Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2436results about "Underground transport" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

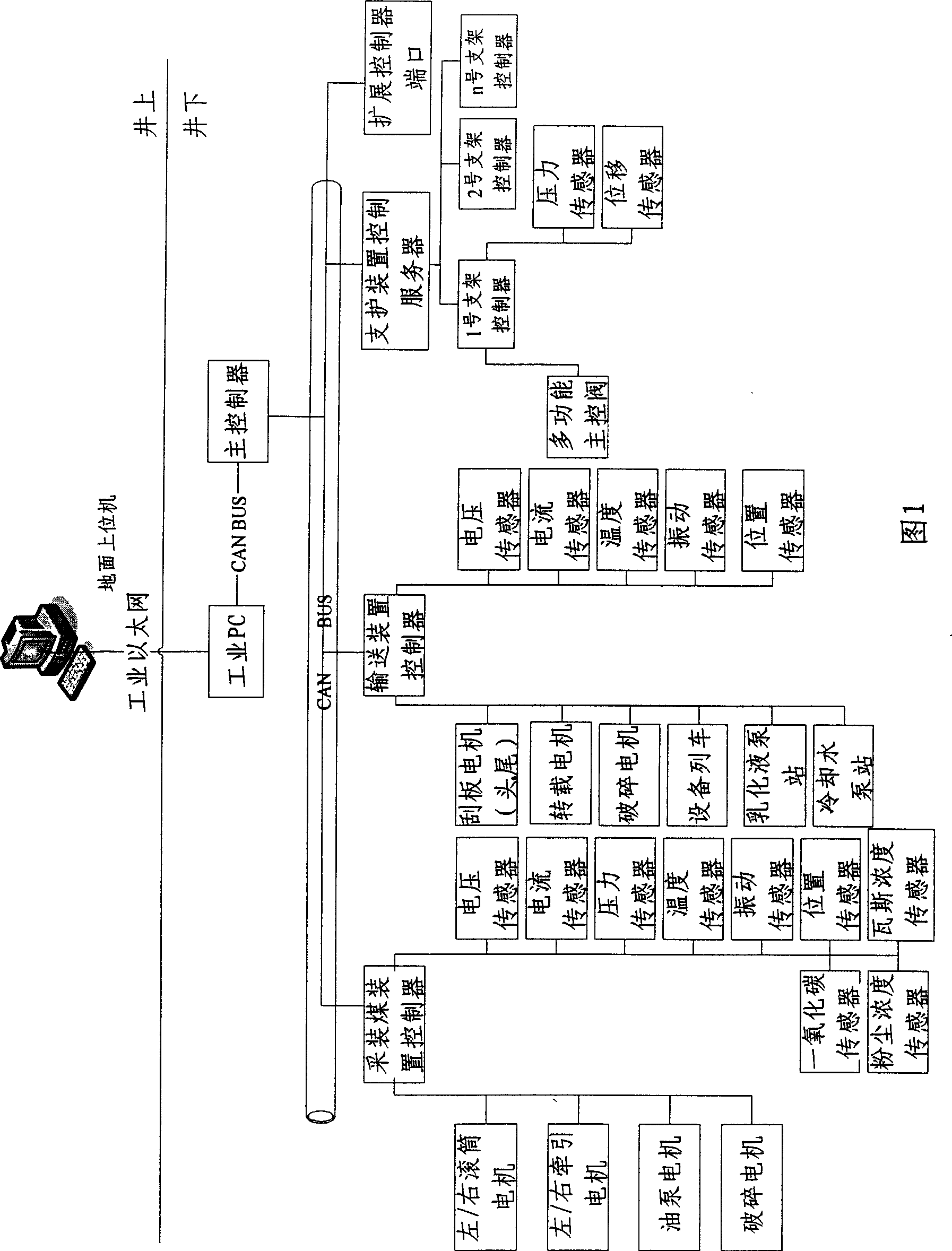

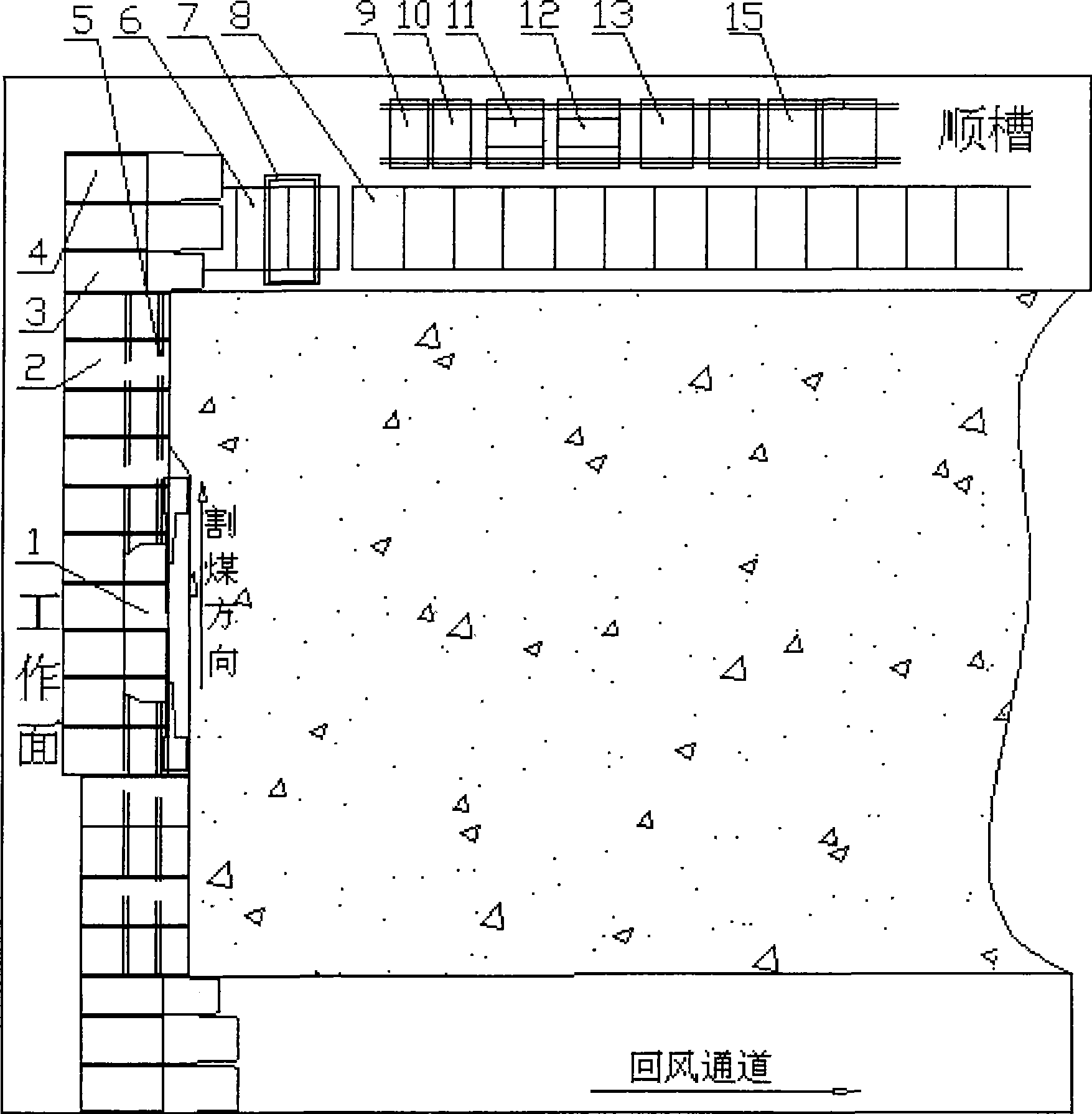

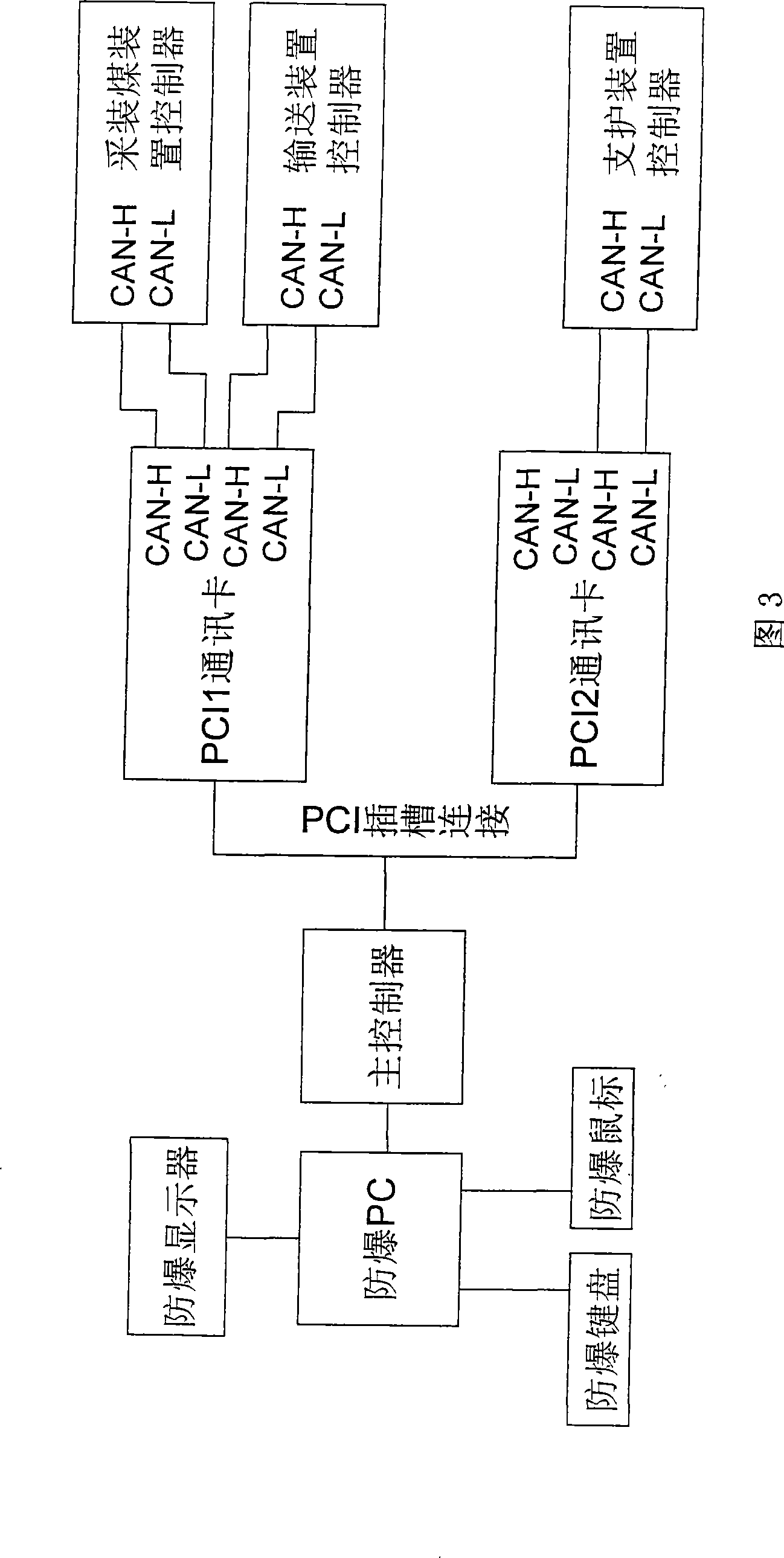

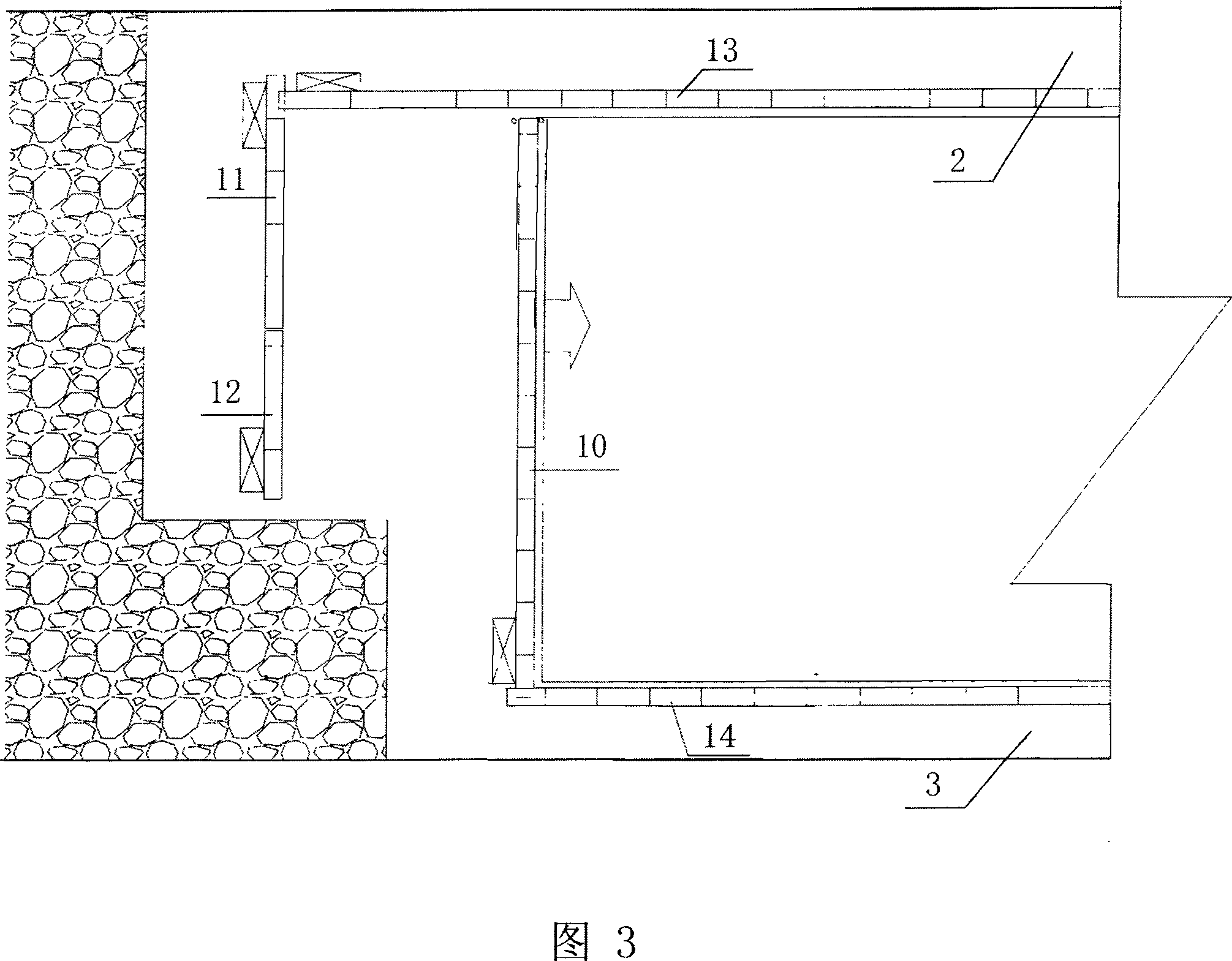

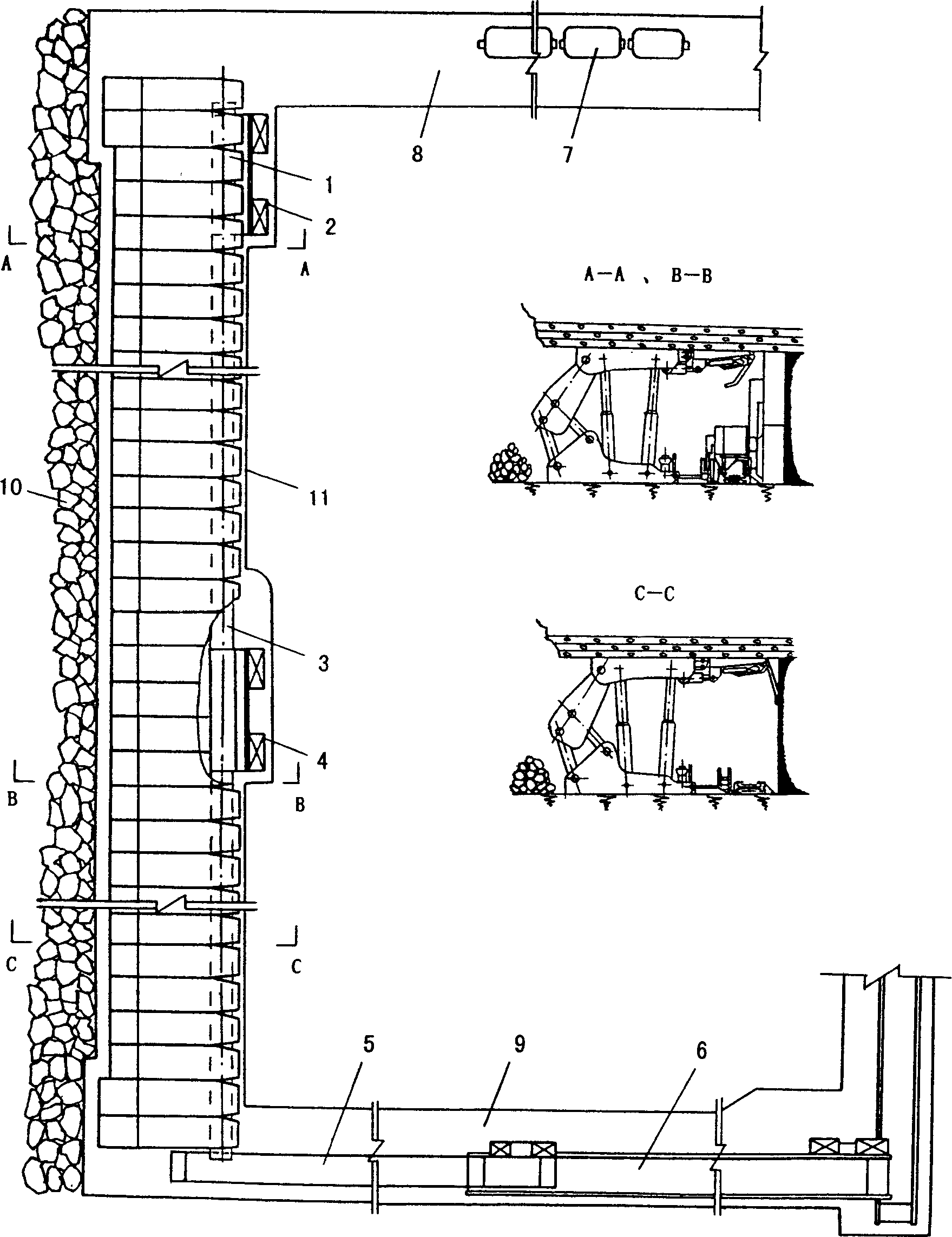

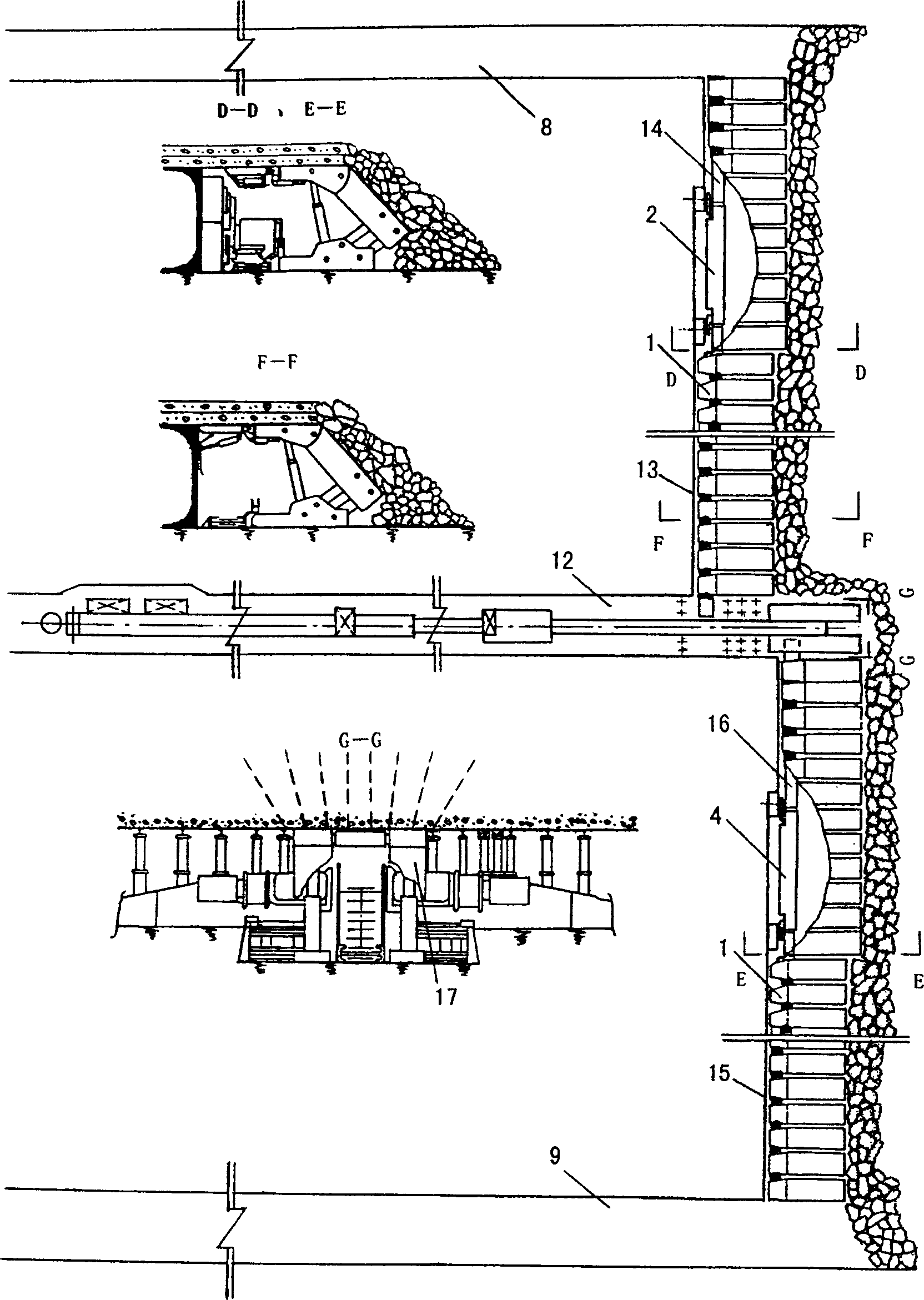

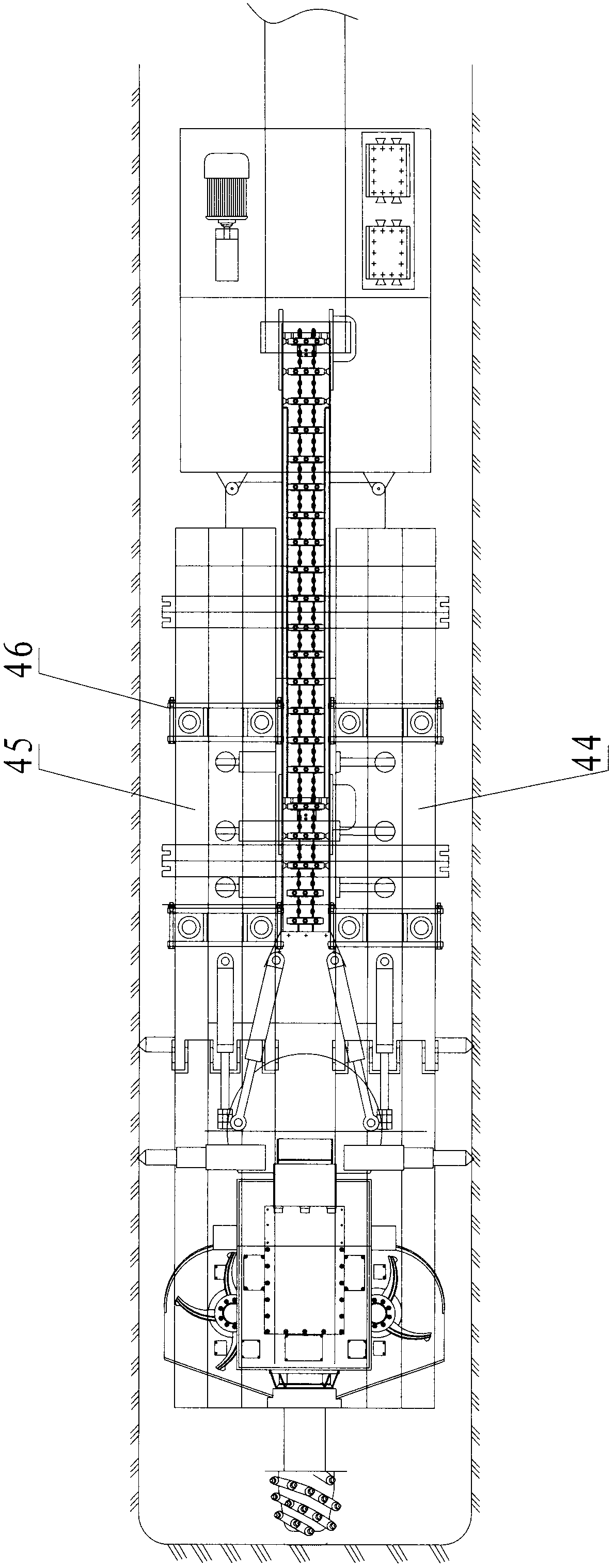

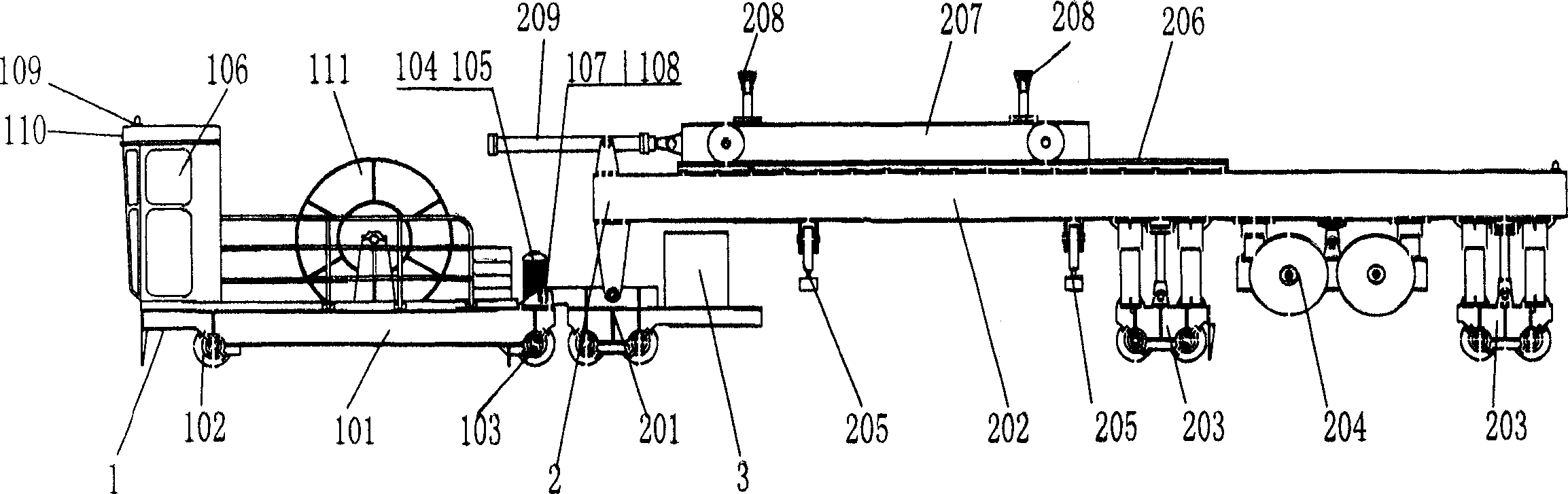

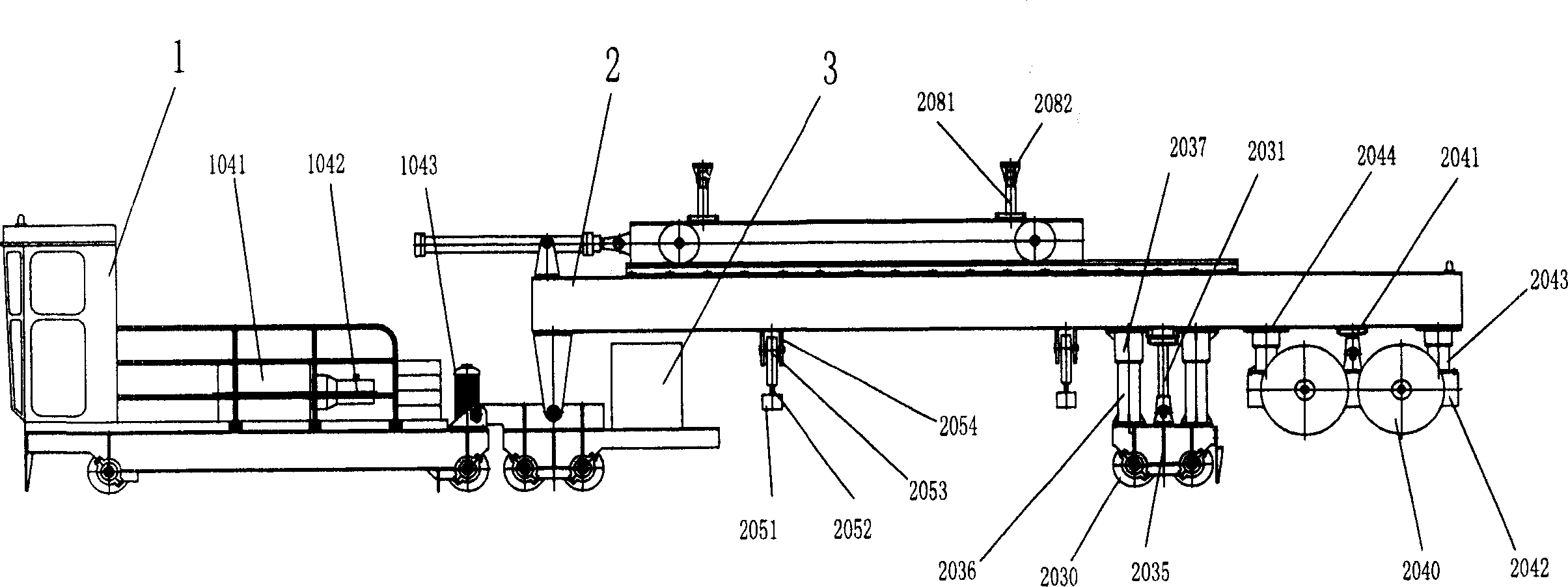

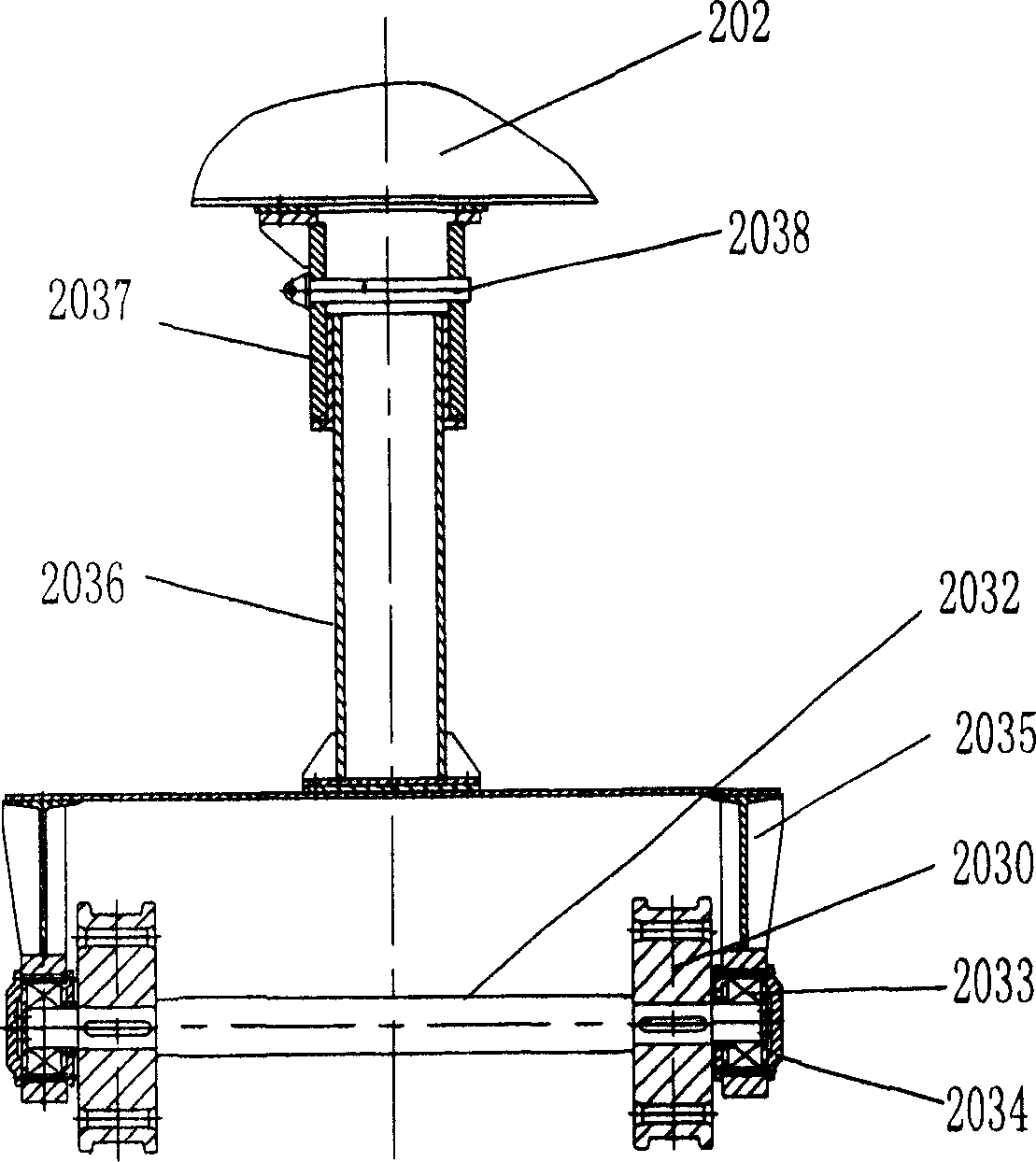

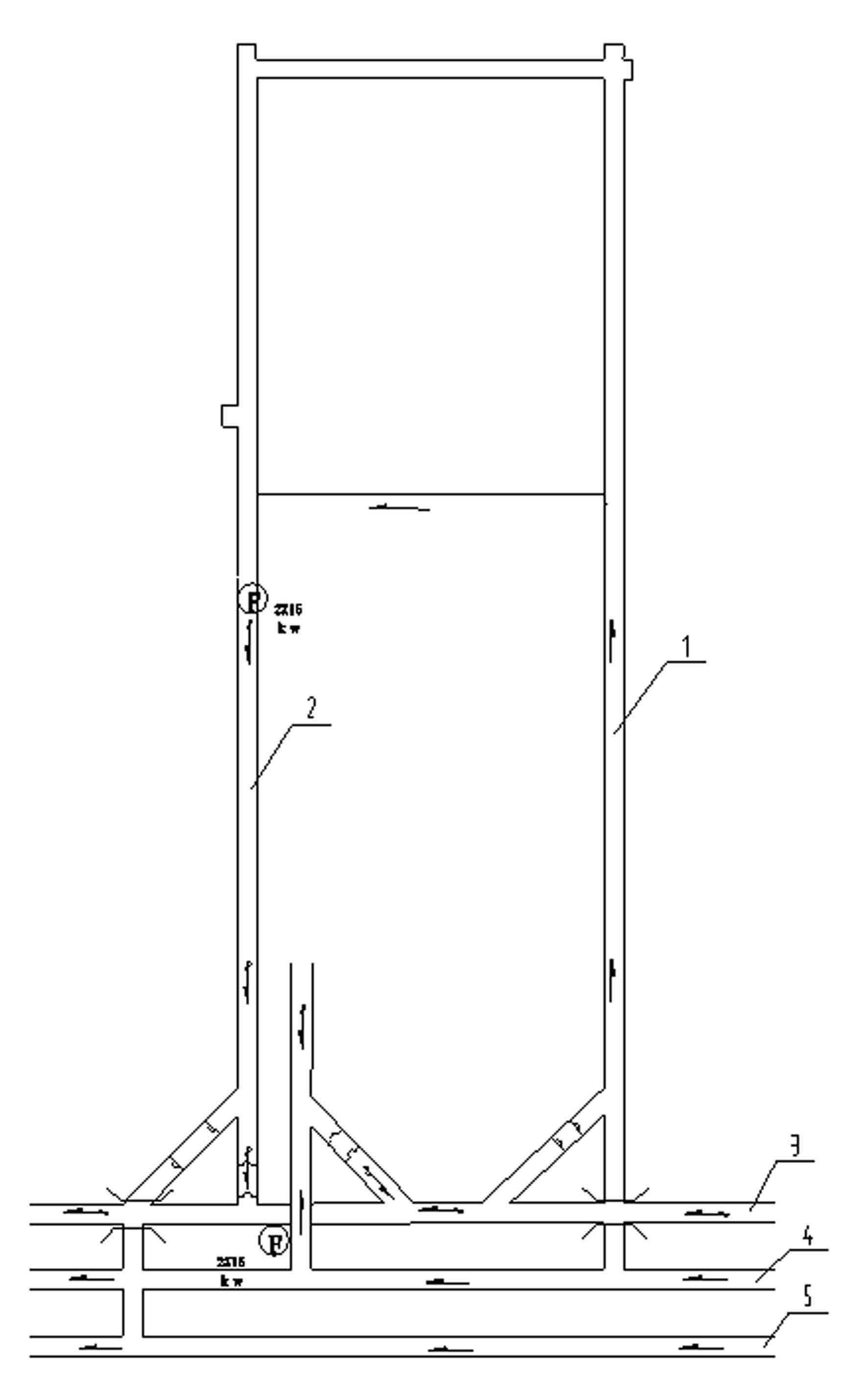

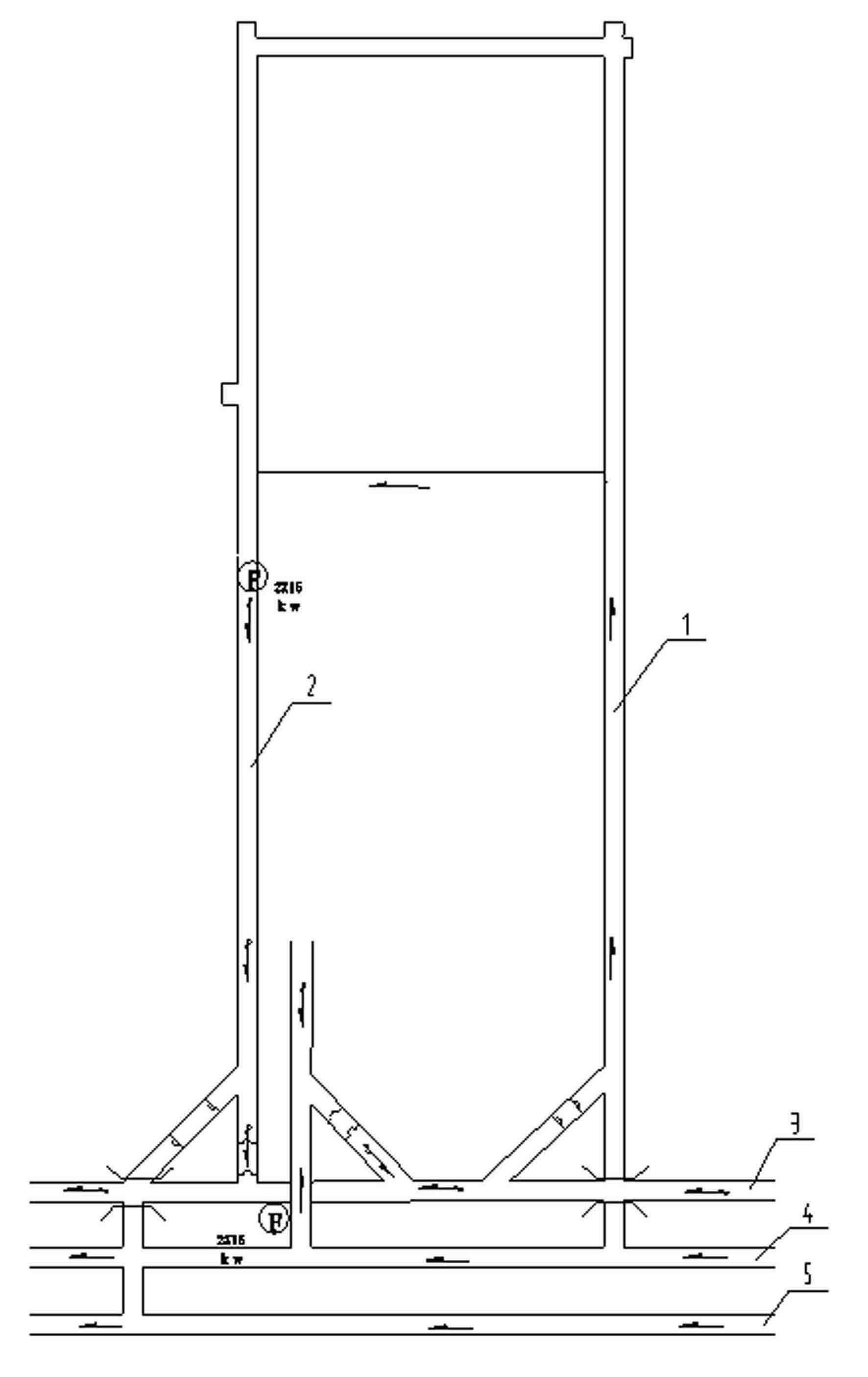

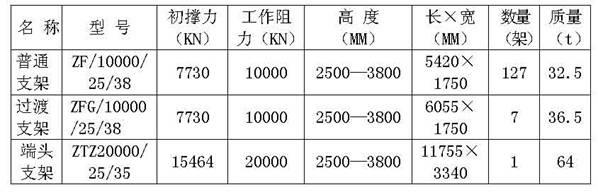

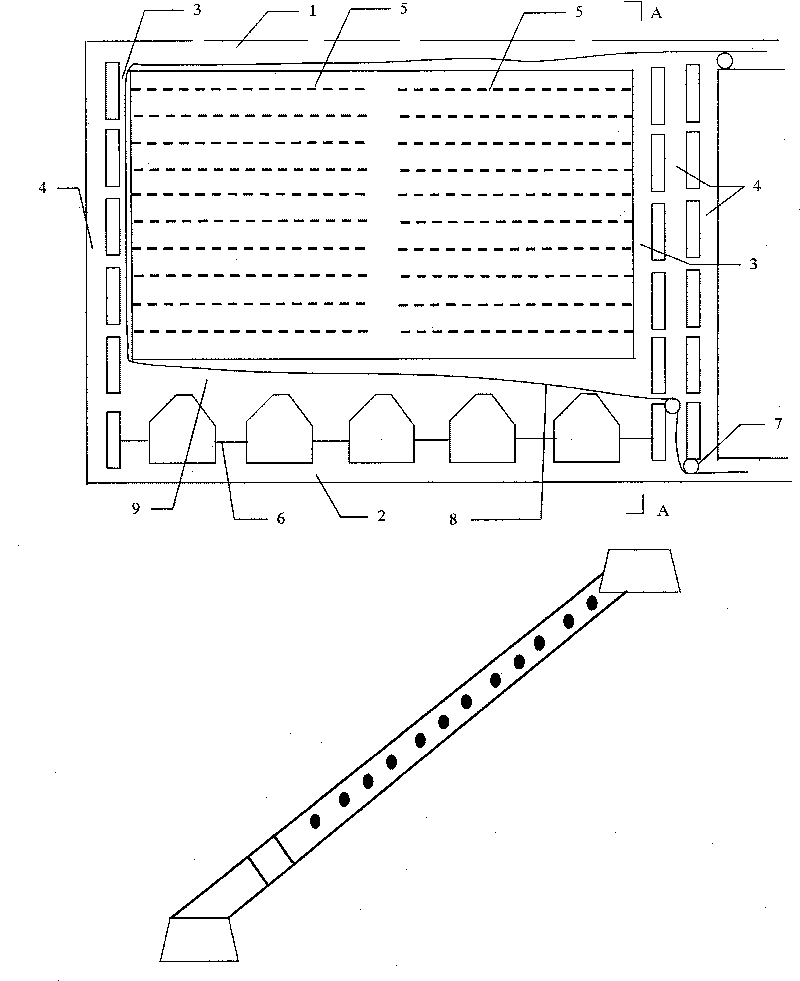

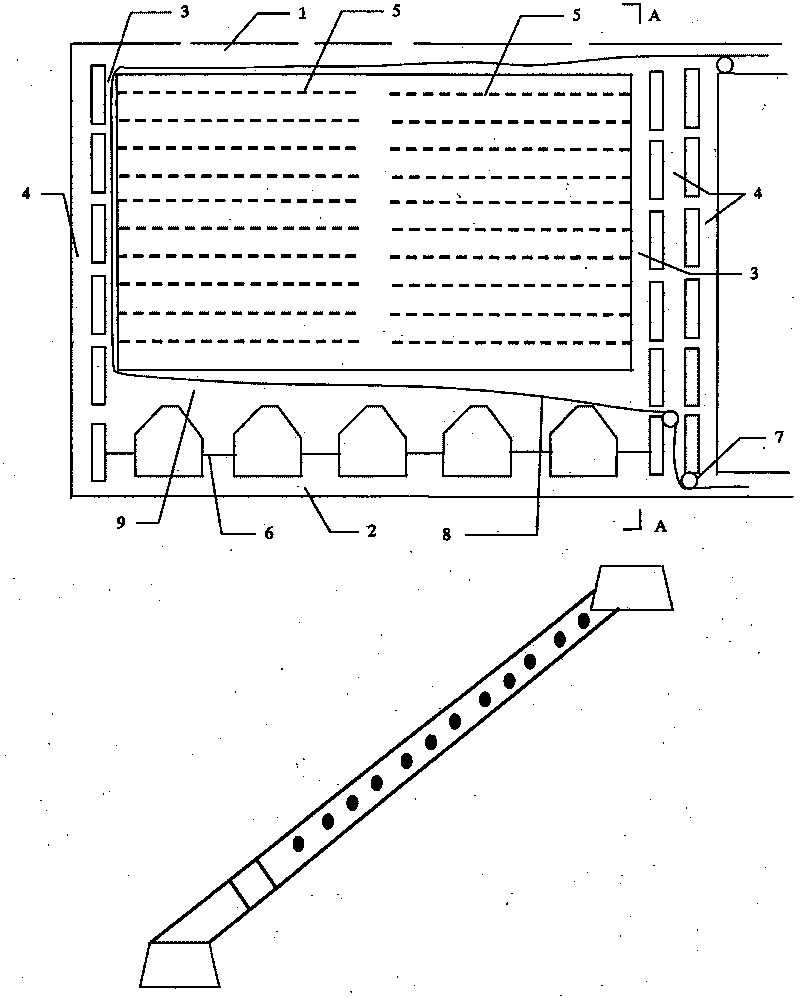

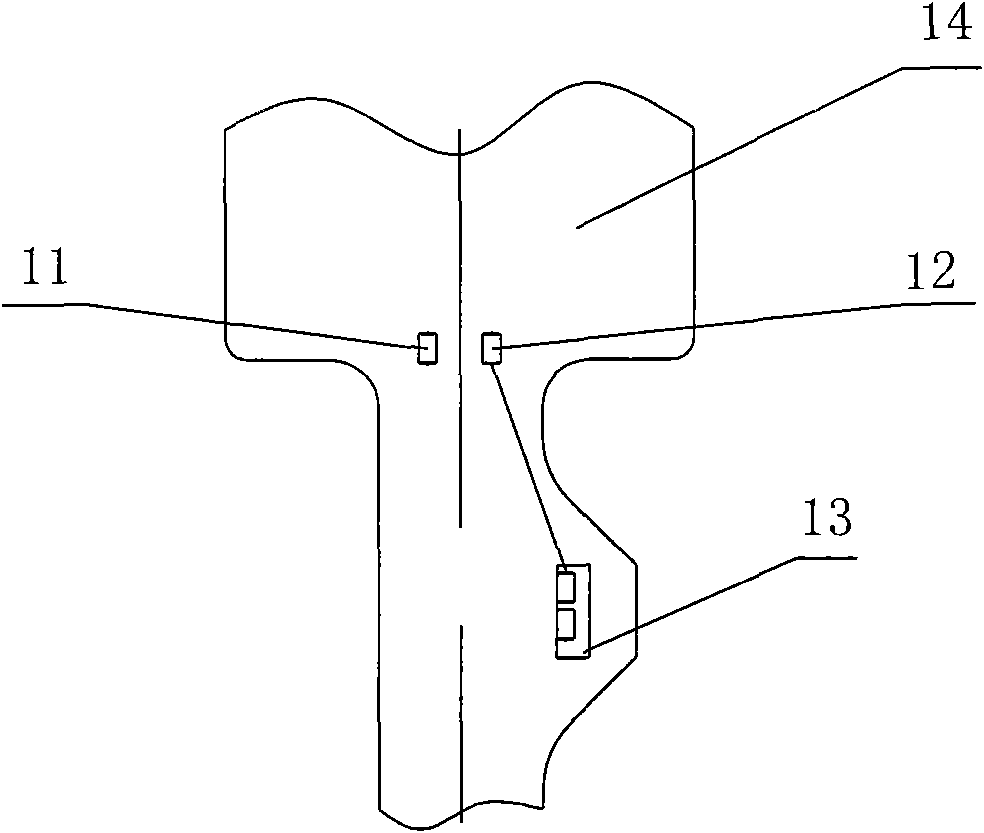

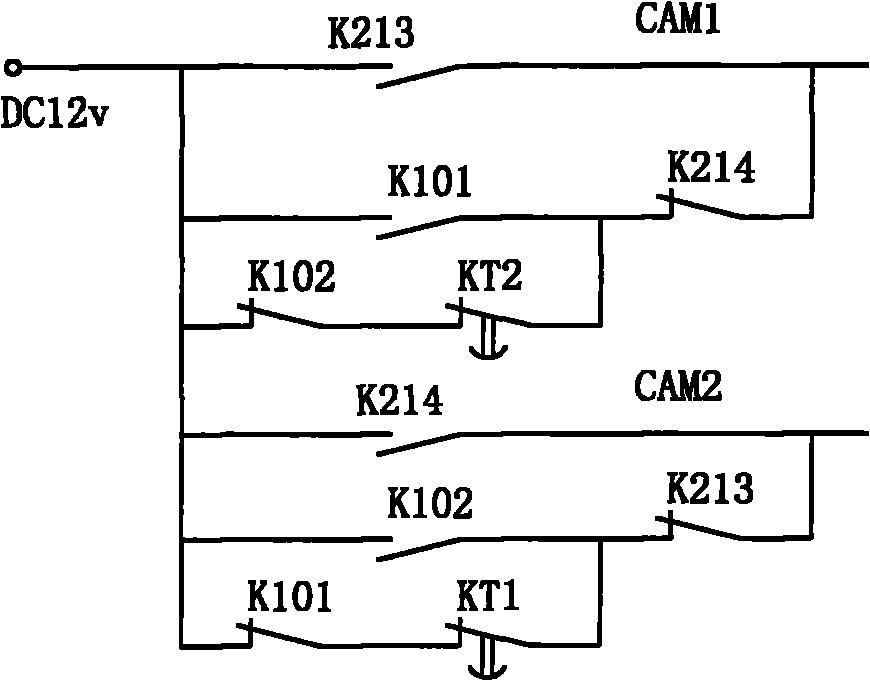

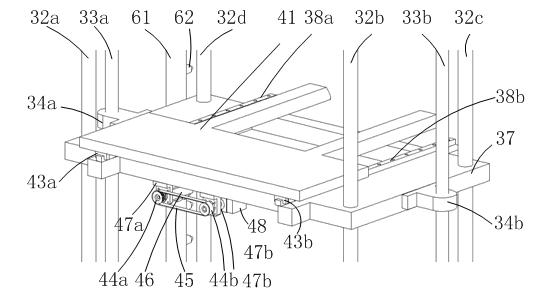

Intelligent full automatic combine coal mining system

ActiveCN101418688ARealize comprehensive applicationImprove completenessMining devicesUnderground miningProcess engineeringControl equipment

The invention relates to an intelligent type full-automatic combined coal mining system, which comprises a coal mining and loading device, a conveying device, a supporting device, and an equipment train, and is mounted in the working face and crossheading in the coal mine well. The coal mining and loading device is mounted on the conveying device, the coal conveying port of the conveying device is conveyed to the outside of the well or the coal bunker through a belt type conveyor in the crossheading, the supporting device is arranged behind the conveying device for supporting the top plate of the coal seam and linking with the conveying device, the equipment train comprises a central control chamber of a central control equipment, a starter, a power device, and a lifesaving cabin, the central control equipment monitors and controls the coordination operation of the devices, the equipment train, and the power device of the equipment train, the power device provide power source for the devices and the equipment train, and the equipment train moves freely in the crossheading with the feeding of the working faces. The invention improves system complete ability and execution efficiency, and has strong function, high intelligent degree, high safety, high production efficiency, and the like.

