Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1010results about "Preparation by halogen halide addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

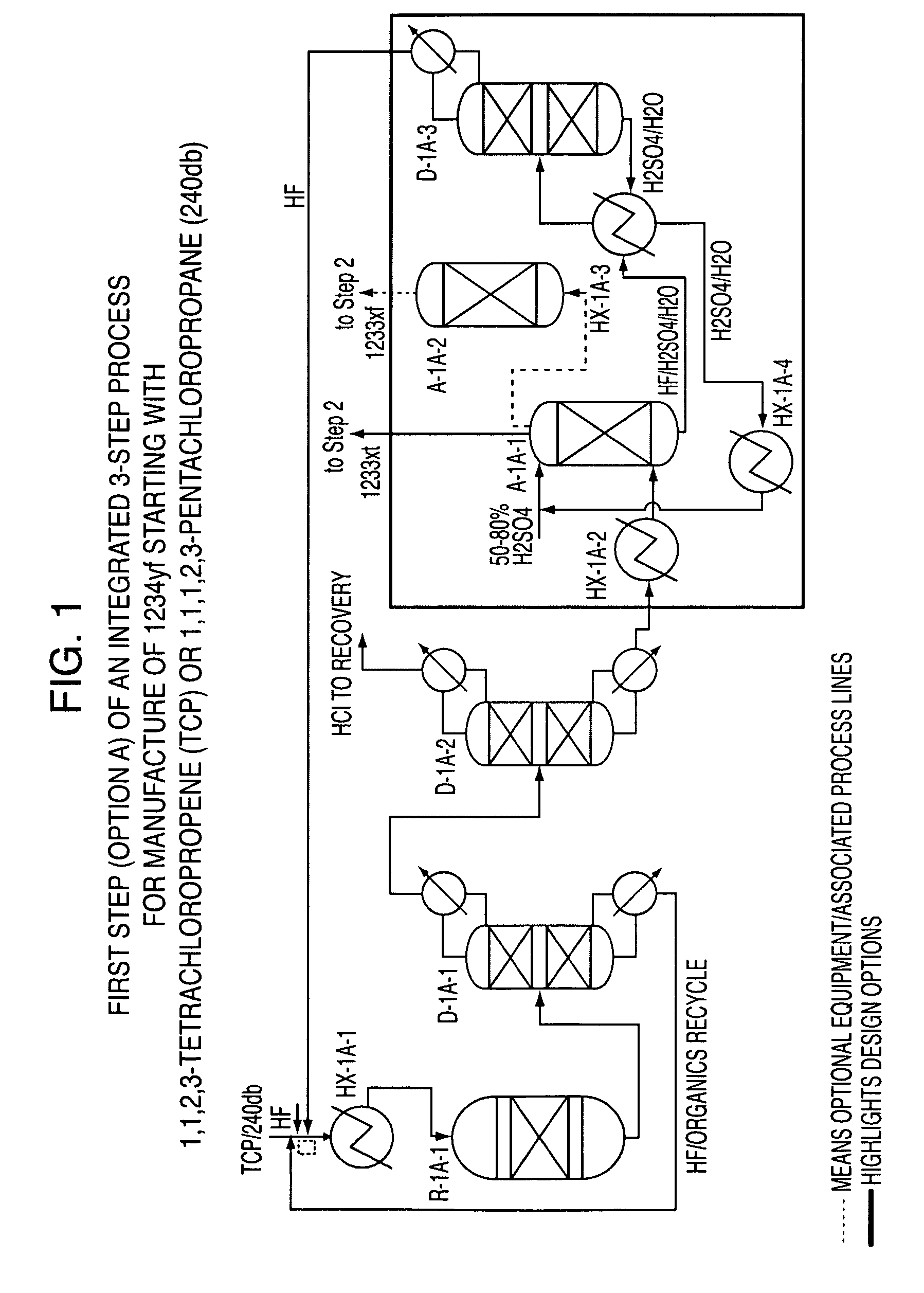

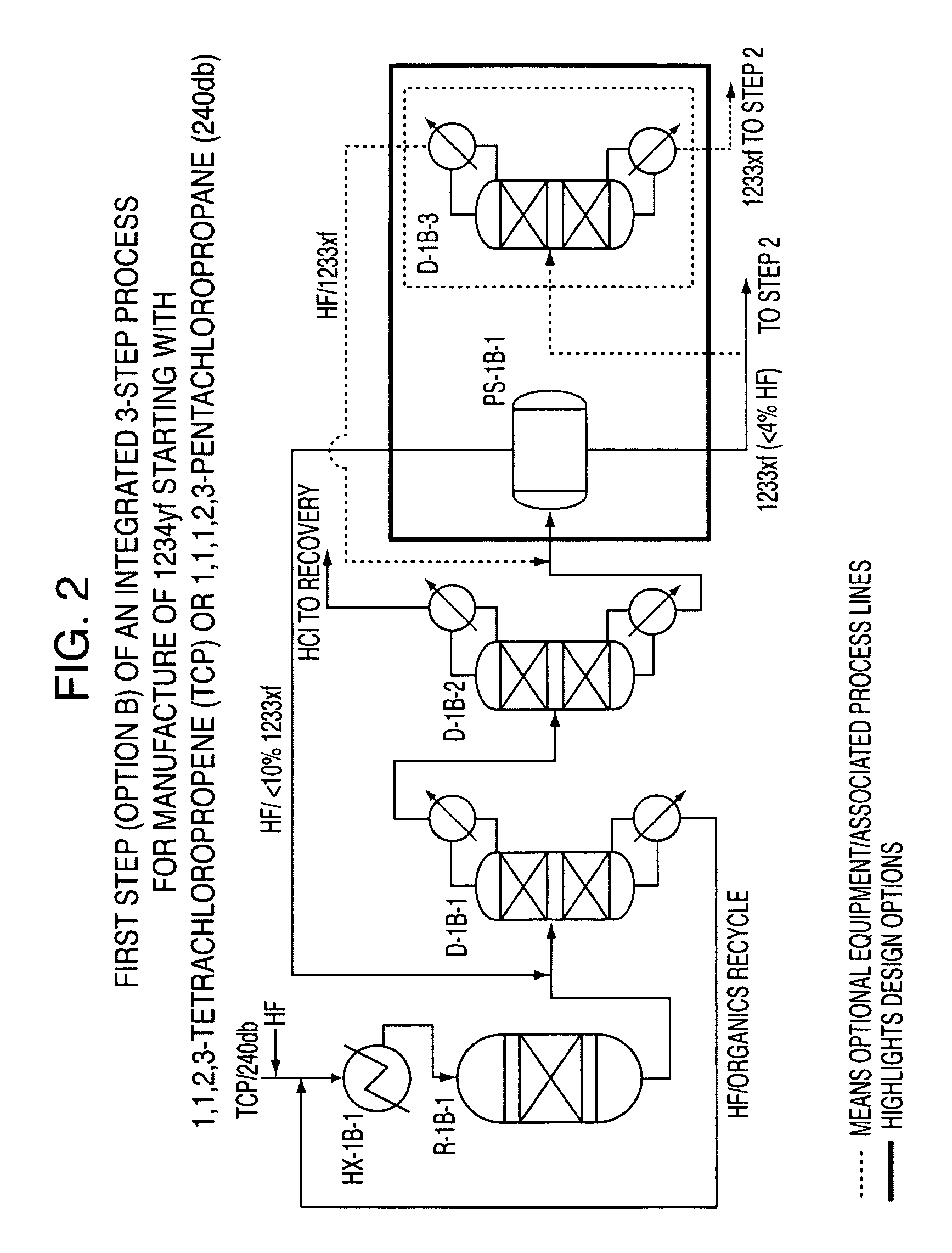

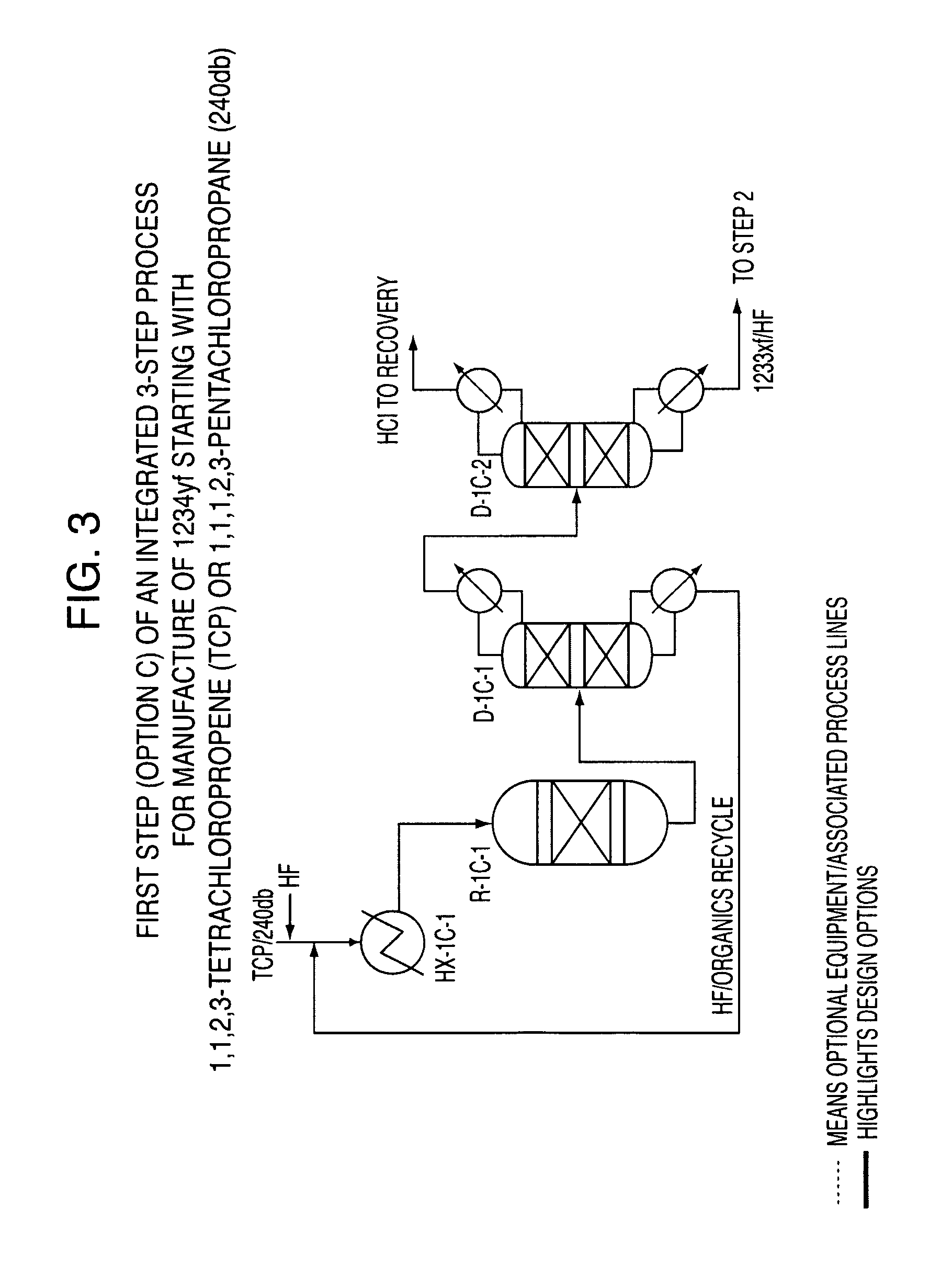

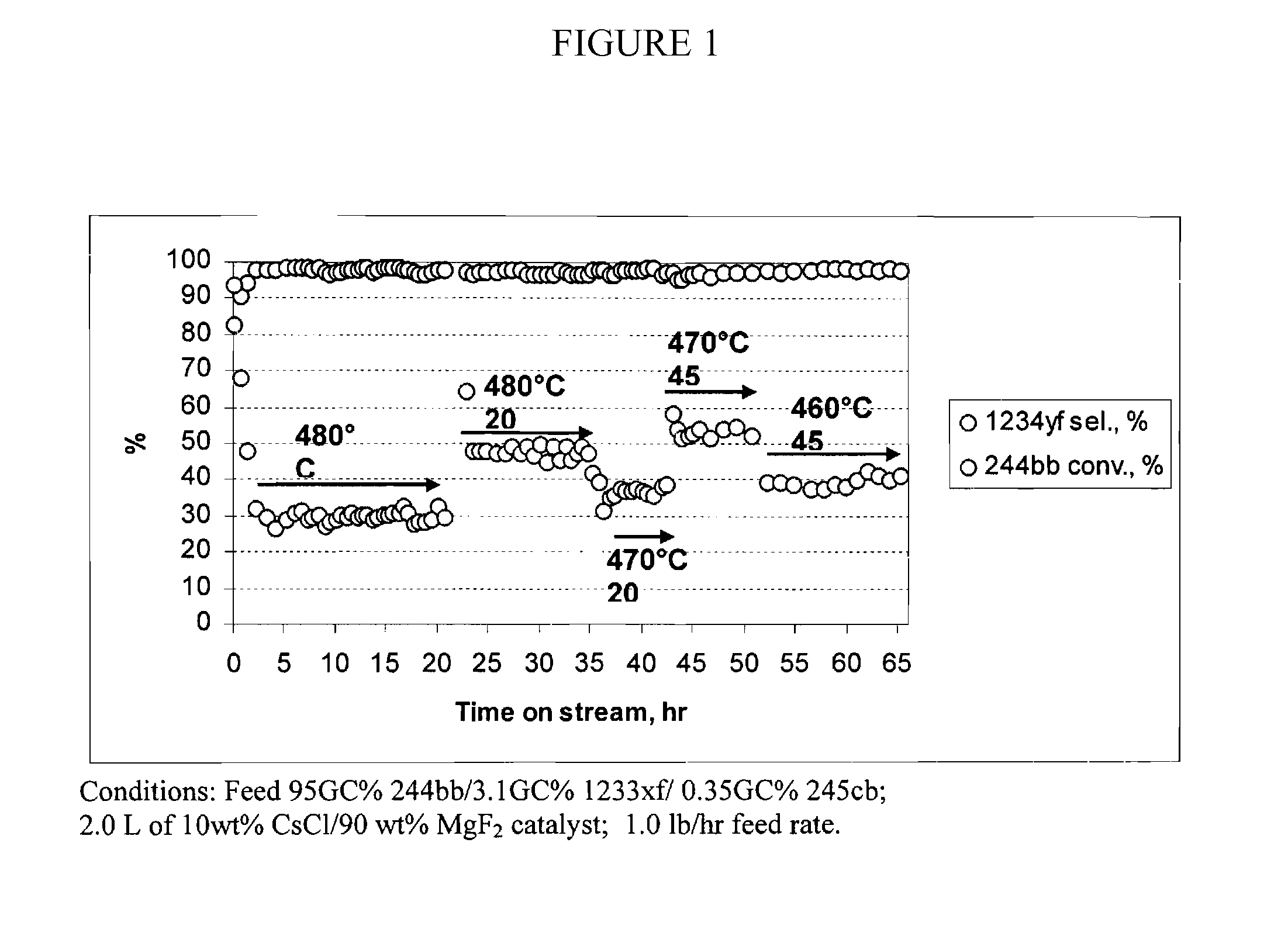

Integrated process to produce 2,3,3,3-tetrafluoropropene

ActiveUS20090240090A1Maximize raw material utilizationMaximize product yieldPreparation by hydrogen halide split-offPreparation by halogen halide additionChromium2,3,3,3-Tetrafluoropropene

A method for preparing 2,3,3,3-tetrafluoroprop-1-ene comprising (a) providing a starting composition comprising at least one compound having a structure selected from Formulae I, II and III:CX2═CCl—CH2X (Formula I)CX3—CCl═CH2 (Formula II)CX3—CHCl—CH2X (Formula III)wherein X is independently selected from F, Cl, Br, and I, provided that at least one X is not fluorine;(b) contacting said starting composition with a first fluorinating agent to produce a first intermediate composition comprising 2-chloro-3,3,3-trifluoropropene and a first chlorine-containing byproduct; (c) contacting said first intermediate composition with a second fluorinating agent to produce a second intermediate composition comprising 2-chloro-1,1,1,2-tetrafluoropropane and a second chlorine-containing byproduct; and (d) catalytically dehydrochlorinating at least a portion of said 2-chloro-1,1,1,2-tetrafluoropropane to produce a reaction product comprising 2,3,3,3-tetrafluoroprop-1-ene.

Owner:HONEYWELL INT INC

Process for producing fluoropropenes

InactiveUS7230146B2Simplifies isolationPreparation by hydrogen halide split-offPreparation by halogen halide additionHalogenHydrogen

Dehydrohalogenation processes for the preparation of fluoropropenes from corresponding halopropanes, in which the fluoropropenes have the formula CF3CY═CXNHP, wherein X and Y are independently hydrogen or a halogen selected from fluorine, chlorine, bromine and iodine; and N and P are independently integers equal to 0, 1 or 2, provided that (N+P)=2.

Owner:HONEYWELL INT INC

Integrated process to produce 2,3,3,3-tetrafluoropropene

