Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

144results about How to "Reduced inactivation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

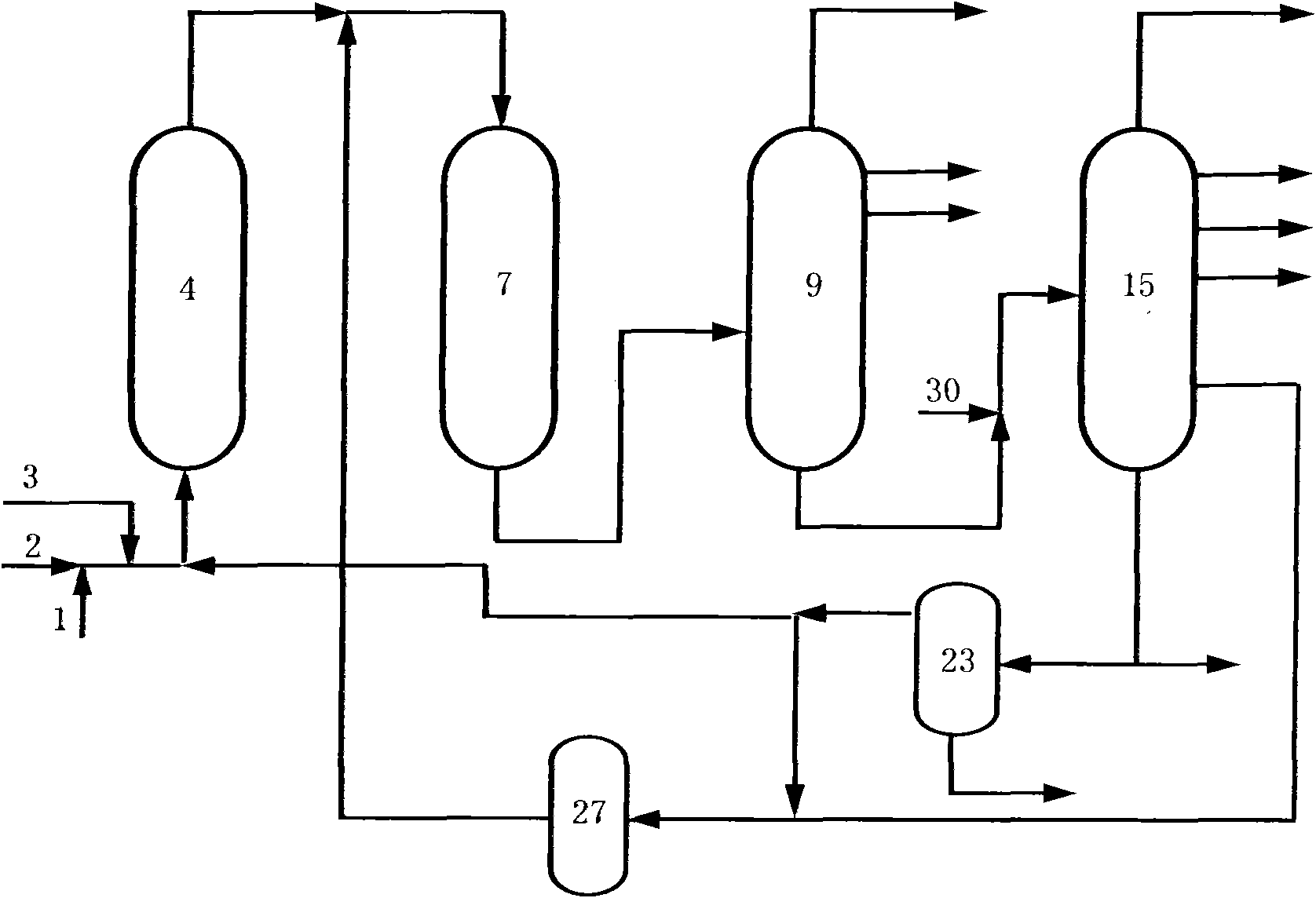

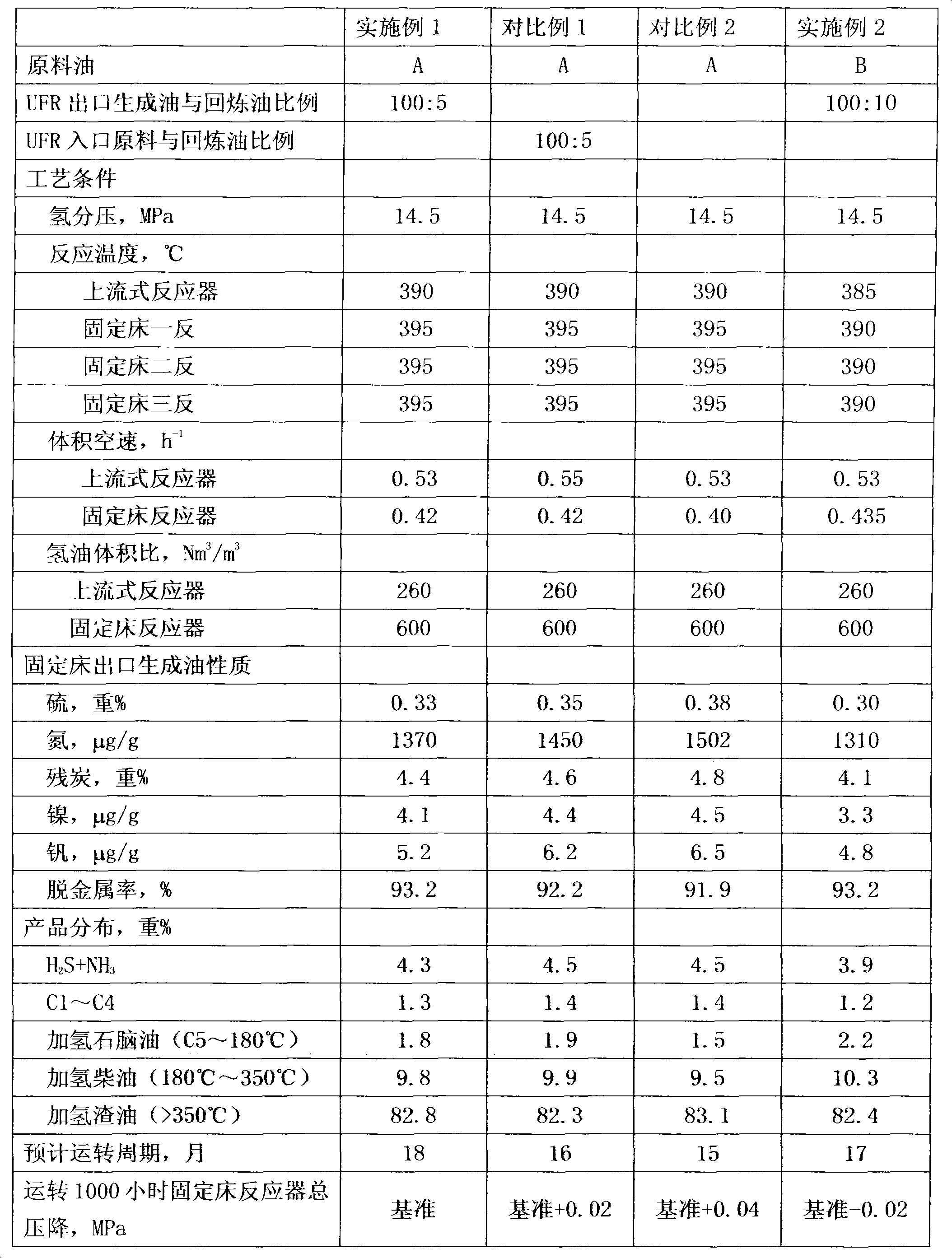

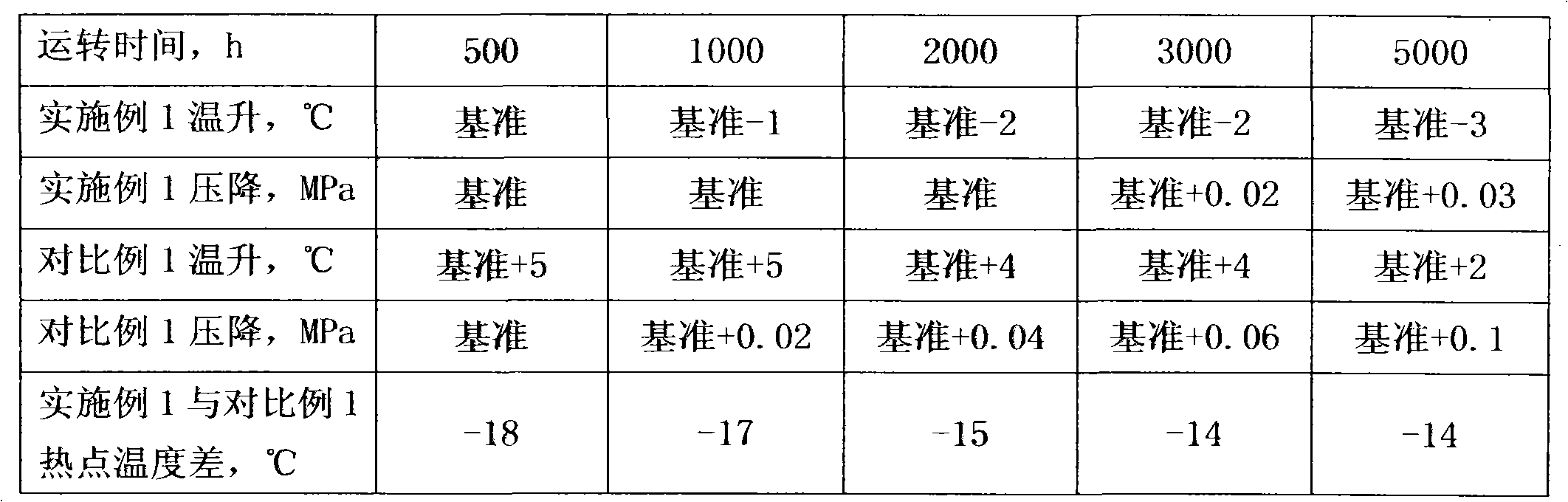

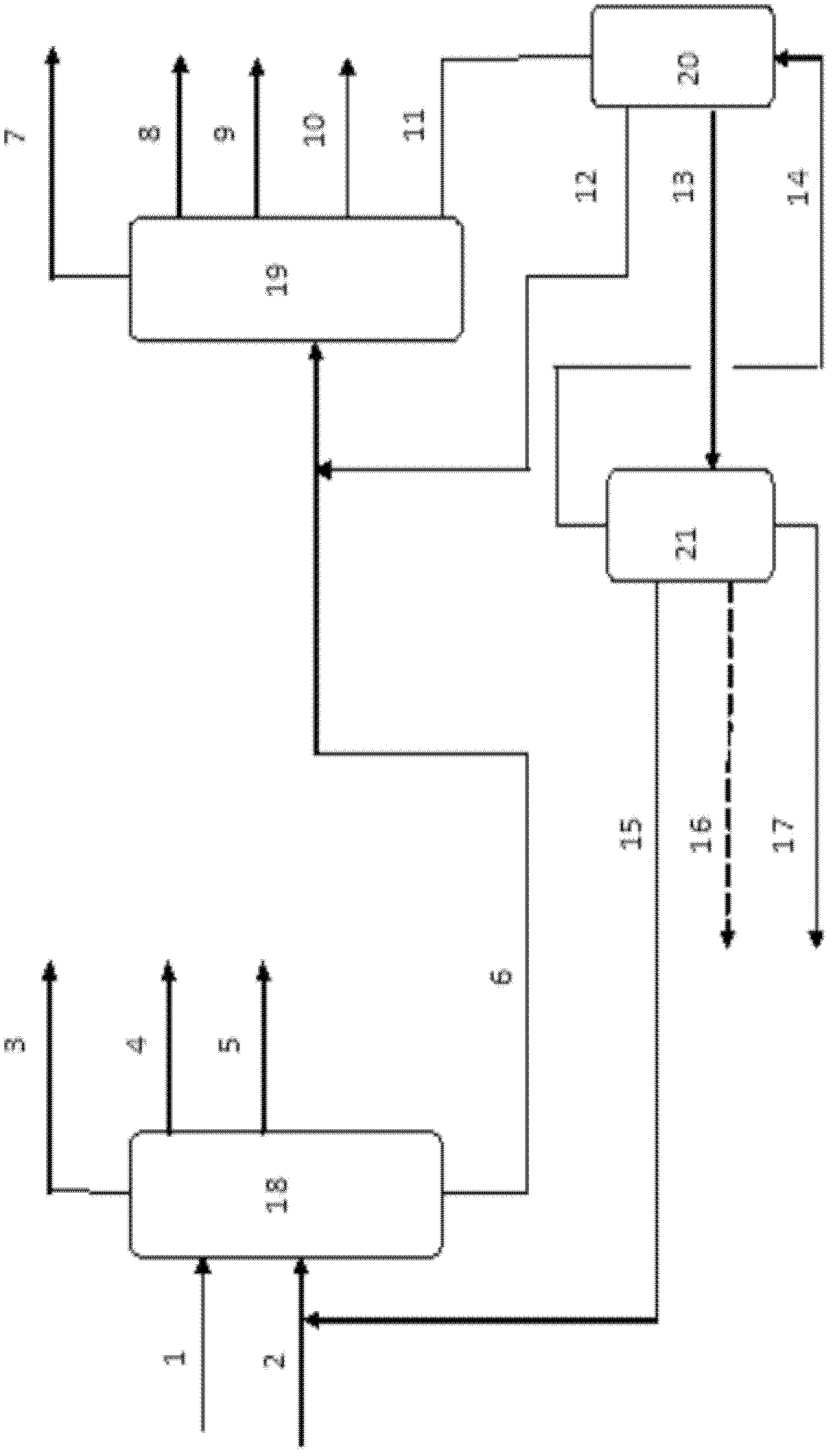

Method for hydrotreating high-sulfur and high-metal residual oil

ActiveCN101519603AHigh porosityReduced inactivation rateRefining to eliminate hetero atomsNaphthaHydrogen

