Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

176 results about "Copper atom" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper has atomic number 29, which means each copper atom has 29 protons (positively charged) in its nucleus and 29 electrons (negatively charged) in its shells.

Substrate processing method

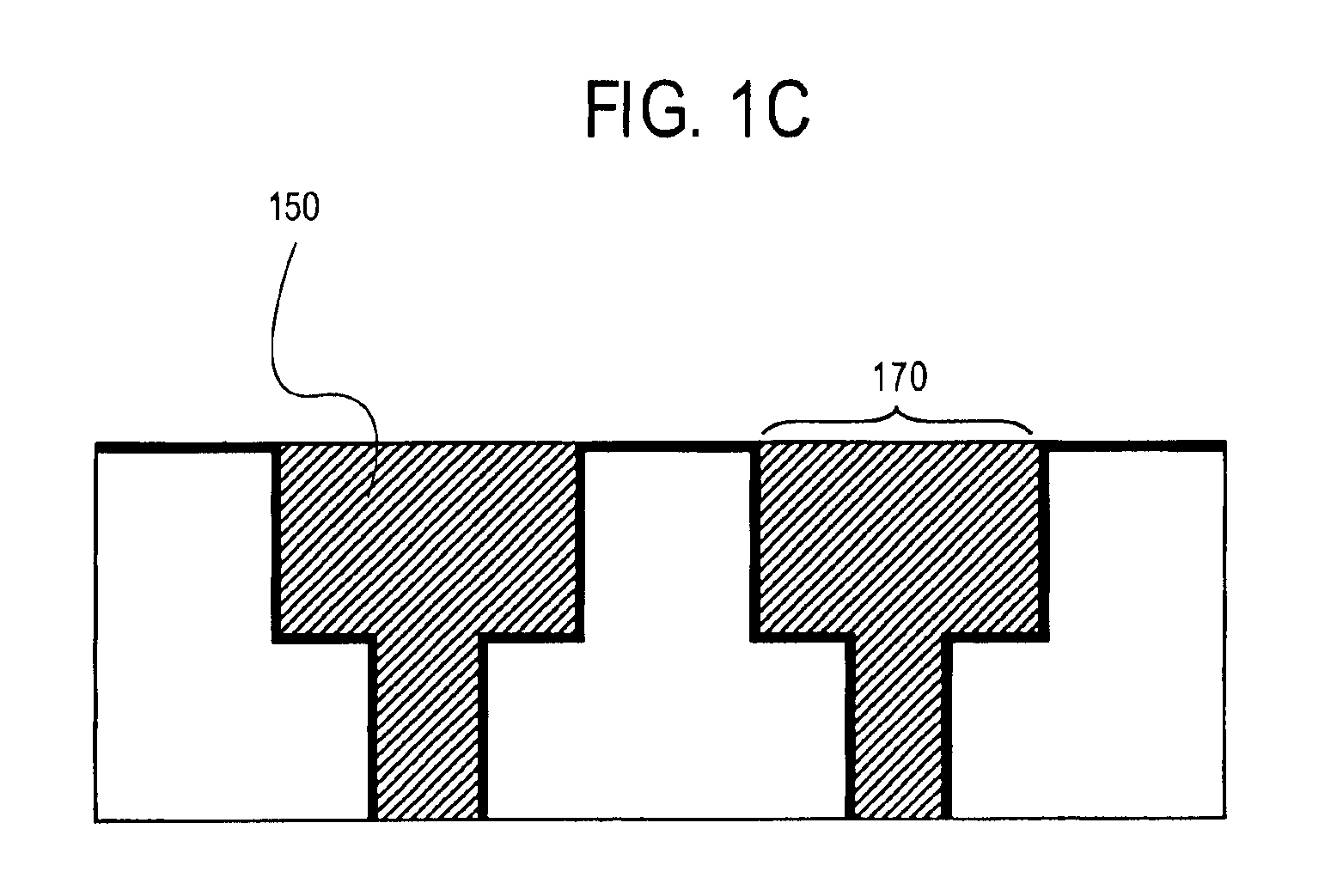

ActiveUS20120164839A1Easy to evaporateIncrease etch rateElectric discharge tubesDecorative surface effectsOrganic acidCopper atom

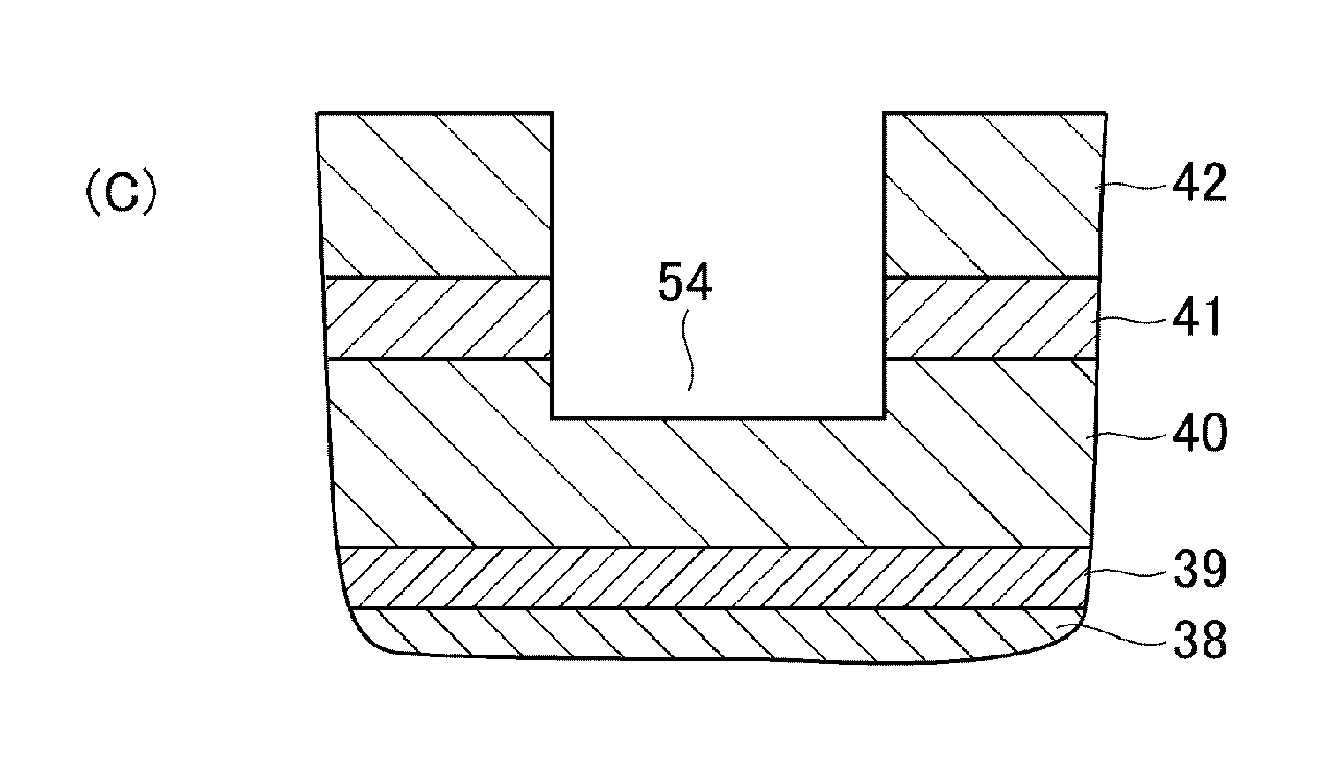

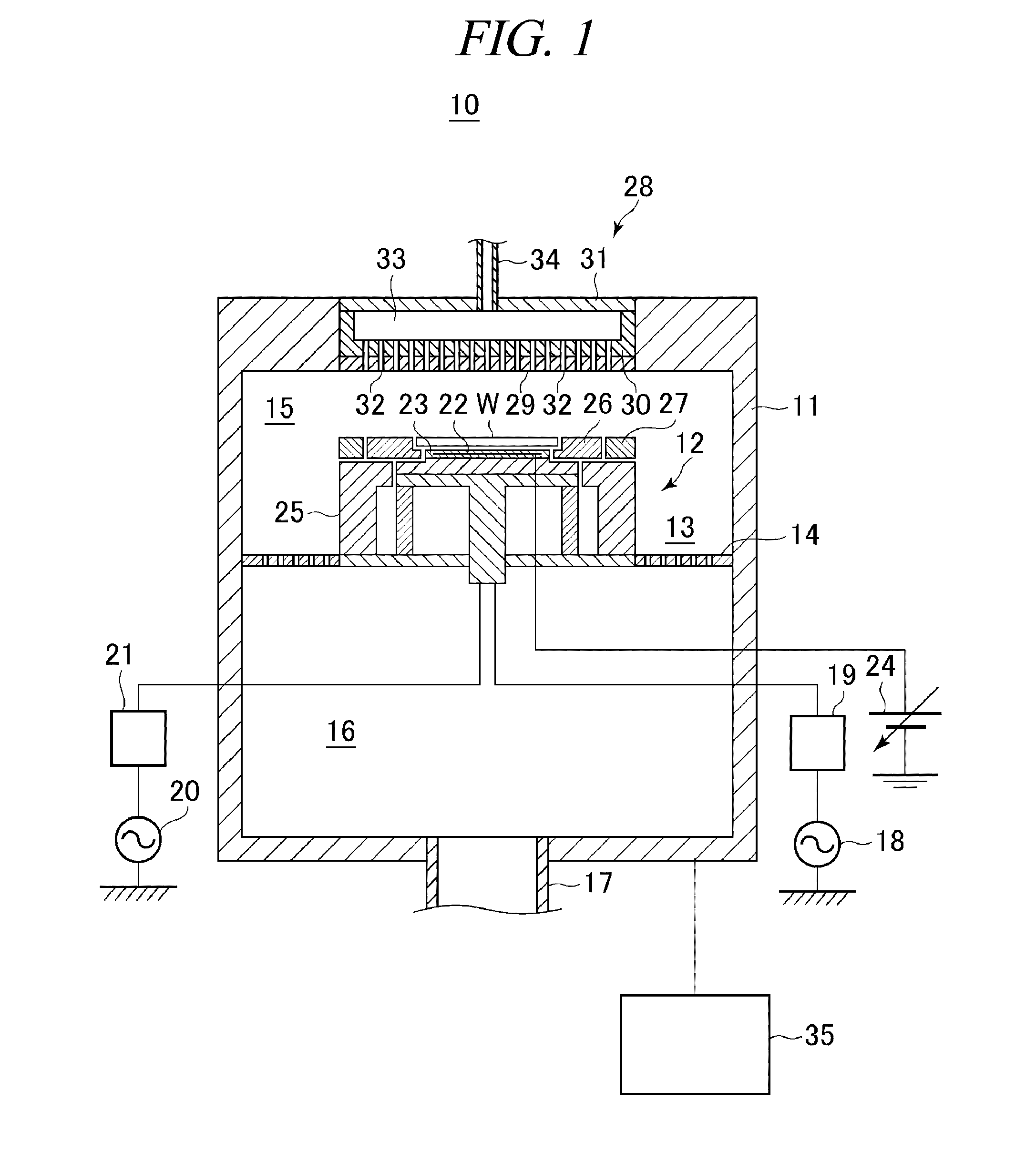

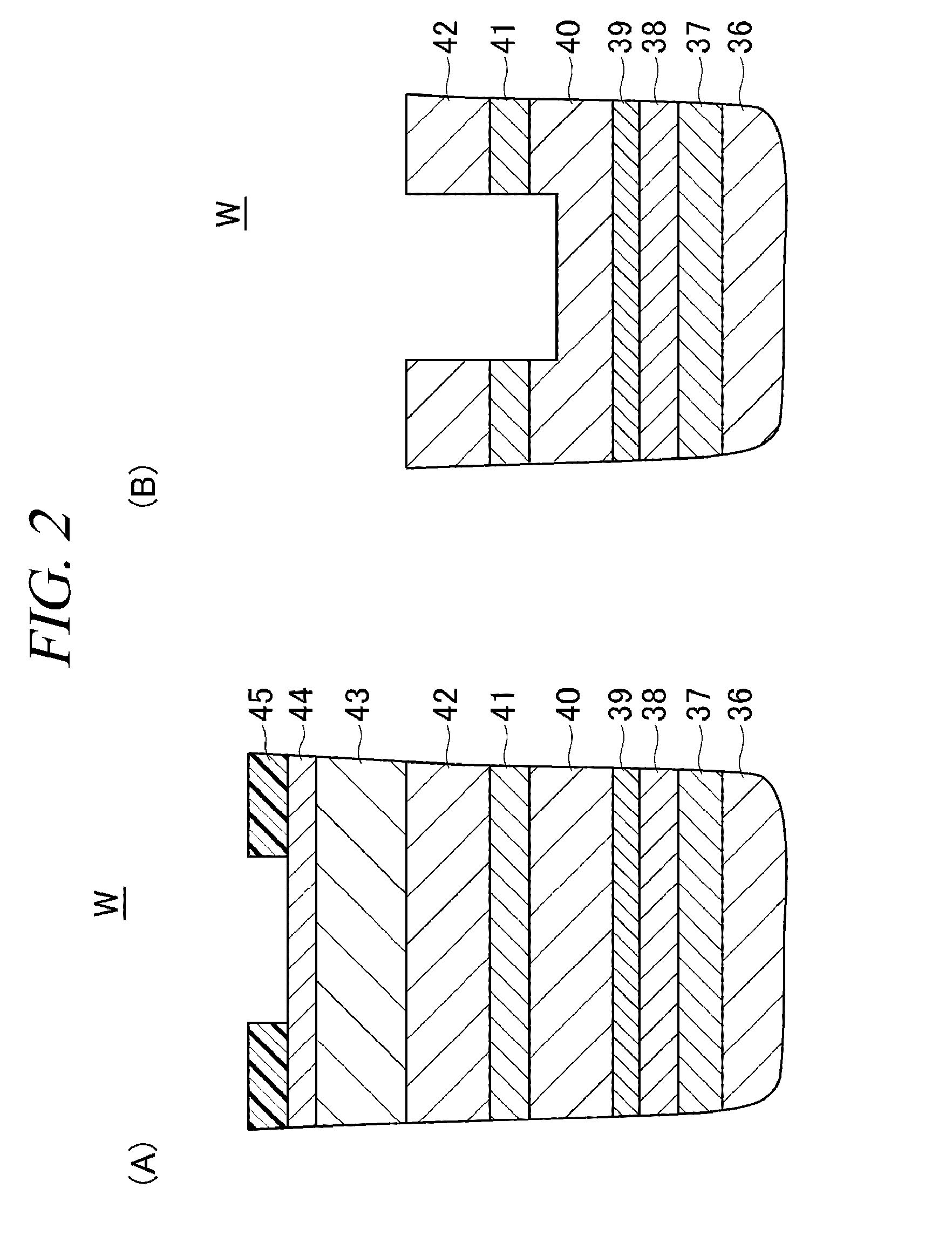

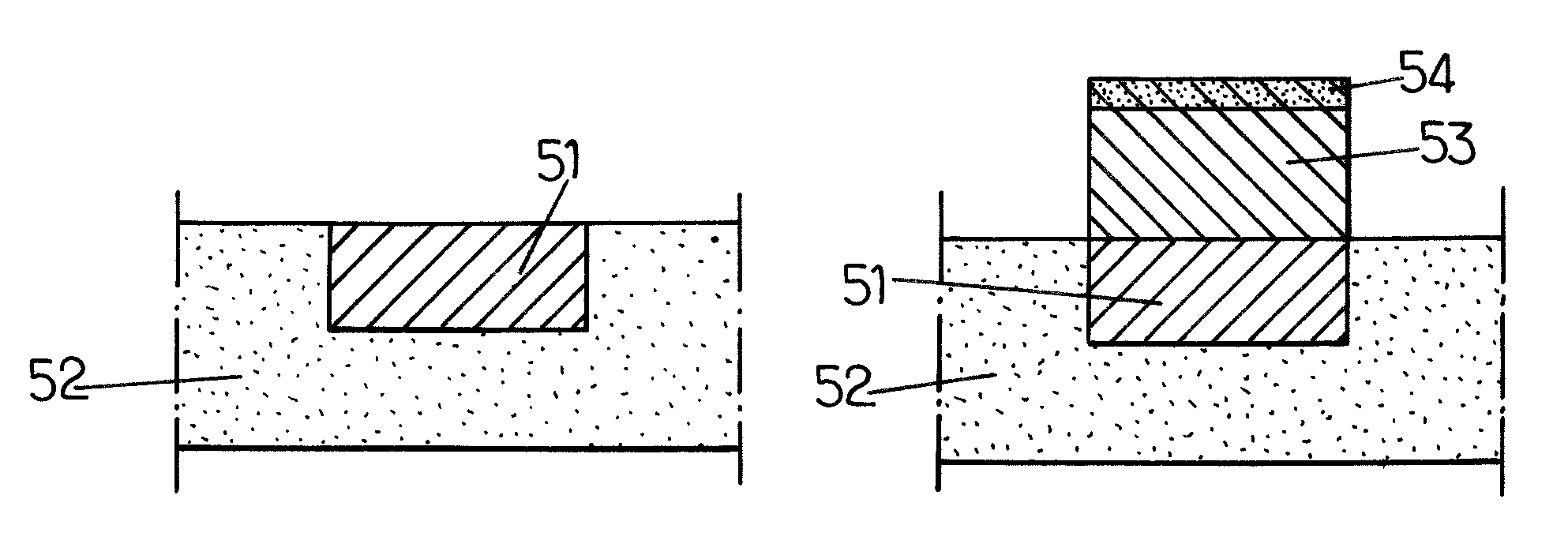

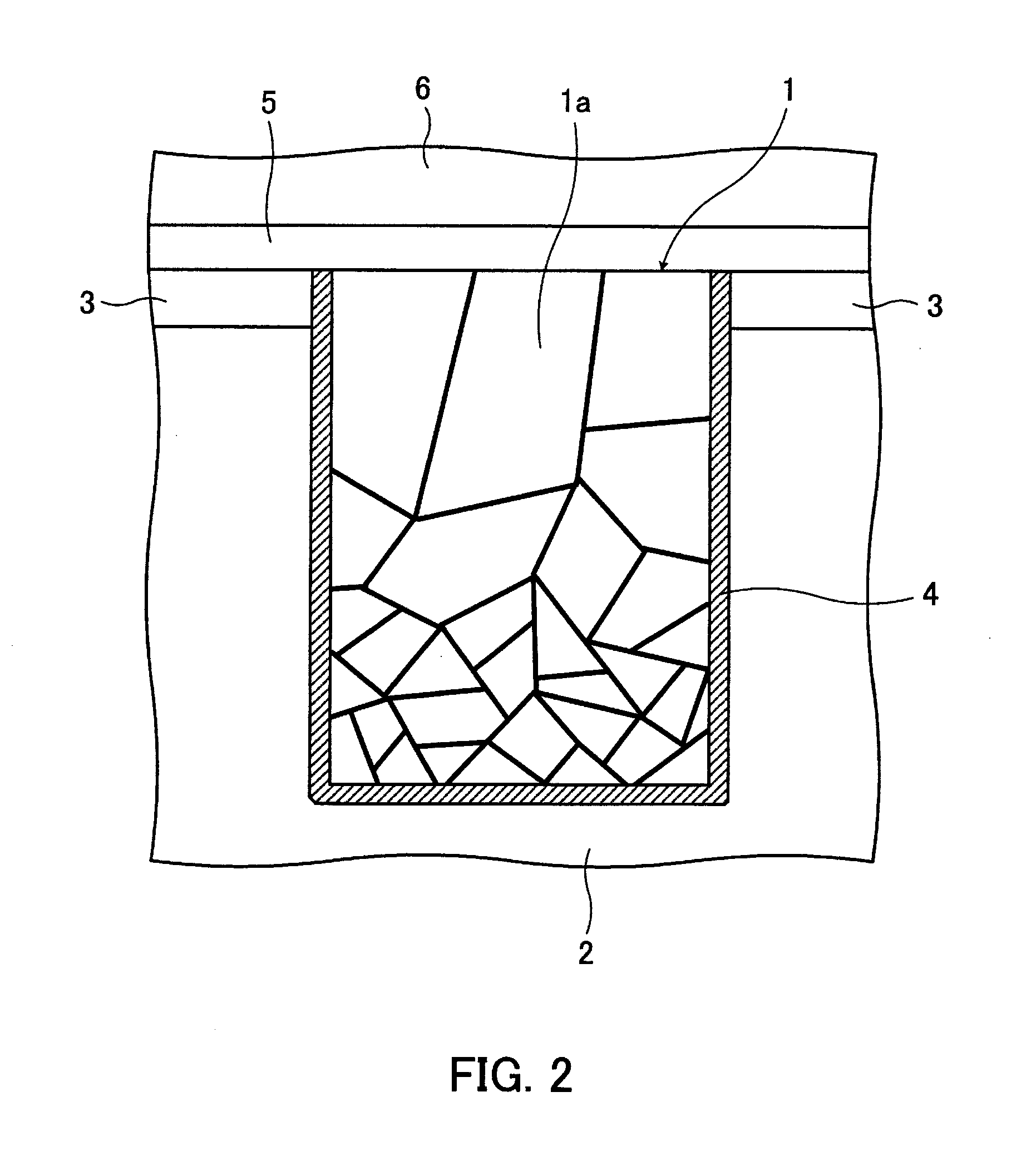

There is provided a substrate processing method capable of increasing an etching rate of a copper member without using a halogen gas. A Cu layer 40 having a smoothened surface 50 is obtained, and then, a processing gas produced by adding a methane gas to a hydrogen gas is introduced into an inner space of a processing chamber 15. Plasma is generated from this processing gas. In the inner space of the processing chamber 15, there exist oxygen radicals 52 generated when an oxide layer 42 is etched, and carbon radicals 53 generated from methane. The oxygen radicals 52 and the carbon radicals 53 are compounded to generate an organic acid, and the organic acid makes a reaction with copper atoms of the Cu layer 40. As a result, a complex of the organic acid having the copper atoms is generated, and the generated organic acid complex is vaporized.

