Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1949results about "Casings/linings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

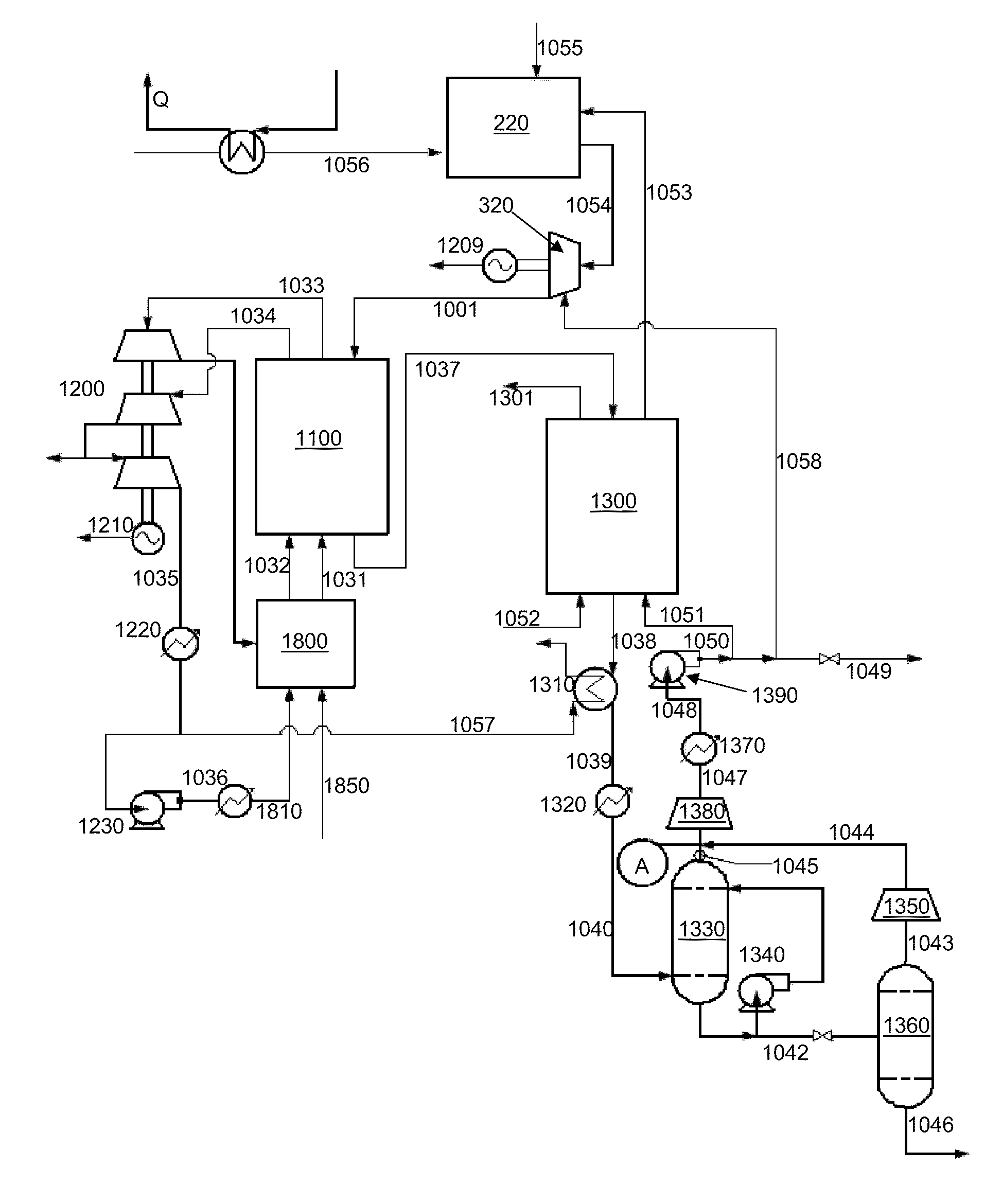

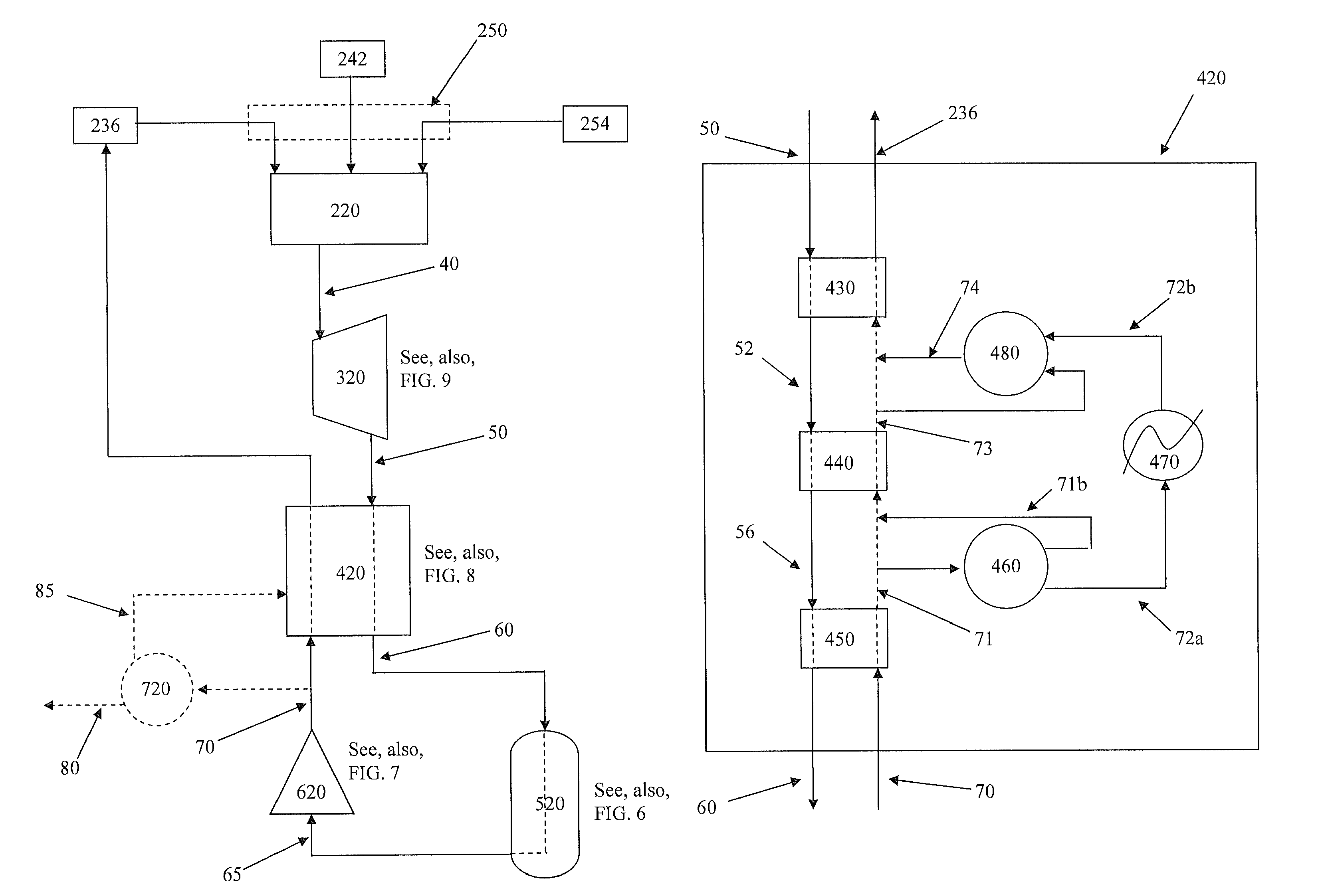

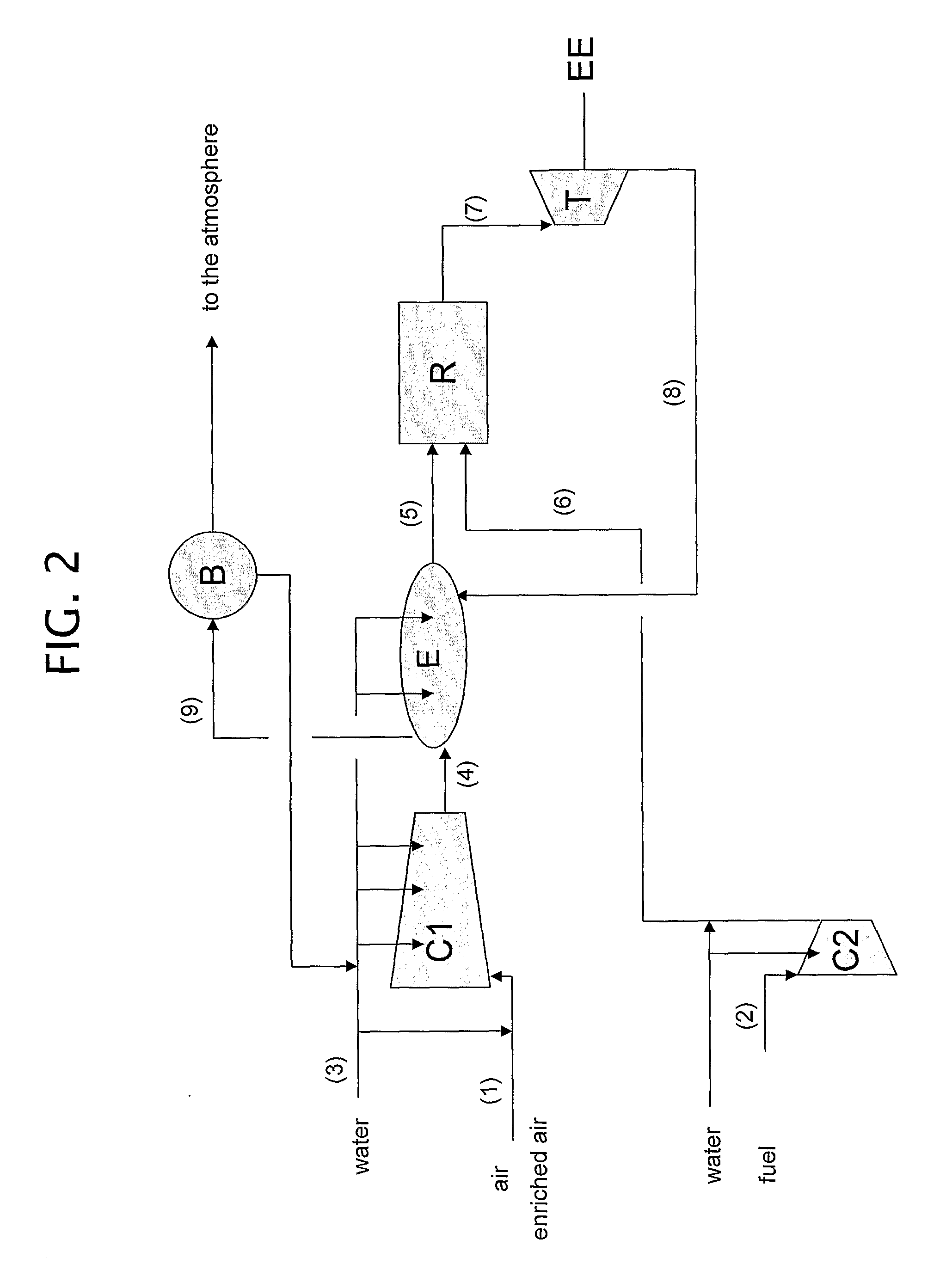

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20110179799A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

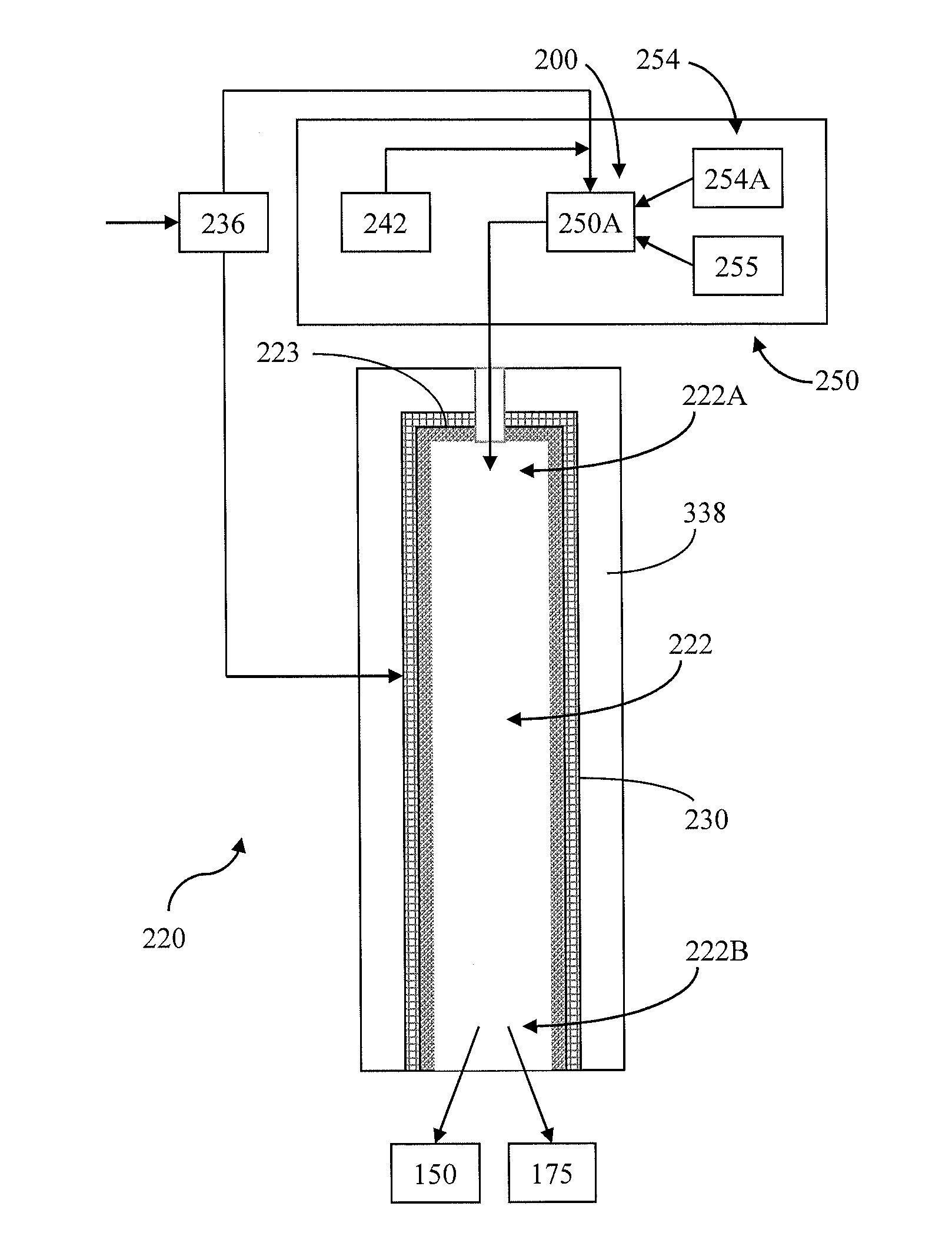

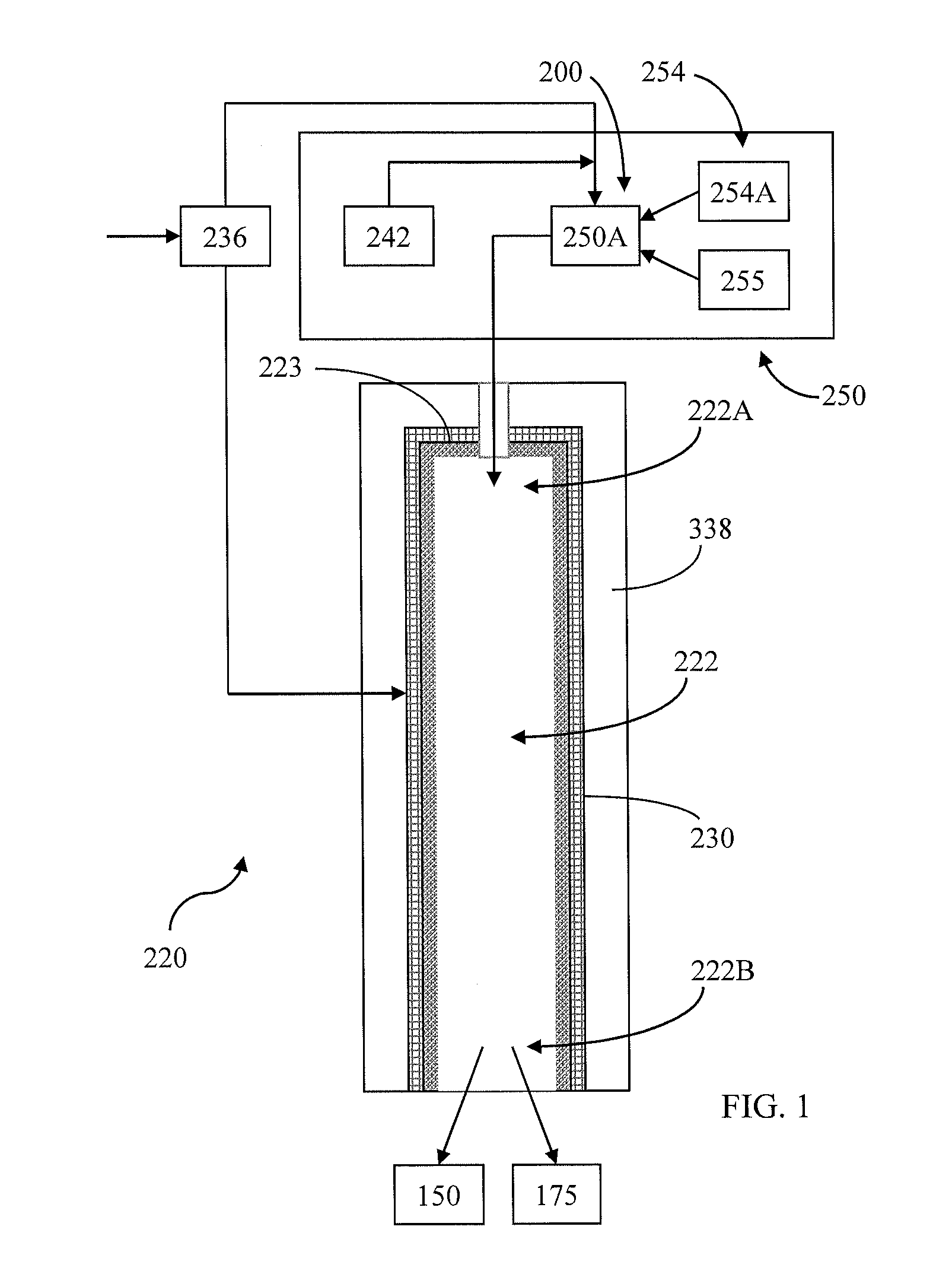

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

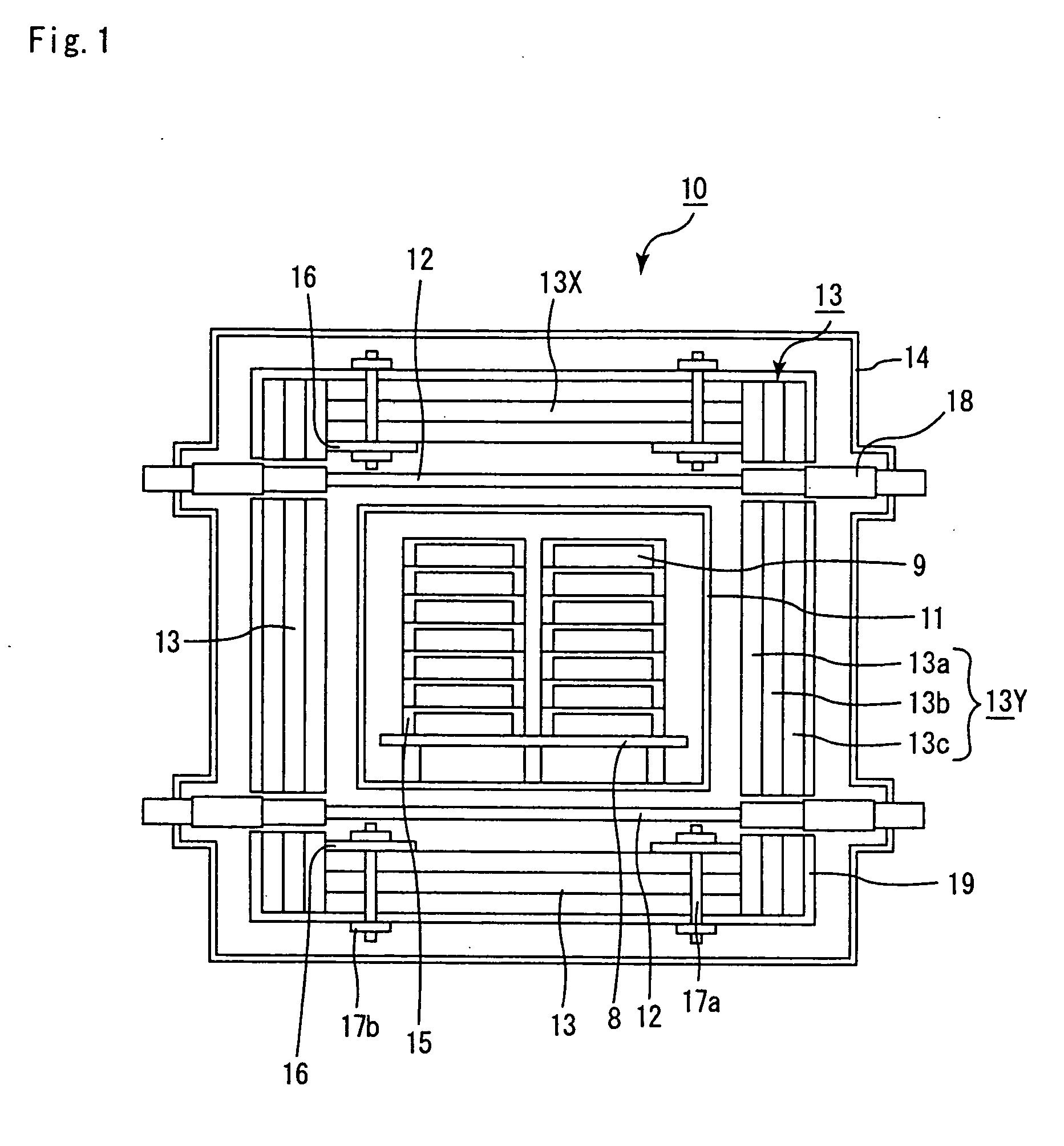

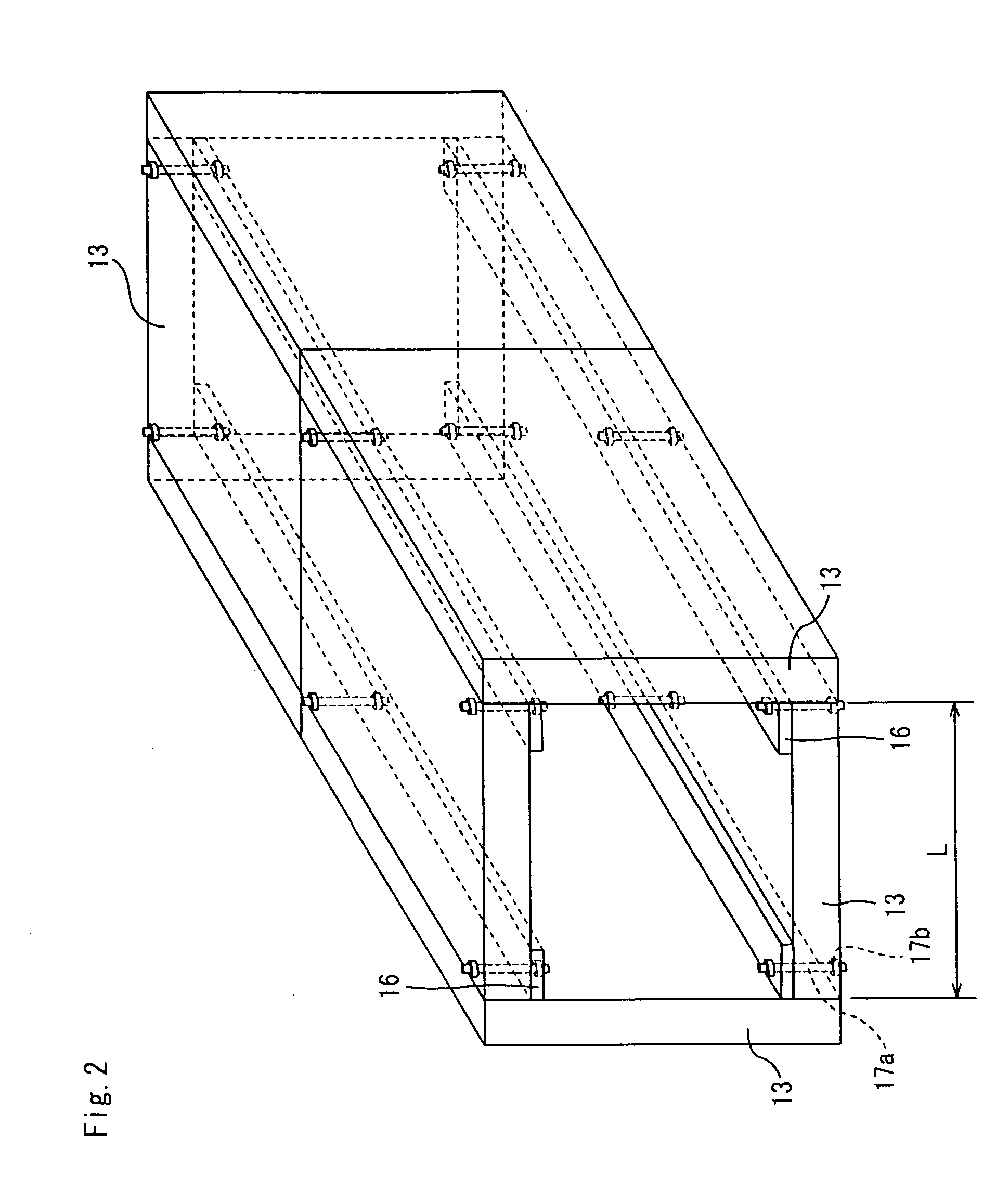

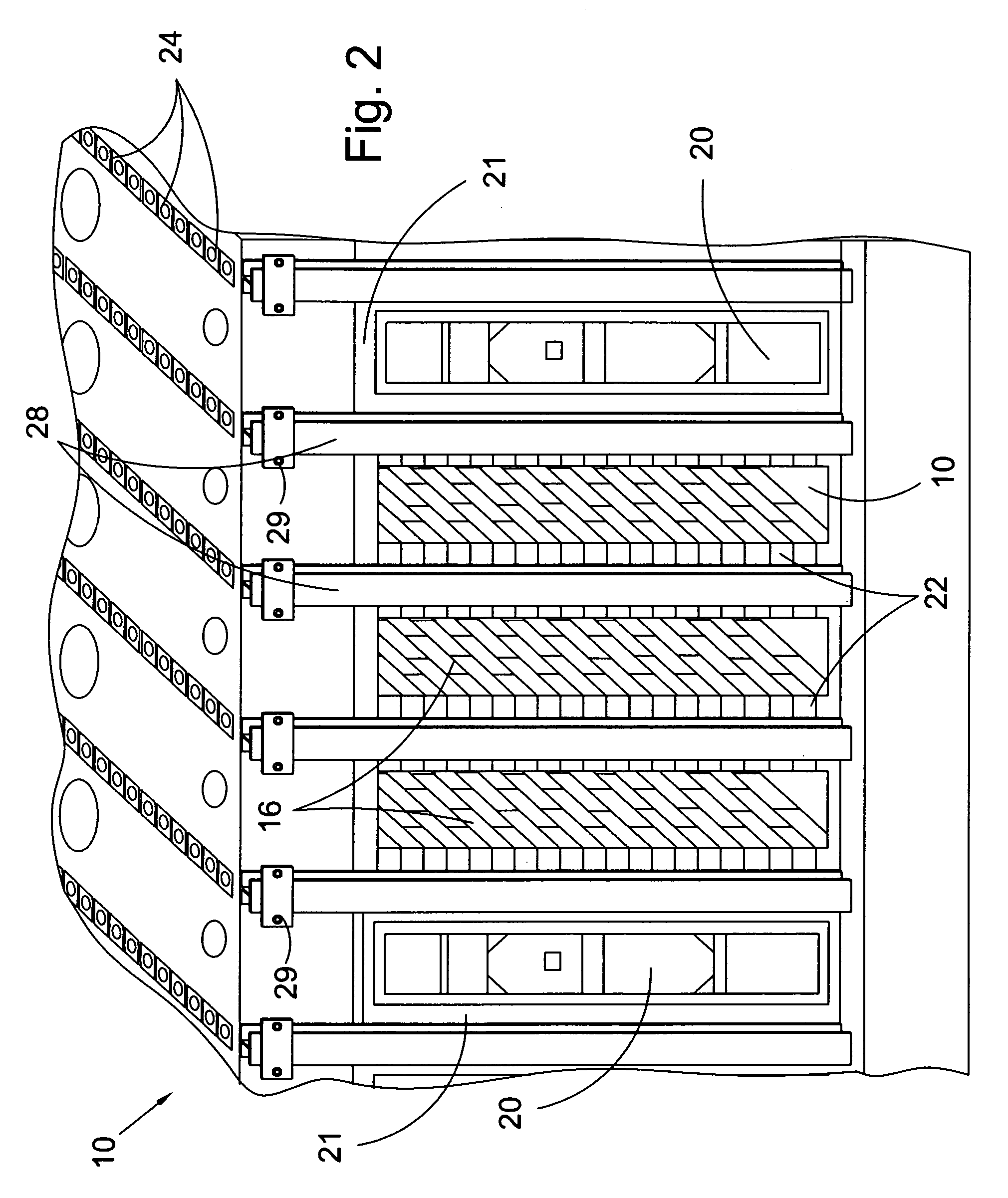

Firing furnace, porous ceramic member manufacturing method using the same, and porous ceramic member manufactured by the manufacturing method

ActiveUS20060029898A1Avoid warpingEnsuring spaceMuffle furnacesIncreasing energy efficiencyPorous ceramicsMaterials science

