Method for preparing transmission electron microscope sample

An electron microscope and sample technology, applied in the field of semiconductor and material analysis, can solve the problems of reducing sample preparation efficiency, affecting observation effect, and inability to clearly image, etc., and achieve the effect of improving preparation efficiency and observation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

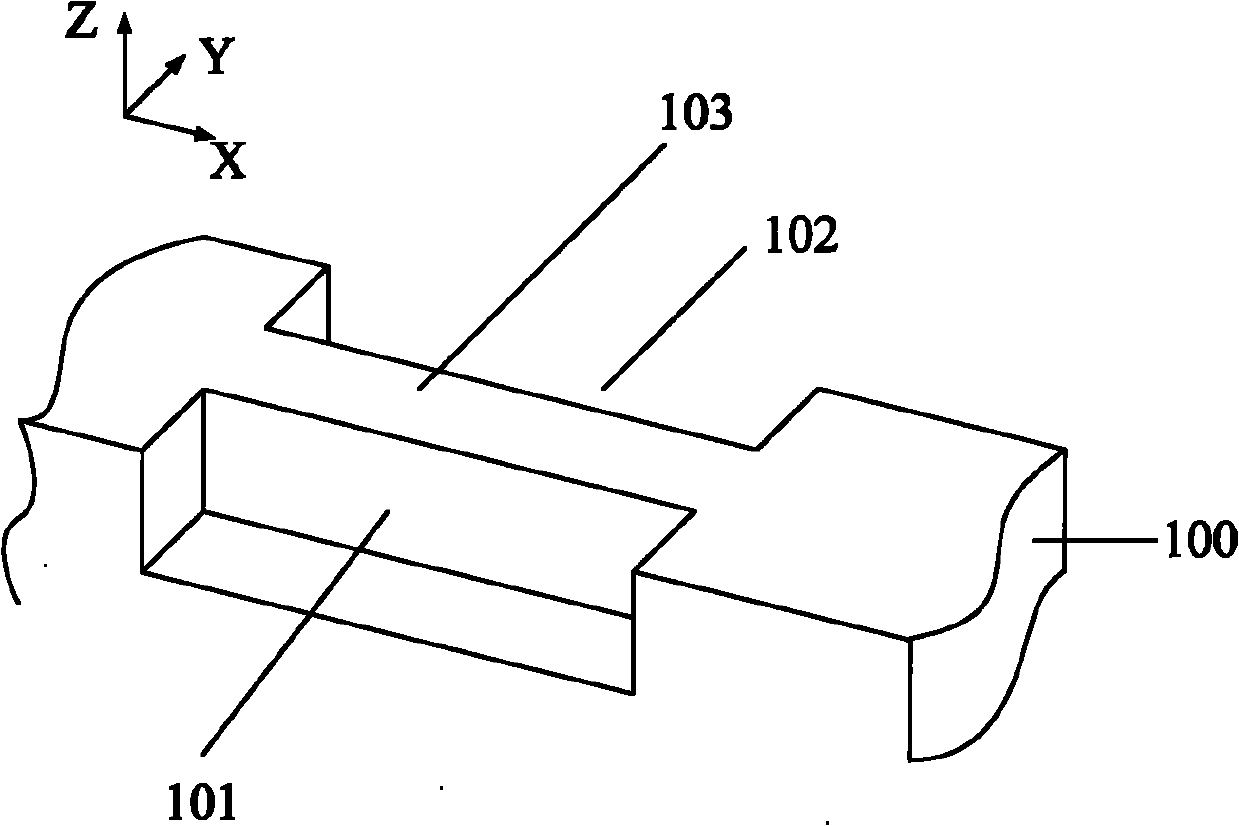

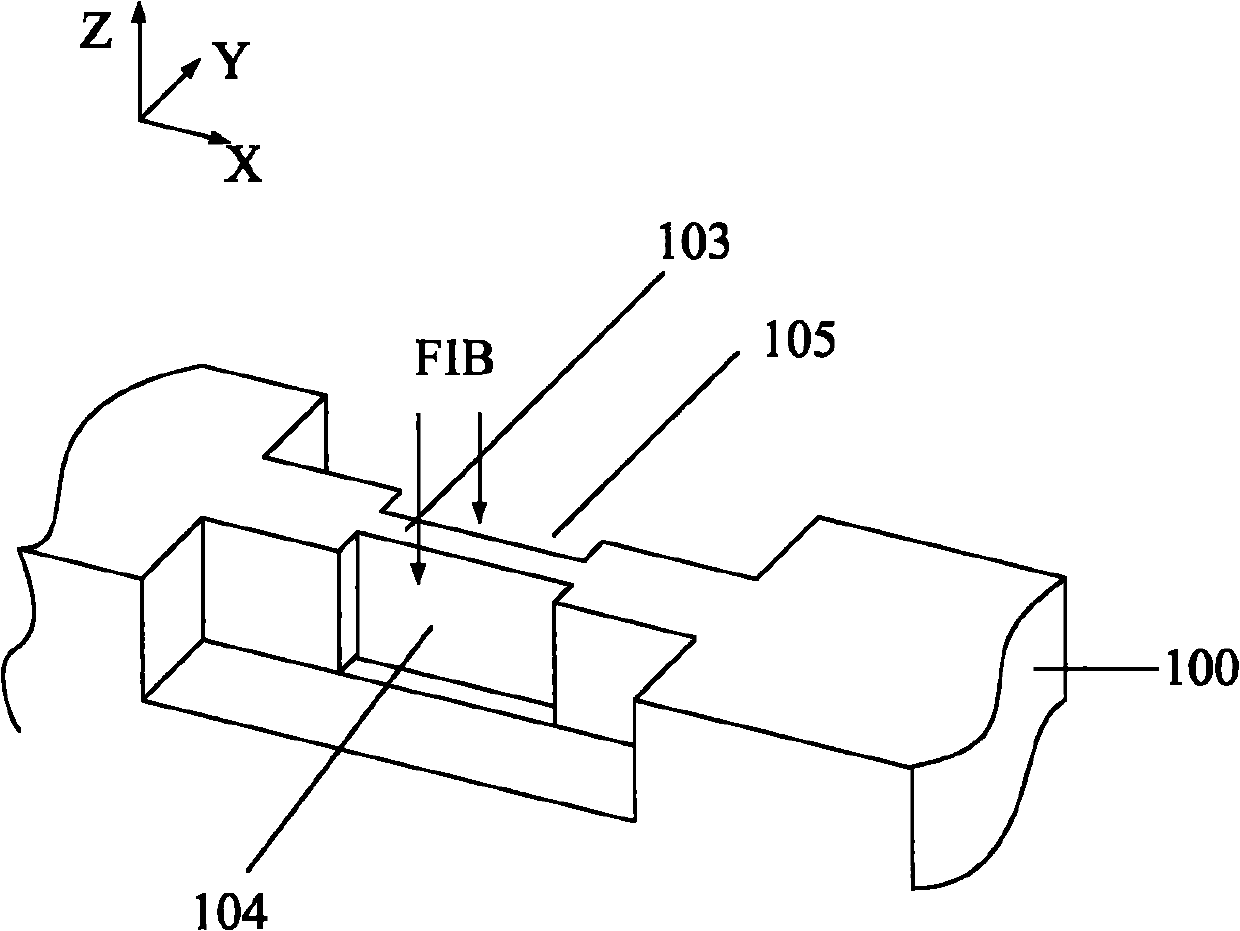

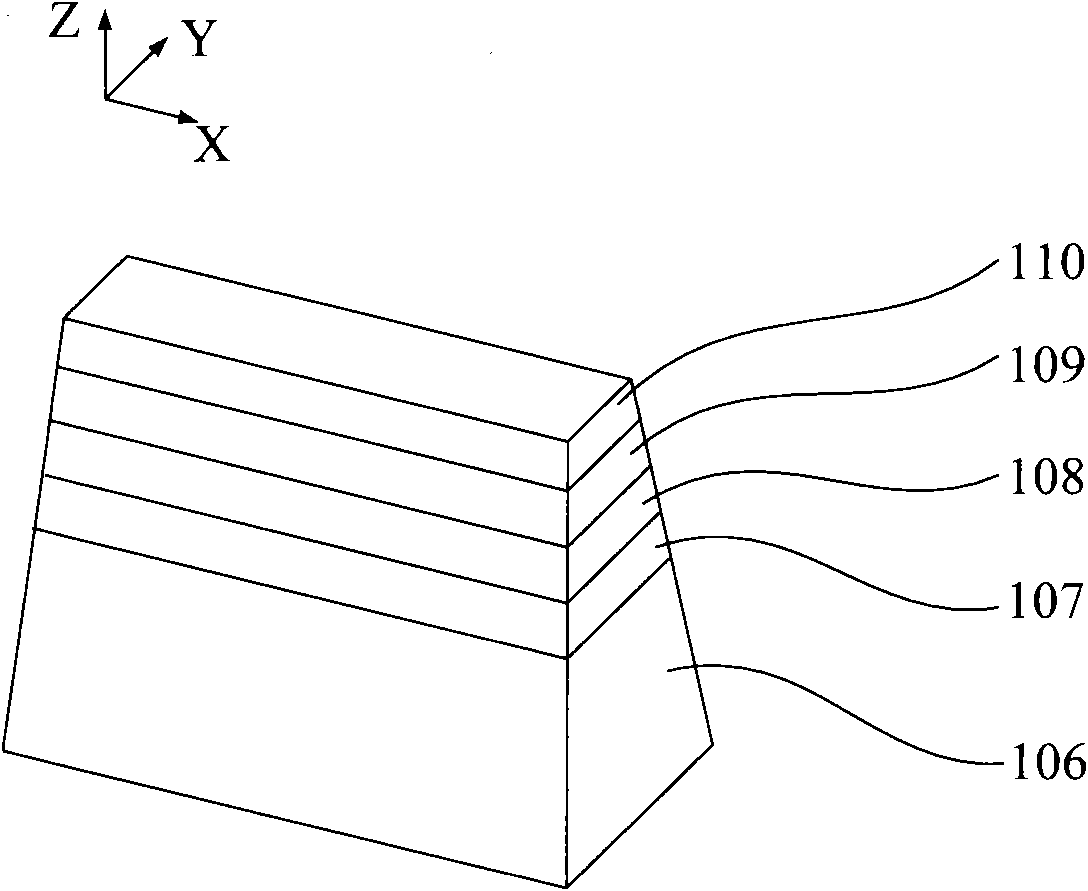

[0033] The invention provides a method for preparing a transmission electron microscope sample. First, the area to be observed is marked, and then the sample is ground along a direction perpendicular to the elongation direction of the elongated structure or the stacking direction of the stacked structure, and then Forming pits on both sides of the area to be observed on the grinding surface and thinning the area to be observed along the pits, avoiding the positive correlation between the amount of grinding and the length of the extended structure or the thickness of the multilayer stacked structure , so that the area to be observed can be clearly imaged under the transmission electron microscope, which improves the preparation efficiency and observation effect.

[0034] During the preparation process, a protective cover is further installed on the surface of the sample, which prevents the sample from being damaged during the grinding process, and also avoids the problem that it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com