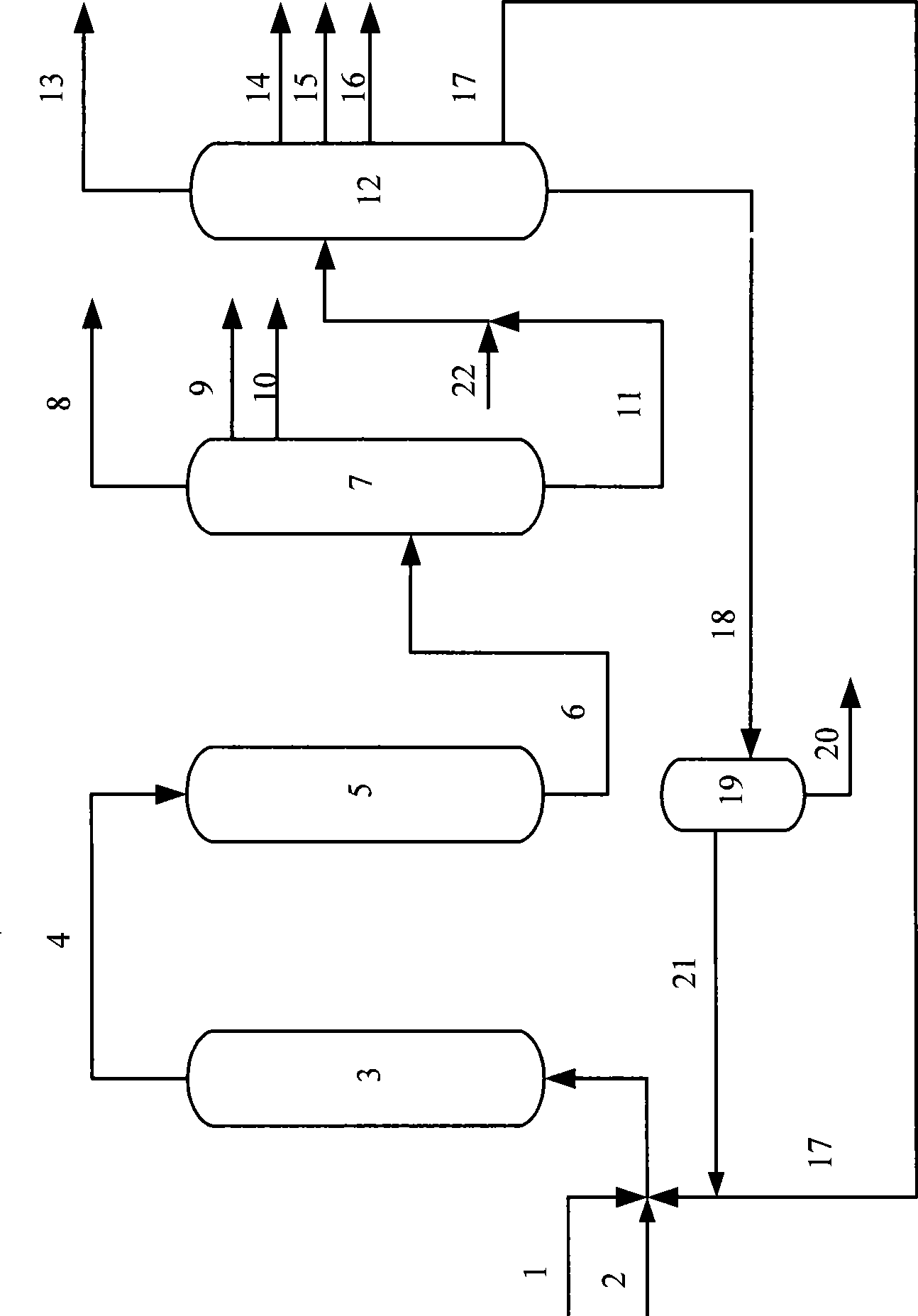

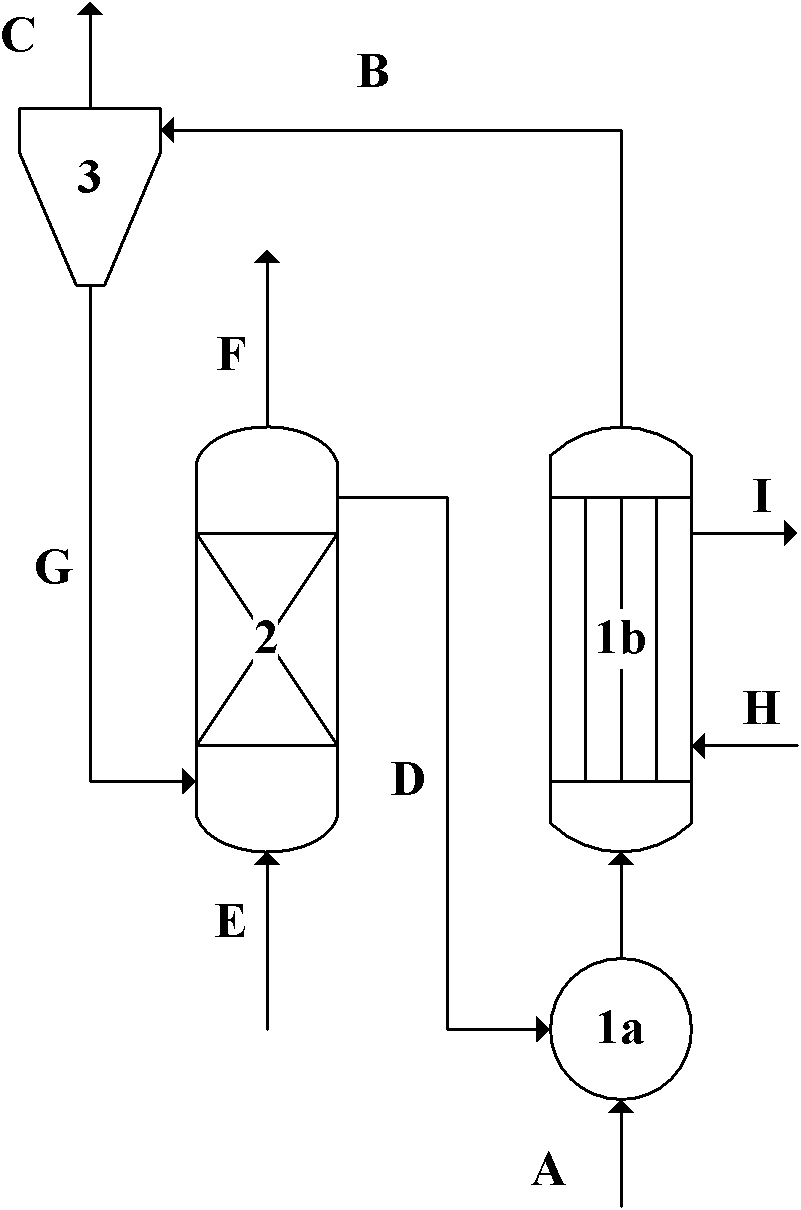

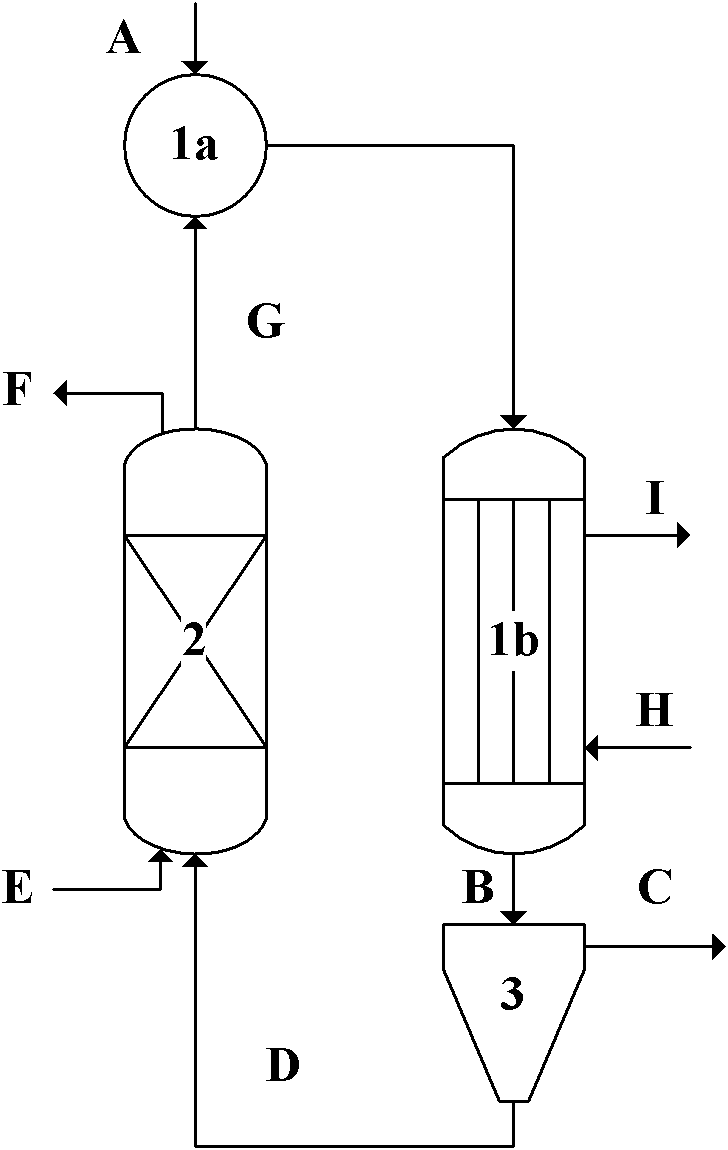

The invention provides a method for hydrotreating high-sulfur and high-metal residual oil, which comprises the following steps: the residual oil and catalytic cracking recycle oil are in contact with a residual oil hydrogenation catalyst in the presence of hydrogen gas and under the hydrotreating reaction condition so as to carry out a hydrotreating reaction; the reaction product is separated to obtain gas, hydrogenated naphtha, hydrogenated diesel oil and hydrogenated residual oil. The residual oil hydrogenation catalyst is a combination of at least two catalysts, namely, an up-flow reactor catalyst and a fixed-bed hydrogenation catalyst and the two catalysts are respectively put in an up-flow reactor and a fixed-bed reactor; the ratio of the up-flow reactor catalyst and the fixed-bed hydrogenation catalyst is 30:70 to 70:30. The method can treat the high-sulfur and high-metal residual oil and effectively slow down the ascending speed of the pressure drop of the fixed-bed catalyst bed, thus realizing the long-term running of the device. Besides, the method can combine the residual oil hydrotreating and catalytic cracking more effectively and has better implementation effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

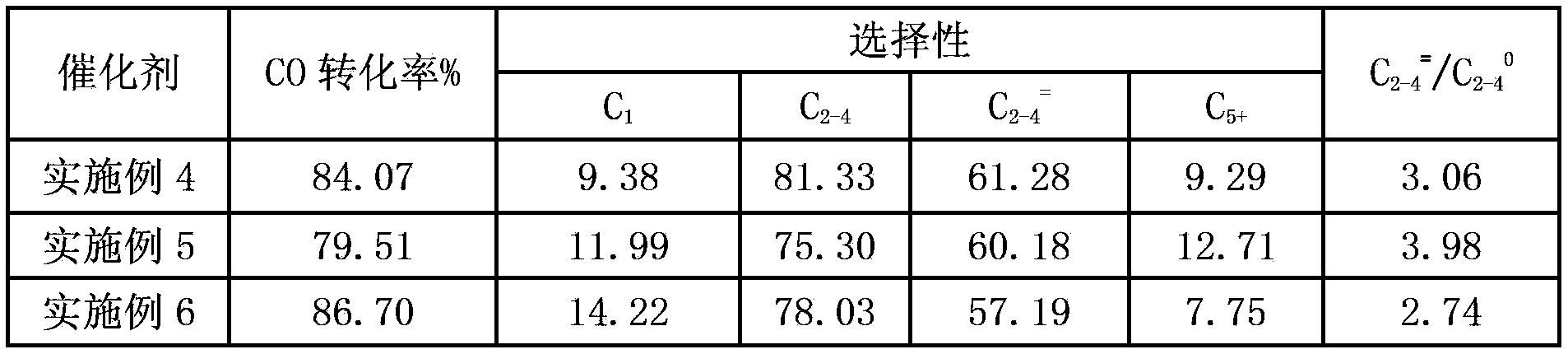

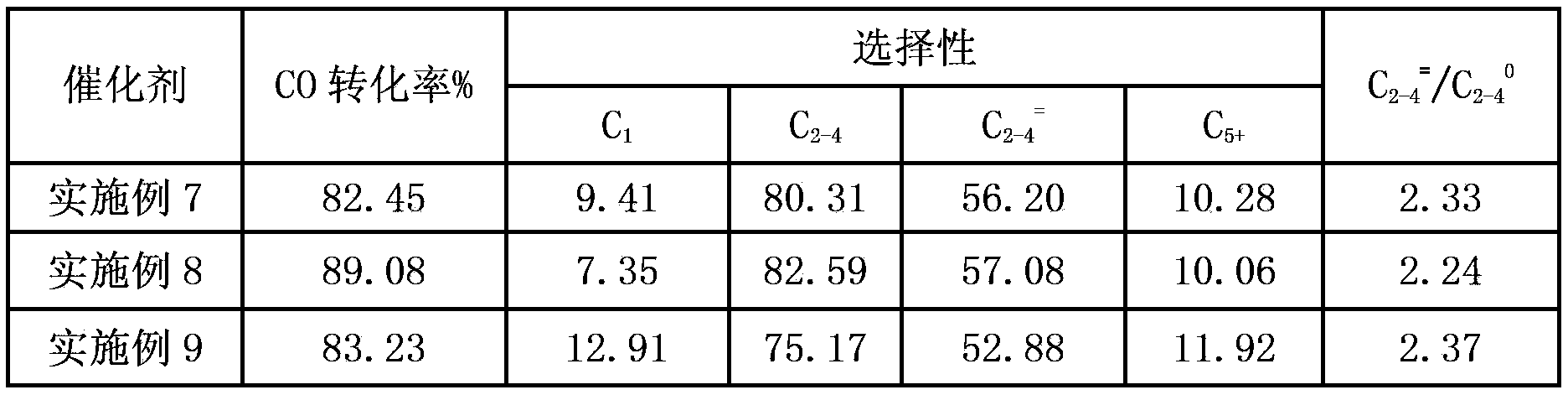

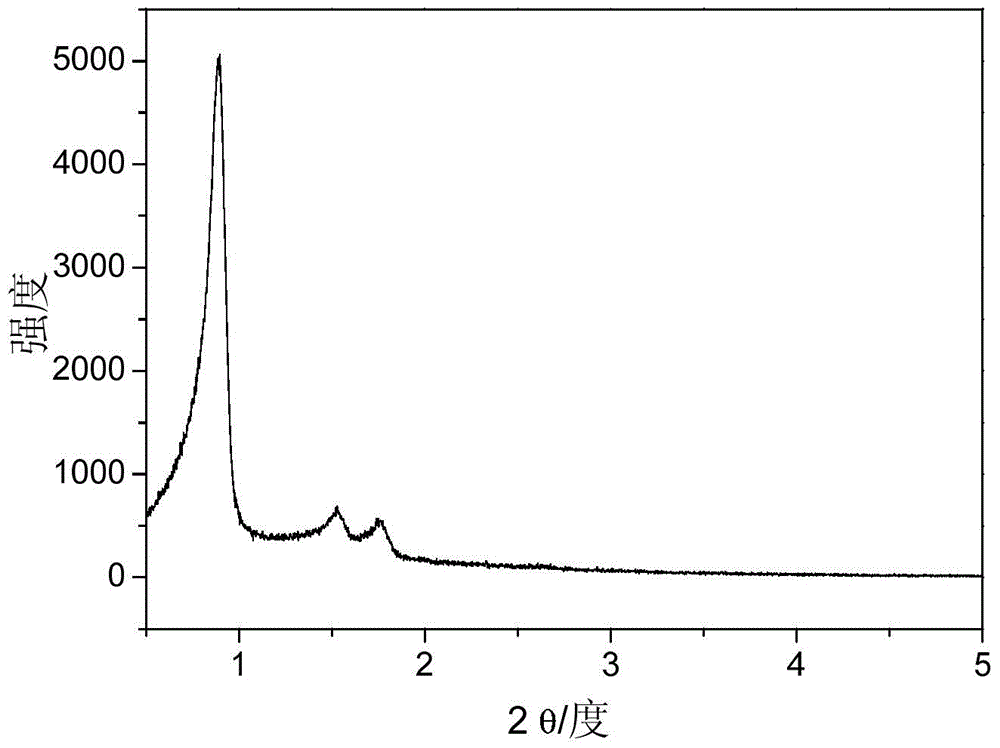

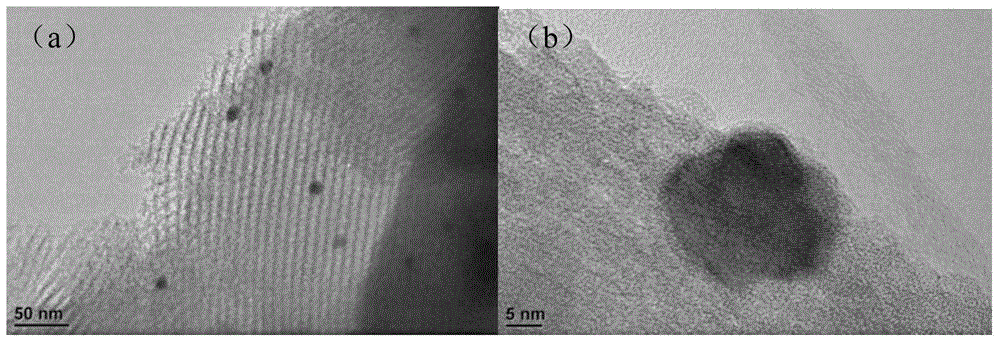

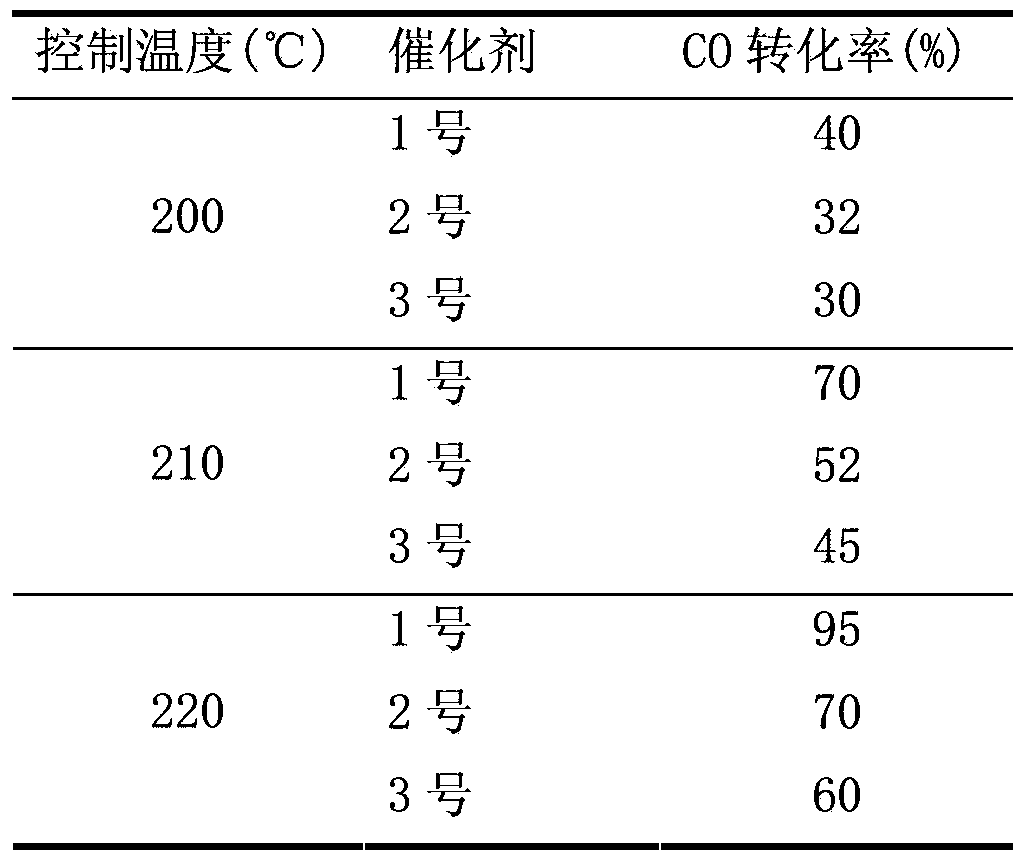

Fischer-Tropsch synthesis iron-based catalyst, preparation method and application thereof

InactiveCN104096564AHigh catalytic activityImprove stabilityHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionHigh selectivityHydrocarbon