Owner:IBIDEN CO LTD

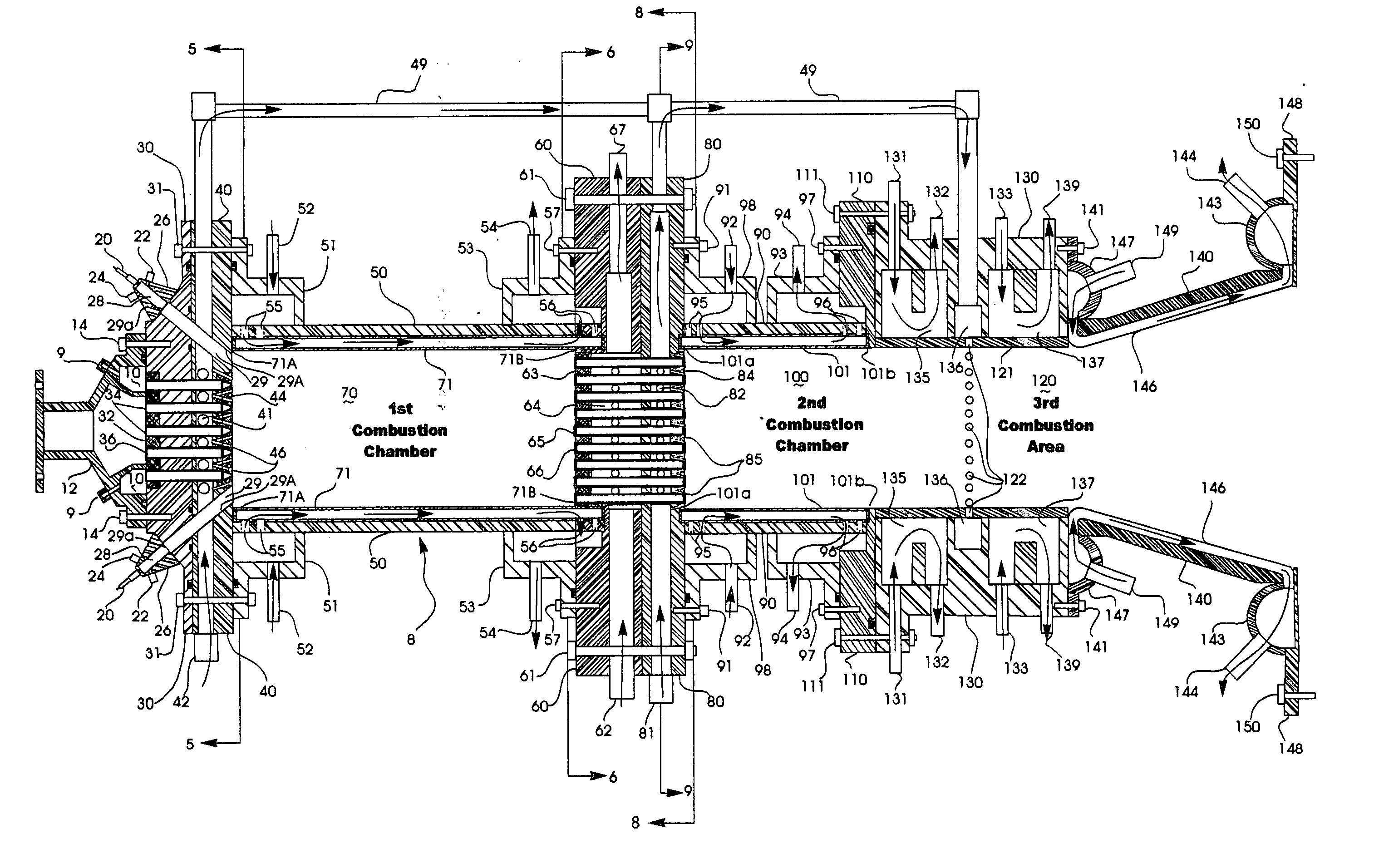

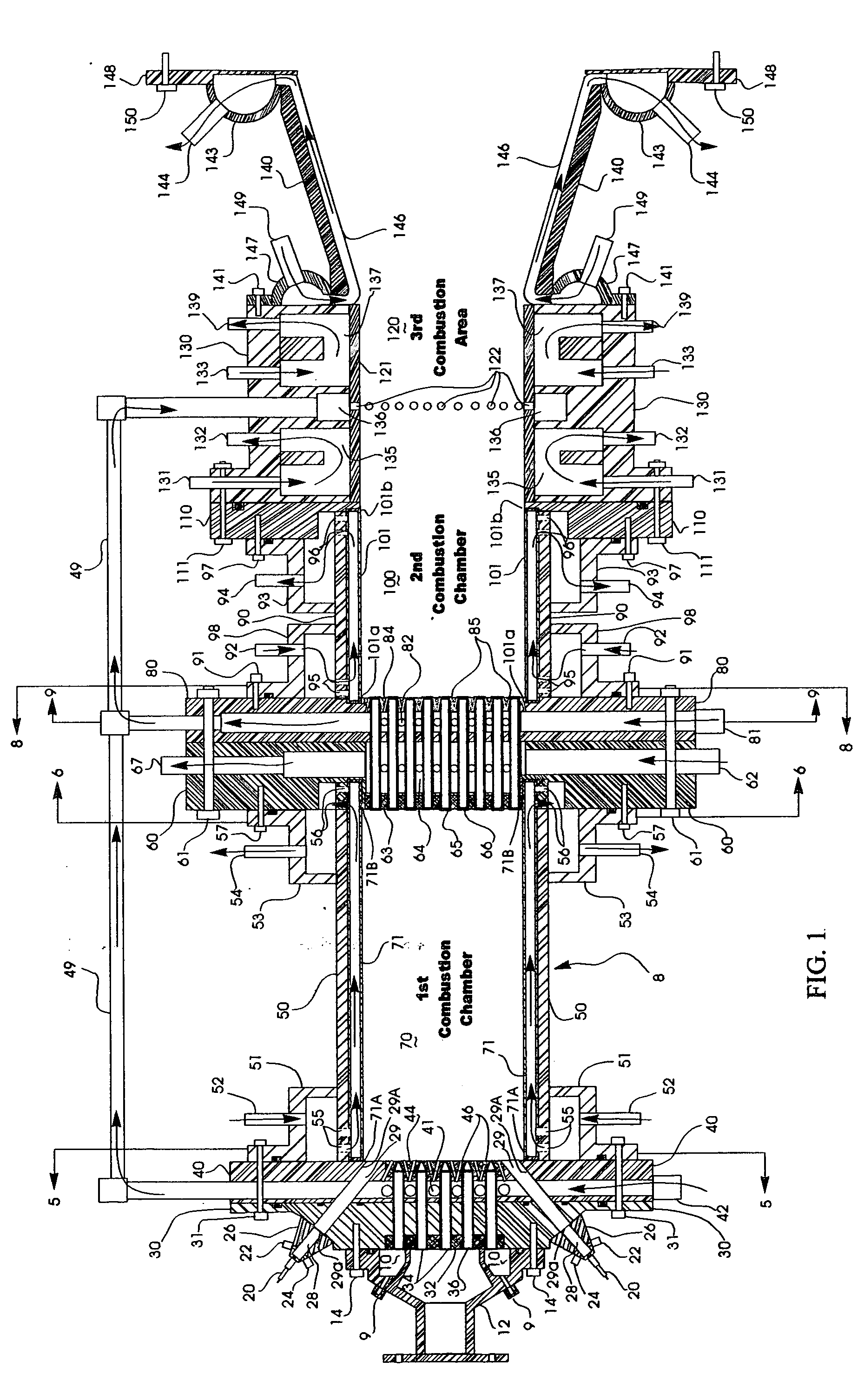

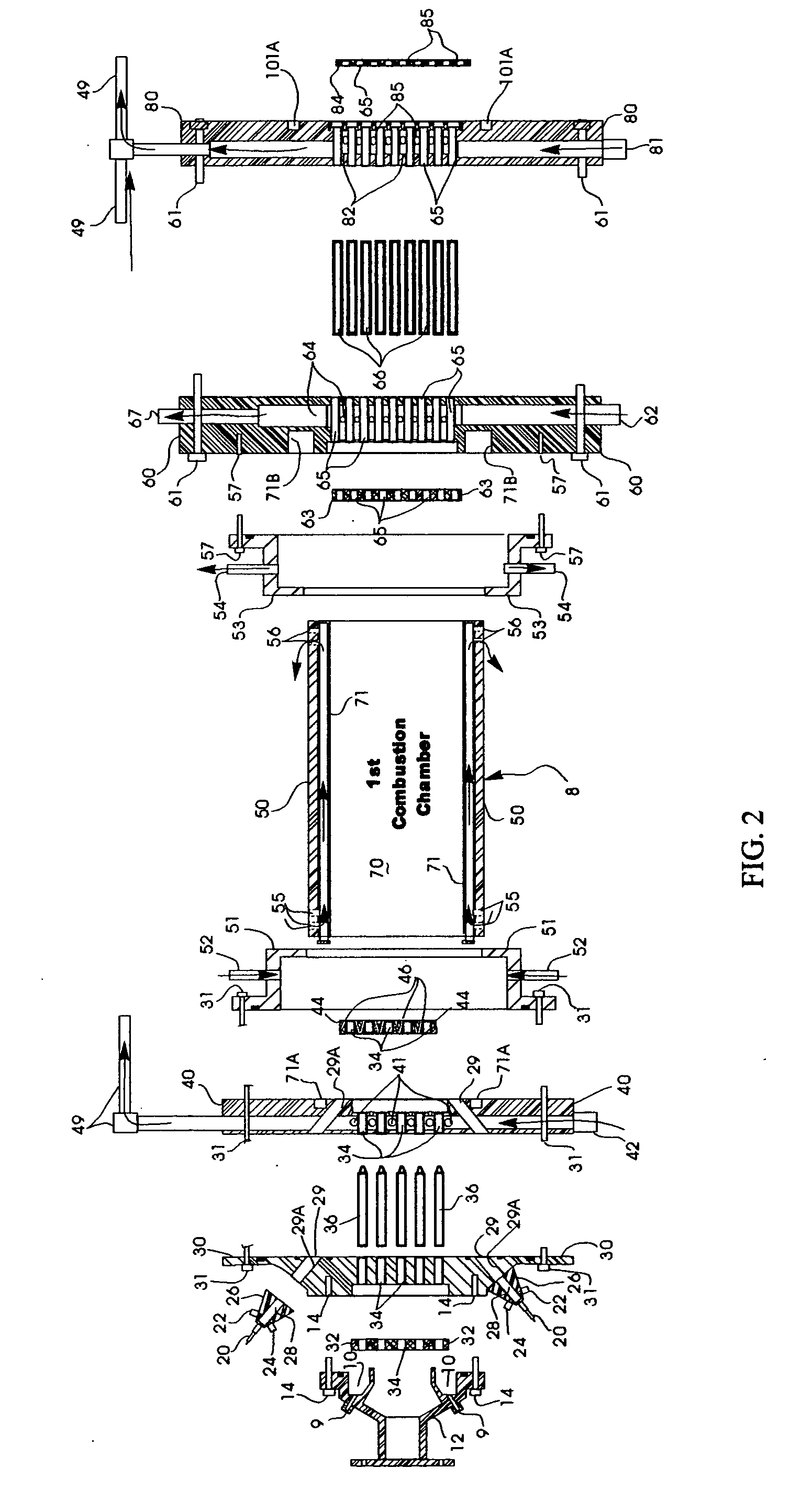

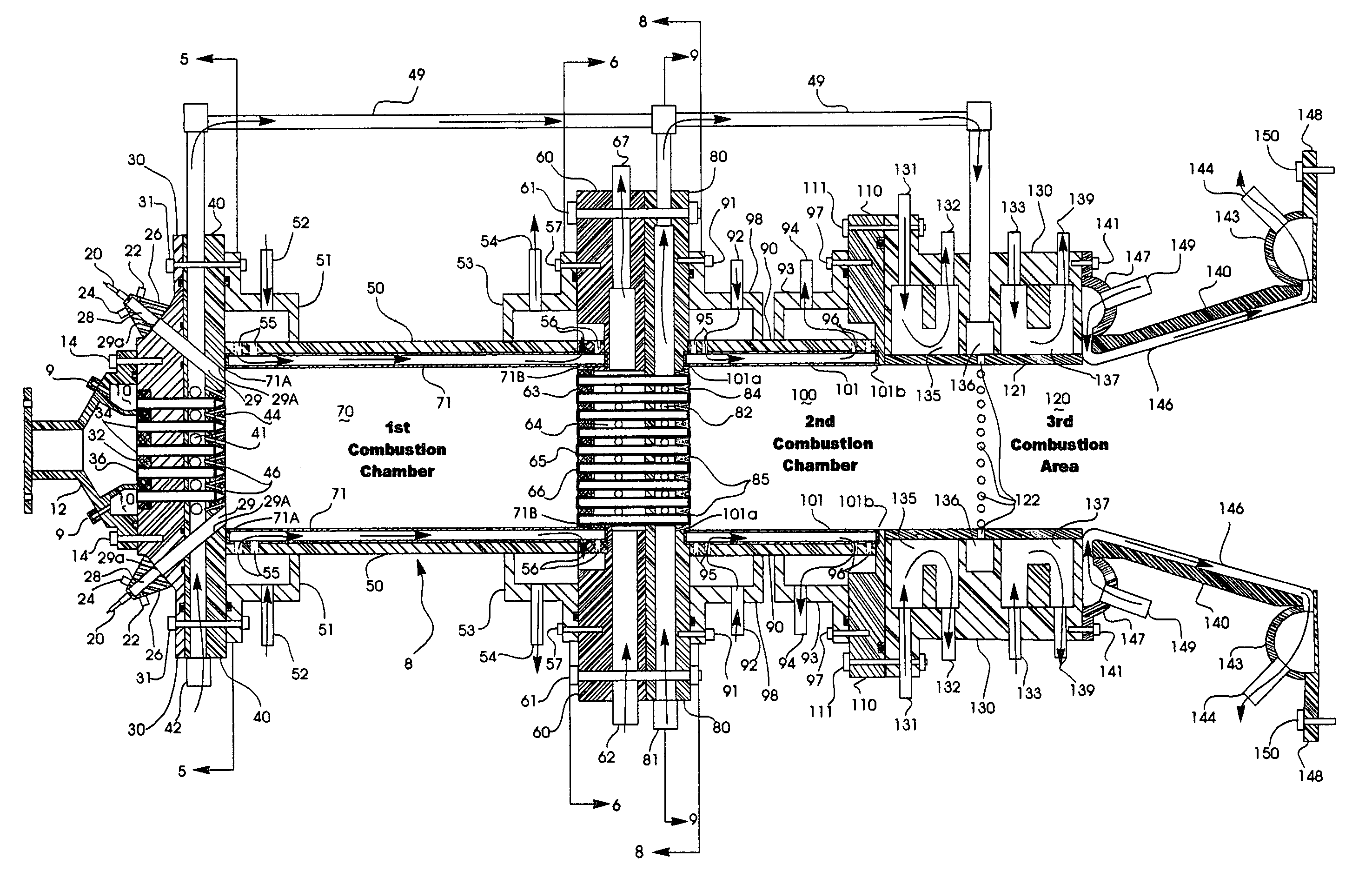

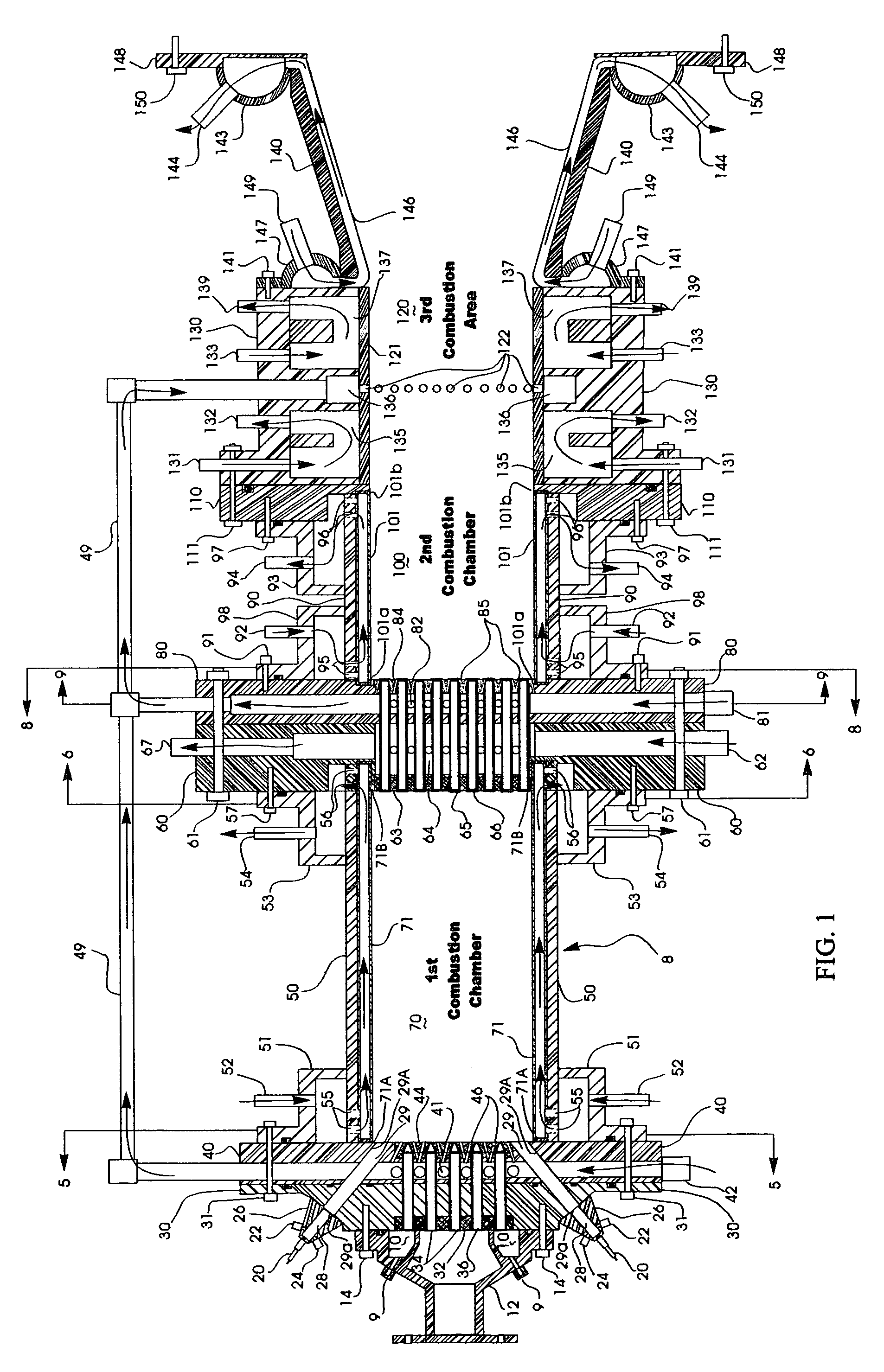

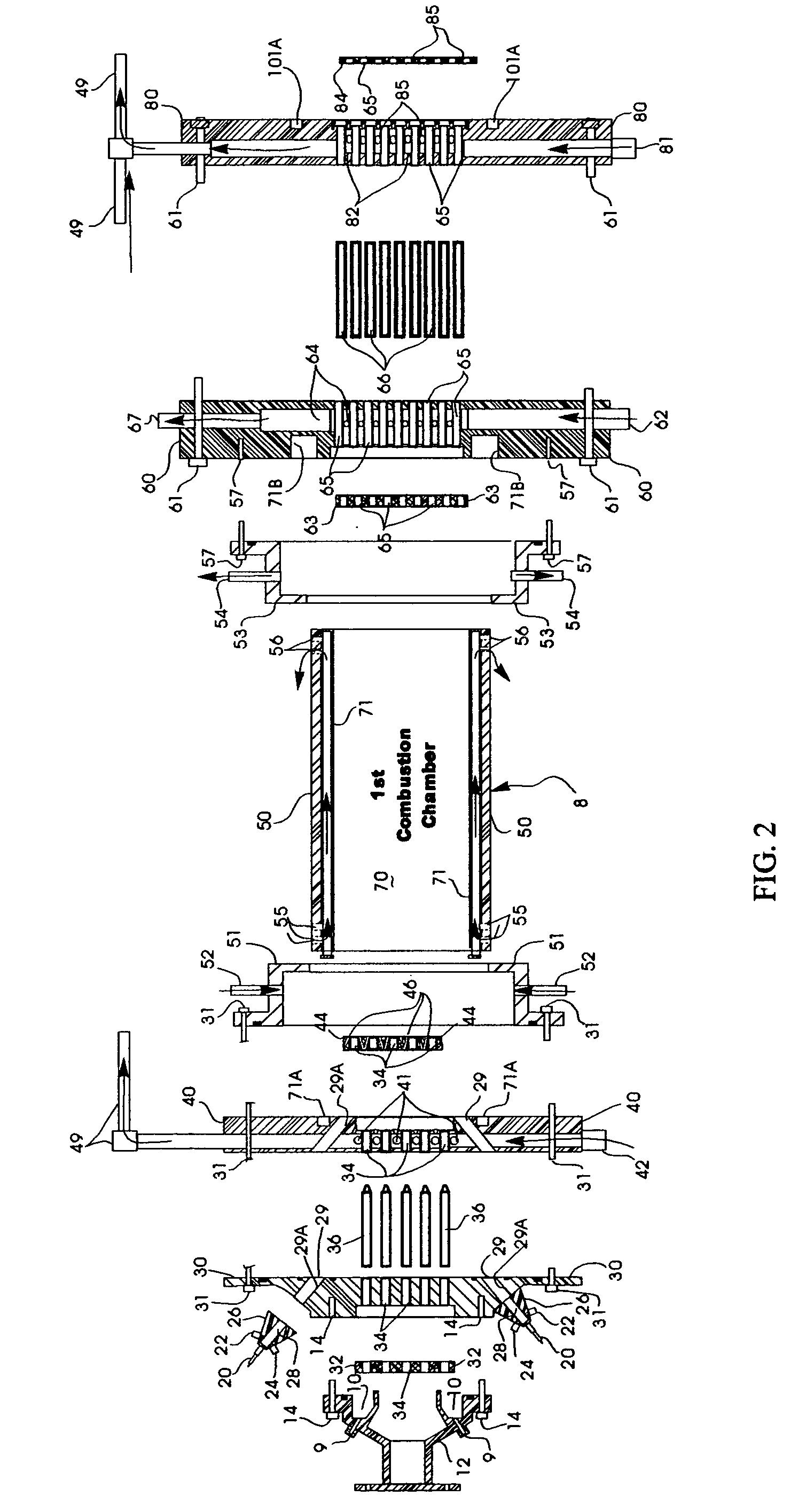

Method and apparatus for the production of energy

ActiveUS20060053791A1Zero atmospheric emissionSafely and rapidly and cost-effectively and efficiently producing and controlling high-energy and high purityIndirect carbon-dioxide mitigationCasings/liningsScrapElectric energy

The invention provides processes and apparatuses for safely, rapidly, cost-effectively and efficiently producing a superheated steam product or dry saturated steam product that can be employed to generate electrical power, or in other manufacturing and / or non-manufacturing processes, in an environmentally clean manner without causing corrosion to electrical power-generating devices. These processes and apparatuses involve the combustion of one or more fuels containing the elements hydrogen and / or carbon, which can be derived from waste materials, such as the rubber from scrap tires. Water that circulates around one or more combustion chambers and / or areas, but that does not enter into the combustion chambers or areas, becomes converted into a high purity steam product The present invention also provides processes and apparatuses for recycling or eliminating waste materials, and for transforming hazardous materials into non-hazardous materials, and fuels that can be employed in the foregoing processes and apparatuses.

Owner:ADVANCED COMBUSTION ENERGY SYST

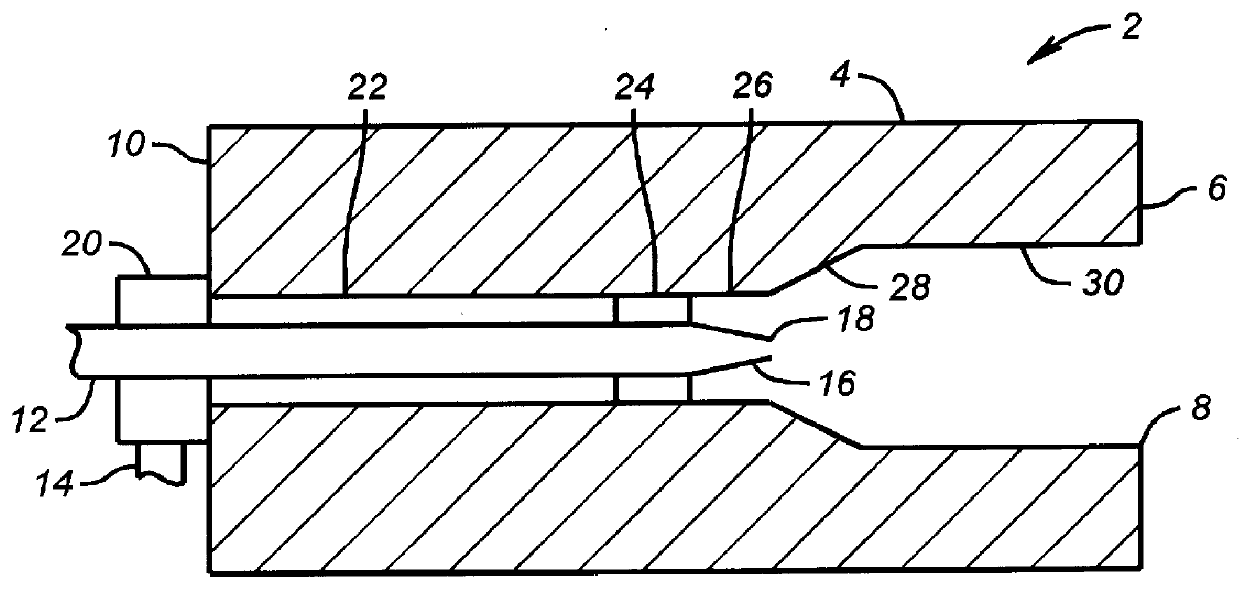

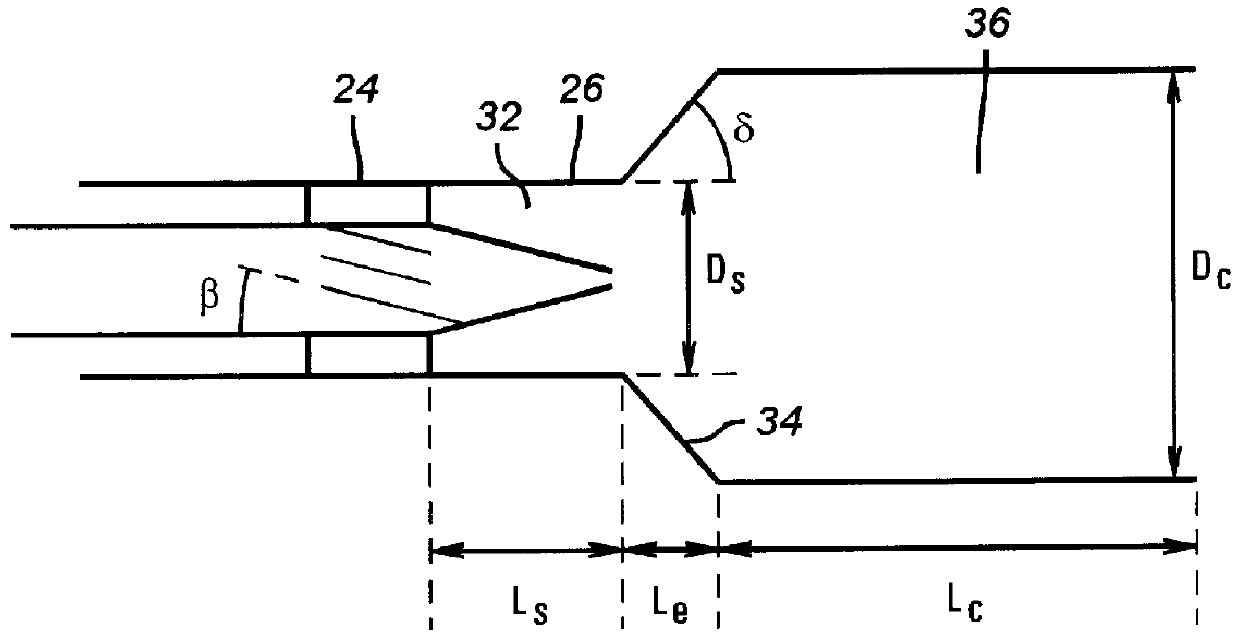

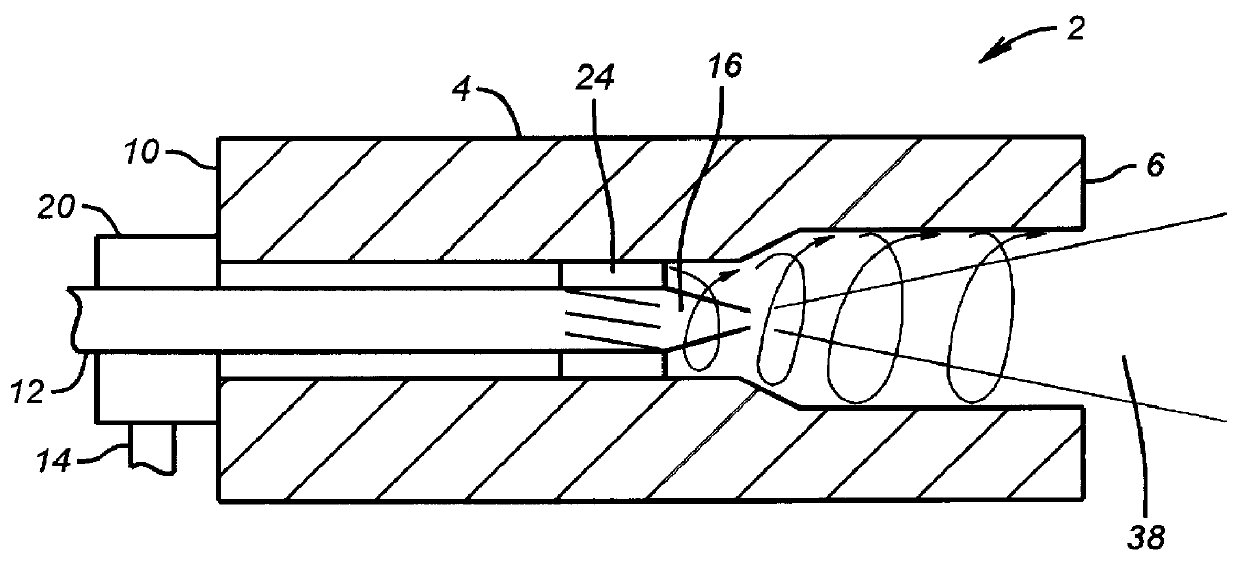

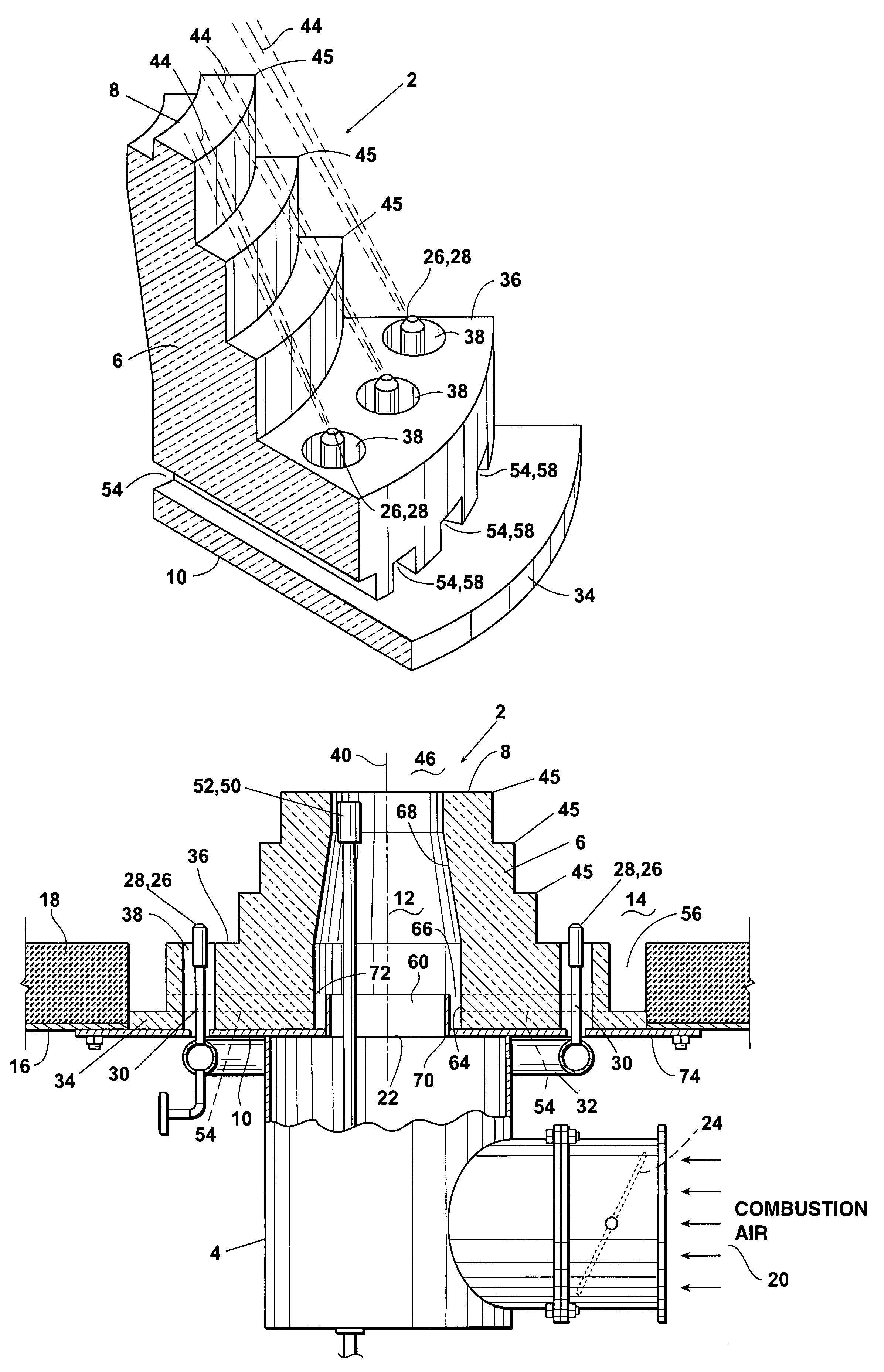

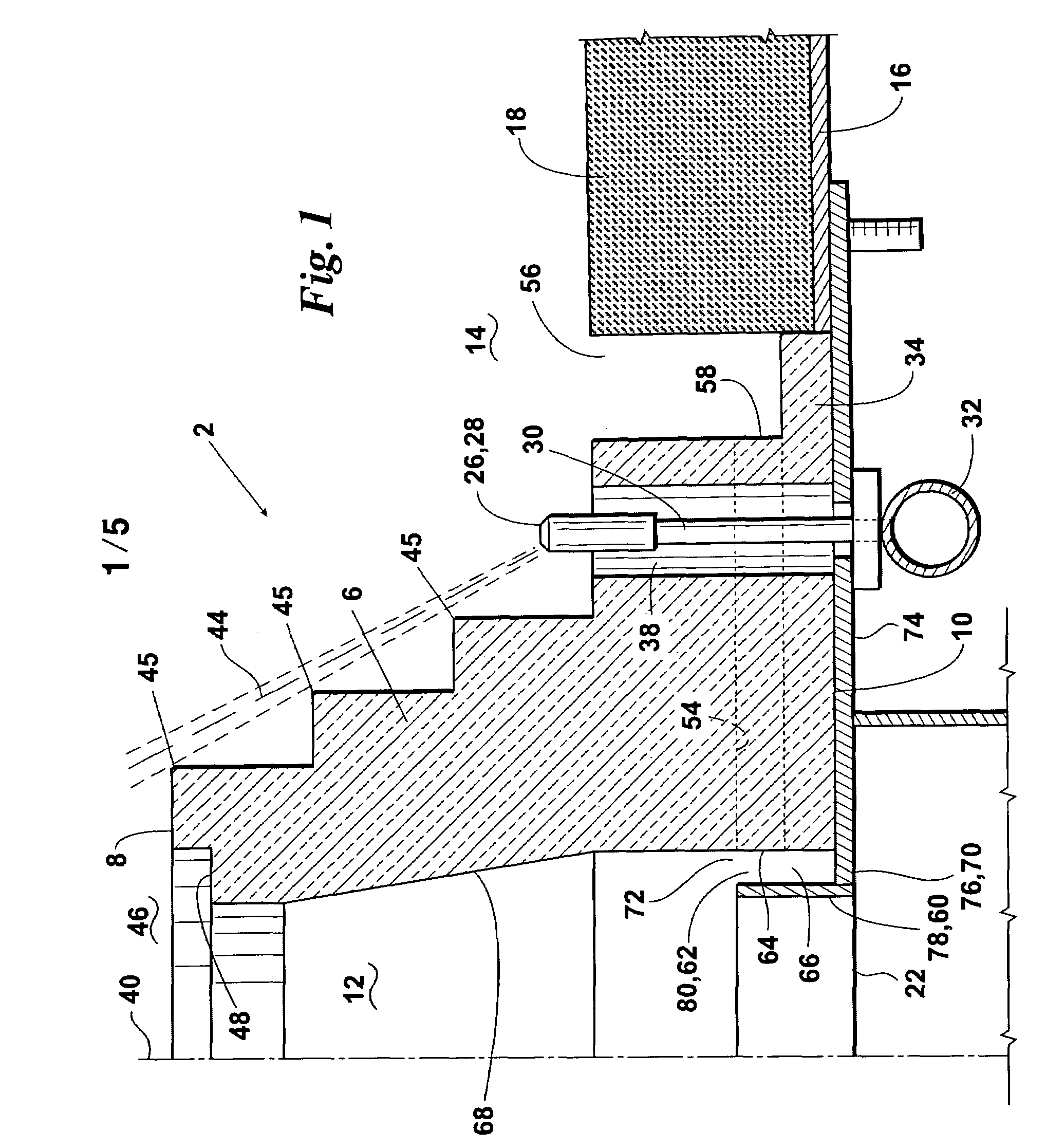

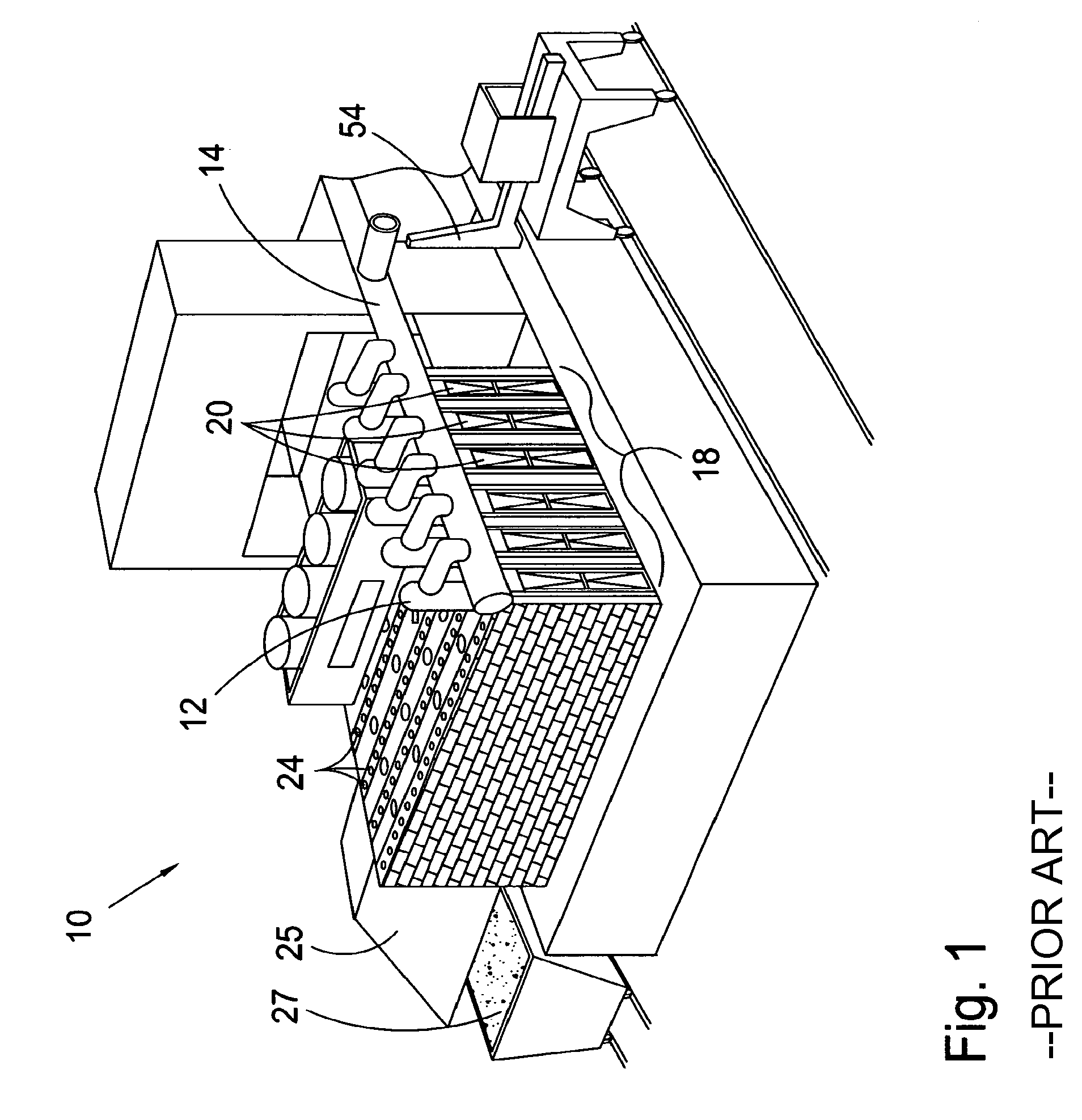

Self-cooled oxygen-fuel burner for use in high-temperature and high-particulate furnaces

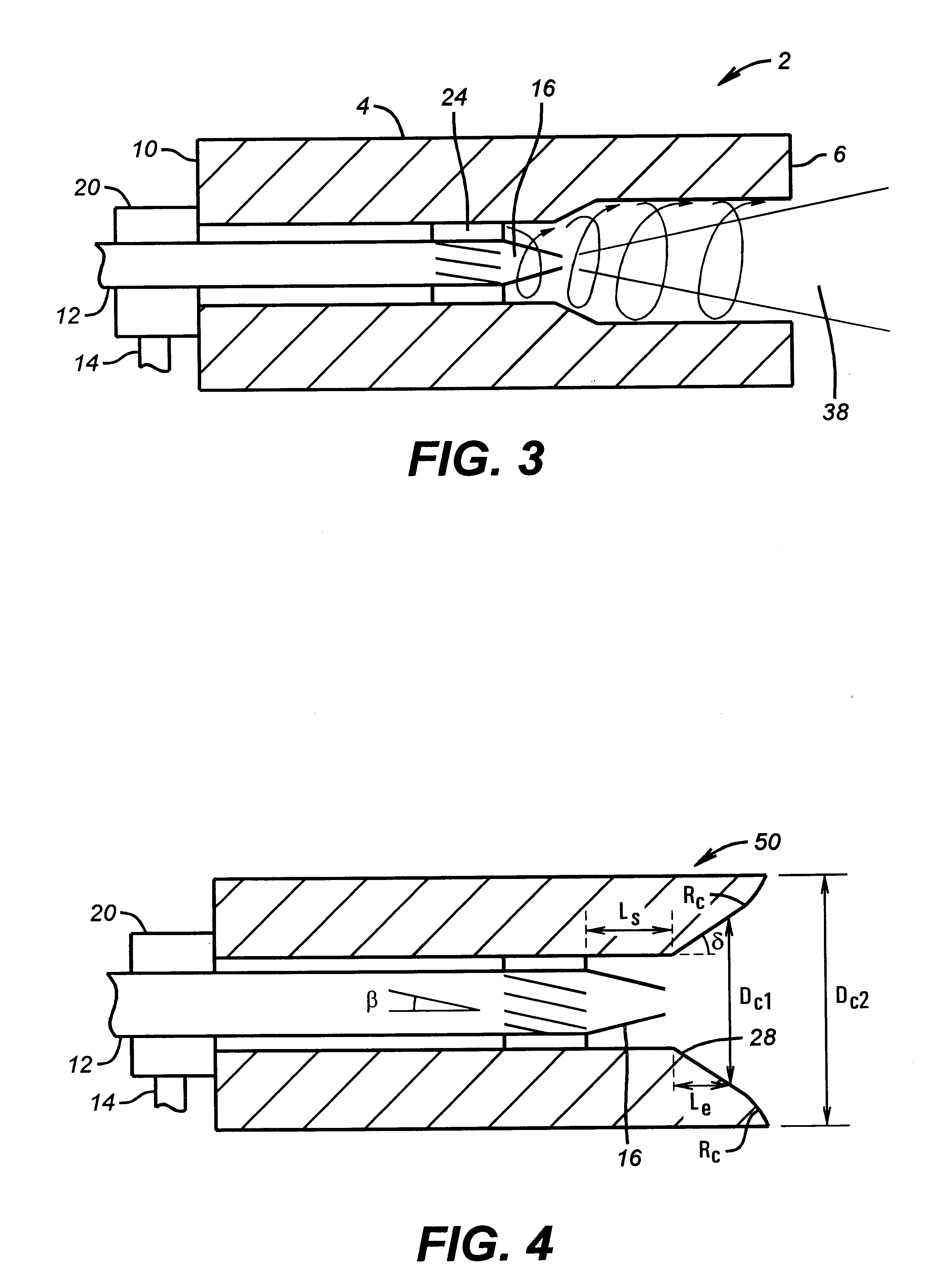

InactiveUS6123542AAvoiding particulate inspiration.TheControl expansionGlass furnace apparatusGlass melting apparatusParticulatesCombustor

