Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4268results about "Cold treatment separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

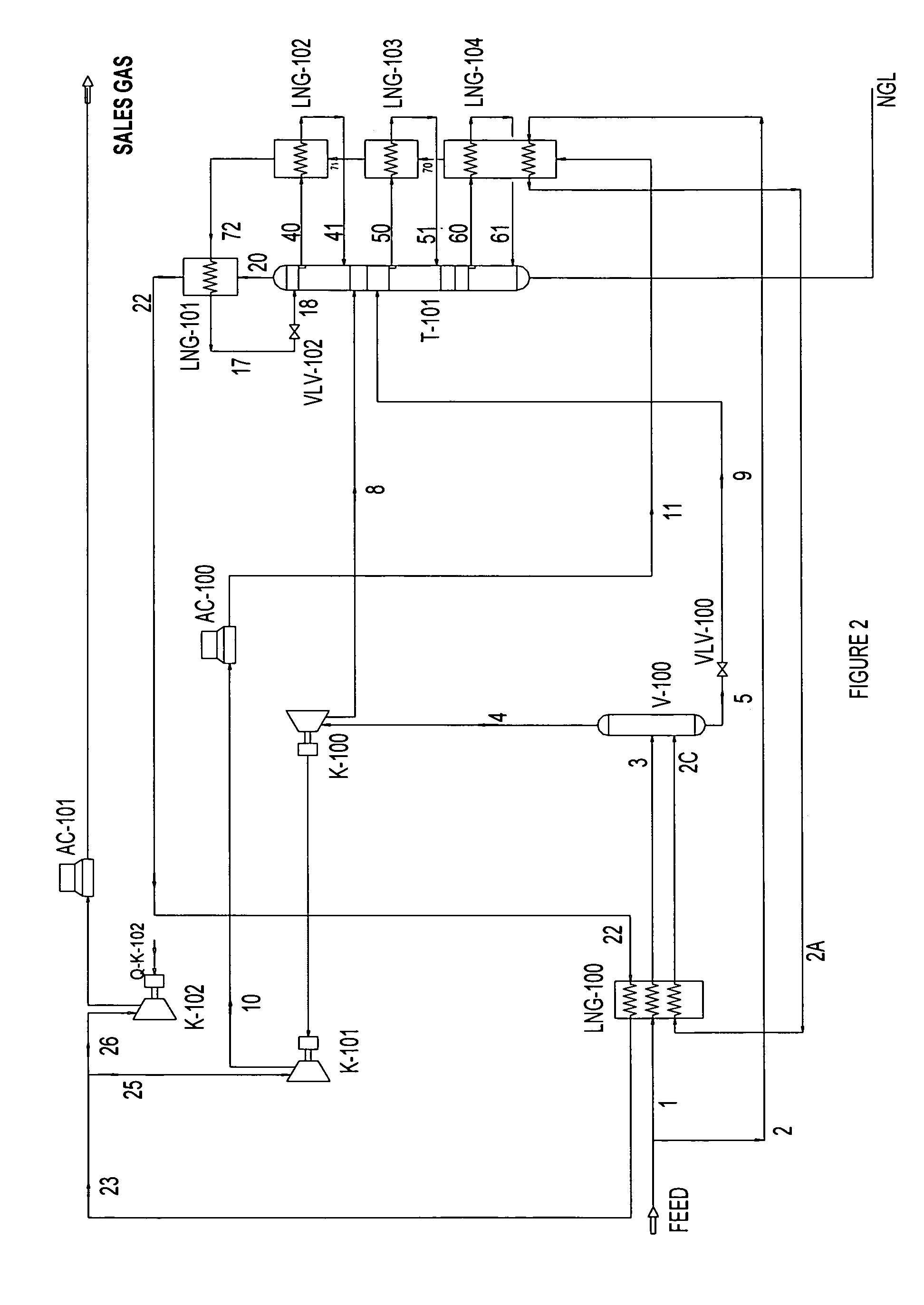

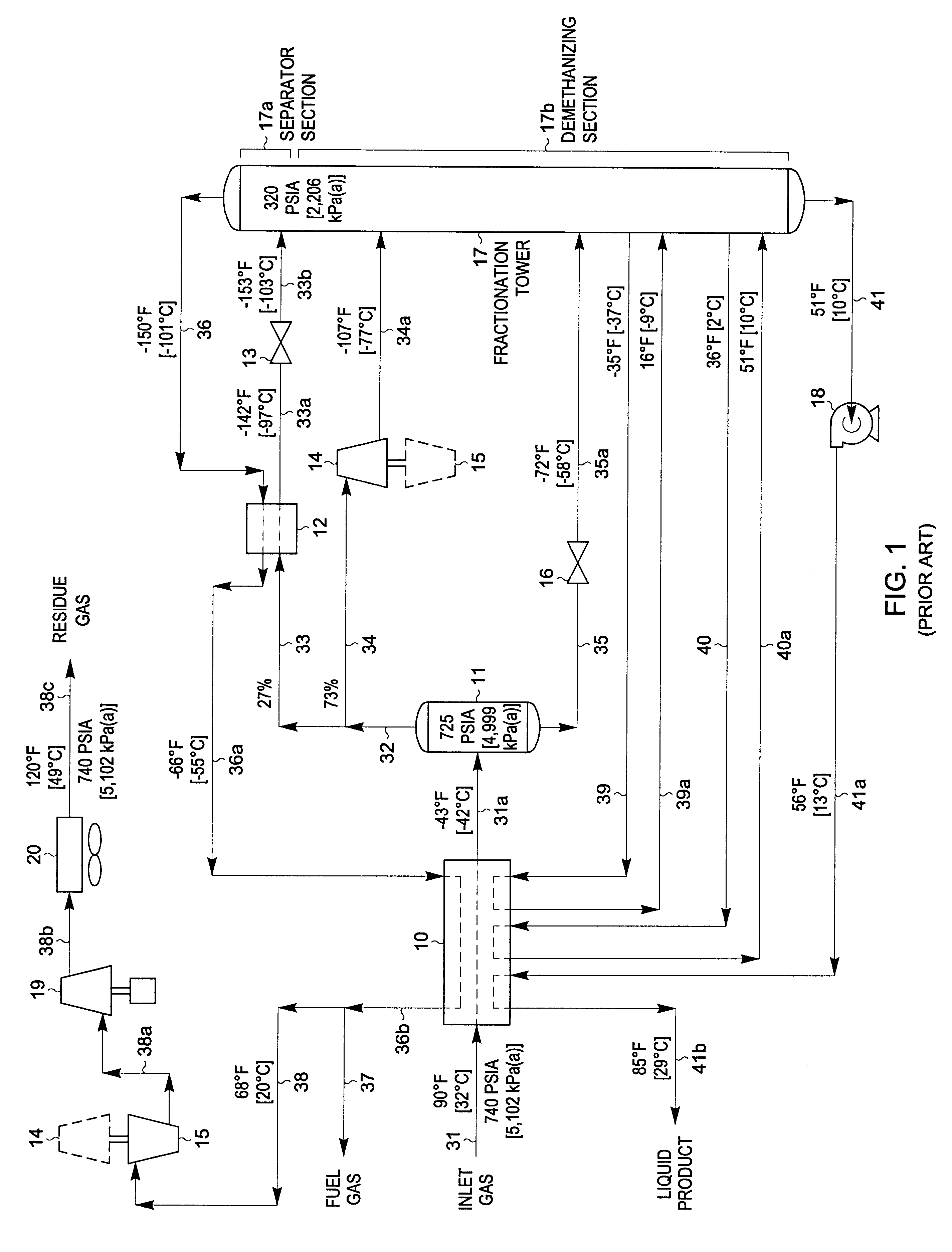

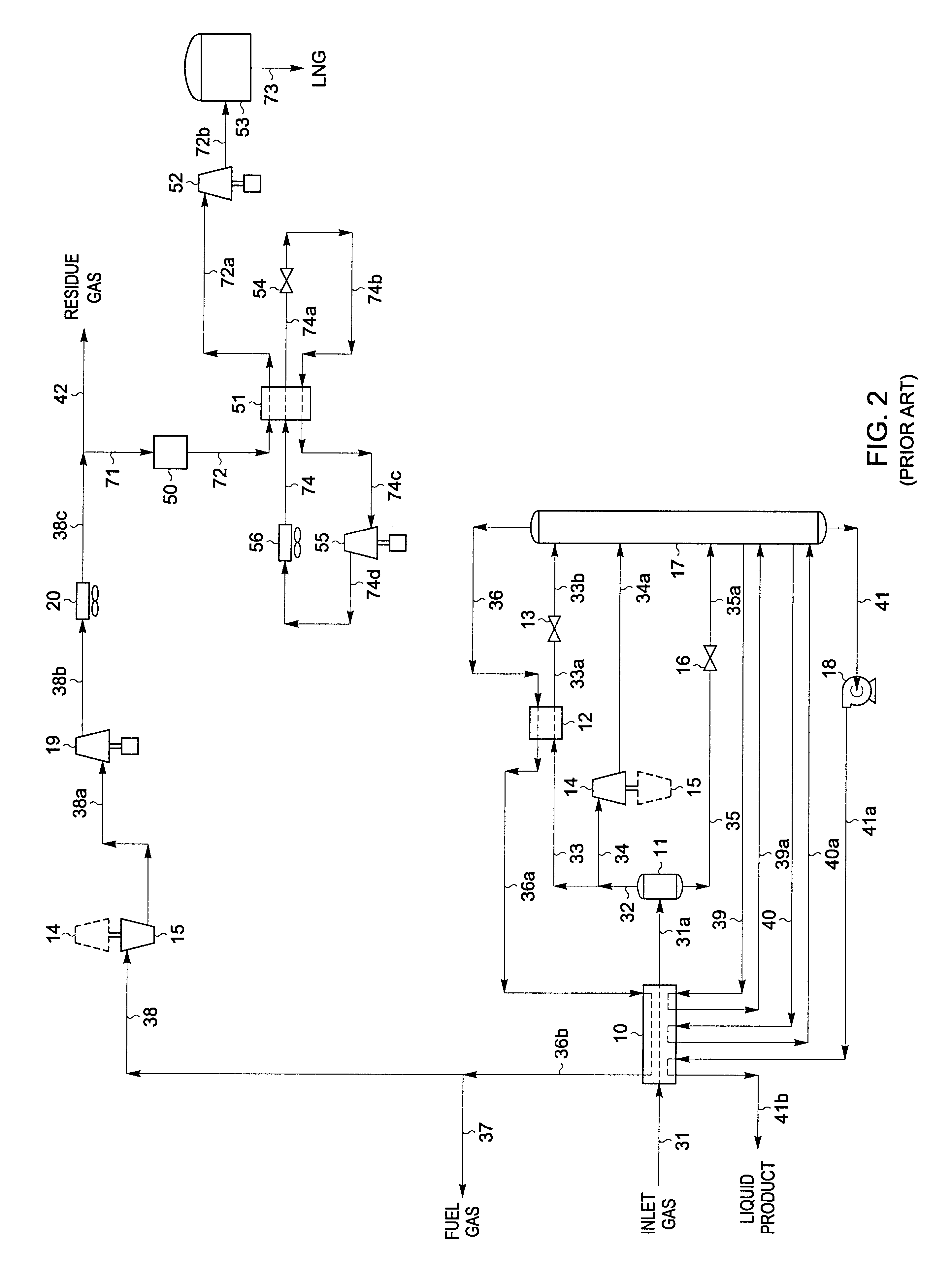

Hydrocarbon gas processing

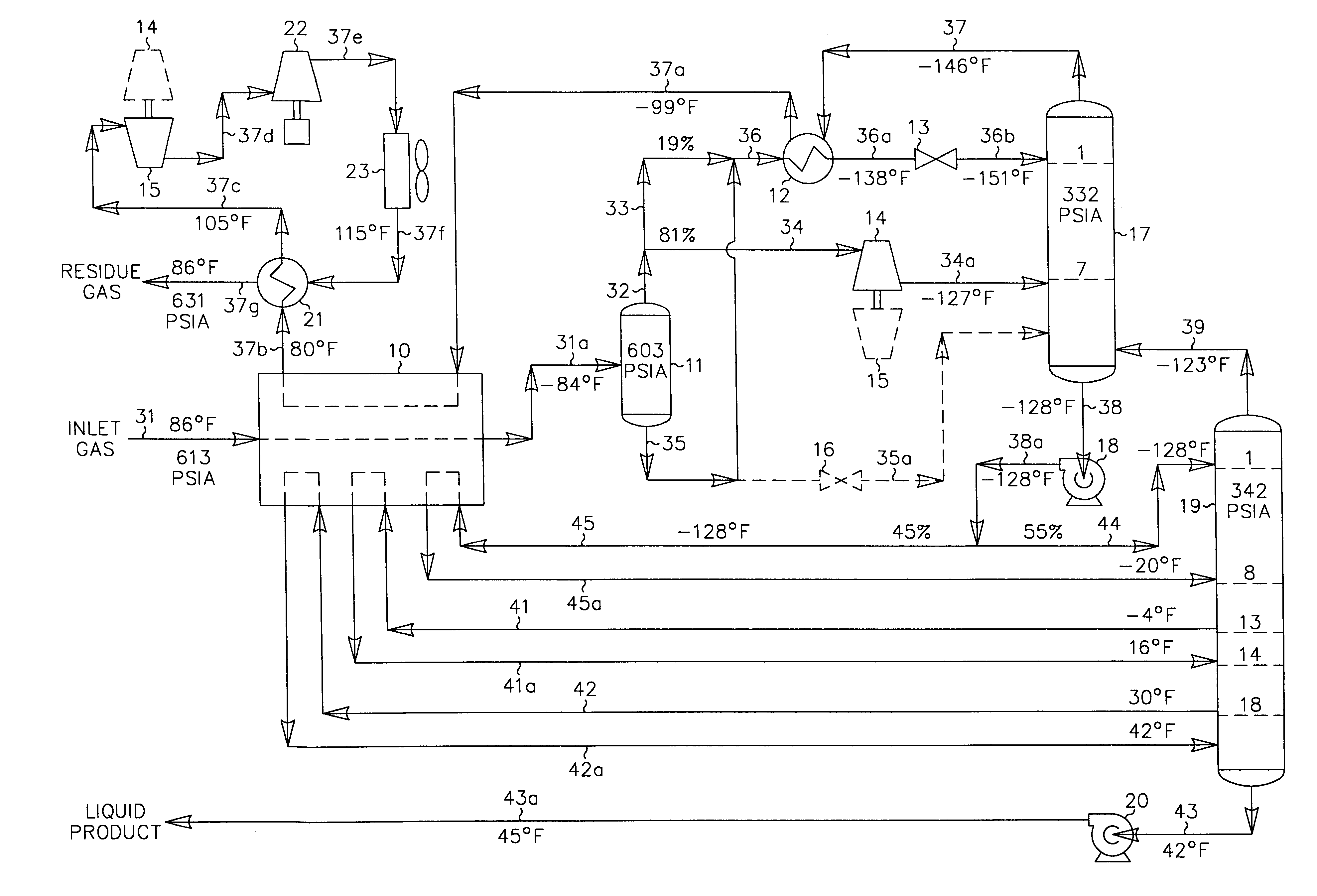

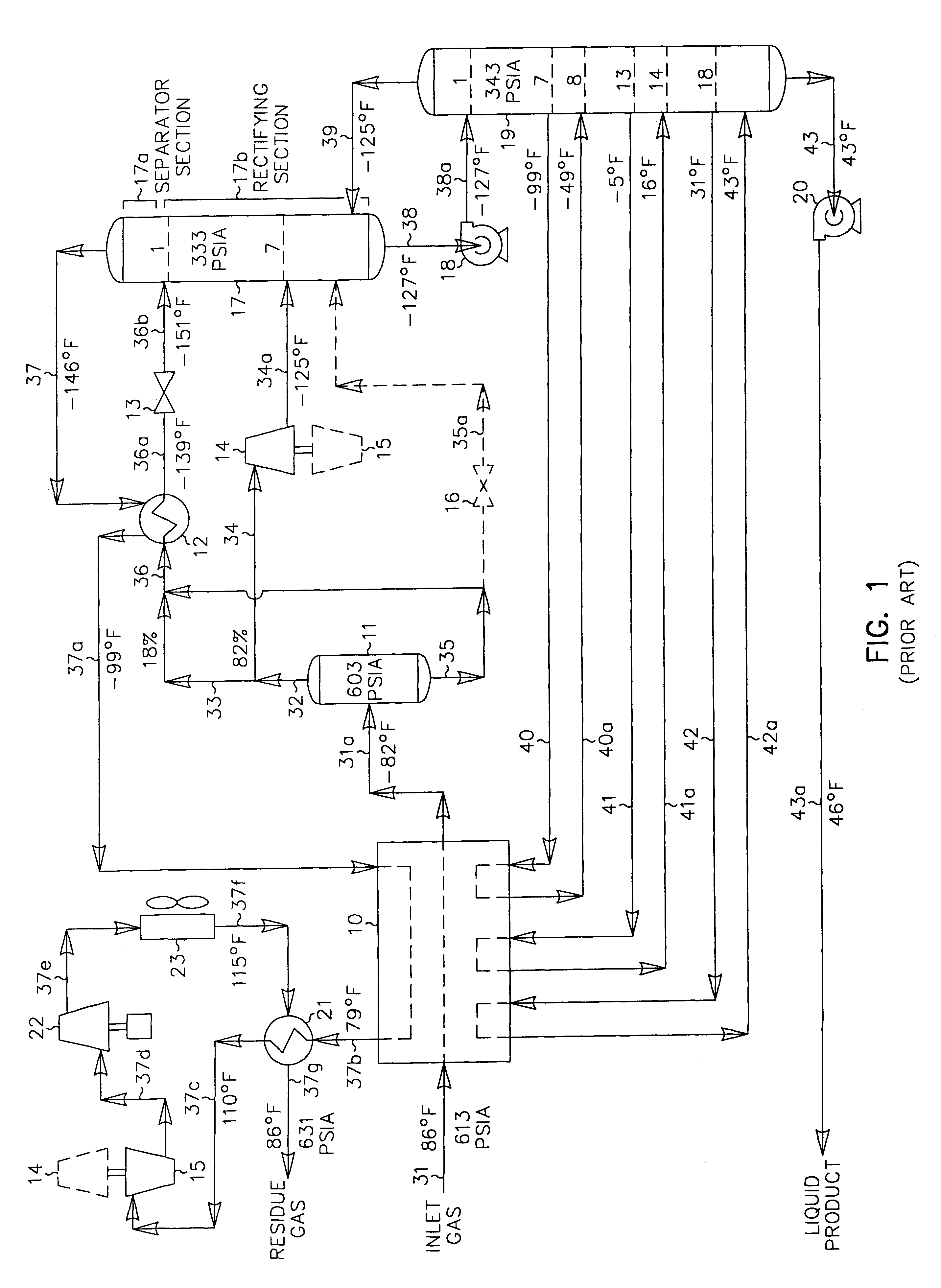

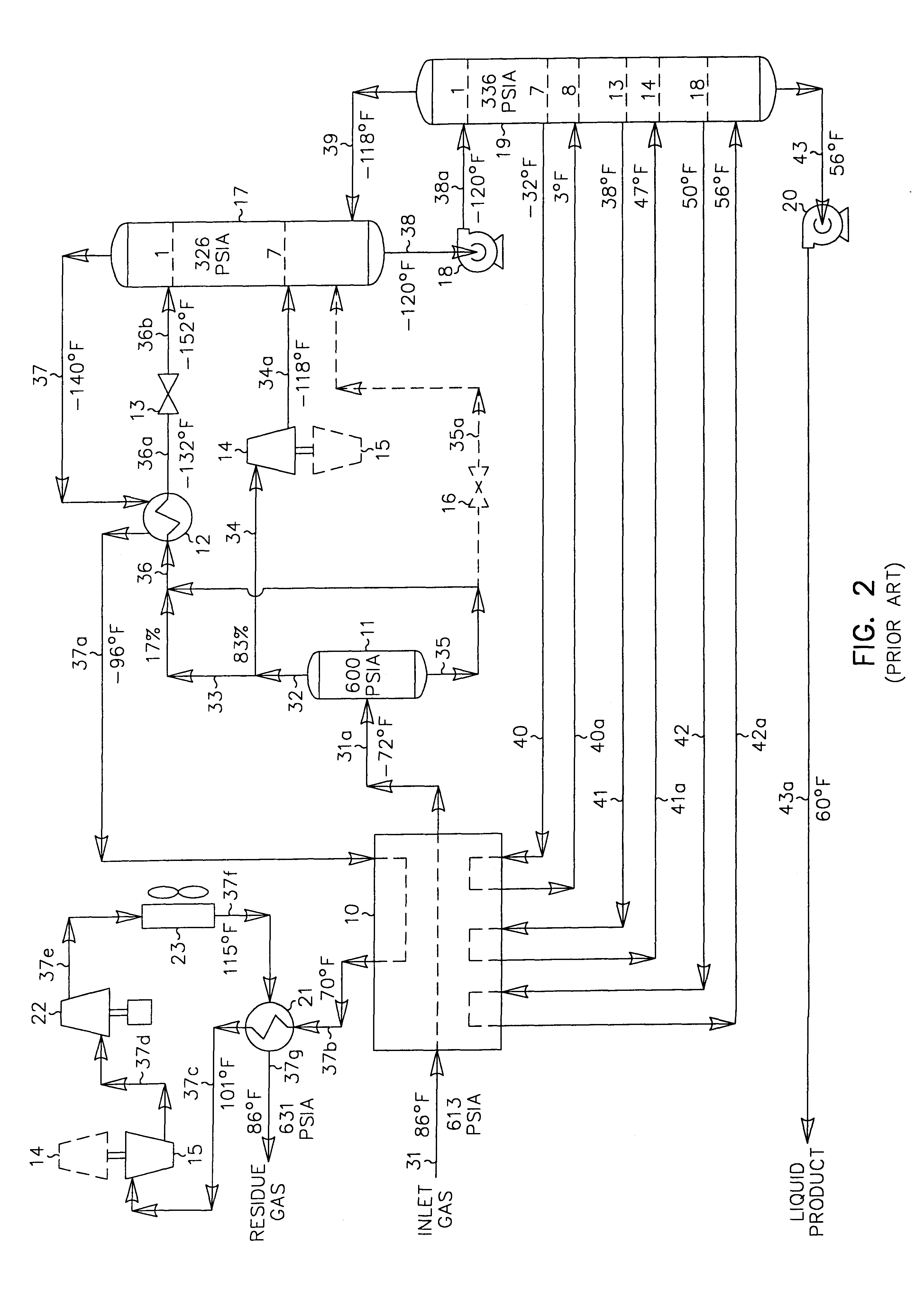

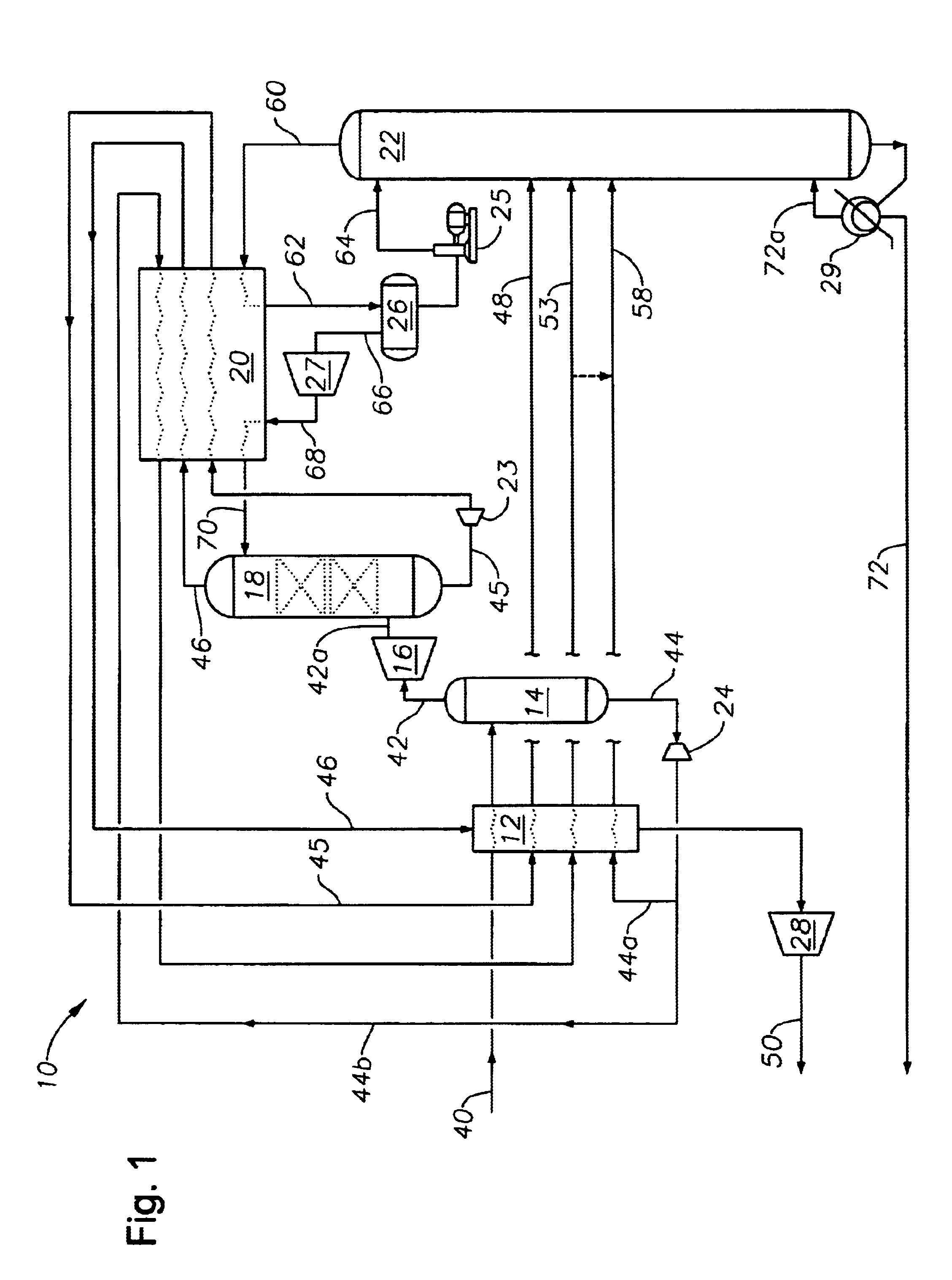

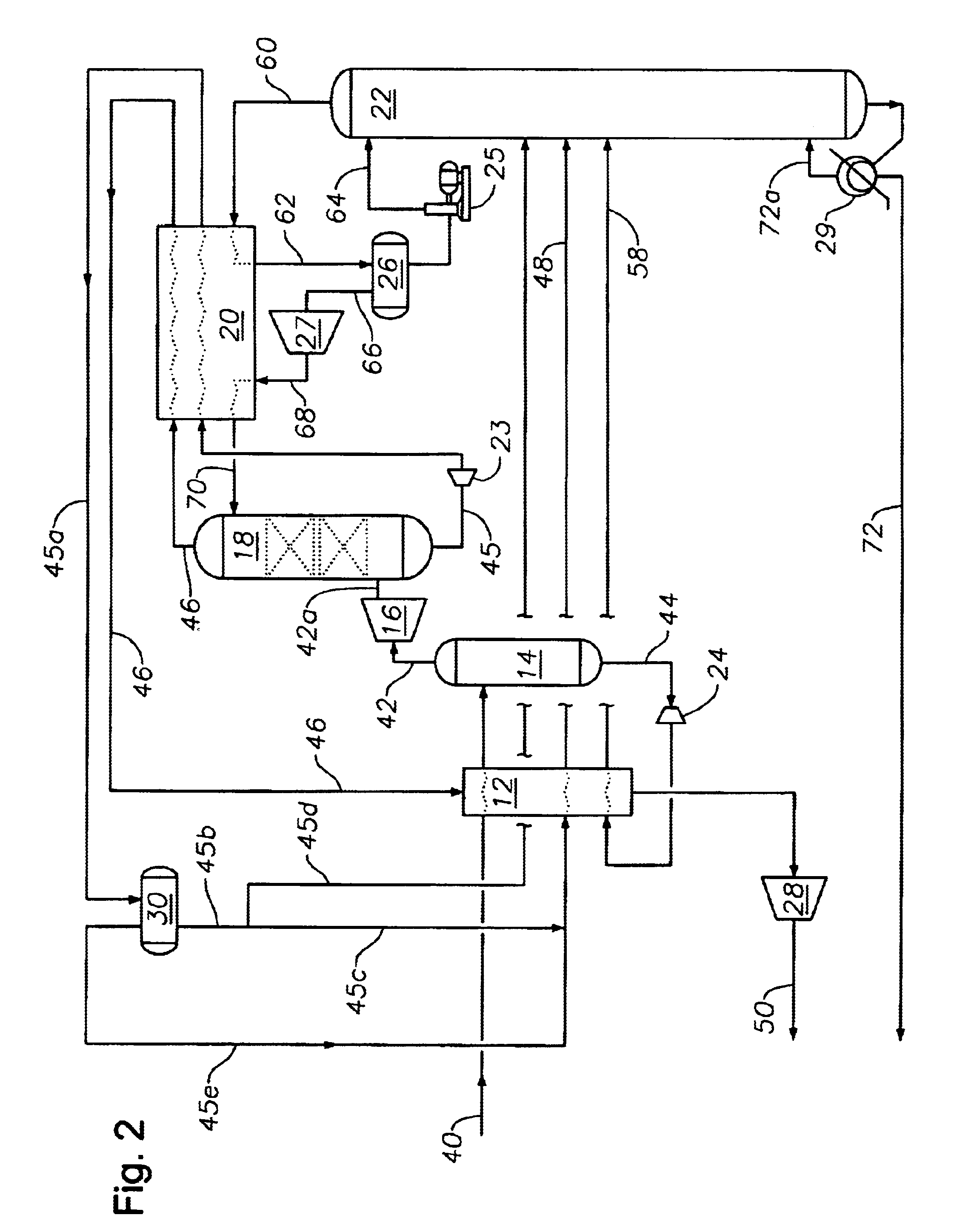

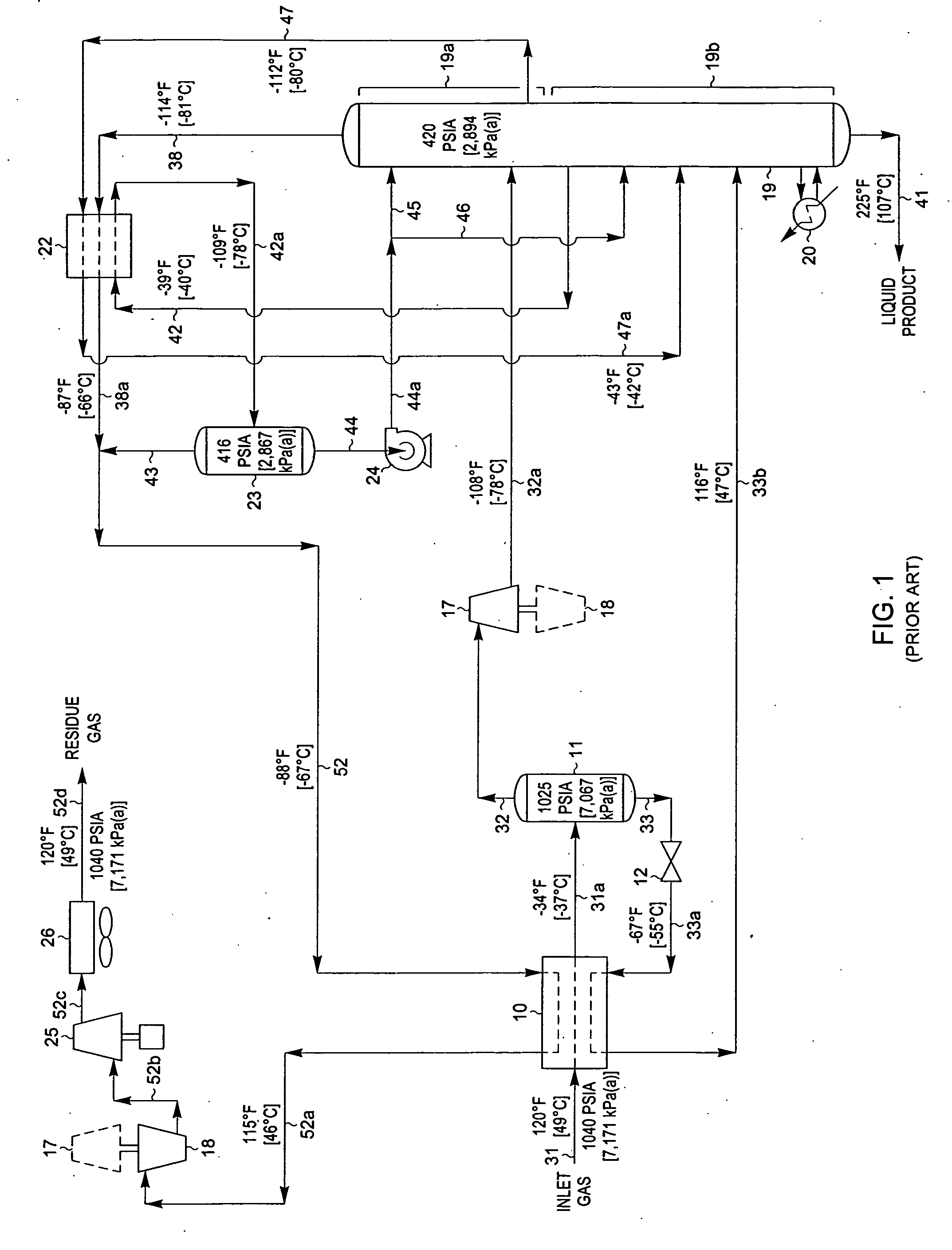

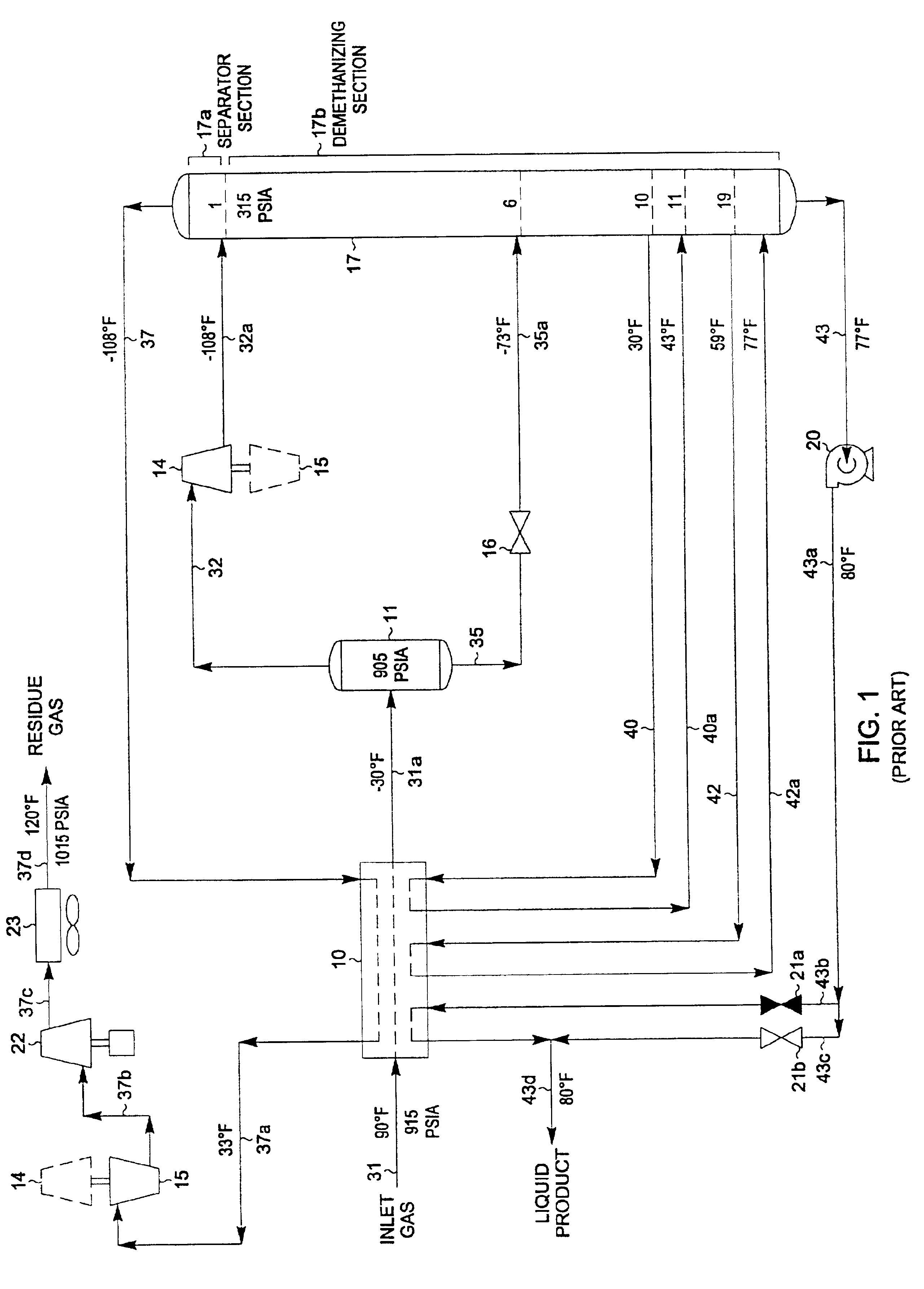

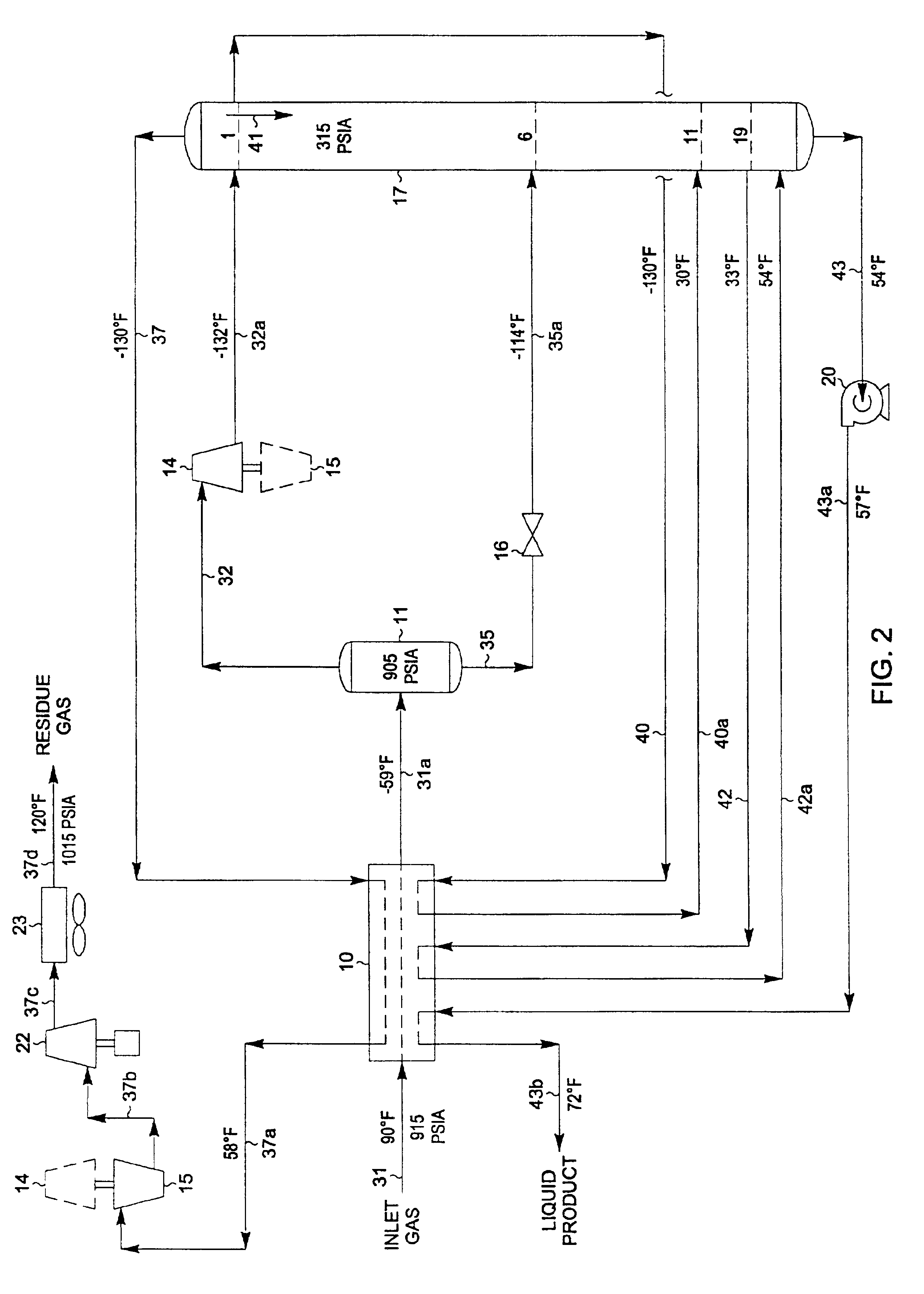

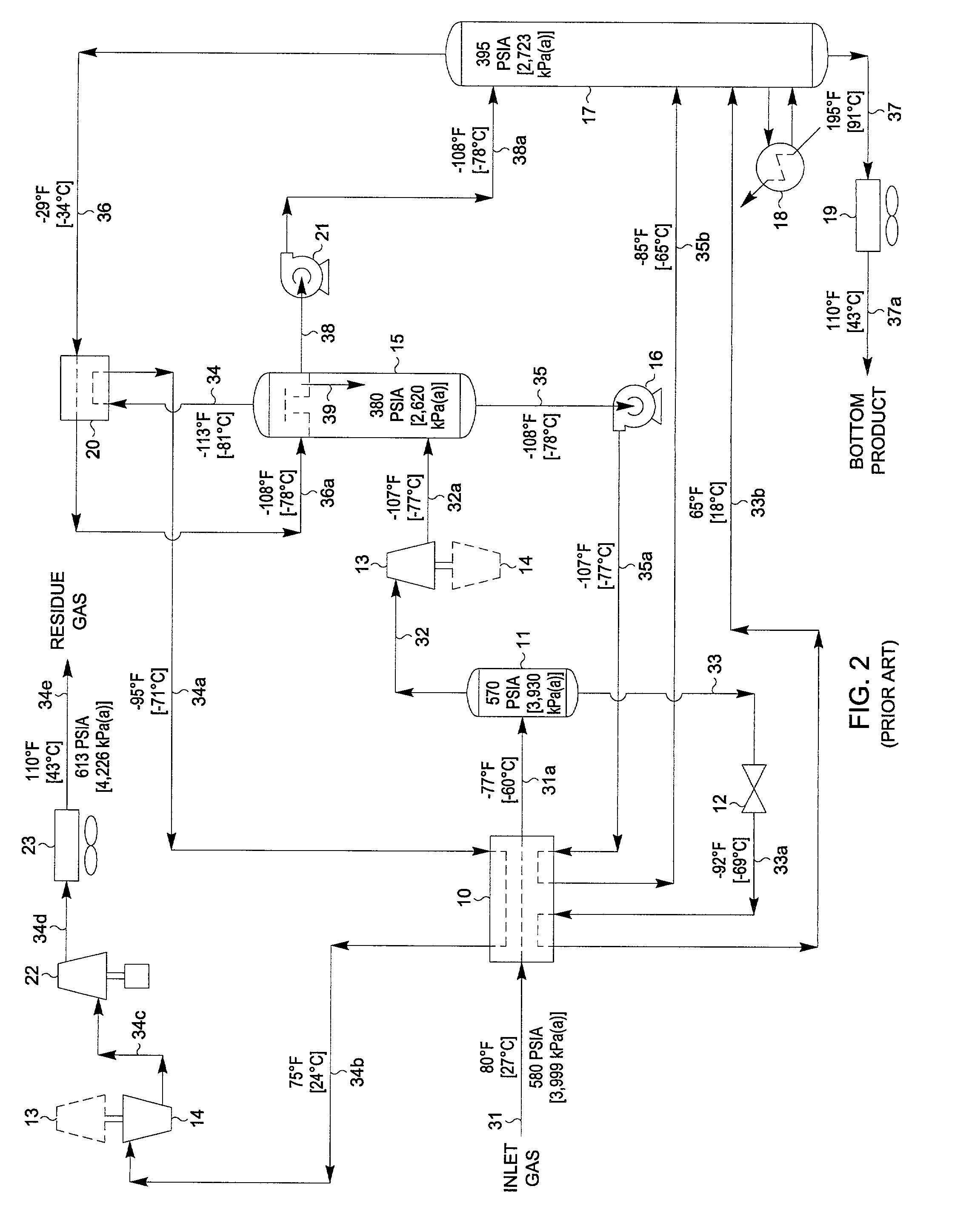

A process for the recovery of ethane, ethylene, propane, propylene and heavier hydrocarbon components from a hydrocarbon gas stream is disclosed. In recent years, the preferred method of separating a hydrocarbon gas stream generally includes supplying at least portions of the gas stream to a fractionation tower having at least one reboiler, and often one or more side reboilers, to supply heat to the column by withdrawing and heating some of the tower liquids to produce stripping vapors that separate the more volatile components from the desired components. The reboiler and side reboilers (if any) are typically integrated into the feed stream cooling scheme to provide at least a portion of the refrigeration needed to condense the desired components for subsequent fractionation in the distillation column. In the process disclosed, the tower reboiling scheme is modified to use one or more tower liquid distillation streams from a point higher in the column than is used in the conventional reboiling scheme, providing colder stream(s) for the reboiler(s) that allow more effective cooling of the feed streams and thereby improve the efficiency with which the desired components are recovered. In addition, the tower liquid streams withdrawn from a higher point in the column contain larger quantities of the more volatile components, which when vaporized provide better stripping of undesirable components like carbon dioxide without reducing the recovery of the desired components. The heated distillation stream is returned to a lower point on the fractionation tower that is separated from the withdrawal point by at least one theoretical stage.

