Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6801 results about "Hydrofluoric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrofluoric acid is a solution of hydrogen fluoride (HF) in water. It is a precursor to almost all fluorine compounds, including pharmaceuticals such as fluoxetine (Prozac), diverse materials such as PTFE (Teflon), and elemental fluorine itself. It is a colourless solution that is highly corrosive, capable of dissolving many materials, especially oxides. Its ability to dissolve glass has been known since the 17th century, even before Carl Wilhelm Scheele prepared it in large quantities in 1771. Because of its high reactivity toward glass and moderate reactivity toward many metals, hydrofluoric acid is usually stored in plastic containers (although PTFE is slightly permeable to it).

System and method for forming a gate dielectric

InactiveUS6858547B2Vacuum evaporation coatingSemiconductor/solid-state device manufacturingHydrofluoric acidGate dielectric

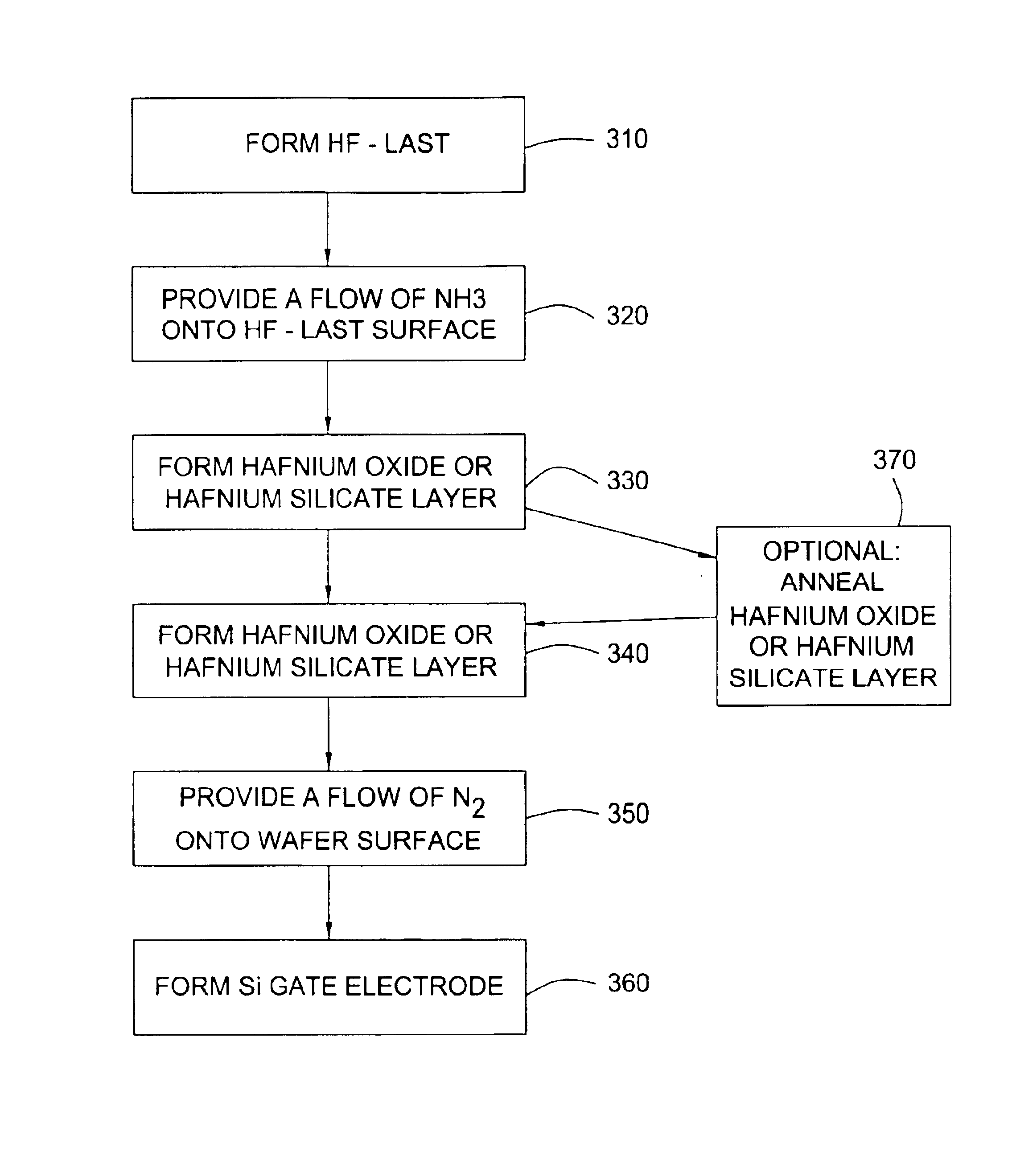

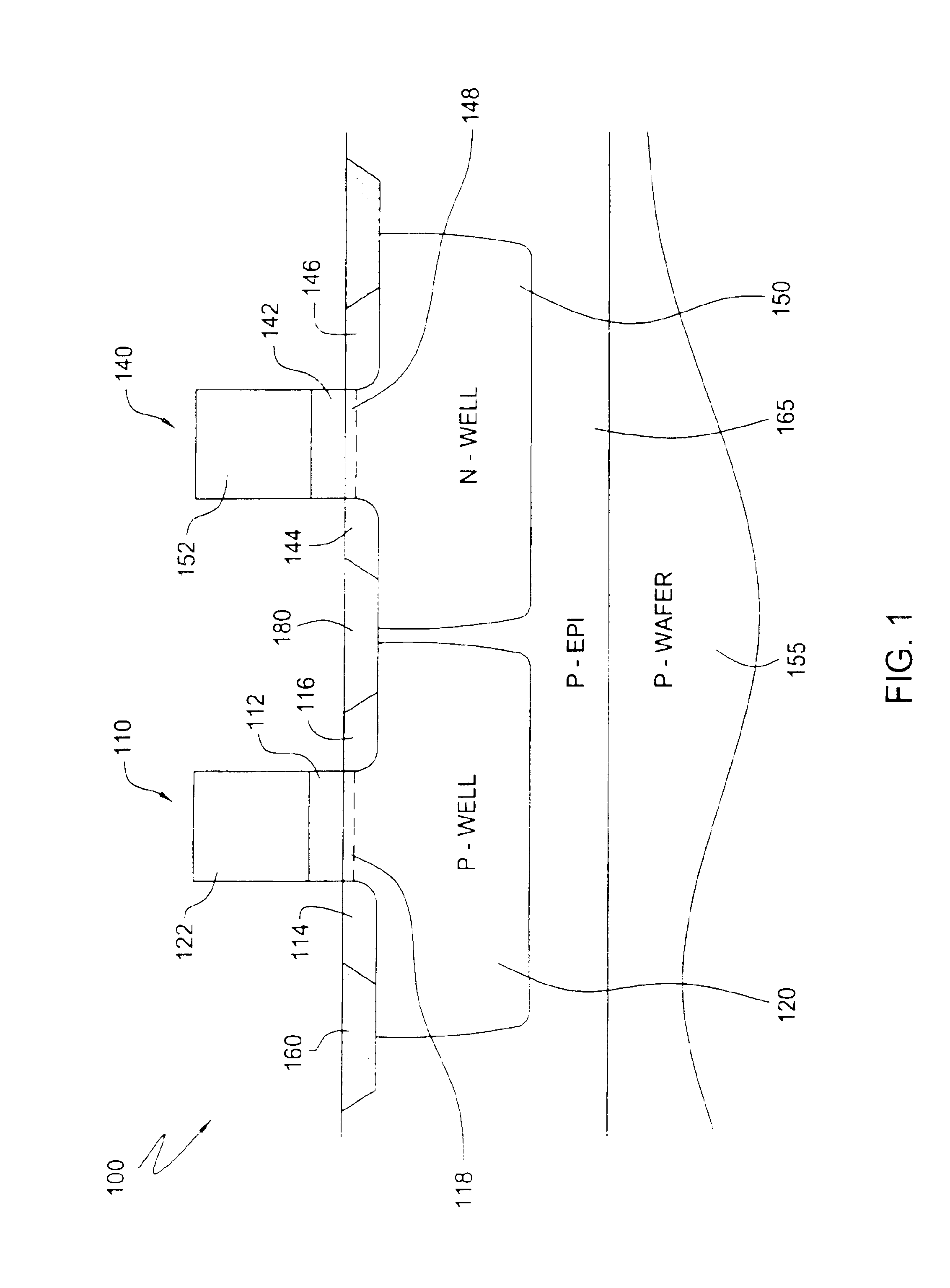

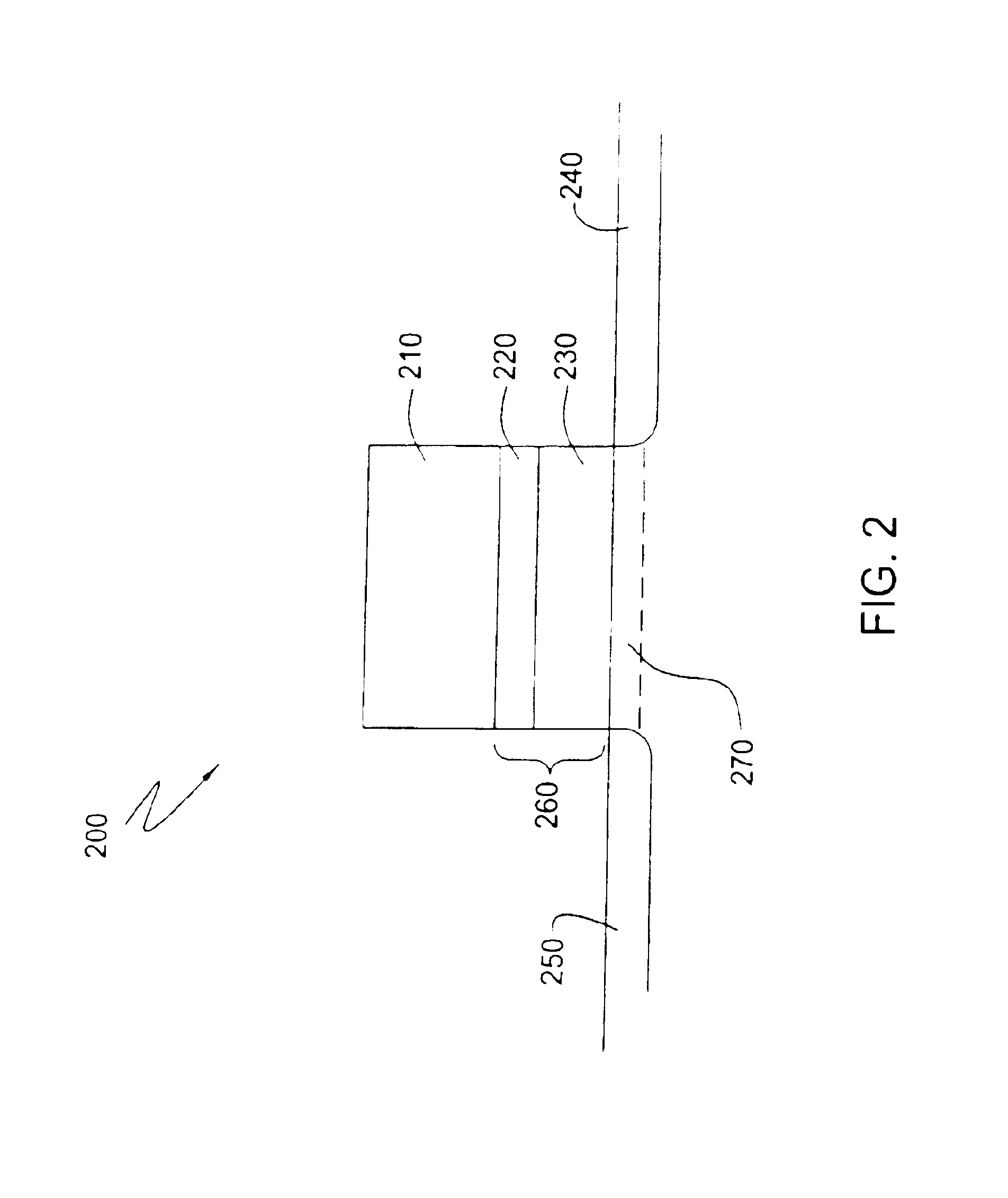

A method of forming a dielectric stack on a pre-treated surface. The method comprises pre-cleaning a semiconductor wafer to remove native oxide, such as by applying hydroflouric acid to form an HF-last surface, pre-treating the HF-last surface with ozonated deionized water, forming a dielectric stack on the pre-treated surface and providing a flow of NH3 in a process zone surrounding the wafer. Alternately, the method includes pre-treating the HF-last surface with NH3, forming the stack after the pre-treating, and providing a flow of N2 in a process zone surrounding the wafer after the forming. The method also includes pre-treating the HF-last surface using an in-situ steam generation process, forming the stack on the pre-treated surface, and annealing the wafer after the forming. The pre-treating includes providing an inert gas flow in a process zone surrounding the HF-last surface, reacting hydrogen with an oxidizer in the process zone for a very short duration, and providing an inert gas flew in the process zone after the reacting.

Owner:APPLIED MATERIALS INC

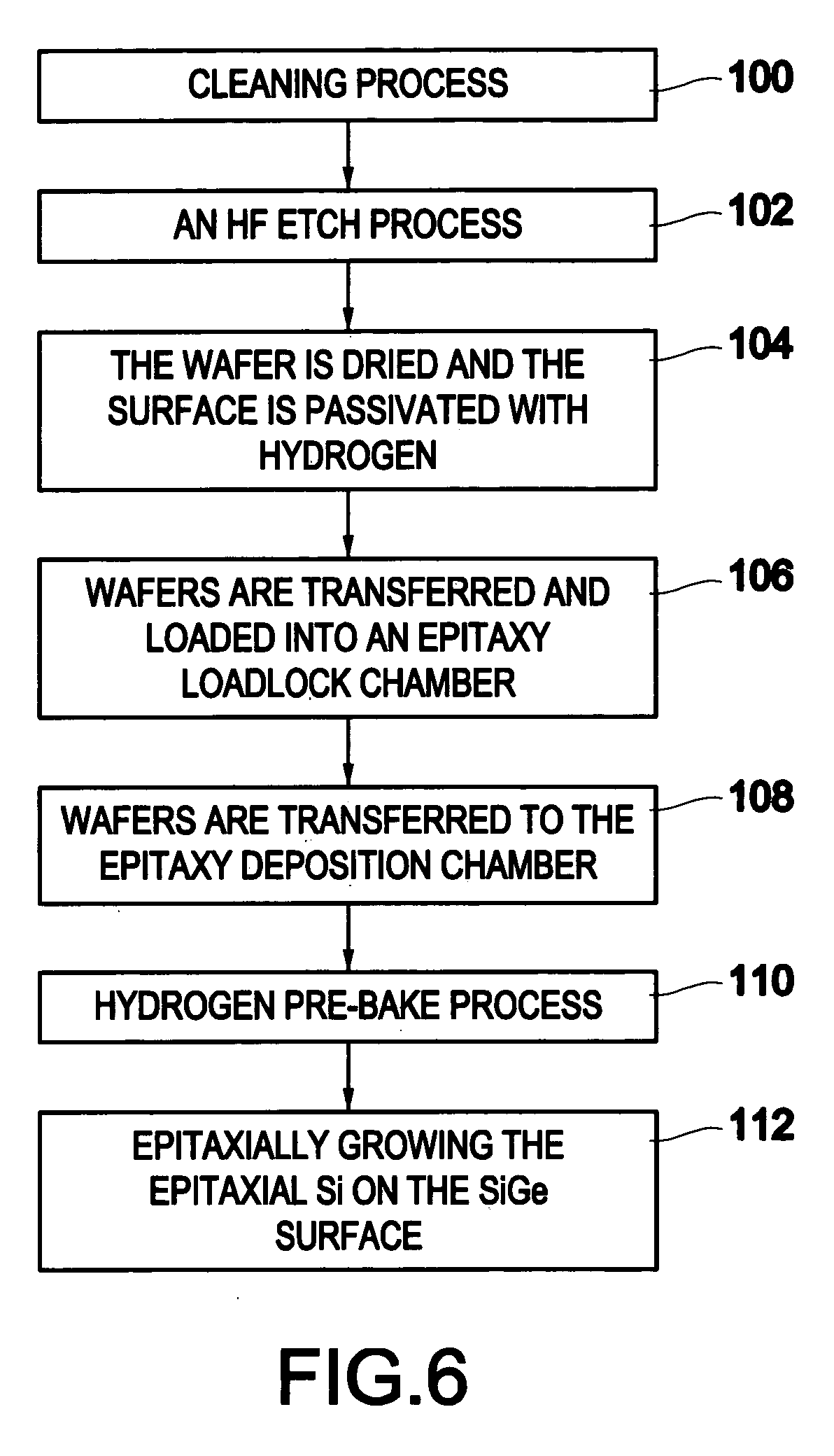

Method of preventing surface roughening during hydrogen pre-bake of SiGe substrates using chlorine containing gases

InactiveUS20050148162A1Prevent surfaceAvoid creatingPolycrystalline material growthSemiconductor/solid-state device manufacturingPartial oxidationSilicon on insulator

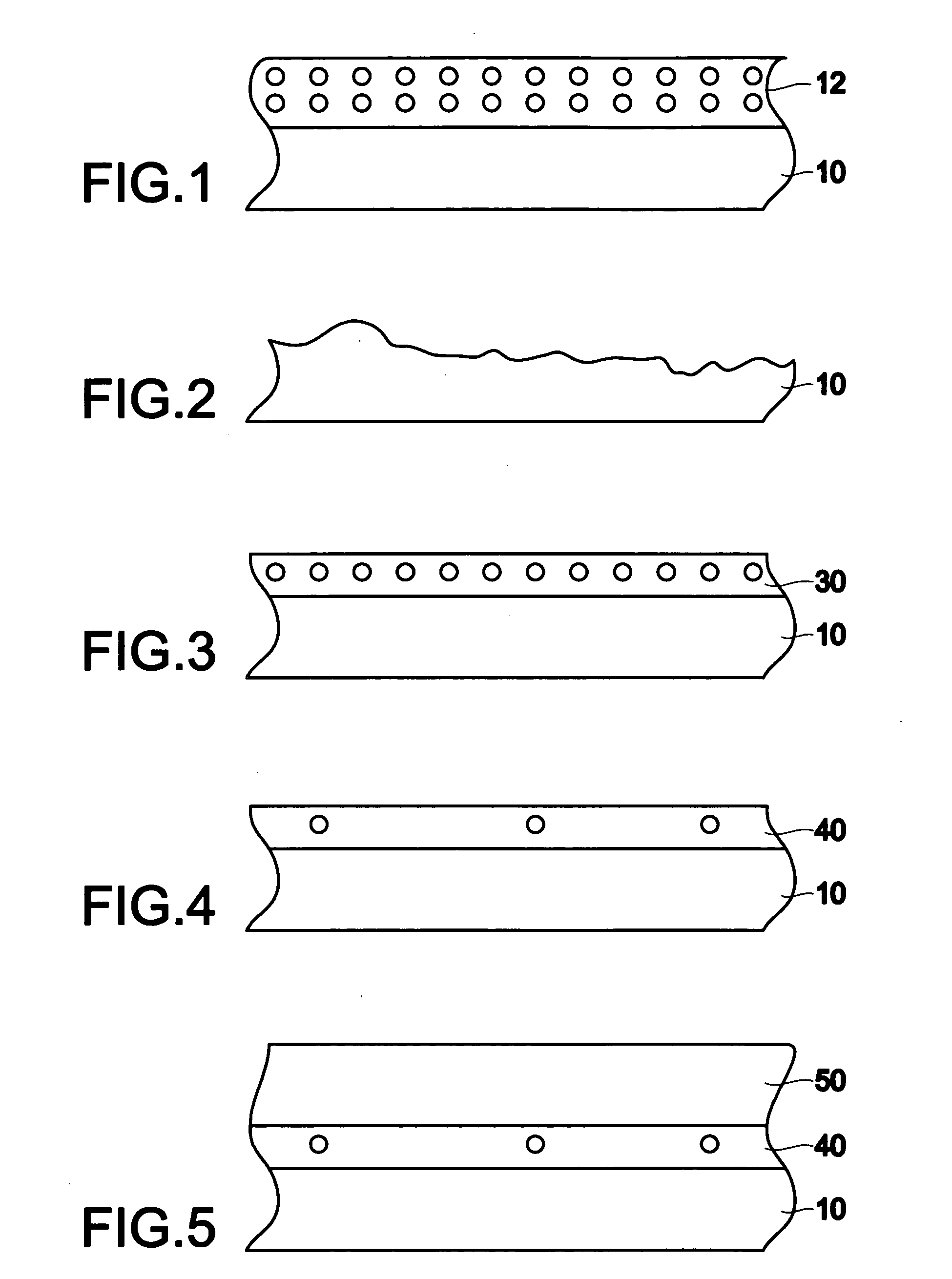

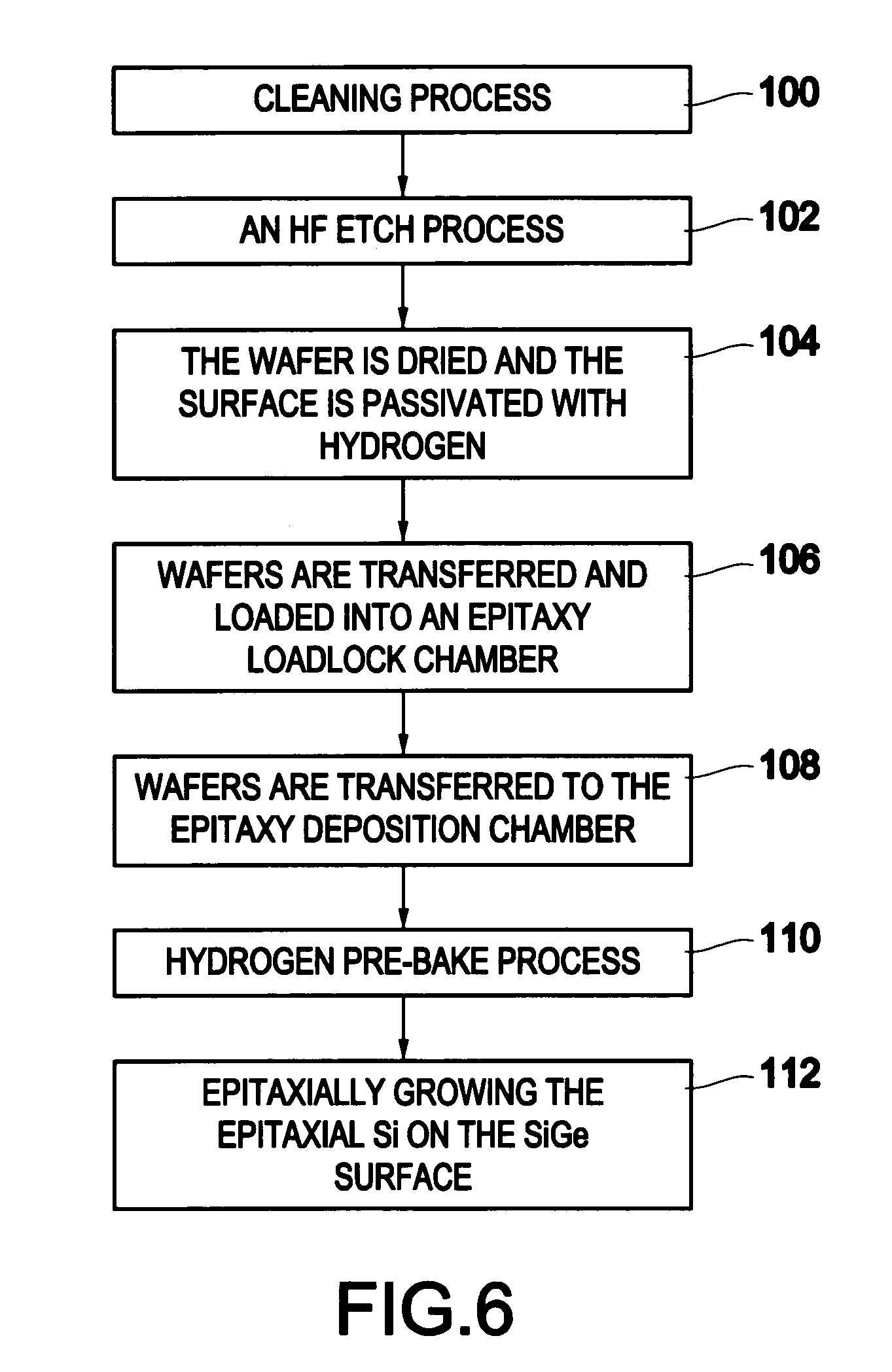

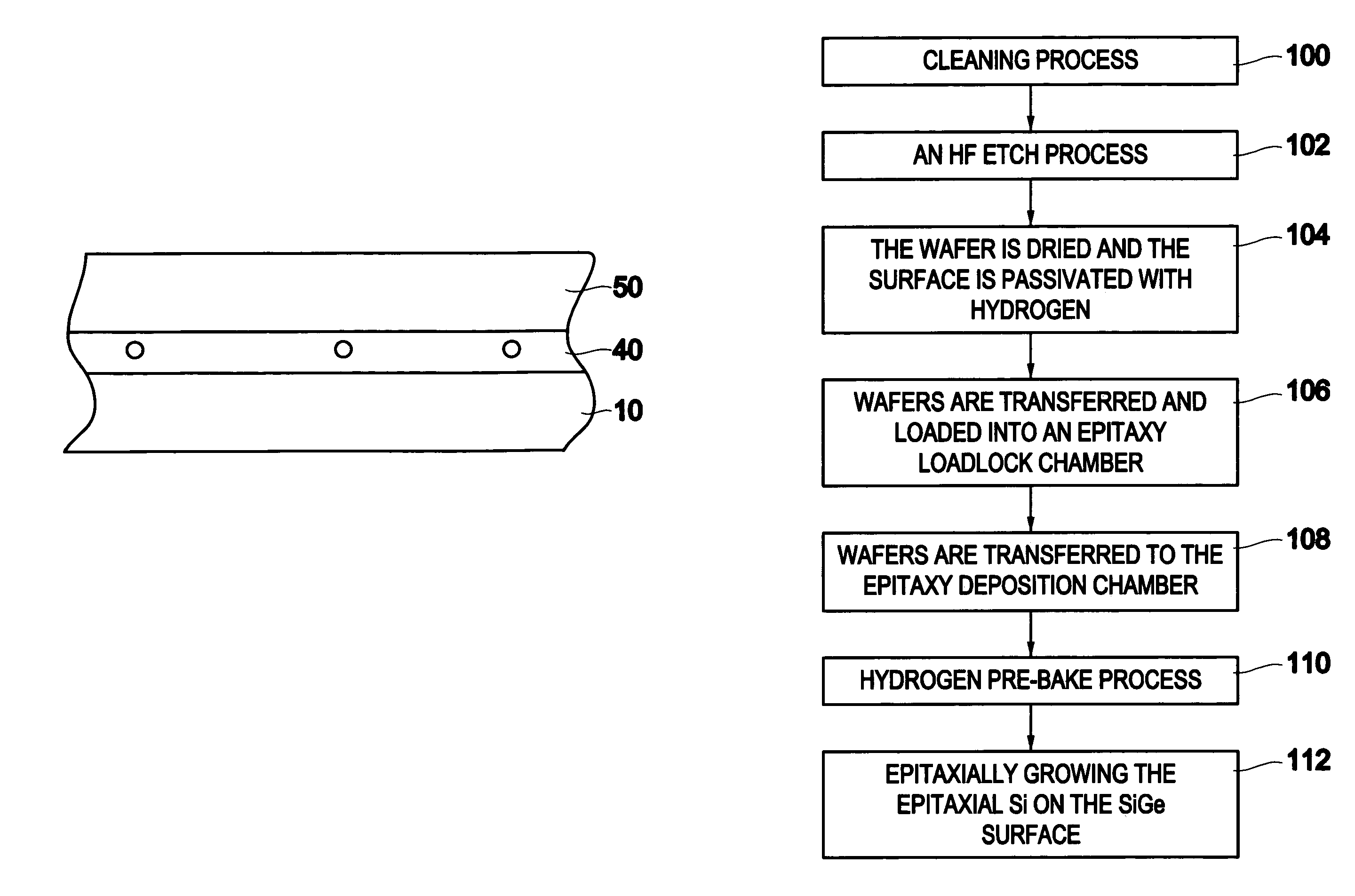

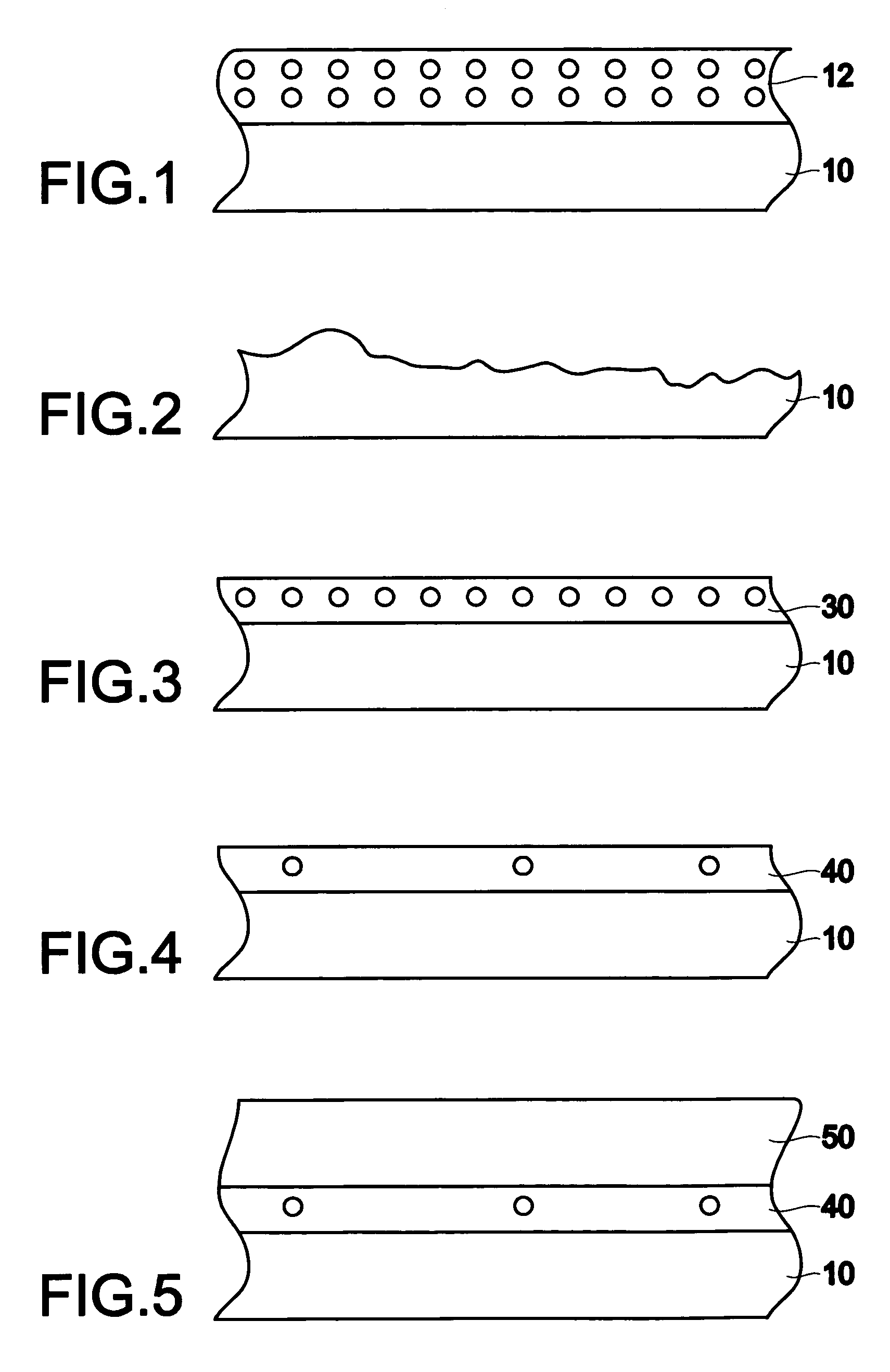

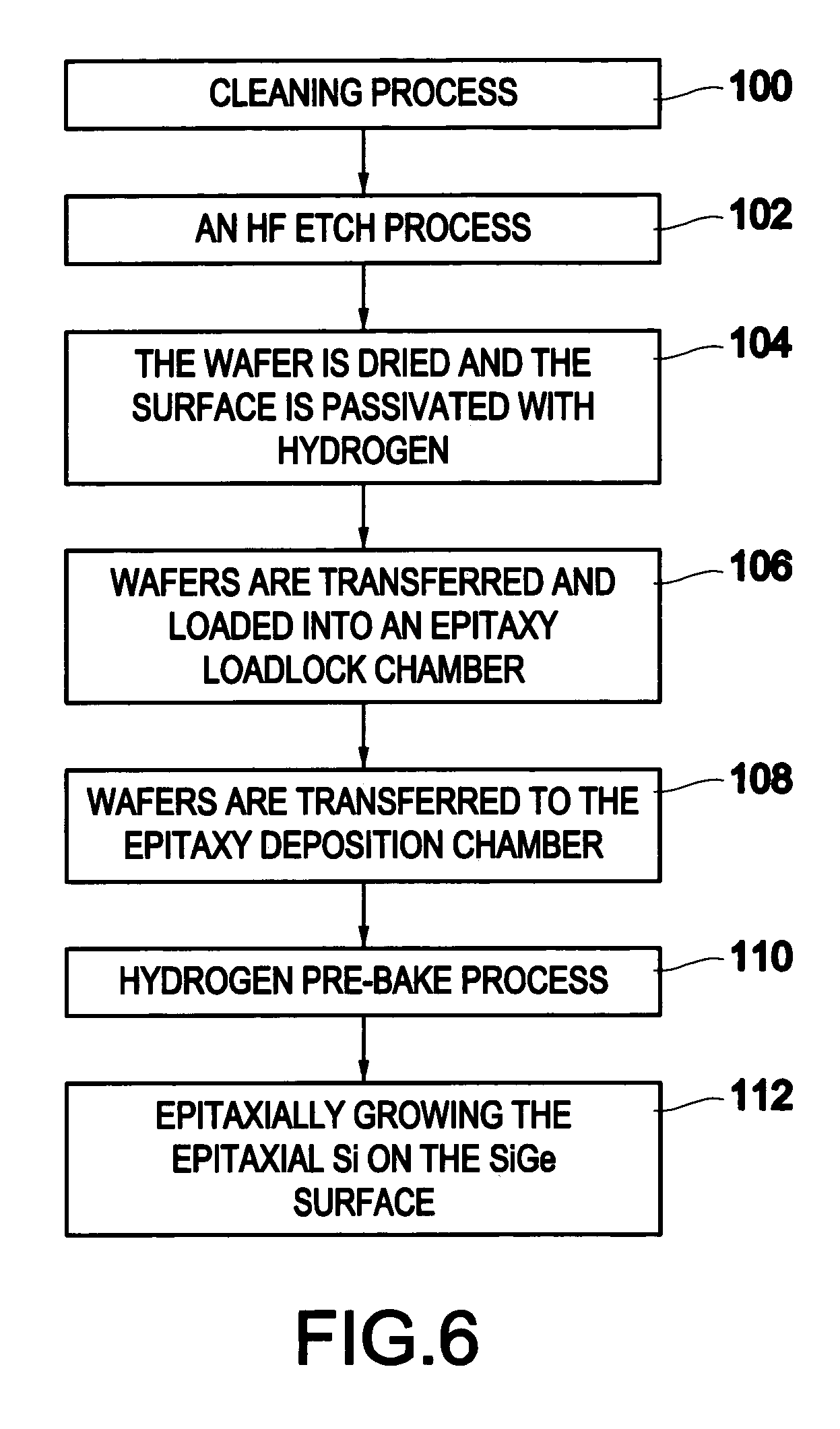

The invention forms an epitaxial silicon-containing layer on a silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface and avoids creating a rough surface upon which the epitaxial silicon-containing layer is grown. In order to avoid creating the rough surface, the invention first performs a hydrofluoric acid etching process on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. This etching process removes most of oxide from the surface, and leaves only a sub-monolayer of oxygen (typically 1×1013-1×1015 / cm2 of oxygen) at the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. The invention then performs a hydrogen pre-bake process in a chlorine containing environment which heats the silicon germanium, strained silicon, or thin silicon-on-insulator surface sufficiently to remove the remaining oxygen from the surface. By introducing a small amount of chlorine containing gases, the heating processes avoid changing the roughness of the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. Then the process of epitaxially growing the epitaxial silicon-containing layer on the silicon germanium, patterned strained silicon, or patterned silicon-on-insulator surface is performed.