Owner:SANY HEAVY EQUIP

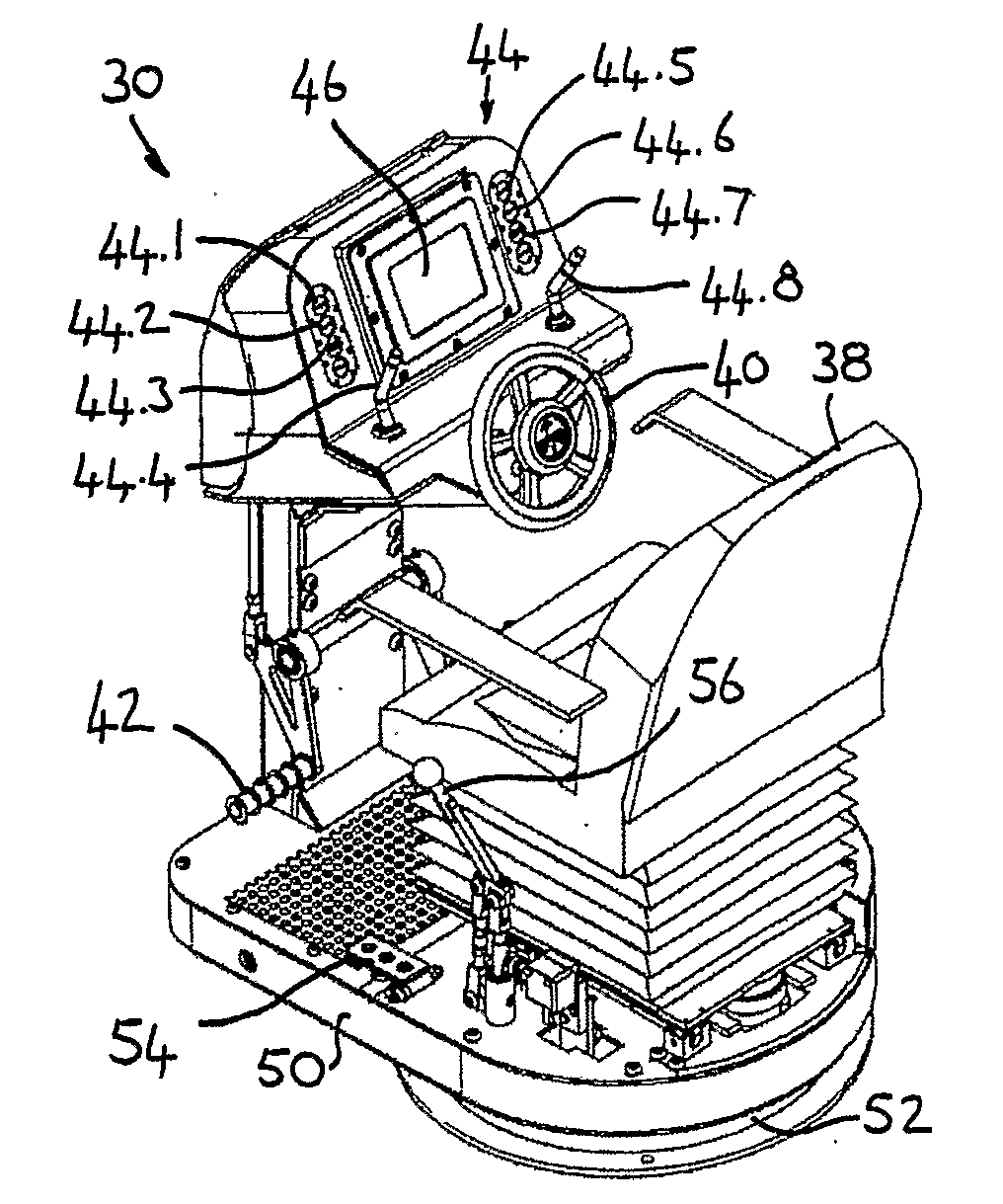

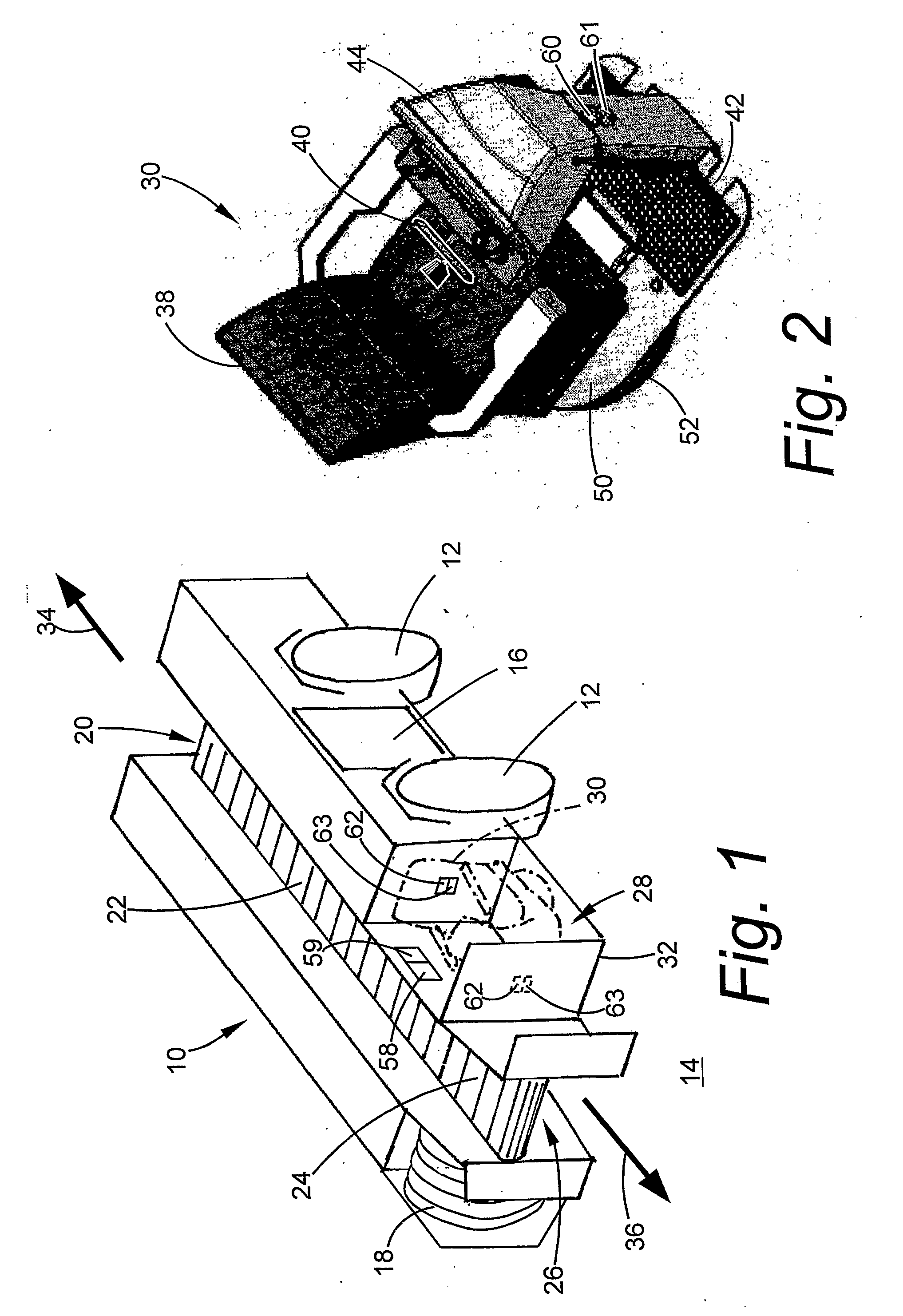

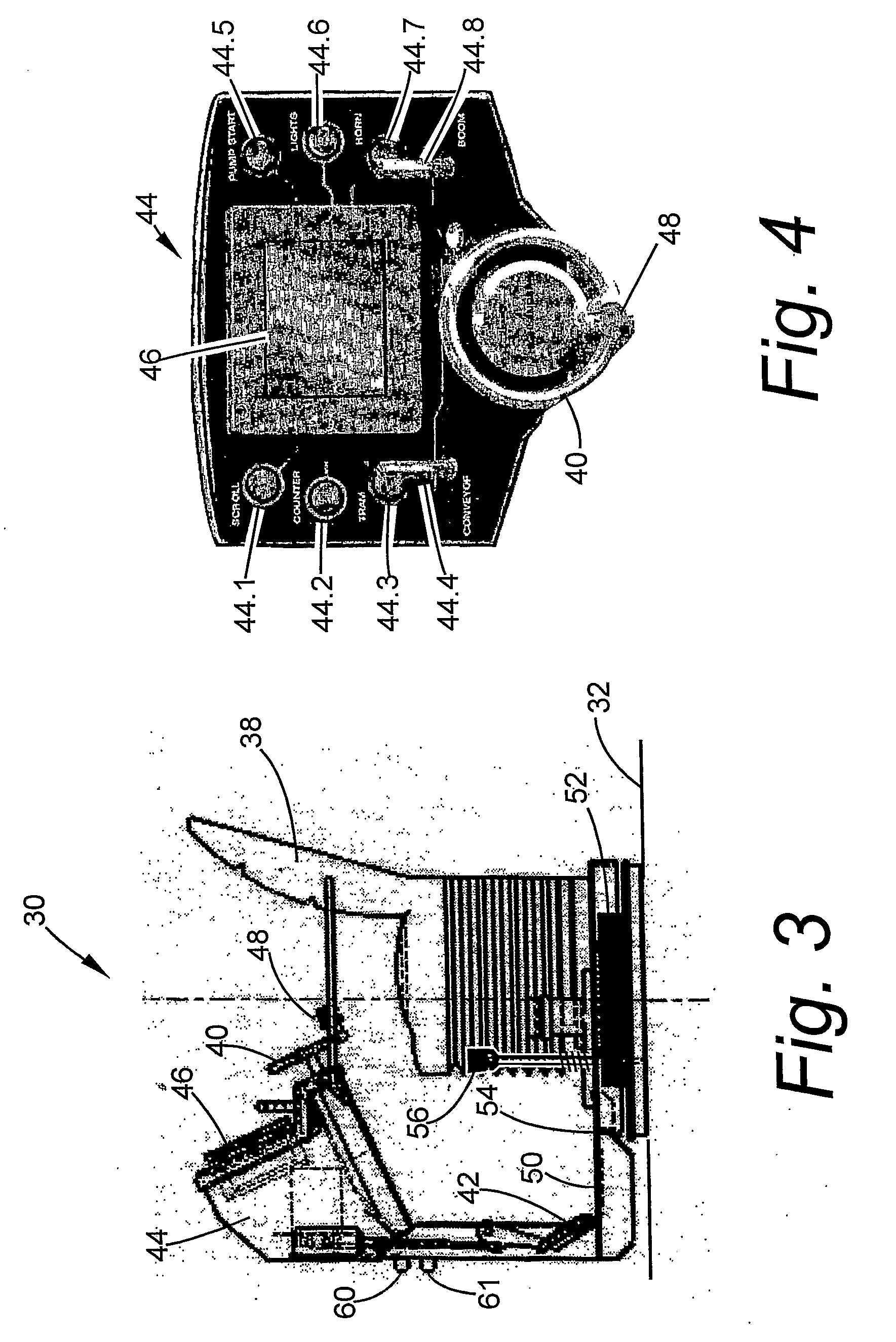

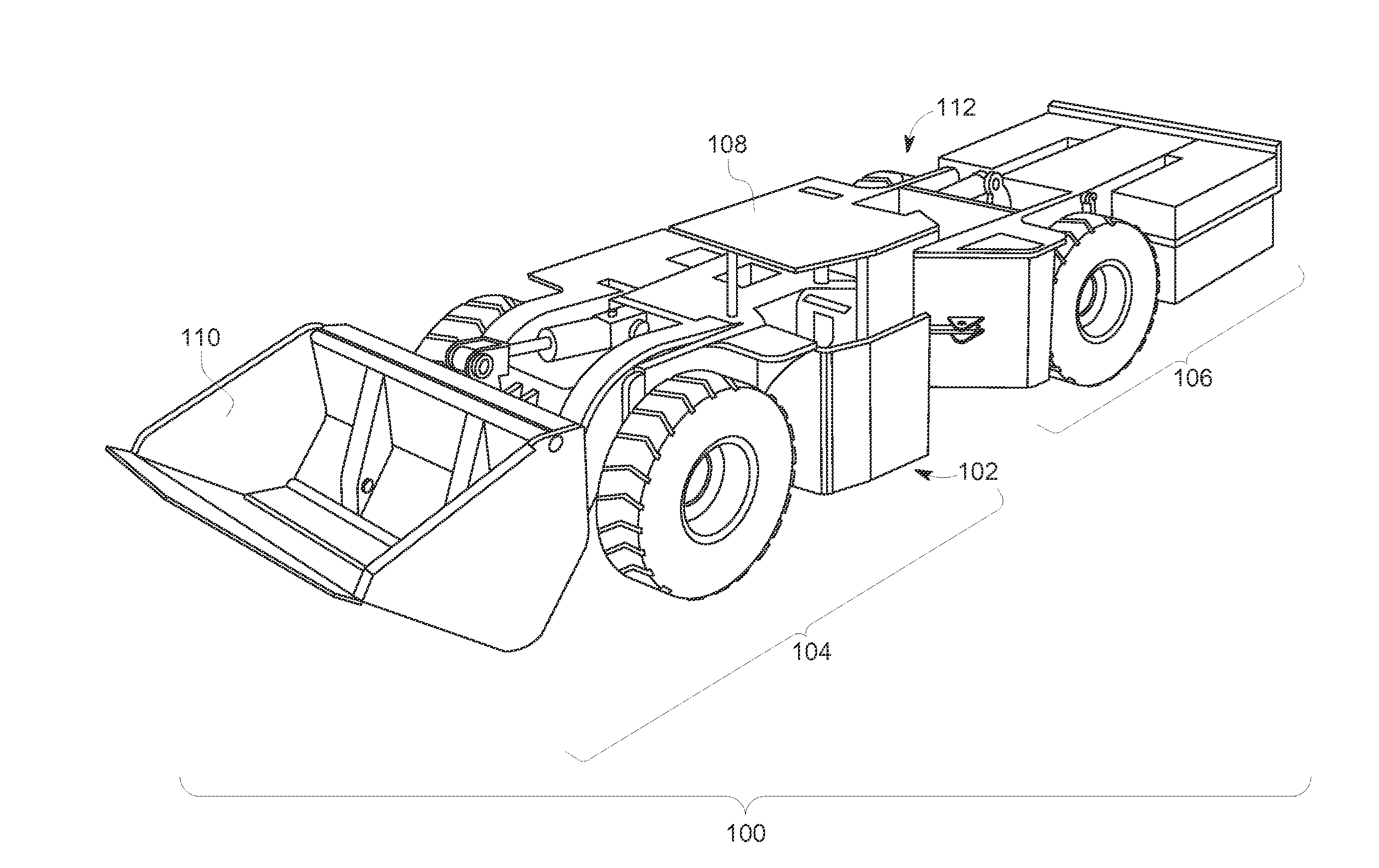

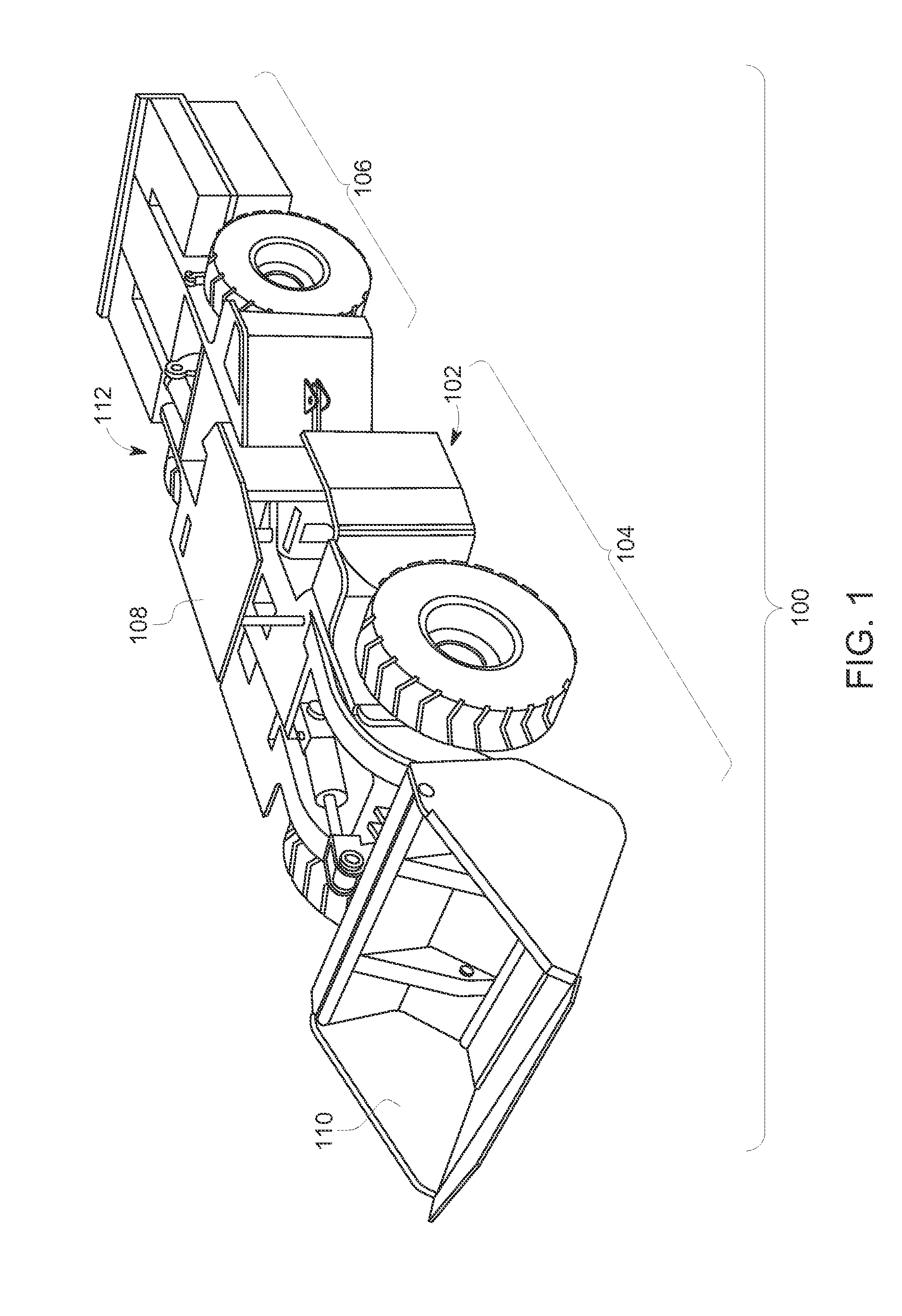

Vehicle with a variable driver position

InactiveUS20100300796A1Prevent rotationPrevent movementVehicle seatsFoot actuated initiationsDriver/operatorSteering wheel

There is disclosed a wheeled vehicle (10) adapted to be driven in a primary direction or an opposite secondary direction. The vehicle has a vehicle platform (32), and a group of vehicle components rotatably mounted on the platform which are rotatable as a group through 180 degrees relative to the platform. The group of components includes a driver's seat (38), steering wheel (40), foot pedals (42) and instrument console (44). Rotation of the group of components enables the driver's seat (and hence the driver) to face in the primary direction or secondary direction.

Owner:PWGK HLDG

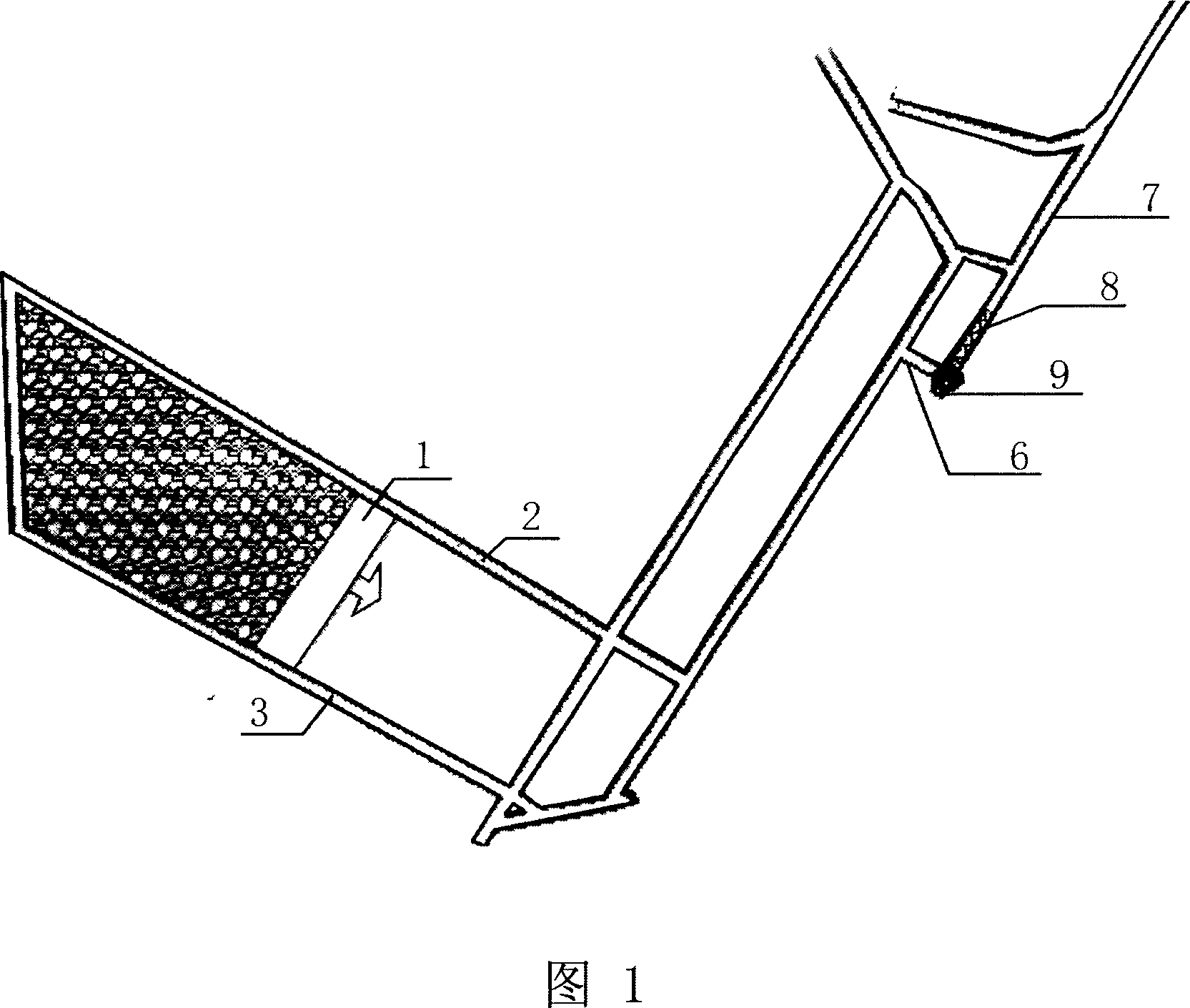

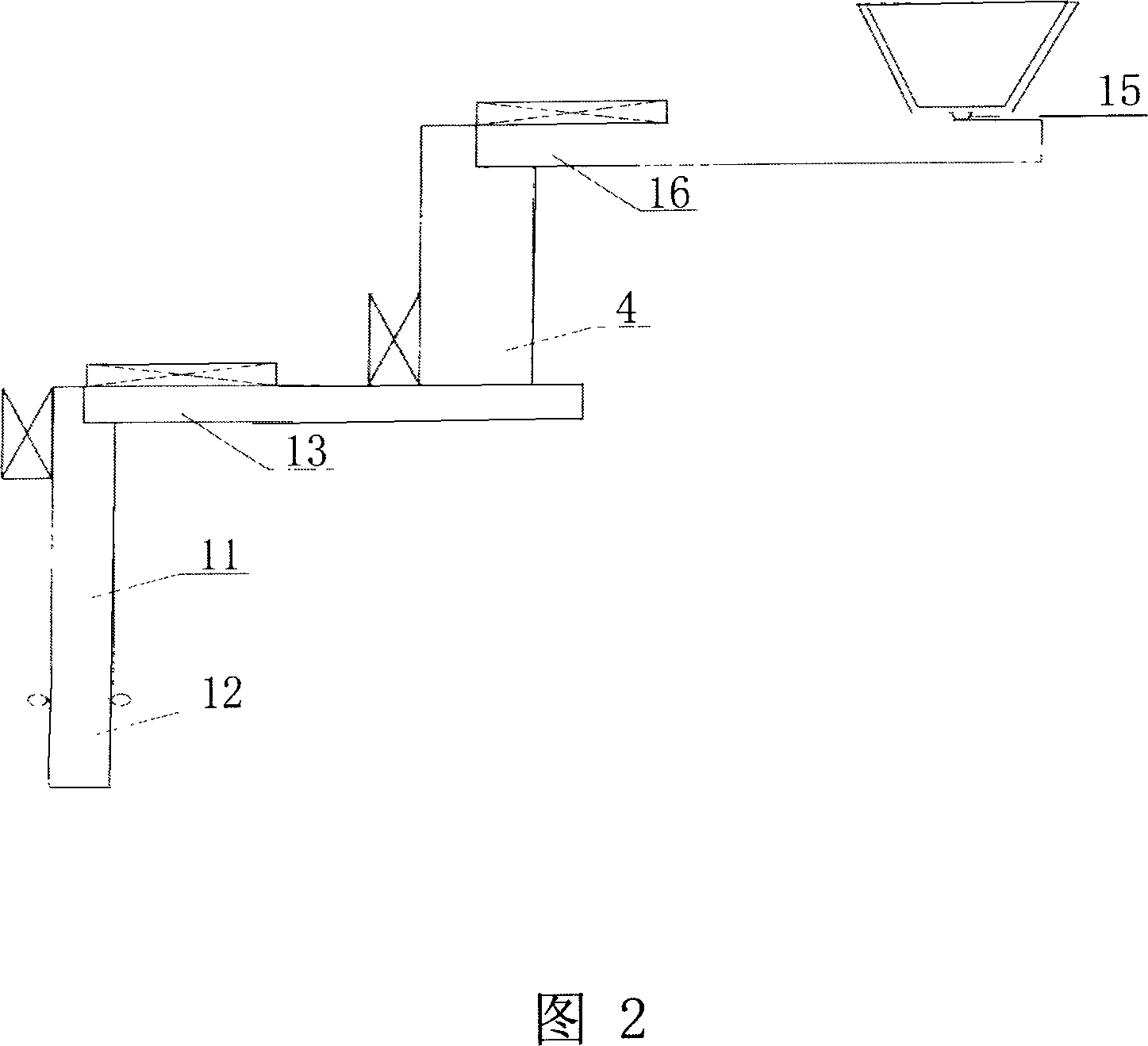

Method for filling coal-steam-free extraction working surface goaf by coal mine waste rock

InactiveCN1936271ARealize no MasuiImprove the environmentUnderground miningSurface miningMining engineeringCoal pillar

The invention relates to a method to filling non-coal column face workplace by gangue. It includes the following steps: directly transferring the gangue to gangue storehouse, discharging to the slat conveyer through hopper gate, transferring the gangue to face through gangue transferring belt, face slat conveyer, and high speed gangue throwing belt. It needs not to smash the gangue and could realize zero stacking of gangue to improve coal mine environment. The invention supplies a new coal mining method for realizing environment protecting exploitation.

Owner:SHANDONG SHENGQUAN MINING

Comprehensive coal-mining process by using long wall mining method

InactiveCN1865657ALow costReduce in quantityUnderground miningSurface miningEngineeringEarth surface

The invention relates to a long-wall coal method, which can be used in stable coal bed, rigid top plate, non-broken incline middle-thickness coal bed, and thick coal bed layered long-wall method. Wherein, it arranges hydraulic support, scrape transporter, and roller coal machine at the long-wall working surface; arranges groove transporter and flexible band transporter at the transport channel; the working surface has ultra long length, which is two times of integrated coal surface; it uses two coal machines on one scrape transporter, to scrape the upper half surface and the lower half surface; and it can arrange middle channel at the middle of integrated surface as the transport channel; and arranges scrape transporters at the upper and lower half working surfaces. The invention has high efficiency, while it can reduce the digging rate and improve the resource recycle rate.

Owner:YANKUANG GRP CO LTD

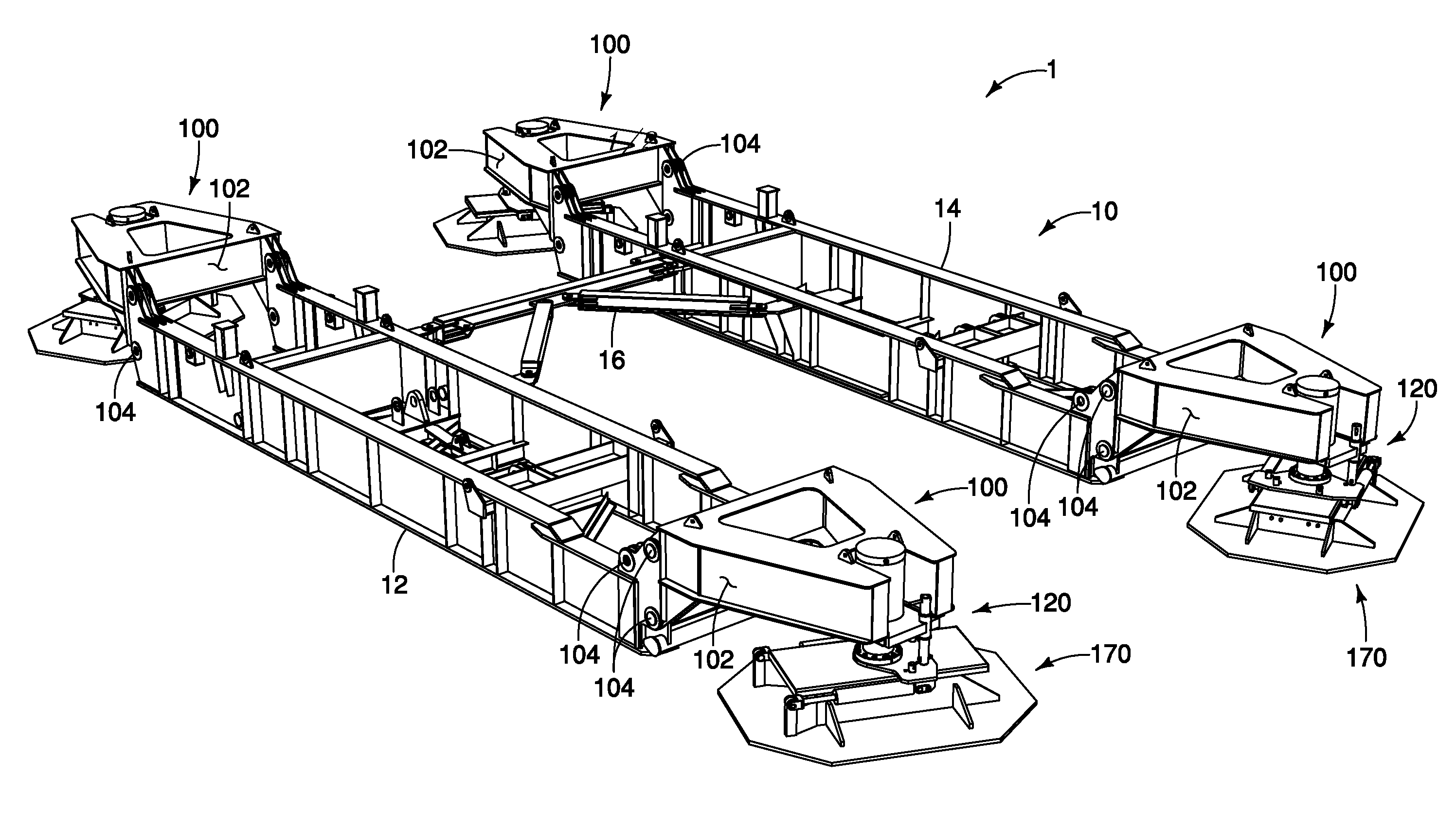

Drill Rig Moving System

ActiveUS20140054097A1Improve protectionSmooth slidingDerricks/mastsUnderground transportSubstructureDrill

The present invention discloses a drill rig relocation system. Lift frames are provided at opposite ends of a base box of a drill rig substructure. A lift cylinder and bearing mat assembly are rotatably connected beneath the lift frame. The bearing mat assemblies may be rotated to the desired direction for moving the drill rig. The lift cylinders are then expanded, placing the bearing mat assemblies onto the ground and lifting the base boxes and drill rig off the ground. The drill rig is supported on linear sleeve bearings slideably mounted in the bearing mat assemblies. Translation cylinders on the bearing mats expanded to move the rig by translating the linear sleeve bearings along the shafts. After the lift cylinder expands to place the bearing mat on the ground, the translation cylinders are retracted, providing the linear bearing with the full length of the shaft for the next movement.