Owner:UOP LLC

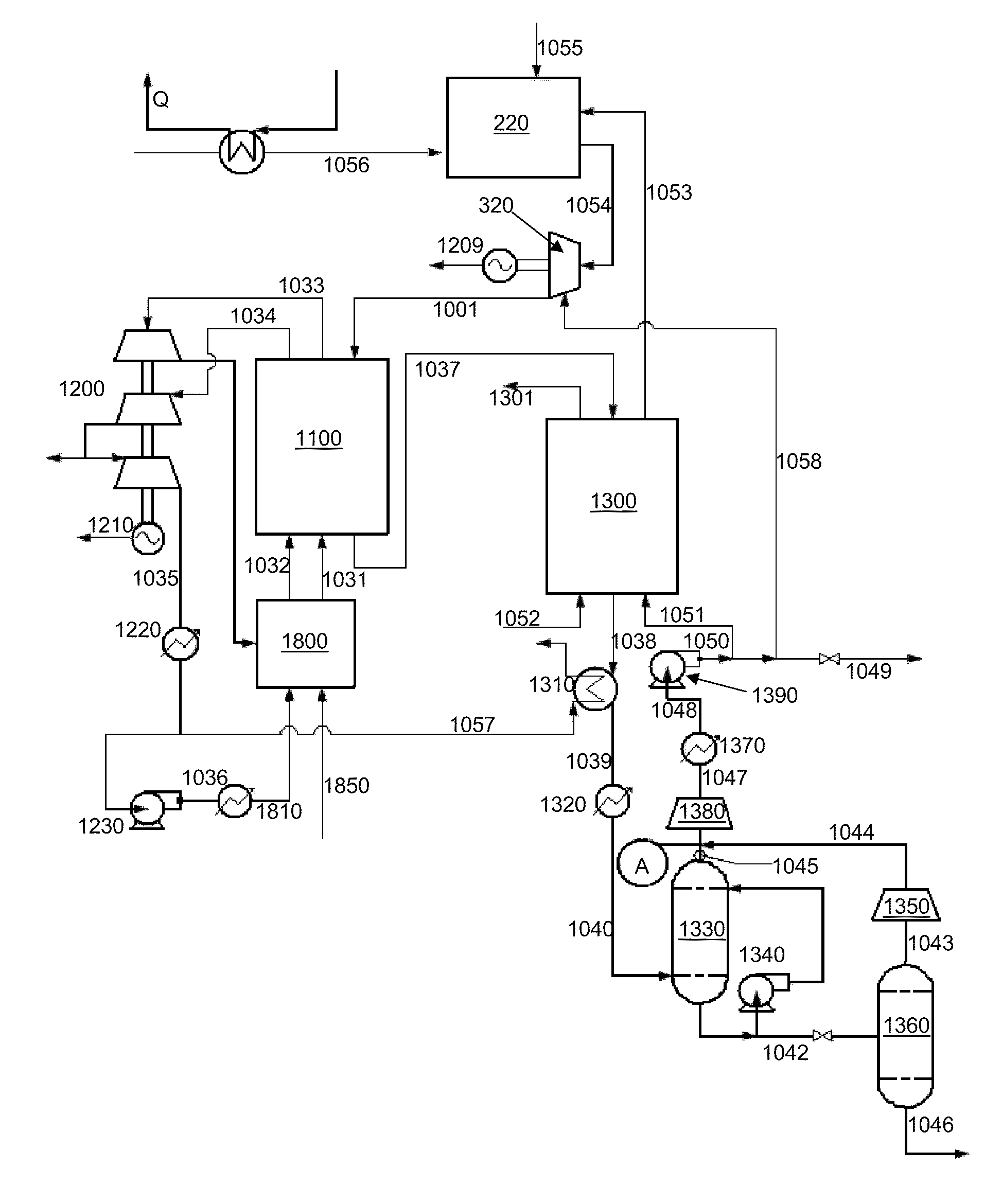

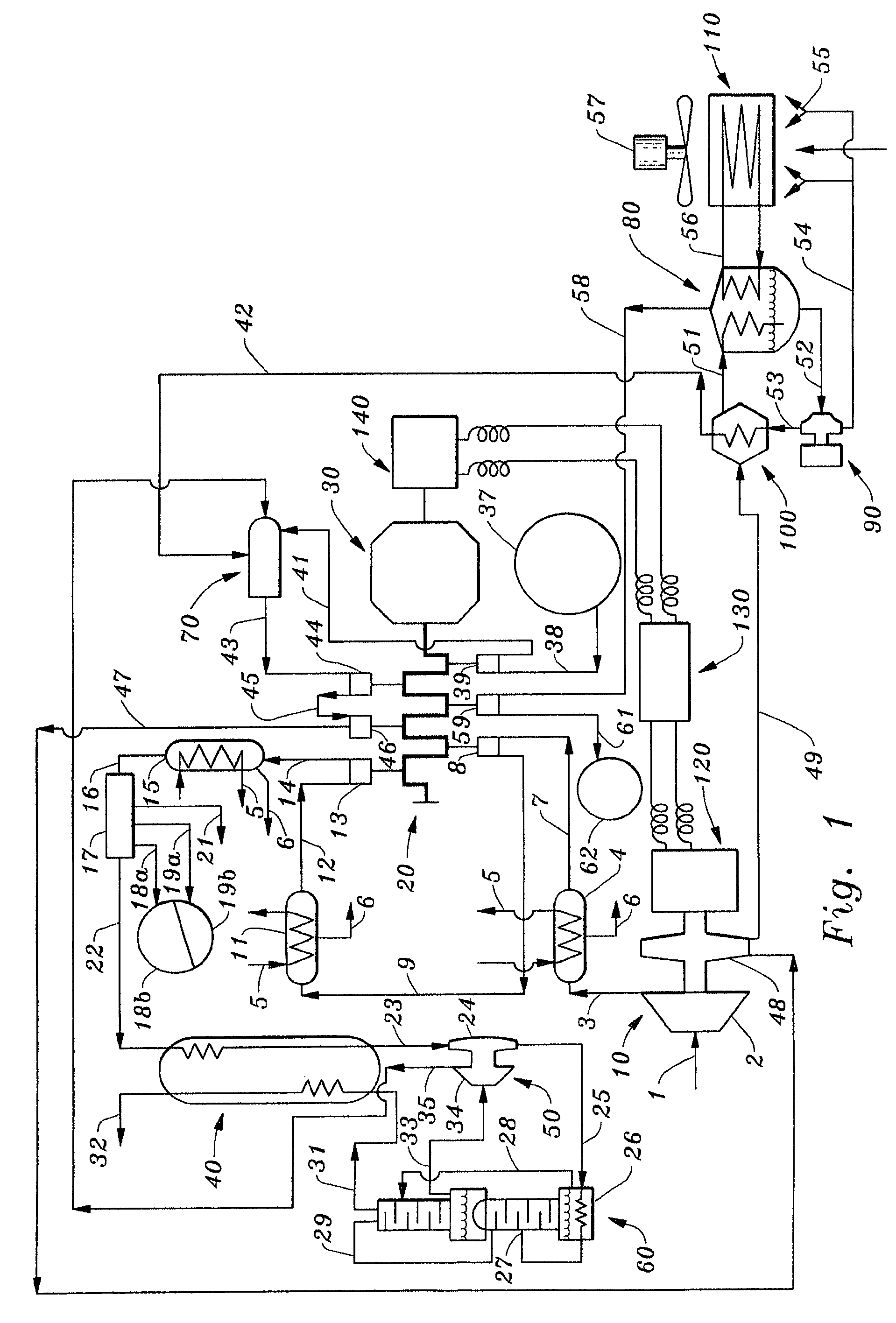

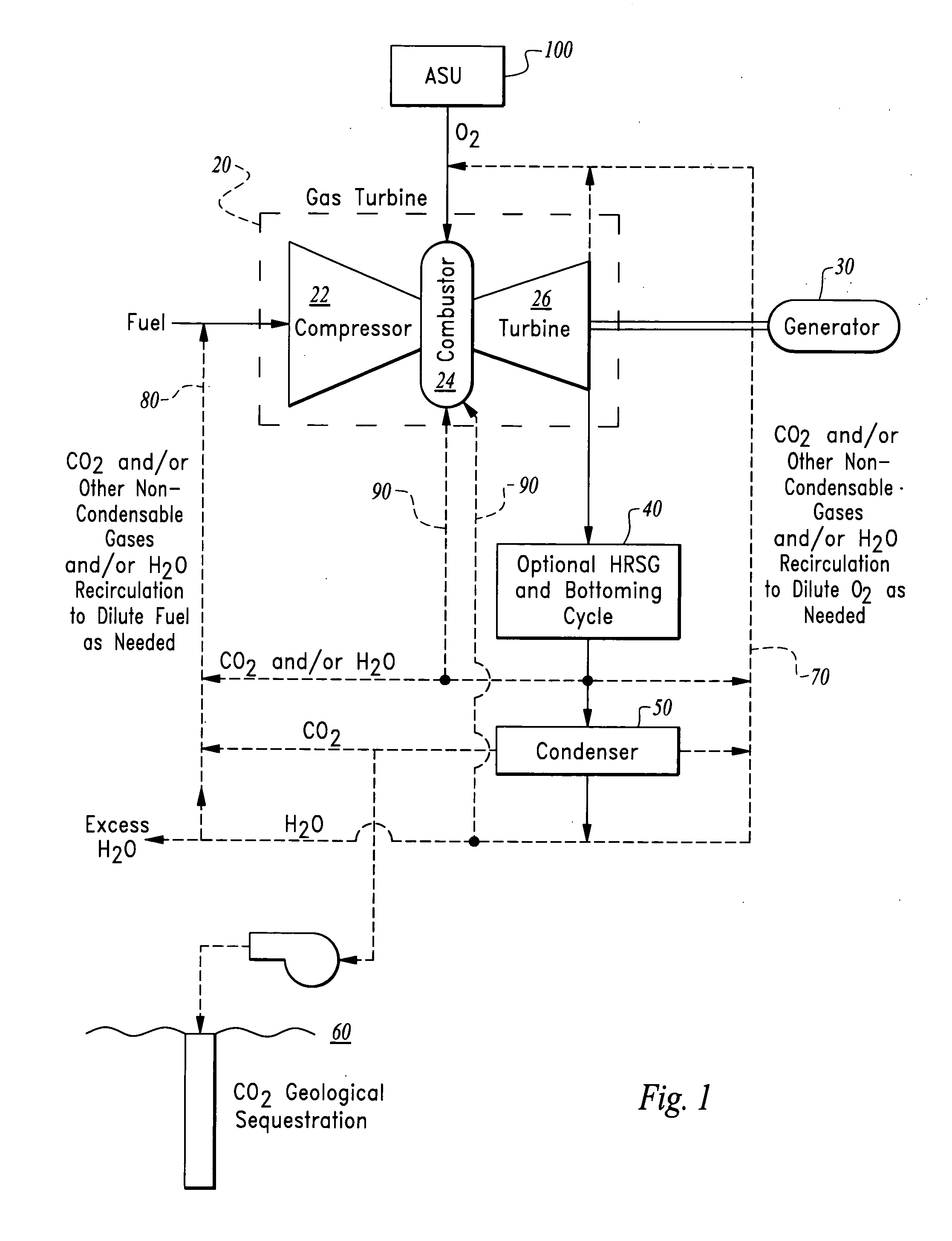

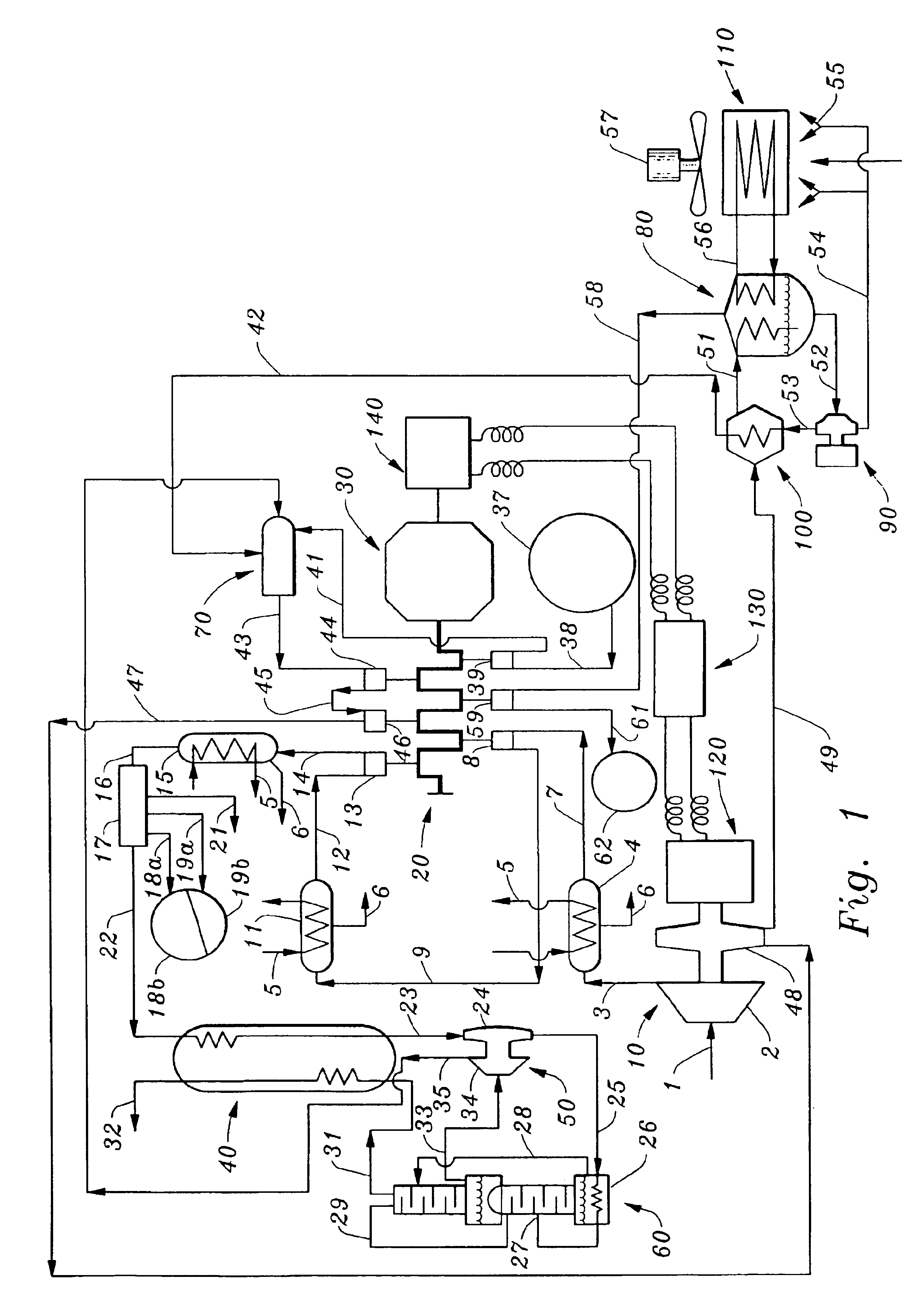

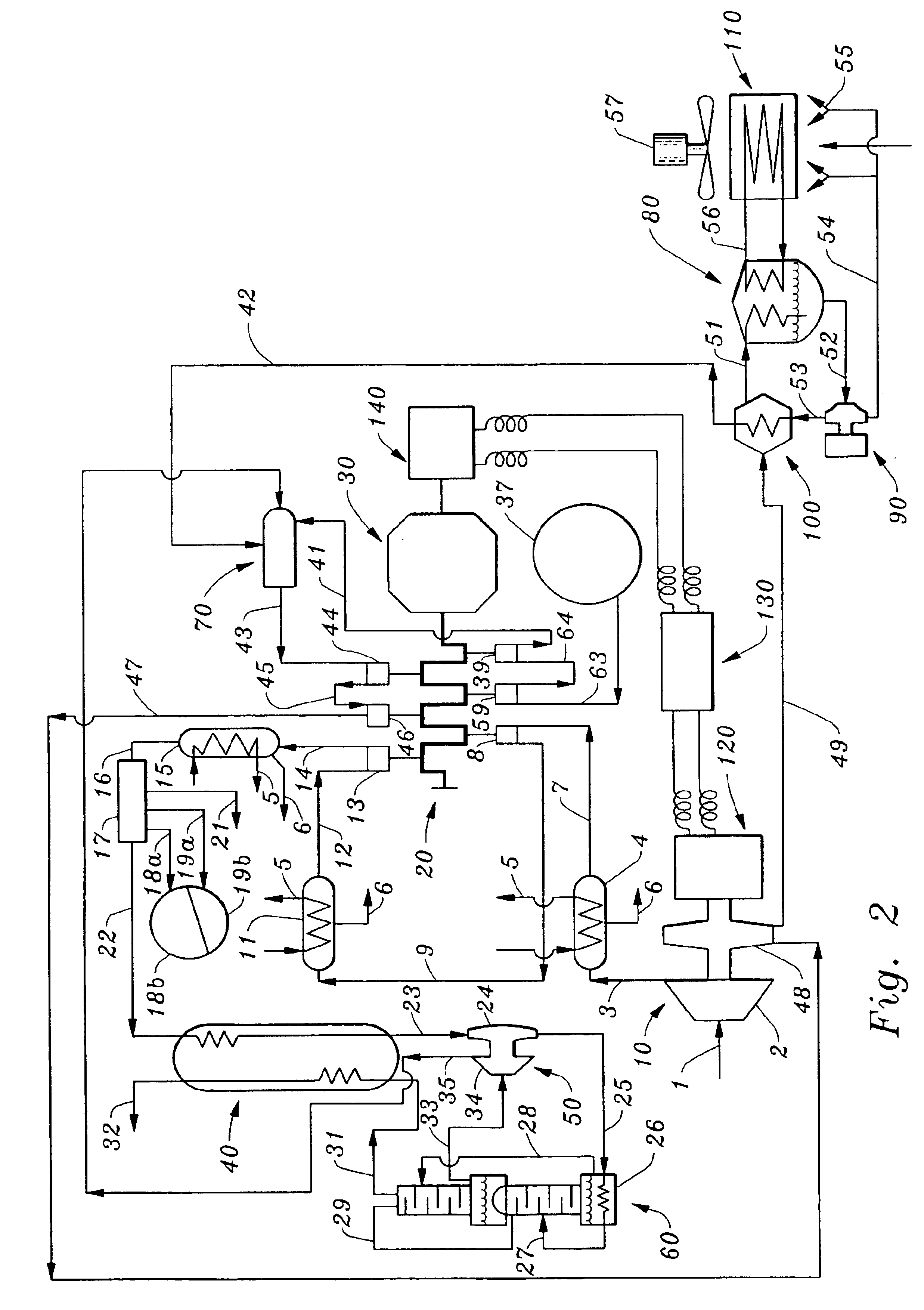

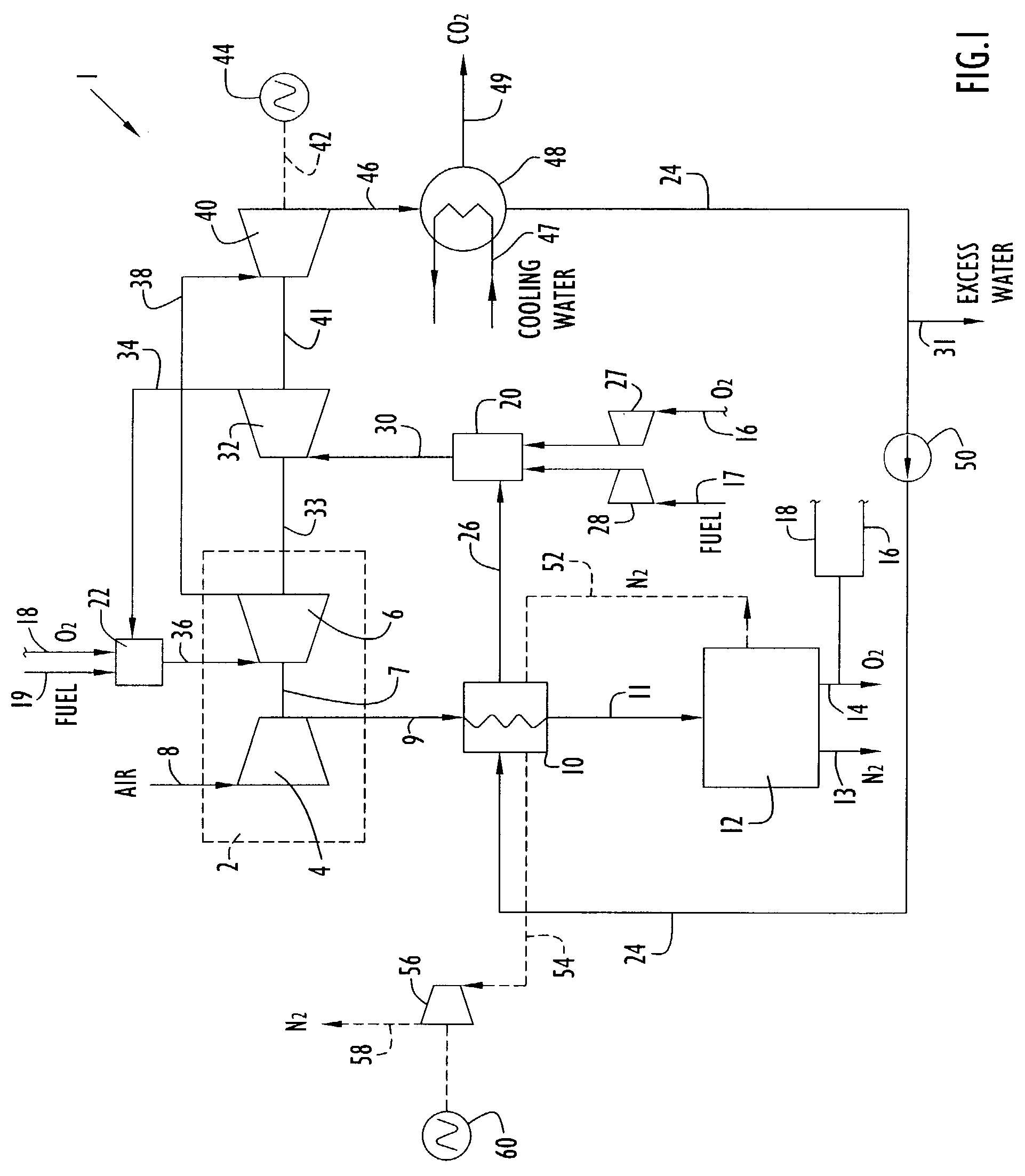

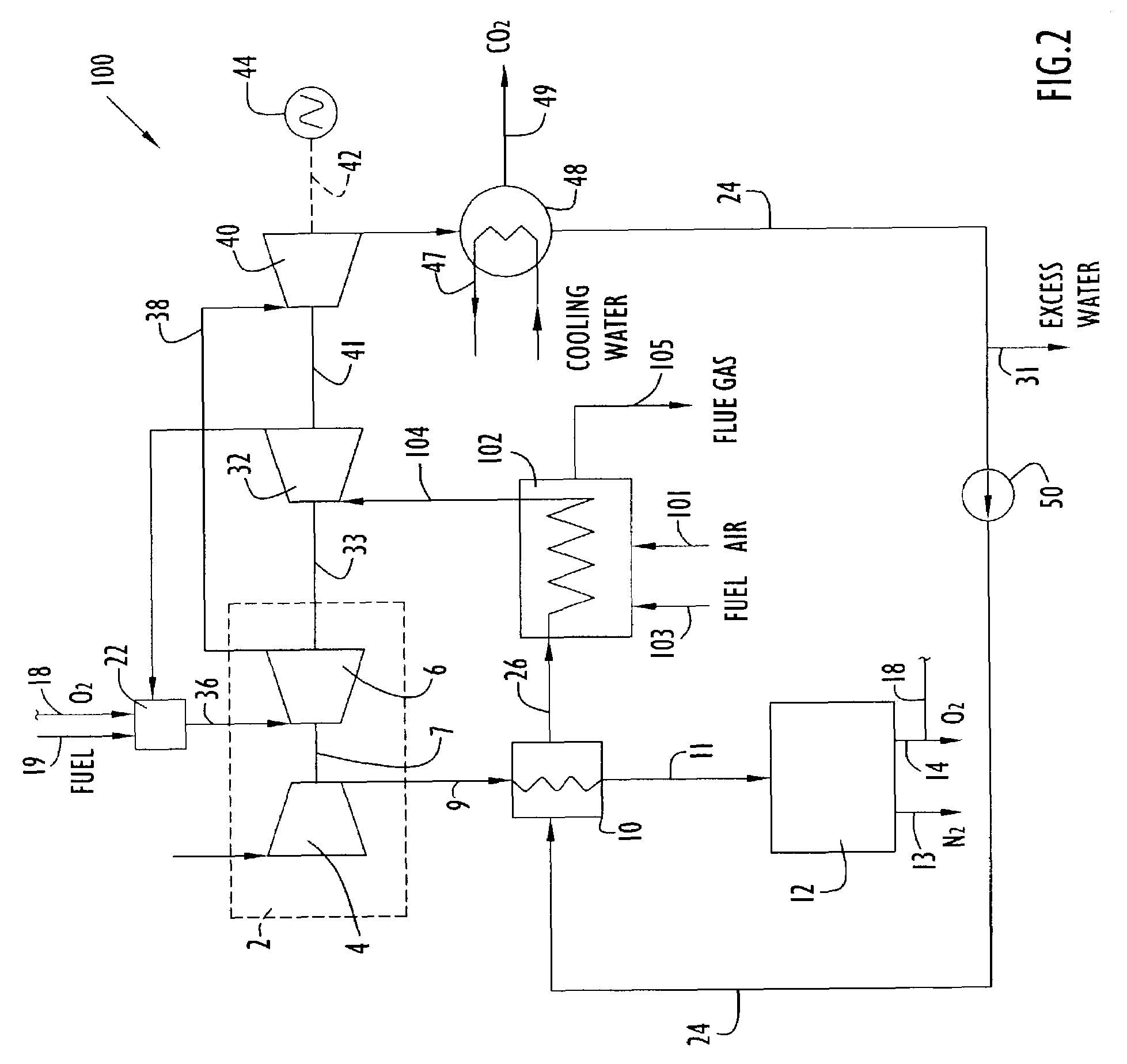

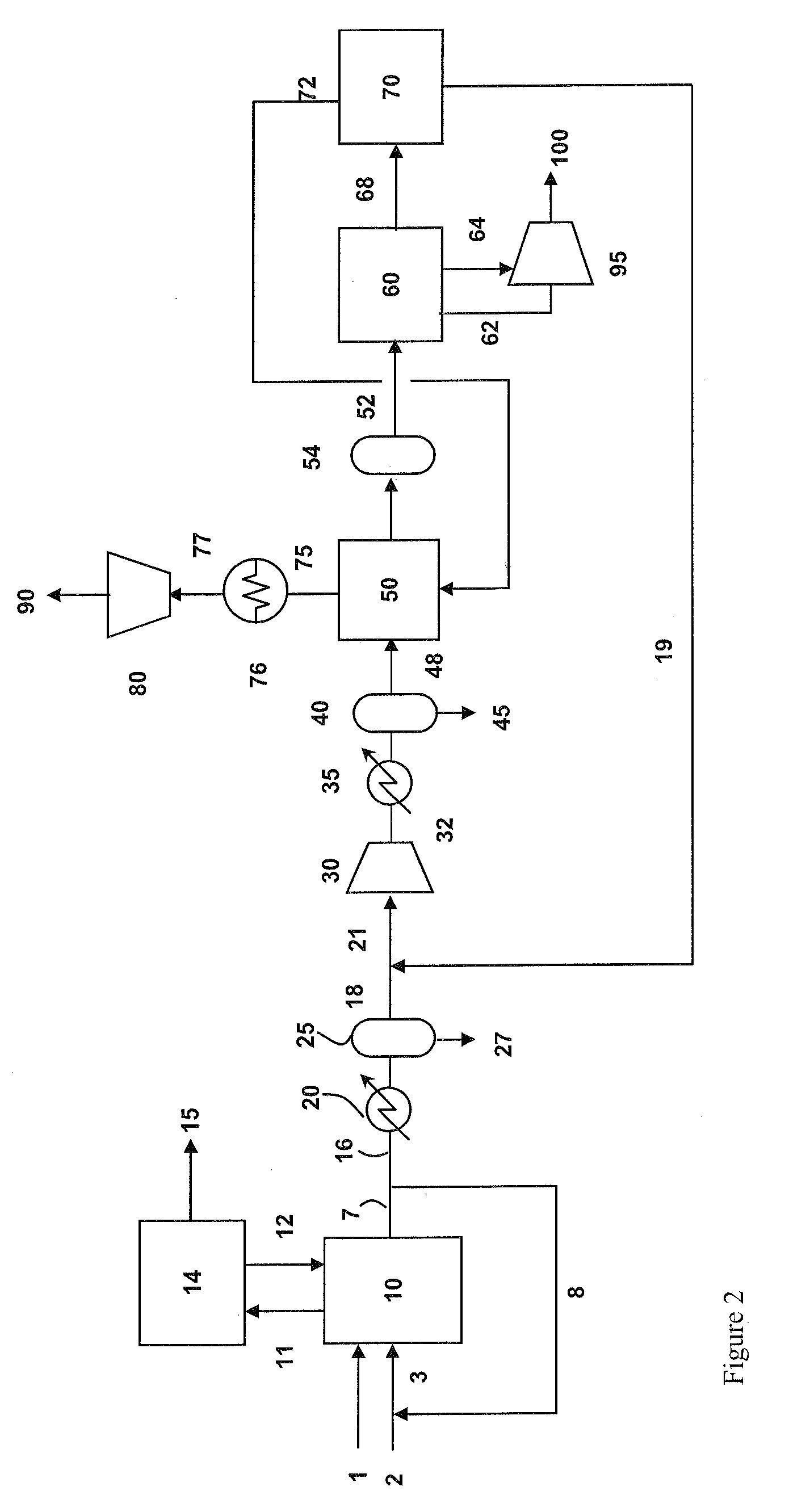

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20110179799A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

