Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4158 results about "Shield tunneling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

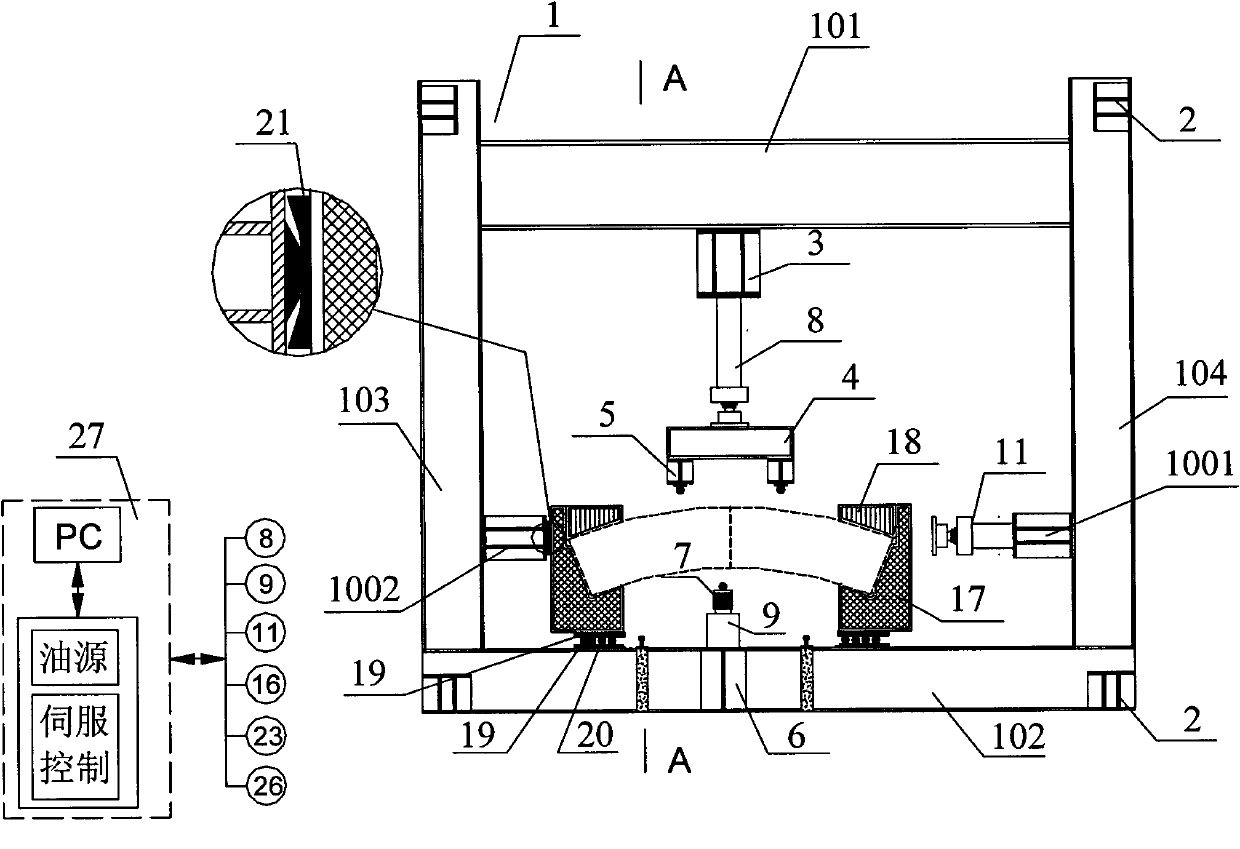

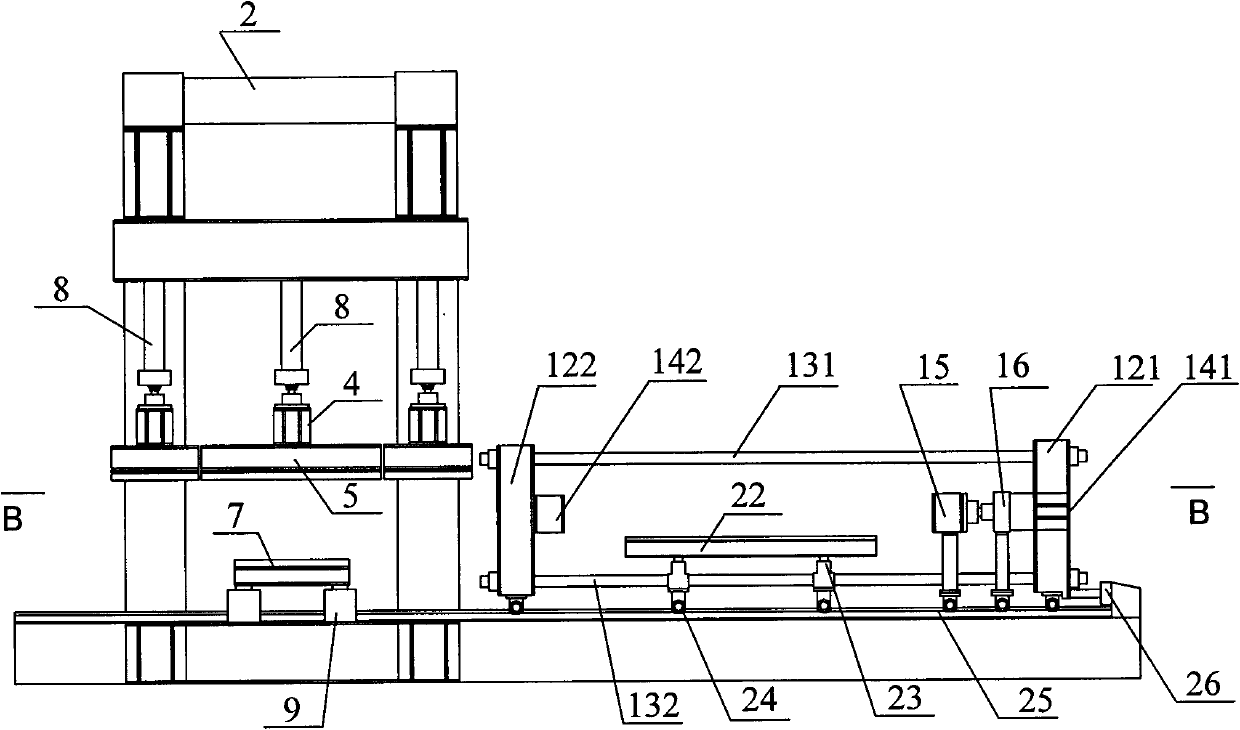

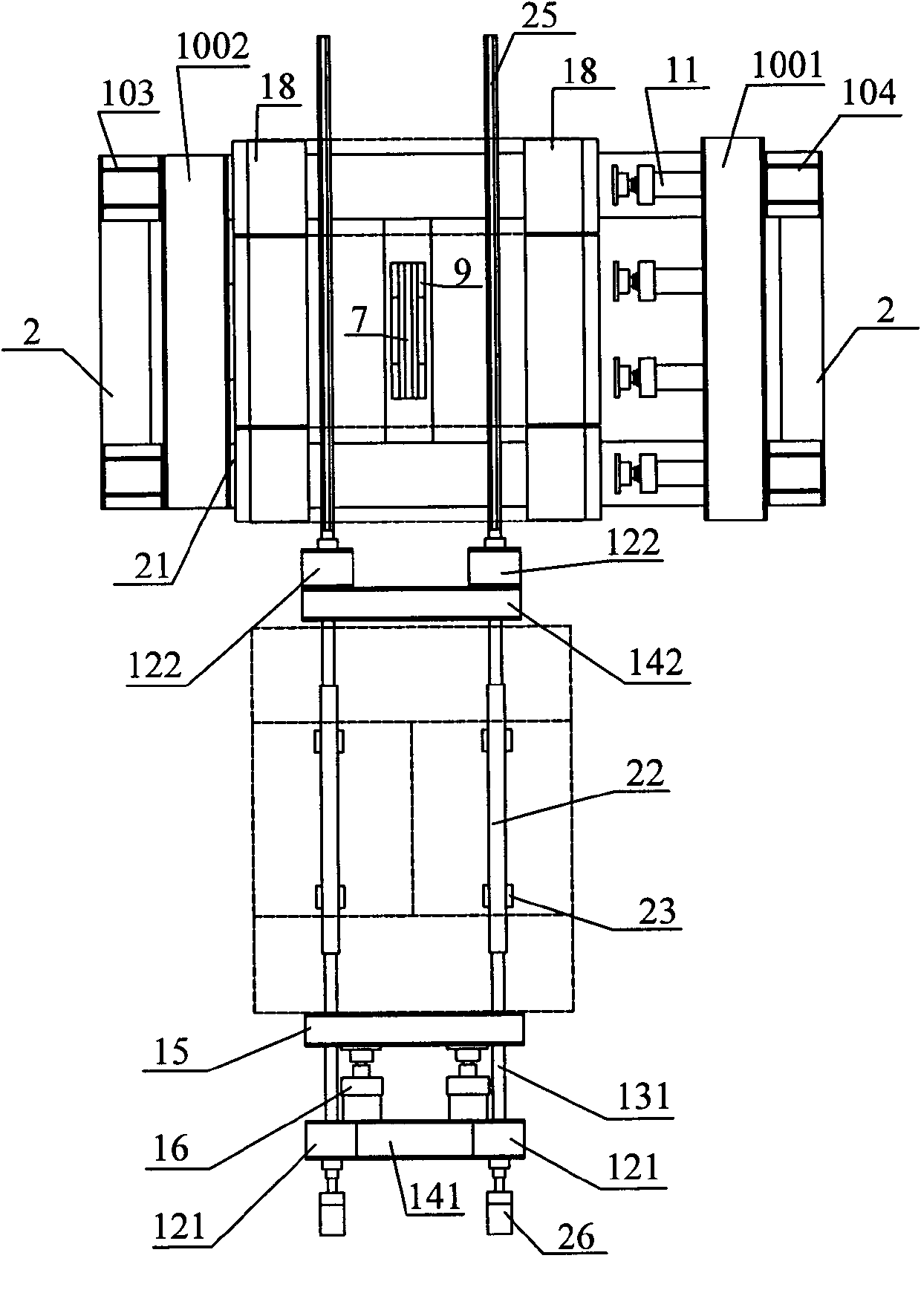

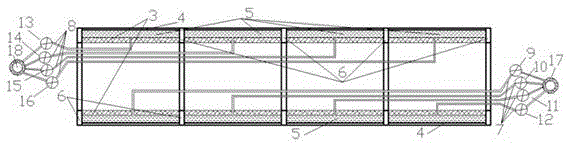

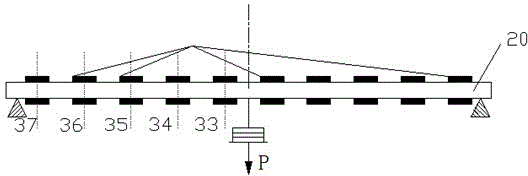

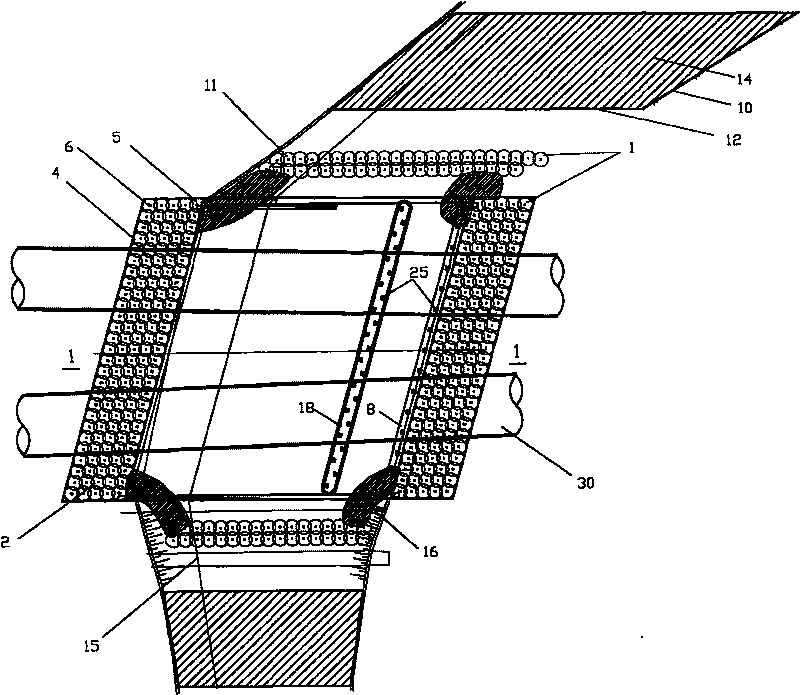

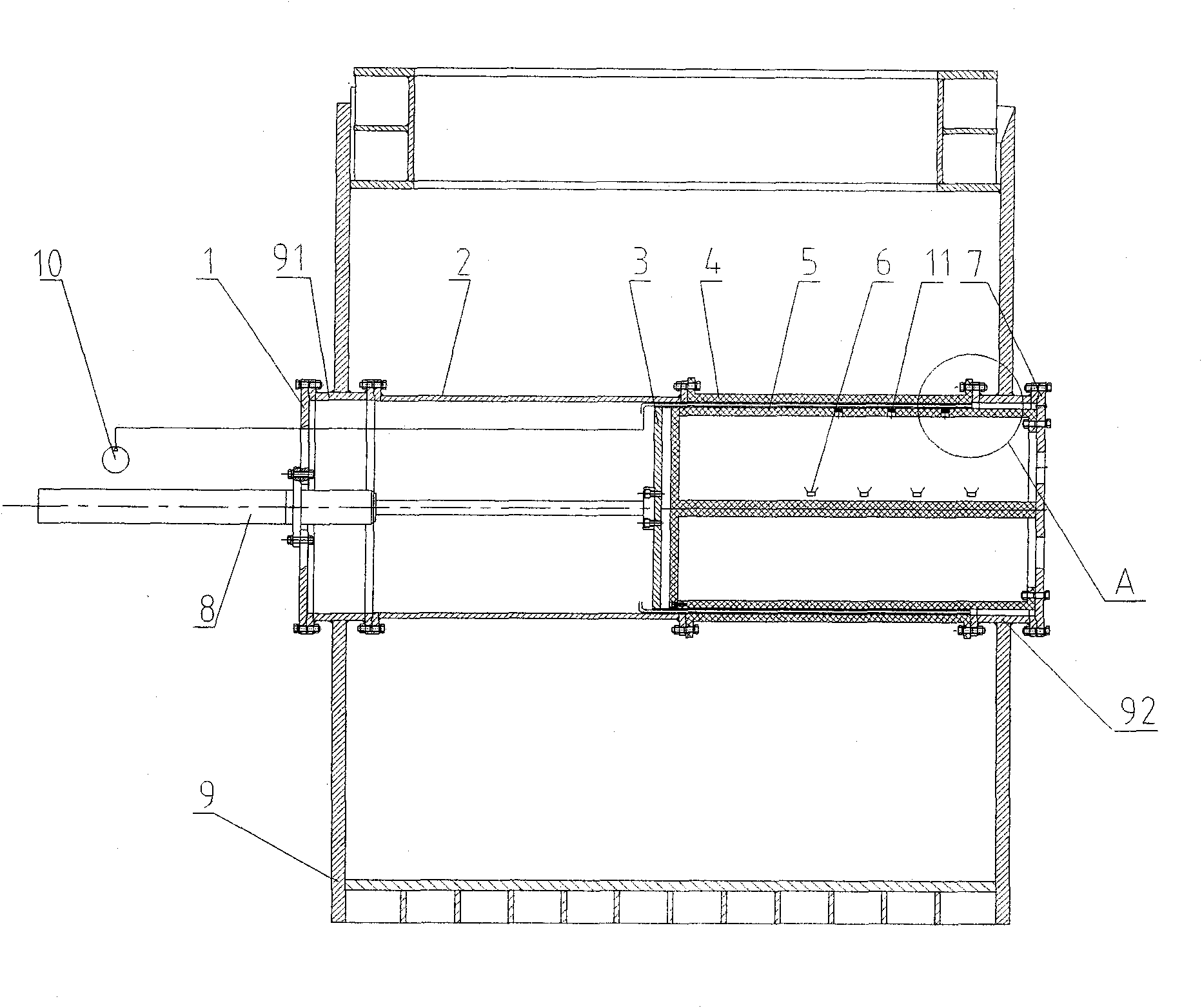

