Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8162 results about "Grinding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

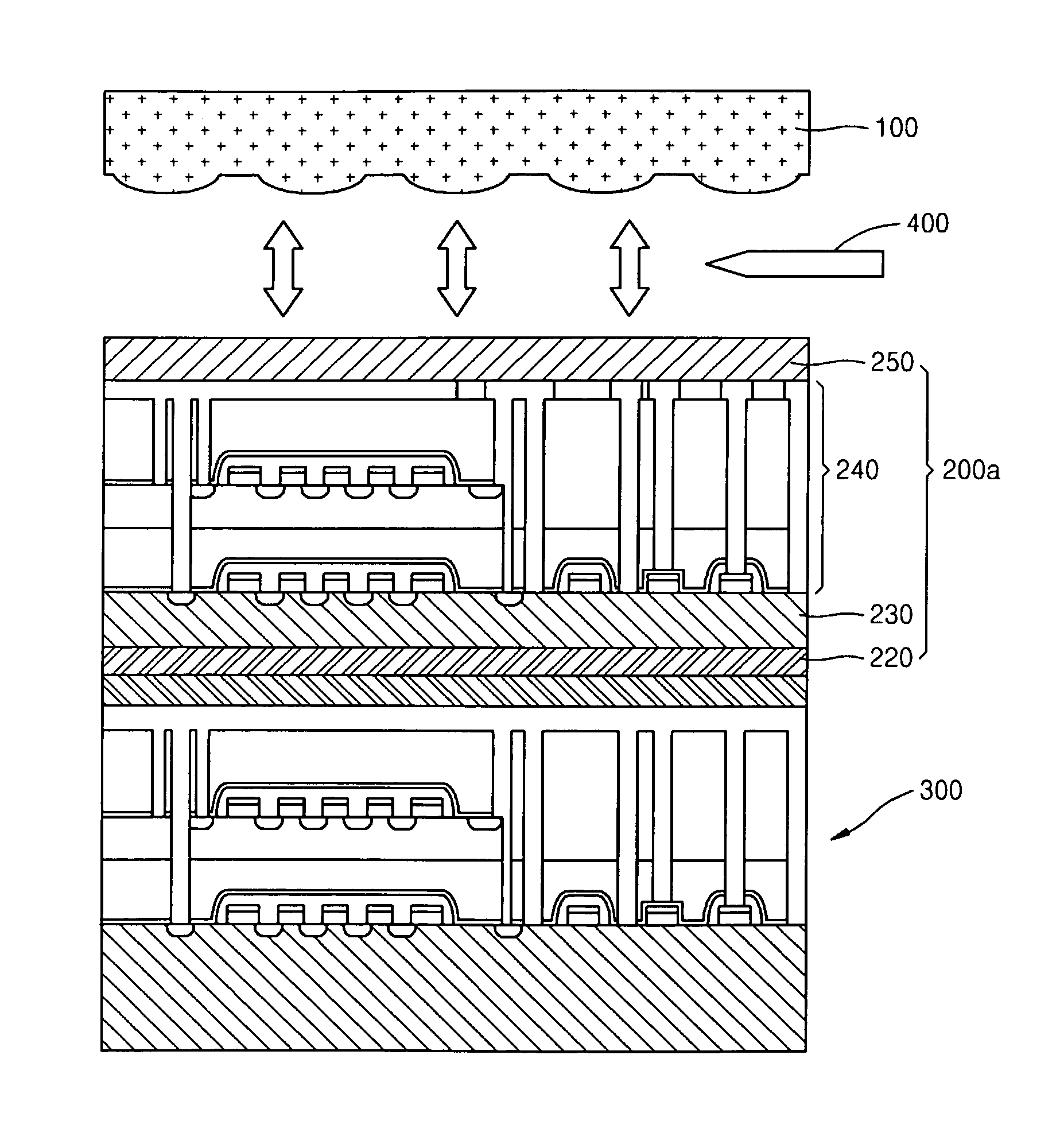

Wafer temporary bonding method using silicon direct bonding

A wafer temporary bonding method using silicon direct bonding (SDB) may include preparing a carrier wafer and a device wafer, adjusting roughness of a surface of the carrier wafer, and combining the carrier wafer and the device wafer using the SDB. Because the method uses SDB, instead of an adhesive layer, for a temporary bonding process, a module or process to generate and remove an adhesive is unnecessary. Also, a defect in a subsequent process, for example, a back-grinding process, due to irregularity of the adhesive may be prevented.

Owner:SAMSUNG ELECTRONICS CO LTD

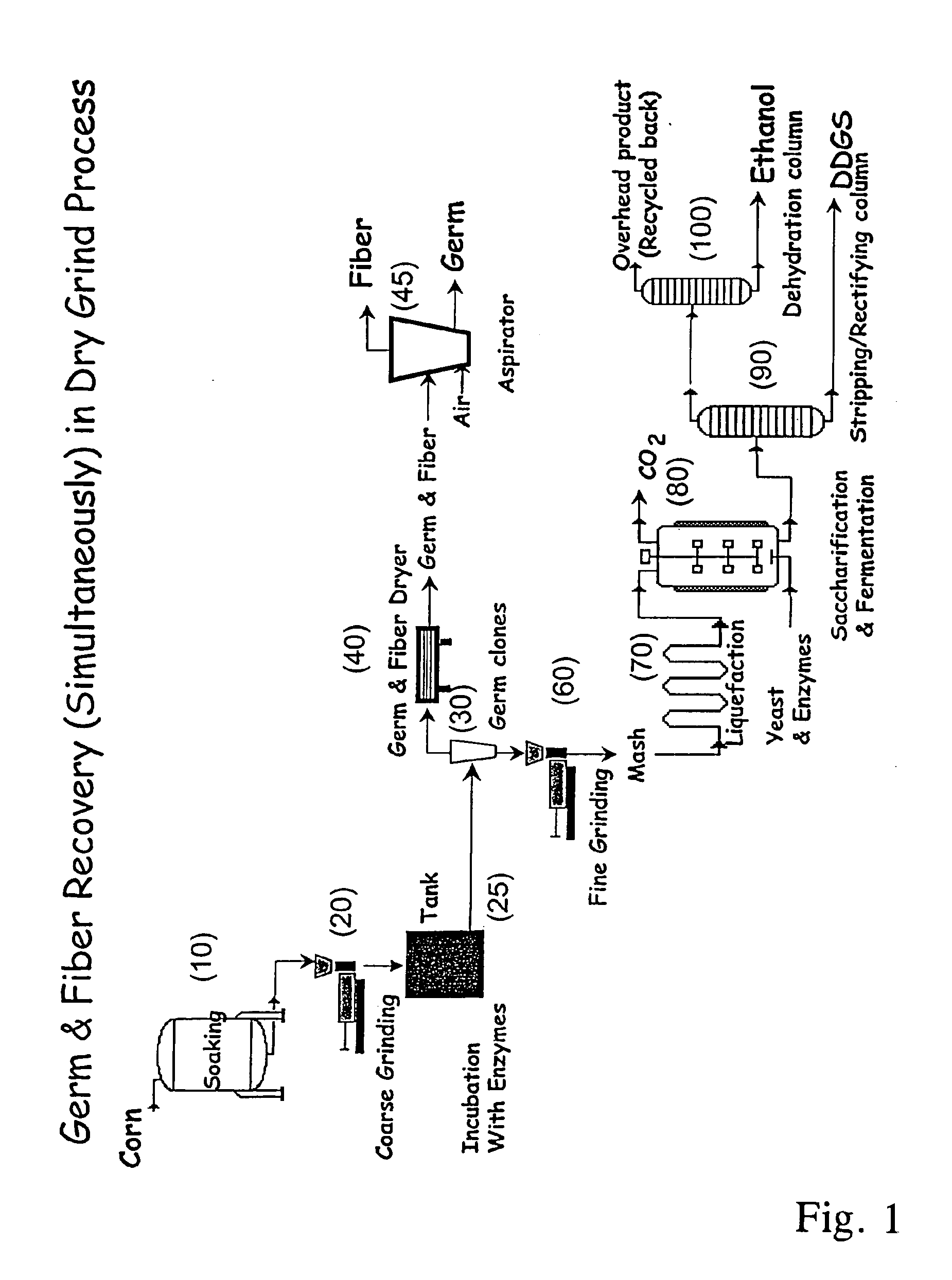

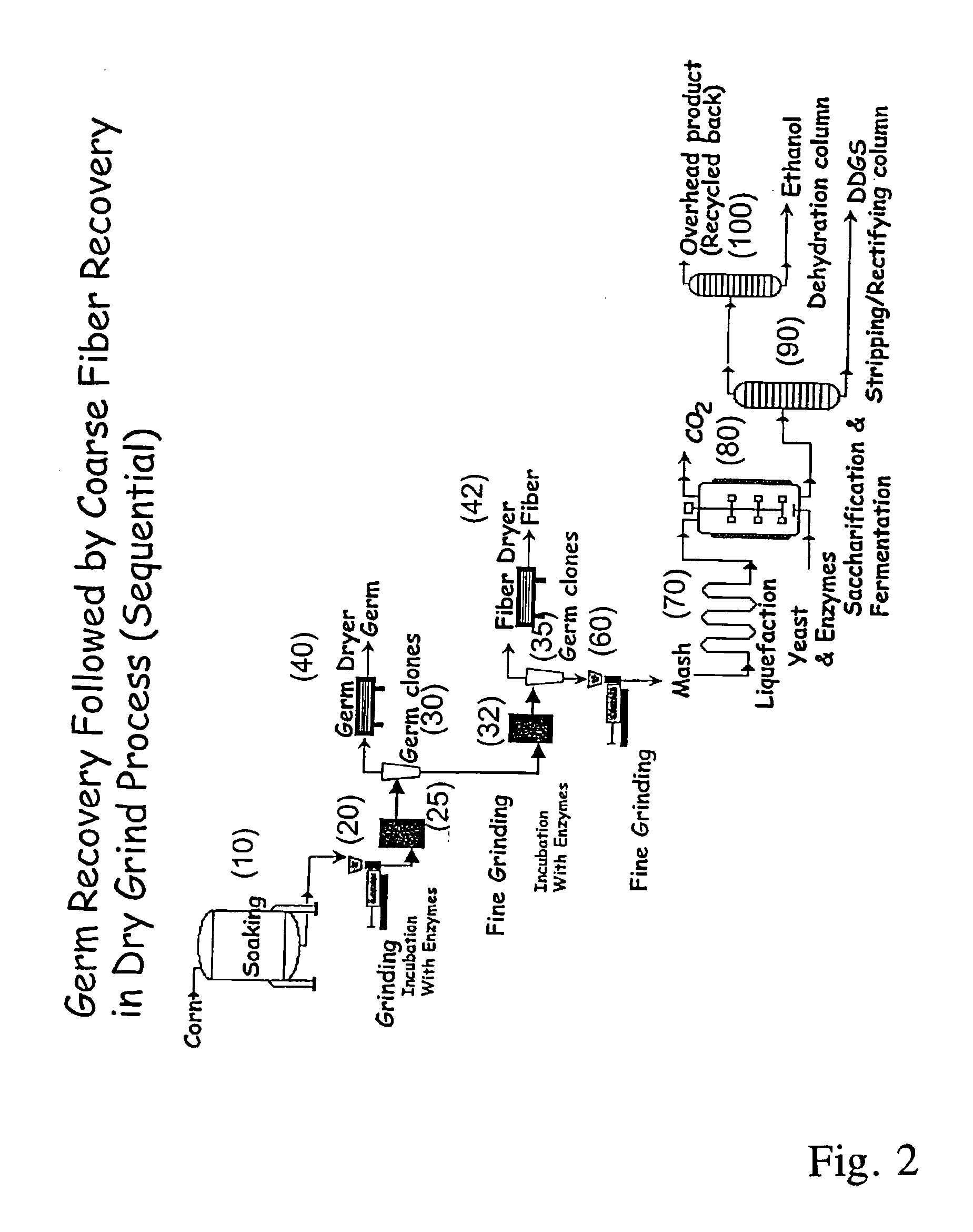

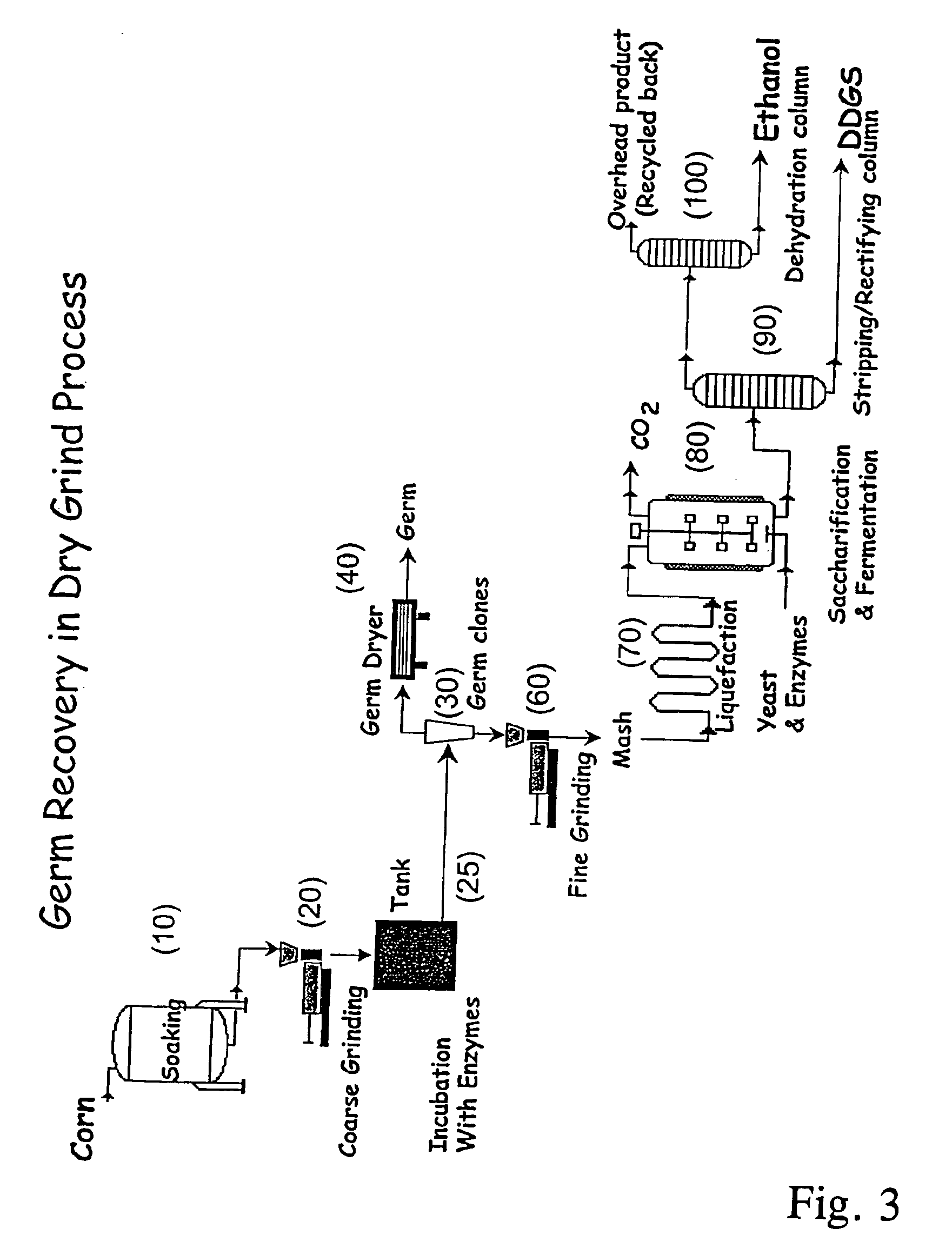

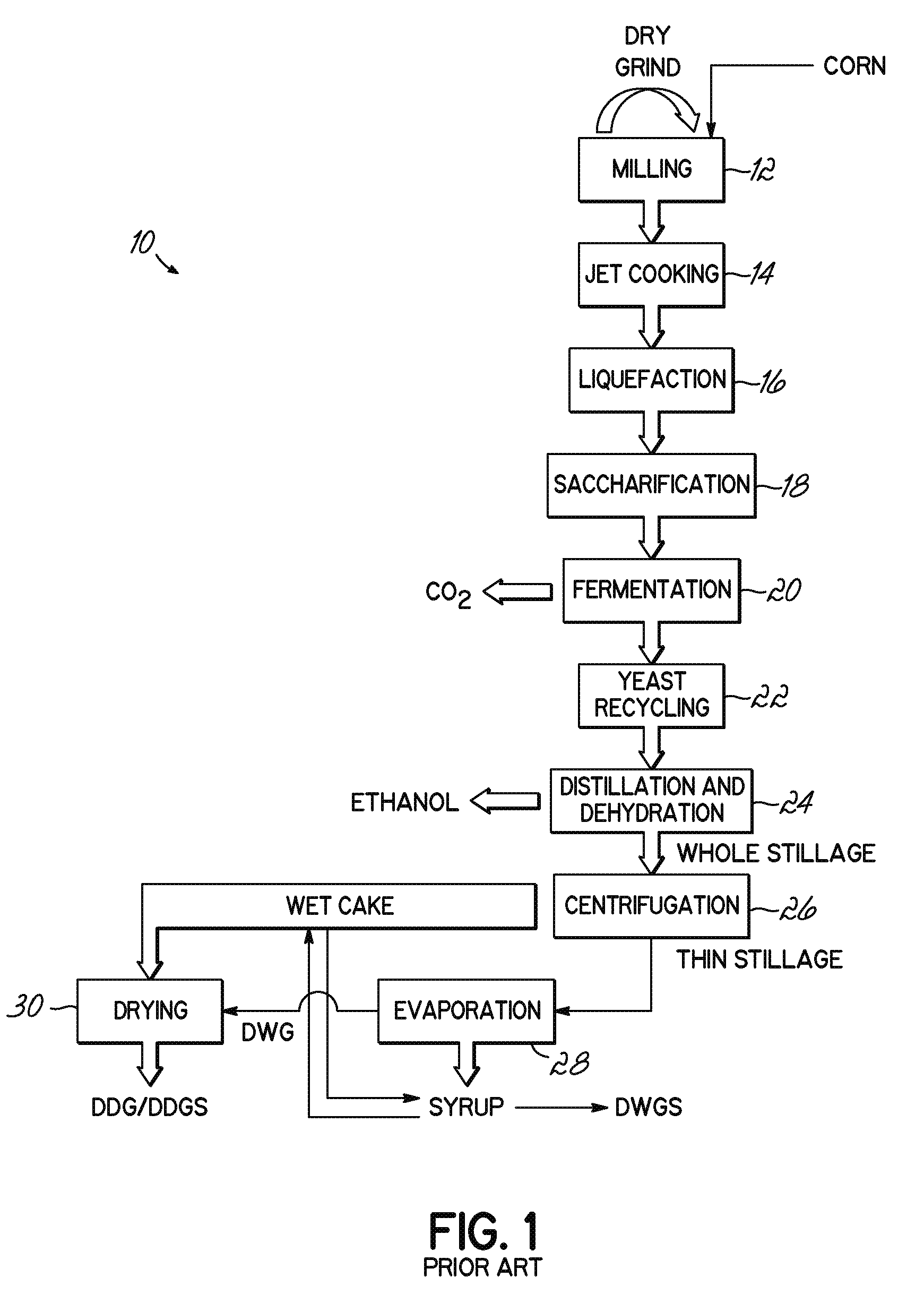

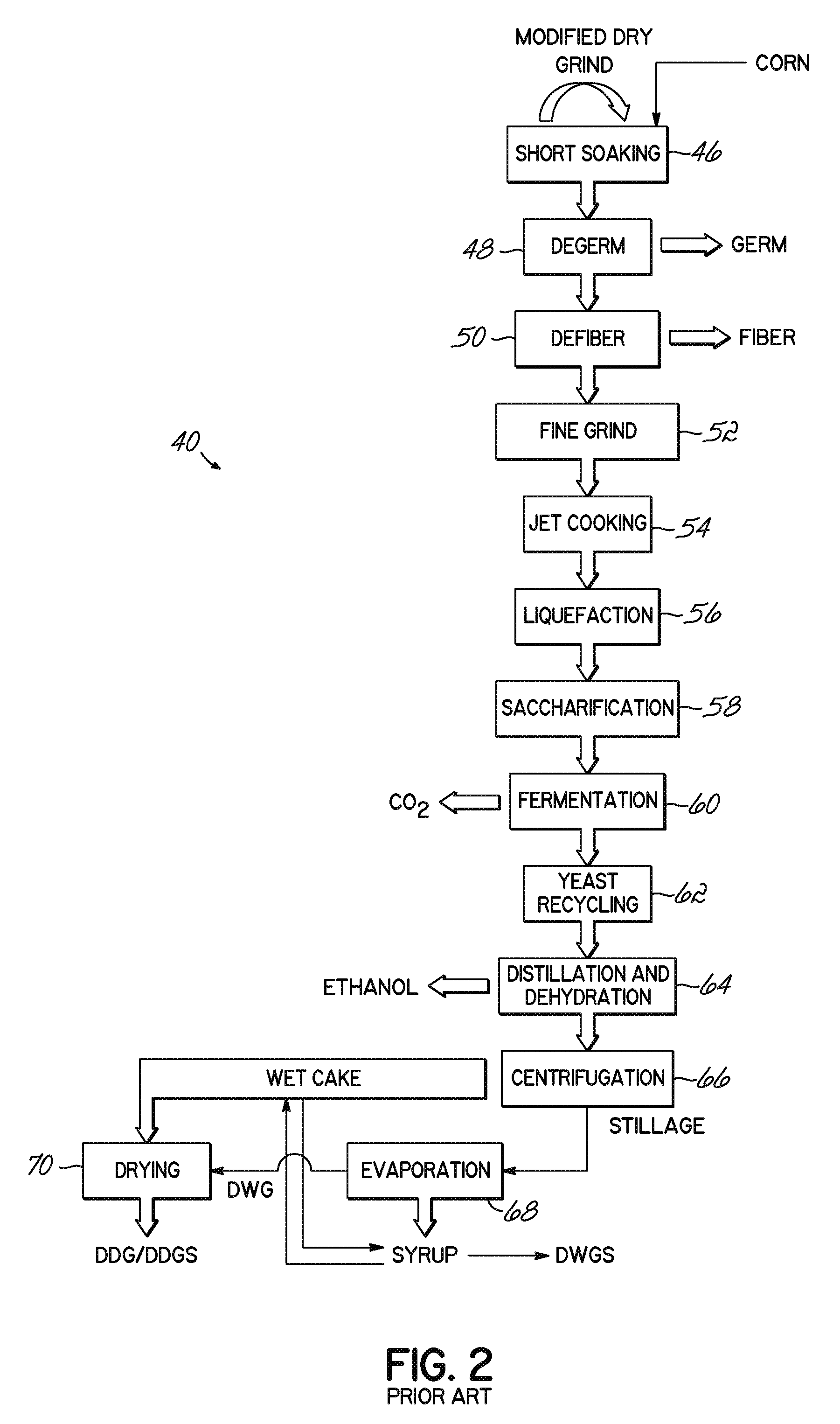

Processes for recovery of corn germ and optionally corn coarse fiber (pericarp)

A process for recovering corn germ and corn coarse fiber from corn in a dry grind process, involving soaking corn kernels in water to produce soaked corn kernels, grinding the soaked corn kernels to produce a ground corn slurry, and incubating the ground corn slurry with at least one enzyme (amylase(s), protease(s), cell wall degrading enzyme(s), or mixtures thereof, and optionally other enzyme(s)) to increase the specific gravity of the slurry to about 10-about 16 Baume so that the corn germ and corn coarse fiber floats to the top of the slurry, recovering the corn germ and the corn coarse fiber, and optionally producing ethanol from the slurry no longer containing the corn germ and corn coarse fiber. The process does not involve the addition of starch, a salt, a sugar syrup, or mixtures thereof to the slurry.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

