Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12099 results about "Belt conveyor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

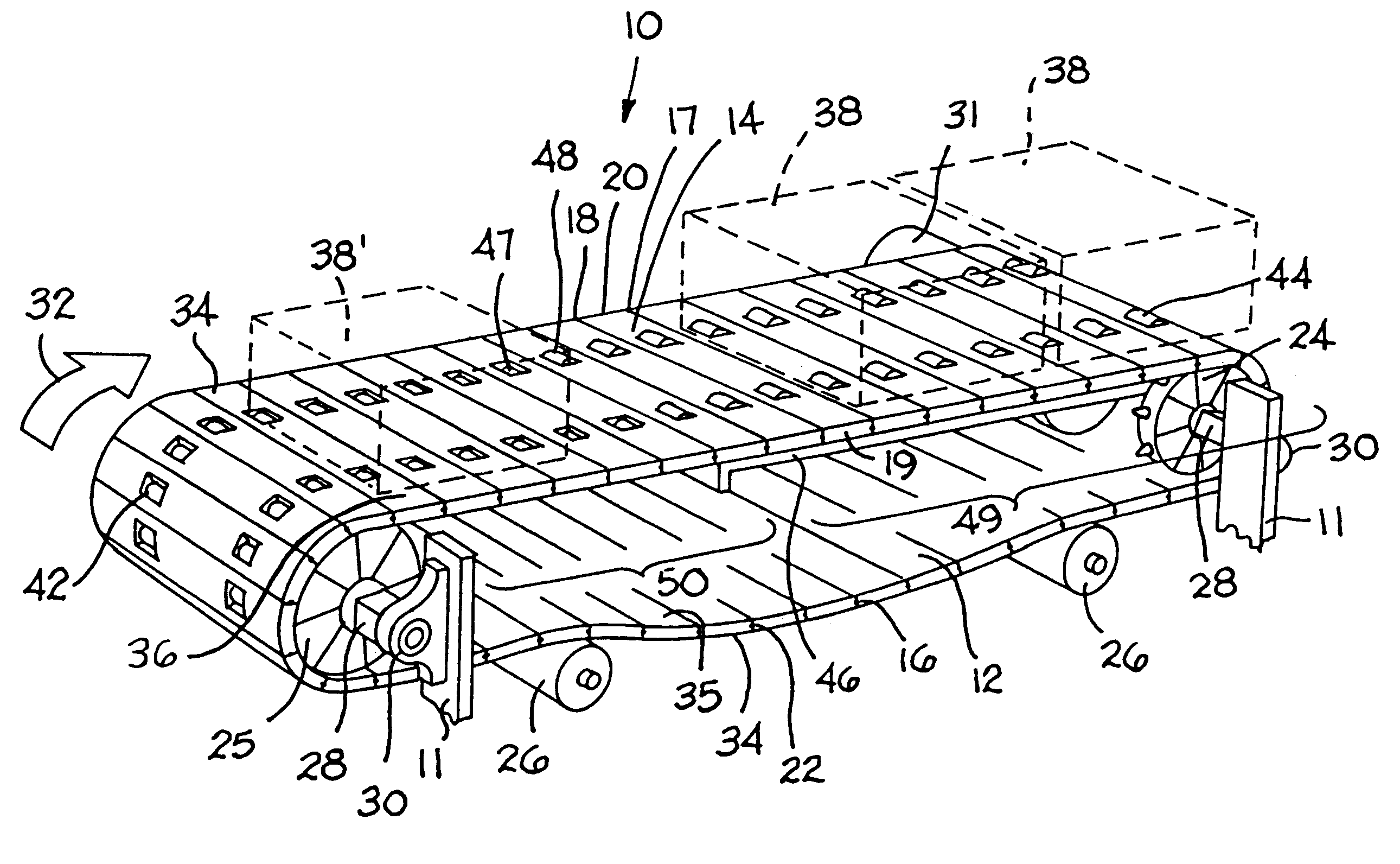

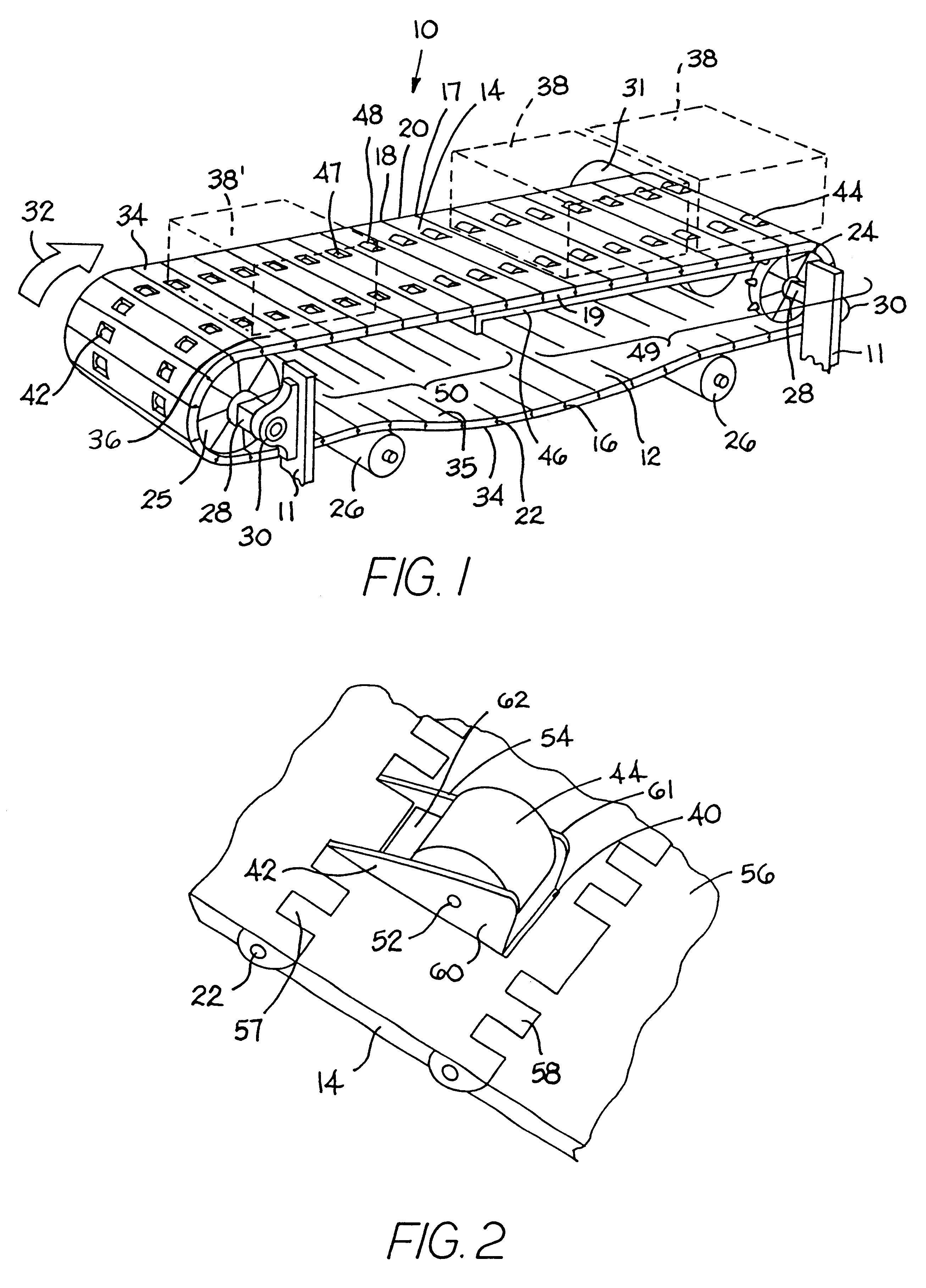

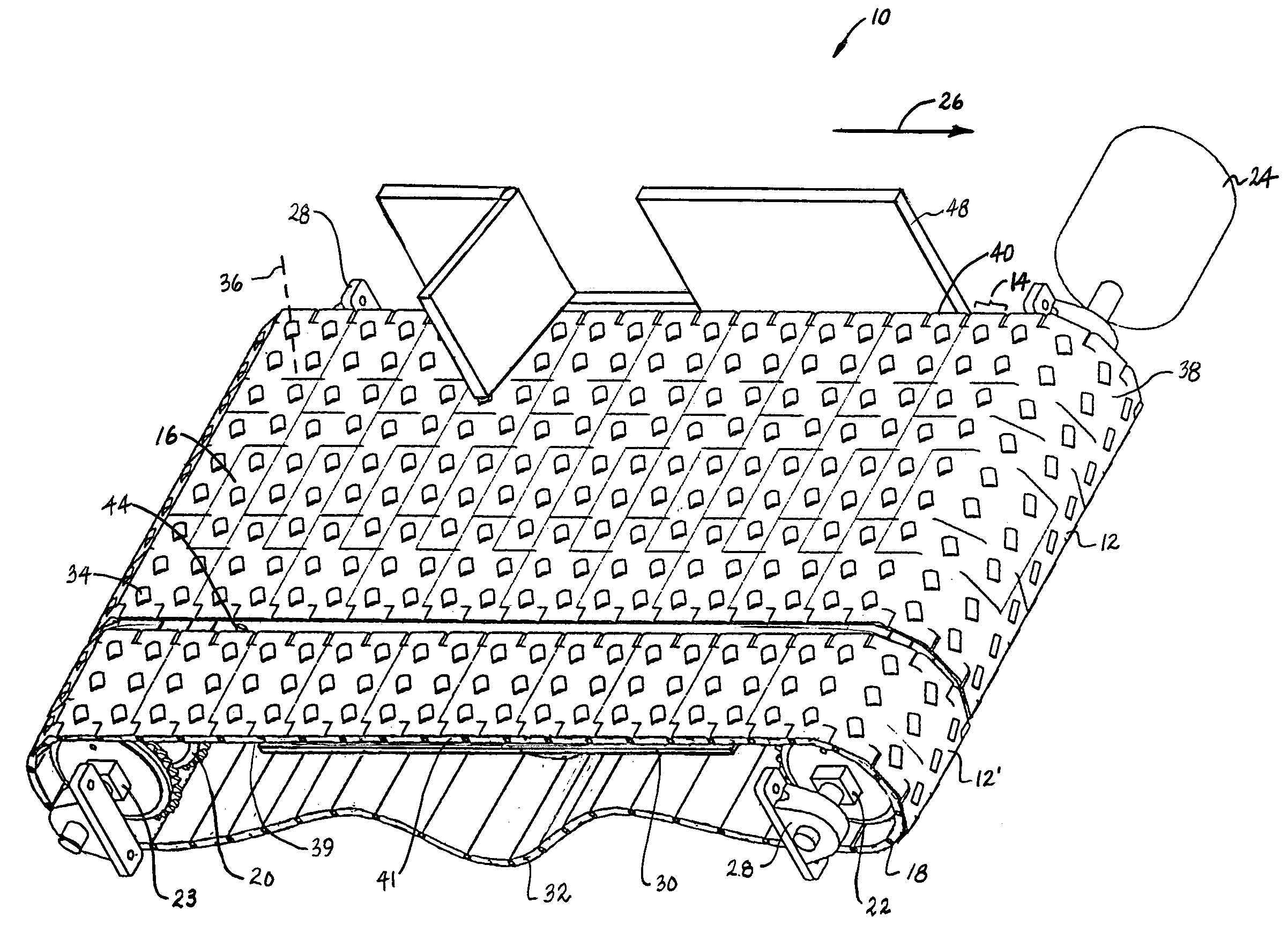

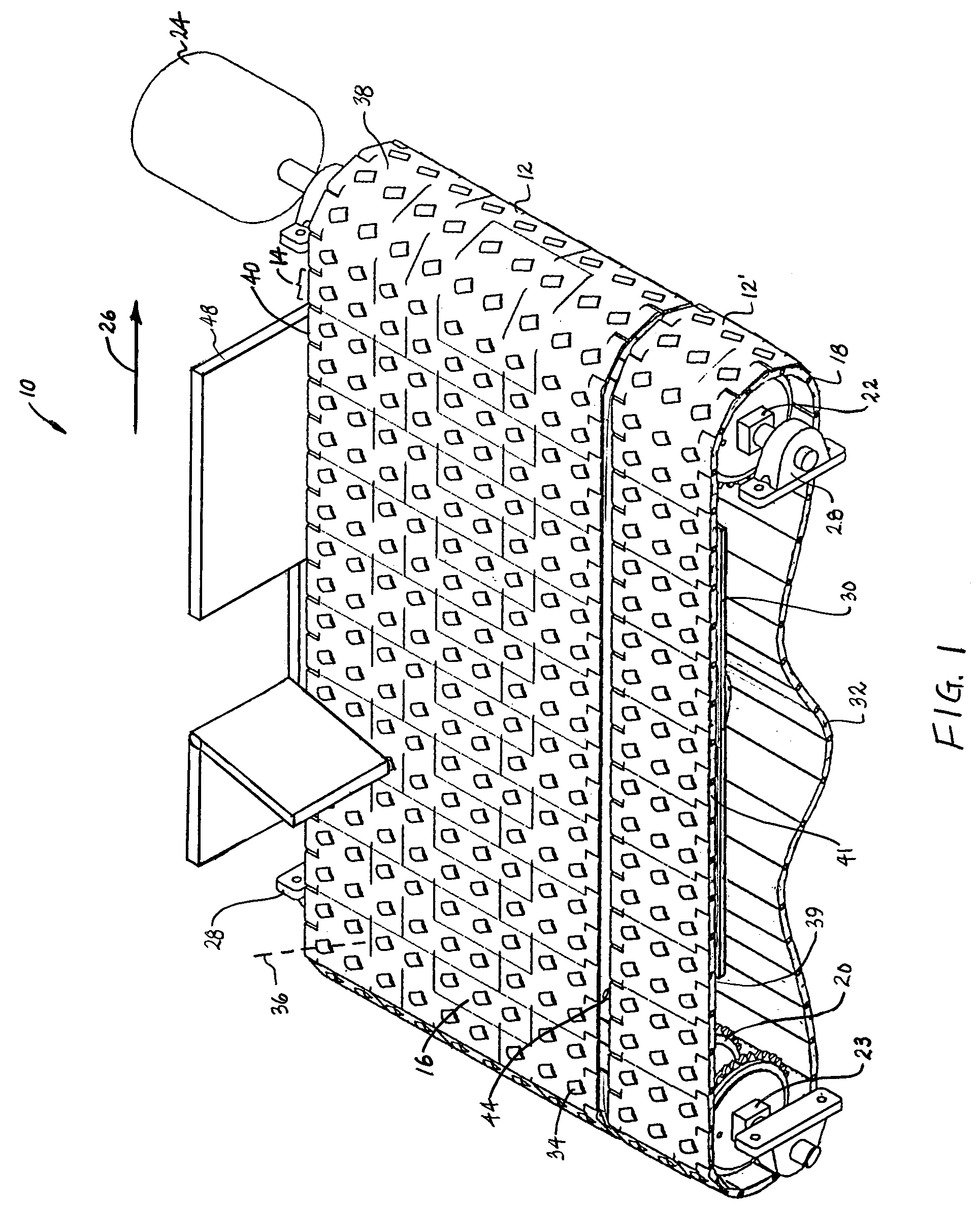

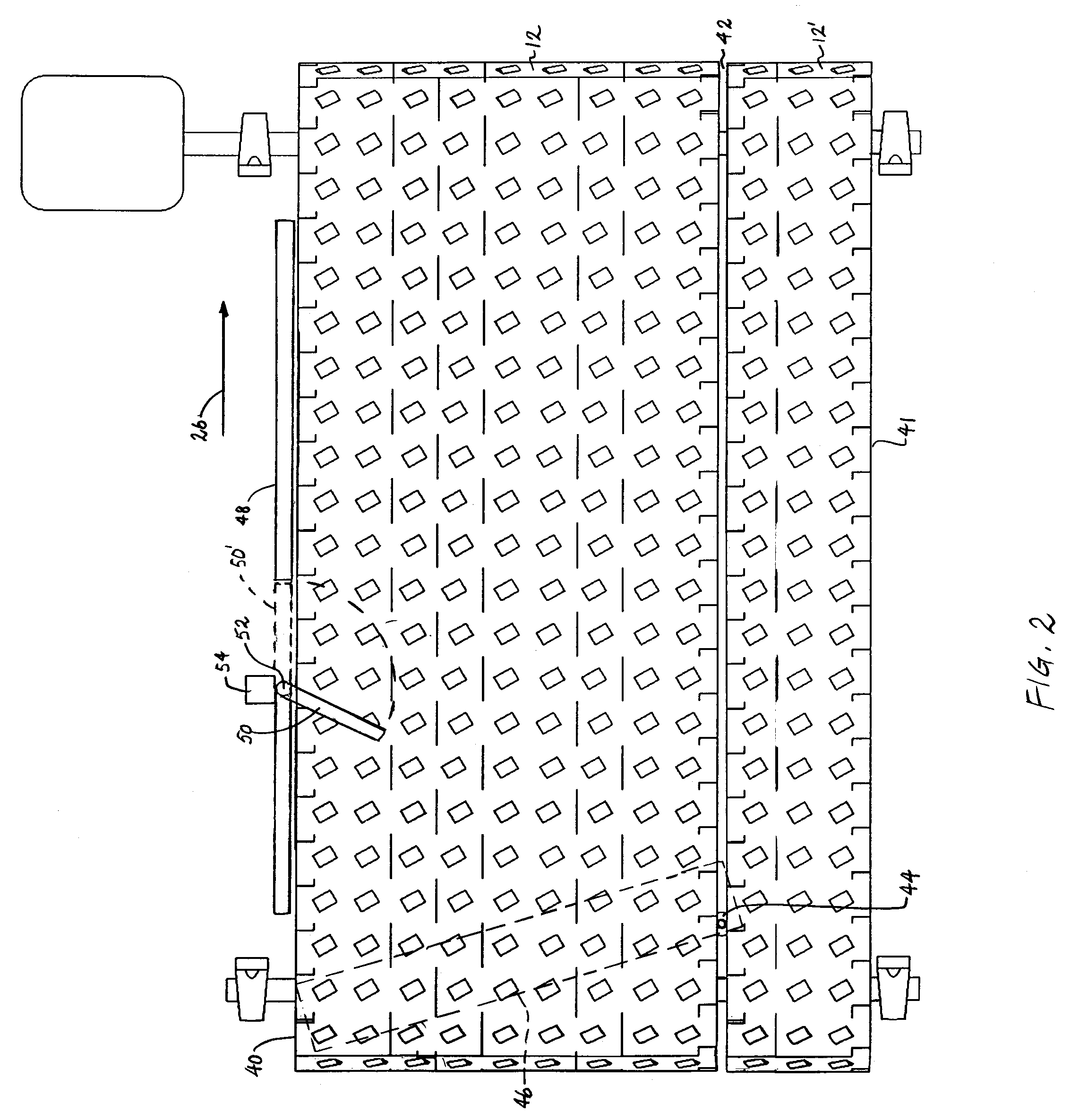

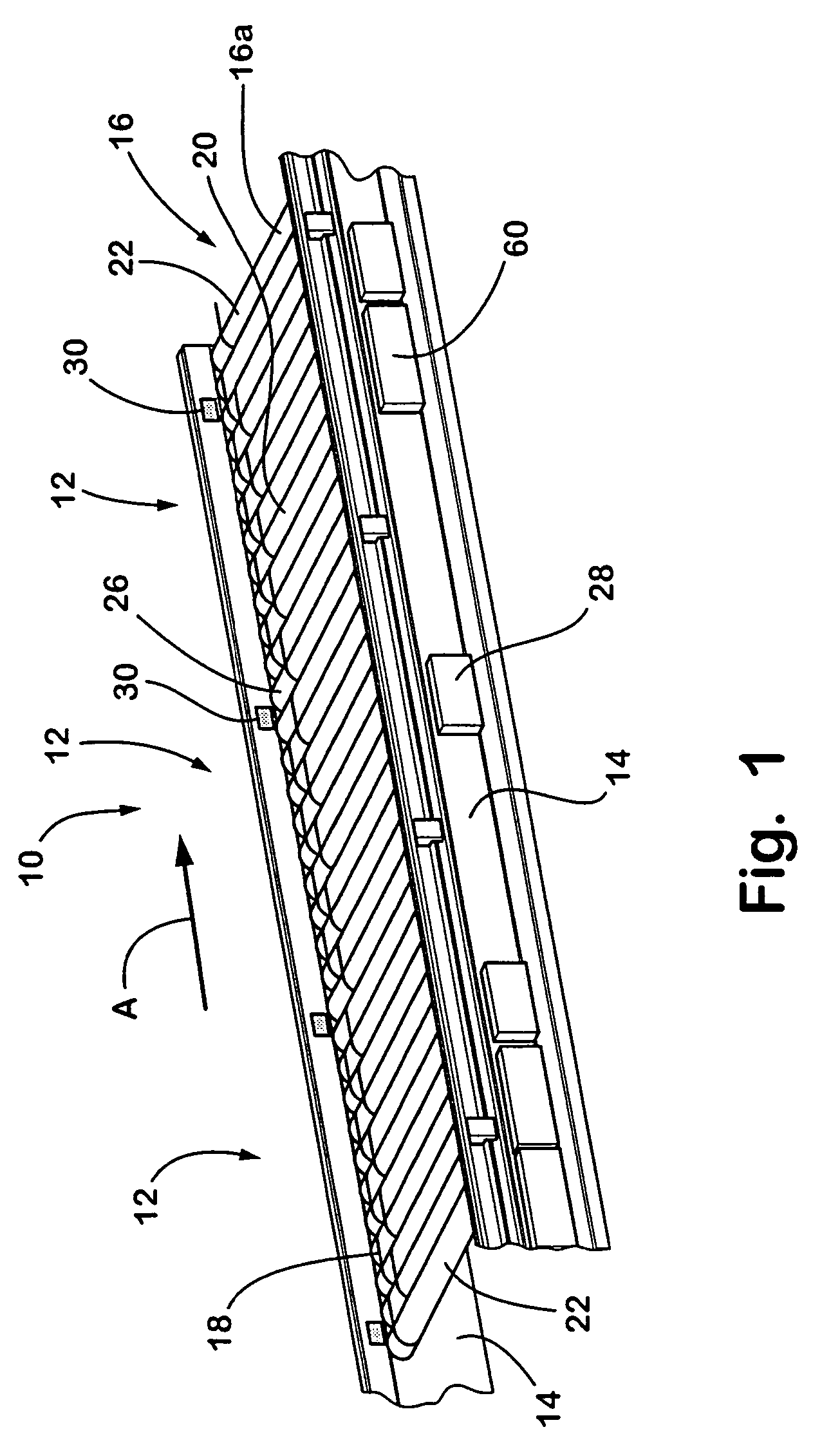

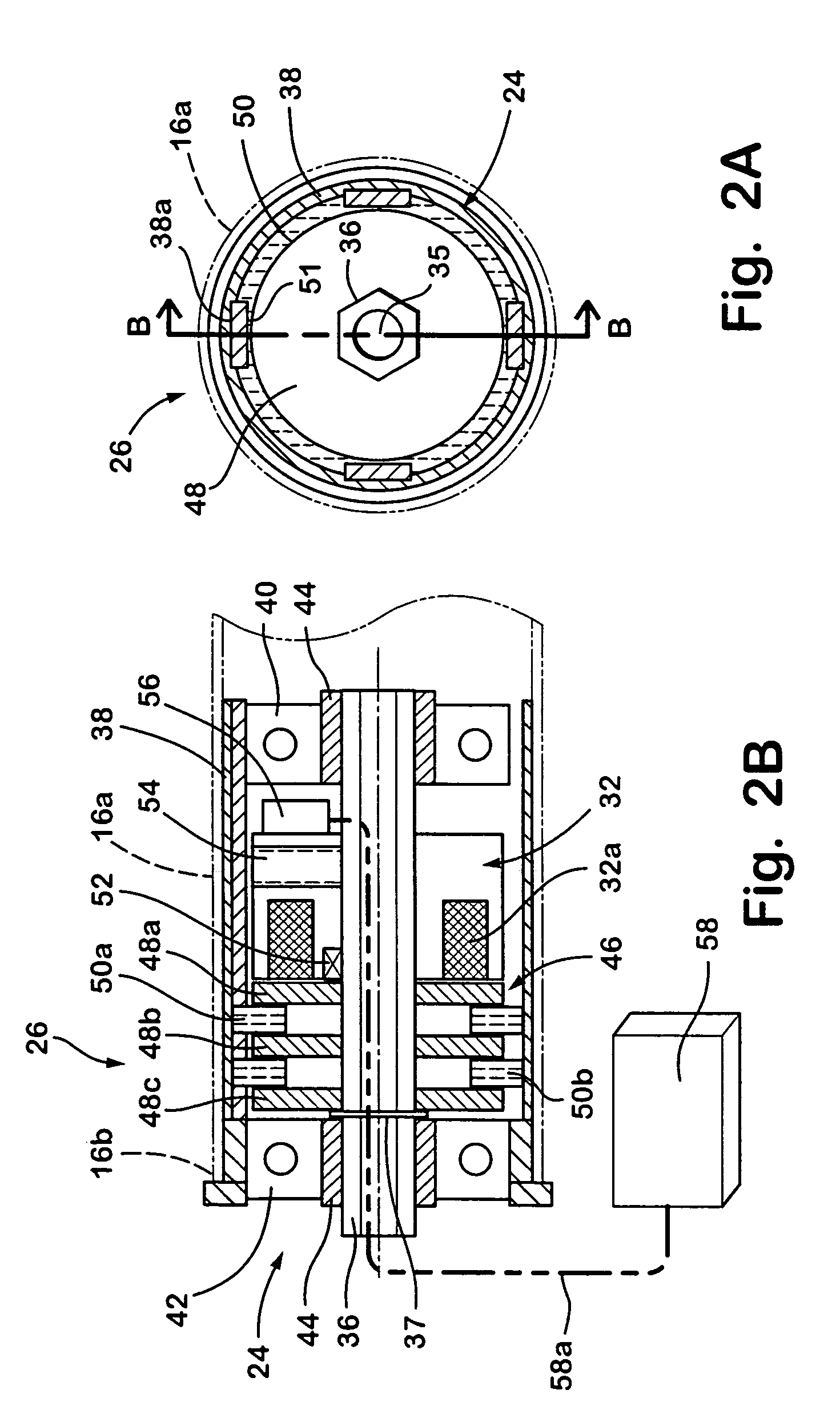

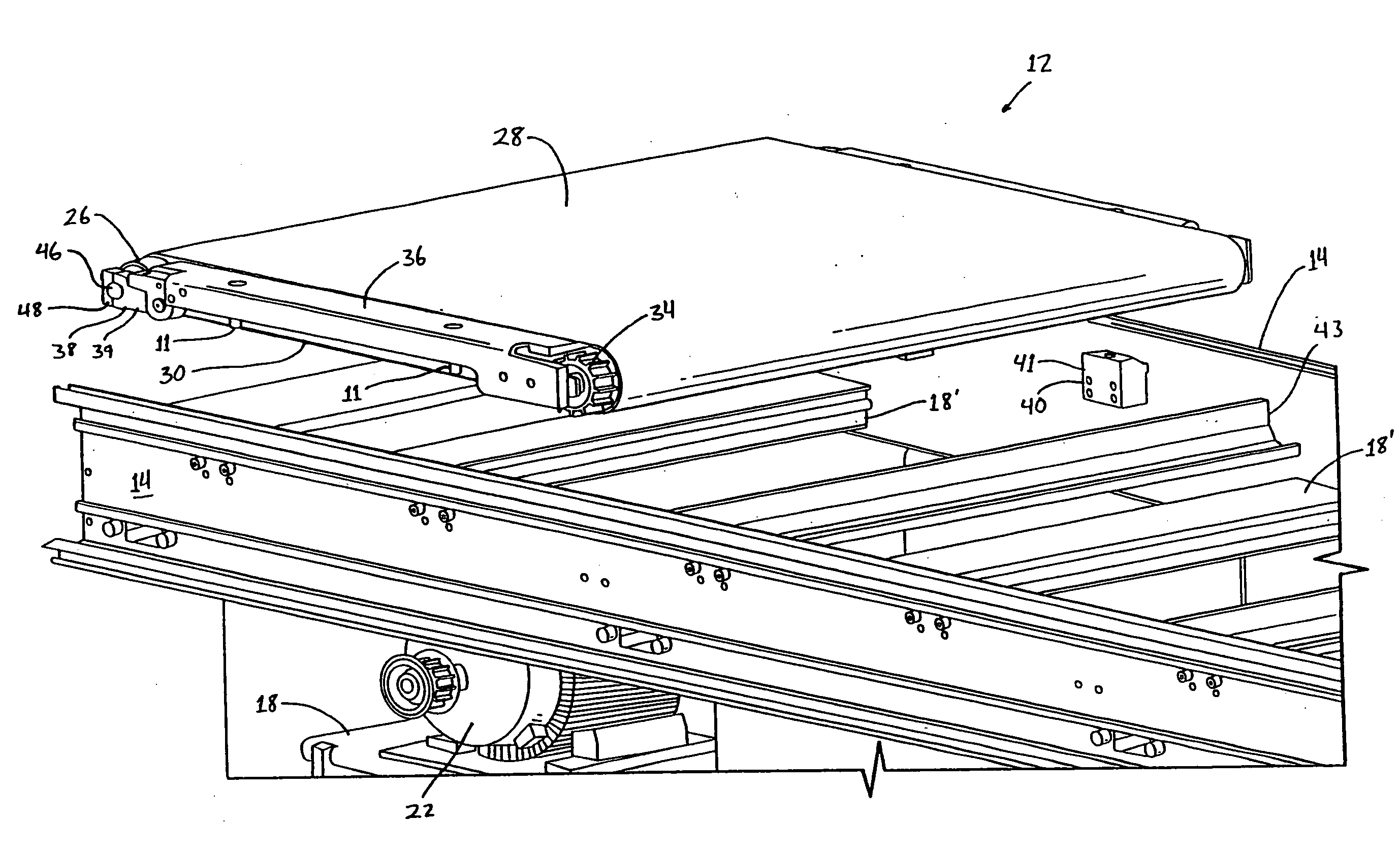

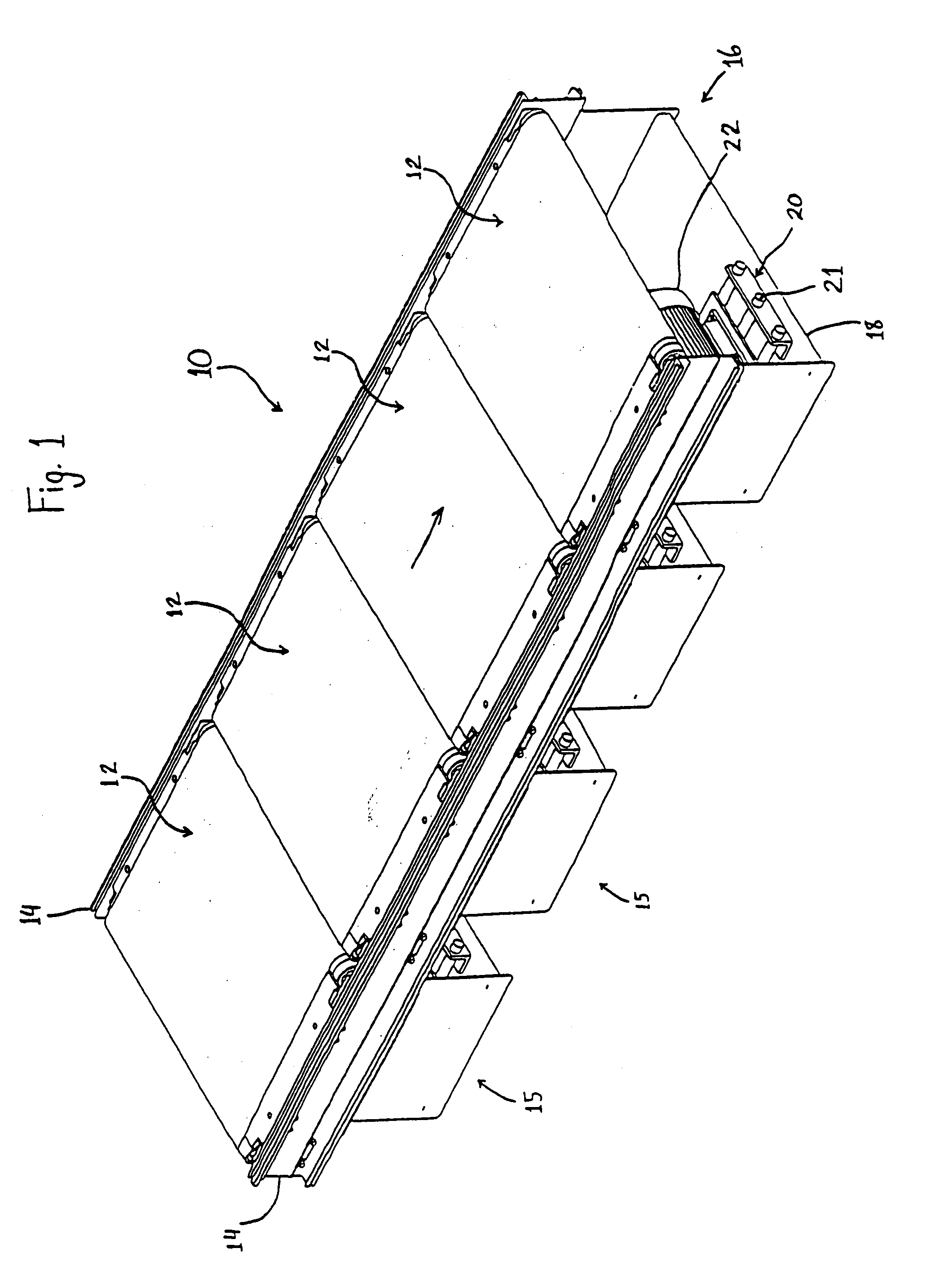

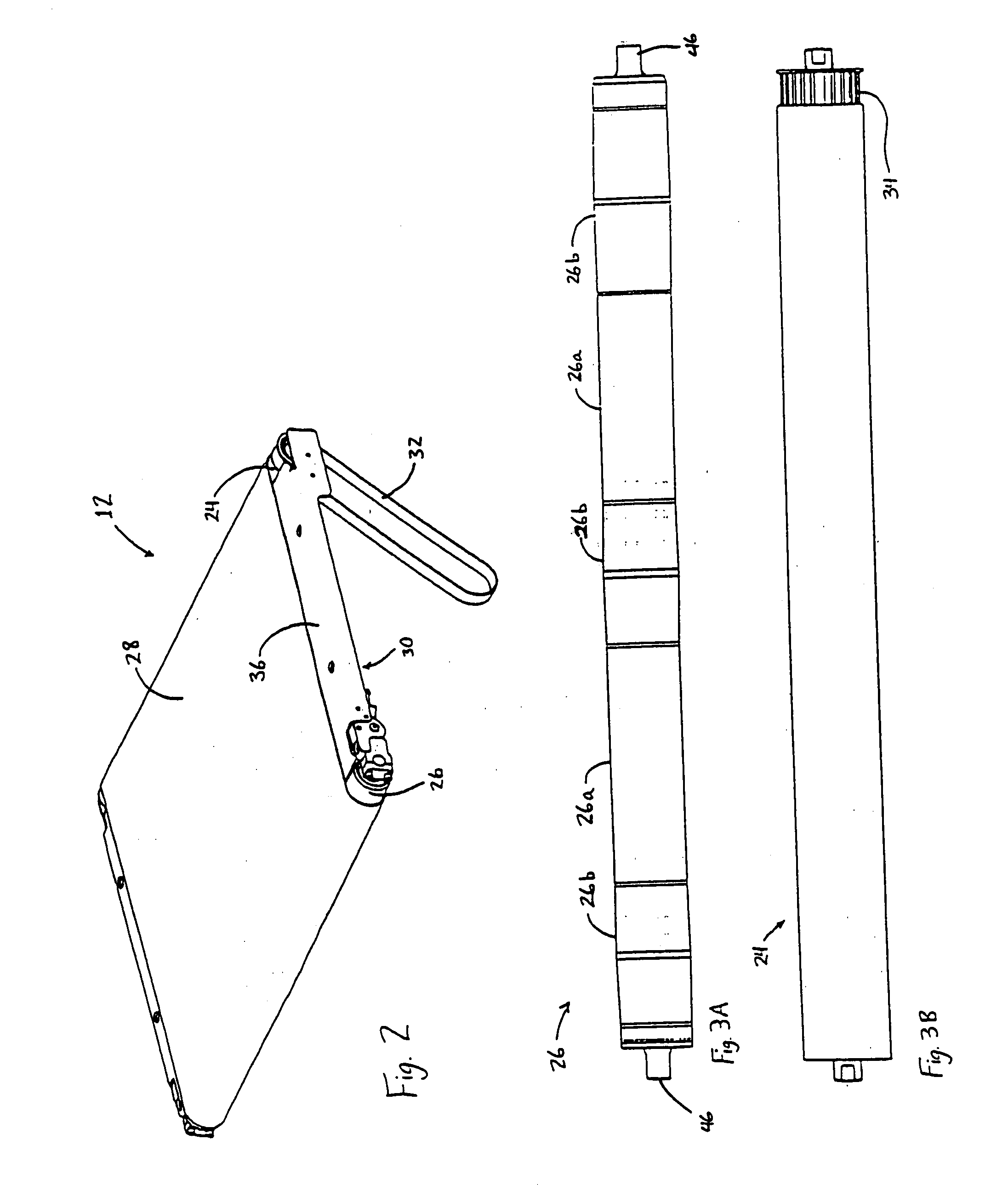

Changing the characteristics of an article-conveying belt surface on a running conveyor

A belt conveyor whose article-conveying characteristics can be changed as the belt is running. The conveyor belt includes a plurality of movable assemblies supporting an article-supporting element and an adjustable element. The adjustable element coacts with an adjustment control element supported in the conveyor frame as the belt is running. The coaction causes the adjustable element to move the article-supporting element to provide a different article-conveying characteristic to articles supported at the conveying surface of the belt in zones defined by the adjustment control elements.