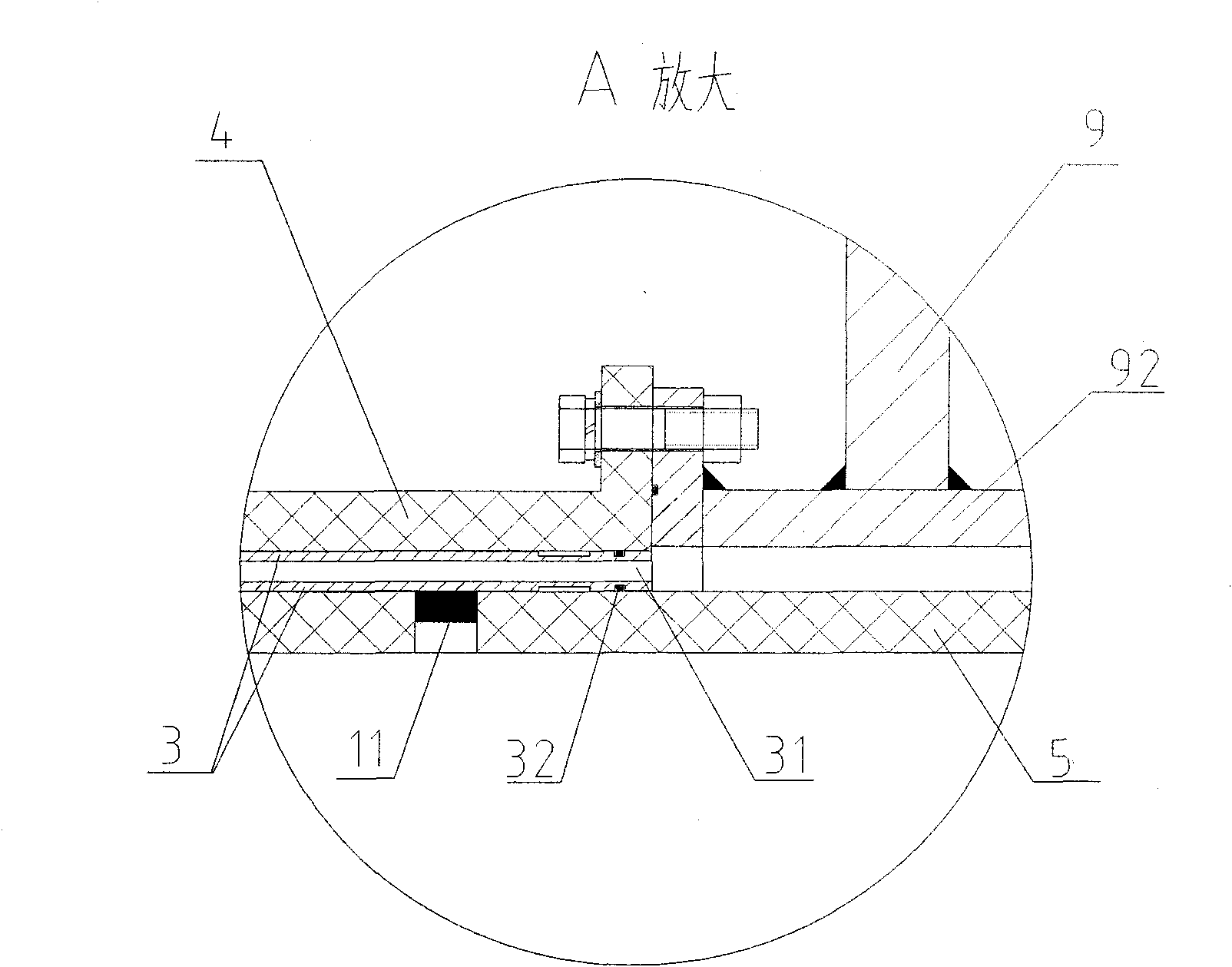

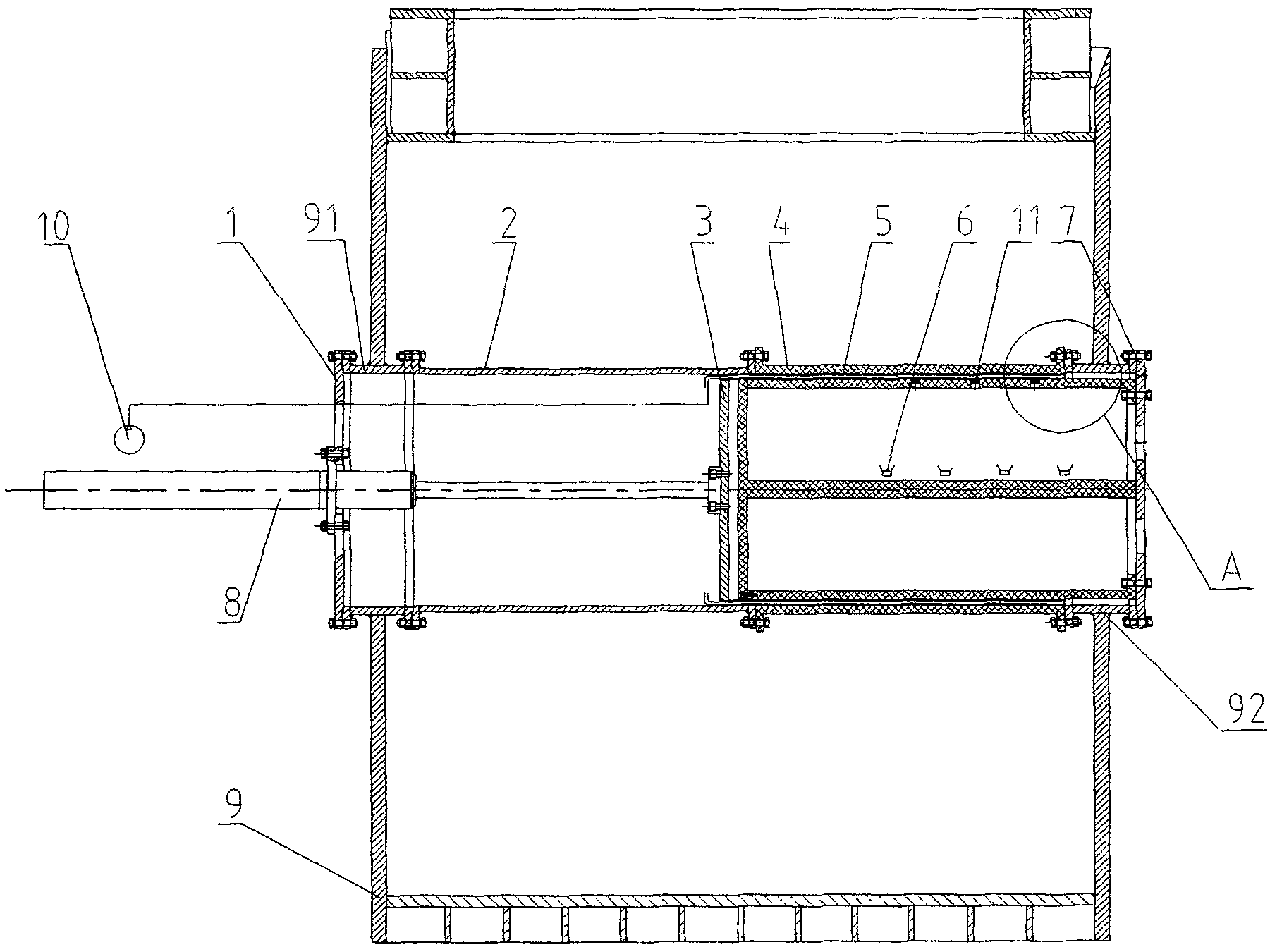

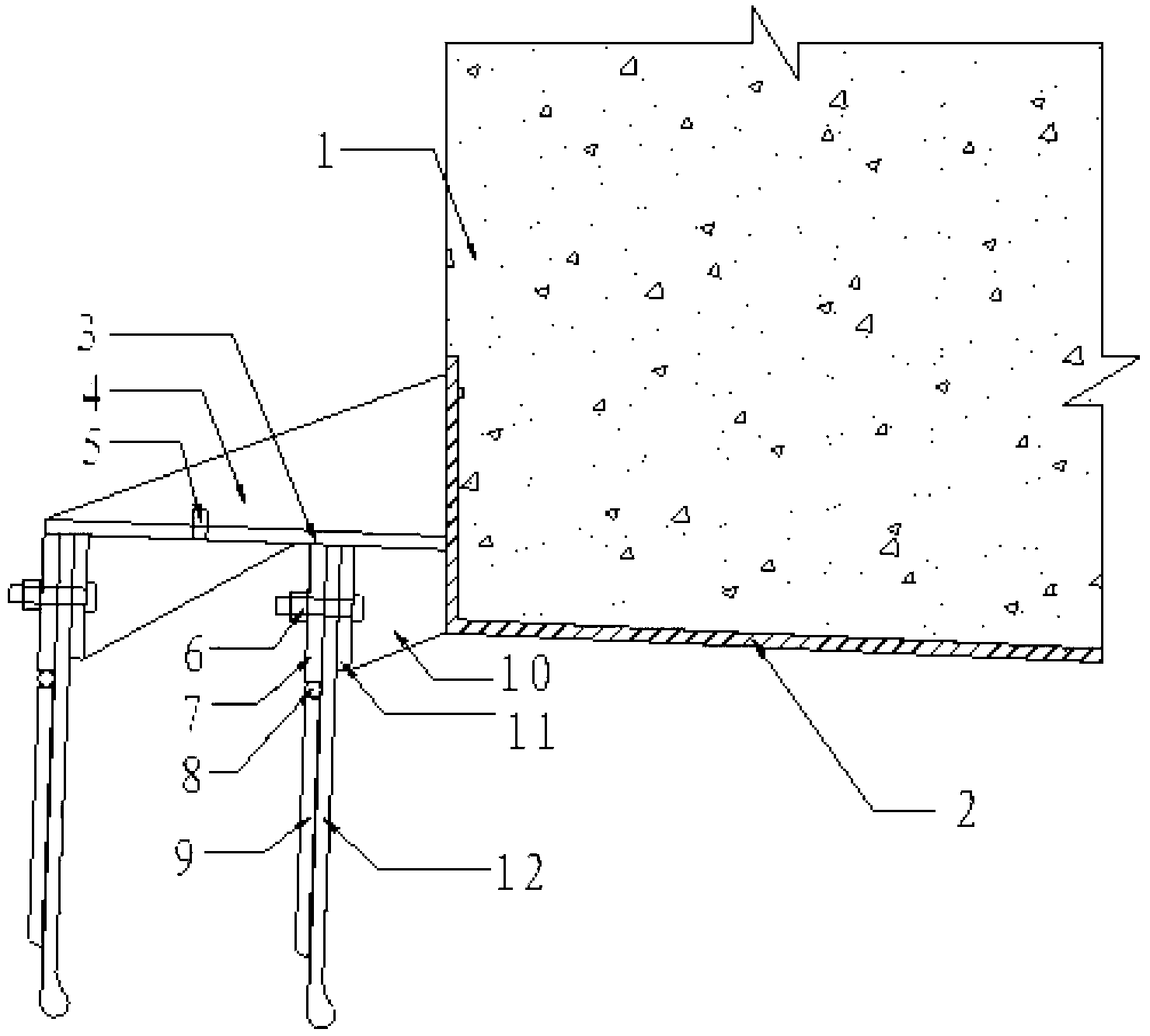

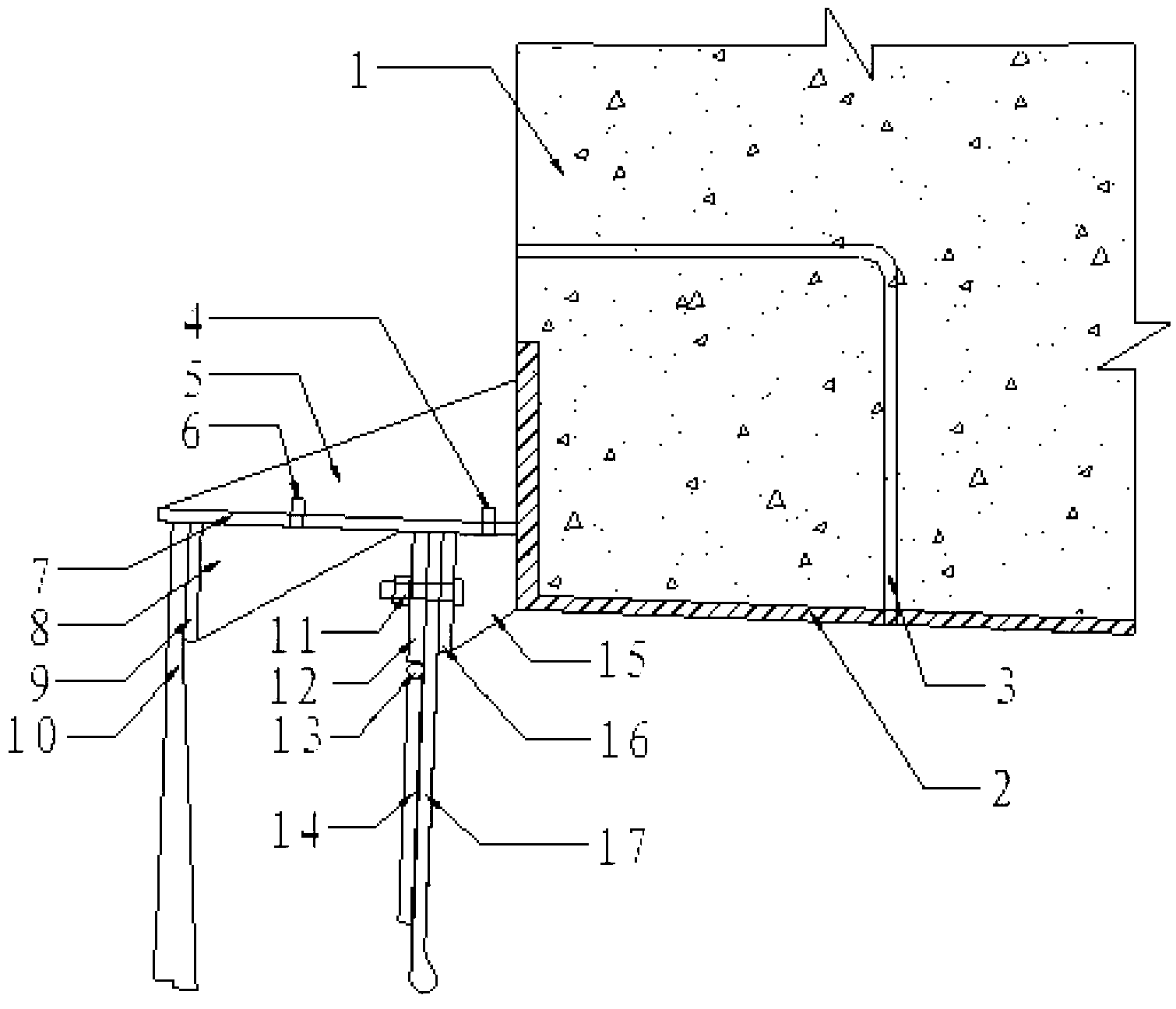

Three-way loading mechanical property test system of multifunctional lining segment joint

ActiveCN102004054AHigh simulationDisplacement boundary conditions are consistentMaterial strength using steady bending forcesMaterial strength using steady shearing forcesPilot systemModular design