Owner:IBM CORP

Method of preventing surface roughening during hydrogen prebake of SiGe substrates

InactiveUS6958286B2Polycrystalline material growthSemiconductor/solid-state device manufacturingRough surfaceHydrofluoric acid

The invention forms an epitaxial silicon-containing layer on a silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface and avoids creating a rough surface upon which the epitaxial silicon-containing layer is grown. In order to avoid creating the rough surface, the invention first performs a hydrofluoric acid etching process on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. This etching process removes most of oxide from the surface, and leaves a first amount of oxygen (typically 1×1013−1×1015 / cm2 of oxygen) on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. The invention then performs a hydrogen pre-bake process which heats the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface sufficiently to remove additional oxygen from the surface and leave a second amount of oxygen, less than the first amount, on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. The heating process leaves an amount of at least 5×1012 / cm2 of oxygen (typically, between approximately 1×1013 / cm2 and approximately 5×1013 / cm2 of oxygen) on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. By leaving a small amount of oxygen on the silicon germanium, patterned strained silicon, or patterned silicon-on-insulator surface, the heating processes avoid changing the roughness of the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. Then the process of epitaxially growing the epitaxial silicon-containing layer on the silicon germanium, patterned strained silicon, or patterned silicon-on-insulator surface is performed.

Owner:INT BUSINESS MASCH CORP

Color stable manganese-doped phosphors

ActiveUS8252613B1Solid-state devicesSemiconductor/solid-state device manufacturingParticulatesHydrofluoric acid

A process for preparing color stable Mn+4 doped phosphors includes providing a phosphor of formula I;Ax[MFy]:Mn+4 Iand contacting the phosphor in particulate form with a saturated solution of a composition of formula II in aqueous hydrofluoric acid;Ax[MFy]; IIwhereinA is Li, Na, K, Rb, Cs, NR4 or a combination thereof;M is Si, Ge, Sn, Ti, Zr, Al, Ga, In, Sc, Y, La, Nb, Ta, Bi, Gd, or a combination thereof;R is H, lower alkyl, or a combination thereof;x is the absolute value of the charge of the [MFy] ion; andy is 5, 6 or 7.In particular embodiments, M is Si, Ge, Sn, Ti, Zr, or a combination thereof.A lighting apparatus capable of emitting white light includes a semiconductor light source; and a phosphor composition radiationally coupled to the light source, and which includes a color stable Mn+4 doped phosphor.

Owner:GE LIGHTING SOLUTIONS LLC

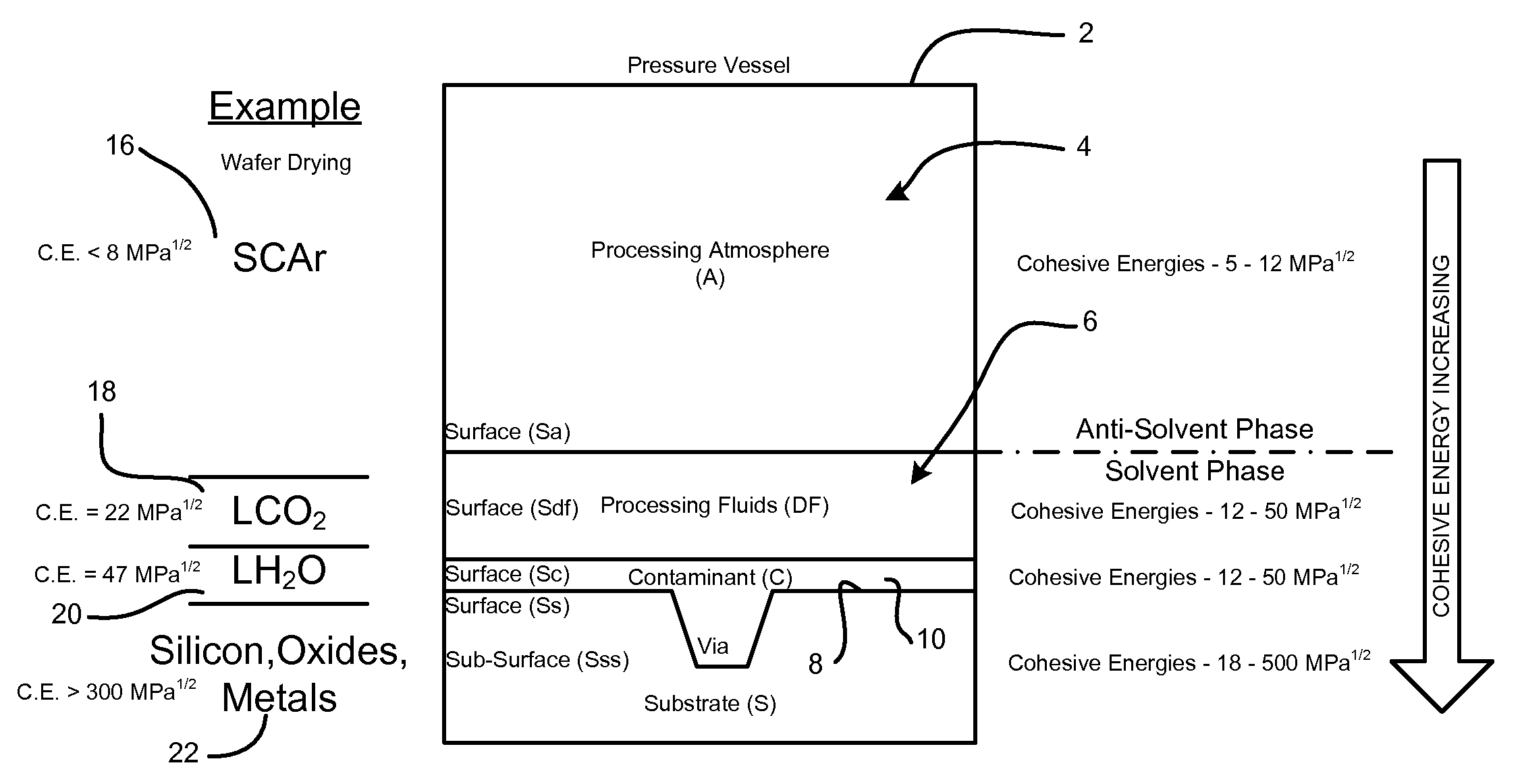

Precision surface treatments using dense fluids and a plasma

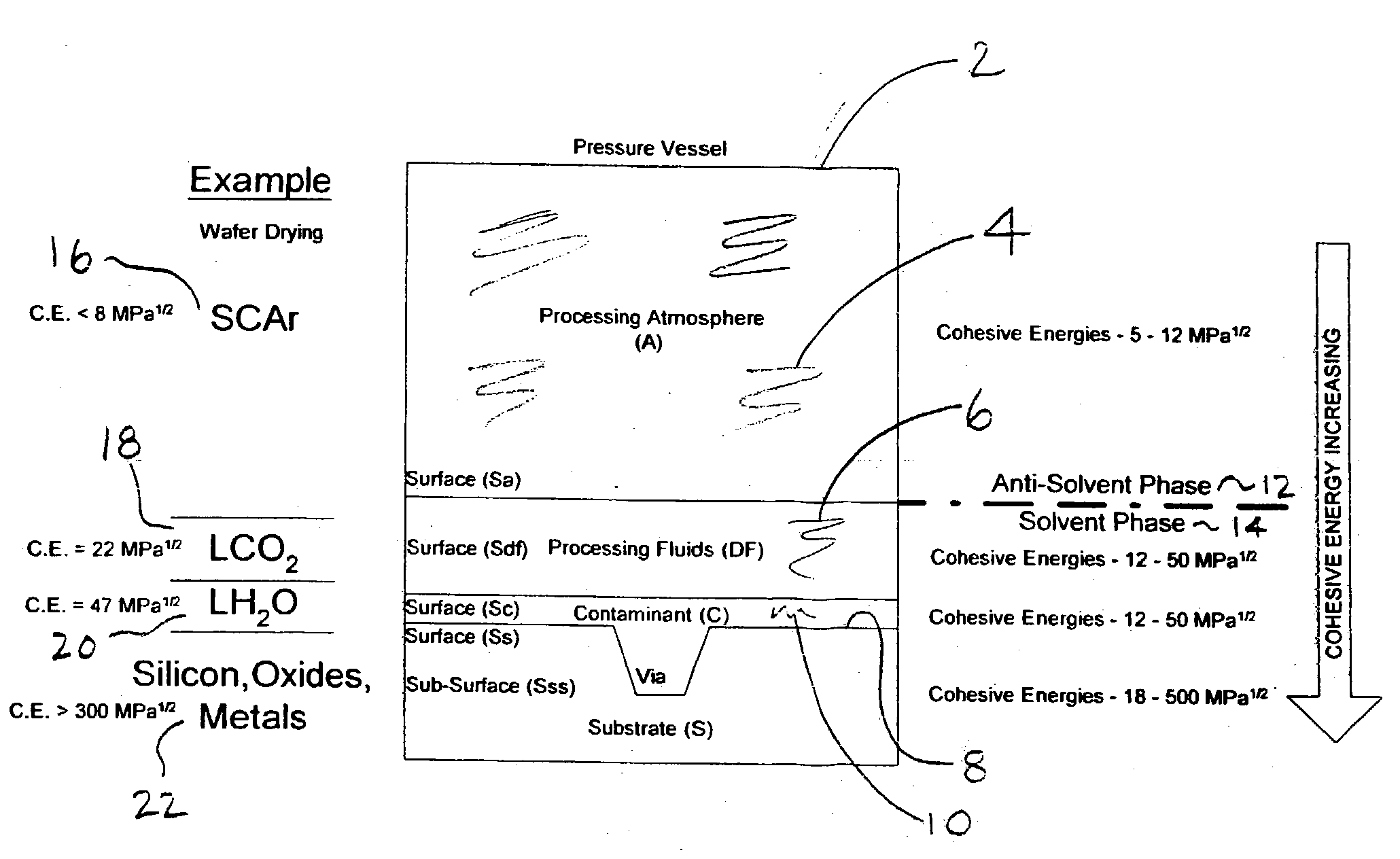

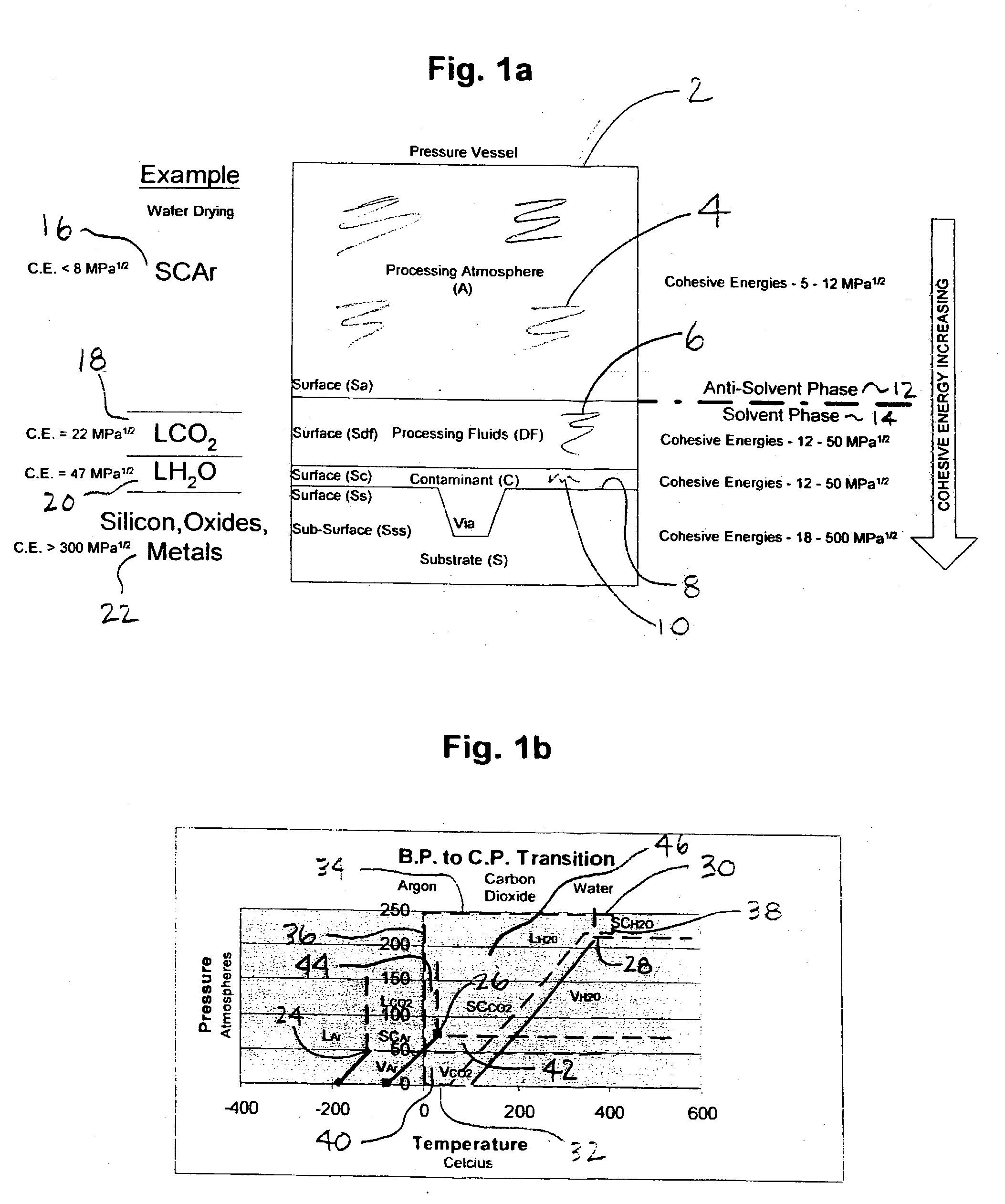

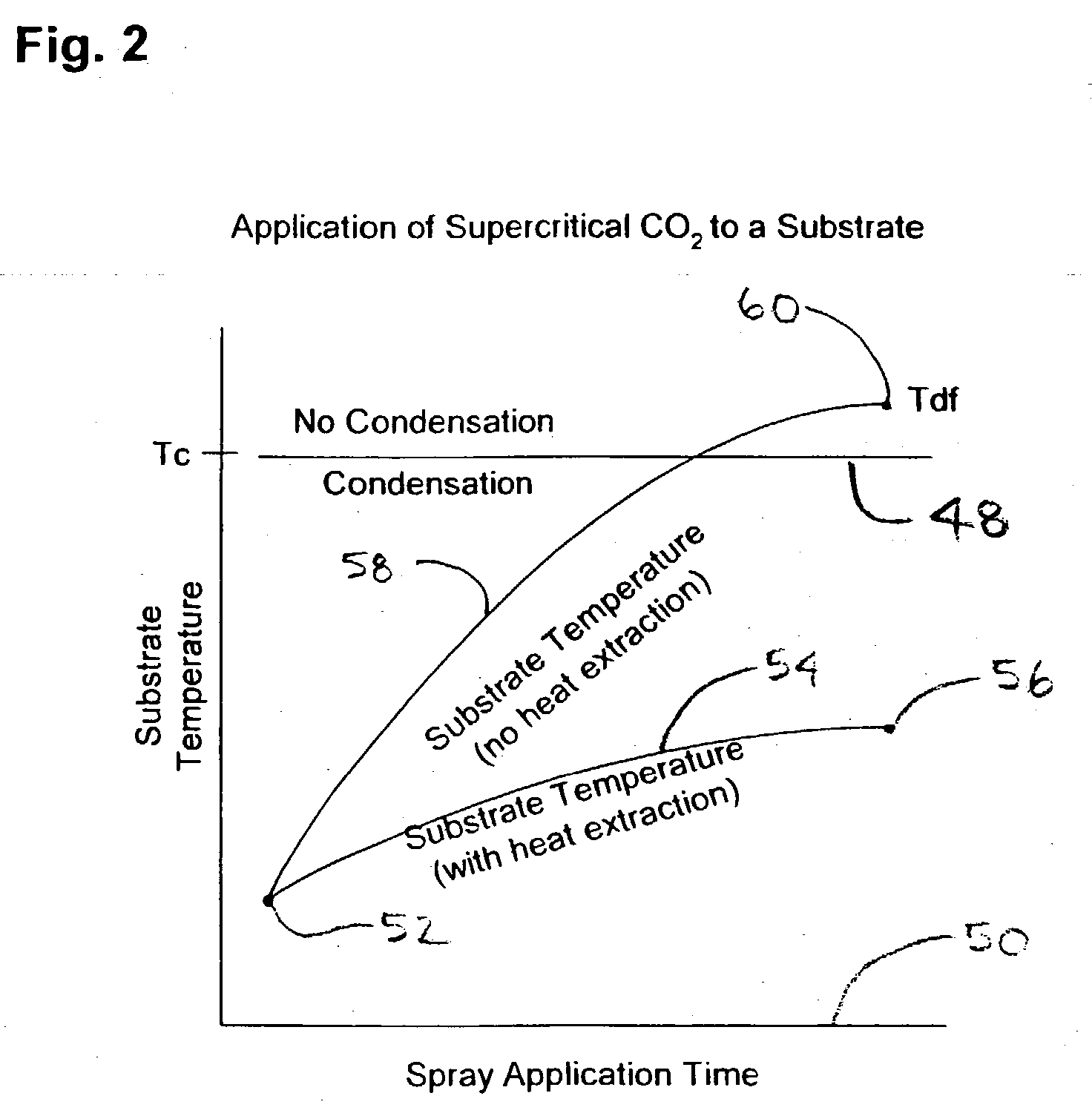

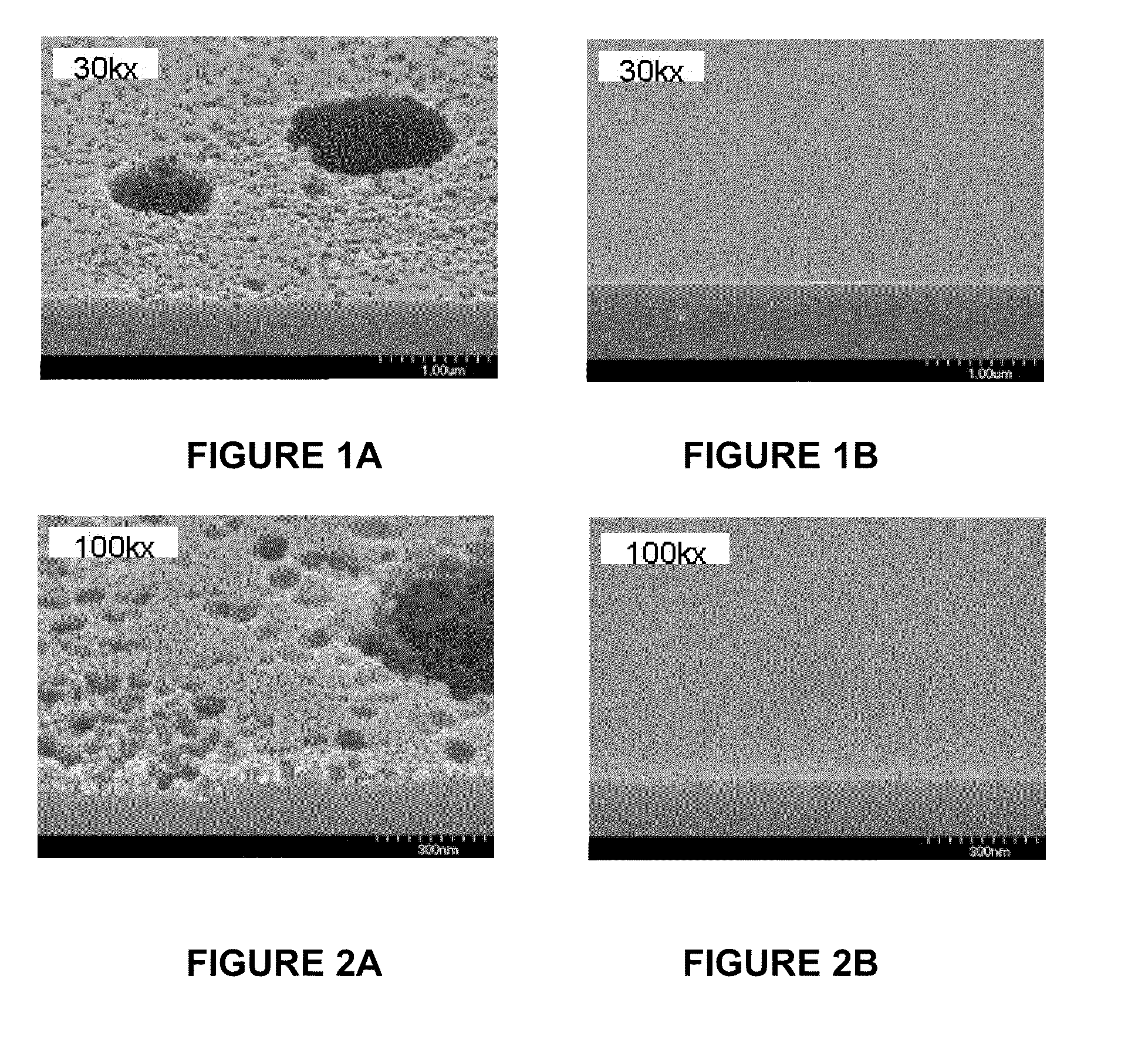

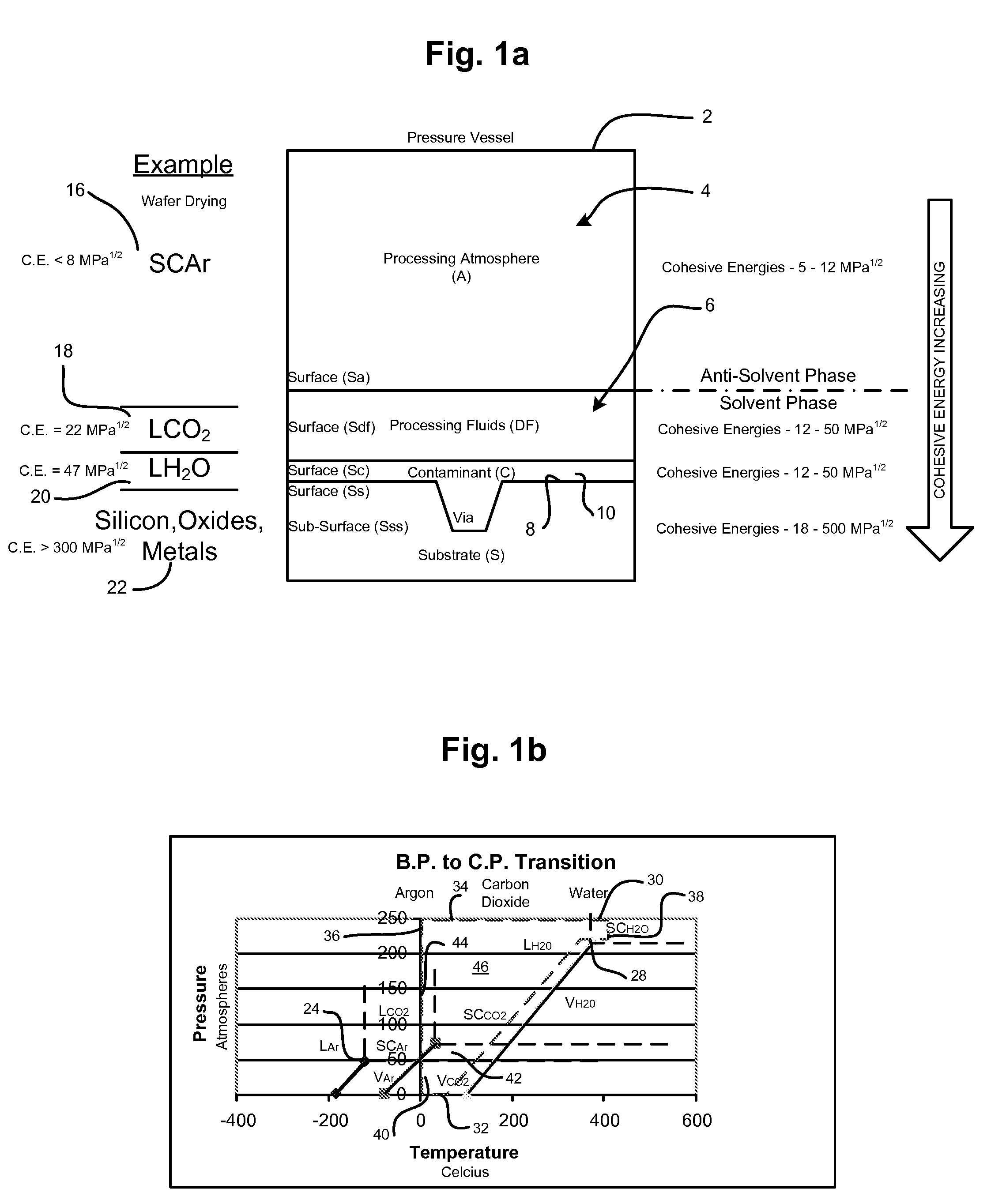

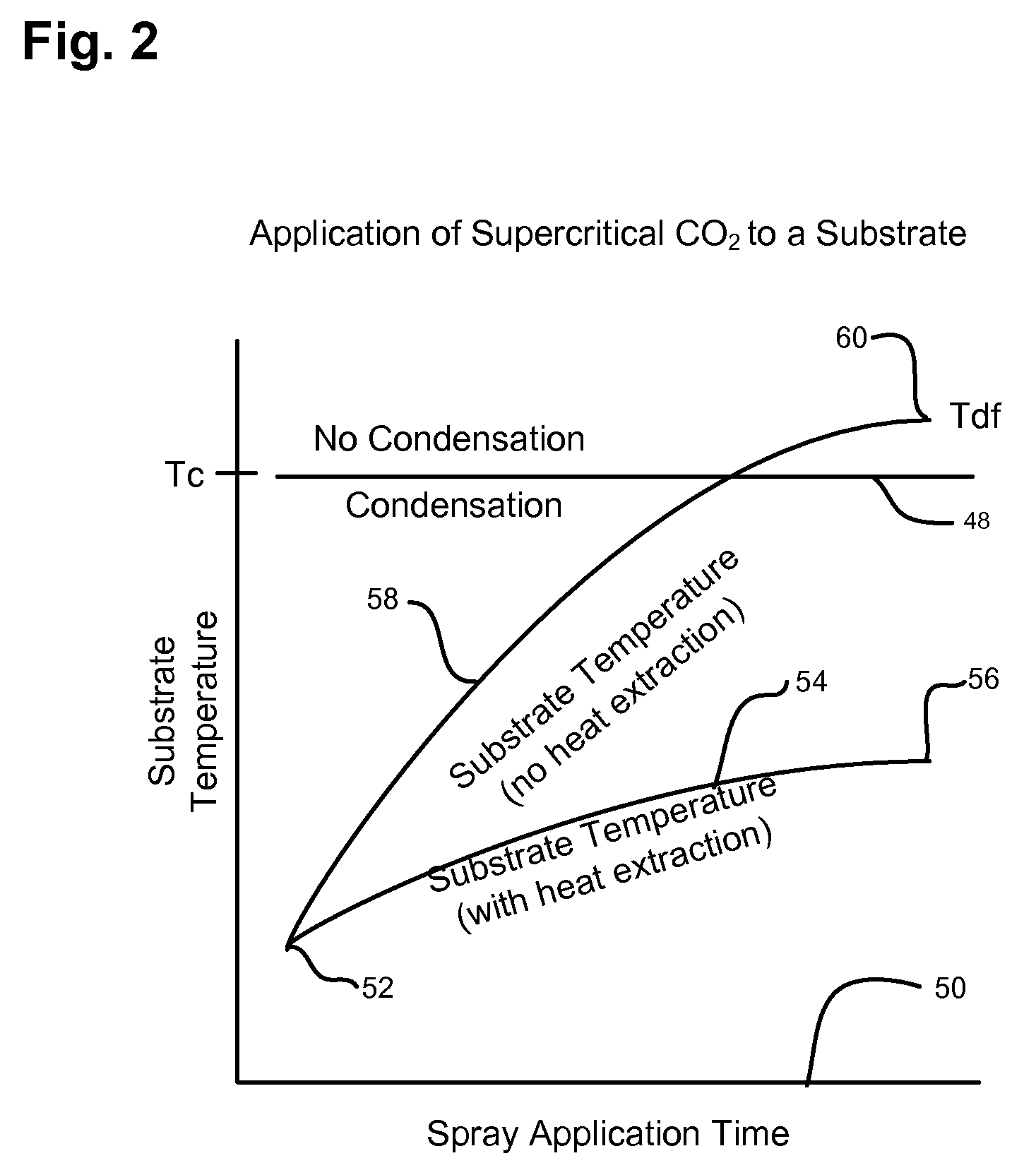

InactiveUS20040003828A1Reduce the temperatureEasy to separateElectric discharge tubesElectrostatic cleaningSolventSolid phases

The present invention is a method, process and apparatus for selective cleaning, drying, and modifying substrate surfaces and depositing thin films thereon using a dense phase gas solvent and admixtures within a first created supercritical fluid antisolvent. Dense fluids are used in combination with sub-atmospheric, atmospheric and super-atmospheric plasma adjuncts (cold and thermal plasmas) to enhance substrate surface cleaning, modification, precision drying and deposition processes herein. Moreover, conventional wet cleaning agents such as hydrofluoric acid and ammonium fluoride may be used with the present invention to perform substrate pre-treatments prior to precision drying and cleaning treatments described herein. Finally, dense fluid such as solid phase carbon dioxide and argon may be used as a follow-on treatment or in combination with plasmas to further treat a substrate surface.

Owner:JACKSON DAVID P

Methods for stripping material for wafer reclamation

InactiveUS20100112728A1Improve concentrationSemiconductor/solid-state device manufacturingSurface treatment compositionsHydrofluoric acid

Removal compositions and processes for removing at least one material layer from a rejected microelectronic device structure having same thereon. The removal composition includes hydrofluoric acid. The composition achieves substantial removal of the material(s) to be removed while not damaging the layers to be retained, for reclaiming, reworking, recycling and / or reuse of said structure.

Owner:ADVANCED TECH MATERIALS INC

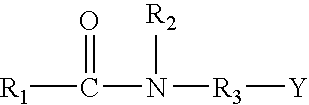

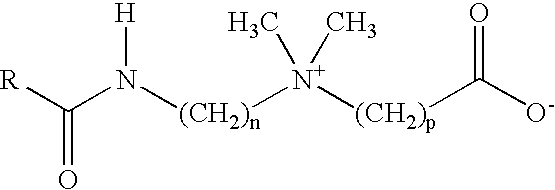

Cleaning composition for removing resists and method of manufacturing semiconductor device

InactiveUS20040106531A1Surface-active detergent compositionsNon-surface-active detergent compositionsResistCopper interconnect

The cleaning composition for removing resists includes a salt of hydrofluoric acid and a base not containing a metal (A component), a water-soluble organic solvent (B1 component), at least one acid selected from a group consisting of organic acid and inorganic acid (C component), water (D component), and optionally an ammonium salt (E1 component), and its hydrogen ion concentration (pH) is 4-8. Thus, in the manufacturing process of a semiconductor device such as a copper interconnecting process, removing efficiency of resist residue and other etching residue after etching or ashing improves, and corrosion resistance of copper and insulating film also improves.

