Intelligent full automatic combine coal mining system

A fully automatic and intelligent technology, applied in ground mining, mining equipment, mining equipment, etc., can solve problems such as low production efficiency, low reliability, and poor safety, and achieve high production efficiency, reduced accident rate, and light system load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The system of the present invention will be further described below with reference to the accompanying drawings and embodiments.

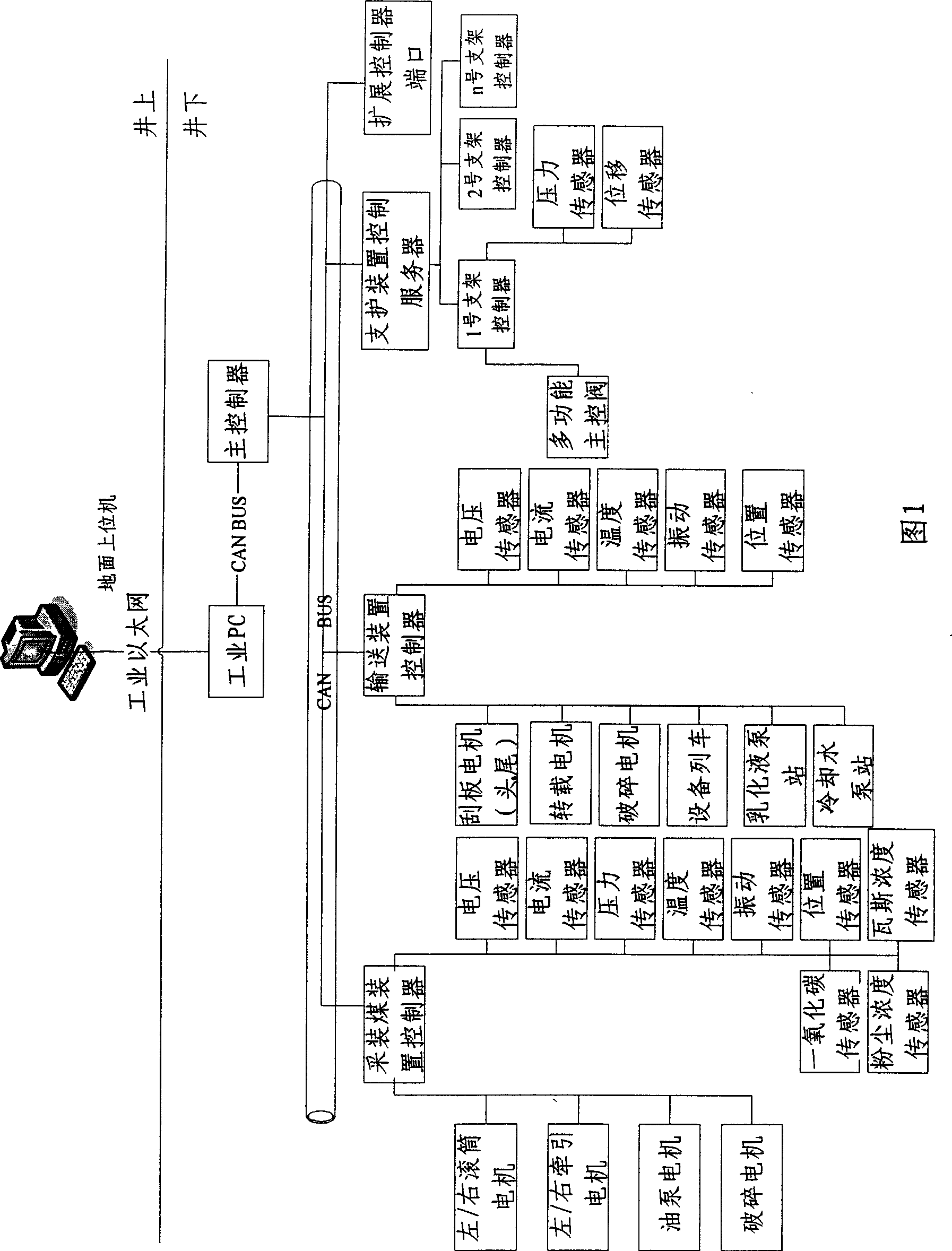

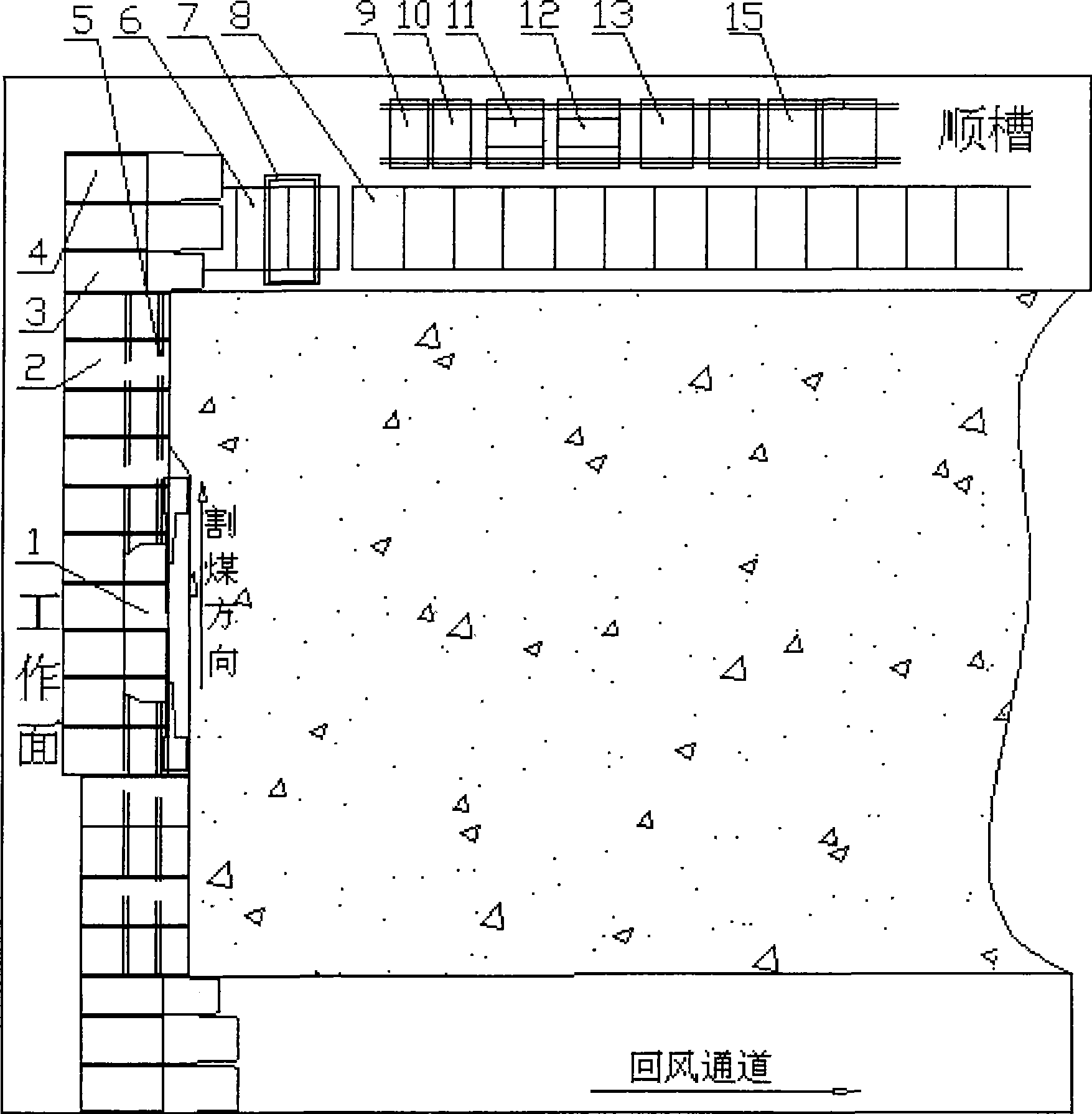

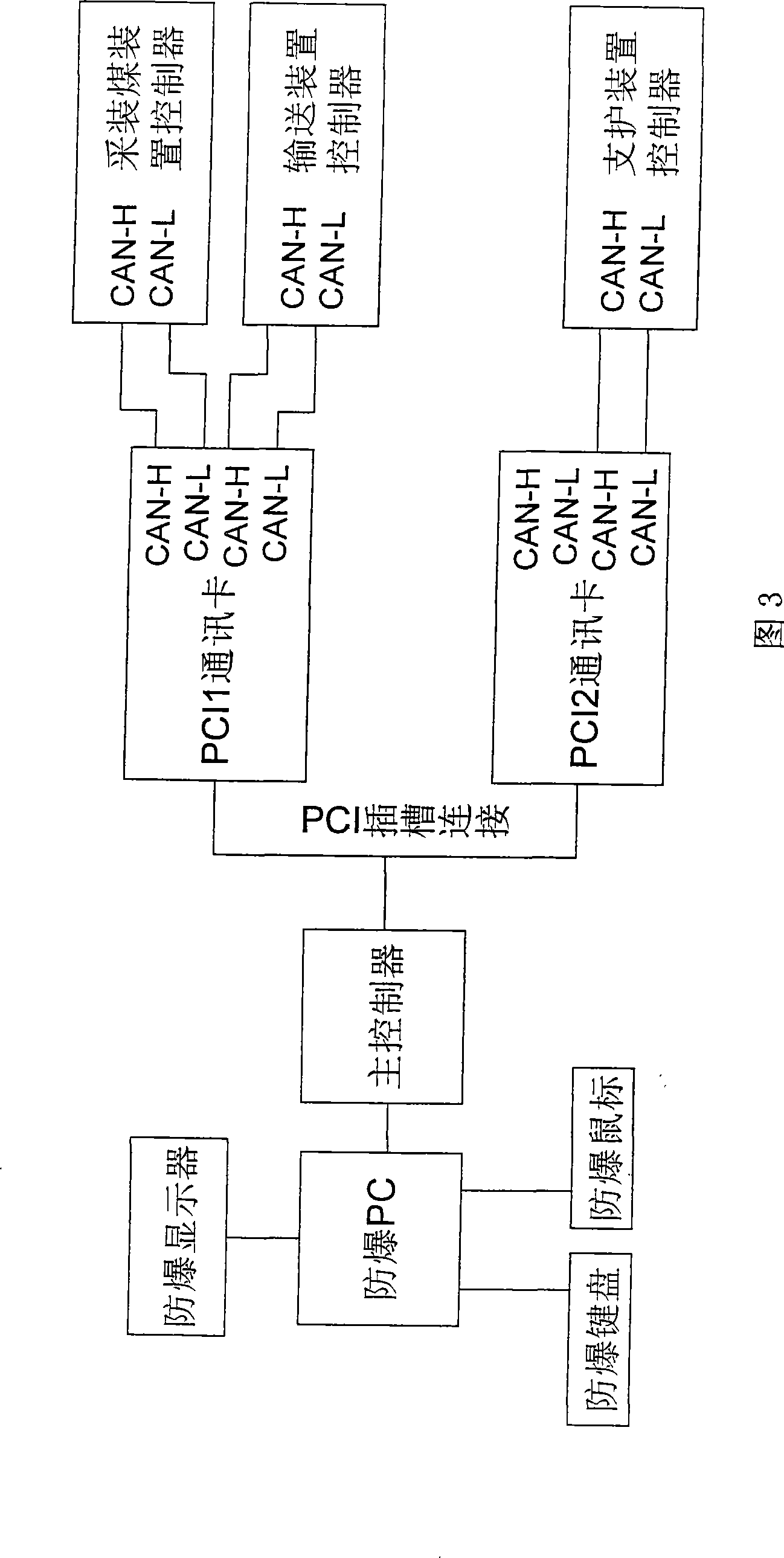

[0031] As shown in Figures 1 to 2, the intelligent automatic combined coal mining system of the present invention includes a coal mining and loading device, a conveying device, a supporting device and an equipment train, which are integrally installed on the working surface and in the trough under the coal mine. The coal charging device is installed on the conveying device, and the coal feeding outlet of the conveying device is conveyed to the outside of the well or into the coal bunker through the belt conveyor 8 arranged in the trough, and the supporting device is arranged behind the conveying device for supporting The roof of the coal seam is linked with the conveying device. The equipment train includes a central control room 9 with central control equipment, a starter 10, power equipment and a rescue cabin 15 with life-saving equipment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com