Six-axis five-linkage spiral taper gear cutting machine tool

A technology for spiral bevel gears and processing machine tools, which is applied to metal processing machinery parts, metal processing, metal processing equipment, etc. It can solve the problems of large floor area, poor workmanship, and easy slipping of friction wheels, etc., and achieve equipment cost reduction , good process performance, the effect of good process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

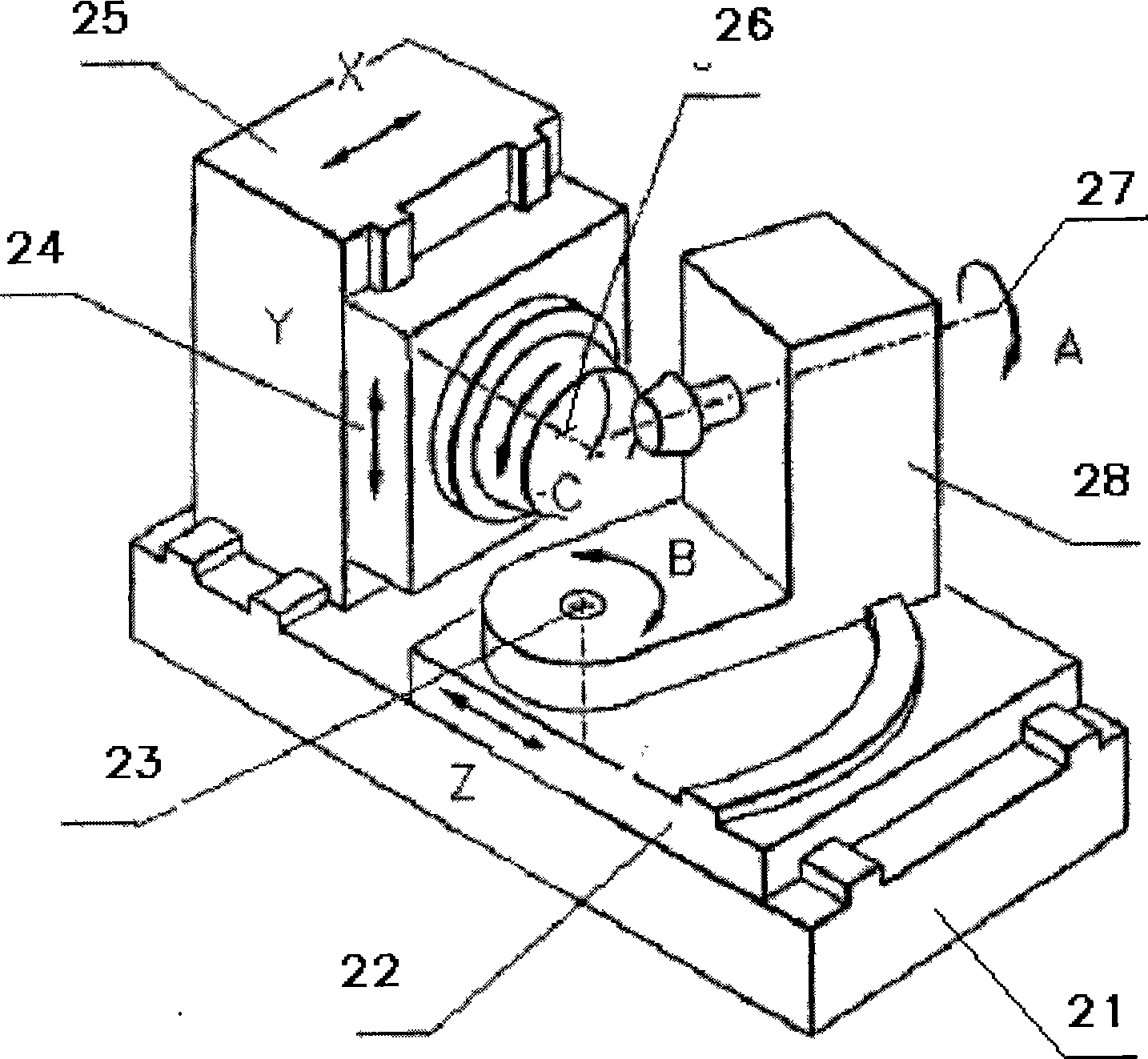

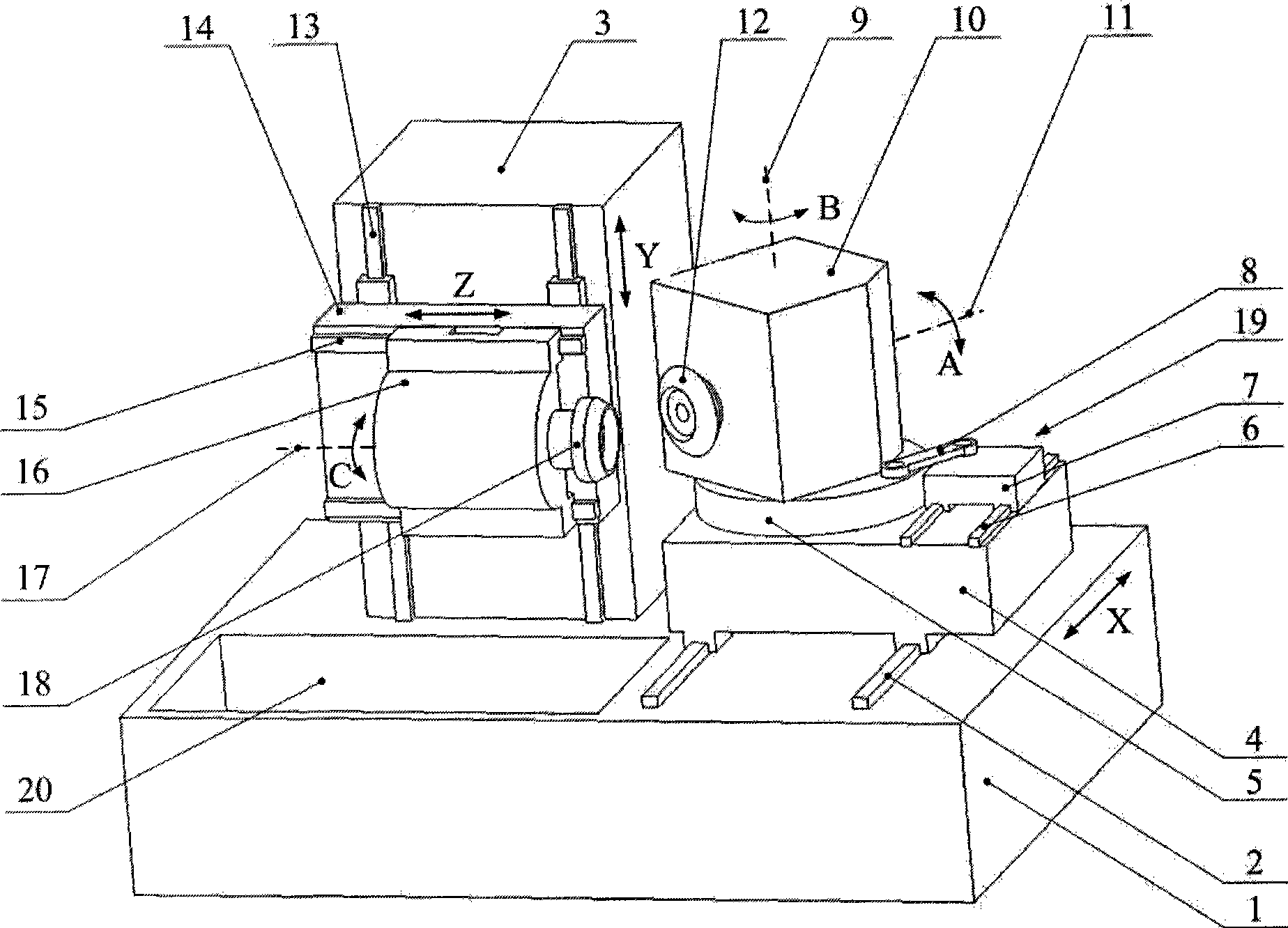

