Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15290 results about "Grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool.

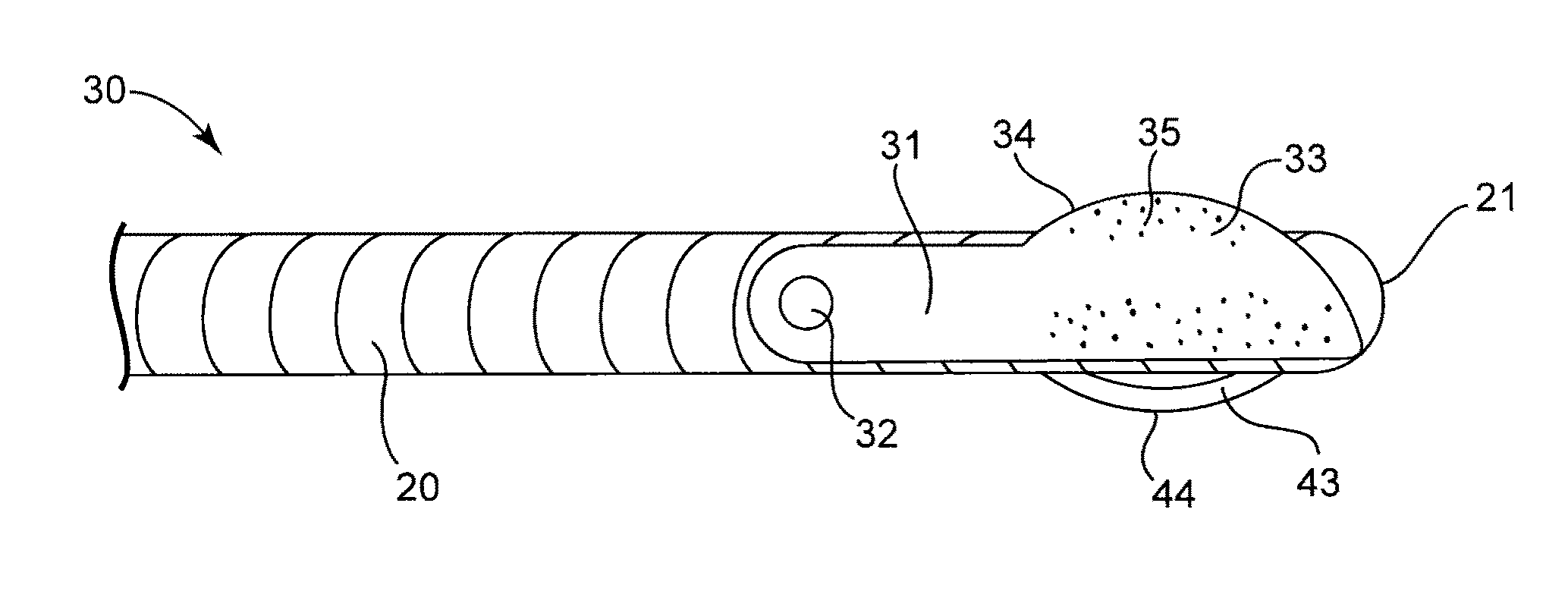

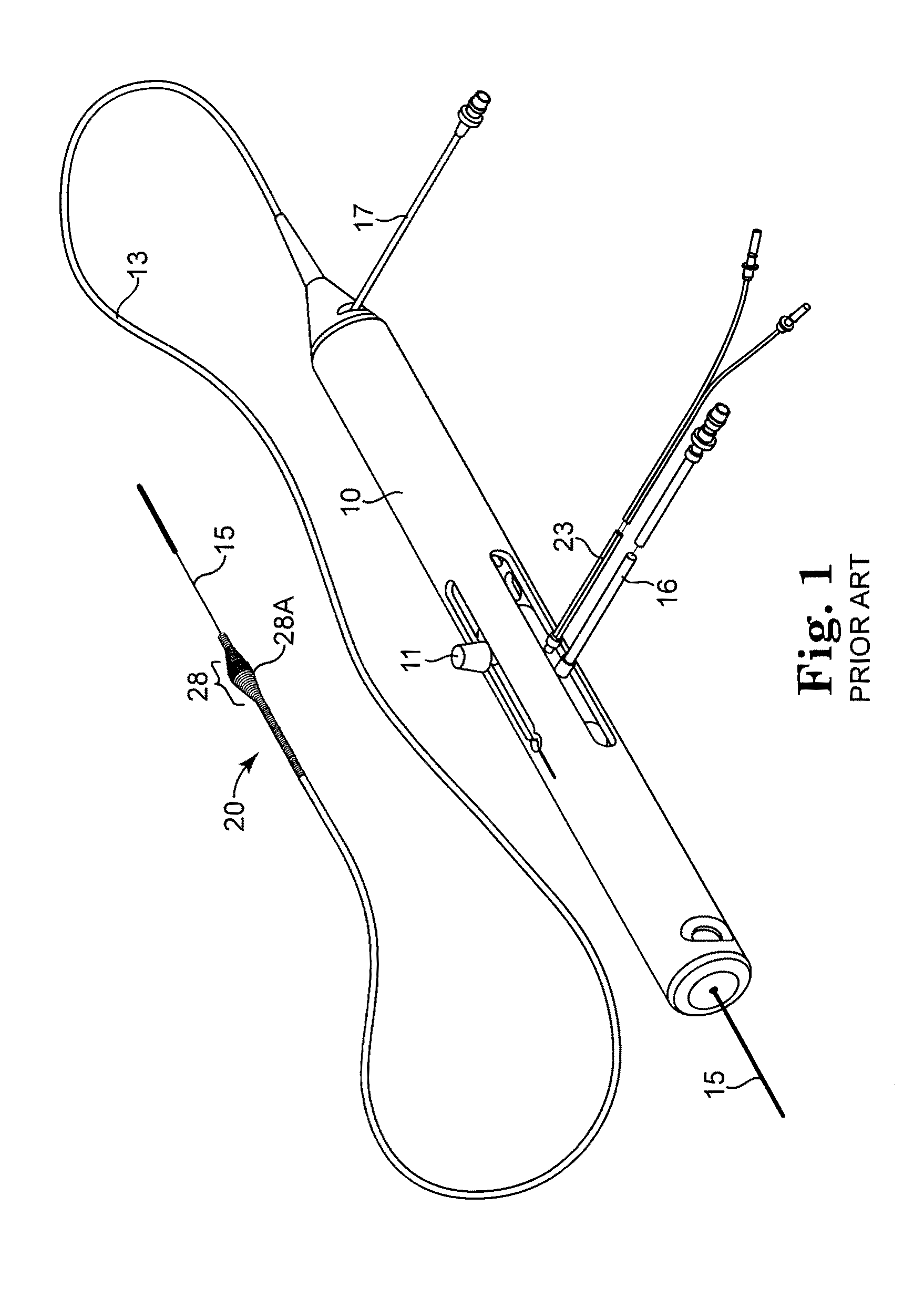

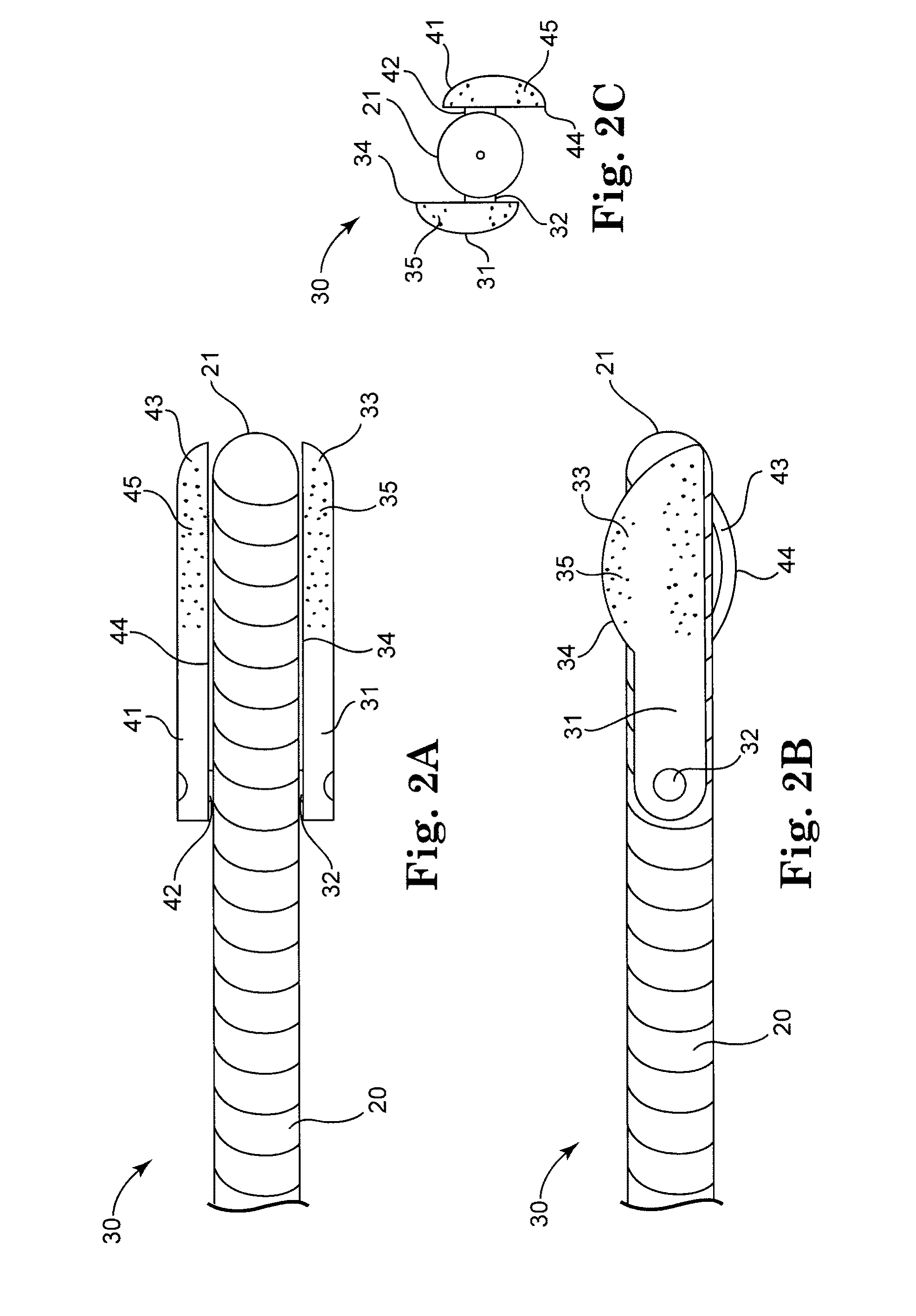

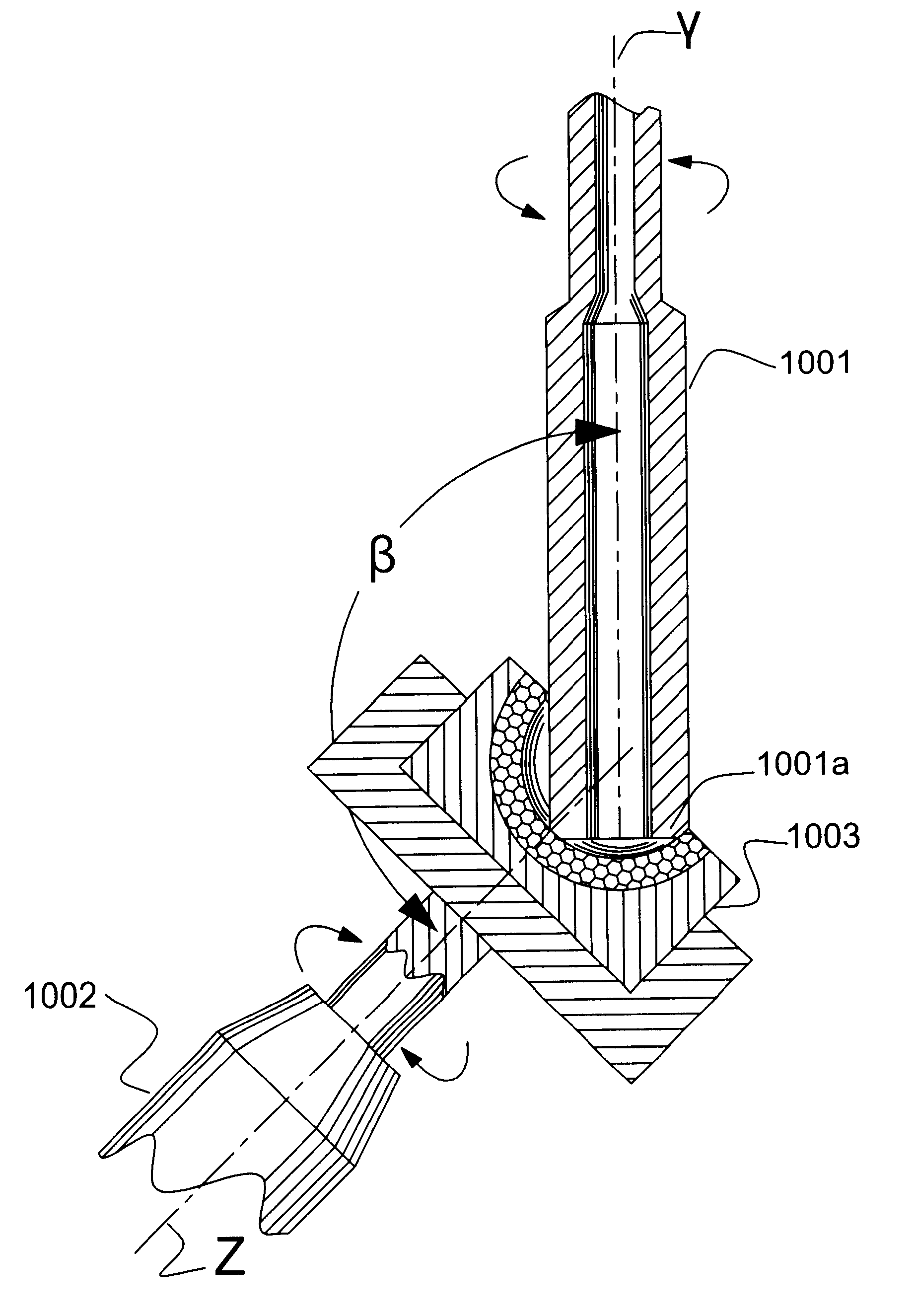

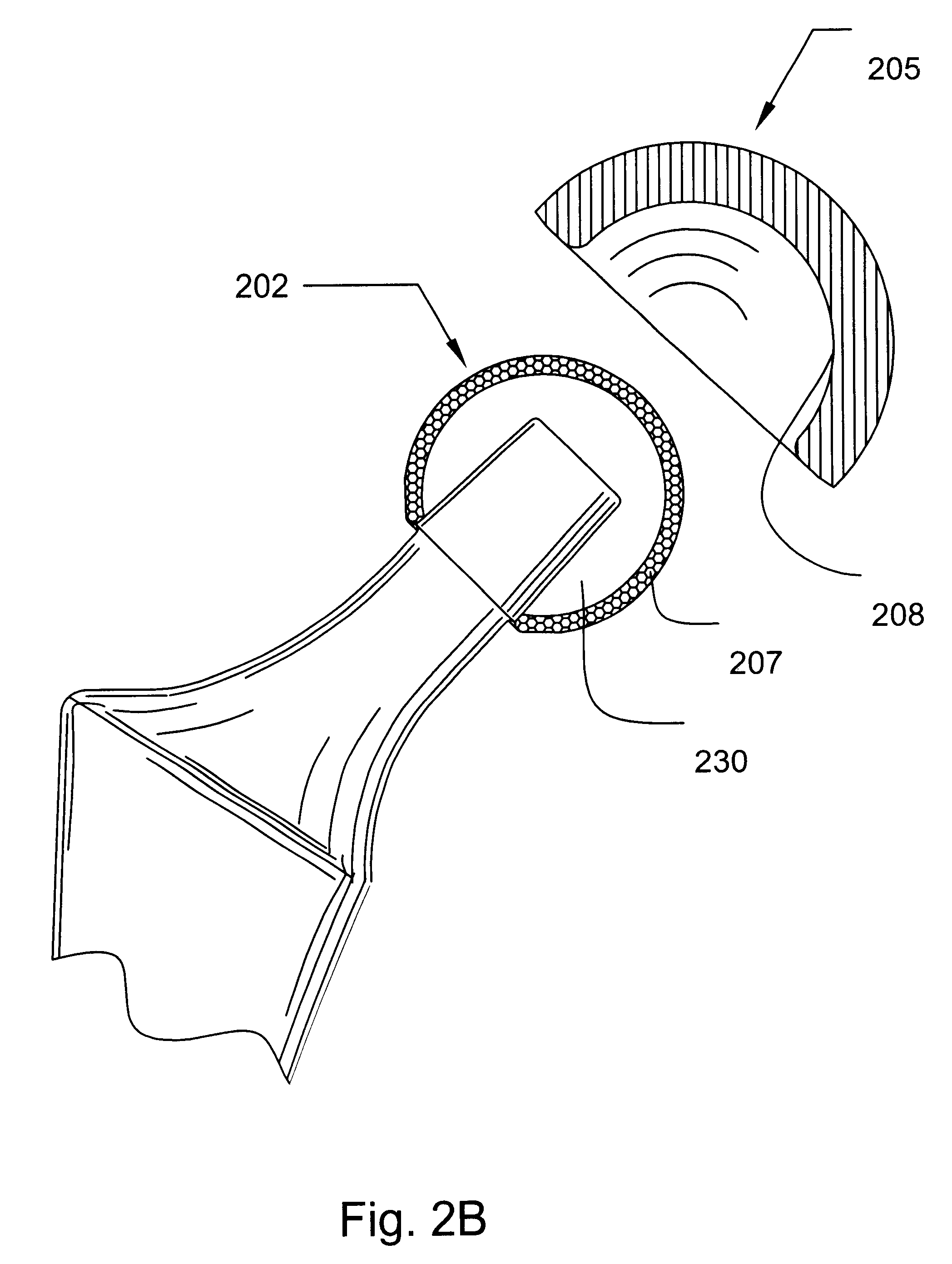

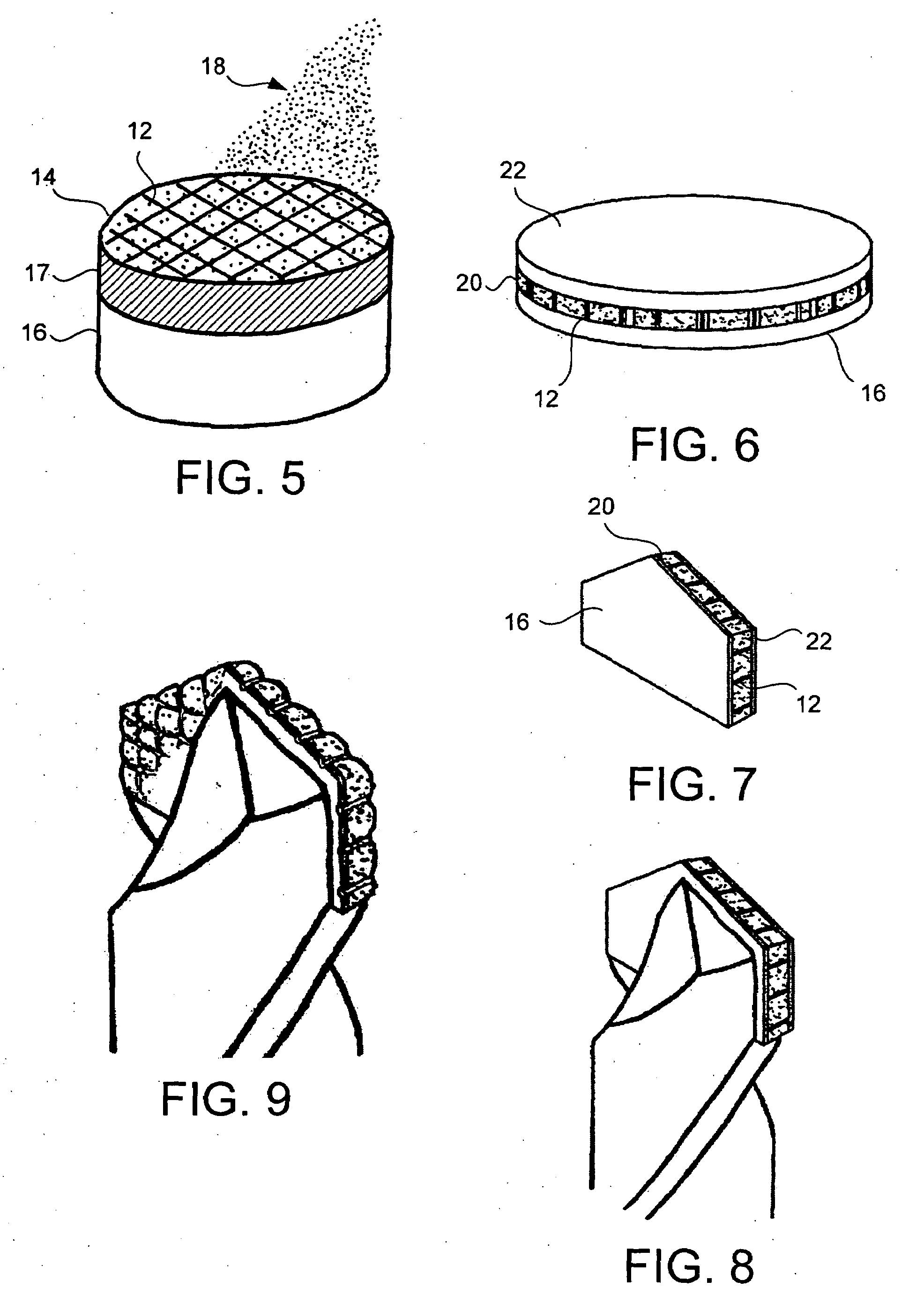

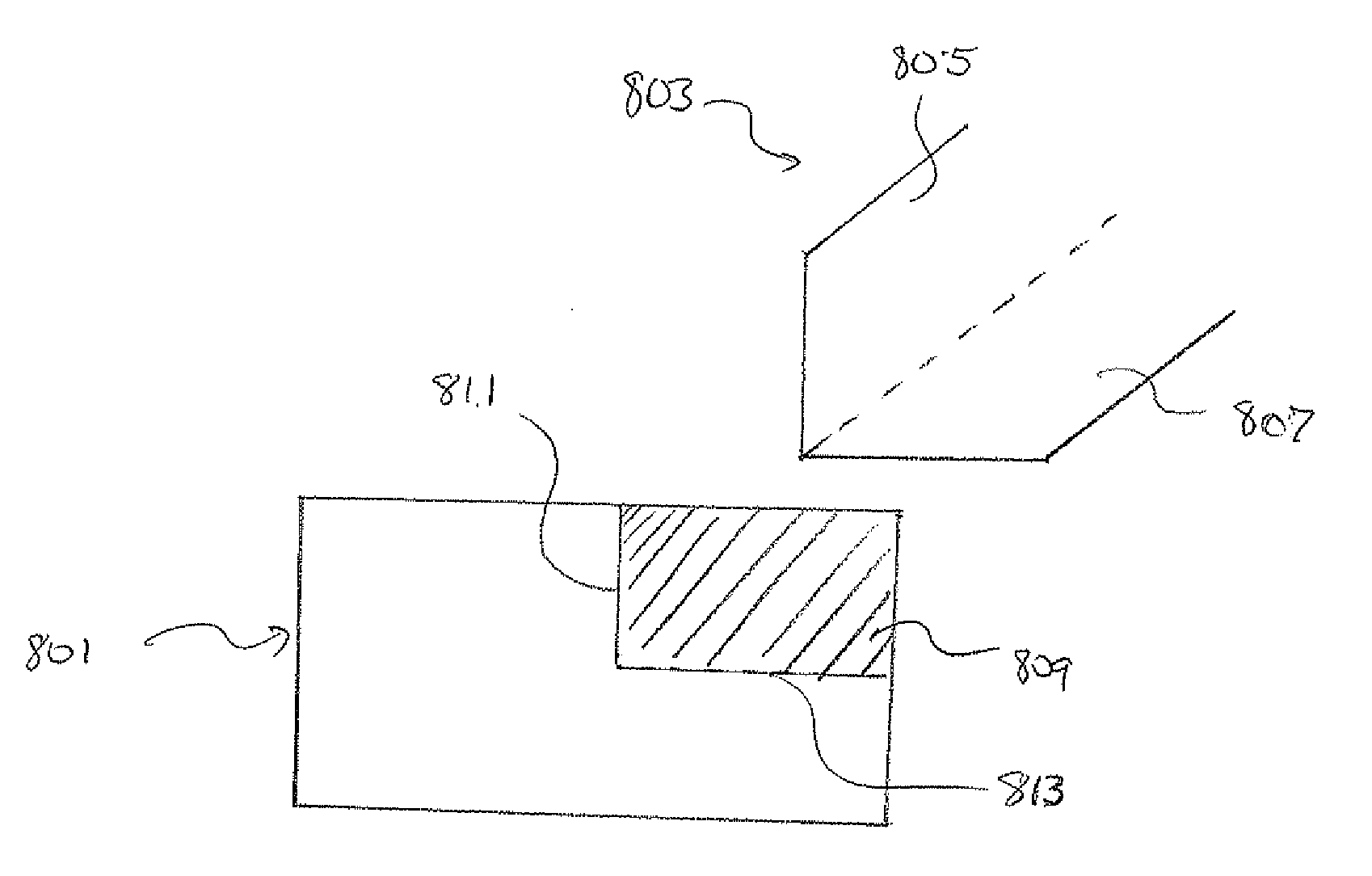

Bidirectional expandable head for rotational atherectomy device

A rotational atherectomy device that includes an expandable head that can clean a blockage from vessel larger than its rest diameter, in which the drive shaft may rotate in two opposite directions and may have different abrasive characteristics for each rotation direction. In one direction, the head may be configured for cutting and / or slicing, which may be well suited to removing particularly soft blockage material. In the other direction, the head may be configured for grinding, scraping and / or sanding, which may be well suited to removing particularly hard blockage material. The head includes one or more arms that are pivotally or hingedly attached to the drive shaft. One or more abrasive elements are disposed on or are attached to the one or more arms. The abrasive elements have a cutting feature, such as a sharpened edge that cuts like a razor blade when the drive shaft is rotated in the “cutting” direction. The abrasive elements also have a grinding feature, such as an abrasive material disposed on the abrasive element adjacent to the sharpened edge, which grinds away a blockage when the drive shaft is rotated in the “grinding” direction.