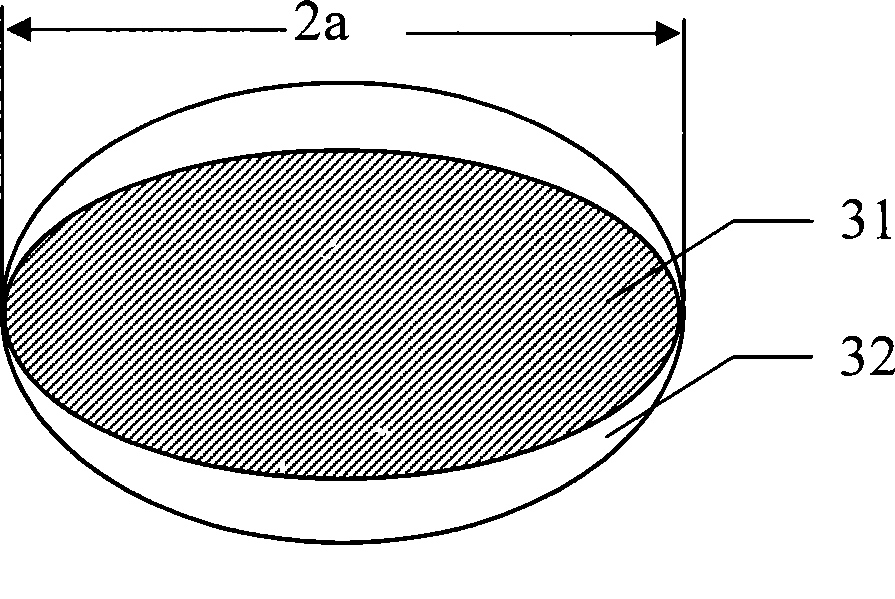

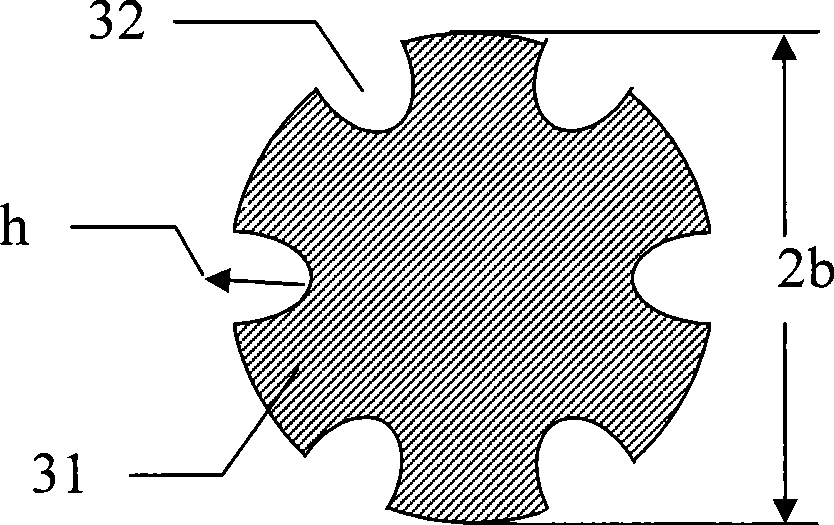

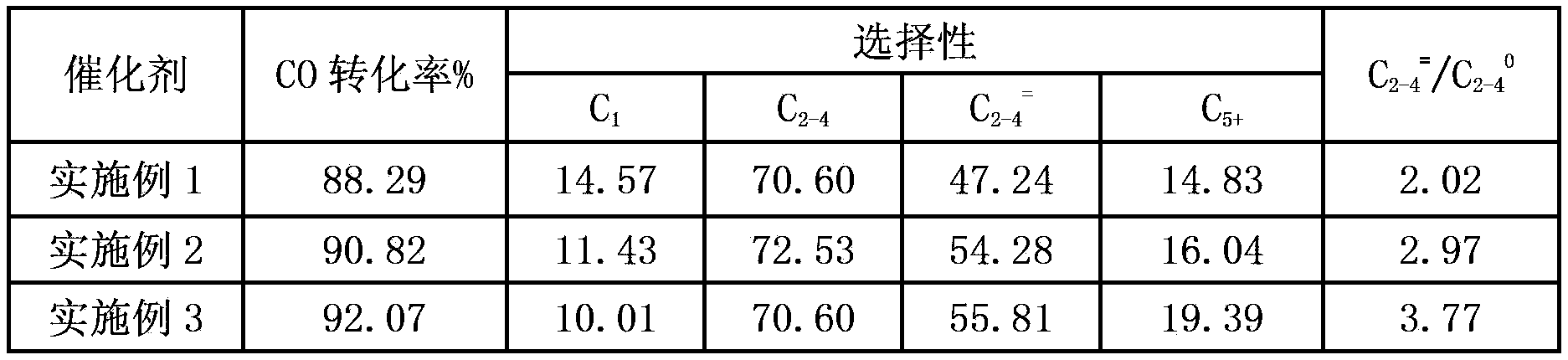

The invention discloses a Fischer-Tropsch synthesis iron-based catalyst, which includes Fe, a reduction assistant, an electronic assistant and a hydrogenation assistant. The reduction assistant is one or more of the following elements: Cu, Zn, Mn, Mg and Zr. The electronic assistant is one of the following elements: Na, K and Rb. The hydrogenation assistant is one of the following elements: Ru, Rh, Pd and Pt. All the components exist in the form of oxides. The Fe atom accounts for 10wt%-80wt% in the catalyst. The catalyst comprises Fe, Cu, Zn, Mn, Mg, Zr, the electronic assistant and the hydrogenation assistant in an atomic ratio of 200:0-50:0-200:0-200:0-200:0-200:0.5-30:0-10. The iron-based catalyst provided by the invention has high catalytic activity, good stability, low inactivation rate, high selectivity on low carbon olefin (C2-4=), C2-4 hydrocarbon selectivity over 70%, and olefin selectivity up to over 90%. The raw materials are cheap and easily available, and the preparation cost of the catalyst is reduced.

Owner:BEIJING UNIV OF CHEM TECH +1

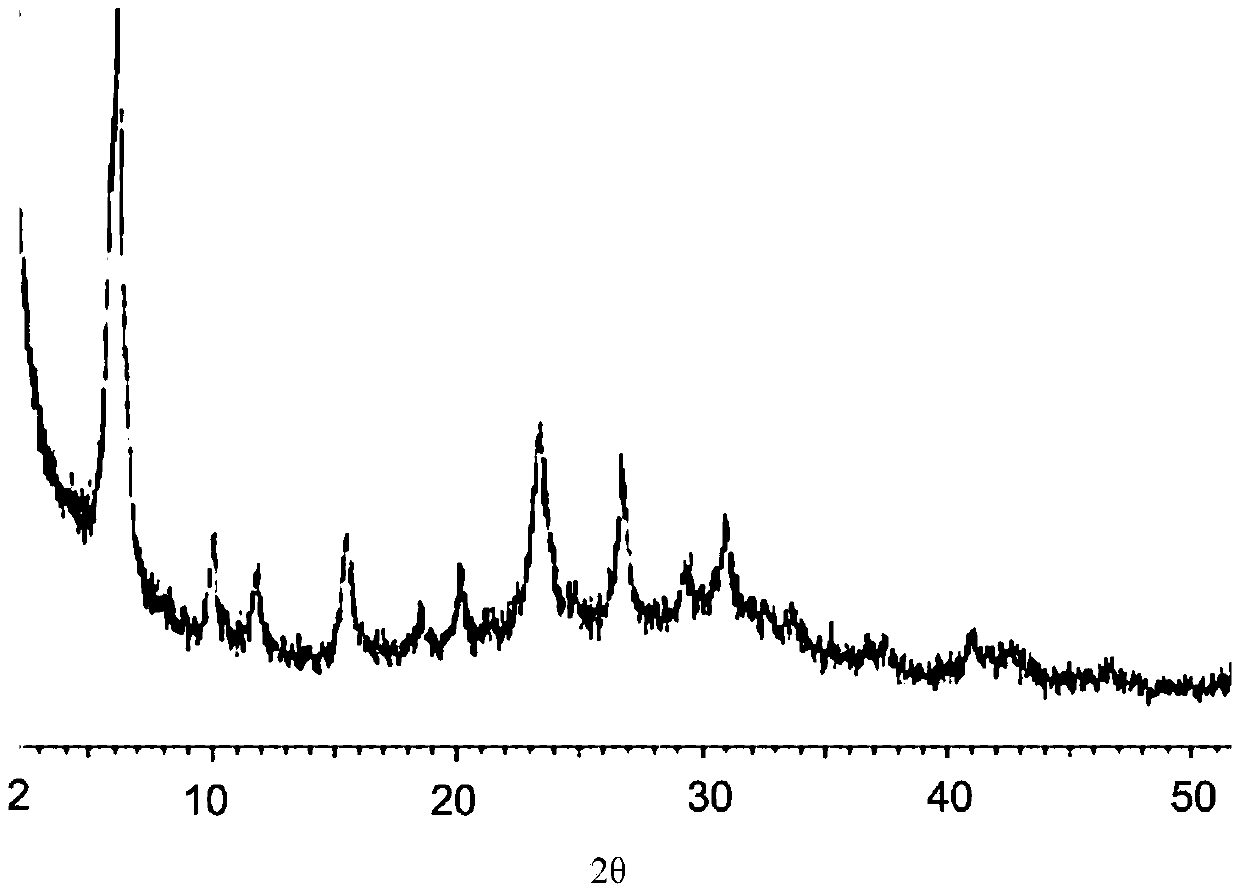

Co-Zr catalyst for Fischer-Tropsch synthesis and its prepn and application

InactiveCN1398669AImprove stabilityReduced inactivation rateCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMetalChemistry

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Dehydrogenation catalyzing material as well as preparation method and application thereof

ActiveCN103816933AImprove stabilitySuppressor enrichmentMolecular sieve catalystsHydrocarbonsPlatinumPtru catalyst

The invention provides a dehydrogenation catalyzing material as well as a preparation method and application thereof. The dehydrogenation catalyzing material comprises the following components by weight: 0.5-5% of platinum element, 1-10% of IVA metal, 0.1-1% of Al and the balance of mesoporous silicon material, wherein the mesoporous silicon material serves as a carrier, the platinum element serves as a catalyst, the IVA metal serves as a first auxiliary and the Al serves as a second auxiliary. Compared with a multiple dipping method, the preparation method has the advantages that the active components and auxiliary elements are dipped and carried on the mesoporous silicon carrier in one step, so that the preparation method is simple in operation and short in preparation cycle; molecules of the active components and auxiliaries of the catalytic material obtained through one-step dipping are in fuller contact, which is beneficial to inhibit the enrichment of carbon on the active components, so that the deactivation rate is reduced and the stability of the catalytic material is increased.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

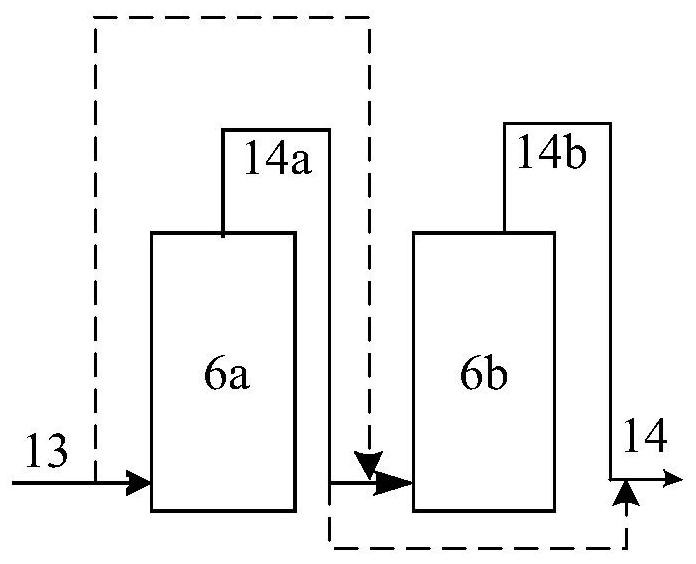

Method for direct methanation of recirculating fluidized bed synthesis gas

InactiveCN102180757AReduced inactivation rateNot easy to fall offHydrocarbon from carbon oxidesSyngasFluidized bed

The invention discloses a method for direct methanation of recirculating fluidized bed synthesis gas, belonging to the technical field of natural gas prepared from coals. The method comprises three main steps: absorbing and strengthening direct methanation of synthesis gas through a channel type reactor; separating a product from an absorbent; and roasting the absorbent. In the channel type reactor for absorbing and strengthening the direct methanation of the synthesis gas, a catalyst is coated on the wall surface of the inner channel in grille in the reactor in a form of coating, and the absorbent is carried by reaction gas so as to pass through the grille type channel in the reactor, thereby avoiding the separation step of the catalyst and absorbent, and solving the problem that the catalyst is repeatedly oxidized and reduced so as to cause the loss of materials and the loss of energy, and the generated heat is rapidly removed by utilizing the efficient heat-transfer capability of amulti-layer channel wall surface, thereby retarding the deactivation speed of the catalyst and ensuring the stable operation of equipment.

Owner:TSINGHUA UNIV

Molecular sieve catalyst for preparing propylene by propane dehydrogenation and preparation method of molecular sieve catalyst

InactiveCN109675548AHigh catalytic activityHigh selectivityMolecular sieve catalystsMolecular sieve catalystDispersityAlkane

The invention discloses a molecular sieve catalyst for preparing propylene by propane dehydrogenation and a preparation method of the molecular sieve catalyst, and belongs to the field of preparationof catalysts. The catalyst consists of a component A and a component B, wherein the component A is one of metal elements Sn, Ga, Fe, Co, Ni or Zn, the use amount of the component A is 1-9wt% of the total amount of the catalyst, the component B is a molecular sieve carrier, and the use amount of the component B is 90-99wt% of the total amount of the catalyst. The preparation method of the catalystcomprises a direct hydrothermal synthesis method and an impregnation method. The high-performance alkane dehydrogenation catalyst is prepared by controlling the use amounts, the structures and the dispersity of active components, has the characteristics of simple preparation process, low price and no toxicity, and has the characteristics of good activity, high selectivity, high stability and the like when applied to preparation of propylene through propane dehydrogenation; and a new technical scheme is provided for development and preparation of a new-generation alkane dehydrogenation catalyst.

