Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31438 results about "Scrap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scrap consists of recyclable materials left over from product manufacturing and consumption, such as parts of vehicles, building supplies, and surplus materials. Unlike waste, scrap has monetary value, especially recovered metals, and non-metallic materials are also recovered for recycling.

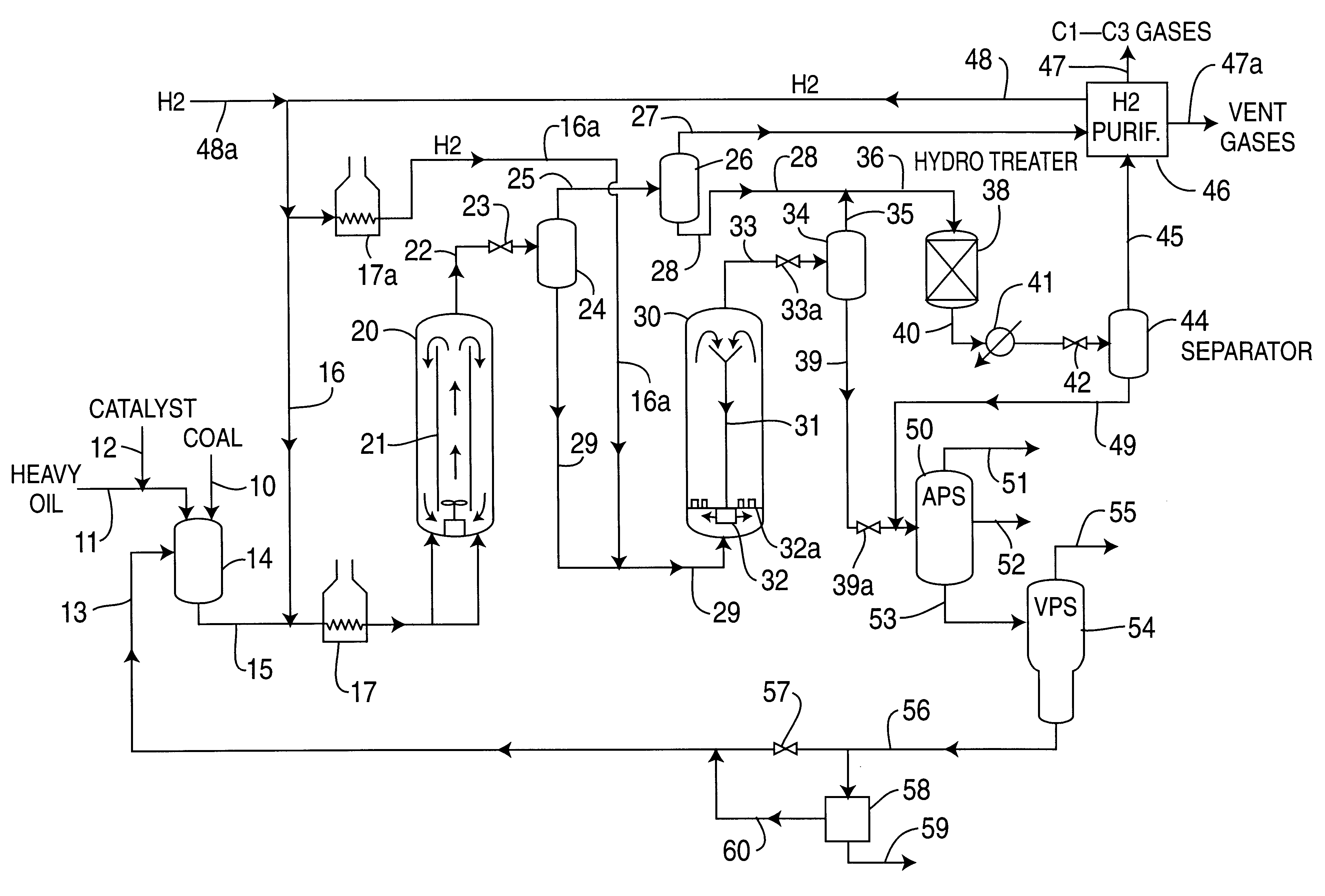

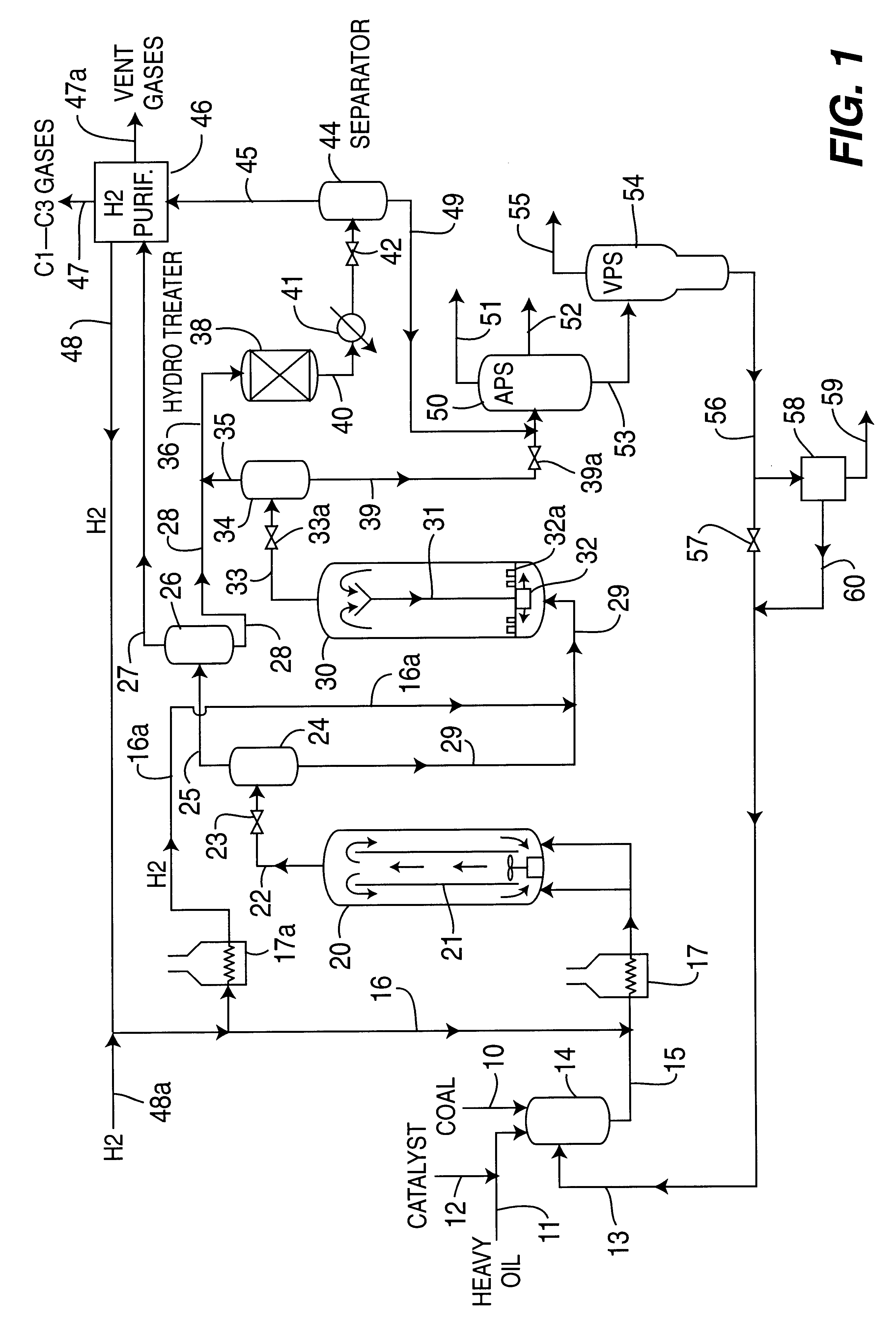

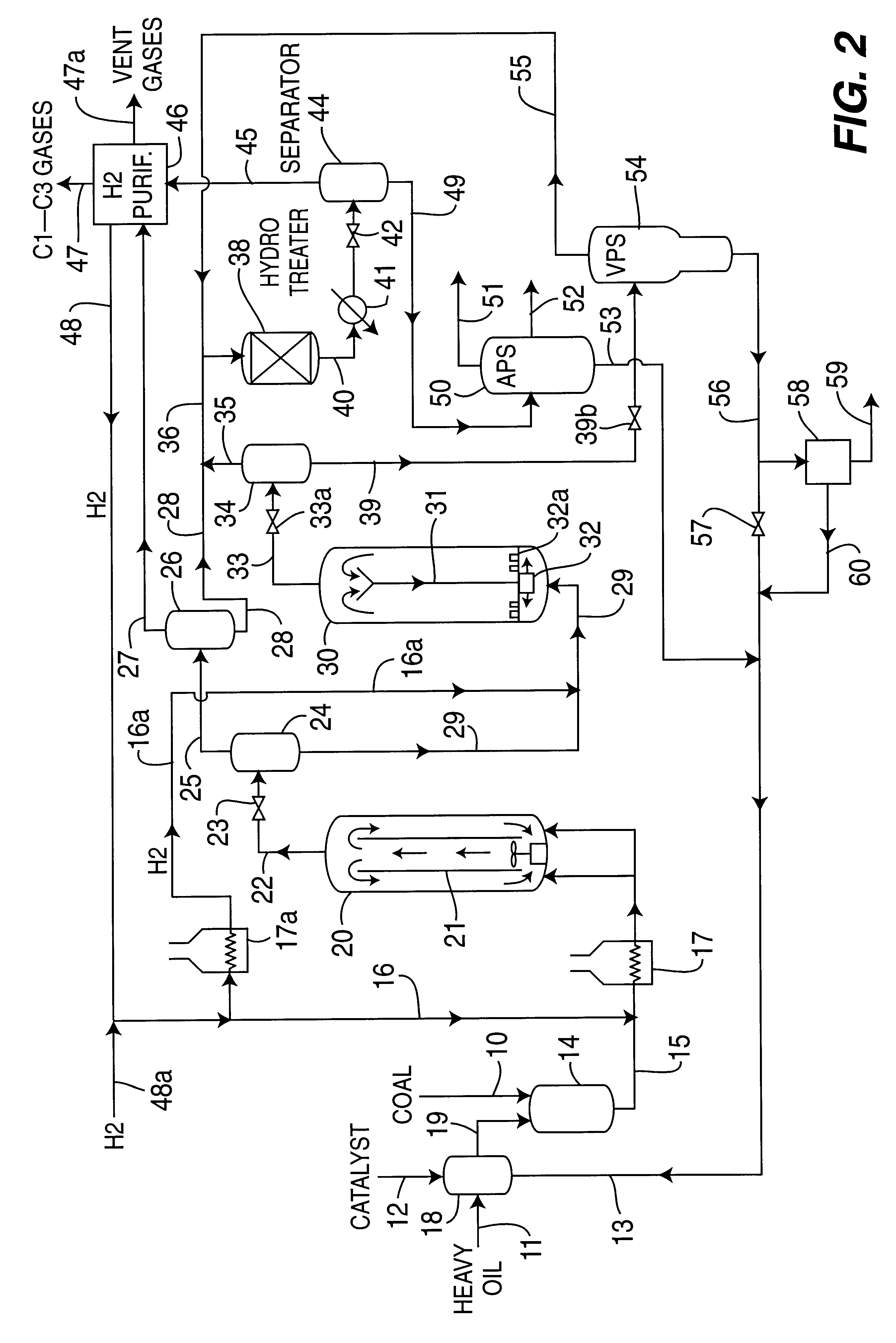

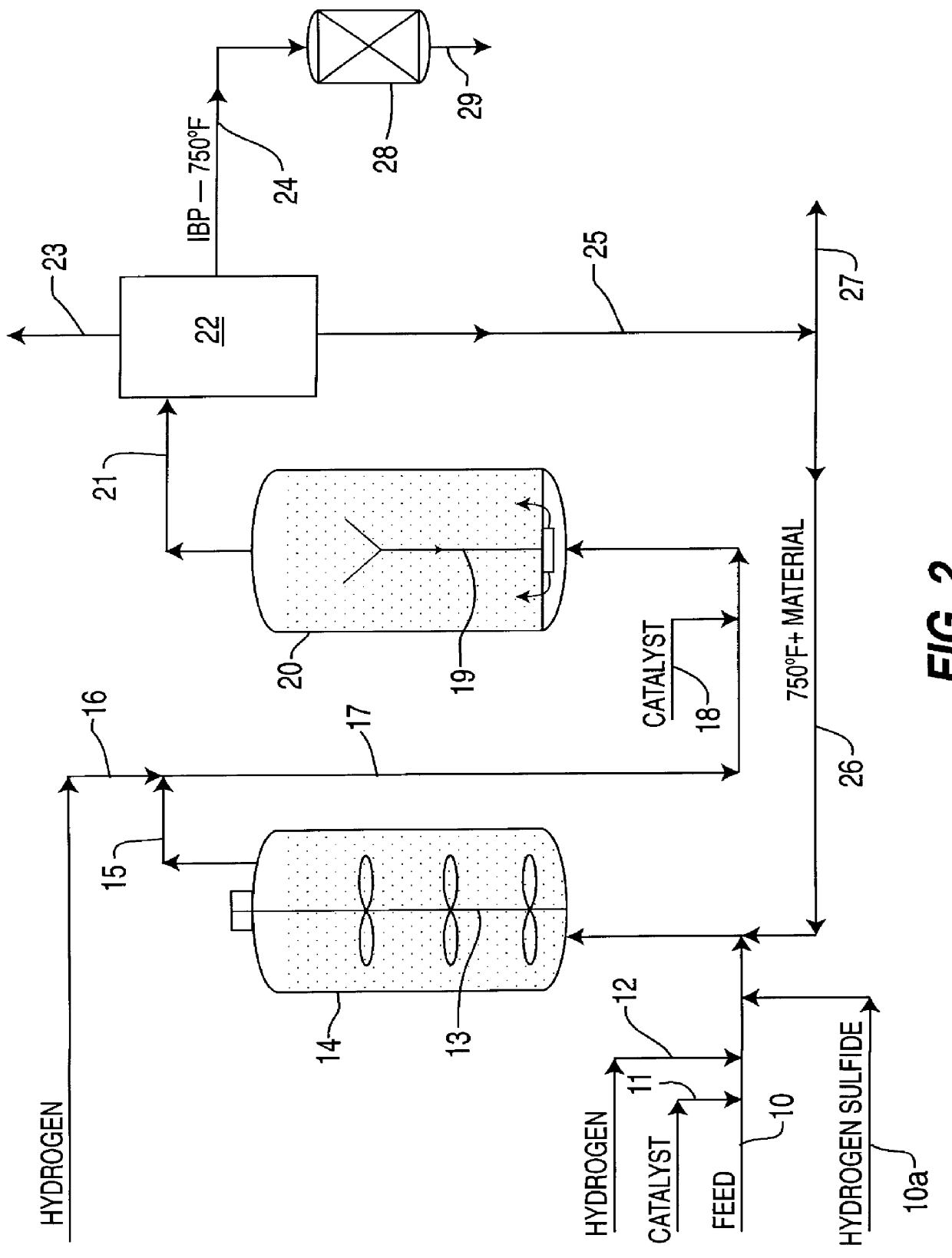

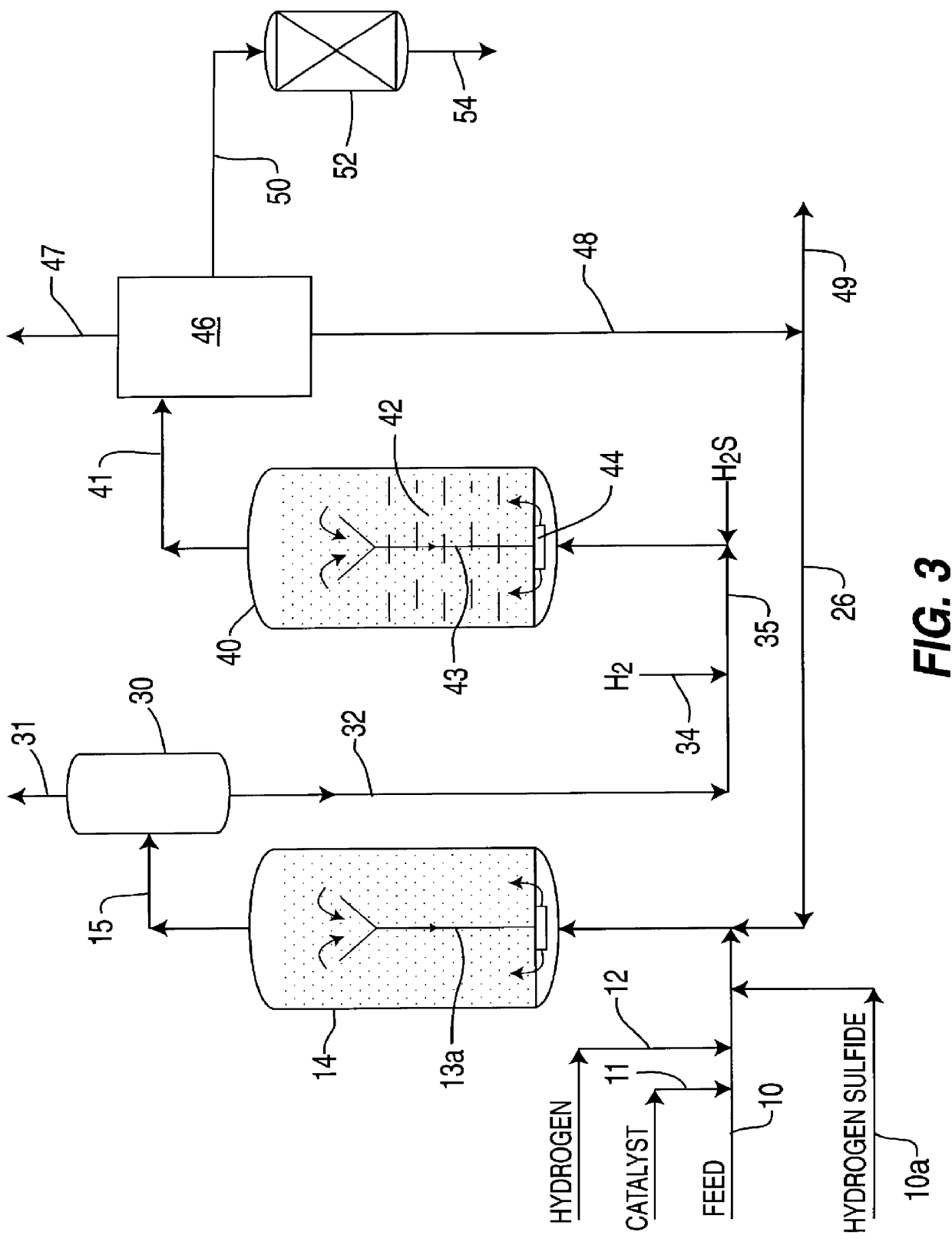

Catalytic multi-stage process for hydroconversion and refining hydrocarbon feeds

InactiveUS6190542B1Improve distillation yieldQuality improvementCatalyst activation/preparationLiquid hydrocarbon mixture productionLiquid productDistillates petroleum

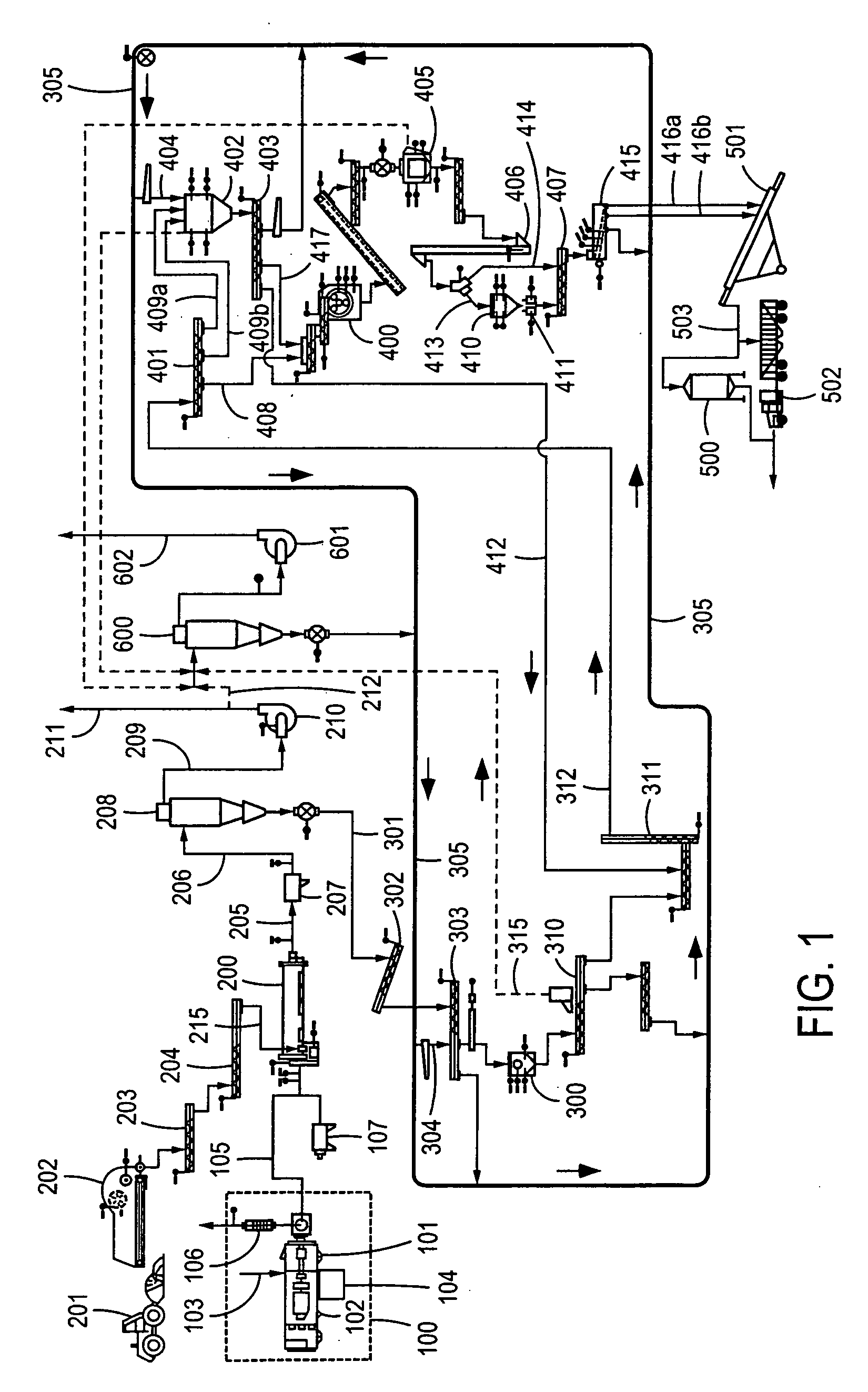

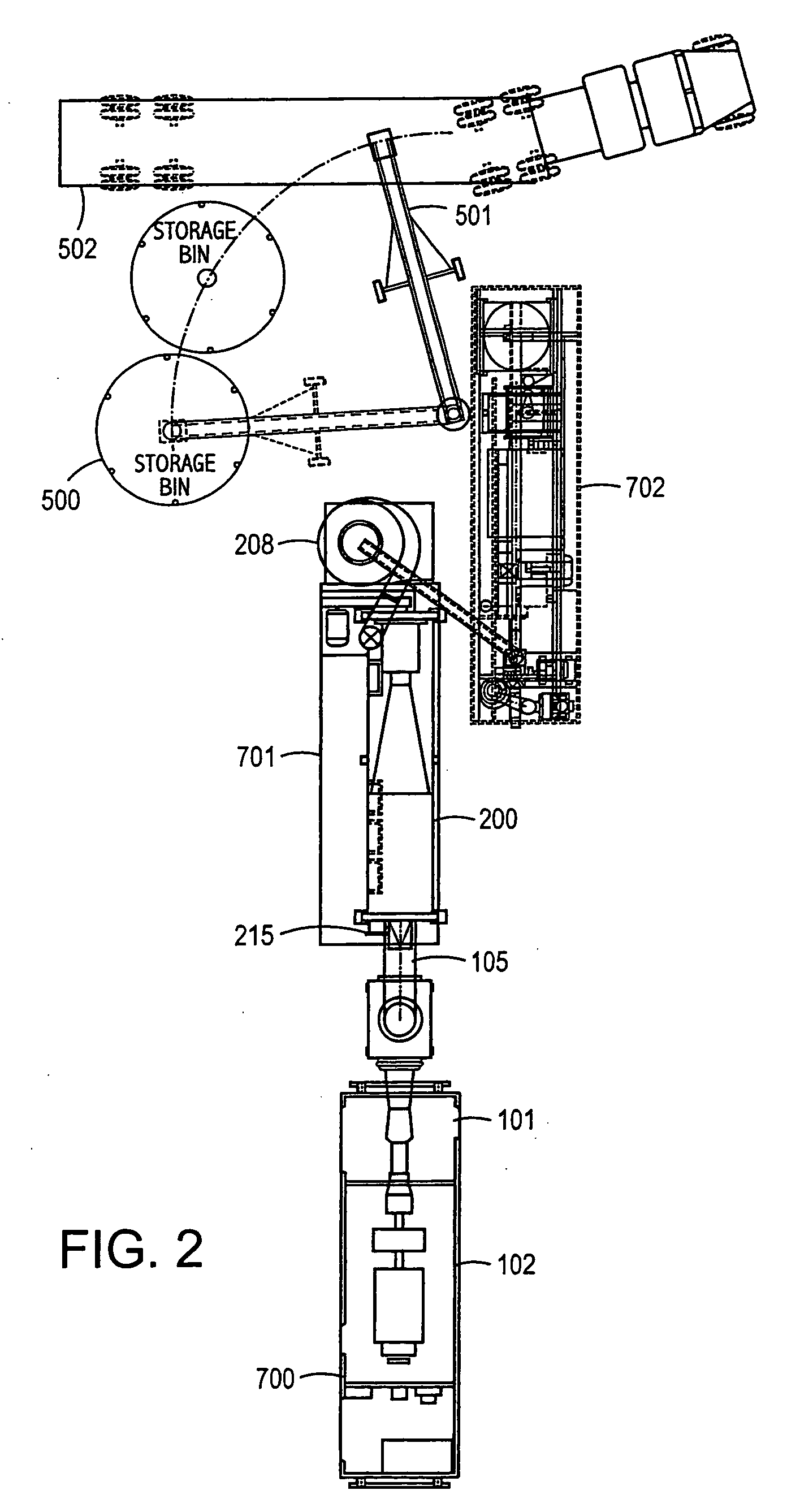

A multi-stage catalytic hydrogenation and hydroconversion process for heavy hydrocarbon feed materials such as coal, heavy petroleum fractions, and plastic waste materials. In the process, the feedstock is reacted in a first-stage, back-mixed catalytic reactor with a highly dispersed iron-based catalyst having a powder, gel or liquid form. The reactor effluent is pressure-reduced, vapors and light distillate fractions are removed overhead, and the heavier liquid fraction is fed to a second stage back-mixed catalytic reactor. The first and second stage catalytic reactors are operated at 700-850.degree. F. temperature, 1000-3500 psig hydrogen partial pressure and 20-80 lb. / hr per ft.sup.3 reactor space velocity. The vapor and light distillates liquid fractions removed from both the first and second stage reactor effluent streams are combined and passed to an in-line, fixed-bed catalytic hydrotreater for heteroatom removal and for producing high quality naphtha and mid-distillate or a full-range distillate product. The remaining separator bottoms liquid fractions are distilled at successive atmospheric and vacuum pressures, low and intermediate-boiling hydrocarbon liquid products are withdrawn, and heavier distillate fractions are recycled and further upgraded to provide additional low-boiling hydrocarbon liquid products. This catalytic multistage hydrogenation process provides improved flexibility for hydroprocessing the various carbonaceous feedstocks and adjusting to desired product structures and for improved economy of operations.

