Ultraviolet light curing elastic self-healing coating composition

A composition and self-repairing technology, applied in the direction of coating, etc., can solve the problems of not showing elastic self-repairing performance and sharp object scratch resistance, not mentioning brightening film coating, complicated process, etc., to achieve good elasticity Self-healing effect, improved light source utilization rate, and simple preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

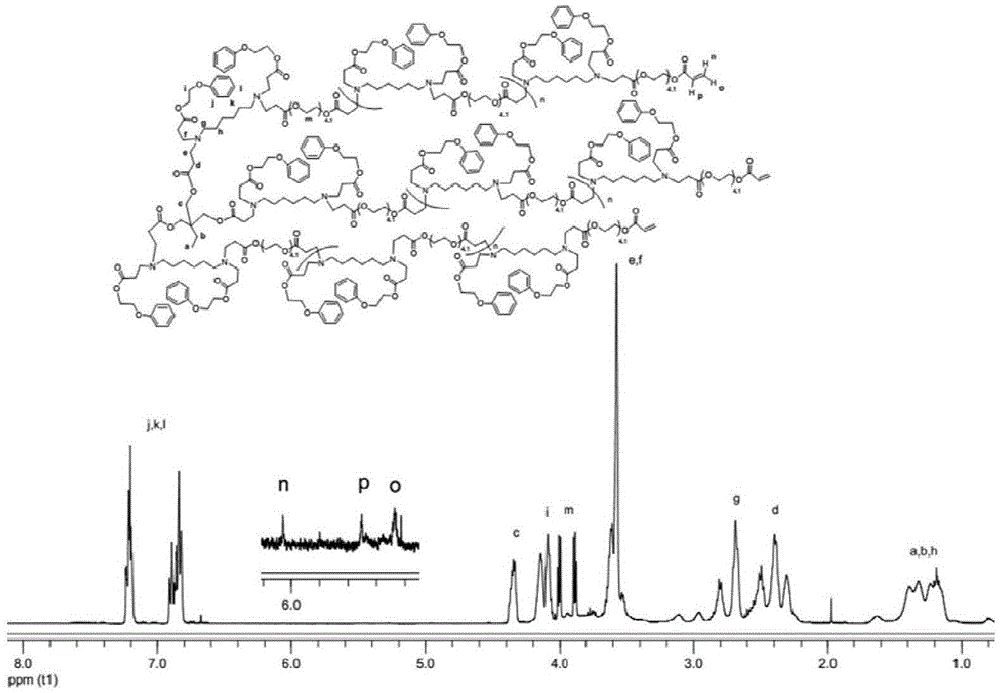

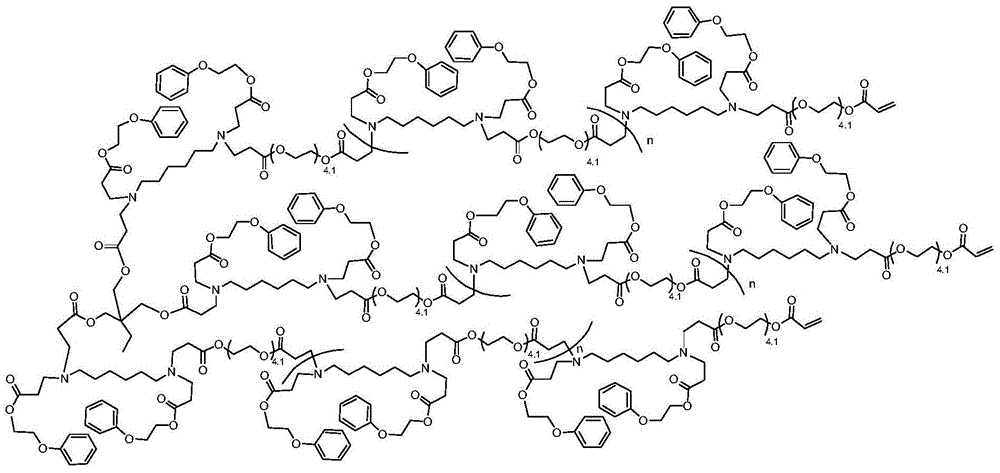

Image

Examples

Embodiment 1~5

[0044] Examples 1 to 5 respectively provide a UV-curable elastic self-repairing coating composition, and the corresponding raw material components, parts by weight and corresponding performance tests of each composition are shown in Table 1;

[0045] The raw material components corresponding to each example were mixed according to their parts by weight, dispersed at a medium speed for 2 hours, and filtered to obtain the corresponding elastic self-healing UV photocurable coating composition.

[0046] Table 1

[0047]

[0048]

[0049] The substances listed in Table 1 are representative of the aforementioned various technical solutions, and are not limited to the substances listed in the table during actual implementation. The monofunctional acrylate can also be selected from 2-phenoxy ethyl acrylate, ethoxylated phenoxy acrylate, o-phenylphenethoxy ethyl acrylate, 2-(to-cumyl-benzene One or more of oxy)-hexyl acrylate, 2-hydroxy-3-phenylphenethoxypropyl acrylate, benzyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com