ActiveUS8058486B2Maximize utilizationYield maximizationPreparation by hydrogen halide split-offPreparation by halogen halide additionChromium2,3,3,3-Tetrafluoropropene

A method for preparing 2,3,3,3-tetrafluoroprop-1-ene comprising (a) providing a starting composition comprising at least one compound having a structure selected from Formulae I, II and III:CX2═CCl—CH2X (Formula I)CX3—CCl═CH2 (Formula II)CX3—CHCl—CH2X (Formula III)wherein X is independently selected from F, Cl, Br, and I, provided that at least one X is not fluorine;(b) contacting said starting composition with a first fluorinating agent to produce a first intermediate composition comprising 2-chloro-3,3,3-trifluoropropene and a first chlorine-containing byproduct; (c) contacting said first intermediate composition with a second fluorinating agent to produce a second intermediate composition comprising 2-chloro-1,1,1,2-tetrafluoropropane and a second chlorine-containing byproduct; and (d) catalytically dehydrochlorinating at least a portion of said 2-chloro-1,1,1,2-tetrafluoropropane to produce a reaction product comprising 2,3,3,3-tetrafluoroprop-1-ene.

Owner:HONEYWELL INT INC

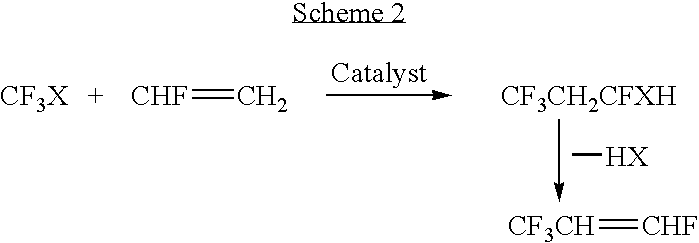

Processes for synthesis of tetrafluoropropene

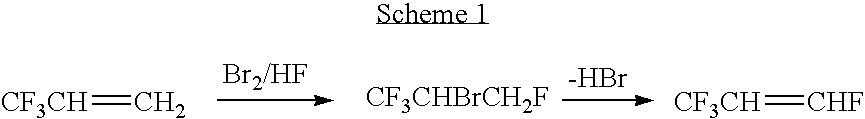

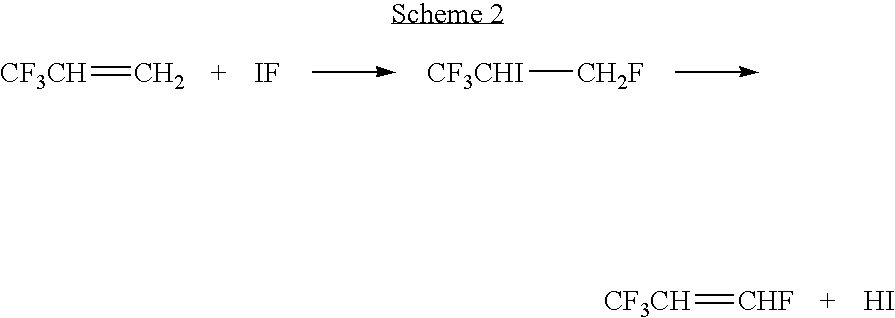

ActiveUS7189884B2Preparation by hydrogen halide split-offPreparation by halogen halide additionBromineCombinatorial chemistry

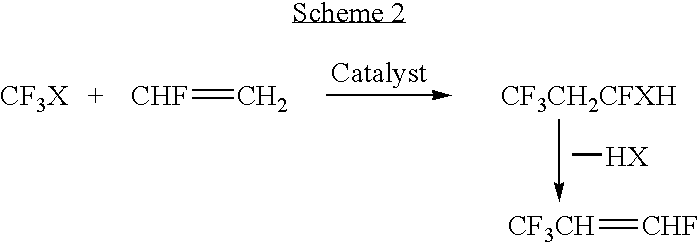

Disclosed in one embodiment is a process for the synthesis of 1,3,3,3-tetrafluoropropene that comprises (a) reacting a compound of formula (I) X1X2 with a compound of formula (II) CF3CH═CH2 to produce a reaction product comprising a compound of formula (III) CF3CHX1CH2X2, wherein X1 and X2 are each independently selected from the group consisting of hydrogen, chlorine, bromine and iodine, provided that X1 and X2 are not both hydrogen; (b) when X2 in formula (III) is not fluorine, fluorinating the compound of formula (III) to produce a reaction product comprising a compound of formula (III) wherein X1 is as described above and X2 is fluorine; and (c) exposing said compound of formula (III) to reaction conditions effective to convert said compound to 1,3,3,3-tetrafluoropropene.