Owner:PANASONIC CORP +2

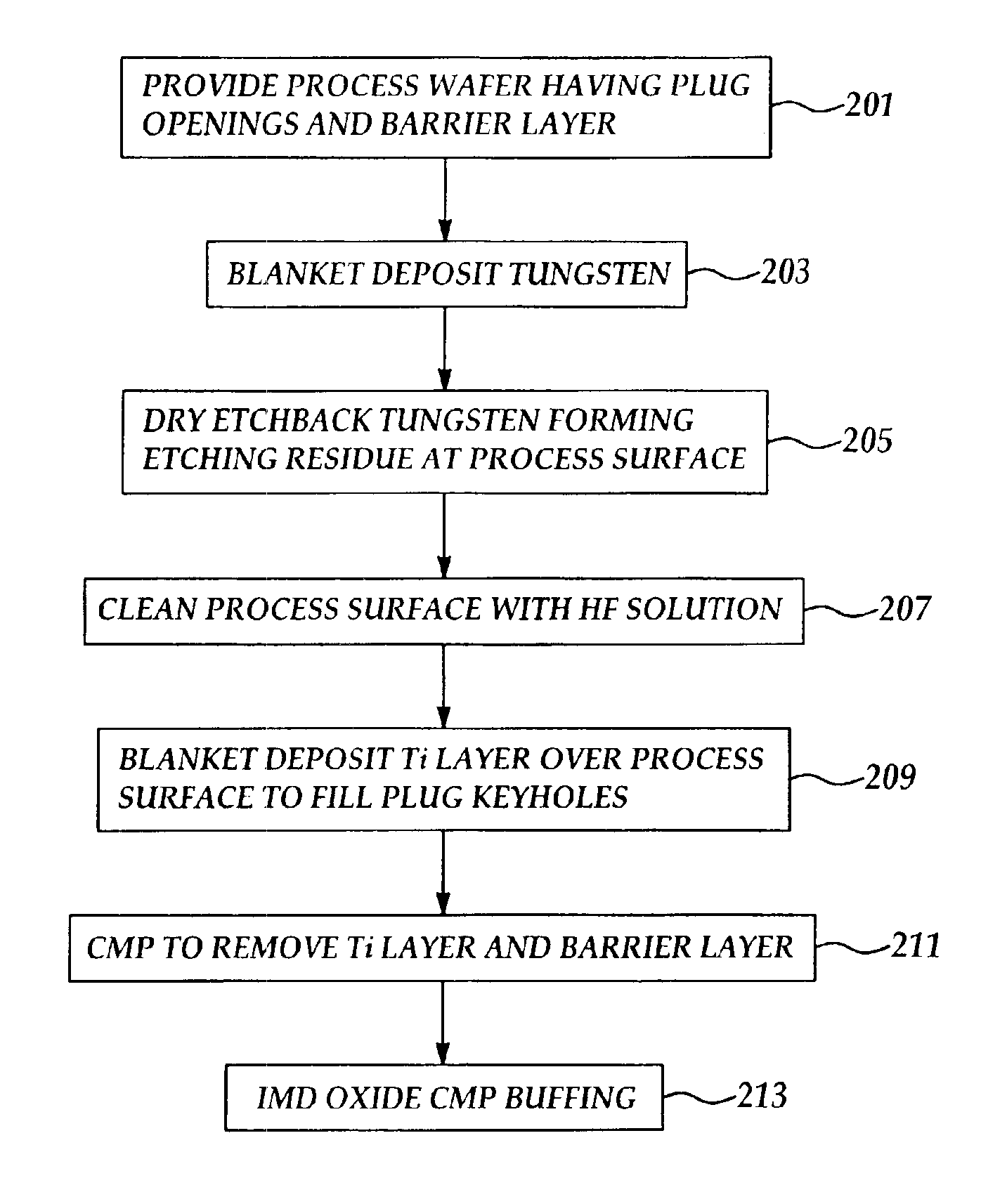

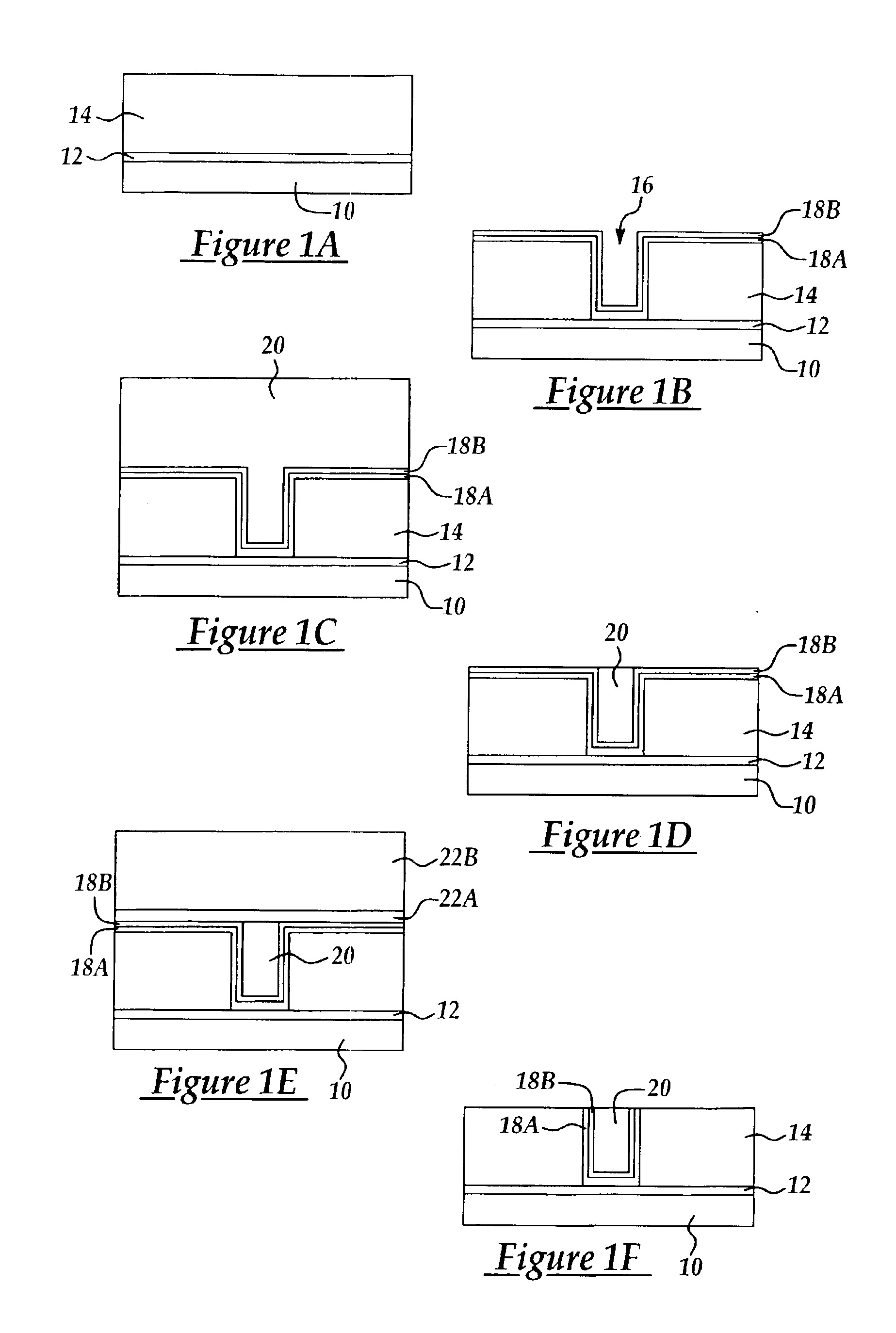

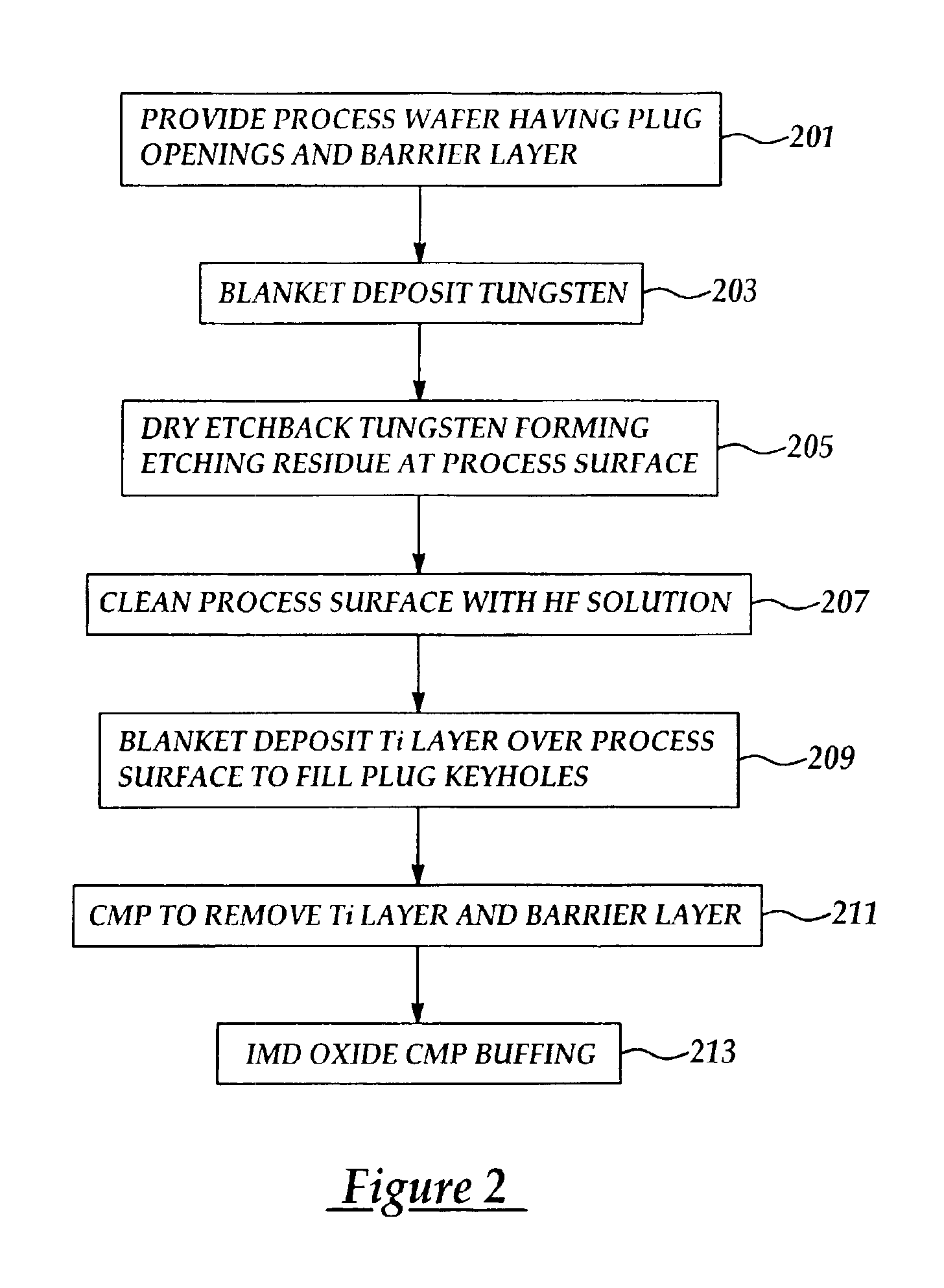

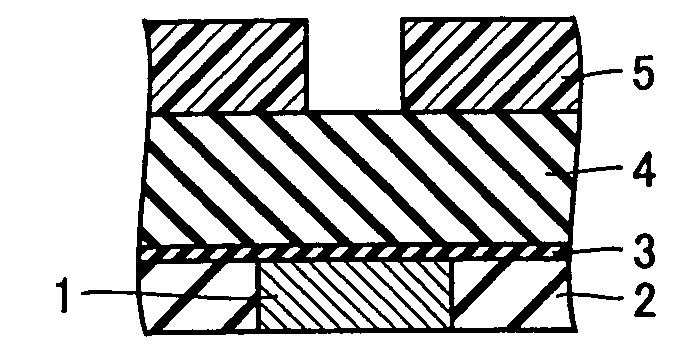

Method of removing metal etching residues following a metal etchback process to improve a CMP process

InactiveUS6936544B2Reduce scratchesSemiconductor/solid-state device manufacturingElectrostatic cleaningHydrofluoric acidCompound (substance)

A method for reducing wafer surface scratching in a metal CMP process including providing a semiconductor wafer having a process surface comprising a blanket deposited metal layer; dry etching in an etchback process comprising a fluorine containing etching chemistry to remove at least a portion of the metal layer forming a metal and fluorine containing etching residue at the process surface; cleaning the process surface with a hydrofluoric acid (HF) containing cleaning solution; and carrying out a subsequent metal chemical mechanical polishing (CMP) process.

Owner:TAIWAN SEMICON MFG CO LTD

Cleaning composition for removing resists and method of manufacturing semiconductor device

InactiveUS7250391B2Good removal effectInhibitionSemiconductor/solid-state device manufacturingNon-surface-active detergent solventsResistCopper interconnect

The cleaning composition for removing resists includes a salt of hydrofluoric acid and a base not containing a metal (A component), a water-soluble organic solvent (B1 component), at least one organic acid or inorganic acid (C component), water (D component), and, optionally, an ammonium salt (E1 component), and having a pH 4-8. Thus, in manufacturing a semiconductor device, such as a copper interconnecting process, efficiency of removing resist residue and other etching residue after etching or ashing is improved, and corrosion resistance of a copper and an insulating film is also improved.

Owner:PANASONIC CORP +2

Substrate processing method and substrate processing apparatus

ActiveUS20080003836A1Achieve effectSelectively remove the flat portion of the nitride filmSemiconductor/solid-state device manufacturingHydrofluoric acidSilicon monoxide

A substrate processing method capable of selectively removing a nitride film. Oxygen plasma containing plasmarized oxygen gas is made to be in contact with a silicon nitride film, which is made of SiN, of a wafer to thereby cause the silicon nitride film to be changed to a silicon monoxide film. The silicon monoxide film is selectively etched by hydrofluoric acid generated from HF gas supplied toward the silicon monoxide film.

Owner:TOKYO ELECTRON LTD

Treatment Fluids Containing Biodegradable Chelating Agents and Methods for Use Thereof

ActiveUS20120097392A1Scale removal and water softeningFluid removalHydrofluoric acidAlaninediacetic acid

Treatment fluids containing biodegradable chelating agents and methods for use thereof are described. The methods can comprise providing a treatment fluid that comprises an aqueous base fluid and a chelating agent composition, and introducing the treatment fluid into at least a portion of a subterranean formation. The treatment fluids can also be used for treatment of pipes or tubing such as, for example, well bore pipes or tubing penetrating a subterranean formation and above-ground pipelines. Illustrative biodegradable chelating agents include, but are not limited to, glutamic acid diacetic acid, methylglycine diacetic acid, β-alanine diacetic acid, S,S-ethylenediaminedisuccinic acid, iminodisuccinic acid, hydroxyiminodisuccinic acid, any salt thereof, any derivative thereof, and any combination thereof. The treatment fluids can optionally comprise an acid, which can include hydrofluoric acid or a hydrofluoric acid generating compound.