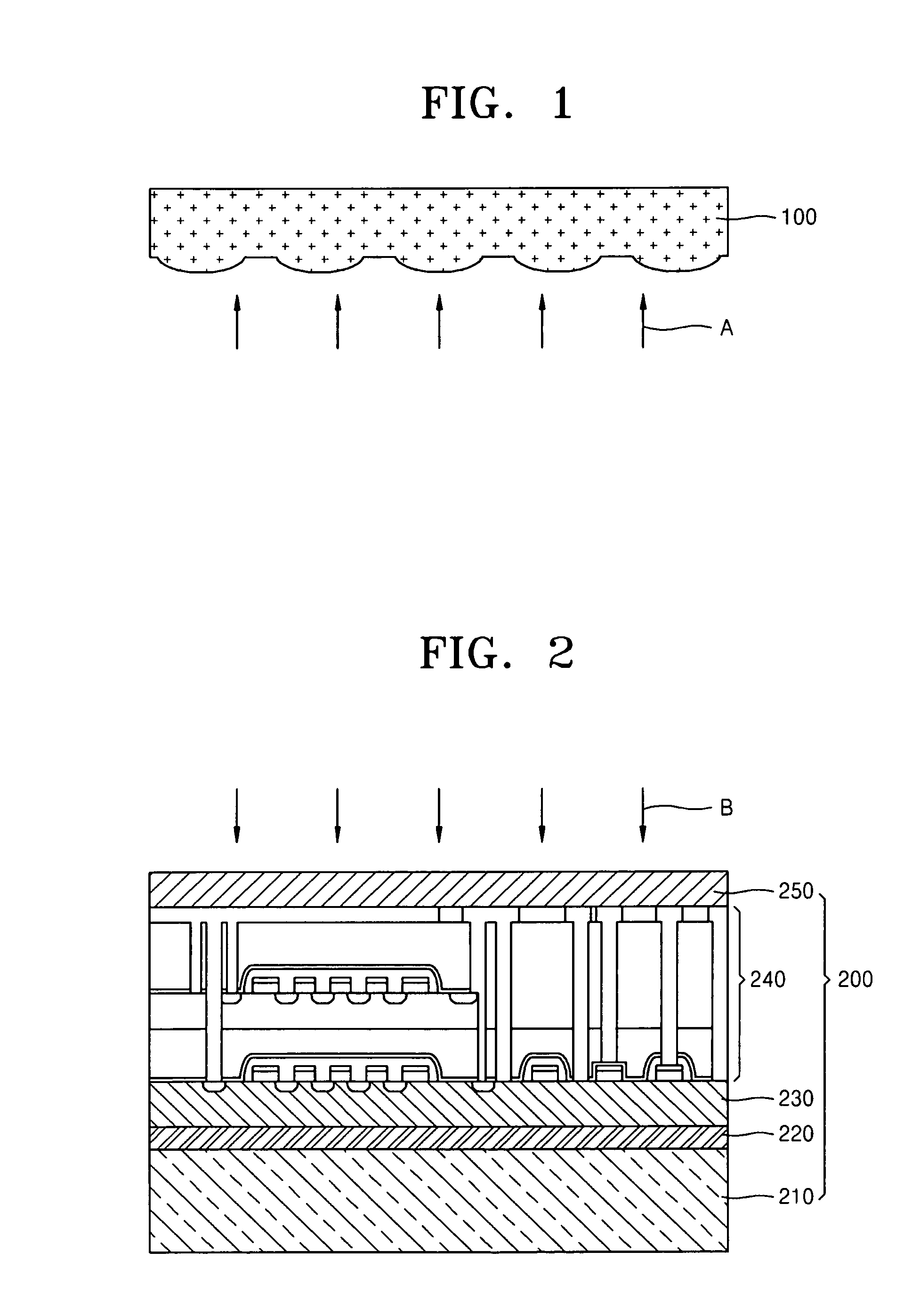

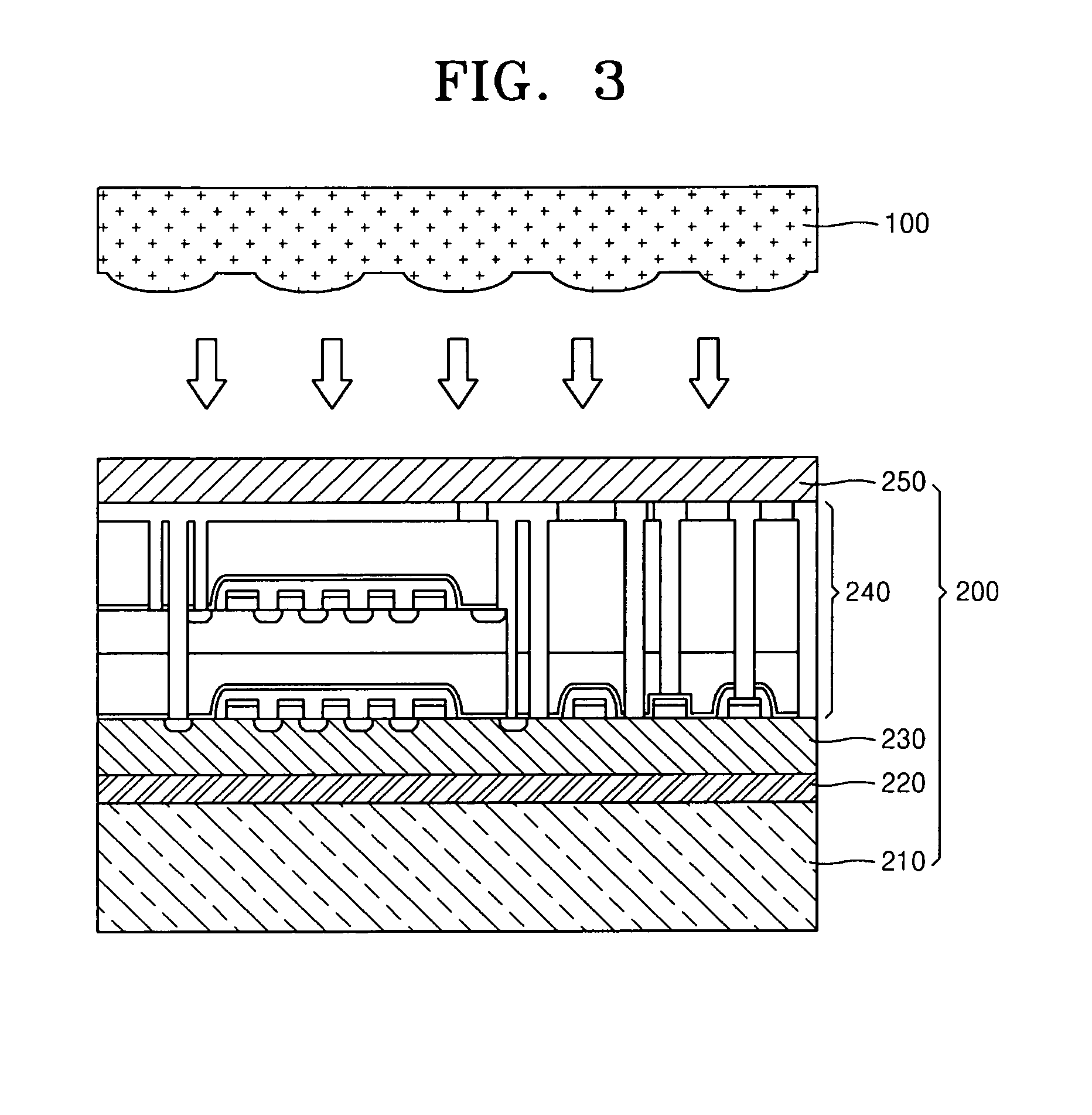

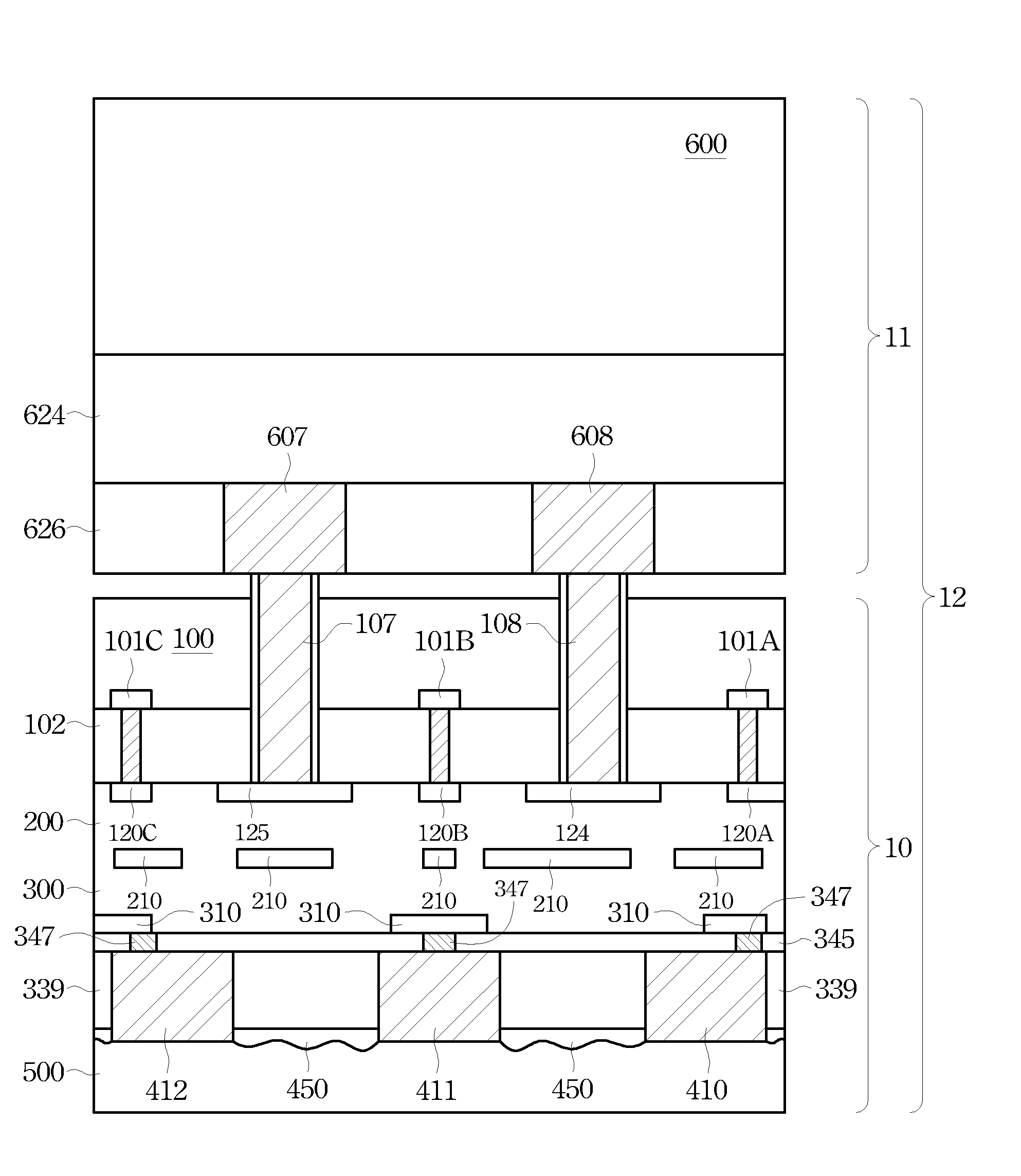

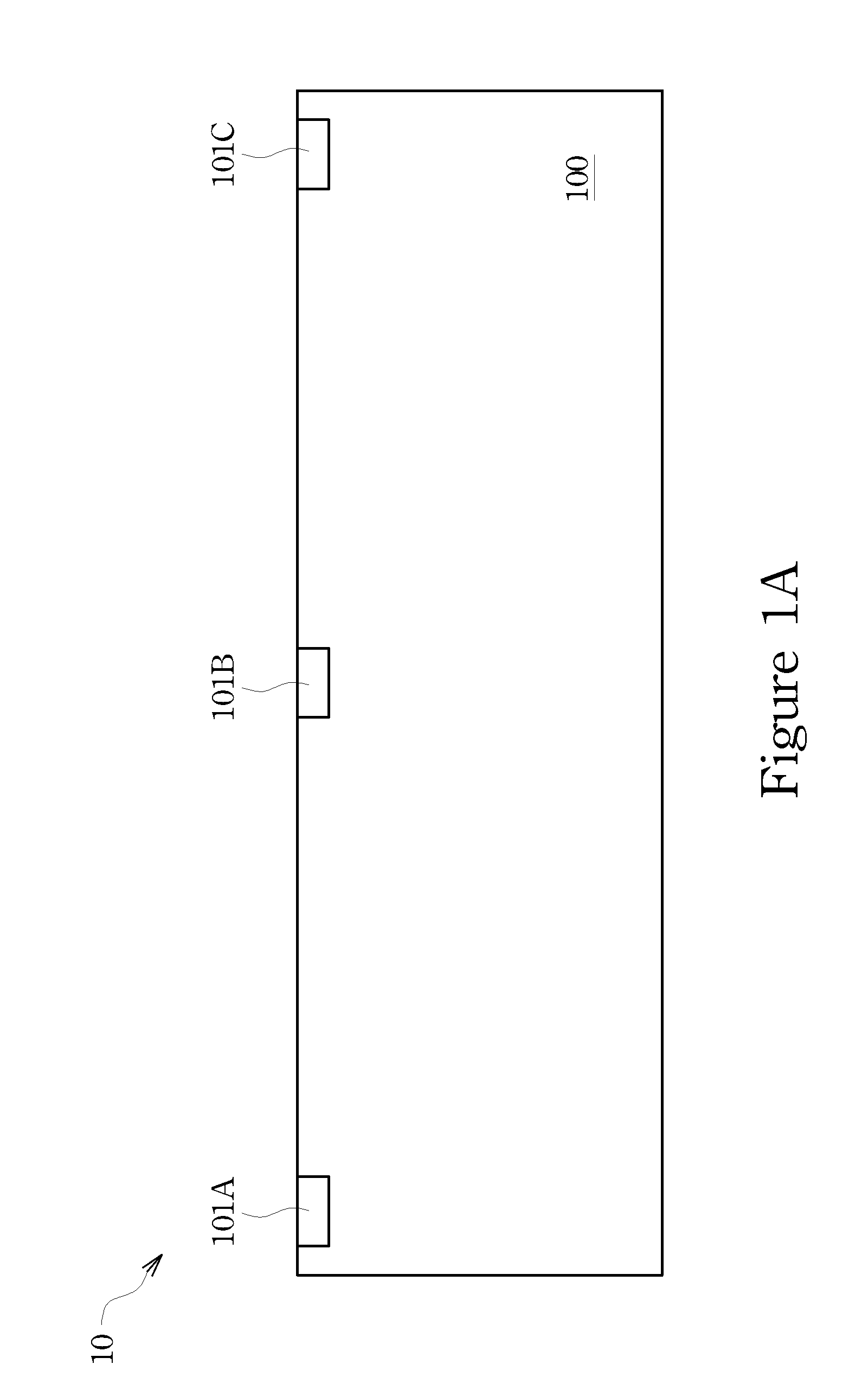

Method of forming stacked dies

ActiveUS8158456B2High aspect ratioReduce riskSolid-state devicesSemiconductor/solid-state device manufacturingWafer backgrindingSilicon

The formation of through silicon vias (TSVs) in an integrated circuit (IC) die or wafer is described in which the TSV is formed in the integration process prior to metallization processing. TSVs may be fabricated with increased aspect ratio, extending deeper in a wafer substrate. The method generally reduces the risk of overly-thinning a wafer substrate in a wafer back-side grinding process typically used to expose and make electrical contacts to the TSVs. By providing deeper TSVs and bonding pads, individual wafers and dies may be bonded directly between the TSVs and bonding pads on an additional wafer.

Owner:TAIWAN SEMICON MFG CO LTD

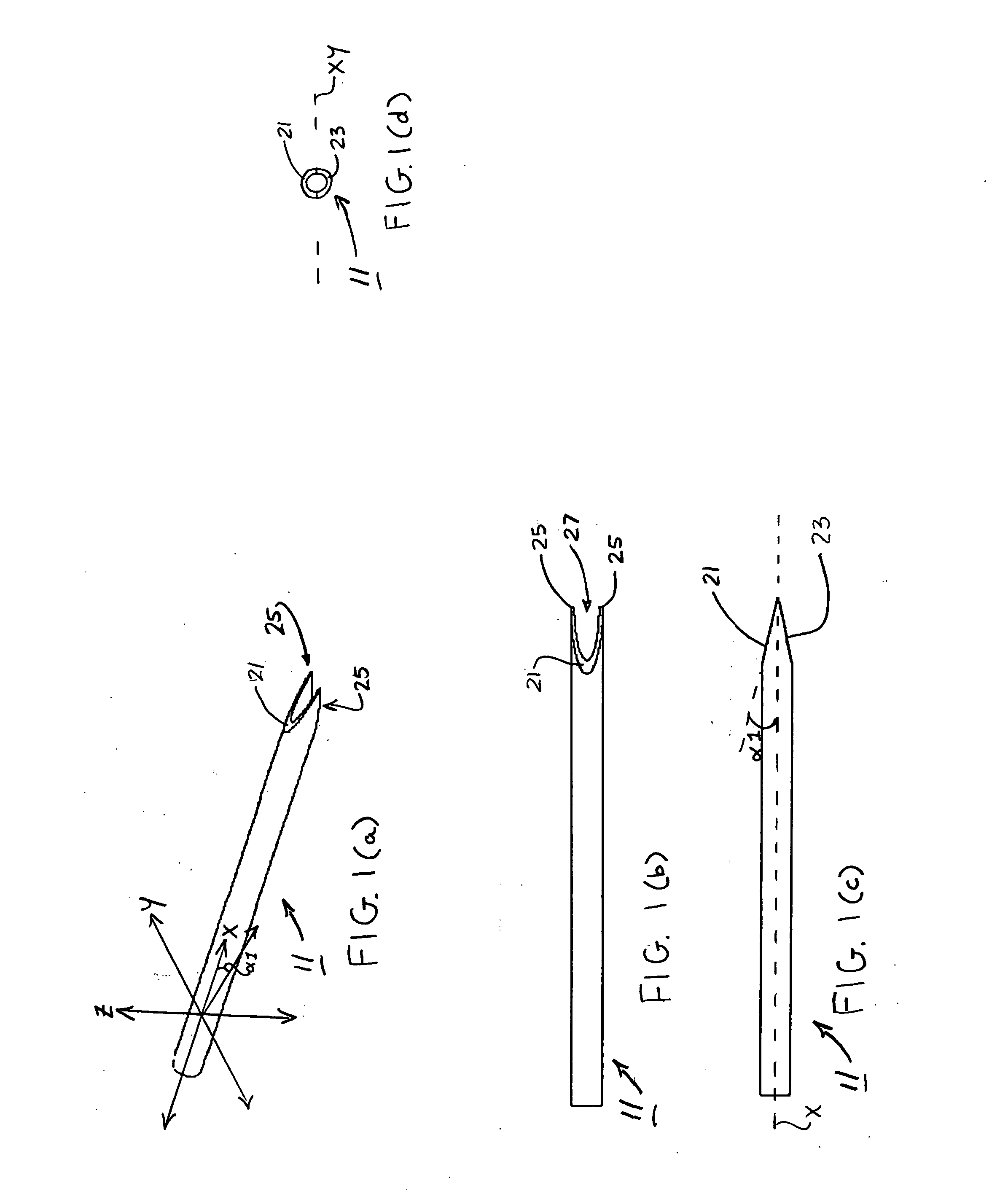

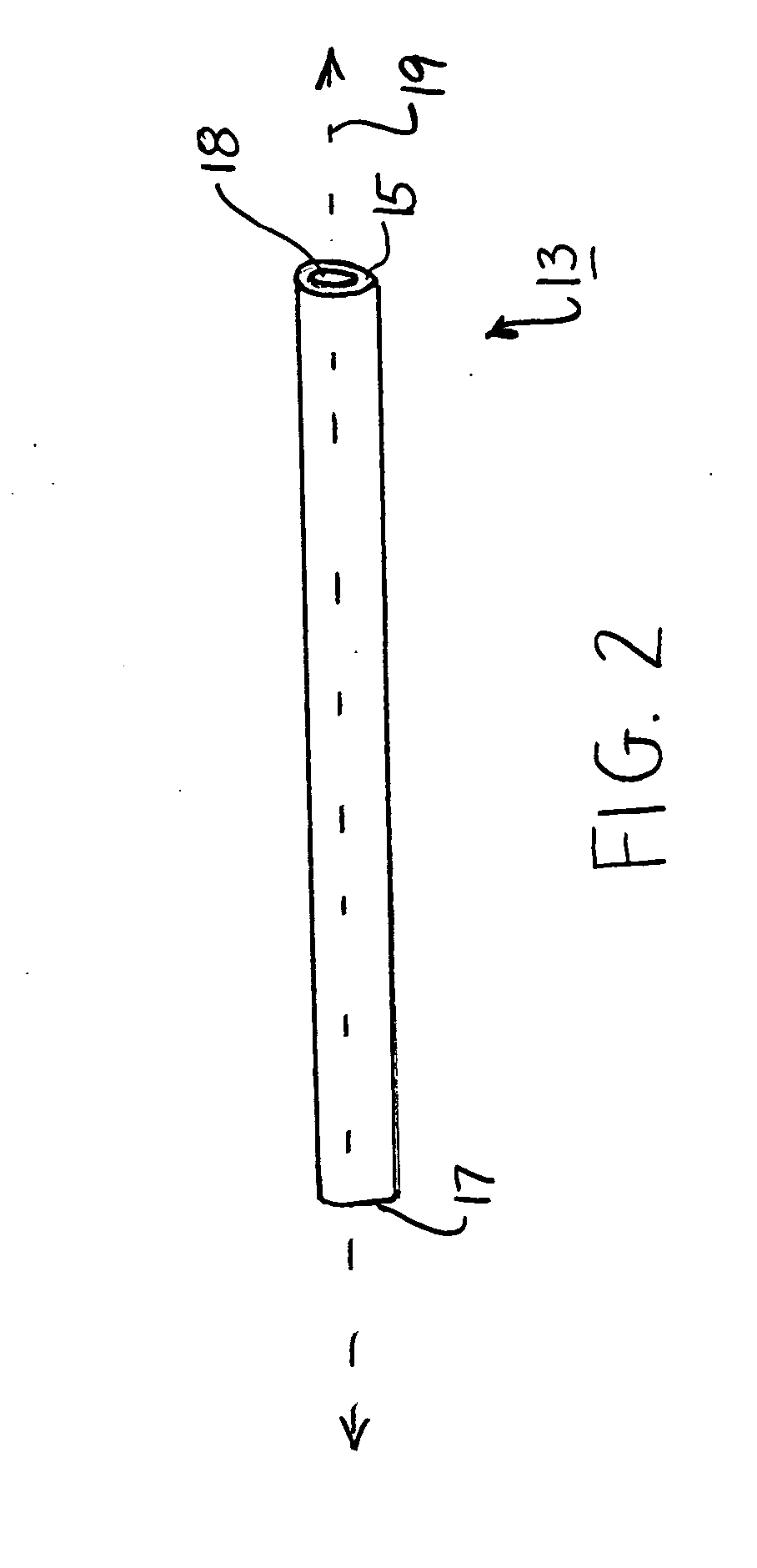

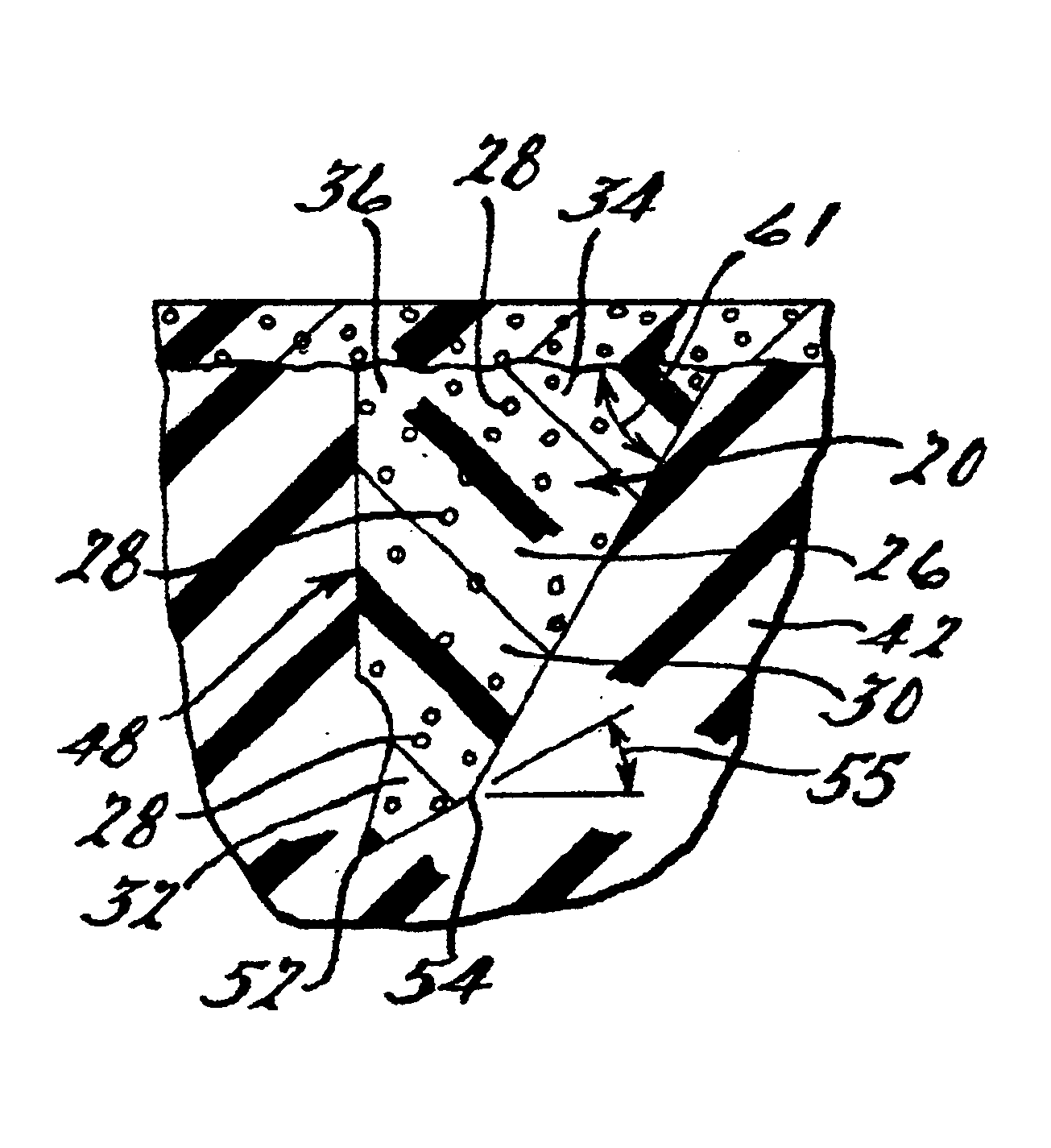

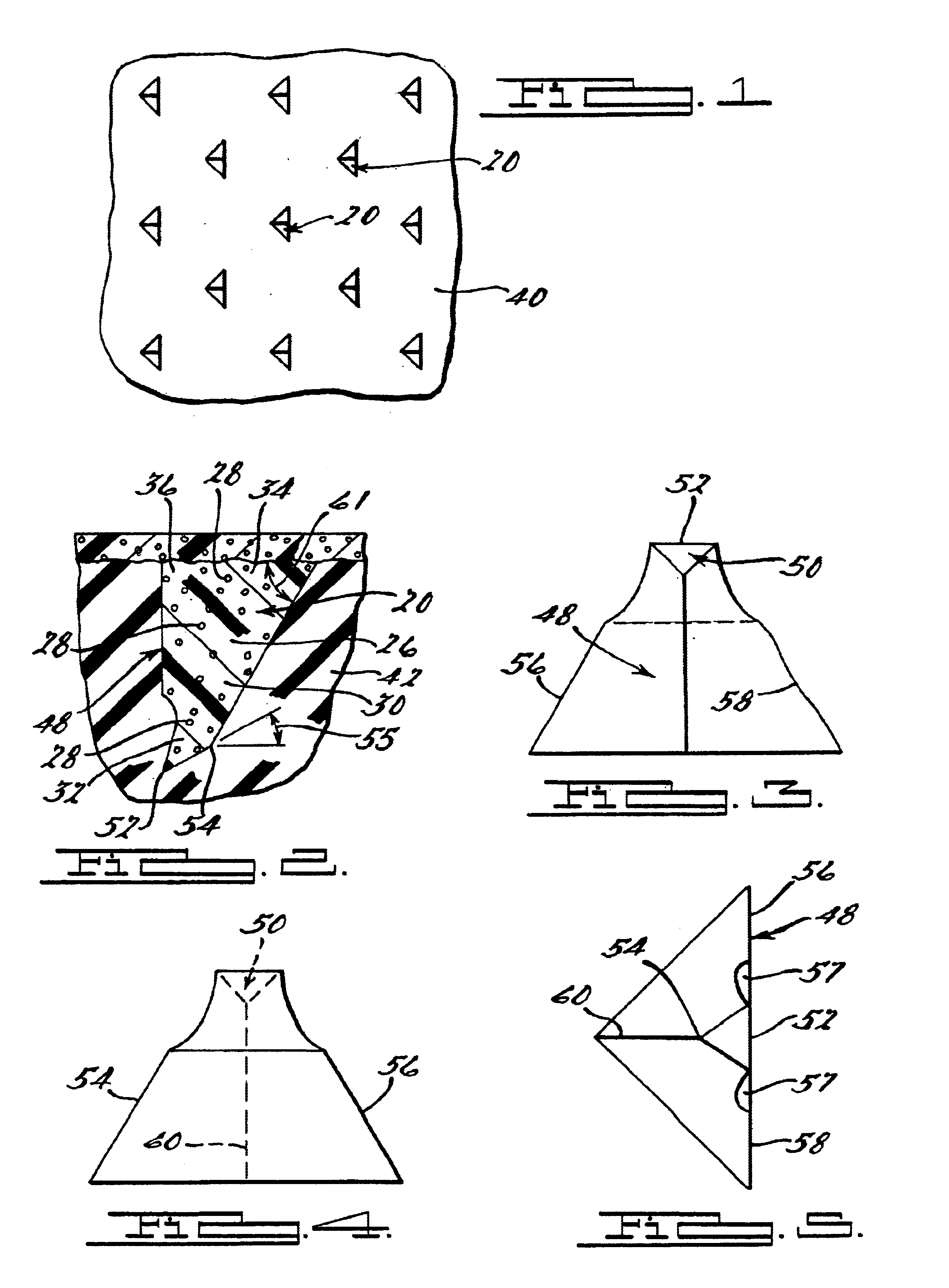

Lancet and method of manufacturing the same

InactiveUS20050171567A1Minimal discomfortSufficient amountSurgical needlesCatheterEngineeringTissue skin

A lancet for acquiring a blood sample includes a unitary member which is hollow along at least a portion of its length. Preferably, the unitary member is in the form of a seamless cylindrical tube which is constructed out of a rigid and durable material, such as stainless steel. During the lancet manufacturing process, a series of individual grinding processes are performed on one end of the unitary member to yield a lancet which includes a plurality of skin-penetrable tips. In one embodiment, one end of the unitary member is subjected to a pair of single angle planar grinds to yield a lancet which includes a pair of sharpened tips. In another embodiment, one end of the unitary member is subjected to four compound angle planar grinds to yield a lancet which includes a pair of sharpened tips. In another embodiment, one end of the unitary member is subjected to three single angle planar grinds to yield a lancet which includes three equidistantly spaced sharpened tips.

Owner:ABBOTT LAB INC

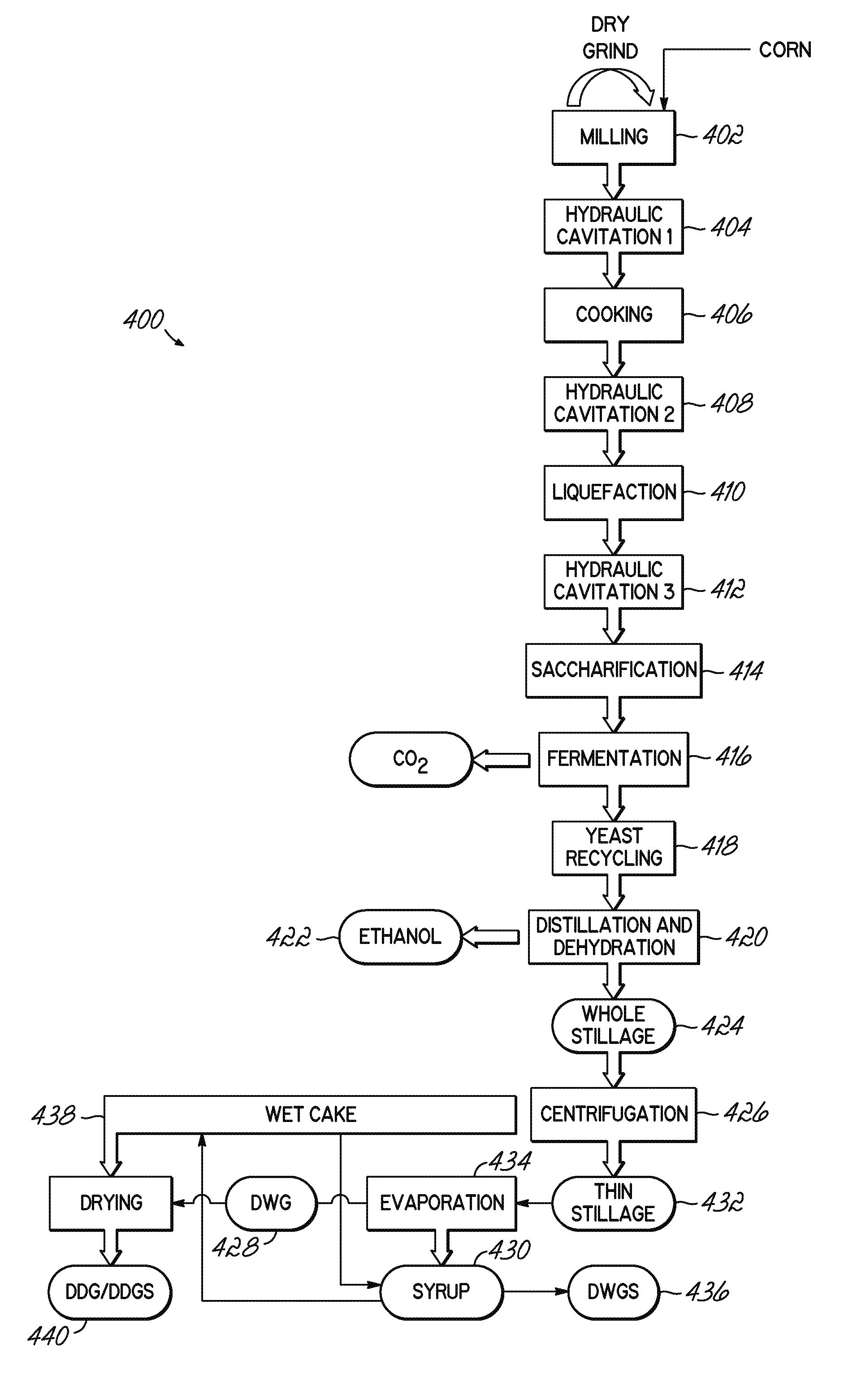

Alcohol production using hydraulic cavitation

InactiveUS20080277264A1Increase speedHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsCavitationLiquid medium

A system and method is provided which includes using a liquid treatment apparatus, which is equipped with cyclonettes, for example, to subject a liquid medium processing stream in an alcohol production process to hydraulic cavitation, i.e., to shear under vacuum, at one or more locations. The liquid treatment apparatus, in one embodiment, is directed to the formation of a central axial jet and a vacuum chamber that can be sealed by the exiting jet. Cavitation is generated by directing a high velocity jet of liquid medium processing stream through a volume of vapor under a vacuum created in the chamber through which the jet travels. This can reduce the production cost of alcohol, such as ethanol, by improving alcohol yield per bushel, among other benefits. In one embodiment, the alcohol production process is a dry grind process, a modified dry grind process, or a wet mill process. In one embodiment the alcohol production process utilizes grain as a starting material.

Owner:FLUID QUIP INC

Wafer level packaging method

ActiveUS20180323227A1Improve Wafer YieldIncrease productionSemiconductor/solid-state device detailsSolid-state devicesEngineeringGrinding process

A wafer level packaging method includes the following steps. A first wafer is bonded over a second wafer. A first grinding process on the first wafer is performed, to remove an upper chamfered edge of the first wafer and reduce a thickness of the first wafer. A trimming process is performed on the first wafer, to remove a lower chamfered edge of the first wafer to form a trimmed first wafer. A second grinding process is performed on the trimmed first wafer, to reduce a thickness of the trimmed first wafer.