Owner:THE LAITRAM CORP

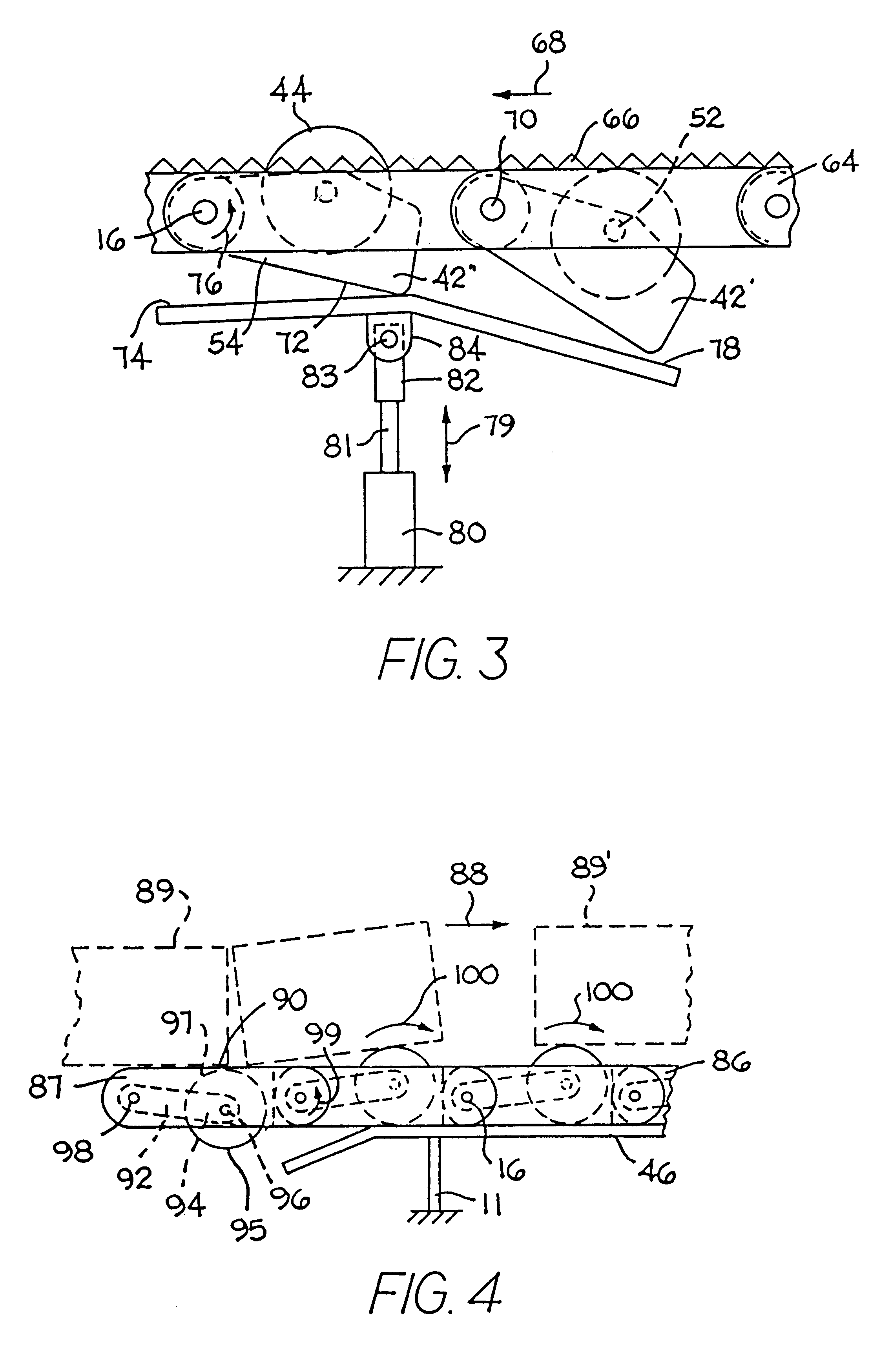

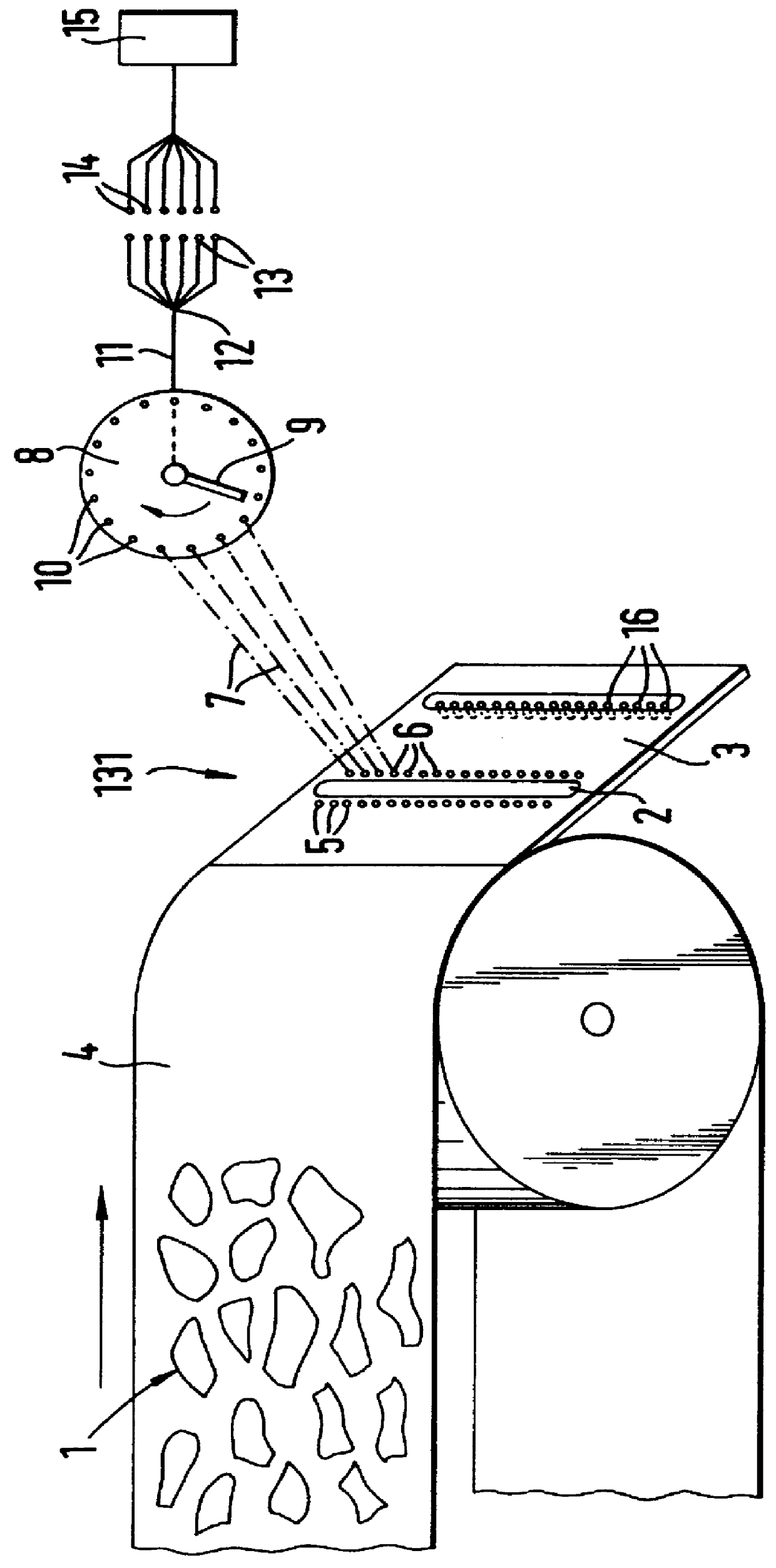

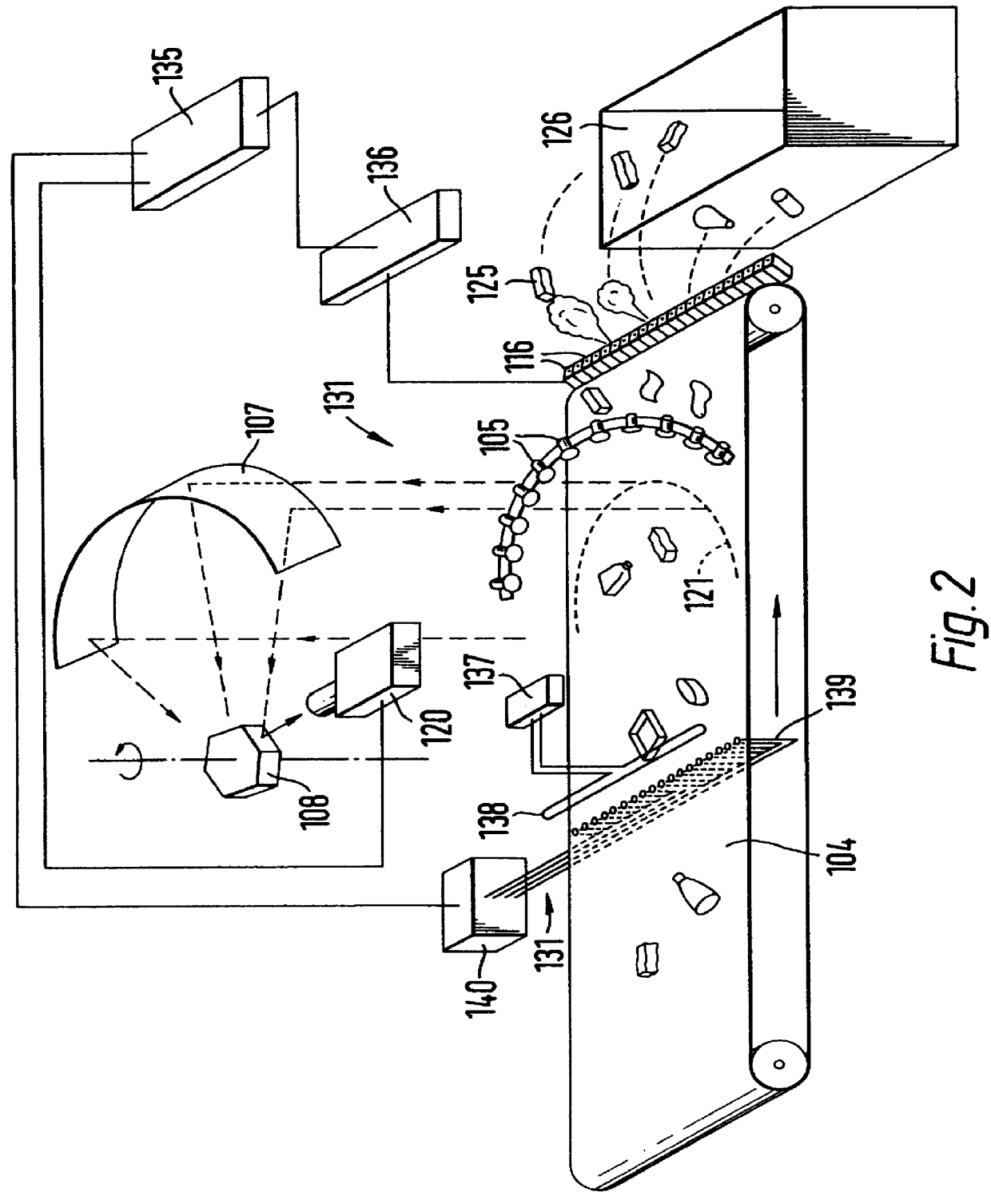

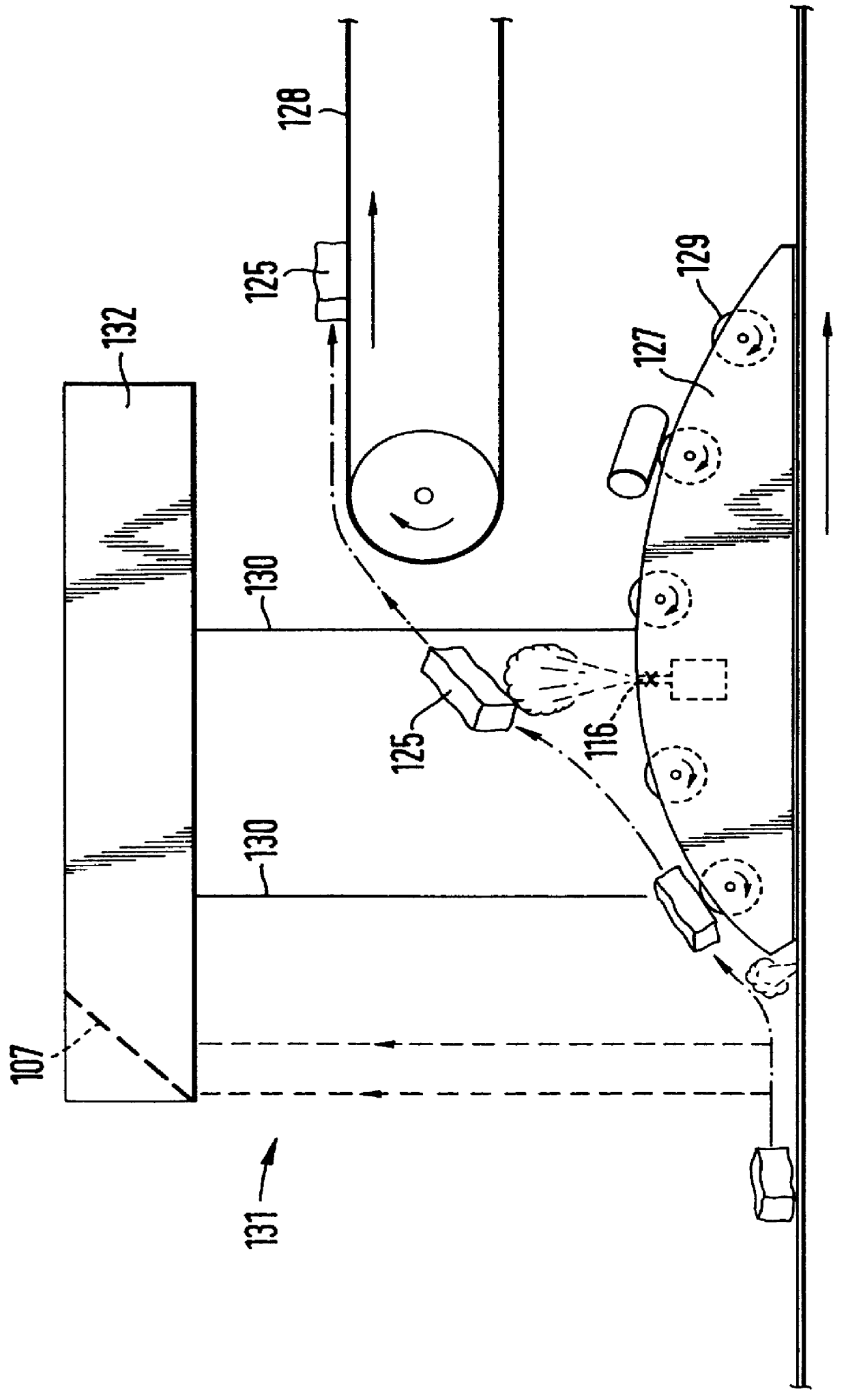

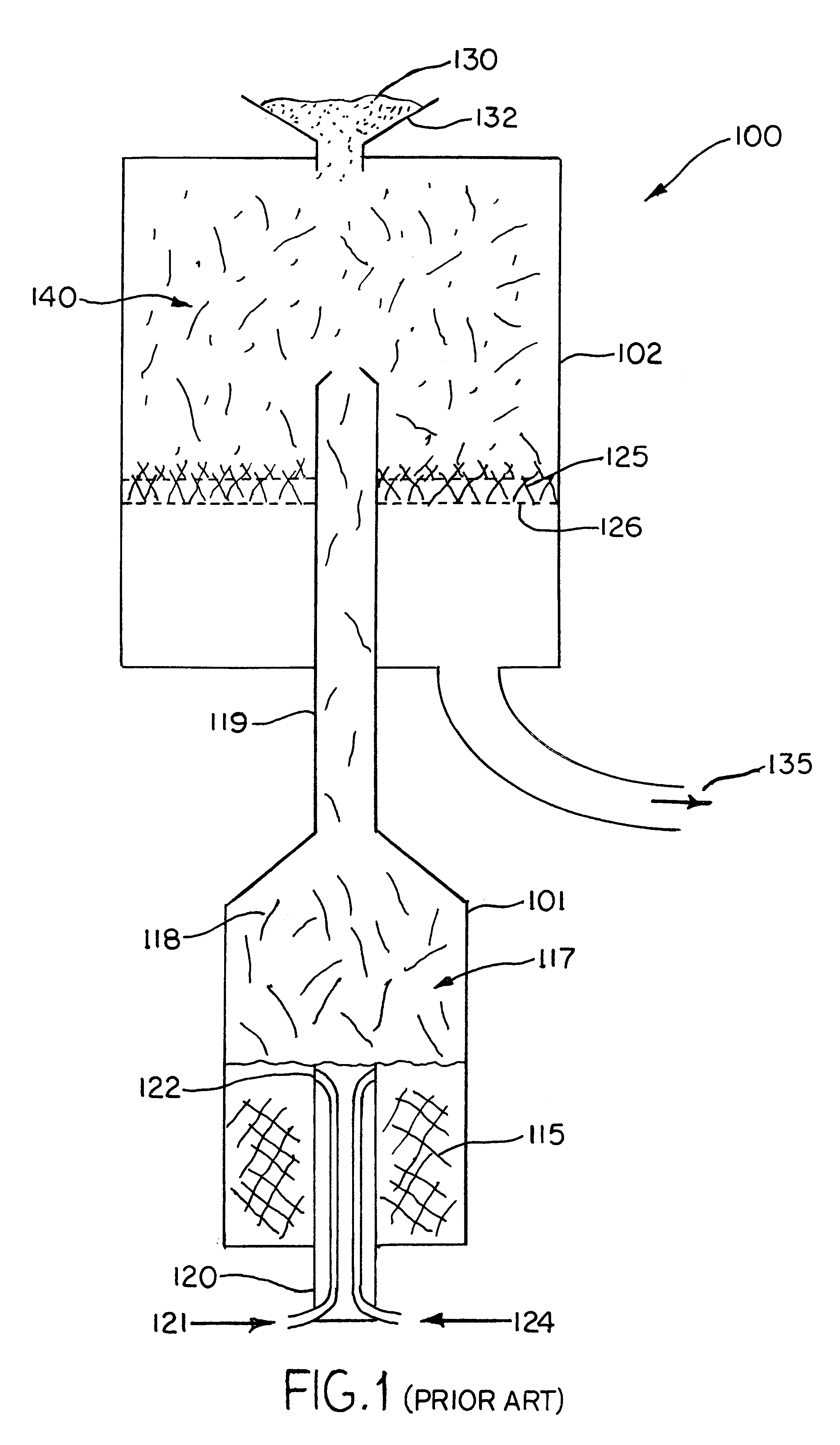

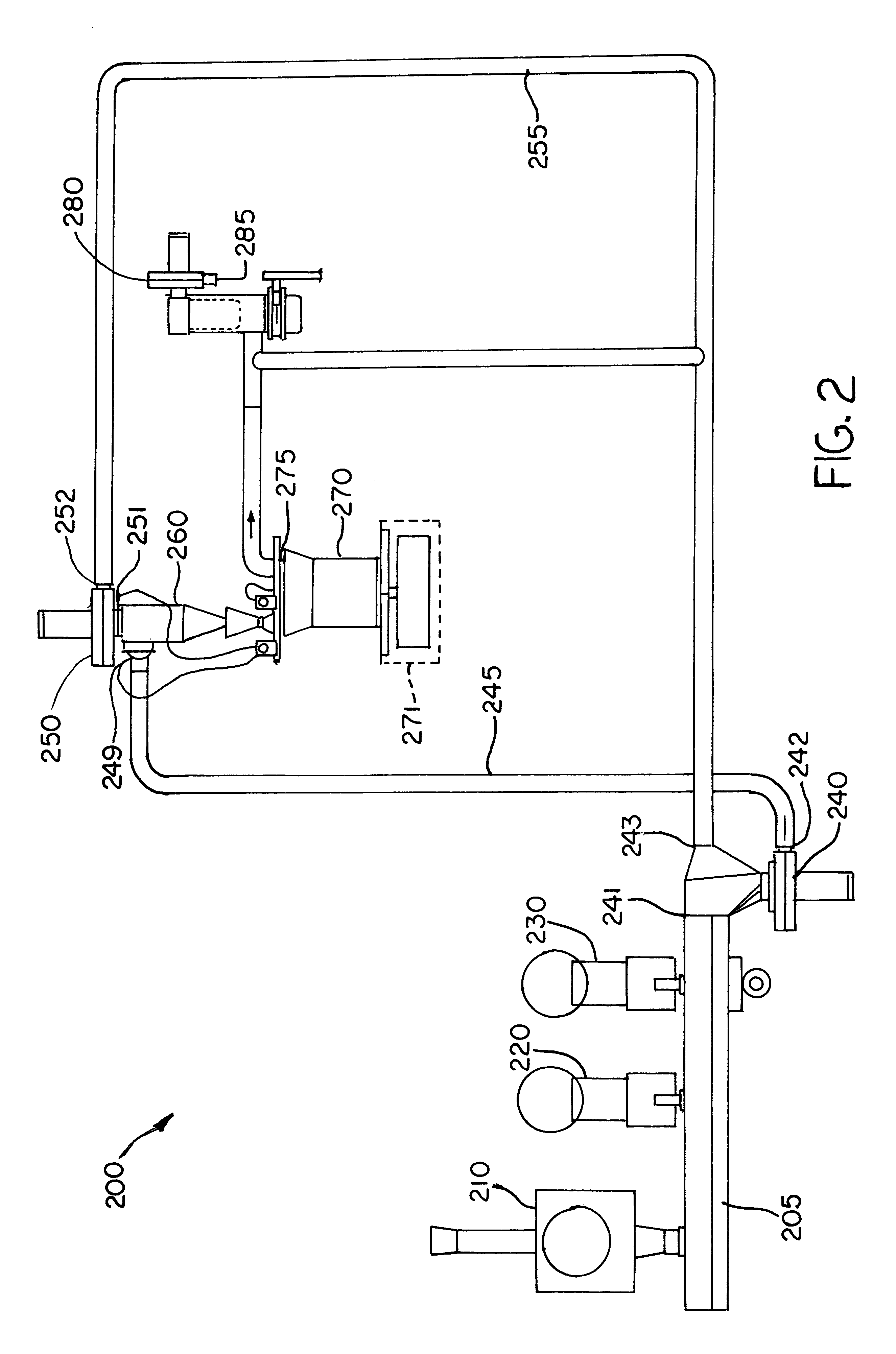

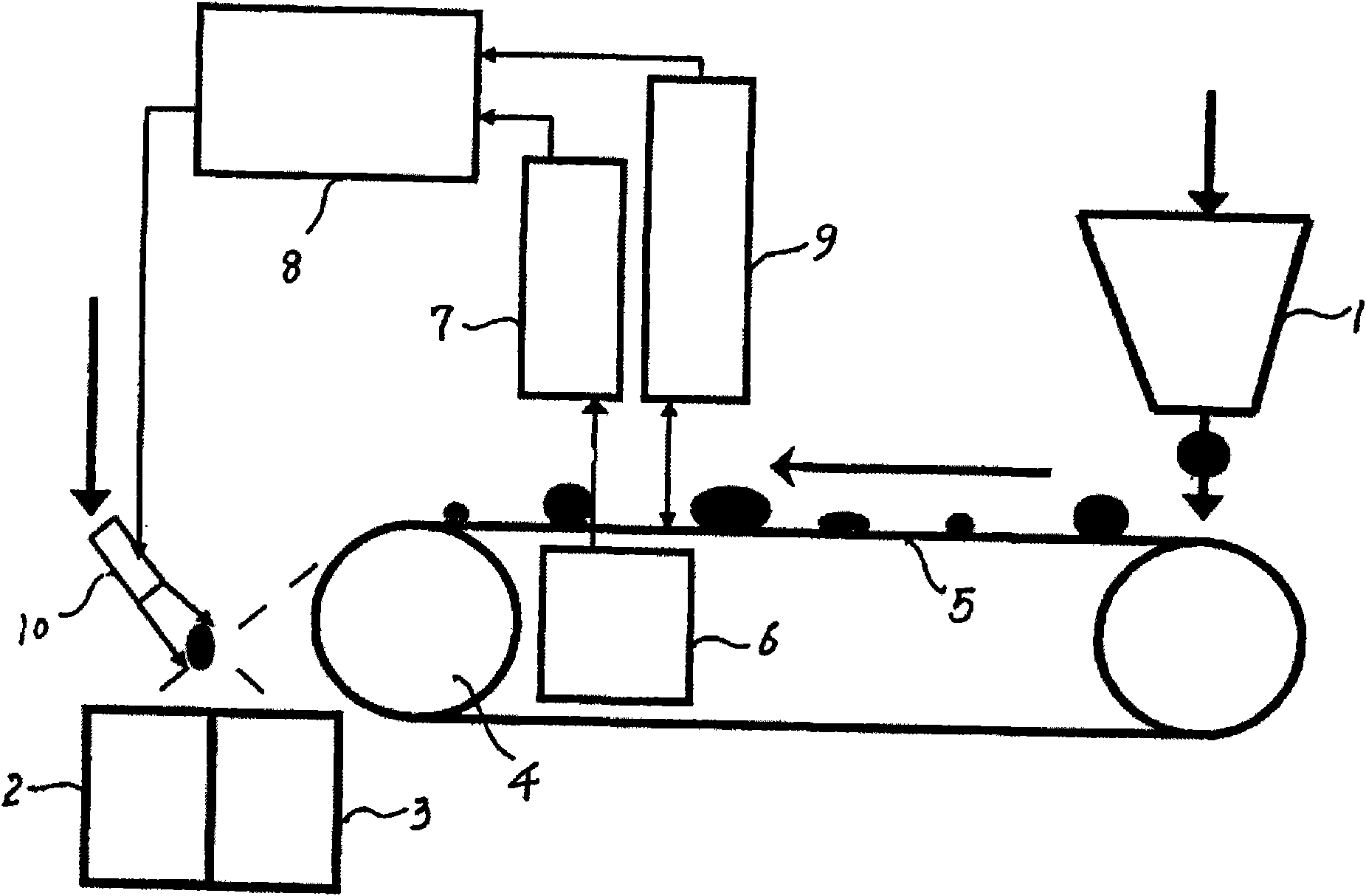

Determination of characteristics of material

InactiveUS6060677ALow costReduce runningSolid waste disposalOptical detectionSolenoid valveLength wave

A system for automatically inspecting matter for varying composition comprises one or more detection stations through which one or more streams of matter are advanced and particular materials therein are detected through their diffusely reflected IR spectra, if any, and / or through their variation of an electromagnetic field by their metallic portions, if any. A row of light sources distributed across the overall width of one or more belt conveyors may cause desired portions of the stream to reflect light diffusely onto a part-toroidal mirror extending over that overall width, whence the light is reflected, by a rotating, polygonal mirror through optical filters dedicated to differing IR wavelengths, onto detectors the data output of which is utilized in controlling solenoid valves operating air jet nozzles which separate-out the desired portions. Alternatively or additionally, an oscillator and an antenna which extends over that overall width generate an electromagnetic field through the belt and sensing coils sense variations therein produced by metallic portions of the stream passing through the detection station and the detection data produced by the sensing coils is used to control the solenoid valves operating the nozzles to separate-out the metallic portions.

