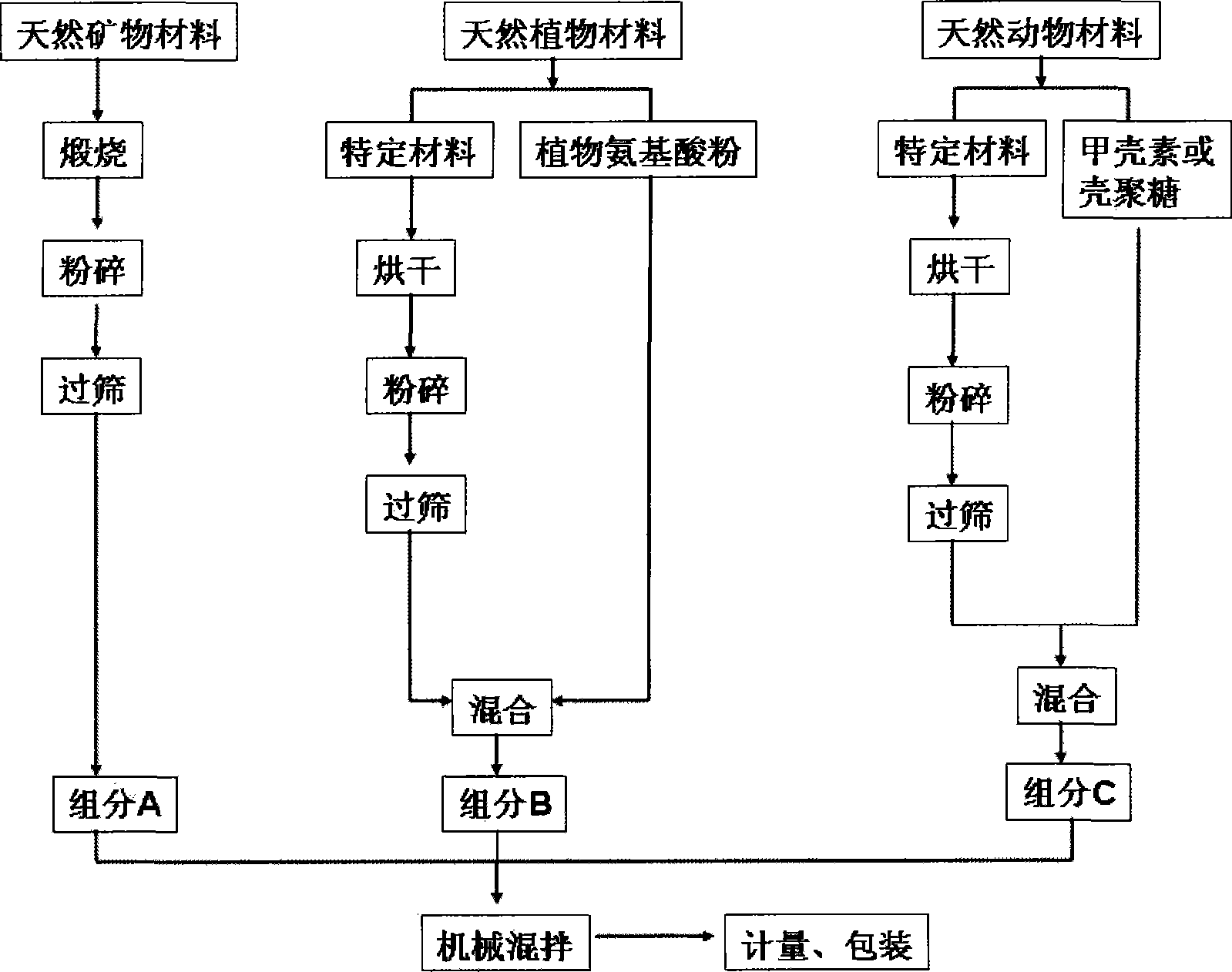

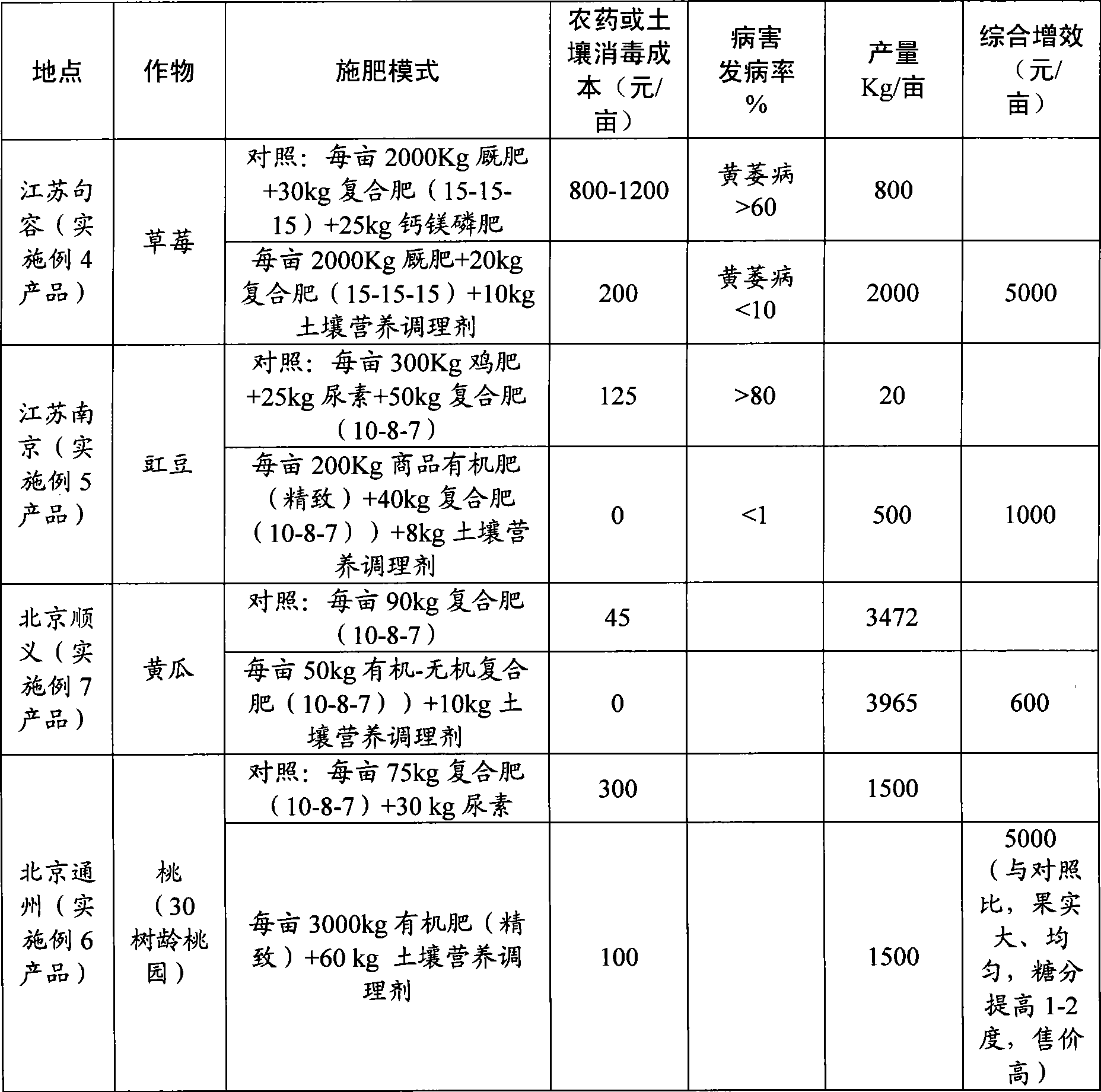

Soil fertility amendment and preparation method thereof

The invention provides a multifunctional soil nutrient conditioner formula with low cost, practicality and effectiveness and a preparation method thereof aiming at the technical problems. The production technology is simple, the production cost is low, and no harmful gas and sewage are generated during production. The product can effectively provide dozens of nutritive elements required for plant growth, is applied by being combined with a common fertilizer and an organic fertilizer, and can obviously improve the utilization rate of the fertilizer, so as to reduce the fertilizer input; and simultaneously the product can obviously stimulate action of beneficial floras of the soil, inhibit action of causal organisms, and increase the disease suppression of the soil and the resistance of plants, and then can effectively control generation of physiological diseases and soil-borne diseases, so as to reduce the pesticide input. The fertilizer input and the pesticide input can be reduced by more than 15 to 30 percent, and the yield can be increased by more than 15 to 30 percent, and simultaneously the product quality is obviously improved and cost conservation and synergism are obvious. Moreover, the soil improvement effect is obvious, and the sustainable utilization capacity can be obviously enhanced.

Owner:仲元(北京)绿色生物技术开发有限公司 +1

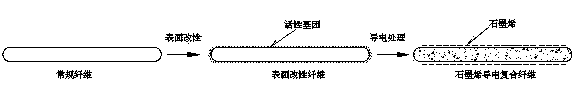

Preparation method of graphene electroconductive composite fiber

The invention provides a preparation method of a graphene electroconductive composite fiber. The method is characterized by comprising the following procedures: in a textile fiber surface modification procedure, a textile fiber is soaked into a silane coupling agent KH560 solution with the concentration of 1-30 percent for 2-3 hours and then is put into an oven of 50-65 DEG C to be dried to prepare the surfactant modified textile fiber; in a graphene dispersion system preparation procedure, graphene is prepared from an oxidized graphene aqueous solution prepared by means of a Hummer's method in a chemical reduction method, and a uniform and stable graphene dispersion system with the concentration of 0.1-5 percent is prepared under the function of a dispersing agent; in a graphene composite fiber preparation procedure, the modified textile fiber is soaked in the graphene dispersion system for 2-3 hours and then put into the oven of 50-65 DEG C to be dried to obtain the graphene electroconductive composite fiber. The preparation method is simple and reasonable in process, easy to operate, high in yield, high in reduction degree and high in conductivity and anti-radiation performance; the using amount of graphene is less and the dispersion system is uniform and stable.

Owner:QINGDAO UNIV

Preparation method of catalytic wet oxidation catalyst and treatment method of organic wastewater

ActiveCN103041818AHigh catalytic activityImprove catalytic stabilityMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationHigh concentrationOrganic acid

The invention discloses a preparation method of a catalytic wet oxidation catalyst and a treatment method of organic wastewater. The preparation method comprises the following steps of: (1) taking a porous inert material as a carrier, and performing pre-impregnation treatment on the carrier by adopting an organic acid solution; and (2) preparing an impregnating solution with a water-soluble compound containing transition metal elements and a water-soluble compound containing auxiliary elements, impregnating the carrier after treatment in the step (1) with the impregnating solution, drying in shade for 12-48 hours in air at appropriate humidity, then drying and roasting to obtain a final catalyst. When the catalyst prepared by the method disclosed by the invention is used for high-concentration organic wastewater, the characteristics of high activity, good stability and the like are realized, and the energy consumption and the investment can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-performance refractory weather-resisting building steel and its production method

InactiveCN1354273AImprove fire resistanceHigh yield strengthManufacturing cost reductionHeat-affected zone

The present invention relates to a high-performance fire-resistant weather-resisting building steel and its production method. Said invention steel contains C, Si, Mn, P, S, Mo, Ti, Al, N, O, Cr, Ni, Cu, Ca, B and one or more than one kind of Nb, V and RE and the rest is Fe. After having been undergone the processes of smelting, rolling and heat treatment, said building steel possesses high strenght, high toughness and excellent fire-resisting and weather-resisting properties. The building steel can be used for providing various steel structural members whose thickness is 4-100 mm in the fields of building, civil engineering and marine structure. Under the large linear energy (50-100 kJ / cm) welding condition of gas-arc welding, electroslag welding and high-frequency resistance welding, its heat affected zone (HAZ) still possesses excellent toughness so as to greatly raise welding efficiency of engineering structure and reduce its manufacture cost.