Owner:FUZHOU UNIV

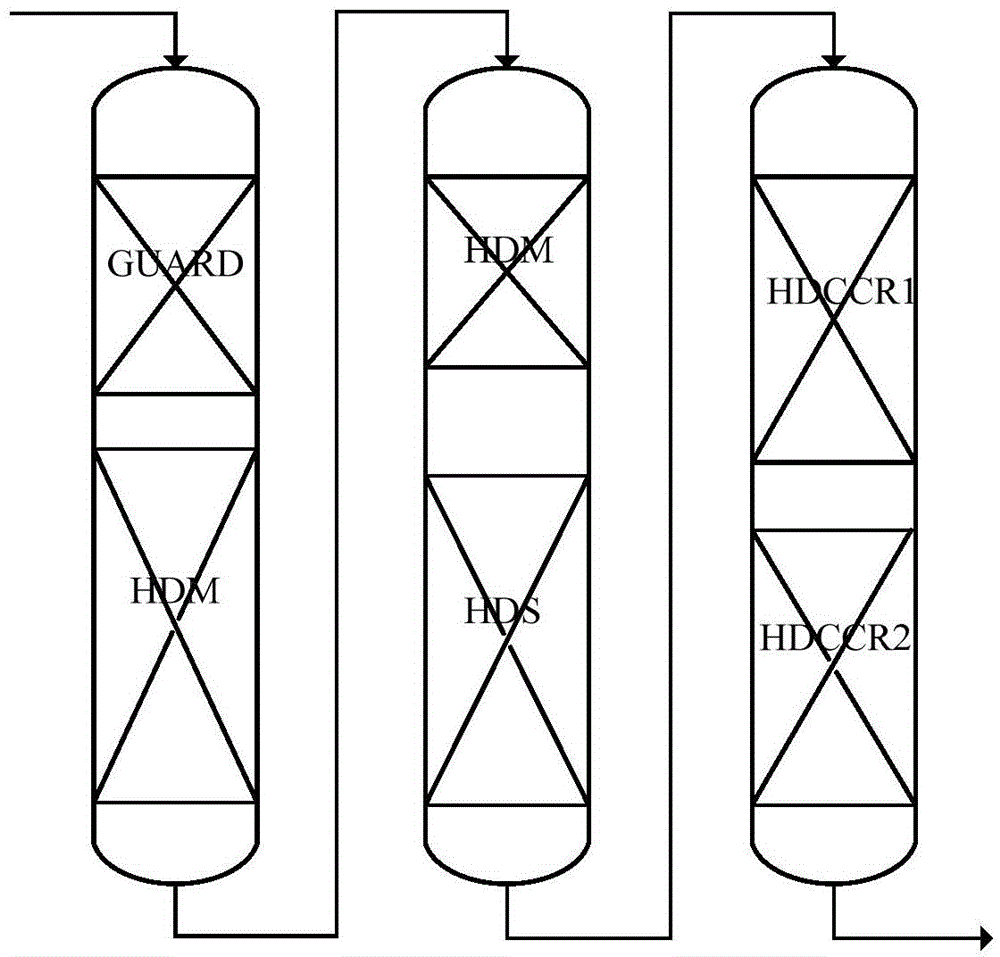

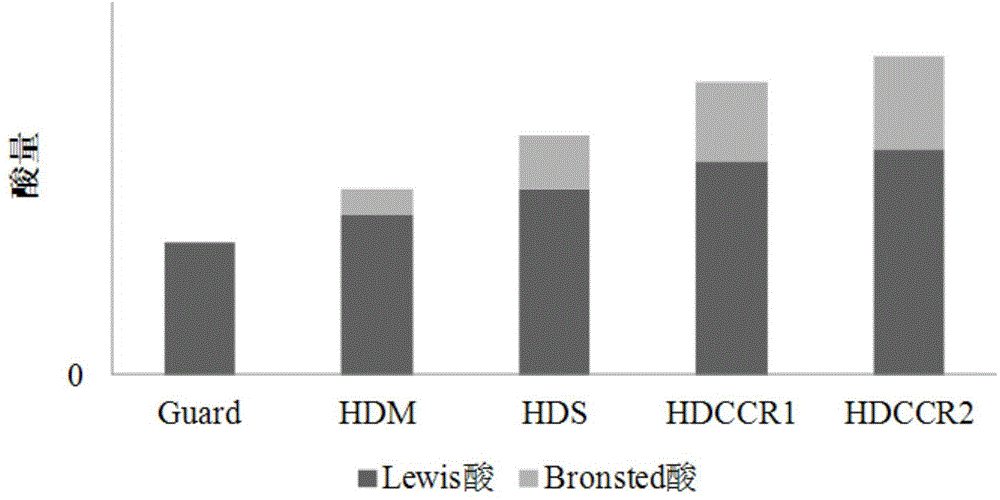

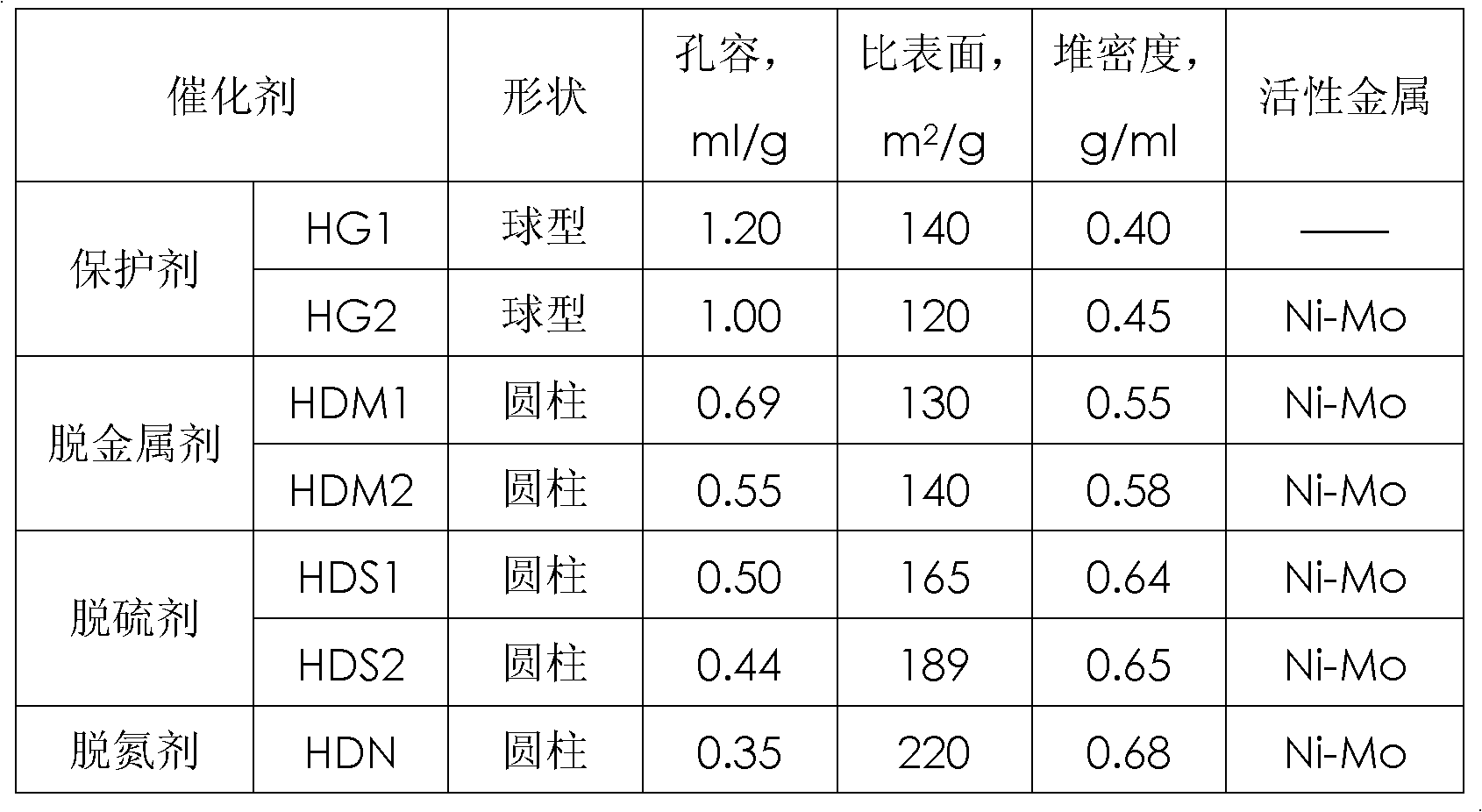

Residue oil hydrotreatment catalyst grading method and residue oil hydrotreatment method

ActiveCN105567311AReduce the risk of problemsWeak cracking functionTreatment with hydrotreatment processesHydrodesulfurizationResidual carbon

The invention relates to a residue oil hydrotreatment catalyst grading method and a residue oil hydrotreatment method. The residue oil hydrotreatment catalyst grading method includes filling a residue oil hydrotreatment device with a hydrogenation protection catalyst, a hydrodemetallization catalyst, a hydrodesulfurization catalyst and a catalyst for residual carbon removal by hydrogenation in order along a material flow direction. Specifically, the total acid amount of each catalyst along the material flow direction increases gradually, the proportion of Lewis acid in total acid decreases gradually, and the proportion of Bronsted acid in the total acid increases gradually. The residue oil hydrotreatment method comprises injecting residual oil into the residue oil hydrotreatment device to perform hydrotreatment, wherein the residue oil hydrotreatment device is filled with the catalyst according to the grading method. In a residue oil hydrotreatment process, the residue oil hydrotreatment catalyst grading method provided by the invention can significantly improve the residual carbon removal rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

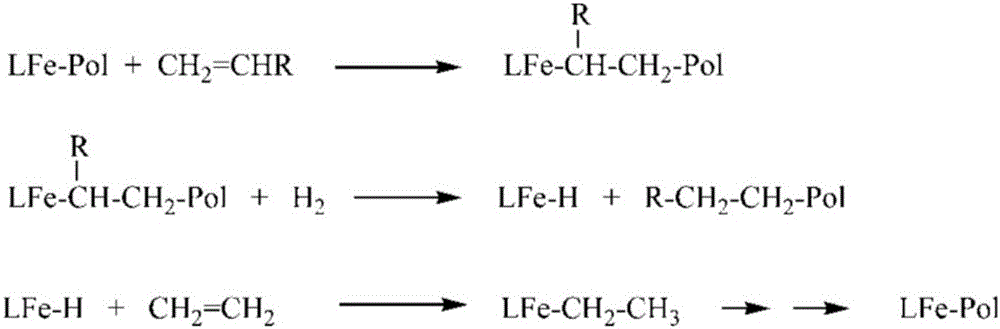

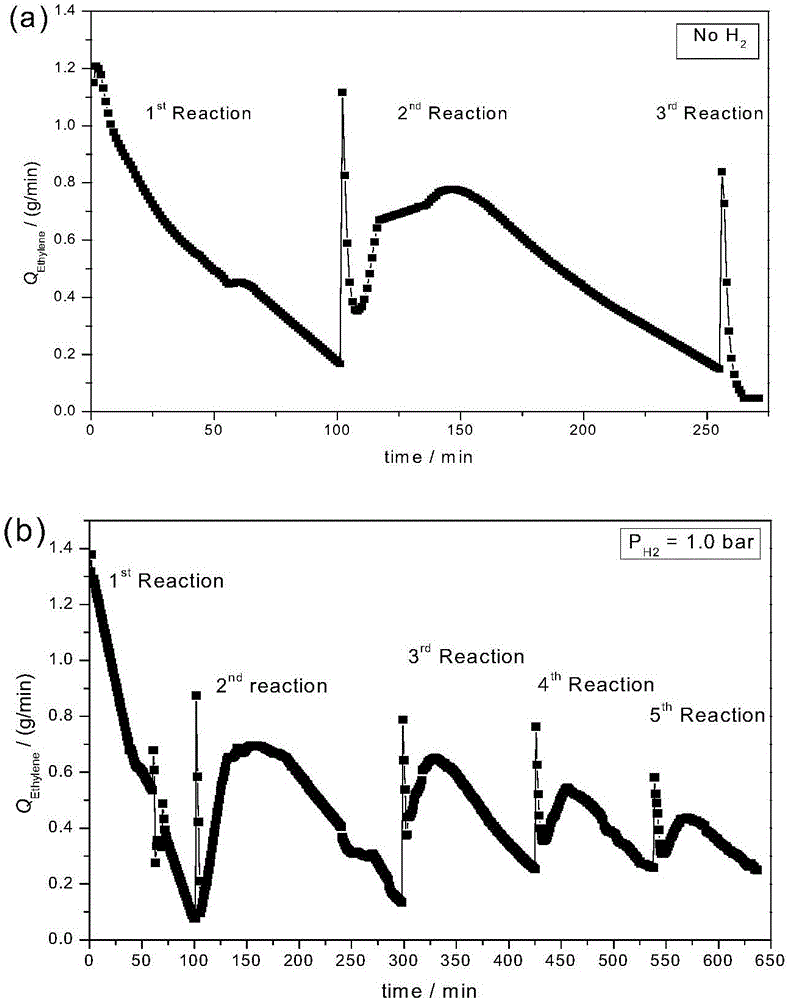

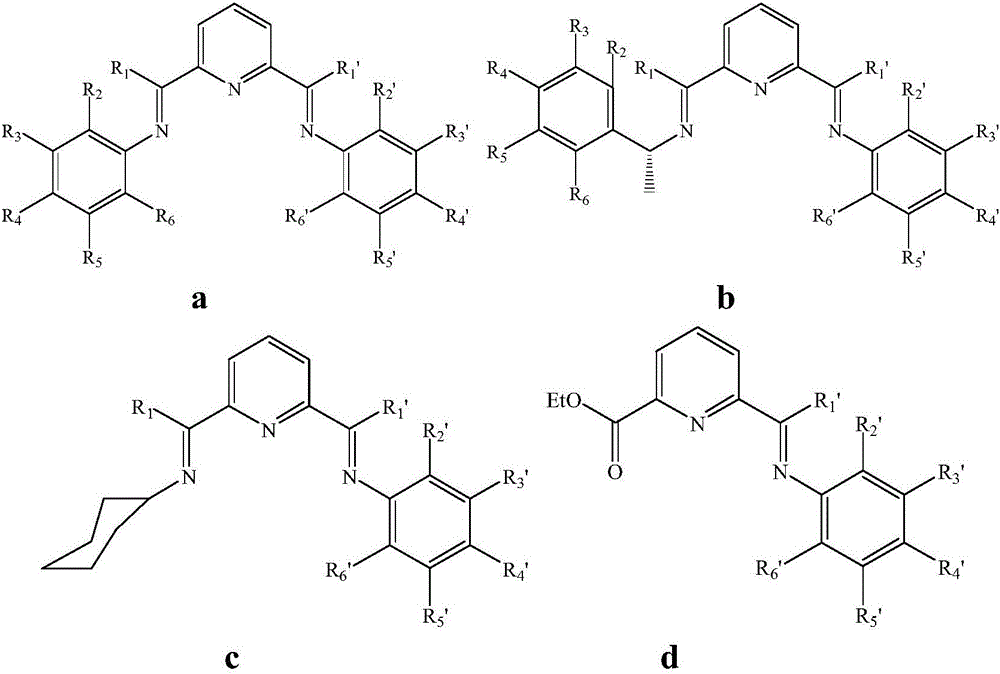

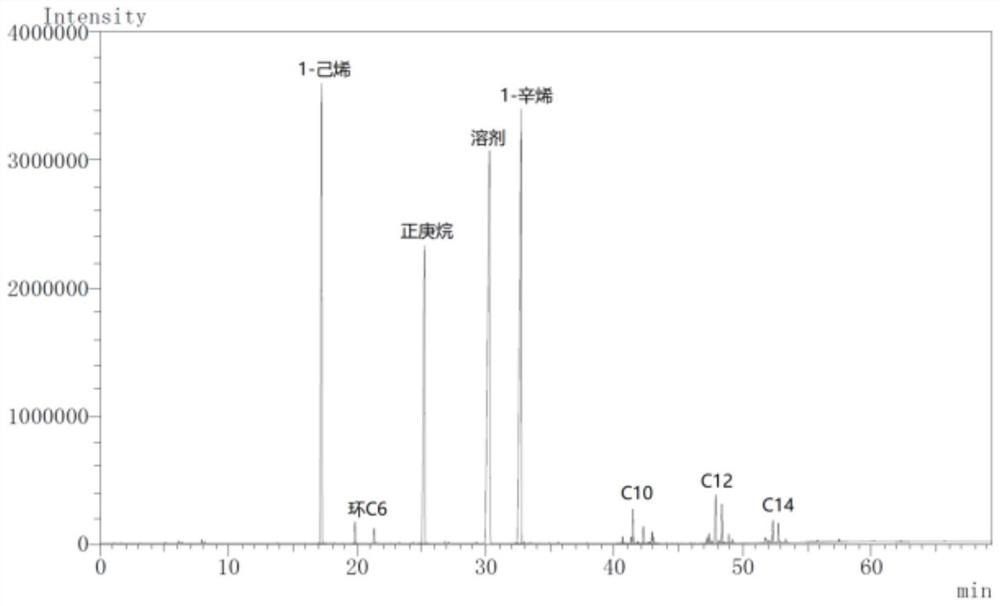

Method for enhancing yield of linear alpha-olefins

InactiveCN105884565AReduced inactivation rateHigh reactivityOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsOrganic solventHydrogen

The invention discloses a method for enhancing yield of linear alpha-olefins. The method comprises the following steps: introducing hydrogen into a catalytic-reaction-medium-containing oligomerization reactor as an activator, controlling at appropriate reaction temperature, introducing a vinyl monomer, keeping the reaction pressure, and carrying out oligomerization to prepare the high-grade linear alpha-olefins. The oligomerization reactor is selected from one or more of stirred tank reactors or tubular reactors, and can adopt series or parallel operation of single or multiple reactors. The hydrogen is added one or more of one-step addition, batch addition or sectionalized addition mode. The catalytic reaction medium is composed of a main catalyst, a cocatalyst and an organic solvent, wherein the main catalyst is selected from late-transition iron catalysts. The method is simple and feasible, is easy to implement, and can obviously enhance the yield of linear alpha-olefins, thereby greatly lowering the cocatalyst consumption of the unit product, and being beneficial to lowering the production cost and enhancing the economic benefits.

Owner:ZHEJIANG UNIV

Heterogenous catalysis solid alkali catalyst, and its preparing method and use

InactiveCN101003018AImprove stabilityReduced inactivation rateOrganic compound preparationChemical industryMulti phaseZirconium oxide

A solid alkali catalyst with high stability and activity for the multi-phase catalytic synthesis of dimethyl carbonate is composed of calcium oxide (10-30 mass %) and zirconium oxide (70-90). Its preparing process is also disclosed, which features that the CaCl2 or Ca (NO3)2 and ZrOCl2 or ZrO (NO3)2 are used as its Ca source and Zr source.

Owner:PETROCHINA CO LTD

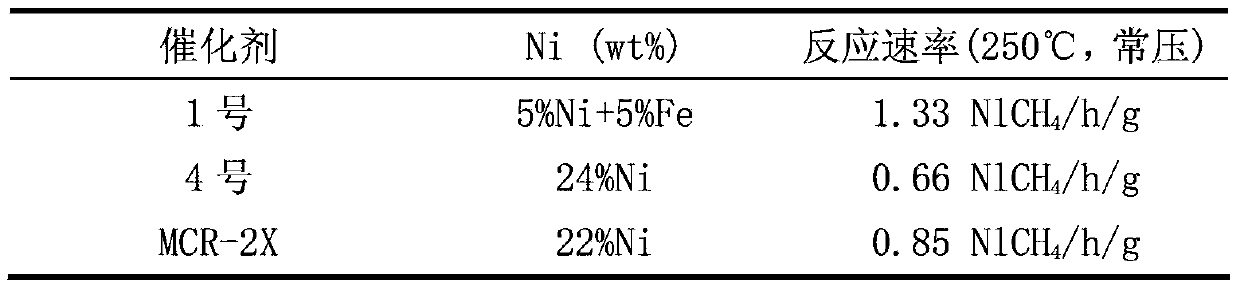

Nickel iron bimetallic methanation catalyst and preparation and application thereof

ActiveCN104209127AExcellent activityExcellent stabilityHydrocarbon from carbon oxidesCatalyst activation/preparationNickel saltMethanation

The invention relates to a nickel iron bimetallic methanation catalyst and preparation and application thereof; according to the ratio of 0.7-1ml of a soluble salt solution to 1g of an alumina carrier, the prepared soluble salt solution is immersed on the carrier; according to the ratio of 0.7-1ml of a soluble nickel salt solution to 1g of an additive-containing carrier, the soluble nickel salt solution is immersed on the carrier to obtain a nickel containing carrier; according to the ratio of 0.7-1ml of a soluble iron salt solution to 1g of the nickel containing carrier, the soluble iron salt solution is immersed on the nickel containing carrier for drying and roasting to obtain the catalyst; nickel oxide is 2.5-10wt%; iron oxide is 2.5-10wt%; an additive is 0.01-5wt%; the additive is at least one substance from lanthanum, cerium, barium and magnesium; the catalyst greatly improves low temperature methanation activity of the catalyst, decreases the cost of the catalyst, improves methane selectivity of the catalyst, and increases the stability of the catalyst.