Owner:TITECH VISIONSORT +1

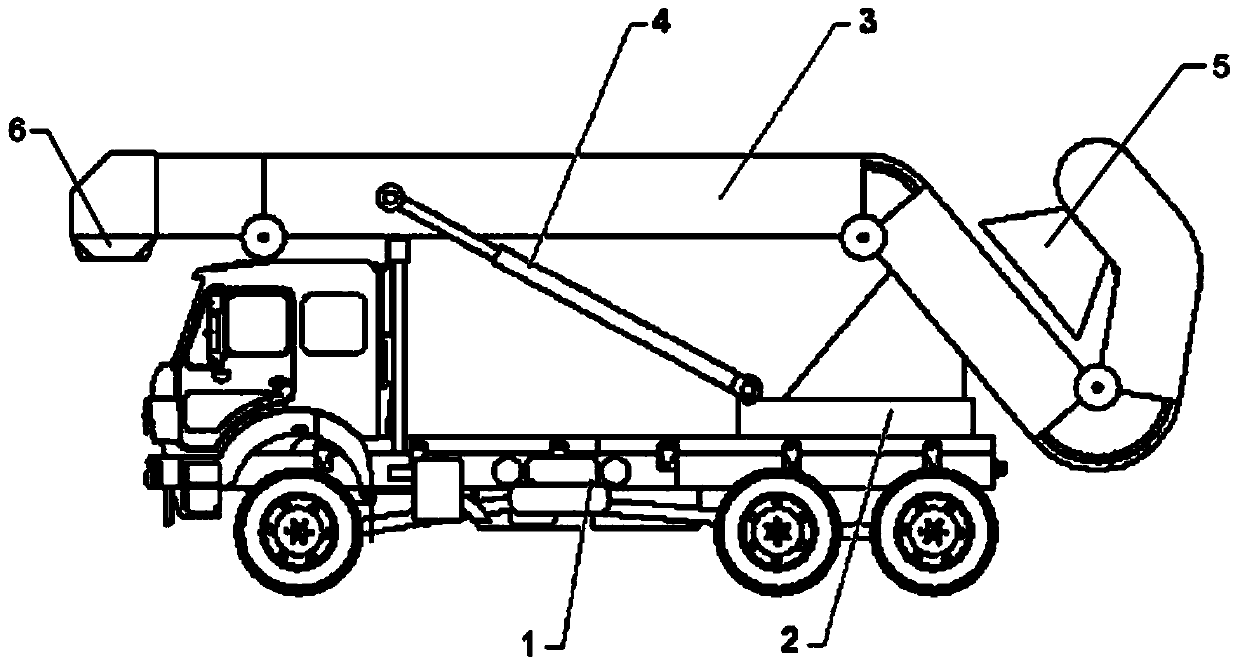

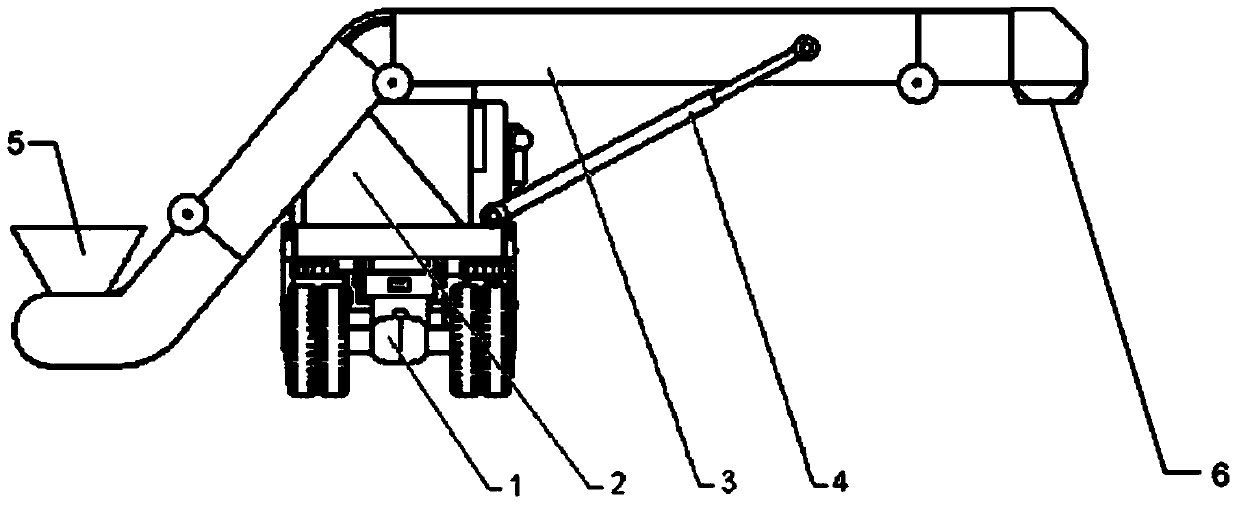

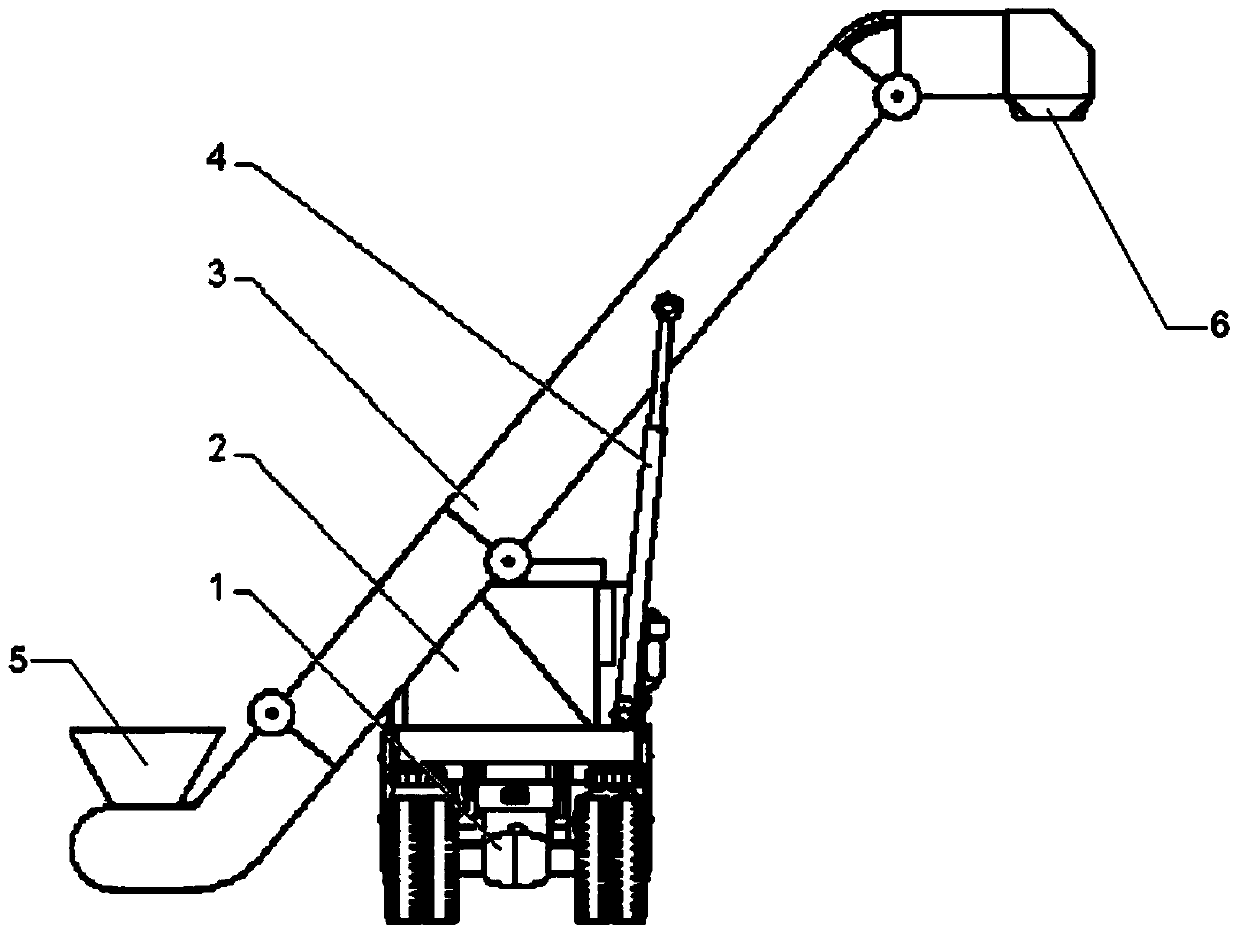

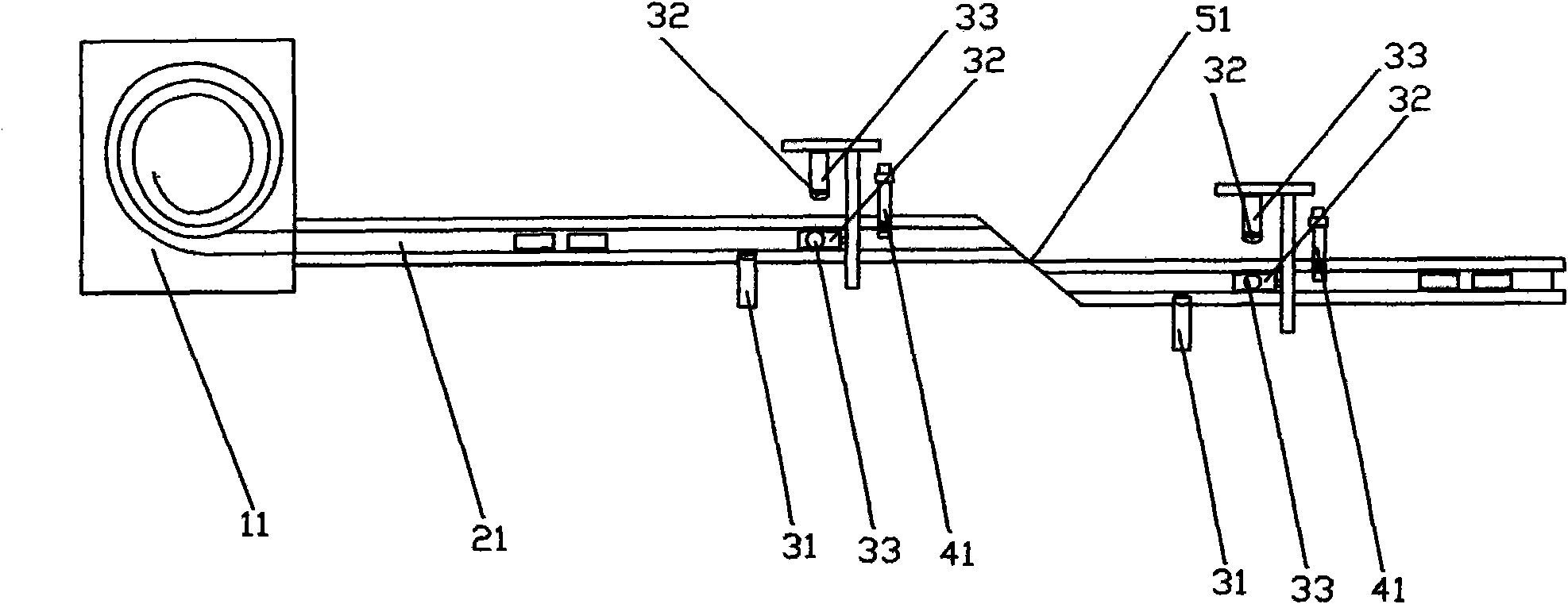

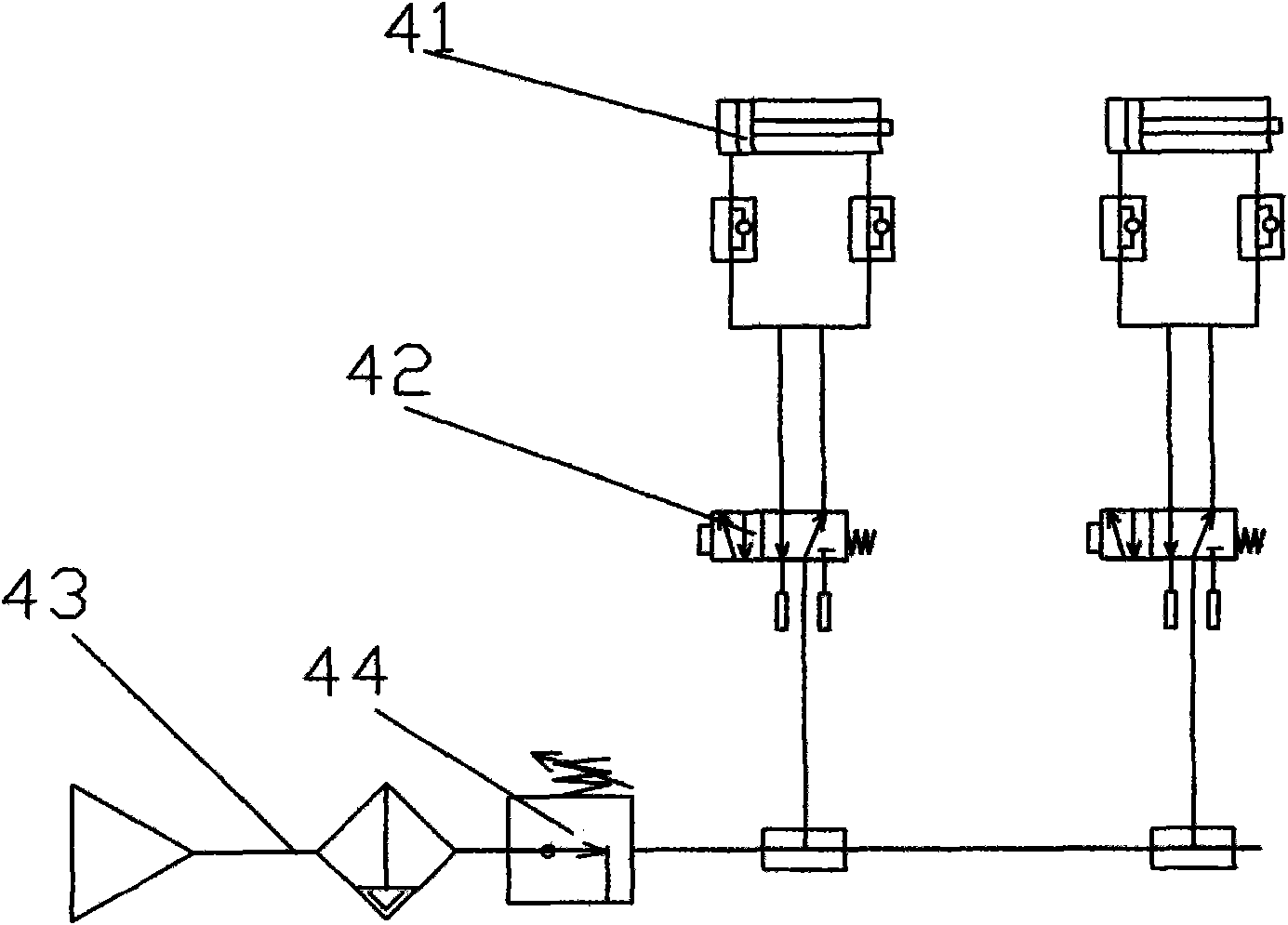

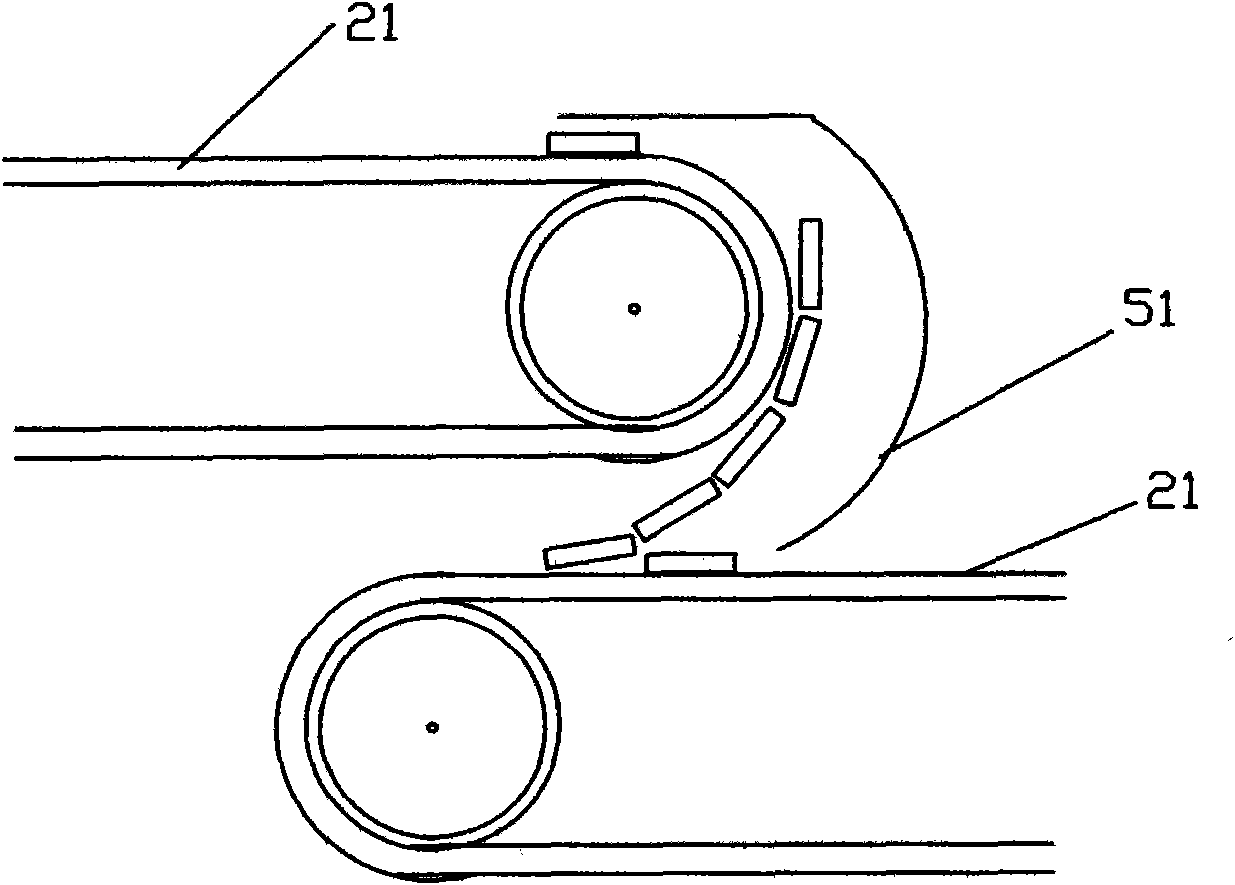

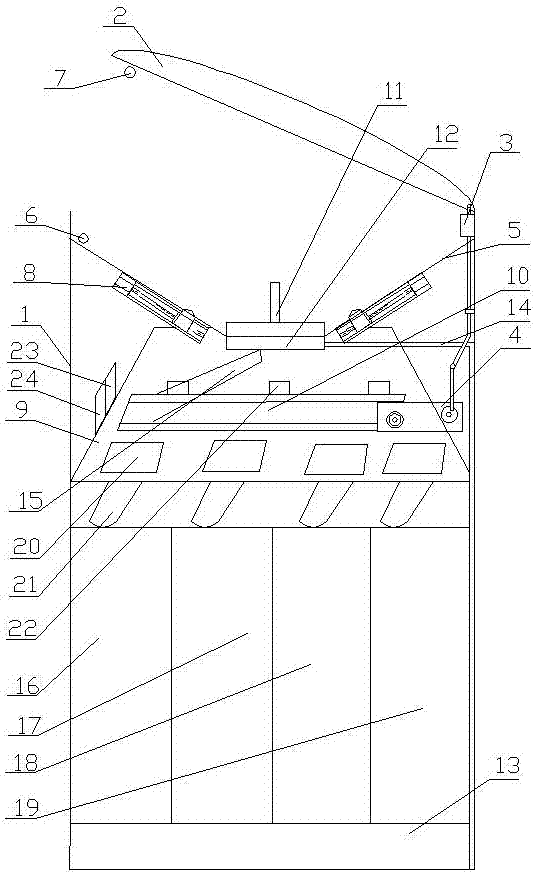

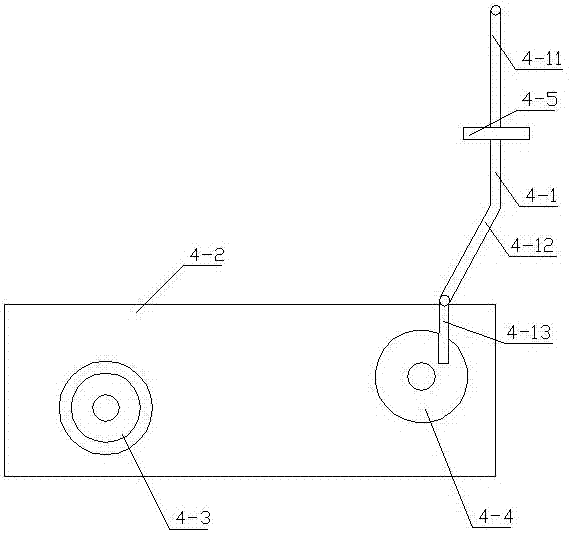

Turnable multi-directional conveyer

InactiveCN104176522AImprove passabilityGaza with continuityLoading/unloadingIndustrial engineeringBelt conveyor

The invention relates to a turnable multi-directional conveyer which comprises a support seat, a belt conveyor and a lifting device, wherein the belt conveyor comprises a supporting section and a lifting section; one end of the supporting section is connected with one end of the lifting section; the supporting section is fixedly arranged on the support seat; the lifting device is used for controlling the ascending and descending of the lifting section; one end of the lifting device is fixedly connected onto the support seat, and the other end of the lifting device is fixedly connected onto the lifting section. According to the invention, the conveying is carried out through the belt conveyor, great convenience and quickness are achieved, the passing property is strong, and the characteristic of continuous sand adding is achieved, and the working efficiency is improved; the ascending and descending of the belt conveyor are realized through the lifting device, so that the turnable multi-directional conveyer can adapt to sand storage containers with different heights, and the ascending and descending amplitude is large. The turnable multi-directional conveyer further has the characteristics of simplicity in operation, low manual labor cost and high safety.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

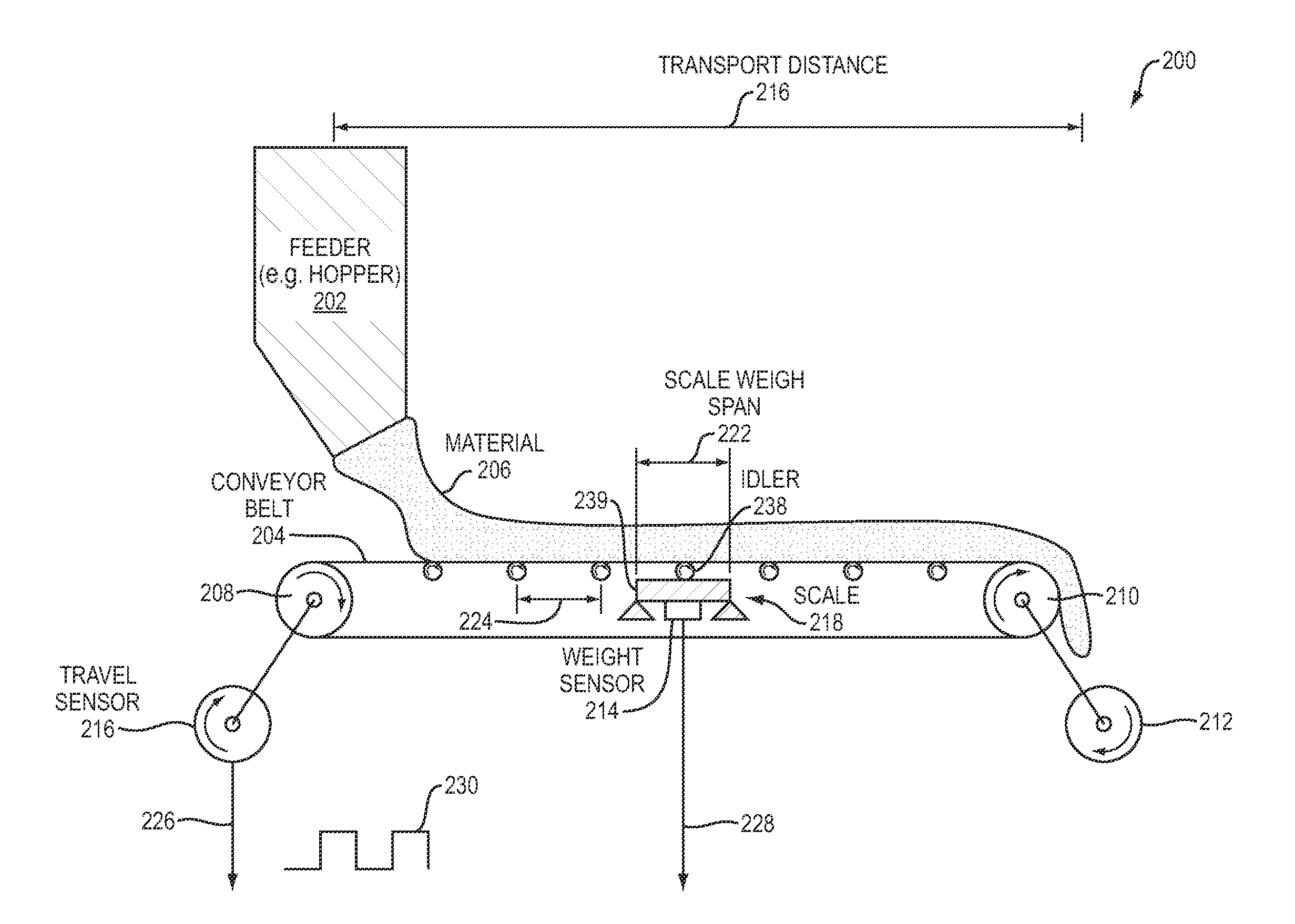

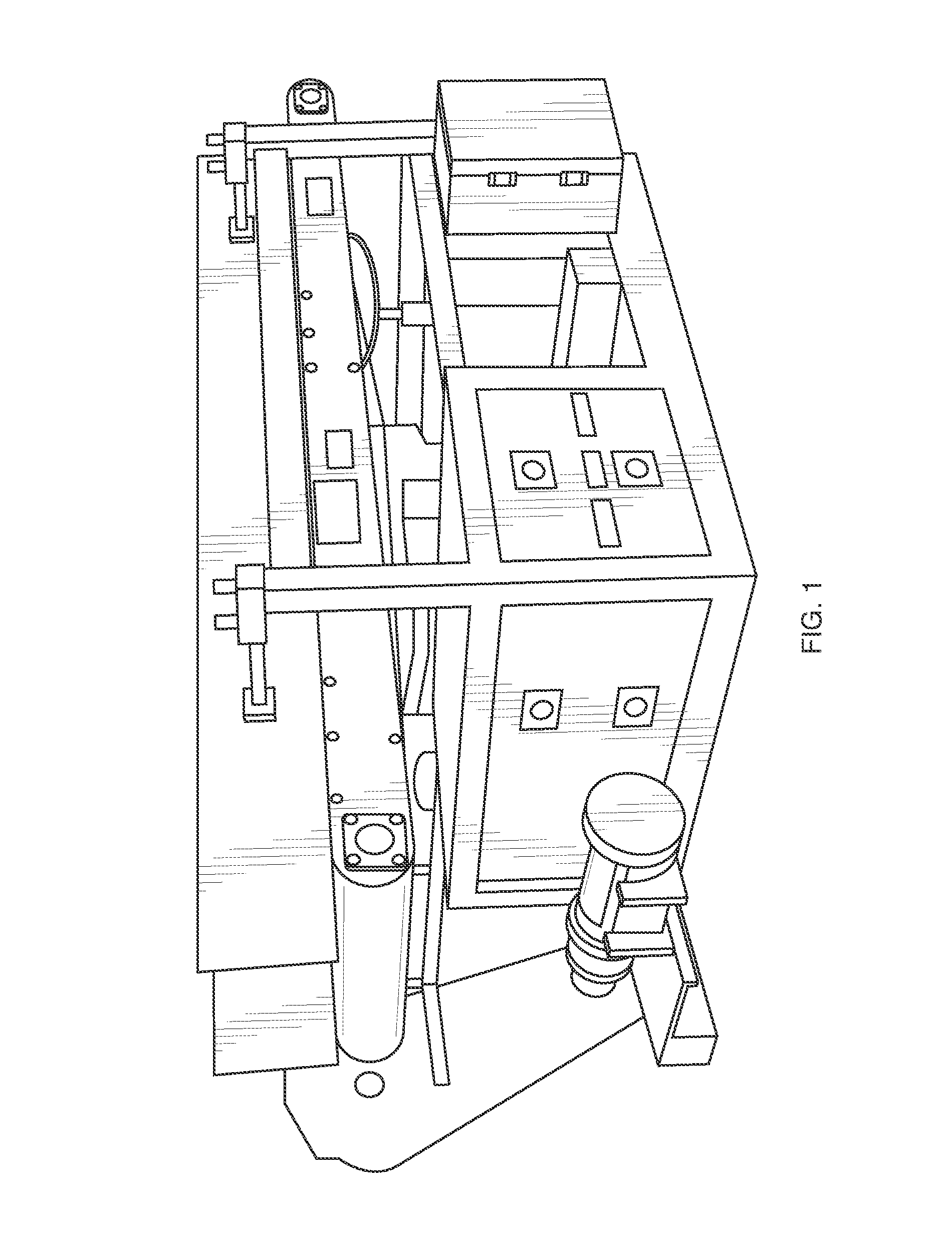

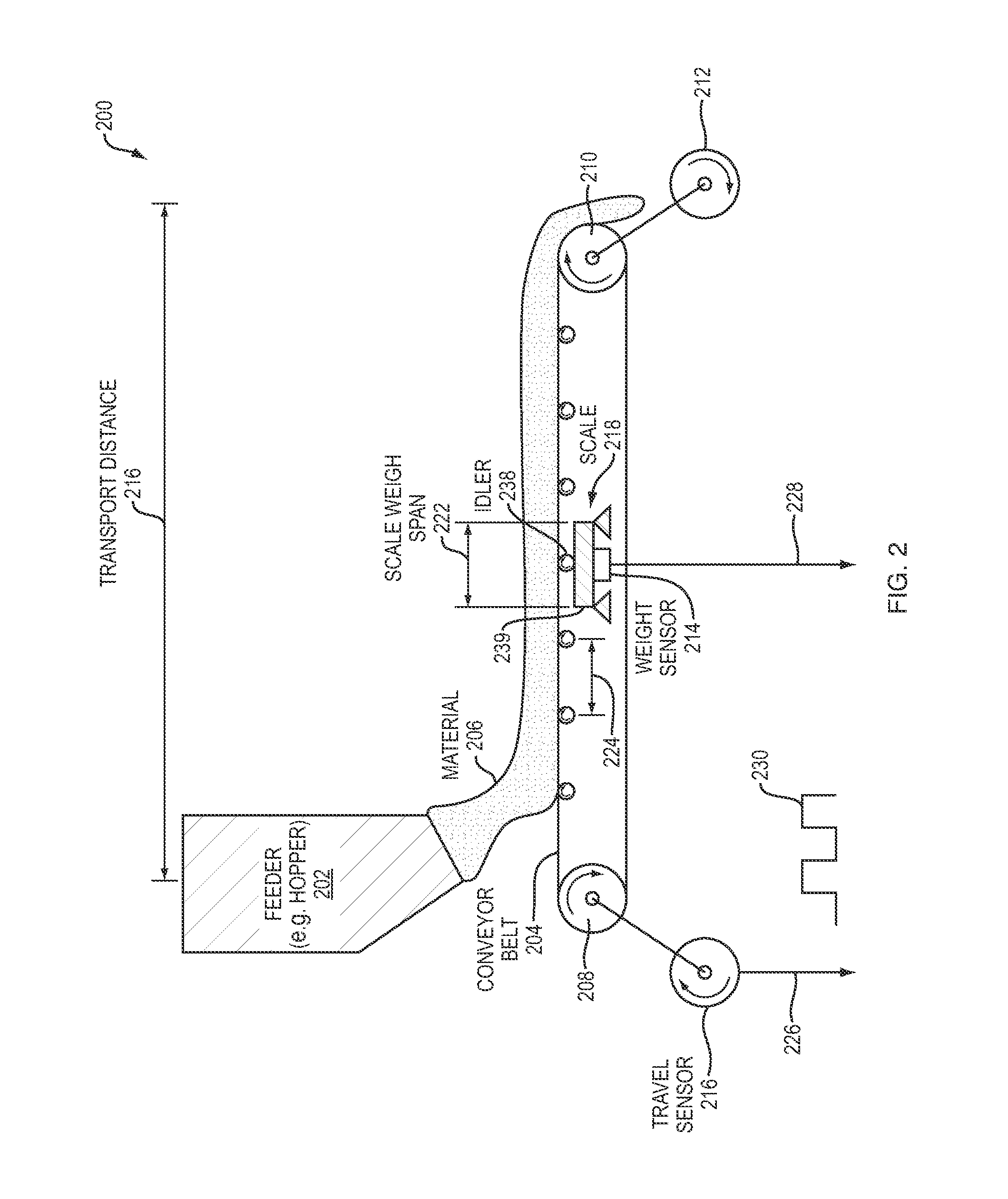

System and methods for belt conveyor weighing

ActiveUS20140062709A1Mass flow measurement devicesWeighing apparatus for materials with special property/formObservational errorSnack food

Imperfections in conveyor belting and its supporting elements can adversely affect weighing accuracy of belt scales, particularly when weighing and / or metering low density materials, such as those encountered in the snack food industry. A system and methods for a belt conveyor according to an embodiment of the present invention provide simultaneous benefits of both short and long weigh spans. According to an embodiment of the present invention, a virtual weigh span may be programmably set to adjust for variations in the belt conveyor weighing system. Advantages include, higher degrees of accuracy and calibration to account for changes in the belt or belting system over time using non-mechanical adjustments. In addition, weight measurement error producing effects, some that may not be particularly known, may be reduced.