Owner:SCHLUMBERGER TECH CORP

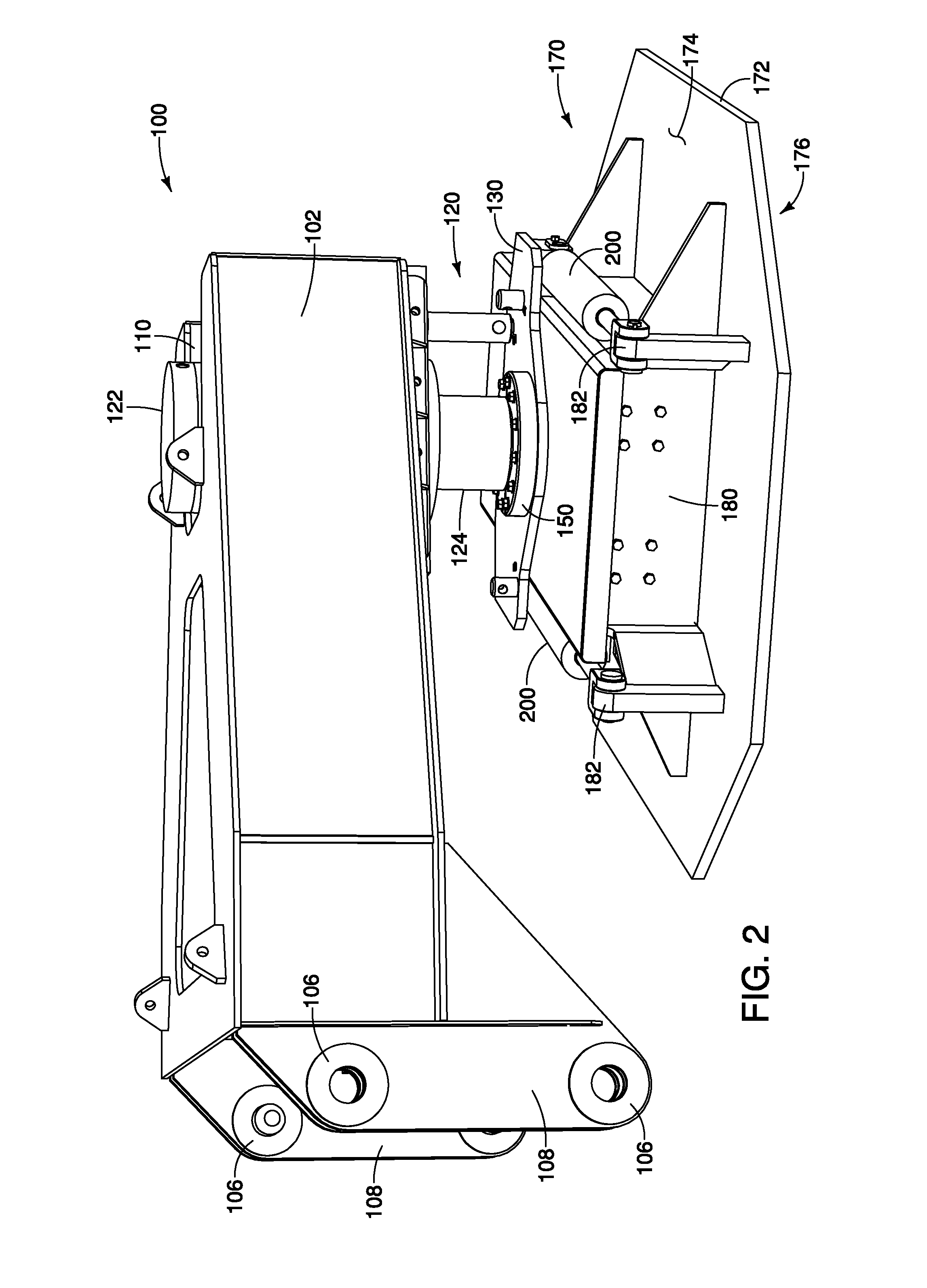

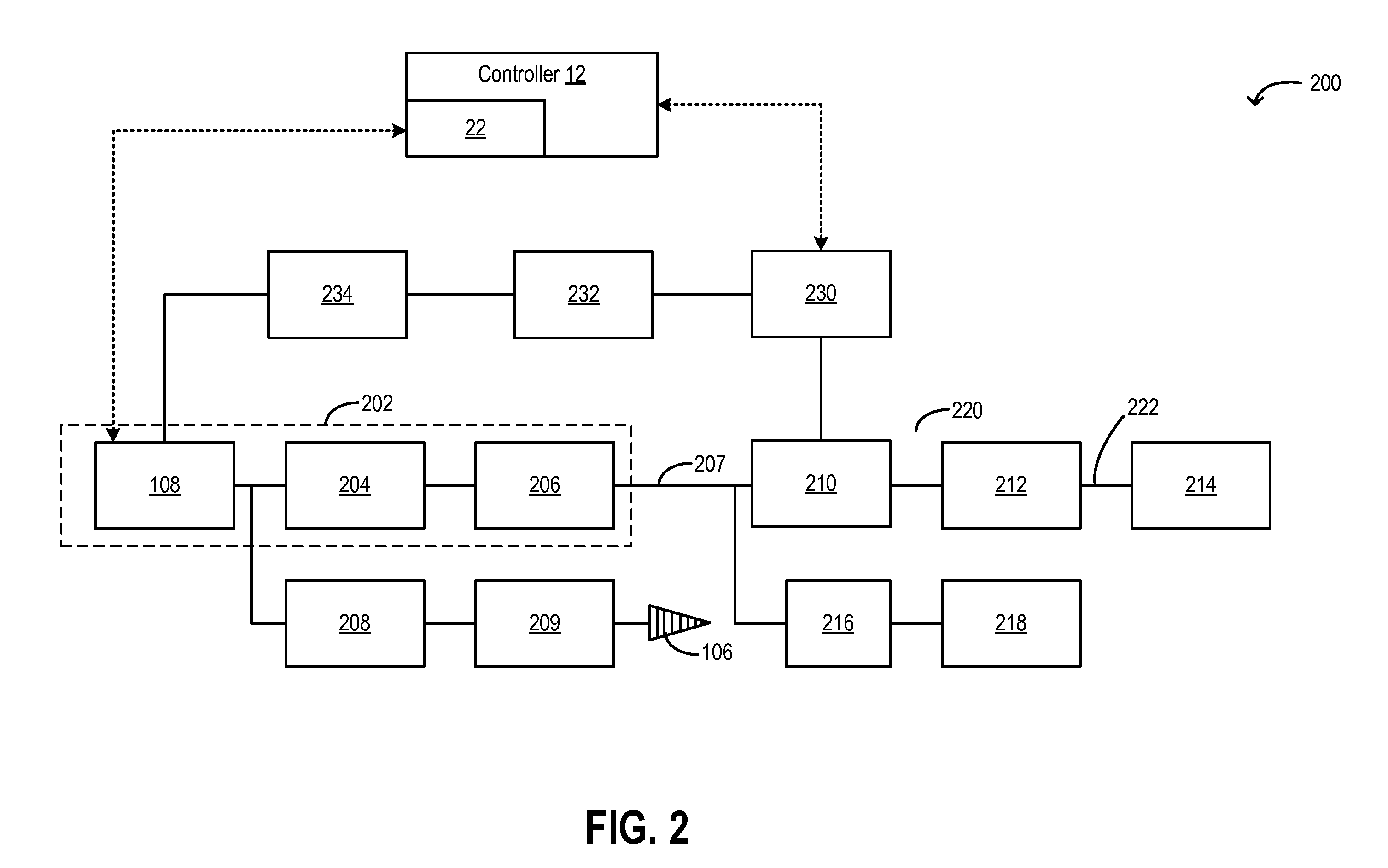

Battery changing system and method

ActiveUS20150071747A1Electric/hybrid propulsionPropulsion by batteries/cellsEngineeringMechanical engineering

A battery changing system includes a grasping assembly and an actuation assembly. The grasping assembly is configured to be disposed onboard a vehicle and to engage a battery box having one or more batteries disposed therein. The actuation assembly is configured to move the grasping assembly away from the vehicle toward the battery box. The actuation assembly also is configured to move the grasping assembly into engagement with a securing assembly of the battery box. The actuation assembly is configured to move the grasping assembly back toward the vehicle while the grasping assembly engages the securing assembly of the battery box to lift the battery box onto the vehicle.

Owner:GE GLOBAL SOURCING LLC

Method for arranging roadways on coal-pillar-free stope

InactiveCN102392642ASolve the overrun problemAlleviate mining tensionsUnderground miningSurface miningDual purposeEngineering

The invention discloses a method for arranging roadways on a coal-pillar-free stope. Particularly, the method comprises the following steps: two roadways are arranged on each working face, one is an excavating roadway, and the other is a gob-side retained or excavated roadway on an upper working face; before a present working face is stopped, a roadway and a cut are excavated in advance on a supersedure working face adjacent to the present working face; the cut is connected with the excavating roadway of the present working face; and the excavating roadway and the cut of the supersedure working face serve as the boundary return airway of the present working face during gob-side roadway retaining, and serve as the construction pathway for the gob-side excavated roadway during gob-side entry driving. Therefore, through the adoption of the method, mining without coal pillars is achieved and a two-in and one-out Y+L type ventilation system is formed. In the method, the excavating roadway and the cut of the supersedure working face serve as the return airway of the present working face and one roadway of the supersedure working face, thereby achieving dual purposes and eliminating the excavating of a roadway; and a pressure peak area is avoided, so that more coal pillars can be extracted, the problem of transfinite methane gas is solved, the excavation tight relationship is relieved, and the method can be widely applied to coal mines, metallurgic mines and other industries.

Owner:王晓利

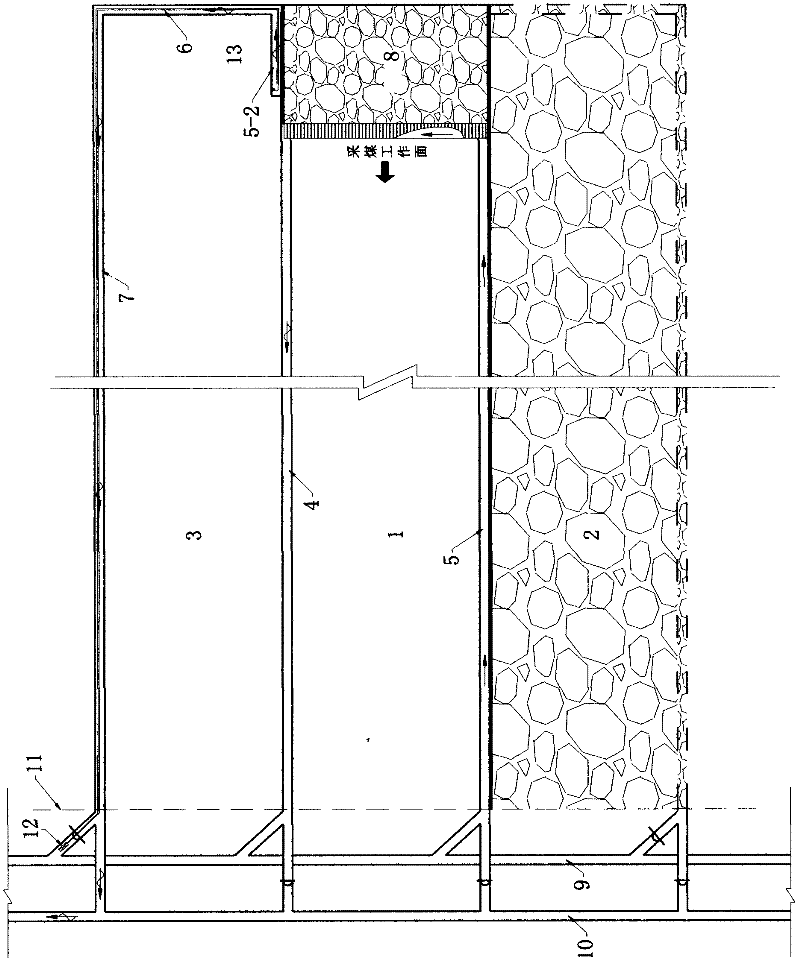

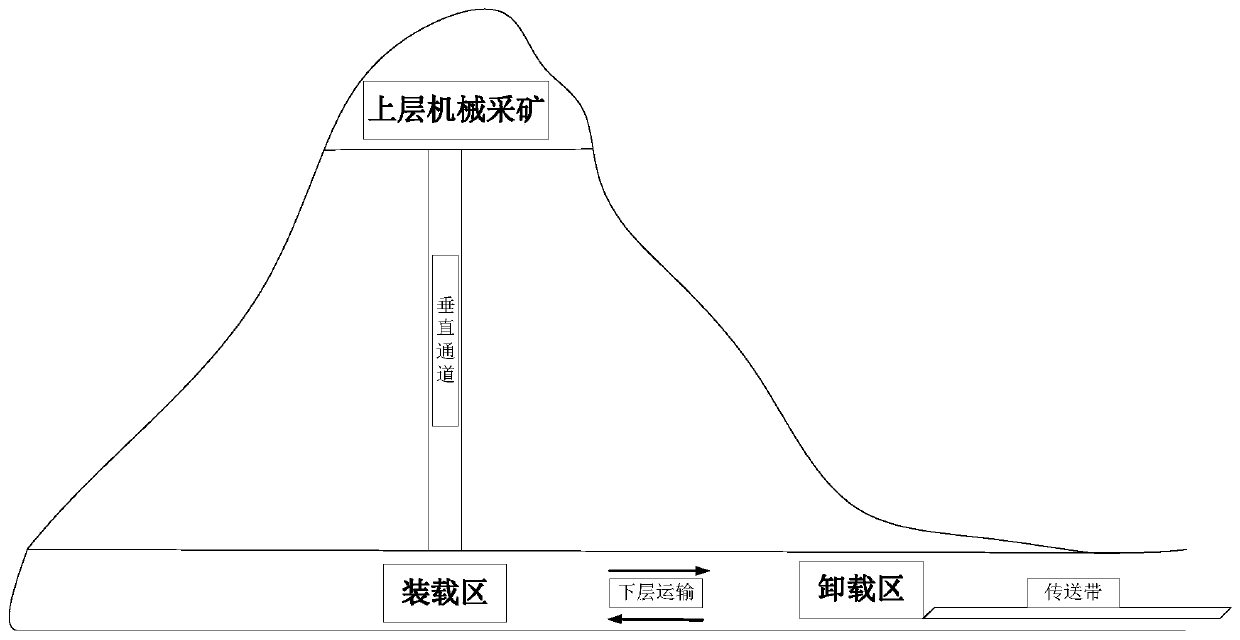

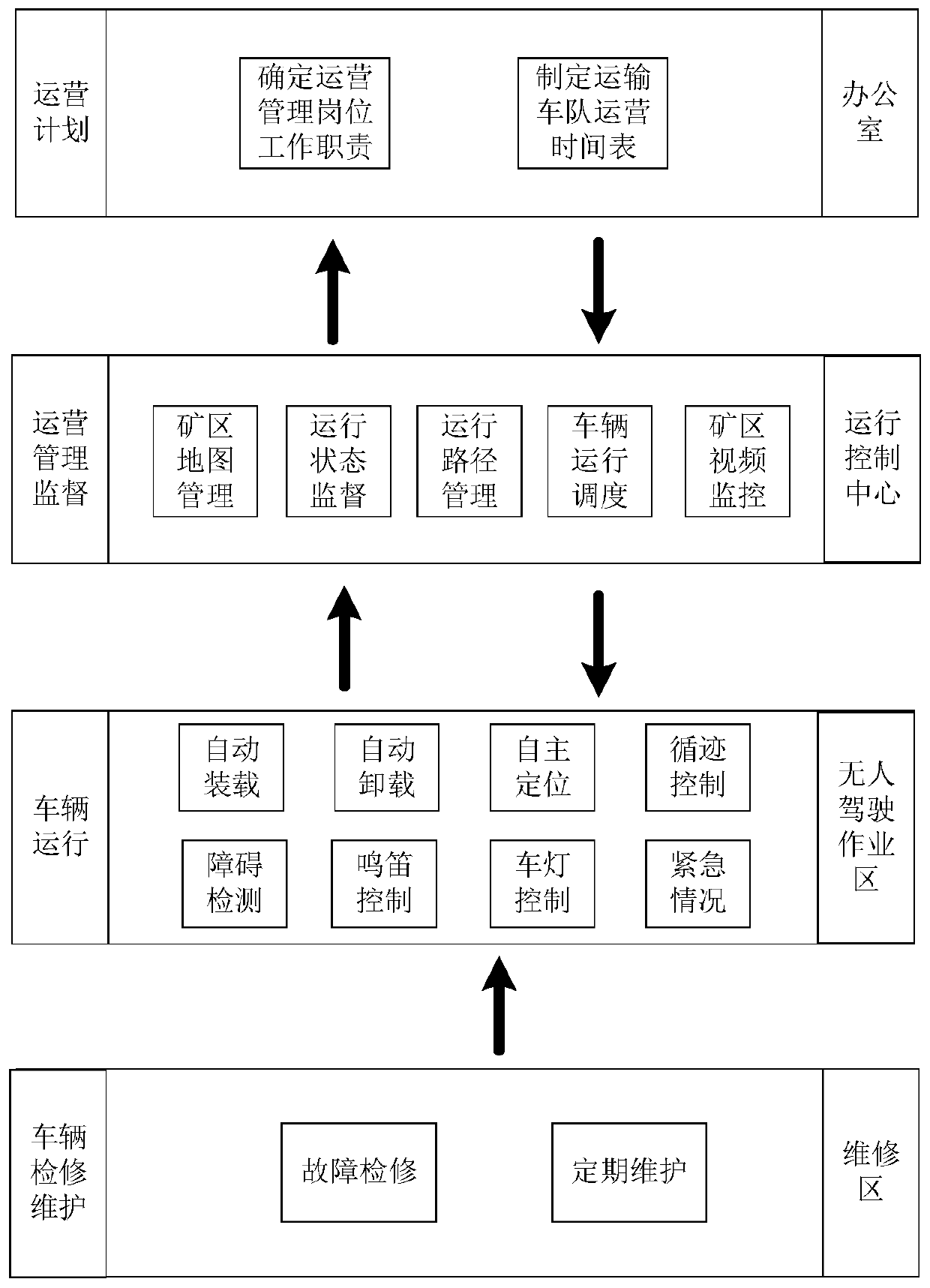

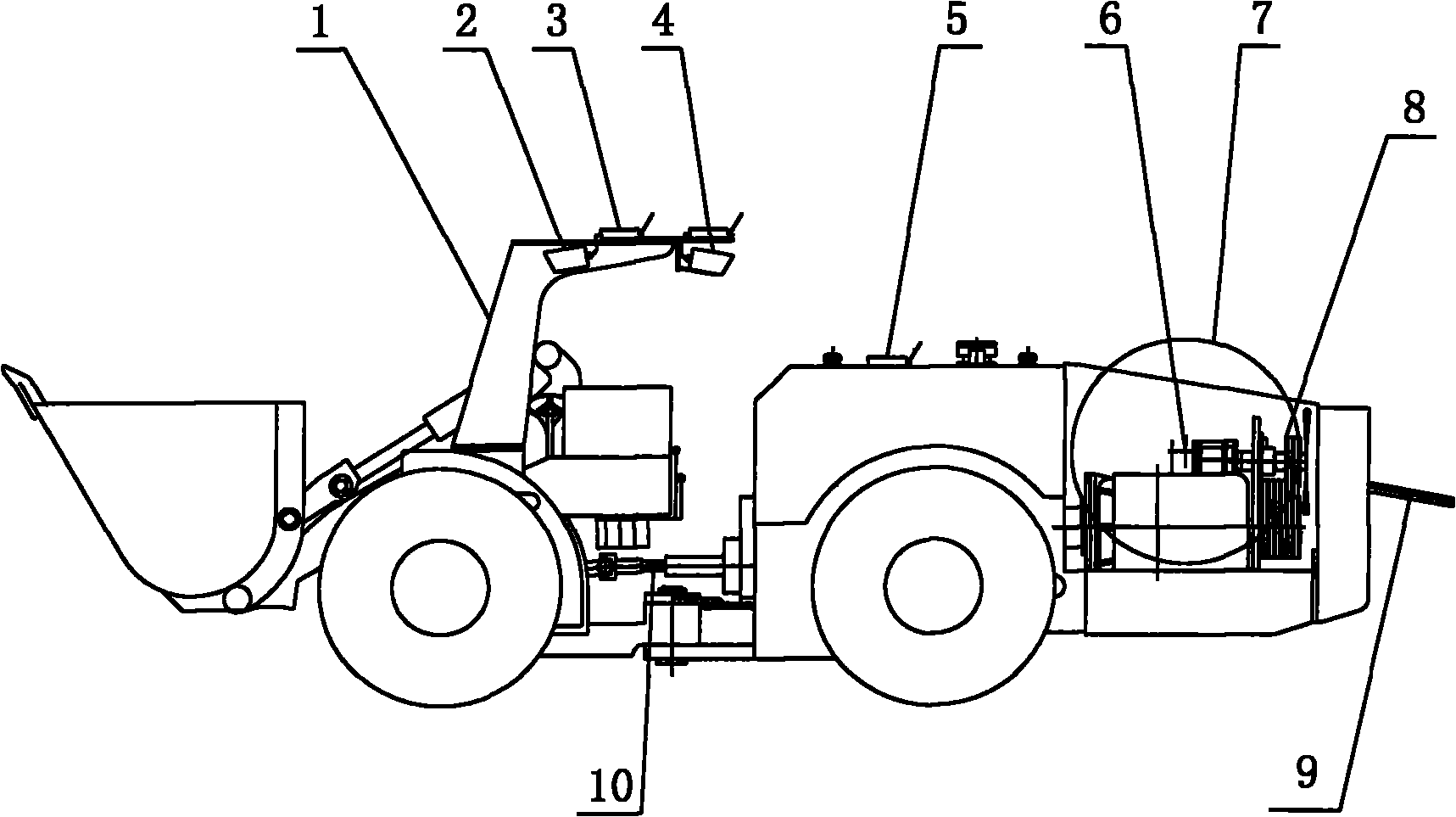

Fully-automatic underground mining transportation system

ActiveCN110456745ARich wireless transmission pathImprove reliabilityUnderground miningSurface miningCommunications systemAutomatic control

Disclosed is a fully-automatic underground mining transportation system; the fully-automatic underground mining transportation system comprises a dispatching control center used for receiving and storing data and sending out a control instruction so as to carry out operation dispatching, operation monitoring, data management and remote control, a vehicle-mounted automatic driving system which is arranged in an engineering vehicle and is used for receiving and analyzing instructions and vehicle tracking, identifying minerals, barriers and surrounding engineering vehicles, and cooperating with the dispatching control center to achieve multi-vehicle collaborative operation, and a vehicle-ground communication system which is coupled between the dispatching control center and the vehicle-mounted automatic driving system to establish a bidirectional high-speed data transmission channel between the dispatching control center and the vehicle-mounted automatic driving system, and transmits theroad side monitoring data to the dispatching control center. According to the fully-automatic underground mining transportation system, by arranging the dispatching control center, the vehicle-mountedautomatic driving system and the vehicle-mounted communication system, the effect of automatic control mining and transportation can be effectively realized.