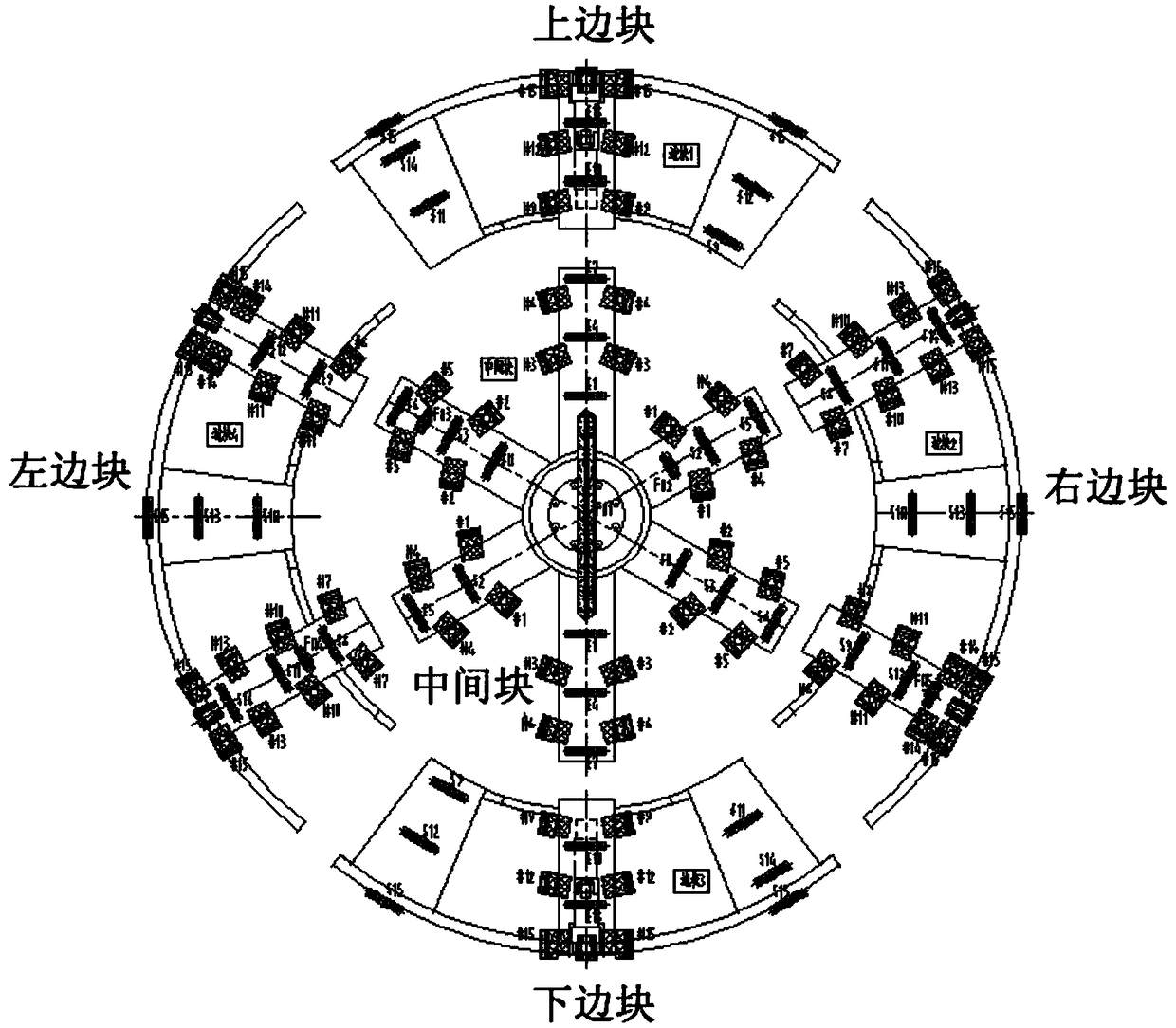

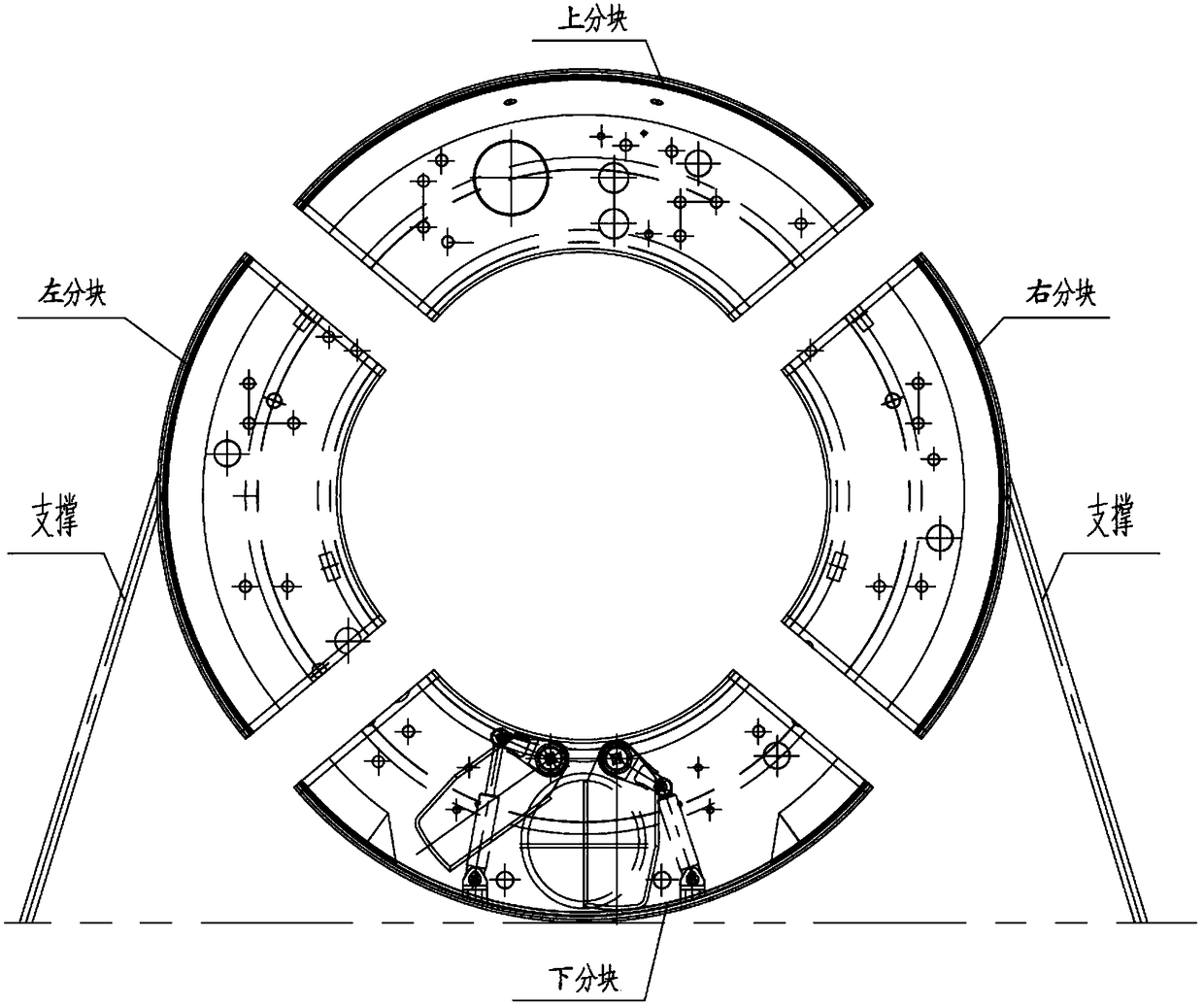

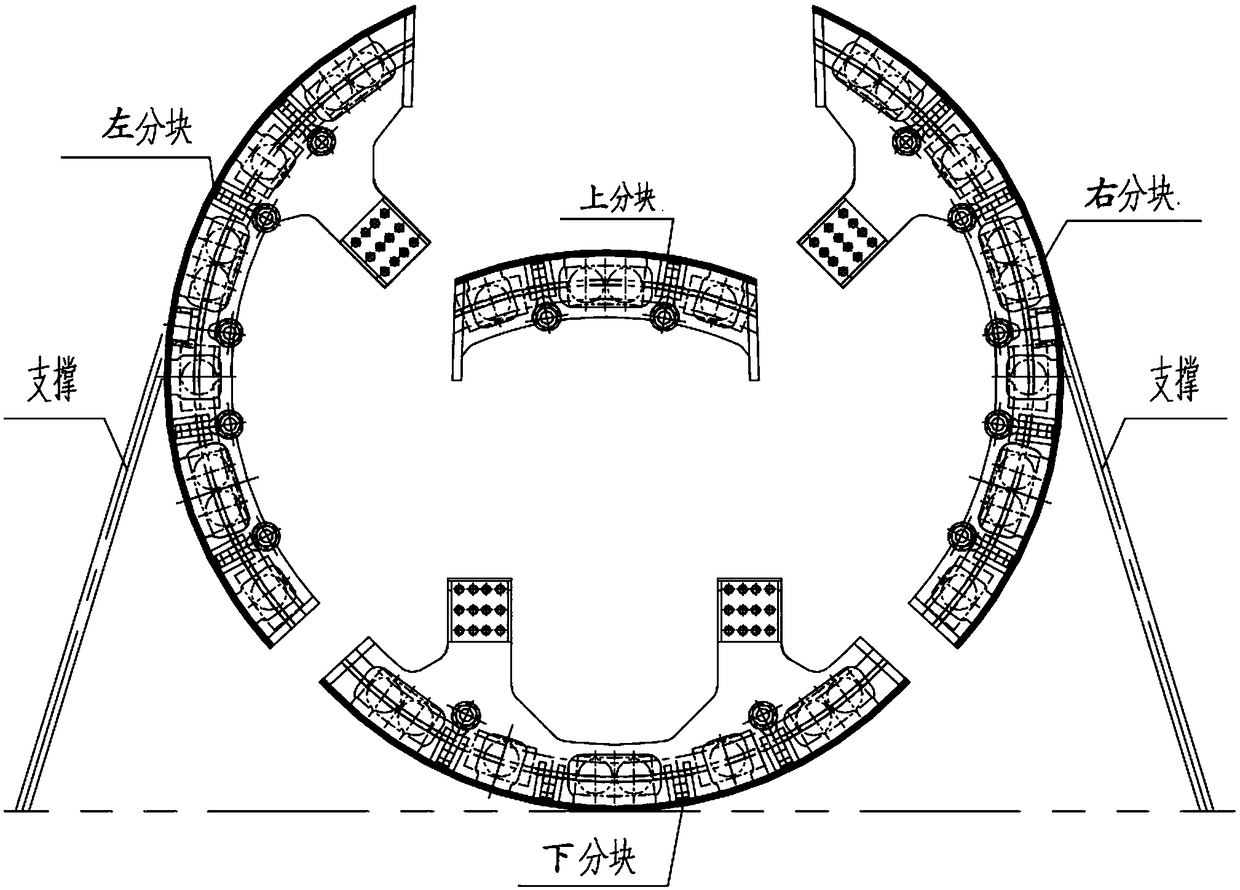

The invention provides a three-way loading mechanical property test system of a multifunctional lining segment joint, which mainly comprises a self-balancing frame sub-system, a loading sub-system, a test-piece support sub-system, a test-piece transporting sub-system, a loading control sub-system and a data acquisition sub-system. The loading sub-system adopts a modular design and can finish a shield tunneling lining segment inter-ring shearing test, a bending moment transferring test, a longitudinal joint corner rigidity test, a longitudinal joint radial shearing test and the like by different combinations. The system of the invention can preferably imitate three-way stress states of the shield tunneling lining segment joint in actual conditions and can finish various different loading modes to obtain mechanical parameters of the shield tunneling lining segment joint and mechanical properties of other similar structures.

Owner:TONGJI UNIV

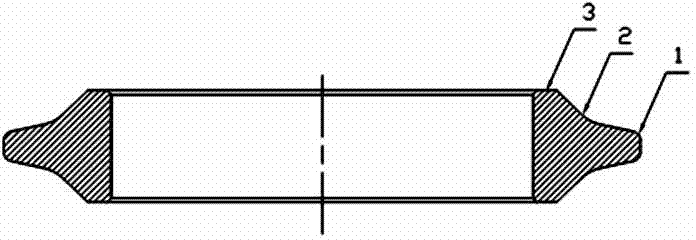

Disk-shaped roller cutter ring and manufacture method thereof

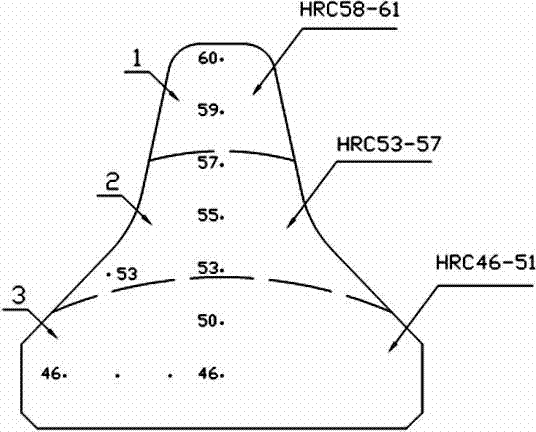

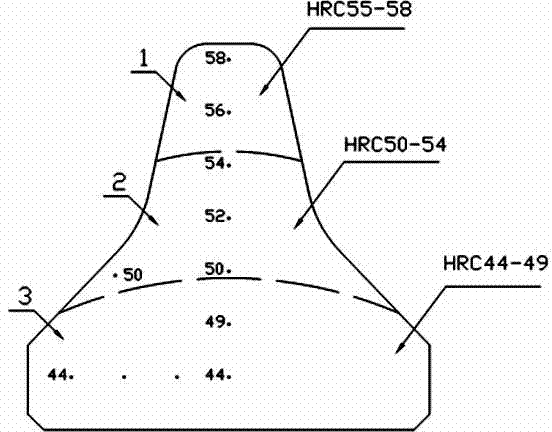

ActiveCN102517502AGuaranteed hardenabilityImprove toughnessFurnace typesHeat treatment furnacesMedium frequencyHardness

The invention discloses a disk-shaped roller cutter ring with high hardness, good toughness and excellent comprehensive performance. The disk-shaped roller cutter ring comprises the following ingredients of: 0.46-0.56% of C, 0.80-1.20% of Si, 0.20-0.65% of Mn, 5.00-5.80% of Cr, 1.15%-1.55% of Mo, 0.85-1.40% of V and the balance Fe and impurities, wherein the content of P is no more than 0.02%, and the content of S is no more than 0.01%; and the overall hardness of the cutter ring is HRC55-61 (Rockwell Hardness C55-61), or the hardness is of graded distribution, i.e. the hardness of a working edge area is HRC55-61, the hardness of a transition surface area is HRC50-57, and the hardness of a step assembly surface area and an inner ring is HRC44-51. A preparation method of the disk-shaped roller cutter ring comprises the following steps of: smelting the raw materials in an electric furnace; carrying out electroslag remelting; preforging; carrying out die forging; carrying out slow cooling; annealing; carrying out rough machining to obtain a disk-shaped roller cutter ring rough blank; carrying out high-temperature vacuum hardening and two-time high-temperature tempering on the cutter ring rough blank; carrying out low-temperature destressing treatment; carrying out fine finishing to obtain the cutter ring with the overall hardness of HRC55-61, wherein the cutter ring with the overall hardness of HRC55-61 is applicable to the tunneling of a hard rock formation by a shield tunneling machine; or carrying out medium-frequency induction tempering treatment prior to the low-temperature destressing treatment to obtain the cutter ring with graded-distribution hardness, wherein the cutter ring with the graded-distribution hardness is applicable to the tunneling of a rock formation with an upper soft part and a lower hard part.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