Owner:HONEYWELL INT INC

Process for producing 1,1,1,3,3-pentafluoro-propane and/or 1-chloro-3,3,3-trifluoropropene

InactiveUS6403847B1Point becomes highManufactured continuously and efficientlyPreparation by dehalogenationPreparation by hydrogen halide split-offBoiling pointPropane

One or more materials selected from 1,1,1,3,3-pentachloropropane, 1,1,3,3-tetrachloropropene and 1,3,3,3-tetrachloropropene are used as the specific materials described above. Before submitting the materials and HF to a fluorination reaction, almost all water is removed from them.To continuously manufacture useful intended products efficiently as well as to prevent deactivation of the catalyst and the accumulation of organic substances with high boiling points when manufacturing said useful 1,1,1,3,3-pentafluoropropane and / or 1-chloro-3,3,3-trifluoropropene, by fluorinating the specific materials with HF in the presence of a catalyst.

Owner:DAIKIN IND LTD

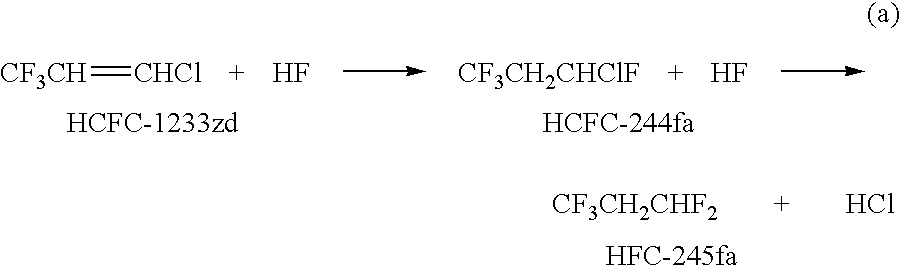

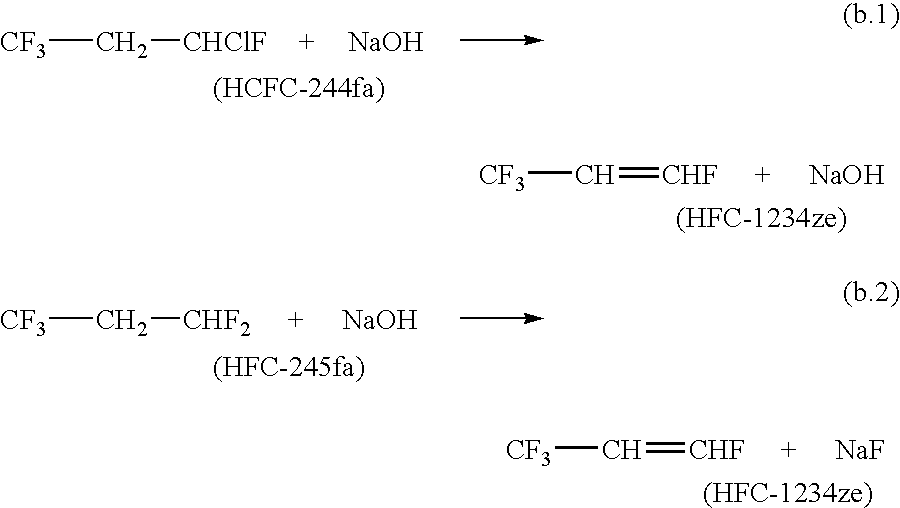

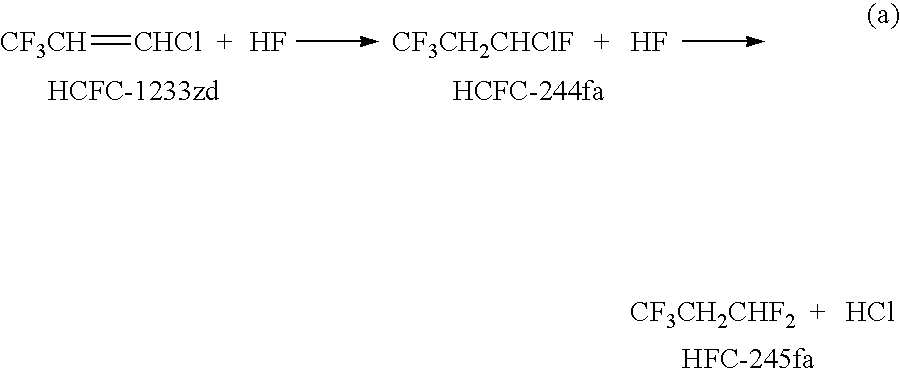

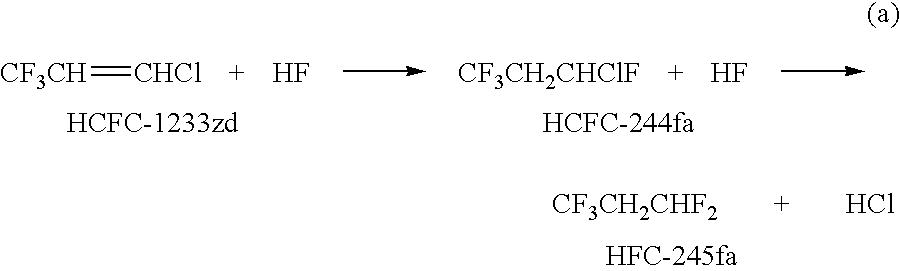

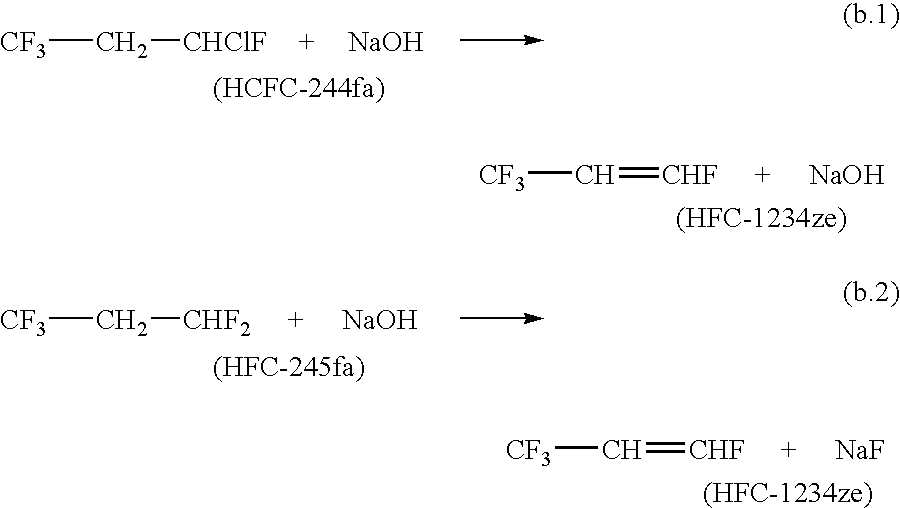

Process for the manufacture of 1,3,3,3-tetrafluoropropene

ActiveUS20050020862A1Physical/chemical process catalystsPreparation by hydrogen halide split-offPentafluoropropaneChemistry

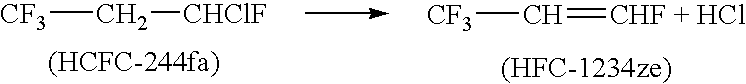

The invention provides an economic process for the manufacture of 1,3,3,3-tetrafluoropropene (HFC-1234ze) by a two stage process. A hydrofluorination of 1-chloro-3,3,3-trifluoropropene (HCFC-1233zd) into 1-chloro-1,3,3,3-tetrafluoropropane (HCFC-244fa) and 1,1,1,3,3-pentafluoropropane (HFC-245fa) is conducted, followed by the dehydrochlorination of HCFC-244fa and dehydrofluorination of HFC-245fa into HFC-1234ze.

Owner:HONEYWELL INT INC

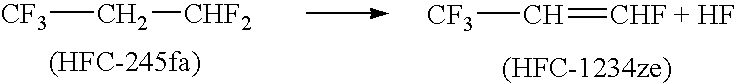

PROCESS FOR THE PRODUCTION OF HFO TRANS-1234ze FROM HFC-245fa

ActiveUS20080051611A1Preparation by hydrogen halide split-offPreparation by halogen halide additionHydrogen fluoride1,3,3,3-Tetrafluoropropene

This invention relates a process for the manufacture of the HFO trans-1,3,3,3-tetrafluoropropene (HFO trans-1234ze). More particularly, the invention pertains to a process for the manufacture of the HFO trans-1234ze by first dehydrofluorinating 1,1,1,3,3-pentafluoropropane to thereby produce a mixture of cis-1,3,3,3-tetrafluoropropene, trans-1,3,3,3-tetrafluoropropene and hydrogen fluoride. Then optionally recovering hydrogen fluoride and then recovering trans-1,3,3,3-tetrafluoropropene.