Owner:TOKYO ELECTRON LTD

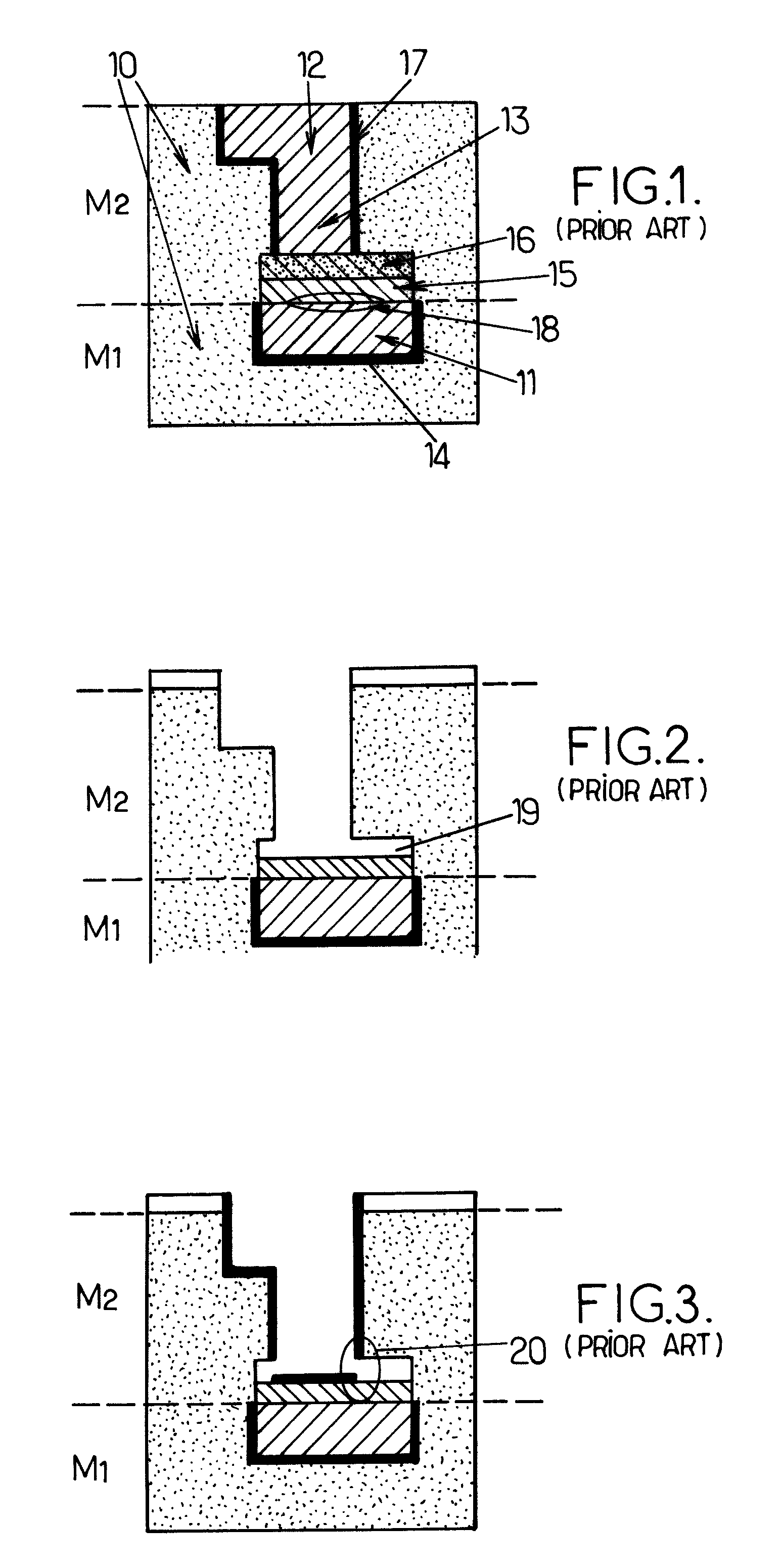

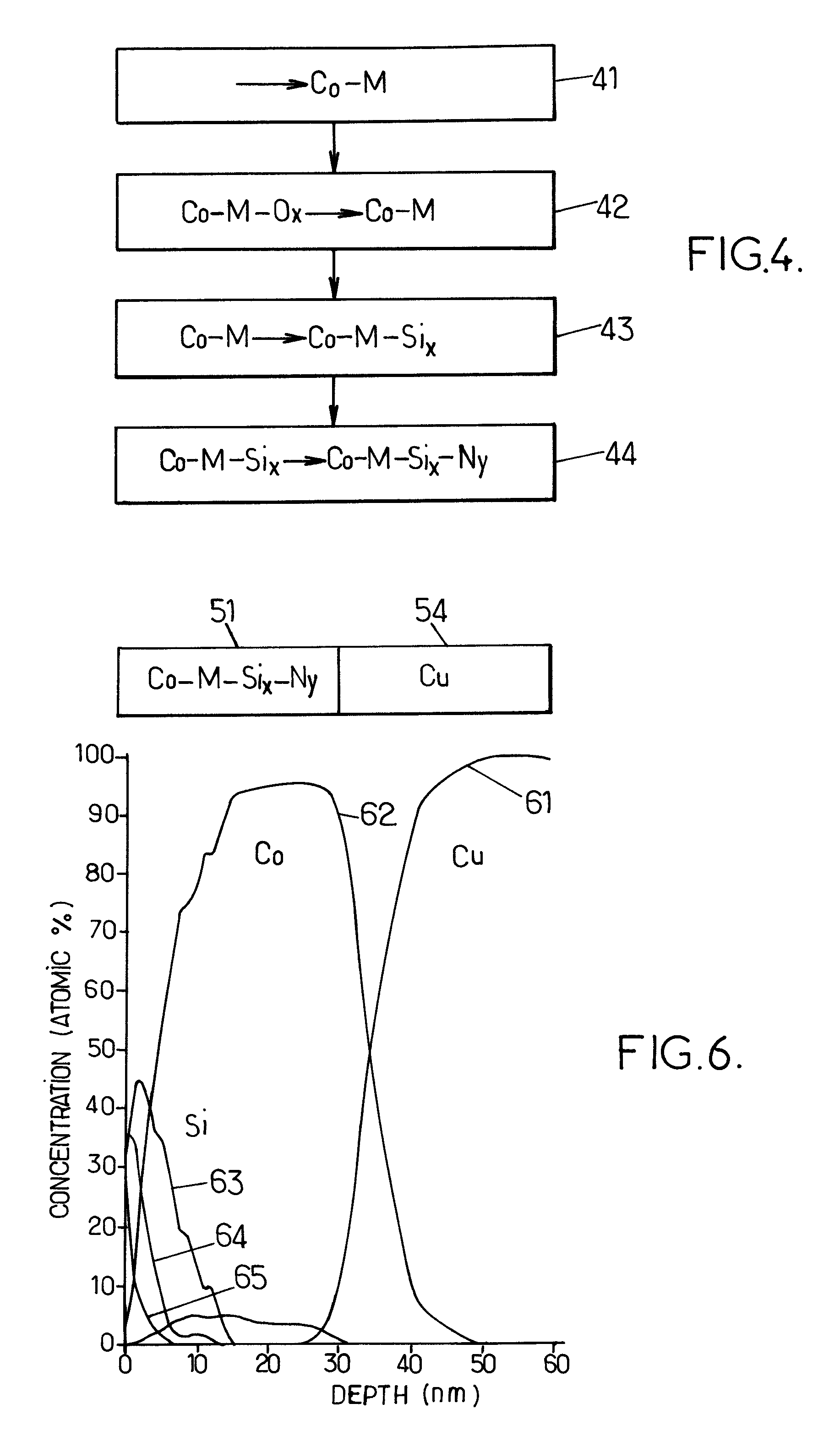

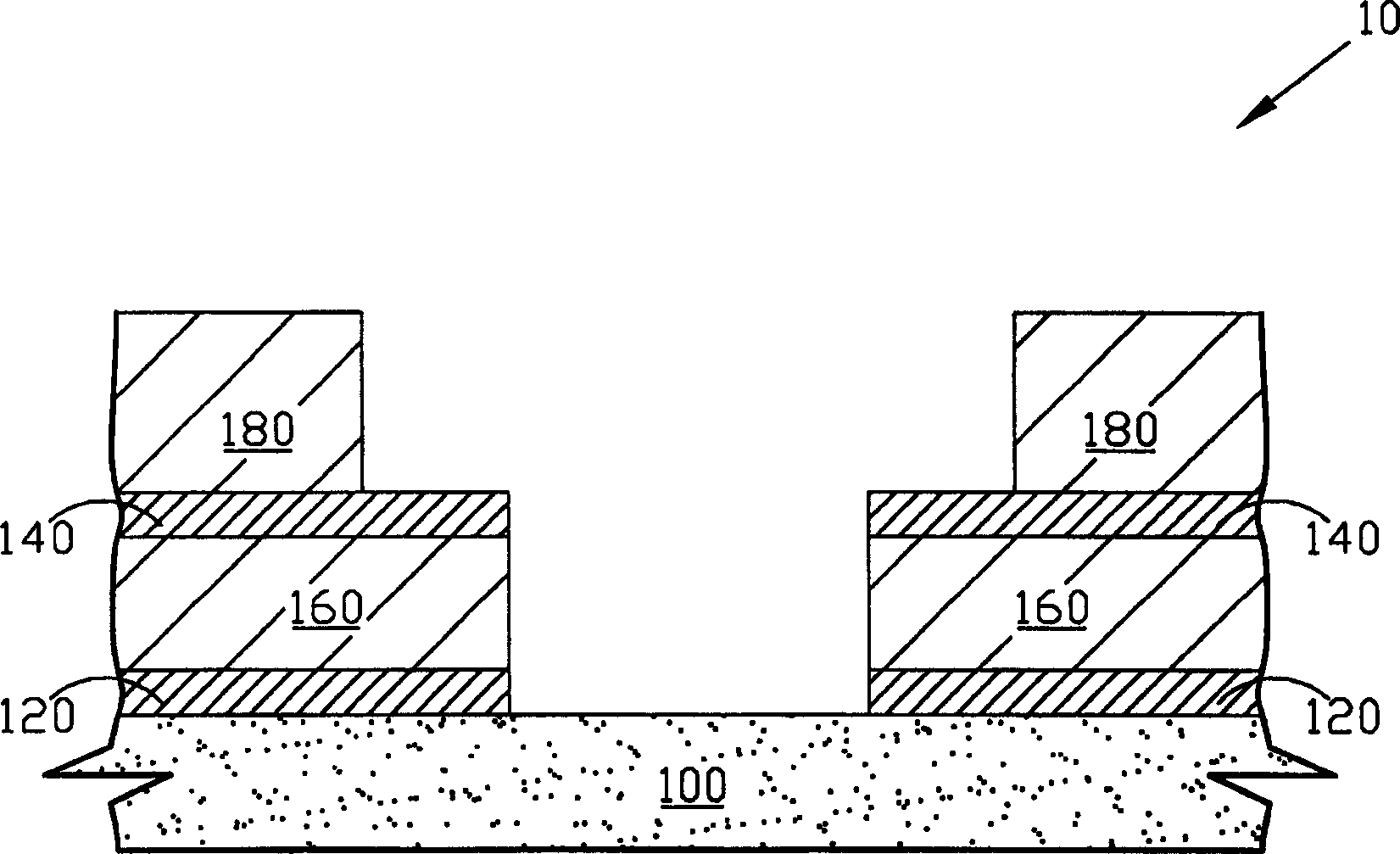

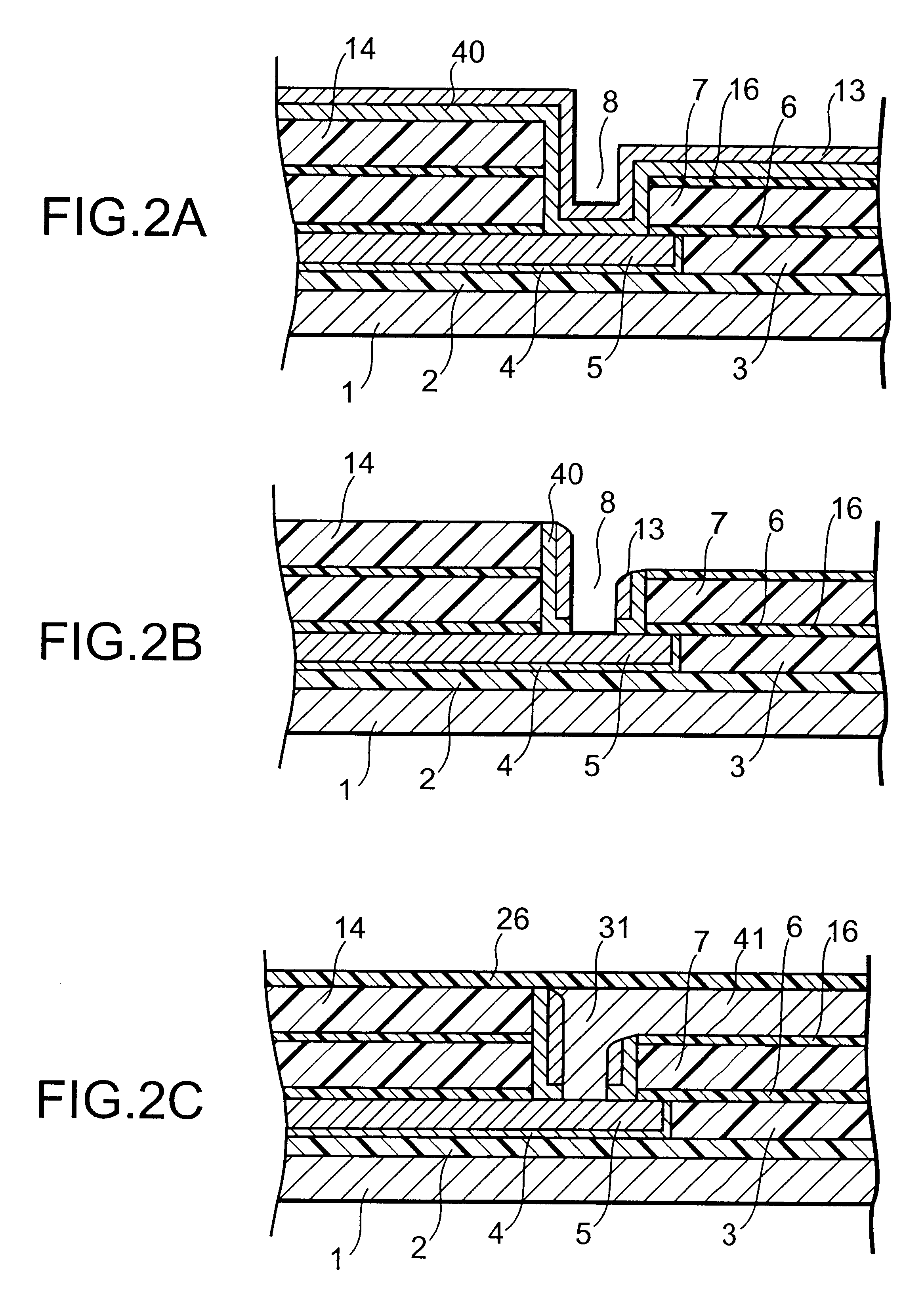

Implementation of a metal barrier in an integrated electronic circuit

ActiveUS7601636B2Improve antioxidant capacityInhibited DiffusionSemiconductor/solid-state device detailsSolid-state devicesCopper atomMetallic materials

Owner:STMICROELECTRONICS SRL

Method to increase electromigration resistance of copper using self-assembled organic thiolate monolayers

Methods and solutions for forming self assembled organic monolayers that are covalently bound to metal interfaces are presented along with a device containing a self assembled organic monolayer. Embodiments of the present invention utilize self assembled thiolate monolayers to prevent the electromigration and surface diffusion of copper atoms while minimizing the resistance of the interconnect lines. Self assembled thiolate monolayers are used to cap the copper interconnect lines and chemically hold the copper atoms at the top of the lines in place, thus preventing surface diffusion. The use of self assembled thiolate monolayers minimizes the resistance of copper interconnect lines because only a single monolayer of approximately 10 Å and 20 Å in thickness is used.