Owner:CARDIOVASCULAR SYST INC

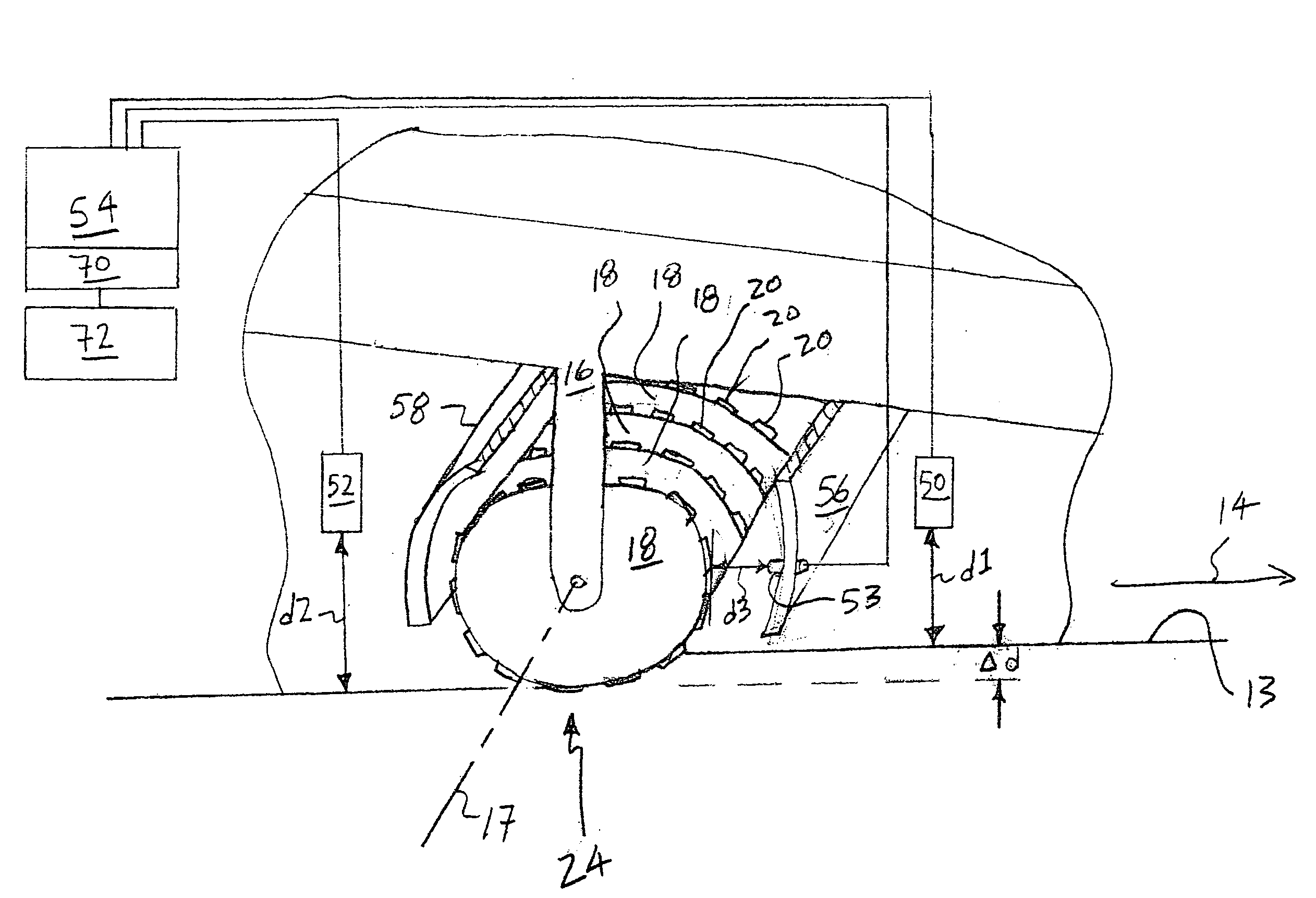

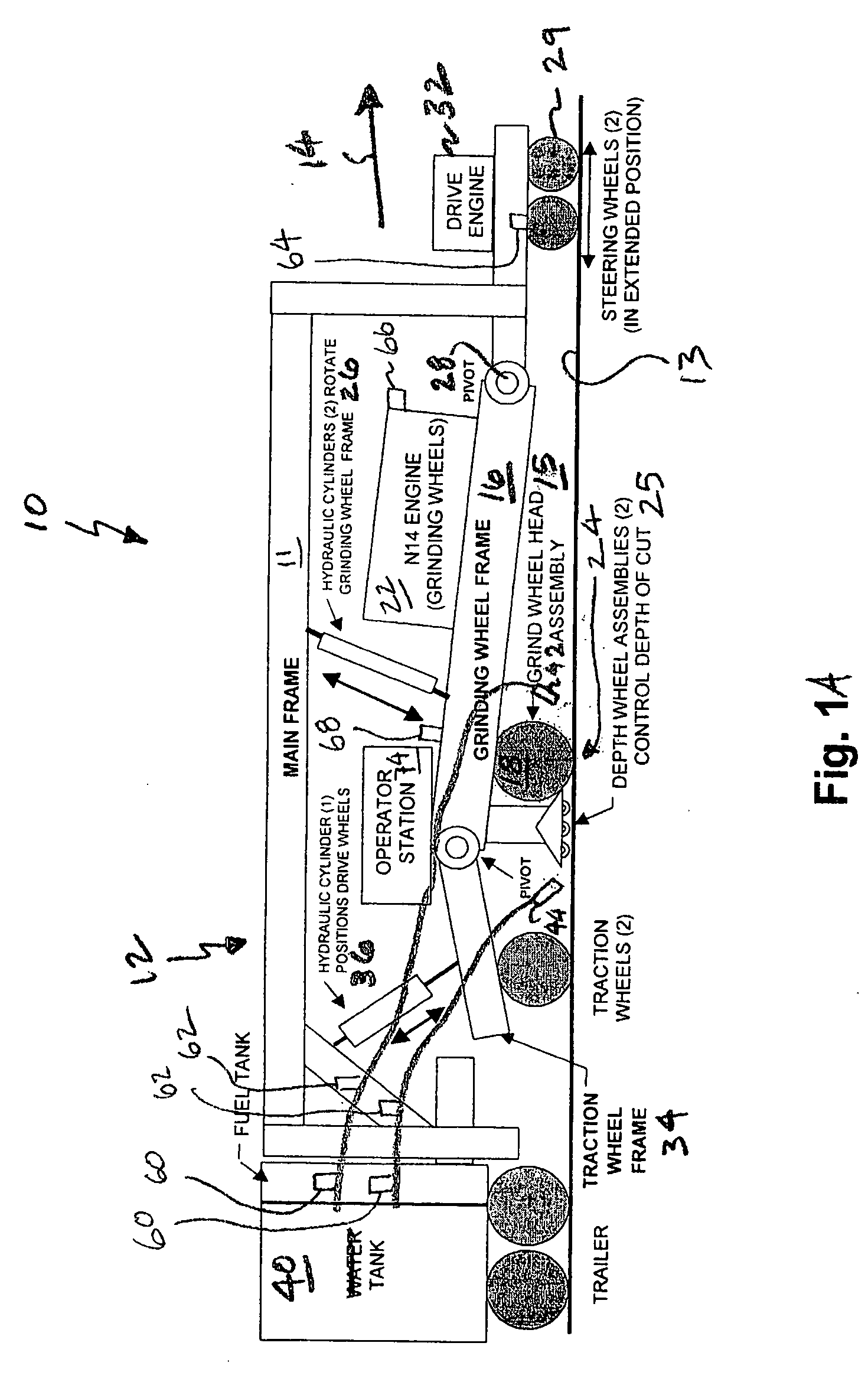

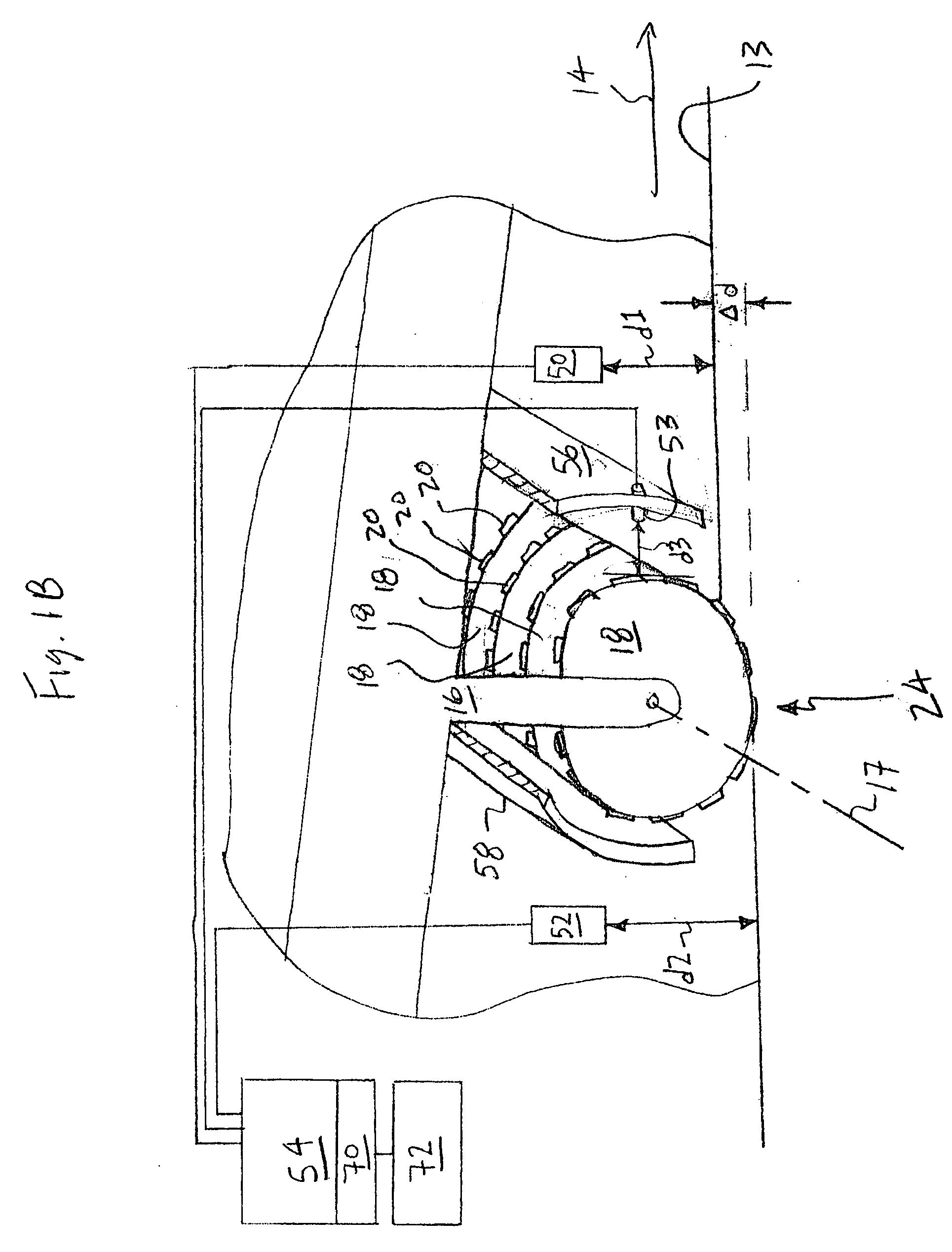

Roadway grinding/cutting apparatus and monitoring system

An apparatus and method is provided for monitoring operation of a roadway grinding / cutting machine of the type configured to travel along a roadway while engaging and grinding the roadway with a grinding / cutting head. A first displacement sensor generates, during the travel, first distance data associated with a distance between a reference level and a location on the roadway ahead of the grinding zone. A second displacement sensor generates, during the travel, second distance data associated with a distance between the reference level and a location on the roadway behind the grinding zone. A processor captures and uses the first and second distance data to determine a depth of cut as grinding / cutting progresses.

Owner:SAINT GOBAIN ABRASIFS INC +1

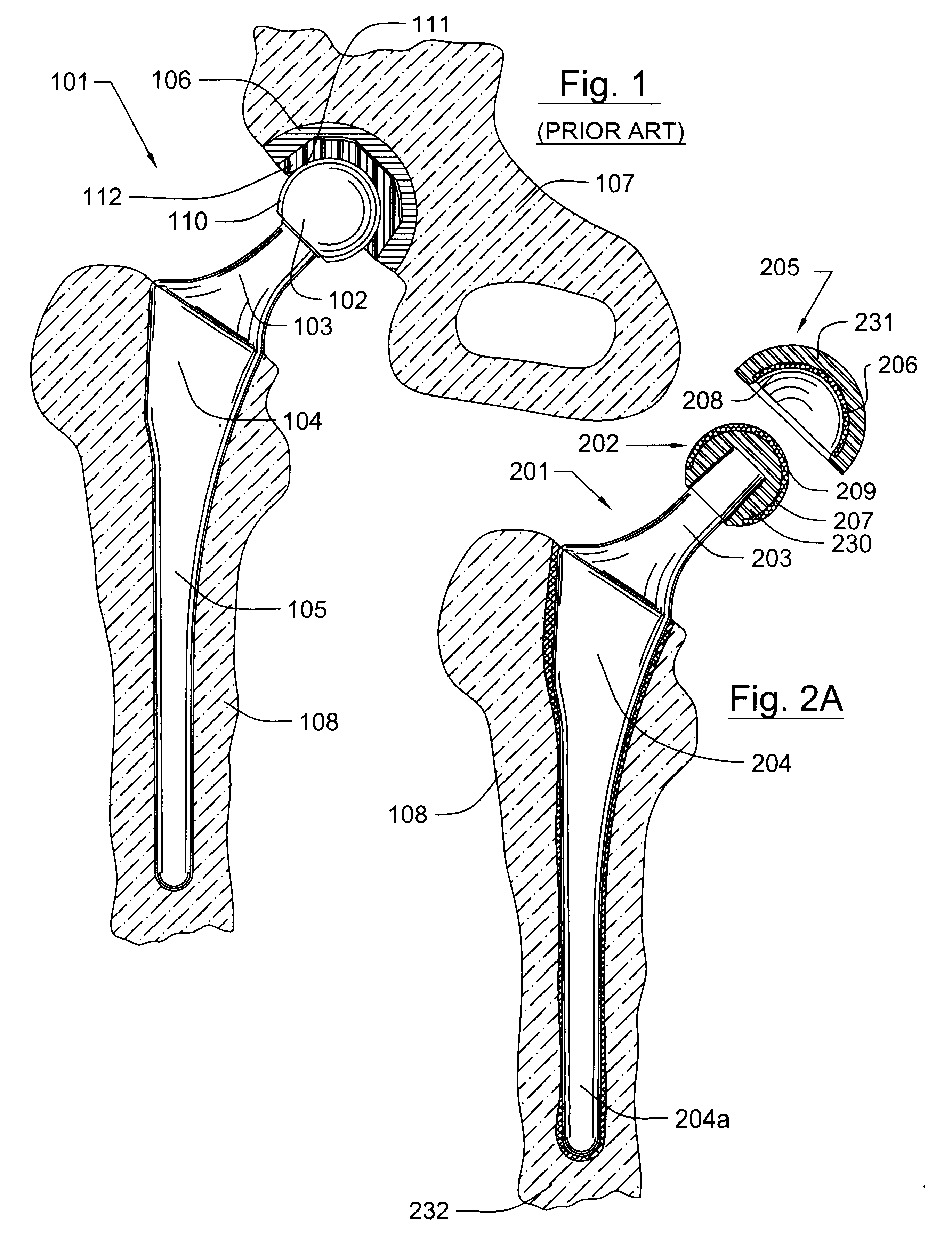

Methods for shaping and finishing prosthetic joint components including polycrystalline diamond compacts

InactiveUS6410877B1Less disruptiveImprove overall utilizationElectrode vibration holdersElectrical-based machining electrodesHeat-affected zoneElectric discharge

A method of rough shaping a prosthetic joint component that includes a generally spherical polycrystalline diamond compact by electric discharge machining is disclosed. The discharge machining electrode roughens a polycrystalline diamond compact sphere while the electrode and the sphere are rotating about different axes. By controlling the amount of discharge current, the depth and amount of the heat affected zone can be minimized. In the case of a polycrystalline diamond compact, the heat affected zone can be kept to about 3 to 5 microns in depth and is easily removable by grinding and polishing.

Owner:DIAMICRON

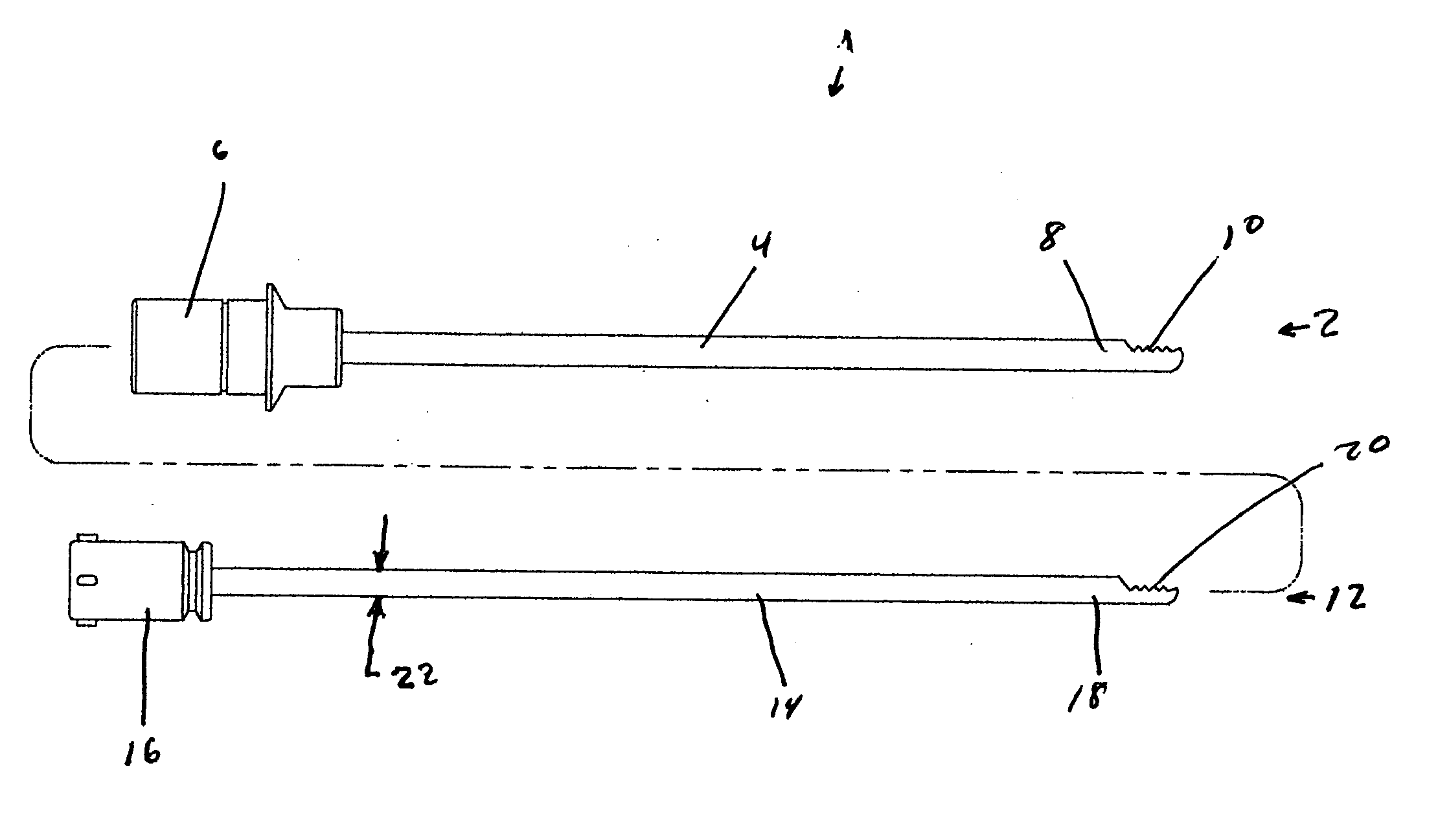

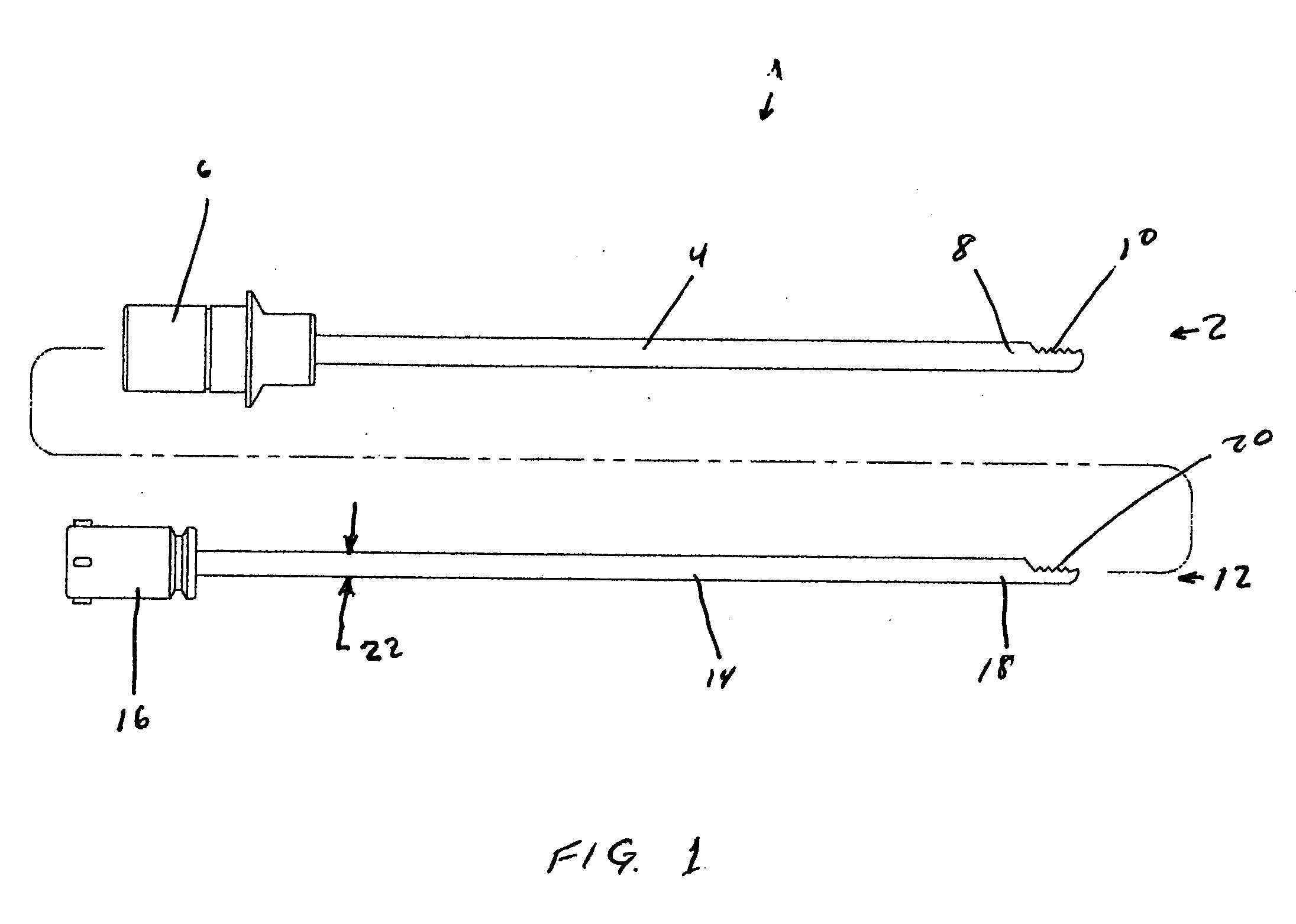

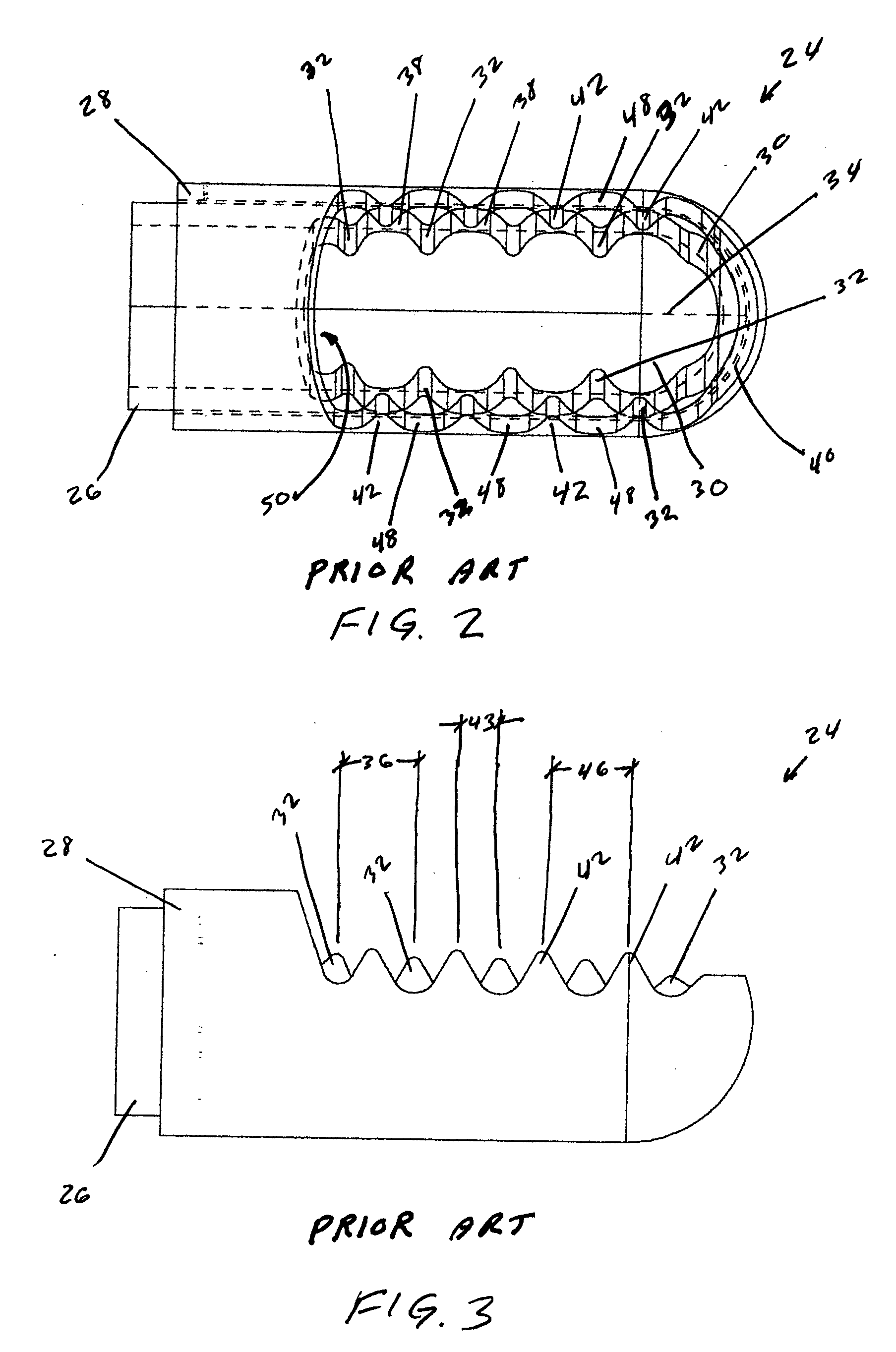

Asymmetric shaver and methods for making same

InactiveUS20050065538A1Improve resection efficiencyImprove efficiencyCannulasSawing tools dressing arrangementsCnc grindingEngineering

A surgical shaver blade is provided with a stationary elongated outer tube, having a cutting window at its distal tip and a rotatable elongated inner tube having a cutting window at its distal tip. Each cutting window is not symmetrical about any line in a sectional view through the window normal to the tube axis. In a preferred embodiment the cutting edges of each window have a plurality of teeth, the teeth of one lateral cutting edge being offset axially from the teeth of the other lateral edge so that the teeth of one edge align axially with the valleys between teeth on the opposite edge. When the shaver is used in oscillate mode, the teeth of one direction of rotation align with tissue that was between teeth during the previous opposite direction rotation thereby enhancing the ability of the teeth to penetrate the tissue and prevent its ejection from the cutting window as the cutting edges approach. In another embodiment the outer window is asymmetric without teeth and the inner window is asymmetric with teeth. In yet another embodiment only the inner cutting edges are asymmetric. The cutting edges are formed in a single grinding operation or multiple grinding operations using a multi-axis CNC grinding machine, or electrochemically.

Owner:ASYMMETRICS

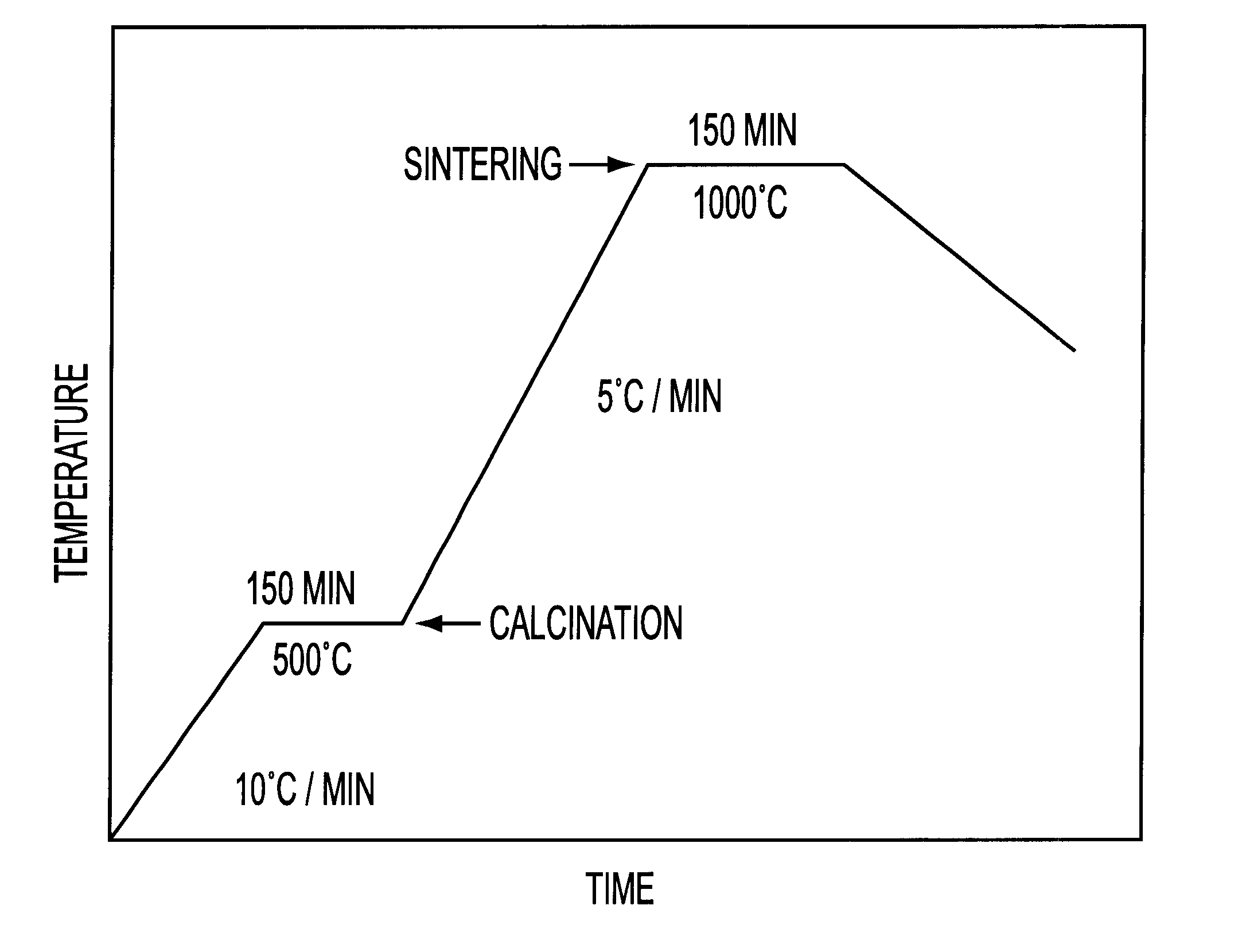

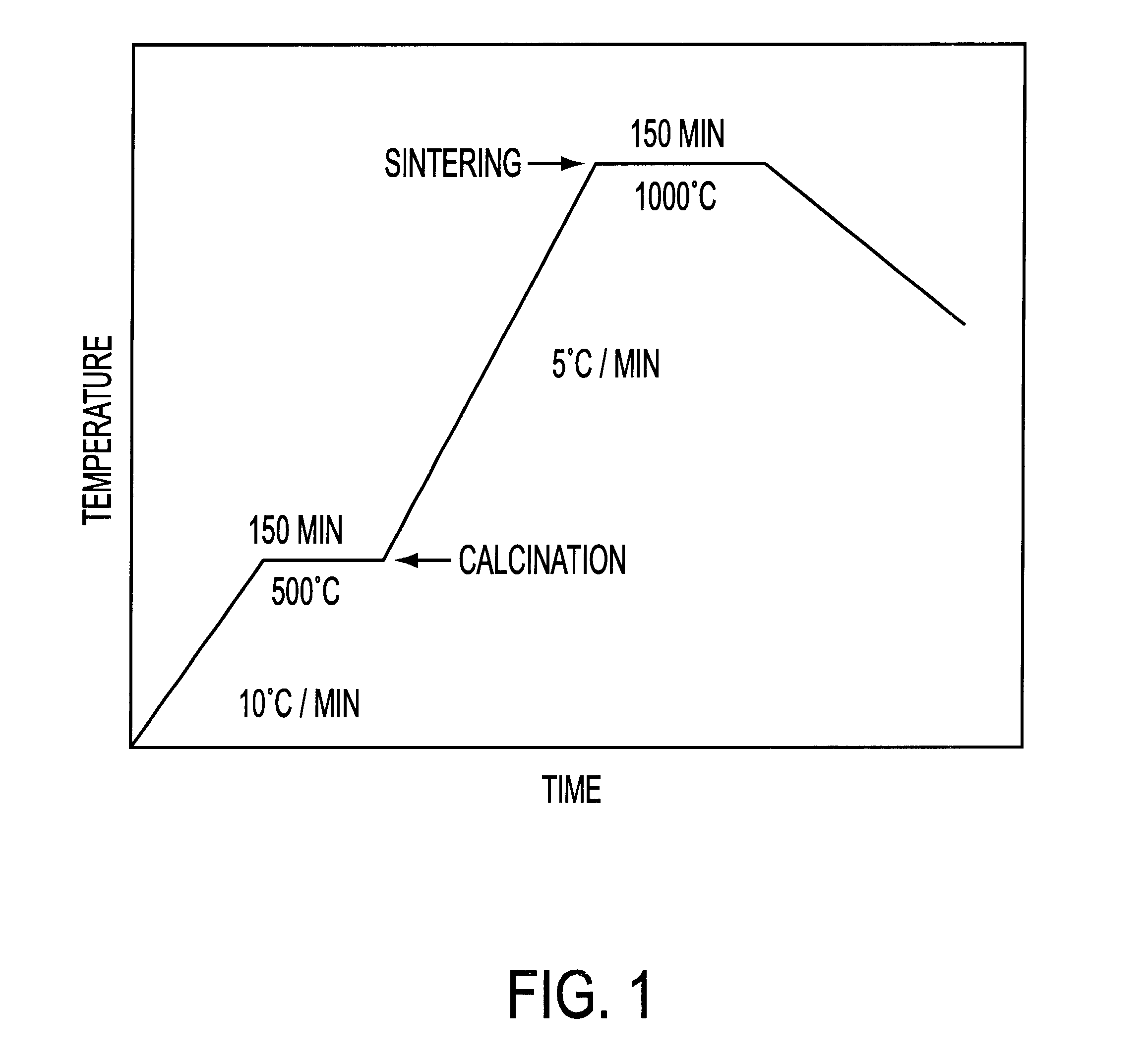

Varistors based on nanocrystalline powders produced by mechanical grinding

InactiveUS6620346B1Lower breakdown voltageImprove breakdown voltageMaterial nanotechnologyConductive materialGrain boundaryBreakdown voltage

The invention concerns novel varistors based on zinc oxide and a method for making same, which consists in using as base products nanocrystalline powders obtained by high-intensity mechanical grinding and in subjecting the mixture resulting from said nanocrystalline powders a consolidating treatment such as sintering, in suitably selected temperature and time conditions so as to retain the smallest possible grain size of ZnO. The resulting varistors have a very fine homogeneous microstructure and an average grain size characteristically not more than 3pm, i.e. five times smaller than standard materials. Said novel varistors have a larger number of grain boundaries per unit length unit and therefore a much higher breakdown voltage. Said voltage is characteristically higher than 10 kV / cm and can reach 17 kV / cm which is almost one order of magnitude above the breakdown voltage of standard varistors. The non-linearity coefficient of the current-voltage curve is also improved, and is greater than 20 and can reach values as high as 60. Moreover, the leakage currents below the breakdown voltage of said varistors, are much lower.

