Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

784 results about "Gear grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flying-shear main-transmission gearwheel steel and preparation method thereof

ActiveCN102162069AReduce the effect of heat treatment distortionOvercoming brittlenessGear grindingHobbing

The invention discloses a flying-shear main-transmission gearwheel steel and a preparation method thereof. The flying-shear main-transmission gearwheel steel comprises the following elements in percentage by mass: 0.10-0.20% of C, 2.00-3.00% of Cr, 2.50-3.50% of Ni, 0.4-1.00% of Mo, 0.10-0.40% of Si, 0.40-1.00% of Mn, at most 0.25% of Cu, at most 0.1% of Al, at most 0.020% of P, at most 0.015% ofS, at most 30ppm of O, at most 100ppm of N and at most 2ppm of H. The preparation method comprises the following steps: (1) smelting according to the percentage by mass to obtain a forging stock; (2)forging; (3) carrying out normalizing heat treatment; (4) carrying out gear hobbing; (5) carrying out surface carburization quenching heat treatment; and (6) carrying out gear grinding. The inventionenhances the bearing capacity and reliability of the gearwheel, and satisfies the production demands of high-carbon high-alloy steel and enhanced specifications, thereby having wide popularization and application prospects.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for operating a dovetail grinding machine

InactiveCN101513684AGear teeth manufacturing toolsGear-cutting machinesGear grindingMechanical engineering

The present invention relates to a method for operating a gear grinding machine, with the following operating phases of the gear grinding machine: machining a workpiece on the gear grinding machine by means of a grinding disk and / or grinding worm and dressing a profiling tool for profiling a grinding disk and / or grinding worm on the gear grinding machine.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

Method for manufacturing bevel gear of axle gear box for diesel locomotives

The invention discloses a method for manufacturing a bevel gear of an axle gear box for diesel locomotives, which comprises the steps of blank forging, blank heat-treatment, gear-blank processing, gear-shape processing, gear-end processing, gear-surface heat-treatment, precise reference modification and gear-shape finish-machining, wherein the step of blank heat-treatment comprises the sub-steps of normalizing and thermal refining; the step of gear-blank processing comprises the sub-steps of rough turning and finish turning; the step of gear-shape processing comprises the sub-steps of gear milling, gear hobbing or gear shaping; the step of gear-surface heat-treatment comprises the sub-steps of nitriding, surface quenching and tempering; the step of precise reference modification comprises the sub-steps of end face modification and centre hole modification; and the step of gear-shape finish-machining comprises the sub-steps of gear grinding and polishing. By using the method disclosed by the invention, the production efficiency of the bevel gear can be improved, and the consumption amount and production cost of raw materials can be reduced; and meanwhile, the method is simple in process, and the manufactured bevel gear is long in service life.