Owner:INTEL CORP

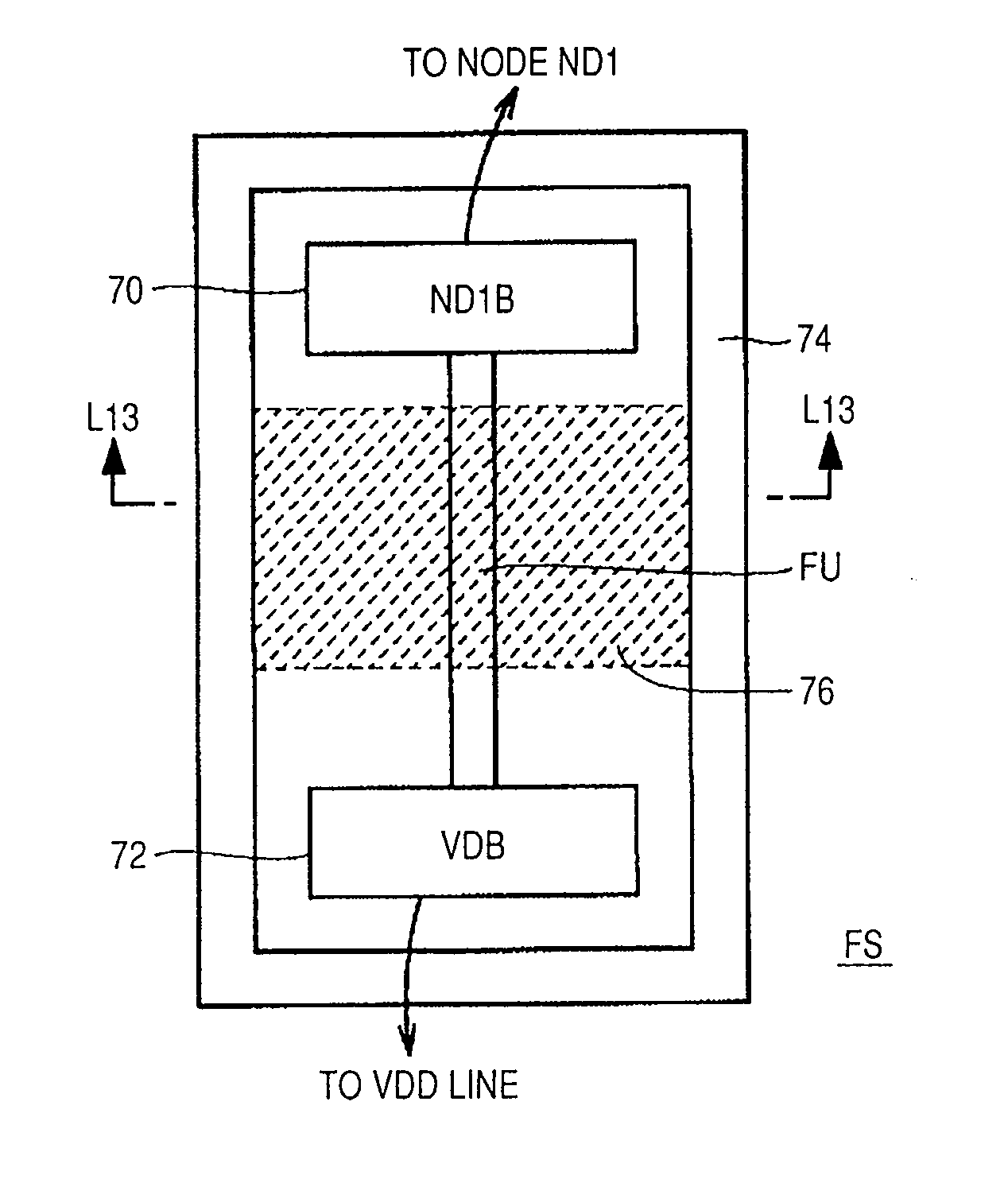

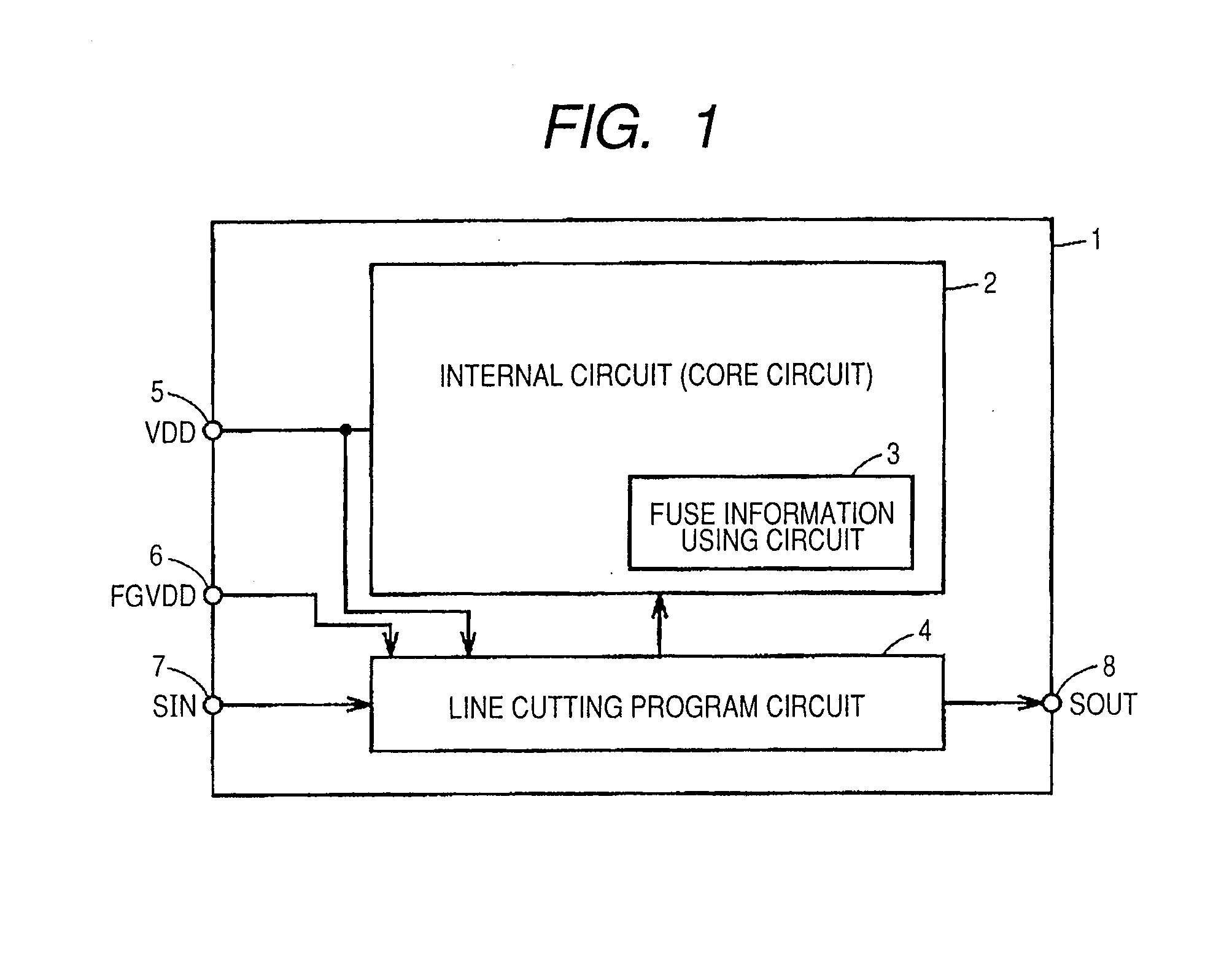

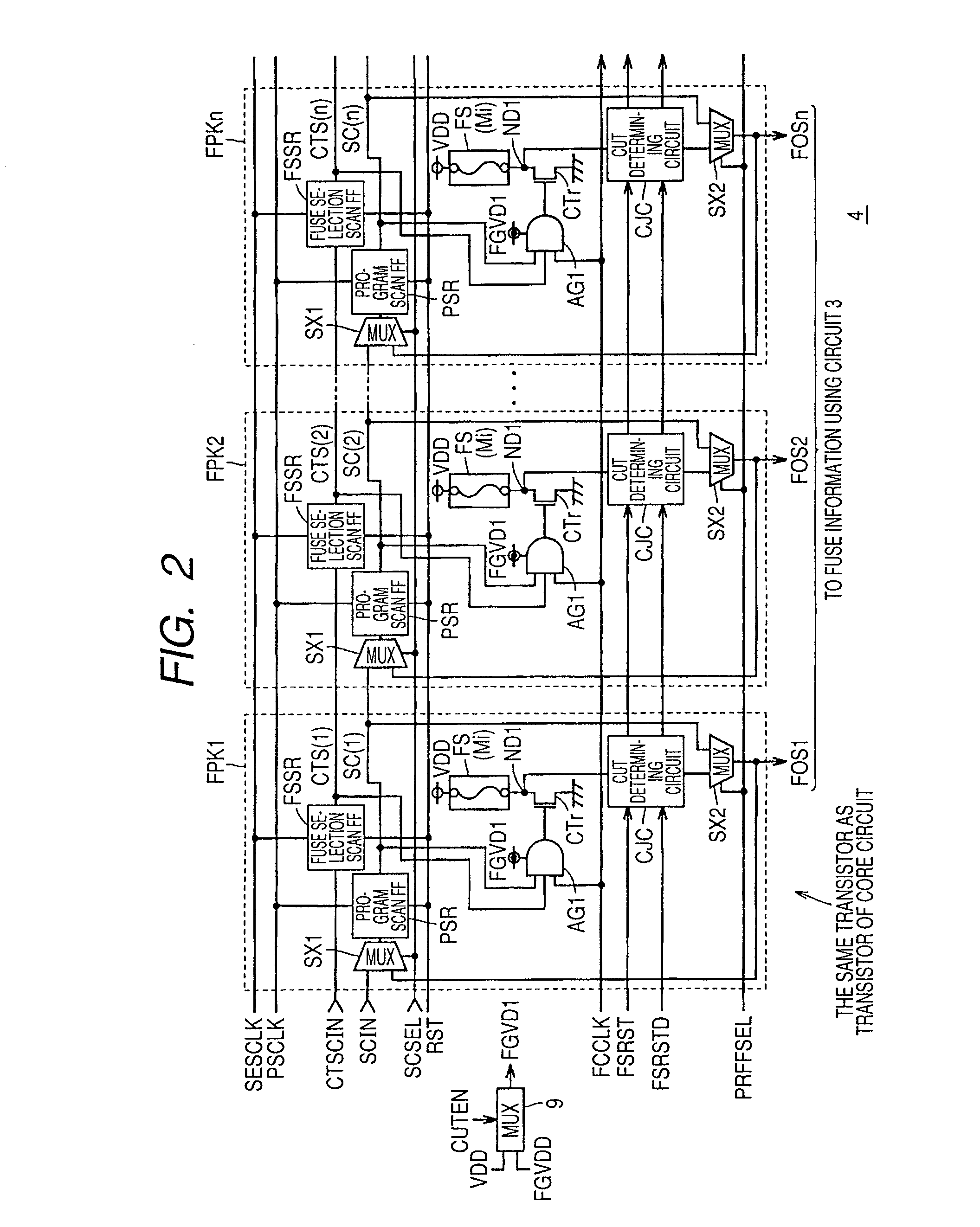

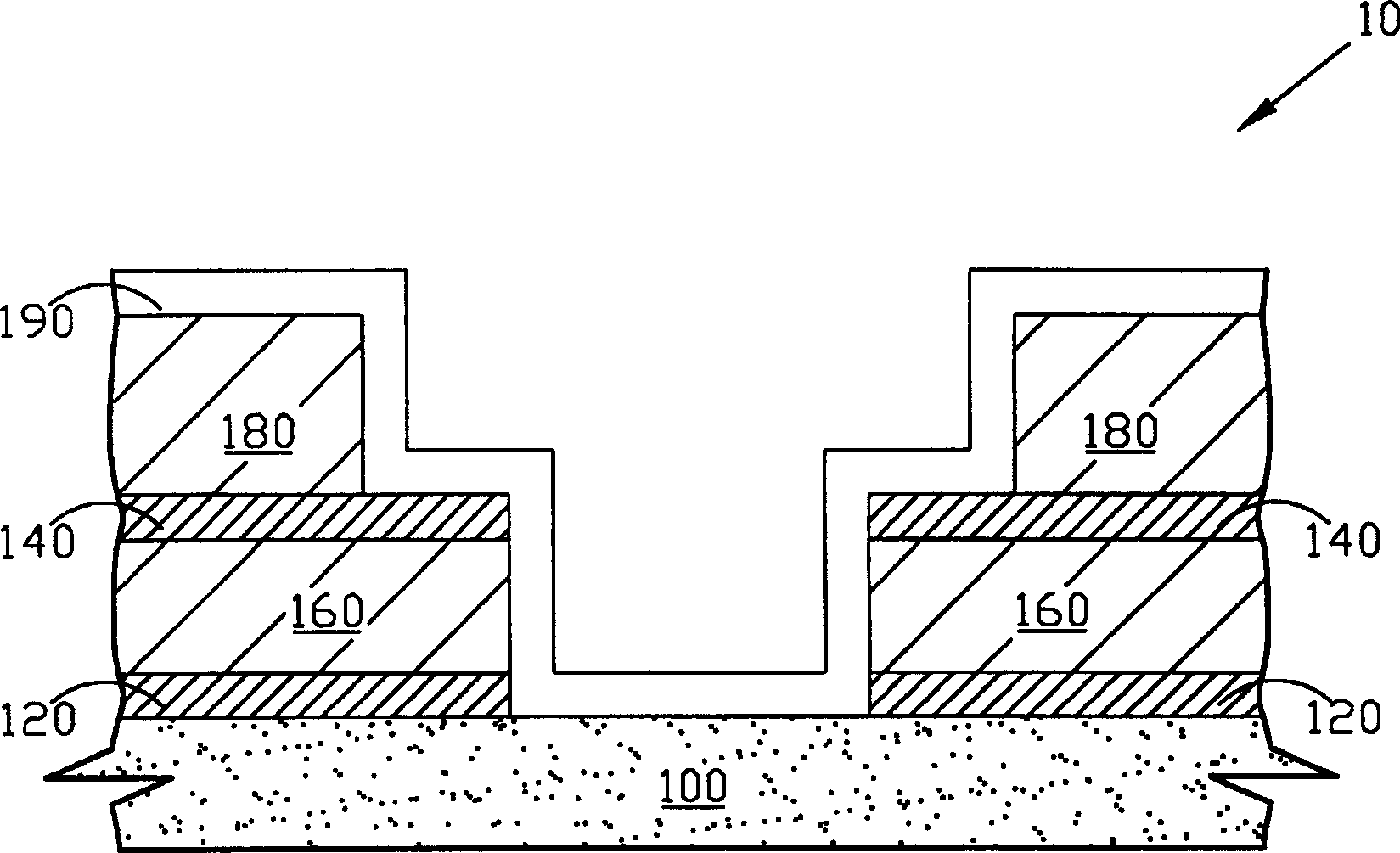

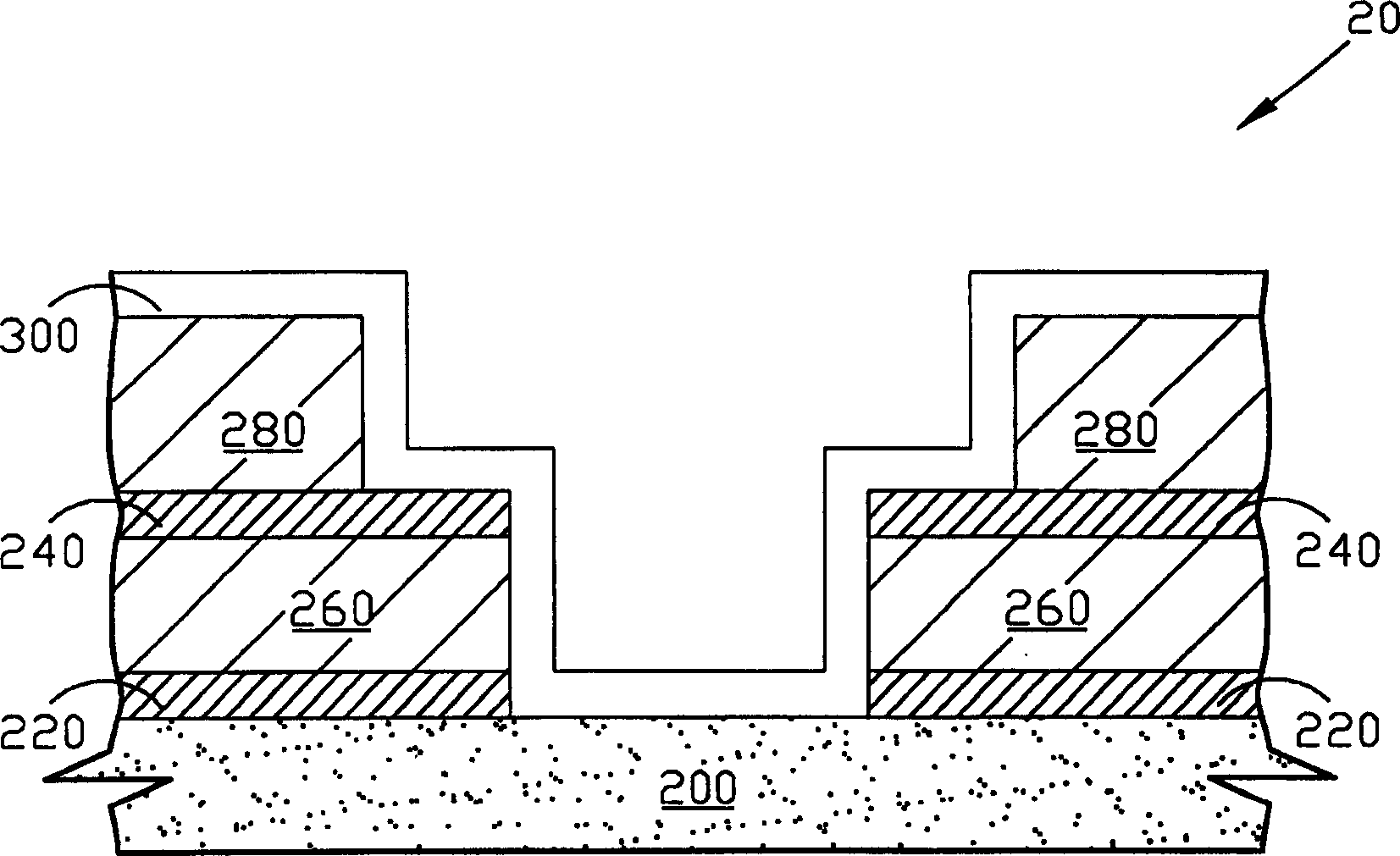

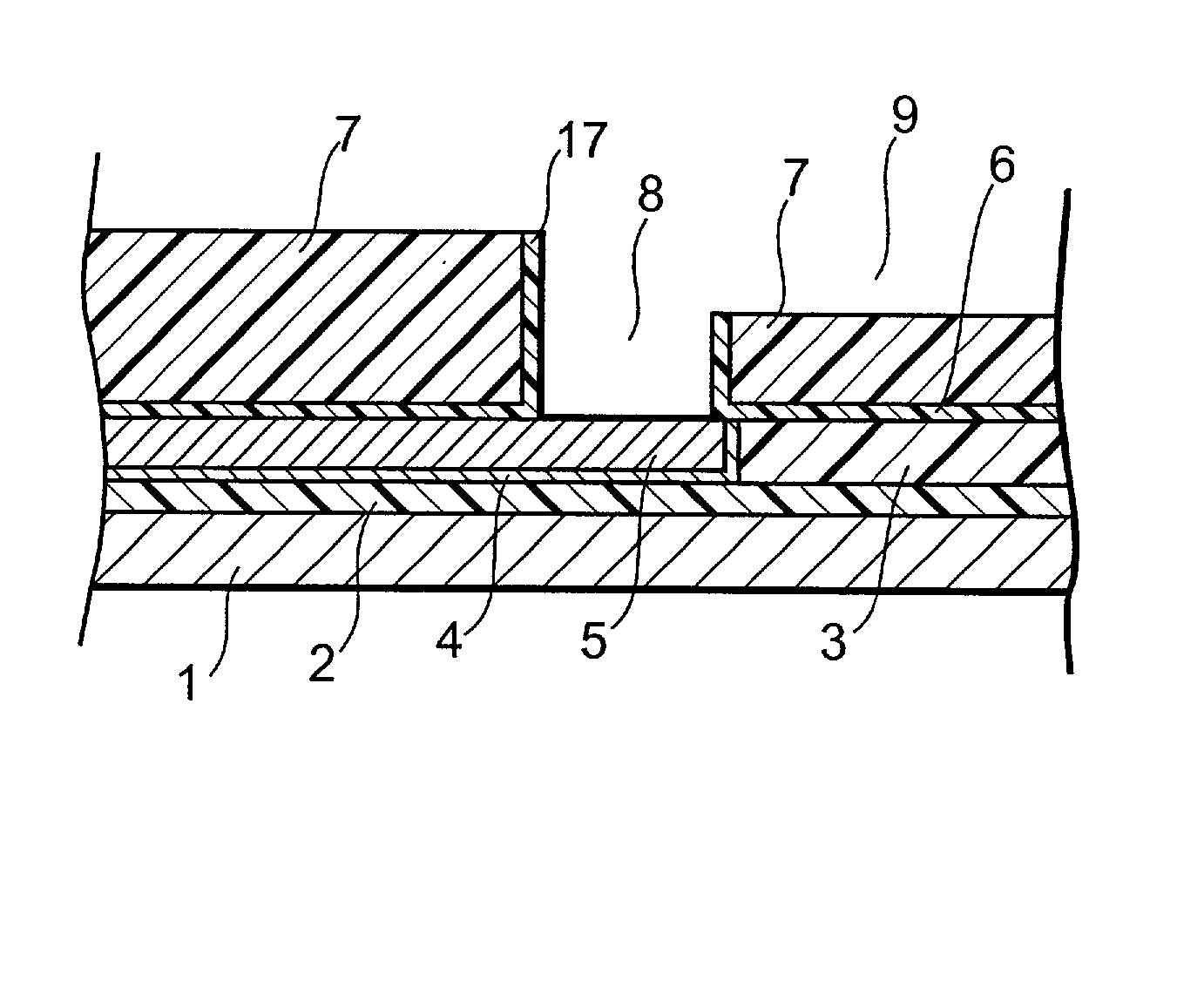

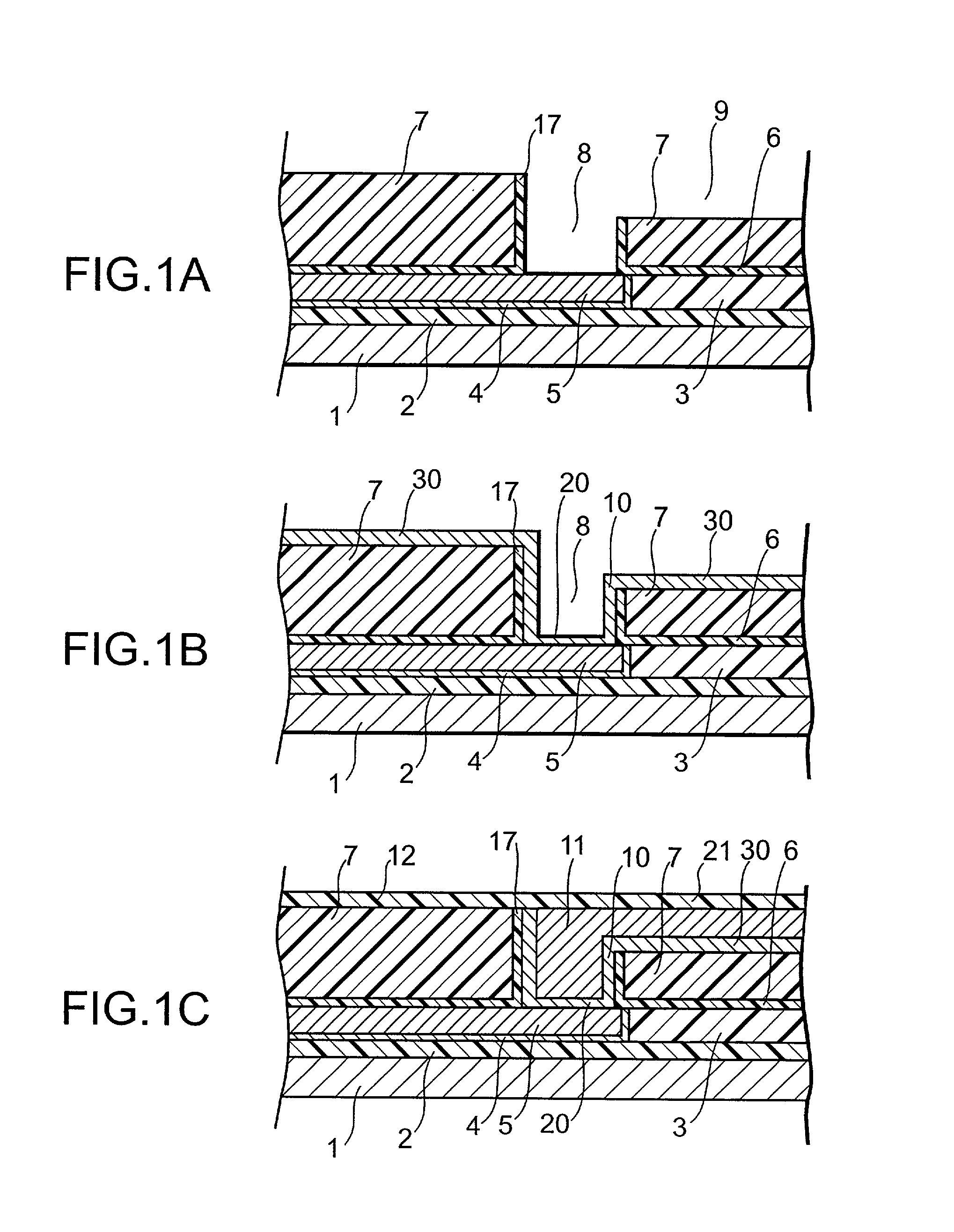

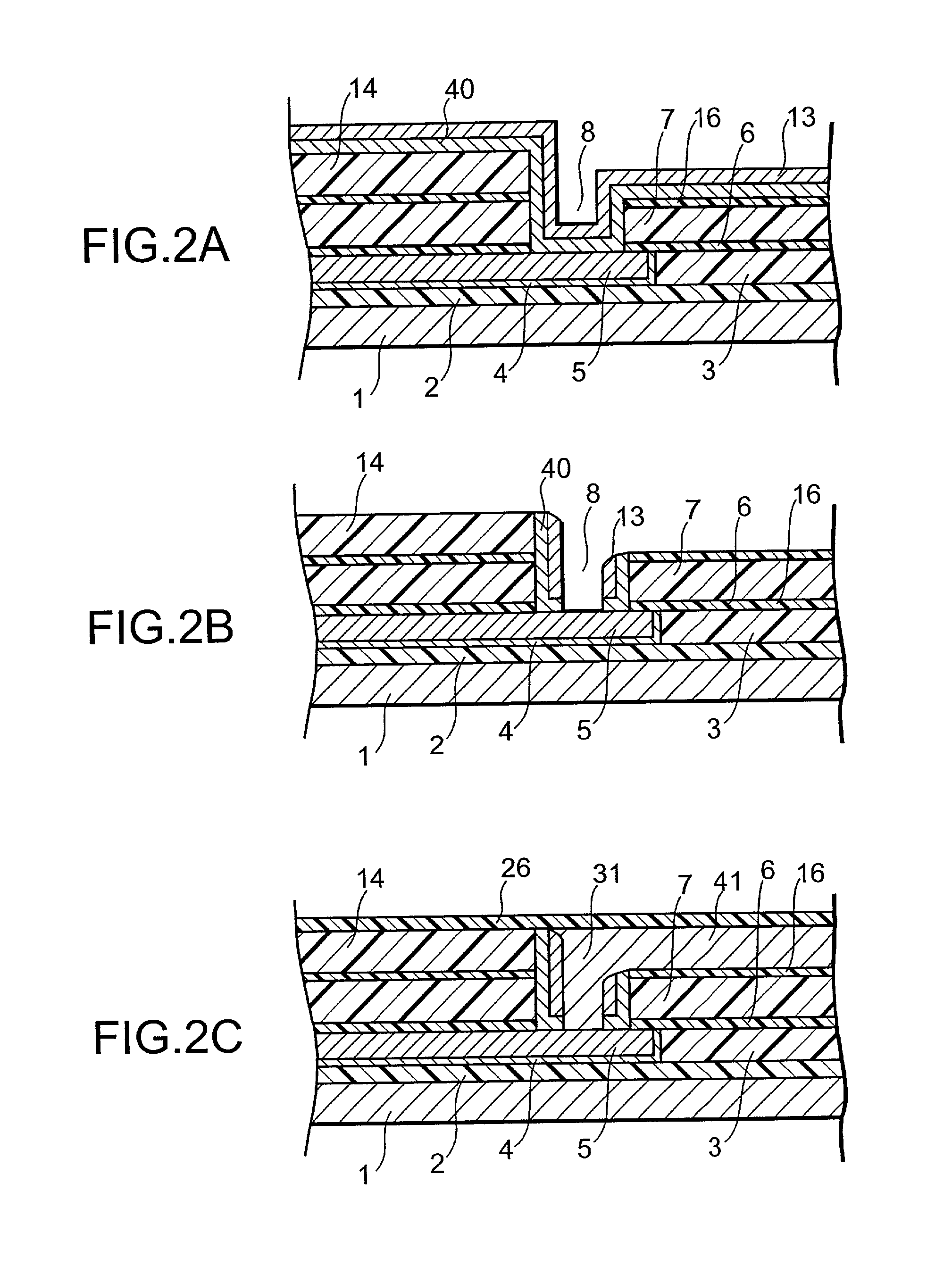

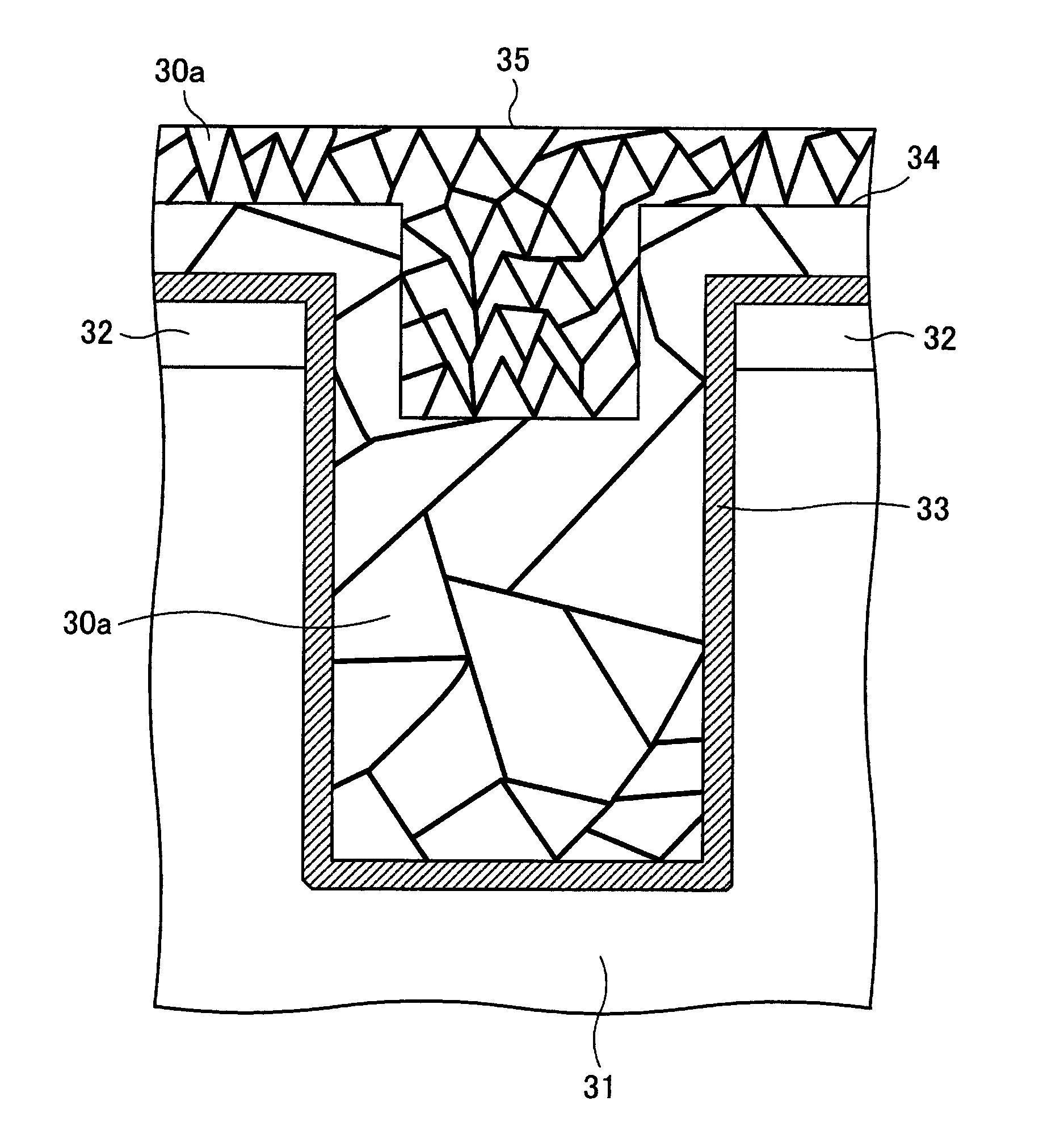

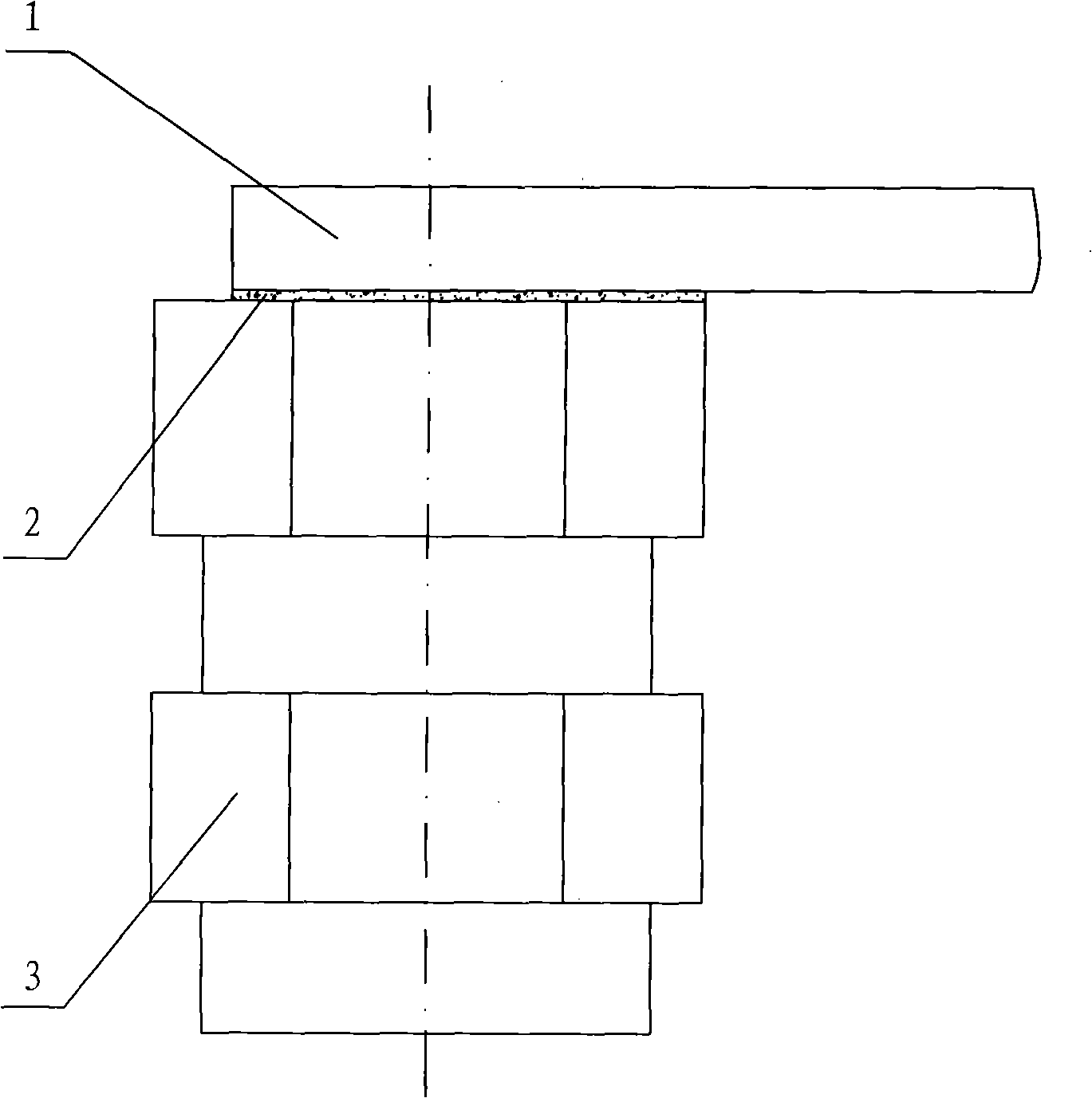

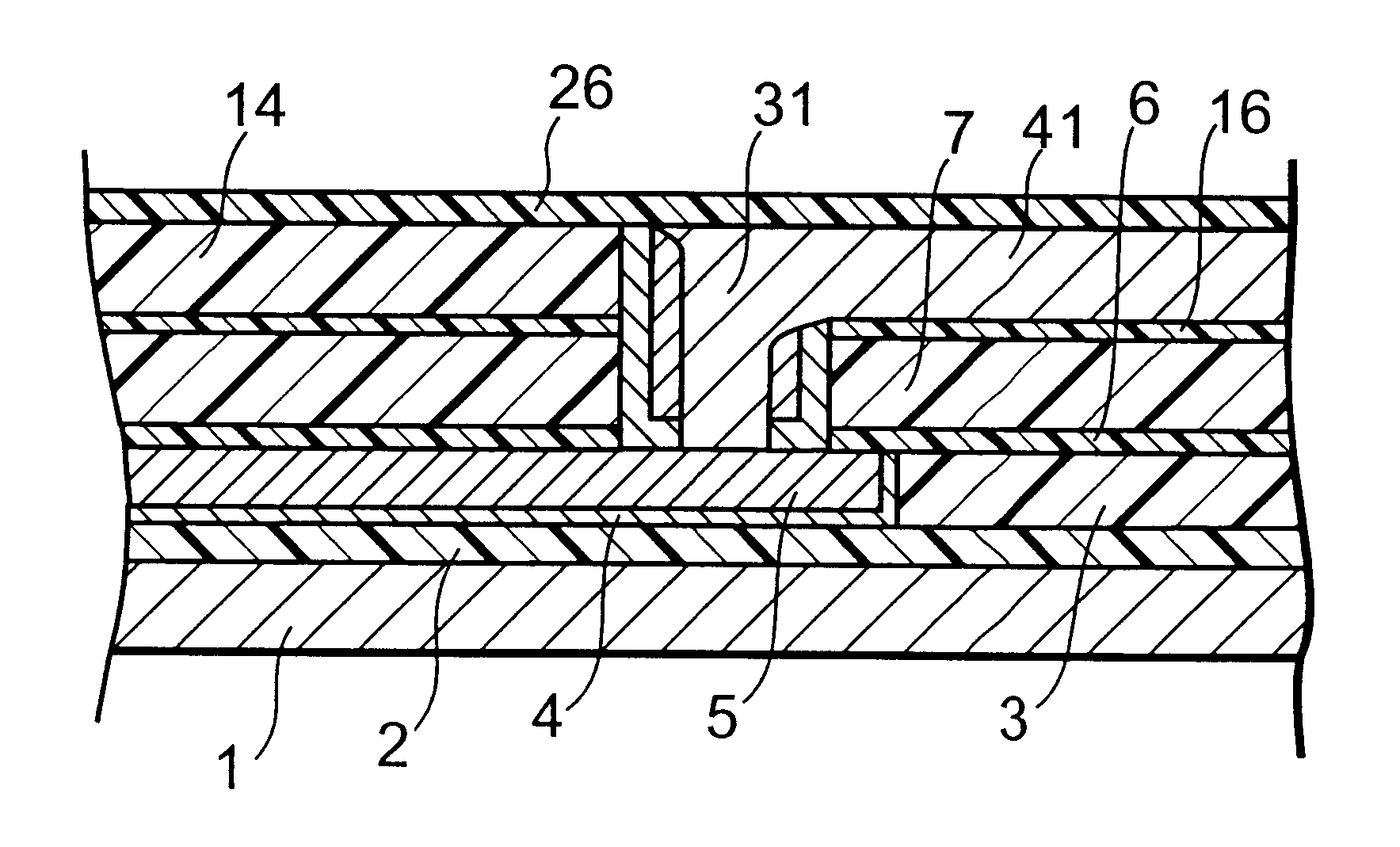

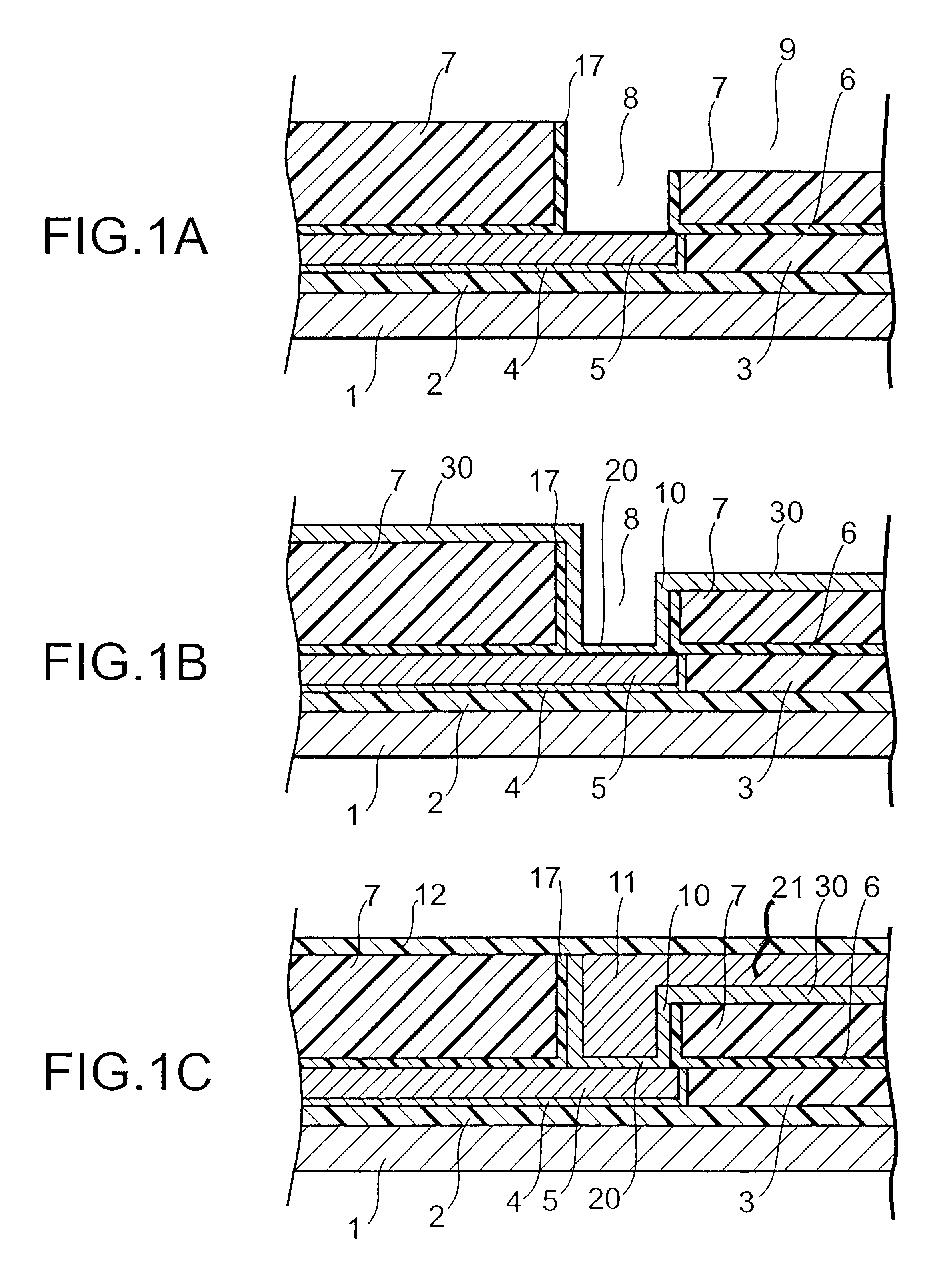

Semiconductor device

ActiveUS20100230780A1Reduce in quantityReduced footprintSemiconductor/solid-state device detailsSolid-state devicesCopper atomTransmitted power

The present invention provides a semiconductor device realizing reliable cutting of a fuse without enlarging layout area of a fuse element and the reduced number of wiring layers of a preventing wall that prevents diffusion of fuse copper atoms. A fuse is formed by using a wire in a metal wiring layer as an upper layer in a plurality of metal wiring layers. Wires are disposed just above and just below a fuse each with a gap of at least two wiring layers. In an upper layer, a power wire that transmits power supply voltage is used as a part covering a preventing wall structure just above the fuse.

Owner:RENESAS ELECTRONICS CORP

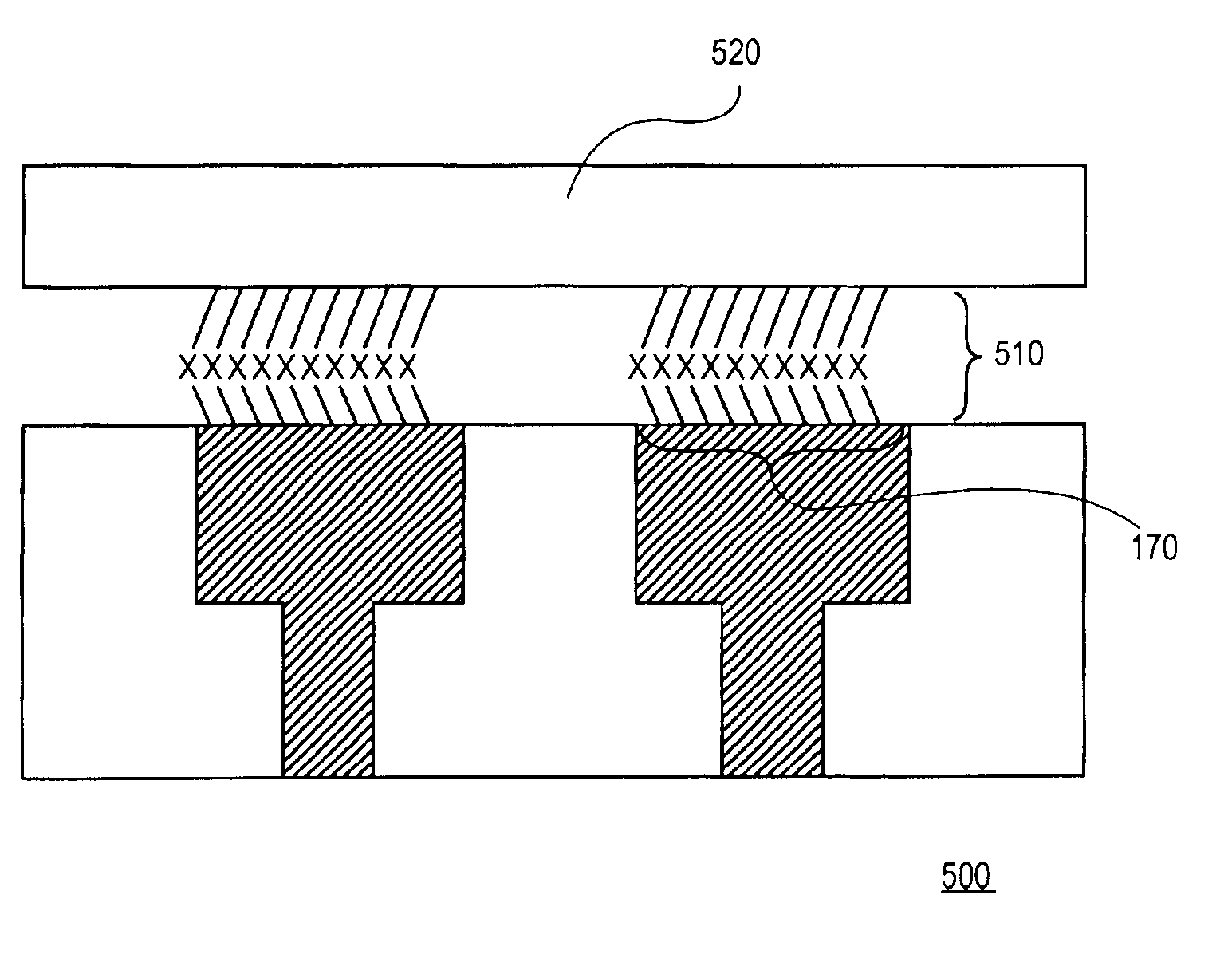

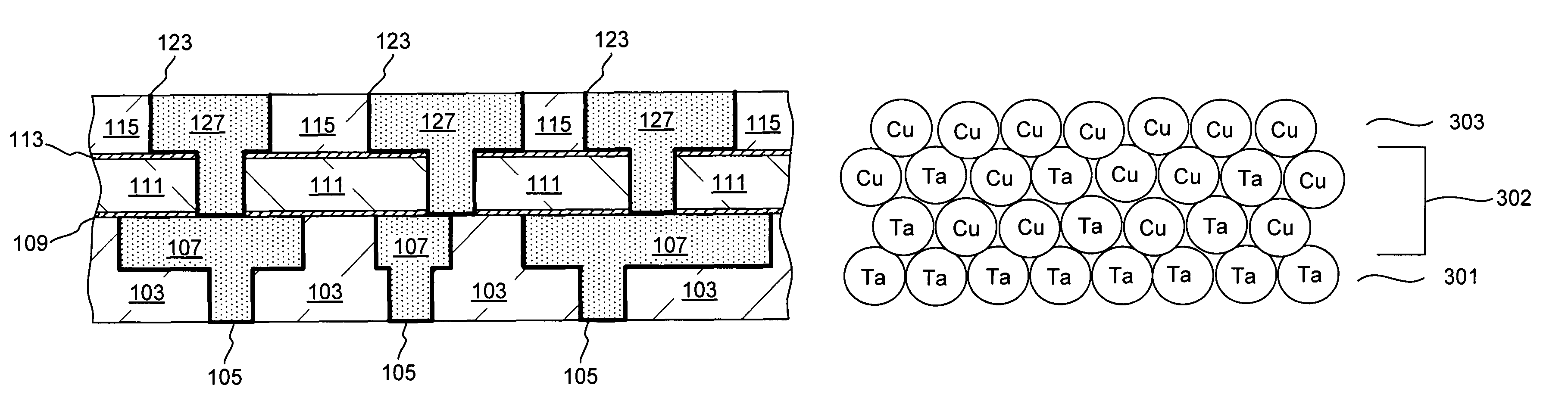

Methods and apparatus for engineering an interface between a diffusion barrier layer and a seed layer

InactiveUS7855147B1Improve adhesionImprove stabilitySemiconductor/solid-state device detailsVacuum evaporation coatingCopper atomLayer interface

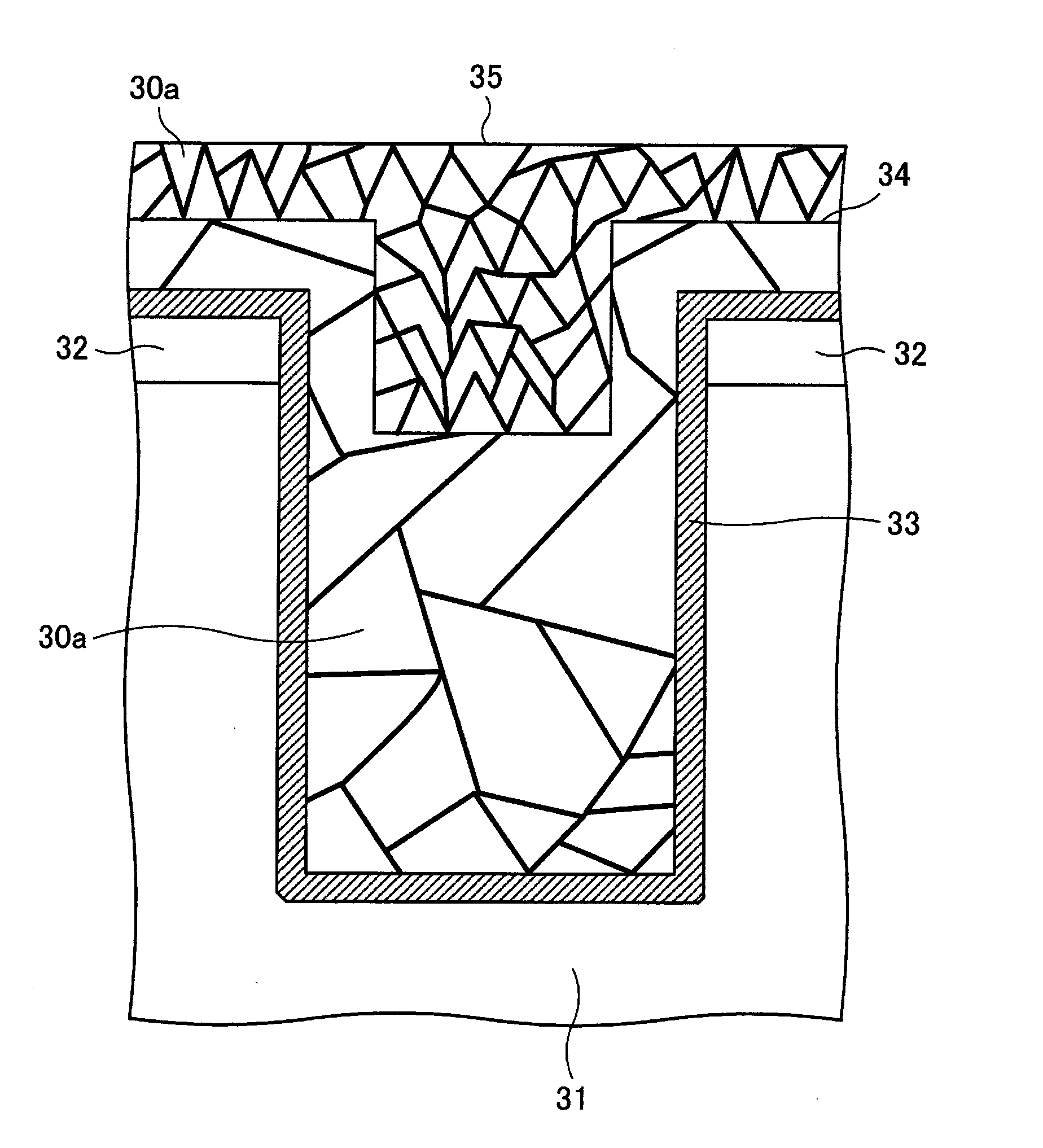

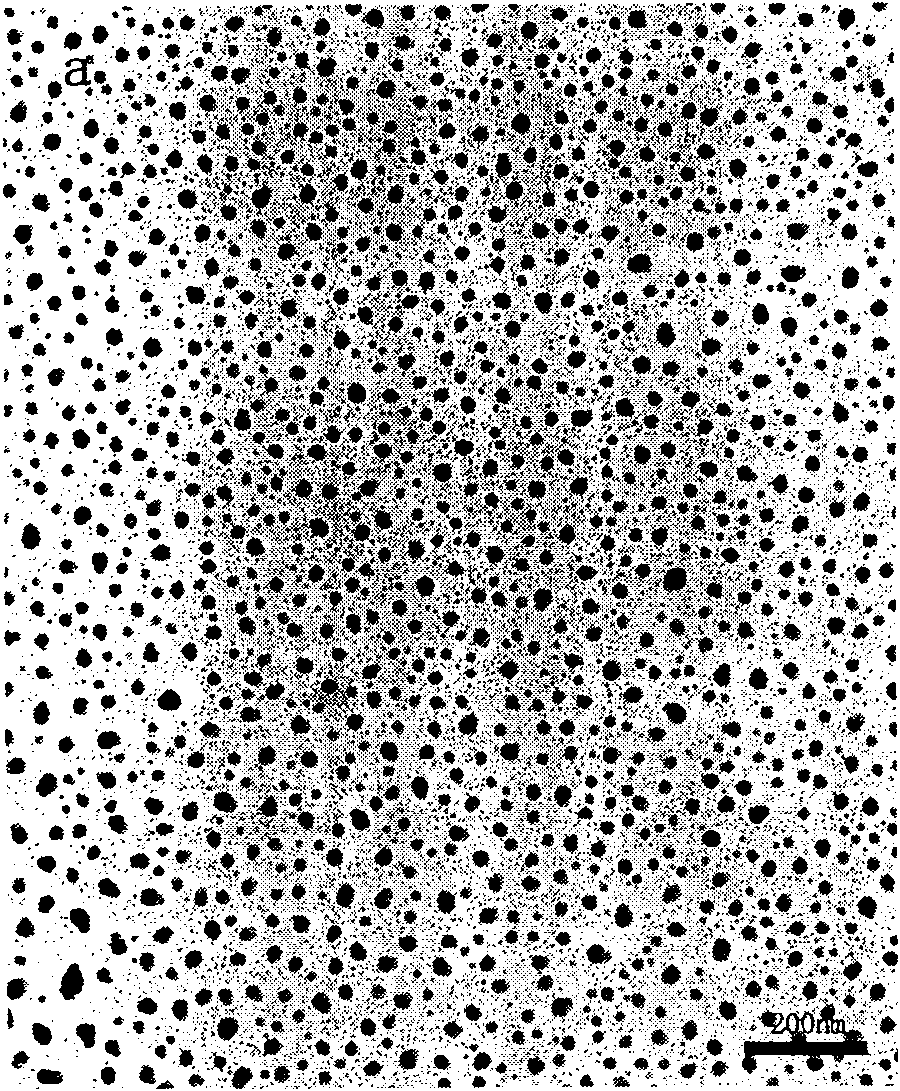

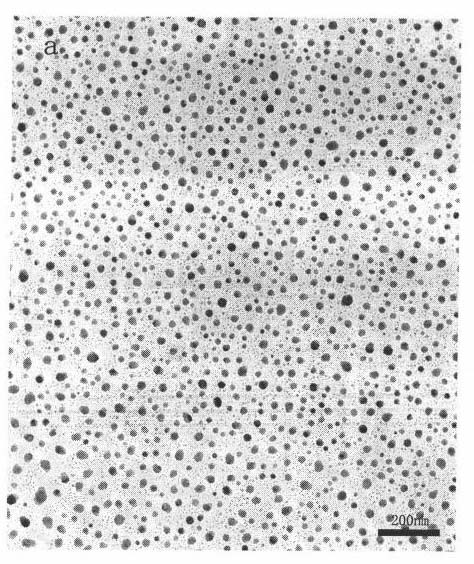

Copper seed layers are formed on diffusion barrier layers (e.g., on Ta, and TaNx layers) without significant agglomeration of copper, with the use of an engineered barrier layer / seed layer interface. The engineered interface includes an adhesion layer, in which copper atoms are physically trapped and are prevented from migrating and agglomerating. The adhesion layer can include between about 20-80% atomic of copper. The copper atoms of the adhesion layer are exposed during deposition of a copper seed layer and serve as the nucleation sites for the deposited copper. Thin, continuous, and conformal seed layers can be deposited on top of the adhesion layer. The trapping of copper within the adhesion layer is achieved by intermixing diffusion barrier and seed layer materials using PVD and / or ALD.