Owner:武钢集团有限公司

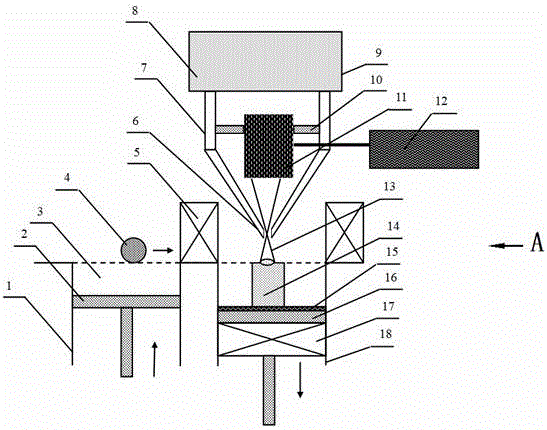

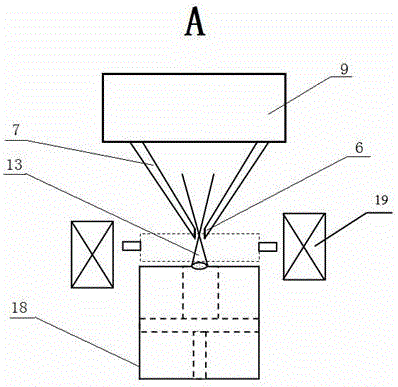

Method for manufacturing metal part solidification structure by non-contact control added material and magnetron metal 3D printing device

ActiveCN105798299ARealize online controlSelectiveAdditive manufacturing apparatusIncreasing energy efficiencyFront edgeElectromagnetic field

The invention discloses a method for manufacturing metal part solidification structure by a non-contact control added material and a magnetron metal 3D printing device. An electromagnetic field is applied in the quick solidification process of metal 3D printing; under the effect of the electromagnetic field, thermocurrent can be generated on a quickly solidified solid / liquid interface; the thermocurrent and the magnetic field are interacted to generate thermal electromagnetic force for triggering flowing of a melt; the end part of a dendritic crystal is shorn after suffering from the effect of the force to cause fragment of the dendritic crystal to form a lot of new crystal nucleus; and on the other hand, the temperature gradient of the front edge of the solid / liquid interface is slowed down through flowing of the melt, so that the constitutional supercooling of two phase regions is increased, the nucleation rate is increased. The method refines grains, improves the morphology of the grains, enables the structure to become uniform and compact, and realizes the structure control of metal 3D printing parts.

Owner:SHANGHAI UNIV

High-carbon high-high-vanadium high-speed steel composite roller and heat treatment method thereof

InactiveCN101037760ASimple production processImprove wear resistanceFurnace typesHeat treatment process controlChemical compositionHigh-speed steel

The invention discloses a high-carbon high-vanadium high-speed-steel complex roll. The outer layer of the high-carbon high-vanadium high-speed-steel complex roll comprises, based on weight percent, C: 1.8%-3.0%, V: 3.0%-6.0%, Cr: 4.0%-6.0%, Mo: 3.0%-6.0%, W: 1.0%-3.0%, Nb: 1.0%-5.0%, Co: 1.0%-5.0%, Si: <1.0%, Mn: <1.5%, P: <0.04%, S: <0.04%; Y: 0.05%-0.20%, Ti: 08%-0.25%, Mg: 0.03%-0.12%, Zr: 0.04%-0.18%, Te: 0.02%-0.12%, the residuel of Fe, the total of 100%. The roll is produced by smelting using electric furnace, casting and forming using centrifugal casting, heat treatment comprising quenching and tempering treatment. The high-speed-steel roll has high rigidity and strength, good toughness and wear resistance, and good anti-thermal fatigue, without roll breakage and desquamation in use. The application of the inventive roll can reduce the consumption of roll, improve the work rates of roll, prolong roll changing cycle, improve the surface quality of roll, with good economic and social effect.

Owner:XI AN JIAOTONG UNIV

Method of preparing aluminum oxide from fly ash

ActiveCN1923695AHigh dissolution rateFewer separation stepsAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium sulfateSlag

The invention discloses a preparing method of alumina through fly ash, which comprises the following steps: grinding fly ash; sintering; activating; stirring with H2SO4 evenly to sinter into dried slag; immersing through hot water; stripping aluminum sulfate; condensing; cooling to evolve aluminum sulfate; crystallizing; heating; dehydrating to obtain anhydrous aluminum sulfate; heating; decomposing to obtain gamma-Al2O3.

