Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1314results about How to "With wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Controlled release fertilizer coated by vegetable oil based polyurethane and preparation method thereof

InactiveCN103304772AWide variety of sourcesSimple film forming processFertilizer mixturesFertilizerIsocyanate

The invention discloses a controlled release fertilizer coated by vegetable oil based polyurethane and a preparation method thereof. The preparation method of the controlled release fertilizer coated by vegetable oil based polyurethane comprises the following steps of: 1) preheating the granular fertilizer; 2) heating plant oil polyhydric alcohol containing 2-6 hydroxys and isocyanate containing at least two isocyanate groups, and uniformly mixing the ingredients to form a vegetable oil based polyurethane coating liquid; 3) spray coating the vegetable oil based polyurethane coating liquid on the surfaces of the preheated fertilizer granules, repeatedly spray coating the vegetable oil based polyurethane coating liquid for 2-10 times after the vegetable oil based polyurethane coating liquid solid is solidified to obtain the controlled release fertilizer coated by vegetable oil based polyurethane. According to the controlled release fertilizer coated by vegetable oil based polyurethane and the preparation method thereof provided by the invention, the adopted coating material is extensive in resource, cheap and liable to obtain, non-toxic, harmless, simple in production process and good in controlled release effect of fertilizer.

Owner:上海永通生态工程股份有限公司

All-in-one water-borne inorganic-organic hybrid architectural coating and preparation method thereof

ActiveCN102408220AWaterproof and breathableIncrease viscosityEmulsion paintsThermal insulationOragene

The invention relates to an all-in-one water-borne inorganic-organic hybrid architectural coating and a preparation method thereof, wherein the all-in-one water-borne inorganic-organic hybrid architectural coating is prepared by taking a compounded product of a water-borne inorganic film-forming matter and an organic polymer emulsion as a base material through the steps of adding various pigments / fillers and auxiliaries into the base material, then carrying out beating, grinding and paint mixing on the obtained mixture. In the invention, through a Si-O-Si polymer net structure which can be formed by compounding alkali metal silicates and small-particle-size silica sols in the process of film forming, the early water resistance of a paint film is greatly increased, and the eventual hardness, scraping resistance and stain resistance of the paint film are greatly increased; and through adding the organic polymer emulsion, the film-forming performance of the coating can be improved, and the defects that the traditional two-component inorganic coating is easy to crack, bad in decorative properties, poor in storage stability, and the like are overcome. The coating prepared by using the method disclosed by the invention has various functions of environmental friendliness, non-toxicity, thermal insulation, ultra scrubbing resistance, abrasion resistance, yellowing resistance, ageing resistance, fouling resistance, good air permeability, sound insulation, and the like.

Owner:SOUTH CHINA UNIV OF TECH

high-filling-content micro-nano powder/polymer composite material for 3D printing and preparation method and product thereof

ActiveCN103980592AEnhanced interactionImprove performance3D object support structuresCross-linkAntioxidant

The invention relates to a high-filling-content micro-nano powder / polymer composite material for 3D printing and a preparation method and a product thereof. The material contains the following raw materials, by weight, 10-30 parts of a polymer, 90-70 parts of a micro-nano powder, 0.05-0.2 part of an irradiation sensitizer and 0.01-0.02 part of an antioxidant. The micro nano powder is used as a main material and polymer resin is used as a binding agent, and moulding is finished by a 3D printing mode. Simultaneously, the irradiation sensitizer is added, and the polymer resin forms a three-dimensional cross-linked network after electron beam irradiation. Then, strength, heat resistance and chemical corrosion resistance are raised after resin bonding. The high-filling-content micro-nano powder endows the moulding material with excellent mechanical properties. In addition, according to changes of product usage environment and demand, types of the micro-nano powder are changed so as to obtain a material with special functionality, such as excellent conductivity, thermal conductivity, flame resistance, impact resistance and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

