Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1772 results about "Methane gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions for Catalytic Gasification of a Petroleum Coke

InactiveUS20090090056A1Cost-effective and high-yielding productionPromote gasificationHydrogenGaseous fuelsParticle compositionMethane gas

The present invention relates to particulate compositions of a lower ash type petroleum coke containing at least two preselected components (alkali metal and calcium) that exhibit an efficient, enhanced-yielding gasification to value added gaseous products, particularly when used in a steady-state integrated gasification process. The compositions of the present invention are particularly useful for catalytic gasification of petroleum coke at moderate temperatures ranging from about 450° C. to about 900° C. Advantageously, the compositions can be readily incorporated into fluidized bed gasification units, and can result in a cost-effective, high-yielding production of methane gas from petroleum coke.

Owner:SURE CHAMPION INVESTMENT LTD

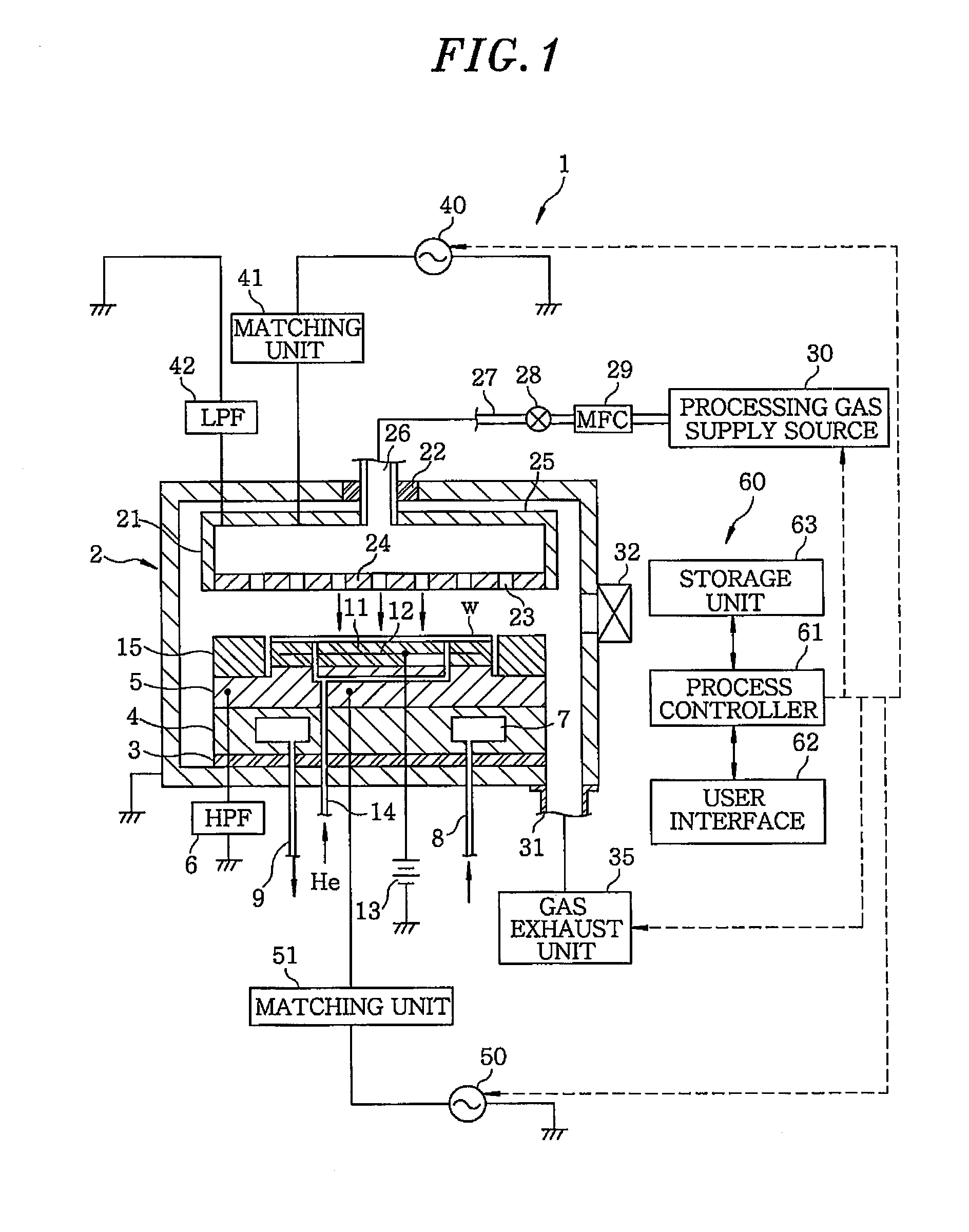

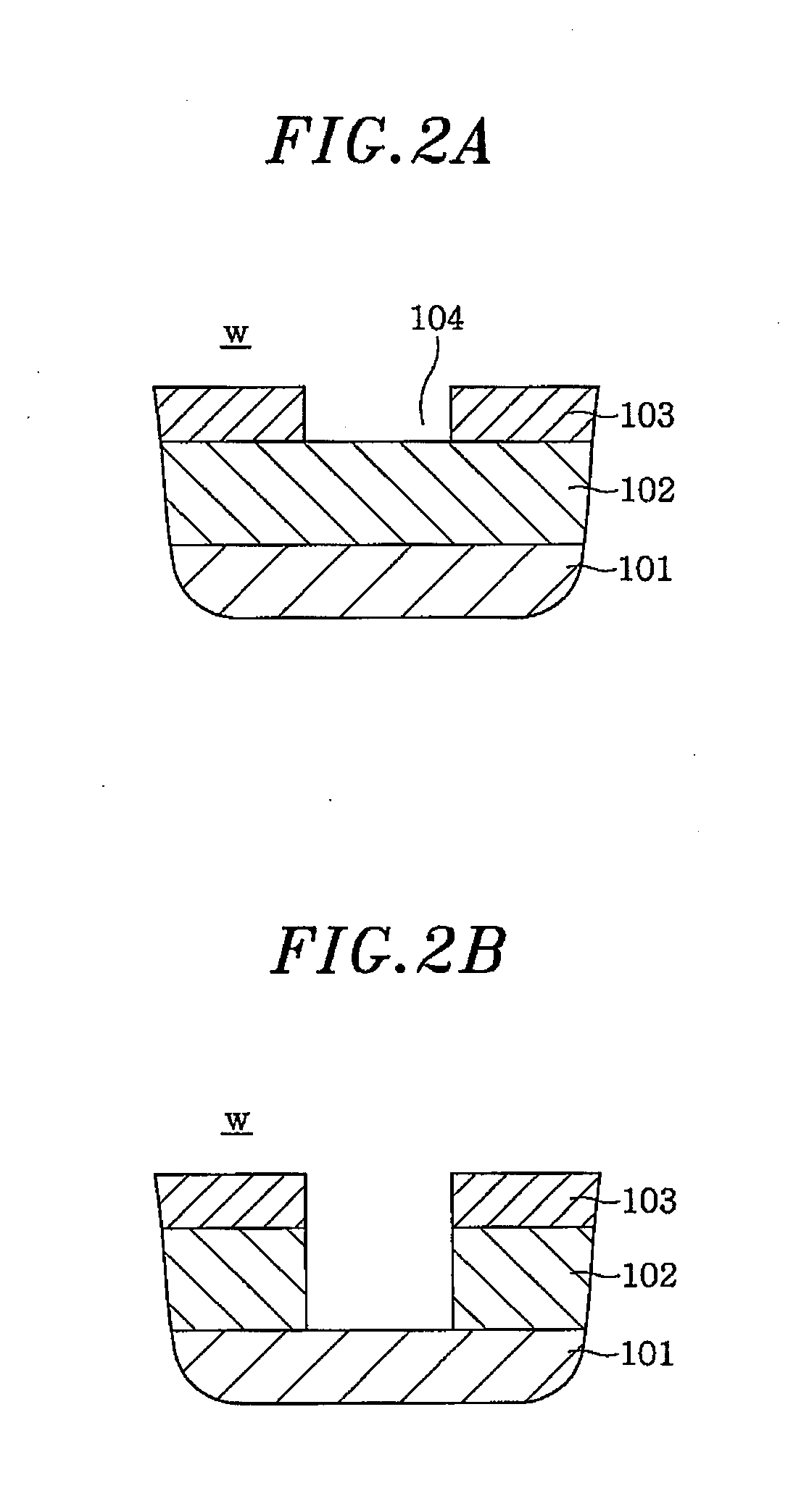

Substrate processing method

ActiveUS20120164839A1Easy to evaporateIncrease etch rateElectric discharge tubesDecorative surface effectsOrganic acidCopper atom

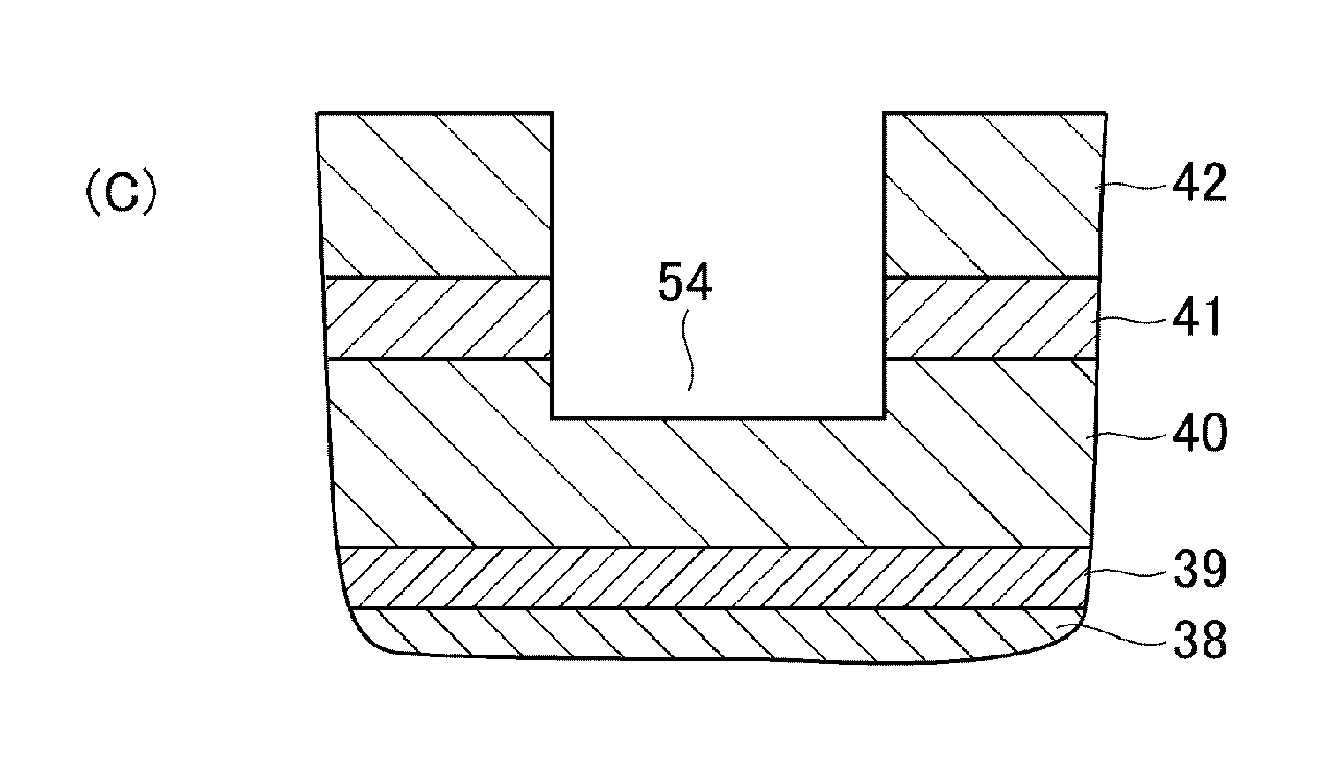

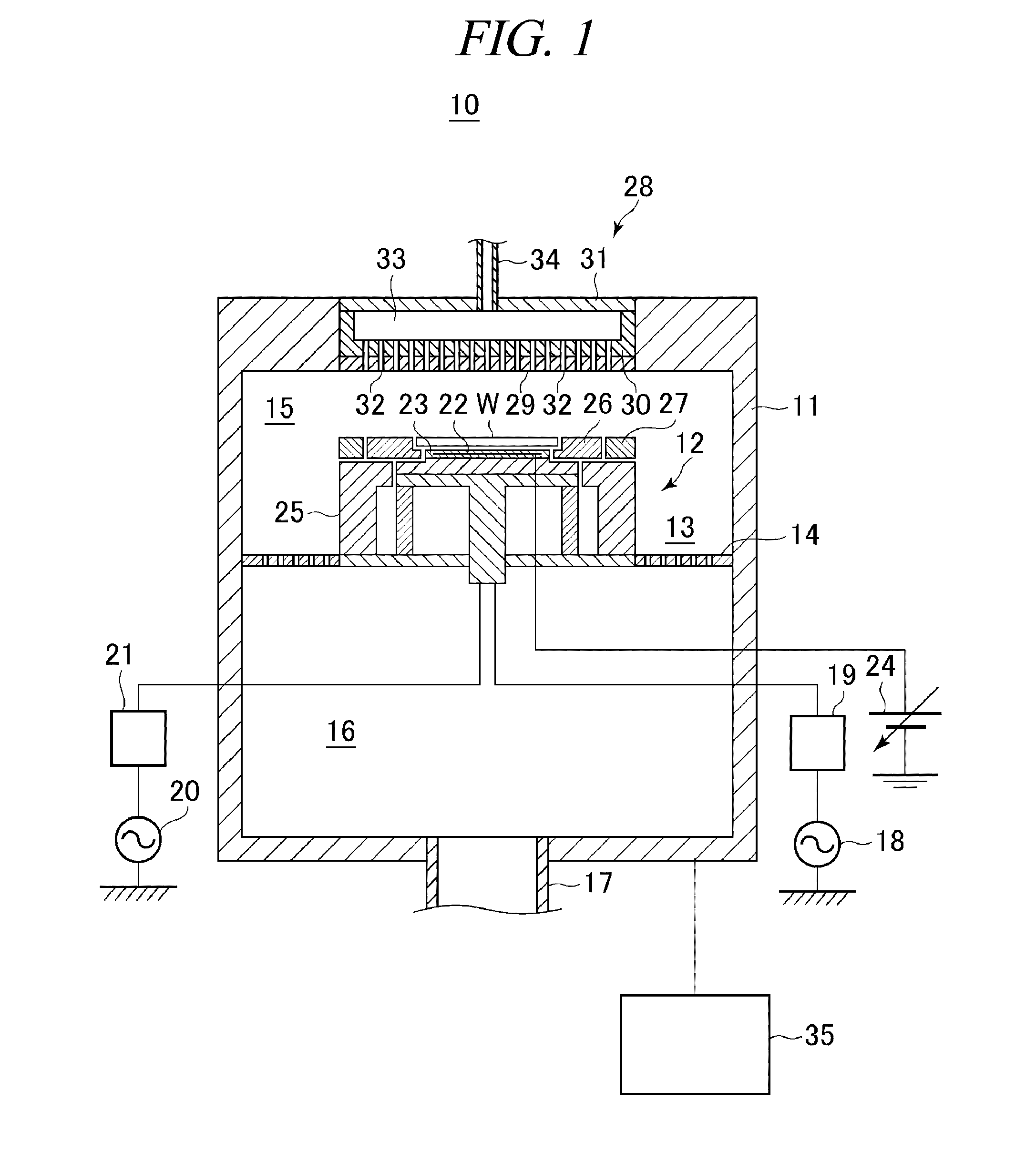

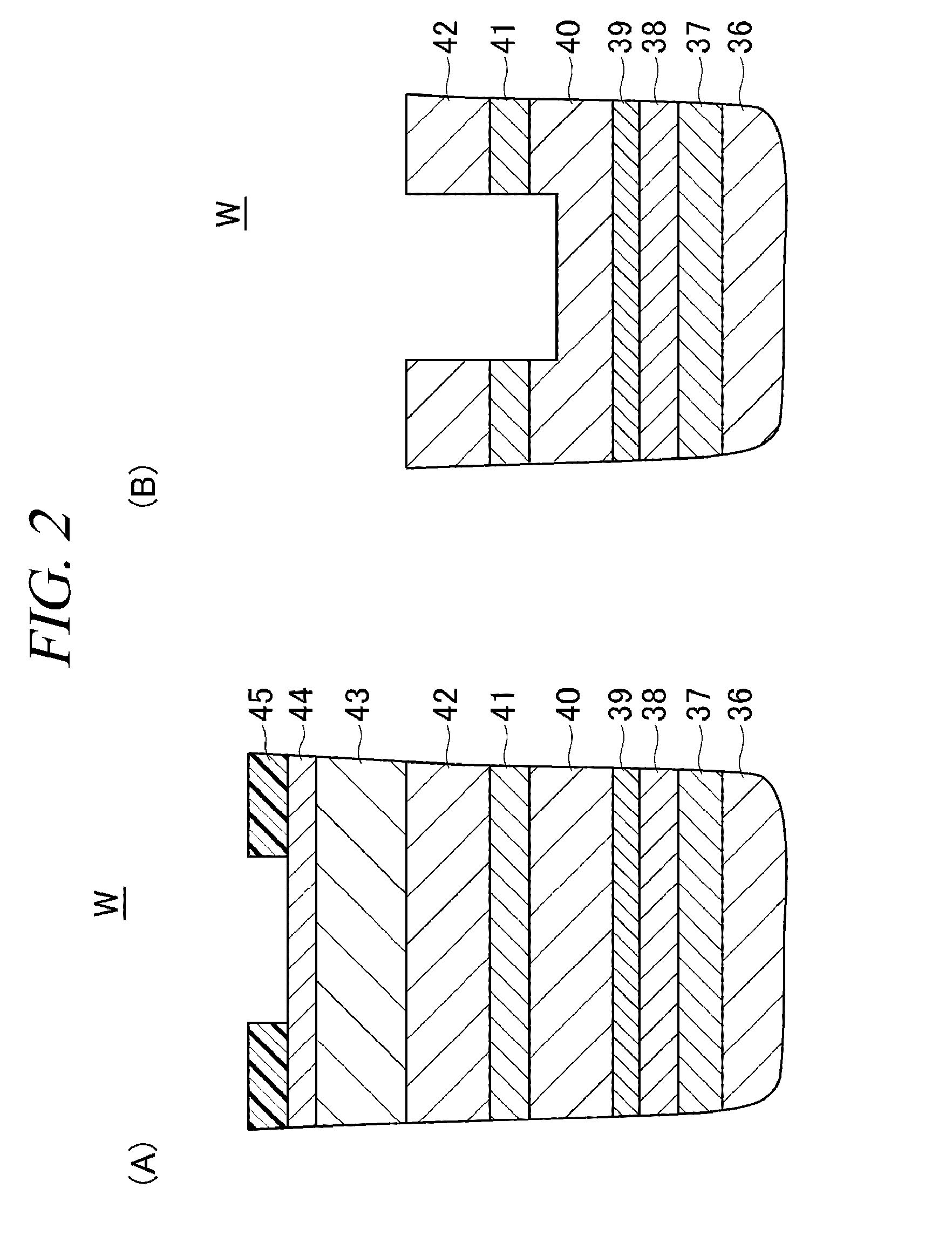

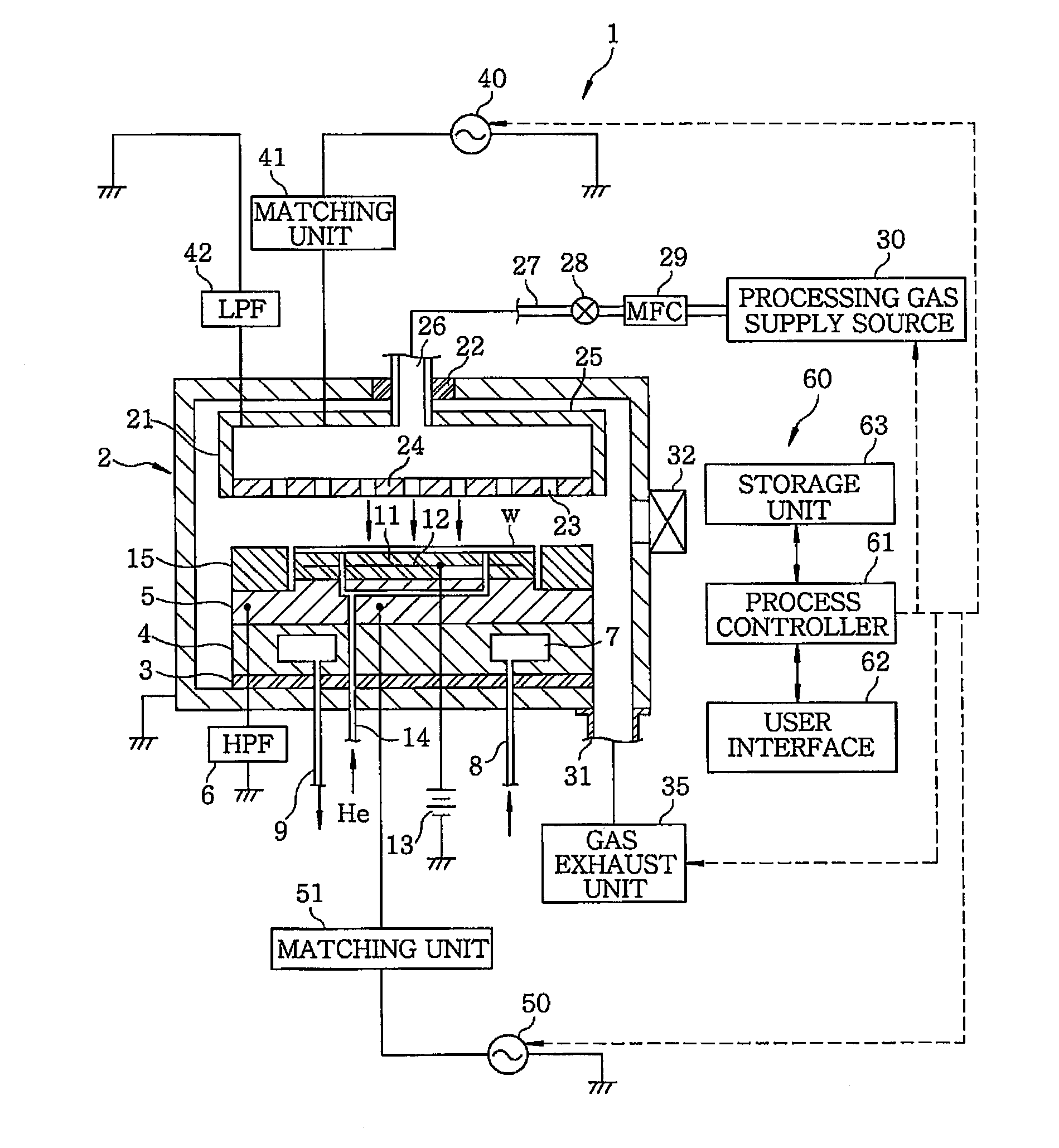

There is provided a substrate processing method capable of increasing an etching rate of a copper member without using a halogen gas. A Cu layer 40 having a smoothened surface 50 is obtained, and then, a processing gas produced by adding a methane gas to a hydrogen gas is introduced into an inner space of a processing chamber 15. Plasma is generated from this processing gas. In the inner space of the processing chamber 15, there exist oxygen radicals 52 generated when an oxide layer 42 is etched, and carbon radicals 53 generated from methane. The oxygen radicals 52 and the carbon radicals 53 are compounded to generate an organic acid, and the organic acid makes a reaction with copper atoms of the Cu layer 40. As a result, a complex of the organic acid having the copper atoms is generated, and the generated organic acid complex is vaporized.

Owner:TOKYO ELECTRON LTD

Dry etching method for metal film

ActiveUS20130098868A1Decorative surface effectsSemiconductor/solid-state device manufacturingHalogenNoble gas

A method for performing dry etching on a metal film containing Pt via a mask layer includes performing dry etching on the metal film by generating a plasma of an etching gas including a gaseous mixture of H2 gas, CO2 gas, methane gas and rare gas. With the dry etching method, it is possible to make a vertical sidewall of a hole or trench more vertical without using a halogen gas.

Owner:TOKYO ELECTRON LTD

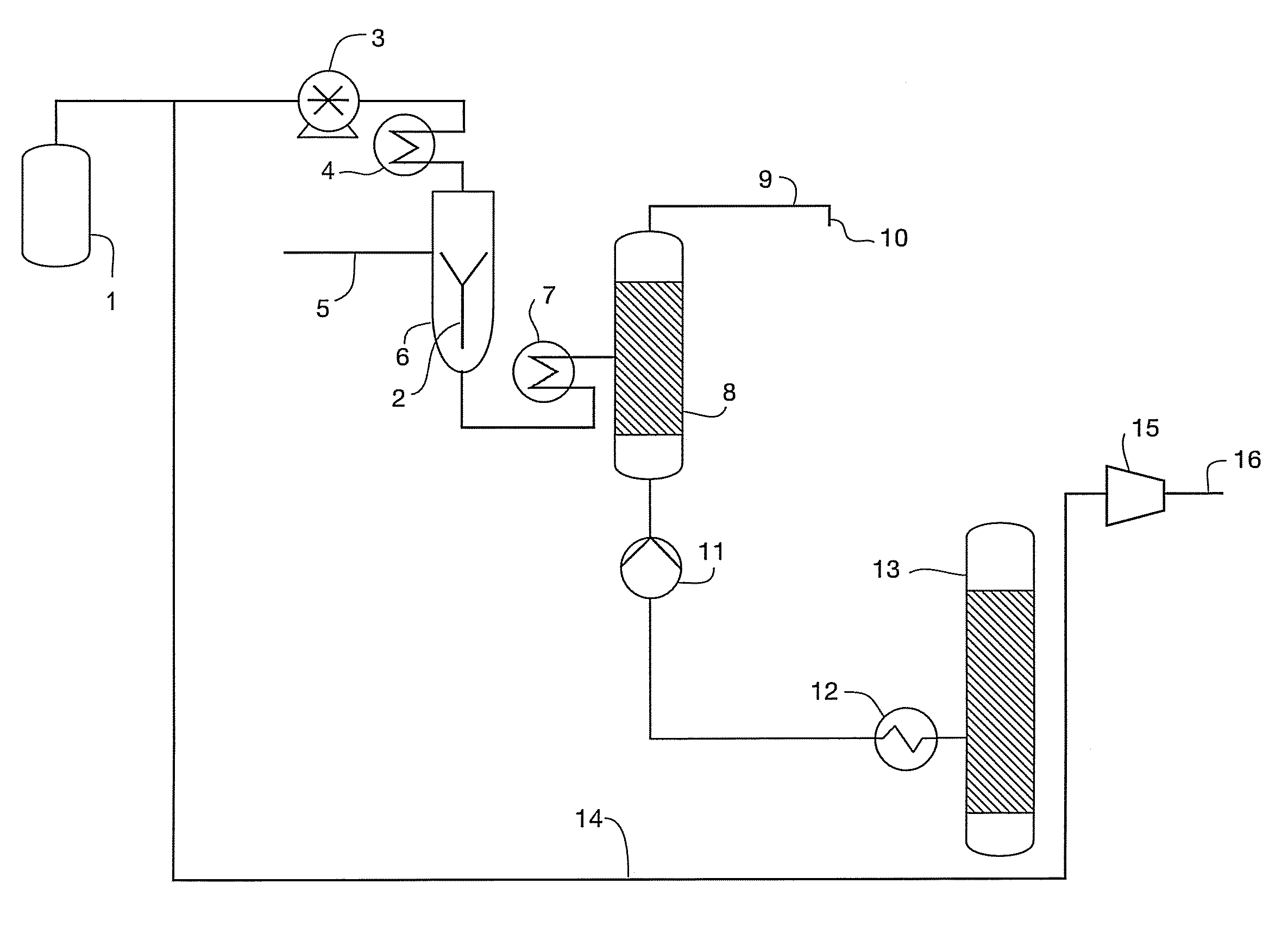

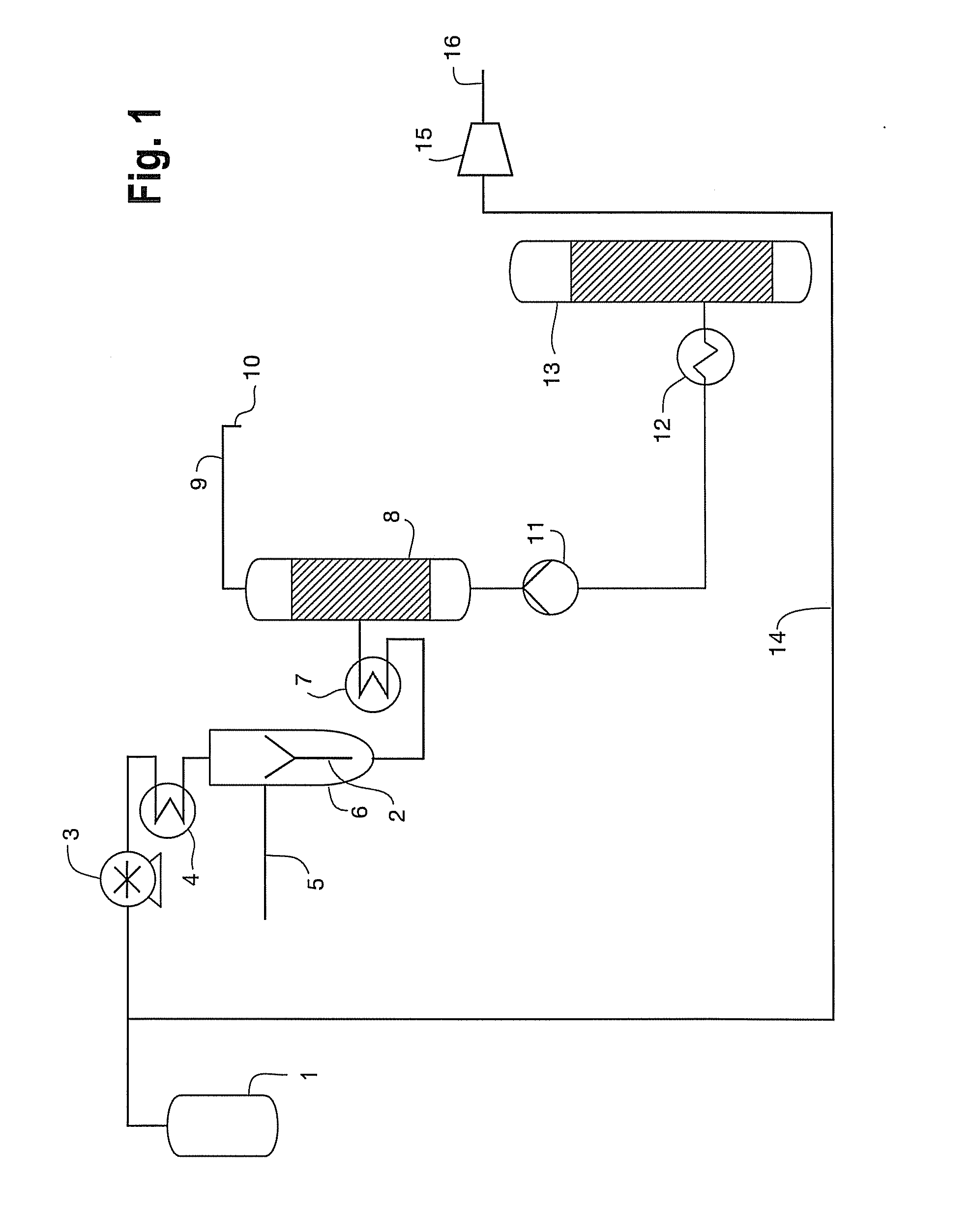

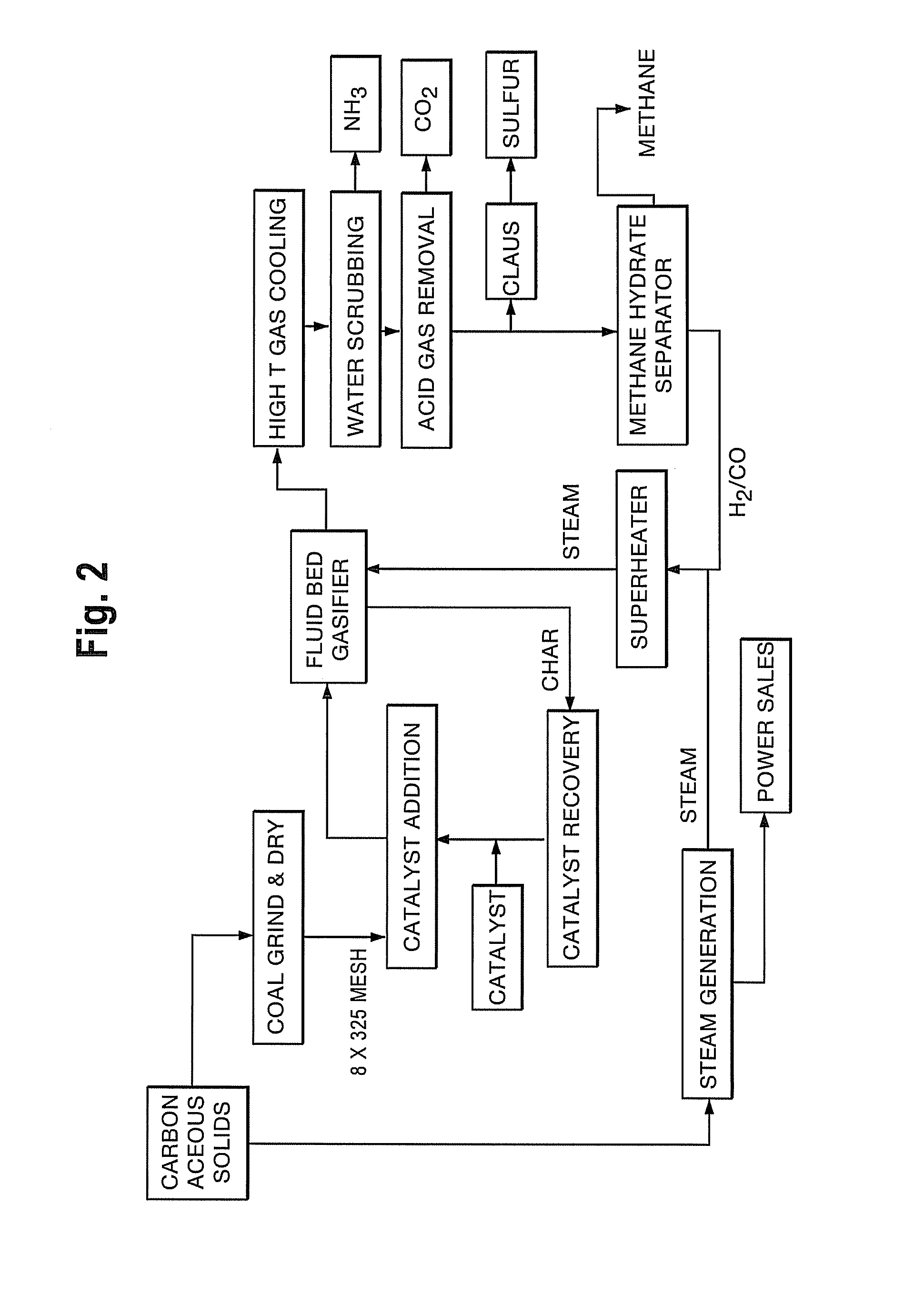

Process and Apparatus for the Separation of Methane from a Gas Stream

InactiveUS20090260287A1Combustible gas chemical modificationHydrogen separation using liquid contactHydrogenWater vapor

Processes for conversion of a carbonaceous composition into a gas stream comprising methane are provided, where an energy-efficient process and / or apparatus is used to separate methane out of a gas stream comprising methane, carbon monoxide, and hydrogen. Particularly, methane can be separated from hydrogen and carbon monoxide using novel processes and / or apparatuses that generate methane hydrates. Because hydrogen and carbon monoxide do not readily form hydrates, the methane is separated from a gas stream. The methane can be captured as a substantially pure stream of methane gas by dissociating the methane from the hydrate and separating out any residual water vapor.