Owner:PINGSHUO INDAL

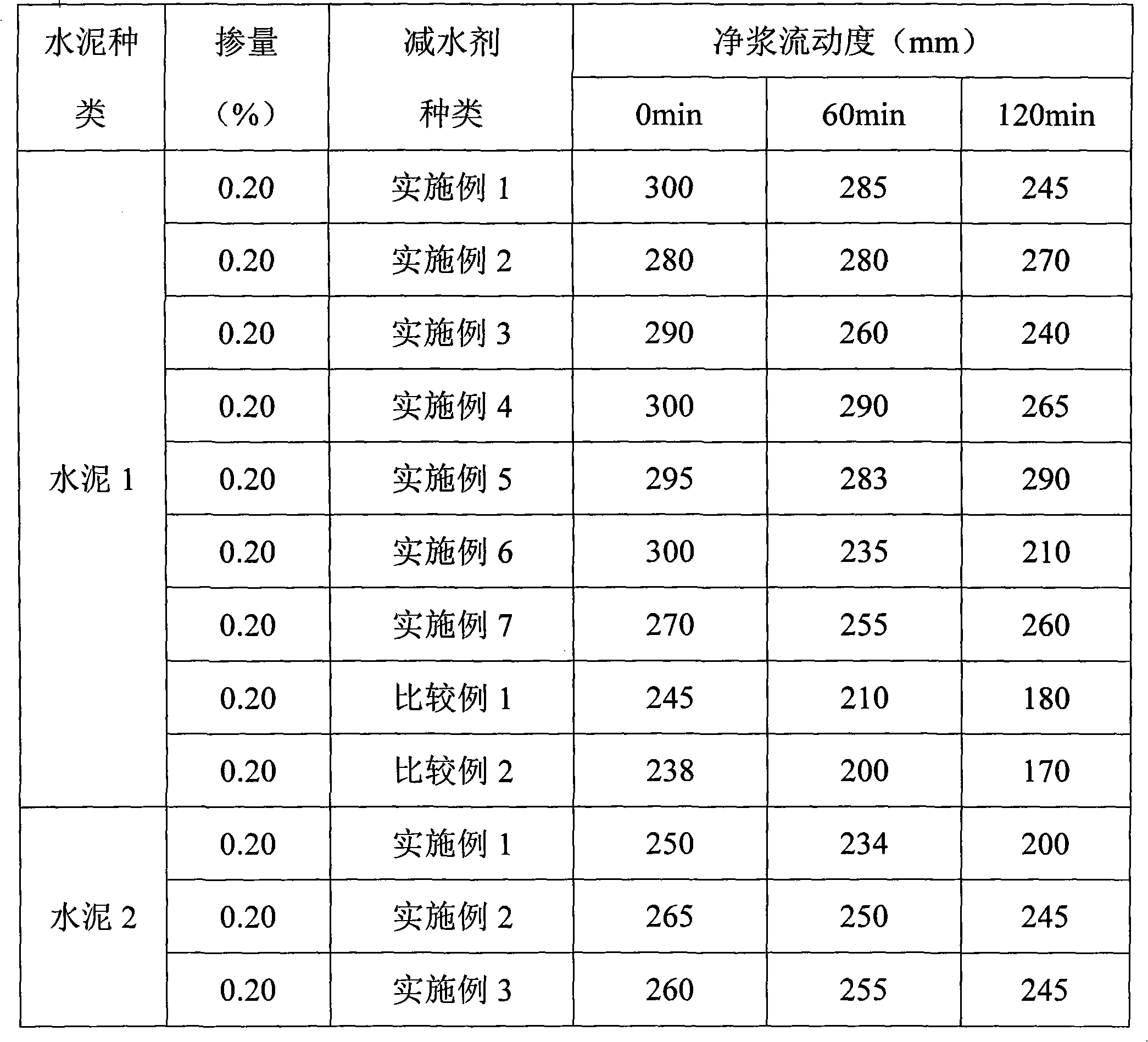

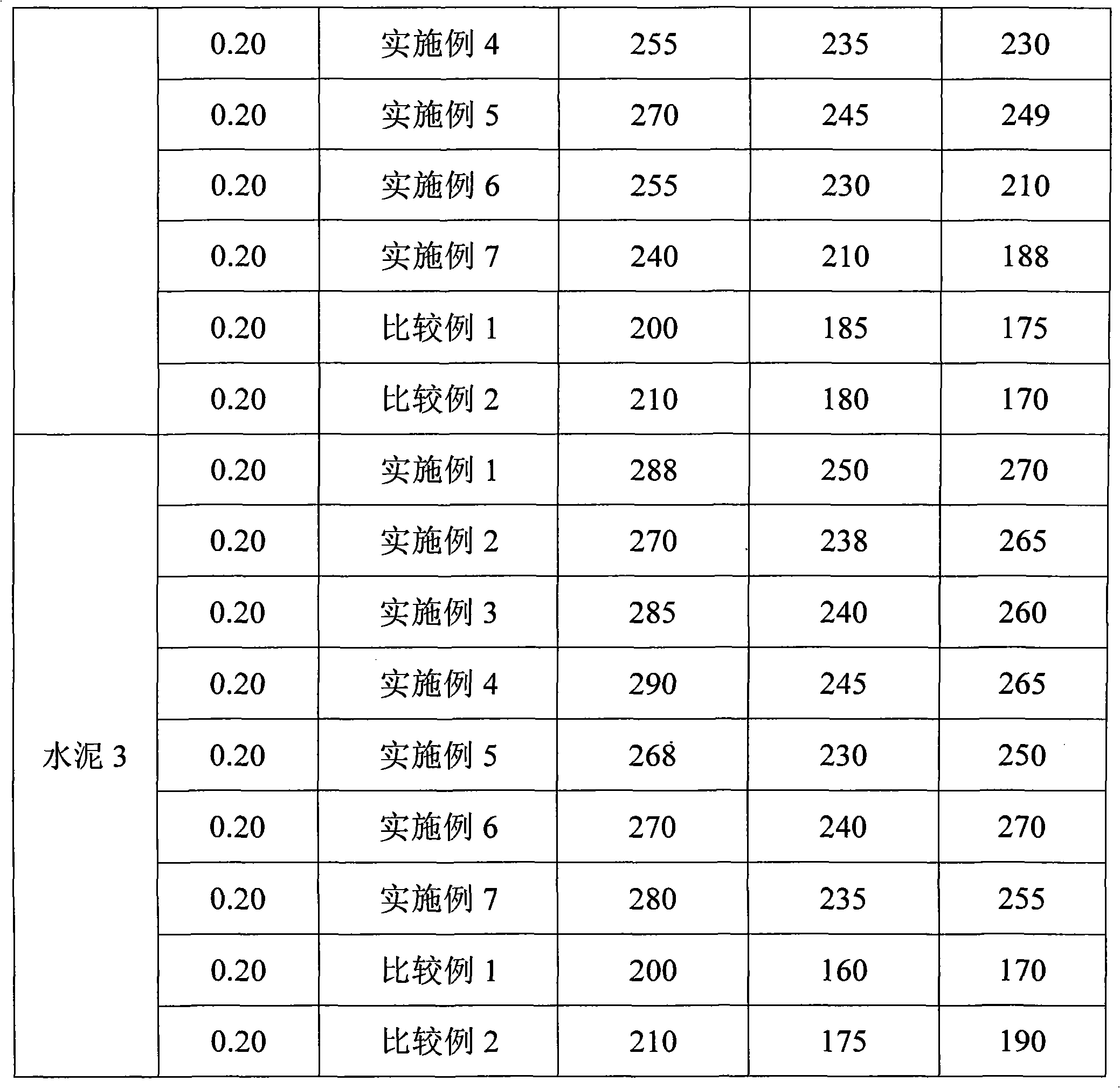

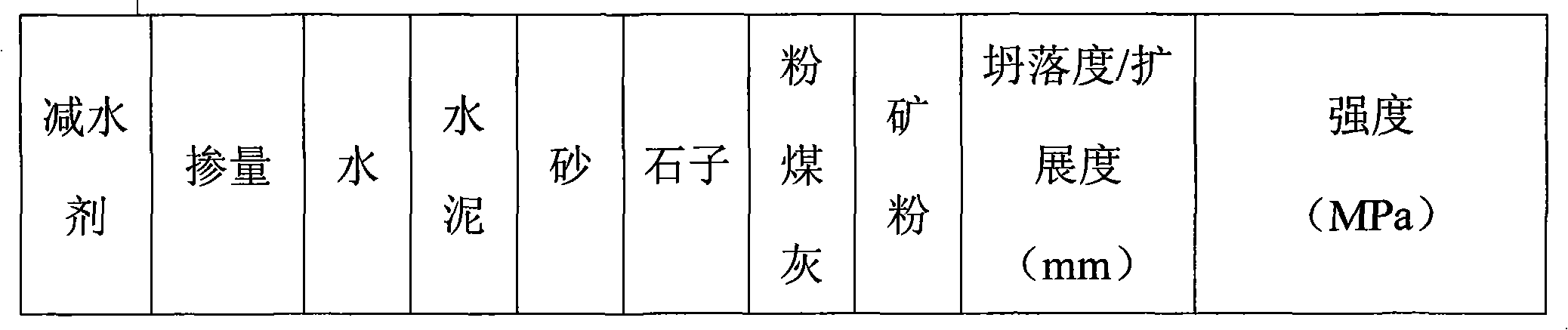

Normal-temperature synthesis method for polycarboxylic acid water-reducing agent

The invention discloses a normal-temperature synthesis method for a polycarboxylic acid water-reducing agent, and belongs to the field of cement concrete water-reducing agents. The water-reducing agent is prepared by the following steps of: copolymerizing polyoxyethylene ether monomer or polyoxyethylene ester monomer a containing unsaturated double bonds, unsaturated monocarboxylic acid and derivative monomer thereof b, unsaturated dicarboxylic acid c and unsaturated sulfonic acid or salt monomer thereof d in aqueous solution under the action of an oxidation reduction initiator, and finally neutralizing the solution by using alkali solution to obtain the water-reducing agent. The reaction can be performed at room temperature by adopting an oxidation reduction initiating system, and the appropriate reaction temperature is between 5 and 30 DEG C; and the synthesis process does not need heating, so energy is saved, and high-temperature side reaction is effectively controlled. The prepared polycarboxylic acid high-performance water-reducing agent has the characteristics of high water-reducing rate and good collapse protecting performance. The water-reducing agent has wide application range, and the method has low production process requirement and is suitable for industrialized large-scale production.

Owner:BEIJING UNIV OF TECH

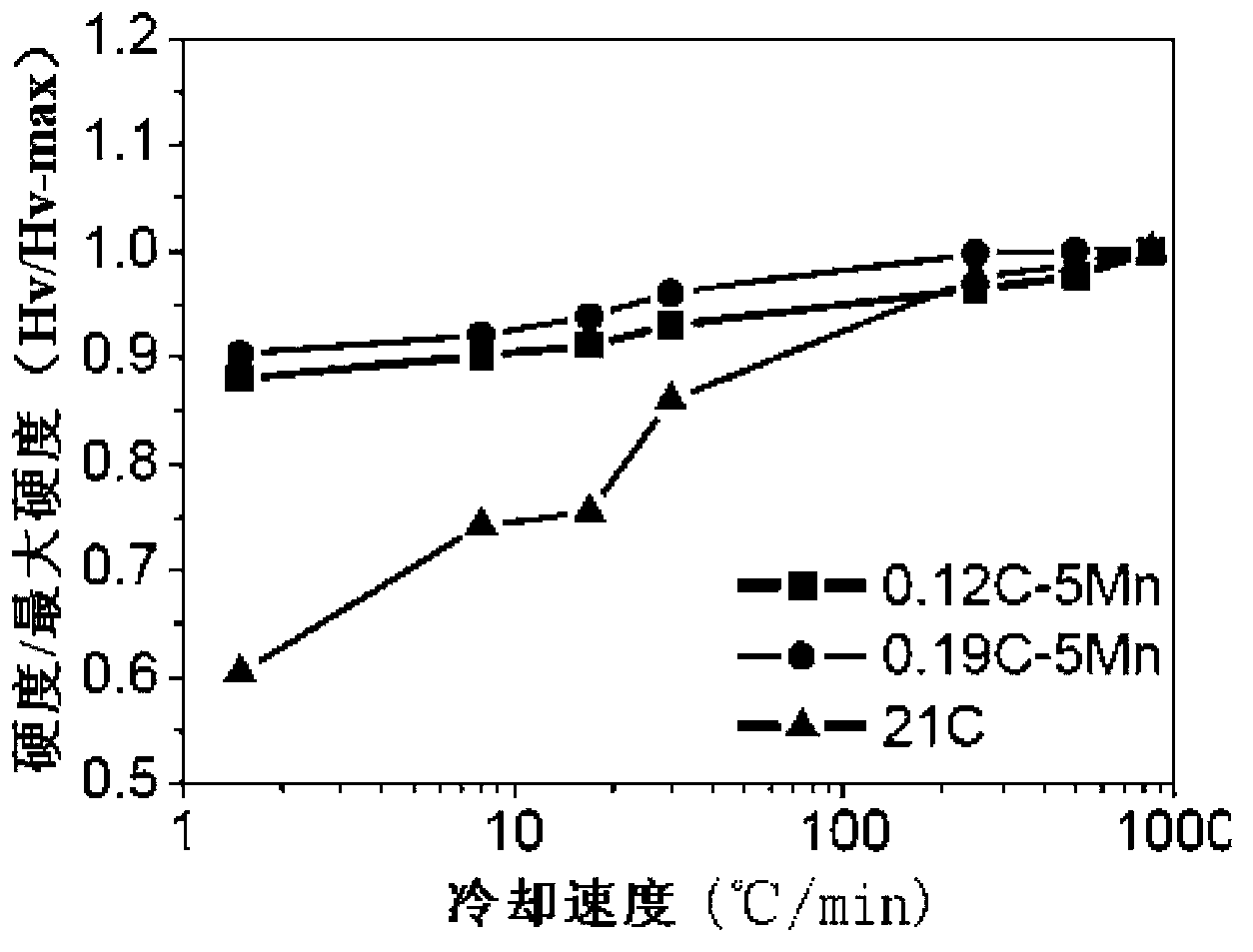

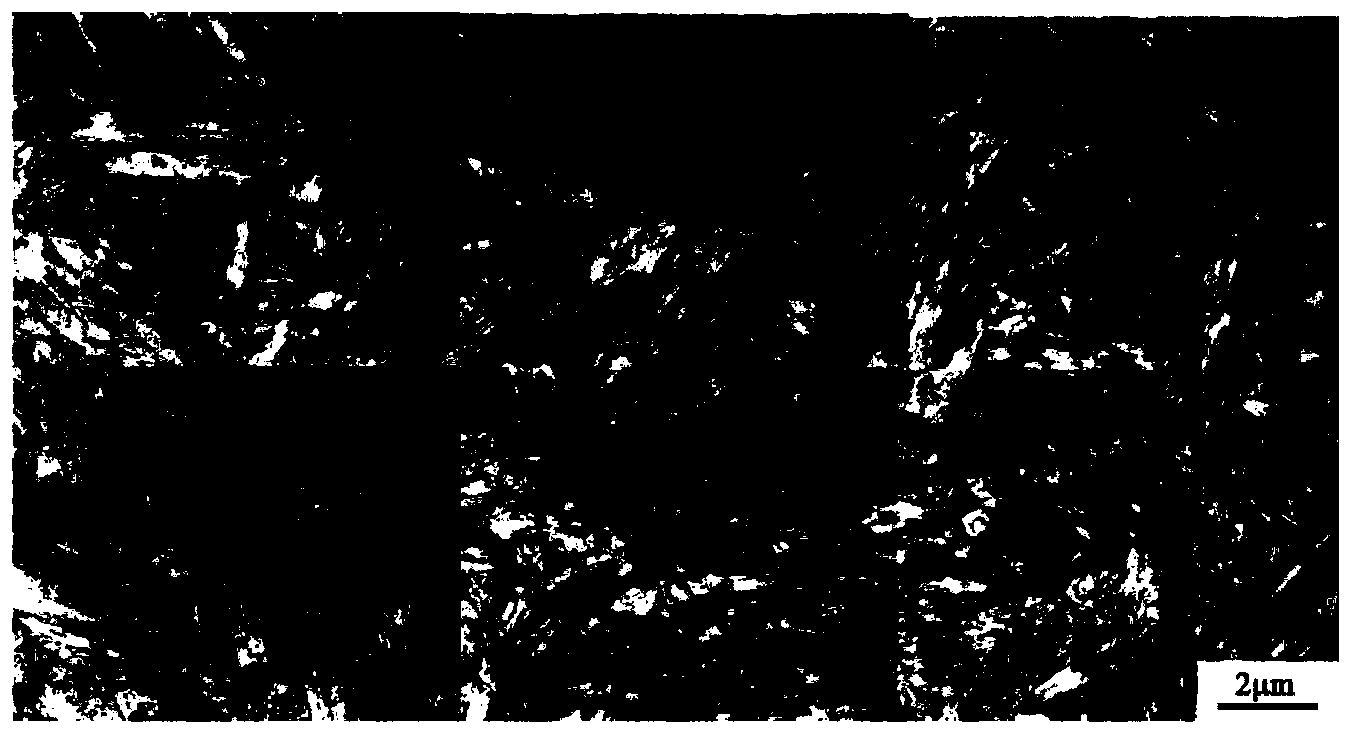

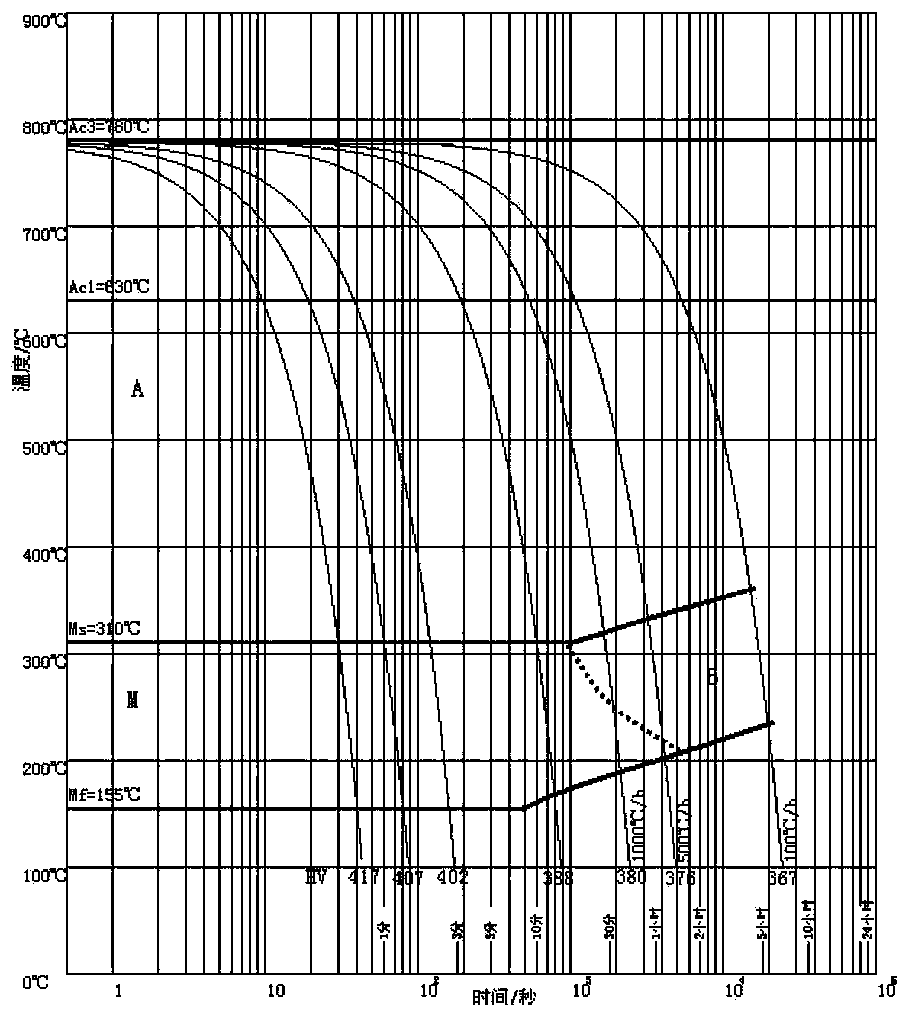

Martensite series wear-resistant steel and preparation method thereof

The invention relates to martensite series wear-resistant steel and a preparation method thereof, belonging to the technical field of wear-resistant steel. The steel comprises the following chemical components: 0.05-0.51wt% of C, 2.0-10wt% of Mn, 0-1.5wt% of Al, 0-1.5wt% of Si, 0-1.5wt% of Cr, 0-1.5wt% of Cu, 0-1.5wt% of Ni and the balance of Fe and inevitable impurities, wherein the Mn / C ratio is not less than 9. Based on this, the following one or more composite elements can be optionally added: 0.02-0.50wt% of Mo, 0.02-0.50wt% of V, 0.02-0.50wt% of Nb, 0.01-0.5wt% of Ti, 0.02-0.50wt% of B and 0.02-0.50wt% of RE. The wear-resistant steel provided by the invention is easy to produce, low in cost and high in performance. The invention is applicable to the technical field of wear-resistant materials for mines, energy, transportation, agricultural machinery, engineering machinery and other industries.