Owner:HYER IND

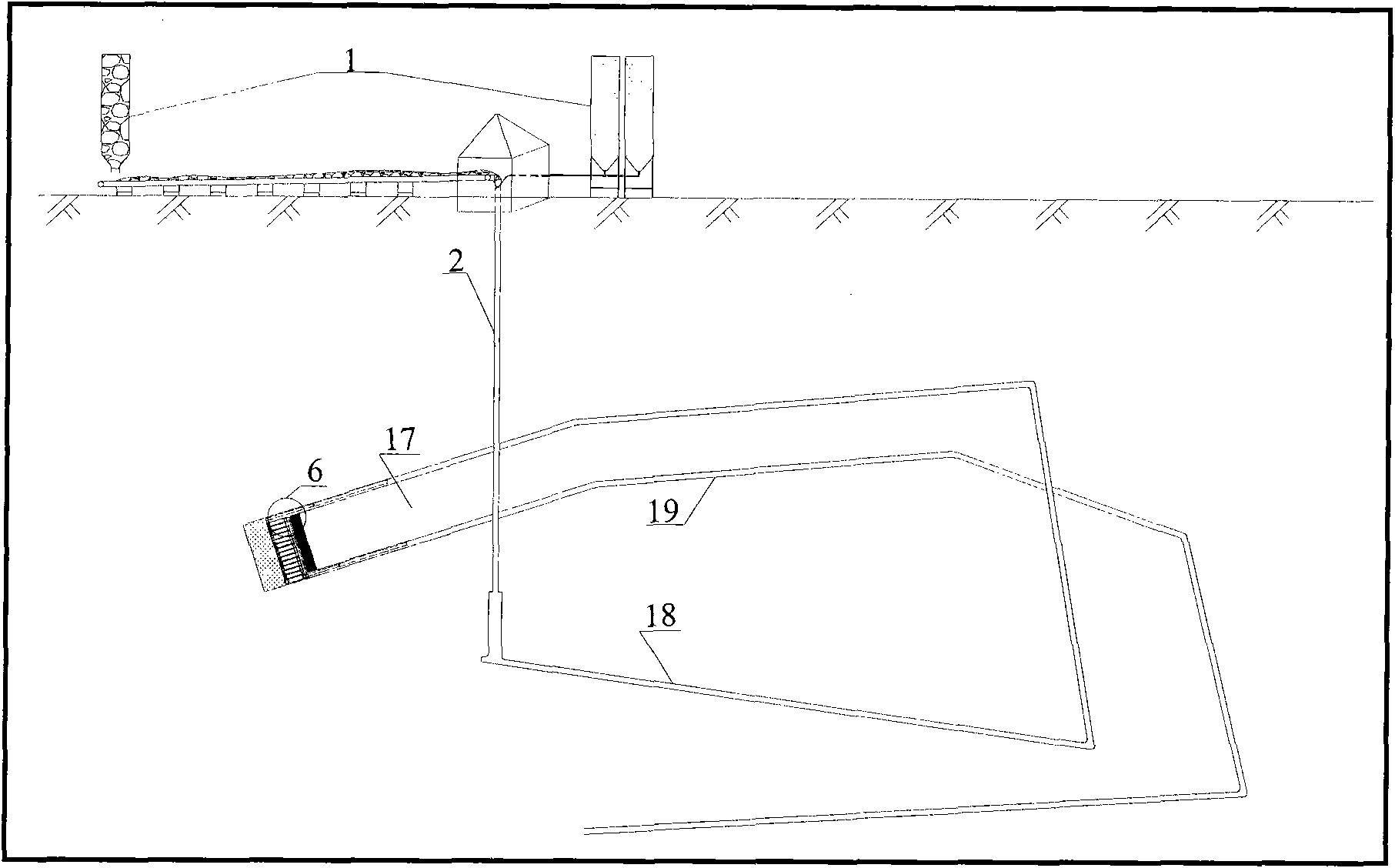

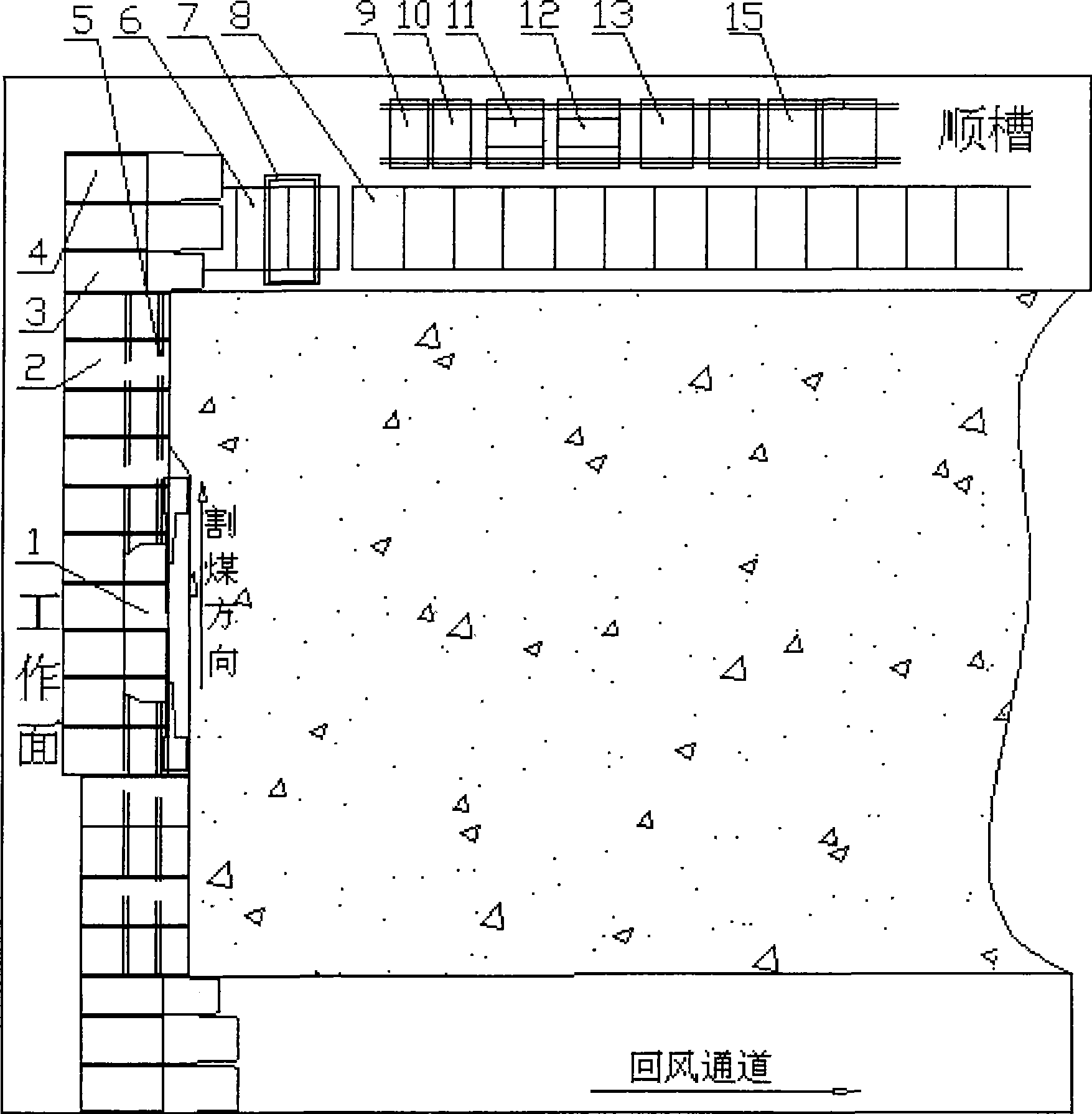

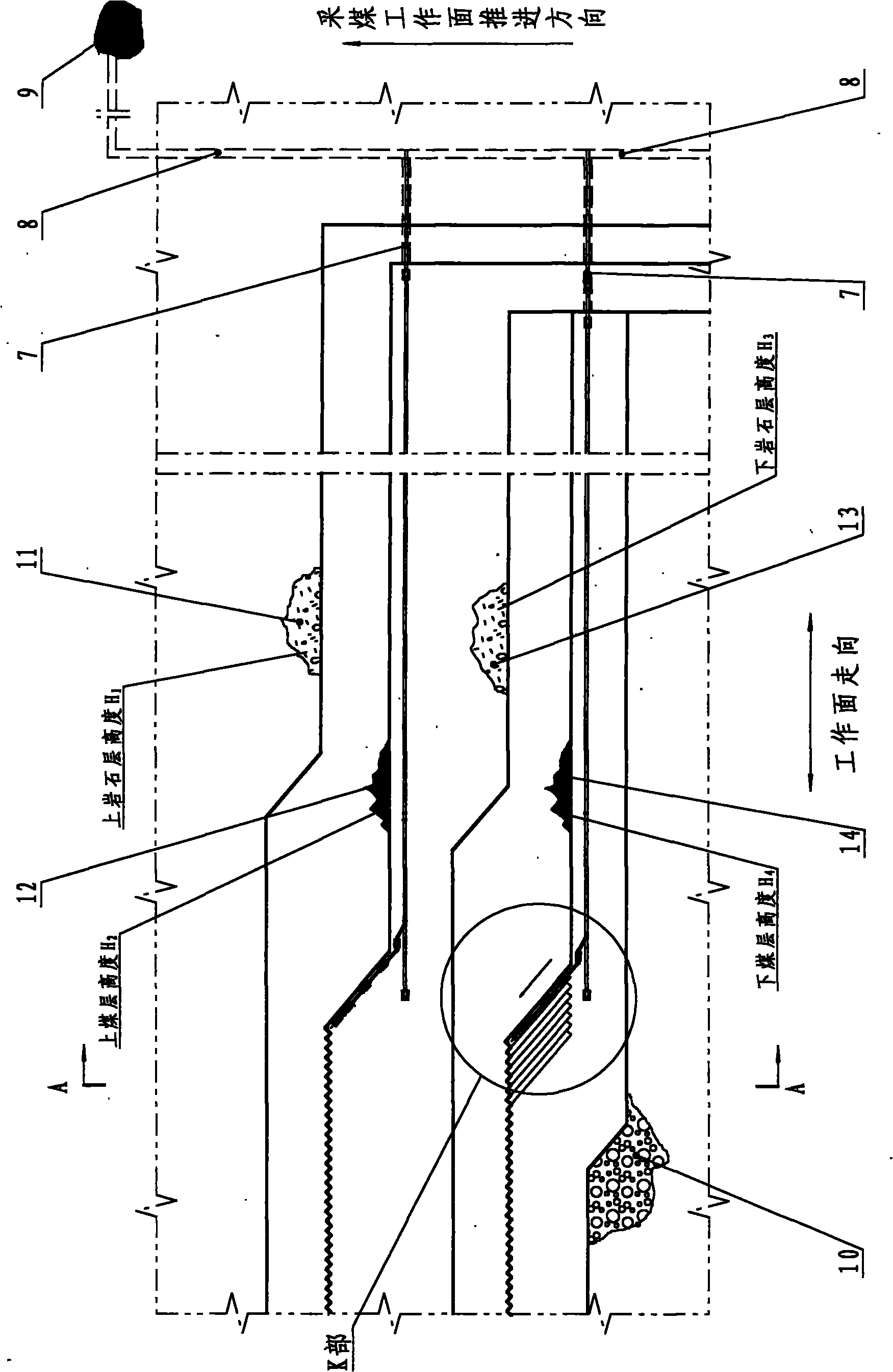

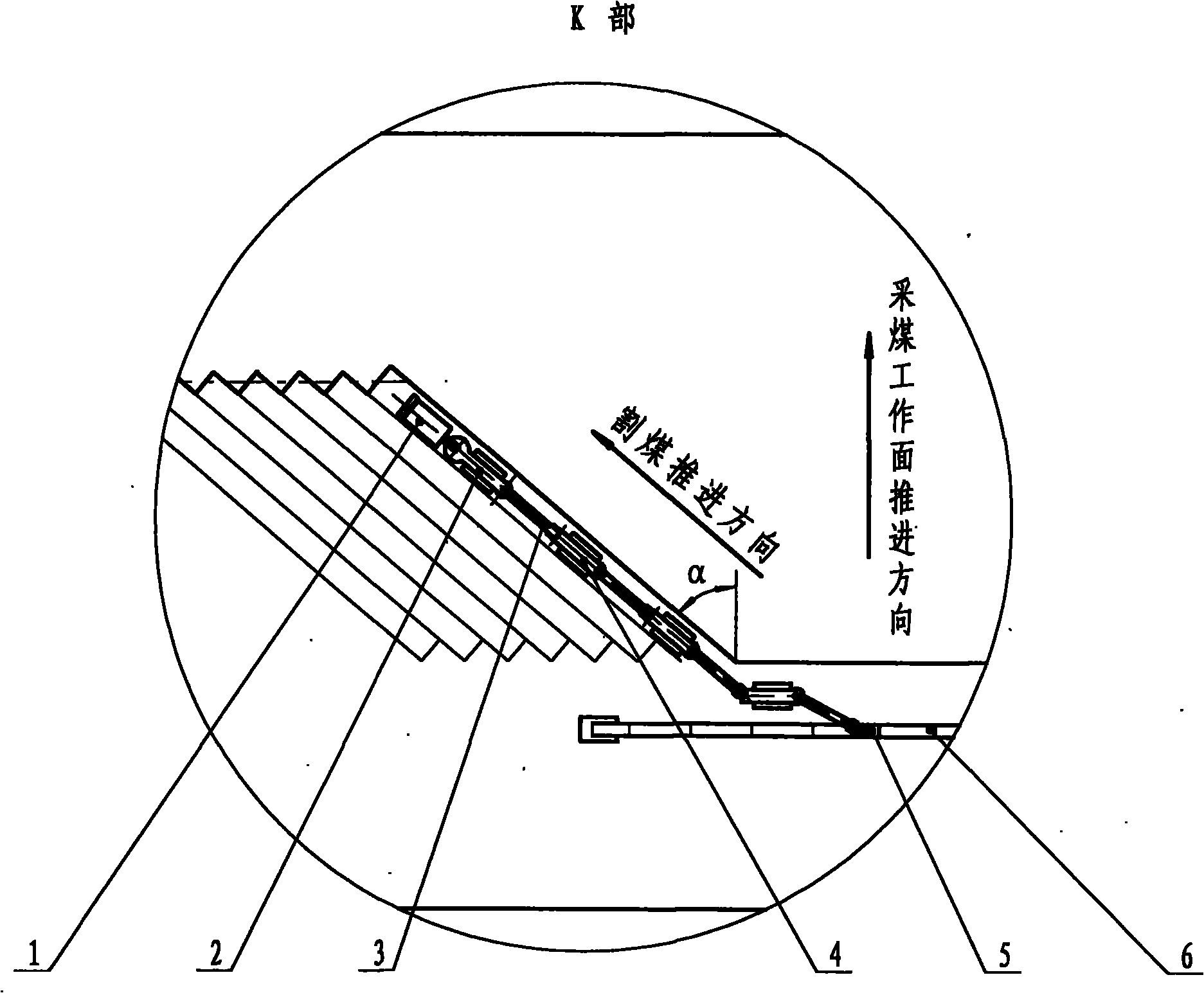

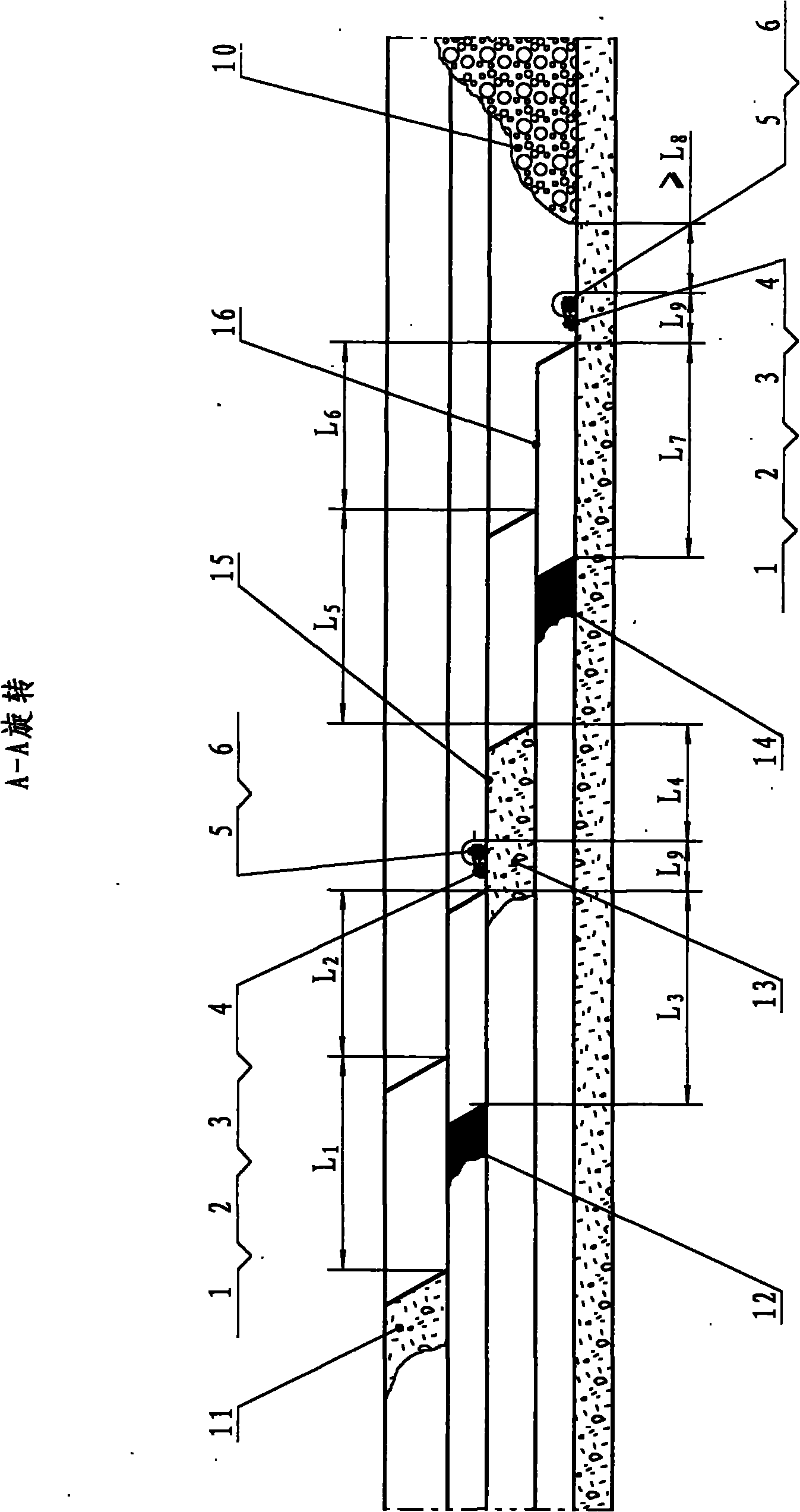

Coal mining solid filling method

InactiveCN101586460AHelps control sinkingEasy to useUnderground miningSurface miningSolid massFilling materials

A coal mining solid filling method comprises following steps: using the stacked solids on the ground as the filling materials for the working surface goaf, directly putting the solid filling materials from the ground to a belt conveyor in the underworkings by a perpendicular feeding well, transporting to the end of a coal face through the underground belt conveyor, reloading the solid filling materials to a solid filling mining conveyor hung under a back tail beam of a self-impacting type filling hydraulic support by a self-moving type filling material reloading machine. In the process of mining work, the coal is mined and the filling materials are filled on the bottom; and the solid filling materials are compacted by means of a compactor of the self-impacting type filling hydraulic support. The method solves the problem of coal compaction under the building and low coal recovery.

Owner:CHINA UNIV OF MINING & TECH +1

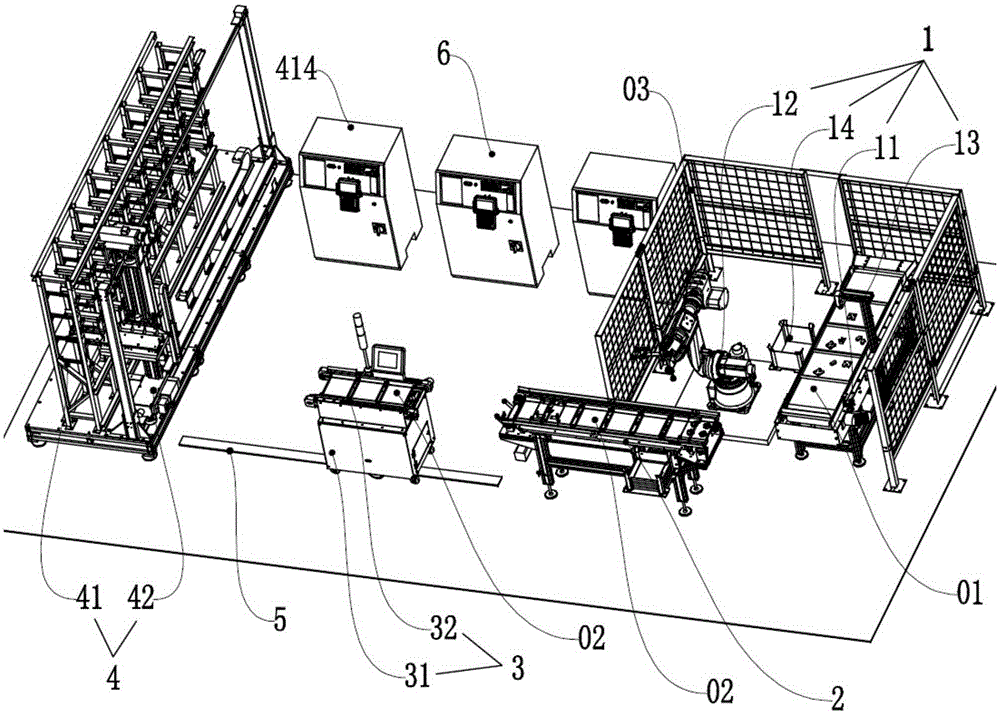

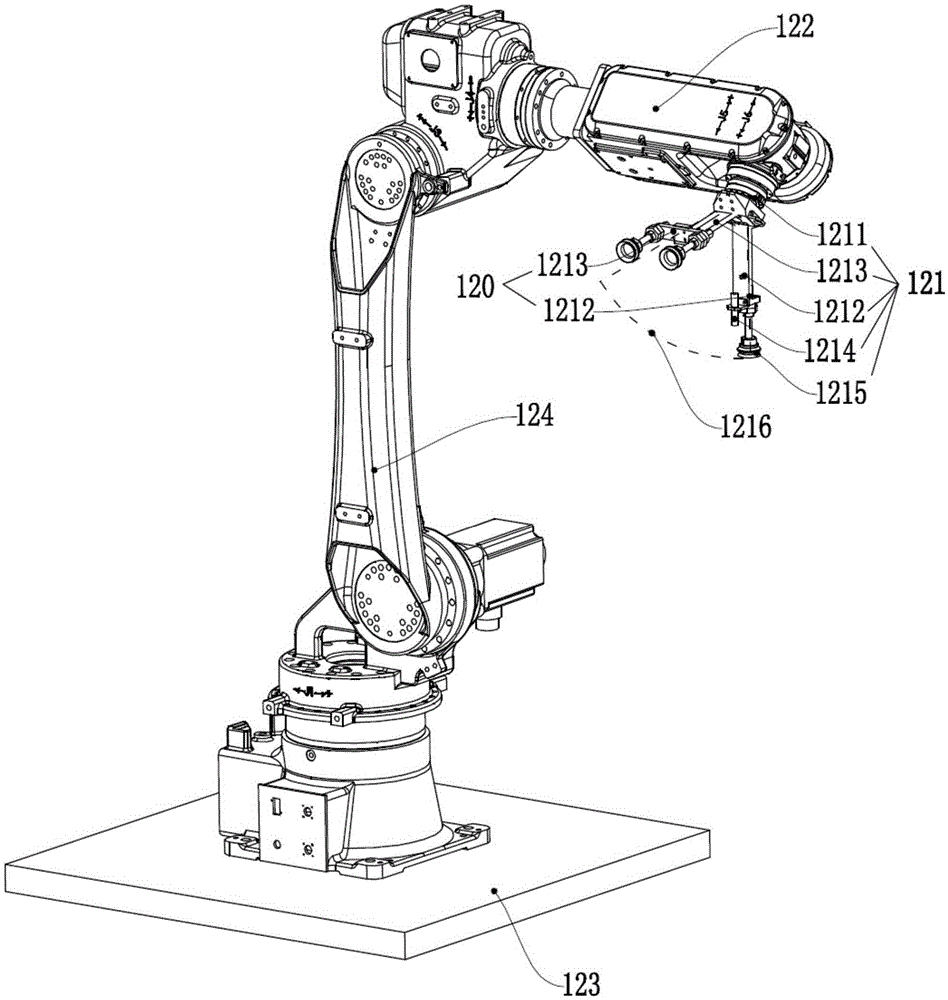

Automatic storage system of industrial robot

InactiveCN105292892AFree laborReasonable assemblyStorage devicesAcquired characteristicIdentification device

The invention discloses an automatic storage system of an industrial robot. The automatic storage system comprises a robot sorting area, a speed-fold chain, an AGV trolley, an intelligent three-dimensional warehouse and a central controller. The robot sorting area comprises a flat belt conveyor, a robot and a vision identification device. The flat belt conveyor receives a signal sent by the central controller and controls trays to move in the conveying direction of the flat belt conveyor. The vision identification device is installed on any side of the flat belt conveyor and located above the trays. A camera of the vision identification device is used for photographing the tray area below the camera, and the photographing area of the camera at least includes one tray. The vision identification device detects and identifies photos photographed by the camera, sends feature data obtained through identification to the central controller and sends a signal to the robot, and the robot receives the signal to transfer and put specified articles on the storage trays of the speed-fold chain to achieve sorting. According to the automatic storage system of the industrial robot, labor force of workers is liberated, and product detecting, sorting and storing efficiency is improved.

Owner:JIANGSU HUIBO ROBOTICS TECH CO LTD +1

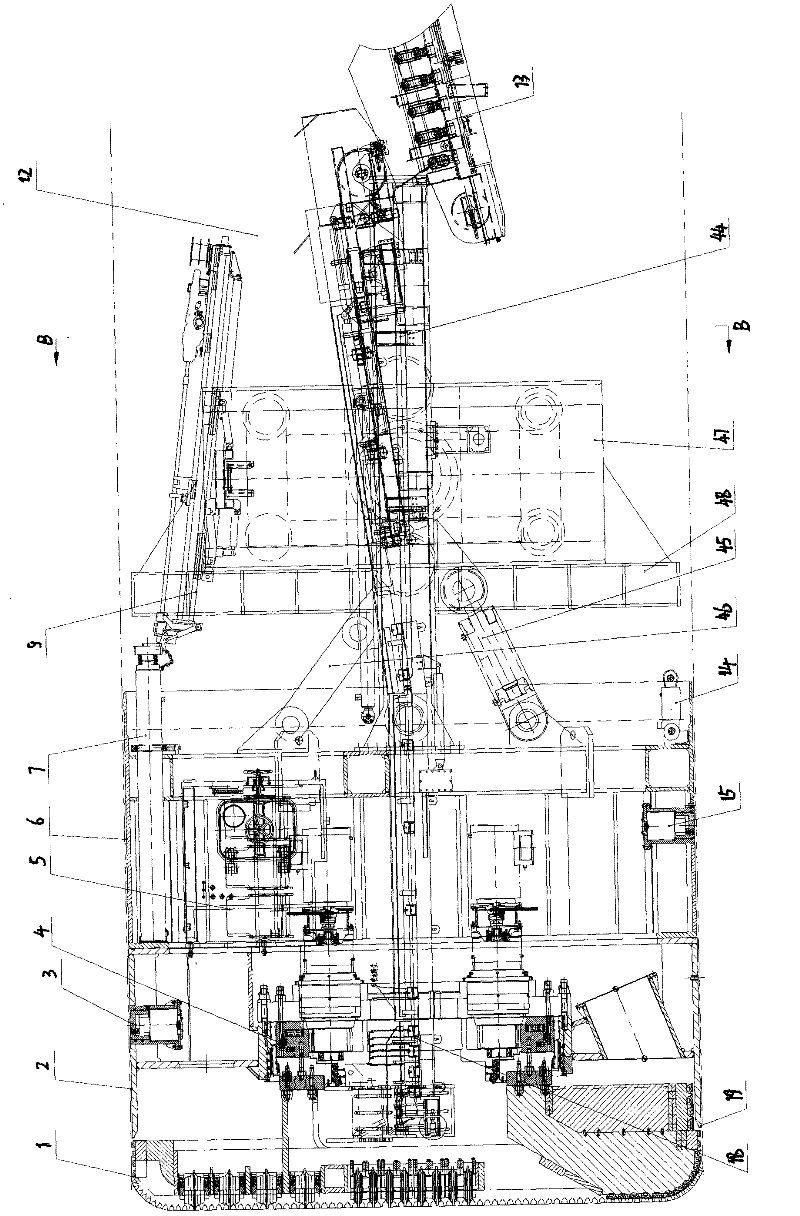

Mixed TBM (Tunnel Boring Machine) with multiple-boring mode and tunnel supporting mode

ActiveCN102383805AControl face stabilityEnsure construction safetyTunnelsSludgeTunnel boring machine

The invention discloses tunnel construction equipment, in particular a mixed TBM (Tunnel Boring Machine) with a multiple-boring mode, which is suitable for sludge, clay, sand, grit, decomposed rock, hard rock and composite transition stratum. According to the invention, three modes of an earth pressure balance mode, a shield open mode and a TBM mode are adopted for construction according to different stratum geological conditions and construction tunnel supporting requirements; a deslagging mode is that a spiral conveyer or a TBM belt conveyor is adopted for deslagging; and simultaneously, a supporting mode can adopt a finned-tube lining or flexible post-supporting mode. The mixed TBM disclosed by the invention has very strong geological adaptability, is especially suitable for soft, hard and complex stratal construction of a mains underground engineering, and simultaneously, has the advantages that the whole machine has low manufacture cost, the mode conversion is relatively simple, the interference to mating construction is small, the control is convenient, the equipment manufacture cost is low, the economic property and practicability are achieved, and the use requirements of the flexible supporting mode of the construction can be met.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