Owner:NOVELLUS SYSTEMS

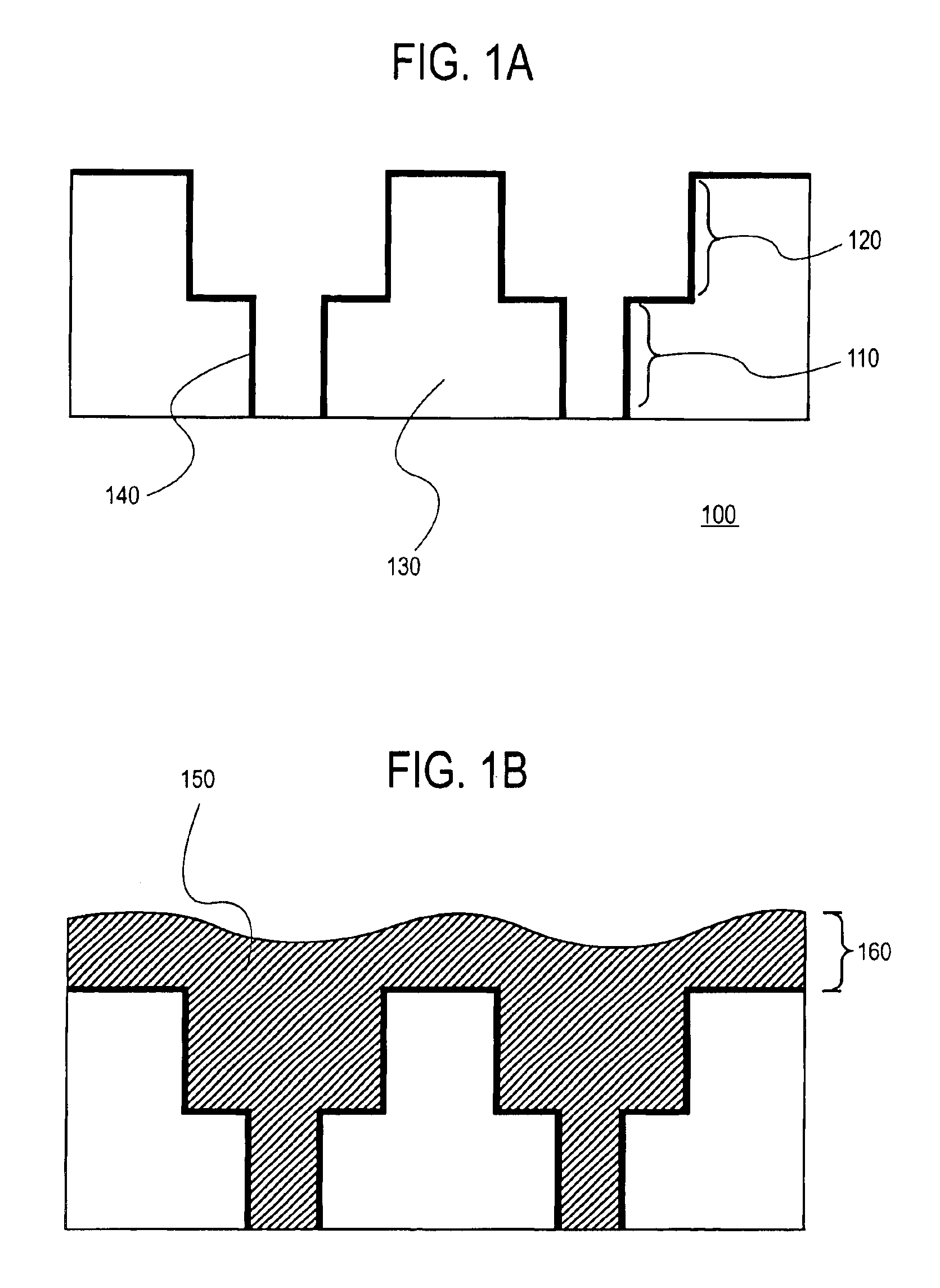

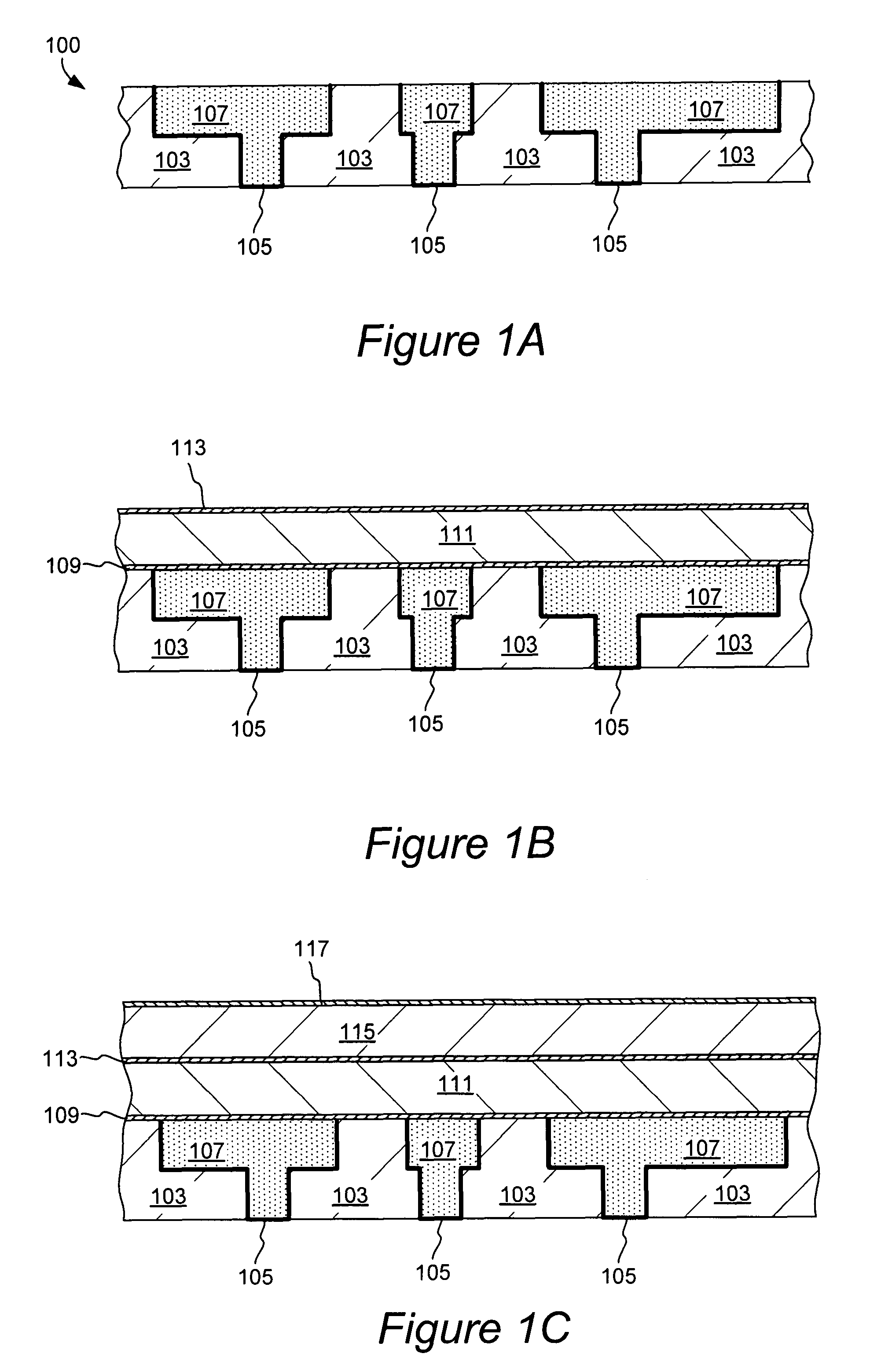

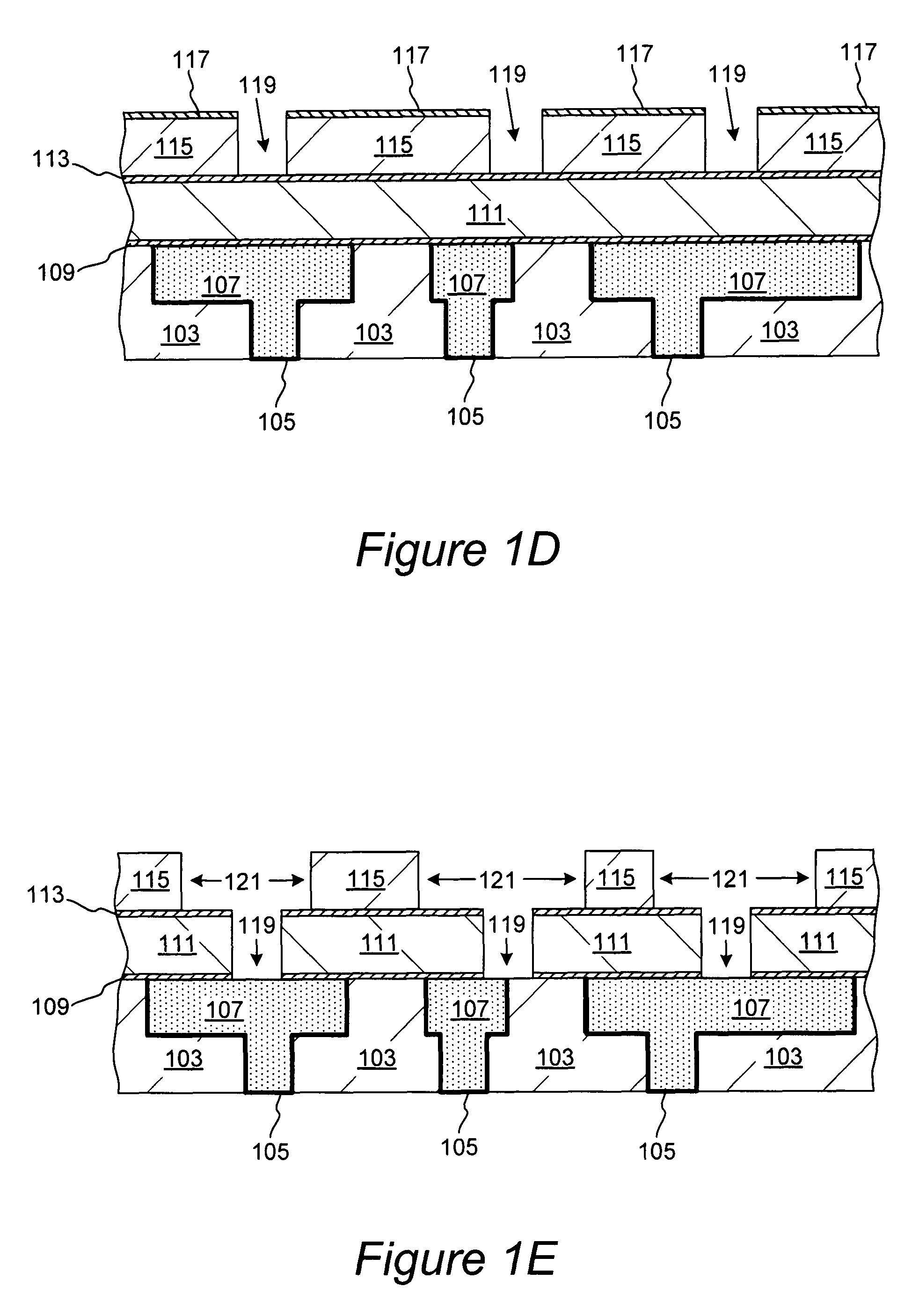

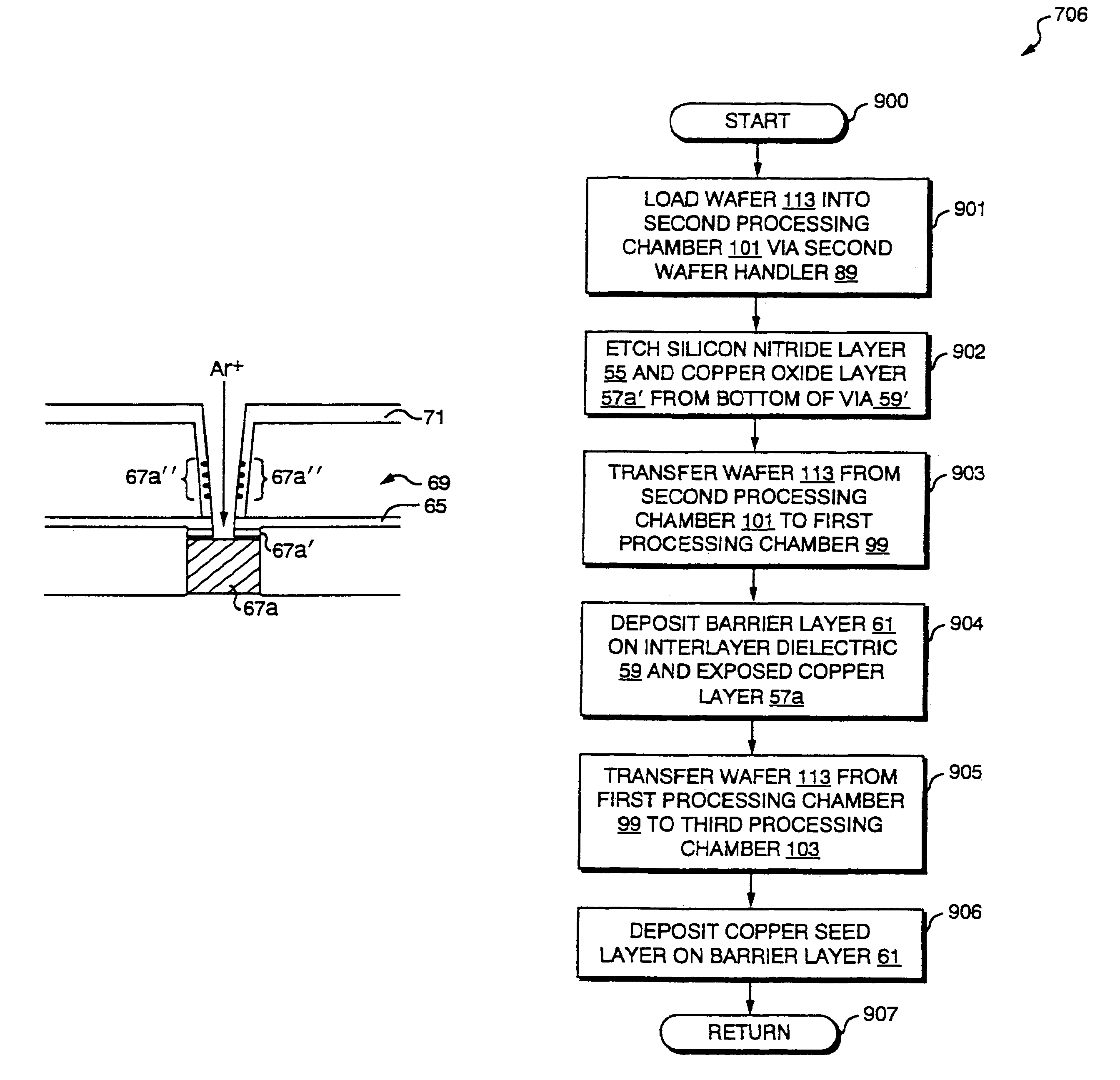

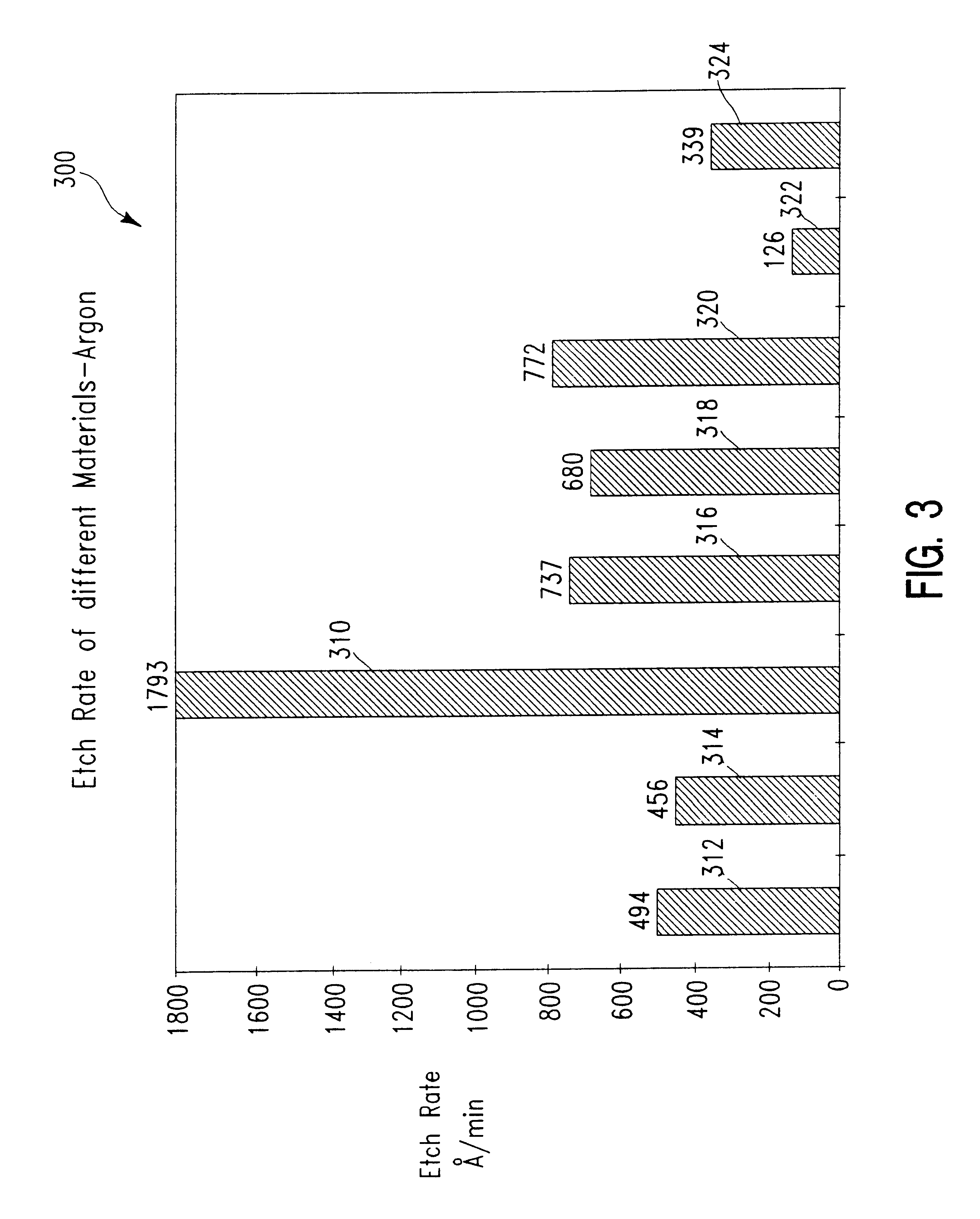

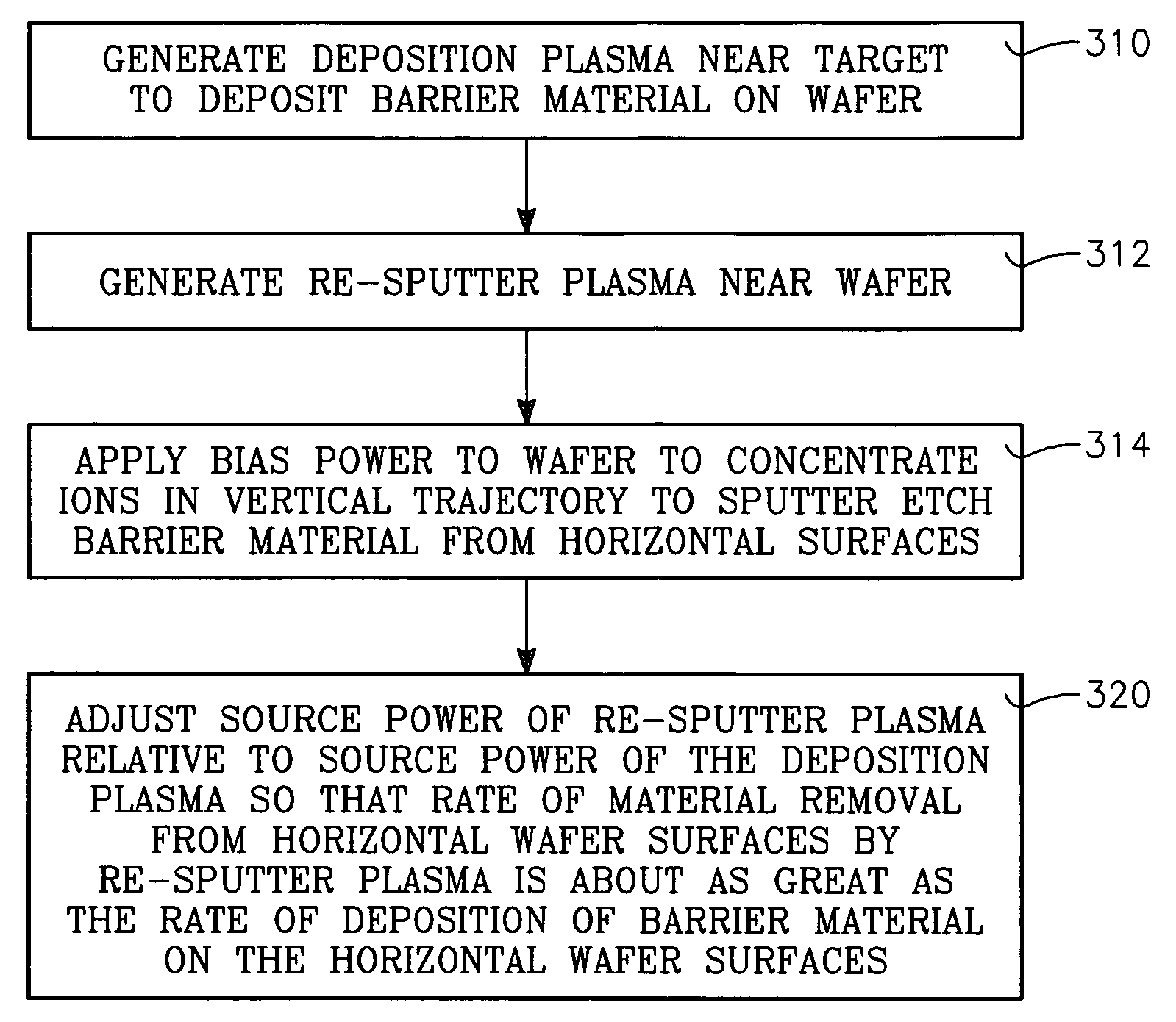

Method and apparatus for forming improved metal interconnects

InactiveUS6992012B2High resistivityLower resistanceSemiconductor/solid-state device detailsSolid-state devicesSputteringCopper atom

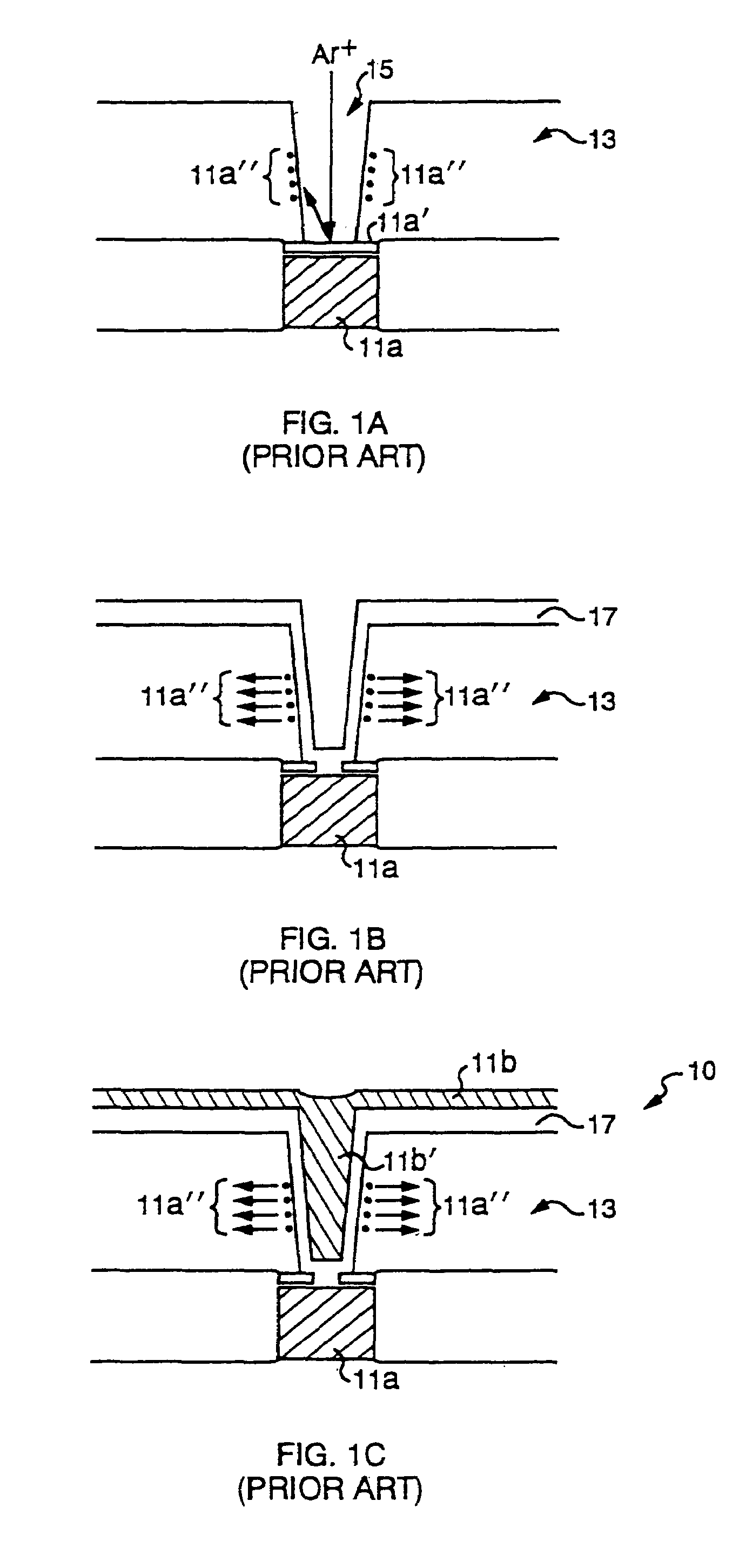

Methods of forming copper interconnects free from via-to-via leakage currents and having low resistances are disclosed. In a first aspect, a barrier layer is deposited on the first metal layer prior to copper oxide sputter-etching to prevent copper atoms from reaching the interlayer dielectric and forming via-to-via leakage current paths therein. In a second aspect, a capping dielectric barrier layer is deposited over the first metal layer prior to sputter etching. During sputter-etching, the capping dielectric barrier layer redistributes on the sidewalls of the interlayer dielectric, preventing sputter-etched copper atoms from reaching the interlayer dielectric and forming via-to-via leakage paths therein. In a third aspect, both a capping dielectric barrier layer and a barrier layer are deposited over the first metal layer prior to sputter-etching to prevent copper atoms produced during sputter-etching from reaching the interlayer dielectric and forming via-to-via leakage paths therein.