Owner:CENT IRON & STEEL RES INST

Method for preparing transparent silicon dioxide aerogel by co-precursor normal atmosphere drying

A method for gelating a co-precursor relates to an aerogel. The invention provides a method for preparing transparent silica aerogel by normal pressure drying through a co-precursor method. The method has the advantages of low cost, simple process, short production cycle, controllable reaction course and continuous production. Tetraethyl silicate and absolute ethyl alcohol are put into a container according to a proportion and stirred, and added with methyl triethoxysilane; added with water and stirred; added with hydrochloric acid to regulate the pH of the solution; added with ammonia water to regulate the pH of the system after stirring; the silica sol is kept stand still after stirring to obtain wet gel; the obtained wet gel is put into a normal hexane solution or a normal hexane solution containing the methyl triethoxysilane with volume concentration of 10%-50% for solvent exchange and aging, after being exchanged by the solution containing the methyl triethoxysilane agent, the gel is washed by the normal hexane solution to remove the methyl triethoxysilane remained on the surface of the sample, and the transparent silica aerogel is obtained by drying.

Owner:XIAMEN UNIV

Fluxless heat-and wear-resistant cast iron alloy surfacing welding electrodes and manufacture thereof

InactiveCN1530201AReduce labor intensityImprove welding productivityArc welding apparatusWelding/cutting media/materialsWear resistantRefractory

An uncoated refractory antiwear welding cast iron alloy electrode for build-up welding contains C (2.5-6.5 wt.%), Si (0.8-2.5), Mn (0.4-1.5), Cr (16-35), Nb (0-1.5), Mo (0-3.5), Ni (0-2.0), W (0-2.5), V (0.1-2.0), Ti (0-0.8), Cu (0-1.0), S (0-0.08), P (0-0.1), O (0-0.08), N (0-0.08), Al (0-0.1) and Fe (rest), and is made up by casing method. Its advantages are high hardness of welded layer (more than 42 HRC), and low cost.

Owner:攀钢集团钢城企业总公司溶解乙炔厂

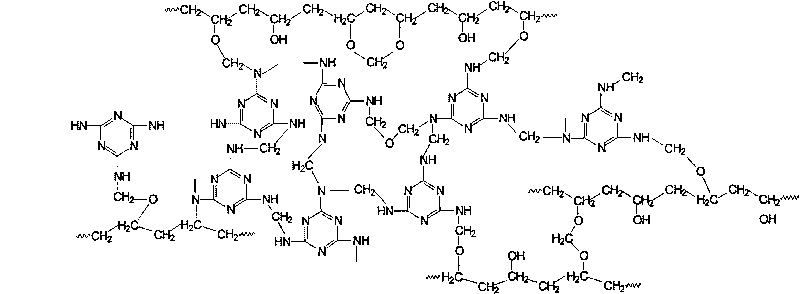

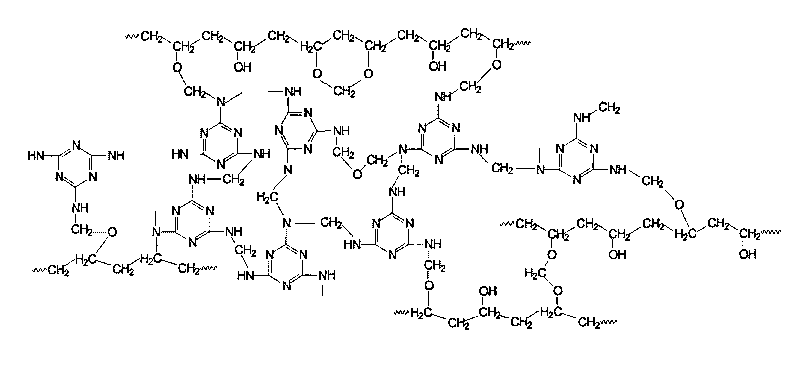

High-flexibility melamino-formaldehyde foam material and preparation method thereof

The invention discloses a high-flexibility melamino-formaldehyde foam material and a preparation method thereof. The preparation method comprises: firstly, preparing melamino-formaldehyde prepolymer modified by polyol into aqueous solution with definite weight concentration; weighting 100 parts by weight of prepolymer aqueous solution; adding 0-15 parts by weight of surfactant, 1-20 parts by weight of foaming agent, 0-10 parts by weight of accelerator and 0-10 parts by weight of curing agent to be fully stirred and mixed to prepare foaming liquid; filling foaming liquid into a microwave chemical reactor or a high-temperature oven; and foaming for 30s-15min at the temperature of 100-300 DEG C to prepare the foam material. The melamino-formaldehyde foam material disclosed by the invention solves the problems of big brittleness, poor flexibility, easy duslting of foam, complex preparation technology, high production cost and the like of the existing melamino-formaldehyde foam material and has wide application prospect.

Owner:SICHUAN UNIV

Copper alloy with no lead

This invention relates to a Pb-free Cu alloy, especially a Pb-free machinable Cu alloy, which is composed of: Cu 55.0-89%, Zn 3.0-45%, Sn 0.1-10%, Ni 0.1-2.0%, Si 0-5.0%, Bi 0.1-5.0%, Se 0-3.0%, Al 0.01-1.0%, P 0.05-0.15%, and RE 0.01-0.5%. RE, Bi, Se and P are added respectively in the forms of RE-Cu intermediate alloy, Cu-Bi intermediate alloy, Cu-Se intermediate alloy and P-Cu intermediate alloy, or RE, Bi, Se and P are added respectively in the forms of Bi-Se alloy and P-Cu alloy. This invention can eliminate harmful effects on environment and human bodies caused by Pb during production and recovery process. The Cu alloy has good machinability, mechanical properties, processability and fluidity, and has no thermal splitting. The production method is simple, and can produce the Cu alloy by using the present apparatus for producing lead-brass alloy. Besides, the contents of Se, Bi and RE are low,.

Owner:JIANGXI UNIV OF SCI & TECH

Lady beer and production technology thereof

The invention relates to a beer produced from materials of 1-7 degree beerwort produced with a common beer production method, fresh fruit and vegetable juice, healthcare plant juice, traditional Chinese medicine extract, vitamins, a microelement mineral preparation, a foam stabilizer, and ethanol, which are blended according to a certain weight ratio. The lady beer provided by the invention has characteristics of digestion and absorbance promoting, beautifying, toxin expelling, freckle reducing, weight reducing, aging resisting, fatigue resisting, bowel loosening, constipation relieving, metabolism balancing, endocrine regulating, blood sugar reducing, and blood fat reducing. The contents of beerwort and ethanol in the beer are low. With the lady beer, original flavors of beer are preserved, abundant nutrients are provided, beer belly is not caused with long-term drinking, obesity is not caused, and a good healthcare effect is provided. The application scope of the lady beer is wide, and the lady beer is especially suitable for ladies.

Owner:张华

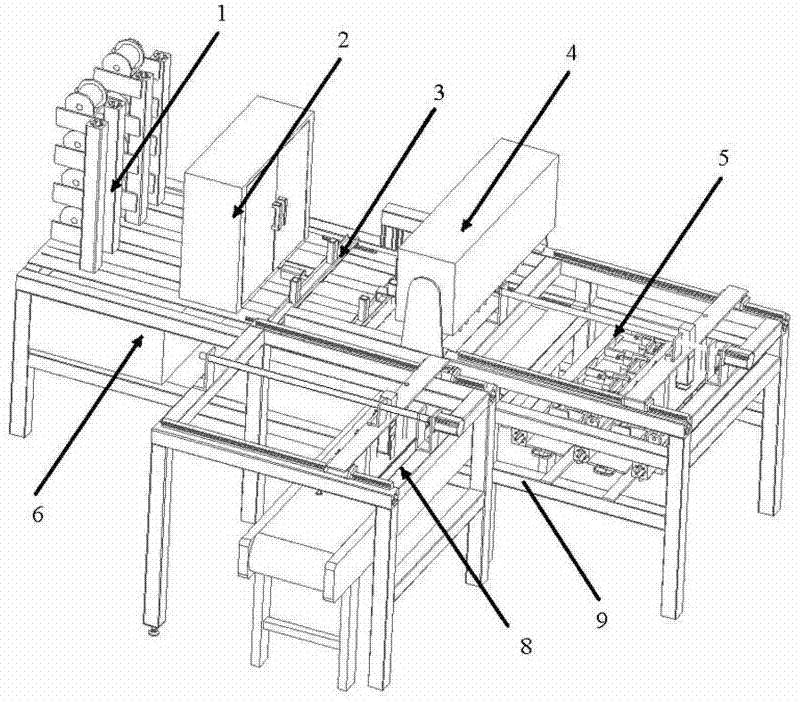

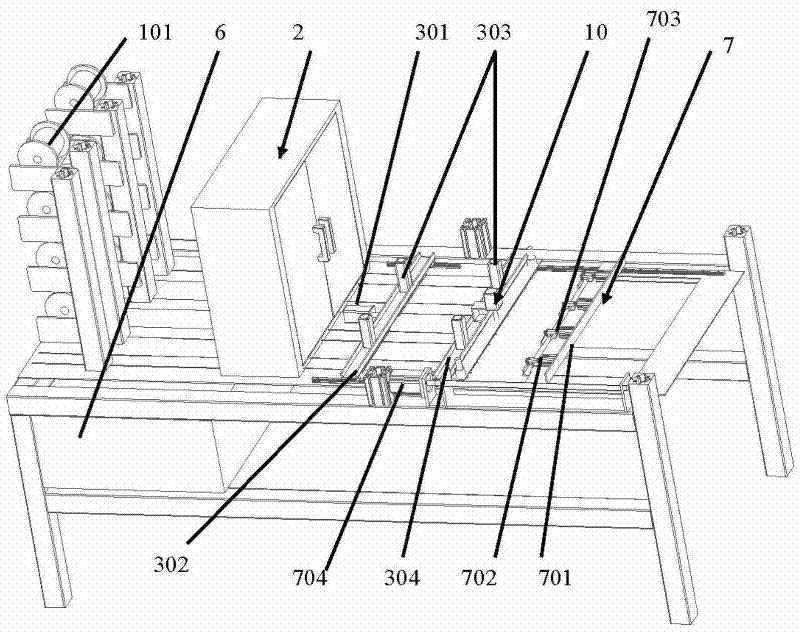

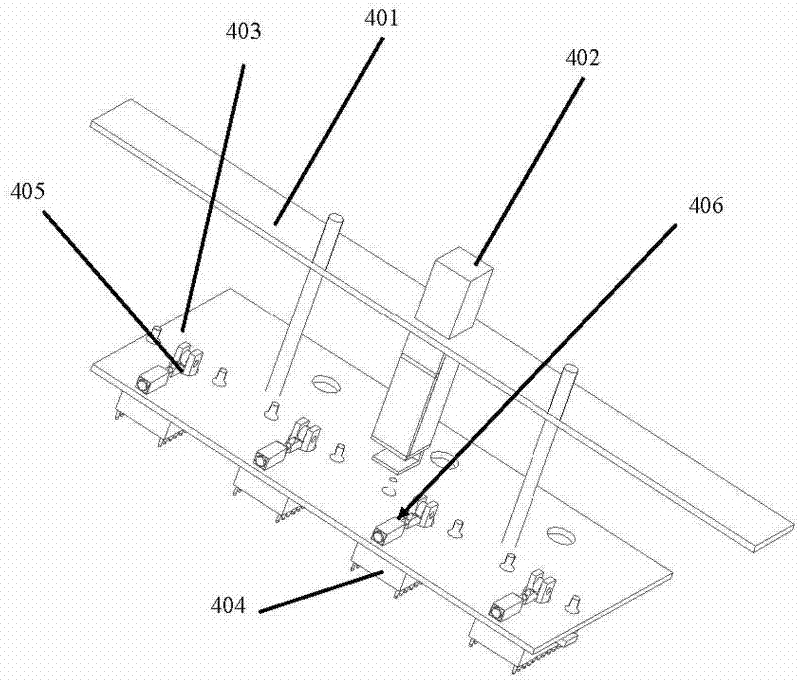

Fully automatic solar cell single welding machine

InactiveCN102294550AAchieve mechanical propertiesFully automatedWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSolar battery

The invention discloses a full-automatic solar cell single-welding machine, which comprises a rack, a welding strip material arranging device, a flux coating and drying device, a welding strip straightening device, a welding strip cut-off device, a welding strip dragging and positioning device, a welding device, a solar cell feeding device, and a product conveying device. The single-welding machine is mainly used for solving the problem of single-side welding of a cathode of a solar cell, and has simple process, high automation degree and relatively low cost, the labor intensity is reduced, and the quality of single-side welding is improved.