Owner:常州市万航工矿设备有限公司

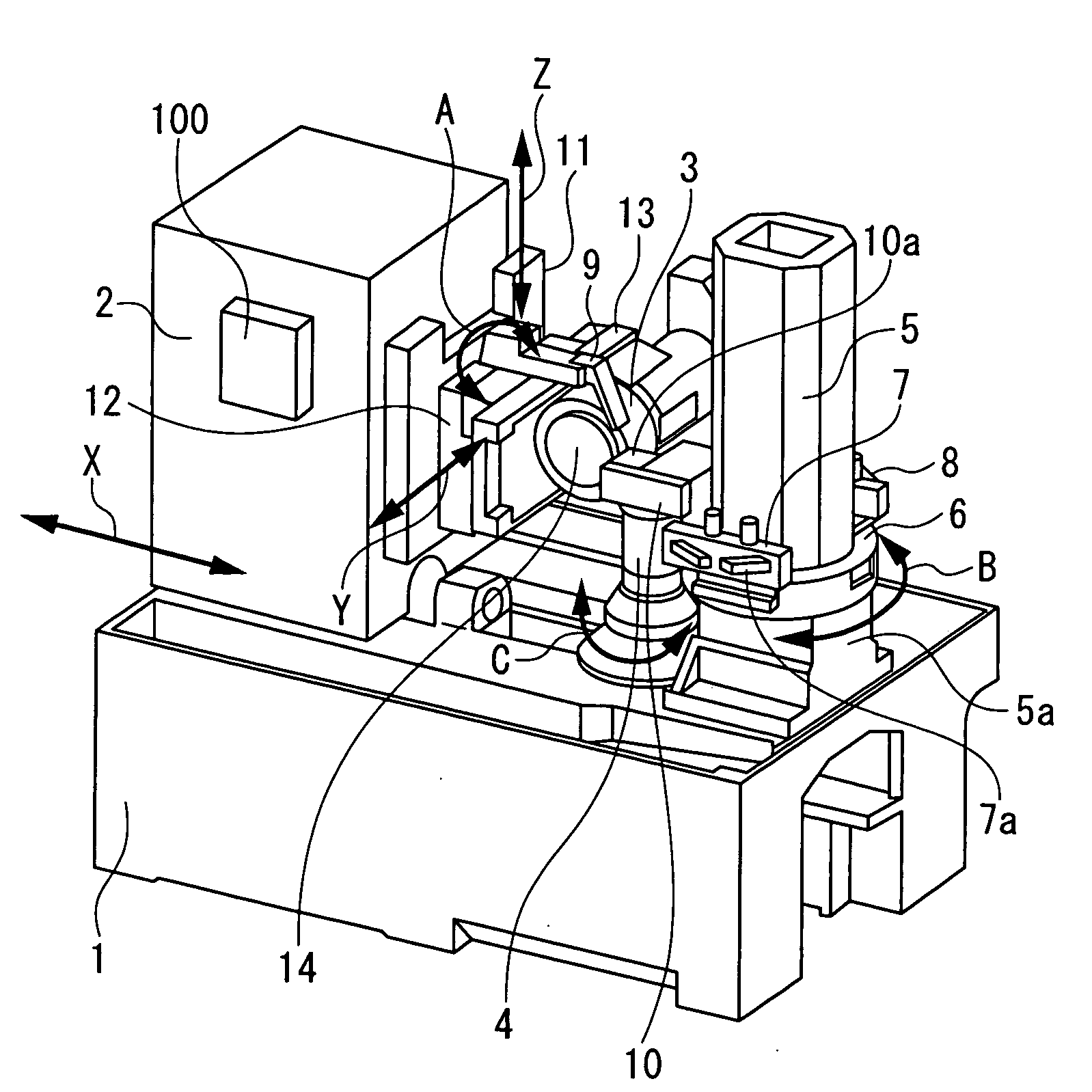

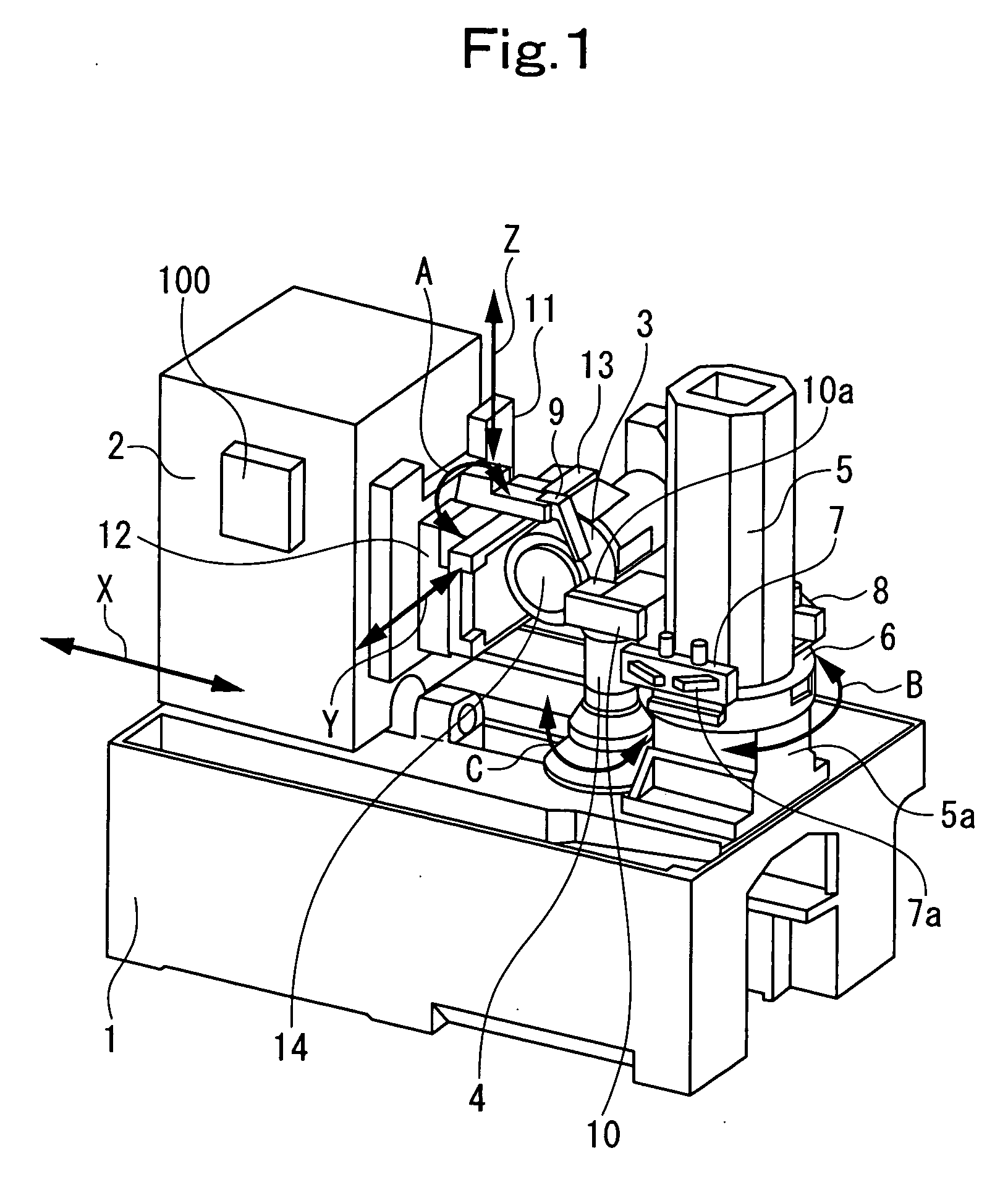

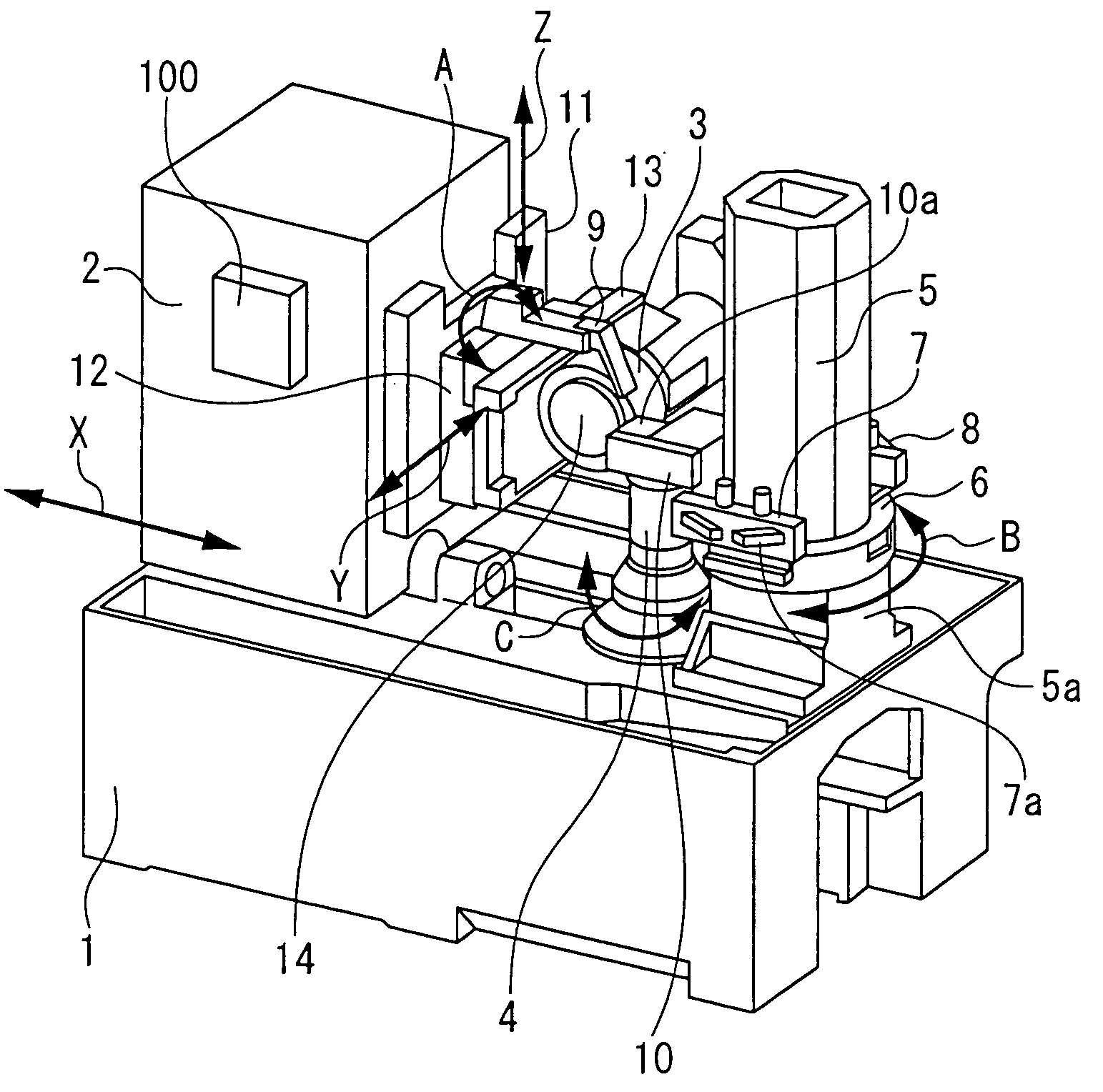

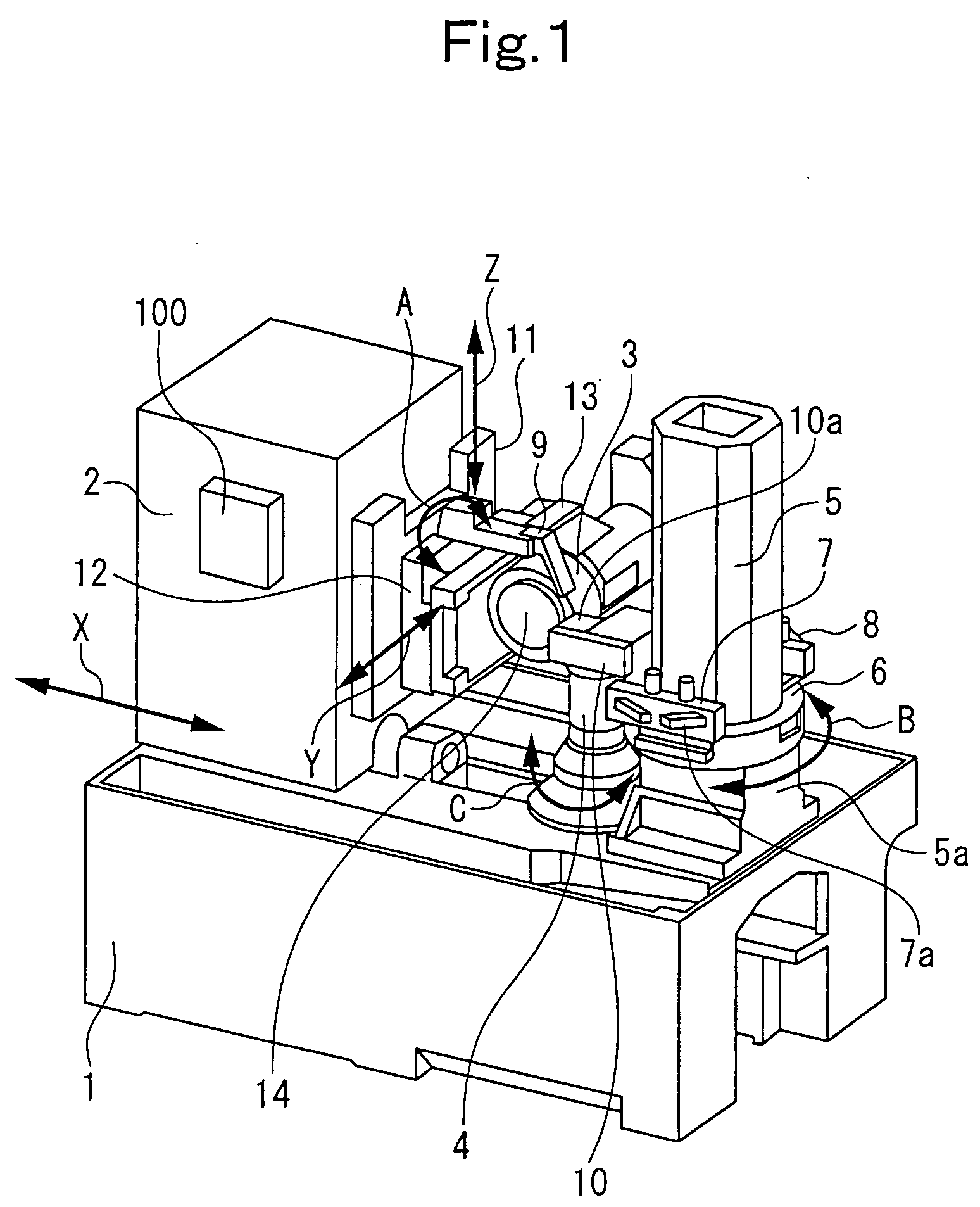

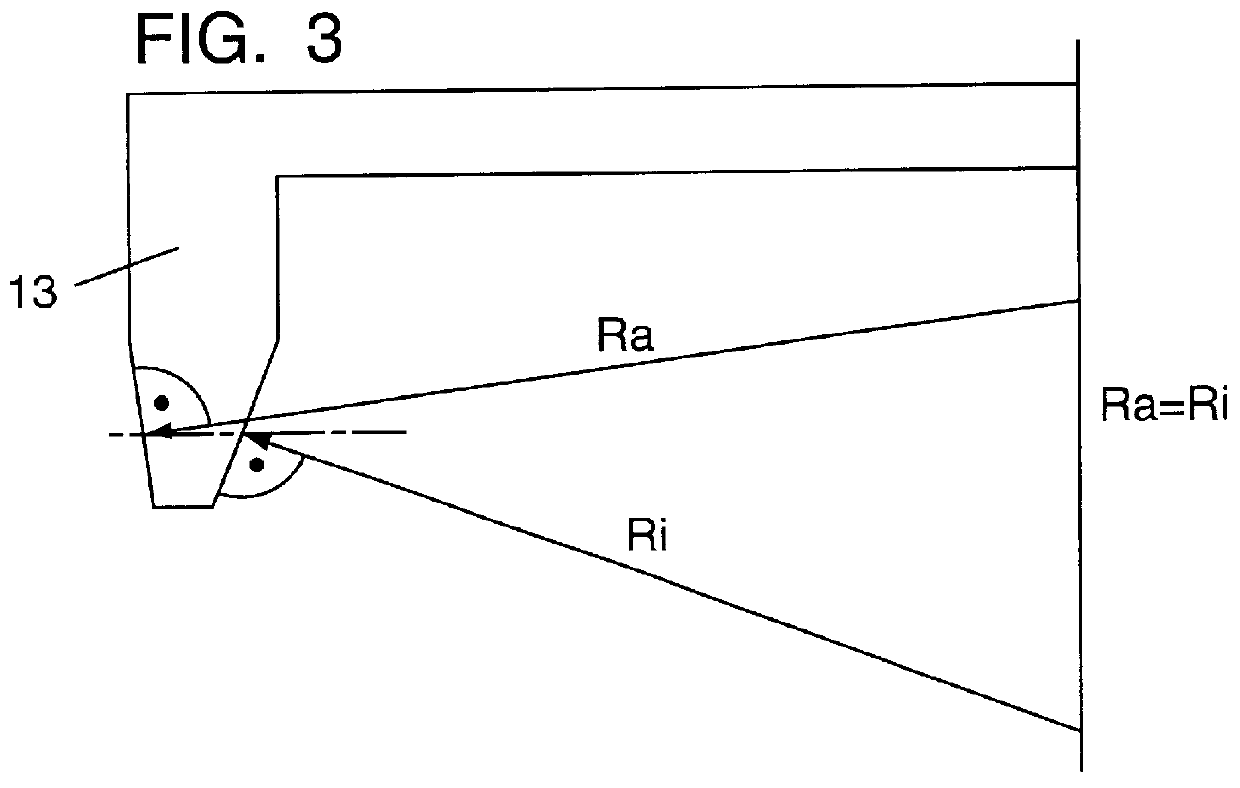

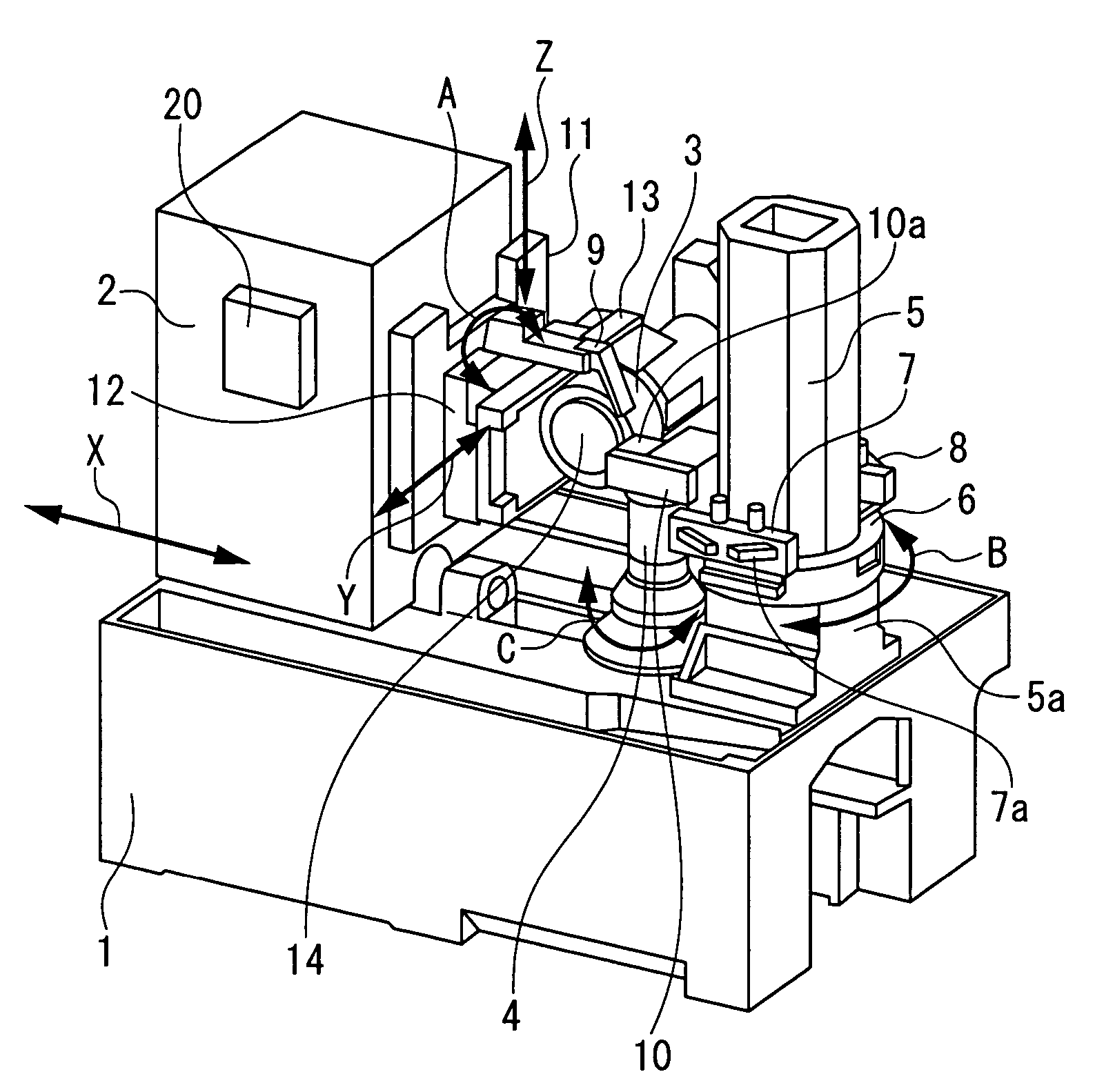

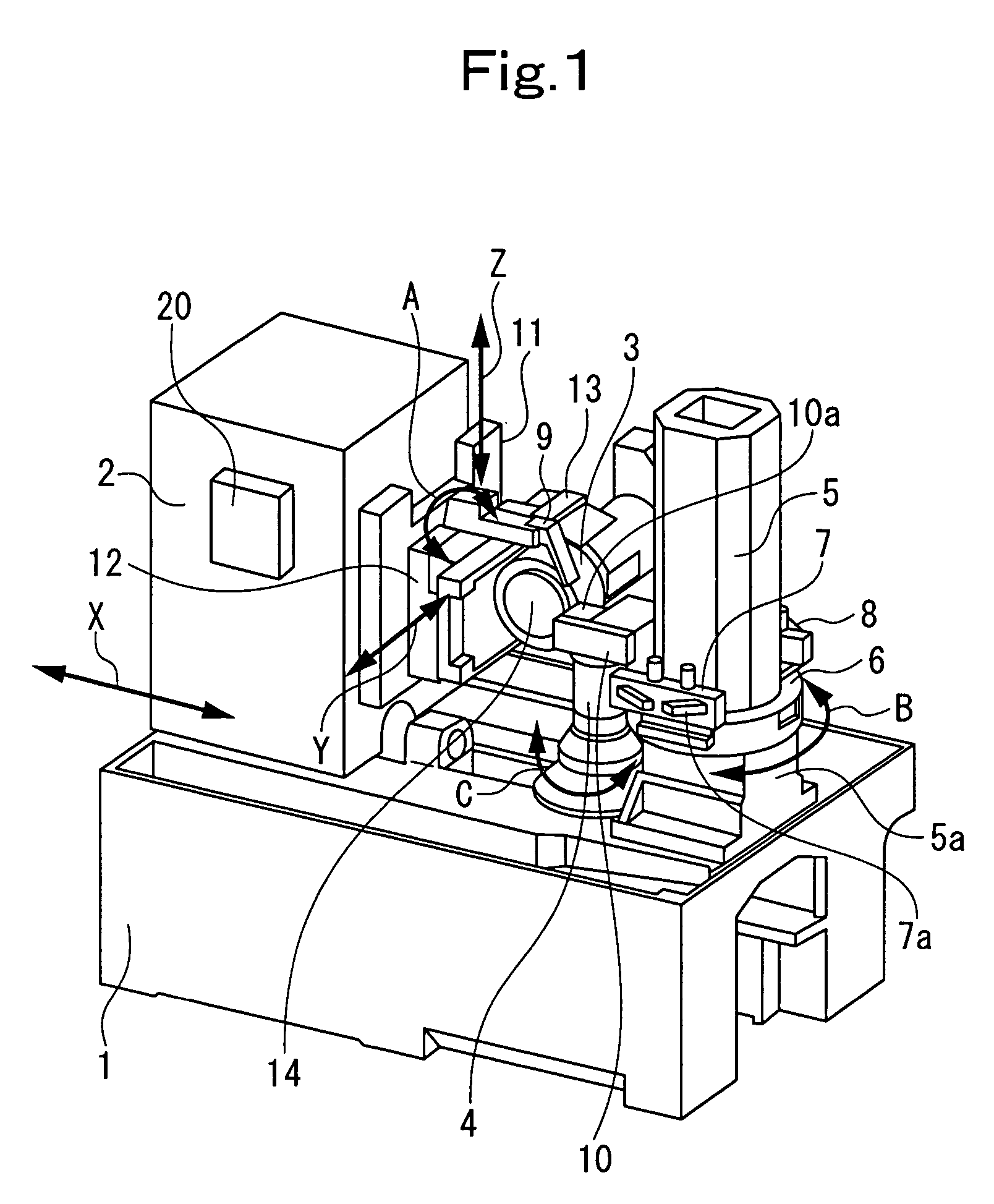

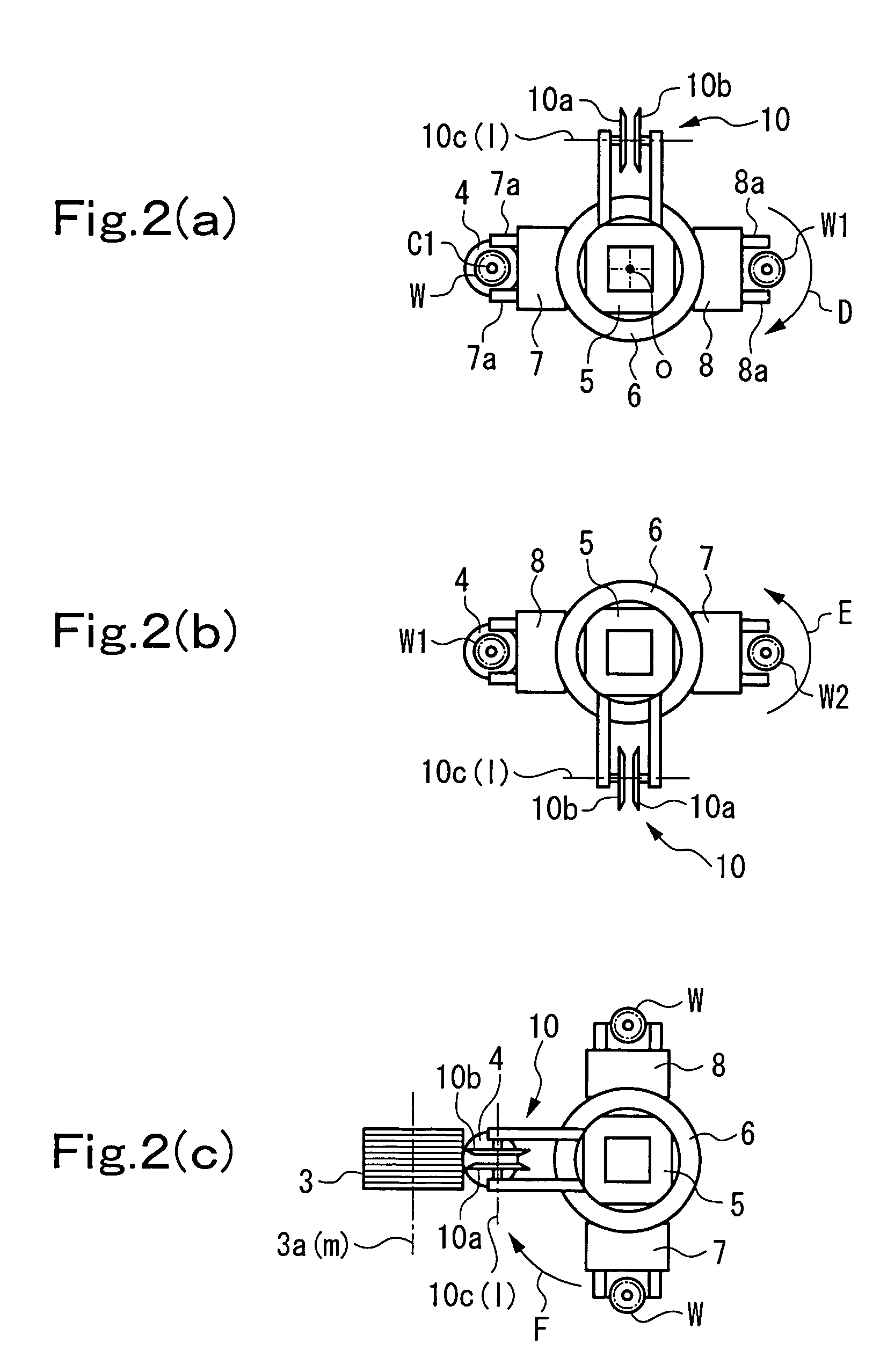

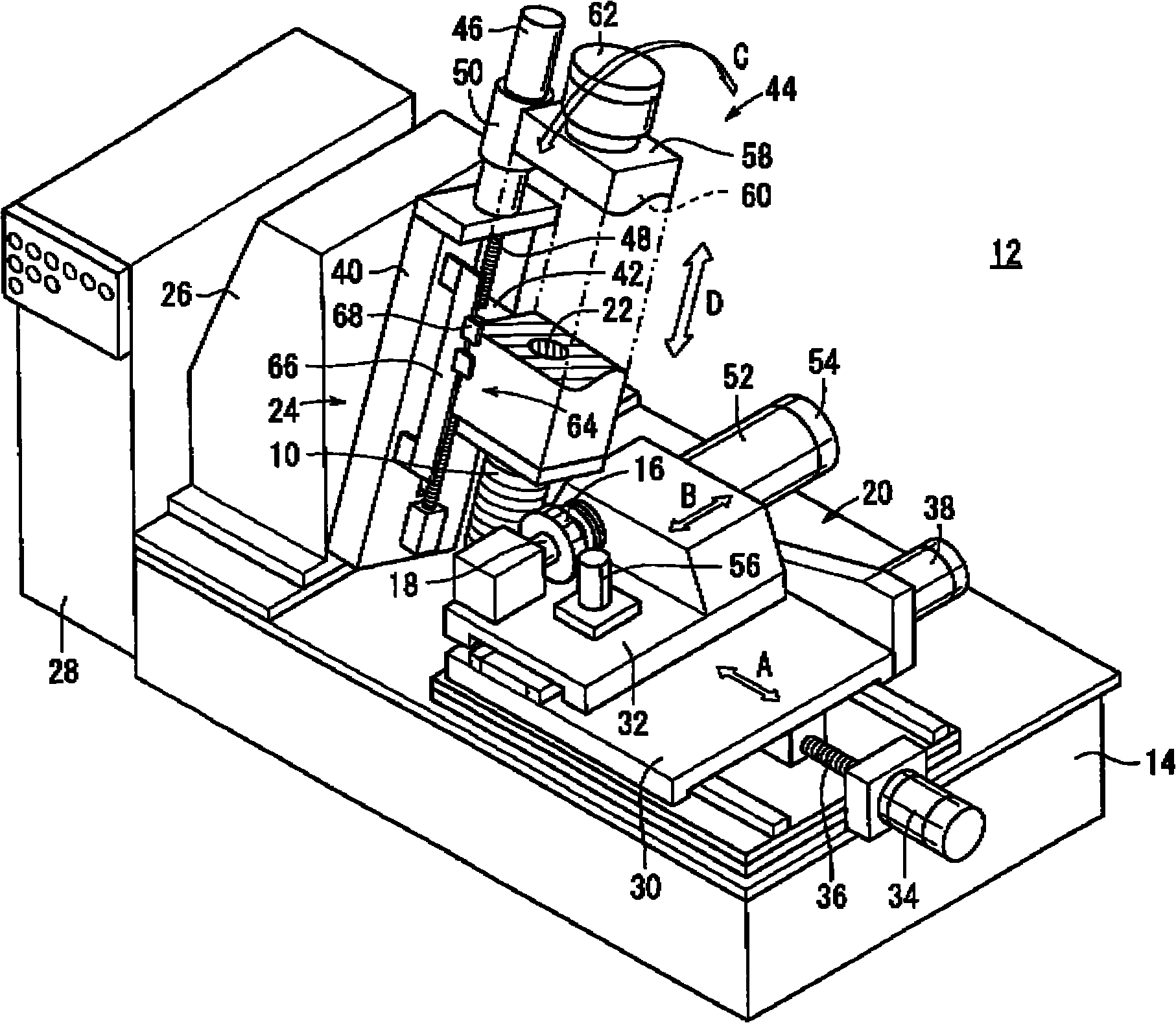

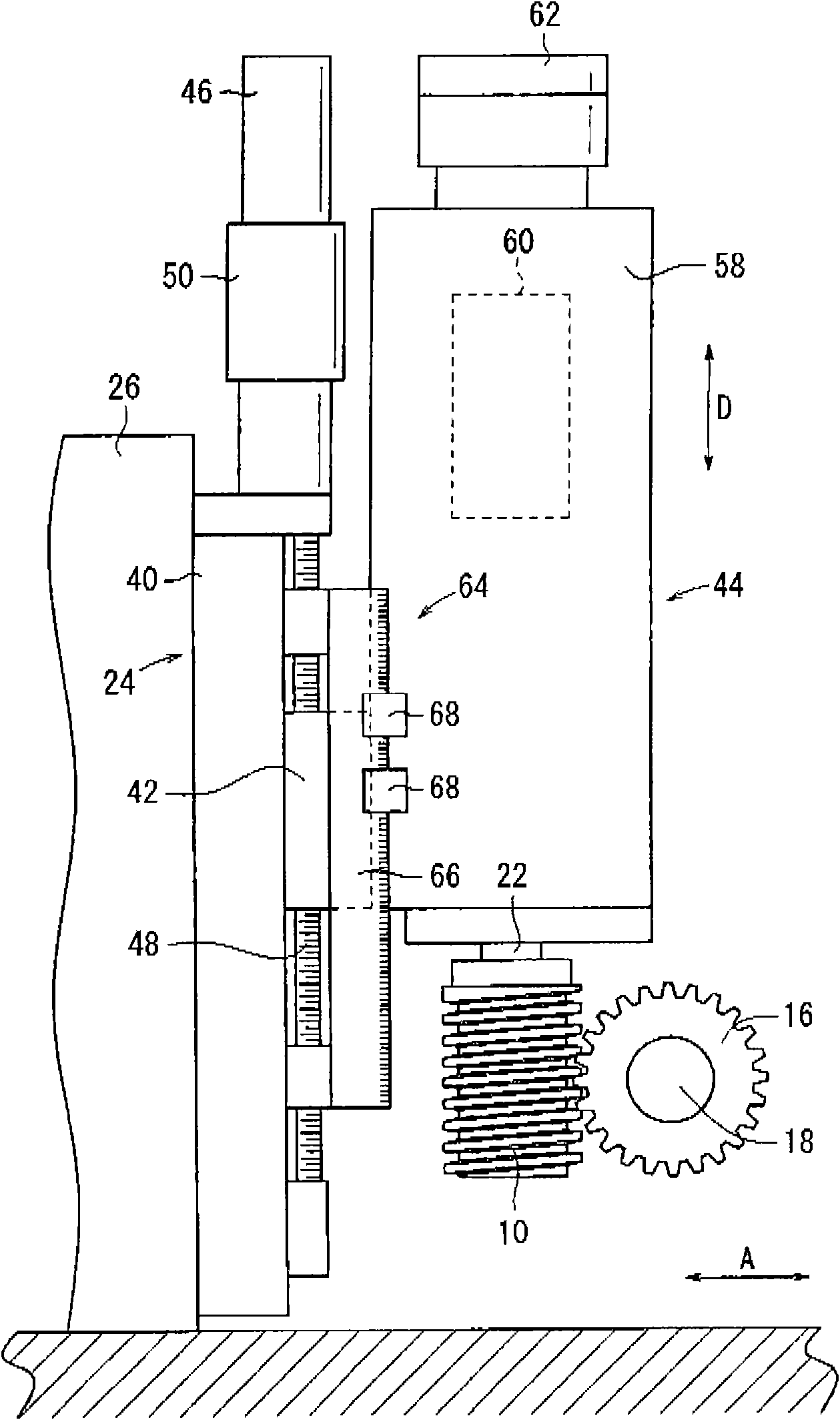

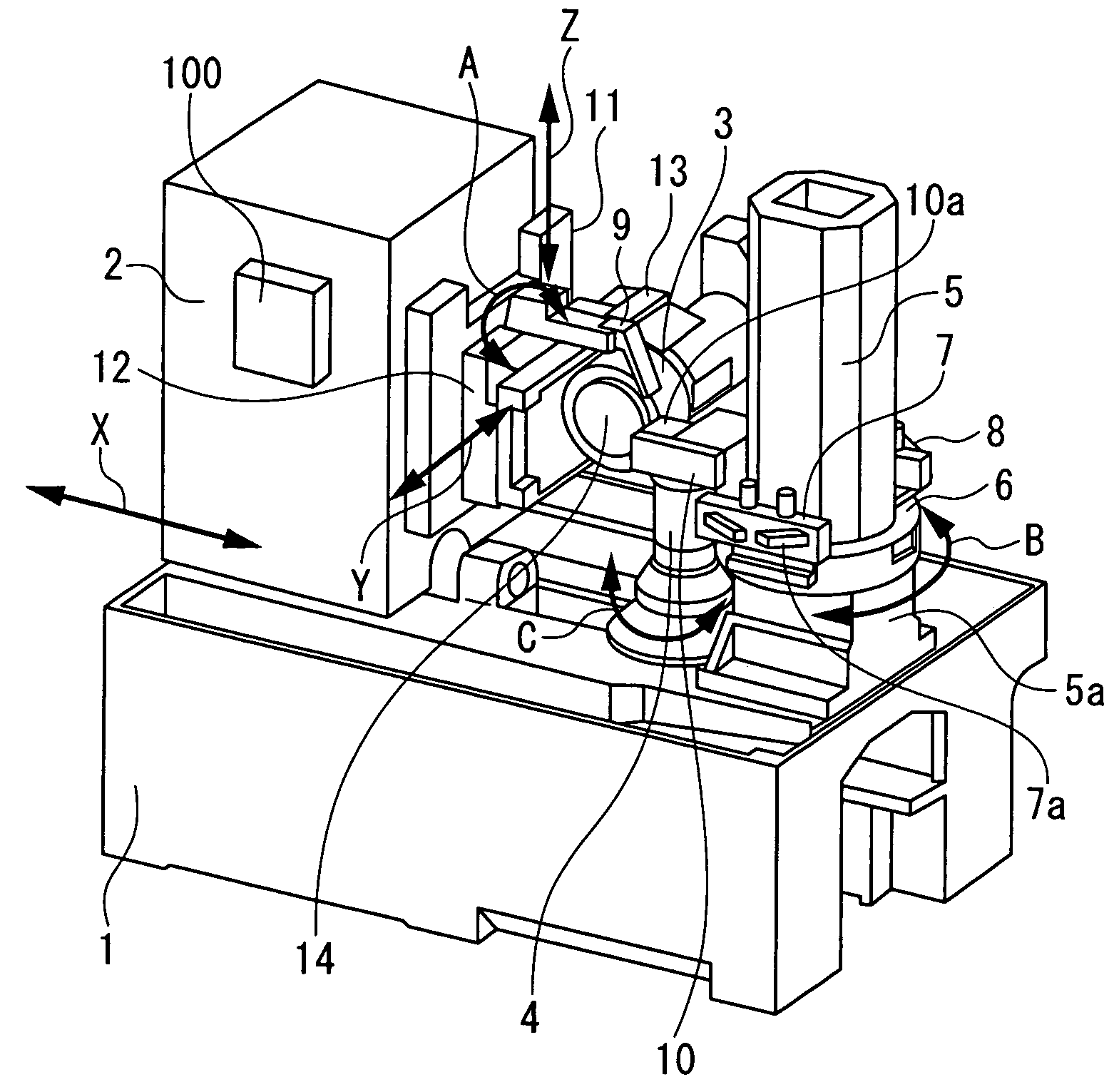

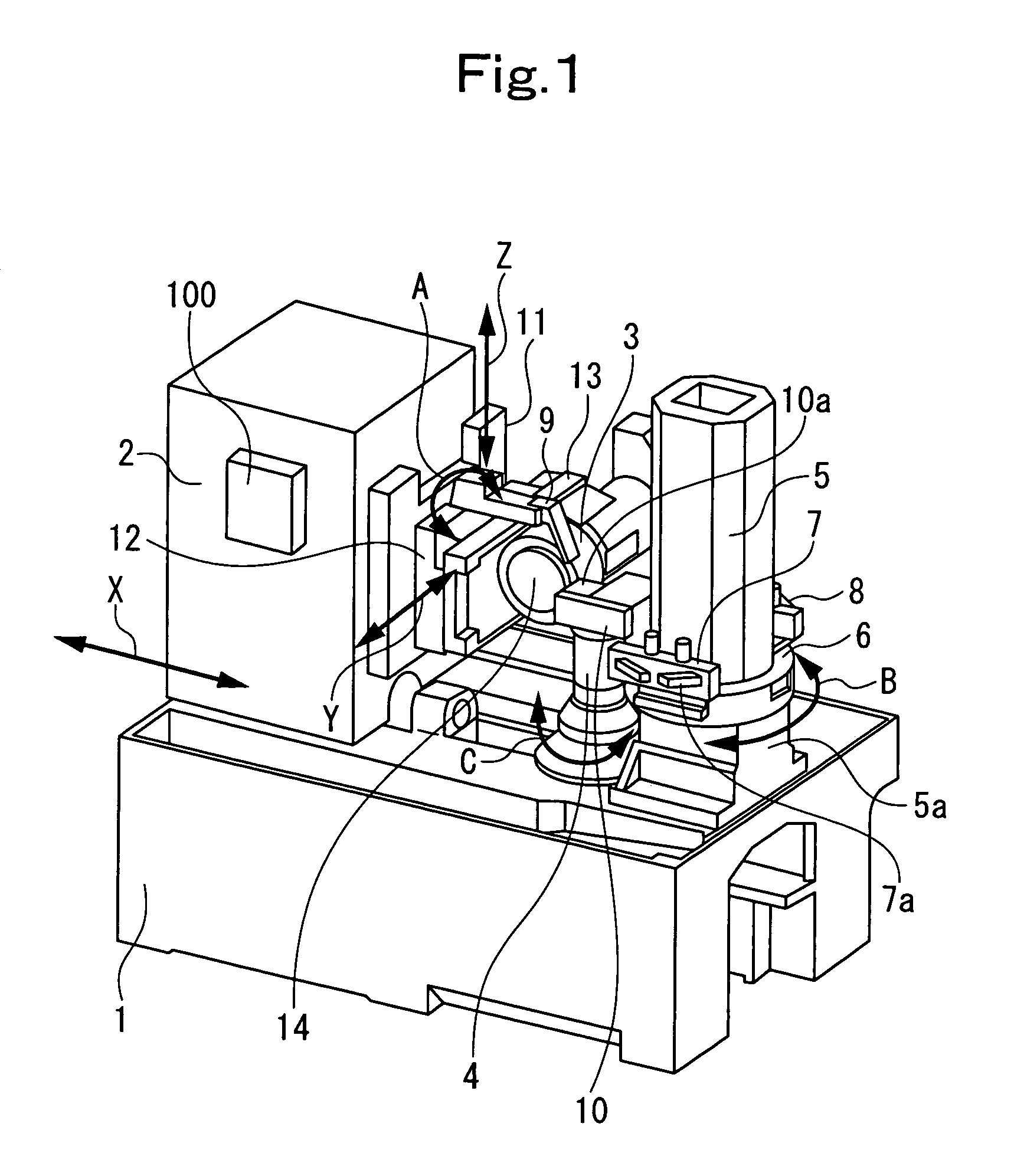

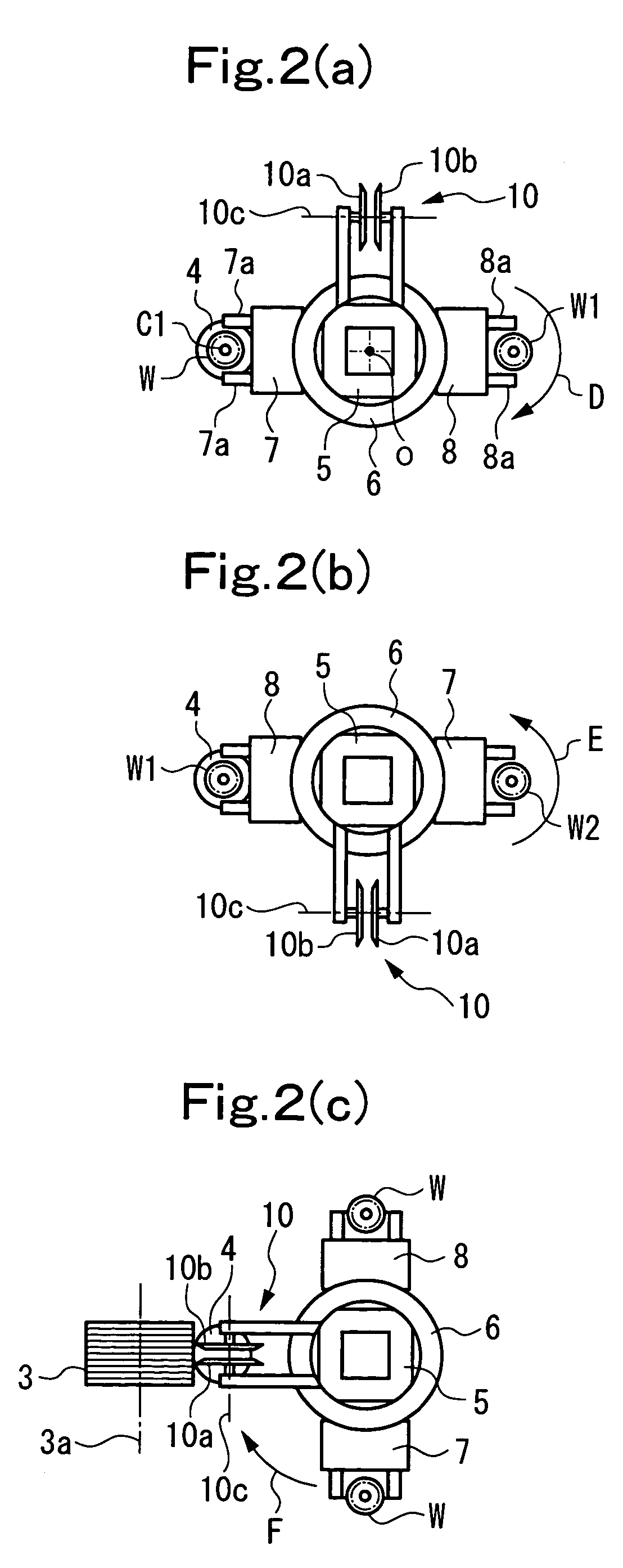

Gear grinding machine, method for dressing threaded grinding wheel and method for grinding work

ActiveUS20070202774A1Easy to retouchGrinding drivesAbrasive surface conditioning devicesGear grindingVertical plane

A gear grinding machine, a method for dressing a threaded grinding wheel, and a method for grinding a work are disclosed. A dressing tool is rotated in a vertical plane, with its position being fixed. The position of a threaded grinding wheel is NC-controlled, whereby the dressing tool is brought into contact with the starting point of the thread of the threaded grinding wheel at a somewhat lower surface of the circumferential surface of the threaded grinding wheel and, in accordance with the rotation of the threaded grinding wheel, the position of contact of the dressing tool with the threaded grinding wheel is moved along the circumferential surface of the threaded grinding wheel.

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

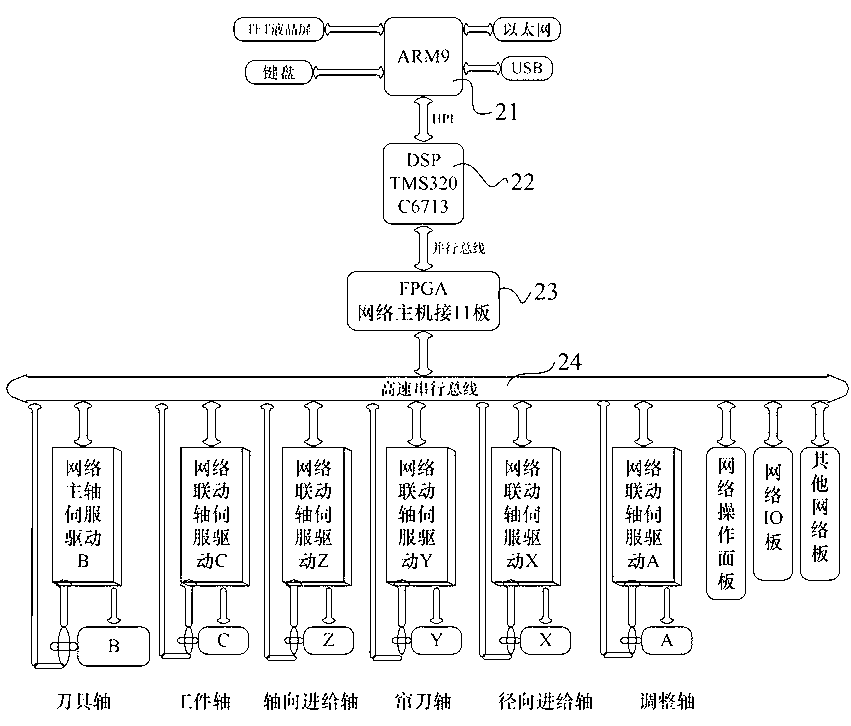

Numerical control generating gear grinding machine and numerical control device thereof and driving method

ActiveCN101332524AReduce failureLow failure rateLarge fixed membersMetal working apparatusNumerical controlGear grinding

The invention discloses a numerical control generating gear grinding machine, a numerical control device of the generating gear grinding machine and a driving method of the generating gear grinding machine. In the invention, the numerical control device respectively controls a motor to drive a sliding block of a work bench to make rectilinear motion and drive the work bench to make reciprocating circumferential swing, that the motor drives the work bench to make reciprocating circumferential swing by virtue of a multistage mechanical drive mechanism is not needed, thus no mechanical drive error caused by the processing precision and installation precision of the drive part exists in the generating motion of a gear to be processed driven by the sliding block of the work bench and the work bench, and the processing precision of the generating gear grinding machine is further improved; by replacing a great number of mechanical drive mechanisms with the motor, the fault probability of the generating gear grinding machine is greatly reduced.

Owner:SIEMENS FACTORY AUTOMATION ENG

Gear grinding machine