Owner:HALLIBURTON ENERGY SERVICES INC

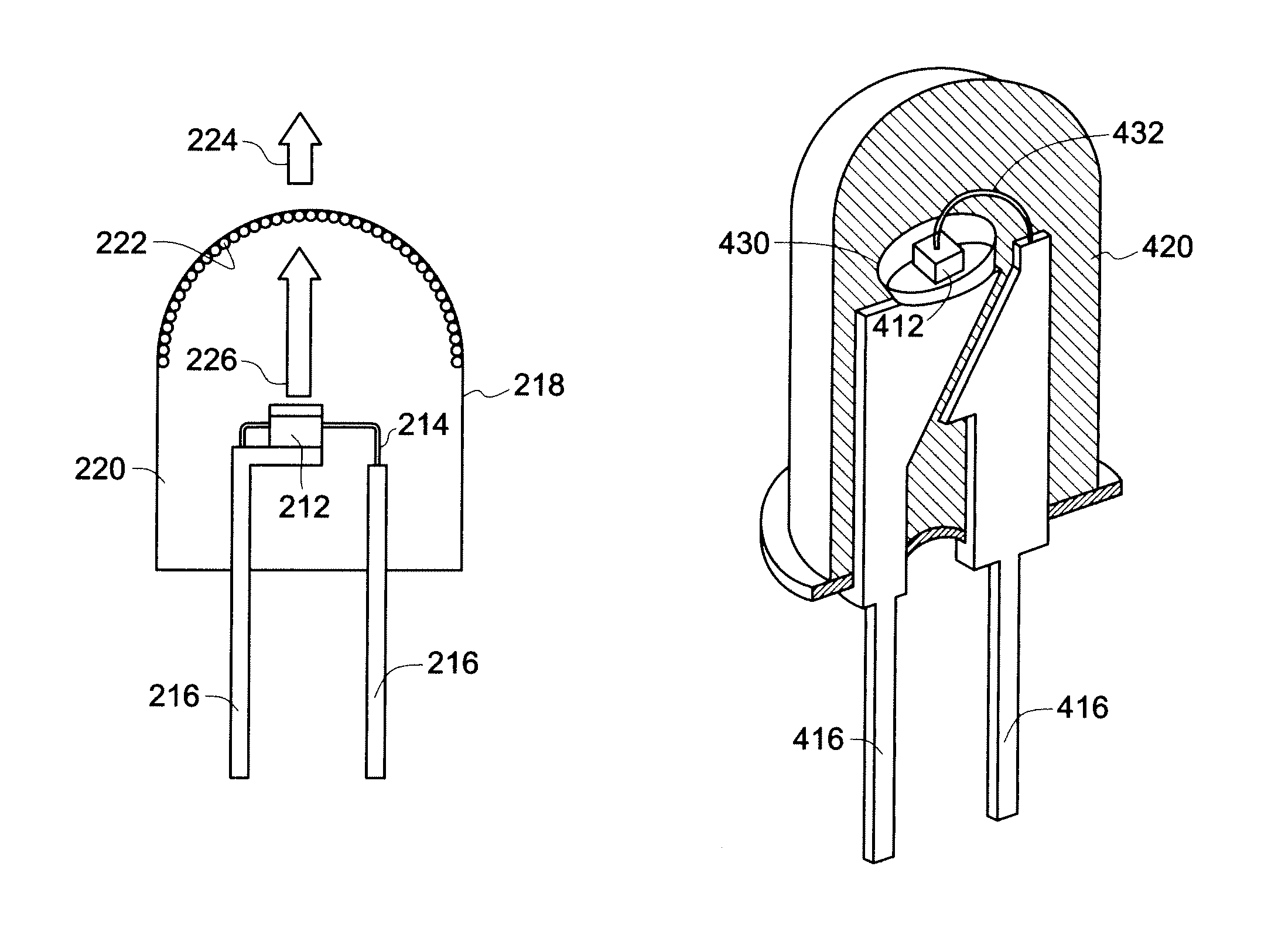

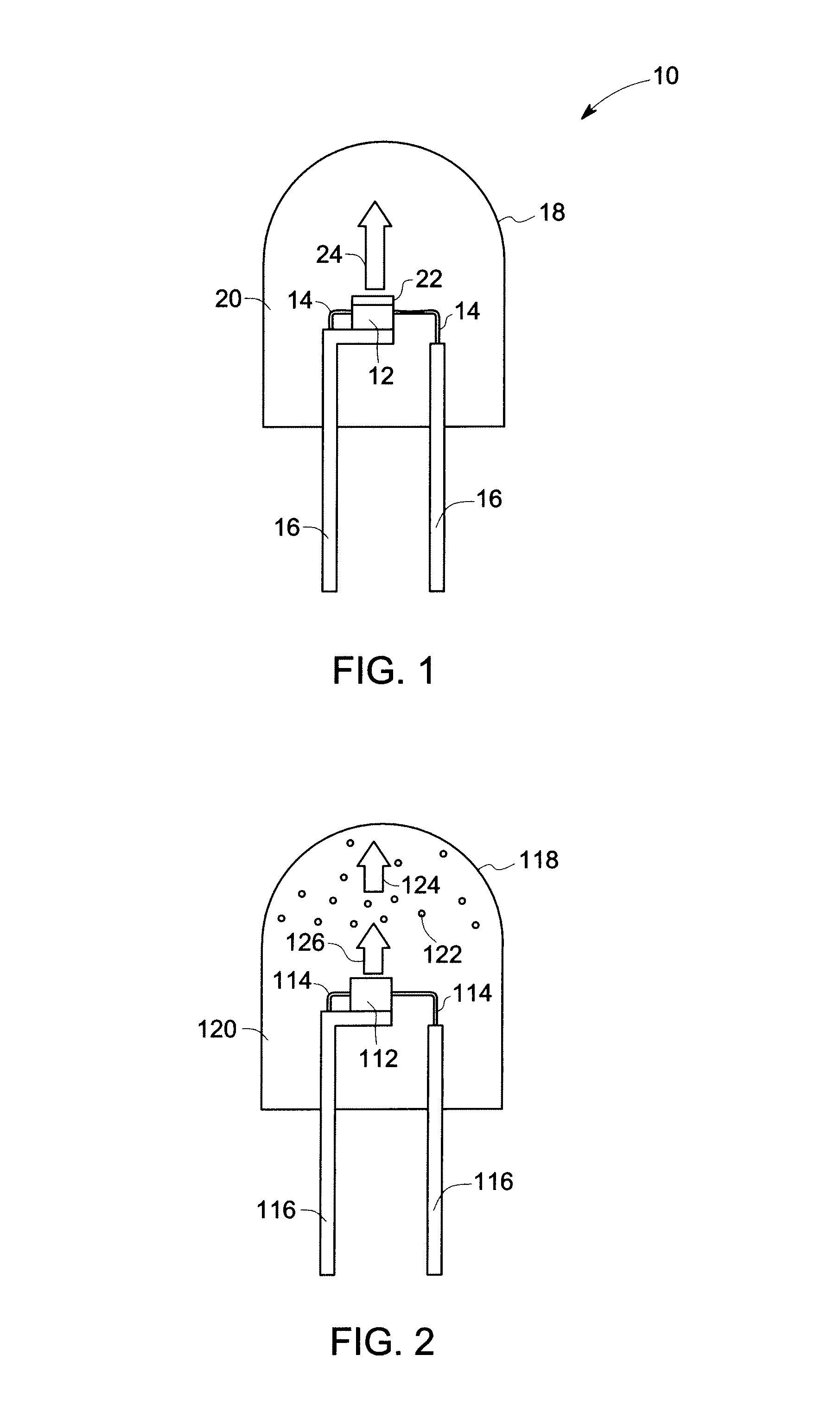

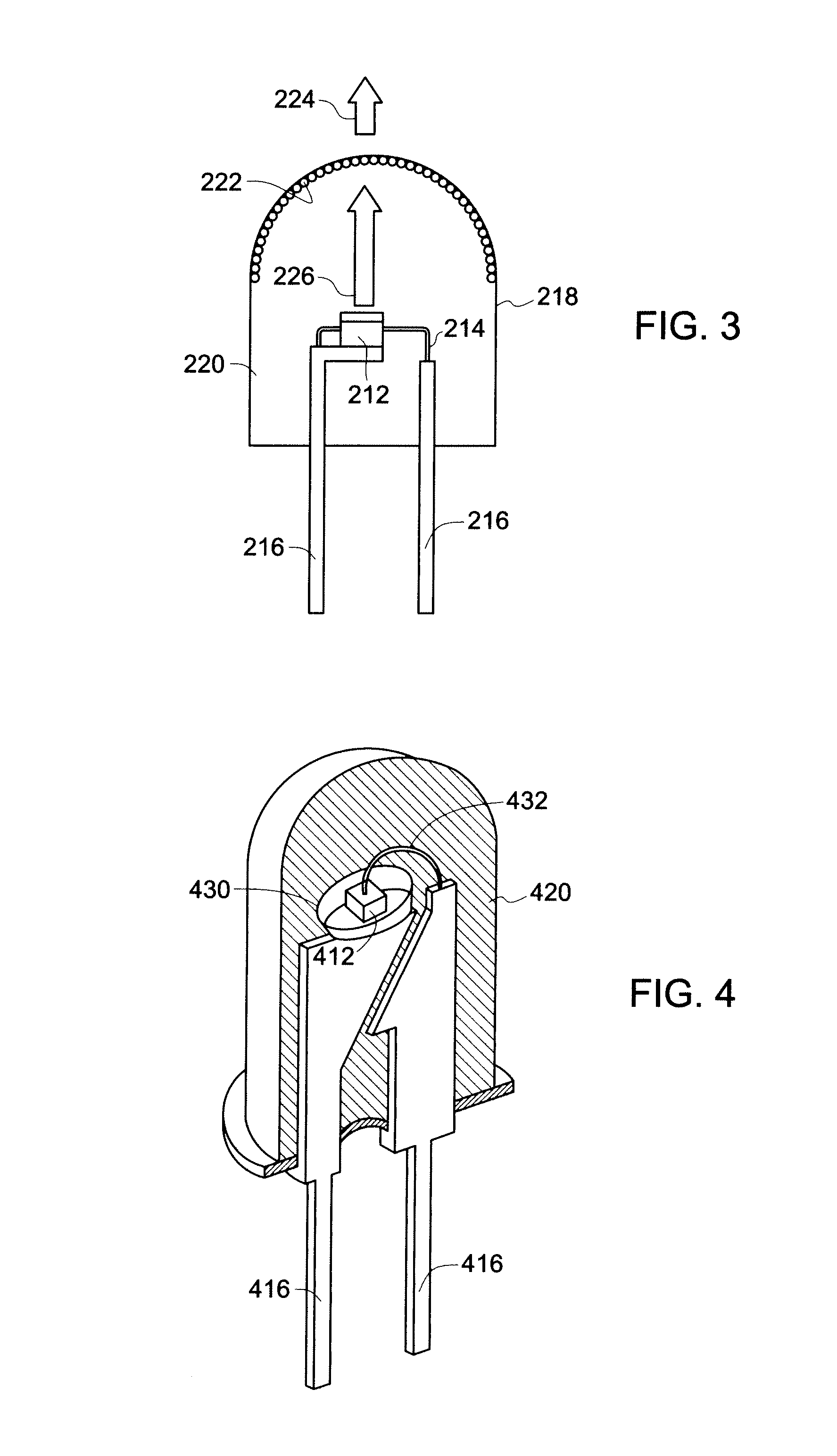

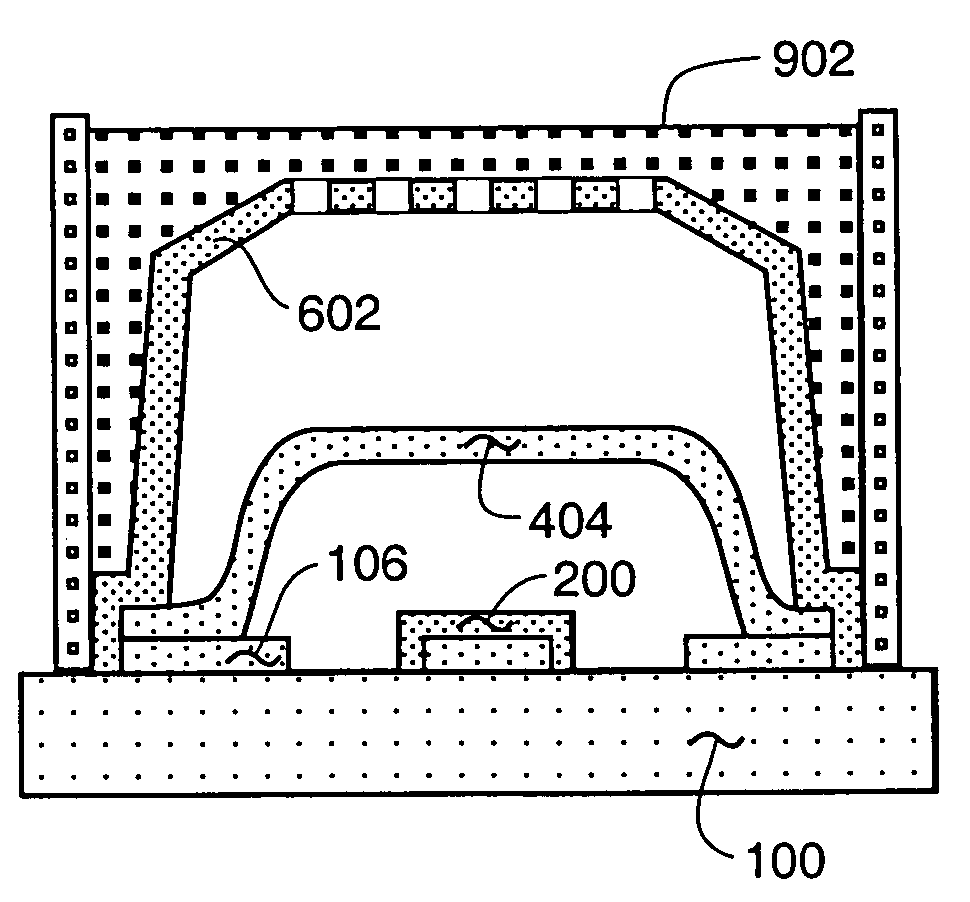

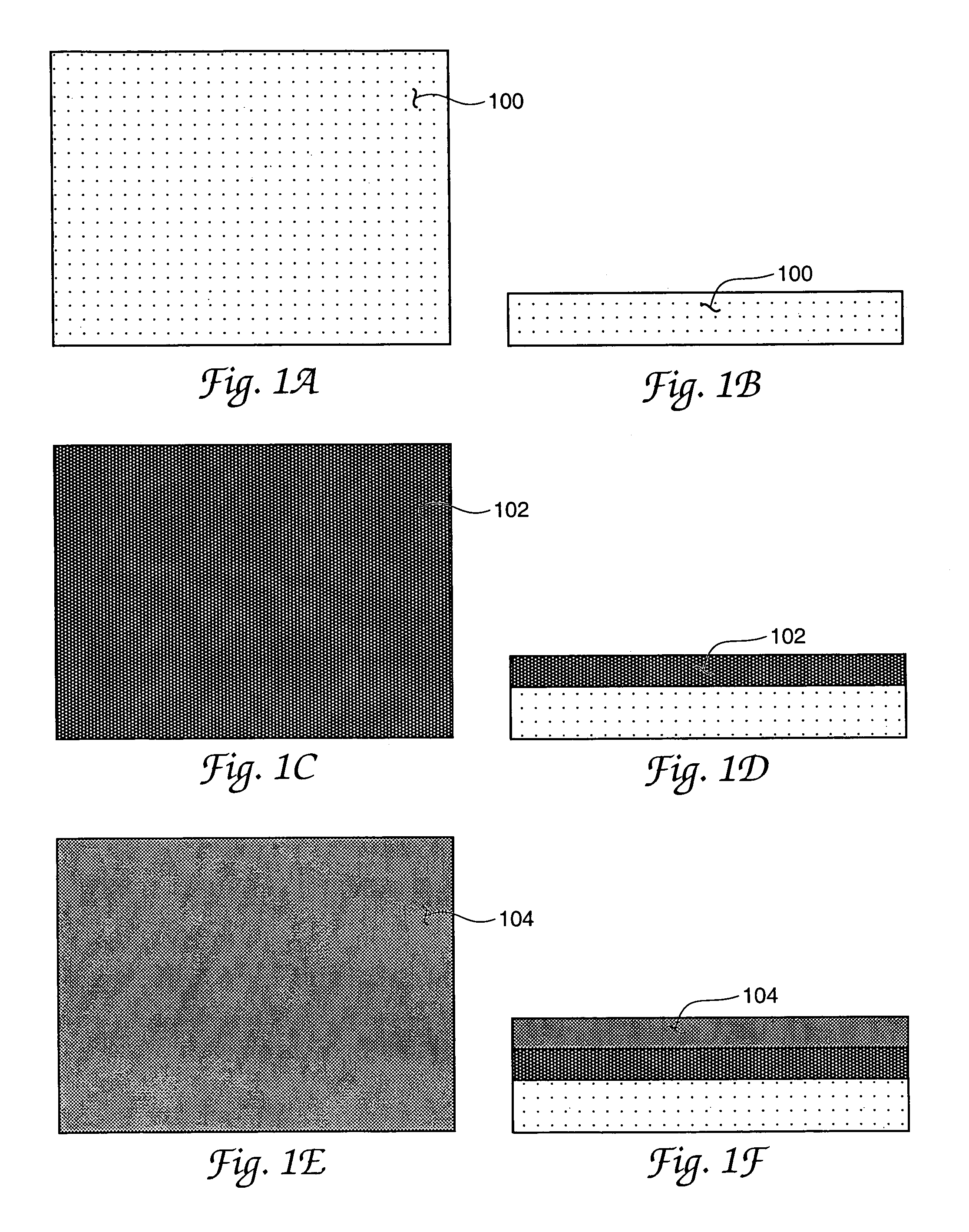

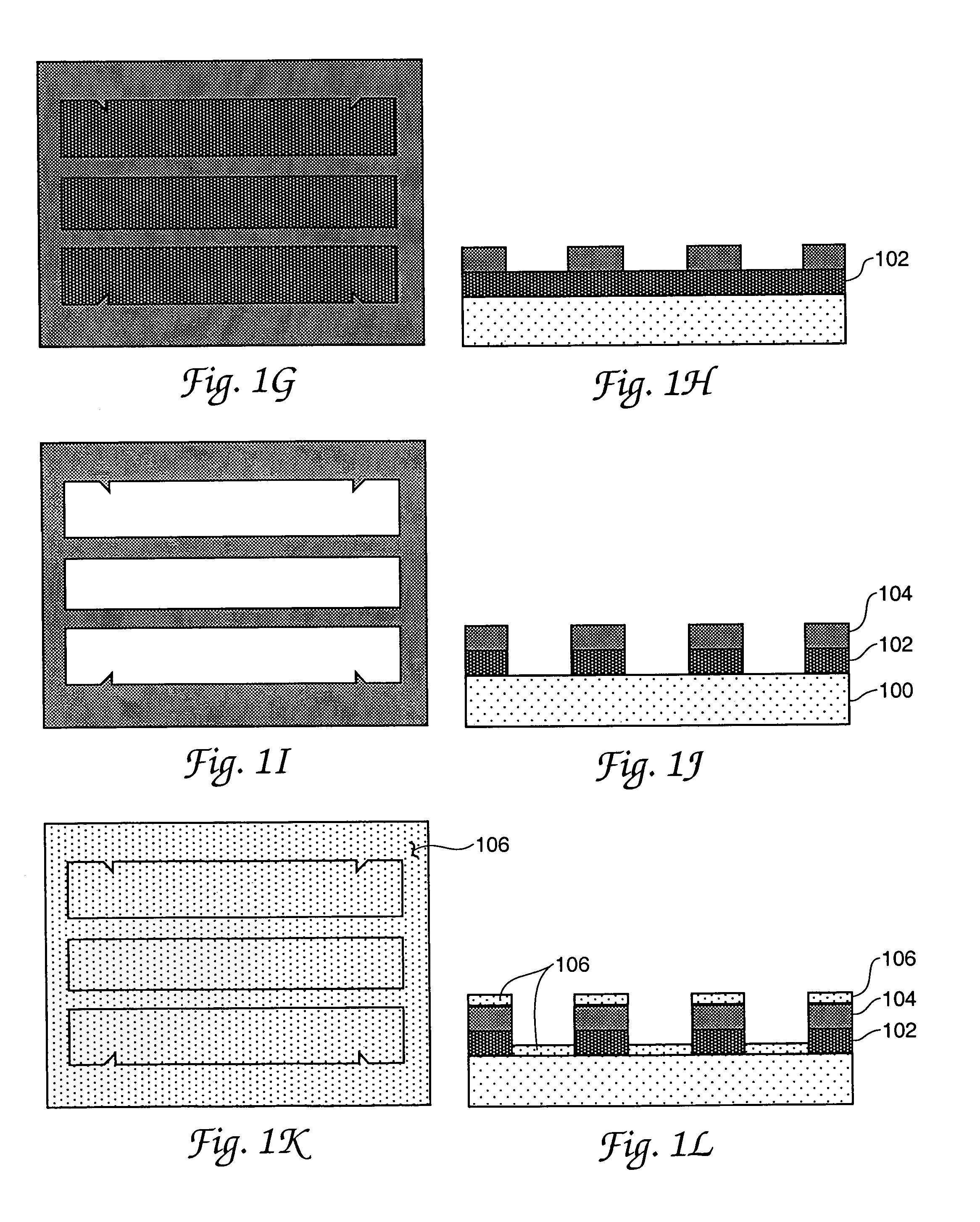

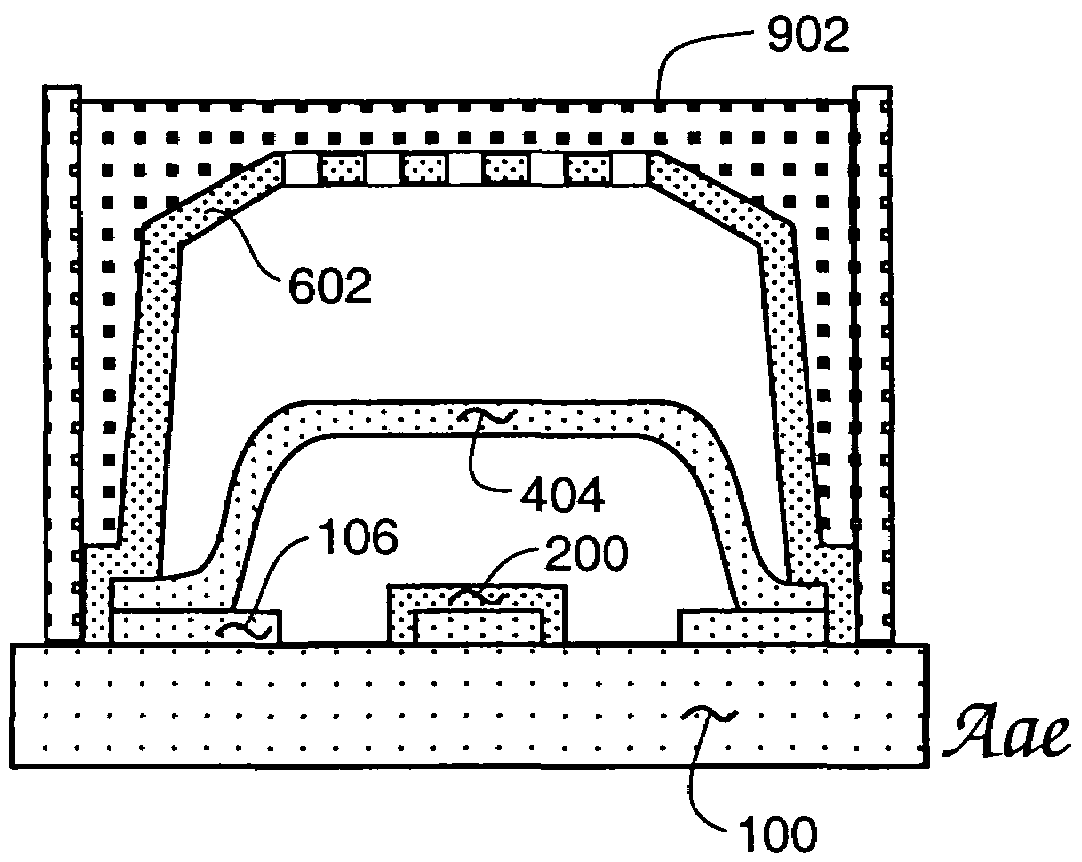

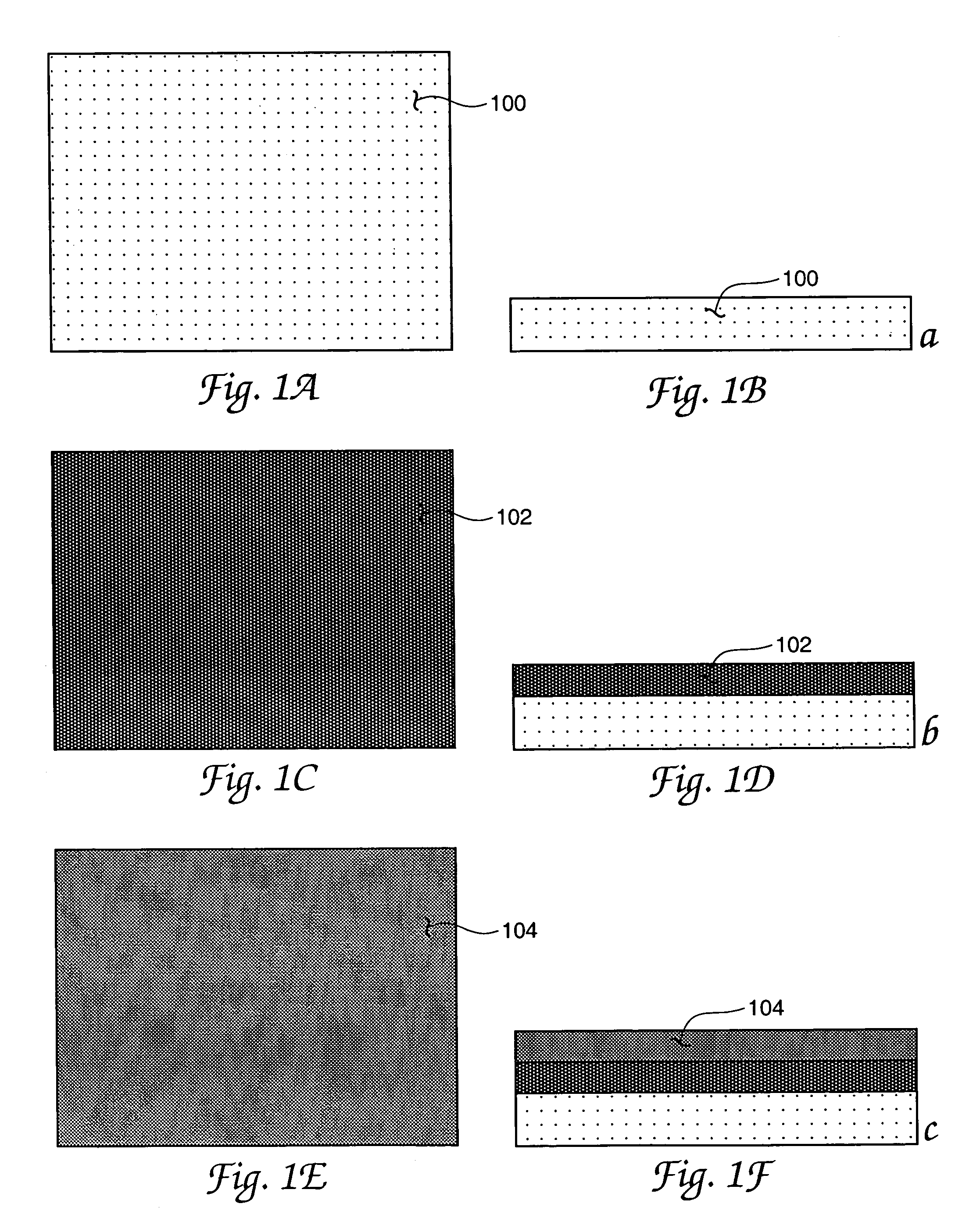

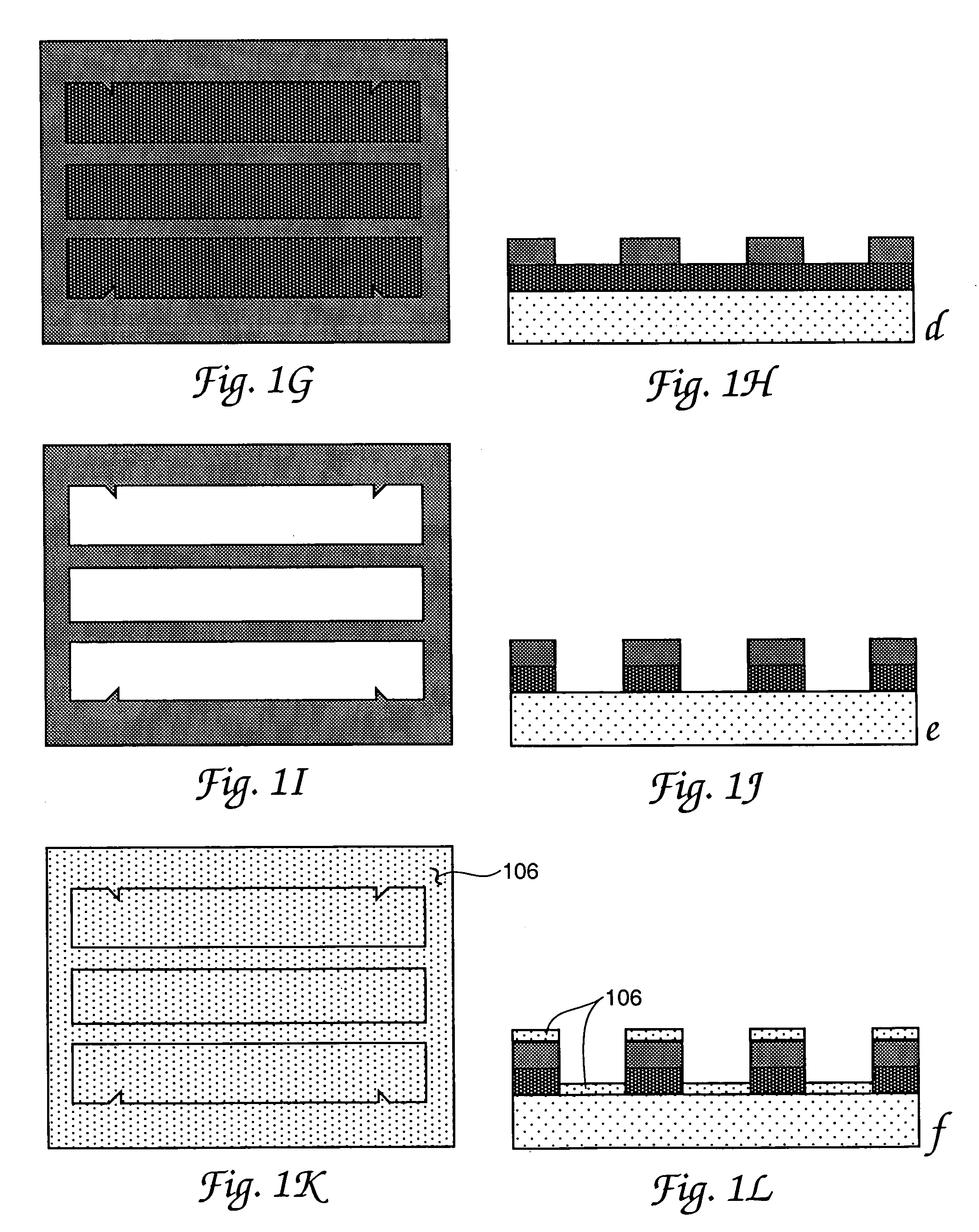

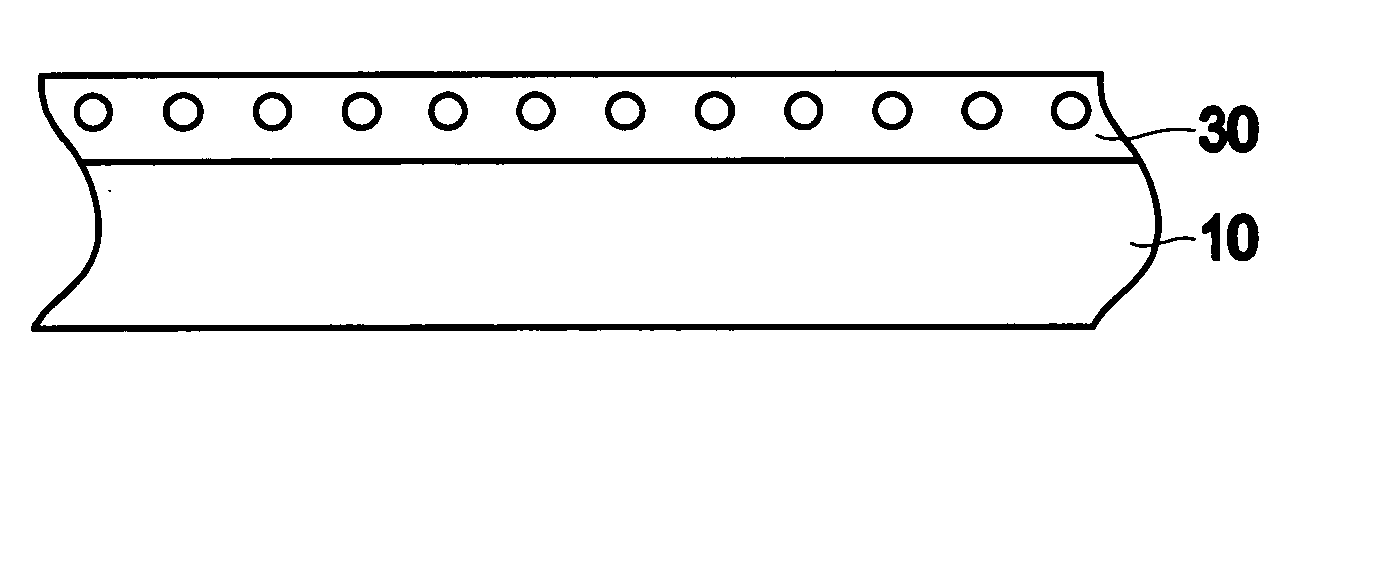

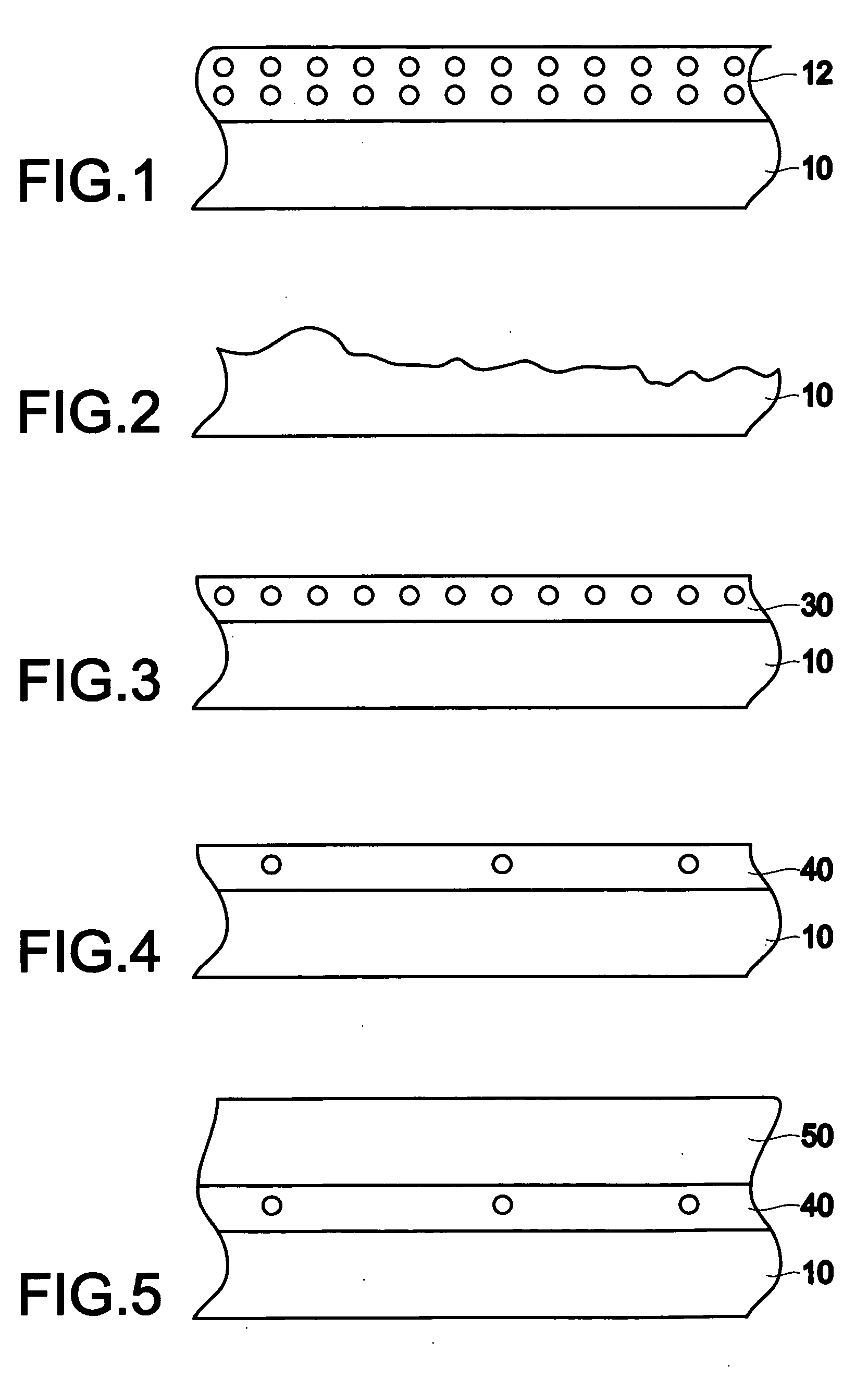

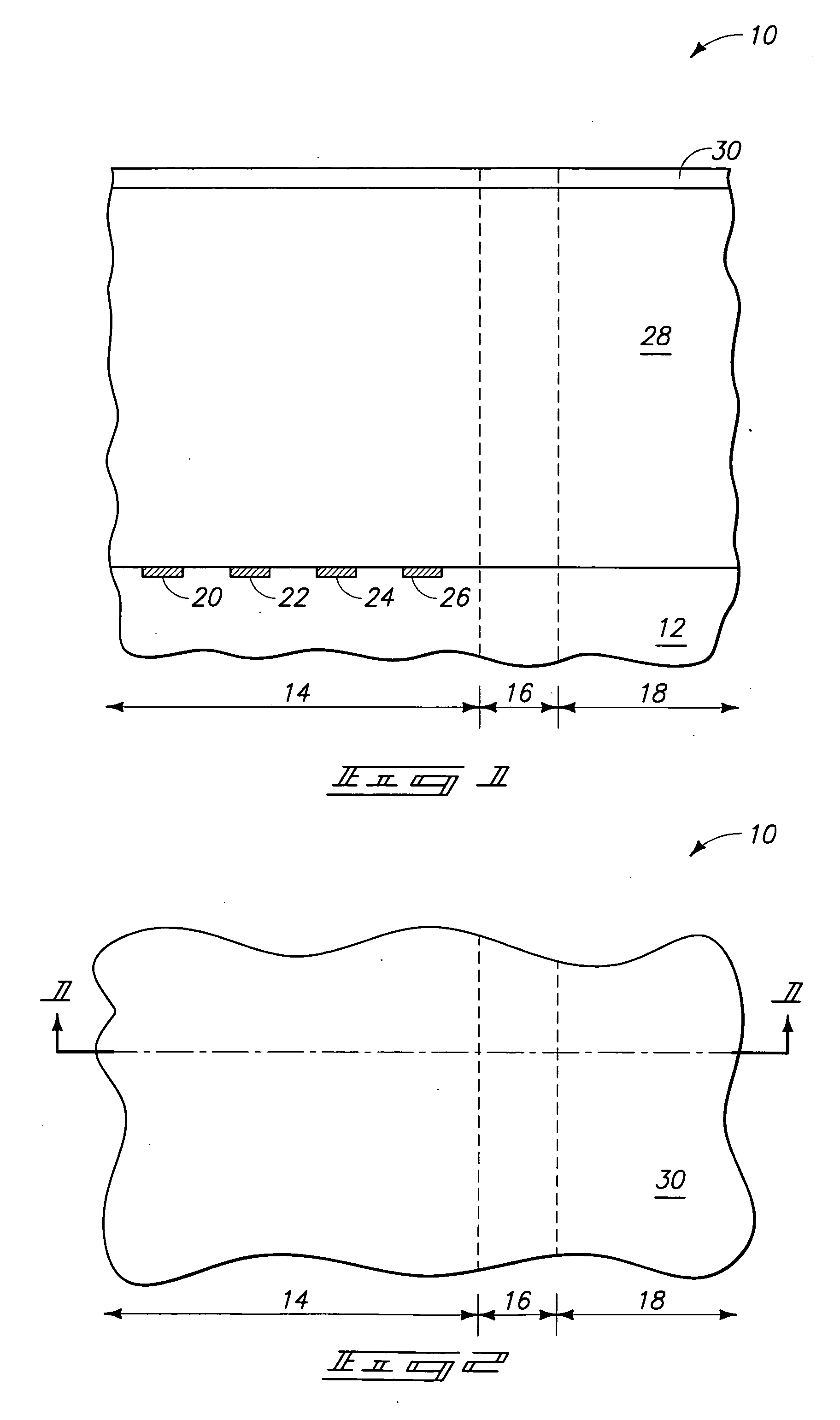

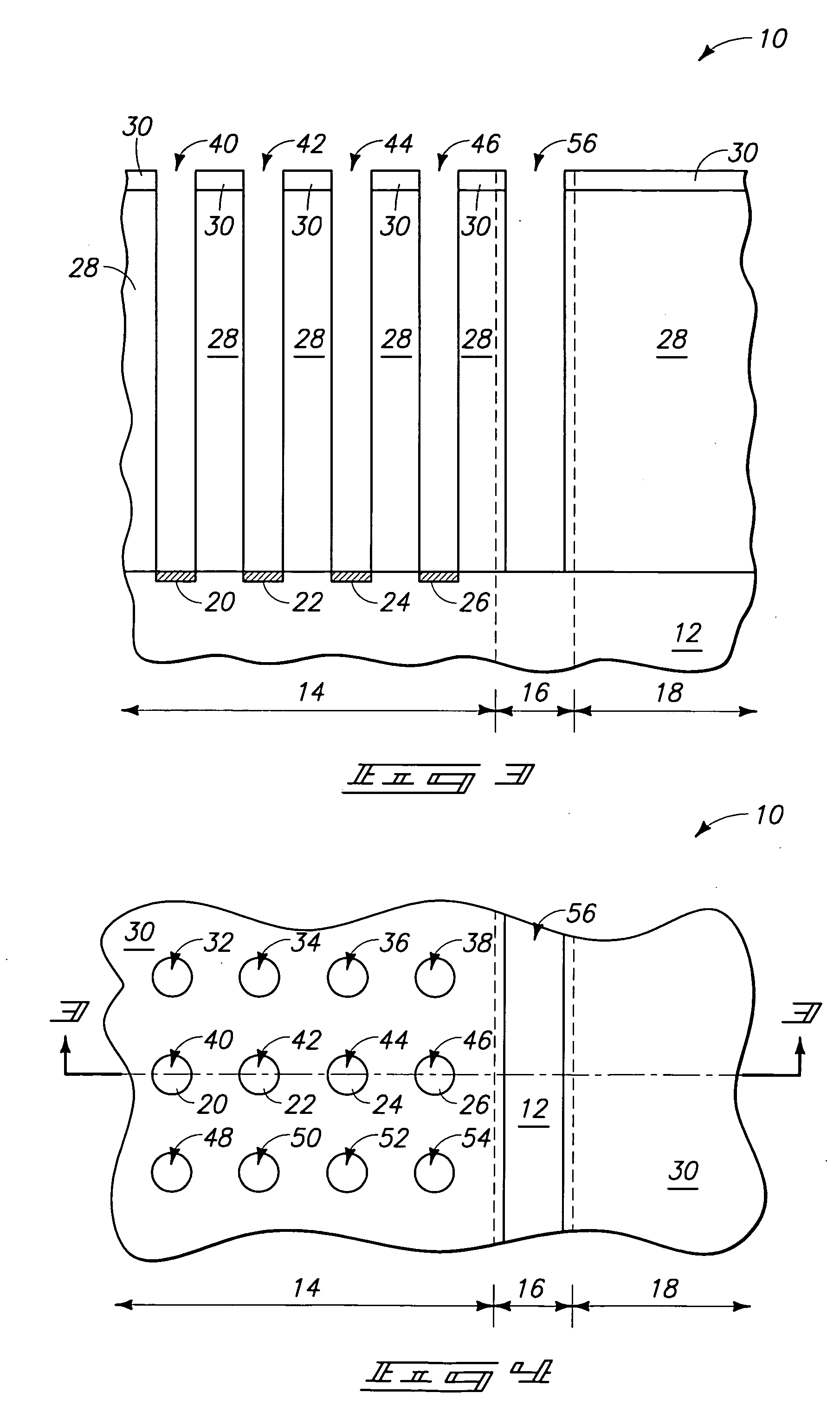

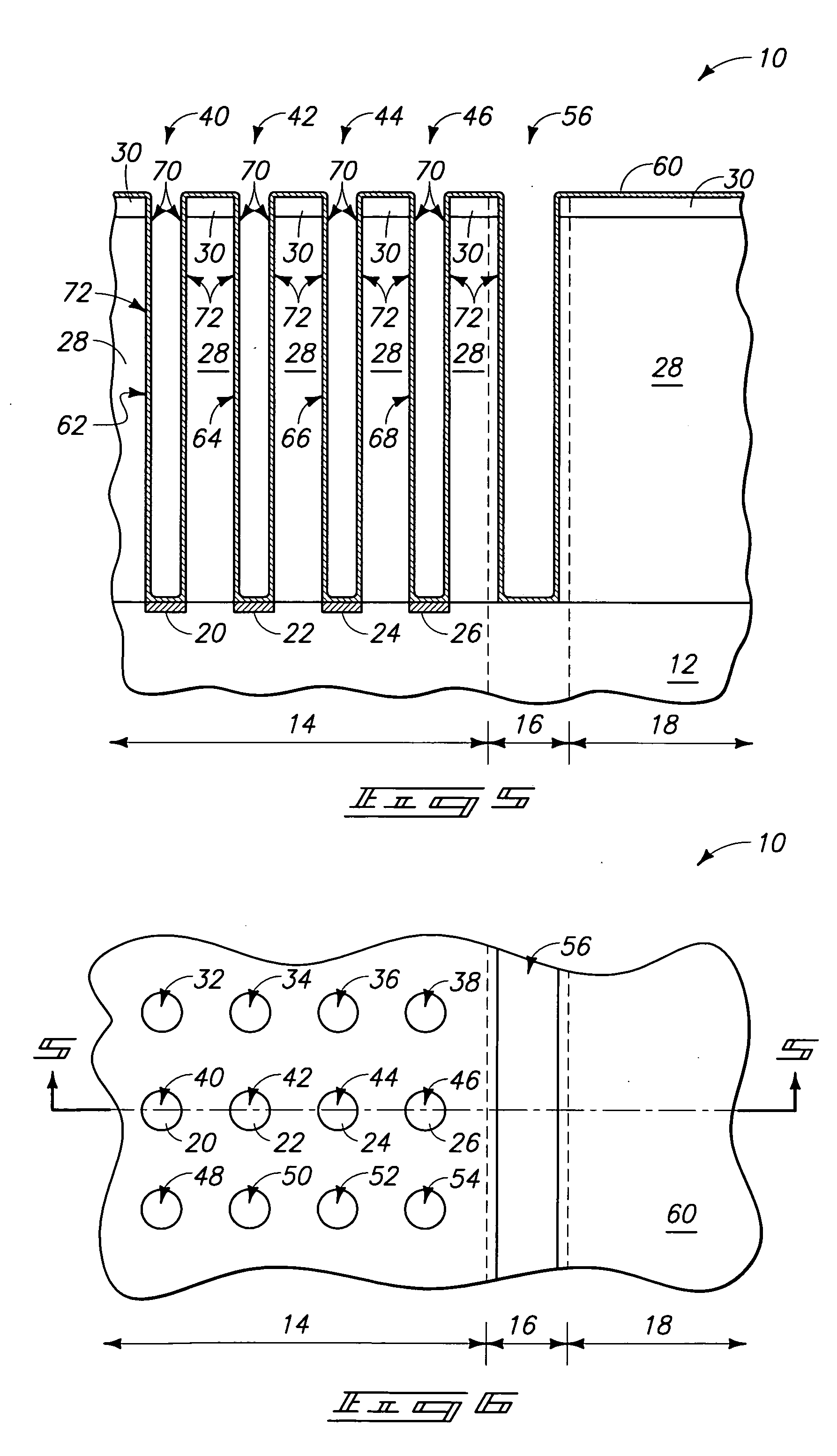

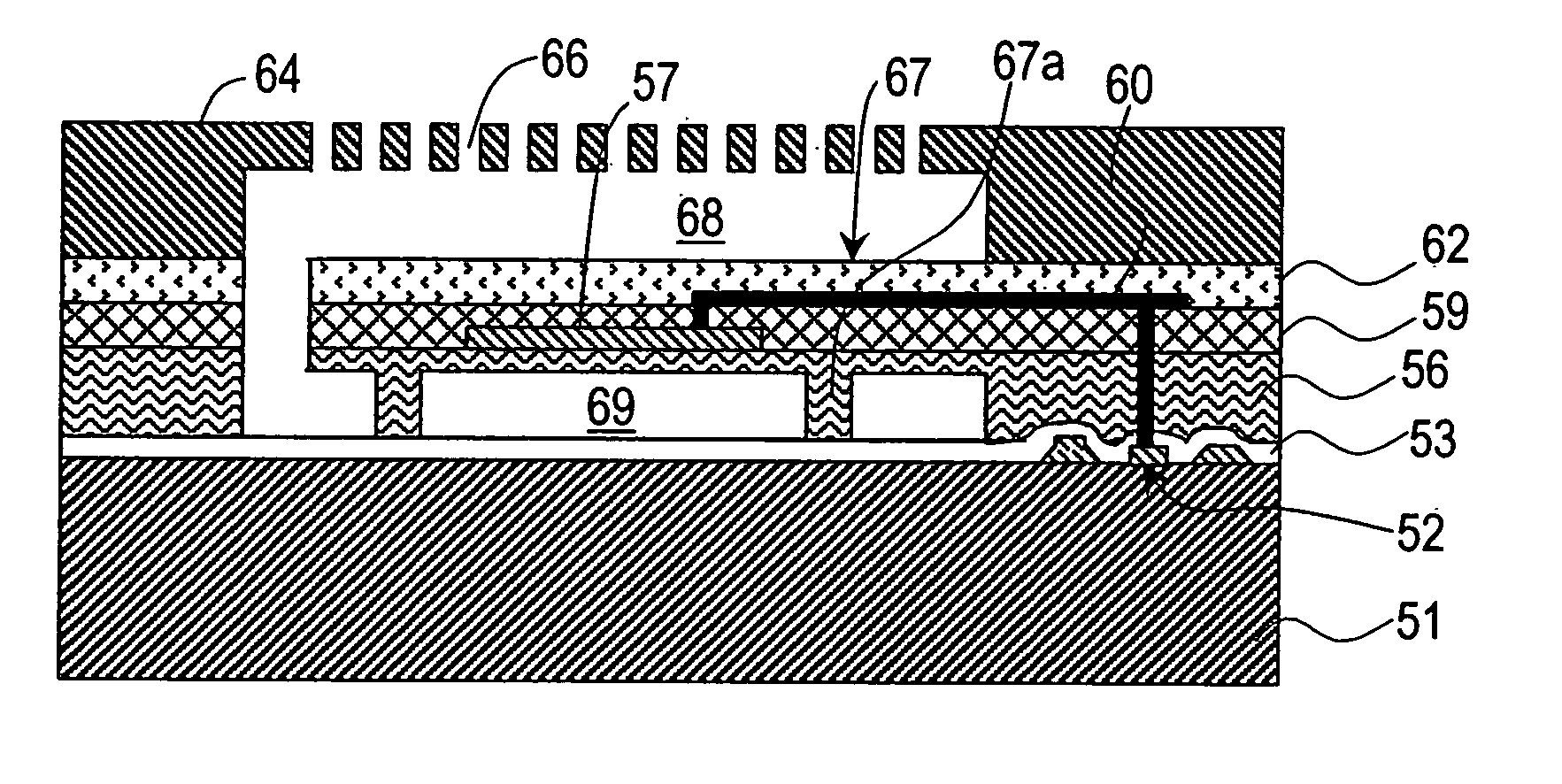

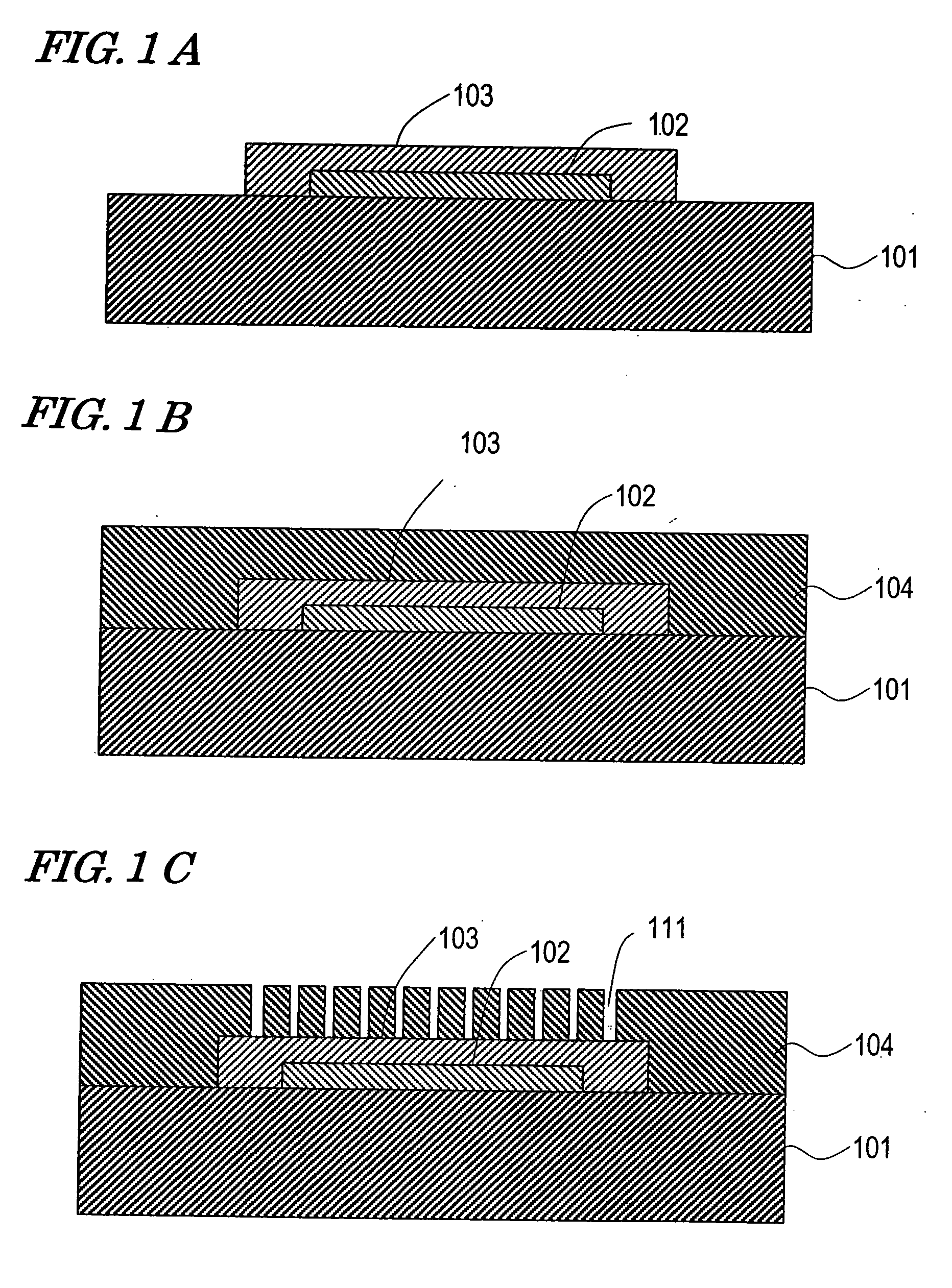

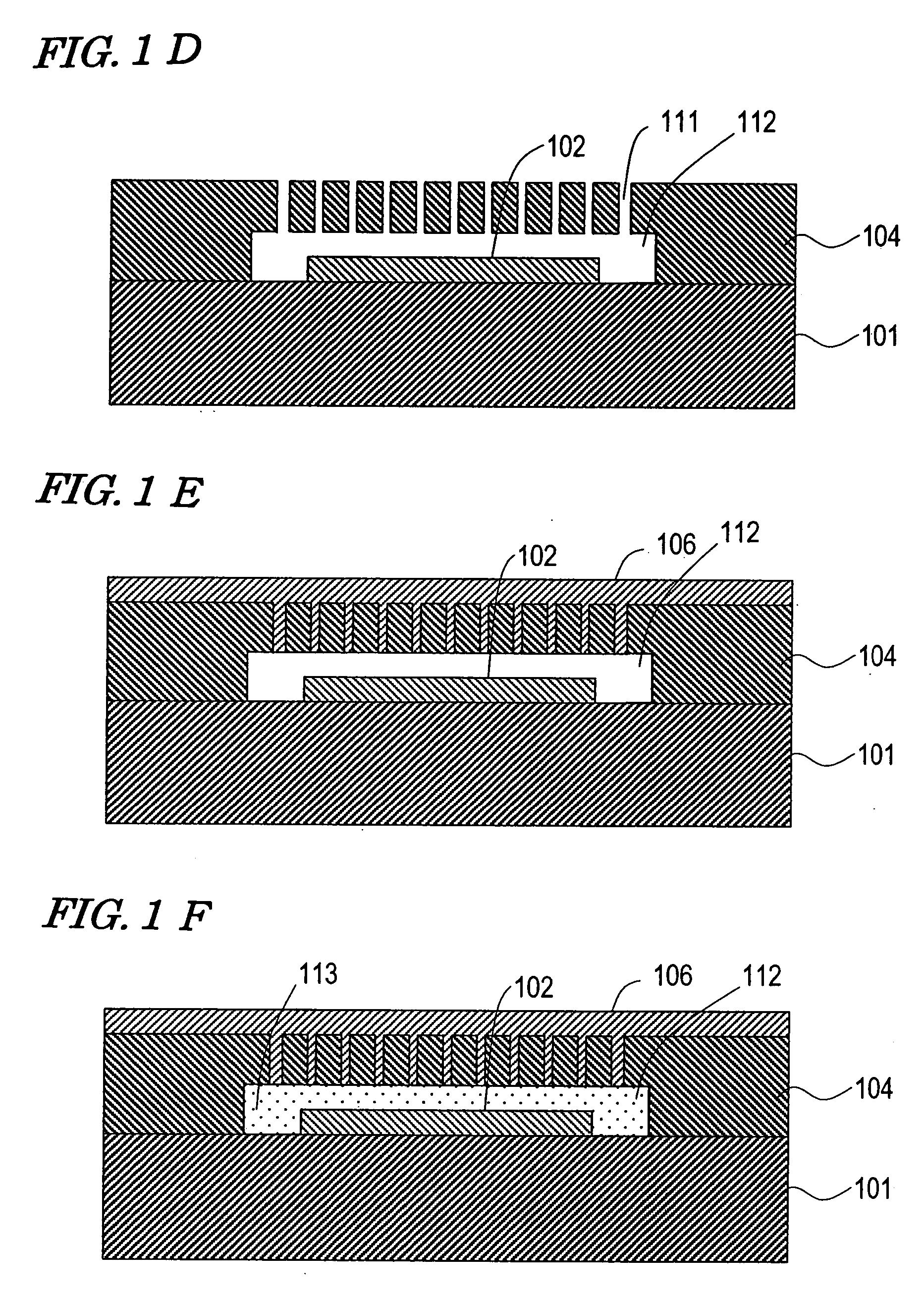

MEMS RF switch

A capacitance coupled, transmission line-fed, radio frequency MEMS switch and its fabrication process using photoresist and other low temperature processing steps are described. The achieved switch is disposed in a low cost dielectric housing free of undesired electrical effects on the switch and on the transmission line(s) coupling the switch to an electrical circuit. The dielectric housing is provided with an array of sealable apertures useful for wet, but hydrofluoric acid-free, removal of switch fabrication employed materials and also useful during processing for controlling the operating atmosphere surrounding the switch—e.g. at a pressure above the high vacuum level for enhanced switch damping during operation. Alternative arrangements for sealing an array of dielectric housing apertures are included. Processing details including plan and profile drawing views, specific equipment and materials identifications, temperatures and times are also disclosed.

Owner:US SEC THE AIR FORCE THE

MEMS RF switch integrated process

InactiveUS7381583B1Electrostatic/electro-adhesion relaysSemiconductor/solid-state device manufacturingHydrofluoric acidCapacitance

A capacitance coupled, transmission line-fed, radio frequency MEMS switch and its fabrication process using photoresist and other low temperature processing steps are described. The achieved switch is disposed in a low cost dielectric housing free of undesired electrical effects on the switch and on the transmission line(s) coupling the switch to an electrical circuit. The dielectric housing is provided with an array of sealable apertures useful for wet, but hydrofluoric acid-free, removal of switch fabrication employed materials and also useful during processing for controlling the operating atmosphere surrounding the switch—e.g. at a pressure above the high vacuum level for enhanced switch damping during operation. Alternative arrangements for sealing an array of dielectric housing apertures are included. Processing details including plan and profile drawing views, specific equipment and materials identifications, temperatures and times are also disclosed.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Composition and Method for Recycling Semiconductor Wafers Having Low-K Dielectric Materials Thereon

ActiveUS20080261847A1Non-surface-active detergent compositionsSemiconductor/solid-state device manufacturingHydrofluoric acidEngineering

A removal composition and process for removing low-k dielectric material, etch stop material, and / or metal stack material from a rejected microelectronic device structure having same thereon. The removal composition includes hydrofluoric acid. The composition achieves at least partial removal of the material(s) from the surface of the microelectronic device structure having same thereon, for recycling and / or reuse of said structure, without damage to the underlying polysilicon or bare silicon layer employed in the semiconductor architecture.

Owner:ENTEGRIS INC

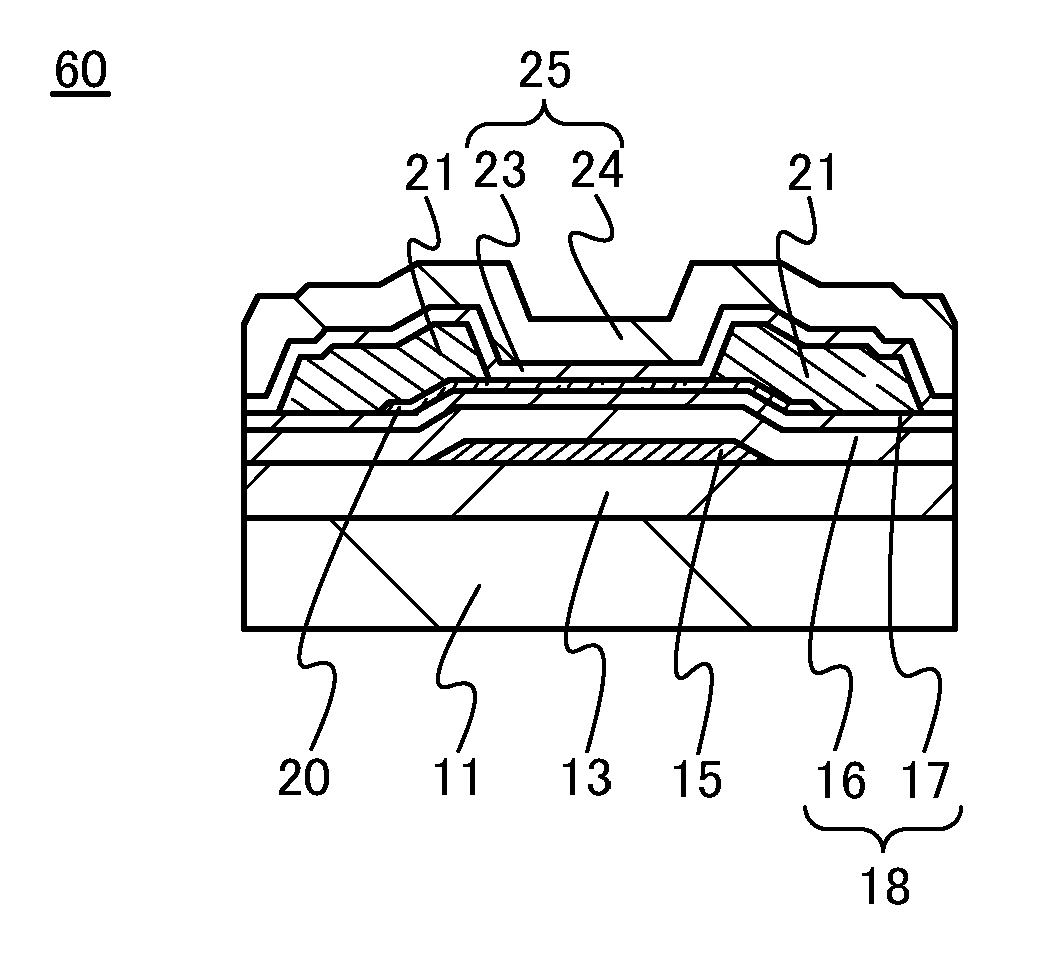

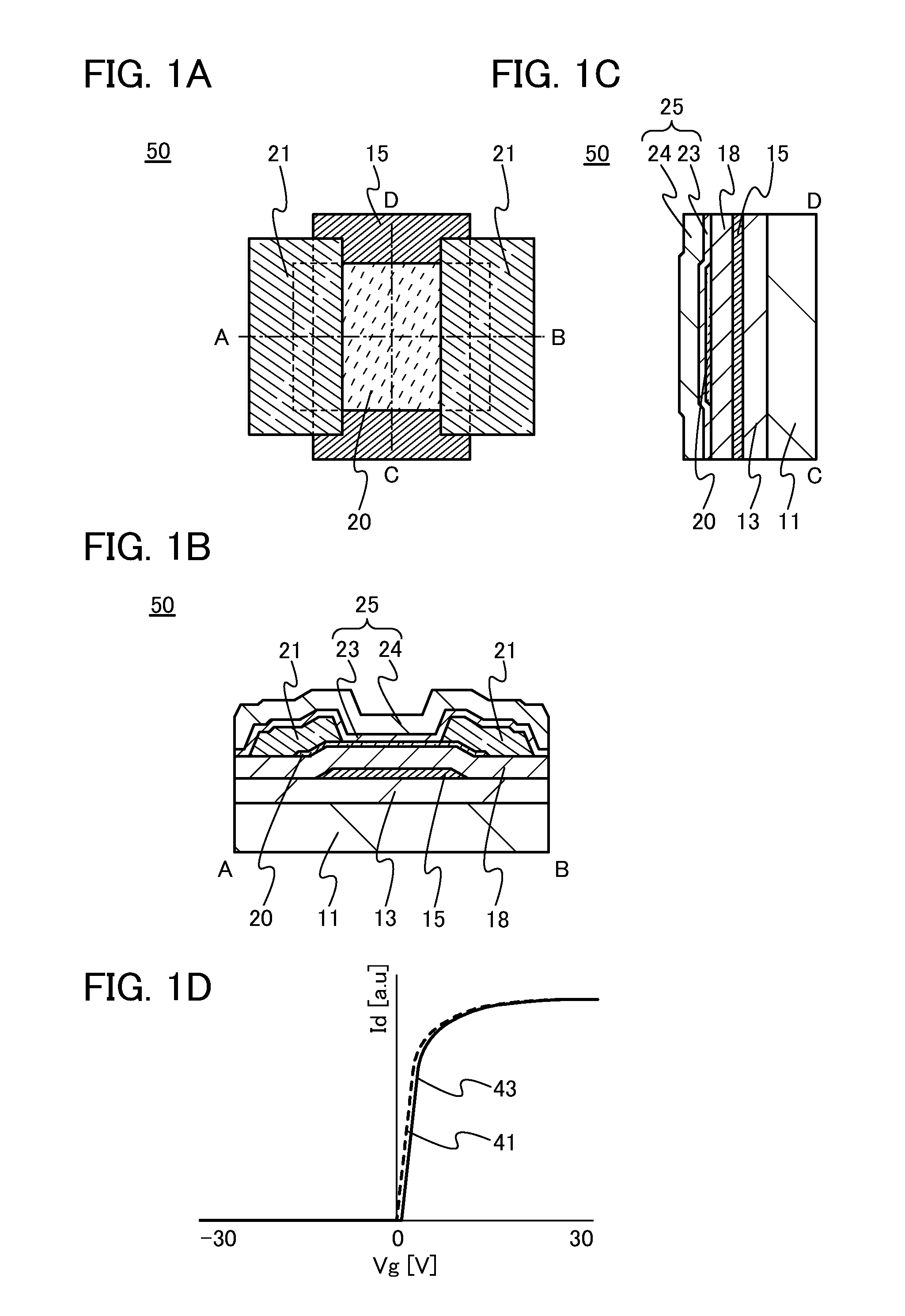

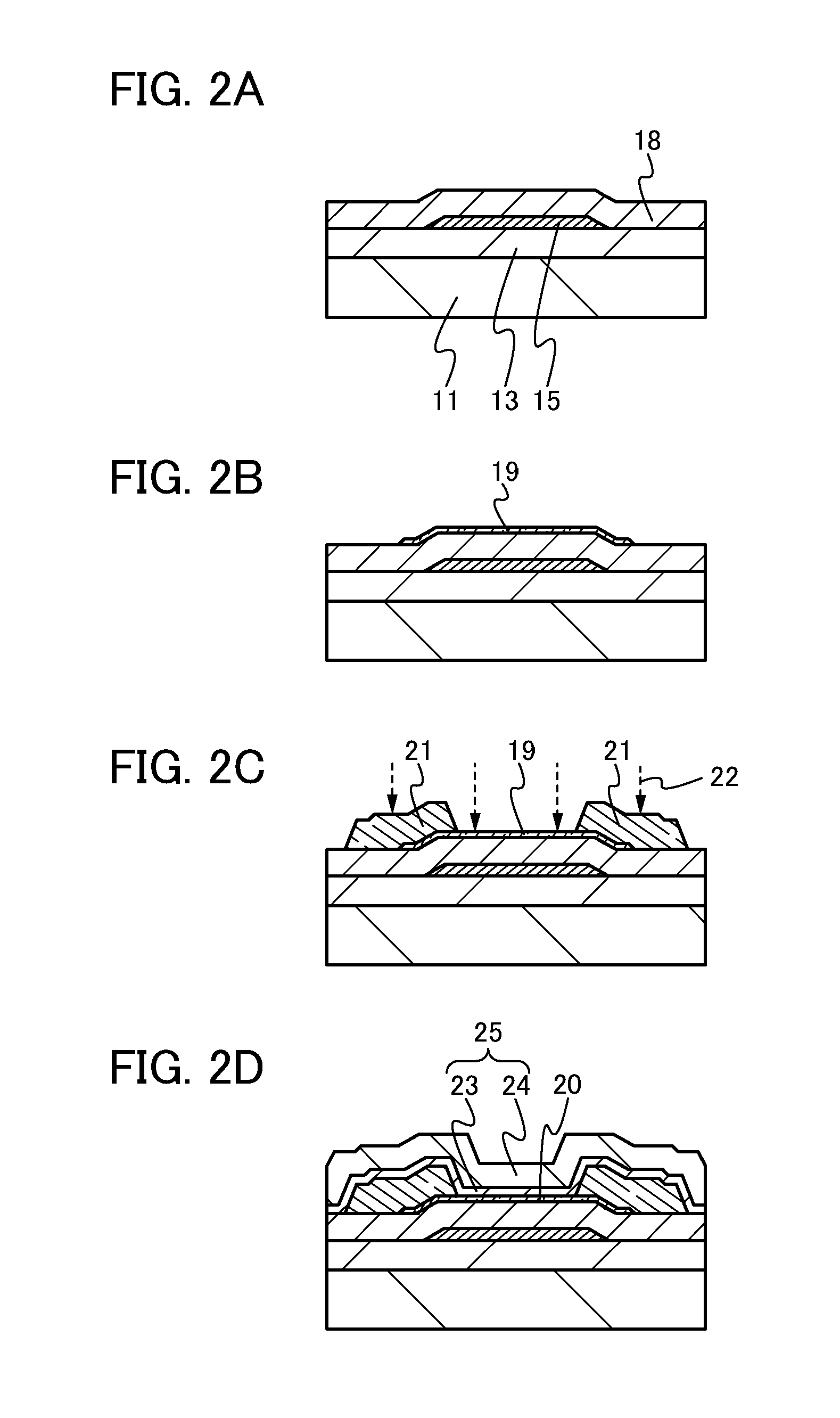