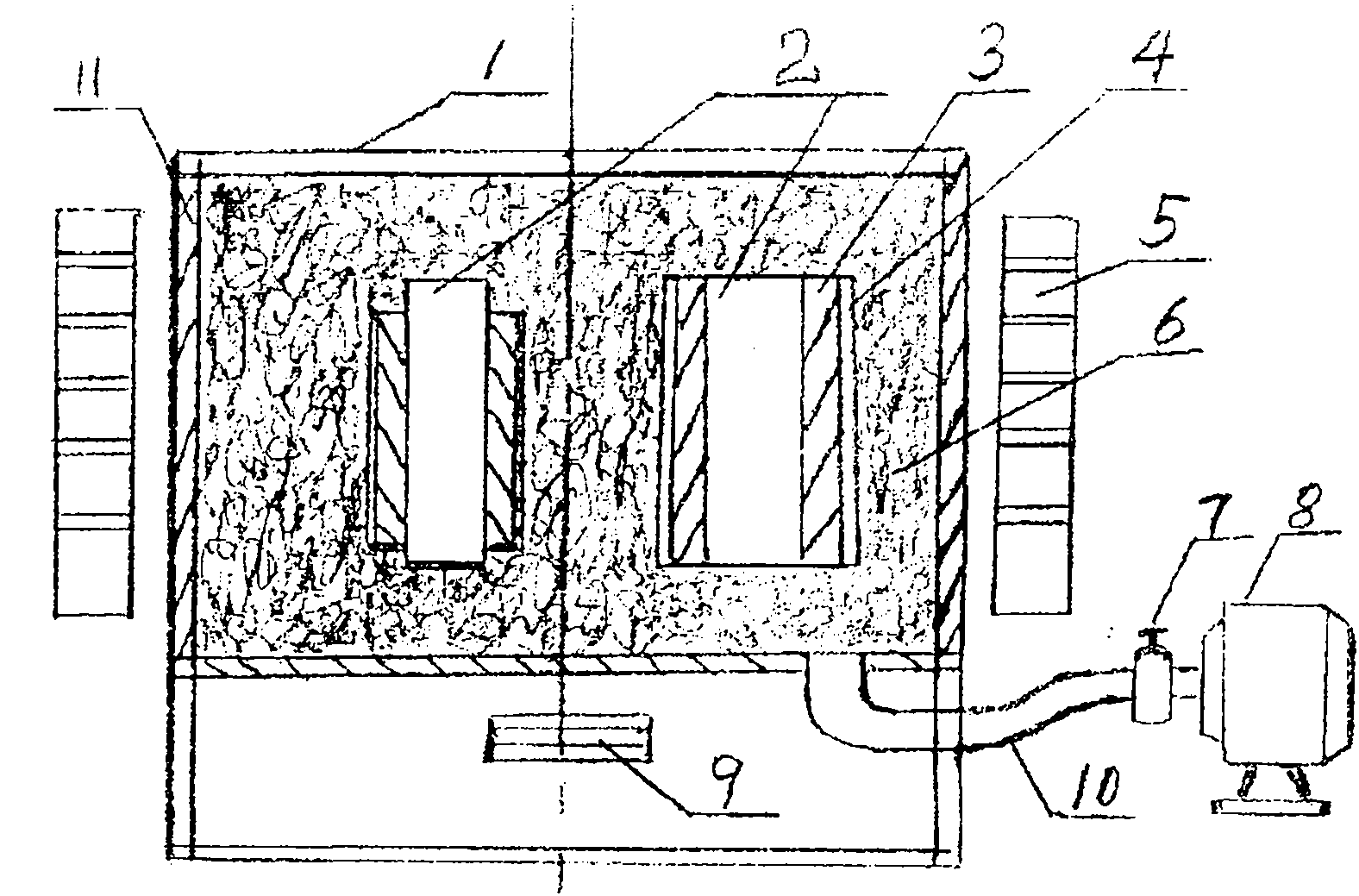

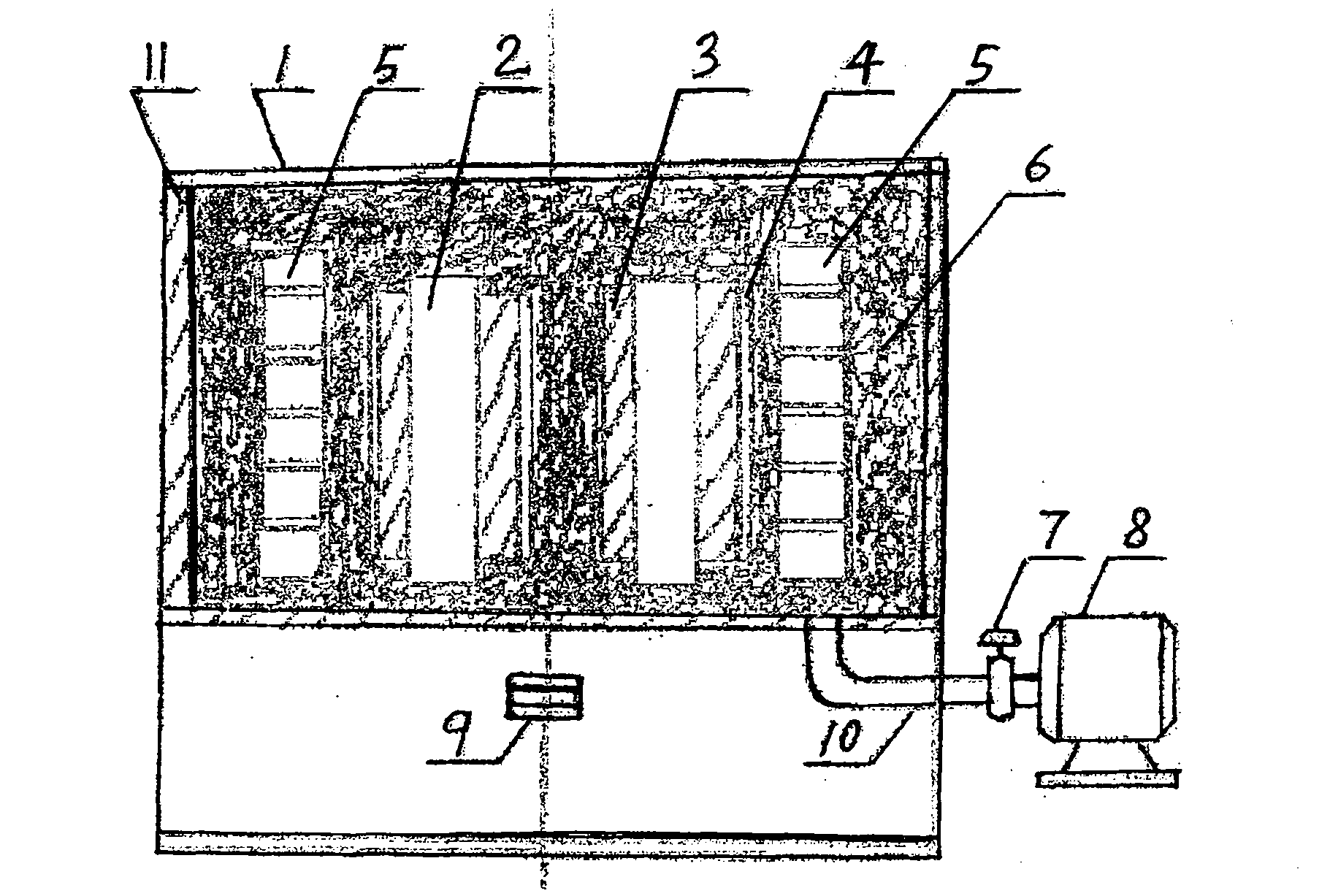

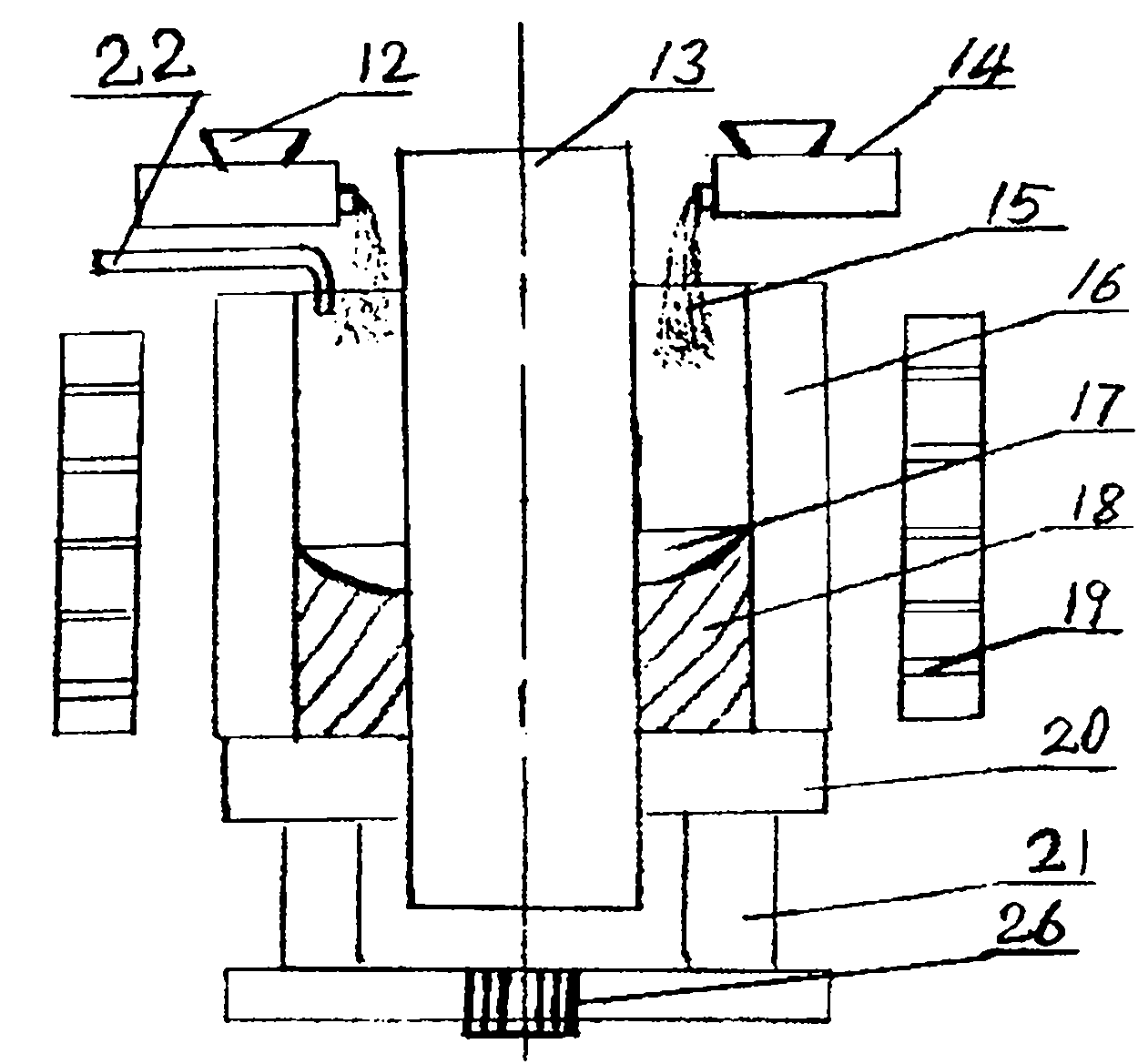

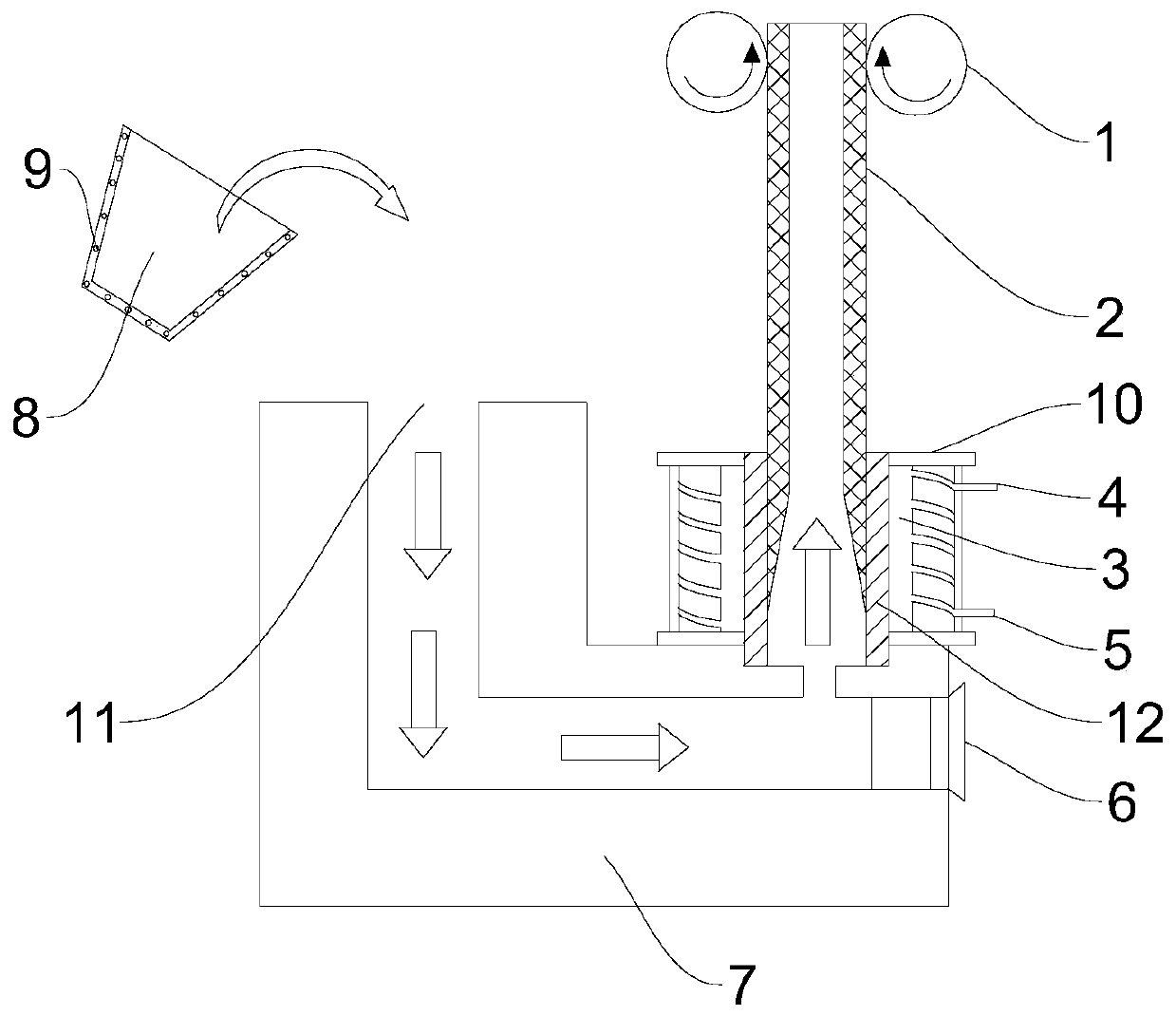

Preparation process and device of nano-particle reinforced bimetal composite

InactiveCN101914767ALow melting pointImprove toughnessMetallic material coating processesCorrosionBonding strength

The invention relates to a preparation process and a device of a nano-particle reinforced bimetal composite, the nano-particle reinforced bimetal composite comprises the following chemical components by weight percent: 6-25% of Cr, 4-18% of Ni, 1.0-4% of Mo, 1.0-1.8% of Si, 1.2-3% of Mn, 0.4-2.2% of B, 0.1-1.2% of MgO, 0.2-2% of CaF2, 0.2-0.7% of C, 0.2-0.8% of Nb, not more than 0.9% of one or the combination of CeO2, Y3O2 and La2O3, 0.0-0.8% of Co, and the balance of Fe, and mixed particles of nano-sized carbides, nitrides, borides or carbonitrides are added in alloy powder. The vacuum induction melting and the cladding processes and equipment are adopted for melting and cladding the mixture on a workpiece, the thickness of a cladding layer is 0.1-25mm, the cladding layer contains 1%-50% of nano-reinforcing particles of one or the combination of the carbides, the nitrides, the borides and silicides, and the cladding layer has special performances of wear resistance, corrosion resistance, electrical conductivity, self-lubrication performance and the like. A coating layer and a base material form the metallurgical bonding, thereby having high bonding strength, overcoming the drawbacks in various coating processes at home and abroad, leading the coating layer to avoid the defects of shrinkage cavities, inclusion, cracking, shedding and the like and having the advantages of high heating temperature, fast speed, high production efficiency, small energy consumption, simple preparation process and low cost.

Owner:丁家伟

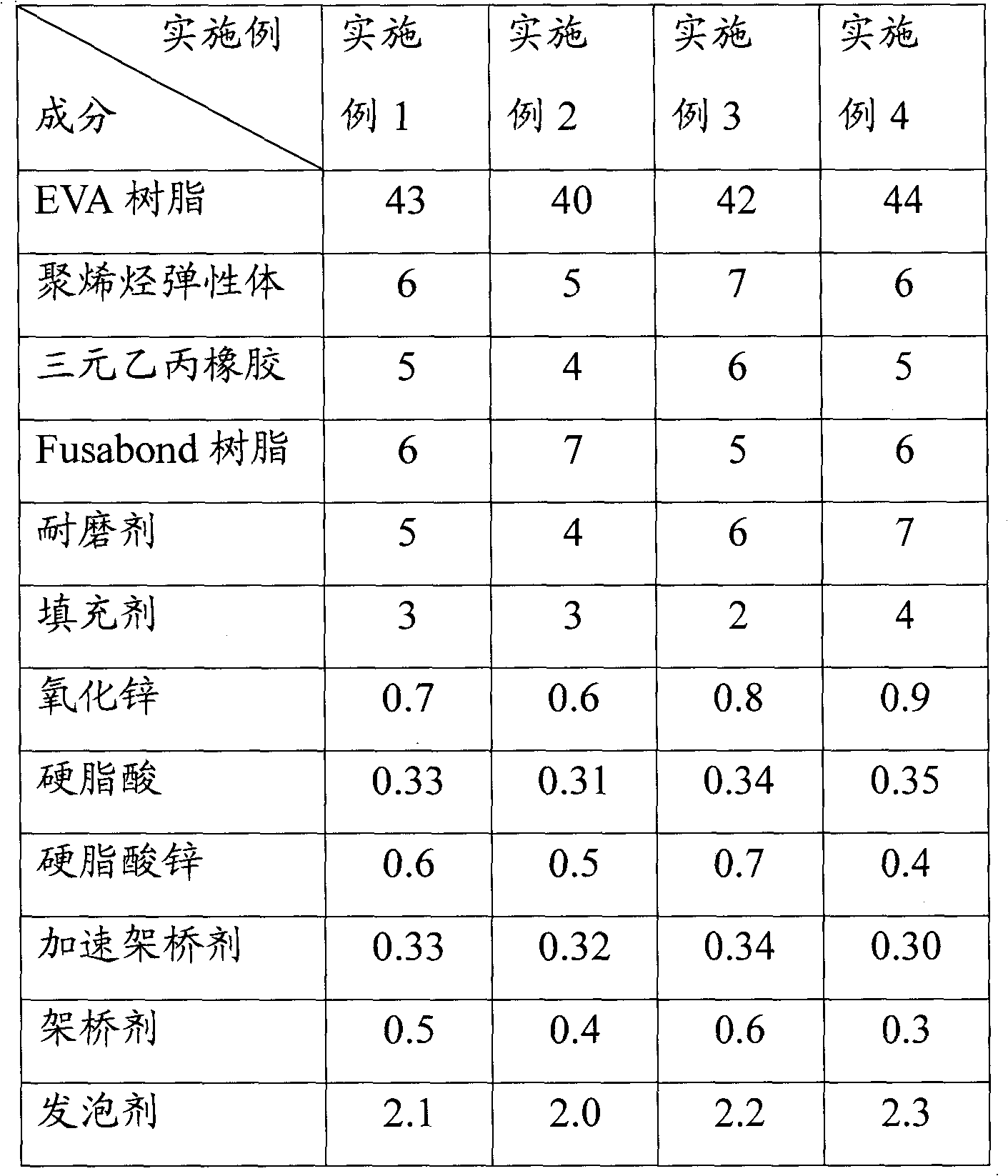

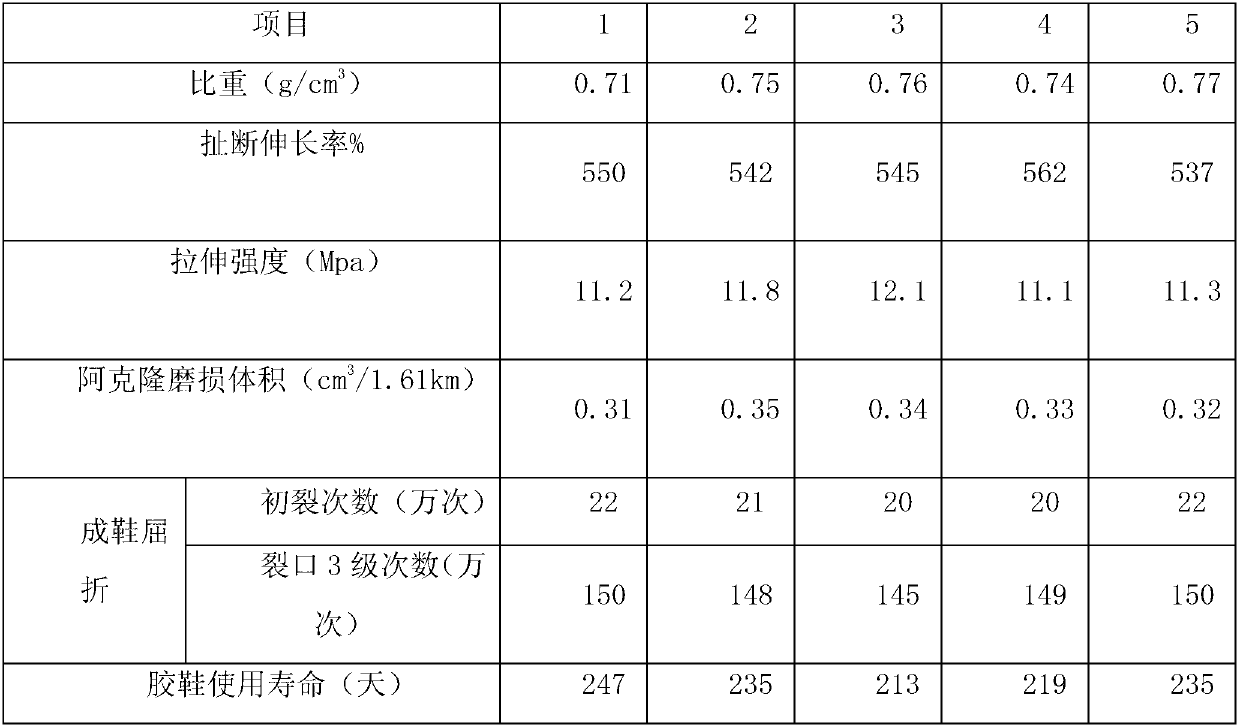

Plastic foam for sport shoe sole

The invention discloses a plastic foam for a sport shoe sole, which comprises the following components in part by weight: 70-74 parts of ethylene-vinyl acetate copolymer, 8-12 parts of ethylene-octylene copolymer, 6-10 parts of ethylene propylene ethylene-propylene-diene monomer, 8-12 parts of ethylene-acrylic acid copolymer, 8-9 parts of wear-resisting agent, 4-6 parts of filler, 1.0 -1.2 parts of zinc oxide, 0.5-0.6 part of stearic acid, 0.8-1.0 part of zinc stearate, 0.5-0.7 part of accelerate bridging agent, 0.8-0.9 part of bridging agent and 3.2-3.8 parts of foaming agent, wherein the ethylene propylene ethylene-propylene-diene monomeris a terpolymer of ethylene-propylene and non-conjugate diolefin. The plastic shoe sole of the sport shoe has the light weight performance, wear resistant performance and comfortable performance which are superior to those of a foam plastic formula injected by common IP, greatly reduces the physical consumption of athletes and has a plurality of performances such as durable comfort, durable buffer resistant performance and the like.

Owner:ANTA CHINA

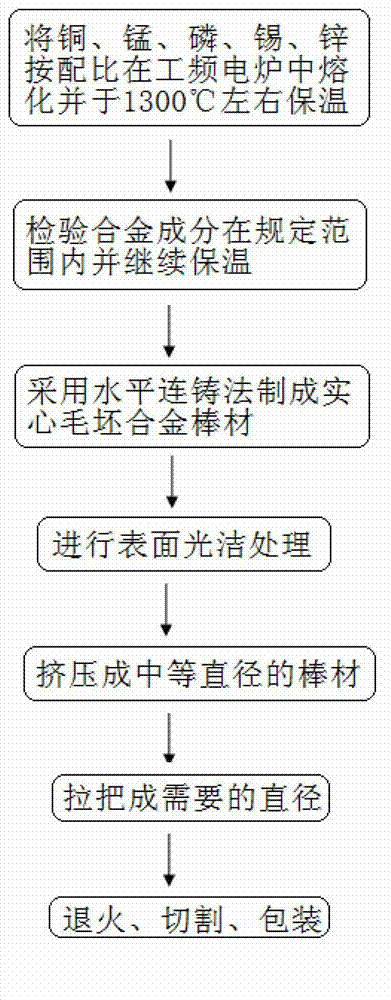

Novel lead-free environment-friendly high-strength wear-resistant copper-base alloy bar and preparation method thereof

The invention relates to a novel lead-free environment-friendly high-strength wear-resistant copper-base alloy bar which is prepared from the following components in percentage by weight: 1-3% of manganese, 2-4% of tin, 0.01-0.5% of phosphorus, 1.5-4.5% of zinc and the balance of copper. The metallic element manganese is used instead of lead; the manganese, zinc, tin, phosphorus and copper are mixed proportionally, extruded by an extruding machine at proper temperature, and drawn by a drawing machine to obtain the alloy bar; the alloy bar has wear resistance in the traditional copper-lead-bronze alloy, can be used for hot working, and has better workability than the copper-lead-bronze alloy; the alloy bar provided by the invention is free of lead, thereby avoiding the environmental pollution caused by the use of lead and being beneficial to environmental protection; and thus, the novel lead-free environment-friendly high-strength wear-resistant copper-base alloy bar provided by the invention can completely substitute the traditional copper-lead-bronze alloy.

