Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

908 results about "Iron source" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The best sources of iron include: Dried beans. Dried fruits. Eggs (especially egg yolks) Iron-fortified cereals. Liver. Lean red meat (especially beef)

Preparation of lithium iron phosphate nano composite microsphere

ActiveCN101475157AImprove conductivityHigh tap densityElectrode manufacturing processesPhosphorus compoundsMicrospherePhosphoric acid

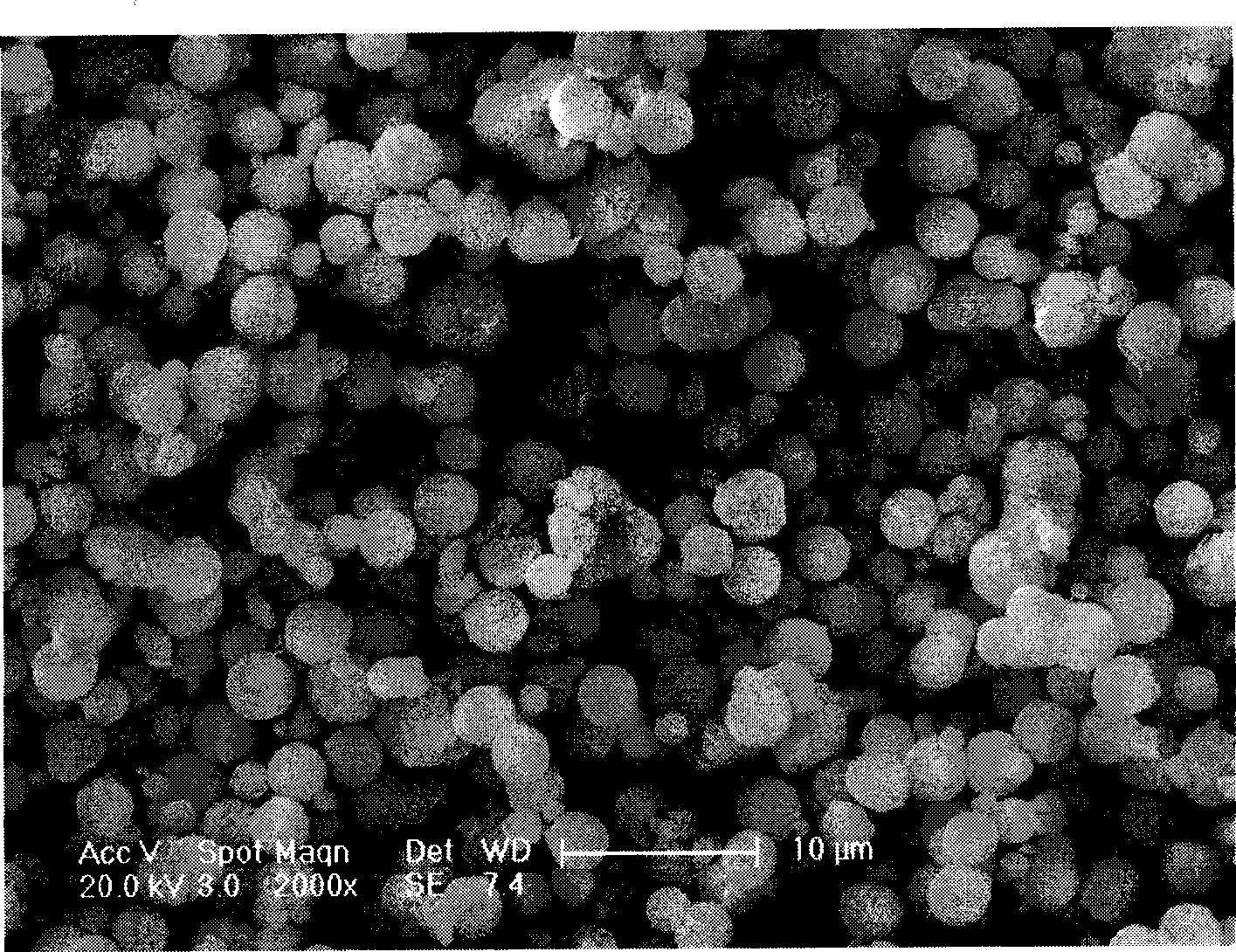

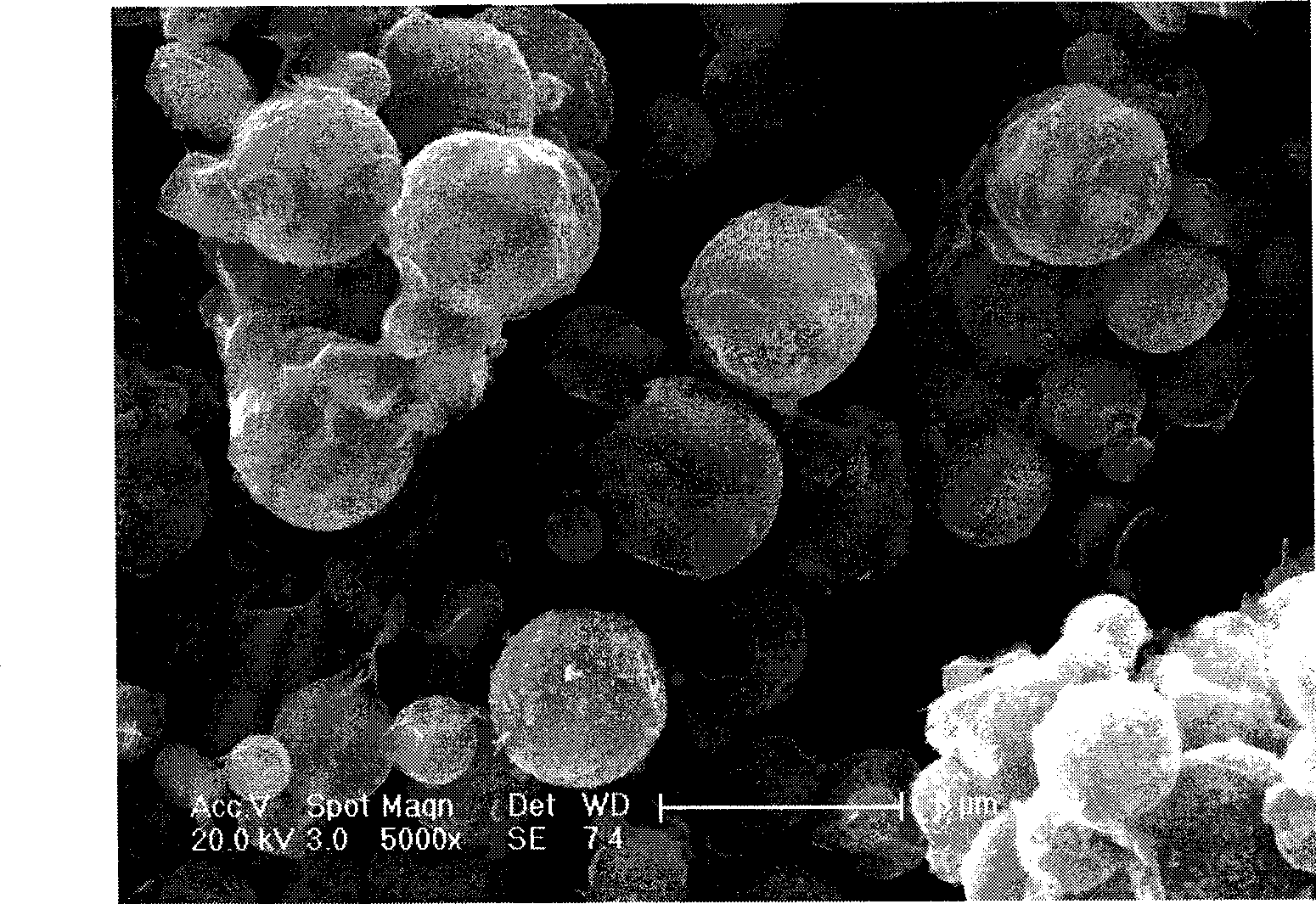

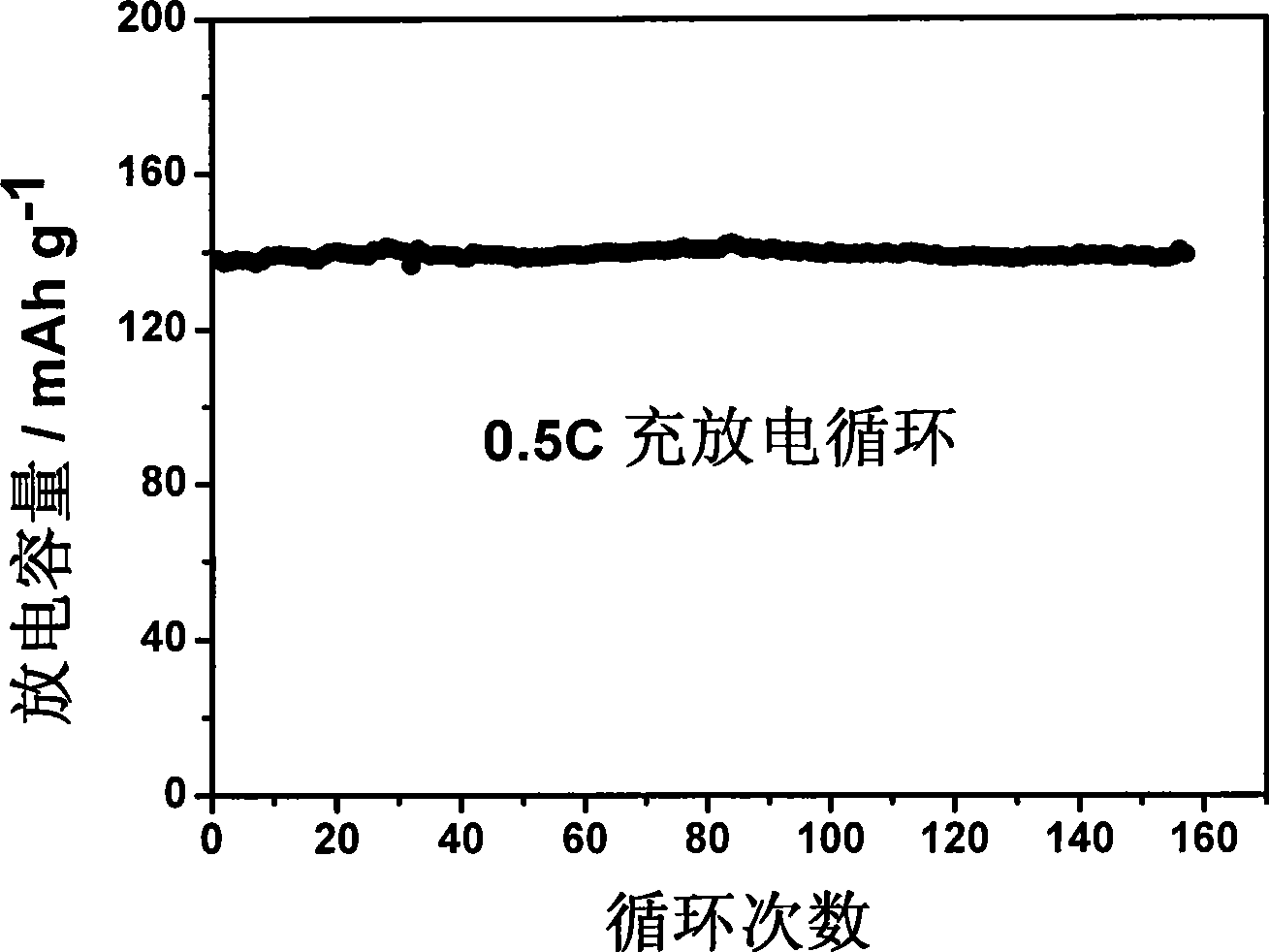

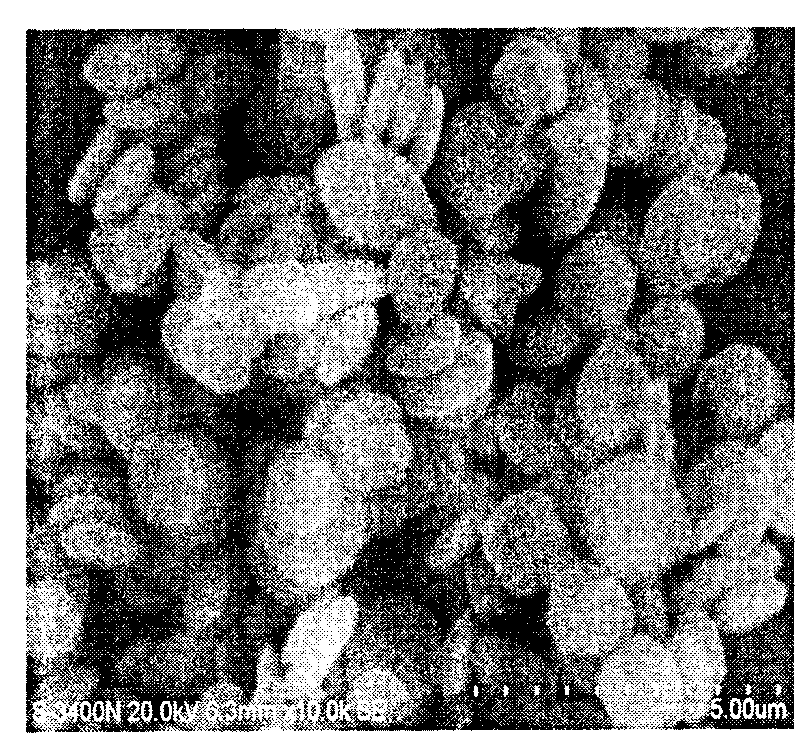

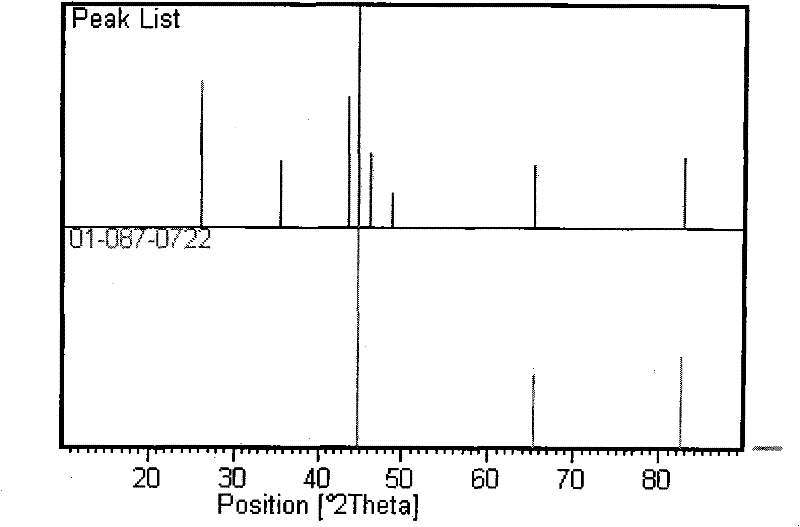

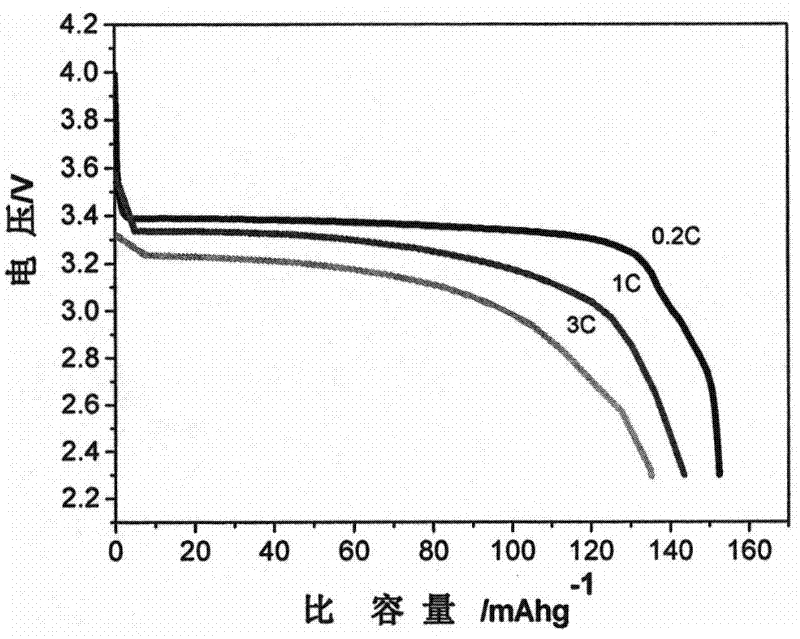

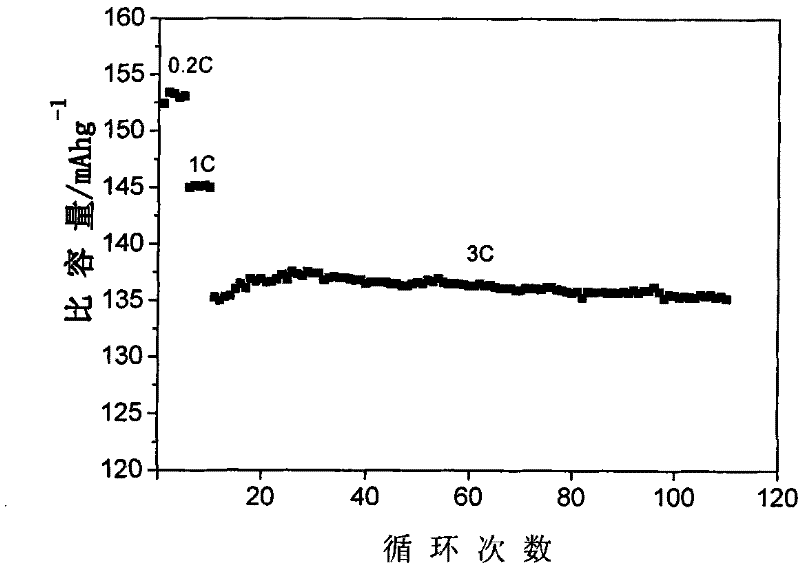

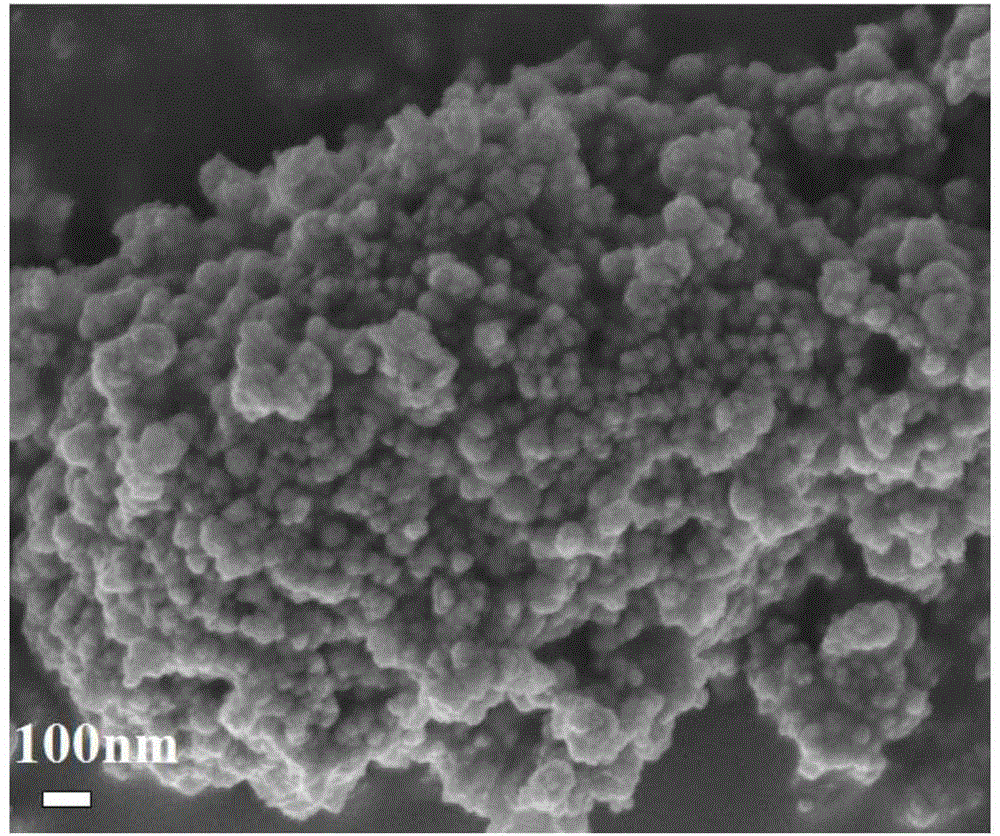

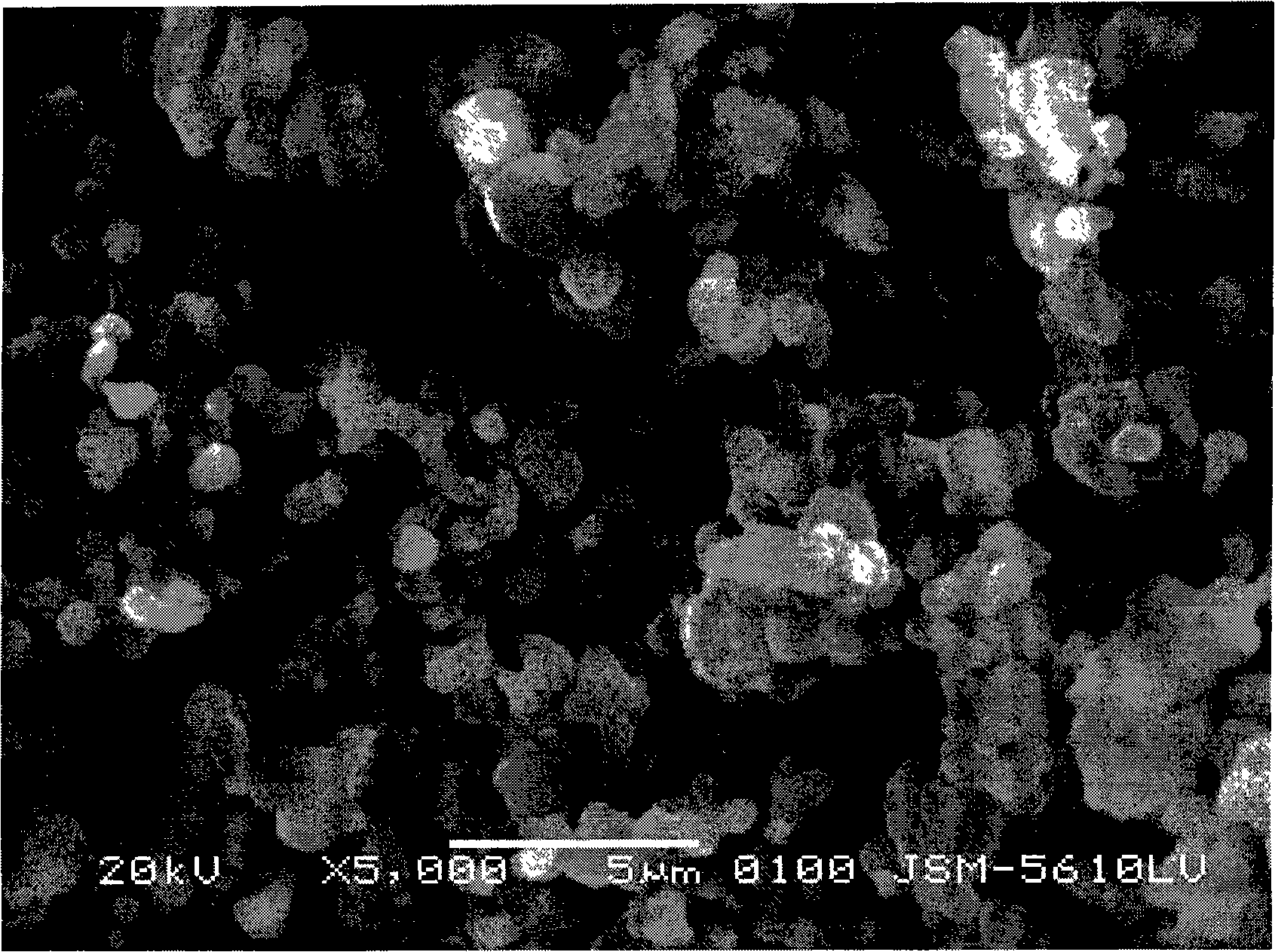

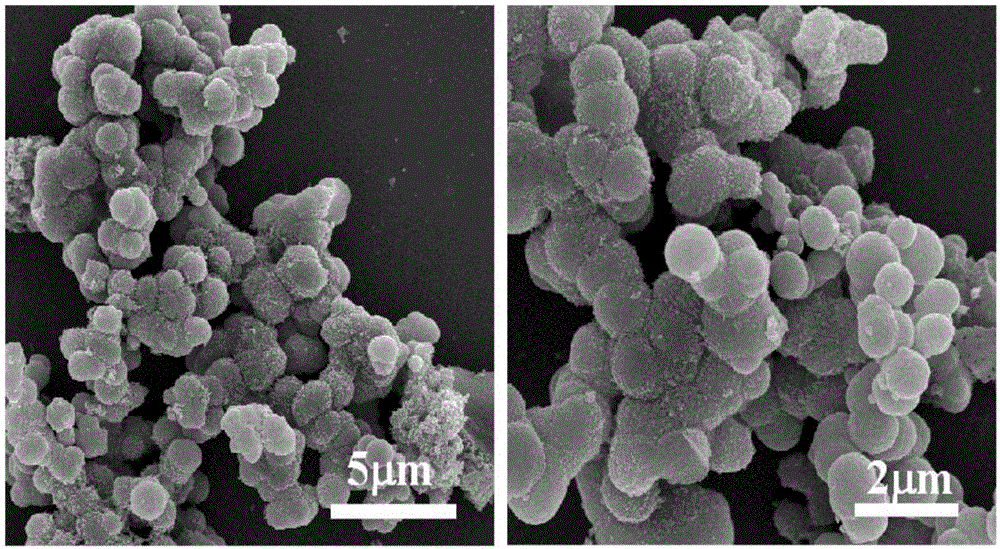

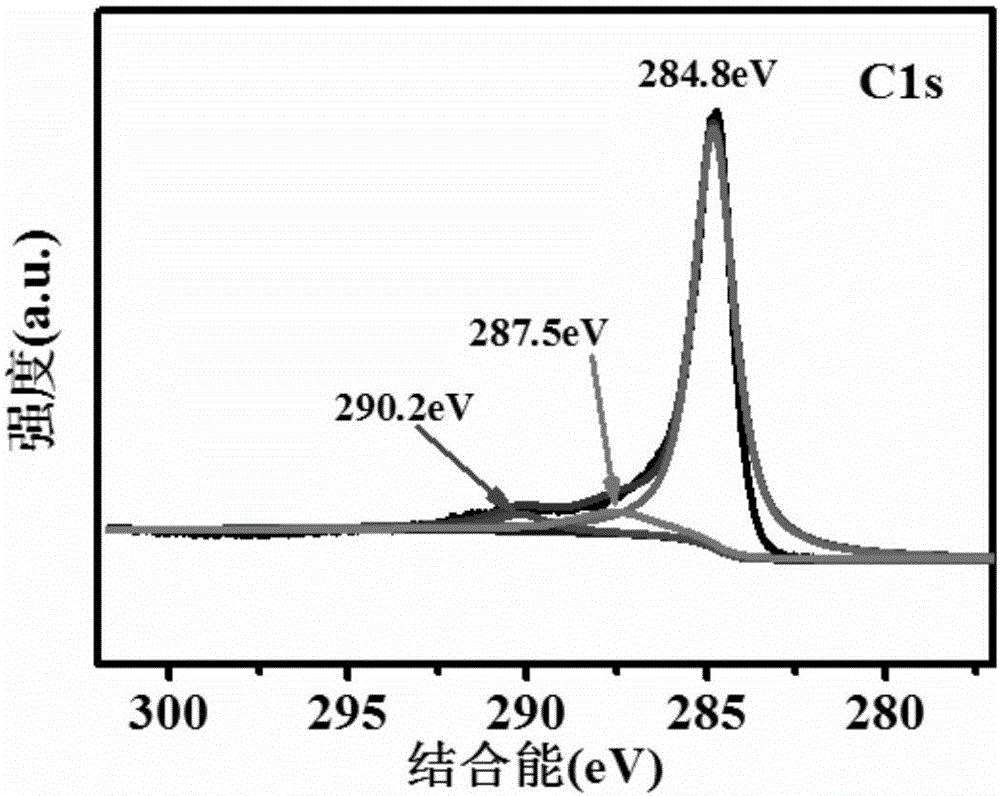

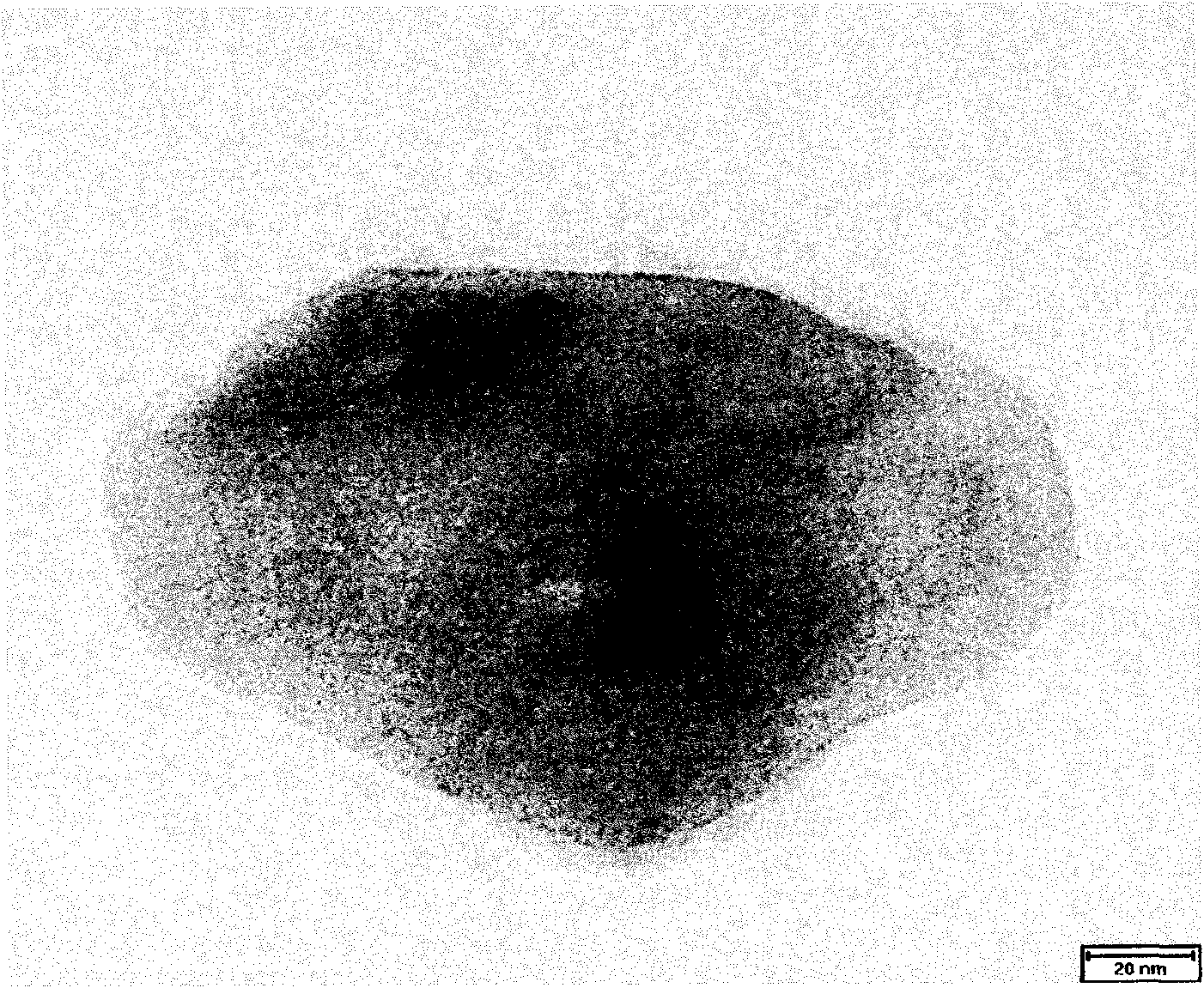