Owner:HEADWATERS CTL

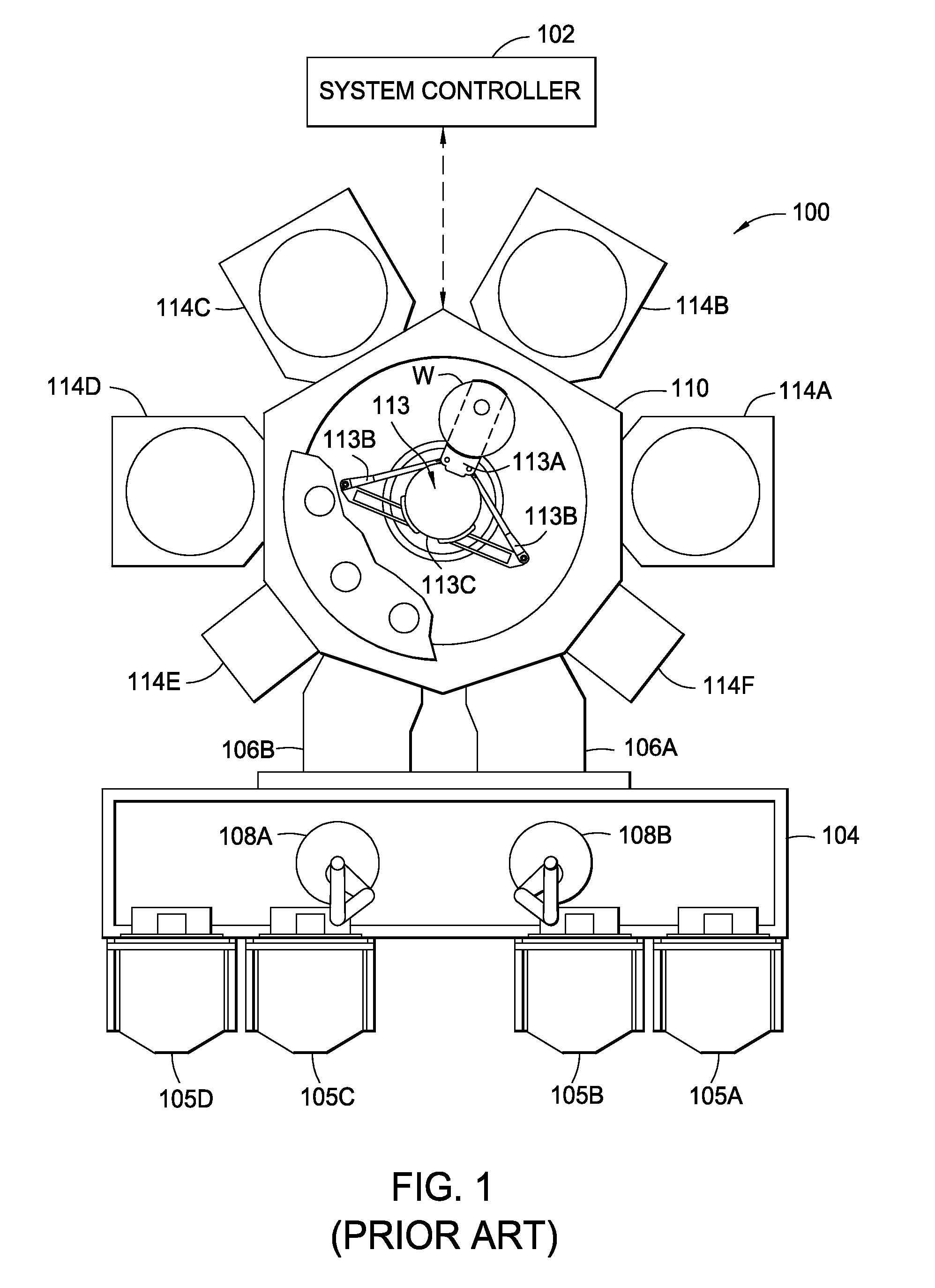

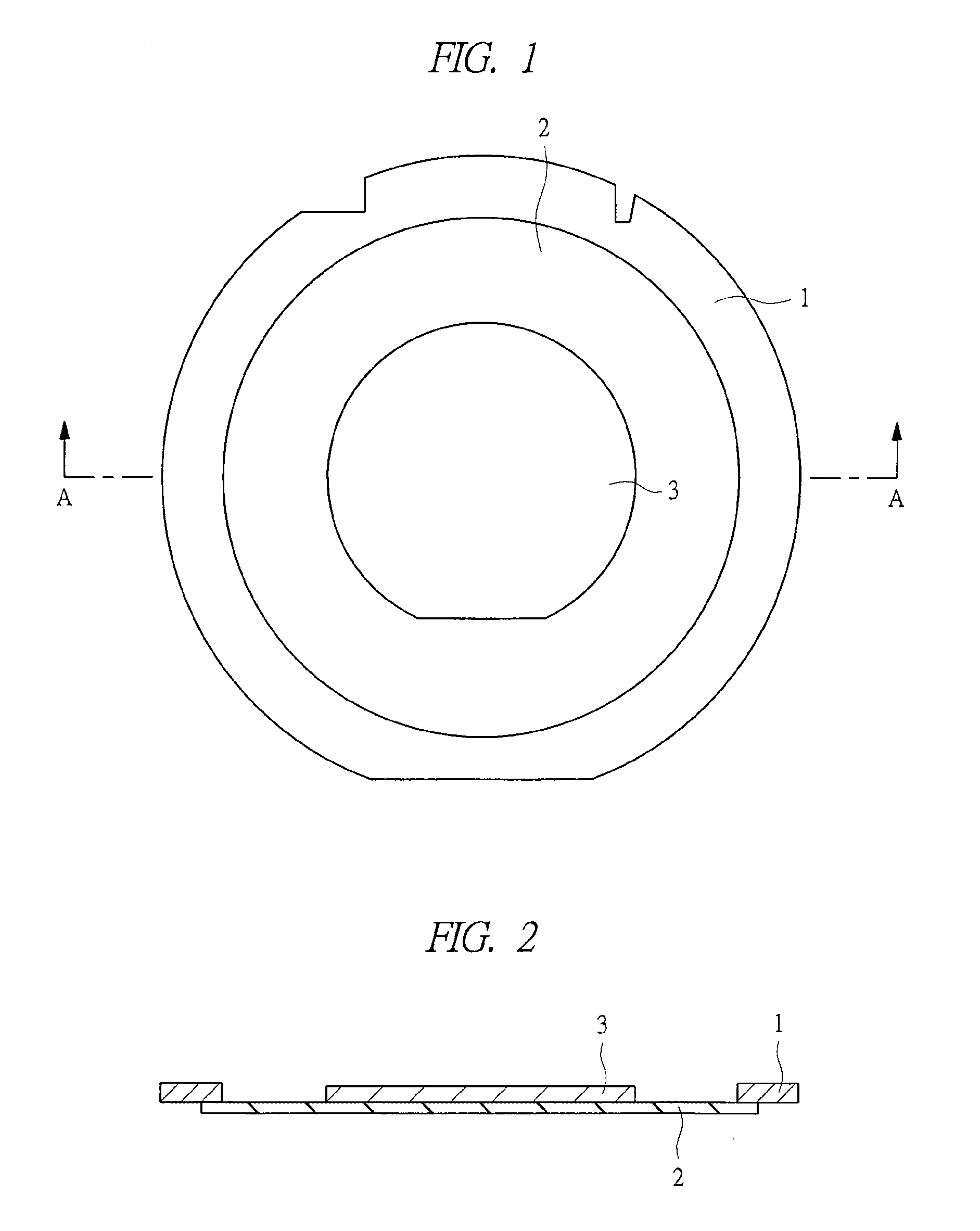

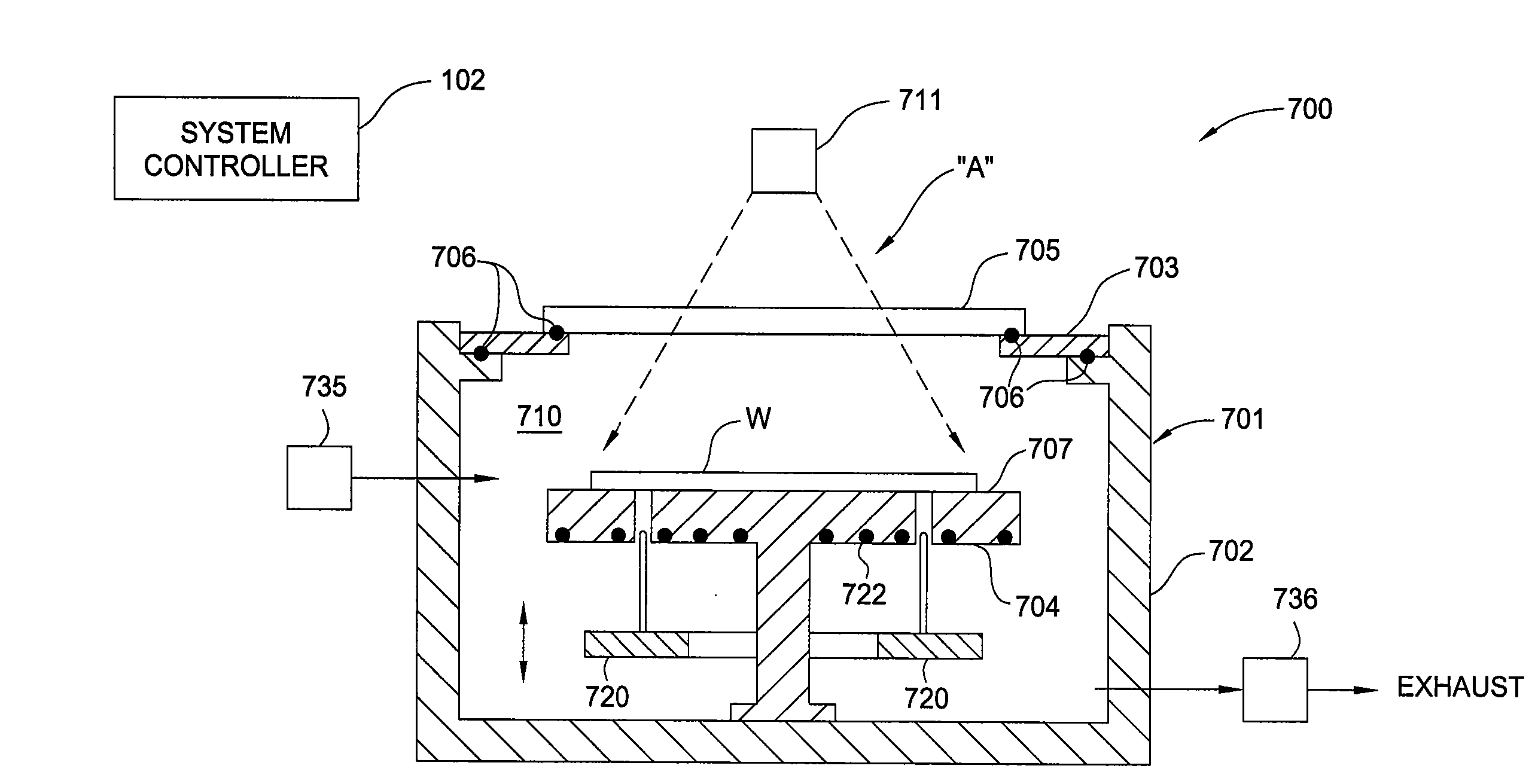

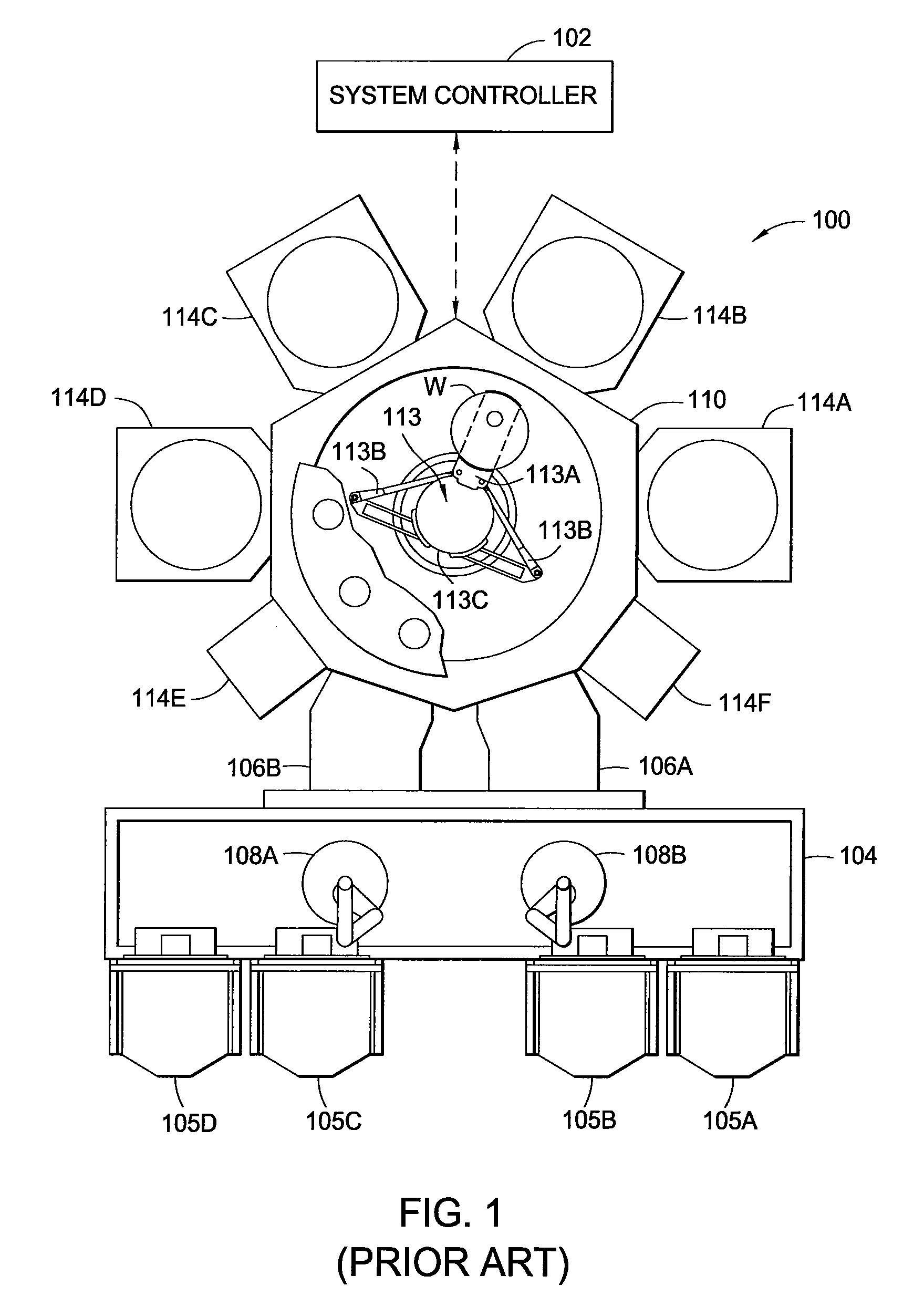

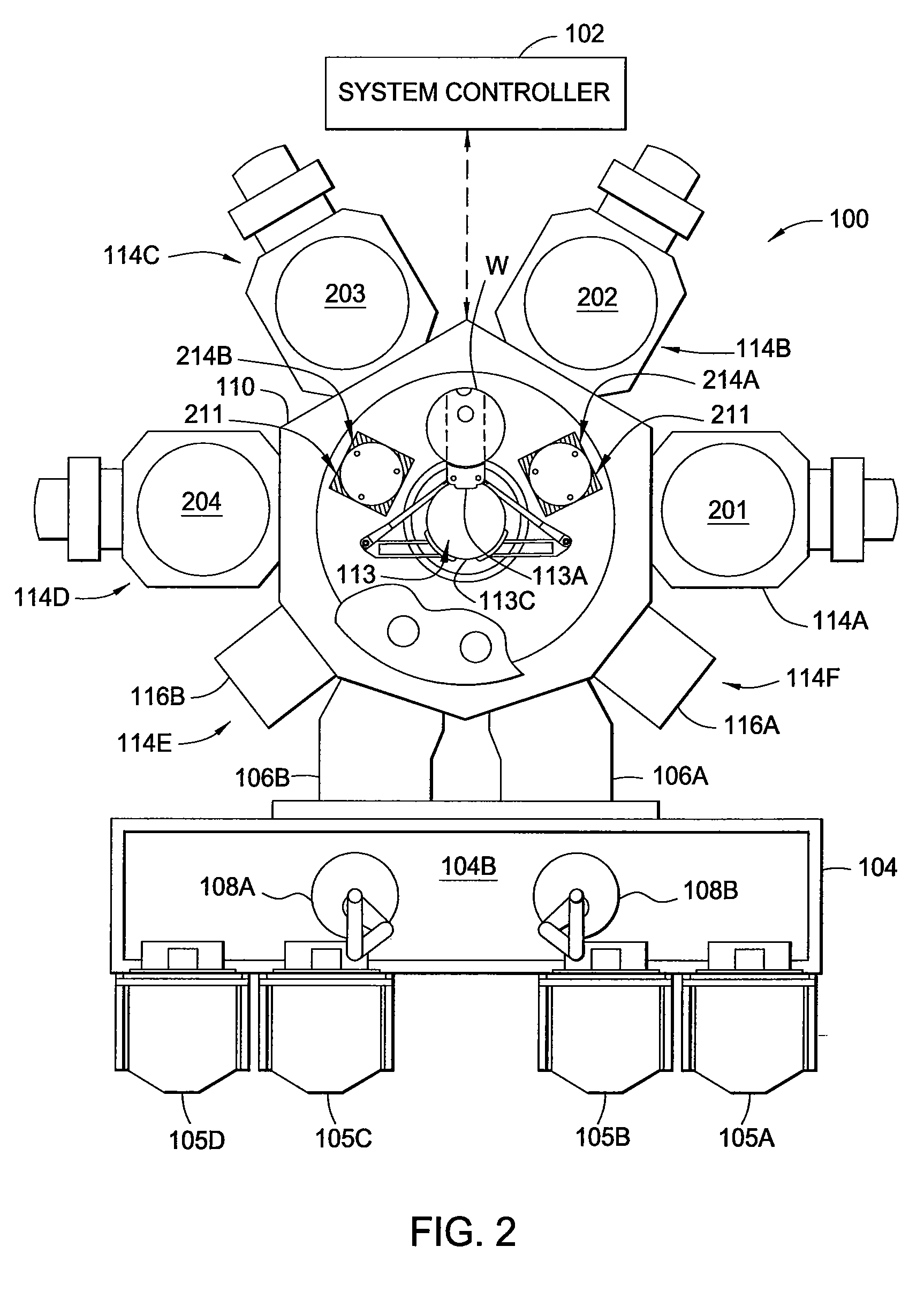

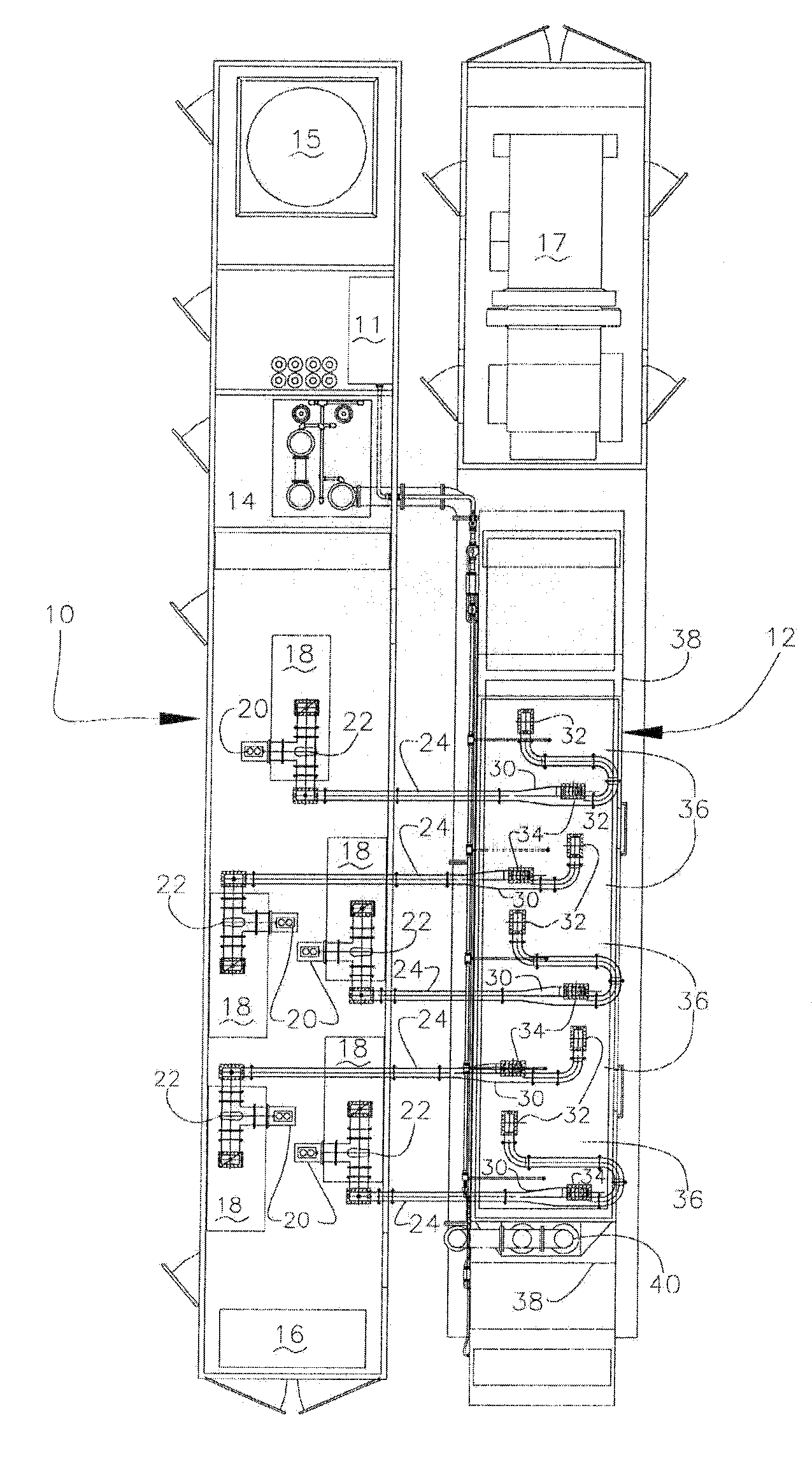

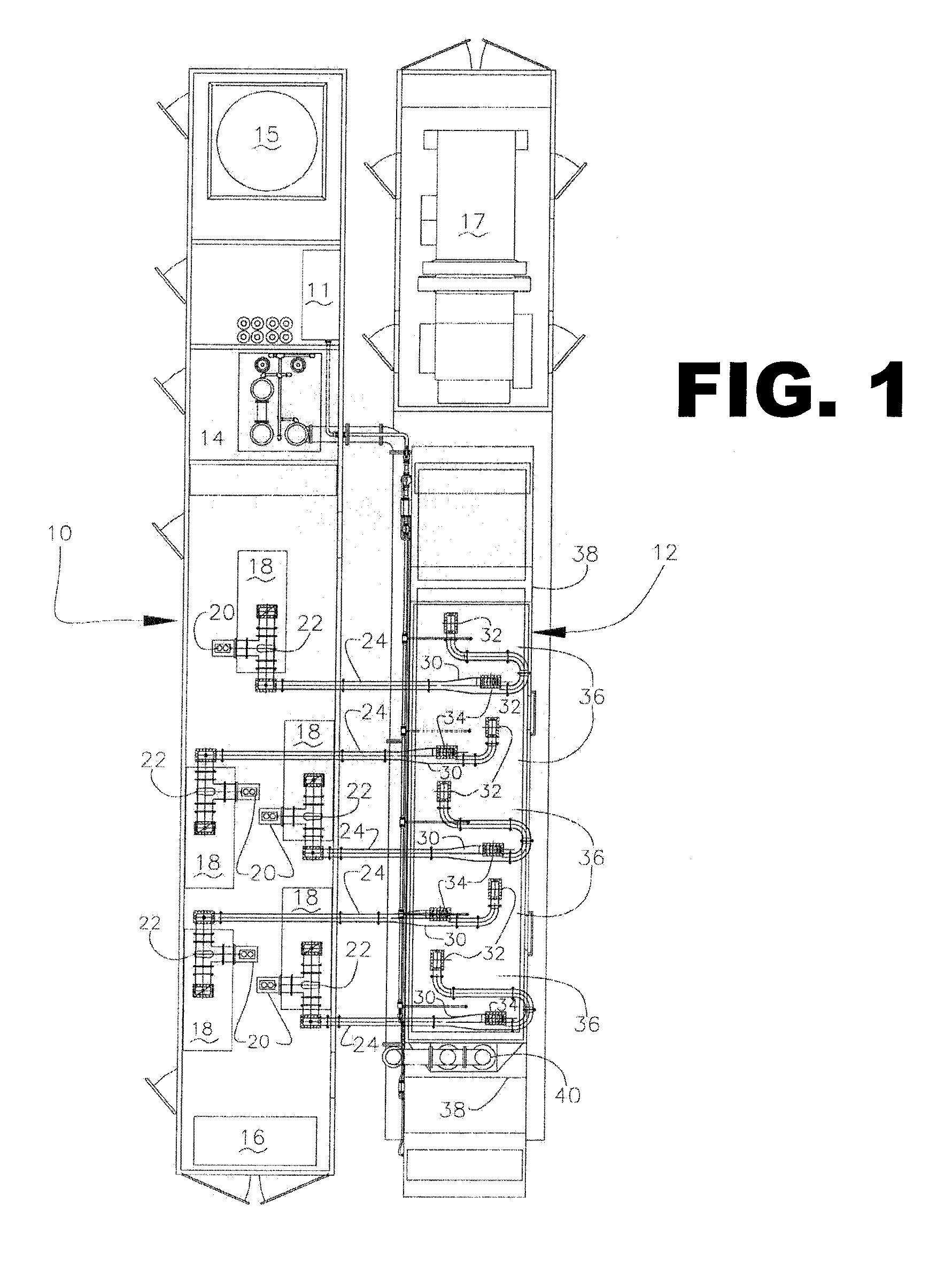

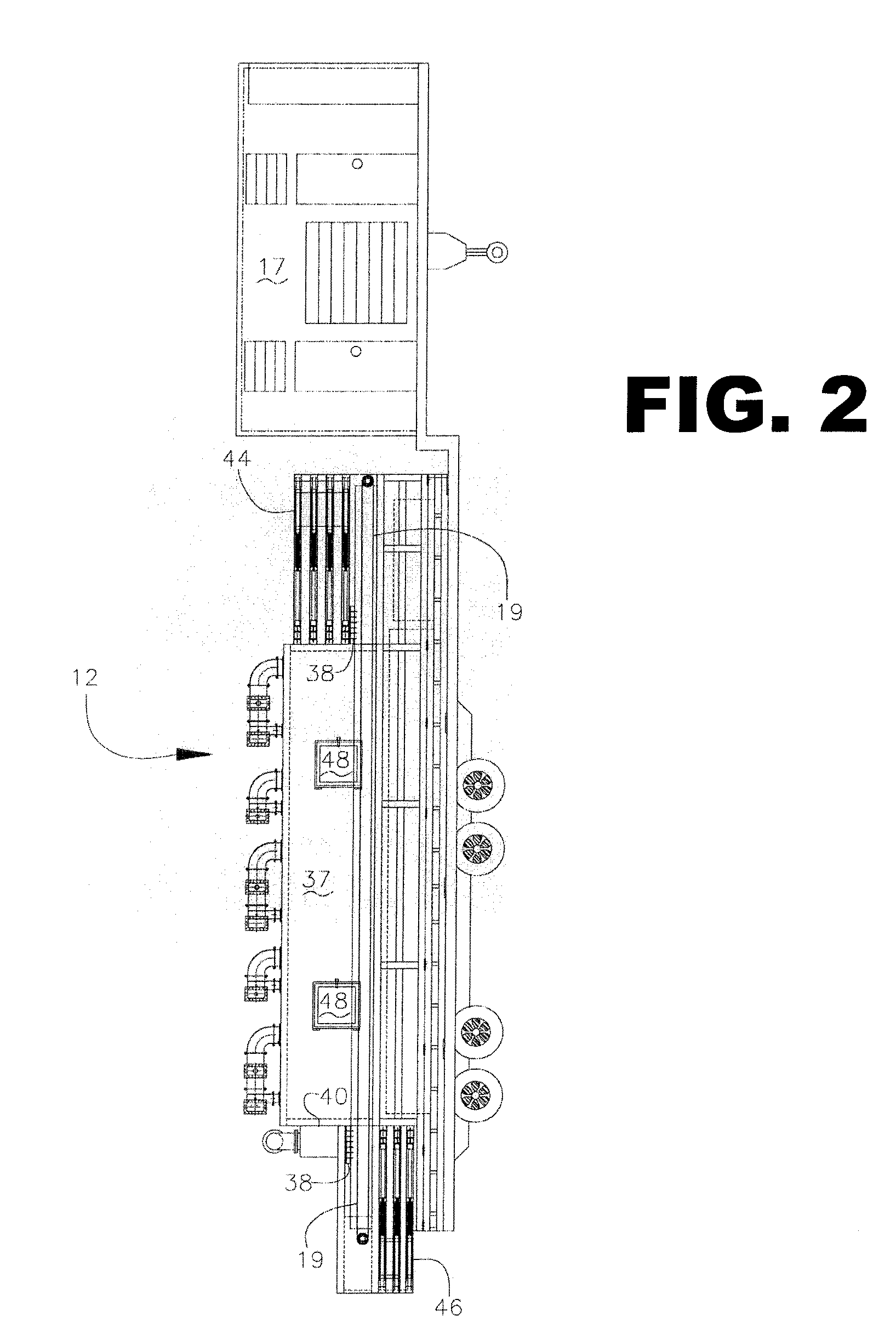

Cluster tool for advanced front-end processing

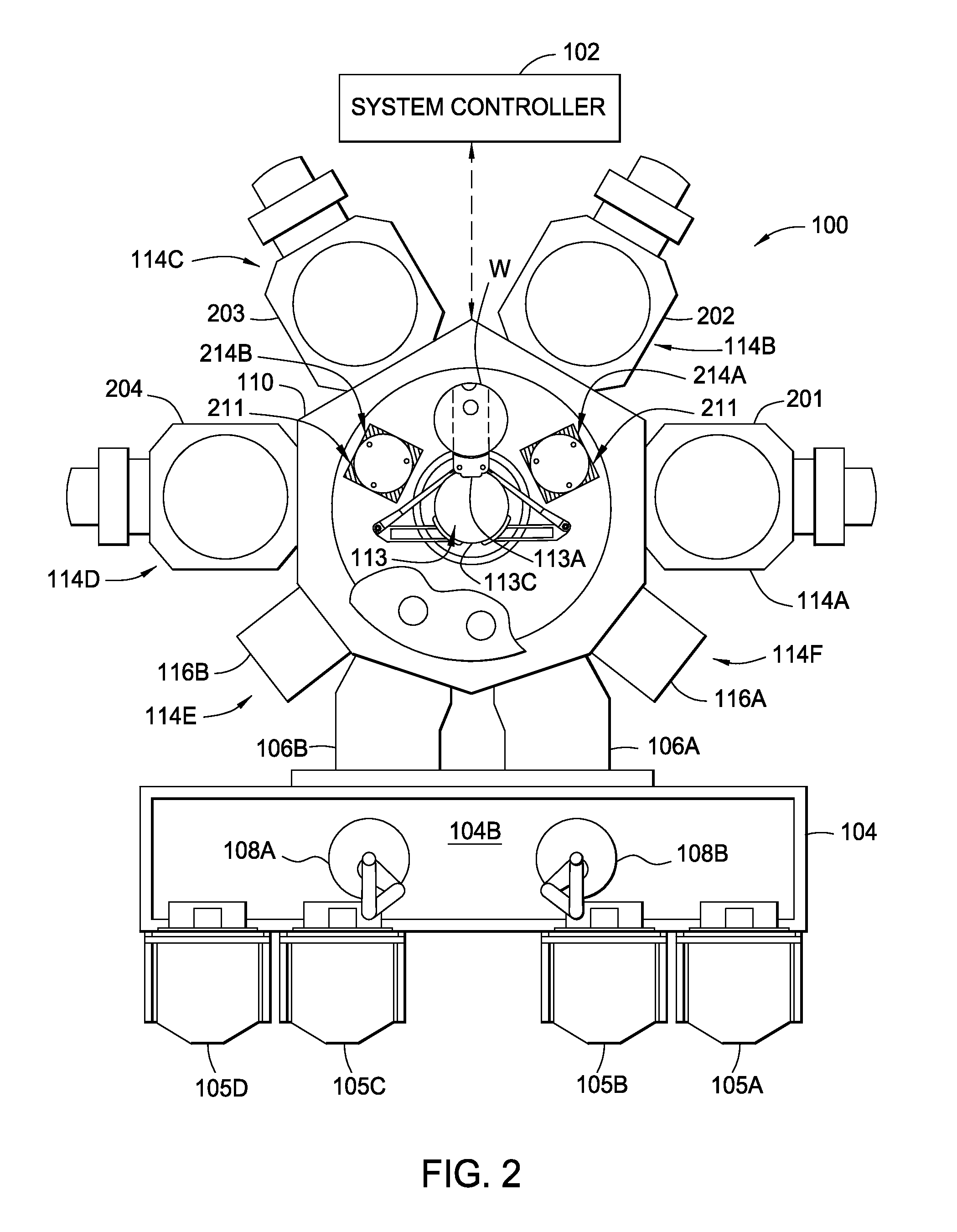

InactiveUS20070134821A1Electrostatic cleaningSemiconductor/solid-state device manufacturingDevice materialEngineering

Aspects of the invention generally provide an apparatus and method for processing substrates using a multi-chamber processing system that is adapted to process substrates and analyze the results of the processes performed on the substrate. In one aspect of the invention, one or more analysis steps and / or precleaning steps are utilized to reduce the effect of queue time on device yield. In one aspect of the invention, a system controller and the one or more analysis chambers are utilized to monitor and control a process chamber recipe and / or a process sequence to reduce substrate scrap due to defects in the formed device and device performance variability issues. Embodiments of the present invention also generally provide methods and a system for repeatably and reliably forming semiconductor devices used in a variety of applications.