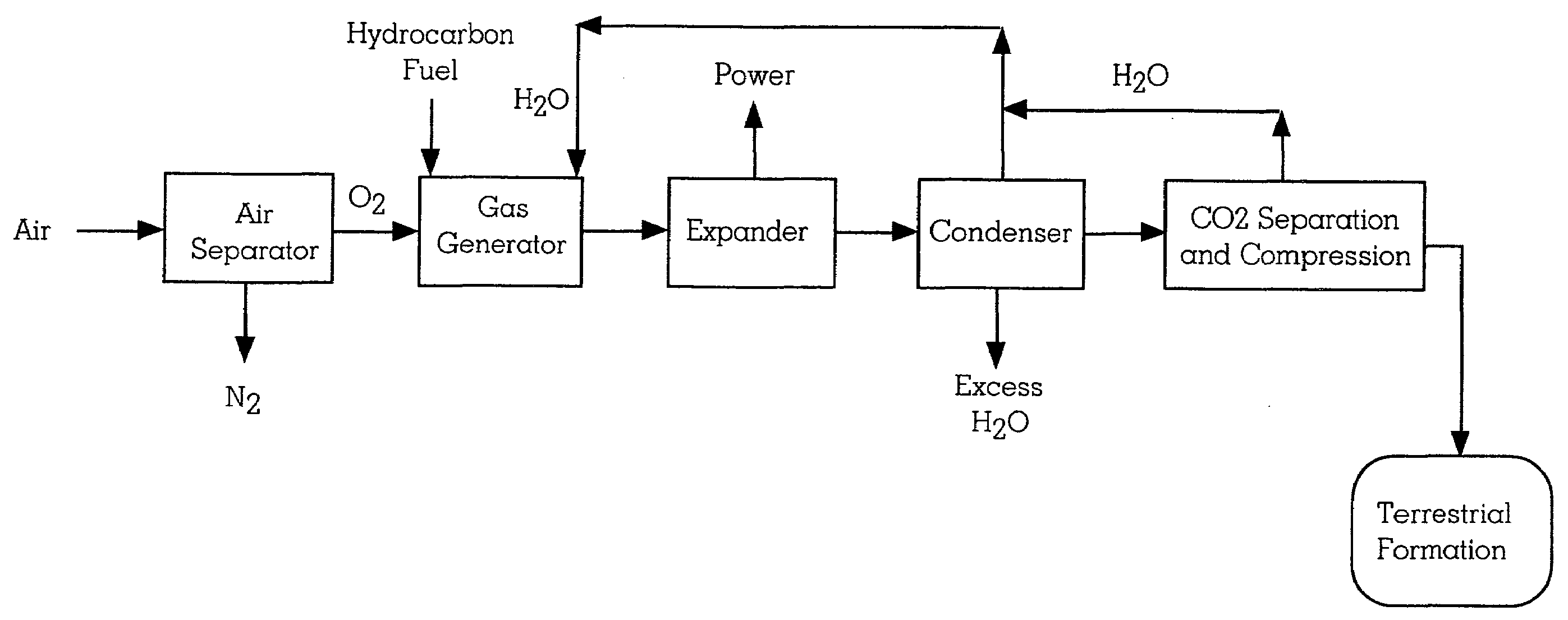

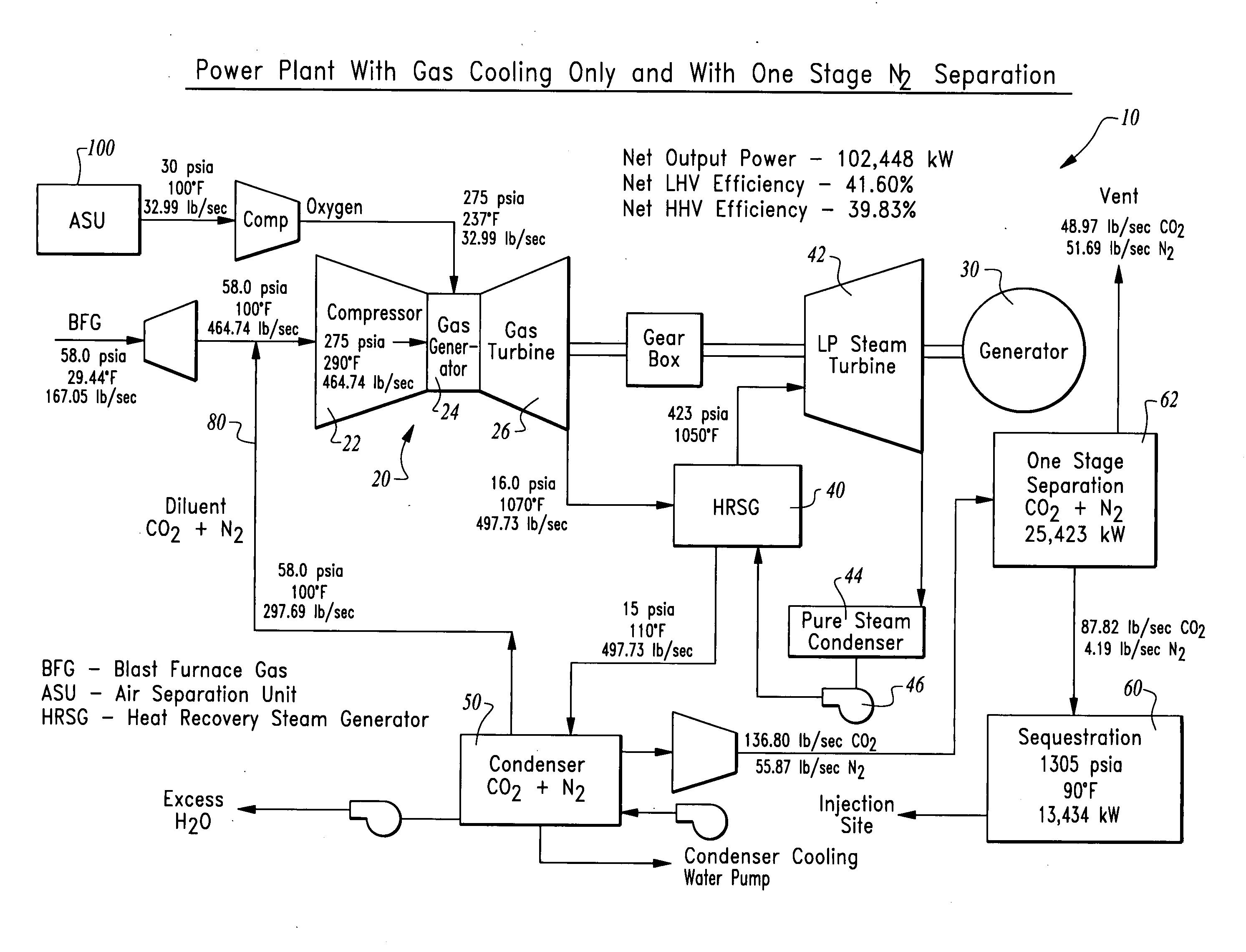

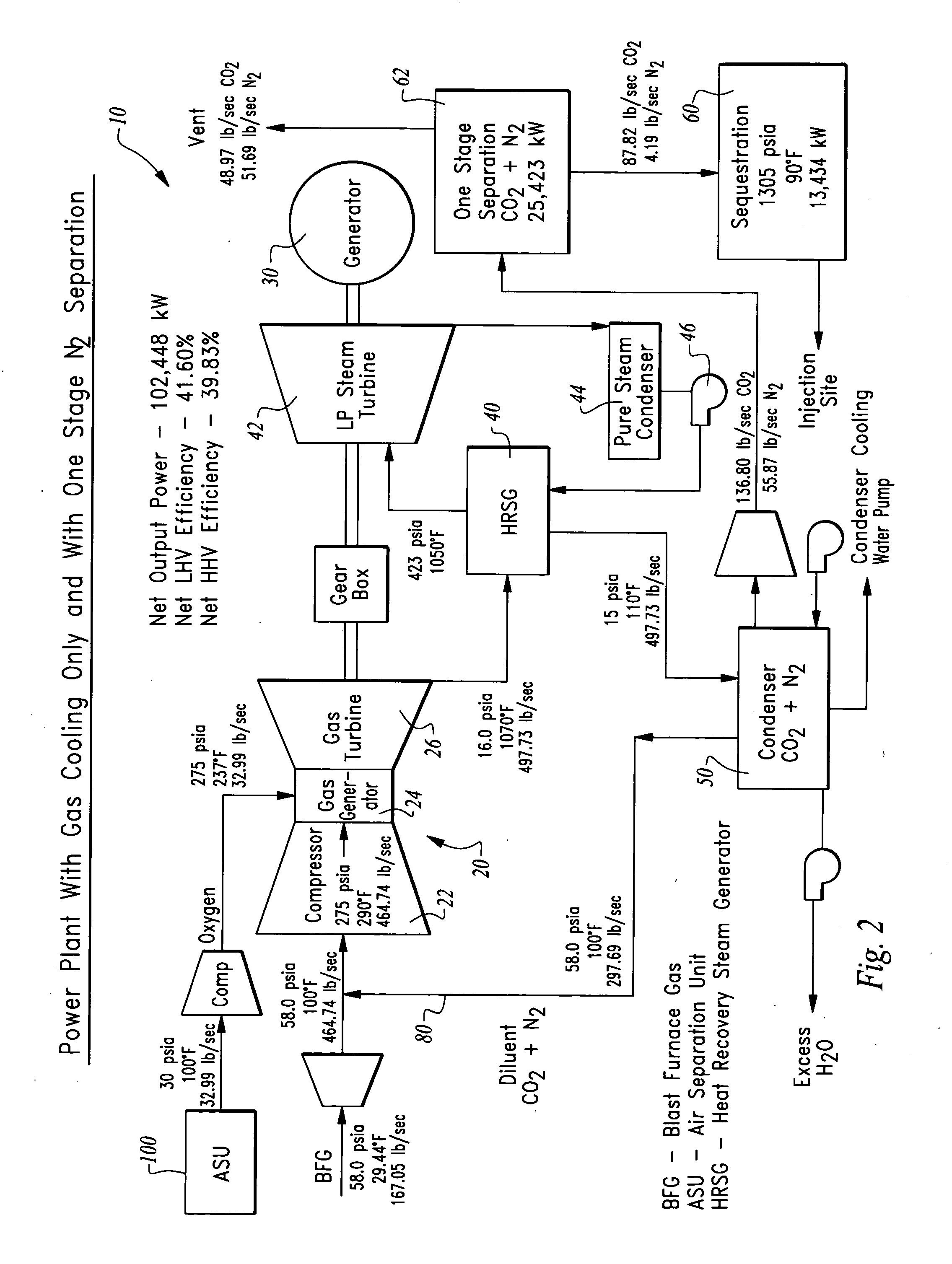

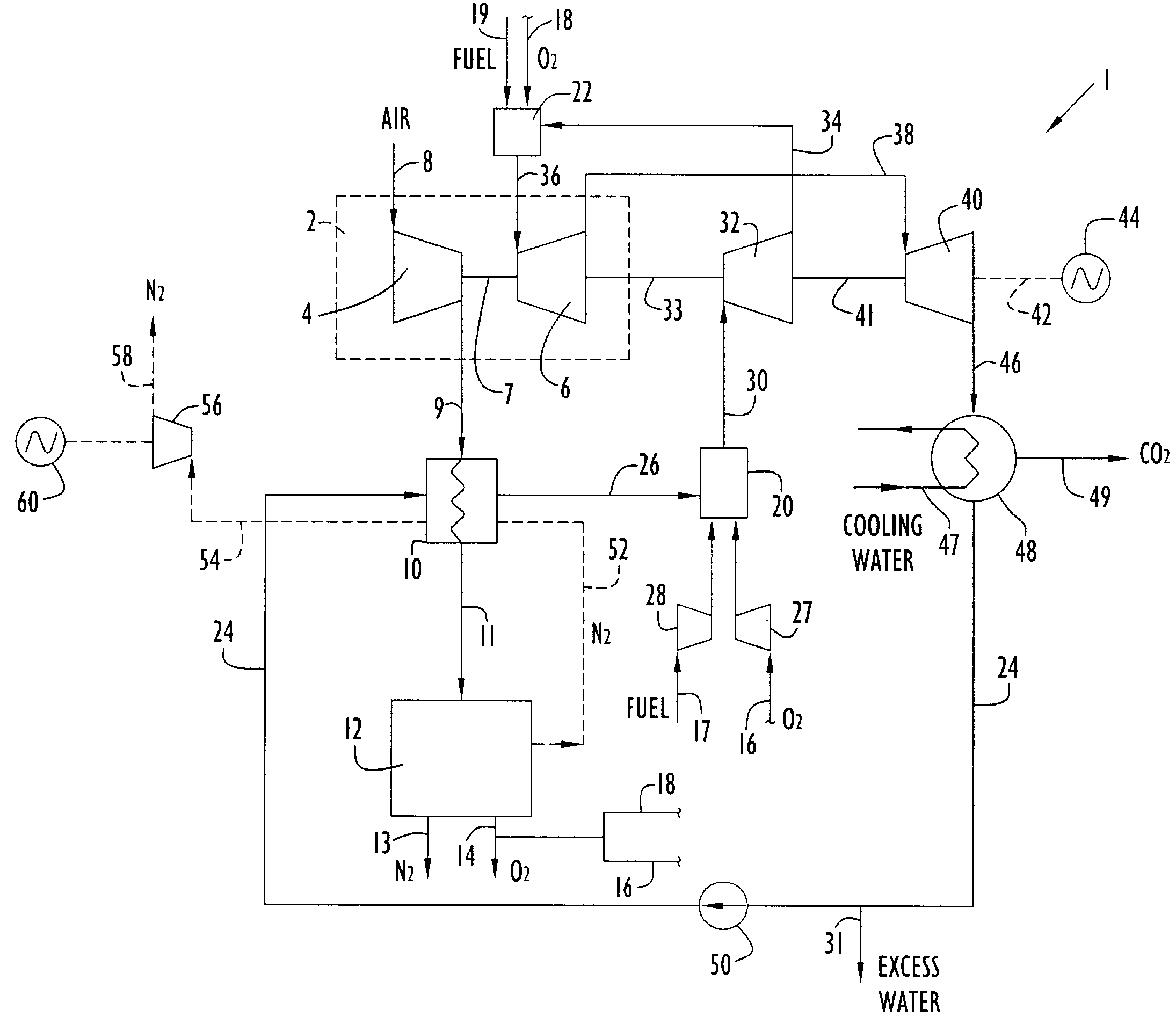

Hydrocarbon combustion power generation system with CO2 sequestration

InactiveUS7043920B2Eliminate needReduce electricity demandReciprocating combination enginesSolidificationAtmospheric airOxygen

A low or no pollution engine is provided for delivering power for vehicles or other power applications. The engine has an air inlet which collects air from a surrounding environment. At least a portion of the nitrogen in the air is removed. The remaining gas is primarily oxygen, which is then routed to a gas generator. The gas generator has inputs for the oxygen and a hydrocarbon fuel. The fuel and oxygen are combusted within the gas generator, forming water and carbon dioxide. The combustion products are then expanded through a power generating device, such as a turbine or piston expander to deliver output power for operation of a vehicle or other power uses. The combustion products are then passed through a condenser where the steam is condensed and the carbon dioxide is collected or discharged. A portion of the water is routed back to the gas generator. The carbon dioxide is compressed and delivered to a terrestrial formation from which return of the CO2 into the atmosphere is inhibited.

Owner:CLEAN ENERGY SYST

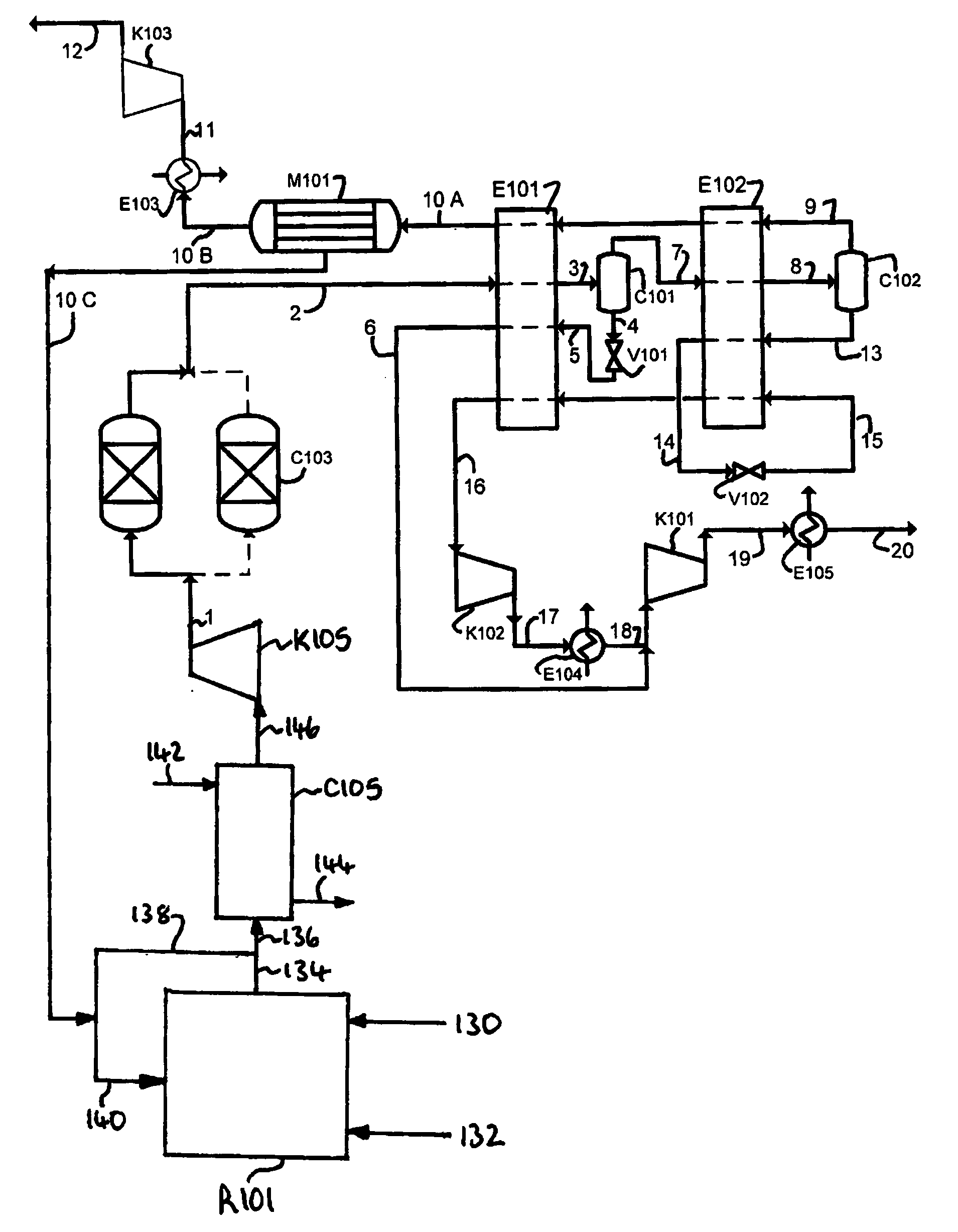

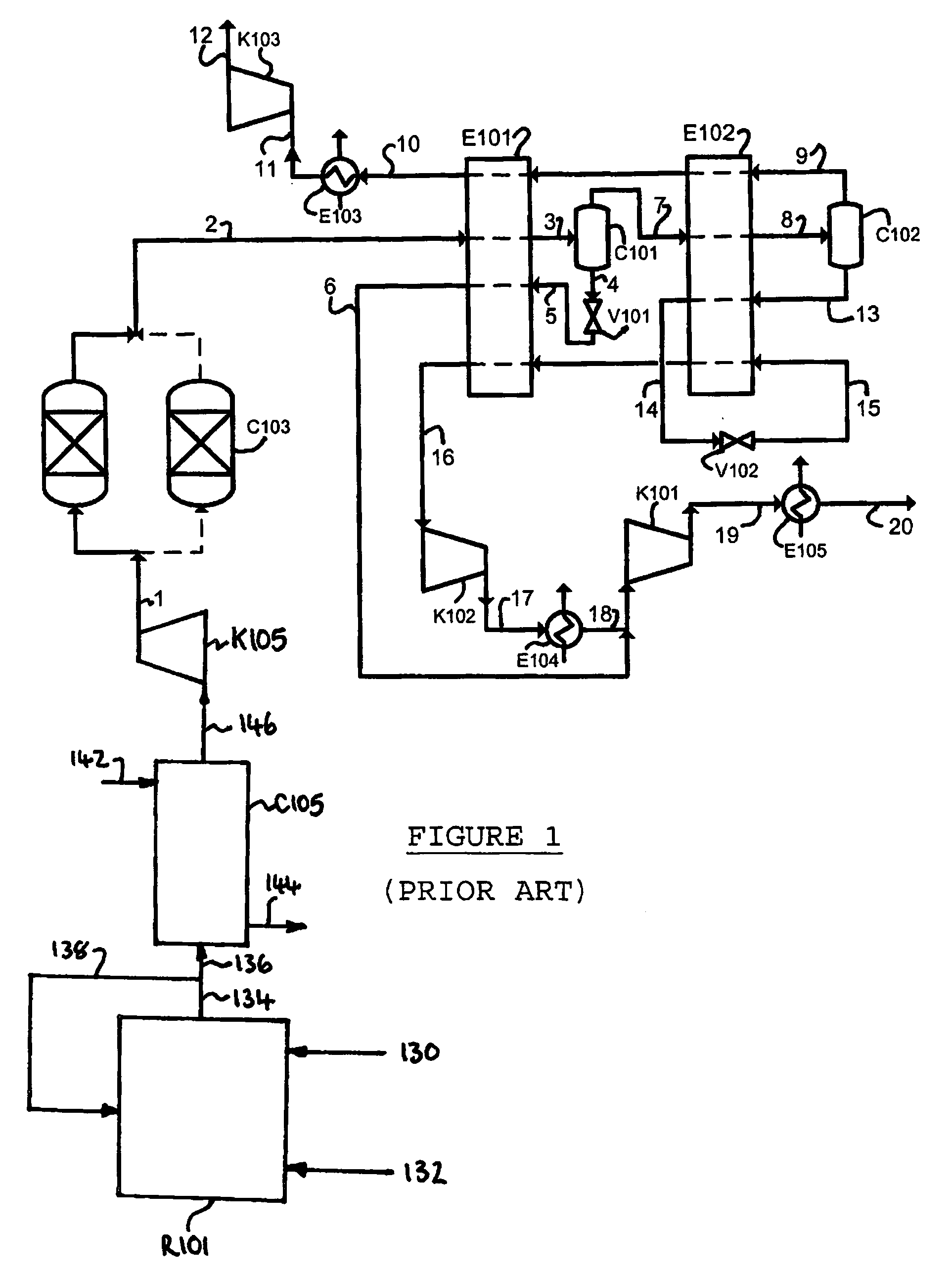

Cryogenic process utilizing high pressure absorber column

Owner:ABB LUMMUS GLOBAL INC

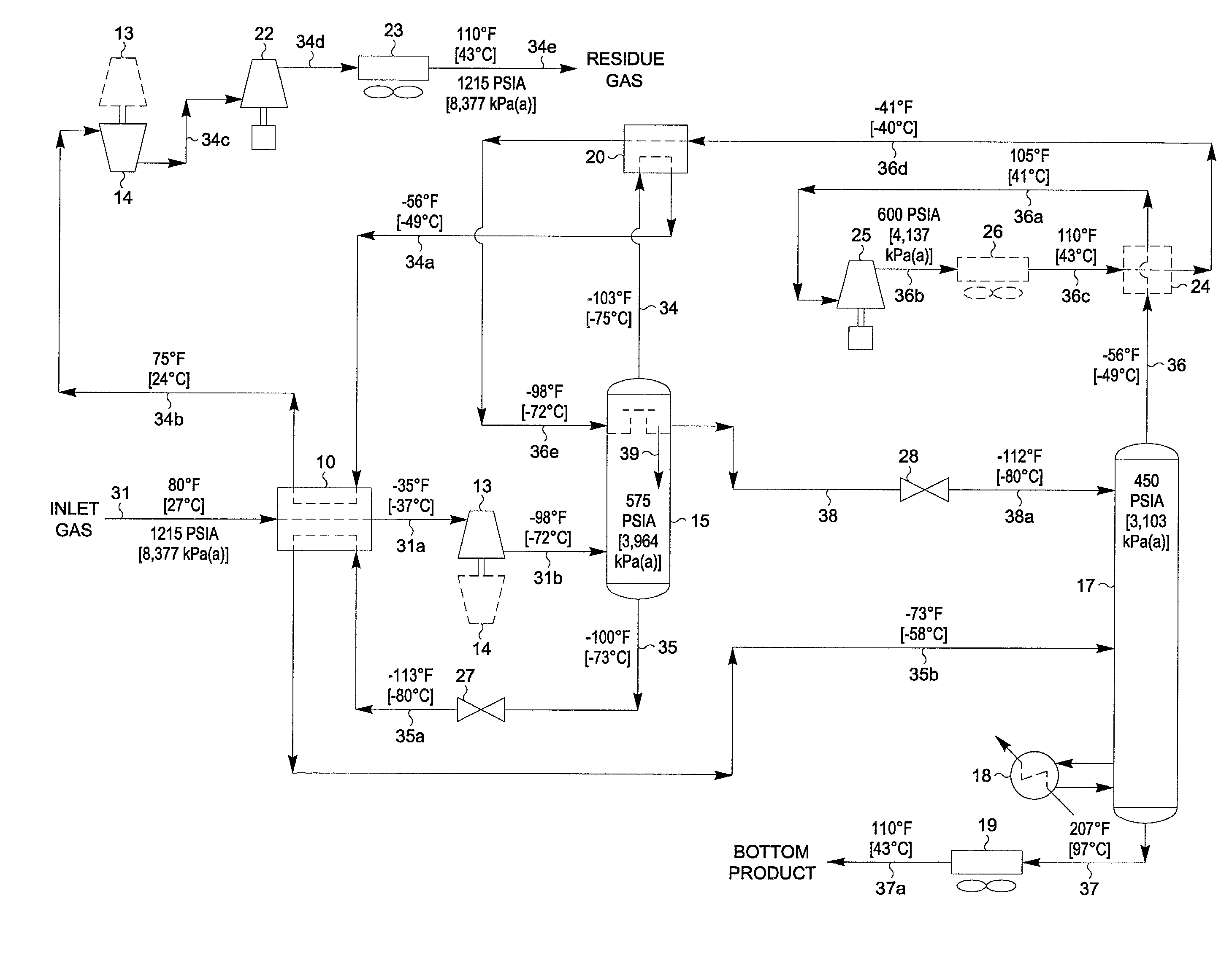

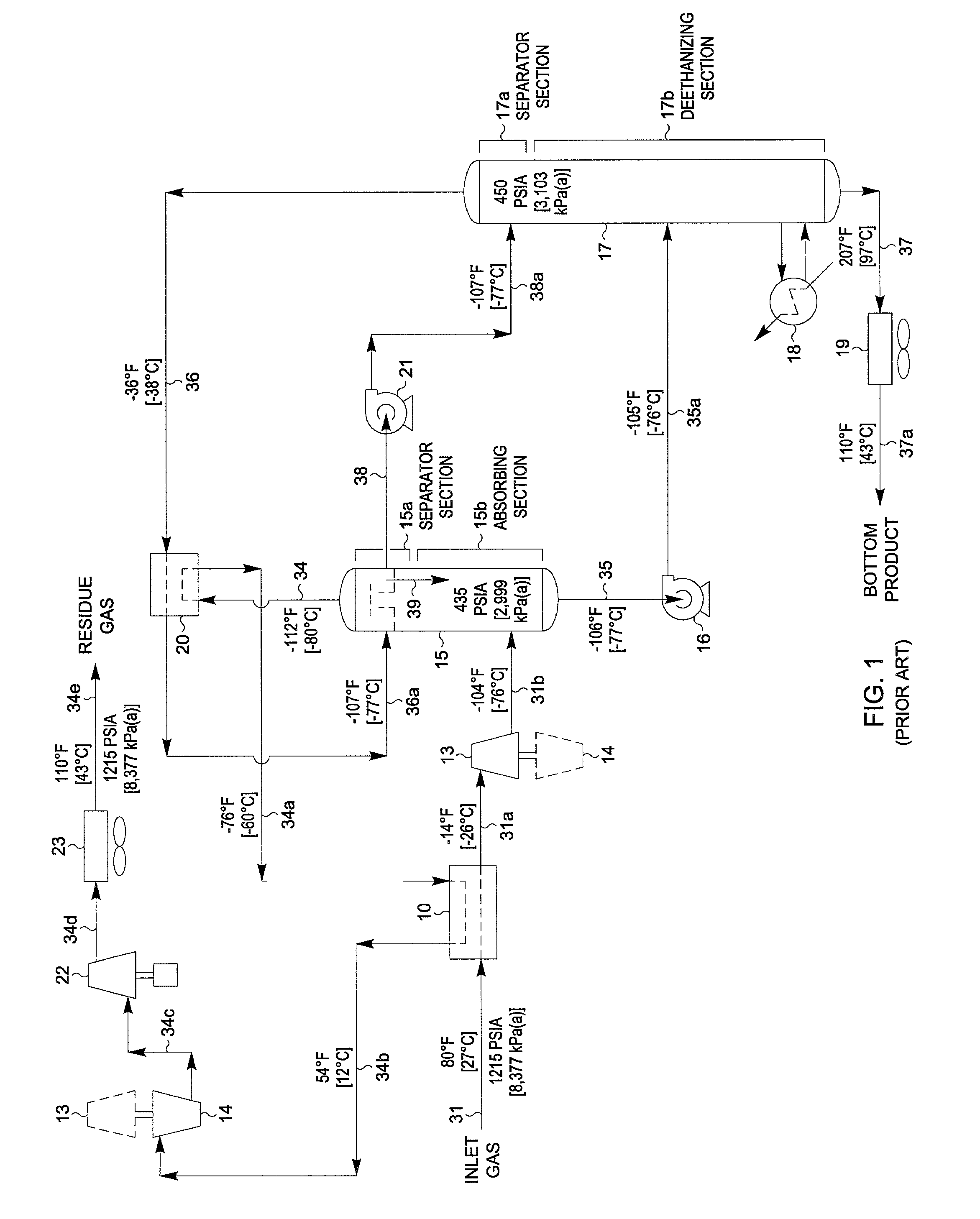

Hydrocarbon gas processing

ActiveUS20060283207A1Reduce the valueReduce investmentSolidificationLiquefactionFractionationFractionating column

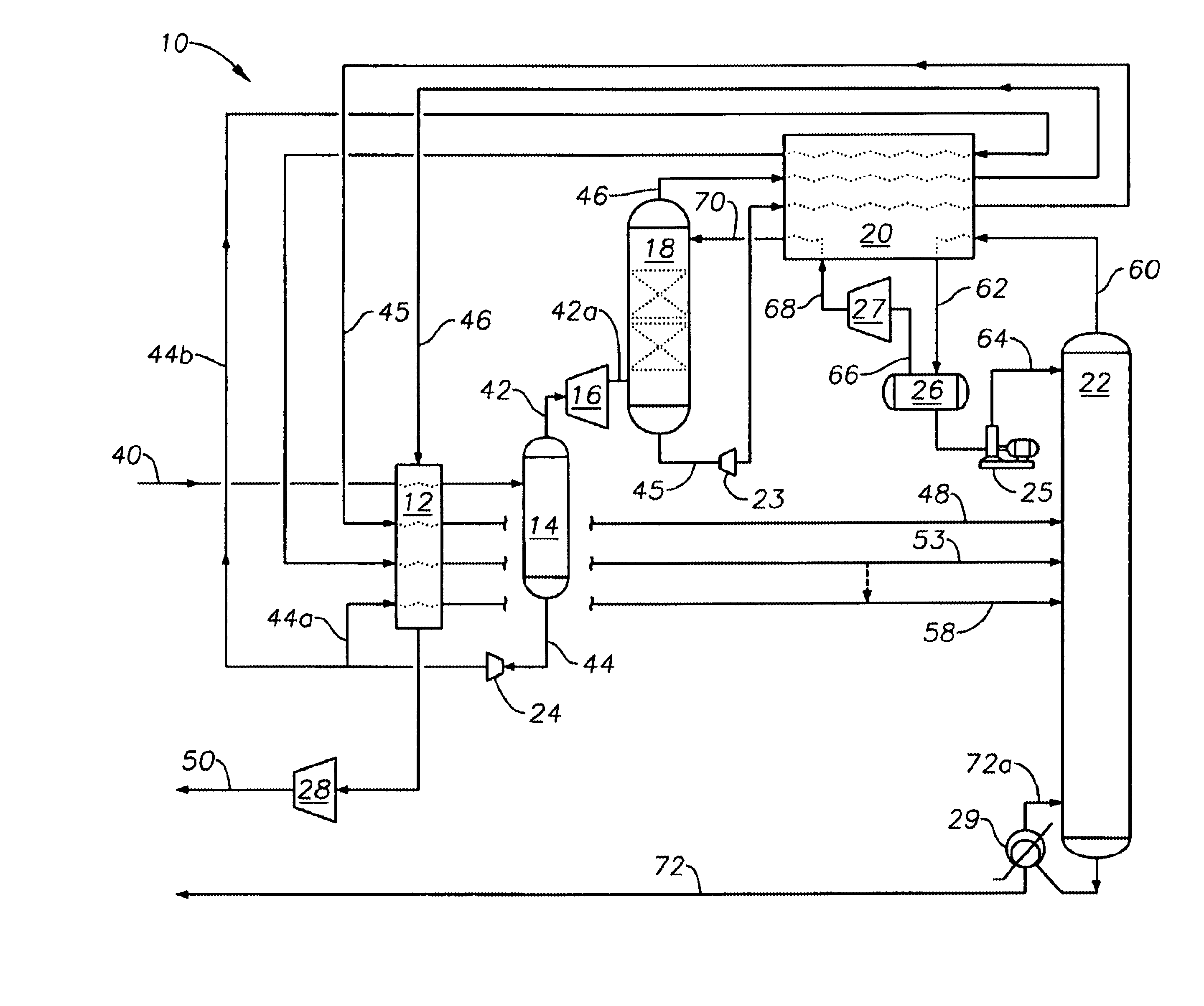

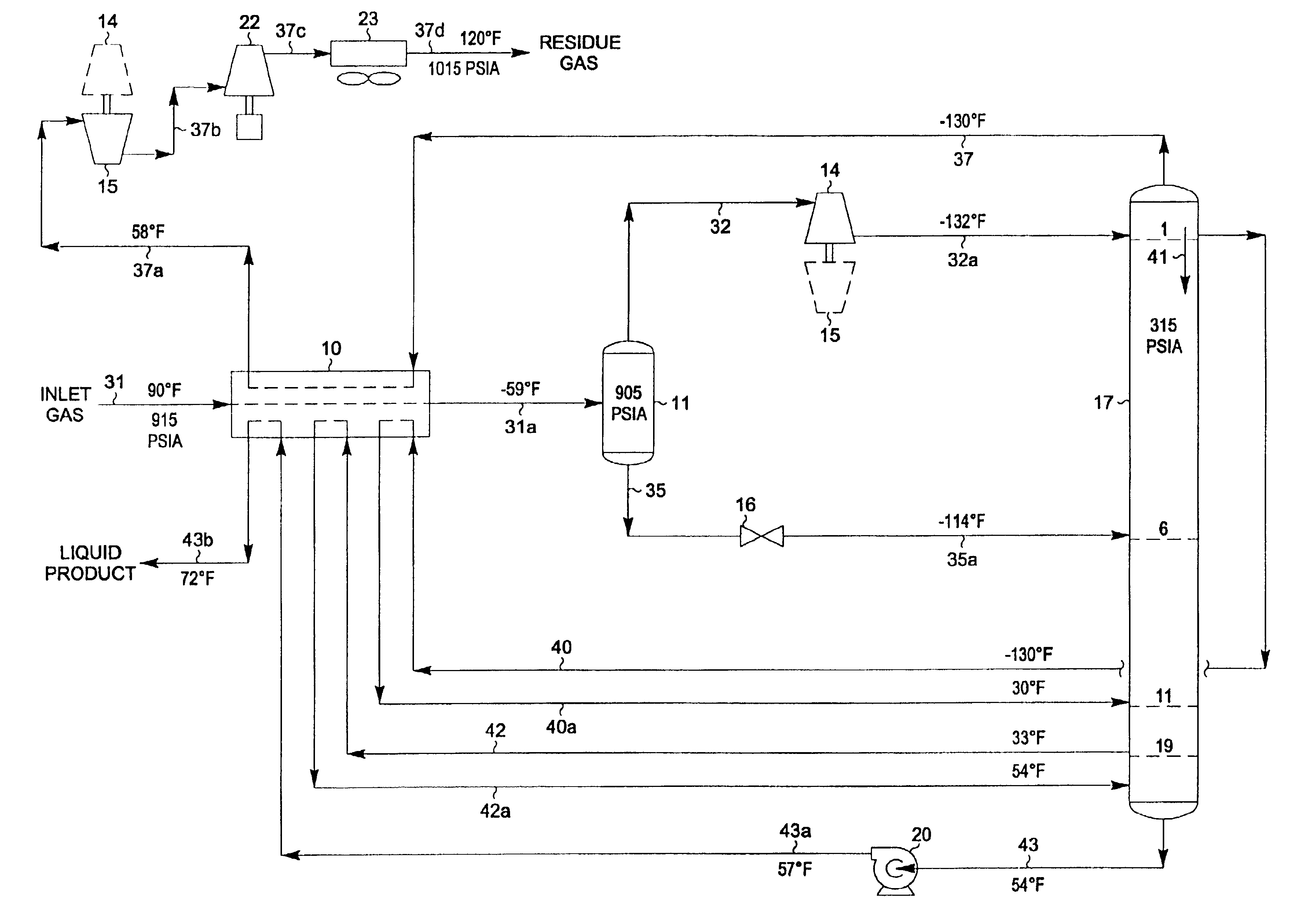

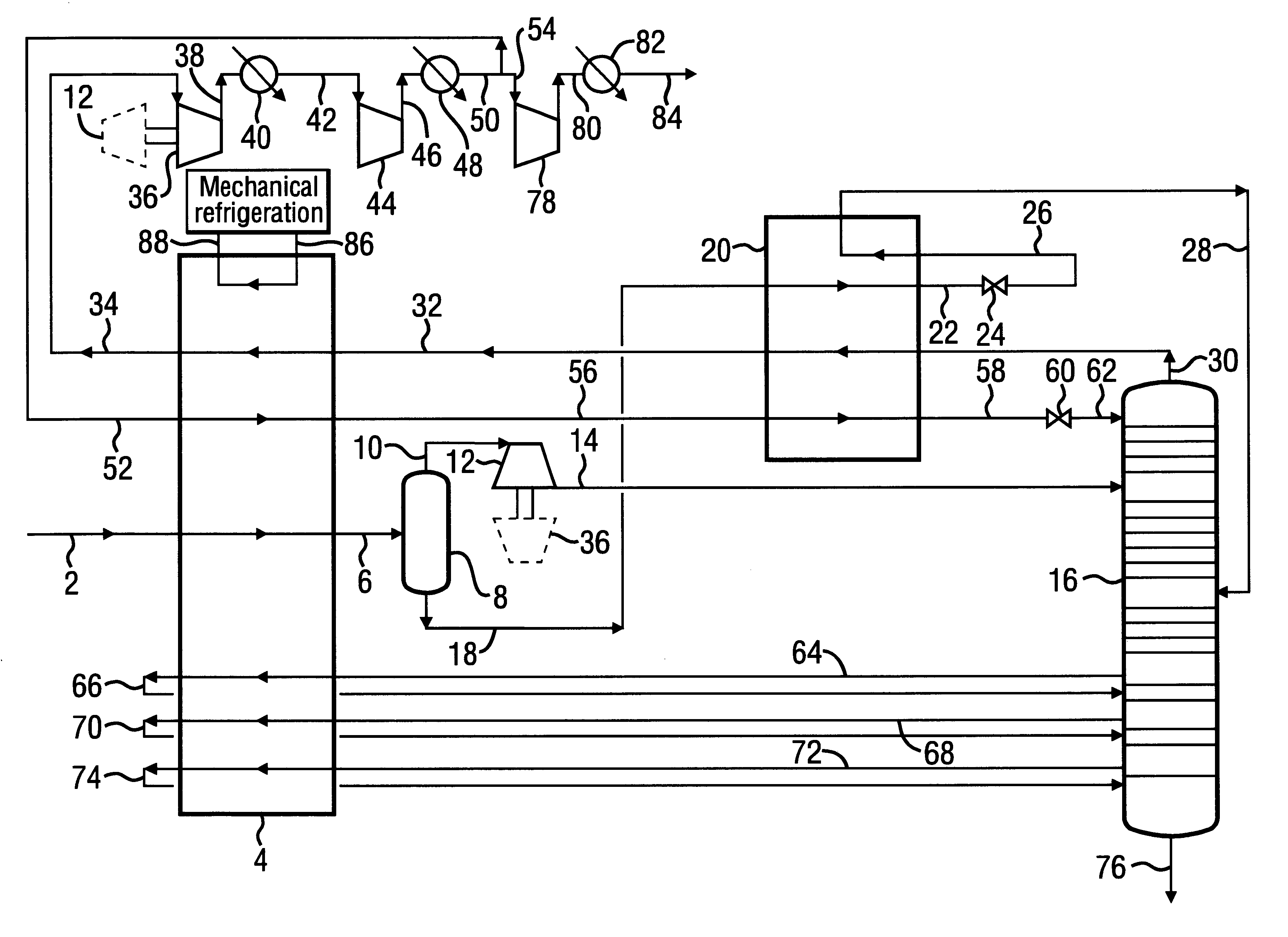

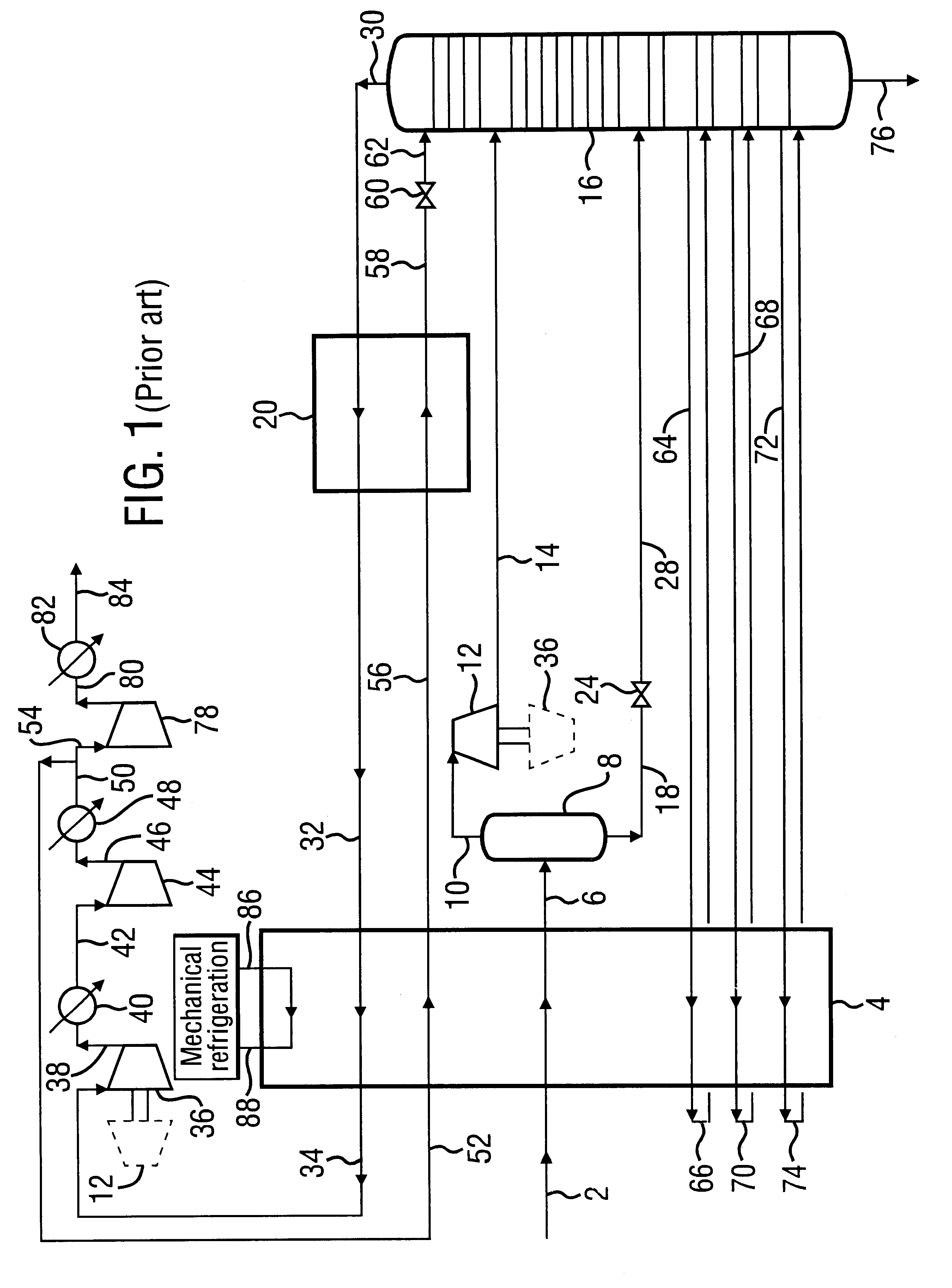

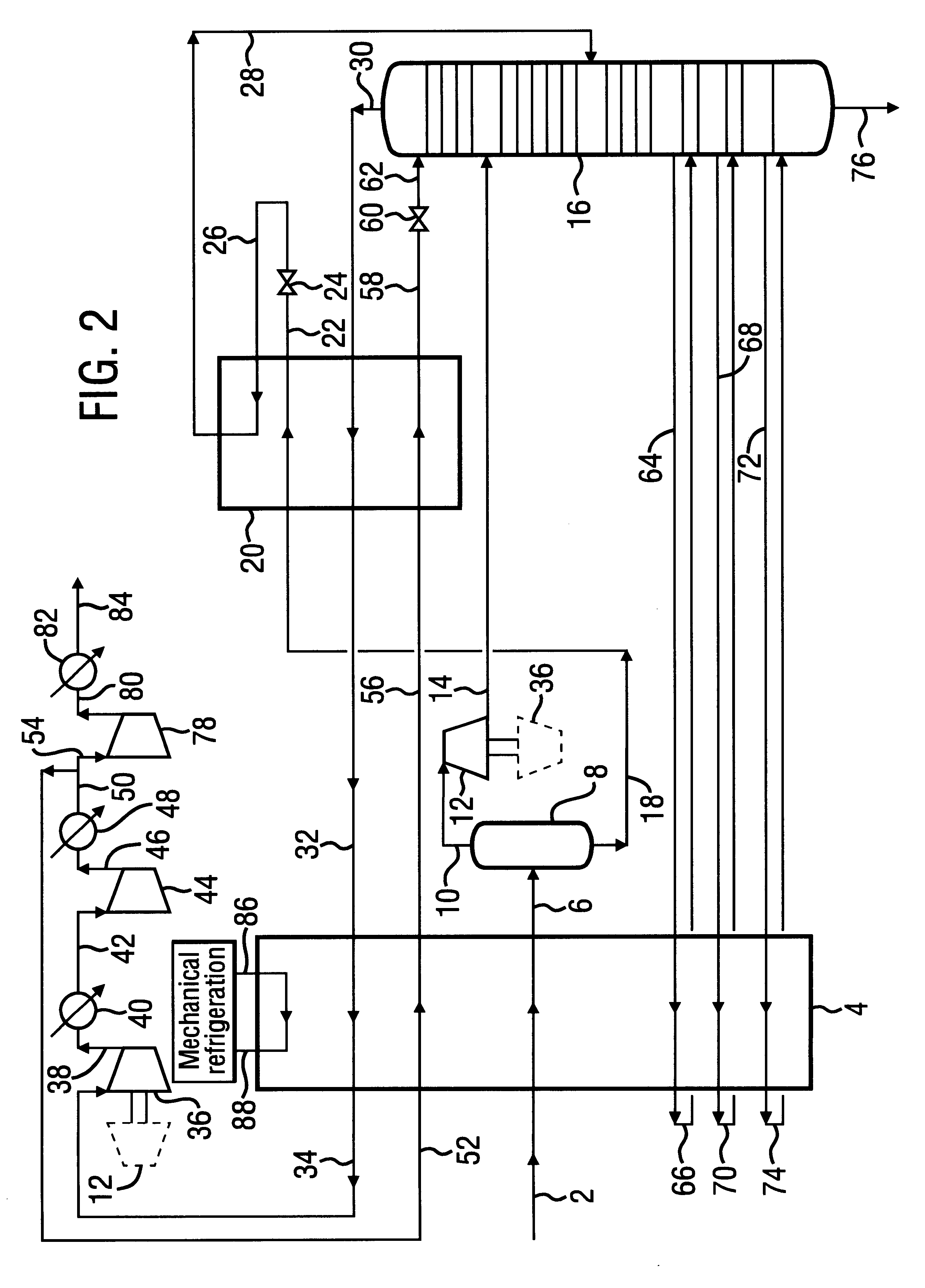

A process for the recovery of ethane, ethylene, propane, propylene, and heavier hydrocarbon components from a hydrocarbon gas stream is disclosed. The stream is cooled and is thereafter expanded to the fractionation tower pressure and supplied to the fractionation tower at a lower mid-column feed position. A distillation stream is withdrawn from the column below the feed point of the stream and is then directed into heat exchange relation with the tower overhead vapor stream to cool the distillation stream and condense at least a part of it, forming a condensed stream. At least a portion of the condensed stream is directed to the fractionation tower at an upper mid-column feed position. A recycle stream is withdrawn from the tower overhead after it has been warmed and compressed. The compressed recycle stream is cooled sufficiently to substantially condense it, and is then expanded to the pressure of the fractionation tower and supplied to the tower at a top column feed position. The quantities and temperatures of the feeds to the fractionation tower are effective to maintain the overhead temperature of the fractionation tower at a temperature whereby the major portion of the desired components is recovered.