Owner:HUNAN UNIV

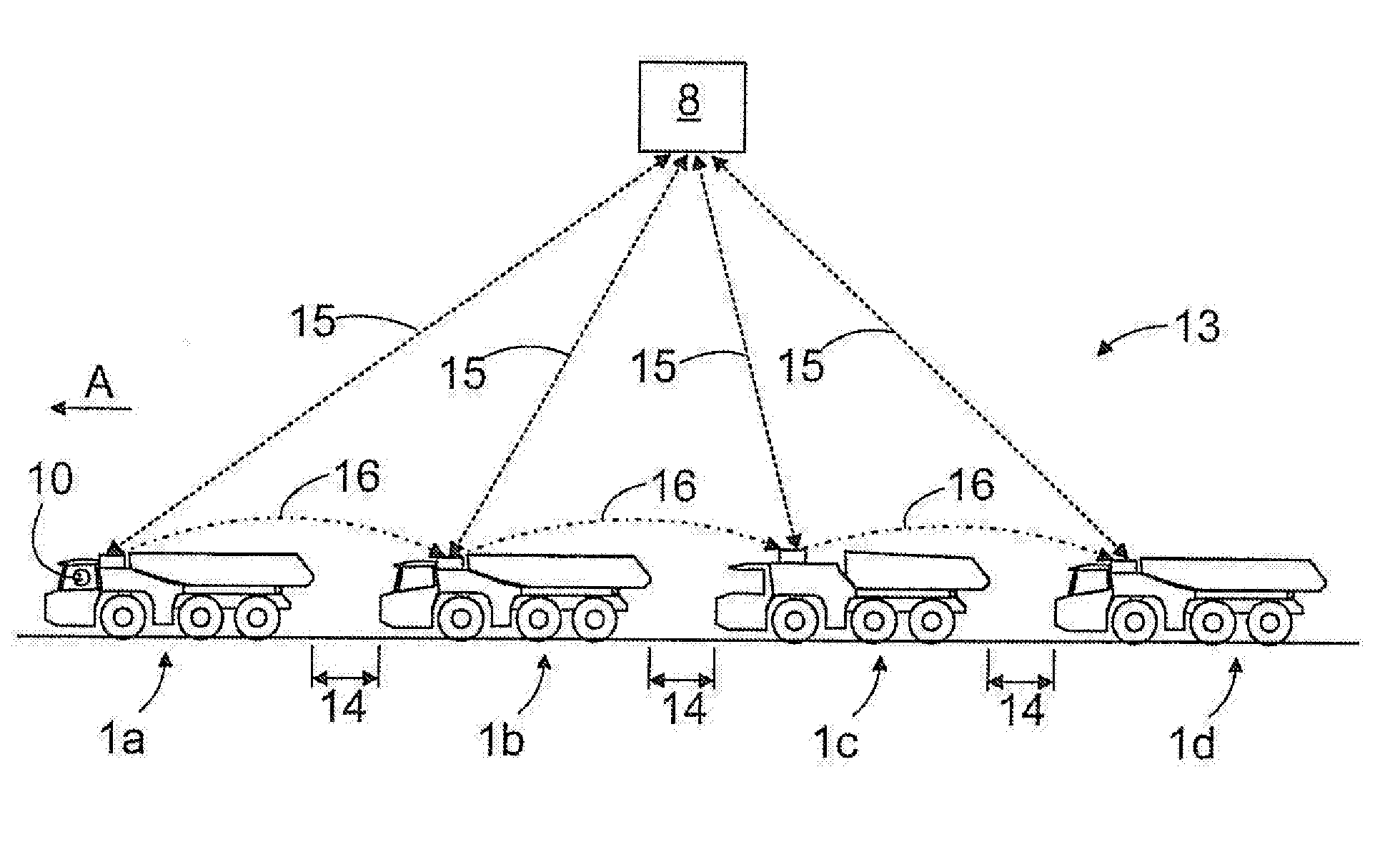

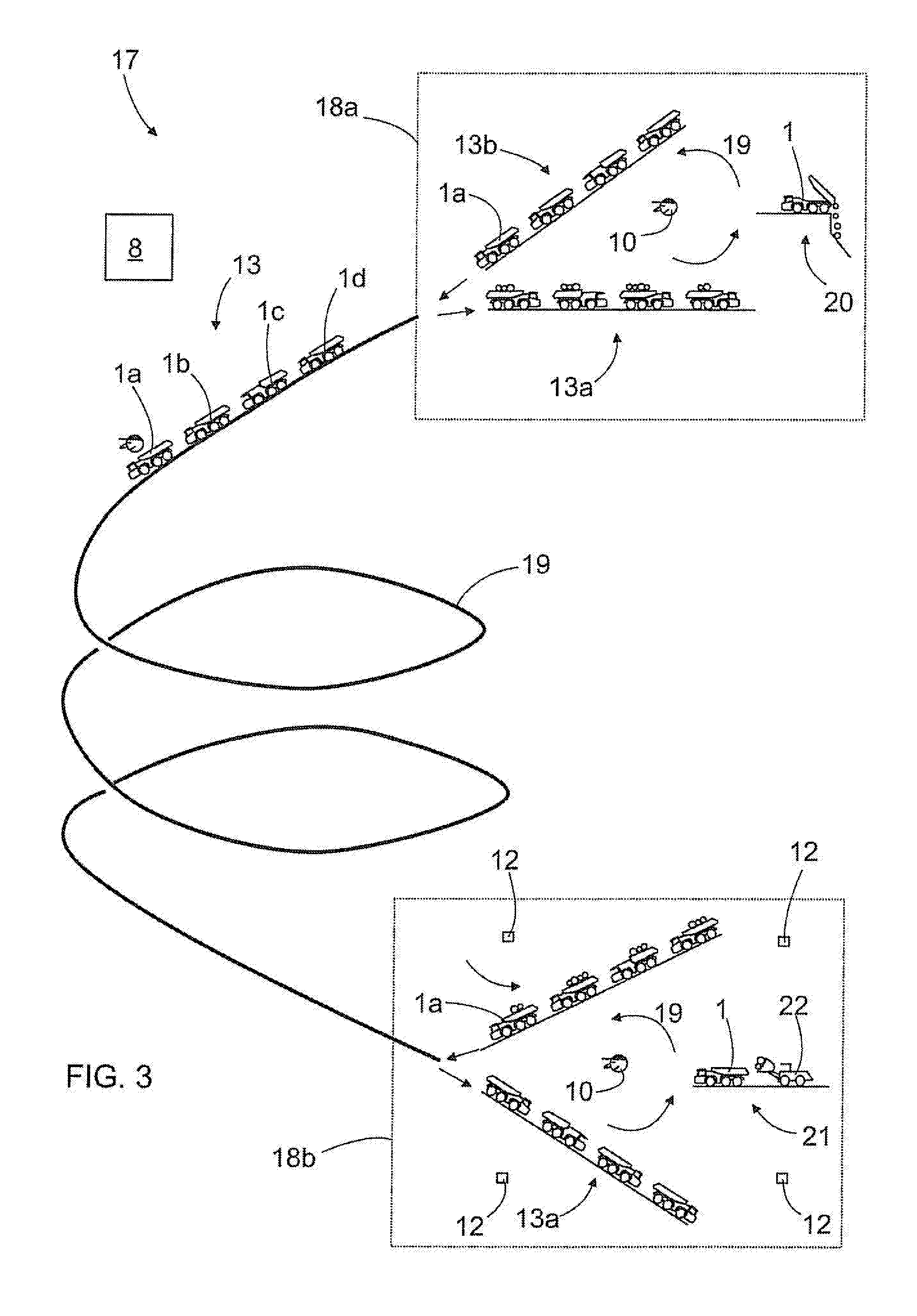

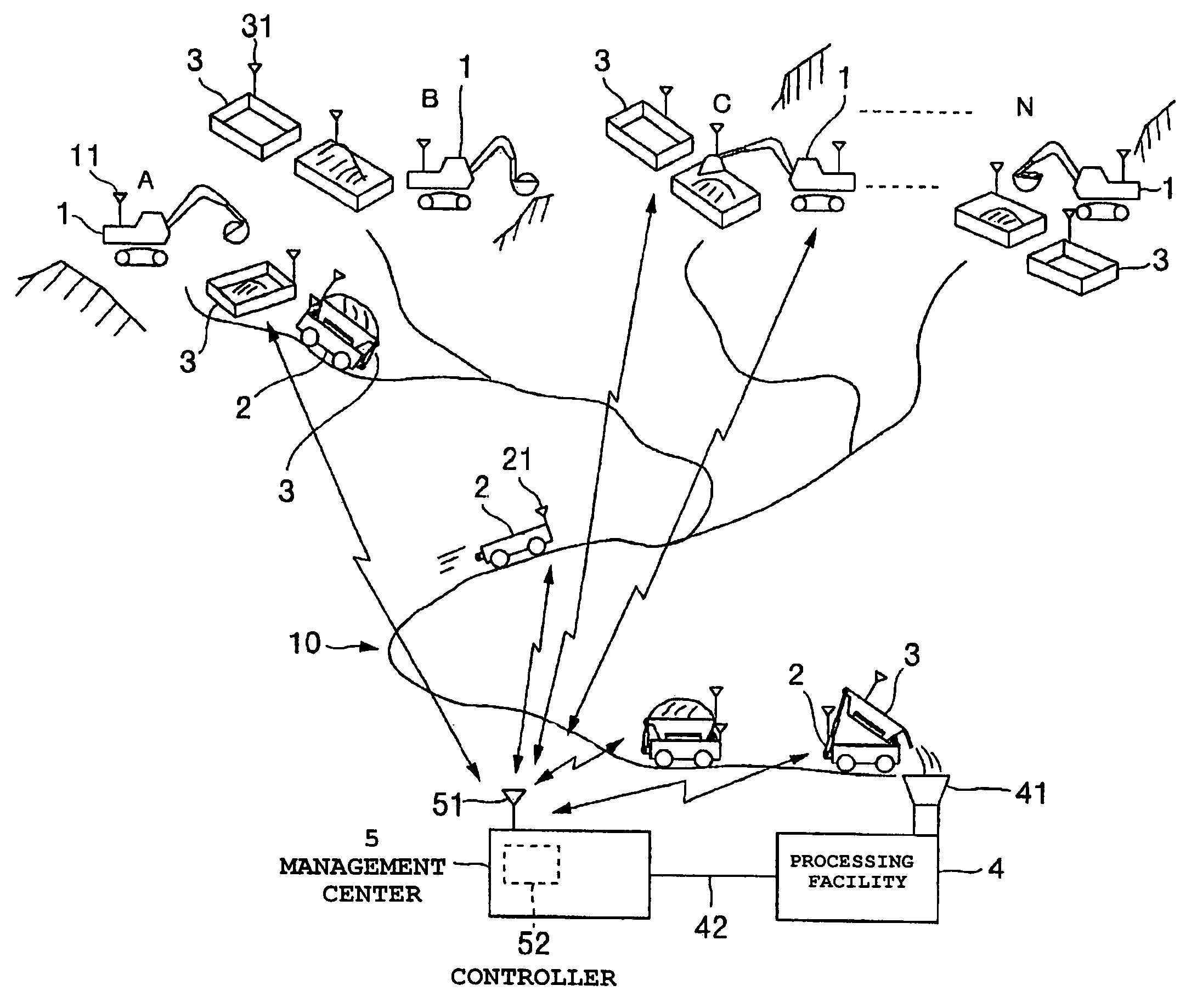

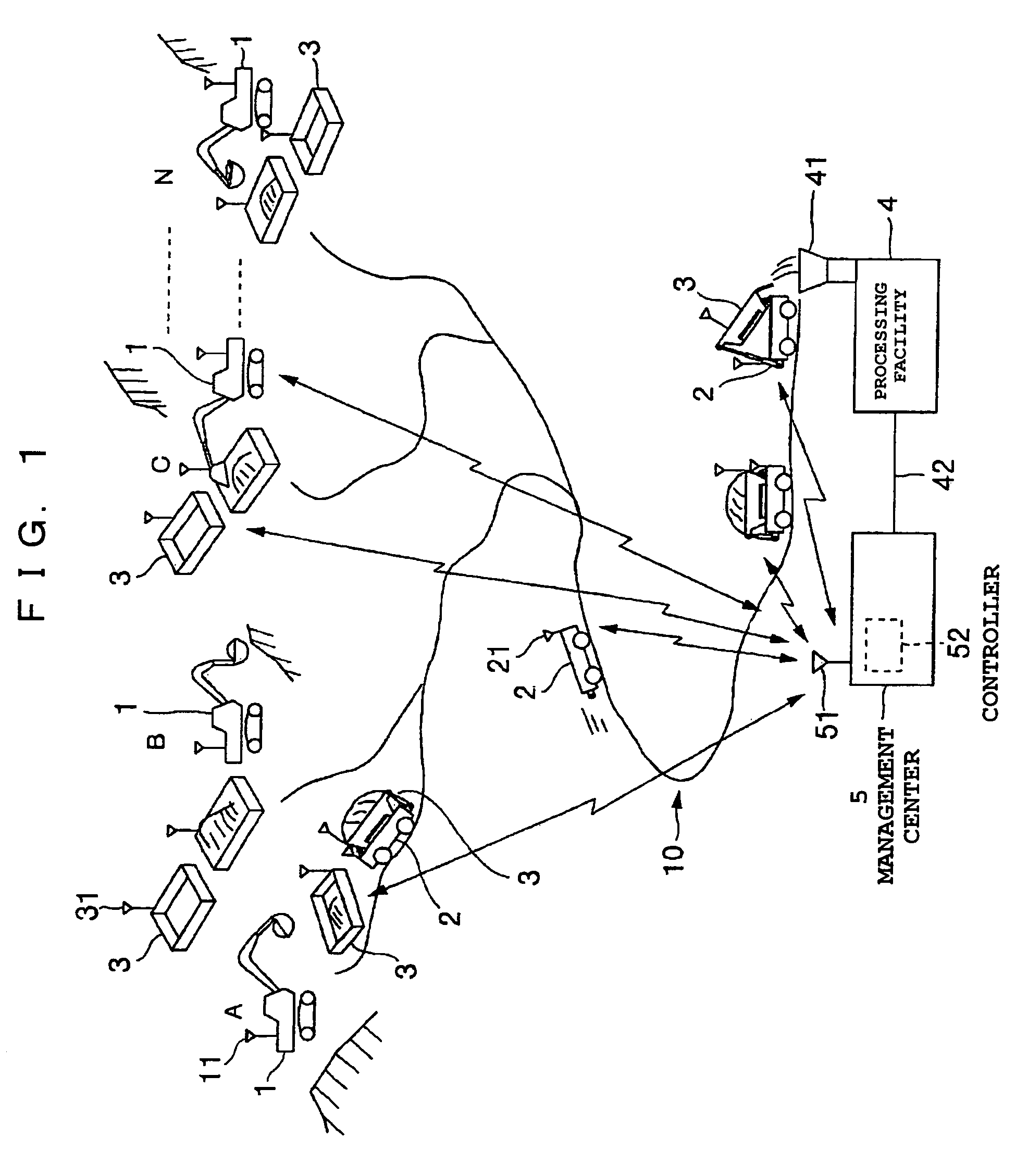

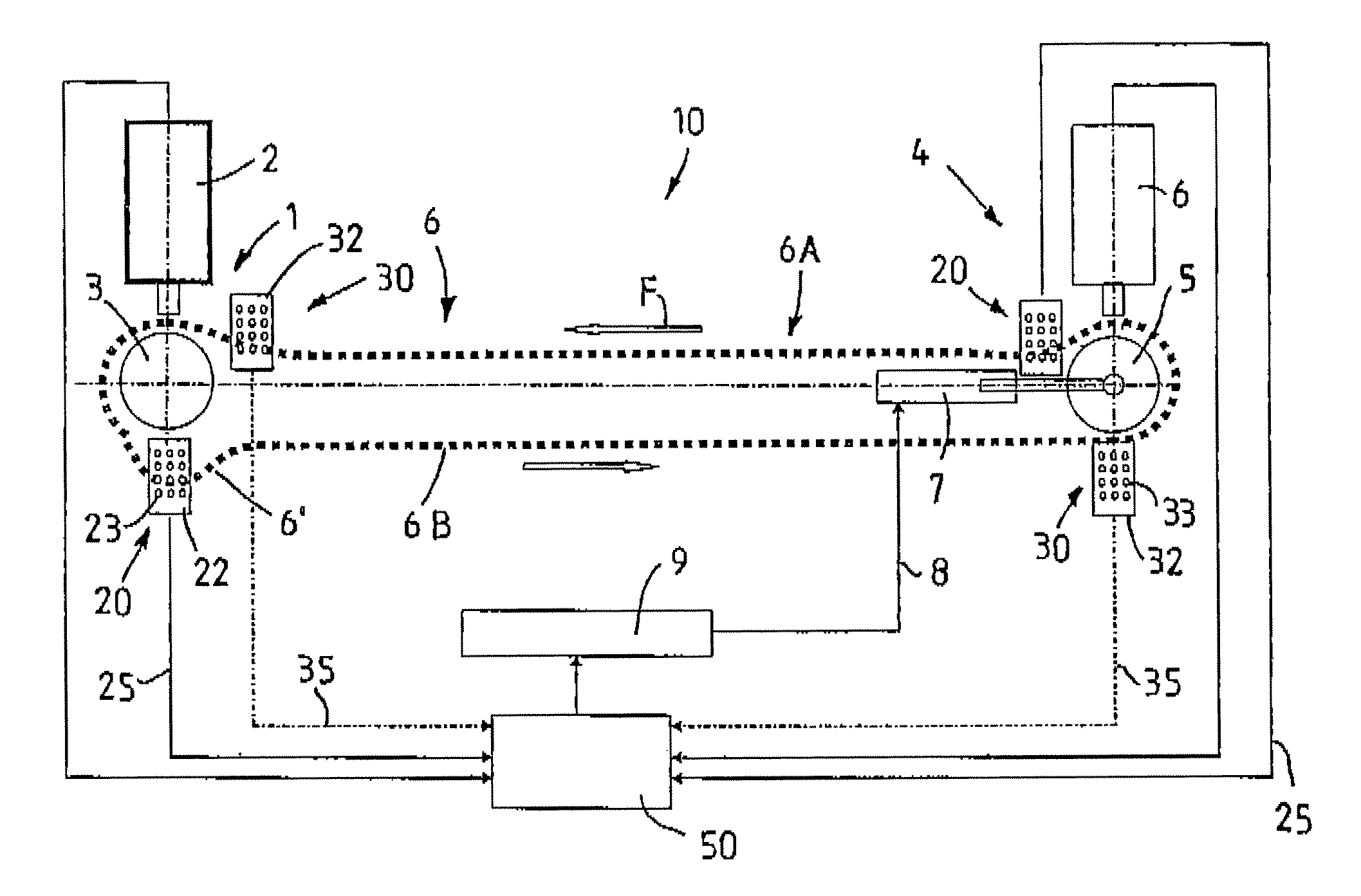

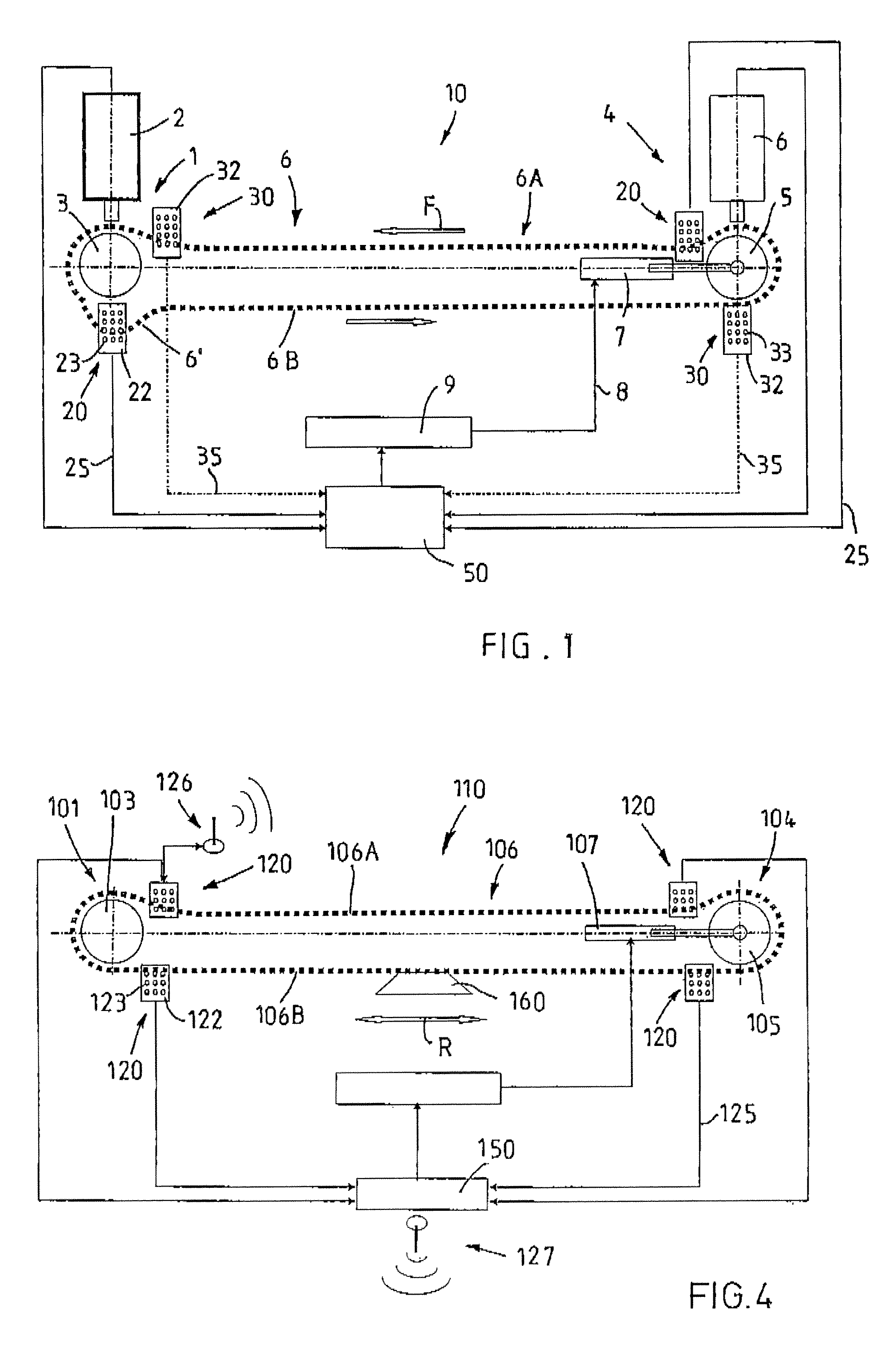

Method of Driving Plurality of Mine Vehicles in Mine, and Transport System

ActiveUS20090118889A1Easy to transportConvenient ArrangementUnderground miningSurface miningTransport systemSingle vehicle

A method of driving mine vehicles in a mine, and a transport system. A plurality of mine vehicles is arranged in succession and driven in convoy between working areas. A master vehicle in the convoy is driven manually, and slave vehicles follow the master, provided with no mechanical connection. In the working areas, the convoy is disassembled, since single vehicles are each driven separately. When assigned tasks in the working areas have been completed, the vehicles are reassembled into a convoy so as to be driven to a next working area.

Owner:SANDVIK MINING & CONSTR OY

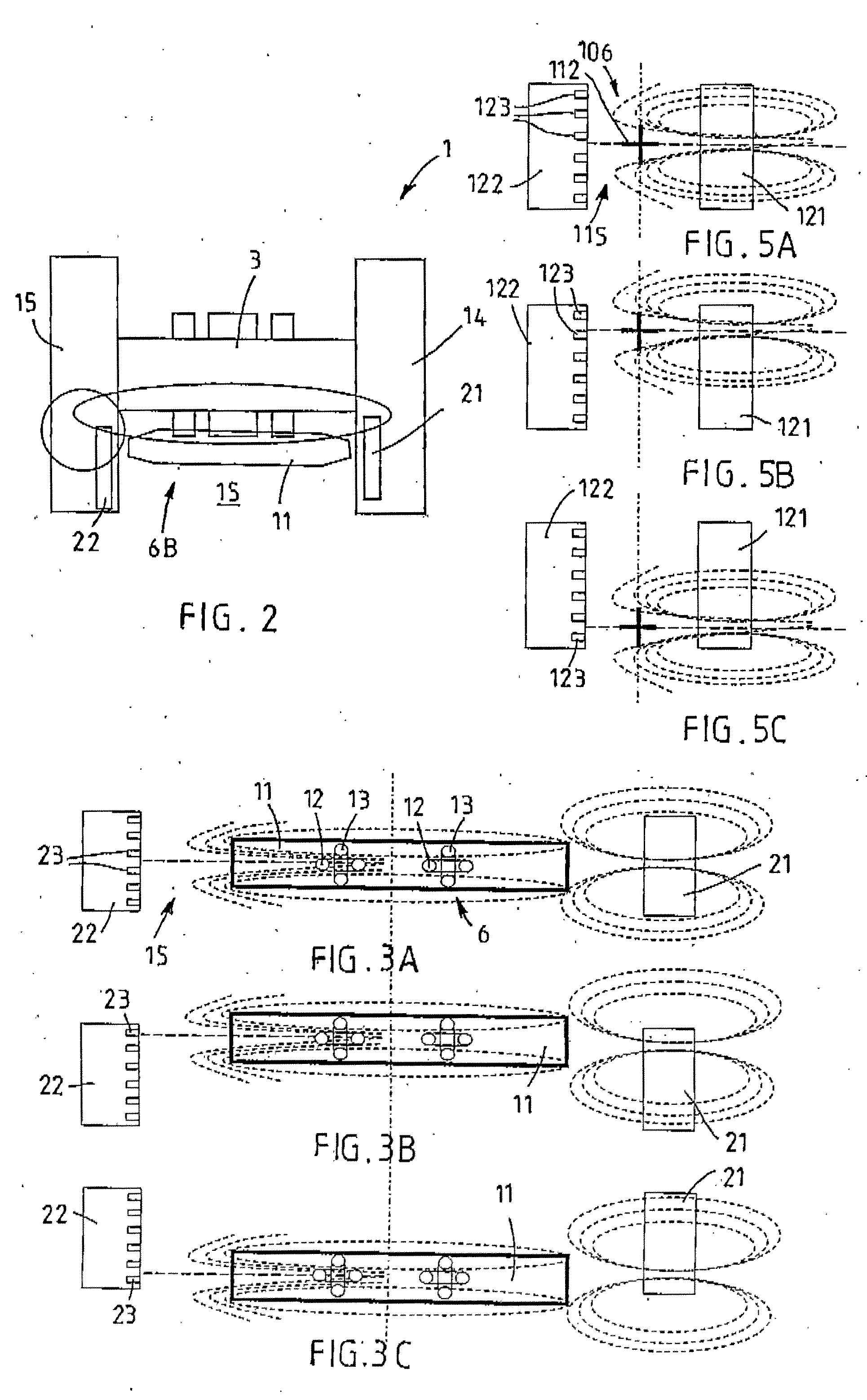

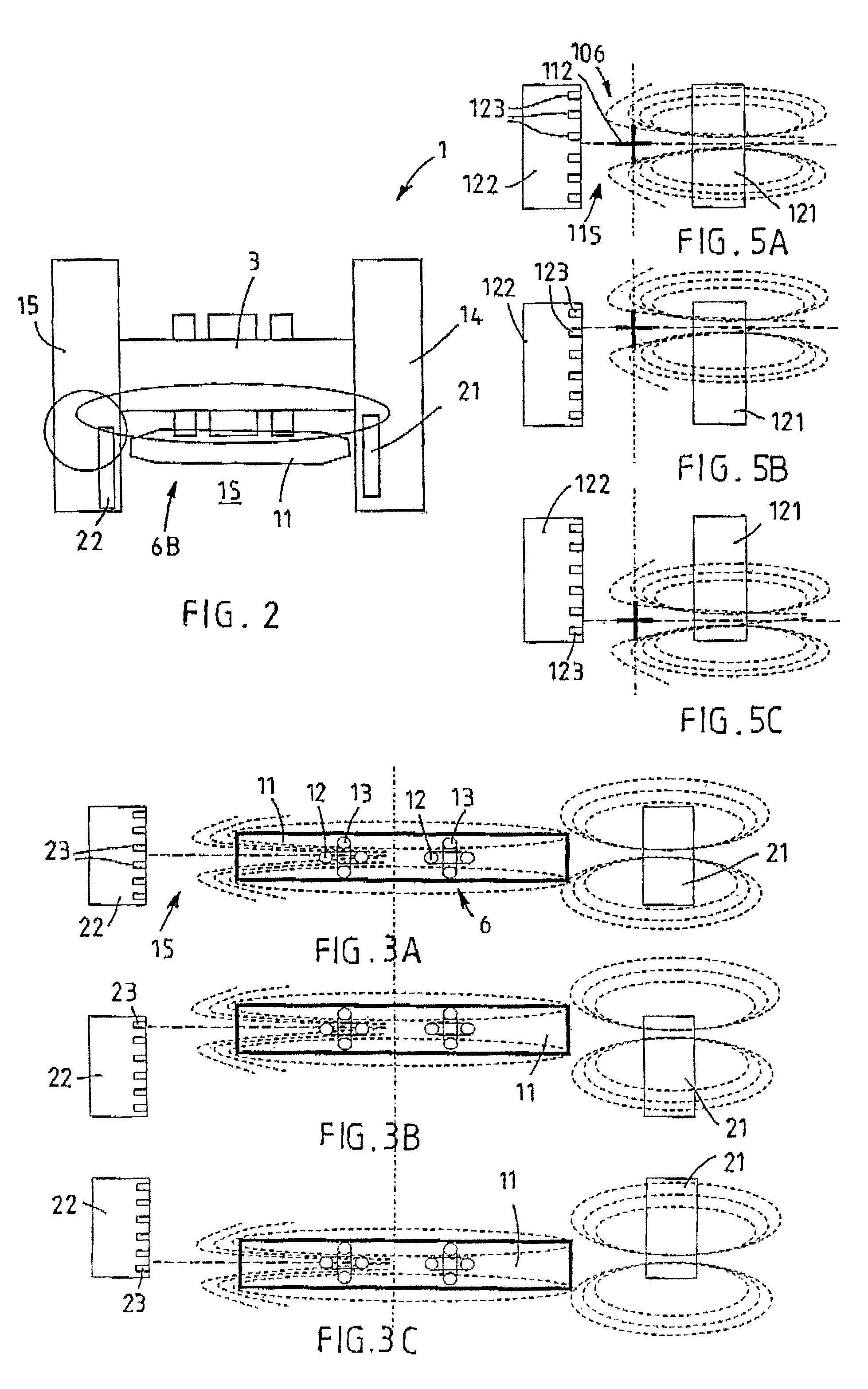

Extraction device, particularly for mining, and method for controlling the extraction device

ActiveUS20110024268A1Easy to useImprove the level ofConveyorsControl devices for conveyorsSprocketTransmitter

An extraction device, particularly for mining, having two drive stations and a drive chain which extends between the sprockets thereof. So that hanging chain or chain wear to a conveyor chain, in the case of a conveyor device, or to a plow chain, in the case of a plow device, can be detected, magnetic sensor units for detecting at least one chain condition of the drive chain are provided, wherein each sensor unit includes a transmitter, which is formed by a static or dynamic magnetic field generator, and a detector field, which is provided with a plurality of magnetic field detectors, as a detector, the detector and the transmitter being arranged to the side of a passage for the run of the drive chain that is to be scanned. The invention also relates to a method for controlling an extraction device for preventing hanging chain.

Owner:CATERPILLER GLOBAL MINING EURO GMBH

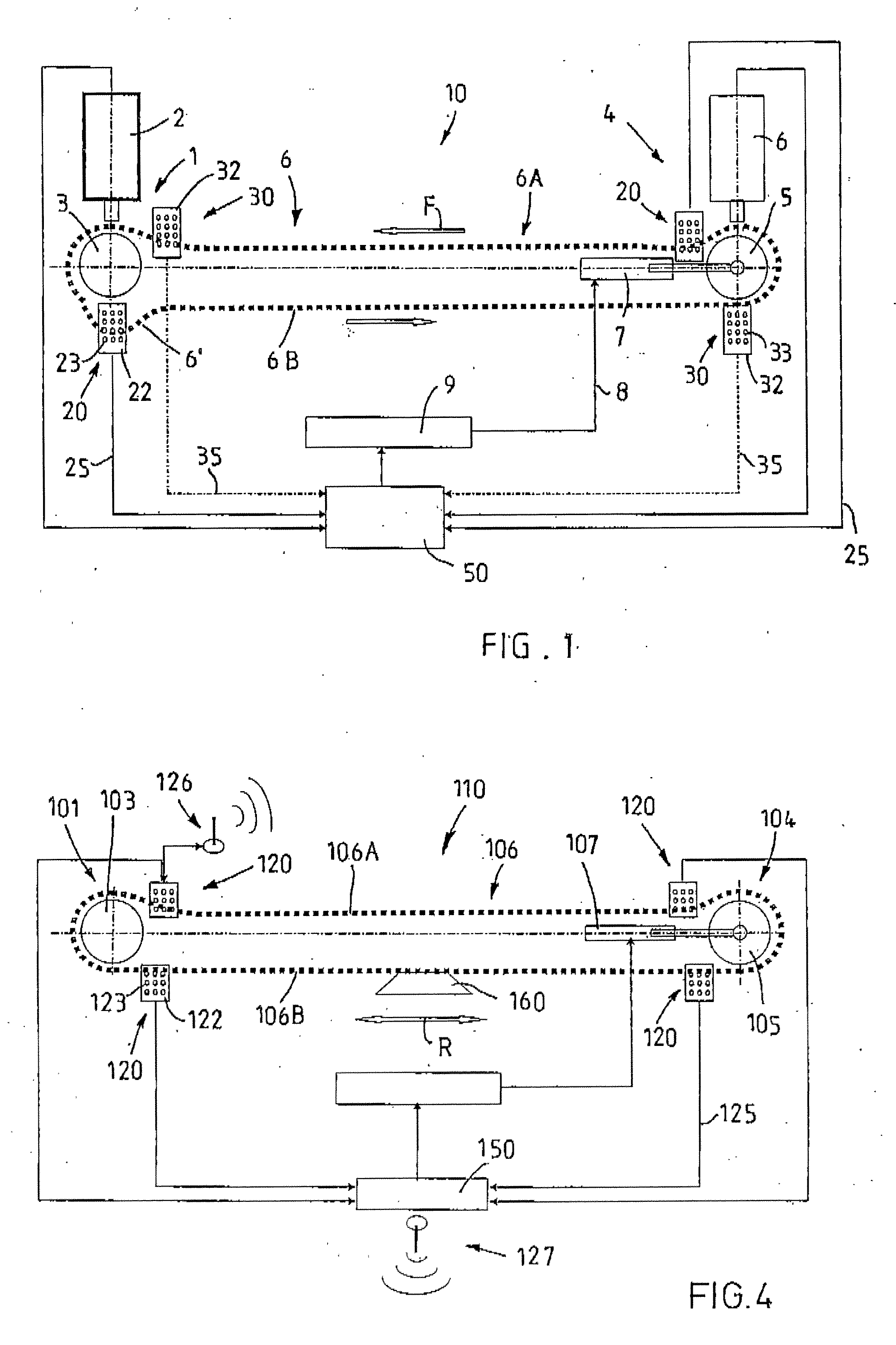

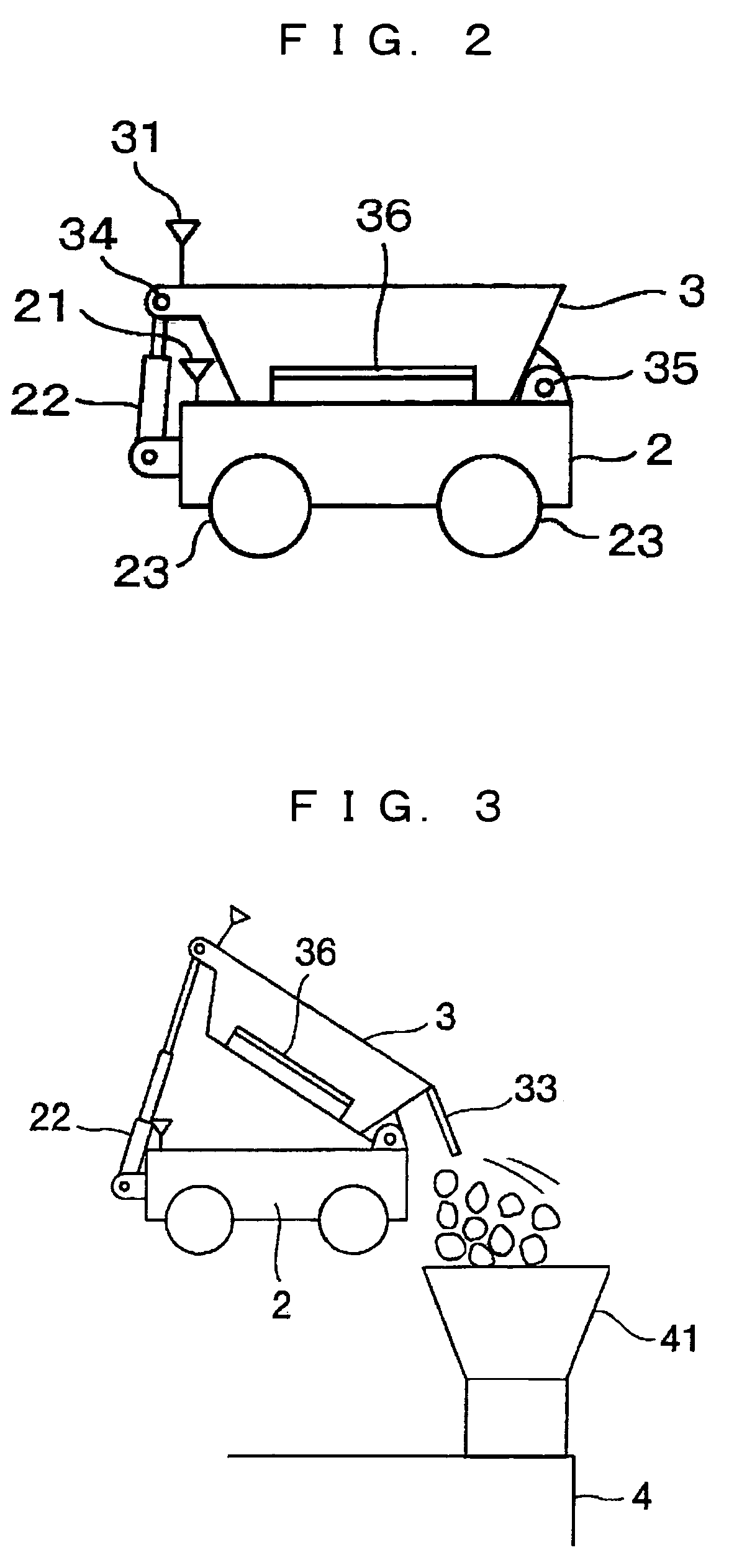

Mine transportation management system and method using separate ore vessels and transport vehicles managed via communication signals

InactiveUS6988591B2Same effectLow costData processing applicationsComputer controlTransportation management systemProcessing plants

A mine transportation management system capable of reducing cost by reducing the number of transportation vehicles is provided. For this purpose, the system includes a plurality of self-propelled vehicles and a plurality of vessels each having a communication section, and each being identifiable, which are connectable to and separable from each other. A loading machine having a communication section, which loads an object into at least one of the vessels. A management center, which has a communication section, selects a vessel to be transported and selects a self-propelled vehicle for transporting the selected vessel based on a transportation demand signal from a processing facility, and transmits a transportation command signal to the selected self-propelled vehicle to connect to the selected vessel and to travel to the processing facility.