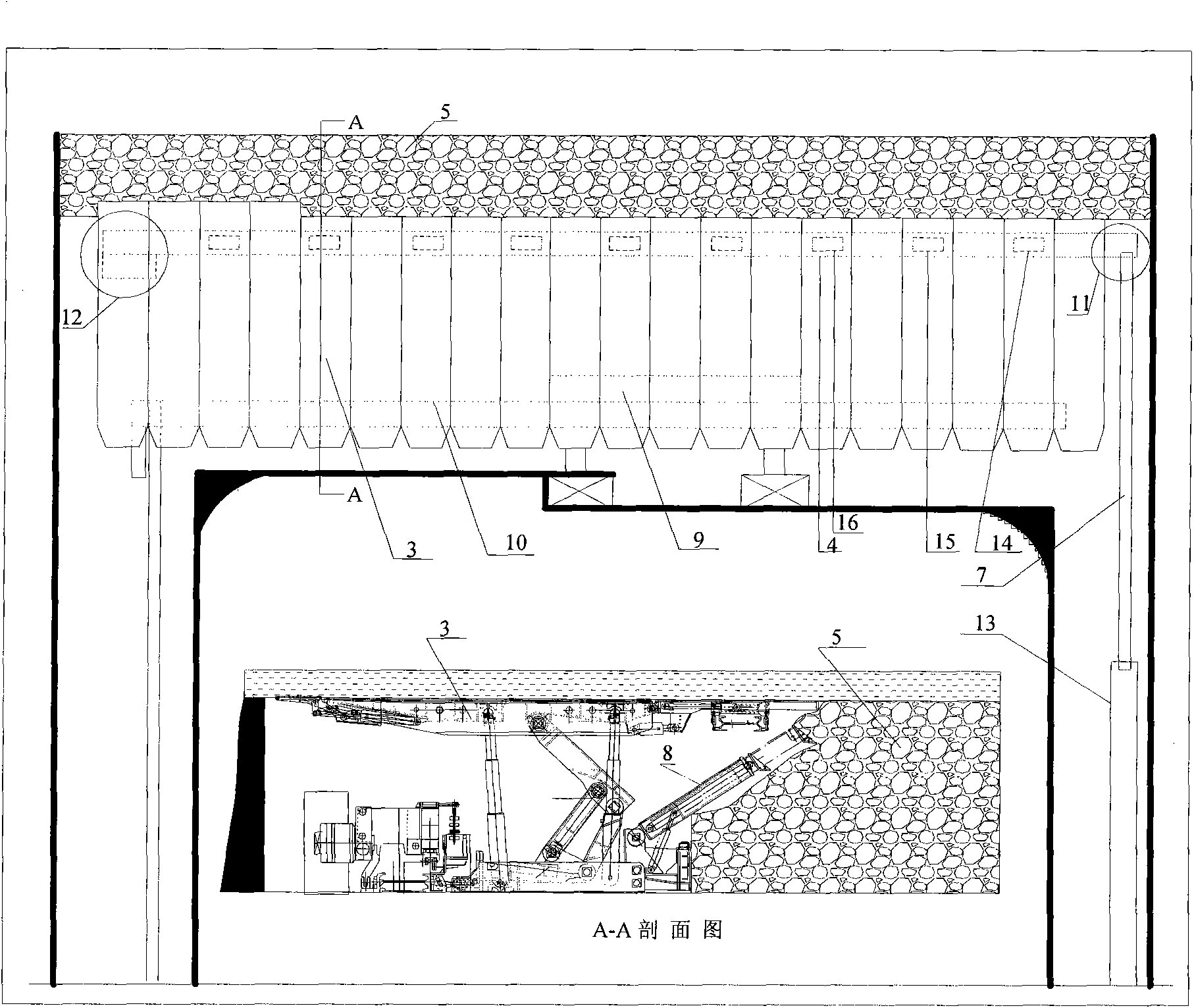

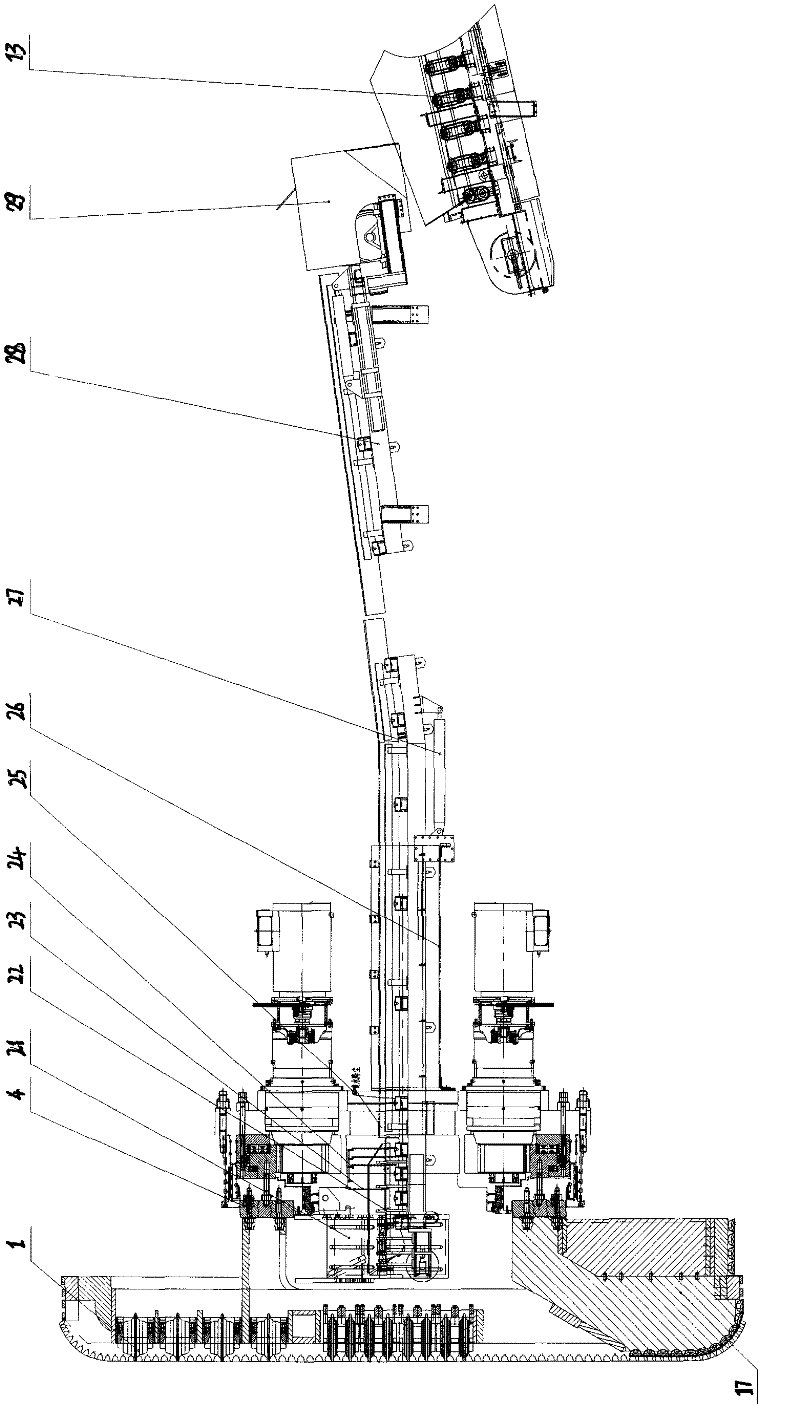

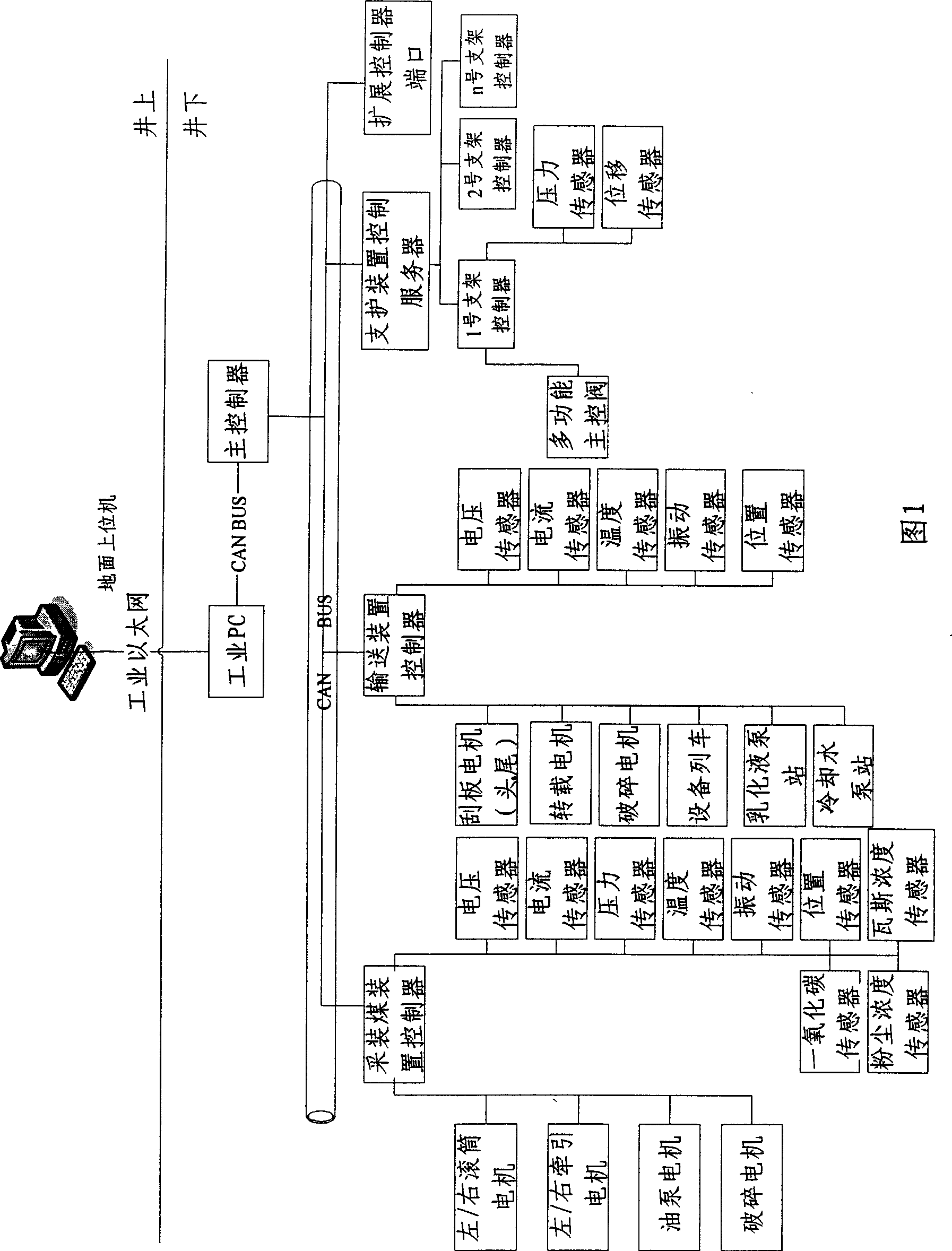

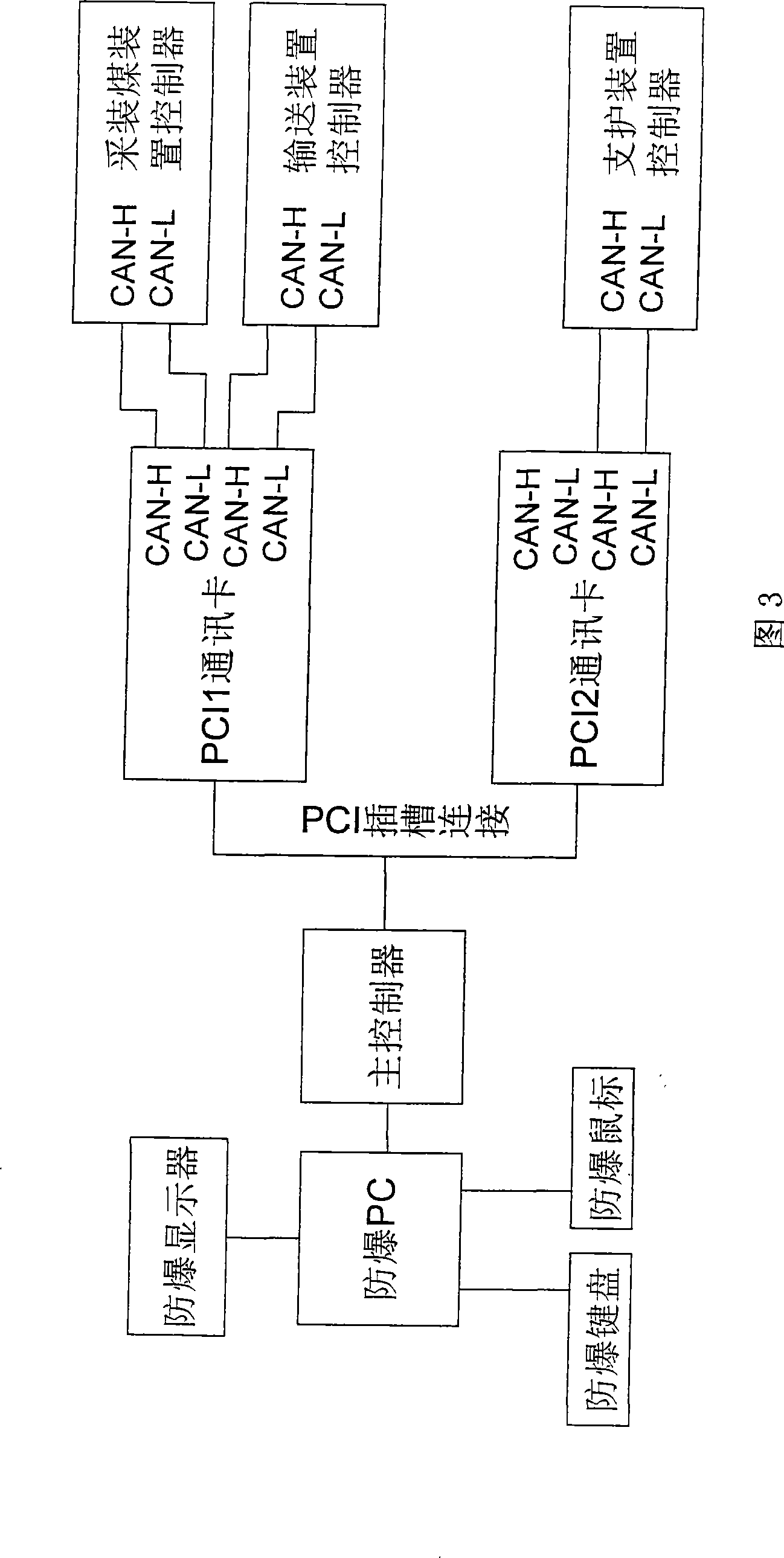

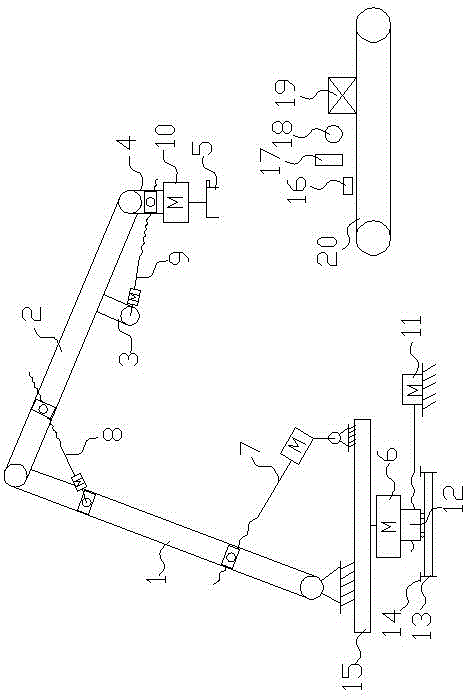

Intelligent full automatic combine coal mining system

ActiveCN101418688ARealize comprehensive applicationImprove completenessMining devicesUnderground miningProcess engineeringControl equipment

The invention relates to an intelligent type full-automatic combined coal mining system, which comprises a coal mining and loading device, a conveying device, a supporting device, and an equipment train, and is mounted in the working face and crossheading in the coal mine well. The coal mining and loading device is mounted on the conveying device, the coal conveying port of the conveying device is conveyed to the outside of the well or the coal bunker through a belt type conveyor in the crossheading, the supporting device is arranged behind the conveying device for supporting the top plate of the coal seam and linking with the conveying device, the equipment train comprises a central control chamber of a central control equipment, a starter, a power device, and a lifesaving cabin, the central control equipment monitors and controls the coordination operation of the devices, the equipment train, and the power device of the equipment train, the power device provide power source for the devices and the equipment train, and the equipment train moves freely in the crossheading with the feeding of the working faces. The invention improves system complete ability and execution efficiency, and has strong function, high intelligent degree, high safety, high production efficiency, and the like.

Owner:SANY HEAVY EQUIP

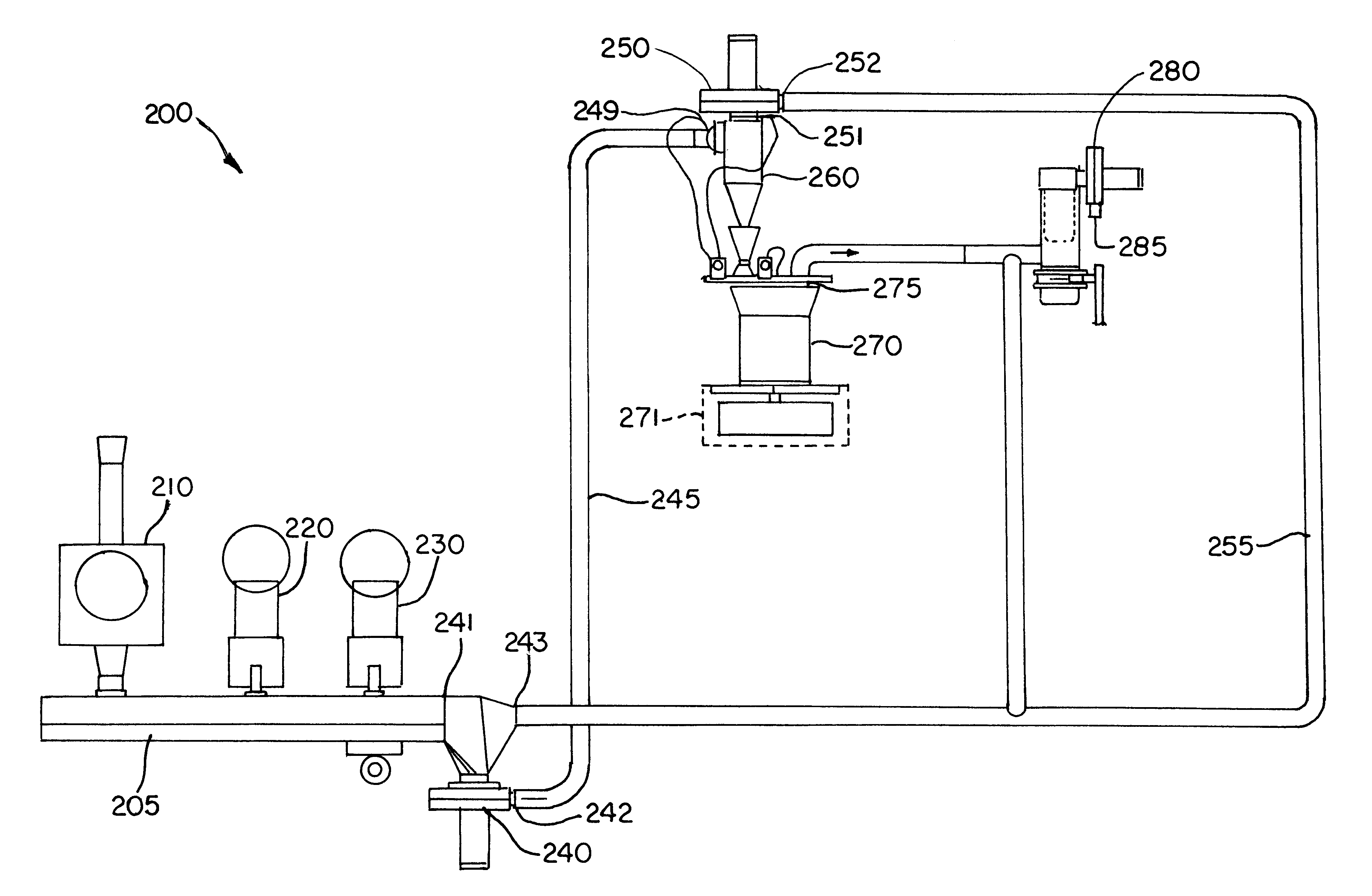

Method for forming fiber reinforced composite parts

A method and apparatus for combining raw fibrous and binding materials in a single mixing step (Step S3), followed by consolidation (Step S5) so as to greatly shorten the overall cycle time to a finished fiber-reinforced composite part. Chopped fibrous materials and binder materials are deposited sequentially onto a belt conveyor (Step S2) so that the materials are successively layered, one on top of each other in a predetermined ratio, and subsequently mixed (Step S3) to achieve uniform dispersion throughout. The mixed materials are then deposited into a rotating mold (Step S4) to further ensure uniform dispersion of fibrous and binder materials. Impregnation of the fibrous materials with the binder material occur in-situ as the uniformly mixed materials are heated and subsequently compacted in the mold (Step S5) to obtain the desired shape of the fiber-reinforced composite part.

Owner:HONEYWELL INT INC

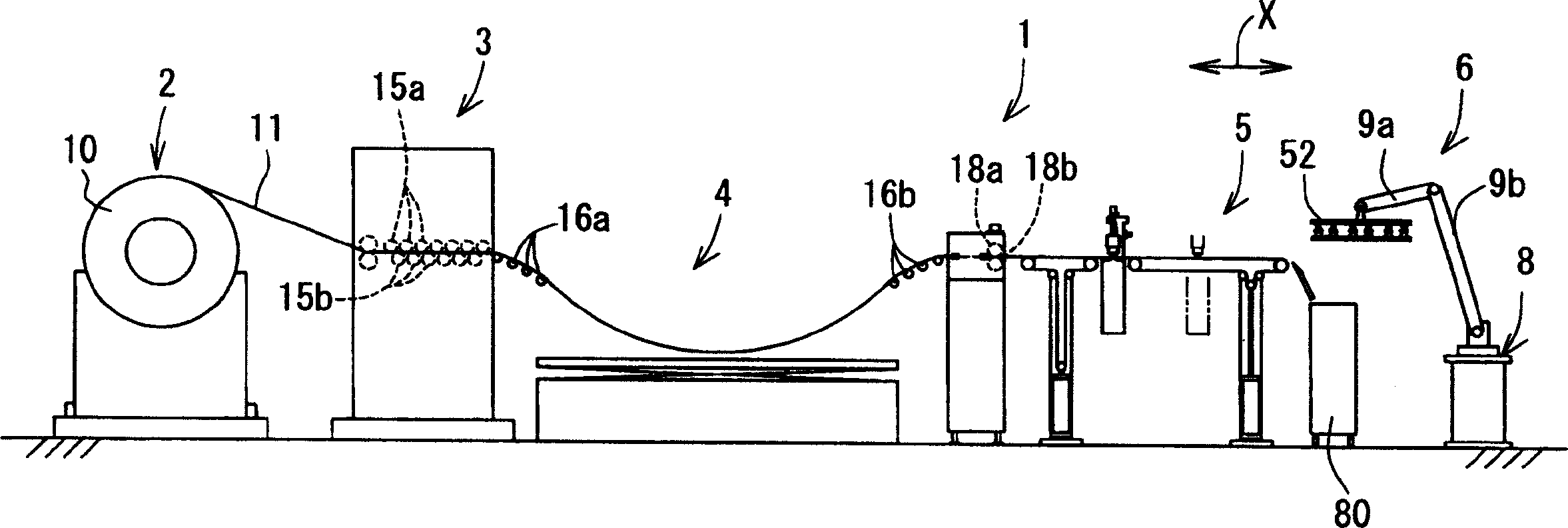

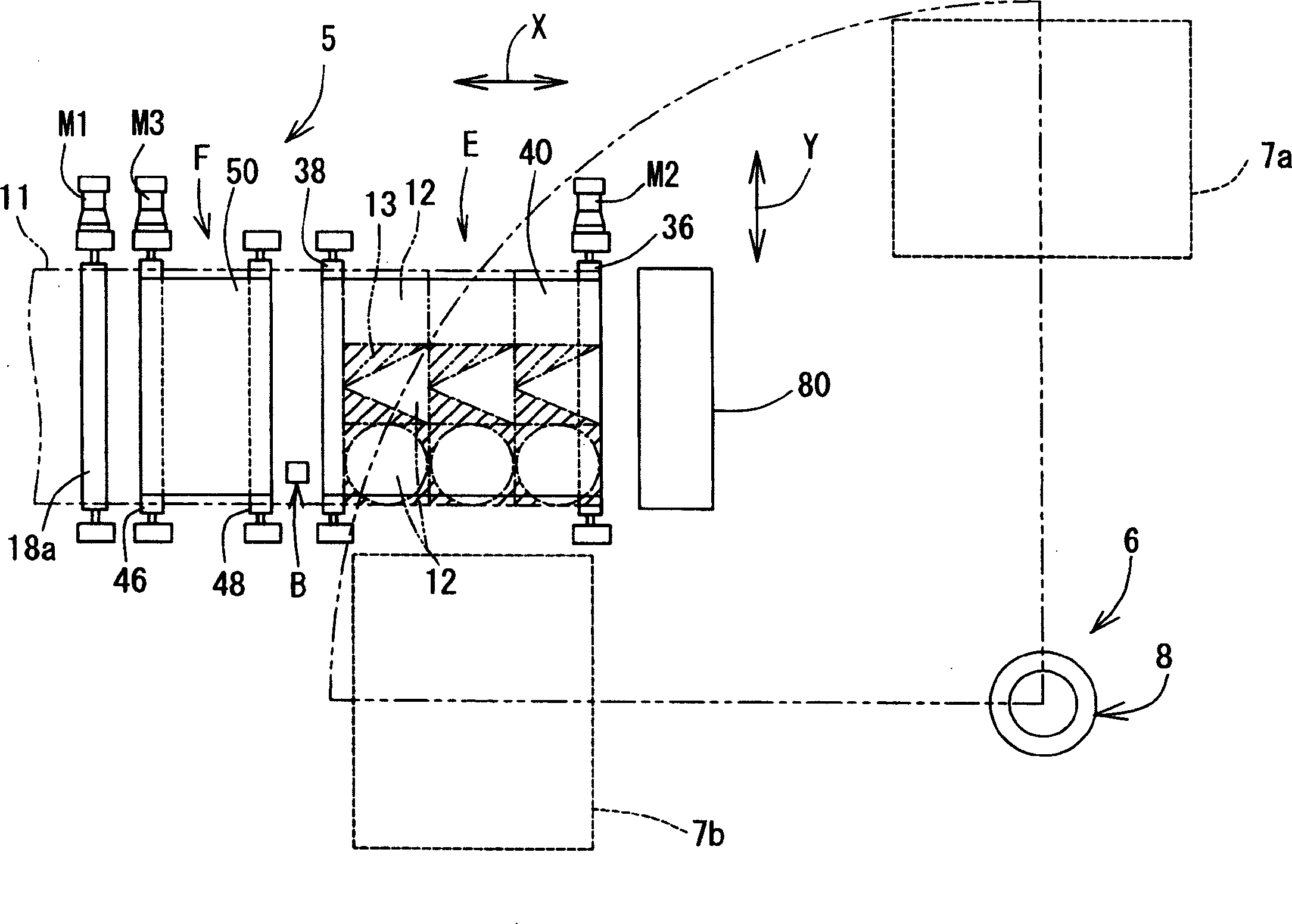

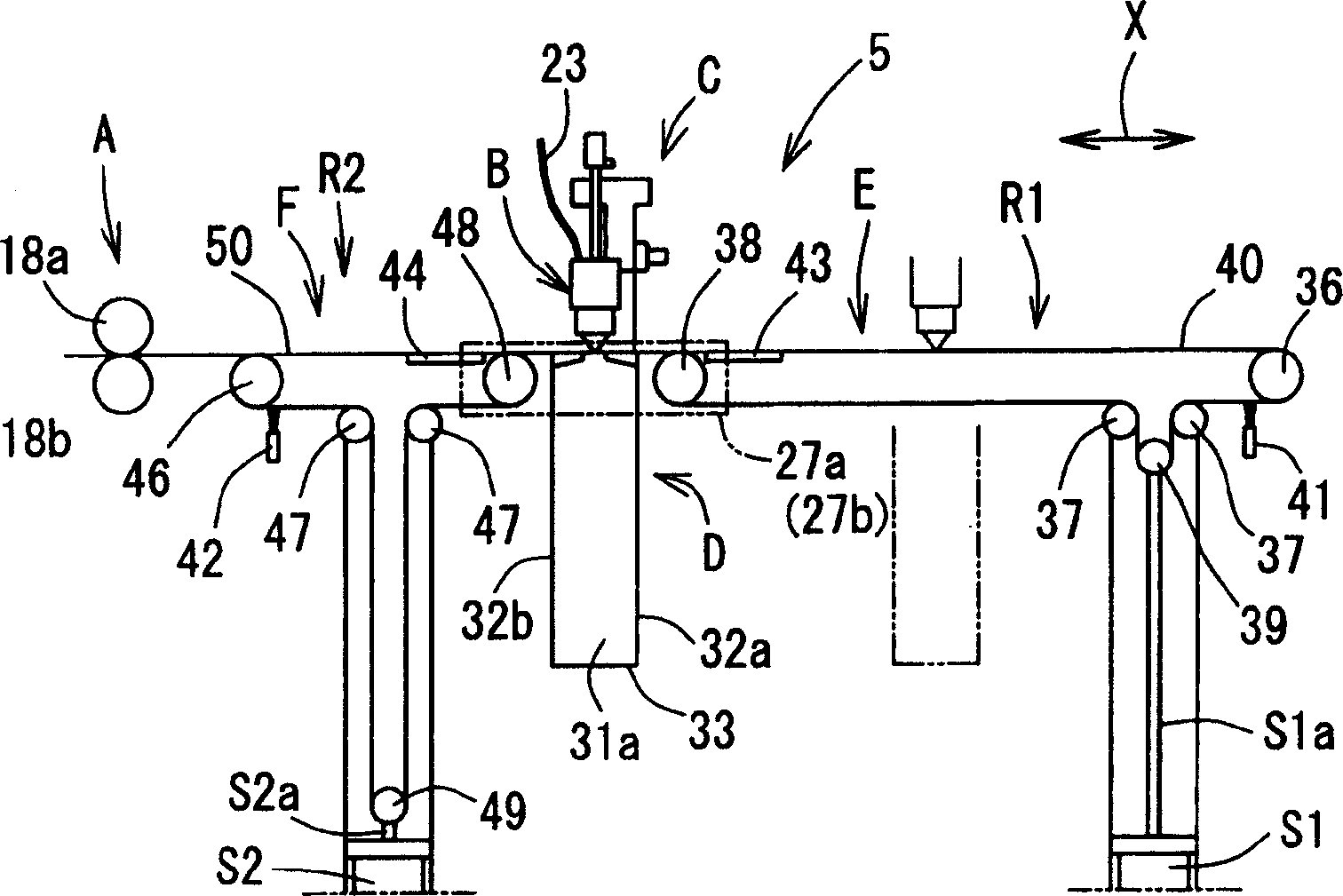

Laser cutting device, laser cutting method and laser cutting system

InactiveCN1652895APrevent adhesionReliable supportConveyorsWelding/soldering/cutting articlesEngineeringLaser cutting

A laser cutting device, comprising a material feeding means for feeding a sheet-like material in a feeding direction, a processing head capable of radiating laser beam toward the material, a head moving means for moving the processing head in a material feeding direction X and a material lateral direction Y, an upstream side support means (belt conveyor mechanism F) for supporting the material on the upstream side of the lower part of the processing head and increasing / decreasing the support area (R2) of the material in the feeding direction according to the movement of the processing head in the feeding direction, and a downstream side support means (belt conveyor mechanism E) for supporting a part cut on the processing side lower part of the processing head and increasing / decreasing the support area (R1) of the cut part in the feeding direction according to the movement of the processing head in the feeding direction.

Owner:TOYOTA STEEL CENT CO LTD

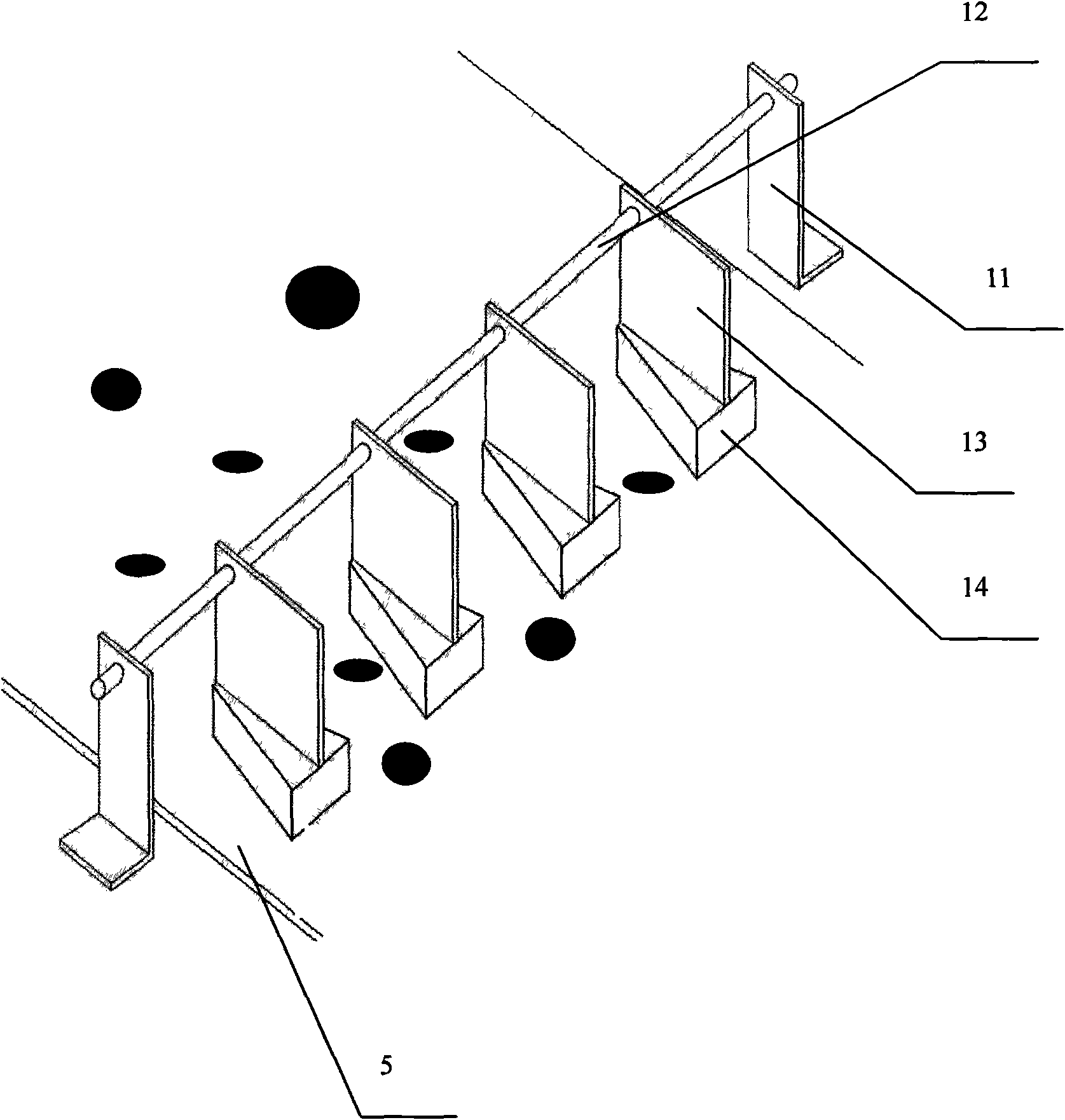

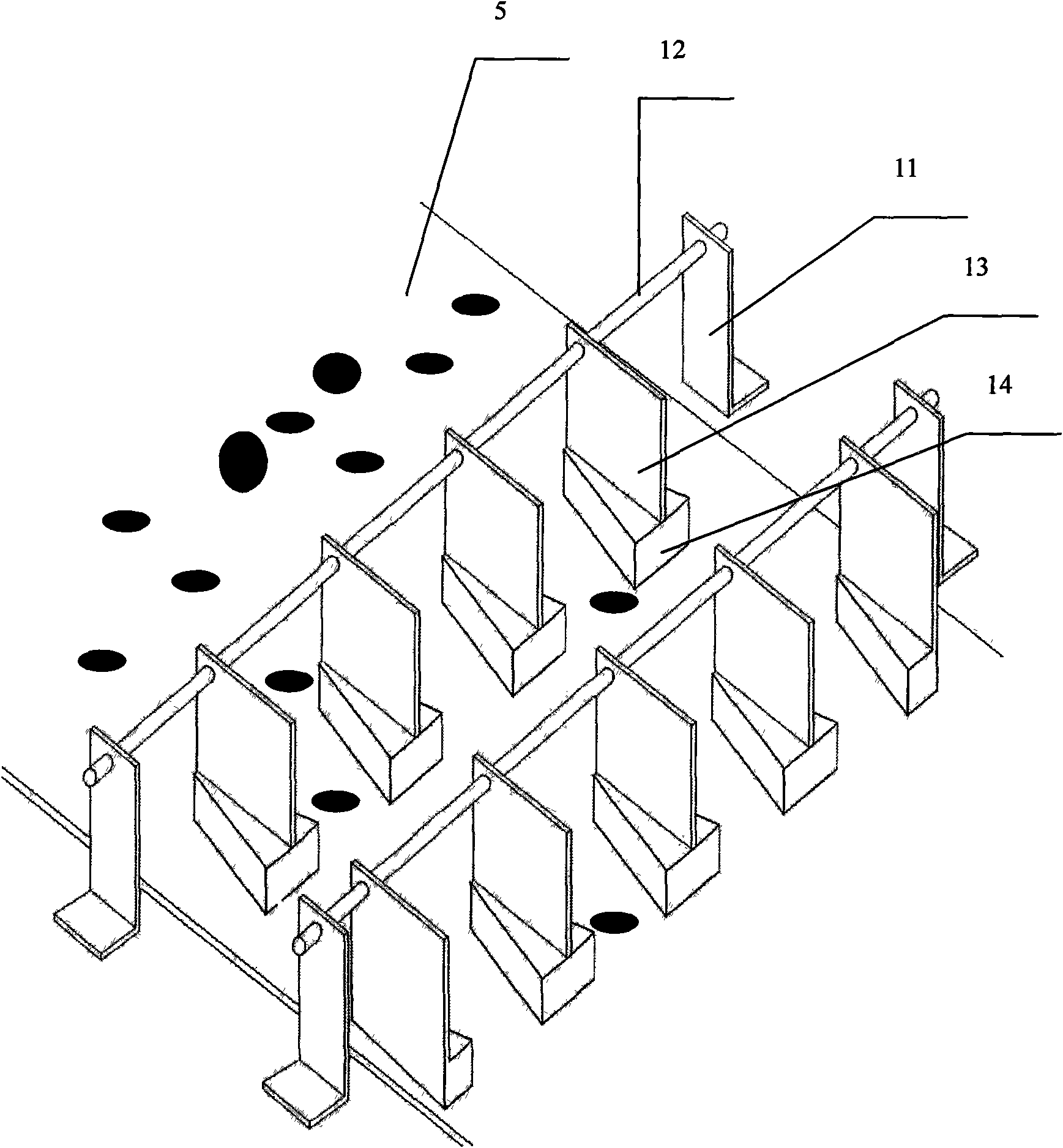

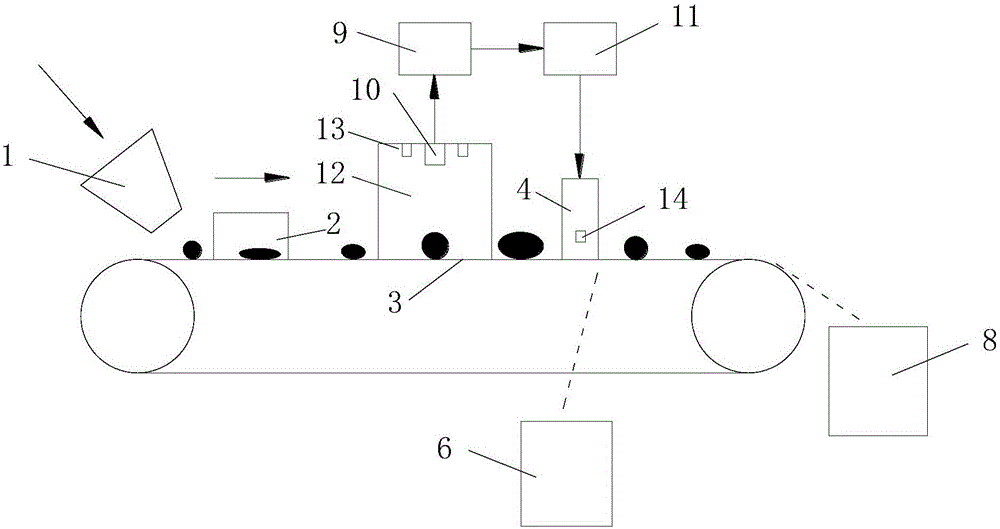

Automatic separator of coal gangue

ActiveCN101637765ANo mutual interferenceSolve the technical problems of poor sorting effectSortingConveyor partsX-rayGamma ray

The invention relates to an automatic separator of coal gangue, which comprises a raw material feeding copper, a coal receiving copper, a gangue receiving copper, a conveying-belt conveyor, an identification and separation controlling mechanism and an executing mechanism, wherein the conveying-belt conveyer is arranged among the raw material feeding copper, the coal receiving copper and the gangue receiving copper; the identification and separation controlling mechanism comprises a single-energy gamma ray source, an X-ray sensor, a measure and control instrument and an ultrasonic transmitter-receiver; the single-energy gamma ray source is arranged below a conveying belt, the X-ray sensor is arranged above the conveying belt and corresponds to the single-energy gamma ray source, the measure and control instrument is electrically connected with the X-ray sensor, and the ultrasonic transmitter-receiver is arranged above the conveying belt and electrically connected with the measure and control instrument; the executing mechanism is a high-frequency air valve arranged above the coal receiving copper and the gangue receiving copper; and the valve port of the high-frequency air valve isarranged towards a throwing track of coal and gangue. As the single-energy gamma ray source is adopted, only one nuclear radiation material exists, and only one spectral line is radiated, the mutualinterference among a plurality of spectral lines can not be generated; and the invention has accurate measurement and good separation effect.