Owner:HYDRO QUEBEC CORP

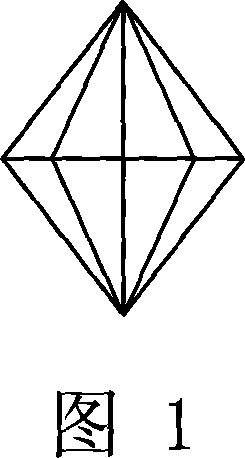

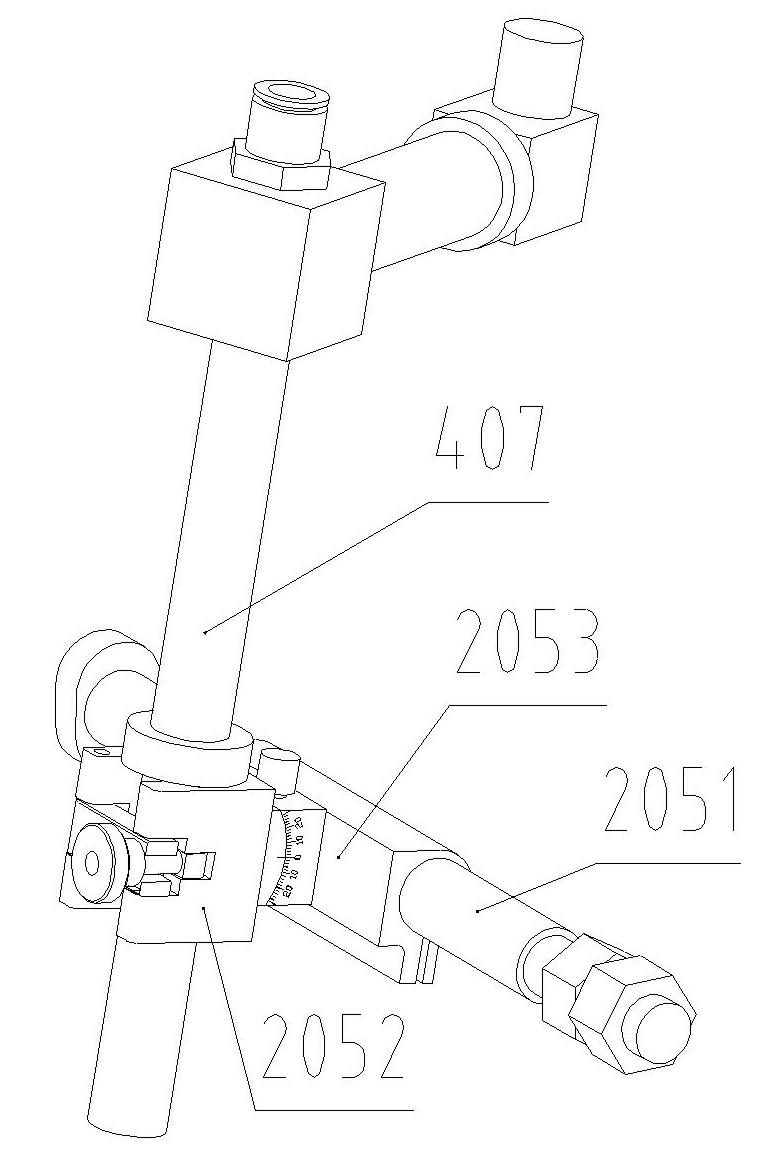

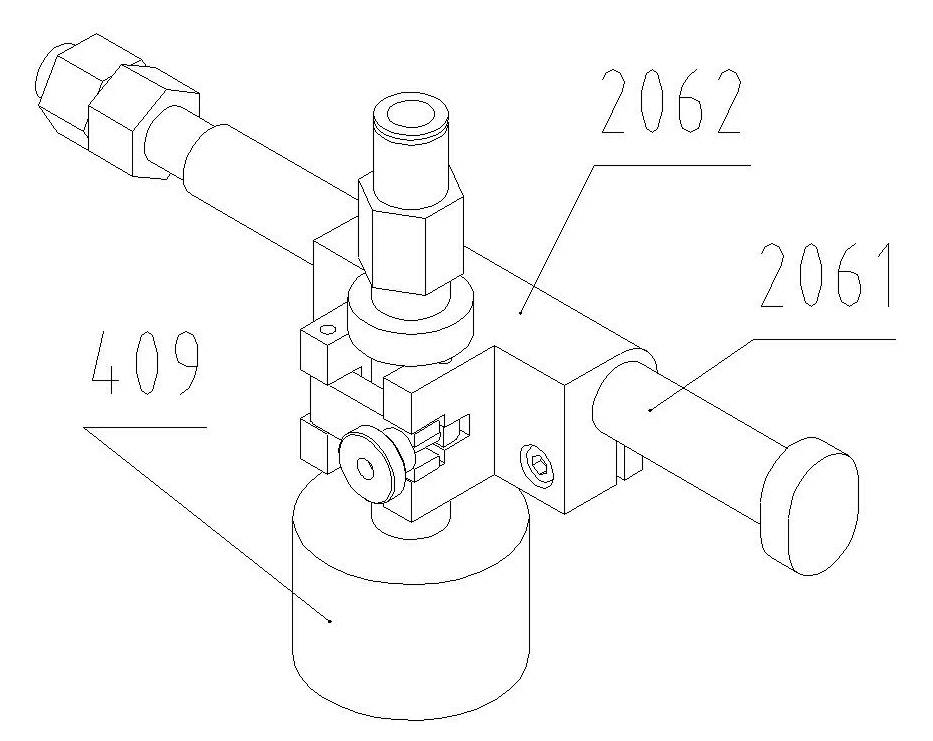

Method for polishing and grinding hydrant drill end and special polishing grinder

ActiveCN101073876AImprove processing efficiencyImprove qualityEdge grinding machinesConvex sideEngineering

The invention is concerned with simulation diamond end face polishing-grinding machining method and the expert polishing-grinding machining. Set stuff and put molding plastics-absorption tray on fixture tray and make the concave face of plastics-absorption tray upside, and the simulation diamond adsorbs on the convexity of the bottom to plastics-absorption tray. Set plastics-absorption tray on the polishing-grinding machining and mill the tine end of simulation diamond on calm millstone. The polishing-grinding machining relates rack with a level millstone at its middle, and there are two level trays. They are centrosymmetric to the axis of millstone on top of millstone and have plastics-absorption tray on them. There is up and down equipment for tray on top of level tray which connecting with two turning axes on two sides of millstone with level rack, and the other end of turning axis has running equipment of turning axis. It has large machining amount of each time, high produce efficiency, good ratio to excellent stuff, long work time, easy operation without waste of material.

Owner:虞雅仙

Polycrystalline superabrasive composite tools and methods of forming the same

ActiveUS20080023230A1Wide applicationProperty is limitedPigmenting treatmentDrill bitsCarbideHigh pressure

A polycrystalline superabrasive composite tool can be produced using high pressure high temperature processes allowing for increased thermal resistance, wear resistance and toughness of abrasive tools, and additionally allowing for increased effective thickness of abrasive tools. A polycrystalline superabrasive compact can include a support substrate and a superabrasive polycrystalline layer having a diffusion bridge embedded therein that includes a carbide former. Additionally, a working layer can be attached adjacent to the superabrasive polycrystalline layer and opposite the support substrate to form a drill bit sandwich segment. The diffusion bridge matrix of the present invention allows for a new welding phase at each interface between the superabrasive polycrystalline layer and support substrate and between the polycrystalline layer and the metal working layer, thus eliminating delamination failure at the interfaces. The superabrasive polycrystalline layer can include superabrasive particles of varying particle sizes such that the final composite tool is tailored for specific abrading characteristics. The polycrystalline superabrasive composite tools can be incorporated for use in machining, drilling, grinding, cutting, polishing and similar abrasive applications.