To correct the tooth profile error of a ground gear, the wheel angle of a threaded grinding wheel is modified by dressing the threaded grinding wheel by a dressing device. To correct the helix form deviation of a ground gear, namely, to modify the helix angle of the gear, synchronization between the moving motion in the Z-direction of the threaded grinding wheel and the rotary motion of a table for installation of the gear is adjusted. When the helix form deviation is corrected by adjustment of the synchronization, a tooth profile change inevitably occurs. In consideration of the tooth profile change, correction of the tooth profile error by dressing is made.

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

Method of grinding the teeth of spiral-toothed bevel gear wheels

PCT No. PCT / EP96 / 02020 Sec. 371 Date Nov. 5, 1997 Sec. 102(e) Date Nov. 5, 1997 PCT Filed May 10, 1997 PCT Pub. No. WO96 / 35541 PCT Pub. Date Nov. 14, 1996Disclosed is a method of grinding bevel gear teeth in an intermittent indexing process using a single grinding wheel provided with different bevel angles ( alpha ) to produce the desired grinding wheel radii (R): one flank is machined during grinding in downward generation as far as a first turning point, another flank is produced in upward generation as far as a second turning point, and machine settings are so adjusted in the turning points as to ensure a correct pressure angle and correct flank topography during the generating process, irrespective of the different bevel angles ( alpha ). The process combines the advantages of the known completing process, by which both flanks can be ground at the same time at the cost of imposing a particular wheel body geometry with conical teeth, with those of the known two-track process for grinding both flanks with a double grinding head, by which various additional correction factors can be introduced to optimize the flank shape for convex and concave flanks.

Owner:KLINGELNBERG AG

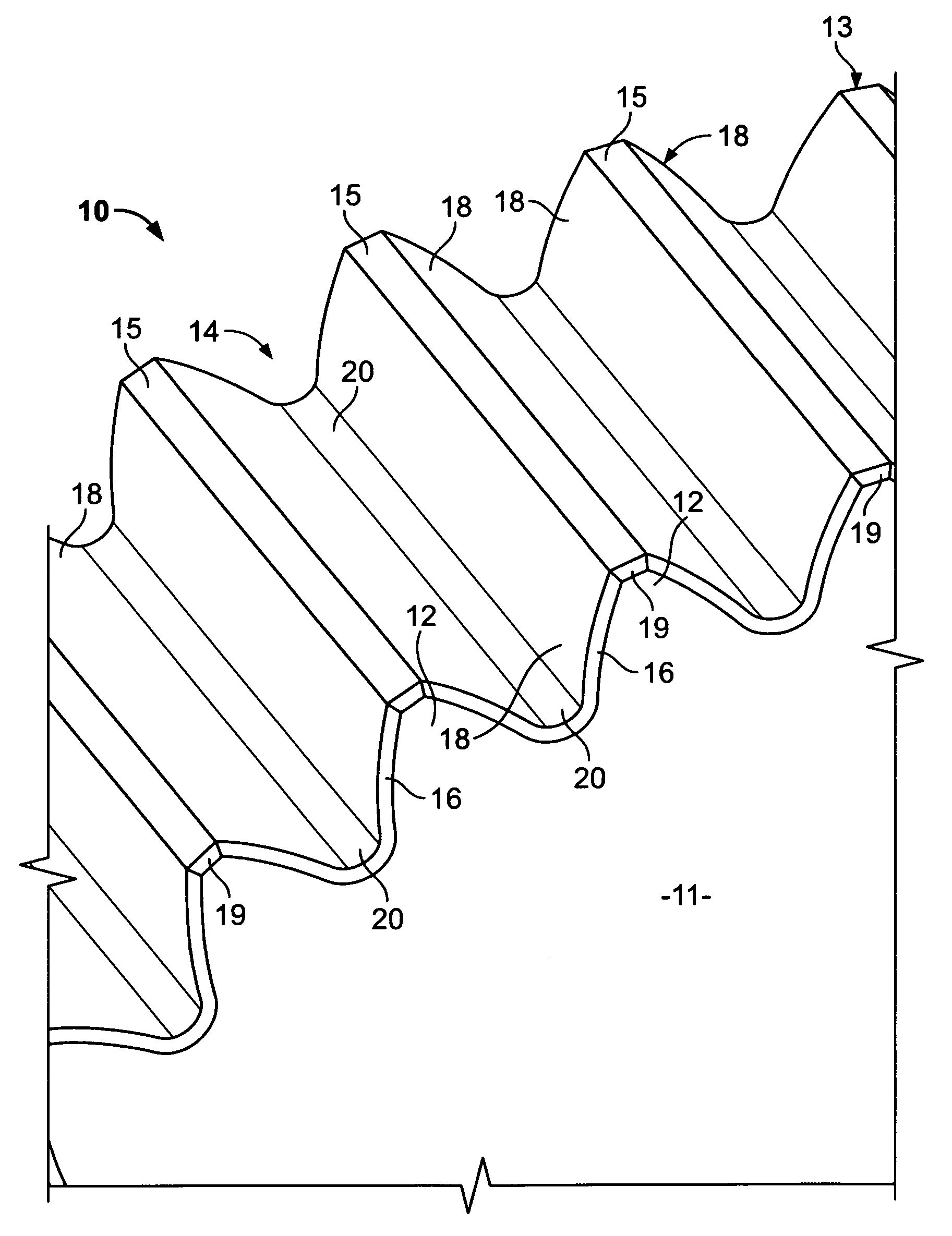

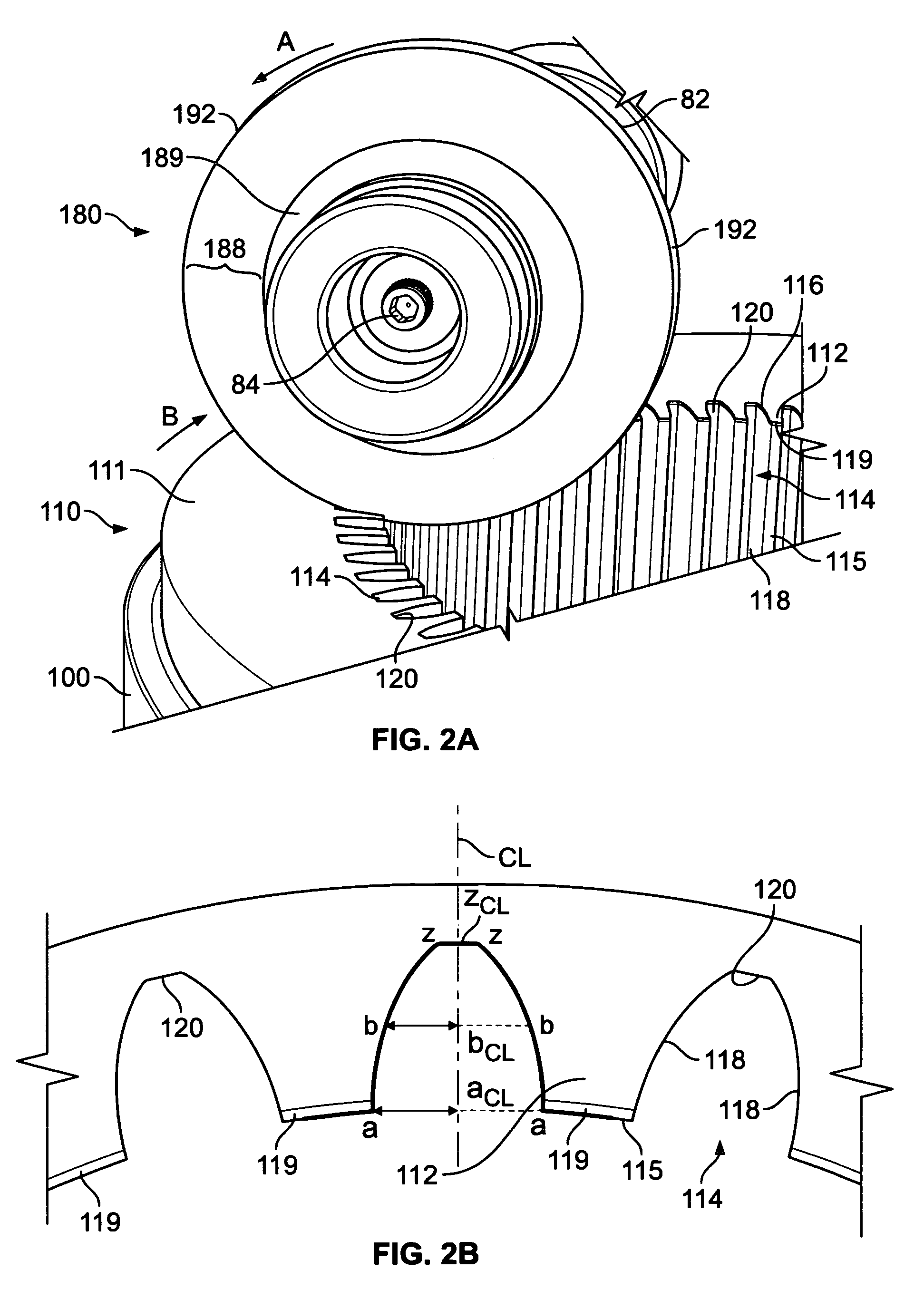

Chamfering cutting tool or grinding wheel and method of making and use thereof

InactiveUS7377731B1Eliminating time consuming hand operations, scrap, rework and the operatorGear teeth manufacturing toolsGear teethGear grindingGear wheel

A work piece having edges comprising teeth, slots, dovetail, keyway or other irregularly shaped artifacts, can be provided with a uniform chamfer around the periphery of the work piece by bringing a grinding wheel or cutter in one single down feed at indexed intervals. The shape or profile of the grinding wheel or cutter is formed from an algorithm depending on the shape and dimensions of the work piece artifacts, such as gear teeth, etc., to provide the uniform chamfer at each slot of, for example, an internal or external gear wheel. A method of providing such a chamfer on irregularly shaped artifacts comprises forming a gear grinding wheel from the dimensions of the desired chamfer, and providing a chamfering tool or grinding wheel in accordance with an algorithm desired for the required chamfer, then bringing the gear chamfering tool in proximity to, and in contact with the edges of the work piece so as to produce a uniform chamfer on the sides and back edge. The method may include a step of moving of the cutter or grinding wheel from one side to another and tilting the cutter or grinding wheel to chamfer the back side.