Owner:HONEYWELL INT INC

Stabilization of polyurethane foam polyol premixes containing halogenated olefin blowing agents

ActiveUS20090099272A1Reduced responseQuality improvementPreparation by halogen halide additionOrganic acidFoaming agent

The invention provides polyurethane and polyisocyanurate foams and methods for the preparation thereof More particularly, the invention relates to open-celled, polyurethane and polyisocyanurate foams and methods for their preparation. The foams are characterized by a fine uniform cell structure and little or no foam collapse. The foams are produced with a polyol premix composition which comprises a combination of a hydrohaloolefin blowing agent, a polyol, a silicone surfactant, and a catalyst which is an adduct of an amine and an organic acid.

Owner:HONEYWELL INT INC

Method for prolonging a catalyst's life during hydrofluorination

ActiveUS20100331583A1Low costHigh purityPreparation by hydrogen halide split-offPreparation by halogen halide additionChemistryHydrogen fluoride

The invention provides an improved process to manufacture 2-chloro-1,1,1,2-tetrafluoropropane (HCFC-244bb) by reacting 2-chloro-3,3,3,-trifluoropropene (HCFO-1233xf) with hydrogen fluoride, in the presence of a fluorination catalyst, where by using 2-chloro-3,3,3,-trifluoropropene (HCFO-1233xf) of high purity, the need to add an oxidizing agent (typically chlorine) to keep the catalyst active can be avoided. The HCFC-244bb is then used as an intermediate in the production of 2,3,3,3-tetrafluoropropene-1 (HFO-1234yf).

Owner:HONEYWELL INT INC

Catalytic isomerization processes of 1,3,3,3-tetrafluoropropene for making 2,3,3,3-tetrafluoropropene

InactiveUS20080058562A1Increase volumePreparation by halogen halide additionIsomerization1,3,3,3-Tetrafluoropropene

The present invention relates to a process of catalyzed isomerization of HFC-1234ze to make HFC-1234yf. The process comprises contacting HFC-1234ze with a suitable catalyst in a reactor to obtain a product mixture comprising HFC-1234yf.

Owner:THE CHEMOURS CO FC LLC

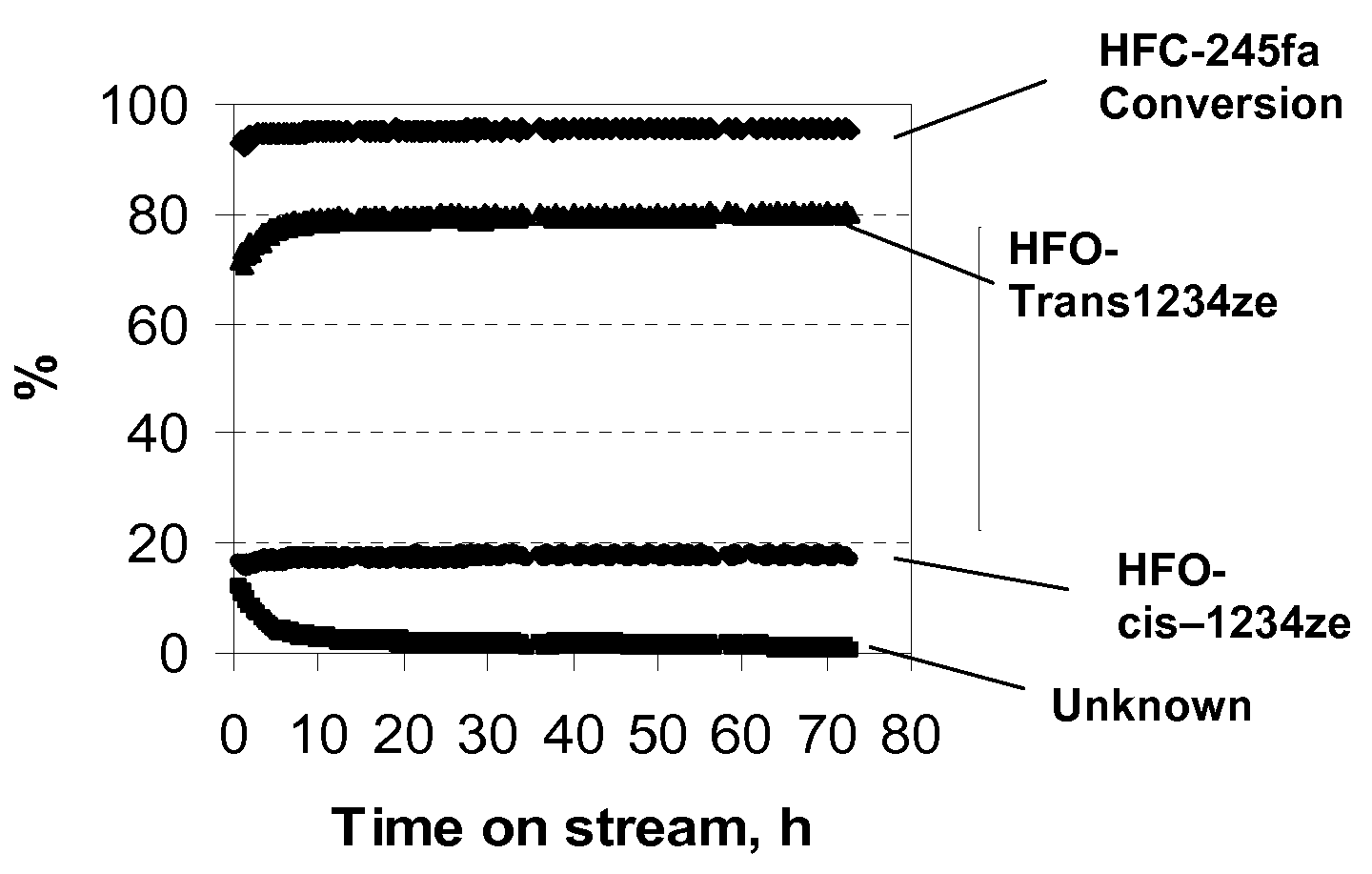

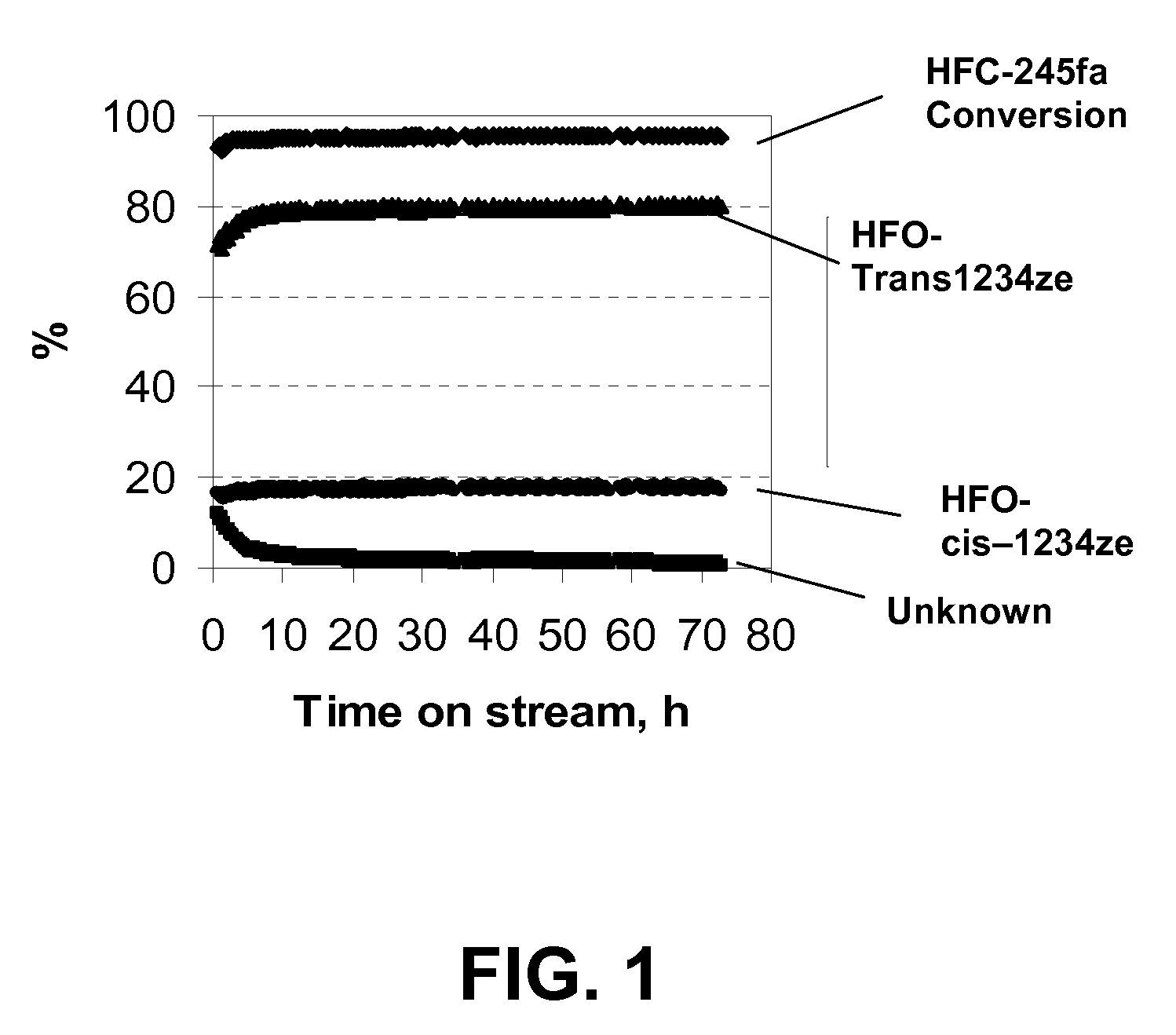

Process for the manufacture of 1,3,3,3-tetrafluoropropene

ActiveUS7829748B1Physical/chemical process catalystsPreparation by hydrogen halide split-offAlkaline earth metalOxidation state

The invention provides an economic process for the manufacture of 1,3,3,3-tetrafluoropropene (HFO-1234ze) by a two stage process. A vapor phase hydrofluorination of 1-chloro-3,3,3-trifluoropropene (HCFC-1233zd) into 1-chloro-1,3,3,3-tetrafluoropropane (HCFC-244fa) and / or 1,1,1,3,3-pentafluoropropane (HFC-245fa) is conducted, followed by the thermal dehydrochlorination of HCFC-244fa and dehydro fluorination of HFC-245fa into HFO-1234ze in the presence of a catalyst which comprises one or more of alkali metal halides, alkaline earth metal halides, halogenated metal oxides, zero oxidation state metals, zinc halides, palladium halides, and activated carbon.