Owner:APPLIED MATERIALS INC

Semiconductor device and method for fabricating the same

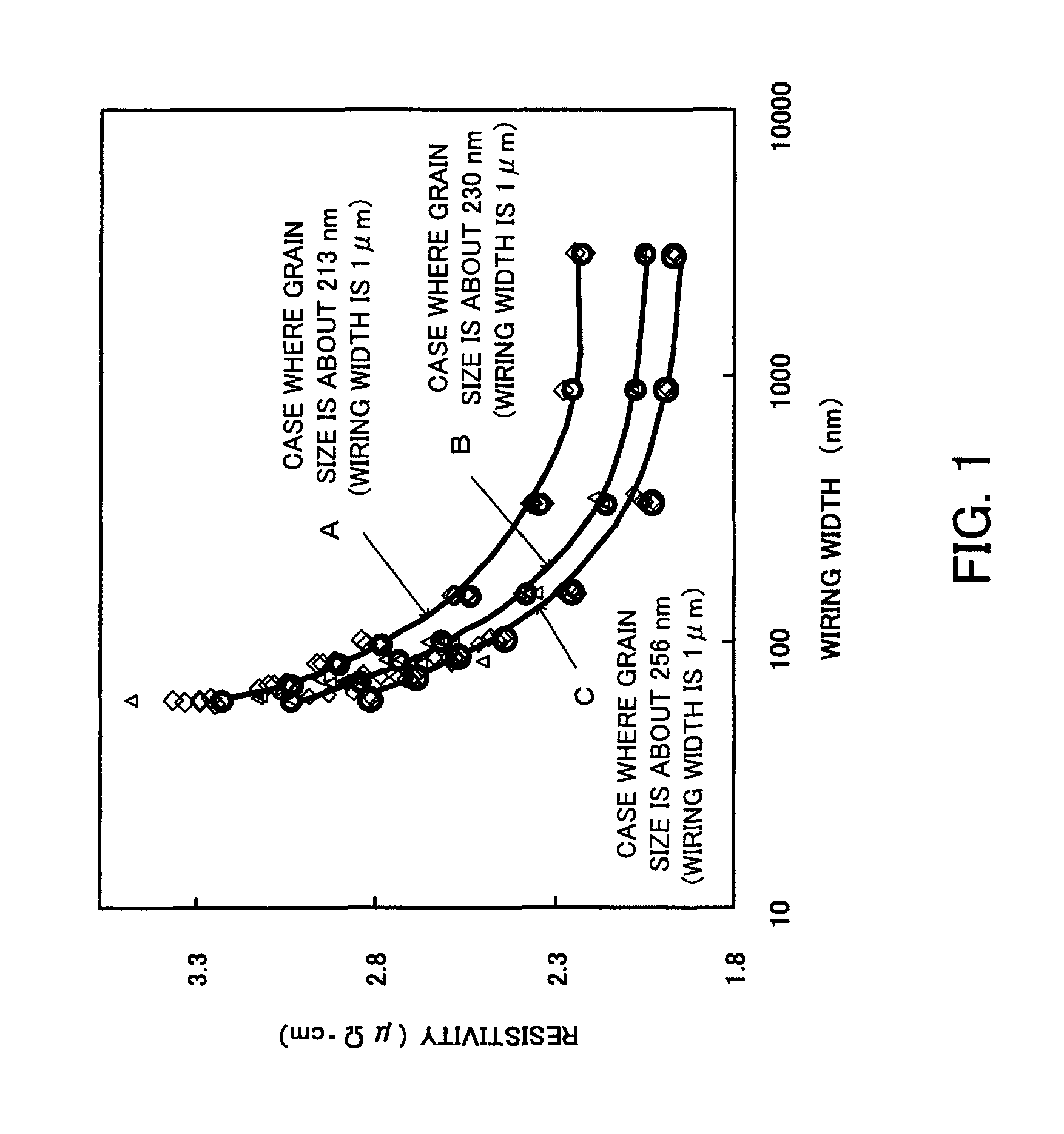

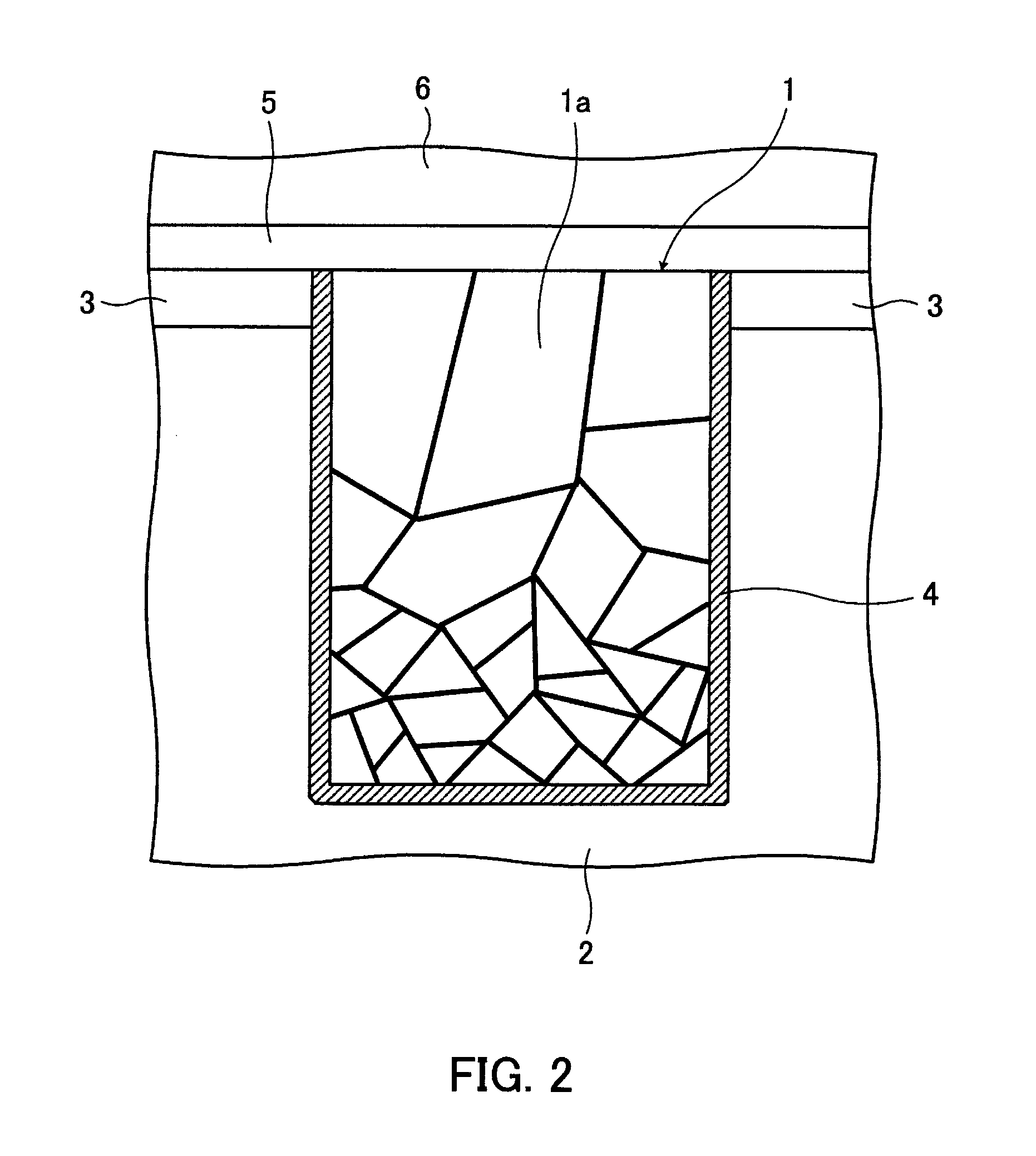

InactiveUS20080211098A1Highly reliable metal wiringStably Semiconductor/solid-state device detailsSolid-state devicesCopper atomCopper-wiring

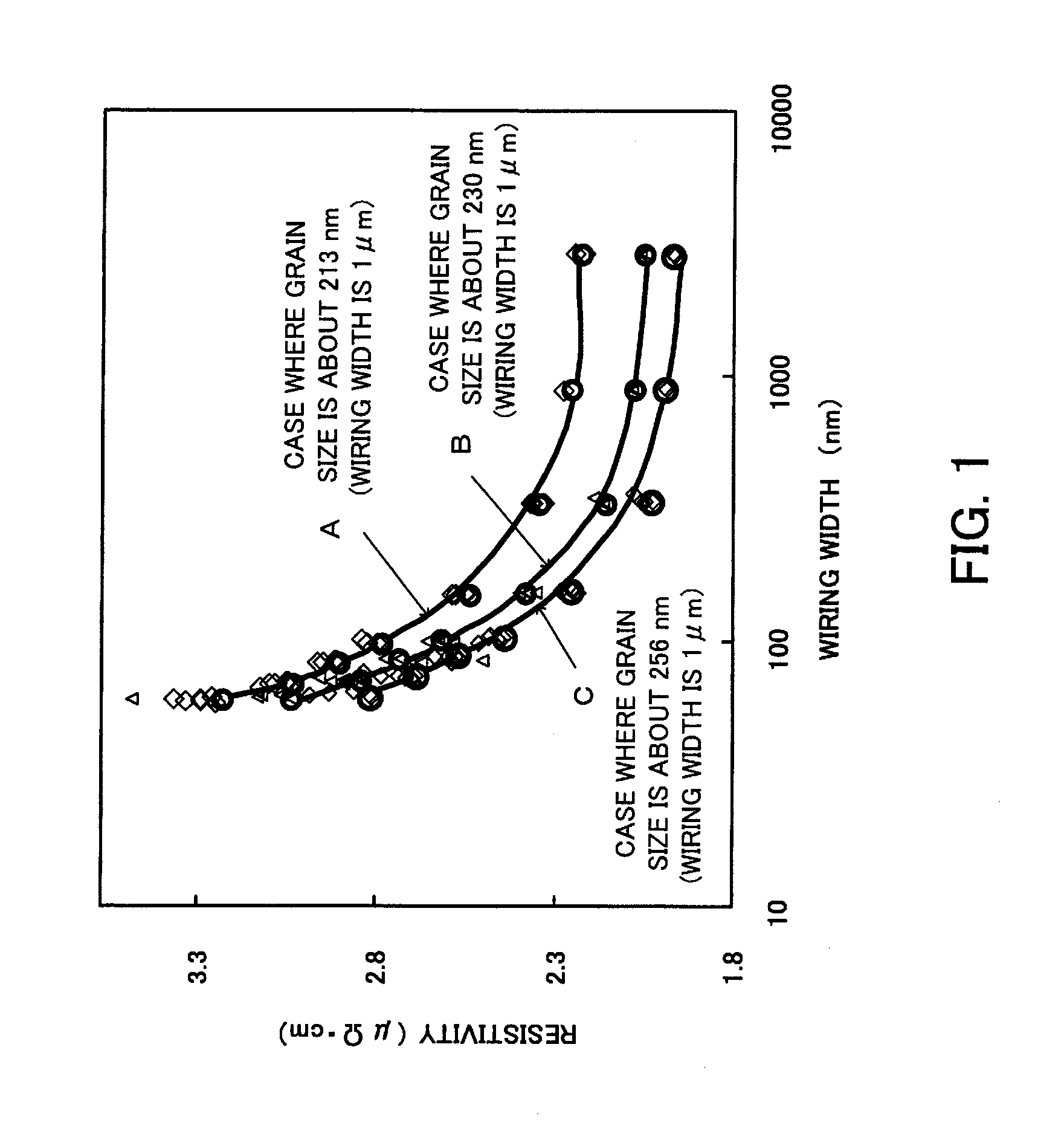

A semiconductor device in which the resistance of a copper wiring to electromigration is increased. The copper wiring is formed so that copper grains will be comparatively large in a central portion of the copper wiring and so that copper grains will be comparatively small in an upper portion and a lower portion of the metal wiring. The copper wiring having this structure is formed by a damascene method. This structure can be formed by controlling electric current density at electroplating time. With the copper wiring having this structure, it is easier for an electric current to run through the central portion than to run through the upper portion. As a result, the diffusion of copper atoms in the upper portion is suppressed and therefore the diffusion of copper atoms from an interface between the copper wiring and a cap film is suppressed.

Owner:FUJITSU LTD

Brazing procedure of aluminium electric-magnetic wires and Guinea gold

ActiveCN101015875AMeet welding requirementsGood resistance to temperature changesCellsMetallic material coating processesCopper atomElectrical resistance and conductance

A method for solder welding aluminum electromagnetic wire and brass comprises aluminum electromagnetic wire and brass connector. The invention comprises that first plating nickel on the surface of brass connector to improve the connecting strength between the solder and the brass connector and the corrosion resistance of aluminum copper connector, while said nickel layer can insulate aluminum atom and copper atom to avoid them to form rigid metal compound layer which will reduce the strength of connector, then using drug Al-Si rigid solder as non-corrosion aluminium fluoride potassium, using flame welding to weld the aluminum electromagnetic wire and the nickel layer of brass connector, the brass connector is treated with neutral oil removing, ultrasonic oil removing, water washing, acid washing, water washing, activating, waster washing, nickel plating, and drying. The inventive aluminum electromagnetic wire and brass connector have same anti-drawing strength, while the resistance of aluminum copper connector is less than the aluminum electromagnetic wire.

Owner:顺特电气设备有限公司

Etched patterned copper features free from etch process residue

InactiveUS6488862B1Decorative surface effectsSemiconductor/solid-state device detailsCopper atomEtching

Owner:APPLIED MATERIALS INC

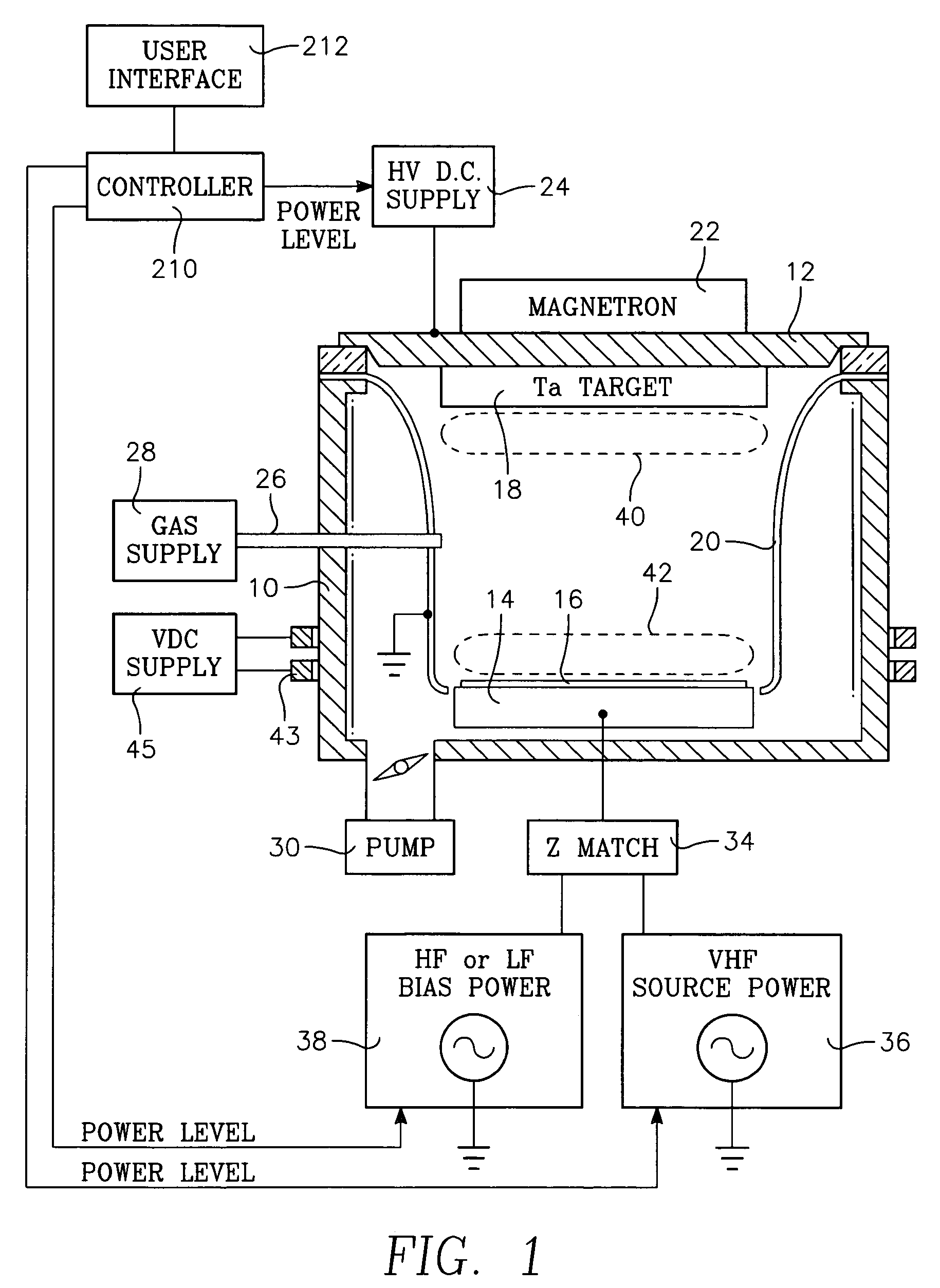

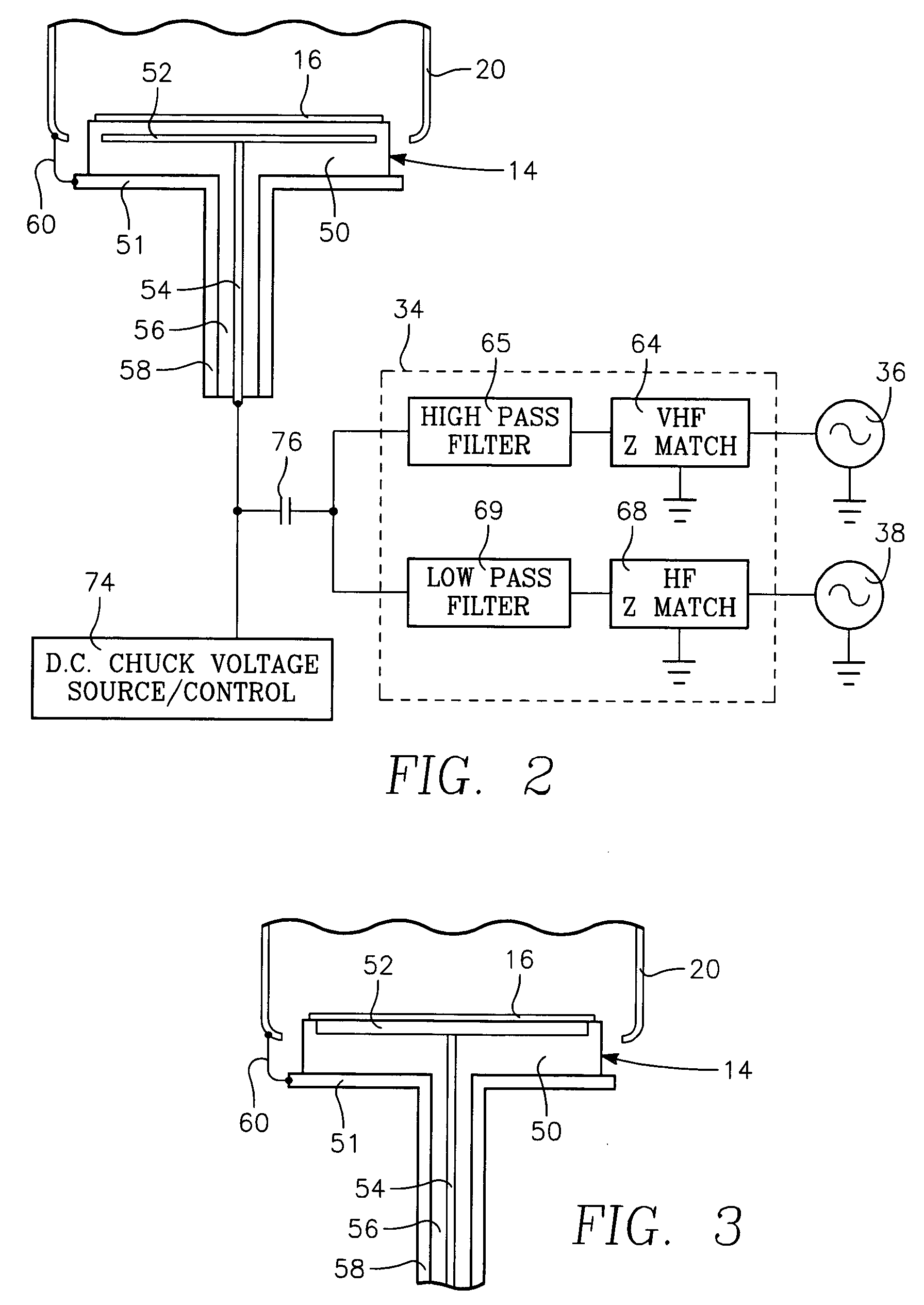

Apparatus for plasma-enhanced physical vapor deposition of copper with RF source power applied through the workpiece

InactiveUS20060172536A1High frequencyAmeliorating and avoiding non-uniform depositionElectric discharge tubesVacuum evaporation coatingCopper atomCapacitance

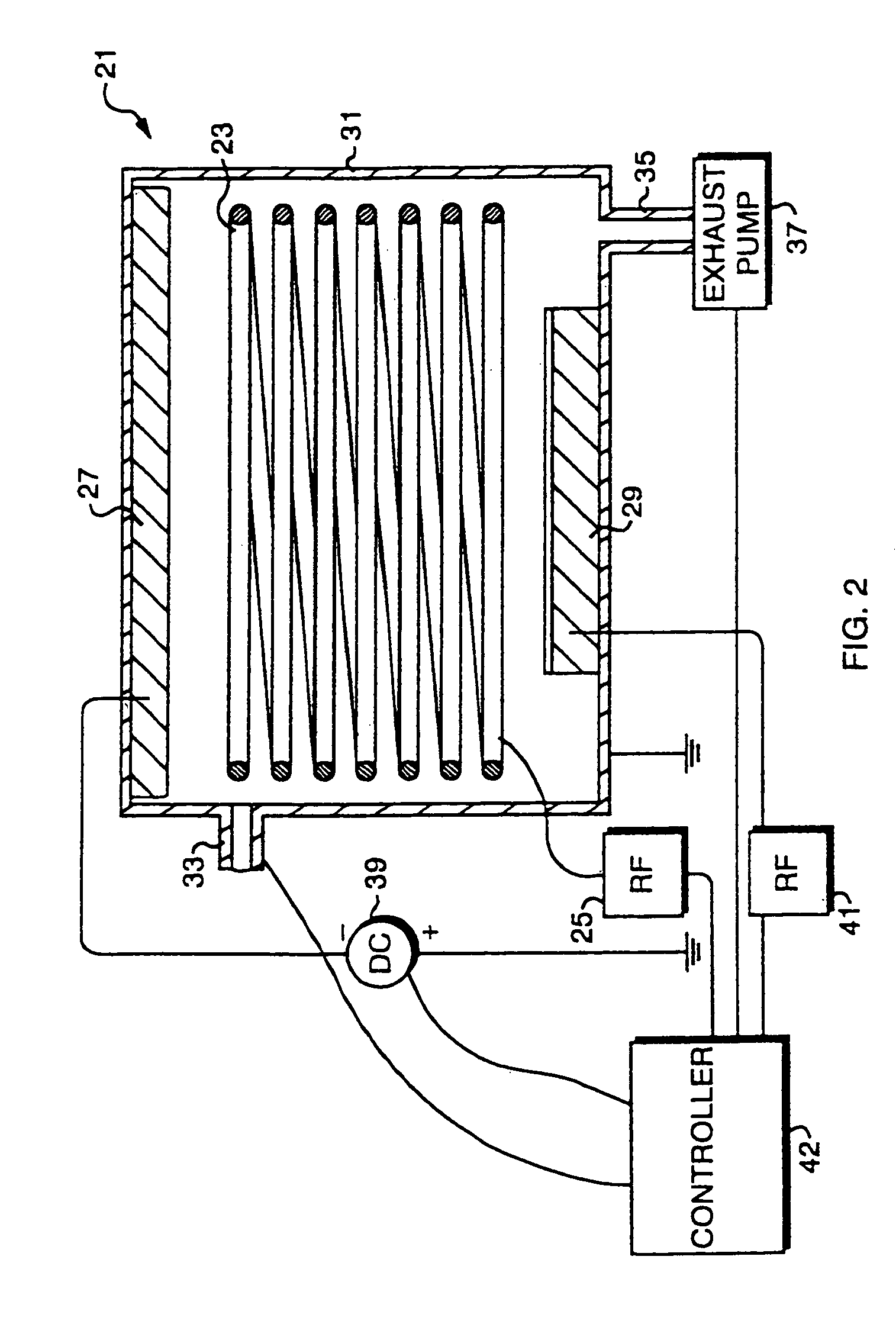

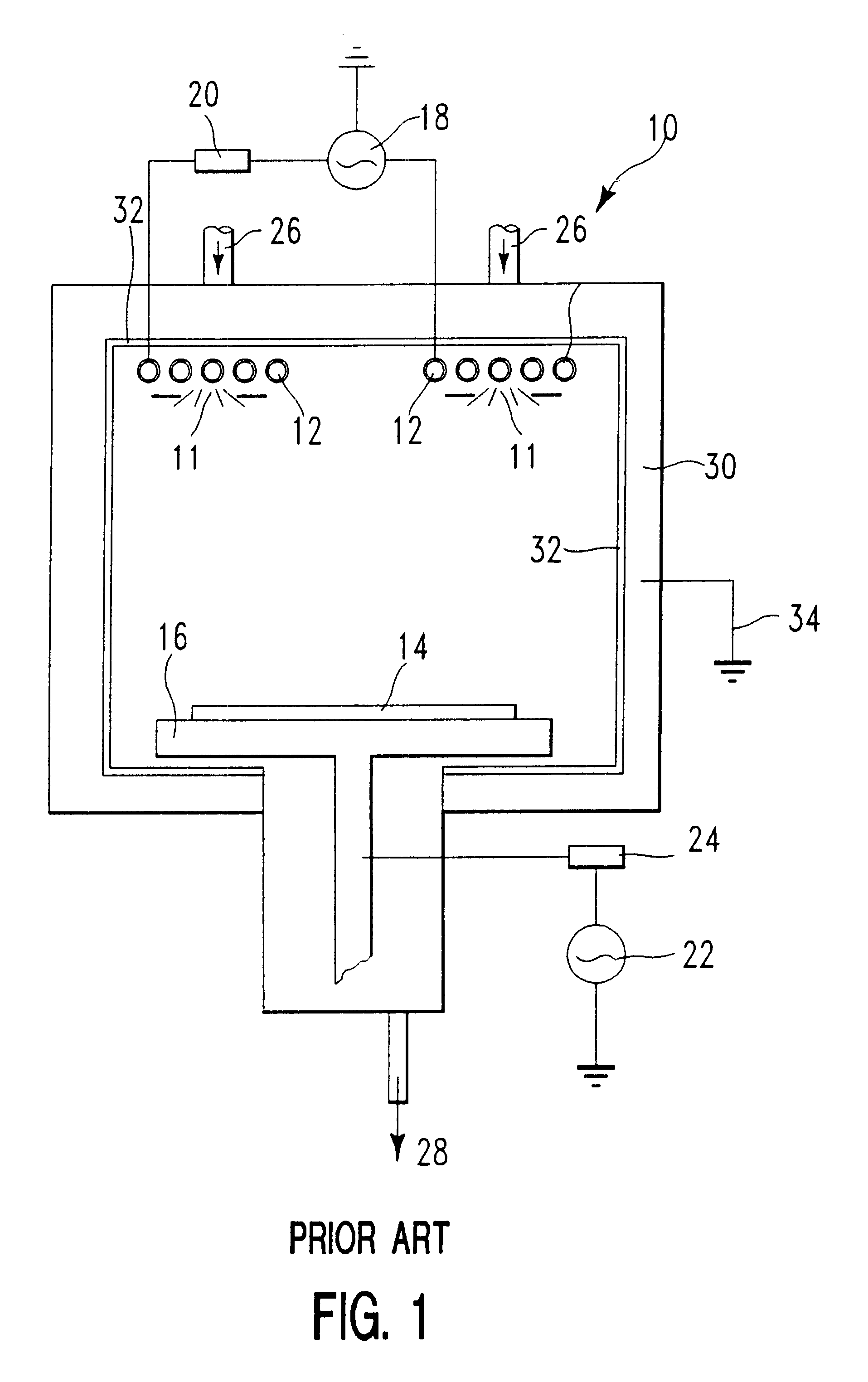

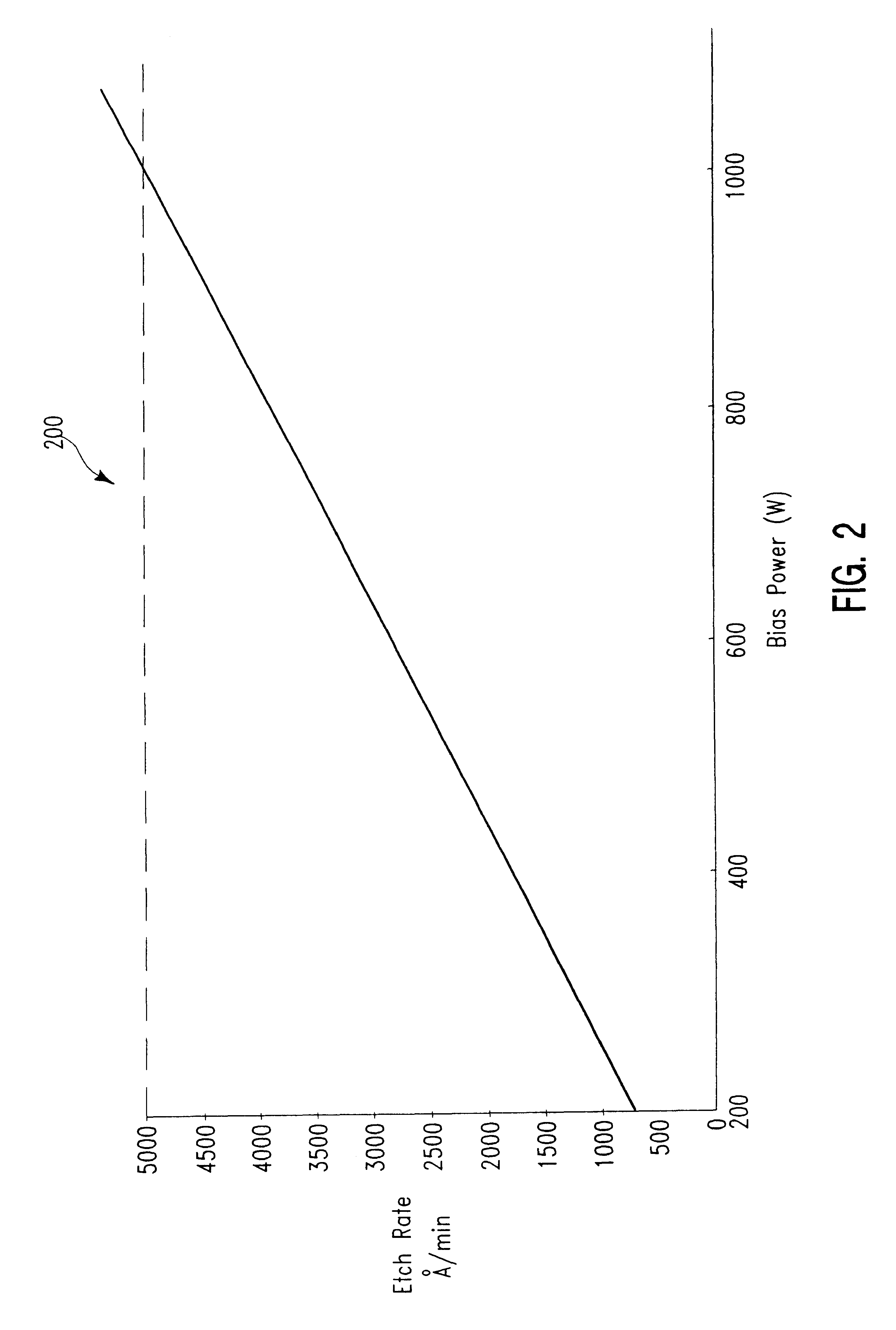

A method of performing physical vapor deposition of copper onto an integrated circuit in a vacuum chamber of a plasma reactor includes providing a copper target near a ceiling of the chamber, placing an integrated circuit wafer on a wafer support pedestal facing the target near a floor of the chamber, introducing a carrier gas into the vacuum chamber, maintaining a target-sputtering plasma at the target to produce a stream comprising at least one of copper atoms and copper ions flowing from the target toward the wafer support pedestal for vapor deposition, and maintaining a wafer-sputtering plasma near the wafer support pedestal by capacitively coupling plasma RF source power to the wafer-sputtering plasma. The frequency of the RF source power is sufficiently high to limit ion energy near the surface of the wafer so that the principal portion of the power provides plasma ion generation. The method further includes maintaining the RF source power at a sufficiently high level to deposit a conformal layer of copper on vertical and horizontal surfaces of the workpiece.