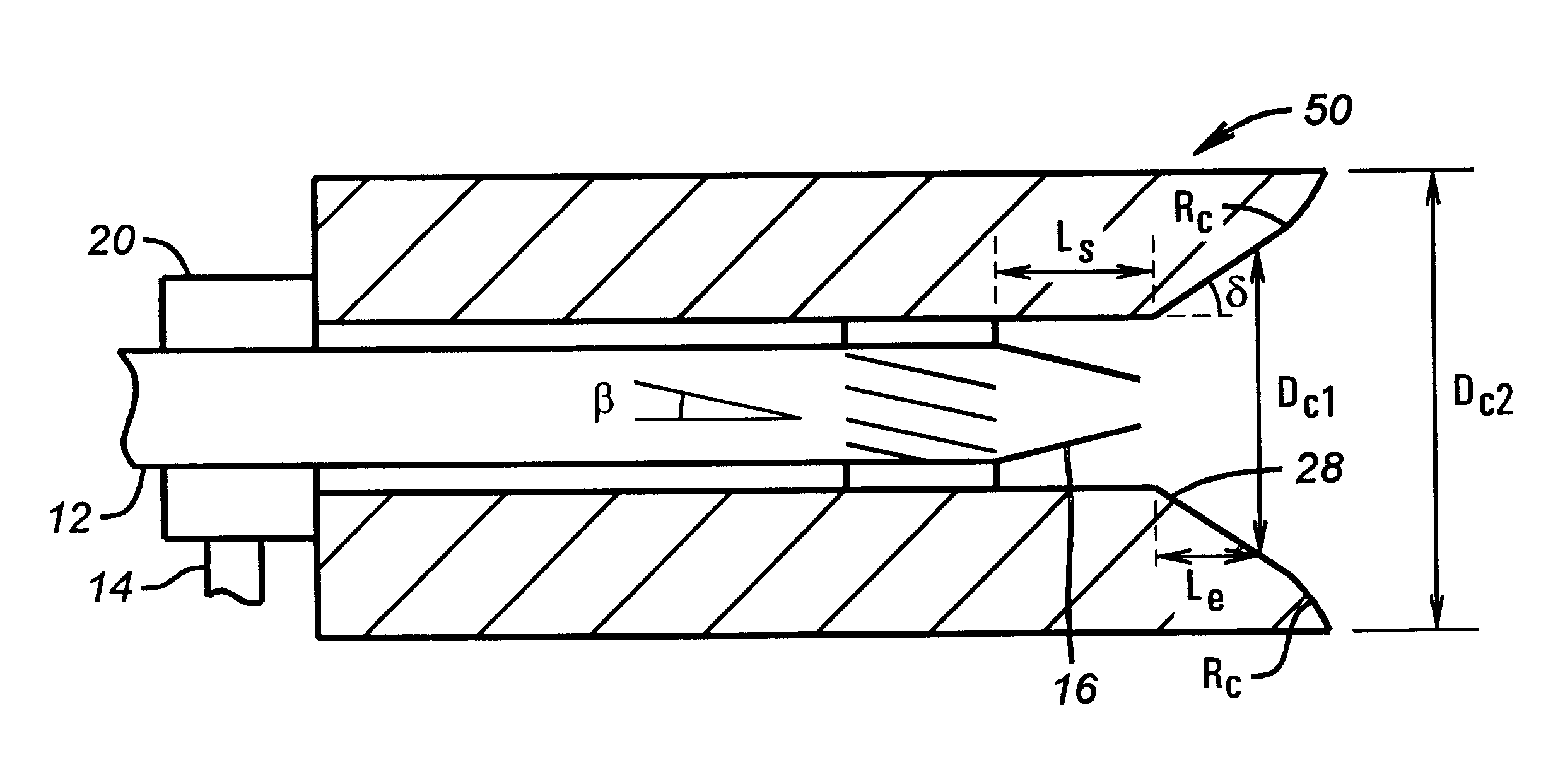

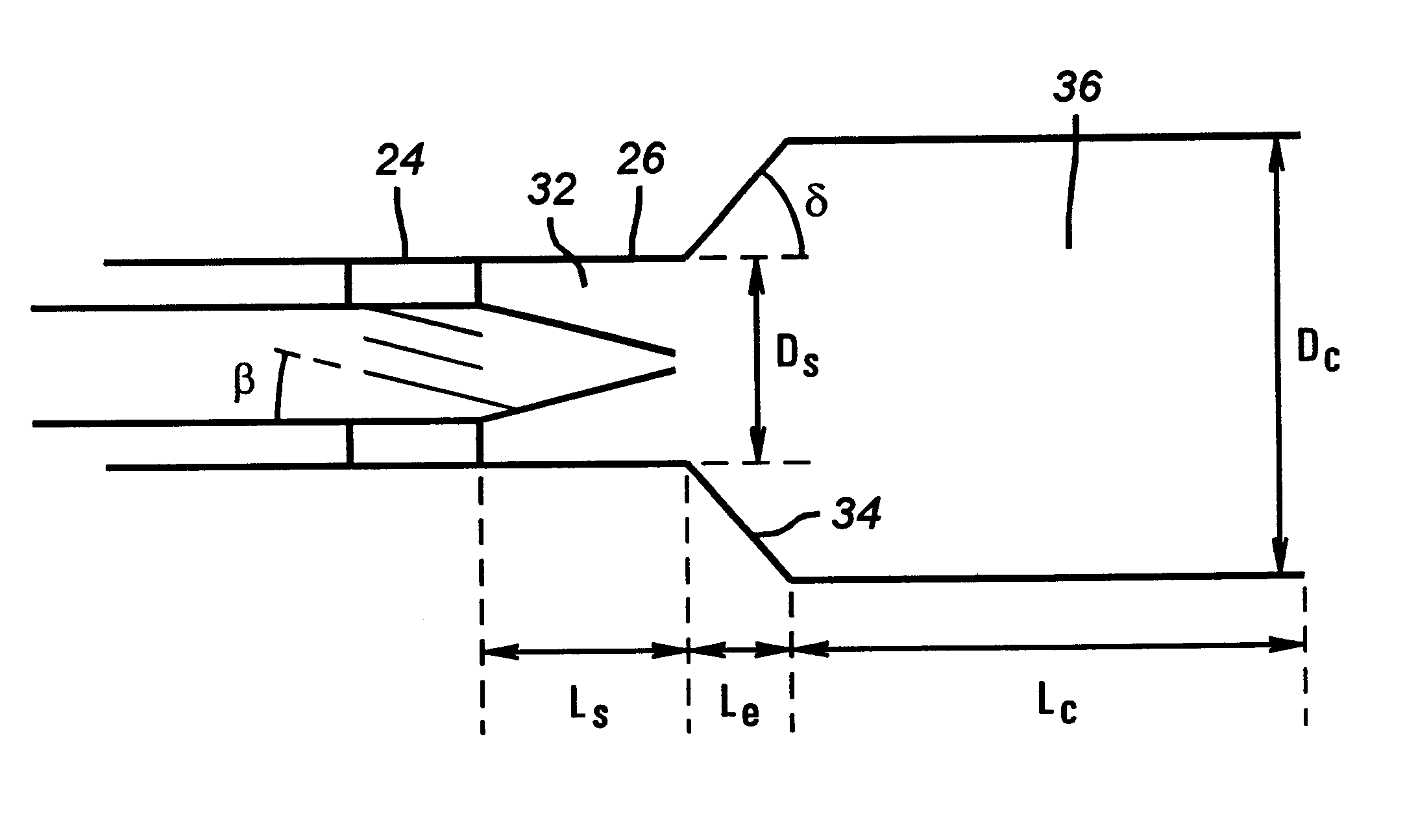

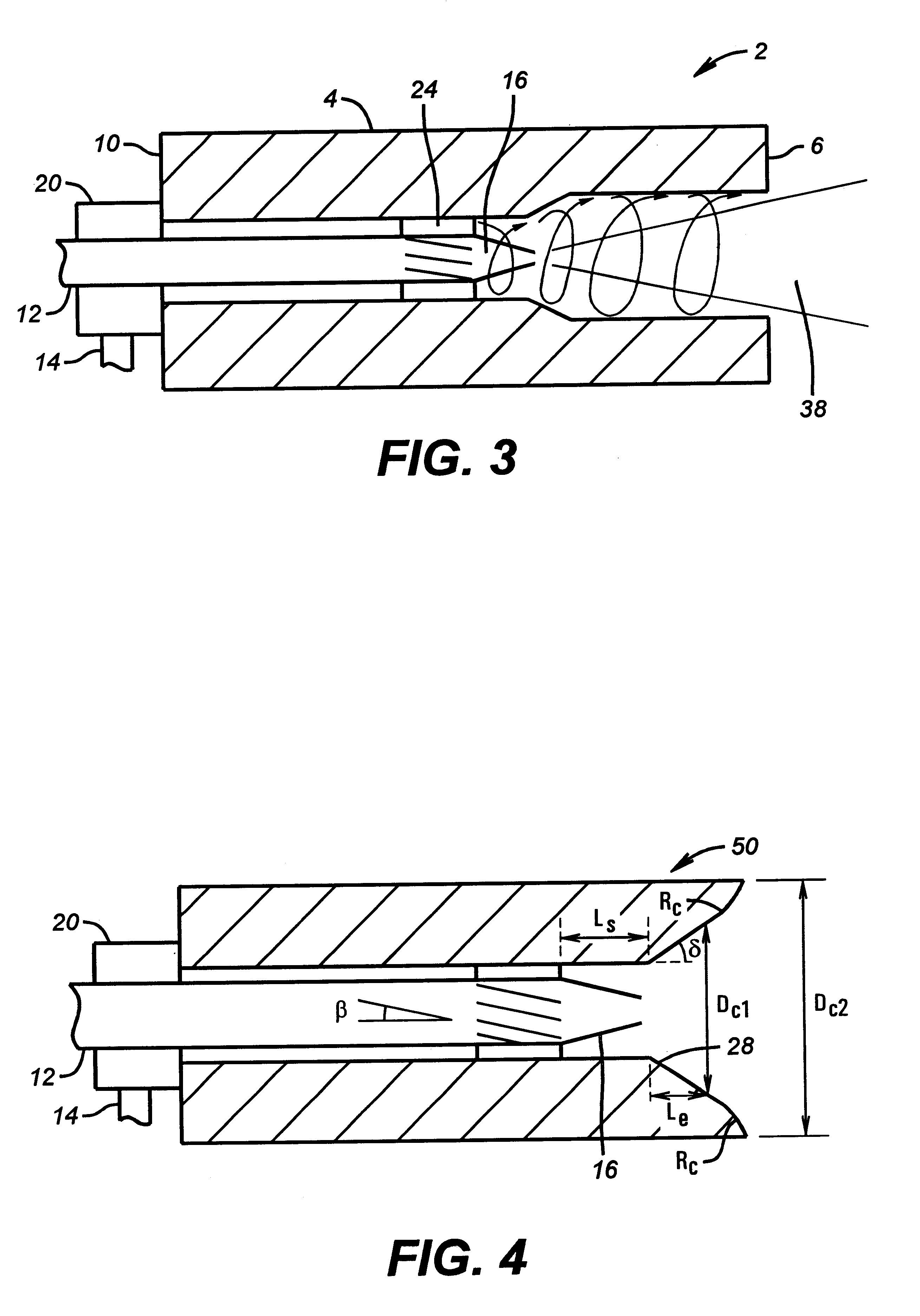

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200 DEG F. to 3000 DEG F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:LAIR LIQUIDE SA POUR L ETUD ET LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

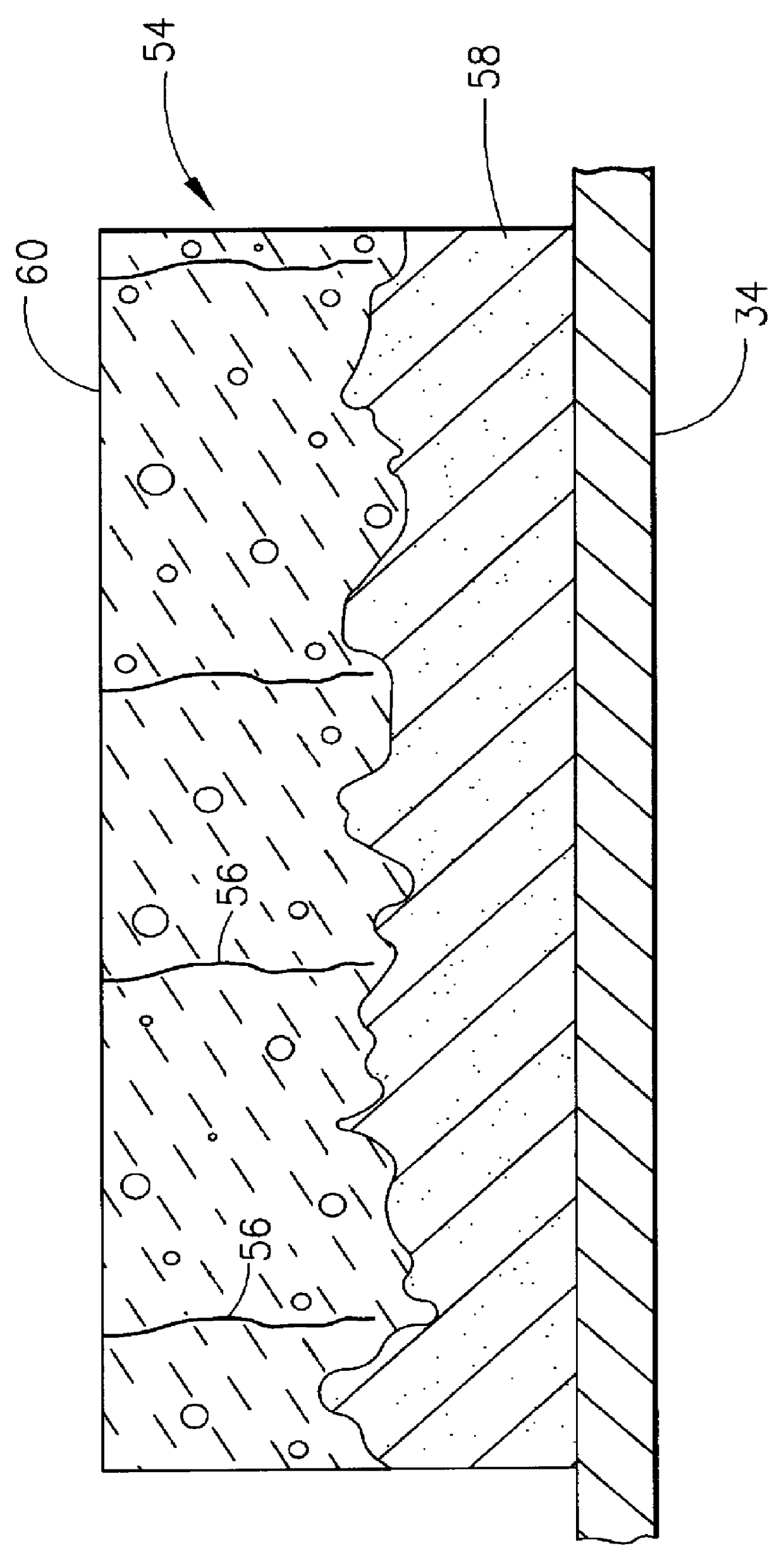

Method of protecting gas turbine combustor components against water erosion and hot corrosion

A method of preventing water erosion and hot corrosion in a combustor of a gas turbine engine, wherein water is injected into said combustor for NOx abatement, which involves the step of applying a dense vertically cracked thermal barrier coating to certain components thereof The dense vertically cracked thermal barrier coating has a porosity of less than approximately 8% and a tensile strength in the range of approximately 4-7 ksi. The dense vertically cracked thermal barrier coating is applied to such combustor components so as to produce a segmented ceramic structure having macrocracks formed therein which are oriented substantially perpendicular to an interface of the combustor component and the segmented ceramic structure.

Owner:GENERAL ELECTRIC CO

Refractory block for use in a burner assembly

InactiveUS6068468ACombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

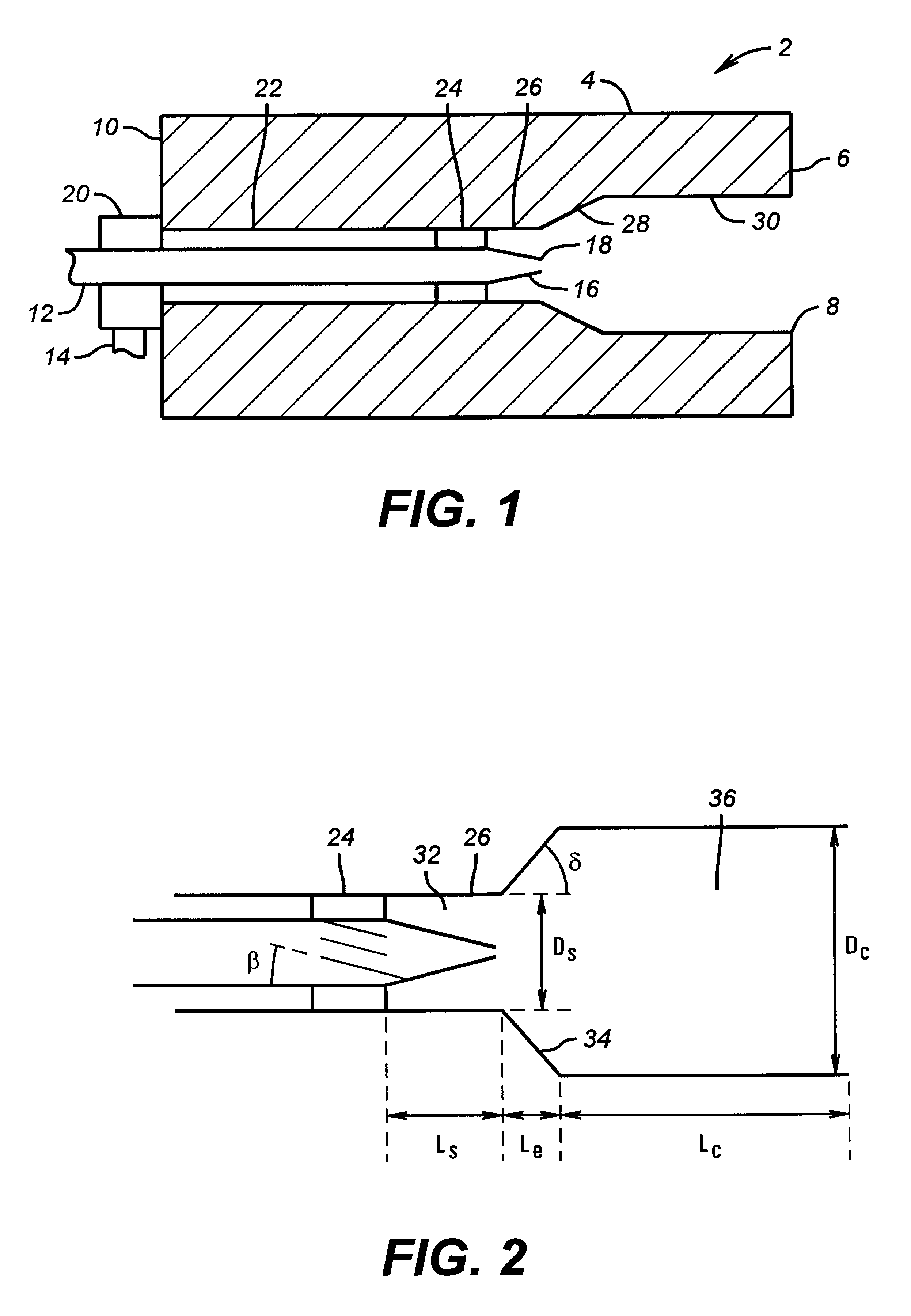

A burner assembly having improved flame length and shape control is presented, which includes in exemplary embodiments at least one fuel fluid inlet and at least one oxidant fluid inlet, means for transporting the fuel fluid from the fuel inlet to a plurality of fuel outlets-, the fuel fluid leaving the fuel outlets in fuel streams that are injected into a combustion chamber, means for transporting the oxidant fluid from the oxidant inlets to at least one oxidant outlet, the oxidant fluid leaving the oxidant outlets in oxidant fluid streams that are injected into the combustion chamber, with the fuel and oxidant outlets being physically separated, and geometrically arranged in order to impart to the fuel fluid streams and the oxidant fluid streams angles and velocities that allow combustion of the fuel fluid with the oxidant in a stable, wide, and luminous flame. Alternatively, injectors may be used alone or with the refractory block to inject oxidant and fuel gases. The burner assembly affords improved control over flame size and shape and may be adjusted for use with a particular furnace as required.

Owner:AIR LIQUIDE AMERICA INC +1

Self-cooled oxygen-fuel burner for use in high-temperature and high-particulate furnaces

InactiveUS6210151B1Avoiding particulate inspiration.TheControl expansionIndirect carbon-dioxide mitigationGaseous fuel burnerParticulatesVolatiles

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS8959887B2Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

Method and apparatus for the production of energy

ActiveUS7028478B2Safely and rapidly and cost-effectively and efficiently producing and controlling high-energy and high purityIndirect carbon-dioxide mitigationAir/fuel supply for combustionHydrogenCombustion chamber

The invention provides processes and apparatuses for safely, rapidly, cost-effectively and efficiently producing a superheated steam. These processes and apparatuses involve the combustion of one or more fuels containing the element hydrogen, the element carbon or the elements hydrogen and carbon. One or more of the combustion reactions are incomplete combustion reactions, and another combustion is a complete combustion reaction. Water that circulates around one or more combustion chambers and areas, but that does not enter into the combustion chambers or areas becomes converted into a high purity superheated steam product or dry saturated steam product containing superheated steam.

Owner:ADVANCED COMBUSTION ENERGY SYST

Reducing mercury emissions from the burning of coal

Processes and compositions are provided for decreasing emissions of mercury upon combustion of fuels such as coal. Various sorbent compositions are provided that contain components that reduce the level of mercury and / or sulfur emitted into the atmosphere upon burning of coal. In various embodiments, the sorbent compositions are added directly to the fuel before combustion; are added partially to the fuel before combustion and partially into the flue gas post combustion zone; or are added completely into the flue gas post combustion zone. In preferred embodiments, the sorbent compositions comprise a source of halogen and preferably a source of calcium. Among the halogens, iodine and bromine are preferred. In various embodiments, inorganic bromides make up a part of the sorbent compositions.

Owner:NOX II LTD

Burner and method for induction of flue gas

ActiveUS7670135B1Reduce nitrogen oxide emissionsEfficient drawingFluegas recirculationCasings/liningsCombustorFlue gas

A low NOx burner and method wherein (a) combustion air flows through the interior of the burner in a manner effective for drawing an amount of inert flue gas diluent from the fired heating system into the combustion air stream, preferably via one or more induction channels provided through the burner wall, and / or (b) air or an inert gas is discharged into the induction channel(s) in a manner effective for delivering flue gas into the combustion air stream.

Owner:ZEECO

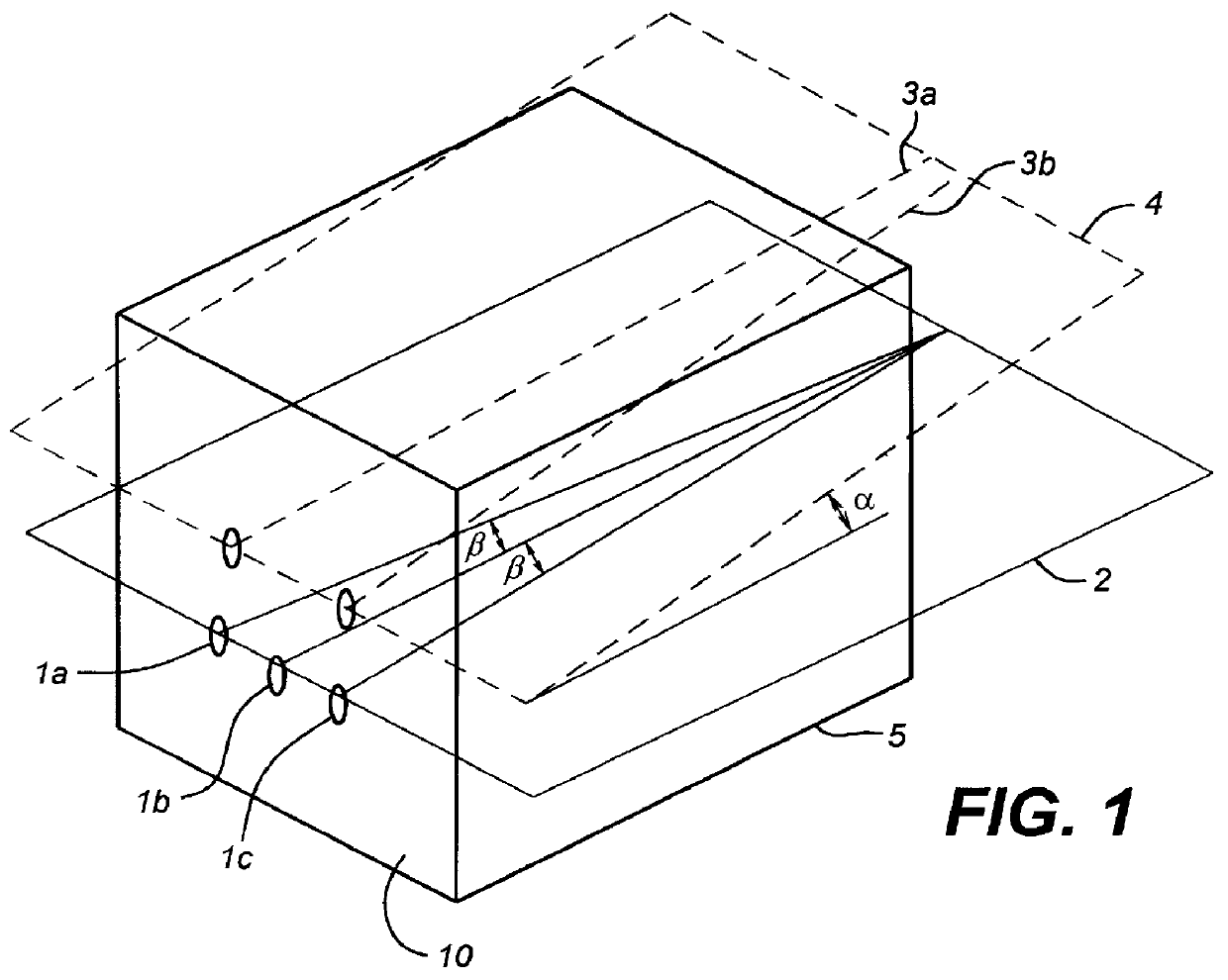

Oxidizing oxygen-fuel burner firing for reducing NOx emissions from high temperature furnaces

InactiveUS6171100B1Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFurnace temperatureEquivalence ratio

Burner firing method and device are presented where an oxidizing oxygen-fuel burner is fired at an angle to the reducing air-fuel burner flame to reduce overall NOx emissions from high temperature furnaces. The oxidizing oxy-fuel burner stoichiometric equivalence ratio (oxygen / fuel) is maintained in the range of about 1.5 to about 12.5. The reducing air-fuel burner is fired at an equivalence ratio of 0.6 to 1.00 to reduce the availability of oxygen in the flame and reducing NOx emissions. The oxidizing flame from the oxy-fuel burner is oriented such that the oxidizing flame gas stream intersects the reducing air-fuel flame gas stream at or near the tail section of the air-fuel flame. The inventive methods improve furnace temperature control and thermal efficiency by eliminating some nitrogen and provide an effective burnout of CO and other hydrocarbons using the higher mixing ability of the oxidizing flame combustion products. The simultaneous air-fuel and oxy-fuel burner firing can reduce NOx emissions anywhere from 30% to 70% depending on the air-fuel burner stoichiometric ratio.

Owner:AIR LIQUIDE AMERICA INC +1

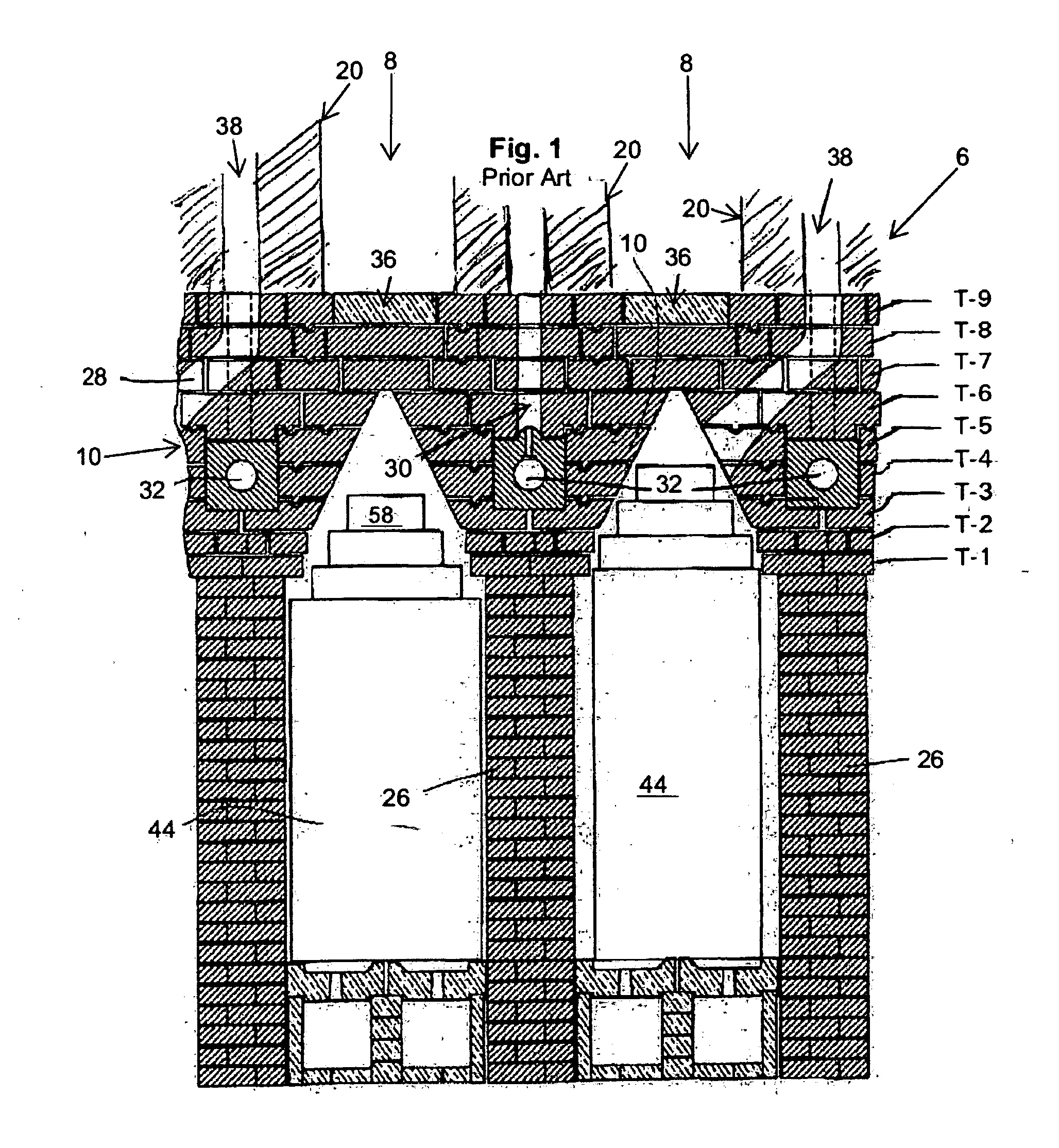

Corbel repairs of coke ovens

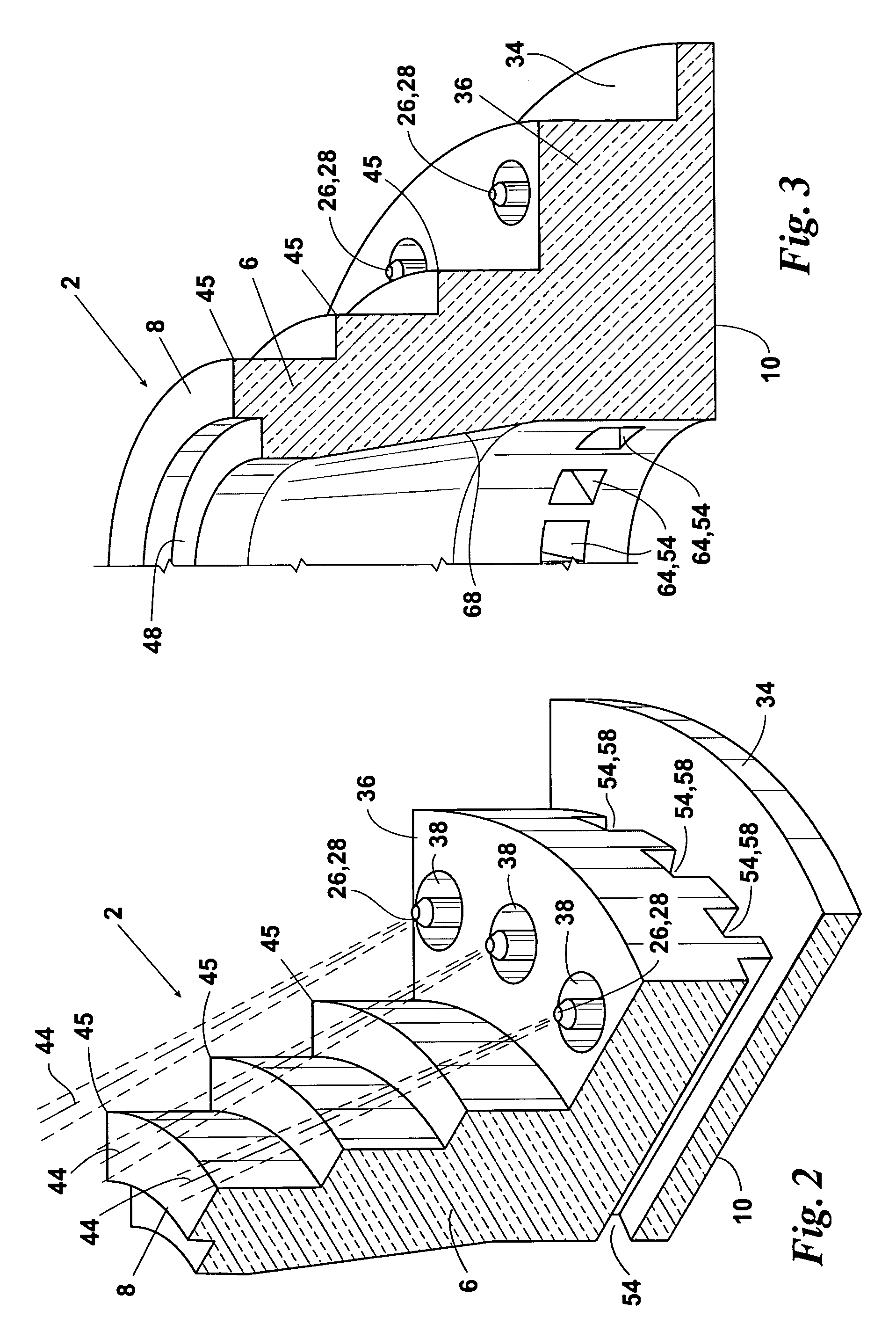

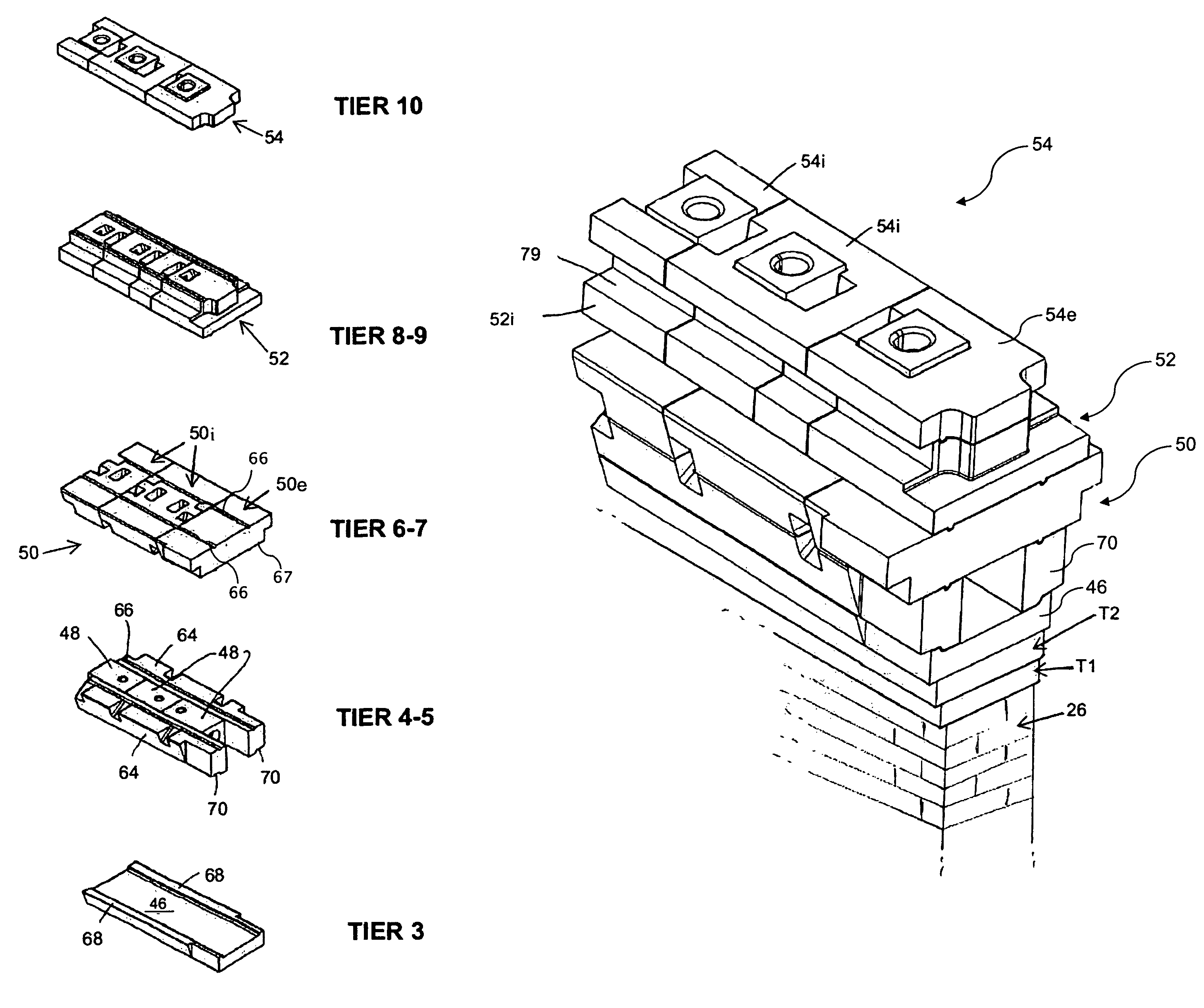

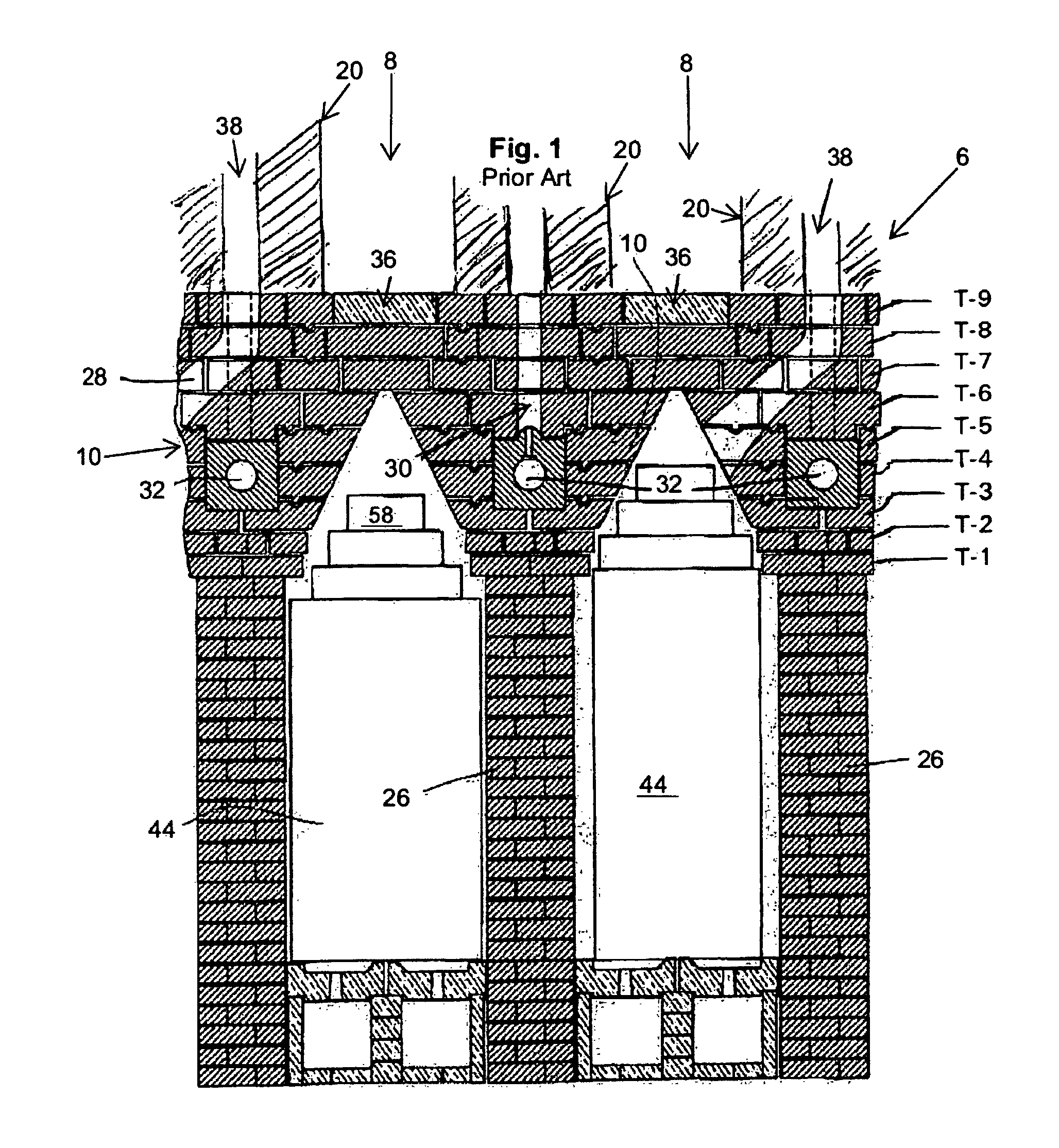

ActiveUS8266853B2Cost-effective constructionSave significant amountFurnace componentsFloorsEngineeringCoke oven

An improved corbel includes a first tier having first blocks and a second tier having second blocks. Each of the first blocks includes a first aperture extending through the block from a first surface to a back surface and a second aperture formed through a top surface of the block, extending into the first aperture. The first blocks are arranged on a substantially planar surface to align the respective first apertures to define a first passageway. Each of the second blocks includes a third aperture extending through the second block from a top surface to a bottom surface. The second blocks are disposed above the first tier to align the third aperture of each of the second blocks with the second aperture of the first blocks to form a second passageway.