The invention discloses a method for preparing a lithium iron phosphate nano composite microsphere for a lithium-ion secondary battery anode material by a hydrothermal method, which comprises the following steps: evenly mixing a lithium source, an iron source and a phosphoric acid source according to the stoichiometric ratio of 1-1.05:1:1 to prepare an aqueous solution with certain concentration, adding proper amount of reducing agent, carbonizing agent, ion dopant and the like into the aqueous solution, growing and curing crystals under high-temperature hydrothermal condition, removing a solvent from a hydrothermal product, and burning the hydrothermal product in inert or reducing atmosphere to obtain a final product. The lithium iron phosphate anode material prepared by the method has a regular nano composite microsphere structure, has a particle diameter of between 2 and 4 mu m, even distribution, tap density up to 1.3 to 1.6 g / cm, and has excellent cycle performance and multiplying power performance. The method has simple and easily-controlled process, can use cheap trivalent iron as the iron source, can obtain rich raw materials, and is a practical technique for preparing lithium iron phosphate.

Owner:湖北金泉新材料有限公司

Methods for Synthesizing Lithium Iron Phosphate as a Material for the Cathode of Lithium Batteries

InactiveUS20090035204A1High purityGuaranteed specific capacityElectrode manufacturing processesPhosphatesLithium iron phosphateCarbon source

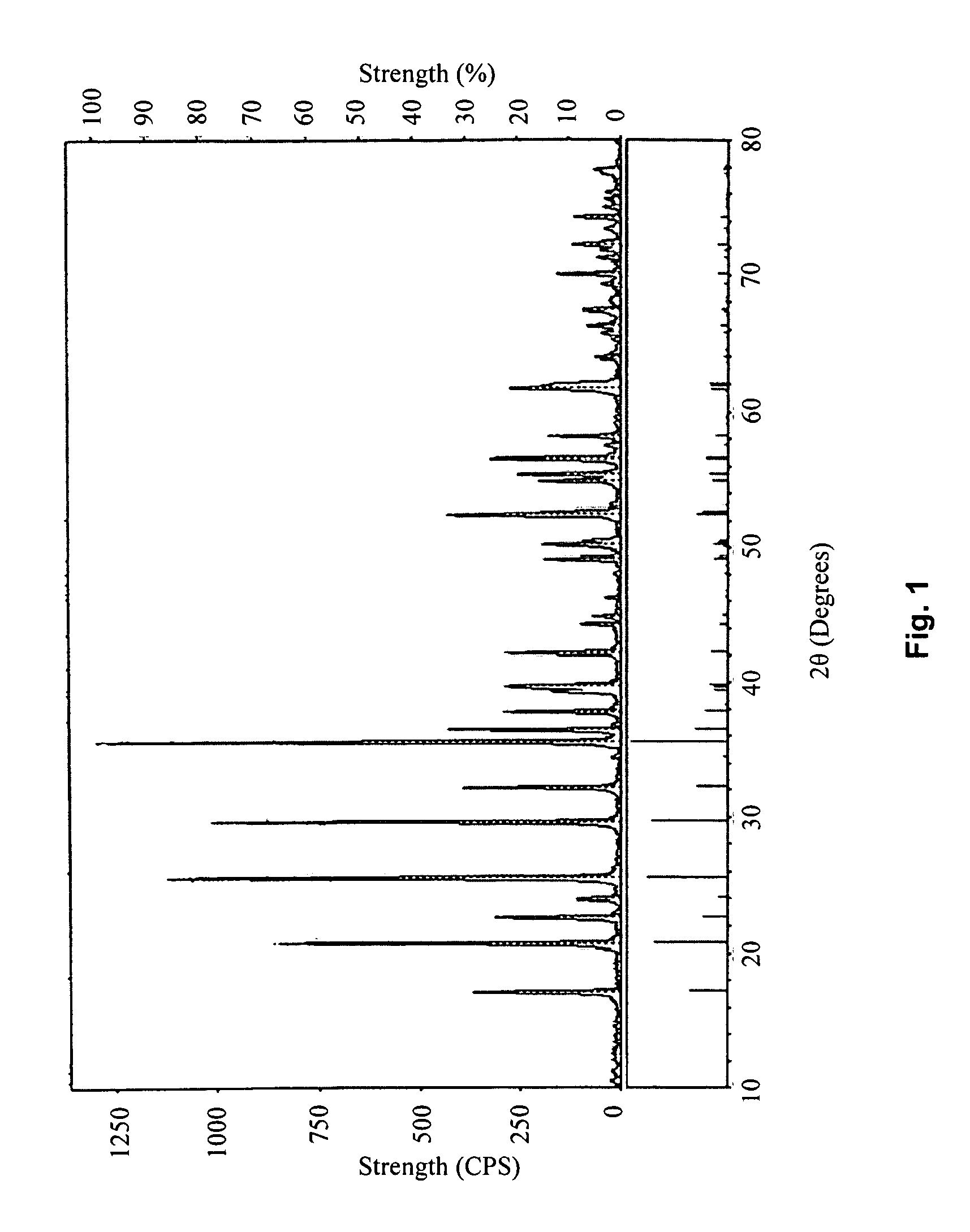

A method for synthesizing lithium iron phosphate as a material for the cathode of lithium batteries is disclosed. This method comprises mixing and sintering the lithium source, iron source, phosphorous source, and carbon source, wherein said iron source is a mixture of FeC2O4 and FeCO3, with a molar ratio of FeC2O4 to FeCO3 of 1:0.5-4. The purity and specific capacity of lithium iron phosphate produced using are both relatively high, and the method of this invention is very safe in practice.

Owner:BYD CO LTD

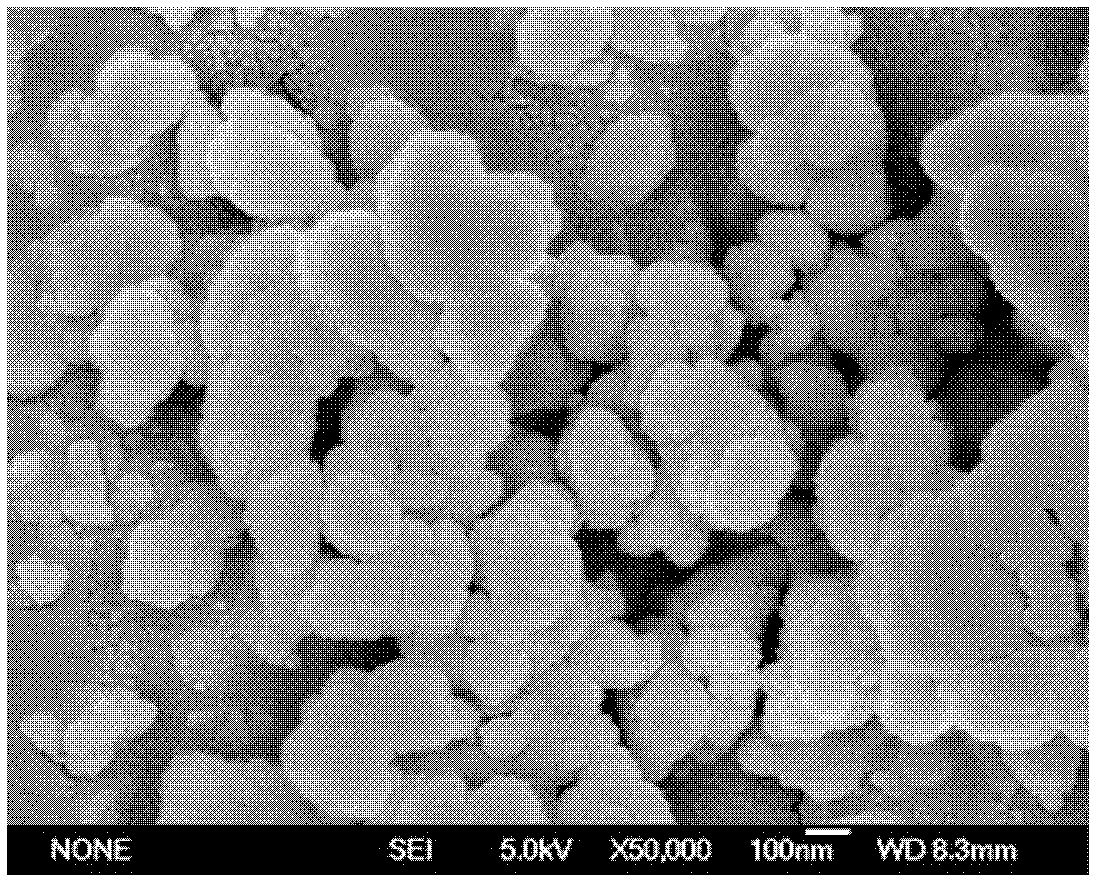

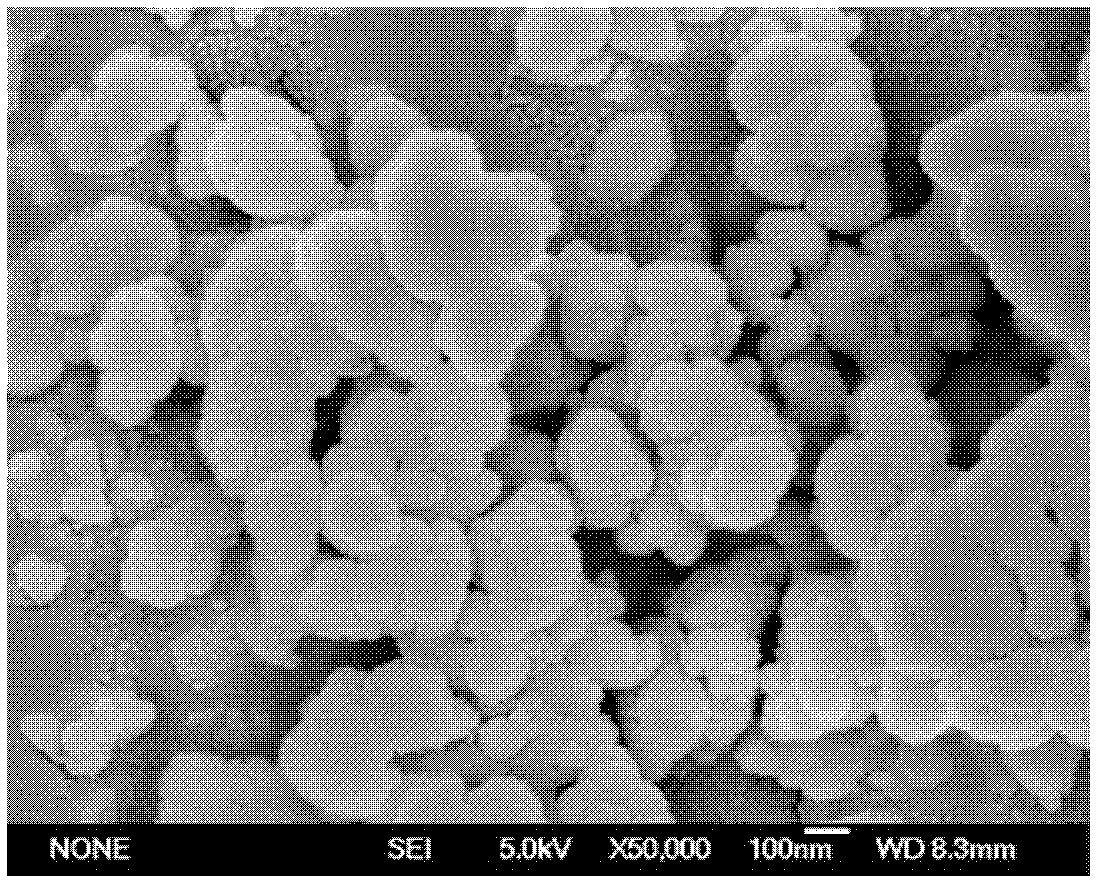

Wafer-like ferric phosphate, preparation method and application thereof

ActiveCN101708834AUniform sizeShort reaction timeCell electrodesPhosphorus compoundsPhosphatePhosphoric acid