Owner:APPLIED MATERIALS INC

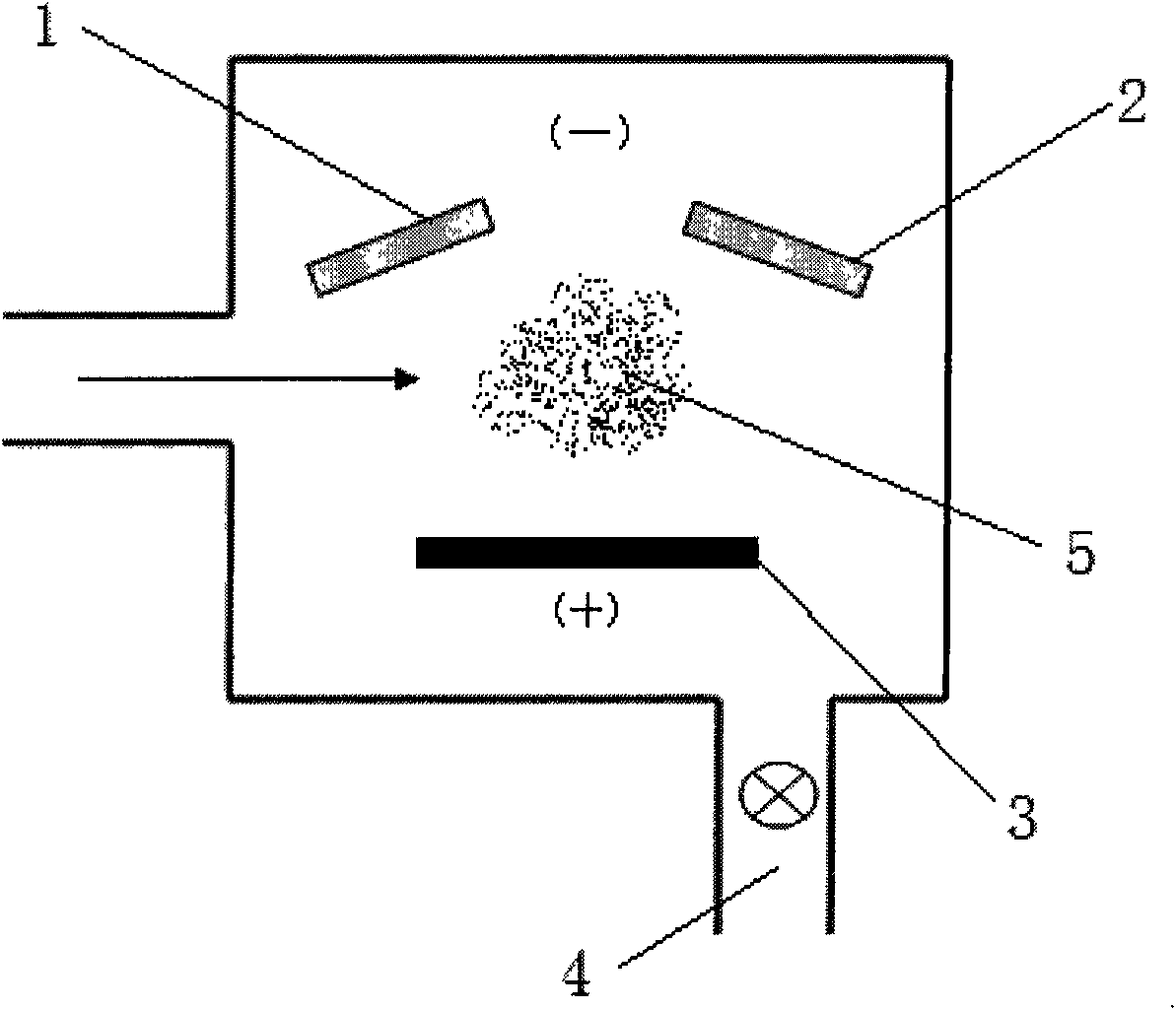

Method for preparing nano copper powder

The invention discloses a method for preparing nano copper powder, which comprises the following steps of: compounding copper sulfate, lauryl sodium sulfate and polyoxyethylene sorbitan monooleate in a molar ratio of 1:0.5-2:0.05-0.3, dissolving the mixture in water, blending the aqueous solution and lauryl mercaptan-containing benzene solution in a molar ratio of copper sulfate to lauryl mercaptan of 1:0.5-2, and uniformly stirring; pouring the emulsion fluid into an electrolytic bath, taking pure copper as an anode and stainless steel as a cathode, and regulating the pH value to between 0.5 and 4; supplying direct current to the anode and the cathode to ensure that the lauryl mercaptan dissolved in an electrolyte performs in-situ clad on precipitated copper atoms, the generated copper powder loosely attaches to the surface of the cathode, copper ions near the anode are continuously migrated to the place near the cathode under the action of diffusion and directional migration of electric charge at the same time, and the electrolytic time is 30 to 120 minutes; adding the cathode to which the copper powder is attached into absolute ethyl alcohol, and putting the cathode in an ultrasonic cleaner for desorption by using ultrasonic waves for 5 to 20 minutes to obtain dark purple copper solution; and filtering the solution, and drying the filtrate for 1 to 3 hours at the temperature of between 60 and 100 DEG C in a vacuum environment to obtain brown powder, namely a nano copper composite.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

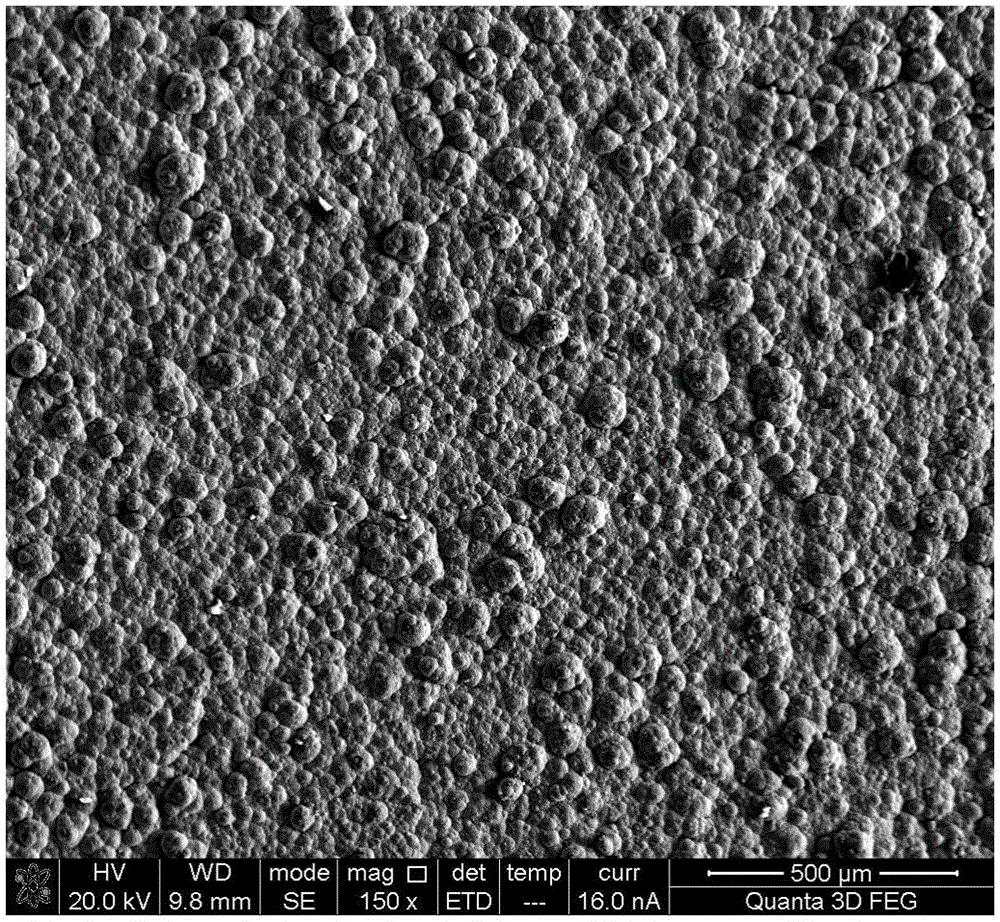

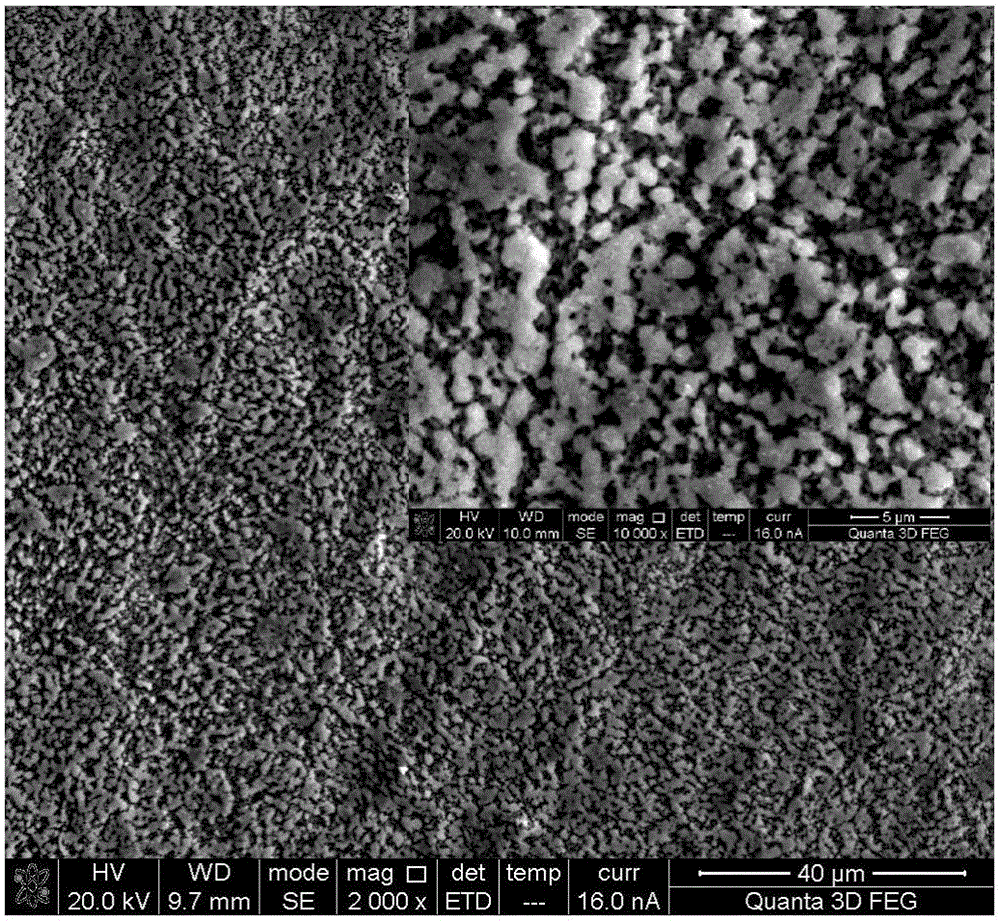

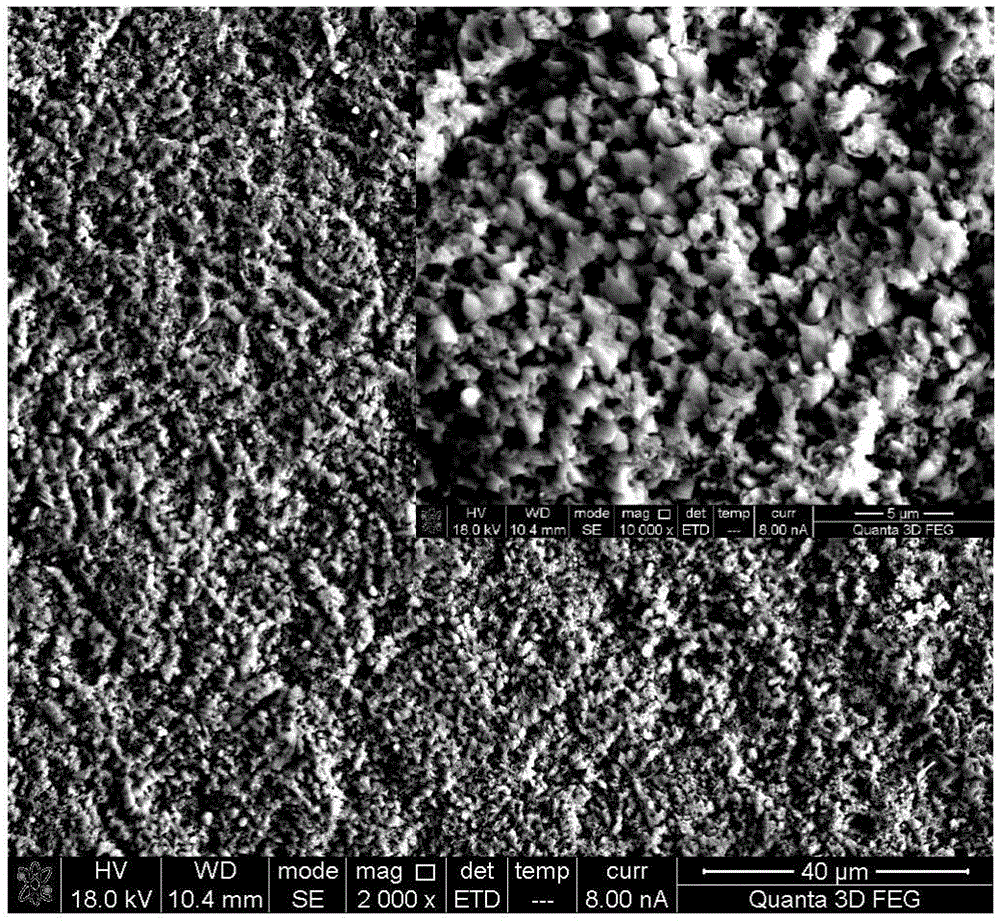

Method for preparing micro-nano porous structure on titanium or titanium alloy surface

ActiveCN105925949ASignificant surface effectSignificant sizeVacuum evaporation coatingSputtering coatingAcid etchingCopper atom

The invention discloses a method for preparing a micro-nano porous structure on a titanium or titanium alloy surface. The method is characterized in that the titanium or titanium alloy surface is subjected to surface copper plating, then heat treatment and dealloying, and particularly comprises the following steps: cleaning the titanium or titanium alloy surface; arranging a copper coating on the titanium or titanium alloy surface via surface electroplating or magnetron sputtering; performing heat treatment to diffuse copper atoms into the titanium or titanium alloy surface; dealloying by adoption of solid-phase method magnesium powder or liquid-phase method molten magnesium; and finally, cleaning and drying with acid and water to obtain titanium or titanium alloy with micro-nano pores in the surface. Compared with the prior art, the method is simple and easy, can overcome the shortcomings of the conventional powder sintering method, acid etching method, anodic oxidation method, spray method and the like, is suitable for small and large titanium or titanium alloy materials, can be used for easily preparing the micro-nano porous structure on the titanium or titanium alloy surface and is wide in applicability.

Owner:SOUTHEAST UNIV

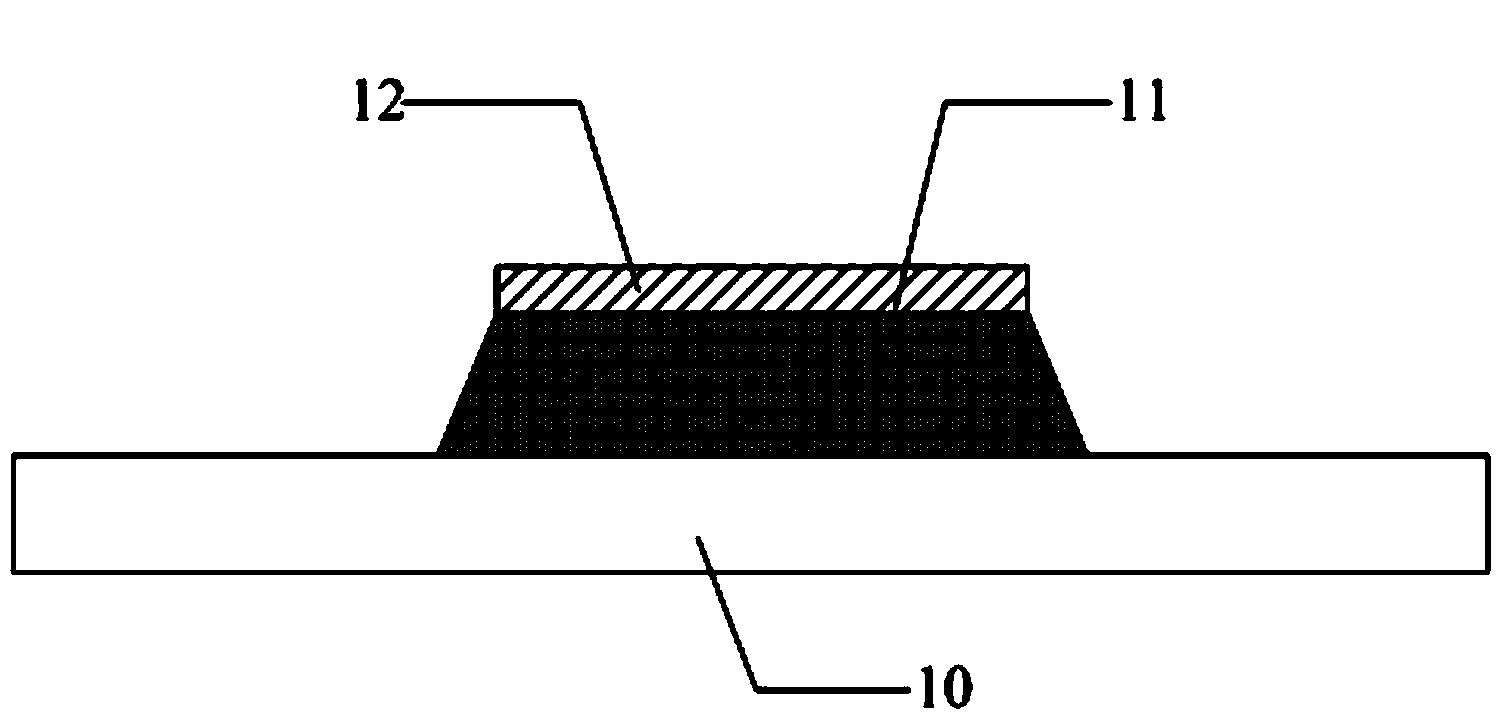

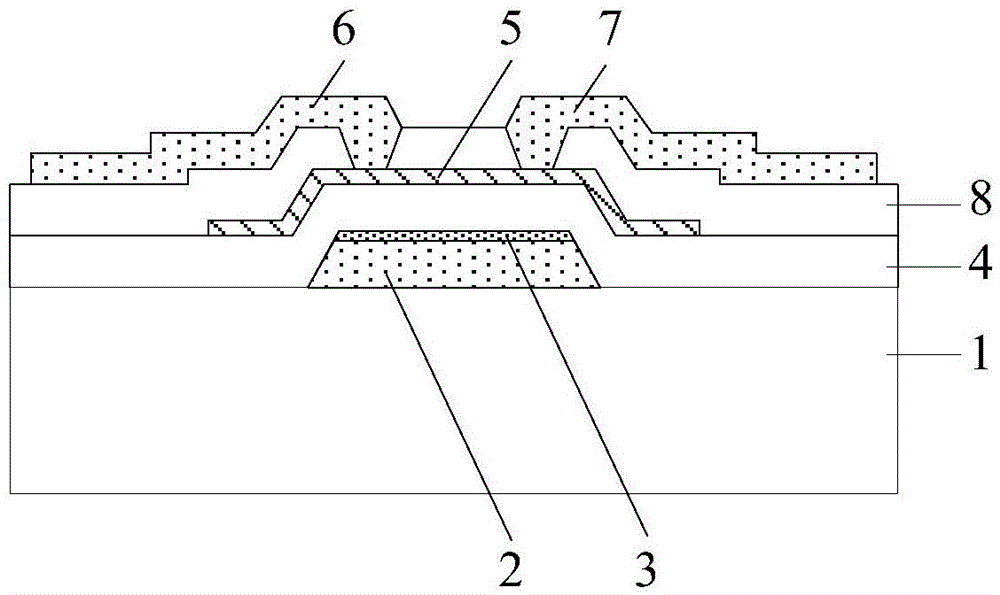

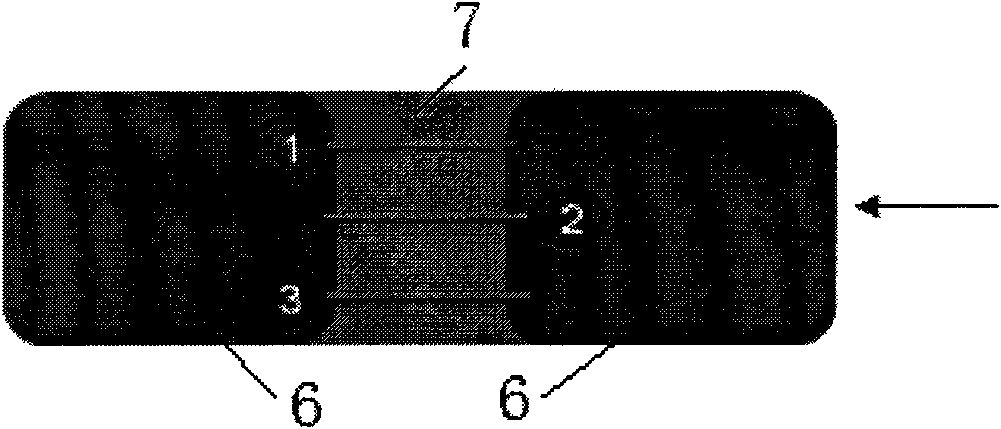

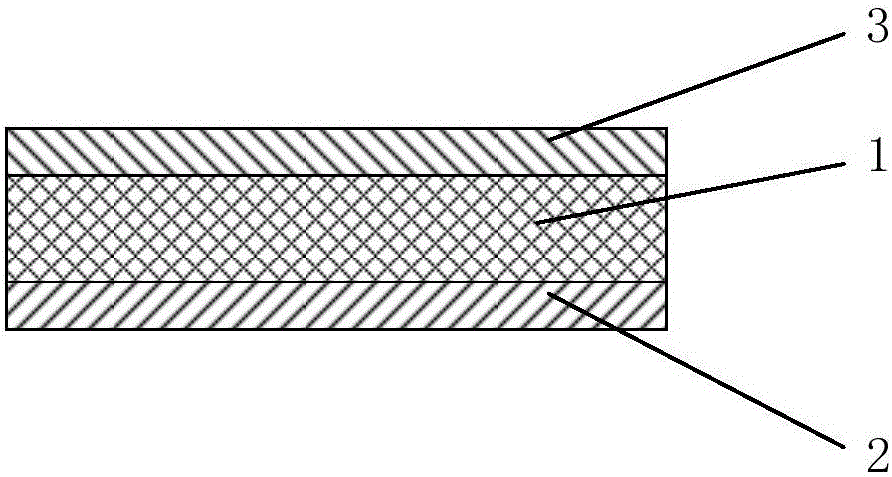

Electrode structure, thin film transistor, array substrate and display panel

ActiveCN104300008AImprove adsorption capacityPrevent proliferationTransistorSolid-state devicesCopper atomMono layer

The invention discloses an electrode structure, a thin film transistor, an array substrate and a display panel. The electrode structure at least comprises a first metal layer and a first graphene layer which are stacked, wherein the first metal layer is made of copper or copper alloy. Because graphene is of a stable single-layer hexagon structure composed of carbon atoms, has a high charge migration rate, and can be strongly combined with copper atoms and adsorb copper atoms well, through the adsorption and blocking effects of the first graphene layer on the copper atoms in the first metal layer, the copper atoms in the electrode structure can be effectively prevented from dispersing; meanwhile, because graphene has very high conductivity, through the compound structure formed by the graphene layer and the metal layer, the conductivity of the electrode structure can be further improved.

Owner:BOE TECH GRP CO LTD

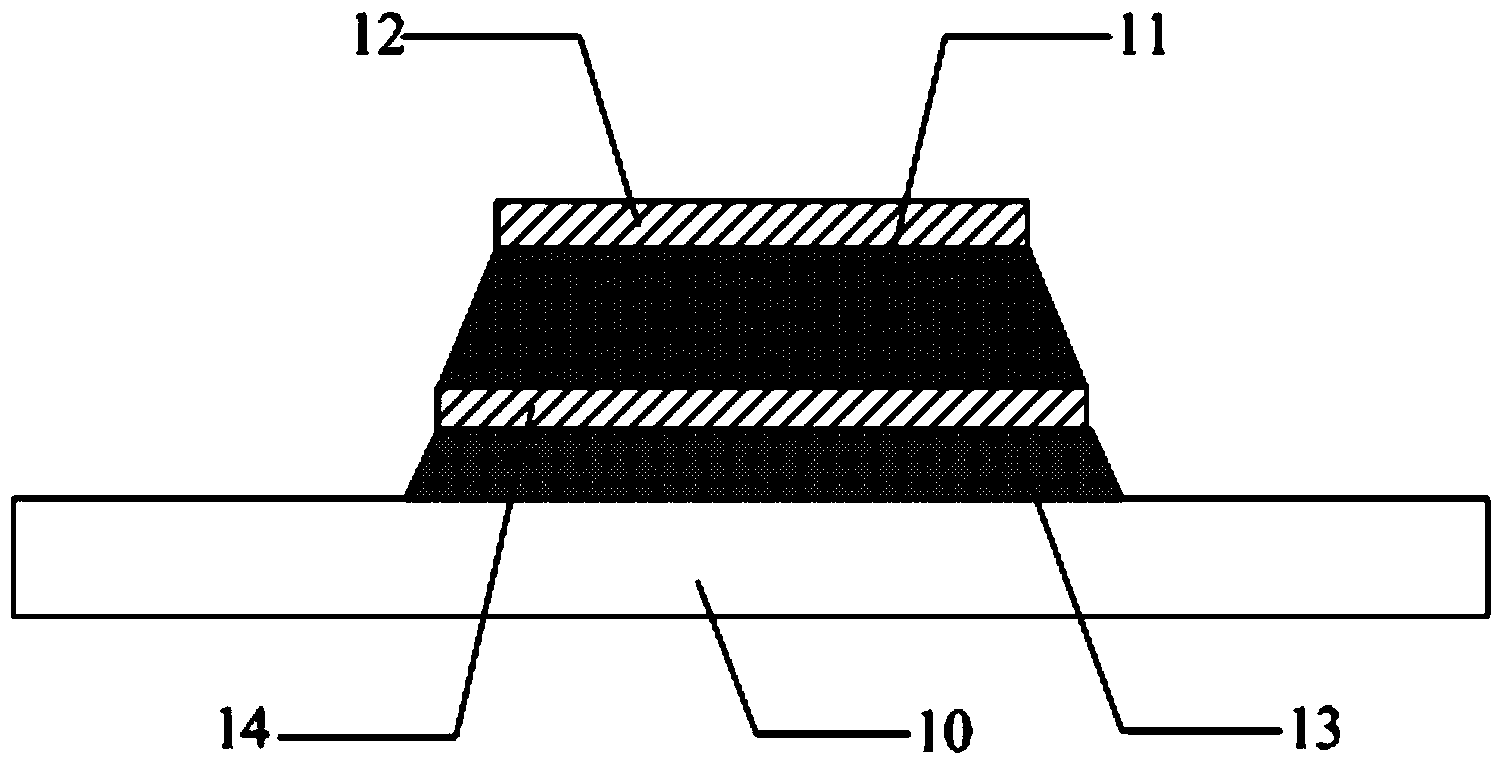

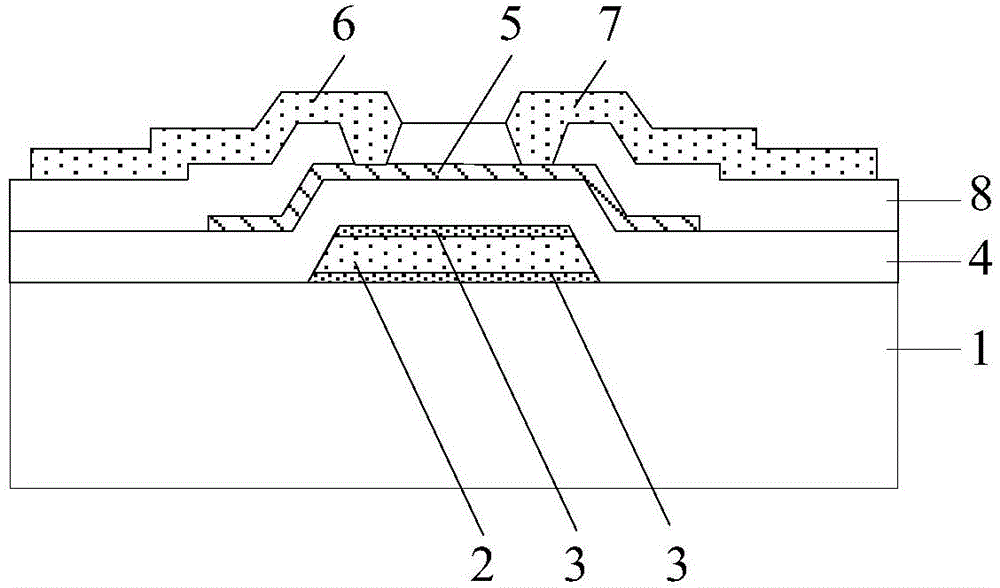

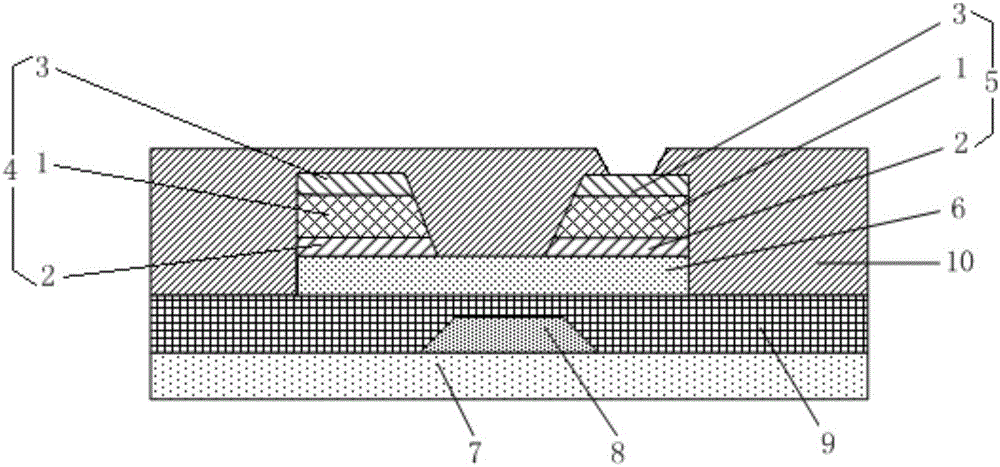

Thin film transistor, preparation method thereof, array substrate and display device

InactiveCN104701384AImprove antioxidant capacityAvoid badTransistorSolid-state devicesCopper atomInsulation layer

The invention discloses a thin film transistor, a preparation method thereof, an array substrate and a display device. The thin film transistor, the preparation method thereof, the array substrate and the display device resolve the problems that an electrode or a wire made of Cu causes poor or abnormal display of the display device due to high diffusion capacity or easy oxidation. The thin film transistor comprises a grid electrode made of pure copper, a grid electrode insulation layer, an active layer, a source electrode, a drain electrode and a copper alloy film layer, wherein the copper alloy film layer is arranged on the surface, facing the active layer, of the grid electrode. The thin film transistor, the preparation method thereof, the array substrate and the display device have the advantages that the copper alloy film layer is arranged on the surface, facing the active layer, of the grid electrode of the thin film transistor, accumulation of alloy elements at the crystal boundary, the crystal surface and the surface can prevent diffusion of copper atoms towards the active layer, the oxidation resistance of the grid electrode is improved, and therefore the problem of poor or abnormal display of the display device caused when the thin film transistor fails or the display device has a Mura defect is avoided.