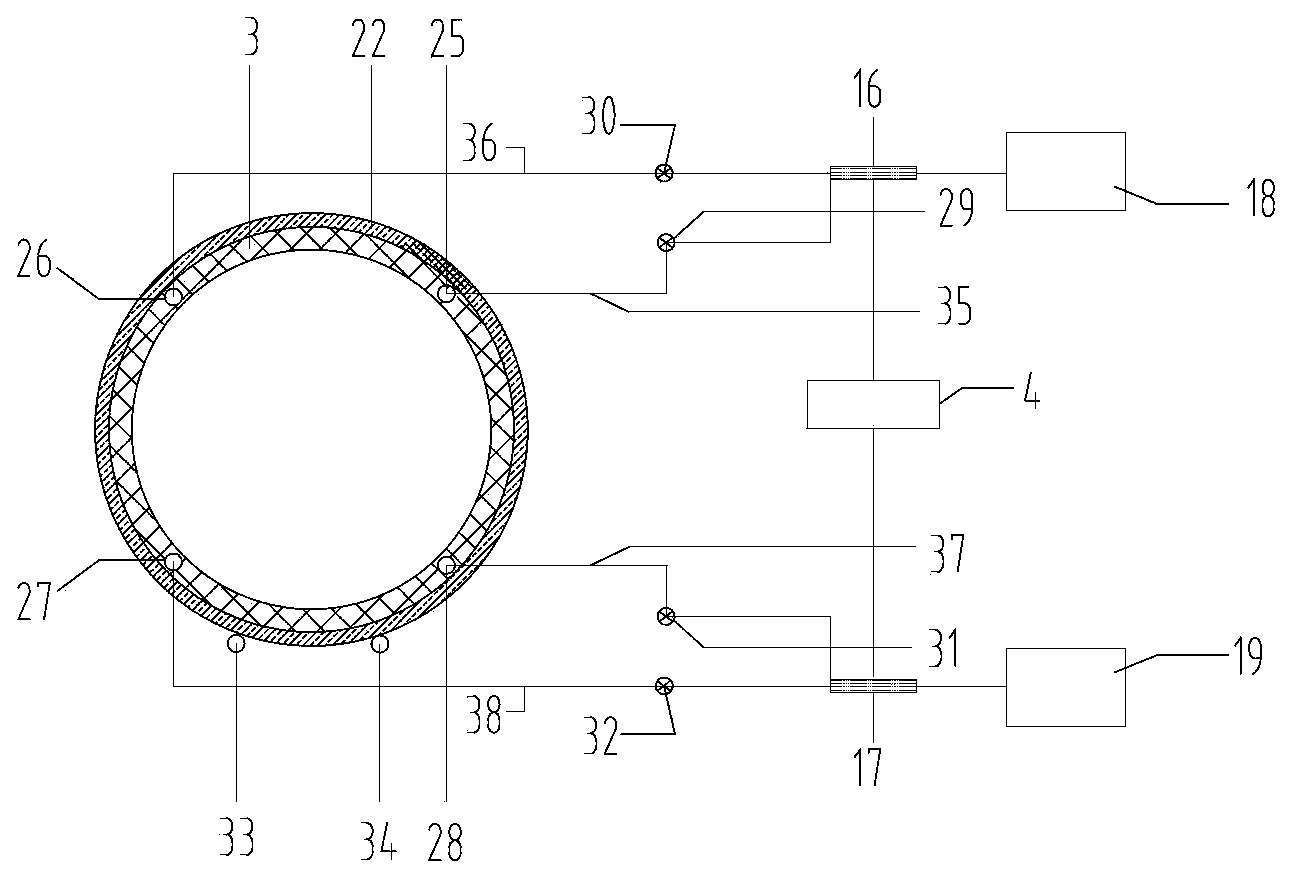

Simulating system used for shield tunnel synchronous grouting test and test method thereof

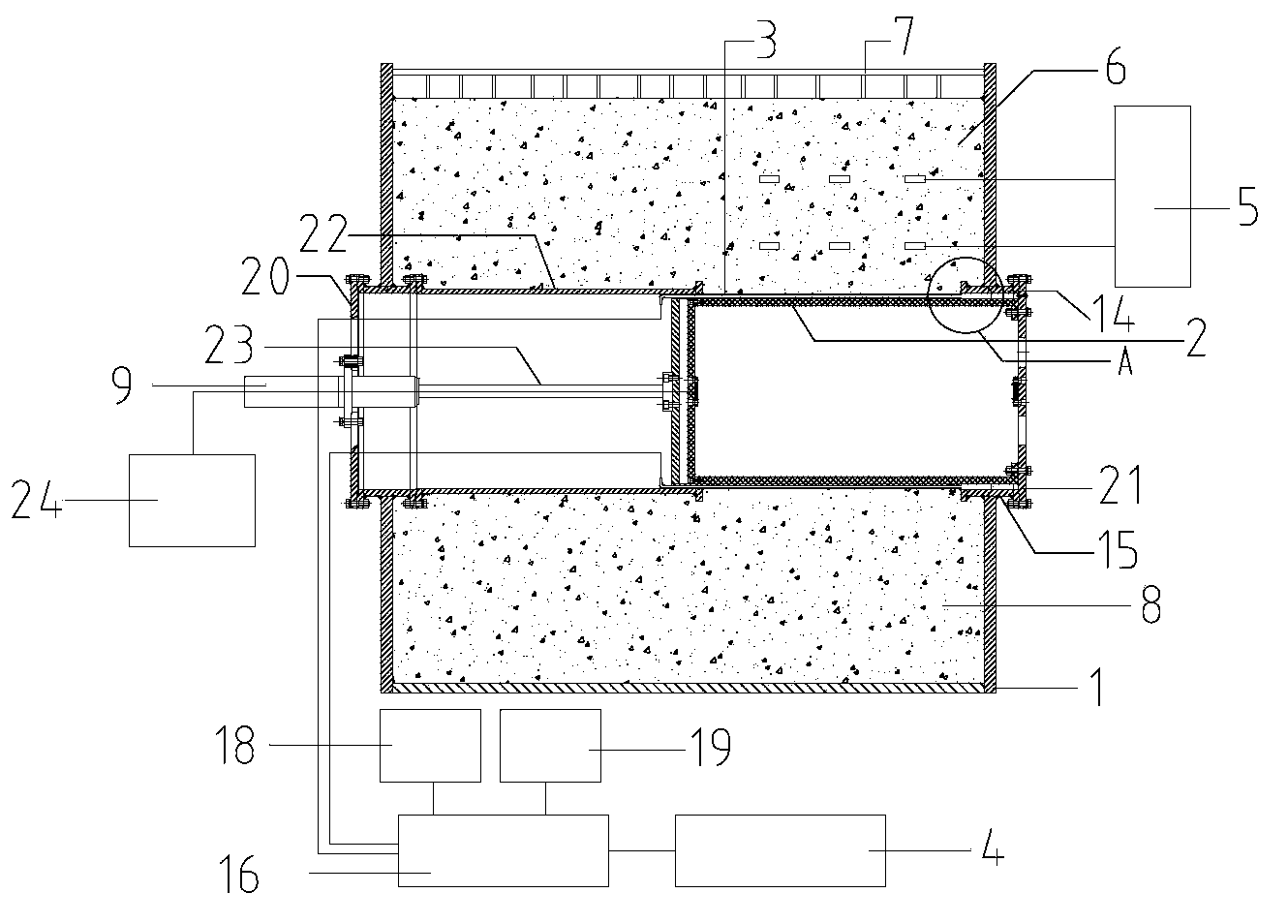

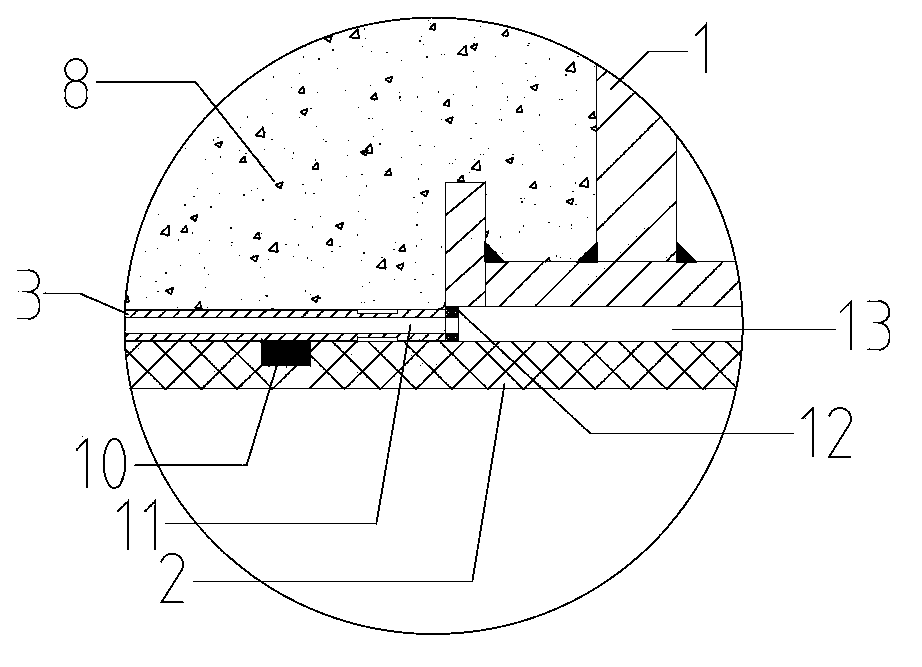

InactiveCN103913289AMonitor changes in real timeMonitor real-time changesHydrodynamic testingSoil scienceControl system

Disclosed is a simulating system used for a shield tunnel synchronous grouting test. The system includes model soil, model grout and a synchronous grouting simulating test platform. The model grout is injected into the model soil through the synchronous grouting simulating test platform. The synchronous grouting simulating test platform includes a soil box, a data acquisition system, a loading system, a shield propulsion control system, a simulating shield tunneling machine, pressure sensors and a grouting system. The simulating shield tunneling machine and the model soil are arranged in the soil box. The invention also discloses a test method which uses the simulating system used for the shield tunnel synchronous grouting test. The method includes: 1) preparing the model soil; 2) preparing the model grout; 3) constructing a shield-soil-grout similar system to carry out synchronous grouting tests of different grouting positions, different grouting holes and different grouting quantity allocation proportions.

Owner:TONGJI UNIV +1

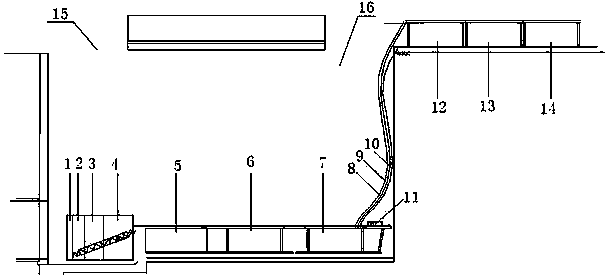

Shield tunneling machine split starting construction method

InactiveCN103711499AImprove construction efficiencyLow construction costTunnelsArchitectural engineeringShield tunneling

The invention discloses a shield tunneling machine split starting construction method and belongs to the technical field of building construction. The method comprises the following steps: (1) cleaning an underground site, (2) starting base seat underground assembling and laying rails, (3) moving a first trolley and a second trolley underground and moving the first trolley and the second trolley backward, (4) moving a duct piece cart underground, (5) moving a connecting bridge and a spiral conveyor underground in a hoisting mode, and moving the connecting bridge and the spiral conveyor backward, (6) moving a starting table underground, smear ing lubricating grease, moving a cutter disk and a shield body underground and locating and assembling the cutter disk and the shield body, (7) assembling, (8) starting trying tunneling, (9) restoring to normal shield tunneling. The method has the advantages of effectively solving the problem that a shield tunneling machine cannot be operated and run normally for being restricted by the actual environment of a shield tunneling staring operation shaft on a construction site, greatly improving construction efficiency, saving construction cost, and reducing construction difficulty.

Owner:CHINA RAILWAY 13TH BUREAU GRP 6TH ENG COMPANY

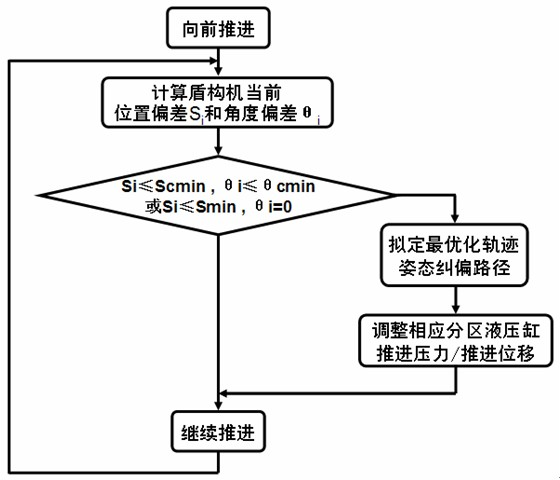

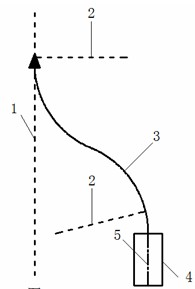

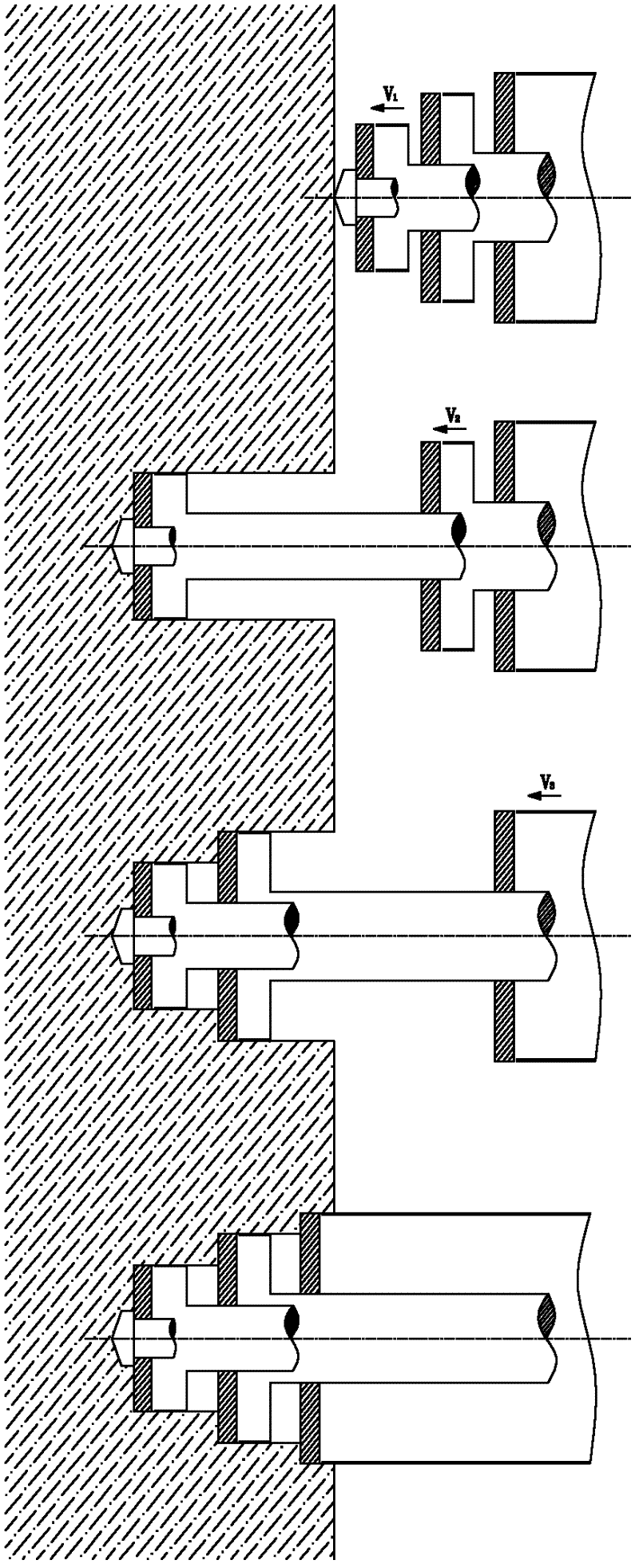

Track and posture composite control method in shield tunneling process

ActiveCN102102522AEliminate positional deviationEliminate Angle DeviationTunnelsHydraulic cylinderAngular deviation

The invention discloses a track and posture composite control method in a shield tunneling process. The method comprises the following steps of: performing control by setting threshold values for a posture and a track; immediately adjusting the posture as long as the posture deviates to exceed the limit even though the track does not reach a deviation correction threshold; solving current positional deviation Si and angular deviation theta I of a shield machine through measurement and calculation when a shield works; continuously propelling the shield machine when the Si is less than or equal to a positional deviation threshold value Scmin of a track and posture composite controller and theta i is less than or equal to an angular deviation threshold value theta cmin of the track and posture composite controller or when the Si is less than or equal to positional allowable deviation Smin of actual tunnel construction and theta i is equal to 0; contrarily, automatically adjusting propelling pressure of a hydraulic cylinder of each sub-region and propelling displacement to simultaneously eliminate the positional deviation and the angular deviation generated in a tunneling process. Thus, an actual tunneling route of the shield machine is controlled within a design axial range of a tunnel, unnecessary overbreak and underbreak are avoided, and the forming quality of the tunnel is improved.