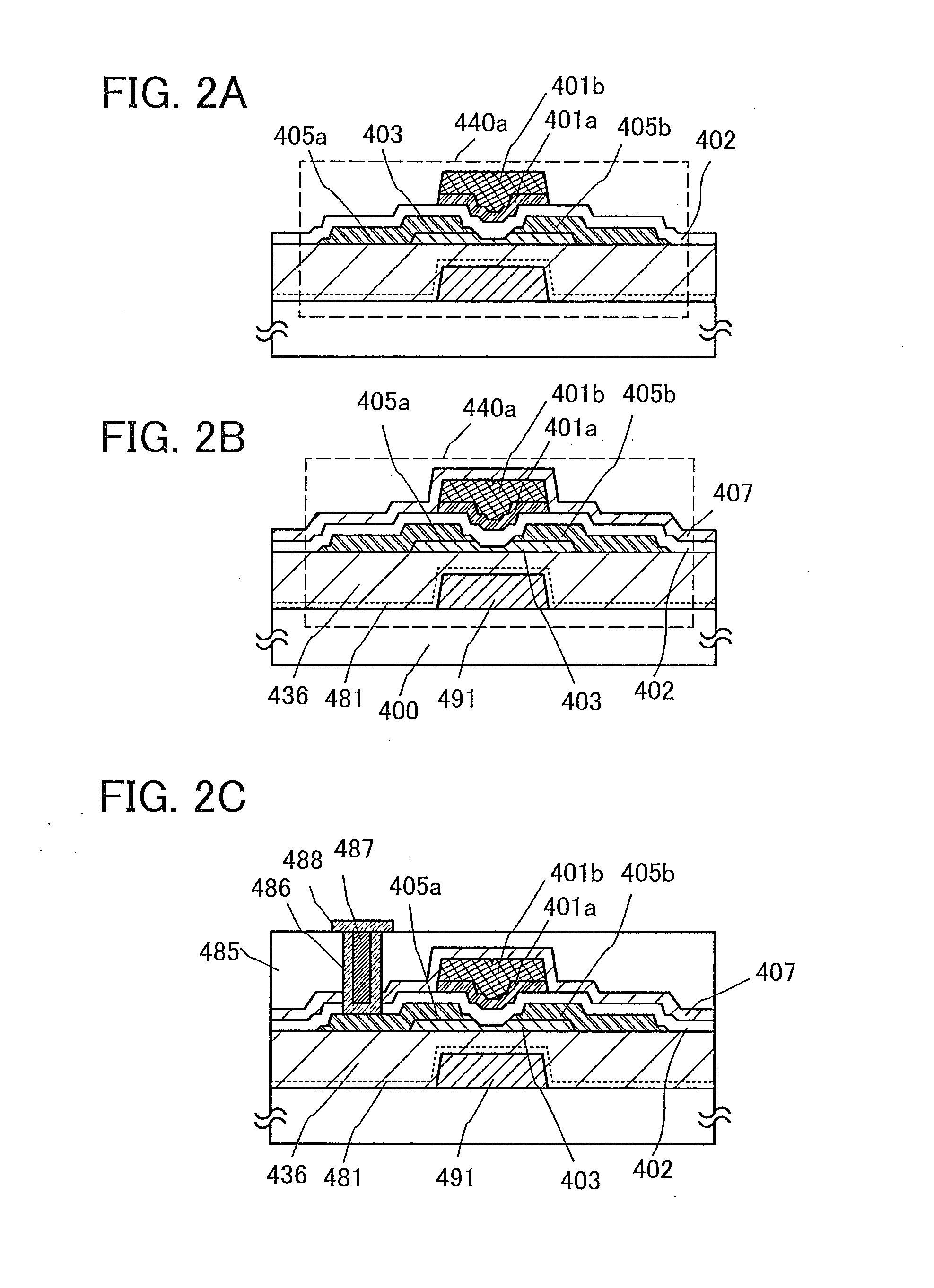

Semiconductor device and method for manufacturing semiconductor device

ActiveUS20130270549A1Excellent electrical propertiesReduce the amount of oxygenTransistorSolid-state devicesHydrofluoric acidOxygen vacancy

In a semiconductor device including an oxide semiconductor, the amount of oxygen vacancies is reduced. Moreover, electrical characteristics of a semiconductor device including an oxide semiconductor are improved. The semiconductor device includes a transistor including a gate electrode over a substrate, a gate insulating film covering the gate electrode, an oxide semiconductor film overlapping with the gate electrode with the gate insulating film provided therebetween, and a pair of electrodes in contact with the oxide semiconductor film; and over the transistor, a first insulating film covering the gate insulating film, the oxide semiconductor film, and the pair of electrodes; and a second insulating film covering the first insulating film. An etching rate of the first insulating film is lower than or equal to 10 nm / min and lower than an etching rate of the second insulating film when etching is performed at 25° C. with 0.5 weight % of hydrofluoric acid.

Owner:SEMICON ENERGY LAB CO LTD

Method of preventing surface roughening during hydrogen prebake of SiGe substrates

InactiveUS20050148161A1Avoid creatingAvoid roughnessPolycrystalline material growthSemiconductor/solid-state device manufacturingHydrofluoric acidRough surface

The invention forms an epitaxial silicon-containing layer on a silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface and avoids creating a rough surface upon which the epitaxial silicon-containing layer is grown. In order to avoid creating the rough surface, the invention first performs a hydrofluoric acid etching process on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. This etching process removes most of oxide from the surface, and leaves a first amount of oxygen (typically 1×1013-1×1015 / cm2 of oxygen) on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. The invention then performs a hydrogen pre-bake process which heats the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface sufficiently to remove additional oxygen from the surface and leave a second amount of oxygen, less than the first amount, on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. The heating process leaves an amount of at least 5×1012 / cm2 of oxygen (typically, between approximately 1×1013 / cm2 and approximately 5×1013 / cm2 of oxygen) on the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. By leaving a small amount of oxygen on the silicon germanium, patterned strained silicon, or patterned silicon-on-insulator surface, the heating processes avoid changing the roughness of the silicon germanium, patterned strained silicon, or patterned thin silicon-on-insulator surface. Then the process of epitaxially growing the epitaxial silicon-containing layer on the silicon germanium, patterned strained silicon, or patterned silicon-on-insulator surface is performed.

Owner:IBM CORP

Methods of forming semiconductor constructions and capacitors

InactiveUS20070048976A1Solid-state devicesSemiconductor/solid-state device manufacturingTetramethylammonium hydroxideOxygen compound

The invention includes methods in which silicon is removed from titanium-containing container structures with an etching composition having a phosphorus-and-oxygen-containing compound therein. The etching composition can, for example, include one or both of ammonium hydroxide and tetra-methyl ammonium hydroxide. The invention also includes methods in which titanium-containing whiskers are removed from between titanium-containing capacitor electrodes. Such removal can be, for example, accomplished with an etch utilizing one or more of hydrofluoric acid, ammonium fluoride, nitric acid and hydrogen peroxide.