Owner:UNITED MICROELECTRONICS CORP

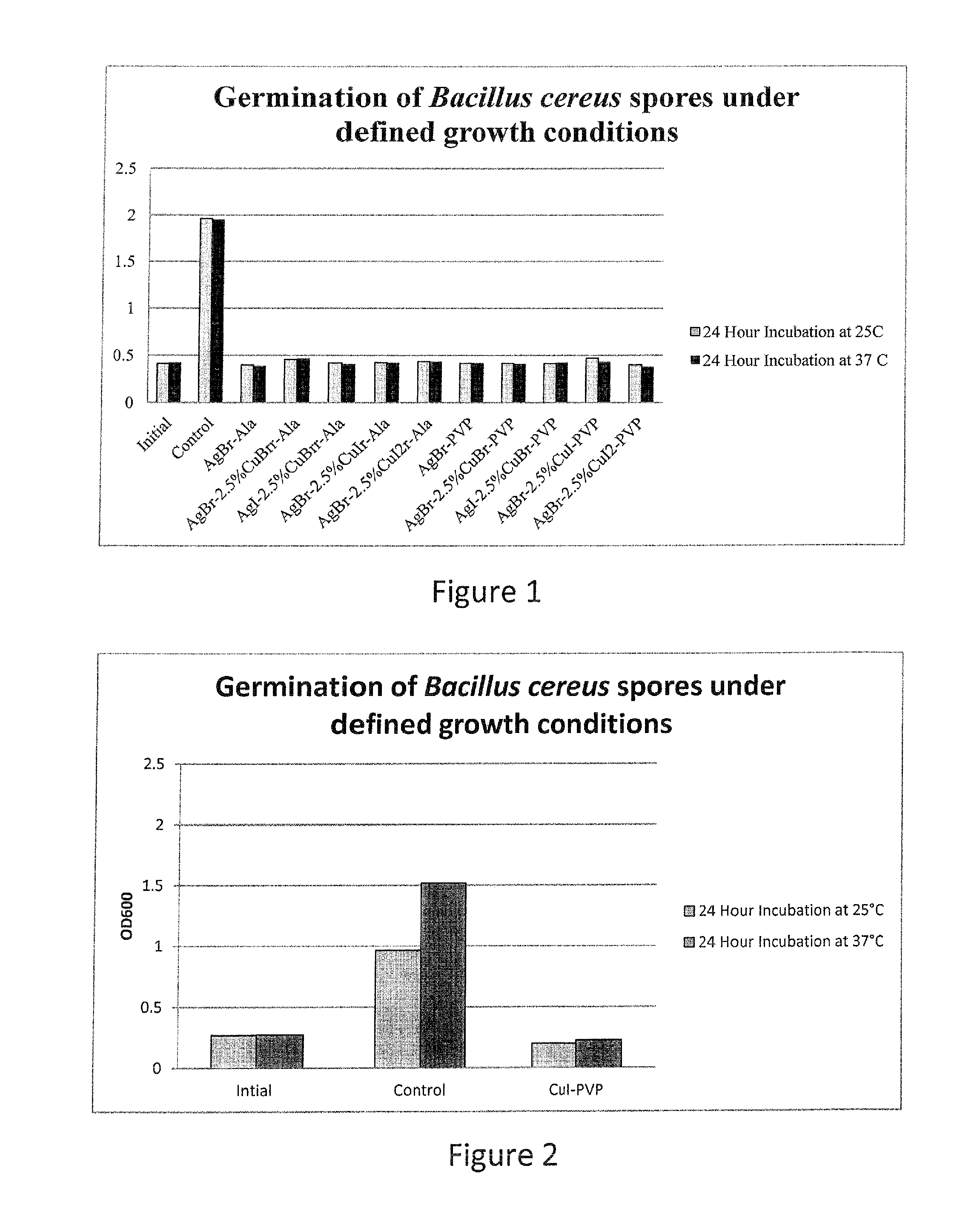

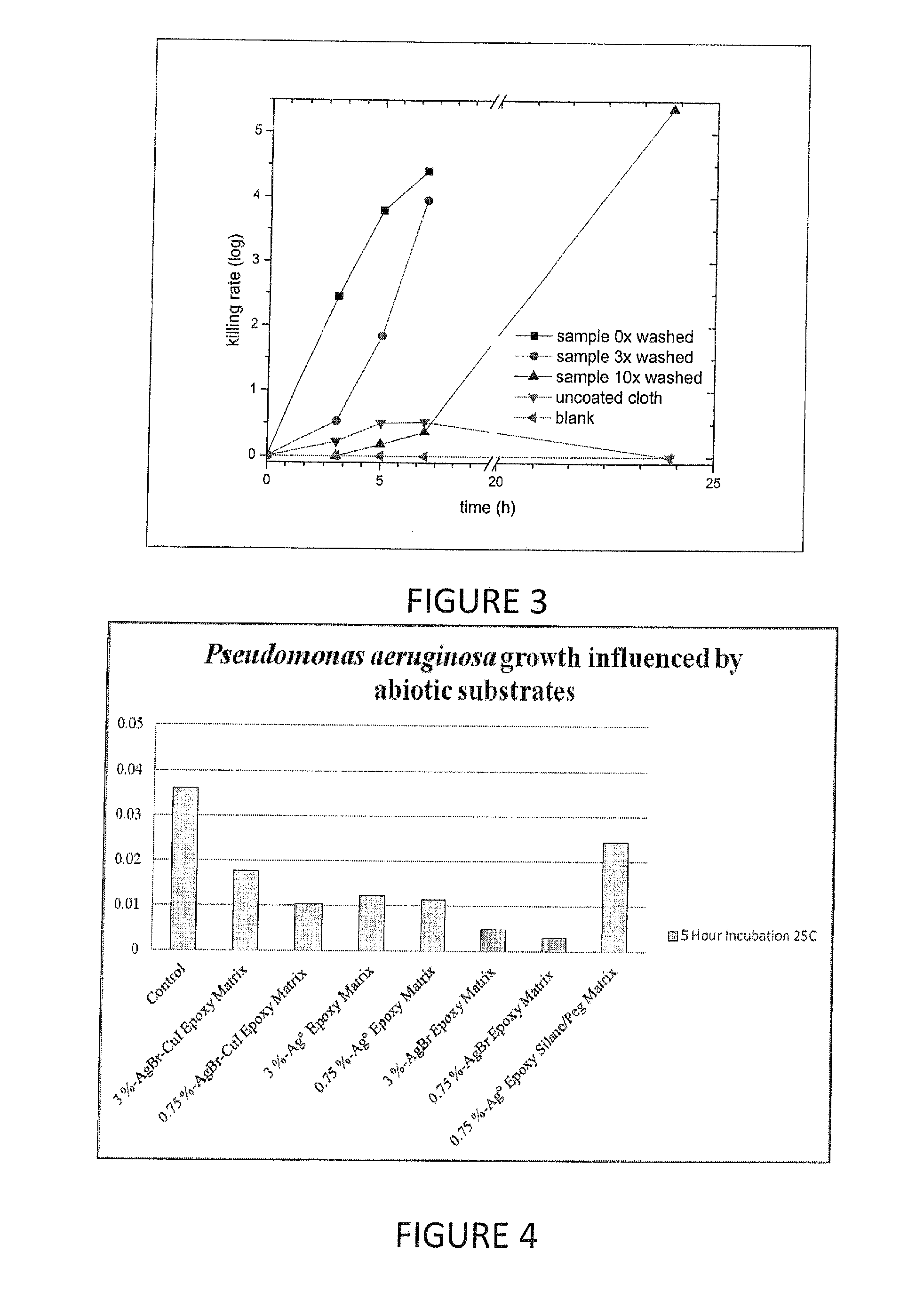

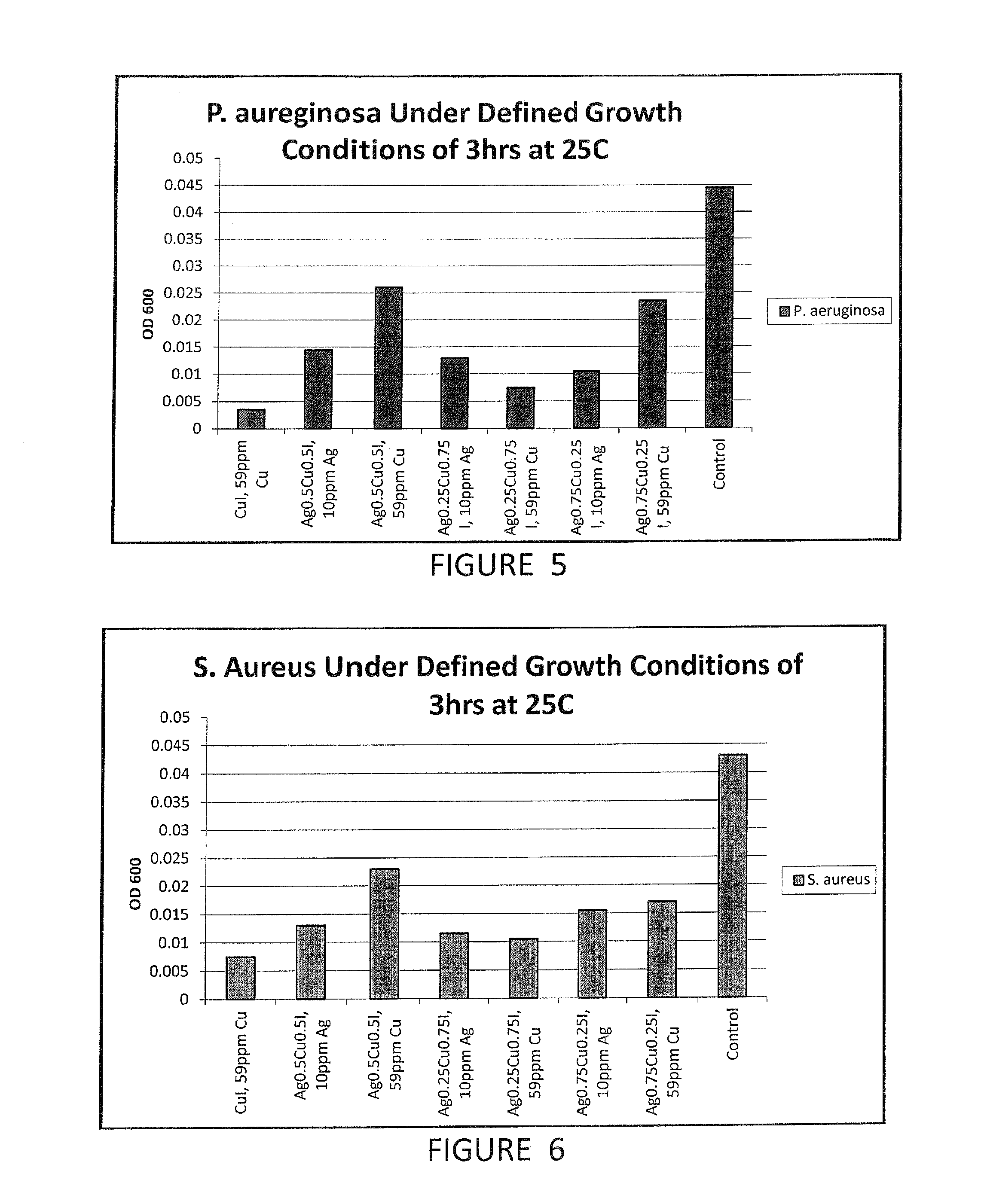

Compositions and methods for antimicrobial metal nanoparticles

InactiveUS20130315972A1Improve efficacyImprove utilizationBiocideInorganic active ingredientsHydrophilic polymersHydrophobic polymer

Compositions having antimicrobial activity contain particles comprising at least one inorganic copper salt; and at least one functionalizing agent in contact with the particles, the functionalizing agent stabilizing the particle in a carrier such that an antimicrobially effective amount of ions are released into the environment of a microbe. The average size of the particles ranges from about 1000 nm to about 3 nm. Preferred copper salts include copper iodide, copper bromide and copper chloride, most preferred being copper iodide. Preferred functionalizing agents comprise materials with a molecular weight of 60 or above, which include amino acids, other acidic materials, thiols, hydrophilic polymers, emulsions of hydrophobic polymers and surfactants. The functionalized particles are preferably made by a grinding process.

Owner:AGIENIC

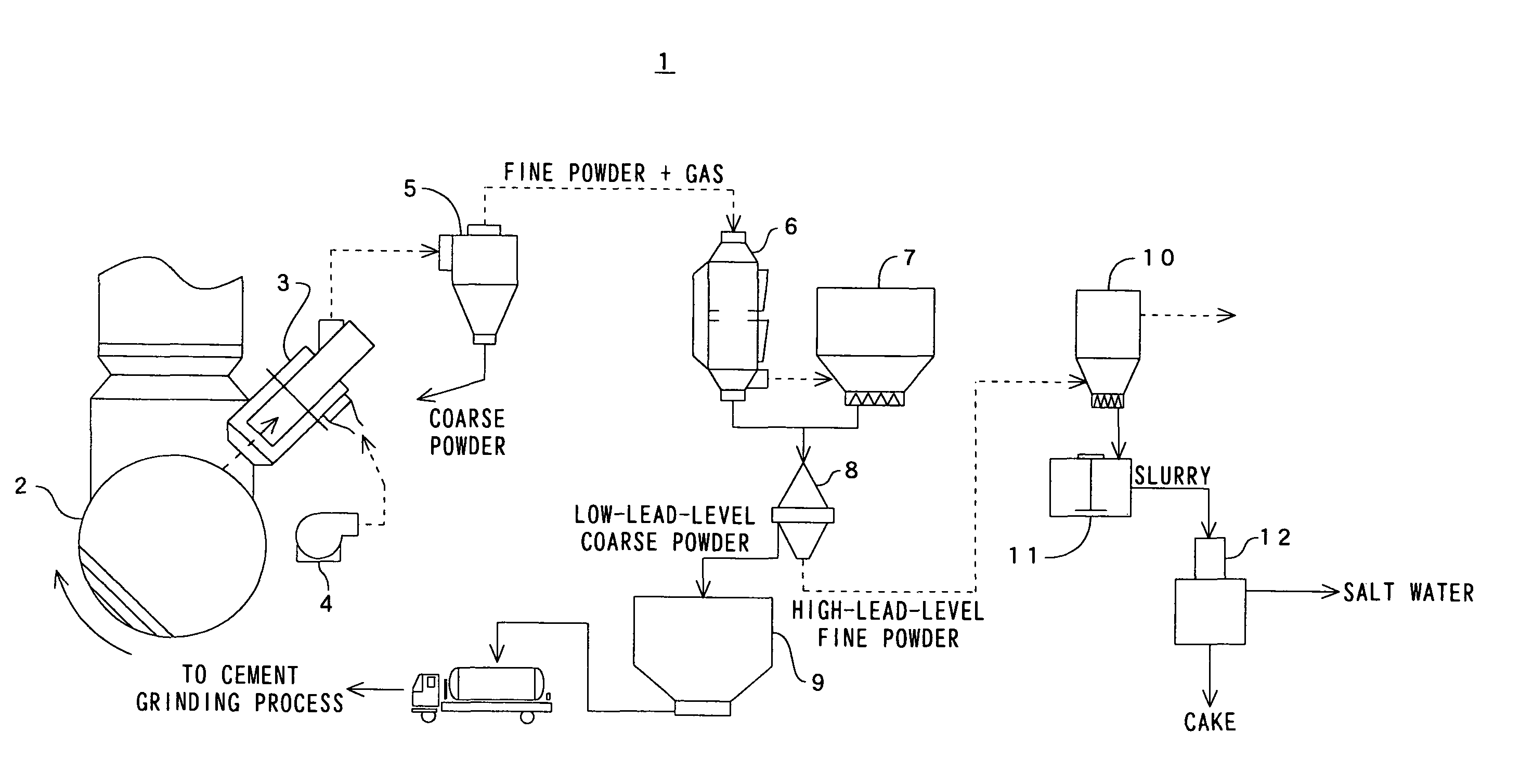

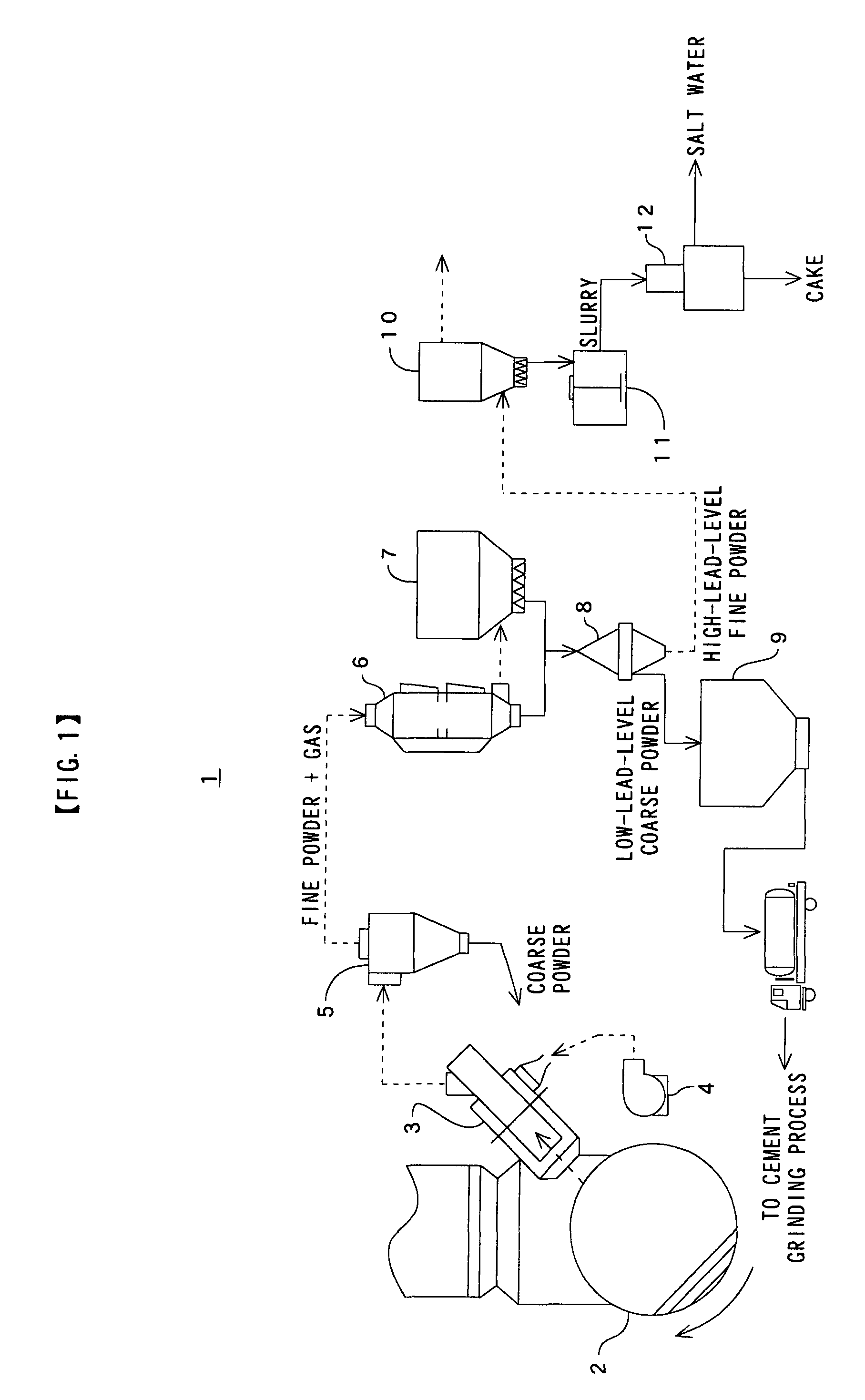

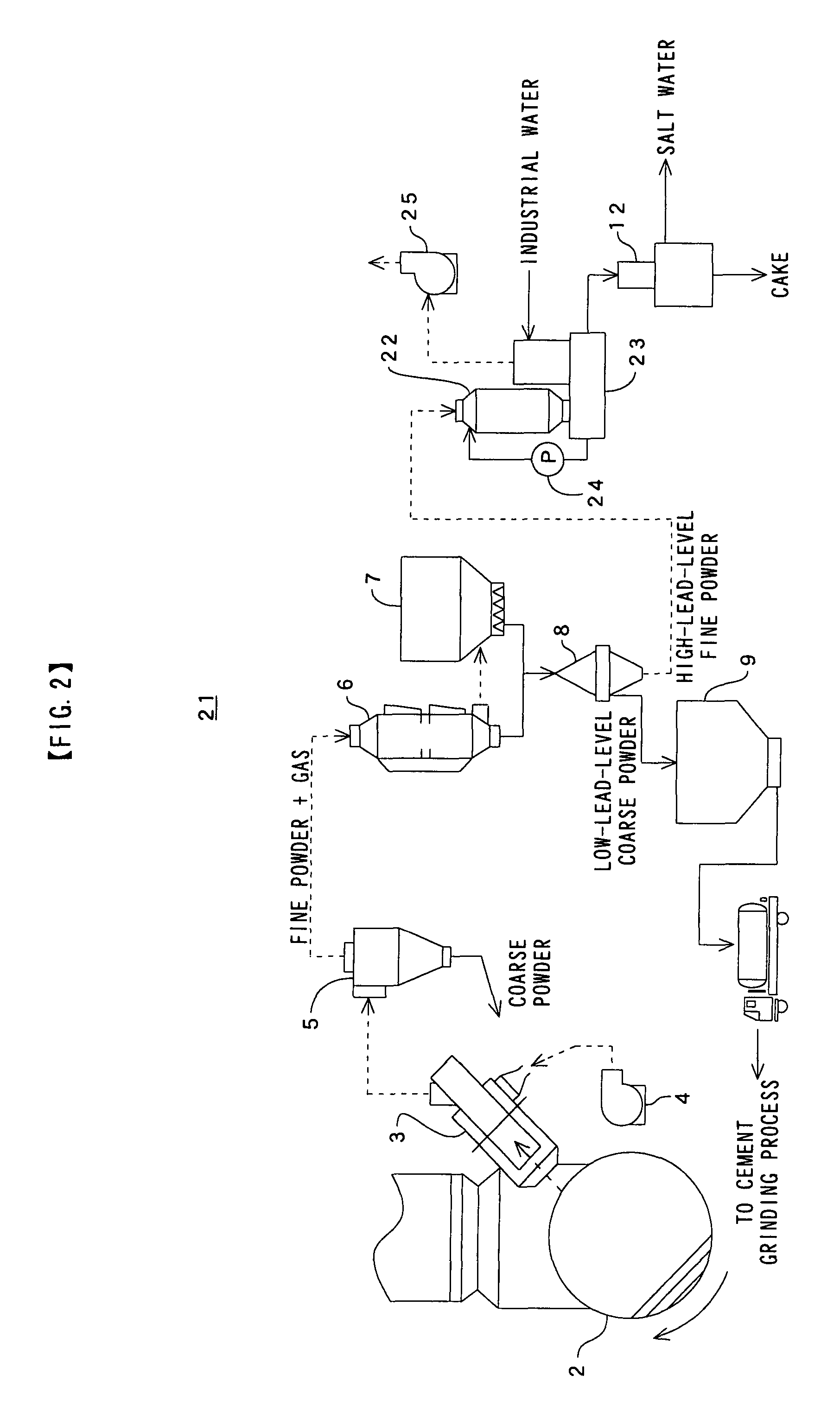

System and method for treating dust contained in extracted cement kiln combustion gas

ActiveUS7749311B2Effectively remove dustLow facility requirementsCombination devicesLiquid degasificationCycloneEngineering

A treatment system to efficiently remove lead from dust contained in extracted cement kiln combustion gas while reducing facility and running costs. A treatment system 1 comprising a probe 3 for extracting a part of combustion gas, while cooling it, from a kiln exhaust gas passage, which runs from an inlet end of a cement kiln to a bottom cyclone; a first classifier 5 for separating coarse powder from dust contained in the combustion gas extracted; a dust collector 7 for collecting dust from the extracted gas containing fine powder discharged from the first classifier 5; and a second classifier 8 for dividing dust discharged from the dust collector 7 into fine powder and coarse powder, and others. Since more lead is distributed on the fine powder side classified by the second classifier 8, lead can efficiently be removed without using chemicals and the like. The fine powder classified by the classifier 8 may be desalted by washing; high-lead-level cake obtained after the washing can be recycled; or salt water can be added to a cement mill. The coarse powder may be added to a cement grinding process or returned to cement material grinding process after the desaltation through washing.

Owner:TAIHEIYO CEMENT CORP

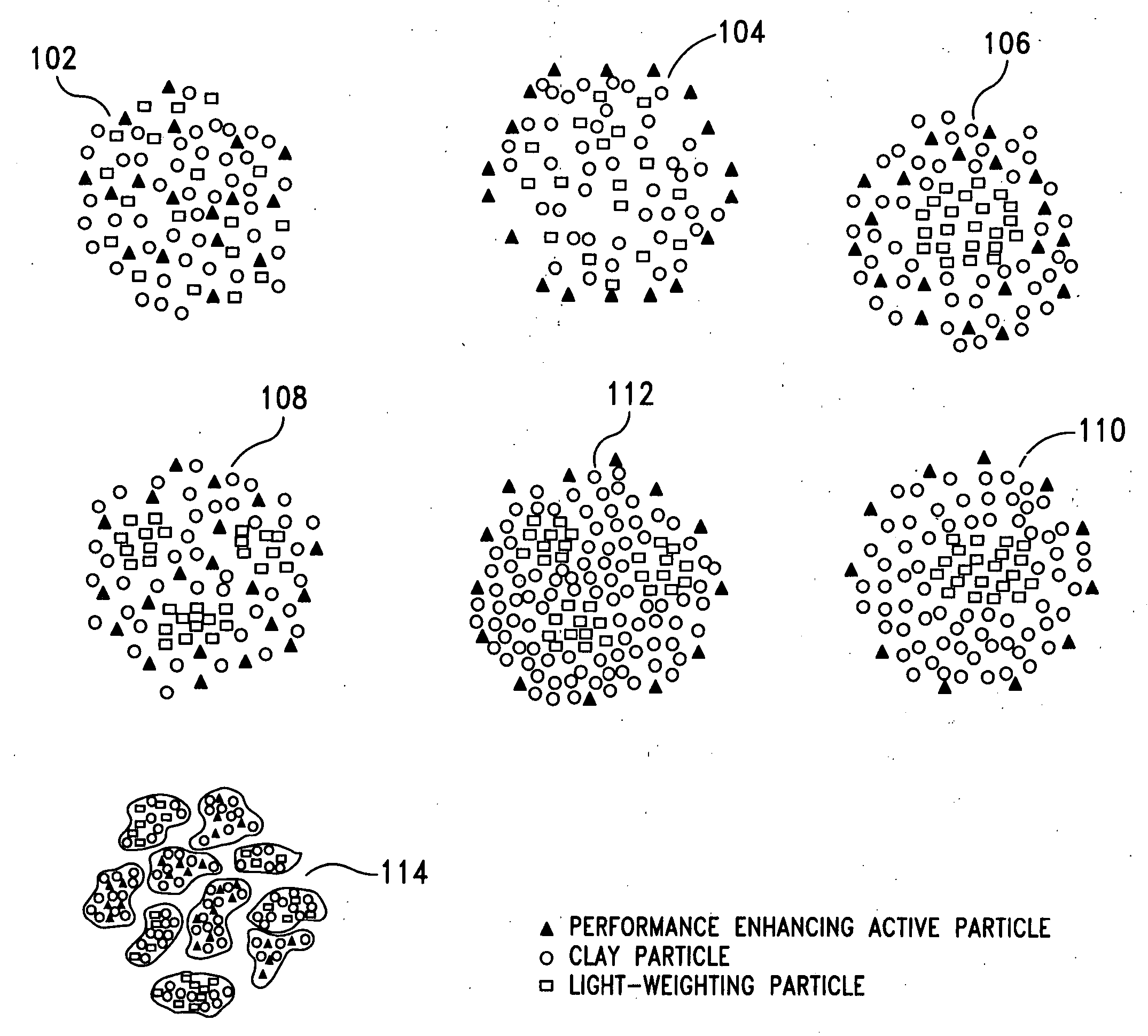

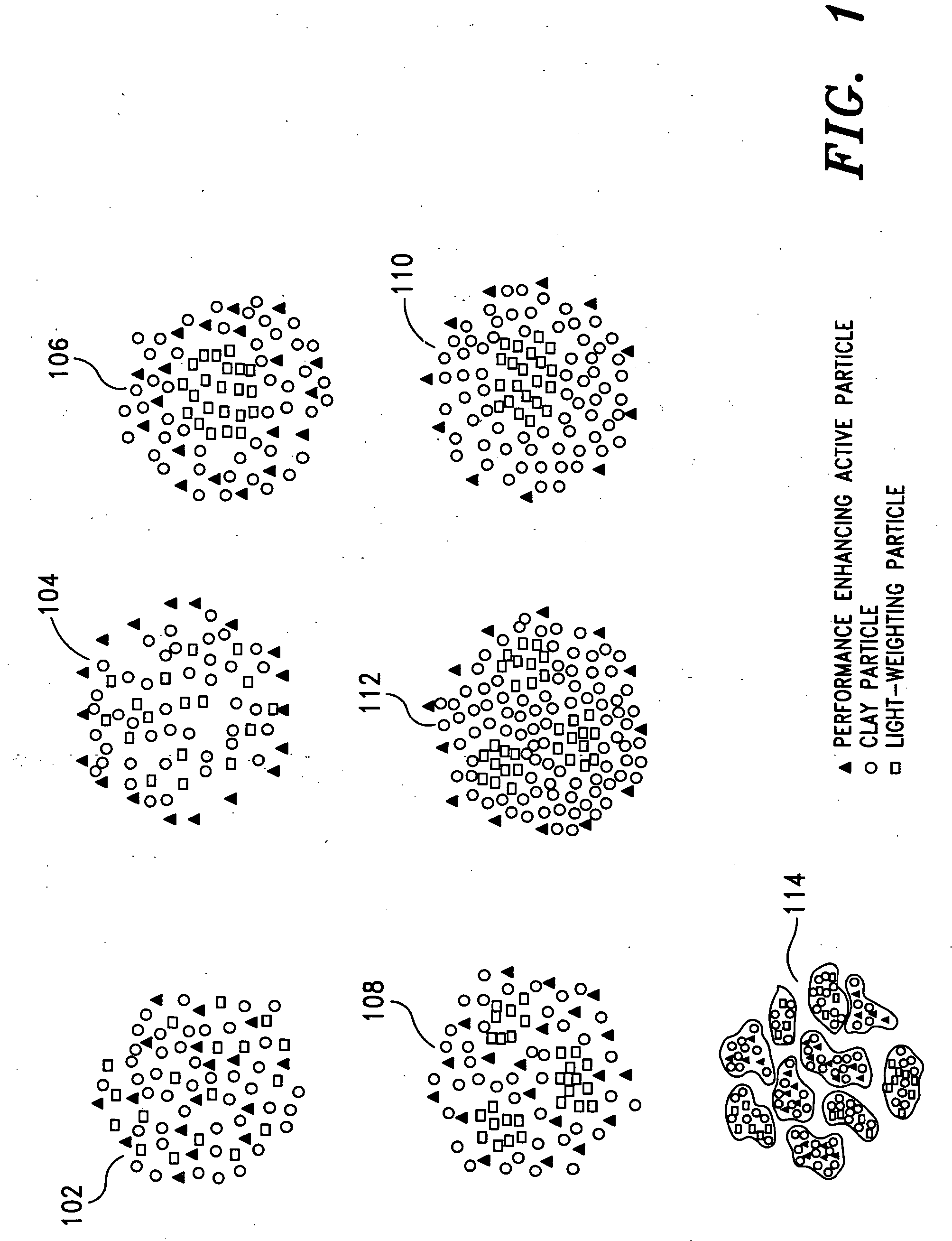

Composite particle animal litter and method thereof

Composites and methods for making the same. A mixture of clay material and a light-weighting material is formed into a composite particle. An optional performance-enhancing active is coupled to the composite particle material before, during, or after the particle-forming process, homogeneously and / or in layers. Preferred methods for creating the composites include a pan agglomeration process, a high shear agglomeration process, a low shear agglomeration process, a high pressure agglomeration process, a low pressure agglomeration process, a rotary drum agglomeration process, a mix muller process, a roll press compaction process, a pin mixer process, a batch tumble blending mixer process, an extrusion process, and a fluid bed process.

Owner:THE CLOROX CO

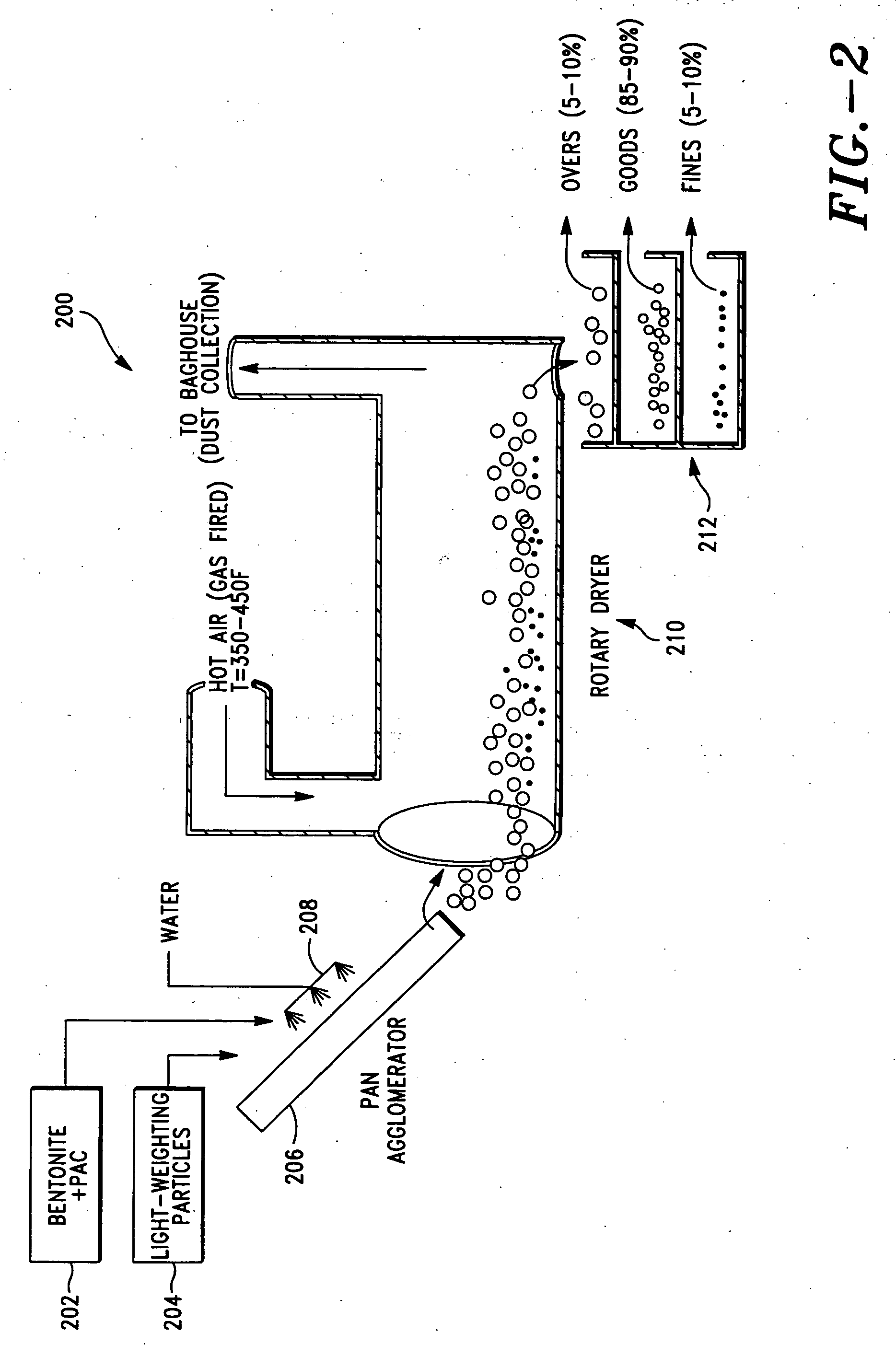

Collophanite direct flotation and reverse flotation technique

The invention relates to a positive-negative floatation technology for cellophane, which comprises the following steps: subjecting siliceous-calcareous collophane ore to breaking and grinding process to dissociate ore monomer; adding water to it get ore pulp with concentration of 20 -50%; Leading the mixture to agitated tank; adding modifying agent sodium silicate and positive collector agent to ore pulp; processing the mixture in positive floating system to get foamed product; adding negative floatation agent inorganic acid and collector agent to the foamed product in negative flotation agitated tank; processing the mixture in negative floating system with carbonate vein mineral negative flotation to get foamed product as negative flotation debris and product in tank as clean ore. The invention can simplify process, deduce cost and recycle the water.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