Owner:ZHEJIANG UNIV

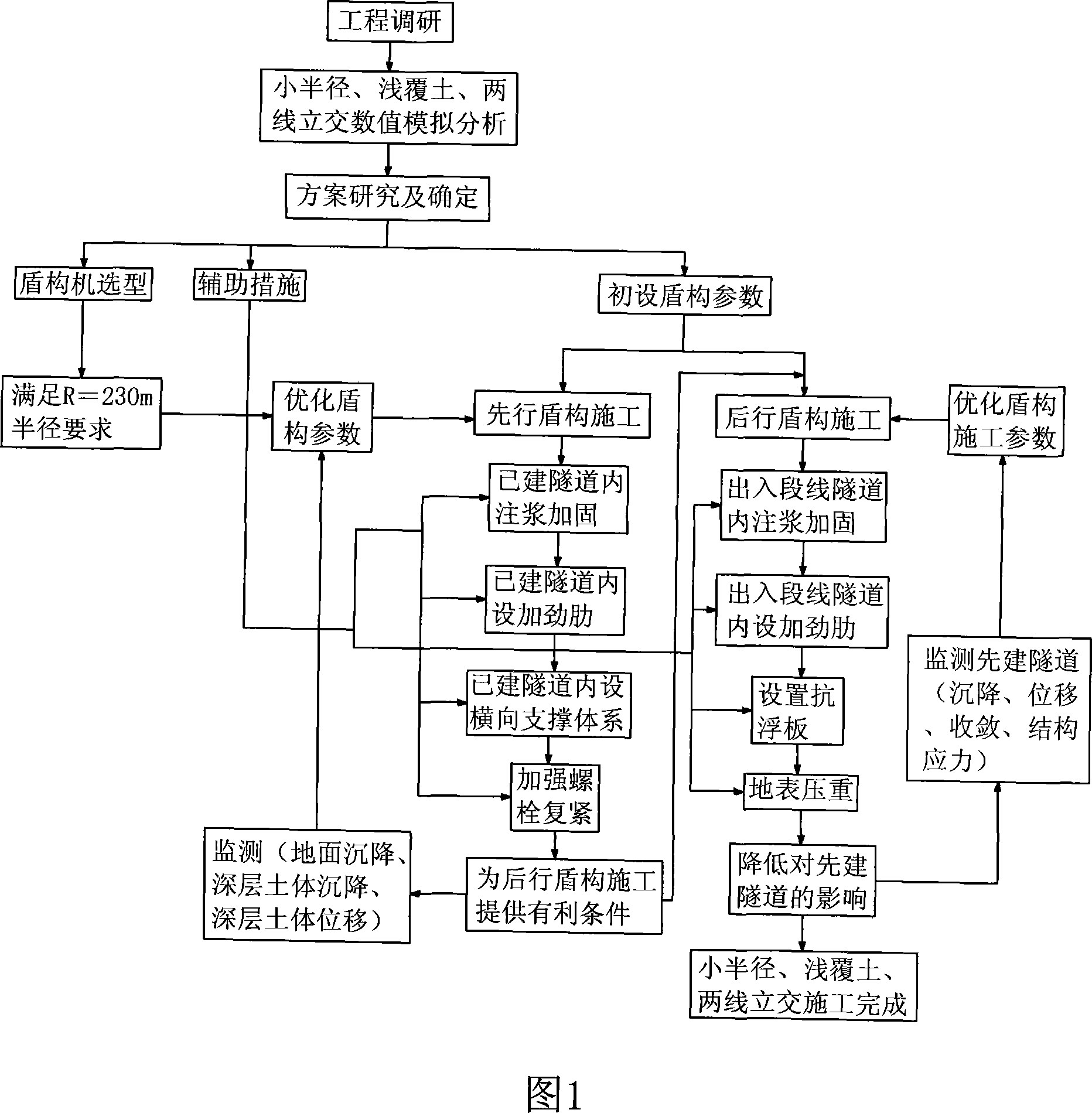

Two lines intersection small radius, shallow earth covering and large longitudinal slope complicated linetype shield construction method

ActiveCN101182772AHigh sensitivityControl deformationArtificial islandsUnderground chambersEarth surfaceShield tunneling

The invention discloses a shield construction method for a two-line overpass with small radius, shallow covering soil and large longitudinal slope complex linear tunnel, which belongs to the technical field of tunnel construction. The construction method of the present invention includes the following steps: determining the advancing sequence of the two-line interchange, selecting a shield machine type, taking auxiliary strengthening measures for the ground surface, strata, and segments, shield advancing, axis control and construction monitoring, and shield tunneling. In the present invention, since the shield increases the hinged part, the sensitivity of the shield is increased, and the control of the axis of the tunnel is more convenient; a suitable reinforcement and pressure scheme, a segment typesetting method and a stiffening rib scheme are selected to make the outer arc of the segment broken. Cracks and segmental water seepage can be improved; and through high-frequency monitoring and information feedback, the shield propulsion parameters are strictly controlled. By taking the above measures, the deformation and displacement of the ground surface and the tunnel are effectively controlled, which effectively reduces the cost of tunnel construction and The complex influence of the post-construction tunnel ensures the smooth progress of the construction and the effective control of the tunnel deformation.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

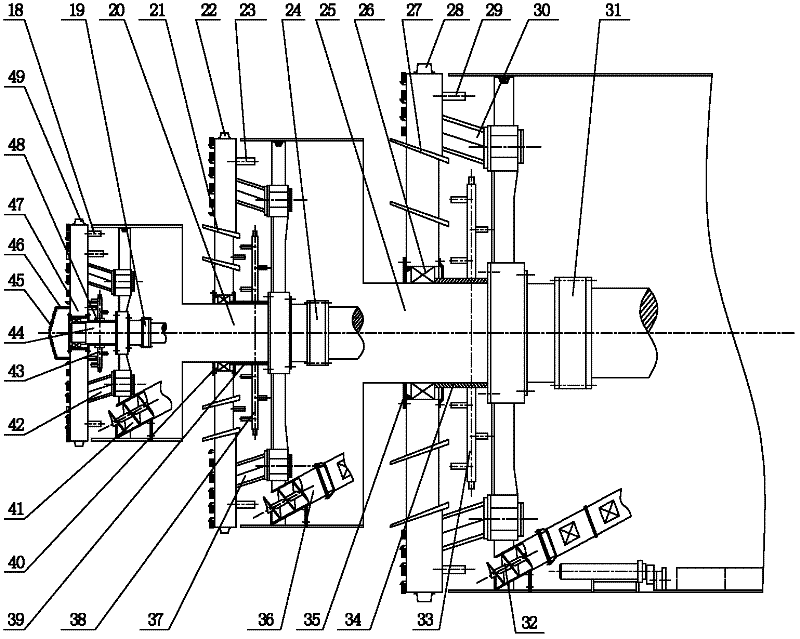

Multistage-separation progressive shield cutter head

InactiveCN102536254ASpeed up the flowEasy control of earth pressure balanceTunnelsEngineeringShield tunneling

The invention discloses a multistage-separation progressive shield cutter head which comprises a plurality of flexible shield cutter heads. During the work, a central shield cutter head primary rotation shaft clutch is closed; a power main shaft drives a primary cutter head to rotate to cut rocks; and at the same time, a rear hydraulic device pushes a central cutter head to tunnel ahead. When a certain distance is tunneled, a primary clutch is separated; after partial components are reassembled, a secondary clutch is closed and a secondary cutter head starts to tunnel ahead; and repeatedly, the multistage cutter head progressive excavation is realized. Cutter heads of a shield tunneling machine of a multistage-separation progressive structure share the same power main shaft and are respectively provided with a central stirring device and an auger delivery chip removal device; and material bulks cut by the cutter heads are crushed and conveyed into a chip removal guiderail at the center of the shield machine.