Owner:ADICO ASIA POLYDIAMOND

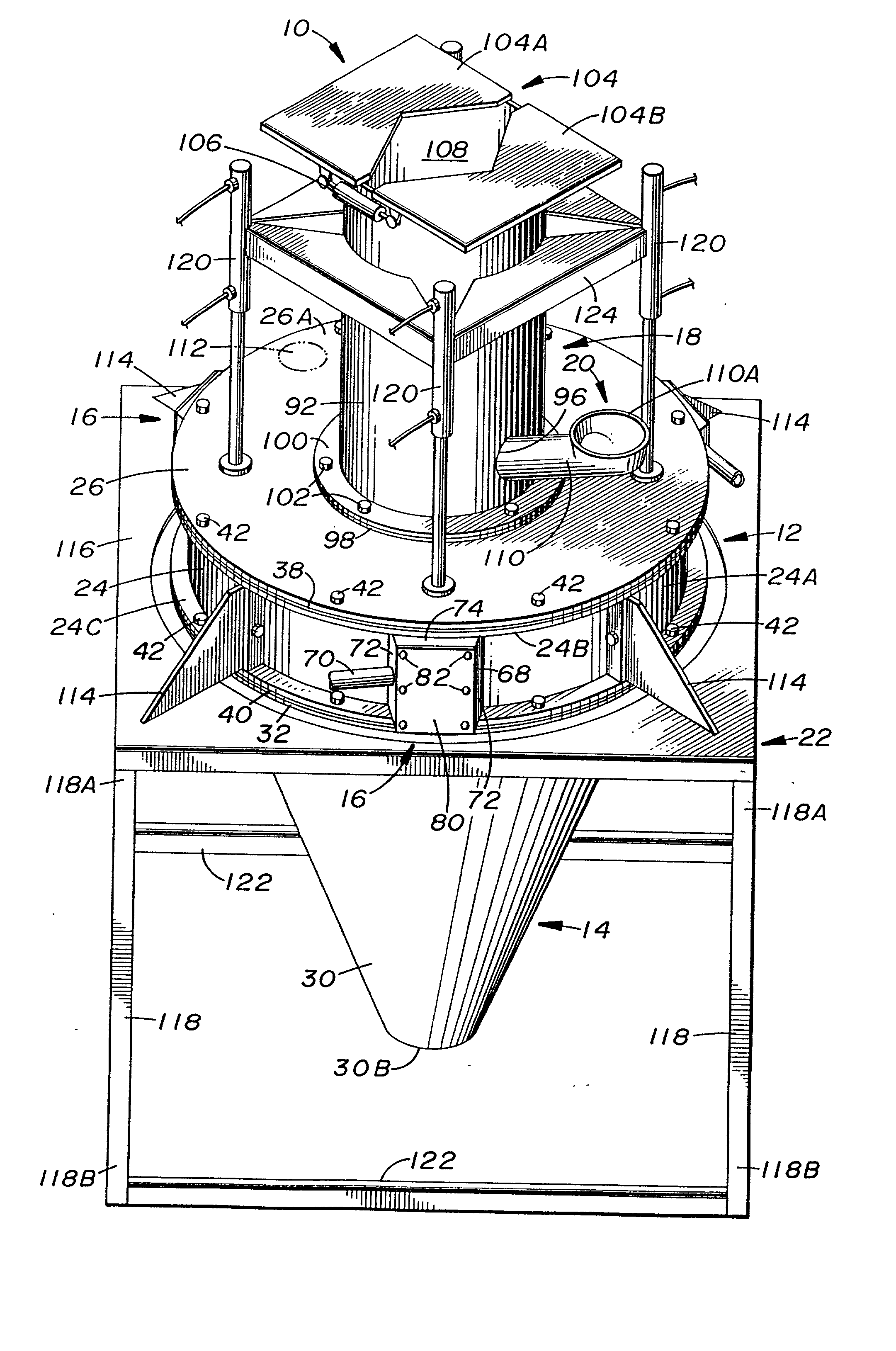

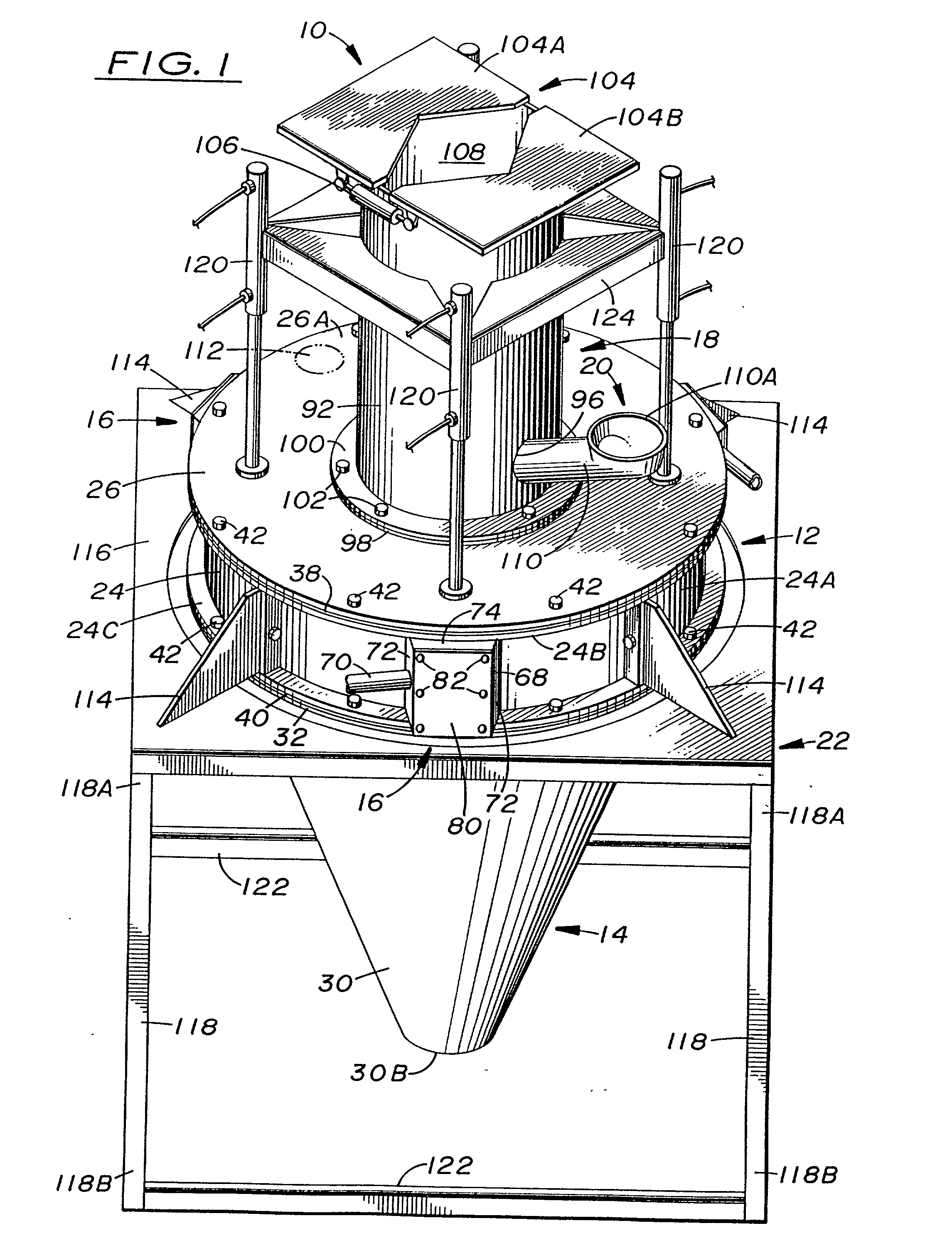

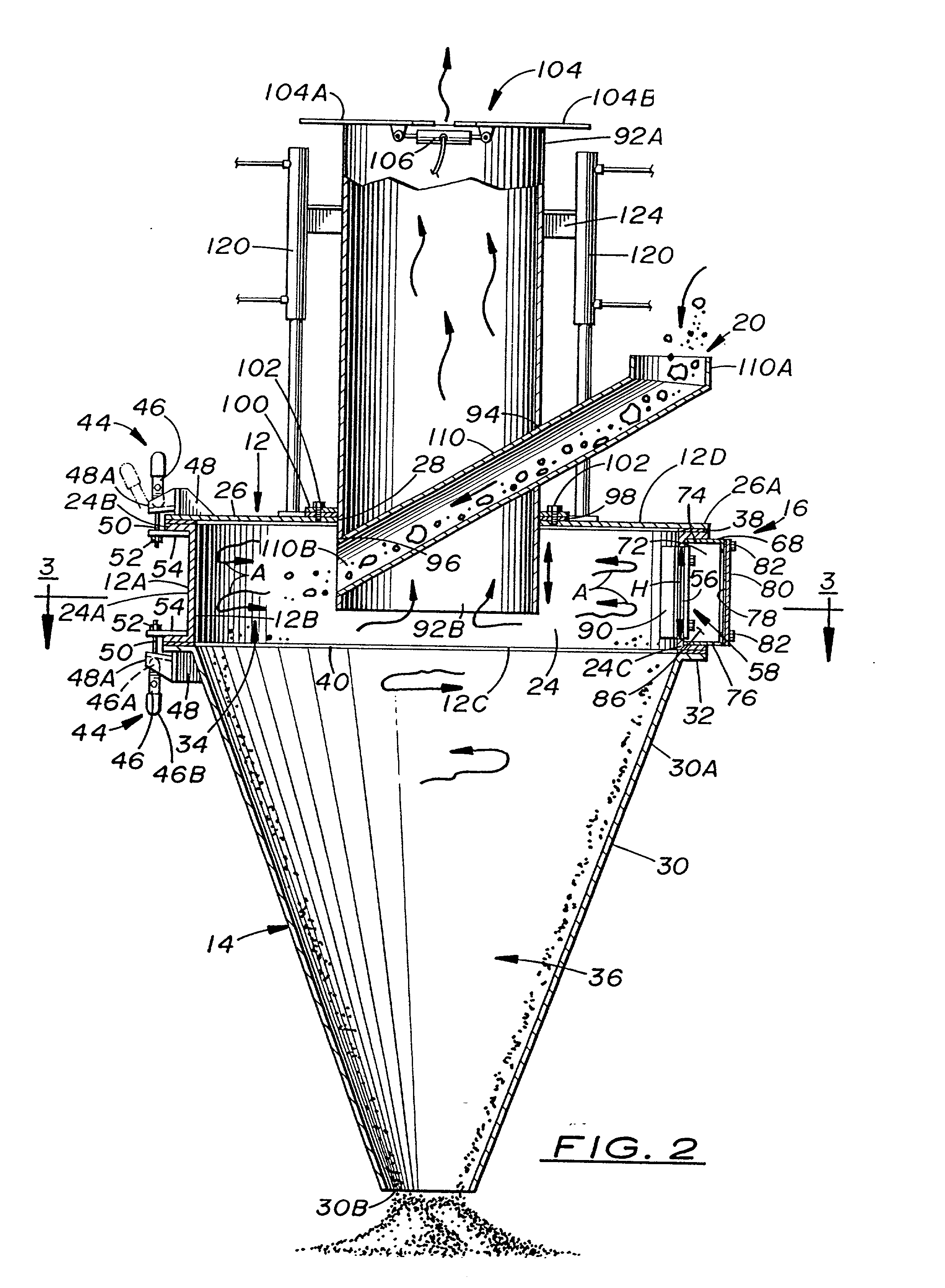

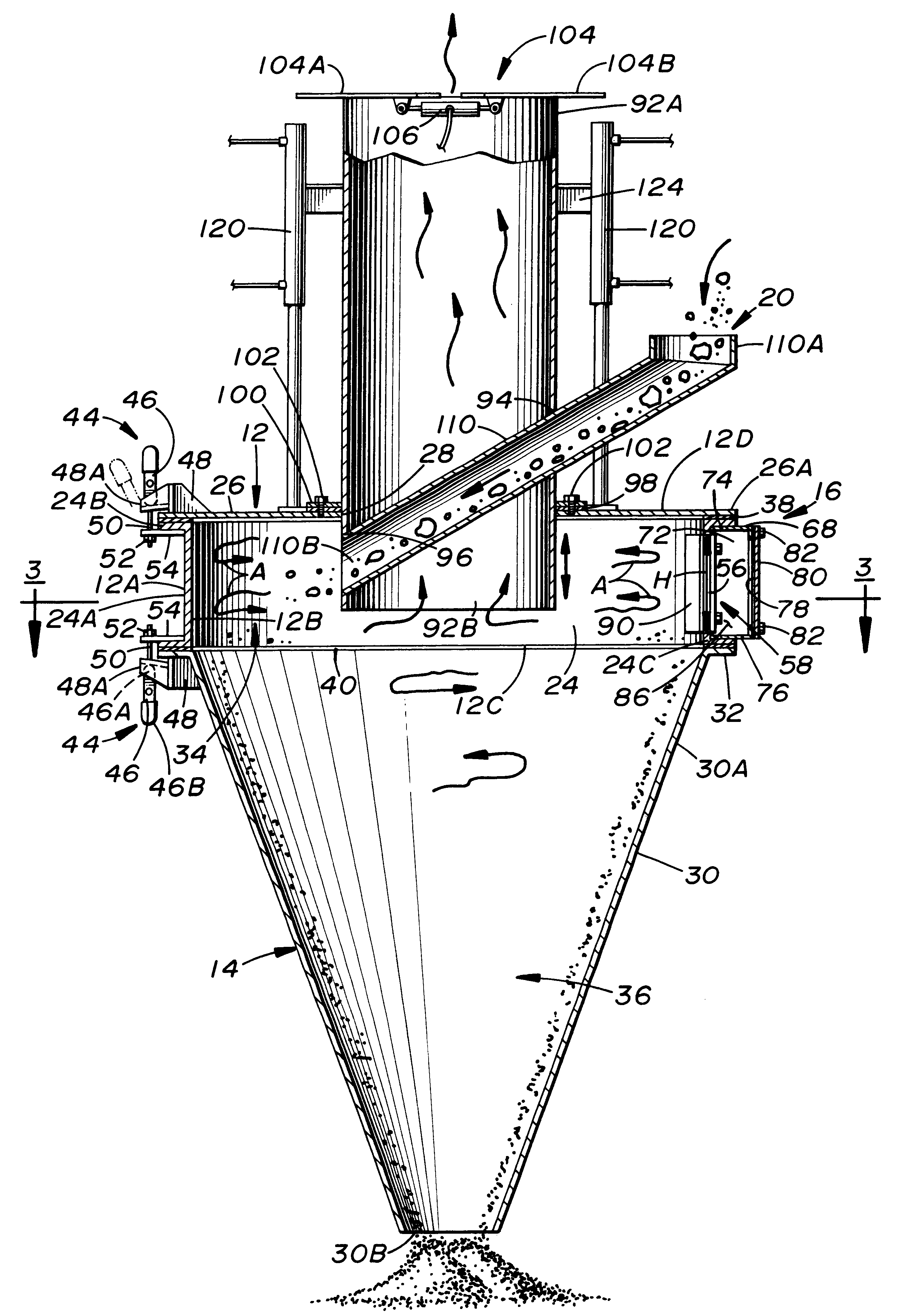

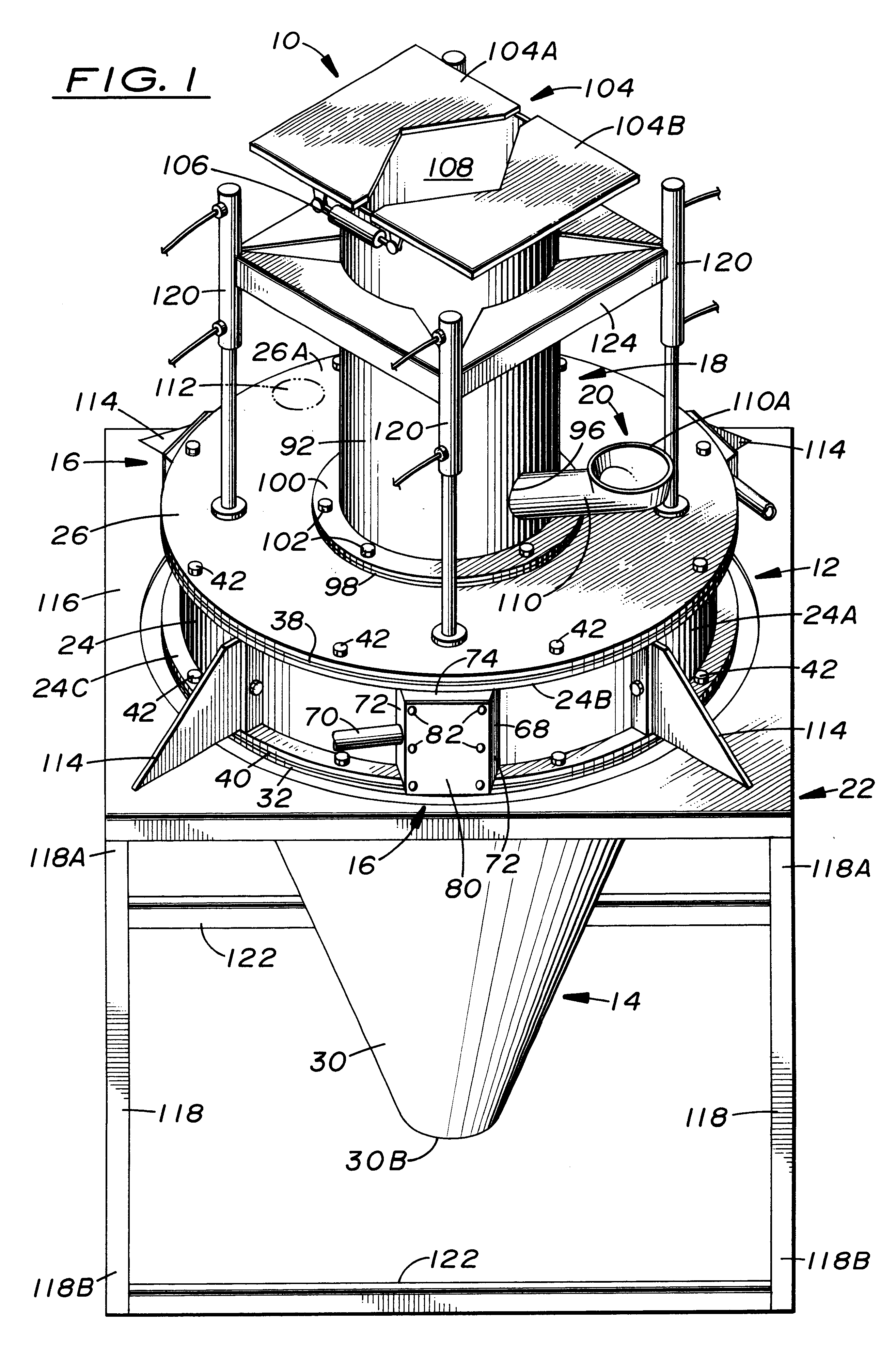

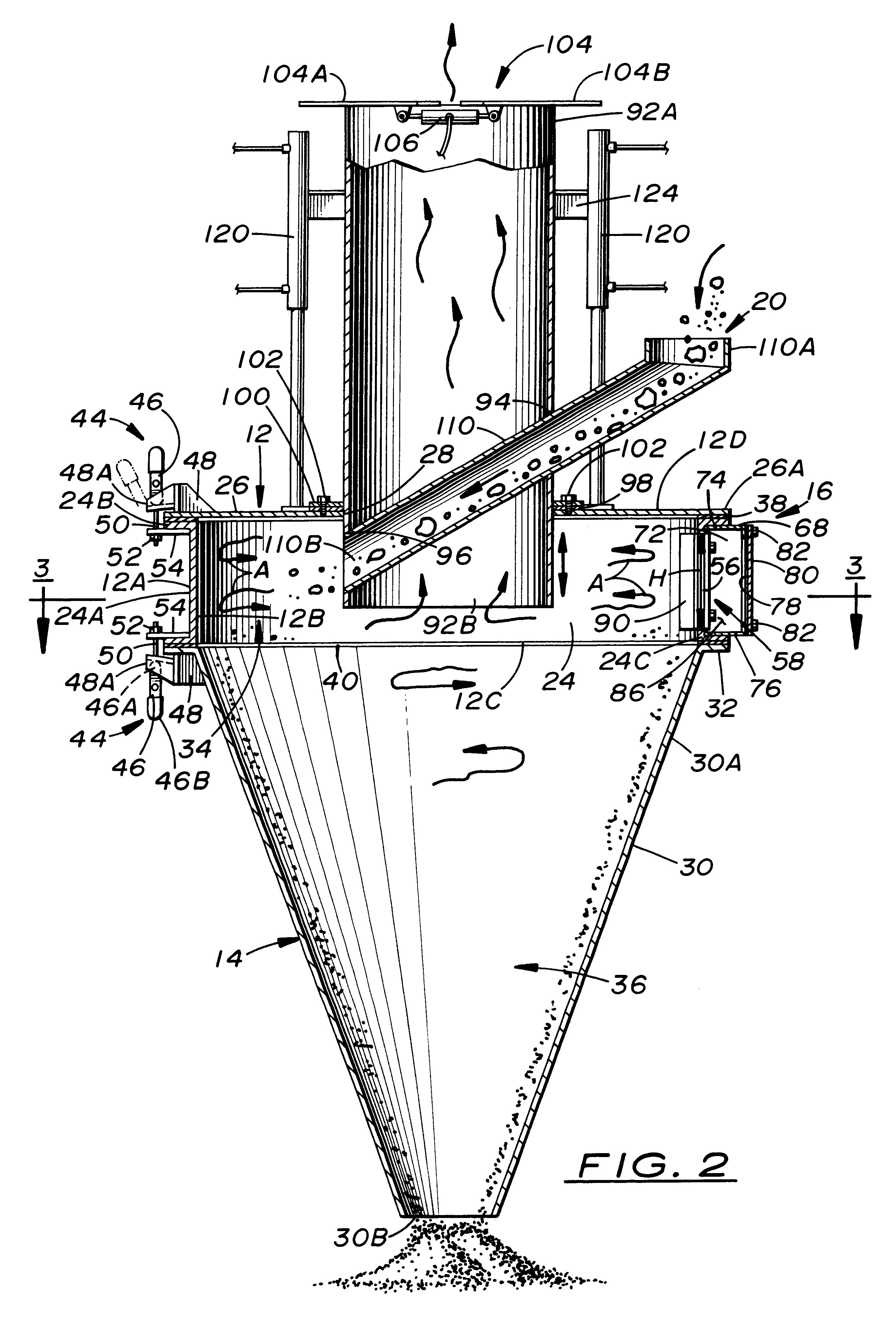

Apparatus and method for circular vortex air flow material grinding

InactiveUS20020027173A1Easy constructionEliminate needGas current separationGrain millingEngineeringAirflow

A material grinding apparatus (10) includes an annular upper enclosure (12) defining an upper chamber (34) into which material to be ground is introduced from above, a conical lower enclosure (14) defining a lower chamber (36) and supported in tandem with the upper enclosure (12), and one or more angled slots (56) defined in the sidewall of the upper enclosure (12) through which compressed air is introduced relatively circumferentially into the upper chamber (34) so as to generate a circular vortex flow of air and material in the upper enclosure (12) for grinding and drying to take place. The air flow is exhausted by a pipe (92) through an upper end of the upper enclosure (12) and the dried ground material is discharged through an open lower end of the lower enclosure (14). The lower enclosure (14) is a downward continuation and extension of the upper enclosure (12) so as not to extend upwardly into nor past the upper chamber (34) thereof.

Owner:VORTEX DEHYDRATION TECH

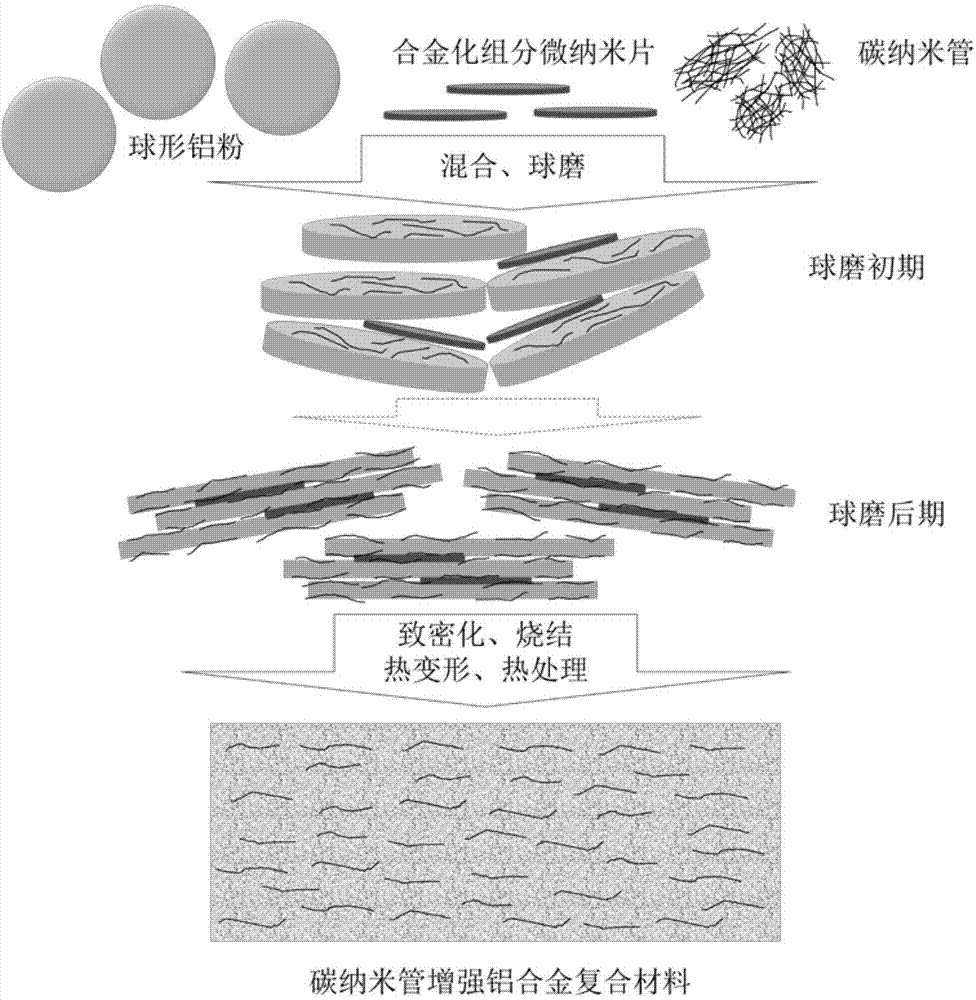

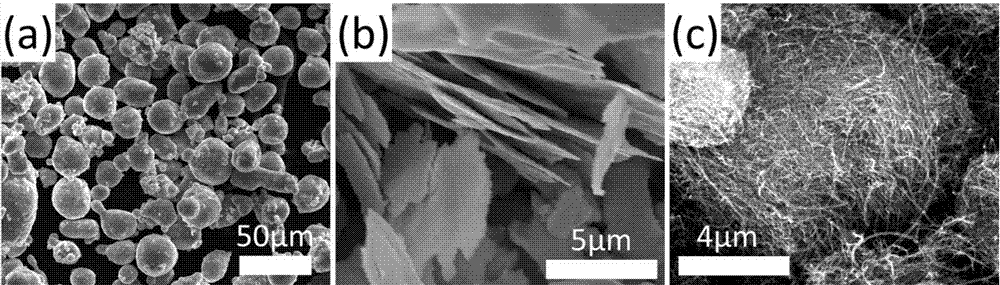

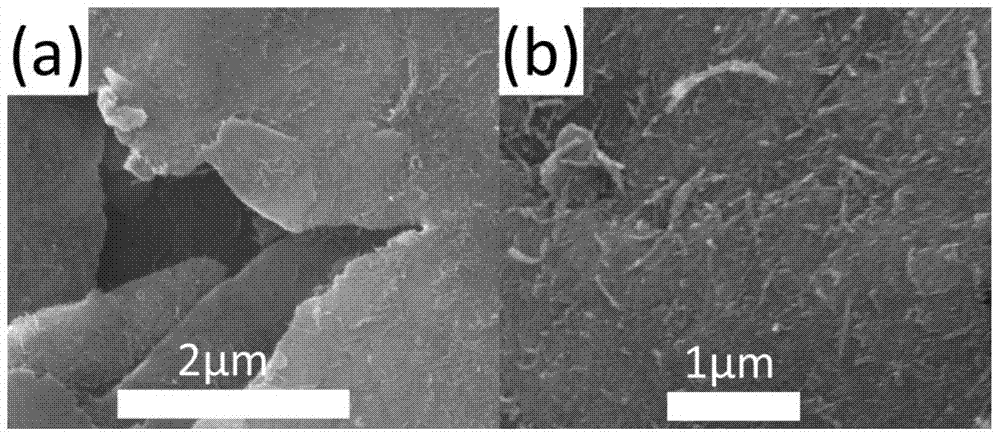

Powder metallurgy preparation method of carbon nanotube reinforced aluminum alloy composite material

ActiveCN103789564ARapid precipitation strengtheningReliable and efficient processMicro nanoThermal deformation

The invention provides a powder metallurgy preparation method of a carbon nanotube reinforced aluminum alloy composite material. The method comprises the following steps: pre-preparing micro-nano flake powder of an alloying component, subsequently ball-milling the powder with a carbon nanotube and spherical pure aluminum powder to prepare flake composite powder, and further performing densifying, sintering, thermal deformation processing and thermal treatment to achieve alloying so as to finally obtain the carbon nanotube reinforced aluminum alloy composite material. Uniform compounding of the matrix aluminum powder, the carbon nanotube and the alloying component can be achieved through limited ball-milling, and meanwhile dangerous elements or uneasy grinding elements such as magnesium and silicon which are high in activity and likely to combust and explode are avoided by adopting the stable and easily ground pre-alloying aluminum powder, so that the security and the reliability are improved; in addition, because of large interlayer boundary and small layer thickness distance, the flake structure is beneficial for uniformly dispersing the alloying component and forming refined dispersed separated phase. The method is beneficial for bringing the effects of composite reinforcement of carbon nanotubes and alloy reinforcement into play to the maximum extent, is energy-saving and time-saving, and is safe and feasible.

Owner:SHANGHAI JIAO TONG UNIV

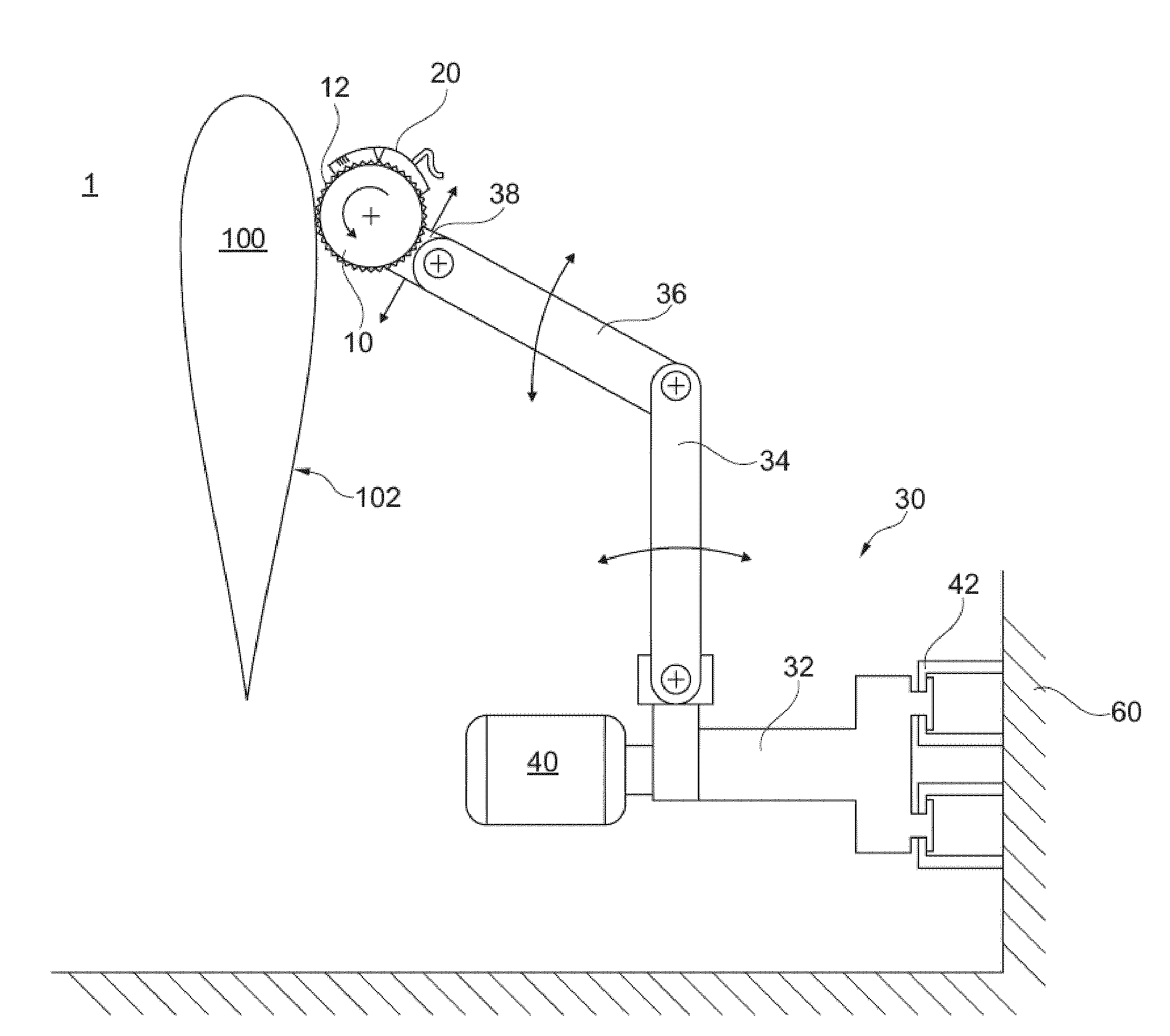

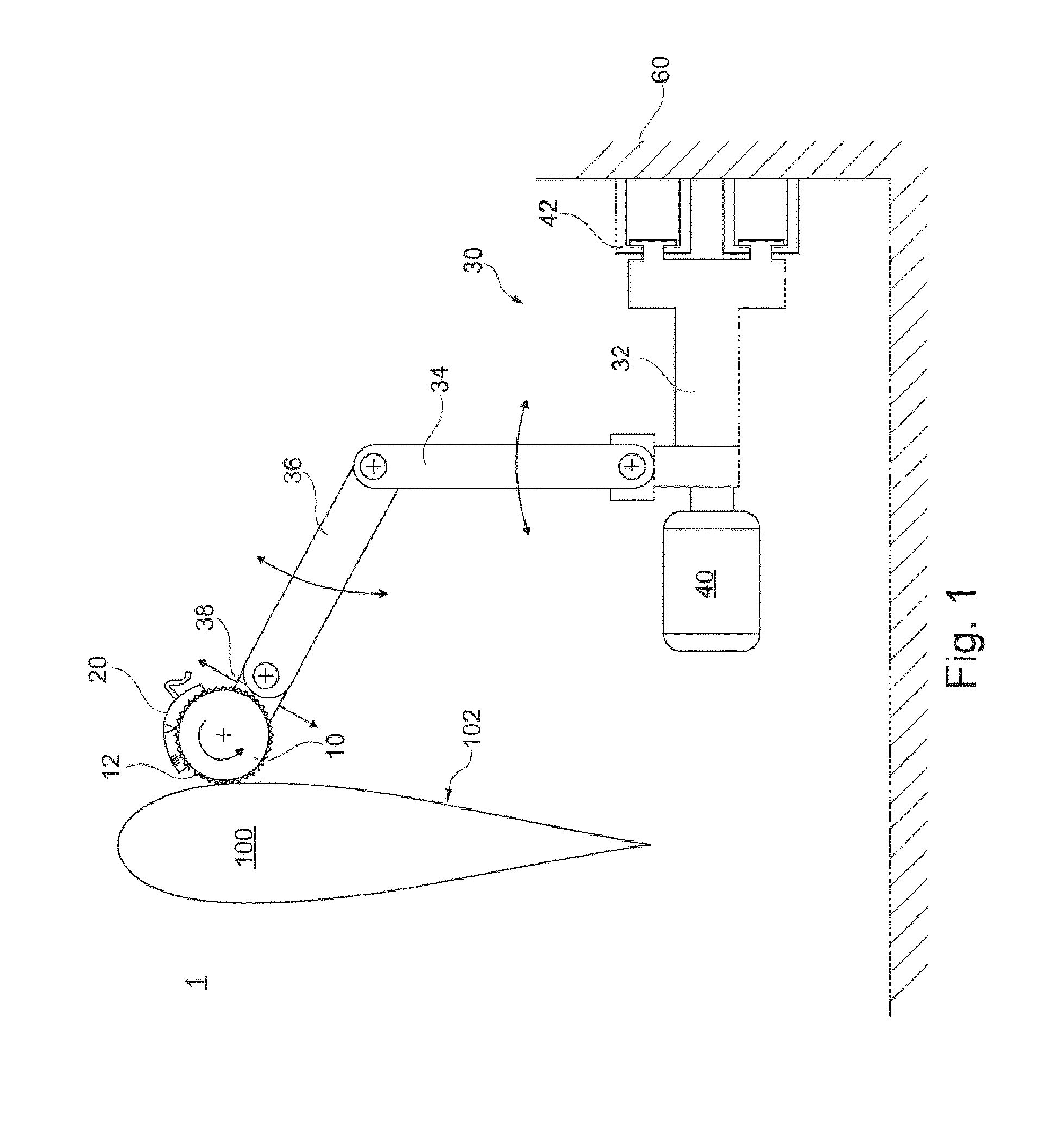

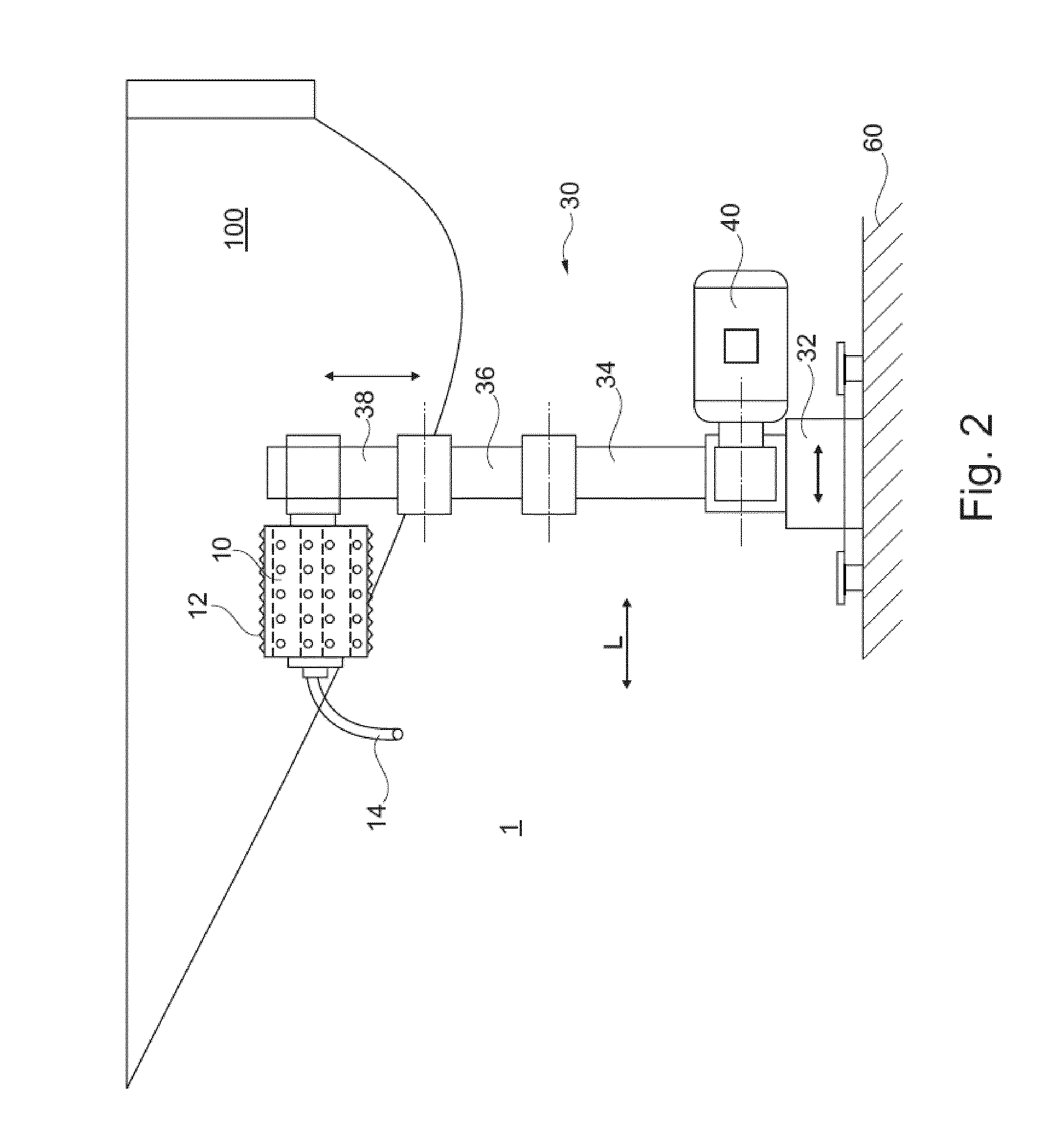

Grinding device for machine based grinding of rotor blades for wind energy systems

InactiveUS20120322349A1Life time of the grinding means is increasedLow investment costEdge grinding machinesSupport wheelsIndustrial machinePulp and paper industry

Grinding device 1 for machine-based grinding of rotor blades 100 for wind energy systems, comprising at least one industrial robot 30 and a grinding unit 10, 50, 70 that is guided by the industrial robot 30, wherein the grinding unit 10, 50, 70 comprises a grinding means, 12, 52 and a cleaning device 20, that cleans the grinding means 12, 52 at its grinding surface 64, 53.

Owner:JOST GMBH & CO KG

Method for preparing environment-friendly water permeable bricks by using iron tailings

InactiveCN103204698AImprove performanceSimple production processCeramicwareCarbide siliconCompressive resistance

The invention discloses a method for preparing environment-friendly water permeable bricks by using iron tailings, belonging to the field of comprehensive utilization of iron tailing resources and construction ceramic materials. The method is characterized in that through taking iron tailings as basic aggregates and introducing a certain amount of waste broken glass, an environment-friendly water permeable brick with excellent performance is prepared. The method comprises the following process steps of raw material crushing, ball milling, material dispensing, mixing, drying, molding, sintering, cutting and grinding. The dispensed material comprises the following ingredients in percentage by weight: 30-60% of iron tailings powder, 5-15% waste glass powder, 15-30% of clay, 15-24% of quartz, 5-15% of potash feldspar, and 0.25-1.5% of silicon carbide. The prepared water permeable brick is high in compressive strength, good in abrasion resistance and excellent in water permeability, and accords with national related standards of water permeable bricks, therefore, the method creates a new way for the high-technology and high value-added application of iron tailing resources.

