Method for preparing iron/nitrogen-codoped ordered mesoporous carbon material

A technology of co-doping and carbon materials, applied in the field of mesoporous carbon materials, can solve the problems of poor fusion between precursors and templates, cumbersome hard template experiment process, complicated and lengthy process, etc., and achieve high yield, uniform pore size, and experimental The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Preparation of carbon source-phenolic resin: Weigh 8 g of phenol and melt it in a beaker at 41 °C, add 1.7 g of NaOH aqueous solution (20 wt%) dropwise, stir for 10 min, add dropwise, 14.16 g of formaldehyde solution (37%), heated to 70 °C for 1 h, 0.6 mol / L hydrochloric acid solution to balance the pH to neutral, and 45 °C rotary steamed for 1 h to obtain phenolic resin, which was prepared into 20 wt% phenolic resin in absolute ethanol solution ;

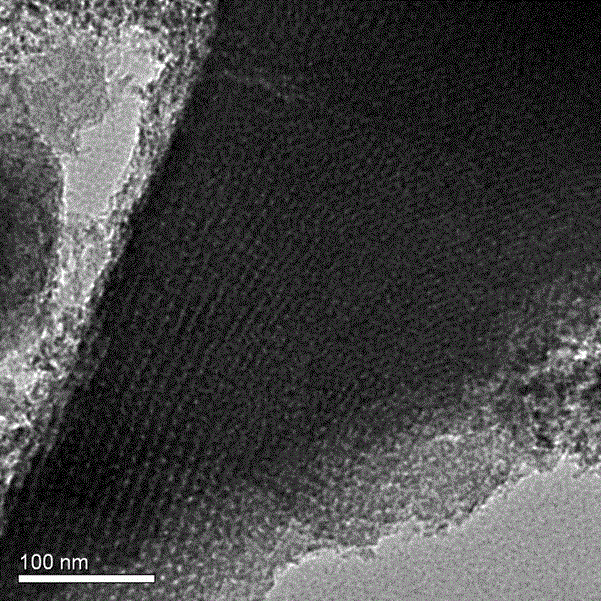

[0048] (2) Dissolve 1.6 g of surfactant F127 in 8 g of absolute ethanol, slowly add 1 g of hydrochloric acid solution (0.2 M), stir at 40°C for 1 h, add 0.2 g of urea, 2.08 g of tetraethyl orthosilicate (TEOS), 5 g of phenolic resin in absolute ethanol solution (20 wt%), continue stirring for 30 min, 1 ml of pyrrole monomer (density 0.967g / ml), 15 ml of ferric chloride solution (concentration 0.289 M) Slowly add dropwise to the mixed solution, keep stirring for 2h at the temperature. Place the above mixed solution in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com