Owner:UOP LLC

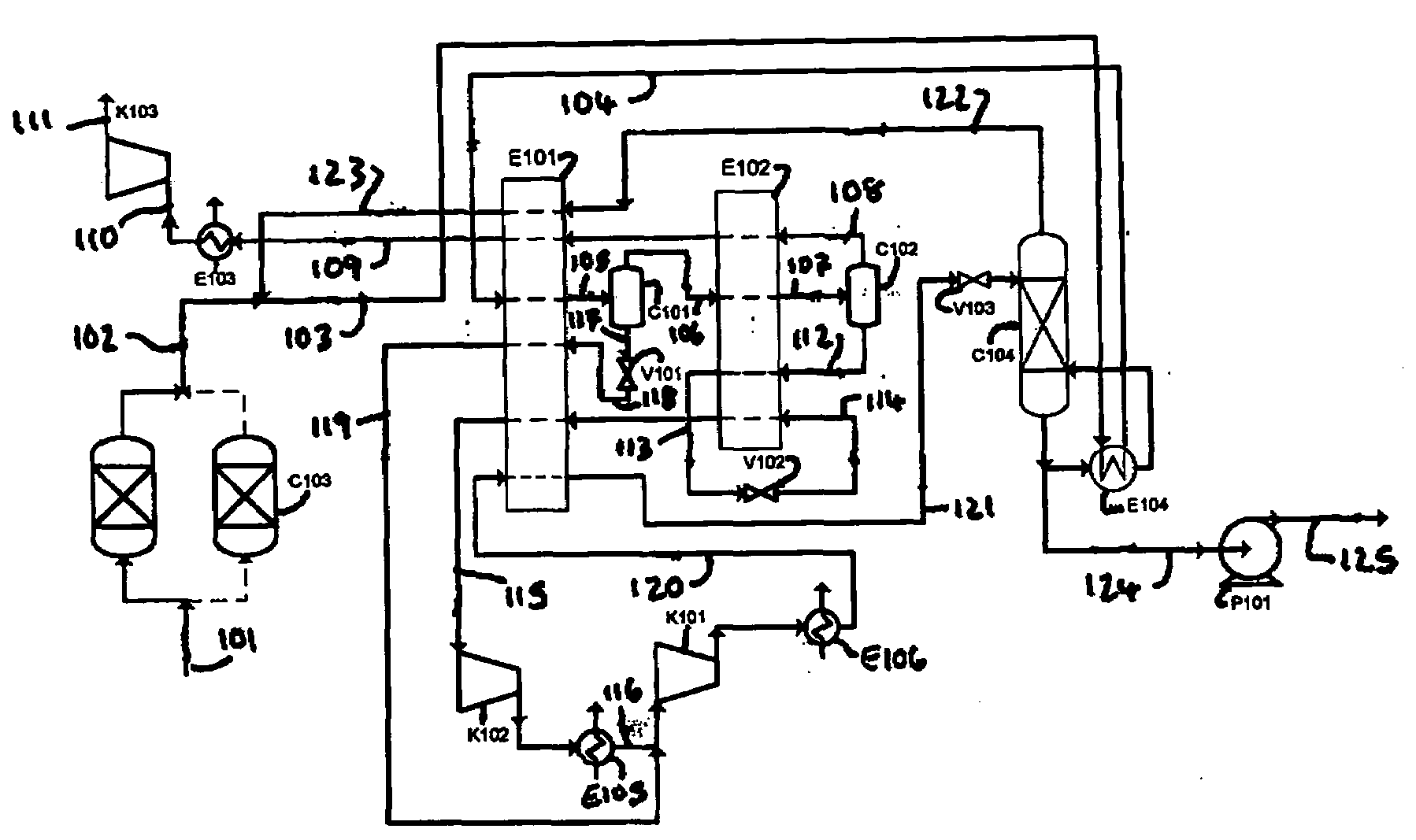

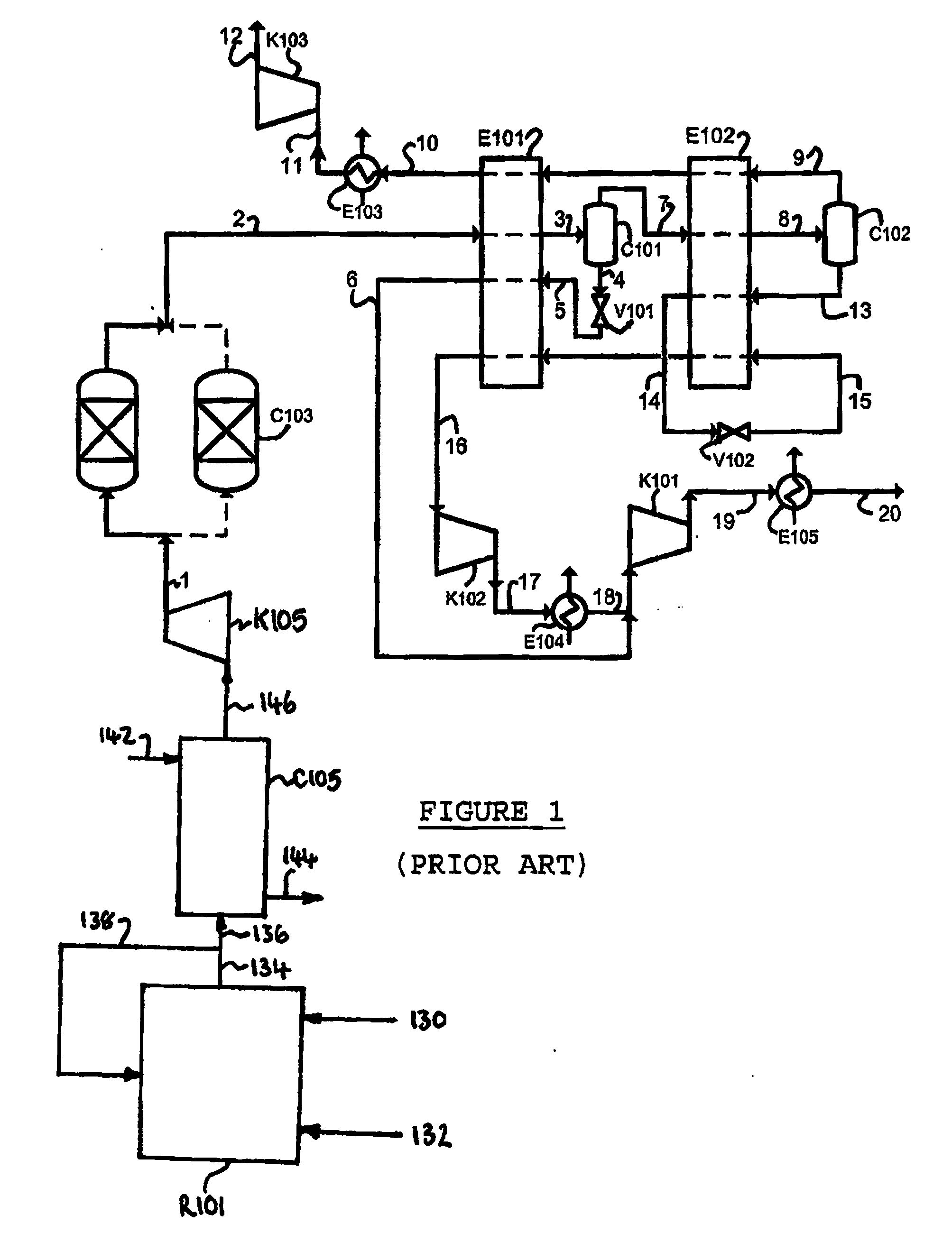

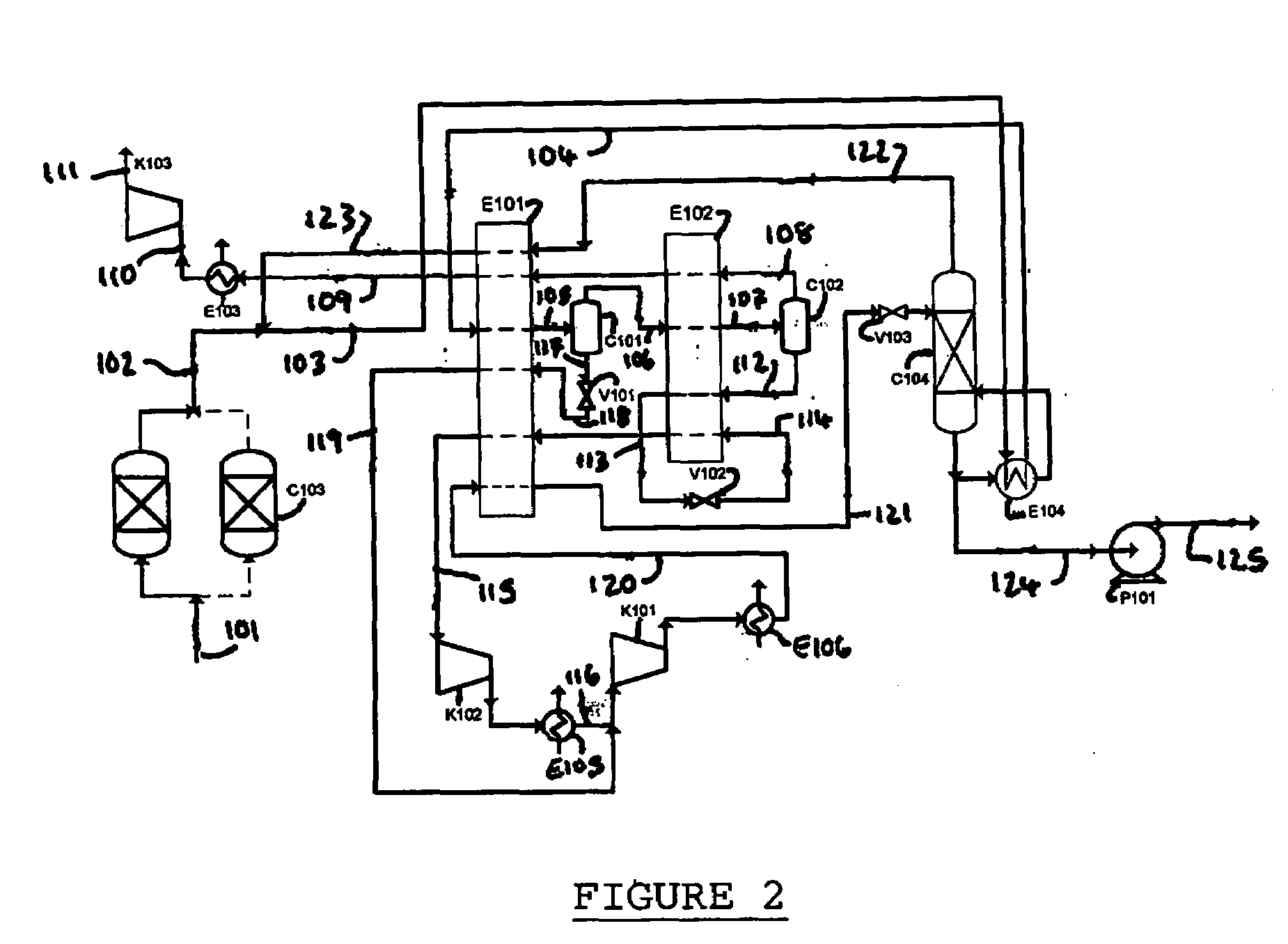

Hydrocarbon gas processing

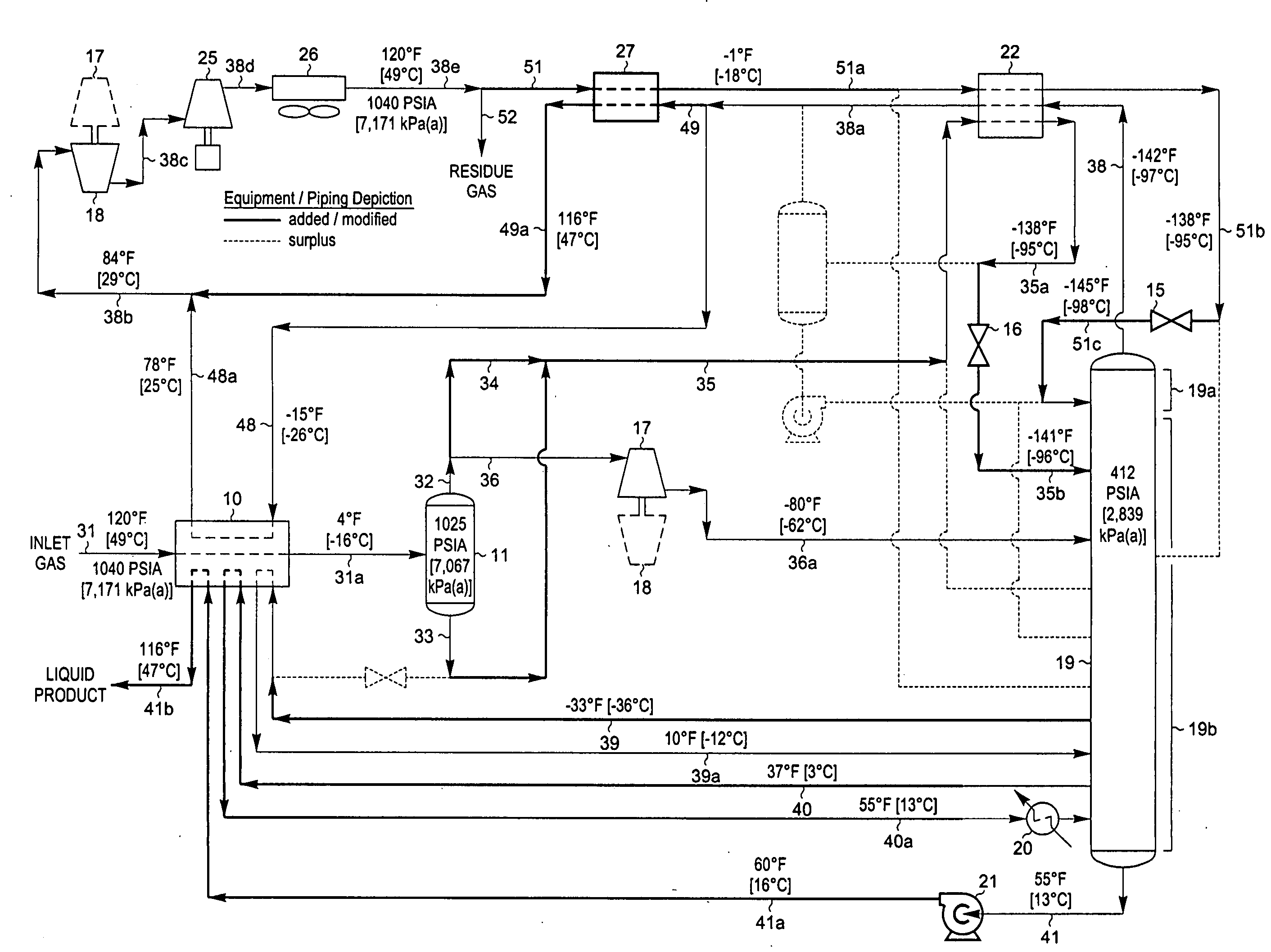

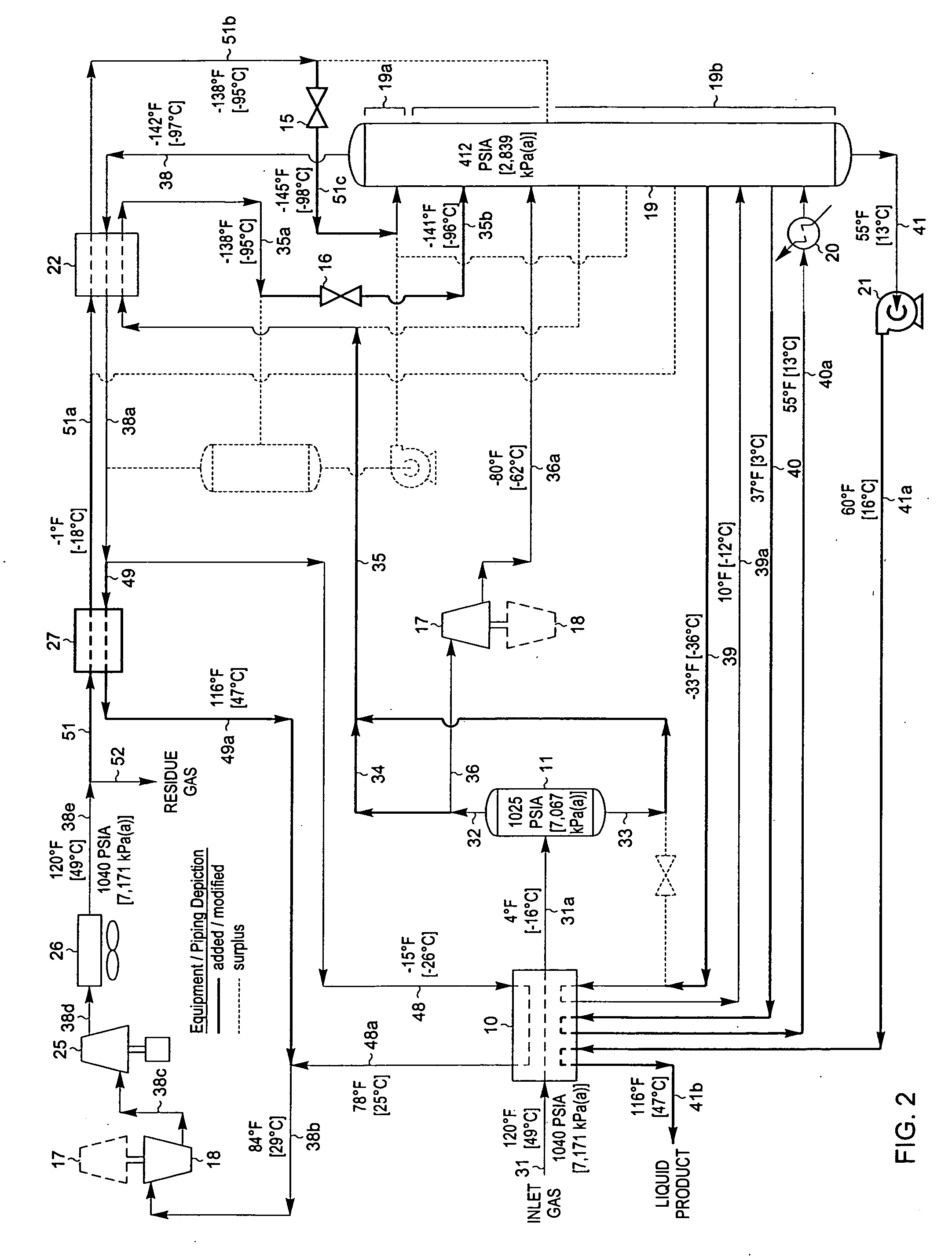

A process for the recovery of ethane, ethylene, propane, propylene and heavier hydrocarbon components from a hydrocarbon gas stream is disclosed. In recent years, the preferred method of separating a hydrocarbon gas stream generally includes supplying at least portions of the gas stream to a fractionation tower having at least one reboiler, and often one or more side reboilers, to supply heat to the column by withdrawing and heating some of the tower liquids to produce stripping vapors that separate the more volatile components from the desired components. The reboiler and side reboilers (if any) are typically integrated into the feed stream cooling scheme to provide at least a portion of the refrigeration needed to condense the desired components for subsequent fractionation in the distillation column. In the process disclosed, the tower reboiling scheme is modified to use one or more tower liquid distillation streams from a point higher in the column than is used in the conventional reboiling scheme, providing colder stream(s) for the reboiler(s) that allow more effective cooling of the feed streams and thereby improve the efficiency with which the desired components are recovered. In addition, the tower liquid streams withdrawn from a higher point in the column contain larger quantities of the more volatile components, which when vaporized provide better stripping of undesirable components like carbon dioxide without reducing the recovery of the desired components. The heated distillation stream is returned to a lower point on the fractionation tower that is separated from the withdrawal point by at least one theoretical stage.

Owner:UOP LLC

Ethane plus and HHH process for NGL recovery

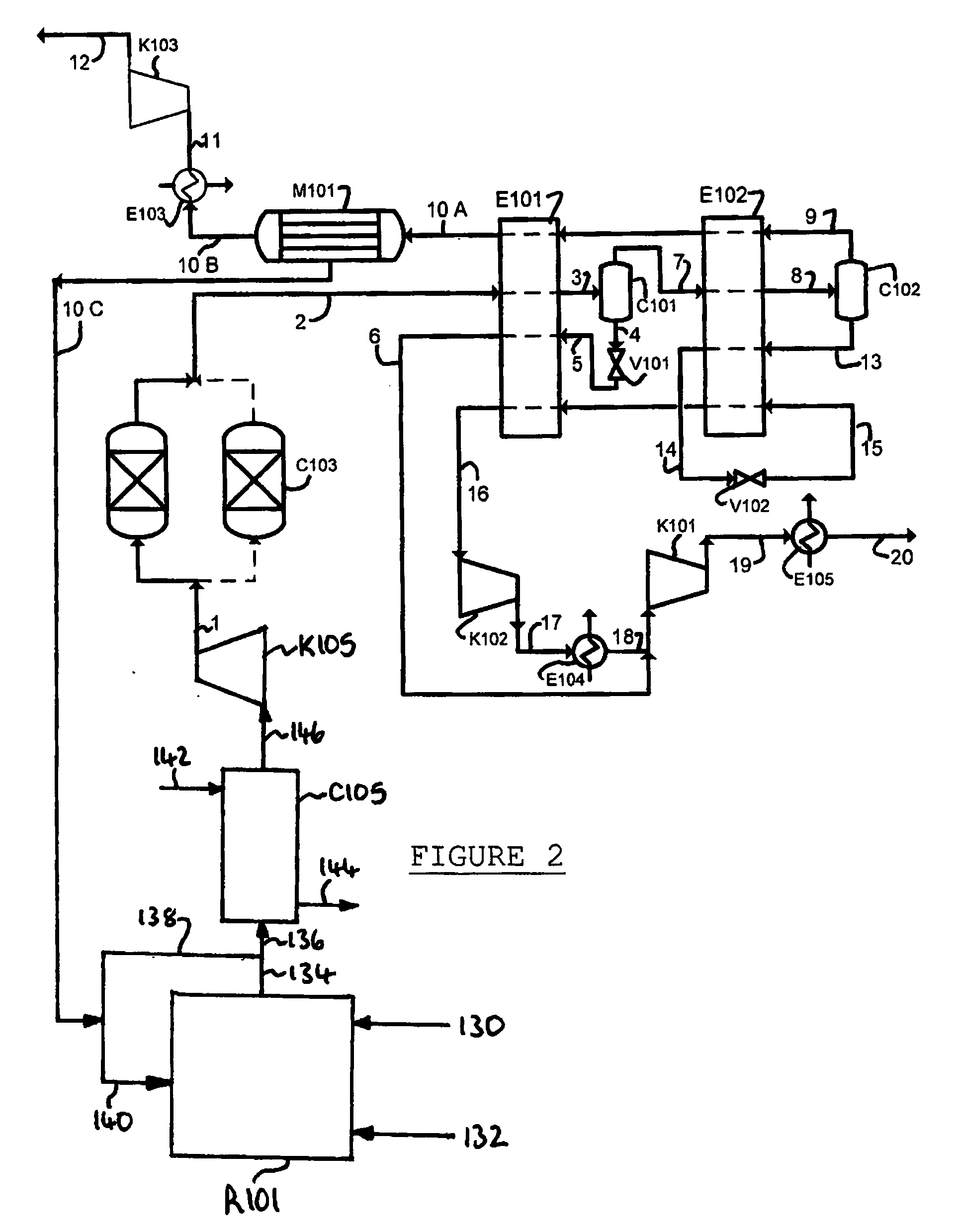

InactiveUS7219513B1Good fractionation effectHeavy componentSolidificationLiquefactionFractionating columnPetrochemical

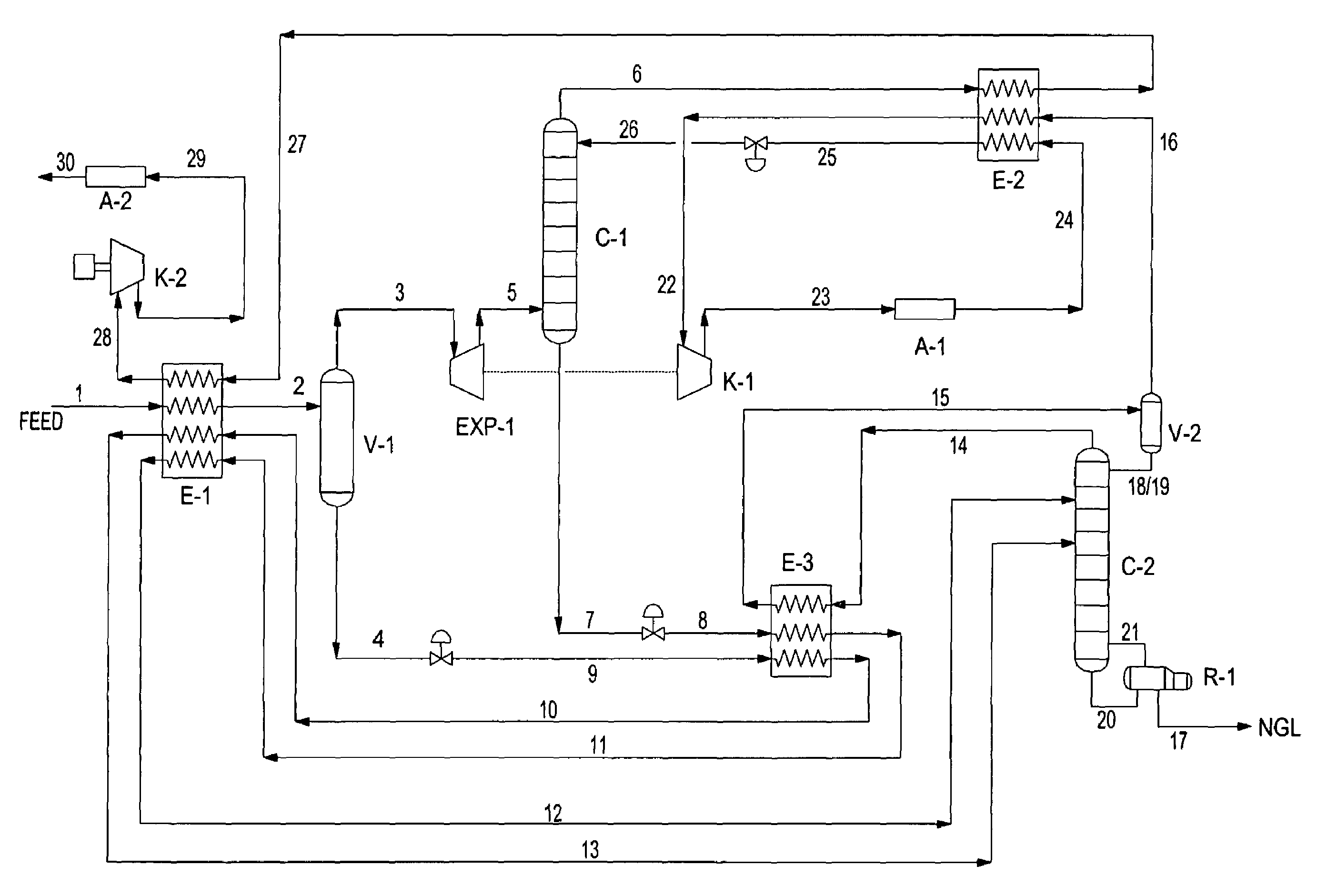

The present invention relates to methods for separating and recovering ethane, propane and heavier components from a feed gas, e.g. raw natural gas or a refinery or petroleum plant gas stream or a petrochemical plant gas stream. These methods employ a common new concept which is the use of the turbo-expander shaft compressor to generate the reflux requirement for the cryogenic absorber or distillation columns. The power of the turbo-expander which is absorbed by the shaft compressor is always high enough so that reflux generation by a specific gas compression through the expander shaft compressor and subsequent cooling, condensation and sub-cooling can always be easily maintained. The present invention allows for higher cryogenic absorber pressure and a lower demethanizer / de-ethanizer column pressure thus eliminating the common cryogenic pump at absorber bottom. The present invention ultimately results in a lower residue compression and utilities consumption. The present invention as such allows for a higher 99+% recovery of NGL from the feed gas stream.

Owner:MOSTAFA HUSSEIN MOHAMED ISMAIL

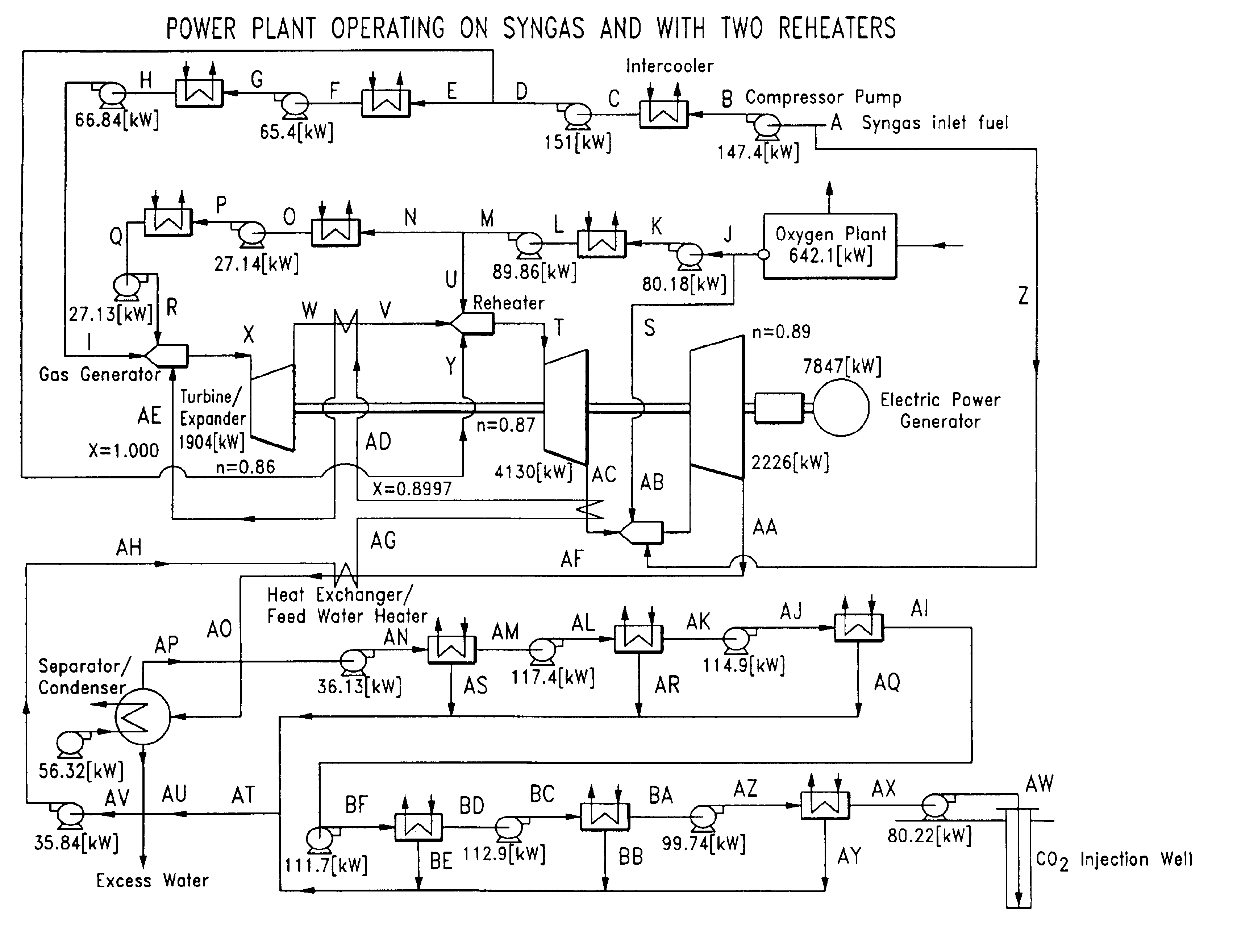

Methods of oxy-combustion power generation using low heating value fuel

An oxy-combustor is provided to combust oxygen with gaseous low heating value fuel. A compressor upstream of the combustor compresses the fuel. The combustor produces a drive gas including steam and carbon dioxide as well as other non-condensable gases in many cases, which pass through a turbine to output power. The drive gas can be recirculated to the combustor, either through the compressor, the oxygen inlet or directly to the combustor. Recirculation can occur before or after a condenser for separation of a portion of the water from the carbon dioxide. Excess carbon dioxide and steam is collected from the system. The turbine, combustor and compressor can be derived from an existing gas turbine with fuel and air / oxidizer lines swapped.

Owner:CLEAN ENERGY SYST

Low pollution power generation system with ion transfer membrane air separation

InactiveUS6945029B2Nitrogen oxideReduce electricity demandSolidificationLiquefactionPollutionCombustion products

A low or no pollution power generation system is provided. The system has an air separator to collect oxygen. A gas generator is provided with inputs for the oxygen and a hydrocarbon fuel. The fuel and oxygen are combusted within the gas generator, forming water and carbon dioxide. Water or other diluents are also delivered into the gas generator to control temperature of the combustion products. The combustion products are then expanded through at least one turbine or other expander to deliver output power. The combustion products are then passed through a separator where the steam is condensed. A portion of the water is discharged and the remainder is routed back to the gas generator as diluent. The carbon dioxide can be conditioned for sequestration. The system can be optimized by adding multiple expanders, reheaters and water diluent preheaters, and by preheating air for an ion transfer membrane oxygen separation.

Owner:CLEAN ENERGY SYST

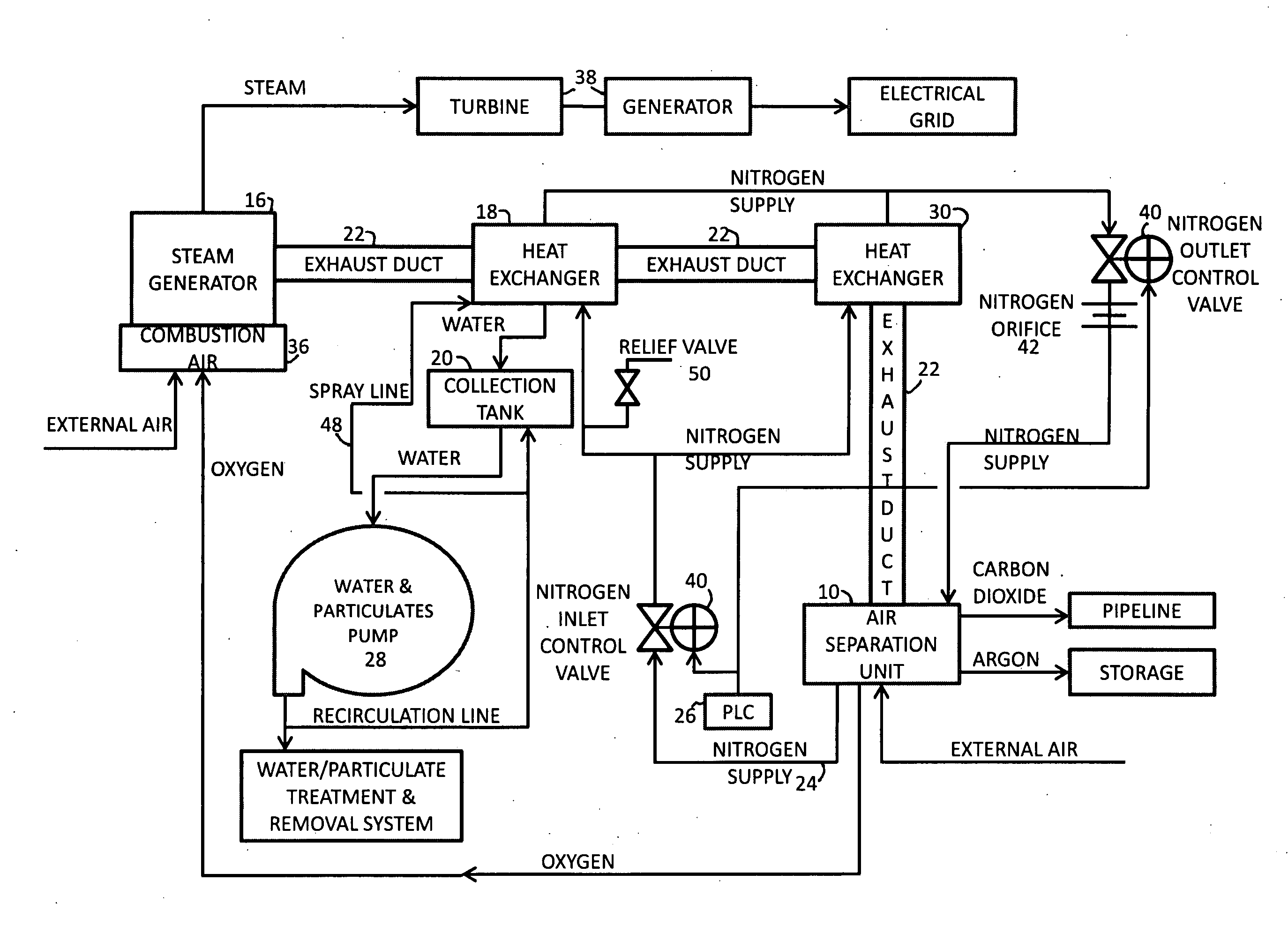

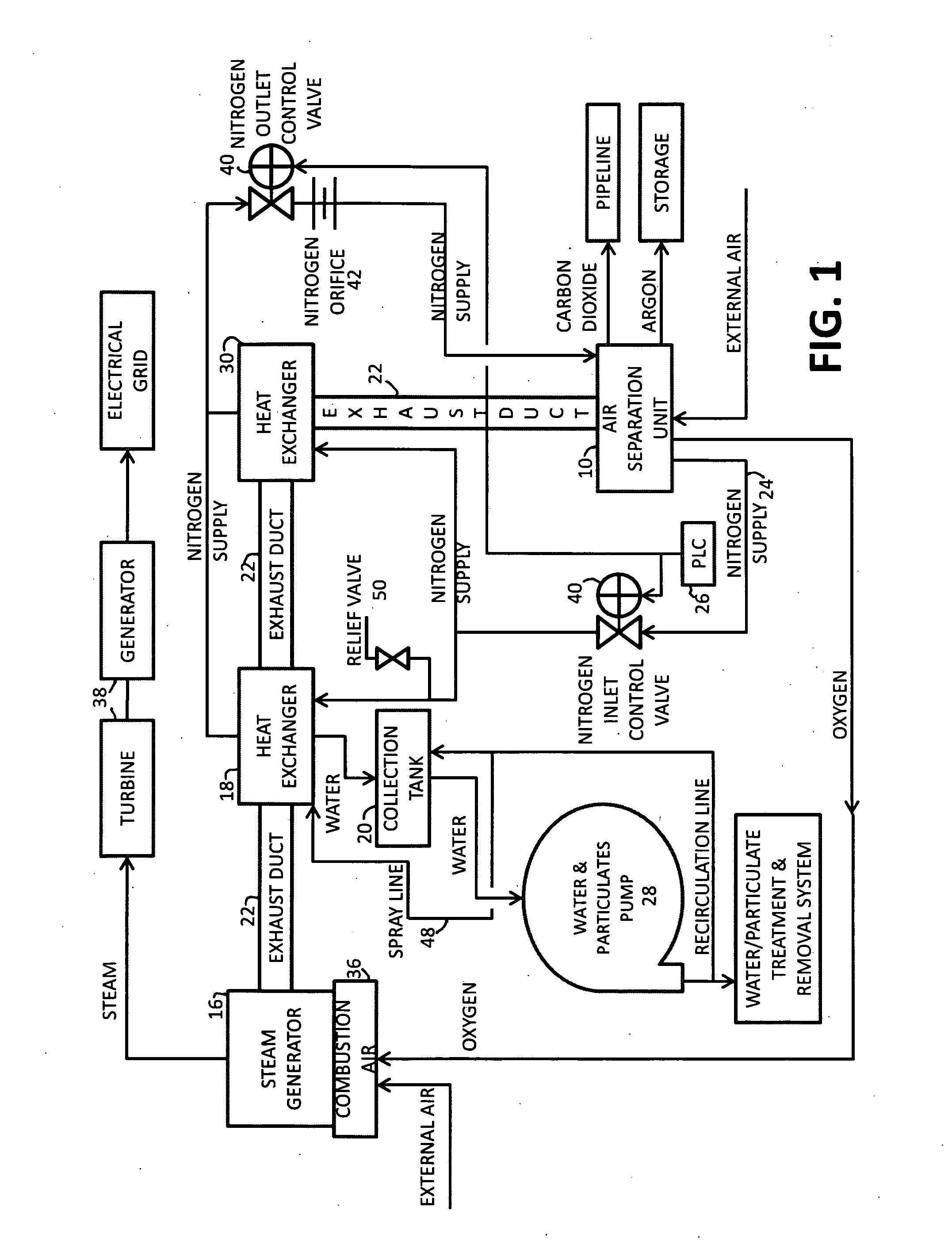

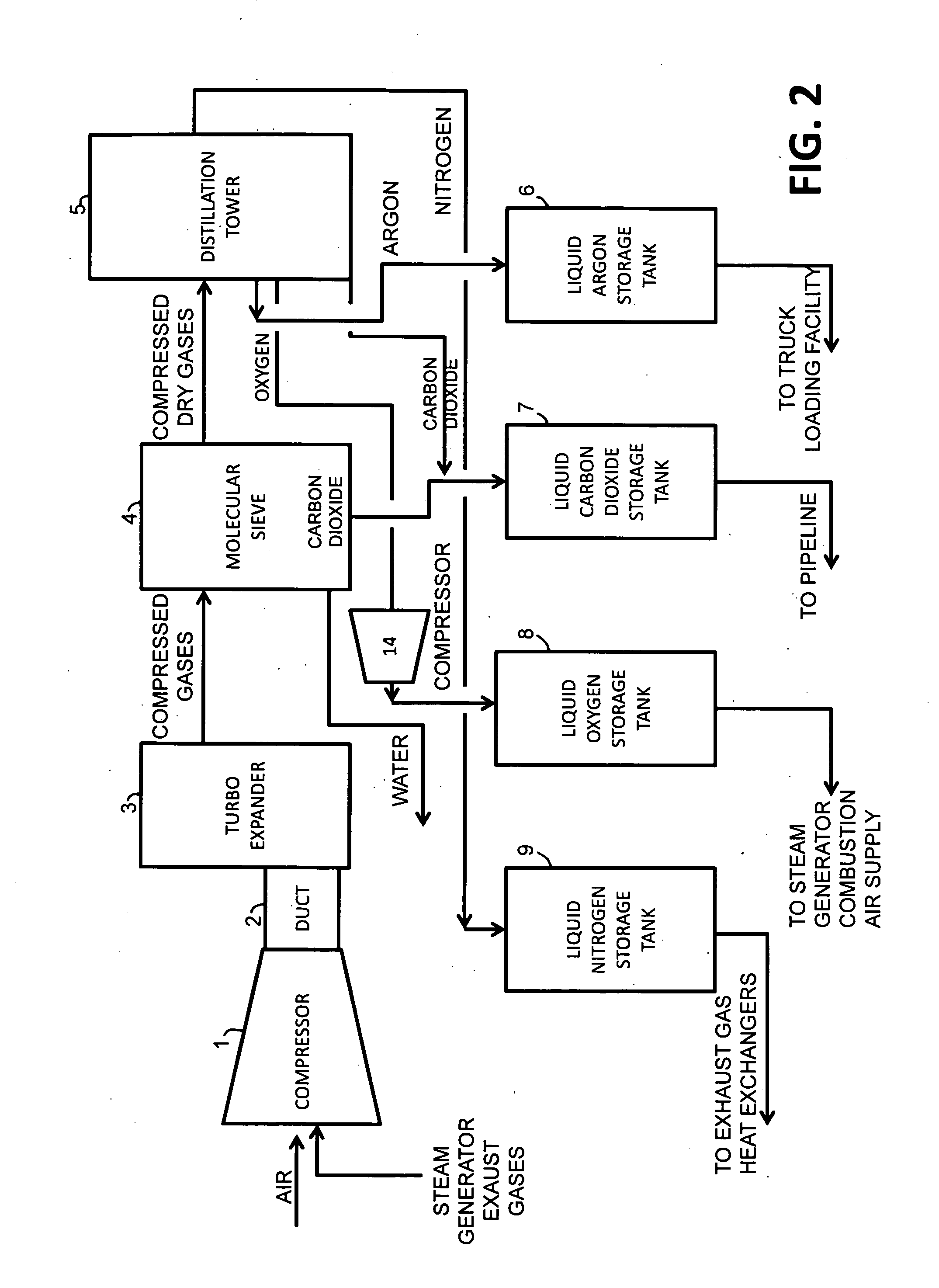

Power plant with emissions recovery

InactiveUS20100018218A1Reduce deliveryEnvironment safetySolidificationLiquefactionParticulatesNitrogen gas