Owner:SURE CHAMPION INVESTMENT LTD

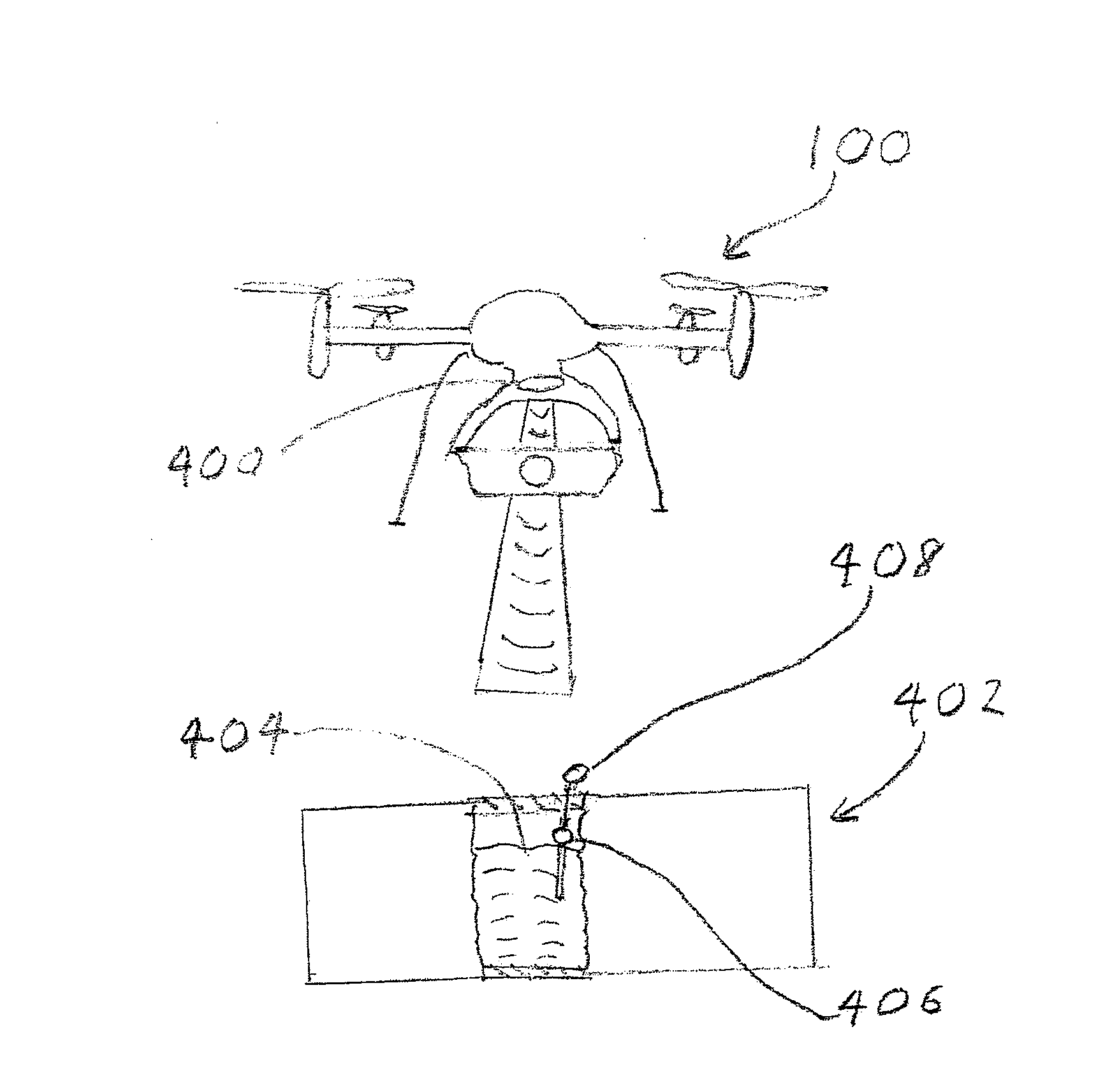

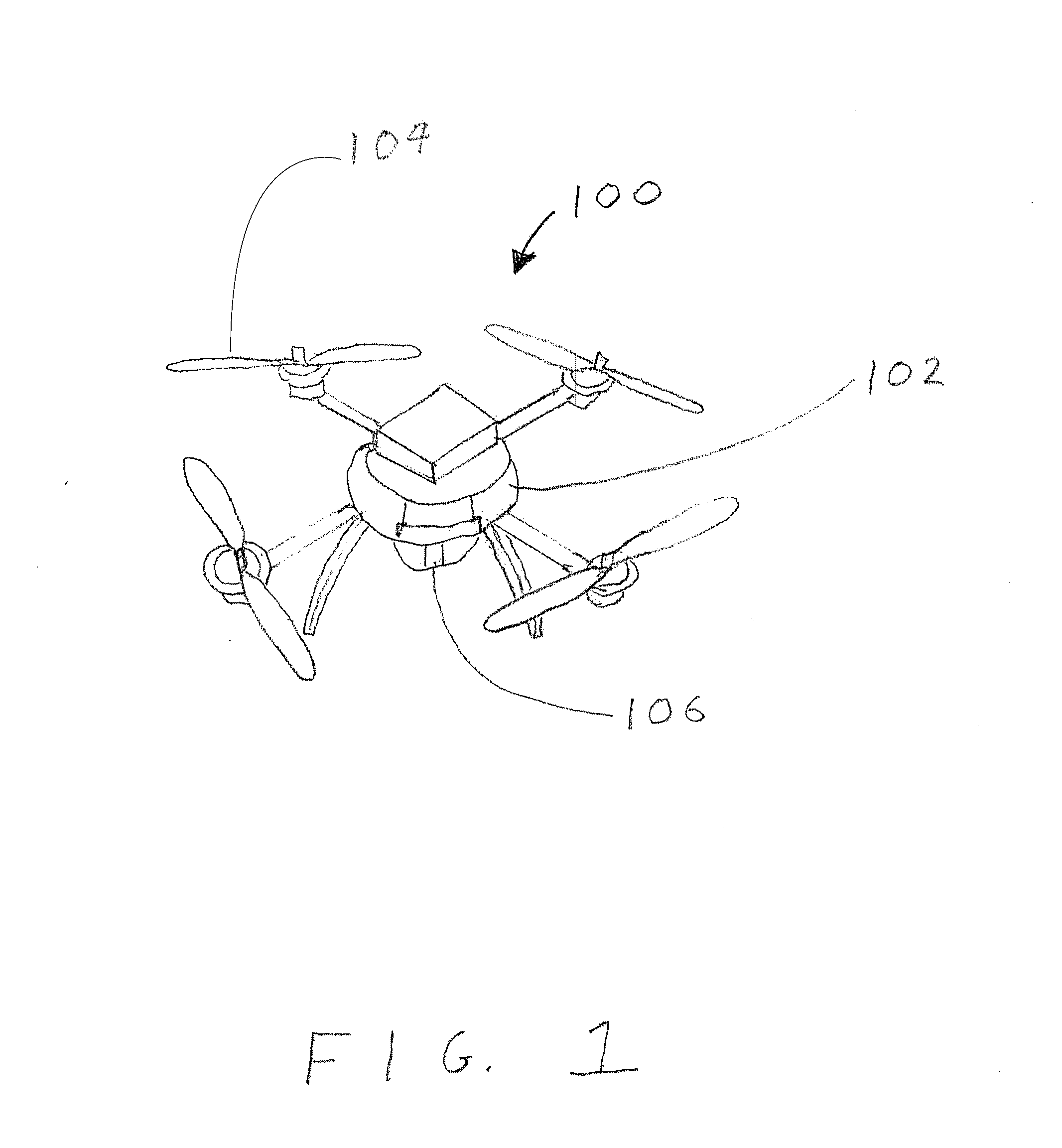

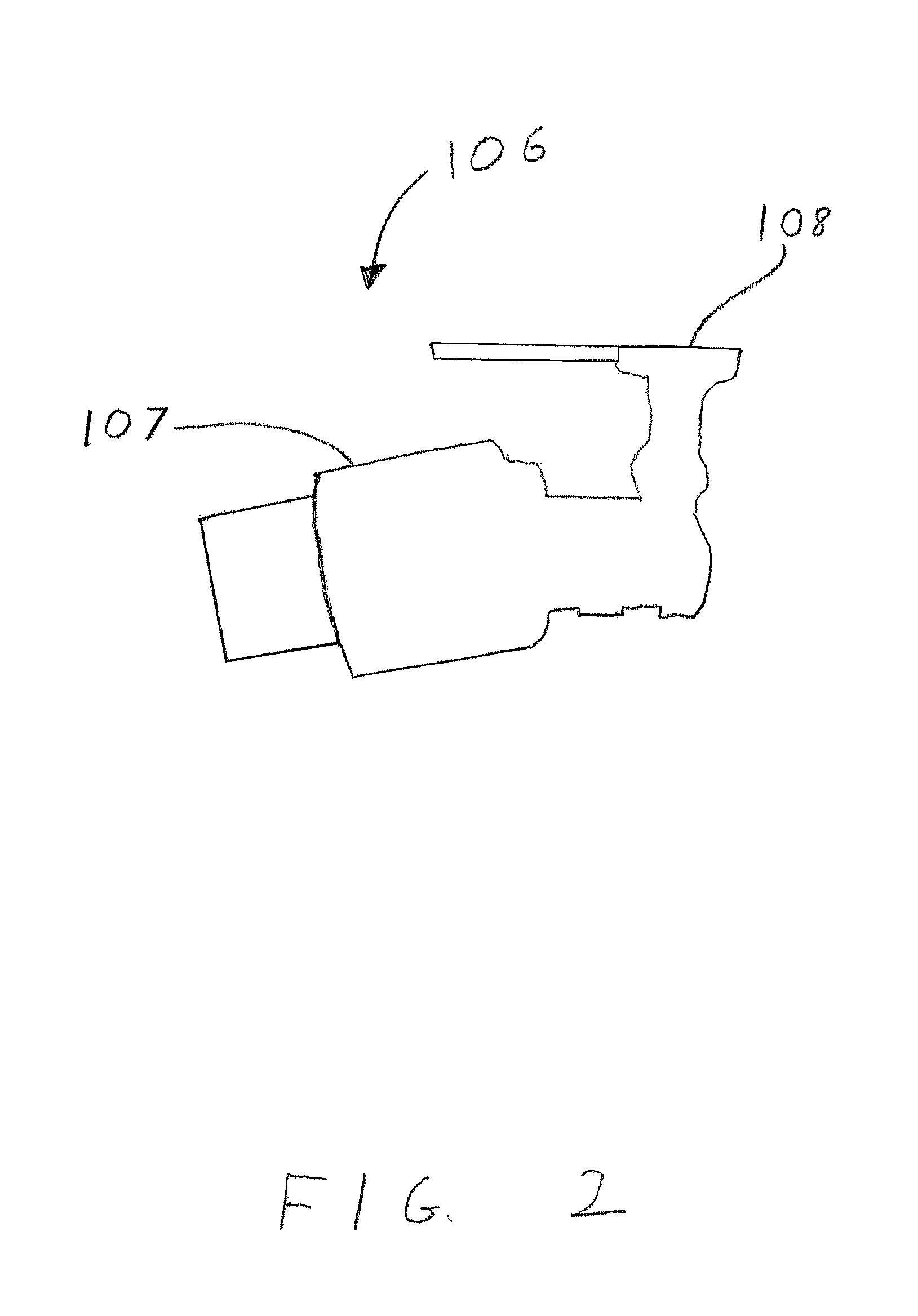

Systems, Methods and Devices for Collecting Data at Remote Oil and Natural Gas Sites

InactiveUS20160214715A1Avoid flyingAccurately determinedAircraft componentsUnmanned aerial vehiclesParticulatesHydrocotyle bowlesioides

Systems, methods and devices are provided for detecting airborne particulates and / or gases at remote oil and natural gas sites, such as wells, and / or processing and refinery plants. One such system comprises an unmanned aerial vehicle (UAV), such as a drone aircraft, configured for aerial dispatch to the remote site and wireless connection to an external processor, cloud apparatus or the like. The UAV includes one or more on-board sensors configured to detect airborne particulates or gases, such as methane gas, hydrogen sulfide, hydrocarbons, weather conditions, ground-based elements or compounds or the like. The on-board sensors may comprise light transmitters, such as lasers, configured for transmitting light or laser pulses into the ambient environment around the remote site and detecting backscatter to detect the concentration and / or velocity vector(s) of the airborne particulates or gases. The UAV is further configured to wirelessly transmit data associated with the airborne particulates or gases to the external processor or cloud apparatus in real-time.

Owner:OIL & GAS IT LLC

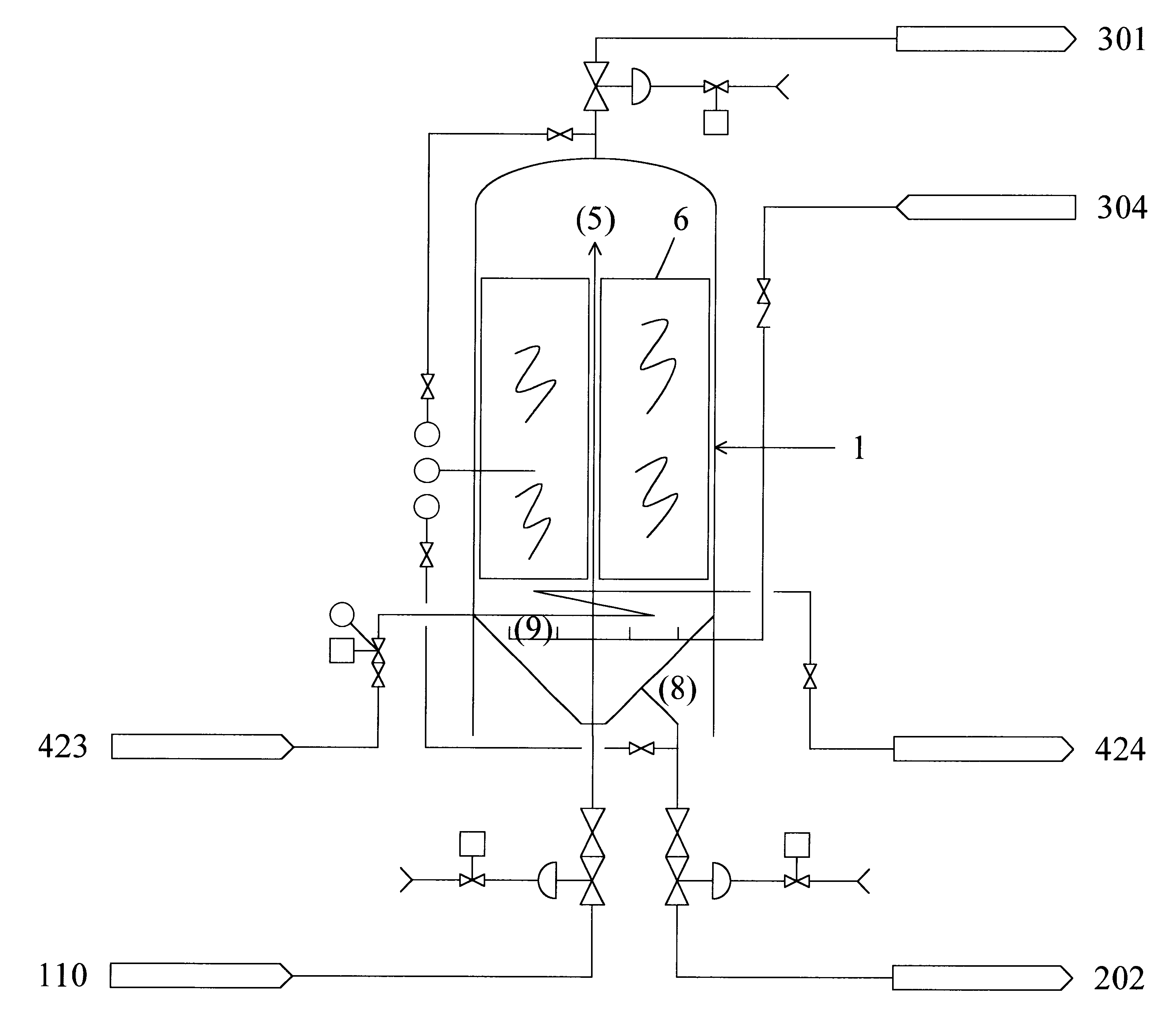

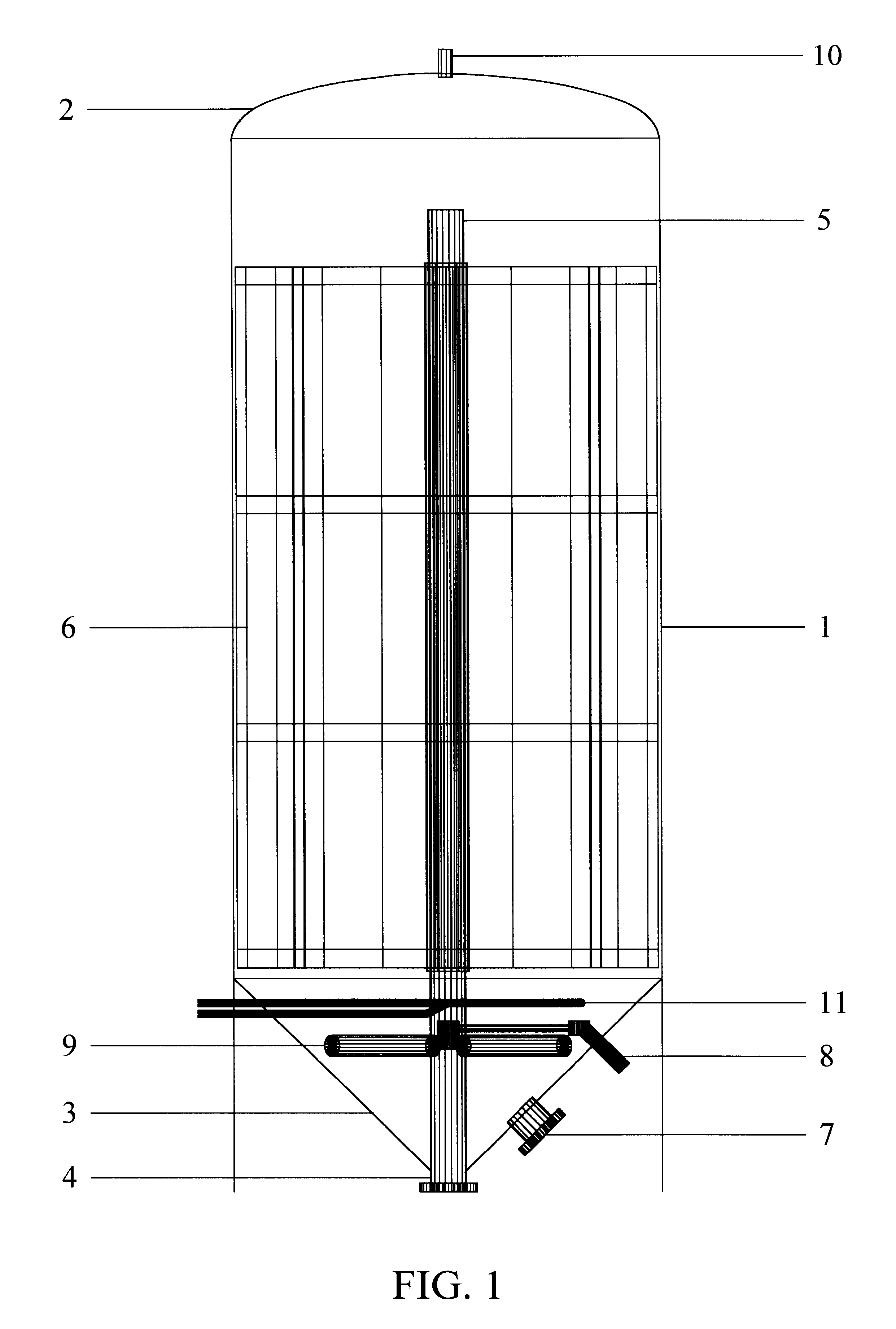

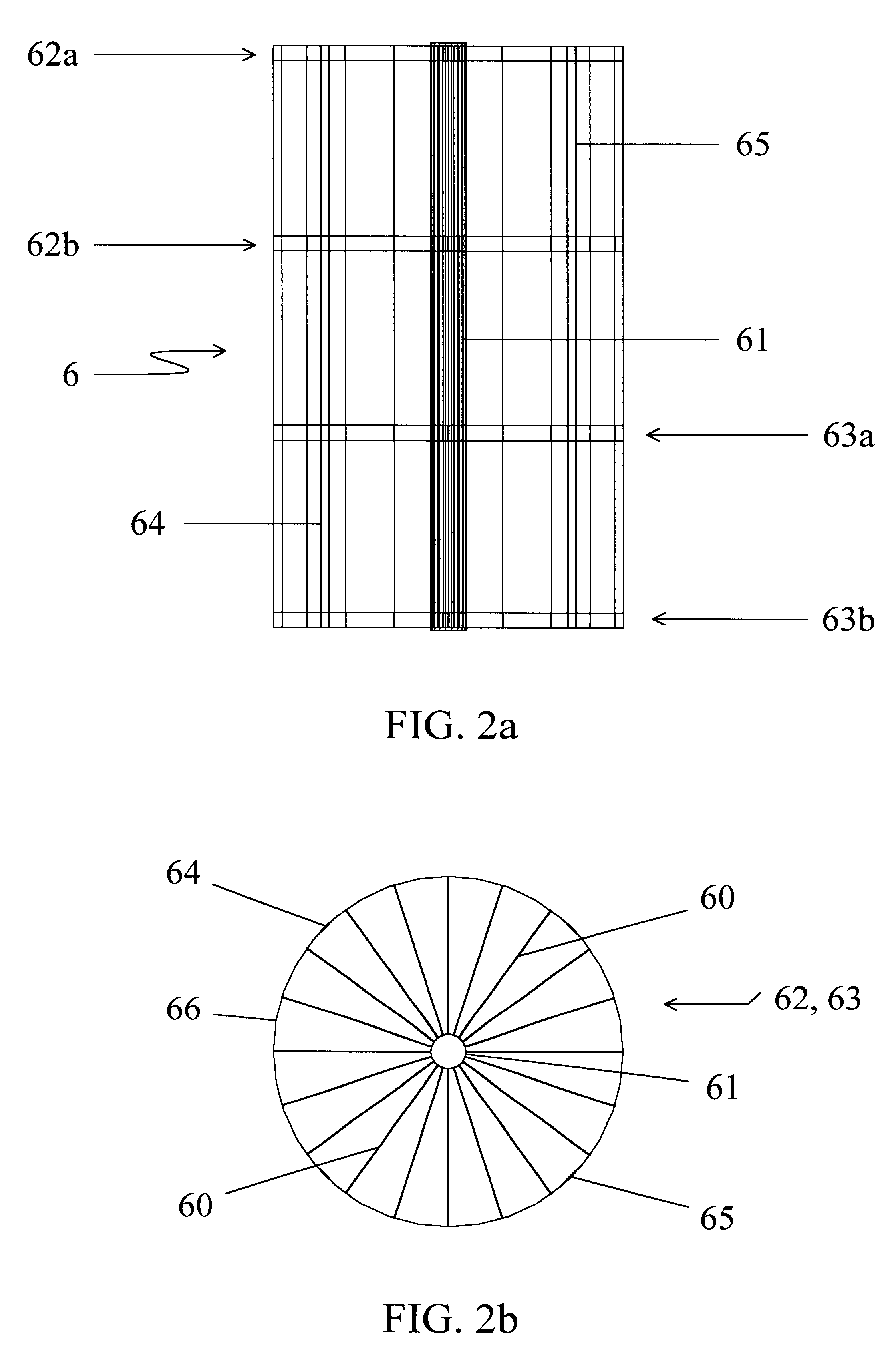

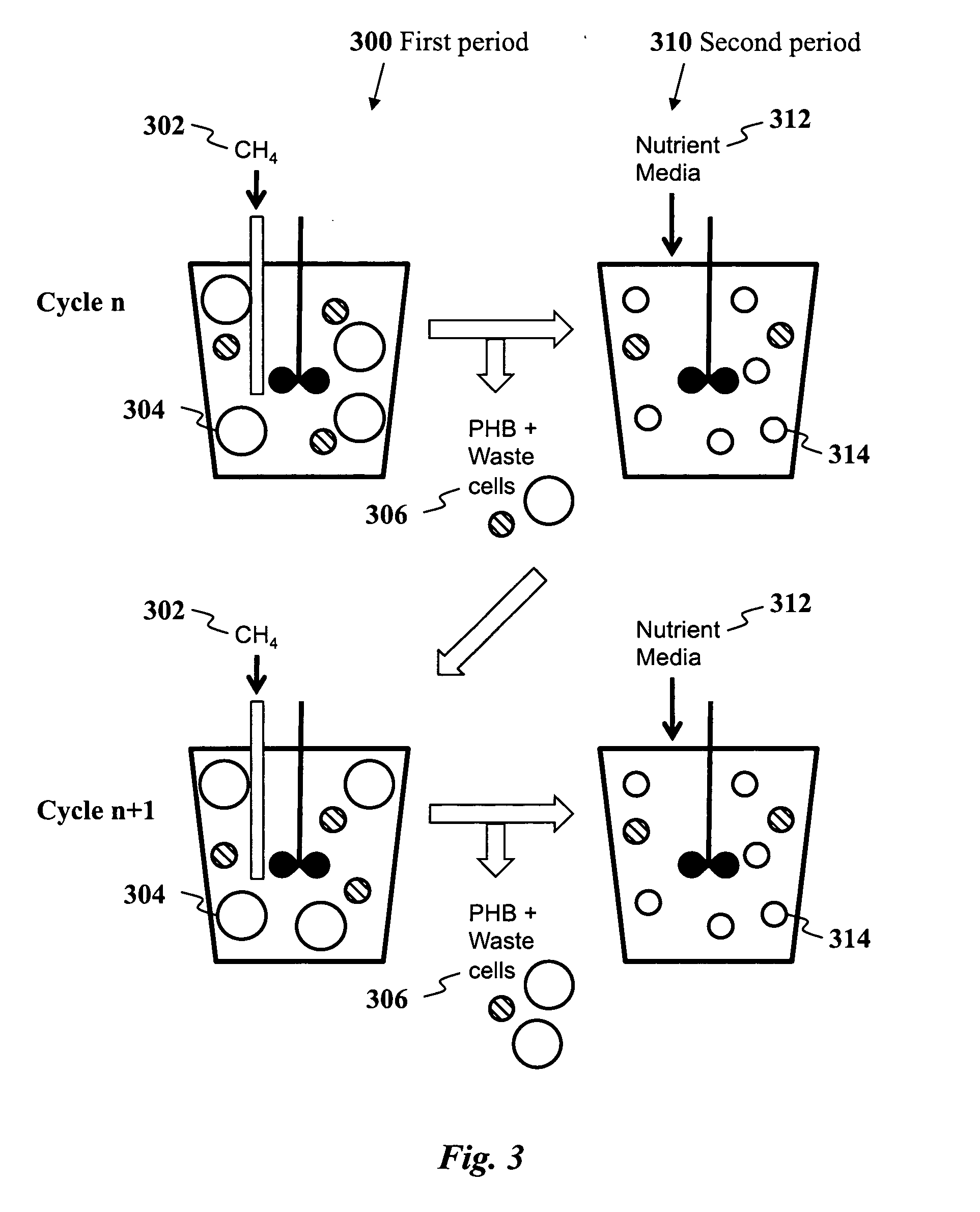

Anaerobic digester system and method

InactiveUS6254775B1High densityIncrease alkalinityGas production bioreactorsTreatment with aerobic and anaerobic processesSlurryMethane gas

An anaerobic digester system has a vertically upright vessel, a matrix arranged in the vessel supporting a microorganism biomass thereon, an input for supplying an input slurry of liquid and suspended solids at an upper portion of the vessel above the matrix, a gas output at the top of the vessel for withdrawing gas generated by anaerobic digestion of solids, and an effluent output at the bottom of the vessel for withdrawing liquid and remaining solids. The vessel has a preferred liquid height to diameter ratio of 2 to 1, and is constructed of inert fiberglass-reinforced plastic coated with a translucent blue gel pigment layer for filtering light at wavelengths that promote biomass cultivation. The matrix is formed as an array of panels mounted to a spindle with wheels fixed at spaced intervals along its vertical height, and the panel are made of a polyethylene grass matting providing a high surface area to volume ratio of at least 20 to 1. Gas from the top of the vessel is recycled to the bottom to generate bubbles for mixing the feedstock. The related method of anaerobic digestion includes comminuting input wastes with a slurry grinder into a pumpable slurry 8-10 % by weight solids, and providing as the biomass hydrolytic bacteria, and fermentative bacteria including acetogenic and methanogenic bacteria to produce a methane gas product. Other products include an organic soil additive, bacterial solids plant food, and a filtrate used as plant tonic.

Owner:RENERGY

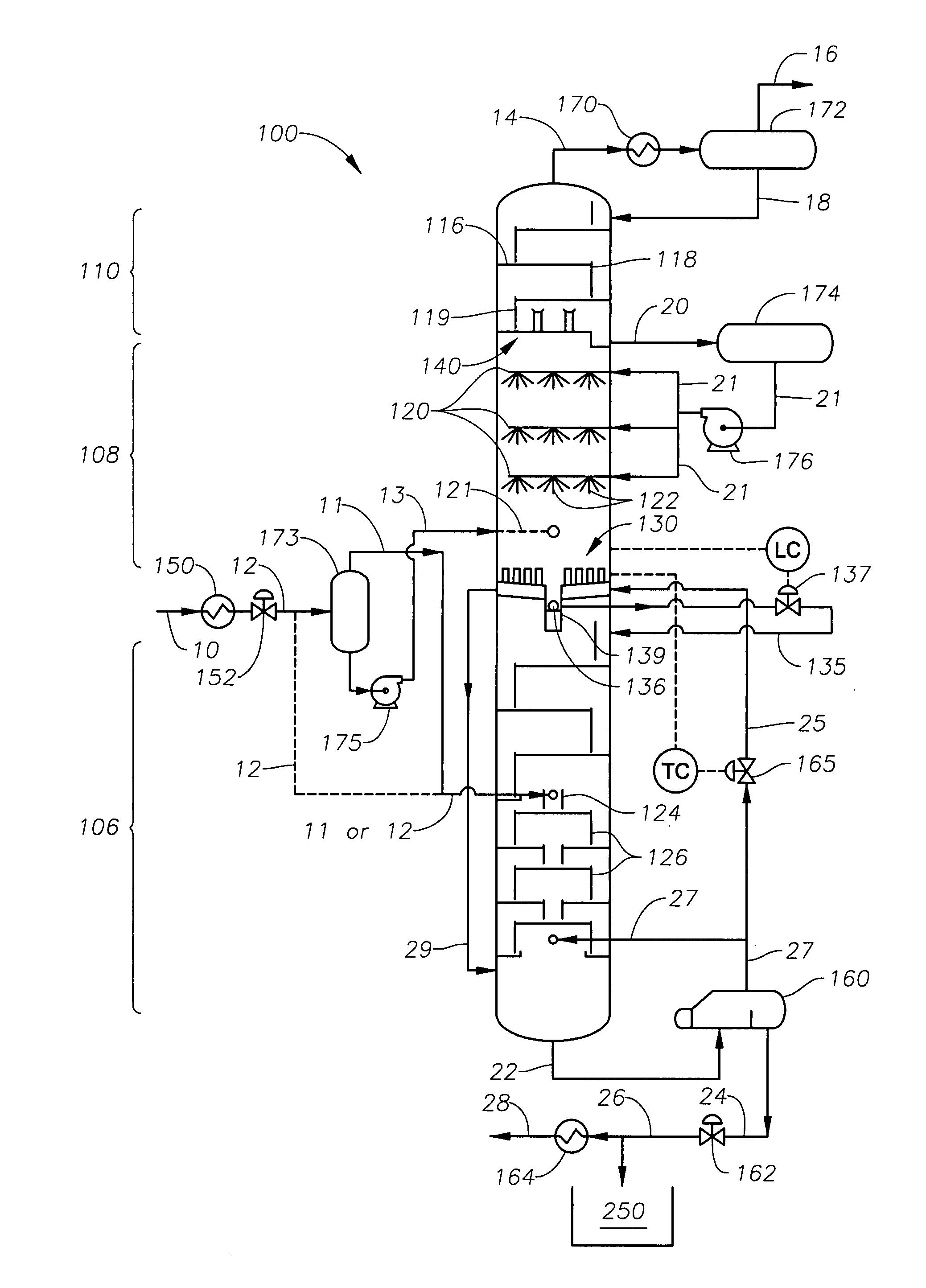

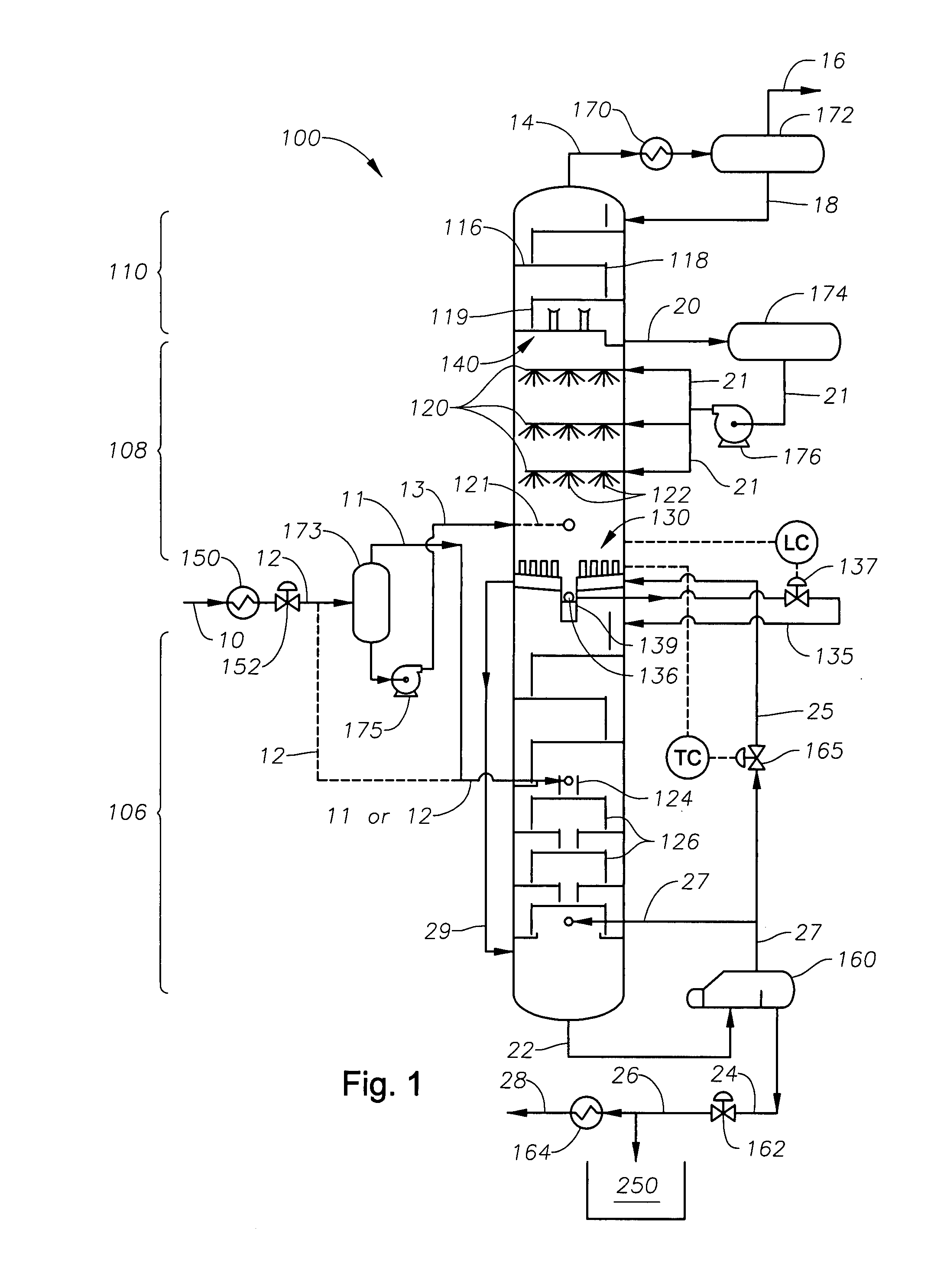

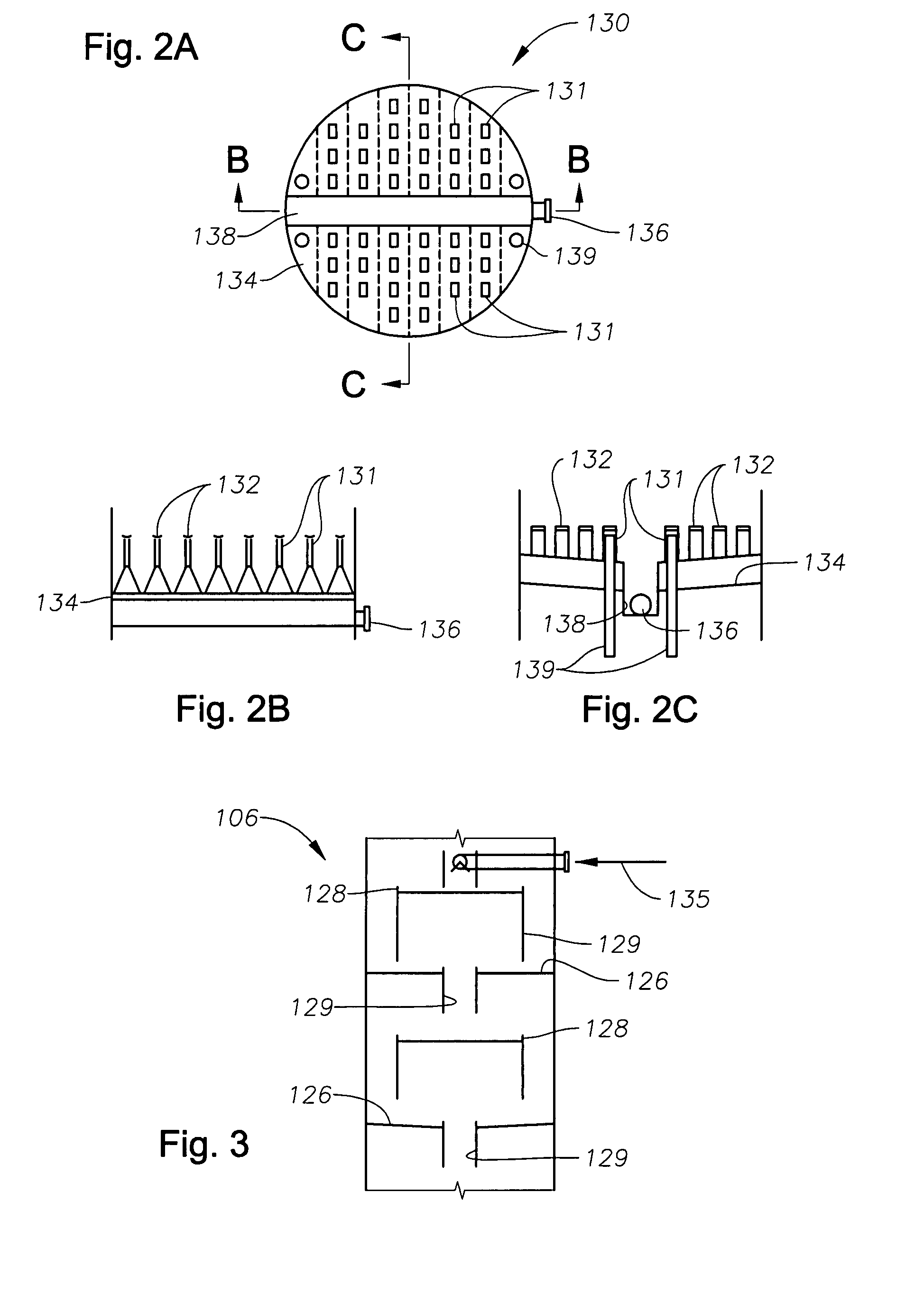

Controlled Freeze Zone Tower

A cryogenic distillation tower is provided for the separation of a fluid stream containing at least methane and carbon dioxide. The cryogenic distillation tower has a lower stripping section, an upper rectification section, and an intermediate spray section. The intermediate spray section includes a plurality of spray nozzles that inject a liquid freeze zone stream. The nozzles are configured such that substantial liquid coverage is provided across the inner diameter of the intermediate spray section. The liquid freeze zone stream generally includes methane at a temperature and pressure whereby both solid carbon dioxide particles and a methane-enriched vapor stream are formed. The tower may further include one or more baffles below the nozzles to create frictional resistance to the gravitational flow of the liquid freeze zone stream. This aids in the breakout and recovery of methane gas. Additional internal components are provided to improve heat transfer and to facilitate the breakout of methane gas.

