Same-wavelength double-beam narrow-spot laser quick cladding method

A dual-beam, same-wavelength technology, applied in the coating process and coating of metal materials, can solve the problems of easy cracking of the cladding layer, low laser cladding efficiency, and high processing cost, and achieve controllable dilution rate and automation. The effect of high degree and reduction of processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A Ni-based alloy coating was prepared on the surface of a 70Mn2Mo cast steel hot roll by rapid cladding with a double-beam narrow-spot laser at the same wavelength, and the thickness of the coating was 2 mm.

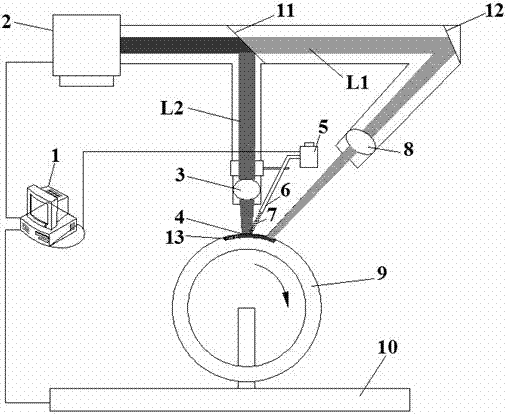

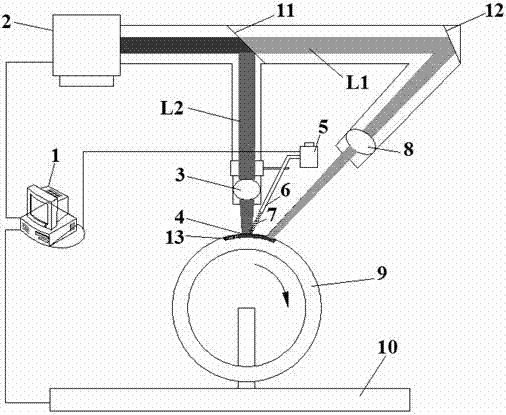

[0021] The implementation process of this embodiment is, as figure 1 shown.

[0022] (1) Use a grinder to derust the surface of the 70Mn2Mo cast steel hot roll 9, then use a mixed solution of sodium hydroxide and sodium carbonate with a volume ratio of 1:1 to degrease, then wash and dry with pure water, Finally, sandblasting;

[0023] (2) The laser beam splitter 11 with a fixed beam splitting ratio is used to split the laser beam emitted by the Nd:YAG laser 2 with a wavelength of 1.06 μm into a laser beam L1 and a laser beam L2, and the laser beam L1 is reflected by the mirror 12 and focused by the focusing mirror 8 After being focused, it acts on the surface of the 70Mn2Mo cast steel hot roll 9, and the laser beam L2 acts on the surface of the 70Mn2Mo cast stee...

Embodiment 2

[0029] WC-12 wt.% Co was clad on the surface of hydraulic cylinder piston rod by rapid cladding method with double-beam narrow-spot laser at the same wavelength. The thickness of the coating was 1.8 mm, and the material of hydraulic cylinder piston rod was No. 35 steel.

[0030] (1) Use a grinding machine to derust the surface of the piston rod 9 of the hydraulic cylinder, then use a mixed solution of steel hydroxide and sodium carbonate with a volume ratio of 1:1 to degrease, then wash and dry with pure water, and finally sandblasting;

[0031](2) The laser beam splitter 11 with a fixed beam splitting ratio is used to split the laser beam emitted by the Nd:YAG laser 2 with a wavelength of 1.06 μm into a laser beam L1 and a laser beam L2, and the laser beam L1 is reflected by the mirror 12 and focused by the focusing mirror 8 After being focused, it acts on the surface of the piston rod 9 of the hydraulic cylinder, and the laser beam L2 acts on the surface of the piston rod 9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com