Owner:VANOCUR REFRACTORIES LLC

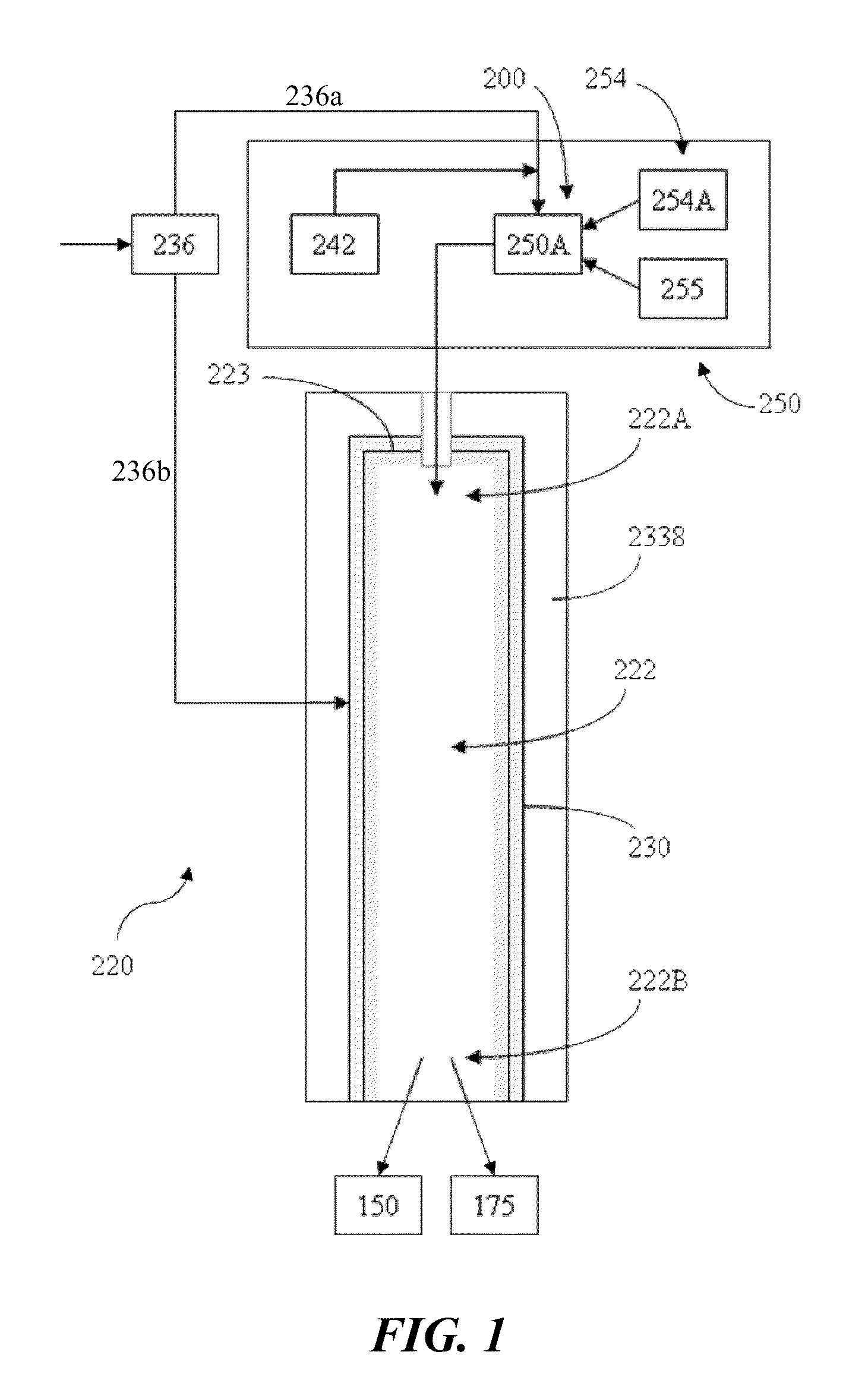

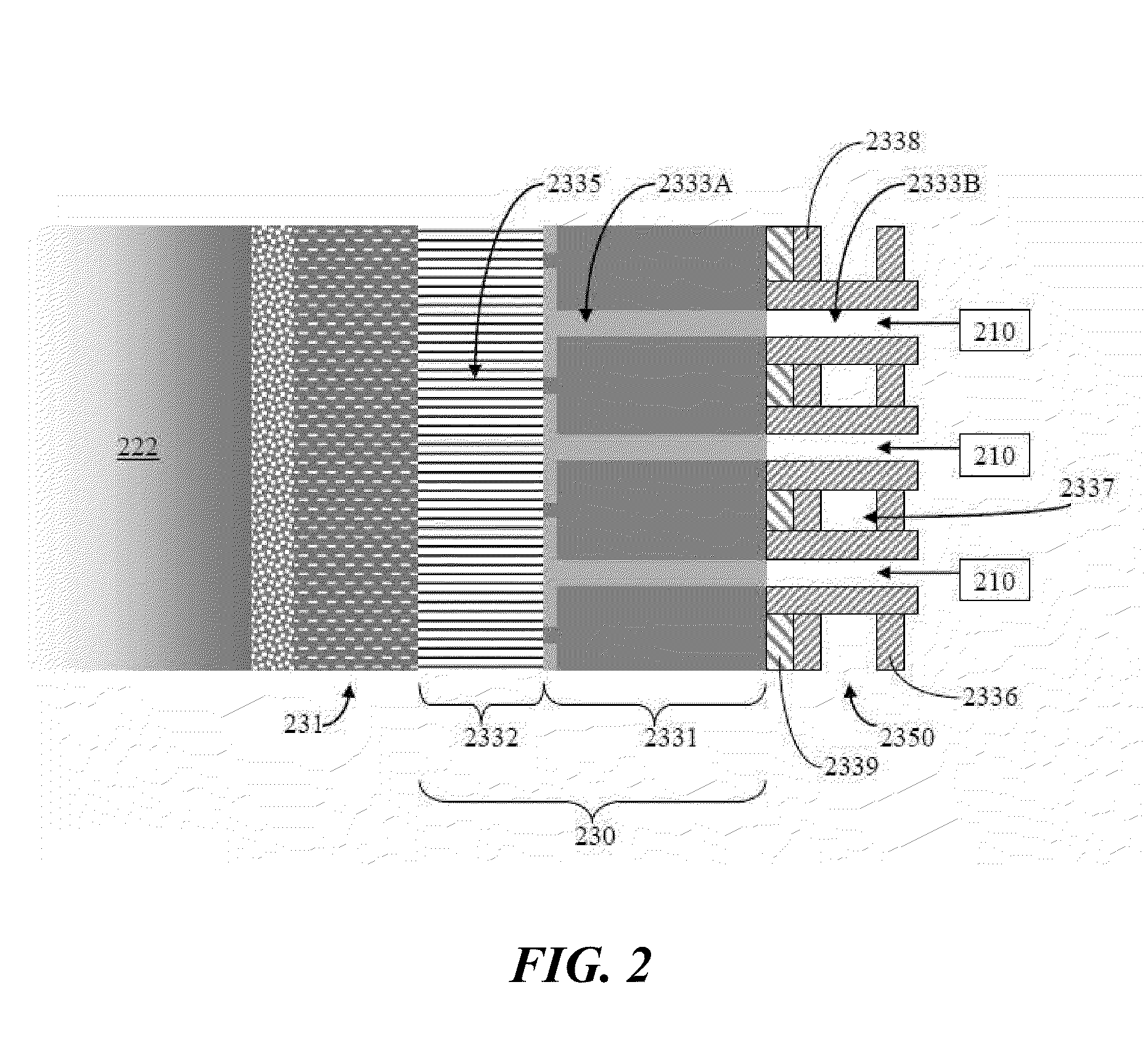

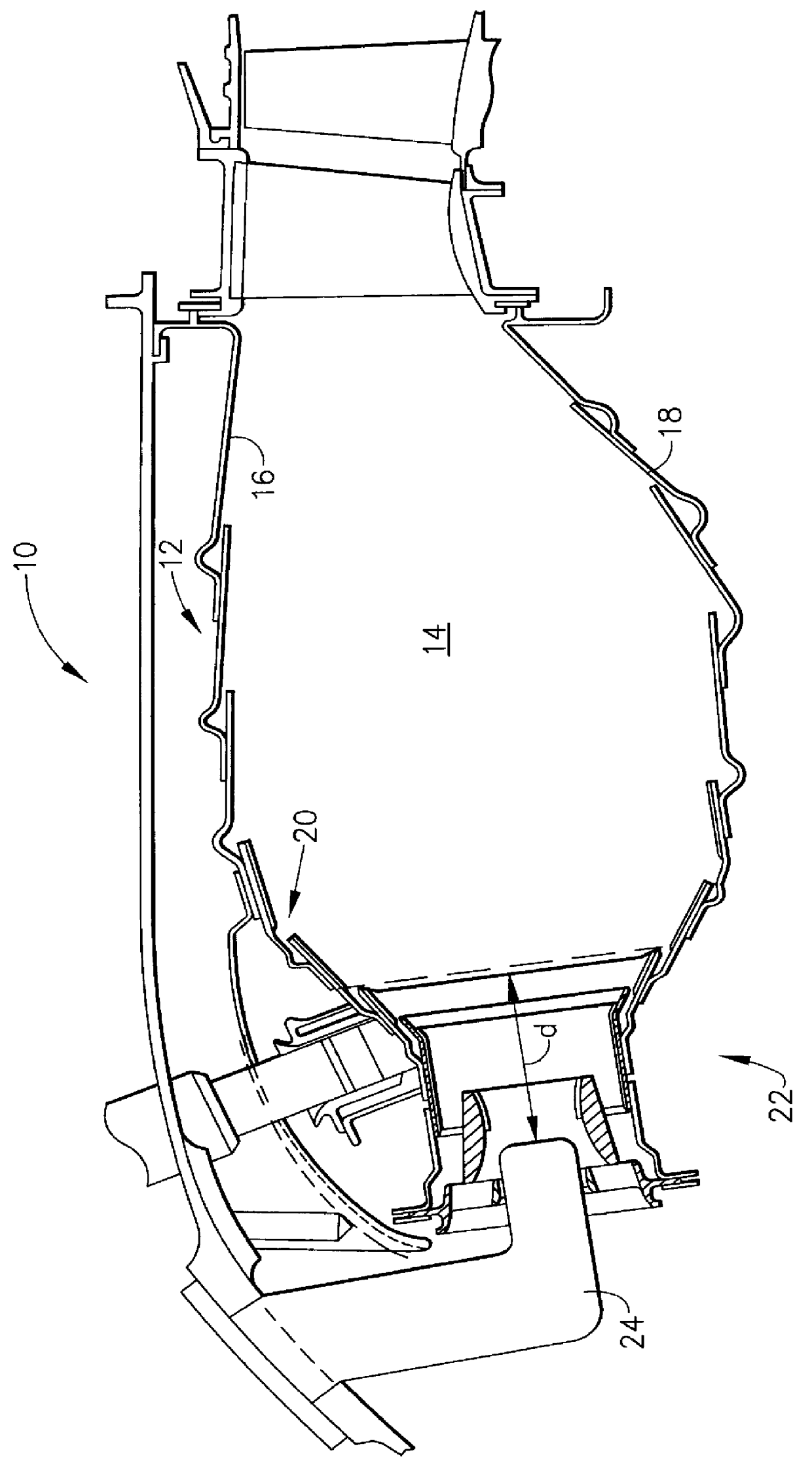

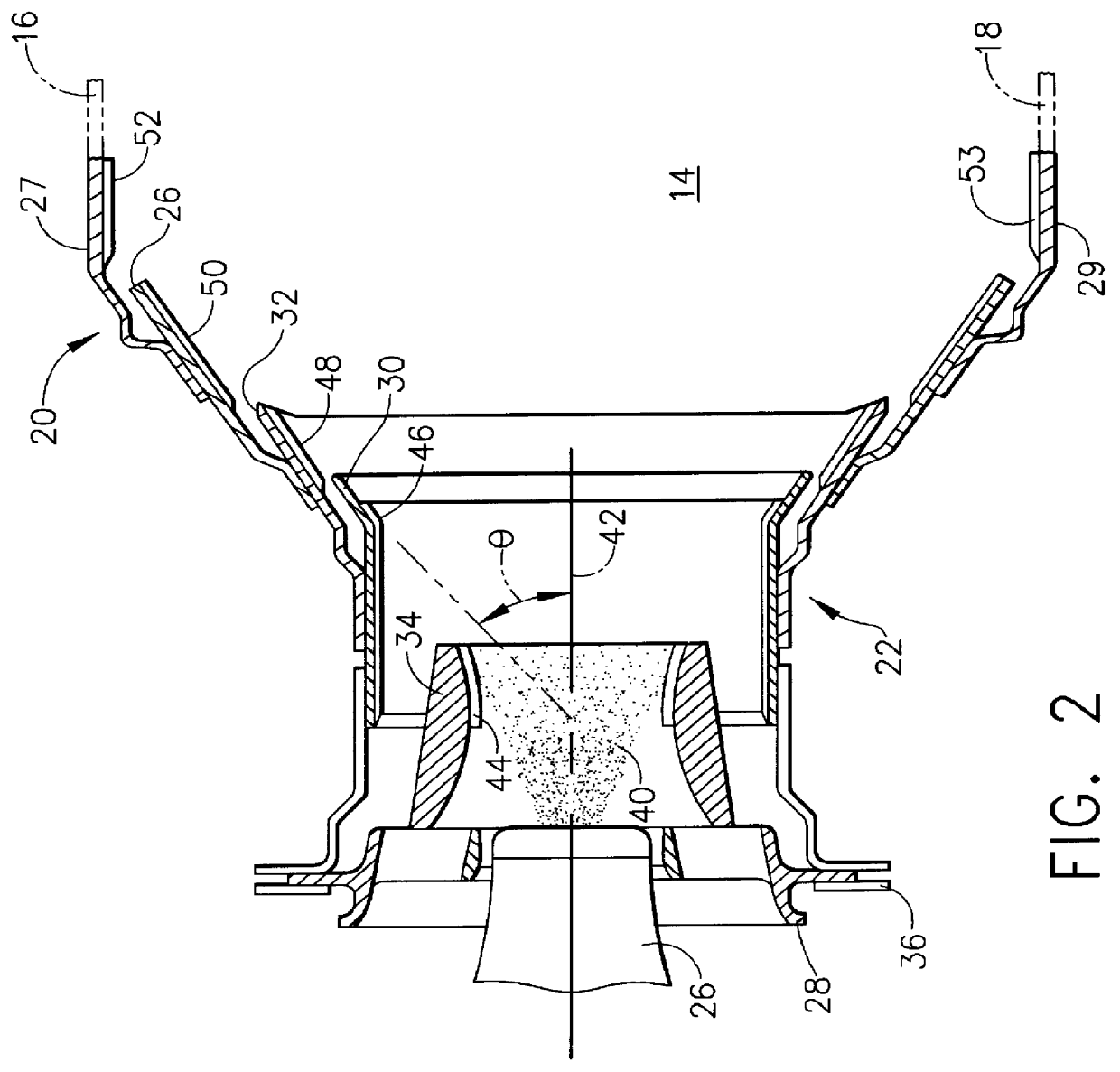

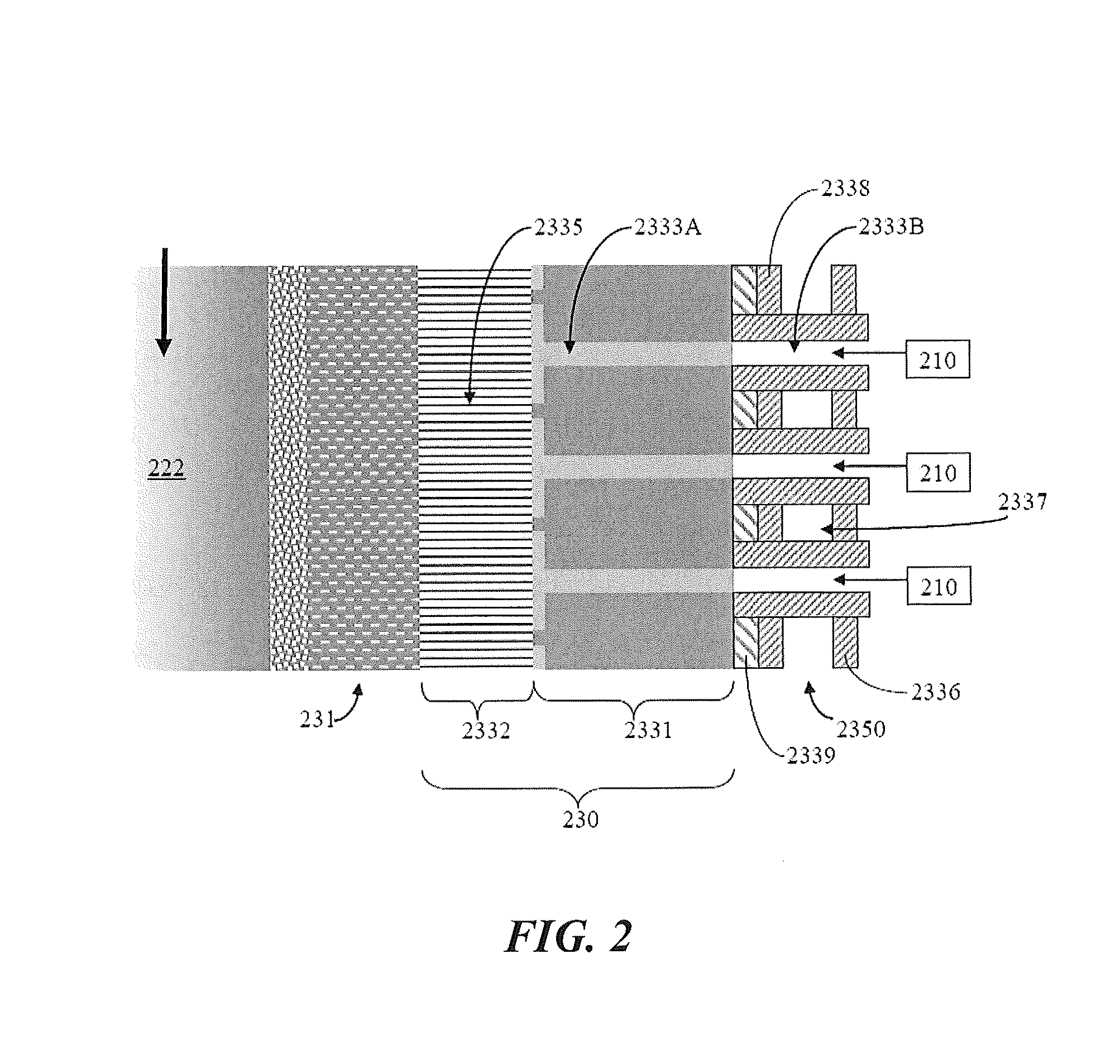

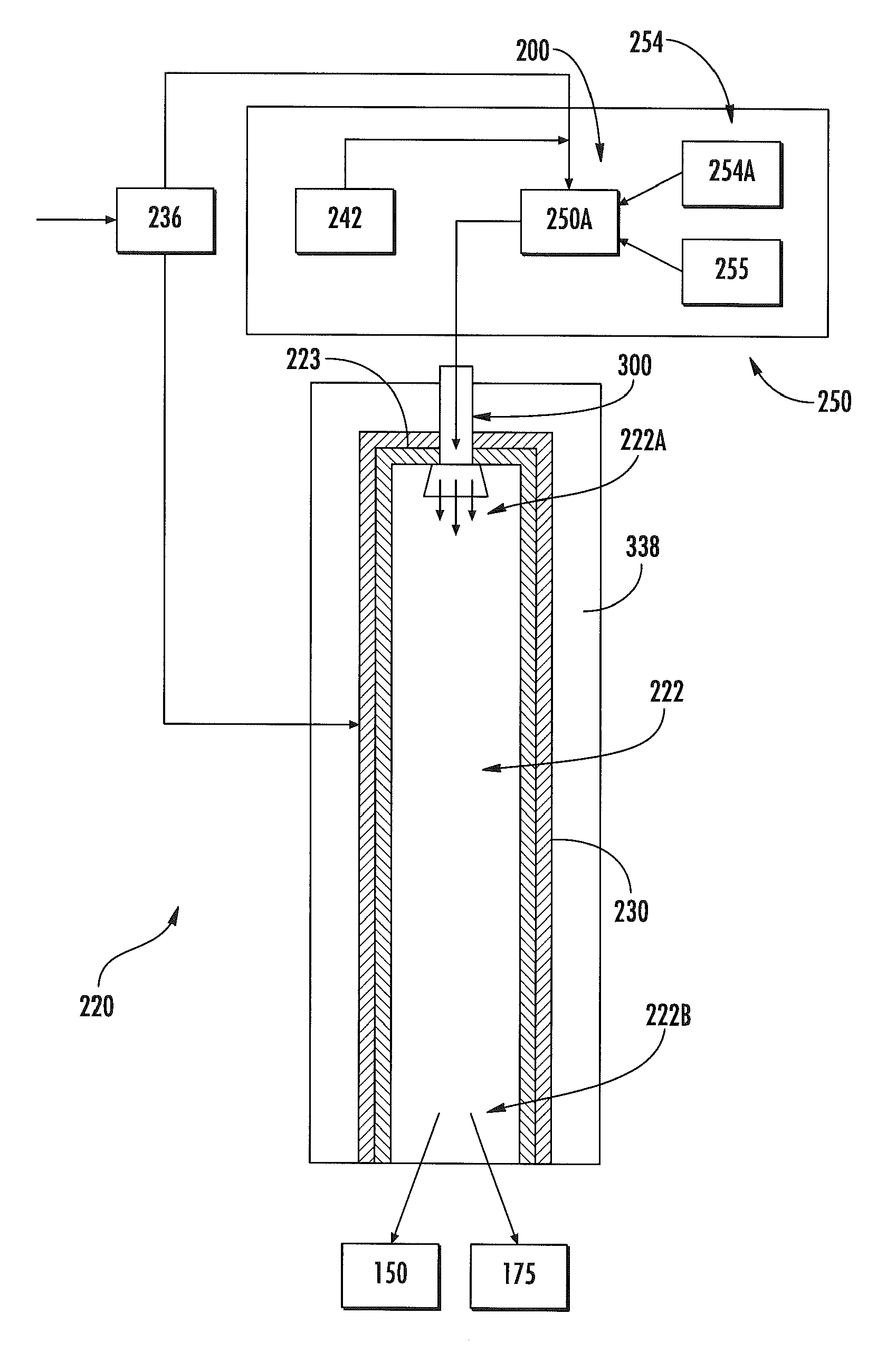

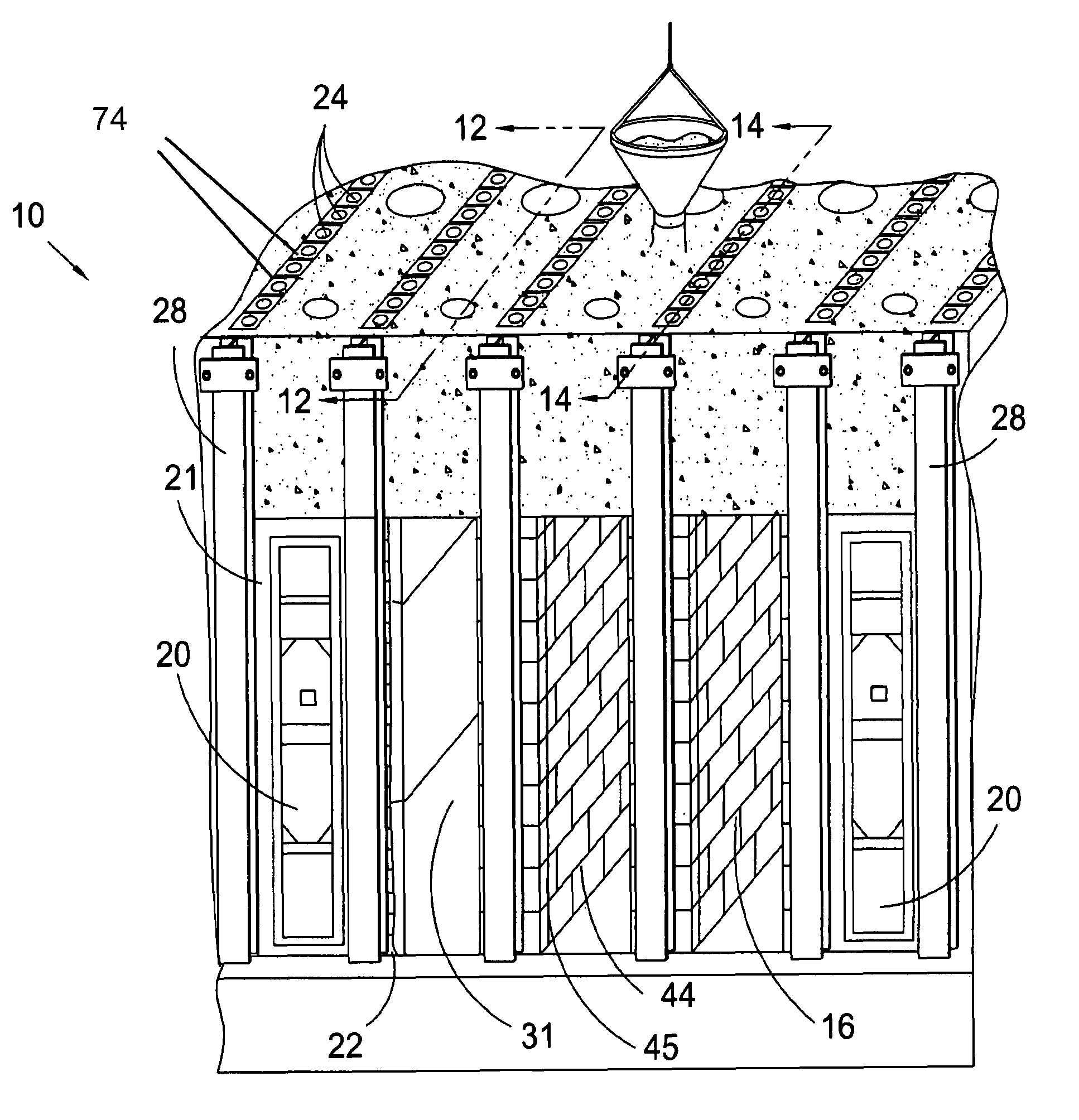

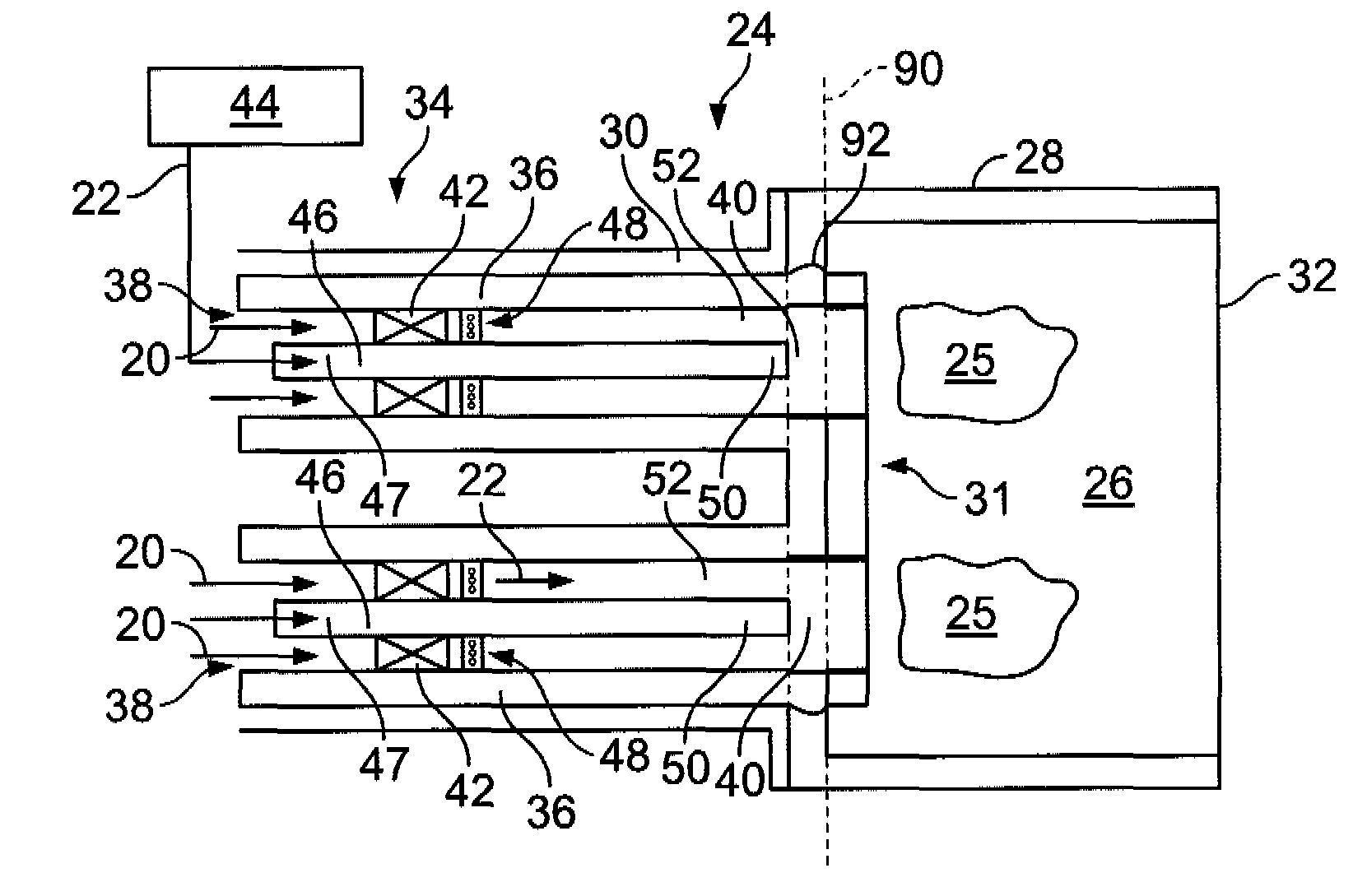

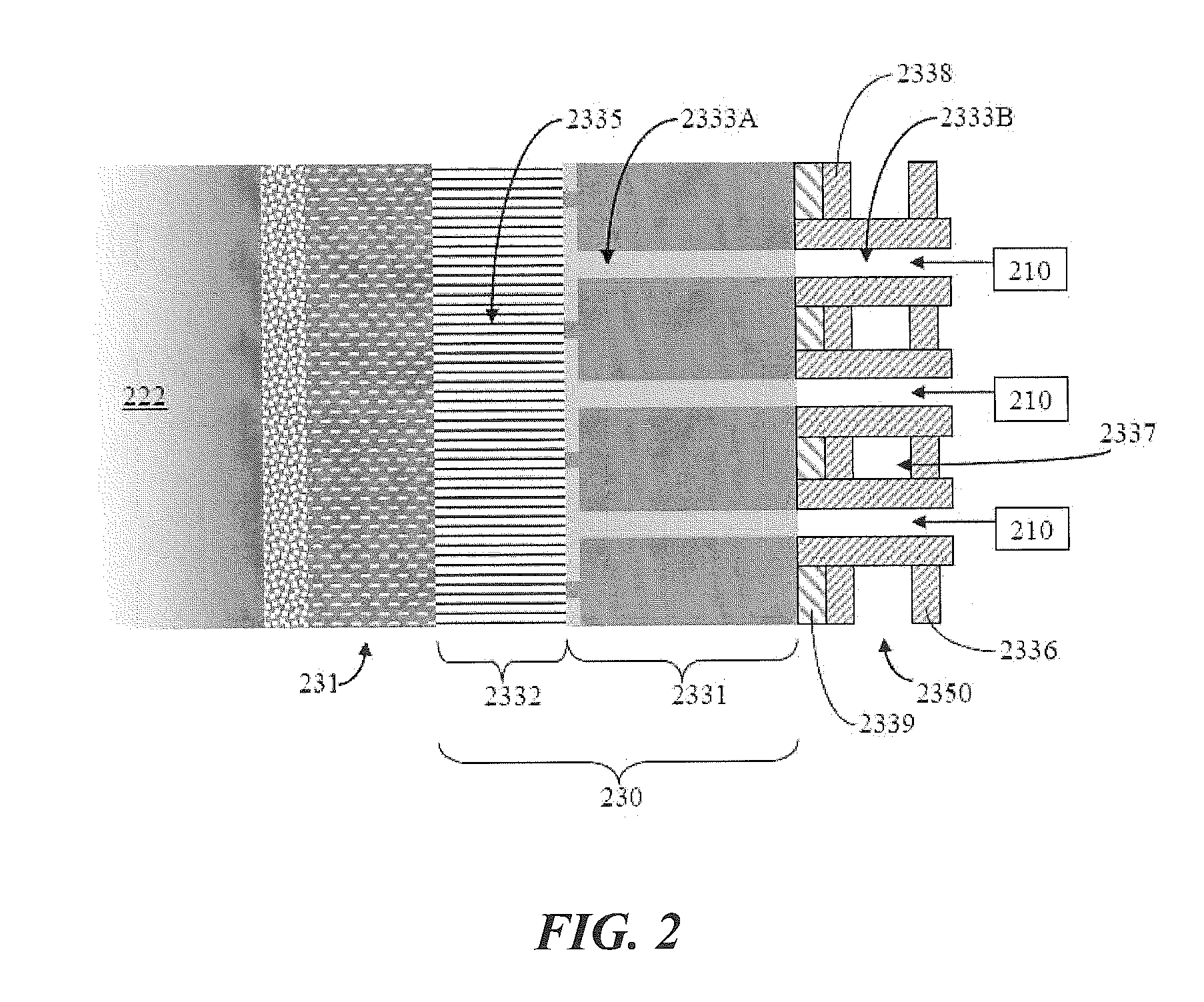

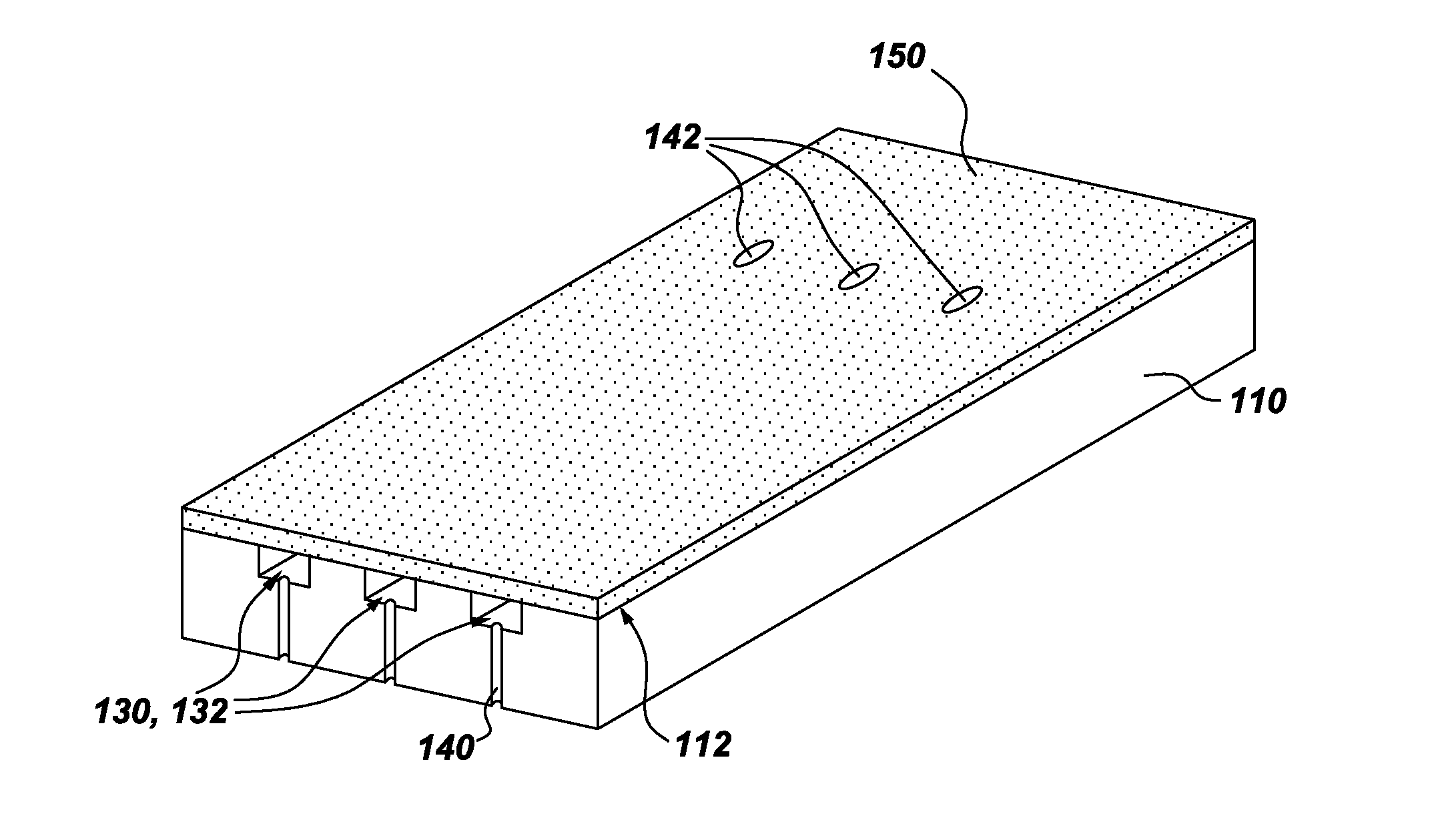

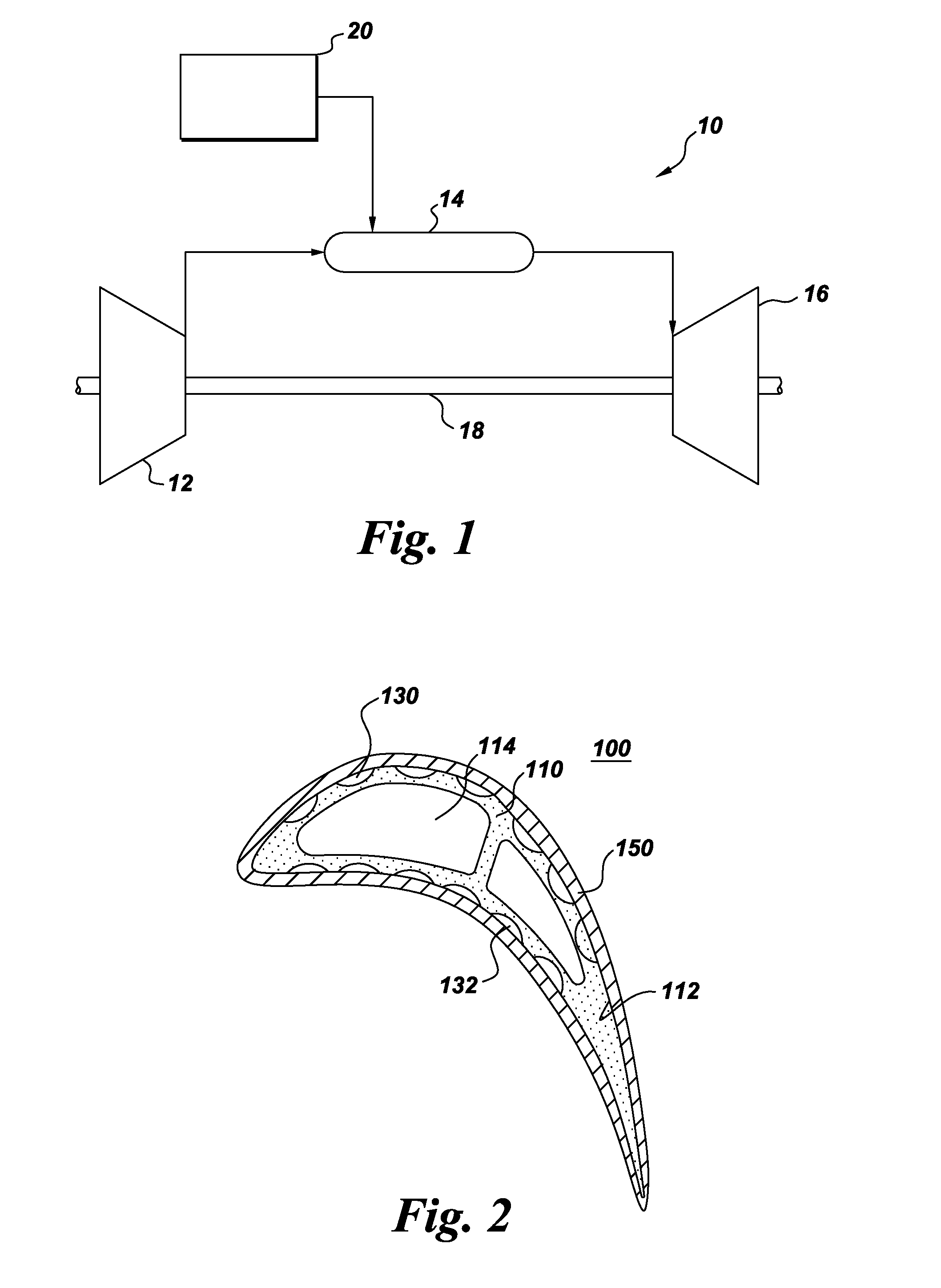

Apparatus for combusting a fuel at high pressure and high temperature, and associated system

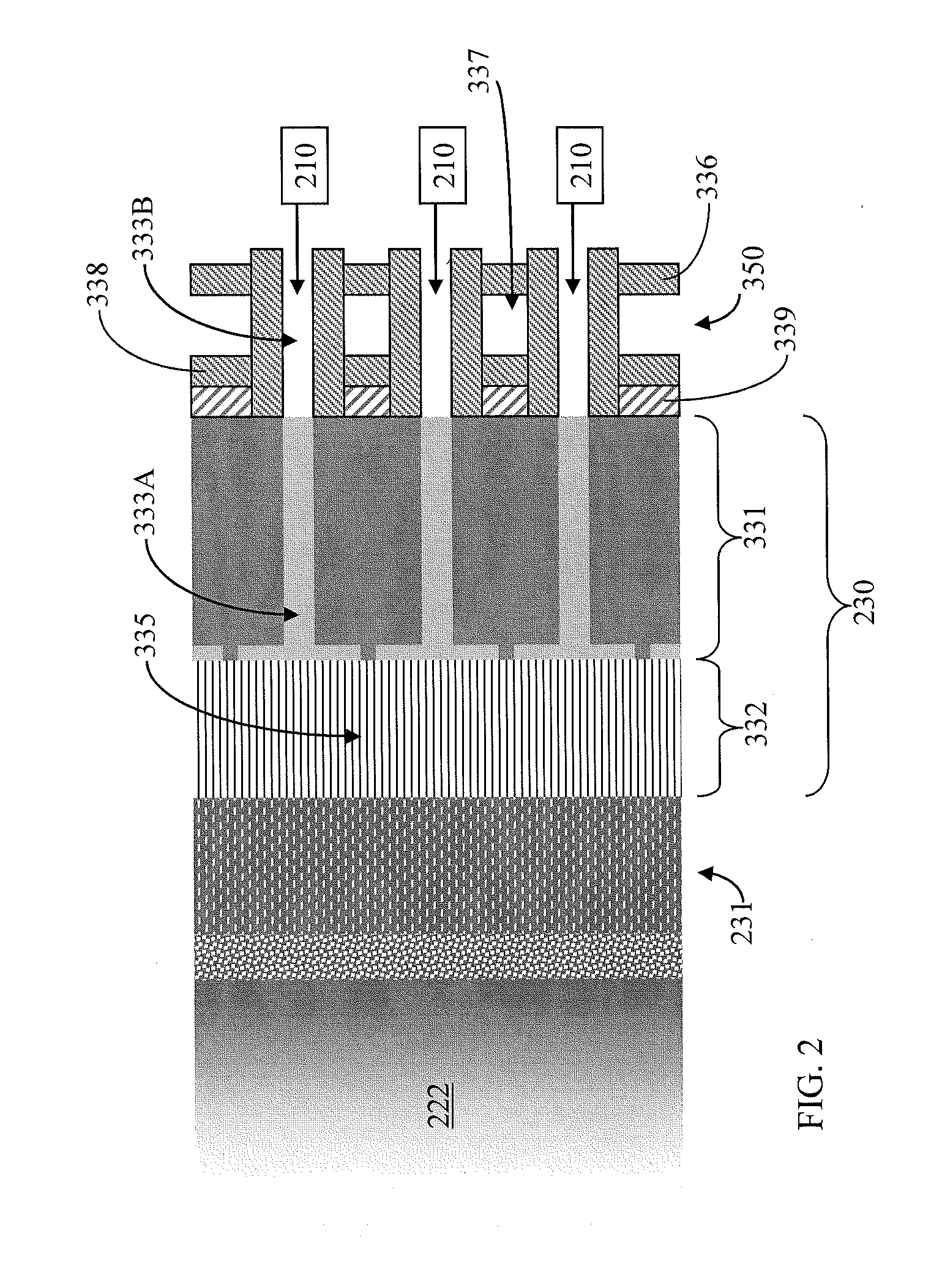

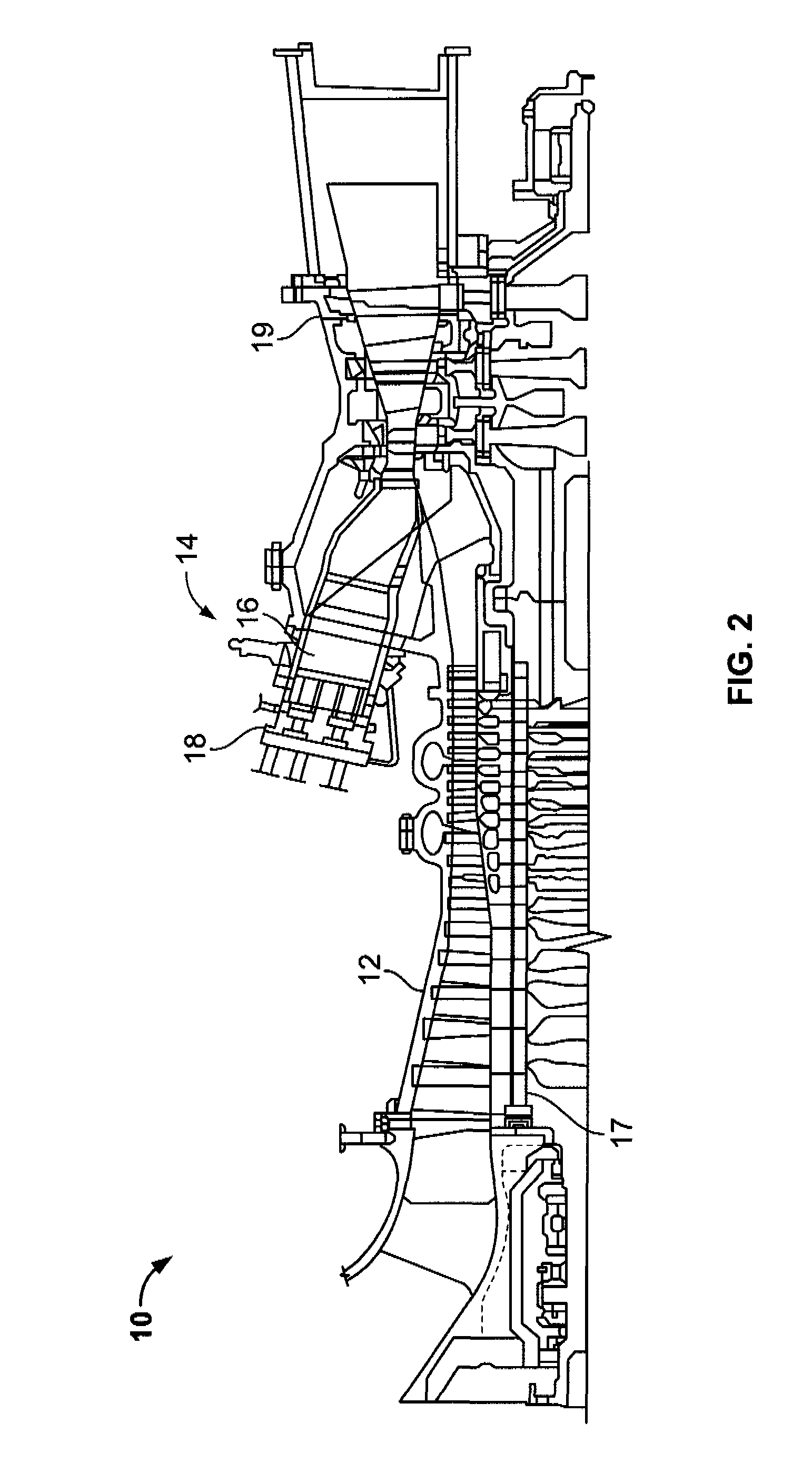

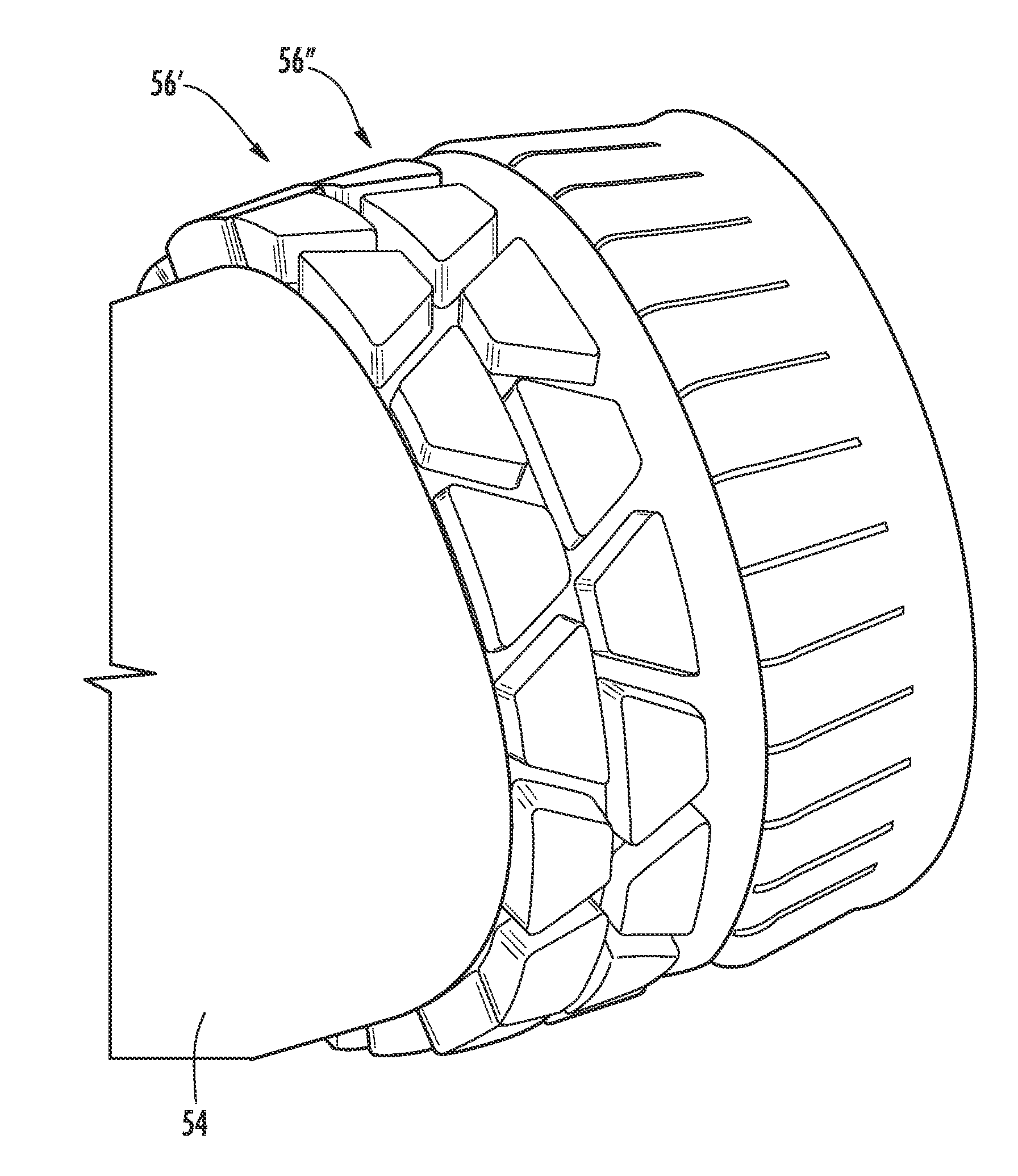

ActiveUS9068743B2Reducing and eliminating needEliminate damage to and build-upGas turbine plantsDirect carbon-dioxide mitigationCombustion chamberWorking fluid

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a porous perimetric transpiration member, at least partially surrounded by a pressure containment member. The combustion chamber has longitudinally spaced apart inlet and outlet portions. The fuel mixture is received by the inlet portion for combustion within the combustion chamber at a combustion temperature to form a combustion product. The combustion chamber further directs the combustion product longitudinally toward the outlet portion. The porous transpiration member is configured to substantially uniformly direct a transpiration substance laterally therethrough, about the perimeter thereof defining the combustion chamber and longitudinally between the inlet and outlet portions, toward the combustion chamber for buffering interaction between the combustion product and the porous transpiration member. Associated systems are also provided.