Owner:KOMATSU LTD

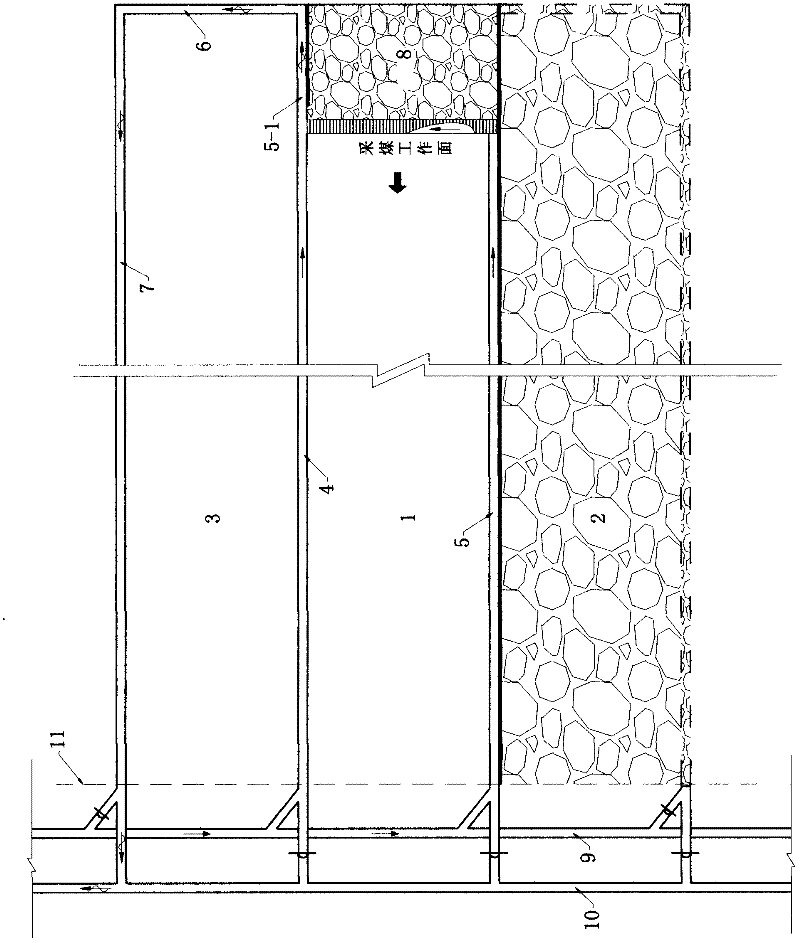

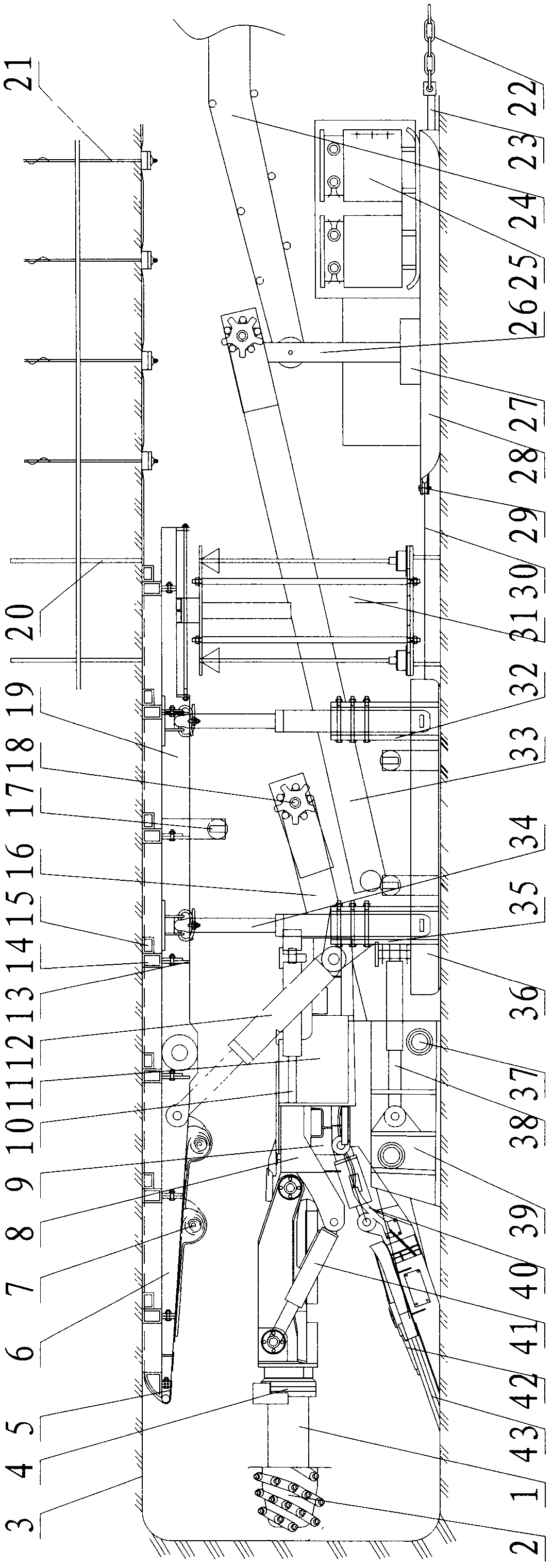

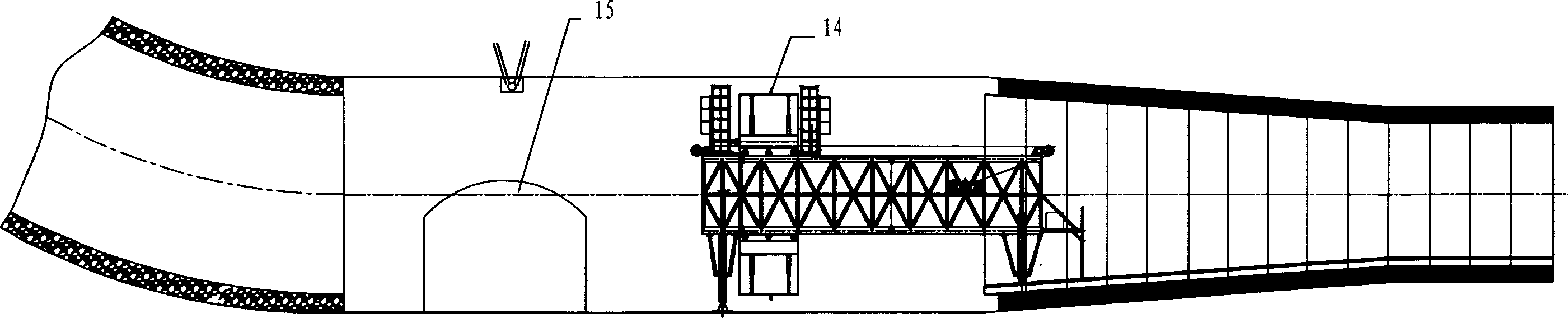

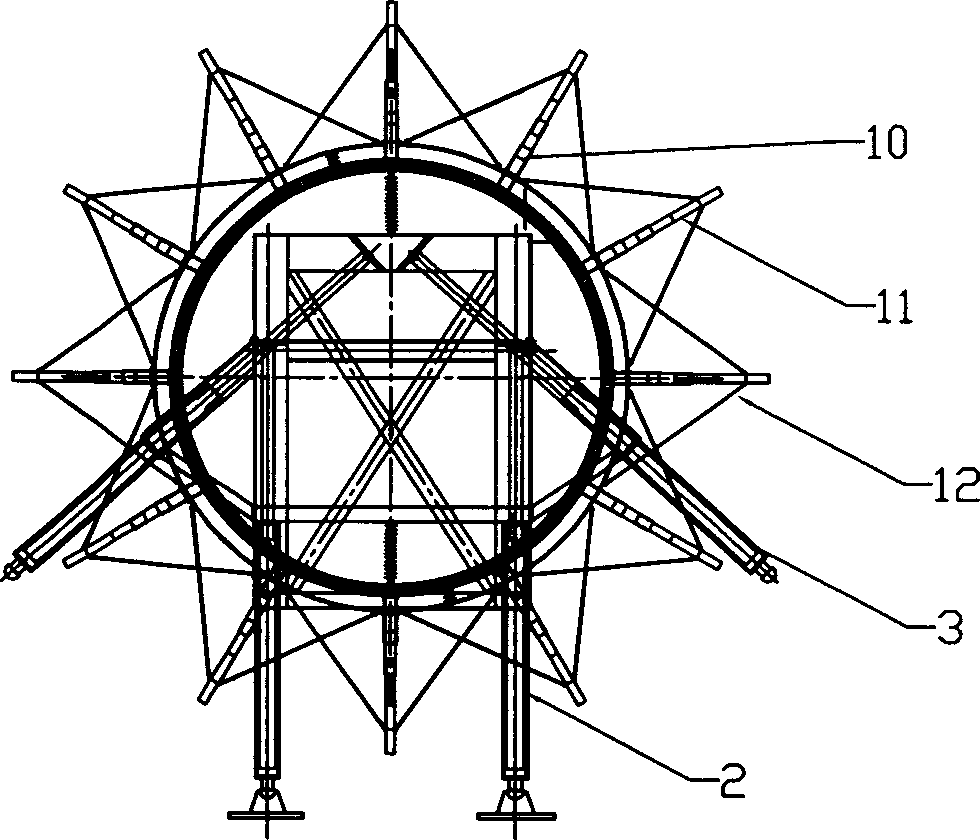

Support-type comprehensive tunneler

ActiveCN102022122AOvercome the disadvantages of not being able to drill holes and support at the same timeIncrease the speed of excavationMine roof supportsTunnelsEngineeringMetal mesh

The invention relates to a support-type comprehensive tunneler which comprises a non-tracked tunneler, a tunneler chassis, a left hydraulic support, a right hydraulic support, a drilling rig and scraper conveyors, wherein the tunneler is arranged on the tunneler chassis, and two advancing jacks are arranged on the tunneler chassis; the other ends of the two advancing jacks are respectively connected with the left hydraulic support and the right hydraulic support, and the two sides of the tunneler chassis are respectively provided with a lateral pushing oil cylinder; forestopes of the left andright hydraulic supports are respectively provided with a group of metal mesh storages, and the tail of a main top beam of the support is hung with the drilling rig; the tail of a first scraper conveyor is arranged on a spade plate of the tunneler, and the head of the first scraper conveyor and the tail of a second scraper conveyor are overlapped; and the head of the second scraper conveyor and the tail of a belt loader are overlapped, and sleds are arranged at the back of the two hydraulic supports. The tunneler has the advantage that the drilling support and the coal cutting of the tunnelerare simultaneously carried out, and also has the automatic lapping function, thus reducing labor intensity and increasing the coal mining efficiency by over 4 times.

Owner:DATONG COAL MINE GRP CO LTD HENGAN EQUIP CO LTD

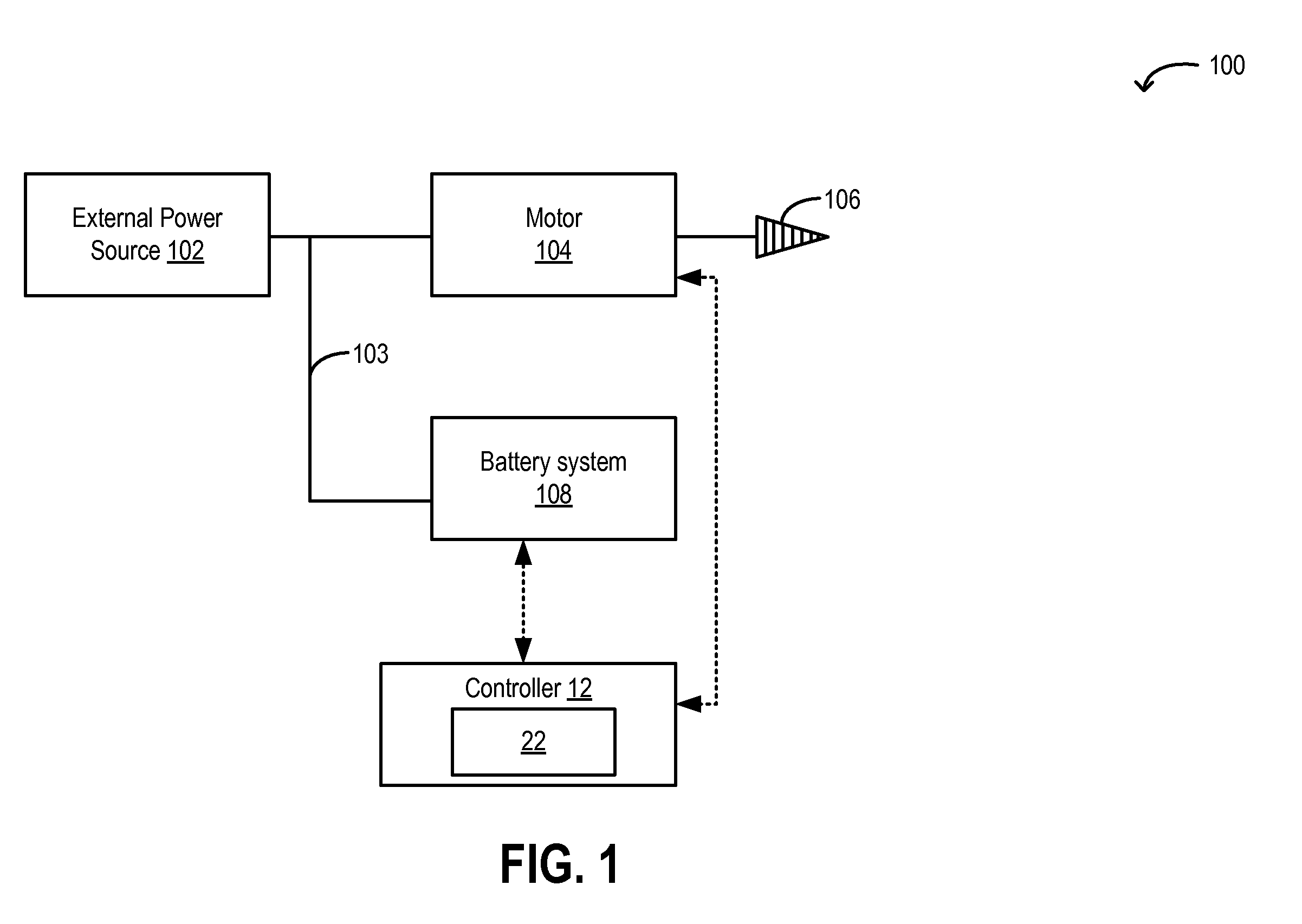

Electric drive vehicle, system and method

ActiveUS20110301794A1Reduce needLarge amount of energyHybrid vehiclesDigital data processing detailsElectricityElectric drive

An electric drive system is provided for use in a vehicle that is operated in environments with stringent emissions and ventilation regulations. In one embodiment, the electric drive system comprises a motor capable of propelling the vehicle and an energy storage device coupled to the motor, and selectively couplable to a catenary line, wherein the catenary line is capable of supplying electrical power to the vehicle and to the energy storage device. Additionally, the vehicle includes a mining device that is operable to be powered by energy from one or more of the catenary line and the energy storage device.

Owner:GE GLOBAL SOURCING LLC

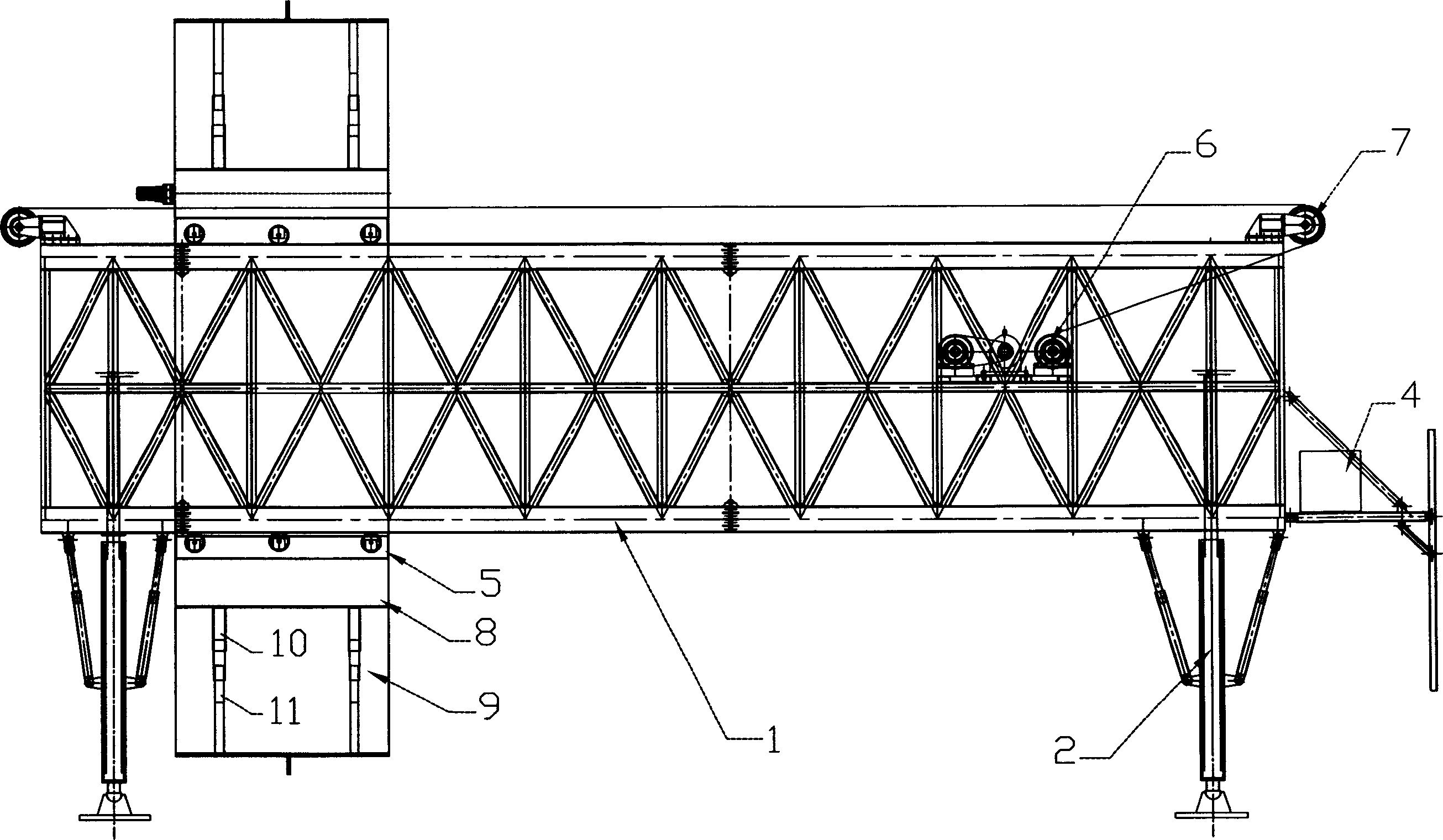

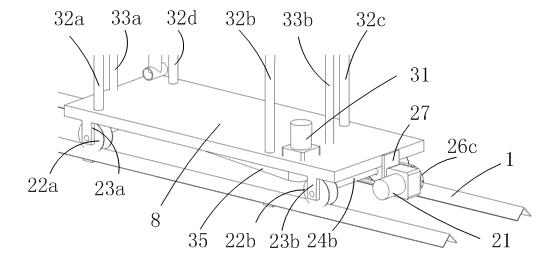

Tunnel pipe transporting mounting vehicle

InactiveCN1380212ACompact structureGuaranteed uptimeEarth drilling and miningWagons/vansDrive wheelPressure transmission

The tunnel pipe trasporting installation vehicle is formed from tractor truck, pipe-carrying vehicle and electric and hydraulic control system. The tractor truck in cludes chassis, driven wheel groupand driving wheel group, power device and speed reducer, cabin, track-cleaning device, warning signal light and headlight; the pipe-carrying vehicle includes front wheel group, front platform, pipe-carrying vehicle beam, lifting wheel group, lifting tyre group, supporting device, pipe-carrying carriage on the pipe-carrying vehicle beam and pipe-carrying lifting device; the described hydraulic control system includes tractor truck static pressure transmission system and hydraulic control system of pipe-carrying vehicle. Said vehicle is compact in structure, stable in operation, can transport, lift and install large-diameter PCCP pipe.

Owner:TAIYUAN HEAVY IND

Steel pipe pallet car and uses thereof

ActiveCN1803567AAchieve precise positioningEvenly adjust the installation gapWelding/cutting auxillary devicesTrolley cranesSteel tubeMaterials science

The invention discloses a large-scale steel pipe car, which comprises the following parts: main beam, longitude walking rack, rotary rack, supporting leg, supporting arm and adjusting support. The car can form a multifunctional mechanic construction platform in the steel making, transportation, assembling, surface antiseptic, detecting and concrete casting course, which realizes the mechanic automatic operation in the finite tunnel.

Owner:CHENGDU ALANGTECH

Extraction device, particularly for mining, and method for controlling the extraction device

ActiveUS8550236B2Reliable conditionsEasy to useConveyorsControl devices for conveyorsSprocketChain link

An extraction device, particularly for mining, having two drive stations and a drive chain which extends between the sprockets thereof. So that hanging chain or chain wear to a conveyor chain, in the case of a conveyor device, or to a plow chain, in the case of a plow device, can be detected, magnetic sensor units for detecting at least one chain condition of the drive chain are provided, wherein each sensor unit includes a transmitter, which is formed by a static or dynamic magnetic field generator, and a detector field, which is provided with a plurality of magnetic field detectors, as a detector, the detector and the transmitter being arranged to the side of a passage for the run of the drive chain that is to be scanned. The invention also relates to a method for controlling an extraction device for preventing hanging chain.

Owner:CATERPILLER GLOBAL MINING EURO GMBH

Safe moving and withdrawing method of complex-structured thick coal seam fully mechanized heavy equipment

ActiveCN102094675AGuarantee support safetySafe and quick removalUnderground transportAnchoring boltsFully developedYard

The invention discloses a safe moving and withdrawing method of complex-structured thick coal seam fully mechanized heavy equipment. A moving and withdrawing route comprises a moving and withdrawing transport route through an assisted transport gate road, i.e. from a working face to the assisted transport gate road to an assisted transport gate road roundabout channel to an assisted transport tunnel to an auxiliary adit to a stock yard, and a moving and withdrawing transport route through a belt gate road, i.e. from the working face to the belt gate rod to a return airway to the assisted transport tunnel to the stock yard; and a reasonable mining-stopping supporting method and a roof supporting method during the period of moving and withdrawing are simultaneously combined. By virtue of the moving and withdrawing method, maximum effectiveness of labor force and equipment resources are fully developed, long-distance comprehensive transportation of the thick coal seam fully mechanized heavy equipment is realized, and safe and fast moving and withdrawing of facilities in the working surface is ensured.

Owner:DATONG COAL MINE GRP

Method for mining coal of steeply inclined thin seam

InactiveCN101737047ALow costEasy dischargeUnderground miningBlastingMining engineeringEconomic benefits

The invention provides a method for mining coal of a steeply inclined thin seam on the basis of learning from a long-hole blasting coal mining method and a wire saw coal mining method, which is a long-hole blasting and wire saw coal mining method and relates to underground coal mining. The method comprises the following steps: long boreholes are arranged in a direction which is parallel to the cross pitch of the coal seam for coal blasting; after finishing blasting a work surface, making the coal slip out from a section coal bin and loading the coal for outward transport through a haulage drift; and when blasting to the vicinity of a tailgate through the long boreholes, stopping the blasting and utilizing a wire saw to mine remaining coal. The method has the advantages of no work surface support, rational tunnel arrangement, simple ventilation management, the capacity of realizing unmanned work surface mining, low cost, strong security, high coal mining rate, low worker labor intensity, good social and economic benefits and the like.