Owner:ARVIN JOSEPH L

Gear grinding machine

A gear grinding machine comprises: a moving mechanism rotatably mounted with a threaded grinding wheel, and arranged to move the threaded grinding wheel along directions of X, Z, and Y, and to turn the threaded grinding wheel in a Y-Z plane; an NC device for controlling the position of the threaded grinding wheel; and a rotary dressing device having a dressing tool which contacts the flanks of the threads of the threaded grinding wheel, while rotationally driven, to perform dressing. The NC device numerically controls the moving mechanism so as to adjust the positions in the directions of X and Z, and the turning position in the Y-Z plane of the threaded grinding wheel, while keeping contact of the dressing tool with the flanks of the threads of the threaded grinding wheel, in order to modify the wheel pressure angle of the threaded grinding wheel.

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

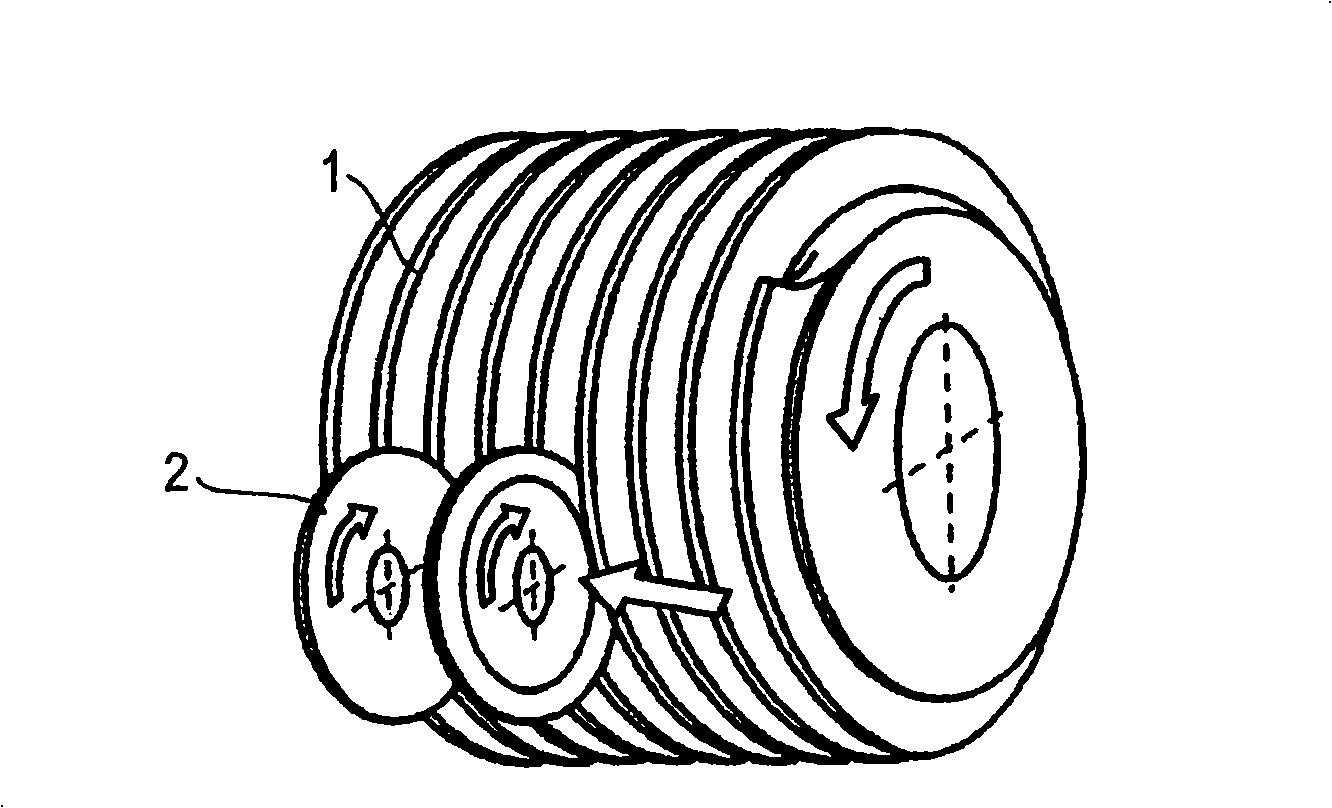

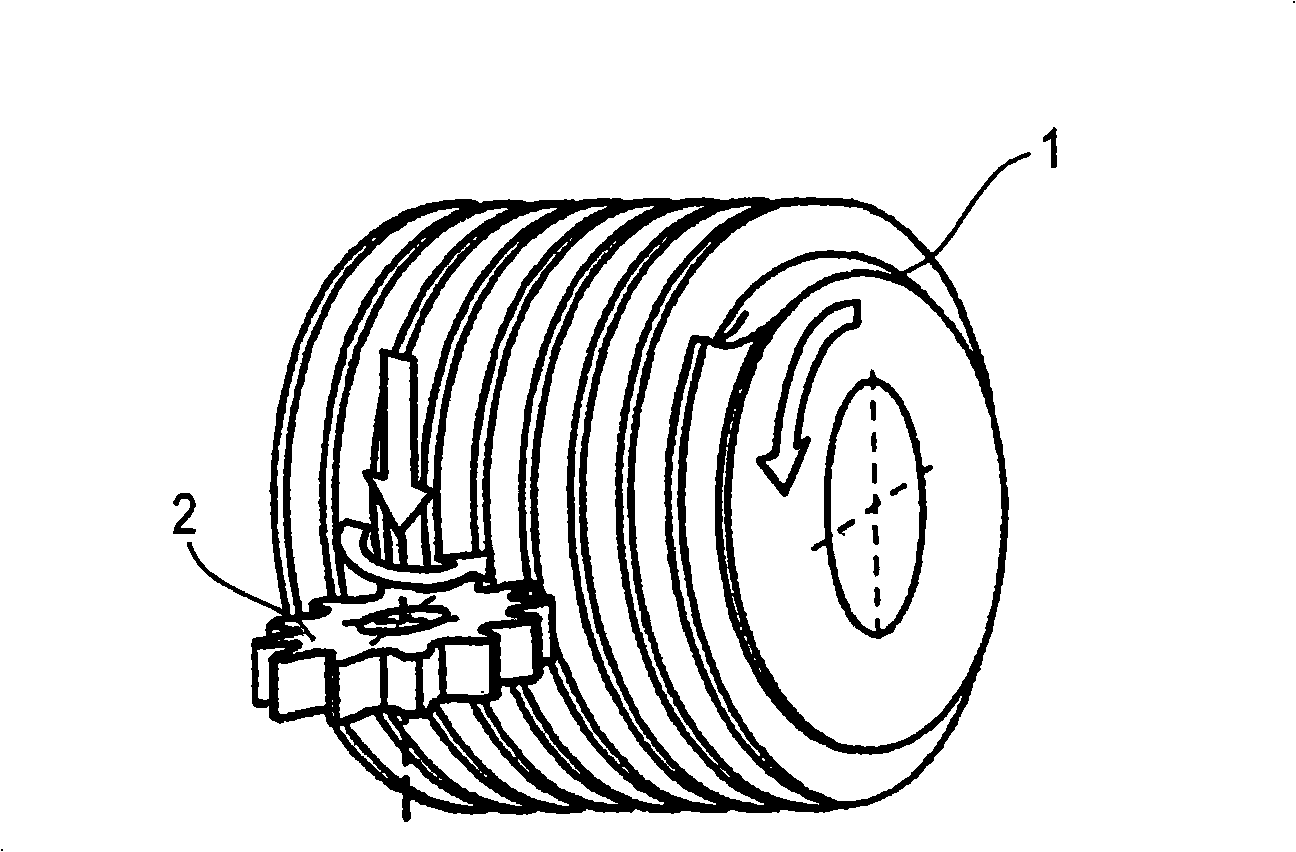

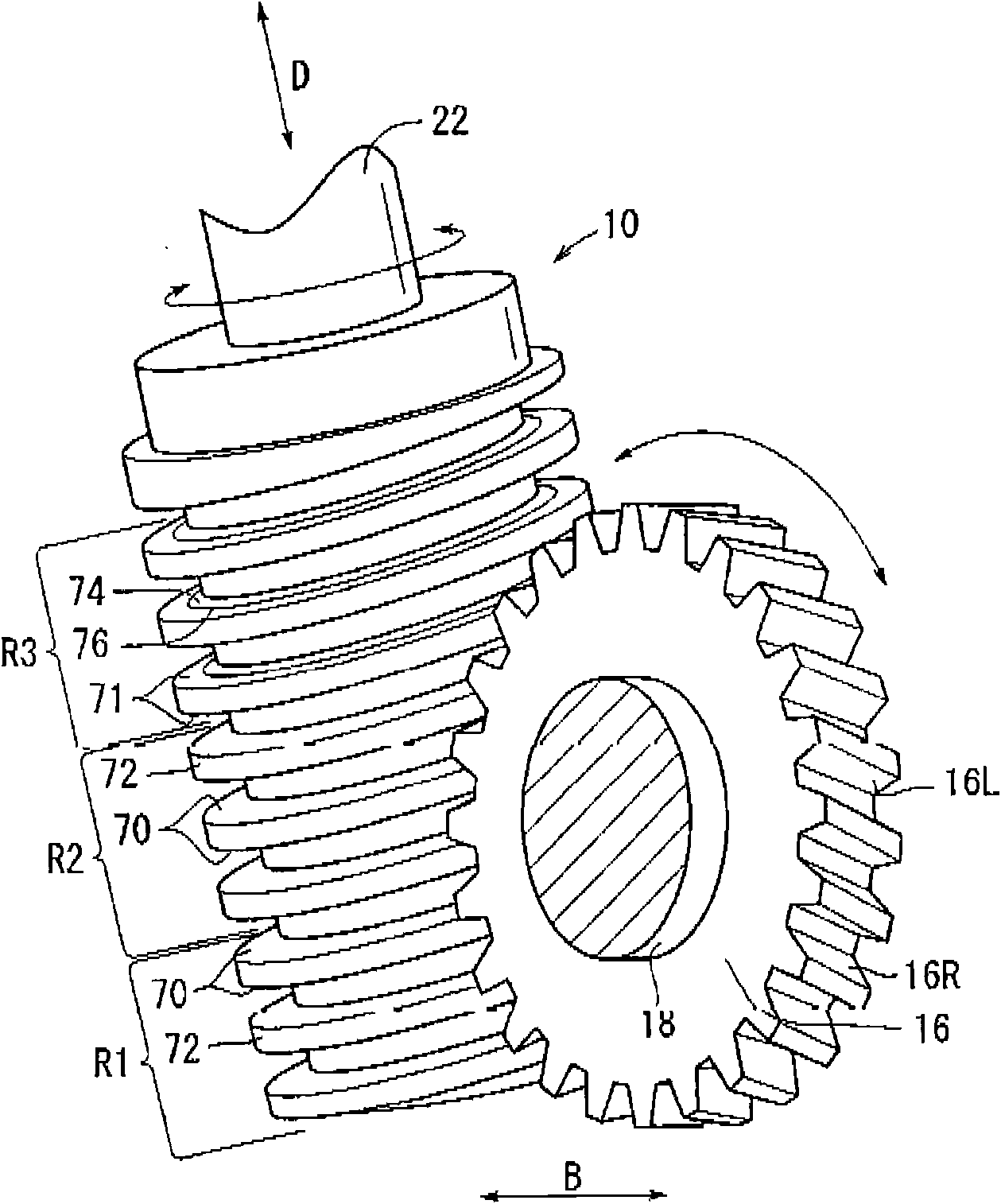

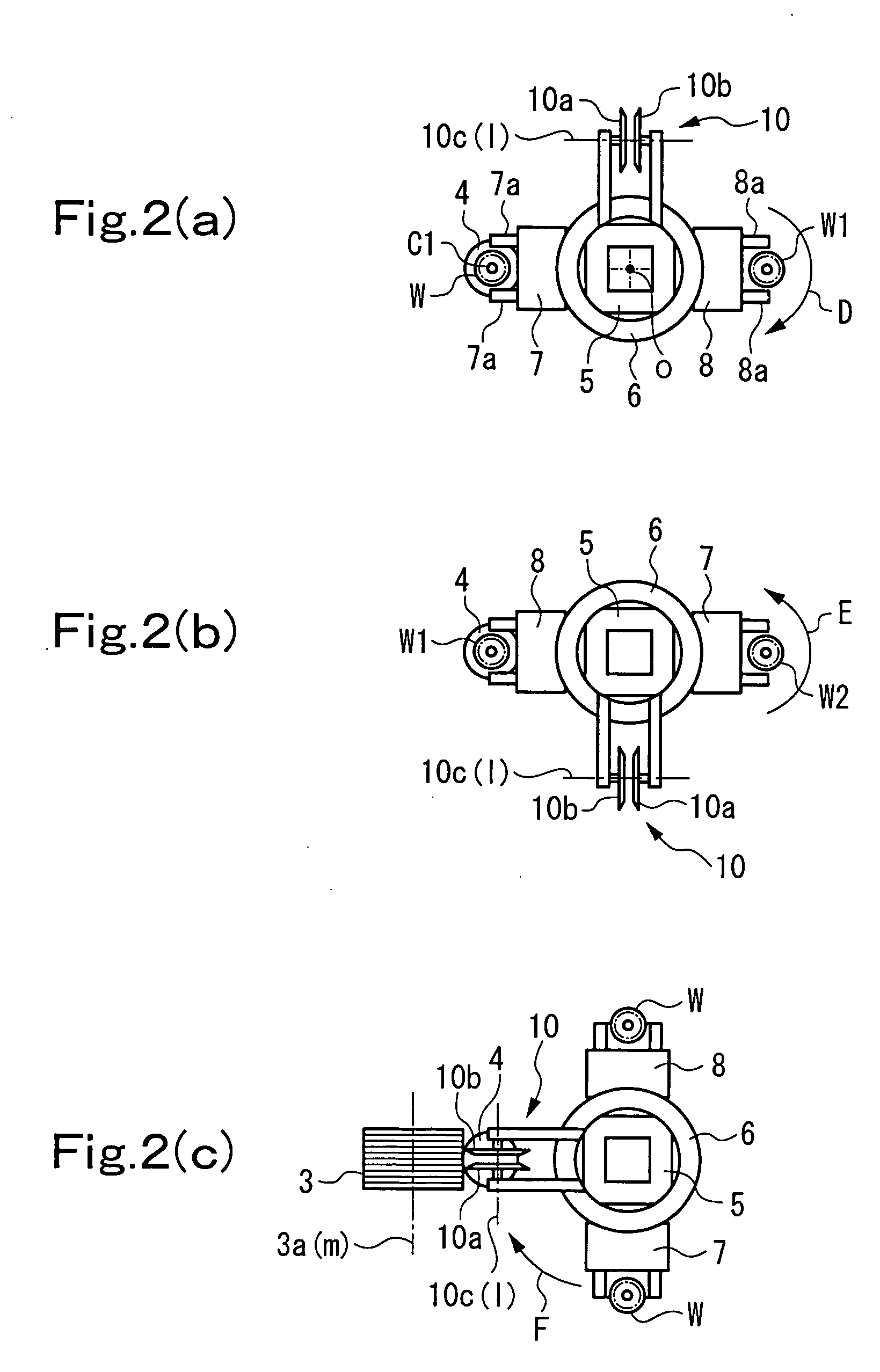

Gear grinding tool and method of using gear grinding tool

InactiveCN102029444AExtended service lifeGear teeth manufacturing toolsGear teethGear grindingEngineering

The invention provides a gear grinding tool and a method of using the gear grinding tool.The gear grinding tool (10) comprises a helical tooth (72) with grinding faces (70, 71) on the surfaces thereof.According to the gear grinding tool (10), tooth flanks of gears (16) as workpieces are ground by the grinding faces (70, 71).The grinding face (70) comprises a rough grinding face (74) for performing a rough grinding process.The grinding face (71) comprises a rough grinding face (74) for performing a rough grinding process.The rough grinding face (74) comprises a forming line (76) for performinga fine finishining process.

Owner:HONDA MOTOR CO LTD

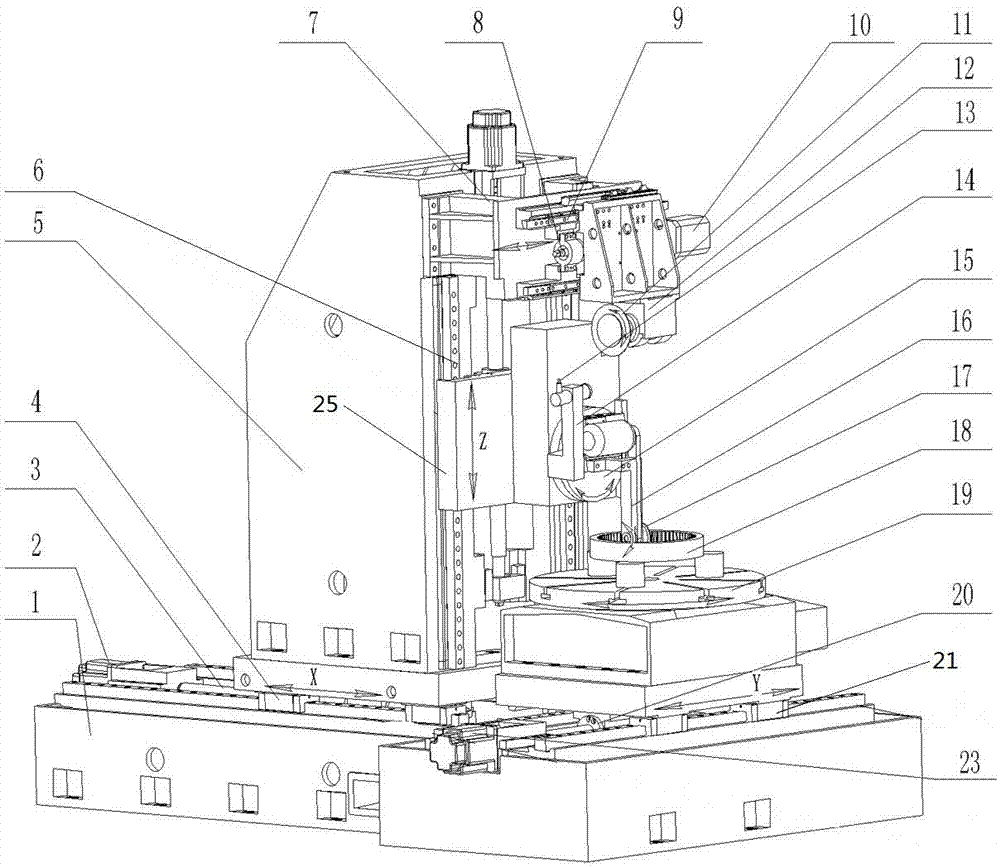

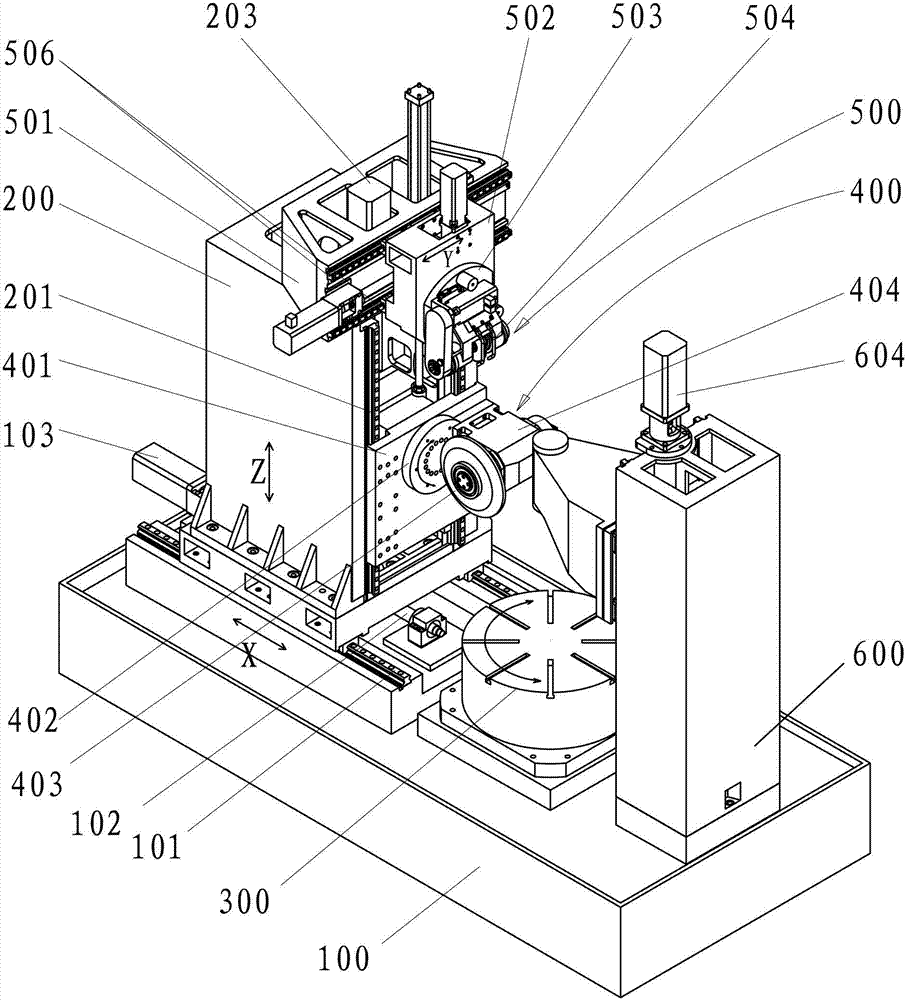

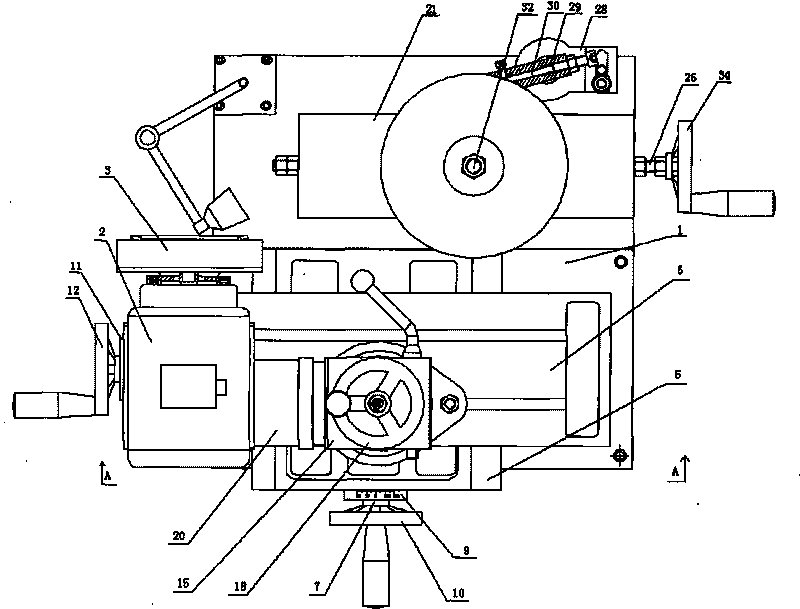

Gear grinding machine with numerical control forming grinding wheel

ActiveCN102814553AHigh precisionImprove processing efficiencyAbrasive surface conditioning devicesGear-cutting machinesGear grindingNumerical control

The invention discloses a gear grinding machine with a numerical control forming grinding wheel; the grinding wheel comprises a stand which is provided with a horizontal sliding guide rail and a longitudinal sliding guide rail; a work piece rotary part is slidably assembled on the longitudinal sliding guide rail in a guiding way; a vertical column is slidably assembled on the horizontal sliding guide rail in a guiding way; and a grinding mechanism which is used for grinding a processed gear is slidably assembled on the vertical column in a guiding way along a vertical direction. The gear grinding machine with the numerical control forming grinding wheel also comprises a grinding wheel forming and finishing device which finishes a grinding wheel; the grinding wheel forming and finishing device comprises a finishing device base which is independently assembled on the vertical column above the grinding mechanism and a finishing wheel with the axis extending along a longitudinal direction; and the finishing wheel is slidably assembled on the sliding guide rail of a longitudinal finishing device of the finishing device base through a finishing wheel frame which extends outwards in a guiding way. According to the gear grinding machine with the numerical control forming grinding wheel, the problems of the prior art that the processing surface of the grinding wheel cannot be finished to be consistent with the shape of the gear slot of the processed gear, and the precise of the processing gear and the processing efficiency of the gear with a large specification are affected are solved.