A power plant including an air separation unit (ASU) arranged to separate nitrogen, oxygen, carbon dioxide and argon from air and produce a stream of substantially pure liquid oxygen, nitrogen, carbon dioxide and argon; a steam generator, fired or unfired, arranged to combust a fuel, e.g., natural gas, liquefied natural gas, synthesis gas, coal, petroleum coke, biomass, municipal solid waste or any other gaseous, liquid or solid fuel in the presence of air and a quantity of substantially pure oxygen gas to produce an exhaust gas comprising water, carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, sulfur oxides and other trace gases, and a steam-turbine-generator to produce electricity, a primary gas heat exchanger unit for particulate / acid gas / moisture removal and a secondary heat exchanger arranged to cool the remainder of the exhaust gases from the steam generator. Exhaust gases are liquefied in the ASU thereby recovering carbon dioxide, nitrogen oxides, nitrogen, sulfur oxides, oxygen, and all other trace gases from the steam generator exhaust gas stream. The cooled gases are liquefied in the ASU and separated for sale or re-use in the power plant. Carbon dioxide liquid is transported from the plant for use in enhanced oil recovery or for other commercial use. Carbon dioxide removal is accomplished in the ASU by cryogenic separation of the gases, after directing the stream of liquid nitrogen from the air separation unit to the exhaust gas heat exchanger units to cool all of the exhaust gases including carbon dioxide, carbon monoxide, nitrogen oxides, nitrogen, oxygen, sulfur oxides, and other trace gases.

Owner:TRIENCON SERVICES

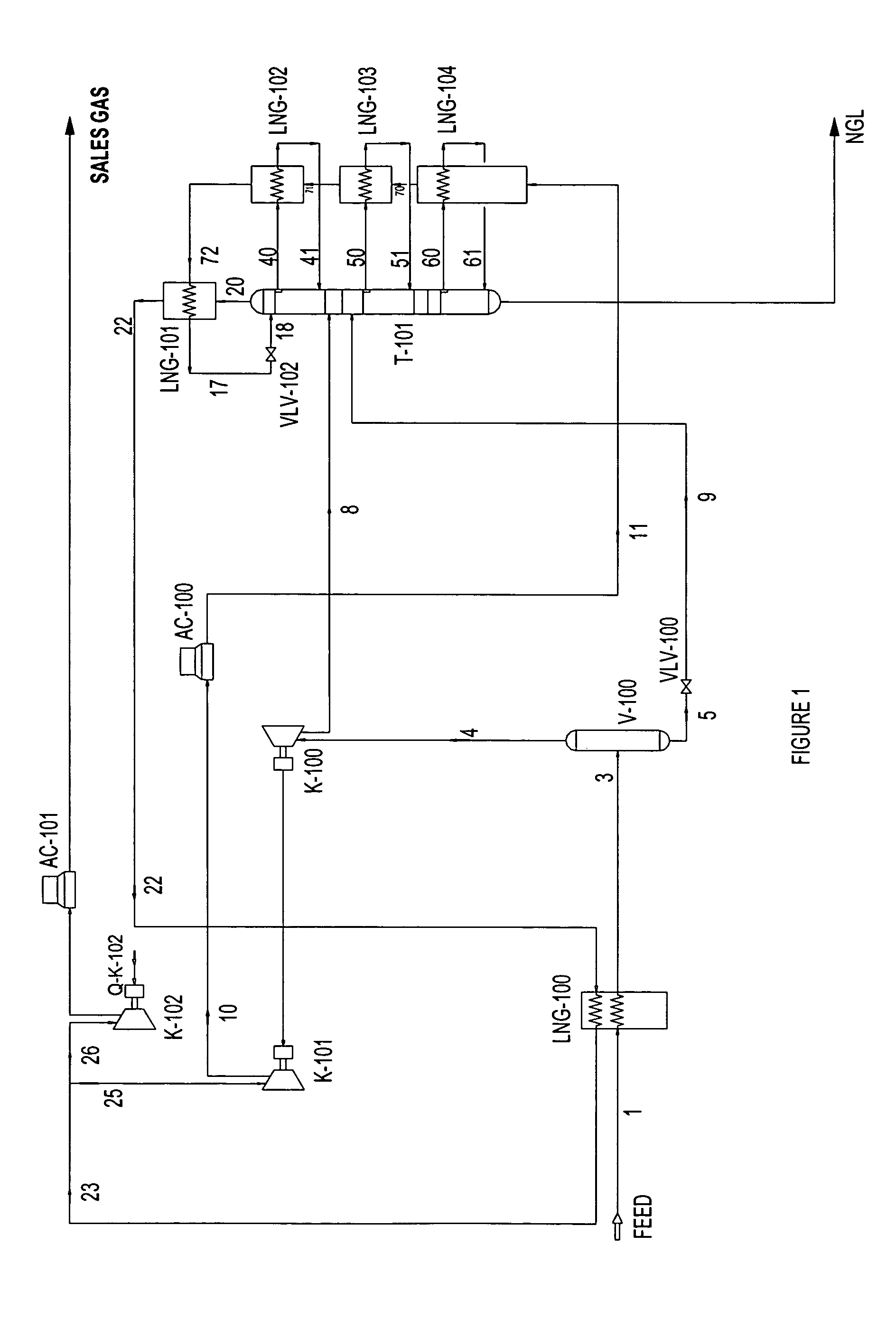

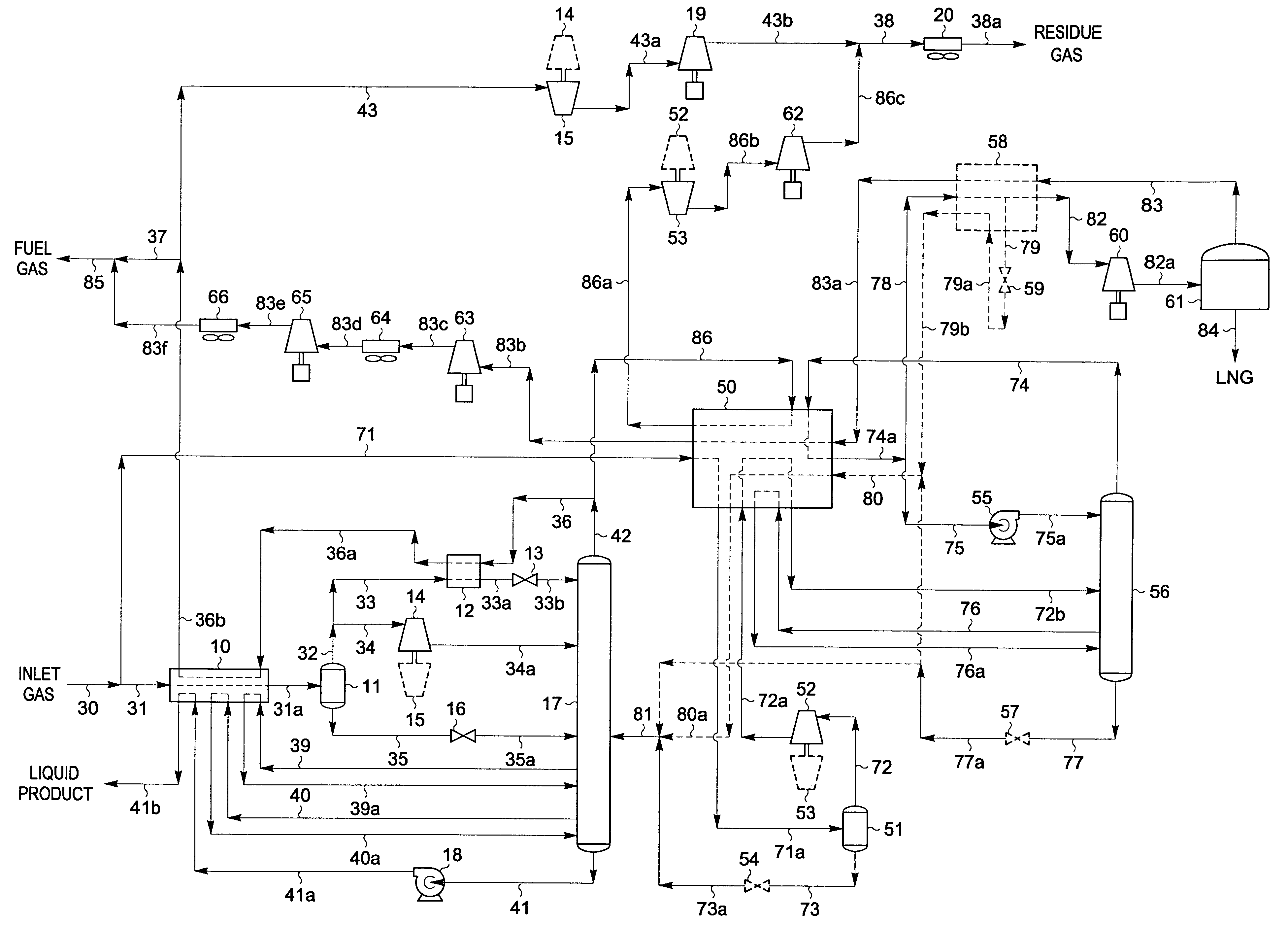

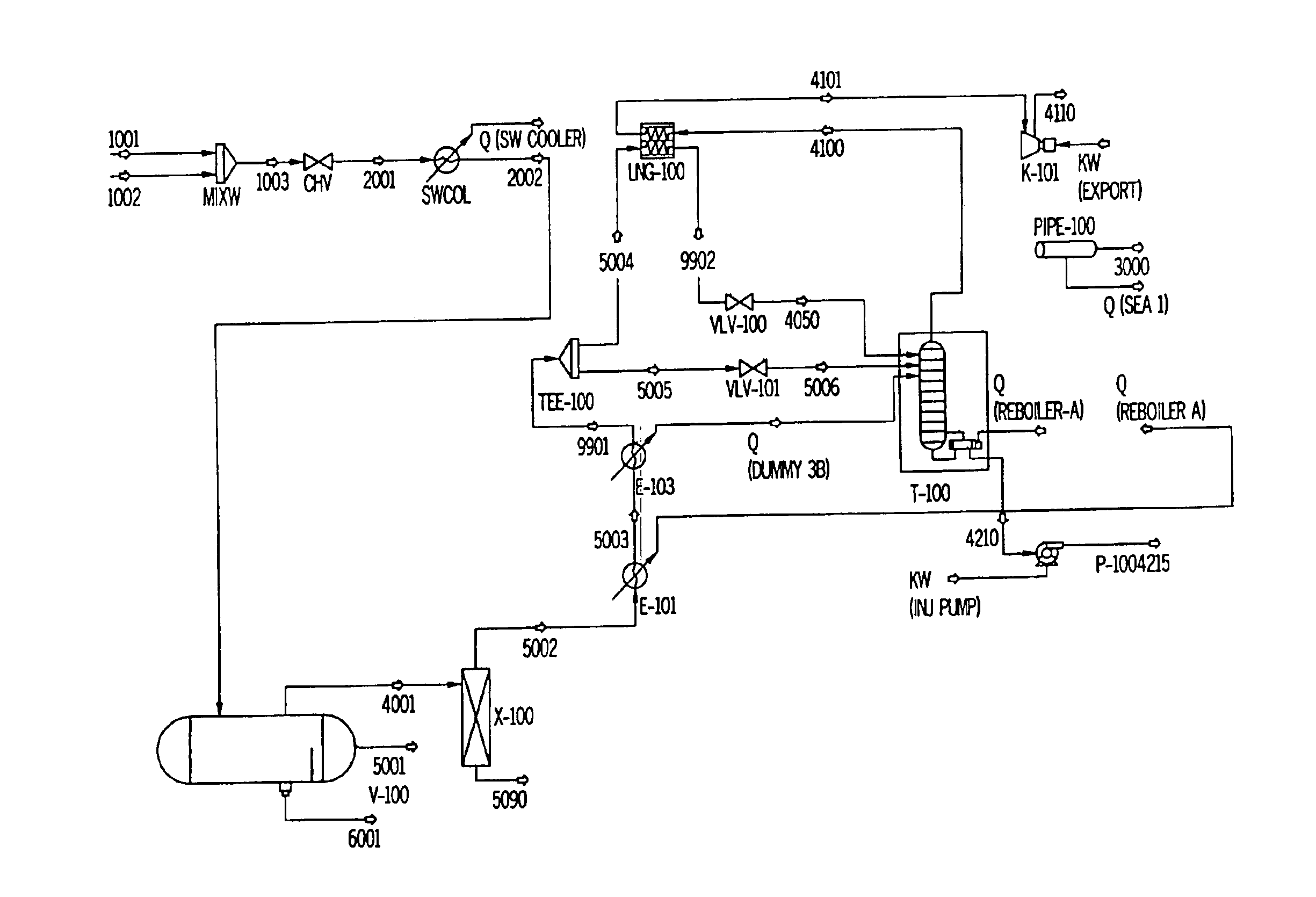

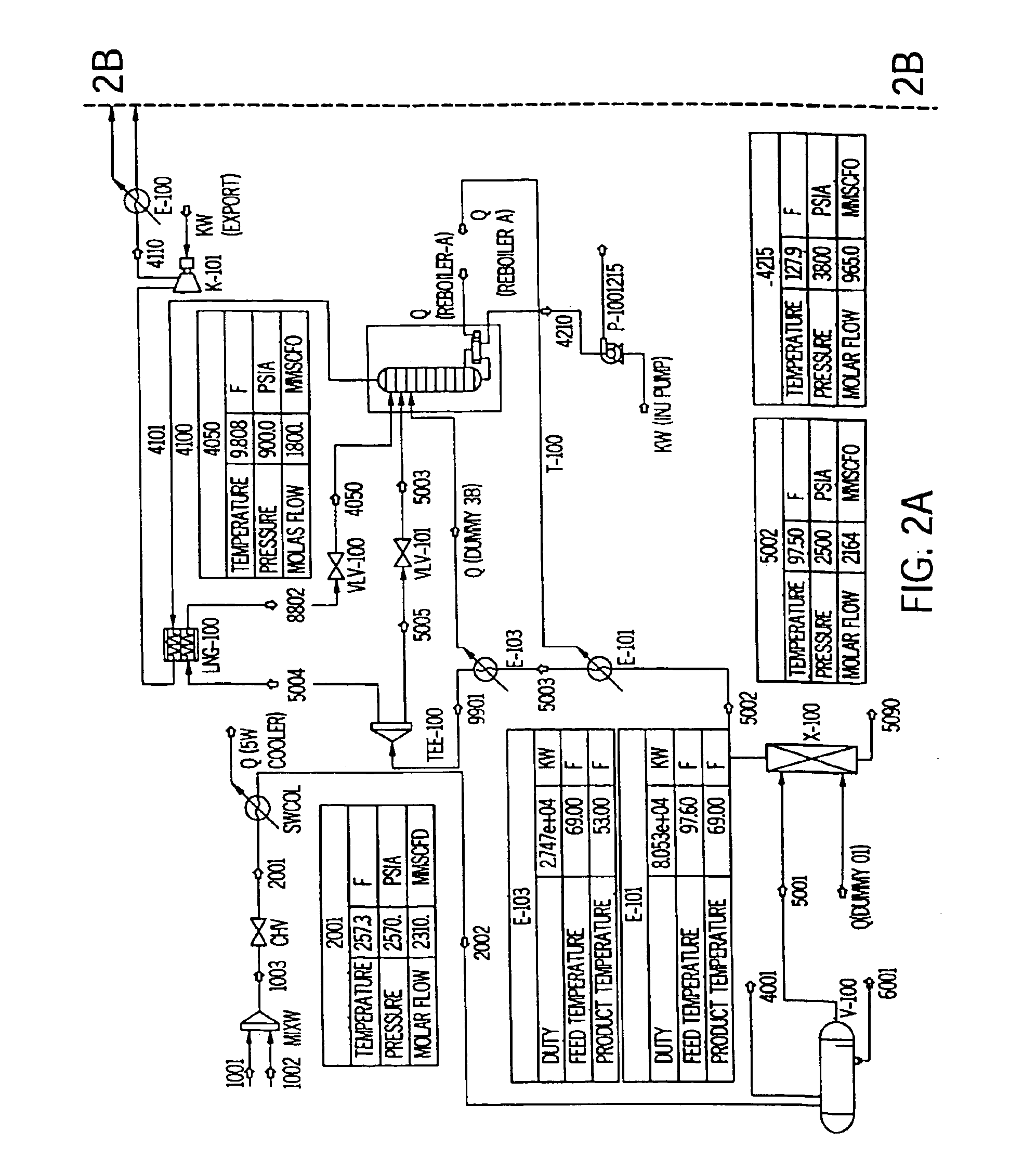

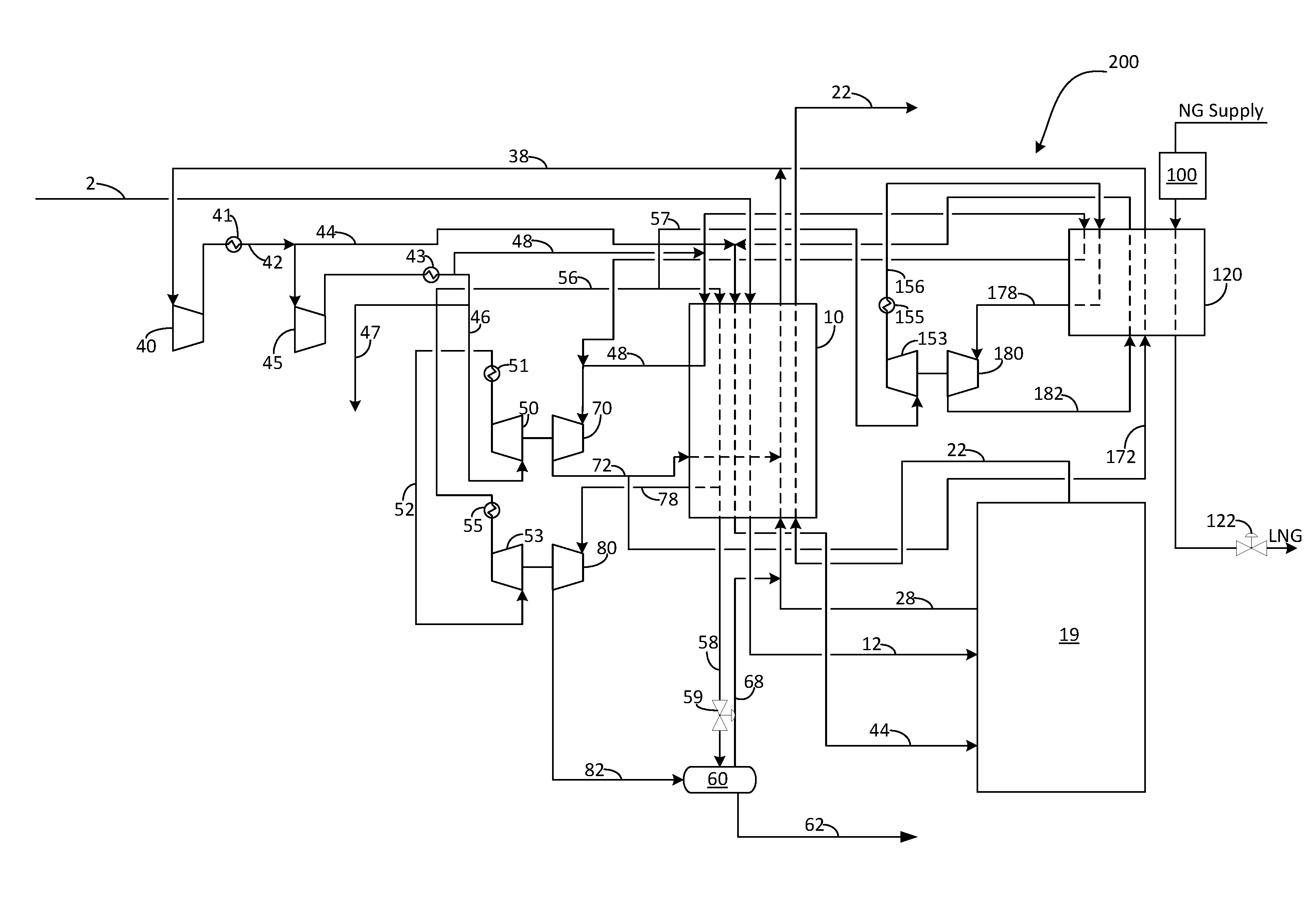

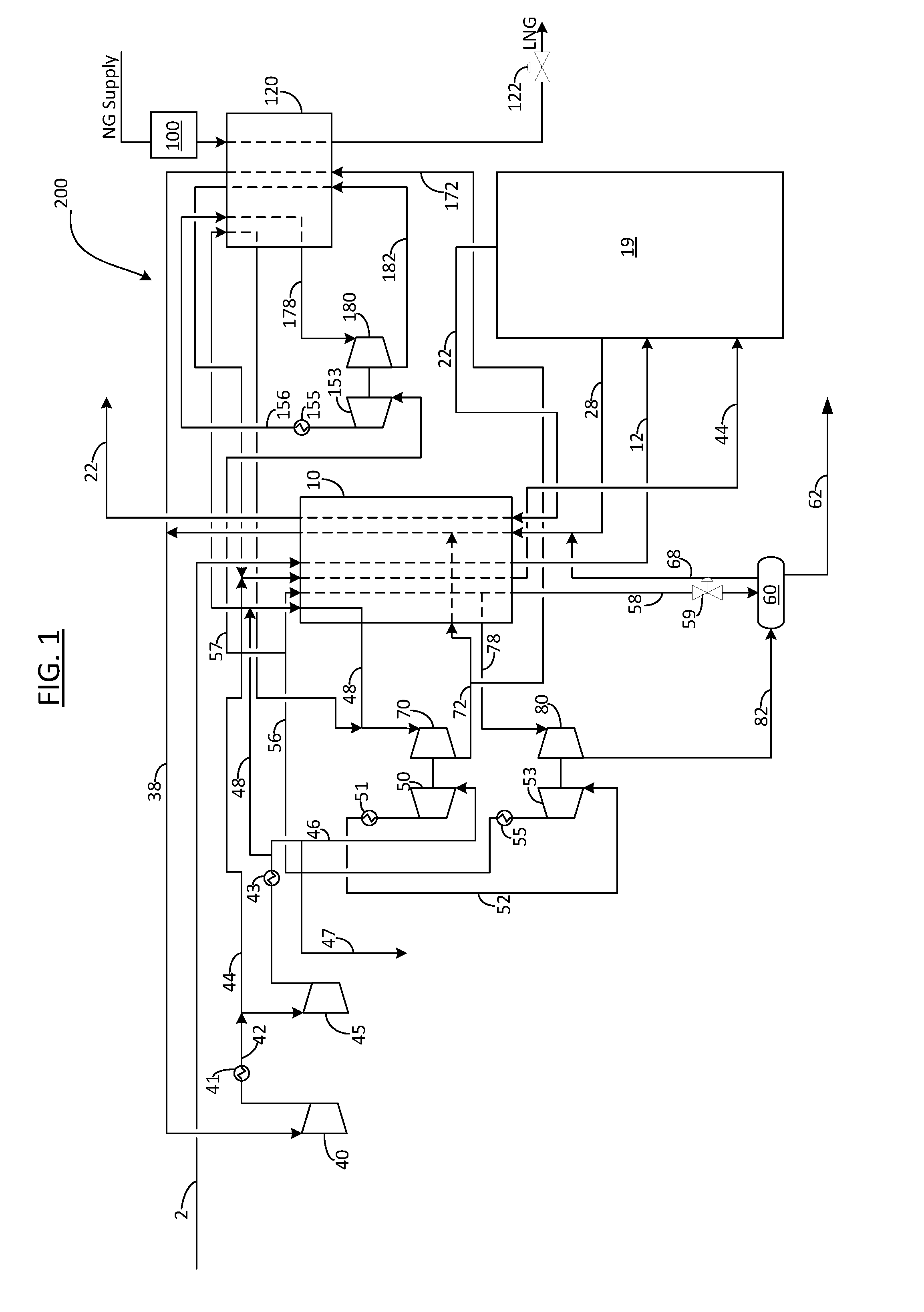

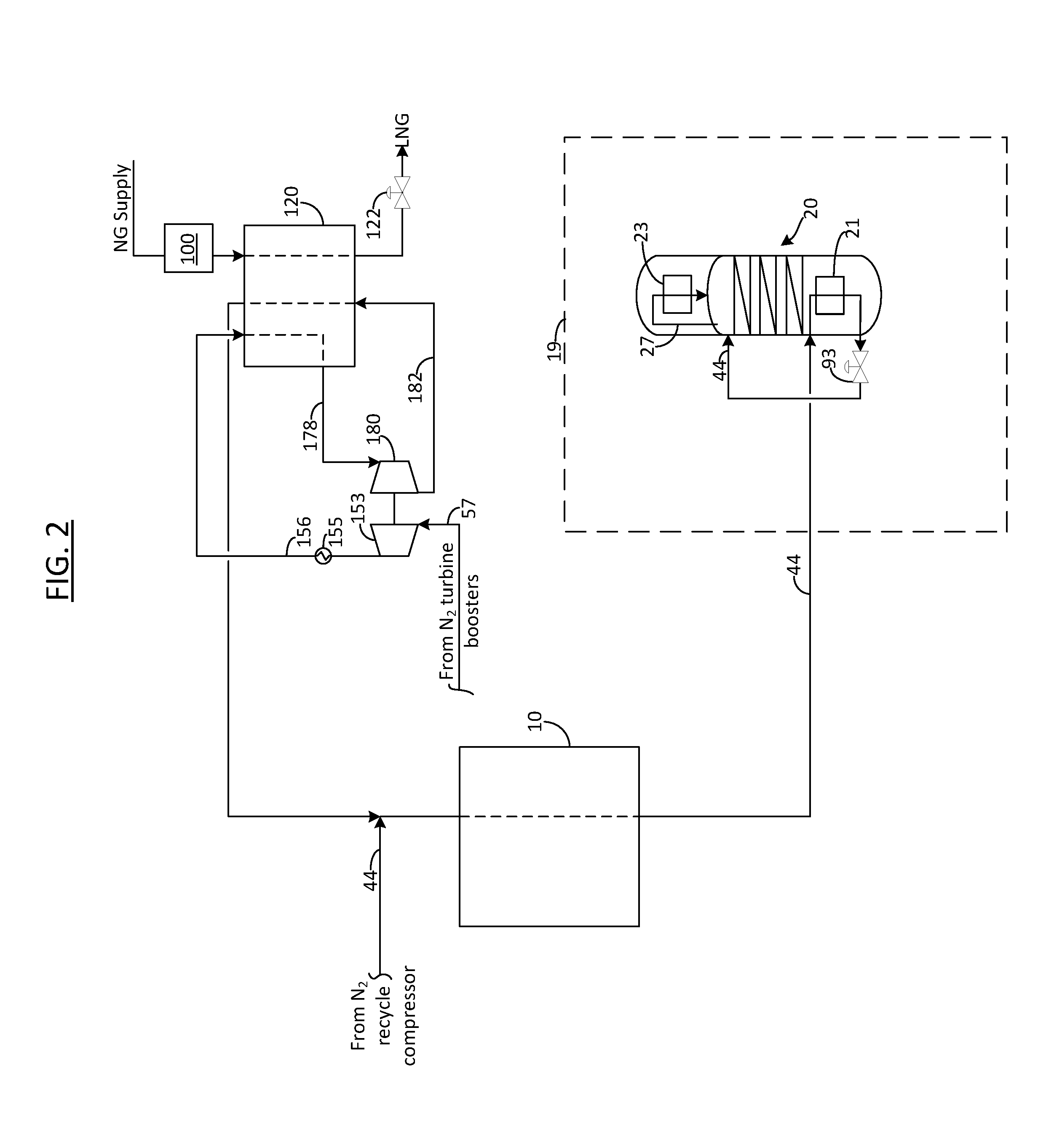

LNG production in cryogenic natural gas processing plants

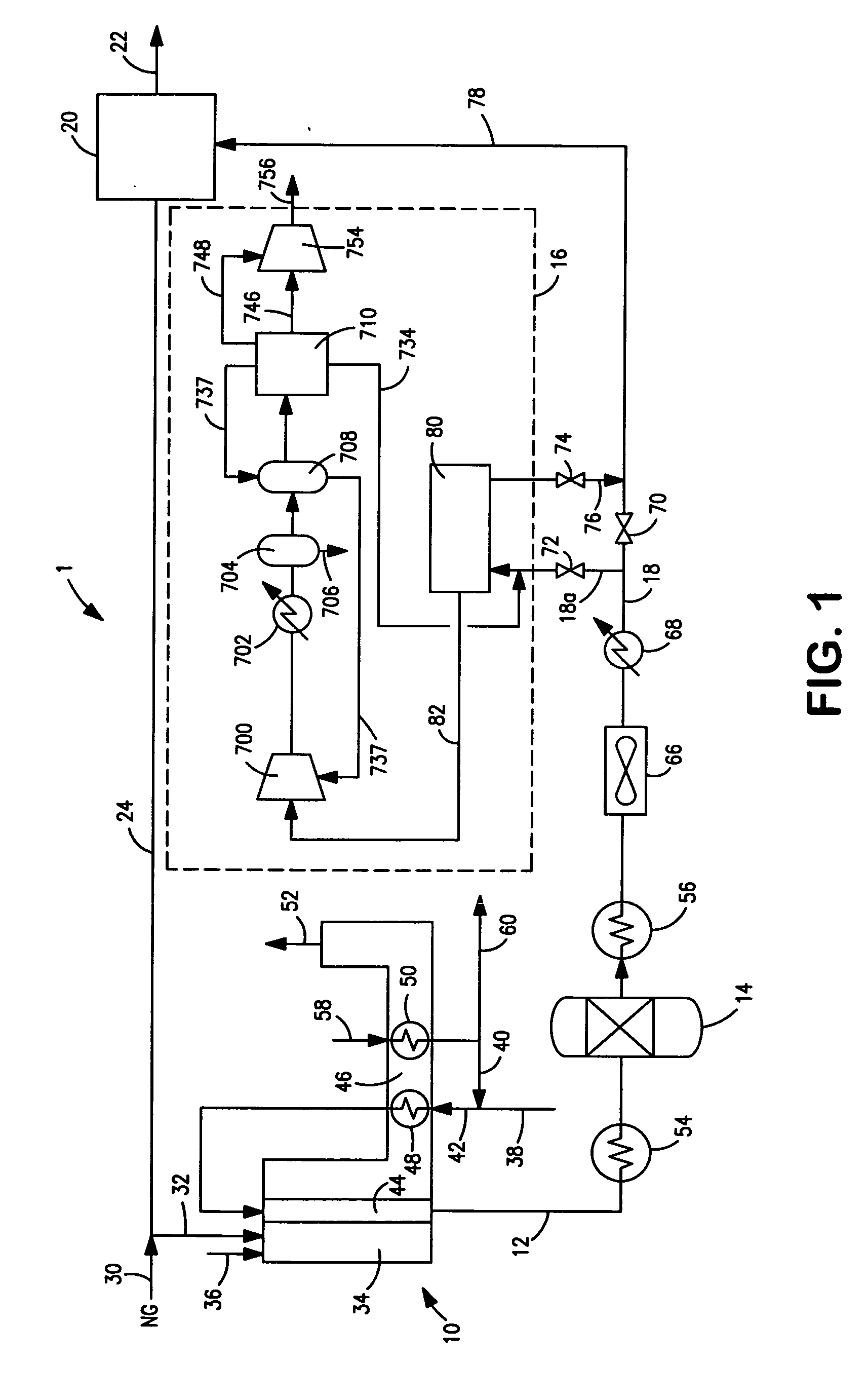

A process for liquefying natural gas in conjunction with processing natural gas to recover natural gas liquids (NGL) is disclosed. In the process, the natural gas stream to be liquefied is taken from one of the streams in the NGL recovery plant and cooled under pressure to condense it. A distillation stream is withdrawn from the NGL recovery plant to provide some of the cooling required to condense the natural gas stream. The condensed natural gas stream is expanded to an intermediate pressure and supplied to a mid-column feed point on a distillation column. The bottom product from this distillation column preferentially contains the majority of any hydrocarbons heavier than methane that would otherwise reduce the purity of the liquefied natural gas, and is routed to the NGL recovery plant so that these heavier hydrocarbons can be recovered in the NGL product. The overhead vapor from the distillation column is cooled and condensed, and a portion of the condensed stream is supplied to a top feed point on the distillation column to serve as reflux. A second portion of the condensed stream is expanded to low pressure to form the liquefied natural gas stream.