Owner:HONEYWELL INT INC

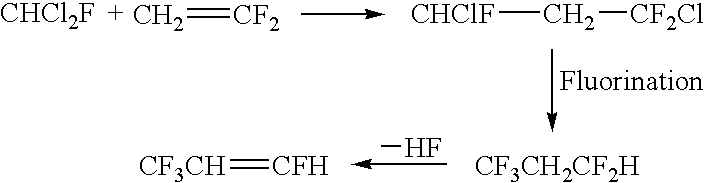

Processes for synthesis of 1,3,3,3-tetrafluoropropene

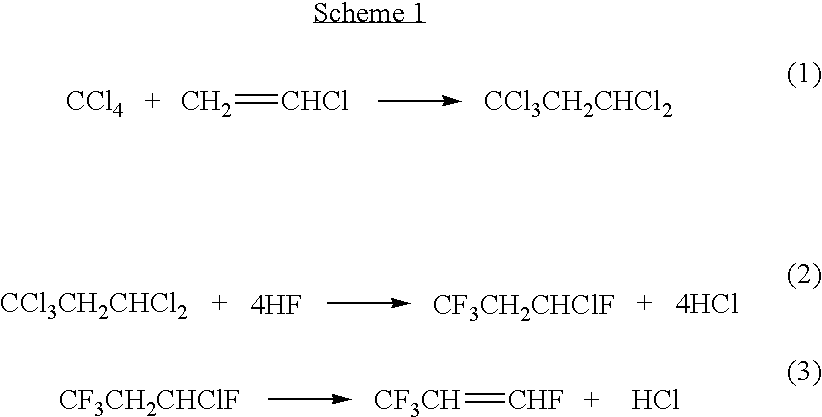

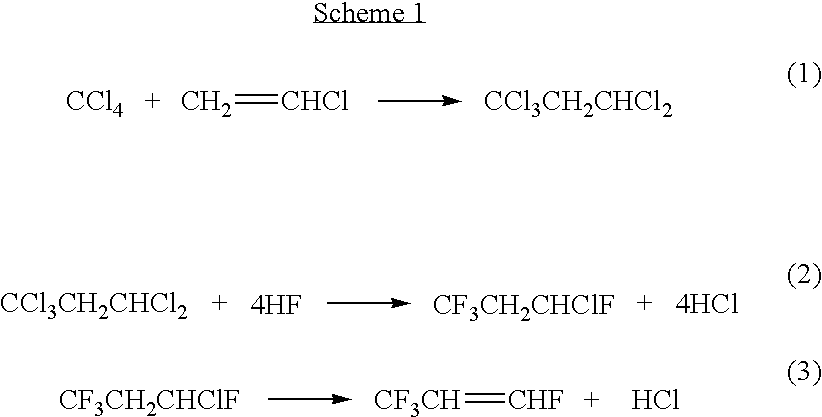

InactiveUS7345209B2Preparation by dehalogenationPreparation by hydrogen halide split-off1,3,3,3-TetrafluoropropeneBromine

Disclosed is a process for the synthesis of 1,3,3,3-tetrafluoropropene that comprises, in one preferred embodiment, providing a compound of the formula CF3CH2CHFX, wherein X is a selected from the group consisting of chlorine, bromine and iodine, and exposing said compound to reaction conditions effective to convert said compound to 1,3,3,3-tetrafluoropropene. Other processes for forming 1,3,3,3-tetrafluoropropene are also disclosed.

Owner:HONEYWELL INT INC

Processes for synthesis of 1,3,3,3-tetrafluoropropene

InactiveUS20050245773A1Overcome deficienciesPreparation by hydrogen halide split-offPreparation by halogen halide addition1,3,3,3-TetrafluoropropeneBromine

Disclosed is a process for the synthesis of 1,3,3,3-tetrafluoropropene that comprises, in one preferred embodiment, providing a compound of the formula CF3CH2CHFX, wherein X is a selected from the group consisting of chlorine, bromine and iodine, and exposing said compound to reaction conditions effective to convert said compound to 1,3,3,3-tetrafluoropropene. Other processes for forming 1,3,3,3-tetrafluoropropene are also disclosed.

Owner:HONEYWELL INT INC

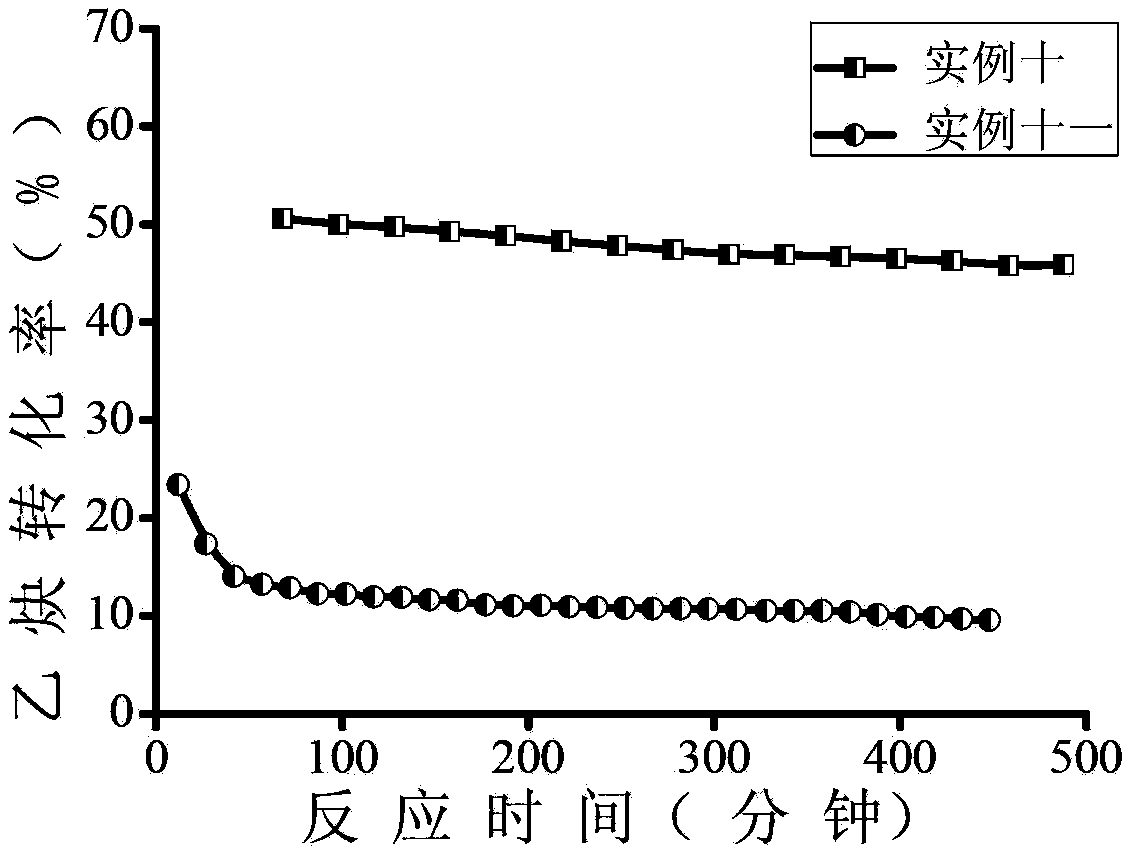

Catalyst system of chloroethylene prepared by hydrochlorinating acetylene and preparation method and application thereof

ActiveCN101716528AEasy to prepareImprove conversion ratePreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsPt elementIonic liquid

The invention discloses a catalyst system of chloroethylene prepared by hydrochlorinating acetylene and a preparation method and application thereof. The catalyst system comprises a catalyst carrier and a catalyst, wherein the catalyst carrier is imidazole ion liquid and the catalyst is any combination of one or more of gold, platinum, palladium, tin, mercury, copper or rhodium chlorides. The preparation method of the catalyst system is to dissolve the catalyst into the catalyst carrier. Acetylene and chlorine hydride are mixed and react in the presence of the catalyst system. The preparation process realizes a liquid phase reaction for preparing chloroethylene by hydrochlorinating acetylene, avoids the loss of the catalyst system, is more environment-friendly and safer, and improves the conversion rate of the acetylene and the selectivity of the chloroethylene.

Owner:于志勇

Mercury-free catalyst with low bullion content for acetylene hydrochlorination and application thereof

InactiveCN101947465AThe content of precious metal elements is reducedLow content of precious metal elementsPhysical/chemical process catalystsPreparation by halogen halide additionPrecious metalNoble metal

The invention discloses a mercury-free catalyst with low bullion content for acetylene hydrochlorination and application thereof and belongs to the technical field of a catalyst for the acetylene hydrochlorination and a preparation technique and a reaction process thereof. The catalyst comprises a noble metal element which accounts for 0.05 to 0.5 weight percent of the total weight of the catalyst, a common metal element which accounts for 0.1 to 5 weight percent of the total weight of the catalyst, and a carrier, wherein the noble metal element and the noble metal element exist in the form of metallic compounds. The noble metal element content of the catalyst is reduced greatly, the loading amount of a cocatalyst metallic element is also low, and the cost of the catalyst is reduced greatly; and the catalyst can replace the highly toxic mercury catalyst and is applied to the industrial production of the acetylene hydrochlorination.