Owner:8 RIVERS CAPTTAL LLC

Apparatus for combusting a fuel at high pressure and high temperature, and associated system

ActiveUS8986002B2Reducing and eliminating needEliminate damage to and build-upContinuous combustion chamberGas turbine plantsWorking fluidCombustor

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a porous perimetric transpiration member, at least partially surrounded by a pressure containment member. The combustion chamber has longitudinally spaced apart inlet and outlet portions. The fuel mixture is received by the inlet portion for combustion within the combustion chamber at a combustion temperature to form a combustion product. The combustion chamber directs the combustion product longitudinally toward the outlet portion. The transpiration member is configured to substantially uniformly direct a transpiration substance therethrough toward the combustion chamber, such that the transpiration substance is directed to flow helically about the perimeter and longitudinally between the inlet and outlet portions, for buffering interaction between the combustion product and the transpiration member. Associated systems are also provided.

Owner:8 RIVERS CAPTTAL LLC

Self-cooled oxygen-fuel for use in high-temperature and high-particulate furnaces

InactiveUS6276924B1Avoiding particulate inspiration.TheControl expansionGlass furnace apparatusGlass melting apparatusParticulatesCombustor

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

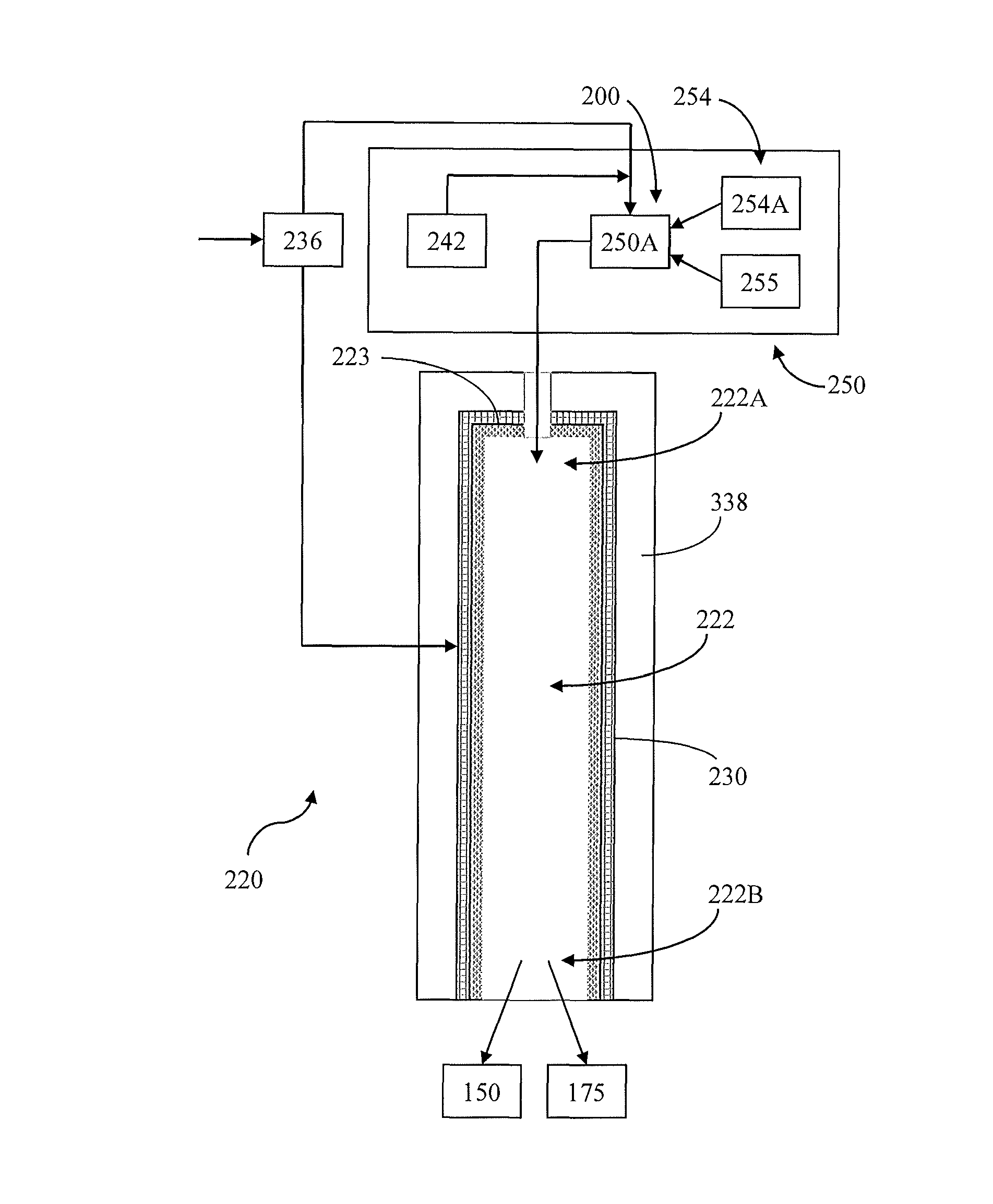

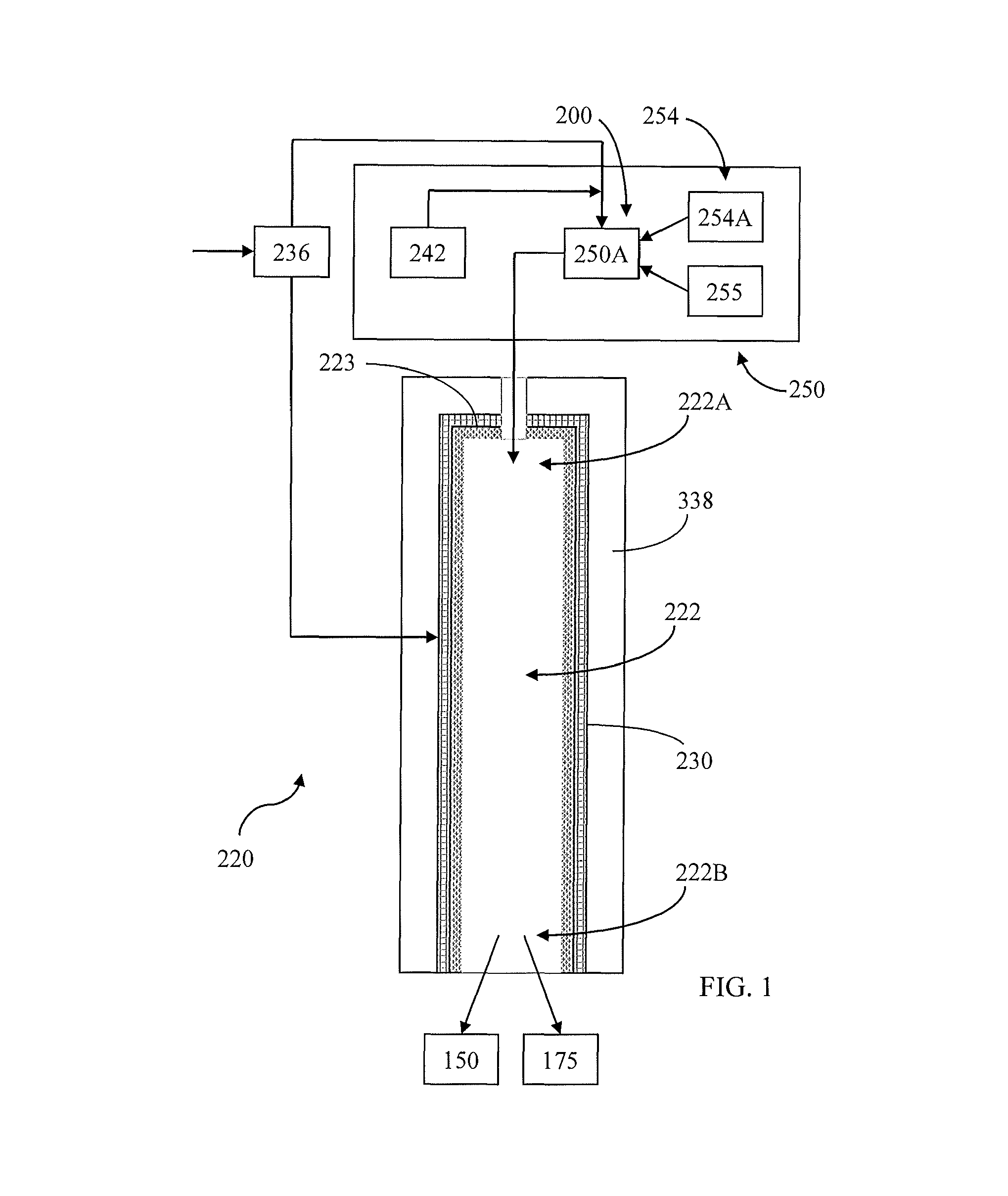

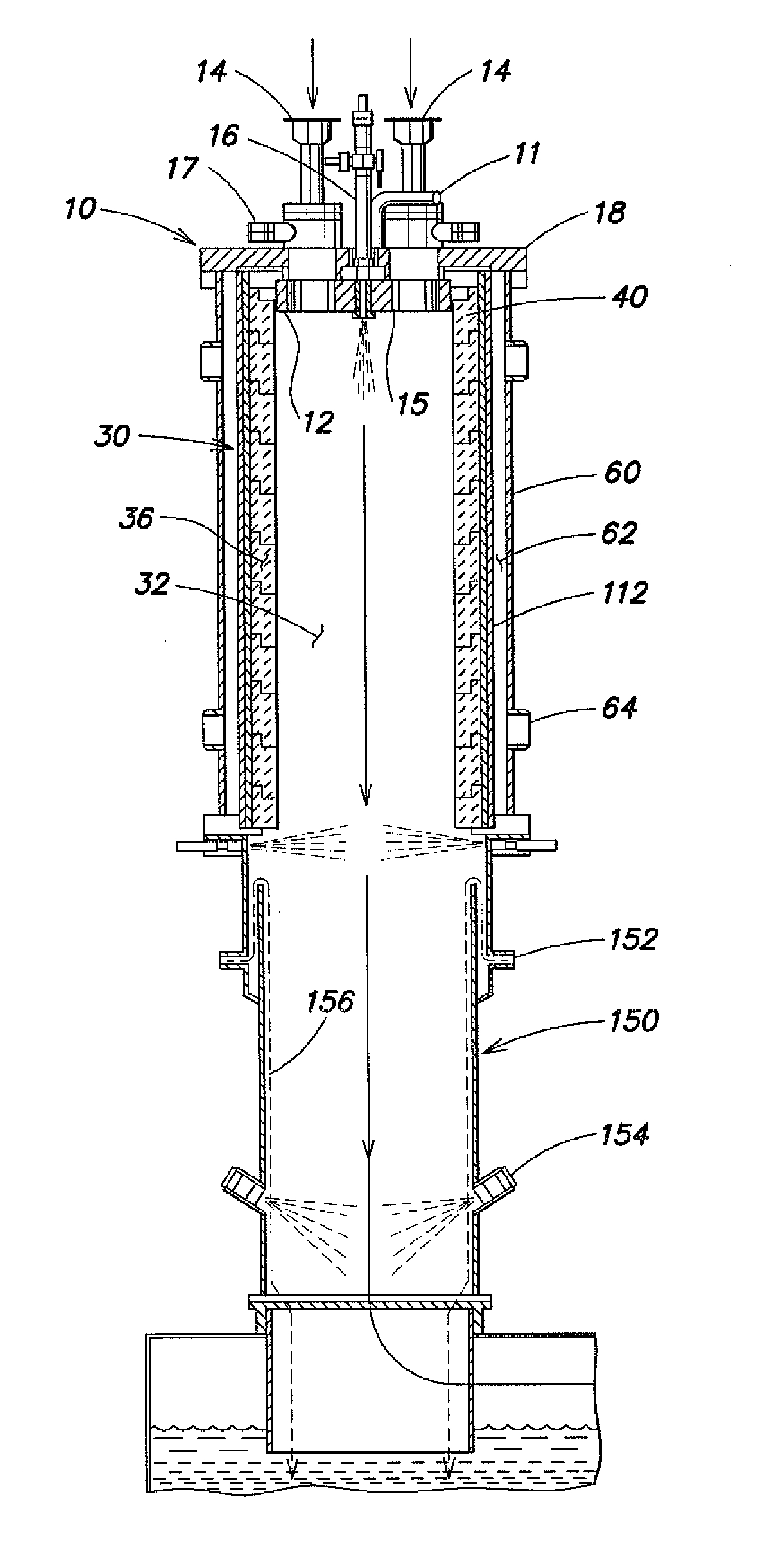

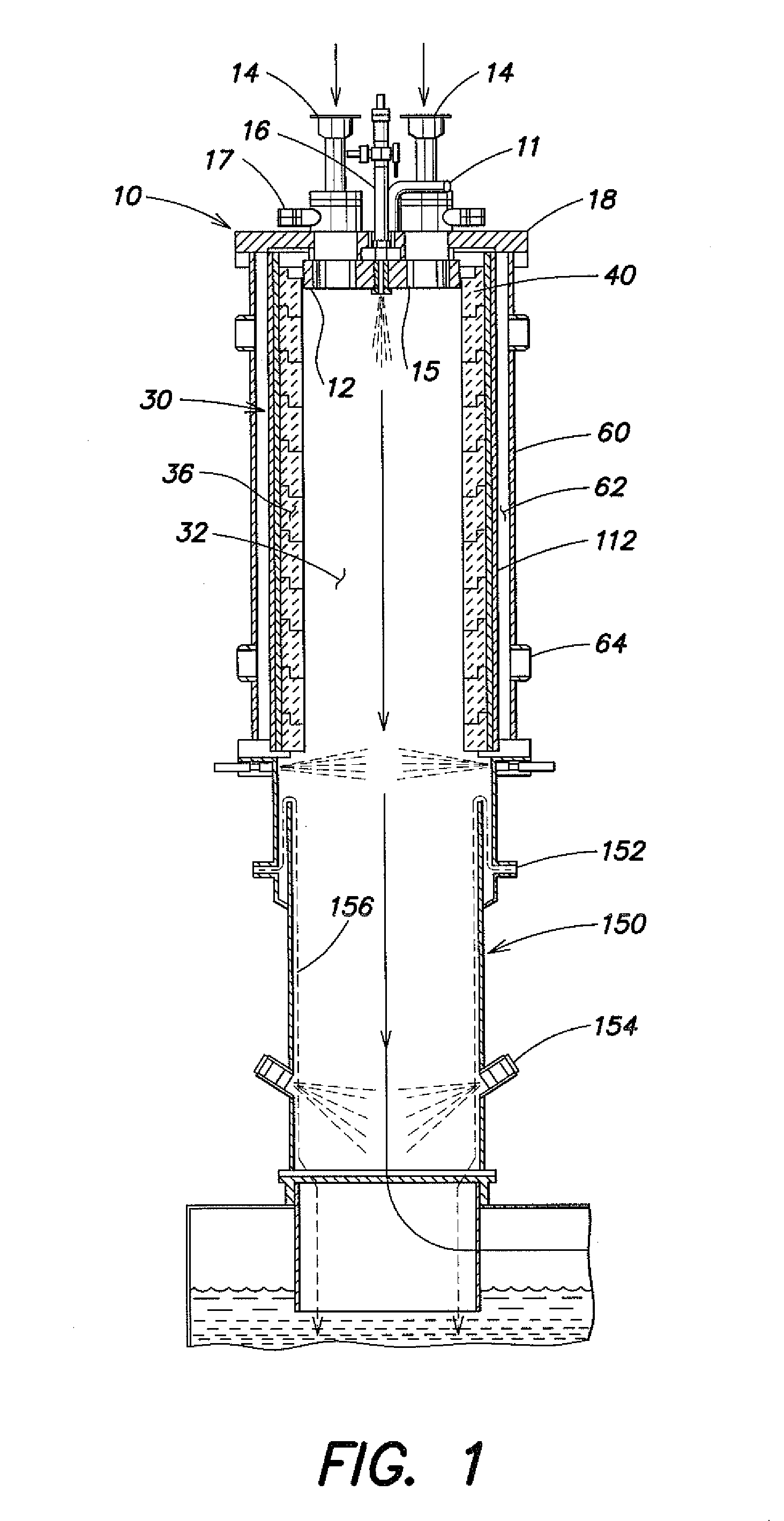

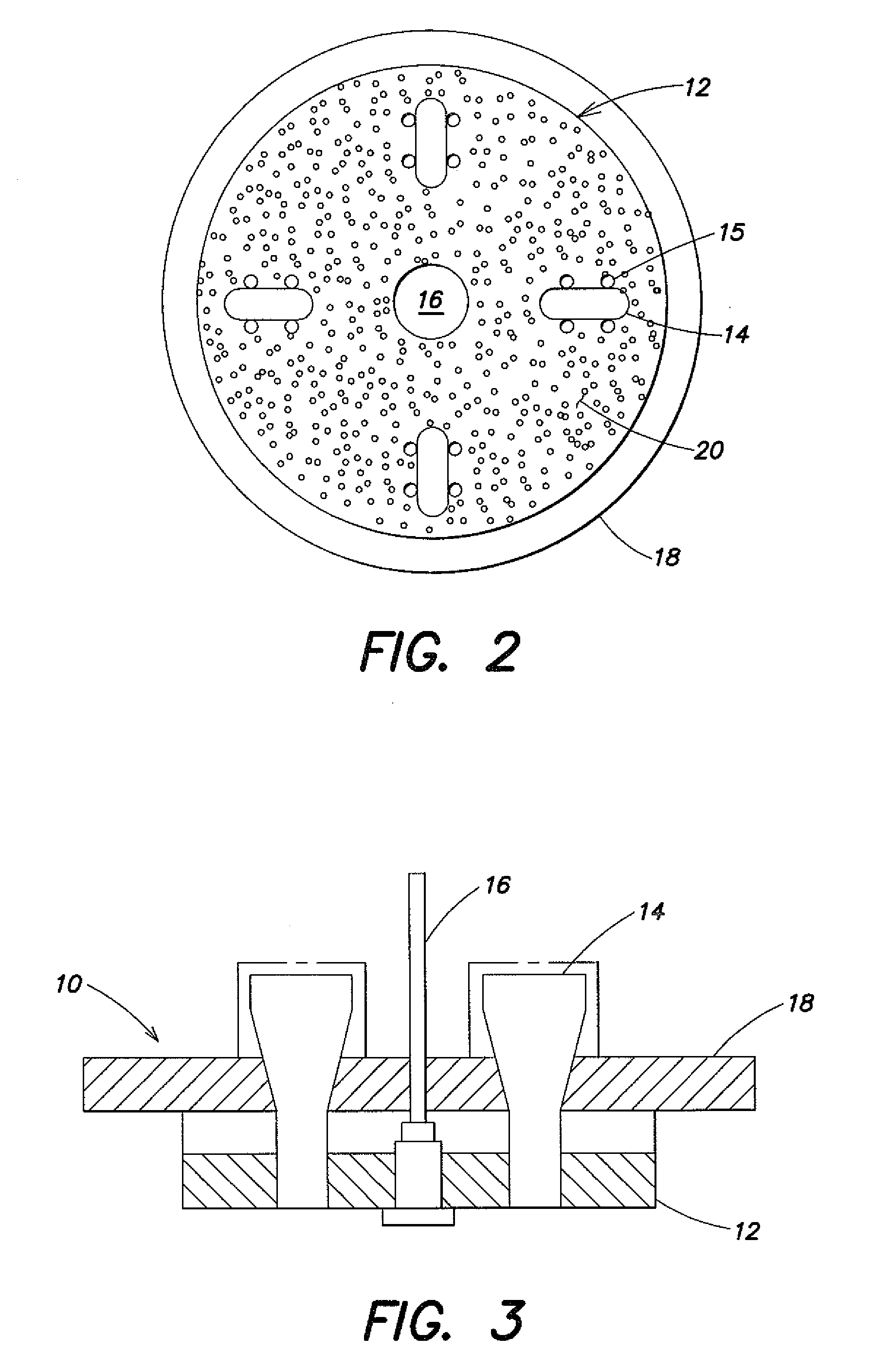

Apparatus and Method for Combusting a Fuel at High Pressure and High Temperature, and Associated System and Device