Owner:ORTLOFF ENGINEERS

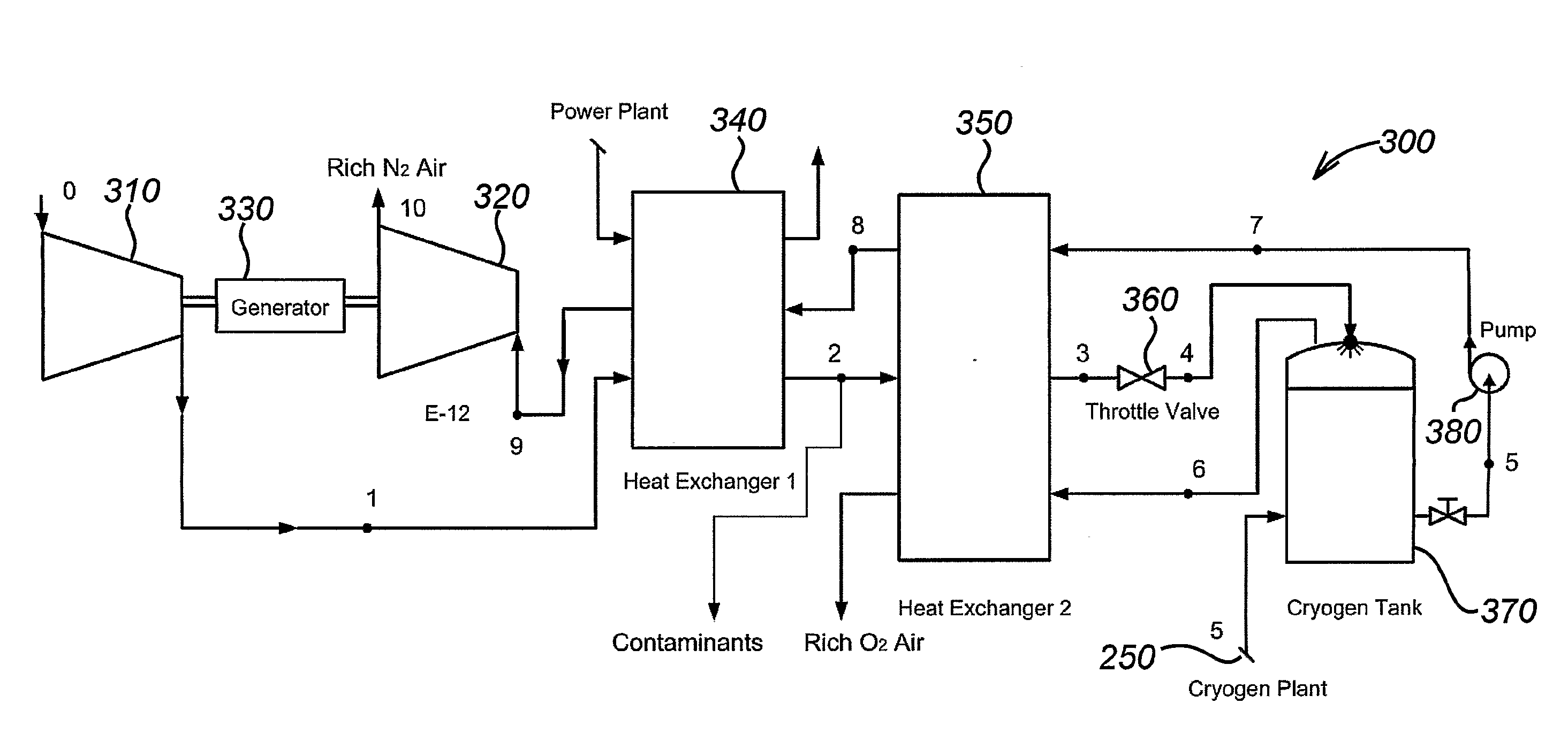

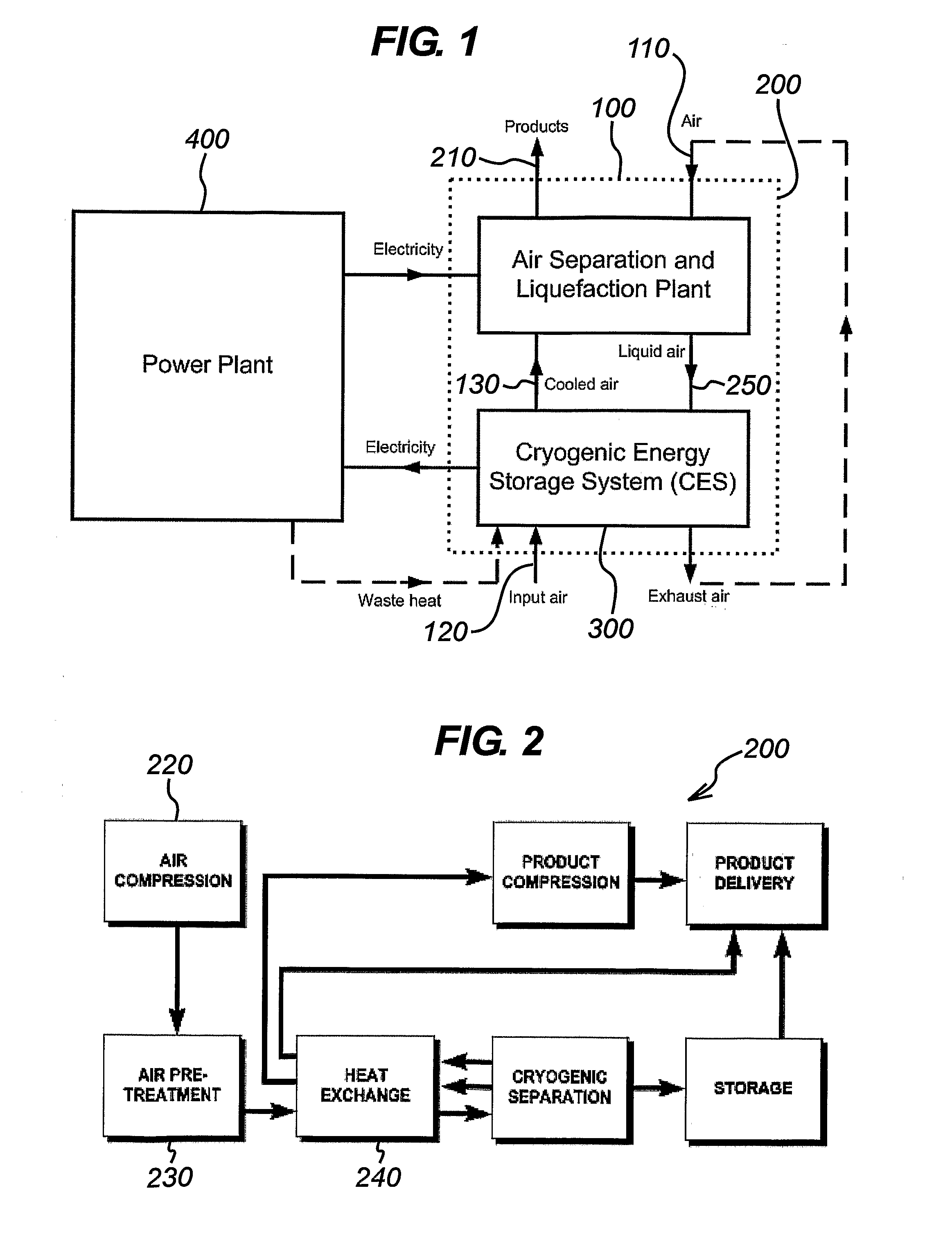

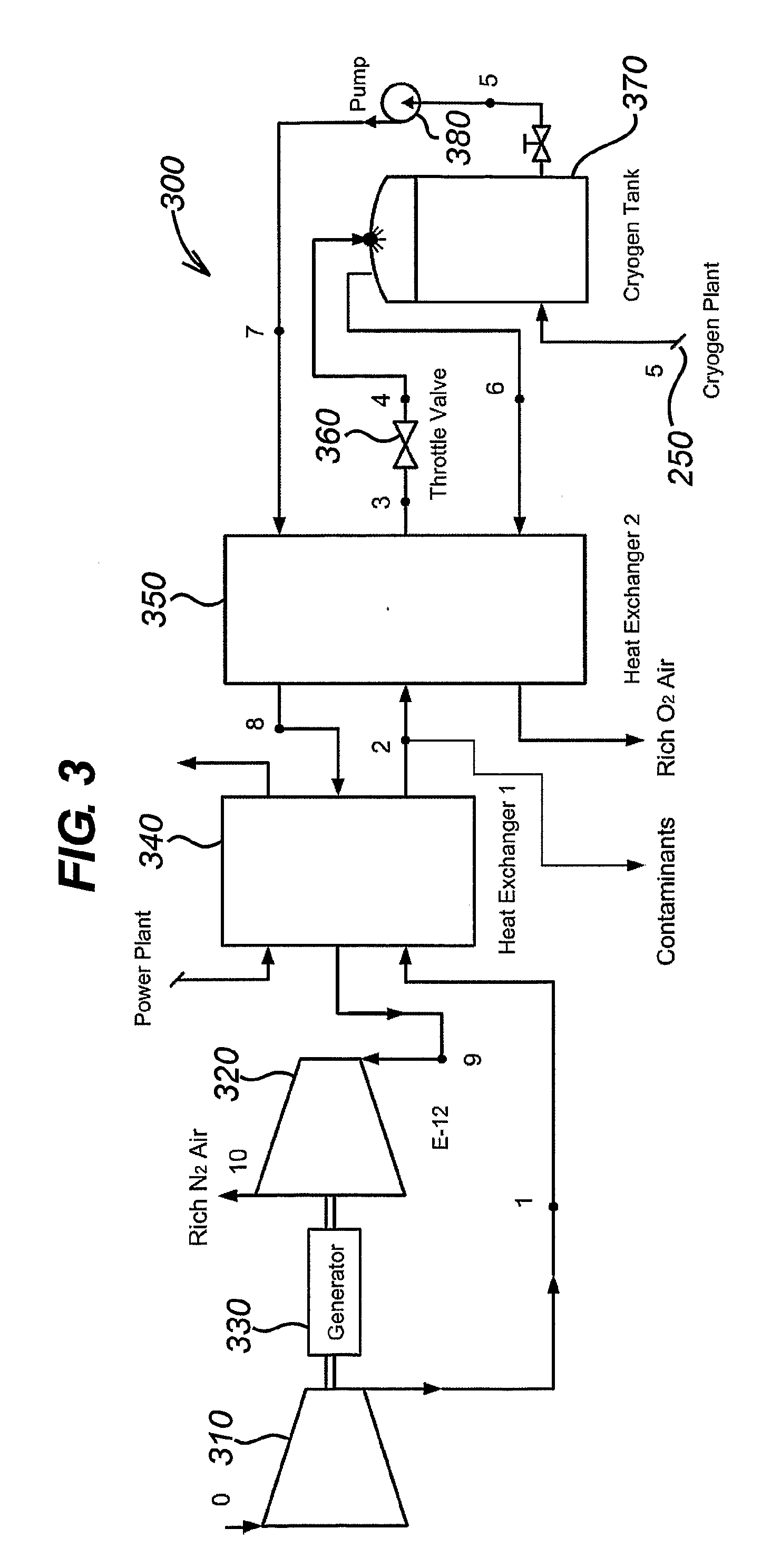

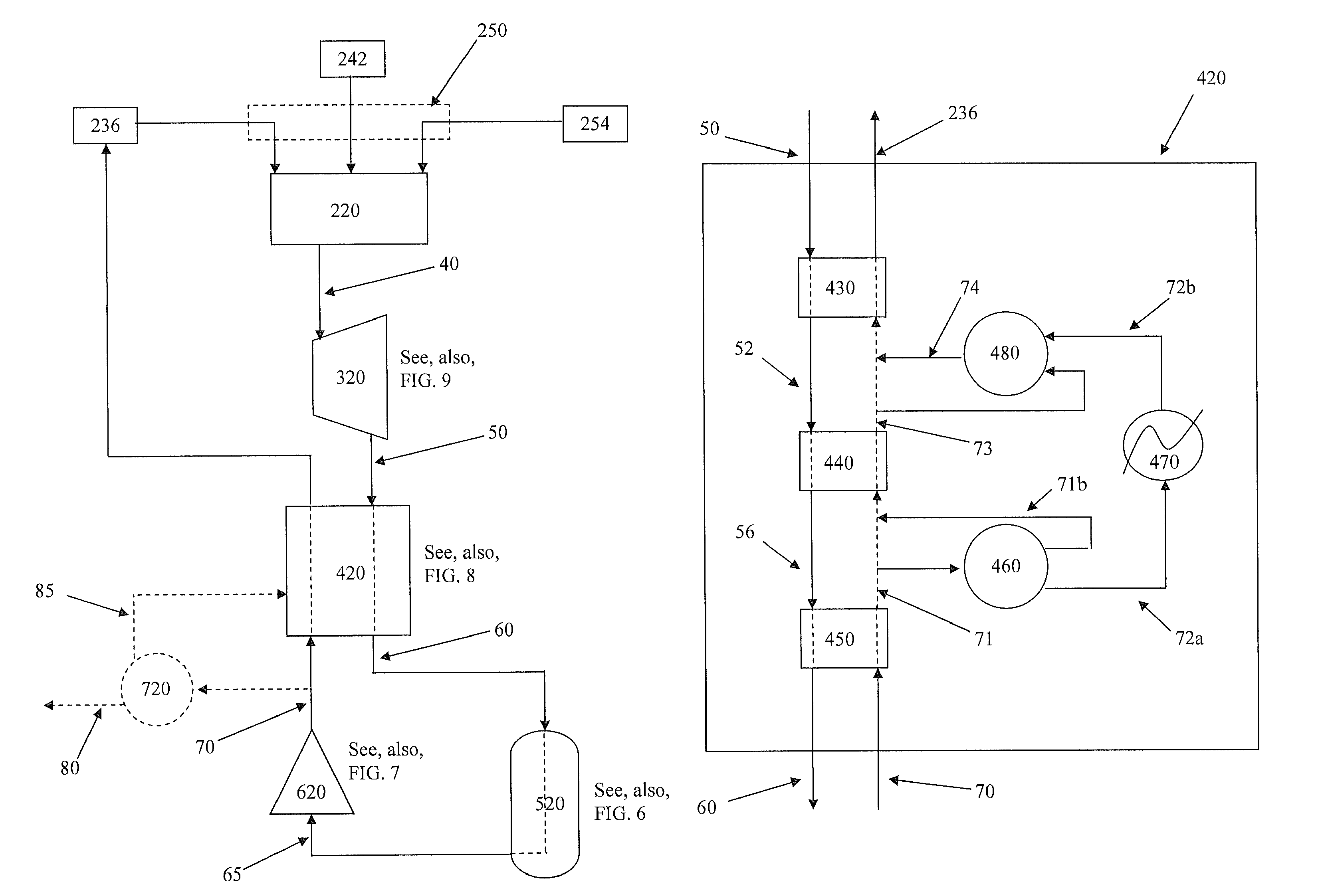

Energy storage and generation

InactiveUS20090282840A1Maximize useMinimize changesSolidificationLiquefactionPropellerProcess engineering

The present invention concerns systems for storing energy and using the stored energy to generate electrical energy or drive a propeller (505). In particular, the present invention provides a method of storing energy comprising: providing a gaseous input, producing a cryogen from the gaseous input; storing the cryogen; expanding the cryogen; using the expanded cryogen to drive a turbine (320) and recovering cold energy from the expansion of the cryogen. The present invention also provides a cryogenic energy storage system comprising: a source of cryogen; a cryogen storage facility (370); means for expanding the cryogen; a turbine (320) capable of being driven by the expanding cryogen; and means (340, 350) for recovering cold energy released during expansion of the cryogen.

Owner:HIGHVIEW ENTERPRISES LTD

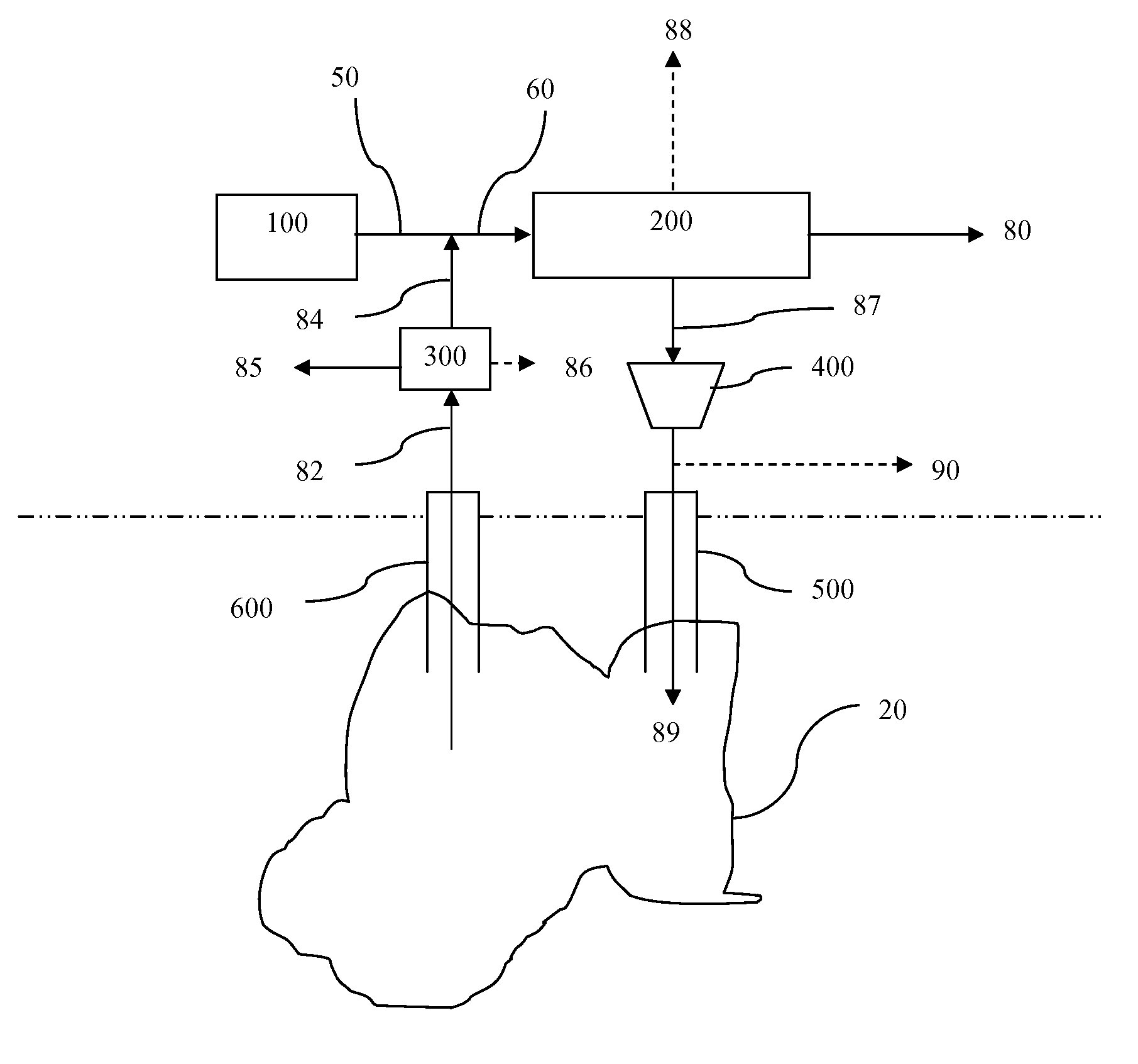

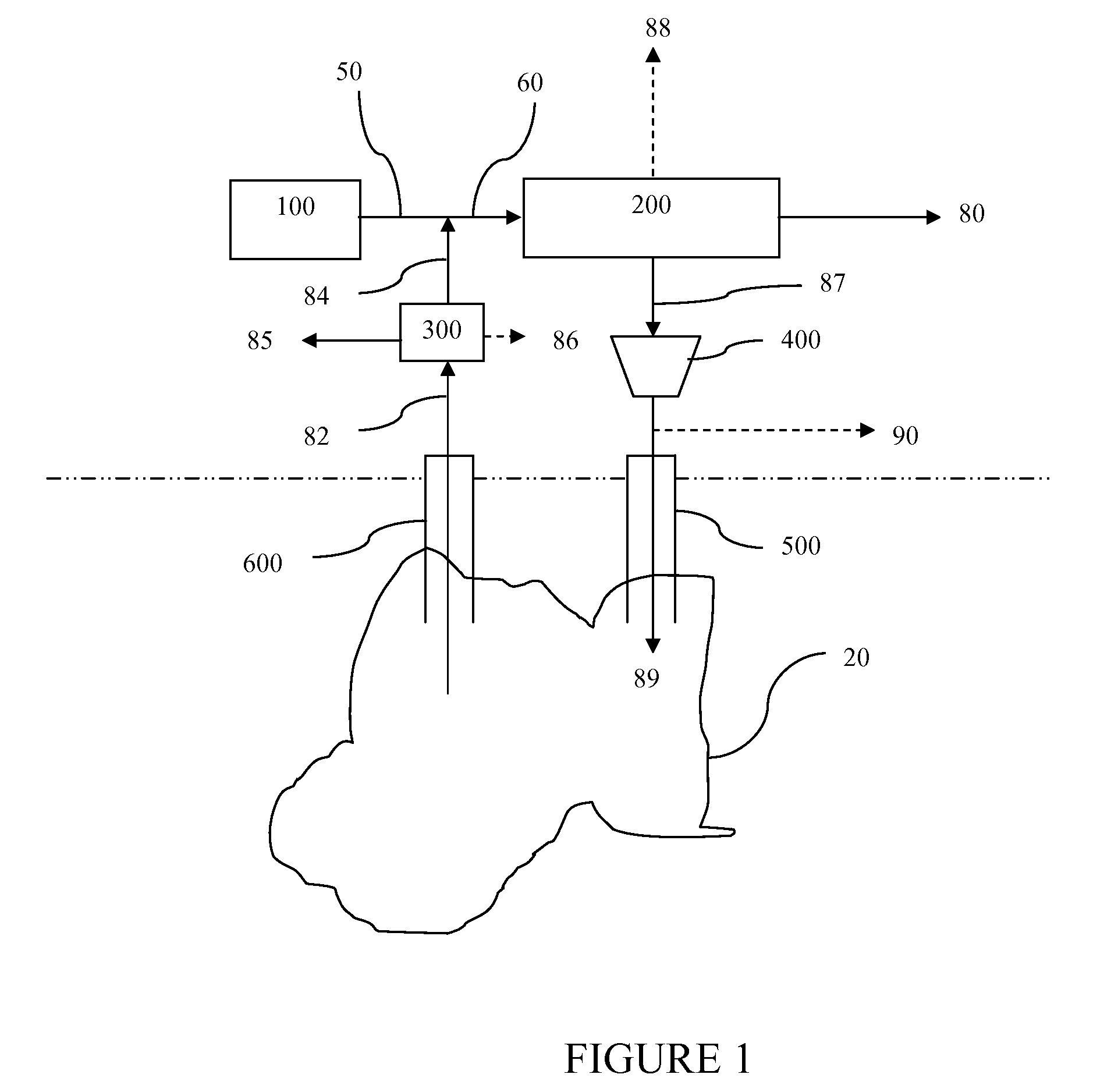

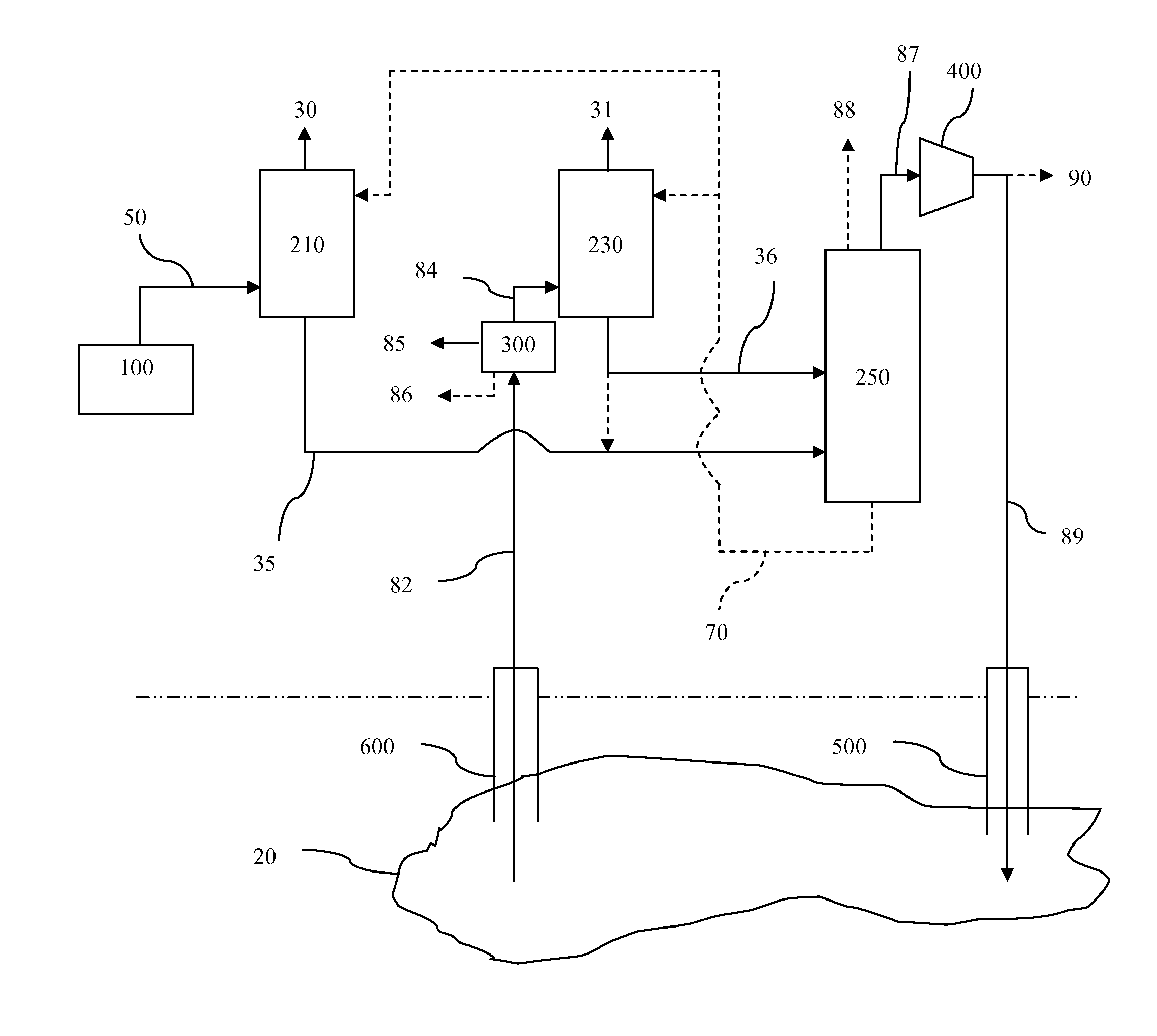

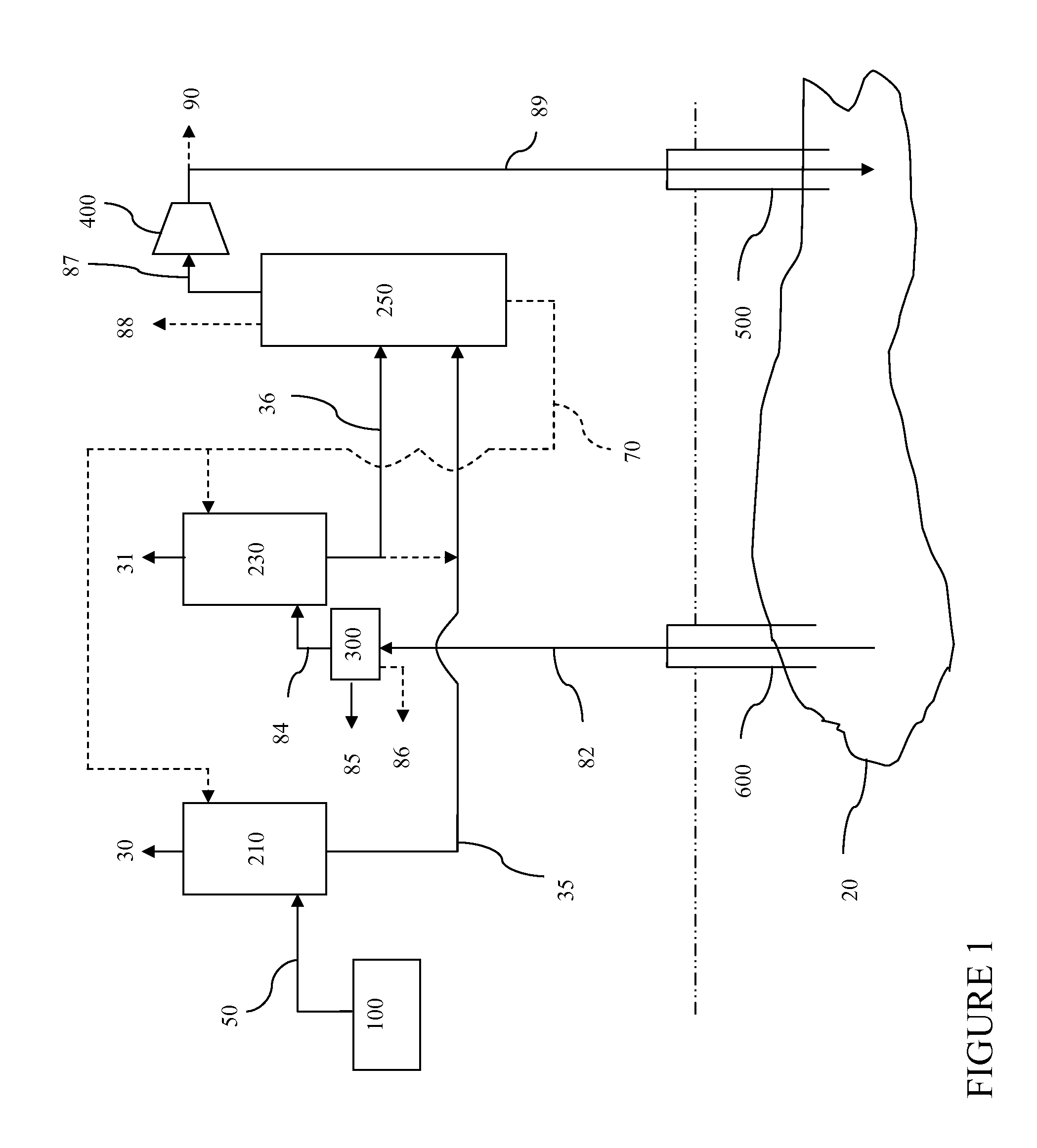

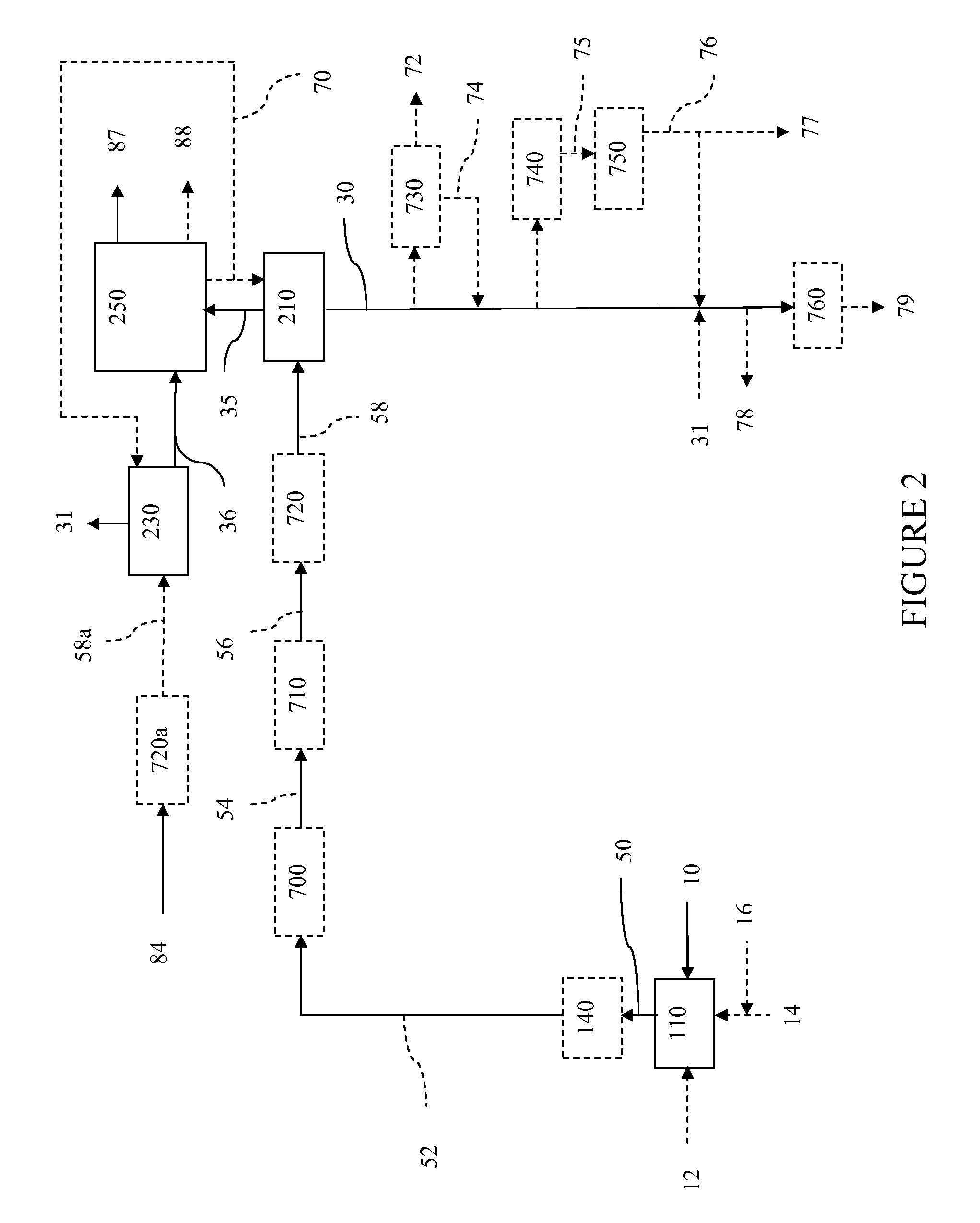

Integrated enhanced oil recovery process

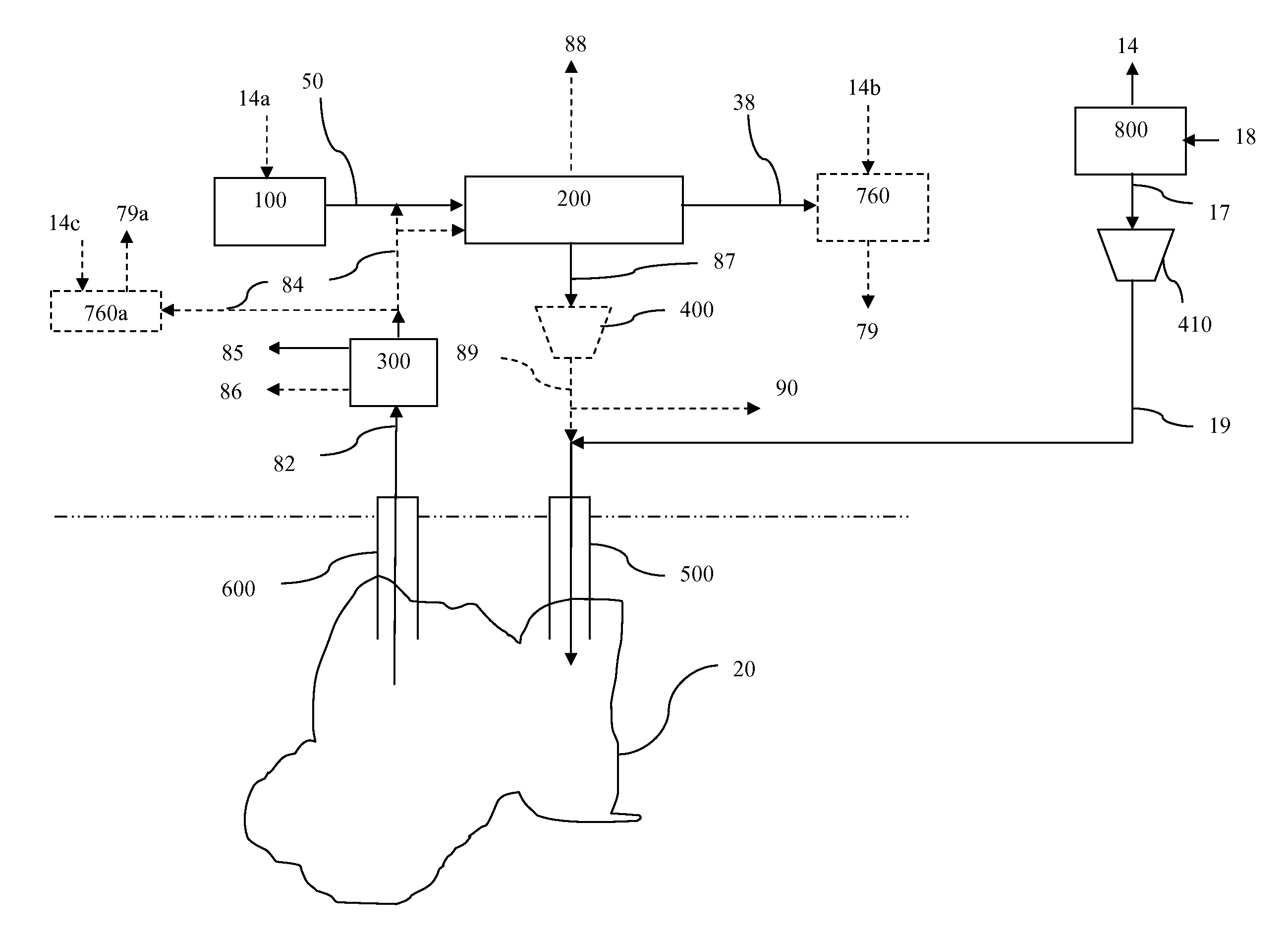

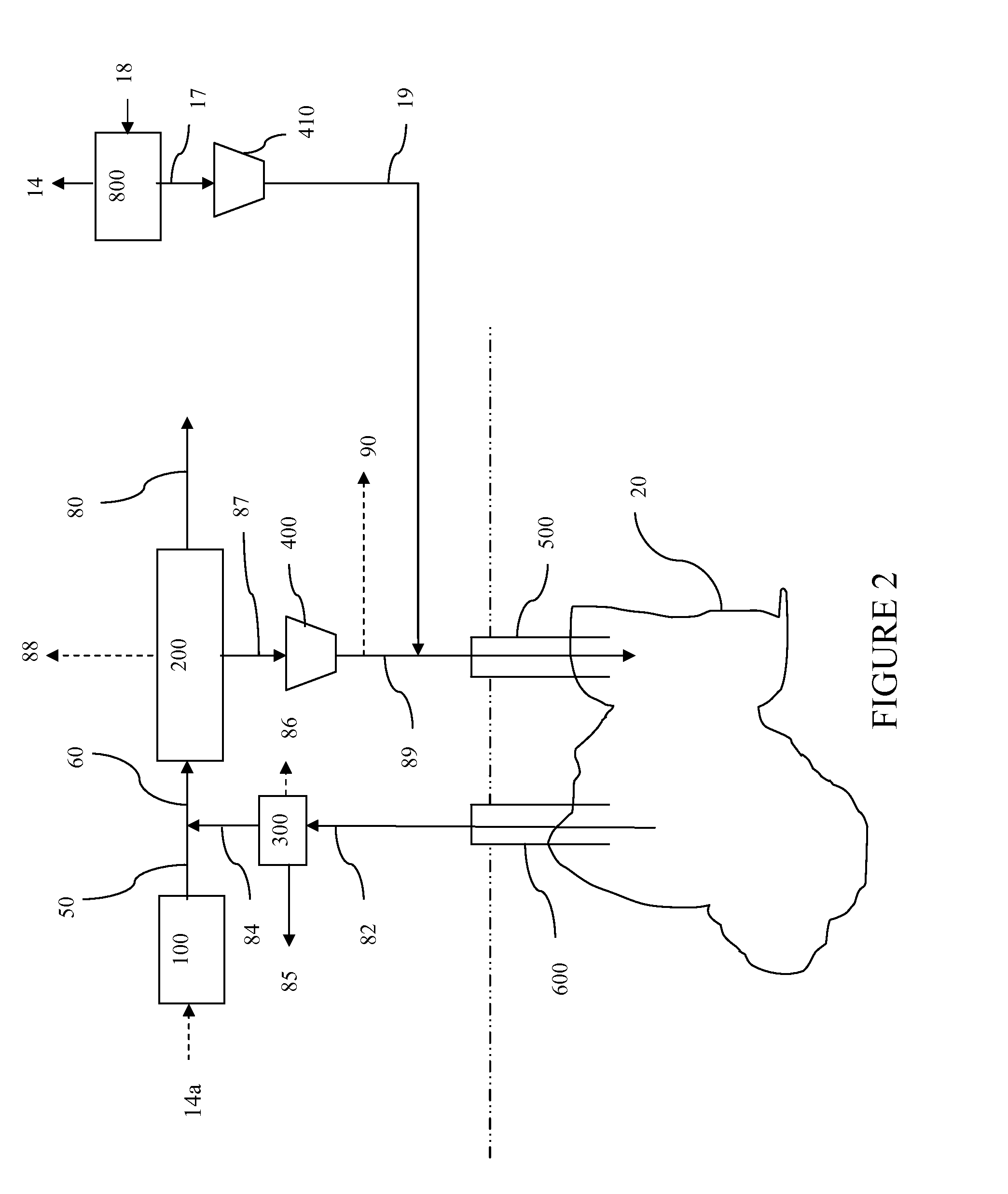

ActiveUS20110088896A1Enhanced overall recoveryIncrease productionSolidificationLiquefactionGeneration processMethane

The present invention relates to an enhanced oil recovery process that is integrated with a synthesis gas generation process, such as gasification or methane reforming, involving combined capture and recycle of carbon dioxide from both processes.