Owner:APPLIED MATERIALS INC

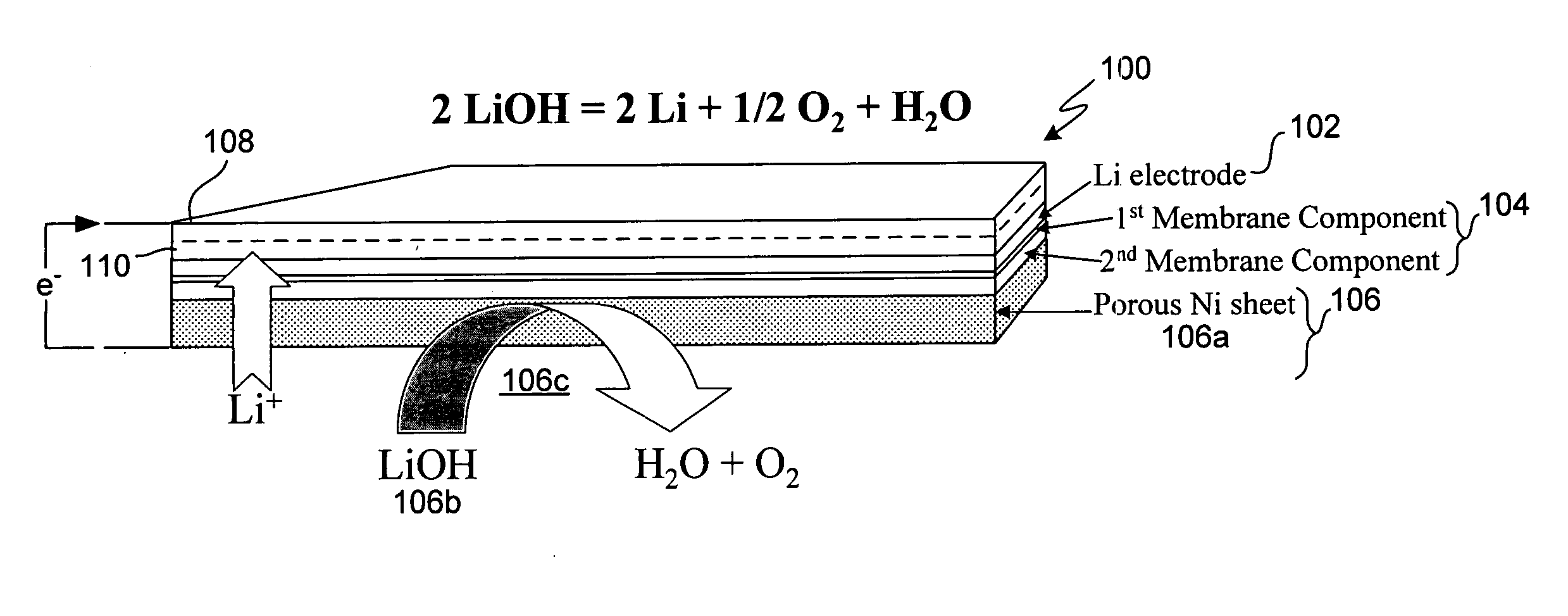

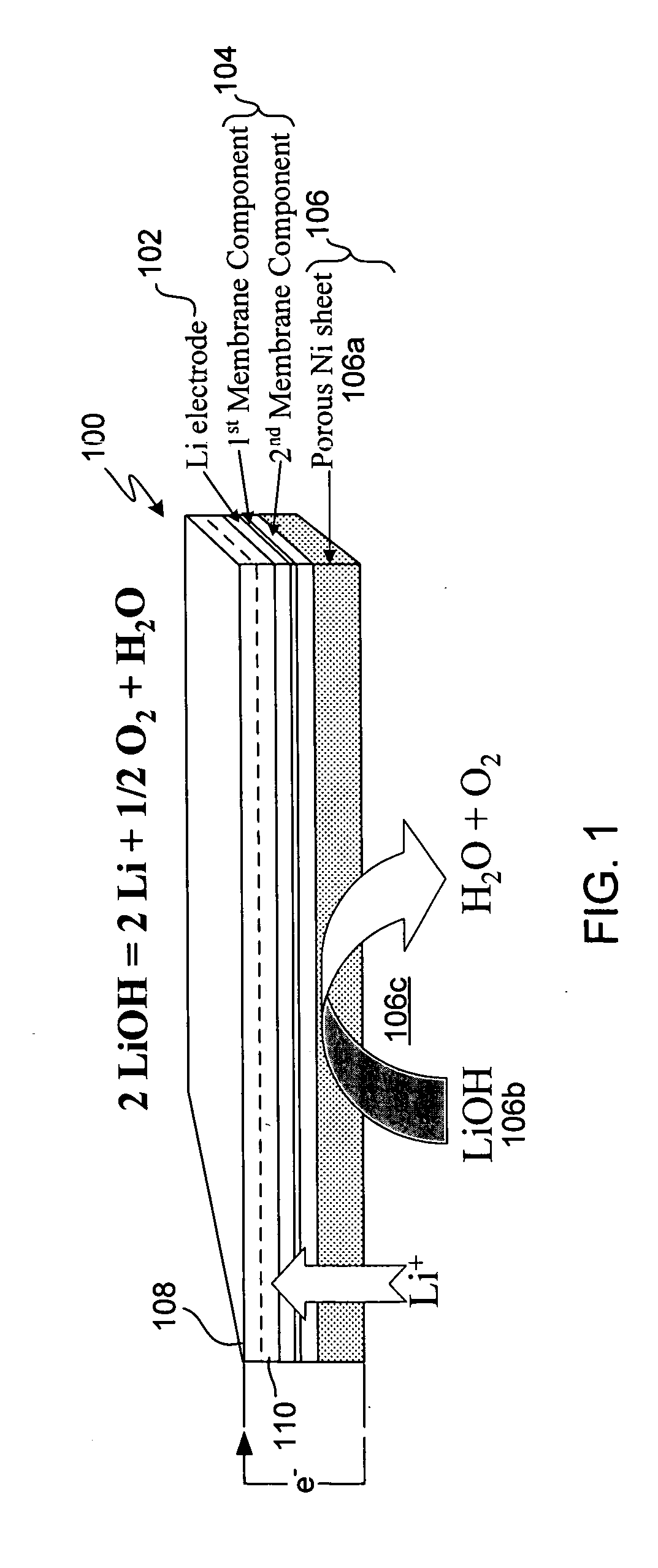

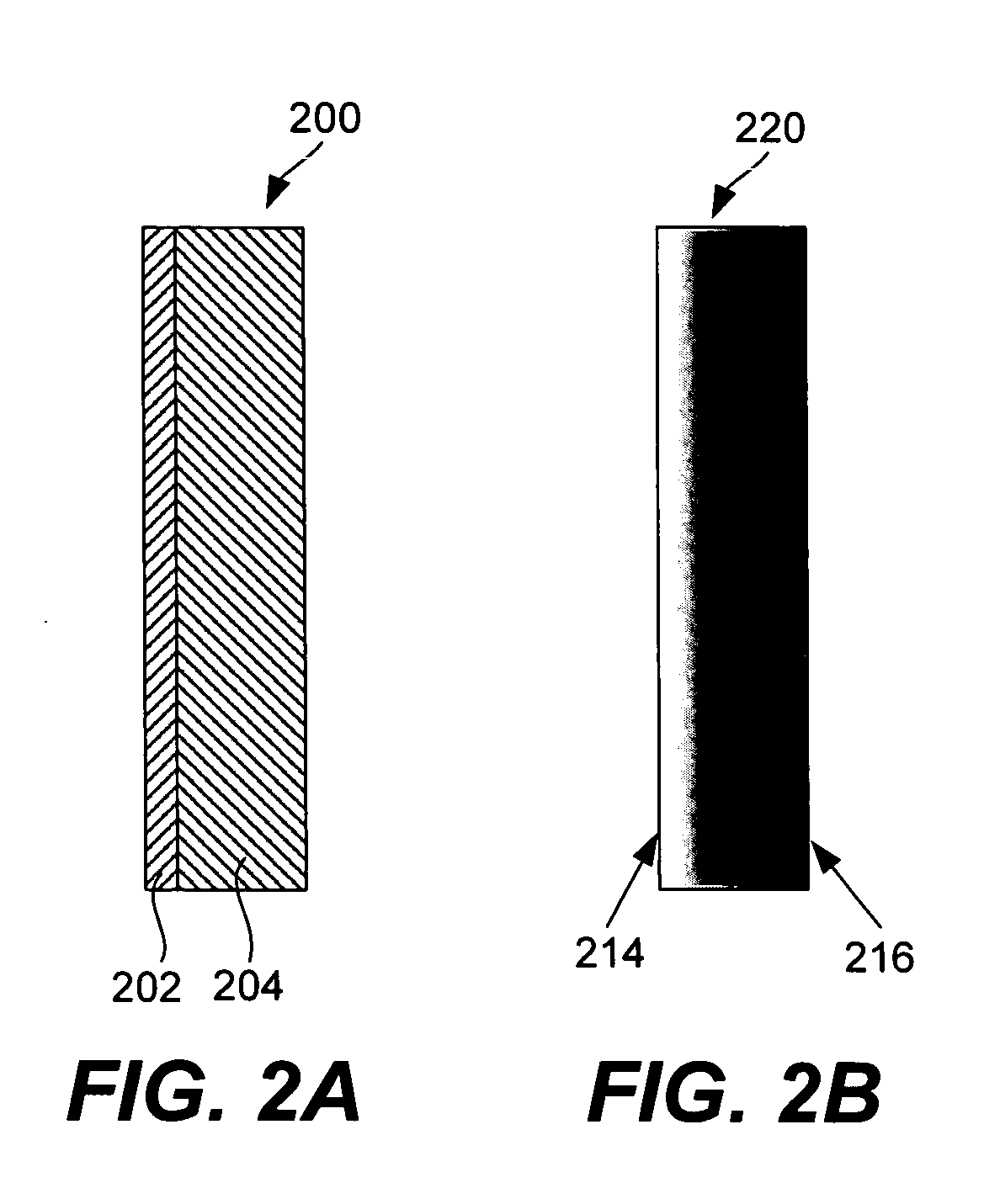

Active metal electrolyzer

InactiveUS20050100793A1Effective isolationReduce environmental pollutionPhotography auxillary processesElectrode manufacturing processesElectrolysisAqueous electrolyte

Electro-winning of active metal (e.g., lithium) ions from a variety of sources including industrial waste, and recycled lithium and lithium-ion batteries is accomplished with an electrolyzer having a protected cathode that is stable against aggressive solvents, including water, aqueous electrolytes, acid, base, and a broad range of protic and aprotic solvents. The electrolyzer has a highly ionically conductive protective membrane adjacent to the alkali metal cathode that effectively isolates (de-couples) the alkali metal electrode from solvent, electrolyte processing and / or cathode environments, and at the same time allows ion transport in and out of these environments. Isolation of the cathode from other components of a battery cell or other electrochemical cell in this way allows the use of virtually any solvent, electrolyte and / or anode material in conjunction with the cathode. The electrolyzer can be configured and operated to claim or reclaim lithium or other active metals from such sources.

Owner:POLYPLUS BATTERY CO INC

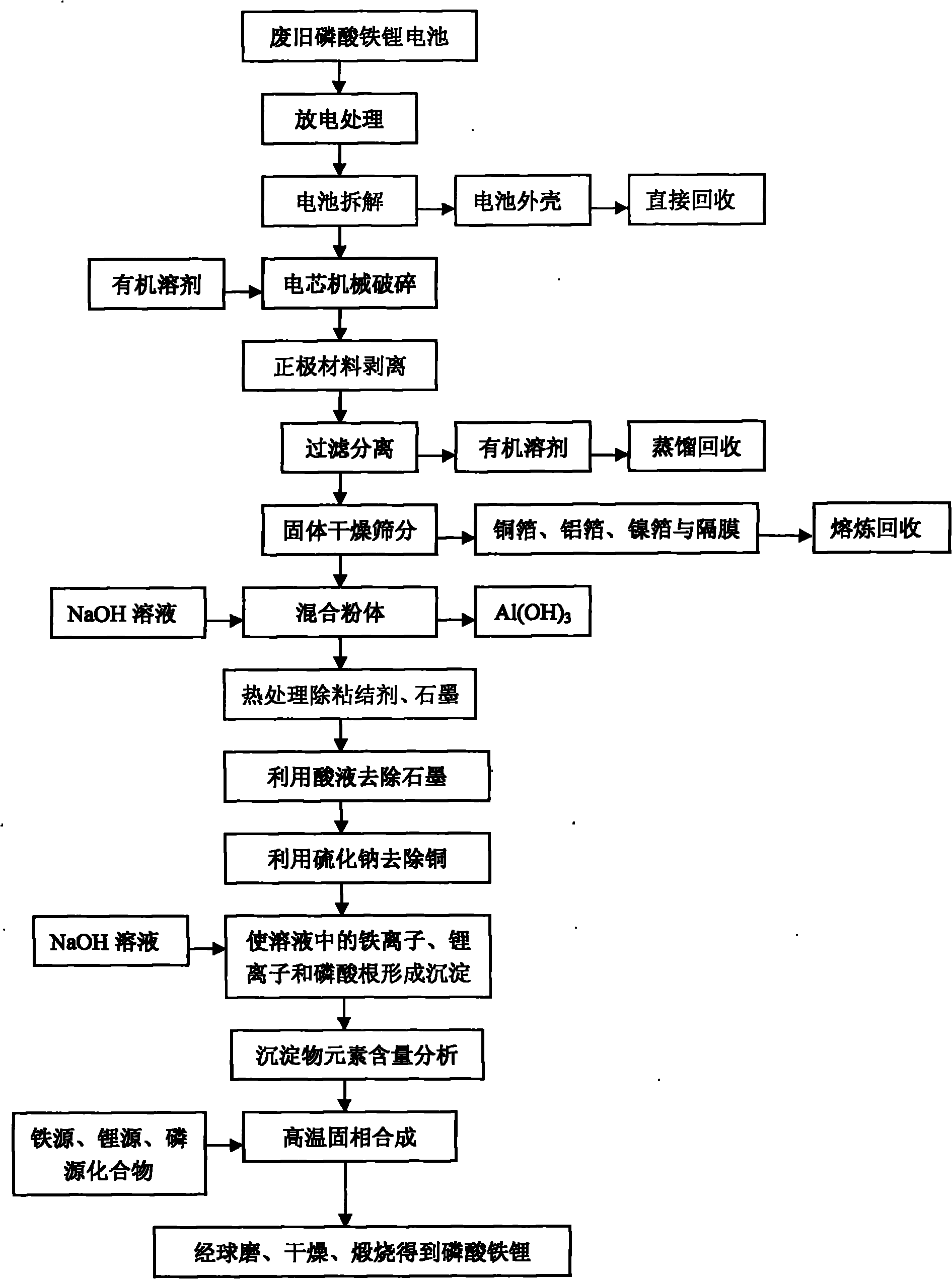

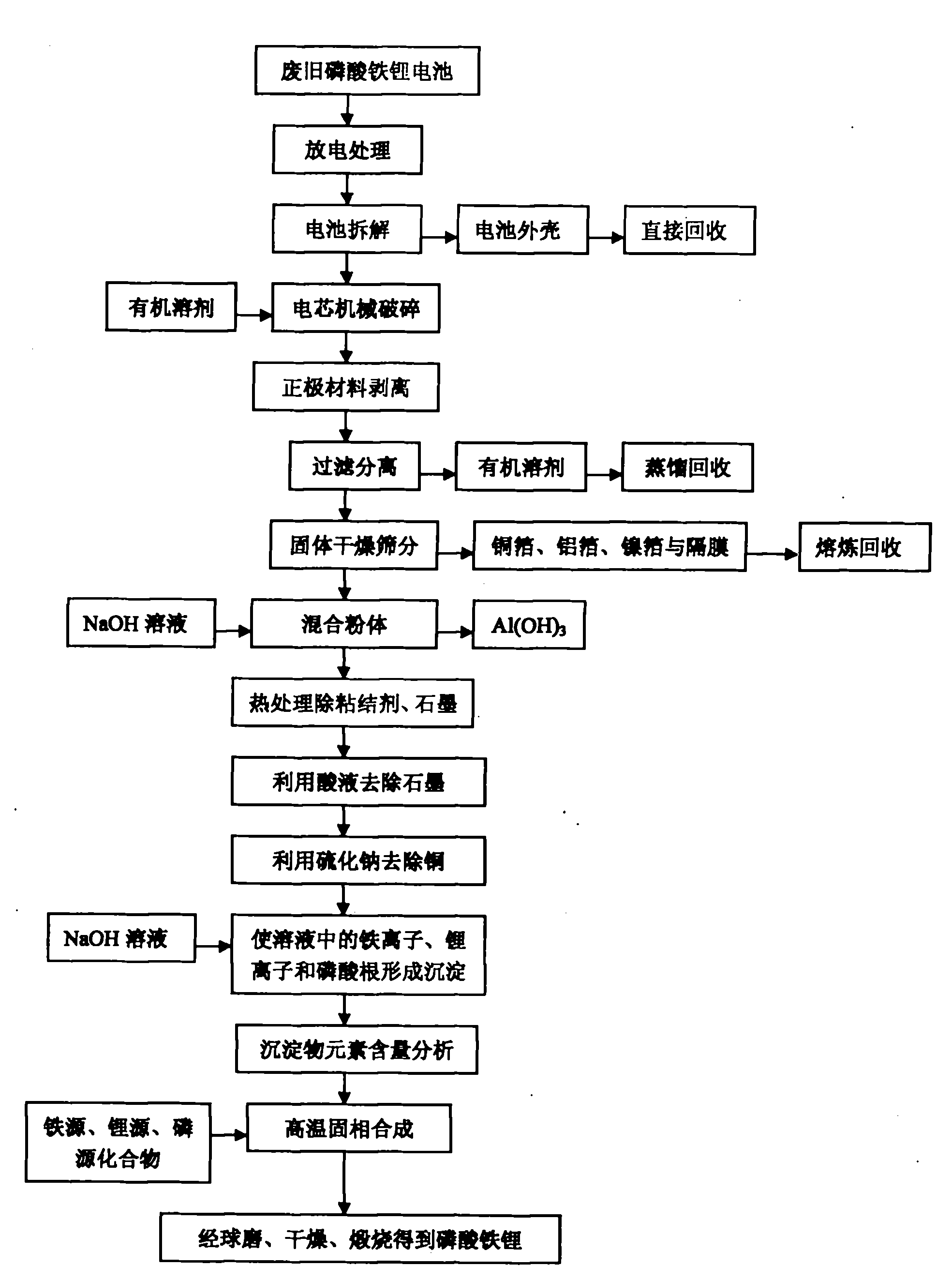

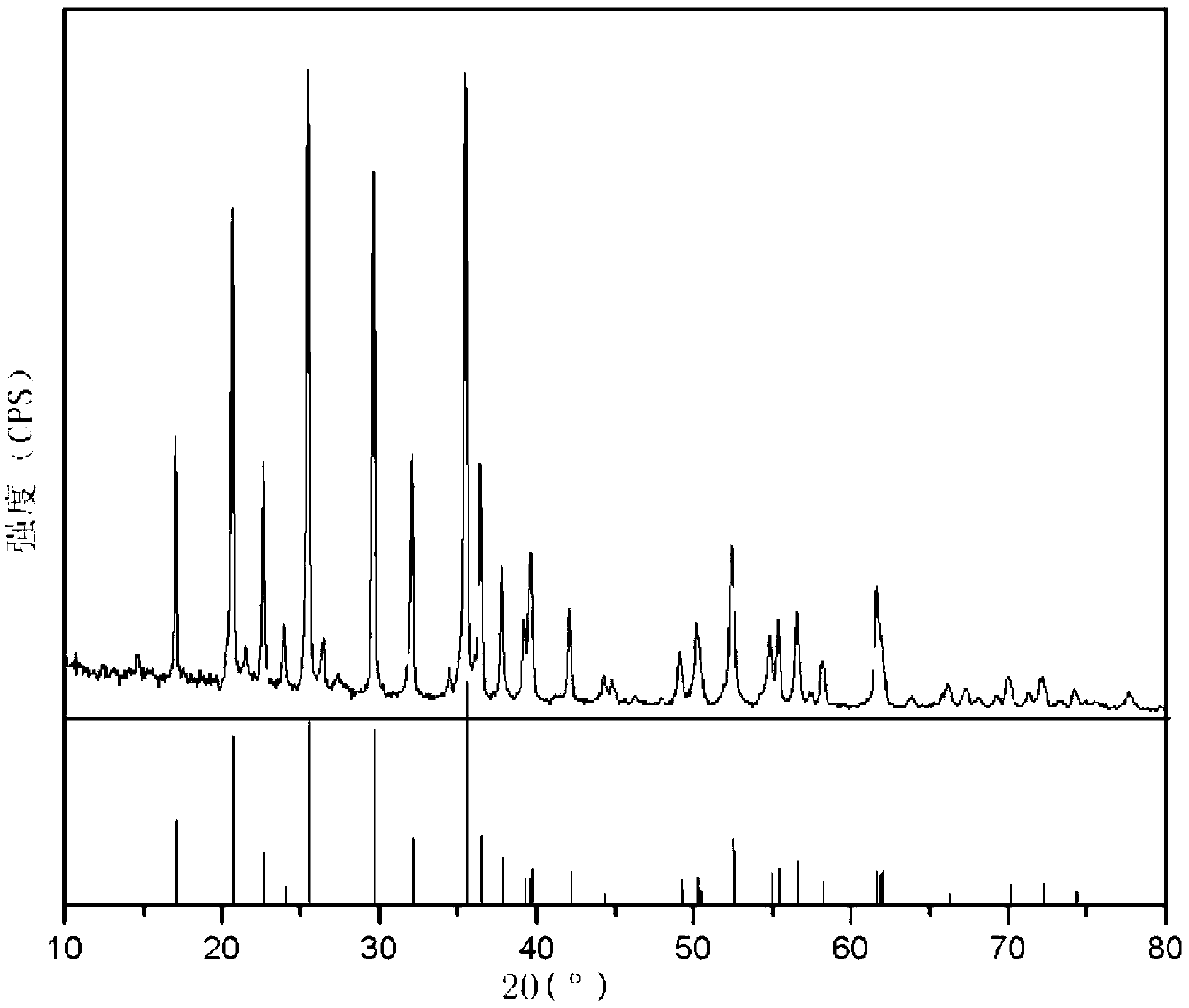

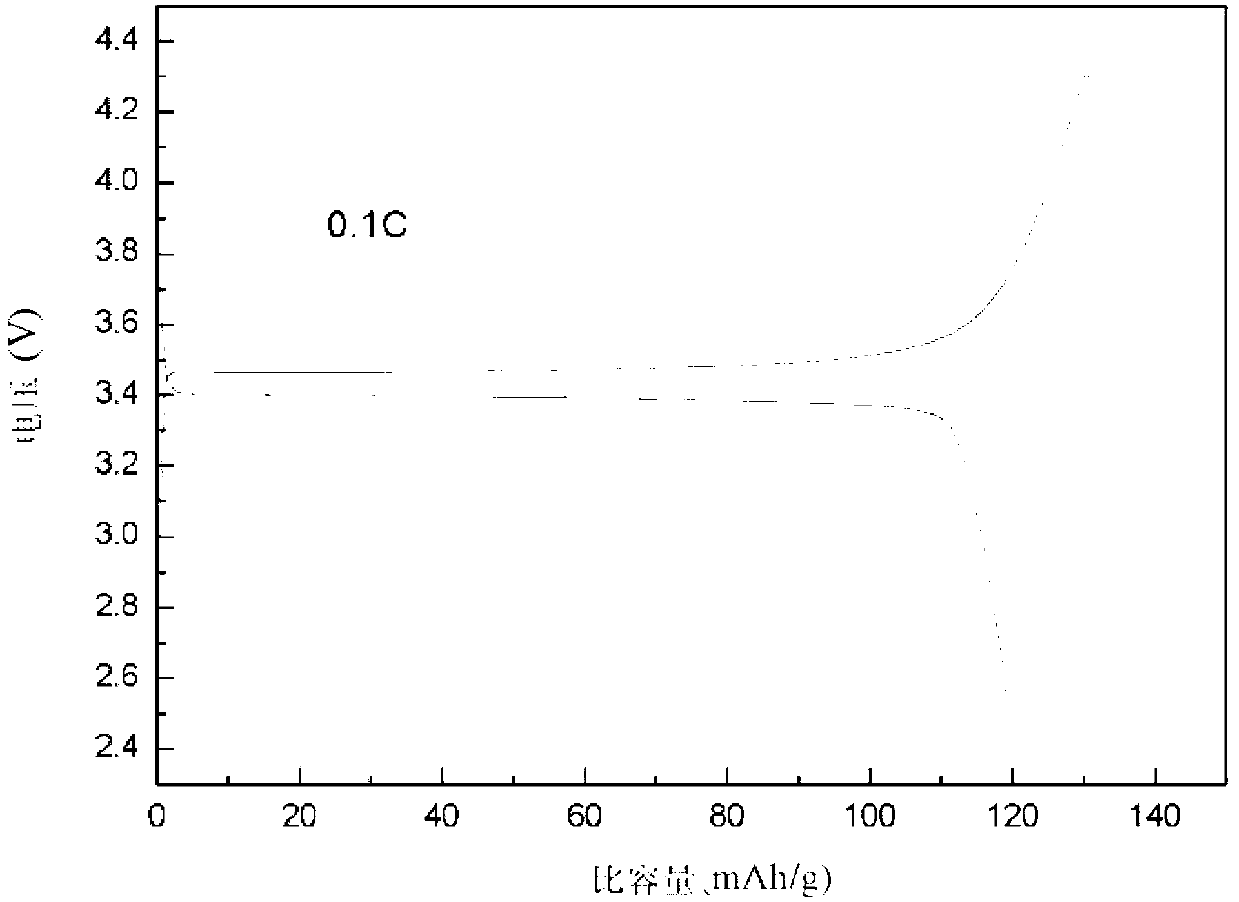

Comprehensive recovering method of waste lithium iron phosphate battery

InactiveCN101847763AImprove performanceLow priceWaste accumulators reclaimingProcess efficiency improvementAdhesiveCalcination

The invention provides a comprehensive recovering method of waste lithium iron phosphate batteries, which has simple and reasonable process, low recovering cost and high added value. The method comprises the following steps: utilizing an organic solvent to dissolve an adhesive on battery cell fragments, and realizing the separation of lithium iron phosphate material and clean aluminum and copper foils through screening, wherein the aluminum and copper foils are recovered by smelting; utilizing a NaOH solution to remove residual aluminum foil scraps in the lithium iron phosphate material, and removing graphite and remaining adhesive by heat treatment; after dissolving the lithium iron phosphate with acid, utilizing sodium sulphide to remove copper ions, and utilizing the NaOH solution or ammonia solution to allow iron, lithium and phosphorus ions in the solution to generate sediments; adding iron source, lithium source or phosphorus source compounds to adjust the molar ratio of iron, lithium and phosphorus; and finally adding a carbon source, and obtaining a lithium iron phosphate cathode material through ball milling and calcination in inert atmosphere. After the treatment of the steps, the recovery rate of valuable metals in the batteries is more than 95%, and the comprehensive recovery rate of the lithium iron phosphate cathode material is more than 90%.

Owner:CHERY AUTOMOBILE CO LTD

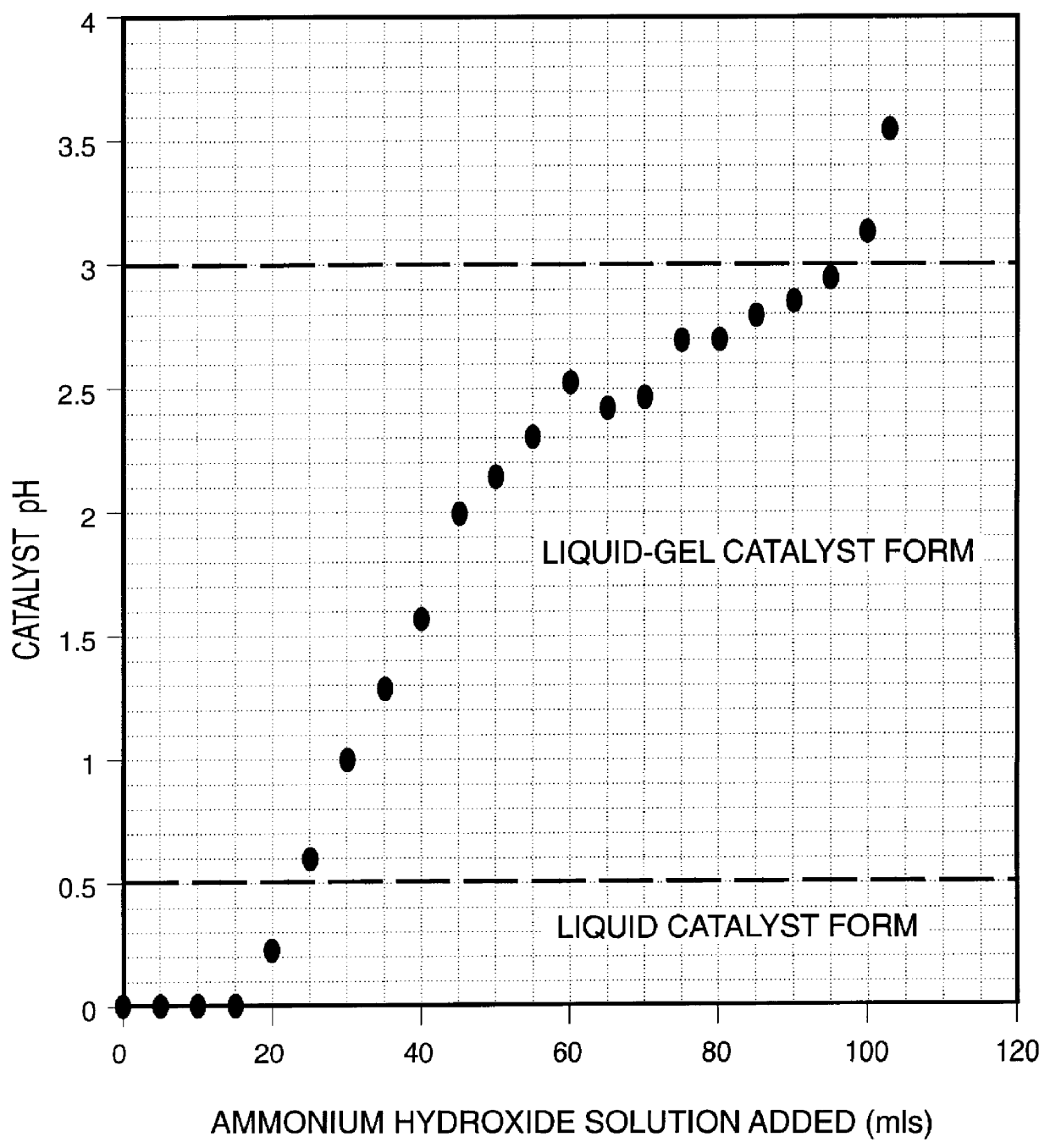

Iron-based ionic liquid catalysts for hydroprocessing carbonaceous feeds

InactiveUS6139723AIncrease hydrocracking ability of catalystIndirect and direct heating destructive distillationCatalyst activation/preparationLiquid productIron salts

A highly dispersed iron-based ionic liquid or liquid-gel catalyst which may be anion-modified and metals-promoted has high catalytic activity, and is useful for hydrocracking / hydrogenation reactions for carbonaceous feed materials. The catalyst is produced by aqueous precipitation from saturated iron salt solutions such as ferric sulfate and ferric alum, and may be modified during preparation with anionic sulfate (SO42-) and promoted with small percentages of at least one active metal such as cobalt, molybdenum, palladium, platinum, nickel, or tungsten or mixtures thereof. The resulting catalyst may be used in a preferred ionic liquid form or in a liquid-gel form, and either fluidic form can be easily mixed and reacted with carbonaceous feed materials such as coal, heavy petroleum fractions, mixed plastic waste, or mixtures thereof. The invention includes methods for making the ionic liquid or liquid-gel catalyst, and processes for using the fluidic catalysts for hydroprocessing the carbonaceous feed materials to produce desirable low-boiling hydrocarbon liquid products.

Owner:HEADWATERS CTL

Method for preparing lithium cobaltate by directly using invalid lithium ion battery

InactiveCN102030375AReduce dispersionHigh purityCell electrodesCobalt compoundsElectrical batteryPotassium hydroxide

The invention provides a method for preparing lithium cobaltate by directly using an invalid lithium ion battery. The method comprises the following steps: crushing the invalid lithium ion battery or scraps generated when a lithium cobaltate battery is produced by a mechanical crusher at normal temperature; adding water and one or more of acetic acid, sulfuric acid, hydrochloric acid or nitric acid to produce mixed aqueous solution of the battery scraps and acid; filling the mixed aqueous solution into a hermetic pressure reactor, and controlling the temperature in the reactor to be between 50 and 150 DEG C; introducing or adding one leaching additive of sulfur dioxide or hydrogen, or adding hydrazine hydrate; stirring and leaching, cooling, and filtering; adding one precipitator of sodium carbonate, potassium carbonate and ammonium carbonate, or adding composite precipitator consisting of one of the sodium carbonate, the potassium carbonate and the ammonium carbonate and one of sodium hydroxide and potassium hydroxide to obtain mixture of lithium carbonate, cobalt carbonate and cobalt hydroxide; drying and calcining at high temperature to produce a lithium cobaltate product. The method is particularly suitable for the treatment scale of medium-sized and small enterprises, and is an effective method for directly materializing cobalt secondary resources.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