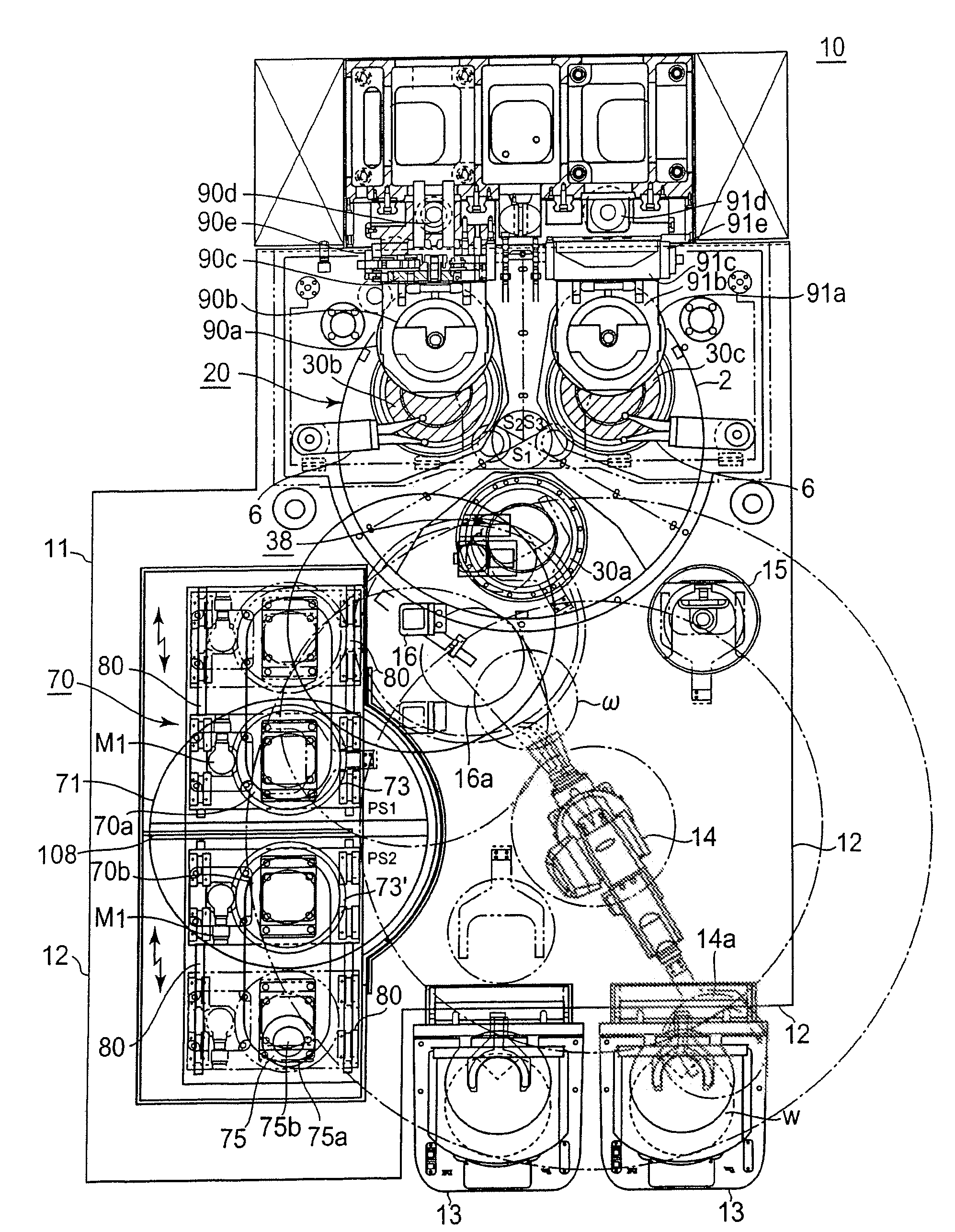

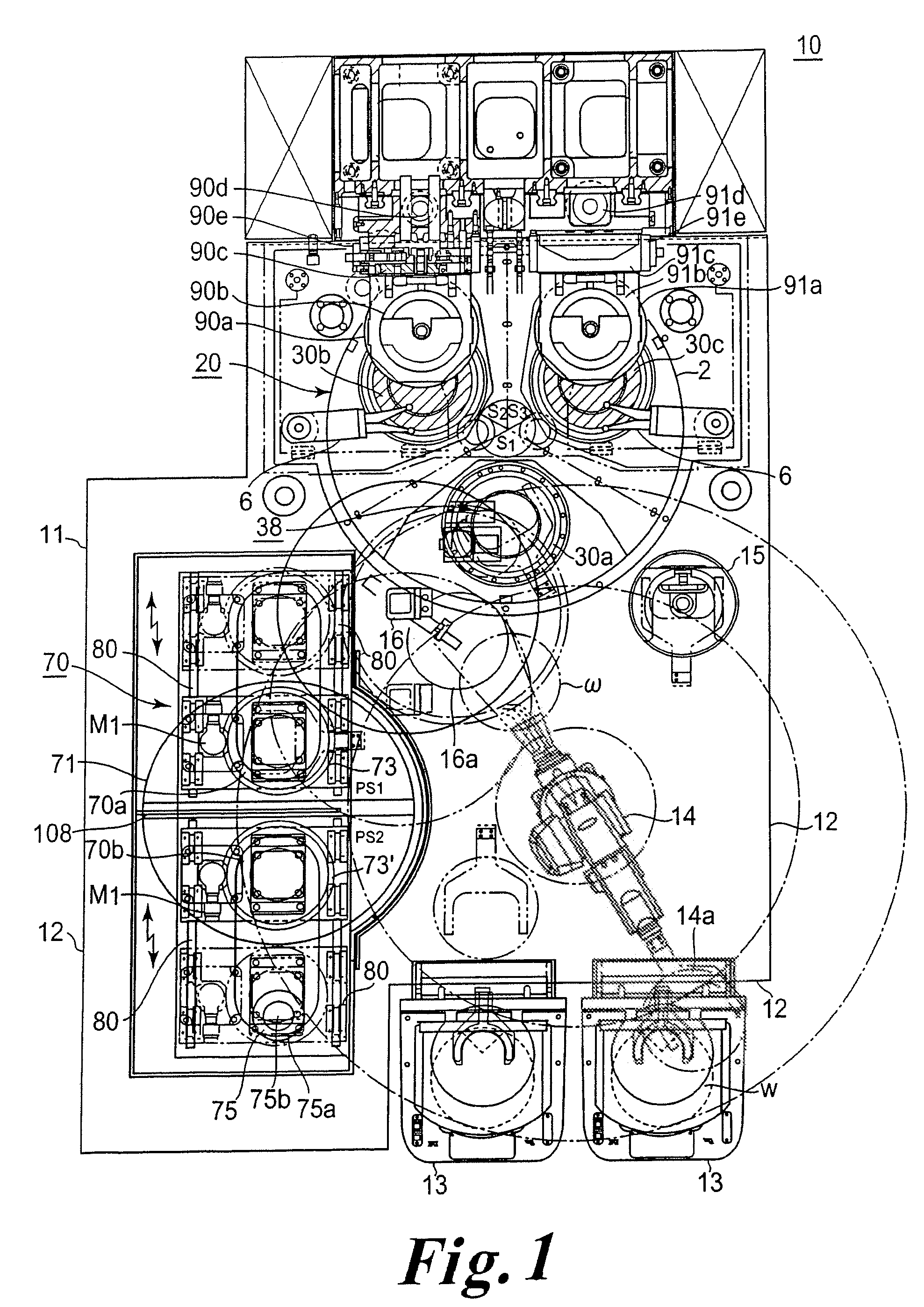

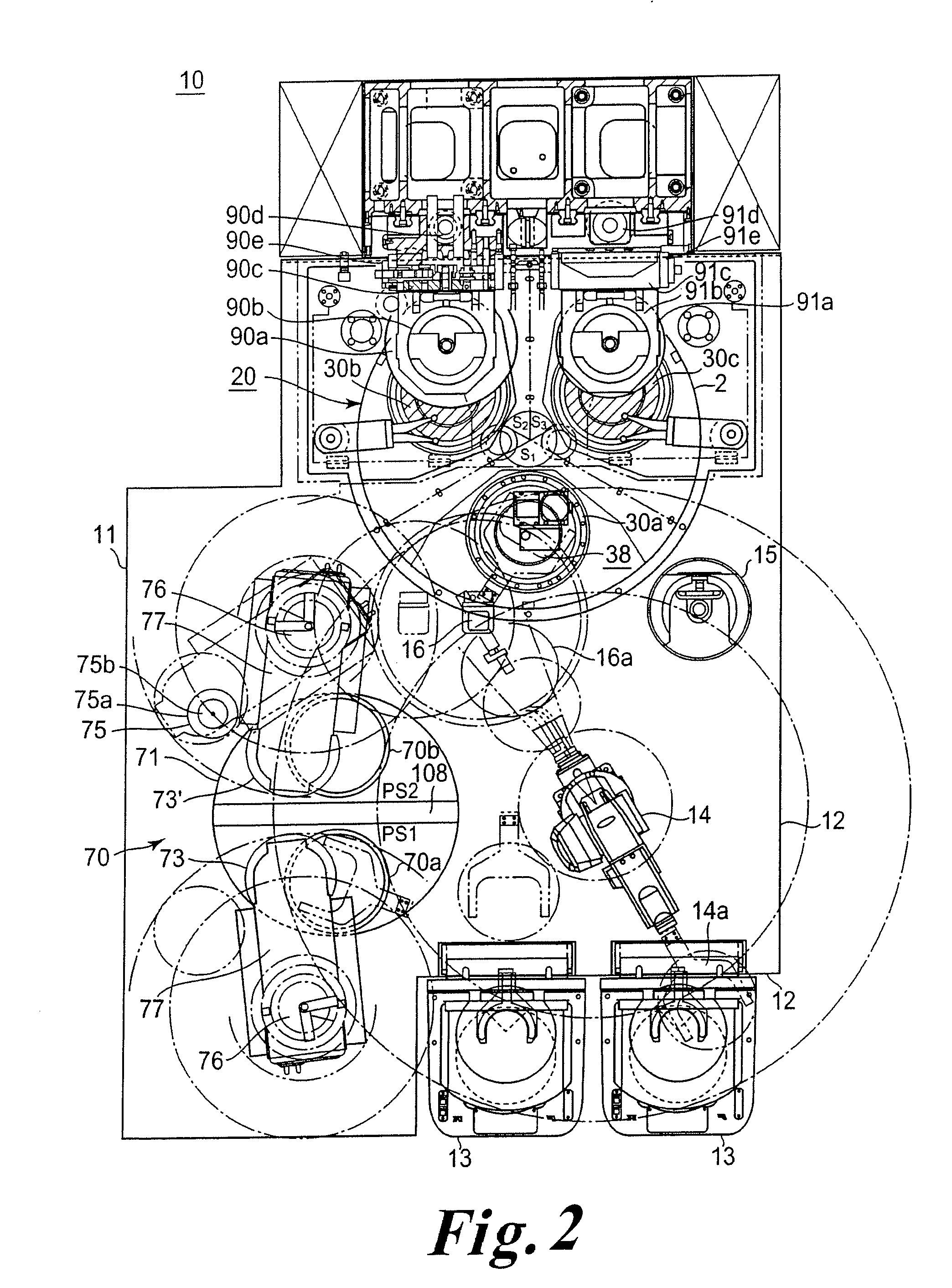

Planarizing device and a planarization method for semiconductor substrates

A substrate-planarizing device and method of using the device comprising a substrate storage stage outside a room, and on a base inside the room, a multi-joint transfer robot, a temporary alignment platform, a movable transfer pad, a grinding process stage in which substrate holders that compose three stages of a substrate loading / unloading stage, a rough grinding stage, a finish grinding stage are arranged in a concentric pattern on the first index rotary table, and a polishing process stage that has a substrate holder table composing a substrate loading / unloading / finish polishing stage as well as a substrate holder table composing a rough polishing stage arranged in a concentric pattern on the second index rotary table.

Owner:OKAMOTO MACHINE TOOL WORKS LTD

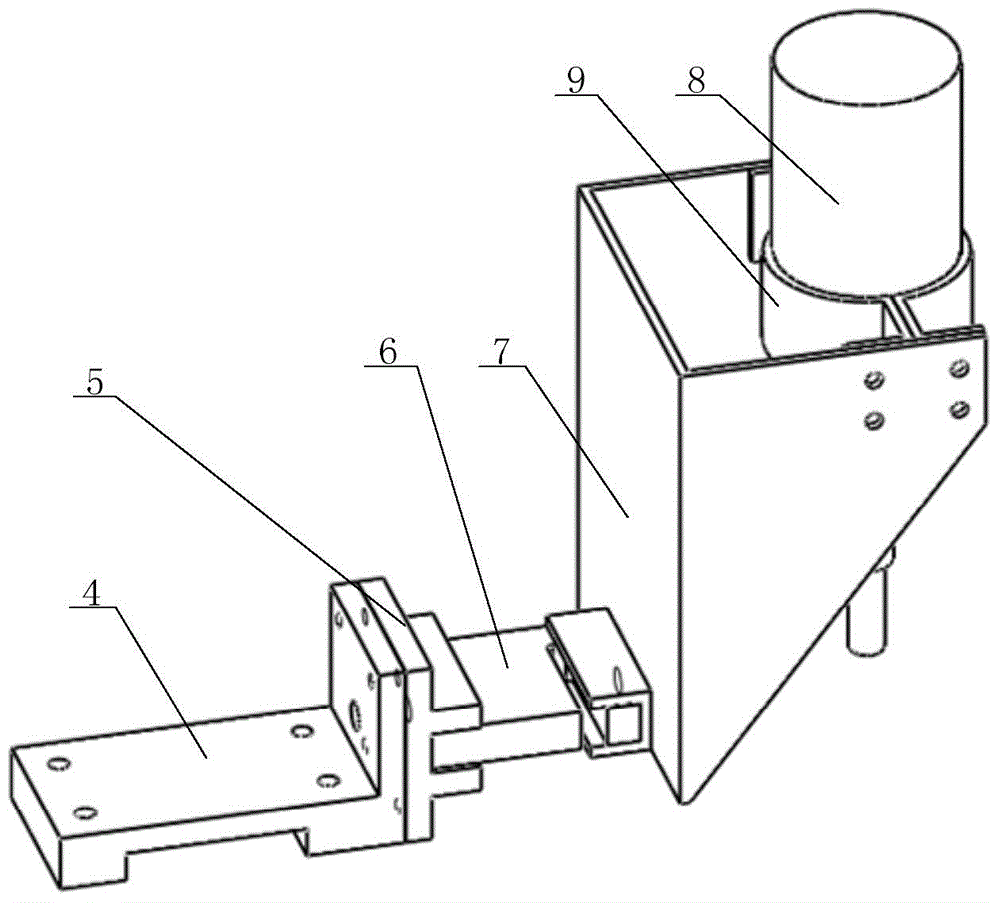

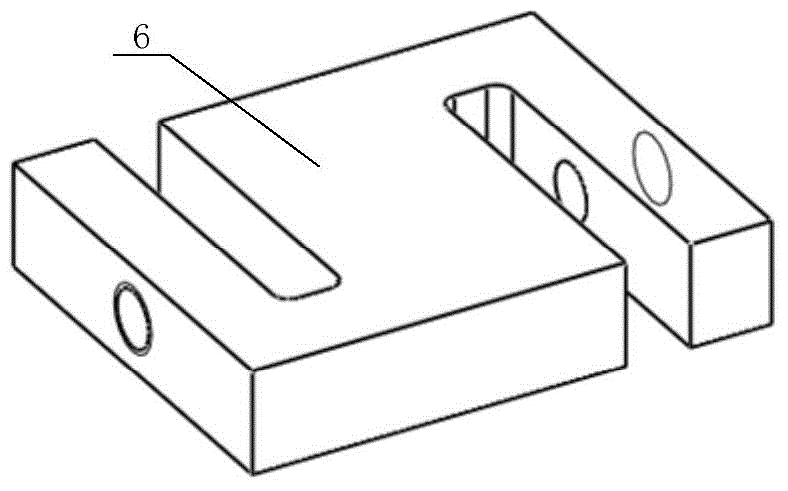

Constant pressure automatic grinding device and method based on fuzzy adaptive force control

InactiveCN104858782AReal-time control of grinding normal forceImprove versatilityGrinding feed controlSpeed/accelaration controlContact forceEngineering

The invention discloses a constant pressure automatic grinding method based on fuzzy adaptive force control. The grinding method comprises the following steps: detecting the contact force of a grinding head and a workpiece in a real-time manner to feed back force signals; changing an analog voltage value output by a controller according to a preset control algorithm, thereby controlling the output torque of an x-axis servomotor to control the contact force. The invention further provides a grinding device for realizing the grinding method. The grinding device comprises an industrial control main engine, a workbench, motion mechanisms, one-dimensional sensing equipment, a position sensor for acquiring the position coordinate of the workpiece, grinding equipment and workpiece clamping equipment. The grinding device can be used for detecting the normal grinding force in a grinding process based on an intelligent force control technology, and feeding back detection results; through the processing of the controller, driving signals are generated for continuous adjustment of the output torque of a driver, so that the normal grinding force can be controlled in a real-time manner and the constant pressure grinding can be realized.

Owner:SOUTH CHINA UNIV OF TECH

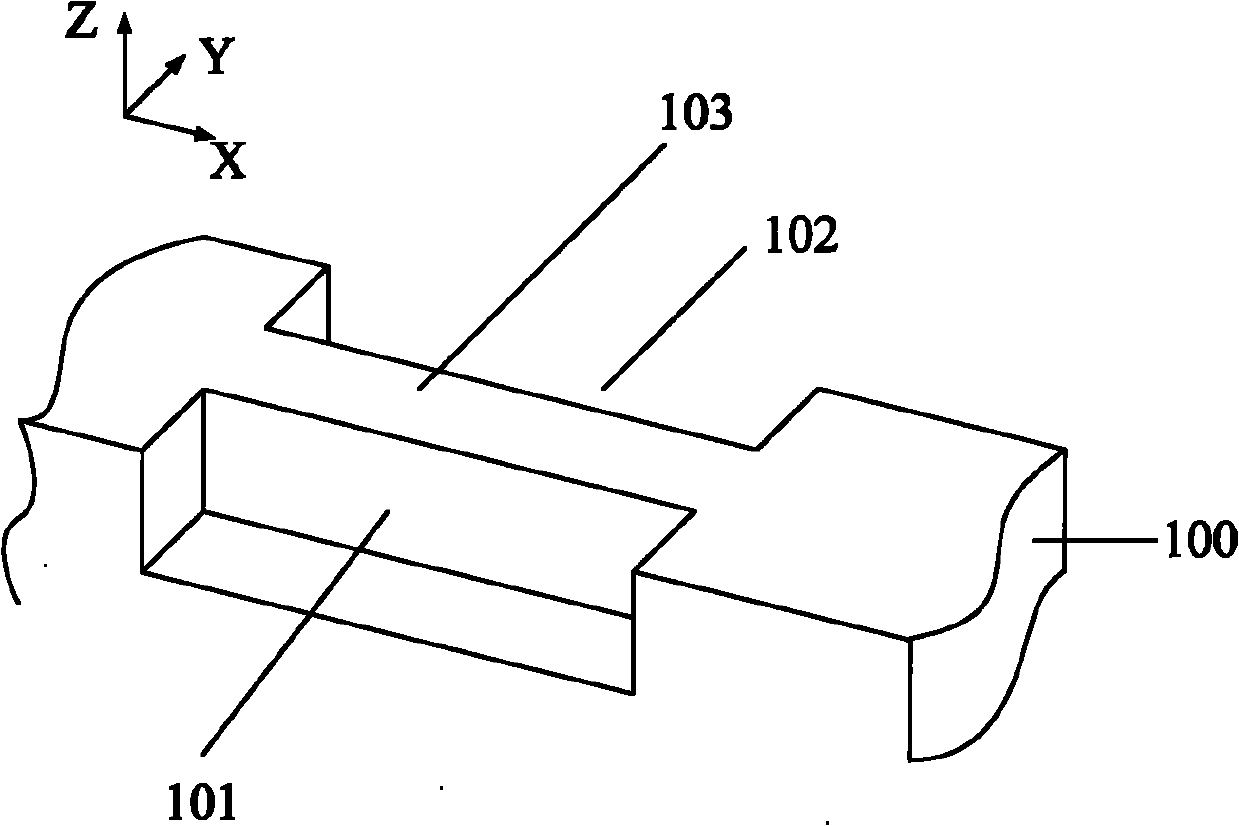

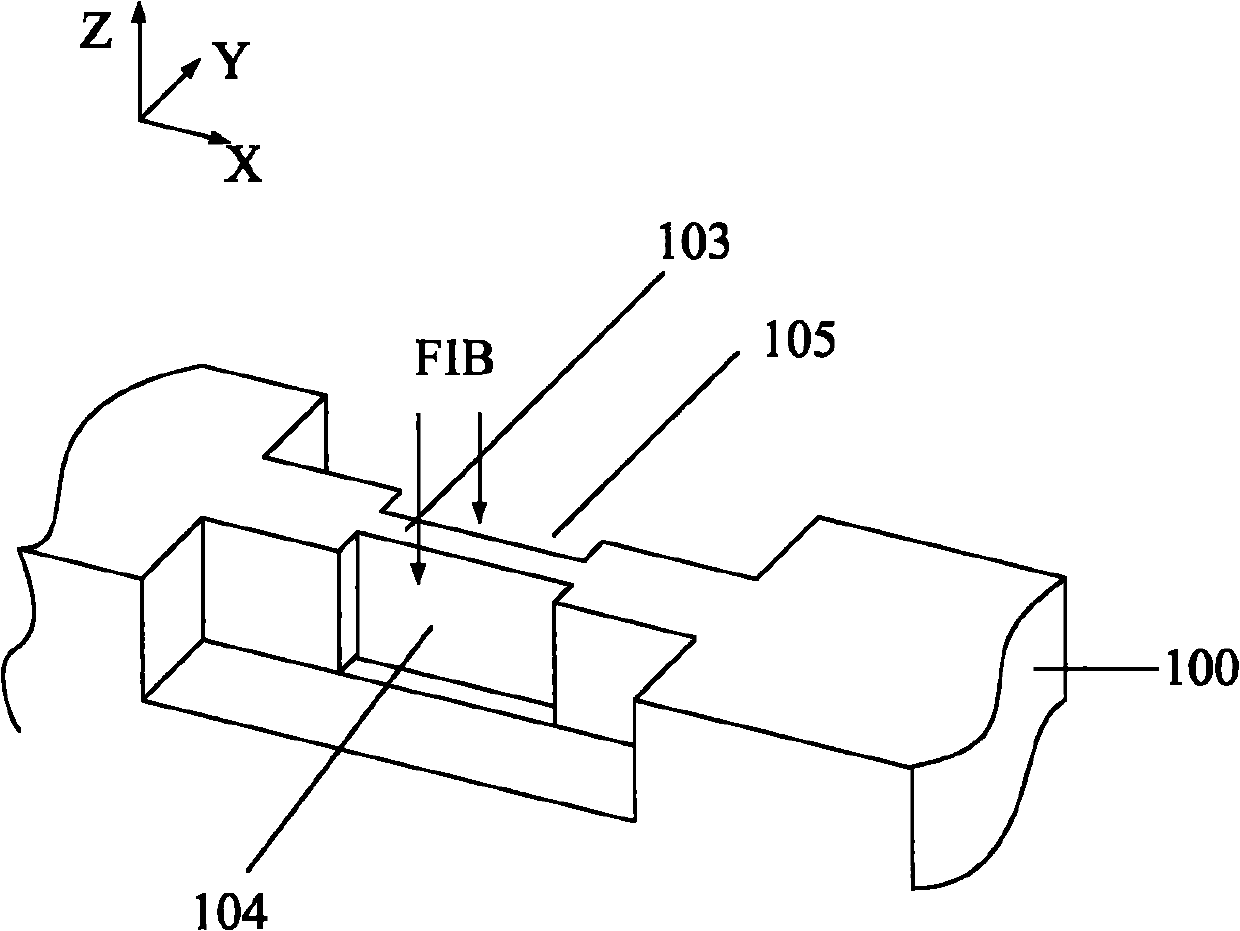

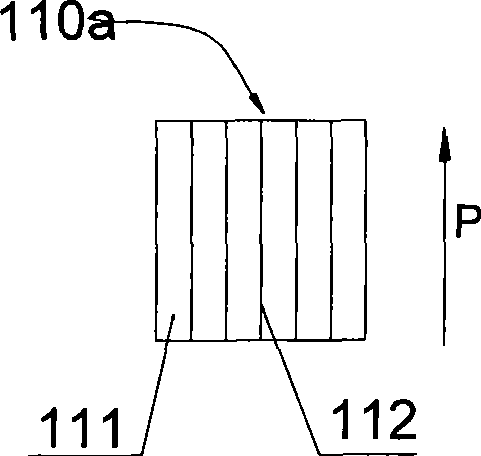

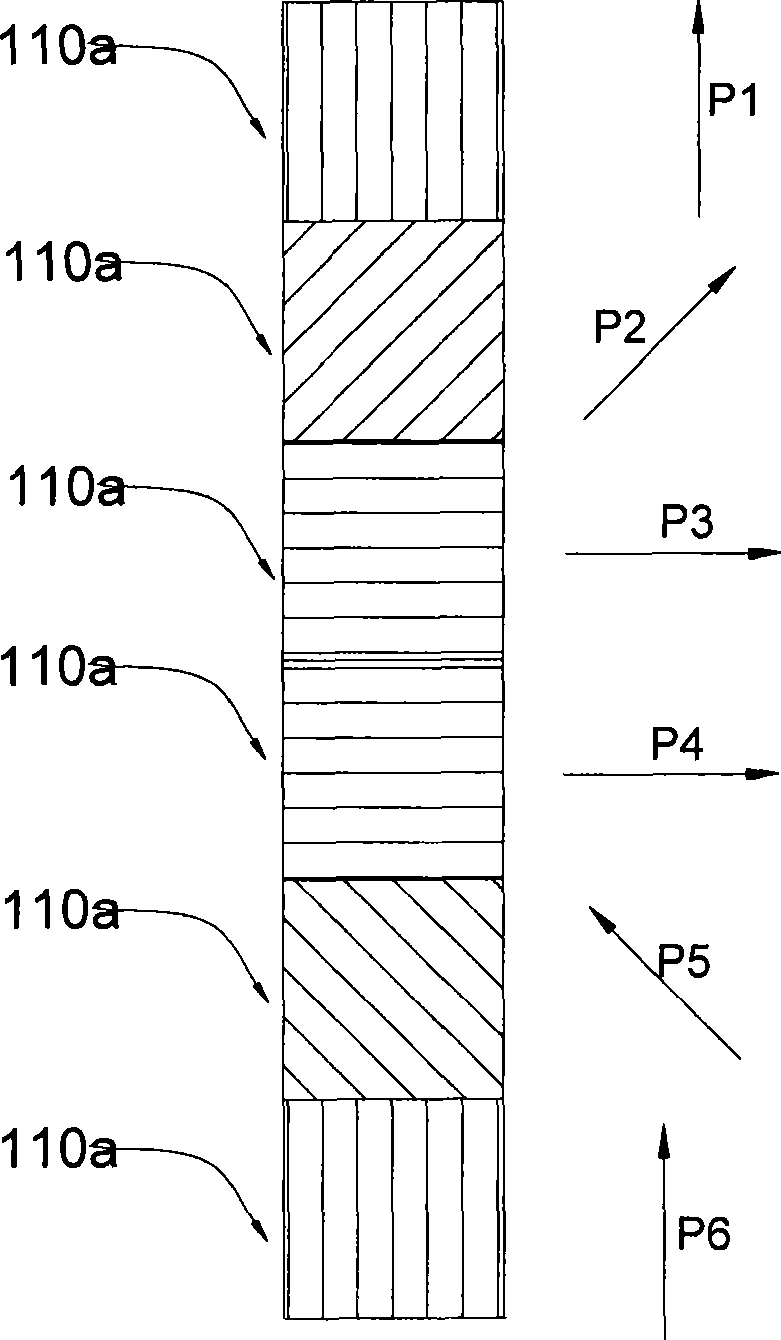

Method for preparing transmission electron microscope sample

InactiveCN102023108AImprove production efficiencyImprove observation effectPreparing sample for investigationElectron microscopePhysics

The invention discloses a method for preparing a transmission electron microscope sample. The method comprises the following steps of: providing a sample with length, width and thickness, wherein at least one elongation structure or multi-layer stack structure along the thickness direction is formed in a region to be observed of the sample; marking the region to be observed of the sample; grinding the sample along a direction which is perpendicular to the elongation direction of the elongation structure or the stacking direction of the stack structure until the mark is exposed; forming a concave pit on the two sides of the region to be observed on a grinding surface respectively; thinning the sample part of the marked region along the concave pit to a specific thickness; and separating and taking the thinned sample part at the region to be observed out. By the method, the preparation efficiency and the observation effect are improved, a protective cover is further assembled on the surface of the sample during the preparation, the sample is prevented from being damaged during the grinding, and the problem that the sample at the region to be observed can easily fall off and bounce out after the preparation is finished is also prevented.