Owner:TSINGHUA UNIV

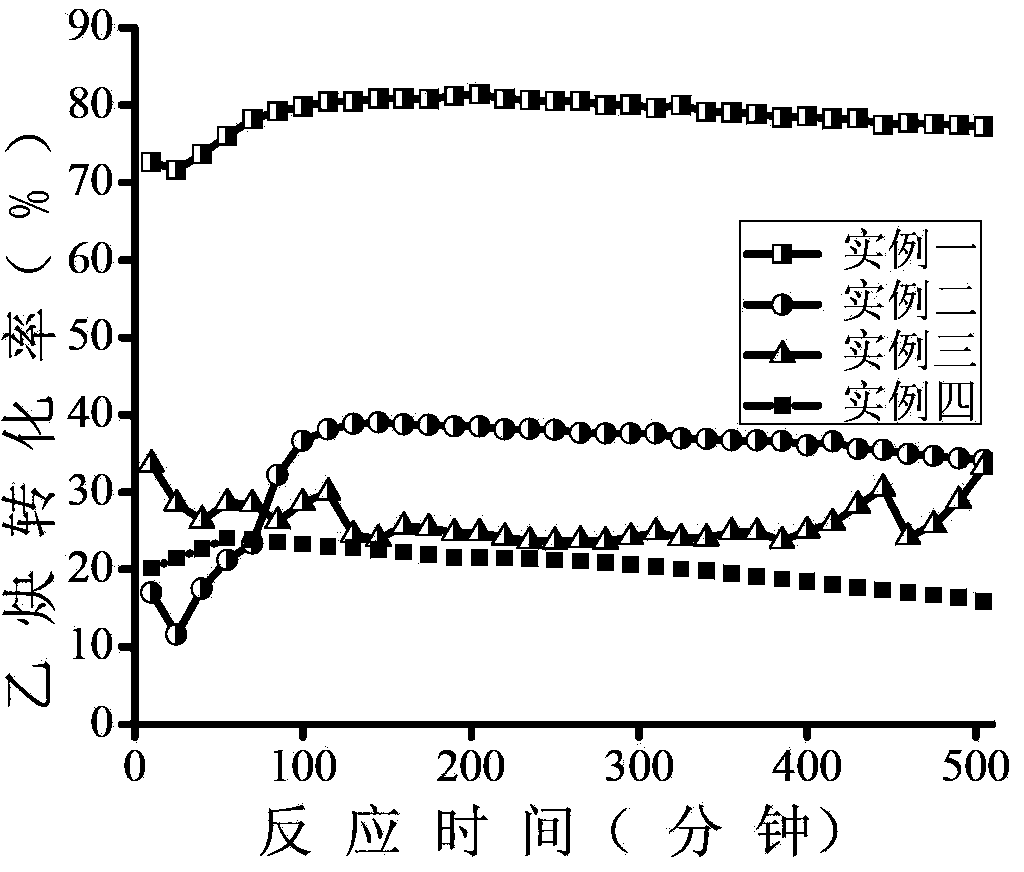

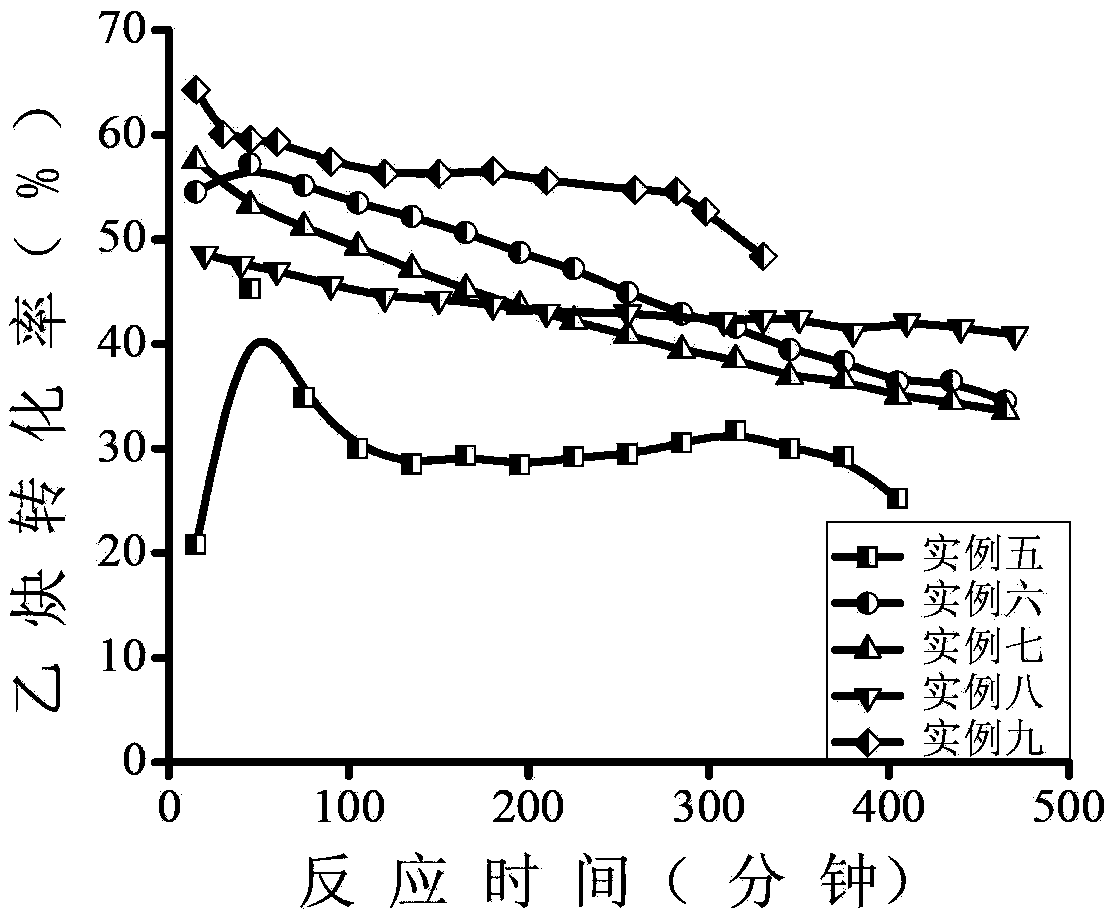

Nitrogen doped carbon material loaded catalyst

InactiveCN103381369AGood dispersionImprove adsorption capacityCatalyst carriersPreparation by halogen halide additionPotassiumNitrogen source

Belonging to the technical field of catalysts, the invention discloses a nitrogen doped carbon material loaded catalyst. The carbon material can realize nitrogen doping by means of nitrogen containing precursor chemical coupling and other surface modification methods, also a nitrogen source and a carbon source can be introduced simultaneously at high temperature for in situ synthesis of a nitrogen doped carbon material, and then a simple substance or compound of one or more of gold, copper, manganese, potassium or bismuth can be loaded on the nitrogen doped carbon material. The nitrogen doped carbon material loaded mercury-free catalyst involved in the invention has activity and stability obviously superior to those of ordinary carbon material loaded catalysts. Under certain reaction conditions, the activity of the nitrogen doped carbon material loaded catalyst is superior to that of ordinary carbon material loaded catalysts by over 10%. The carbon material and the catalyst disclosed in the invention are green and non-toxic, and have good environmental benefits. The process involved in the invention is simple, economical and feasible.

Owner:TSINGHUA UNIV +1

Hydrofluorination of 2-chloro-3,3,3-trifluoropropene to 2-chloro-1,1,1,2-tetrafluoropropane with catalysts of sbcl3, sbcl5, sbf5, ticl4, sncl4, cr2o3 and fluorinated cr2o3

Owner:HONEYWELL INT INC

PROCESS FOR THE PREPARATION OF 2,3,3,3-TETRAFLUOROPROPENE (HFO-1234yf)

A process for the preparation of 2,3,3,3-tetrafluoropropene (HFO-1234yf). HFO-1234yf is a refrigerant with low global warming potential. A process comprises a) reacting chlorotrifluoroethylene with a methyl halide to form an intermediate product stream; and b) reacting the intermediate product stream with hydrogen fluoride to thereby produce a result comprising 2,3,3,3-tetrafluoropropene.

Owner:HONEYWELL INT INC

Compositions containing chromium, oxygen, and at least two modifier metals selected the group consisting of gold, silver, and palladium, their preparation, and their use as catalysts and catalyst precursors

InactiveUS20080207962A1Preparation by dehalogenationPreparation by hydrogen halide split-offNitrateAmmonium hydroxide

A catalyst composition is disclosed that includes chromium, oxygen, and at least two of gold, silver, and palladium as essential constituent elements. The amount of modifier metals (gold, silver, and / or palladium) in the composition is from about 0.05 atom % to about 10 atom % based on the total amount of chromium and modifier metals. Also disclosed is a process for changing the fluorine distribution (i.e., content and / or arrangement) in a hydrocarbon or halogenated hydrocarbon in the presence of the catalyst composition; and methods for preparing said catalyst composition. One preparation method involves (a) co-precipitating a solid by adding ammonium hydroxide (aqueous ammonia) to an aqueous solution of soluble salts of modifier metals and a soluble chromium salt that contains at least three moles of nitrate per mole of chromium in the solution and has a modifier metal content of from about 0.05 atom % to about 10 atom % of the total content of modifier metals and chromium in the solution to form an aqueous mixture containing co-precipitated solid; (b) drying the co-precipitated solid formed in (a); and (c) calcining the dried solid formed in (b) in an atmosphere containing at least 10% oxygen by volume. Another preparation method involves (a) impregnating solid chromium oxide with a solution of a soluble modifier metal salts; (b) drying the impregnated chromium oxide prepared in (a); and optionally; (c) calcining the dried solid. Yet another preparation method involves mixing multiple compositions, each comprising chromium, oxygen, and at least one modifier metal.

Owner:EI DU PONT DE NEMOURS & CO

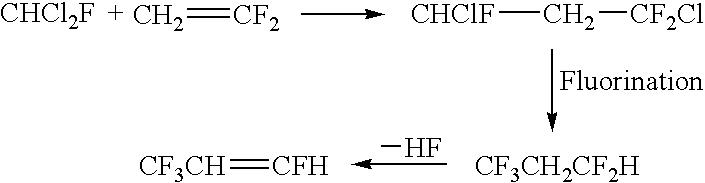

Process for the preparation of fluorine containing hydrohalocarbons

InactiveUS6187976B1Preparation by dehalogenationPreparation by halogen halide additionHydrogen fluorideHydrogen

The invention relates to the preparation of 1-chloro-1,1,3,3,3-pentafluoropropane (HCFC-235fa), useful as an intermediate in the production of 1,1,1,3,3-pentafluoropropane (HFC-245fa). The invention further relates to a process for the preparation of HFC-245fa comprising reacting HCFC-235fa with hydrogen in the presence of a reduction catalyst wherein the said HCFC-235fa is prepared by reacting CCl3CHCCl3 with hydrogen fluoride in the presence of fluorination catalyst in either the liquid phase or the vapor phase.