Owner:MICRON TECH INC

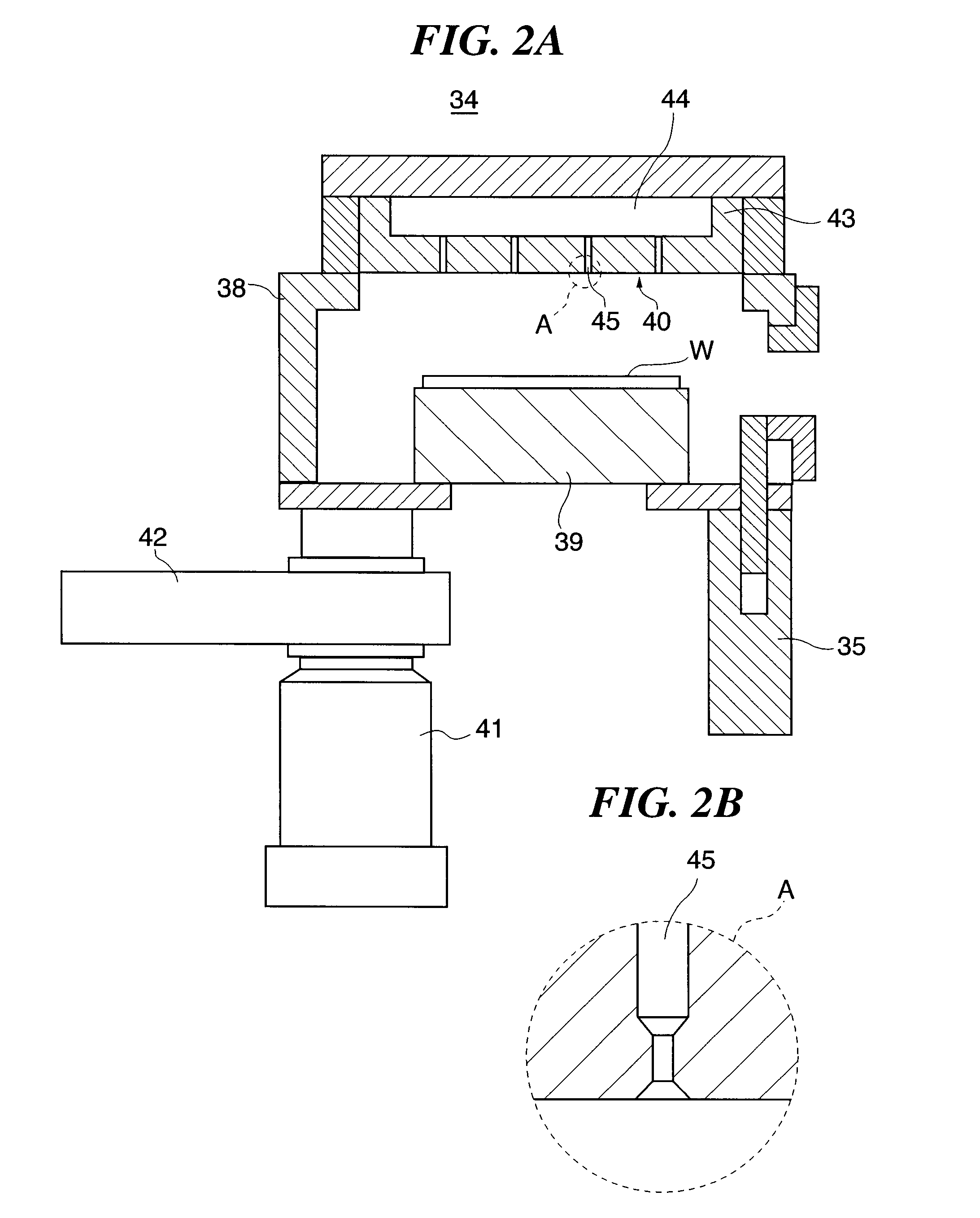

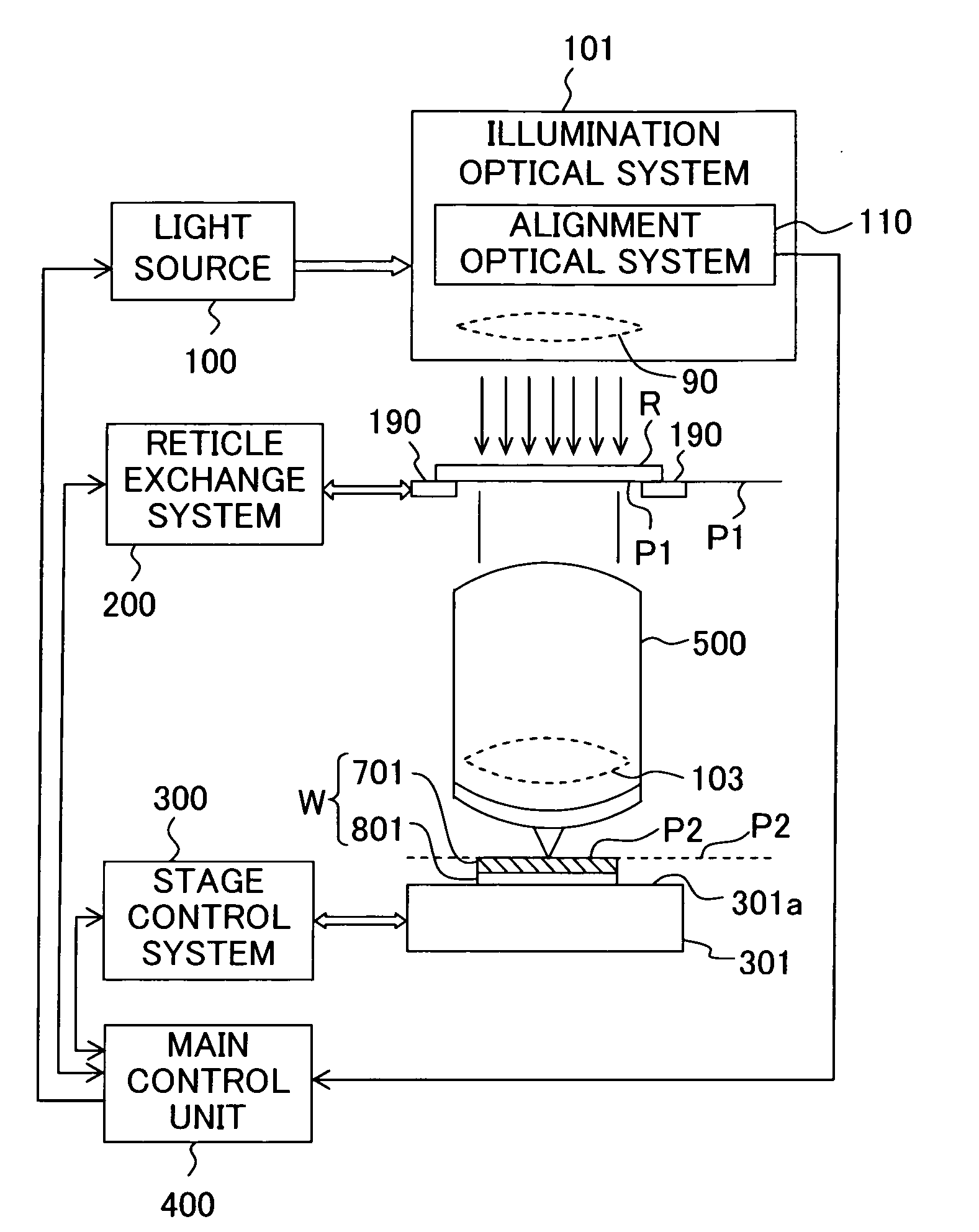

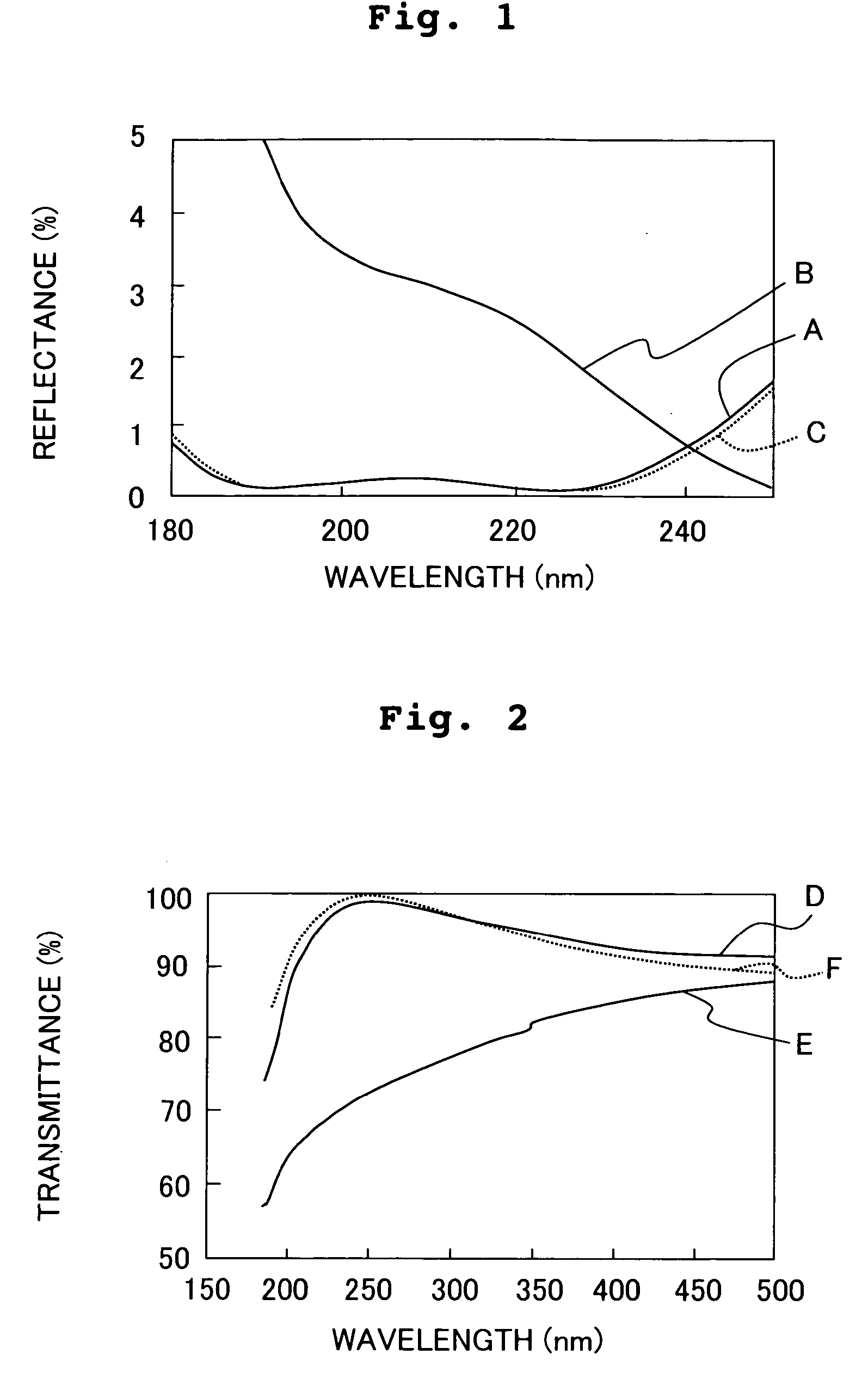

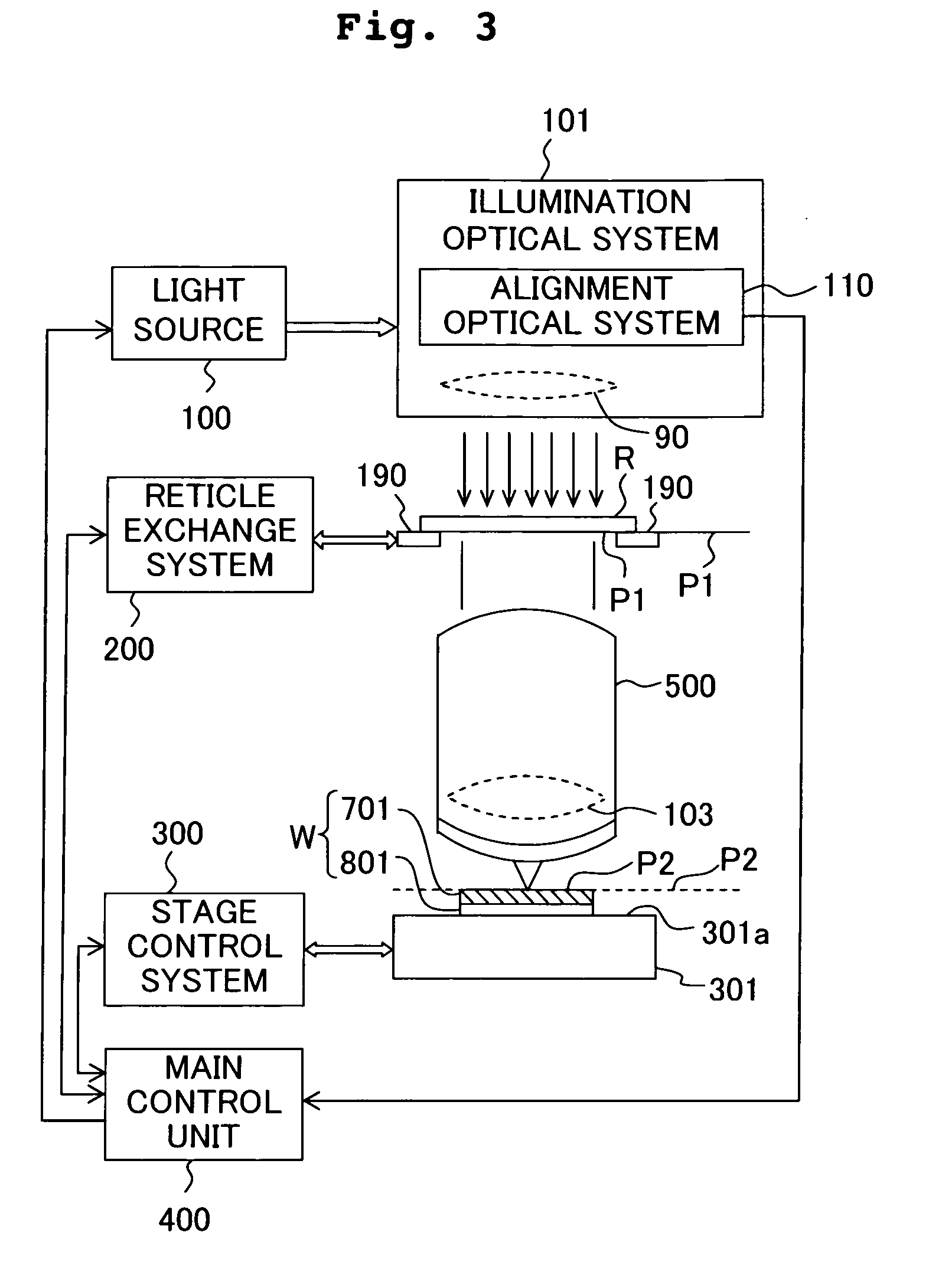

Pollutant removal method and apparatus, and exposure method and apparatus

InactiveUS20050274898A1Easy to removeMaterial analysis by optical meansPhotomechanical exposure apparatusHydrofluoric acidReciprocating motion

A method for quickly removing pollutants adhered to a predetermined optical member in an optical system. To remove the pollutants adhered to a lens (32A) disposed at the upper end of a projection optical system (PL), a cylindrical protecting member (53) is disposed through the openings in a reticle stage (22) and a reticle base (23). The bottom surface of a support section (56) at the tip section of a rod section (58) is brought into contact with the surface of the lens (32A) through the inner surface of the protecting member (53). A wiping cloth soaked with a washing solution containing hydrofluoric acid is attached to the bottom surface of the support section (56). The support section (56) is reciprocated via the rod section (58) to remove the pollutants on the lens (32A) with the wiping cloth.

Owner:NIKON CORP

Method and apparatus for treating a substrate with dense fluid and plasma

ActiveUS20060278254A1High densityDivergent cohesion energyElectric discharge tubesElectric arc lampsSolid phasesWet cleaning

The present invention is a method, process and apparatus for selective cleaning, drying, and modifying substrate surfaces and depositing thin films thereon using a dense phase gas solvent and admixtures within a first created supercritical fluid anti-solvent. Dense fluids are used in combination with sub-atmospheric, atmospheric and super-atmospheric plasma adjuncts (cold and thermal plasmas) to enhance substrate surface cleaning, modification, precision drying and deposition processes herein. Moreover, conventional wet cleaning agents such as hydrofluoric acid and ammonium fluoride may be used with the present invention to perform substrate pre-treatments prior to precision drying and cleaning treatments described herein. Finally, dense fluid such as solid phase carbon dioxide and argon may be used as a follow-on treatment or in combination with plasmas to further treat a substrate surface.

Owner:HITACHI HIGH-TECH CORP

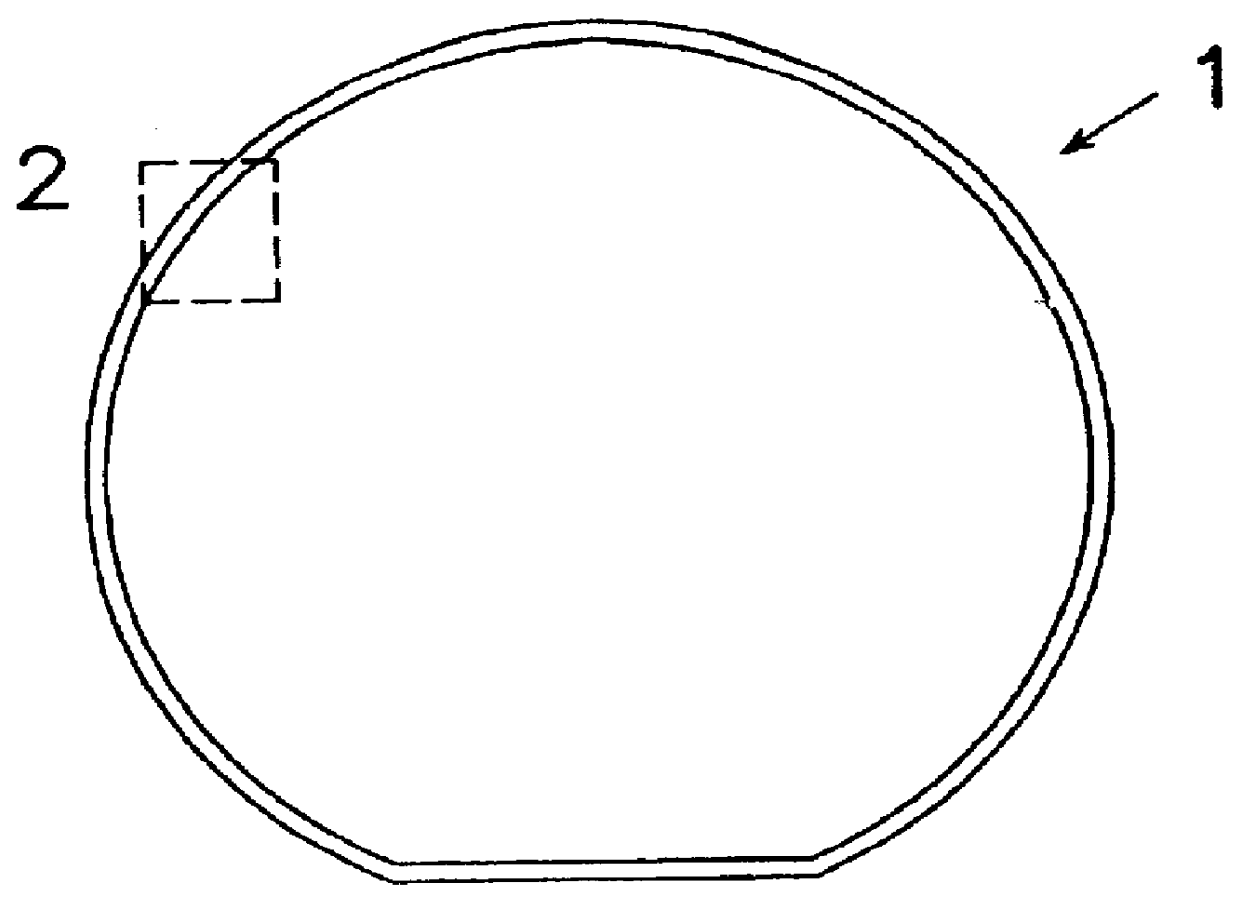

Process for wet etching of semiconductor wafers

A process of controlled wet etching of semiconductor wafers having a silicon dioxide layer on each of two surfaces, includes entirely removing the silicon dioxide layer from a top side and selectively removing the silicon dioxide layer from the opposite side bottom in a defined area which extends to the inside from the peripheral edge of the semiconductor wafer using an etching medium which includes hydrofluoric acid or a combination of hydrofluoric acid and ammonium fluoride and at least one carboxylic acid.

Owner:LAM RES AG

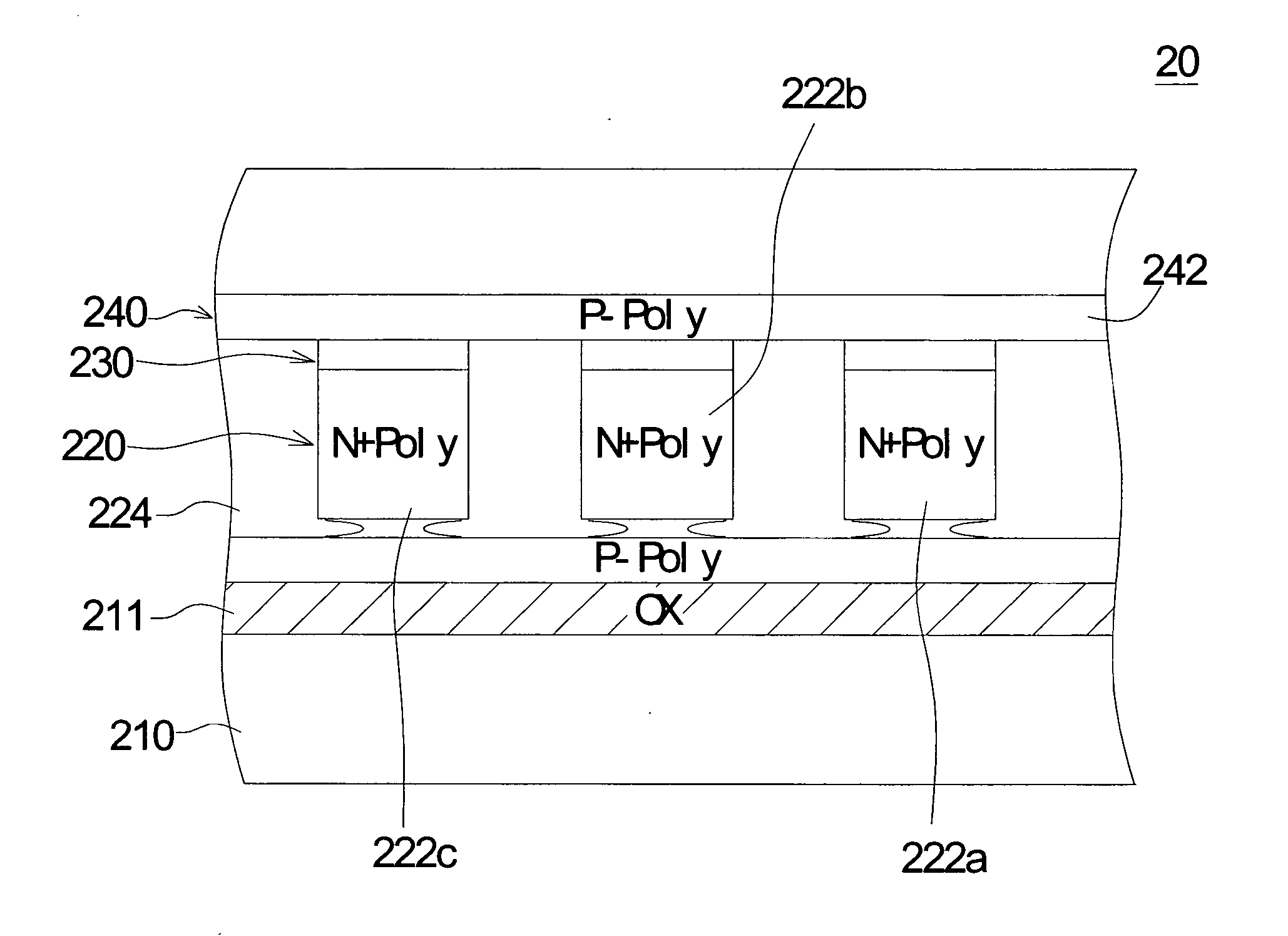

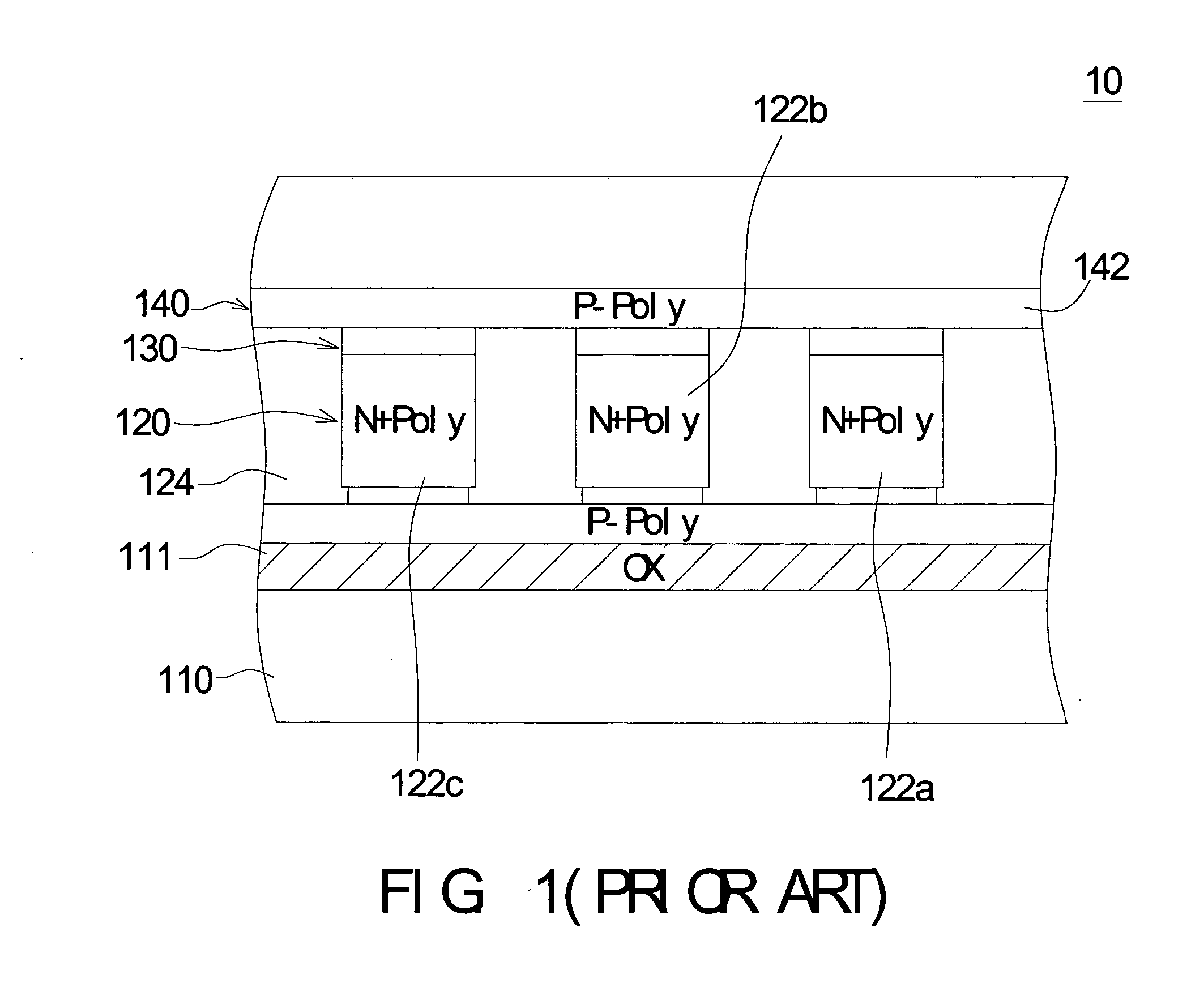

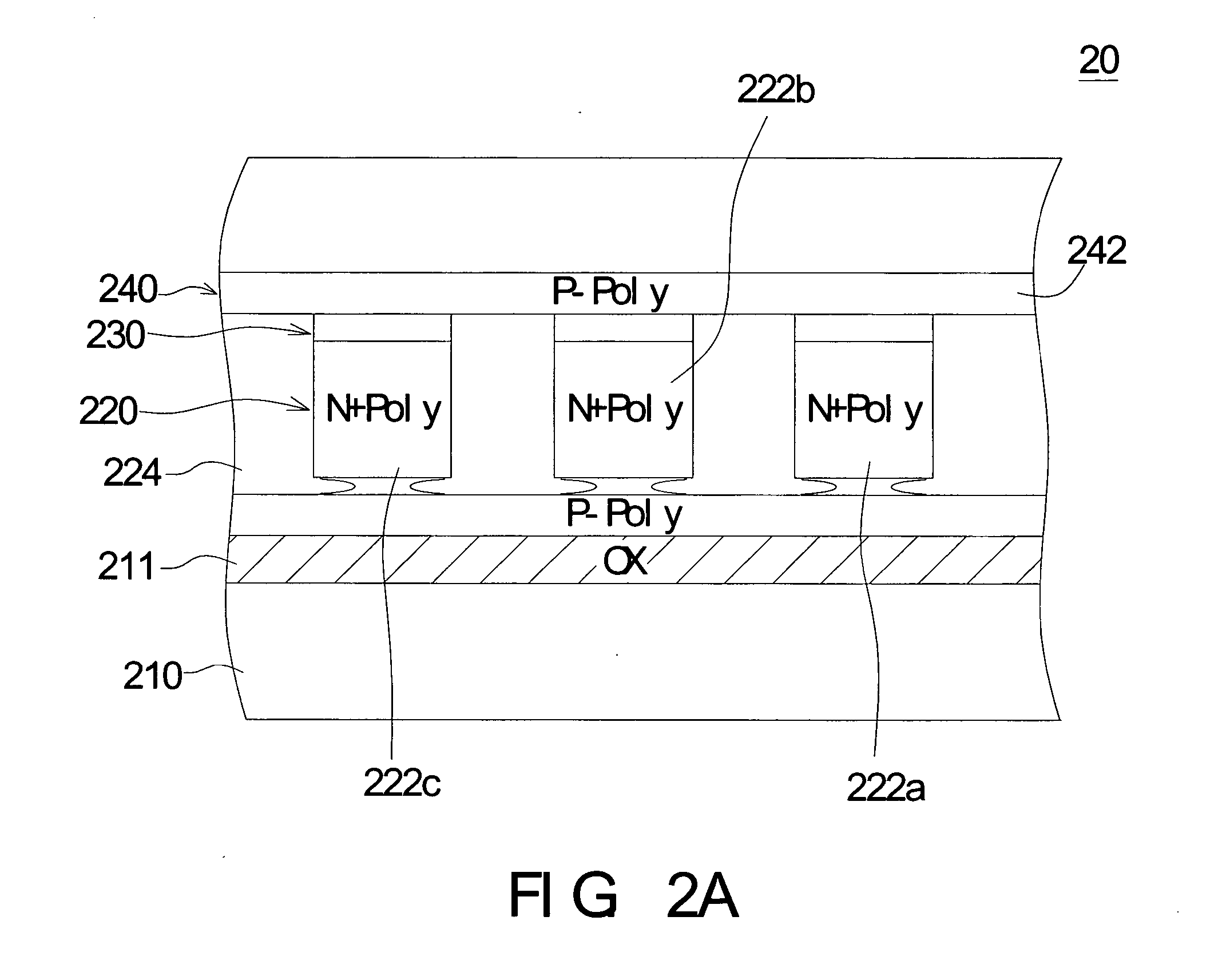

3D polysilicon ROM and method of fabrication thereof

ActiveUS20050124116A1Lower requirementYield in processing can be improvedTransistorSolid-state devicesHydrofluoric acidNeck structure

A 3D polysilicon read only memory at least including: a silicon substrate, an isolated silicon dioxide (SiO2) layer, a N-Type heavily doped (N+) polysilicon layer, a first oxide layer, a dielectric layer, a P-Type lightly doped (P−) polysilicon layer, at least a neck structure, and a second oxide layer. The isolated SiO2 layer is deposited on the silicon substrate, and the N+ polysilicon layer is deposited on the isolated SiO2 layer. The N+ polysilicon layer is further defined a plurality of parallel, separate word lines (WL), and the first oxide layer is filled in the space between the word lines. The dielectric layer is deposited on the word lines and the first oxide layer. The P-Type lightly doped (P−) polysilicon layer is deposited on the dielectric layer and is further defined a plurality of parallel, separate bit lines (BL). The bit lines overlap the word lines, from a top view, to form a shape approximately as a cross. There are at least a neck structure individually formed between the first polysilicon layer and the second polysilicon layer by isotropy wet etching the dielectric layer, with using dilute hydrofluoric acid (HF) as the example. The second oxide layer is filled in the space between the bit lines and is on the word lines and the first oxide layer.