Owner:SEMICON MFG INT (SHANGHAI) CORP

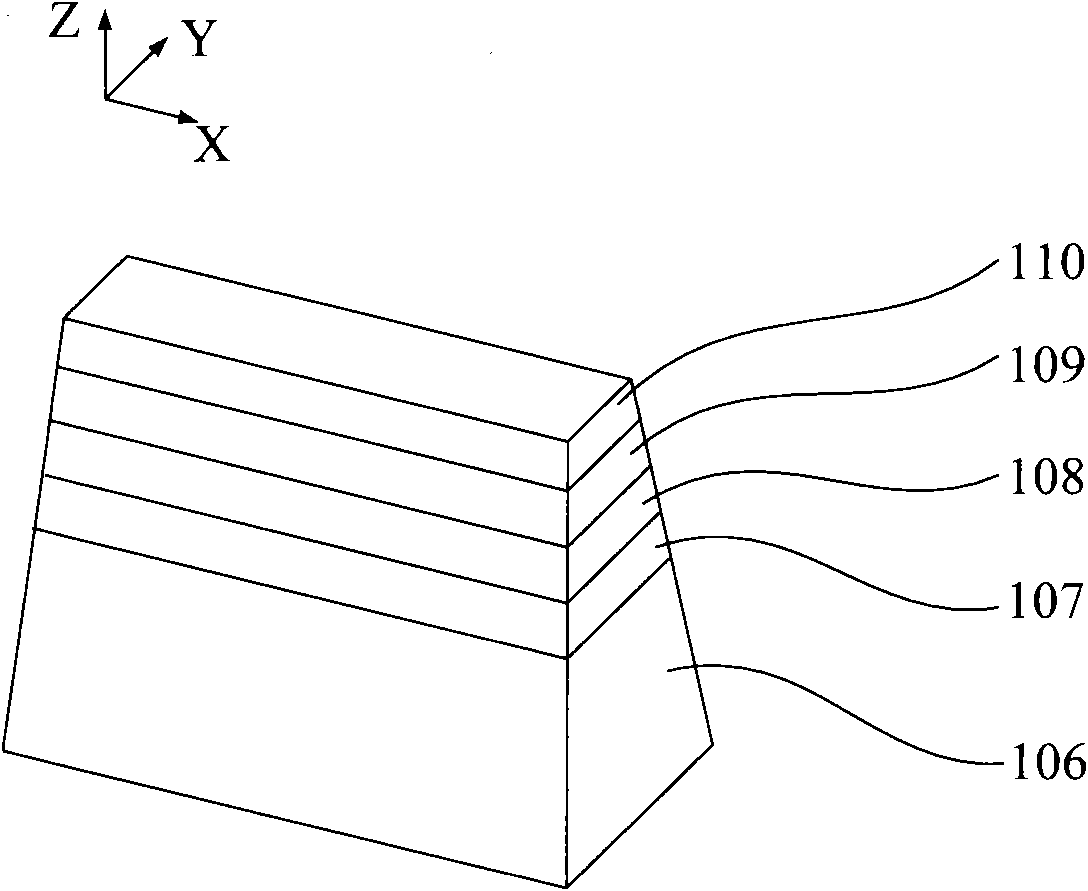

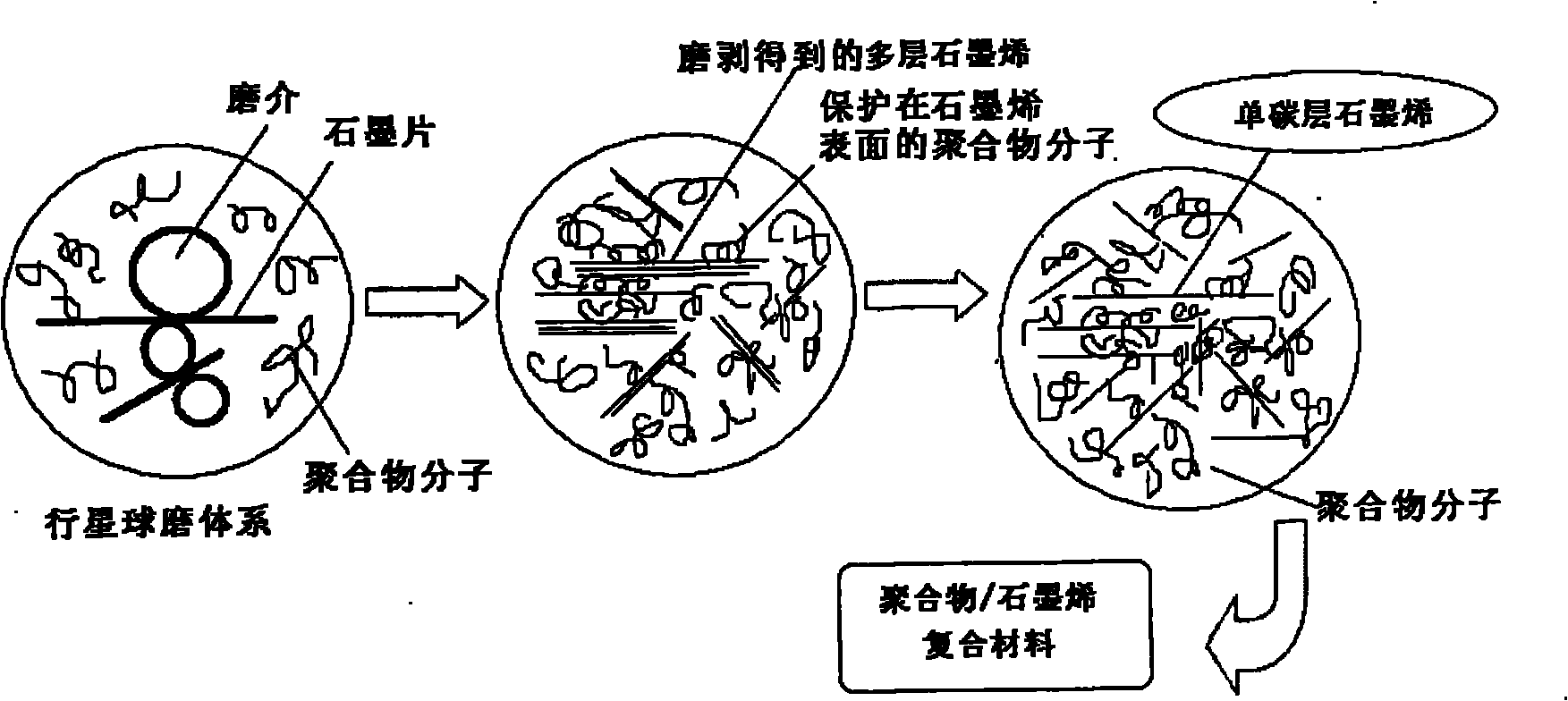

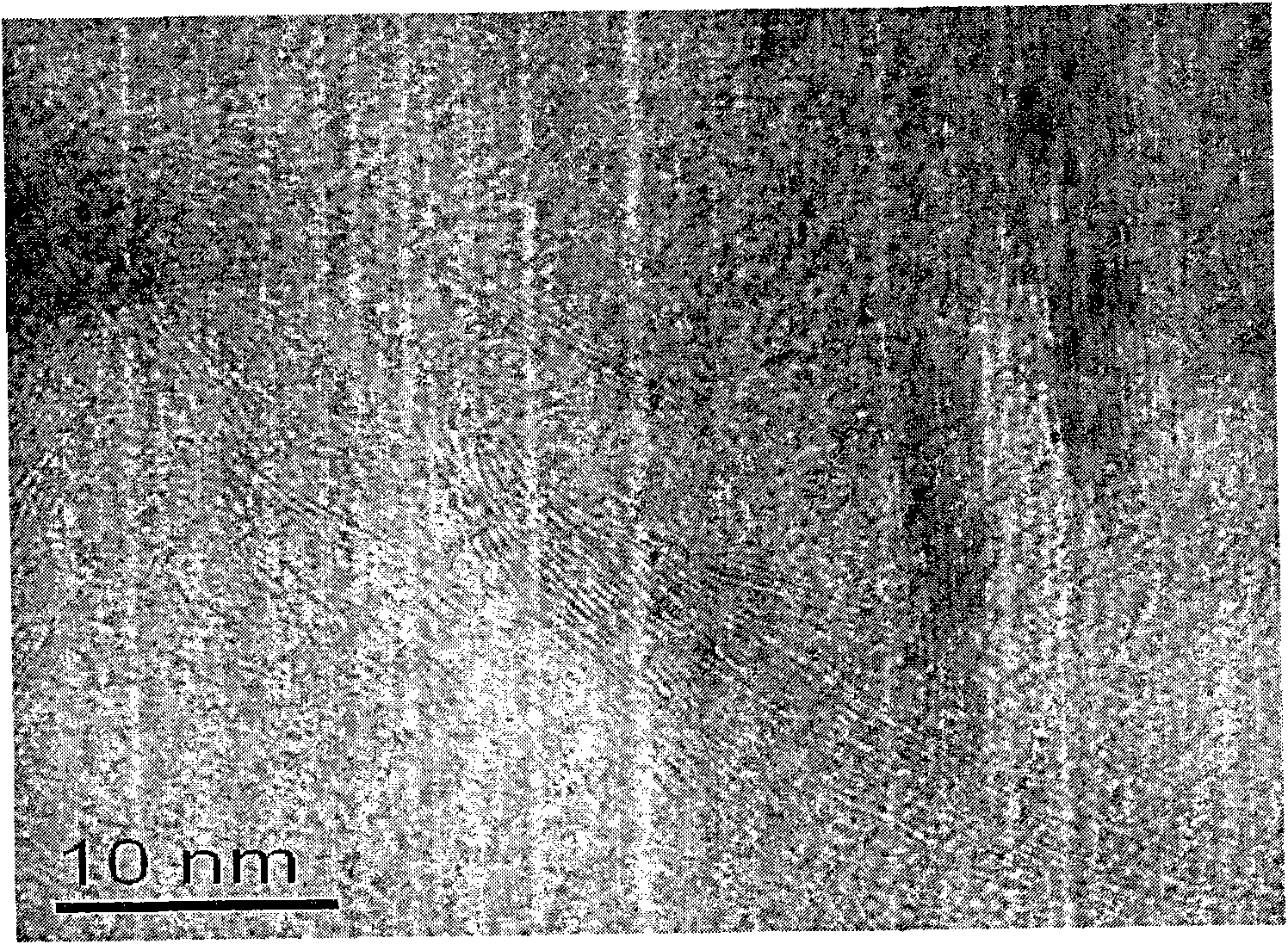

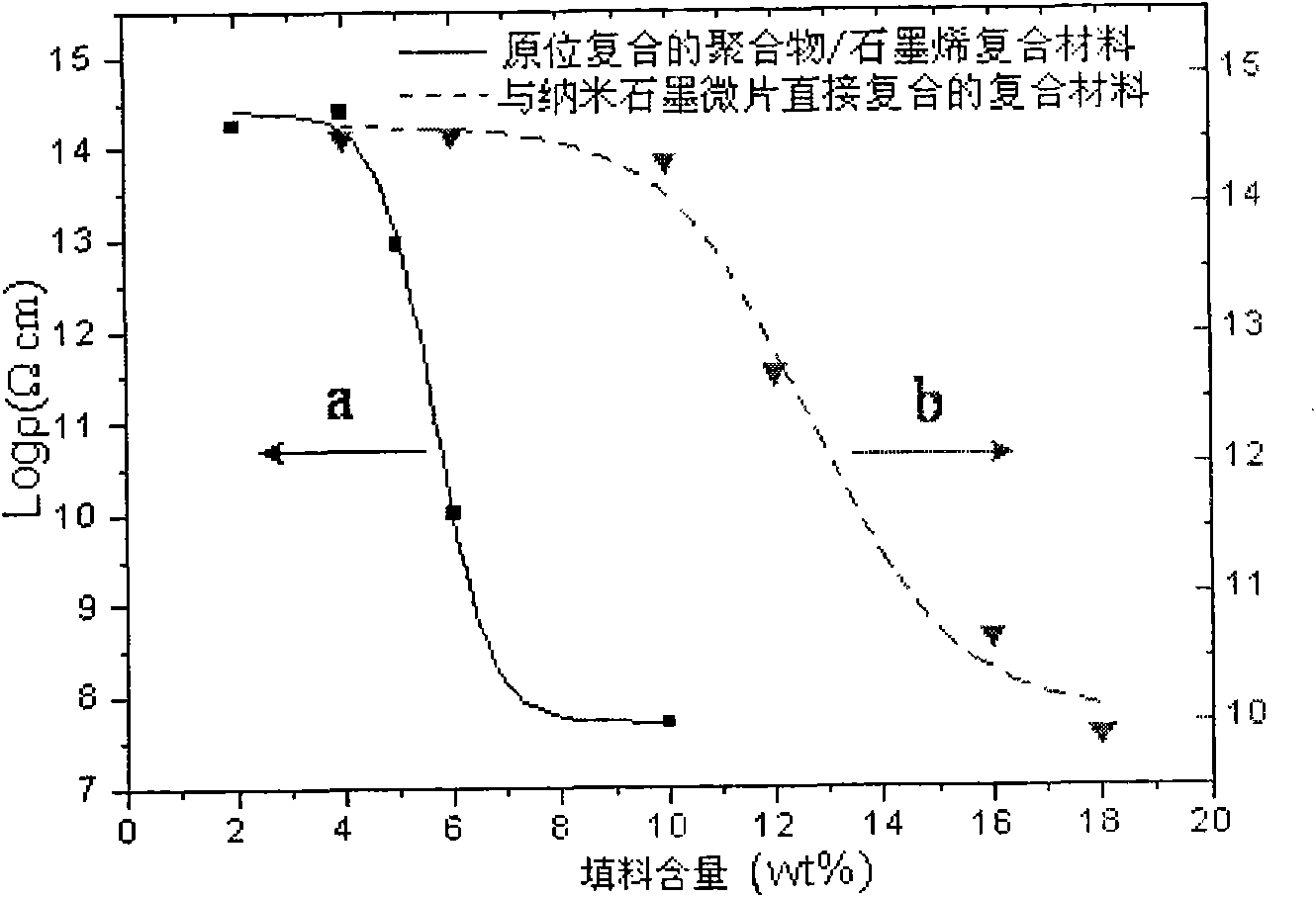

Method for preparing polymer/graphene composite material

ActiveCN101864005AChemical bond breakdownAvoid self reunionPigment physical treatmentPolymer scienceLiquid medium

The invention discloses a method for preparing a polymer / graphene composite material, which comprises: firstly, uniformly dispersing graphite powder in a polymer liquid medium, and grinding and stripping the graphite by using grinding balls to obtain polymer / graphene suspension; and secondly, obtaining the polymer / graphene composite material by adopting a method of adding a precipitator into the polymer / graphene suspension to precipitate the polymer and graphene from the solution, or a method of directly initiating the polymerization of a polymer monomer or a method of curing a prepolymer of the polymer. The method is a new in-situ graphene preparation and compounding method. Once generated, the graphene is enveloped and isolated by polymer molecules or the prepolymer monomer, so the self-agglomeration of the graphene is prevented effectively. In addition, the mechanical grinding in the polymer liquid medium ensures the full mixing of the filler and the polymer, so that the graphene can disperse in a polymer substrate more effectively. And the mechanical ball grinding process makes scale expansion and the realization of industrial production easier.

Owner:HUAQIAO UNIVERSITY +1

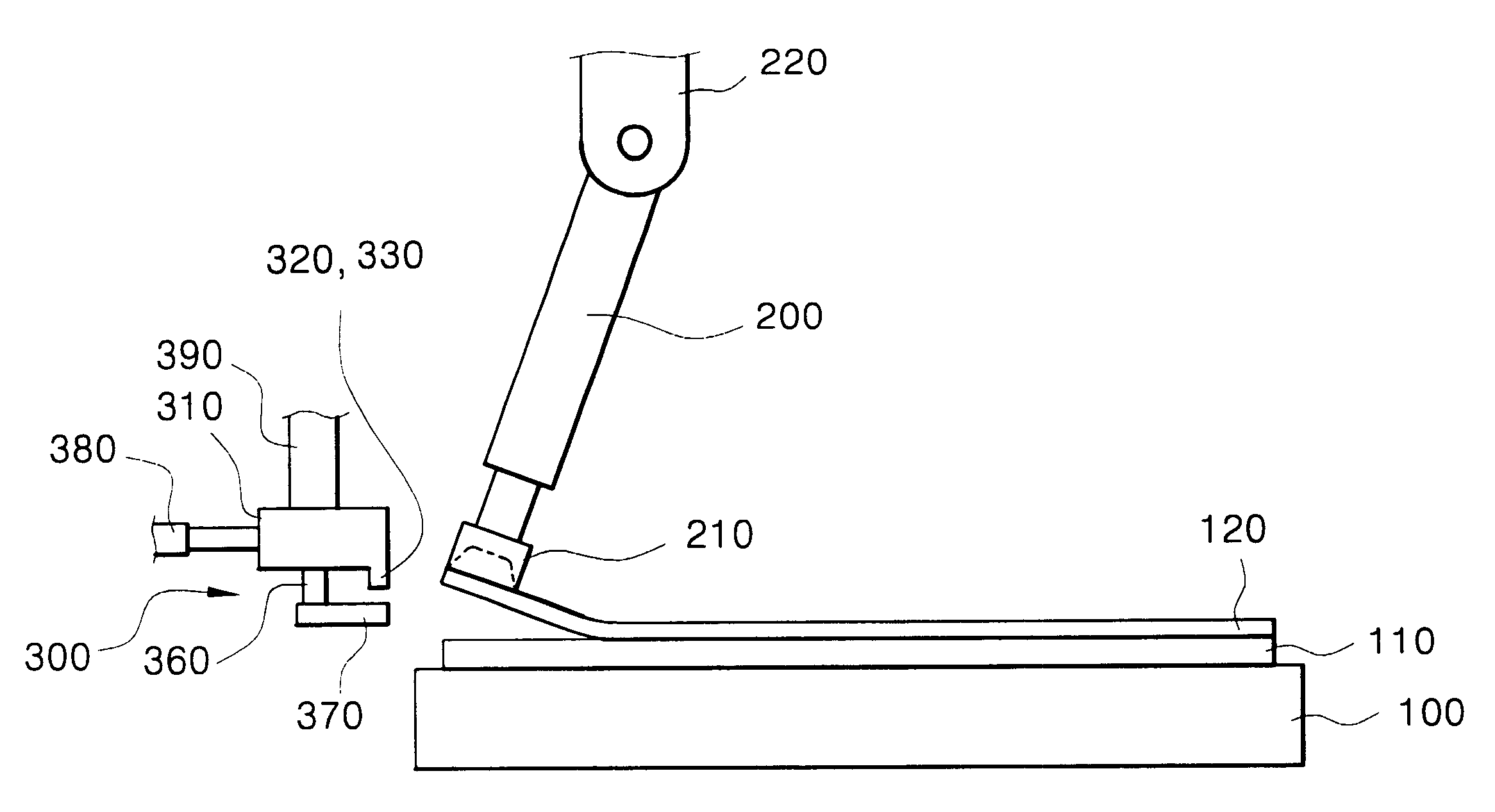

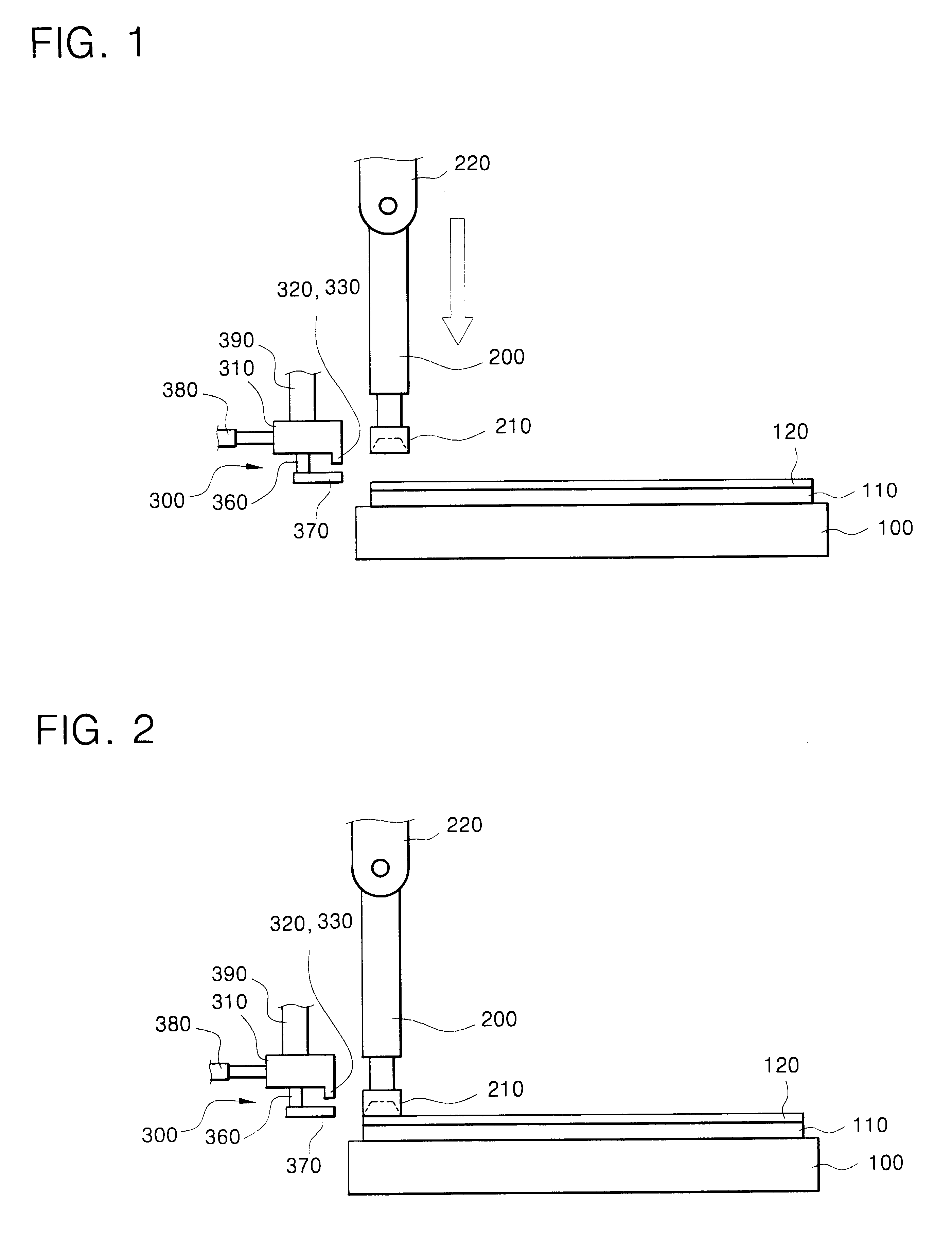

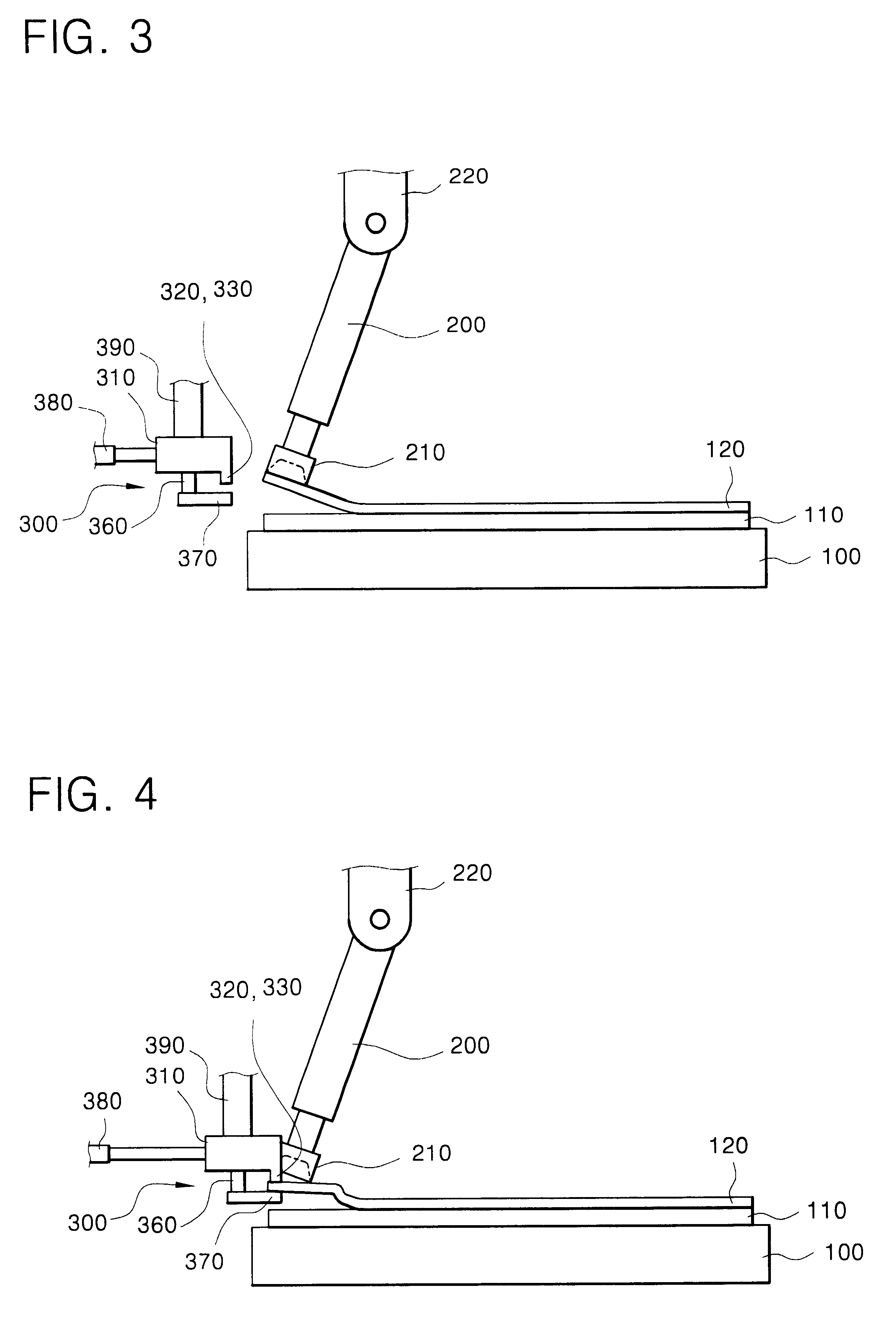

Protective film separator in semiconductor wafer grinding process

InactiveUS6503130B2Polishing machinesRevolution surface grinding machinesTectorial membraneEngineering

A protective film separator comprising an adsorption means and a peeling means for removing the protective film in a semiconductor wafer backside grinding process. The adsorption means uses a vacuum to separate a part of a protective film adhered to an electrical circuit patterned side of a wafer from the patterned side of the wafer. The peeling means presses each side of the part of the protective film separated from the wafer by the adsorption means, and separates unpeeled parts thereof from the patterned side of the wafer.The protective film separator of the present invention reduces costs and expenses for raw materials by eliminating the need for extra removing tape or heat-activated adhesive tape. The present invention may also improve semiconductor yields by reducing the external force applied to a wafer during removal of the protective film, thereby allowing better protection from impurities.

Owner:SAMSUNG ELECTRONICS CO LTD

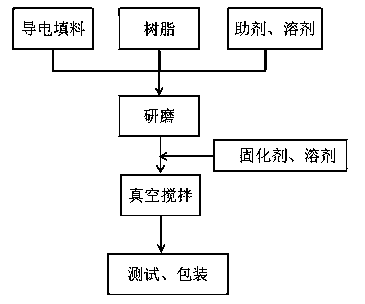

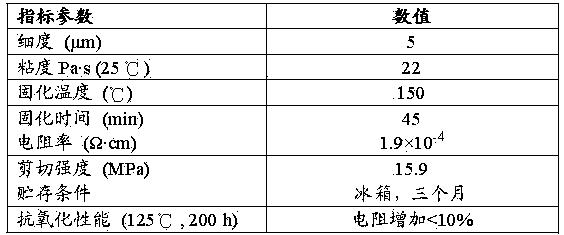

Silver coated nickel powder conductive adhesive and preparation method thereof

InactiveCN103468159AImprove antioxidant capacitySimple production processPolyureas/polyurethane adhesivesAldehyde/ketone condensation polymer adhesivesPolymer sciencePolymer chemistry

The invention relates to a silver coated nickel powder conductive adhesive. The silver coated nickel powder conductive adhesive comprises, by mass, 40-90% of a conductive filler, 5-45% of a resin, 0.5-20% of a curing agent, 0-50% of a solvent and 0.1-20.0% of an assistant, and the conductive filler comprises at least one of micro-silver coated nickel powder and nano-silver coated nickel powder. The silver coated nickel powder conductive adhesive has the advantages of excellent conductivity, low cost, no lead, no halogens and the like. The invention also discloses a preparation method of the silver coated nickel powder conductive adhesive. The method is characterized in that the curing agent is added in a dispersion process after grinding, so the conductivity, the cementability, the viscosity and the like can be effectively regulated, and the untoward influences of the interaction of all components of the conductive adhesive in the dispersion and grinding processes to the storage, application and stability of the conductive adhesive are avoided.

Owner:SUZHOU NIUJIAN NEW MATERIAL

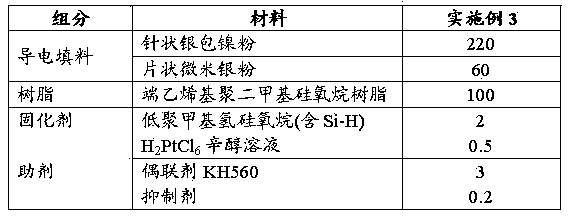

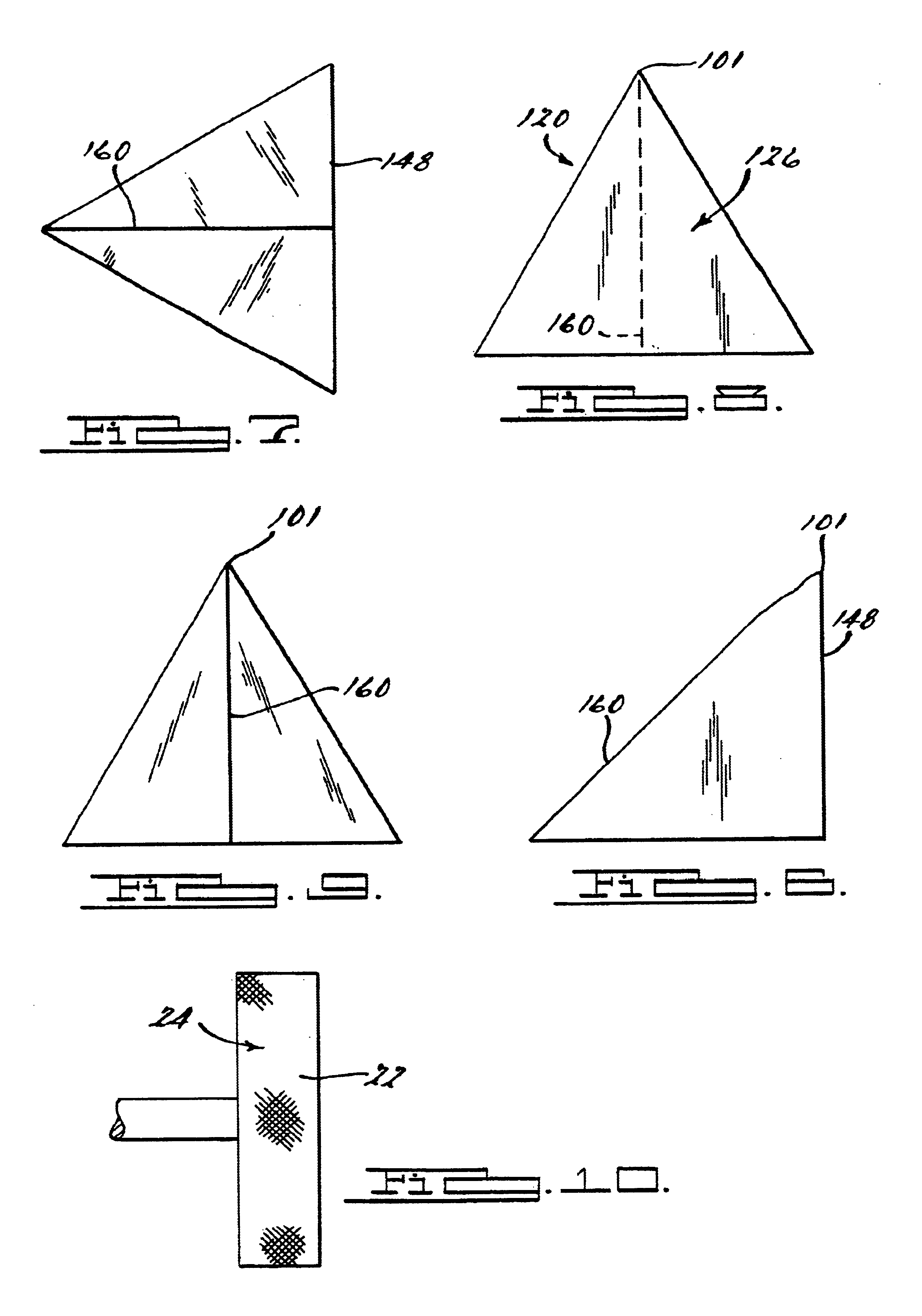

Pyramidal molded tooth structure

InactiveUS6821196B2Simple designLow costRevolution surface grinding machinesAbrasion apparatusMetallic materialsEngineering

A molded tooth design of generally pyramidal form made of various hard grit materials for use on a grinding wheel for grinding non-metal materials. The tooth structure generally includes a raked face having a neutral to positive rake angle that terminates to a sharp point. The tooth structure also includes on the raked face edge portions below the point extending from both sides thereof having a predetermined clearance angle to increase penetration and reduce friction of the tooth during the grinding process. The tooth structure may also include at a top end of the rake face a truncated clearance surface which will produce a wider cutting edge that is flat, for use in attacking the work surface of the work piece being ground. The rake face of the tooth generally may also be formed to have positive rake in the truncated surface.

Owner:L R OLIVER

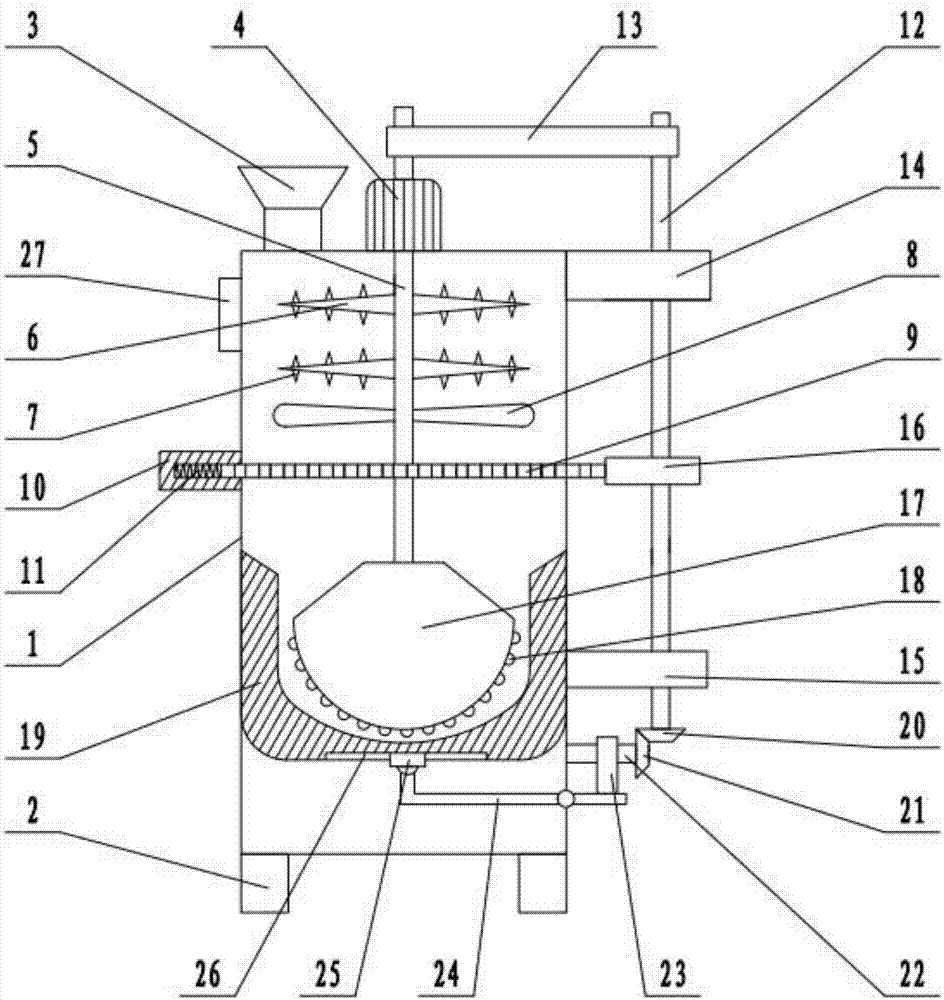

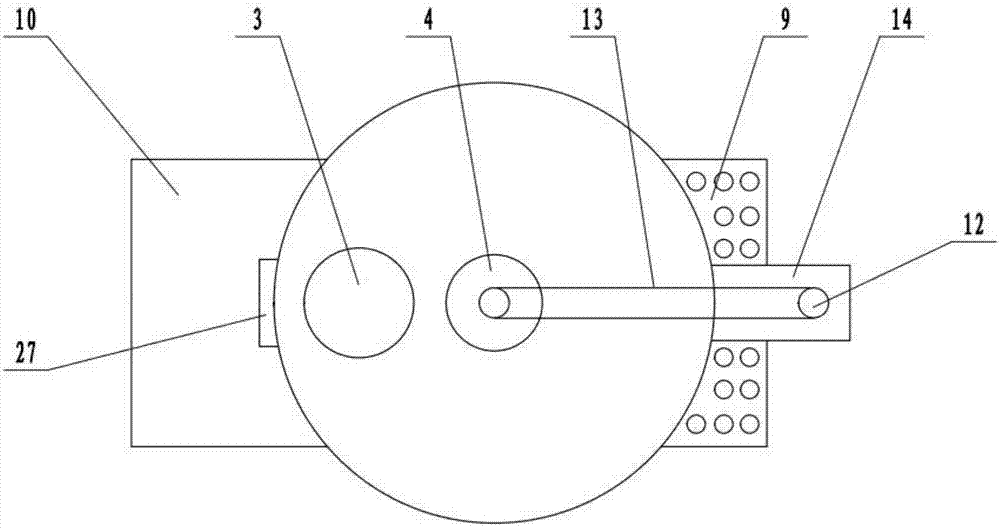

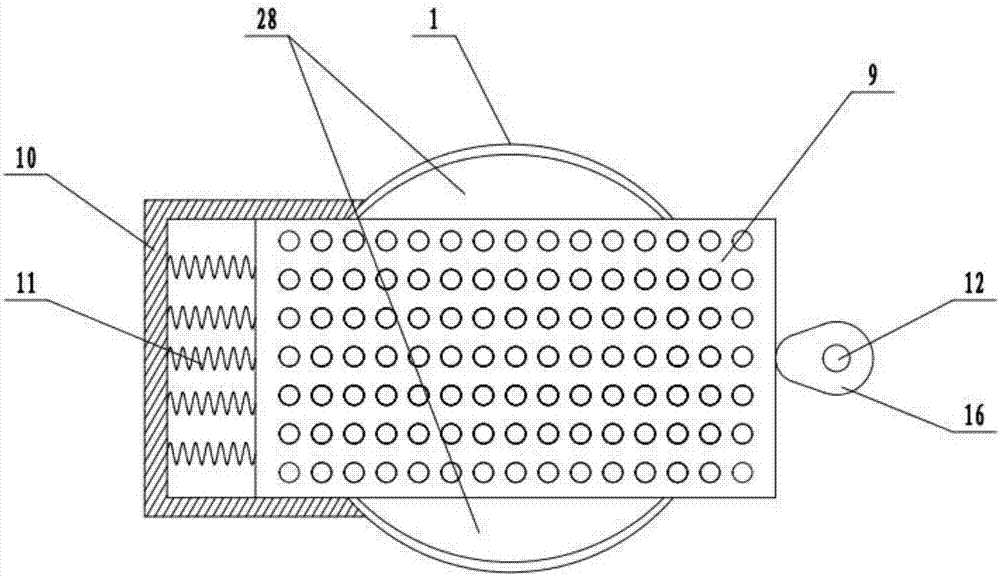

Traditional Chinese medicine smashing and grinding integrated machine

InactiveCN107486318ASmash thoroughlyEasy to passRotary stirring mixersTransportation and packagingDrive shaftPulp and paper industry

The invention discloses a traditional Chinese medicine smashing and grinding integrated machine. The traditional Chinese medicine smashing and grinding integrated machine comprises a shell, support legs, a feed port, smashing blades, stirring blades, a screen plate, a grinding hammer and a grinding barrel. The upper surface of the shell is fixedly connected with a double-shaft motor. The extension end of a lower shaft of the double-shaft motor is fixedly connected with a smashing shaft. The smashing blades are fixedly connected to the smashing shaft. The screen plate is arranged below the stirring blades. The right side of the shell is provided with a driving shaft. The lower end of the smashing shaft is fixedly connected with the grinding hammer. The interior of the shell is slidably connected with the grinding barrel. Chinese medicinal materials to be processed are fed into the feed port and are smashed through the smashing blades and smashing edges and stirred through the stirring blades in the smashing process, and the Chinese medicinal materials are smashed more thoroughly. In the smashing process, the screen plate moves left and right to enable the smashed Chinese medicinal materials to pass through the screen plate more easily. The processing efficiency is improved. The grinding barrel is vibrated up and down in the grinding process, the grinding efficiency is improved, the Chinese medicinal materials are smashed and ground synchronously, and the processing efficiency is greatly improved.