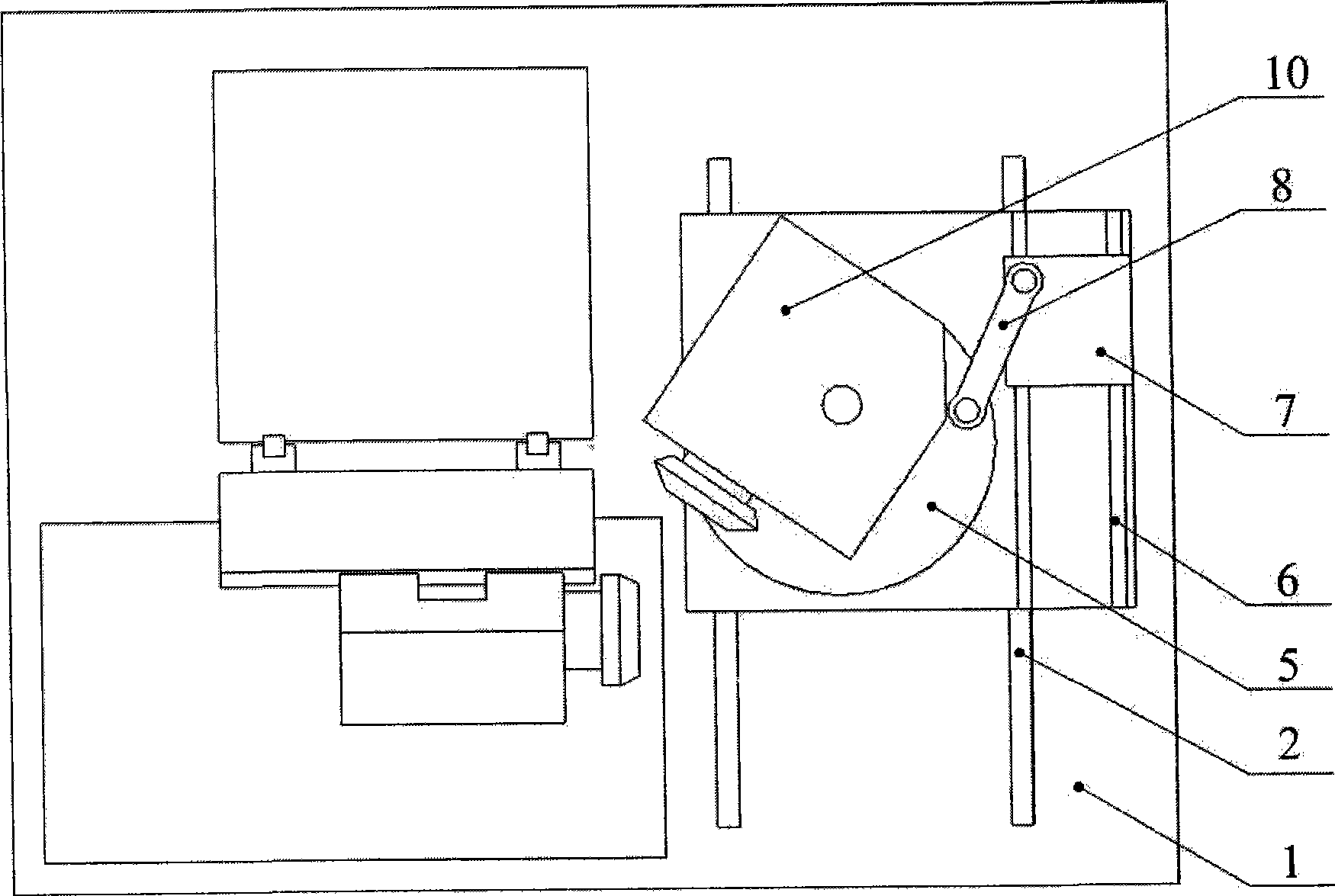

[0042] according to figure 2 and image 3 And the machine tool with the above structure has a bed 1, the top surface of the bed 1 is provided with a horizontal first X-direction linear guide rail 2 and a fixed column 3, and the first X-direction linear guide rail 2 is equipped with a The X-axis slide table 4 that moves along the first X-direction linear guide rail is provided with a turntable 5 and a turntable drive mechanism 19 that can rotate around the B-axis 9 perpendicular to the horizontal plane on the X-axis slide table 4, and is fixedly installed on the turntable The workpiece box 10 on the 5 is provided with a horizontal A-axis 11 that can be rotated under the driving mechanism, and one end of the A-axis 11 is equipped with a processed workpiece 12; The linear guide rail 2 is a vertical Y-direction linear guide rail 13, and the Y-direction linear guide rail 13 is equipped with a Y-axis slide 14 that can move along the Y-direction linear guide 13 under the drive of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com