Owner:江苏爱动力自动化设备有限公司

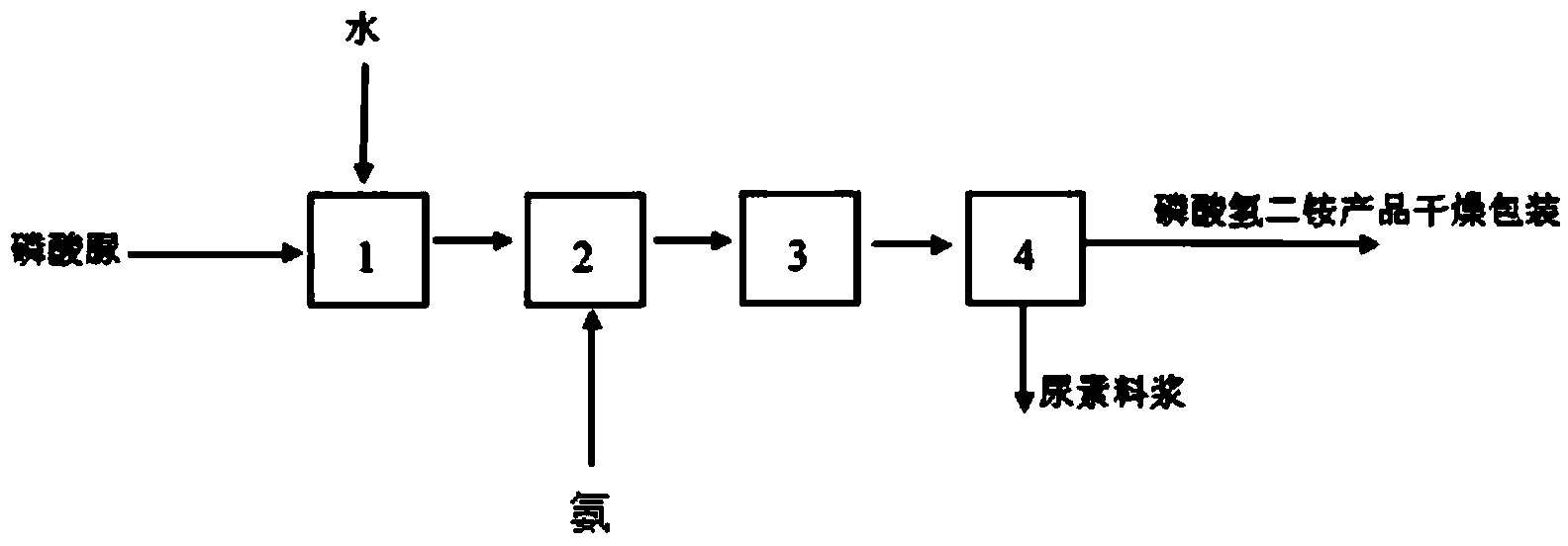

Production method for monoammonium phosphate

InactiveCN104016323AReduce energy consumptionReduce manufacturing costPhosphatesWater insolubleDecomposition

The invention relates to the technical field of chemical engineering, and particularly relates to a production method for monoammonium phosphate. A monoammonium phosphate product is prepared by directly subjecting high pure urea phosphate and ammonia to a double decomposition reaction and reacting for 20-60 min with stirring by controlling a reaction temperature at 40-80 DEG C and a pH value at a reaction endpoint being 4.2-4.6, and through the steps of cooling for crystallization; separating by centrifugation and drying. Measurements of physical and chemical indexes of the produced product show that the physical and chemical indexes of the produced monoammonium phosphate product meet an industrial first level standard. Specifically, the total nutrient content of monoammonium phosphate is higher than 73%; the content of total nitrogen is 12.01-12.23%; the content of phosphorus pentoxide is 61.05-61.25%; the content of moisture is 0.35-0.52%; a pH value is 4.2-4.6; the content of water insoluble materials is 0.090-0.096%; and the content of fluoride is 0.15-0.19%.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

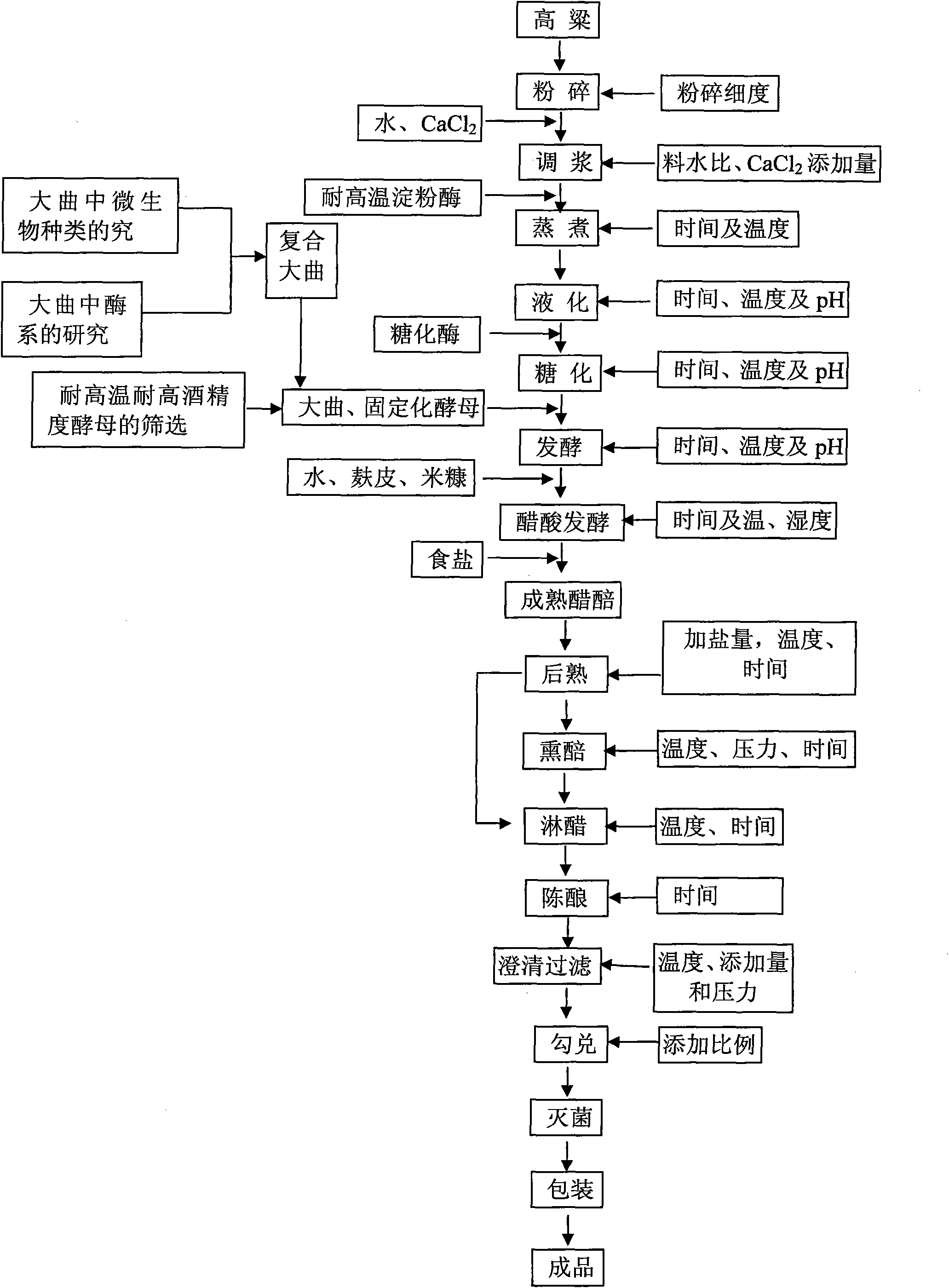

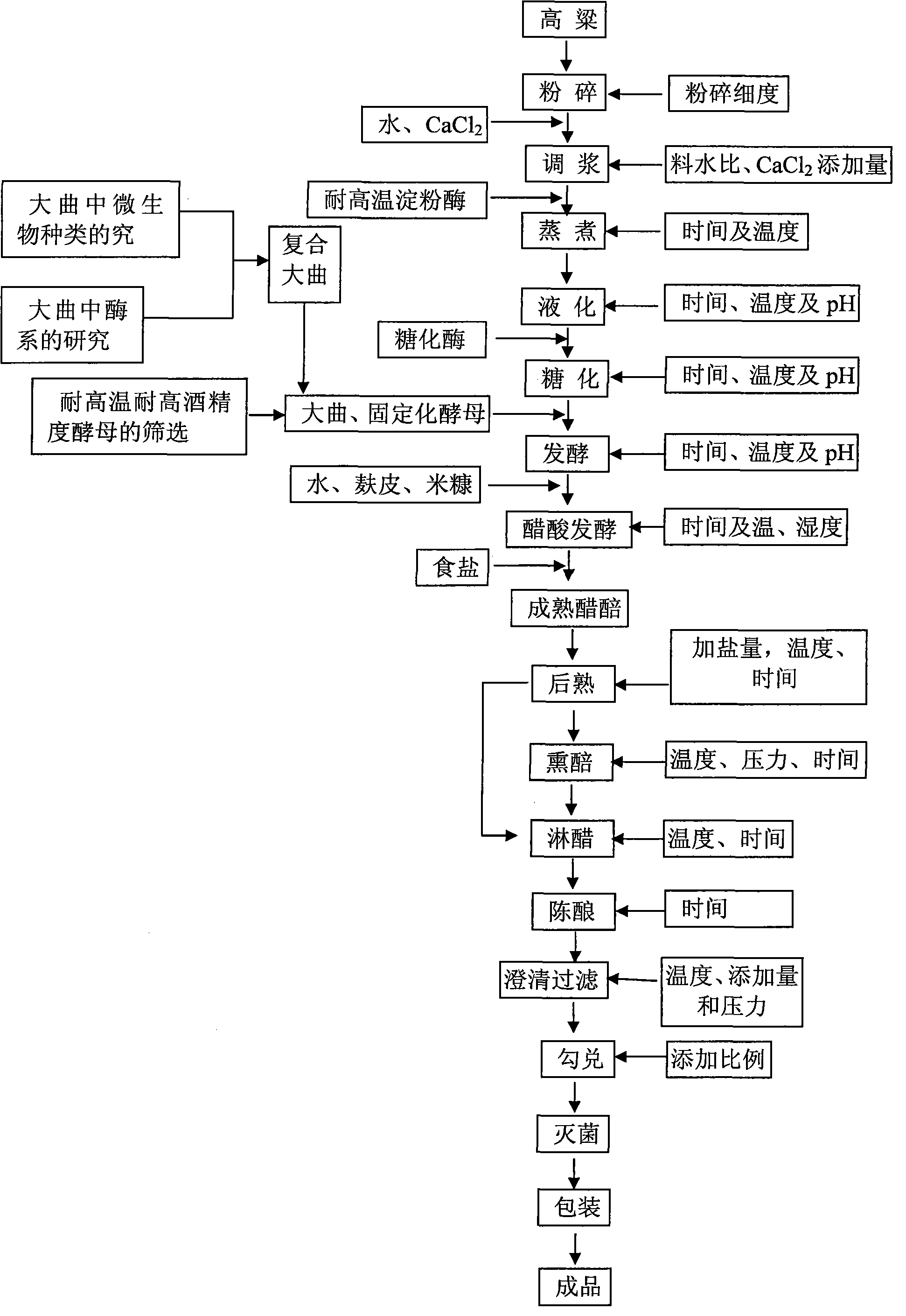

Standardized and industrialized production process for Shanxi mature vinegar

ActiveCN101857833ASystematization of processHigh technology contentMicroorganism based processesVinegar preparationMaterials processingSaccharomyces

The invention relates to a production process for vinegar, in particular to the standardized and industrialized production process for Shanxi mature vinegar, which solves the problems of long production process period, complex process, unstable product quality, low raw material utilization rate and the like, of the prior production process. The production process comprises the following steps of: performing material processing before alcoholic fermentation, crushing, mixing, liquefaction and saccharification; selecting high-temperature resistant and high-alcoholic strength resistant saccharomyces, and adding a composite yeast to perform alcoholic fermentation; adding the composite acetic bacteria into vinegar residue, stirring with a vinegar residue stirrer, fermenting the vinegar residue in an acetyl hydrate fermenting tank, and turning the vinegar residue with a vinegar residue turning machine; tamping the vinegar residue in the acetyl hydrate fermenting tank, covering a layer of table salt on the tamped vinegar residue, and standing the vinegar residue; fuming the vinegar residue by the combination of a vinegar residue fuming furnace and a steam vinegar residue fuming jar; pouring vinegar; ageing the vinegar; clarifying the vinegar with a crude acidic protease, and filtering the vinegar with kieselguhr; blending the vinegar and the traditional Shanxi mature vinegar; sterilizing the vinegar; and packing the vinegar. The process of the invention has the advantages of systematized flow, standardized technological parameters, scale production procedure, normalized product quality and optimized production process.