Owner:FIELER ELEANOR R +3

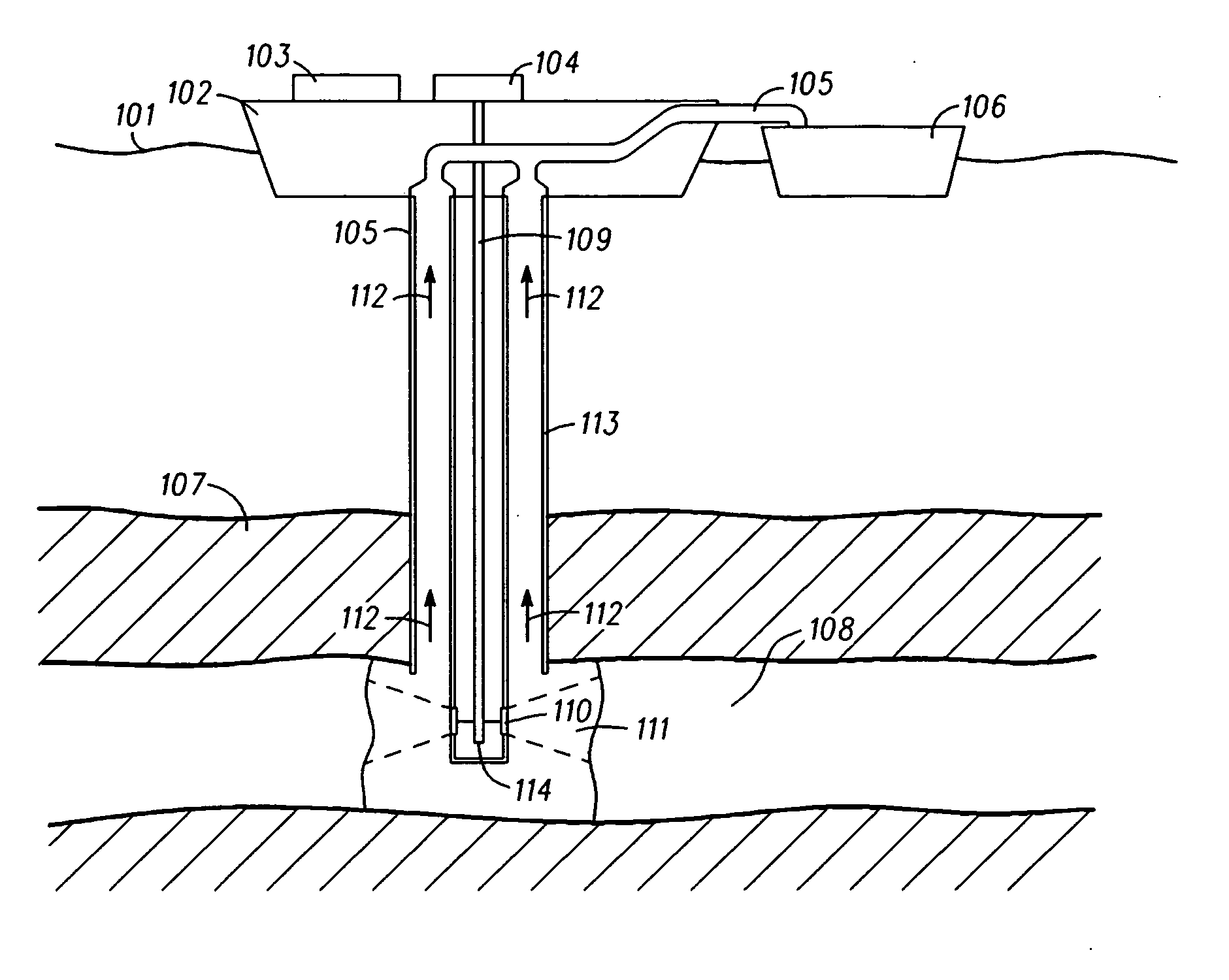

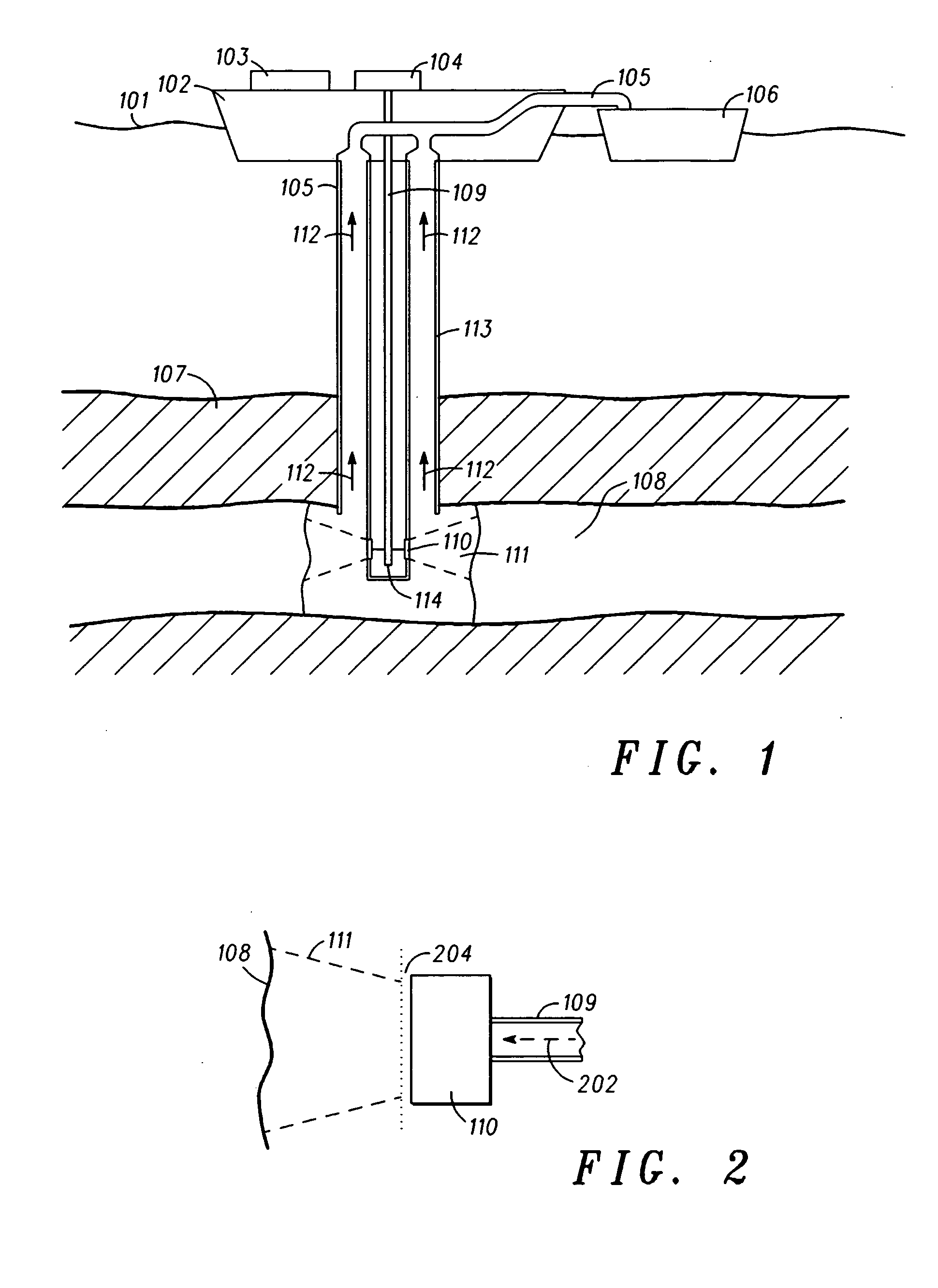

Methane extraction method and apparatus using high-energy diode lasers or diode-pumped solid state lasers

InactiveUS20070267220A1Efficient productionConstructionsDisloding machinesFiberDiode-pumped solid-state laser

A method and apparatus for extracting methane gas from methane hydrate. The method includes heating the methane hydrate with a laser apparatus. The laser apparatus includes a diode laser or a solid state laser that is pumped with a diode laser. The laser is guided to a working end of a tool with a fiber optic bundle. The tool is guided to heat the methane hydrate with the laser, which emanates from a beam expander at the working end of the tool. The tool can be modified for removing obstructions of methane hydrate in pipelines. Also, the tool can be modified for extracting methane from mined methane hydrate, which is in a container. The characteristics of diode lasers or diode-pumped solid state lasers such as efficiency, size, nature of operation, environmental impact and durability, make methane gas extraction from methane hydrate economically feasible.

Owner:NORTHROP GRUMAN CORP

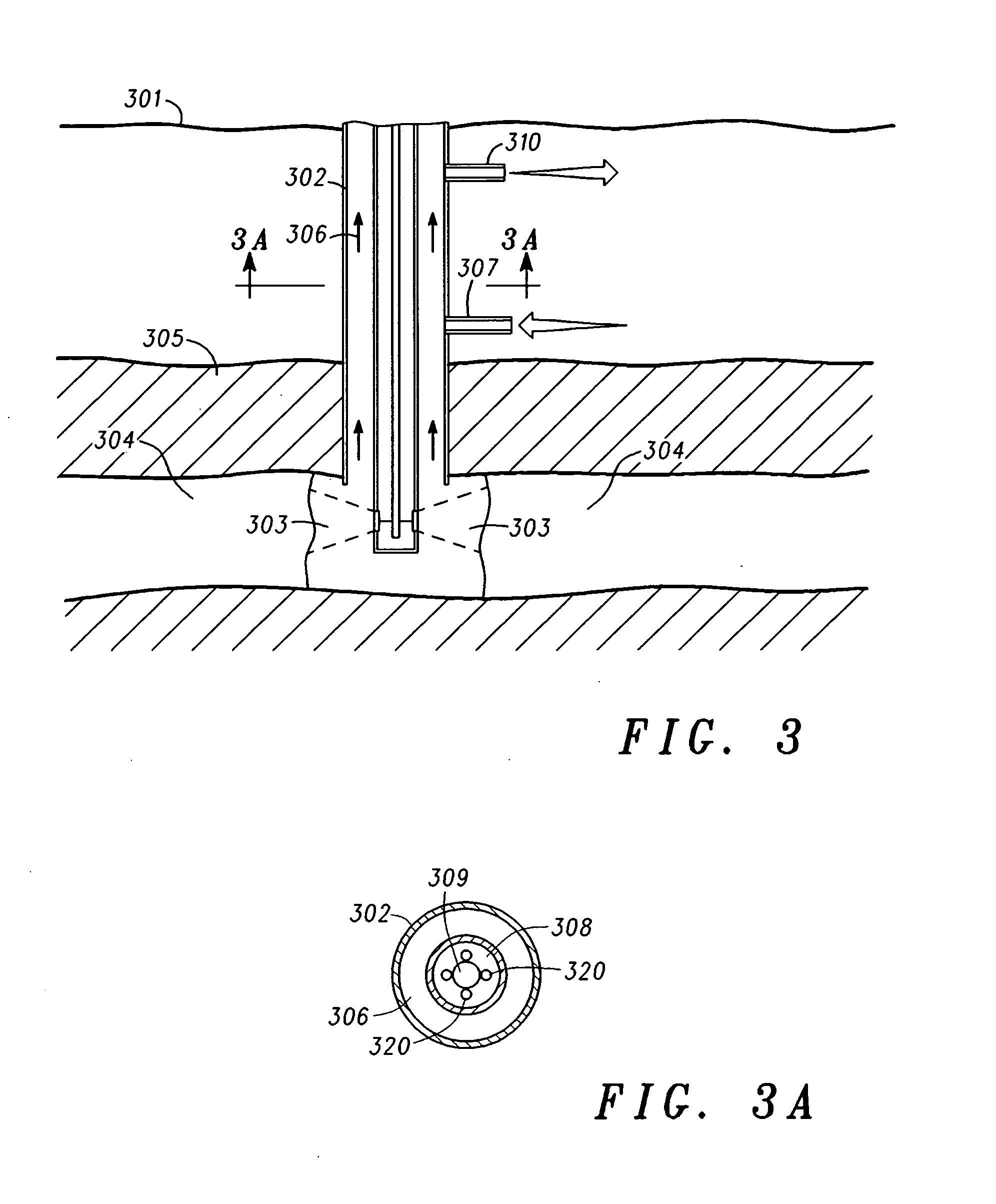

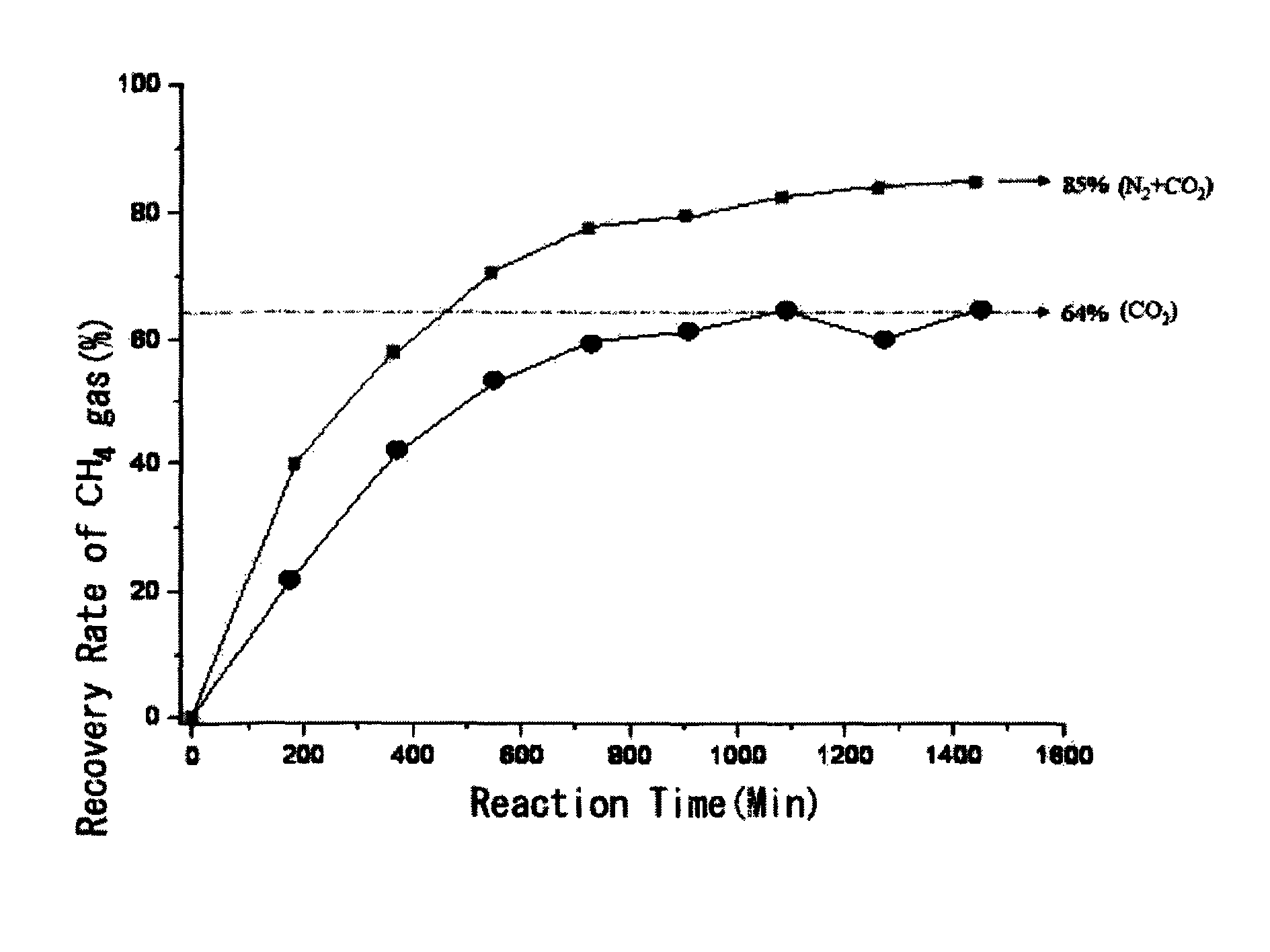

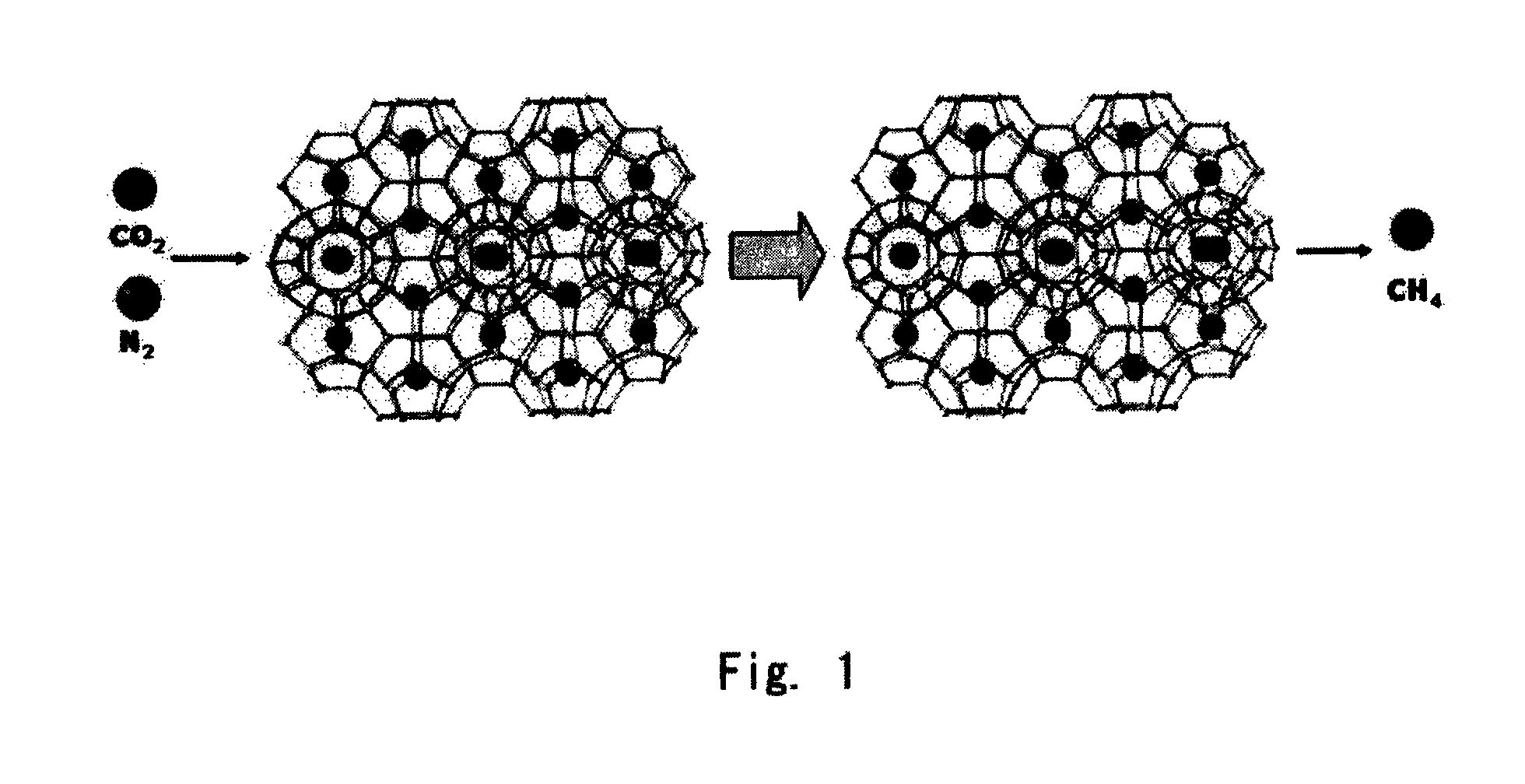

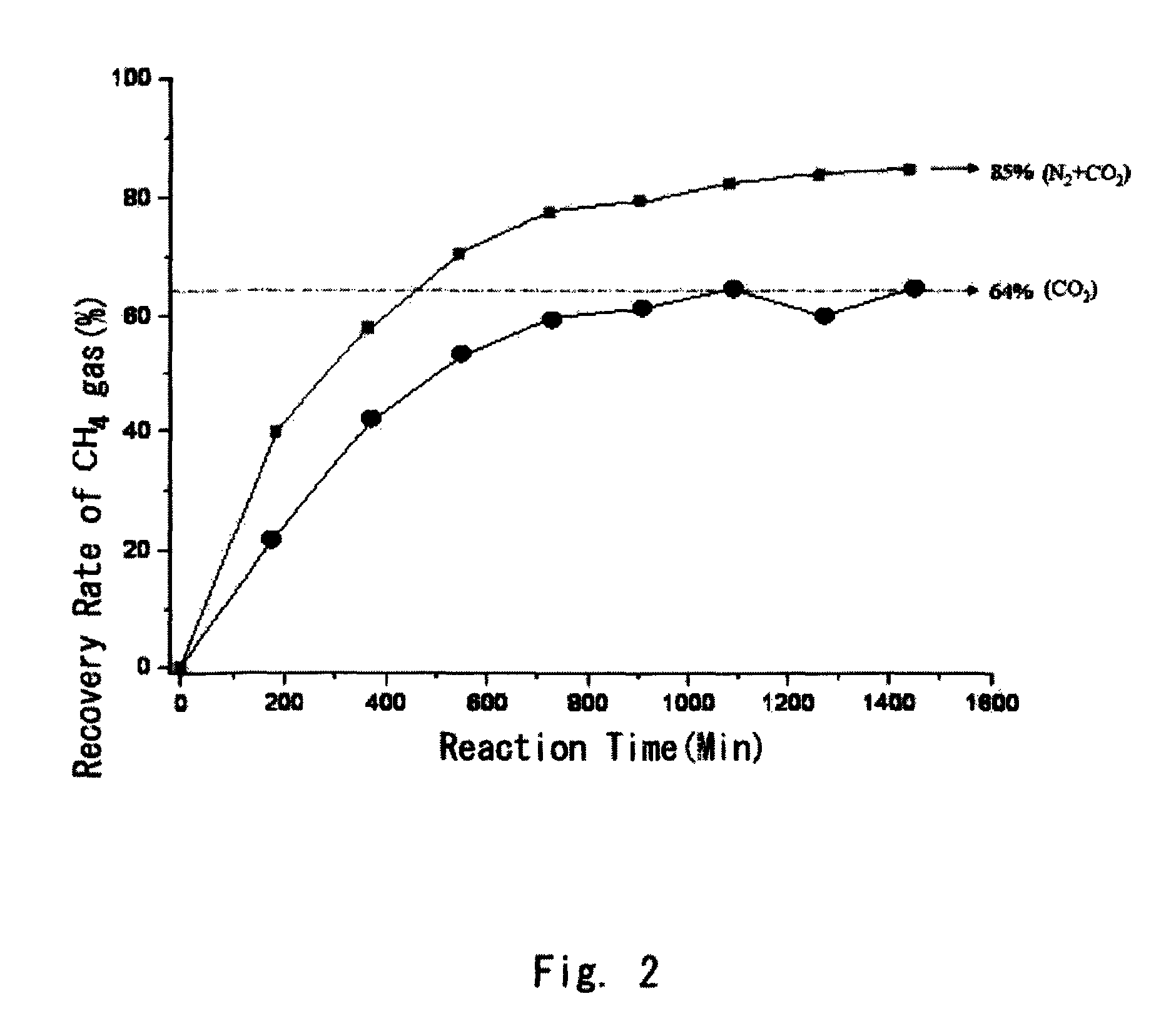

Method for recovering methane gas from natural gas hydrate

The present invention relates to a method for recovering methane gas by adding a gas mixture containing N2 and CO2 gases to natural gas hydrate and reacting them. The method for recovering methane gas from natural gas hydrate of the present invention comprises the step of replacing CH4 gas in natural gas hydrate with a gas mixture containing N2 and CO2 gases by adding the gas mixture to the natural gas hydrate. The method for recovering methane gas of the invention assures a recovery rate of CH4 gas much higher than prior art method without dissociating natural gas hydrate layer and utilization of flue gas as a gas mixture containing N2 and CO2 gases, which makes possible its practical application for the production of natural gas in terms of economy and environmental protection.

Owner:KOREA ADVANCED INST OF SCI & TECH

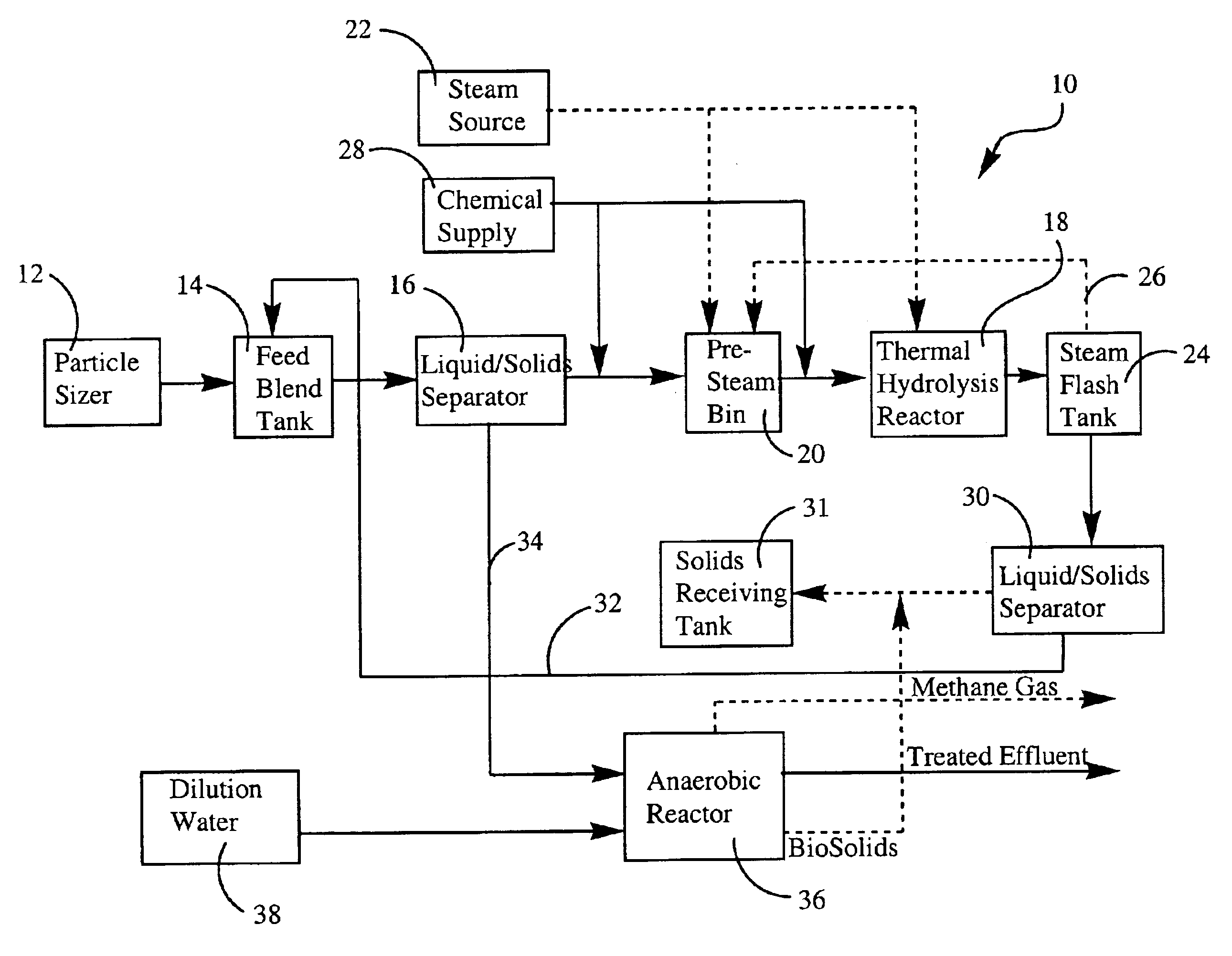

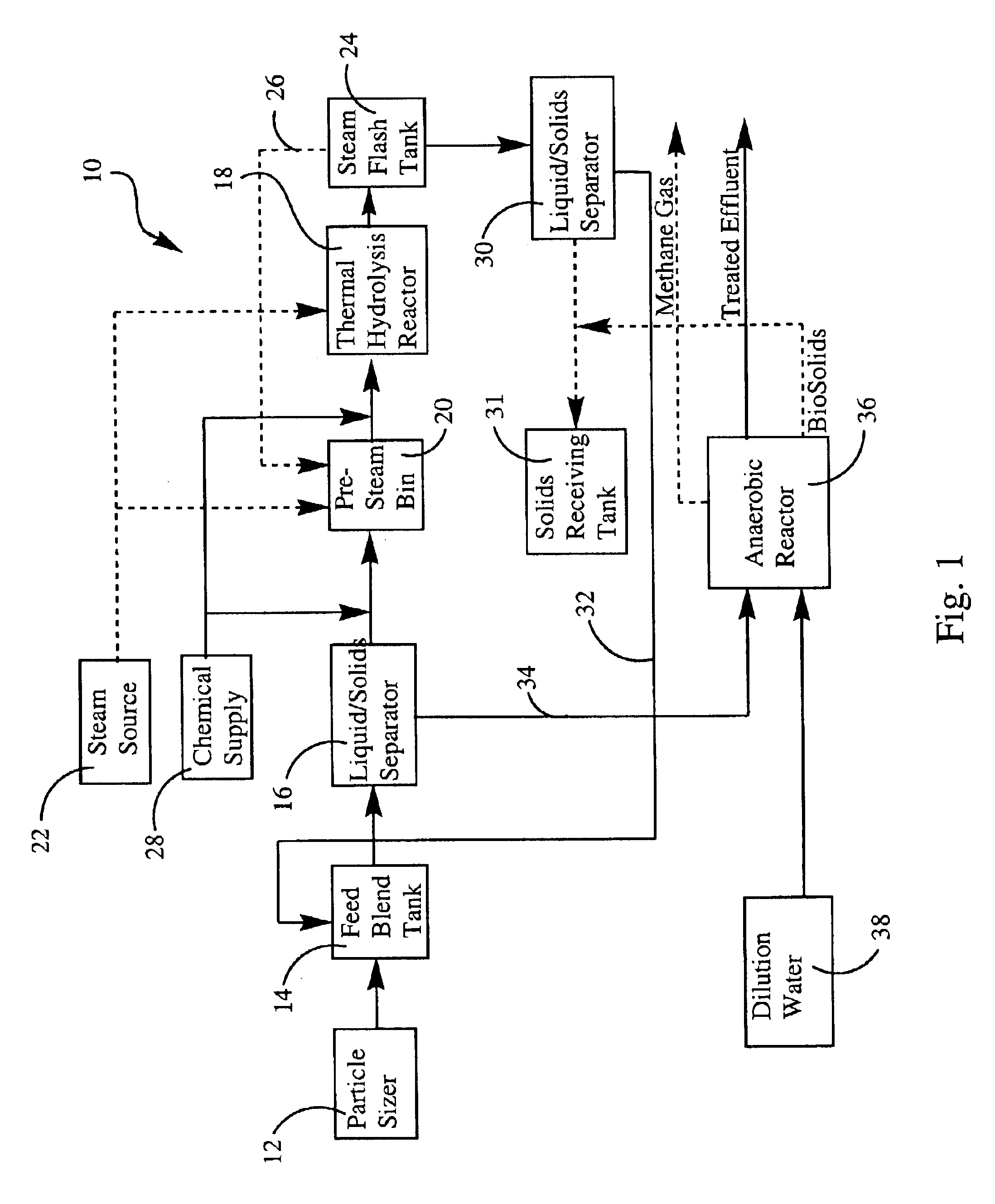

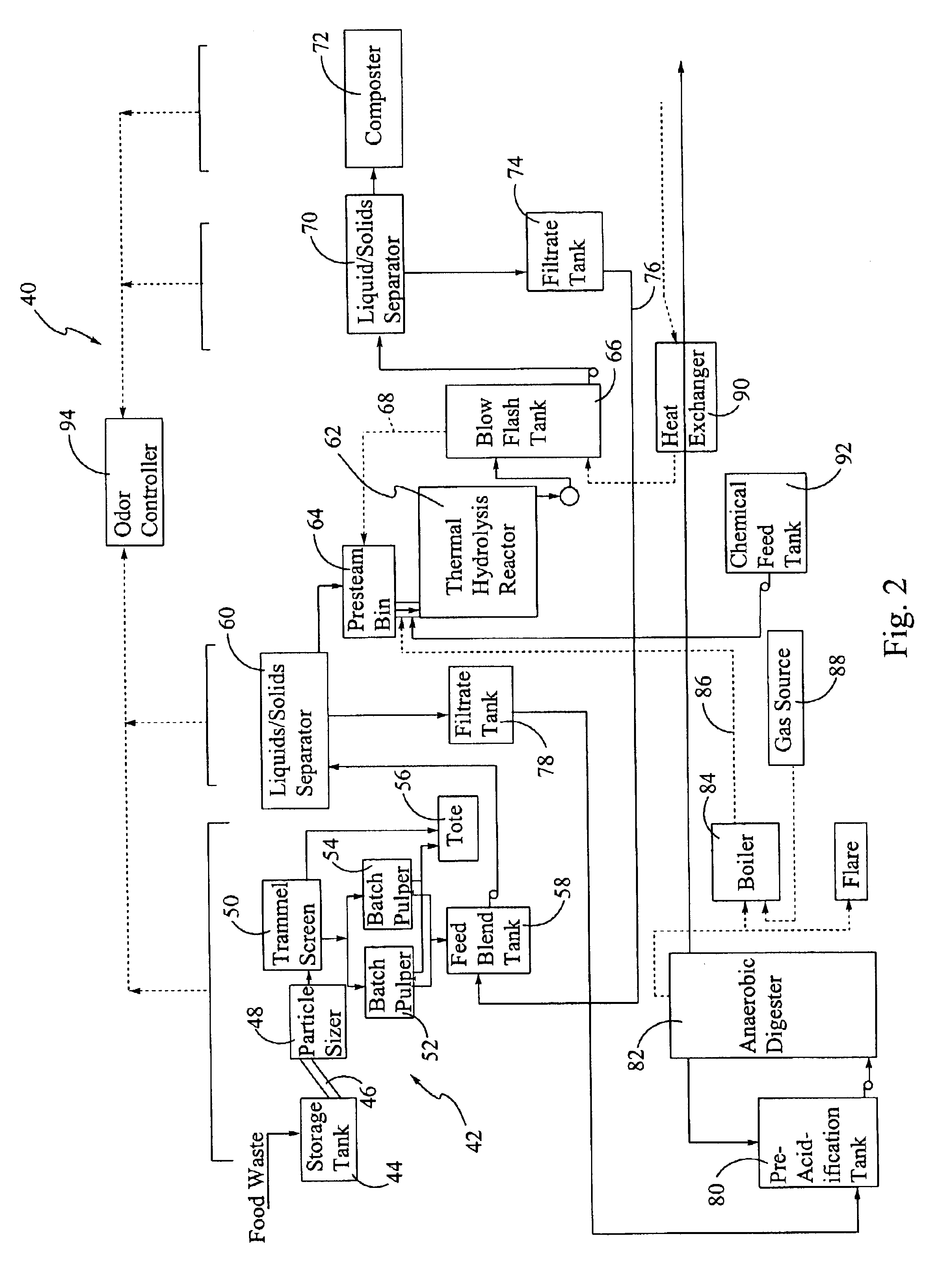

Method and apparatus for the treatment of particulate biodegradable organic waste

InactiveUS6905600B2Lower the volumeSaving in volume requirementBio-organic fraction processingBiological substance pretreatmentsPotassium hydroxideSaturated water vapor

A method for treating particulate biodegradable organic waste includes sizing the waste and adding a base prior to introducing the waste to a thermal hydrolysis reactor and hydrolyzing the waste at a temperature of about 130° C. or greater and a pressure greater than the saturated water vapor pressure to produce a slurry including solubilized organic material and residual solids. The solubilized organic material is separated from the residual solids using a liquid / solid separator and the solubilized organics are subjected to anaerobic digestion to produce a methane gas. The base is preferably potassium hydroxide (KOH) at a concentration of about 1%. The method may further include preheating the particulate biodegradable organic waste with latent heat of the separated solubilized organic material prior to thermal hydrolysis.