Owner:洛阳科大越格数控机床有限公司

Gear grinding machine, method for dressing threaded grinding wheel and method for grinding work

ActiveUS7341501B2Easy to retouchGrinding drivesAbrasive surface conditioning devicesGear grindingVertical plane

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

Low oil mist gear grinding oil composition

ActiveCN101701163AHigh viscosity indexExcellent antioxidant stabilityAdditivesBase-materialsGear grindingEcological environment

The invention discloses a low oil mist gear grinding oil composition, belonging to the field of metalworking liquid. The composition according to the invention is composed of the following components by weight percent: 70-81% of refined mineral oil, 10-20% of synthesized fatty acid ester oiliness agent, 5-10% of sulfulrized fatty acid ester, 0-3% of phosphate, 0.3-1.0% of oil mist inhibitor and 0.01-0.1% of antifoaming agent; in the composition, the polymer of oil mist inhibitor is innovatively introduced by means of the coordinate proportioning of the refined mineral oil and the fatty acid ester oiliness agent as main component, thus enhancing lubricity, quickening the sedimentation of the oil mist and effectively reducing the concentration of the oil mist in the operating environment, and in addition, lubricating agent and anti-abrasive agent are scientifically proportioned and used, so the composition contains no chlorine which does harm to ecological environment and human body, has strong universality, can be used for processing black and non-ferrous metals and is non-corrosive to copper, therefore, the composition according to the invention not only imparts excellent processing performance to gear grinding oil, but also effectually improves oil mist environment, which is favorable for environmental protection and body health of operating staff.

Owner:BOER TECH WUHAN

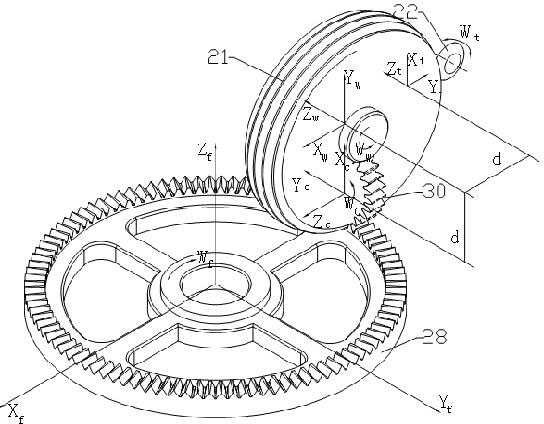

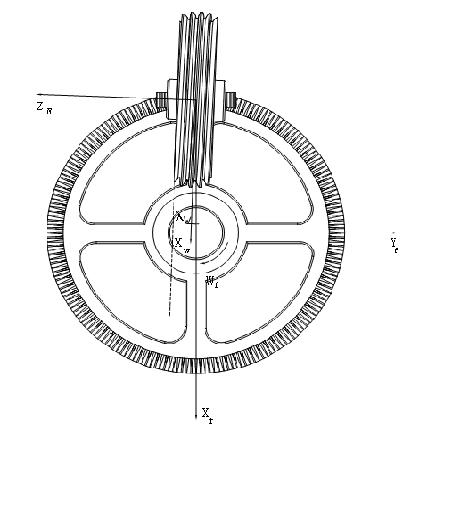

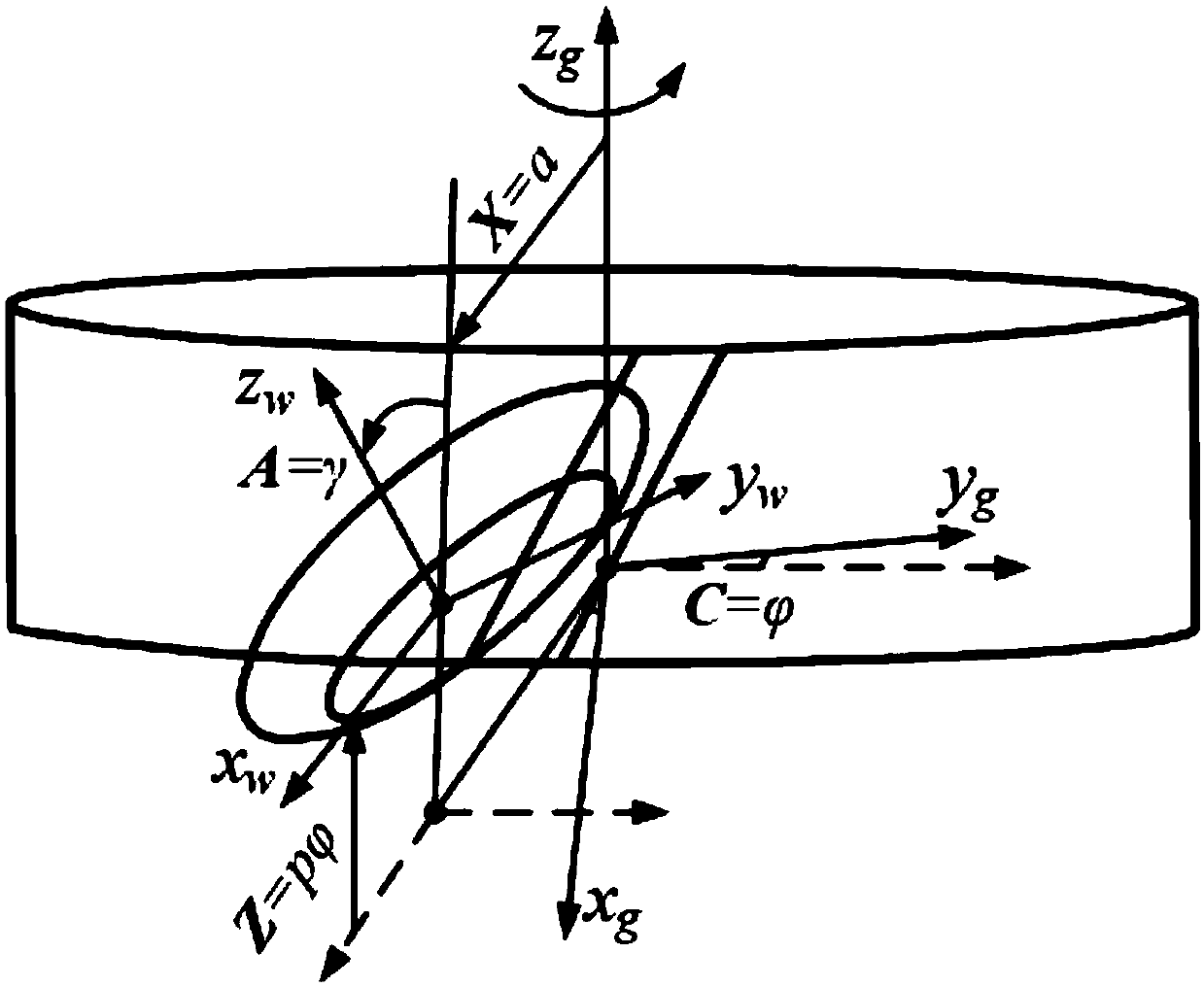

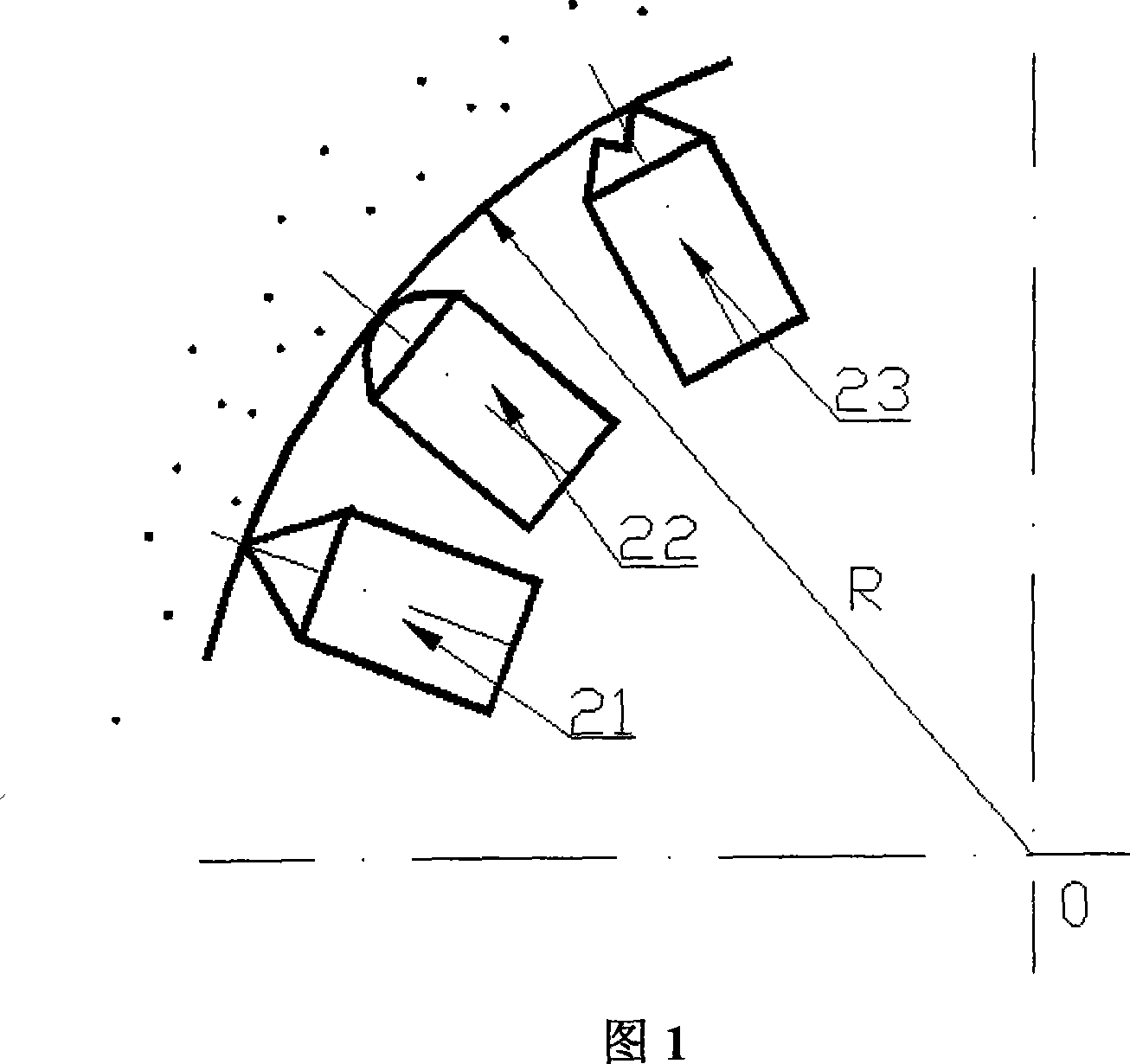

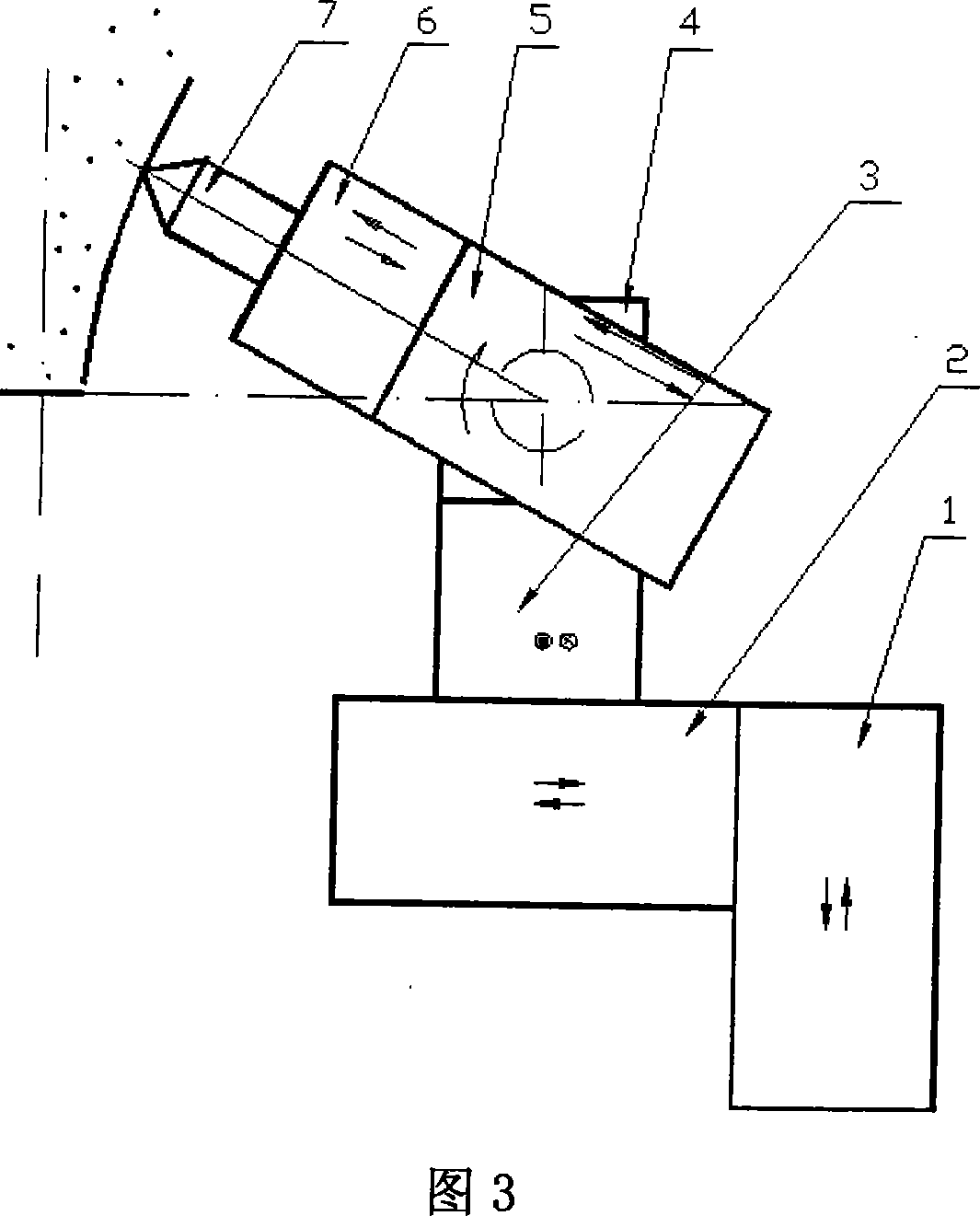

Face gear grinding method based on worm grinding wheel

InactiveCN102423820AImprove performanceAbrasive surface conditioning devicesGear teethGear grindingGear wheel

The invention provides a face gear grinding method based on a worm grinding wheel. A face gear 28, the worm grinding wheel 21, a straight gear 30 and a grinding wheel 22 for finishing a worm are adopted in the method. The face gear grinding method is characterized in that during the machining process, the face gear 28 rotates around Z-f at a constant rotating speed Wf, the worm grinding wheel 21 rotates around Zw at a constant rotating speed Ww, the straight gear 30 rotates around a Zc axis at a constant rotating speed Wc, and the grinding wheel 22 rotates around an Xt axis at a constant rotating speed Wt. During the rotation process, the tooth surface of the worm grinding wheel can be used for grinding off the tooth surface of the face gear contacted with the tooth surface so as to reach the effect of grinding the face gear; and meanwhile the worm grinding wheel 21 performs linear feed movement along the direction of the tooth width Xf of the face gear until the whole tooth profile of the face gear is completely machined. The face gear grinding method based on the worm grinding wheel provided by the invention has the beneficial effects of realizing high-precision generation of the tooth surface of the face gear, reaching the effect of high-precision machining of the face gear, and improving the comprehensive transmission performance of the face gear.

Owner:唐进元

Numerical control gear grinding machine for formed grinding wheel

ActiveCN102773565ALighten the loadReduce drive (motor) powerAbrasive surface conditioning devicesGear-cutting machinesNumerical controlGear grinding

The invention discloses a numerical control gear grinding machine for a formed grinding wheel. The numerical control gear grinding machine comprises an engine base, a main stand column, a workpiece rotating part, a grinding device and a finishing device, wherein the finishing device comprises a finishing base, a finishing sliding base, a finishing turntable and a finishing wheel, the finishing base is fixedly assembled at the top of the main stand column, the finishing base is provided with a Y-direction finishing guide rail, the finishing sliding base is assembled on the Y-direction finishing guide rail in a matching manner; the finishing wheel is fixedly arranged on the finishing turntable and can rotate along a central axis; and the finishing turntable can be fixedly installed on the finishing sliding base in a rotating manner. The finishing device of the gear grinding machine is installed at the top of the main stand column independently, the bearing weight of the grinding turntable is lightened, the size is also reduced, and the power of the driving (motor) power of the grinding turntable and the driving (motor) power of a Z shaft are reduced; and in the finishing process, the less time is consumed, the production efficiency is high, and the error caused by reciprocating rotation of the grinding turntable ca be reduced.