Owner:BOE TECH GRP CO LTD

Brazing method of aluminum electromagnetic wire and brass

InactiveCN101537521AMeet welding requirementsGood resistance to temperature changesCellsMetallic material coating processesCopper atomPotassium

The invention relates to a brazing method of an aluminum electromagnetic wire and brass. The method comprises the following steps: an aluminum electromagnetic wire and a brass connector are included; firstly nickel electroplating treatment or chemical nickel plating treatment is performed on the surface of the brass connector to enhance the connection strength of a solder and a brass connecting piece and the corrosion resistance of a copper aluminum connector; the nickel plating layer can isolate aluminum atoms from copper atoms to prevent the mutual diffusion and to form a compound layer between friable metals, thus reducing the strength of the copper aluminum connector; and then flux-cored Al-Si hard solders are adopted, the solders adopt non-corrosive potassium fluoroaluminate soldering flux, and the nickel plating surfaces of the aluminum electromagnetic wire and the brass connecting piece are partially lapped and brazed through gas brazing. During the braze welding, the mass percents of the main components of the flux-cored Al-Si hard solders are 9.0 to 13.0 percent of Si, less than 4.70 percent of Cu, and less than 0.20 percent of Zn in sequence. In the aluminum electromagnetic wire and the connector of the brass connecting piece which are welded by adopting the method, the tensile strength of the connector is approximately equal to that of the aluminum electromagnetic wire.

Owner:顺特电气设备有限公司

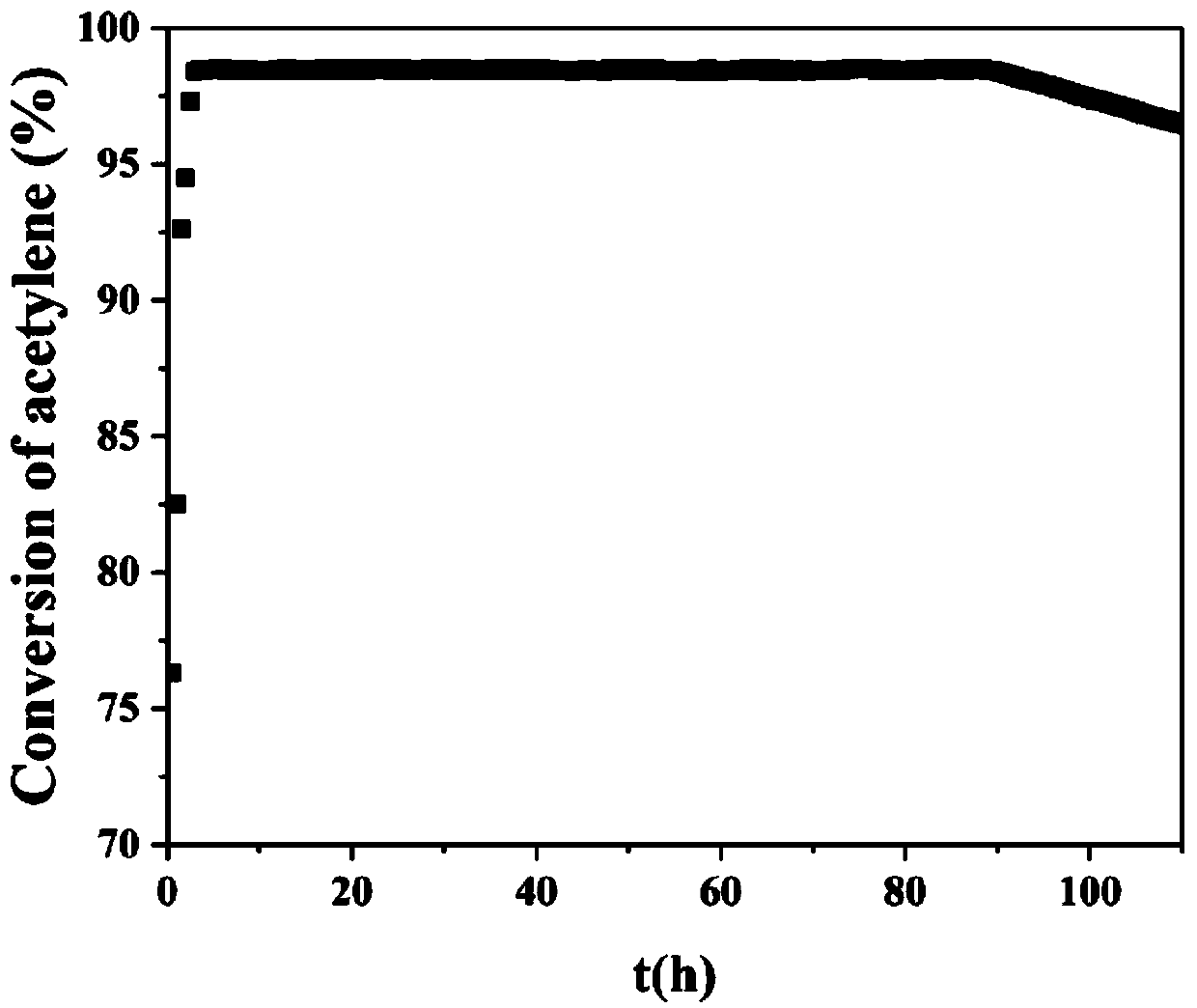

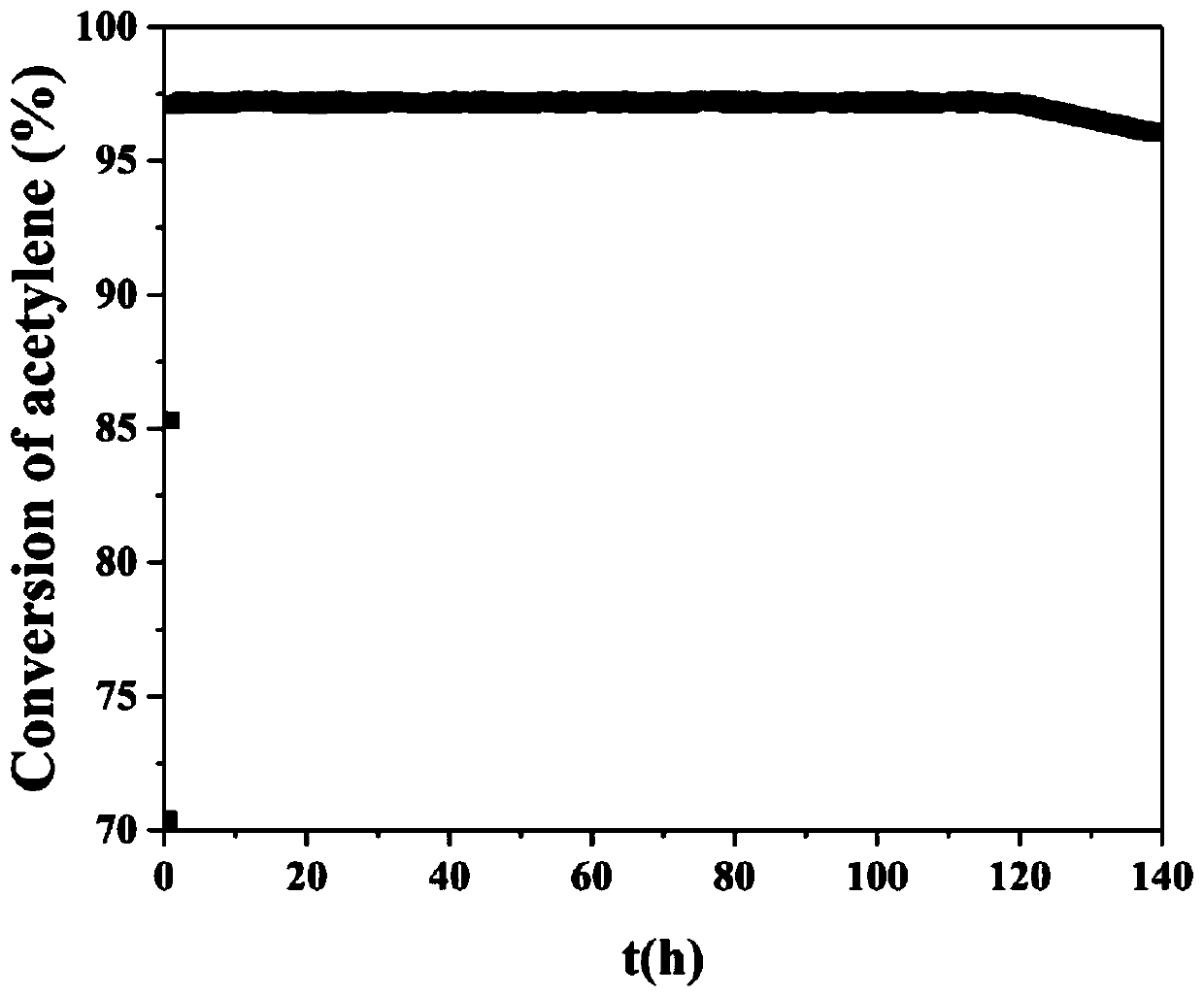

Copper-based alloy catalyst and preparation method and application thereof

ActiveCN110743556AImprove stabilityHigh activityPreparation by halogen halide additionCatalyst activation/preparationCopper atomPtru catalyst

The invention discloses a copper-based alloy catalyst and a preparation method and application thereof. The preparation method of the copper-based alloy catalyst comprises the steps that a copper salt, a metal salt and ionic liquid are mixed and dissolved in a solvent to prepare a mixed solution, then a porous solid carrier is impregnated in the obtained mixed solution for 0.5-5 h at the temperature of 25-100 DEG C, and then obtained solid is heated and dried under the condition of blue light irradiation to obtain treated solid; and the obtained treated solid is roasted under mixed gas of thereducing atmosphere and inert gas under the condition of 200-900 DEG C for 0.5-12 h, and thus the copper-based alloy catalyst is obtained. The characteristic that metal atoms and copper atoms in a copper alloy act to form a stable structure is utilized, and thus the stability of the copper-based alloy catalyst on the carrier is improved; as for drying treatment, blue light is used for irradiation,and performance of the catalyst is improved; and through the roasting process, production of the copper-based alloy catalyst is stable in structure, meanwhile, active sits are exposed, and the catalytic activity of the catalyst is improved.

Owner:ZHEJIANG UNIV OF TECH

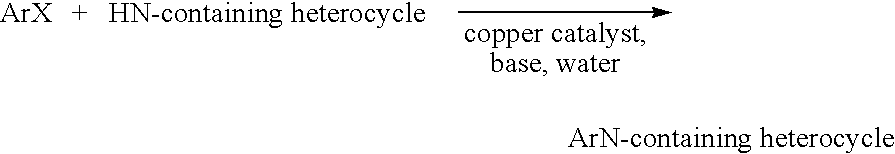

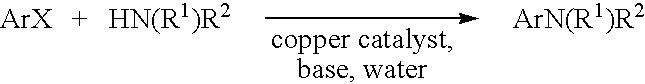

Copper catalyzed arylation

InactiveUS20060149076A1Minimizing reactor agitationMinimizing capacity issueUrea derivatives preparationOrganic compound preparationCopper atomAryl

Owner:SHASUN PHARMA SOLUTIONS LTD

Method and structure for forming barrier layer

InactiveCN1567548ALow resistivitySemiconductor/solid-state device manufacturingCopper atomTantalum nitride

The invention is a method of forming blocking layer, firstly making a double inserted structure on a metallic layer, where the structure contains a first dielectric layer and a second one, the former containing a hole and the latter containing a groove, successively forming a first tantalum metal layer on the structure, then forming a tantalum nitride layer on the first tantalum metal layer, eliminating the tantalum metal layer above the bottom of the hole in the first dielectric layer in an ion spattering mode, where the tantalum atoms in the eliminated tantalum nitride layer will deposit on the side wall of the hole in the first dielectric layer, and finally forming a second tantalum metal layer on the remained tantalum nitride layer, where there are only the first and second tantalum metal layers above the bottom of the hole, and the made blocking layer will have lower resistivity at the bottom of the hole and an ability to completely block copper atoms from diffusing to the dielectric layer.

Owner:UNITED MICROELECTRONICS CORP

Preparation method of thin film of diffusion impervious layer

InactiveCN101673705AImprove performanceFlat surfaceVacuum evaporation coatingSputtering coatingCopper atomSputtering

A preparation method of a thin film of a diffusion impervious layer relates to a preparation method of a new diffusion impervious layer between copper and silicon in an integrated circuit. The preparation method solves the problem that an N element in the existing diffusion impervious layer Ru-N between copper and silicon easily overflows at high temperature, thus causing the Ru-N diffusion impervious layer to lose efficacy. The preparation method comprises the following steps: 1. cleaning a silicon substrate; 2. using a magnetic control sputtering method for depositing the thin film; and 3. obtaining the Ru-N diffusion impervious layer after annealing. The method has simple technology; and the obtained Ru-N diffusion impervious layer can effectively inhibit the diffusion between copper atoms and silicon atoms.

Owner:HARBIN INST OF TECH

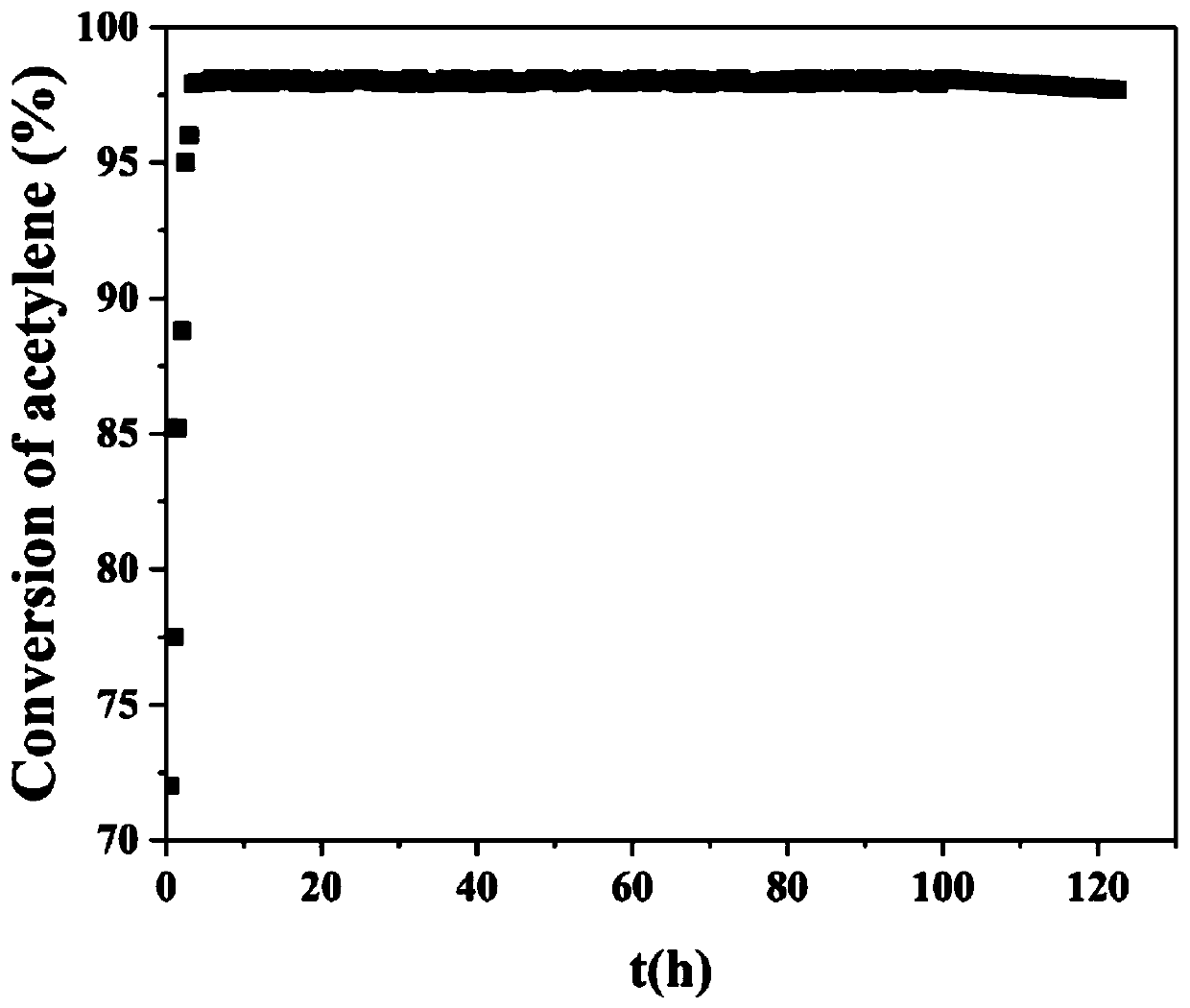

Catalysts for oxychlorination of ethylene to 1,2-dichlorethane

InactiveUS20060129008A1Satisfactory performanceSolution to short lifeHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsCopper atomEthane Dichloride

Catalysts for oxychlorination of ethylene to 1,2-dichlorethane, comprising compounds of copper and magnesium supported on gamma alumina, wherein the copper, expressed as metal, is present in a quantity from 7 to 12% by weight and the Mg / Cu ratio is from 0.05 to 1, wherein the distribution of copper in the catalyst particle is such that the ratio X / Y between the concentration of the copper atoms on the surface given by the Al / Cu ratio (X) on the surface (20-30 nm layer) and the concentration given by the Al / Cu ratio (Y) referred to the entire particle is greater than 1.3 and can reach 3.

Owner:SUD CHEM CATALYSTS ITAL SRL

CuPd metal nano catalyst, and preparation and applications thereof

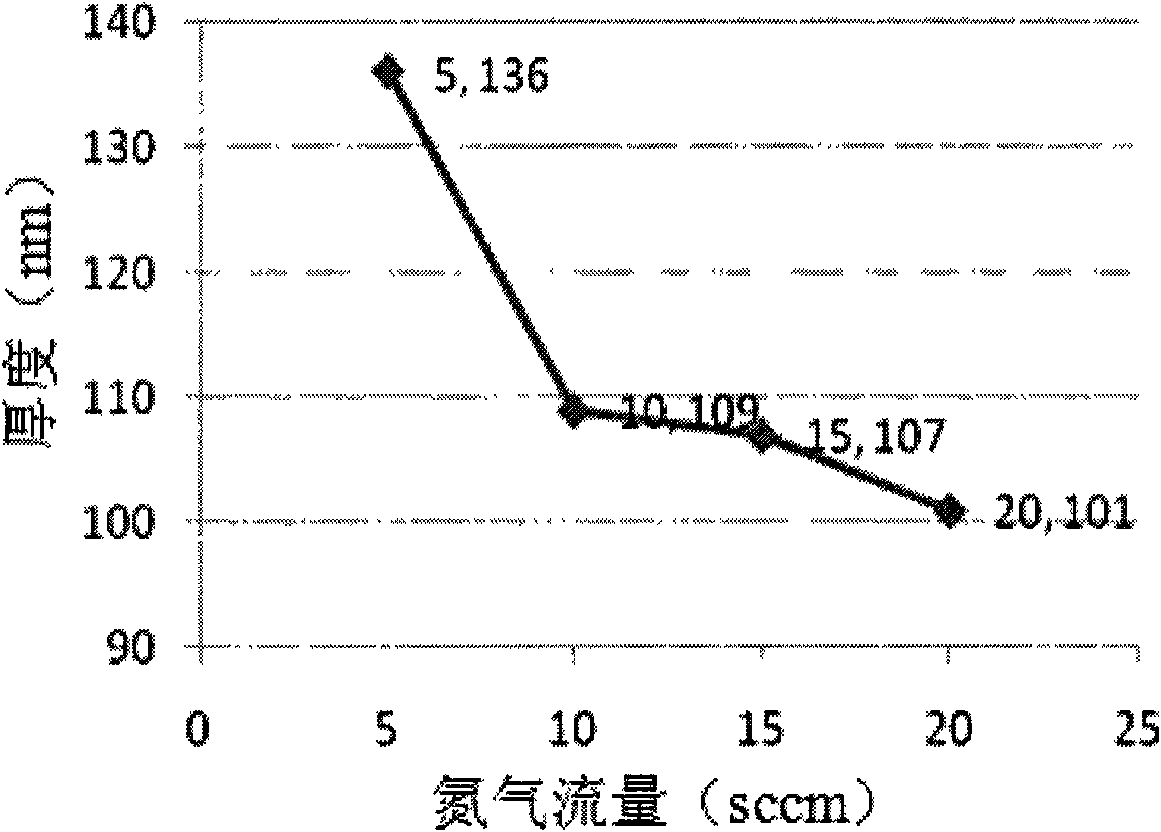

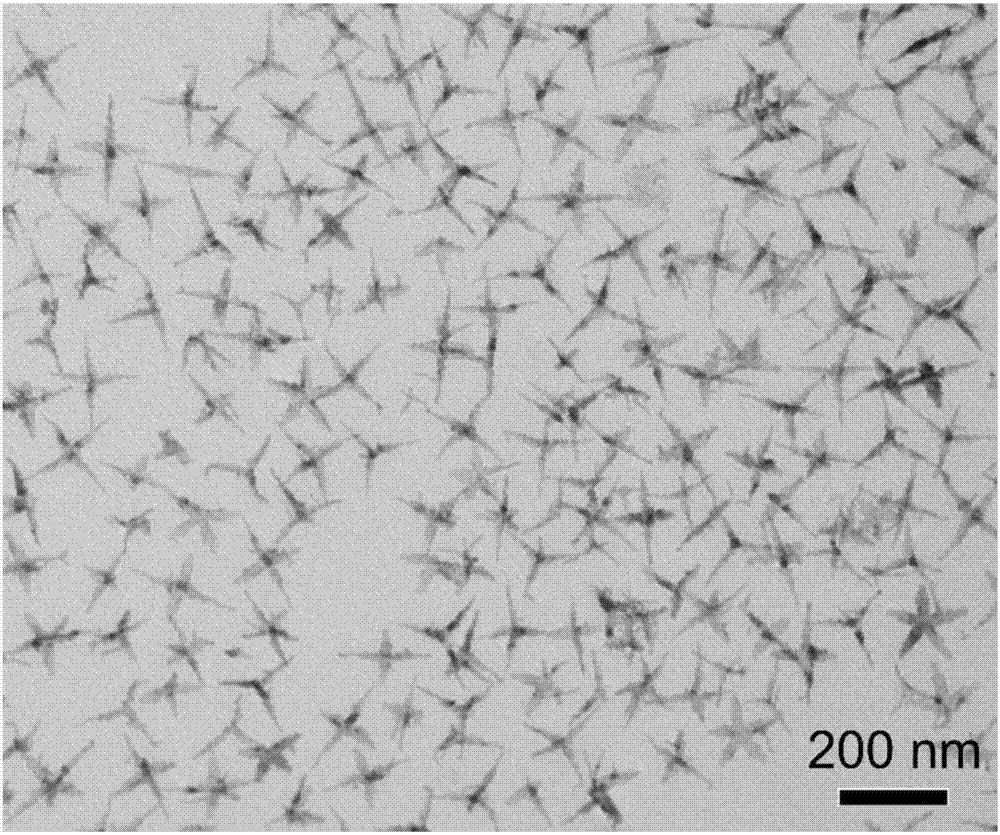

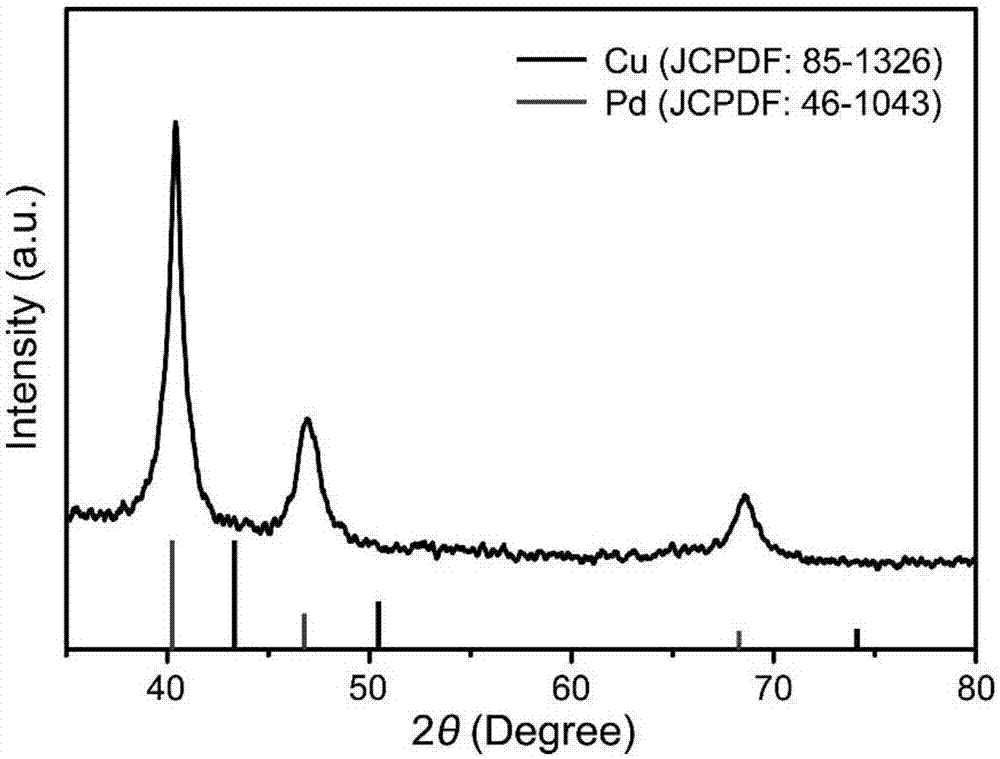

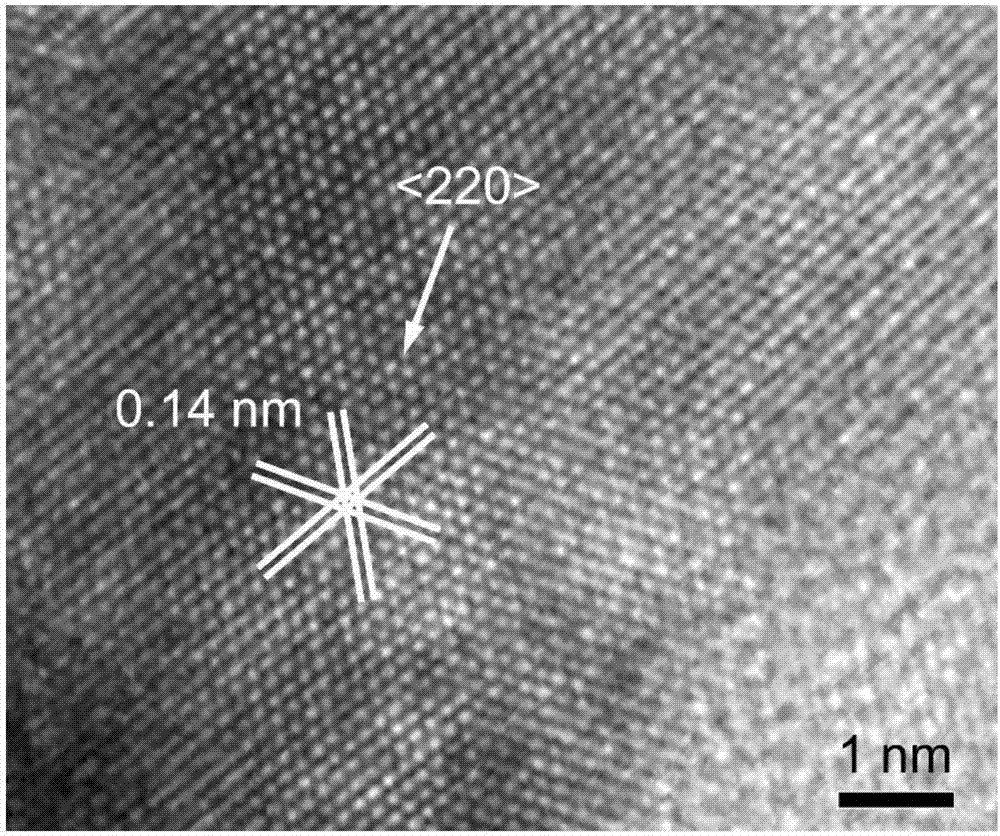

InactiveCN106861717ALower d-band centerModerate adsorption energyMaterial nanotechnologyCell electrodesCopper atomNano catalyst

The invention discloses a CuPd metal nano catalyst of a four-feet structure, and a preparation method of the CuPd metal nano catalyst, and also discloses a CuPd / C metal nano catalyst, a preparation method of the CuPd / C metal nano catalyst, and applications of the CuPd / C metal nano catalyst in fuel battery cathodic oxygen reduction. According to the CuPd / C metal nano catalyst, the surface of carbon black is loaded with the CuPd metal nano catalyst. According to the CuPd metal nano catalyst of a four-feet structure, electrons on copper atoms are transferred onto palladium atoms, and the electrons are gathered on the tips of the four-feet structure, so that electron density of tip palladium atoms is increased further, d band center of palladium atoms is reduced, the strong adsorption between palladium atoms and oxygen is reduced, and catalytic activity is increased.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

Purificant for adsorbing formaldehyde and method of preparing the same

InactiveCN101279238AWell-developed pore structureLarge specific surface areaOther chemical processesCopper atomSorbent

The invention discloses a formaldehyde purificatory absorbent and a preparation method thereof. The main adsorption active component of the formaldehyde adsorption purificant is an aluminum bronze multiple oxide provided with aluminate bronze crystal phase. As a further improvement of the invention, the adsorption active component of the formaldehyde adsorption purificant also comprises a tantalum that is a mixture of one or more of manganese, cobalt, zinc, nickel and iron. The method of the invention adopts the aluminum bronze multiple oxide provided with aluminate bronze crystal phase as the active component of the formaldehyde adsorption purificant; the oxide is of developed pore structure, large specific surface, good thermal stability and is more suitable for the formaldehyde adsorption than alumina as a absorbent owing to the pore structure, thus having better adsorptive performance to the micromolecule of formaldehyde, while the copper atom in the oxide has strong electron adsorption ability and can be combined with the carbonyl group of formaldehyde, thus further improving the adsorption effect to formaldehyde.