Owner:CH2M HILL

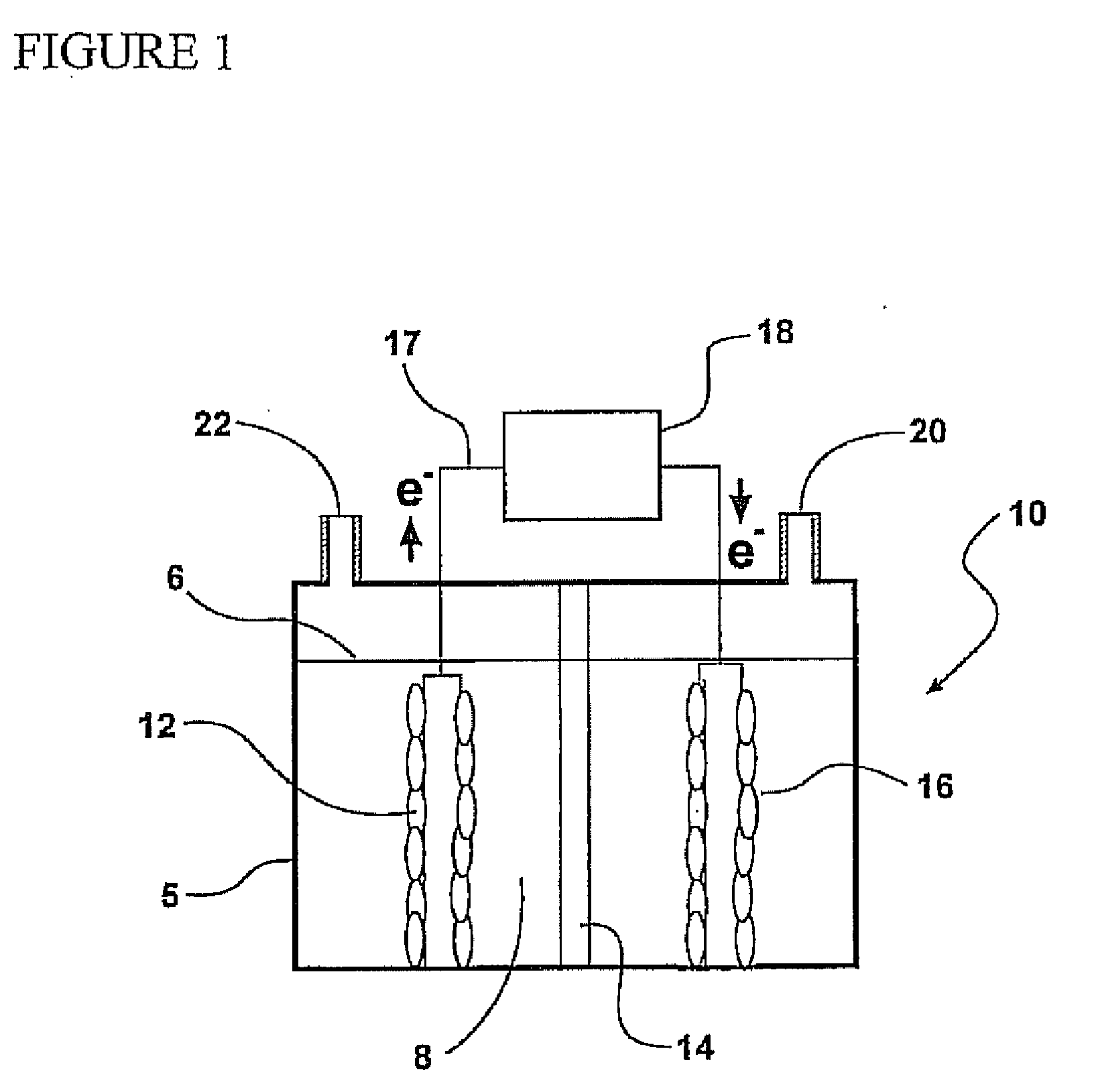

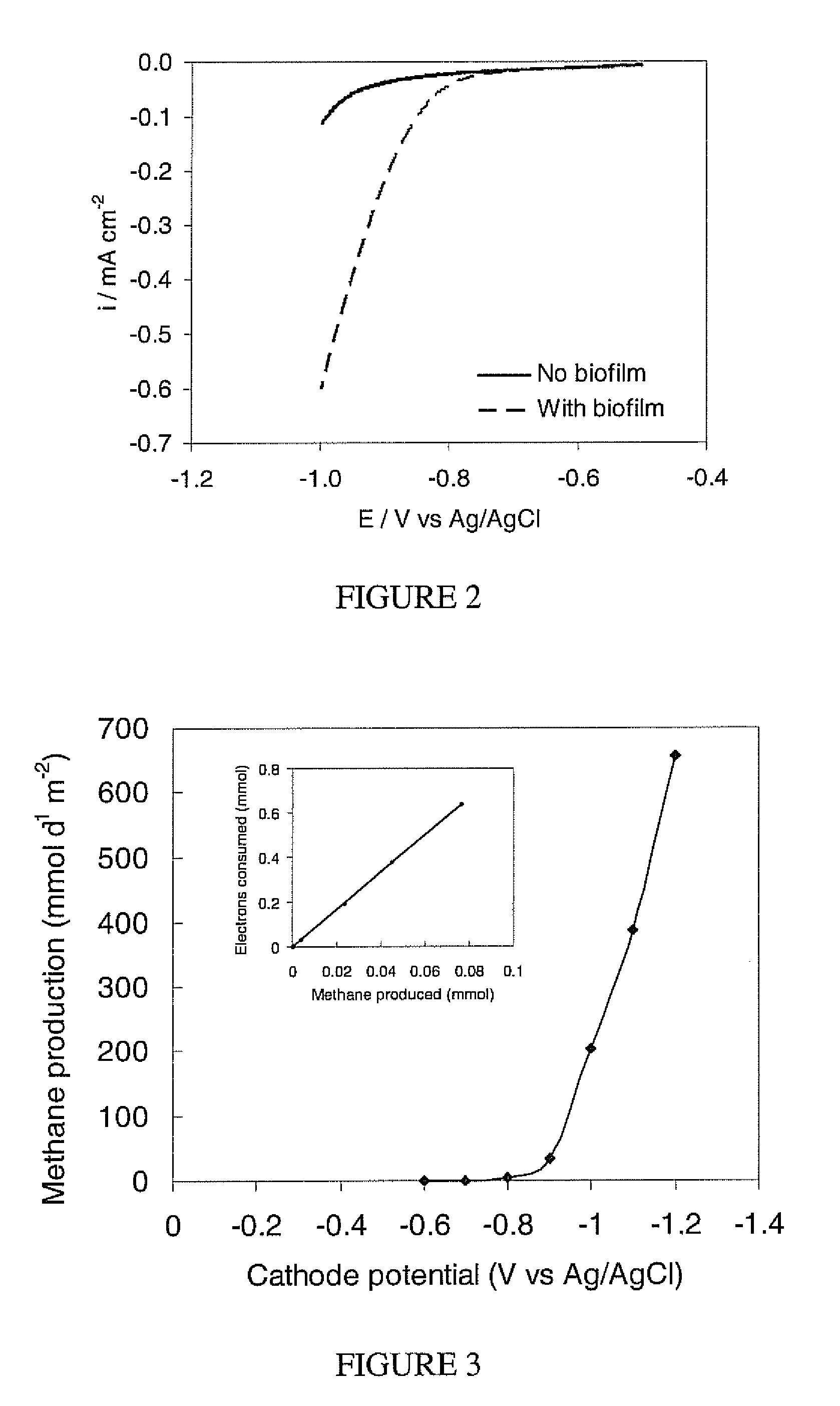

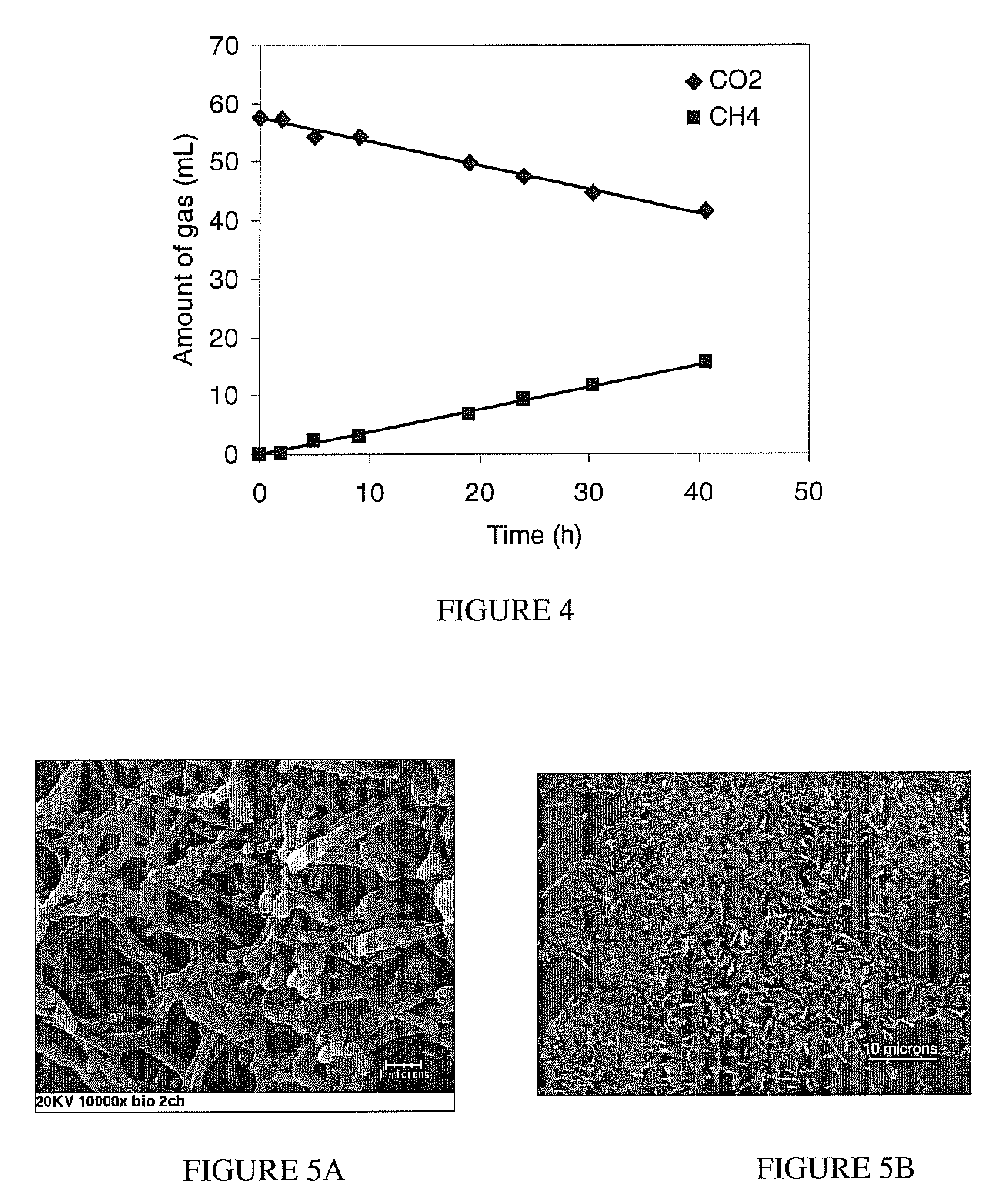

Electromethanogenic reactor and processes for methane production

ActiveUS20090317882A1Reduce deliveryImprove methane production efficiencyMicroorganismsGas production bioreactorsHydrogenCombustion

Increasing competition for fossil fuels, and the need to avoid release carbon dioxide from combustion of these fuels requires development of new and sustainable approaches for energy production and carbon capture. Biological processes for producing methane gas and capturing carbon from carbon dioxide are provided according to embodiments of the present invention which include providing an electromethanogenic reactor having an anode, a cathode and a plurality of methanogenic microorganisms disposed on the cathode. Electrons and carbon dioxide are provided to the plurality of methanogenic microorganisms disposed on the cathode. The methanogenic microorganisms reduce the carbon dioxide to produce methane gas, even in the absence of hydrogen and / or organic carbon sources.

Owner:PENN STATE RES FOUND

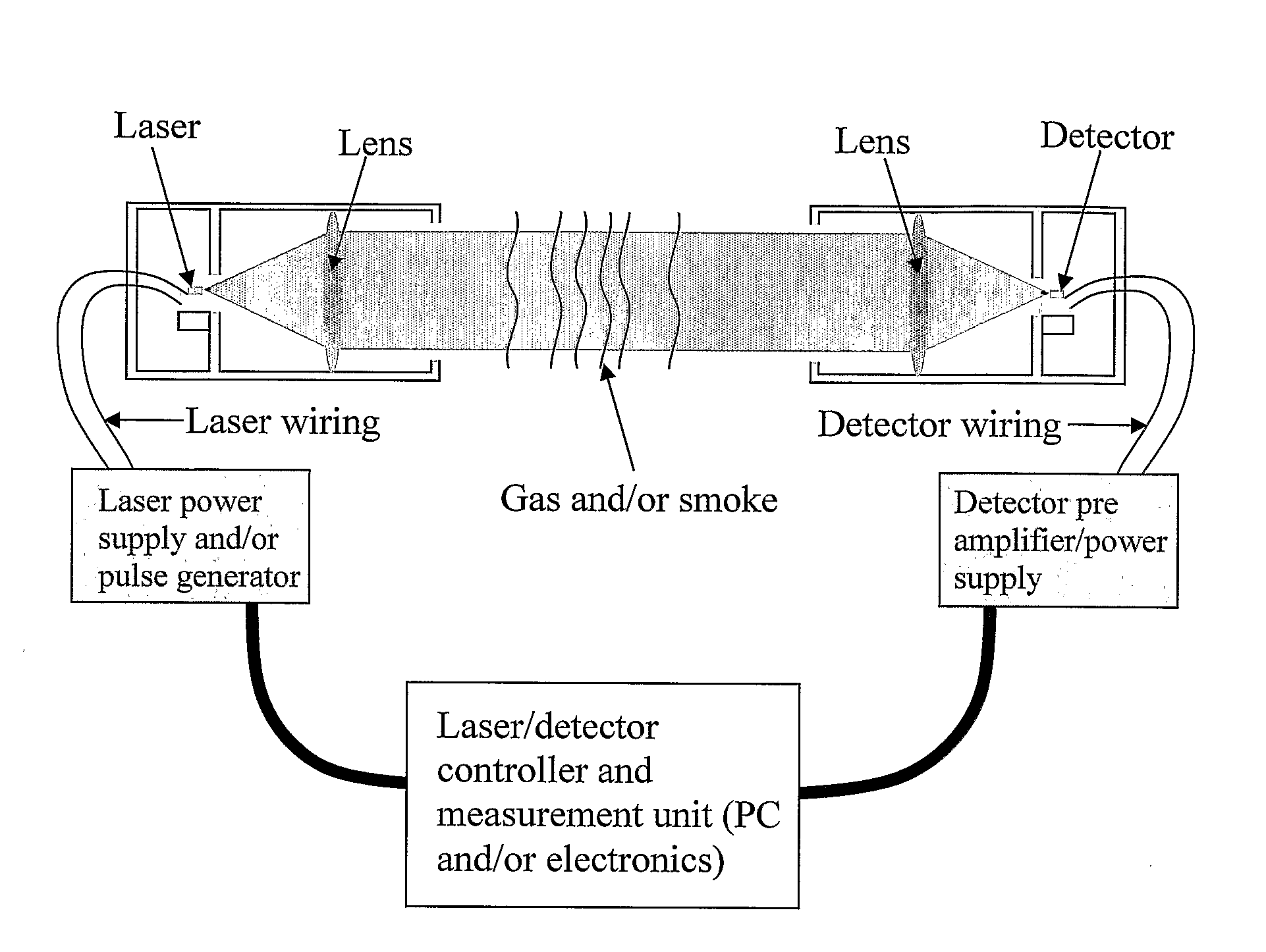

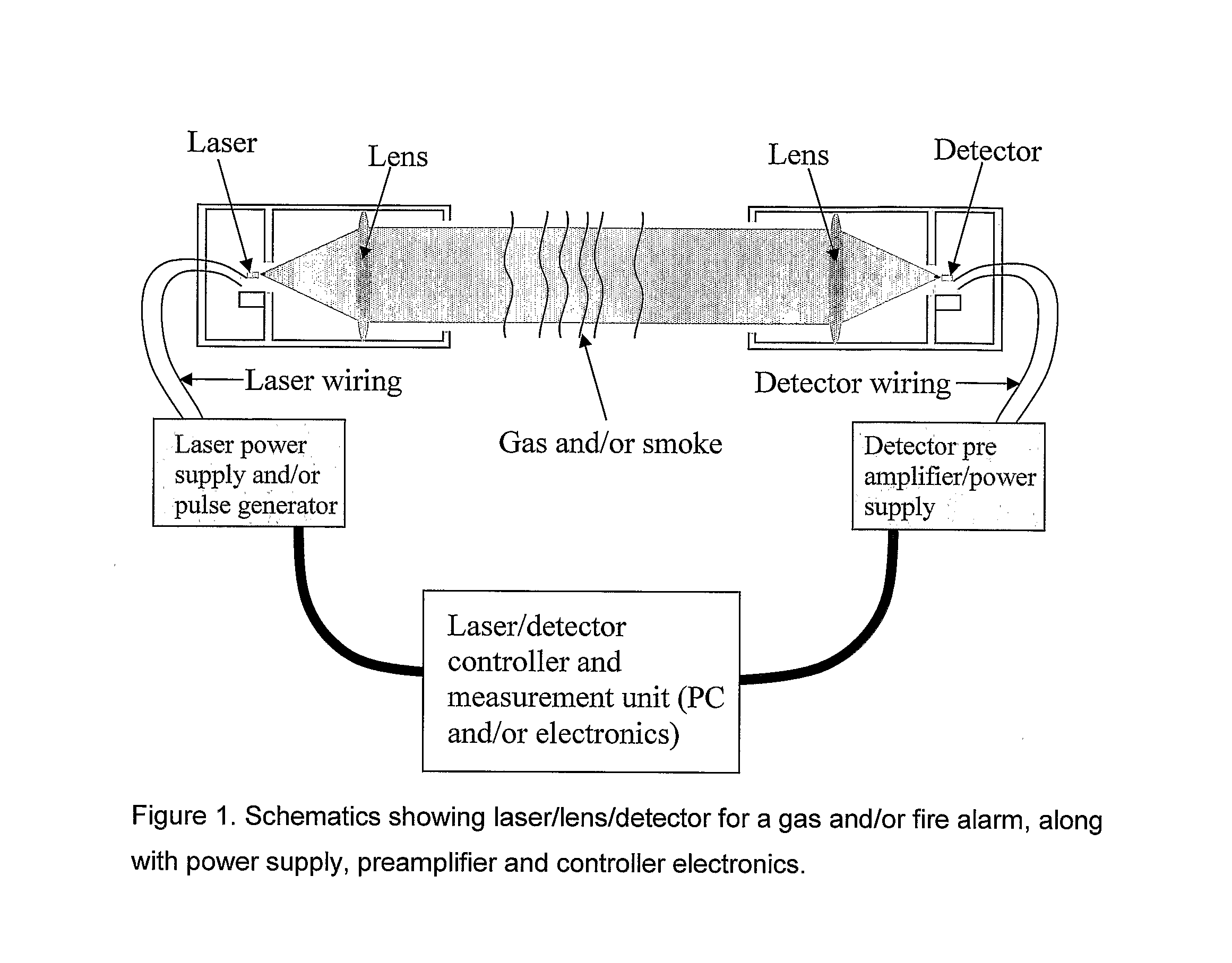

Infrared Laser Based Alarm

InactiveUS20080198027A1Avoid frostAvoid corrosion damageInvestigating moving fluids/granular solidsScattering properties measurementsGas compositionParticle density

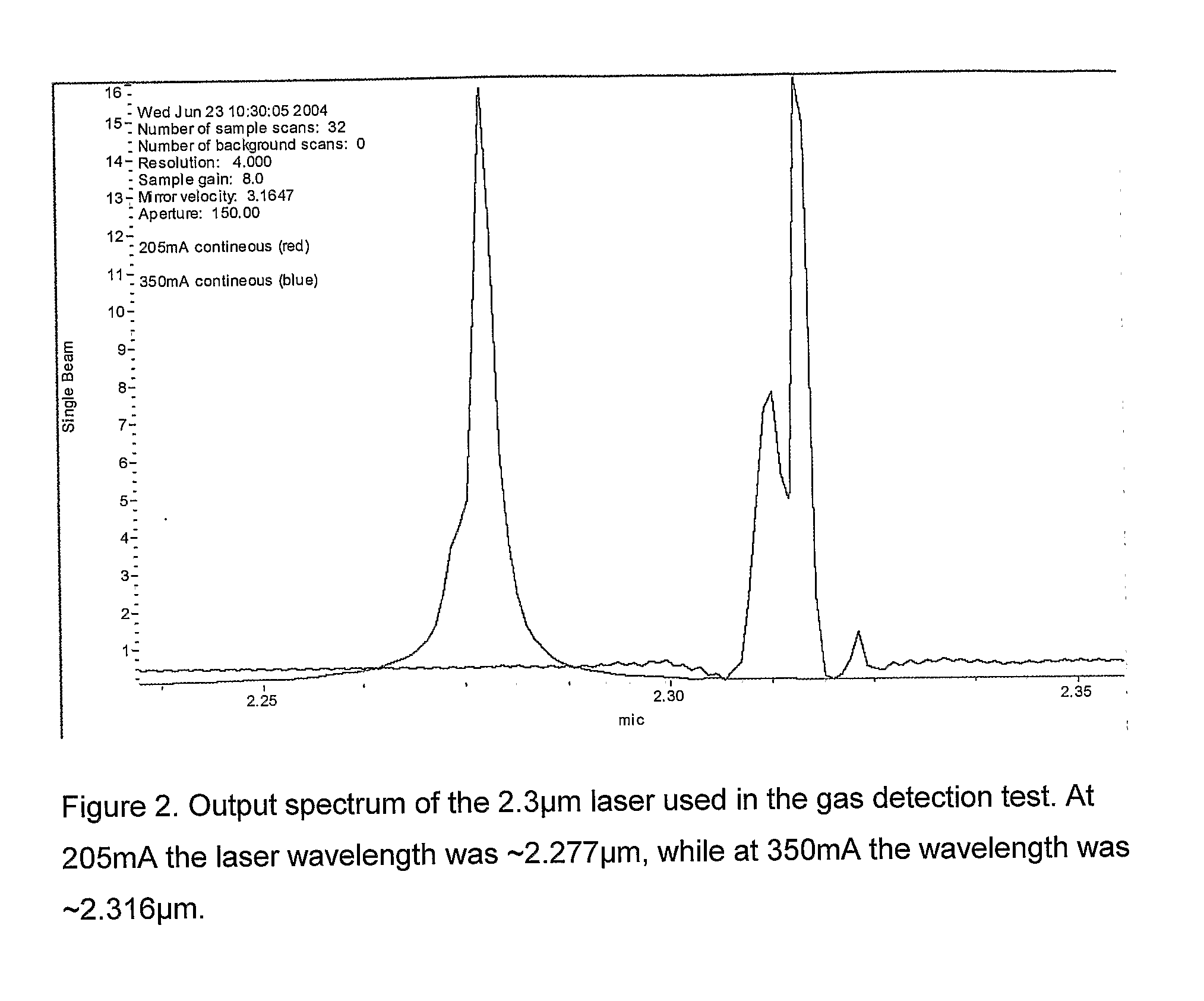

The subject invention relates to a new alarm which is based on using a quarternary tunable Mid-IR laser to measure both particles and gas at the same time. The measurement is done within an area of which the gas of interest will absorb the Mid-IR radiation. By widely tuning the emission wavelength of the laser, several wavelengths can be measured in order to accurately find both gas composition and particle density with one laser based sensor. We tested a new device which use radiation between 2.27 μm and 2.316 μm. Methane gas reduces intensity of the radiation at certain wavelengths in this device, while particles / fog reduce intensity for all wavelengths. In this case, fog should not trigger an alarm, while methane leaks should. This can also be applied for CO and smoke in which one sensor will measure both parameters to sound an alarm instead of just one parameter.

Owner:INTEGRATED OPTOELECTRONICS

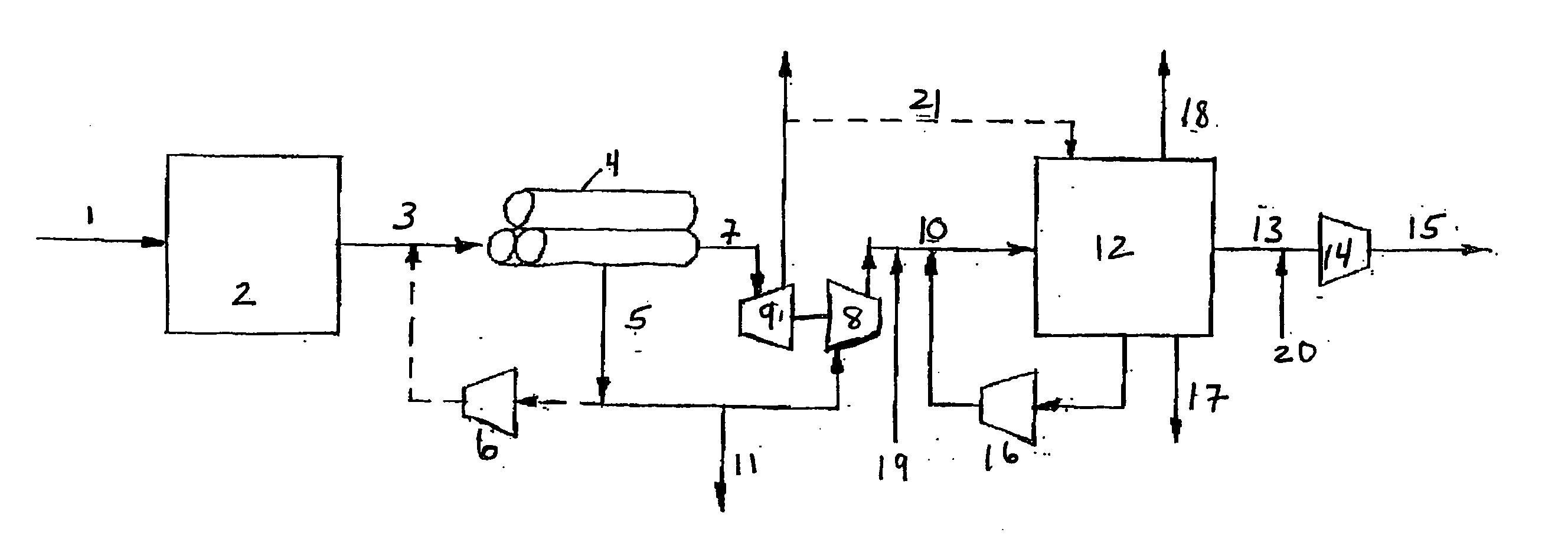

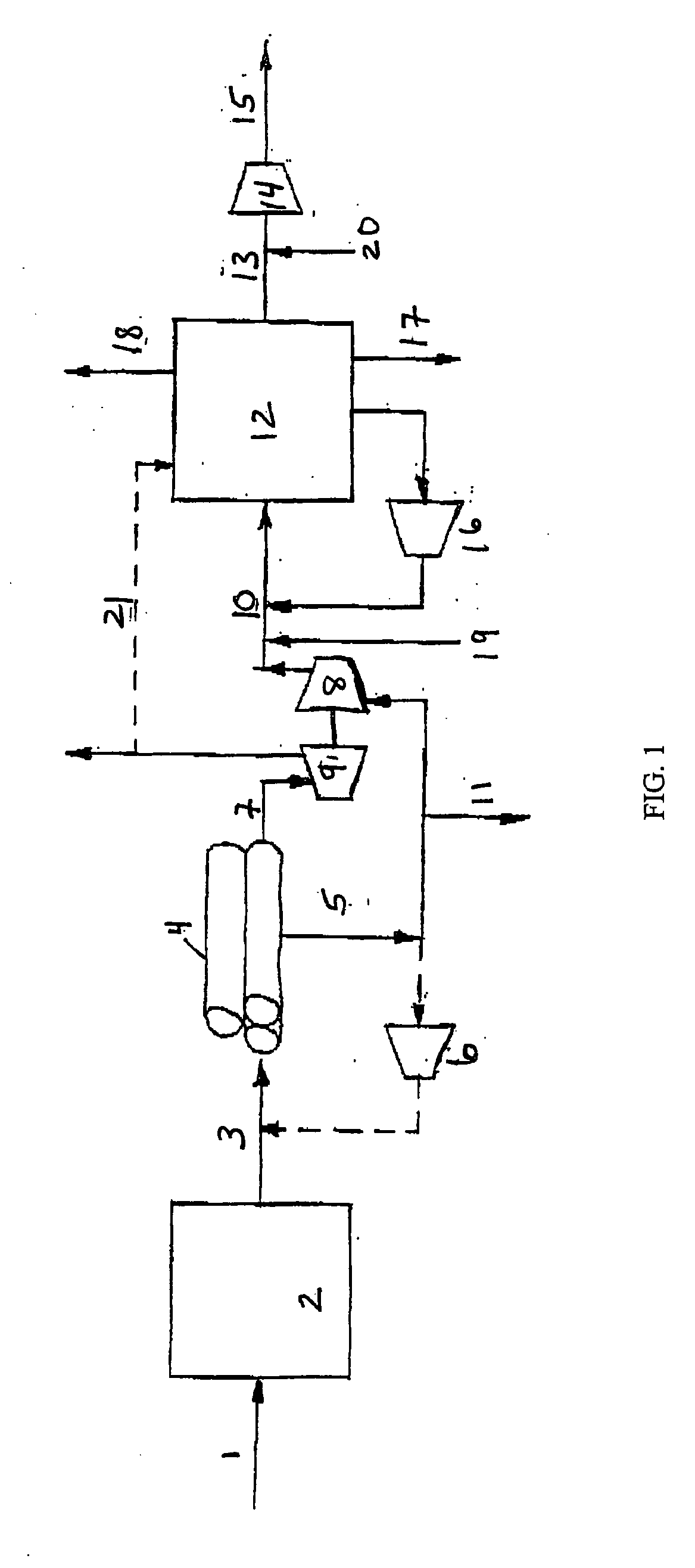

Method and device for producing synthetic natural gas, and natural gas product thereof