Owner:SUZHOU TIANJIAN METAL NEW MATERIAL

Method for producing emulational leather

ActiveCN101545211AHigh peel strengthHigh tear strengthLamination ancillary operationsPattern makingWoven fabricWork in process

The invention provides a method for producing emulational leather by cold pressing treatment to prepare high emulational synthetic leather, which comprises the following steps that: firstly, preparation of basic fabric: non-woven fabric passes through an impregnation groove containing PU resin, dimethylfomamide and a colorant, is subjected to pre-solidification treatment and coated with a layer of a coating material on the surface of the non-woven fabric; the nonwoven fabric passes through a coagulating tank and a rinsing bath to be subjected to solidification and water washing treatment and dried and shaped to manufacture the basic fabric; the surface of release paper is coated with a layer of a surface material containing the PU resin, dimethylfomamide and the colorant through a No.1 coating head; then a layer of a bottom material is coated on the surface material; the surface material and the bottom material are preheated and compounded with the basic fabric; the mixture is subjected to drying treatment to manufacture a semifinished product; the semifinished product is heated to the temperature of between 160 and 190 DEG C and subjected to embossing treatment through a pair of cold pressing rollers; and after the cold pressing treatment, the semifinished product is cooled and furled to manufacture a finished product.

Owner:福建兰峰制革有限公司

Refractory far infrared radiation ceramics coating

The invention provides a high temperature resistance infrared radiation pottery dope, which belongs to the thermal engineering field. The dope is a mixture of the following materials in mass share: 200 mesh zirconium dioxide 10, 200 mesh zircon quartz sand 20, 300 mesh feldspar 10, 300 mesh cerium oxide 7, 300 mesh manganese sesquioxide 15, 300 mesh manganic oxide 3, 600 mesh titanium dioxide 2, 200 mesh alumina 10, 400 mesh graphite 10, 400 mesh boron nitride 3 and 200 mesh carborundum 10. The graphite and boron nitride in the dope are of lubricating and anti-bonding functions, the carborundum is of wear resistance function, the manganic oxide, titanium dioxide and alumina are of strong infrared ray emission and the dope mad of zirconium dioxide, zircon quartz, feldspar and cerium oxide has good compact structure and strong fire-proof and the manganese sesquioxide can catalyze C, S and N for conversion. Therefore, the invention is applicable for use in dynamic furnaces such as coal dust furnace, boiling furnace and fluidized bed furnace.

Owner:颐珑达绝热材料技术(北京)有限公司

Warm eye-protection matte glaze for building ceramic tiles, and preparation technology thereof

The invention discloses a warm eye-protection matte glaze for building ceramic tiles, and a preparation technology thereof. The preparation technology comprises the following steps: (1) weighing clay,feldspar, quartz, talcum, dolomite, limestone, borax, zirconium silicate, zinc oxide, alumina, barium carbonate and strontium carbonate according to the chemical composition range, crushing the weighed materials to form 180-350 mesh particles, mixing the particles, sintering the obtained mixture at 1480-1580 DEG C to form a glassy melt, and quenching the glassy melt with water to obtain a matte frit for the ceramic tile glaze; and (2) adding clay raw materials and a glaze slip performance regulator to the frit, and performing full wet ball-milling to obtain a matte glaze slip. The compositionof the formula is slightly changed, so the glaze obtained after sintering has the advantages of high strength, high wear resistance, high aging resistance and long service life; the glaze is flat, fine and smooth, is free of pinholes, and has silky or velvet gloss, and the glossiness of the glaze is 3-5 DEG less than that of existing products, so the glaze makes people have soft, quiet and comfortable eye-protection feeling; and the tile matte glaze has tender and soft hand feeling, and is warm.

Owner:FOSHAN UNIVERSITY +1

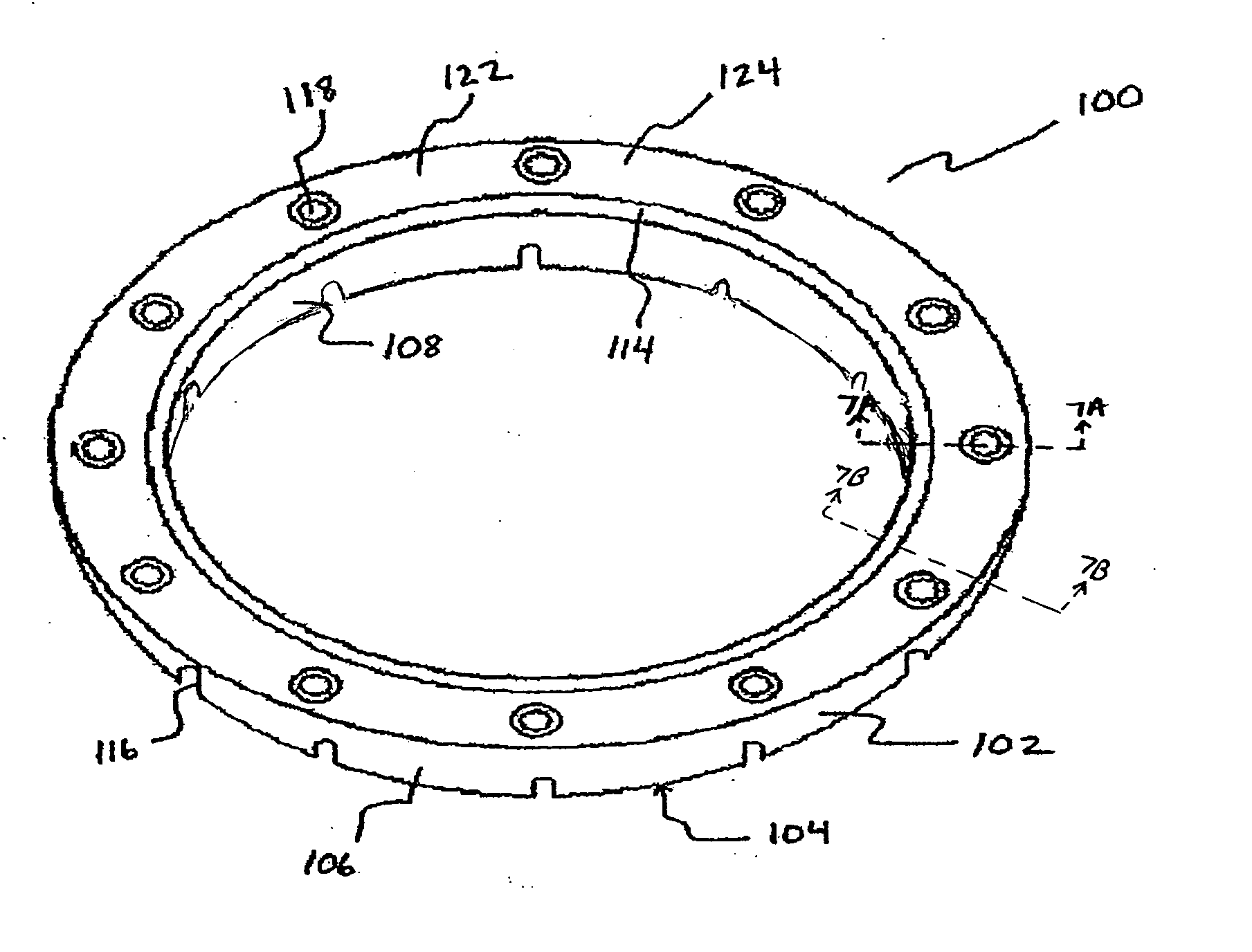

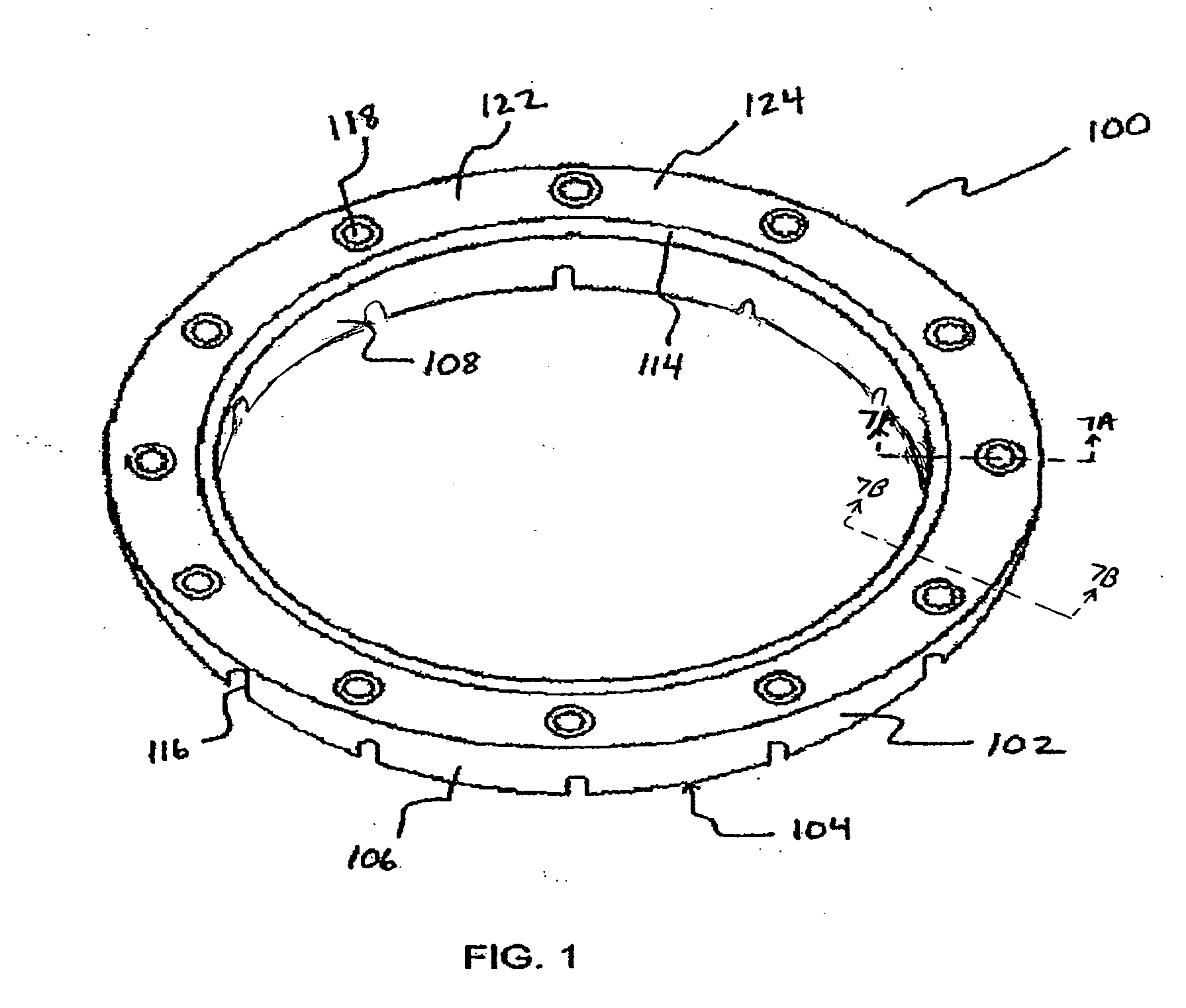

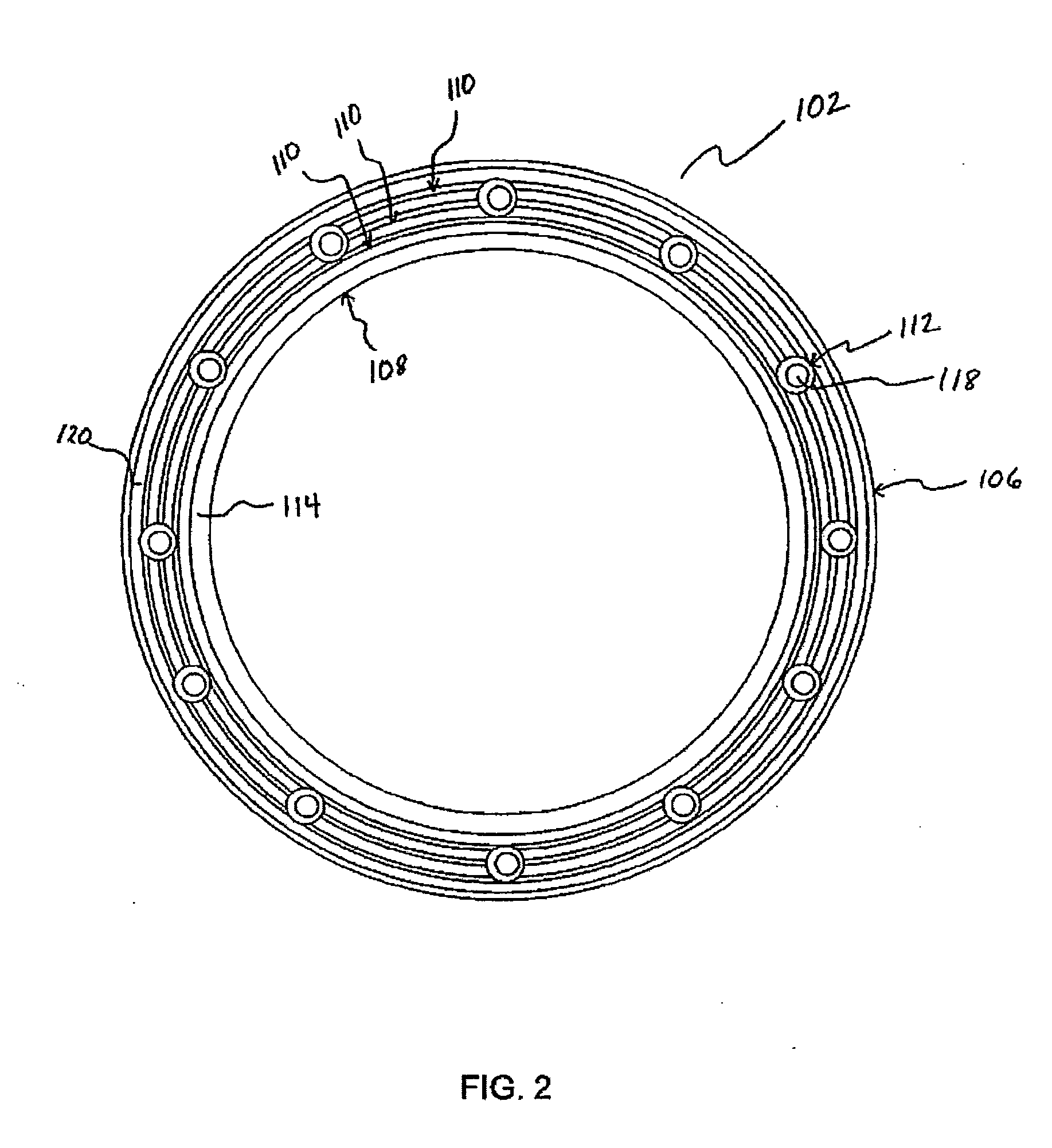

CMP retaining ring

InactiveUS20070224864A1Reduces and eliminates deformationLow compressibilityElectrically conductive connectionsSemiconductor/solid-state device manufacturingWear resistantPlastic materials

An improved chemical mechanical polishing retaining ring. A representative embodiment comprises a base portion made from a wear-resistant plastic material, and an upper portion, or backbone portion, made from a stiffer and more wear resistant material. One of the base or backbone portion is preferably overmolded onto the other. The base portion can be generally defined by a flat pad-contacting surface, an outer surface, and an inner surface. The base portion can additionally include channels extending from the outer surface to the inner surface to facilitate transfer of slurry to and from the substrate to be polished during the process. One or both of the base portion or backbone portion further includes a plurality of circular ribs that serve to create additional bonding surface with the overmolded material. The retaining ring may additionally includes a plurality of bosses with threaded insert holes by which the retaining ring is attached to a chemical mechanical polishing system.