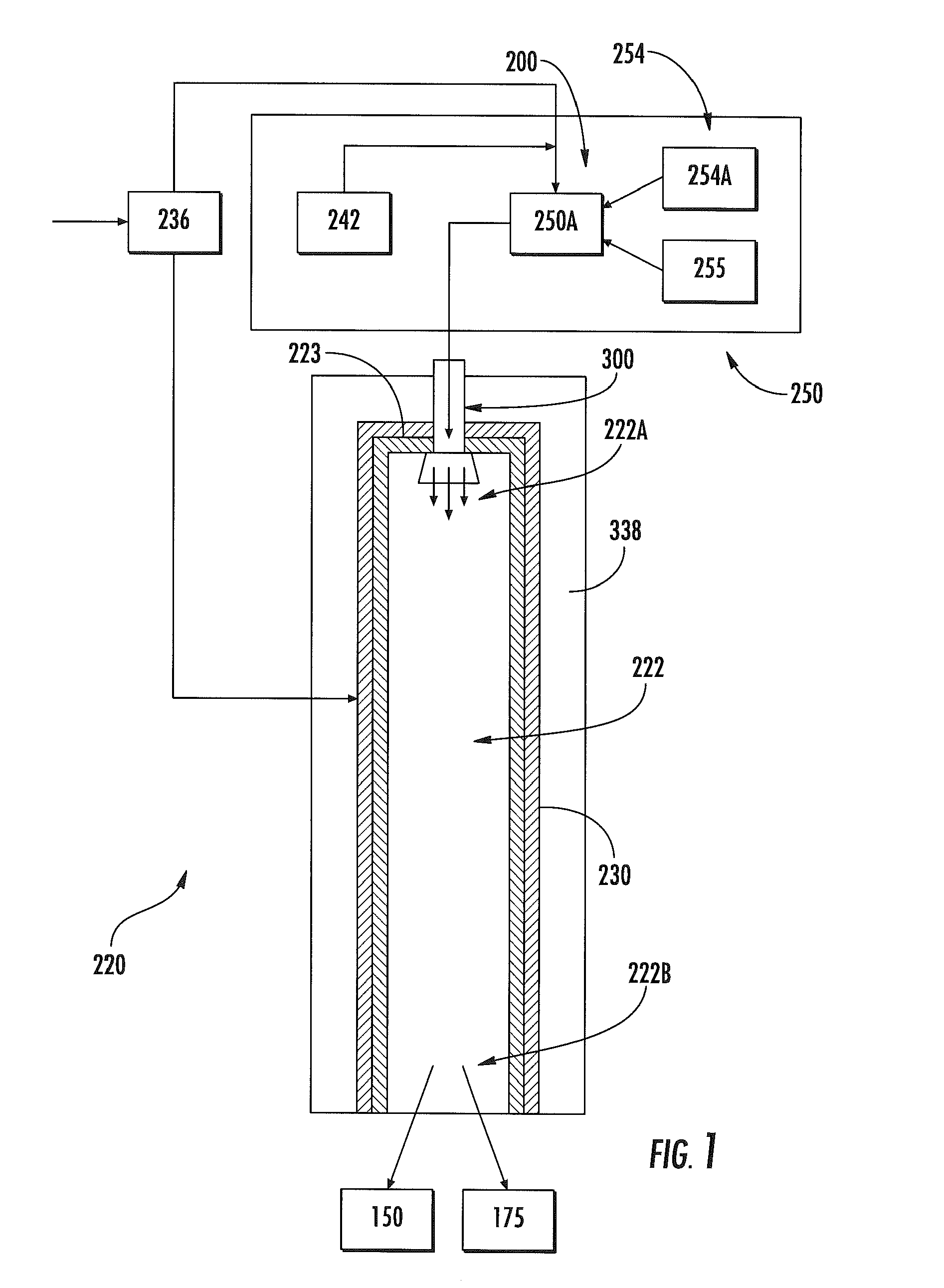

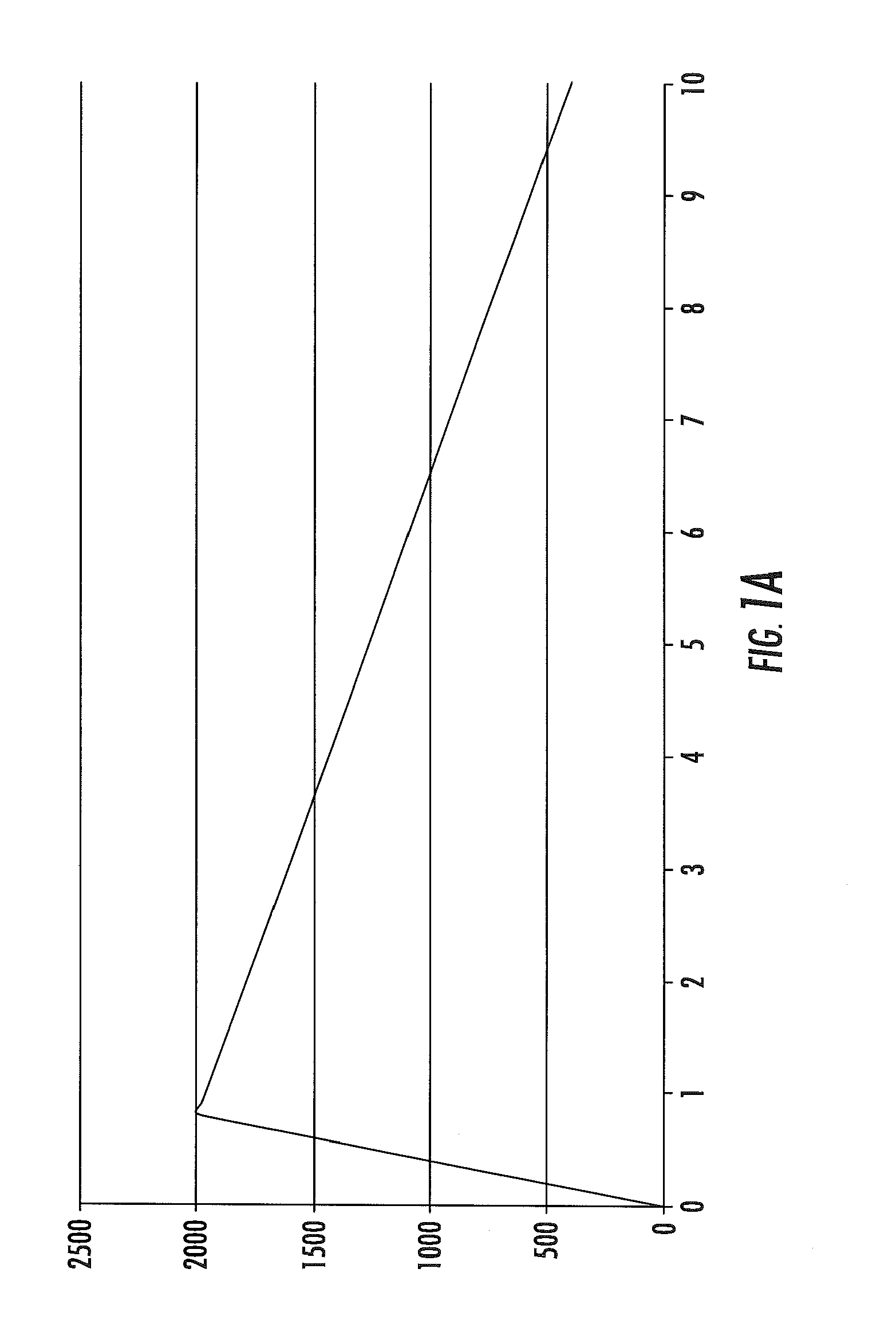

ActiveUS20100300063A1Enhanced overall recoveryReducing and eliminating needSolidificationLiquefactionWorking fluidCombustion chamber

A combustor apparatus is provided, comprising a mixing arrangement for mixing a carbonaceous fuel with enriched oxygen and a working fluid to form a fuel mixture. A combustion chamber is at least partially defined by a transpiration member. The transpiration member is at least partially surrounded by a pressure containment member. The combustion chamber has opposed inlet and outlet portions. The inlet portion of the combustion chamber is configured to receive the fuel mixture for the fuel mixture to be combusted at a combustion temperature. The combustion chamber is further configured to direct the resulting combustion product toward the outlet portion. The transpiration member directs a transpiration substance therethrough toward the combustion chamber for buffering interaction between the combustion product and the transpiration member. Associated systems, apparatuses, and methods are also provided.

Owner:8 RIVERS CAPTTAL LLC

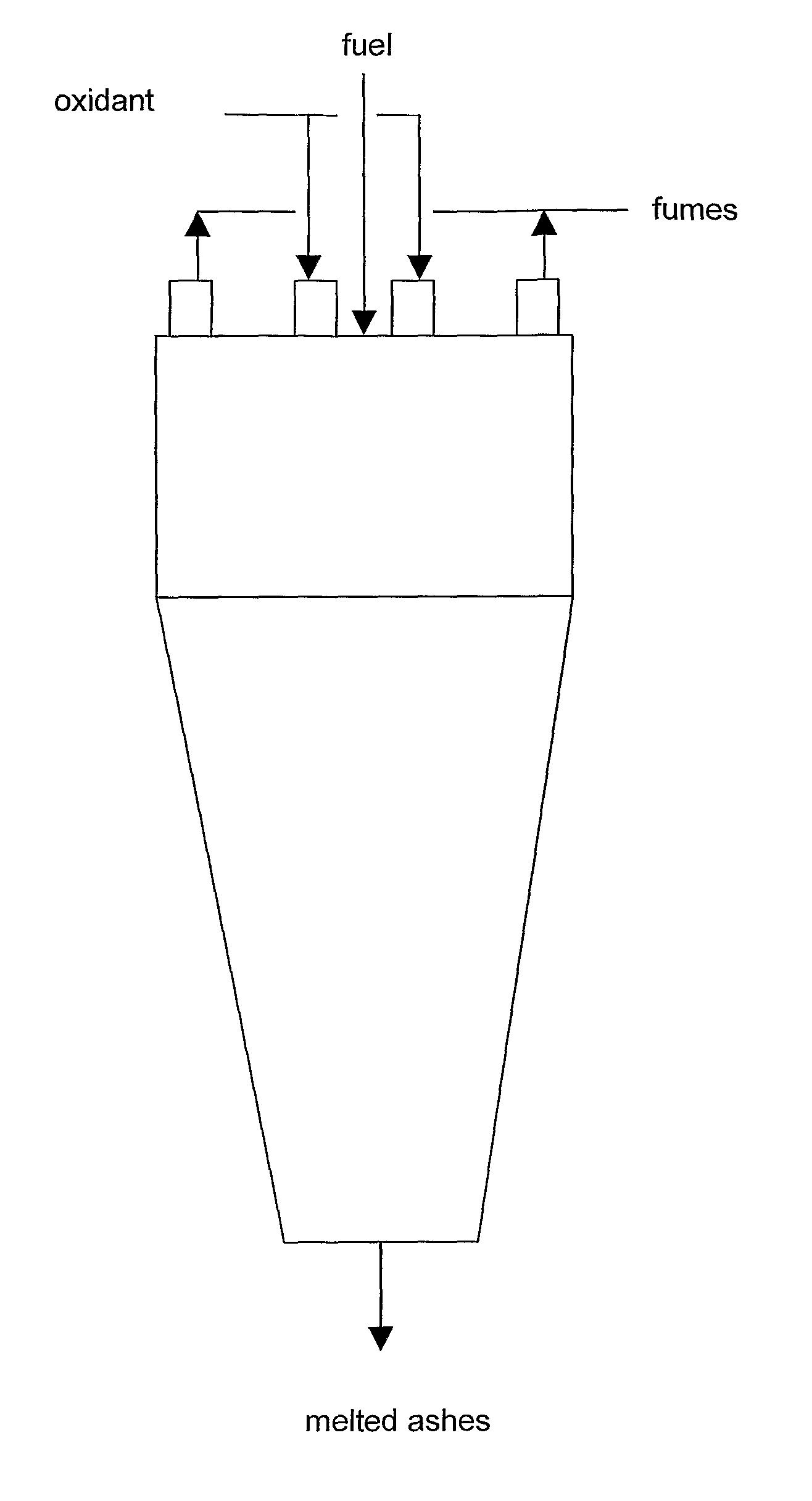

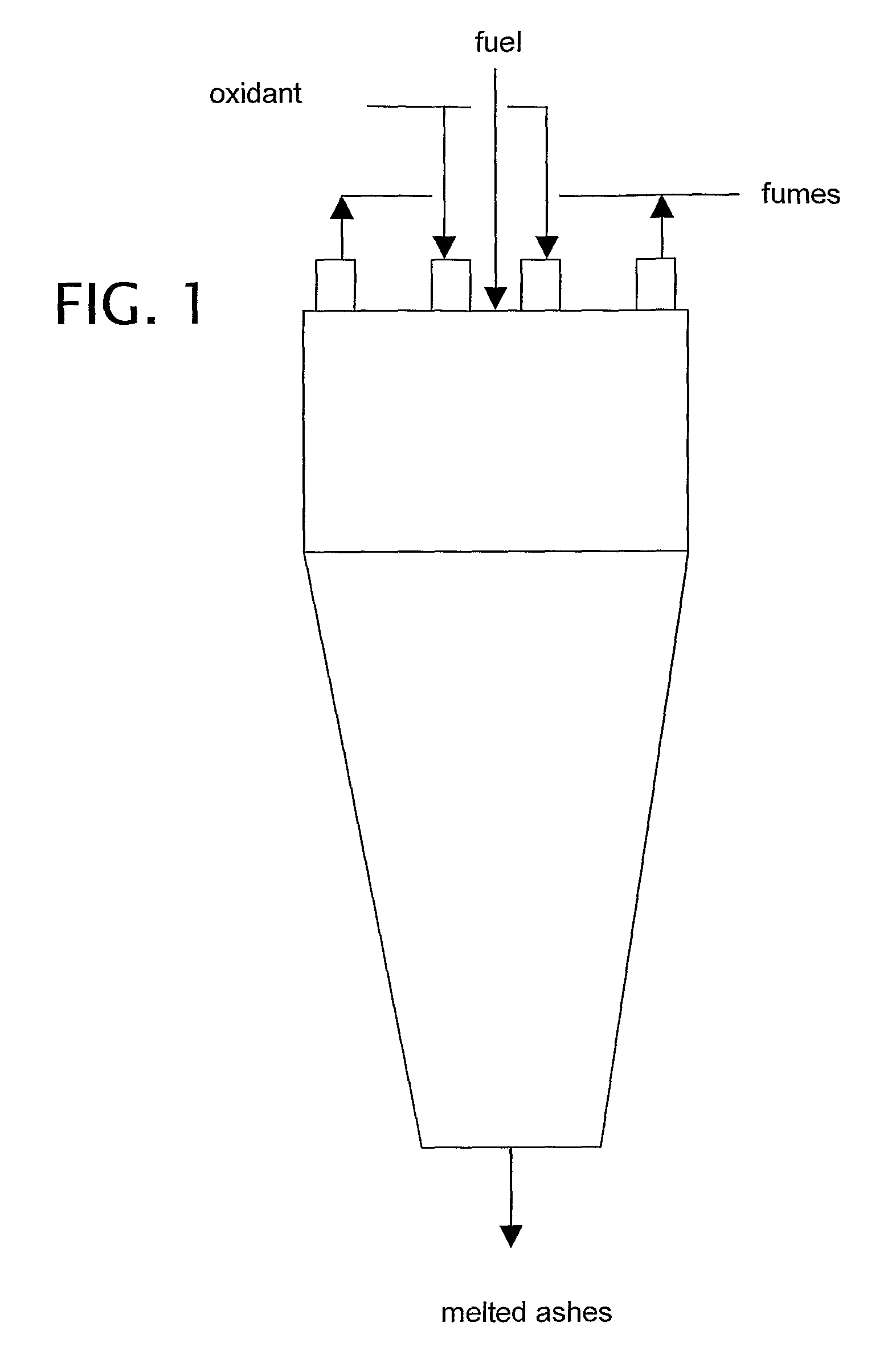

High-efficiency combustors with reduced environmental impact and processes for power generation derivable therefrom

A process for combusting solid liquid or gaseous fuels in a high temperature refractory-lined reactor with the aim of generating electric power comprises mixing at least one fuel with steam. The refactory material of the reactor and the opaque gases of the reaction environment bring about high power infrared radiation which substantially instantaneously preheats the reactants on input including said reactants being intrinsically transparent to infrared radiation (N2 / O2) but rendered opaque and thus absorbers of energy from infrared radiation thanks to dilution with steam. A high efficiency combustor is provided for carrying out the above-stated process.

Owner:ITEA SPA

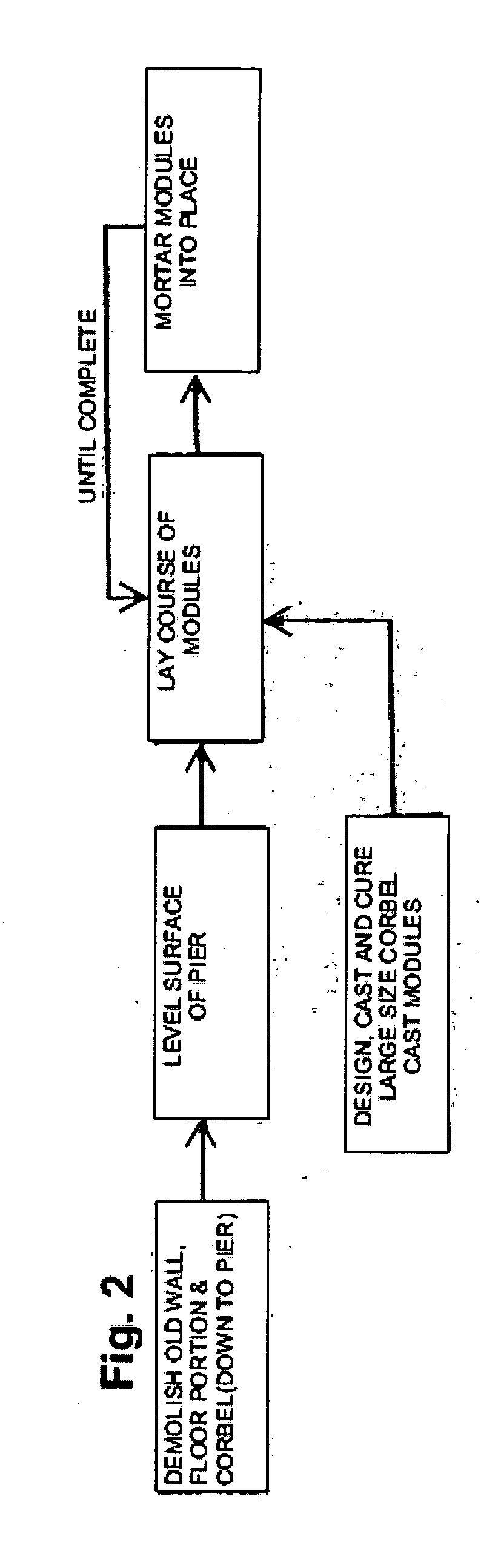

Coke oven reconstruction

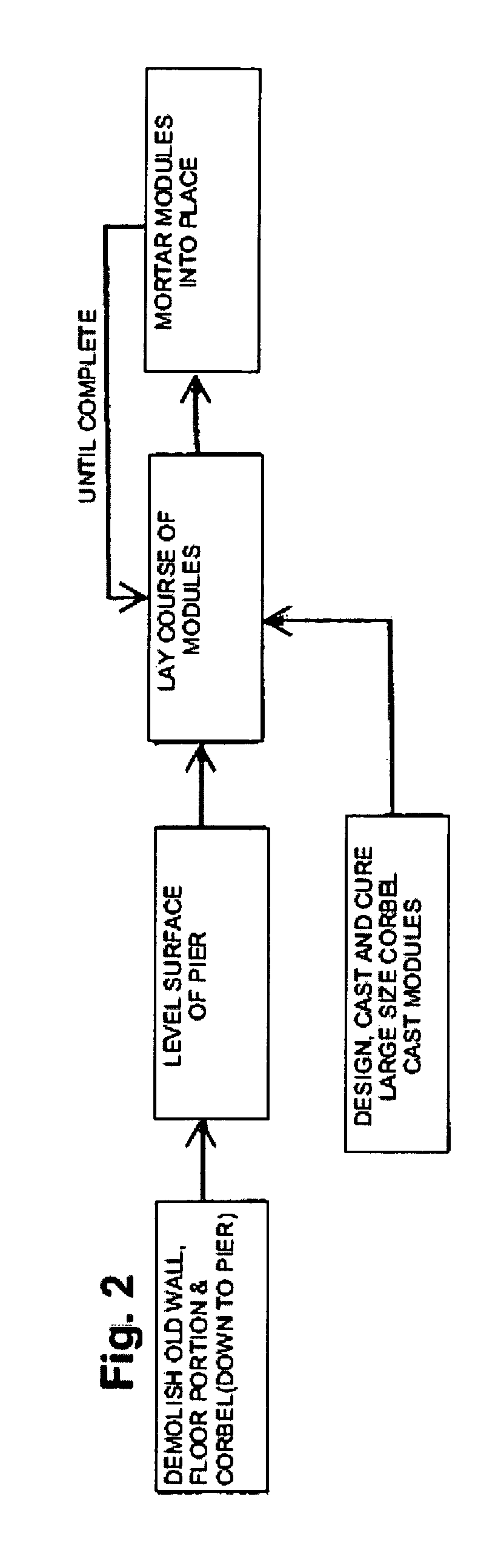

ActiveUS7827689B2Good dimensional stabilityNegligible heatingConstruction materialCoke oven brickworkComputer moduleEngineering

A new, faster and more efficient process to replace heating walls and ceilings in coke oven batteries. Thus, when replaced, at least one heating wall is constructed of thermally stable non-expanding large size modular cast modules from end to end and the ceiling adjacent the heating wall is constructed of thermally stable non-expanding large modular cast blocks.