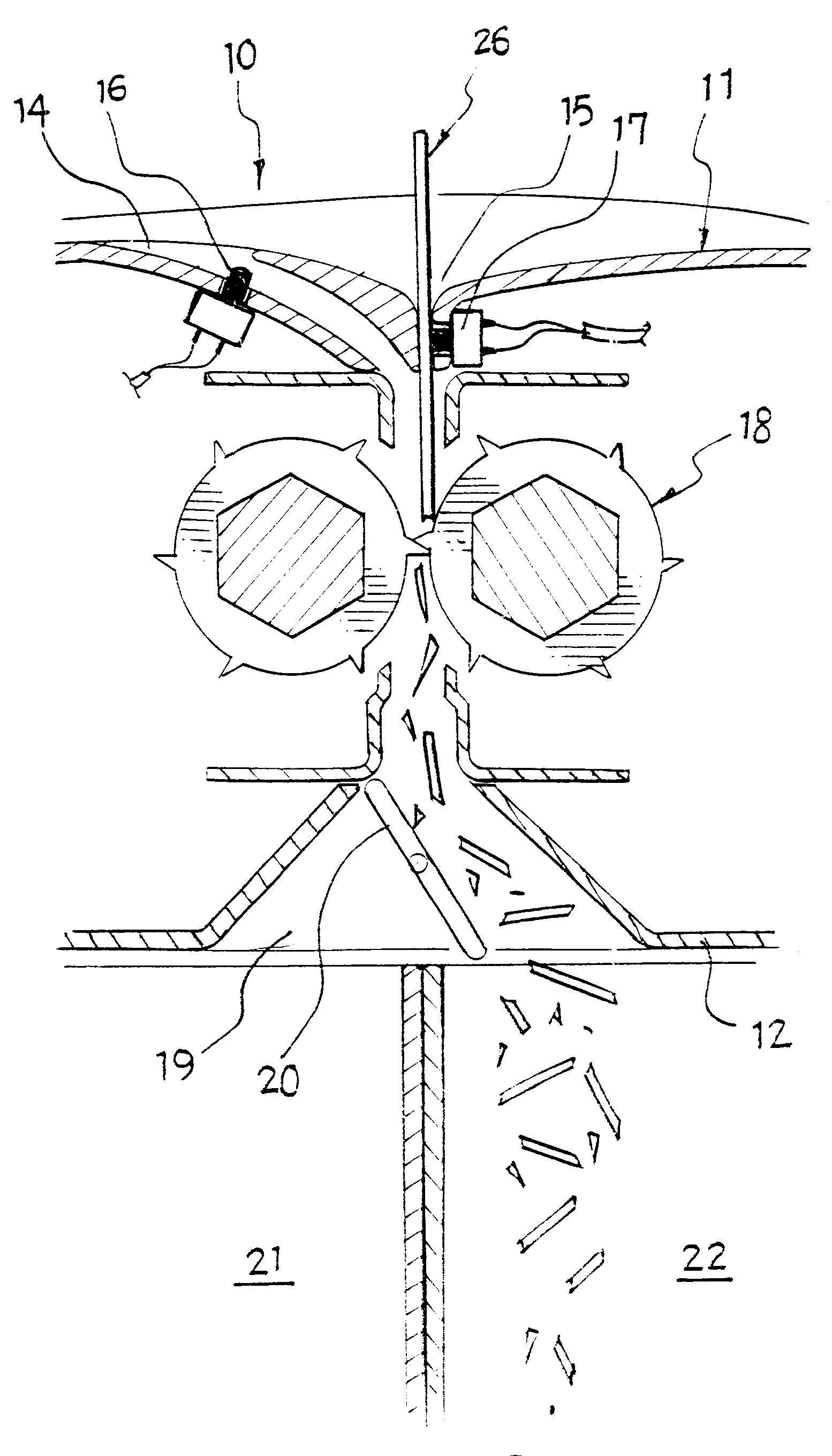

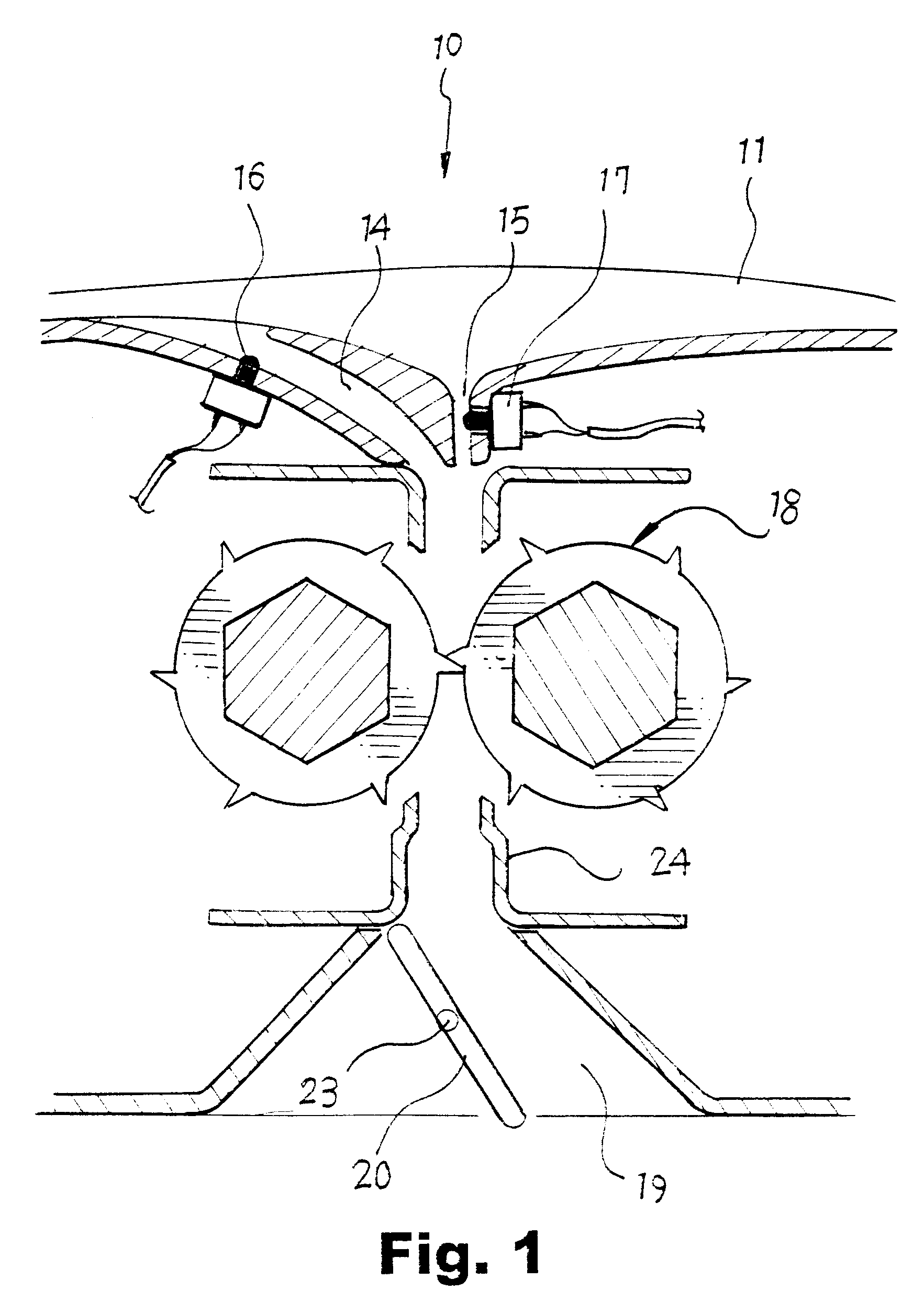

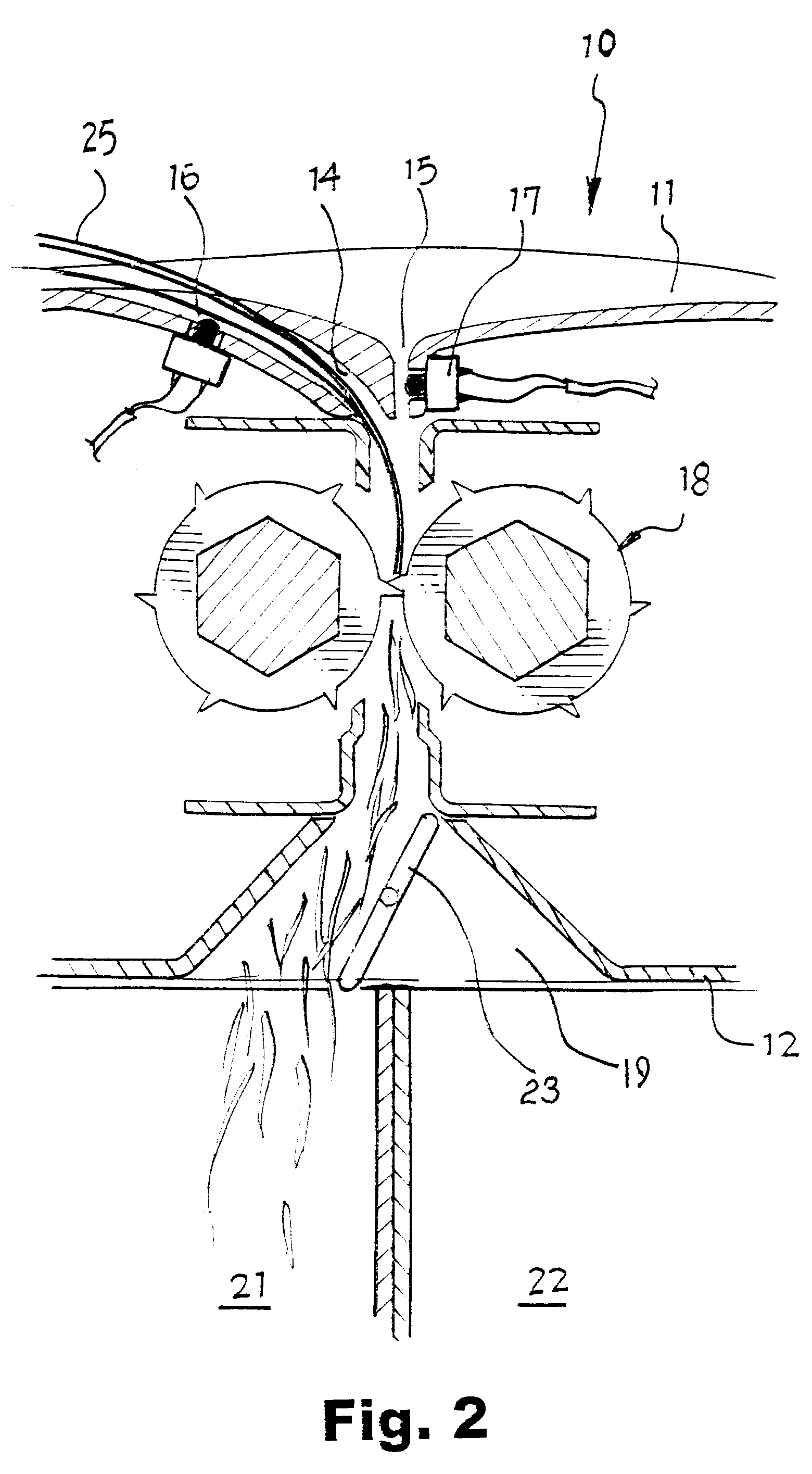

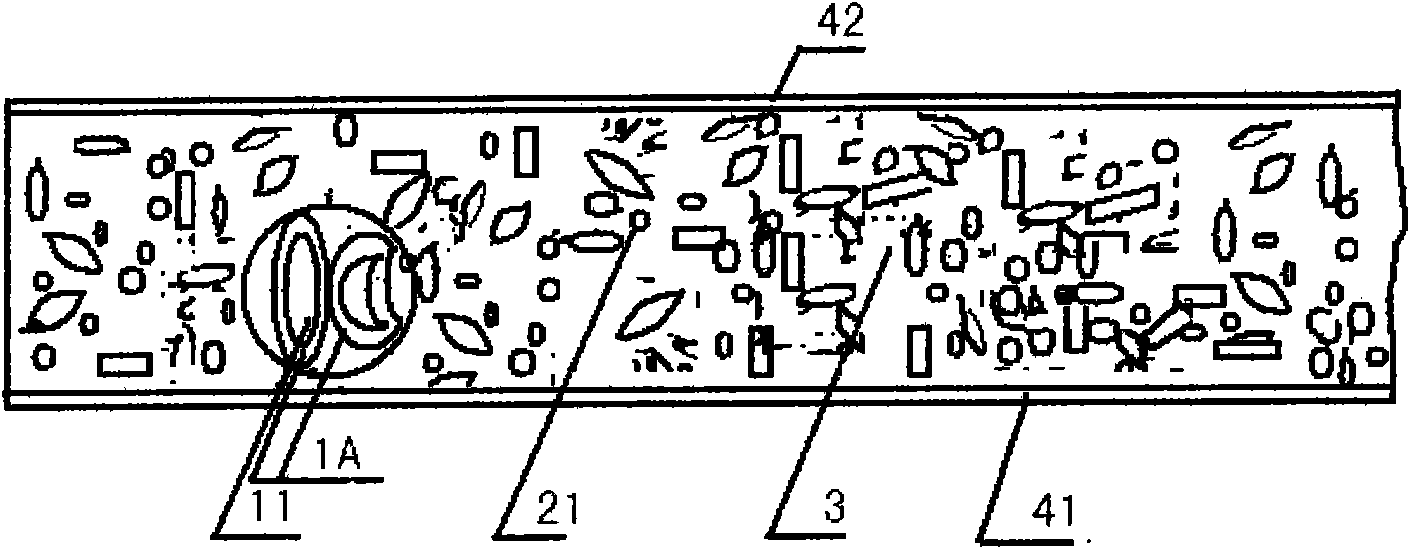

Dual-functional medium shredding machine structure

This invention is related to a dual-functional medium shredding machine structure, specifically designed for shredding or destroying paper printed with data to be destroyed, optical discs containing data to be destroyed, or expired credit cards. This invention mainly implements a pair of shredding roller blades with sharp teeth as shredding means, and is characterized by providing separate feeding inports, including a paper inport for feeding paper in an inclined orientation, and a disc inport for feeding discs in a vertical orientation, wherein the inports are each led to the same shredding roller blades such that, regardless of the type of substance being fed by the user, the paper or the discs can both be shredded by the shredding roller blades, and the shredded scraps are dispensed to separate collectors through an identical exit by means of an auto-revolving switch plate; and a touch switch at each of the inports such that, while feeding the paper or the discs, the touch switch activates the shredding roller blades to perform shredding task, and drives the switch plate so as to dispense shredded scraps of different substance into different collectors.

Owner:MICHILIN PROSPERITY

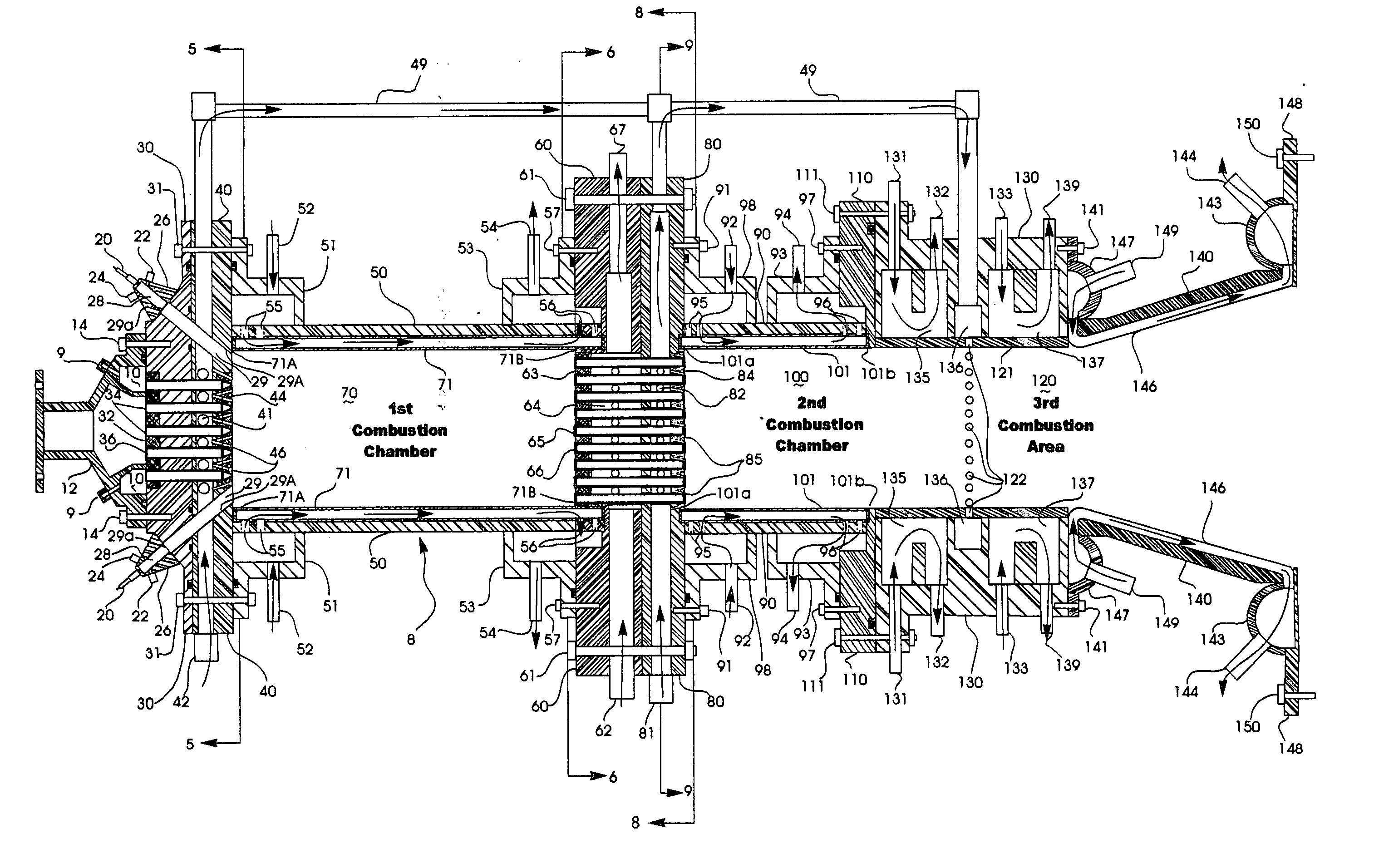

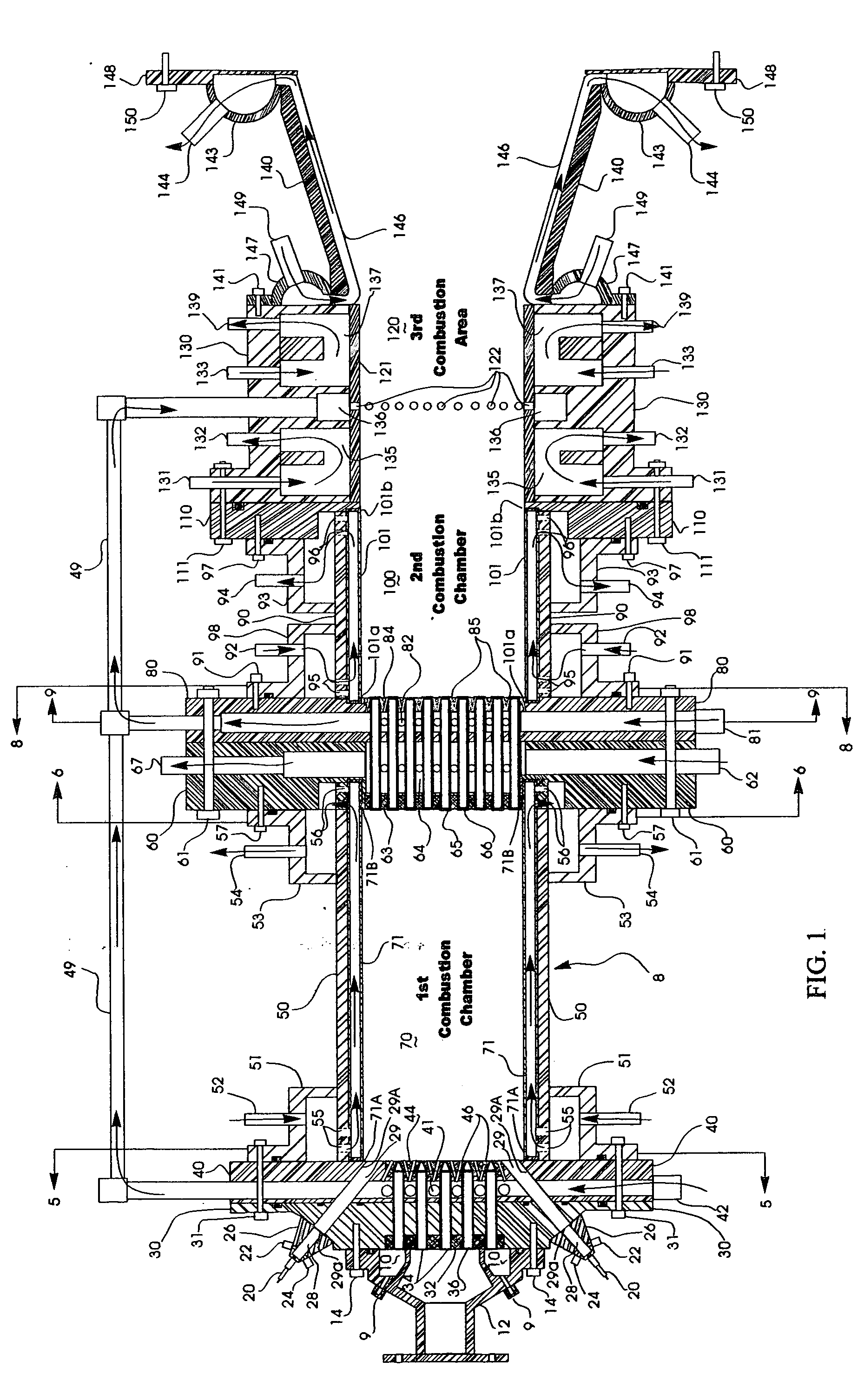

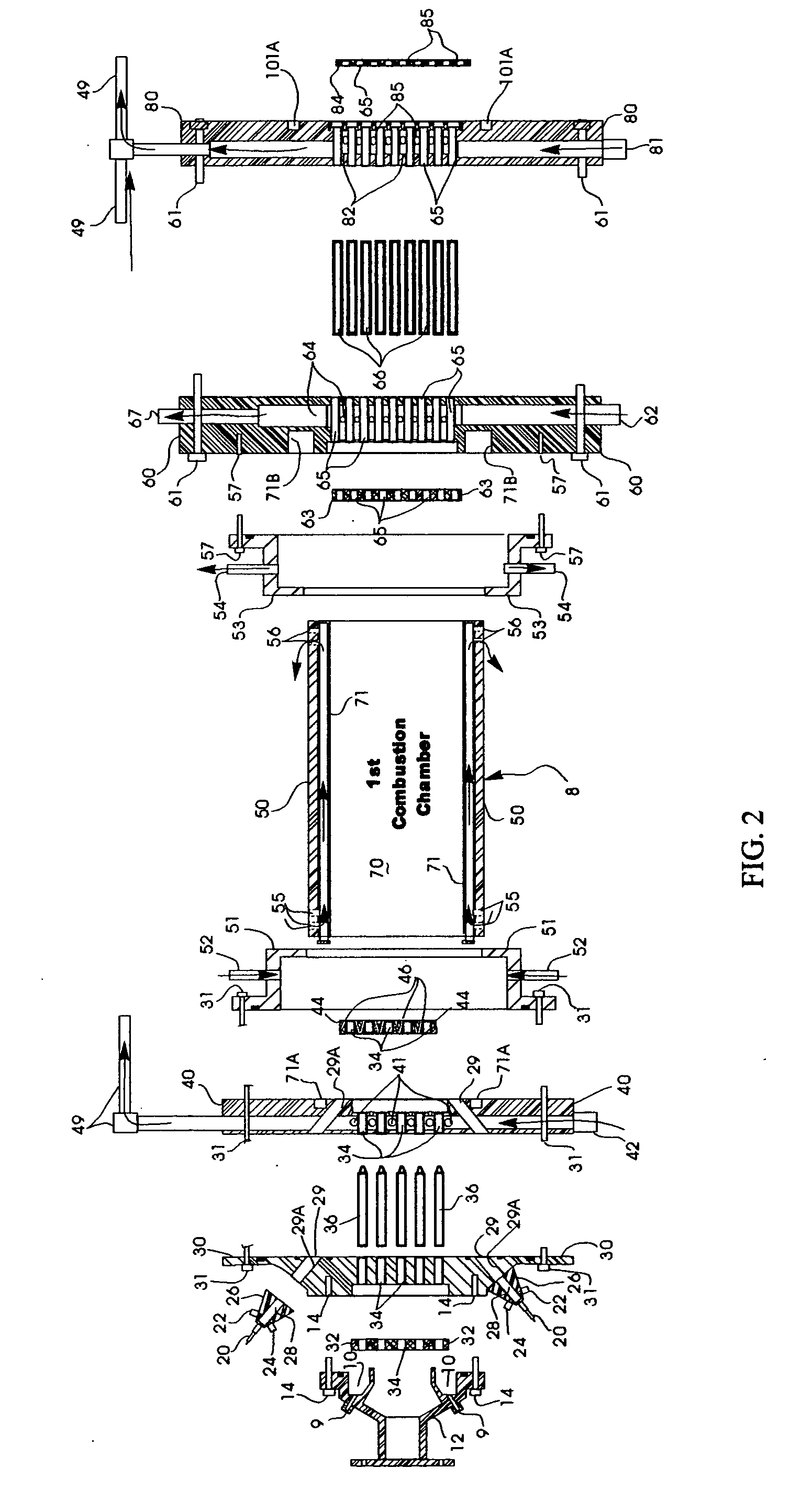

Method and apparatus for the production of energy

ActiveUS20060053791A1Zero atmospheric emissionSafely and rapidly and cost-effectively and efficiently producing and controlling high-energy and high purityIndirect carbon-dioxide mitigationCasings/liningsScrapElectric energy

The invention provides processes and apparatuses for safely, rapidly, cost-effectively and efficiently producing a superheated steam product or dry saturated steam product that can be employed to generate electrical power, or in other manufacturing and / or non-manufacturing processes, in an environmentally clean manner without causing corrosion to electrical power-generating devices. These processes and apparatuses involve the combustion of one or more fuels containing the elements hydrogen and / or carbon, which can be derived from waste materials, such as the rubber from scrap tires. Water that circulates around one or more combustion chambers and / or areas, but that does not enter into the combustion chambers or areas, becomes converted into a high purity steam product The present invention also provides processes and apparatuses for recycling or eliminating waste materials, and for transforming hazardous materials into non-hazardous materials, and fuels that can be employed in the foregoing processes and apparatuses.

Owner:ADVANCED COMBUSTION ENERGY SYST

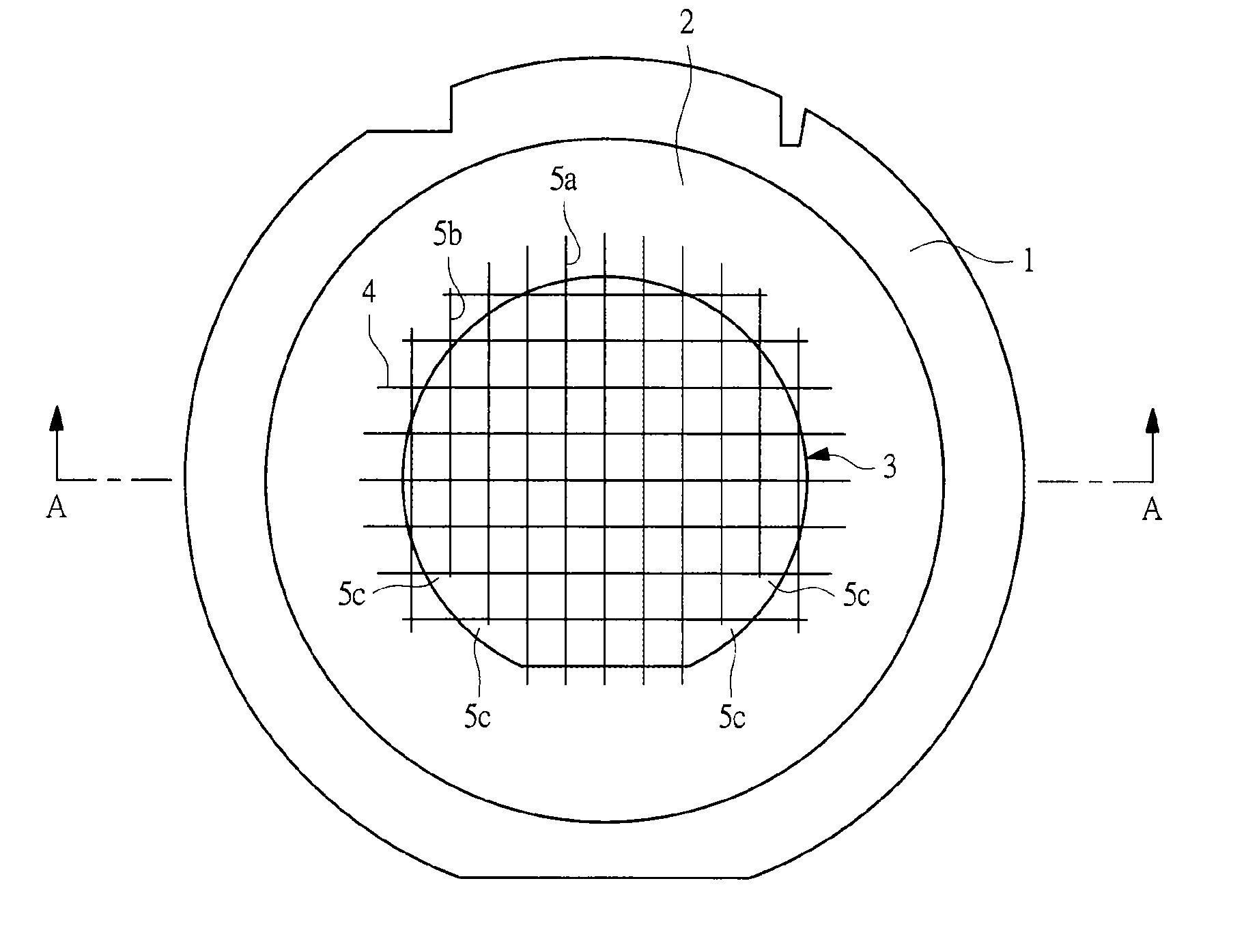

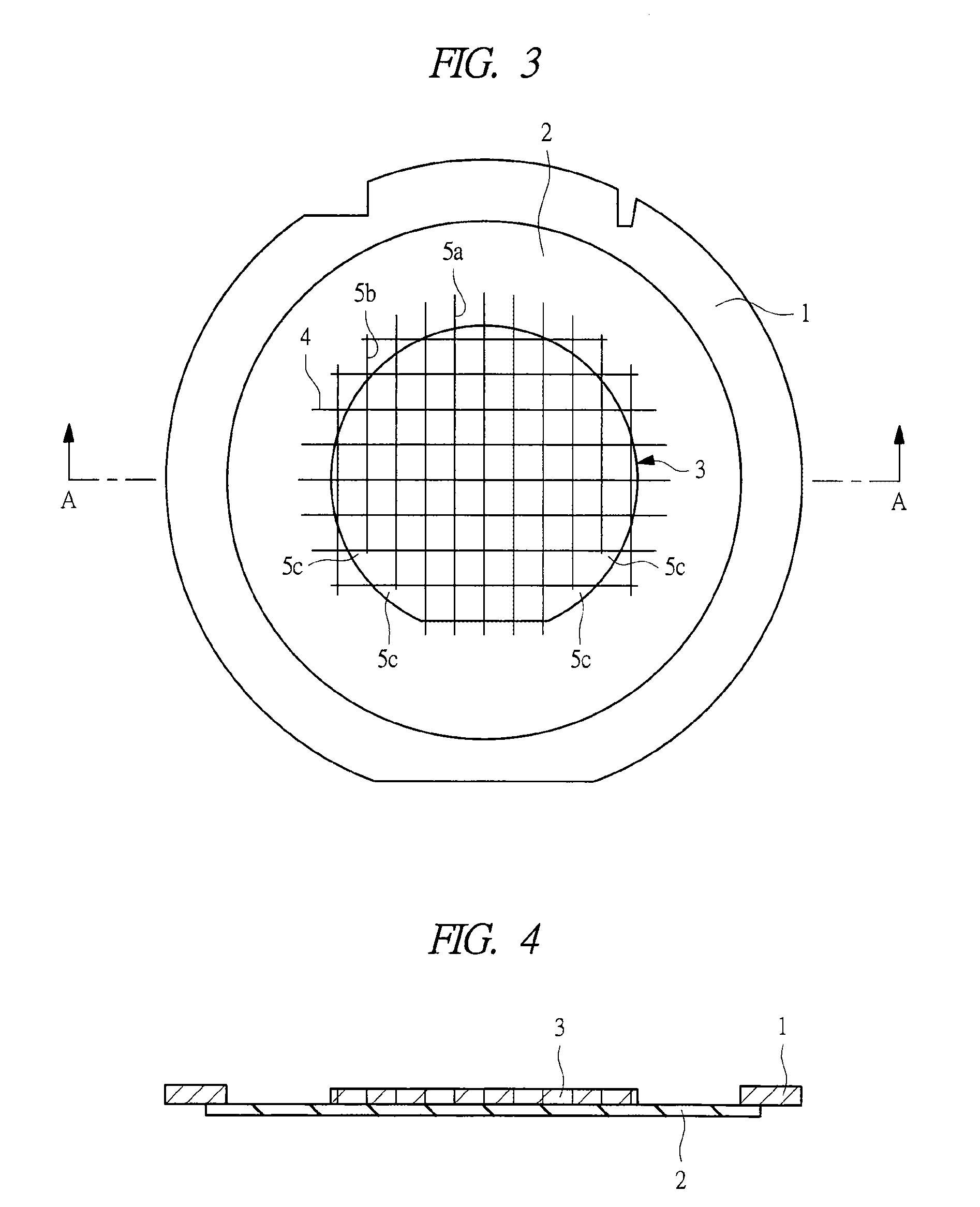

Method for fabricating semiconductor device

ActiveUS20090162993A1Small sizeLower manufacturing yieldSemiconductor/solid-state device manufacturingFine working devicesSemiconductorSemiconductor device

An object is to provide a technology capable of improving a manufacturing yield of semiconductor devices by preventing scattering of irregular-shaped scraps formed at the time of dicing. To achieve the above object, for dicing lines, by which an irregular-shaped outer periphery may possibly be cut off, among a plurality of dicing lines, formation of the dicing lines starts from an outside of a semiconductor wafer, and after the semiconductor wafer is cut off partway, formation of the dicing lines is ended before reaching the irregular-shaped outer periphery formed on a outer periphery of the semiconductor wafer. For other dicing lines, formation of the dicing lines starts from the outside of the semiconductor wafer, and after the semiconductor wafer is cut off, is ended outside the semiconductor wafer.