Owner:威海广宇大成数控机床有限公司

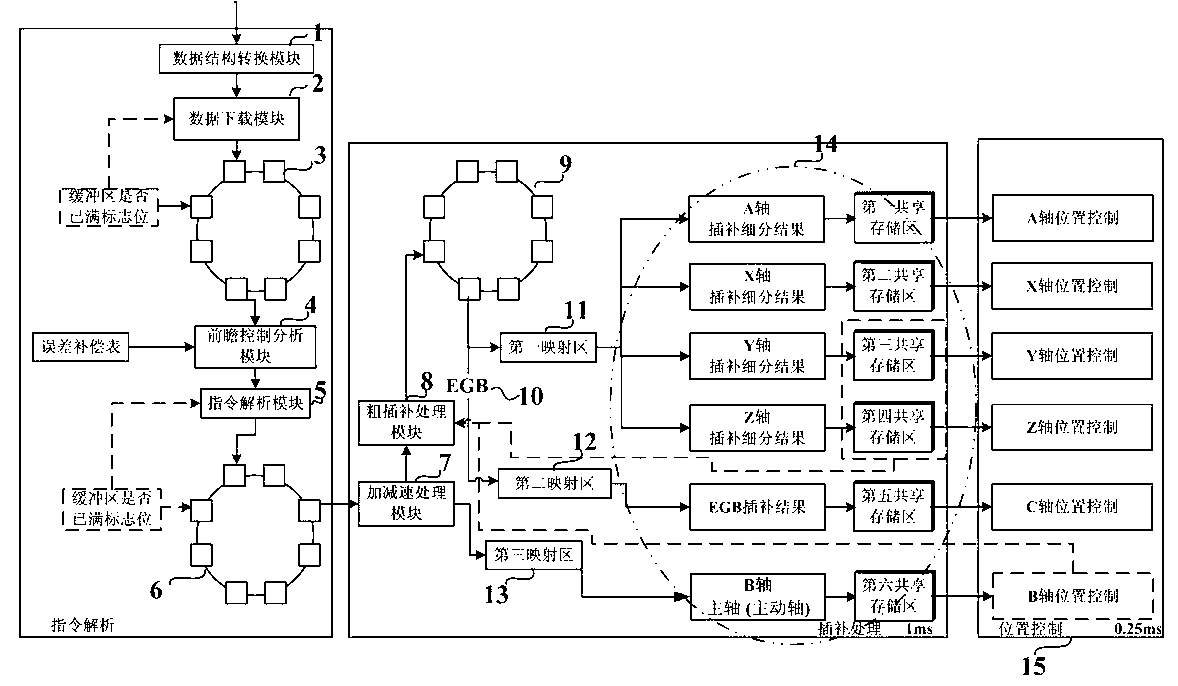

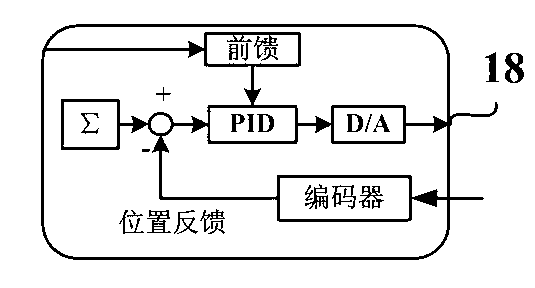

High-speed high-precision flexible electronic gear box control method

ActiveCN103294007AShorten programming timeImprove programming efficiencyProgramme controlComputer controlGear grindingGrating

The invention discloses a high-speed high-precision flexible electronic gear box control method based on an open numerical control system. An electronic gear box is a core part of a gear processing numerical control system, and by parameter setting, requirements, on multi-axis linkage strict speed ratio relationships, of different machine tools for gear hobbing, gear grinding and the like can be met. Each axis servo motor and a spindle motor are connected with the system through motor interfaces, main movement signals are fed back through a motor encoder or a grating ruler, processed by the numerical control system and distinguished and computed through the flexible electronic gear box, and follow-up numerical control shafts are controlled to complete master-slave electronic gear ratio movement.

Owner:HEFEI UNIV OF TECH

Gear grinding machine

ActiveUS20060014474A1Adjustable positionGrinding drivesBelt grinding machinesGear grindingEngineering

A gear grinding machine comprises: a moving mechanism rotatably mounted with a threaded grinding wheel, and arranged to move the threaded grinding wheel along directions of X, Z, and Y, and to turn the threaded grinding wheel in a Y-Z plane; an NC device for controlling the position of the threaded grinding wheel; and a rotary dressing device having a dressing tool which contacts the flanks of the threads of the threaded grinding wheel, while rotationally driven, to perform dressing, and wherein the NC device numerically controls the moving mechanism so as to adjust the positions in the directions of X and Z, and the turning position in the Y-Z plane of the threaded grinding wheel, while keeping contact of the dressing tool with the flanks of the threads of the threaded grinding wheel, in order to modify the wheel pressure angle of the threaded grinding wheel.

Owner:MITSUBISHI HEAVY IND MACHINE TOOL CO LTD

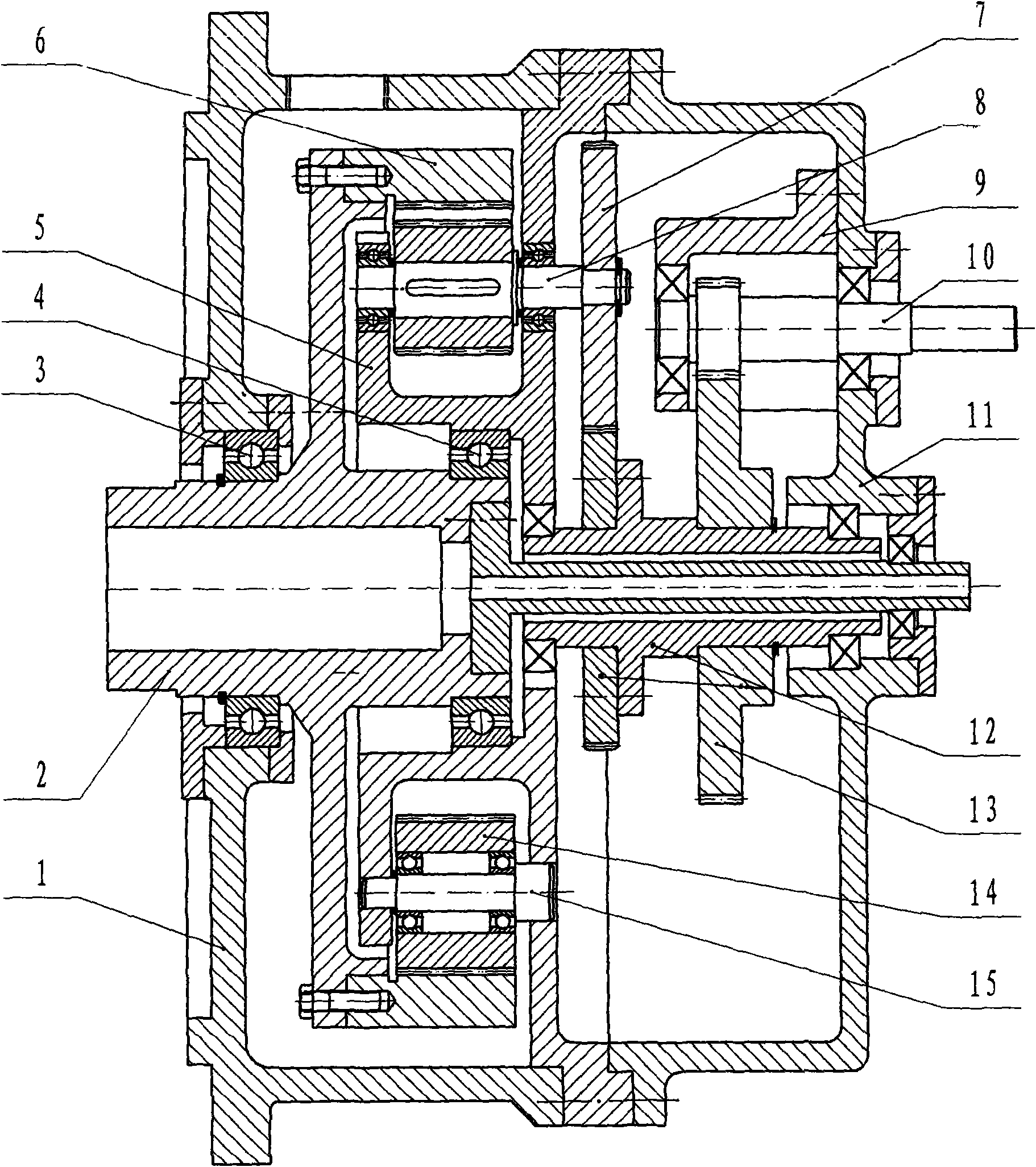

Megawatt ten-shunt wind power generation speed increasing box

InactiveCN101539187AReduce weightLight single pieceGearboxesEngine fuctionsManufacturing cost reductionGear grinding

The invention relates to a megawatt ten-shunt wind power generation speed increasing box, which relates to the technical field of wind power generation speed increase and is a fixed shaft type multi-shunt speed increasing box using a fixed shaft driving theory as a basis and a moving shaft planet structure as a framework. The speed increasing box comprises a machine base, an input shaft, a ring gear, a duplex gear, a sun gear and a third stage speed increasing gear pair, and is characterized in that two intermediate gears are arranged between a center shaft gear of the duplex gear and the ring gear, and five shunts are divided between a driving gear and a center shaft gear sleeve, thus (2*5) ten shunts are formed. The megawatt ten-shunt wind power generation speed increasing box has the following advantages that: (1) the weight is 35 to 45 percent lighter than that of the prior product, and the shape is reduced by 40 to 50 percent; (2) a single piece is light and is convenient to assemble, disassemble and maintain; and (3) a gear slotting machine and a gear grinding machine made in China can process 5 MW model gears, and thus the manufacturing cost is greatly reduced.

Owner:JIANGSU TAILAI REDUCER

Gear machining process

The invention discloses a gear machining process. The gear machining process comprises the following steps of 1 blanking, 2 gear blank manufacturing by means of a forging or casting method, 3 gear blank machining, 4 spline, key groove and thread machining by means of pulling, insertion, tuning and grinding methods, 5 gear profile rough machining and semi-finishing machining, 6 gear profile finish machining, 7 gear-end chamfering and deburring according to the requirement for a certain shape and meanwhile gear two-edge sharpening and deburring, 8 heat treatment by means of a tempering, carburizing and quenching or high-frequency quenching method, 9 gear profile re-machining on unfinished products subjected to heat treatment by means of a gear grinding, lapping or shaving method, 10 strong shot blasting, 11 gear face cleaning to remove gear face burrs and dirt, 12 paired inspection or final inspection of finished products, and 13 rust prevention, packaging and warehousing. The gear machining process is perfect, the quality of the gears can be ensured, rejection ratio can be reduced, and the problem of resource waste of enterprises is effectively solved.

Owner:高灵军

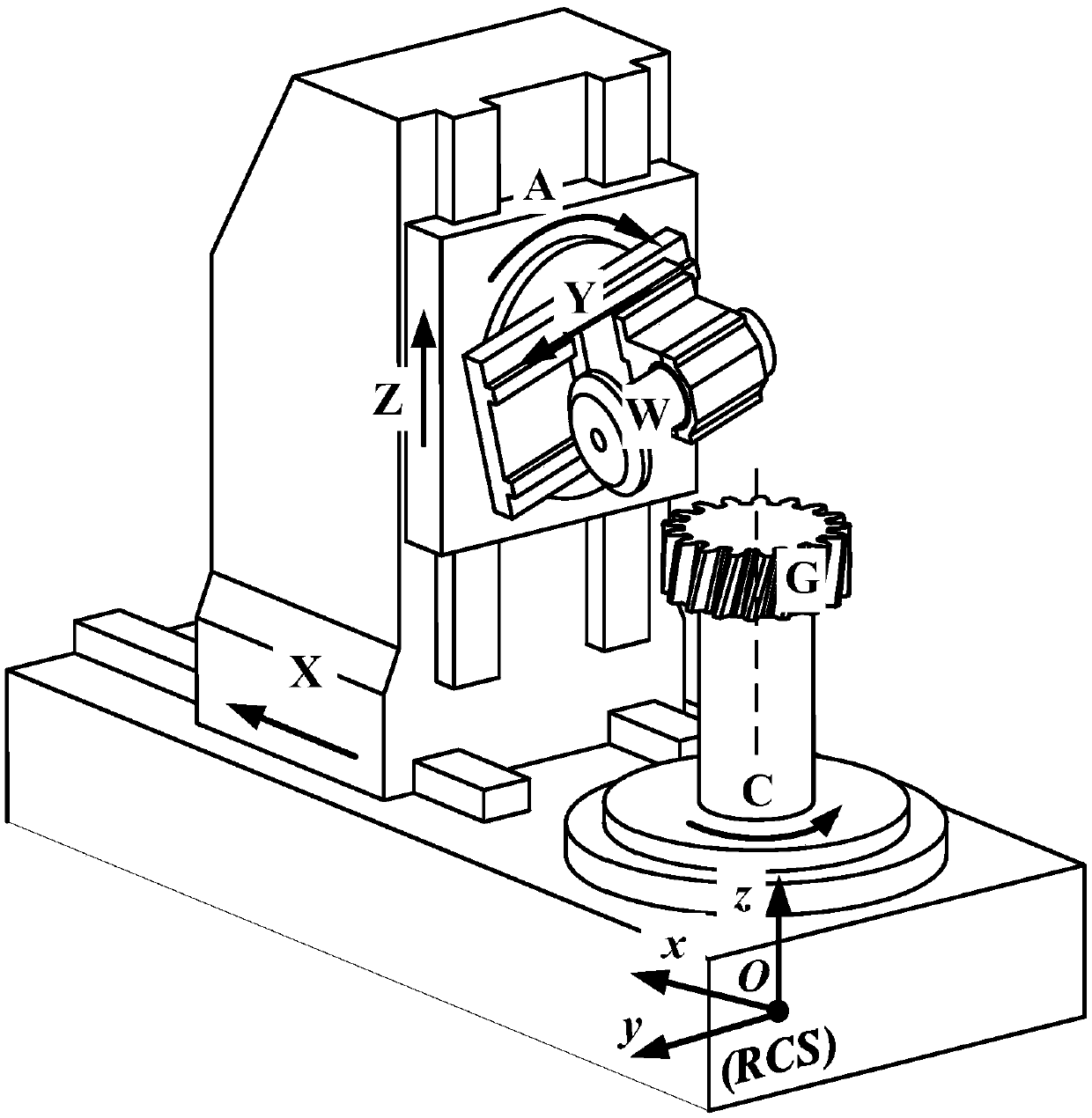

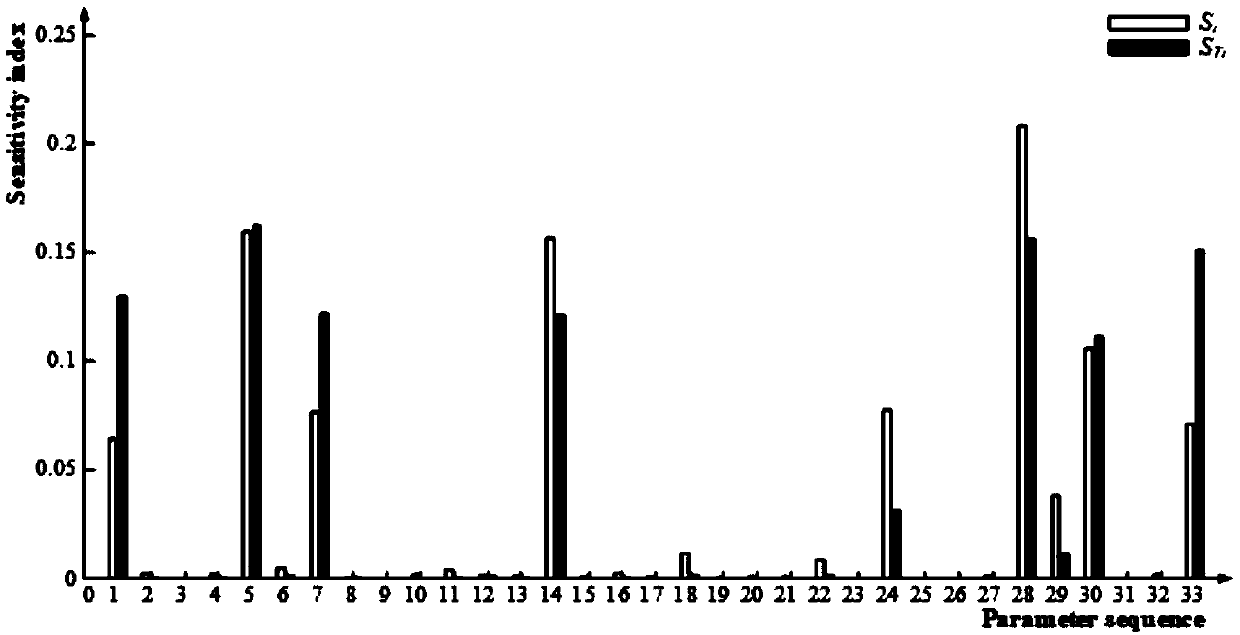

Screening method for key geometric errors of forming gear grinding machine based on gear surface error model

ActiveCN109014437ALow sample countHigh precisionAutomatic control devicesFeeding apparatusGeometric errorGear grinding

The invention discloses a screening method for key geometric errors of a forming gear grinding machine based on a gear surface error model. The screening method comprises the following steps that step1, a gear surface error model is established, specifically, step 11, geometric errors are defined, step 12, the geometric errors are considered, and the pose transformation between a grinding wheel coordinate system and a gear coordinate system is calculated; and step 13, according to a forming conjugate grinding principle, the gear surface error model is established; and step 2, the key geometric errors which affect the grinding precision of a gear are screened, specifically, step 21, according to the gear surface error model, a first-order sensitivity index is used for representing the contribution rate of a single parameter to a model output variance, and a higher-order sensitivity index is used for representing the contribution rate of the coupling effect of multiple parameters to themodel output variance; meanwhile, the individual effect of the single parameter and the coupling effect with other parameters are considered, and a global sensitivity index is used for representing the comprehensive contribution rate of the parameter to the model output variance; and step 22, a modified Sobol method is adopted, and the first order sensitivity index and the global sensitivity index are calculated based on Monte-Carlos estimated valves.

Owner:CHONGQING UNIV +1

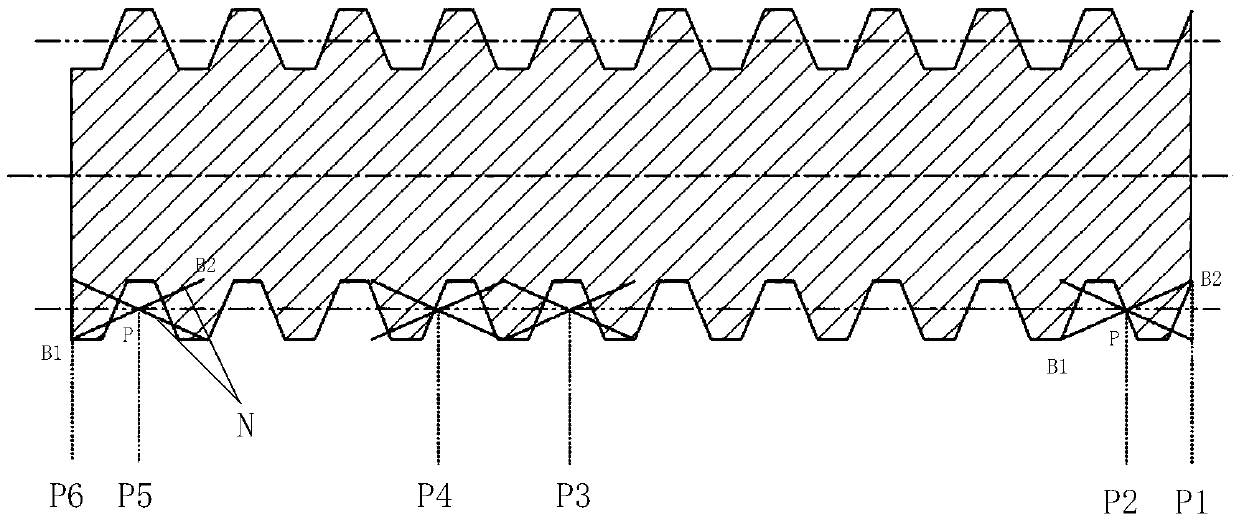

Worm grinding wheel gear grinding surface distortion compensation method

ActiveCN104942380ACompensate distortion errorAbrasive surface conditioning devicesGear teeth manufacturing toolsGear grindingGear wheel

The invention belongs to the field of gear manufacturing, and relates to a worm grinding wheel gear grinding surface distortion compensation method which solves the problem of tooth surface distortion of a bevel wheel gear with axial modification in the grinding process. According to the worm grinding wheel gear grinding surface distortion compensation method, dressing movement is different from a standard worm grinding wheel dressing process, deflection movement of a diamond rolling wheel is needed, and axial screw lead and a spiral angle of the grinding wheel are changed. The method comprises the steps that firstly, according to the wheel gear grinding technology, the worm grinding wheel is divided into a coarse grinding zone, a fine grinding zone and a middle transition zone in the width direction, the diagonal grinding principle is utilized, and appropriate diagonal ratio is selected to make a strict mapping relation exist between the section in the width direction of the wheel gear and the section in the width direction of the worm grinding wheel; secondly, according to distortion amounts of the left tooth surface and the right tooth surface of each section of the wheel gear to be machined, distortion compensation of each tooth surface is achieved by utilizing two methods of combining a deflecting rolling wheel and changing the axial screw lead of the grinding wheel. Due to the fact that excursion exists in the deflection center of the diamond rolling wheel, when deflection exists on the rolling wheel, calculation and compensation need to be conducted on the position variation quantity of a tooth profile of the rolling wheel.