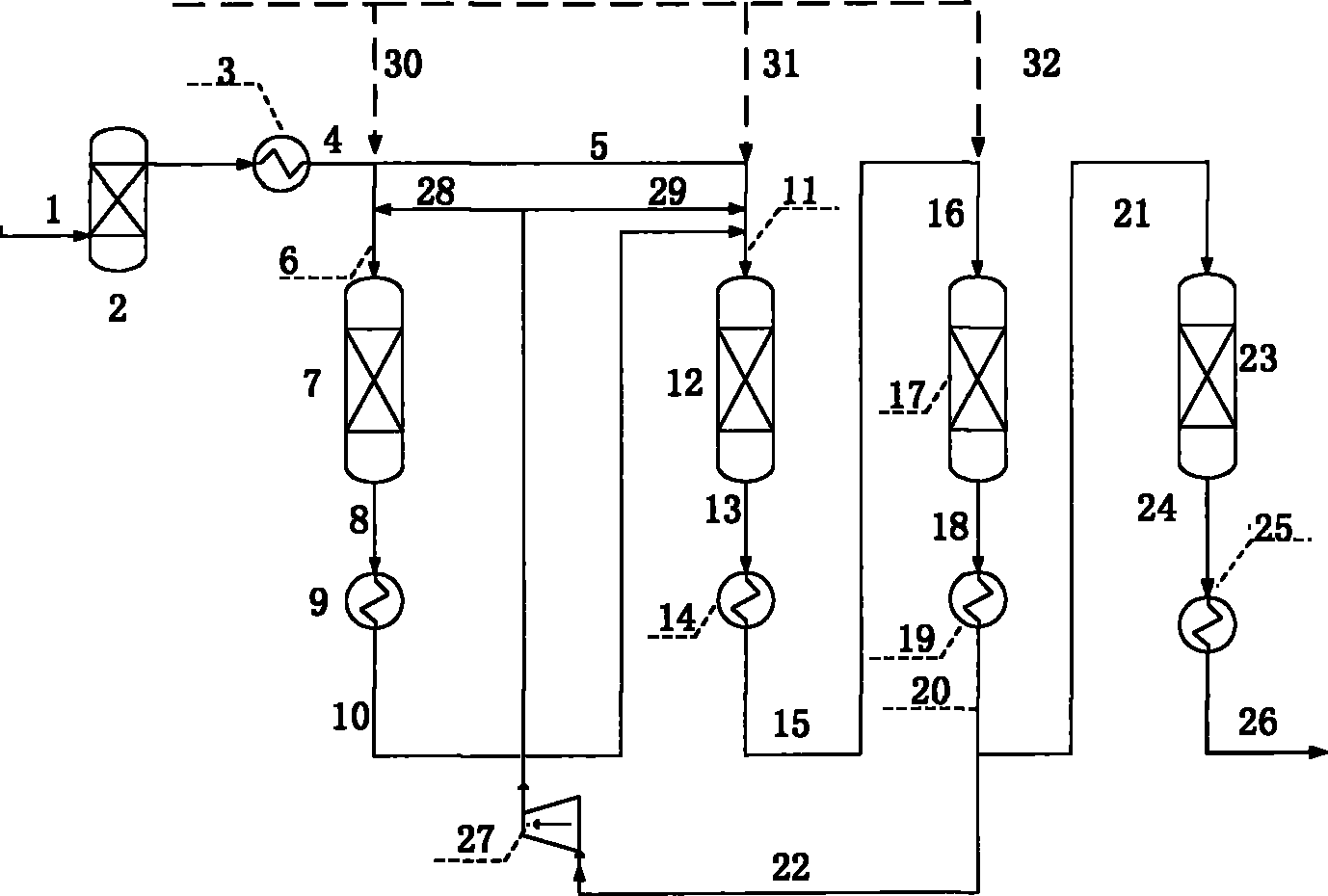

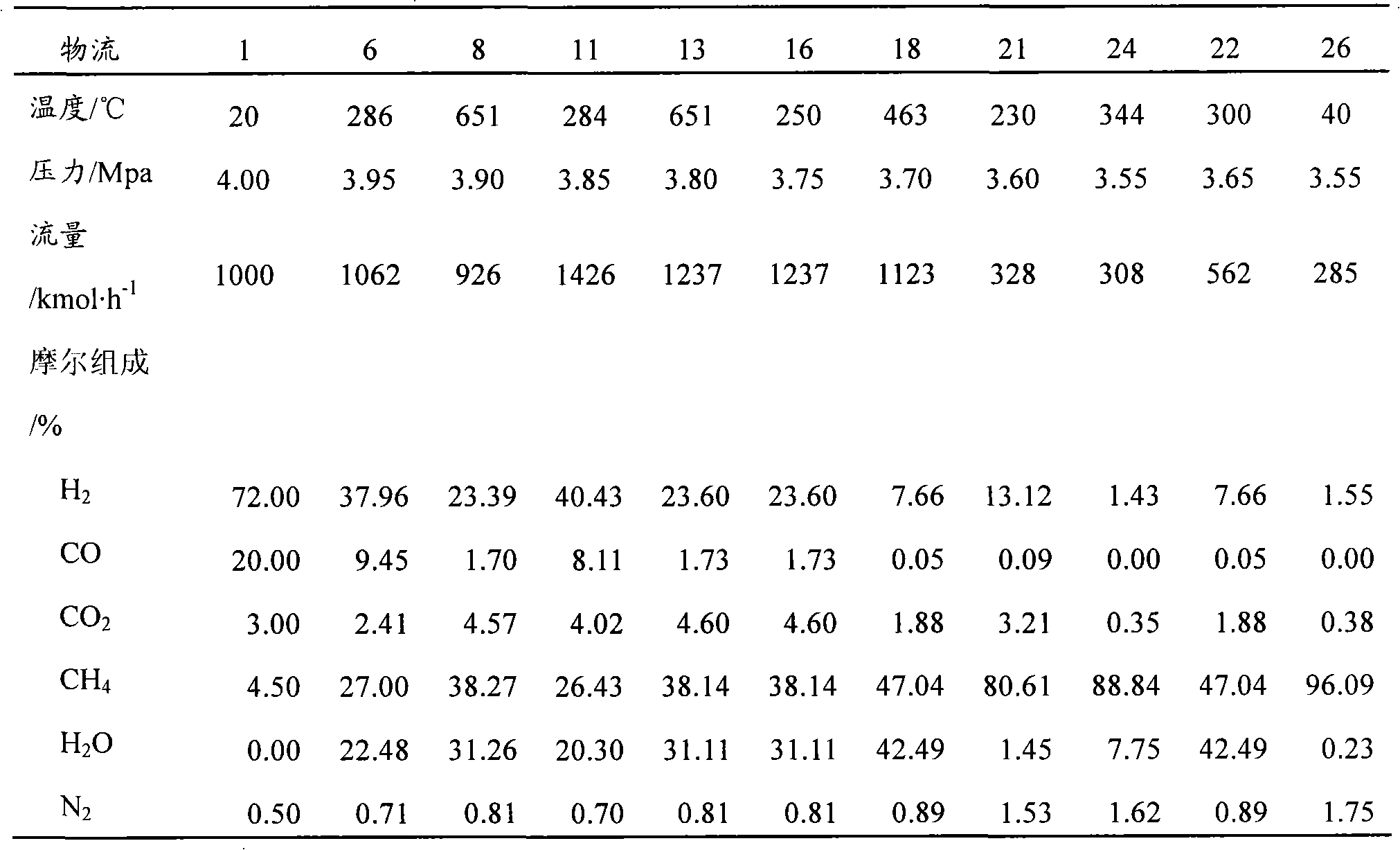

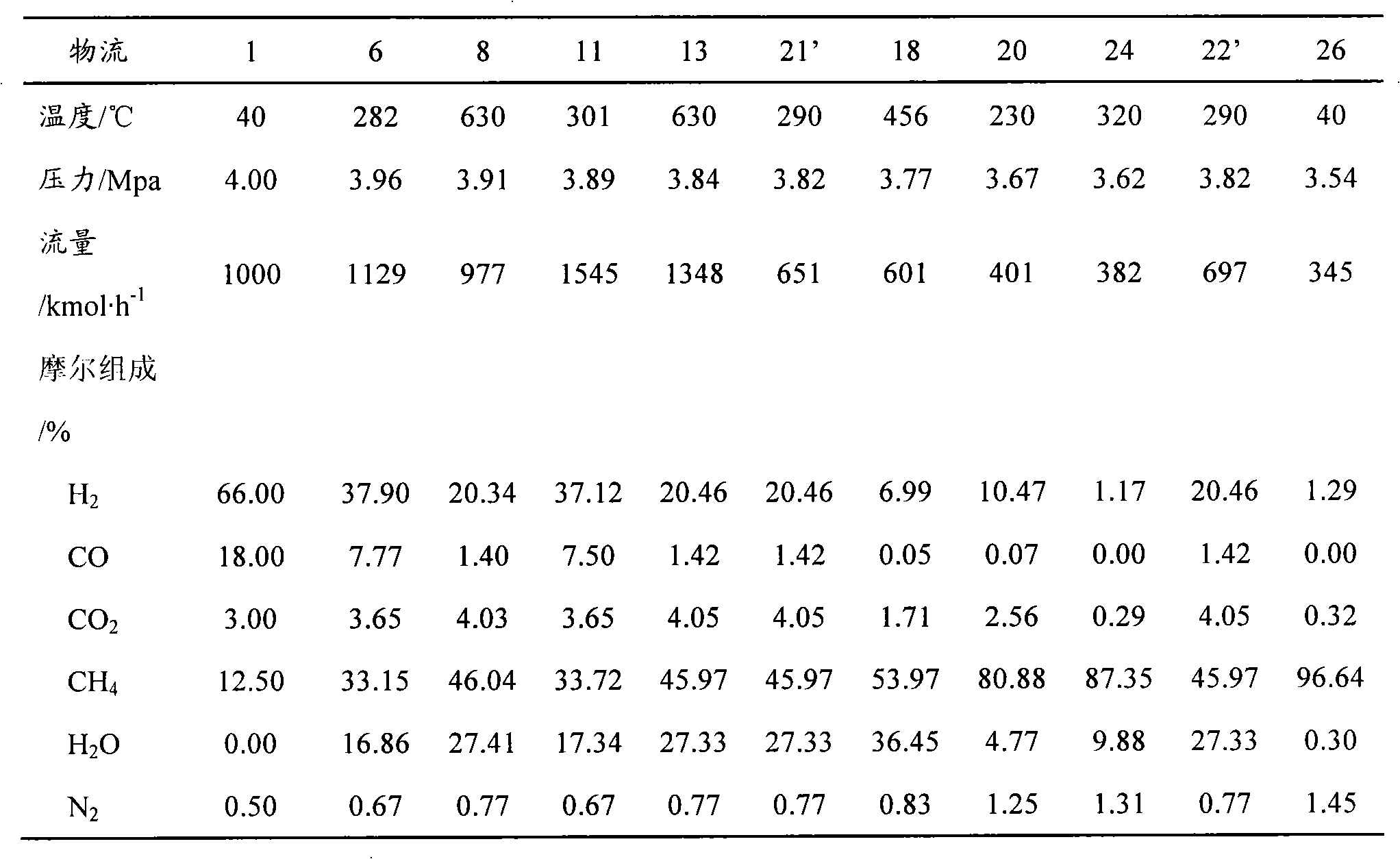

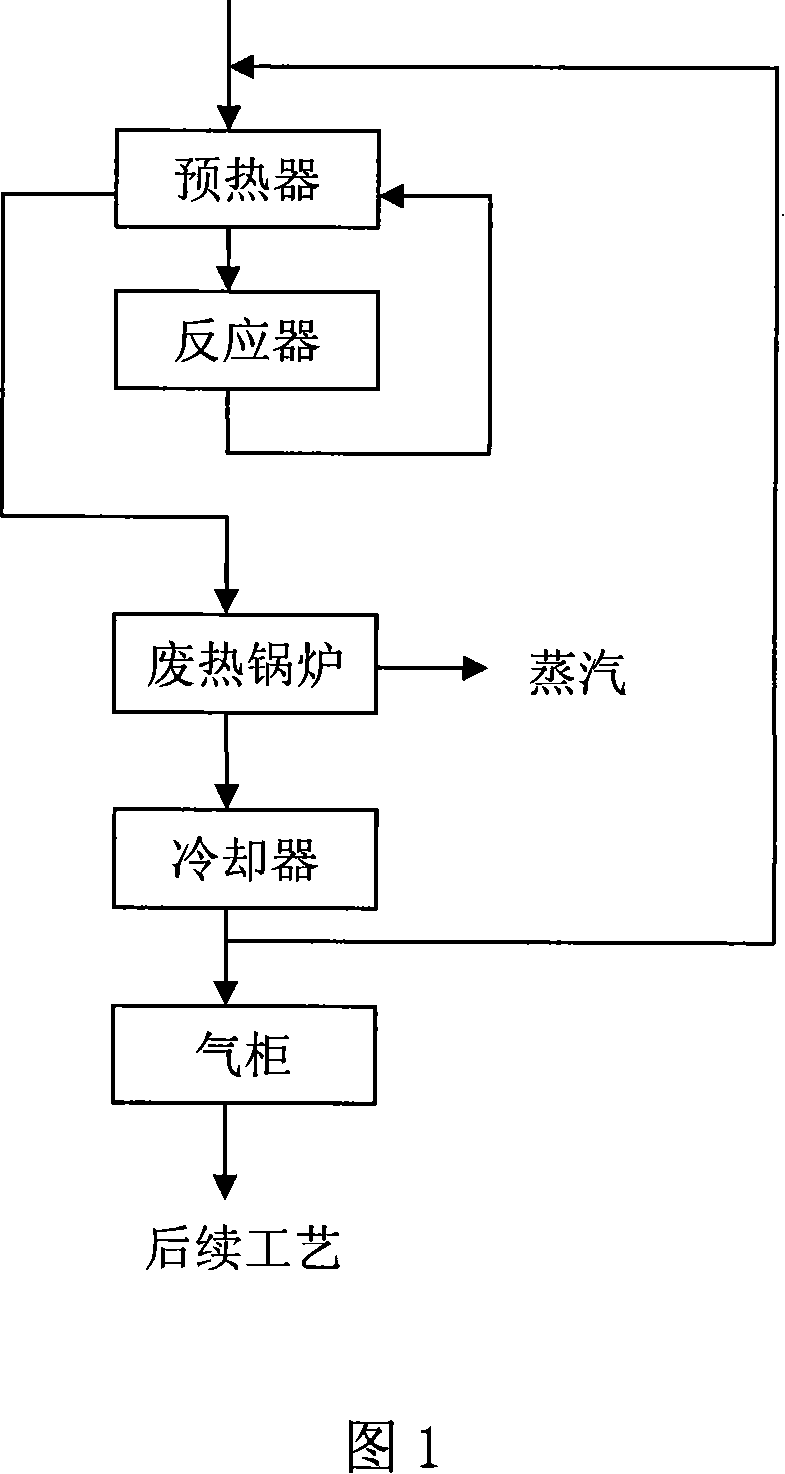

InactiveCN101812339AImprove utilization efficiencyControl reaction temperatureGaseous fuelsNatural productMethanation

The invention provides a method for producing synthetic natural gas and a device thereof. The continuous technological process of the invention is realized in a way that gasified product gas is used as the raw material for producing high methane gas containing more than 94 mol% of methane. The method can well adjust the methanation reaction temperature and avoid the problems of catalyst temperature-runaway sintering and the like due to improper material composition, excessive fluctuation or unexpected accident, thereby reducing the recycle gas amount and enhancing the energy comprehensive utilization efficiency.

Owner:DATANG INT CHEM TECH RESINST

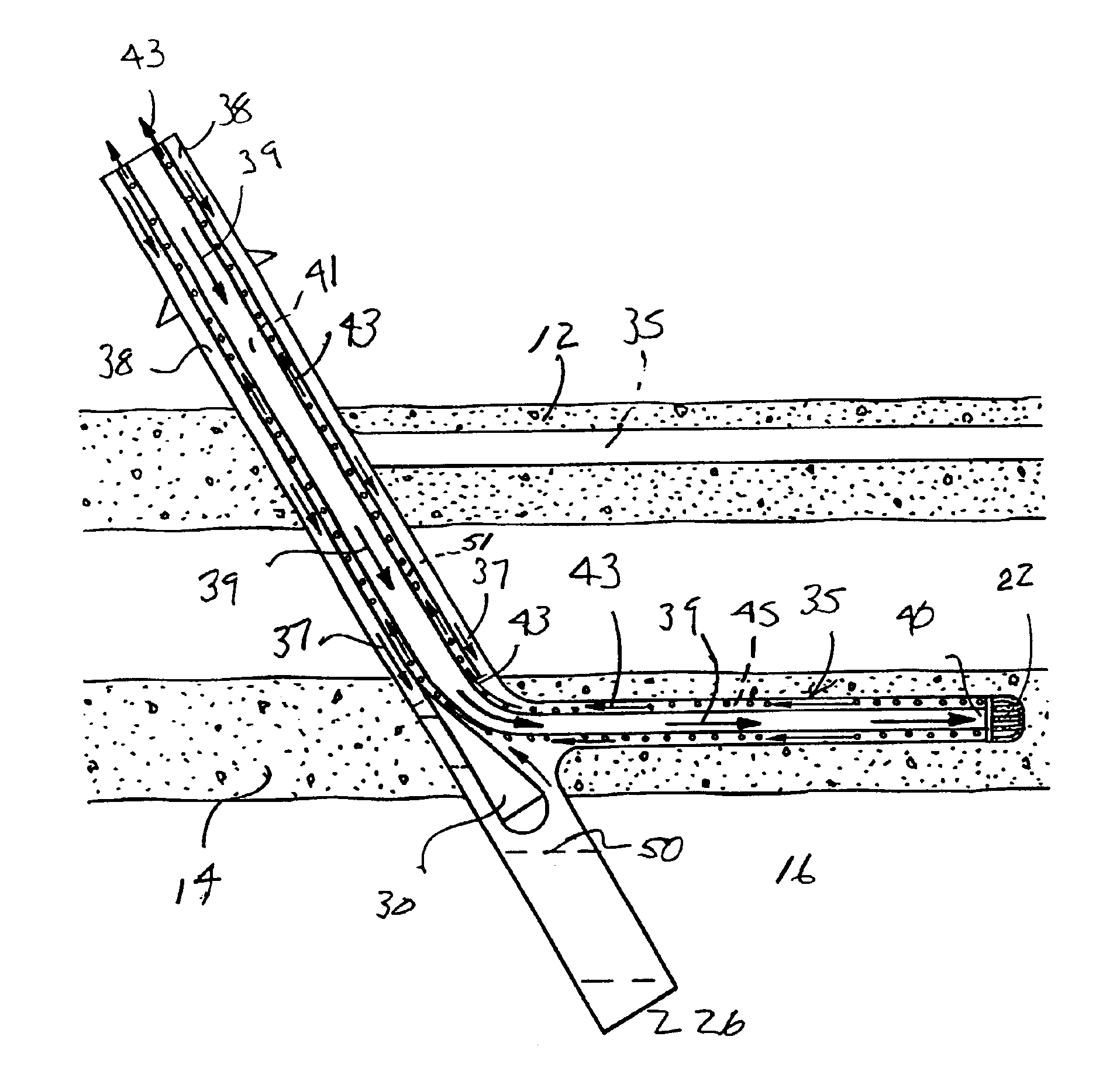

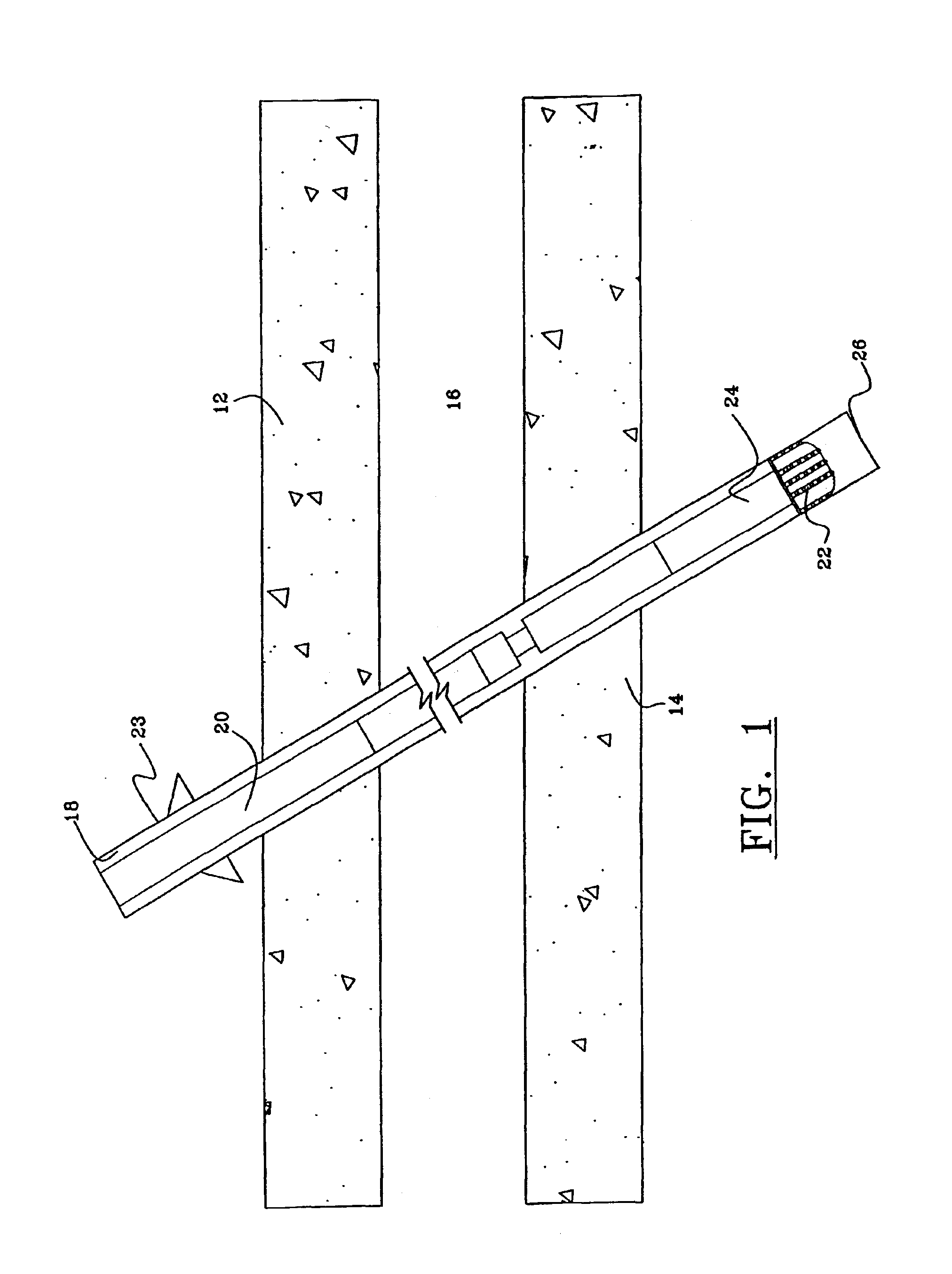

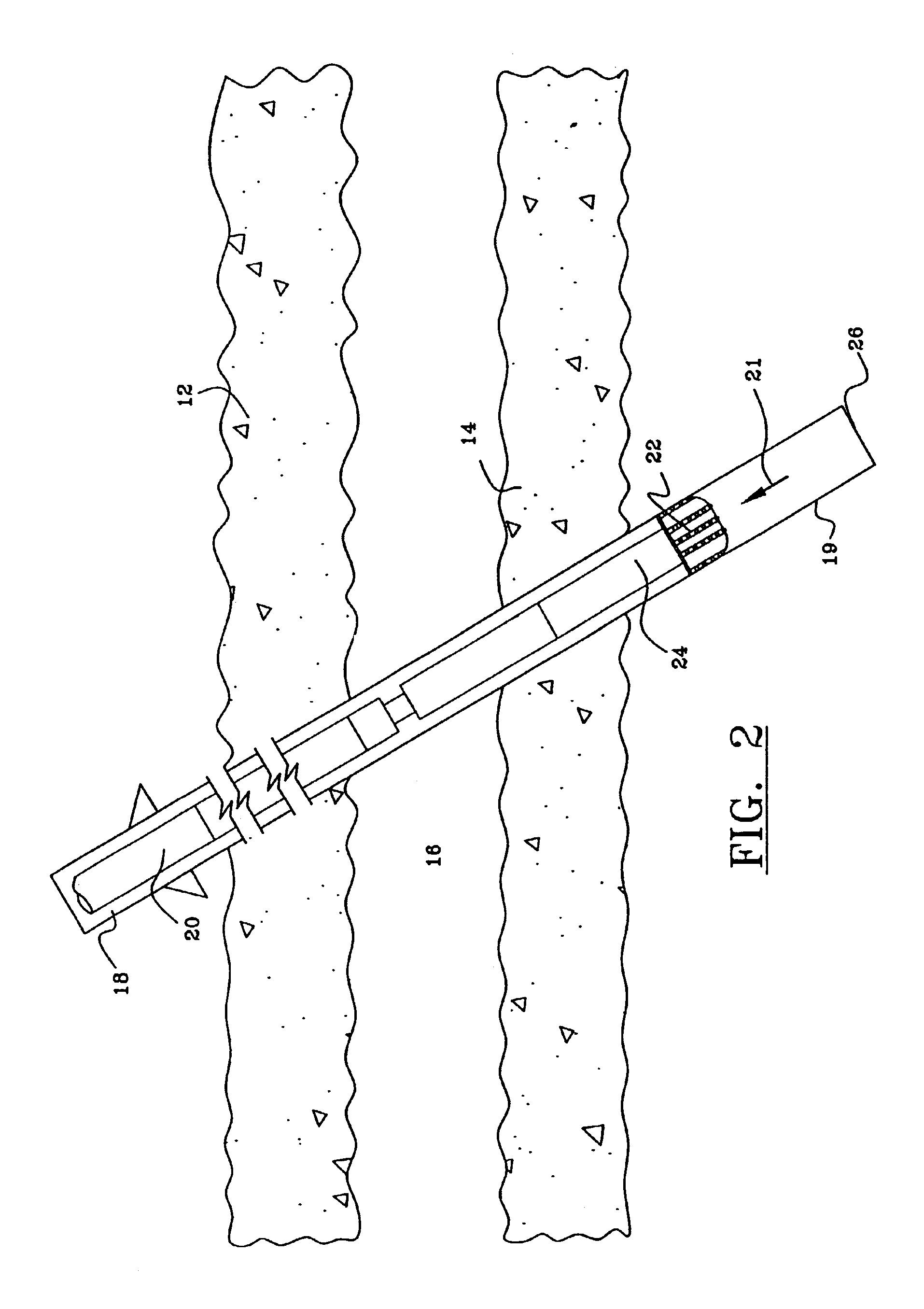

Multi seam coal bed/methane dewatering and depressurizing production system

InactiveUS6923275B2Minimal environmental impactEliminate infrastructure long-term maintenance and environmental impactFluid removalDirectional drillingWell drillingProduct gas

A process for underbalanced drilling into multiple coal and shale formations, and dewatering the drilled formations, which includes drilling a first borehole through several coal seams to a certain depth, defined as a cased borehole; lowering an upstock on the end of a carrier string to the depth of the upper coal seam; lowering a drill string in the carrier string, and angling off of the upstock, to drill a lateral or horizontal borehole within the coal seam; repeating the process for the second coal seam; setting a packer in place above the first coal seam in the annulus between the cased borehole and the carrier string; forming perforations in the wall of the carrier string below the packer; retrieving the upstock from the carrier string; lowering an electrical submersible pump to the bottom of the principal borehole, defined as a sump portion of the borehole; collecting methane gas from the two coal seams through the annulus between the second drill string and the carrier string to the surface; pumping water from the sump portion to the surface within the annulus of the second drill string, while gas within the annulus between the carrier string and the outer casing enters the plurality of perforations in the carrier string to be carried up to the surface.

Owner:GARDES ROBERT

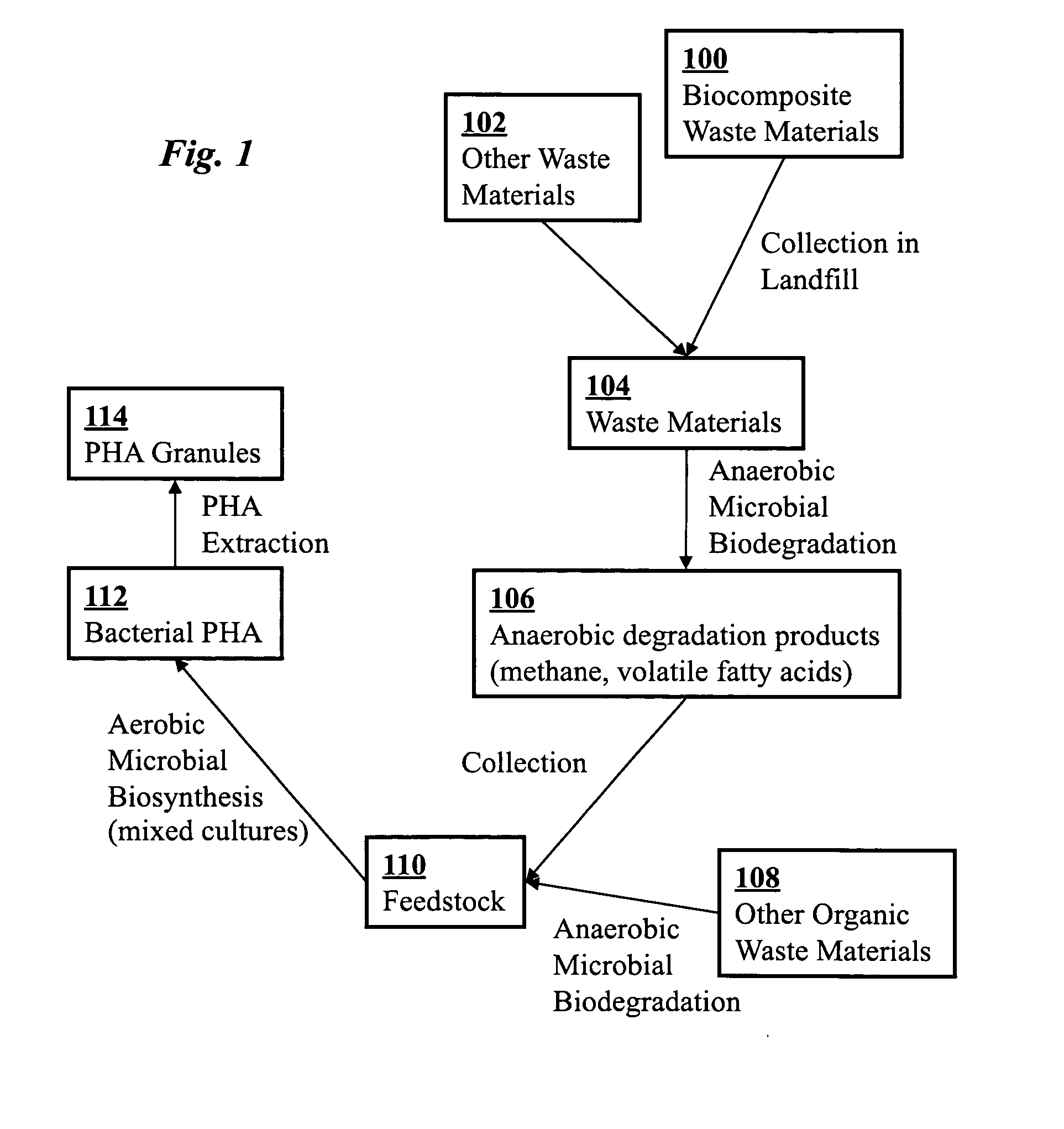

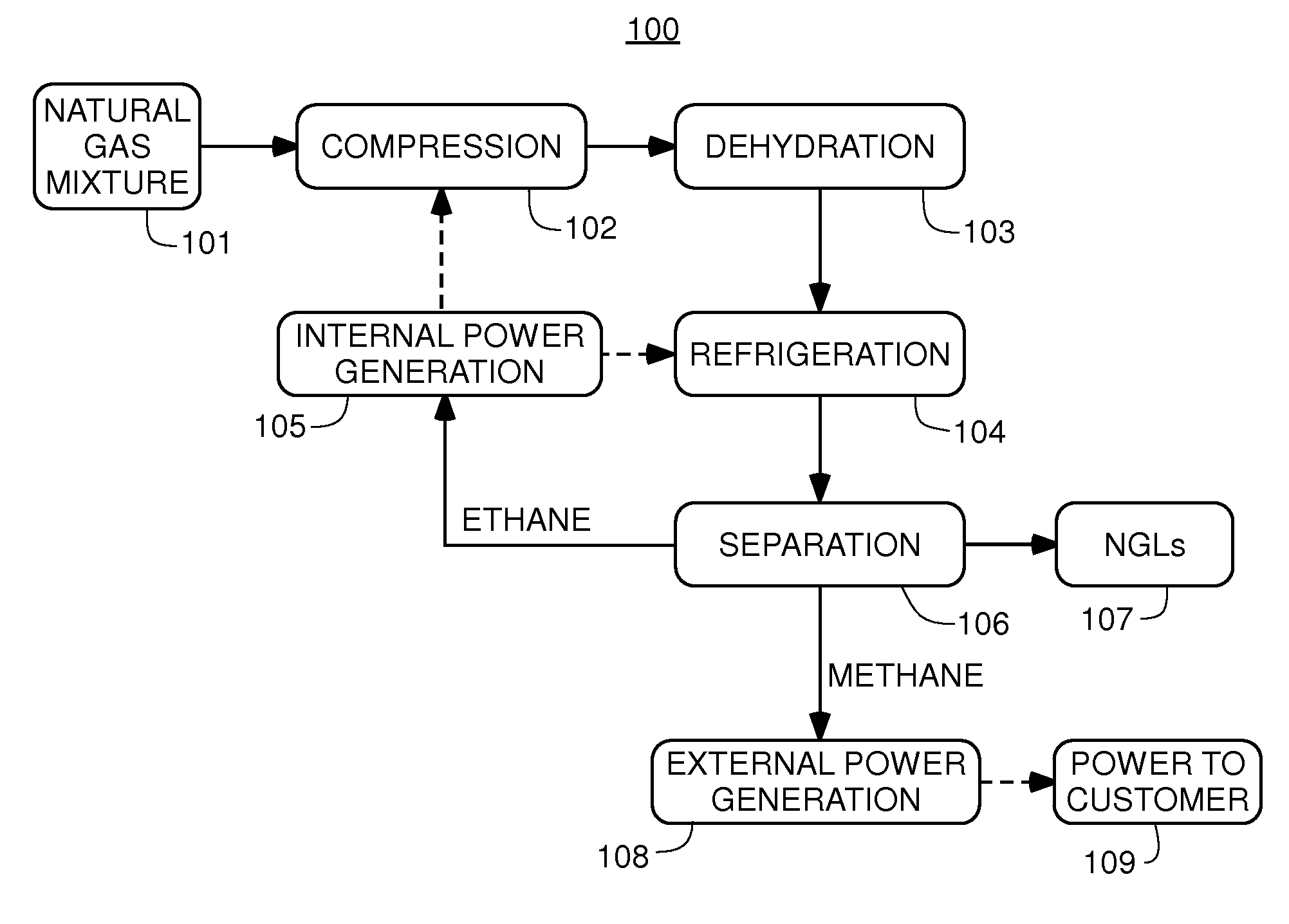

Use of selection pressures to enable microbial biosynthesis of polyhydroxyalkanoates from anaerobic degradation products

InactiveUS20090317879A1Cost of producingImprove the level ofWaste based fuelFermentationVolatile fatty acidsMethane gas

A method for inexpensive and efficient PHA biosynthesis includes operating a sequencing bioreactor in alternating phases of nutrient deprivation and carbon feedstock deprivation to select for robust PHA-producing microbes. Preferably, the bioreactor is operated in a non-sterile manner with mixed cultures of methanotrophs. The method also preferably uses periodic biomass-wasting (PHA harvesting) at the end of the carbon feed phase, gradually lengthening the time period of carbon deprivation phase to create a penalty for rapid PHA degradation and incentive for PHA accumulation. Also, bacterial enrichment cultures may be introduced periodically. The PHA-accumulating bacteria are preferably grown on common anaerobic degradation products, specifically volatile fatty acids, such as acetate and propionate, and methane gas. The PHA has useful applications in bioplastics and other products.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

