High-carbon high-high-vanadium high-speed steel composite roller and heat treatment method thereof

A technology of composite roll and high-speed steel, applied in the field of high-carbon high-vanadium high-speed steel roll and its heat treatment, can solve the problems of high energy consumption, complex process, low efficiency, etc., and achieve simple production process, good wear resistance, good resistance abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

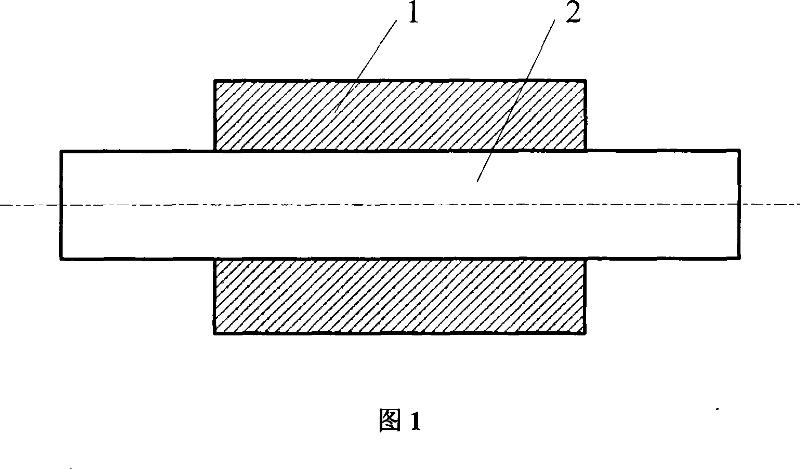

Image

Examples

Embodiment 1

[0038] The high-carbon high-vanadium high-speed steel roll prepared in this embodiment is produced in an intermediate frequency induction furnace with a capacity of 500 kilograms, and its manufacturing process steps are:

[0039] ①Mix ordinary steel scrap, pig iron, ferrochrome, ferrotungsten, ferromolybdenum, ferroniobium and metal cobalt according to the chemical composition requirements, put them into the furnace to heat and melt, add ferromanganese after the molten steel is melted, and add ferrovanadium before leaving the furnace;

[0040] ② After adjusting the composition before the furnace, the temperature is raised to 1580°C, and 0.16% of Al and 0.08% of Si-Ca alloy by weight are added to the molten steel for composite deoxidation and then released from the furnace;

[0041] ③Crush yttrium-based magnesium rare earth, ferro-titanium, ferro-zirconium, and ferro-tellurium into small pieces with a particle size of less than 12mm, and after drying below 220°C, place them at t...

Embodiment 2

[0049] The high-carbon high-vanadium high-speed steel roll of the present embodiment is produced in an intermediate frequency induction furnace with a capacity of 750 kilograms, and its manufacturing process steps are:

[0050] ①Mix ordinary steel scrap, recarburizer, ferrochrome, ferrotungsten, ferromolybdenum, ferroniobium and metal cobalt into the furnace for heating and melting according to chemical composition requirements, add ferromanganese after molten steel is melted, and add ferrovanadium before leaving the furnace;

[0051] ② After adjusting the composition before the furnace, the temperature is raised to 1593°C, and 0.18% of Al and 0.12% of Si-Ca alloy by weight are added to the molten steel for composite deoxidation and then released from the furnace;

[0052] ③Crush yttrium-based magnesium rare earth, ferro-titanium, ferro-zirconium, and ferro-tellurium into small pieces with a particle size of less than 12mm, and after drying below 220°C, place them at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com