Owner:PETROCHINA CO LTD +1

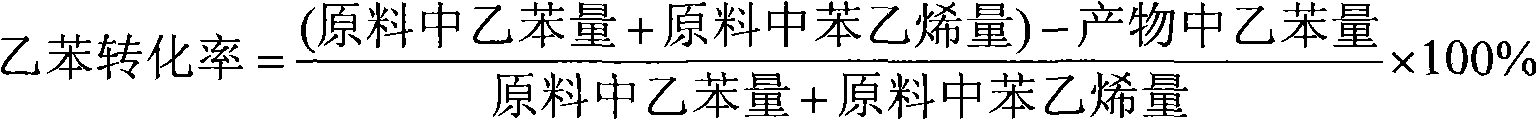

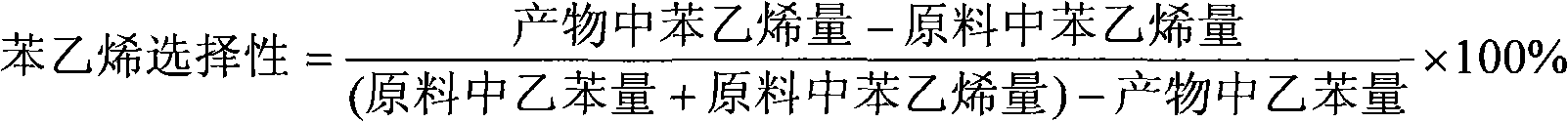

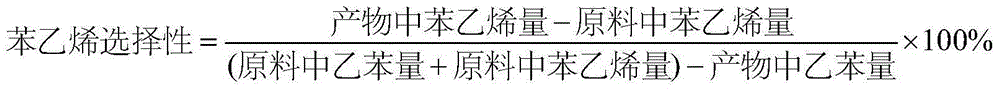

Ethylbenzene dehydrogenating catalyst and preparation method thereof

ActiveCN101829576AHigh selectivityHigh activityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsPolymer science4-isopropenyltoluene

The invention relates to an ethylbenzene dehydrogenating catalyst and a preparation method thereof. A plurality of metallic oxide stabilizing additives of WO3 and / or MoO3, CaO, BaO, CuO, ZnO2, Co2O3 and La2O3 are added into a catalyst which uses Fe-K-Ce-Mo (or W or Mo-W) as the main system. The catalyst has higher activity and selectivity, low inactivation speed and high stability, is suitable for preparing stryrene by dehydrogenating ethylbenzene, and is also suitable for preparing isopropenylbenzene by dehydrogenating isopropyl benzene, and preparing 4-isopropenyltoluene by dehydrogenating p-cymene. The catalyst is prepared by adopting a kneading method.

Owner:PETROCHINA CO LTD

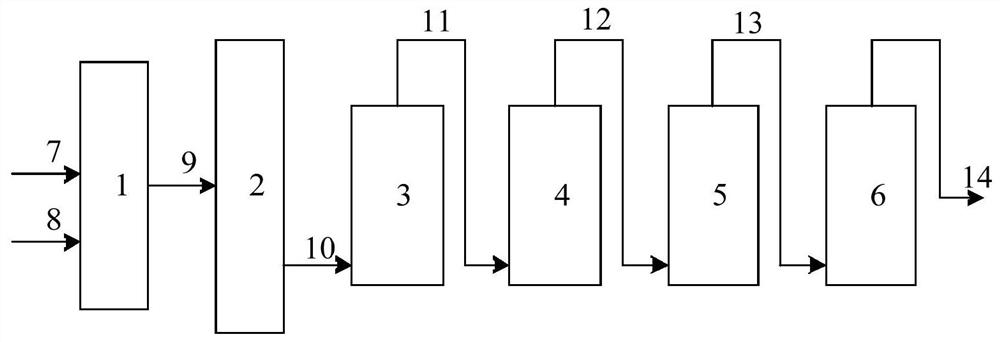

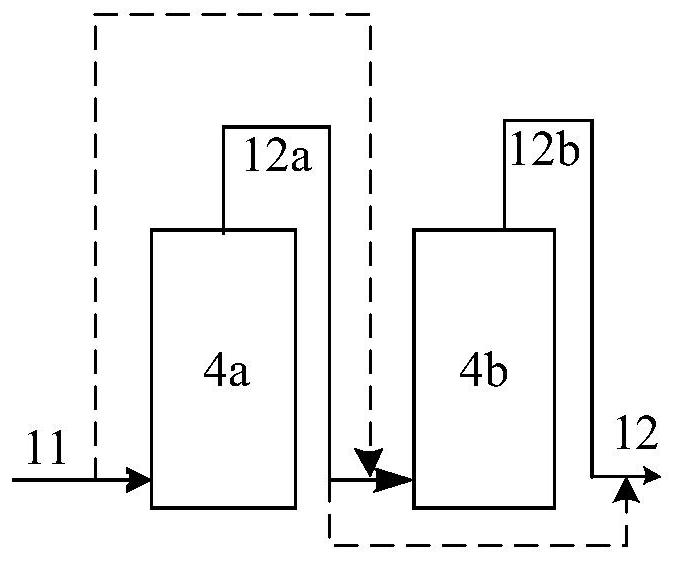

Processing method of inferior residuum

ActiveCN102465034AHigh porosityReduced inactivation rateTreatment with hydrotreatment processesCycle oilChemistry

The invention discloses a processing method of an inferior residuum. The method comprises steps that: residuum and any heavy distillate oil are subject to an up-flow hydrogenation reaction; a reaction effluent is mixed with catalytic cracking cycle oil, and the mixture is subject to a trickle bed hydrogenation reaction; a reaction product is separated, such that gas, hydrogenated naphtha, hydrogenated diesel oil and hydrogenated residuum are obtained; the hydrogenated residuum is subject to a catalytic cracking reaction with any vacuum gas oil; a catalytic cracking reaction product is separated, such that gasoline, diesel oil, catalytic cracking cycle oil and catalytic cracking oil slurry are obtained; the catalytic cracking cycle oil is recycled and delivered to the inlet of a trickle bed reactor. Compared to prior art, with the method provided by the invention, residuum hydrogenation treatment and catalytic cracking can be more effectively combined, and an implementation effect is better. Also, the operation period of the reaction apparatus can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

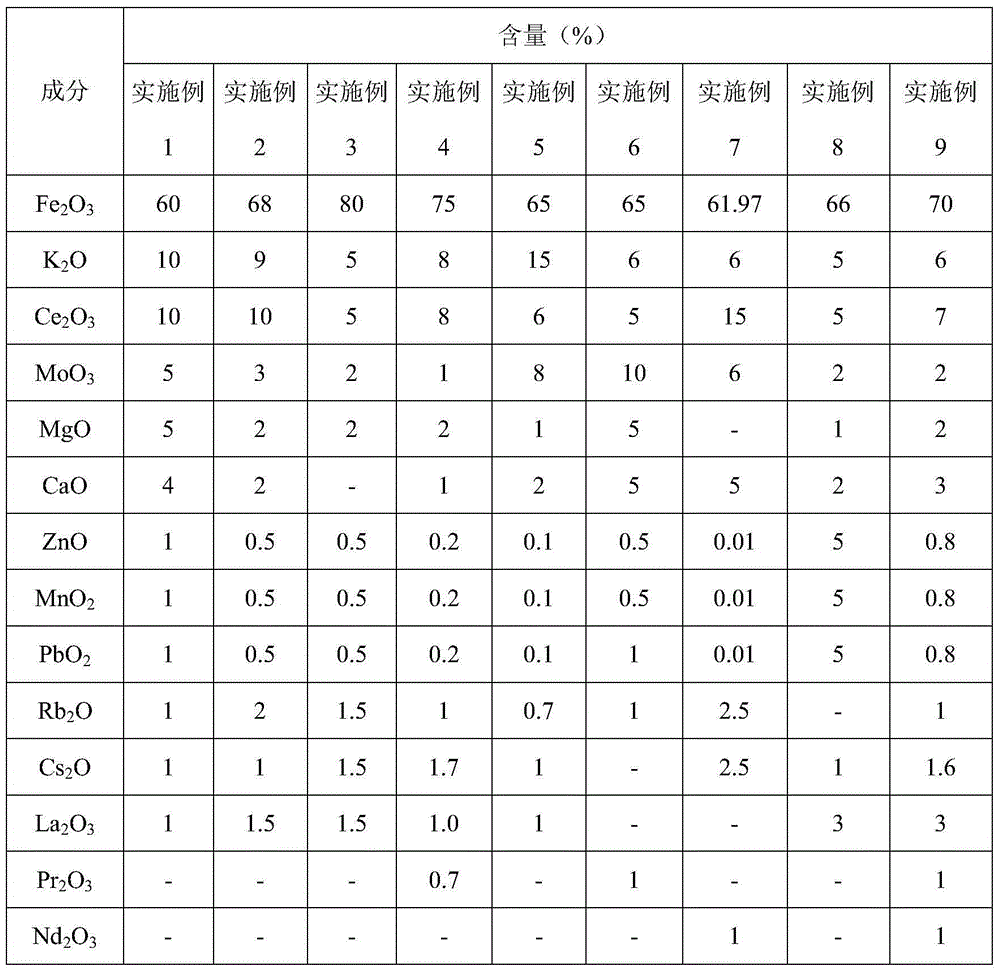

Catalyst used for low steam-to-oil ratio ethylbenzene dehydrogenation to prepare styrene, and preparation method thereof

ActiveCN105749934AHigh activityImprove resistance to reductionHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkali metal oxideDehydrogenation

The invention relates to a catalyst used for low steam-to-oil ratio ethylbenzene dehydrogenation to prepare styrene. The catalyst comprises, by mass, 60-80 parts of iron oxide by Fe2O3, 5-15 parts of potassium oxide by K2O, 5-15 parts of cerium oxide by Ce2O3, 1-10 parts of molybdenum oxide by MoO3, 1-10 parts of magnesium or / and calcium oxide by MgO or / and CaO respectively, 1-5 parts of at least one of alkali metal oxides of Rb and Cs, respectively by Rb2O and Cs2O, wherein the alkali metal oxides are modified on the surface of the catalyst in a salt solution form; and light rare earth metal oxides of La, Pr and Nd without Ce, and oxides of Mn, Zn and Pb. The catalyst has a high activity and a good stability under a low steam-to-oil ratio.

Owner:PETROCHINA CO LTD

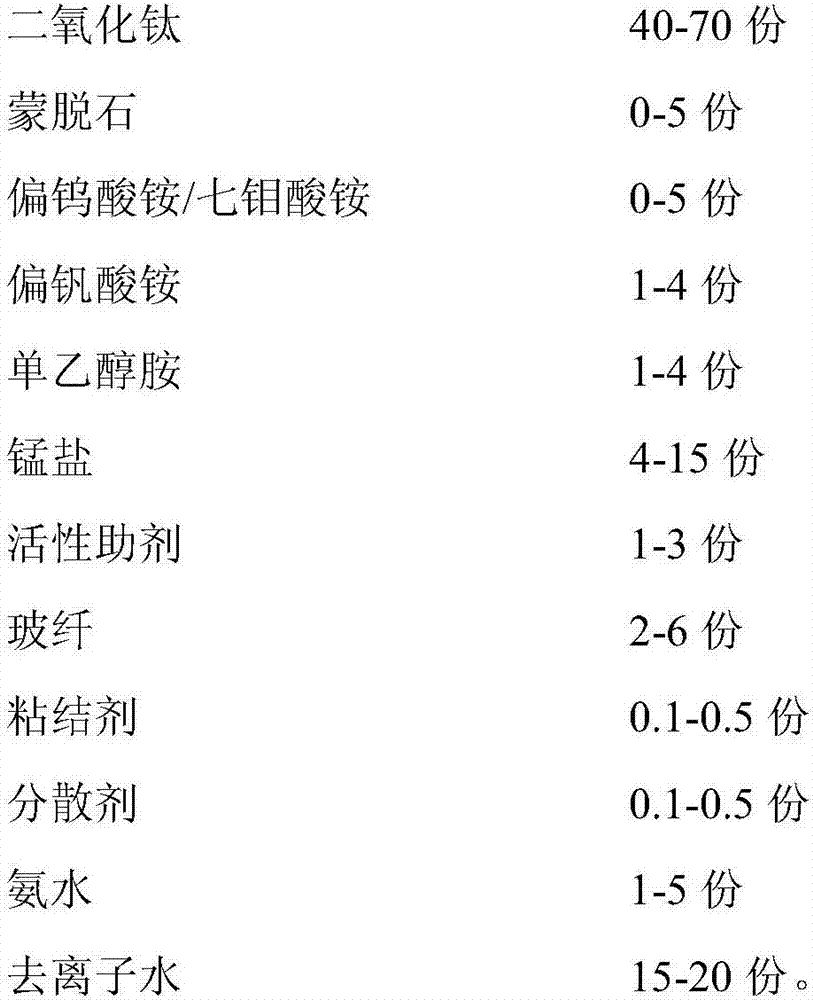

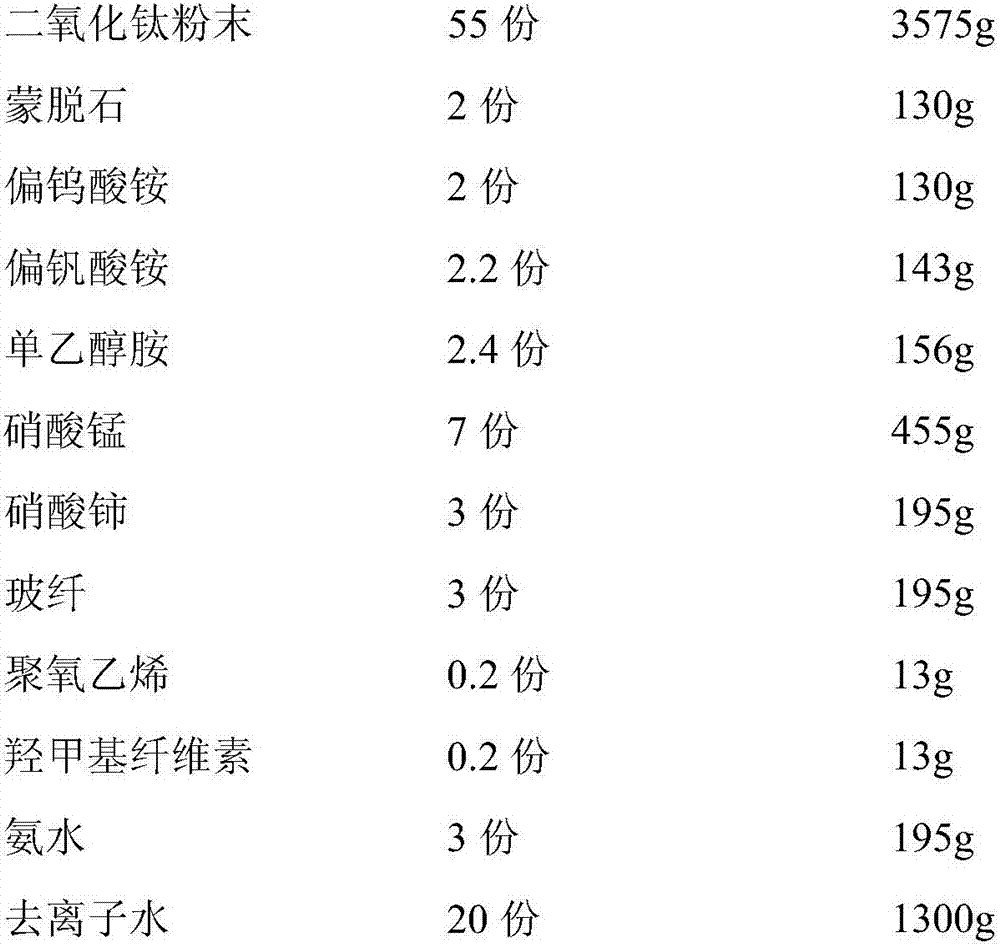

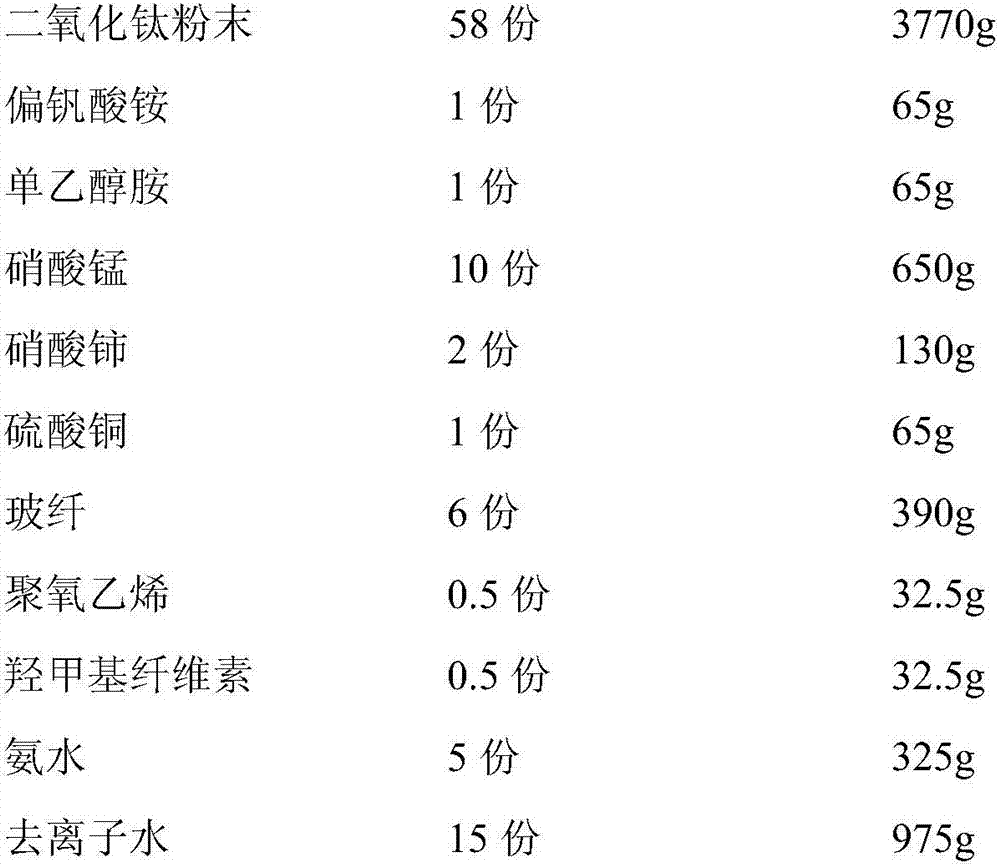

Vanadium-manganese-titanium system low-temperature plate catalyst and preparation method thereof