Owner:CHONGQING UNIV

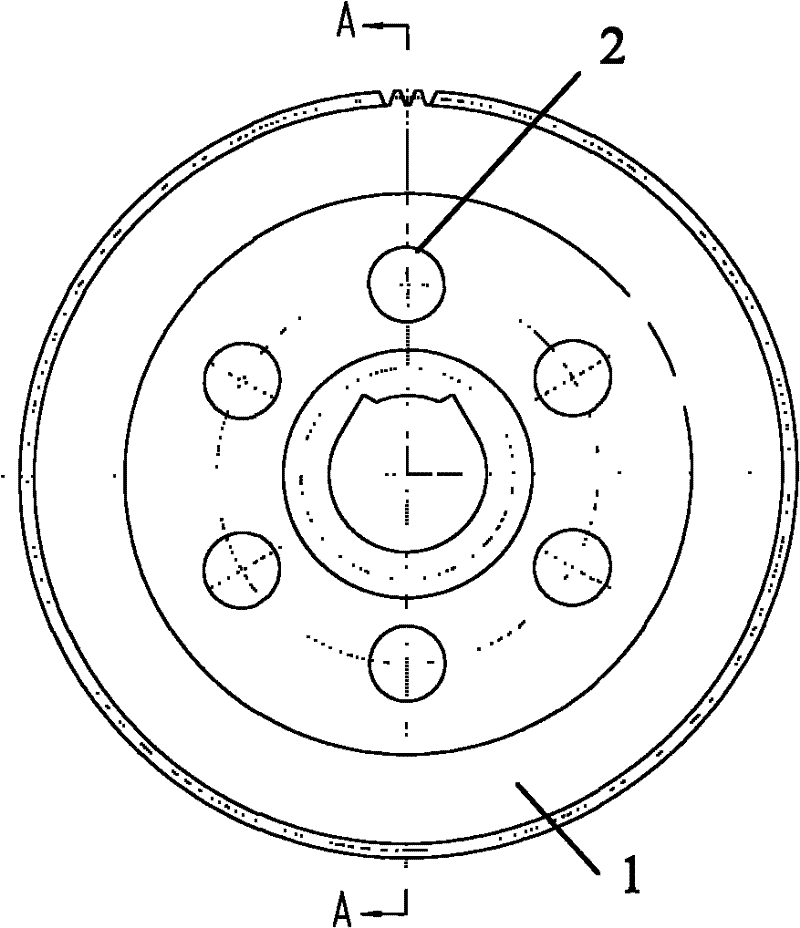

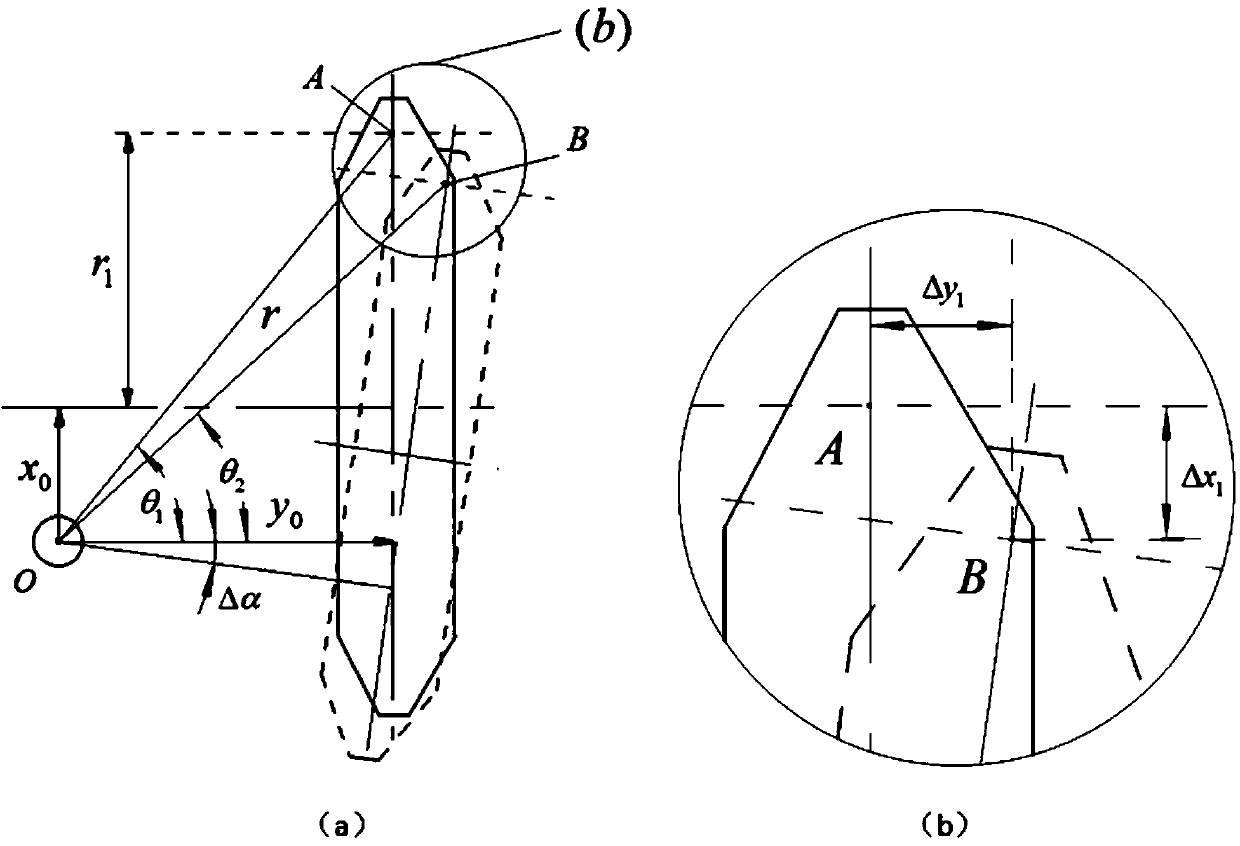

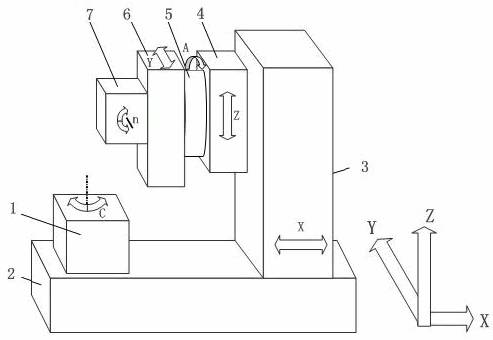

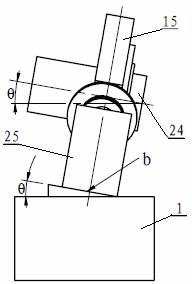

Displacement analog loading device of form grinding wheel gear grinding machine and method for detecting rigidity distribution

InactiveCN101941102ARealize static stiffness distribution detectionSimple structureMachine part testingMeasurement/indication equipmentsGear grindingMachine

The invention relates to a displacement analog loading device of a form grinding wheel gear grinding machine, comprising a loaded test piece and a loading assembly, wherein the loaded test piece is arranged on the form grinding wheel gear grinding machine, and the loading assembly is used for analog loading; the form grinding wheel gear grinding machine has the functions of rectilinear motion on an X axis, forward and backward rectilinear motion on a Y axis, rectilinear motion on a Z axis, n rotary motion around the Y axis, C rotary motion around the Z axis and A rotary motion around the X axis; and an included angle alpha is formed between the axial lead of a ball seat of the loading assembly and the X axis direction of a Y axis assembly, and the included angle between the normal of the loaded surface and the X direction of a machine tool coordinate system is alpha. The method for detecting rigidity distribution in the invention comprises the following steps of: moving the loading assembly to a loading position for loading by using the matched motions of the Z axis, the Y axis and the X axis; detecting the displacement by using a displacement sensor, detecting an analog load by using a force sensor, and then calculating the rigidity of the loading position under the analog load; and changing the loading position and repeating the process to obtain the rigidity distribution under the analog load. The device and the method in the invention realize the detection of the static rigidity distribution.

Owner:XIAN UNIV OF TECH

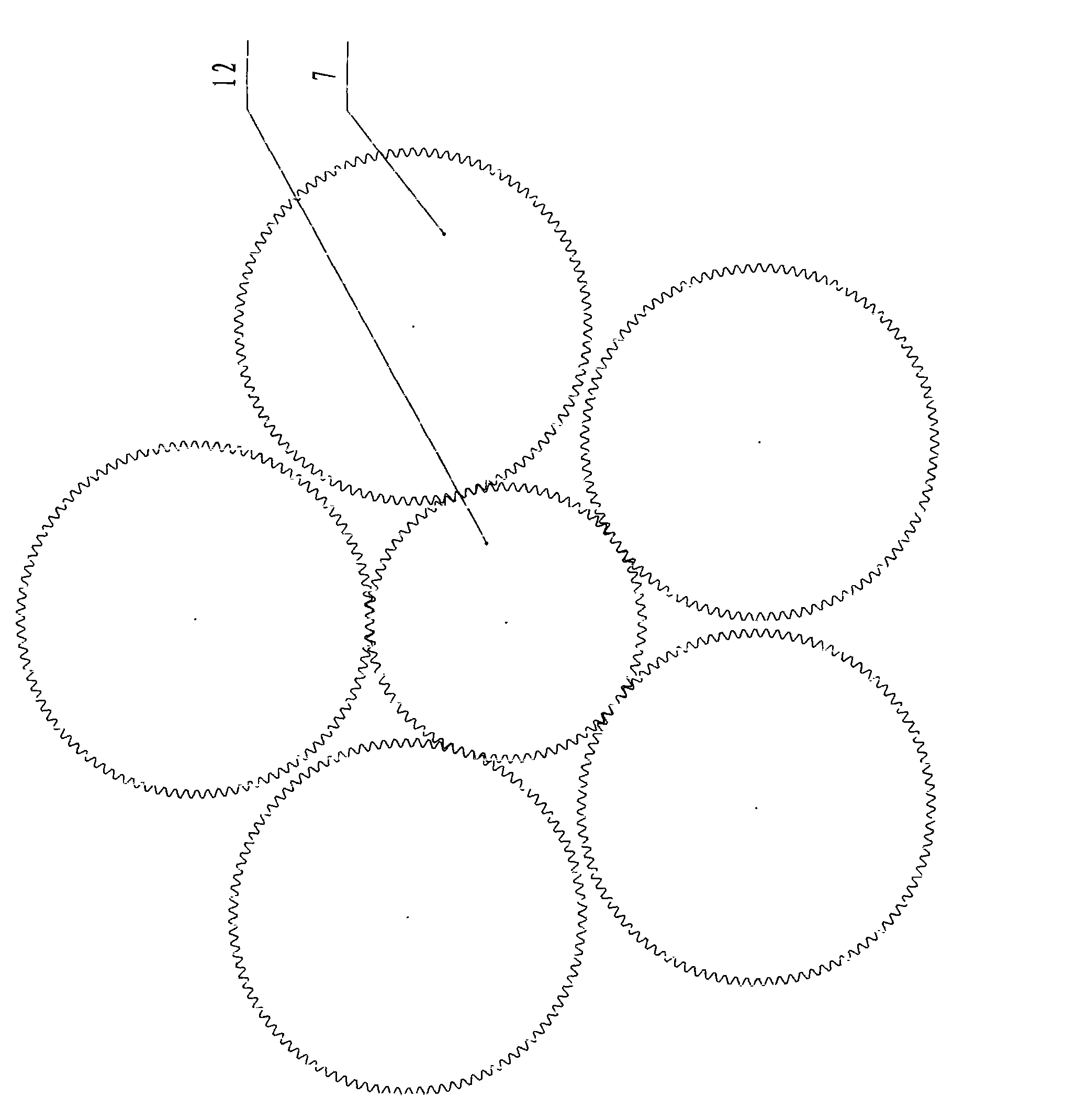

Megawatt multi-split wind power speed-increasing gearbox

InactiveCN101539115AExtended service lifeImprove the lubrication effectGearboxesEngine fuctionsElectricityGear grinding

The invention relates to a megawatt multi-split wind power speed-increasing gearbox, in particular to a fixed shaft type multi-split speed-increasing gearbox taking the fixed axle transmission principle as the basis and a movable axle planetary structure as the framework, belonging to the technical field of wind power speed-increasing gearboxes. The speed-increasing gearbox comprises a machine seat, an input shaft, an internal tooth ring, duplicate gears, a central gear or a third-stage speed-increasing gear pair and is characterized in that 3-6 duplicate gears are evenly distributed on the fixed stand, two idle gears are arranged between a shaft gear in each duplicate gear and the internal tooth ring, the transmission gear is meshed with the central gear, and 6-12 split flows or 3-6 split flows are respectively formed. The invention has the advantages that: (1) the weight is lighter by 35 to 45 percent than that of the prior product home and aboard, and the contour is reduced by 40 to 50 percent; (2) the single part is light, and the assembly, the disassembly and the maintenance are convenient; and (3) the domestically produced gear shaper, the gear grinding machine and other devices can be processed into a 3-5MW extra-large machine type, therefore, the manufacturing cost is greatly reduced.

Owner:吴小杰

Grinder dresser for gear grinding

InactiveCN101066584AEliminate the effects of blunt uncertaintyEliminate errorsAbrasive surface conditioning devicesGear teethGear grindingEngineering

The grinding wheel dresser for gear grinding consists of a numerically controlled X-coordinate module, a numerically controlled Y-coordinate module, a numerically controlled Z-coordinate module, a numerically controlled rotating module, a diamond pen installing module and a diamond pen. The diamond pen installing module consists of a proximating numerically controlled rotating module and a compensating numerically controlled rotating module, and the diamond pen is mounted vertically on the compensating numerically controlled rotating module axis. During the trimming, the numerically controlling device simulates and drives the numerically controlled modules to ensure the diamond pen axis always perpendicular to the curved grinding wheel surface so as to trim grinding wheel tooth form with very high precision.

Owner:CHONGQING UNIV

Processing method of involute of gear with large module and a few teeth

Owner:重庆市华丰动力配件有限公司

Automatic saw blade gear grinding machine

InactiveCN101704131ASimple structurePractical and convenientSawing tools dressing arrangementsGear grindingVertical plane

The invention discloses an automatic saw blade gear grinding machine, which comprises a base, an electric motor, a grinding wheel arranged on a main shaft of the electric motor, a saw blade gear shifting device, an electric motor displacement adjusting device for adjusting a lateral displacement and a longitudinal displacement of the electric motor on the base, an electric motor lifting adjusting device for adjusting a distance between the electric motor and the base, and an electric motor angle adjusting device for adjusting a rotation angle of the electric motor in a horizontal plane or in a vertical plane. The electric motor displacement adjusting device is arranged on the base. The electric motor lifting adjusting device is rotationally arranged on the electric motor displacement adjusting device and can be locked and positioned by a fastening piece; the electric motor angle adjusting device is rotationally arranged on the electric motor lifting adjusting device and can be locked and positioned by the fastening piece; the electric motor is arranged on the electric motor angle adjusting device; and the saw blade gear shifting device is arranged on the base, drives a saw blade to carry out reciprocating motion and pushes the saw blade to rotate. The automatic saw blade gear grinding machine can carry out multiaspect and multi-angle adjustment on the electric motor and realize automatic grinding of different saw blades.

Owner:南京唯高机械制造有限公司

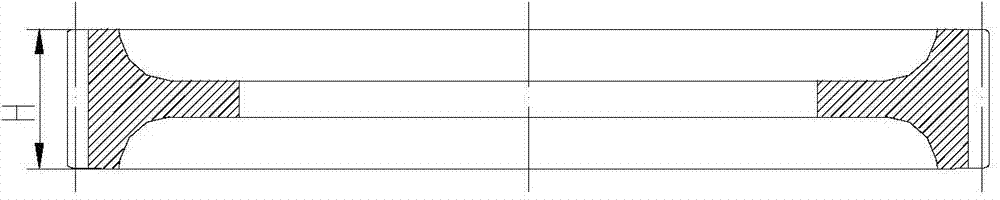

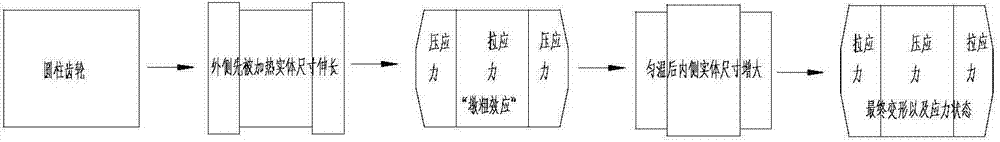

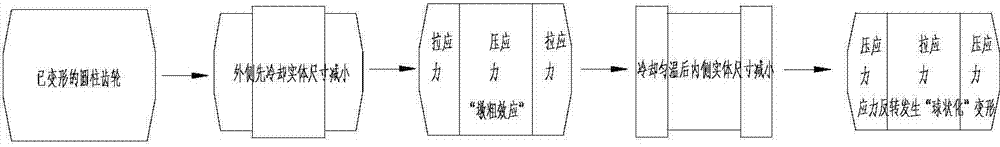

Carburizing and quenching method for cylindrical gear

InactiveCN104498965ACompensation corrects cone distortionEliminate internal stressSolid state diffusion coatingFurnace typesGear grindingElastic plastic

The invention relates to a carburizing and quenching method for a cylindrical gear, and belongs to the technical field of heat treatment. The method comprises the following steps: heating until the temperature exceeds elastic-plastic transformation temperature of low-carbon steel for primary preheating; heating until the temperature is less than the phase-transition temperature Ac1 of the low-carbon steel for preheating again; performing carburizing, high-temperature tempering, quenching, and low-temperature tempering. According to the carburizing and quenching method for the cylindrical gear, effective measures for inhibiting or removing deformation are respectively performed for a plurality of process stages and supplement each other and are organically combined, so that the deformation of the cylindrical gear carburizing and quenching thermal treatment can be obviously reduced, the preset grinding allowance of the gear can be properly decreased, and as a result, the gear grinding time is reduced, and conditions are created for lowering the gear manufacturing cost.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