Owner:UNIV OF SCI & TECH BEIJING +2

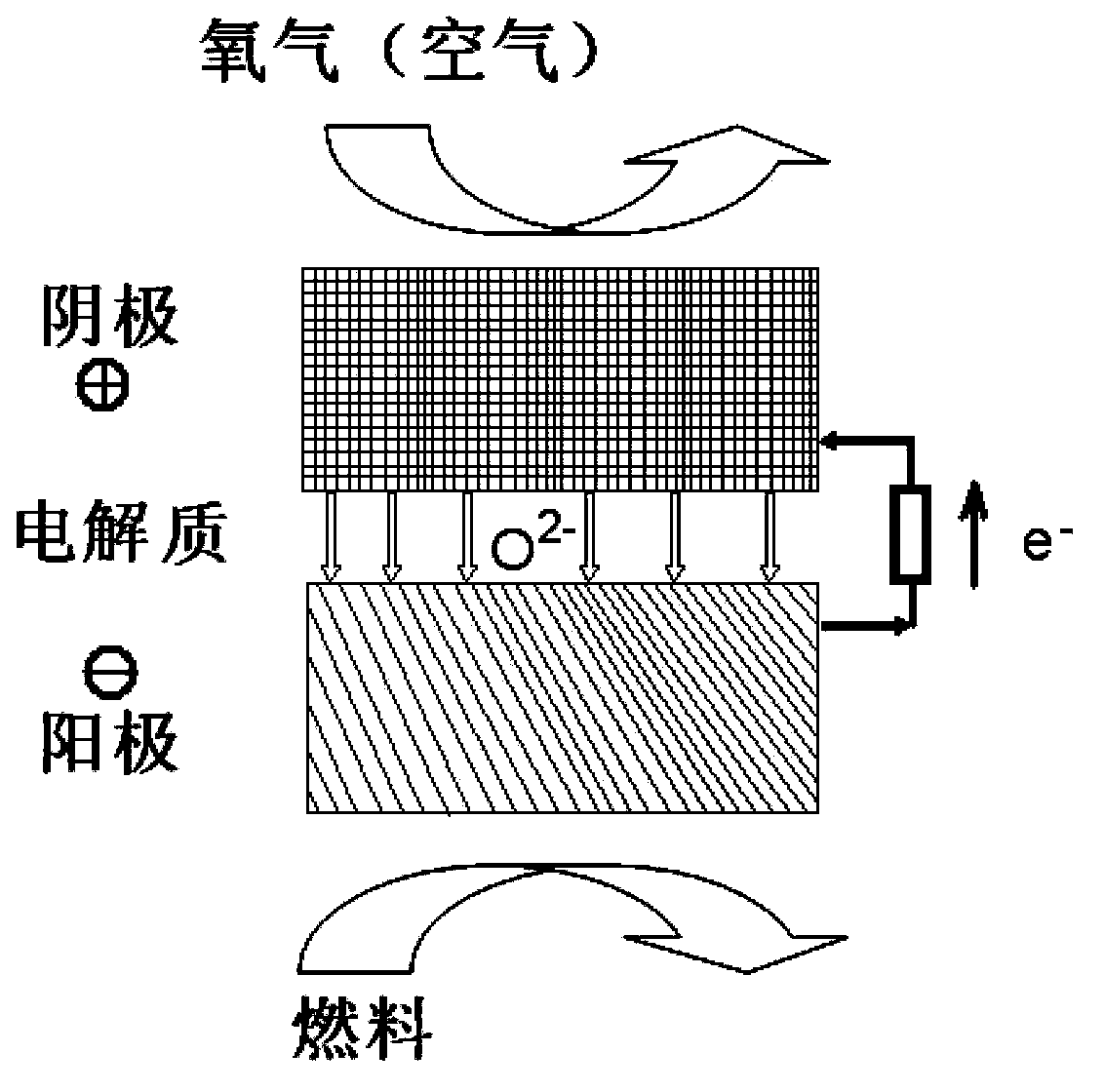

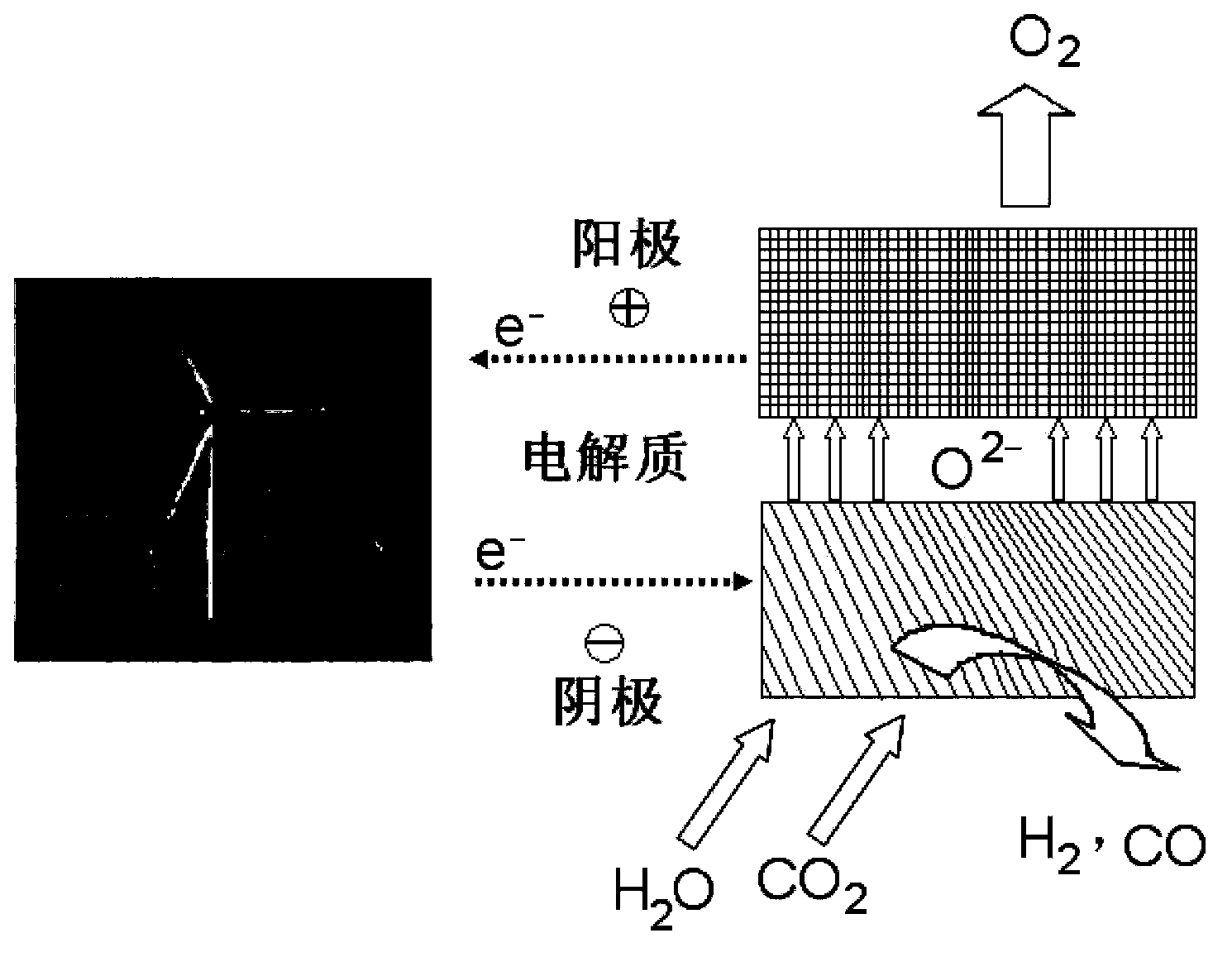

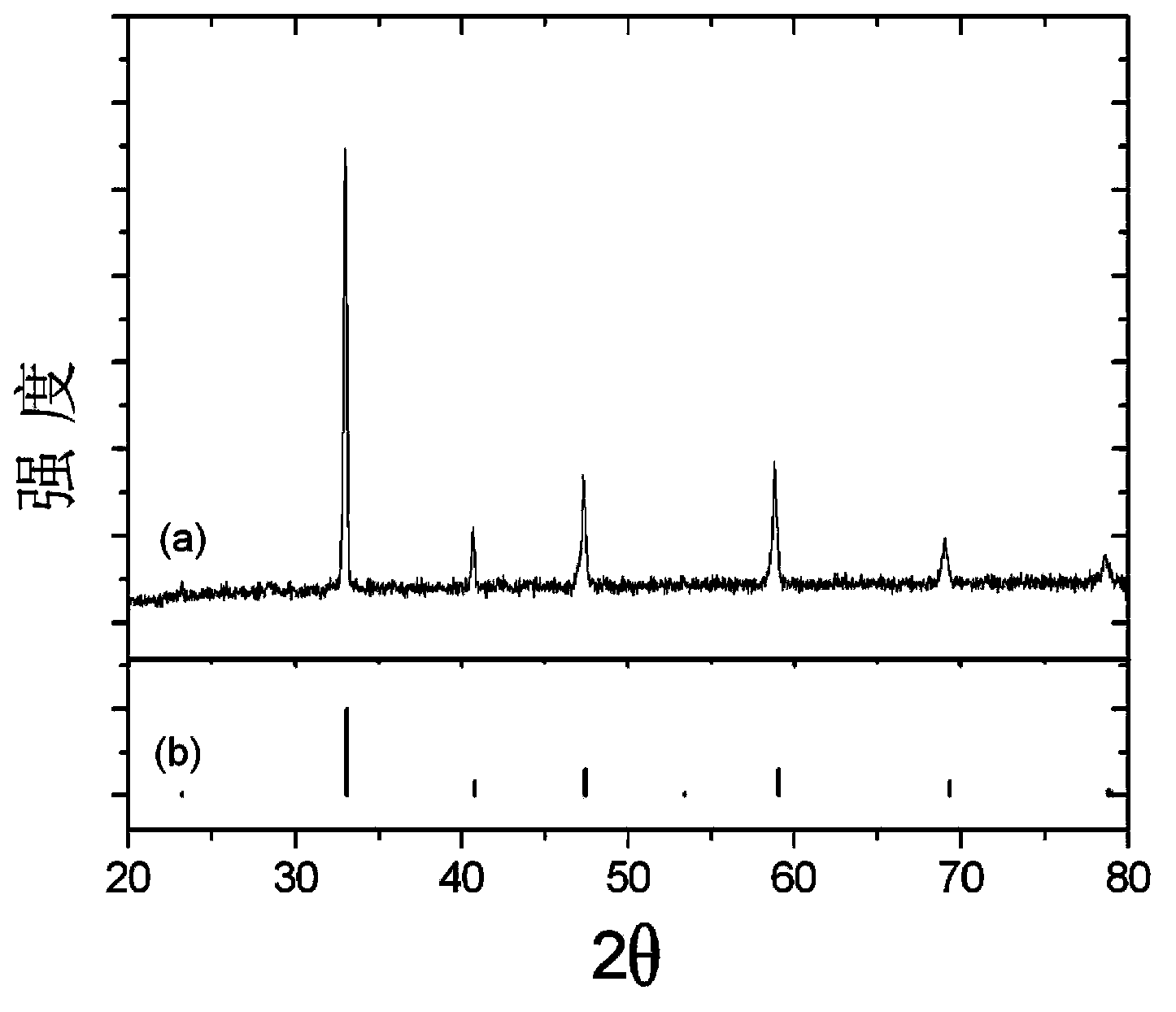

Composite material containing perovskite structure oxide, preparation method and application thereof

The invention provides a composite material containing a perovskite structure oxide, a preparation method and application thereof. The composite material contains, by weight, 20%-99.99% of the perovskite structure oxide and 0.01%-80% of an oxygen ion conductor oxide. According to the invention, a sol-gel method can be employed to prepare the perovskite structure oxide, a combustion method can be employed to prepare the oxygen ion conductor oxide, and then the perovskite structure oxide and the oxygen ion conductor oxide can be mixed uniformly by means of ball milling or mechanical grinding, thus obtaining the composite material. The invention also relates to application of the composite material in solid oxide fuel cells and solid oxide electrolysis cells.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

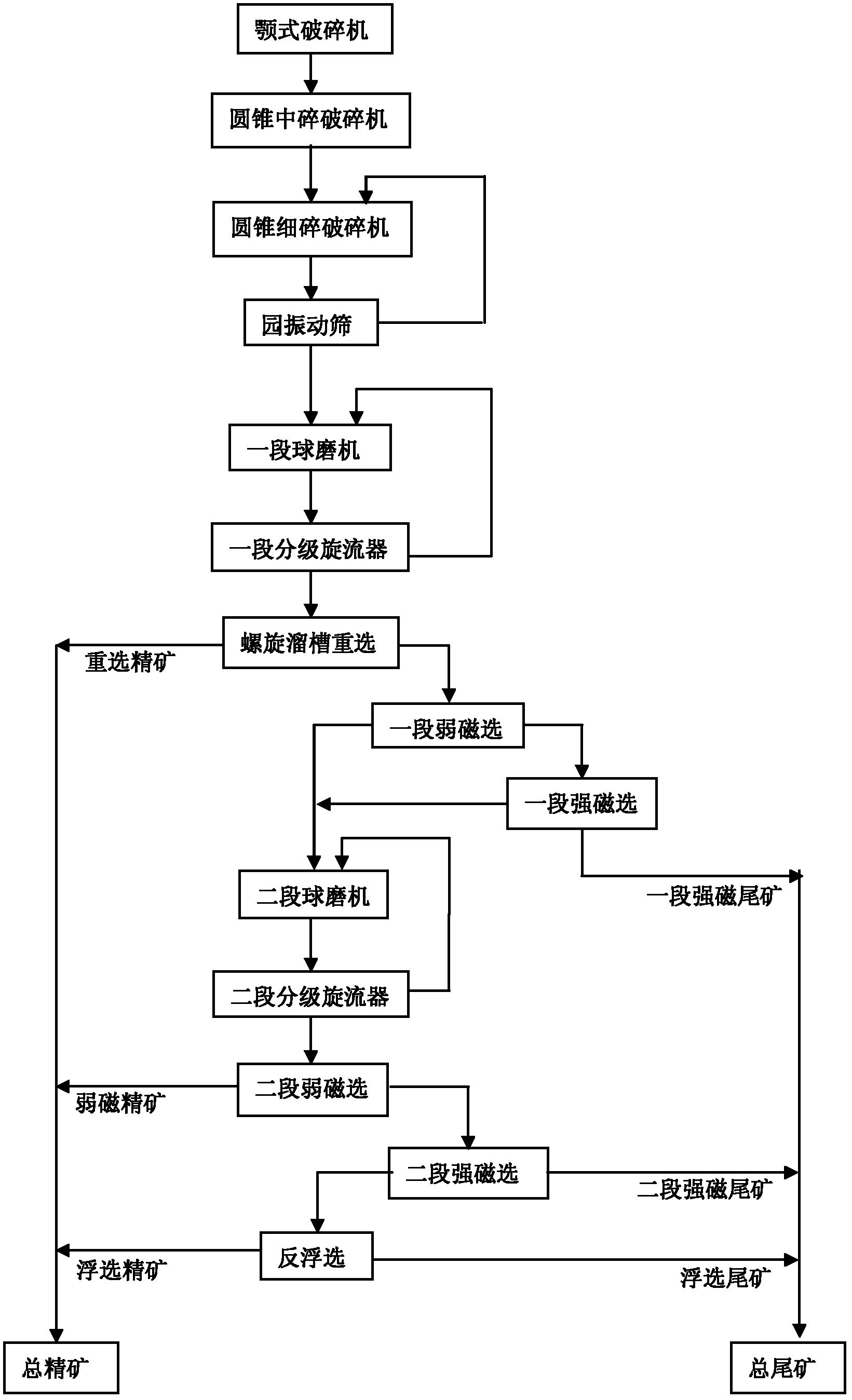

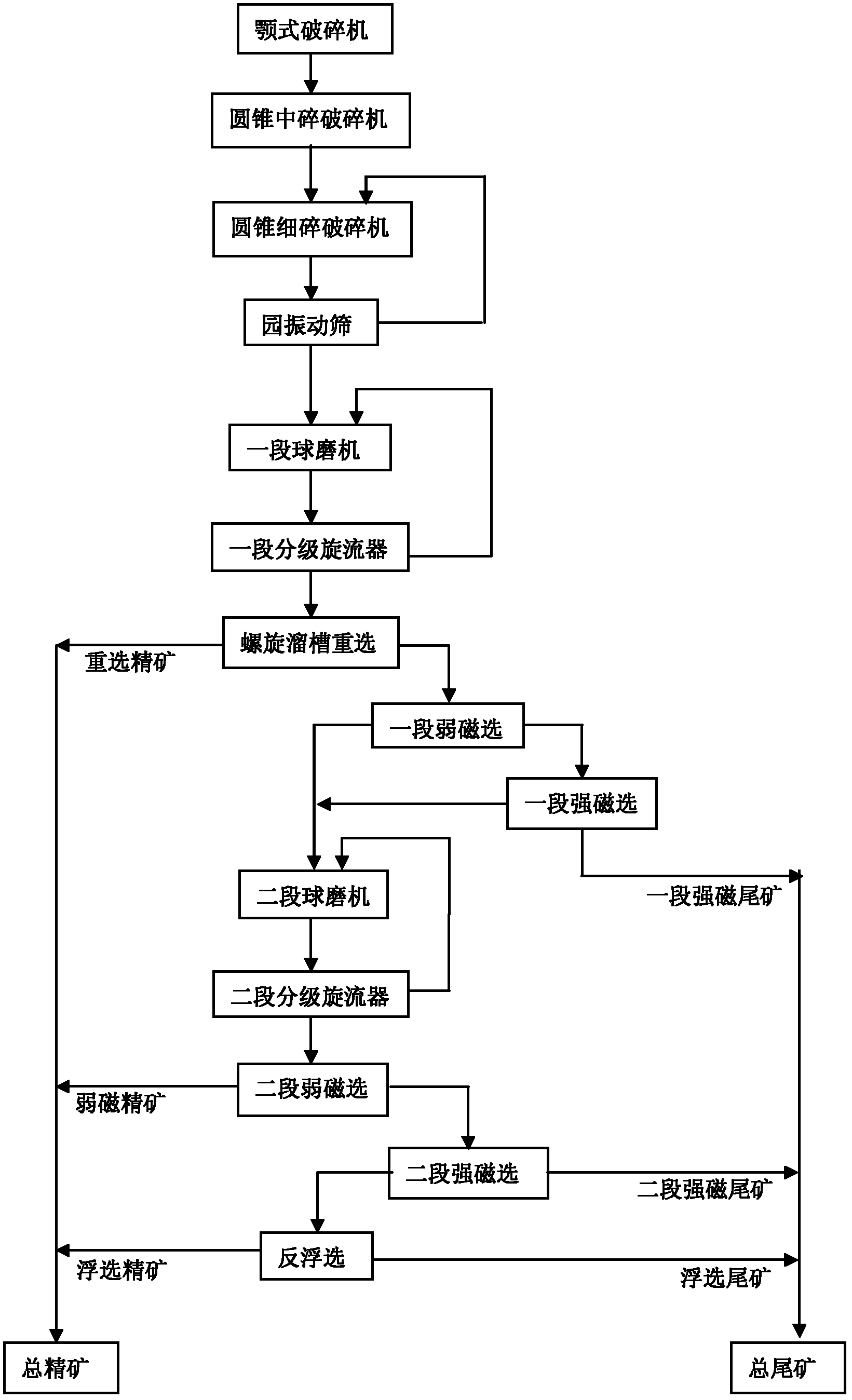

Beneficiation process of low-grade magnetite and specularite mixed ore

ActiveCN102205273AReduce loadReduce energy consumptionMagnetic separationMining engineeringMagnetite

The invention relates to the technical field of black metal ore exploitation and beneficiation, in particular to a beneficiation process of low-grade magnetite and specularite mixed ore, which is especially suitable for associated magnetite and specularite mixed ore of Zhouyoufang iron ore. The novel beneficiation process is realized according to an operation procedure and the process proceduressuch as ore crushing, one-stage grinding and grading, reselecting, one-stage weak magnetic separation, one-stage strong magnetic separation, two-stage grinding and grading (crude concentrate re-grinding), two-stage weak magnetic separation, two-stage strong magnetic separation, reverse floating and the like. The iron ore is comprehensively recycled, and a high-quality iron concentrate product is produced. The process has the characteristics of energy saving, high beneficiation efficiency and low beneficiation cost.

Owner:ANHUI JINRISHENG MINING

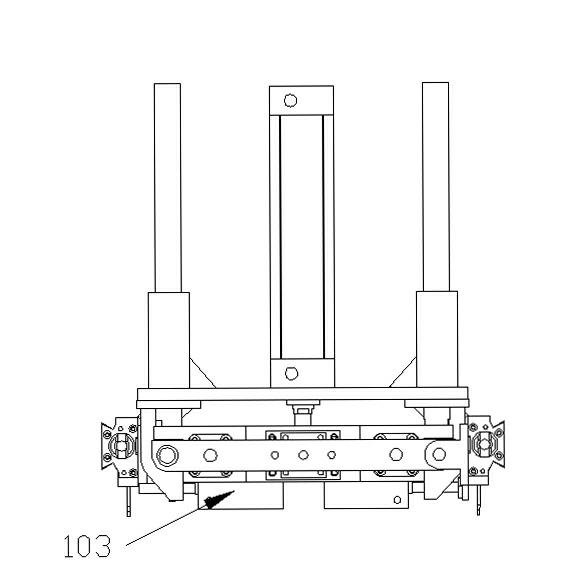

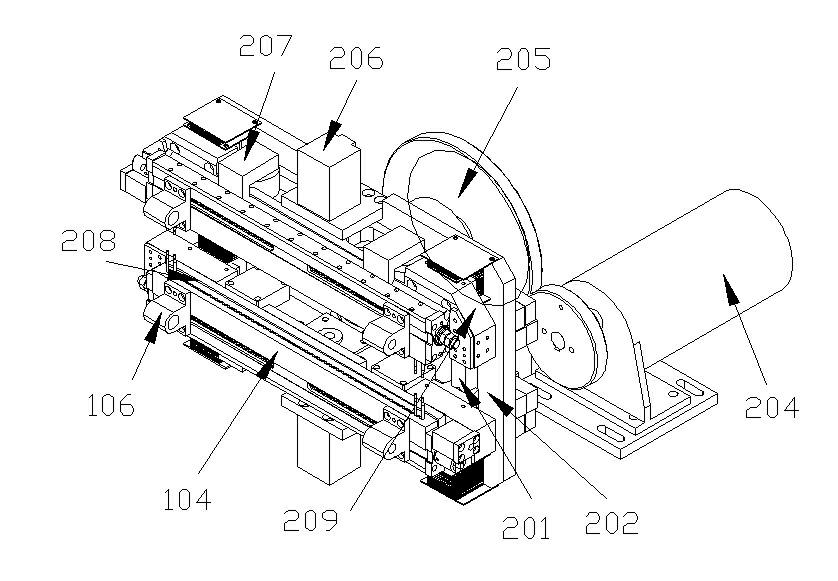

Full-automatic ornament grinding and polishing machine

ActiveCN102152190AReduce volumeSimple structureEdge grinding machinesMetal working apparatusEngineeringManipulator

The invention relates to a grinding and polishing machine for processing ornamental artificial gems, crystals or glass beads, in particular to a full-automatic ornament grinding and polishing machine. The invention discloses the full-automatic ornament grinding and polishing machine with the characteristics of one-step product forming, integration of all working procedures, high production efficiency and simple structure. The invention realizes the full-automatic processing of crystal diamonds and other ornaments by using one machine. In a main scheme provided by the invention, a spindle assembly is arranged in the middle of a rack, the upper end of the spindle assembly is provided with a turntable, the turntable is provided with a plurality of cantilevers which are uniformly distributed by taking a center axis position of the spindle assembly as a center, and the tail end of each cantilever is provided with a mechanical arm; a feeding and discharging integrated assembly, at least onefront grinding integrated assembly, at least one front polishing integrated assembly, a through-connection integrated assembly, at least one rear grinding integrated assembly and at least one rear polishing integrated assembly are respectively distributed on the rack in a working sequence; and all the assemblies are connected end to end.

Owner:ZHEJIANG JINJIU MACHINERY

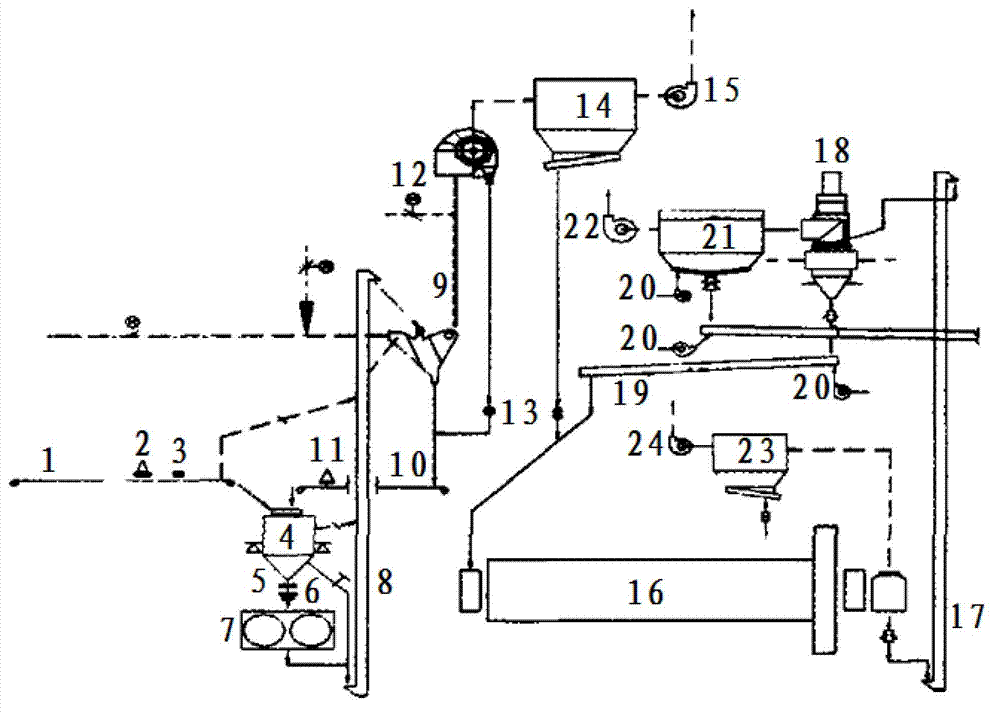

Slag micropowder grinding system and technology

The invention discloses a slag micropowder grinding system and a technology. The system consists of a roller press, an air flow classifier, a dynamic classifier, a ball mill and a high-efficiency powder concentrator. Slag is subjected to de-ironing by a de-ironing separator, sent into the roller press by a belt conveyor for high-pressure treatment, and then sent into the air flow classifier by a cake elevator for separation; if the particle size of the slag is large, the slag returns to the roller press for extrusion again; fine powder with a small particle size enters the dynamic classifier along with an air flow for the separation; coarse powder separated by the dynamic classifier returns to the roller press for the extrusion again; the fine powder is sent to the ball mill for grinding; the ground material is sent to the high-efficiency powder concentrator for the separation; the separated coarse powder is returned to the ball mill for the grinding again; and the separated fine powder enters air box pulse bag dust collectors along with the air flow for collection, and then serves as the finished slag for warehousing. According to the slag micropowder grinding system and the technology, the roller press, the air flow classifier and the dynamic classifier form a circle flow, and the ball mill and the high-efficiency powder concentrator form a circle flow, so that slag micropowder can be subjected to repeated crushing and grinding, and the particle shape of the finished micropowder is good.