Owner:BURNS JOHN +4

High-temperature tempered glass ink and preparation method thereof

InactiveCN104893410ASimple processEasy to operate and controlInksTemperature resistanceWeather resistance

The invention relates to the technical field of ink, and particularly relates to high-temperature tempered glass ink and a preparation method thereof. The high-temperature tempered glass ink comprises the following raw materials in parts by weight: 40 to 50 parts of glass glaze, 25 to 35 parts of coloring agent, 10 to 18 parts of varnish and 0.3 to 1.5 parts of additive. The high-temperature tempered glass ink is not only efficient, environment-friendly and rich in color, but also has excellent characteristics such as high temperature resistance, high hardness, high weather resistance, ultrahigh wear resistance, acid-alkali resistance and the like.

Owner:陈养生

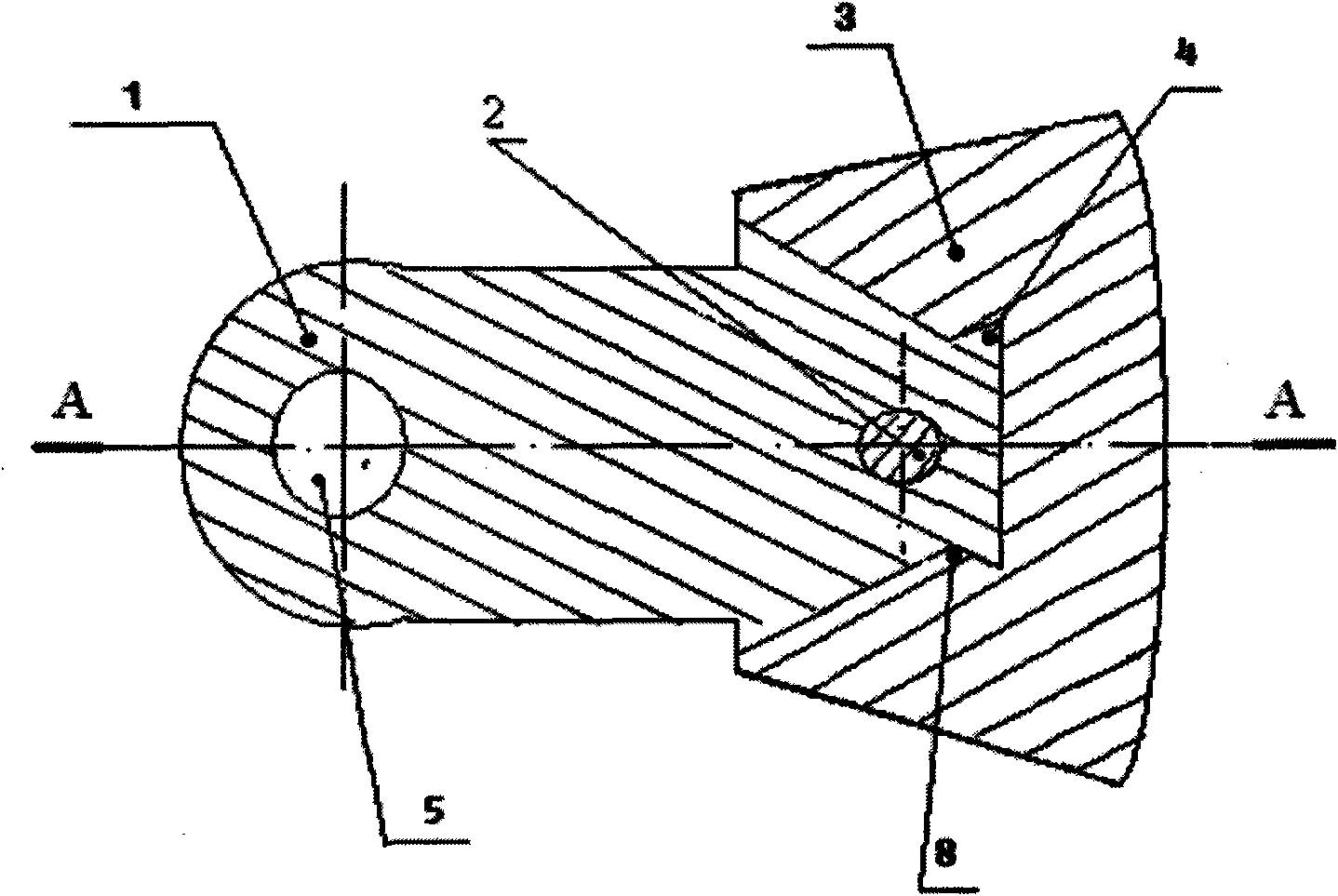

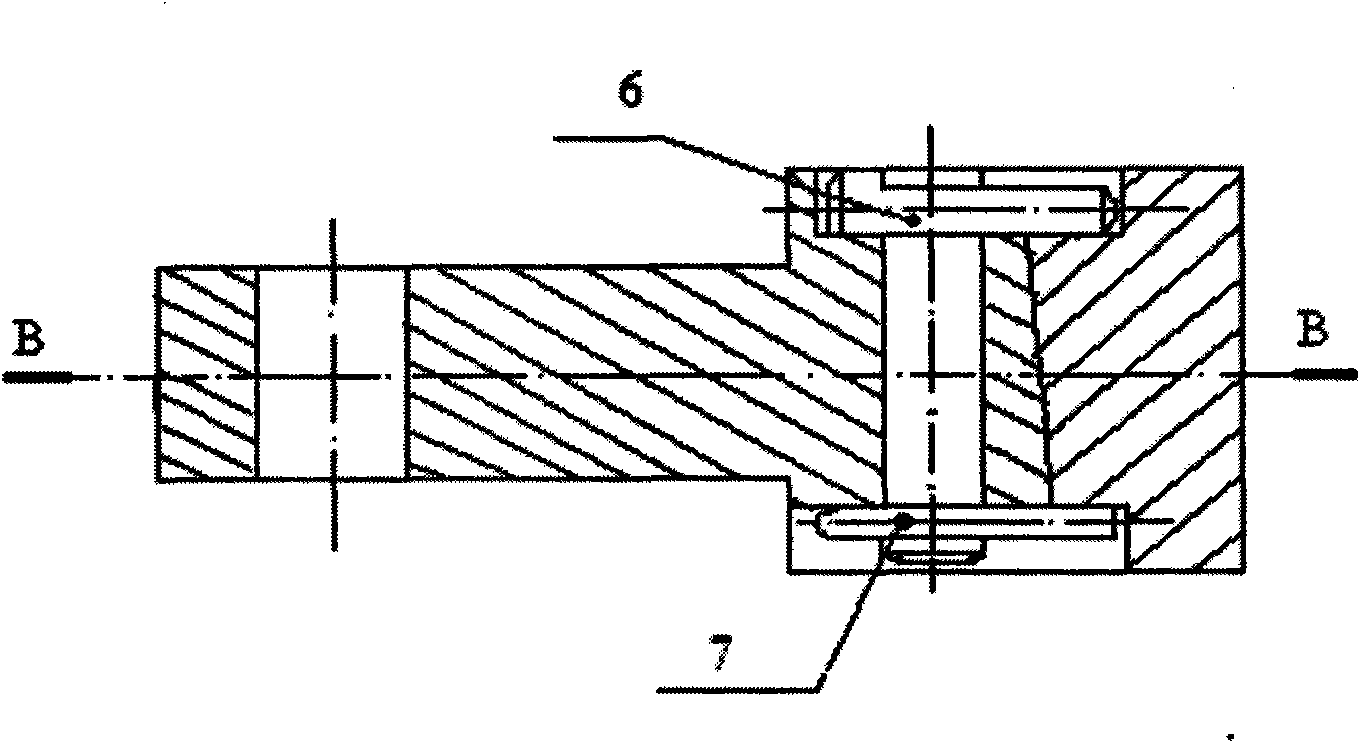

Combined type mechanically crushing machine hammer and manufacturing method thereof

The invention discloses a combined type mechanically crushing machine hammer and a manufacturing method thereof. The hammer comprises a head part (3) and a handle part (1) which are mechanically combined for forming the hammer, the head part (3) is formed by high-chromium cast iron lost foam casting, the handle part (1) is formed through high-manganese steel lost foam casting, an installing hole (5) connected with a circular disc of a crushing machine is arranged above the handle part (1), a rabbet (4) is arranged under the handle part (1), the head part (3) is provided with a mortice (8) matched with the rabbet (4) of the handle part, and the handle part (1) and the head part (3) are connected through the mutually matched rabbet (4) and the mortice (8) for forming the integral hammer. The hammer of the invention has the advantages of simple manufacture, wear resistance, good toughness, fast replacement of the head part, repeated use of the handle part, production efficiency improvement and metal material saving. The invention is particularly suitable for manufacturing reversible hammer type crushing machine hammers.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

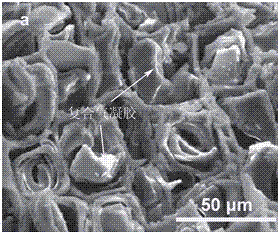

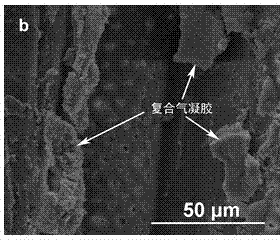

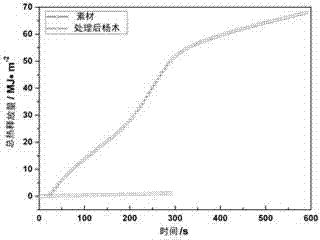

Ammonium polyphosphate/SiO2 composite aerogel flame-retardant reinforced timber and preparation method thereof

ActiveCN104760103AImprove permeabilityEvenly dispersedRadiation/waves wood treatmentWood treatment detailsSolid woodCorrosion prevention

The invention discloses an ammonium polyphosphate / SiO2 composite aerogel flame-retardant reinforced timber which comprises a timber and an ammonium polyphosphate / SiO2 composite aerogel in timber pores. The invention also discloses a preparation method of the flame-retardant reinforced timber, which comprises the following steps: pretreating the timber with microwaves to form new flow channels in the timber, thereby enhancing the timber permeability; hydrolyzing the previously prepared ammonium polyphosphate and silicon source by pressure dipping treatment, and introducing the generated uniform sol solution into the timber; and carrying out condensation reaction and normal-pressure drying to generate the ammonium polyphosphate / SiO2 composite aerogel in the timber pore structure in situ. The ammonium polyphosphate / SiO2 composite aerogel flame-retardant reinforced timber has favorable flame-retardant and smoke-inhibition functions, and can effectively prevent the flame retardant from loss. The composite aerogel in the timber pores has the effect of enhancing wear resistance and corrosion resistance. The method can be widely used in flame retardancy, reinforcement and corrosion resistance of the solid wood or composite wood, has the advantages of feasible technical process, cheap raw materials and favorable effect, and is worthy of popularization.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Radar wave absorbing paint with hollow microsphere as filling material and preparation method thereof

InactiveCN101294047AImprove bindingImprove stability and service lifeInorganic pigment treatmentLiquid/solution decomposition chemical coatingFilling materialsSolvent

The invention discloses a radar wave absorbing coating with the filler of hollow microsphere, which consists of epoxy-silicone resin 30 to 40wt%, a leveling agent 0.2 to 0.4wt%, a thickening agent 0.2 to 0.4wt%, hollow microsphere plated with metal coating 40 to 55wt%, and solvent being the rest. The radar wave absorbing coating with the hollow microsphere filler has the maximal absorptivity of 20 dB at the electromagnetic wave frequency band of 2 to 18 GHz, and has the frequency width of 5 GHz larger than 10 dB.