Owner:SURE CHAMPION INVESTMENT LTD

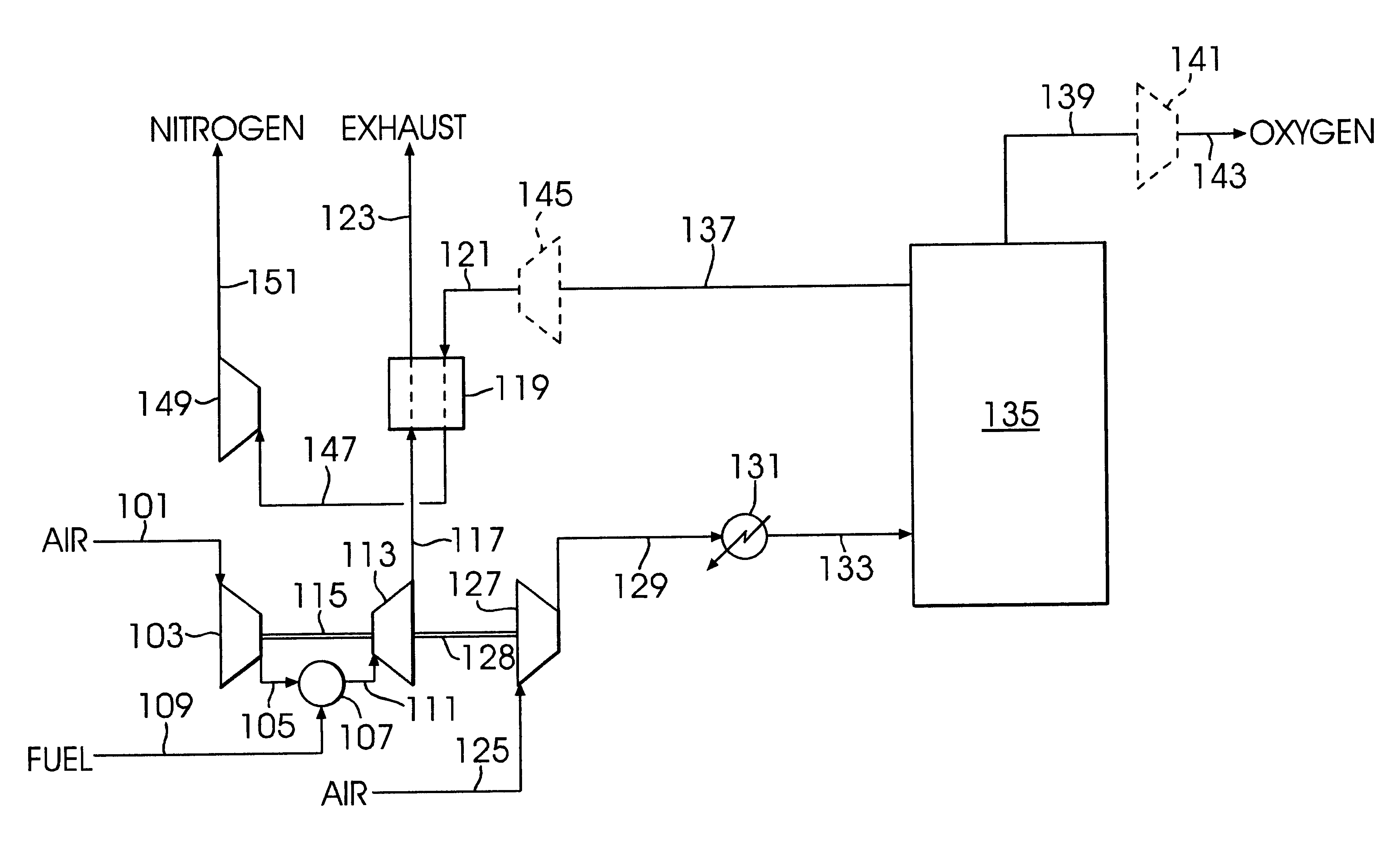

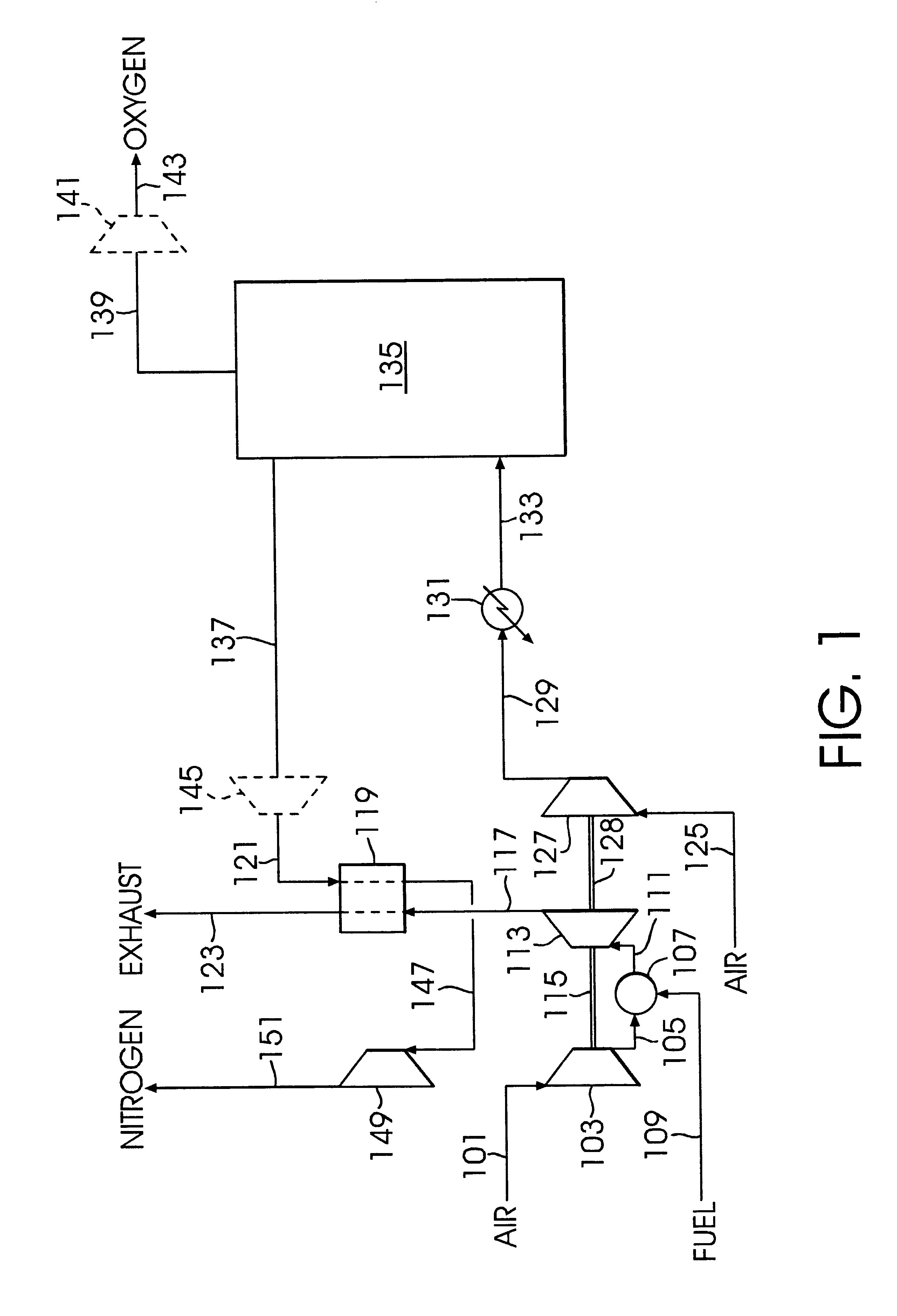

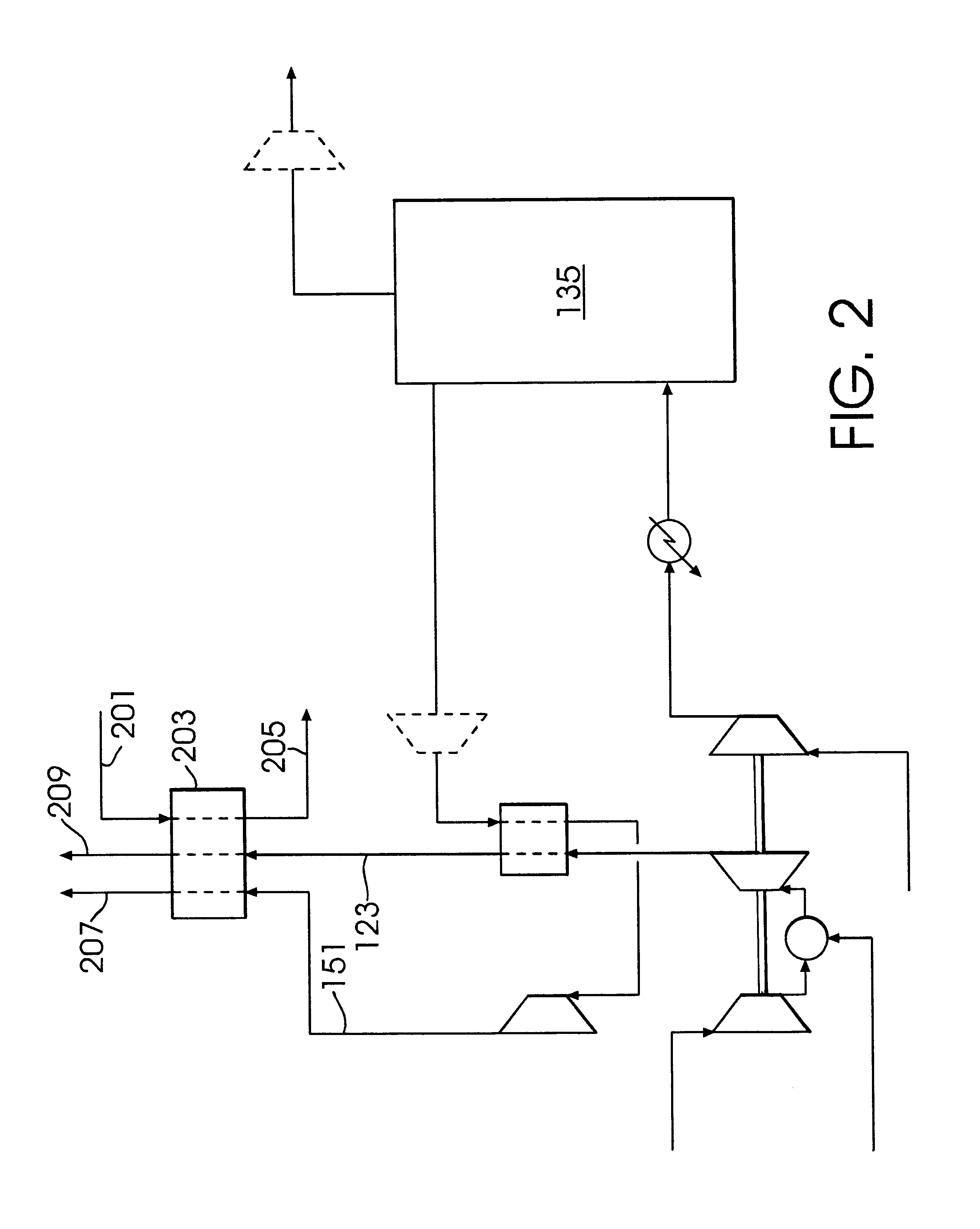

Integrated air separation and oxygen fired power generation system

An integrated air separation and oxygen fired power generation system includes an air separation unit and a gas turbine including an air compressor to provide compressed air for the air separation unit. The system further includes a gas turbine expander and at least one additional turbine to drive the air compressor, as well as at least one combustion unit to provide drive gas for expander and additional turbine(s). A portion of oxygen produced by the air separation unit is delivered to the combustor(s) to facilitate production of drive gas for use by the expander and additional turbine(s). Turbine inlet temperatures are controlled by recycling water or steam to the combustor(s).

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

Purification of carbon dioxide

Carbon dioxide is separated from a feed gas, preferably derived from flue gas from an oxyfuel combustion process, in a membrane separation system to produce separated carbon dioxide gas which is fed to the oxyfuel combustion process to improve the performance of the process.

Owner:AIR PROD & CHEM INC

Integrated enhanced oil recovery process

ActiveUS20110088897A1Increase productionEnhanced overall recoverySolidificationLiquefactionGeneration processCarbon dioxide

The present invention relates to an enhanced oil recovery process that is integrated with a synthesis gas generation process, such as gasification or methane reforming, involving combined capture and recycle of carbon dioxide from both processes.

Owner:SURE CHAMPION INVESTMENT LTD

Purification of carbon dioxide

Impure carbon dioxide (“CO2”) comprising a first contaminant selected from the group consisting of oxygen (“O2”) and carbon monoxide (“CO”) is purified by separating expanded impure carbon dioxide liquid in a mass transfer separation column system. The impure carbon dioxide may be derived from, for example, flue gas from an oxyfuel combustion process or waste gas from a hydrogen (“H2”) PSA system.

Owner:AIR PROD & CHEM INC

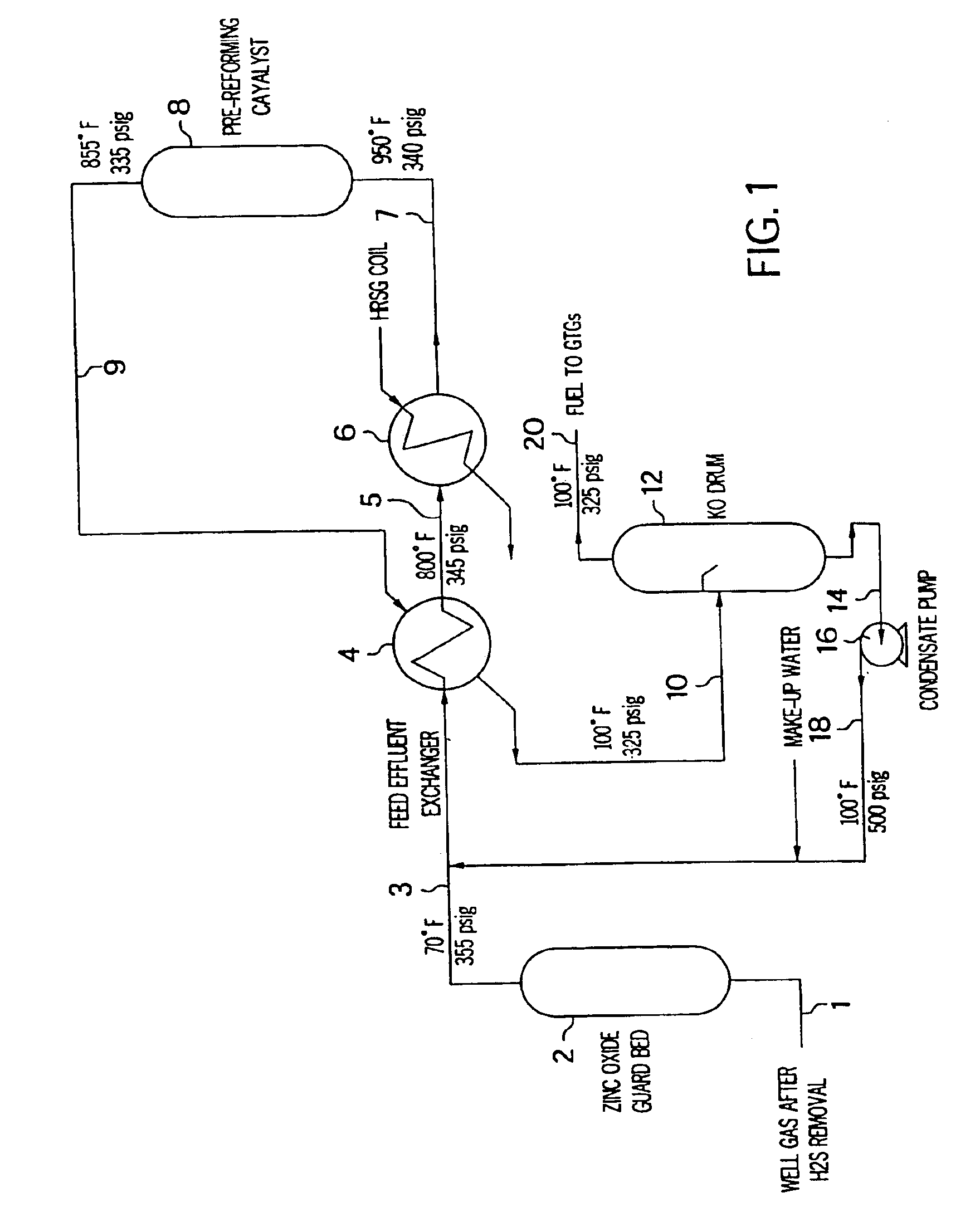

Method for utilizing gas reserves with low methane concentrations and high inert gas concentrations for fueling gas turbines

InactiveUS6907737B2Improve flammabilityLow costSolidificationLiquefactionProcess engineeringCurrent technology

The invention is directed to a method of fueling gas turbines from natural gas reserves with relatively low methane concentrations. The invention uses such reserves to generate electric power. The invention permits the use of these reserves at significantly lower cost than by producing pipeline natural gas to fuel gas turbines to generate electric power. These reserves currently generally are used only after the removal of impurities to produce pipeline natural gas quality turbine fuel. The latter current technology is capital intensive, and at current natural gas prices, economically unattractive. The process of the invention can remove the impurities from the gas from the natural gas reserve necessary for protection of the environment, and leaves inert gasses in the fuel in an amount which will increase the output of a gas turbine for the generation of power by about 5 to about 20%.

Owner:EXXONMOBIL UPSTREAM RES CO

Hydrocarbon gas processing

A process for the recovery of propane, propylene and heavier hydrocarbon components from a hydrocarbon gas stream is disclosed. The stream is cooled and / or expanded to partially condense it, then separated to provide a first vapor stream. The first vapor stream is directed into a contacting device whereby vapors and liquids are formed. The liquids are directed to a distillation column operating at lower pressure wherein a second vapor stream is separated to recover a product containing the major portion of the C3 components and heavier hydrocarbon components. The second vapor stream is directed into heat exchange relation with the vapors to cool the second vapor stream and condense at least a part of it, forming a condensed stream. At least a portion of the condensed stream is directed to the contacting device to intimately contact the first vapor stream; the remaining portion (if any) of the condensed stream can be supplied to the distillation column as its top feed. The quantities and temperatures of the feeds to the contacting device and the distillation column are effective to maintain the overhead temperatures of the contacting device and the distillation column at temperatures whereby the major portion of the desired components is recovered.

Owner:ELCOR CORP

Air separation process integrated with gas turbine combustion engine driver

A method for the separation of a feed gas mixture comprising oxygen and nitrogen in which an oxidant gas and fuel are combusted in a combustion engine to generate shaft work and a hot exhaust gas, the feed gas mixture comprising oxygen and nitrogen is compressed, and the resulting compressed feed gas mixture is separated into two or more product gas streams with differing compositions. The shaft work of the combustion engine is utilized to provide at least a portion of the work required for compressing the feed gas mixture, one of the product gas streams by is heated by indirect heat exchange with the hot exhaust gas from the combustion engine, and the resulting heated product gas is work expanded to generate shaft work and yield an expanded product gas stream. The combustion engine may be a gas turbine combustion engine.

Owner:AIR PROD & CHEM INC

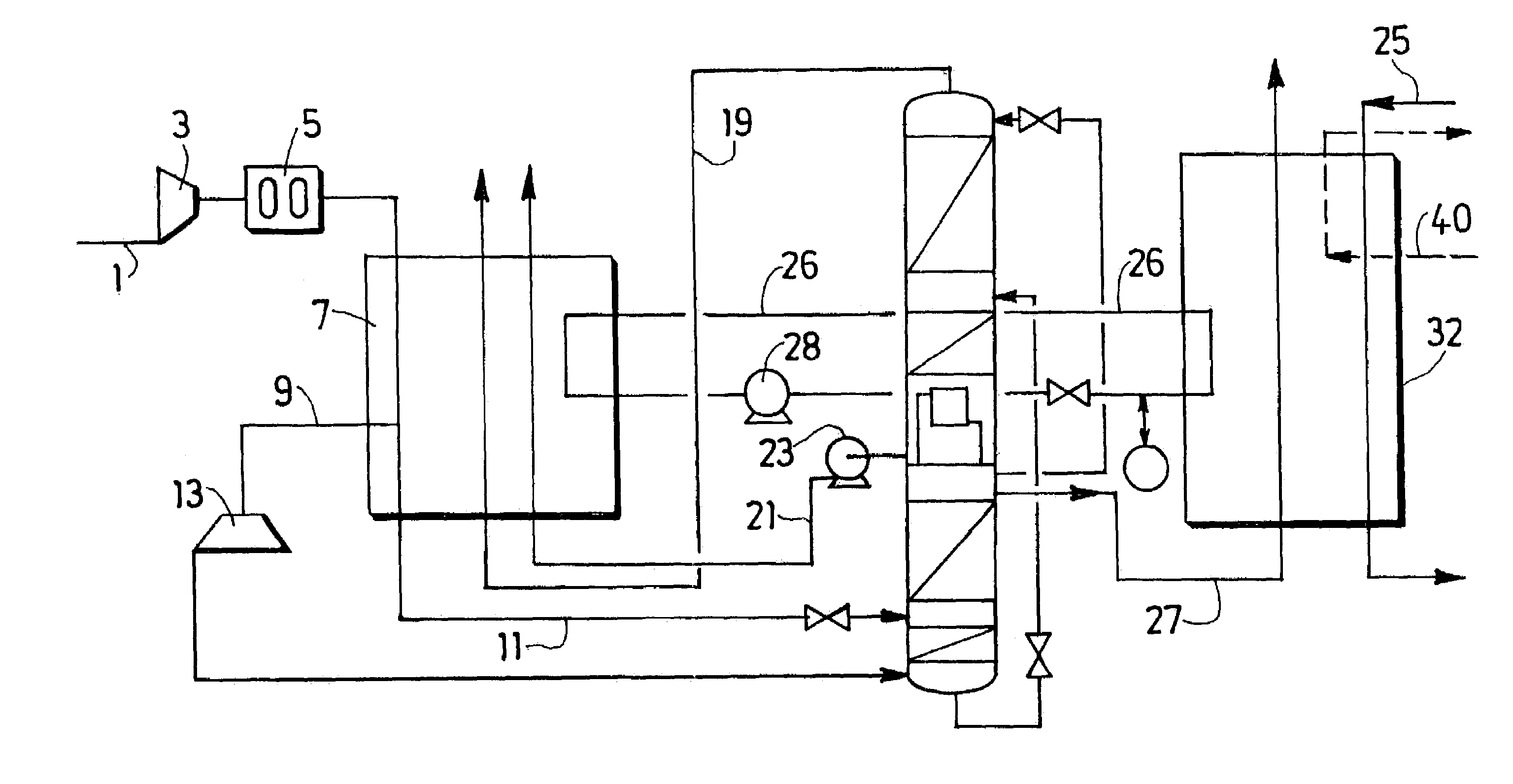

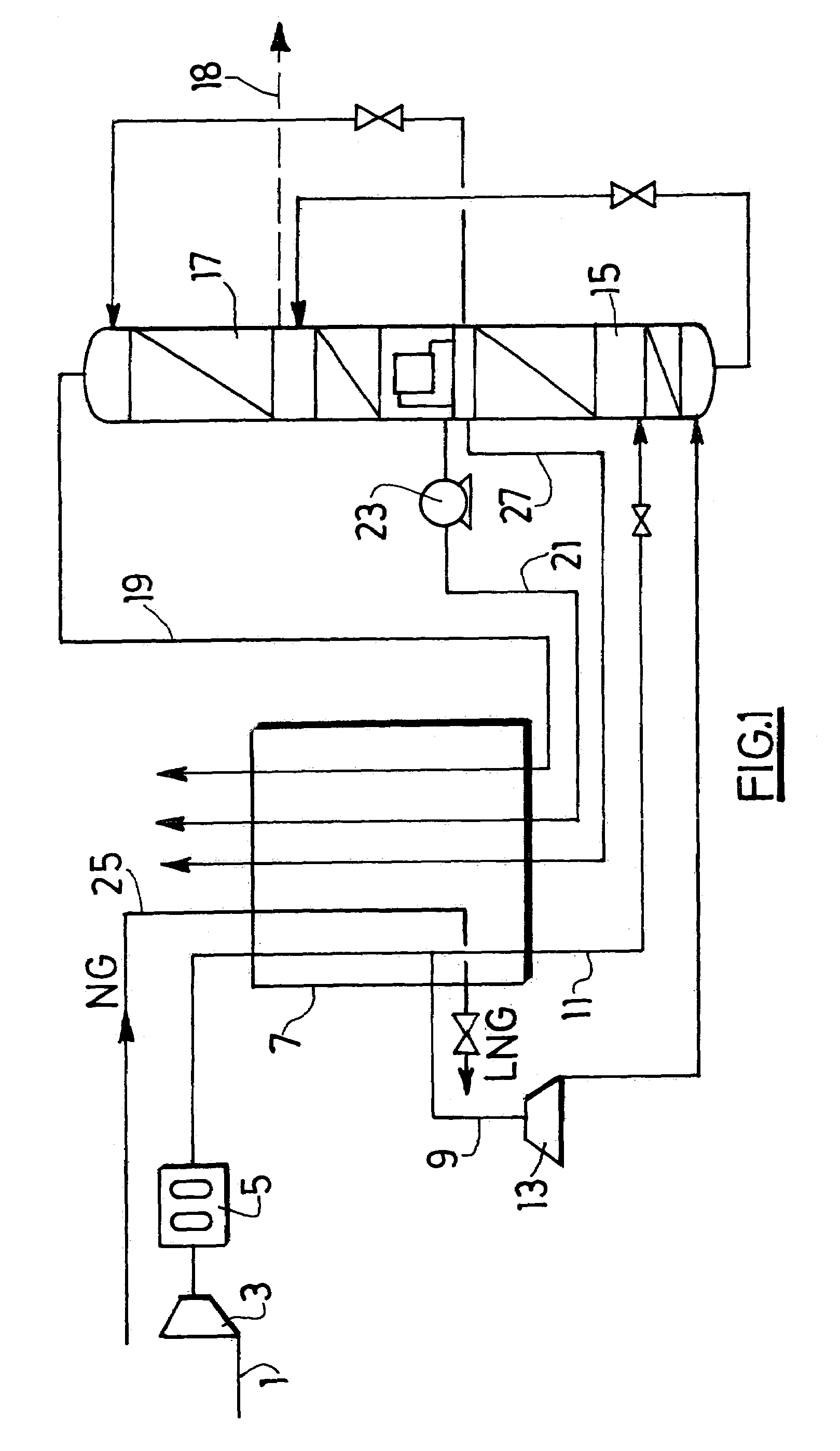

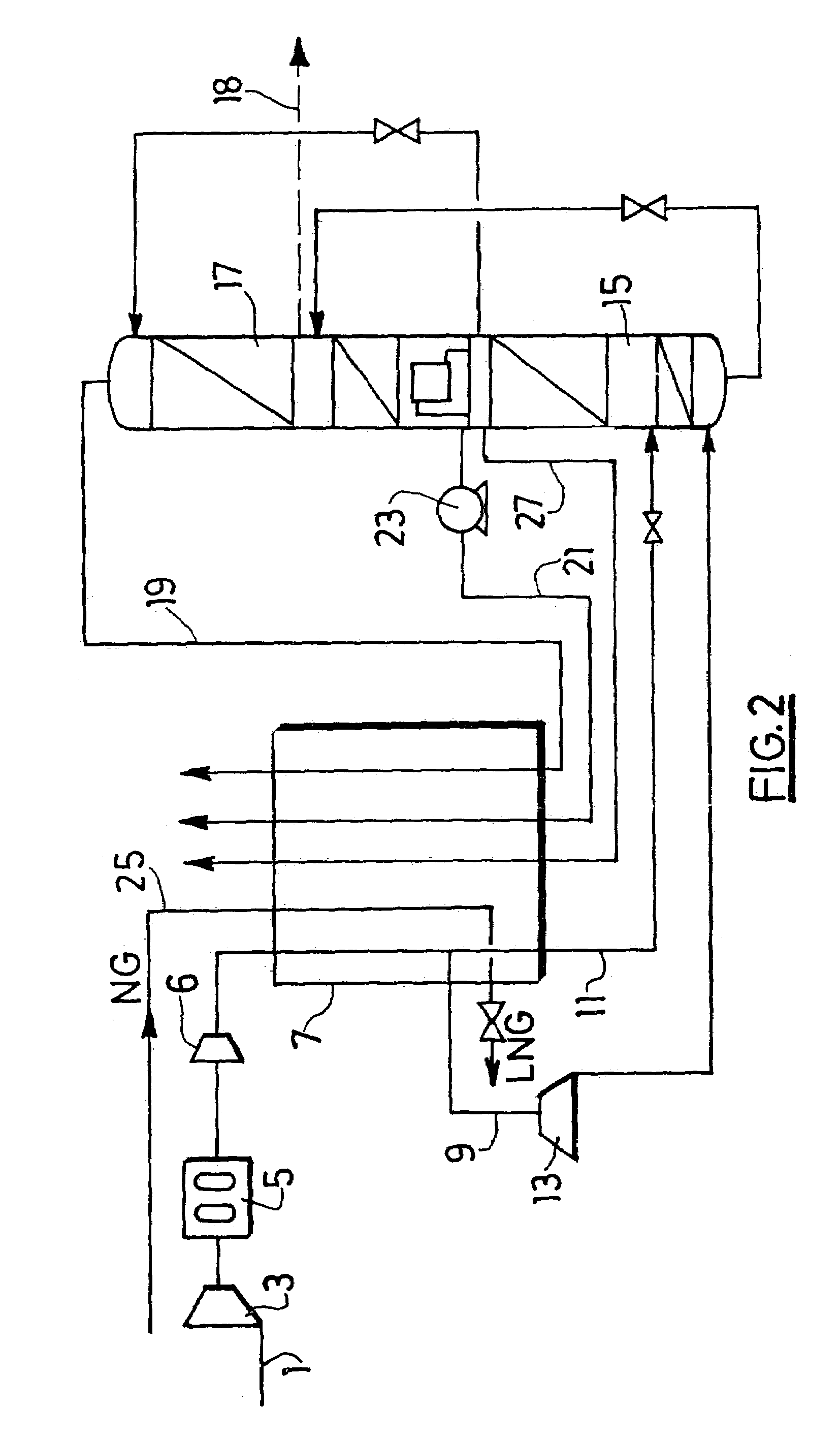

Combined air separation natural gas liquefaction plant

ActiveUS7143606B2Increase power consumptionIncrease the number ofSolidificationLiquefactionFractionating columnProcess engineering

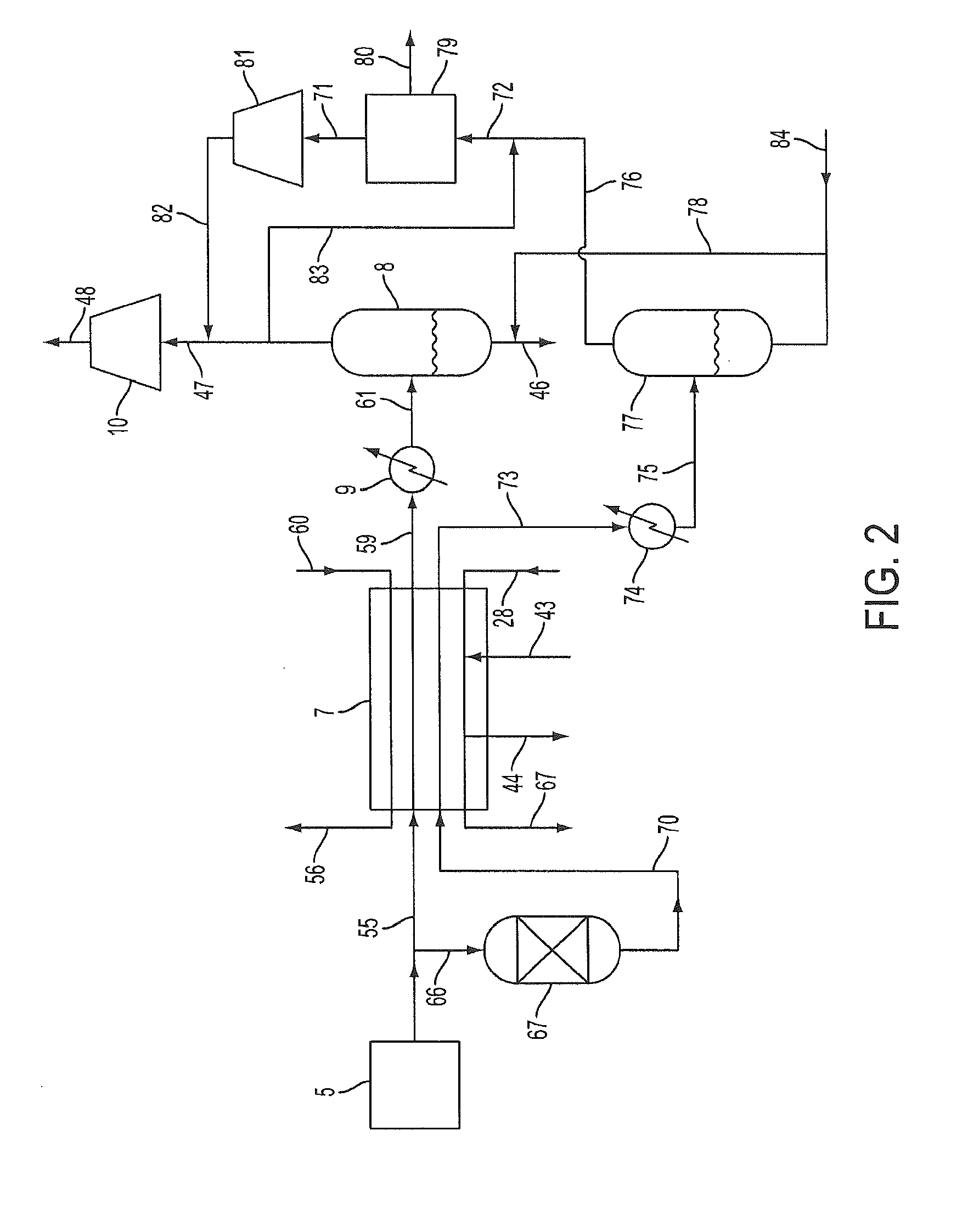

In an integrated process and apparatus for the separation of air by cryogenic distillation and liquefaction of natural gas in which at least part of the refrigeration required to liquefy the natural gas is derived from at least one cryogenic air distillation plant comprising a main heat exchanger (7) and distillation columns (15, 17), wherein the natural gas (25) liquefies by indirect heat exchange in a heat exchanger (7, 32, 34) with a cold fluid (21, 26), the cold fluid being sent to the heat exchanger at least partially in liquid form and undergoing at least a partial vaporisation in the heat exchanger.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

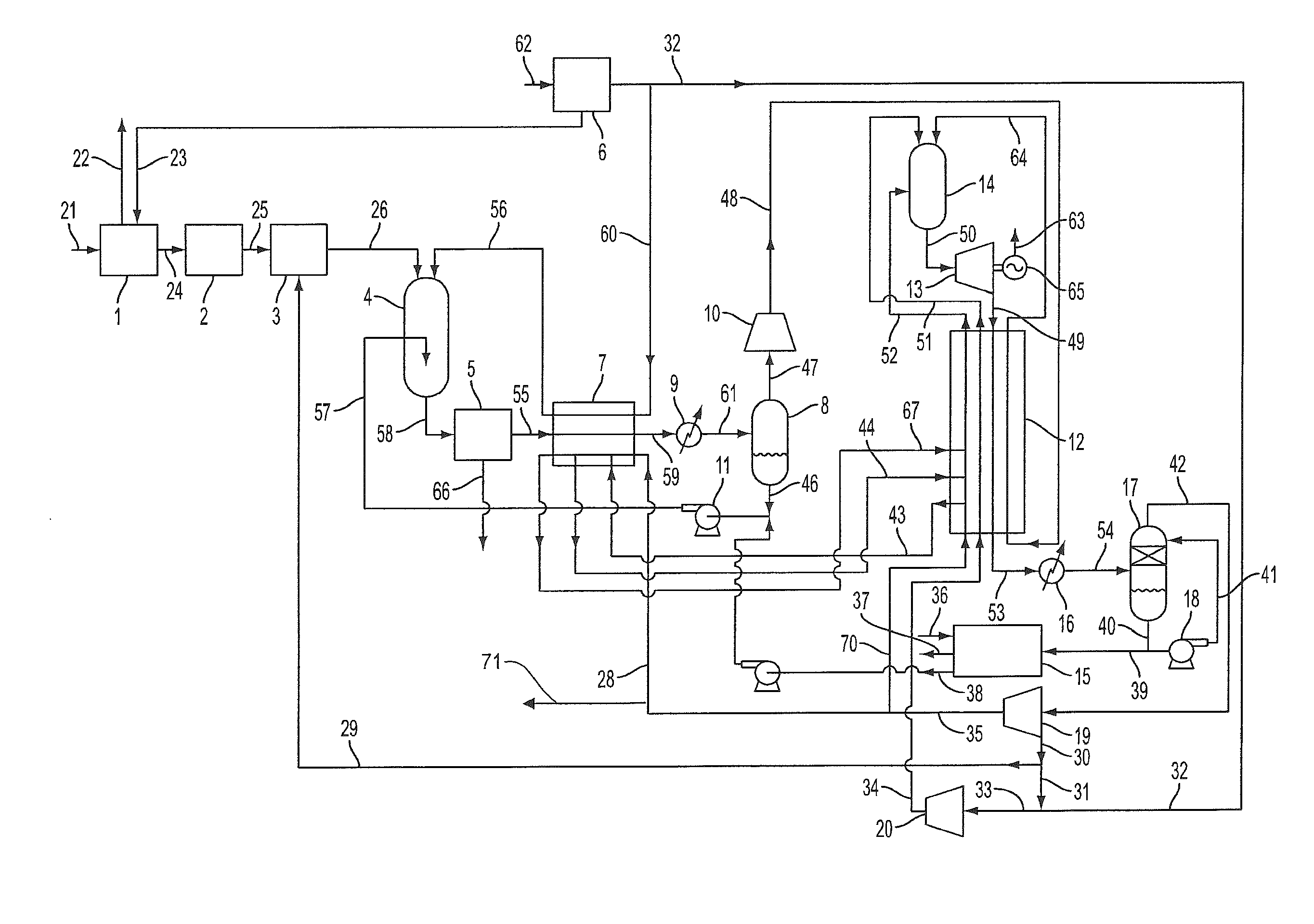

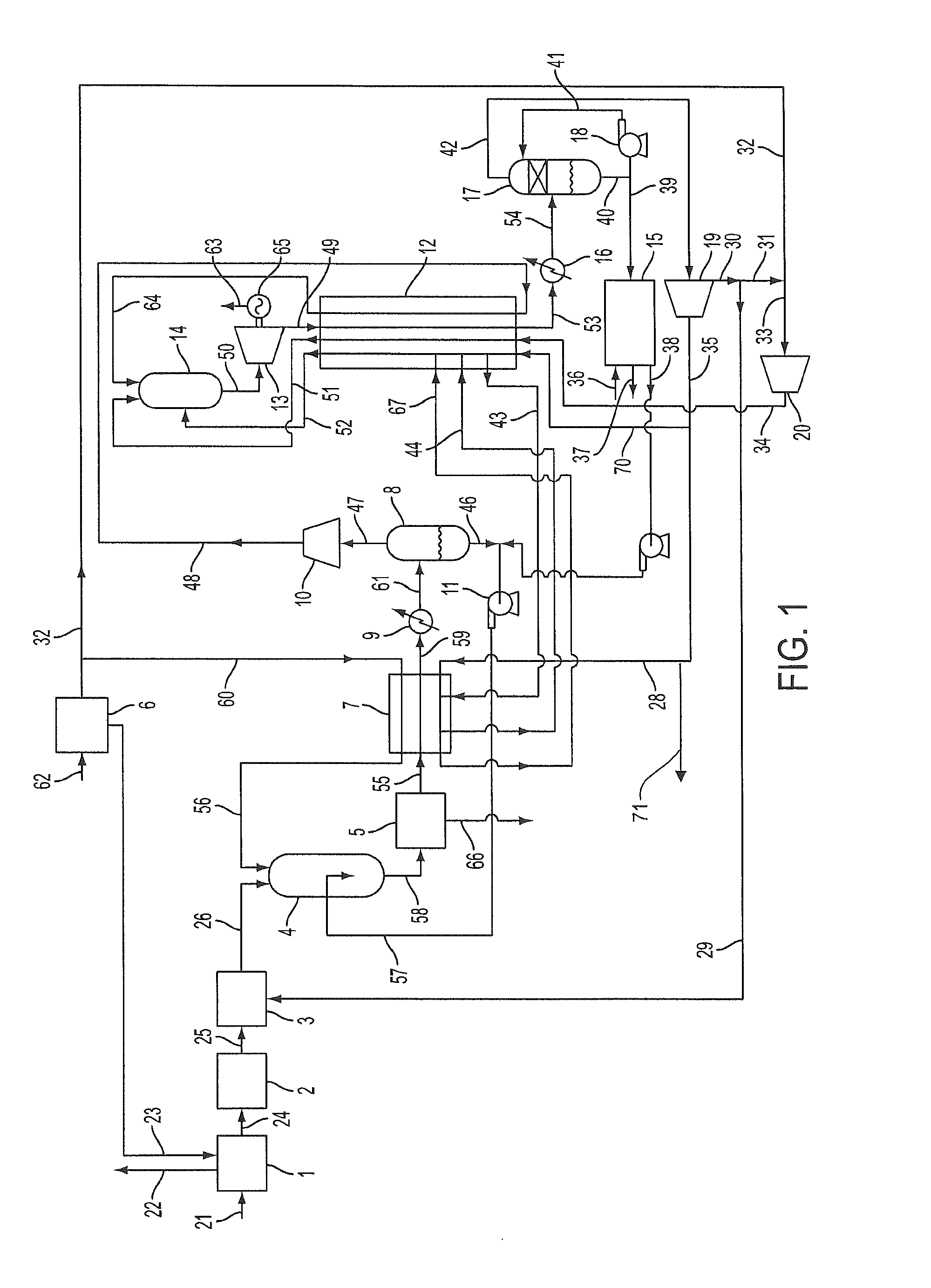

Method for the production of liquefied natural gas and nitrogen

InactiveUS20170038137A1Low costEfficient and flexible to produceSolidificationLiquefactionNitrogenProcess engineering

A method for the production of liquefied natural gas (“LNG”) and nitrogen is provided. The method may include the steps of: a) providing a nitrogen production facility, wherein nitrogen production facility comprises: a main heat exchanger, an air separation unit, a nitrogen recycle compressor, a first nitrogen refrigeration supply configured to provide refrigeration to the main heat exchanger for cooling a main air feed, b) providing a secondary refrigeration supply; c) liquefying a natural gas stream using refrigeration from the secondary refrigeration supply to form an LNG product stream; wherein the secondary refrigeration supply is configured to compress and expand a refrigerant to produce refrigeration, wherein the refrigerant of the secondary refrigeration supply is shared with refrigerant of the first nitrogen refrigeration supply

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Partial oxidation reaction with closed cycle quench

ActiveUS8776532B2Prevent metal dustingReaction is slowSolidificationLiquefactionPartial oxidationCombustor

The present disclosure relates to a power production system that is adapted to achieve high efficiency power production with complete carbon capture when using a solid or liquid hydrocarbon or carbonaceous fuel. More particularly, the solid or liquid fuel first is partially oxidized in a partial oxidation reactor. The resulting partially oxidized stream that comprises a fuel gas is quenched, filtered, cooled, and then directed to a combustor of a power production system as the combustion fuel. The partially oxidized stream is combined with a compressed recycle CO2 stream and oxygen. The combustion stream is expanded across a turbine to produce power and passed through a recuperator heat exchanger. The expanded and cooled exhaust stream is scrubbed to provide the recycle CO2 stream, which is compressed and passed through the recuperator heat exchanger and the POX heat exchanger in a manner useful to provide increased efficiency to the combined systems.