Owner:湖南三泓建材有限公司

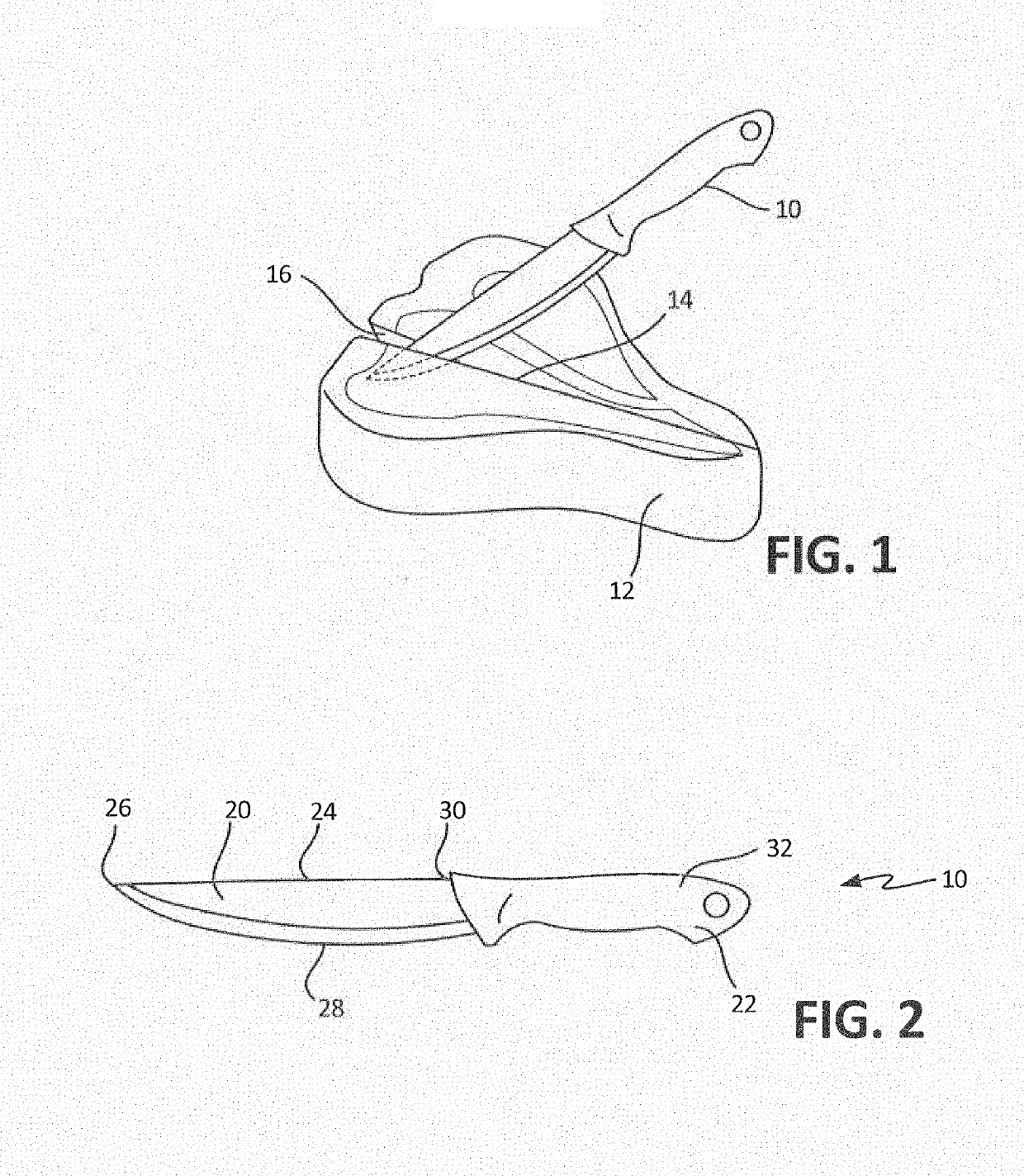

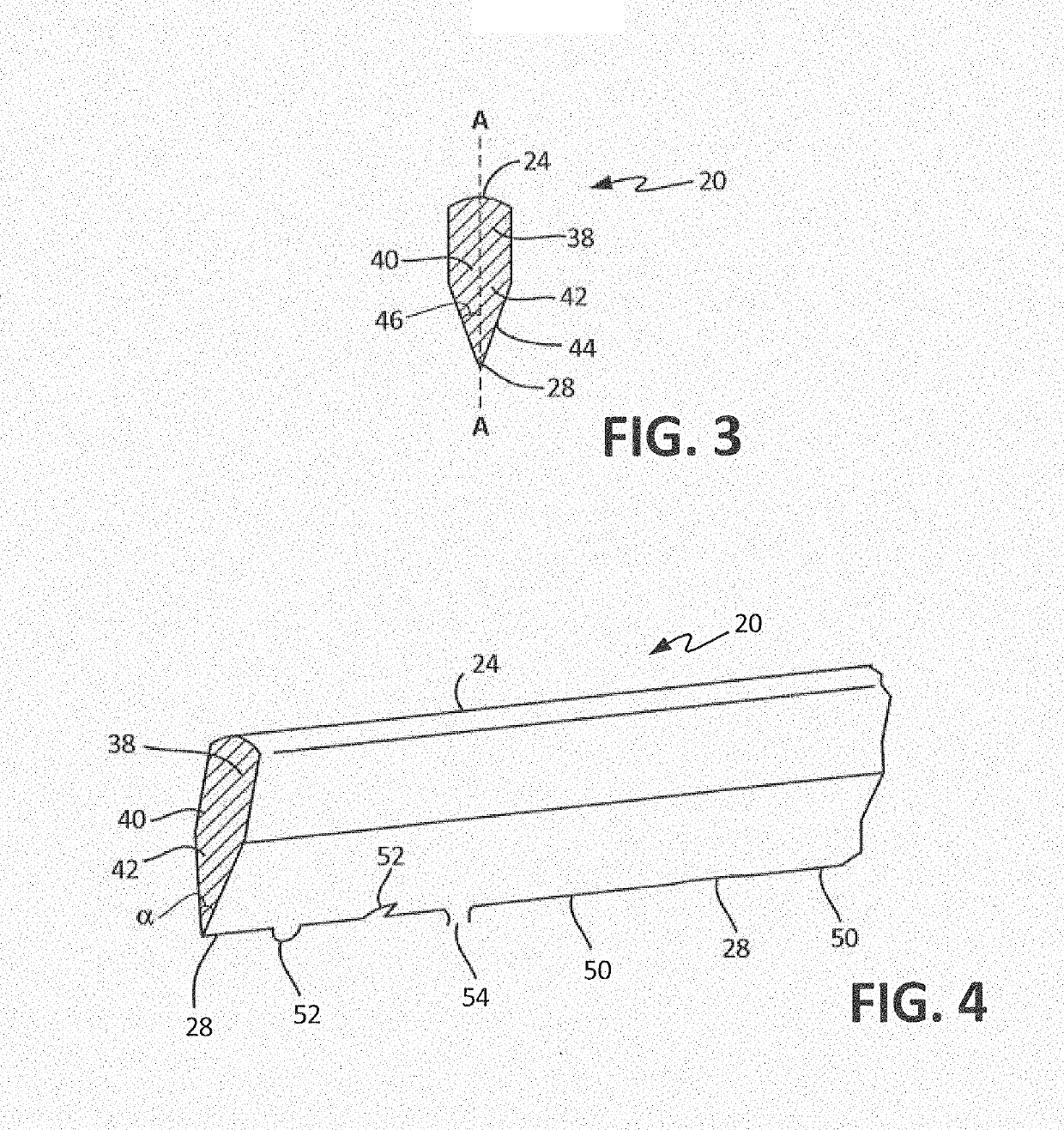

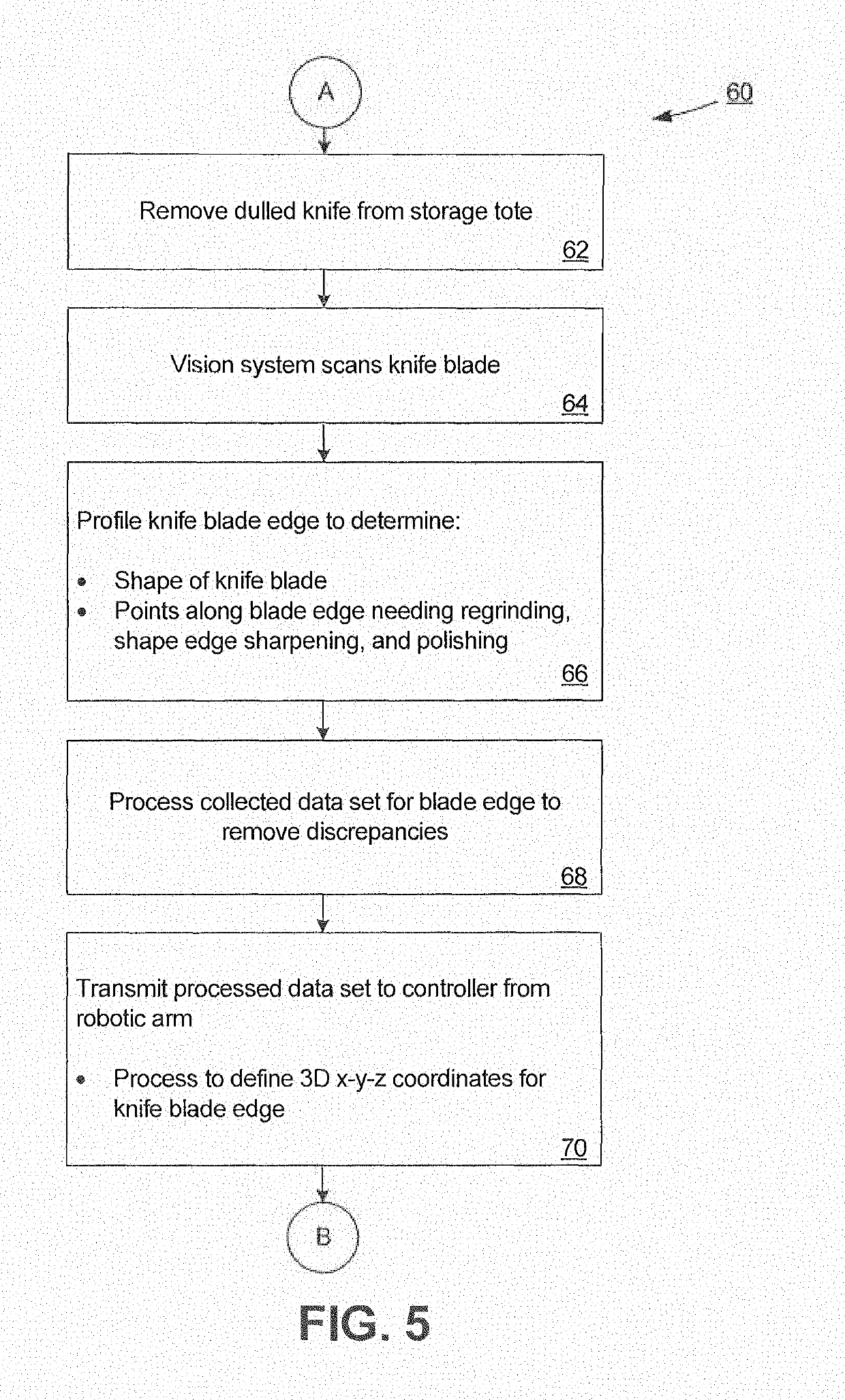

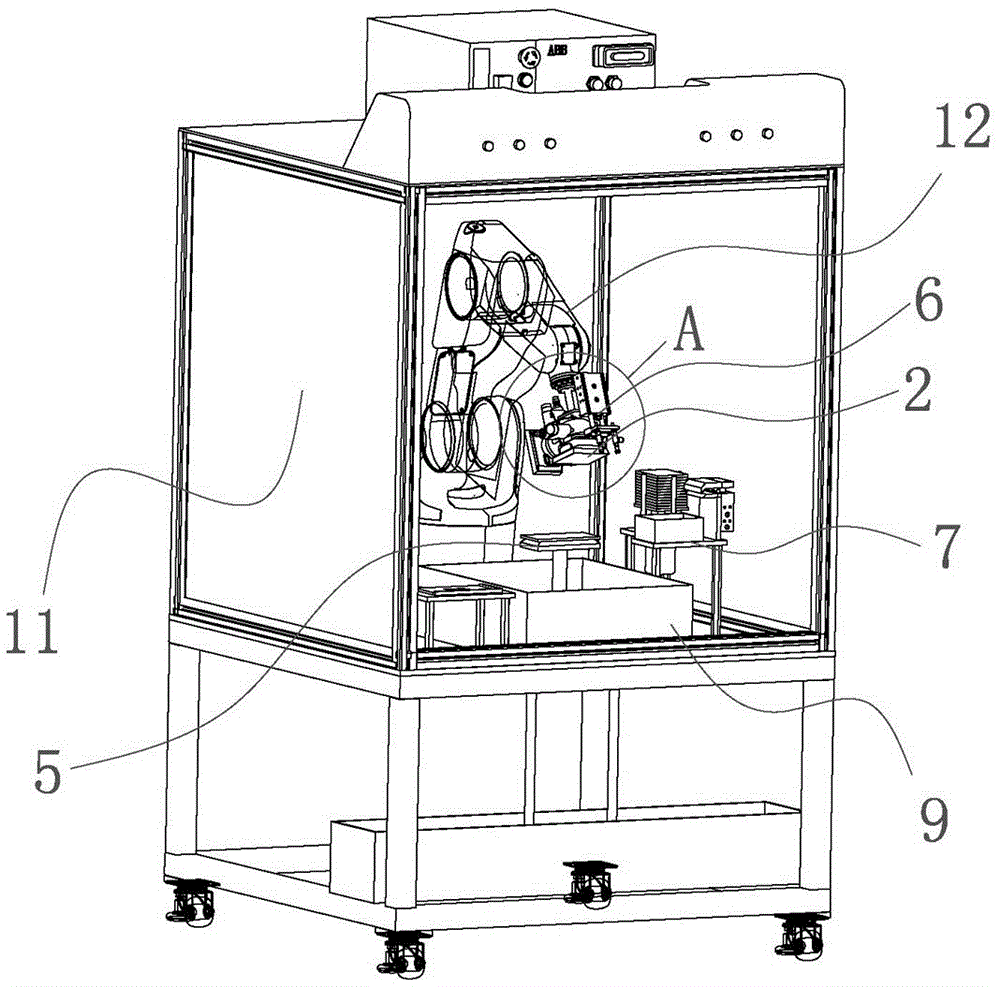

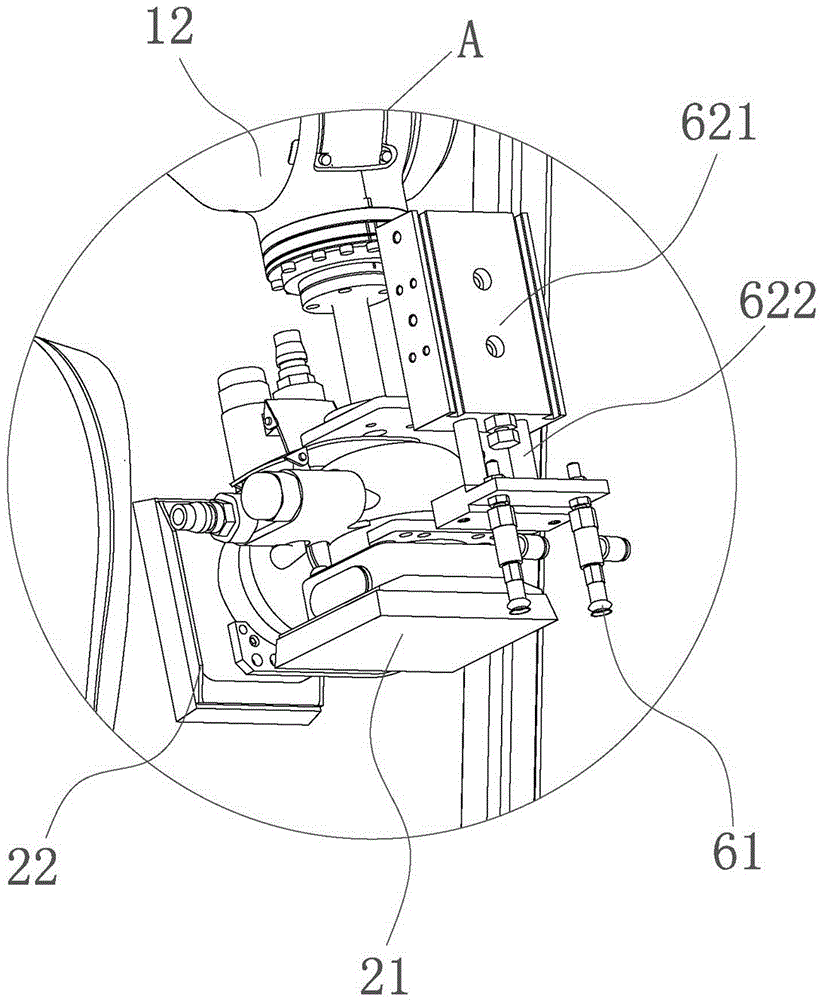

Robotic hand tool sharpening and cleaning apparatus

ActiveUS20190210177A1Improve throughputLess operator repetitive stressProgramme controlProgramme-controlled manipulatorCamera imageRobotic hand

An automated hand tool sharpening and cleaning system for sharpening the two opposed cutting edges of domestic, industrial, sport, or hobby hand tool like a knife blade is provided by the invention. The apparatus comprises a six-axis robotic arm, a pneumatic gripper, a vision sensor camera for profiling the blade edges, a robotic controller, and sequentially-arranged grinding, coarse sharpening, fine sharpening, and buffing rotating wheel assemblies used to grind, sharpen, and buff or polish the cutting edges of the knife blade. The blade cutting edges are profiled by the camera image that is processed by associated software to define the blade by multiple points defined along its edge, followed by a set of algorithms that are used to clean up any discrepancies in the profile data. The resulting corrected profile data is then translated into a set of machine control commands fed to the robotic arm and pneumatic gripper via the robot controller for manipulating the knife blade edges via the robotic arm with respect to each of the grinding, coarse sharpening, fine sharpening, and buffing / polishing wheels and an associated wash station for remove bits of metal and other residue resulting from the sharpened knife blade.

Owner:RAZOR EDGE SYST

Apparatus and method for circular vortex air flow material grinding

Owner:POLIFKA RUTH

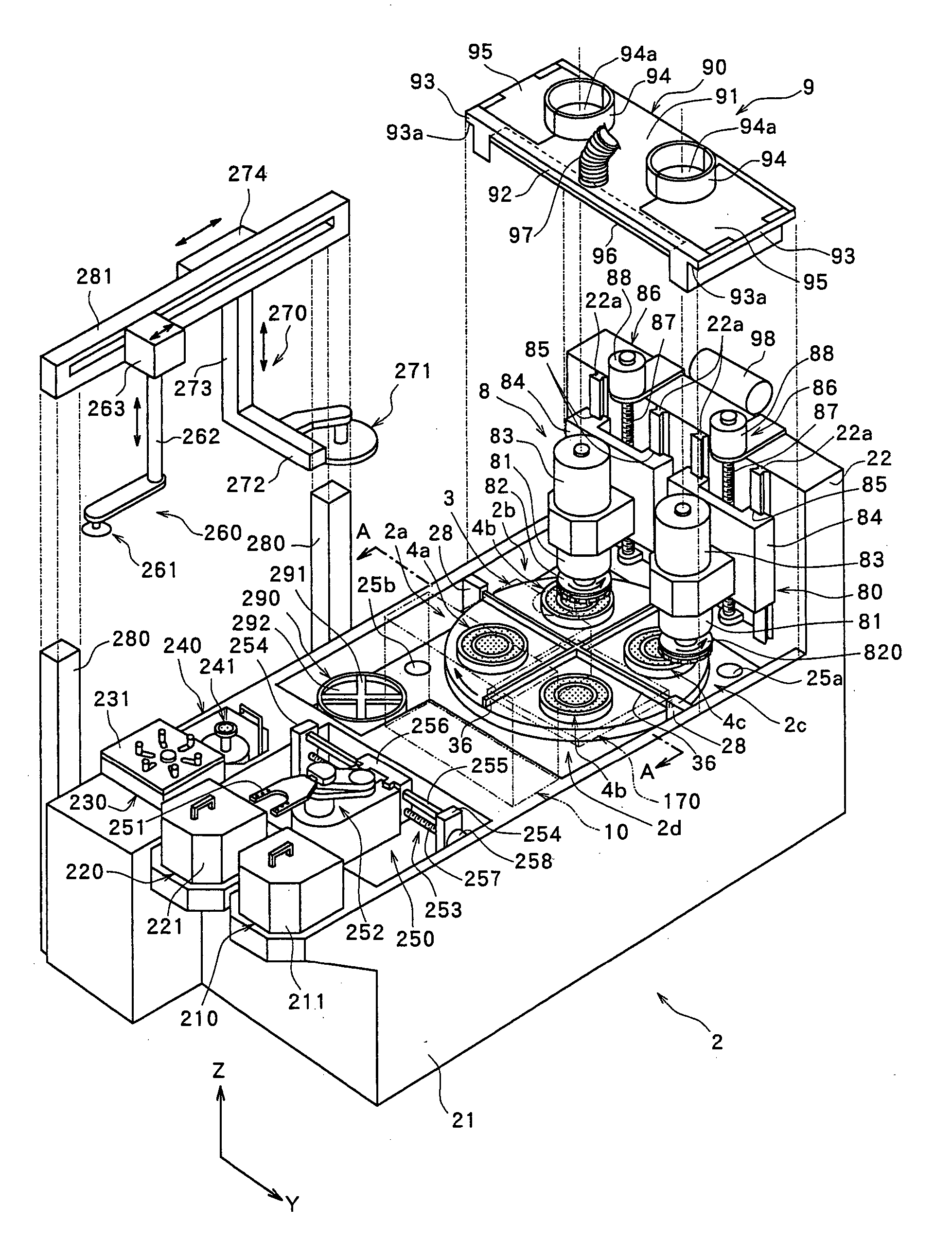

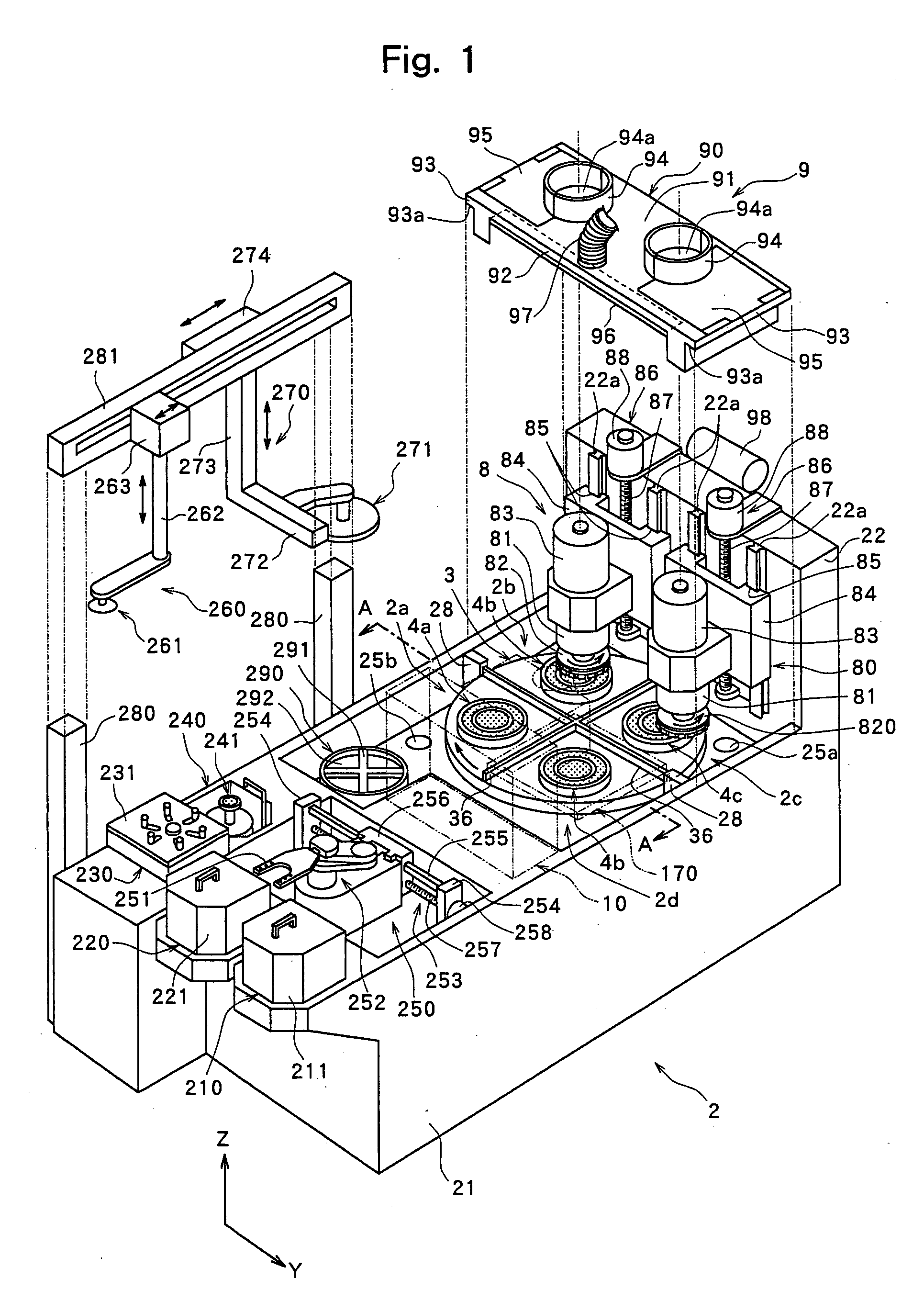

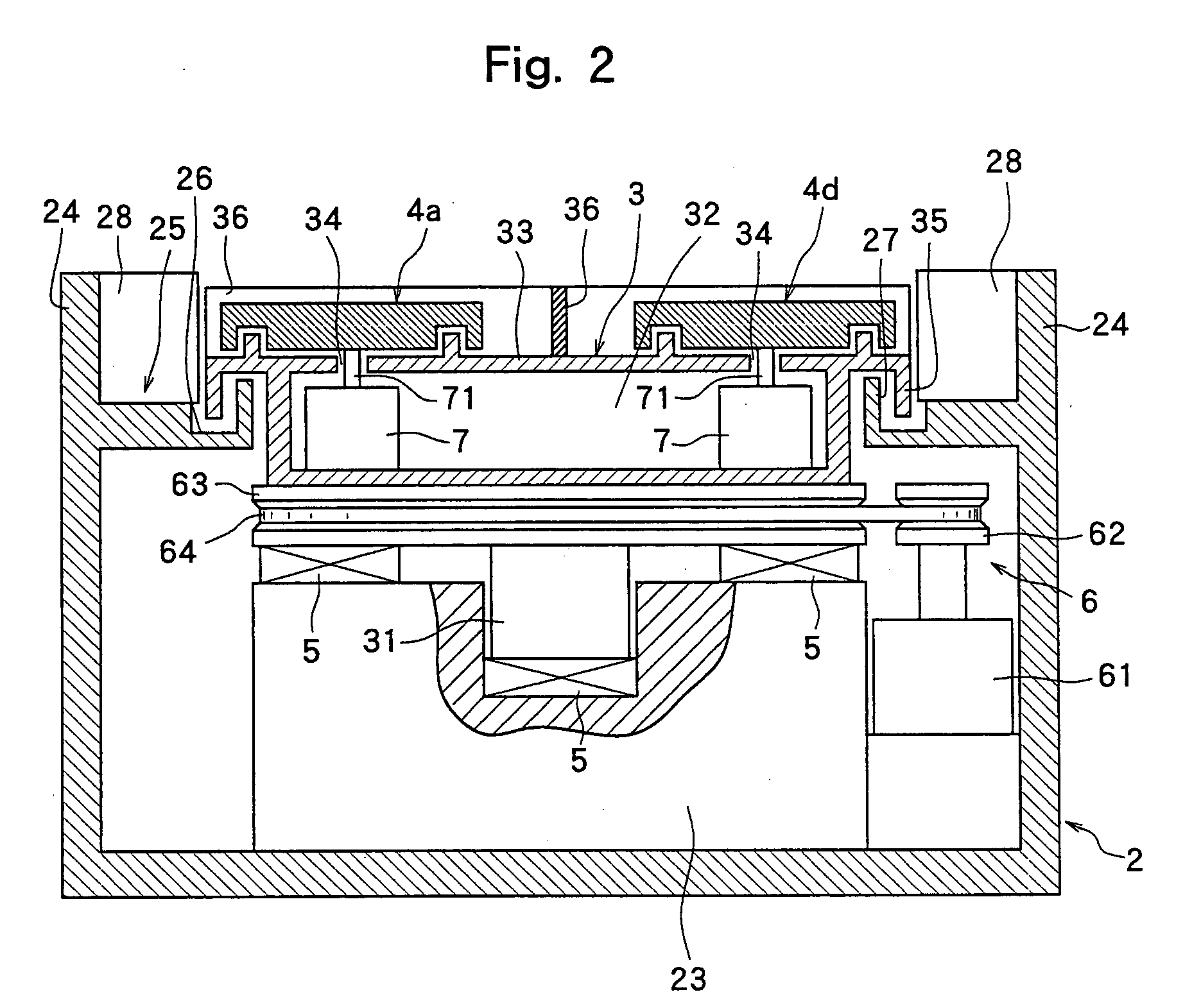

Wafer processing machine

A wafer processing machine comprising a turntable, a plurality of chuck tables mounted on the turntable, a grinding means for grinding a wafer held on the chuck table, and a multipurpose polishing means for polishing the ground surface of a wafer held on a chuck table, wherein the multipurpose polishing means comprises a mounter for detachably mounting a polishing tool, a spindle unit for rotating the mounter, a spindle unit support means for supporting the spindle unit in such a manner that the spindle unit can move in a direction perpendicular to the holding surfaces of the chuck tables and in a direction parallel to the holding surfaces of the chuck tables, a first polishing-feed means for moving the spindle unit in a direction perpendicular to the holding surfaces of the chuck tables, and a second polishing-feed means for moving the spindle unit in a direction parallel to the holding surfaces of the chuck tables.