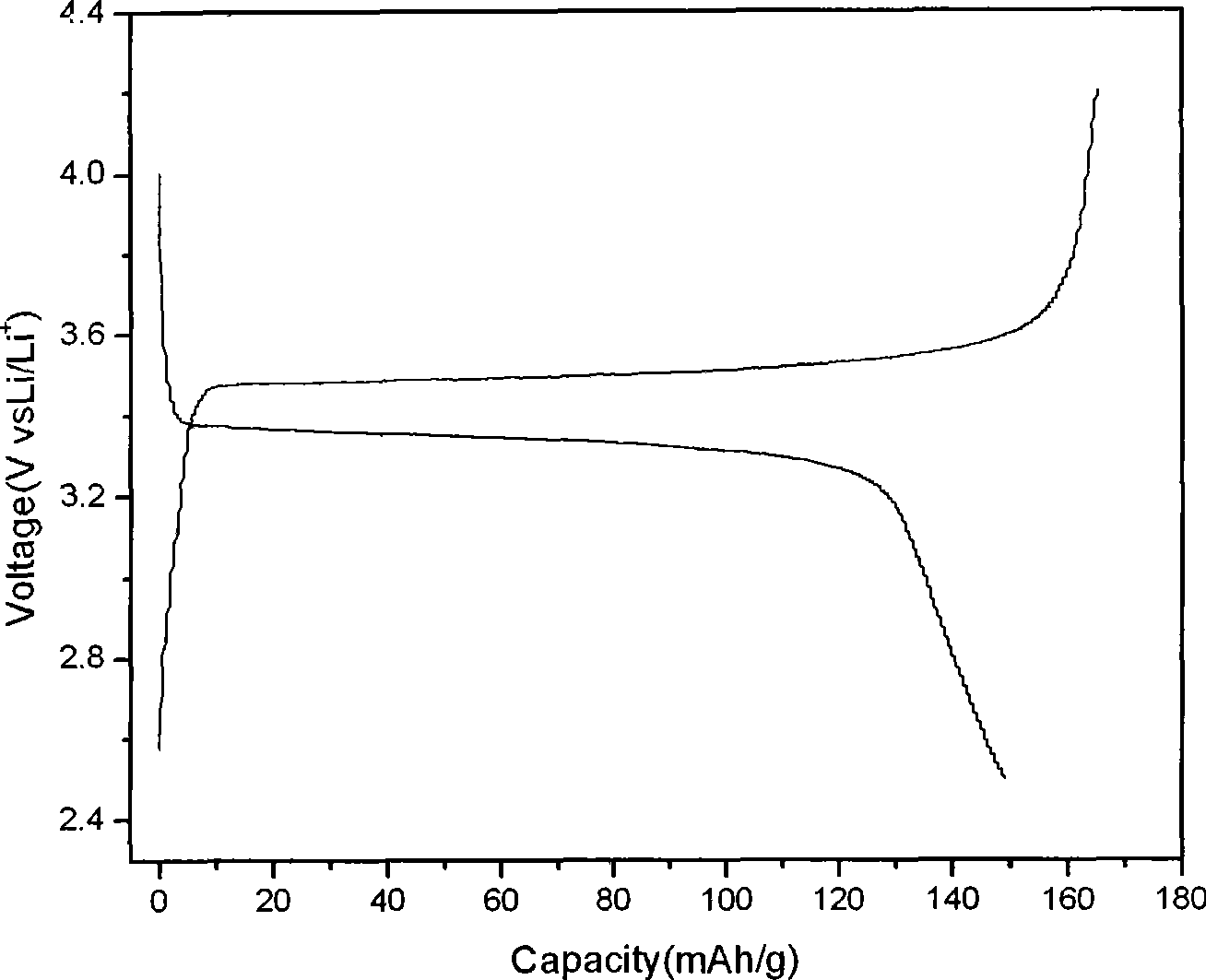

The invention discloses a method for preparing wafer-like ferric phosphate, which comprises the following steps of: adding deionized water of which the pH value is pre-adjusted to 1 by nitric acid into a reactor with stirring, then adding an iron source into the reactor, completely dissolving the iron source with the stirring, then adding a certain amount of phosphoric acid or phosphate, urea and surfactant into the reactor respectively, adjusting the pH value of reaction solution by using the nitric acid or sodium hydroxide, heating the solution in the reactor to be between 80 and 100 DEG C, performing reaction for 1.5 to 3 hours within the temperature range to obtain a white suspension, cooling and filtering the suspension, washing a filter cake by using the deionized water, and drying the filter cake for 3 to 6 hours in a baking oven at the temperature of between 102 and 120 DEG C to obtain ferric phosphate powder. The product has good whiteness, is of wafer shapes and has more uniform particle sizes; the average particle size is between 0.3 and 0.5 microns; and the tap density is more than or equal to 0.95g / cm3. The discharge capacity of lithium ferric phosphate, which is further synthesized by using the ferric phosphate prepared by the method as a raw material and is taken as an anode material of a lithium ion battery, can reach more than 140mAh / g under the condition of 0.5C. The method has the advantages of short reaction time, simple process, high product purity, and more regular morphology, and is easy to realize industrialization.

Owner:GUANGXI RES INST OF CHEM IND CO LTD +1

Boron containing lithium iron phosphate/carbon composite material and preparation thereof

ActiveCN101364643AHigh bonding strengthHigh tap densityElectrode manufacturing processesChemical/physical/physico-chemical processesCarbon compositesCarbon layer

The invention relates to an anode material for secondary lithium batteries, in particular to a lithium iron phosphate / carbon composite material containing boron, and the preparation method thereof, and mainly solves the technical problems of lower bonding strength of coating the carbon layer and the lithium iron phosphate surface, relatively low product tap density, rapid growth of the grain size, non-uniform and non-centralized distribution, and poor uniformity in the electrical property of lithium iron phosphate and the product quality, etc., in the prior art. The chemical formula of the lithium iron phosphate / carbon composite material is Li1-xMxFe1-yNyP1-zSizO4.XiB2O3 / C or Li1-xMxFe1-yNyP1-zSizO4.ZetaLiBO2 / C. The preparation method comprises the following steps: adding a boric acid ester surface active agent or / and a fluxing agent to a ball milling tank filled with a solvent; stirring uniformly; further adding iron-source compounds, lithium-source compounds, phosphorus-source compounds and carbon-coated carbon source respectively and mixing; evaporating the solvent to dryness and sintering the obtained solid powder under the protection of inert gases; cooling and taking out; and pulverizing, grading and obtaining the finished product.

Owner:杭州金马新能源科技有限公司

Novel method for preparing load nano zero valent iron

InactiveCN102205419AUniform size distributionPrevent restoreMaterial nanotechnologyCoalReducing agent

The invention discloses a novel method for preparing load nano zero valent iron. The iron source is iron-containing compounds of Fe<2+> and Fe<3+>, such as ferric oleate, ferric hydroxide oxide, ferric chloride, ferric nitrate and the like; and the loads are carbon black, active carbon, kieselguhr, zeolite and other load materials. The method is characterized in that: the iron-containing compounds on the loads are reduced into nano zero valent iron under the atmosphere condition and under the reduction action of reducing agents, such as H2, CO, and reduction carbon (such as coke, reduction coal and the like). The preparation method is environment-friendly, and simple and is low in cost; the expensive reducing agents (such as NaBH4 and the like) are avoided, and organic pollutants (such as halogenated hydrocarbon, pesticide, polychlorinated biphenyls (PCBs) and polycyclic aromatic hydrocarbons (PAHs), inorganic negative ions (such as NO<3->), and heavy metal (such as Cr<6+>, As<3+>, As<5+>, Cu<2+>, Pb<2+>) and the like can be efficiently removed effectively.

Owner:BEIJING NORMAL UNIVERSITY

Application and preparation method of nanometer Fe(0)-porous sludge carbon material

InactiveCN106076256AGood dechlorination and detoxification effectSolve pollutionOther chemical processesWaste water treatment from textile industryToxicity reductionIron salts

The invention discloses a preparation method of a nanometer Fe(0)-porous sludge carbon material. The method includes: taking iron salt as an iron source of nanometer Fe(0), taking sludge as a precursor for thermal reduction of porous carbon and iron salt, taking an organic matter capable of generating a great quantity of gas by thermal decomposition at 300-500 DEG C as a pore forming agent, taking waste organics as a carbon regulating agent (in order to solve the problem of difference of organic carbon composition of sludge different in source), taking water as a harmonizing agent, and performing pyrolysis carbonization and thermal reduction at 500-900 DEG C to obtain the nanometer Fe(0)-porous sludge carbon material being 0.01-100micron in pore diameter, wherein Fe(0) average particle size is 30-80mm. The nanometer Fe(0)-porous sludge carbon material is effective in dechlorination and toxicity reduction and has a promising application prospect in various environmental pollution control fields including dehalogenation reduction, soil remediation, heavy metal wastewater treatment, printing and dyeing wastewater treatment and / or anaerobic wastewater treatment and the like, and sludge recycling and 'using waste to treat waste' are realized.

Owner:SUN YAT SEN UNIV

A novel preparation method for LiFePO4/C composite positive pole material

InactiveCN101504979AUniform particle distributionImprove cycle stabilityElectrode manufacturing processesPhosphorus compoundsPhosphoniumEvaporation

The invention discloses a LiFePO4 / C composite anode material and a method for preparing the same, and in particular relates to a method for preparing a lithium ion buttery anode material. The LiFePO4 / C composite anode material is synthesized by a liquid phase evaporation drying method, and the method comprises the following steps: firstly, according to a stoichiometric ratio, weighing certain amount of lithium source compounds, iron source compounds and phosphonium source compounds to prepare mixed solution with certain concentration, and adding right amount of carbon sources; secondly, synthesizing a precursor by controlling the reaction temperature, the stirring speed and the ultrasonic dispersion; thirdly, drying and grinding the precursor; and finally, processing the precursor powder at a temperature of between 500 and 800 DEG C for 2 to 15 hours, and cooling the product to room temperature to obtain the LiFePO4 / C composite anode material. The method has the advantages of easy control, low energy consumption, short cycle, lithium source saving, low cost and the like; and the LiFePO4 / C composite anode material prepared by the method has the characteristics of high purity, small particle size, even distribution of particles, good electrochemical performance and the like.

Owner:SHANGHAI HUAMING HI TECH GRP +1

Hydrothermal synthesis method of LiFePO4 of anode material of lithium ion battery with one-dimensional nanometer structure

InactiveCN101752564AImprove rate discharge performancePromote environmental protectionCell electrodesPhosphorus compoundsLithium hydroxidePhosphoric acid

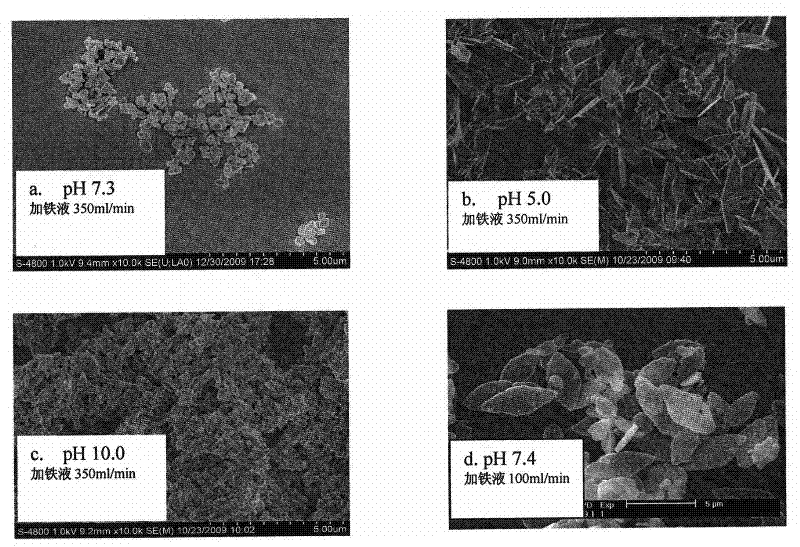

The invention discloses a hydrothermal synthesis method of LiFePO4 of anode material of lithium ion battery with one-dimensional nanometer structure, which comprises the steps of: 1. respectively adding lithium hydroxide solution and phosphoric acid, evenly adding iron source solution with a certain speed, wherein the molar ratio of the proportion of the added materials Li: Fe: P is 3.0:1.0:1.0-1.15, stirring 10-30 for minutes, adding pH value adjusting agent, leading the initial pH value of a reaction system to be 6.5-8.0, and reacting for 60-480 minutes at 40-180 DEG C; 2. filtering, washing and drying resultant; and 3. packing carbon. The hydrothermal synthesis method can take raw material solution for generating ferrous sulfate as iron source, produces a product with good performance by adjusting the pH value of the reaction system and controlling the feeding speed, eliminates working procedures for crystallizing and drying the ferrous sulfate and the like, is good for reducing water electricity consumption, and has less equipment investment, simple and controllable technology and good batch stability of the product.