Owner:山西金龙鱼梁汾醋业有限公司

Super-light foam cement concrete and preparation method thereof

The invention discloses a super-light foam cement concrete and a preparation method thereof. The super-light foam cement concrete comprises the following raw materials by weight parts: 9-36 parts of dead burnt magnesium oxides, 9-32 parts of dihydric phosphates, 0.5-7 parts of adjustable solidification agents, 6-25 parts of light burnt magnesium oxides, 0.5-7 parts of sulfur-containing components, 1-25 parts of industrial slag powder, 1-20 parts of kieselguhrs, 0.3-3.9 parts of waterproof agents, 0.2-1.7 parts of foam stabilizing agents, 1.0-8.9 parts of foaming agents and 25-90 parts of water. The preparation method of the high-performance super-light foam cement concrete comprises the following steps of: metering raw materials; preparing the slurry containing the foam stabilizing agents; uniformly mixing the foaming agents; pouring and standing by; foaming and expanding; coagulating and curing; and naturally maintaining. The super-light foam cement concrete has the advantages of light weight, high strength, heat preservation and insulation, stable volume, low production cost, energy-saving property, no environmental pollution, and the like. The super-light foam cement concrete is simple in production process and is especially suitable for the heat-insulating material of external building wall, roof and floor.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

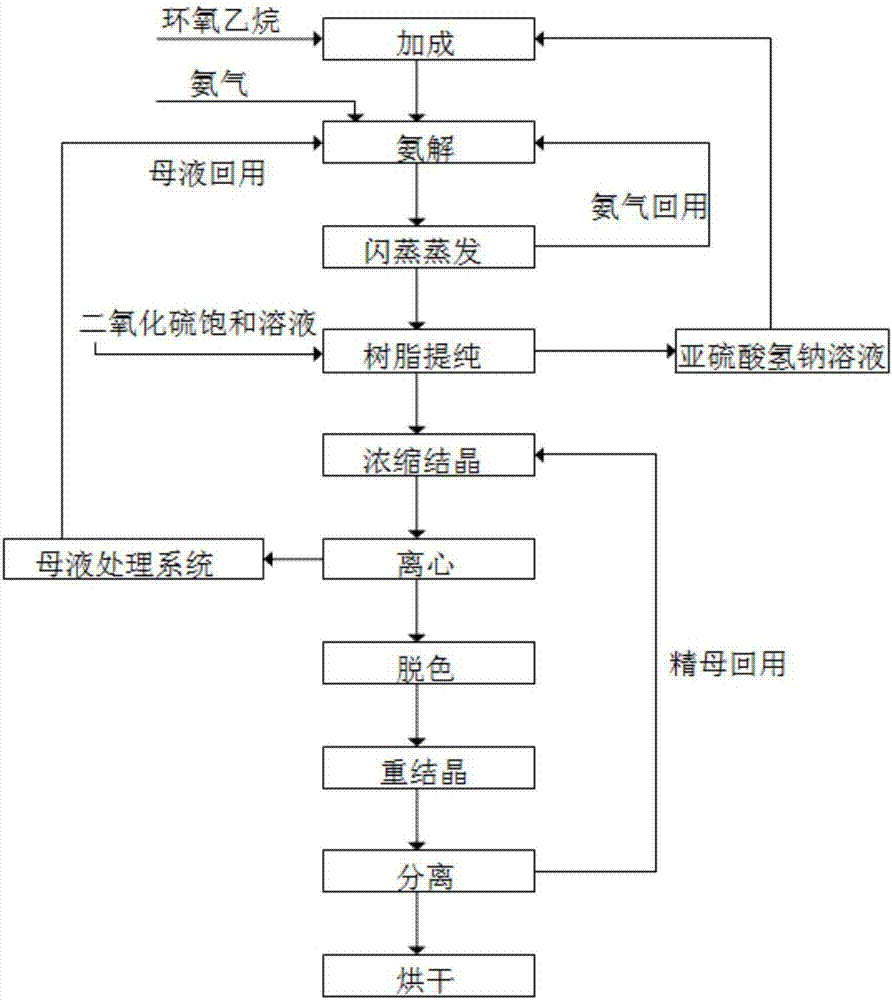

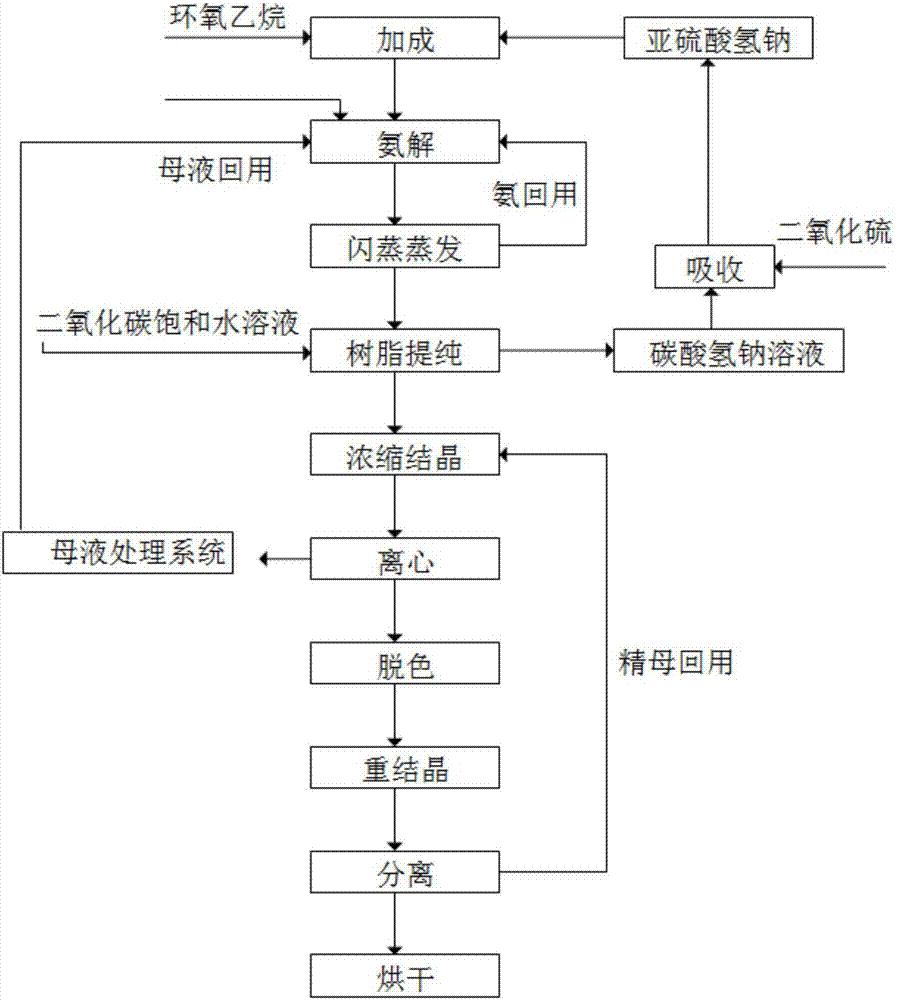

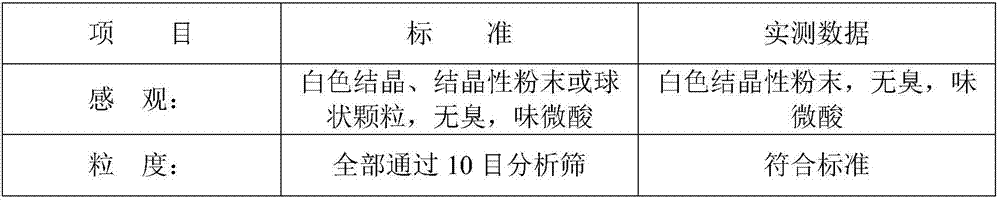

Method for cyclically producing taurine at high yield

ActiveCN107056659AReduce productionEfficient recyclingPhysical/chemical process catalystsOrganic compound preparationAfter treatmentHydrogen

The invention relates to a method for cyclically producing taurine at a high yield. The method includes the following steps that S1, ethylene oxide reacts with a sodium hydrogen sulfite solution to generate sodium hydroxyethyl sulfonate; S2, sodium hydroxyethyl sulfonate obtained in S1 is subjected to an ammonolysis reaction in ammonium hydroxide, flashing is carried out after the reaction is completed, and ammonia gas is recycled; S3, taurine-containing feed liquid of reaction liquid obtained after flashing in S2 is collected through an acid cation exchange resin column, the resin column is regenerated with a sulfur dioxide or carbon dioxide water solution after being inactivated, and eluant obtained during regeneration can be directly reused or reused after being treated with sulfur dioxide; S4, the feed liquid collected in S3 is subjected to after-treatment, and taurine is obtained. The method has the advantages that the generation amount of waste liquid in the whole process is small, part of substances are effectively and cyclically utilized in the process, the cost is reduced, the yield of taurine can reach 90% or above, meanwhile, the production process is relatively simple, and large-scale production is easy.