Owner:BEIHANG UNIV

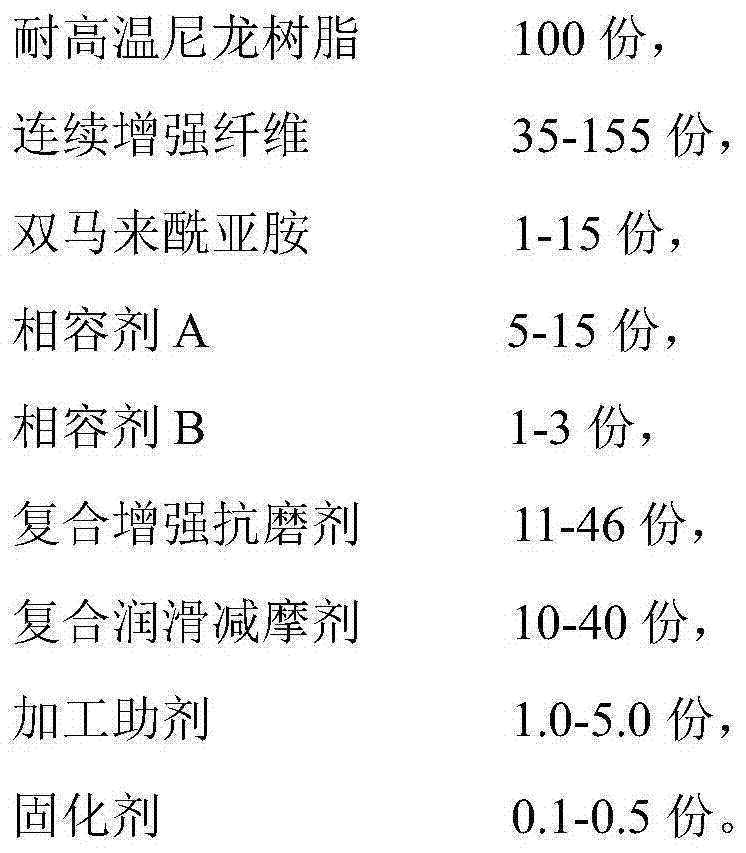

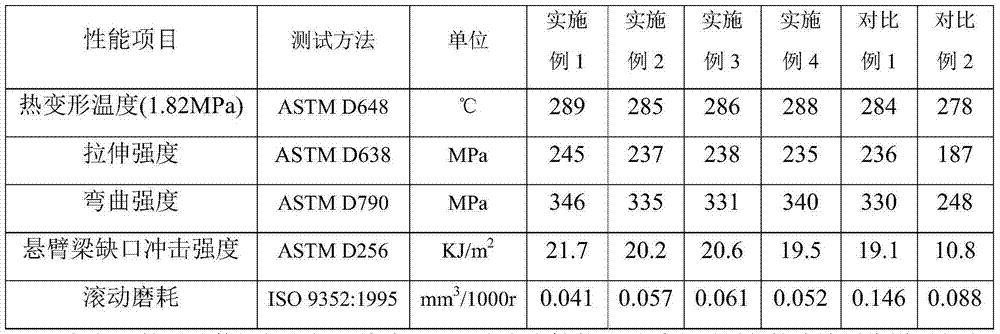

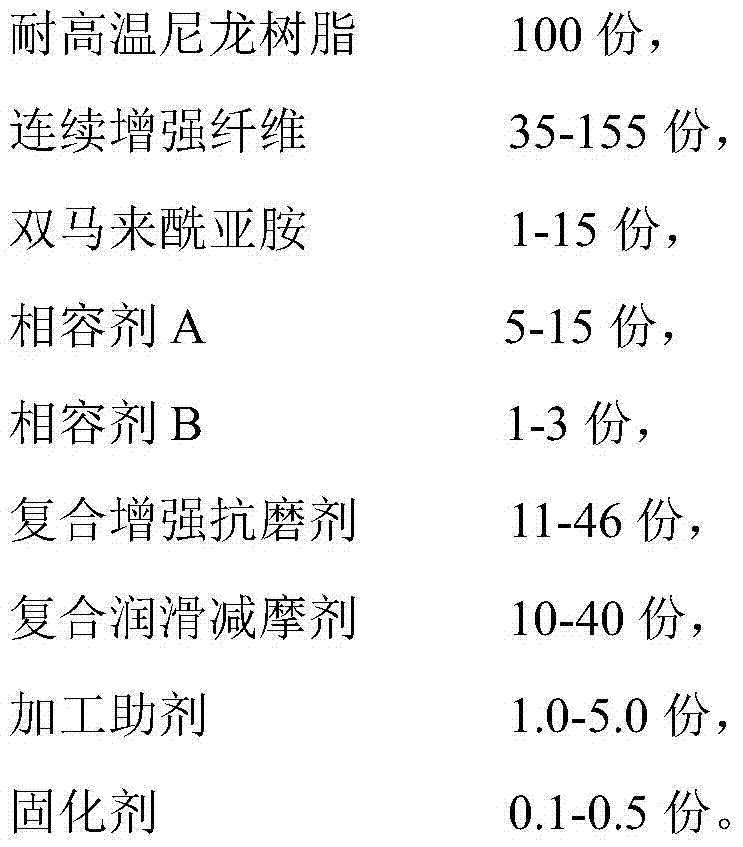

High wear resistant and high self-lubrication continuous long fiber reinforced high temperature resistant nylon composite material and preparation method thereof

InactiveCN104744926AImprove the lubrication effectImprove wear resistanceWear resistantTemperature resistance

The invention belongs to the high temperature resistant nylon composite material field, and relates to a continuous long fiber reinforced high temperature resistant nylon composite material including the following components by weight: 100 parts of high temperature resistant nylon resin, 35-155 parts of continuous reinforced fiber, 1-15 parts of bismaleimide, 5-15 parts of a compatible agent A, 1-3 parts of a compatible agent B, 11-46 parts of a composite reinforced antiwear agent, 10-40 parts of a composite lubrication antifriction agent, 1.0-5.0 parts of a processing aid and 0.1-0.5 part of a curing agent. The high wear resistant and high self-lubrication continuous long fiber reinforced high temperature resistant nylon composite material has enough wear resistance, self lubrication property, mechanical properties, high temperature resistance and dimensional stability, and can be used in the manufacture of sliding parts such as gears, turbines, cam and other transmission parts and bearings, bushings, guide rails, pistons and other wear resistant, antifriction and self self-lubrication parts and general structural parts working in the high temperature environment.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Preparation method of high-temperature abrasion proof ceramic wafer

The invention provides a preparation method of high-temperature abrasion proof ceramic wafer, using the fused brown alumina, fused sub-white corundum, silicon carbide, fused mullite with a grain size of 1-3mm as the main material; using the dense brown alumina, fused sub-white corundum, silicon carbide, silicon nitride, boron carbide with grain sizes of 180 mesh, 0.088-1mm, 325 mesh and active a-Al2O3 powder with a grain size <=2Mum and nano micro silica powder with a grain size <=200nm as the adjuvant, using soft clay, spodumene, bentonite, metallic silicon with grain sizes of 180 mesh or 325 mesh as the agglutinant; using the pure calcium aluminate cement or sulphite pulp waste-liquor as the temporary binding agent; using the sodium hexametaphosphate, zirconia as the additive; stirring the above materials in a high-power stirrer for 10-15 minute; adding the clean water or the sulphite pulp waste-liquor into the mixture and continuously stirring the mixture for 5-10 minute; casting molding or pressure molding the mixture; drying the molded mixture at 250-300 DEG C and incubating the dried mixture for 4-8 hour; sintering the mixture at above 1350-1650 DEG C in a high-temperature furnace and incubating the sintered mixture for 4-10 hour.

Owner:重庆罗曼科技有限公司

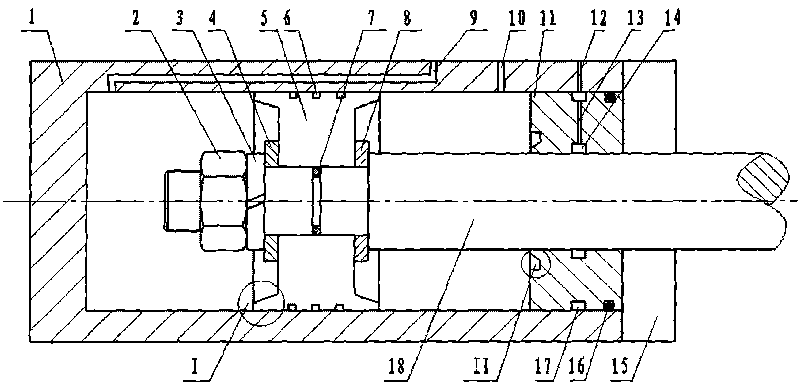

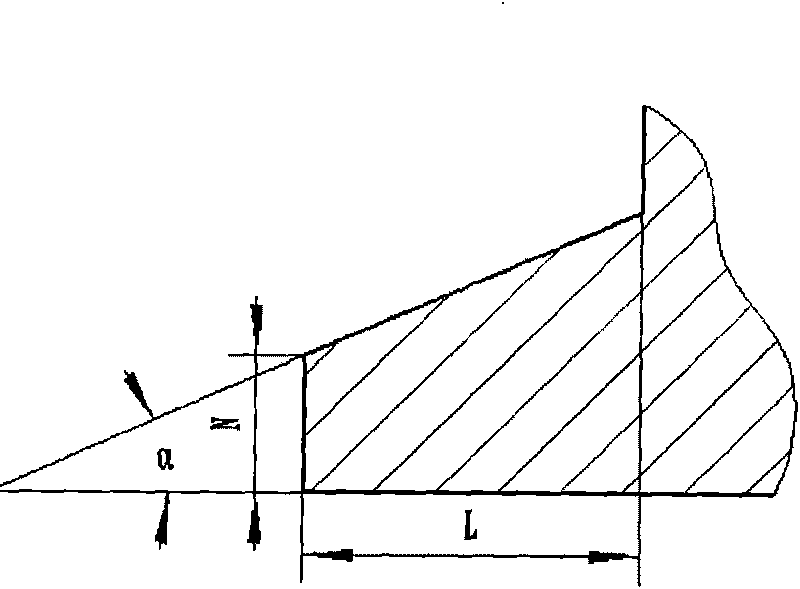

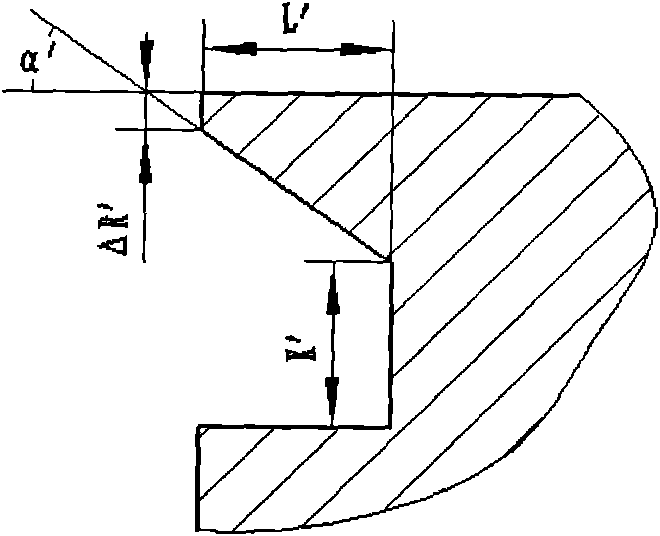

Hydraulic cylinder with clearance sealed type deformed piston

InactiveCN101725588AReduce leakageReduce frictional resistanceFluid-pressure actuatorsHydraulic cylinderPiston rod

The invention particularly relates to a hydraulic cylinder with a clearance sealed type deformed piston, which adopts the following technical scheme that: an excircle of a piston [5] is uniformly and symmetrically provided with 3 to 5 balance slots [6]; a piston rod [18] of the piston [5] is provided with a first seal groove [7]; an annular boss of which the outer diameter is the same as that of the piston [5] is arranged on the end faces of two sides of the piston [5] respectively; an excircle of a guide sleeve [11] is provided with a second seal groove [16]; a first drain pan [14] and a second drain pan [17] are arranged on an inner circle and the excircle of the guide sleeve [11] respectively; the first drain pan [14] is communicated with the second drain pan [17] through a second oil drain channel [13]; the second drain pan [17] is communicated with a first oil drain channel [12] arranged on a cylinder body [1]; and an end face, close to the inner circle, of the inner side of the guide sleeve [11] is provided with am annular groove. The hydraulic cylinder has the characteristics of simple structure, convenient assembly and disassembly and maintenance, long service life, small friction, high frequency response, high reliability, external leakage prevention, and the like.

Owner:WUHAN UNIV OF SCI & TECH

Anti-ageing matt polyurethane composition and preparation method thereof

The invention provides an anti-ageing matt polyurethane composition, comprising the following components in percentage by weight: 30%-60% of thermoplastic polyurethane, 2%-10% of a matt agent, 5%-13% of amine-terminated polyether, 0-1% of a vulcanizing agent, 0-15% of graft, 0-25% of a softener, 1%-3% of a delustering agent and 0.5%-3% of a processing agent. According to the composition, rubber substances are replaced with high molecular weight amine-terminated polyether free of double bonds, thus the content of unsaturated double bonds in the composition is lowered; the composition has the advantages of excellent long-term ageing resistance, mechanical property and tensile break strength; and the matt degree of the surface of a cable or a wire prepared from the composition is kept.

Owner:马艳荣

Reinforced PA6/ABS(Polyamide 6/Acrylonitrile-Butadiene- Styrene) alloy material and preparation method thereof

InactiveCN102558849AFix stability issuesSolve the disadvantage of easy warpingGlass fiberHeat resistance

The invention relates to a reinforced PA6 / ABS(Polyamide 6 / Acrylonitrile-Butadiene- Styrene) alloy material, belonging to the technical field of polymer materials. The reinforced PA6 / ABS alloy material is characterized by comprising the following components in percentage by weight: PA6 30-70, ABS 10-50, anti-impact modifier 5-15, glass fiber 10-40, compatilizer 1-10, antioxidant 0.2-1 and lubricant 0.3-0.8. The reinforced PA6 / ABS alloy material has the characteristics of stable size, high strength, high fluidity, chemical resistance, wear resistance, good heat resistance performance,etc. The reinforced PA6 / ABS alloy material can be used for injection molding automotive interior parts, automobile wheel covers, printer gears, sports equipment and other motor products.