Owner:XIAN RUITE RAPID MFG ENG +1

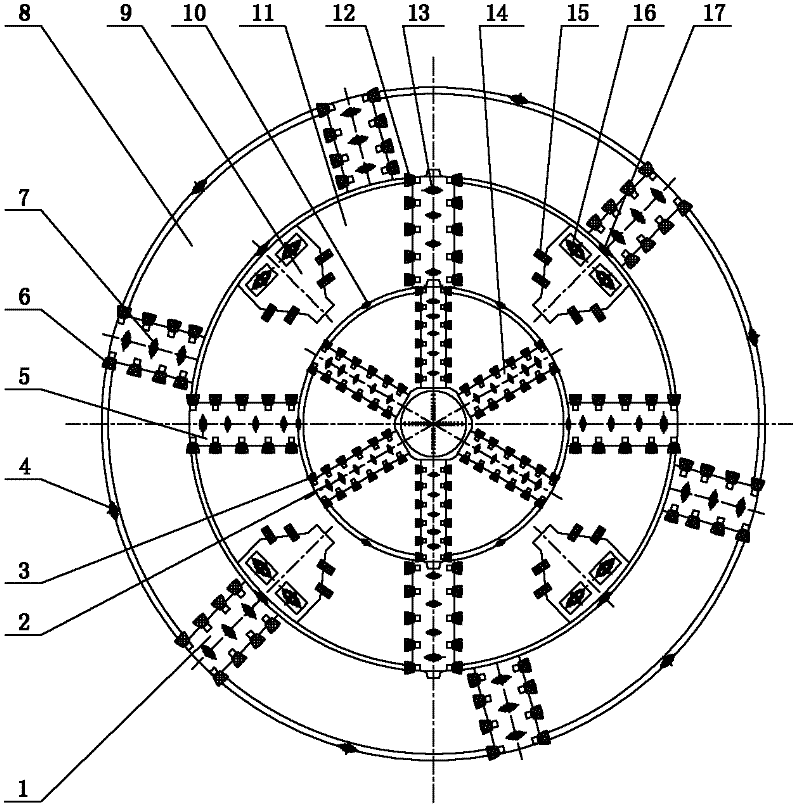

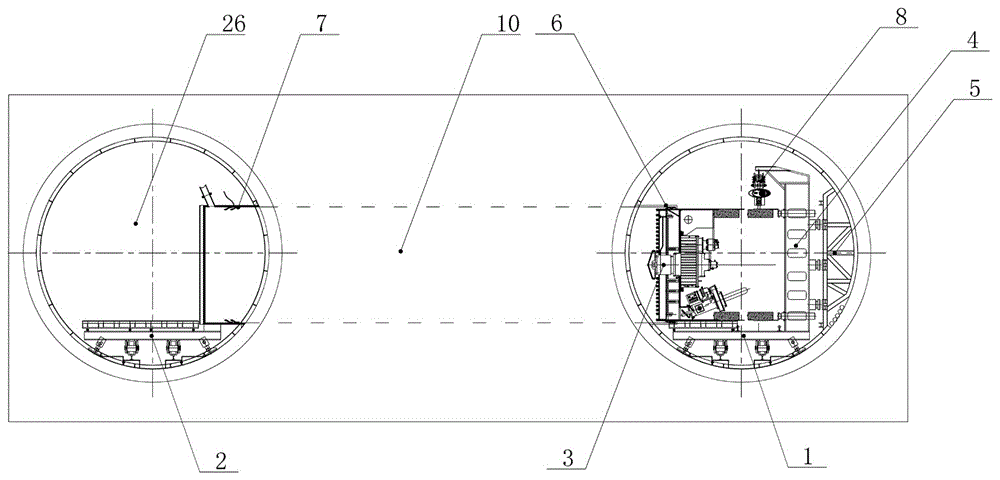

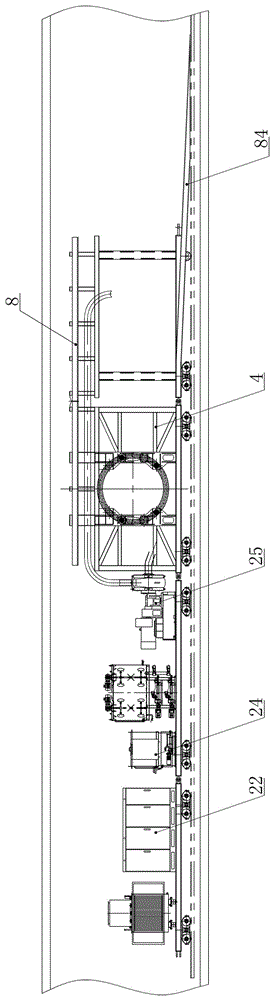

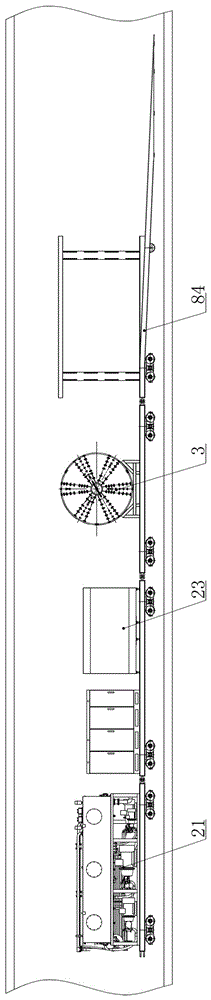

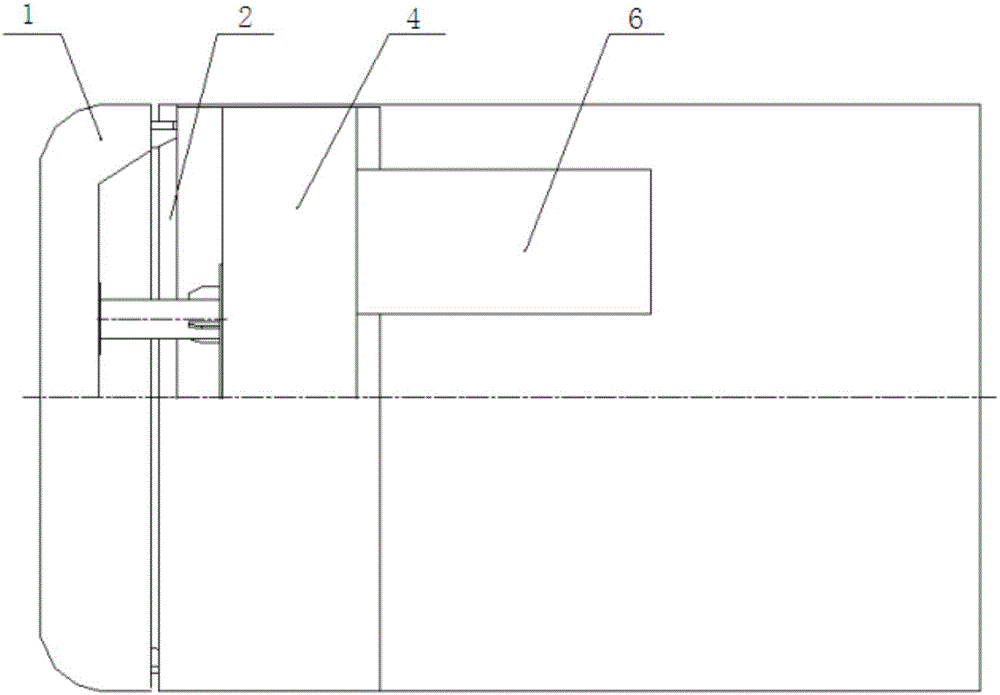

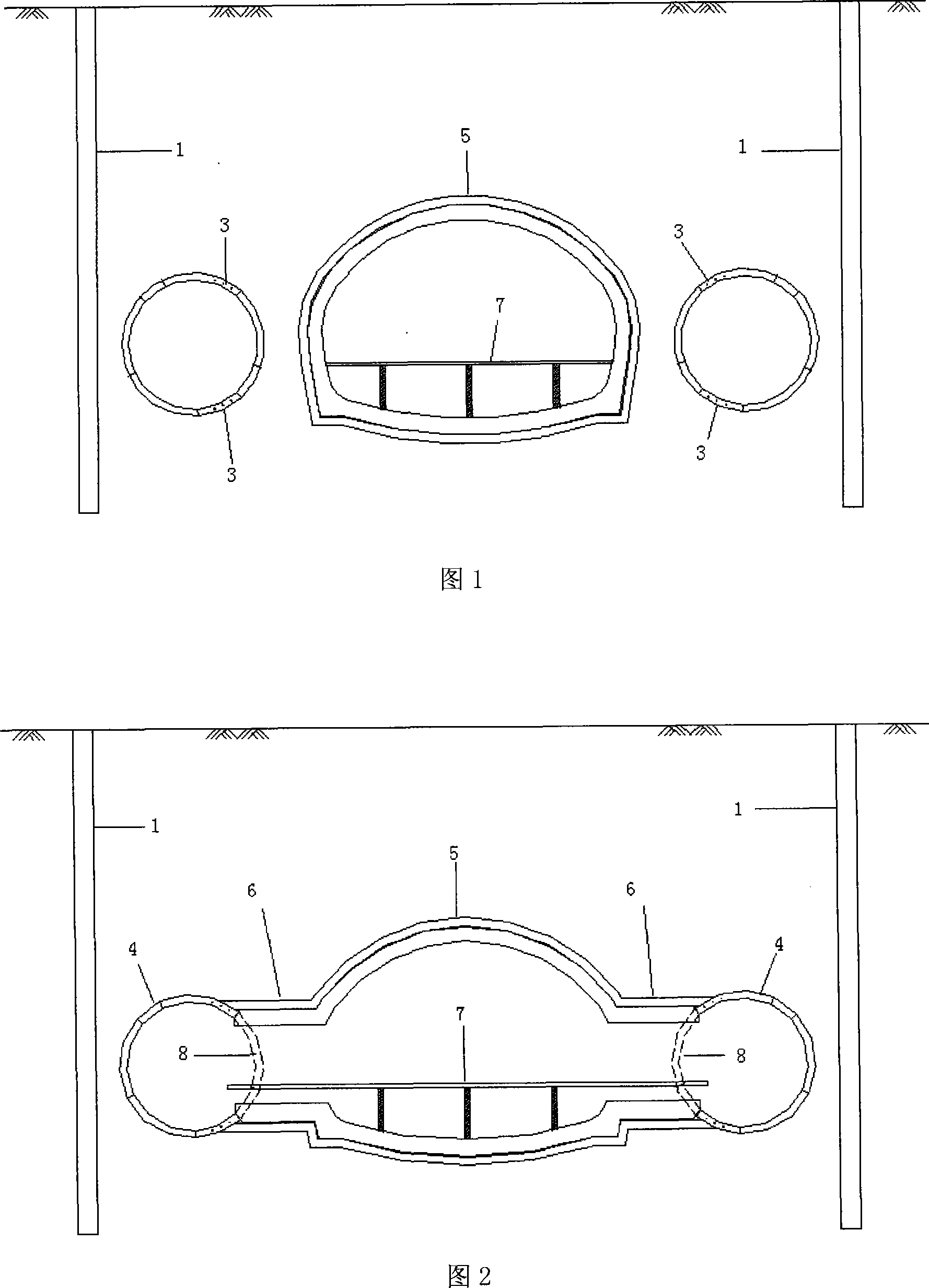

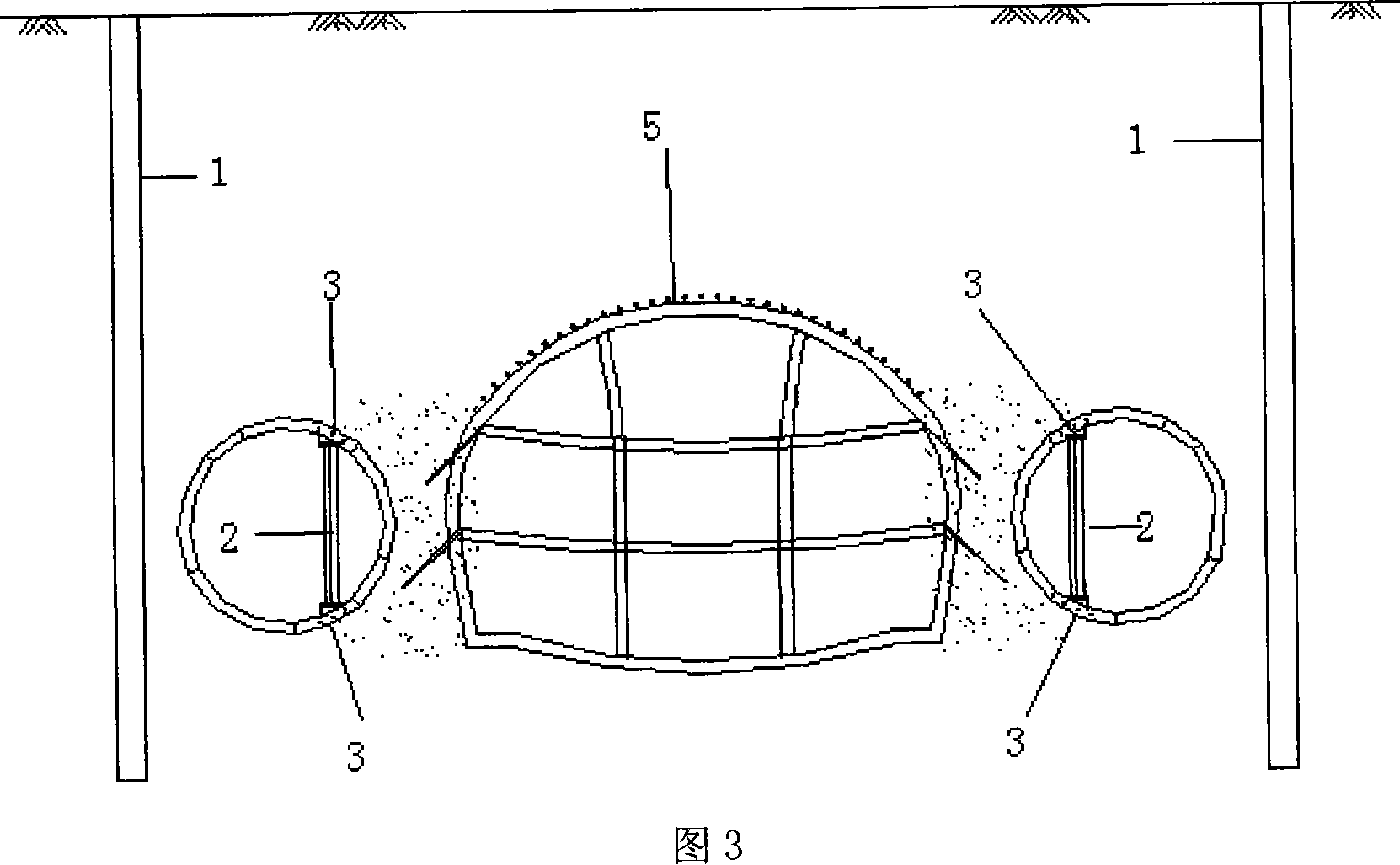

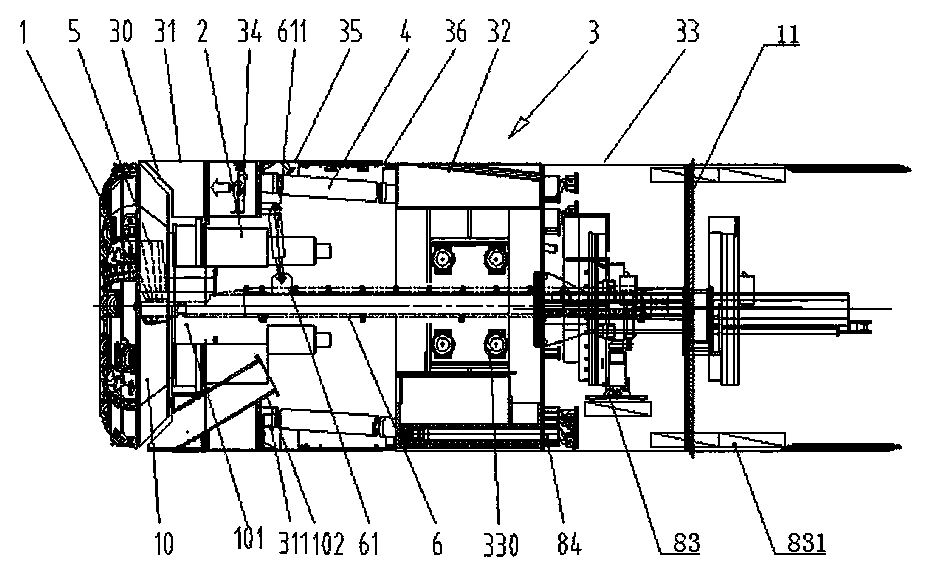

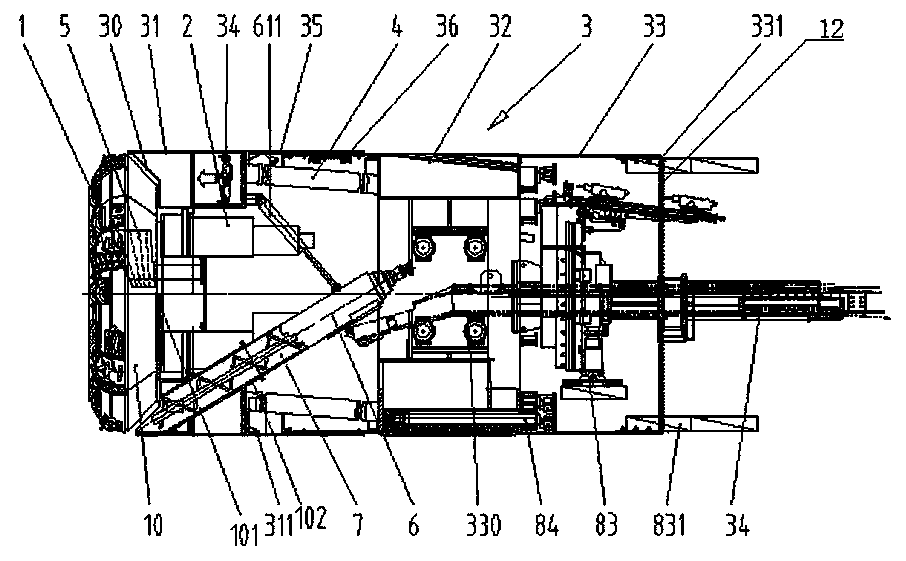

Shield tunneling machine for tunnel connecting passageway and connecting passageway tunneling method of shield tunneling machine

ActiveCN106437735AReaction support enoughCompact and reasonable structure designTunnelsShield tunnelingUltimate tensile strength

The invention belongs to the technical field of tunnel construction equipment, and relates to a shield tunneling machine for a tunnel connecting passageway and a connecting passageway tunneling method of the shield tunneling machine. The shield tunneling machine comprises a start end supporting walking platform and a receiving end supporting walking platform which are respectively arranged on material transportation rails in two main tunnels, a shield tunneling machine main unit, a counterforce supporting frame and a main tunnel supporting assembly which are respectively arranged on the start end supporting walking platform and a corresponding main tunnel duct piece, and a start end socket sealing assembly and a receiving end socket sealing assembly which are respectively arranged at the start end and the receiving end of the connecting passageway, wherein a duct piece hanging assembly is arranged on the start end supporting walking platform; a jacking tunneling assembly is arranged between the counterforce supporting frame and the shield tunneling machine main unit. The shield tunneling machine can realize automatically mechanical excavation; the labor intensity is greatly reduced, the energy consumption is reduced, and the cost is reduced; meanwhile, equipment construction is stable, and the efficiency is high; settling of the ground is effectively controlled, and the construction risk is reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