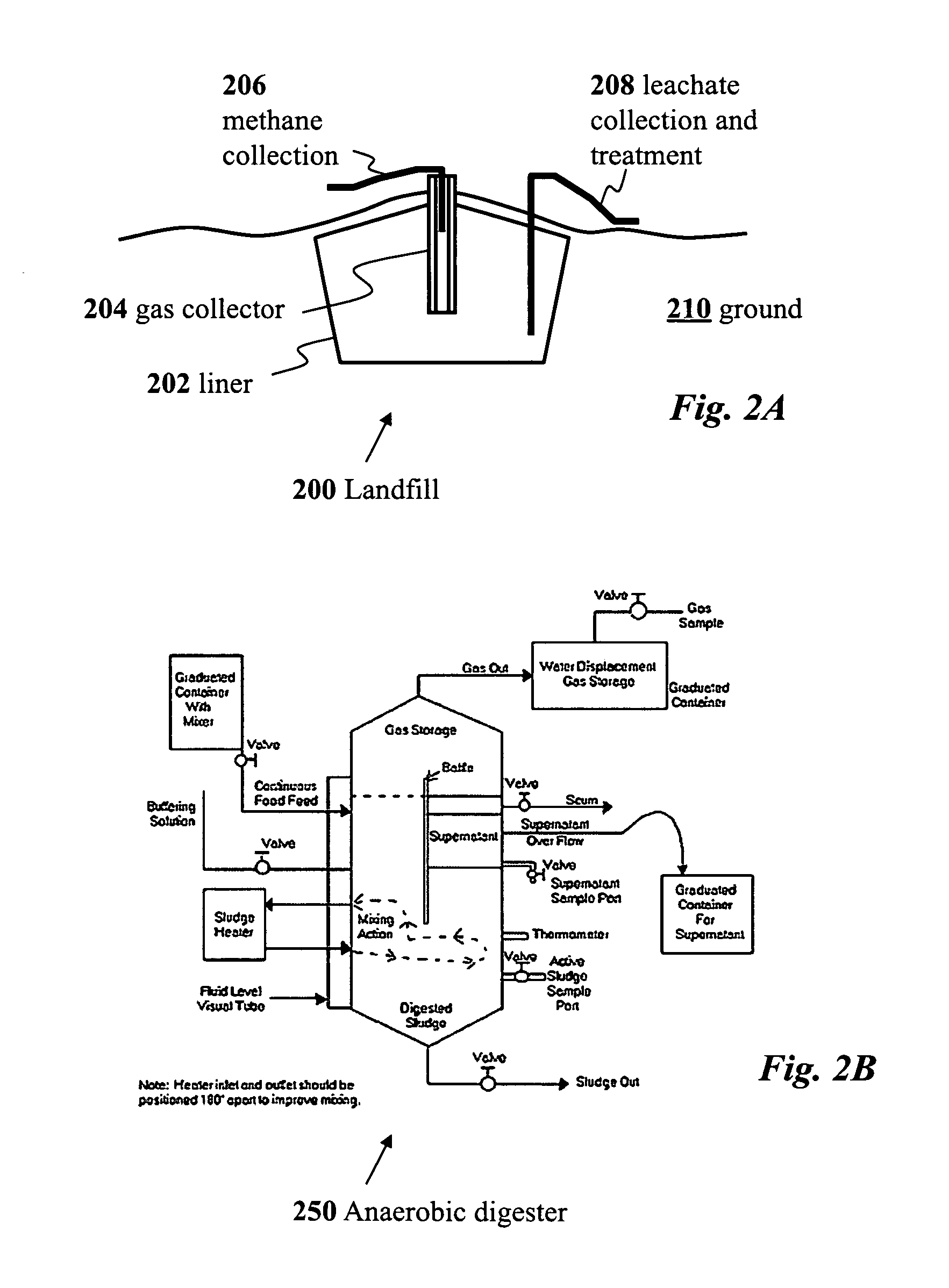

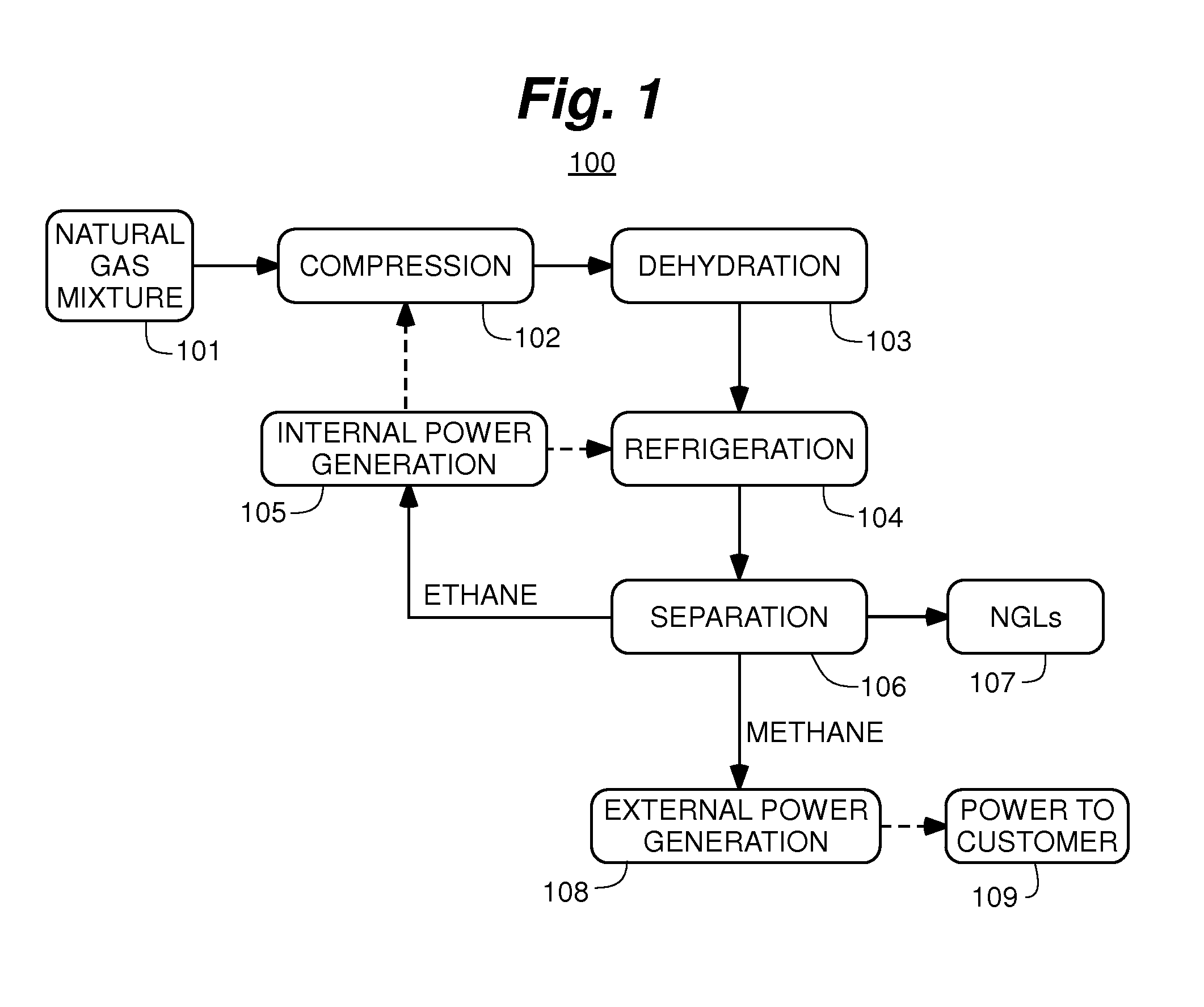

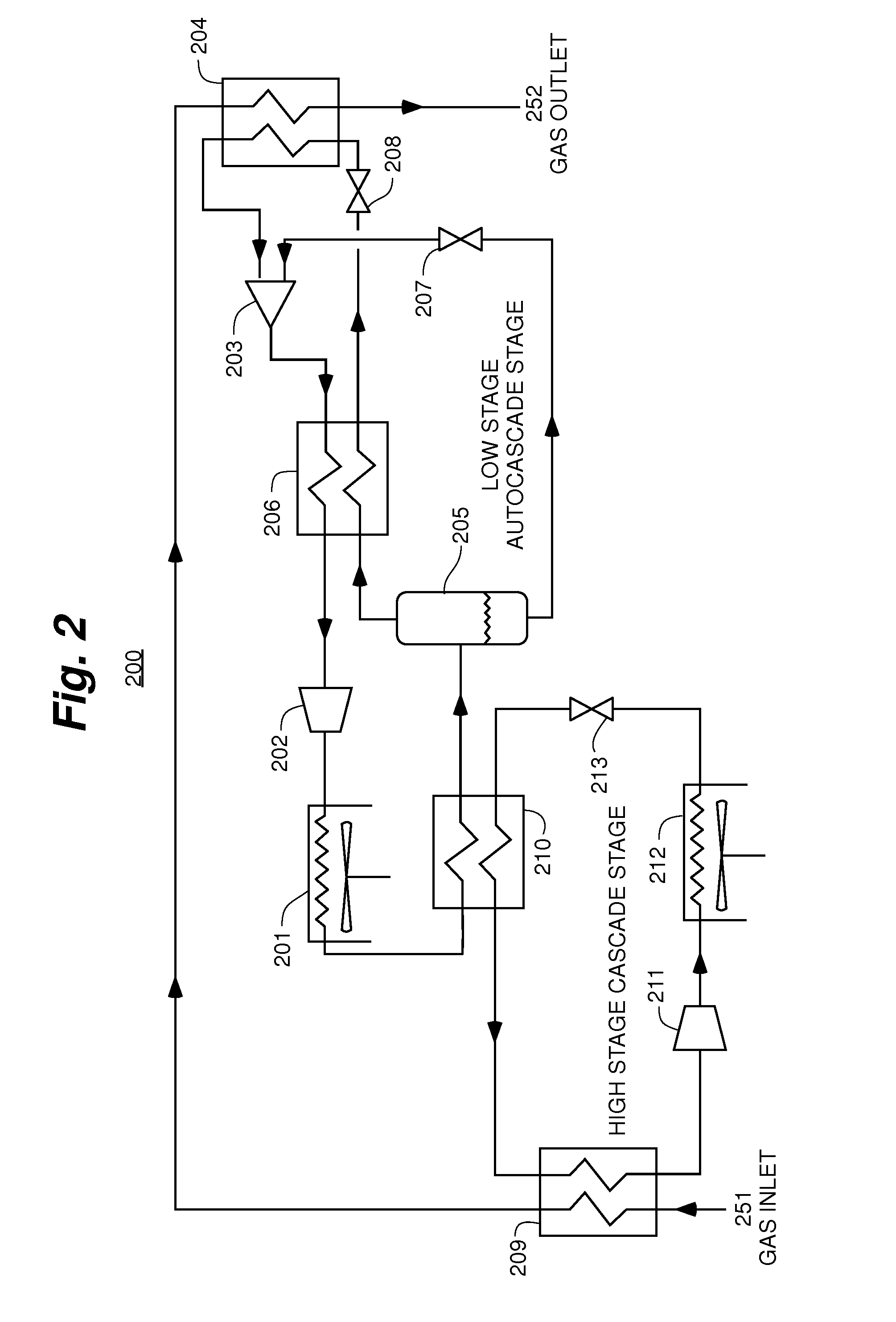

Systems and methods for separating alkane gases with applications to raw natural gas processing and flare gas capture

InactiveUS20140366577A1Reduce stepsHigh quality separationSolidificationLiquefactionAlkaneNatural-gas processing

The present invention is a field-deployable system for separating methane and natural gas liquids (NGLs) from a raw gas stream comprising a compressor; a dehydrator; a refrigerator having one or more stages; and a separation subsystem adapted to separate the raw gas stream into three product streams including a methane stream that is at least 80% methane, an ethane-rich stream, and a NGLs stream having a vapor pressure of no more than 250 psia at 38° C. The methane stream is sufficiently lean to be useable in existing natural gas engines without modification. The NGLs stream has a sufficiently low vapor pressure to be transportable in standard propane containers. The ethane-rich stream may be utilized within the system itself to power its own operations. The system can be utilized to reduce flaring from liquids-rich gas production sites to an absolute minimum, produce natural gas liquids for transport, and provide dry methane gas suitable for use in portable field generators.

Owner:PIONEER ENERGY

Preparation method and use of carbon molecular sieve

InactiveCN101935032ASolve the problem of difficult and efficient separation of methane-nitrogenNitrogen purification/separationOther chemical processesHigh concentrationLoss rate

The invention relates to a preparation method and use of a carbon molecular sieve. The preparation method comprises the following steps: preparing a conventional carbon molecular sieve; and expanding the pores in the conventional carbon molecular sieve by using a secondary activation technique and modifying the conventional carbon molecular sieve by adjusting the pores. The new carbon molecular sieve is prepared by using coal, coconut shell or phenolic resin, and the like as raw materials, by the conventional production steps of crushing, forming, carbonizing, steam activating, hydrocarbon settling and shrinking and the like and by secondary activation with KOH or CO2 as an activator. The activation temperature is between 550 and 850 DEG C; and the ignition loss rate of the product is kept be between 0.1 and 30 percent. In aspect of use, the carbon molecular sieve can be used for absorbing nitrogen molecules and can also be used for absorbing and separating methane and nitrogen in seam gas under a variable pressure while achieving an adsorption dynamic separation effect and allowing high-concentration methane gas to be collected at the exit of an adsorption tower directly; and thus, the methane in the seam gas can be used efficiently.

Owner:TONGJI UNIV

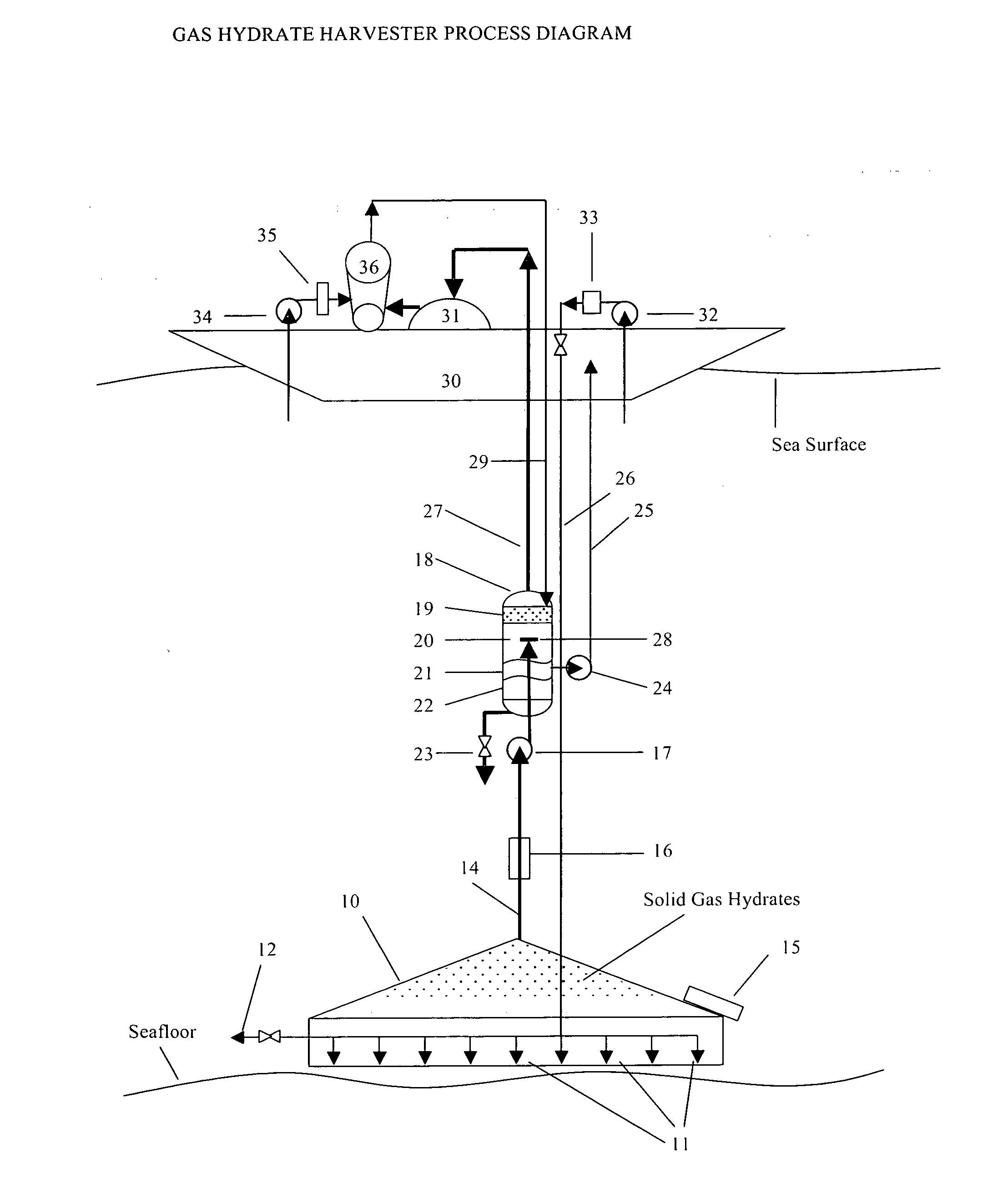

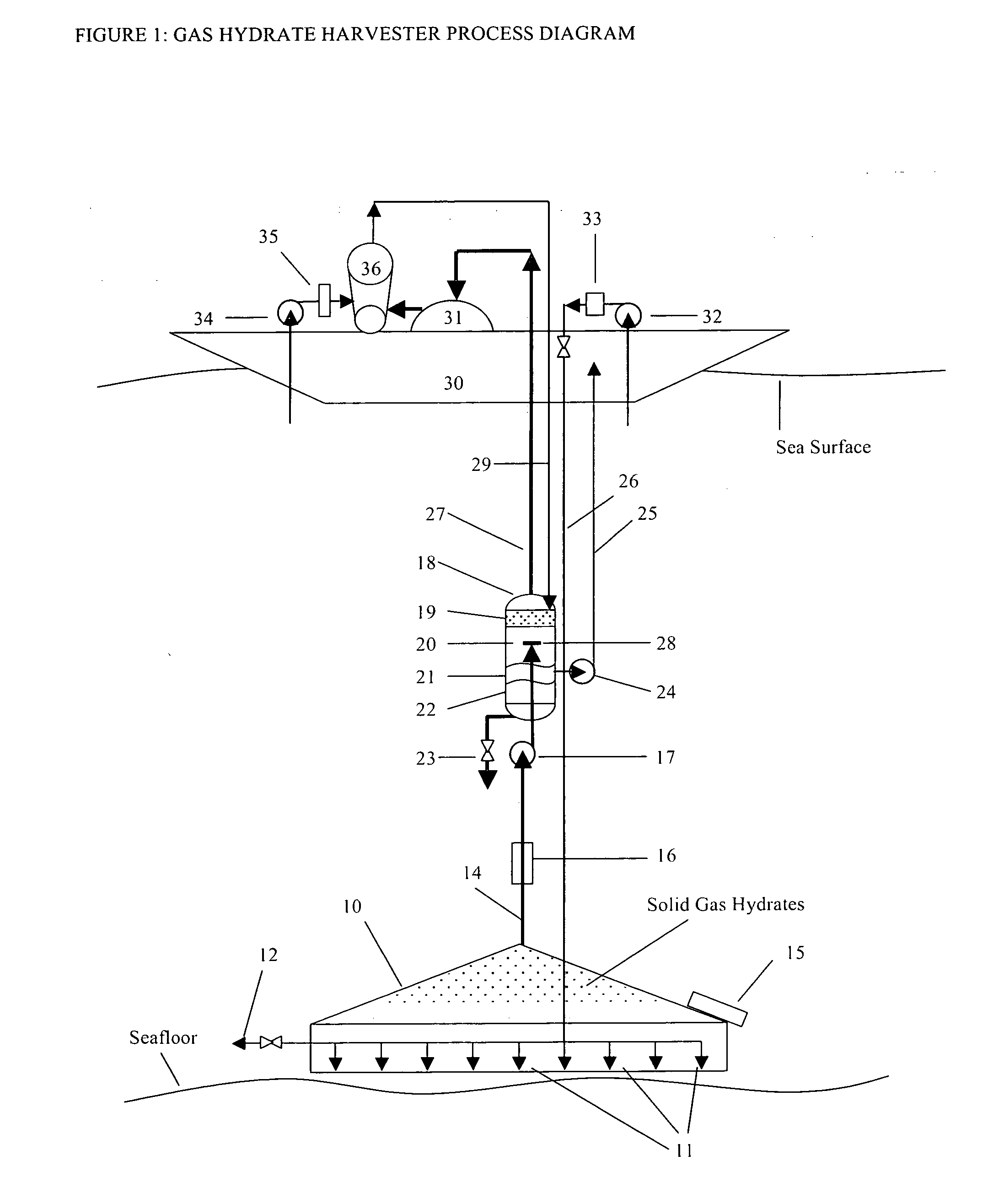

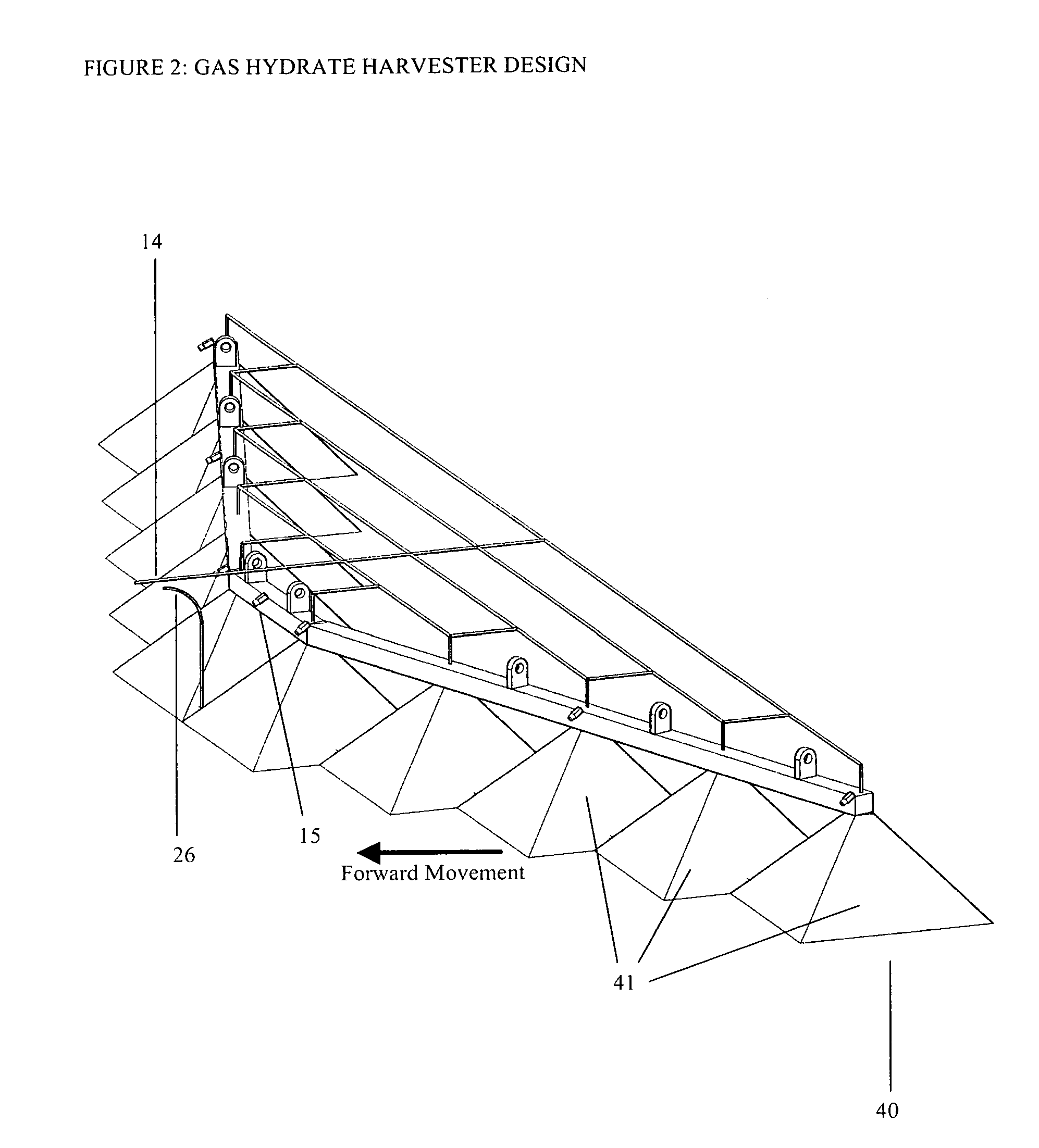

Gas Hydrate Harvesting

A harvester (10) with warm water spray jets (11) that fluidizes and releases gas hydrates from seafloor sand and soil. The released gas hydrates float into the harvester (10) and are then transferred through a hydrate slurry pipe (14) to a separation vessel (18). Dissociation of the gas hydrates into methane gas occurs in the separation vessel (18) from its lower pressure than the seafloor and the optional use of heat. The liberated methane gas flows upward in a gas vent pipe (27) to a topside vessel (30) for storage from the pressure of the submerged separation vessel (18). Alternatively, the vent pipe can be fed directly into an available natural gas pipeline. Crude oil collected in the separation vessel (18) can be separated and pumped to a topside vessel (30) for storage and use in a refinery. No other processing is required to produce commercial quality natural gas harvested directly from gas hydrates on or near the seafloor.

Owner:WILLMAN TODD JENNINGS

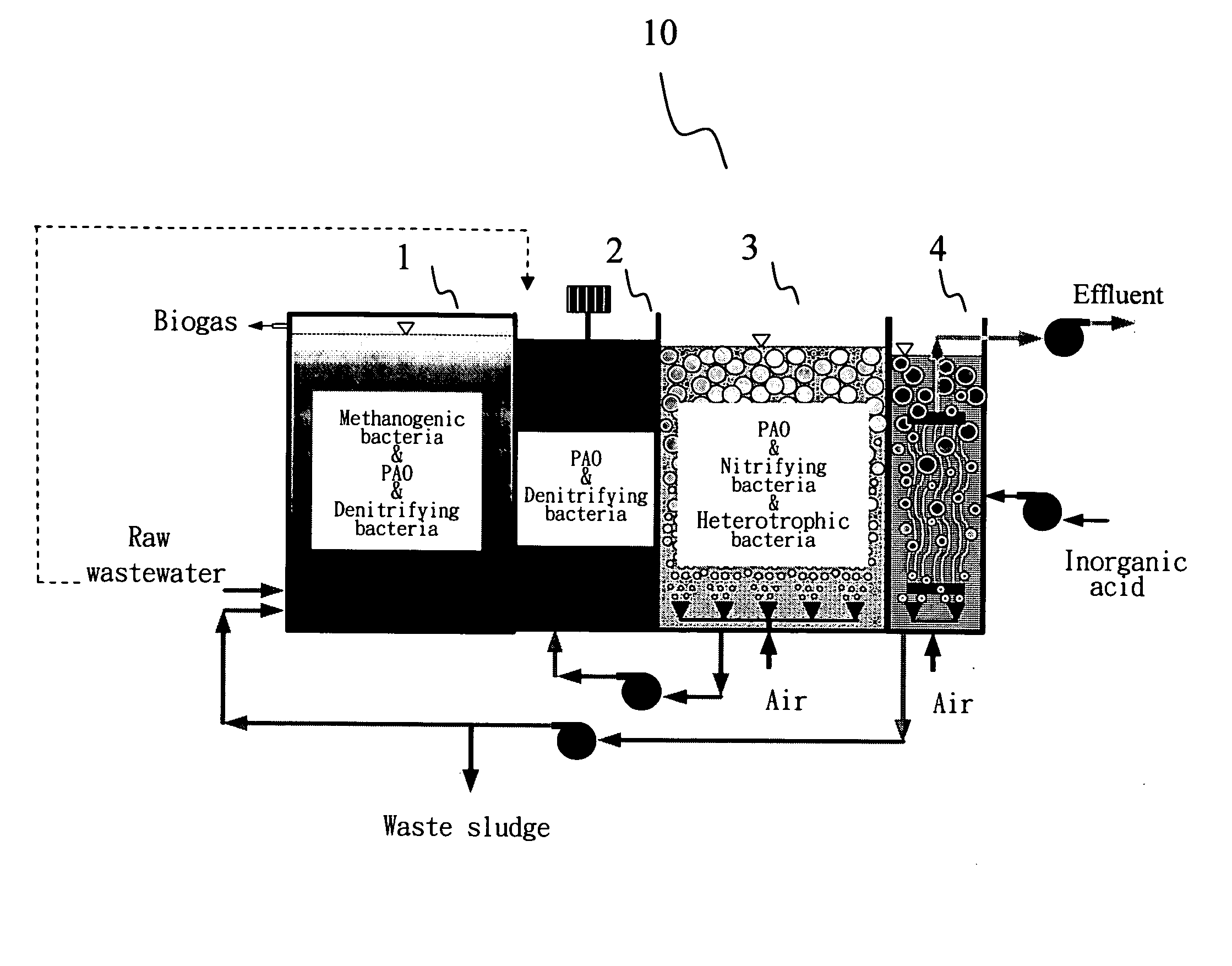

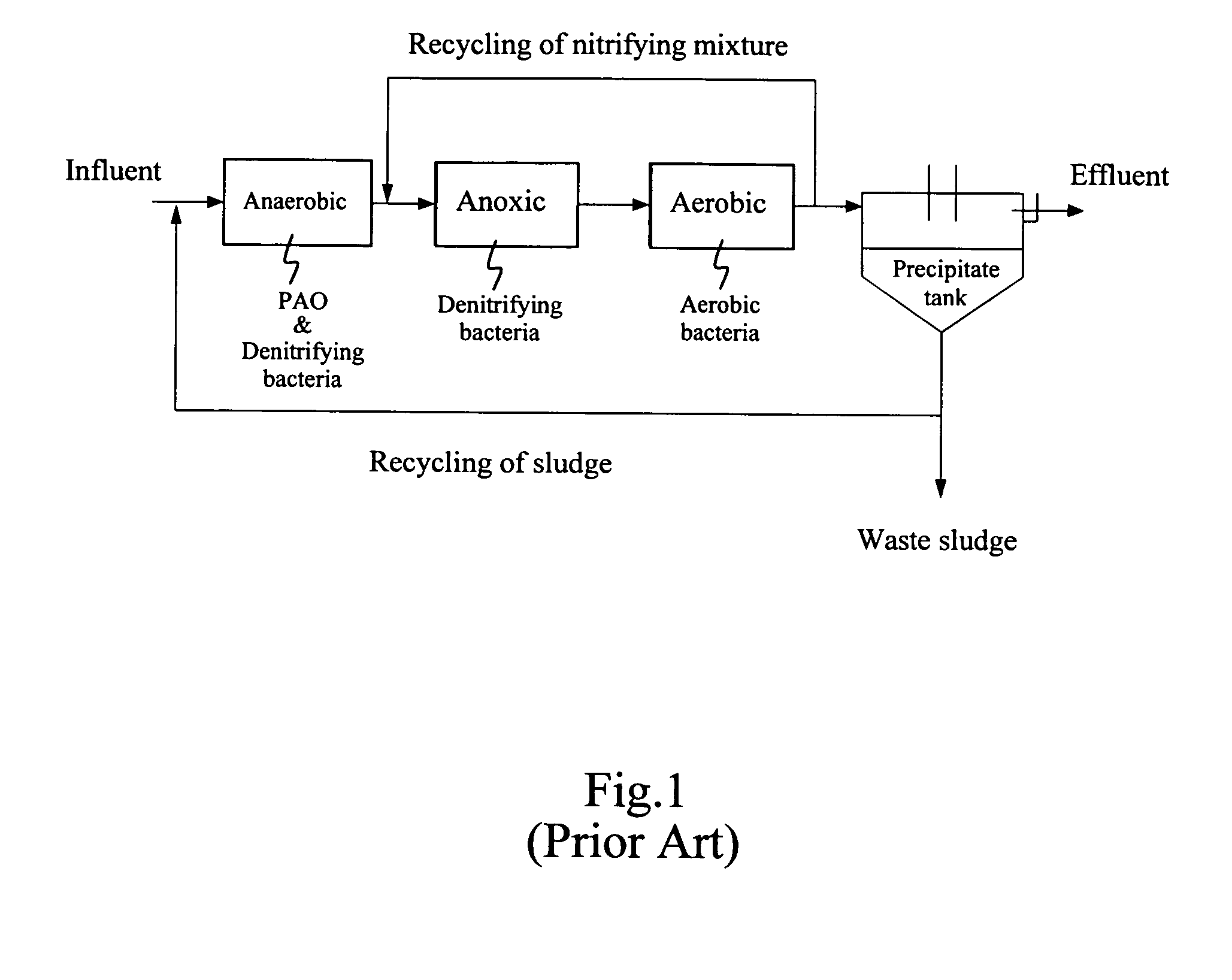

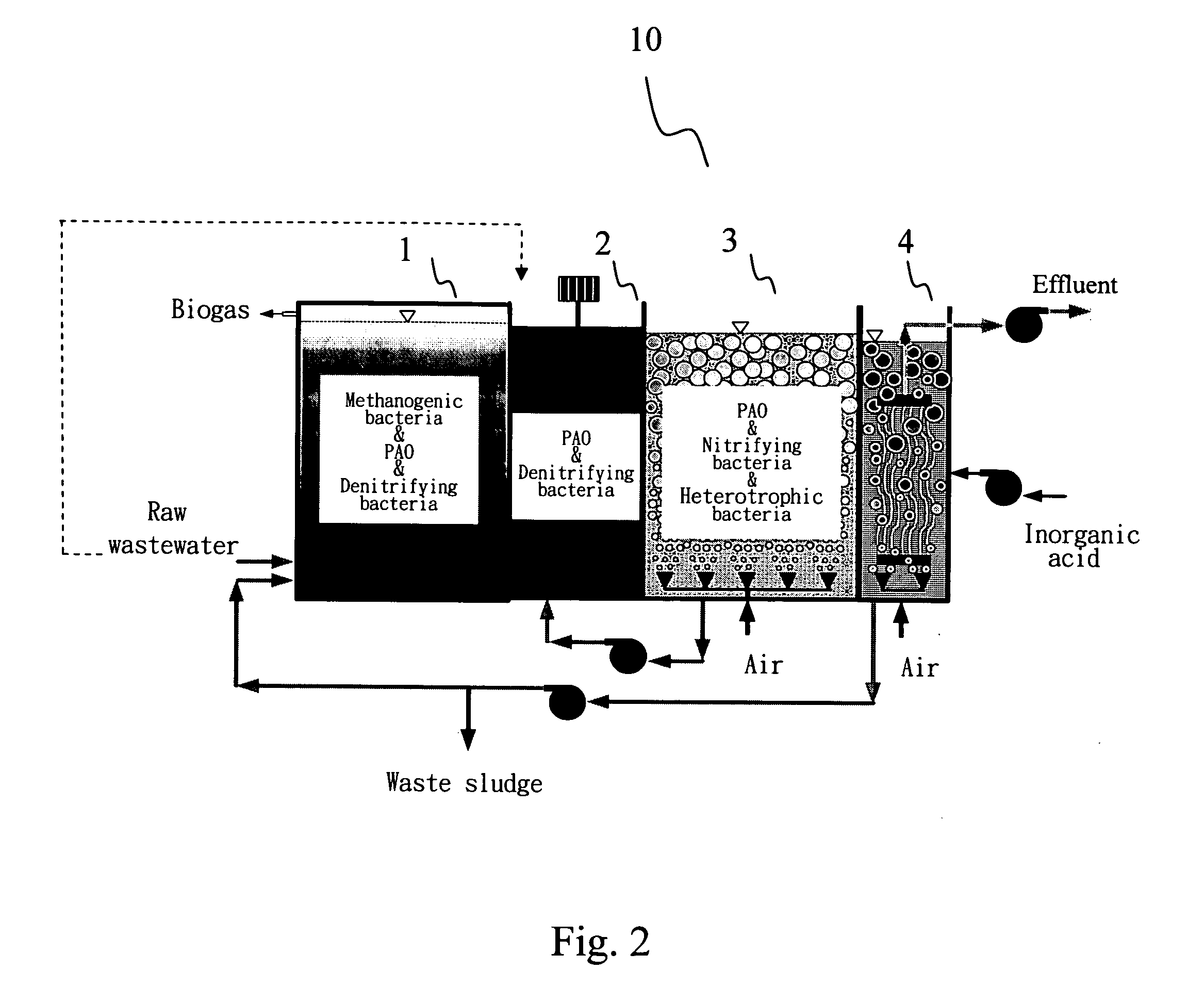

System and method for treating carbon, nitrogen, phosphorous containing wastewater

ActiveUS20070193949A1Easy loadingReduce power consumptionWaste based fuelSeparation devicesSludgePhosphate

The present invention relates to a wastewater treating system and method for removing pollutants of carbon, nitrogen, phosphorous, comprising: a first reactor contains methanogenic bacteria, PAO and denitrifying bacteria for eliminating the organic carbon in denitrification by denitrifying bacteria, adsorbing partial organic carbon and releasing phosphate by PAO and; metabolizing organic carbon to form methane gas by methanogenic bacteria; a second reactor disposed at the rearward of first reactor, second reactor treats the effluent from first reactor by denitrifying bacteria and PAO, denitrifying bacteria is able to denitrifying the nitrate and PAO is able to process the phosphorous releasing; a third reactor disposed rearward of second reactor, which comprises PAO, heterotrophic bacteria and nitrifying bacteria, wherein PAO is applied for phosphorous accumulating process, the heterotrophic bacteria is applied for carbon removal process, the nitrifying bacteria is applied for nitrifying process; and a membrane separation reactor disposed inside or rear of third reactor to separate various microorganisms and the treated effluent. The present invention applies methanogenic bacteria in the system for decreasing the amount of waste sludge efficiently and reduce power consuming.