Owner:徐州腾飞工程塑料有限公司

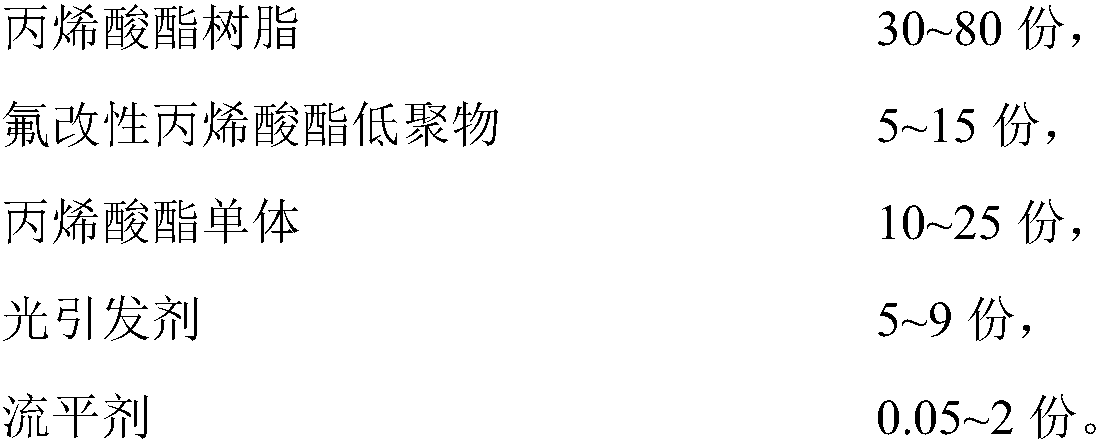

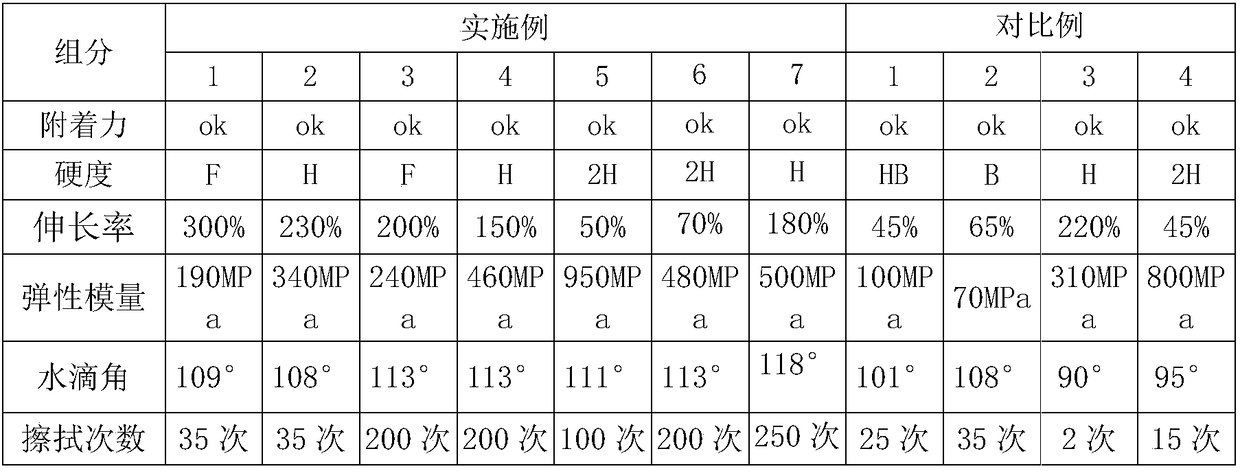

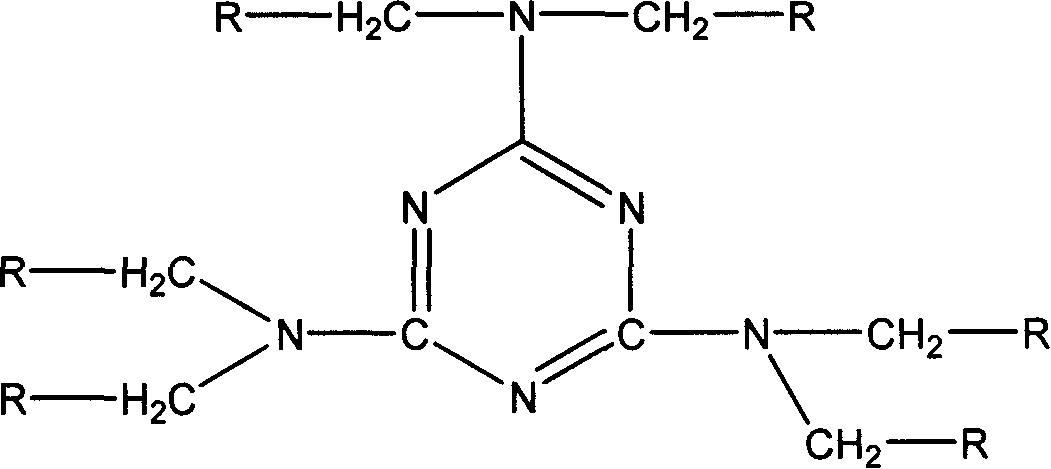

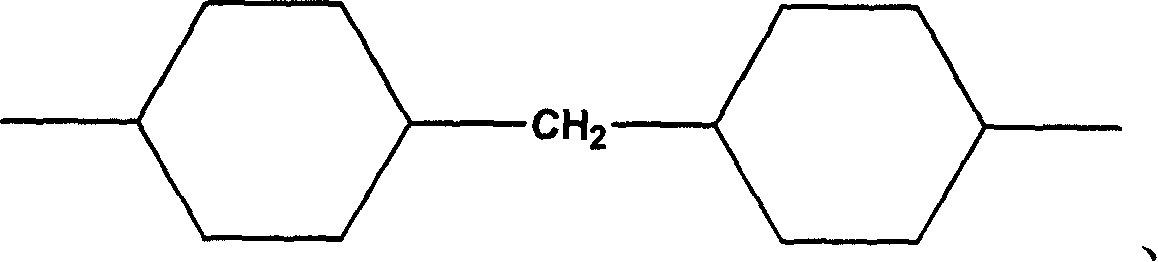

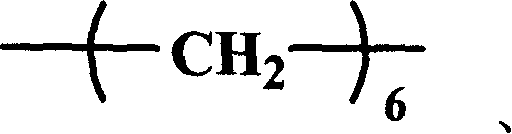

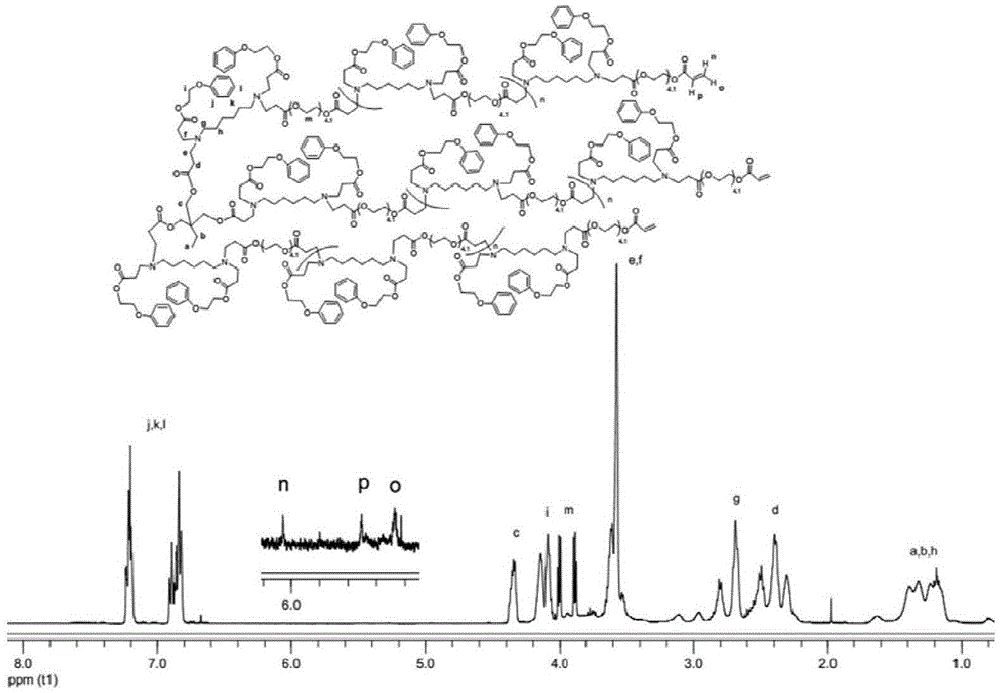

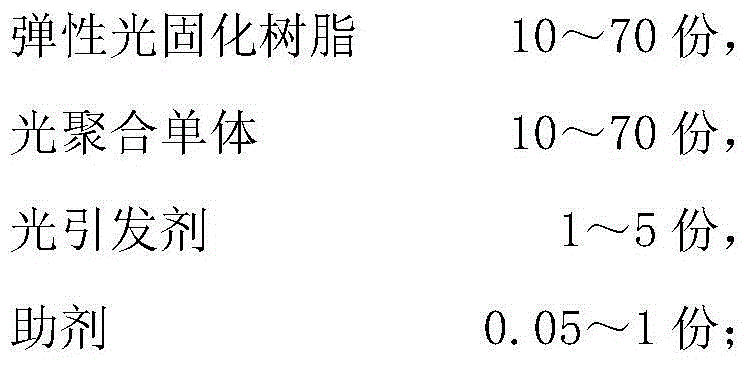

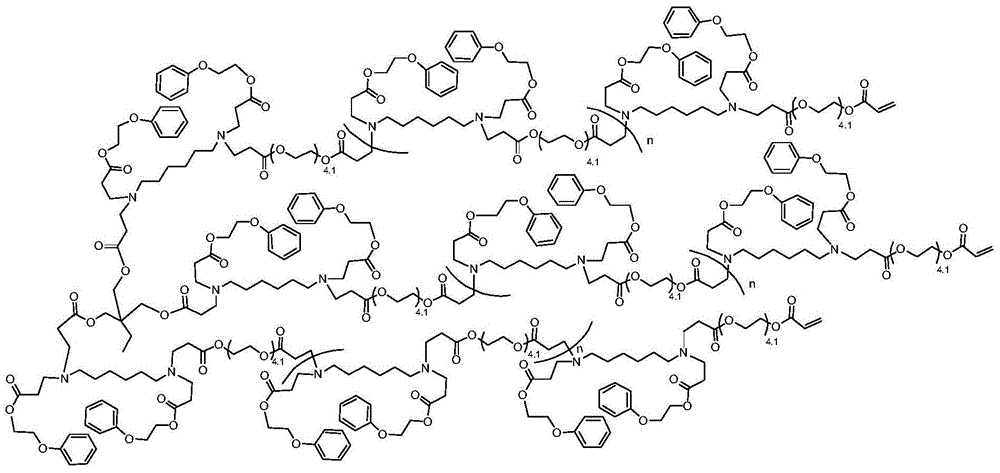

Flexible and stain-resistant ultraviolet curable coating composition and preparation method thereof

InactiveCN108264838AHas hardnessWith highlightsAntifouling/underwater paintsPaints with biocidesOligomerHardness

The invention provides a flexible and stain-resistant ultraviolet curable coating composition. The composition comprises, by weight, 30-80 parts of acrylate resin, 5-15 parts of a fluorine-modified acrylate oligomer, 10-25 parts of an acrylate monomer, 5-9 parts of a photoinitiator and 0.05-2 parts of a leveling agent. Compared with coatings in the prior art, the coating composition in the invention has a higher flexibility, and has the advantages of certain hardness, wear resistance, stain resistance, suitableness for bendable and crimped substrates, excellent comprehensive performances and wide applicability .

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

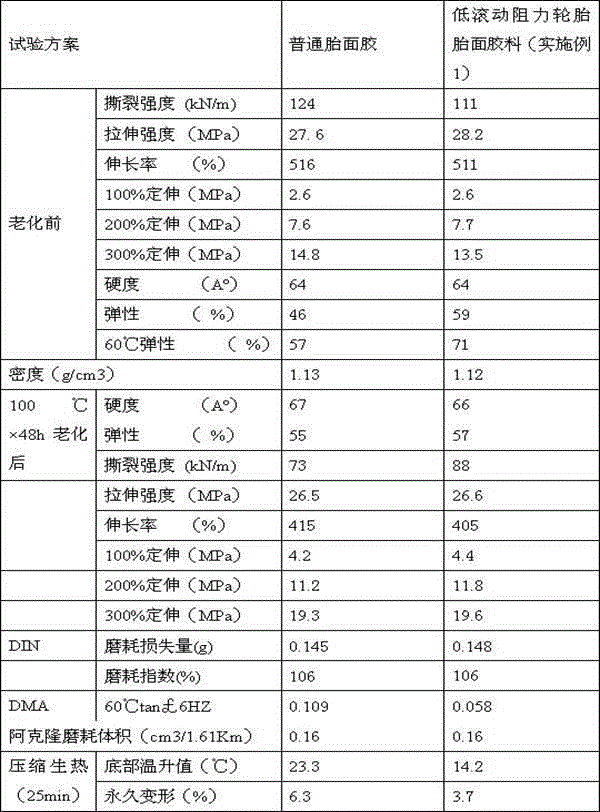

Abrasion and pierce proof low-resistance tire rubber compound and preparation method thereof

The invention discloses an abrasion and pierce proof low-resistance tire rubber compound and a preparation method thereof. The abrasion and pierce proof low-resistance tire rubber compound comprises, by weight, 40-70 parts of natural rubber SIR20, 10-15 parts of cis-polybutadiene rubber, 3-5 parts of styrene butadiene rubber SBR1500, 5-6 parts of N234 high-structure medium super abrasion furnace black, 5-6 parts of white carbon black, 1-1.5 parts of a silane coupling agent Si-69, 1-1.5 parts of polyethylene glycol, 0.5-1.0 part of toluene diisocyanate, 0.5-1.0 part of stannous chloride, 0.5-1.0 part of hydroxy-terminated polybutadiene, 1-1.5 parts of softening plasticizer aromatic oil, 1-2 parts of stearic acid, 2-3 parts of an antioxidant, 1-1.5 parts of tackifier 204 resin, 1-1.5 parts of a homogenizing agent UB4000, 0.5-1.0 part of zinc oxide, 1-1.5 parts of sulfur, 0.5-1.0 part of an XY900 anti-reversion agent, 1-1.5 parts of a promoter TBBS and 0.5-1.0 part of an anti-fatigue agent G-108. The tire rubber compound obtained in the invention has the advantages of good compatibility, abrasion proofing, pierce proofing, low resistance, fatigue proofing, ageing proofing, deformation proofing and wide application prospect.

Owner:QINGDAO LANNONGGU AGRI PROD RES & DEV

Ultraviolet light solidified wear resistant lacquer in use for coating layer on surface of dense board plastes

InactiveCN1696225AImprove performanceSoft matte finishPolyurea/polyurethane coatingsMethacrylateHigh density

An ultraviolet solidified antiwear paint for the surface of high-density board with hot-pressed surficial paper layer contains proportionally acrylate (or methylacrylate) modified amino resin, polyurethane acrylate or polyurethane methylacrylate, epoxy acrylate or epoxy methyl acrylate, acrylate or methylacrylate, optical trigger, antiwear inorganic powder and dulling powder.

Owner:湖南亚大新材料科技股份有限公司

Self-lubricating wear-resistant eutectic graphitic steel and preparation method thereof

The invention discloses self-lubricating wear-resistant eutectic graphitic steel and a preparation method thereof, and relates to the field of ferrous materials. The eutectic graphitic steel is different from ordinary isothermal quenching nodular cast iron in the preparation method, graphite shape and engineering service response behavior. Sectionoal materials are drawn through a continuous casting method with the rapid cooling ability, the composition of molten iron is strictly controlled at the eutectic point, and thus eutectic graphite nodules with the spheroidization rate of 100% are obtained; in addition, the fine graphite nodules are in dispersed distribution, the peripheries of the graphite nodules are coated with layers of amorphous mechanical impurities, impurity elements in the molten iron are collected, and the grain boundary of a matrix is purified; and tiny high-frequency elastic deformation of the materials in service can appear rings of 'strain aging and heat aging' softening structures around the graphite nodules, initiation of fatigue cracks is effectively inhibited, and the fatigue life is prolonged. In summary, the eutectic graphite steel has excellent mechanicalperformance of quenched steel and physical properties of self-lubrication, sound absorption and noise reduction, shock absorption and friction reduction of cast iron materials.