Owner:MACRONIX INT CO LTD

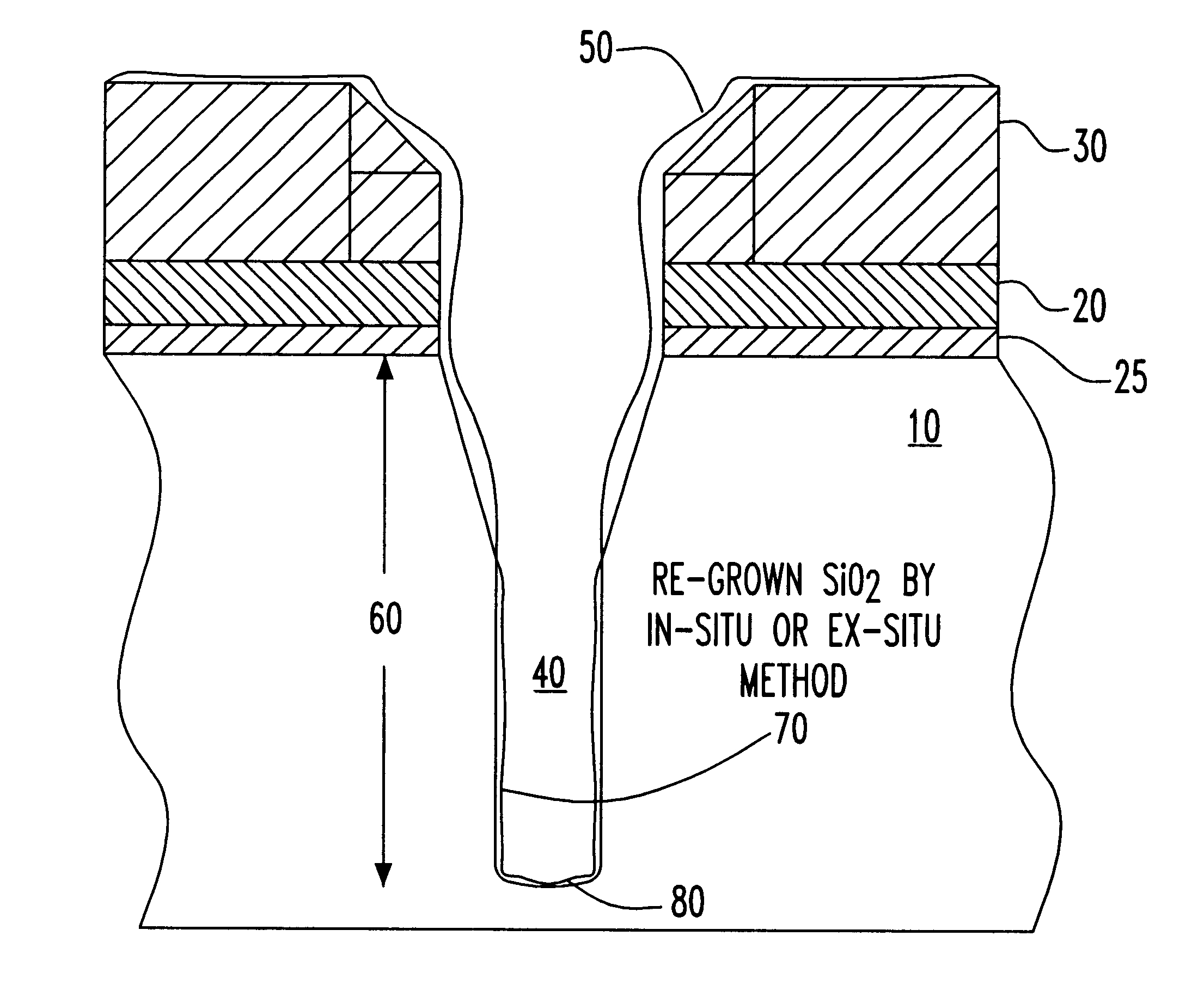

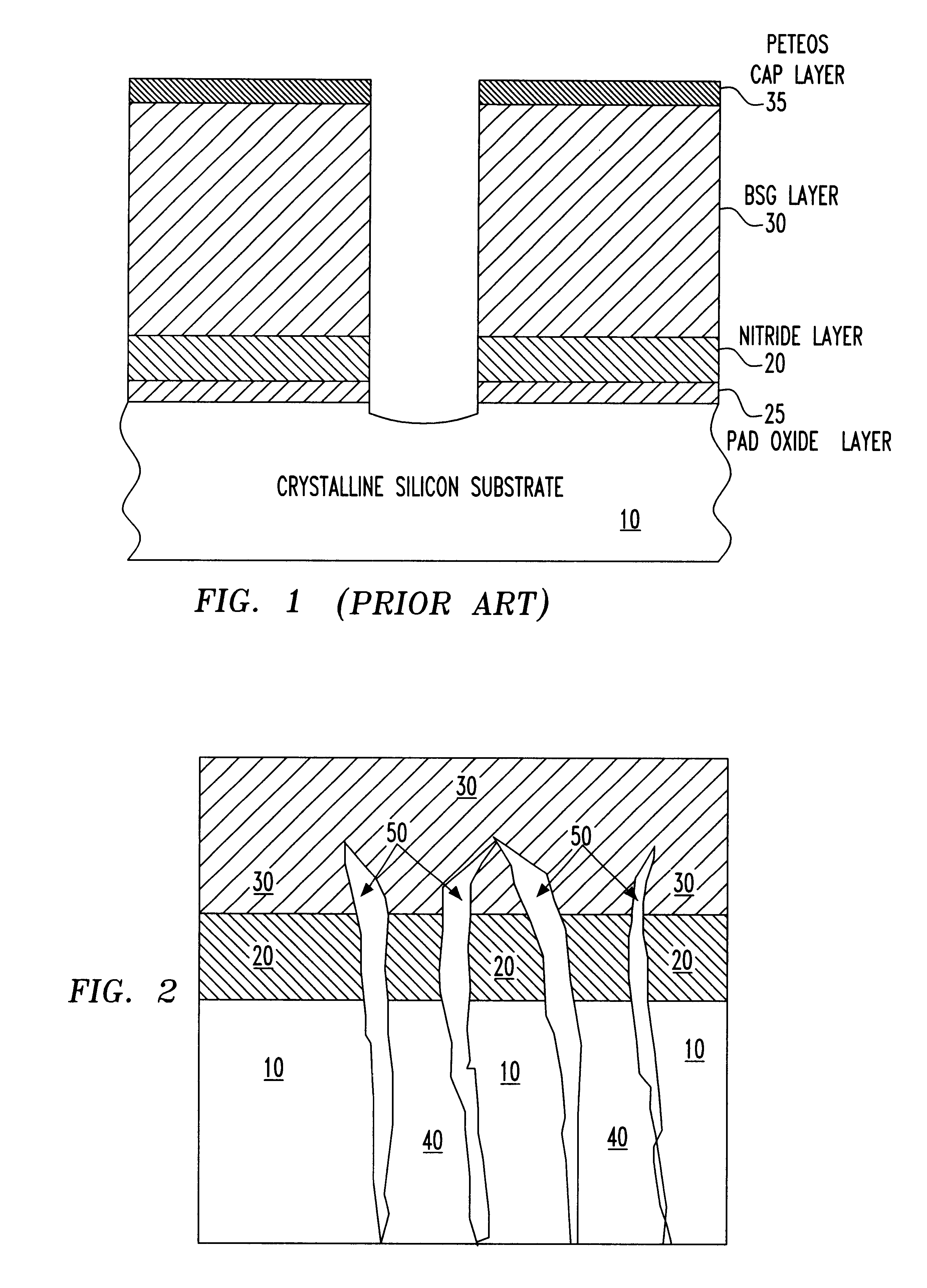

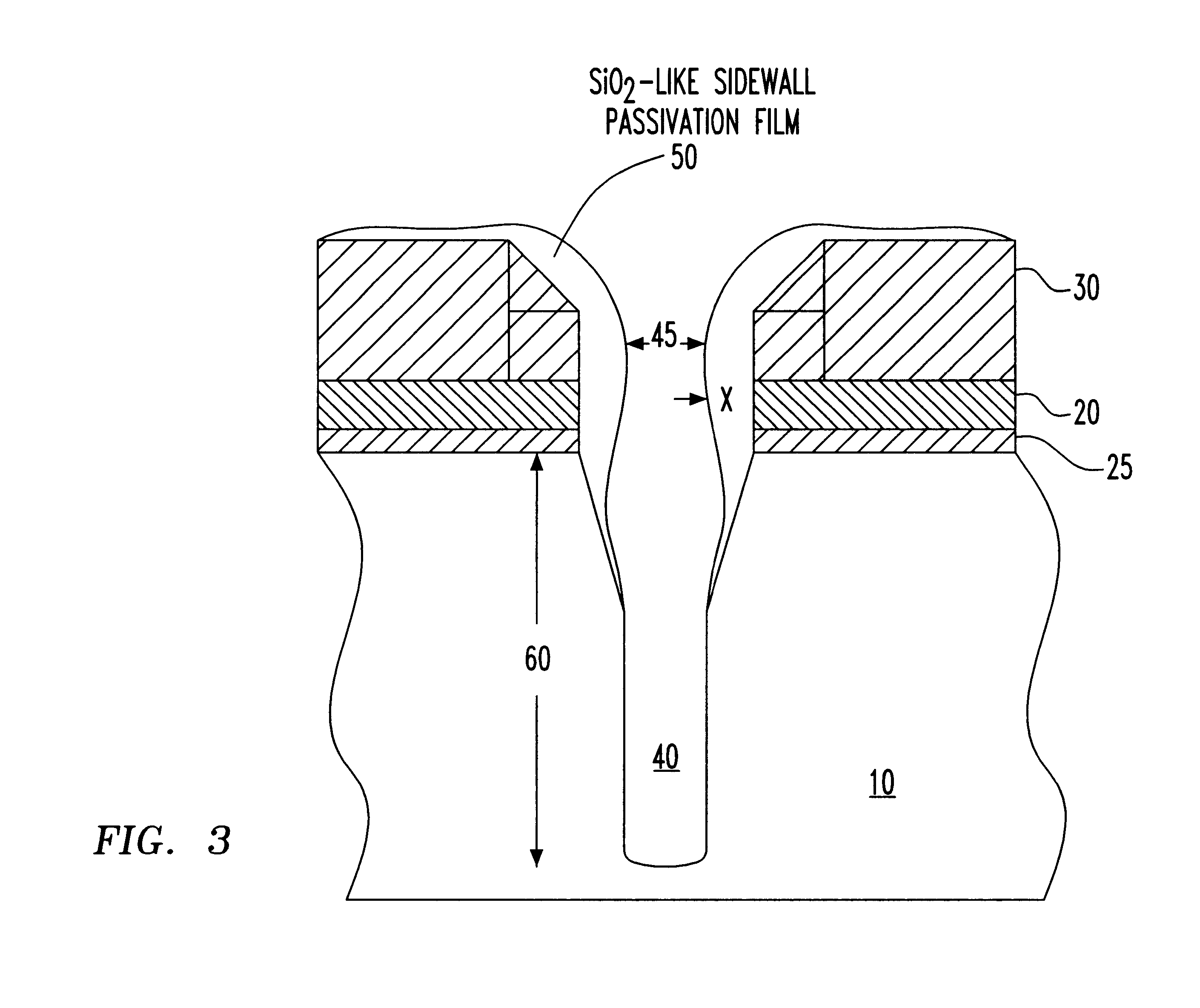

Method of reducing RIE lag for deep trench silicon etching

InactiveUS6284666B1Eliminating and at least minimizing RIE lagEliminating or at least minimizing RIE lagTransistorSemiconductor/solid-state device manufacturingHydrofluoric acidGas phase

A method of minimizing RIE lag (i.e., the neutral and ion fluxes at the bottom of a deep trench (DT) created during the construction of the trench opening using a side wall film deposition)) in DRAMs having a large aspect ratio (i.e., <30:1) is described. The method forms a passivation film to the extent necessary for preventing isotropic etching of the substrate, hence maintaining the required profile and the shape of the DT within the substrate. The RIE process described provides a partial DT etched into a substrate to achieve the predetermined depth. The passivation film is allowed to grow to a certain thickness still below the extent that it would close the opening of the deep trench. Alternatively, the passivation film is removed by a non-RIE etching process. The non-RIE process that removes the film can be wet etched with chemicals, such as hydrofluoric acid (buffered or non buffered) or, alternatively, using vapor phase and / or non-ionized chemicals, such as anhydrous hydrofluoric acid. The controlled thickness of the film allows achieving a predetermined DT depth for high aspect ratio structures.

Owner:INFINEON TECH AG +1

Stainless steel cleaning agent

InactiveCN101135056AImprove cleaning efficiencySimple cleaning processPhosphoric acidCleansing Agents

The stainless steel detergent for washing stainless steel product is prepared with acids, basic salts, surfactant, assistant, stabilizer and water, and through stirring and reaction at normal temperature. Specifically, it consists of sodium carbonate, sodium tripolyphosphate, tartaric acid, citric acid, hydrofluoric acid, nitric acid, phosphoric aicd, JFC, OP-10, triethanolamine, urotropin, trisodium phosphate, acetic acid, alcohol and water in certain weight proportion. It has the features of simple preparation process, environment friendship, high cleaning efficiency, low cleaning cost, etc.

Owner:吴铭鑫

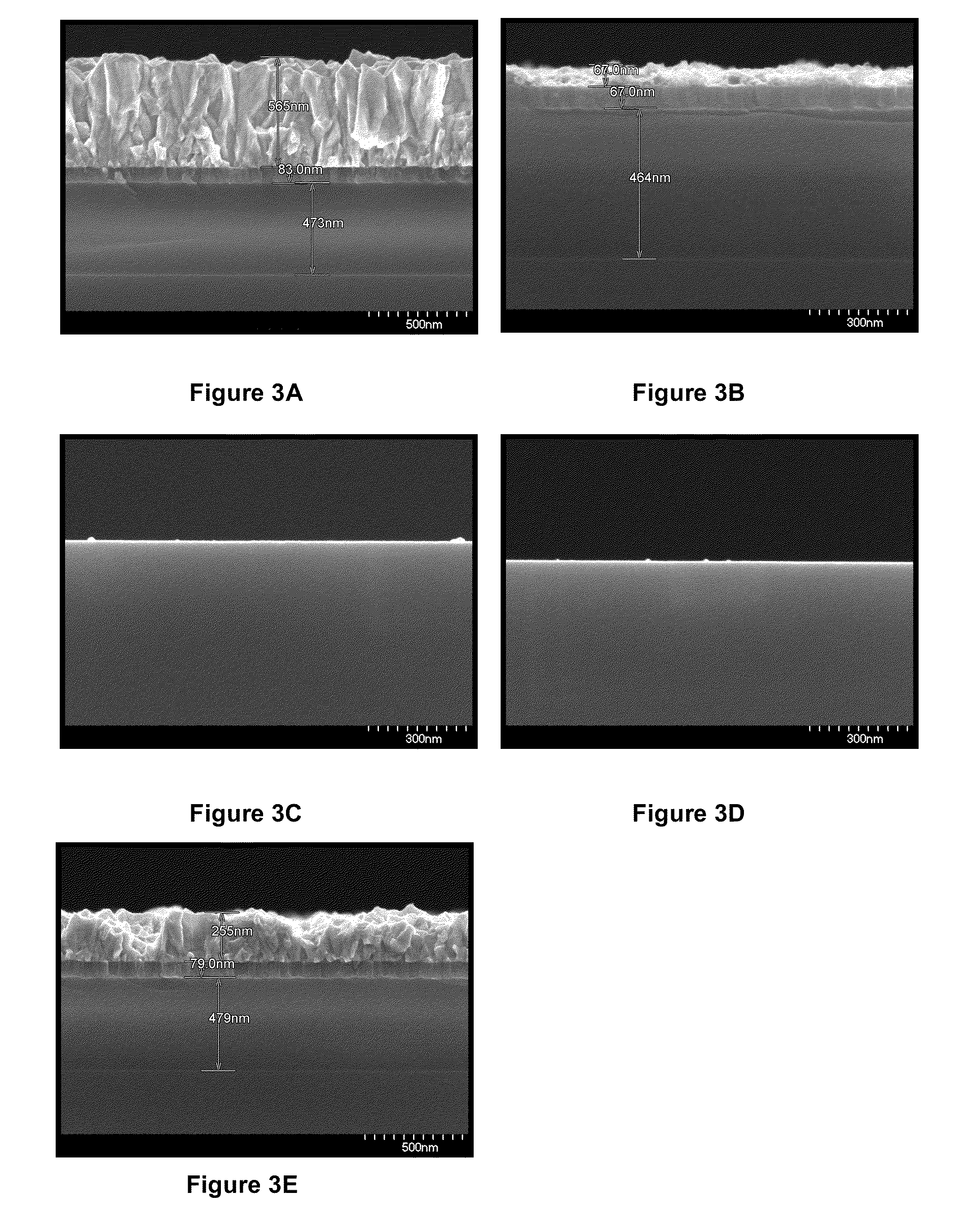

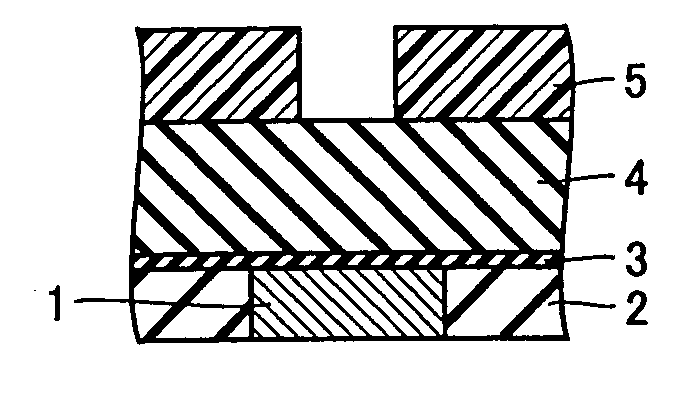

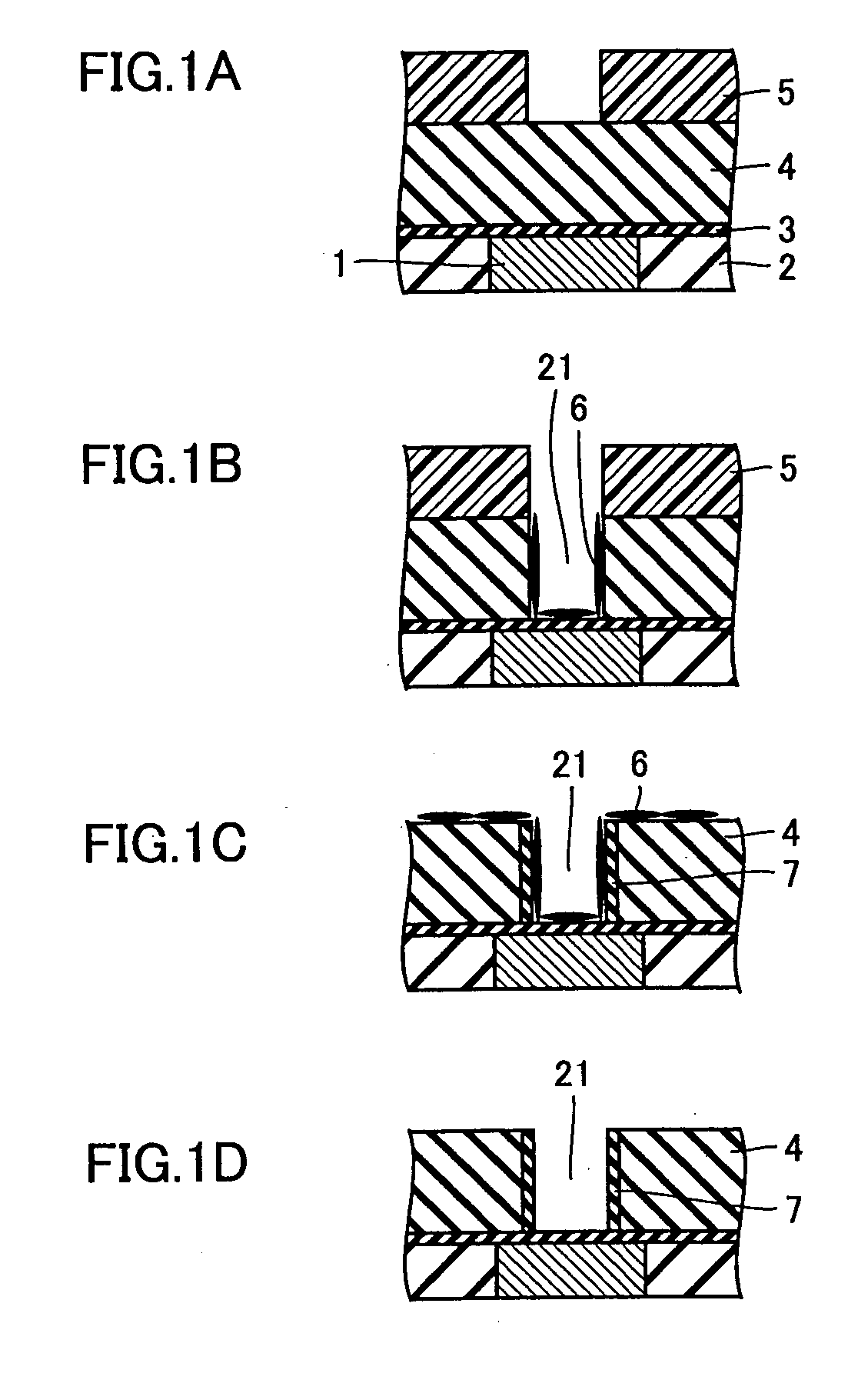

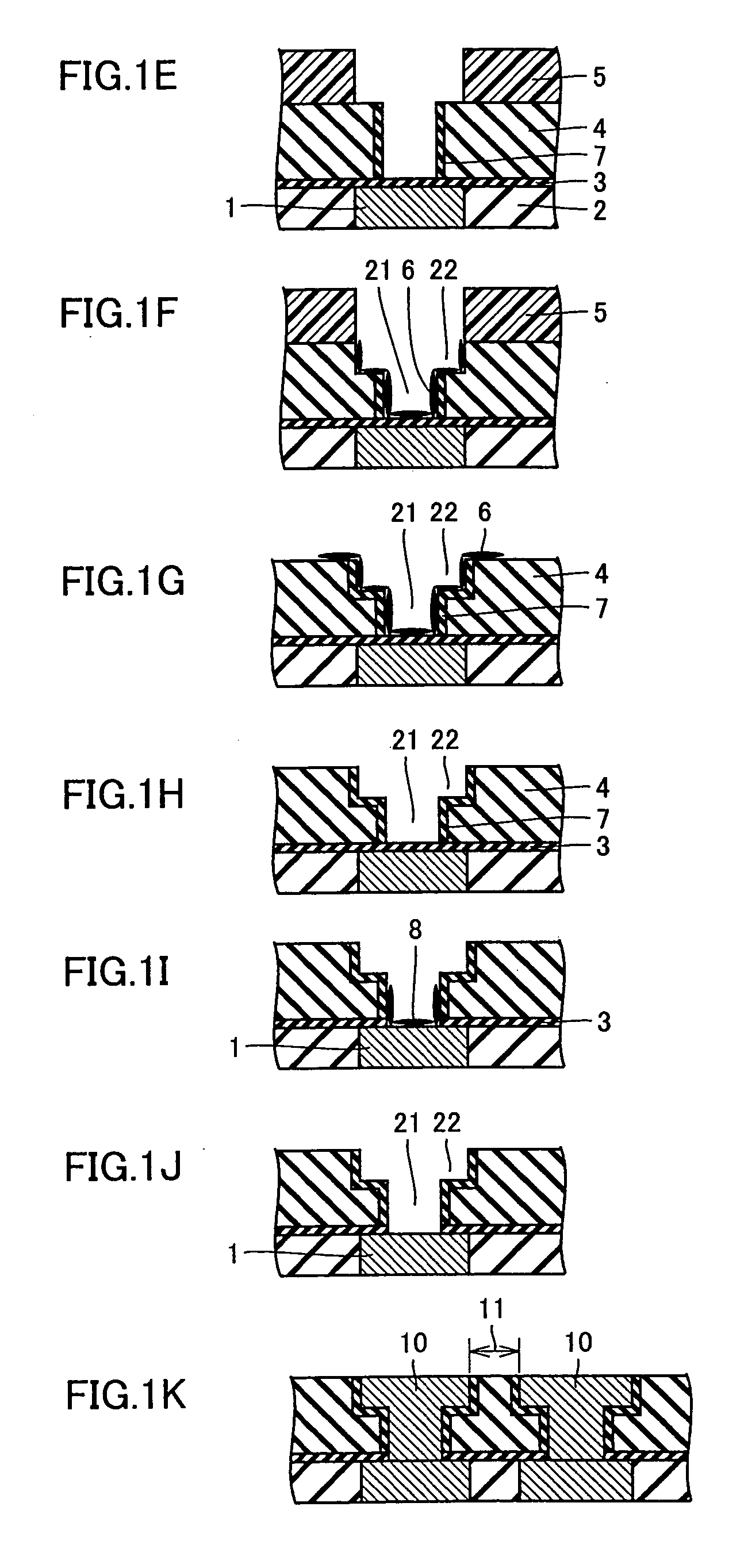

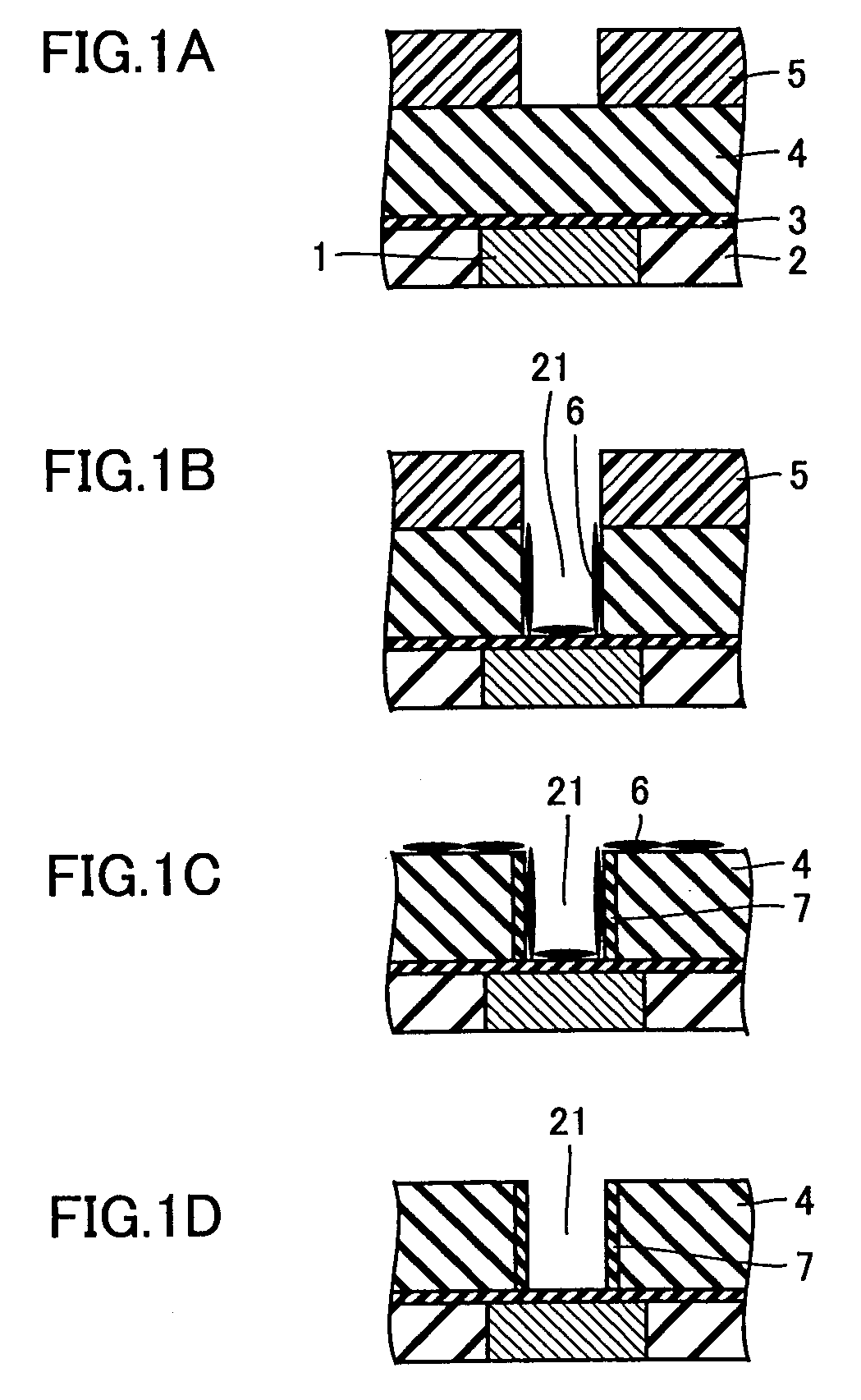

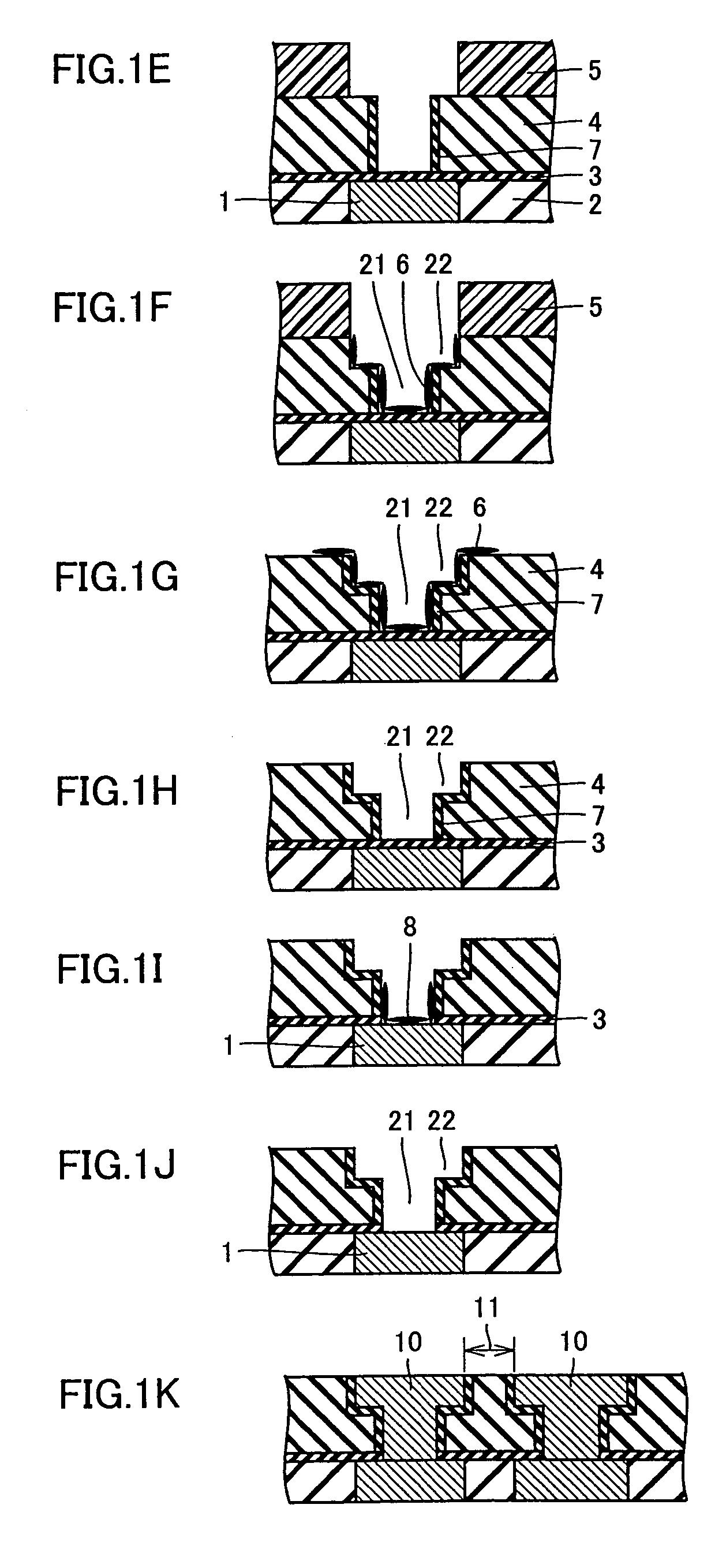

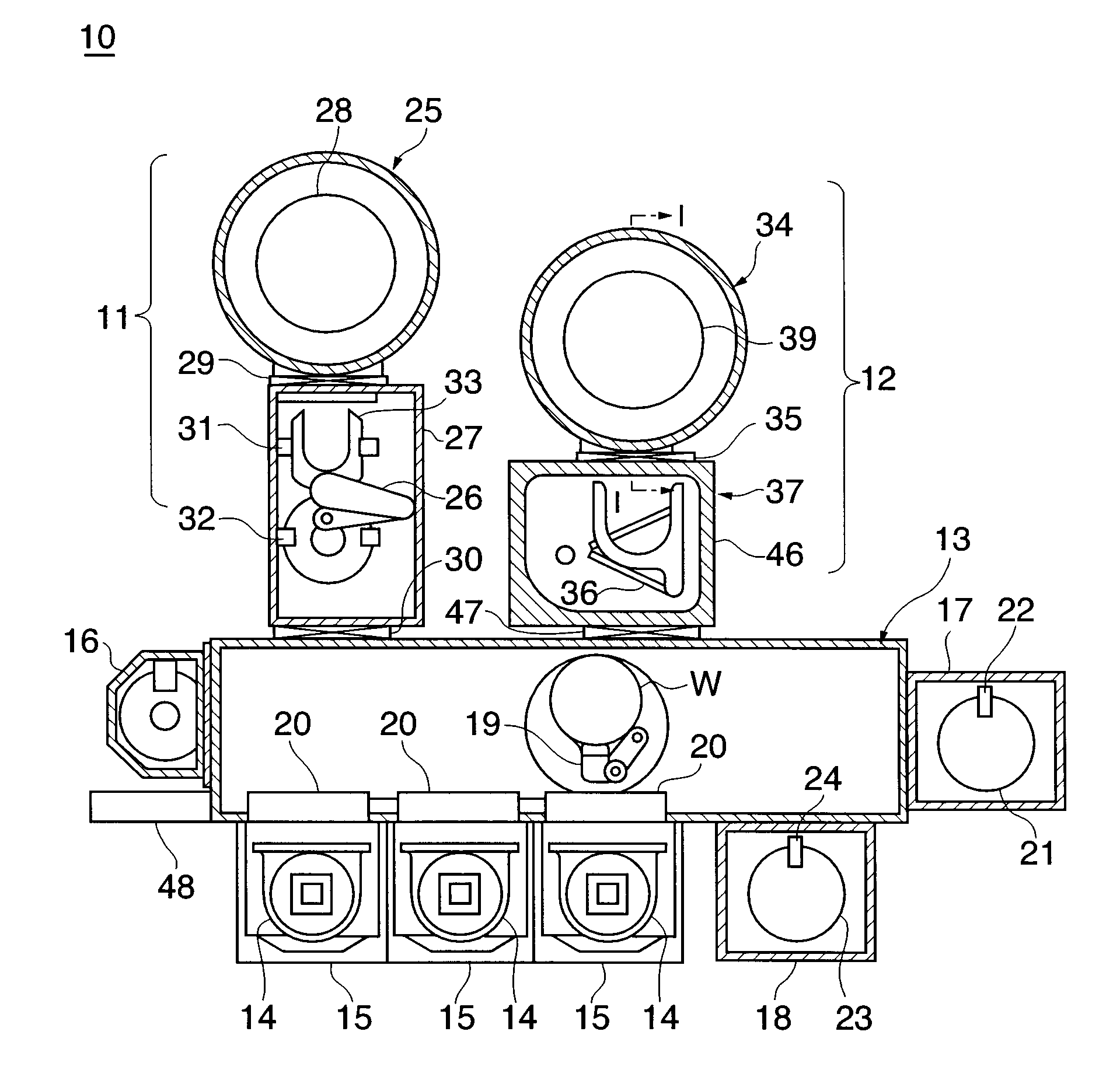

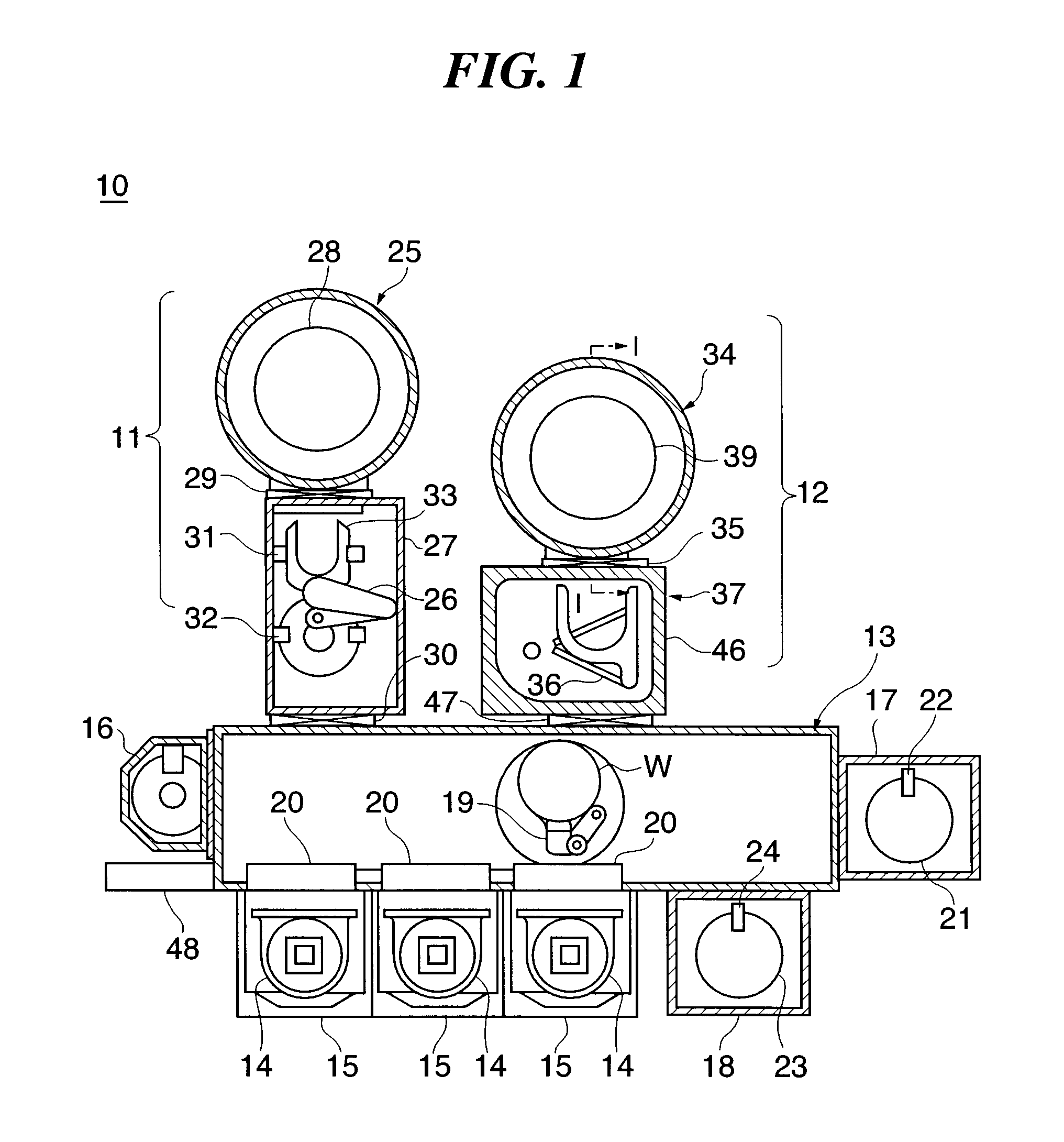

Electronic device and method of manufacturing the same

ActiveUS20050176179A1Small openingTelevision system detailsThermoelectric device with dielectric constant thermal changeSputteringHydrofluoric acid

In the present invention, an etching hole 21 is formed in a polysilicon film 14 as a cavity-wall member. Through the etching hole 21, hydrofluoric acid is injected, so as to dissolve a silicon oxide film 13, thereby forming a cavity 22. In the cavity 22, a detecting unit 12 of a sensor is in an exposed condition. Next, by sputtering, an Al film 16 is deposited in the etching hole 21 and on an upper face of a substrate. Thereafter, a portion of the Al film 16 positioned on the polysilicon film 14 is removed by etching back, thereby leaving only a metal closure 16a of Al which closes the etching hole. The sputtering step is performed under a pressure of 5 Pa or less, so that the pressure in the cavity can be held to be low.