Owner:RENESAS ELECTRONICS CORP

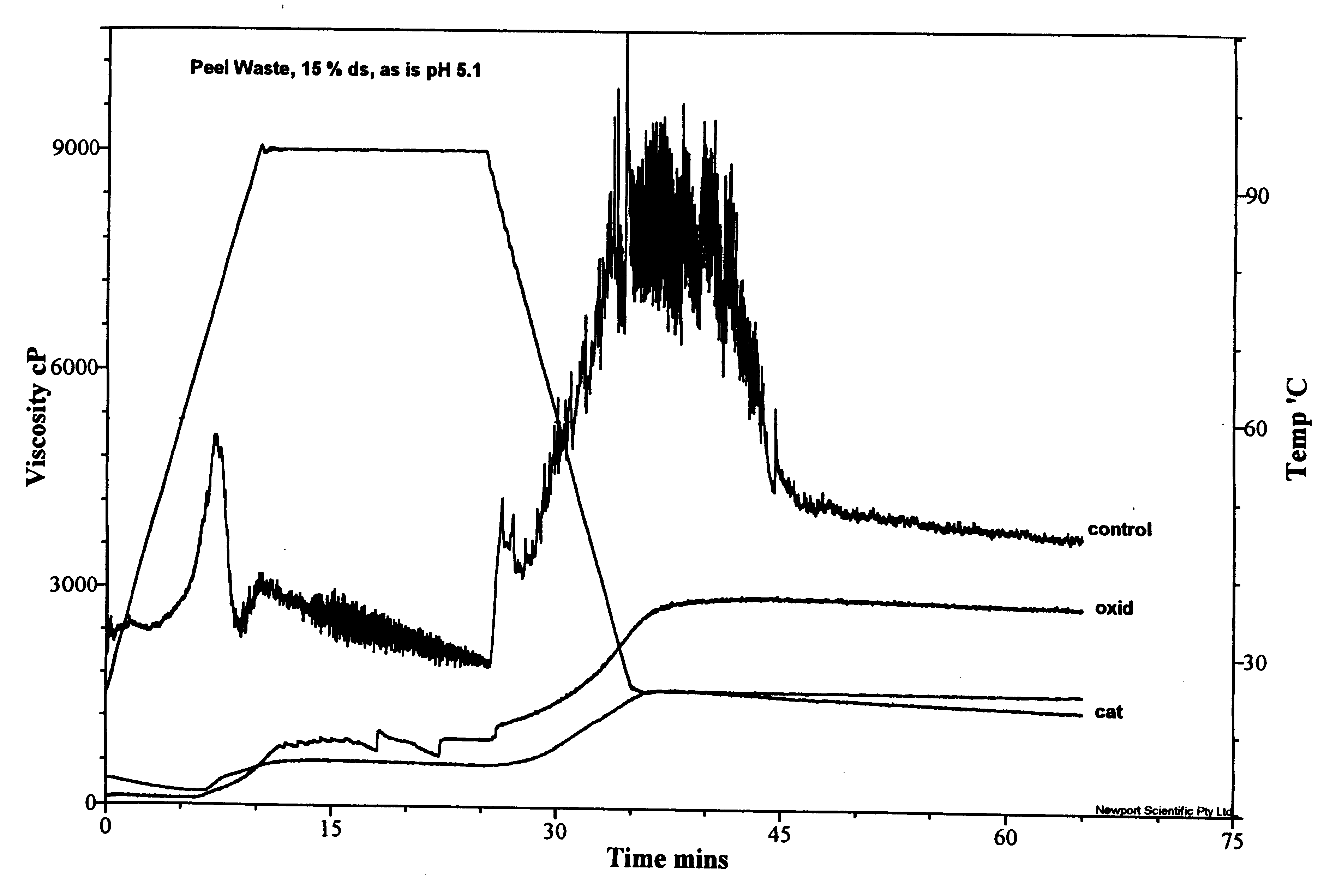

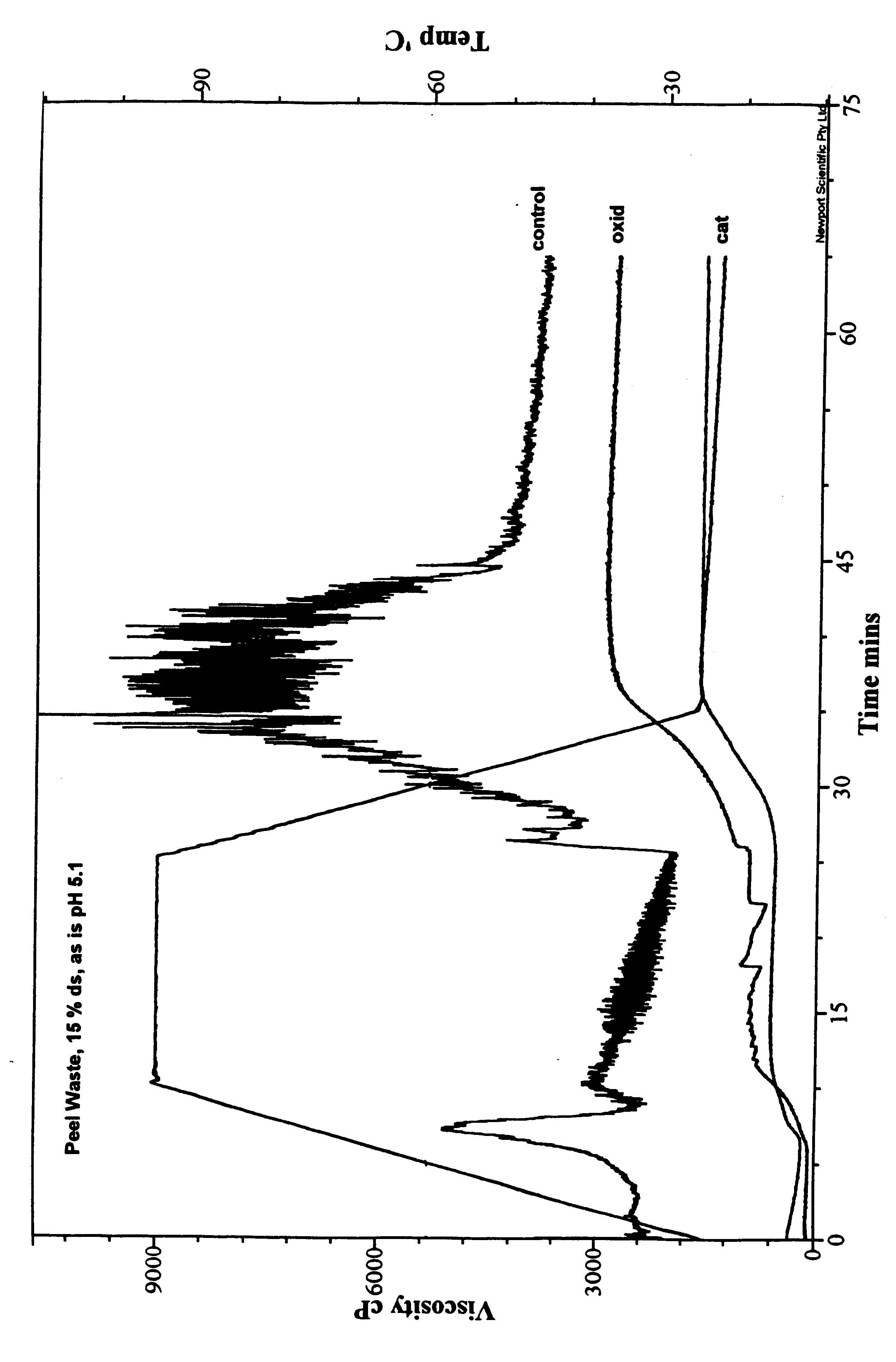

Packaging and structural materials comprising potato peel waste

InactiveUS6440204B1Inhibit migrationImprove stabilityProtein waste adhesivesLayered productsFiberAdhesive

Owner:HARRIS TRUST & SAVINGS BANK AS ADM AGENT +1

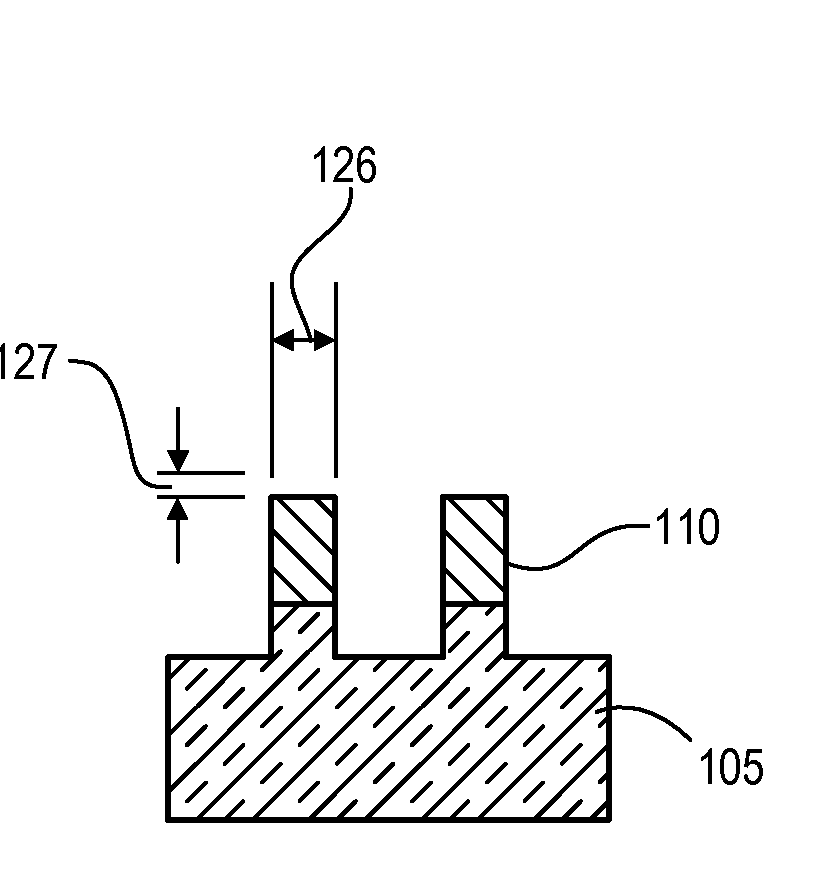

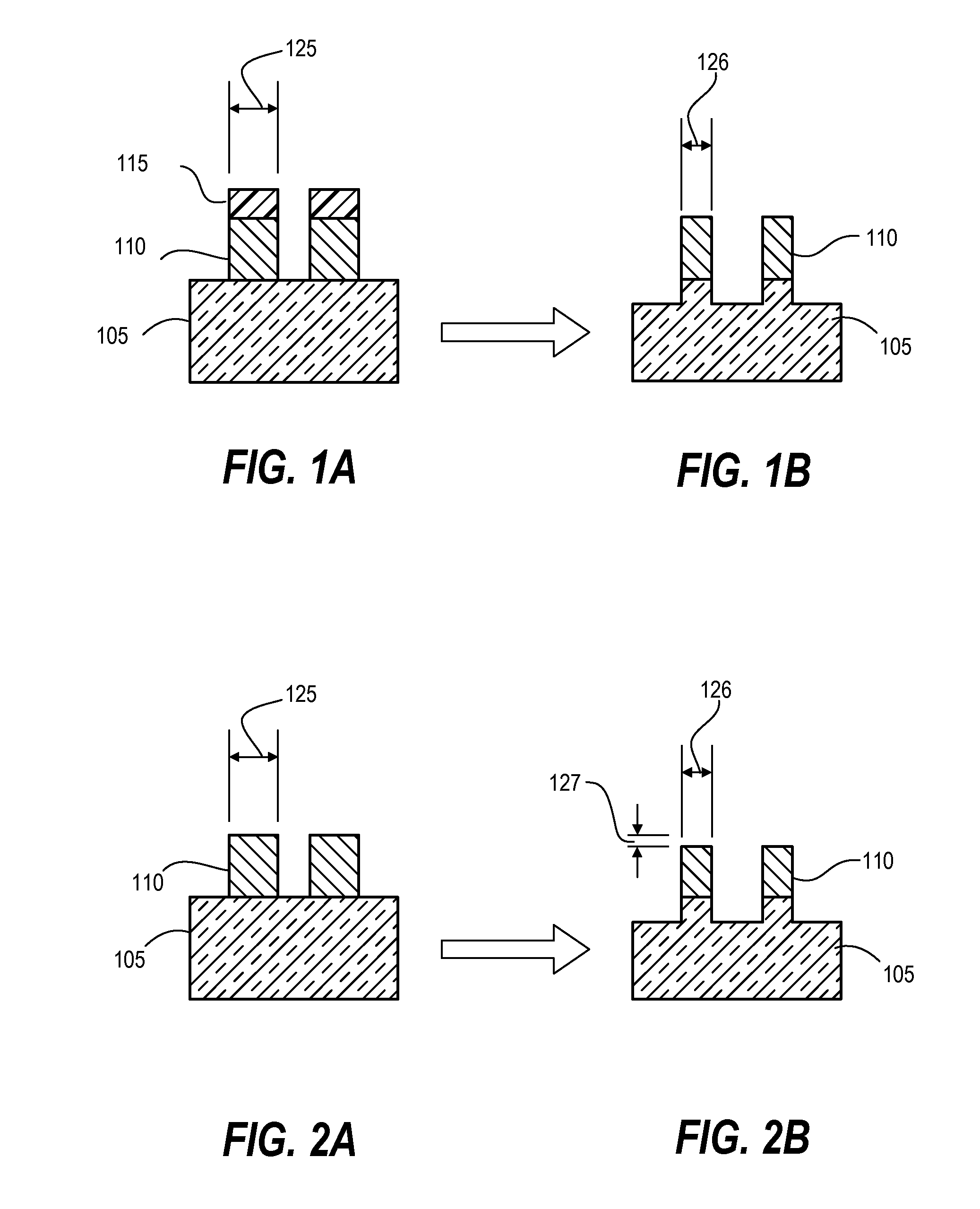

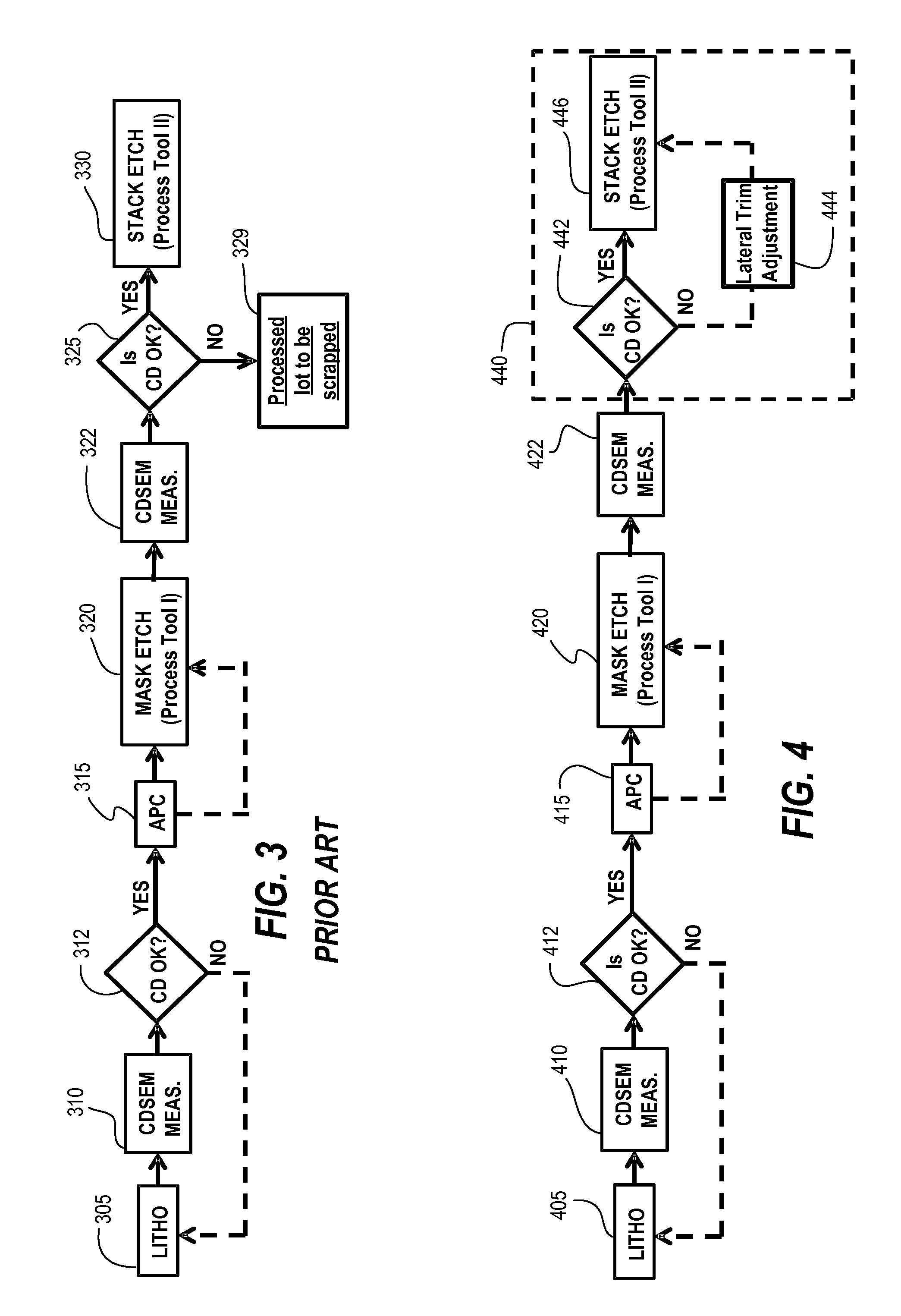

Method for Laterally Trimming a Hardmask

ActiveUS20150064918A1Reduce decreaseReduced dimensionSemiconductor/solid-state device manufacturingDielectricFluorocarbon

Techniques herein include methods for controllable lateral etching of dielectrics in polymerizing fluorocarbon plasmas. Methods can include dielectric stack etching that uses a mask trimming step as part of a silicon etching process. Using a fluorocarbon mixture for dielectric mask trimming provides several advantages, such as being straightforward to apply and providing additional flexibility to the process flow. Thus, techniques herein provide a method to correct or tune CDs on a hardmask. In general, this technique can include using a fluorine-based and a fluorocarbon-based, or fluorohydrocarbon-based, chemistry for creating a plasma, and controlling a ratio of the two chemistries. Without the hardmask trim method disclosed herein, if a hardmask CD is not on target, then a wafer is scrapped. With hard-mask trim capability in silicon etch as disclosed herein, a given CD can be re-targeted to eliminate wafer-scraps.

Owner:TOKYO ELECTRON LTD

Environment-friendly light heat-insulating material and manufacturing method thereof

The invention relates to an environment-friendly light heat-insulating material for fireproof doors and buildings, and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: pretreating plant hollow core bodies and / or flexible porous fillers by using a water glass adhesive; mixing with inorganic fire-resistant hollow particles; and performing mould pressing, shaping and drying to obtain the environment-friendly light heat-insulating material. The hollow core bodies and the flexible porous fillers are arranged multidirectionally; one layer of water glass adhesive is arranged at least on the surfaces of the hollow core bodies and the flexible porous fillers; and discontinuous holes are reserved between the hollow core bodies and / or the flexible porous fillers and the inorganic fire-resistant hollow particles. Preferably, the hollow core bodies are rice husks and straw sections; and the flexible porous fillers are foam and fibers. Renewable plant resources and recovered foam and fiber waste are adopted, so the environment-friendly light heat-insulating material is energy-saving and environment-friendly; and a large number of sealed holes are formed among the material particles through the penetration and coating of the modified water glass adhesive, and a heat-insulating hydrophobic corrosion-resistant multi-effect protective layer is provided, so the environment-friendly light heat-insulating material has good fireproof, heat-insulating and heat-preserving effects, high weather resistance, combined rigidity and toughness, low density and low cost.

Owner:重庆恒宏致嘉全过程建设项目管理有限公司

Method for recovering rare earth from rare earth-containing aluminum-silicon materials

ActiveCN101705380AAvoid enteringLess fixed investmentProcess efficiency improvementMolecular sieveSelective leaching

The invention relates to a method for recovering rare earth from rare earth-containing aluminum-silicon materials, which comprises the following steps: taking the rare earth-containing aluminum-silicon materials including rare earth-loaded molecular sieves, catalyst wastes, and the like as raw materials, conducting prioritized selective leaching by acid so as to lead the majority of the rare earth and a small amount of aluminum to be dissolved and separated from silicon and other impurities, leading the rare earth to form precipitates and be separated from the aluminum by adopting a double salt precipitation or oxalate precipitation method, and then recovering and purifying the rare earth. The method has the advantages of directly realizing the extraction of the rare earth from the aluminum-silicon materials including the molecular sieves and the like, with over 98% purity of the obtained rare earth, and avoiding impurities such as aluminum, silicon and the like entering the rare earth; and meanwhile, the technology also has the characteristics of little fixed investment, low production cost and easiness for realizing industrialized production.