Owner:武晓丹

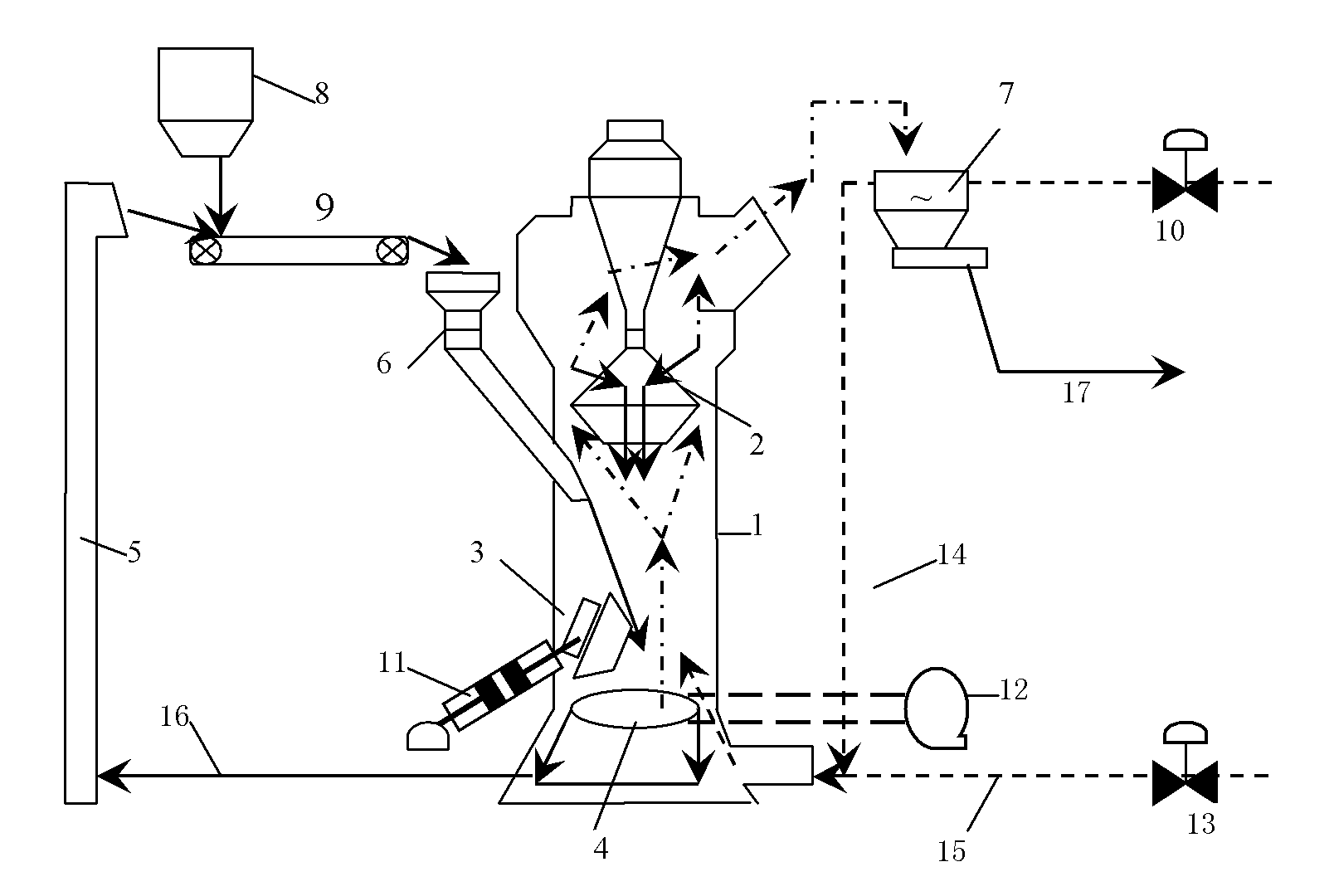

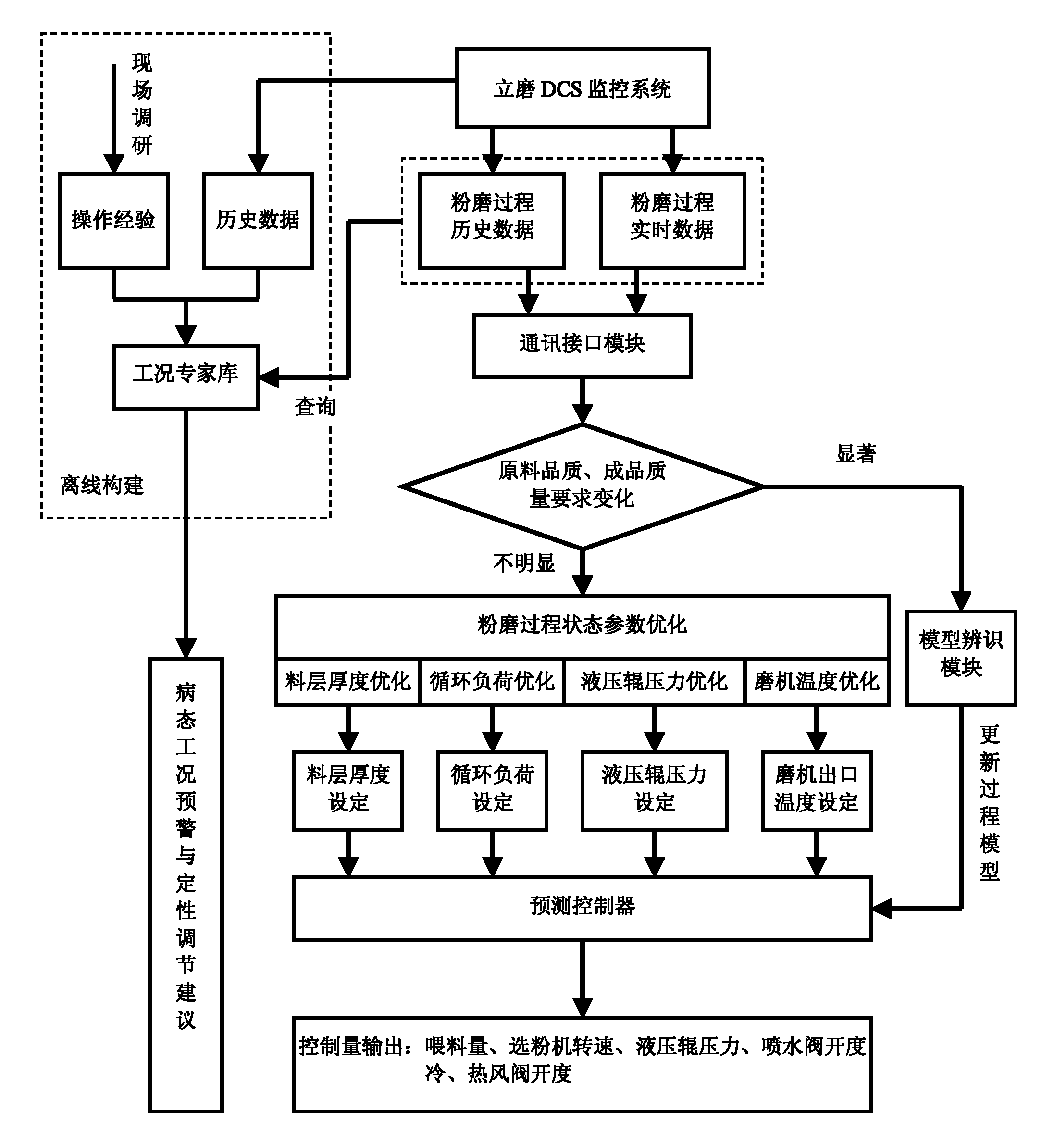

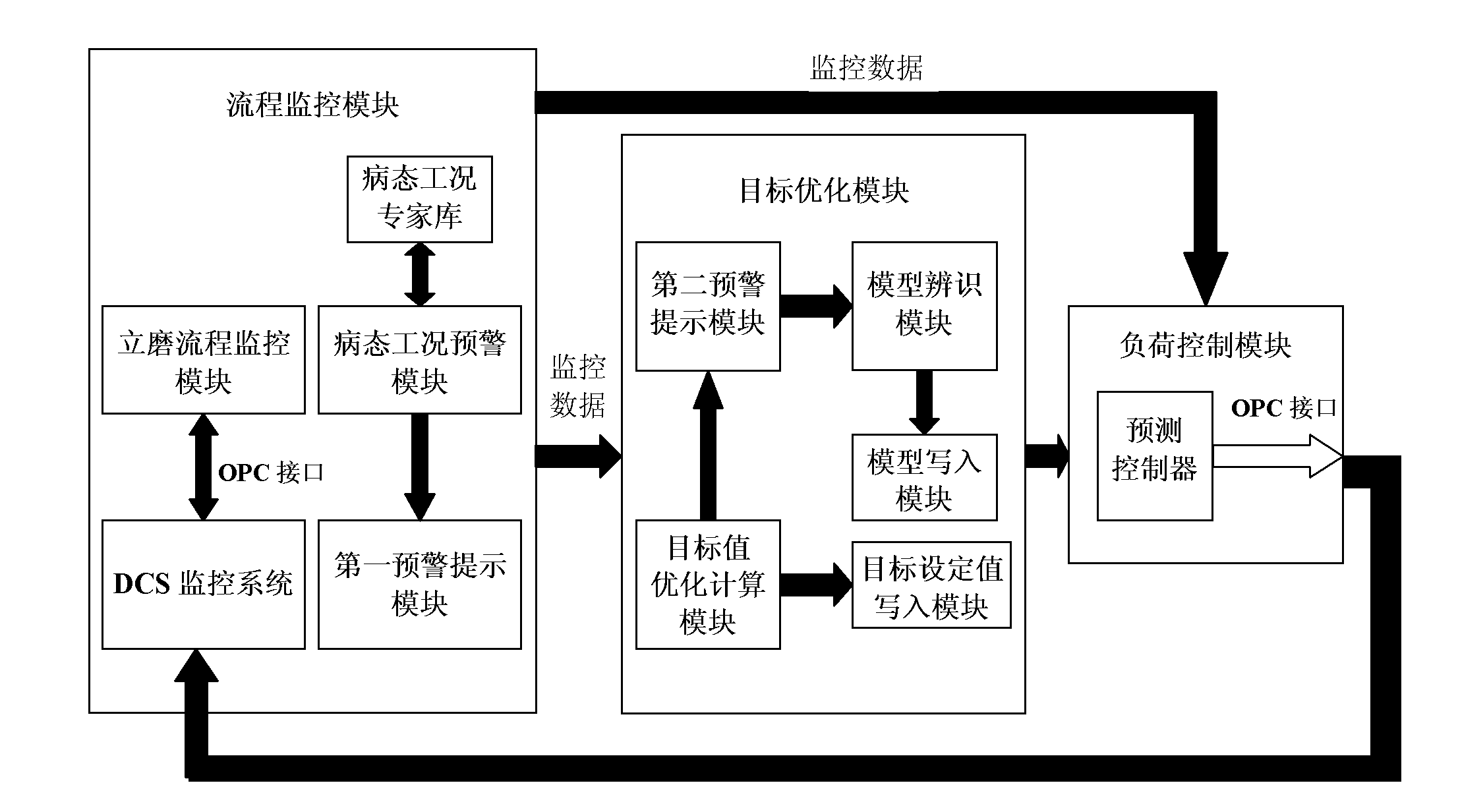

Advanced control method and system for vertical mill based on model identification and predictive control

InactiveCN102151605AIncrease the level of automationQuality improvementCement grindingCement productionMathematical modelOptimal control

The invention relates to raw material grinding in the field of cement process industries, and aims to provide an advanced control method and system for a vertical mill based on model identification and predictive control. The method comprises the following steps of: acquiring real-time data from a distributed control system (DCS) monitoring system; analyzing a variation trend of the operation and technology parameters, and then invoking a pathological working condition expert database for performing trend matching; if a pathological working condition appears, issuing early warning display and giving qualitative adjustment suggestion remind; giving an optimal target set value according to the basic operation condition of the vertical mill and the variation situation of the product quality requirement, and writing into a predictive controller; setting an optimal controlled quantity output according to the optimal target set value, and outputting to the DCS monitoring system to control a field actuator to take action. By adopting the invention, the qualitative adjustment suggestion can be precisely given; a mathematical model of the grinding process of the vertical mill is established and updated in real time; the steady-state error of the control system is reduced; and the grinding process of the vertical mill is instructed, so that the mill can operate stably for long term at a maximum efficiency point, and stable margin is maintained.

Owner:ZHEJIANG UNIV

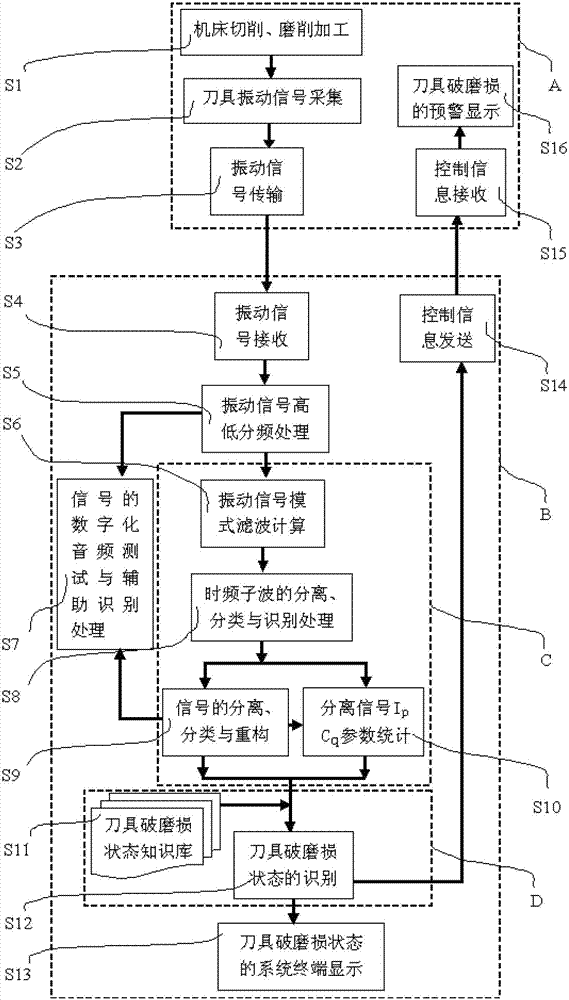

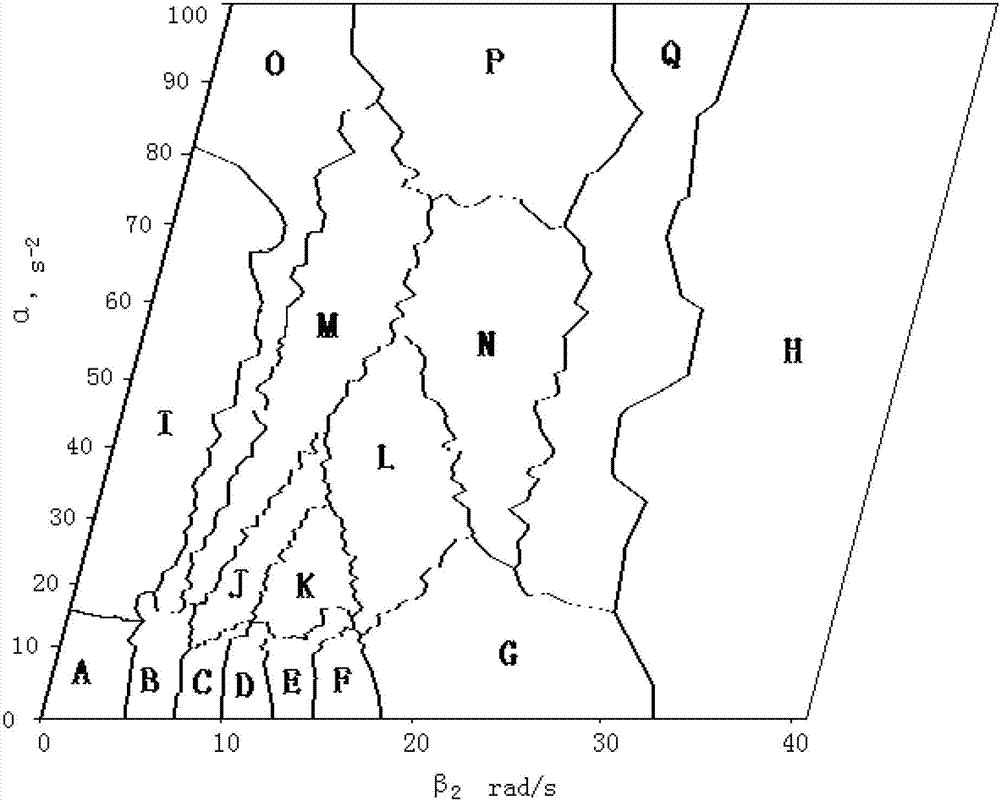

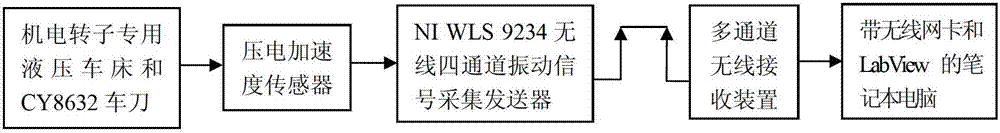

Cutter damage and abrasion state detecting method and cutter damage and abrasion state detecting system

ActiveCN102765010ARealize online dynamic monitoringHigh precisionMeasurement/indication equipmentsProduction rateFeature extraction

The invention relates to a cutter damage and abrasion state detecting method, which comprises the following steps that 1, vibration signals in the cutter cutting and grinding processes are measured; 2, the vibration signals are subjected to mode filtering calculation; 3, time-frequency wavelets of the vibration signals are subjected to classification sorting and feature extractions; and 4, the time-frequency wavelets are subjected to classification, collection and signal separation processing, various kinds of time-frequency wavelets are subjected to signal reconstruction, the kurtosis index (Cq) and the peak index (Ip) of various kinds of signals are then counted, the cutter damage and abrasion state and the machine tool operation state are detected under the dynamic distribution condition of a Cq-Iq plane according to various kinds of separation signal index parameters, and the identification detection and the quantitative early warning and forecast of the cutter damage and abrasion state are realized. Through single monitoring equipment, the detection of the cutter damage and abrasion state is realized, the signal identification stability is good, the mechanical processing production safety is ensured, the precision of processing parts is improved, and the production rate and the utilization rate of a machine tool are improved.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

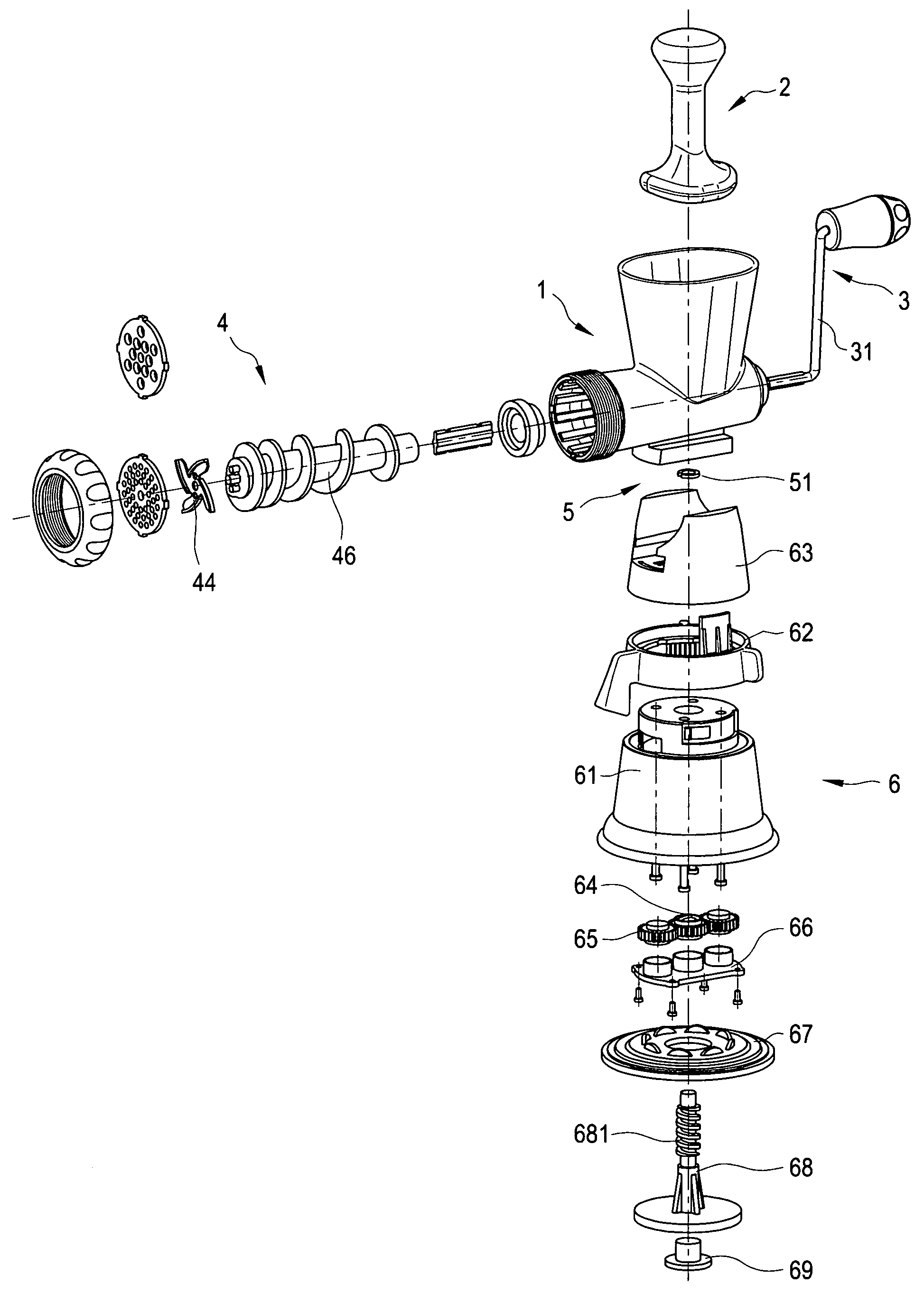

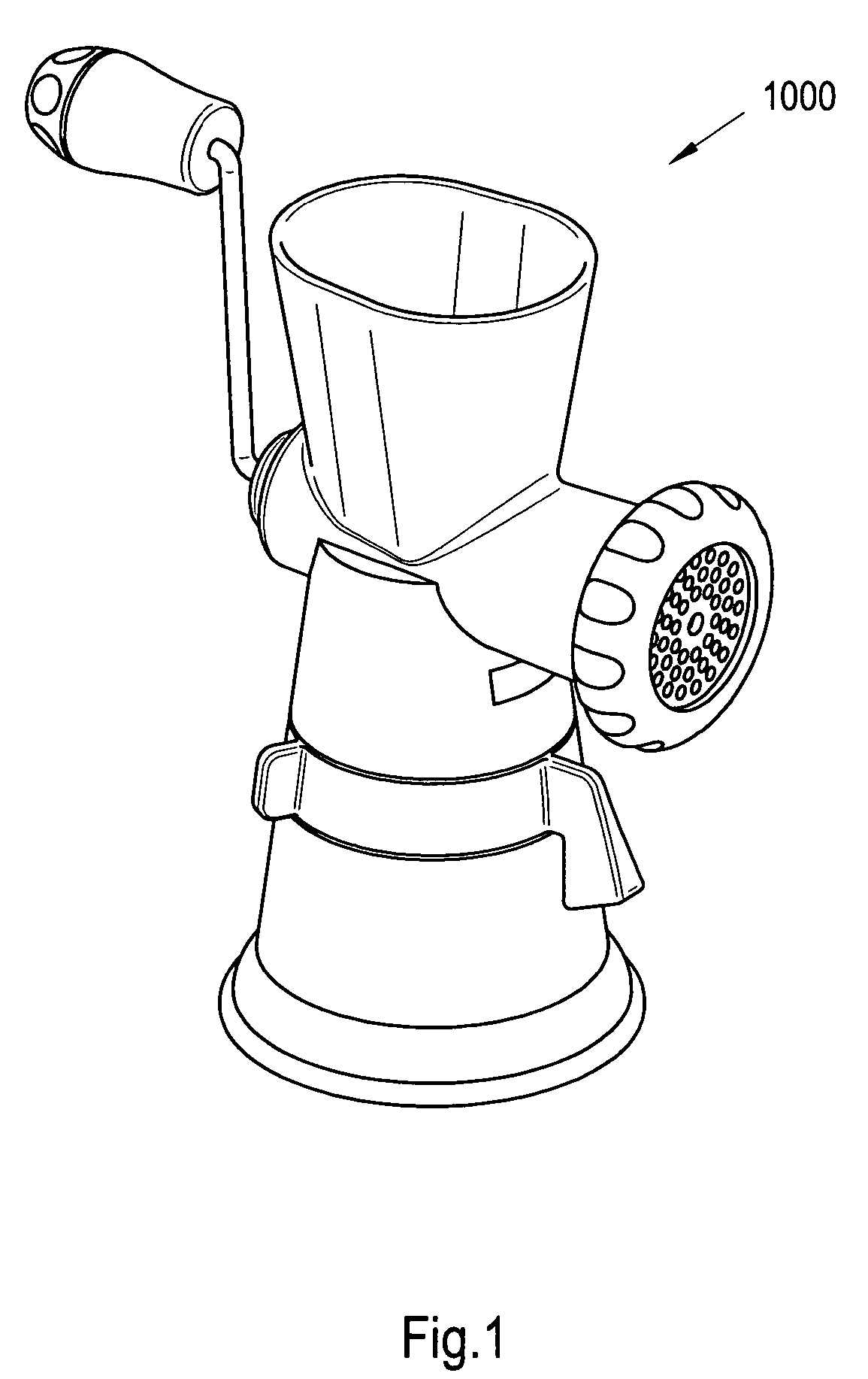

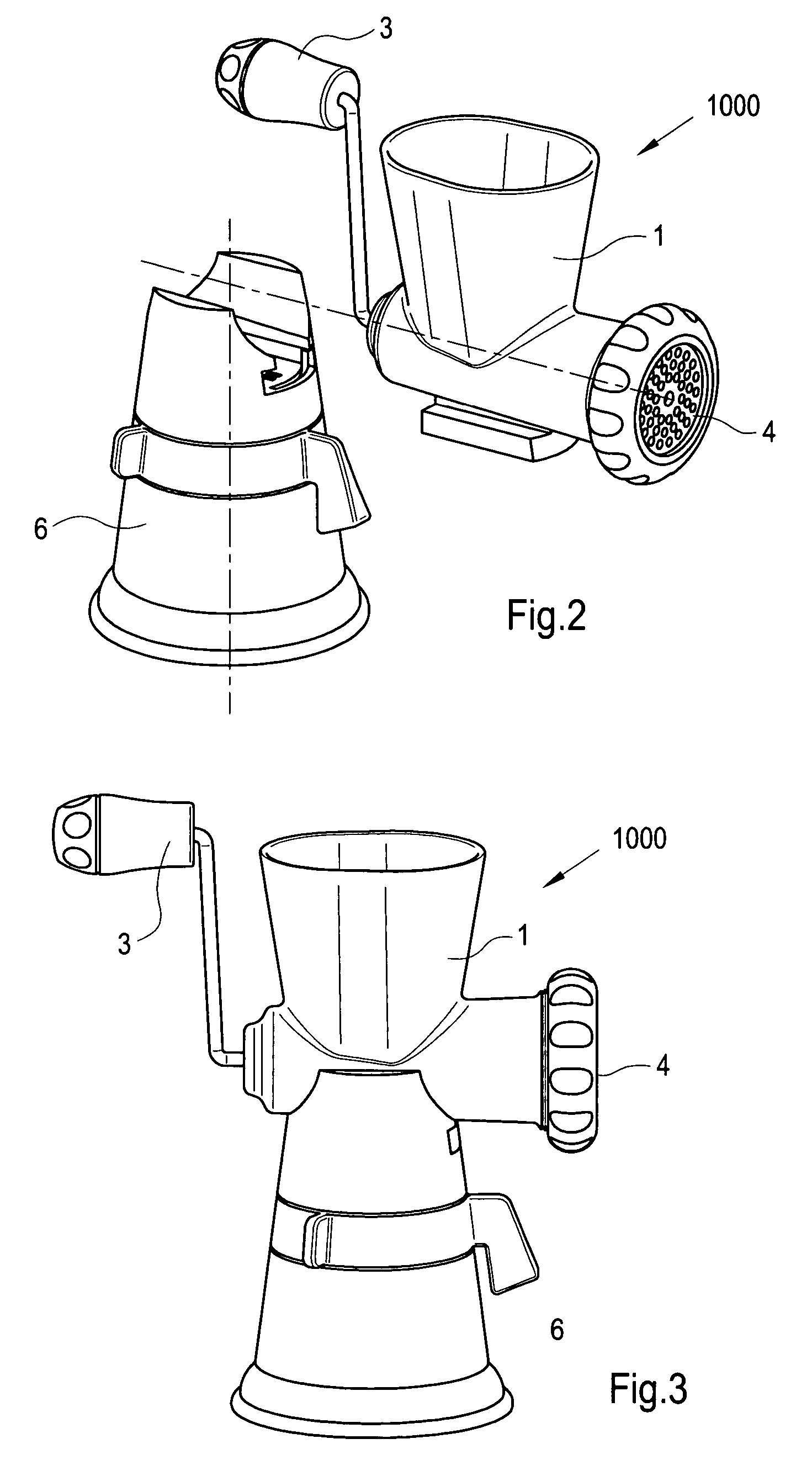

Meat grinder with suction base

ActiveUS7207510B2Cleansing timeEasy to cleanPicture framesAnimal feeding stuffEngineeringHand maneuver