Owner:IND TECH RES INST

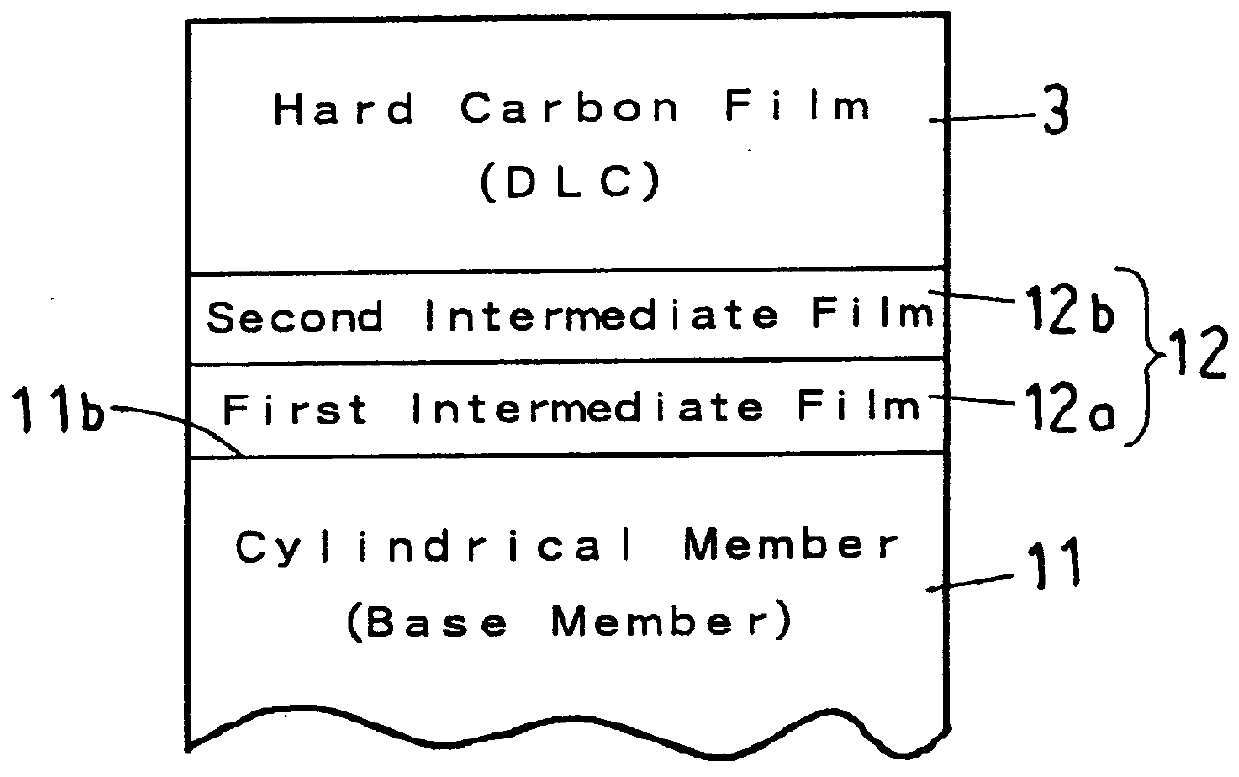

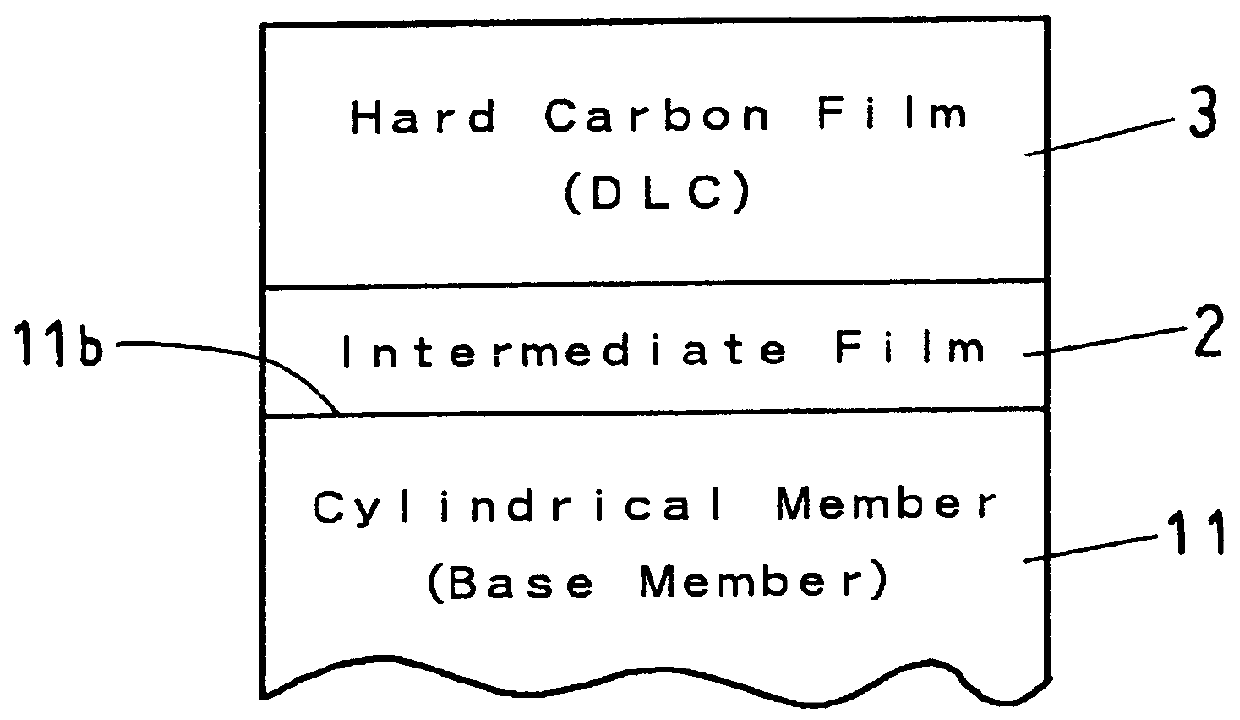

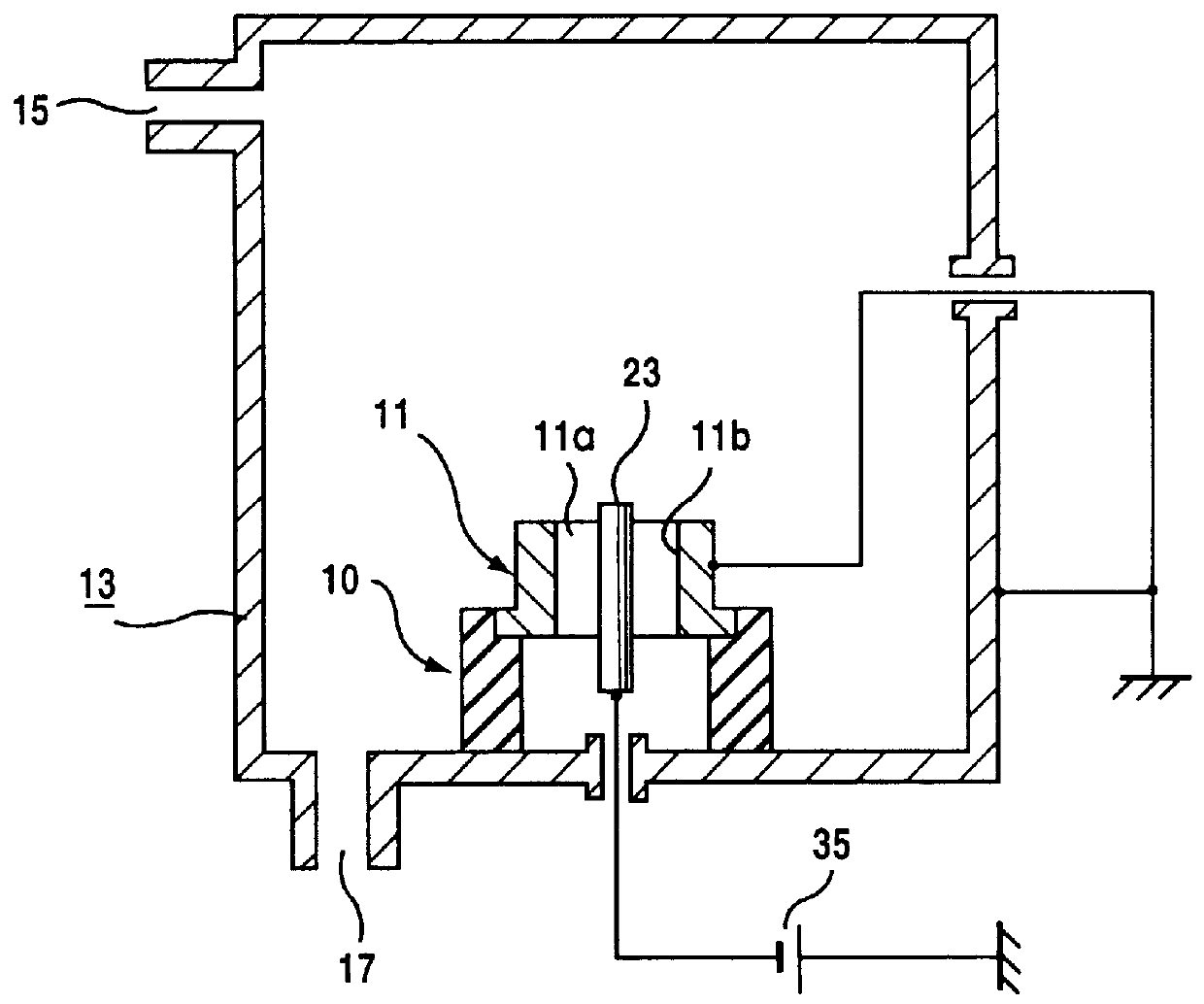

Method of forming films over inner surface of cylindrical member

InactiveUS6126793AImprove adhesionVacuum evaporation coatingPretreated surfacesSputteringCarbon film

The present invention relates to a method of forming an intermediate film and a hard cabon film over the inner surface of a cylindrical member having a bore, such as a bushing or a cylinder, with the hard carbon film being formed on the intermediate film with a uniform thickness, greatly enhancing of abrasion resistance of the inner surface. The cylindrical member is placed in a vacuum vessel, an auxiliary electrode of an intermediate film forming material, such as a titanium-silicon alloy or the like, is inserted in the bore of the cylindrical member, a sputtering gas is supplied into the vacuum vessel, a voltage is applied to the auxiliary electrode to produce a plasma around the auxiliary electrode in order that the intermediate film forming material is sputtered from the auxiliary electrode and an intermediate film is formed over the inner surface of the cylindrical member. Subsequently, a gas containing carbon, such as methane gas or the like, is supplied into the vacuum vessel, and a voltage is applied to the cylindrical member to produce a plasma in the vacuum vessel in order that a hard carbon film (DLC film) is formed on the previously formed intermediate film over the inner surface of the cylindrical member.

Owner:CITIZEN WATCH CO LTD

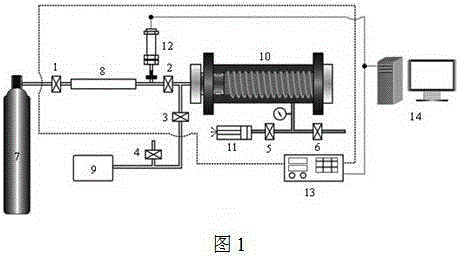

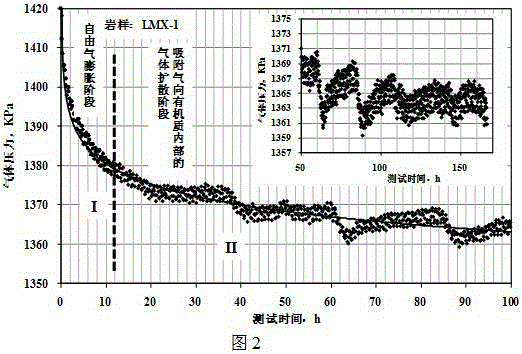

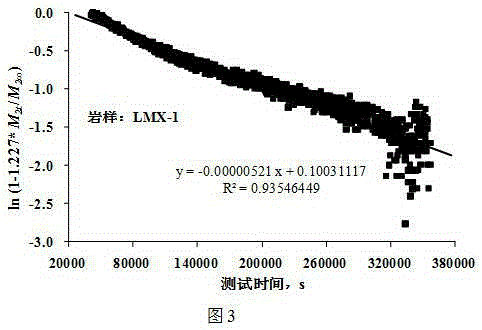

Shale gas reservoir gas diffusion coefficient experiment test method

InactiveCN105259080AFully reflectEffects of the overall diffusion processSurface/boundary effectDesorptionRock sample

The invention discloses a shale gas reservoir gas diffusion coefficient experiment test method. According to a method, a one-dimensional diffusion mathematic model is built by monitoring pressure attenuation data in a shale plunger rock sample under effective stress conditions of methane gas with a certain initial pressure in a constant-temperature closed system with the micro-pore structure and the gas existence state of a shale reservoir as bases, the diffusion coefficient of the gas (methane) in shale is calculated, and the diffusion mass-transfer capacity of the gas (methane) in the shale is quantitatively assessed. In the experiment testing process, the diffusion process of gas in the shale gas reservoir can be effectively simulated, and influences of effective stress, gas adsorption / desorption and other factors on the diffusion coefficient are reflected. Besides, the method can overcome influences of gas free expansion stage data in a traditional adsorption / desorption method on the diffusion coefficient. The method can assess the diffusion mass-transfer capacity of the gas in the shale and provide experiment support for researches in the aspects of shale gas reservoir productivity models, productivity prediction and the like.

Owner:SOUTHWEST PETROLEUM UNIV

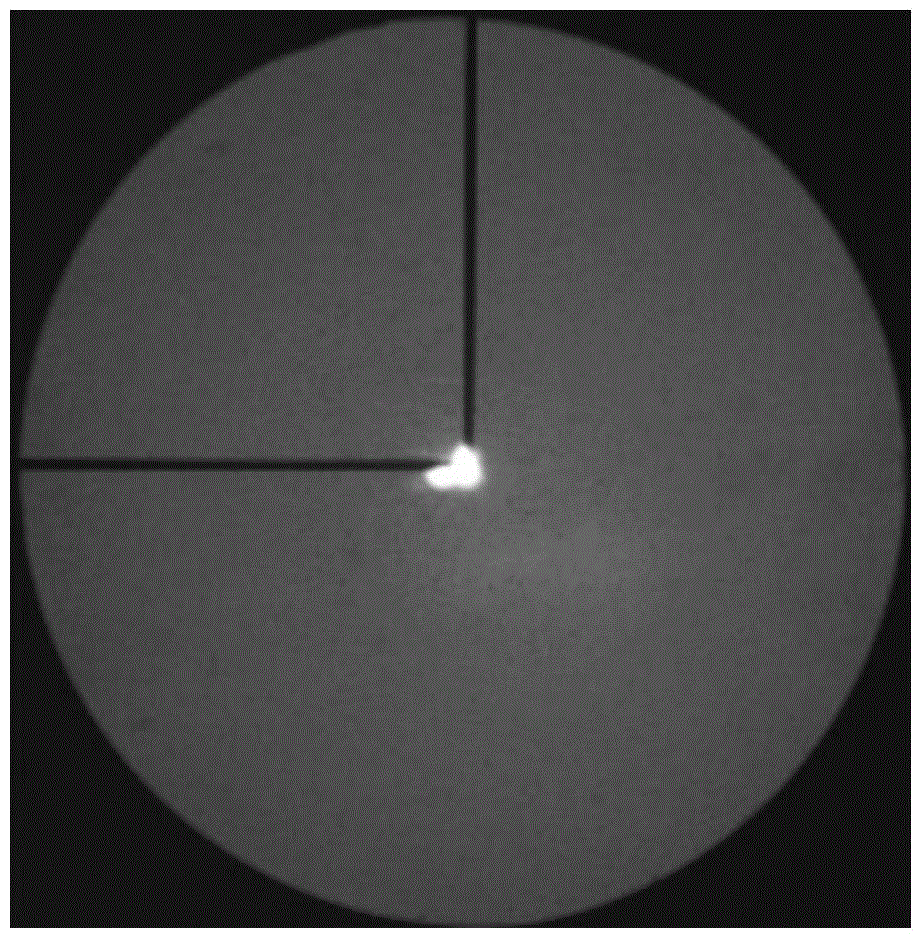

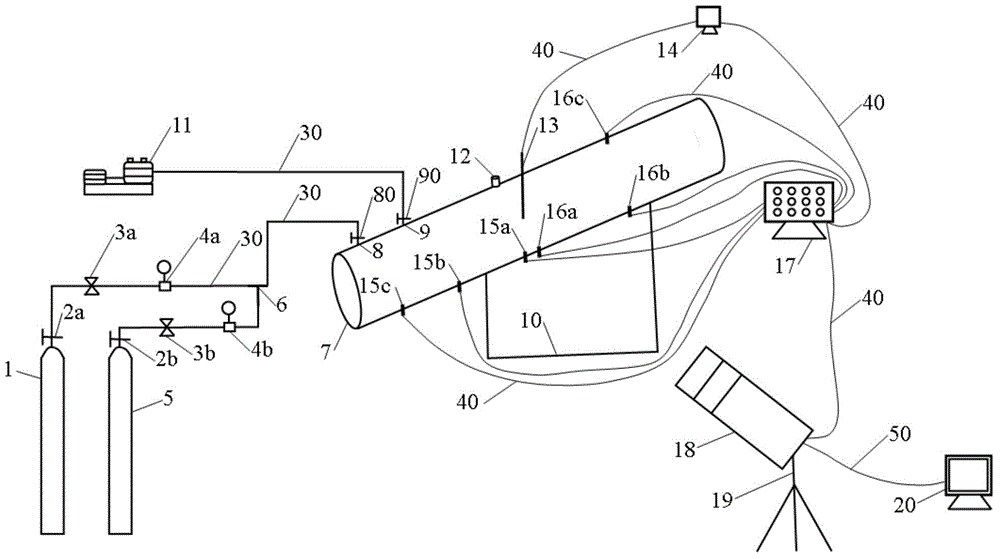

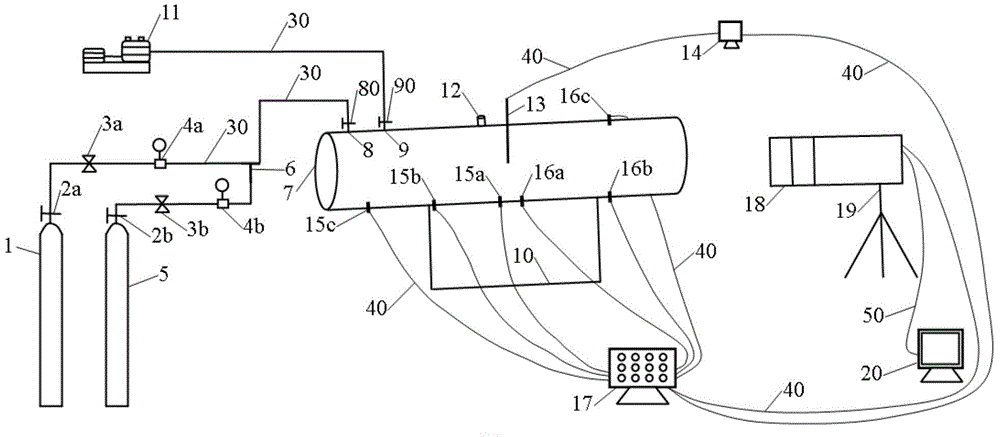

Gas explosion simulation test system and method

Owner:ANHUI UNIV OF SCI & TECH

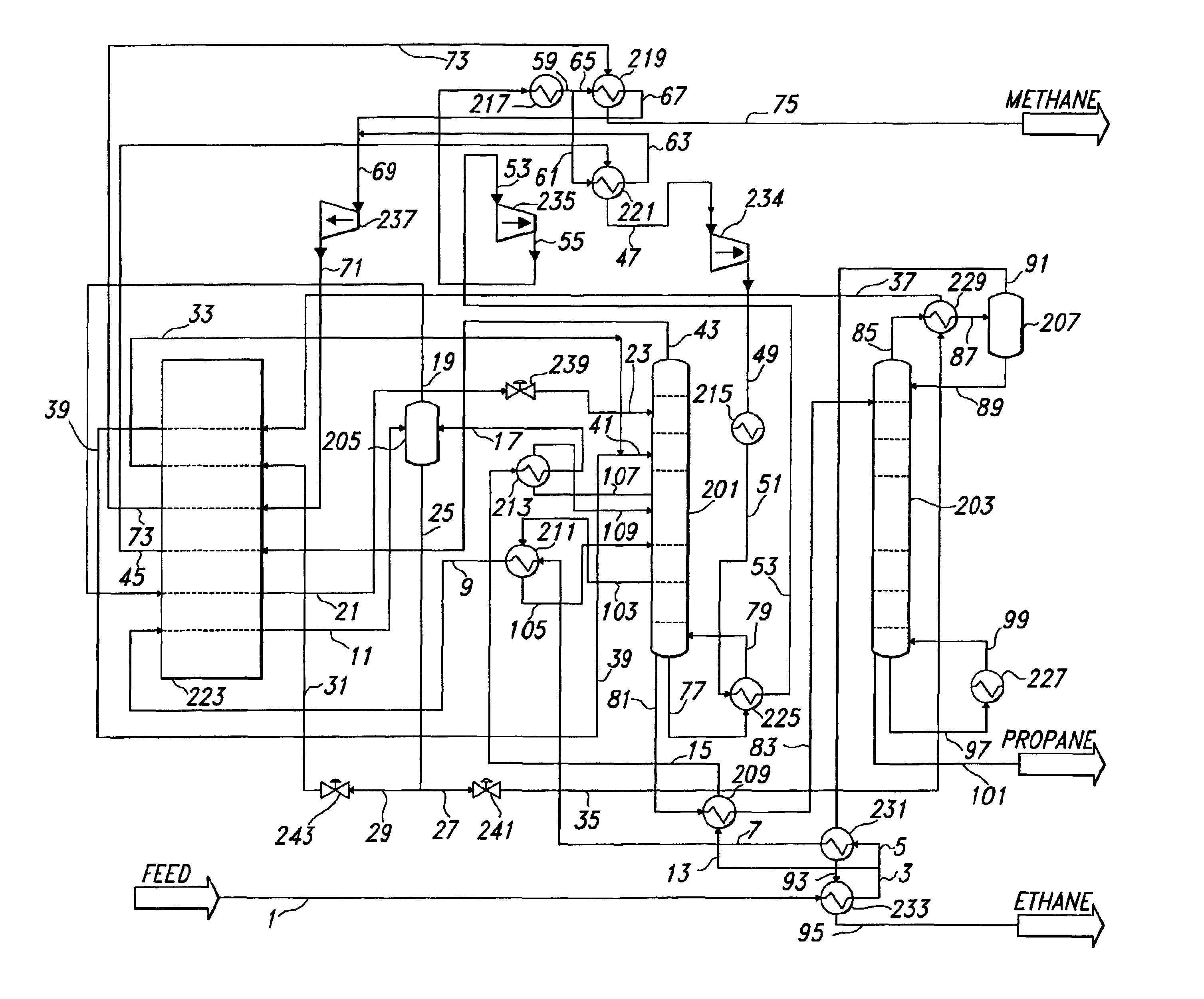

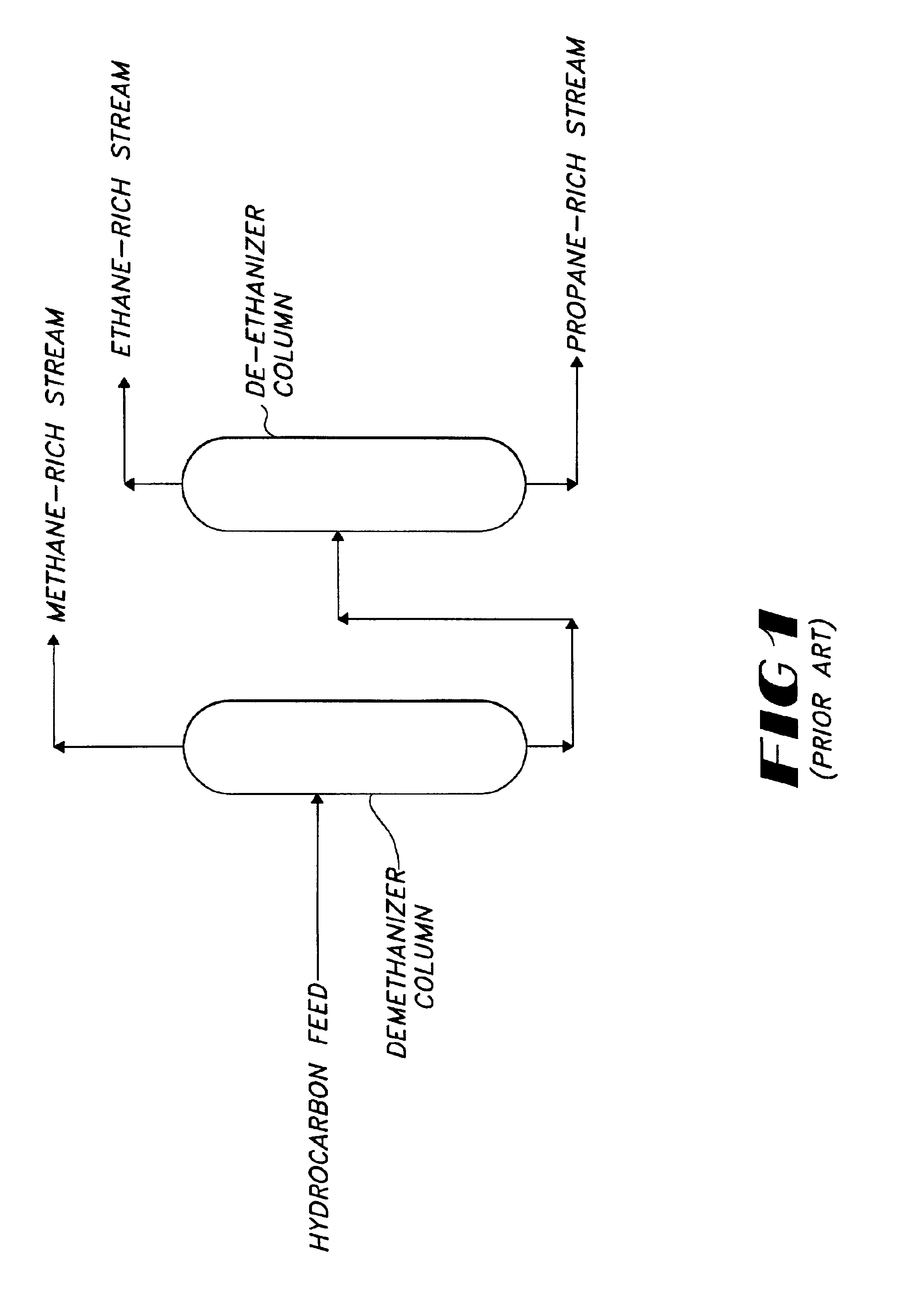

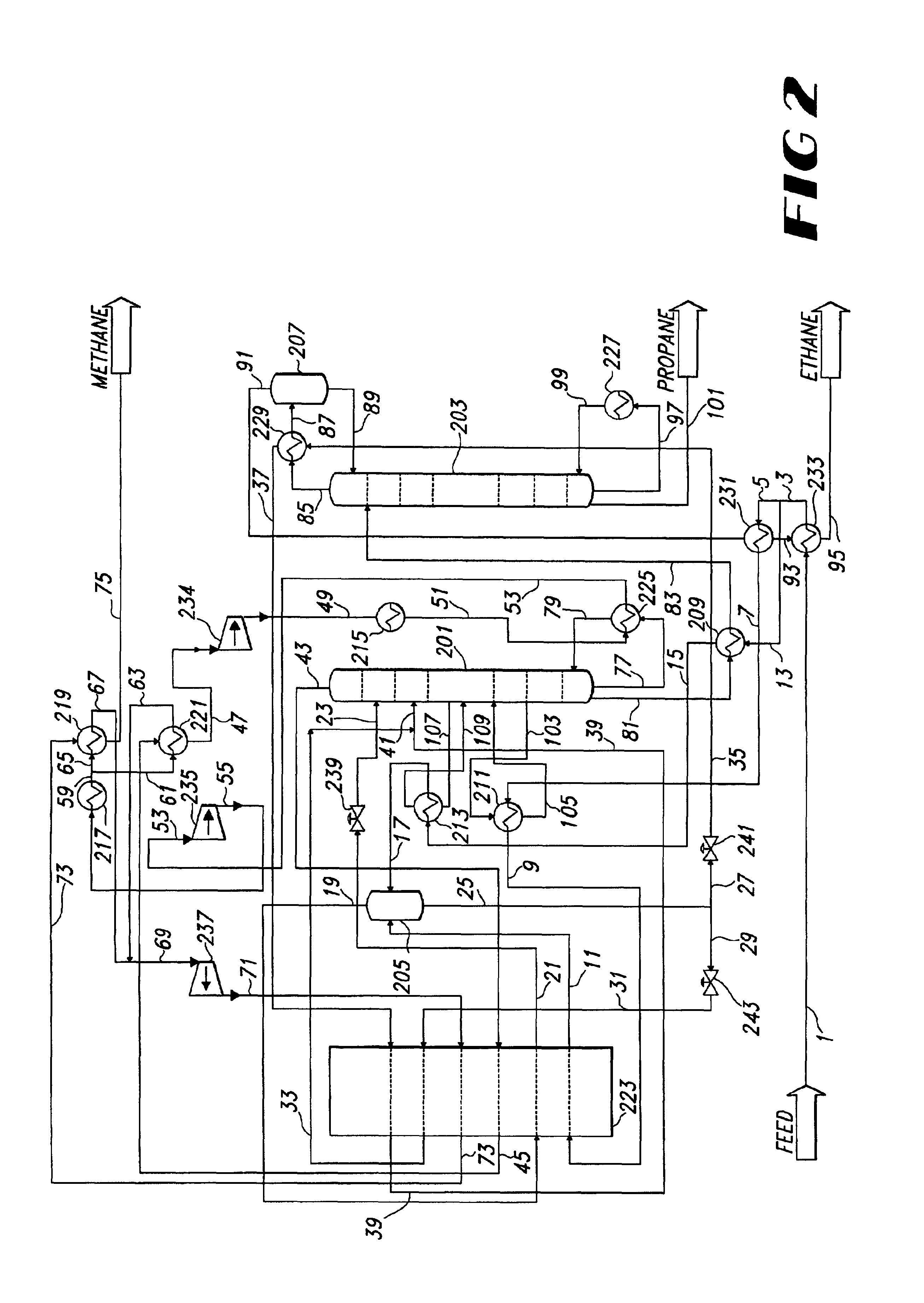

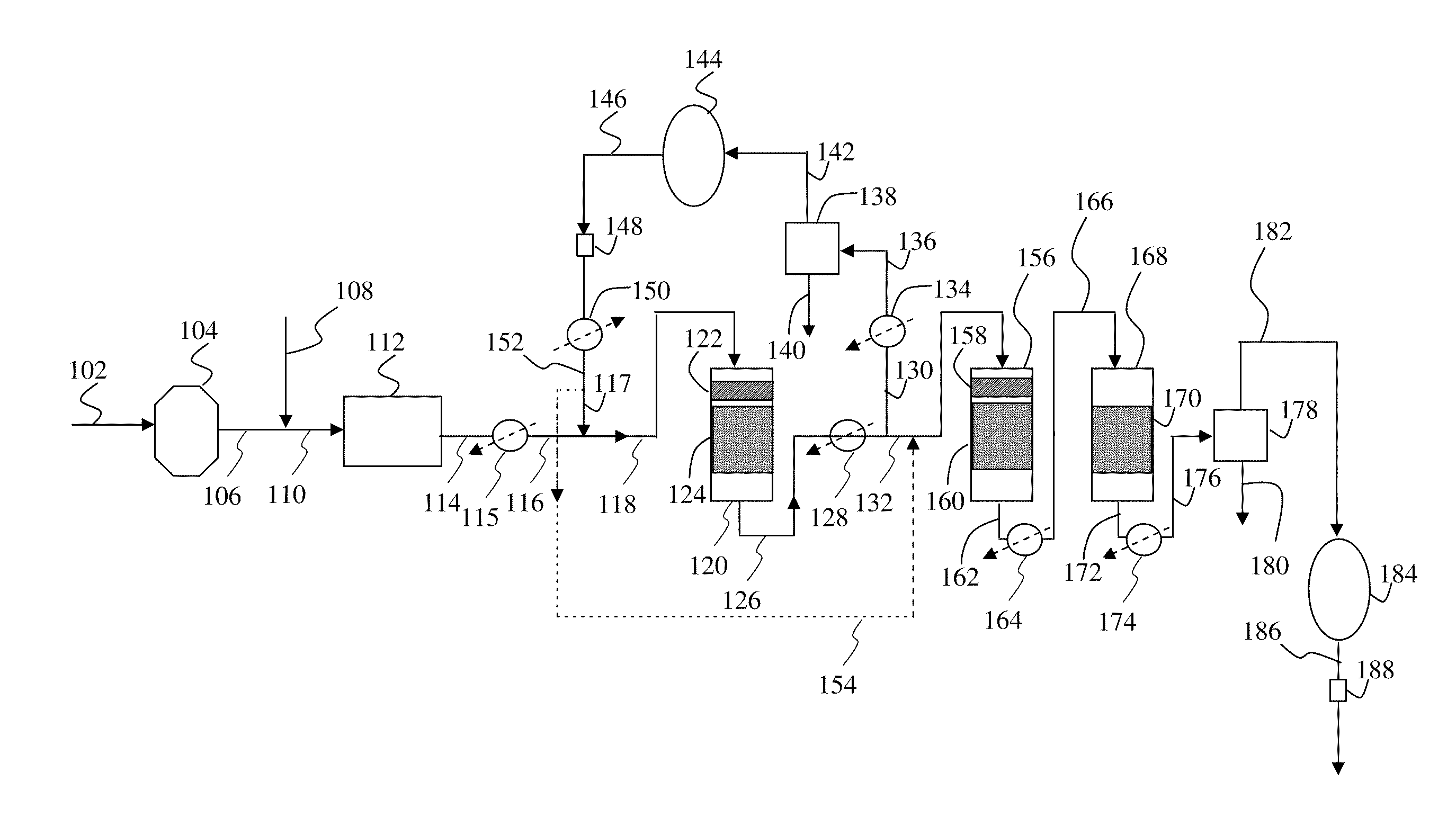

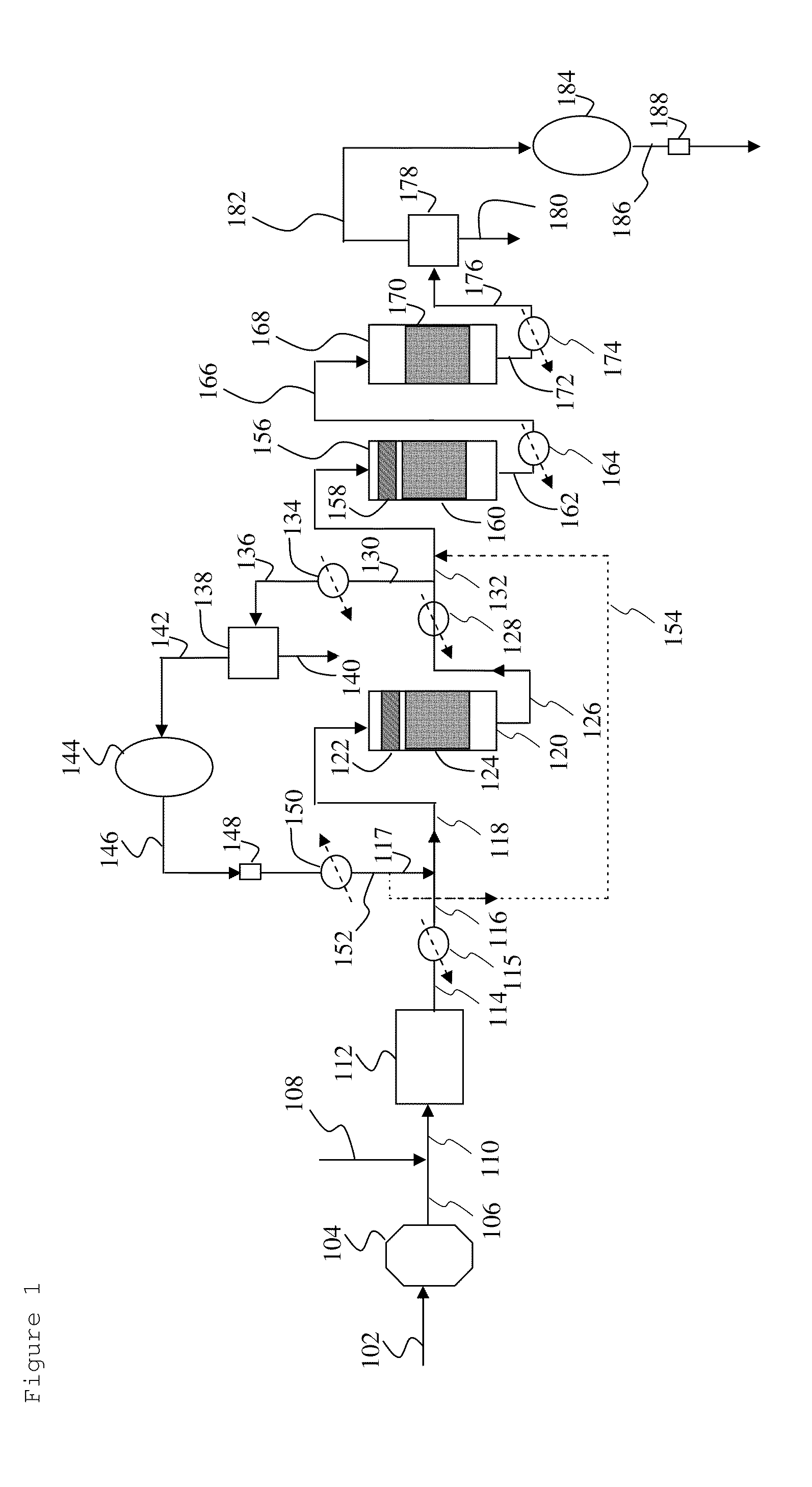

Ethane extraction process for a hydrocarbon gas stream

A process for ethane extraction from a gas stream based on turboexpansion and fractionation with no mechanical refrigeration is provided. The feed gas is sweetened and dehydrated by a conventional amine process and by a molecular sieve unit, to remove carbon dioxide and water. After this pretreatment, the feed gas undergoes to a series of cooling steps through a cryogenic brazed aluminum heat exchanger and fed to a demethanizer column. A stream rich in methane is recovered from the top of this column and fed to a centrifugal compressor and subsequently routed to a booster / turboexpander. The temperature of the methane gas is greatly reduced by the expansion allowing the cooled methane stream to be a cooling source for cryogenic heat exchanger. Feed for a de-ethanizer column comes from the bottom liquids of the de-methanizer column. Ethane is recovered overhead at the de-ethanizer column.