Owner:GREAT DRAGON RISING ELECTROMECHANICAL TECH BEIJING

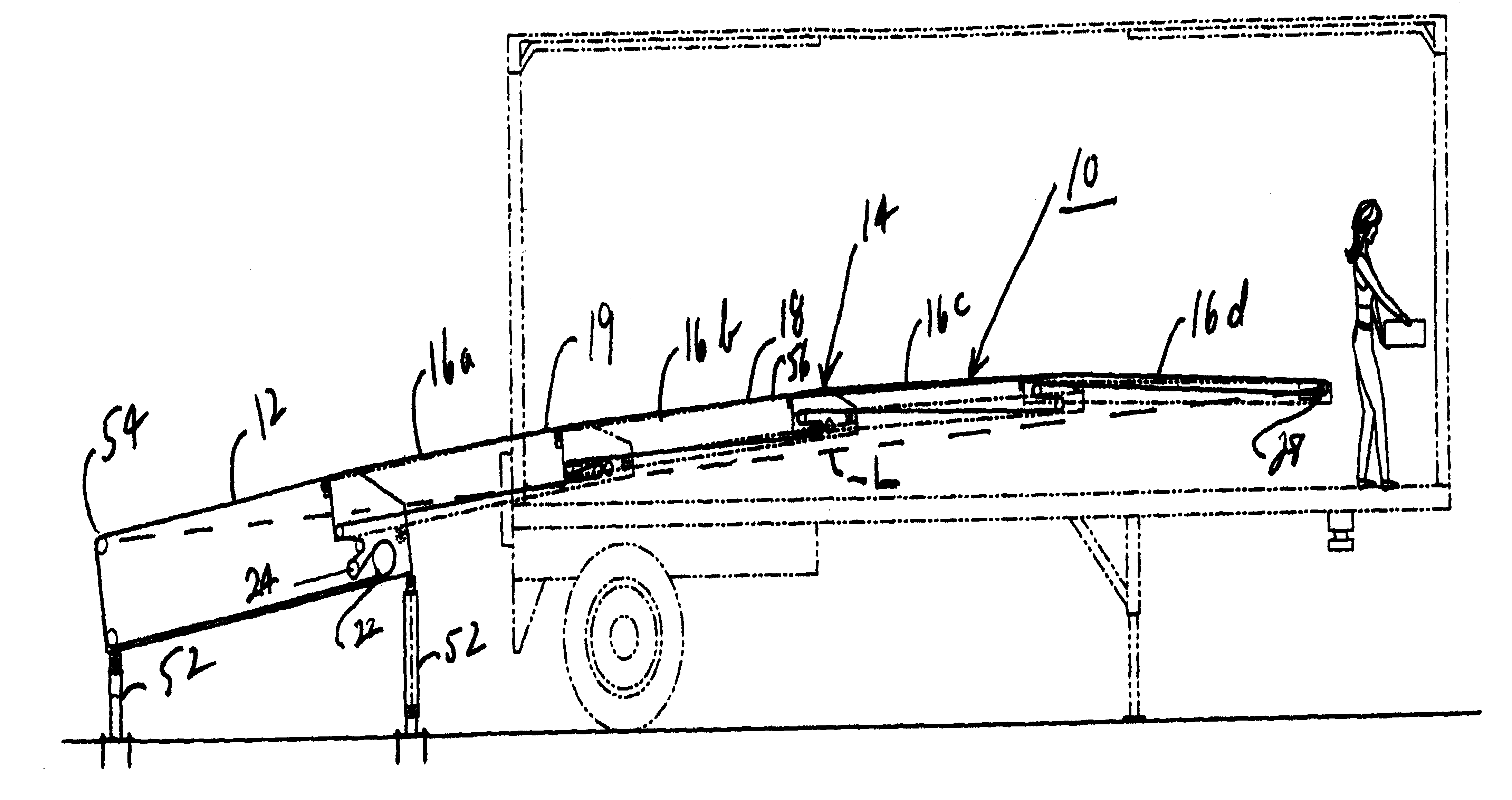

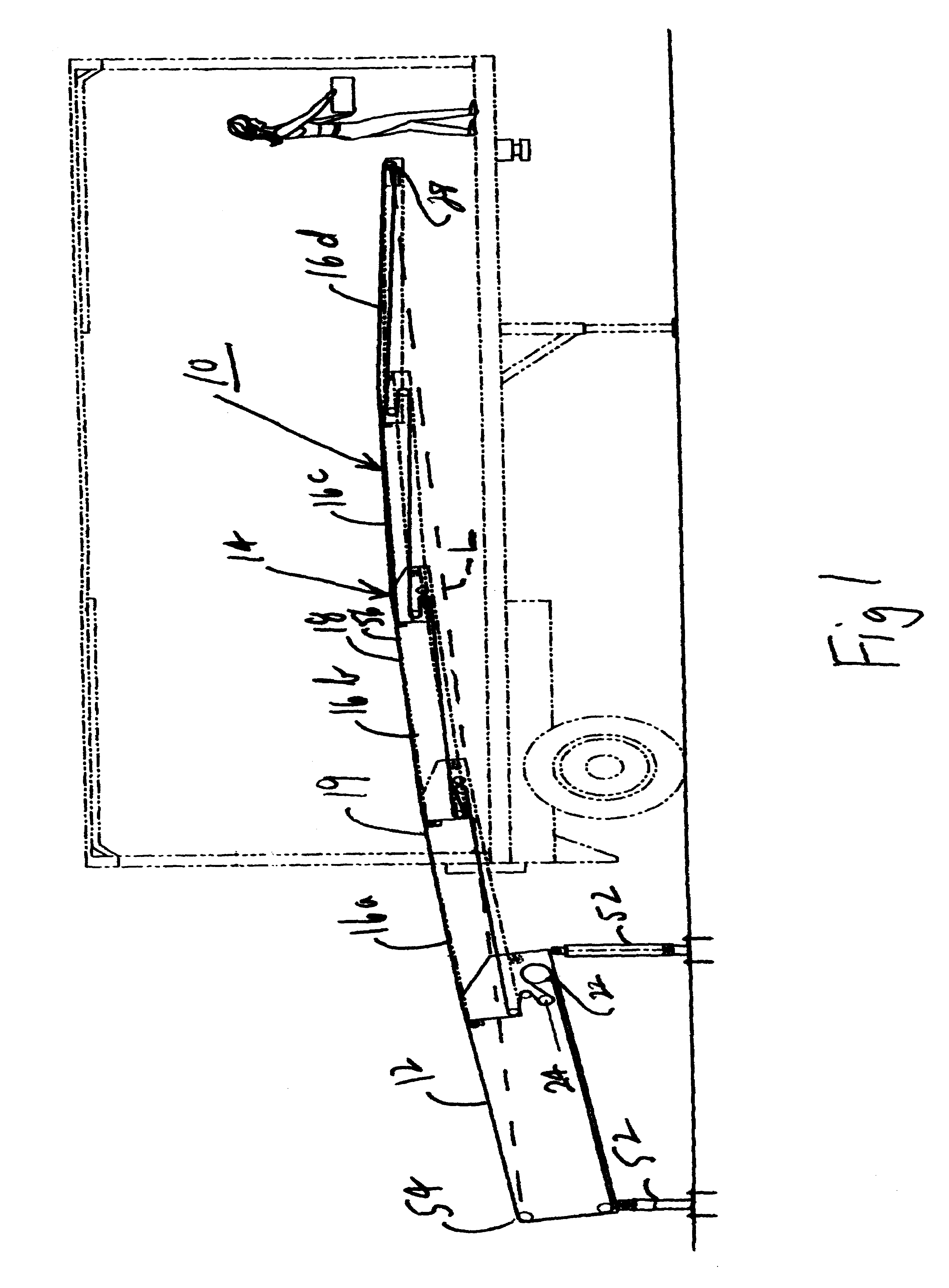

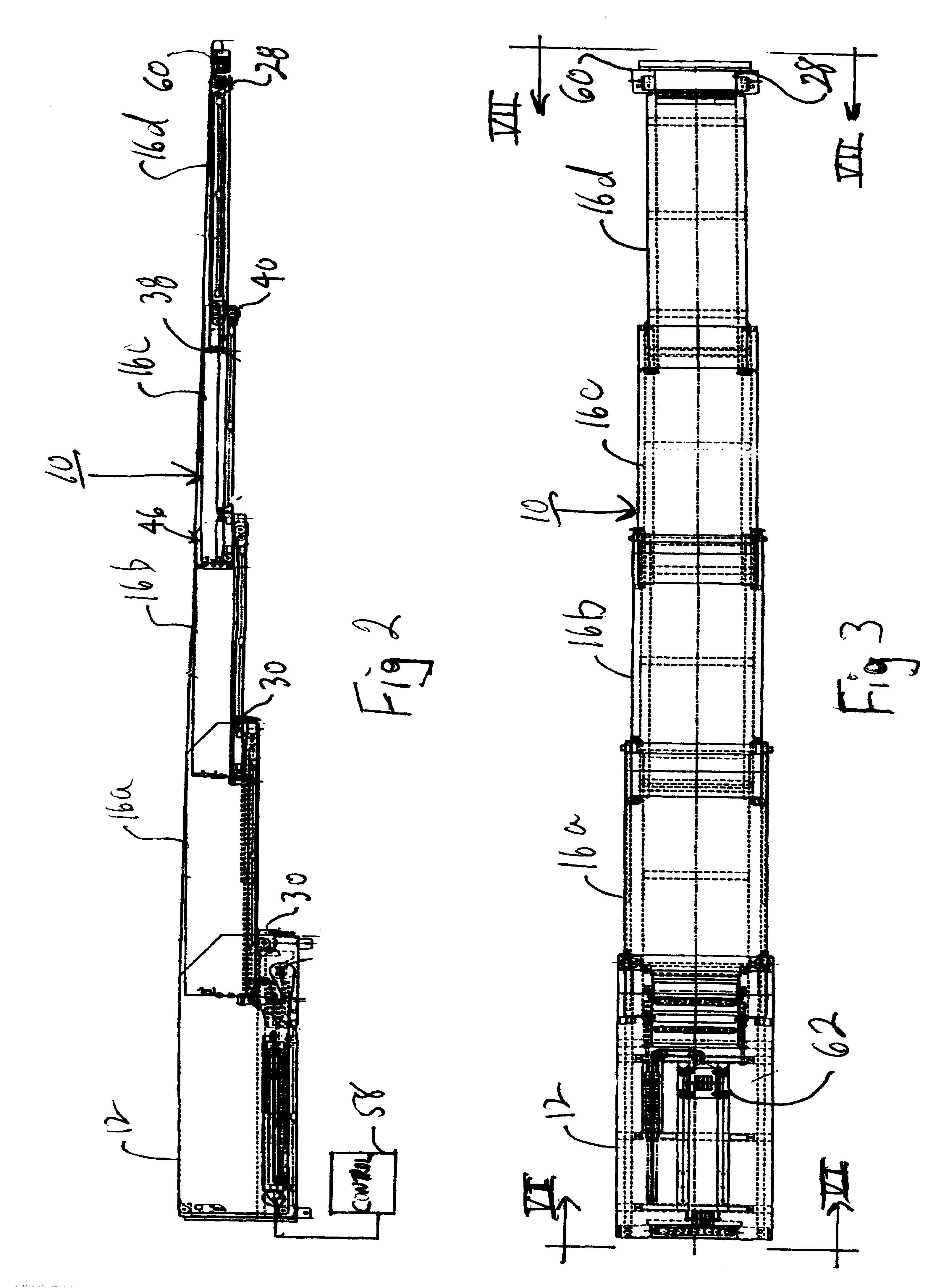

Extendable belt conveyor

An extendable conveyor includes a support structure, a mechanically extendable section which is extendable along the longitudinal axis between a fully retracted position and a fully extended position, a conveyor belt reeved among the mechanically extendable section thereby defining a conveying surface and a drive. The drive is operable to drive the conveyor belt in at least one direction. The extendable section may be extended by driving the conveyor belt in one direction and retracted by driving the conveyor belt in an opposition direction. The mechanically extendable section may include a plurality of sections at least one made substantially from a unitary sheet of material.

Owner:KÖRBER SUPPLY CHAIN LLC

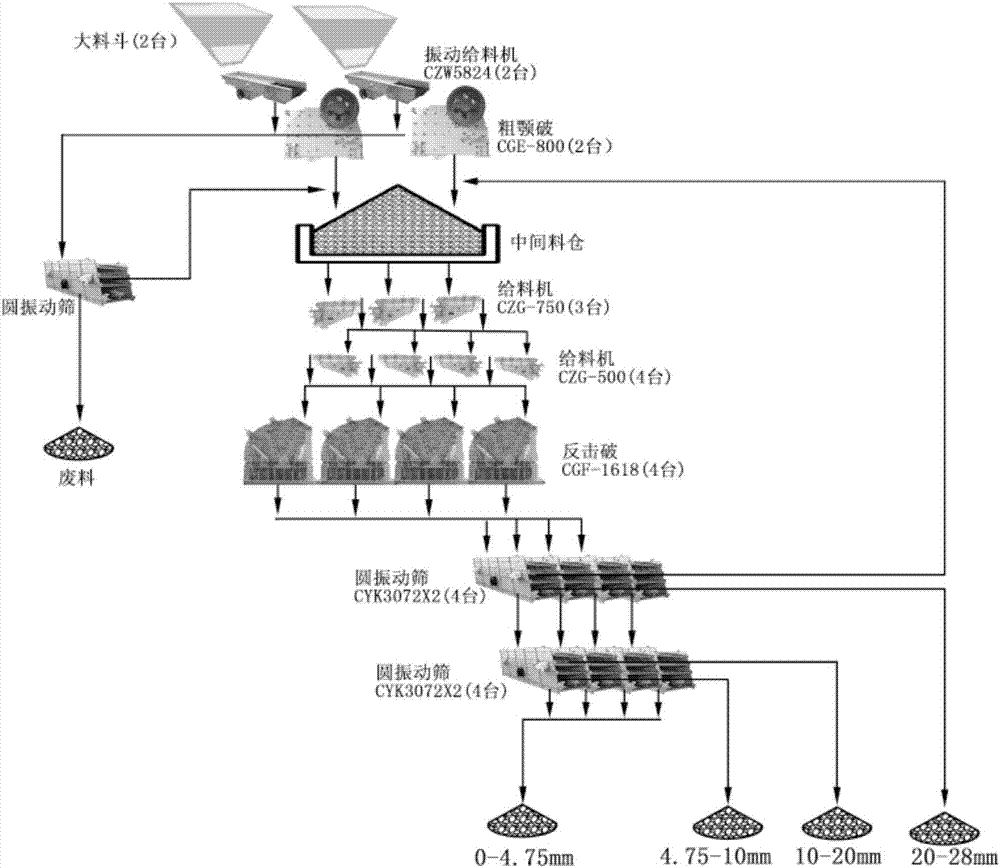

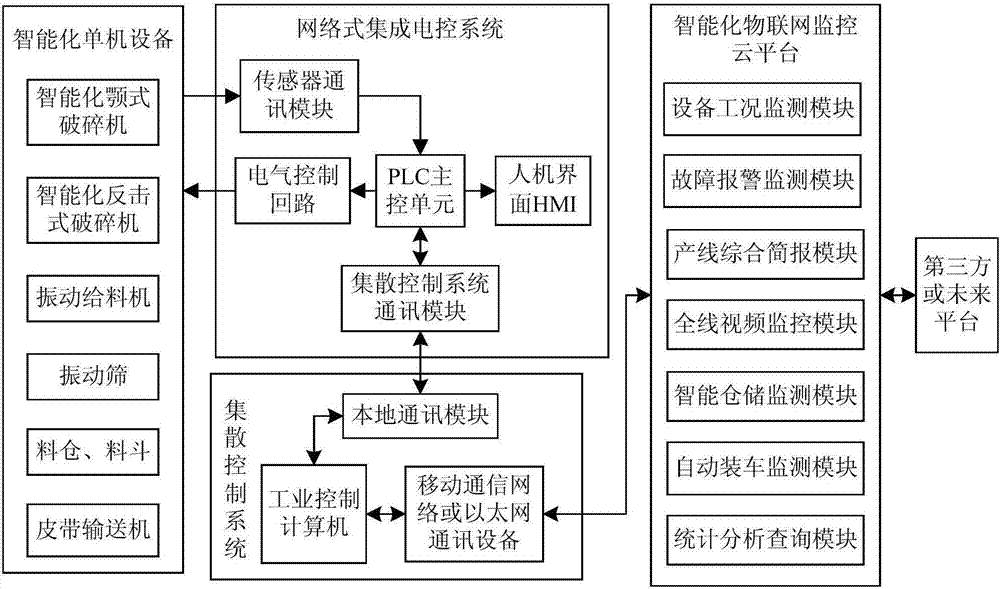

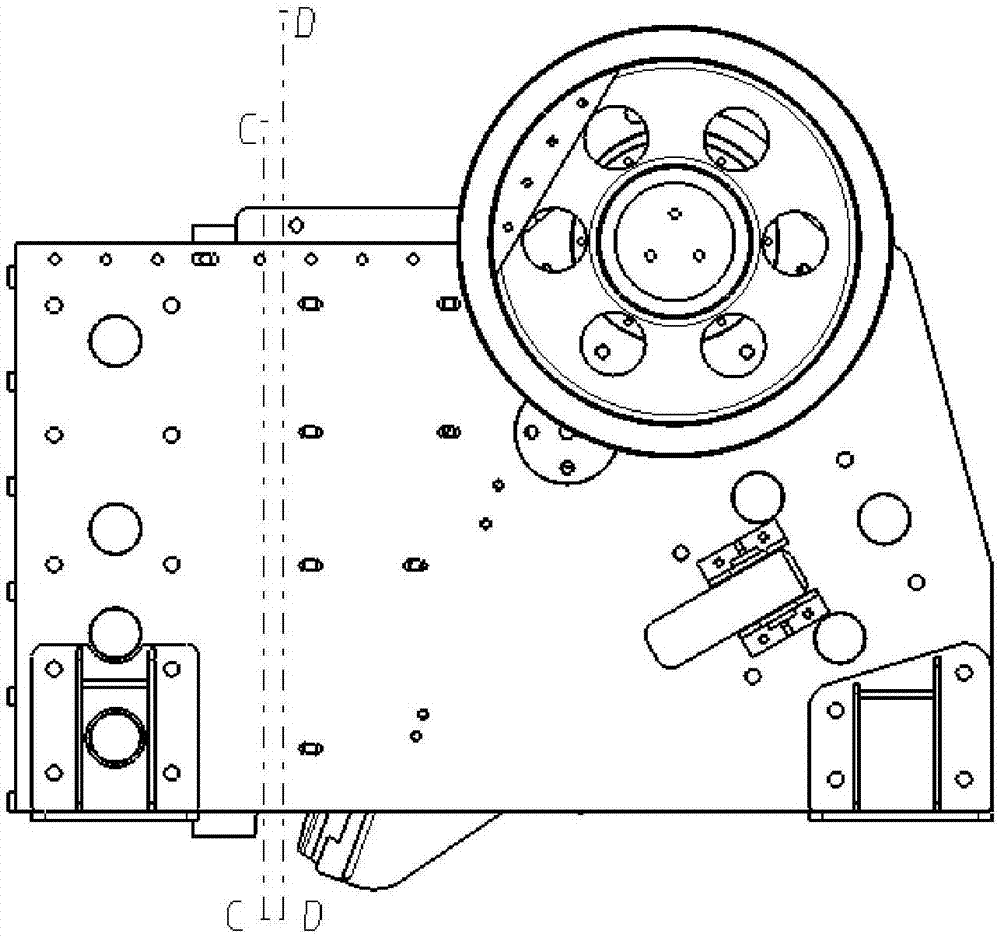

Intelligent gravel aggregate production line

ActiveCN107153410AIncrease the level of automationReduce work intensityTotal factory controlProgramme total factory controlProduction lineDowntime

The invention provides an intelligent gravel aggregate production line, and relates to the technical field of gravel aggregate production. The intelligent gravel aggregate production line comprises an intelligent jaw type crusher, an intelligent impact type crusher, a vibrating screen, a vibrating feeder, a material bin, a hopper, a belt conveyor, a control-related network type integrated electric control system, a distributed control system and an intelligent internet of things monitoring cloud platform, wherein various sensors are additionally arranged on the basis of an original crushing screening production line; sensor information is transmitted to the distributed control system through the network type integrated electric control system, so that automatic regulation and control on the production process is realized, and therefore, the sensor information is transmitted to the intelligent internet of things monitoring cloud platform; and production data storage and safety are managed in a unified mode on the basis of classifying and combing through cloud computation. The intelligent gravel aggregate production line has a fault early-warning function and a real-time alarm function, and quickly increases response speed; internet of things intelligent control and remote monitoring are introduced, the production process is automatically regulated and control, operation is performed with optimal load, the yield is increased, and downtime maintenance is reduced.

Owner:SHANGHAI UNITRUSTON INTELLIGENT TECH CO LTD

Angled-roller belt conveyor

A conveyor and a method for rotating and registering an article against a rail. The conveyor includes an angled-roller conveyor belt whose article-supporting rollers are arranged to rotate about axes directing conveyed articles toward a side rail. An obstruction is selectively activated to move into a position just above a top article-conveying surface of the belt. In that position, the obstruction intercepts conveyed articles. The obstruction forms a pivot about which the articles rotate as the belt advances and the angled rollers rotate. An electric eye or other sensor sensitive to oversized or misoriented articles controls the positioning of the obstruction to rotate misoriented articles 90° or to let correctly oriented articles pass without contact and reorientation.

Owner:LAITRAM LLC

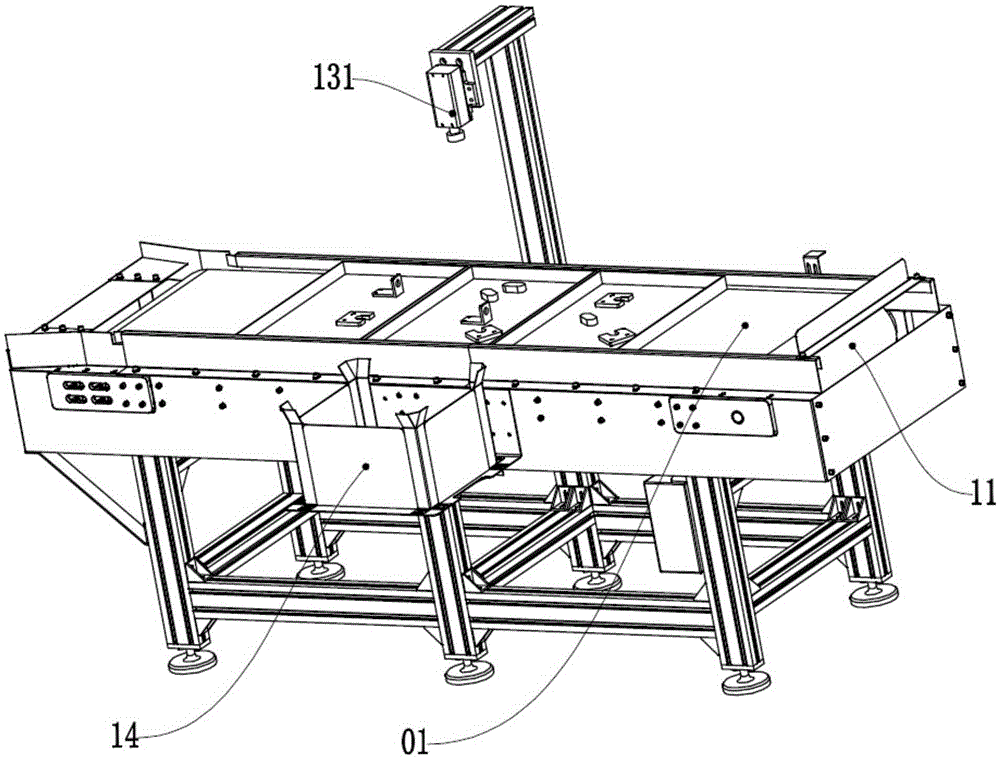

Automatic detection system for hardware appearance

InactiveCN101865861AHigh precisionHigh speedOptically investigating flaws/contaminationAutomatic controlEngineering

The invention discloses an automatic detection system for hardware appearance. The structure of the system comprises a loading mechanism, a feeding mechanism, a detection device, a sorting device and a control system; the loading mechanism comprises an electromotor, a vibrating disk and a guide pipe; the feeding mechanism comprises a belt conveyer, a workpiece positioning guide rail and an unqualified product discharge groove; the detection device comprises detection software and two sets of hardware; the detection software comprises a detection control program, a standard workpiece technical parameter and a data calculating and processing program; the hardware comprises a workpiece position inductor, two LED light sources and two industrial CCD camera; the sorting device comprises a cylinder, an electromagnetic valve, an air pipe and a pressure reducing valve; and a turnover mechanism comprises a U-shaped chute and a turnover rack. The system combines computer processing and image technology and is used in an industrial automatic control production line so as to realize automatic loading and feeding, secondary intelligent detection and automatic sorting and improve the detection precision and production efficiency. The system is suitable to be used in a workpiece appearance detection process.