Owner:HEBEI UNIV OF TECH

Method for preparing low-carbon olefin catalyst through carbon dioxide hydrogenation

InactiveCN104624194AForm evenlyImprove conversion rateHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMicrowaveHydrogen

The invention relates to a method for preparing a low-carbon olefin catalyst through carbon dioxide hydrogenation. The low-carbon olefin catalyst comprises the following element components: iron, zirconium, potassium and oxygen, the atomic molar ratio of zirconium to iron is (0-1):1, and the atomic molar ratio of iron to potassium is 10:1. The method for preparing the low-carbon olefin catalyst through carbon dioxide hydrogenation comprises the following steps: (1) weighing an iron source and a zirconium sourse, preparing aqueous solution, and marking the prepared aqueous solution as solution A; (2) adding a precipitator into the solution A, stirring, and marking the obtained solution as solution B; (3) carrying out microwave induction on the solution B; (4) centrifuging, filtering and washing reaction products, drying and roasting the obtained sample, and marking the roasted sample as a sample C; (5) weighing a potassium source, dissolving the potassium source in deionized water, impregnating the sample C, drying, and marking the dried sample as a sample D; and (6) carrying out tabletting, pelletizing and hydrogen gas reduction on the sample D, so that a catalyst sample is obtained. The method for preparing the low-carbon olefin catalyst through the carbon dioxide hydrogenation has the advantages that conversion ratio of carbon dioxide raw material is high, selectivity of low-carbon olefin is high, few CH4 and CO byproducts are produced, the catalyst is stable, and powder particles of the obtained catalyst are small and uniform.

Owner:NINGXIA UNIVERSITY

Preparation method for lithium ion secondary battery anode material ferric lithium phosphate

InactiveCN101494288AGood coating effectImprove conductivityElectrode manufacturing processesLithium compoundsTwo stepPolymer

A method for preparing lithium iron phosphate which is a cathode material of lithium ion secondary battery, the method comprises the following procedures: A. a lithium source compound, a bivalence iron source compound, a phosphorus source compound and a small organic molecular carbon source additive are mixed, ball ground and sintered to obtain a sintering precursor; and B. the sintering precursor which is obtained from the procedure A and an organic high molecular polymer carbon source additive are mixed, ball ground, sintered and crushed to obtain the lithium iron phosphate power of finished products. In the method, the carbon source is added into the precursor in two steps: adding the organic small organic molecular carbon source first and then adding the organic high molecular polymer carbon source, thus obtaining a lithium iron phosphate carbon with good packing effect. The large current discharge performance of the battery made of the lithium iron phosphate is obviously raised.

Owner:广西荷美新能源车辆科技有限公司

Hydrothermal synthesis preparation method of ion doping high-performance lithium iron phosphate

InactiveCN102315450ASimple particle distributionUniform particle distributionCell electrodesAutoclaveInorganic chemistry

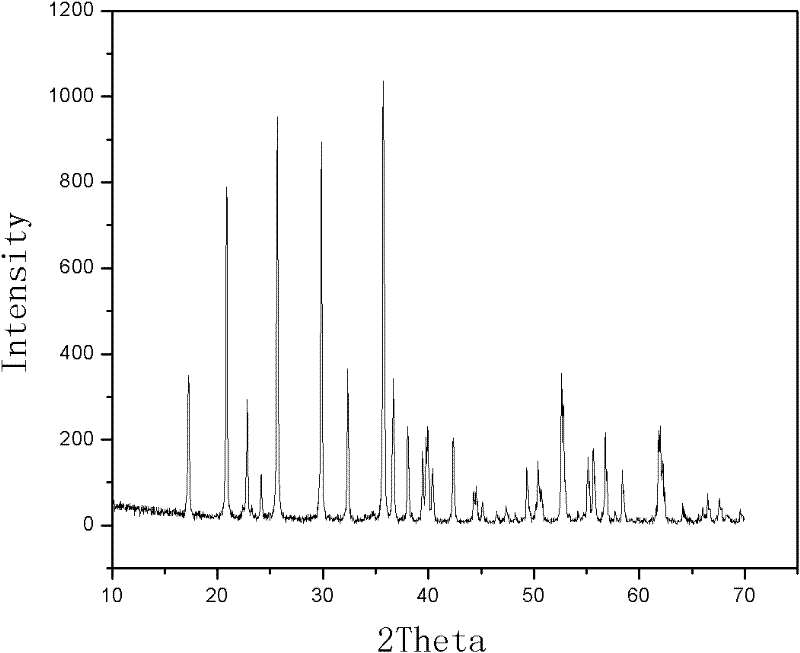

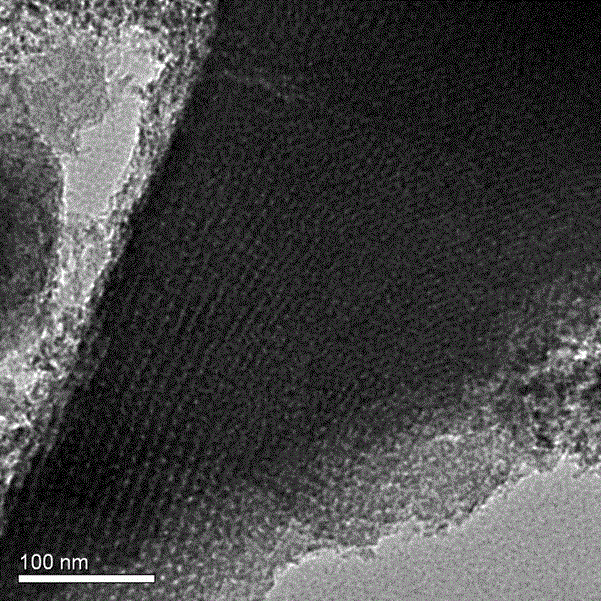

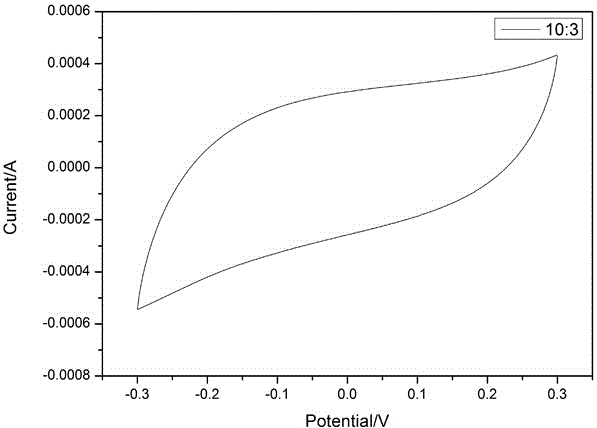

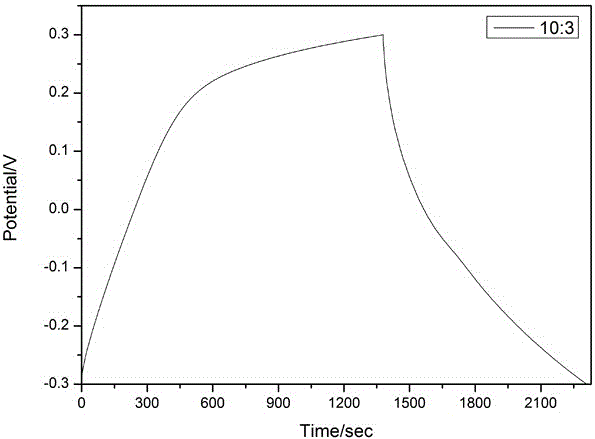

The invention relates to a hydrothermal synthesis preparation method of ion doping high-performance lithium iron phosphate. Iron source, nickel source, organic acid and phosphorus source are dissolved in deionized water according to a certain proportion, added with a dispersing agent, and mixed to obtain a mixed solution; lithium source which is uniformly dissolved in deionized water is dropwise and slowly added into the mixed solution; a pH is adjusted to 7.5-8.2 after dropping; the obtained alkalescent mixed solution is transferred to an autoclave; the autoclave is enclosed and insulated at 80-220 DEG C for 1 h-3 h; after cooling the autoclave is opened, and products are taken out, filtered with deionized water for several times and washed; an obtained filter cake is dried; then the obtained nickelic lithium iron phosphate powder and carbon contained organic compound in a mass ratio of 10:1-4 are treated with ball-milling for 1-3 h in alcohol, dried and sintered for 1-4 h at 600-800 DEG C under protection of nitrogen to obtain the product.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Nanometer ferrous silicate lithium material and preparation method thereof

ActiveCN101546828AHigh purityHigh charge and discharge capacityElectrode manufacturing processesPhosphorus compoundsCarbon nanotubeReaction temperature

The invention relates to a nano ferrous silicate lithium material and a preparation method thereof. The preparation method comprises the following steps: a lithium source, an iron source, a silicate source and a doping element compound are dissolved into a water solution which contains a complexing agent according to a certain stoichiometric ratio, a high-conductivity carbon nano tube dispersed by an auxiliary agent is added into the water solution and used as a wrapping material, an obtained solution is heated under the temperature of 100-200 DEG C for 1-3 hours to obtain gelatin, the obtained gelatin is sintered in an inert atmosphere furnace, the reaction temperature is 600-900 DEG C, and the reaction time is 3-16 hours. The invention effectively controls the chemical composition, the phase composition and the grain diameter of ferrous silicate lithium, and the obtained ferrous silicate lithium is nano ferrous silicate lithium wrapped by the carbon nano tube and has small and uniform grains with high purity quotient, higher charge-discharge capacity and good multiplying power property and circulation property, thus the ferrous silicate lithium is an ideal material for producing lithium ion batteries.

Owner:SHENZHEN DYNANONIC

Method for preparing iron/nitrogen-codoped ordered mesoporous carbon material

ActiveCN106517136AImprove wettabilityImprove electrochemical performanceCarbon preparation/purificationEtchingReaction temperature

The invention provides a method for preparing an iron / nitrogen-codoped ordered mesoporous carbon material. The method comprises the following steps: taking a triblock copolymer F127 as a template, under acidic condition, a silicon source-tetraethoxysilane, a carbon source-phenolic resin, a nitrogen source 1-urea, a nitrogen source 2-pyrroles monomer and an iron source-ferric trichloride are added, the micelle having a three-dimensional porous structure is synthesized with one step by a solvent volatilization induction self-assembly method, and the ordered mesoporous carbon material is obtained through high temperature carbonization and hydrofluoric acid etching. The method of the ordered mesoporous carbon material has the advantages of simple operation, low reaction temperature, and controllable condition, the prepared ordered mesoporous carbon material has the ordered three-dimensional tunnel structure, high specific surface area and excellent electrochemistry performance, and has good application prospect in the field of electrochemistry.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method of flaky nanometer FeS2/C negative electrode material

ActiveCN107611409AImprove ionic conductivityFast ion conductivityMaterial nanotechnologyCell electrodesMass ratioSolvent

The invention discloses a preparation method of a flaky nanometer FeS2 / C negative electrode material. The preparation method comprises the following steps: (1) dissolving an iron source and an organicligand into a solvent I, and stirring uniformly to obtain a homogeneous solution; (2) performing a hydrothermal reaction on the homogeneous solution obtained in the step (1), naturally cooling to room temperature, filtering, washing, depositing and drying to obtain yellow or red powder; (3) dispersing the yellow or red powder obtained in the step (2) and a sulfur source compound in a solvent II in the mass ratio of 1:(3 to 4), performing a hydrothermal reaction on mixed solution, natural cooling to room temperature, filtering, washing, precipitating and drying to obtain black powder; and (4)calcining the black powder obtained in the step (3) in a protective atmosphere, and cooling to room temperature to obtain the flaky nanometer FeS2 / C negative electrode material. The obtained flaky nanometer FeS2 / C negative electrode material is uniform in shape and size. A carbon material can be effectively compounded with ferrous sulfide, so that the ionic conductivity and electronic conductivityof the material are increased. The two-dimensional structure has the characteristics of shorter diffusion distance of lithium ions, high transmission rate, high specific surface area, high conductivity, high ion transmission speed and the like.

Owner:CENT SOUTH UNIV

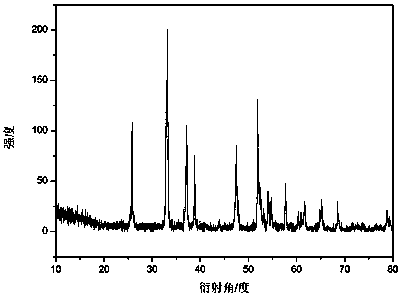

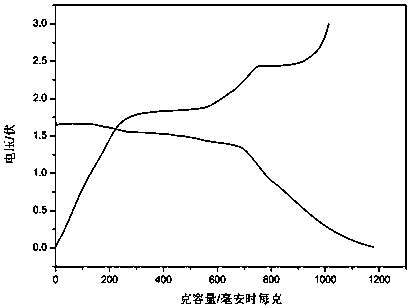

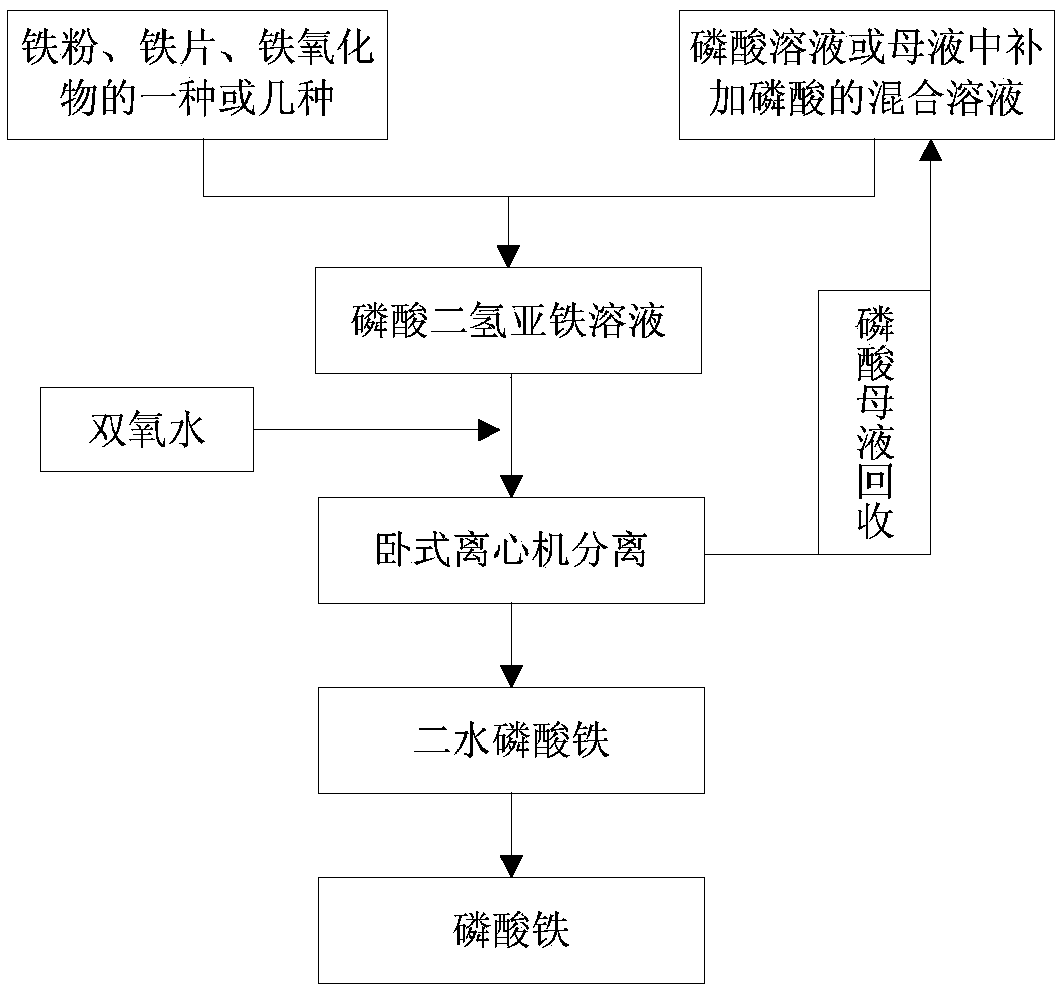

Ferric phosphate as well as preparation method and application thereof

ActiveCN108609595AImprove compactnessSmall repulsionCell electrodesPhosphorus compoundsIron powderLithium iron phosphate