Owner:INELECTRA

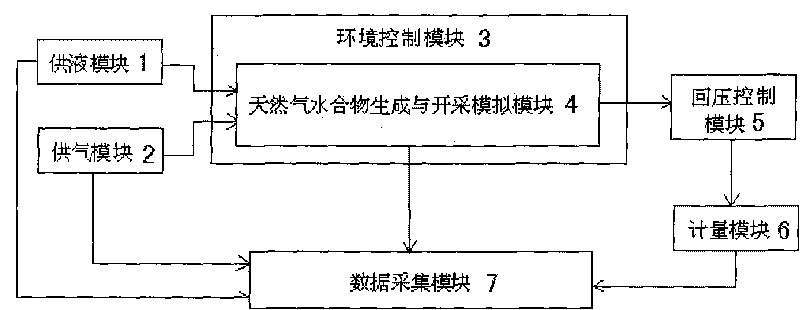

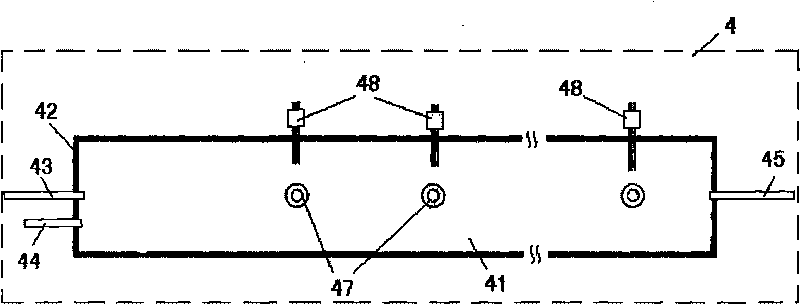

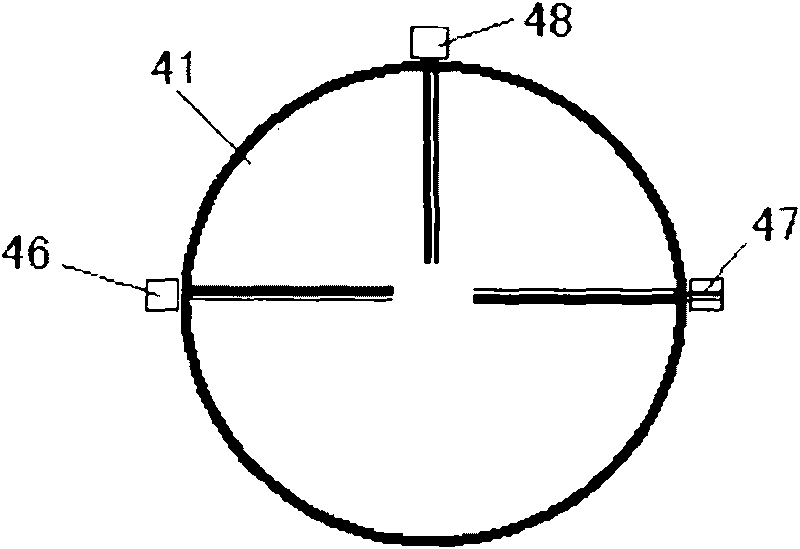

Method and device for testing formation and decomposition of gas hydrate

InactiveCN101710088AMonitor the amount of synthesisControl generationMaterial resistanceDecompositionData acquisition

The invention relates to a method and device for testing formation and decomposition of gas hydrate. The method comprises: 1) filling a one-dimensional sand-filling resistivity model tube with sand, closing an end cover, checking leak tightness and putting the model tube into a thermostat; 2) injecting water and methane gas into the model tube, maintaining constant temperature state to gradually generate hydrate, detecting change values of temperature, pressure and resistivity in the tube through a thermocouple, a pressure sensor and an electrode arranged on the wall of the model tube respectively and transmitting the change values to a data acquisition module; 3) reducing pressure after opening the model tube through a back pressure control module during decomposition so as to gradually decompose the hydrate, or injecting hot water into the model tube so as to gradually decompose the hydrate; and 4) passing water and methane gas produced after decomposition through a measurement module, transmitting data to the data acquisition module, detecting the change values of the pressure, the temperature and the resistivity in the tube through the thermocouple, the pressure sensor and the electrode at the same time, transmitting the change values into the data acquisition module, recording and storing the change values. The method and the device can be widely applied in the field of various detection of the formation and decomposition of gas hydrate.

Owner:CHINA NAT OFFSHORE OIL CORP +2

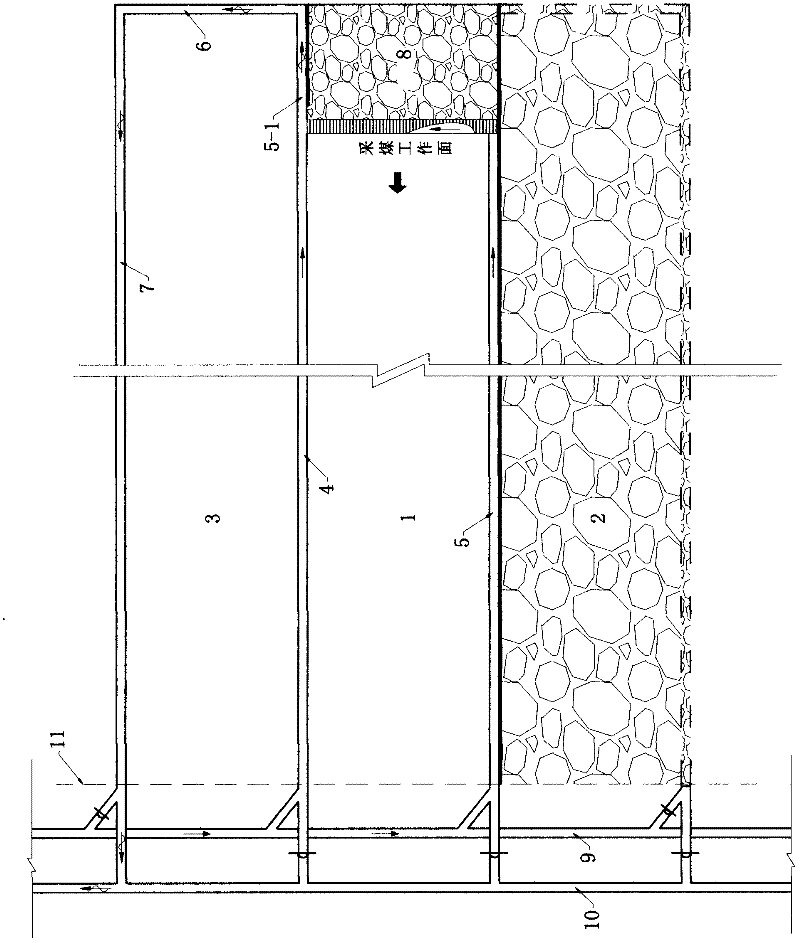

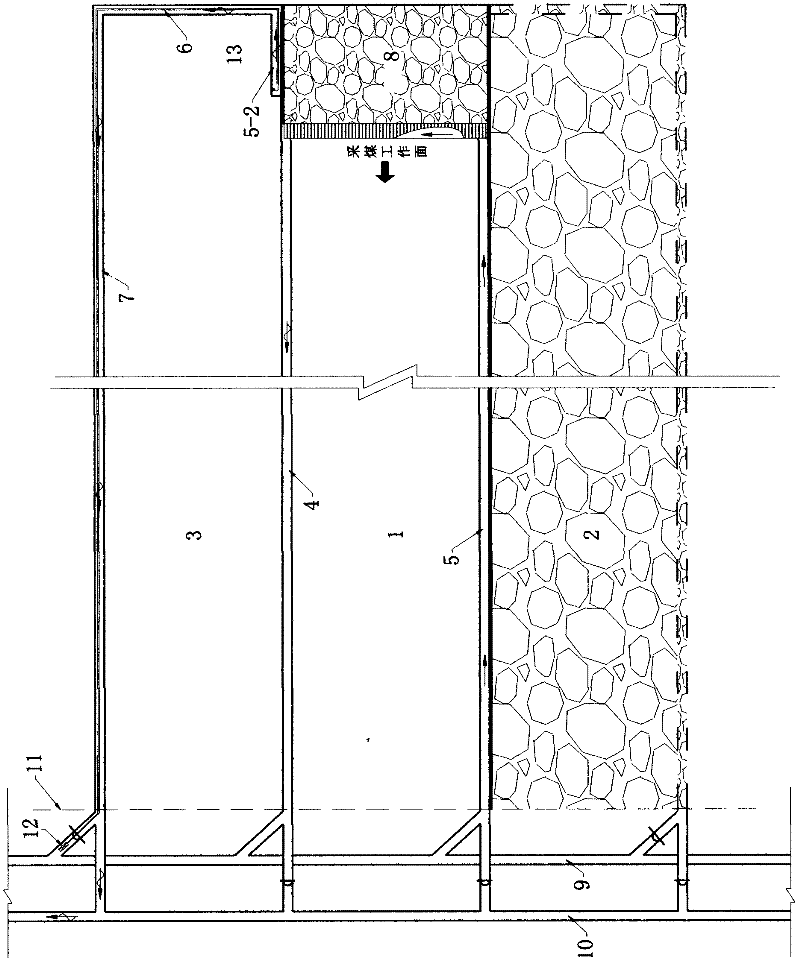

Method for arranging roadways on coal-pillar-free stope

InactiveCN102392642ASolve the overrun problemAlleviate mining tensionsUnderground miningSurface miningDual purposeEngineering

The invention discloses a method for arranging roadways on a coal-pillar-free stope. Particularly, the method comprises the following steps: two roadways are arranged on each working face, one is an excavating roadway, and the other is a gob-side retained or excavated roadway on an upper working face; before a present working face is stopped, a roadway and a cut are excavated in advance on a supersedure working face adjacent to the present working face; the cut is connected with the excavating roadway of the present working face; and the excavating roadway and the cut of the supersedure working face serve as the boundary return airway of the present working face during gob-side roadway retaining, and serve as the construction pathway for the gob-side excavated roadway during gob-side entry driving. Therefore, through the adoption of the method, mining without coal pillars is achieved and a two-in and one-out Y+L type ventilation system is formed. In the method, the excavating roadway and the cut of the supersedure working face serve as the return airway of the present working face and one roadway of the supersedure working face, thereby achieving dual purposes and eliminating the excavating of a roadway; and a pressure peak area is avoided, so that more coal pillars can be extracted, the problem of transfinite methane gas is solved, the excavation tight relationship is relieved, and the method can be widely applied to coal mines, metallurgic mines and other industries.

Owner:王晓利

Sulfur-resistant catalytic deoxidization process for methane-rich gas

InactiveCN101139239ALow priceSulfur resistanceMetal/metal-oxides/metal-hydroxide catalystsChemical modification purification/separationReaction temperatureManganese

The present invention discloses a sulfur wearable and catalyzing and oxidizing method for gas abundant of firedamp; the raw material gas abundant of firedamp such as coal bed gas firstly passes through a preheater for preheating, and then enters a oxidizing reaction device; under the condition of 0-0.5MPa of pressure, 500-750 DEG C of reaction temperature, 1000-3000h-1of reaction air speed, the firedamp in the air is reacted with oxygen to produce carbon dioxide and water in manganese base sulfur wearable and catalyzing and oxidizing bed; at the same time, a small quantity of firedamp is decomposed to produce carbon and hydrogen gas; the carbon and the hydrogen after being decomposed are also reacted with oxygen so as to reach the purpose of getting rid of oxygen in the airs abundant of firedamp effectively. The present invention adopts much newer and more economical new catalyzer, which does not need to desulfurize firstly for the air; the air can directly enter the oxidization reaction device for oxidization. So the present invention can decrease the cost and simplify the technics process.

Owner:HAO HUA CHENGDU TECH

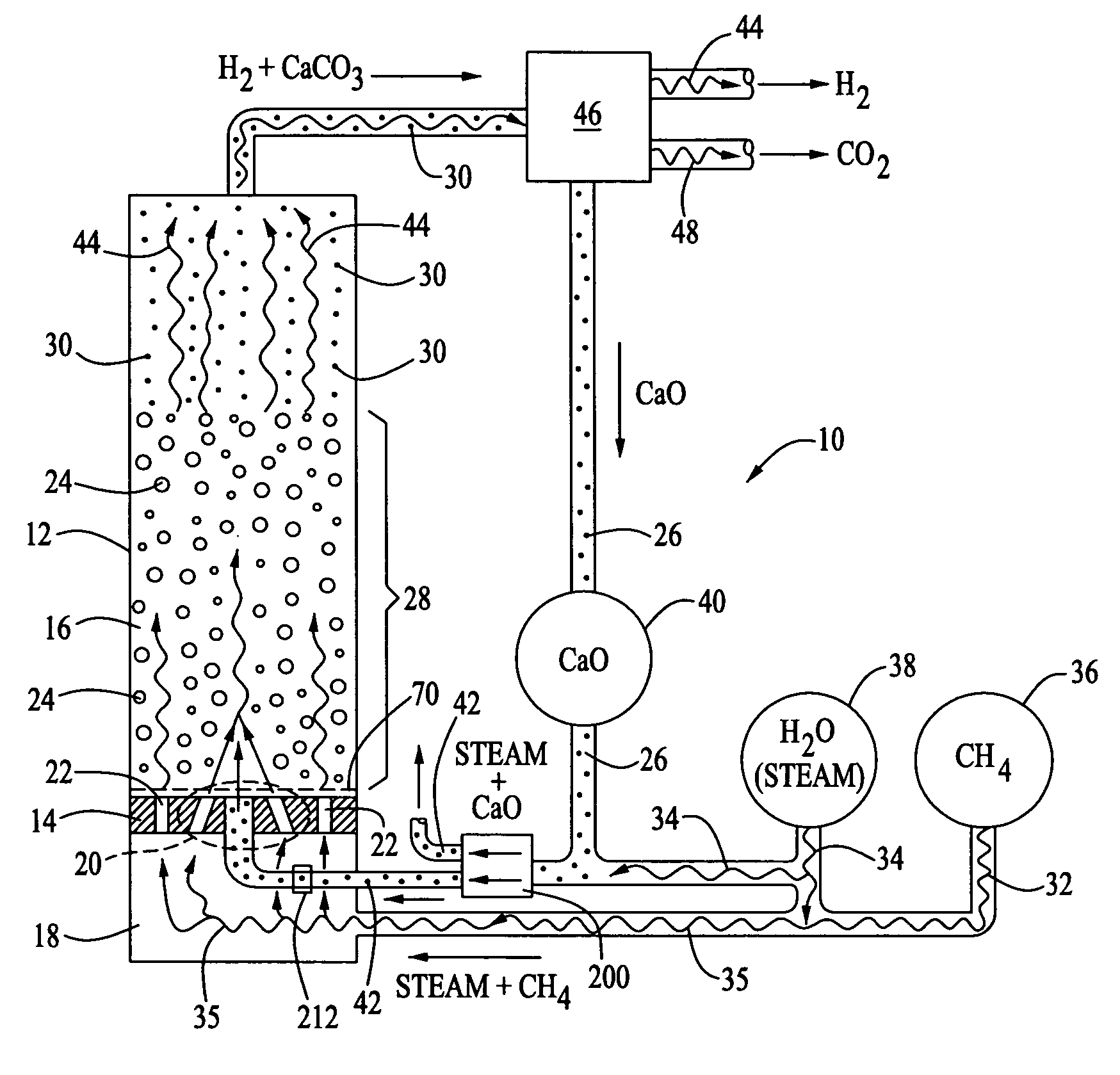

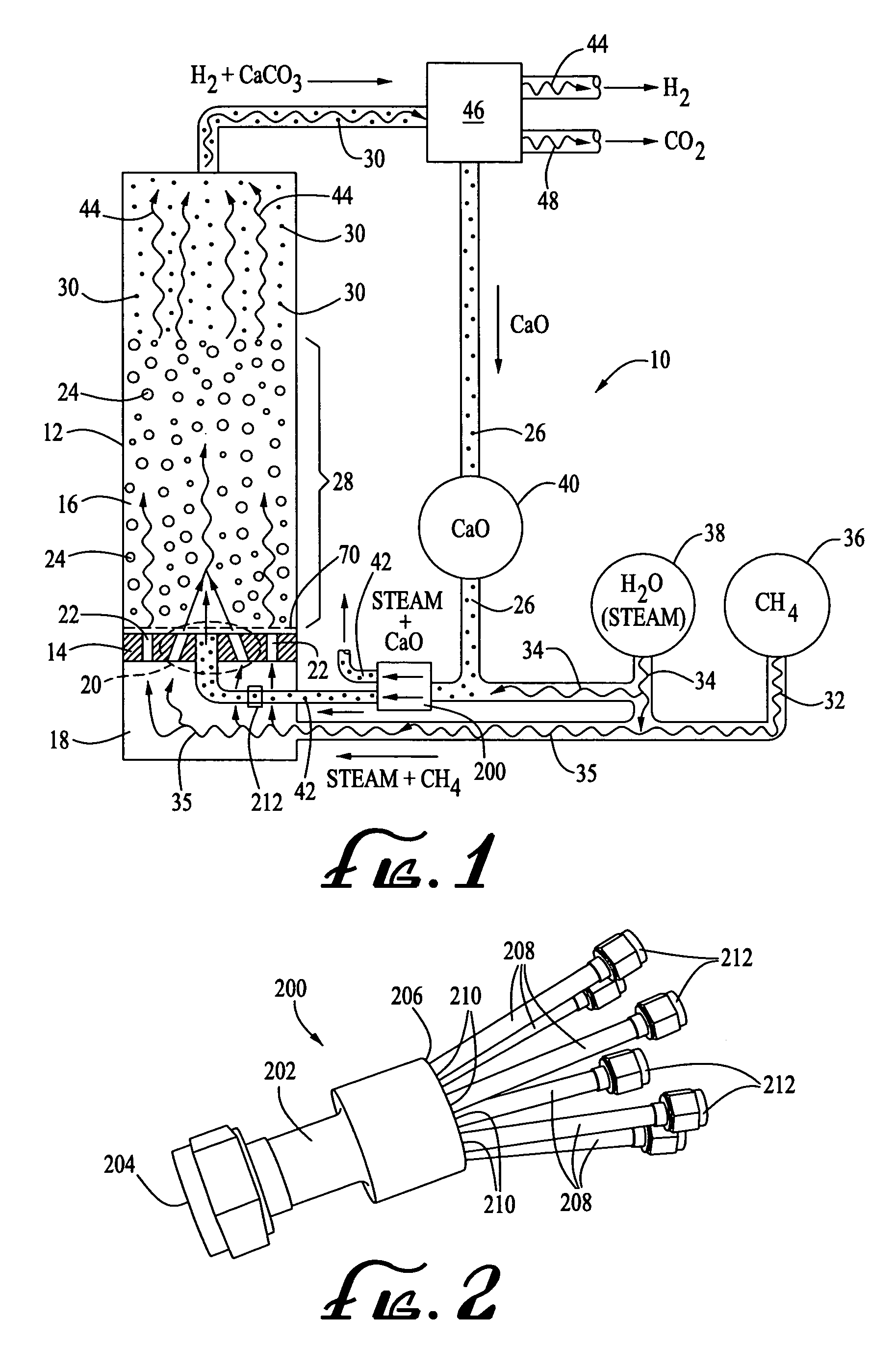

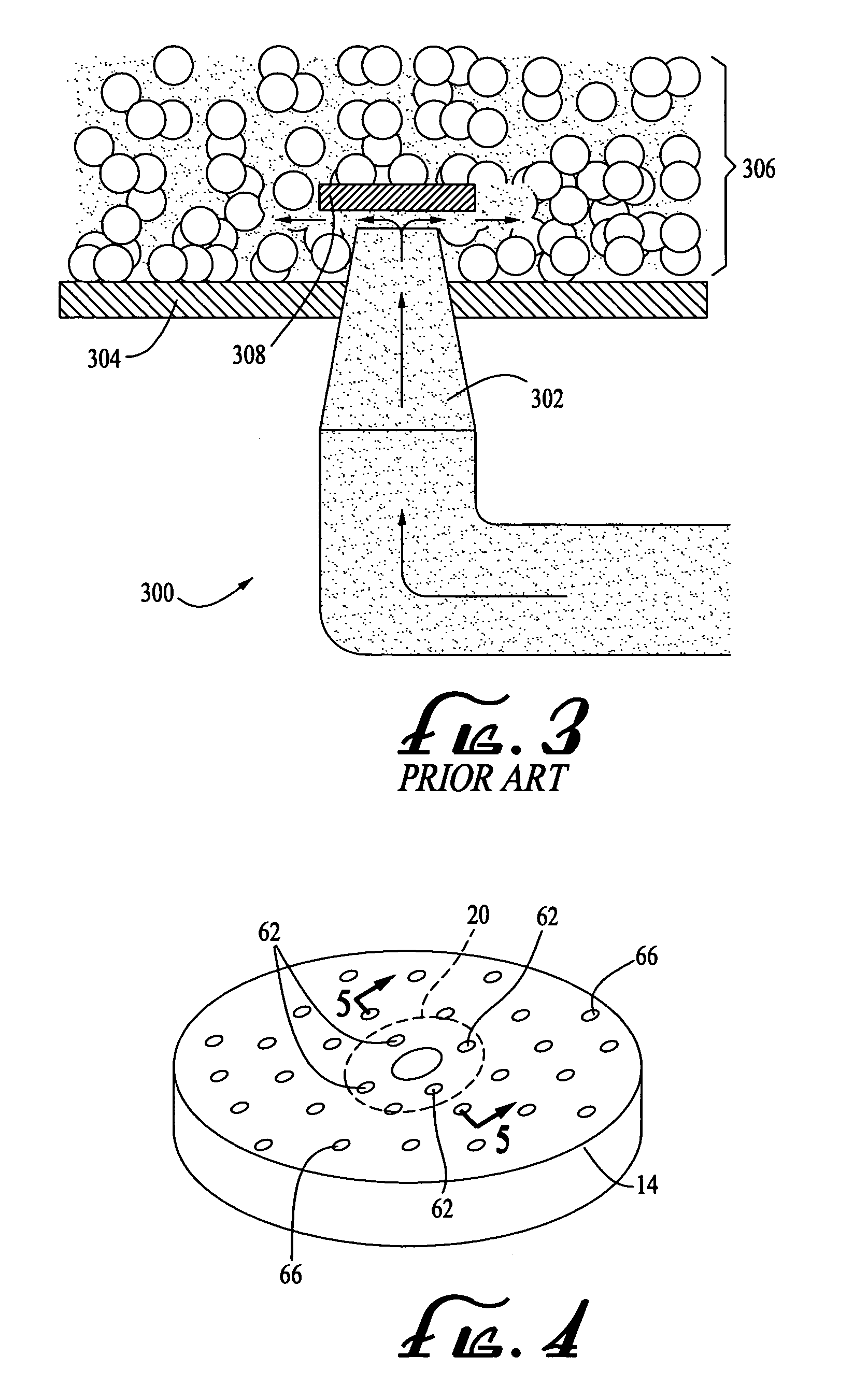

Two phase injector for fluidized bed reactor

A fluidized-bed reactor for producing hydrogen from methane by steam reforming includes a flow splitter that splits a dense-phase flow of a gas having entrained calcium oxide particles into a plurality of equal flow streams. The reactor also incorporates an orifice plate having at least one high-velocity, rocket-style impinging injector for injecting reactants into the reactor bed. The injector includes a central orifice extending perpendicularly through the plate, and one or more adjacent peripheral orifices that extend through the plate at such an angle that respective streams of reactants injected into the reactor bed through the peripheral orifices impinge on a stream of reactants injected vertically into the reactor bed through the central orifice. The injector cooperates with adjacent base-bleed orifices in the plate to provide a uniform distribution and rapid mixing of the calcium oxide particles with a steam / methane gas mixture across the entire bottom of the reactor bed.

Owner:THE BOEING CO +2

Process to remove nitrogen and/or carbon dioxide from methane-containing streams

ActiveUS20050139072A1Configuration economyLower cost of capitalSolidificationGas treatmentSorbentNitrogen

A process for the removal of inert gases, such as nitrogen and carbon dioxide, from methane-containing gases, such as natural gas, including a first stage removal which lowers the total combined inert content to about less than 30% and a second stage removal utilizing a pressure swing adsorption process comprising one or more adsorbent beds comprising contracted titanosilicate-1 adsorbent, wherein the purified methane-containing gas contains less than about 6% total combined inerts.

Owner:REG SYNTHETIC FUELS LLC +1

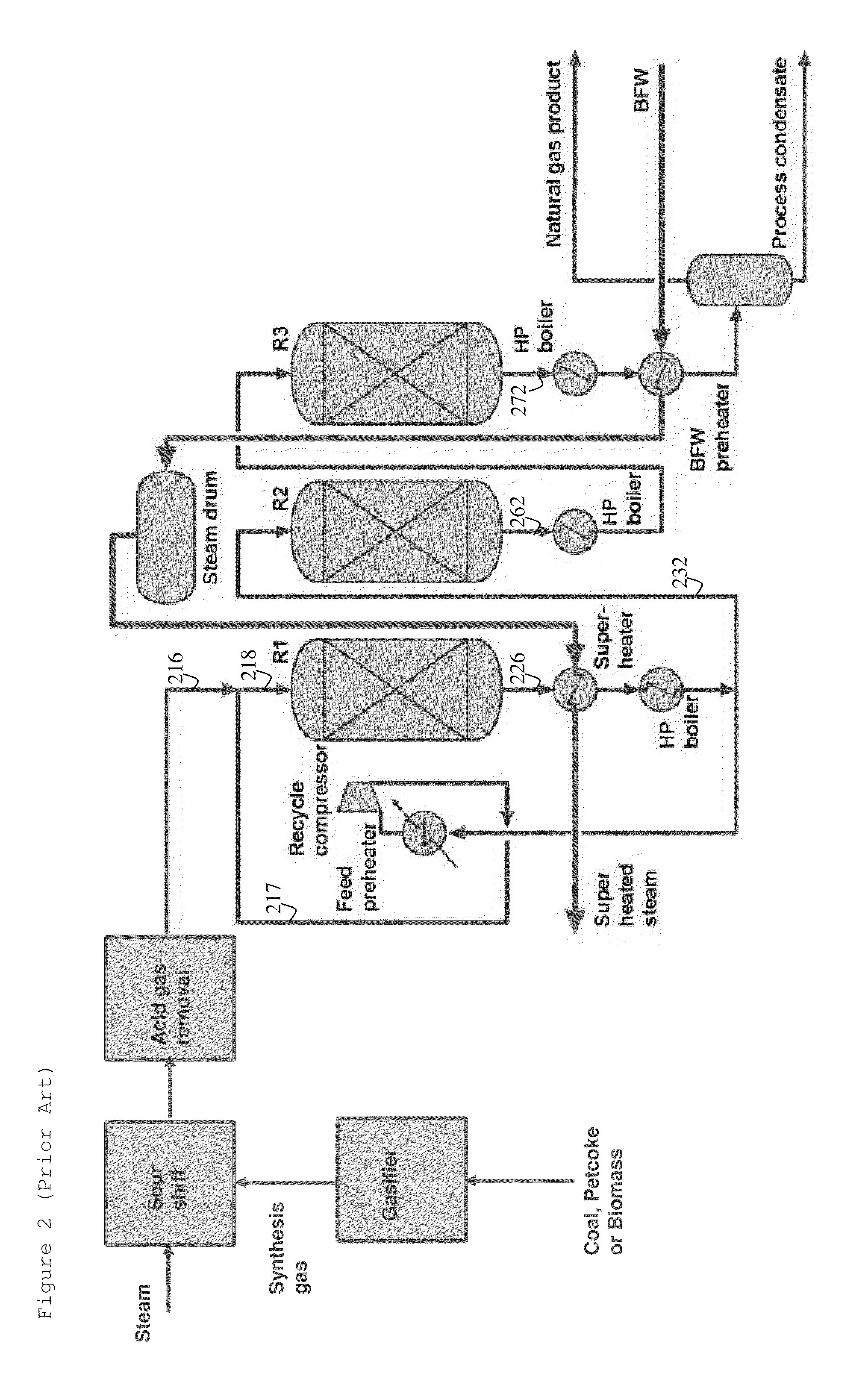

Process for producing a methane-rich gas

ActiveUS20100162627A1Lower the volumeLoad moreHydrogenHydrocarbon from carbon oxidesMethanationProduct gas

A process for producing a methane-rich gas comprising the steps of:a) mixing a feed gas, comprising carbon monoxide and hydrogen, and a recycled methane-rich gas, comprising methane, to produce a gas mixture, comprising carbon monoxide, hydrogen and methane;b) reacting at least part of the carbon monoxide and hydrogen in the gas mixture in the presence of a methanation catalyst to produce a methane-rich product gas comprising methane, carbon dioxide and water;c) treating at least part of the methane-rich product gas to remove carbon dioxide to produce a methane-rich carbon dioxide-lean gas; andd) recycling at least part of the methane-rich carbon dioxide-lean gas to mixing step a) as recycled methane-rich gas.

Owner:SHELL USA INC

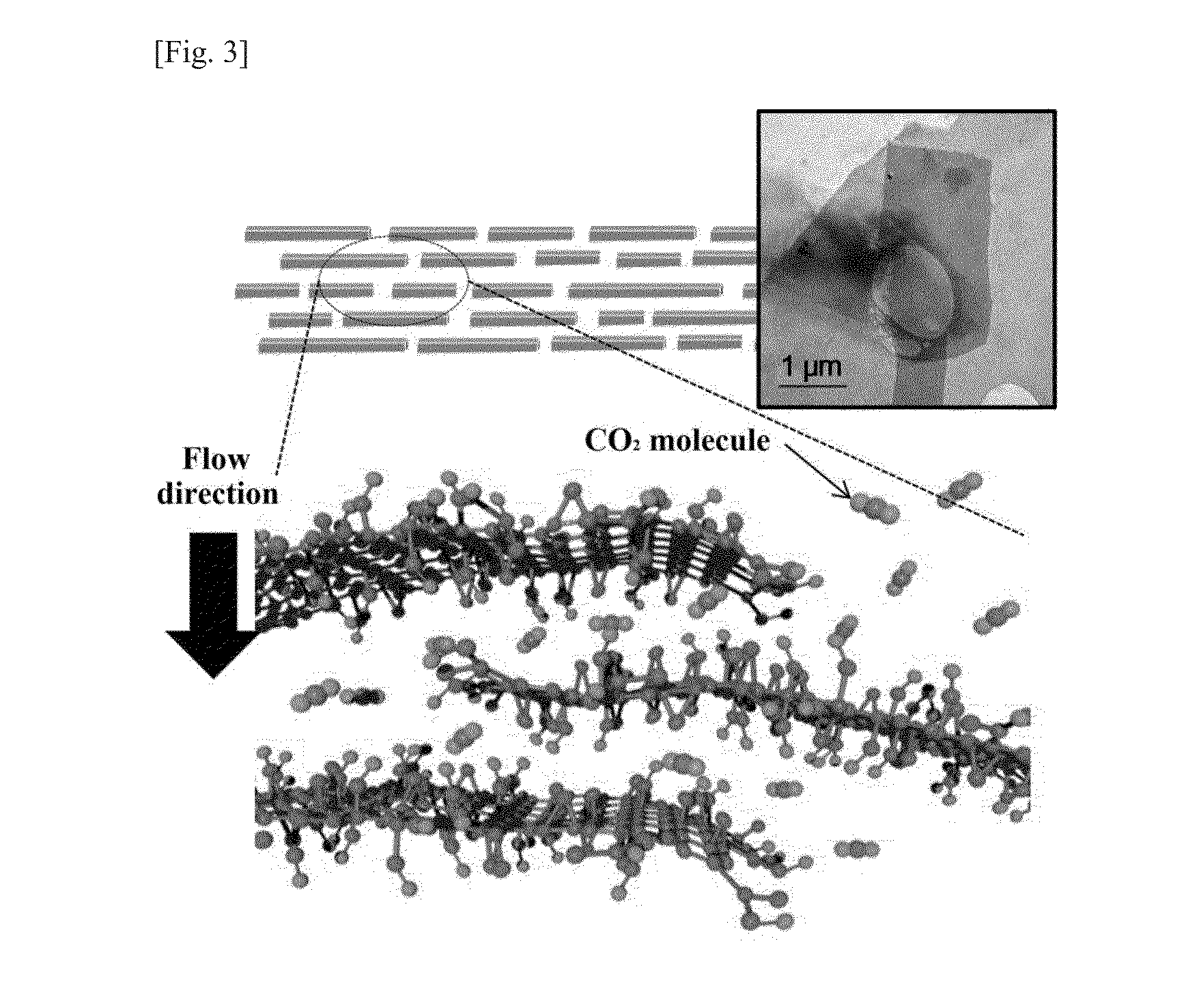

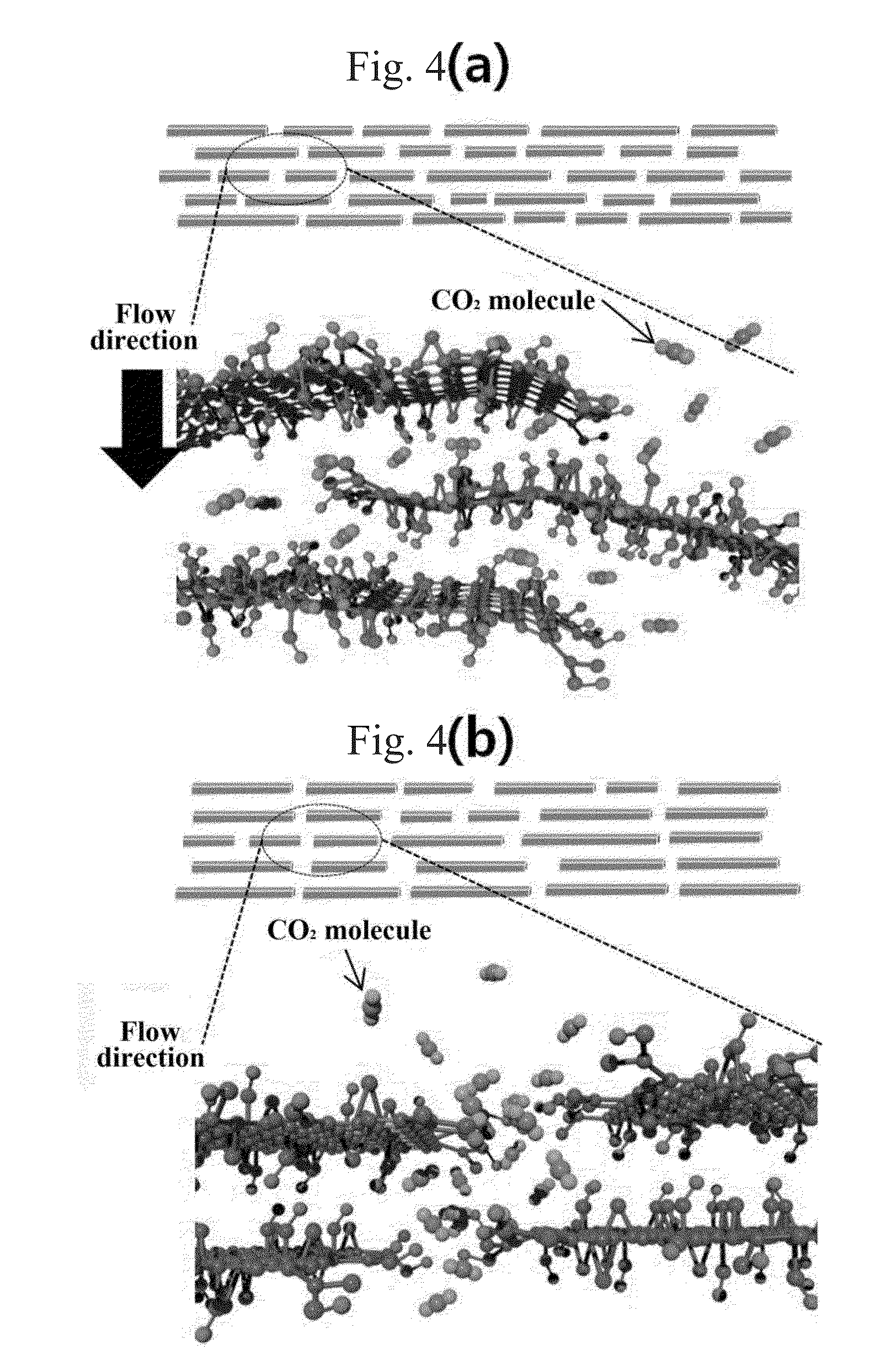

Composite separation membrane including graphene oxide coating layer and method for manufacturing the same

ActiveUS20160074814A1High carbon dioxide permeabilityHigh selectivitySemi-permeable membranesMembranesHydrogenNitrogen

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com