Owner:8 RIVERS CAPTTAL LLC

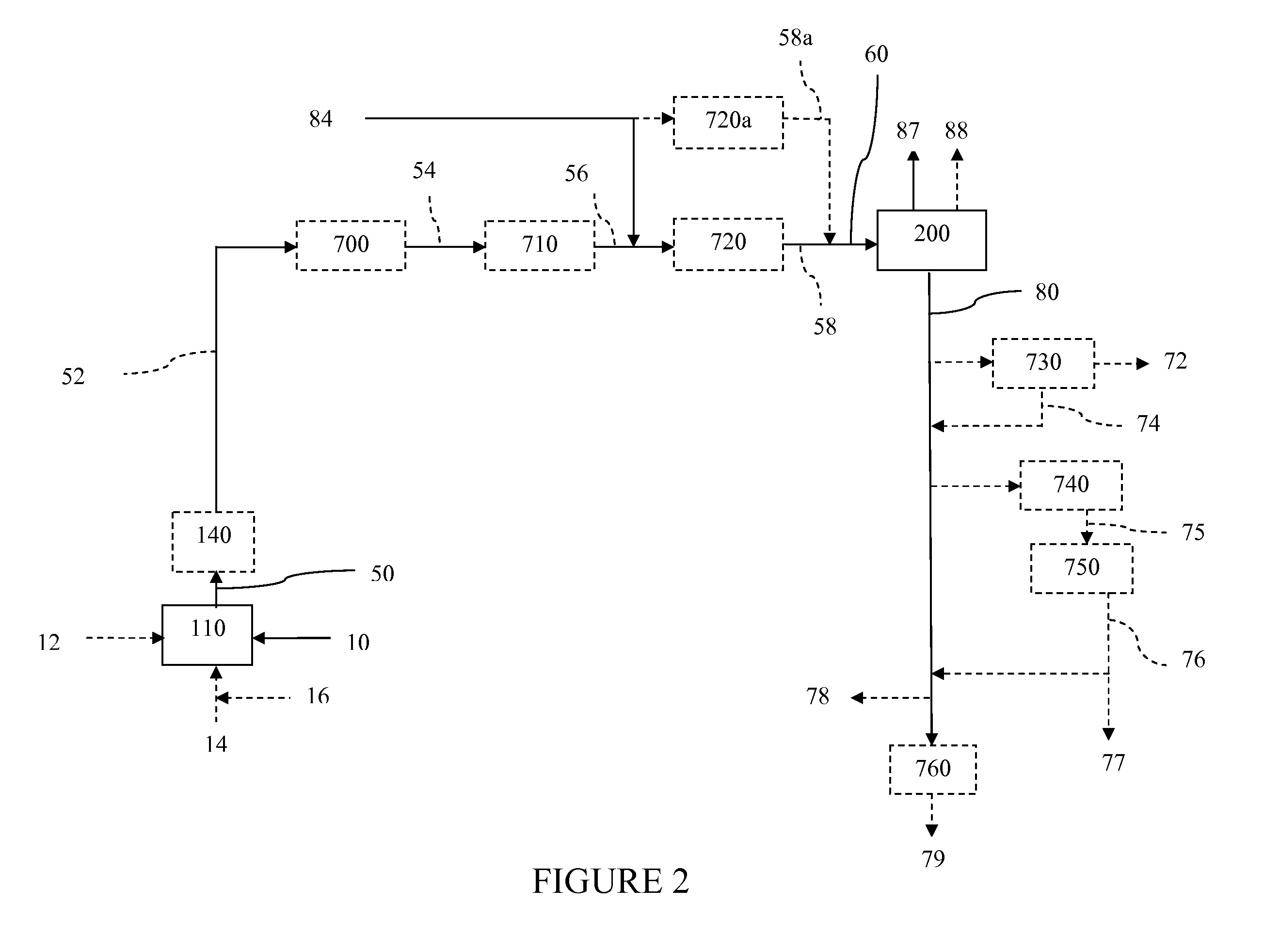

Integrated enhanced oil recovery process

InactiveUS20110146978A1Enhanced overall recoveryIncrease productionSolidificationLiquefactionGeneration processSyngas

The present invention relates to an enhanced oil recovery process that is integrated with a synthesis gas generation process, such as gasification or reforming, and an air separation process for generating (i) an oxygen stream for use, for example, in the syngas process or a combustion process, and (ii) a nitrogen stream for EOR use.

Owner:SURE CHAMPION INVESTMENT LTD

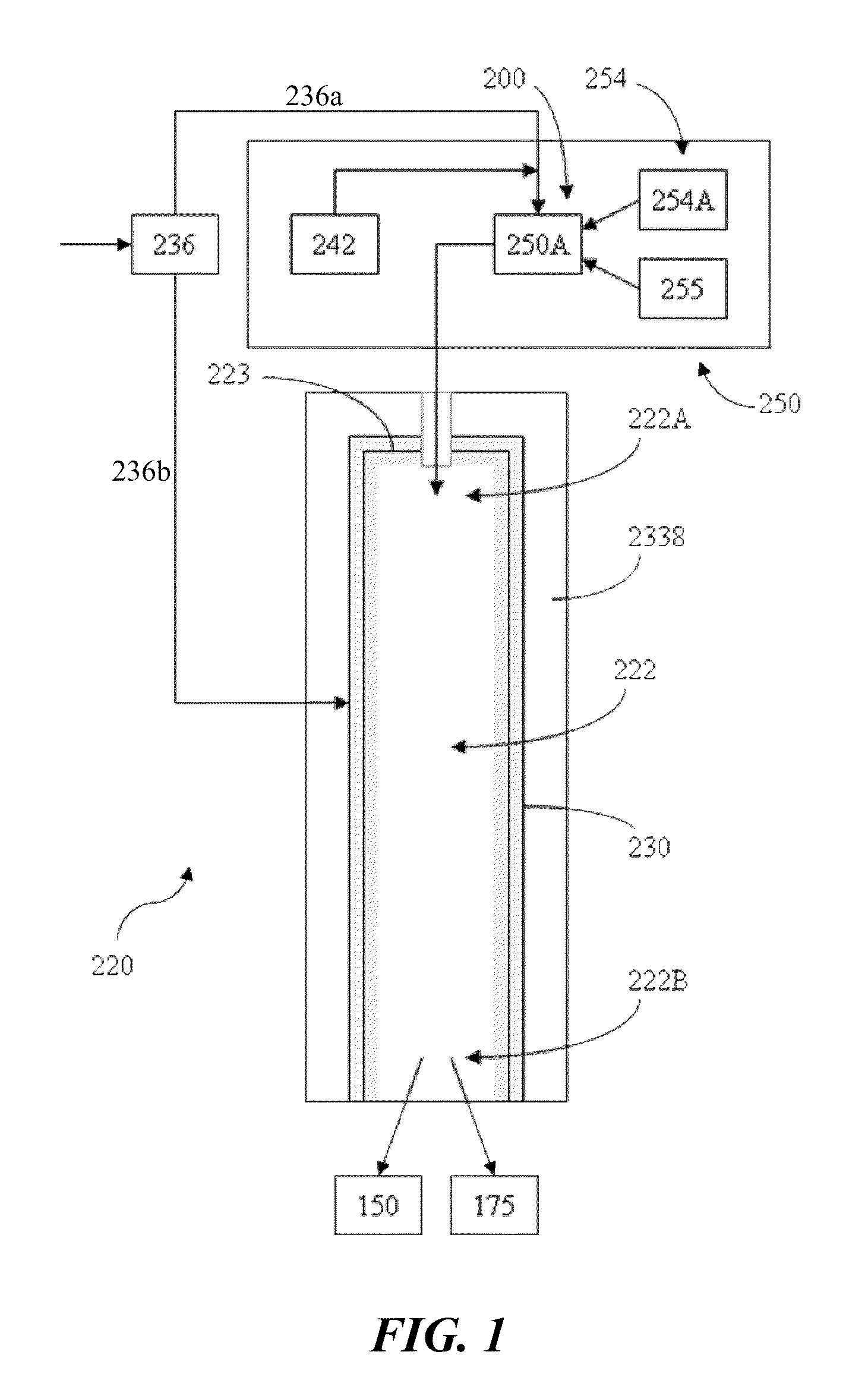

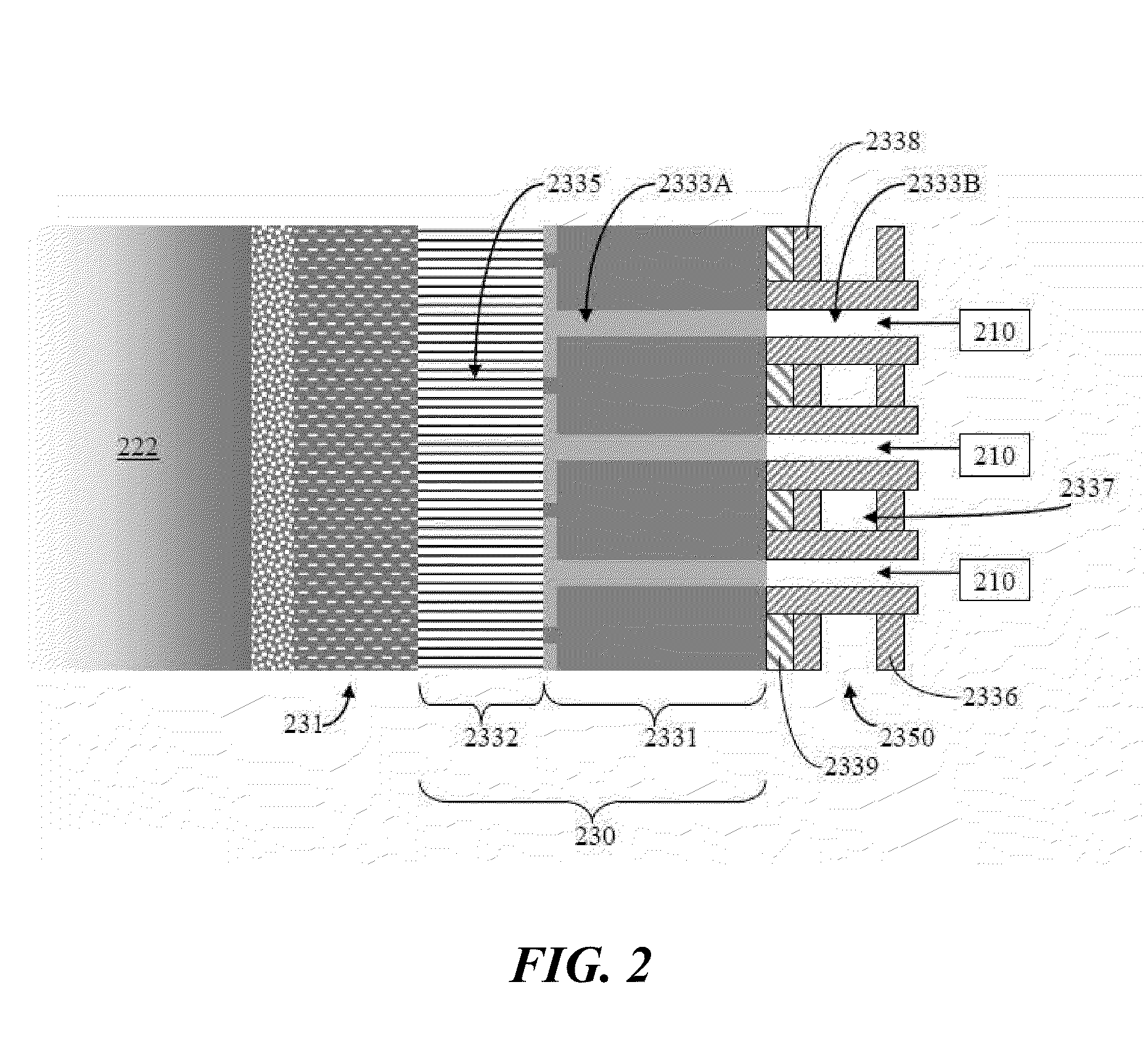

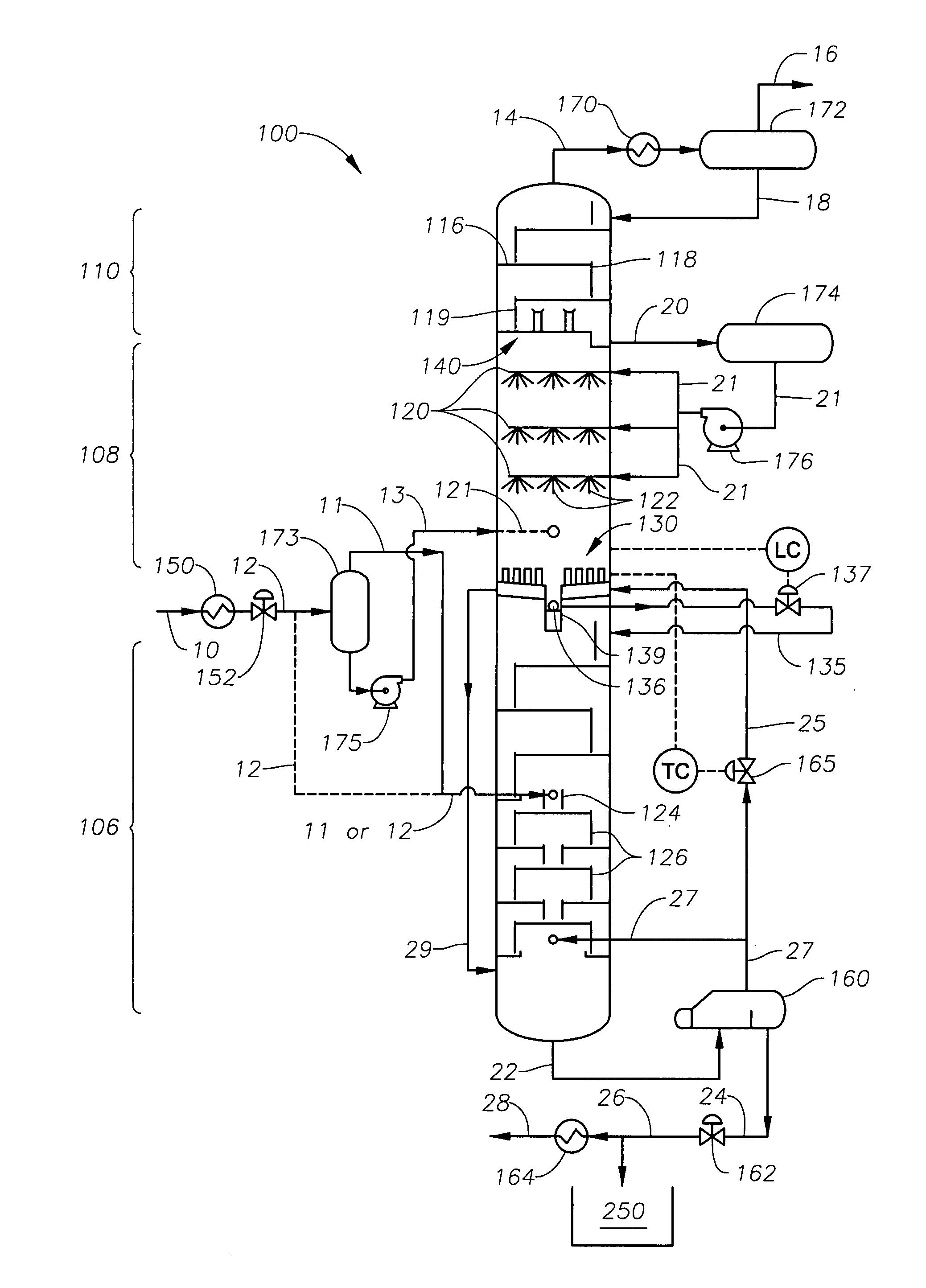

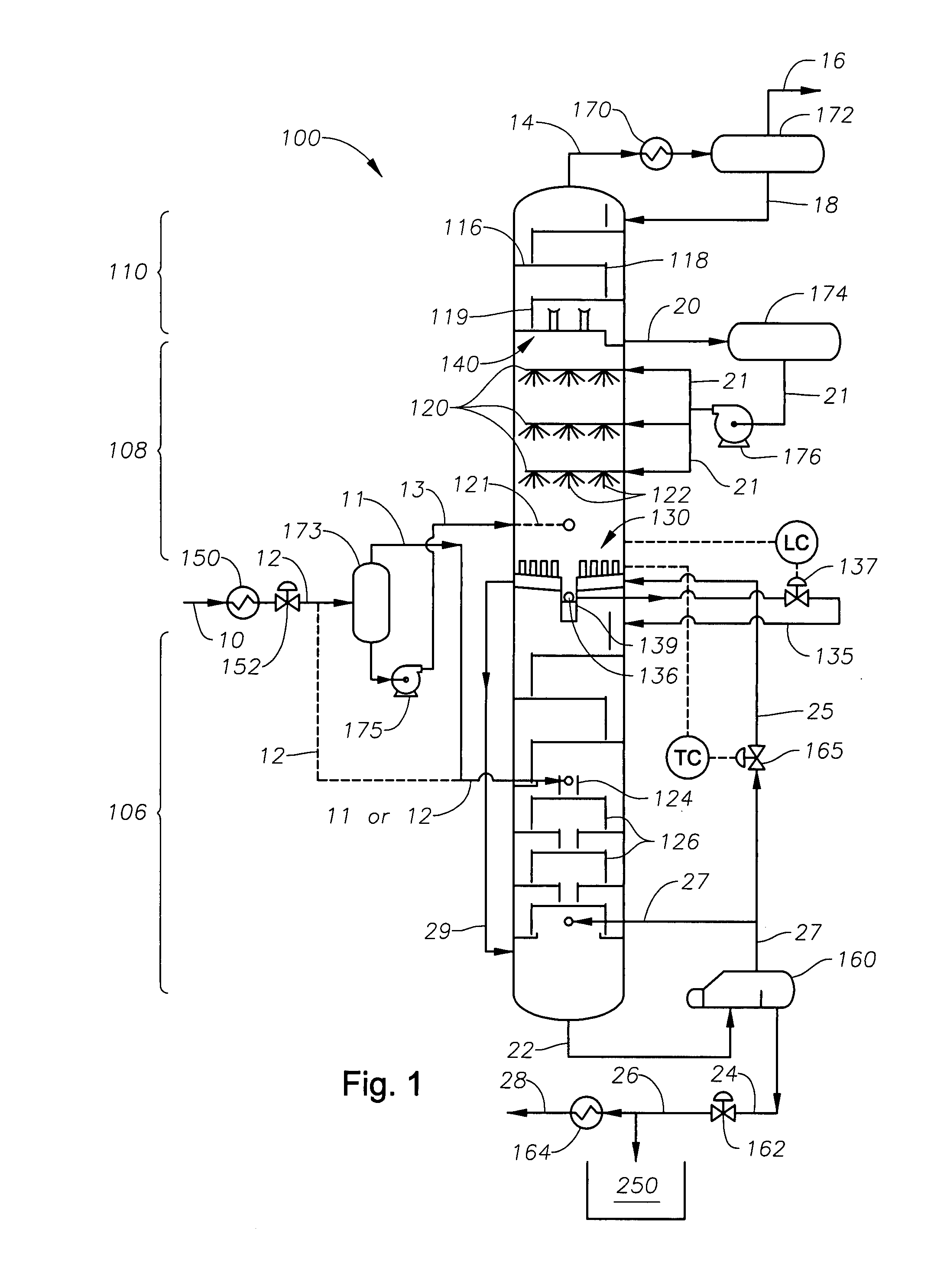

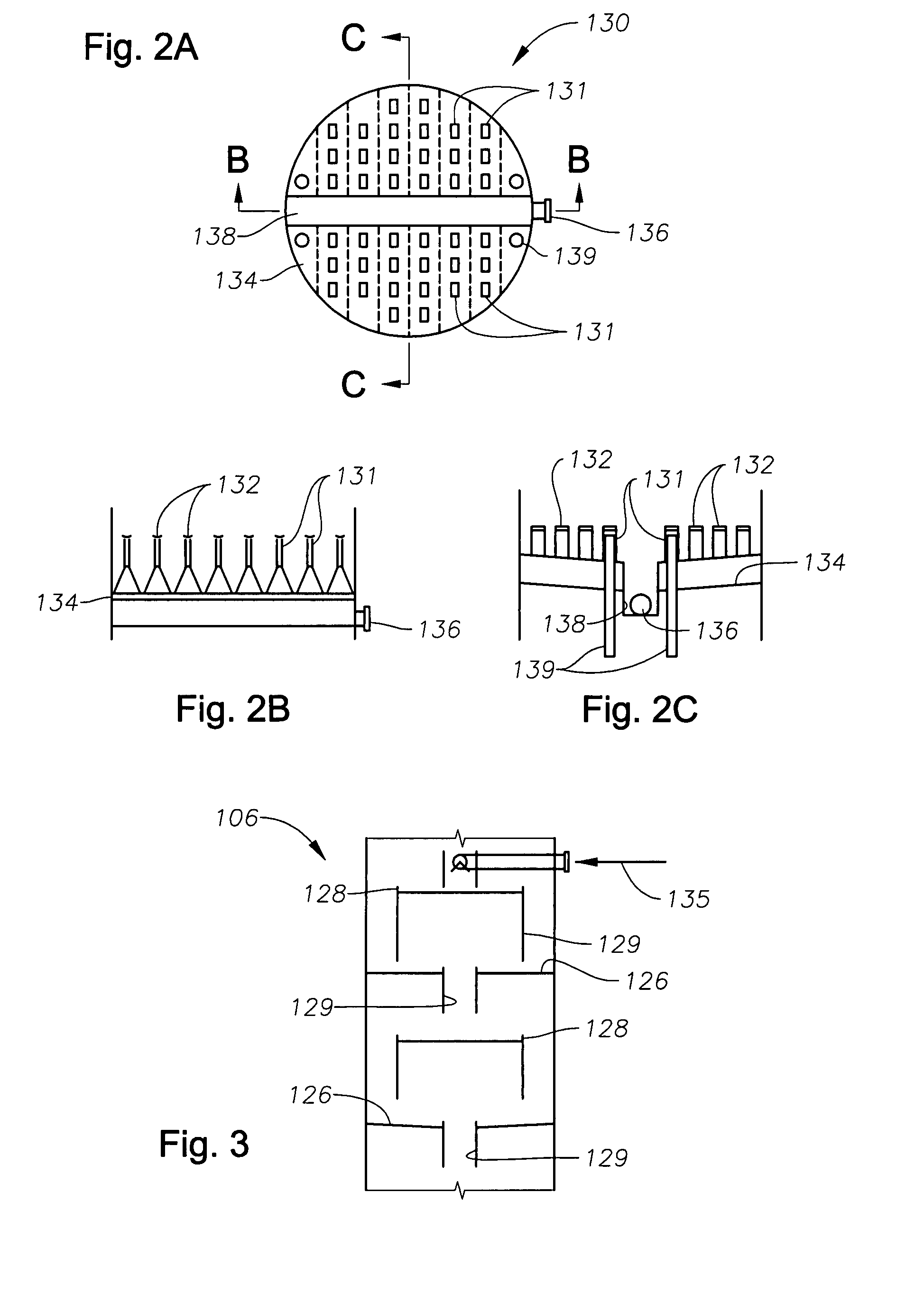

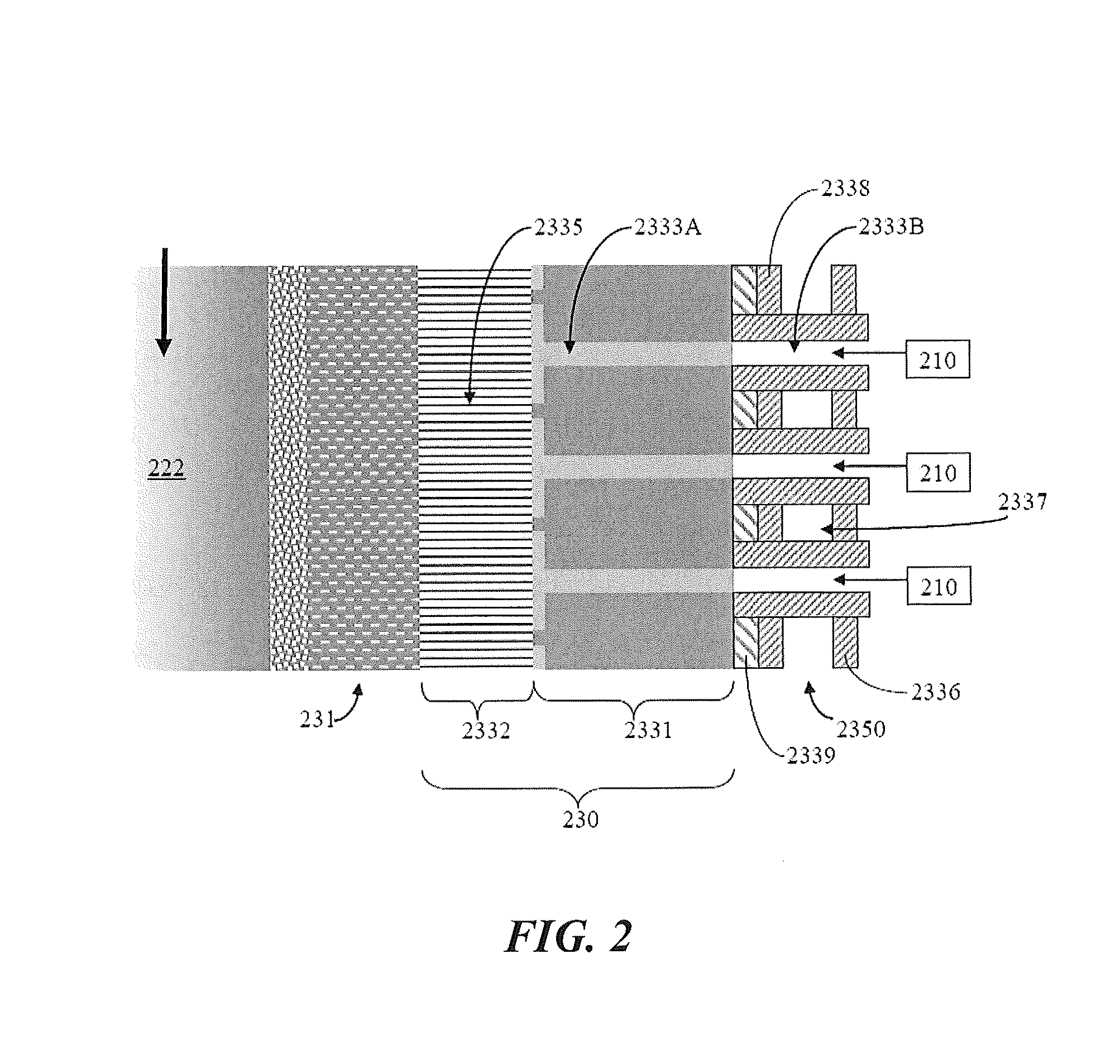

Controlled Freeze Zone Tower

A cryogenic distillation tower is provided for the separation of a fluid stream containing at least methane and carbon dioxide. The cryogenic distillation tower has a lower stripping section, an upper rectification section, and an intermediate spray section. The intermediate spray section includes a plurality of spray nozzles that inject a liquid freeze zone stream. The nozzles are configured such that substantial liquid coverage is provided across the inner diameter of the intermediate spray section. The liquid freeze zone stream generally includes methane at a temperature and pressure whereby both solid carbon dioxide particles and a methane-enriched vapor stream are formed. The tower may further include one or more baffles below the nozzles to create frictional resistance to the gravitational flow of the liquid freeze zone stream. This aids in the breakout and recovery of methane gas. Additional internal components are provided to improve heat transfer and to facilitate the breakout of methane gas.

Owner:FIELER ELEANOR R +3

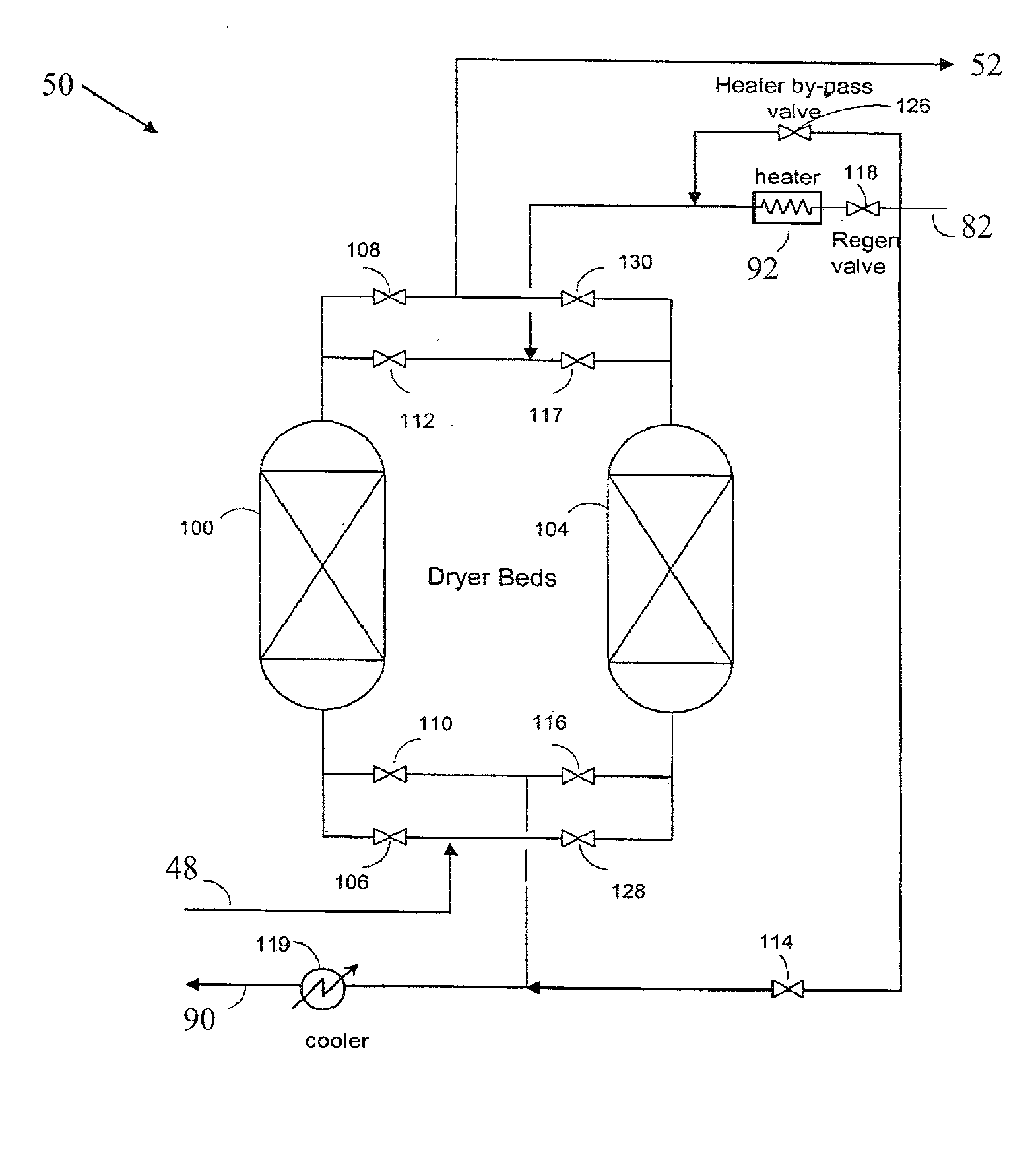

Recovery of carbon dioxide from flue gas

Carbon dioxide-containing gas such as flue gas and a carbon dioxide-rich stream are compressed and the combined streams are then treated to desorb moisture onto adsorbent beds and then subjected to subambient-temperature processing to produce a carbon dioxide product stream and a vent stream. The vent stream is treated to produce a carbon dioxide-depleted stream which can be used to desorb moisture from the beds, and a carbon dioxide-rich stream which is combined with the carbon dioxide-containing gas.

Owner:PRAXAIR TECH INC

Hydrocarbon separation process and apparatus

InactiveUS6363744B2Reduce the temperaturePromote recoverySolidificationLiquefactionPhysical chemistryRefrigeration

A process is described for separating the heavier hydrocarbons from a gaseous hydrocarbon feed wherein a first separator is employed to separate partially condensed gaseous feed and wherein the vapour portion undergoes work expansion and is fed to a fractionation column. The liquid portion is subcooled in heat exchange with the overhead vapour from the fractionation column, expanded, evaporated to provide refrigeration at a low temperature level, and fed to the fractionation column. The rewarmed residual vapour is subsequently compressed to a pressure suitable for export, with a portion of the compressed gas being cooled, condensed and recycled back to reflux the top section of the fractionation column.Also described is a process wherein a first separator is employed to separate partially condensed gaseous feed and wherein the vapour portion undergoes work expansion and is fed to a high pressure wash column. The liquid portion is expanded and fed to the base of the high pressure wash column. Bottoms liquid from the wash column is subcooled in heat exchange with the overhead vapour from a fractionation column, expanded, evaporated to provide refrigeration at a low temperature level, and fed to the fractionation column. Vapour from the high pressure wash column is partially condensed, with the liquid portion used to provide reflux to the high pressure wash column and the fractionation column.The processes are especially applicable to recovery of ethane and heavier components from natural gas. Overall process power requirements are reduced, recovery of the desired heavy hydrocarbons is increased or both of these effects are realised.

Owner:COSTAIN OIL GAS & PROCESS

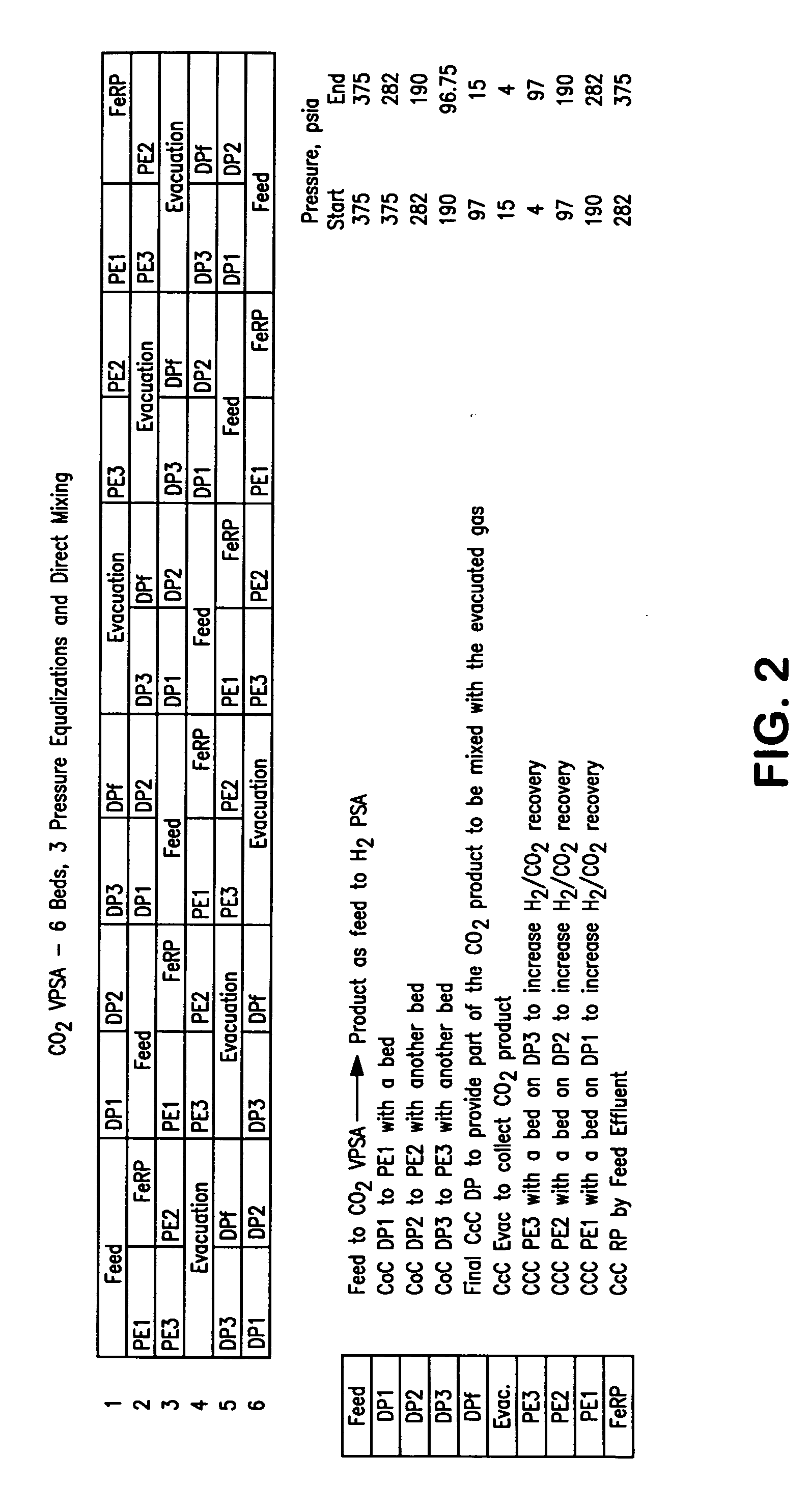

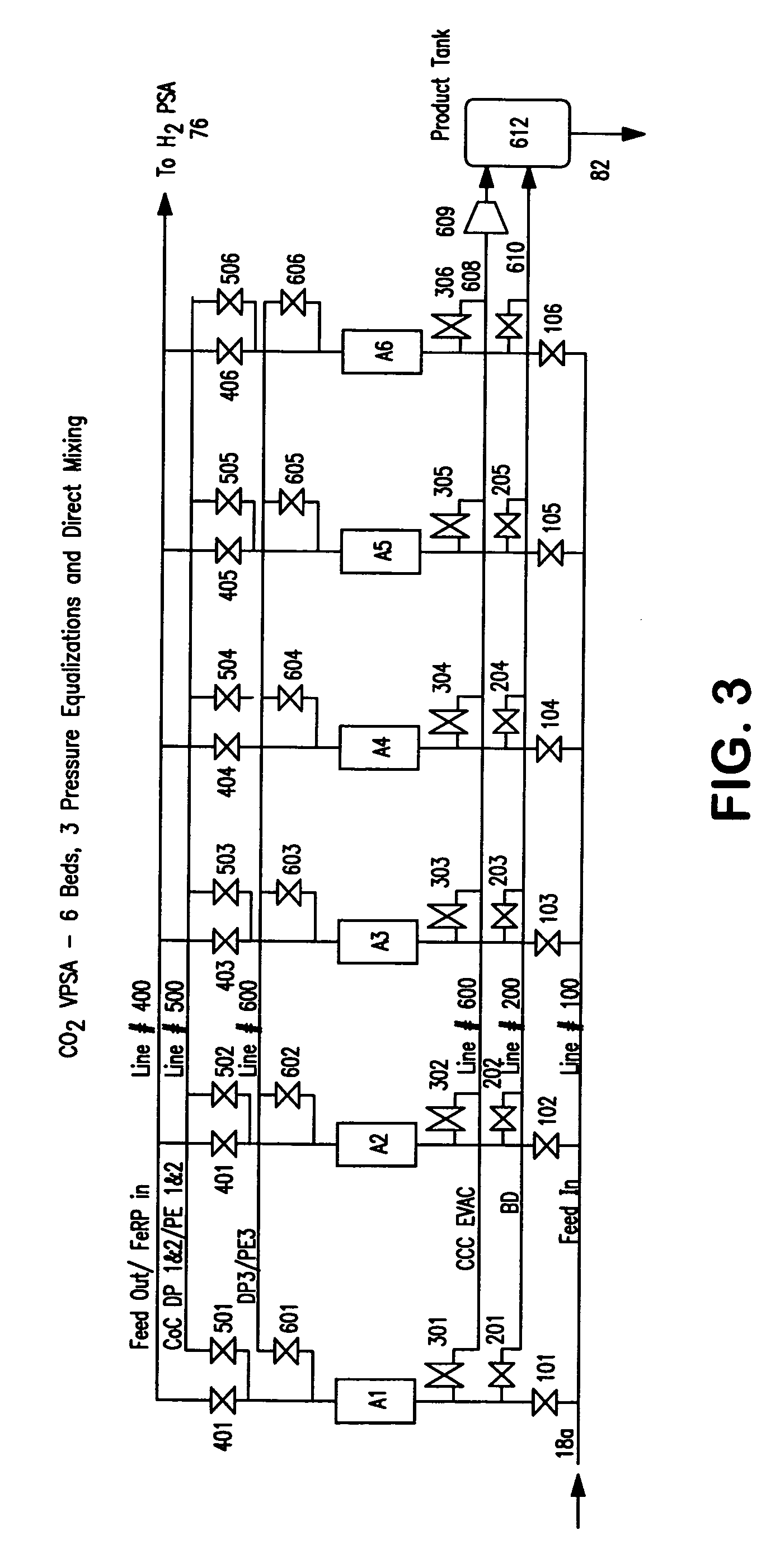

Carbon dioxide production method

ActiveUS20070232706A1Increased hydrogen recoveryPromote recoverySolidificationLiquefactionVacuum pressureCarbon dioxide production

A method of producing a carbon dioxide product stream from a synthesis gas stream formed within a hydrogen plant having a synthesis gas reactor, a water-gas shift reactor, located downstream of the synthesis gas reactor to form the synthesis gas stream and a hydrogen pressure swing adsorption unit to produce a hydrogen product recovered from the synthesis gas stream. In accordance with the method the carbon dioxide from the synthesis gas stream by separating the carbon dioxide from the synthesis gas stream in a vacuum pressure swing adsorption system, thereby to produce a hydrogen-rich synthesis gas stream and a crude carbon dioxide stream and then purifying the crude carbon dioxide stream by a sub-ambient temperature distillation process thereby to produce the carbon dioxide product. A hydrogen synthesis gas feed stream to the hydrogen pressure swing adsorption unit is formed at least in part from the hydrogen rich stream.

Owner:PRAXAIR TECH INC

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS8959887B2Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

Power plant and method of operation

A power plant and method of operation is provided. The power plant comprises at least one main air compressor, an oxidizer unit configured to deliver a compressed oxygen-rich gas flow to at least one gas turbine assembly. Each assembly comprises a turbine combustor for mixing the compressed oxygen-rich gas flow with a recirculated gas flow and a fuel stream to burn a combustible mixture and form the recirculated gas flow. The assembly also comprises a recirculation loop for recirculating the recirculated gas flow from a turbine to a turbine compressor. The assembly further comprises a recirculated gas flow extraction path for extracting a portion of the recirculated gas flow from the assembly and delivering this to a gas separation system. The gas separation system separates the portion of the recirculated gas flow into a nitrogen portion and a carbon dioxide portion.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com