The invention discloses anhydrous ferric phosphate as well as a preparation method and the application thereof. The preparation method comprises the following steps: (1) mixing a ferric source with aphosphorus source, heating to carry out a reaction so as to obtain a reaction liquid, and controlling a pH value of a final reaction point as 1.8-2.5, wherein the ferric source is one or more of ferric powder ferric pieces and a ferric oxide; (2) putting hydrogen peroxide into the reaction liquid obtained in the step (1), after a reaction is completed, heating to 85-98 DEG C, and carrying out a reaction continuously so as to obtain ferric dehydrate phosphate; (3) calcining the ferric dehydrate phosphate obtained in the step (2), namely obtaining ferric phosphate. The invention provides an anhydrous ferric phosphate preparation method which is high in purity, free of waste water emission and simple in process. By adopting the prepared anhydrous ferric phosphate as a precursor for synthesizing high vibration compacting spherical lithium iron phosphate, demands of high compacting densities and electrochemical properties can be met.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

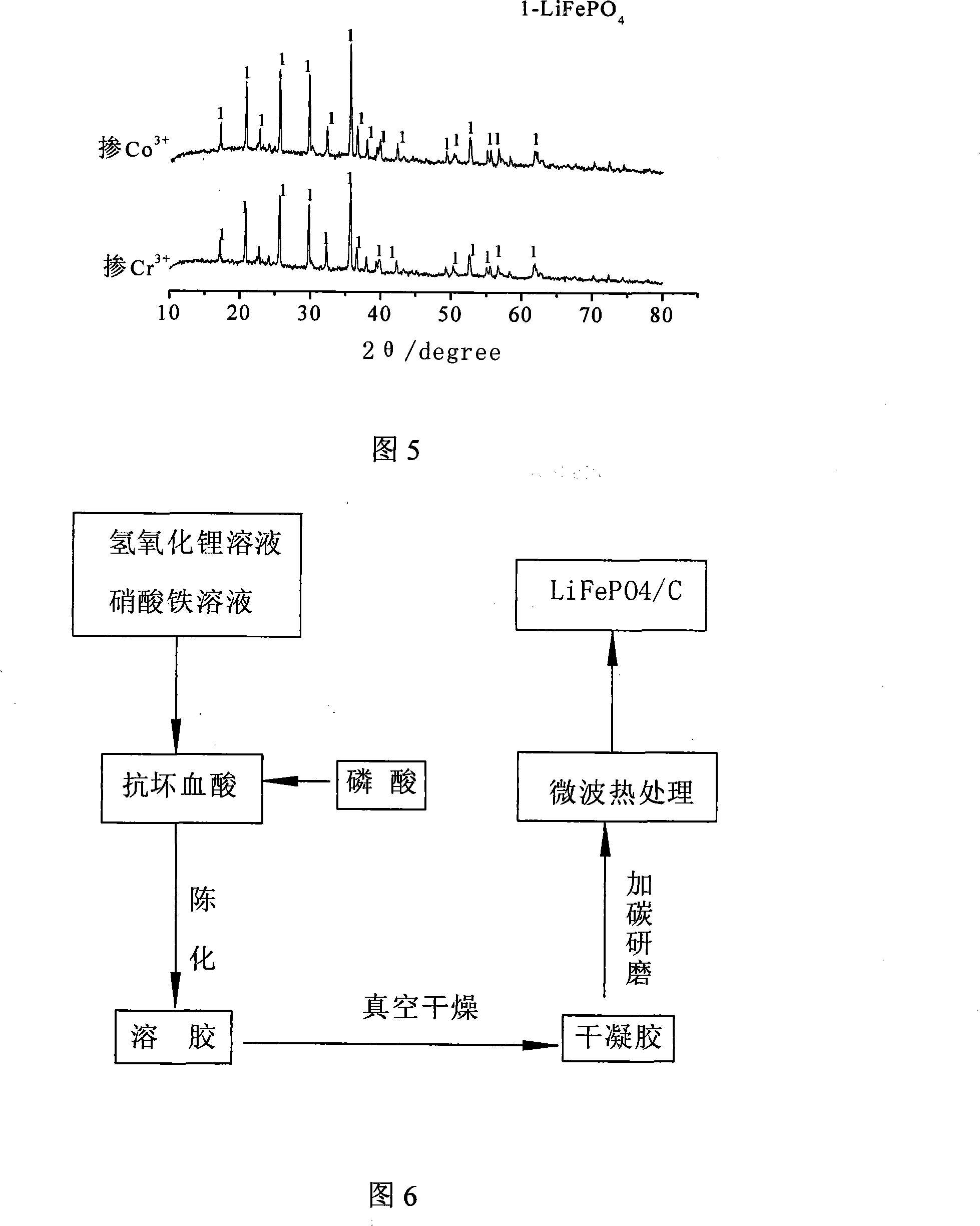

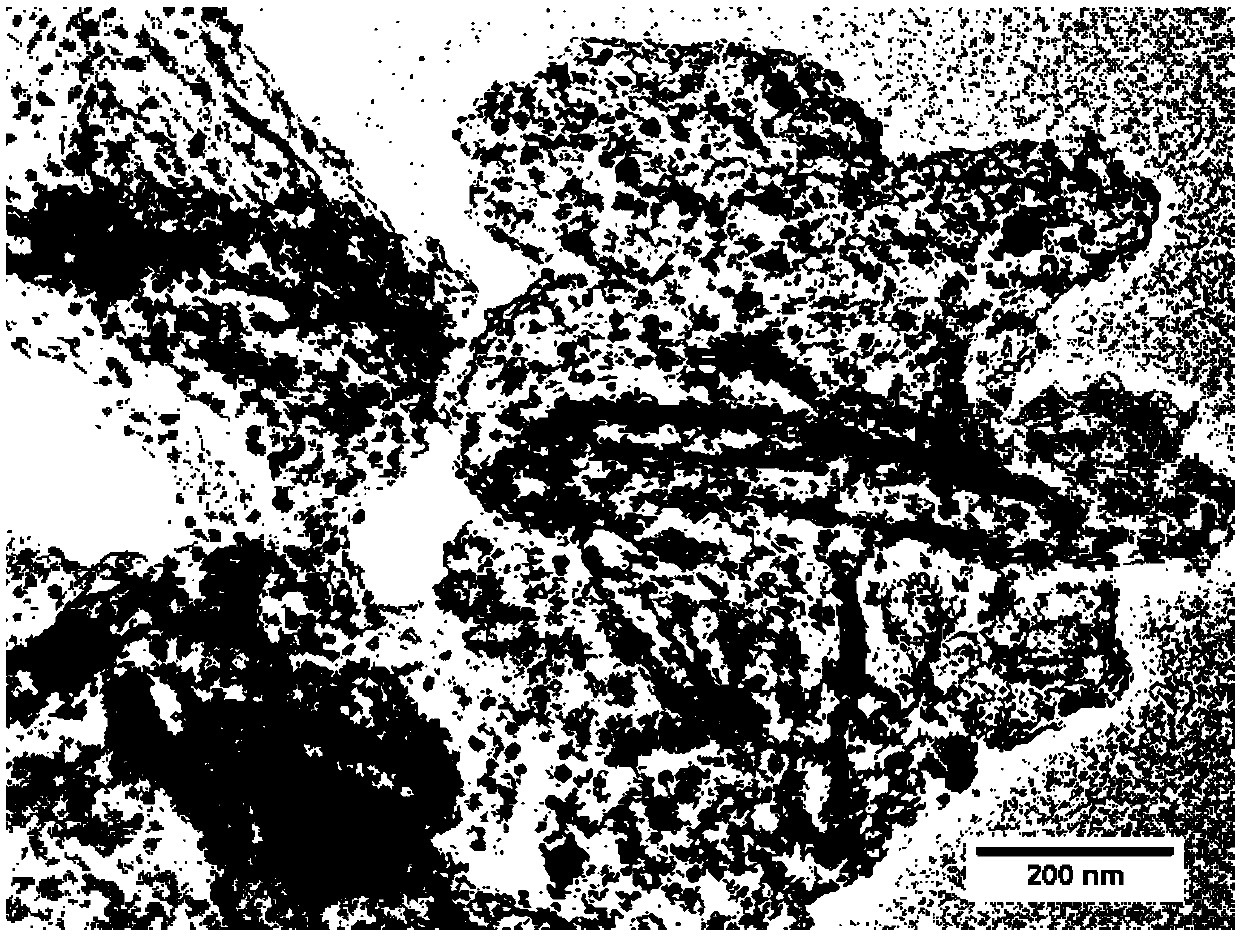

Method for producing high performance lithium ion battery anode material LiFePO4/C

InactiveCN101179124AIncrease the cell volumeIncreased Diffusion ChannelElectrode manufacturing processesPhosphorus compoundsHigh rateCharge discharge

The invention relates to a preparation method for making lithium ion battery cathode materials of LiFePO4 / C by using the reducing agent and inorganic salts of iron source, phosphorus source, lithium source, carbon source and so on as raw materials. Adopt the combining method of sol-gel and microwave treatment and prepare ultrafine particles of LiFePO4 and carbon coat the particles at the same time. On this basis, change the property of LiFePO4 / C by metal doping of Cr3 plus , Co3 plus . By processing with industrial microwave oven of high power, the invention shortens processing time greatly, increases the yield remarkably, reduces material cost and energy loss, simplifies the processes, improves the efficiency of industrial production of lithium ion battery and is convenient for implementation in industry. Take it as cathode materials of lithium ion battery with high-rate discharge. The invention raises conductivity of lithium iron phosphate and at the same time improves charge discharge capacity and cycle numbers by carbon coating and metal element doping.

Owner:江苏君明高新科技有限公司

Preparation method of iron, cobalt and nitrogen co-doped hierarchical pore carbon nanosheet oxygen reduction catalyst

InactiveCN108682872ALarge specific surface areaHighly graded pore structureCell electrodesCobaltNitrogen doped

The invention provides a preparation method of an iron, cobalt and nitrogen co-doped hierarchical pore carbon nanosheet oxygen reduction catalyst. According to the method, a ZnO nanosheet is taken asa template and a zinc source, 2-methylimidazole is taken as organic ligand, iron acetylacetonate is taken as an iron source, cobalt salt is taken as a cobalt source, and a core-shell structure ZnO@Zn / Fe / Co-ZIF precursor taking the ZnO nanosheet as a core and trimetallic hybrid zeolitic imidazolate skeleton compound Zn / Fe / Co-ZIF as a shell is obtained through the regulation of the ratio of the cobalt source to the iron source and adoption of a solvothermal method. ZnO@Zn / Fe / Co-ZIF is subjected to high-temperature calcinations in inert atmosphere, and the iron, cobalt and nitrogen co-doped hierarchical pore carbon nanosheet oxygen reduction catalyst is directly obtained. The method has the advantages that acid pickling is not required to remove a core layer template, an obtained carbon nanosheet is high in specific surface area, has a hierarchical pore structure, is rich in catalytic activity sites, and shows higher oxygen reduction catalytic activity than that of an iron and nitrogen doped carbon nanosheet and a cobalt and nitrogen doped carbon nanosheet.

Owner:JIANGSU UNIV OF TECH

Carbon-cladded sodium ferric pyrophosphate material and preparation method thereof as well application of carbon-cladded sodium ferric pyrophosphate material serving as sodium-ion battery positive electrode material

InactiveCN108123129AIncrease contact areaShort diffusion pathMaterial nanotechnologySecondary cellsCarbon layerHydrocarbon mixtures

The invention discloses a carbon-cladded sodium ferric pyrophosphate material and a preparation method thereof as well application of the carbon-cladded sodium ferric pyrophosphate material serving asa sodium-ion battery positive electrode material. The carbon-cladded sodium ferric pyrophosphate material has an ordered nano-structure and the surface of the material is uniformly cladded with a carbon layer; the preparation method of the carbon-cladded sodium ferric pyrophosphate material comprises the following steps: sequentially carrying out ball milling and mixing on an organic macromolecular surfactant, a phosphorous source, a hydrocarbon type mixture, an iron source and a sodium source to obtain a precursor; putting the precursor into a protective atmosphere and calcining to obtain the carbon-cladded sodium ferric pyrophosphate material. The carbon-cladded sodium ferric pyrophosphate material has the ordered nano-structure and a large contact area with electrolyte; an ion dispersion path is short and an ion dispersion speed in a battery system is effectively improved; an electron transmission speed and the stability of the electrode material are effectively improved through aconductive carbon layer; the carbon-cladded sodium ferric pyrophosphate material is used as the sodium-ion battery positive electrode material and has excellent electrochemical performance, and is anideal sodium-ion battery positive electrode material; a preparation process is simple in technology and low in cost; large-scale production is easy to enlarge and the carbon-cladded sodium ferric pyrophosphate material has a very great application prospect.