Owner:QIANGJIANG YONGAN PHARMA

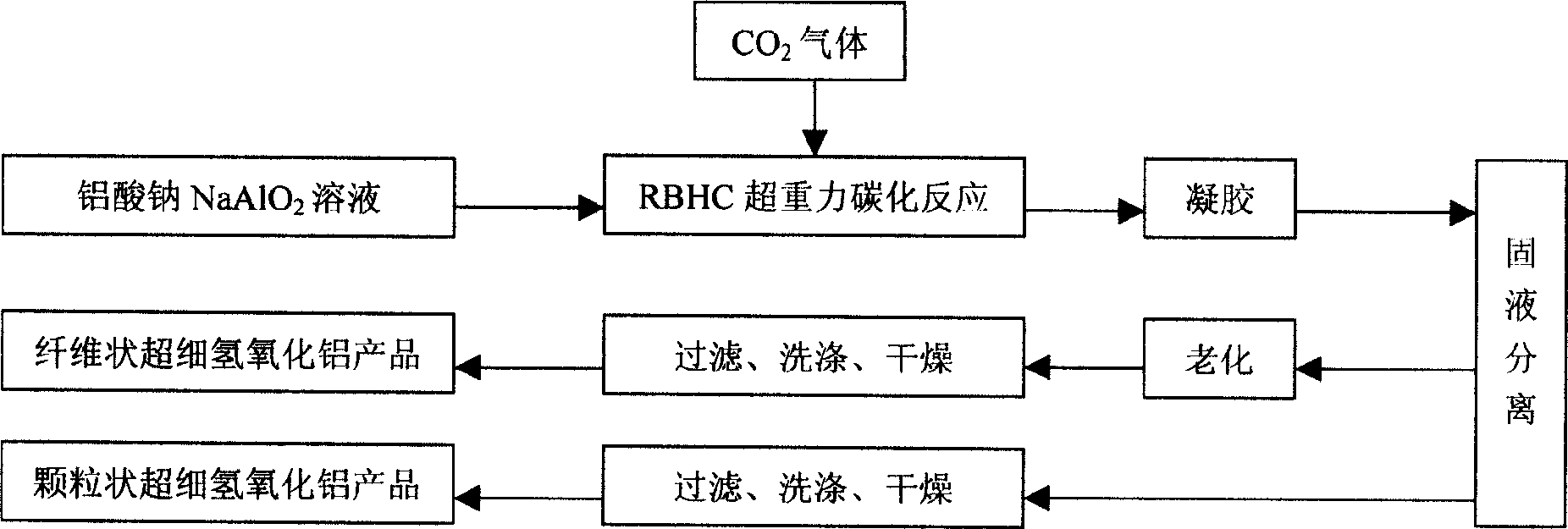

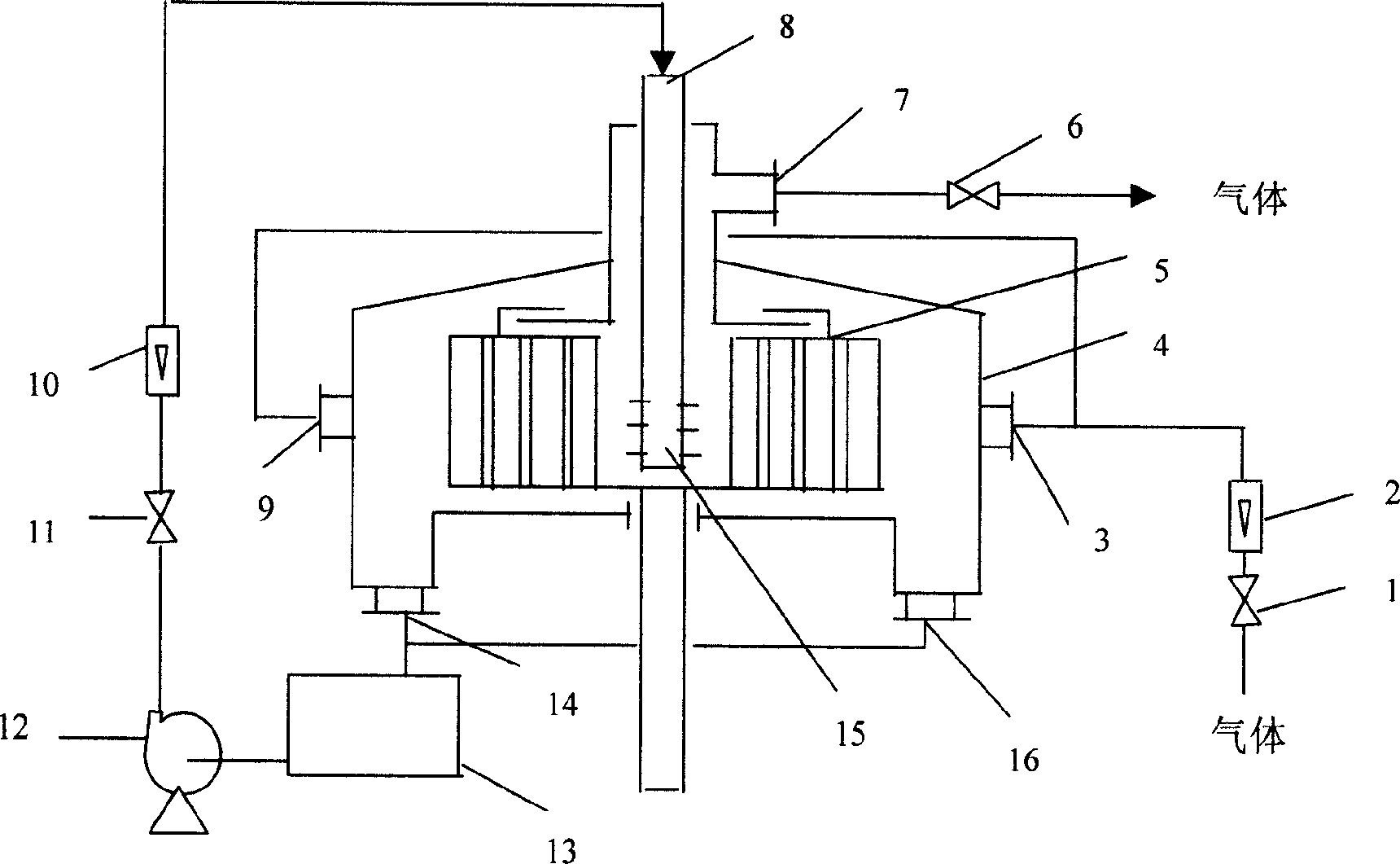

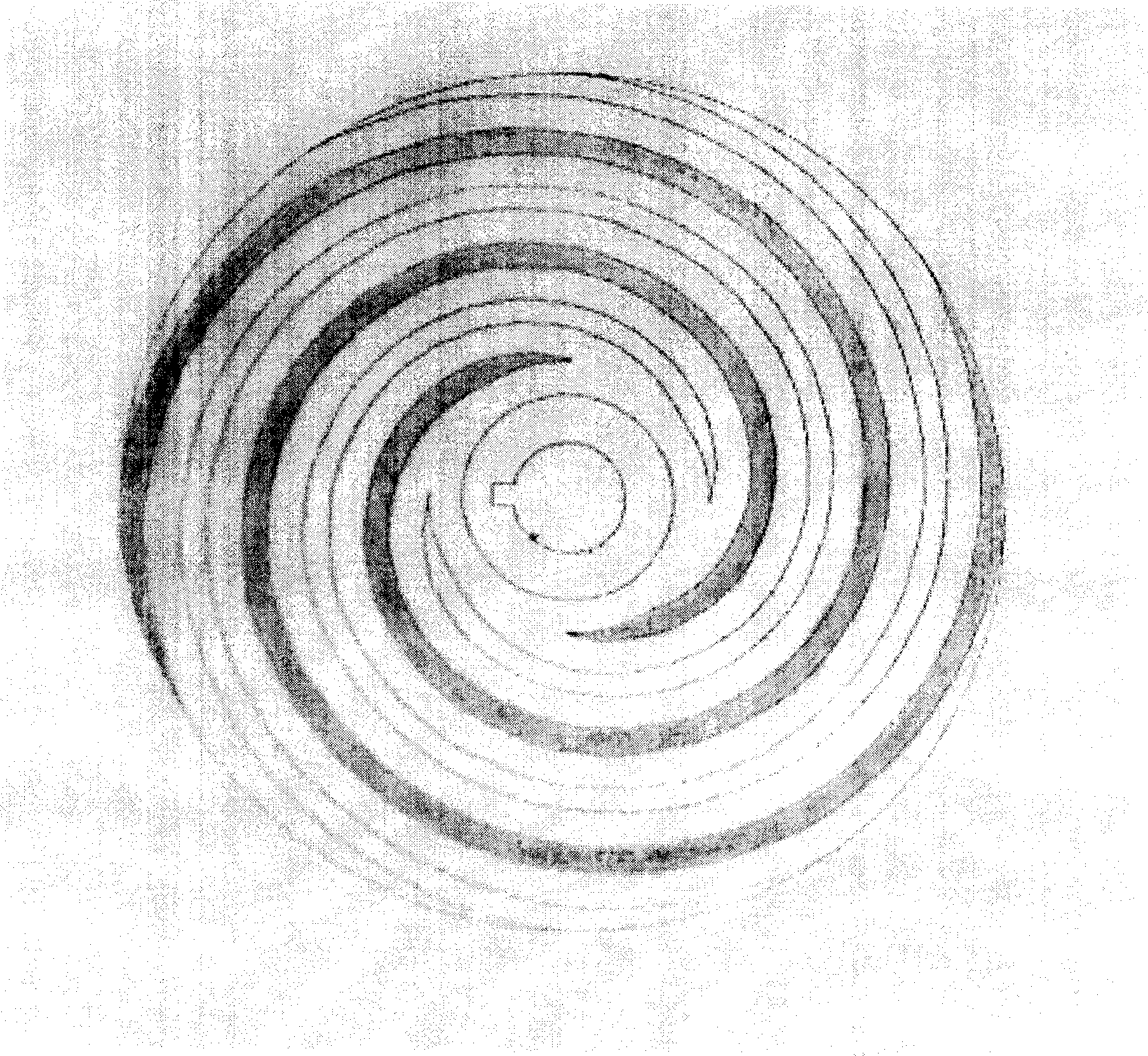

Preparation method of ultrafine aluminium hydroxide

InactiveCN1752006ASolve defects that are prone to clogging equipmentLow miscellaneous crystal contentAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationNanoparticleAluminium hydroxide

A process for preparing superfine aluminium hydroxide includes such steps as carbonifying reaction between NaAlO2 solution and the gas containing CO2 in gravitation condition to obtain aluminium hydroxide gel, preparing superfine aluminium hydroxide, filtering, washing, and drying. The product (nanofibers or nanoparticles of aluminium hydroxide) can be used as inorganic flame-retarding agent or for preparing catalyst.