Owner:GRIREM ADVANCED MATERIALS CO LTD

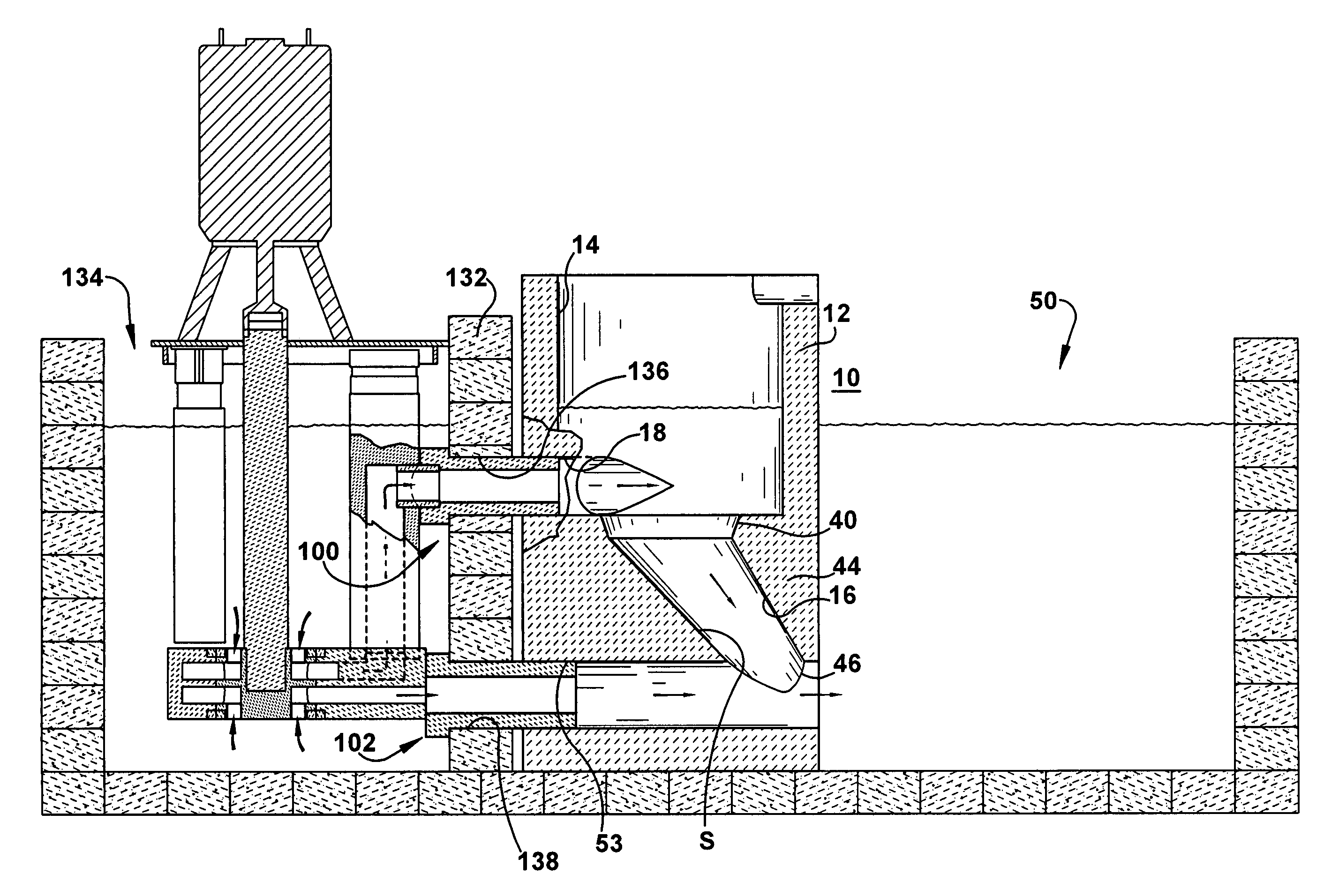

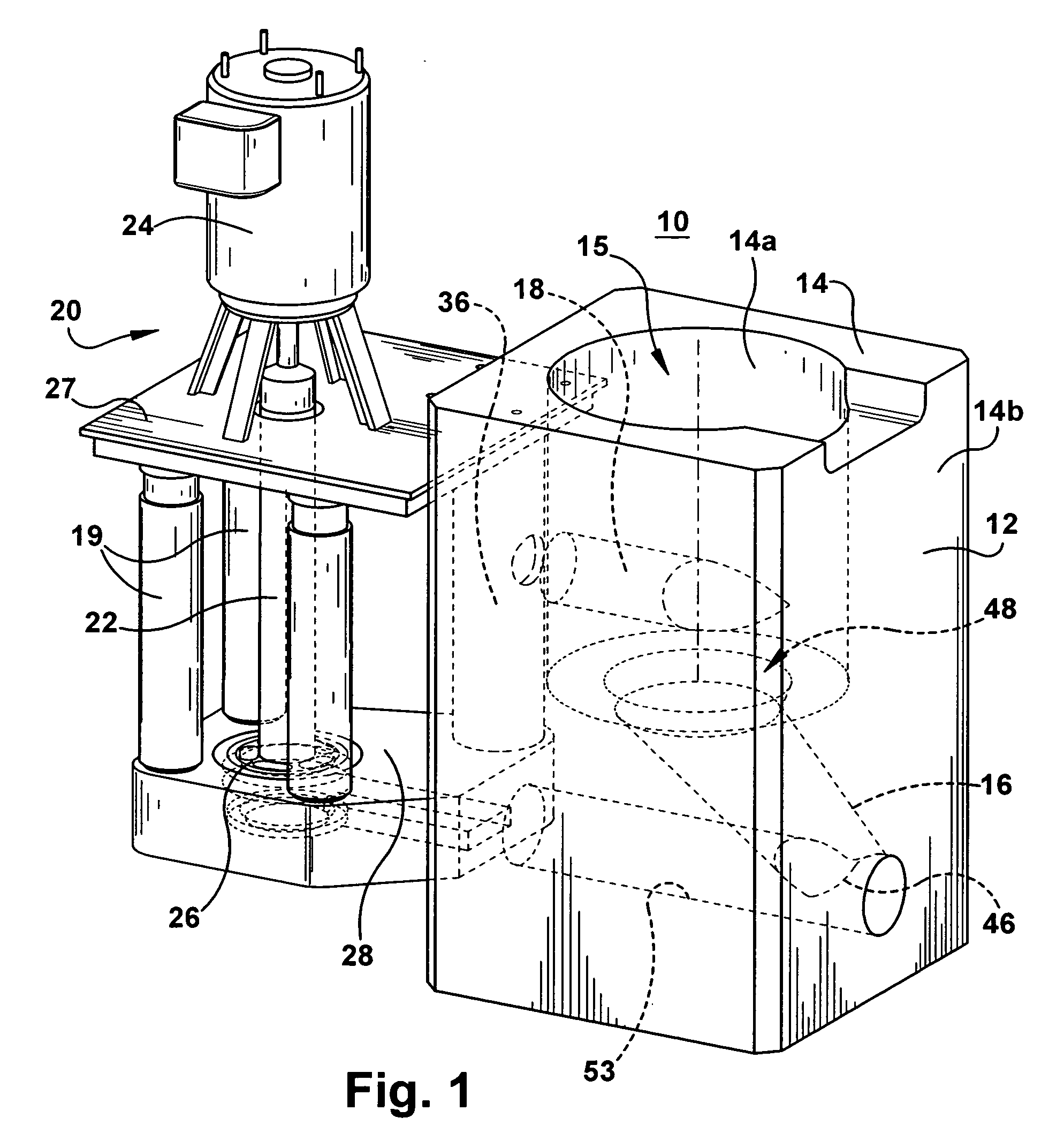

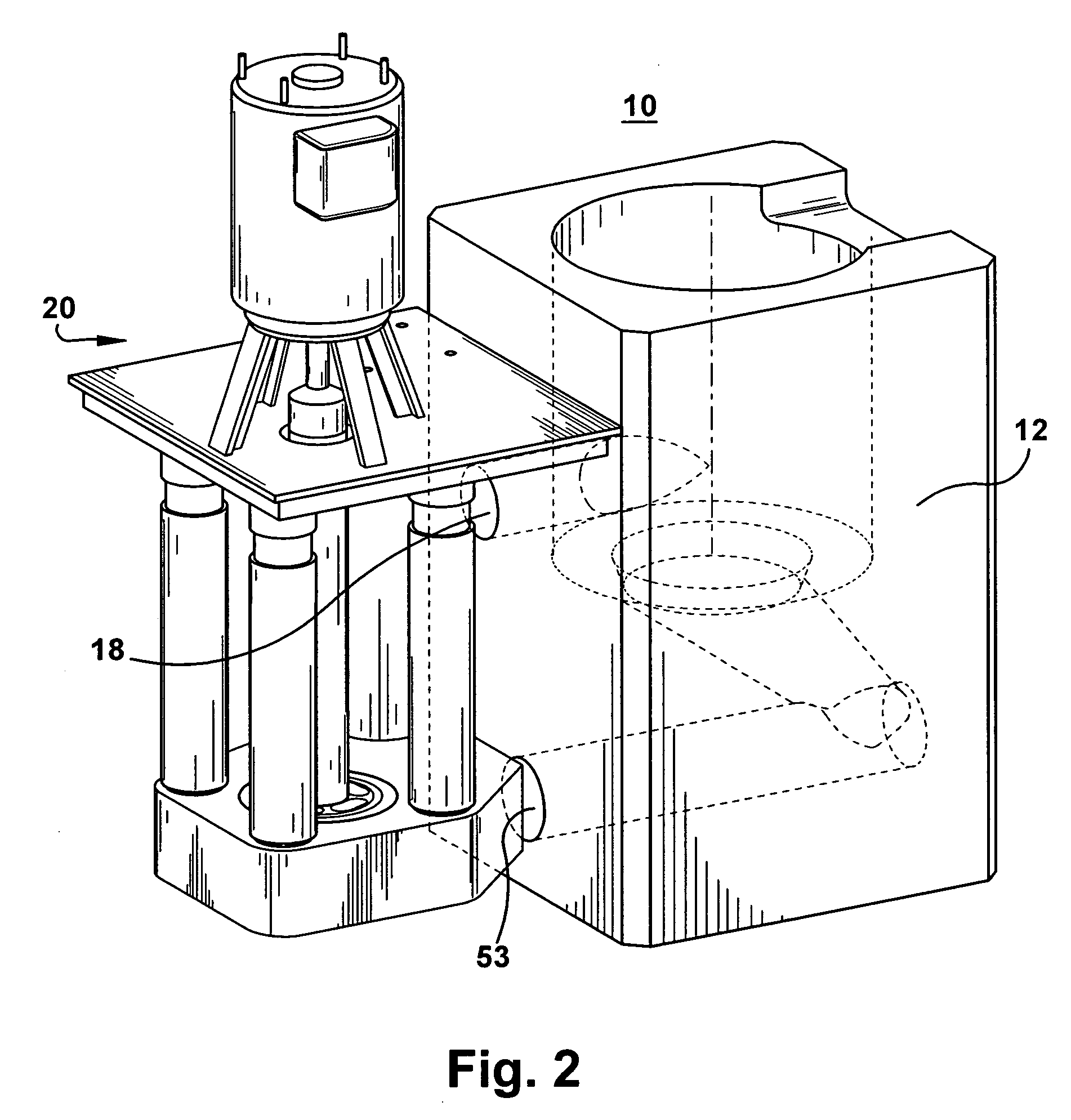

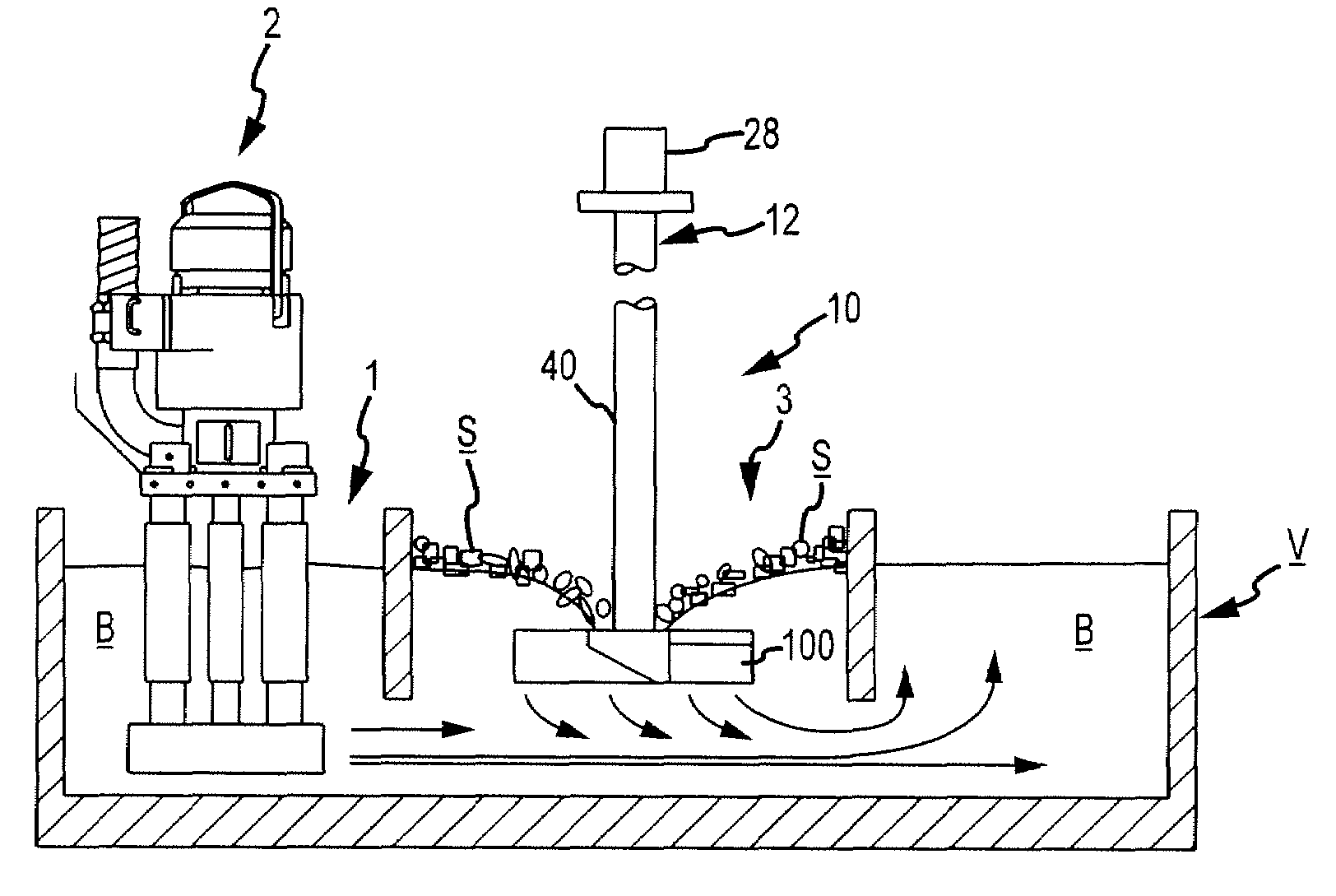

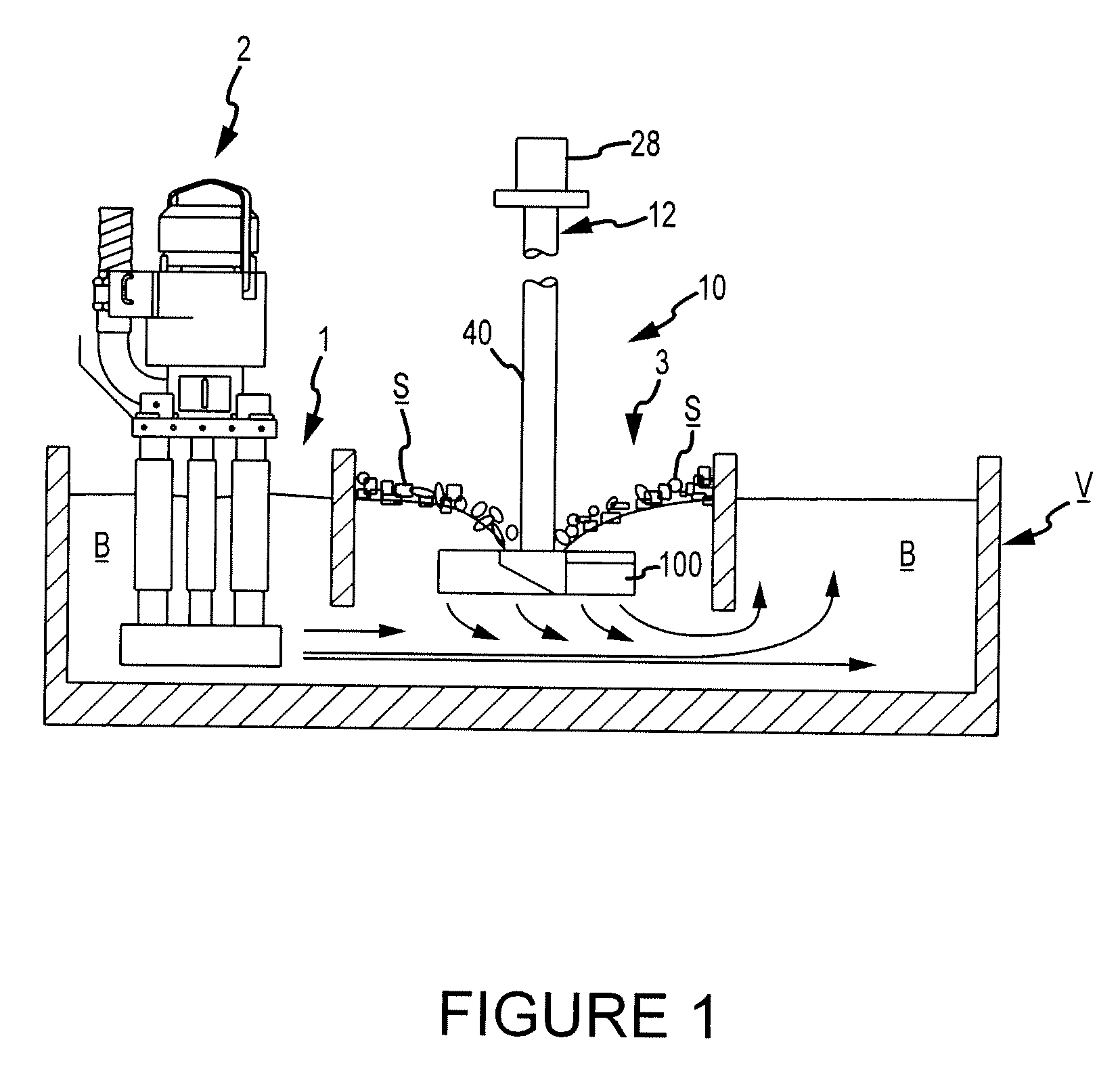

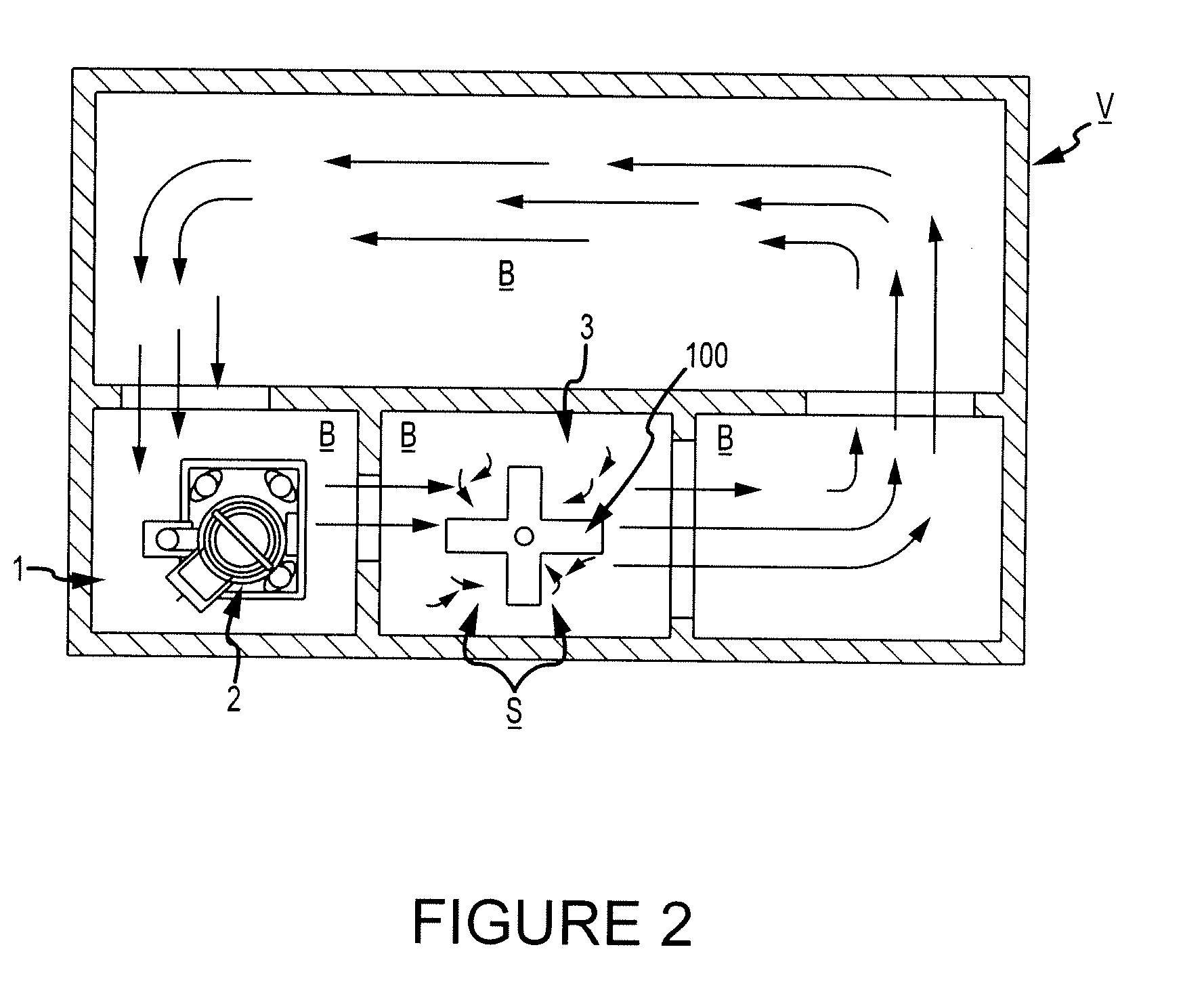

Vortexer apparatus

ActiveUS20060180963A1Facilitates submergence and meltingMaintain temperatureStirring devicesCharge manipulationImpellerPositive pressure

The present invention features a vortexer apparatus including a vessel comprising an exterior surface, an interior surface containing fluid and a mouth for receiving material at an upper end portion of the interior surface. In one application the material is metal scrap that is melted in molten metal as the fluid. All components that contact the molten metal are formed of refractory material. An outlet passageway extends downwardly from the interior surface. A vessel inlet opening is located between the exterior and interior surfaces above the outlet passageway. A center line passes through a center of the interior surface and the vessel inlet opening is disposed at a location offset from the center line. A pump is adapted to pump fluid into the vessel effective to form a vortex of fluid in the vessel. The base and impeller are configured and arranged effective to provide molten metal leaving the base outlet with a positive pressure. An outlet conduit extends from the base outlet to near the vessel inlet opening and can be maintained at a temperature above which molten metal solidifies, along its entire length. Instead of the vortexer vessel, the inventive vortexer apparatus may integrate a chamber of a furnace (e.g., a charge well). The chamber may be rectangularor include arcuate portions. Corner inserts may be used to provide the chamber with an oval or generally circular shape that may facilitate the vortex. One feature of the invention is a vortex vessel that includes an offset inlet opening and lower circulation opening. Also featured is a baffle impeller that may be vaned or barrel type. In addition, the invention features a pump having upper and lower impeller chambers separated by a web in the base, and impeller outlets that are isolated from fluid communication with each other.

Owner:THUT BRUNO H

Cement-based composite material used for 3D printing technology as well as preparation method and application thereof

ActiveCN104310918AEasy to get materialsLow costSolid waste managementHouse buildingConstruction 3D printing

The invention provides a cement-based composite material used for a 3D printing technology as well as a preparation method and application thereof. The cement-based composite material is prepared from the following raw materials based on the total weight of the composite material: 33%-40% of cement, 0%-8% of inorganic powder, 32%-38% of tailing machine-made sand, 2.5%-3% of a high-molecular polymer, 0.1%-0.5% of a water reducing agent and 16.7%-20% of mixing water; a composite thickening time control agent, a thixotropic agent, a volume stabilizer and the like are added into a mixture to prepare an inorganic composite material; and then the inorganic composite material can be directly pumped into a 3D printer for building to be applied to construction. The cement-based composite material is an inorganic material and the materials are easily available; a lot of industrial waste materials can be used; therefore, the cement-based composite material is low in cost, energy-saving and environment-friendly; the condensation time can be flexibly controlled, and the material has super early strength, good caking property and strong stability; the requirements of 3D printing construction continuity of the building and the building strength are met so that the house building has good global stability and use safety; and the application and popularization of 3D printing technology can be greatly promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

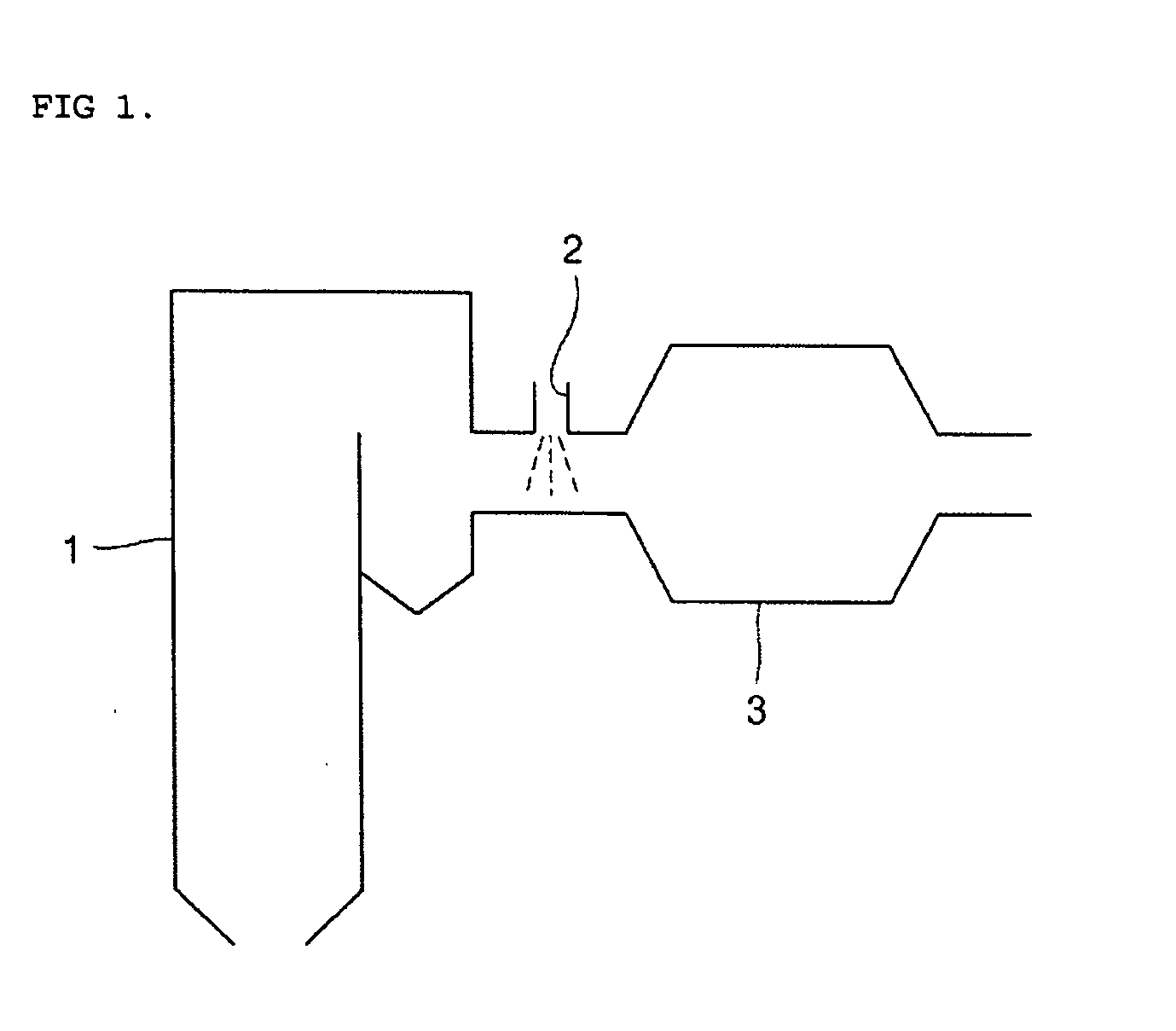

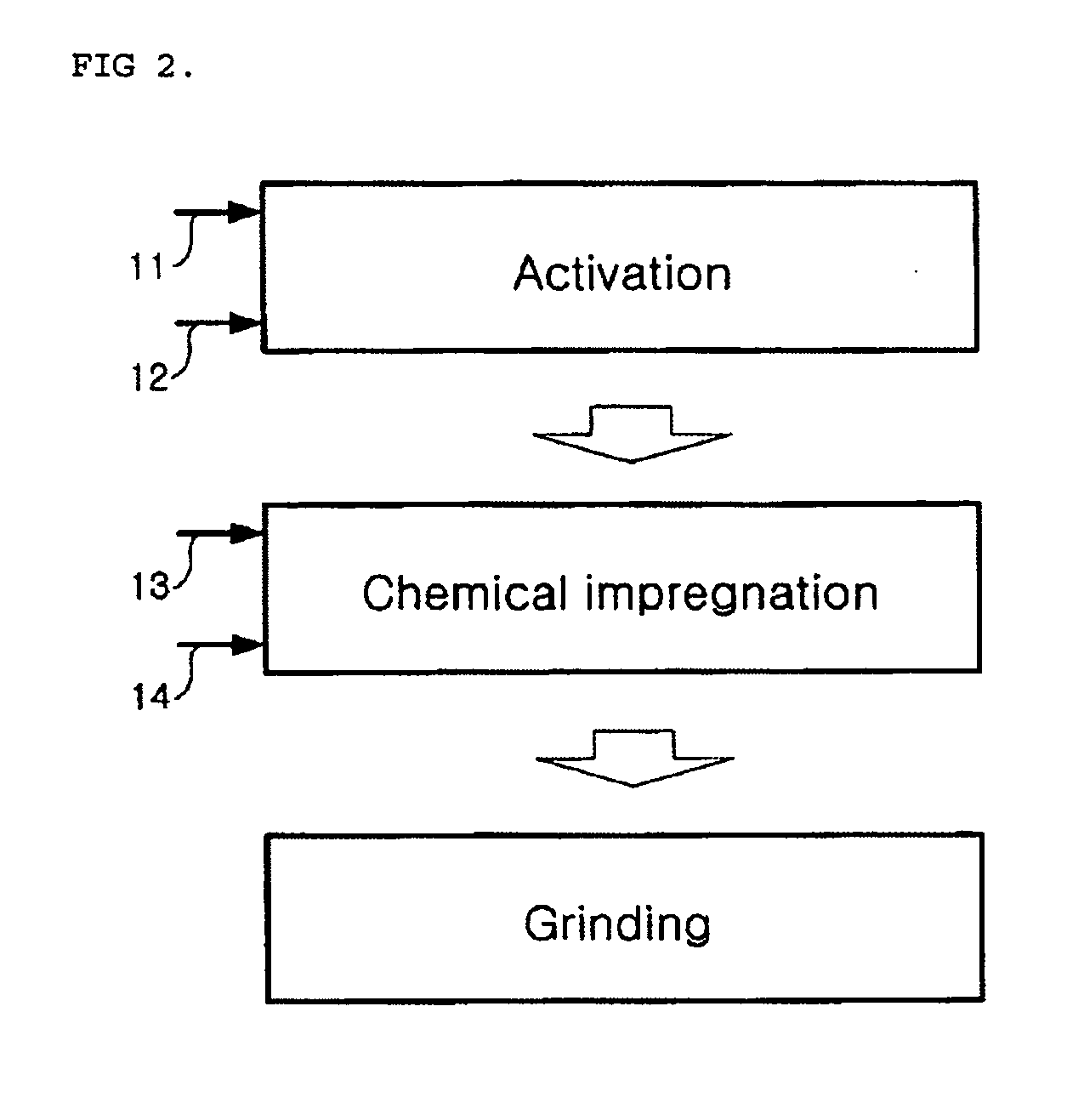

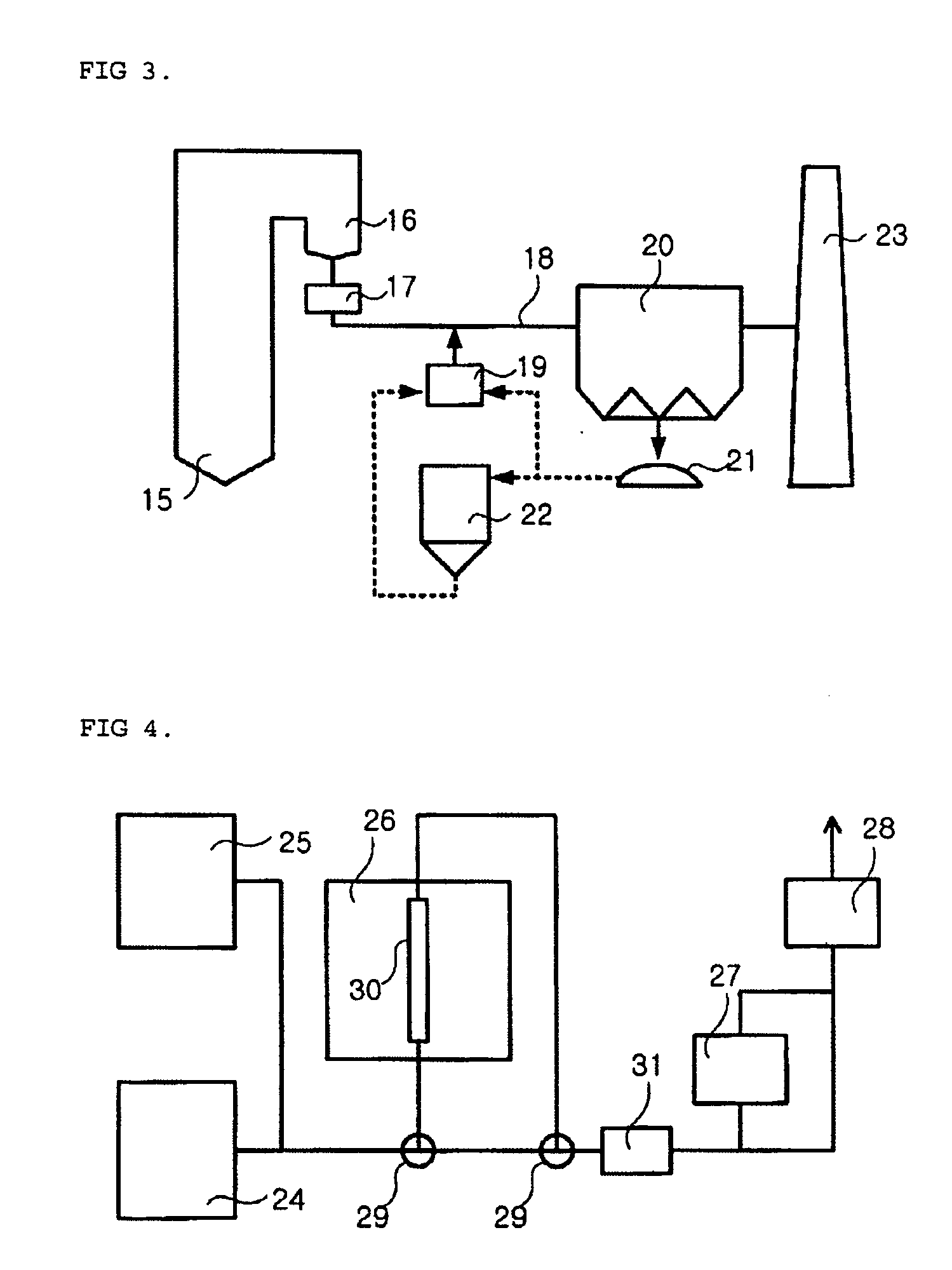

Sorbent for removal of trace hazardous air pollutants from combustion flue gas and preparation method thereof

InactiveUS20070179056A1Low costLow raw material costGas treatmentOther chemical processesSorbentToxic industrial waste

Disclosed is a sorbent for the removal of mercury from combustion flue gas and a preparation method thereof. The sorbent includes an activated heavy oil heavy ash impregnated with 0.1-30% by weight of any chemical substance selected from sulfur, iodine, bromine and chlorine. The sorbent is prepared in an economical manner using heavy oil fly ash, industrial waste generated from heavy oil-fired boilers, and has excellent sorption performance for mercury, so that a low concentration of mercury contained in combustion flue gas discharged from large-scale boilers can be removed by injection of a small amount of the sorbent. Thus, the invention can prevent a reduction in the recycling rate of coal fly ash in coal-fired power plants and minimize operation cost.