InactiveCN106861679AImprove denitrification efficiencyReduced inactivation rateGas treatmentHeterogenous catalyst chemical elementsExhaust gasChemistry

The invention discloses a vanadium-manganese-titanium system low-temperature plate catalyst and a preparation method thereof. The catalyst is beneficial to reducing the effective temperature of the catalyst, maintains high denitration efficiency within the range of 160 to 240 DEG C, is applicable to a low-sulfur exhaust gas environment, not only can enable a denitration method to be arranged after dedusting and desulfurizing so as to reduce the deactivation rate of the denitration catalyst, but also can remove nitric oxide in the low-sulfur exhaust gas, and brings great economic benefit and environment benefit for national sustainable development.

Owner:TIANHE BAODING ENVIRONMENTAL ENG

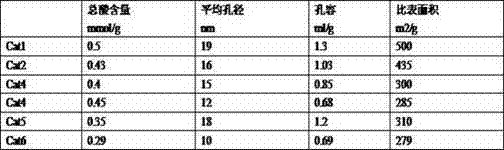

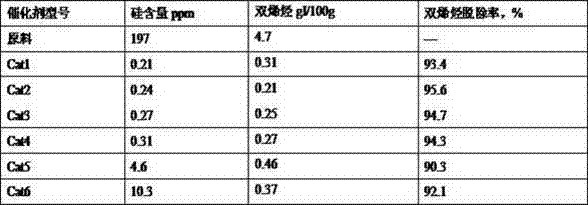

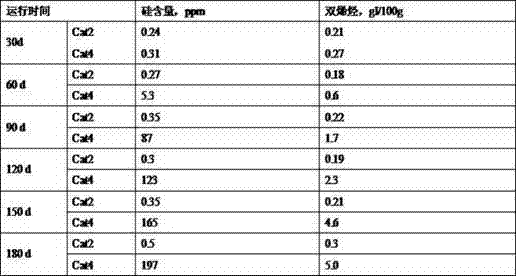

Coked gasoline desilication catalyst and preparation method thereof

ActiveCN104492450AEfficient removalLarge hole volumeOther chemical processesMetal/metal-oxides/metal-hydroxide catalystsHydrogenActive component

The invention discloses a coked gasoline desilication catalyst and a preparation method thereof. The coked gasoline desilication catalyst disclosed by the invention contains an Al2O3-TiO2-B2O3 composite oxide as a carrier and Ni-Mo-W-Ce as an active component; the used Al2O3-TiO2-B2O3 carrier comprises the following components in percentage by weight: 10-20% of TiO2, 3-10% of B2O3, and the balance of Al2O3; and, in terms of the weight percentage of the catalyst, the active component comprises the following components in percentage by weight: 1.2-3.9% of NiO, 4.2-9.5% of MoO3, 5-15% of WO3, 1.5-2.5% of CeO2, and the balance of the carrier. The coked gasoline desilication catalyst disclosed by the invention is roasted in the atmosphere of water vapor, has a special pore diameter and higher pore volume, and is capable of effectively adsorbing and desorbing silicon impurities and protecting subsequent purification of the catalyst by mainly adding hydrogen into coked gasoline.

Owner:WUHAN KELIN FINE CHEM

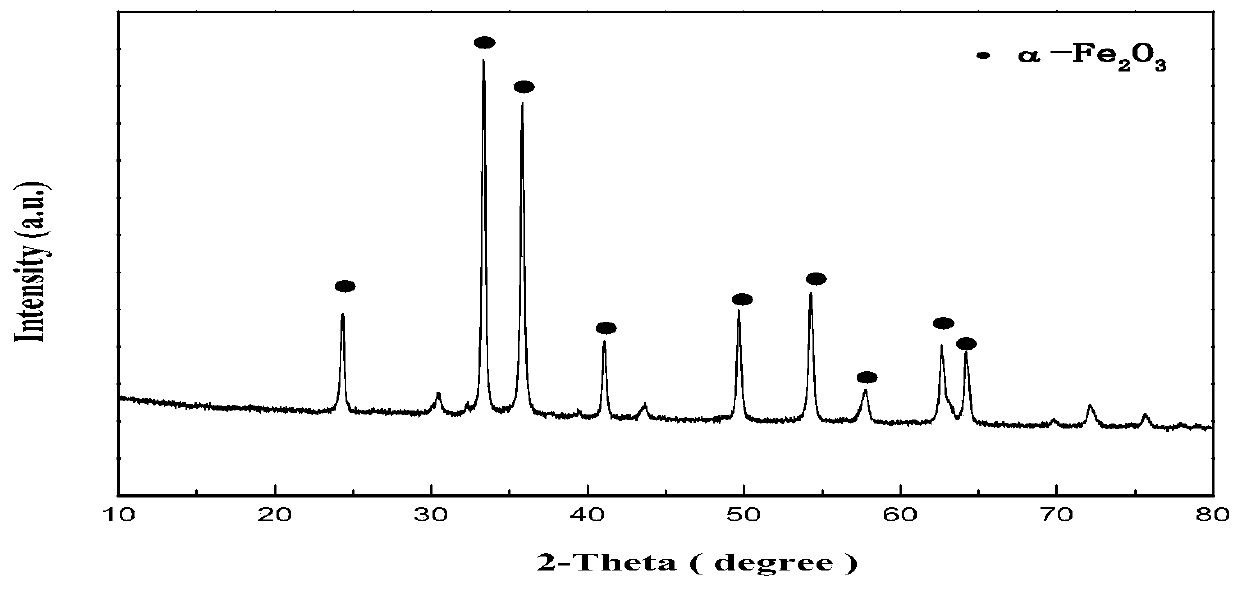

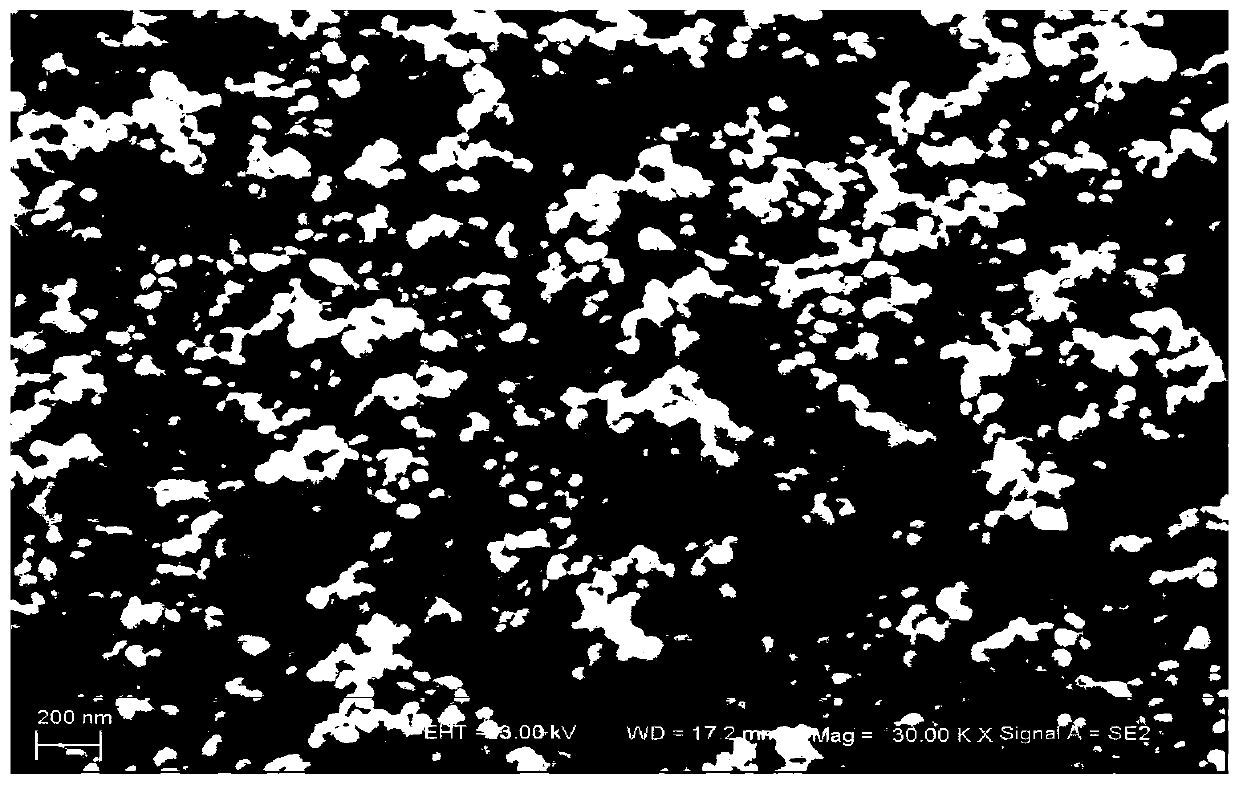

Method for preparing ethylbenzene dehydrogenation catalyst by utilizing spherical nanometer alpha-ferric oxide as iron source

ActiveCN109999810AGood dispersionImprove stabilityHeterogenous catalyst chemical elementsCatalystsRare earthDehydrogenation

The invention relates to a method for preparing an ethylbenzene dehydrogenation catalyst by utilizing spherical nanometer alpha-ferric oxide as an iron source. The method comprises the following steps: mixing 50-75nm spherical alpha-ferric oxide and cerium oxide to obtain metastable suspension; slowly pouring a certain number of erbium nitrate, potassium carbonate and a mixed solution of one or two rare earth metallic oxide into the suspension; regulating the pH to be 9-12 through ammonium hydroxide to obtain heavy sizing; drying for 1-2h under the temperature of 80-120 DEG C; roasting the obtained product for 2-3h under the temperature of 300-500 DEG C to obtain a catalyst precursor; mixing the catalyst precursor and additives through proper amount of deionized water to obtain sizing; extruding the sizing into strips; drying for 3-4h under the temperature of 80-120 DEG C; and roasting for 2-3h under the temperature of 600-900 DEG C to obtain the finished product of catalyst. Accordingto the method, the preparation method of ferric oxide is improved; the spherical nanometer alpha-ferric oxide being 50-75nm in size is obtained; and meanwhile, the preparation technology of a ceriumsource is improved; the coprecipitation method is carried out to prepare Fe-K-Ce series ethylbenzene dehydrogenation catalyst, so that the catalyst is high in activity and stability.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY +1

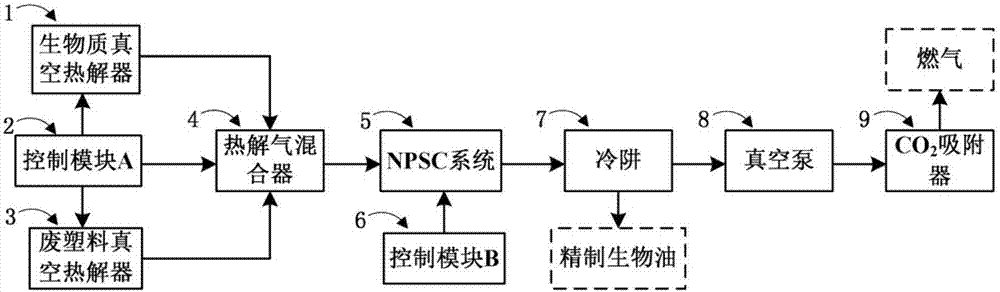

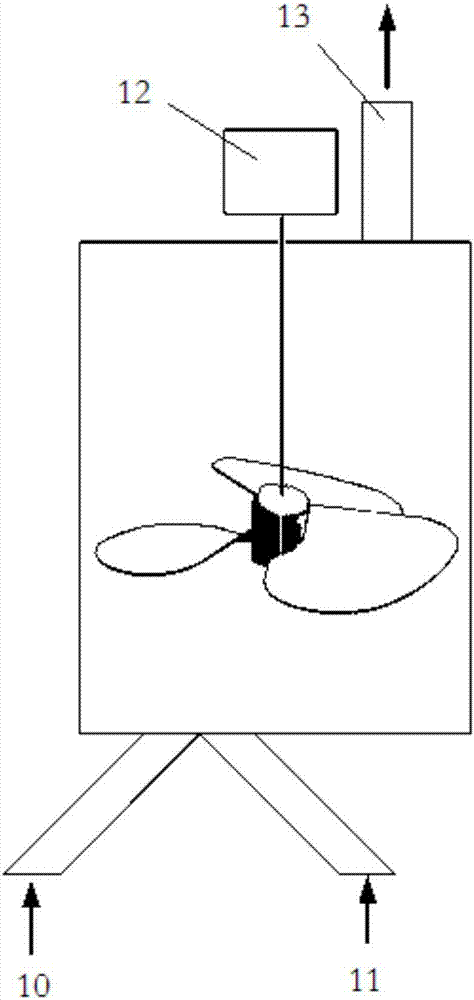

Device for preparing bio-oil and fuel by using biomass and waste plastic and use method

PendingCN107987864AImprove conversion efficiencyImprove qualityProductsReagentsNew energyProduct gas

The invention belongs to the field of development, utilization and study of new energy sources, and relates to a device for preparing bio-oil and fuel by using biomass and waste plastic and a use method. The device comprises a biomass vacuum pyrolyzer, a waste plastic vacuum pyrolyzer, a pyrolysis gas mixer, a control module A, a plasma synergistic catalyzing system, a control module B, a cold trap, a vacuum pump and a CO2 (carbon dioxide) adsorber, wherein the biomass vacuum pyrolyzer is used for decomposing biomass; the waste plastic vacuum pyrolyzer is used for decomposing waste plastic; the pyrolysis gas mixer is used for receiving the gas produced by the biomass vacuum pyrolyzer and the waste plastic vacuum pyrolyzer; the control module A is used for respectively adjusting the temperatures and heating rates of the biomass vacuum pyrolyzer, the waste plastic vacuum pyrolyzer and the pyrolysis gas mixer; the plasma synergistic catalyzing system is used for catalyzing the gas produced by the pyrolysis gas mixer. The device has the advantage that the defects in the existing method for preparing the bio-oil or fuel by using the co-pyrolysis of the biomass and the waste plastic canbe effectively overcome.

Owner:YANCHENG INST OF TECH

Catalytic reforming catalyst for catalytic pyrolysis of waste plastic for preparing fuel oil and preparation method thereof

InactiveCN101954292AGood technical effectVersatilityMolecular sieve catalystsLiquid hydrocarbon mixture productionCatalytic reformingCatalytic pyrolysis

The invention relates to a catalytic reforming catalyst for catalytic pyrolysis of waste plastic for preparing fuel oil and a preparation method thereof. The catalyst consists of oxides and an MCM-22, ZSM-35, Beta or MOR molecular sieve, wherein the oxides are any two of molybdenum oxide, cerium oxide, bismuth oxide, zirconium oxide, tin oxide or lead oxide in a weight ratio of 1 / 10 to 10 / 1; and secondary catalytic pyrolysis, isomerization and an aromatized reforming reaction are performed on crude oil formed by cracking the waste plastic, so that the ratio of cracked gasoline fractions to cracked diesel fractions is increased. The catalyst of the invention has the advantages of high activity, high selectivity and particular suitability for pyrolysis of mixed waste plastic in urban and rural household garbage with complex components for preparing oil, wherein the yield of the qualified fuel oil is over 70 percent based on the weight of the waste plastic.