Owner:益伸电子(东莞)有限公司

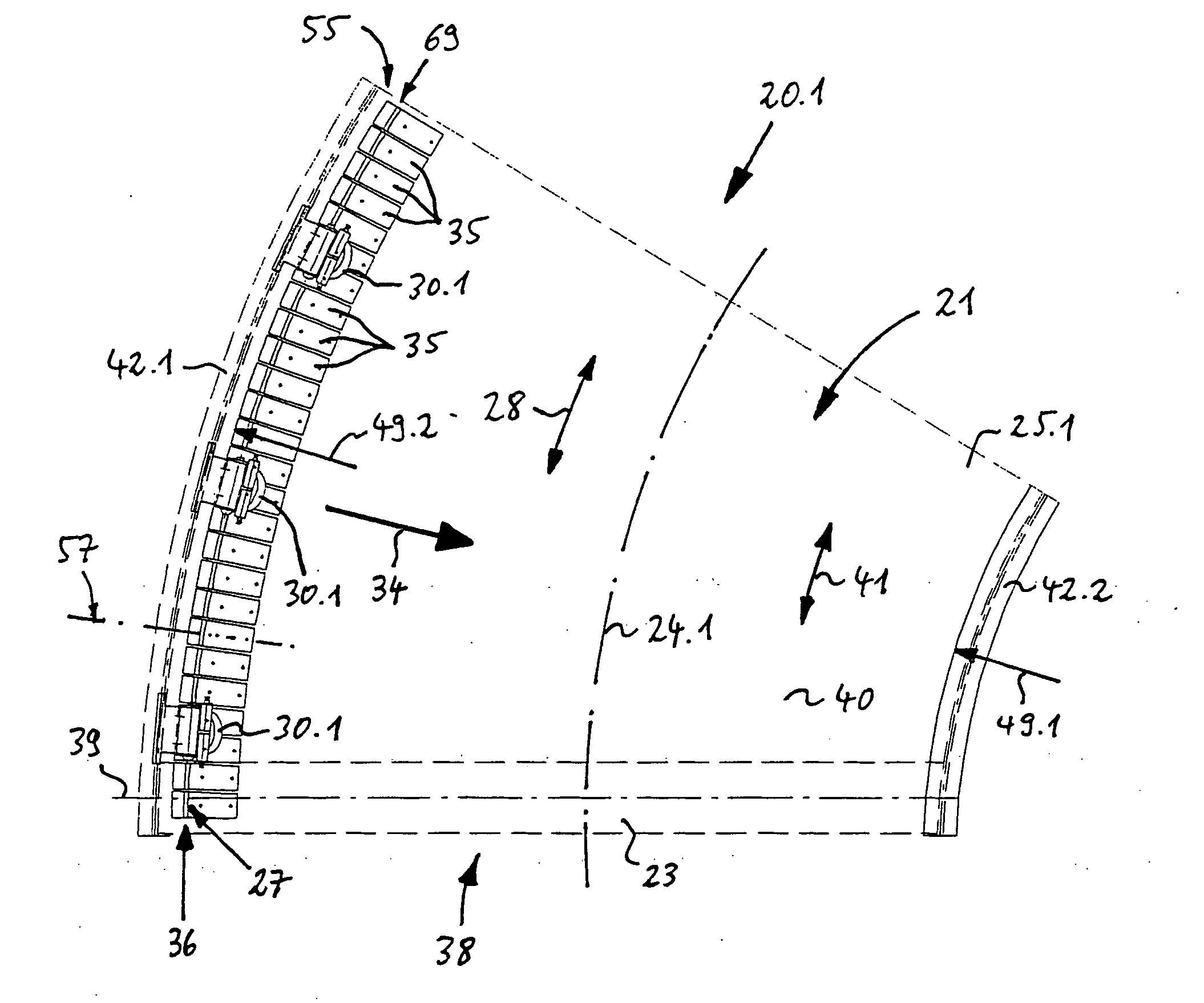

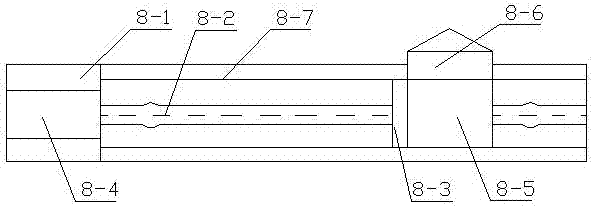

Belt band conveyor having separate guide shoes

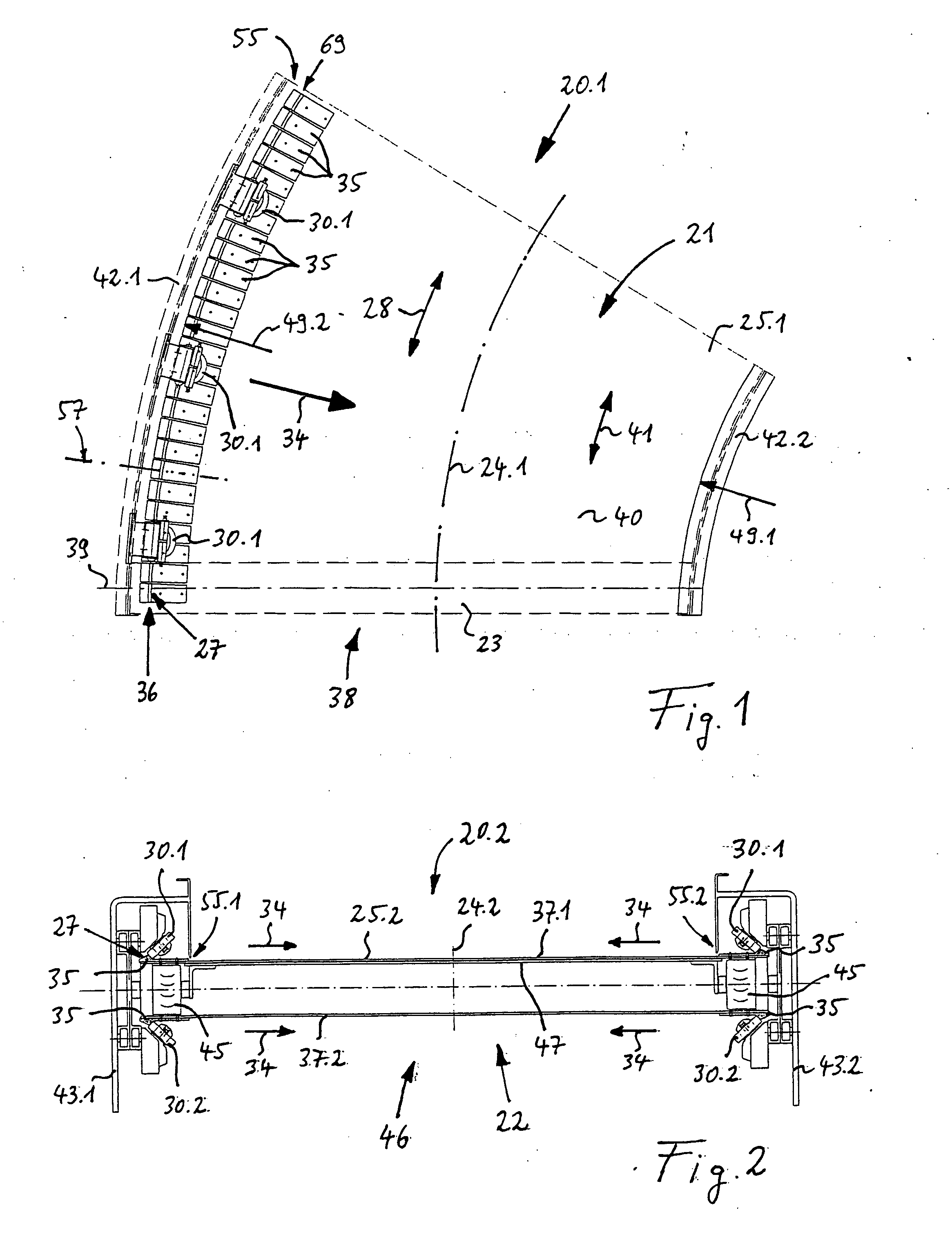

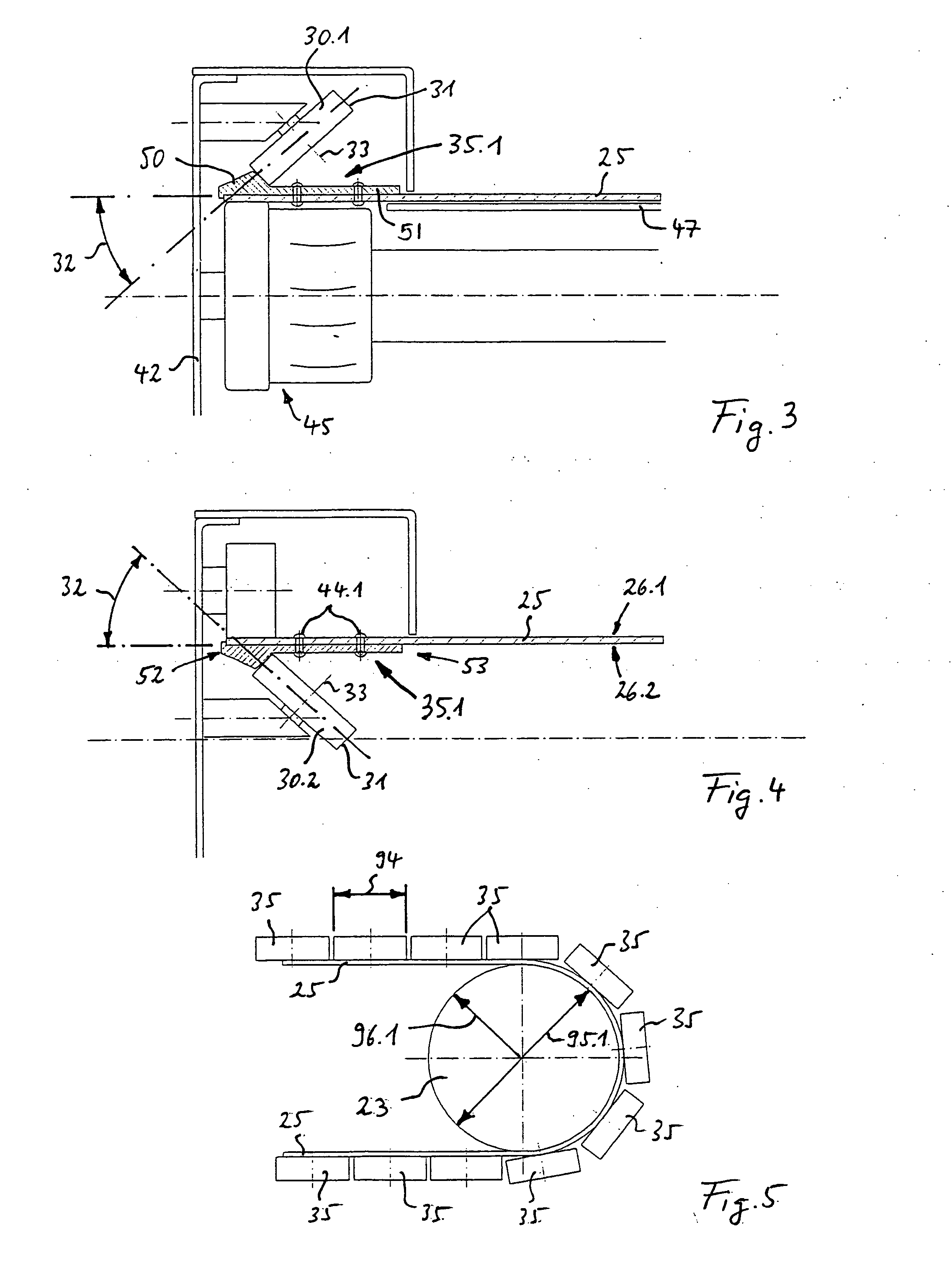

InactiveUS20050082146A1Small deflectionSpeed up the cycleConveyorsRollersEngineeringMechanical engineering

The invention relates to a belt band conveyor such as a curved belt conveyor having an endless transport belt that is guided over deflection rollers. There is a guide element that projects beyond the belt plane wherein this guide element can be handled separately before it is attached to the transport belt. This guide element moves along as the transport belt moves, and on whose guide surfaces, which extend in the transport direction of the transport belt has running surfaces that are inclined relative to the belt plane roll off from rotating guide rollers as the transport belt moves. Thus, lateral forces that occur crosswise to the transport direction of the transport belt can be compensated. A plurality of separate guide shoes are attached to the transport belt, forming a guide strip for the guide rollers that extends in the transport direction, circulates, and is divided into multiple parts.

Owner:INTERROLL HLDG

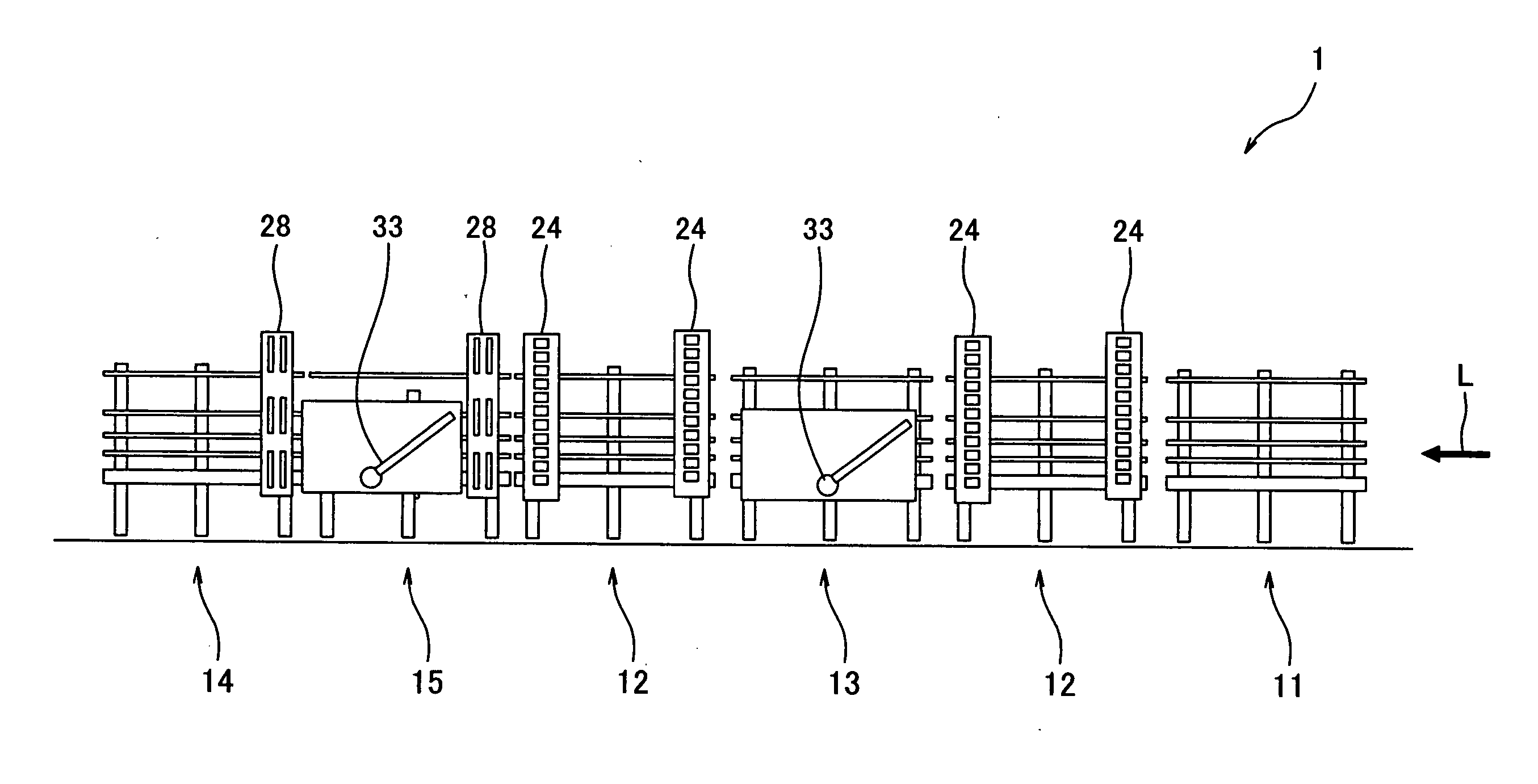

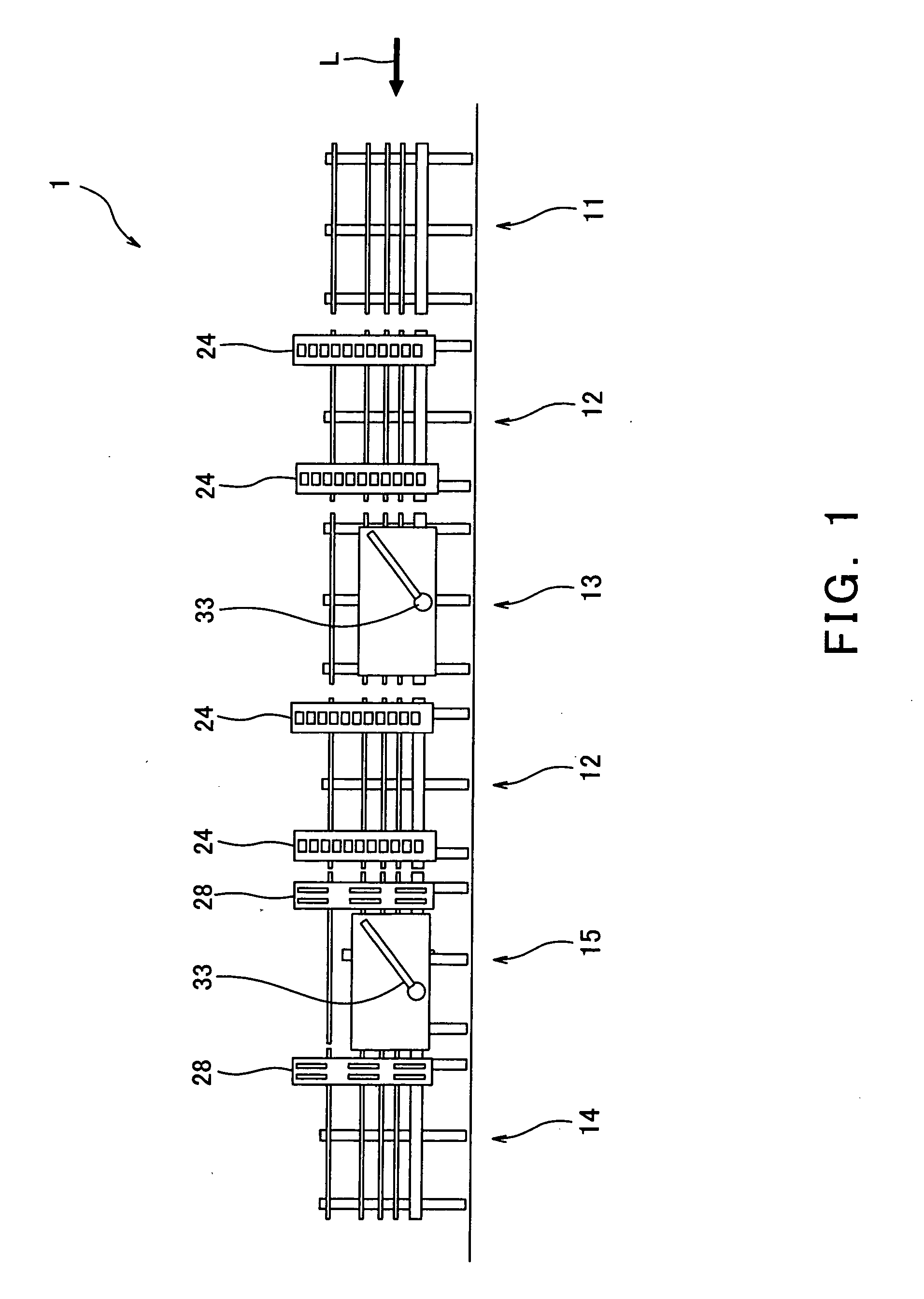

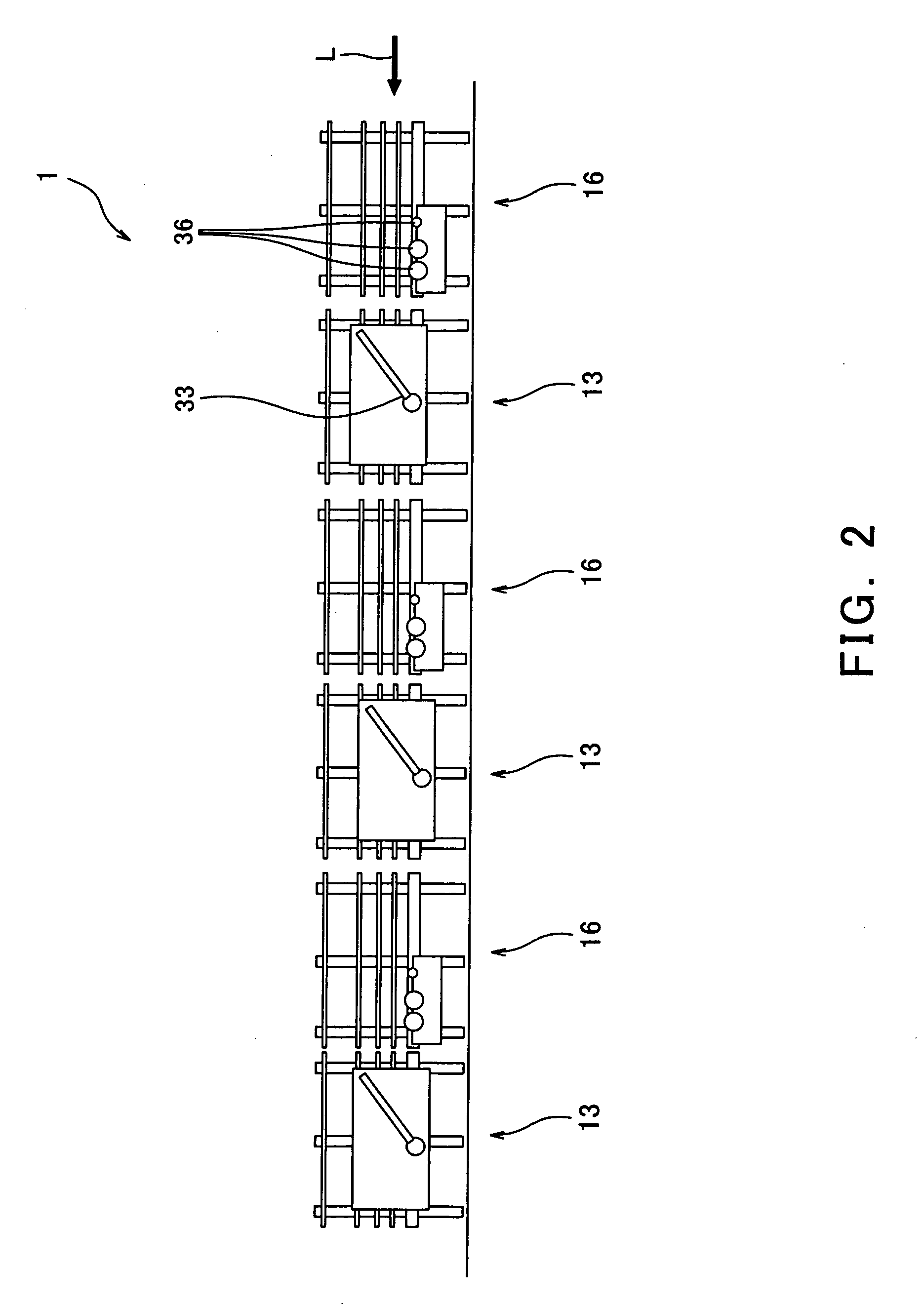

Plate Material Vertical Processing Line

ActiveUS20070271756A1Quality improvementSave installation spaceCharge manipulationSupporting framesHigh pressure waterHigh pressure

A plate material vertical processing line that is capable of subjecting large-sized and thinned glass plates to scribing, venting, etc without degrading their quality, comprises a plurality of processing devices each having a modular structure; wherein each of the processing devices includes a platform; a belt conveyor that is mounted on the platform and is configured to convey a glass plate placed in a substantially upright position while supporting a lower end of the glass plate; and a fluid guide that is mounted on the platform and is configured to apply a fluid pressure to a surface of the glass plate to support the glass plate in the substantially upright position and in a non-contact state; and wherein the processing devices include a combination of at least two processing devices selected from a scribing device, a venting device, a chamfering device, a cleaning agent washing device, a water washing device, a high-pressure water spray device, and a glass plate turn device.

Owner:KAWASAKI HEAVY IND LTD

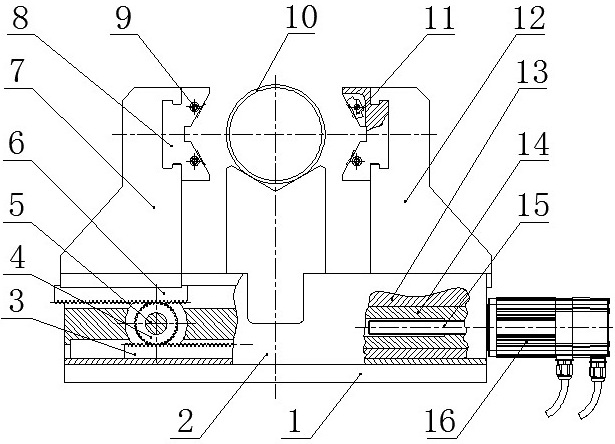

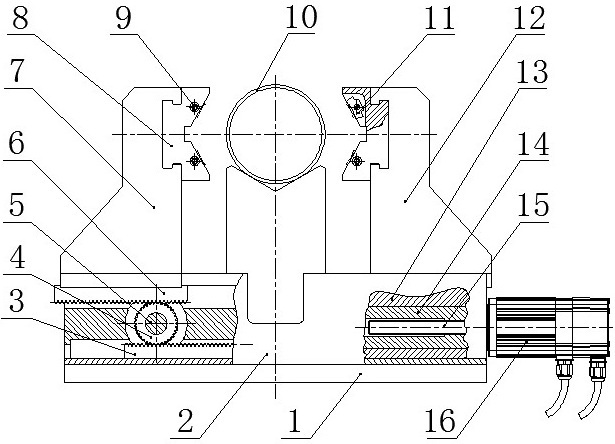

Center-aligning floating clamping fixture

InactiveCN102632404AAvoid deformationDecrease the jump valuePositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a center-aligning floating clamping fixture used in a machine tool for two ends of a steel pipe. The structure of the center-aligning floating clamping fixture comprises a fixture supporting frame, a driving mechanism, a transmission mechanism, a clamping mechanism and a floating aligning mechanism, wherein the transmission mechanism and the clamping mechanism are connected with each other, the clamping mechanism is provided with two chuck uprights which are parallel to each other in opposite directions, the uprights are provided with V-shaped jaws and connected with a bracket, a V-shaped clamp is provided with two pairs of floating clamping blocks, clamping surfaces of the clamping blocks are multidentate clamping surfaces, and the multidentate clamping surfaces are positioned on a same cylindrical surface. The center-aligning floating clamping fixture can be used for special machine tool equipment for machining the two ends of the steel pipe of a DT II type roller of a belt conveyor, and the geometric axis center of the steel pipe to be automatically aligned with the axis center of the machine tool so as to control radial deformation of the steel pipe.

Owner:SHENZHEN CEMCN

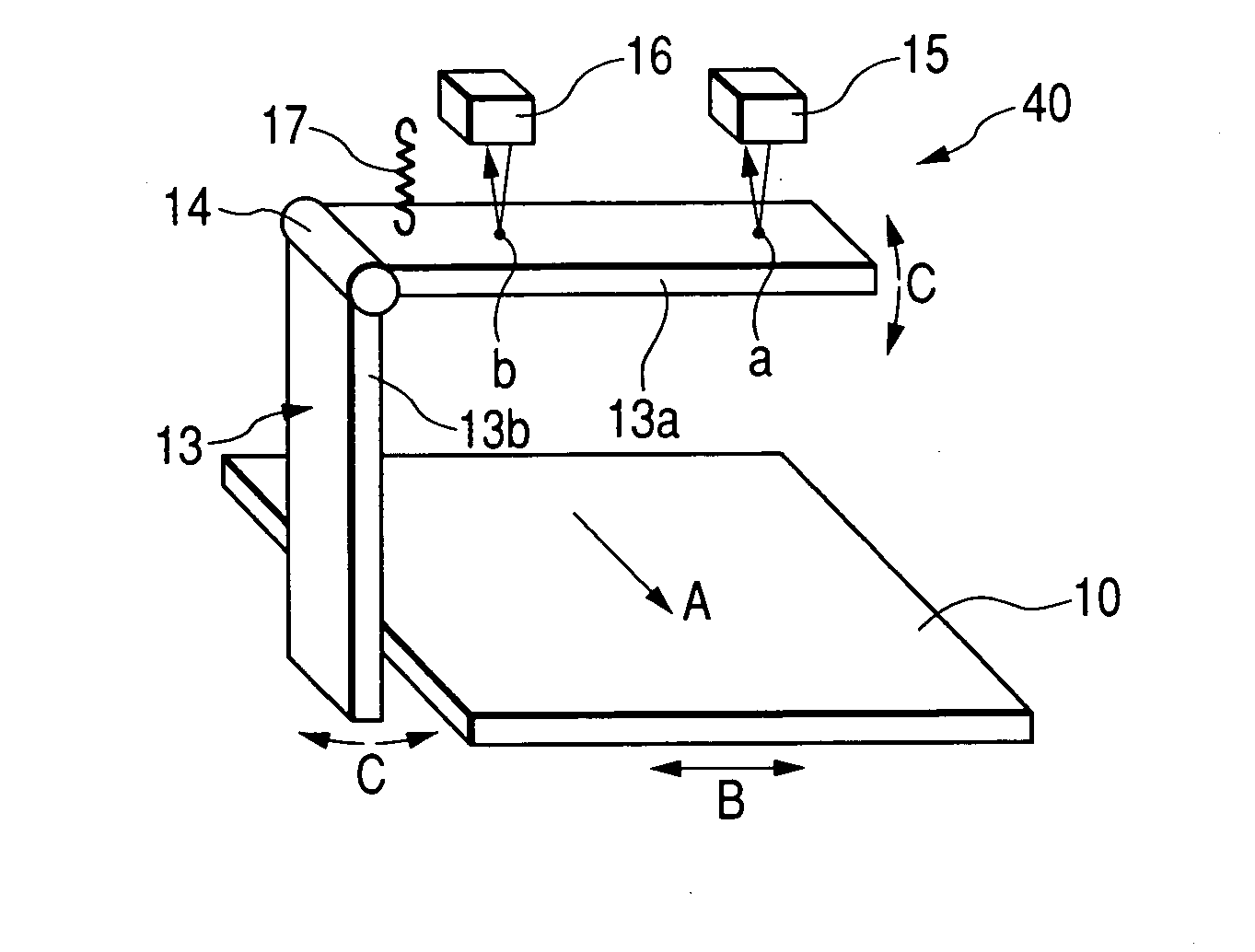

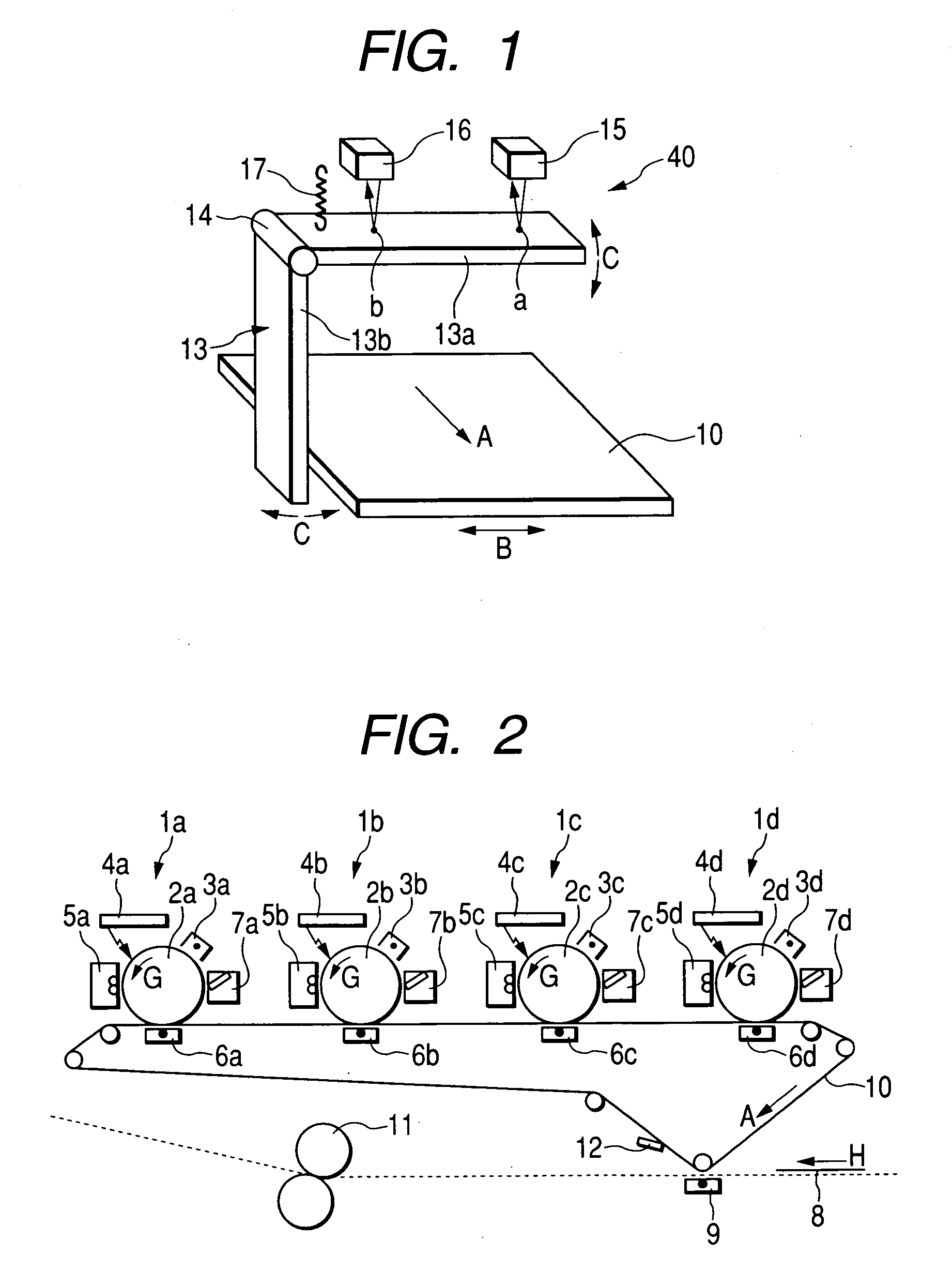

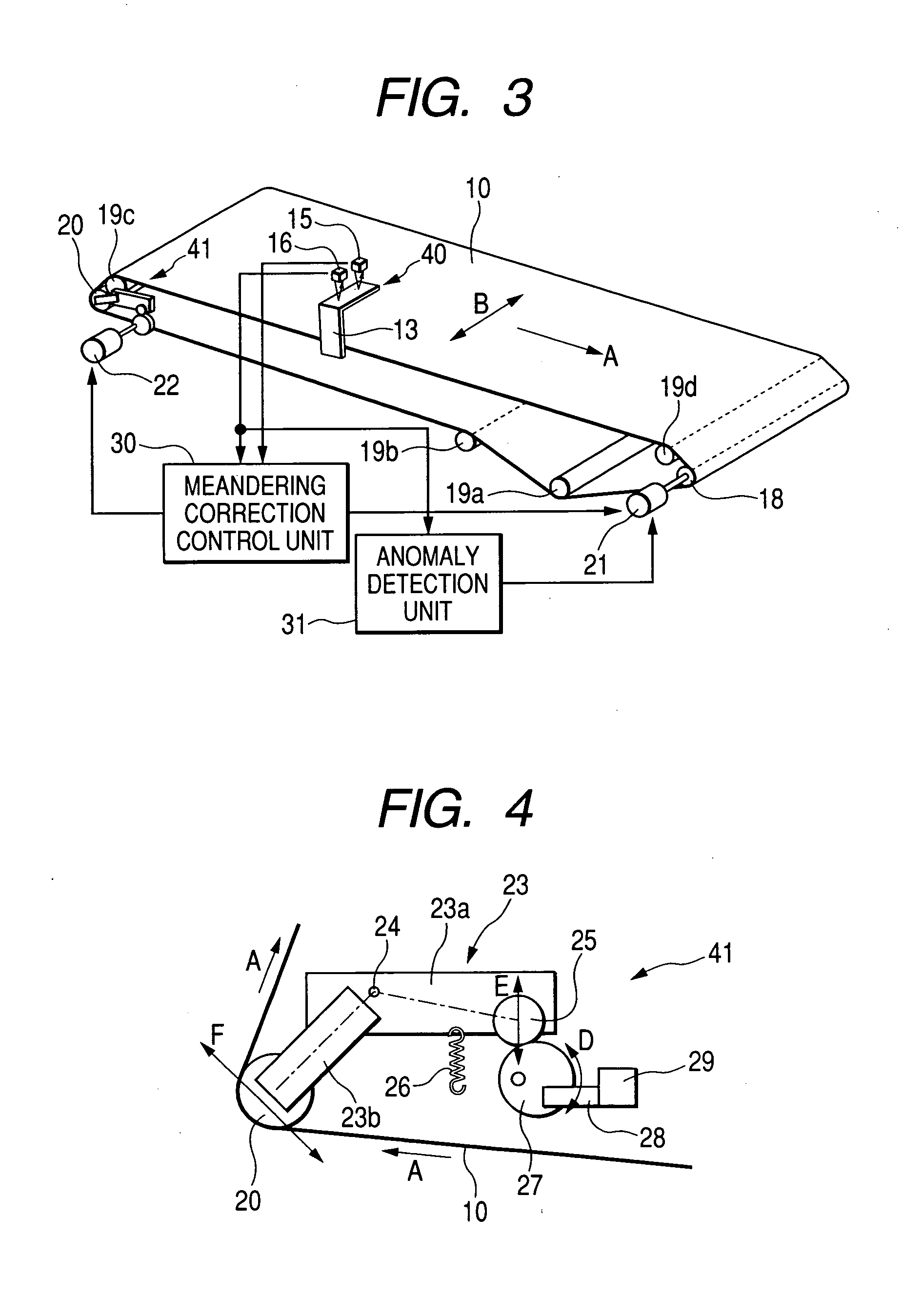

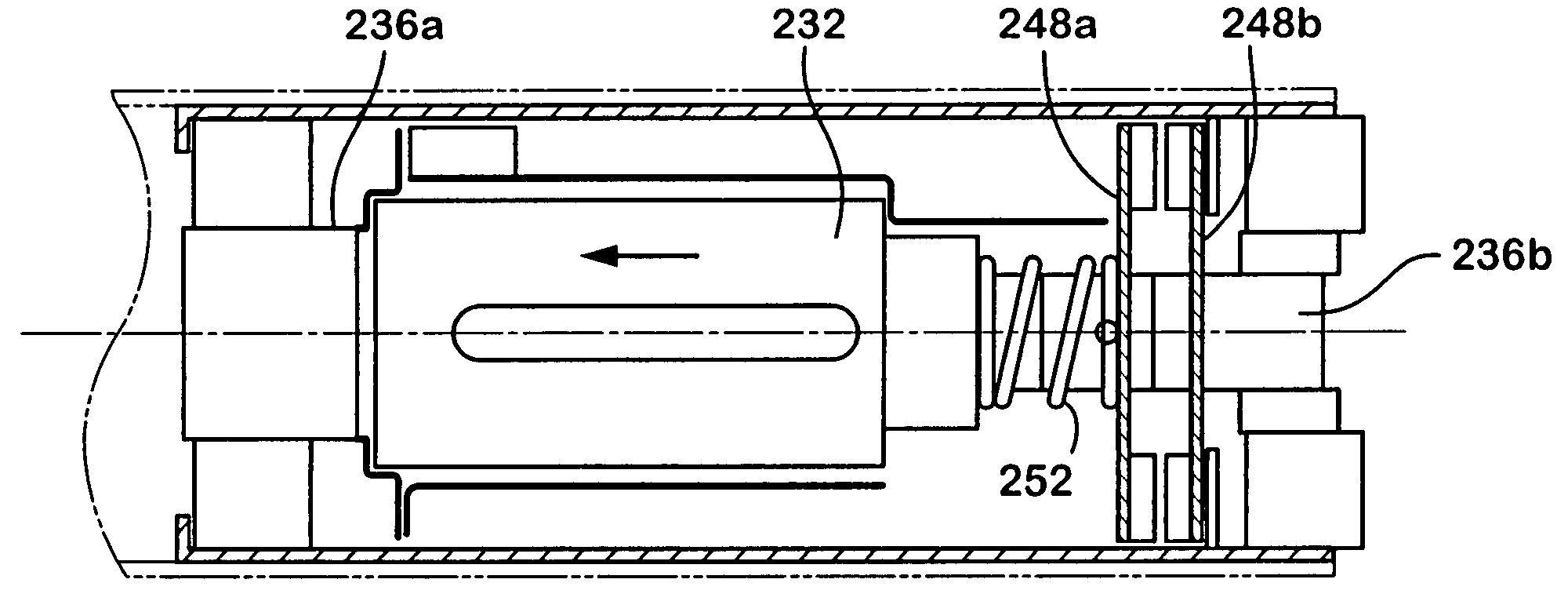

Belt conveyor and image forming apparatus using the same

InactiveUS20060289280A1Improve accuracyImprove picture qualityElectrographic process apparatusRollersImage formationBelt conveyor

A belt conveyor includes: an endless belt that is looped over a plurality of rollers, the plurality of rollers including a drive roller and a meandering correction roller; a drive unit that rotates the drive roller to drive the endless belt; a meandering correction unit that adjusts an inclination of the meandering correction roller to correct meandering of the endless belt in a width direction thereof; a plurality of position detection units that detect positions of the endless belt in the width direction thereof and output detection signals; and a meandering correction control unit that selectively uses the detection signals from the plurality of detection units to control the meandering correction unit.

