Nitrogen doped carbon material loaded catalyst

A nitrogen-doped carbon, catalyst technology, applied in catalyst carrier, physical/chemical process catalyst, organic chemistry and other directions, to achieve the effect of non-volatile, good activity and pollution avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

[0052] Specific example 1: 0.35 wt% gold catalyst supported on nitrogen-doped activated carbon. Take 10g of ordinary coconut shell charcoal and wash the impurities with deionized water. The specific steps are: take 100ml of deionized water and soak the coconut shell charcoal at room temperature for 24 hours, then filter; repeat this 3 times. Then place the activated carbon at 120 ? Dry in an oven at C for 10 hours. Under the condition of 600 oC without air, 50ml / min of ammonia gas and 10ml / min of hydrogen gas (Beijing North Temperature Gas, high purity, ≥99.99%) were introduced for 5 hours, then gradually lowered to room temperature, and then the ammonia gas was turned off ( Beijing Lvling Gas, high purity, ≥99.99%) and hydrogen, at this time the nitrogen content of the activated carbon bulk phase can be increased from 0.25% to 1.80%. Take 0.035g chloroauric acid (HAuCl 4 ·H 2 O, Acros, ≥99.9%) was dissolved in 8.5g of deionized water, and 5g of nitrogen-doped coconut shel...

specific example 2

[0055] Specific example two: 0.05wt% gold catalyst supported by nitrogen-doped activated carbon. Get 5g common coconut shell charcoal, wash impurity with deionized water, its preparation step is identical with example one. Place activated carbon at 120 ? After drying in an oven at C for 10 hours, add 100 ml of 10 mol / L ammonia water at 25 o C, and stir for 24 hours. After filtering, place activated carbon in an air-isolated and 500 ? Under the condition of C, 10ml / min hydrogen gas is passed for 8 hours, at this time, the nitrogen content on the surface of the activated carbon can be increased from 0.25% to 1.00%. The evaluation condition of the catalyst in the example two is the same as the example one, and the volumetric space velocity of acetylene is 600 h -1 , hydrogen chloride flow / acetylene flow=1.1:1.0.

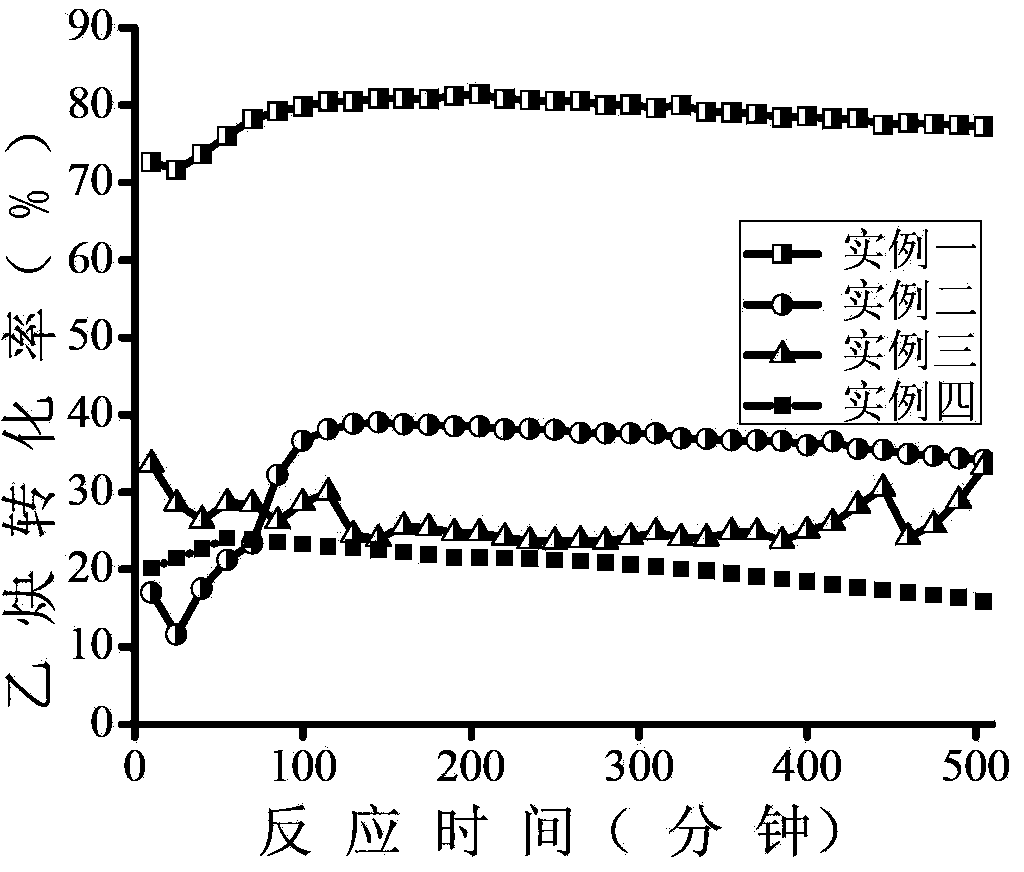

[0056] The initial activity, maximum activity and selectivity of the catalyst are shown in Table 1, and the change curve of the conversion rate with time is as follow...

specific example 3

[0057] Specific example three: 5.0wt% copper catalyst supported by nitrogen-doped activated carbon. Weigh 5g of the same nitrogen-doped coconut shell charcoal as example one, get 0.68g copper chloride (CuCl 2 2H 2 O, Beijing Chemical Plant, analytically pure) was dissolved in 8.5g deionized water, nitrogen-doped activated carbon was added under the condition of stirring at room temperature, and after stirring for 2 hours, it was put into 130 ? Dry in an oven at C for 8 hours. The evaluation condition of the catalyst in the example three is the same as that of the example one, and the volume space velocity of acetylene is 600 h -1 , hydrogen chloride flow / acetylene flow=1.1:1.0.

[0058] The initial activity, maximum activity and selectivity of the catalyst are shown in Table 1, and the change curve of the conversion rate with time is as follows figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com