Owner:CENT SOUTH UNIV

Preparation method of stable nano ferroferric oxide magnetofluid

InactiveCN104528837ASlow growth rateHigh crystallinityMaterial nanotechnologyNanomagnetismSynthesis methodsBiocompatibility Testing

The invention belongs to the technical field of the preparation of iron oxide magnetofluids and particularly relates to an aqueous reduction based synthesis method of superparamagnetic ferroferric oxide nanoparticles. According to the aqueous reduction based synthesis method, an inorganic metal water-soluble compound (ferric salt) serves as an iron source, a reducing compound and a stabilizer which can be coordinated with iron serve as raw materials, and reduction reaction is carried out in an aqueous solution to generate the ferroferric oxide magnetofluid in situ. The aqueous reduction based synthesis method provided by the invention has the advantages of mild reaction condition and good repeatability, is easy to operate and safe, and the ferroferric oxide nanoparticles prepared by adopting the aqueous reduction based synthesis method overcome the defects that the ferroferric oxide particles prepared by adopting the traditional aqueous co-precipitation method are easy to agglomerate, can not be dispersed uniformly and are affected in application. The ferroferric oxide nanoparticles with stable performance are prepared successfully by adopting the aqueous reduction based synthesis method, and the ferroferric oxide nanoparticles have good biocompatibility, can form the magnetofluid in an aqueous solution and can be widely applied to the biomedical fields of magnetic resonance imaging, magnetofluid thermotherapy, cell separation, protein separation, DNA purification, immunodetection, magnetically targeted medicine carriers.

Owner:SHENYANG PHARMA UNIVERSITY

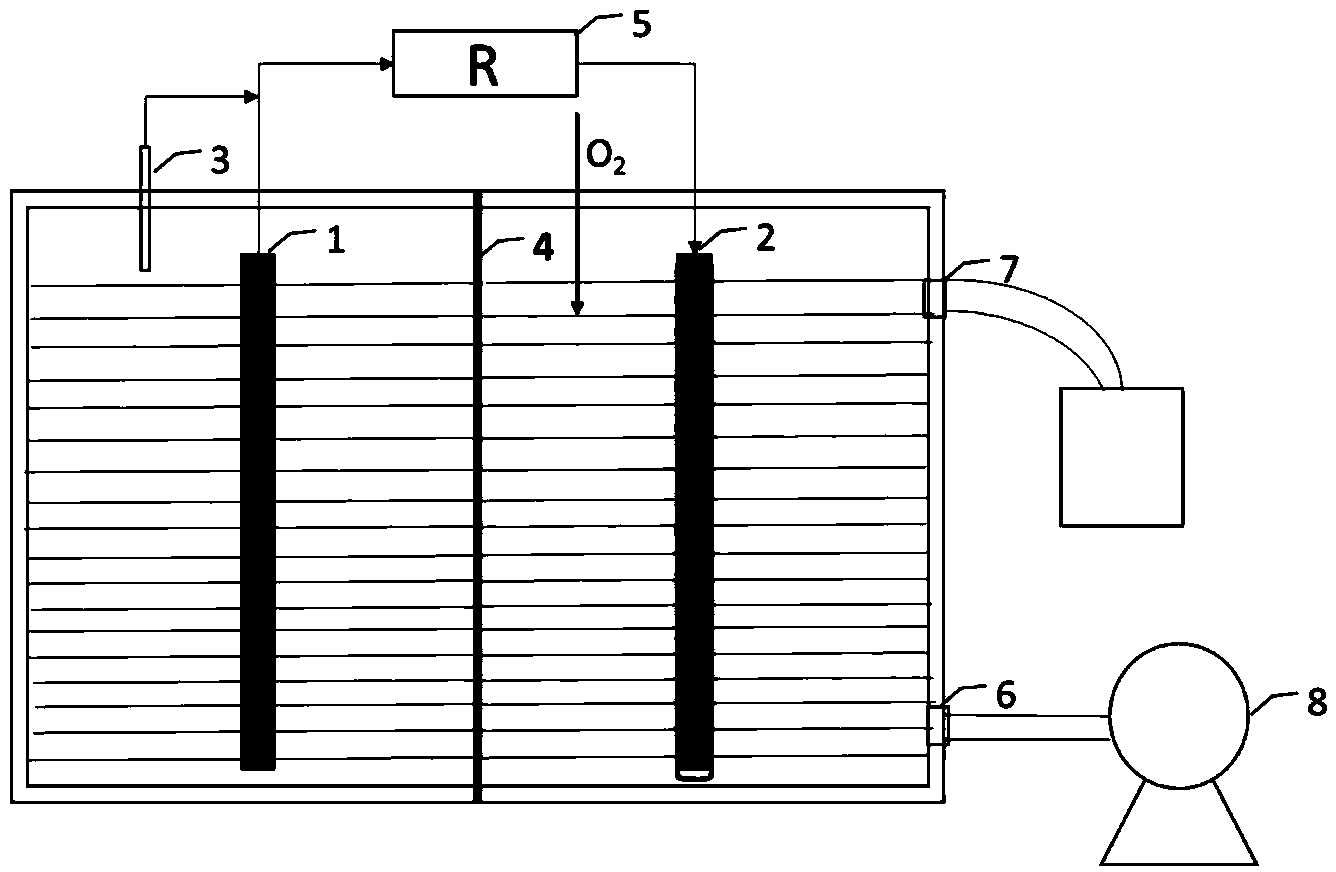

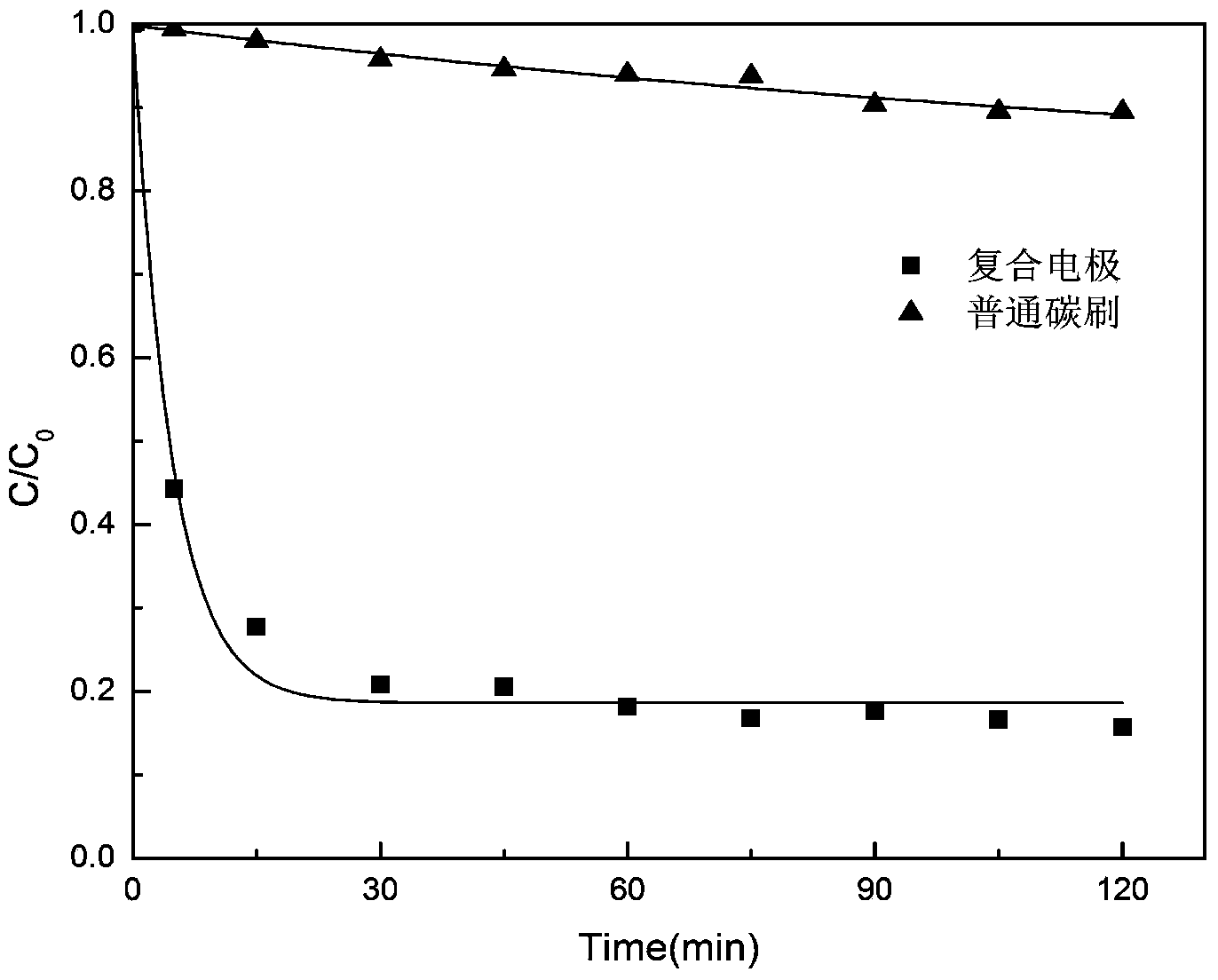

Combination electrode preparation method and application of combination electrode preparation method in bioelectricity Fenton system

InactiveCN104310573ARealize processingEasy to handleWaste water treatment from textile industryBiological water/sewage treatmentElectronBioelectrochemistry

The invention discloses a combination electrode preparation method and the application of the combination electrode preparation method in a bioelectricity Fenton system, and belongs to the field of environmental engineering and waste water treatment. According to a combination electrode prepared through the combination electrode preparation method, a bioelectrochemistry system serves as a reactor to treat azo dye waste water, anode electro-microorganisms oxidize organic matter so that electrons and protons can be generated, the electrons and the protons are transferred to a cathode chamber through an external circuit and an ion exchange membrane, H2O2 is generated on a cathode in an in-situ mode with O2 as the electron acceptor, a cathode iron source is slowly released, Fenton reaction is performed between iron and H2O2 generated in the in-situ mode, and thus non-biodegradable pollutants are treated.

Owner:JIANGNAN UNIV

Preparation method of positive electrode material LiFePO4/C of lithium ion battery

The invention discloses a method for preparing the positive electrode material LiFePO4 / C of a lithium ion battery by adopting carbon sources of the polystyrene sphere series. A carbon thermal reduction and solid phase sintering method is adopted in the preparation process. The method comprises the following concrete steps: firstly, uniformly mixing a lithium source, an iron source and a phosphorus source, and then, mixing the mixture with a carbon source; then, adding a solvent for ball milling, and drying to obtain a precursor; and pretreating and calcining the precursor in the protective atmosphere, and then, cooling the precursor in a furnace to synthesize the LiFePO4 / C of which the particle size distribution is uniform and the particle diameter is 200-500nm. The invention has the advantages of wide sources of raw materials, simple preparation method, convenient control and operation, good carbon coating effect, excellent electrochemical performance and the like.

Owner:XINJIANG JINSHENGDA NONFERROUS METAL MATERIALS CO LTD +1

Nitrogen-doped Fe/Fe3C/C microbial fuel cell cathode catalyst material and preparation method thereof

The invention discloses a nitrogen-doped Fe / Fe3C / C microbial fuel cell cathode catalyst material and a preparation method thereof, and relates to a microbial fuel cell cathode catalyst material and a preparation method thereof, which aim to solve the problem that the cost is high due to a platinum-carbon catalyst adopted as the microbial fuel cell cathode catalyst material in the prior art. The nitrogen-doped Fe / Fe3C / C microbial fuel cell cathode catalyst material is a composite material prepared from a ferrum source and a carbon source, and is a composite material with Fe particles and Fe3C particles uniformly distributed on a graphitization carbon framework, and the particle diameter is 10nm-300nm. The method comprises the following steps of dissolving, water bath heating, drying, and high-temperature carbonization reduction, thereby obtaining the nitrogen-doped Fe / Fe3C / C microbial fuel cell cathode catalyst material. The preparation method is used for preparing the nitrogen-doped Fe / Fe3C / C microbial fuel cell cathode catalyst material.

Owner:哈尔滨市道外区大化化验仪器批发站

Cathode material LiMn1-xFexPO4 for lithium ion cell and preparation method of cathode material LiMn1-xFexPO4

ActiveCN104577119AIncrease energy densityImprove cycle performanceCell electrodesPhosphorus compoundsHigh energyManganese

The invention discloses a cathode material LiMn1-xFexPO4 for a lithium ion cell and a preparation method of the cathode material LiMn1-xFexPO4. The preparation method comprises the following steps: manganese source compounds and iron source compounds are adopted as the raw materials to prepare manganese-rich solution and a manganese-poor solution respectively, a FeMnPO4 precursor with a gradient structure is synthesized through a coprecipitation method by controlling the sample adding speed, and then lithium doping and high-temperature calcination are performed to prepare the LiMn1-xFexPO4 with a gradient structure, that is the manganese content of the LiMn1-xFexPO4 is gradually reduced while the iron content of the LiMn1-xFexPO4 is gradually increased from inside to outside along the particle radius of the LiMn1-xFexPO4. The anode material LiMn1-xFexPO4 with the gradient structure has the characteristics of high energy density, good cycle performance and excellent rate capability and is applied to the field of application of power lithium-ion batteries.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for preparing iron-free aluminium sulfate and superfine active carbon white utilizing aluminium first-class ore

InactiveCN1850607AConcentration easyDo not reduce the concentrationSilicaAluminium sulfatesSurface-active agentsActive particles

The invention discloses a method for preparing iron-free aluminum sulfate and superfine active white carbon black with bauxite, crushing the bauxite and removing dissociative iron source by magnetic separation, and then reacting with vitriol; adding in dithiocarbamate with medium and high molecular weights and multiple functionalities to remove iron ions by solid phase reaction, and filtering, where the filtrate is iron-free aluminum sulfate; washing filter residue with alkaline water solution, surface active agent water solution, and tap water, respectively, to neutralize it, then after reacting with alkali, filtering, making filtrate, inorganic acid and active particles react mutually, filtering, water-washing, and drying to obtain the superfine active white carbon black. And the method has simple process, and low cost, applied to industrialized production, where the iron content of the prepared aluminum sulfate is less than 15 ppm, and the grain size, specific surface area, tensile strength, added value of the superfine white carbon black are 0.5-5 mum, greater than 200 m2 / g, higher than 17.0 MPa, and high, respectively.