Owner:XIAN UNIV OF TECH

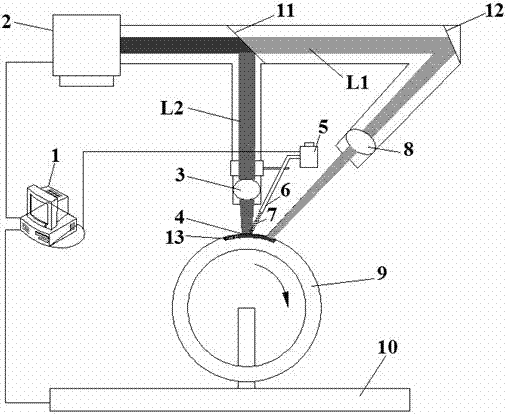

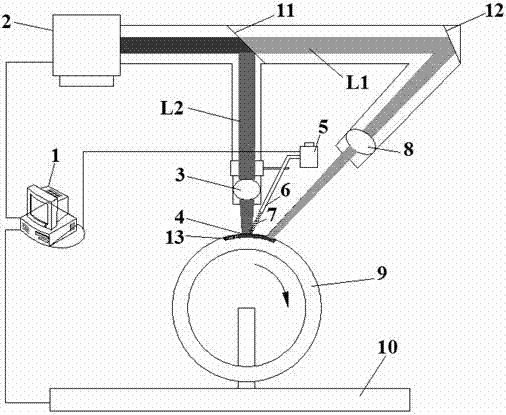

Same-wavelength double-beam narrow-spot laser quick cladding method

InactiveCN102409338AEasy loading and unloadingEasy to operateMetallic material coating processesNumerical controlHeat-affected zone

The invention discloses a same-wavelength double-beam narrow-spot laser quick cladding method, which is characterized by comprising the following steps of: (1) performing rust removing, oil removing, cleaning and sand blasting treatment on the surface of a substrate; (2) splitting a laser beam of the same wavelength into two beams of laser by using a laser beam splitter mirror; (3) applying a first beam of laser to the surface of the substrate for performing preheating treatment on the substrate; (4) blowing alloy powder into a molten pool formed on a second beam of laser on the surface of the substrate by using a powder nozzle of an automatic powder feeder; (5) moving a numerically-controlled machine too along the vertical direction of a laser scanning speed by 40-80 percent of the diameter of a laser spot; and (6) repeating the steps (2)-(5) till the thickness of a coating reaches a required thickness, or ending work. The method has the advantages: (1) the processing cost is reduced greatly; (2) the substrate has a small heat affected zone, and is not deformed; and (3) the shape and size of the substrate are unlimited.