Owner:ALLIEDSIGNAL INC

Azeotropic composition, comprising 1, 1, 1, 3,3-pentafluoropropane and 1, 1, 1-trifluoro-3-chloro-2-propene, method of separation and purification of the same, and process for producing 1, 1, 1,3,3-pentafloropropane and 1, 1, 1-trifluoro-3-chloro-2-propene

InactiveUS7183448B2Delayed recoveryIncrease production costPreparation by hydrogen halide split-offOther chemical processesDistillationPentafluoropropane

A mixture comprising at least 1,1,1,3,3-pentafluoropropane and 1,1,1-trifluoro-3-chloro-2-propene is subjected to a distillation operation, and thereby, a distillate comprising an azeotropic composition consisting substantially of 1,1,1,3,3-pentafluoropropane and 1,1,1-trifluoro-3-chloro-2-propene is obtained and a bottom product comprising 1,1,1,3,3-pentafluoropropane or 1,1,1-trifluoro-3-chloro-2-propene which each is separated and purified.

Owner:DAIKIN IND LTD

Non-mercuric catalyst used in hydrochlorination of acetylene and method for preparing vinyl chloride by using catalyst

InactiveCN102029189AGood stability in continuous useSolution to short lifePreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsPhosphatePotassium

The invention relates to a non-mercuric catalyst used in hydrochlorination of acetylene and a method for preparing vinyl chloride by using the catalyst. The non-mercuric catalyst used in hydrochlorination of acetylene for preparing vinyl chloride comprises main active ingredients-gold salts, auxiliary active ingredients-non precious metal salts and a carrier, wherein the main active ingredients are gold salts and can be halides, complexes and the like of gold; gold in the gold salts accounts for 0.1-10% by weight of the catalyst; the auxiliary active ingredients are non precious metal salts and can be halides, acetates, phosphates, complexes and the like of potassium, barium, lanthanum and copper; the non precious metal salts account for 0.1-10% by weight of the catalyst; and the carrier is activated carbon, comprising coconut shell carbon, coal carbon, nutshell carbon or silica gel. The non-mercuric catalyst can be prepared by the conventional impregnation method, has simple preparation method, is environment-friendly and has the advantages of less by-products, good stability and long service life. The conversion rate of acetylene can be 90-99% and the selectivity of vinyl chloride is not lower than 99%.

Owner:EAST CHINA UNIV OF SCI & TECH

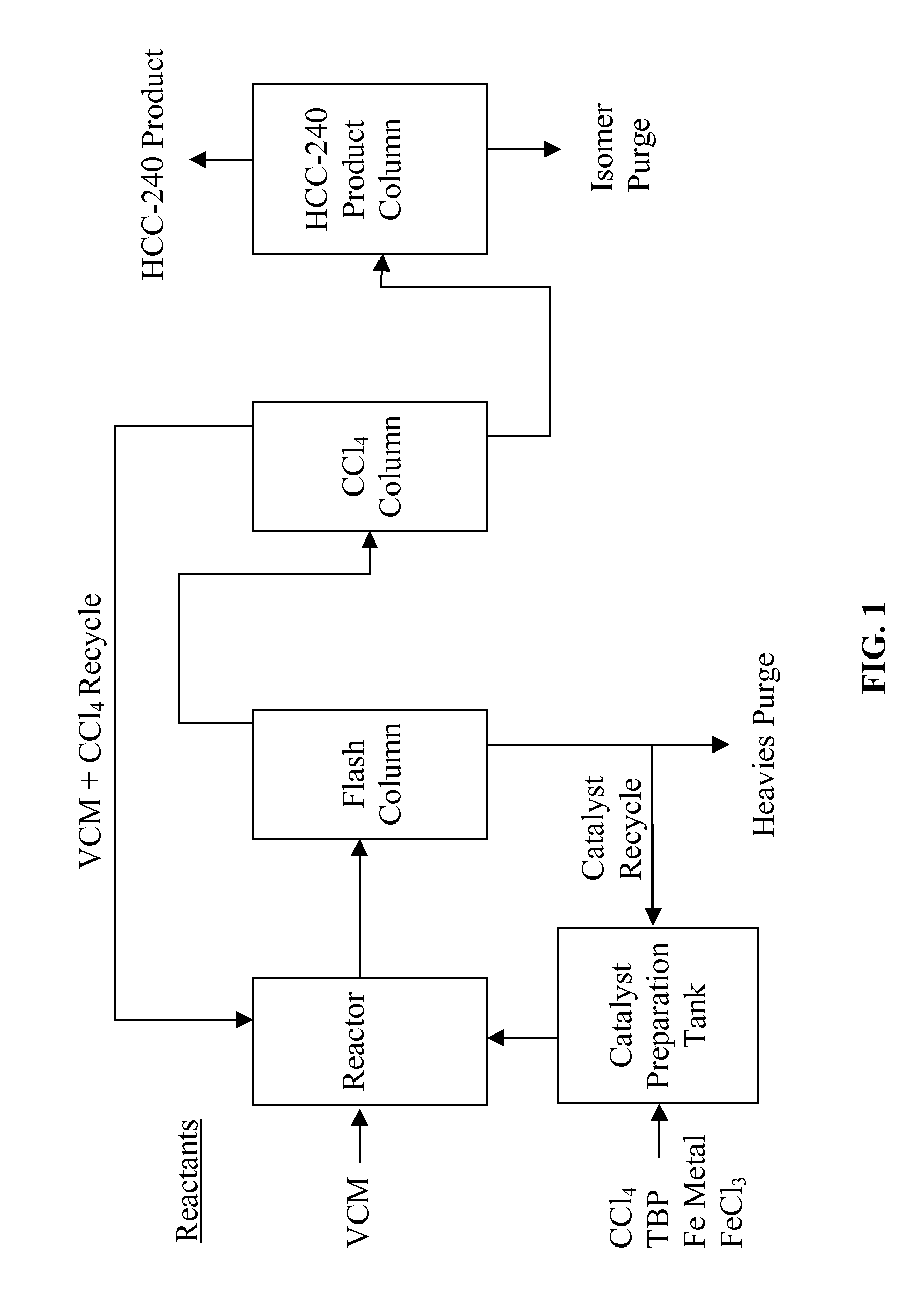

Process for the manufacture of 1,1,1,3,3-pentachloropropane

ActiveUS20080091053A1High yieldHigh selectivityPreparation by halogen halide additionHalogenated hydrocarbon separation/purificationAlkeneHaloalkane

A process for the manufacture of haloalkanes, or more particularly to a process for the manufacture of 1,1,1,3,3-pentachloropropane (HCC-240fa) and / or and / or 1,1,1,3-tetrachloropropane (HCC-250fb). The process includes (a) mixing a catalyst, co-catalyst and a haloalkane starting material under conditions suitable to produce a homogeneous mixture; (b) reacting the homogeneous mixture with a haloalkene and / or alkene starting material under conditions suitable to produce a haloalkane product stream; and (c) recovering a haloalkane product from said product stream.

Owner:HONEYWELL INT INC

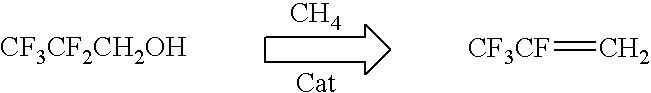

Catalytic conversion of hydrofluoroalkanol to hydrofluoroalkene

ActiveUS7026520B1High-yieldPreparation by hydrogen halide split-offPreparation by halogen halide addition1-PropanolHigh pressure

Methane is used as the selective dehydrating agent for the production of 2,3,3,3-tetrafluoro-1-propene (R1234yf) from 2,2,3,3,3-pentafluoro-1-propanol. Supported transition metal catalysts are prepared and used for this reaction with high activity. Almost 58% selectivity to R1234yf is obtained at an alcohol conversion level of 60% using unsupported Ni-mesh as the catalyst. Pd and Pt show almost similar level of conversion; however, the selectivity to the desired product is low. The activity of the metal catalyst was found to be a function of the type of support material, activated carbon showing better activity than alumina. Different important process parameters such as temperature, pressure, and contact time are studied to optimize the process. High pressure and temperature are deleterious to the rate of 1234yf formation; yet, the highest yield to 1234yf is obtained while performing a reaction at 494° C. with a contact time of 23 sec.

Owner:HONEYWELL INT INC

Method of making 1,1,3,3,3-pentafluoropropene

InactiveUS20050070746A1Low costPreparation by dehalogenationPreparation by hydrogen halide split-offFoaming agentSolvent

The invention provides an economic process for the manufacture of the hydrofluorocarbon 1,1,3,3,3-pentafluoropropene (HFC-1225zc). HFC-1225zc can be made from the dehydrochlorination of 1-chloro-1,1,3,3,3-pentafluoropropane (HCFC-235fa). Alternatively, HFC-1225zc can also be made from the dehydrofluorination of 1,1,1,3,3,3-hexafluoropropane (HFC-236fa). HFC-1225zc) is a compound that has the potential to be used as a low Global Warming Potential refrigerant, blowing agent, aerosol propellant, or solvent.

Owner:HONEYWELL INT INC

Process for the manufacture of 1,3,3,3-tetrafluoropropene

ActiveUS7592494B2Physical/chemical process catalystsPreparation by hydrogen halide split-off1,3,3,3-TetrafluoropropenePentafluoropropane

The invention provides an economic process for the manufacture of 1,3,3,3-tetrafluoropropene (HFC-1234ze) by a two stage process. A hydrofluorination of 1-chloro-3,3,3-trifluoropropene (HCFC-1233zd) into 1-chloro-1,3,3,3-tetrafluoropropane (HCFC-244fa) and 1,1,1,3,3-pentafluoropropane (HFC-245fa) is conducted, followed by the dehydrochlorination of HCFC-244fa and dehydrofluorination of HFC-245fa into HFC-1234ze.