Owner:DISCO CORP

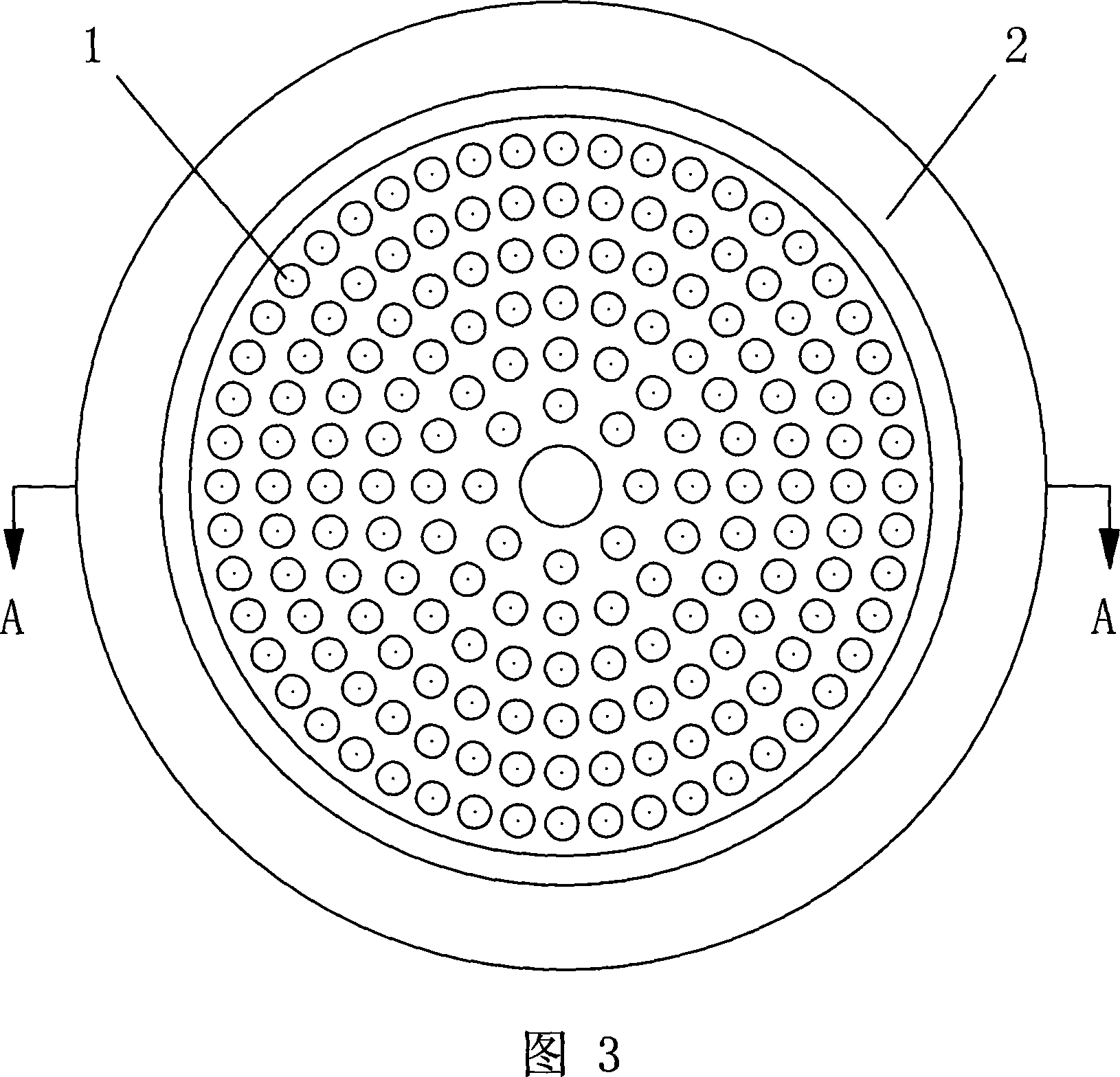

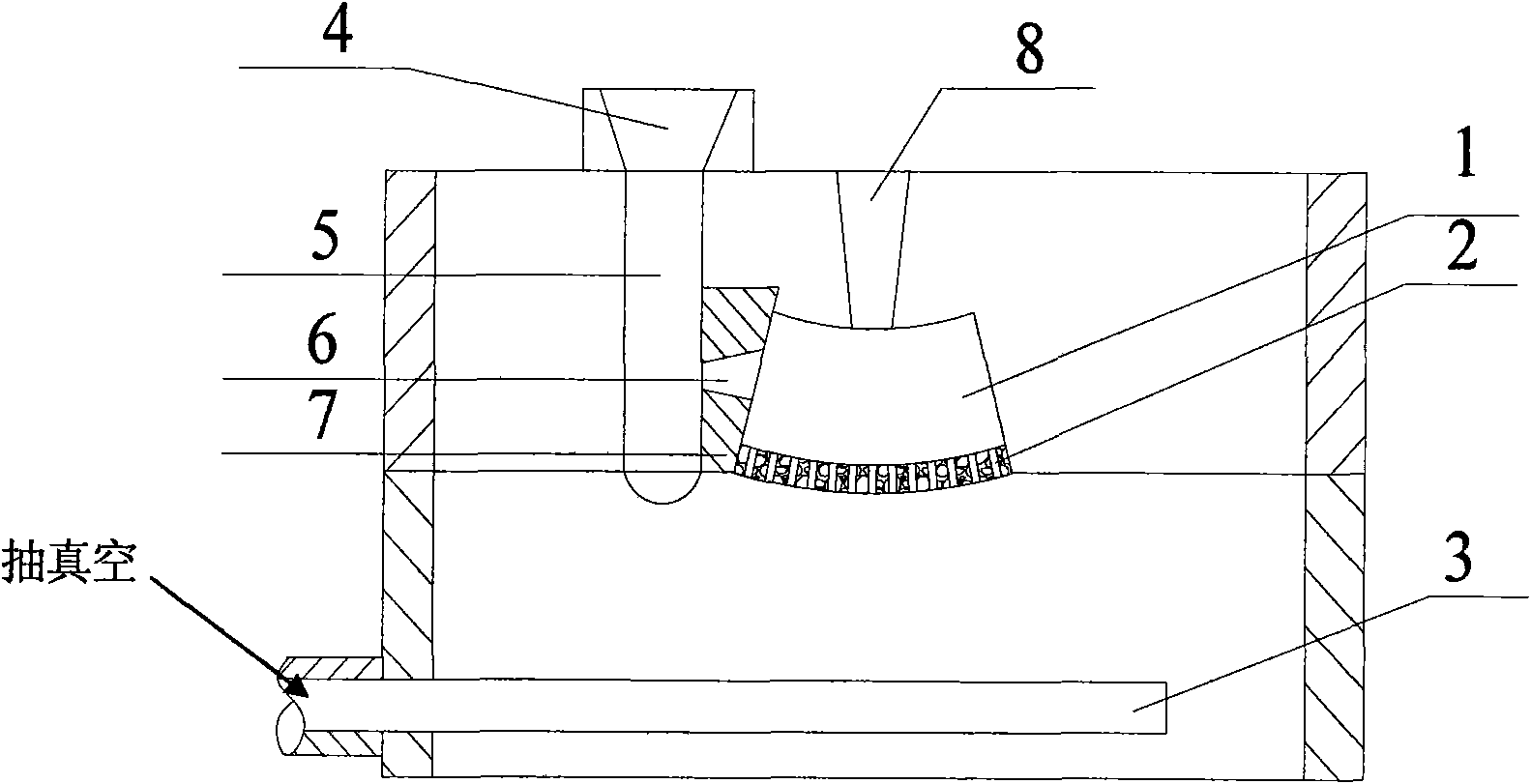

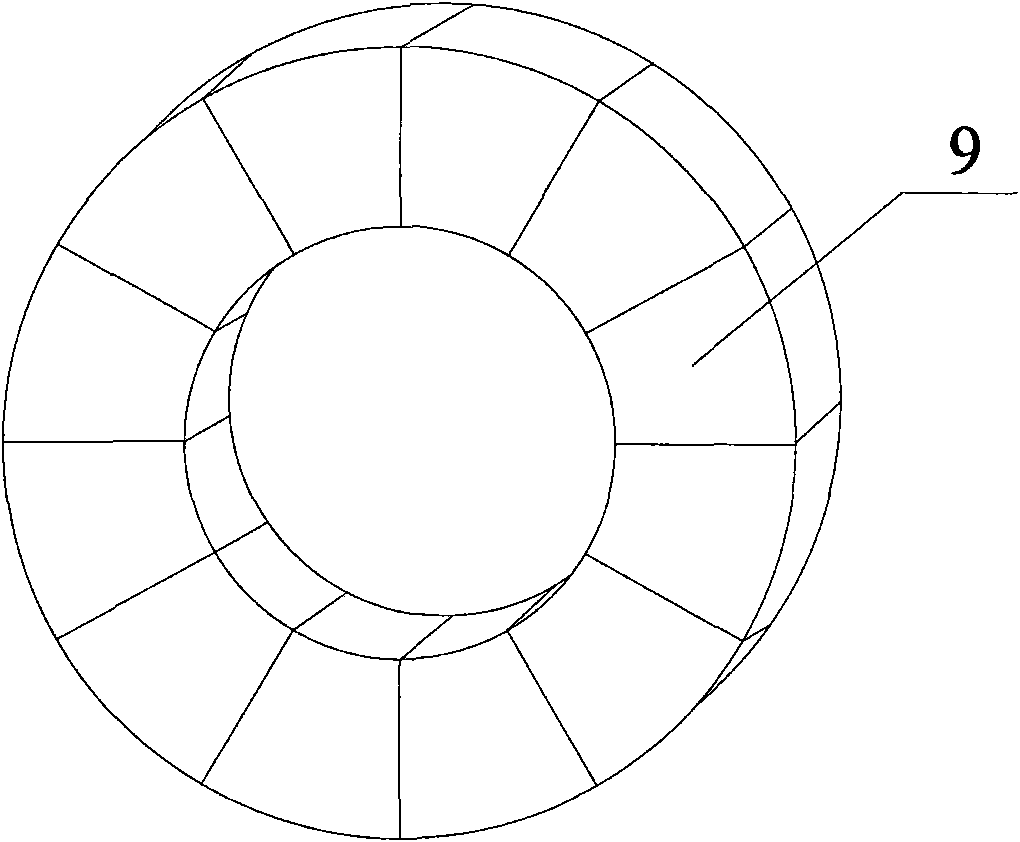

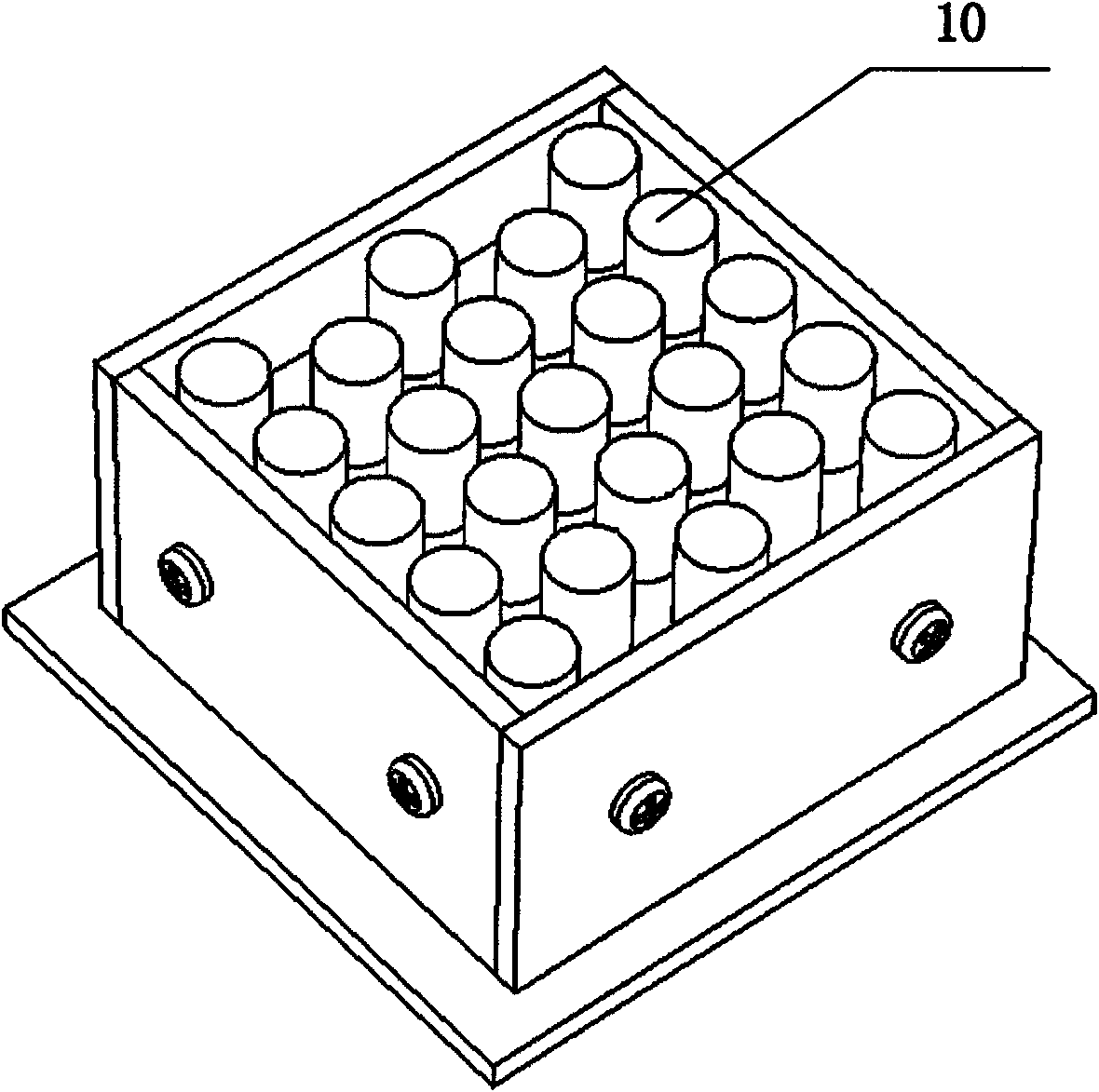

Composite-material grinding roller, grinding disc, and negative-pressure casting method thereof

InactiveCN101585081AQuality improvementHelps prevent scourGrain treatmentsShadow effectPressure casting

The invention provides a composite-material grinding roller, a grinding disc, and a negative-pressure casting method thereof. The method comprises: preparing WC particles and binder into paste; filling a mold with the paste to form a honeycomb-like prefabricated body; placing the prefabricated body on the side of the end face of a casting mold cavity; melting metal parent material to form molten metal; allowing the molten metal to enter the bottom of the casting mold cavity from a straight pouring channel and an inner pouring channel of a pouring cup; and forming the composite-material grinding roller and the grinding disc after the molten metal solidifies. As a reinforcement body of the invention adopts a honeycomb-like structure, on the one hand, the reinforcement body is favorable for blocking the scouring effect of the molten metal, benefiting the stable production of castings and reducing reject rate, and on the other hand, the honeycomb-like reinforcement body can realize macro-shadow effect during the service of the composite-material grinding roller, helps to improve the wear resistance of materials, and can also avoid the phenomena that the purely block-shaped reinforcement body peels off or falls.

Owner:XI AN JIAOTONG UNIV +1

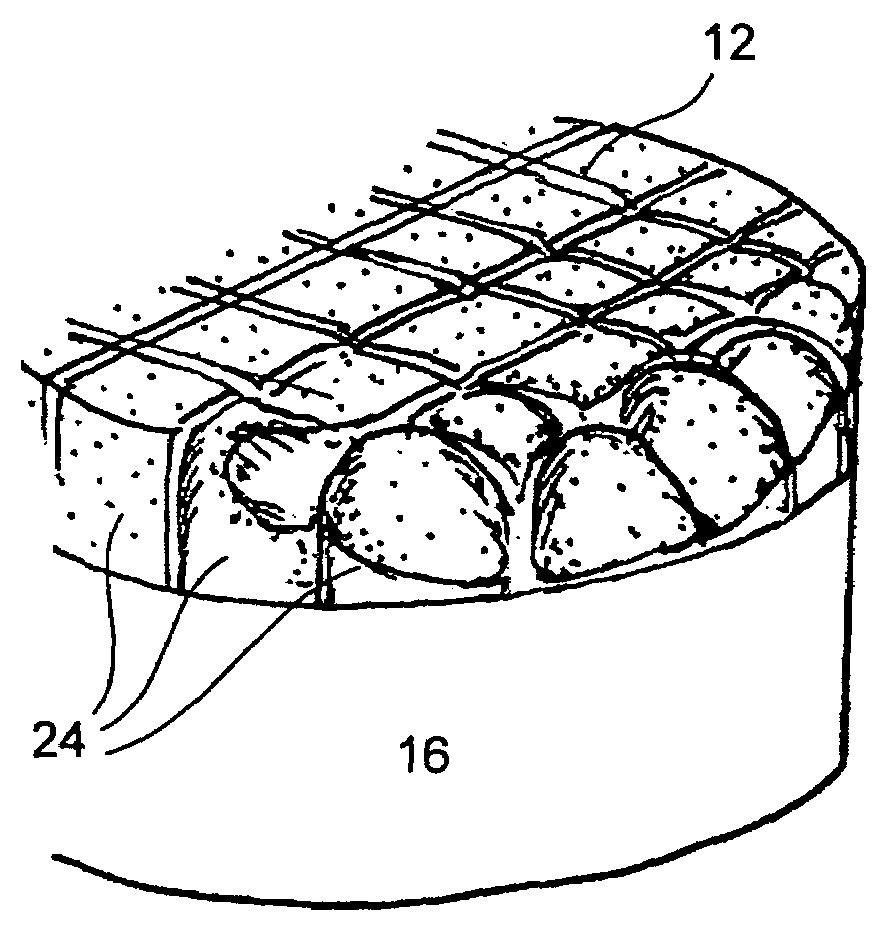

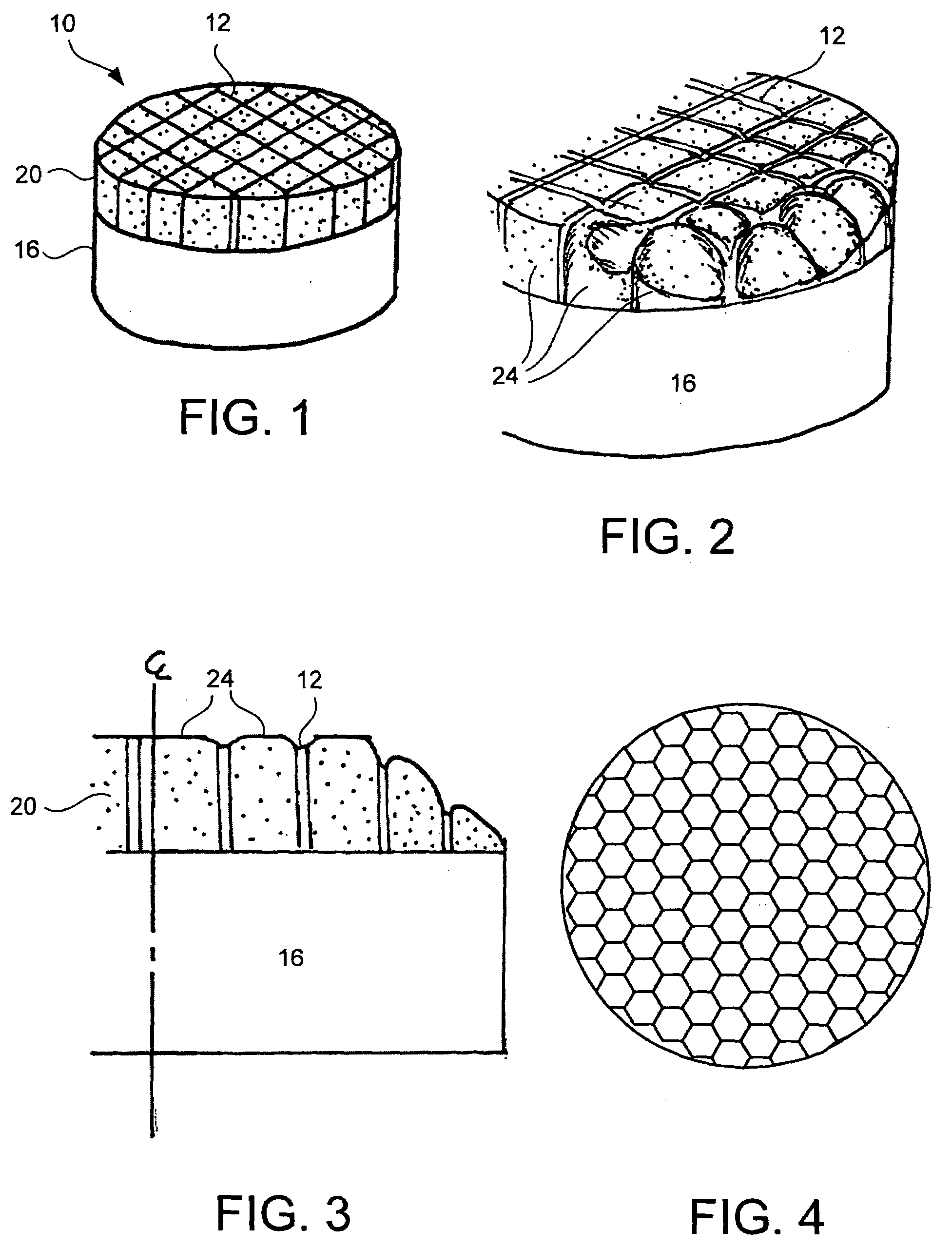

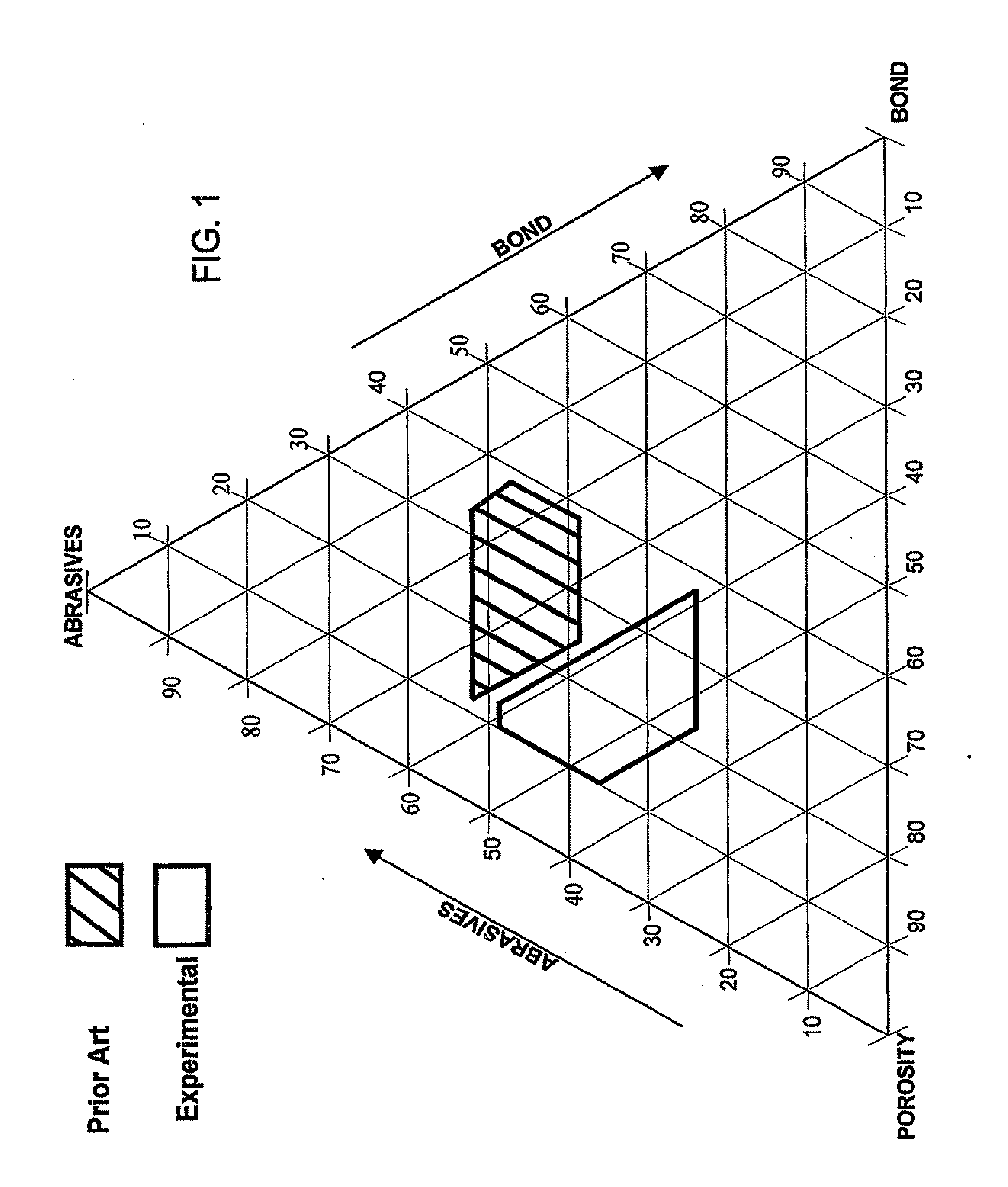

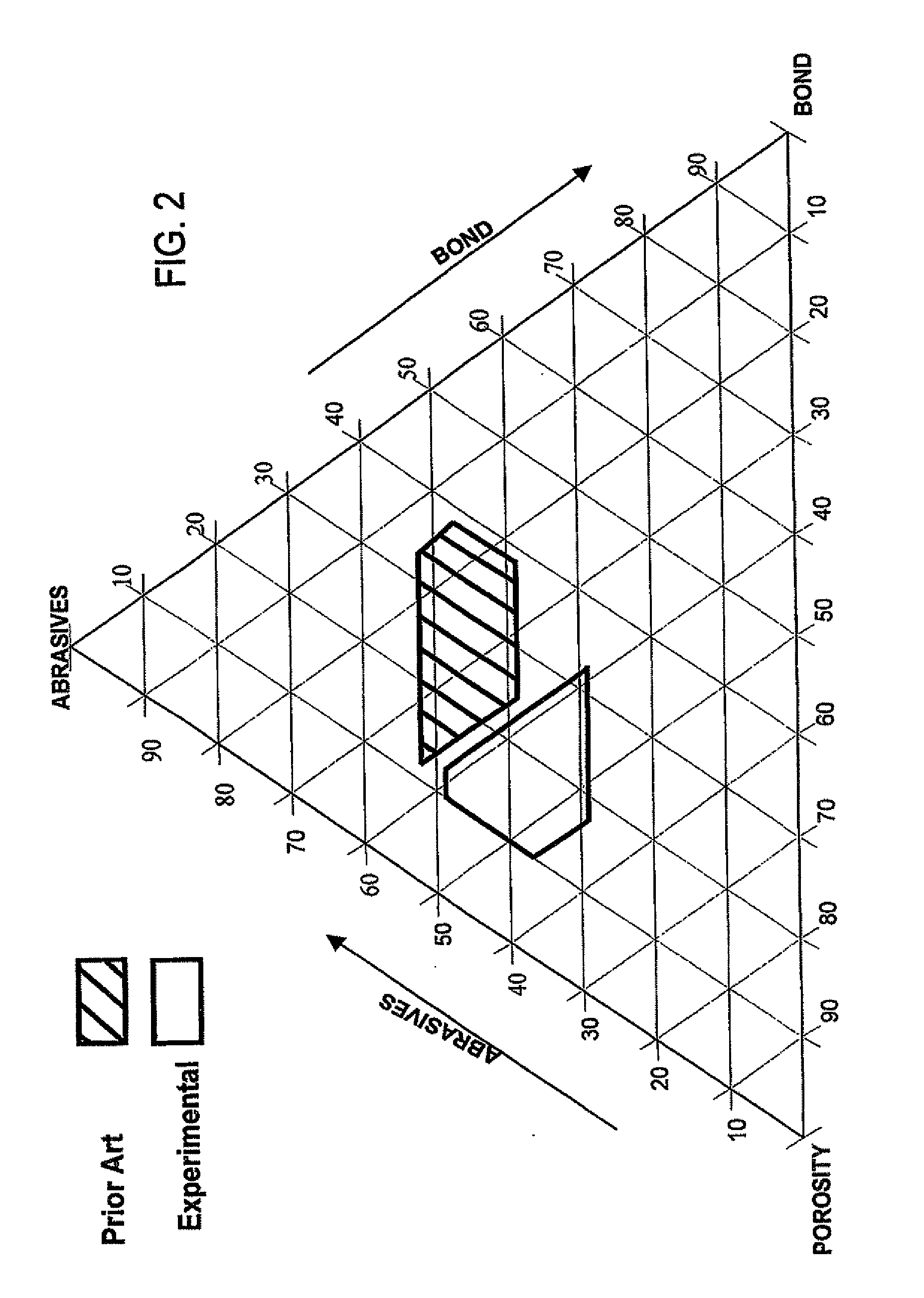

Abrasive Articles with Novel Structures and Methods for Grinding

InactiveUS20080085660A1Edge grinding machinesBonded abrasive wheelsHardnessUltimate tensile strength

Bonded abrasive tools, having novel porous structures that are permeable to fluid flow, comprise a relatively low volume percentage of abrasive grain and bond, and a relatively low hardness grade, but are characterized by excellent mechanical strength and grinding performance. Methods for making the abrasive tools utilizing agglomerated abrasive grain are described.

Owner:SAINT GOBAIN ABRASIFS INC +1

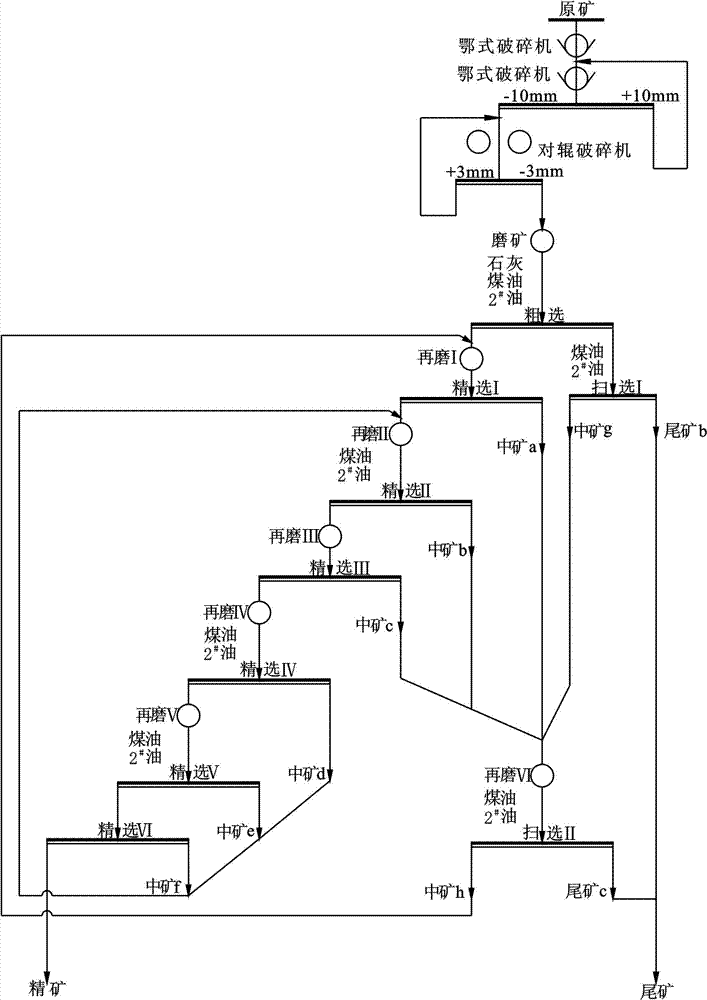

Fine flaky-cryptocrystalline mixed graphite separation technique

The invention discloses a fine flaky-cryptocrystalline mixed graphite separation technique which comprises the following steps: primary rough grinding and rough separation, quintic regrinding and sextic concentrating, and middling centralized processing. According to the technique, in the rough separation step, the grinding fineness is -0.074mm, and the content is 90-95%; in the concentrating step, the regrinding fineness is -0.045mm, and the content is 90-95%; and thus, the graphite monomer is sufficiently dissociated, thereby sufficiently ensuring the fixed carbon content and recovery rate of the concentrated concentrate. The technique adopts gradually decreased low concentrating concentrations in multiple concentrating process to ensure the dispersity of ore slurry, thereby solving thesevere problem of entrapped impurities in floatation foam; and thus, in the final concentrate, the fixed carbon content is 91.35%, and the recovery rate is 91.30%, thereby solving the problems of lowtechnical indexes, low grade, low recovery rate and high cost in the fine flaky-cryptocrystalline mixed graphite concentrate separation, so that the fine flaky-cryptocrystalline mixed graphite ores are utilized in an efficient, economical and reasonable way.