Owner:XIANGTAN UNIV

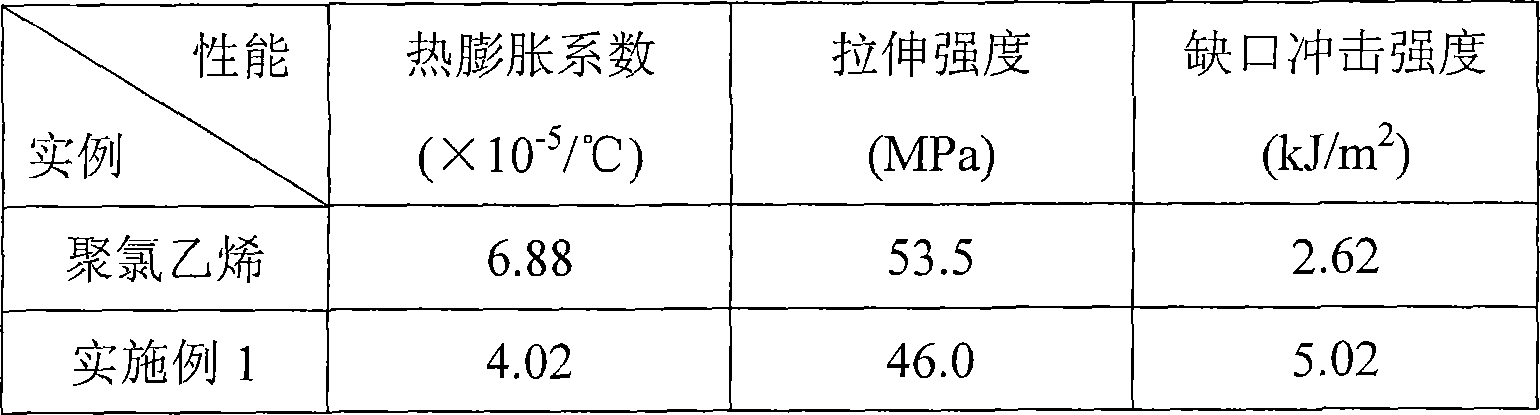

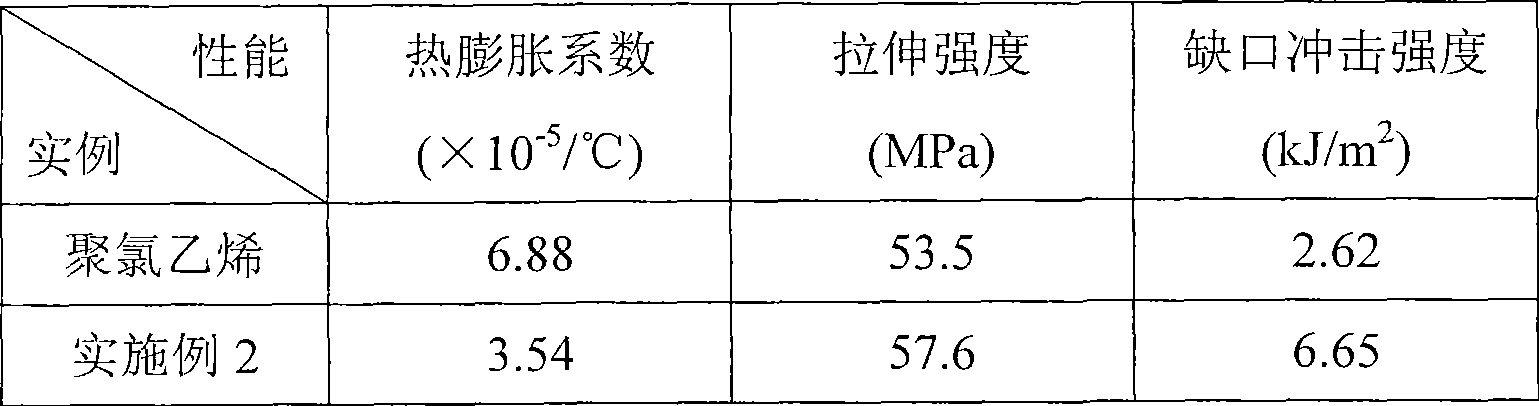

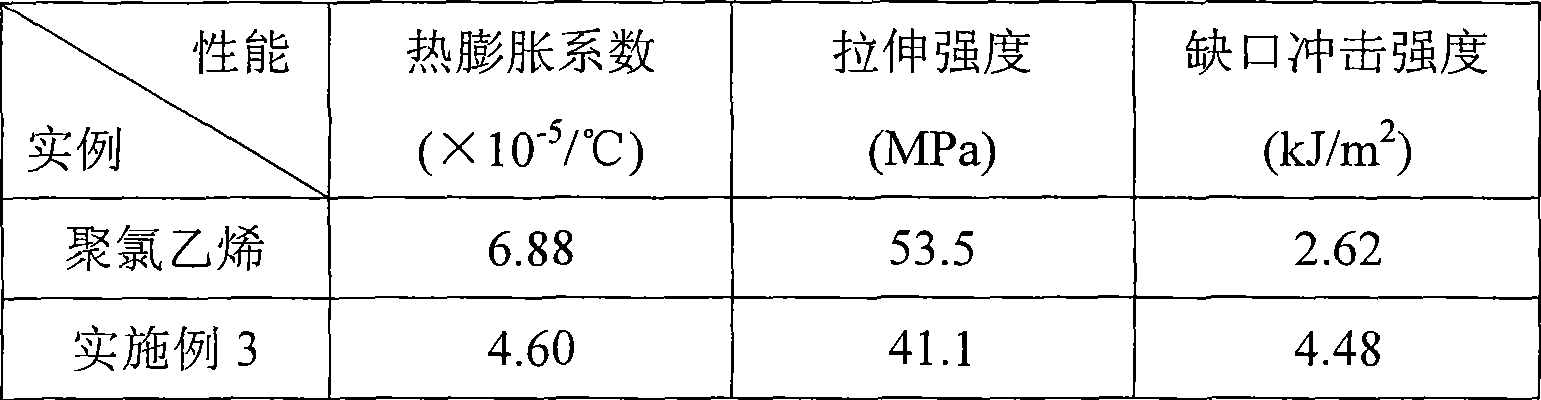

Low-expansion coefficient polyvinyl chloride alloy material and manufacturing method thereof

The invention provides a low-expansion coefficient polyvinyl chloride alloy material and a manufacturing method thereof. The ingredients of raw materials of the alloy material comprise a polyvinyl chloride substrate, a heat-resistant modifier, a heat stabilizer, a lubricator, a filler and a processing agent, and the alloy material is manufactured by a melt blending technique. The processing agent and the filler in the ingredients of the raw materials of the invention are the processing agent that is subjected to modification by a new method and the filler that is subjected to organic treatment, and by means of a mechanochemical reaction, self-plastification, toughening and reinforcement of the PVC can be combined organically to improve compatibility and dispersity of the polyvinyl chloride, the filler and heat-resistant resin, thus settling the problem about the contraction between the improvement of heat expansion performance and heat resistance of the PVC, and processing performance, strength and toughness of the PVC; the polyvinyl chloride engineering plastic with low expansion coefficient, high heat resistance, high strength, high toughness, excellent aging resistance and outstanding processing performance is manufactured; the invention has extensive industrial market prospect and the manufacturing method thereof is simple in technology, convenient in operation and control, stable in quality and high in production efficiency.

Owner:SICHUAN UNIV

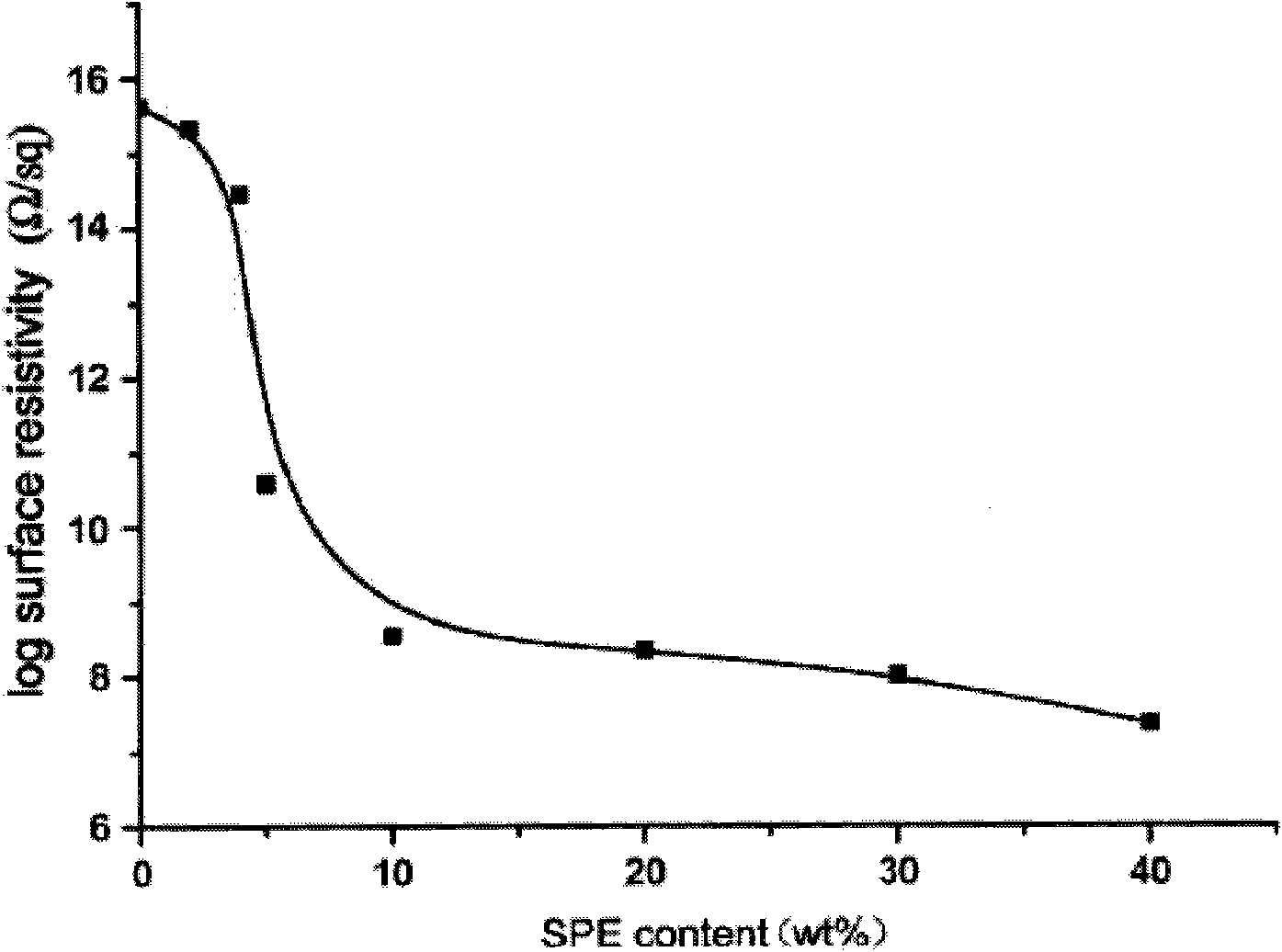

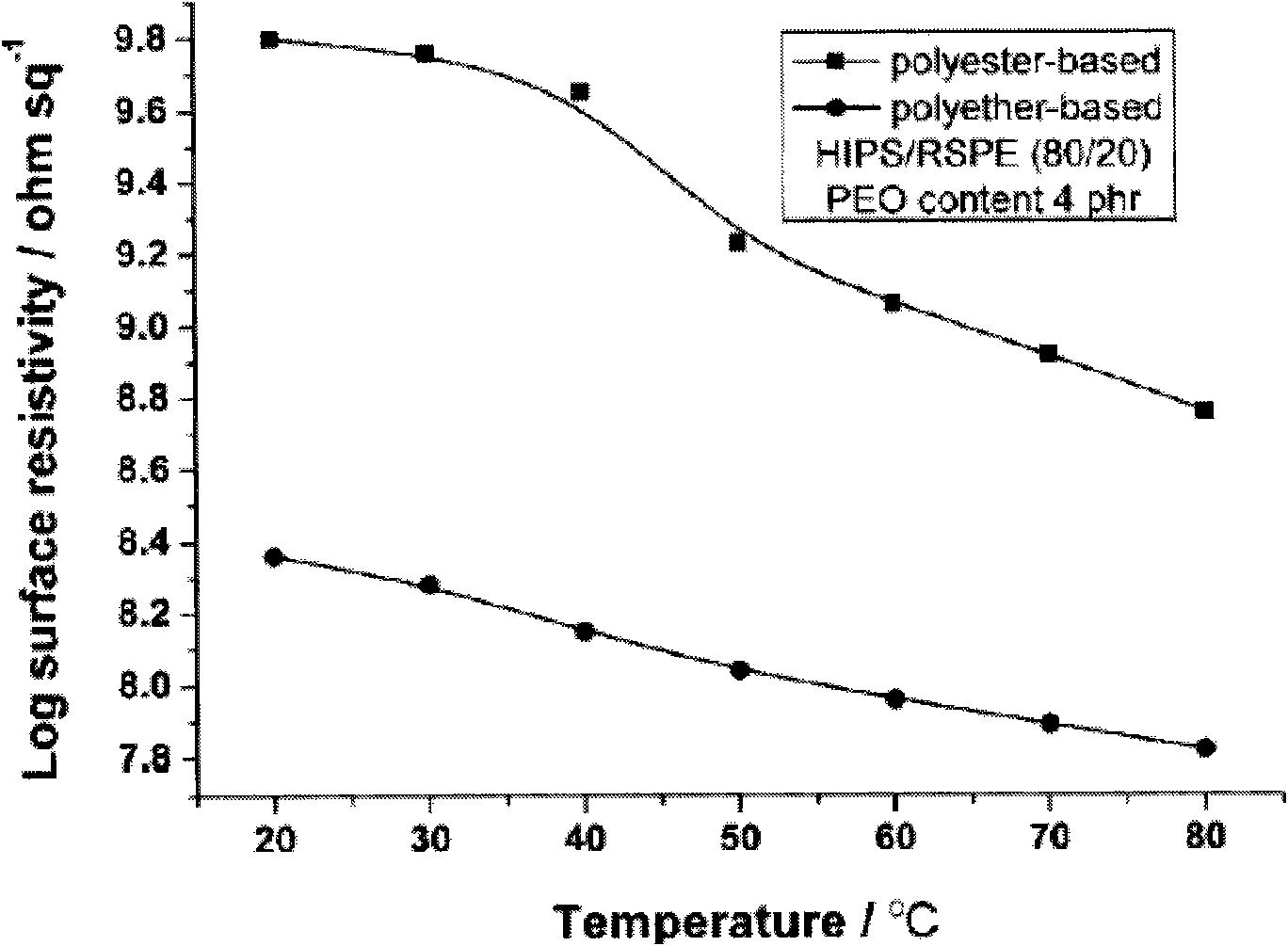

All-weather persistent antistatic master batch capable of being subjected to thermoplastic processing and antistatic composite material

The invention belongs to the field of preparation of macromolecular composite materials and particularly relates to an all-weather persistent antistatic master batch capable of being subjected to thermoplastic processing and an antistatic composite material. The antistatic master batch is prepared by forming of a low-dissociation-energy compounding agent, a processing auxiliary agent and thermoplastic macromolecular resin containing polar groups through macromolecular thermoplastic processing equipment at the temperature of 25-300 DEG C; and the mass ratio of the compounding agent to the thermoplastic macromolecular resin is equal to (1:10)-(1:50). The invention also discloses the antistatic composite material which is obtained after the persistent antistatic master batch and a macromolecular base material are formed through the thermoplastic processing equipment. The antistatic composite material has the characteristics that: 1. the antistatic composite material has light color and dyeability; 2. The master batch of the antistatic composite material and the compounding agent are wider in selection range, low in cost and easy to obtain, and the production process is simple, safe and non-hazardous; and 3. the influence of the ambient environment on the antistatic performance of the antistatic composite material is less, and the antistatic performance is persistent.

Owner:浙江三和塑料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com