Owner:KOREA ELECTRIC POWER CORP

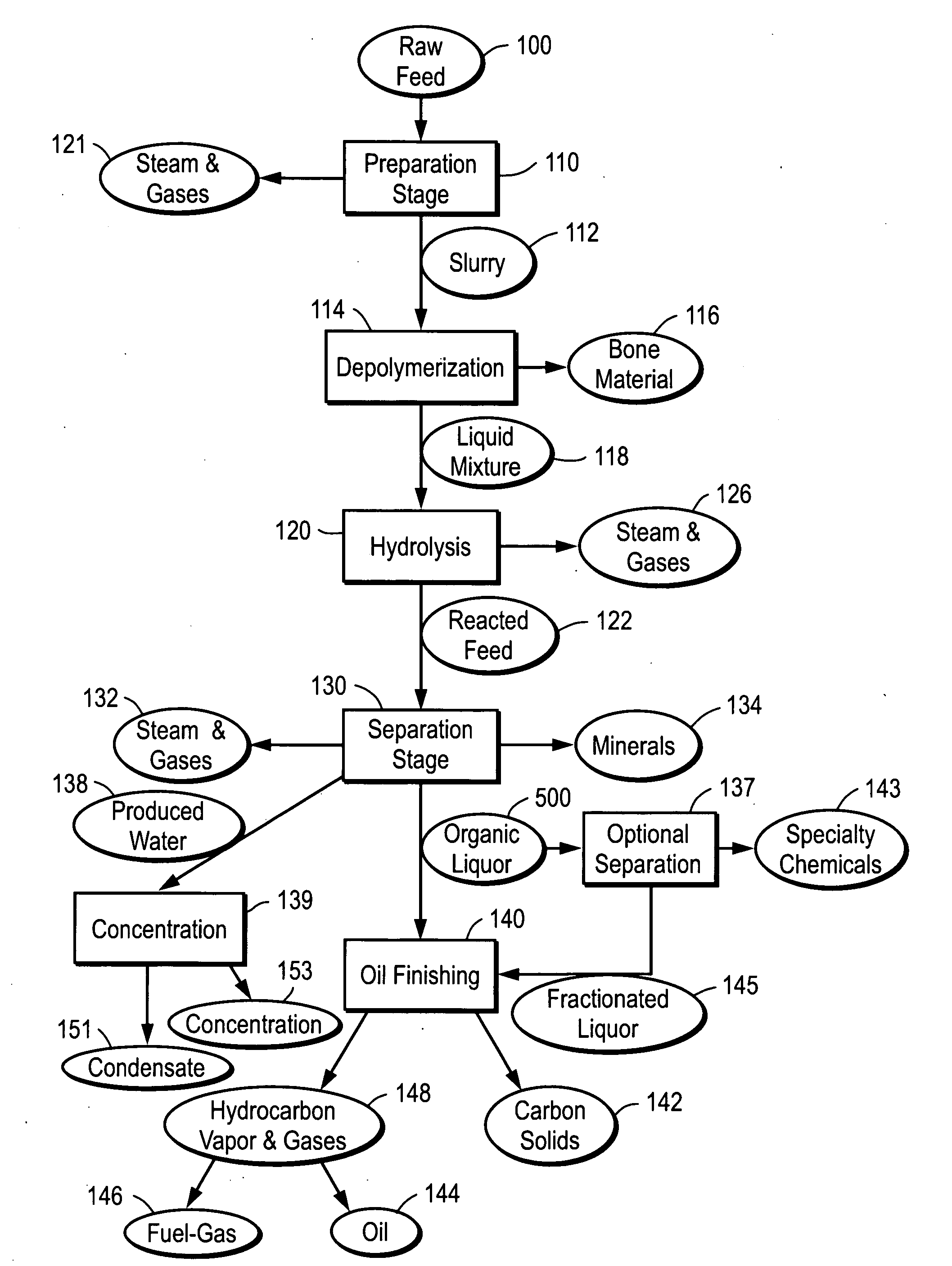

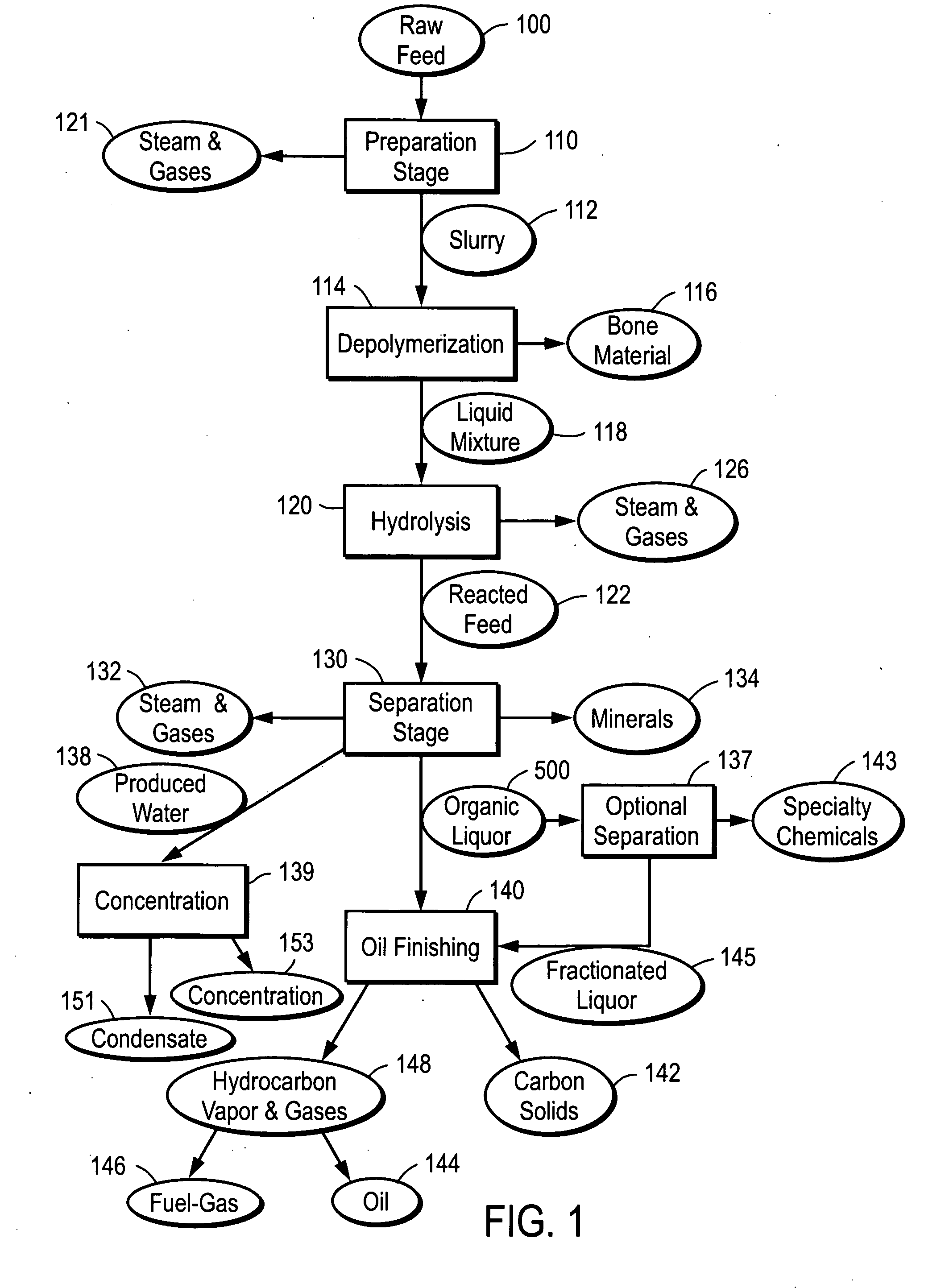

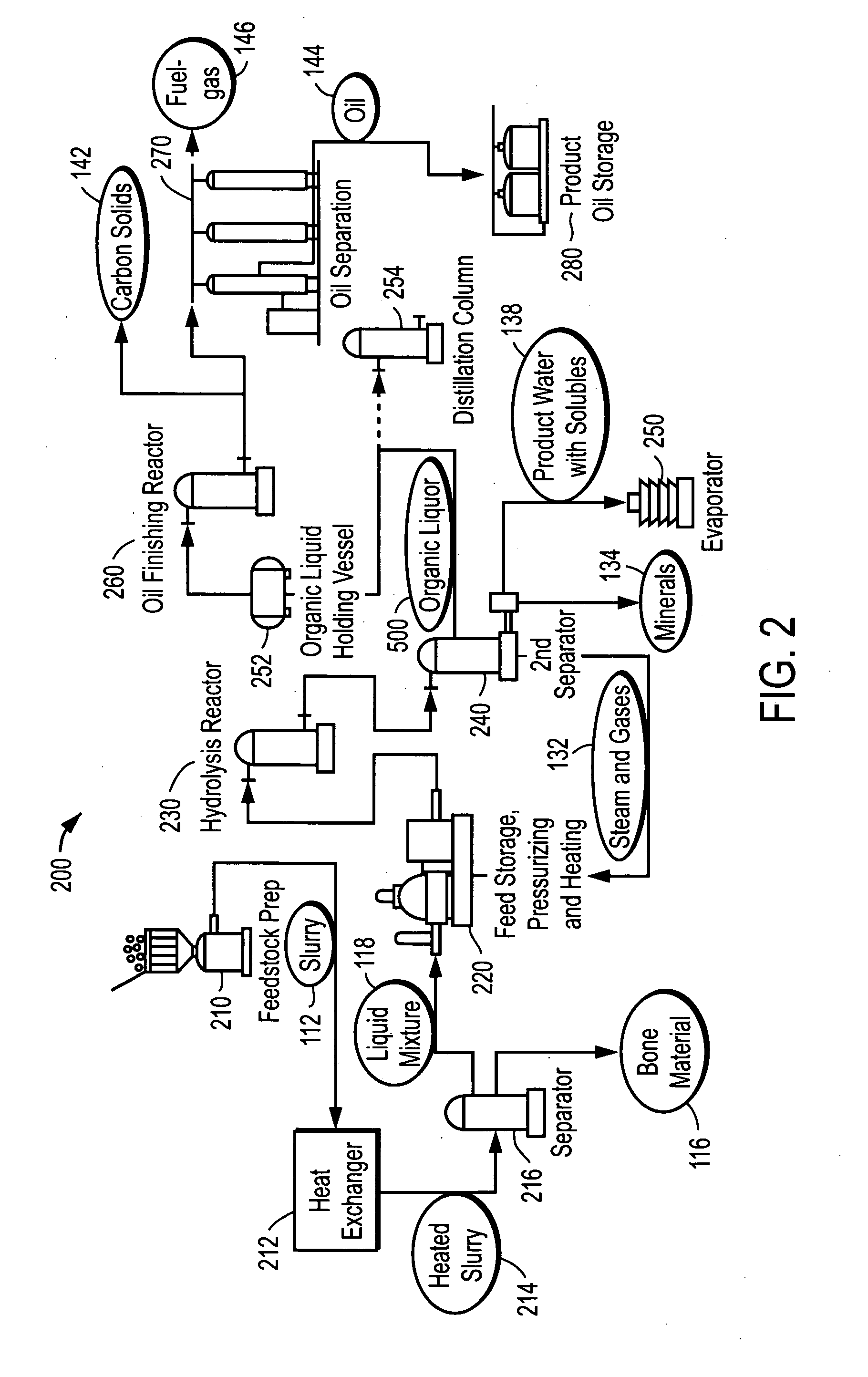

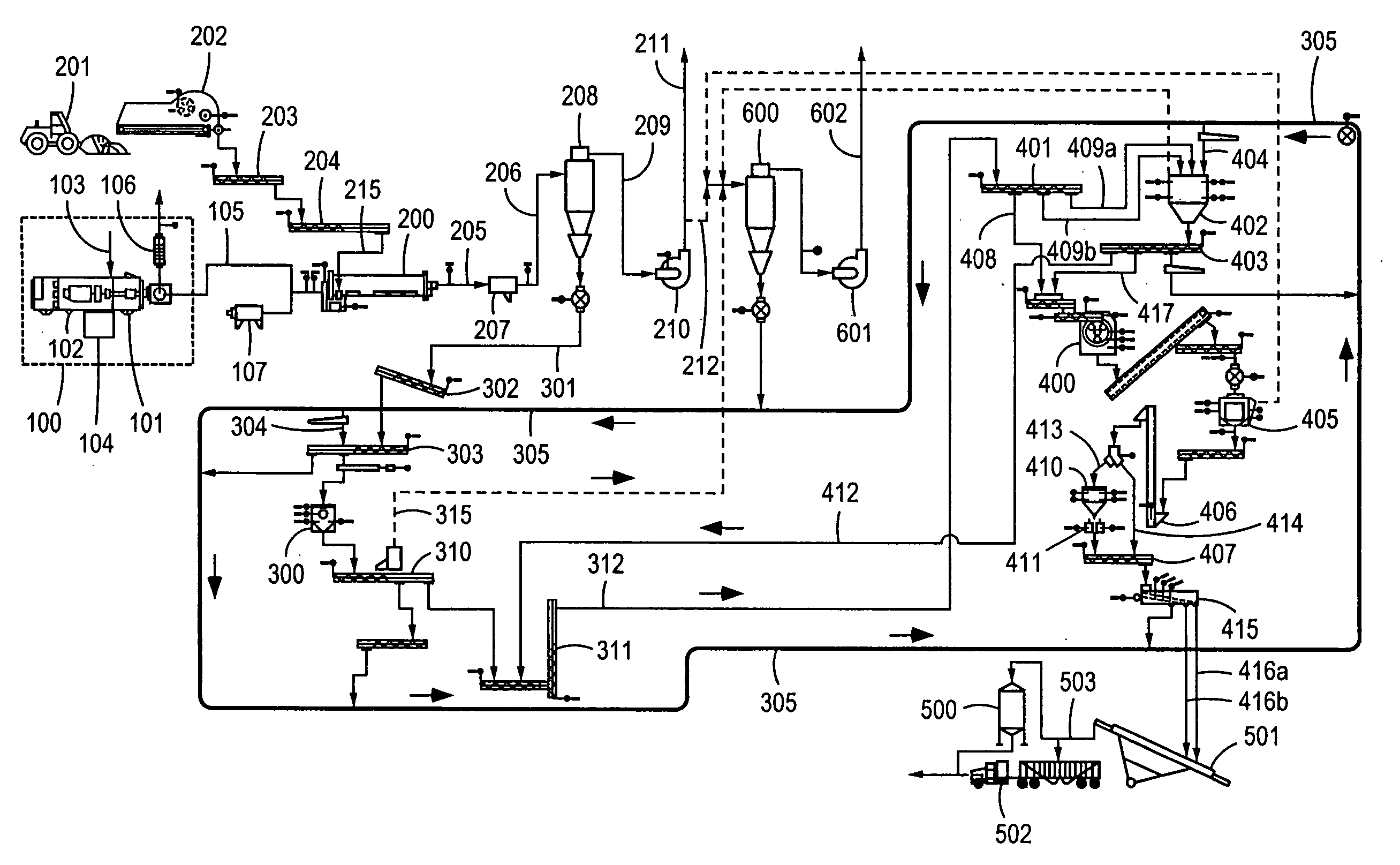

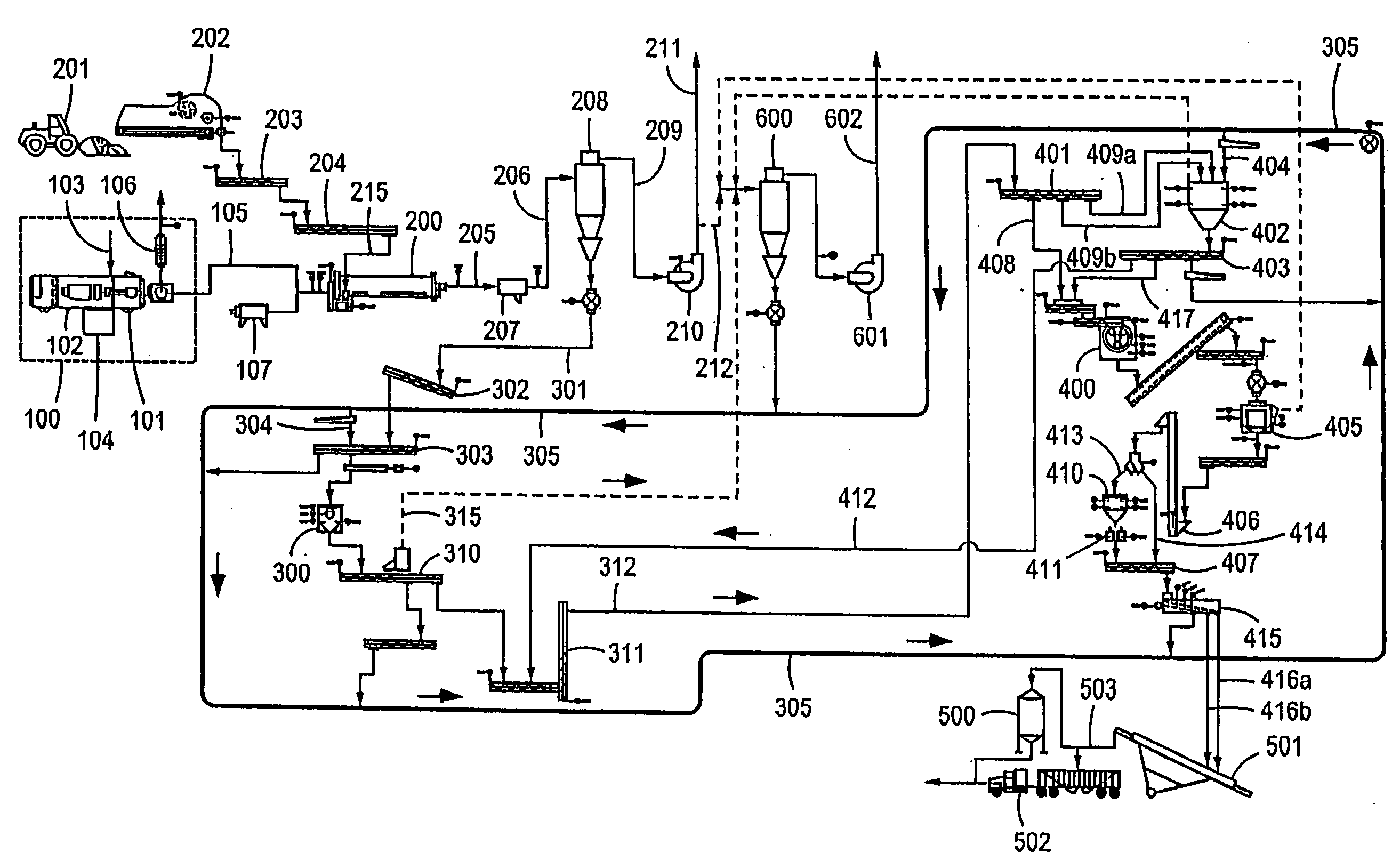

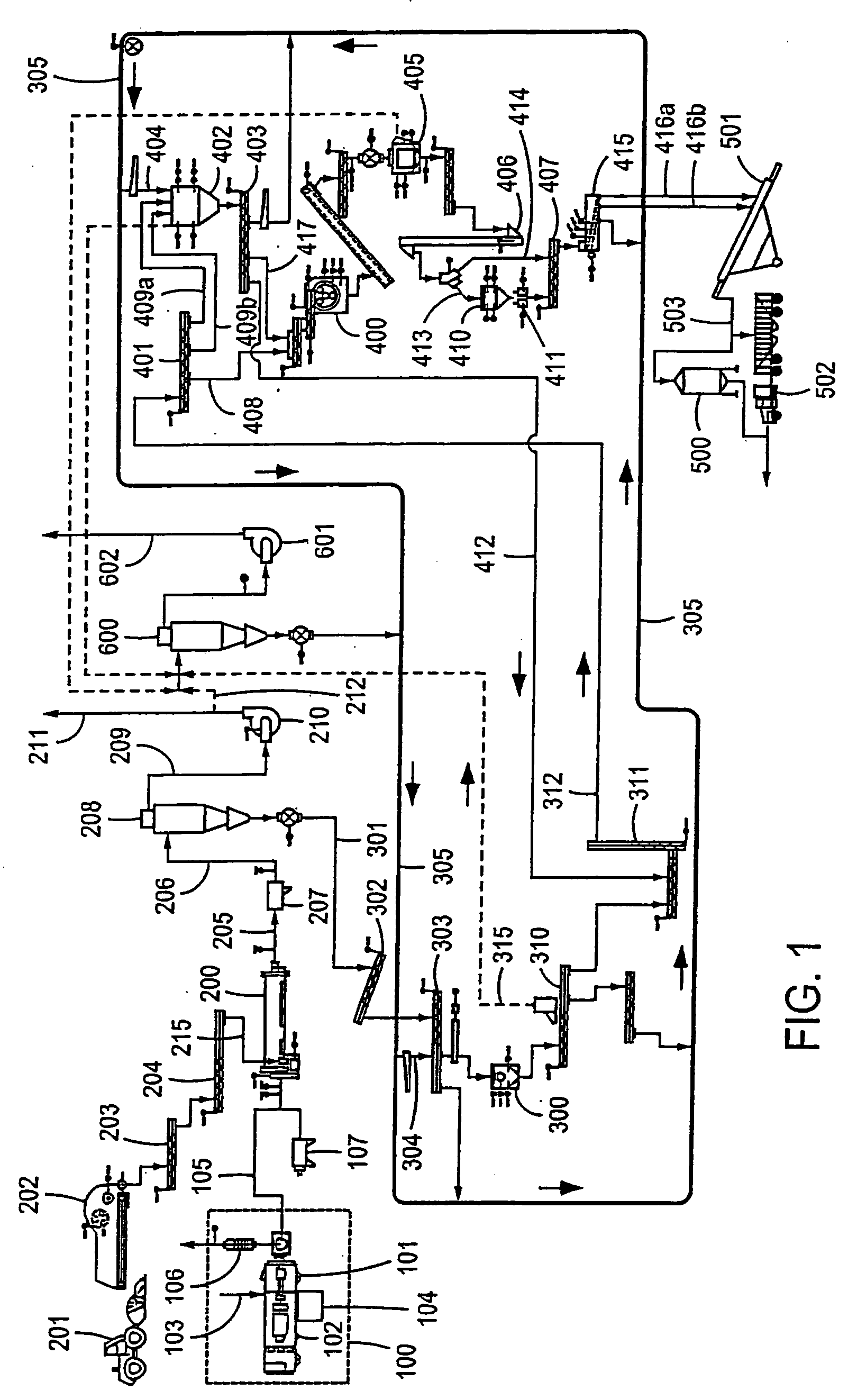

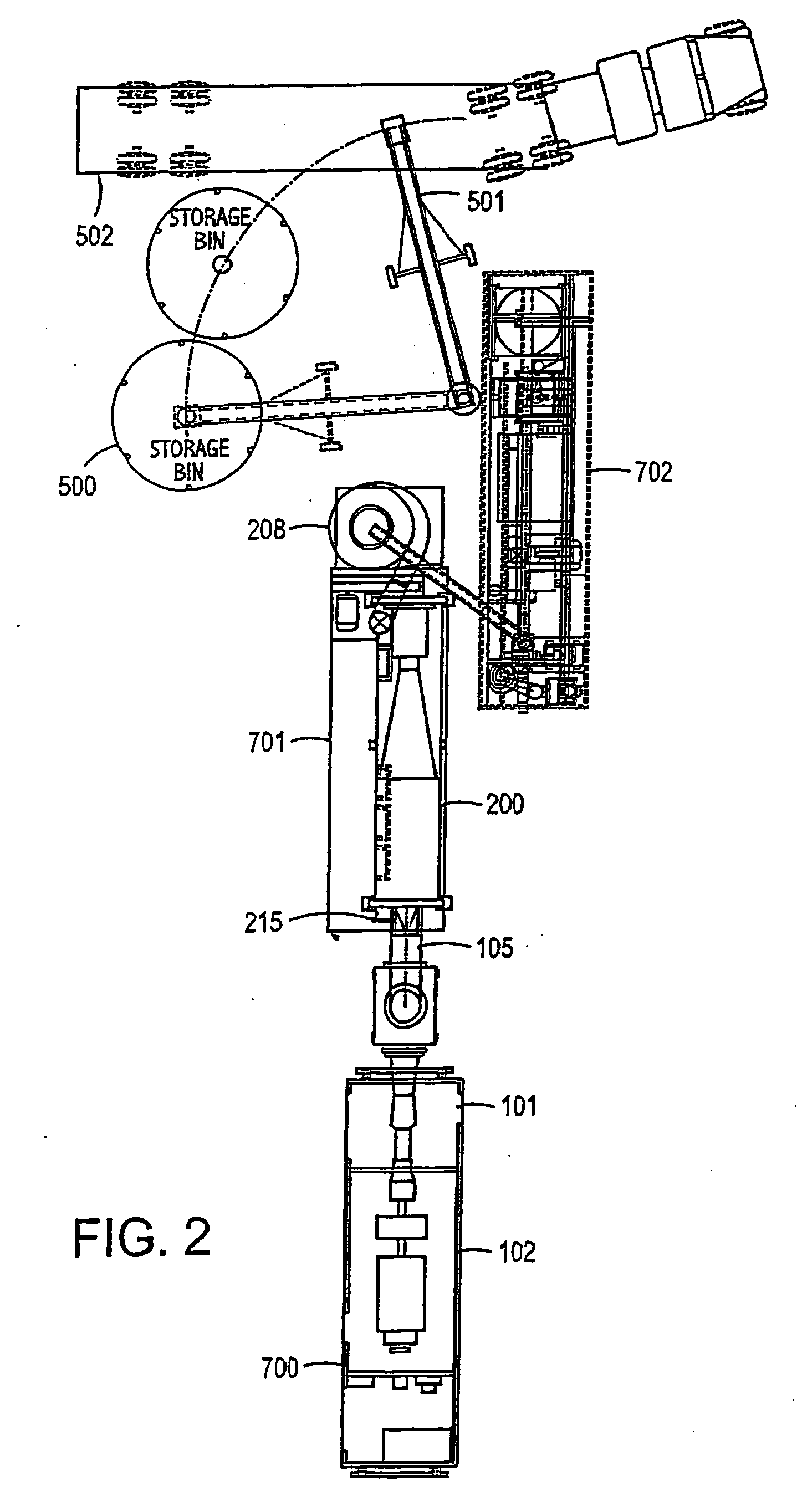

Depolymerization process of conversion of organic and non-organic waste materials into useful products

ActiveUS20070098625A1Improve energy efficiencyAcceptable costWaste based fuelLiquid hydrocarbon mixture productionDepolymerizationCost effectiveness

The present invention relates to the conversion of waste and low-value materials into useful products in reliable purities in a cost-effective and energy-efficient manner. More specifially, the invention provides processes that can handle mixed streams of various feedstocks, e.g. shredder residue, offal, animal manures, municipal sewage sludge, tires, and plastics, that otherwise have little commercial value, to useful products including gas, oil, specialty chemicals, and carbon solids. The process subjects the feedstock to heat and pressure, separates out various components, then further applies heat and pressure to one or more of those components, according to processes based on thermal or catalytic cracking. The invention further comprises an apparatus for performing a multi-stage process of converting waste materials into useful materials, and at least one oil product that arises from the process. Useful products can also be obtained or derived from materials diverted at different points of the process.

Owner:SYNPET TEKNOLOJI GELISTIRME

Process and system for drying and heat treating materials

InactiveUS20060010714A1Drying solid materials with heatExcrement fertilisersEngineeringProcess engineering

This invention discloses systems and methods for conversion of high moisture waste materials to dry or low moisture products for recycle or reuse. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel and wherein the processing unit forms the dried material from the dryer vessel into granules, pellets or other desired form for the final product. Optionally, the systems and methods further provide for processing ventilation air from manufacturing facilities to reduce emissions therefrom.

Owner:EARTHRENEW INC

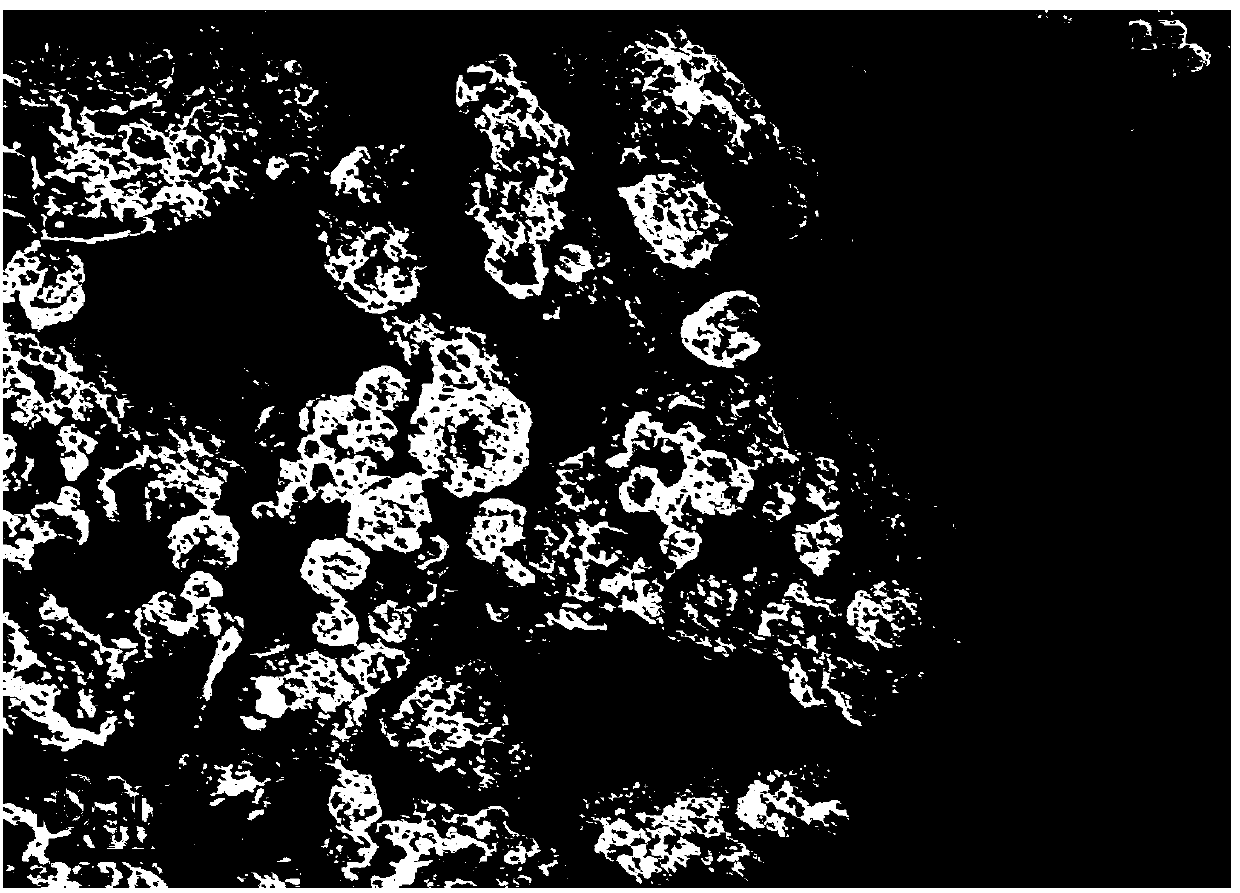

Method for recovering and preparing lithium iron phosphate from waste lithium iron phosphate battery

ActiveCN102751548AEasy to separateImprove electrochemical performanceWaste accumulators reclaimingPhosphorus compoundsLithium iron phosphateHigh energy

The invention discloses a method for recovering and preparing lithium iron phosphate from waste lithium iron phosphate batteries. The method comprises: 1) dismantling the recovered waste lithium iron phosphate batteries, stripping battery cases, immersing the batteries, separating the electrode plates from the powder material of positive and negative terminals through a method of alternation of ultrasonic and mechanical stirring, taking out the electrode plates and diaphragms, and obtaining mixed liquor; 2) performing a preliminary ball milling to the mixed liquor, and drying the uniformly mixed slurry obtained by the preliminary ball milling; 3) calcining the dried material in oxidizing atmosphere to obtain a recovered material, adding iron source, phosphorous source and optionally new lithium iron phosphate, then adding carbon source, high energy ball milling the obtained material, drying the material to obtain a pre-burning material of the recovered material; 4) microwave sintering or solid state sintering the pre-burning material of the recovered material in protective atmosphere to obtain the product of lithium iron phosphate. The preparation method has the advantages of environmental protection, no pollution, simpleness and practicality, high production utilization rate, simple

Owner:ZHEJIANG UNIV

Integrated vacuum metrology for cluster tool

InactiveUS20070196011A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMetrologyDevice material

Aspects of the invention generally provide an apparatus and method for processing substrates using a multi-chamber processing system that is adapted to process substrates and analyze the results of the processes performed on the substrate. In one aspect of the invention, one or more analysis steps and / or pre-processing steps are performed on the substrate to provide data for processes performed on subsequent substrates. In one aspect of the invention, a system controller and one or more analysis devices are utilized to monitor and control a process chamber recipe and / or a process sequence to reduce substrate scrap due to defects in the formed device and device performance variability issues. Embodiments of the present invention also generally provide methods and a system for repeatably and reliably forming semiconductor devices used in a variety of applications.

Owner:APPLIED MATERIALS INC

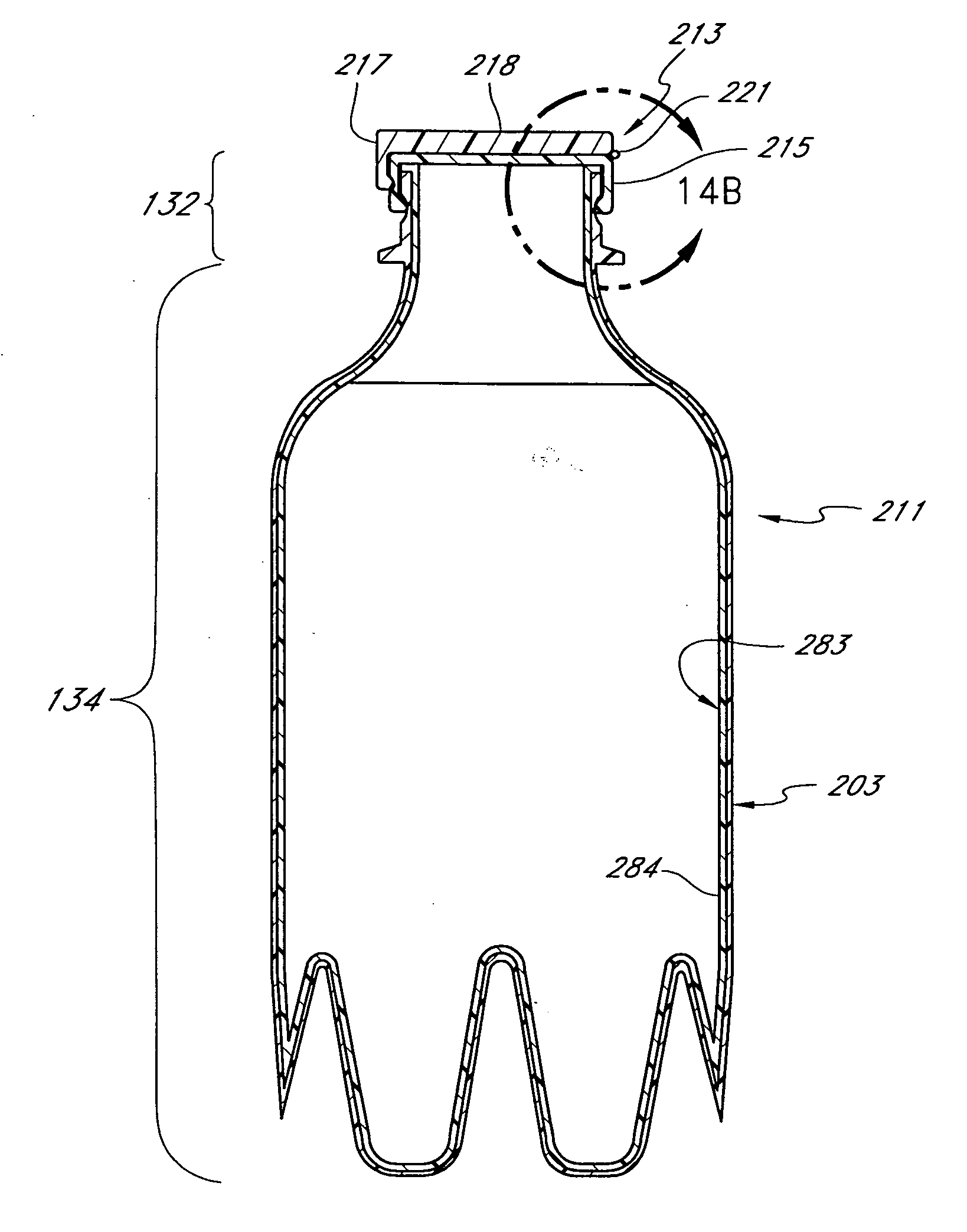

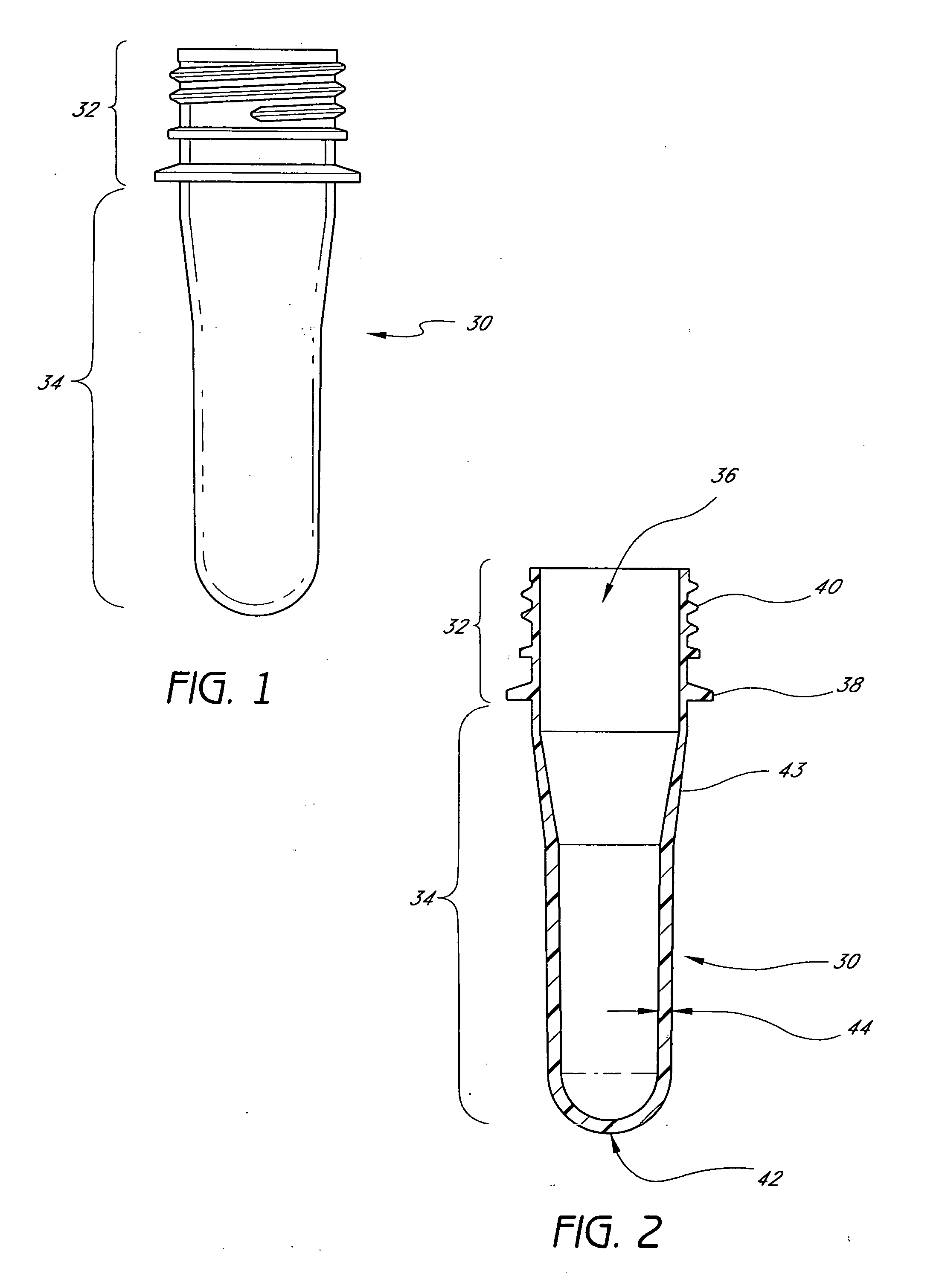

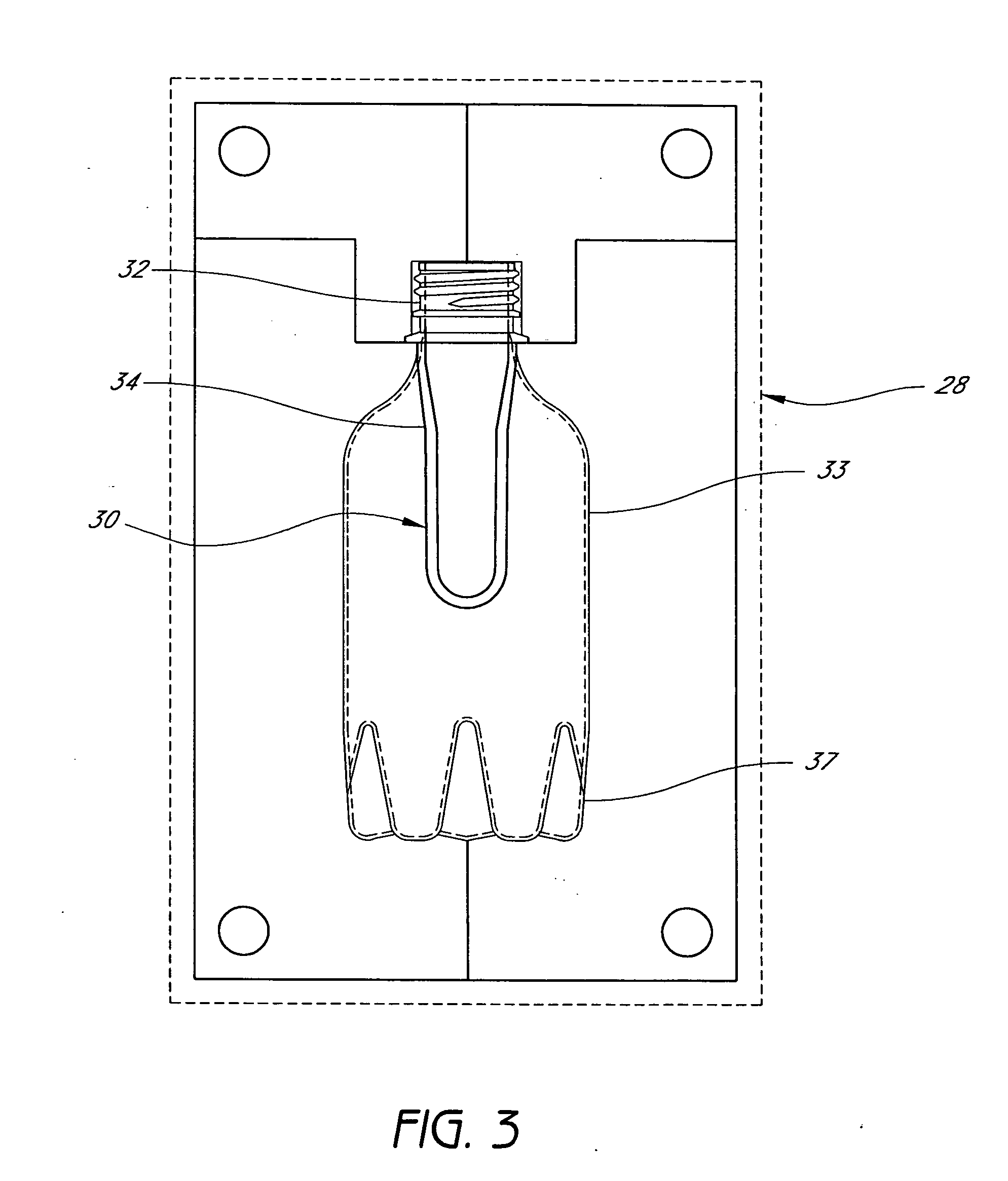

Mono and multi-layer articles and extrusion methods of making the same

InactiveUS20060073298A1Easy to processImprove melt strengthBottlesSynthetic resin layered productsThermoplasticPolyester

An extruded blow molded bottle comprises a neck portion and a body portion. The body portion comprises a first inner layer and a second layer. The first inner layer comprises a first material selected from a group consisting of polyester, phenoxy type thermoplastics, phenoxy-polyolefin thermoplastic blends, and combinations thereof. The second layer comprises a second material selected from a group consisting of virgin PET, recycled PET, PETG, foam, polypropylene, polyester, polyolefins, phenoxy type thermoplastic, phenoxy-polyolefin thermoplastic blends, regrind scrap materials, and combinations thereof. The second material is different from the first material.