Owner:HONEYWELL INT INC

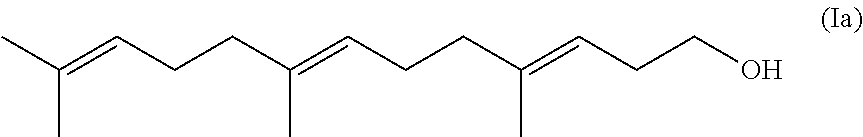

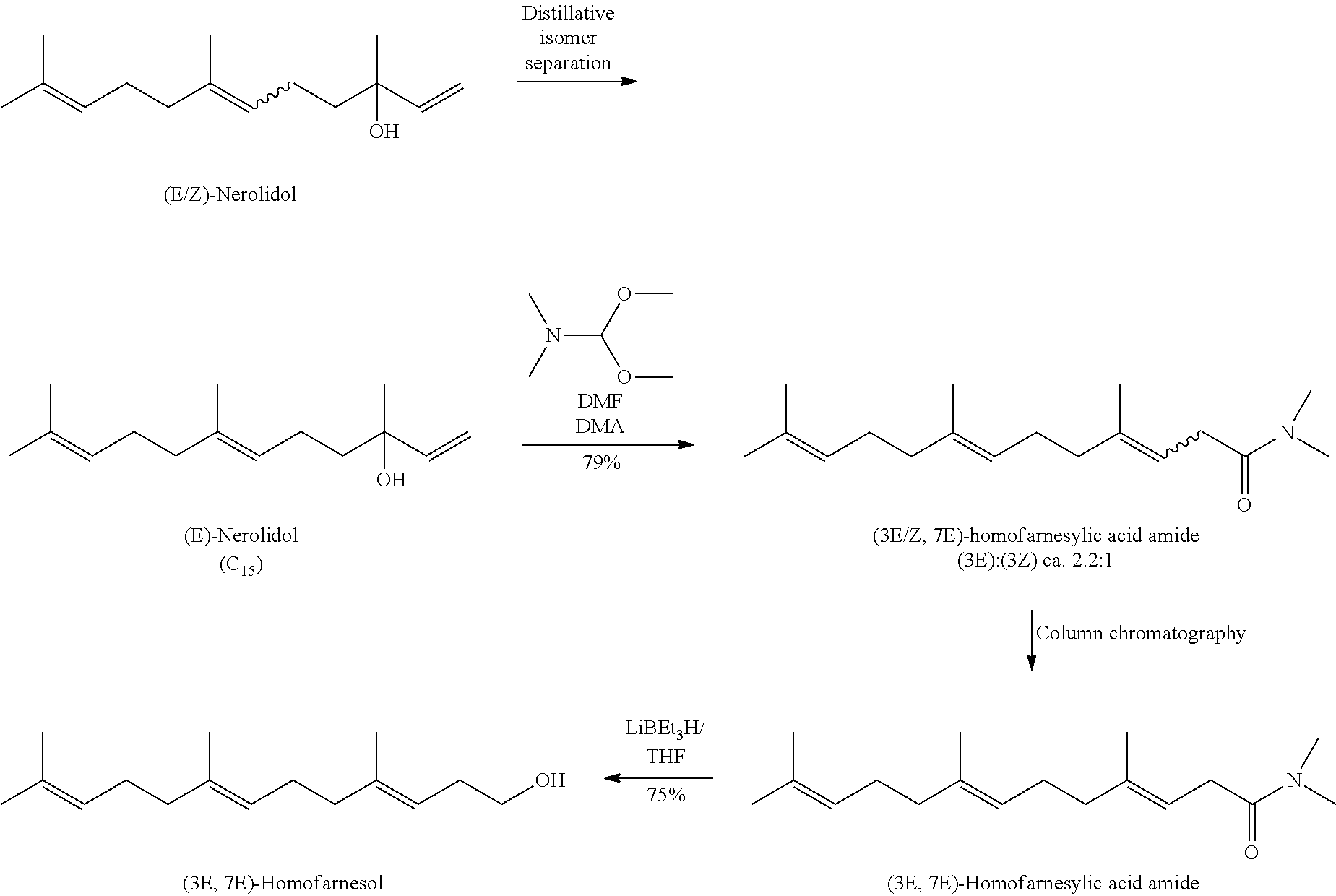

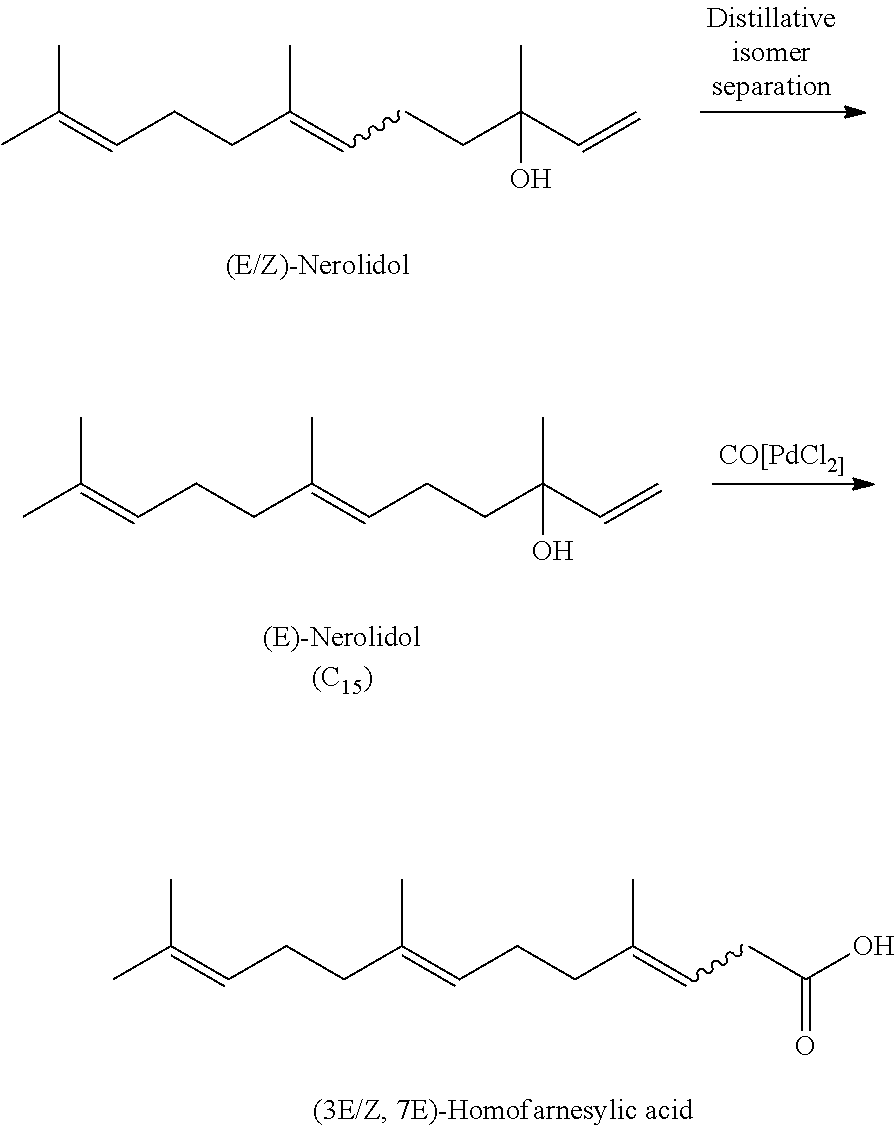

Process for the Preparation of (3E, 7E)-Homofarnesol

InactiveUS20130273619A1Organic compound preparationPreparation by halogen halide additionMedicinal chemistryFarnesyl alcohol

Owner:BASF AG

Method for separating halocarbons

ActiveUS20100048961A1Preparation by hydrogen halide split-offPreparation by halogen halide additionHalocarbonHFO-1234yf

Owner:HONEYWELL INT INC

Nitrogen-doped active carbon catalyzer and application thereof in chloroethylene synthesis

InactiveCN104525237AImprove catalytic performanceImprove conversion ratePhysical/chemical process catalystsPreparation by halogen halide additionActivated carbonTube furnace

The invention discloses a nitrogen-doped active carbon catalyzer and application of the nitrogen-doped active carbon catalyzer in chloroethylene synthesis. The preparation method of the nitrogen-doped active carbon catalyzer comprises the following steps that a nitrogen-containing compound is dissolved in water to obtain a nitride solution, then active carbon is added in the nitride solution to be dipped, at last the dipped active carbon is dried completely and calcined in nitrogen, and the nitrogen-doped active carbon catalyzer is prepared. Additionally, the active carbon can be placed in a tube furnace, nitrogen is pumped in the tube furnace at high temperature, and the nitrogen-doped active carbon catalyzer is prepared. The nitrogen-doped active carbon catalyzer has a good catalytic performance in catalyzing ethyne and chlorine hydride to react with each other to synthesize chloroethylene. The catalyzer is more environmental friendly than an active carbon catalyzer carrying metal ions in the prior art.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Low-mercury catalyst for acetylene hydrochlorination

InactiveCN102380407AEasy to makeLow costPhysical/chemical process catalystsPreparation by halogen halide additionO-Phosphoric AcidPtru catalyst

Disclosed is a low-mercury catalyst for acetylene hydrochlorination. Mercuric chloride is carried on activated carbon. Raw materials comprise, by weight, 100 parts of activated carbon, 4-5 parts of mercuric chloride, 8-10 parts of total essential assistant, 1-5 parts of total non-essential assistant, wherein the essential assistant comprises 2-5 parts of bismuth chloride, 1-5 parts of cerium chloride, 1-5 parts of barium chloride and 2-5 parts of copper chloride; and the non-essential assistant comprises at least one of potassium chloride, phosphoric acid, zinc chloride and cuprous chloride. After being subjected to surface subtraction and drying on acid and oxidizing conditions, activated carbon is in reflux treatment with urea solution; and the catalyst can be prepared by soaking the treated activated carbon with HgC12 dissolved in hydrochloric acid and assistant solution sufficiently after urea is removed by steps of heating, washing the activated carbon with hydrochloric acid and finally drying the same. The carrying capacity of mercuric chloride in the catalyst is lower so that cost for the catalyst is reduced and consumption of mercury resources is decreased. Furthermore, activity and stability of the low-mercury catalyst are much higher than those of the existing high-mercury catalyst, and reforming rate and selectivity of reaction of vinyl chloride can be 99.7% and be higher than 99.8%. Accordingly, the low-mercury catalyst for acetylene hydrochlorination is suitable for industry production and is environment-friendly.

Owner:CHENGDU HUIEN FINE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com