Owner:WONG

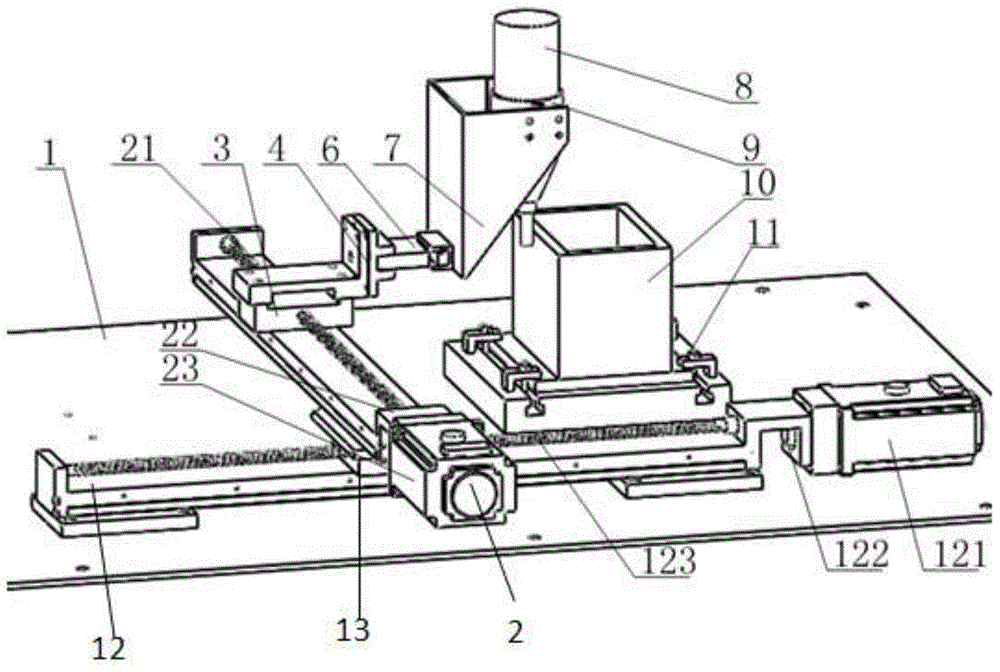

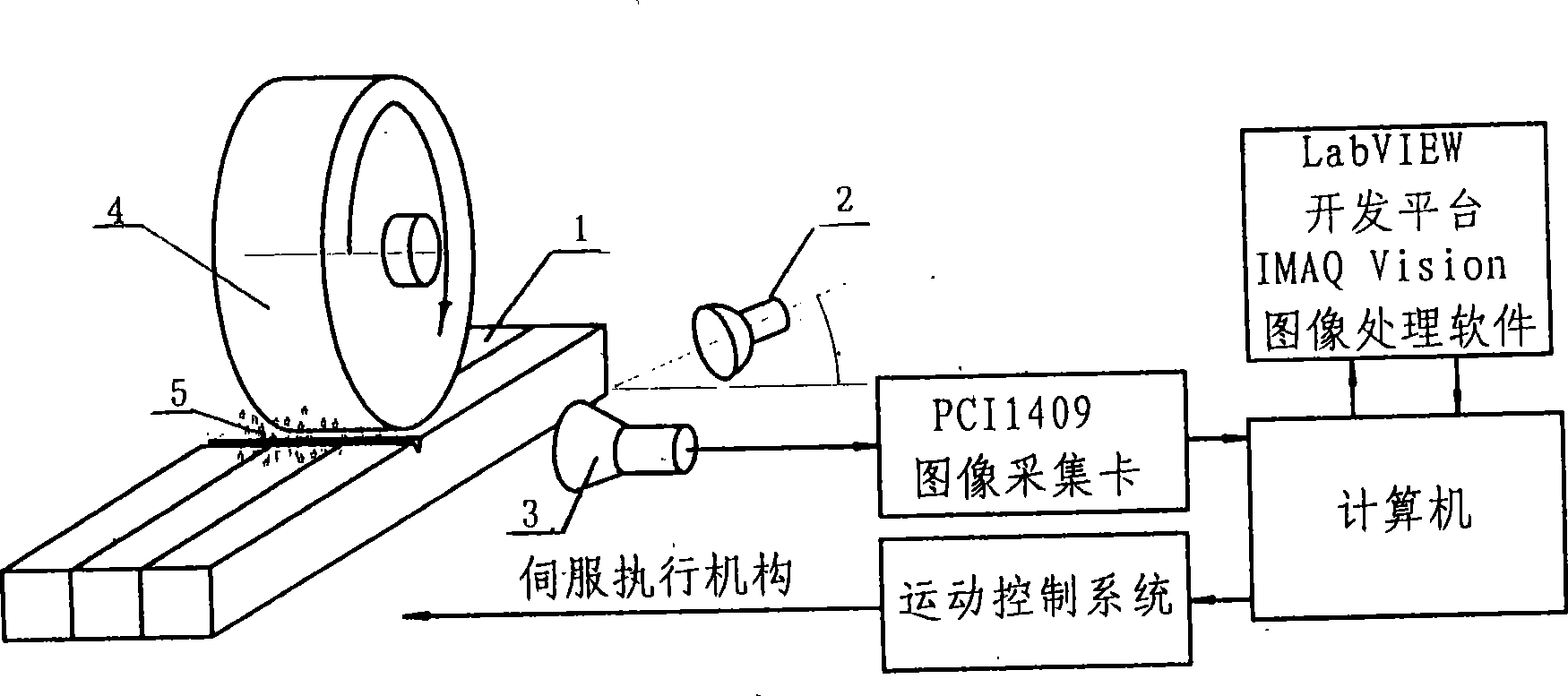

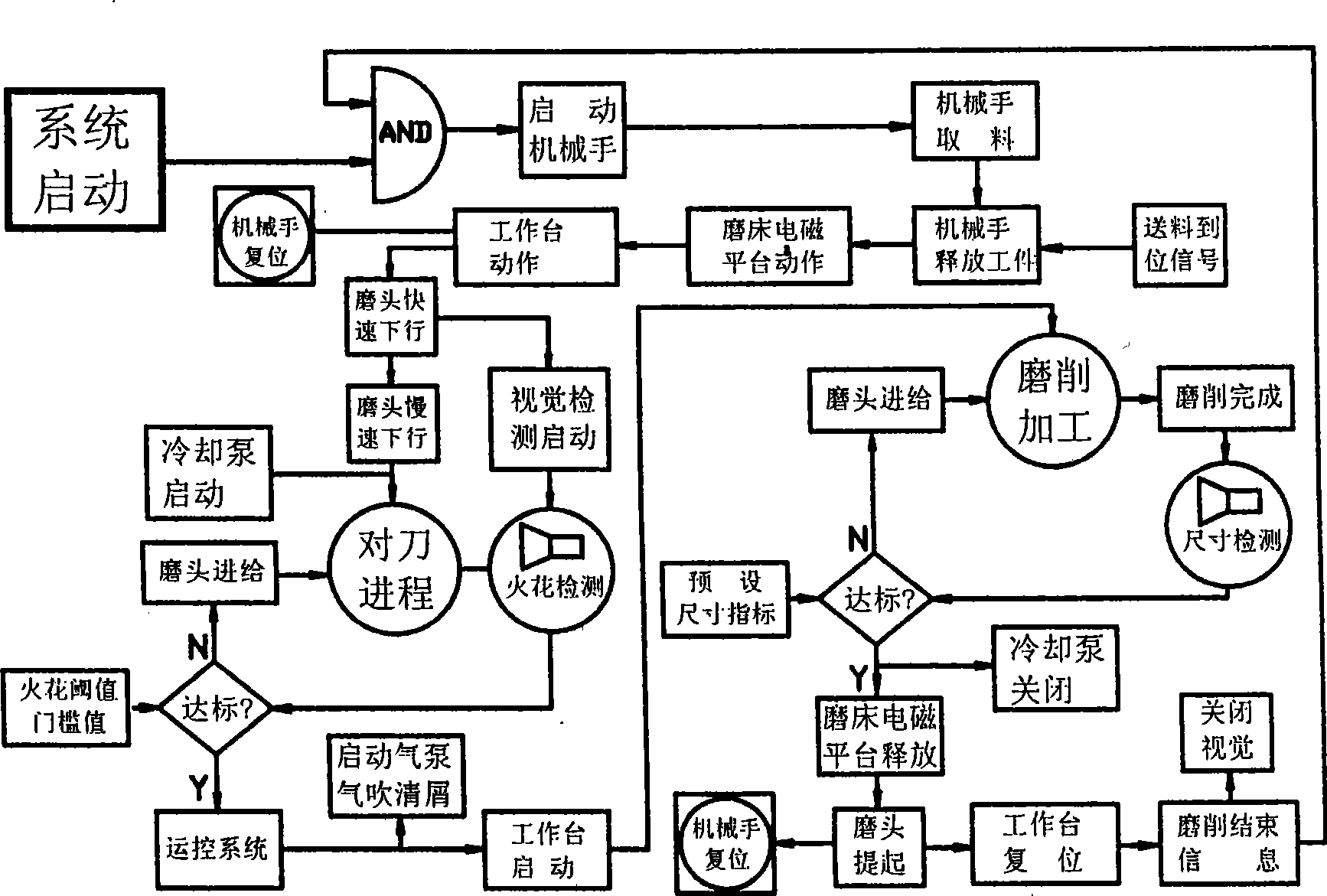

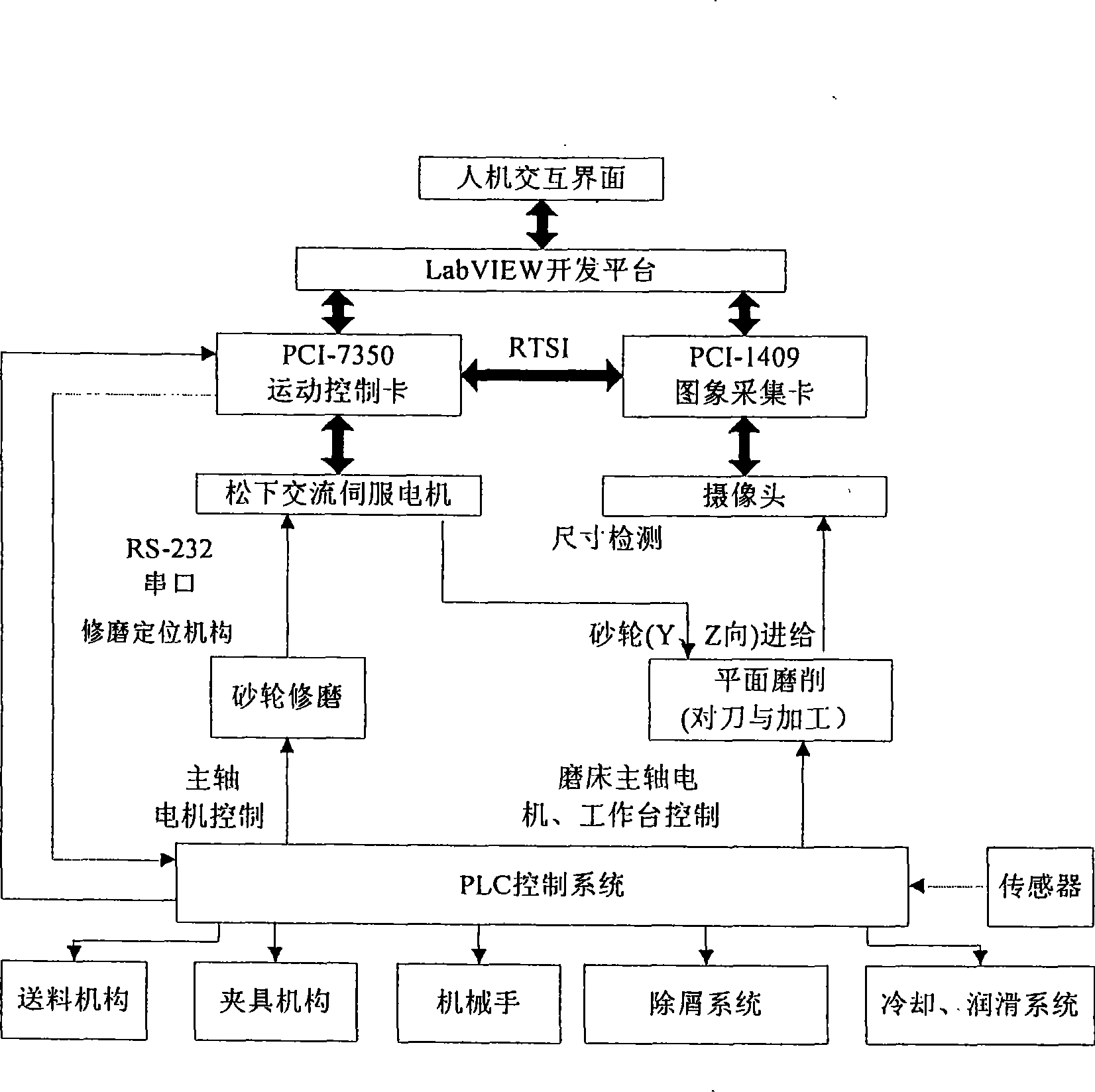

Spark identification tool-setting method and abrasive machining automatic system

The invention discloses a method for setting a tool through sparkle identification and an automatic system for grinding processing. The method and the system achieve the intelligent automatic control for the whole grinding process and accurately and reliably solve the problem of automatic tool setting, the problem of dimension compensation caused by the abrasion of a grinding wheel, and the problems of on-line dimension measurement and motion servo control in the grinding process. The method organically combines a vision technique, a PLC technique and a motion control technique, and provides a solution for solving the problems of tool setting, on-line dimension measurement and grinding wheel wear compensation by using the vision technique, and the problem of motion servo control by using the PLC technique and the motion control technique. The method makes use of the vision technique to automatically identify the operating condition contacted with a workpiece, and switch the operating condition to a grinding processing state instantly so as to solve the problem of automatic tool setting, thus the method can combine a plurality of mature correlation techniques to construct the automatic system which integrates detection and motion control. The method and the automatic system achieve the accurately automatic tool setting, solve the problems of the wear measurement and compensation of the grinding wheel, and open up a novel approach for fully automatic and intelligent control in the grinding process.

Owner:QIQIHAR HUAGONG MACHINE +1

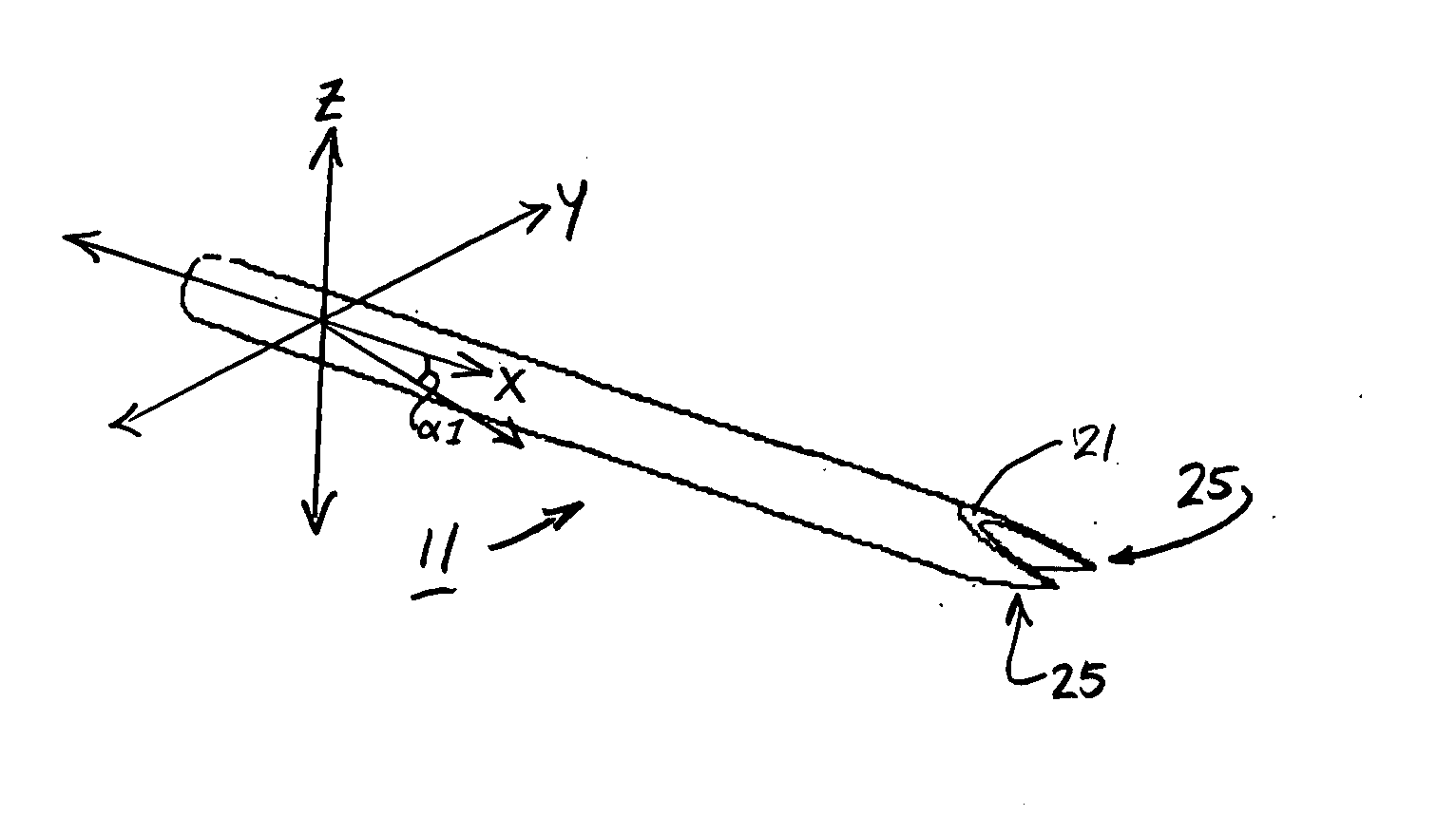

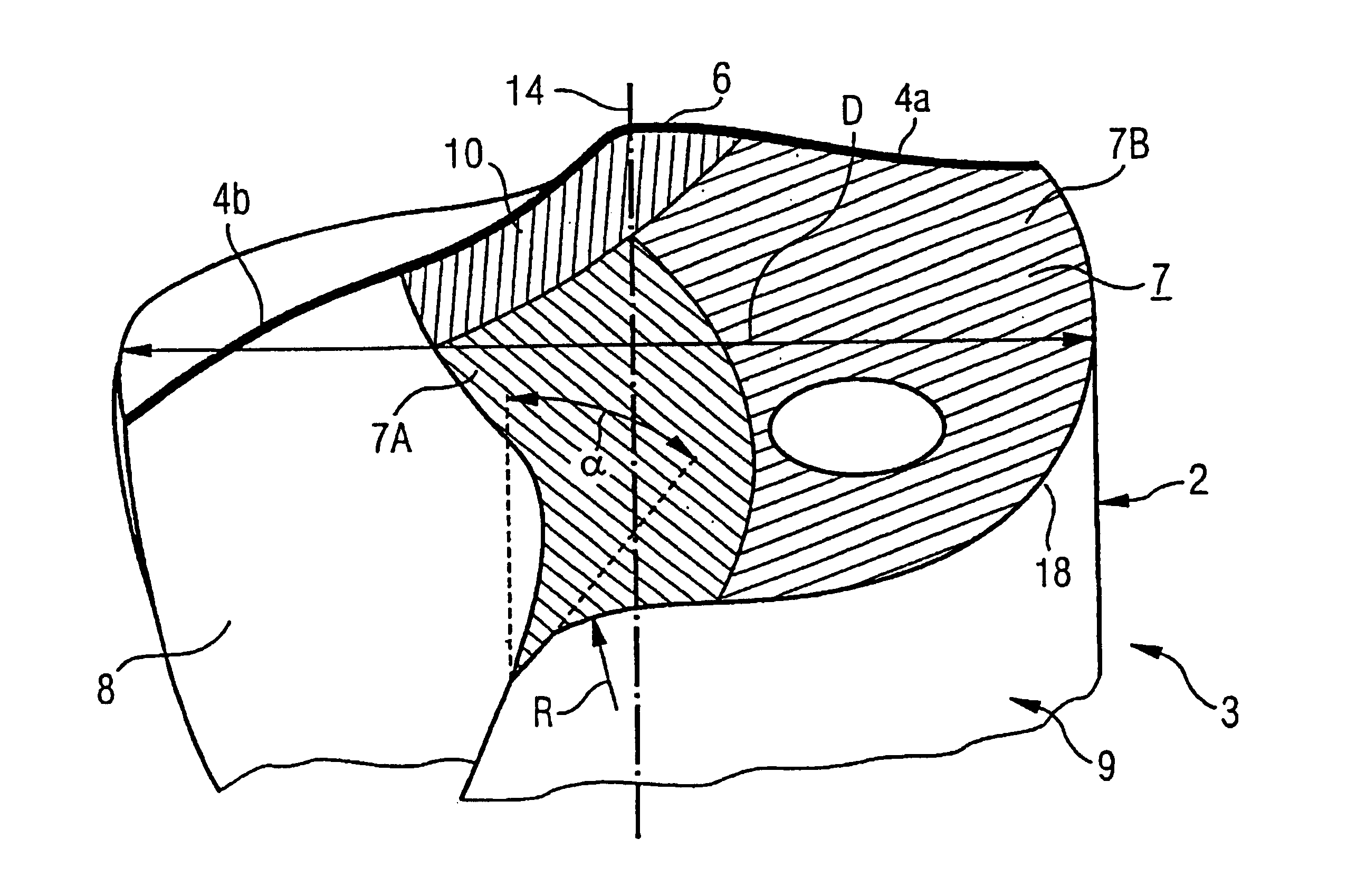

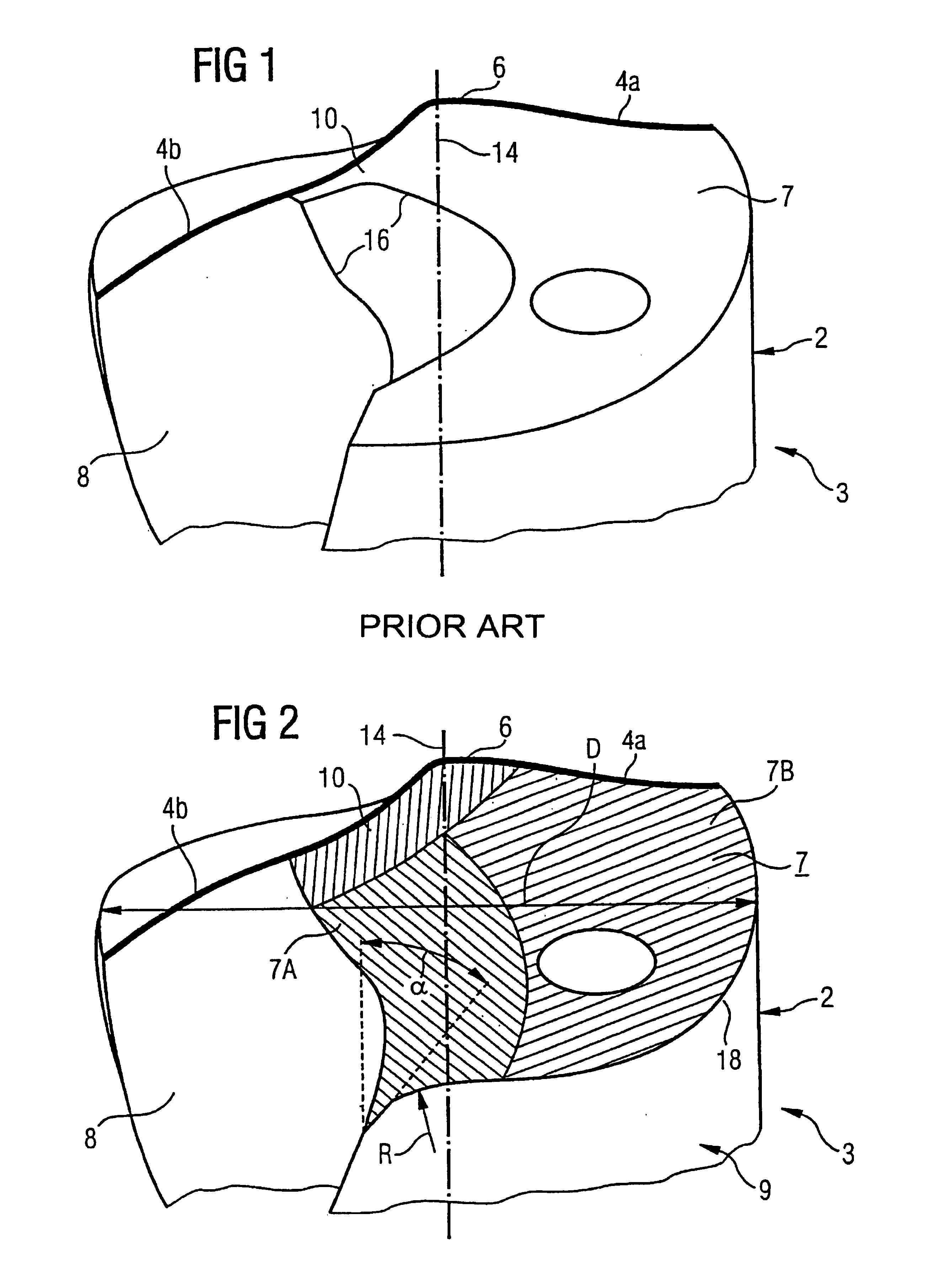

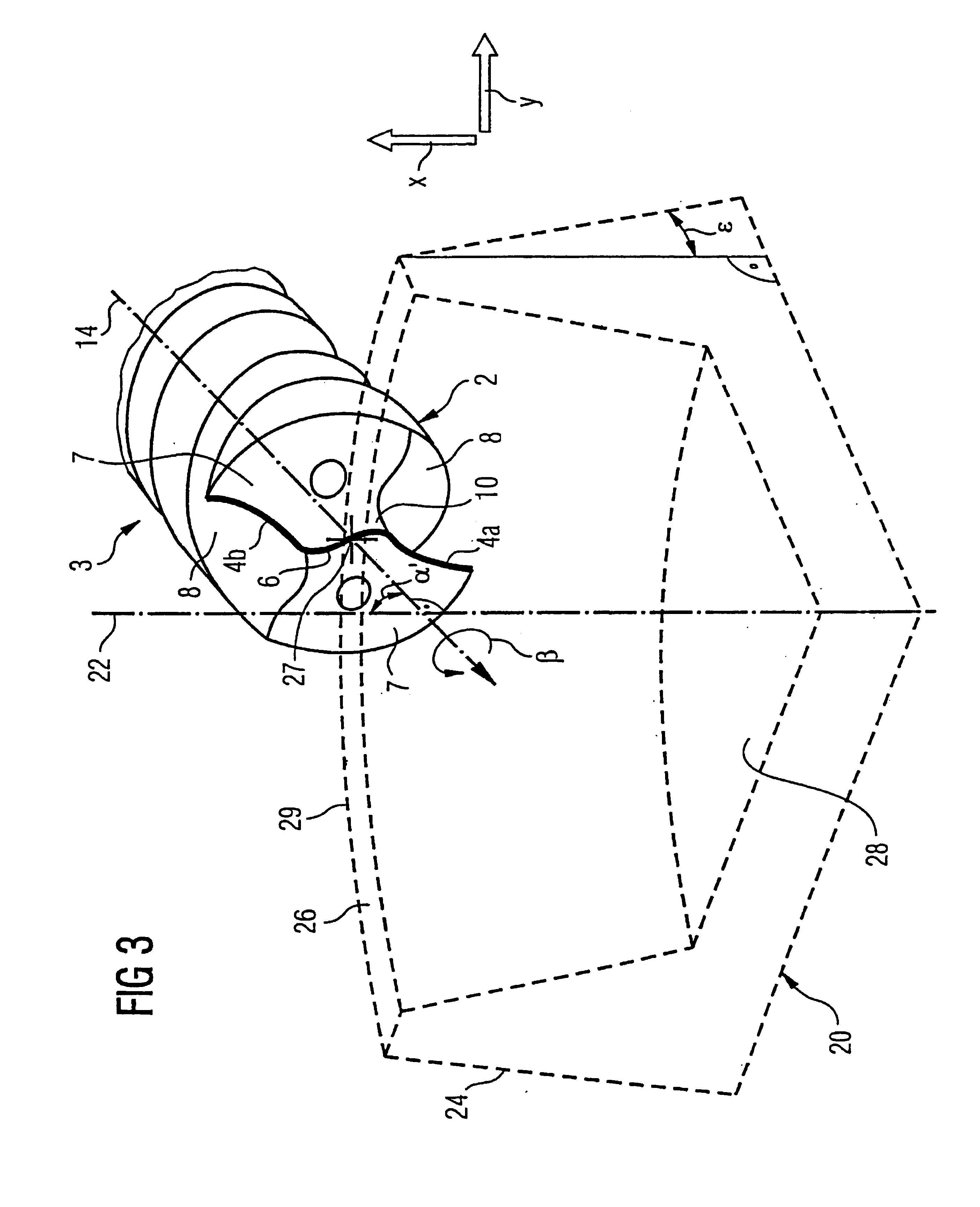

Drill bit and method for grinding a drill bit

InactiveUS6988859B2Reduce loadEasy to replaceWood turning toolsTransportation and packagingFluteEngineering

The invention relates to a drill bit (2), having main cutting edges (4a, 4b) which are connected together by a transversal cutting edge (6). An open surface (7) which extends into a flute (8) lies adjacent to each main cutting edge. The drill bit (2) is ground, in particular, during a continuous three-dimensional grinding process in such a way that the open surface (7) forms a continuous curved surface which follows a radius of curvature (R) running from the main cutting edge (4a) in the direction of the flute (8). The continuous grinding process, in comparison to a conventional two-stage process, produces an improved drill bit geometry which is devoid of ridges (16). The ridge-free configuration reduces the mechanical stress during drilling to a minimum.