Owner:PEPSICO INC +1

Method and Apparatus for Microwave Reduction of Organic Compounds

InactiveUS20070102279A1Maximum protectionElectrical coke oven heatingSolid waste disposalEngineeringVolumetric Mass Density

The invention described herein generally pertains to utilization of high power density microwave energy to reduce organic compounds to carbon and their constituents, primarily in a gaseous state. The process includes, but is not limited to, scrap tires, plastics, asphalt roofing shingles, computer waste, medical waste, municipal solid waste, construction waste, shale oil, and PCB / PAH / HCB-laden materials. The process includes the steps of feeding organic material into a microwave applicator and exposing the material to microwave energy fed from at least two linear polarized sources in non-parallel alignment to each other, and collecting the material. The at least two sources of microwave energy are from a bifurcated waveguide assembly, whose outputs are perpendicular to each other and fed through waveguide of proper impedance, such that the microwave sources are physically and electrically 90° out of phase to each other. The microwave frequency is between 894 and 1000 MHz, preferably approximately 915 MHz.

Owner:NOVAK JUDITH

Air filtration media

A glass fiber composite air filtration media is fabricated from glass fibers and plastic-containing boding fibers. The glass fibers may be virgin rotary fibers, loose-fill blowing wool insulation, bindered glass fibers such as batting insulation, or scrap rotary fibers.

Owner:CERTAINTEED CORP

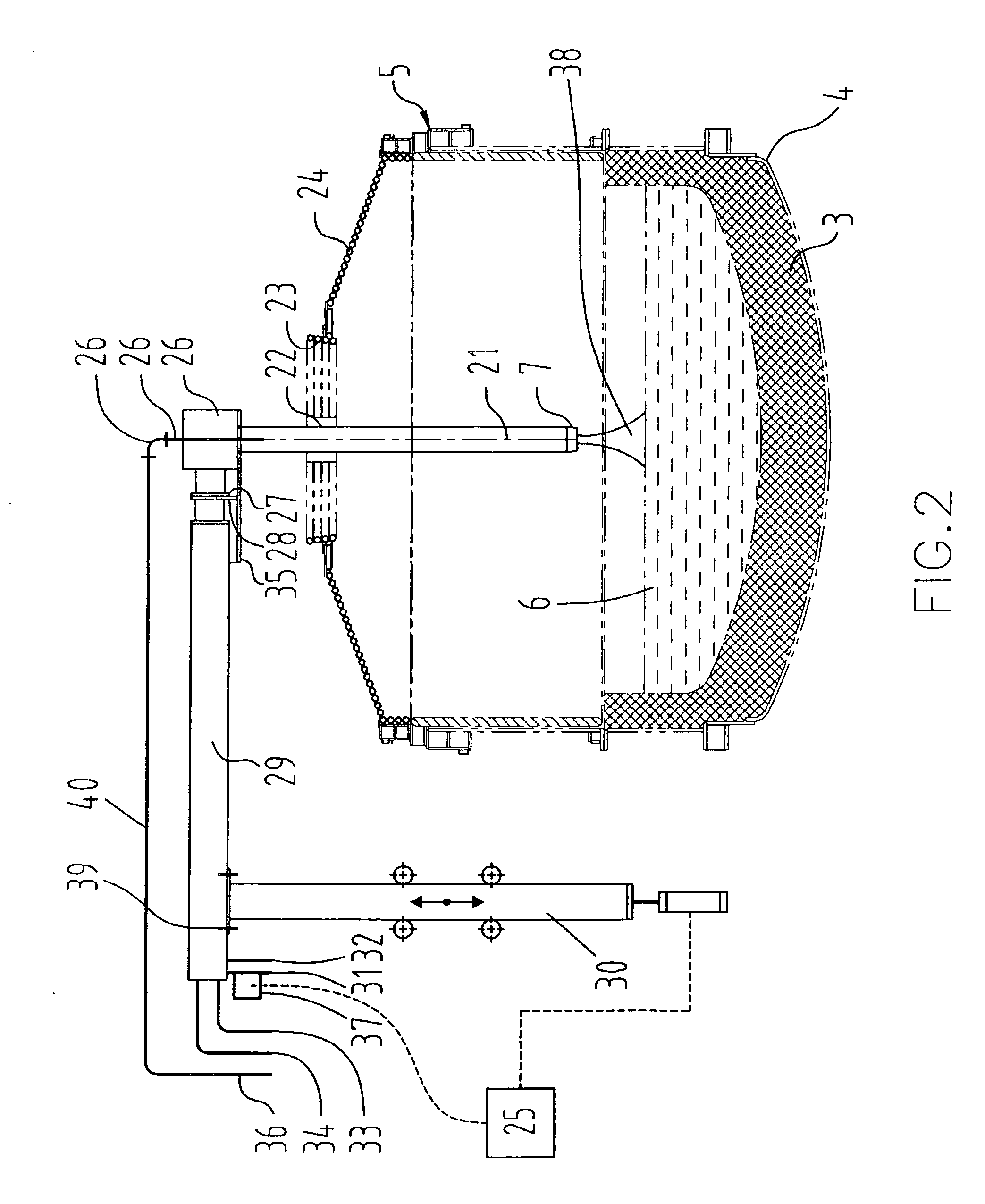

Scrap melter and impeller therefore

InactiveUS20080230966A1Reduce jammingReduce cloggingMelt-holding vesselsStirring devicesImpellerDrive shaft

A device for submerging scrap metal includes: (a) a drive source, (b) a drive shaft having a first end and a second end, the first end being connected to the drive source, and (d) an impeller connected to the second end of the drive shaft, the impeller preferably having two or more outwardly-extending blades. Preferably, each of the blades has a portion that directs molten metal at least partially downward. The impeller design leads to lower operating speeds, lower vibration, longer component life and less maintenance. Additionally, the impeller preferably has a connective portion. The connective portion is used to connect the impeller to the shaft and preferably comprises a nonthreaded, tapered bore extending through the impeller.

Owner:COOPER PAUL V

Composite tailing non-fired and non-steamed building block brick and preparation method thereof

InactiveCN102093004AHigh waste rateSolve the problem of excessive dosageSolid waste managementBrickSlag

The invention discloses a composite tailing non-fired and non-steamed building block brick and a preparation method thereof. The brick comprises the following raw materials in parts by weight or volume: 50-300 parts of tailing and 3-30 parts of cement; and at least two components are selected from the active wastes such as fly ash, coal gangue, shale slag, alkaline residue, carbide slag, chemical gypsum and the waste residue of metallurgical industry to be mixed with the raw materials. The preparation method comprises the following steps: mixing to stir, compressing and shaping, performing natural curing or utilizing the solar heaing hydrating maintenance to prepare the composite tailing building block brick. By adopting the preparation method of the invention, the single performances of the tailings and slags can be changed, thus the product can have higher strength and quality owning to the interaction of materials; the technology does not adopt firing and steaming, the cost is low; different sizes of solid bricks, perforated bricks, hollow blocks, floor tiles, grass planting bricks, roadside bricks and artistic rails can be prepared by changing the mould; and various harmful slags such as tailings can become good, the Chinese development direction of the comprehensive utilization of resources is satisfied and the brick of the invention has development and application prospect.

Owner:郭东京 +2

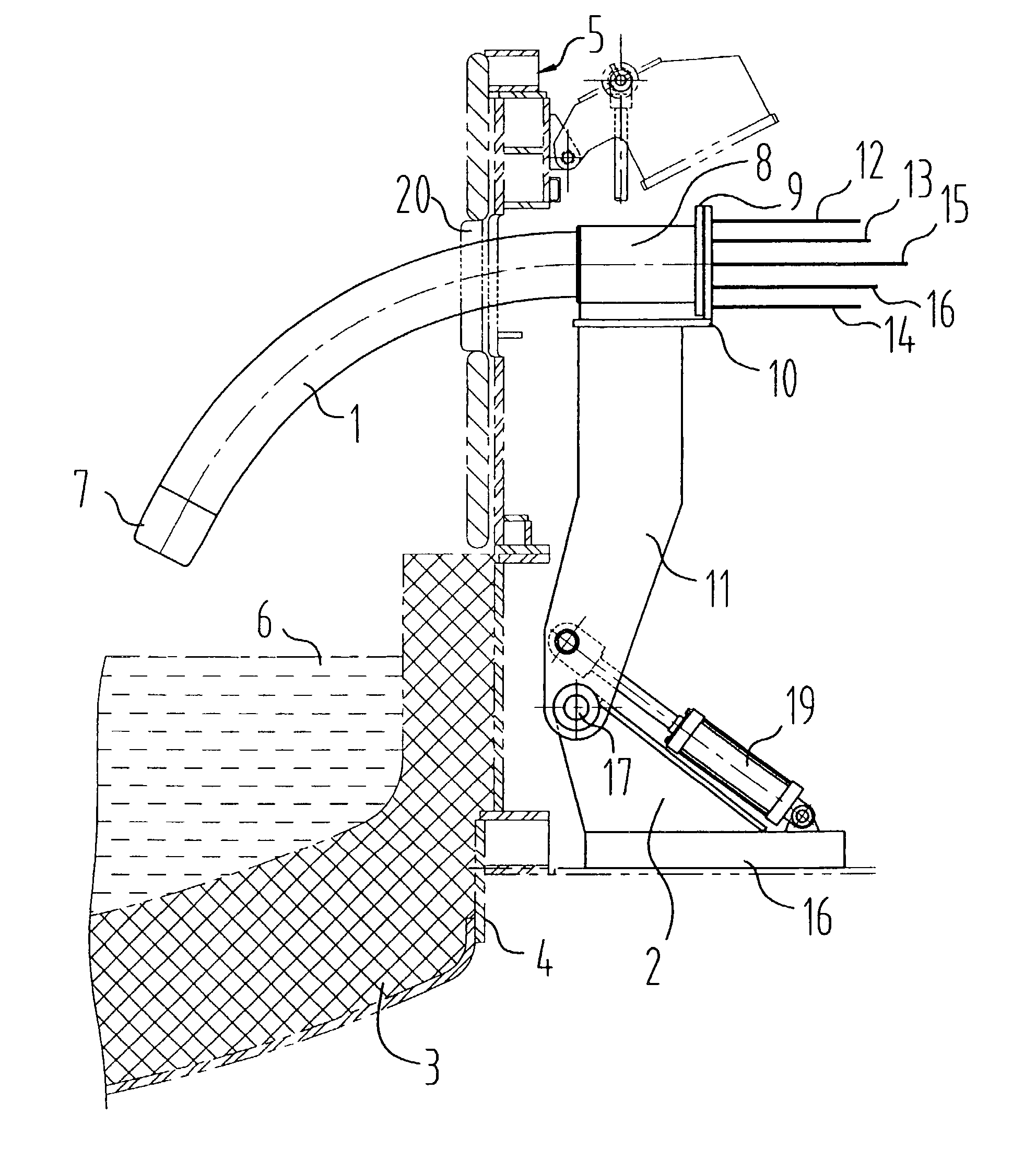

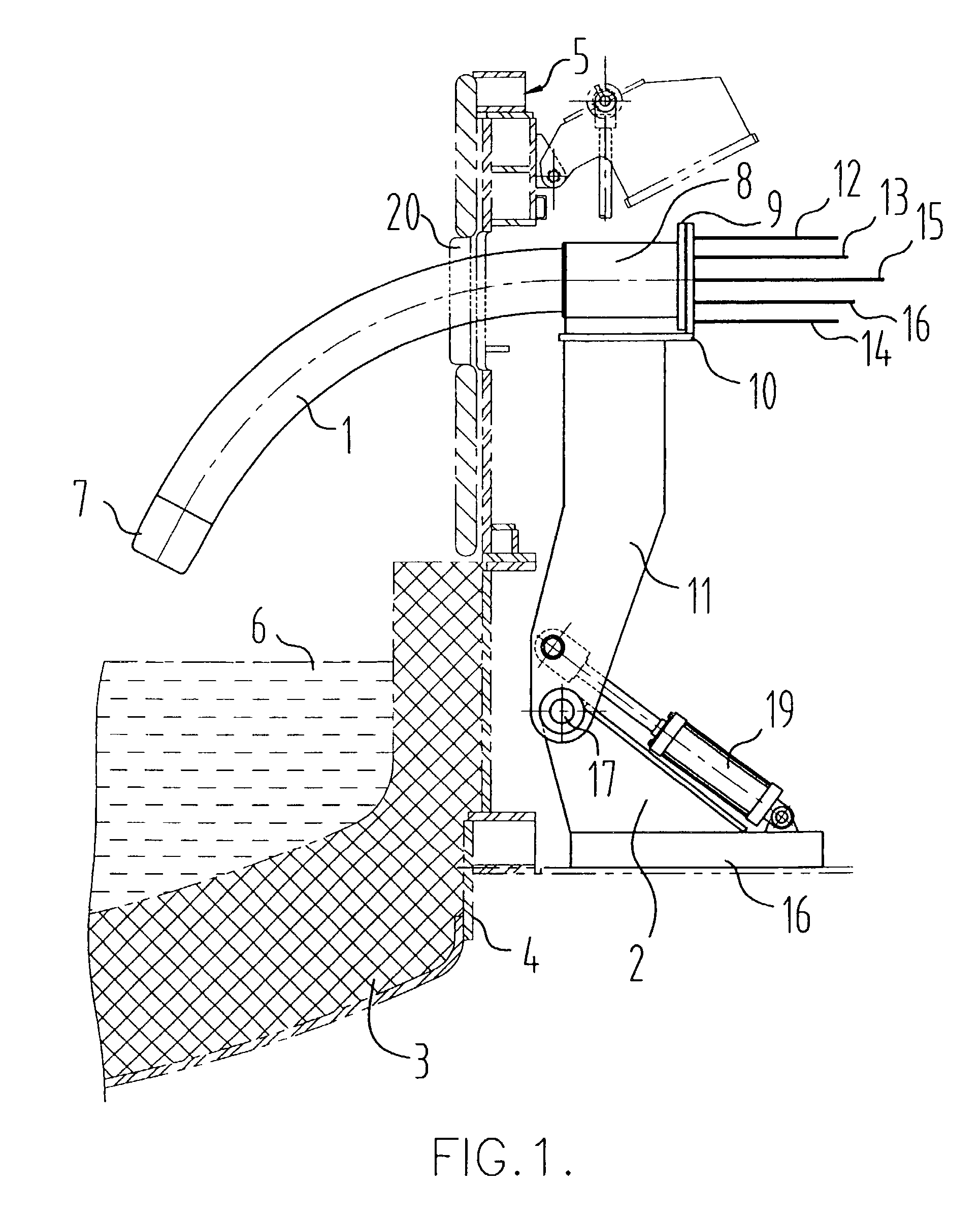

Multi-purpose, multi-oxy-fuel, power burner/injector/oxygen lance device

InactiveUS20030075843A1Reduce the numberSmall sizeTuyeresCharge manipulationSteelmakingLiquid medium

A multi-purpose, multi-oxy-fuel High Temperature Power Burner / Injector / Oxygen Lance, Mechanical System Apparatus Device, for steelmaking from recycled scrap and / or virgin ferrous charge, which can be employed in multi-oxy-fuel (natural gas; pulverized carbonaceous matter; heavy oil), especially by Oxygen Combusted mixture of Natural Gas / Pulverized Carbonaceous Matter in High Temperature Power Burner Mode, for efficient and rapid melting of solid ferrous charge (cold or preheated) in a special steelmaking Metallurgical Furnace or Open Hearth Furnace, Tandem Furnace, BOF, EAF, as its augmenting or only source of thermal energy; more than one Device in Oxygen-Natural Gas / Pulverized Carbonaceous Matter Power Burner Mode, can be employed as the only source of thermal energy in a modified, originally Electric Arc Furnace, as total replacement of Graphite Electrodes and Electric Arc System, the replacement being noticeably more primary energy efficient than the thermal energy provided by Graphite Electrode / Arc System; it also can be employed in an Solid Particles Injector Mode, for injecting of adequately granulated carbonaceous materials or lime into the molten steel for its carburizing or for foamy slag control; further it can be employed in a natural gas shrouded, pulsating oxygen stream, for vertically to the charge oriented soft blow supersonic Oxygen Injection Lance Mode, for decarburization of the molten metal contained in the hearth of the metallurgical furnace and foamy slag control; in one of the embodiments-generally arcuate-pivotally mounted, liquid media cooled composite body, is pivoted into and out of a furnace vessel through a small opening in the shell wall for auto-regulated constant optimal positioning of the Composite Body Tip against solid or molten charge, in each and all multi-purpose modes; furthermore, when inserted into the furnace vessel, the arcuate composite body can be rotated about its longitudinal axis for directing the oxy-fuel high temperature flame towards unmolten charge in the furnace; in an other-generally linear-embodiment, the liquid cooled composite body is attached to the mast type carrier allowing vertical movement of the composite body which enters the furnace vessel through a small opening in the furnace roof; the bimetallic, liquid cooled special tip assembly of both-arcuate and linear embodiments-of the composite body includes easy replaceable, independent, multi-opening nozzles, mounted in a protective, retracted position inside of the liquid cooled special tip assembly.

Owner:EMPCO (CANADA) LTD

Method for recycling silica powder and carborundum powder from cut waste mortar

The invention discloses an extracting method of high-purity silicon powder and carborundum powder from waste slurry of monocrystalline silicon cutting or grinding course, which comprises the following steps: separating solid from liquid for the waste slurry; using organic solvent to remove suspending agent and adhesive; doing gas float for solid sand; obtaining certain purity silicon powder; doing liquid float and gravity sorting for the silicon powder further; acidifying the silicon powder through acid; obtaining high-purity silicon powder; doing magnetic float for the composite powder of carborundum-metal through gravity; obtaining the pure carborundum powder. The invention can recycle high-purity silicon from waste slurry in the silicon bar cutting manufacturing course effectively, which changes waste into value with high receiving rate to solve the problem of resource shortage of high-purity silicon.

Owner:XI AN JIAOTONG UNIV

Fuel pellet briquettes from biomass and recovered coal slurries

The invention makes burnable renewal fuel (RF) briquettes from recovered coal from coal slurry ponds, biomass, and a binder. The briquettes may be augmented with one or more of recovered environmental burnable fraction from municipal solid waste (MSW), agricultural livestock waste, lumber processing residue, solid wood waste material, agricultural by-products and crops, and like burnable waste material. Accordingly, the method for making burnable renewal fuel (RF) briquettes includes the steps of recovering coal from coal slurry ponds; recovering biomass; adding a binder to said recovered coal and said biomass; and forming solid burnable RF fuel briquettes therefrom.

Owner:NEW ENERGY USA

Process and system for drying and heat treating materials

InactiveUS20060101665A1Water/sewage treatment by centrifugal separationReversed direction vortexProcess engineeringMoisture

This invention discloses systems and methods for conversion of high moisture waste materials to dry or low moisture products for recycle or reuse. The equipment systems comprise a gas turbine generator unit (preferred heat source), a dryer vessel and a processing unit, wherein the connection between the gas turbine and the dryer vessel directs substantially all the gas turbine exhaust into the dryer vessel and substantially precludes the introduction of air into the dryer vessel and wherein the processing unit forms the dried material from the dryer vessel into granules, pellets or other desired form for the final product. Optionally, the systems and methods further provide for processing ventilation air from manufacturing facilities to reduce emissions therefrom.

Owner:EARTHRENEW INC

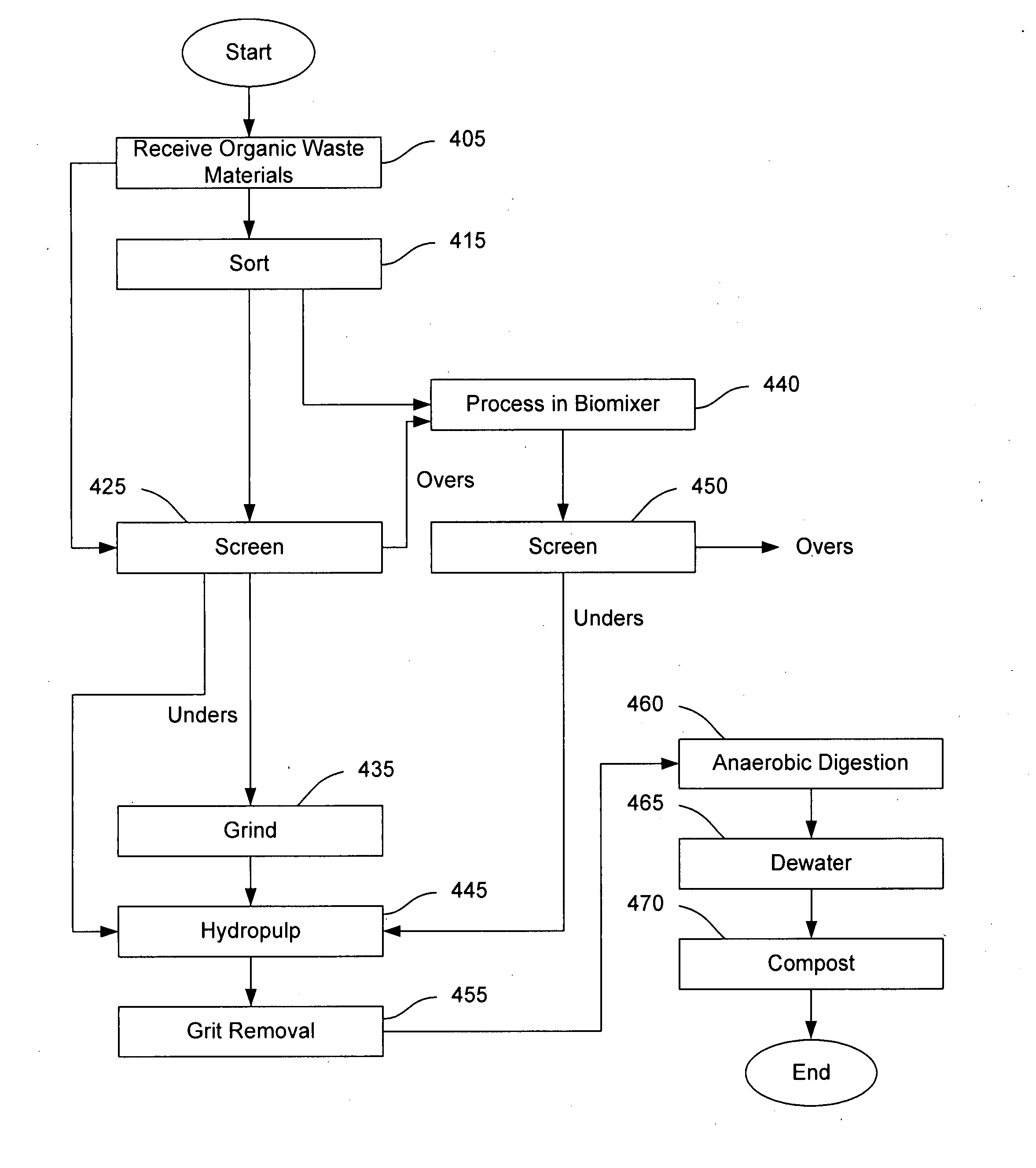

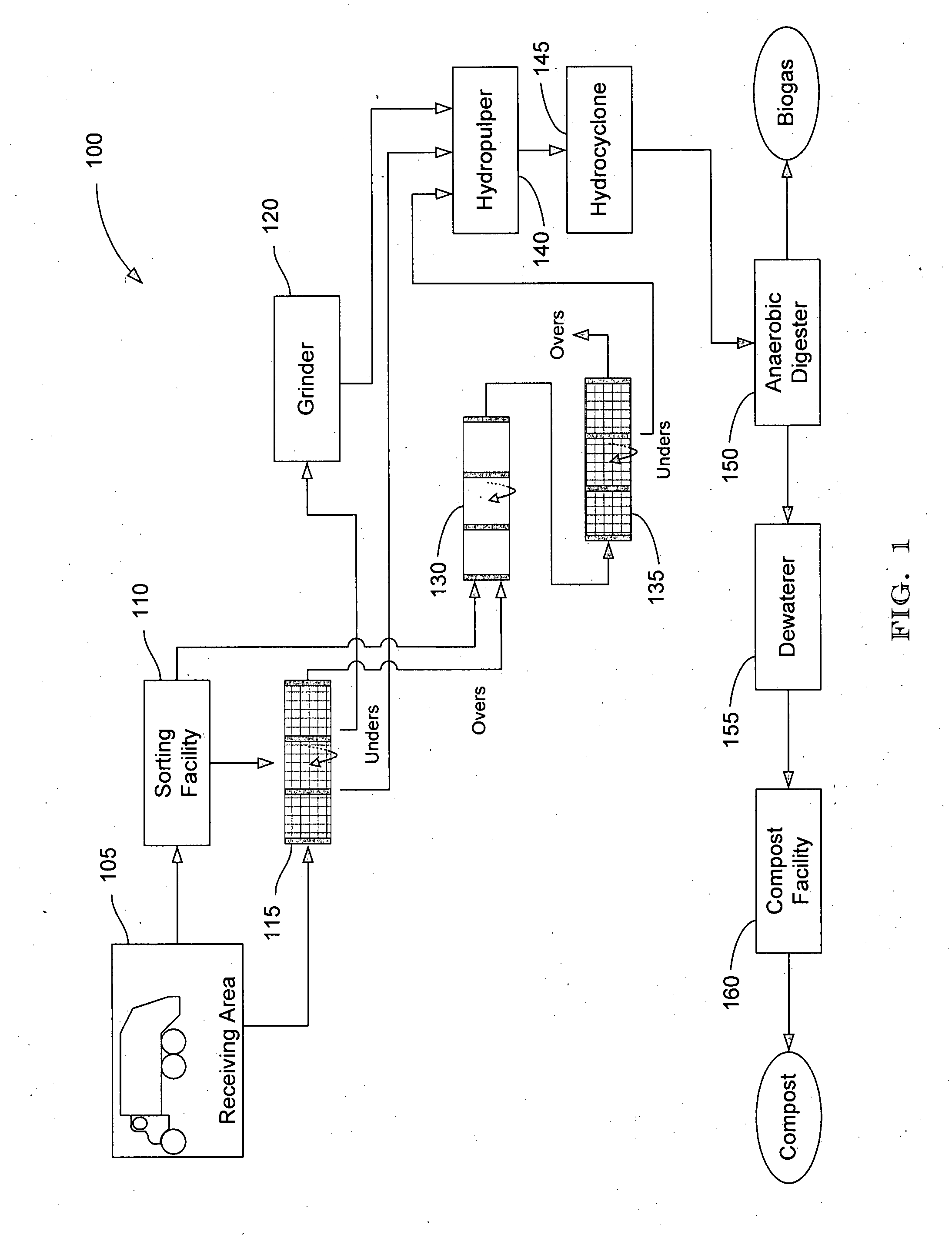

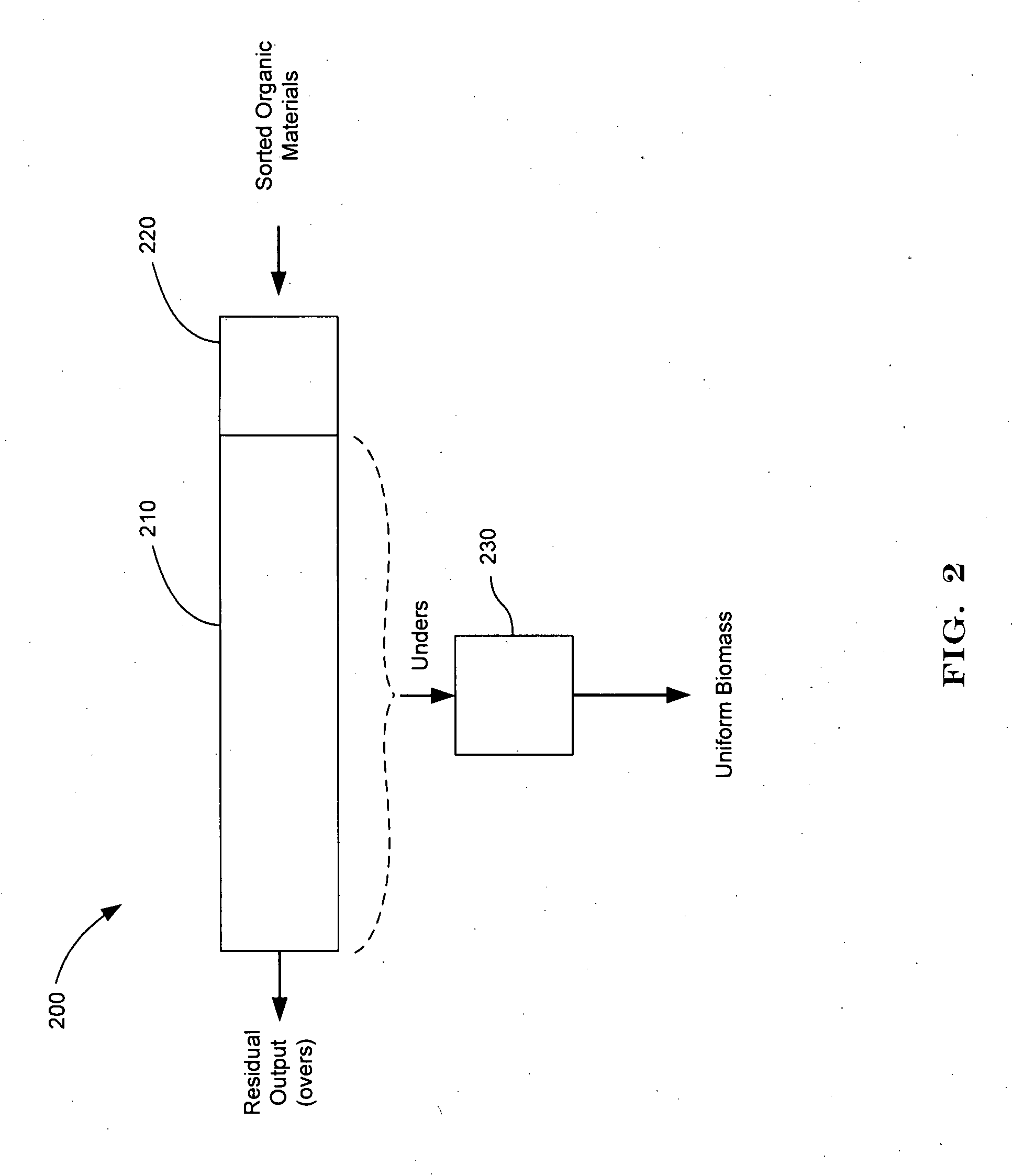

Systems and methods for converting organic waste materials into useful products

ActiveUS20080020456A1Bioreactor/fermenter combinationsBio-organic fraction processingOrganic fractionProduct system

Systems and methods are provided for converting organic waste materials from a municipal waste stream to useful products. Organic waste materials having a wide range of compositions such as, for example, yard waste, food waste, paper, and the organic fraction of municipal solid waste are converted into a uniform biomass that is suitable for conversion to useful products, such as fuels. Through the use of a biomixer and a hydropulper, as well as through sorting and screening, the organic waste materials are progressively reduced in size and cleaned of contamination. The resulting uniform biomass is suitable for anaerobic digestion to produce biogas and a residual solid that is suitable for producing a high quality compost.

Owner:RECOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com