Owner:孙广义 +2

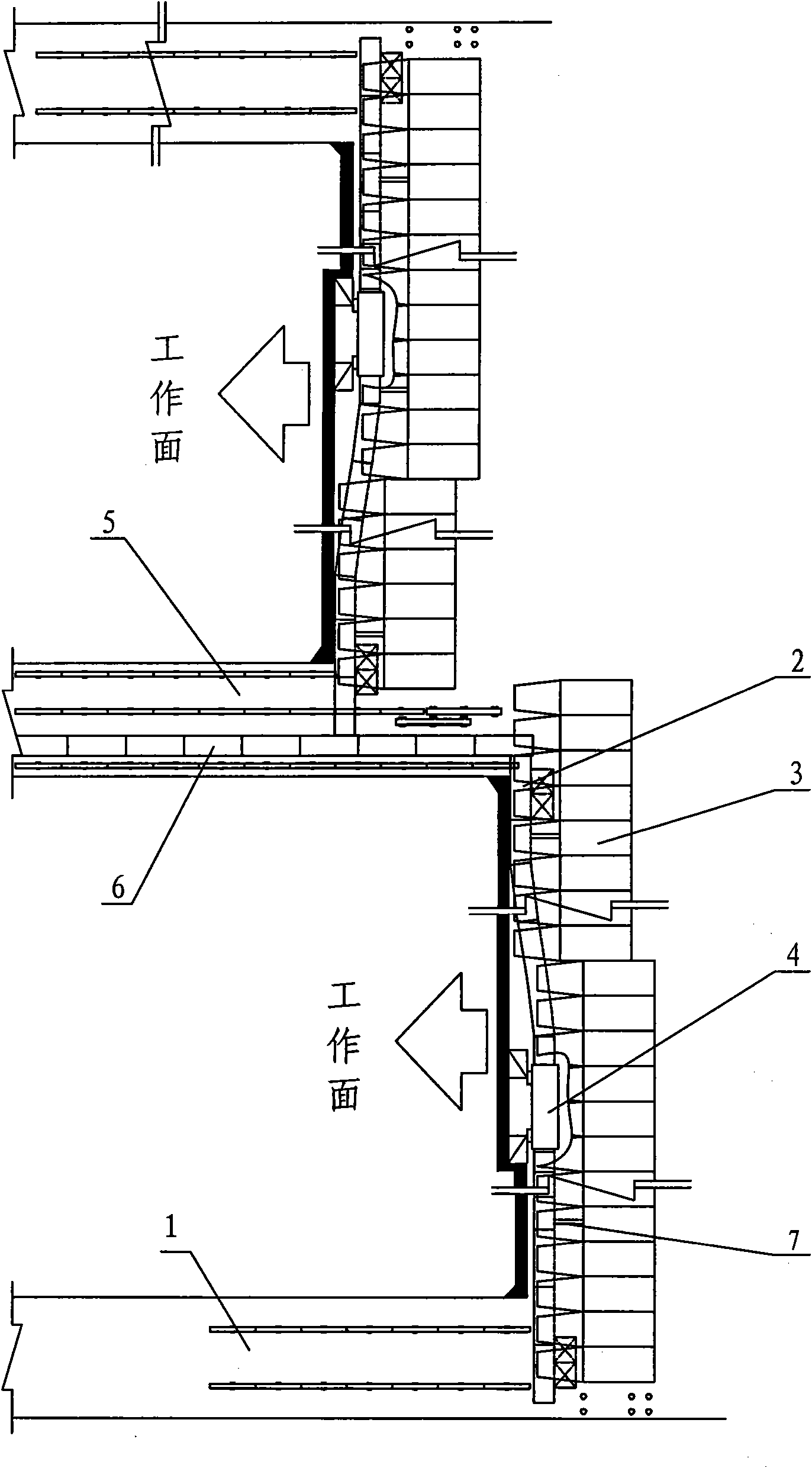

Thin coal bed highly effective fully mechanized mining process

InactiveCN101187308AReduce the tunneling rate of 10,000 tonsReduce storage rateUnderground miningSurface miningMaterial resourcesEngineering

A high efficiency fully-mechanized mining process of low coal seam is developed by combining double-unit face mining technology on the basis of comprehensive mechanized coal mining technology of low coal seam, which comprises following steps that two face material roadways and a face sharing conveyance road are parallel arranged, the space between the adjacent roads is used as working faces, the face sharing conveyance in the middle is chosen to be used as a sharing road, and a face coal-winning machine, a face scraper conveyer, and a hydraulic support are evenly arranged on each working face, and the two working faces simultaneously proceed comprehensive mechanized coal mining in parallel. Compared with the comprehensive mechanized coal mining technology, the invention lacks a road, which reduces myriatonne drivage ratio of mines, and saves costs, and the two working faces are simultaneously arranged to produce, which is beneficial for management, can effectively use labor resources, material resources, reduces storage rate of equipment part, and lowers cost input, such as reducing a bridge transfer machine.

Owner:ZAOZHUANG MINING GRP CO LTD

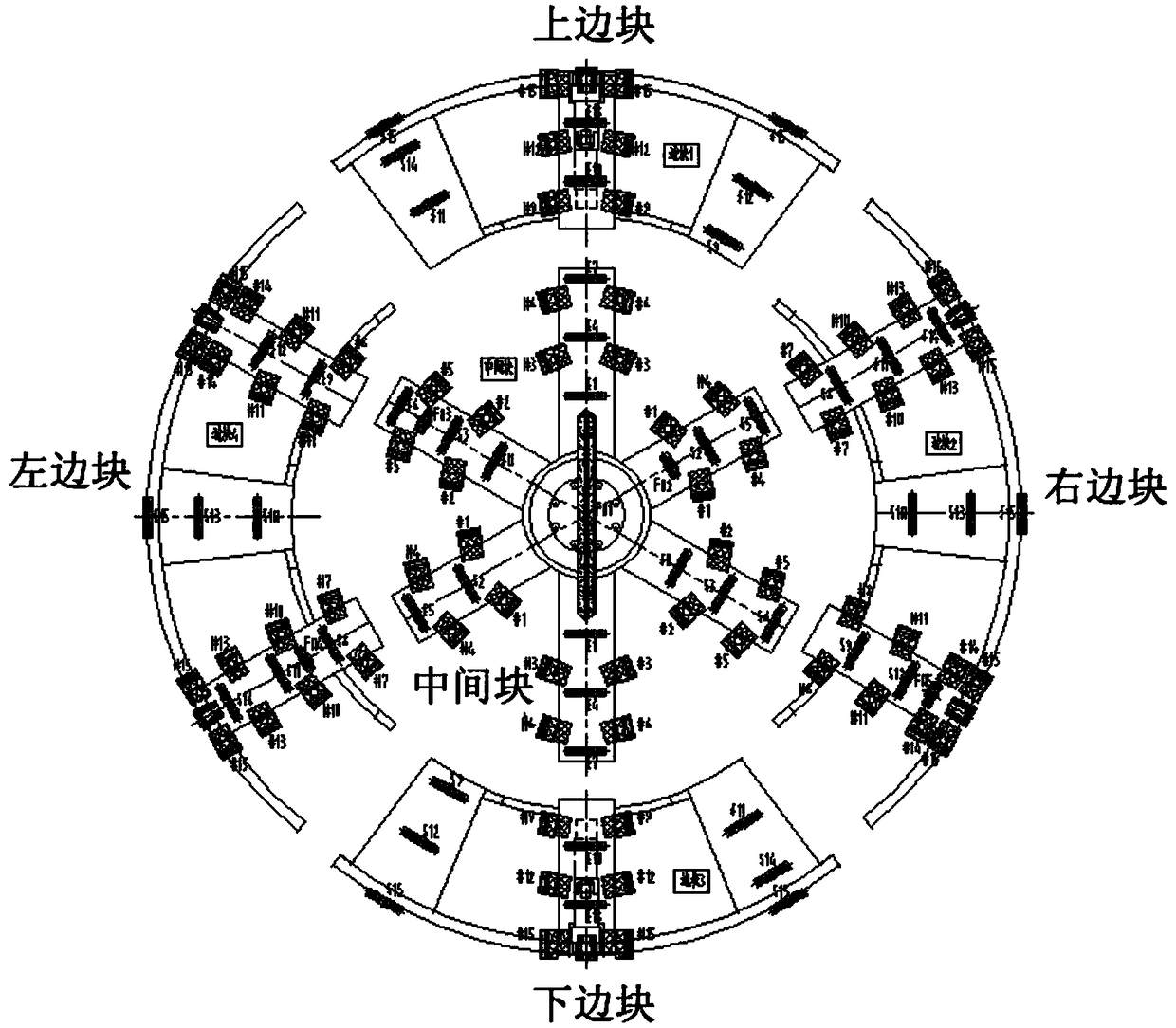

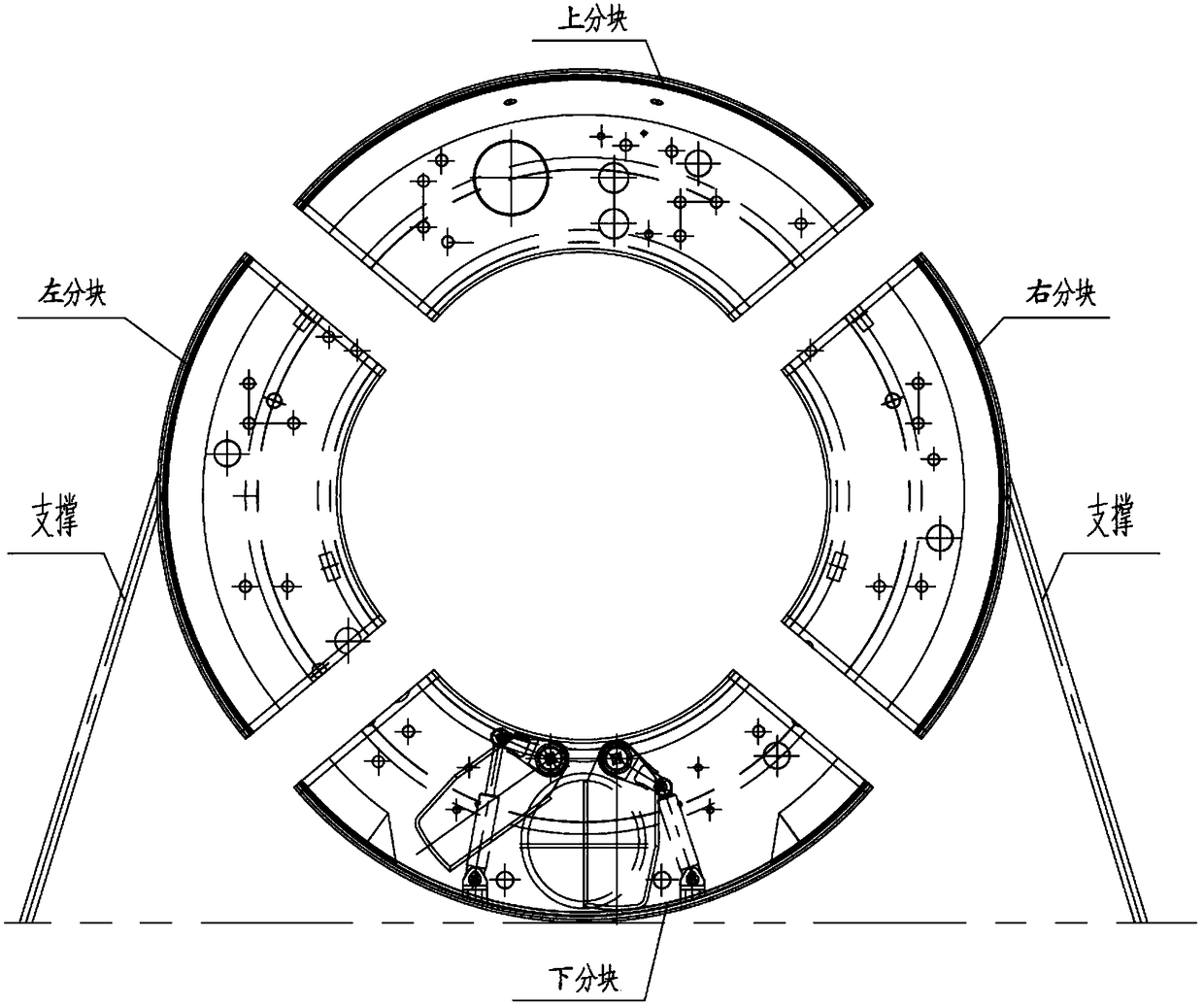

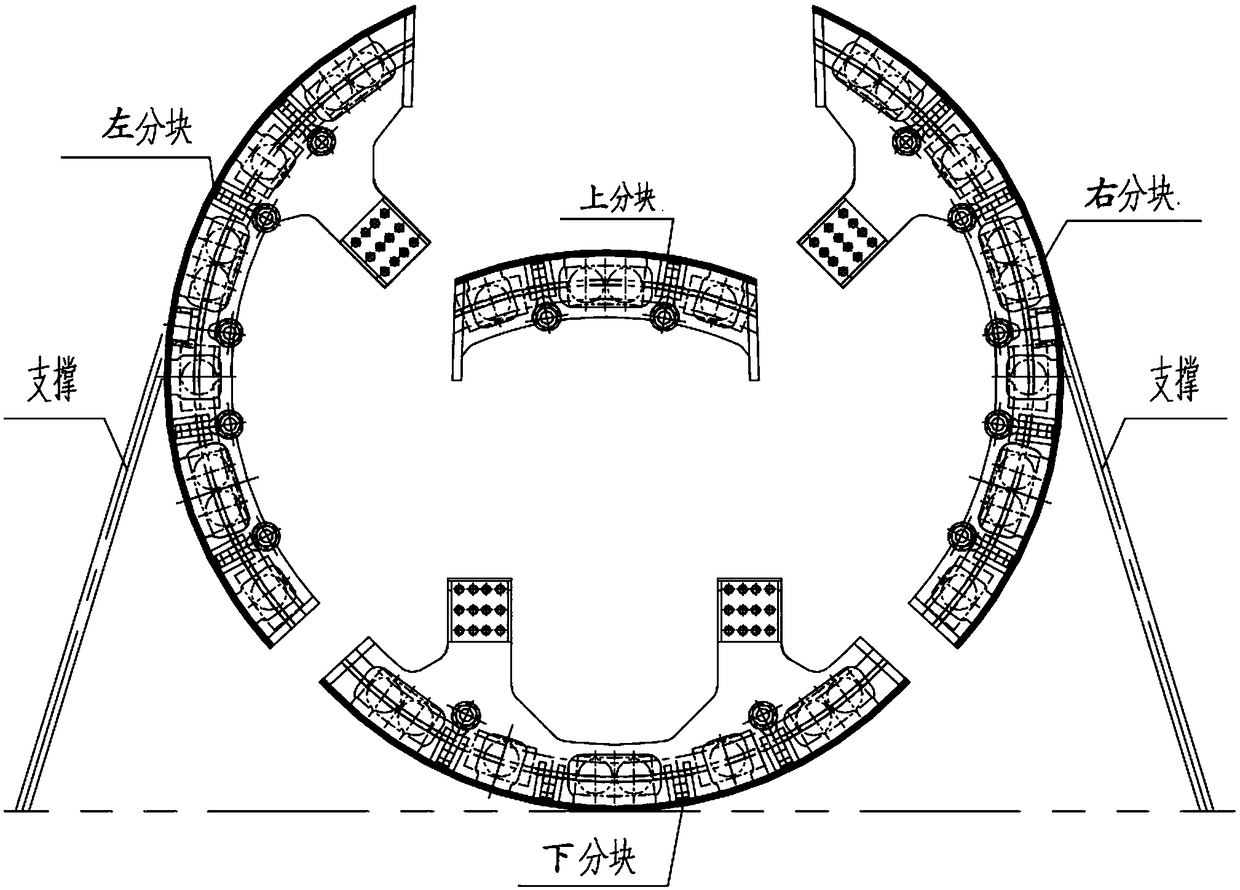

Construction method for disassembling of shield tunneling machine in narrow and small space

The invention discloses a construction method for disassembling of a shield tunneling machine in a narrow and small space. The construction method comprises the following steps that 1, shield bodies of the shield tunneling machine are designed into assembly-type shield bodies; 2, the shield tunneling machine tunnels, arrives and receives; 3, a track beam is mounted, and an electric block is mounted on the track beam; and 4, the shield tunneling machine is disassembled. According to the construction method, ground hoisting holes do not need to be formed, after a shield cutterhead comes out of atunnel, the cutterhead is disassembled, and then a front shield and a middle shield are pushed sequentially through power of the shields to disassemble the front shield and the middle shield; and then a shield tail is pulled away from the tunnel through external arrangement of a jack to be disassembled, by pushing one of the shield bodies, one or two segments are spliced, and the disassembled components of the shield tunneling machine are transported in the mode of disassembling one of the shield bodies.

Owner:POWERCHINA RAILWAY CONSTR

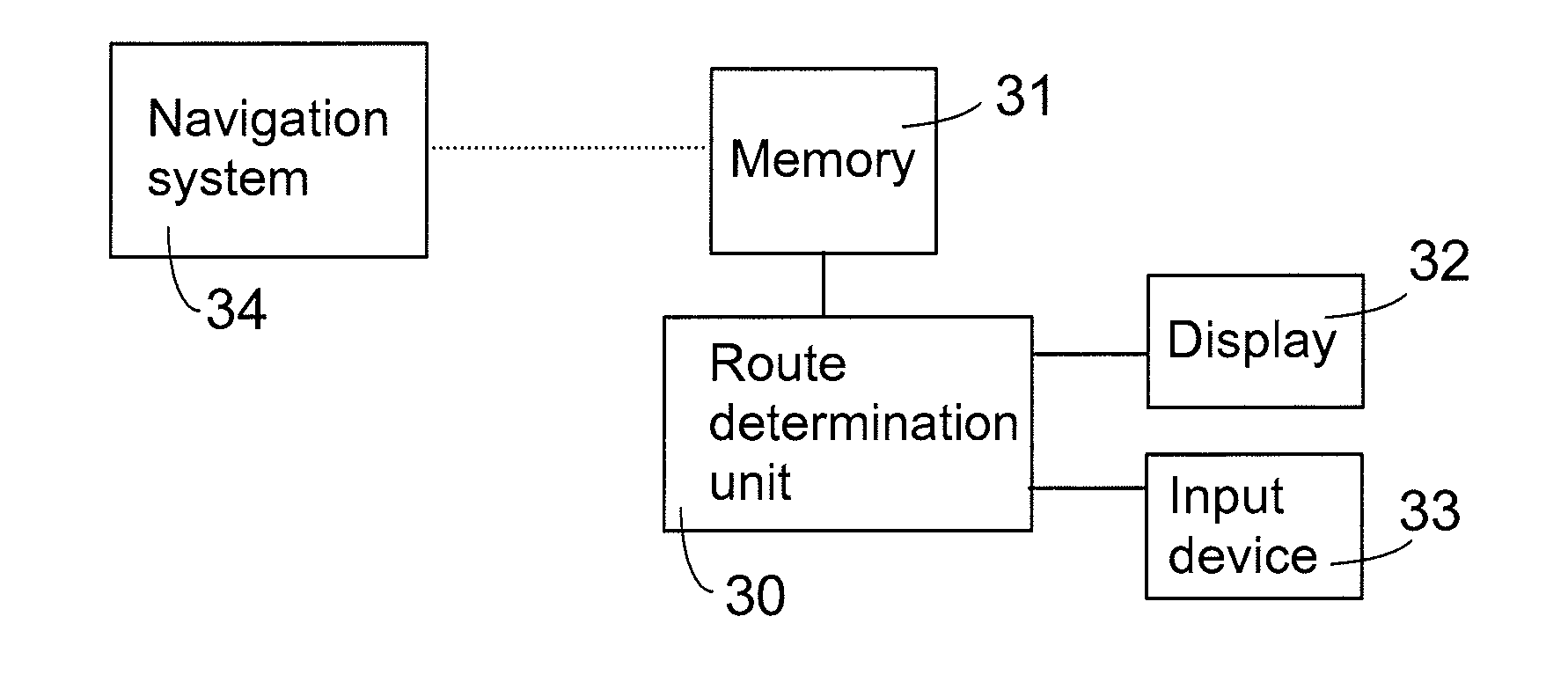

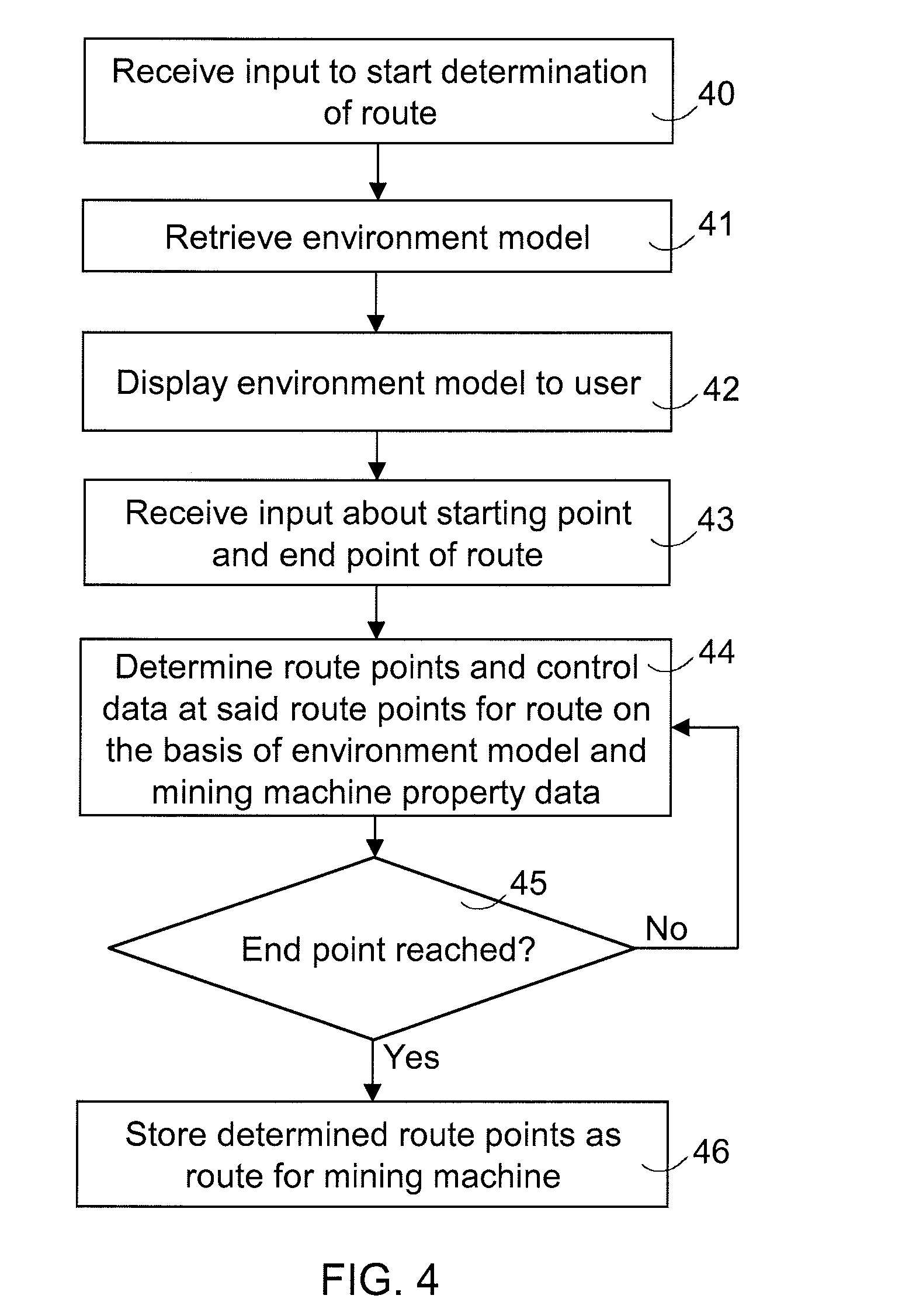

Determination of Route for Arranging Automatic Control of Mobile Mining Machine

ActiveUS20120116666A1Easy to solveShorten the time necessarily taken by a routeNavigation instrumentsEarth drilling and miningPresent methodAutomatic control

The present method relates to a method of determining a route for automatically controlling a mobile mining machine. The route is determined computer-aidedly by executing, by a data processing machine configured for generating routes, the following steps of: retrieving an environment model comprising wall location data, receiving from a user at least an input for determining a starting point of the route and an input for determining an end point of the route, determining the route between the starting point and the end point on the basis of the environment model and data concerning properties of the mining machine, wherein the route is determined as route points at least for which position data are calculated, and storing the data determining the route to be used for automatically guiding the mining machine.

Owner:SANDVIK MINING & CONSTR OY

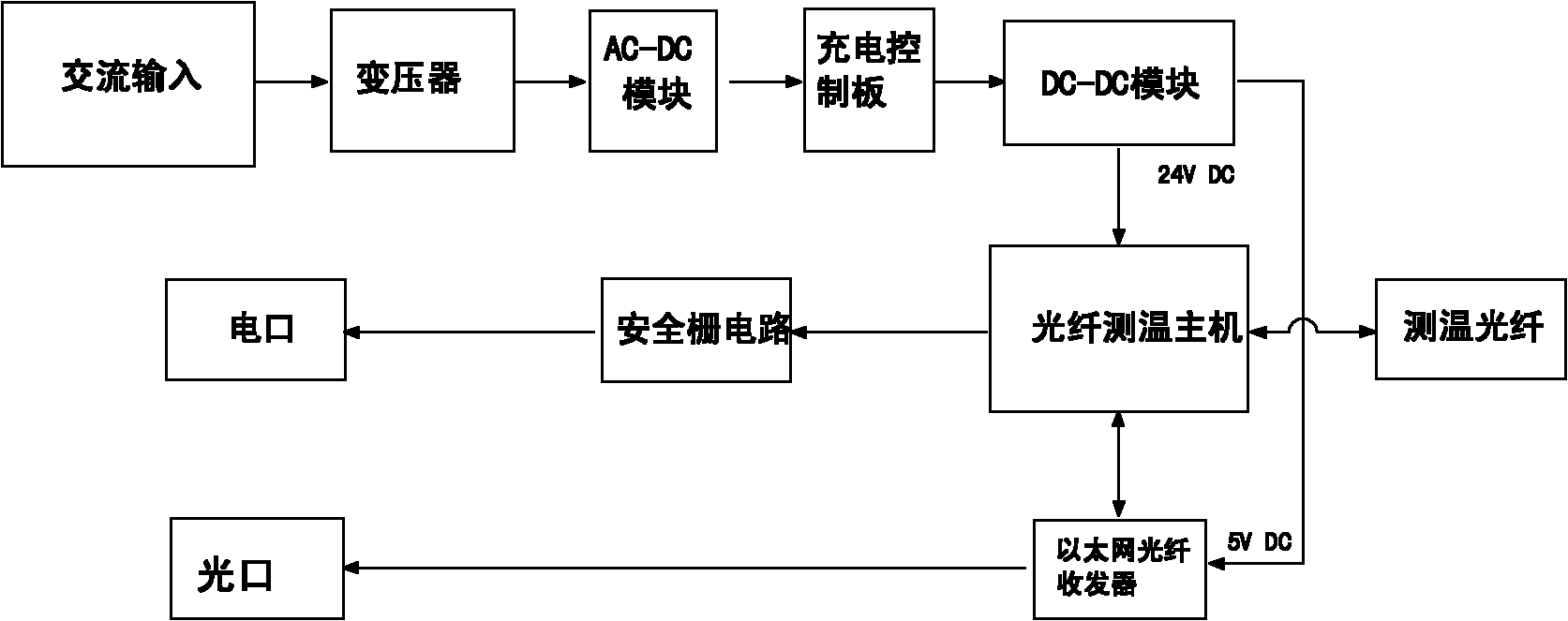

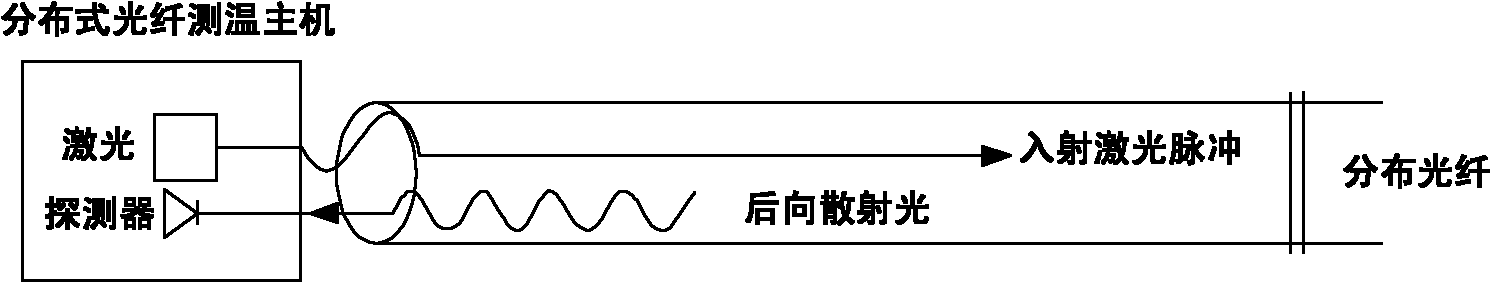

Distributed optical fiber temperature measurement-based fire early warning method for belt conveyor

The invention relates to the field of coal mine safety, in particular to a distributed optical fiber temperature measurement-based fire early warning method for a belt conveyor. The method comprises the following steps of: dividing a temperature measuring optical fiber into a temperature measuring point, a channel and an area, and processing temperature data measured by the temperature measuring optical fiber by an absolute temperature early warning method, an area relative temperature difference early warning method, an area normal distribution early warning method, a measuring point temperature rise slope early warning method and a measuring point temperature rise variation trend early warning method to acquire a channel threshold early warning characteristic value, an area threshold early warning characteristic value, an area relative temperature early warning characteristic value, an area temperature normal distribution statistical characteristic value, a measuring point threshold early warning characteristic value, a measuring point temperature rise slope early warning characteristic value and a measuring point temperature rise accumulated trend early warning characteristic value; inputting the characteristic values and the measuring point temperature rise accumulated trend early warning characteristic value into a back propagation (BP) neural network model; and outputting a warning coefficient, an early warning coefficient and a safety coefficient by using the BP neural network model.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