Owner:KENNAMETAL INC

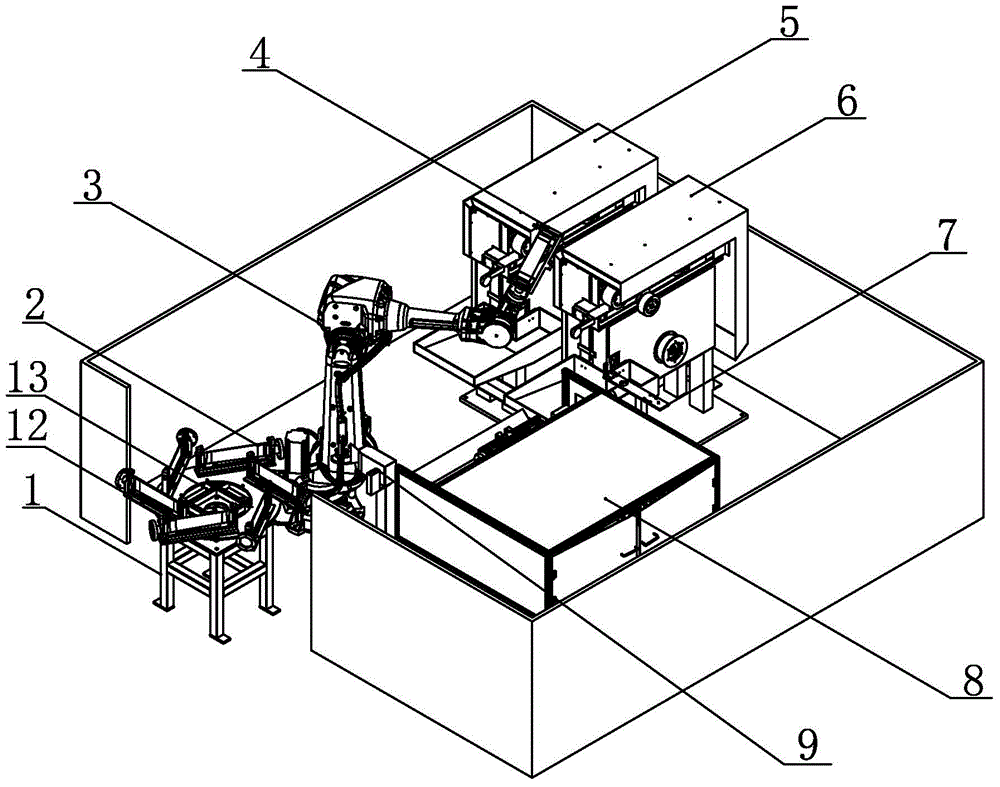

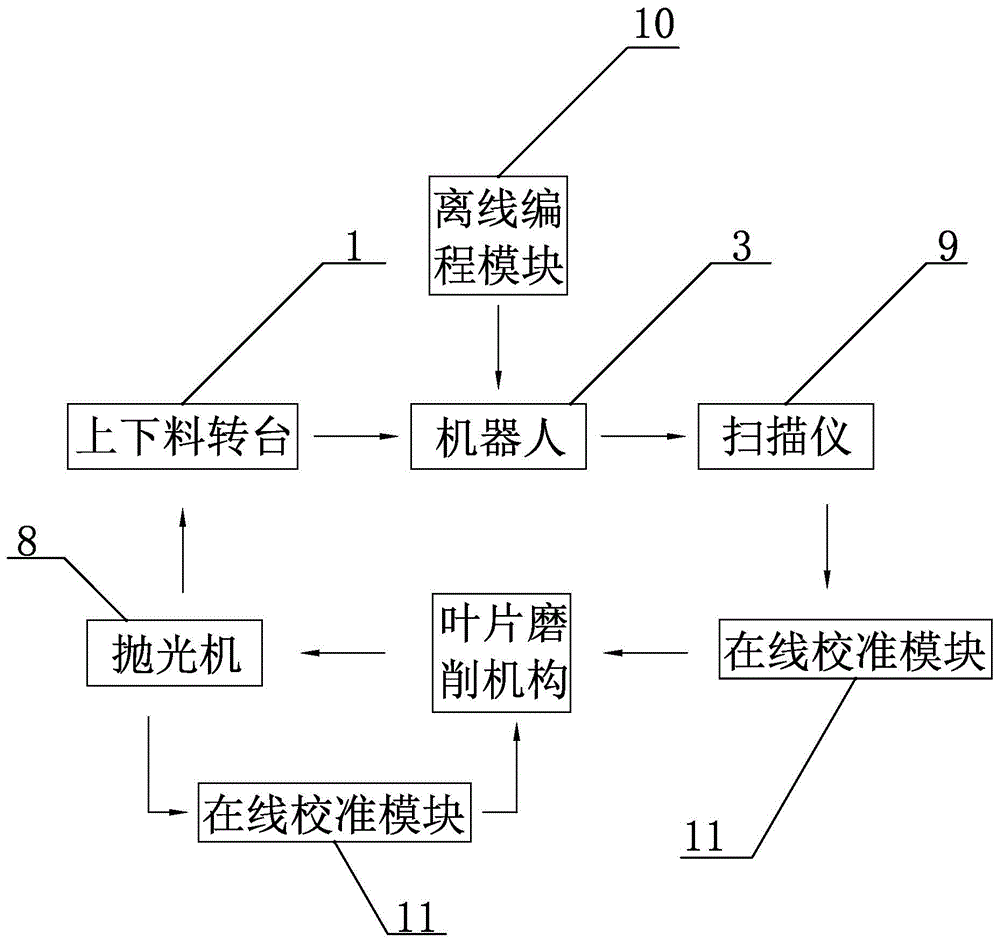

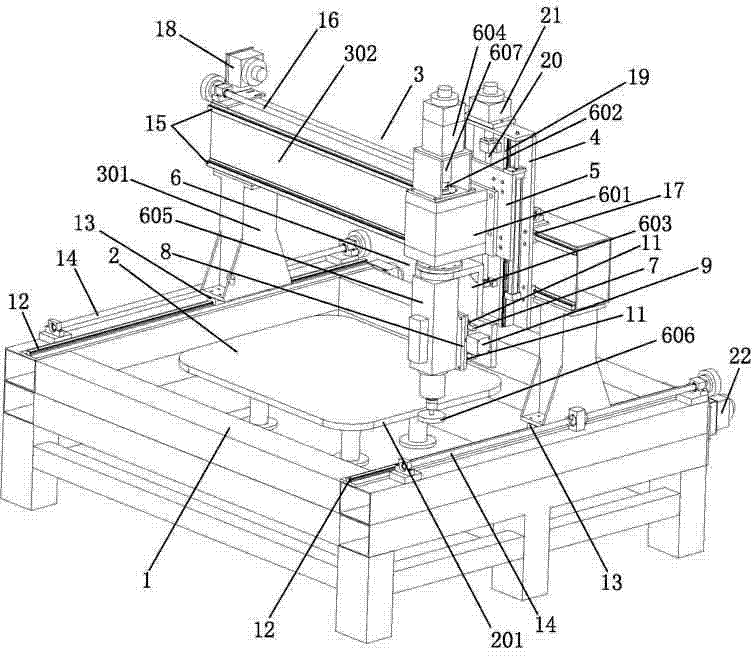

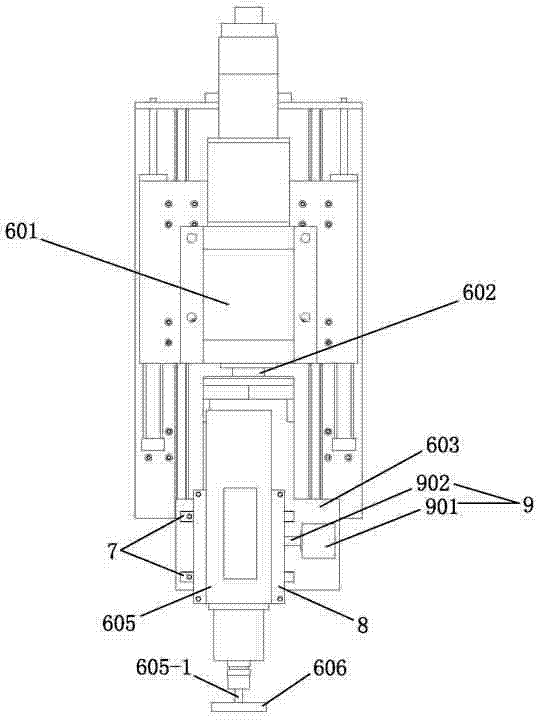

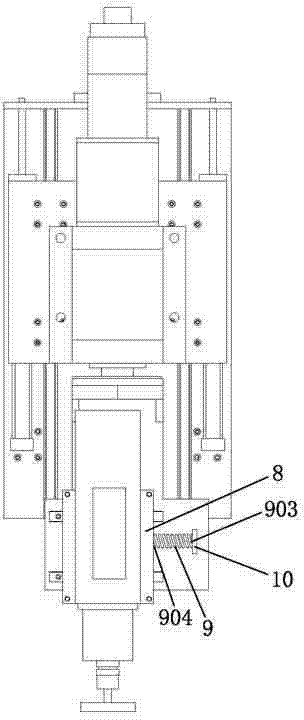

Automatic grinding polishing system

ActiveCN104889864AHigh precisionImprove scalabilityGrinding machinesSpecial data processing applicationsControl systemComputer module

The invention relates to a mechanical machining system used for conducting machining on blade surfaces, and aims at proving an automatic grinding polishing system which is high in machining accuracy, high in flexibility and low in cost. The automatic grinding polishing system comprises a feeding and blanking rotary table, a robot, a blade grinding mechanism, a polisher, a scanner and a software control system, wherein the feeding and blanking rotary table comprises a base, a rotating platform is movably installed on the base and provided with multiple workpiece installing clamping positions, a mechanical arm of the robot is provided with a rapid replacing clamping tool used for clamping a workpiece, the blade grinding mechanism is used for conducting the grinding process, the polisher is used for conducting the polishing process, the scanner is used for scanning the workpieces before or after being machined to obtain coordinate data of the workpieces, and the software control system comprises an off-line programming module, an online calibrating module and a robot controller.

Owner:徐州智畅机器人系统有限公司

Novel numerically controlled special-shaped glass edge grinding machine

InactiveCN104759962AEnsure consistencyBest force contact areaEdge grinding machinesGrinding machine componentsEngineeringSlide plate

The invention provides a novel numerically controlled special-shaped glass edge grinding machine. A glass workpiece is adsorbed on a frame; a portal frame sliding along the Y axis is mounted on the frame; an X-axis sliding plate sliding along the X axis is mounted on the portal frame; a Z-axis sliding plate sliding up and down along the Z axis is mounted on the X-axis sliding plate; a main shaft mechanism is mounted on the Z-axis sliding plate; a tilt-angle main shaft sleeve is fixed on the Z-axis sliding plate; a tilt-angle main shaft is mounted in the tilt-angle main shaft sleeve; one end of the tilt-angle main shaft is in driving connection with a tilt-angle servo motor, while the other end of the tilt-angle main shaft is connected with a tilt-angle rotating stand; a transversely sliding assembly is arranged on the tilt-angle rotating stand; a grinding head motor is connected to the transversely sliding assembly by use of a transversely sliding plate; an elastic compensation assembly for driving the transversely sliding plate to slide front and back is connected to one side of the transversely sliding plate; a cutting tool is mounted on the output shaft of the grinding head motor; an automatic grinding wheel compensation function can be realized, so that the cutting tool is always held down in contact with the glass workpiece in the grinding process; as a result, a consistent grinding effect can be achieved, and the glass workpiece can be consistent in smoothness after being ground.

Owner:刘忠文 +1

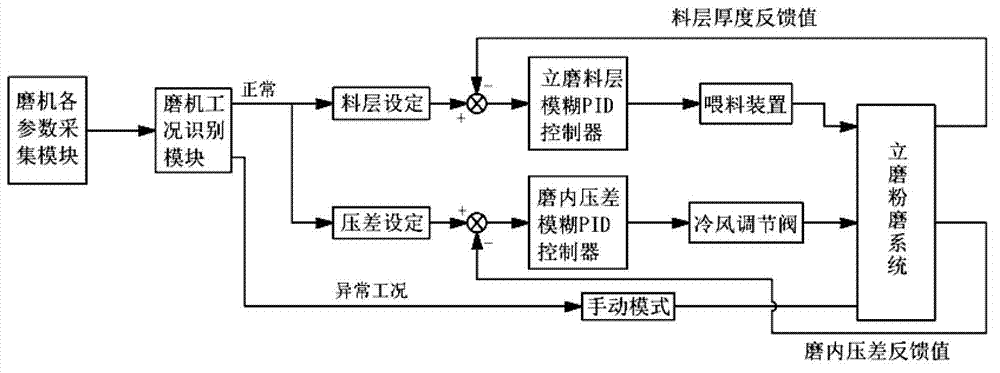

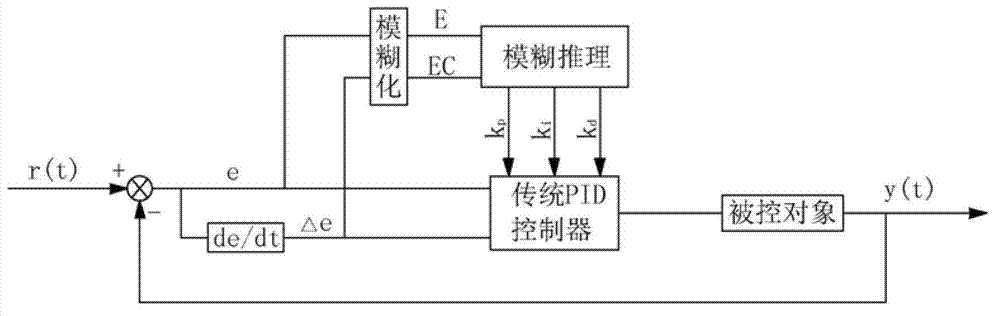

Intelligent control system for vertical mill based on fuzzy PID (proportion integration differentiation) algorithm

ActiveCN103028480AStable thicknessStable mill internal pressure differenceGrain treatmentsAdaptive controlCold airProportion integration differentiation

The invention relates to the technical field of control on production equipment, and particularly relates to an intelligent control system for a vertical mill based on a fuzzy PID (proportion integration differentiation) algorithm. The intelligent control system comprises the vertical mill, a dust remover and a feeding device, wherein the feeding device comprises an unloader, a bucket elevator and a storage bin; and the intelligent control system is characterized in that an air inlet in the bottom of the vertical mill is connected with a fan via a pipeline, a cold-air device and a hot-air stove are arranged on the pipeline between the air inlet and the fan, a cold-air adjusting valve and a hot-air adjusting valve are respectively arranged on the cold-air device and the hot-air stove, a vertical mill material layer PID controller is arranged on the feeding device, and an in-mill pressure difference fuzzy PID controller is arranged on the cold-air adjusting valve. According to the intelligent control system disclosed by the invention, mathematical models of the change of the vertical mill material layer thickness and an in-mill pressure difference along with parameters of a feeding amount, a mill inlet hot-air temperature and the like can be established only by inputting and outputting data without analyzing the complex grinding process of the vertical mill; and the intelligent control system is simple in process, high in adaptability, fast in the dynamic response time of a controller algorithm, high in robustness, high in control accuracy, and good in market prospect.

Owner:SHANGHAI TRIUMPH ENERGY CONSERVATION ENG TECH CO LTD

Fresh grinding process for nutritious drink

InactiveCN102028040AFull of nutritionEasy to operateMilk substitutesFood scienceDietary fiberRaw material

The invention discloses a fresh grinding process for a nutritious drink. The nutritious drink is prepared by boiling and pulping raw materials in turn. In the process, the method for boiling and pulping the materials in turn is adopted, so residue is not needed to be separated, and the method is convenient to operate; meanwhile, protein and dietary fiber of the raw materials are maintained, and the nutritious drink contains rich nutrition and meets health requirements of modern people.

Owner:GUANGDONG FOOD IND INST

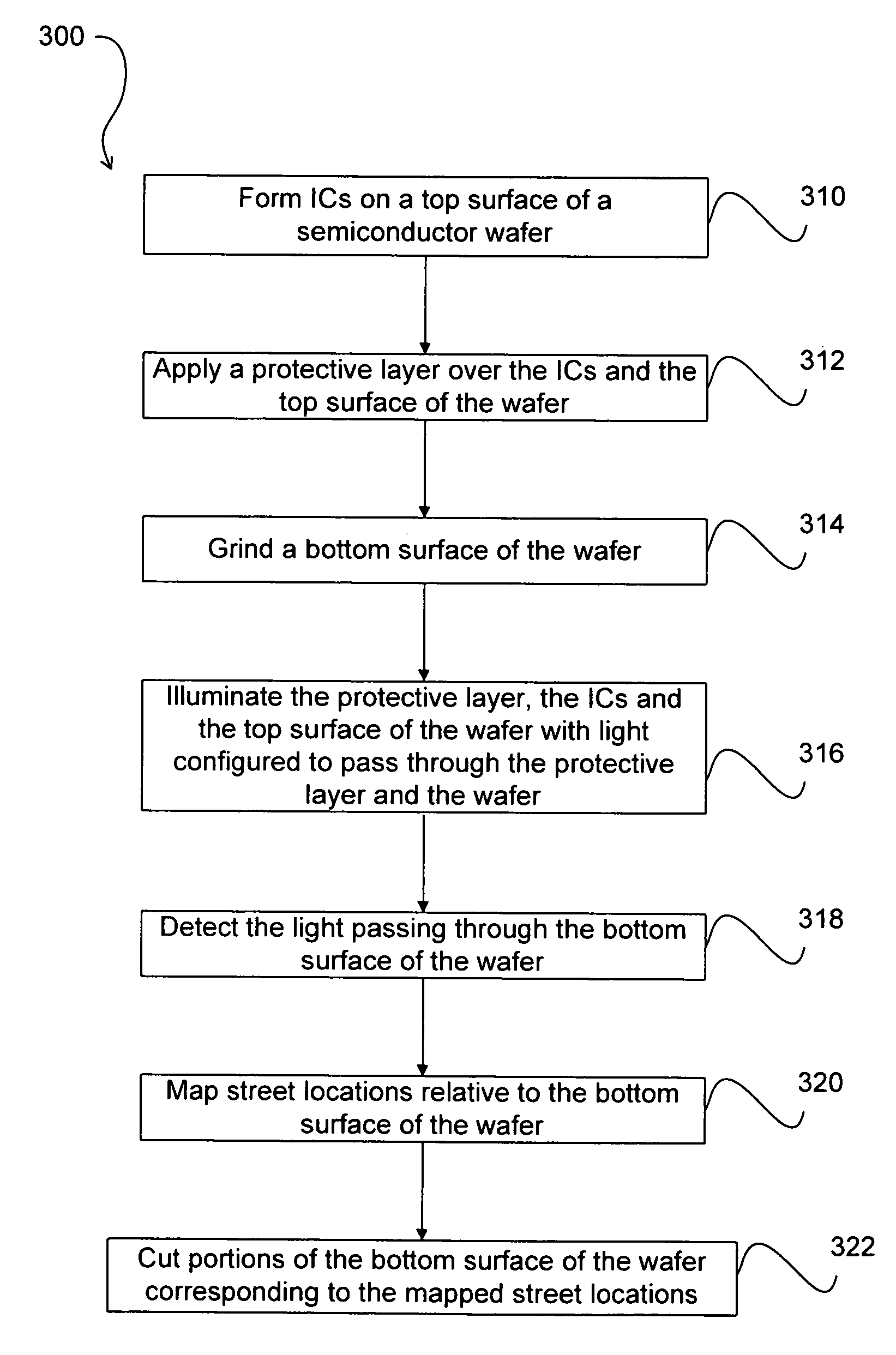

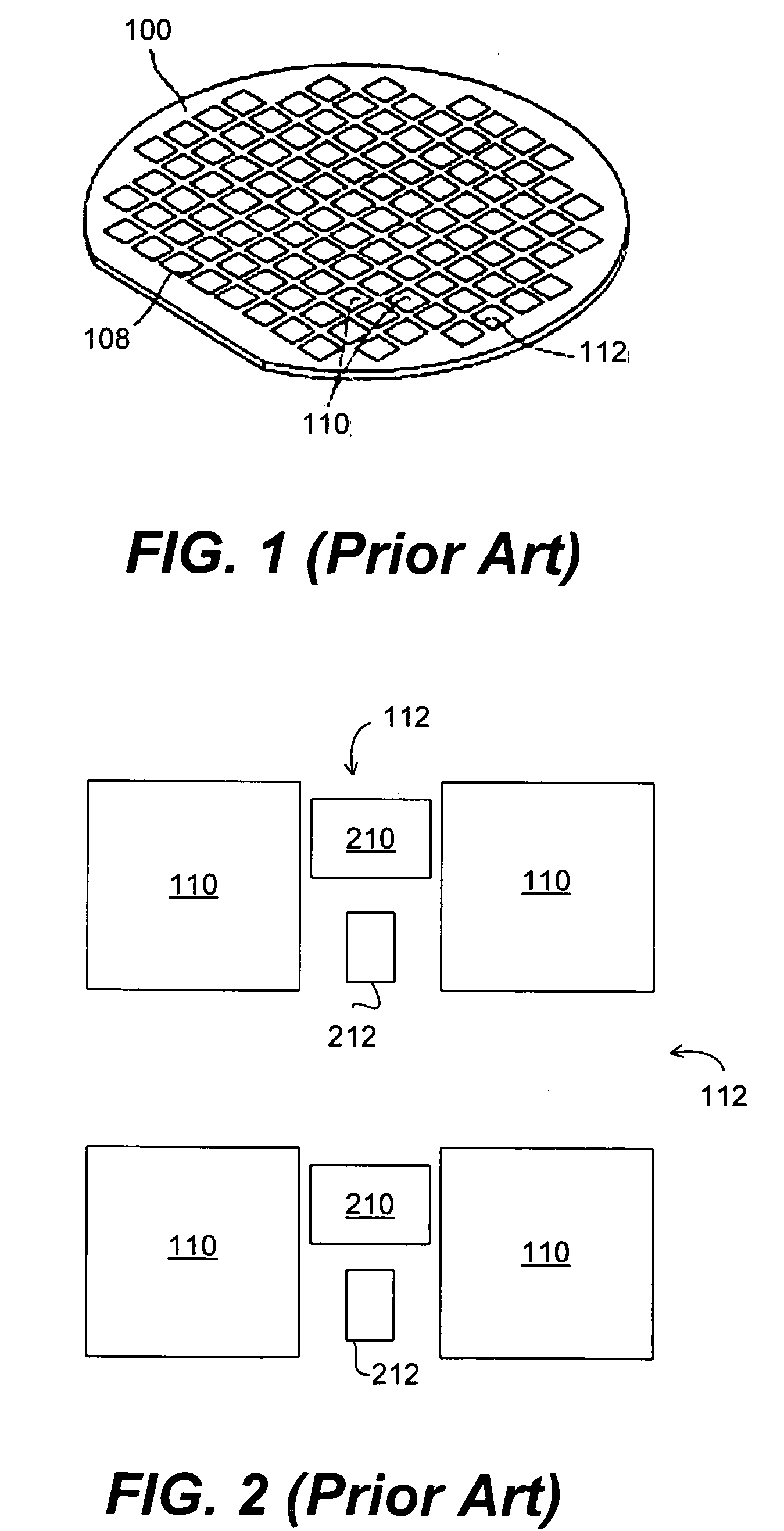

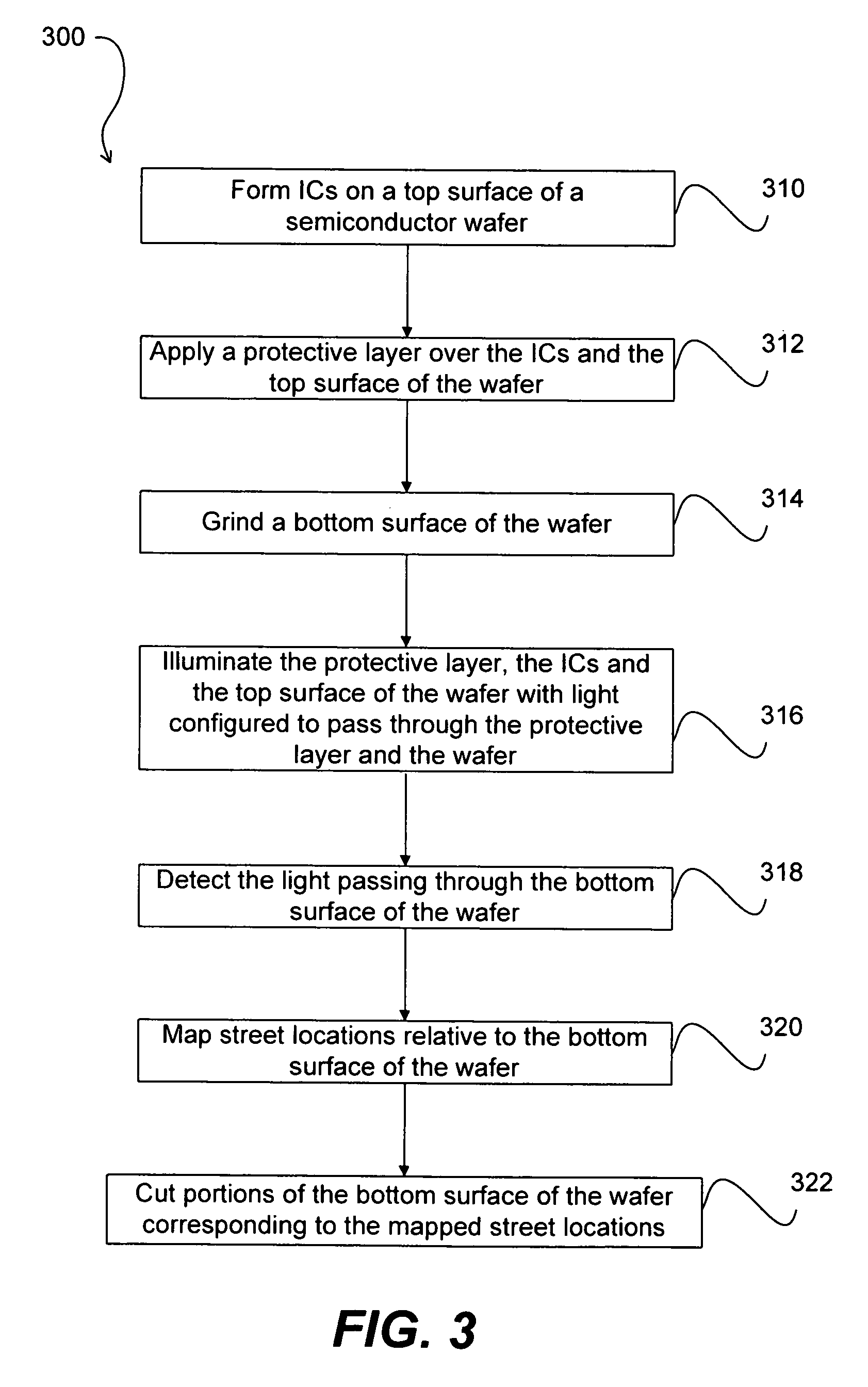

Back side wafer dicing

InactiveUS20070275541A1Reduced and no damageReduced and no and debrisSemiconductor/solid-state device manufacturingFine working devicesWaferingWafer dicing

Systems and methods for scribing a semiconductor wafer with reduced or no damage or debris to or on individual integrated circuits caused by the scribing process. The semiconductor wafer is scribed from a back side thereof. In one embodiment, the back side of the wafer is scribed following a back side grinding process but prior to removal of back side grinding tape. Thus, debris generated from the scribing process is prevented from being deposited on a top surface of the wafer. To determine the location of dicing lanes or streets relative to the back side of the wafer, the top side of the wafer is illuminated with a light configured to pass through the grinding tape and the wafer. The light is detected from the back side of the wafer, and the streets are mapped relative to the back side. The back side of the wafer is then cut with a saw or laser.

Owner:ELECTRO SCI IND INC

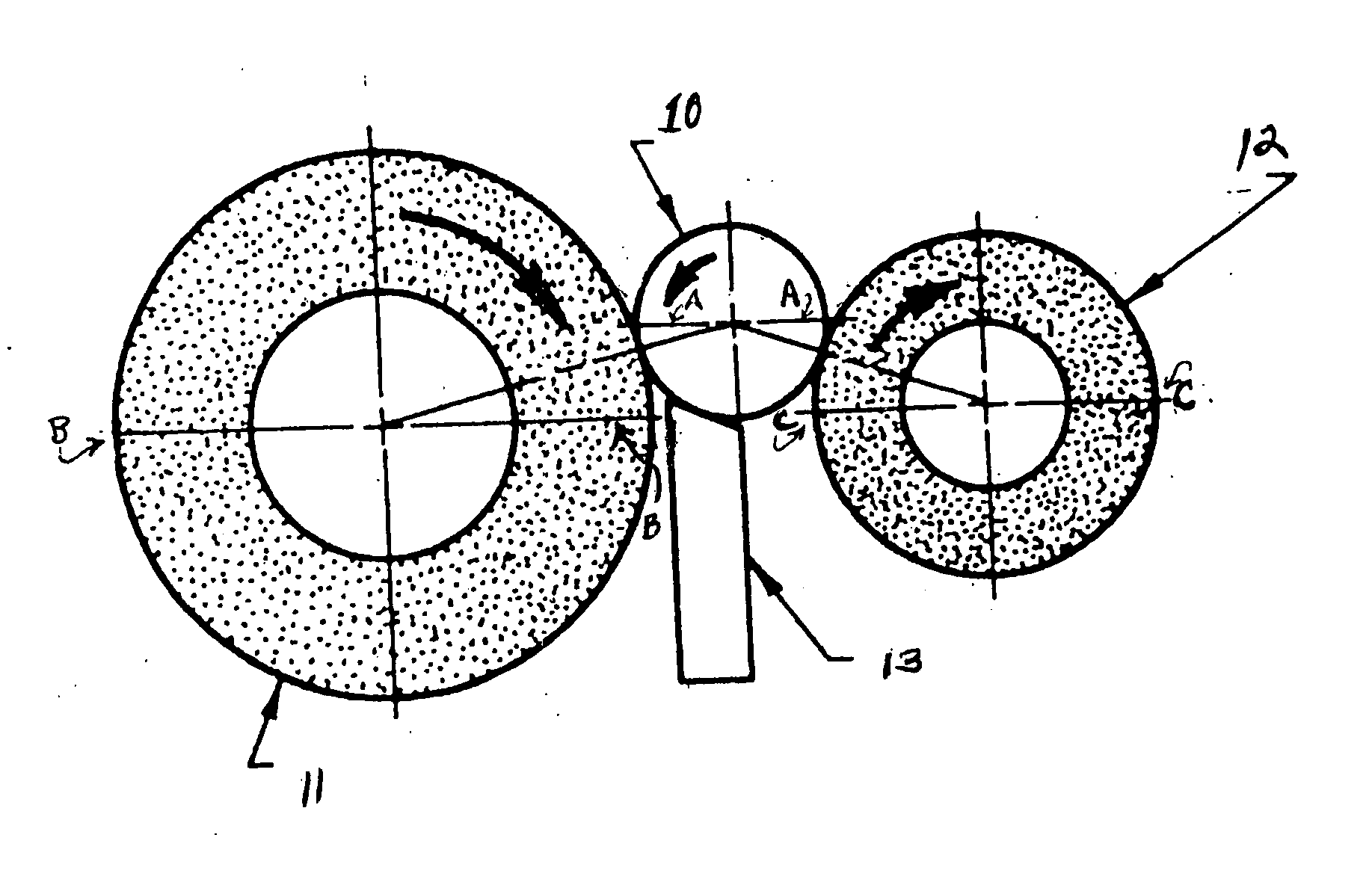

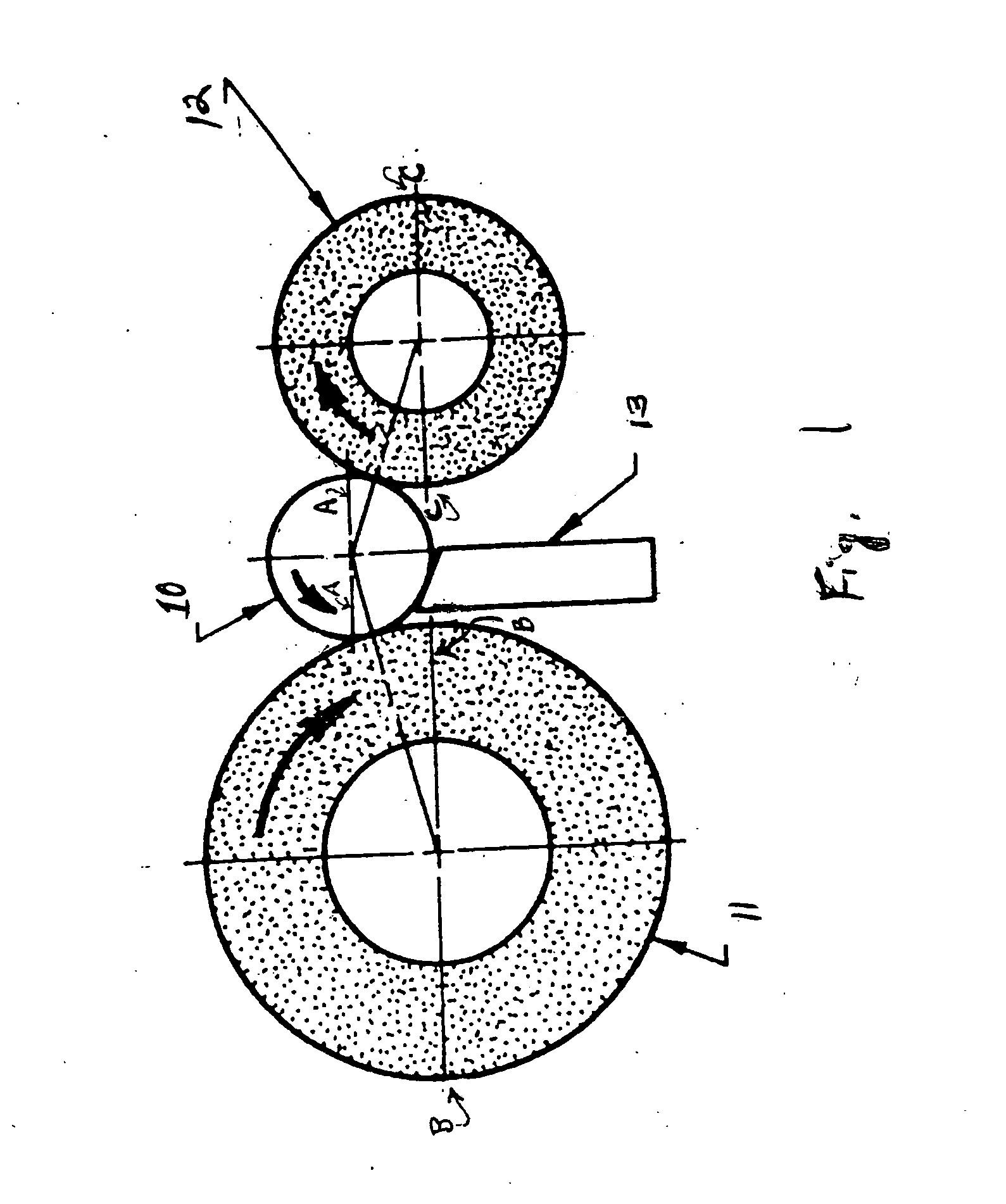

Method of centerless grinding

Organic bonded abrasive tools, having controlled microstructures, comprise a relatively low volume percentage of abrasive grain and a relatively low hardness grade, but are characterized by the excellent mechanical strength and efficient grinding performance of much harder grade, lower porosity tools, especially in versatile grinding processes, such as centerless grinding. A method for centerless grinding with these tools is provided. Methods for making the abrasive tools utilizing agglomerated abrasive grain are described.

Owner:SAINT GOBAIN ABRASIVES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com