Owner:VANOCUR REFRACTORIES LLC

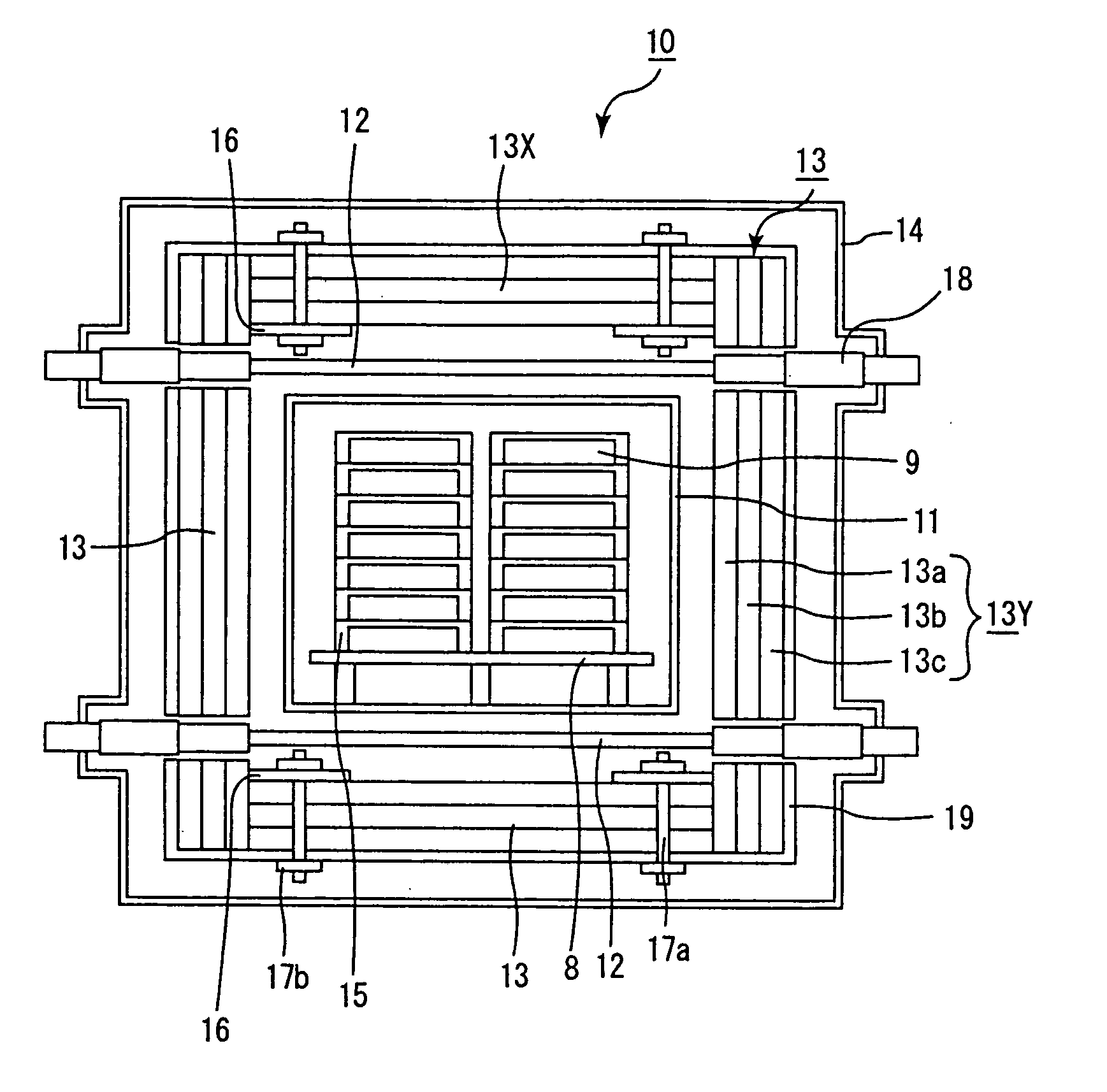

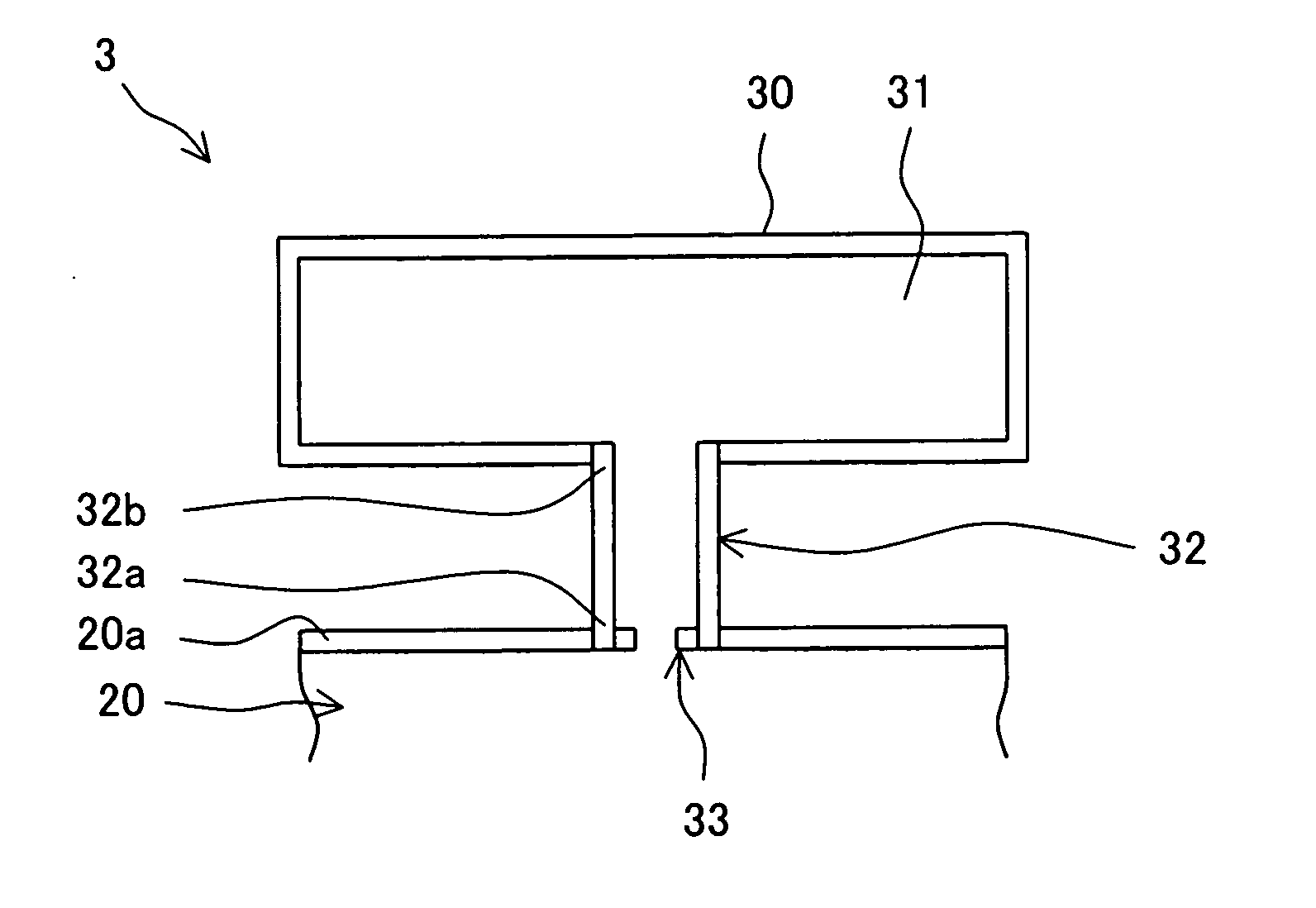

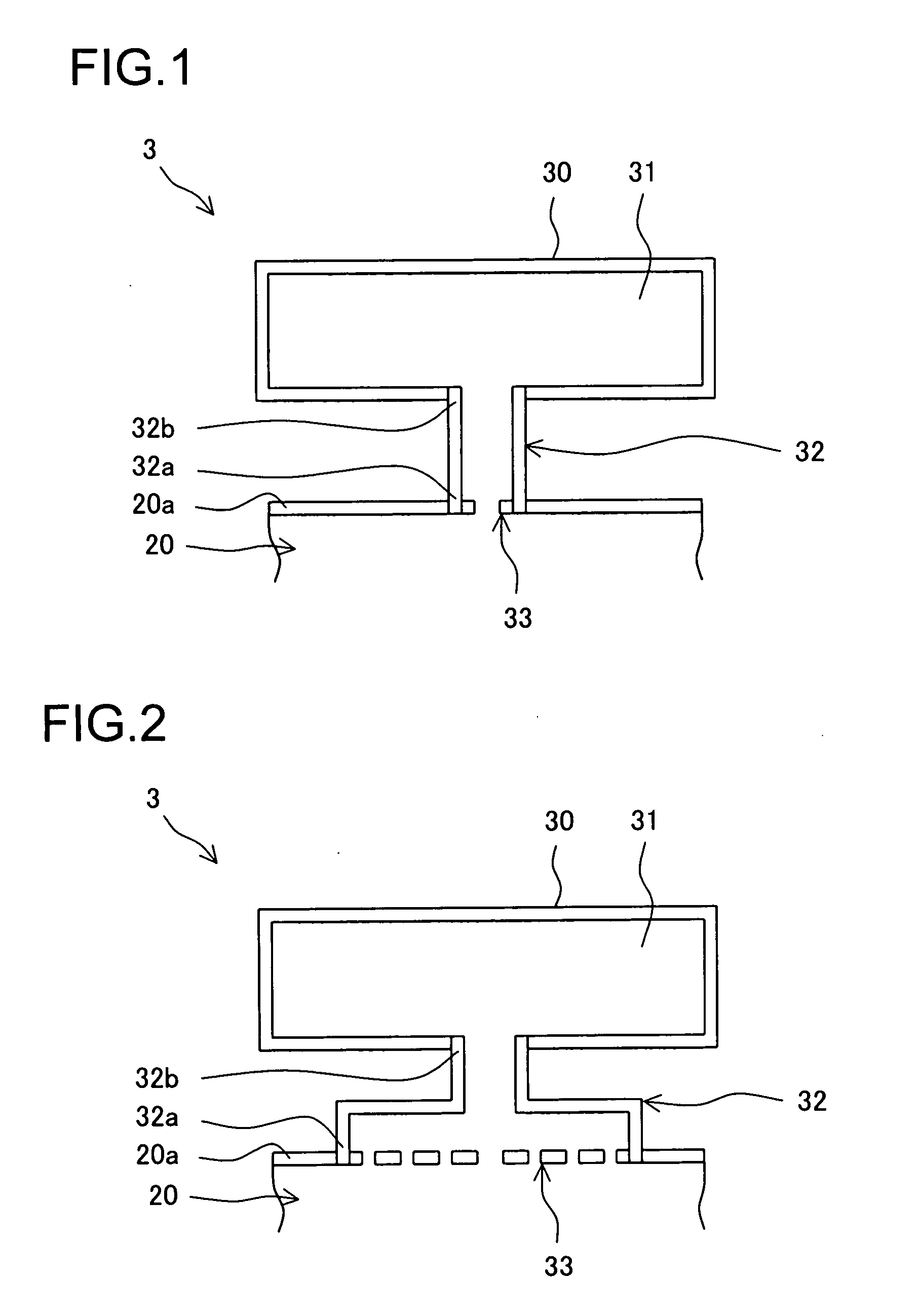

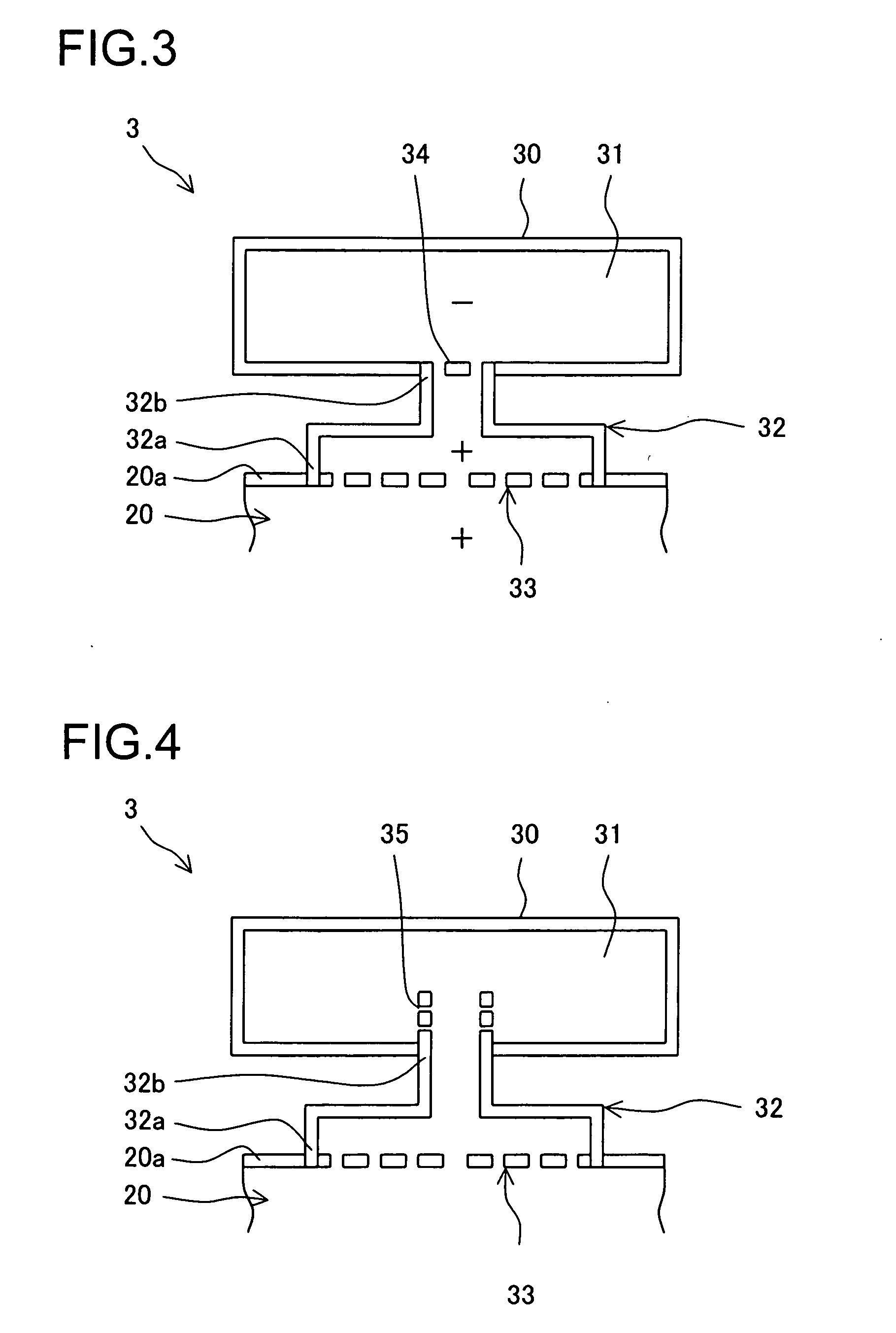

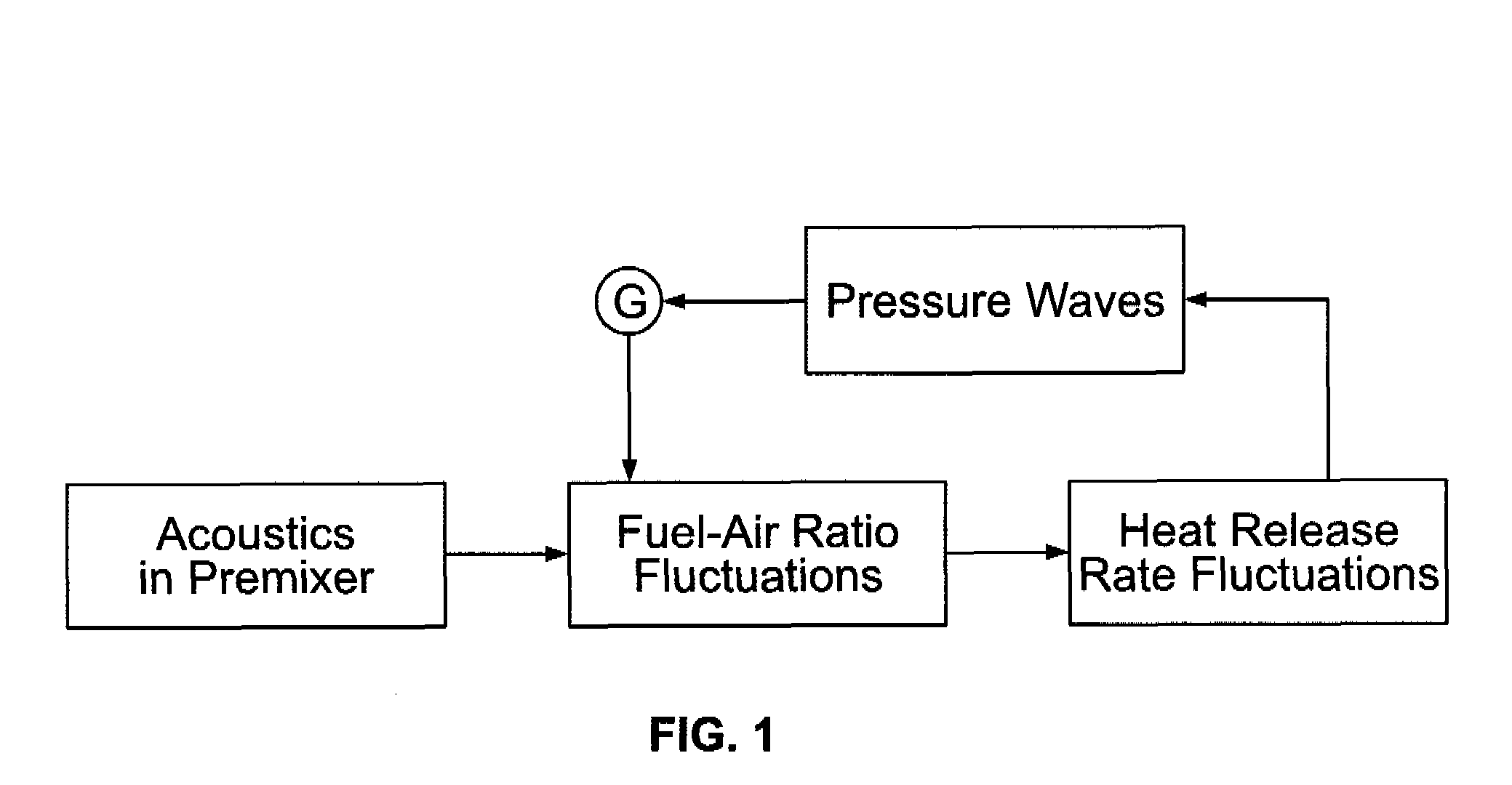

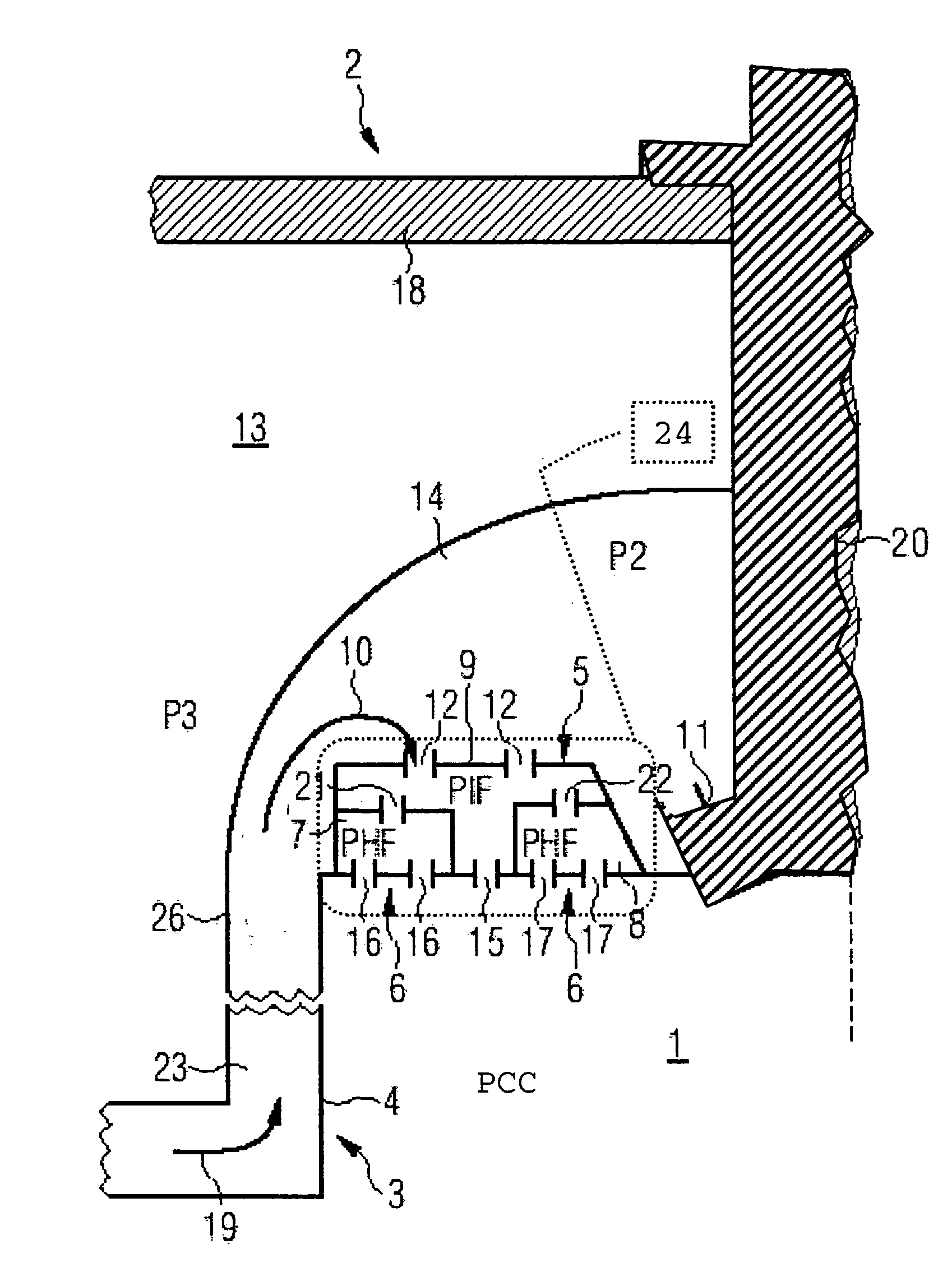

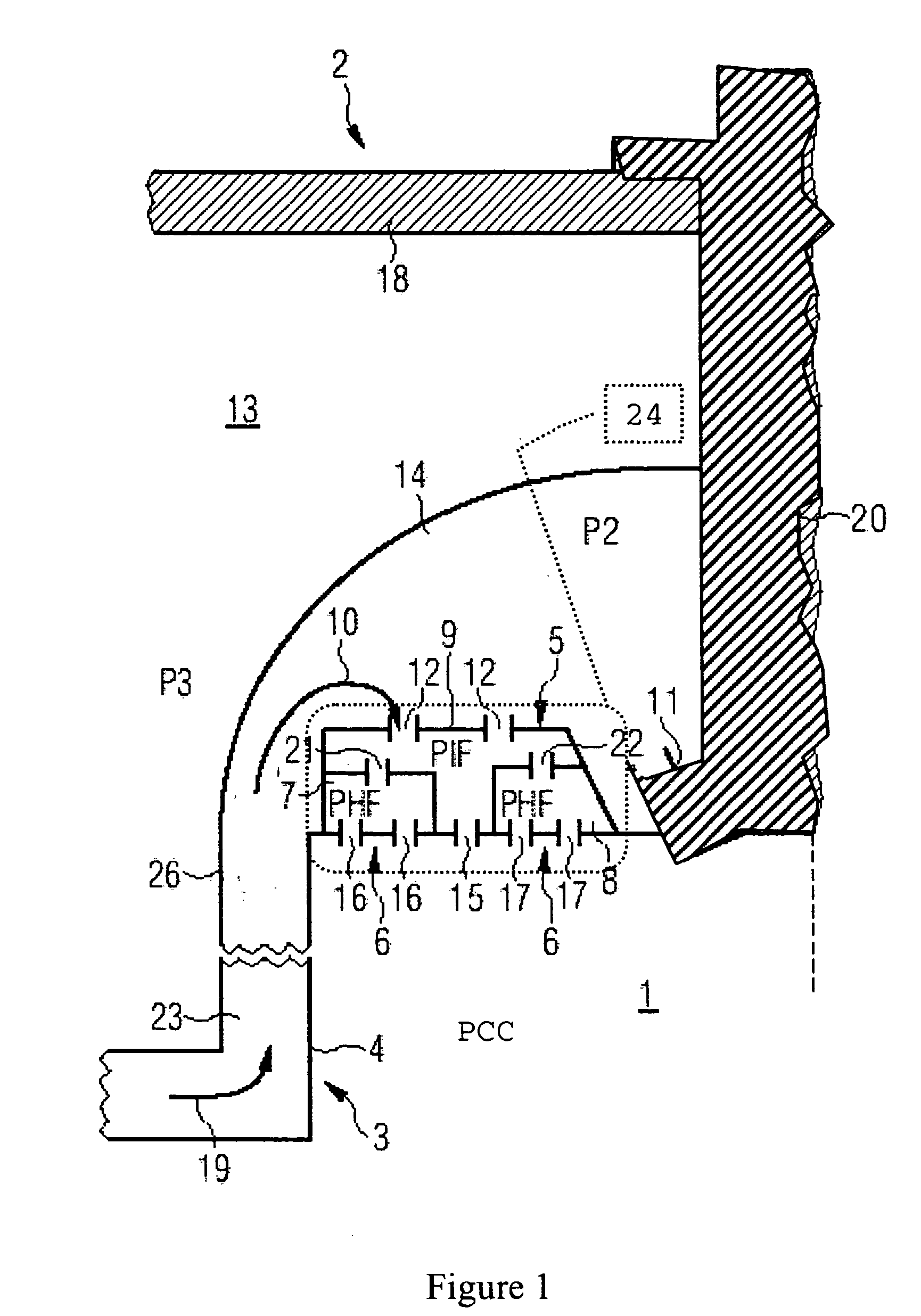

Gas turbine combustor, and gas turbine with the combustor

ActiveUS20050223707A1Reduce vibrationReduce NOxContinuous combustion chamberEngine fuctionsVibration amplitudeCombustor

In order to realize a stable decrease in NOx, a gas turbine combustor is supplied which can reduce combustion vibration. A combustor (3) is provided with a first box body (30), which is installed outside an object body (20) such as a combustor basket (6), a transition piece (7) or a bypass duct (11) so as to form a first internal space (31) having a predetermined capacity; and a first throat (32) having a predetermined length which has one end (32a) open to a side wall (20a) of the object body (20) and has the other end (32b) open to a first internal space (31); wherein, a first resistive element (33) having a multiple number of through-holes is inserted and engaged to one end (32a). Fluid particles serving as vibration elements of combustion vibration caused in a combustion region are effectively trapped by the first resistive element (33) and at the same time resonate with the air of the first internal space (31) being connected through the first throat (32) and vibrate in the neighborhood of the first resistive element (33), thereby damping vibration amplitude thereof.

Owner:MITSUBISHI POWER LTD

Reactor design to reduce particle deposition during process abatement

InactiveUS20070274876A1Reduce accumulationReduce crackingCombination devicesBurnersCombustionDecomposition

The present invention relates to systems and methods for controlled combustion and decomposition of gaseous pollutants while reducing deposition of unwanted reaction products from within the treatment systems. The systems include a novel thermal reaction chamber design having stacked reticulated ceramic rings through which fluid, e.g., gases, may be directed to form a boundary layer along the interior wall of the thermal reaction chamber, thereby reducing particulate matter buildup thereon. The systems further include the introduction of fluids from the center pilot jet to alter the aerodynamics of the interior of the thermal reaction chamber.

Owner:APPLIED MATERIALS INC

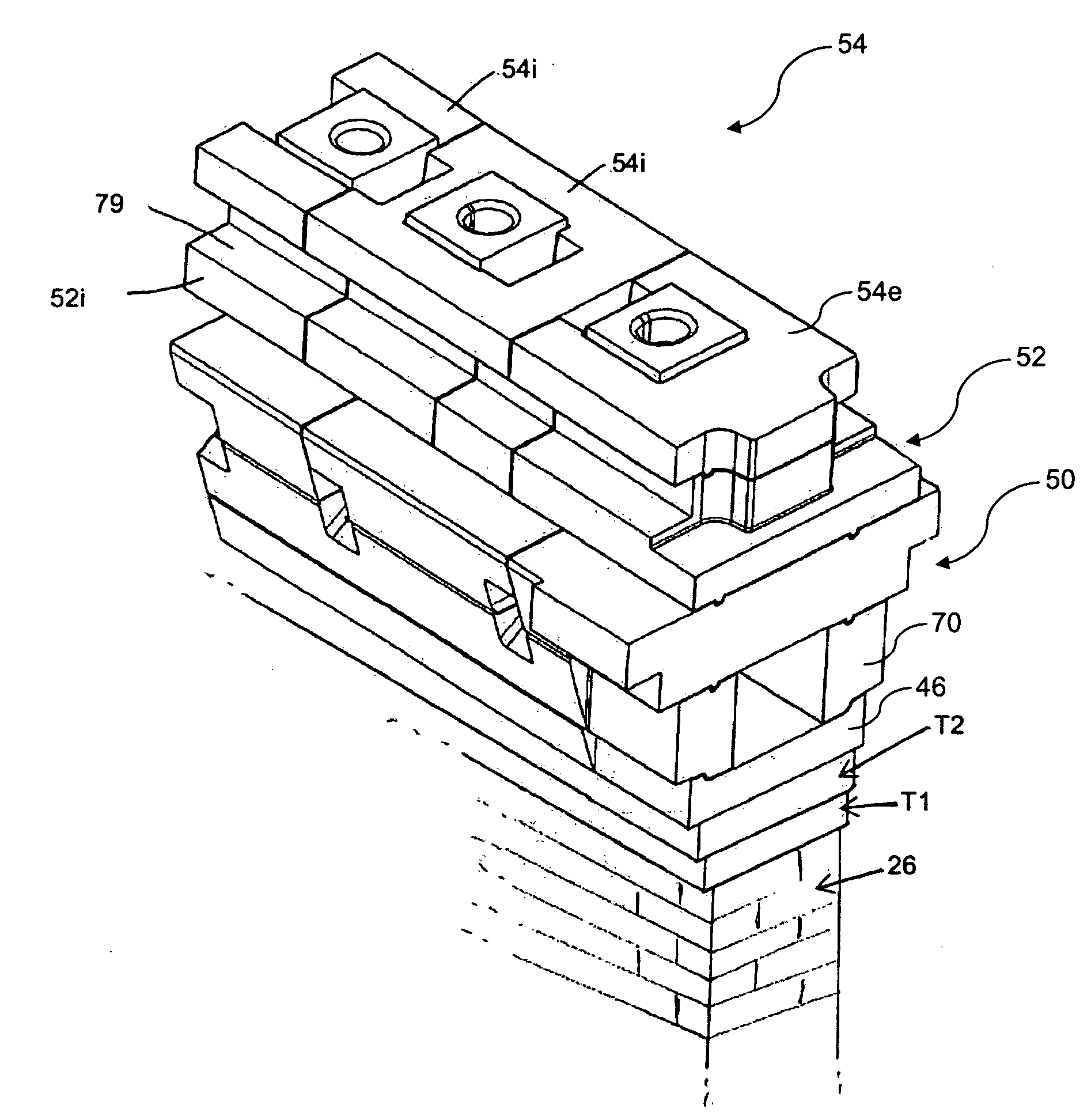

Corbel repairs of coke ovens

ActiveUS20100287871A1Cost-effective constructionSave significant amountFurnace componentsWallsEngineeringCoke oven

An improved corbel includes a first tier having first blocks and a second tier having second blocks. Each of the first blocks includes a first aperture extending through the block from a first surface to a back surface and a second aperture formed through a top surface of the block, extending into the first aperture. The first blocks are arranged on a substantially planar surface to align the respective first apertures to define a first passageway. Each of the second blocks includes a third aperture extending through the second block from a top surface to a bottom surface. The second blocks are disposed above the first tier to align the third aperture of each of the second blocks with the second aperture of the first blocks to form a second passageway.

Owner:VANOCUR REFRACTORIES LLC

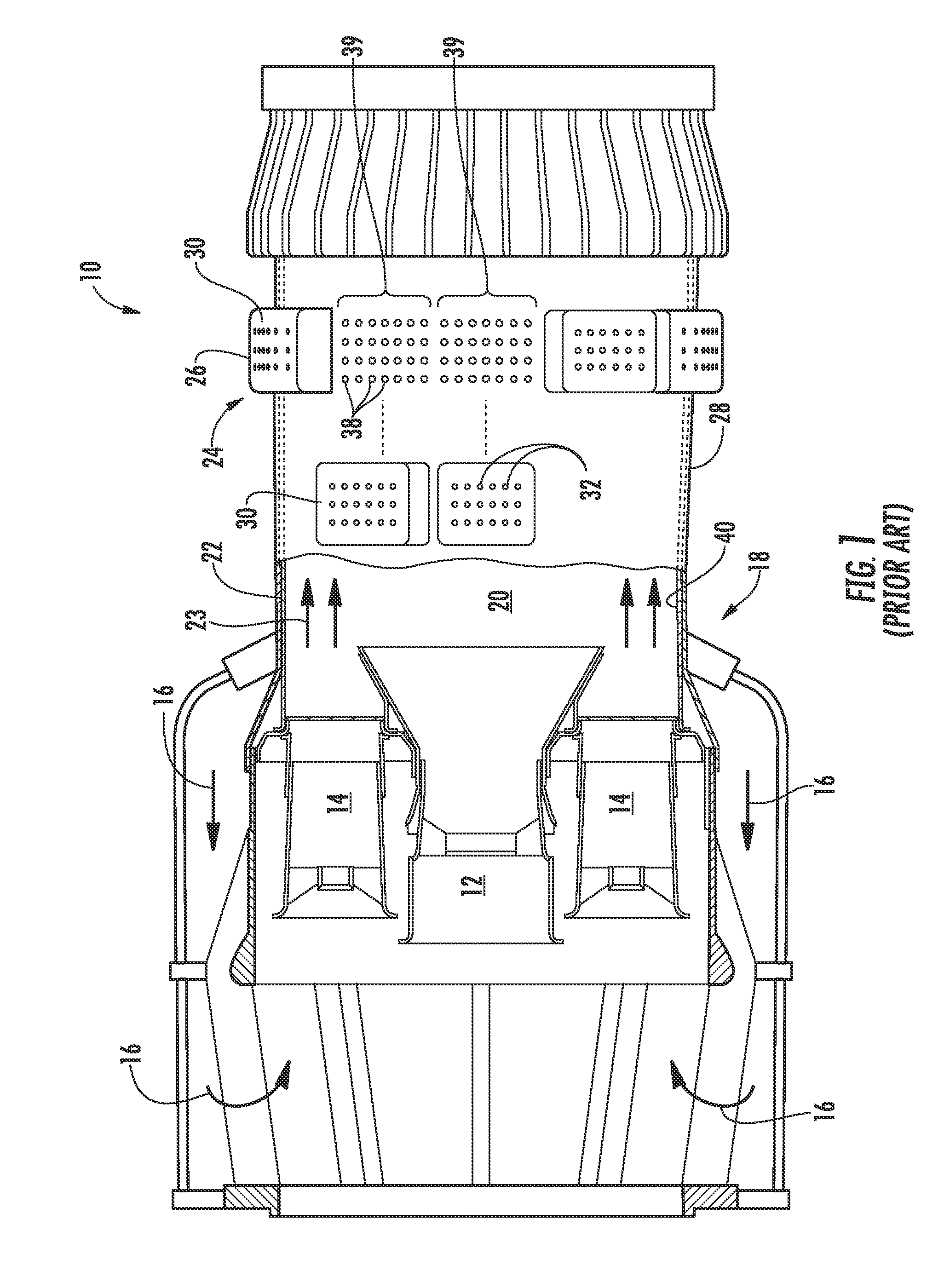

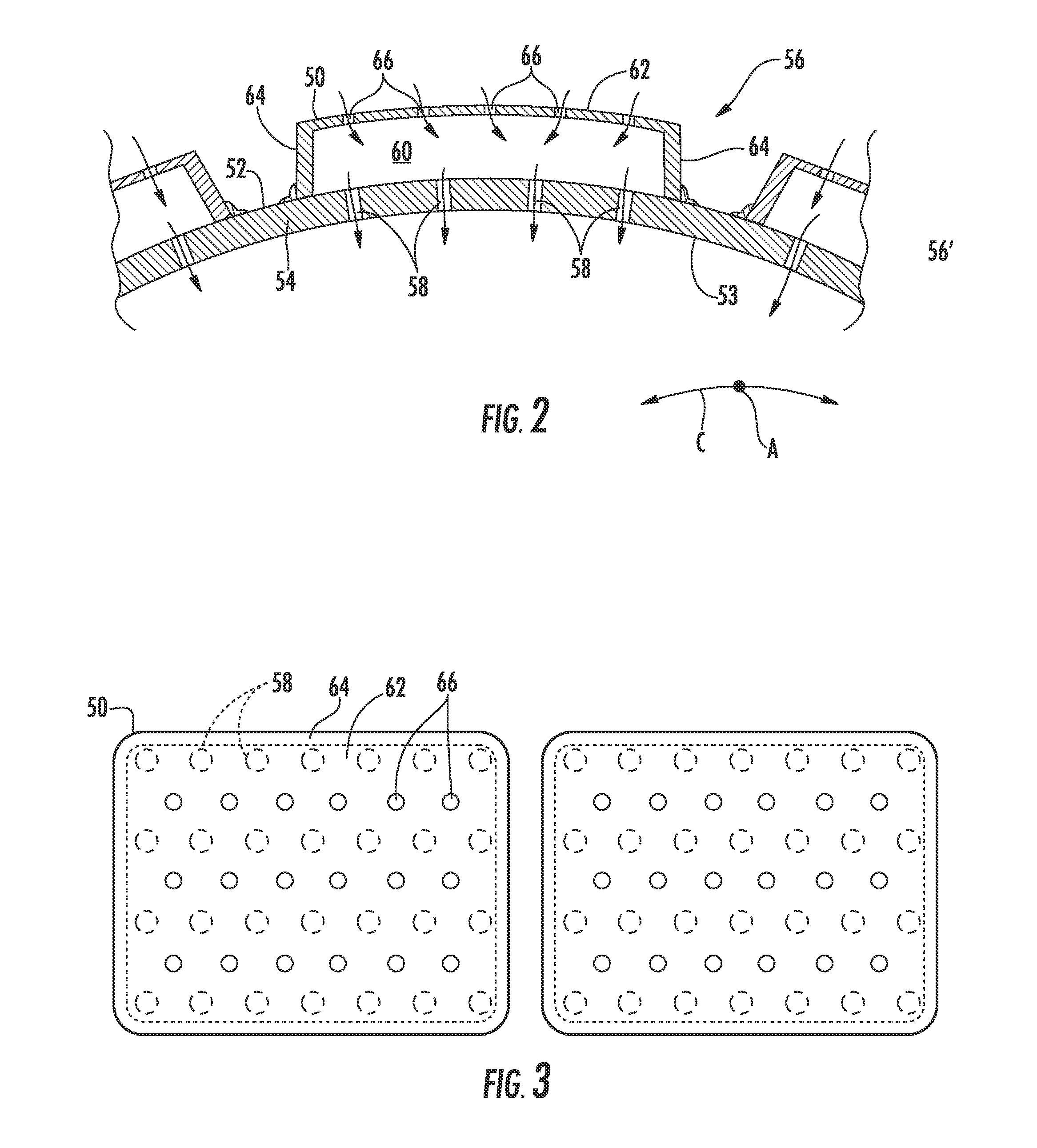

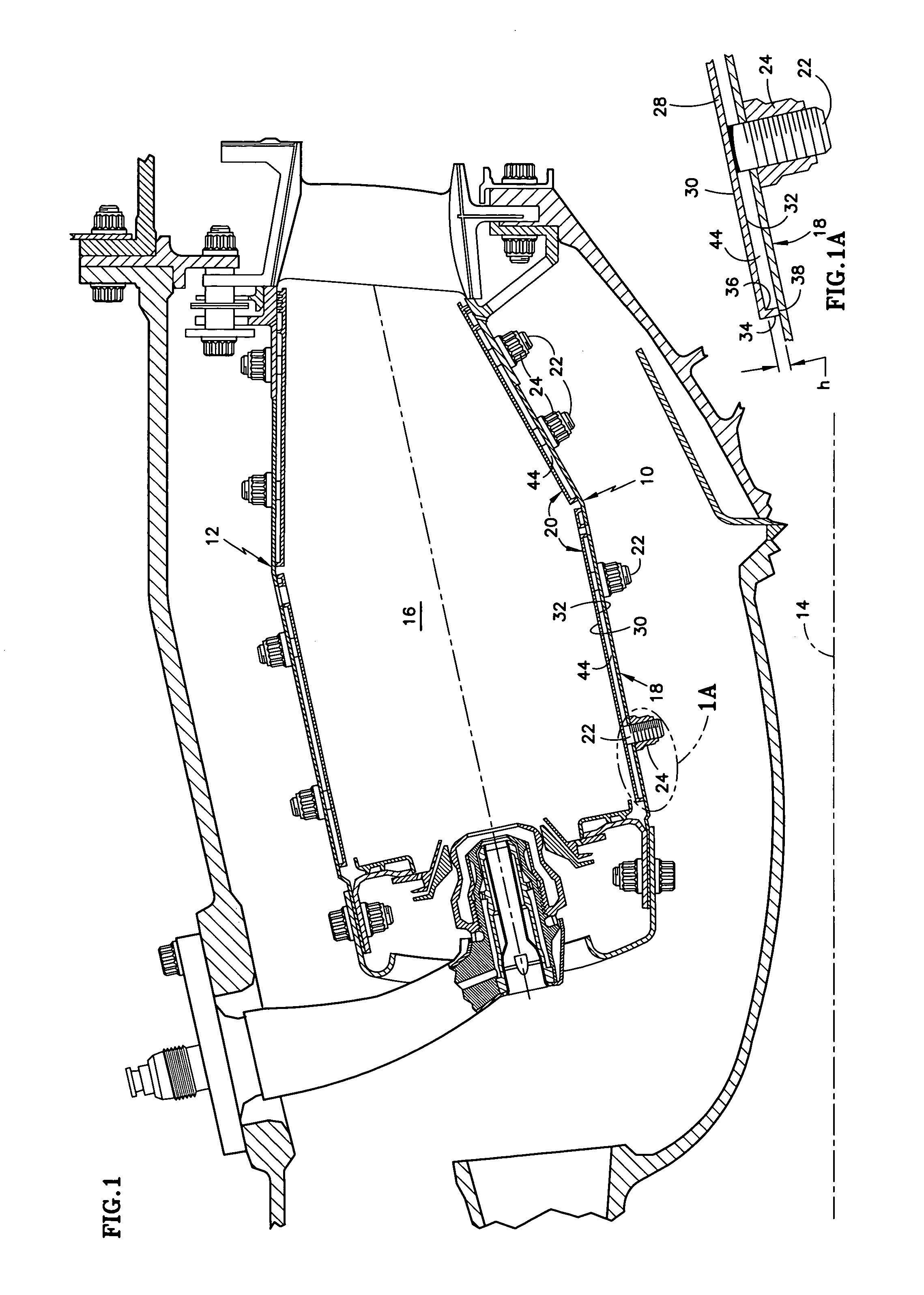

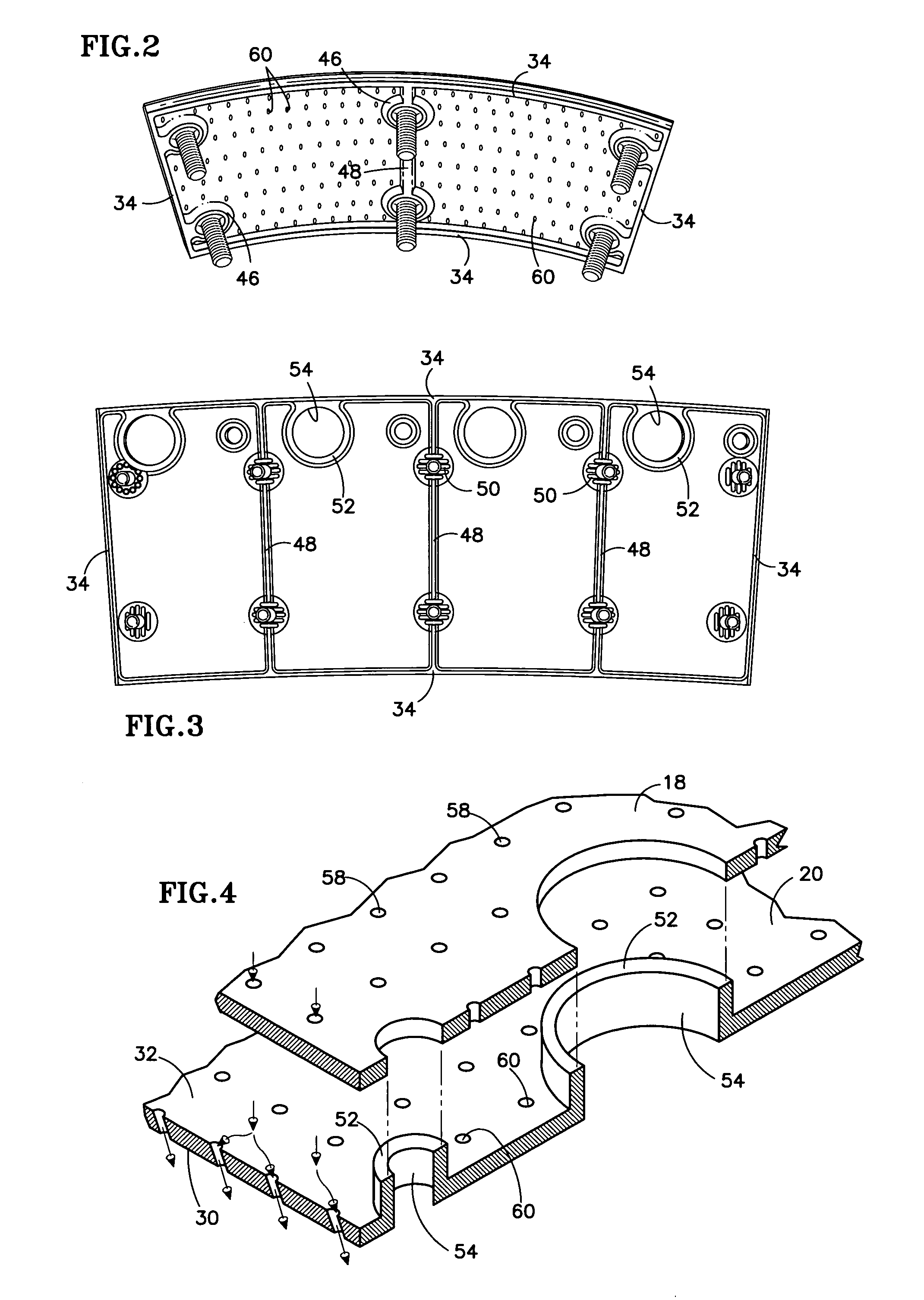

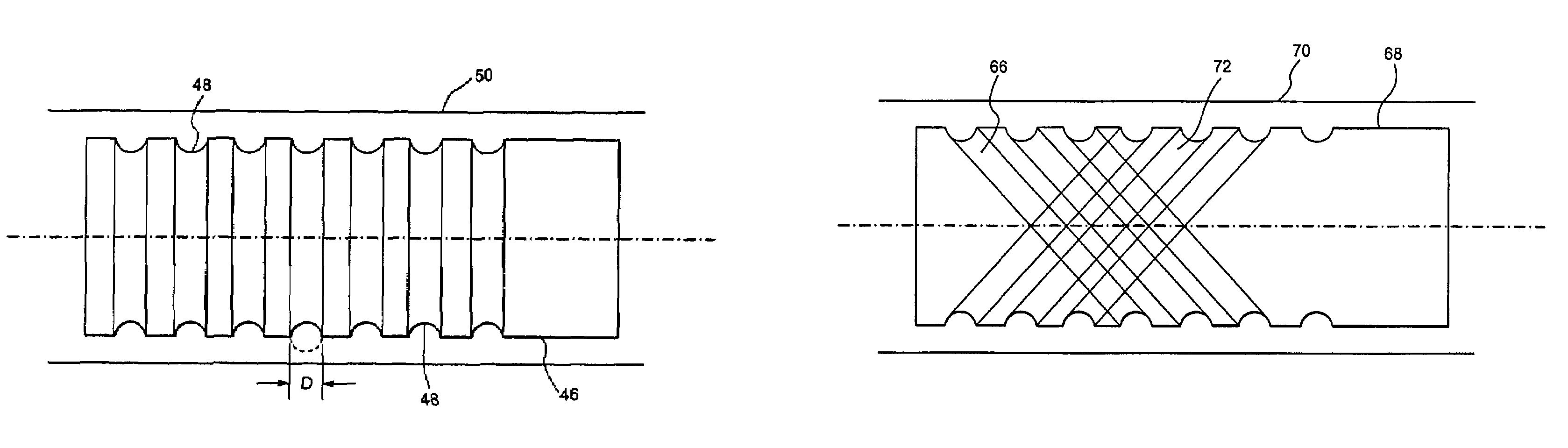

Injection assembly for a combustor

ActiveUS20080053097A1Facilitate reducing dynamicContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorEffusion

An injection assembly for use with a combustor is provided. The injection assembly includes an effusion plate that has a plurality of plate openings and a plate sleeve having a sidewall portion that includes a forward edge. The forward edge is coupled to the effusion plate such that the effusion plate is oriented obliquely with respect to a centerline extending through the combustor. The injection assembly also includes a plurality of ring extensions where each of the ring extensions is coupled to one of the plurality of plate openings. Each ring extension extends rearwardly into the plate sleeve.

Owner:GENERAL ELECTRIC CO

Resonator System for Turbine Engines

A resonator system for a turbine engine can improve acoustic performance and cooling effectiveness. During engine operation, a combustor liner exhibits alternating hot and cold regions in the circumferential direction corresponding to the non-uniform temperature distribution of the combustion flame. Accordingly, high flow resonators are formed with the liner in substantial alignment with the hot regions of the fluid flow within the liner, and low flow resonators are formed with the liner in substantial alignment with cold regions of the fluid flow within the liner. As a result, appropriate amounts of cooling can be provided to the liner so that cooling air usage is optimized. Alternatively or in addition, the liner can include two or more rows of resonators, which can provide an enhanced acoustic damping response. The resonators in the first row can be aligned with or offset from the resonators in the second row.