Owner:NANCHANG HANGKONG UNIVERSITY

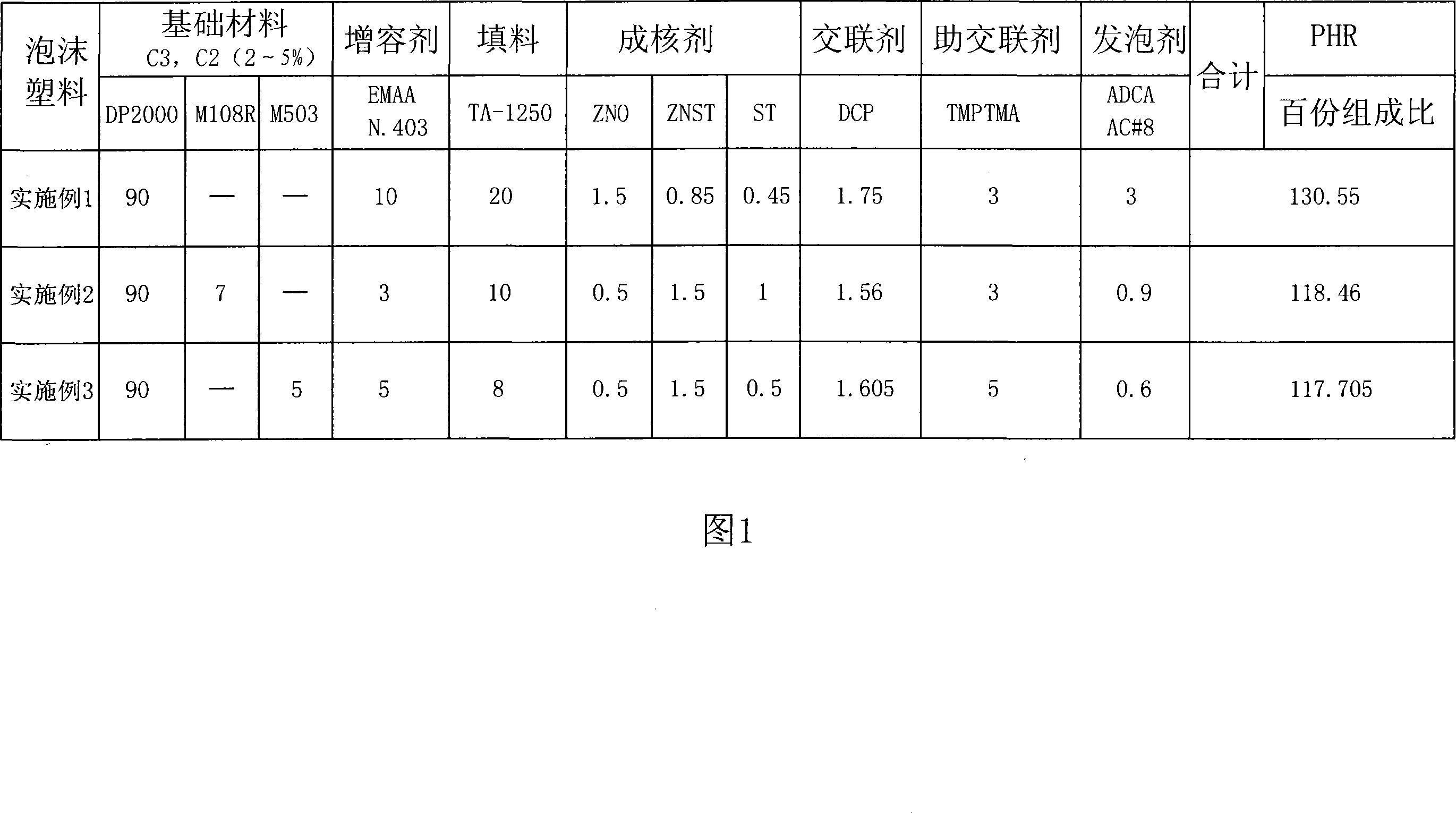

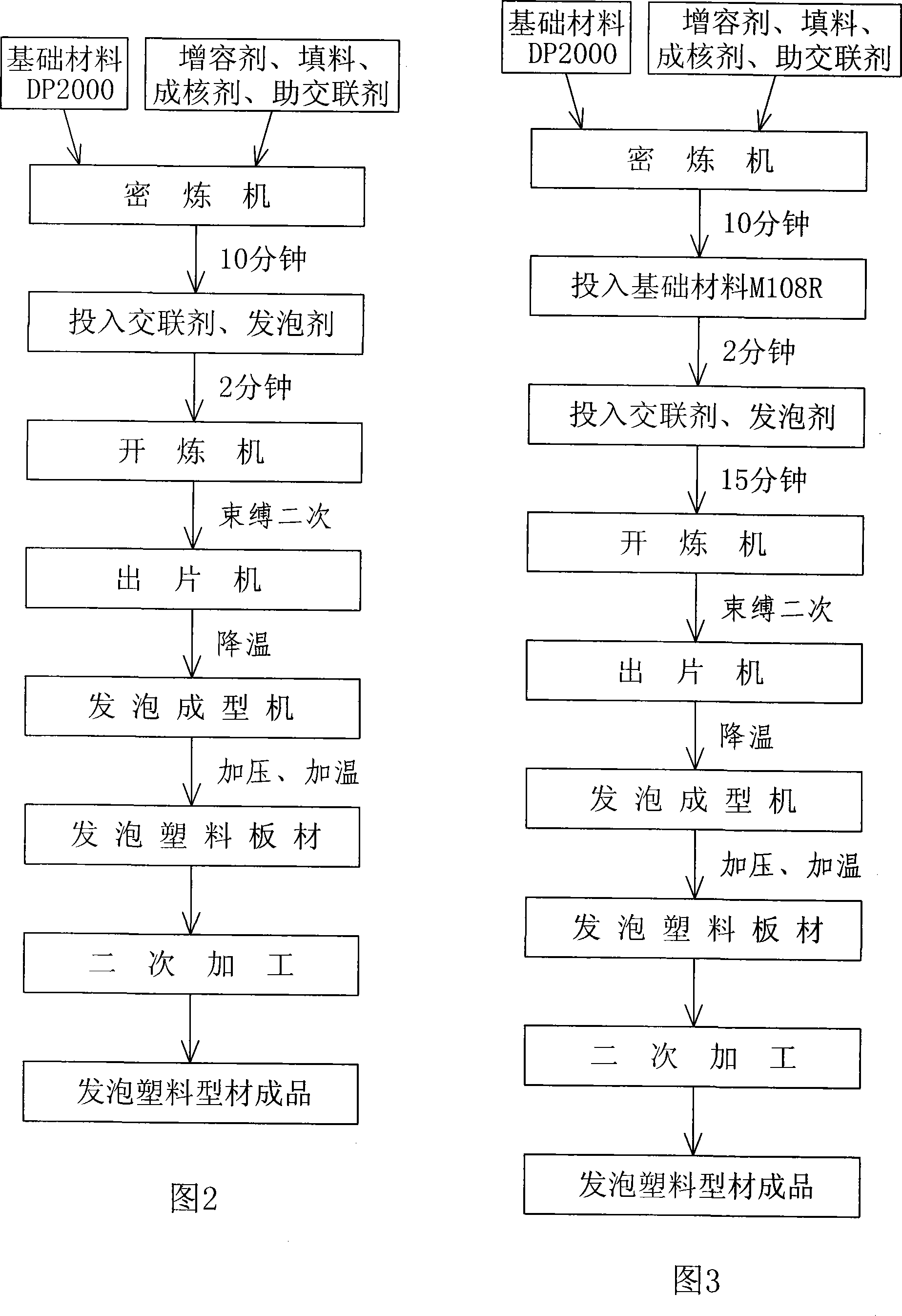

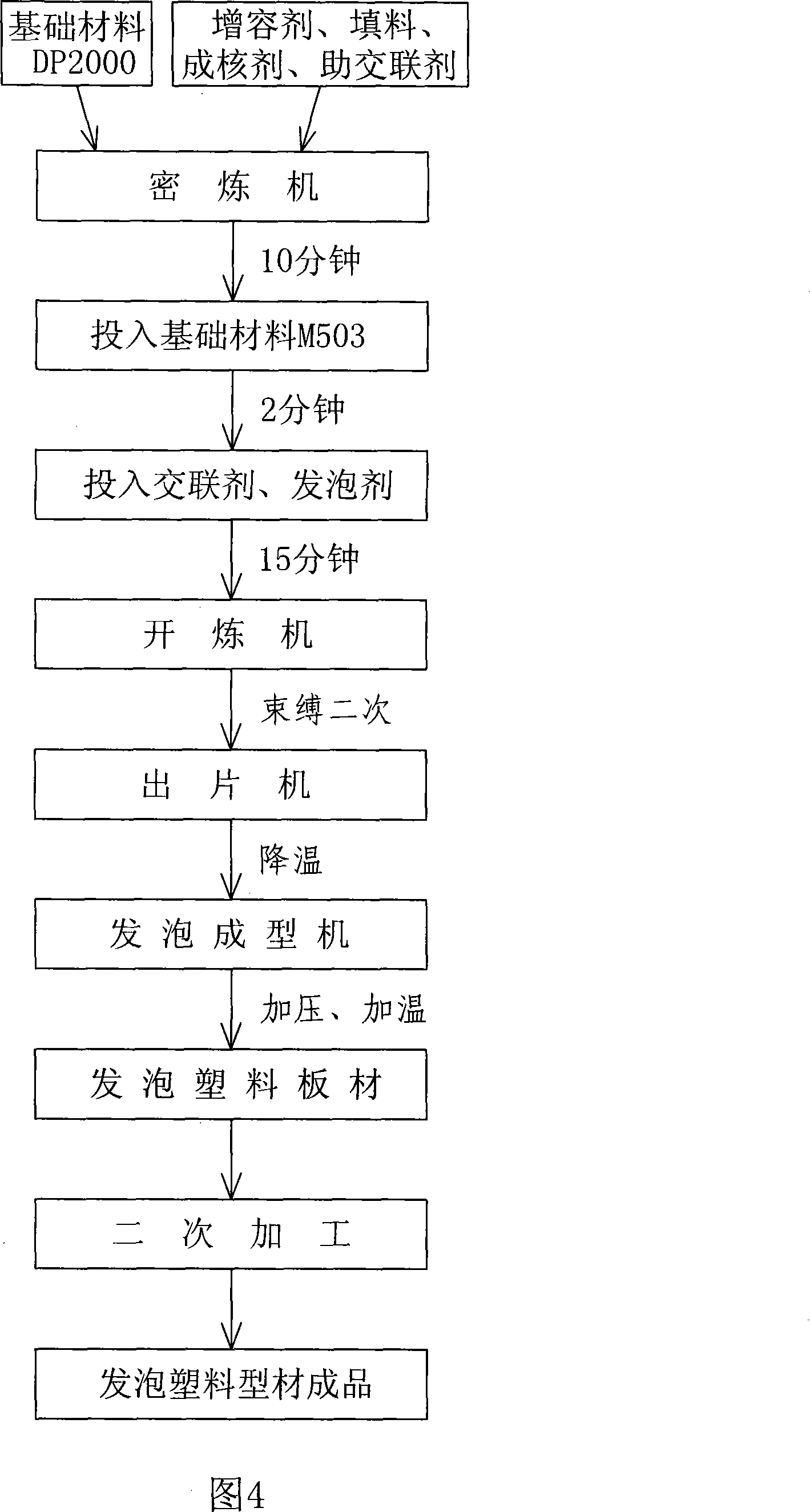

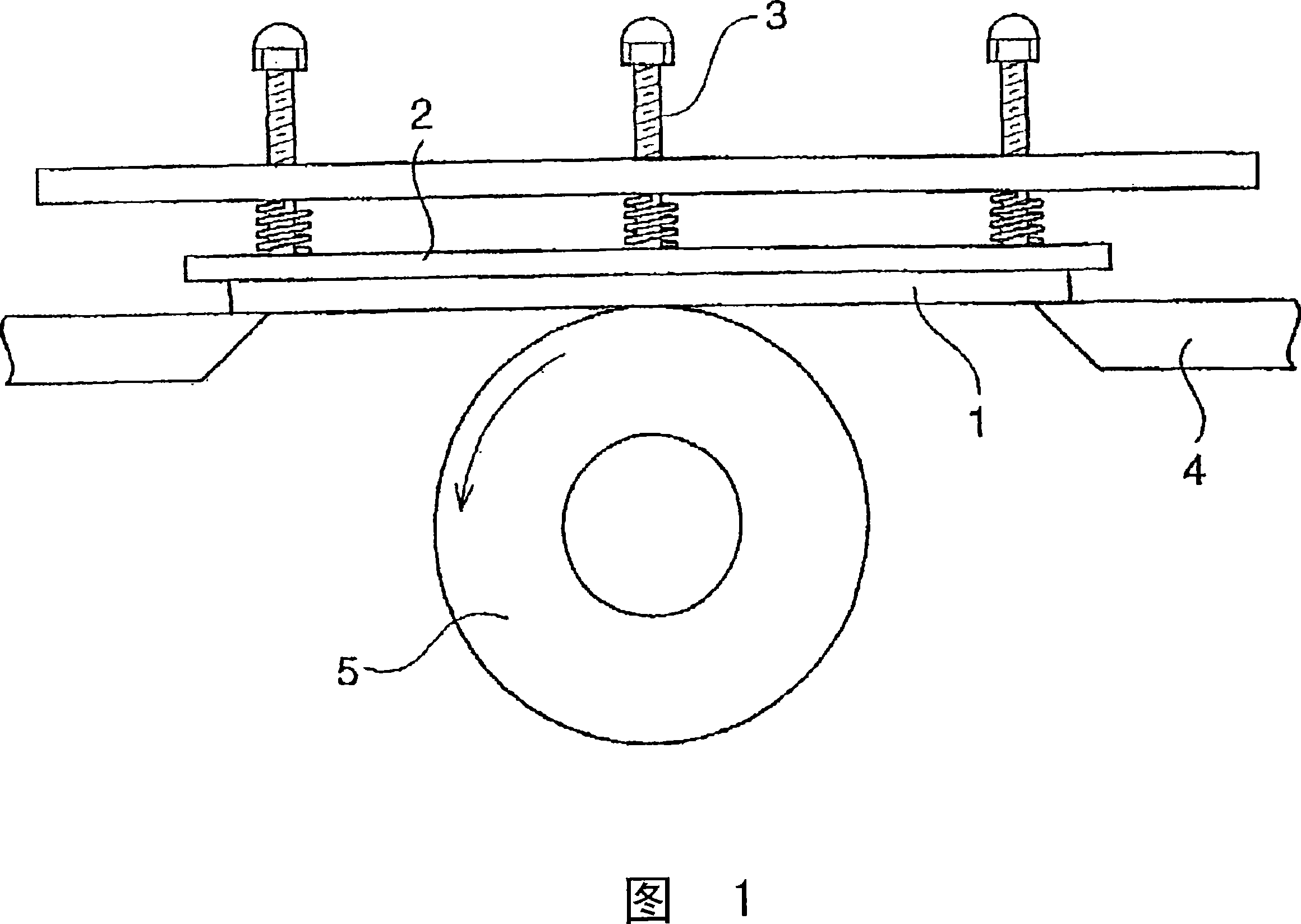

Degradable environment-friendly type polypropylene(PP) foam plastic and preparation method thereof

The invention provides an environment-friendly-type polypropylene (pp) aerated plastics and a process for preparation, and the aerated plastics utilizes plastic projectile body to be basis material, a third monomer is led in to be auxiliary crosslinking agent to crosslink and control degradation products, aerated plastics section products are made by processing graft copolymerization and cross-linking reaction to polypropylene, and closely welding, openly welding, tabletting, and foaming to shape with compatibilizer, filling material, nucleating agent, cross linking agent and inflating agent. The invention modifies the shortcomings that the traditional homopolymerized polypropylene can not get higher breakpoint extension force, high melt intensity and viscosity to foam and shape in the process of thermal foaming and shaping. The polypropylene (pp) aerated plastics products which are provided by the invention have excellent fire-resisting property and little heat distortion degree, and the softening point is between 100 DEG C and 130 DEG C. The invention can be used for long term in the temperature scope, and the application area is wide, wastes can be recycled, and can be automatically degraded, and the invention has no pollution to environment.

Owner:FUJIAN ZHENGYI IND

Method for differential arc oxidation treatment of Nickel-titanium alloy for medical purpose

InactiveCN101063221ANo reduction in mechanical propertiesSmall mechanical propertiesSurgerySurface reaction electrolytic coatingPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a method of medical nickel titanium alloy differential arc oxidation treatment, which comprises the following steps: (1) pre-treating surface; (2) putting into hydraulic fluid; choosing NiTi ally as positive pole and loading trough as negative pole; treating; (3)washing; drying; getting the product. This invention possesses simple method, which can inhibit discharging of Ni ion in nickel titanium alloy and reinforce safety.

Owner:HARBIN INST OF TECH

Golden ornament and its manufacturing method

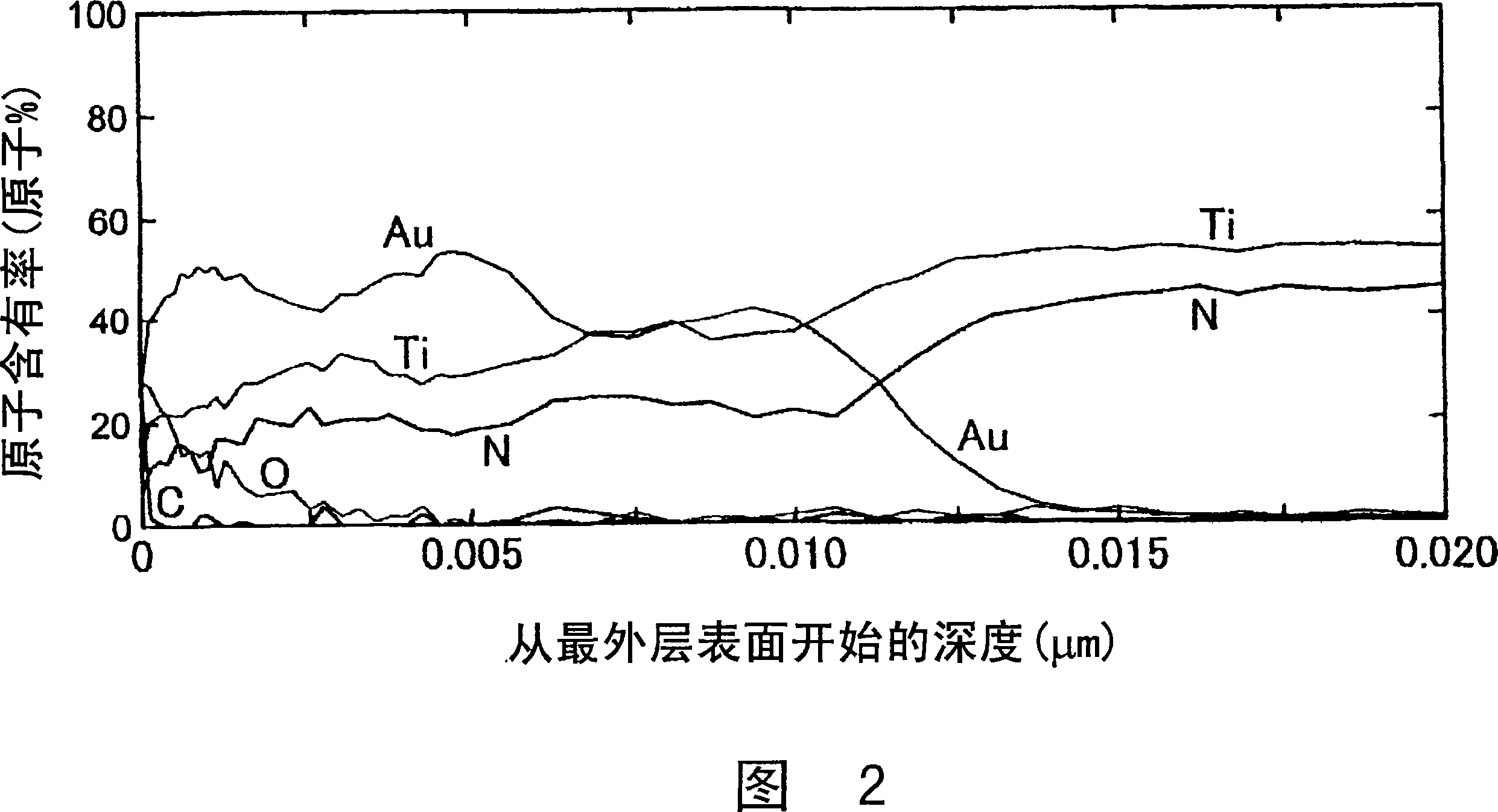

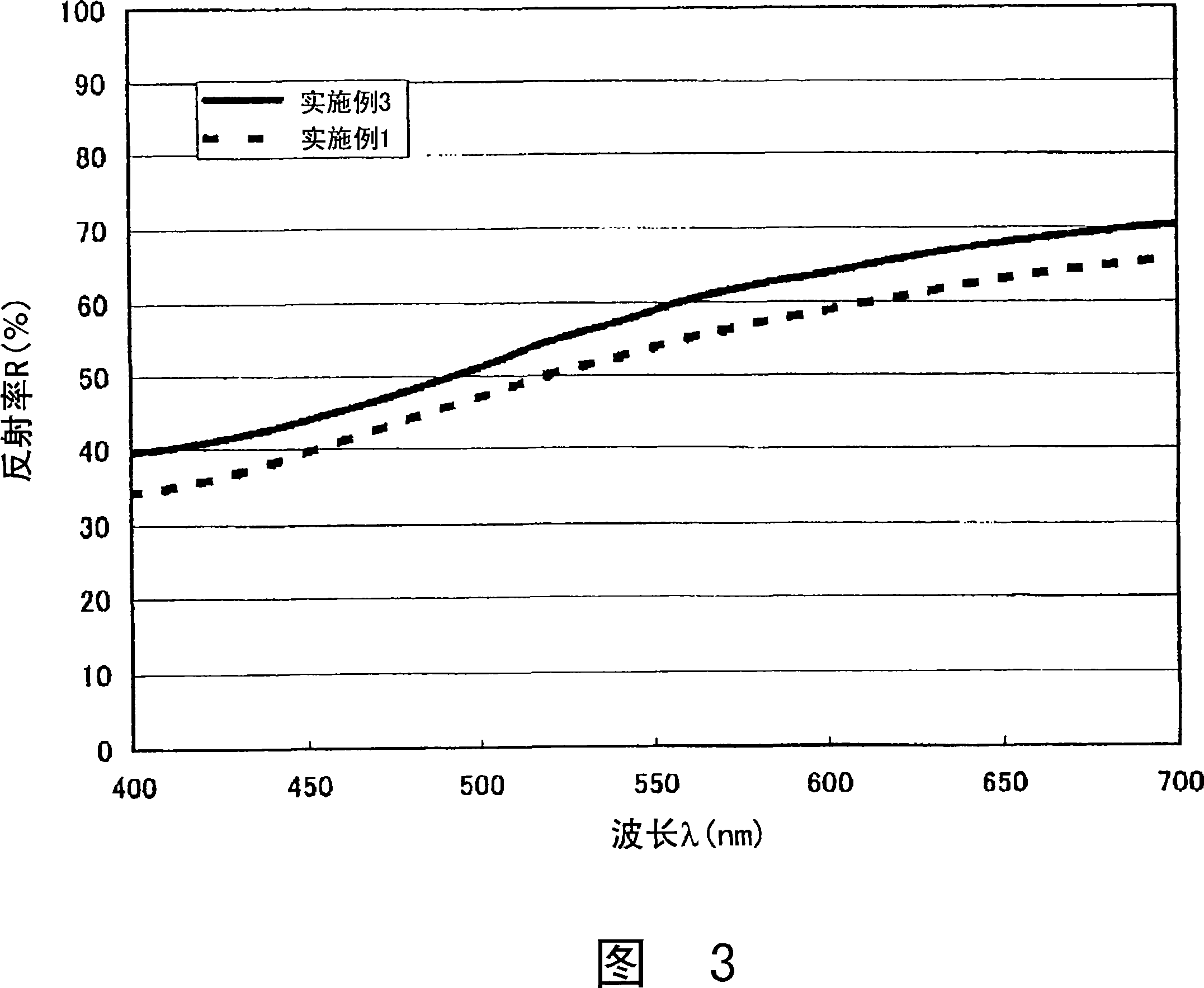

InactiveCN101160418AGood adhesionHigh surface hardnessVacuum evaporation coatingSputtering coatingNitrogen gasNitrogen

A golden ornament comprising a base material; a Ti coating whose Ti atom content is constant in the direction of coating thickness, formed on the base material in an atmosphere of inert gas other than nitrogen; a TiN gradient coating whose N atom content is sloped in the direction of coating thickness, formed on the Ti coating; a TiN coating whose Ti atom and N atom contents are constant in the direction of coating thickness, formed on the TiN gradient coating; an Au-TiN mixture gradient coating whose Au atom content is sloped in the direction of coating thickness, formed on the TiN coating; and an Au-TiN mixture coating whose Au atom, Ti atom and N atom contents are constant in the direction of coating thickness, formed on the Au-TiN mixture coating. Further, on this Au-TiN mixture coating, there may be formed an Au coating or Au alloy coating whose Au atom content is constant in the direction of coating thickness.

Owner:CITIZEN WATCH CO LTD

Light anti-slipping high-wear-resistance rubber material for sole and preparation method thereof

The invention relates to a rubber composite material and particularly relates to a light anti-slipping high-wear-resistance rubber material for a sole and a preparation method thereof. The light anti-slipping high-wear-resistance rubber material for the sole is prepared from the following raw materials in parts by weight: 55-75 parts of EVA (Ethylene Vinyl Acetate), 8-25 parts of NR (Natural Rubber), 8-25 parts of SBR (Styrene Butadiene Rubber), 2-6 parts of CaCO3, 2-6 parts of wear-resisting agent, 1-5 parts of ZnO, 1-5 parts of ZnST, 0.5-2.5 parts of ST, 0.5-1.5 parts of DCP (Dibasic Calcium Phosphate) and 1.2-2.5 parts of AC (Azodicarbonamide). Compared with the prior art, the components and the ratios of all raw materials are optimized and the light anti-slipping high-wear-resistance rubber material has the advantages of light weight, anti-slipping performance and wear resistance under the synergistic effect of the components with the ratios. The light anti-slipping high-wear-resistance rubber material is particularly suitable for manufacturing a light and anti-slipping sneaker sole.

Owner:MAOTAI FUJIAN SOLES CO LTD

Ultraviolet light curing elastic self-healing coating composition

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

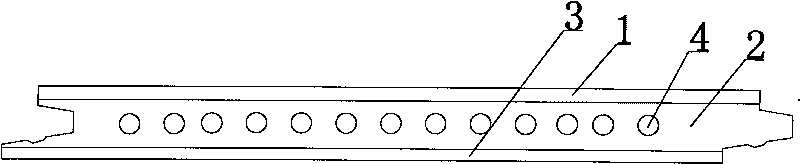

Plastic wood composite floor

The invention relates to the technical field of civil construction plate, particularly to a plastic wood composite floor, which comprises a PVC floor surface layer and a plastic-wood substrate, the PVC floor surface layer and the plastic-wood substrate are cemented together through environment-protective waterproof glue. Since the PVC floor with various color and good waterproof performance is selected as the surface layer, users can choose the color of indoor floor according to personal taste. Meanwhile, the plastic-wood substrate is adopted and cemented under the PVC floor surface layer by glue, thus, comparing to conventional PVC floor, the invention has the advantages of convenient paving, low paving cost, and leaving no welding seams after pavement.

Owner:CHANGZHOU DONGJIA DECORATIVE MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com