Process for synthesizing nano linear carbon array

A nano-silicon wire and array technology is applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., to achieve the effect of reducing costs and simple preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

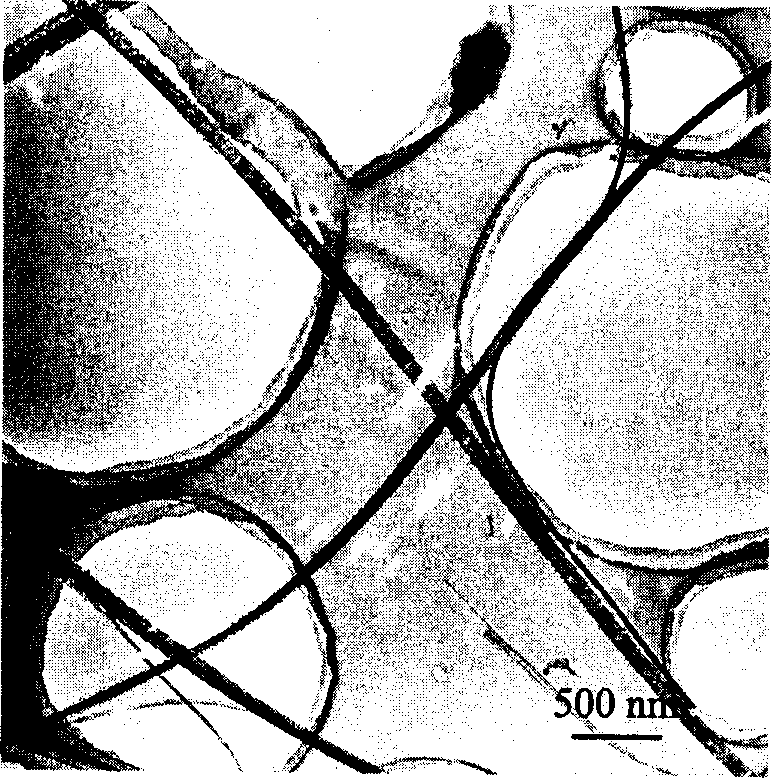

Image

Examples

Embodiment 1

[0017] First, the reaction solution prepared to contain 5mol / l hydrofluoric acid, 0.02mol / l silver nitrate and 0.08mol / l nickel nitrate is put into the hydrothermal kettle, and the filling degree is 80%; Put the monocrystalline silicon wafer cleaned by acid and deionized water ultrasonically into the kettle; treat it at 50°C for 60 minutes, take out the kettle and wait for the kettle to cool down, open the kettle to take out the silicon wafer, and peel off the coating on its surface; The sheet is soaked and cleaned in deionized water for 3-4 times, and dried naturally to obtain the nano silicon wire array.

Embodiment 2

[0019] First, the reaction solution containing 5mol / l hydrofluoric acid, 0.10mol / l silver nitrate and 0.06mol / l nickel nitrate will be prepared into the hydrothermal kettle, and the filling degree is 80%; Put the monocrystalline silicon wafer cleaned by acid and deionized water ultrasonically into the kettle; treat it at 50°C for 60 minutes, take out the kettle and wait for the kettle to cool down, open the kettle to take out the silicon wafer, and peel off the coating on its surface; The silicon chip is soaked and cleaned in deionized water for 3-4 times, and then dried naturally to obtain the nano-silicon wire array.

Embodiment 3

[0021] First, put the reaction solution containing 5mol / l hydrofluoric acid and 0.01mol / l silver nitrate into the hydrothermal kettle, and the filling degree is 80%; Put the processed monocrystalline silicon wafer into the kettle; treat it at 50°C for 60 minutes, take out the kettle and wait for the kettle to cool down, open the kettle to take out the silicon wafer, and peel off the coating on its surface; put the silicon wafer through deionized water for 3- After soaking and cleaning for 4 times, and drying naturally, the nano-silicon wire array is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com