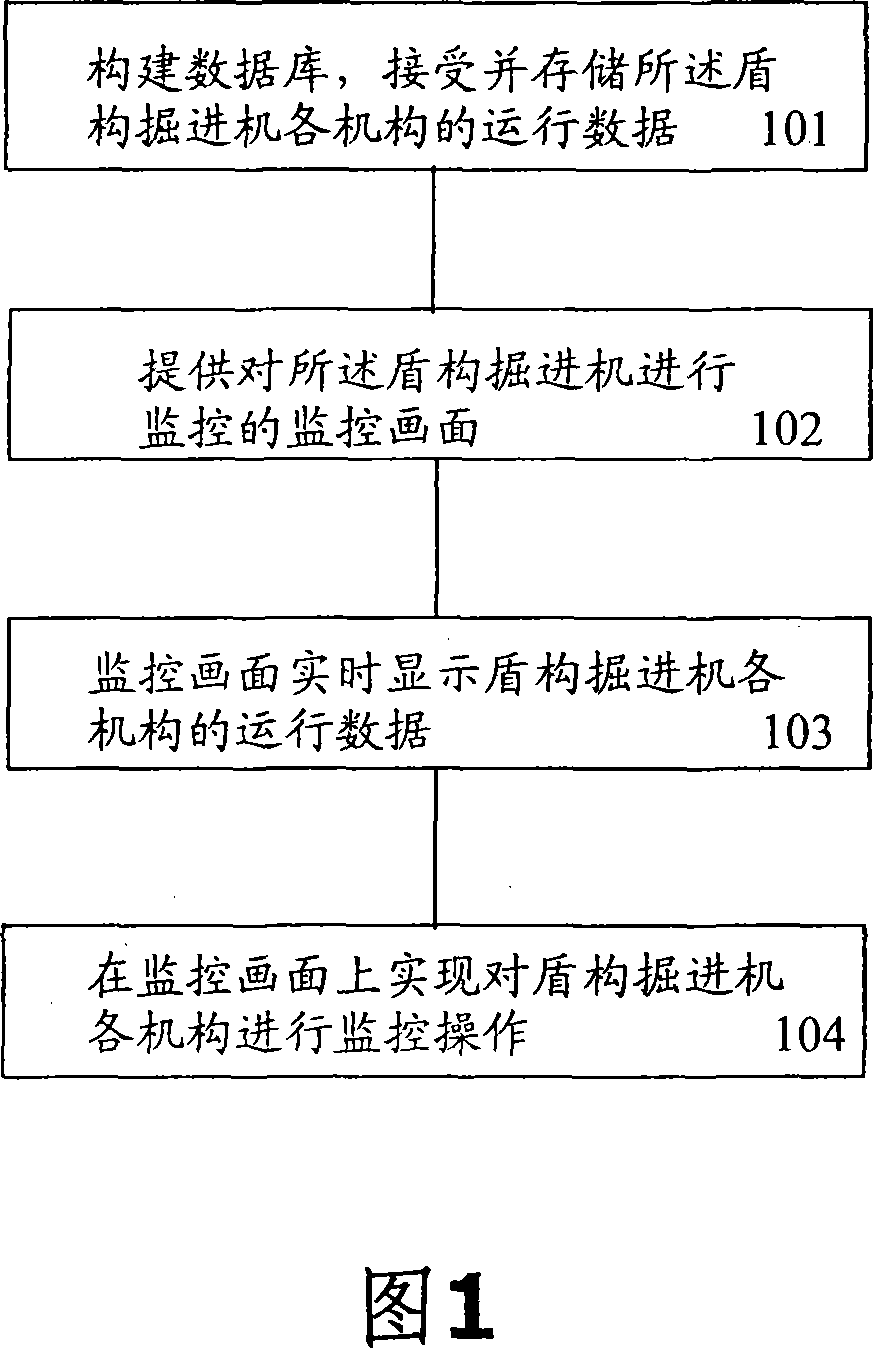

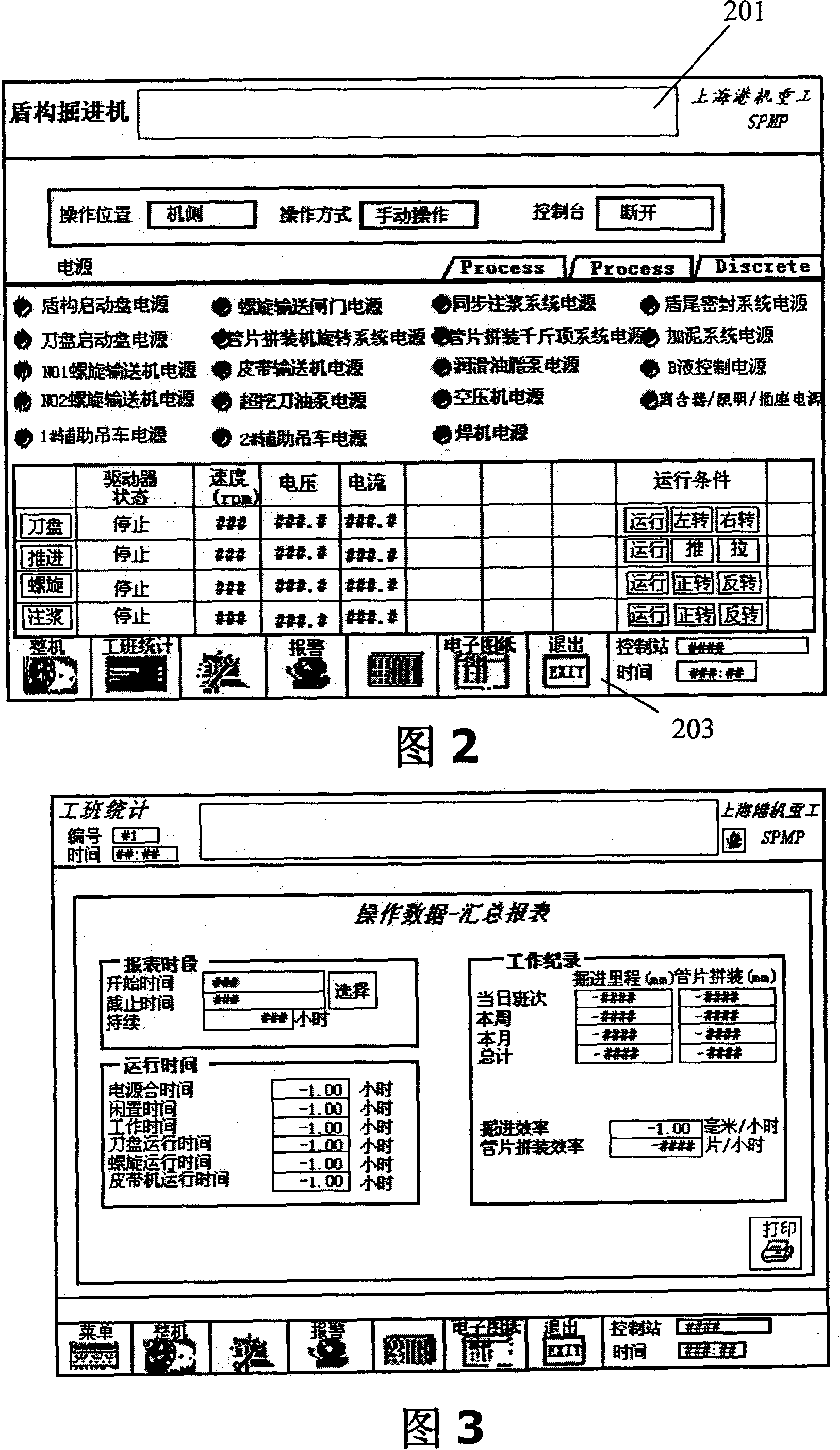

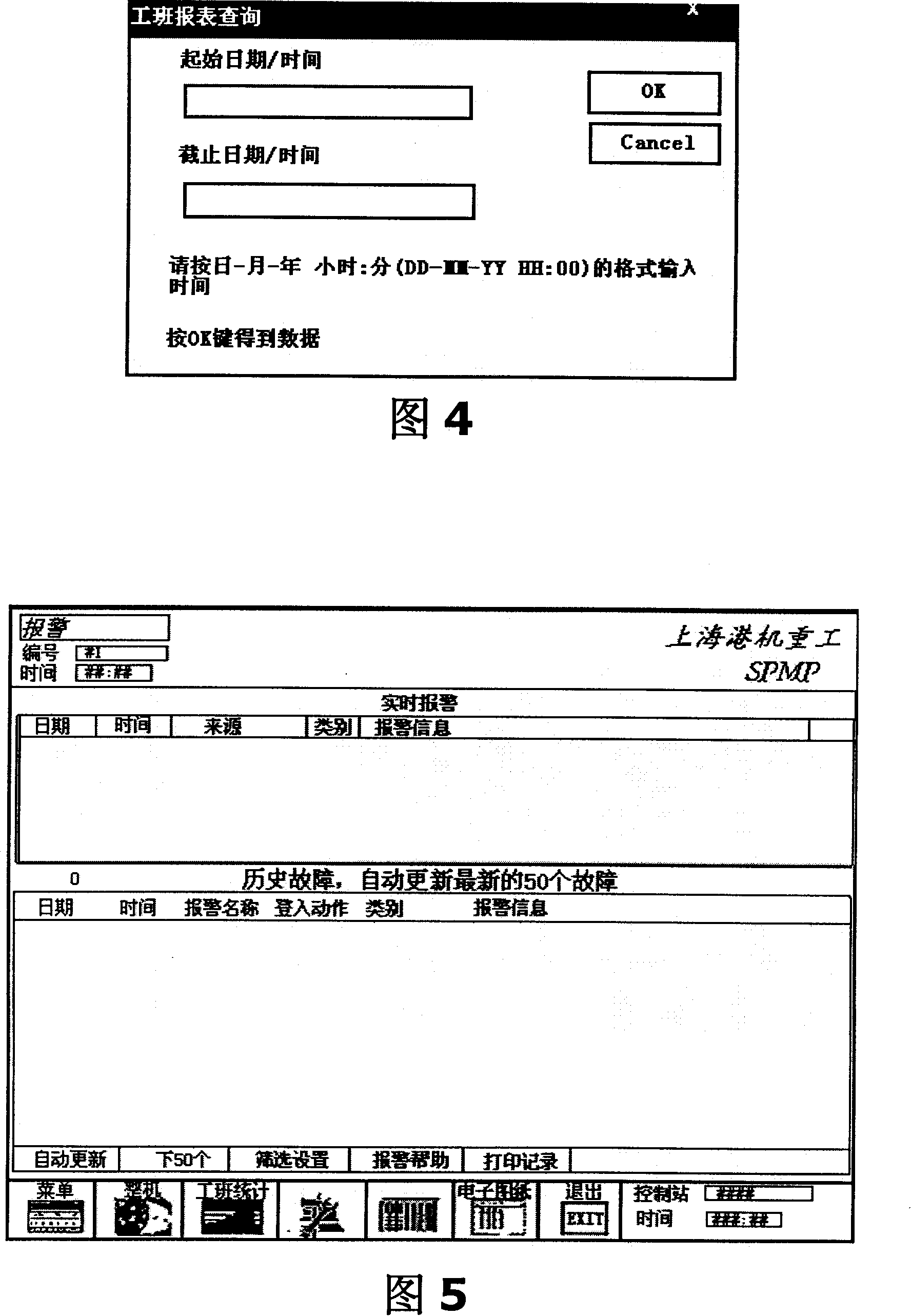

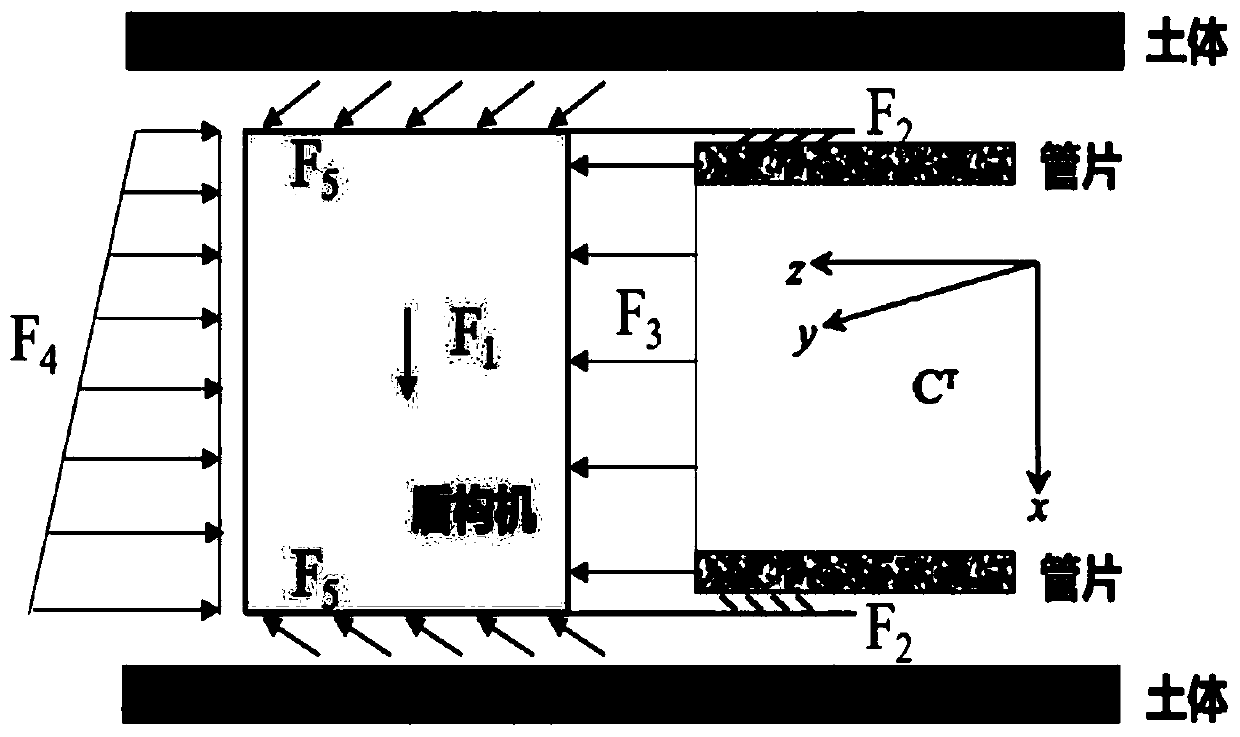

Tunnel shield digging machine local and remote monitoring method

The local and remote monitoring method for shield tunneling machine includes: establishing a database to accept and store the real-time running data of the mechanisms in the shield tunneling machine; providing the monitoring picture of the shield tunneling machine; showing the real-time running data of the mechanisms in the shield tunneling machine in the display; and completing the monitoring operation on the shield tunneling machine in the monitoring display. The method is intuitive, accurate and comprehensive, and may be combined with remote network technology for remote management and maintenance in a common PC.

Owner:TIANHE MECHANICAL EQUIP MFG

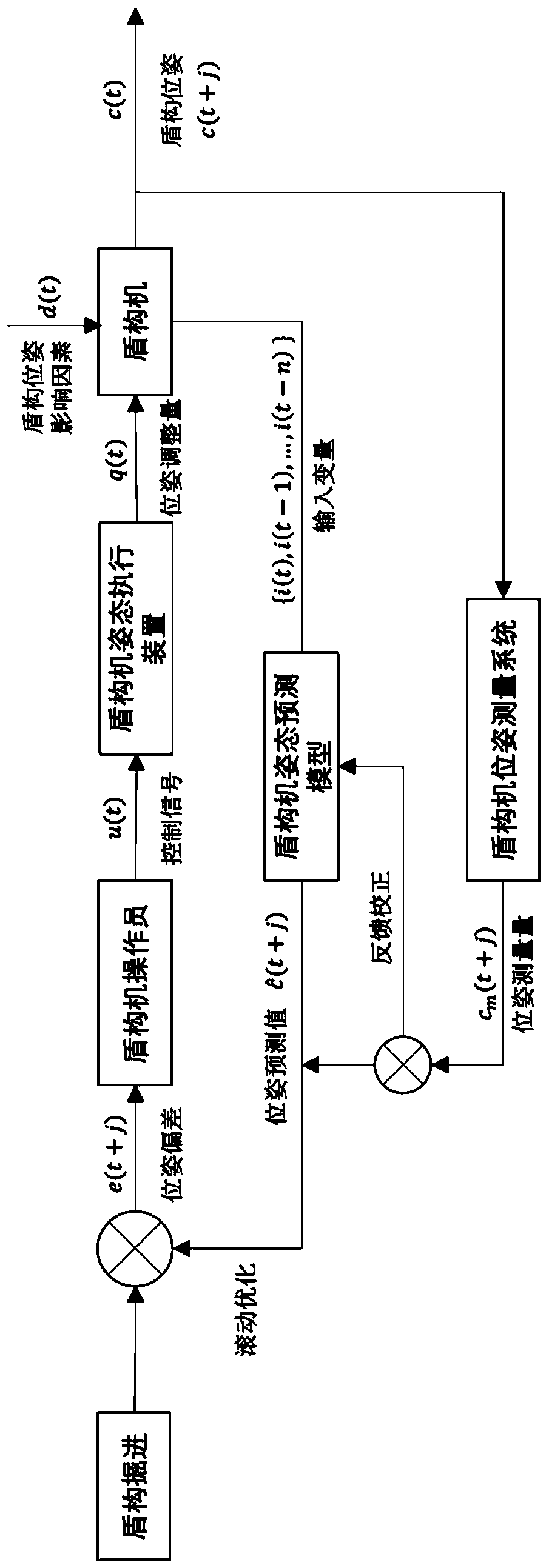

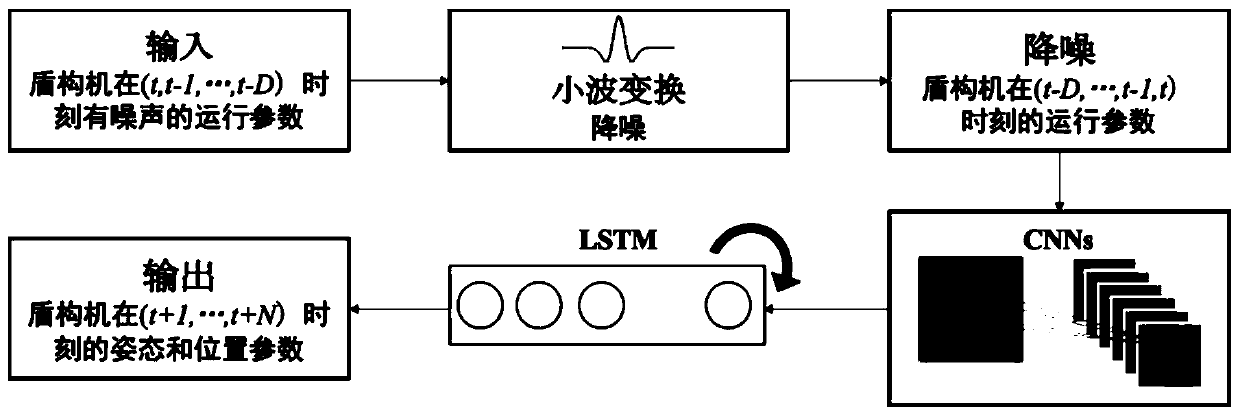

Shield tunneling position and pose intelligent prediction method and system based on hybrid depth learning

ActiveCN110195592AFacilitates early interventionEasy to controlMining devicesTunnelsControl engineeringShield tunneling

The invention discloses a shield tunneling position and pose intelligent prediction method and system based on hybrid depth learning, and belongs to the field of construction of subway shields. According to the method, a prediction control principle and an artificial intelligence technology are adopted based on a shield misalignment mechanism, positions and poses in a shield tunneling stage are predicted according to a built hybrid depth learning model WCNN-LSTM, an adjustment strategy of the shield positions and poses is formulated, and pre-adjustment and prior control of operation parametersare realized so that the problem of shield misalignment is improved. The method is used for performing intelligent prediction of subsequent change of the positions and poses in a tunneling process ofa shield machine, supports a shield machine driver to adjust the shield positions and poses in advance, solves the snake-shaped motion difficulty of the shield machine, alleviates the modulation control hysteretic effect of the shield positions and poses, realizes accurate control of a tunneling axis of the shield machine, can effective promote formation quality of the tunnels and has higher engineering practical values.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Process for grouting on back of shield segment

The invention discloses a process for grouting on the back of a shield segment to control stratum settlement in shield tunnel construction. The process comprises steps of synchronous grouting, secondary grouting and a special treatment process; during synchronous grouting, when a shield advances and a shield tail is formed, a grouting pump of a shield tunneling machine is used for symmetrical grouting through a synchronous grouting system of the shield tunneling machine; during secondary grouting, double grout is injected to the back of the segment through a shield segment secondary grouting hole, and a gap on the back of the segment is subjected to secondary filling and compression; and the special treatment process comprises steps of adding a triallyl cyanurate (TAC) high-molecular polymer material solution and pressing and injecting epoxy resin seal reinforcing rings. By the process, particularly the TAC high-molecular polymer is added to improve a soil layer and the epoxy resin reinforcing rings are pressed and injected to reinforce the stratum in the special treatment process, the grouting effect is good in a safe and convenient way, the flow and loss of the grout are prevented, the grouting plumpness is ensured, the soil body can be well improved, the stratum is reinforced, the settlement amount is effectively controlled, and the shield tunneling construction is safely and smoothly carried out.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