Owner:杭州百事特实业股份有限公司

Method for preparing lithium iron phosphate serving as cathode material of nano-level lithium ion battery

ActiveCN102522546ASmall particle sizeLow costMaterial nanotechnologyCell electrodesCarbon compositesSlurry

The invention discloses a method for preparing lithium iron phosphate serving as a cathode material of a nano-level lithium ion battery. The method is characterized by comprising the following steps of: adding a composite carbon source into a solvent, and uniformly dispersing; mixing a lithium source, iron source and phosphorus source compound and the composite carbon source, putting the mixture into a ball grinder for grinding to obtain slurry; drying and smashing the slurry to obtain a precursor; calcining the precursor under a protective atmosphere; and along with the thermal cracking of the carbon source compound, coating a layer of carbon source on a crystal to form a carbon-coated film with relatively high graphitized crystallinity at high temperature, and thus obtaining the lithium iron phosphate with a carbon composite olivine structure. According to the lithium iron phosphate cathode material prepared by using the method, the chemical constituent, the phase composition and the particle size of the LiFePO4 can be controlled effectively; the primary particle size of the LiFePO4 is 20 to 600 nanometers; and the LiFePO4 has relatively high electronic conductivity and relatively high specific capacity.

Owner:连云港华海诚科电子材料有限公司

Method for preparing carbon-coated LiFePO4 by microwaves and carbon-coated LiFePO4 material

InactiveCN101714634AComplete carbon coatingEasy to processCell electrodesPhosphorus compoundsShielding gasChemical measurement

The invention provides a method for preparing carbon-coated LiFePO4 by microwaves, which comprises the following steps: respectively obtaining a lithium source compound, a ferrous iron source compound and a phosphorous source compound in a stoichiometric ratio of the LiFePO4 required to be prepared, and adding a microwave absorber, an organic carbon source and a liquid dispersant; performing ball milling on the obtained raw material and drying treatment; putting the dried product in a microwave heating reaction cavity, and introducing protective gas into the reaction cavity; and heating to the temperature of between 550 and 850DEG C with the microwaves, introducing carbon source gas, and performing pyrolysis on the carbon source gas at the temperature of between 550 and 850DEG C to prepare the carbon-coated LiFePO4. The invention also provides a carbon-coated LiFePO4 material prepared by the method. The preparation method adopts microwave heating, and the carbon source gas is subjected to pyrolysis, so that the carbon species are deposited on the surface of the LiFePO4 to obtain the complete, uniform and firm carbon-coated LiFePO4; and simultaneously, by the preparation method, the machining property and the electrochemical performance of the LiFePO4 material can be obviously improved.

Owner:SHENZHEN UNIV

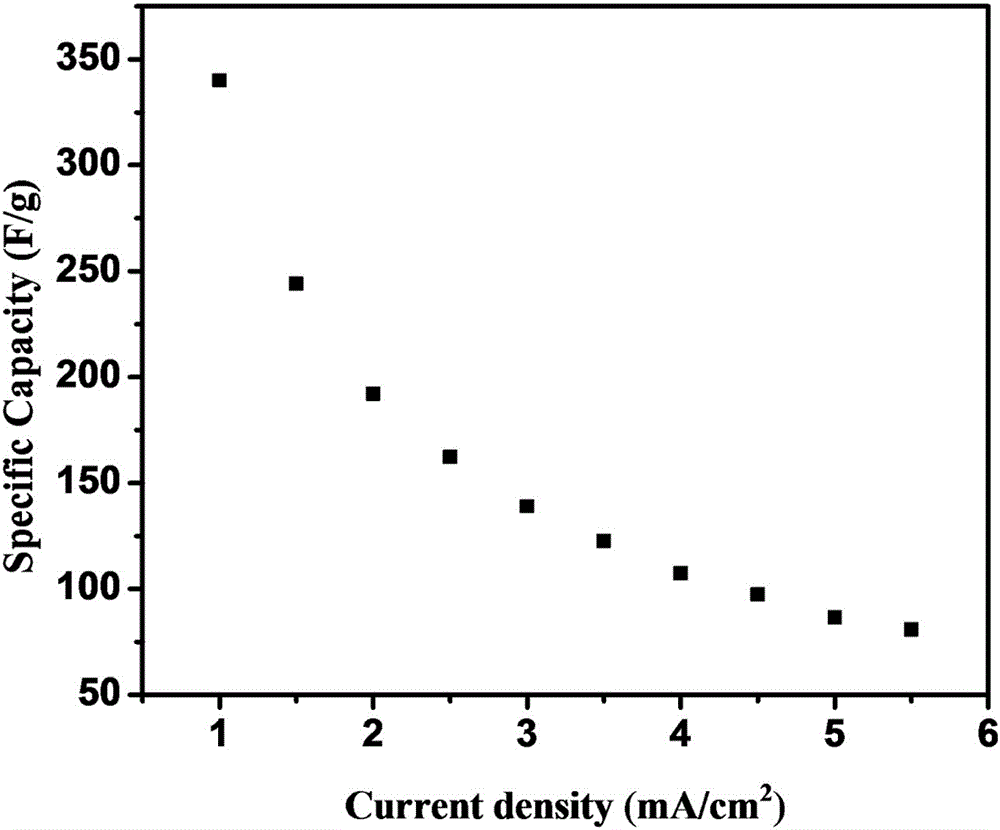

Vulcanized modification method for Ni-Fe LDH electrode material

InactiveCN106601500AIncrease capacityEasy transferHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceVulcanization

The invention discloses a vulcanized modification method for a Ni-Fe LDH electrode material. Urea is used as a precipitant and ferrous chloride is used as an iron source. Ni-Fe LDH grows on a nickel net substrate; and with a solvothermal method, vulcanization is carried out on the Ni-Fe LDH by using thiourea, sodium sulphide, or thioacetamide as a vulcanizing agent to obtain Ni-Fe LDH-S growing uniformly on the surface of the nickel net based on a cellular structure. Electrochemical performance evaluation is carried out on the Ni-Fe LDH-S in a 1M KOH electrolyte; and a potential window range is stabilized to be -1.1 to 0V. When constant-current charging and discharging are carried out in the potential window, the specific capacitance of the Ni-Fe LDH-S can reach 340 F / g, wherein the specific capacitance of the sample being Ni-Fe LDH without second-step vulcanization is only 45F / g. The result demonstrates that the specific capacity of the Ni-Fe LDH can be improved substantially.

Owner:CHINA THREE GORGES UNIV

Iron-nitrogen codope carbon microspheres as well as preparation method, application and oxygen reduction electrode

ActiveCN106784865AImprove performanceImprove electrochemical performanceCell electrodesMicrosphereHigh pressure

The invention relates to a preparation method of an iron-nitrogen codope carbon microsphere composite material. The preparation method comprises the following steps: S1, performing sealed reaction on hexachlorobutadiene, an iron source compound and a nitrogen-containing compound at high temperature and high pressure; S2, after the reaction is completed, releasing the pressure to normal pressure, naturally cooling to the room temperature, and drying obtained solids so as to obtain a dried sample; S3, performing high-temperature roasting treatment on the dried sample in the presence of an inert gas, thereby obtaining the iron-nitrogen codope carbon microsphere composite material. The invention further relates to a composite material, application of the composite material, and an oxygen reduction electrode with the composite material. The iron-nitrogen codope carbon microsphere composite material is excellent in property, can be used for preparing the oxygen reduction electrode of a fuel battery, thus can be used in fuel batteries, is good in electrochemical property, and has great application potential and industrial values in the electrochemical field.

Owner:温州邦欣源科技有限公司

Industrial preparation method for lithium iron phosphate

InactiveCN101955175AEvenly dispersedParticles are small and uniformCell electrodesPhosphorus compoundsSource materialNew energy

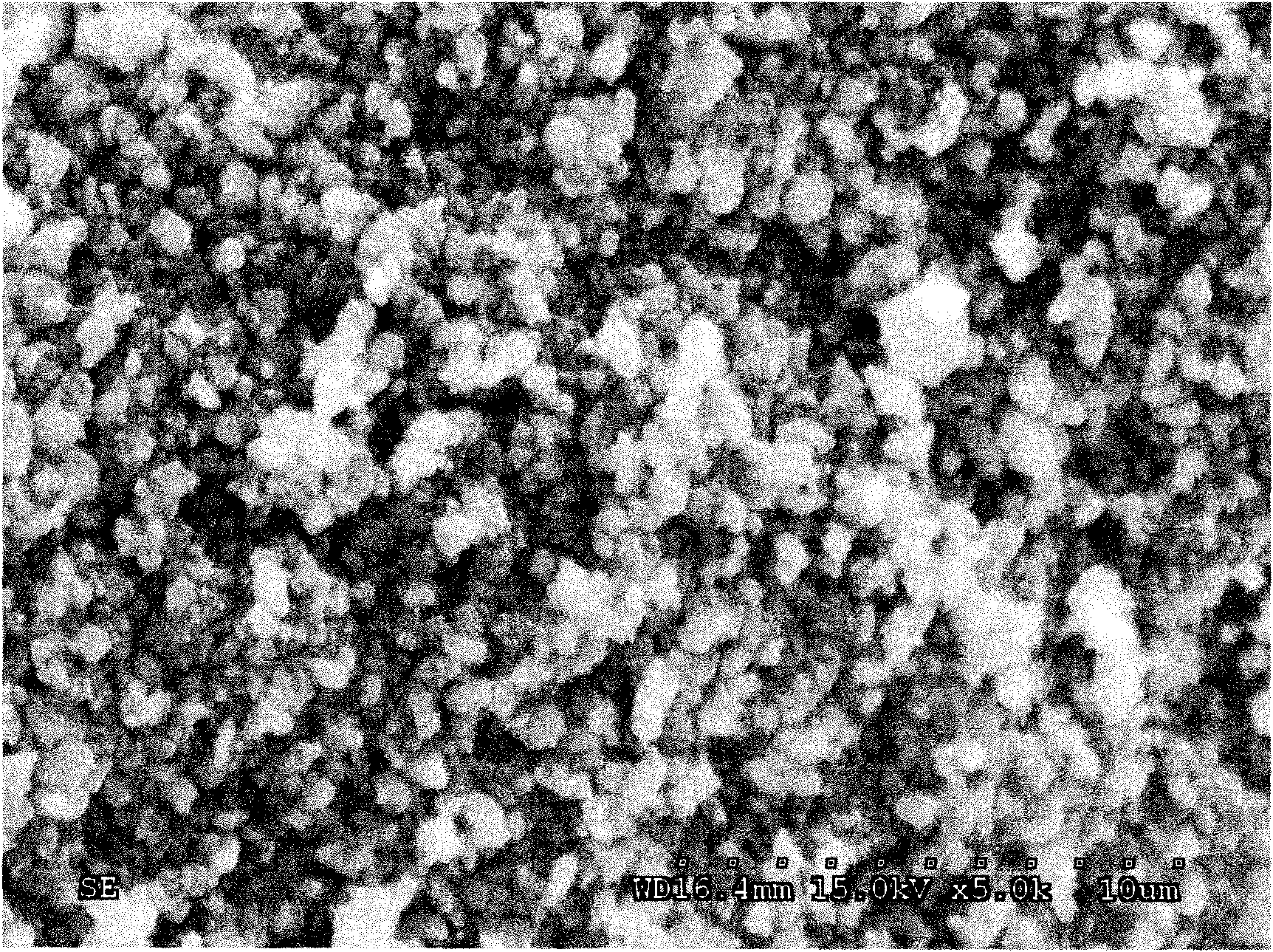

The invention belongs to an energy material, and particularly relates to a method for preparing a lithium iron phosphate anode material suitable to be used by a power type lithium ion battery and the like by using PVP (polyvinylpyrrolidone) as a dispersant and a carbon source at the same time in an aqueous solution. The method comprises the following steps of: weighing a lithium source compound, an iron source compound and a phosphorus source compound in a weight ratio, adding the compounds into water, adding a proper amount of PVP into the mixture, grinding the mixture for certain time, drying the mixture, transferring the obtained precursor into an atmosphere protection furnace, treating the precursor for certain time at a high temperature under inert atmosphere, and cooling the product to obtain the lithium iron phosphate. By observing, one-time particles are uniform and fine, and the first discharge capacity is 157.6mAh / g. The method has the advantages of low energy consumption, high grinding efficiency and environment-friendly and pollution-free production process, and is an excellent method for synthesizing a green new energy source material. The prepared material has the advantages of uniform particle size distribution, good circulating stability and prominent magnification performance, and is a battery anode material suitable for high-capacity energy storage equipment such as substations and the like and large-sized mobile equipment such as electric automobiles and the like.

Owner:BEIJING CENT PRESS UNION TECH

A transition metal element doped and transition metal oxide-coated lithium iron phosphate composite cathode material and preparation method

InactiveCN102280639AImprove conductivityImprove discharge capacityCell electrodesLithium iron phosphateBall mill

The invention relates to the field of lithium iron cell electrode materials and preparation technologies thereof, in particular to a transition metal element-doping and transition metal oxide-coating lithium iron phosphate composite anode material and a preparation method. The preparation method of the material comprises the following steps of: (1) carrying out ball-milling on a lithium source, an iron source, a phosphorous source and a transition metal element according to the atomic ratio of Li: Fe: PO4: M being (0.995-0.95): 1:1: (0.005-0.05), drying, and calcining at the inert atmosphere to obtain a transition metal element-doping lithium iron phosphate composite anode material; and (2) mixing and ball-milling the transition metal element-doping lithium iron phosphate composite anode material obtained in the step (1) and an transition metal oxide, and then calcining at the inert atmosphere to obtain the transition metal element-doping and transition metal oxide-coating lithium iron phosphate composite anode material. The invention has the advantages of improving the specific capacity and the cycling property per se since a transition metal element is doped to the lithium iron phosphate and a transition metal oxide coats the lithium iron phosphate.

Owner:ZHONGKE LITHIUM BATTERY NEW ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com