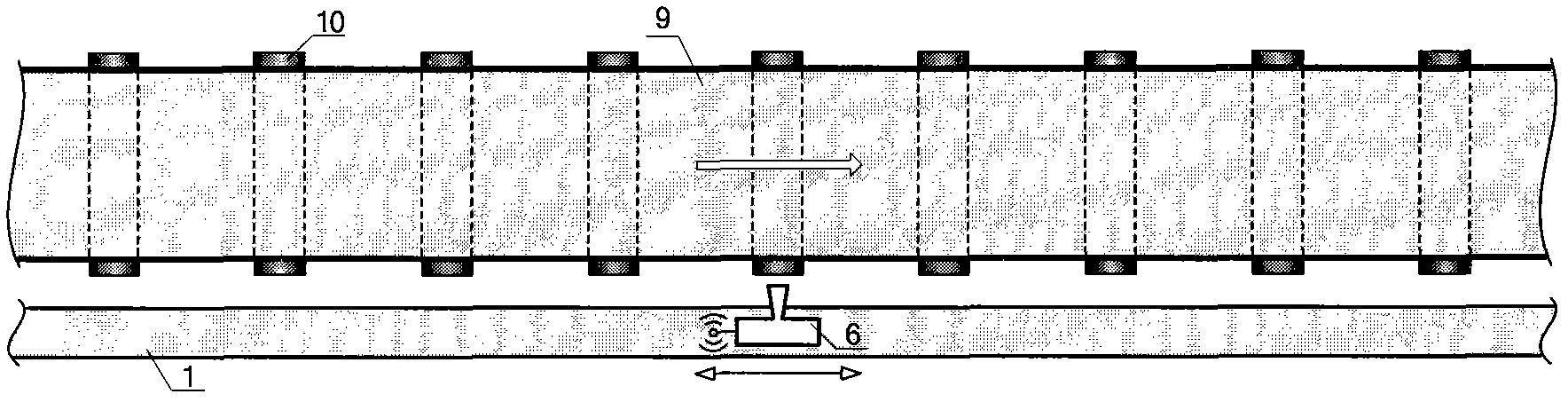

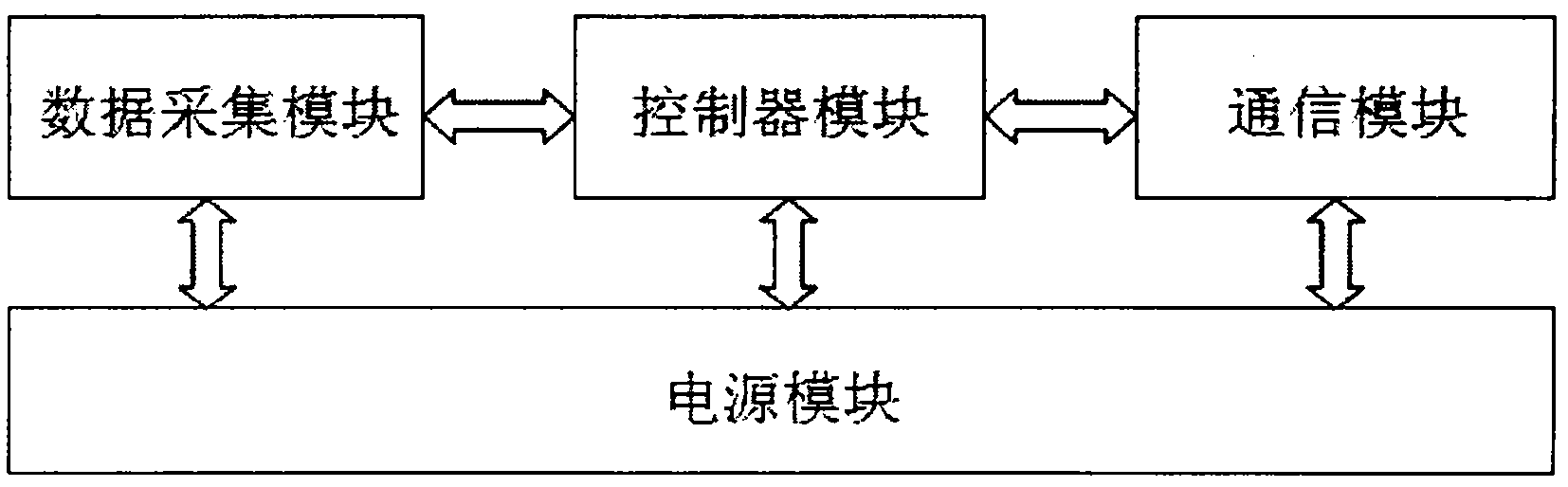

Roller failure monitoring system of belt conveyer

InactiveCN101975083ARealize automatic monitoring functionControl devices for conveyorsEarth drilling and miningAutomatic routingData acquisition

The invention relates to a failure monitoring system of a roller of a belt conveyer, which mainly comprises a sensor, a mechanical device for moving the sensor, a communication substation and the like, wherein the sensor comprises a power module, a data acquisition module, a controller module and a communication module; a sensitive element of the data acquisition module is a unidirectional type electret microphone; the mechanical device comprises a synchronous belt, synchronous belt wheels on both ends of the synchronous belt, a supporting wheel in the middle of the synchronous belt and a stretching wheel; the sensor fixed on the synchronous belt is moved to the position near to any roller position by utilizing the operation of the mechanical device; the sensor collects sound signals and the like generated by the rotation of rollers and carries out the data processing and the extraction of failure signals; and the failure diagnosis result is sent to the communication substation and transmitted to a monitoring room through an optical network. The system is especially suitable for automatic routing inspection of the belt conveyer under a coal mine, discovers the abnormal working condition of the roller in time and guarantees the normal production of the coal mine.

Owner:ZHEJIANG UNIV

Manual control and remote control integrated electric fork lift truck

InactiveCN101982618AOperational securityImprove securityMechanical machines/dredgersClosed circuit television systemsWireless controlRemote control

The invention discloses a manual control and remote control integrated electric fork lift truck, which belongs to the field of electric fork lift truck and comprises an electrically-driven fork lift truck on a working face. The fork lift truck is provided with an operating room; the operating room is provided with a manipulation button which is connected with a control system; and a power supply end of the control system is connected with a power supply cable arranged on the rear part of the fork lift truck. The fork lift truck is characterized in that: the fork lift truck on the working face is provided with a wireless monitoring system and a wireless control system; a terminal operating floor of the wireless monitoring system and the wireless control system are arranged in a work station; and the wireless control system is connected in parallel and mutually locked with the manipulation button in the operating room and then connected with the control system. An operator can monitor the conditions of the working face and control the work of the electric fork lift truck on the terminal operating floor of the work station. When the wireless control system controls the fork lift truck, the manual operation system stops so that the fork lift truck receives only one command; and the fork lift truck operates in a large range and is convenient to control.

Owner:SHANDONG UNIV OF TECH

Comprehensive mining opposite-pull working face coal excavating process for thin coal bed

InactiveCN101526001AReduce the tunneling rate of 10,000 tonsReduce storage rateUnderground miningSurface miningCoal pillarIndustrial engineering

The invention relates to a comprehensive mining opposite-pull working face coal excavating process for a thin coal bed, comprising the following steps: 1, two working face material lanes and a working face common transporting lane are arranged in parallel, wherein part between two adjacent lanes is a working face, and the middle working face common transporting lane is selected as a common lane; 2, each working face is provided with a working face coal mining machine, a working face scraper transporter and a hydraulic bracket, and two working faces simultaneously carry out comprehensive mining in parallel. In order to leave a channel of the common transporting lane for passing in and out for workers between the hydraulic brackets of the two working faces, the two working faces are staggered with a certain distance. The invention reduces the ten-thousand-ton drivage ratio of a mine, saves the cost, realizes non-coal pole exploitation between the working faces, improves the recovery ratio of resources and increases the yield of the same unit workers by almost one time.

Owner:BINHU COAL MINE ZAOZHUANG MINING GRP

Automatic carrying, replacing and blowing device for tunnel air purification material modules

The invention relates to an automatic carrying, replacing and blowing device for tunnel air purification material modules. The device comprises a guide rail, a traveling mechanism, a lifting mechanism, a telescopic mechanism, an anti-tilting structure and a blowing structure. Carrying and replacement of the designated position of a purification material frame and blowing of the designated purification material modules are realized by traveling of the traveling mechanism along the guide rail and through the lifting mechanism; and the anti-tilting structure ensures that the whole device does not tilt during carrying, replacing and blowing. The automatic carrying, replacing and blowing device relates to the technical fields of mechanical transmission, tunnel air treatment and the like.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Apparatus and method for mining coal

InactiveUS20140056646A1Prevent subsidencePumping operationDisloding machinesUnderground miningEngineeringSolvent

The present invention relates to a novel method of retrieving gas from a gas-containing subterranean formation, the method including digging a mine shaft to reach the subterranean formation; constructing a ventilated underground control center wherein the center includes a computerized control panel, wherein the computerized control panel controls the movements of a hot head device such as a plasma torch, an electro-chemical apparatus, a hydrogenating solvent or heated ceramic particles; a hollow drill pipe; a movable hydraulic shield; a movable resin roof bolting machine; and a movable waste extrusion device; providing mining personnel to the ventilated underground control center; and allowing the mining personnel to operate the computerized control panel wherein they perform the tasks of moving the hot head device into the subterranean formation, recovering the gas, and extruding waste material into a mined-out space of the subterranean formation.

Owner:AULISIO GEORGE ANTHONY +1

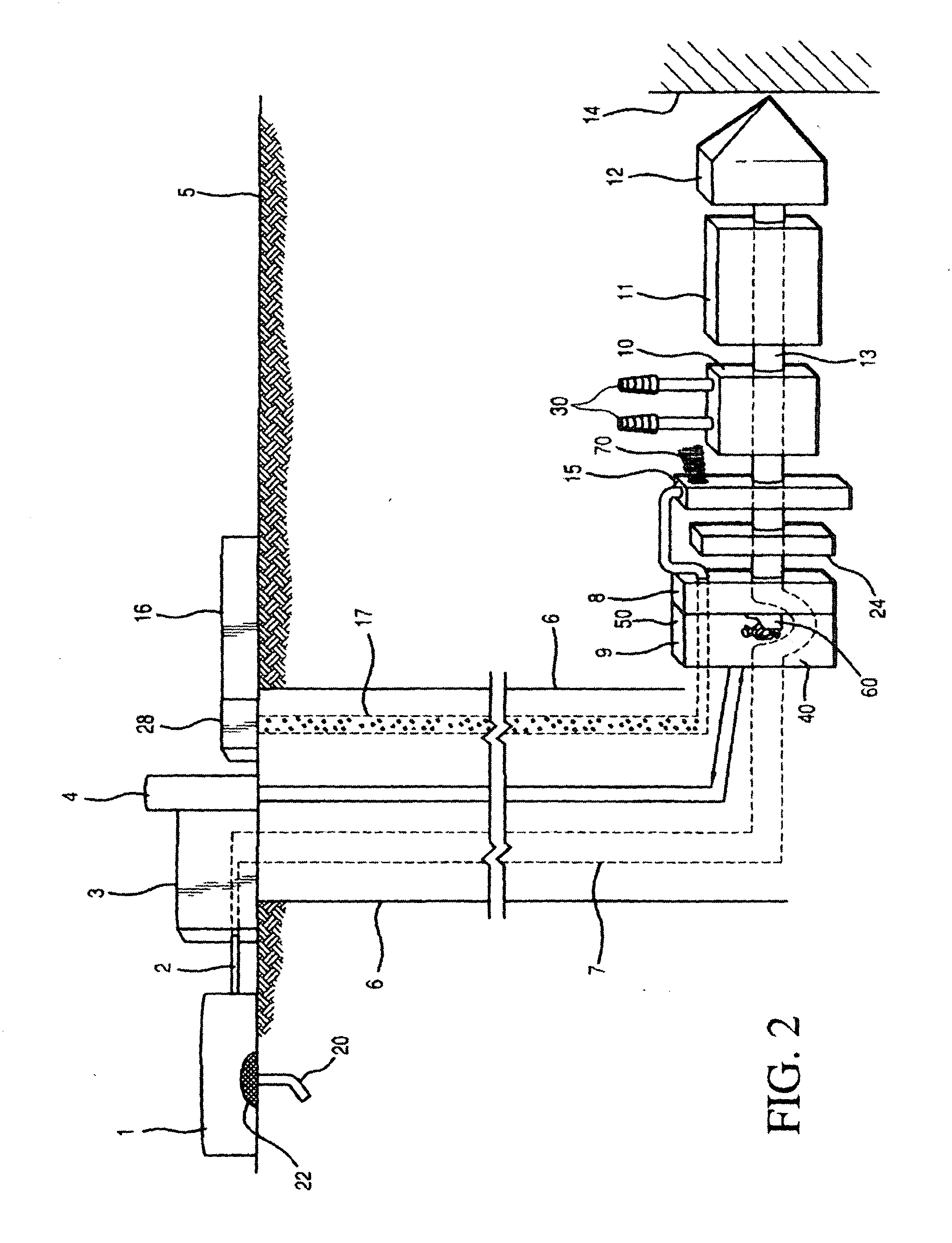

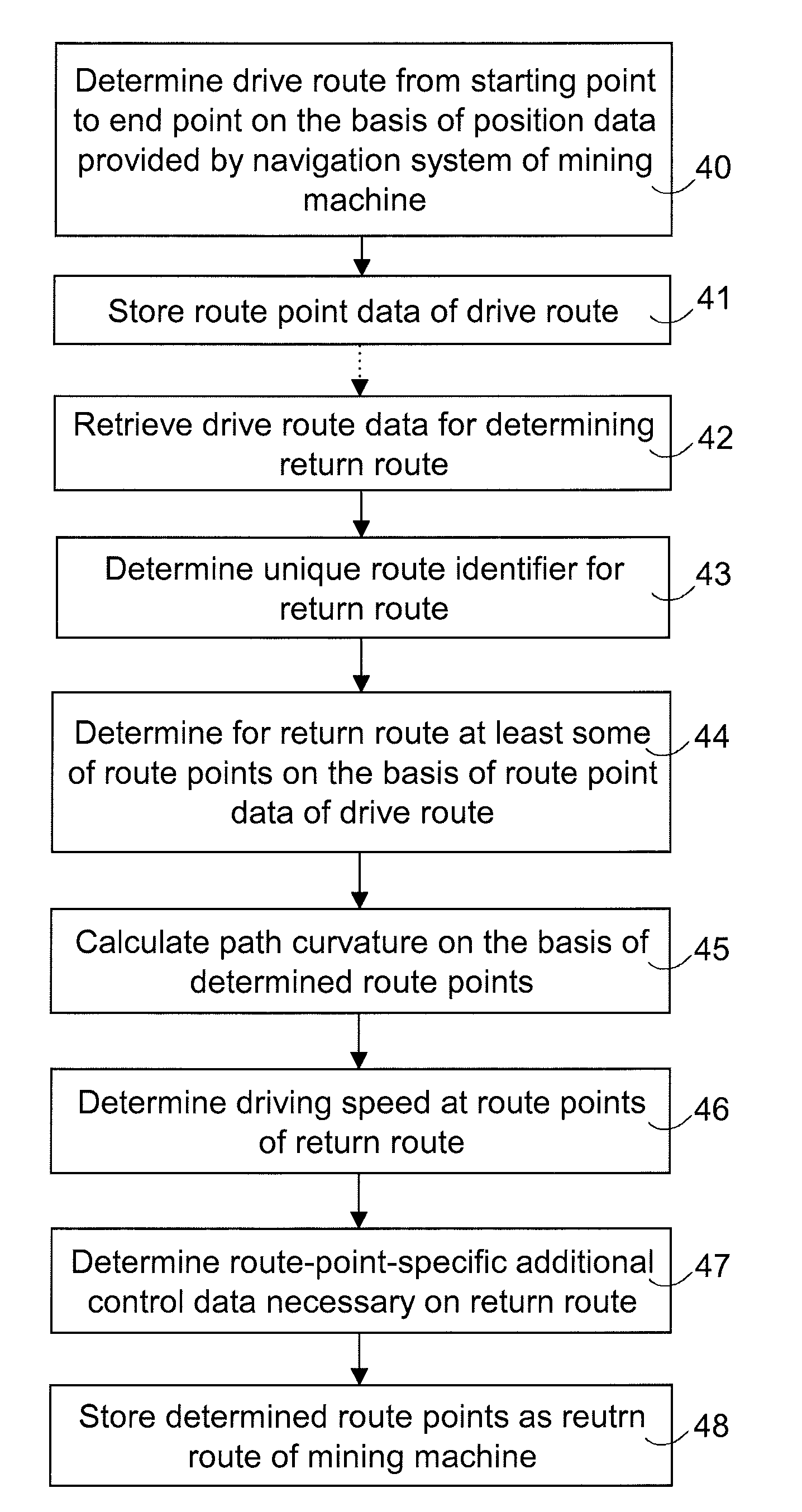

Determination of Routes for Arranging Automatic Control of Mobile Mining Machine

ActiveUS20120095639A1Shorten the timeConsiderable amount of timeInstruments for road network navigationEarth drilling and miningAutomatic controlReverse order

The present invention relates to a method of determining routes for arranging automatic control of a mobile mining machine. A return route is determined computer-aidedly for the mining machine on the basis of data concerning a route taught by driving by executing, by a data processing device configured for generating return routes, at least the following steps: determining a route identifier for the return route, determining as route points of the return route at least some of the route points of the drive route in a reverse order, wherein when determining route point data of the return route on the basis of the route point data of the drive route, deleting additional control data associated with one or more route points of the drive route, and storing the data determining the return route to be used for automatically controlling the mining machine.

Owner:SANDVIK MINING & CONSTR OY

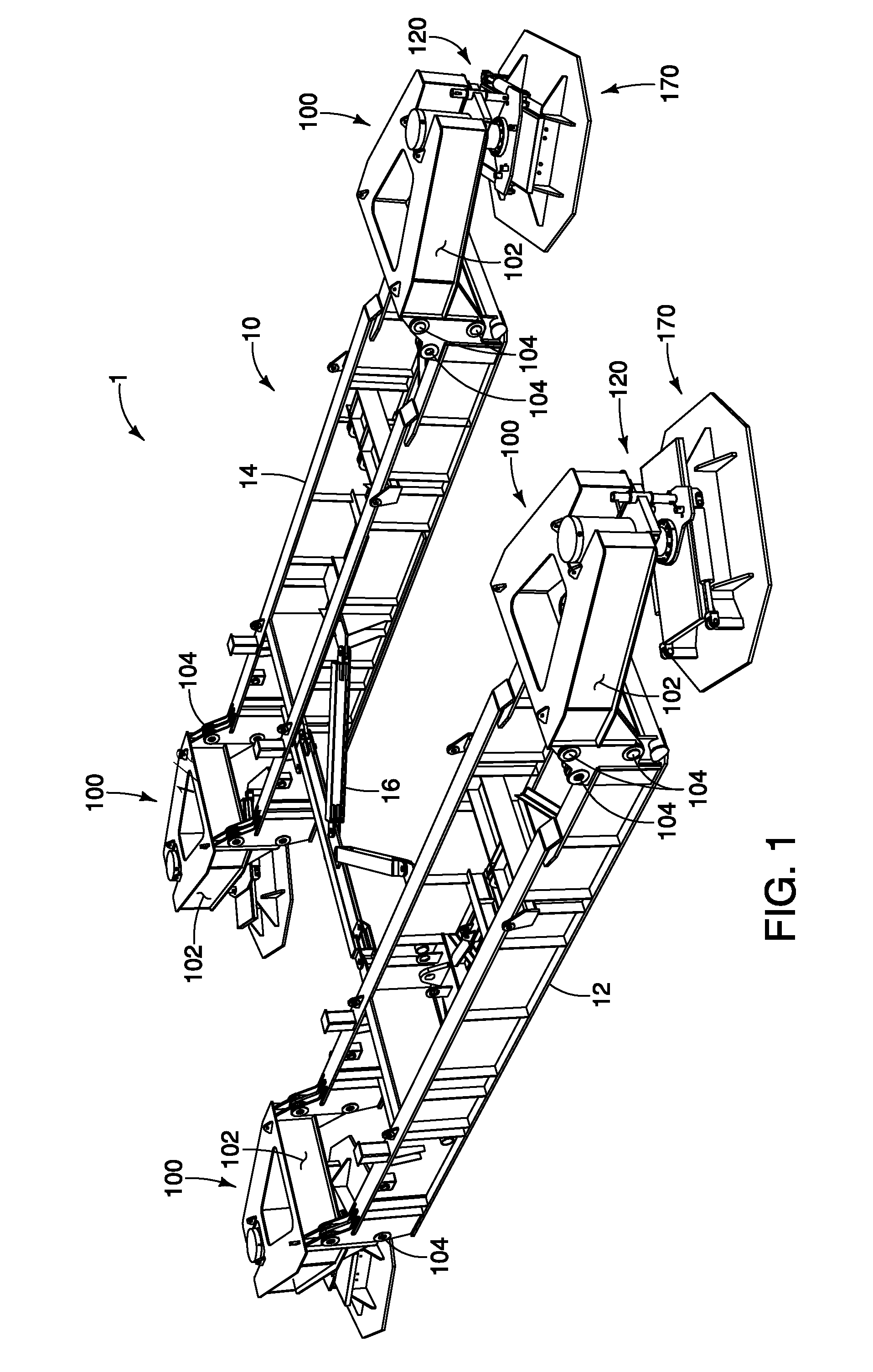

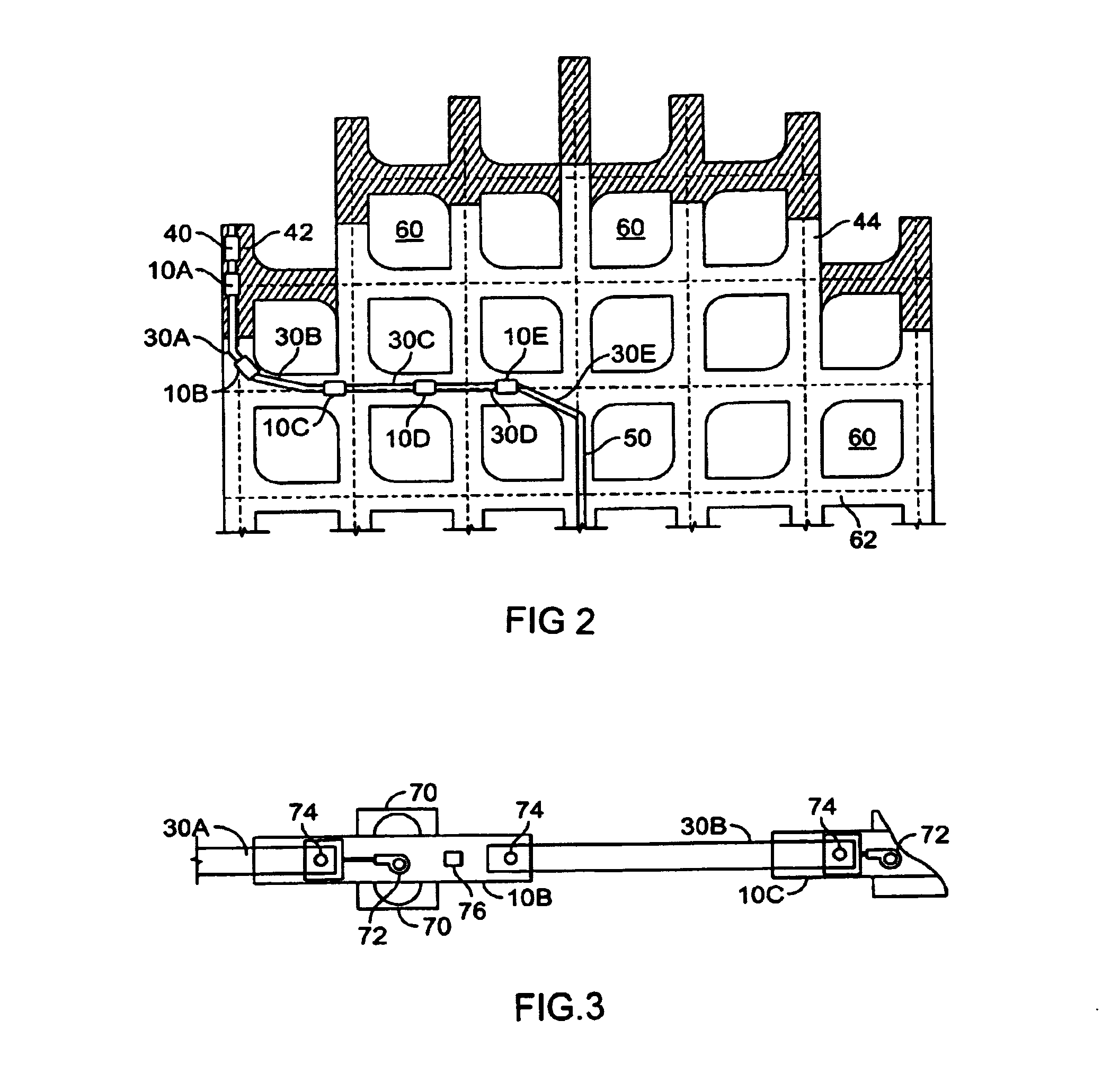

Automated continuous haulage system

The present invention relates to an automated continuous haulage apparatus and method designed for use in underground environments. Each mobile bridge carrier (10) contains distance measurement (70) and angular position (74) means for determining the mobile bridge carrier's (10) position and the angular position of attached piggyback conveyors (30). Means for determining the ceiling height (76) are utilized to adjust the height of the piggyback conveyors (30). On each mobile bridge carrier (10), input from the various sensors is received by an electronic controller (80) that calculates the position and orientation of the bridge carrier (10) and attached piggyback conveyors (30). The controller then plans an optimal path of movement for the bridge carrier (10) and computes the rate of movement for each independently operated track assembly on the bridge carrier such that the bridge carrier (10) and piggyback conveyors (30) arrive as close as possible to the planned path.

Owner:CATERPILLAR GLOBAL MINING LLC +1

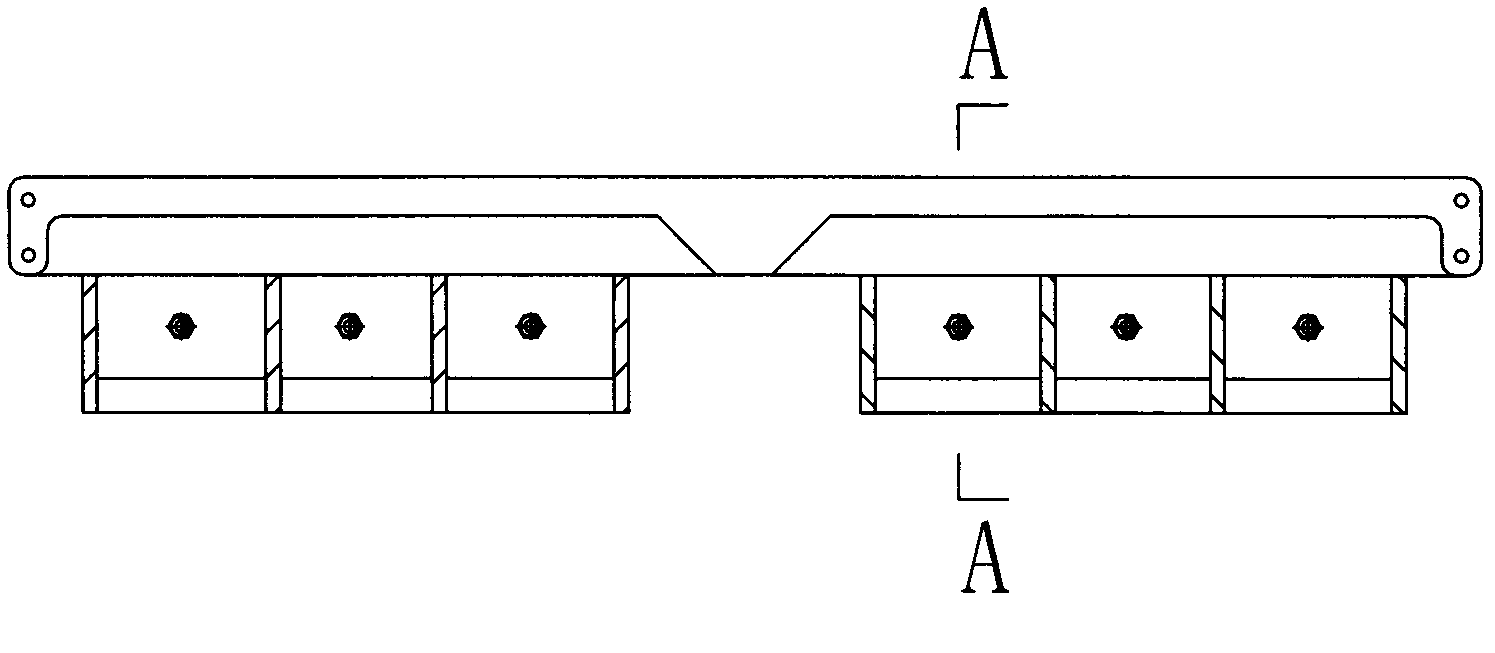

Main shaft skip weight-measuring device for coal supply machine

InactiveCN101332944AAdapt to a wide rangeEasy to installConveyorsControl devices for conveyorsWeight changeInlet valve

The invention discloses a coal feeder type main shaft bucket standard weight device provided with a weighing device on the existing belt conveyor type coal feeder in mines, without occupying other space. The weighing device comprises: an instantaneous weighing device connected with a conveyer belt, a speed sensor connected with a driven roller and a calculator installed outside a machine; the calculator is connected with an inlet valve of a feed inlet by a signal wire. The instantaneous weighing device comprises: a weighing bridge, a weighing sensor, a weighing roller, and the like; the weighing bridge is in floating mode, which floats up and down along with the material weight change at the upper part of the conveyor belt; the weighing sensor connected with the weighing roller and the speed sensor connected with the driven roller input signals into the calculator for calculation so as to calculate the weight of transported material on the conveyor belt in a period of time. When the bucket standard weight load is reached, the calculator sends out signals to close a feed valve so as to realize continuous and uninterrupted bucket standard weight loading.

Owner:李文昌 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com