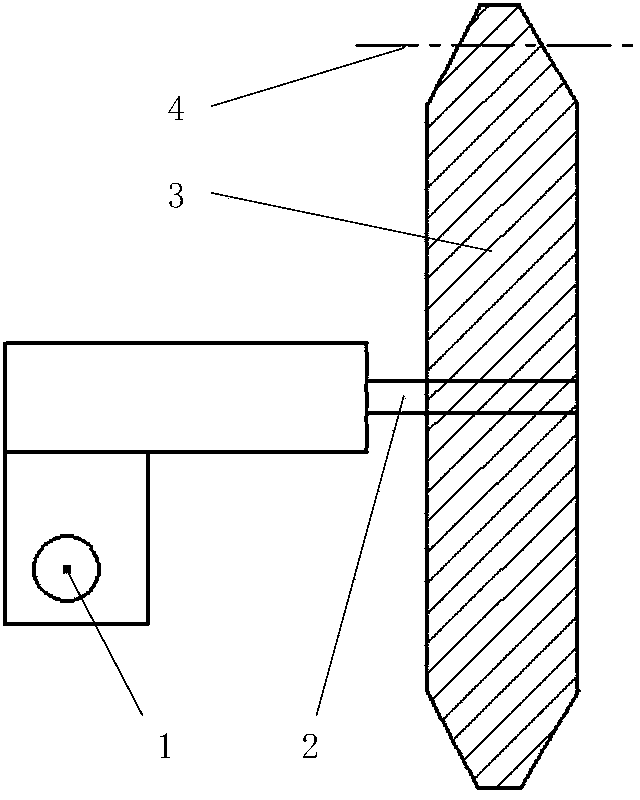

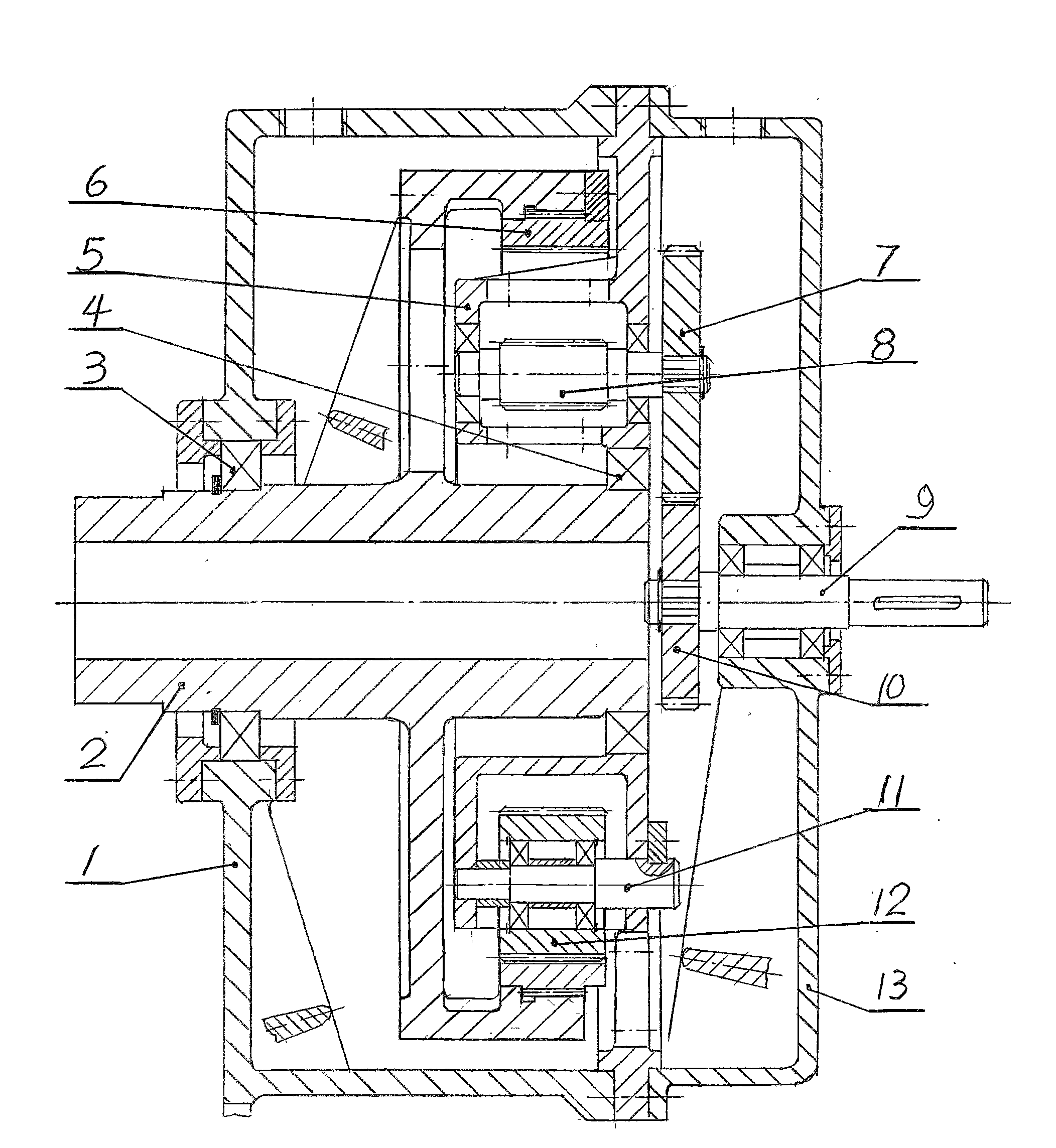

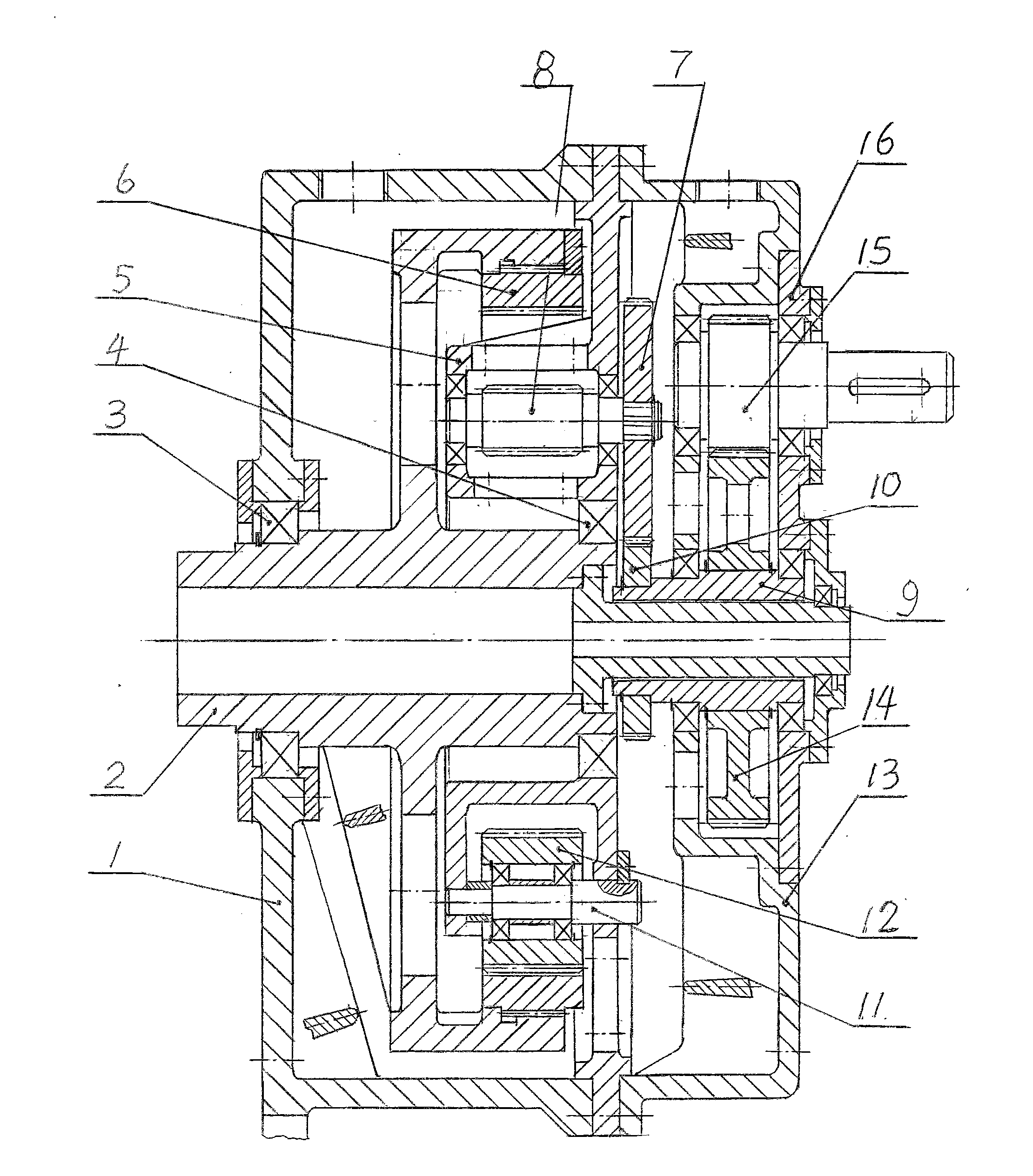

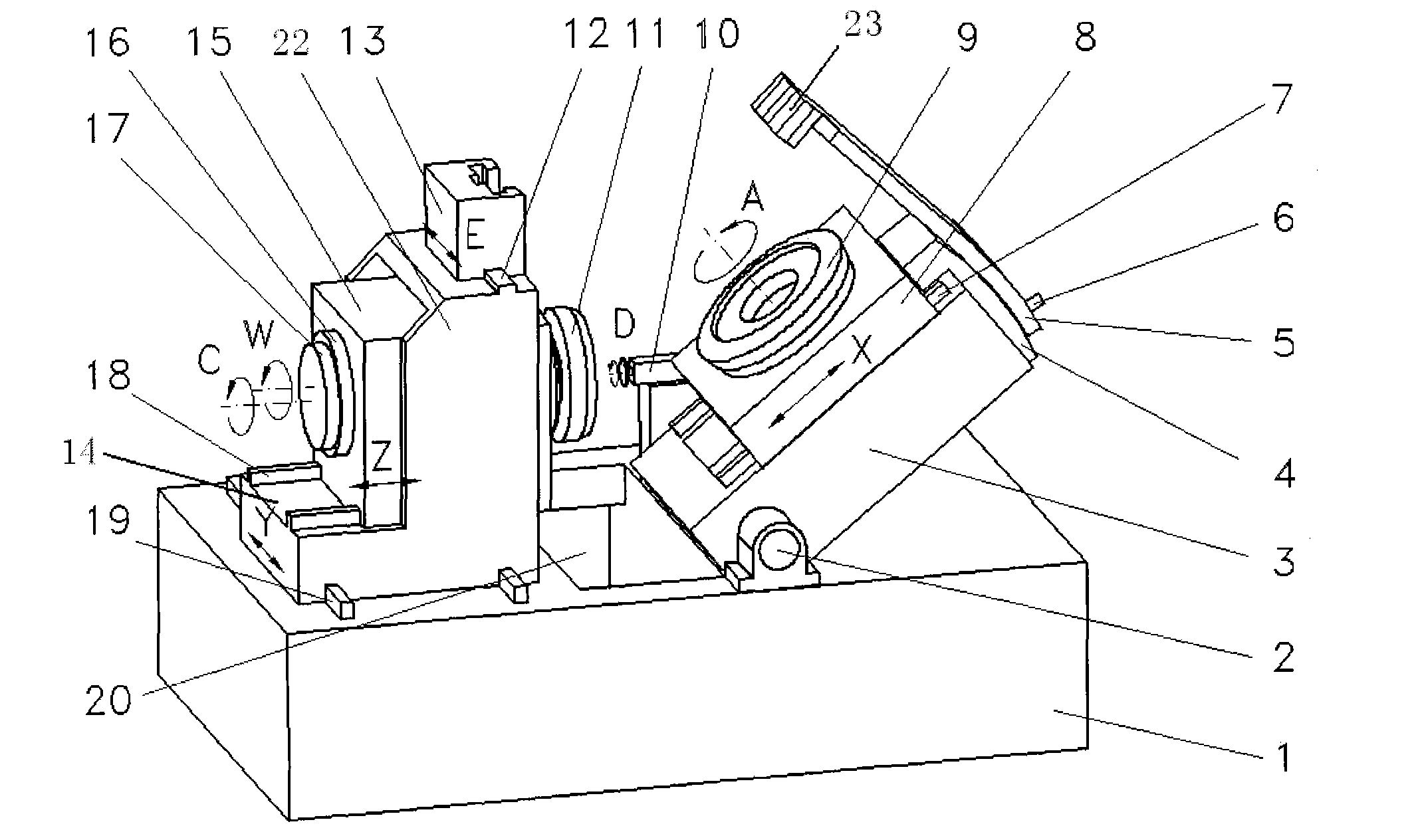

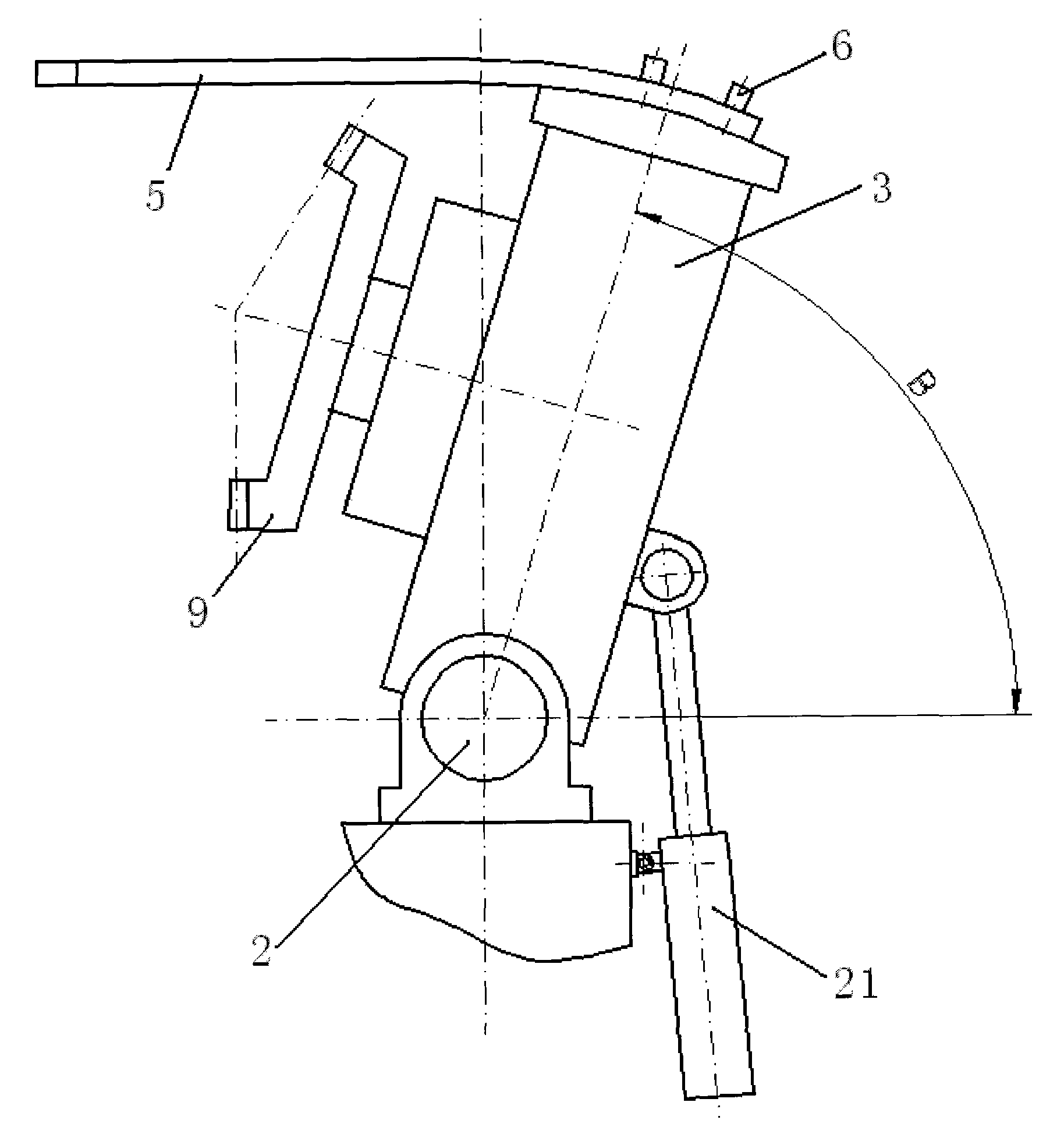

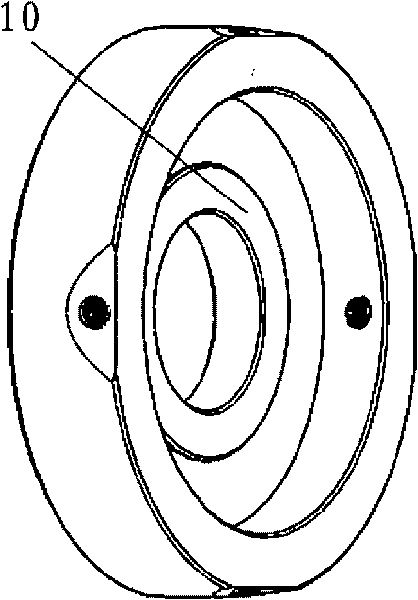

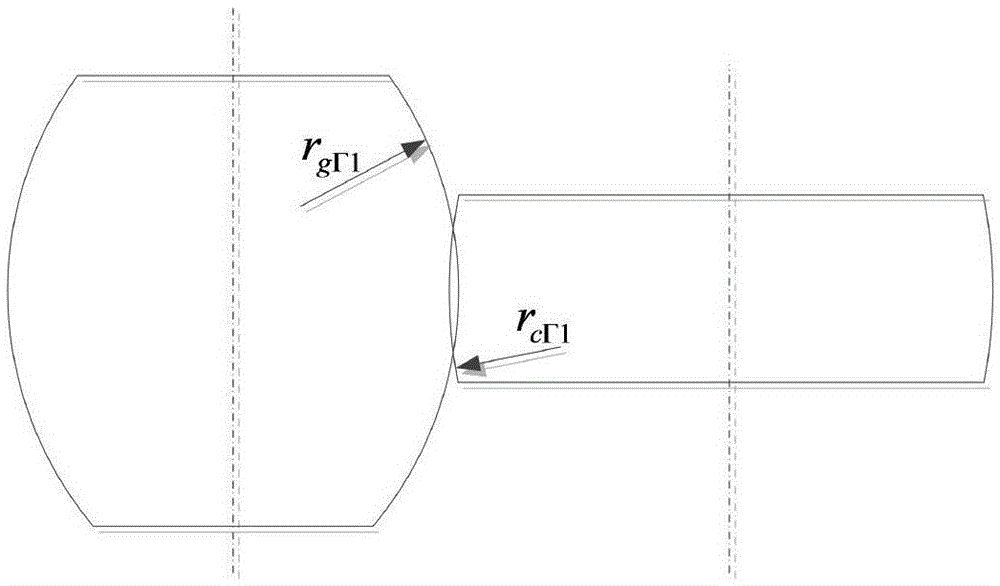

Spiral bevel gear and hypoid gear forming method large-gear grinding machine

InactiveCN101791725ASimple structureImprove stabilityGear-cutting machinesGear teethGear grindingHydraulic cylinder

The invention relates to a spiral bevel gear and hypoid gear forming method large-gear grinding machine. One side of the top surface of a machine tool body is provided with a Y-shaft slide carriage, and the Y-axis slide carriage is provided with a grinding wheel box moving along a Z shaft; the grinding wheel box is provided with a W shaft, an eccentric C shaft is installed in the W shaft, and one end of the C shaft is provided with a grinding wheel; the other side of the top surface of the machine tool body is provided with a rocker, and the rocker is articulated with the machine tool body through a hinge shaft; the rocker is provided with a hydraulic cylinder; the rocker is provided with an X-shaft slide carriage, a revolving A shaft is installed on the X-shaft slide carriage, and one end of the A shaft is used for installing a processed forming method large-gear. The invention has the characteristics of simple structure, good stability and reliability, high efficiency, small occupied area, easy protection and dust removal, convenient installation and removal of work pieces and grinding wheel, and the like.

Owner:CHANGSHA HALIANG KAISHUAI PRECISION MASCH CO LTD

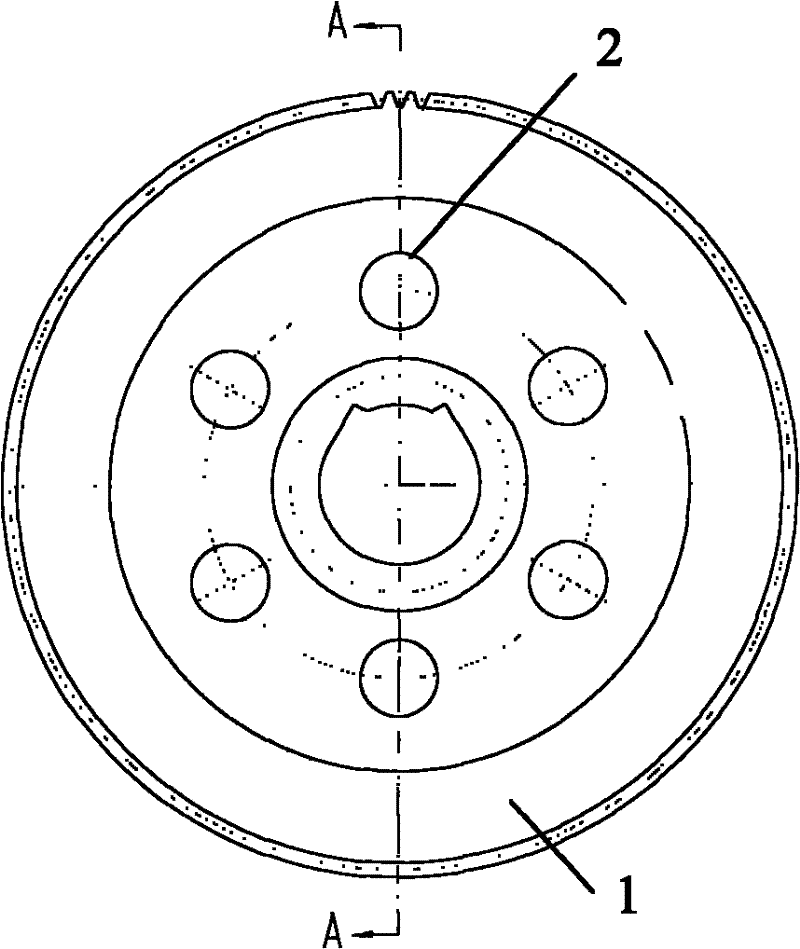

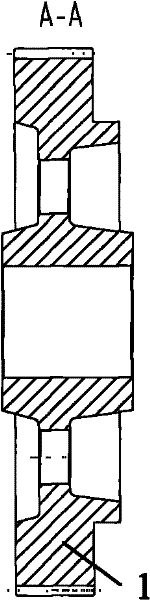

High-precision end-tooth automatic dividing device for gear grinding machine

InactiveCN101695775AHigh precisionHigh repeatabilityGear-cutting machinesGear teethGear grindingManufacturing technology

The invention discloses a high-precision end-tooth automatic dividing device for a gear grinding machine, belonging to the technical field of gears and gear cutter precision manufacture techniques. The high-precision end-tooth automatic dividing device is characterized in that a pair of end-tooth discs is designed according to the shafting structure of a main processing shaft of the gear grinding machine, a fixed end-tooth disc is fixed on an outer shaft sleeve of the main processing shaft of the gear grinding machine, and a movable end-tooth disc is fixed on a main shaft; a radial cam of an original machine tool dividing system is modified into an end-surface cam to drive the separation and reunion of the end-tooth discs; a geneva mechanism and a dividing change gear of the original machine tool dividing system drive the rough division of the movable end-tooth disc, or a stepping motor respectively drives the separation and reunion and the rough division of the movable end-tooth disc, thus the automation degree is high; the dividing precision of the end-tooth discs achieves + / -0.2 under a free state after the end-tooth discs are arrayed and mutually abraded, the dividing precision of the end-tooth discs achieves + / -1 to + / -3 after the end-tooth discs are combined on a machine tool, and the positioning repeated precision meets + / -0.1 so as to meet the requirements of a gear or a gear cutter which is processed with 1-grade tooth pitch precision.

Owner:DALIAN UNIV OF TECH

Grinding force model for worm-shaped grinding wheel gear grinding

The invention relates to a grinding force model for worm-shaped grinding wheel gear grinding, and belongs to the field of gear machine manufacturing. On the basis of a G.Wener grinding force model, the invention provides a new grinding force model for the worm-shaped grinding wheel gear grinding. Firstly, an approximate model is established according to the relationship of the geometrical shape and the speed of a honing wheel and a workpiece on a contact point in a worm-shaped grinding wheel gear grinding process; secondly, establishing a cuttings model on the basis of the approximate model, and calculating speed, grinding thickness and equivalent diameter in a grinding process; and finally, on the basis of the approximate model, establishing an intermedian-gear gear honing grinding force model. The grinding force model is suitable for the worm gear grinding and intermedian-gear gear honing processing method. The method is suitable for calculating grinding force in the gear grinding processing which adopts a worm-shaped grinding wheel and comprises a worm grinding wheel gear grinding method and an intermedian-gear gear honing processing method. The method makes a gear grinding process be approximate into an excircle grinding process so as to simplify a calculation process and fill up the blank in the grinding force model for the worm-shaped grinding wheel gear grinding.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com