Owner:TONGJI UNIV

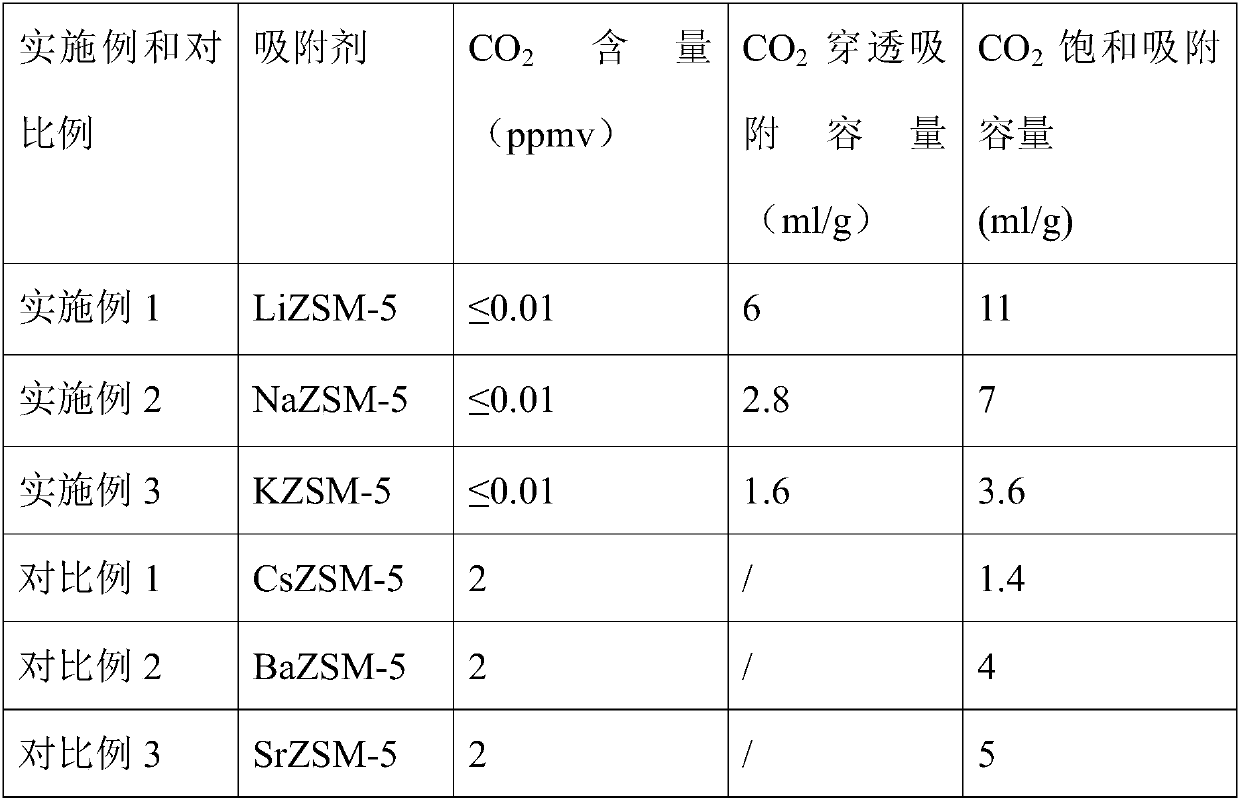

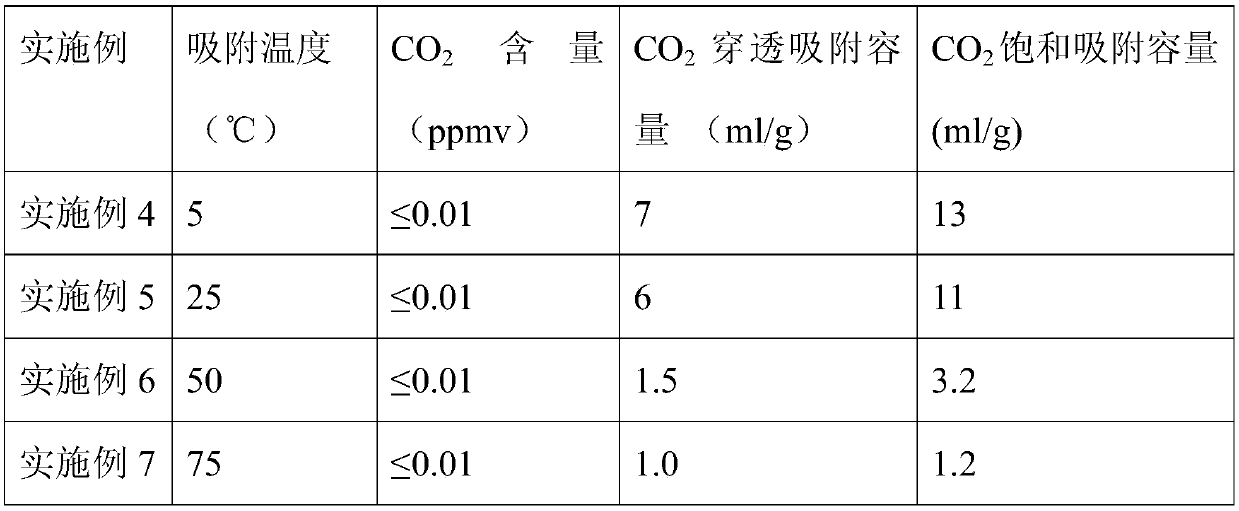

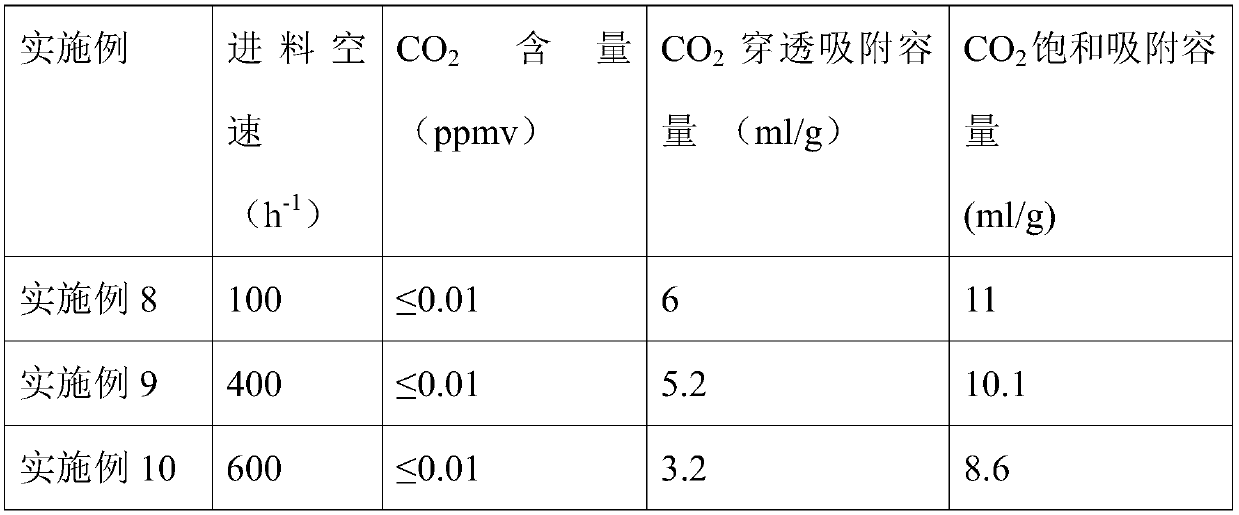

Method for adsorbing CO2 in gases

ActiveCN109513421AReduced Diffusion ResistanceEnhanced gas diffusionNitrous oxide captureGas treatmentIonProduct gas

The invention provides a method for adsorbing CO2 in gases. The adsorbing method comprises the following steps: taking an alkali metal ion modified ZSM-5 molecular sieve as an adsorbent, and adsorbingelectronic gases of low-concentration CO2 gases, wherein the concentration of CO2 in the electronic gases is 100-1000ppmv. According to the alkali metal ion modification, base sites can be included in the ZSM-5 molecular sieve, and due to acid-base interactions, the low-concentration CO2 in the high-purity gas is efficiently adsorbed, and the CO2 impurity concentration in the high-purity gas is lower than 0.01ppmv; and meanwhile, the adsorption method disclosed by the invention is environmental-friendly, low in operating cost, high in heat stability of the adsorbent and high in hydrophobic property, namely excellent water resistance.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +2

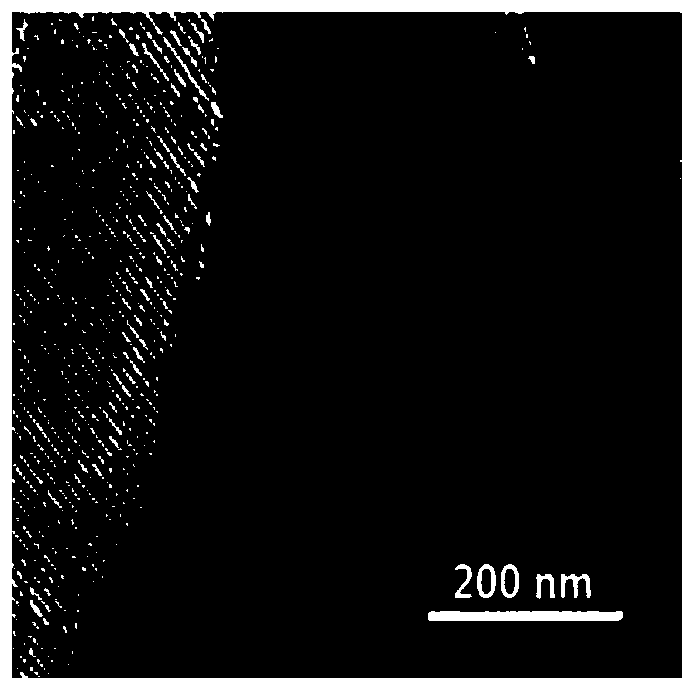

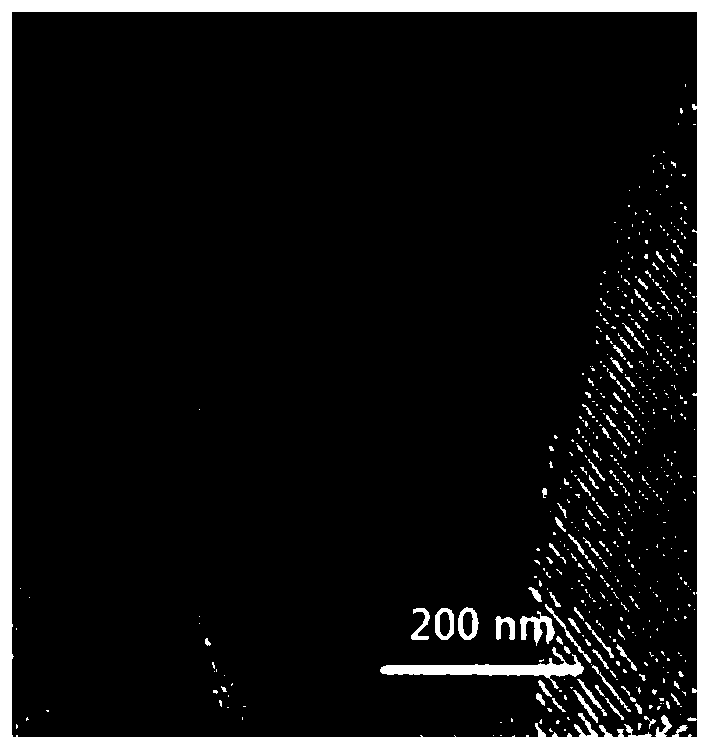

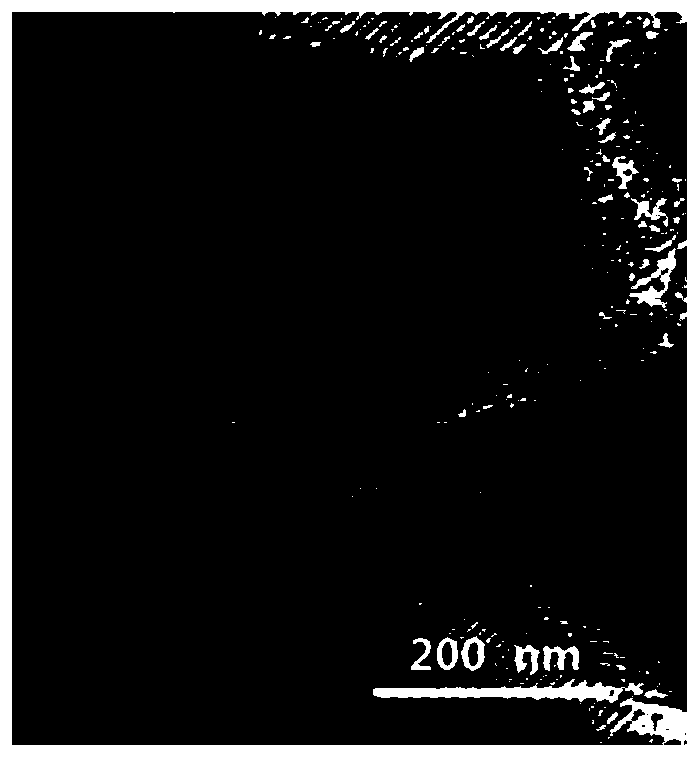

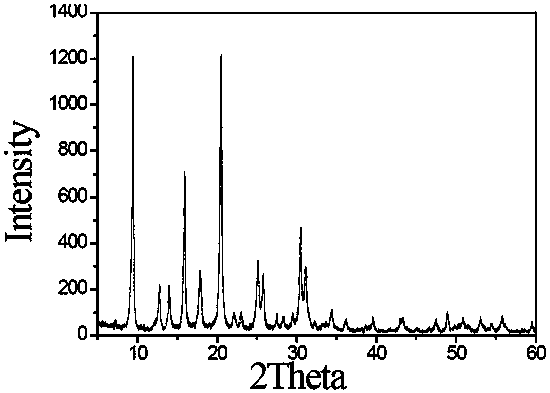

Submicron SAPO-5/SAPO-18 composite molecular sieve and preparation method thereof

ActiveCN103706394AShorten the diffusion pathShort stayMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveGranularity

The invention discloses a submicron composite molecular sieve for preparing a catalyst for producing low-carbon olefin through organic oxygen compound and a preparation method of the submicron composite molecular sieve. The composite molecular sieve is formed by compounding an SAPO-5 molecular sieve and an SAPO-18 molecular sieve. Raw materials for preparing the composite molecular sieve satisfy the following condition: the molar ratio of SiO2: Al2O3: P2O5 is (0.1-0.6): 1: (0.7-1.3); the addition quantity of the SAPO-5 / SAPO-18 composite sieve screen crystal seed is 1.0 to 5.5 percent by adopting the weight of effective solid content in mixed gel as a benchmark. The SAPO-5 / SAPO-18 composite molecular sieve has submicron-meter granularity and is good in catalytic activity, long in service life and high in qualification molecular sieve yield.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Combined process of hydrotreatment-catalytic cracking for residuum

InactiveCN103254936AIncrease aromaIncrease peptization abilityTreatment with hydrotreatment processesSlurrySolvent

The invention relates to a combined process of hydrotreatment-catalytic cracking for residuum. According to the invention, the residuum and hydrogen are introduced into a residuum hydrogenation apparatus to be separated into dry gas, hydrogenated naphtha, hydrogenated diesel oil and hydrogenated residuum; the hydrogenated residuum is introduced into a catalytic cracking apparatus to react and be separated into the dry gas, liquefied gas, catalytic gasoline, heavy cycle oil and oil slurry; the heavy cycle oil and the oil slurry are introduced into a solvent extraction apparatus; a raffinate returns back to the catalytic cracking apparatus; an extract phase is introduced into a fractionating tower for separation, wherein a tower top is an extraction solvent, a lateral line is intermediate fractions and a tower bottom is heavy fractions; the extraction solvent returns back to the solvent extraction apparatus; the intermediate fractions are sent to the residuum hydrogenation apparatus; part of the intermediate fractions are sent to a lubricating oil apparatus; and the heavy fractions at the tower bottom is used as an asphalt improver to produce the asphalt. According to the method, aromatic hydrocarbon which is used as a raw material of the residuum hydrotreatment is increased in content and reduced in viscosity, contents of sulfur, nitrogen, metal and other impurities are reduced, and severity for operating the apparatus is reduced.

Owner:PETROCHINA CO LTD

Microwave-assisted method for preparing biomass-based motor gasoline by rapidly pyrolyzing straws and waste nigre under co-catalysis of double bed layers

InactiveCN107858169AHigh yieldImprove qualityLiquid hydrocarbon mixture productionHydrocarbon oils treatmentCatalytic reformingMolecular sieve

The invention discloses a microwave-assisted method for preparing biomass-based motor gasoline by rapidly pyrolyzing straws and waste nigre under the co-catalysis of double bed layers. The microwave-assisted method comprises the steps: 1) weighing straws and waste nigre according to the mass ratio of 1:1 to 1:10, and uniformly mixing the straws and the waste nigre; 2) placing a catalyst into a U-shaped quartz tube connected with a pyrolysis steam outlet of a double-neck quartz bottle according to the mass ratio (1:1 to 1:10) of an HZSM-5 molecular sieve based catalyst to a mixture of the straws and the waste nigre, and adding a microwave absorbent into a quartz cup; and 3) embedding the double-neck quartz bottle and the U-shaped quartz tube into the quartz cup, placing the quartz cup intoa microwave pyrolysis instrument, carrying out heating to 450-650 DEG C, rapidly adding the mixture of the straws and the waste nigre into the double-neck quartz bottle, carrying out catalytic reforming on the U-shaped quartz tube by using the catalyst, and carrying out condensation by using a condensation tube to form hydrocarbon-enriched biomass-based motor diesel oil. By using the microwave-assisted method, the carbonization time is greatly shortened, the yield and quality of bio-oil are improved, and the content of hydrocarbons in the bio-oil is remarkably increased.