Owner:PANASONIC CORP

Alkali-free liquid accelerating agent and preparation method thereof

The invention belongs to the technical field of tunnel construction, and relates to an alkali-free liquid accelerating agent for tunnel wet jet concrete and a preparation method thereof. The alkali-free liquid accelerating agent is characterized in that aluminium sulphate is adopted to serve as a main accelerating component; aluminium is added to an aluminium sulphate solution to be polymerized in a form of aluminium fluoride; aluminium ions are introduced to the greatest extent so as to reduce other ion introduction; and the accelerating effect is ensured. The alkali-free liquid acceleratingagent comprises the following components in percentage by mass: 30-55% of aluminium sulphate, 5-15% of aluminium hydroxide, 10-30% of hydrofluoric acid, 0.5-5% of water glass, 0-0.2% of stabilizing agent, and the balance of water. For jetting concrete, the alkali-free liquid accelerating agent disclosed by the invention has the positive effects that: ordinary cement can be initially solidified within 2 min in lower doping quantity and finally solidified within 4 min; the 1d strength of cement plaster can achieve above 15 MPa; the 28d compressive strength ratio is more than 100%; and the alkali-free liquid accelerating agent has good adaptability to different types of cements.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

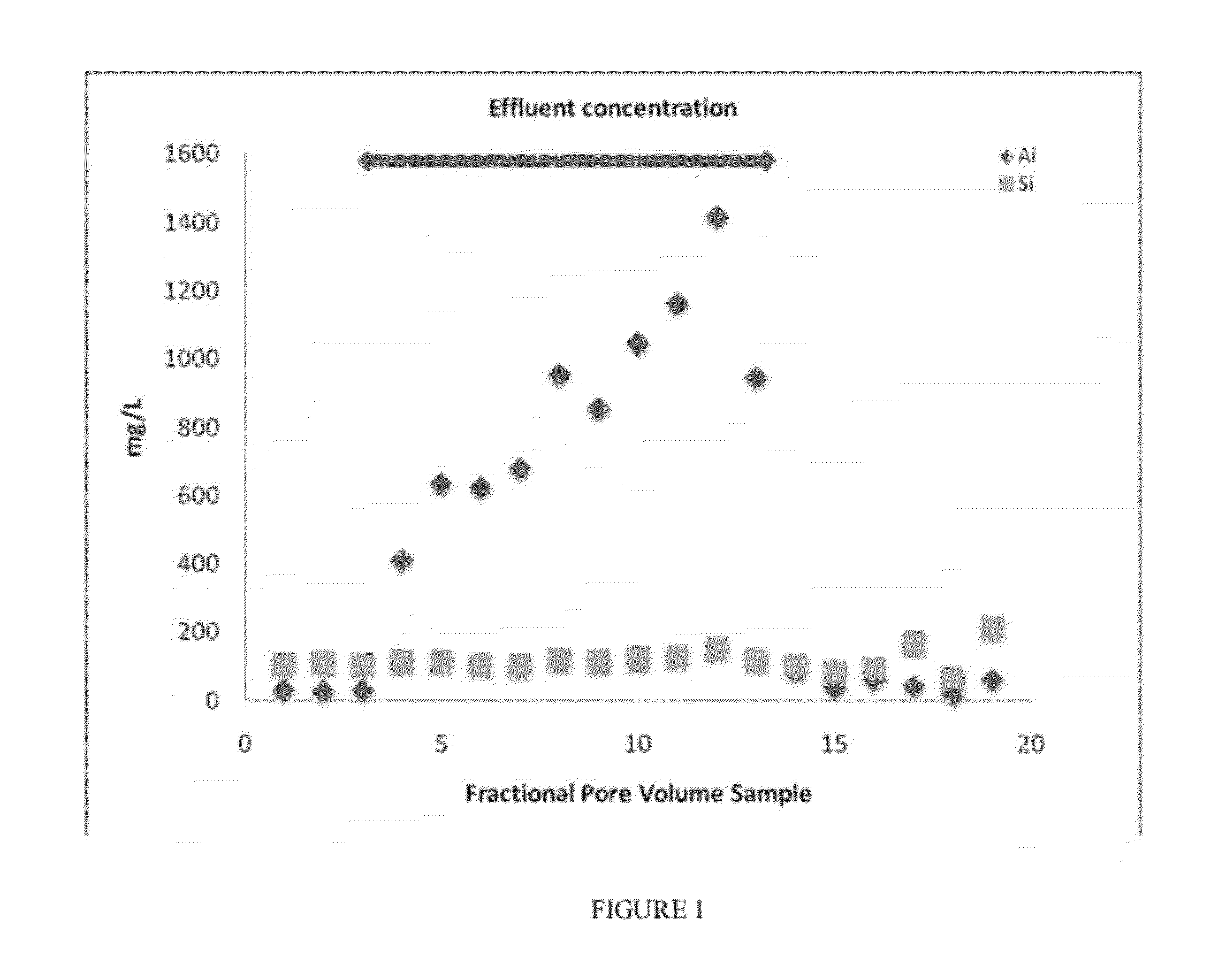

Method for Treating a Subterranean Formation

Acidizing methods for subterranean formations formed of predominantly siliceous material as well as acidizing compositions. Some methods include injecting into a predominantly siliceous subterranean formation, an aqueous acidic mixture formed by blending an aqueous liquid, a fluoride source, and an effective amount of an alkane sulfonic acid, preferably methane sulfonic acid, to adjust the pH of the fluid where the alkane sulfonic acid where the alkane group may be an unbranched, a branched or a cyclic alkyl residue. Hydrofluoric acid (HF) may not be added to the fluid in some embodiments as the fluoride source, such as the case for an HF free fluid, and, in some instances, hydrochloric acid is not added to the fluid to adjust pH. Also described are compositions containing an aqueous acidic mixture formed by blending an aqueous liquid, a fluoride source, and an effective amount of an alkane sulfonic acid to adjust pH.

Owner:SCHLUMBERGER TECH CORP

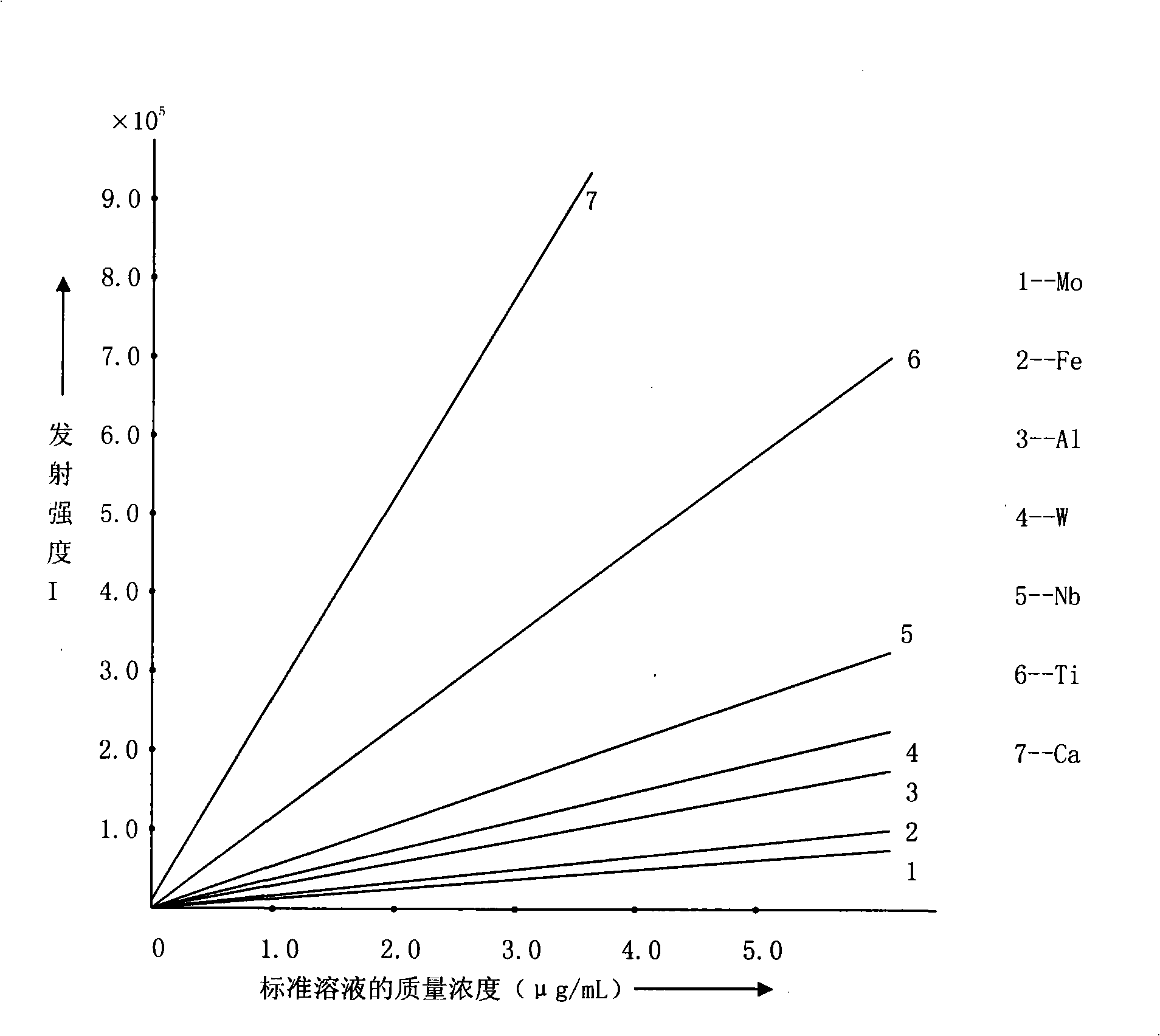

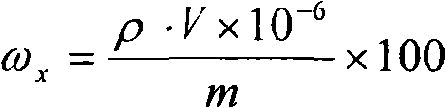

Analyses testing method of aluminum, calcium, iron, molybdenum, niobium, titanium, tungsten impurity elements in chromium carbide

ActiveCN101303307ASolve difficult technical problemsImprove measurement accuracyPreparing sample for investigationAnalysis by thermal excitationNiobiumDecomposition

The invention discloses an analysis and detection method for impurity elements such as aluminum, calcium, ion, molybdenum, niobium, titanium, tungsten and the like in chromium carbide. The method comprises adding a chromium carbide sample into a dissolving cup, adding hydrofluoric acid, sulphuric acid and nitric acid sequentially, stirring, charging into a sealed high-pressure jar; putting the sealed high-pressure jar into a microwave extinguishing instrument for two times of microwave extinguishment; taking the high-pressure jar out of the microwave extinguishing instrument for cooling, transferring the dissolved chromium carbide liquid sample into a volumeric flask, diluting to a predetermined index, stirring; preparing a chromium substrate matched mixed standard solution series of aluminum, calcium, iron, molybdenum, niobium, titanium and tungsten; measuring element emission power of aluminum, calcium, iron, molybdenum, niobium, titanium, tungsten or the like in a blank liquid sample, a chromium carbide liquid sample and the prepared series mixed standard solution by an inductively coupled plasma atomic emission spectrometer in the same time, obtaining the analysis result by checking a standard working curve or by linear equation calculation. The invention adopts two times of microwave extinguishment using the mixed acid, solves the problem of hardness in chromium carbide decomposition, having a measurement range from 0.010% to 1.00%, which is high in accuracy, and good in precision.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

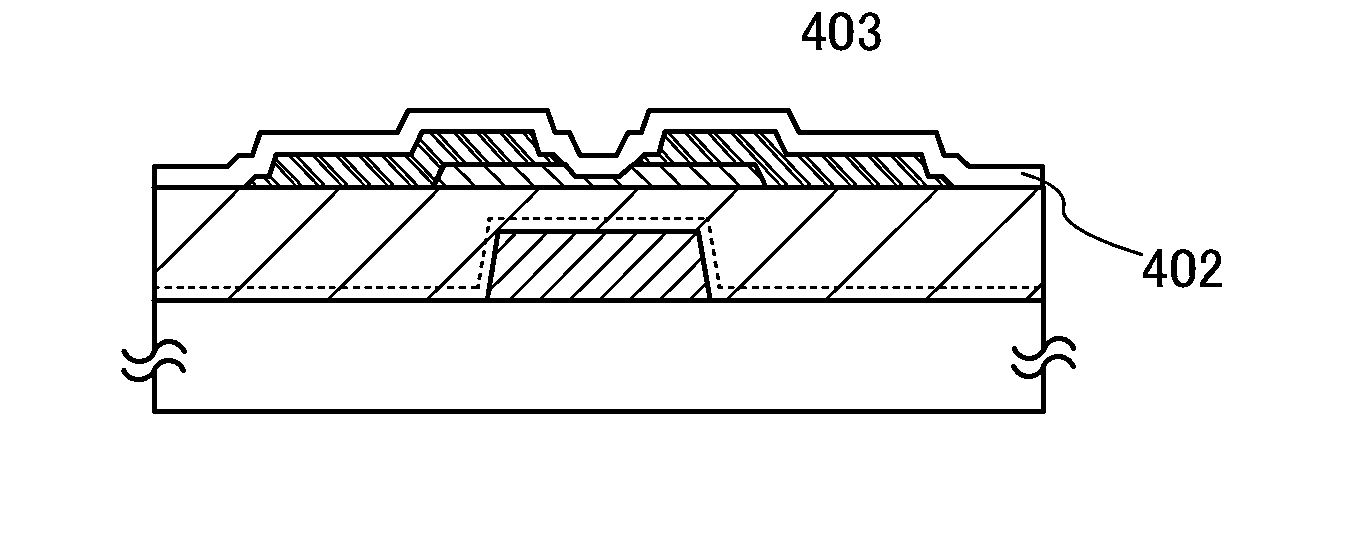

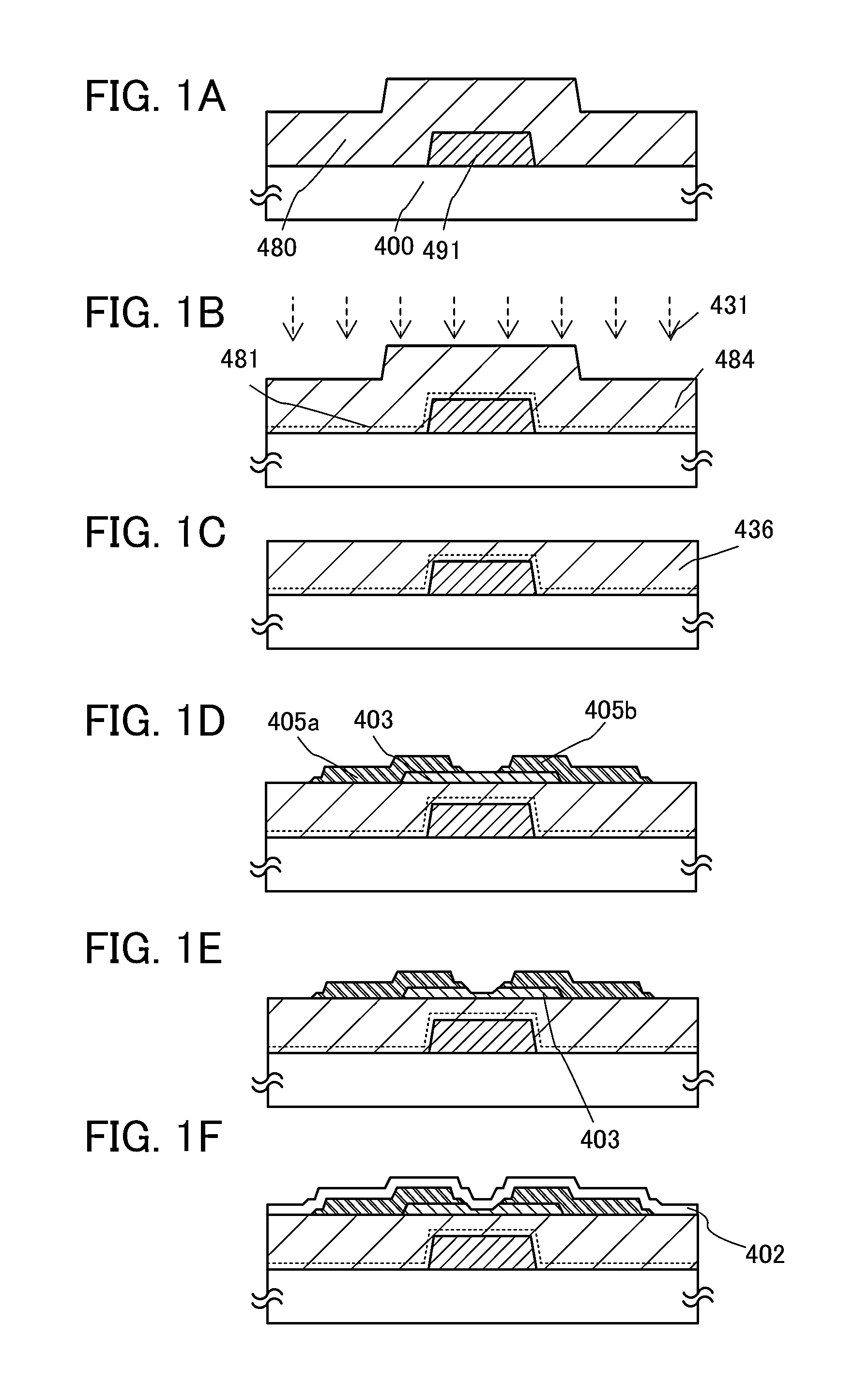

Semiconductor device and method for manufacturing semiconductor device

ActiveUS20140004656A1Stable characteristicsImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesHydrofluoric acidCrystal structure

Provided is a method for manufacturing a transistor by which the defective shape of a semiconductor device is prevented in the case where a source electrode layer and a drain electrode layer are formed on an oxide semiconductor film. A source electrode layer and a drain electrode layer are formed each having a cross-sectional shape with which disconnection of a gate insulating film is unlikely to occur even when the gate insulating film over the source electrode layer and the drain electrode layer has a small thickness. An oxide semiconductor film having a crystal structure over an insulating surface is formed; an electrode layer on the oxide semiconductor film is formed; and a thickness of an exposed portion of the oxide semiconductor film is reduced by exposing the oxide semiconductor film to dilute hydrofluoric acid with a concentration higher than 0.0001% and lower than or equal to 0.25%.

Owner:SEMICON ENERGY LAB CO LTD

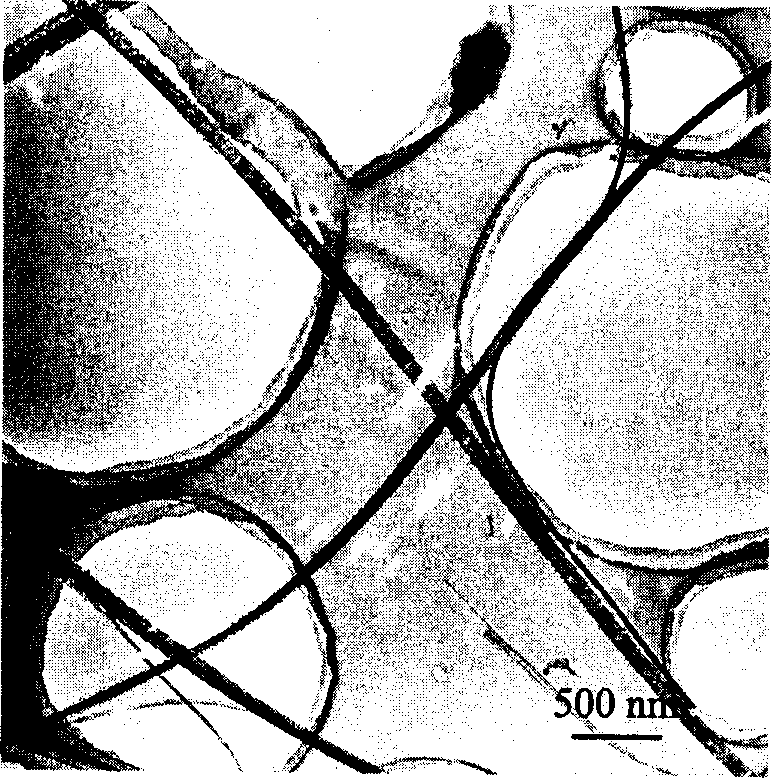

Process for synthesizing nano linear carbon array

InactiveCN1382626ASimple preparation conditionsLow costSilicon compoundsHydrofluoric acidNano carbon

A process for synthesizing linear nano carbon array includes putting monosilicon wafer in a hydrothermal reactor containing the reacting solution of hydrofluoric acid (0.2-15 mol / L) and silver nitrate (0.05-0.10 mol / L), and reaction at 30-80 deg.C for 30-150 min to generate large-area linear nano carbon array on the monosilicon wafer. Its advantages are low reaction temp and low cost.

Owner:TSINGHUA UNIV

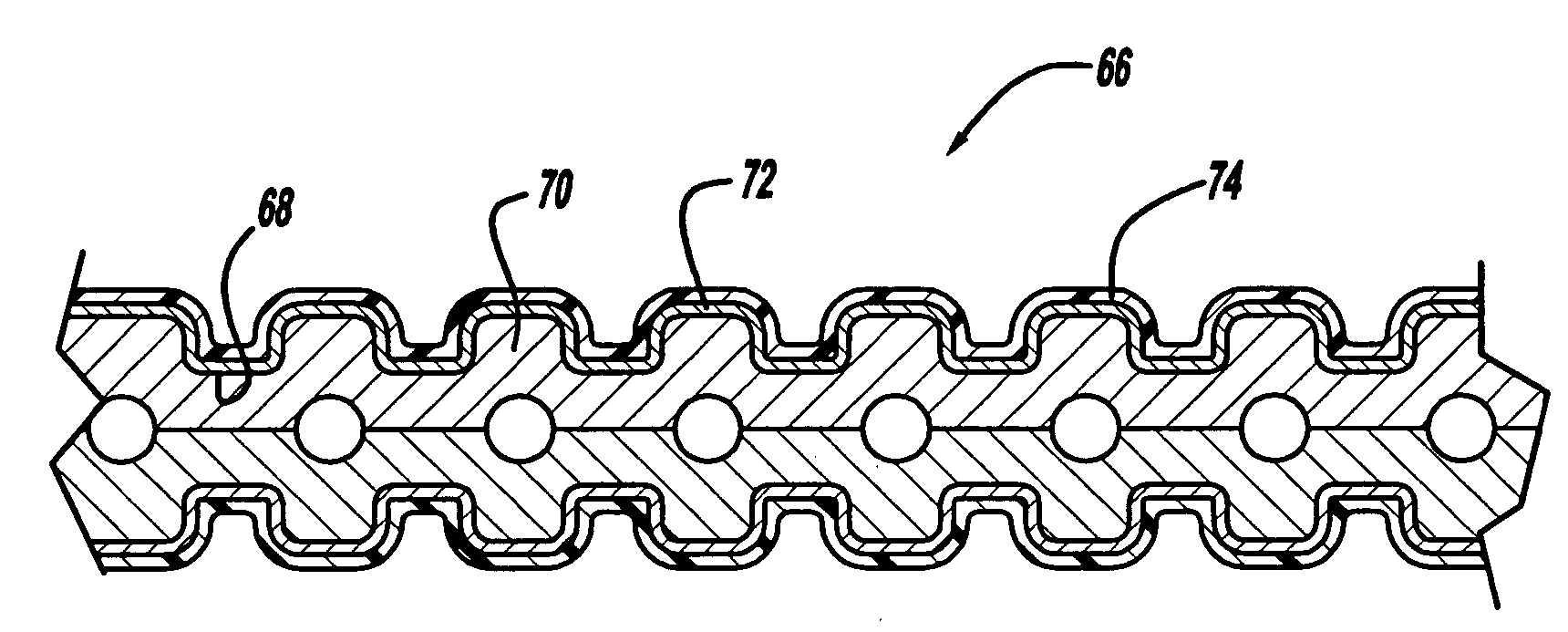

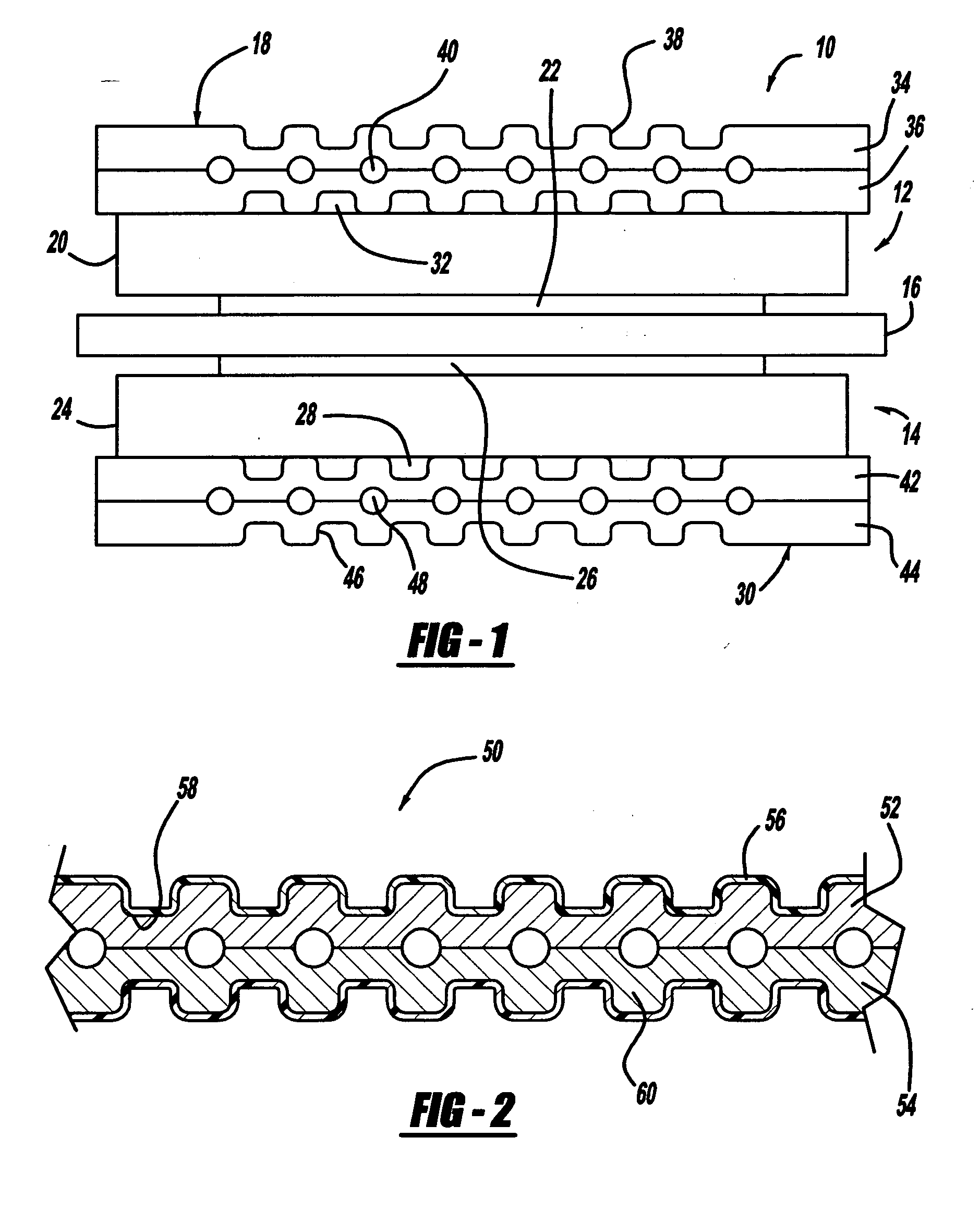

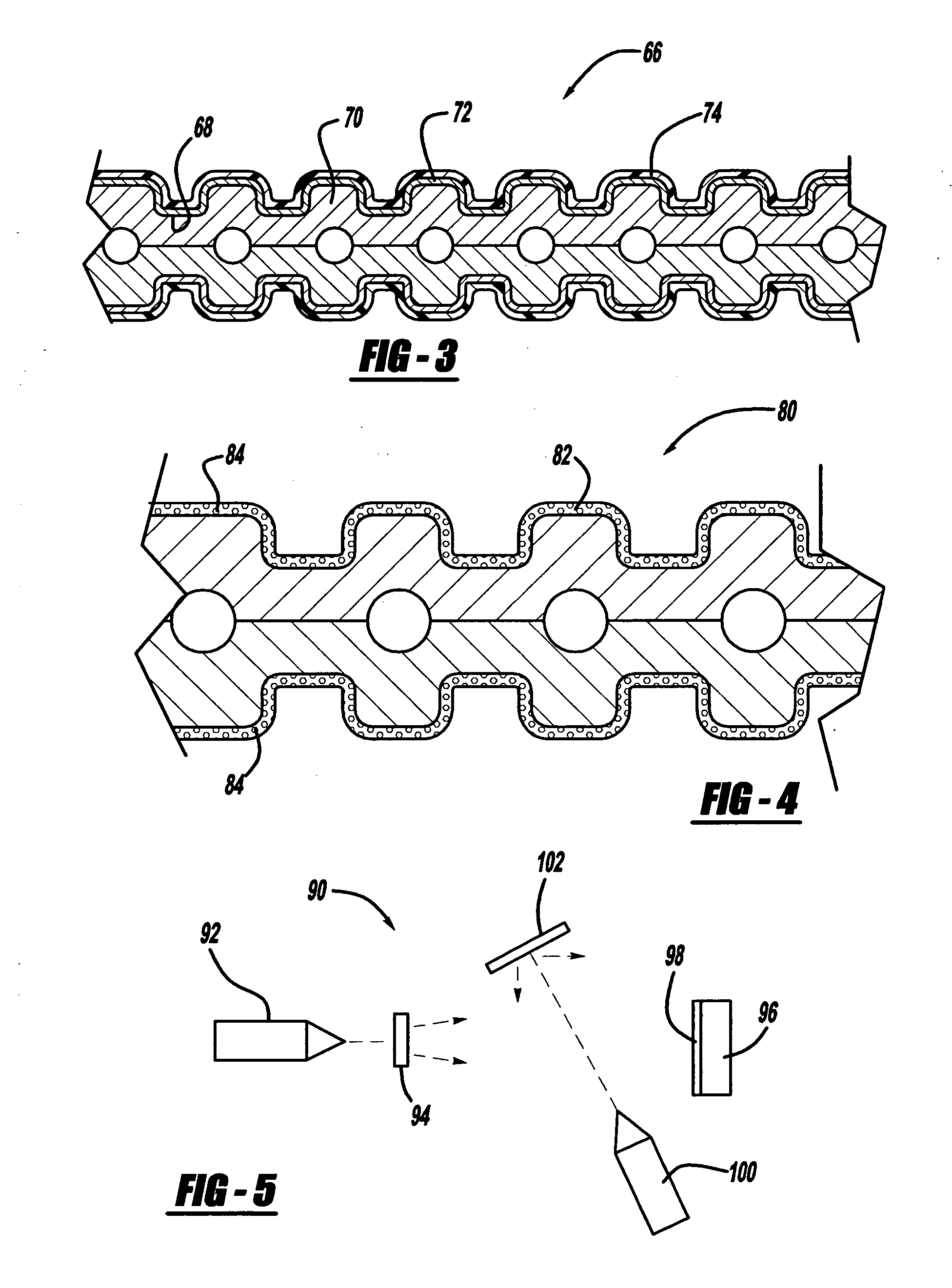

Method to make conductive hydrophilic fuel cell elements

ActiveUS20060194095A1Low fluoride solubilityFinal product manufactureElectrode carriers/collectorsSolubilityHydrofluoric acid

A flow field plate for a fuel cell that has one or more outer layers that makes the plate more conductive and hydrophilic. In one embodiment, the coating is co-deposited as combination of a conductive material and a metal oxide coating. A suitable conductive material is gold and suitable metal oxides include SiO2, HfO2, ZrO2, Al2O3, SnO2, Ta2O5, Nb2O5, MoO2, IrO2, RuO2 and mixtures thereof. The conductive material and metal oxide can also be deposited as two separate layers, where the metal oxide is the outer layer. According to another embodiment, a metal layer is deposited on the plate with nanopores that provide the hydrophilicity. Also, doping ions can be added to the metal oxide to provide low fluoride solubility of the coating to control the rate that hydrofluoric acid etches away the oxide layer.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com