Owner:刘永能

Manufacturing method of a semiconductor device

InactiveUS20020072226A1Large aspect ratioExcellentlySemiconductor/solid-state device detailsSolid-state devicesCopper atomSemiconductor

The manufacturing method of a semiconductor device according to the present invention includes a step of forming a lower wiring on a semiconductor substrate, a step of forming a layer insulating film on the lower wiring, a step of forming an opening that exposes the lower wiring by removing a part of the layer insulating film, a step of forming a barrier film in the opening and a step of forming an upper wiring in the opening, where the lower wiring and the upper wiring are copper including wirings composed of copper or a copper alloy, the barrier film covers the bottom face and the side face of the opening, and the barrier film on the bottom face of the opening is formed so as to have its thickness to be less than twice the diffusion length of the copper atoms in the barrier film.

Owner:RENESAS ELECTRONICS CORP

Semiconductor device and method for fabricating the same

InactiveUS7868456B2Highly reliable metal wiringStably Semiconductor/solid-state device detailsSolid-state devicesCopper atomCopper-wiring

A semiconductor device in which the resistance of a copper wiring to electromigration is increased. The copper wiring is formed so that copper grains will be comparatively large in a central portion of the copper wiring and so that copper grains will be comparatively small in an upper portion and a lower portion of the metal wiring. The copper wiring having this structure is formed by a damascene method. This structure can be formed by controlling electric current density at electroplating time. With the copper wiring having this structure, it is easier for an electric current to run through the central portion than to run through the upper portion. As a result, the diffusion of copper atoms in the upper portion is suppressed and therefore the diffusion of copper atoms from an interface between the copper wiring and a cap film is suppressed.

Owner:FUJITSU LTD

Brazing method of aluminum electromagnetic wire and brass

InactiveCN101537520AMeet welding requirementsGood resistance to temperature changesWelding/cutting media/materialsWelding/soldering/cutting articlesCopper atomPotassium

The invention relates to a brazing method of an aluminum electromagnetic wire and brass. The method comprises the following steps: an aluminum electromagnetic wire and a brass connector are included; firstly nickel electroplating treatment or chemical nickel plating treatment is performed on the surface of the brass connector to enhance the connection strength of a solder and a brass connecting piece and the corrosion resistance of a copper aluminum connector; the nickel plating layer can isolate aluminum atoms from copper atoms to prevent the mutual diffusion and to form a compound layer between friable metals, thus reducing the strength of the copper aluminum connectors; and then flux-cored Al-Si hard solders are adopted, the solders adopt non-corrosive potassium fluoroaluminate soldering flux, and the nickel plating surfaces of the aluminum electromagnetic wire and the brass connecting piece are partially lapped and brazed through gas brazing. During the braze welding, 0.001 to 0.10 MPa golden flame gas pressure is adopted, the welding torch is H01 to 12A, the welding tip is number 1 to 5, and the oxygen pressure is 0.4 to 0.7 MPa. In the aluminum electromagnetic wire and the connector of the brass connecting piece which are welded by adopting the method, the tensile strength of the connector is approximately equal to that of the aluminum electromagnetic wire.

Owner:顺特电气设备有限公司

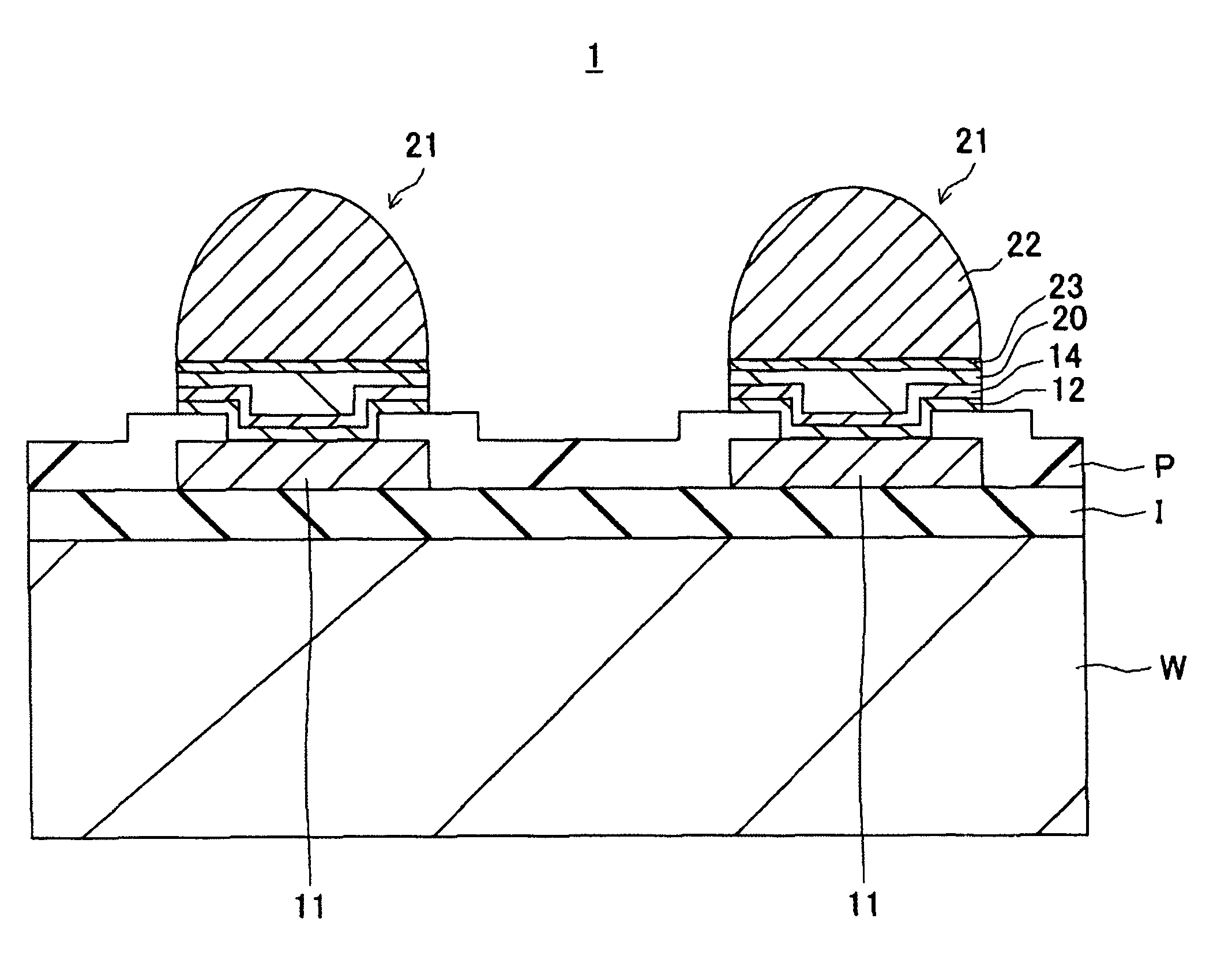

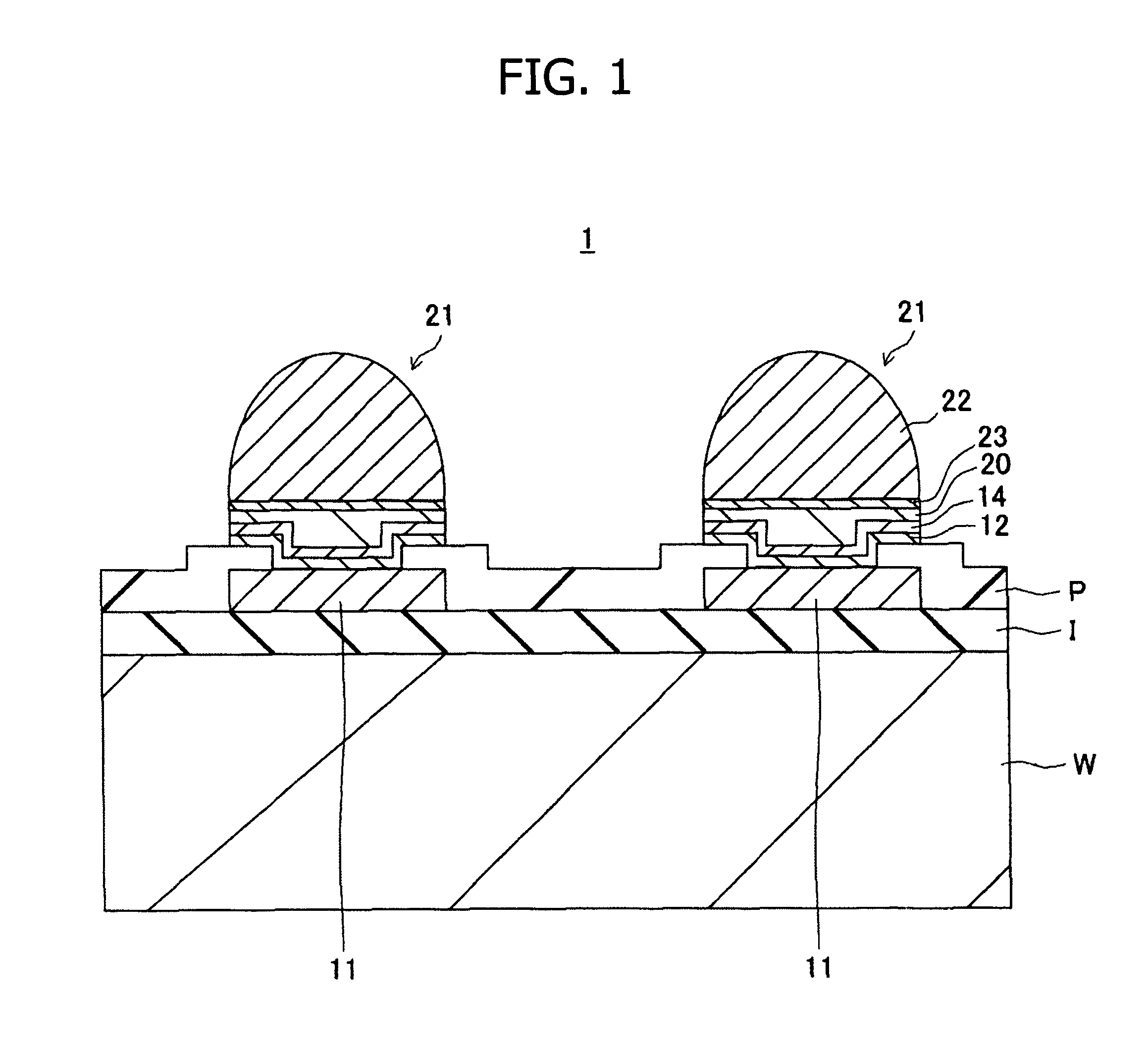

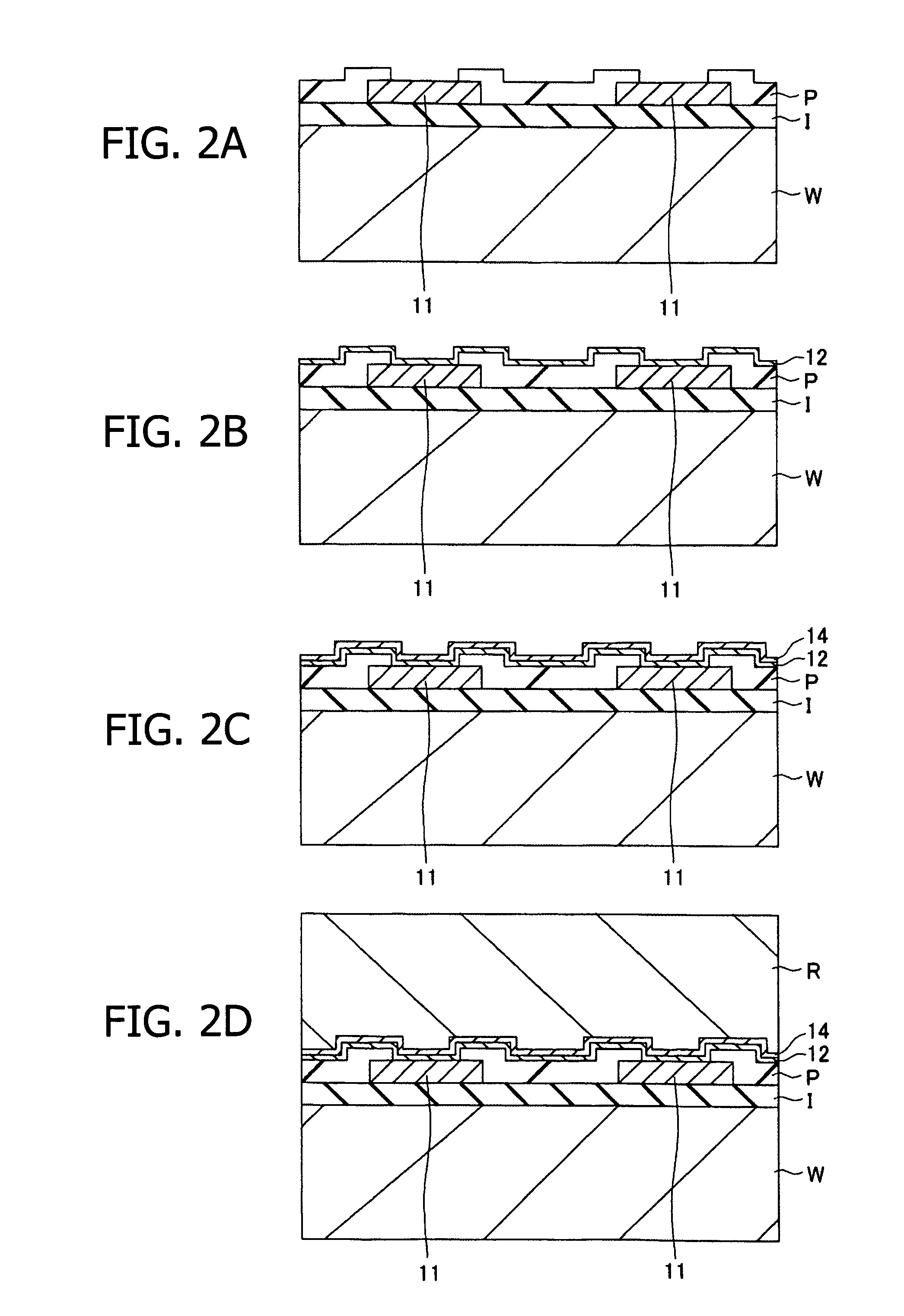

Semiconductor chip and manufacturing method thereof

InactiveUS7863741B2Low reliabilityEasy to installSemiconductor/solid-state device detailsSolid-state devicesCopper atomIndium

Owner:SONY CORP

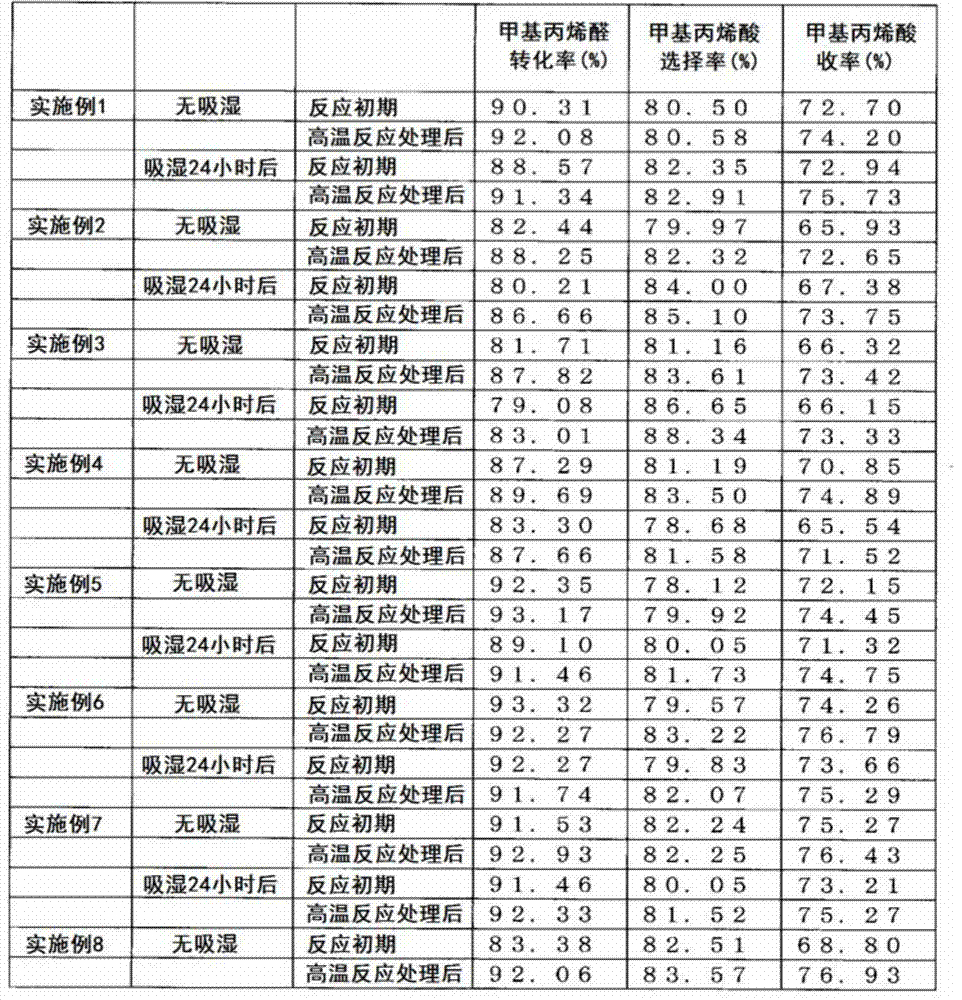

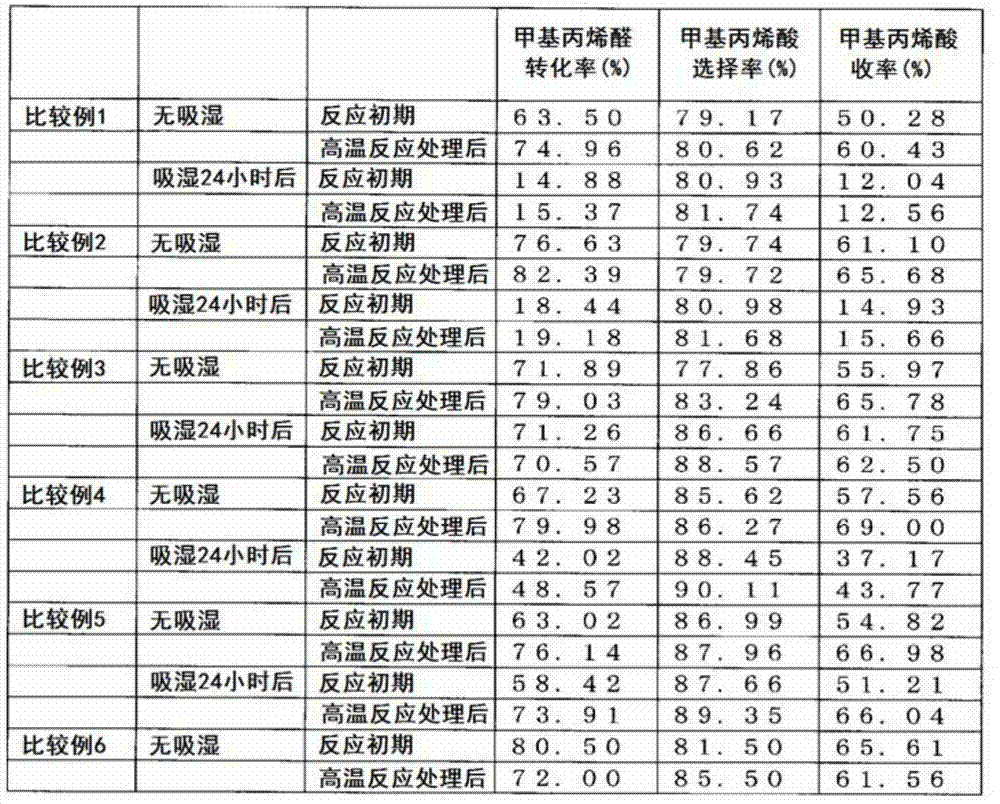

Catalyst for production of methacrylic acid and method for producing methacrylic acid using same

ActiveCN103945938AImprove performanceGood moisture absorptionOrganic compound preparationOrganic chemistry methodsCopper atomProton

Provided is a heteropolyacid catalyst for the production of a methacrylic acid, which has more excellent performance, service life and moisture absorption during storage. A catalyst for the production of a methacrylic acid, which is obtained by substituting protons in MoaPbVcCudYeZfOg (wherein Y represents cesium or the like, Z represents iron or the like, and a-g respectively represent atomic ratios of the constituent elements relative to 10 Mo atoms) so that A, B and C satisfy the following conditions: alpha = A + (B C) and 0.5 <= alpha <= 1.4, where A is the atomic ratio of alkali metal atoms relative to 10 Mo atoms, B is the atomic ratio of copper atoms relative to 10 Mo atoms and C is the valence of the copper atoms.

Owner:NIPPON KAYAKU CO LTD

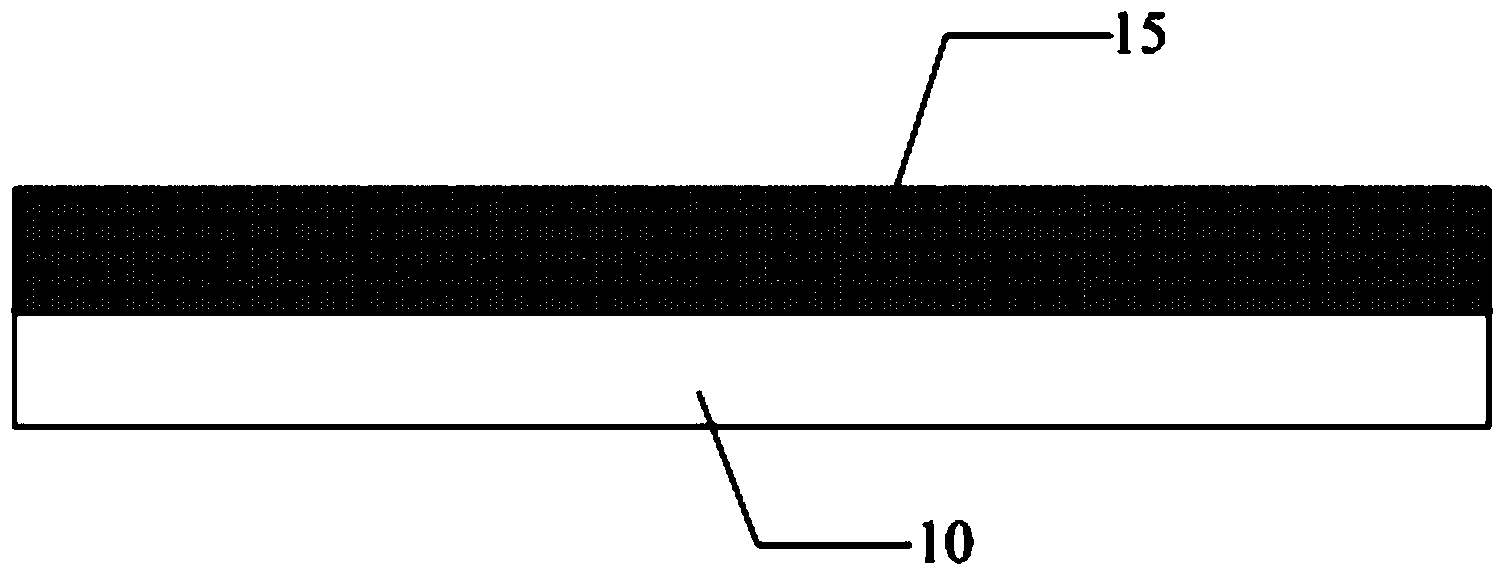

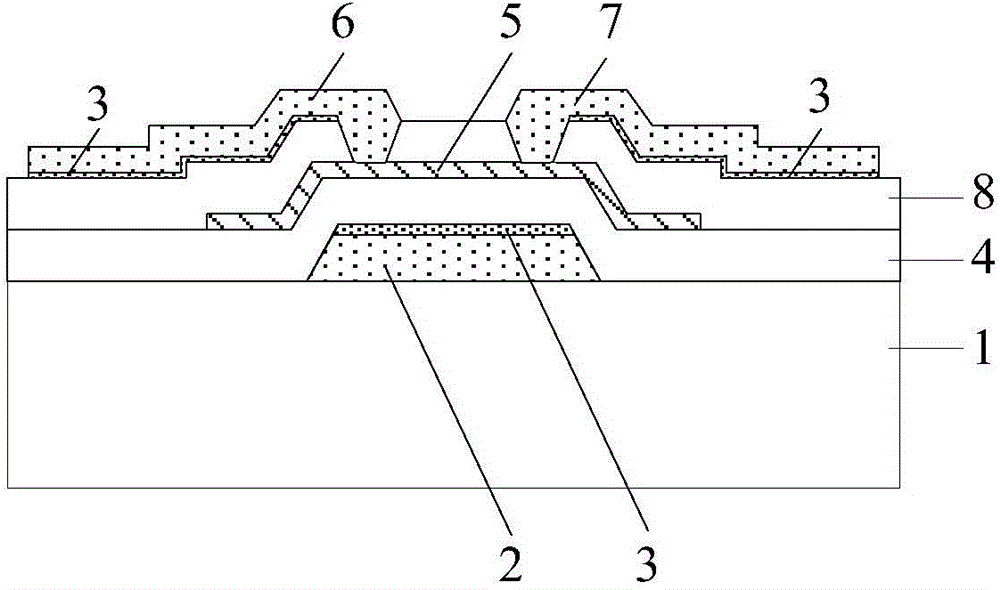

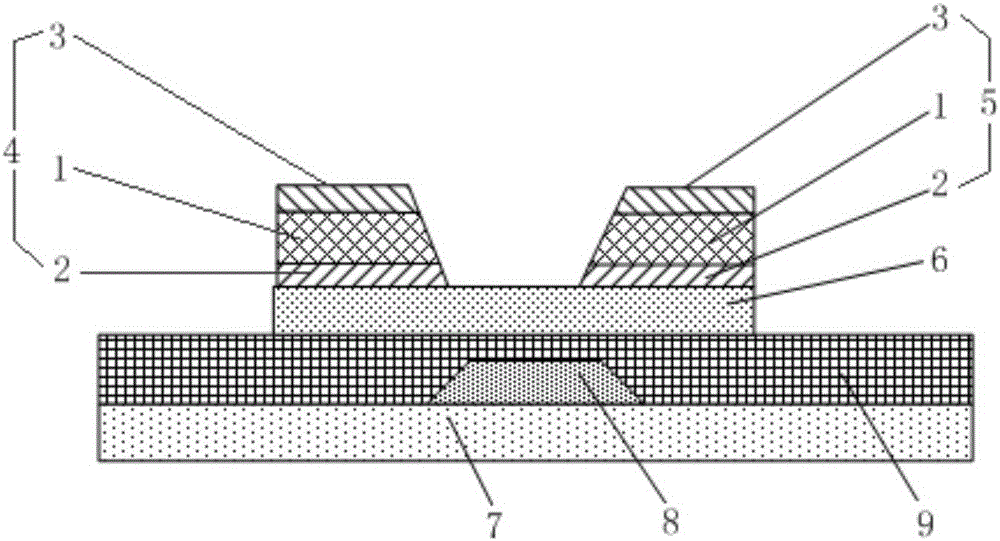

Electrode, thin film transistor (TFT), array substrate and display device

ActiveCN105161523AReduce overscalingReduce manufacturing costTransistorSolid-state devicesCopper atomImaging quality

The invention discloses an electrode, a TFT, an array substrate and a display device, and belongs to the field of display equipment. The electrode comprises a copper electrode, a diffusion barrier layer and an etching protective layer, wherein the both the diffusion barrier layer and the etching protective layer are made of zinc-based nitrogen oxide. The electrode serves as the source and drain of the TFT to reduce the resistance of the source and drain, stable image signal transmission speed and high image quality of the display are ensured, it is not required to install drive circuits at the two sides of the TFT respectively to drive the electrode, and the manufacture cost of the TFT is reduced; and the diffusion barrier layer and the etching protective layer are arranged at the two sides of the copper electrode respectively, and both the diffusion barrier layer and the etching protective layer are made of zinc-based nitrogen oxide, so that copper atoms of the copper electrode are prevented from diffusion, the over etching amount of the copper electrode is reduced, and damage of copper atom diffusion on a channel layer of the TFT is reduced.

Owner:BOE TECH GRP CO LTD

Nickel-copper (111) alloy single crystal film and preparation method thereof

PendingCN108754608AMaintain catalytic performanceNo breakagePolycrystalline material growthAfter-treatment detailsCopper atomCrystal orientation

The invention relates to a method for preparing a nickel-copper (111) alloy single crystal film. The method comprises: S1, providing a sapphire base, S2, depositing a metal film with thickness of 50 to 5000 nm on the crystal plane Al2O3 (0001) of the sapphire base to obtain a sapphire substrate on which a nickel-copper alloy is deposited, wherein the metal film is an alloy thin film composed of 1-40% of nickel atoms, and copper atoms, and S3, putting the sapphire substrate in a chemical vapor deposition furnace and carrying out annealing treatment in a gas atmosphere of argon gas and hydrogengas to obtain a single crystal thin film with (111) crystal orientation. The invention also relates to a nickel-copper (111) alloy single crystal film obtained by the method. The nickel-copper (111) alloy single crystal film greatly improves the performances of graphene and lays a foundation for the application of graphene in the field of microelectronics.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Manufacturing method of a semiconductor device

InactiveUS6680247B2ExcellentlyLarge aspect ratioSemiconductor/solid-state device detailsSolid-state devicesCopper atomEngineering

The manufacturing method of a semiconductor device includes a step of forming a lower wiring on a semiconductor substrate, a step of forming a layer insulating film on the lower wiring, a step of forming an opening that exposes the lower wiring by removing a part of the layer insulating film, a step of forming a barrier film in the opening and a step of forming an upper wiring in the opening, where the lower wiring and the upper wiring are copper including wirings composed of copper or a copper alloy, the barrier film covers the bottom face and the side face of the opening, and the barrier film on the bottom face of the opening is formed so as to have its thickness to be less than twice the diffusion length of the copper atoms in the barrier film.

Owner:RENESAS ELECTRONICS CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com