Owner:RICOH KK

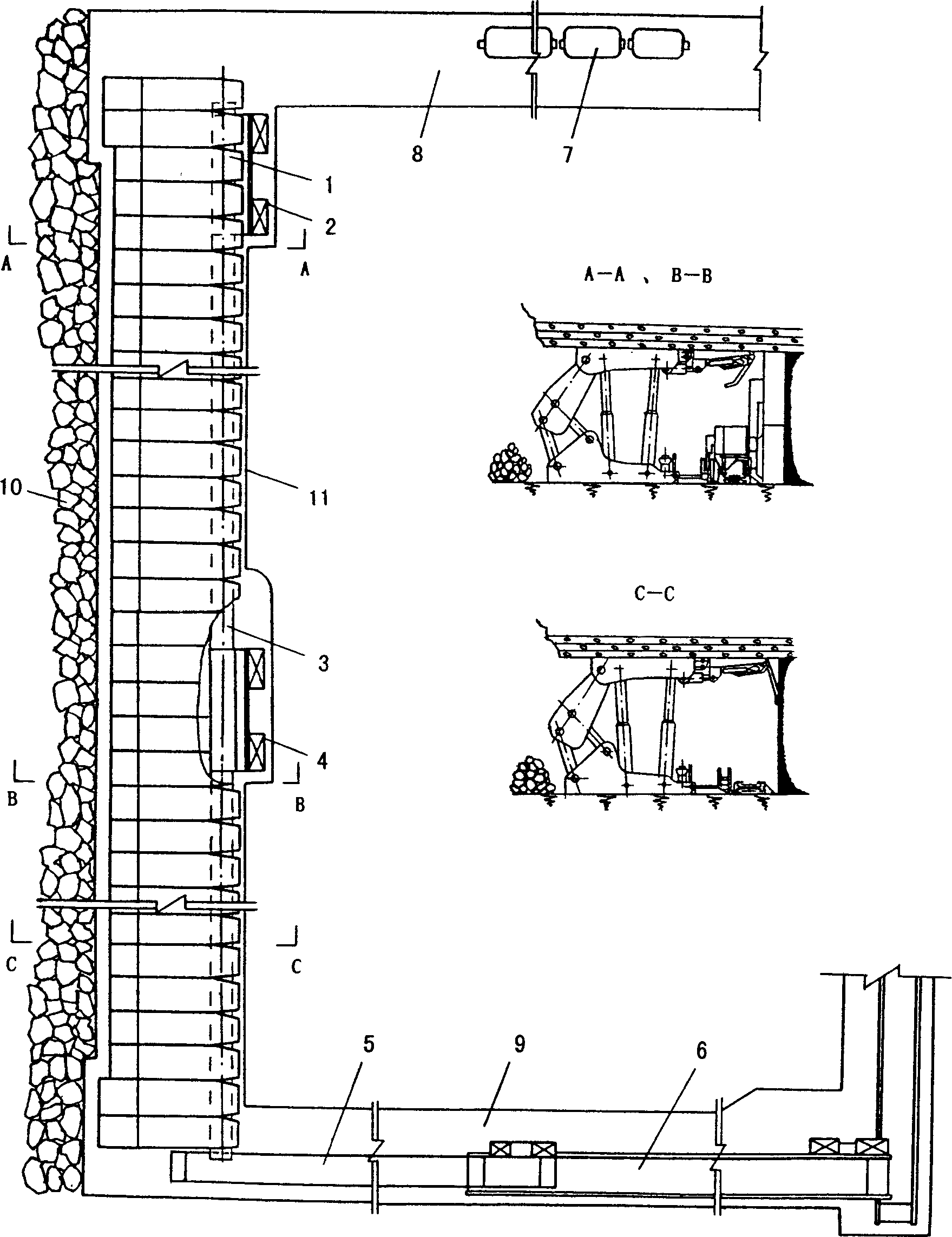

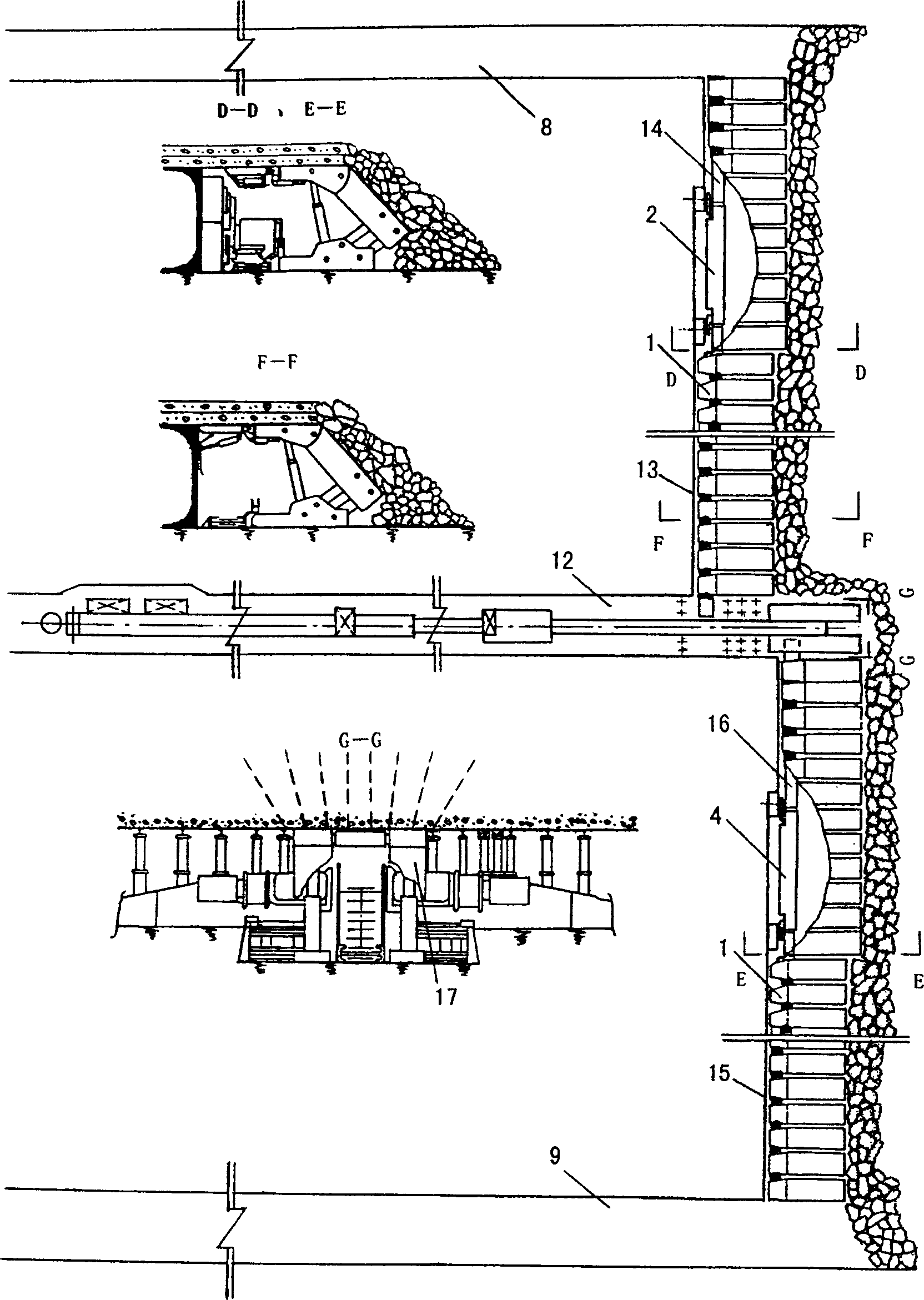

Comprehensive coal-mining process by using long wall mining method

InactiveCN1865657ALow costReduce in quantityUnderground miningSurface miningEngineeringEarth surface

The invention relates to a long-wall coal method, which can be used in stable coal bed, rigid top plate, non-broken incline middle-thickness coal bed, and thick coal bed layered long-wall method. Wherein, it arranges hydraulic support, scrape transporter, and roller coal machine at the long-wall working surface; arranges groove transporter and flexible band transporter at the transport channel; the working surface has ultra long length, which is two times of integrated coal surface; it uses two coal machines on one scrape transporter, to scrape the upper half surface and the lower half surface; and it can arrange middle channel at the middle of integrated surface as the transport channel; and arranges scrape transporters at the upper and lower half working surfaces. The invention has high efficiency, while it can reduce the digging rate and improve the resource recycle rate.

Owner:YANKUANG GRP CO LTD

Automatic classifying garbage can based on pattern recognition technology

InactiveCN106904386AEasy post-processingApplicable fine classificationWaste collection and transferRefuse receptaclesEngineeringManipulator

The invention discloses an automatic classifying garbage can based on the pattern recognition technology and relates to the garbage can. The automatic classifying garbage can comprises a can body and a can cover. A garbage putting bin is arranged in the can body. A first infrared sensor is arranged in the garbage putting bin. Bag breaking mechanisms are installed on the side walls of the garbage putting bin. A classifying device platform is arranged below the garbage putting bin. A manipulator and a belt conveyor are installed on the classifying device platform. A plurality of garbage classifying storage boxes are arranged below the classifying device platform. The output end of the belt conveyor corresponds to the inlet end of the garbage classifying storage box located at the tail end. A garbage recognition device used for recognizing the garbage type is installed on the can body. The manipulator is used for picking garbage into the corresponding garbage classifying storage box according to information collected by the garbage recognition device. The garbage enters the classifying device platform through bag breaking and separating, and then according to the garbage type recognized by the garbage recognition device, the garbage is classified in detail, and post-processing of the garbage is facilitated.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

Heat-resistant wear-resistant belt conveyor cover rubber and preparation method thereof

The invention relates to a heat-resistant wear-resistant belt conveyor cover rubber and a preparation method thereof. The product has favorable wear resistance. The preparation method comprises the following steps: carrying out plastification or co-plastification on styrene-butadiene rubber and cis-1,4-polybutadiene rubber on an open mill, and banburying the plastified rubber in a Banbury mixer; opening a ram piston, adding reinforcing filler, vulcanization activator, coupling agent, plasticizer, anti-aging agent and vulcanization retarder, carrying out turn milling, discharging, and cooling with a fan at normal temperature to obtain a first-section compounded rubber; and carrying out second-section compounding to obtain the product heat-resistant wear-resistant belt conveyor cover rubber, wherein the second-section compounding comprises the following steps: compounding the first-section compounded rubber, vulcanizing agent and vulcanization accelerator in a Banbury mixer, carrying out turning milling, discharging, and cooling with a fan at normal temperature. The heat-resistant wear-resistant belt conveyor cover rubber satisfies the requirement of material conveying in a steel factory for temperature, and greatly prolongs the service life of the belt conveyor, thereby implementing favorable economic benefit.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

Conveyor roller with brake

Owner:DEMATIC

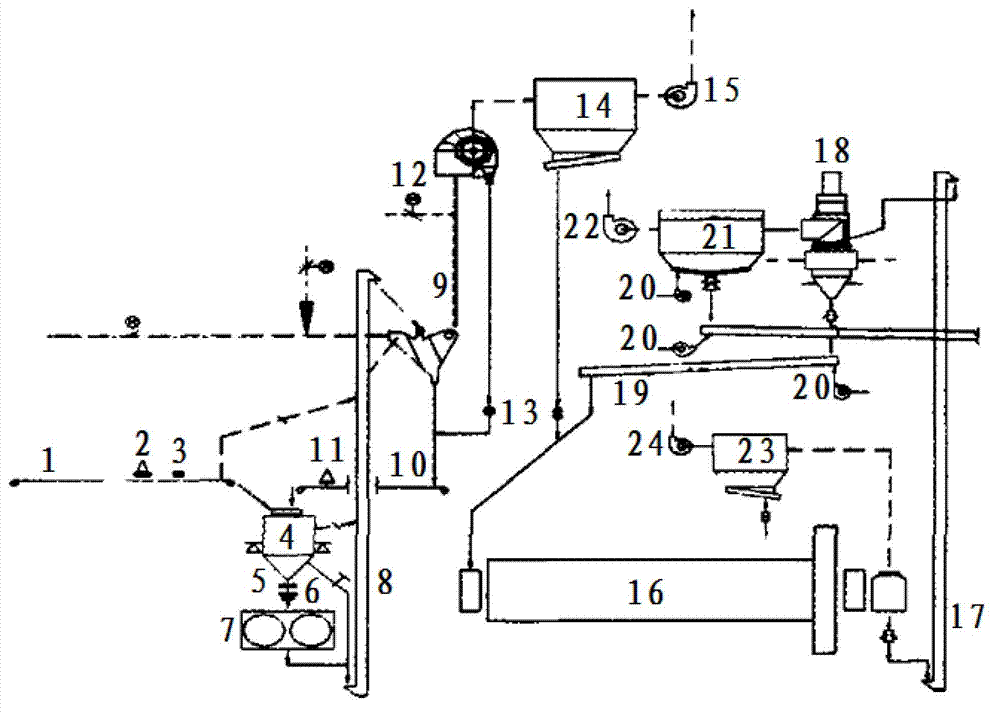

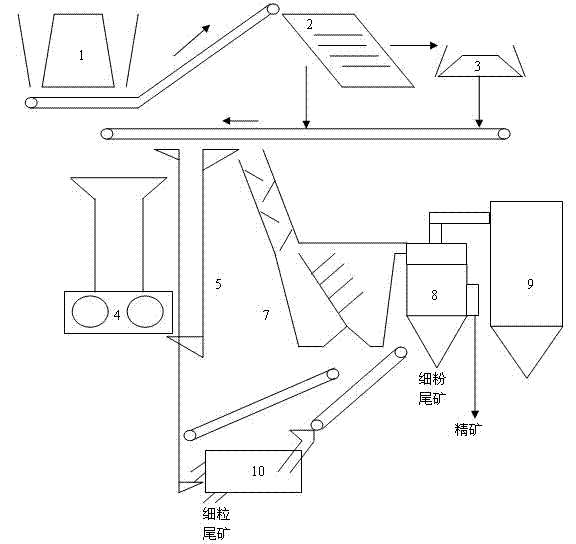

Slag micropowder grinding system and technology

The invention discloses a slag micropowder grinding system and a technology. The system consists of a roller press, an air flow classifier, a dynamic classifier, a ball mill and a high-efficiency powder concentrator. Slag is subjected to de-ironing by a de-ironing separator, sent into the roller press by a belt conveyor for high-pressure treatment, and then sent into the air flow classifier by a cake elevator for separation; if the particle size of the slag is large, the slag returns to the roller press for extrusion again; fine powder with a small particle size enters the dynamic classifier along with an air flow for the separation; coarse powder separated by the dynamic classifier returns to the roller press for the extrusion again; the fine powder is sent to the ball mill for grinding; the ground material is sent to the high-efficiency powder concentrator for the separation; the separated coarse powder is returned to the ball mill for the grinding again; and the separated fine powder enters air box pulse bag dust collectors along with the air flow for collection, and then serves as the finished slag for warehousing. According to the slag micropowder grinding system and the technology, the roller press, the air flow classifier and the dynamic classifier form a circle flow, and the ball mill and the high-efficiency powder concentrator form a circle flow, so that slag micropowder can be subjected to repeated crushing and grinding, and the particle shape of the finished micropowder is good.

Owner:湖南三泓建材有限公司

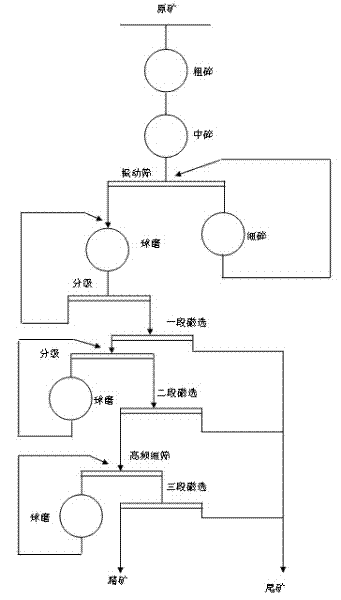

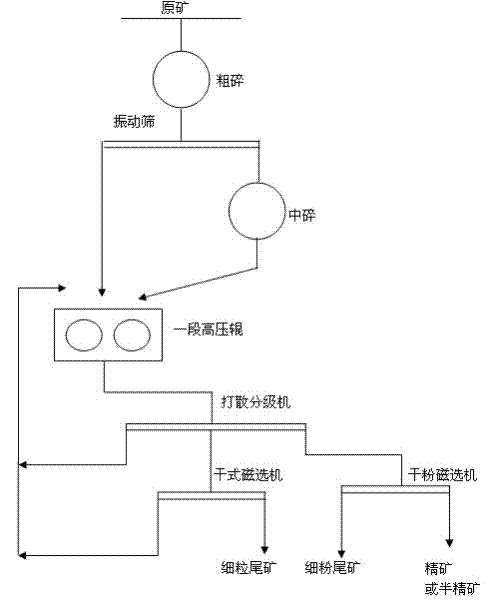

Dry-grinding and dry-separation method of magnetite

ActiveCN102240588ASimplify the crushing processSave moneyGas current separationGrain treatmentsMagnetiteClosed loop

The invention discloses a dry-grinding and dry-separation method of magnetite, which comprises the following steps of: feeding the crude ore of magnetite into a crusher for coarse crushing, and then feeding the crushed magnetite into a vibrating sieve for sieving; controlling the sieve meshes within a range of 35-75 mm; feeding the oversize product to the crusher for intermediate crushing and then feeding the crushed oversize product into a high-pressure roller mill along with the undersize product for fine crushing; breaking and grading the fine-crushed ore by a breaking-grading machine, thereby obtaining the products of three grain grades, i.e. coarse grains, fine grains and fine powder; returning the coarse-grain grade product to the high-pressure roller mill through an elevator, and feeding the fine-grain grade product to a dry type magnetic separator for magnetic separation and discarding tailings, wherein the magnetic field intensity is controlled within a range of 1200-3000 Gs; directly dryly stacking the discarded fine-grain grade tailings, and returning the fine-grain grade concentrate to the high-pressure roller mill through a belt conveyor and the elevator to form a closed loop; and feeding the fine-powder grade product into a cyclone magnetic separator, wherein the magnetic field intensity is controlled within a range of 600-1200 Gs, thereby obtaining concentrate or semi-concentrate. The dry-grinding and dry-separation method is low in power consumption, steel consumption and water consumption, and the tailings are easy to be disposed of.

Owner:CHENGDU LEEJUN IND

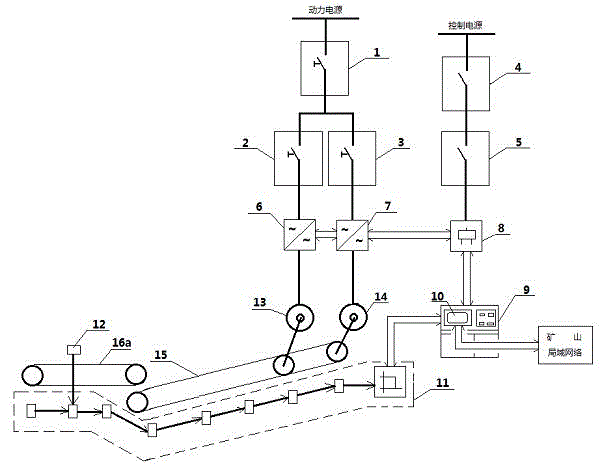

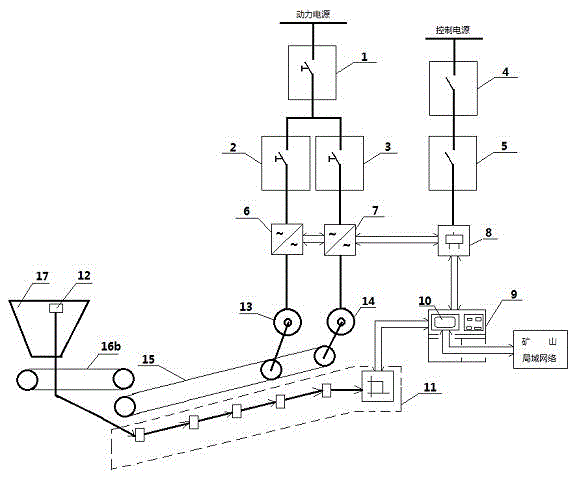

Belt conveyor control system and method capable of adjusting belt speeds automatically according to material flows or material levels

ActiveCN102942039AExtend your lifeReduce usage costsControl devices for conveyorsFrequency changerProgrammable logic controller

The invention provides a belt conveyor control system capable of adjusting belt speeds automatically according to material flows or material levels, and belongs to the belt conveyor control technology. The control system comprises a frequency conversion system, a programmable logic controller (PLC) system, a monitoring system and a detection system. The frequency conversion system comprises a power wire inlet device, a power feed device and a frequency converter. The PLC system comprises a power wire inlet control device, a power feed control device and a PLC device. The monitoring system comprises an operation platform and a display screen. The detection system comprises a material sensor which can use a contactless sensor. The control system sets the operation speed of a belt conveyor reasonably according to material flows or material levels and the operation state of a front conveyor and in additional conditions of time and motor currents, and the belt speed is adjusted by the controlling of the output frequency of the frequency converter.

Owner:SHANXI SANYUAN COAL IND +1

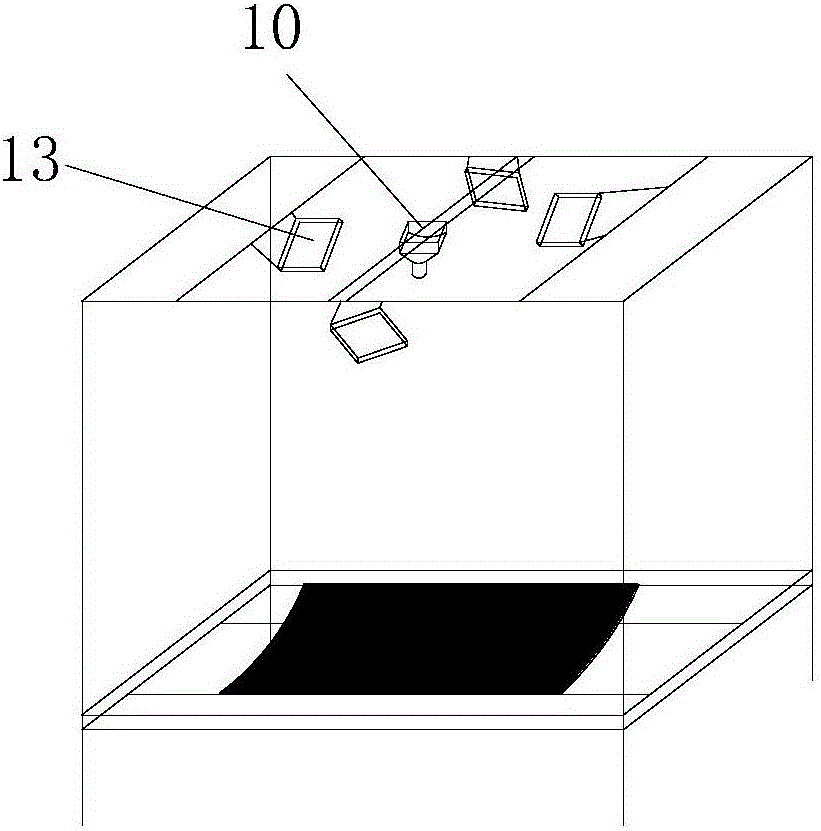

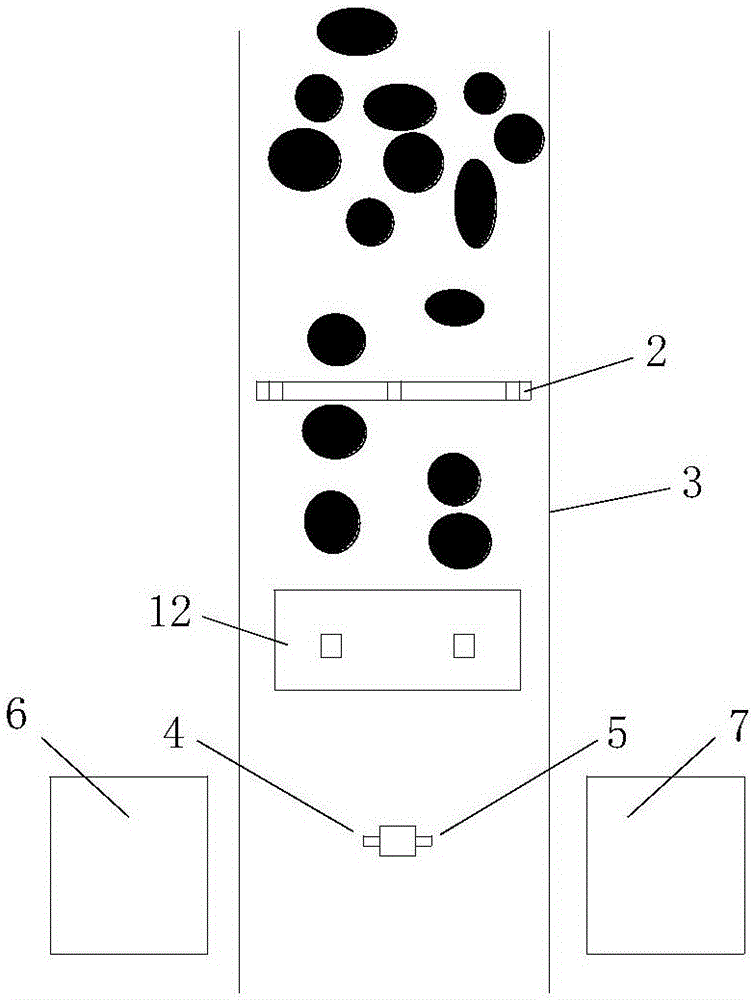

Automatic coal and gangue sorting system and method

The invention discloses an automatic coal and gangue sorting system and method, and belongs to a coal and gangue sorting system and method. The sorting system comprises a vibrator feeder, a queuing device, a coal collecting hopper, a gangue collecting hopper, a belt conveyor, a detecting device, a camera, an industrial personal computer, a lens hood, an LED light source, an executing device, a controller, a high-speed electromagnetic valve and a spray gun. A belt is monitored in real time through the camera, and two square sub-regions are selected, wherein side lengths of belt imaging regions corresponding to the sub-regions are smaller than the lower limit of granularity of coal and gangue; the grey level histogram average value of the two sub-regions is calculated in real time and compared with a threshold, determined through a test, of gangue, coal and the belt, when the grey level histogram average value of the sub-regions is larger than the threshold, the material is judged as gangue, the controller controls the high-speed electromagnetic valve to be switched on, the spray gun blows the gangue into the gangue collecting hopper, and coal continues to move and fall to the coal collecting hopper or the conveying belt. Real-time monitoring is conducted through the camera, control is timely, the sorting result is accurate, the layout is close to that of site artificial gangue discharge, and actual transformation is easy.

Owner:CHINA UNIV OF MINING & TECH

Continuous coal mining process method of open-pit coal mine

The invention relates to a continuous coal mining process method of an open-pit coal mine, the used main devices comprises a continuous coal mining machine, a walking type crushing machine of a continuous conveying machine unit, a bridge type transloading machine, a walking type transloading machine, an unloading car, a working face belt type conveyor, an outward transport heading belt type conveying machine and an outward transport machine lane belt type conveying machine, and the continuous coal mining process method adopts the continuous mining-continuous conveying way, and adopts the automatic mining, crushing, transloading, unloading and transportation. The coal mining method has advanced process, reasonable design, compact and continuous arrangement of the devices, safety, stability and reliability, high excavating efficiency, multi-stage transportation, smooth conveying and small occupied area, and can effectively improve the recovery rate of resources, reduce the consumption of fuel oil, reduce the carbon emission, be applicable to needs on low carbon, energy conservation and environmental protection and be a very ideal continuous coal mining process method of the open-pit coal mine.

Owner:TAIYUAN INST OF COAL SCI RES INST +1

Wall building robot

InactiveCN104141391APrecise positioningAutomated precisionBuilding material handlingBrickAutomatic control

The invention relates to a wall building robot which comprises a mechanical arm, a guide rail work table, a belt conveyor and an automatic control system. After computing, the mechanical arm controls a paw to grab bricks and place the bricks at pointed positions by being adjusted in position through all linear stepped devices and a rotary stepped motor, and after the bricks are grabbed, a conveyor belt is started to continue whitewashing, plaster browning and turning over circularly in sequence.

Owner:殷家土

Belt conveyor and method

A belt conveyor includes at least one belt module defined by at least one drive pulley and at least one other pulley that is generally an idler pulley positioned between opposite sidewalls of the conveyor, and having a continuous belt routed around the drive pulley and the other pulley. The drive pulley is operable to drive the continuous belt around the pulleys to move articles along the zone assembly. The belt conveyor may incorporate features that allow for improved maintenance methods and reduced down time during service intervals. These features may include a removable belt module, at least one pulley mounted on at least one pivot arm, or a combination thereof. The belt may have a low modulus characteristic and may be initially stretched when the belt is reeved or routed around the pulleys and the pivot arms are moved into their operating position.

Owner:DEMATIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com