Owner:SICHUAN PILOT GRAPHITE PROD

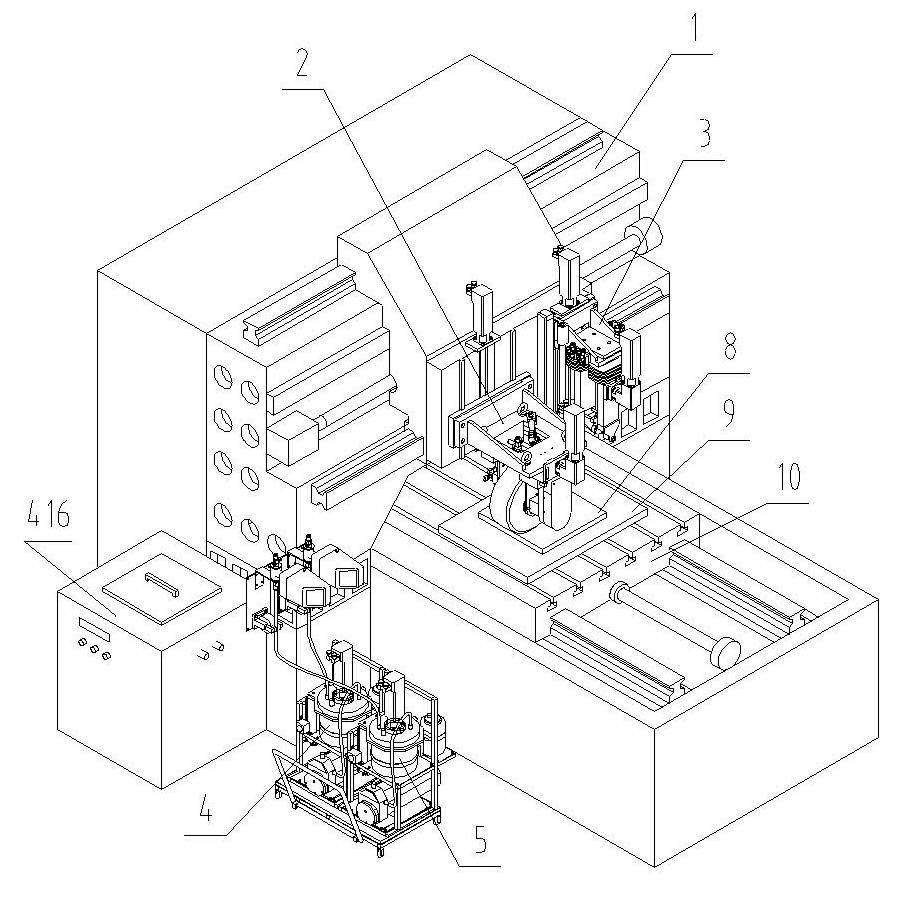

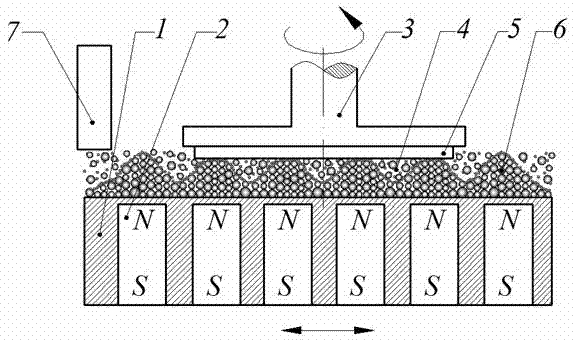

Double-flexible-grinding-head magnetorheological polishing device

ActiveCN102632435AEfficient removalEffectively match processing efficiencyGrinding drivesGrinding feed controlMagnetic currentEngineering

The invention discloses a double-flexible-grinding-head magnetorheological polishing device. In the device, a vertical gantry of a bed body and an X-axis are both fixed on a horizontal base; a worktable is fixed on a sliding block of the X-axis; a Y-axis is fixed on a horizontal beam of the vertical gantry; and a first Z-axis and a second Z-axis are arrangedon the Y-axis in parallel. A large flexible grinding head is installed on the first Z-axis; and a small flexible grinding head is arranged on the second Z-axis. A high-flow circulation system connected with the large flexible grinding head and a low-flow circulation system connected with the small flexible grinding head are arranged on a trolley. A control cabinet is arranged at the rear part of the vertical gantry; and a circulation system cabinet and a cleaning system are arranged at the side surface of the vertical gantry. The double-flexible-grinding-head magnetorheological polishing device provided by the invention has the advantages of high accuracy, high rigidness, high stability and high dynamic property. The double-flexible-grinding-head magnetorheological polishing device not only can be used for processing of large-caliber phase elements, but also can be used for high-accuracy processing of large-caliber planar optical elements within the range of full caliber. The optimal matching of the processing efficiency and the processing accuracy can be realized.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

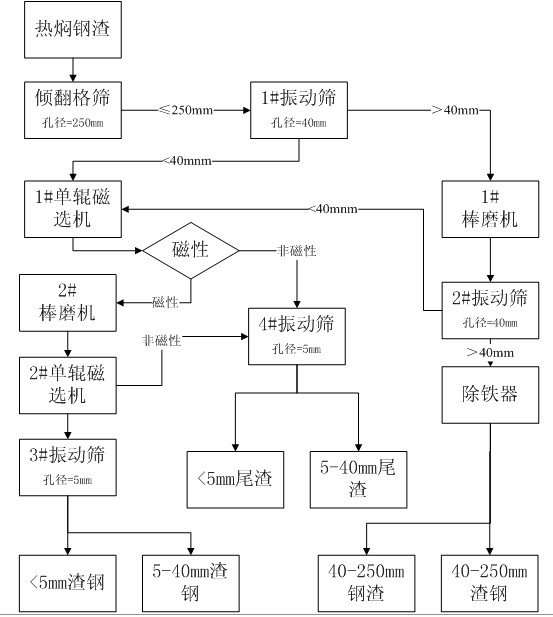

Method for reusing common steel slag

The invention relates to a method for reusing common steel slag. The method comprises the process links of performing hot closed treatment on slag, airing, sieving, performing magnetic separation and grinding and particularly comprises the following steps of: transporting red hot common steel slag to a hot splashing field and performing hot splashing; preliminarily crushing large common steel slag with the grain size of more than 2 m to the slag with the grain size of less than 2 m; placing the common steel slag into a hot closed treatment pool and uniformly heating for 30 minutes; covering a cover of the hot closed treatment pool; continuously and uniformly spraying water on the steel slag by using a spraying device in the cover, wherein the water spraying flow is 20 tons per hour and the water spraying time is 7 hours; after stopping spraying water, continuously performing hot closed treatment for more than 5 hours; opening the cover and measuring the temperature to 50 to 80 DEG C and the water content of the common steel slag is 6 to 8 percent; and conveying the steel slag subjected to hot closed treatment to a stacking field and airing for more than 24 hours, wherein the water content is 4 to 6 percent. Compared with the traditional treatment process, the method has the advantages that: metal recycling capacity is high; product grade is high; all the common steel slag can be treated; and the product can be utilized well.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Stainless steel weldless steel tube for ship and producing technique

InactiveCN101220443AHigh mechanical strengthGood extensibilityFurnace typesHeat treatment furnacesNo productionUltimate tensile strength

The invention relates to a stainless steel seamless pipe in metallurgical industry and the manufacturing process for the stainless steel seamless pipe; wherein, the steel pipe is made of 00Cr24Ni6Mo2N dual phase stainless steel; the manufacturing process for preparing the ship borne stainless steel seamless pipe comprises the following production steps of a. round steel preparation; b. heating; c. hot-puncturing process; d. end cropping; e. pickling; f. repair grinding; g. lubrication; h. cold rolling processing; i. degreasing; j. solution heat treatment; k. straightening; l. pipe cutting; m. pickling; n. inspection of finished products. The invention solves the problems of lower mechanical strength and extensibility, shorter service life and high prices in present 316L stainless steel pipes used in ship seawater channels and provides a novel ship borne dual phase stainless steel seamless pipe and the manufacturing process and has the advantages of no production of pitting corrosion and grain boundary corrosion of the steel pipes, higher mechanical strength and extensibility, longer service life as well as low price and low cost.

Owner:江苏长盈不锈钢管有限公司

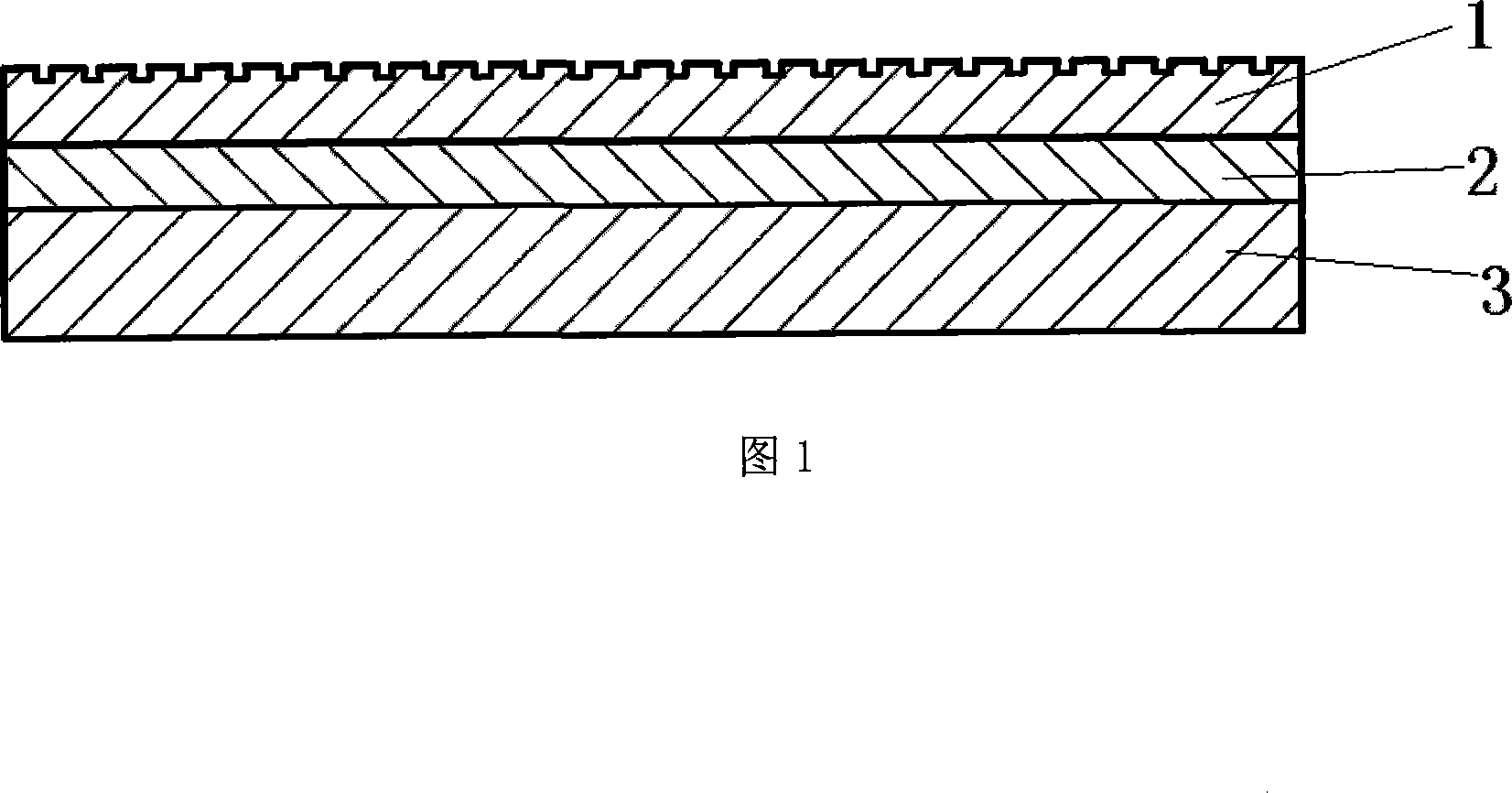

Solidified abrasive lapping polishing pad having self-modifying function and preparation method

InactiveCN101096080AReduce surface roughnessImprove flatnessAbrasion apparatusGrinding devicesCross-linkScreen printing

The invention relates to a grinding and polishing pad of consolidation abrasive with self-adjusting function and the preparation method, belonging to ultra-precision grinding and polishing machining technical field, which is characterized in that components of the abrasive layer (3)comprises 1-20% by wt of abrasive with granularity of 1-40 nanometer, 20-80% by wt of acrylic pre-polymer, 1-3% by wt of free radical photo initiator, 0-2% by wt of poly (dimethylsiloxane) / acrylic polymer, 0-20% by wt of adjustment additive with system cross-linking density performance, and 5-40% by wt of acrylic active diluent. The preparation process comprises (1)mixing stock fully and uniformly, (2)preparing rigid polymer matrix, (3)daubing uniformly by screen-printing, and (4)solidifying by ultraviolet cured machine. The invention is provided with stable grinding and polishing performance and self-adjustment performance. It is suitable for precision machining.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

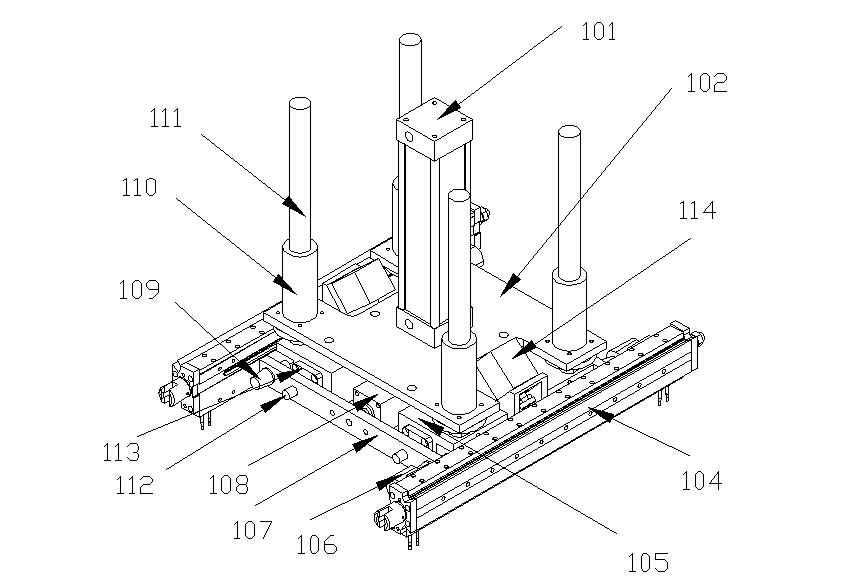

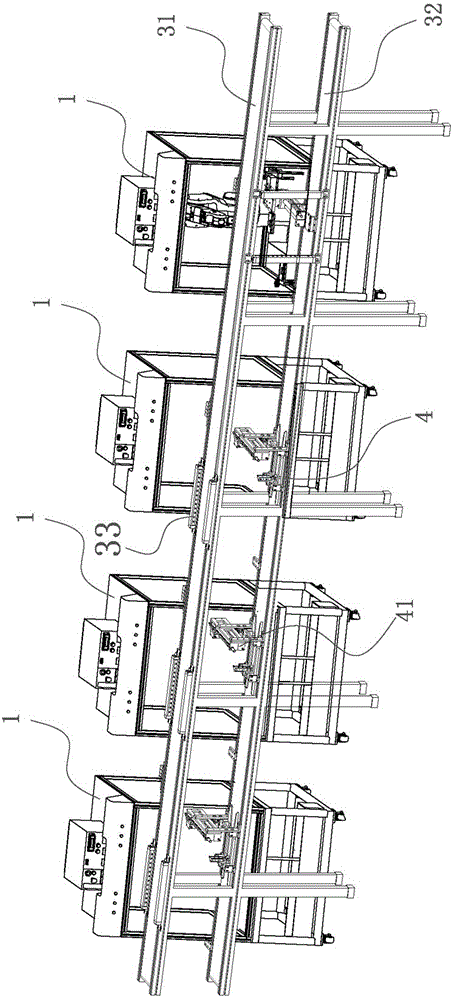

Manipulator grinding system

ActiveCN105666275AVersatileCompact structureEdge grinding machinesGrinding carriagesEngineeringManipulator

The invention relates to the technical field of grinding, and in particular relates to a manipulator grinding system. The manipulator grinding system comprises a grinding robot device and a conveying belt, wherein the grinding robot device comprises a mechanical arm, a grinding tool mounted at the tail end of the mechanical arm, and a grinding bench for fixing a product; the grinding tool comprises a first grinding tool and a second grinding tool; the mechanical arm is provided with a first mounting part and a second mounting part which are arranged in a certain angle; the first grinding tool is mounted at the first mounting part, and the second grinding tool is mounted at the second mounting part; the conveying belt comprises a first conveying belt and a second conveying belt which run oppositely and are arranged up and down; a stop mechanism for stopping the product is arranged on the second conveying belt; and a transplanting mechanism for catching the product from the second conveying belt to the grinding bench is arranged on the conveying belt. Compared with the prior art, the manipulator grinding system disclosed by the invention has complete functions and is compact in structure and higher in automation degree.

Owner:GUANGDONG TOPSTAR TECH

Combined machining method for chemistry cluster magneto-rheological of monocrystal silicon carbide wafer

The invention provides a combined machining method for chemistry cluster magneto-rheological of a monocrystal silicon carbide wafer. The method based on the magneto-rheological effect comprises the following steps: a monocrystal silicon carbide wafer is pasted on an antimagnetic tool head through a binder; the antimagnetic tool head is mounted on a motor spindle, and swings to a certain extent relatively to a polishing disc while the antimagnetic tool head and the polishing disc rotate around respective axial lines of the antimagnetic tool head and the polishing disc; grinding material and acid-base chemical reagent both mixed into magneto-rheological fluid are used as polishing working solution; small grinding heads with the magneto-rheological effect are produced based on a magnetic substance to limit gathered free grinding material; a flexible polishing film is formed by the array combination of multipoint small grinding heads with the magneto-rheological effect based on the cluster action principle; the distance between a workpiece and an antimagnetic polishing disc and the relative rotating speed of the workpiece to the polishing disc can be controlled to reduce surface defect and layer damage of the monocrystal silicon carbide wafer; and a super smooth surface with high quality can be obtained. According to the invention, the method integrates the advantages of high mechanical efficiency of cluster magneto-rheological and chemocatalysis of chemical polishing; and the polishing efficiency is high.

Owner:GUANGDONG UNIV OF TECH

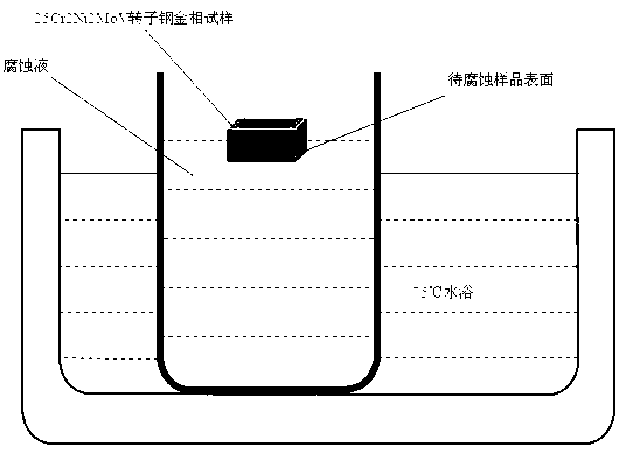

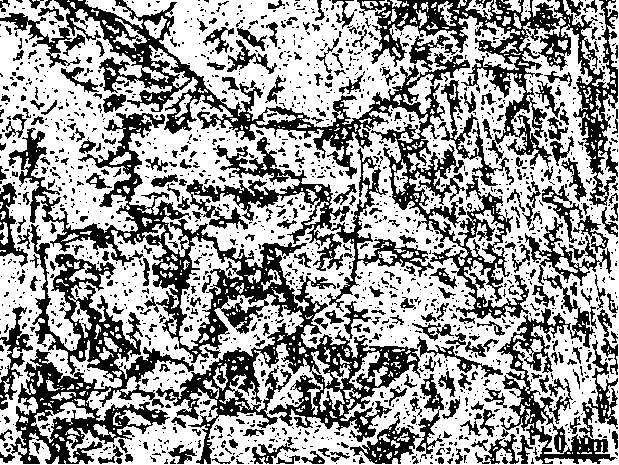

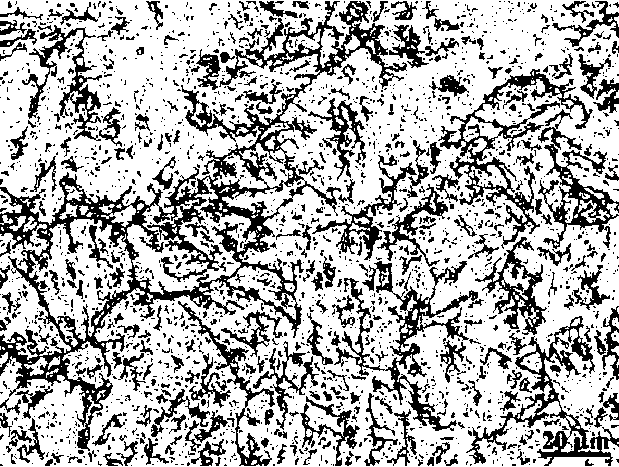

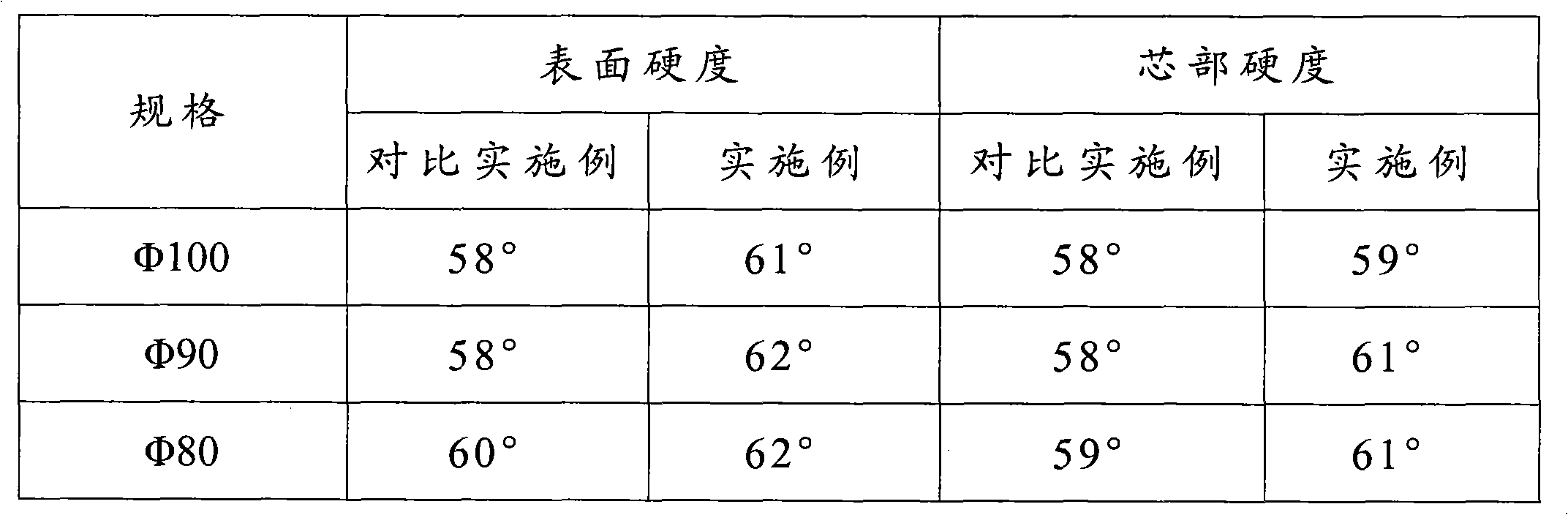

Metallographic corrosion method for clearly displaying original austenite grain boundary of NiCrMoV type rotor steel

The invention relates to a metallographic corrosion method for clearly displaying the original austenite grain boundary of a NiCrMoV type rotor steel, and belongs to the field of metallographic sample preparation. The method comprises the steps of: coarse grinding, fine grinding, polishing and corroding; putting a polished sample into a corrosive liquid of 75 DEG C, wherein the formula of the corrosive liquid comprises 200ml of distilled water, 5g of picric acid, 2ml of 5% diluted hydrochloric acid and 4g of sodium dodecyl benzene sulfonate; etching for 2minutes, taking the sample out, cleaning the sample with flowing water, cleaning the sample with alcohol and drying; and observing the clear original austenite grain boundary through an optical microscope. The method has the advantages that a difficult displaying problem of the original austenite grains of the NiCrMoV type rotor steel is solved, the original austenite grain boundary can be very clearly displayed, and the method is simple and practicable.

Owner:SHANGHAI UNIV +1

Polishing film and method for making same

ActiveCN101225281AUniform performanceReduce manufacturing costOther chemical processesPolishing compositionsOrganic solventRoller Coating Method

The invention discloses a polishing film and the preparation method, which adopts the ultrafine micro mist as the grinding material and prepares in flow-casting coating method, namely the powdered or granular resin is dissolved into the organic solvent and then added in functional additive to make the resin adhesive, then the abrasive of surface-modified ultrafine micro mist is added into the resin adhesive and the spread coating liquid can be obtained after fully mixing, finally the paint is painted on the surface of soft base in flow-casting coating method and the polishing film can be obtained after drying and curing. The preparation method of the polishing film has the advantages of small equipment investment, simple operation, high productivity and automation level, steady craft, even film performance and low manufacturing cost. The polishing film can adjust the craft parameters of the flow-casting craft conveniently according to the different quality requirement and standards of the products, and can achieve production in multi-specification and small lot production and overcomes the problems that the rapid transformation of the product specification is difficult due to the limit of the equipment structure in roller coating method.

Owner:HENAN UNION ABRASIVES

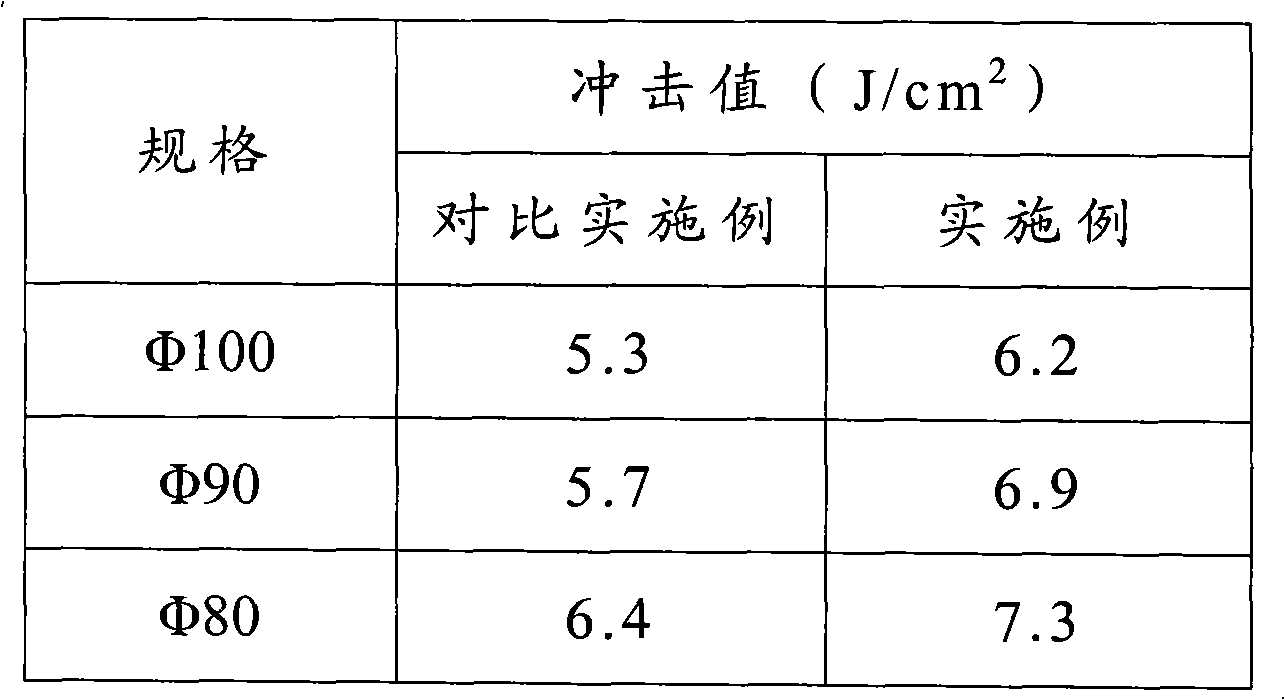

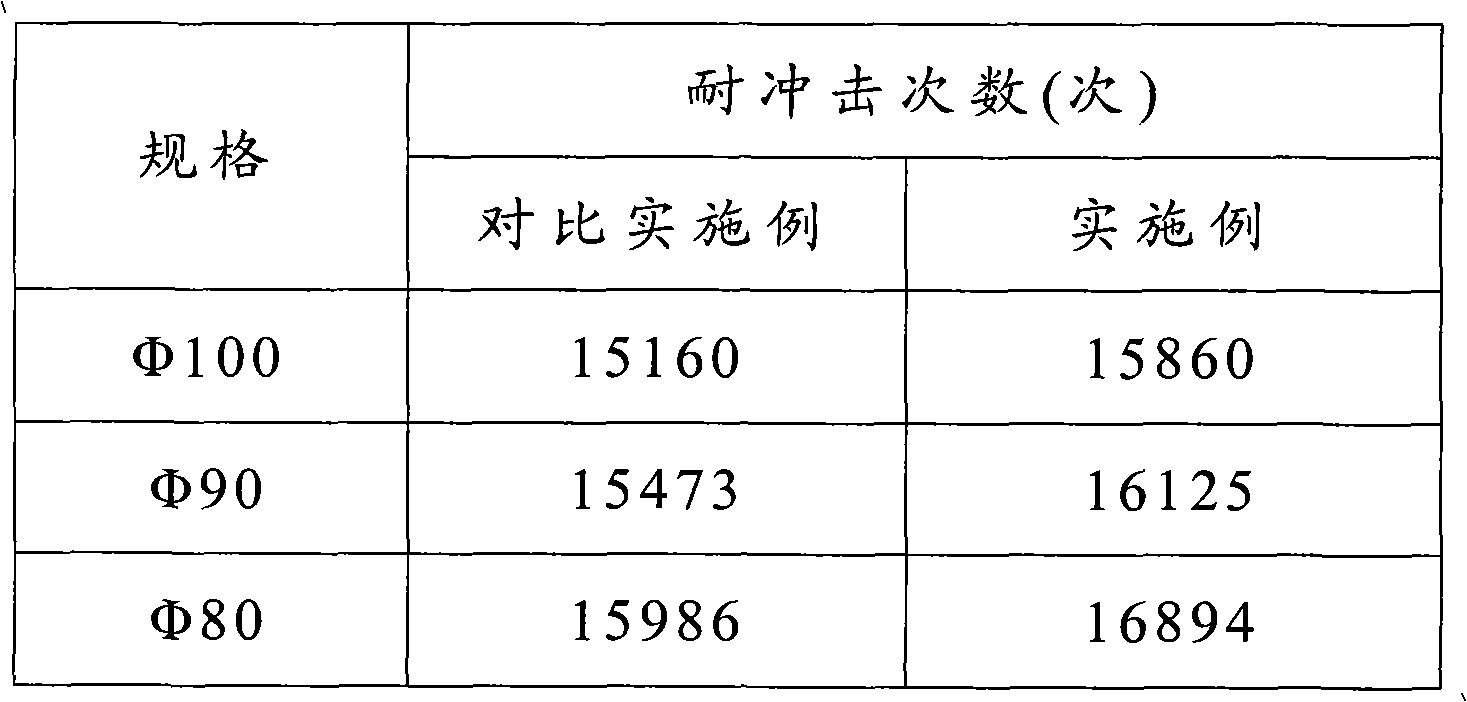

High-chromium grinding ball and secondary modification process thereof

InactiveCN101876027AHigh hardnessImprove toughnessProcess efficiency improvementWear resistanceToughness

The invention discloses a high-chromium grinding ball which is prepared from the following materials in percentage by weight: 1.80-3.20% of C, 0.30-1.00% of Si, 0.20-1.00% of Mn, 10.00-13.00% of Cr, 0-0.10% of S, 0-0.10% of P, 0-0.10% of Mo, 0-0.005% of B, 0-0.020% of Ti, 0-0.060% of V and balance of Fe, and is processed by a special secondary modification process, wherein the weight ratio of Ti to B is larger than 3, and the weight ratio of V to Ti is larger than 2.8. The high-chromium grinding ball prepared by using the formula and the process of the invention has the characteristics of favorable wear resistance, high rigidity, high toughness and high impact resistance.

Owner:宁国市开源电力耐磨材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com