Owner:SIEMENS ENERGY INC

Combustion chamber for a gas turbine with at least two resonator devices

ActiveUS20060059913A1Effective reduction in oscillationReduce impactBurnersContinuous combustion chamberCombustion chamberCooling fluid

A combustion chamber according to the invention, in particular for a gas turbine, includes at least one combustion chamber wall through which cooling fluid flows and at least one resonator device. The combustion chamber according to the invention is distinguished in that the resonator device is integrated into the combustion chamber wall in such a way that it has the cooling fluid flow passing there through.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

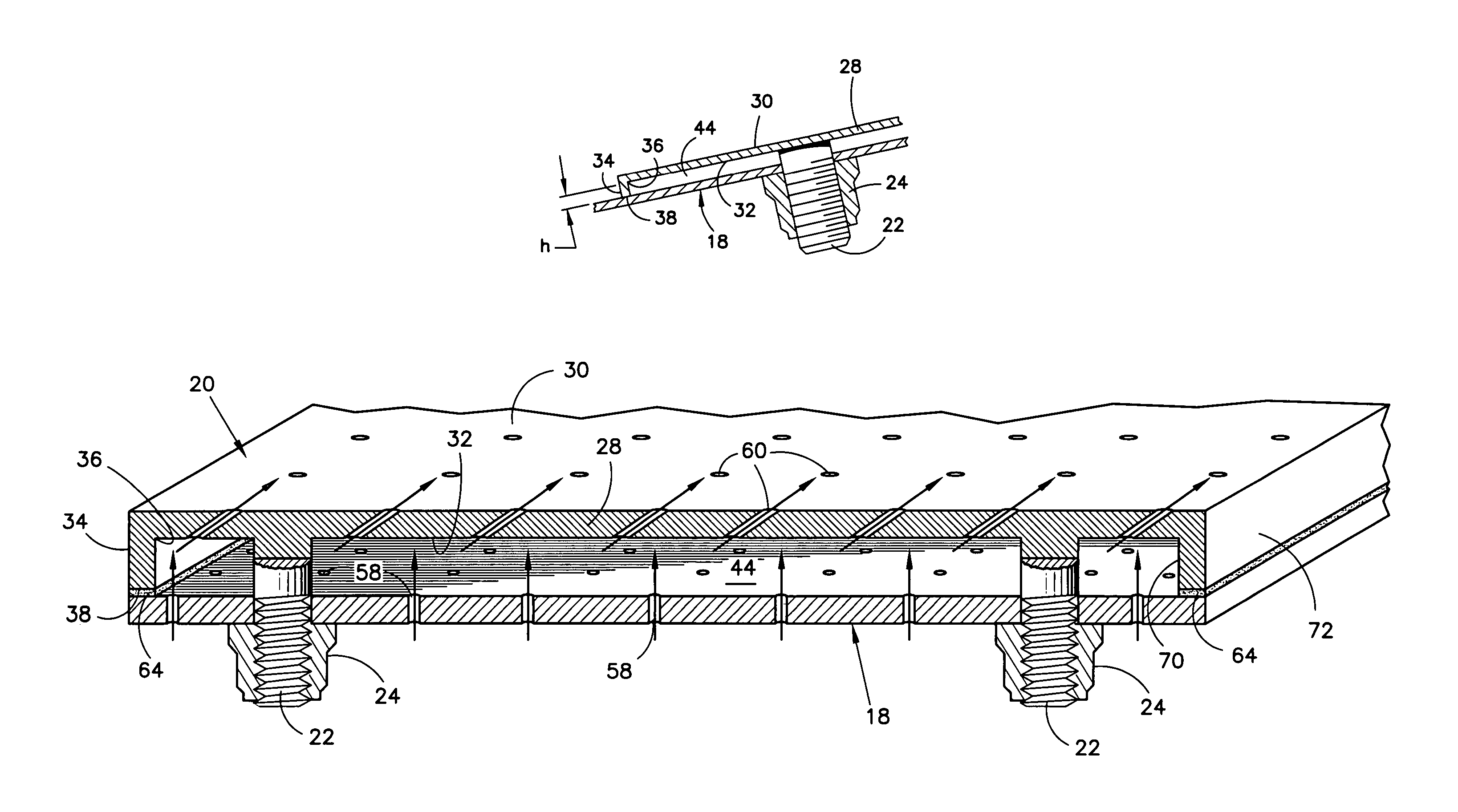

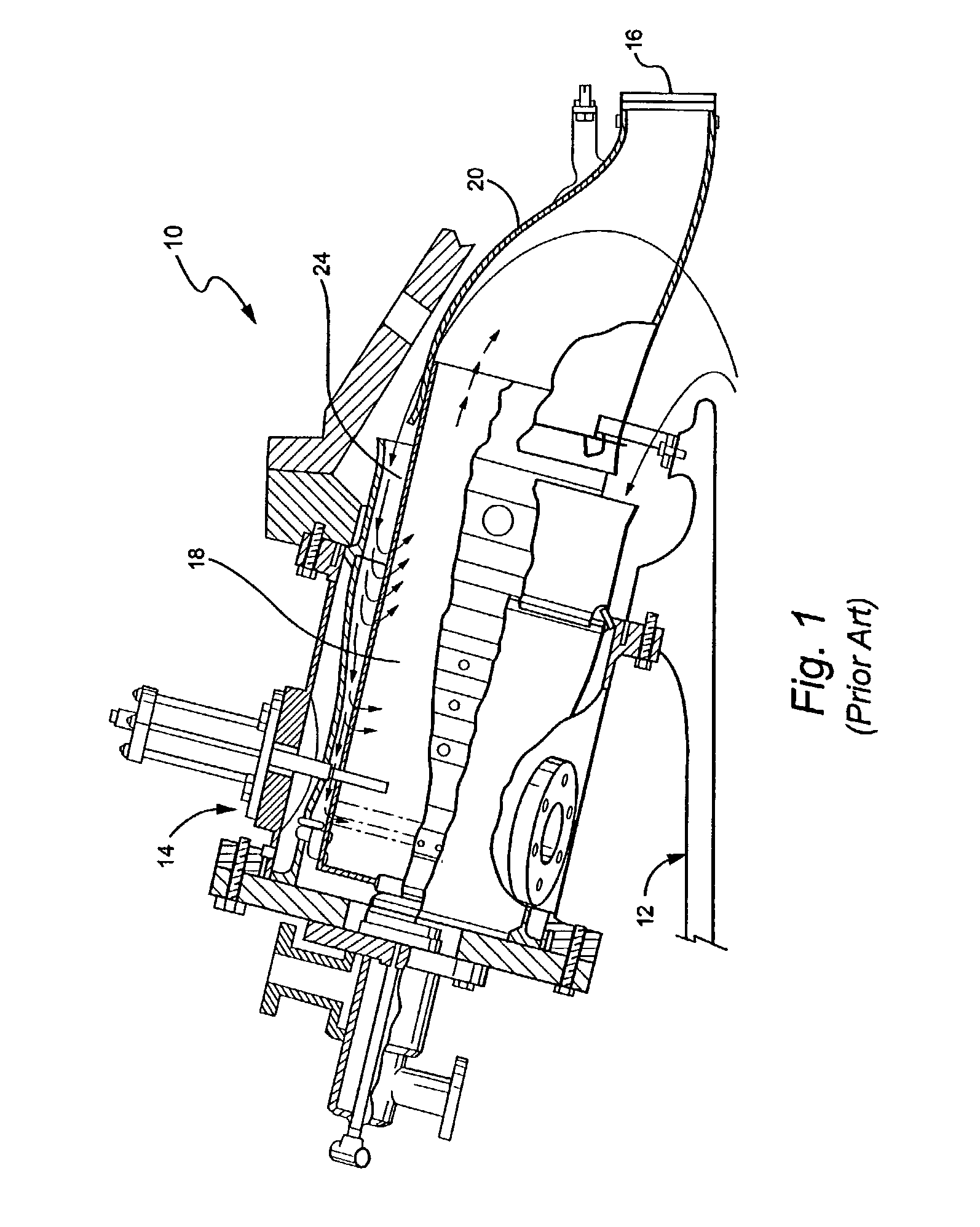

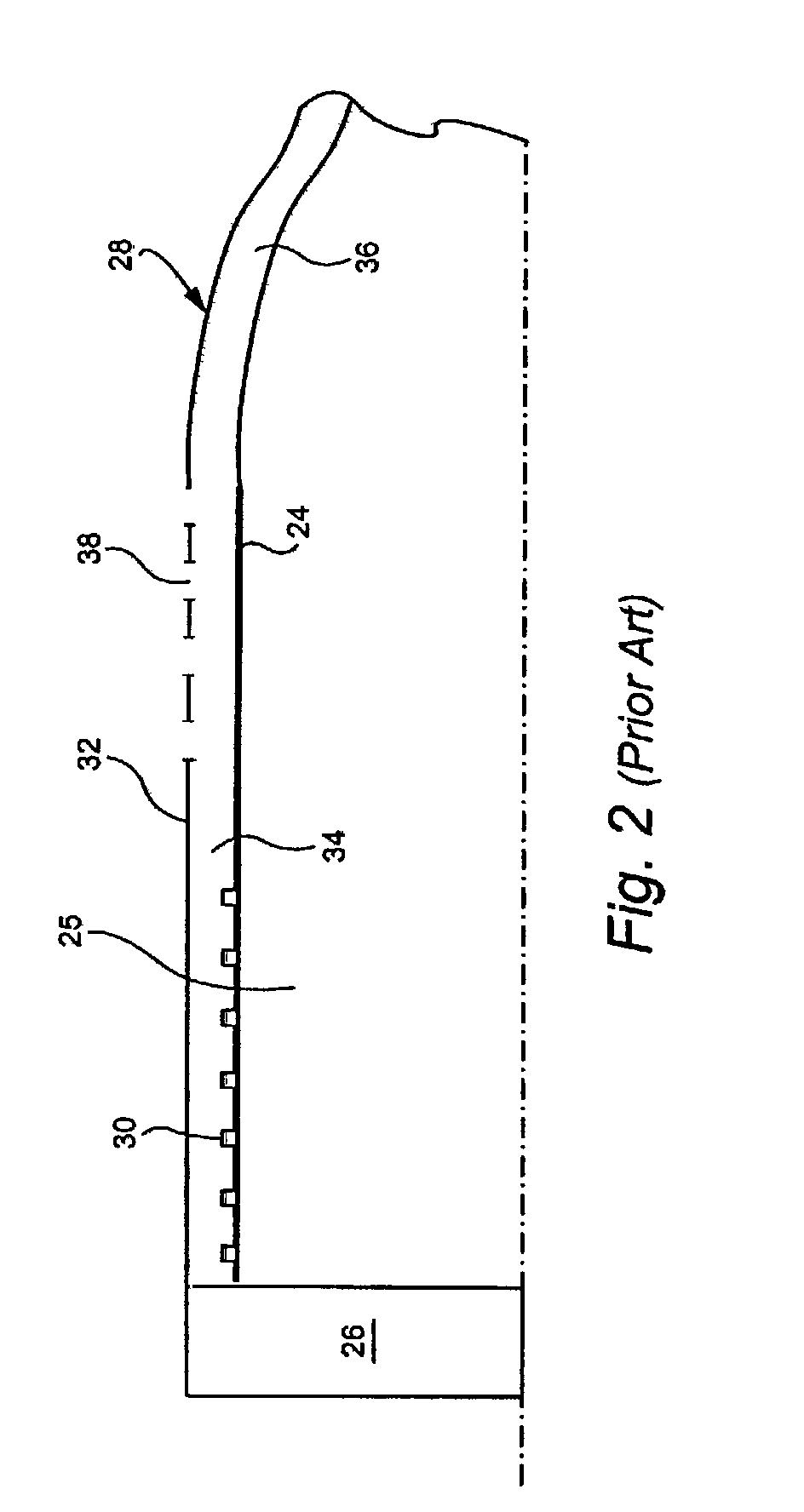

Heatshielded article

InactiveUS7140185B2Change heightEasily and inexpensively changedContinuous combustion chamberGas turbine plantsCold sideEngineering

A heatshielded article includes a support 18 and at least one heatshield 20 secured adjacent to the support. The heatshield includes a shield portion 28 spaced from the support. The shield portion includes a hot side 30 and an uncoated cold side 32. A projection projects from an origin 36 at the shield portion to a terminus 38 remote from the shield portion. The terminus includes a protective coating 64 along at least a portion of its length.

Owner:UNITED TECH CORP

Combustor liner with inverted turbulators

InactiveUS7104067B2Reduce total pressure lossContinuous combustion chamberTurbine/propulsion engine coolingCombustorEngineering

Owner:GENERAL ELECTRIC CO

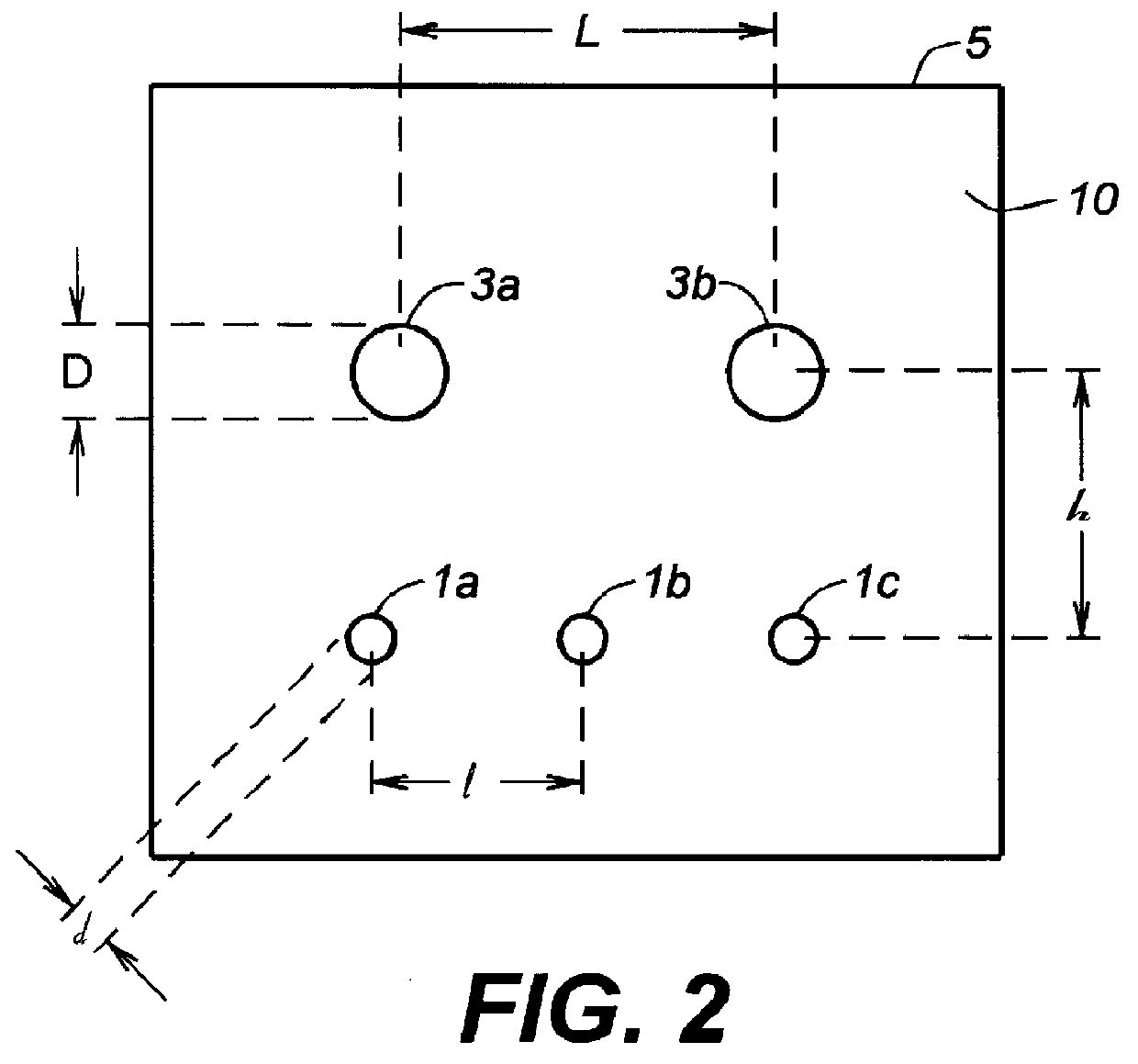

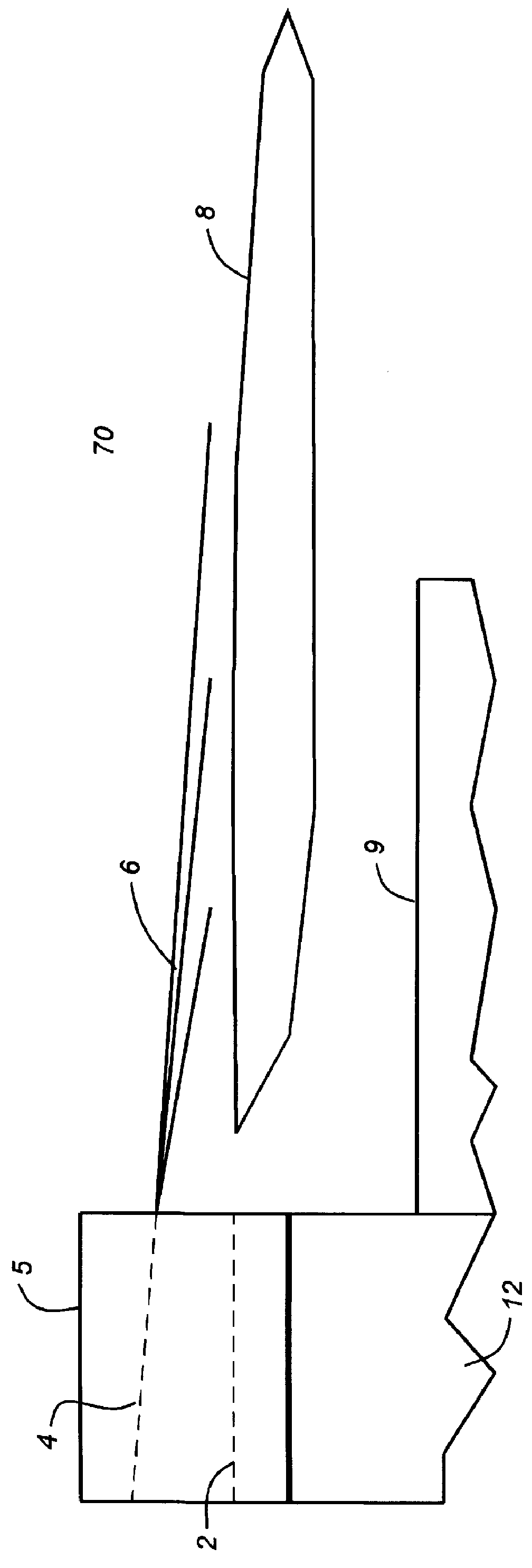

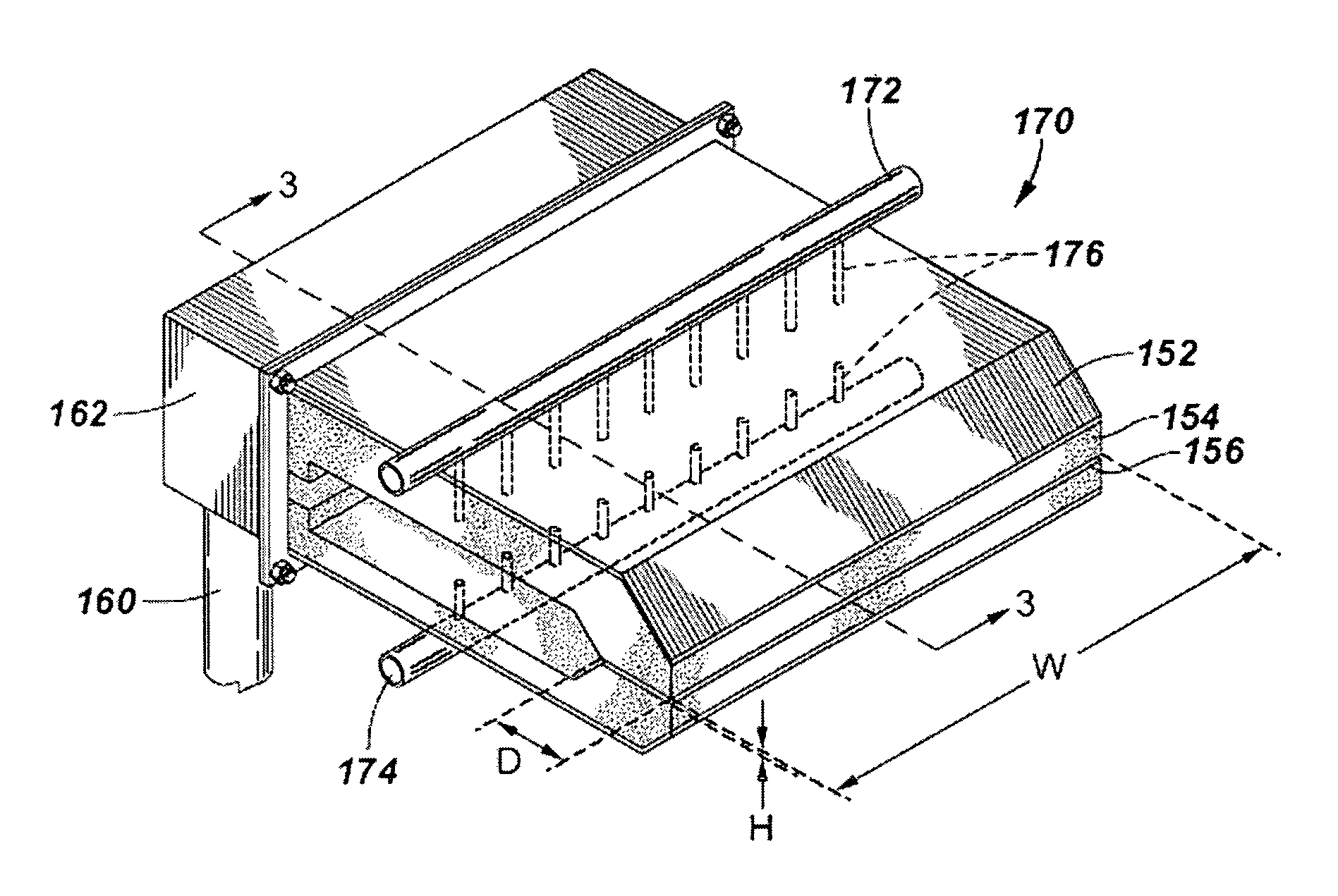

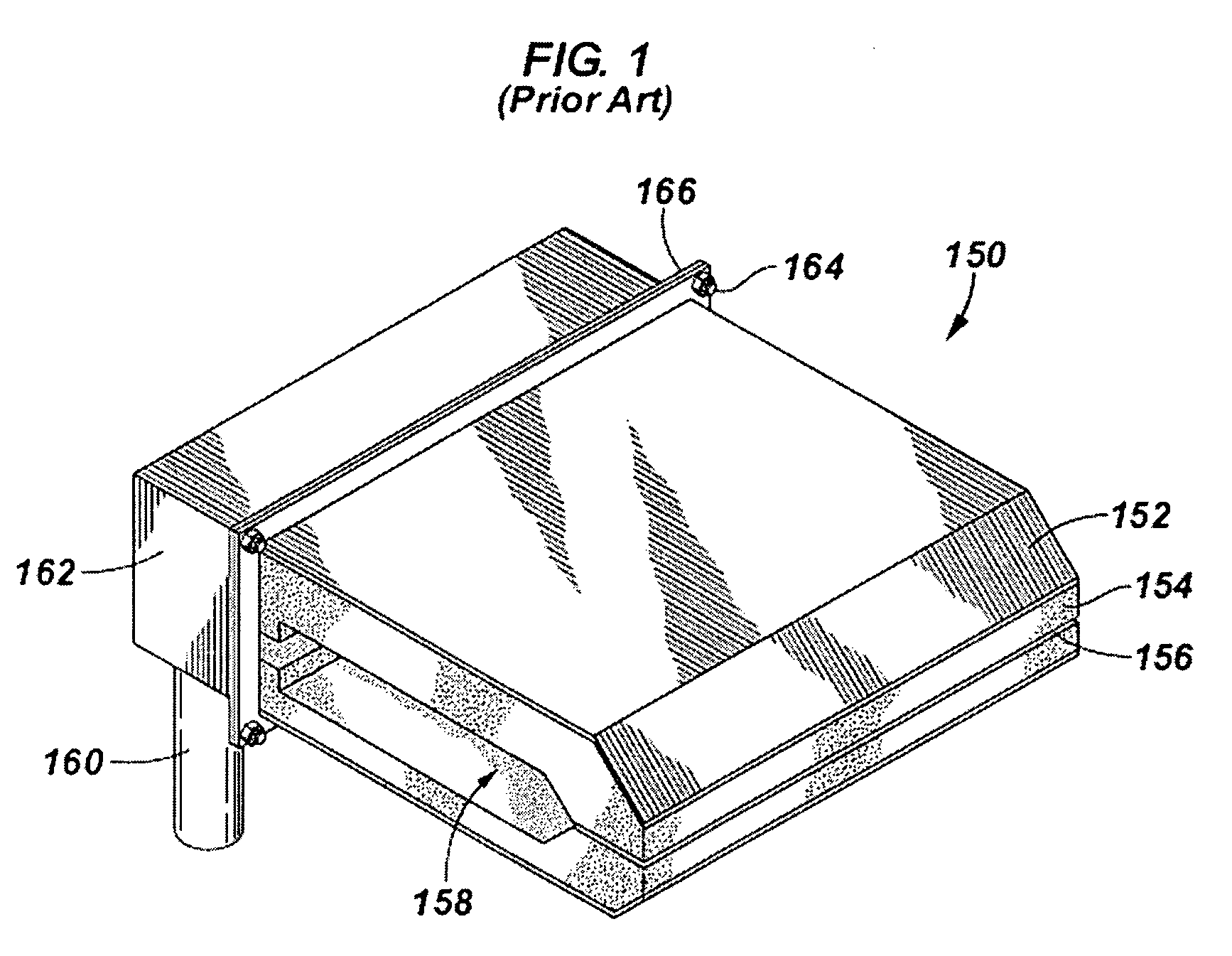

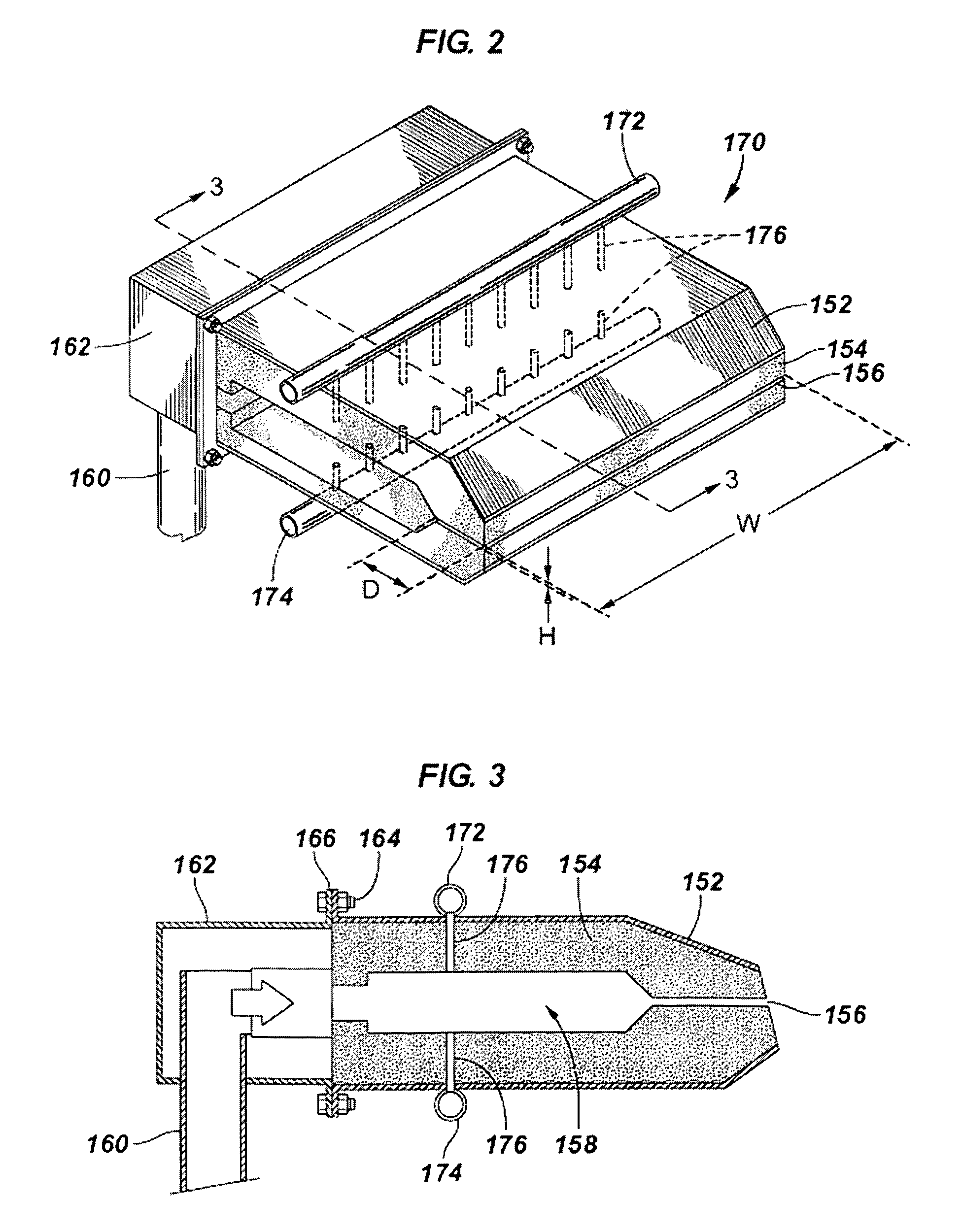

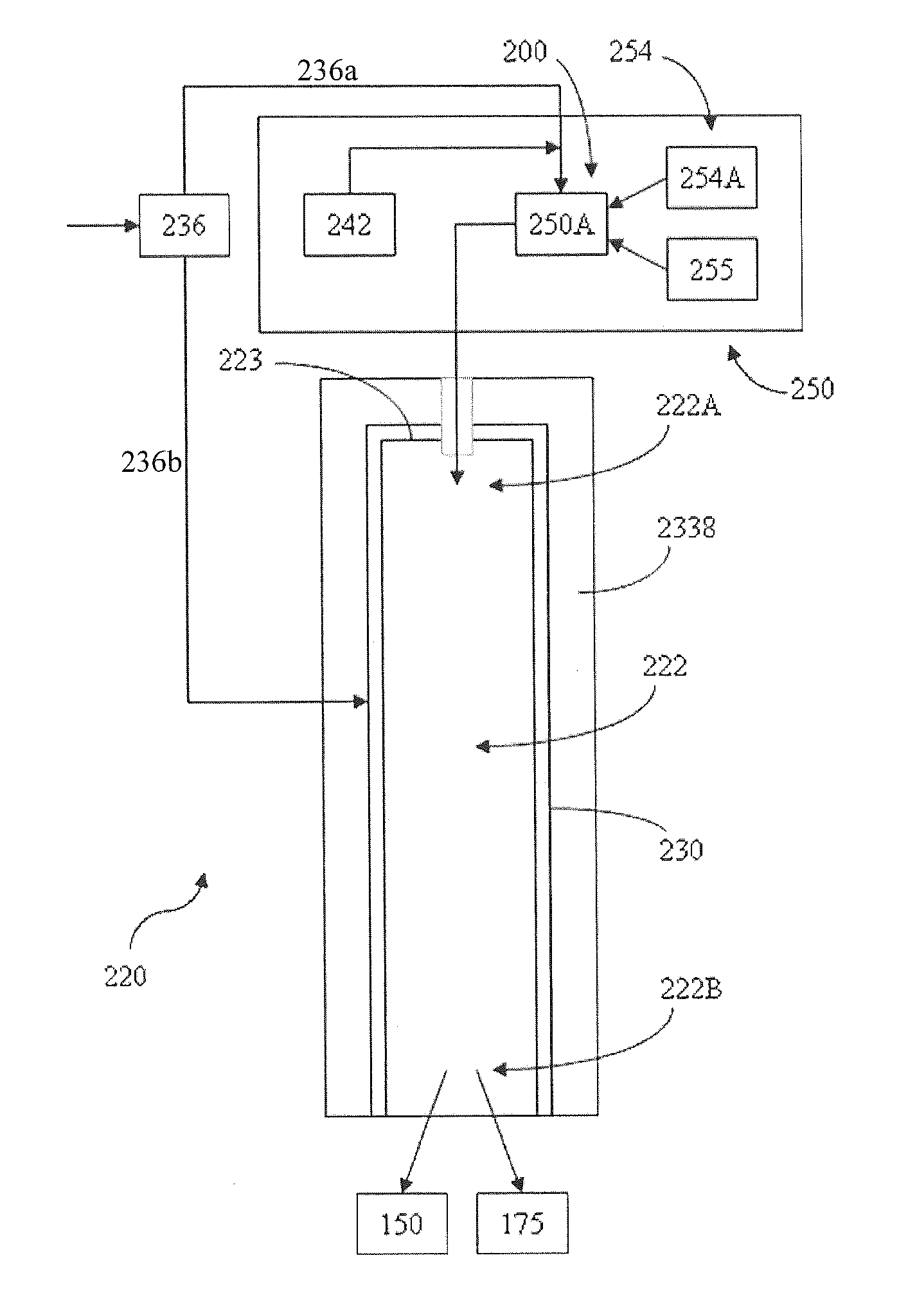

Burner apparatus and methods for making inorganic fibers

Inorganic fiber production burner apparatus and methods of use are disclosed. One burner includes a refractory block adapted to be in fluid connection with sources of primary oxidant and fuel, the refractory block having a fuel and primary oxidant entrance end and a flame exit end, the flame exit end having a substantially rectangular flame exit having a width greater than its height, the refractory block defining a combustion chamber and a second chamber fluidly connecting the combustion chamber and the flame exit end; and an oxygen manifold fluidly connected to the combustion chamber and adapted to route oxygen to the combustion chamber through a plurality of passages through the refractory block. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:JOHNS MANVILLE CORP

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20130213049A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

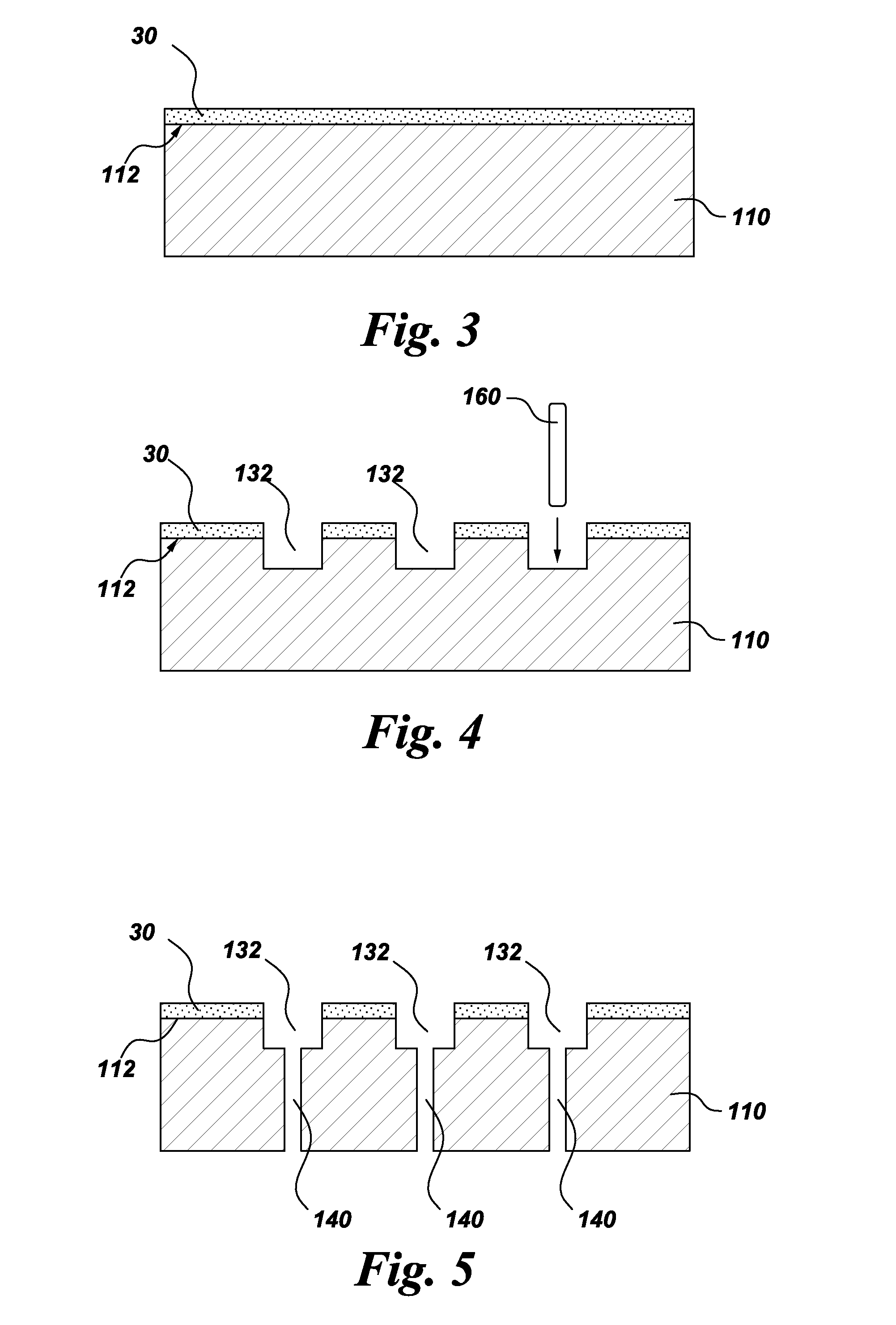

Method of fabricating a component using a fugitive coating

InactiveUS20120114868A1Molten spray coatingElectrolysis componentsInterior spaceBiomedical engineering

A method of fabricating a component is provided. The method includes depositing a fugitive coating on a surface of a substrate, where the substrate has at least one hollow interior space. The method further includes machining the substrate through the fugitive coating to form one or more grooves in the surface of the substrate. Each of the one or more grooves has a base and extends at least partially along the surface of the substrate. The method further includes forming one or more access holes through the base of a respective one of the one or more grooves to connect the respective groove in fluid communication with the respective hollow interior space. The method further includes filling the one or more grooves with a filler, removing the fugitive coating, disposing a coating over at least a portion of the surface of the substrate, and removing the filler from the one or more grooves, such that the one or more grooves and the coating together define a number of channels for cooling the component.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com