Owner:NANCHANG UNIV

Supported copper-based catalyst preparation method and applications of supported copper-based catalyst in synthesis of ethylene glycol

ActiveCN110694672AImprove catalytic performanceImprove stabilityMolecular sieve catalystsOrganic compound preparationPtru catalystAqueous ethanol

The invention discloses a supported copper-based catalyst preparation method and applications of the supported copper-based catalyst in synthesis of ethylene glycol. The method comprises: taking a silicon mesoporous molecular sieve, carrying out a reaction with sulfonic acid, carrying out a hydroxyl condensation reaction with a silane coupling agent, carrying out a graft copolymerization reactionon the obtained modified silicon mesoporous molecular sieve, an initiator and an acrylic acid compound, adding the obtained solid sample into an ethanol / aqueous solution mixed solvent of a soluble copper salt, carrying out a heating reflux reaction, filtering the obtained product, repeatedly washing with deionized water, drying, and roasting to obtain the modified silicon mesoporous molecular sieve supported copper-based catalyst. According to the invention, with the preparation method, the dispersity of the copper species in the final catalyst can be regulated, and the synergistic effect of monovalent copper and zero-valent copper can be improved, so that the high-dispersion supported nanometer copper catalyst is obtained; with the application of the catalyst in a reaction for synthesizing ethylene glycol through hydrogenating dimethyl oxalate, the conversion rate of dimethyl oxalate is more than 99.4%, and the selectivity of ethylene glycol is more than 96%; and the preparation process of the catalyst is simple, the cost is low, and the industrial application is easily achieved.

Owner:CHINA CATALYST HLDG CO LTD

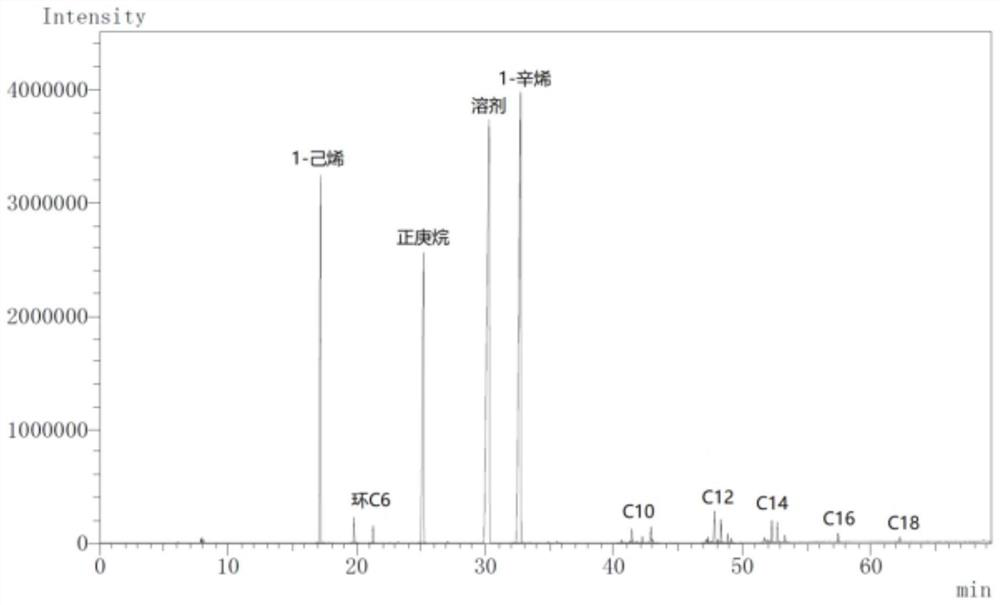

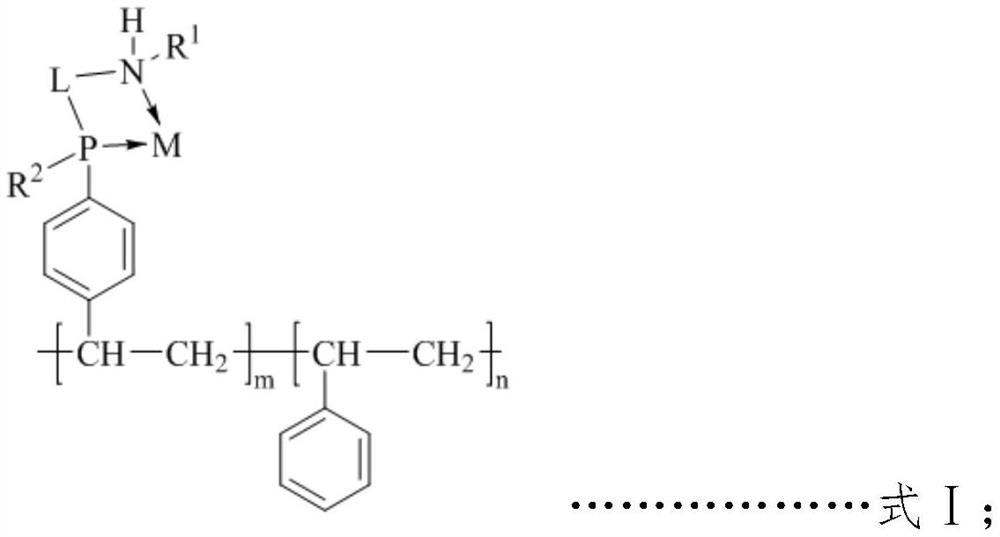

Catalyst composition for ethylene oligomerization and preparation method and application thereof

ActiveCN114192192ASimple post-processingConducive to long-term continuous operationOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsPtru catalystAluminium alkyl

The invention provides a catalyst composition for ethylene oligomerization as well as a preparation method and application thereof, and relates to the field of ethylene oligomerization catalysis. The catalyst composition comprises a self-supported metal complex and an aluminum alkyl cocatalyst, the self-supported metal complex is generated through a coordination reaction of a self-supported phosphine-nitrogen ligand and a transition metal, and the self-supported phosphine-nitrogen ligand is obtained by copolymerization of a phosphine-nitrogen ligand monomer containing terminal double bonds and styrene. The invention further discloses an ethylene oligomerization method using the catalyst composition, a three-kettle series oligomerization process is adopted, appropriate reaction conditions are adopted according to the characteristics of different catalysis stages, the retention time of the catalyst is effectively prolonged, and the content of high polymers is reduced. The catalyst is easy to separate from a reaction system, high in temperature tolerance and long in high activity duration, the activity of the catalyst reaches up to 12.5 * 10 < 6 > g / (mol Cr.h), and the total selectivity of 1-hexene and 1-octene exceeds 90%.

Owner:ZHEJIANG SATELLITE PETRO CHEM CO LTD

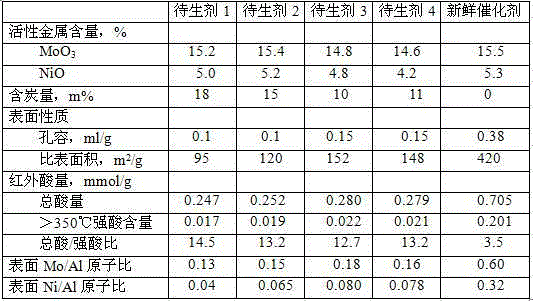

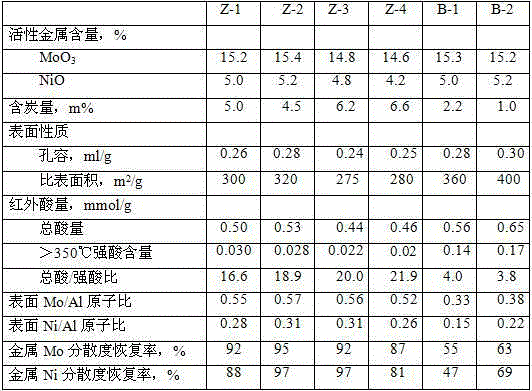

Regenerating method for catalyst for catalyzing diesel oil hydrocracking

ActiveCN106669710ABest catalytic diesel hydroconversion reaction performanceShorten initial life stabilization timeHydrocarbon oil crackingMetal/metal-oxides/metal-hydroxide catalystsOxygenDecarburization

The invention discloses a regenerating method for a catalyst for catalyzing diesel oil hydrocracking. The method comprises the following steps: (1) roasting an inactivated hydrocracking catalyst in the process of catalyzing the diesel oil hydro-conversion under an oxygen-containing atmosphere till the decarburization rate is 40%-80%, thereby acquiring a decarburized catalyst; and (2) processing the decarburized catalyst acquired in the step (1) at high temperature in an inert atmosphere, thereby acquiring a regenerated hydrocracking catalyst. After the catalyst regenerated according to the invention is applied to the process of catalyzing the diesel oil hydro-conversion, the initial activity stabilizing time of the catalyst of the device is shortened, the working time is shortened, the deactivation rate of the catalyst is reduced, and the running period of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

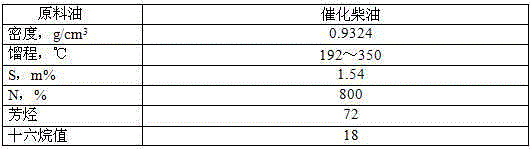

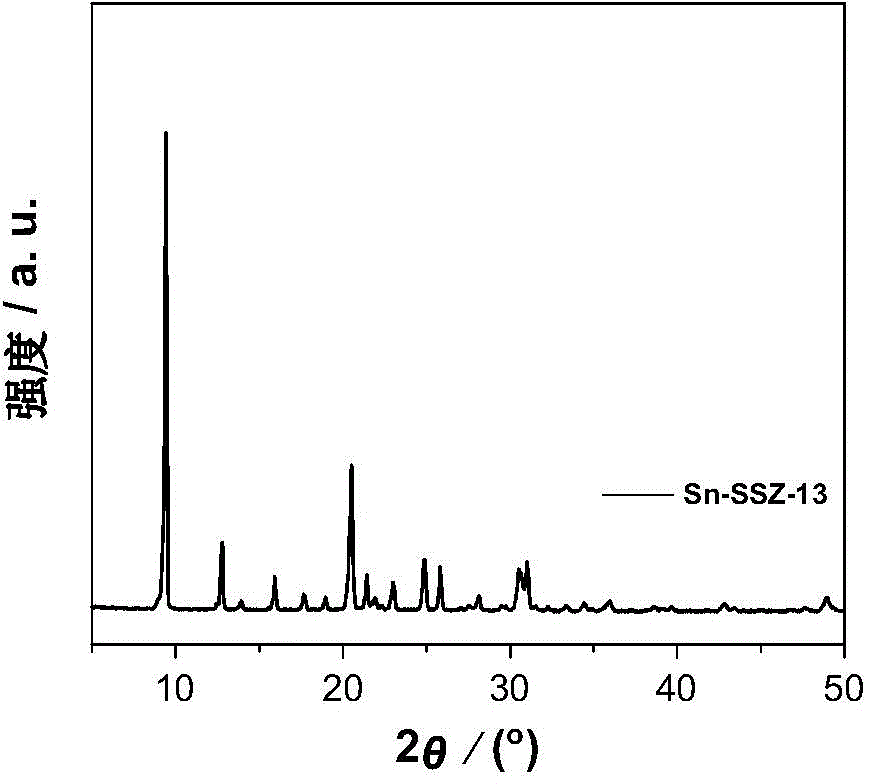

Tin-containing molecular sieve catalyst used for preparing ethylene glycol by hydrating ethylene oxide and application method

ActiveCN104437607AHigh selectivityReduced inactivation rateMolecular sieve catalystsBulk chemical productionHydration reactionWater vapor

The invention relates to a tin-containing molecular sieve catalyst used for preparing ethylene glycol by hydrating ethylene oxide and an application method of the tin-containing molecular sieve catalyst. The tin-containing molecular sieve catalyst is prepared by taking H-SSZ-13 zeolite molecular sieve raw powder as a raw material, carrying out water steam treatment or water steam and acid combined treatment on the raw material, and introducing active central metal in a manner of roasting by a vacuum pipe type furnace. The preparation method comprises the following steps: mixing an H-SSZ-13 zeolite molecular sieve treated by the water steam or acid with an organic metal compound precursor at a ratio and roasting in vacuum. According to the tin-containing molecular sieve catalyst, the problems of high water ratio, high energy consumption, environmental pollution caused in a production process and the like in a traditional process can be solved. According to the catalyst, a carrier is cheap and easy to obtain, a preparation process of the catalyst is simple and the stability of the catalyst is good; and the catalyst has excellent catalyzing activity and selectivity when being applied to a process of preparing ethylene glycol by directly hydrating ethylene oxide under a warm condition, is easy to recycle and can be used for industrial production for preparing ethylene glycol by hydrating ethylene oxide.

Owner:NANKAI UNIV

Solid acid alkylation method of isoparaffin and olefin

ActiveCN112143519AExtend your lifeReduced inactivation rateLiquid hydrocarbon mixtures productionTreatment with hydrotreatment processesOxygen compoundChemical compound

The invention relates to a solid acid alkylation method of isoparaffin and olefin, wherein the method comprises the steps of alkylation raw material pretreatment, alkylation reaction and reaction product separation, and is characterized in that the raw material pretreatment comprises the steps of pre-hydrogenation, rectification, dehydration, sulfide removal, nitrogen-containing compound removal and oxygen-containing compound removal; in the alkylation reaction, the solid acid catalyst particles have a macroporous specific volume of 0.30-0.40 ml / g, a ratio of the macroporous specific volume tothe particle specific length of 1.0-2.5 ml / g*mm and a total specific pore volume of at least 0.40 ml / g, and in the optional particles, a ratio of the specific surface area to the particle length is 3.4-4.5 cm<2> / g*mm, and the macropores refer to pores with diameters of more than 50 nm.

Owner:CHINA PETROLEUM & CHEM CORP +1

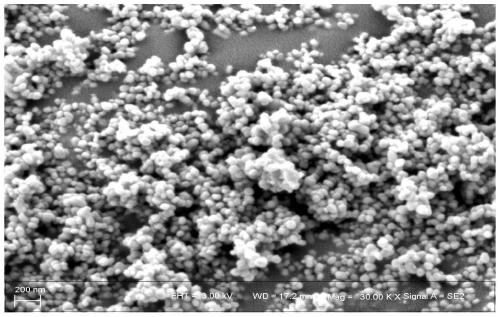

Synthesis method of nano Y zeolite, synthesized nano Y zeolite and application

ActiveCN110562995AImprove thermal stabilityGood nanostructureMaterial nanotechnologyMolecular sieve catalystsMolecular sieveIce water

The invention relates to a synthesis method of nano Y zeolite, the synthesized nano Y zeolite and an application. The method comprises steps as follows: a) an aluminum source and a sodium hydroxide solution make contact at the temperature of 50-95 DEG C to obtain an aluminum source solution; b) a silicon source and the sodium hydroxide solution make contact at the temperature of 70-100 DEG C to obtain a silicon source solution; c) the aluminum source solution and the silicon source solution make contact under the condition of an ice water mixed bath, and a mixture is obtained; and d) the mixture is crystalized to obtain a nano Y molecular sieve. The method can be used for industrial production of the nano Y zeolite.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthesis method of SAPO-34 molecular sieve with large specific surface area

ActiveCN107827121AQuick in and outHigh crystallinityMaterial nanotechnologyMolecular sieve catalystsFiltrationSynthesis methods

The invention discloses a synthesis method of an SAPO-34 molecular sieve with a large specific surface area. The synthesis method comprises the steps as follows: (1) an aluminum source and water are mixed and pulped, tetraethylammonium hydroxide is added, the mixture is stirred, and a solution A is formed; (2) phosphoric acid, acidic silica sol and water are mixed to form a solution B; (3) the solution A and the solution B are subjected to parallel mixing, a mixed solution formed through parallel mixing is stirred in real time, the pH of the system is adjusted to 5.5-7.5, stirring is performed, and gel is obtained; (4) the gel is dewatered and dried, and a precursor is obtained; (5) the precursor is ground, the ground precursor is placed at the upper part of a reaction kettle, water is putin the lower part of the reaction kettle, and crystallization is performed; and (6) filtration is performed, filter residues are dried and calcined, and the SAPO-34 molecular sieve is synthesized. The prepared SAPO-34 molecular sieve is formed by polymerization of crystal grains of 50-200 nm, has the larger specific surface area and higher mesoporous capacity, contributes to quick access of reaction substances into pores and can improve the catalytic activity.

Owner:SHAANXI YANCHANG PETROLEUM GRP

Ethylbenzene dehydrogenating catalyst and preparation method thereof

ActiveCN101829576BHigh selectivityHigh activityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsPolymer science4-isopropenyltoluene

The invention relates to an ethylbenzene dehydrogenating catalyst and a preparation method thereof. A plurality of metallic oxide stabilizing additives of WO3 and / or MoO3, CaO, BaO, CuO, ZnO2, Co2O3 and La2O3 are added into a catalyst which uses Fe-K-Ce-Mo (or W or Mo-W) as the main system. The catalyst has higher activity and selectivity, low inactivation speed and high stability, is suitable for preparing stryrene by dehydrogenating ethylbenzene, and is also suitable for preparing isopropenylbenzene by dehydrogenating isopropyl benzene, and preparing 4-isopropenyltoluene by dehydrogenating p-cymene. The catalyst is prepared by adopting a kneading method.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com