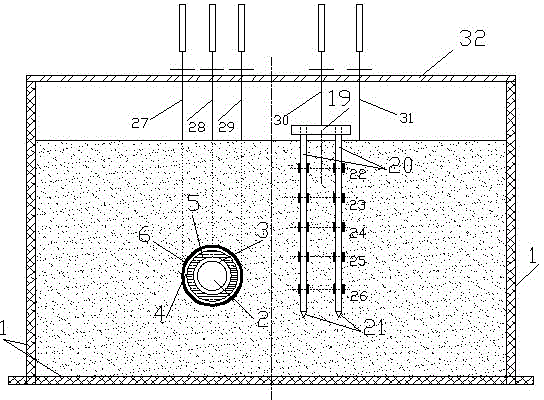

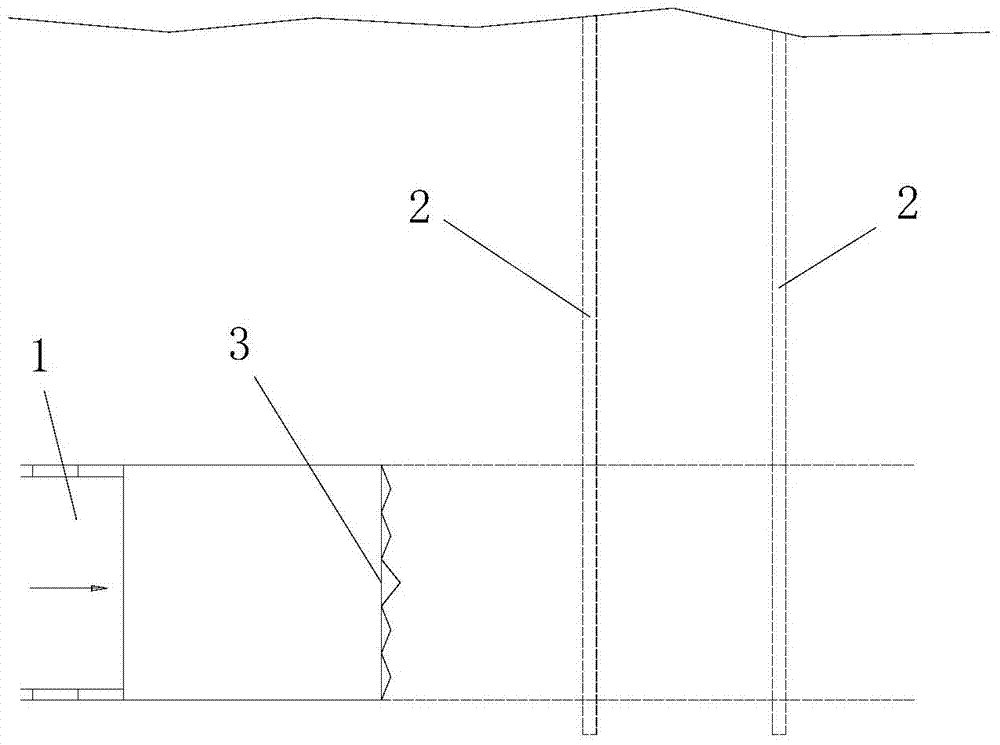

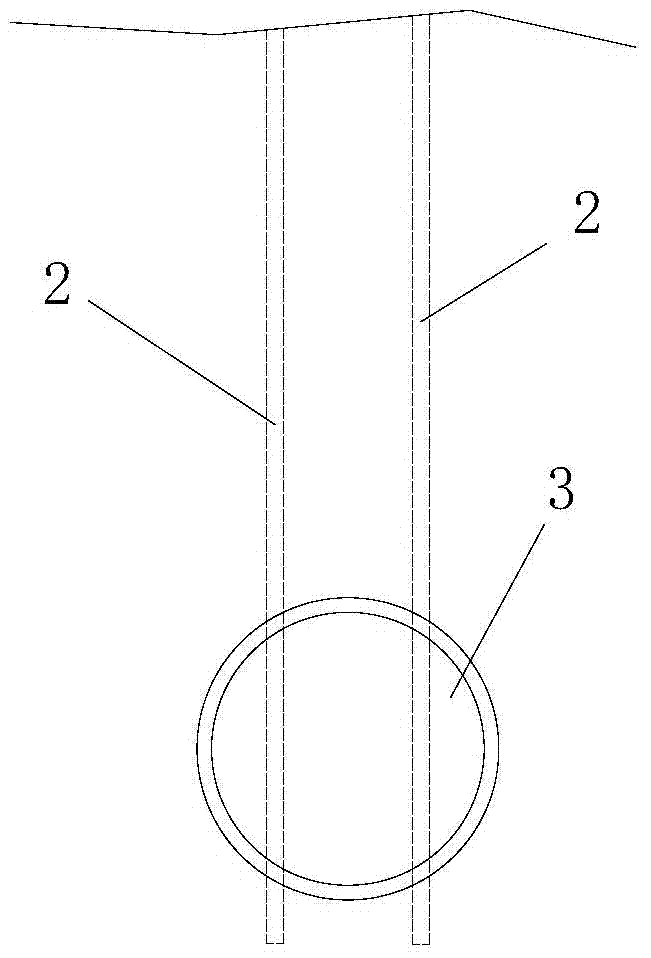

Indoor model testing apparatus for analyzing influences of shield tunnel grouting construction on adjacent pile foundations

InactiveCN103558044AImprove scalabilityAccurate measurementStructural/machines measurementSolenoid valveSlurry

The invention relates to an indoor model testing apparatus for analyzing influences of shield tunnel grouting construction on adjacent pile foundations. The indoor model testing apparatus comprises a model box, a tunnel grouting construction simulator, a tunnel lining model and a pile foundation model. The model box is filled with sandy soil mass, the tunnel lining model comprises longitudinally-segmented aluminum alloy hollow pipes and is placed in the left half part of the model box, and lining segments are separated by annular thin rubber plates; the pile foundation model is placed in the right half part of the model box and vertical to the tunnel lining model; a displacement meter support is fixed to the top surface of the model box; multiple displacement meters are respectively fixed to the corresponding sandy soil mass and the surfaces of piled raft foundations of the pile foundation model through the displacement meter support; the tunnel grouting construction simulator comprises a latex film surrounding the periphery of the tunnel lining model and an annular liquid cavity formed between the tunnel model and the latex film, the annular liquid cavity is filled with grouting liquid, one end of the annular liquid cavity is connected with a liquid injection guide pipe provided with a liquid injection solenoid valve, and a liquid discharge guide pipe provided with a liquid discharge solenoid valve is arranged at the other end of the annular liquid cavity in the horizontal direction.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

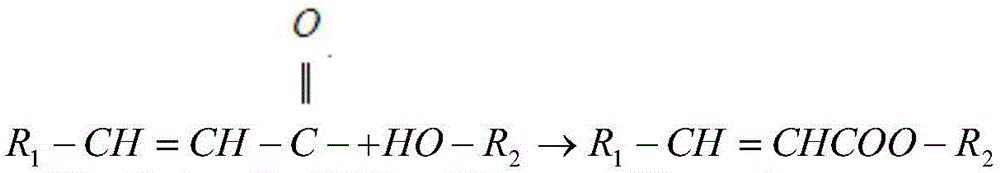

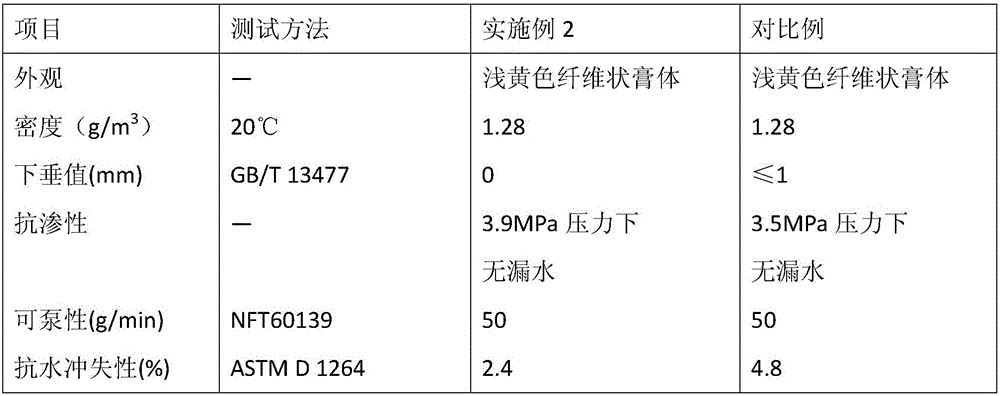

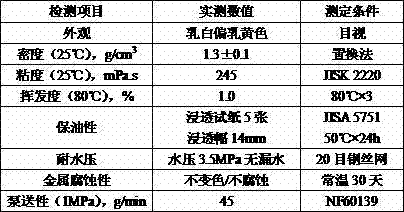

Shield tail sealing grease and preparation method thereof

The invention discloses shield tail sealing grease and a preparation method thereof. The shield tail sealing grease for tunnel construction tunneling equipment namely a shield tunneling machine consists of the following components: 15-30% of base oil, 10-20% of lubricating grease, 2-8% of a tackifier, 1-5% of an adhesion promoter, 5-10% of fibers, and 30-50% of a flour filler. The shield tail sealing grease is mainly formed by the combination of the base oil, the lubricating grease, the fibers and the filler, particularly the adhesion promoter is added, and the adhesion and the stability of a product are enhanced by the interaction force between the adhesion promoter and the surface of a base material; the product is stable in performance, avoids phenomena of segregation and sun crack when exposed in the air for a long time, does not generate sag and flow when encountering heat, and can still keep a relatively good pumping performance at a low temperature; and the shield tail sealing grease has relatively high impermeability, is convenient to operate and easy to pump, has excellent adhesion and certain corrosion resistance to metals, has outstanding water-stop and lubricating effects, and is easily biodegradable, environment-friendly and nontoxic.

Owner:XIAMEN NORNS TECH

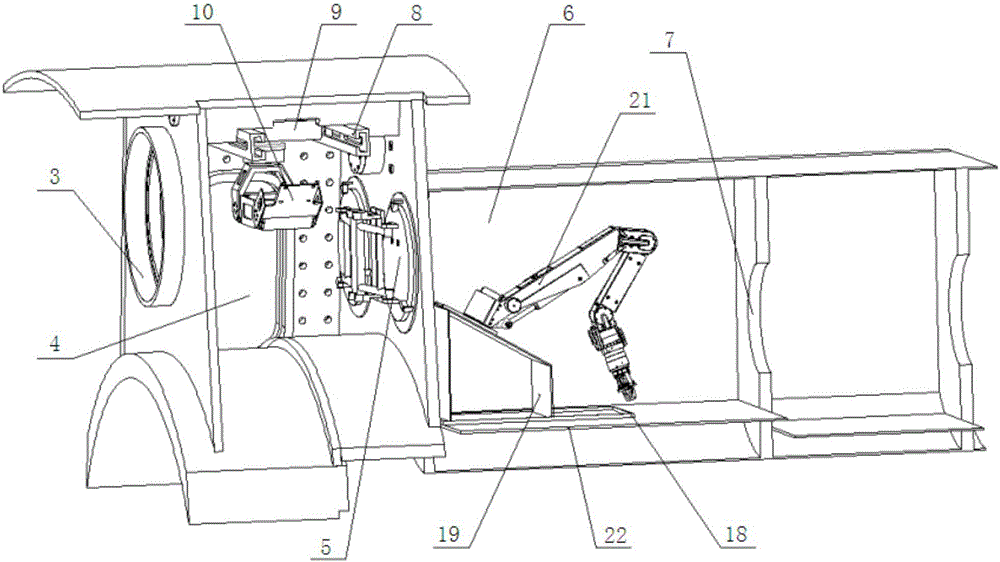

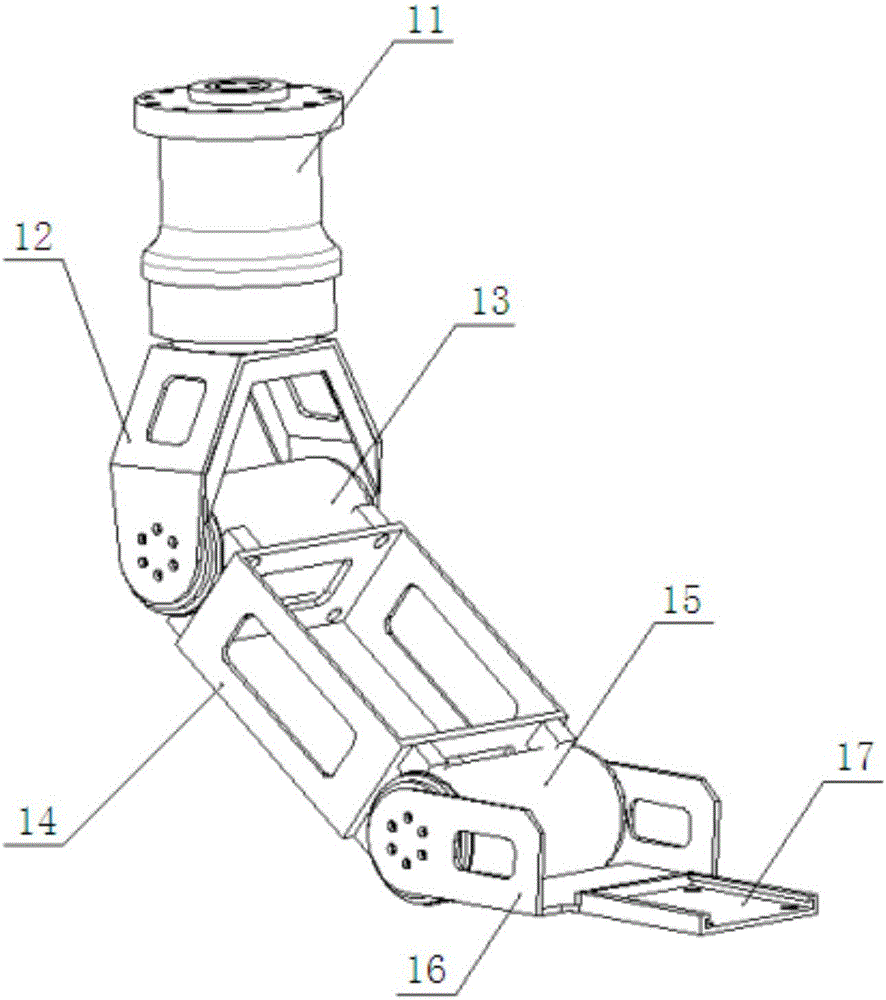

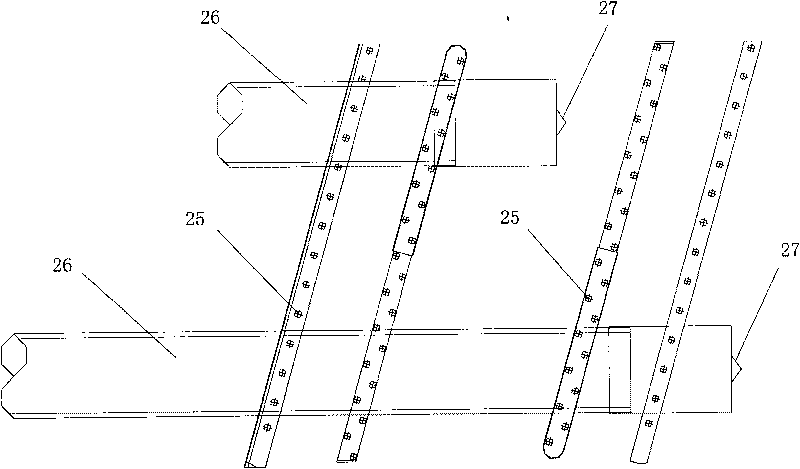

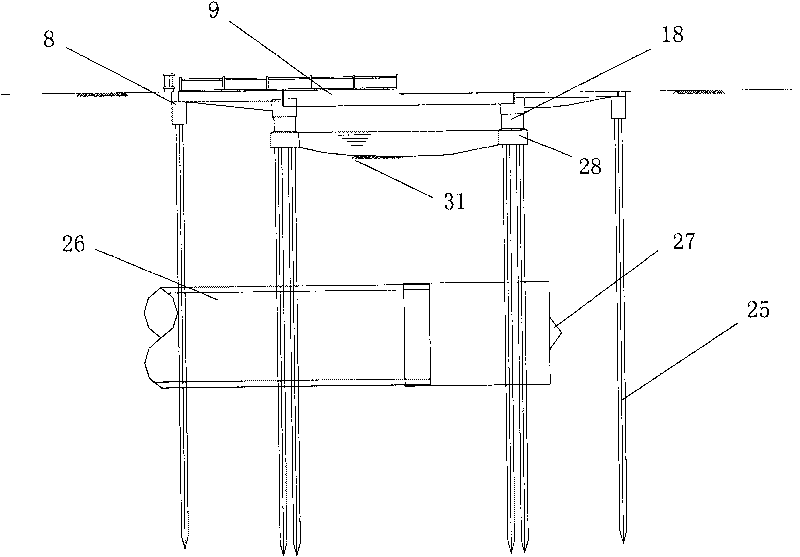

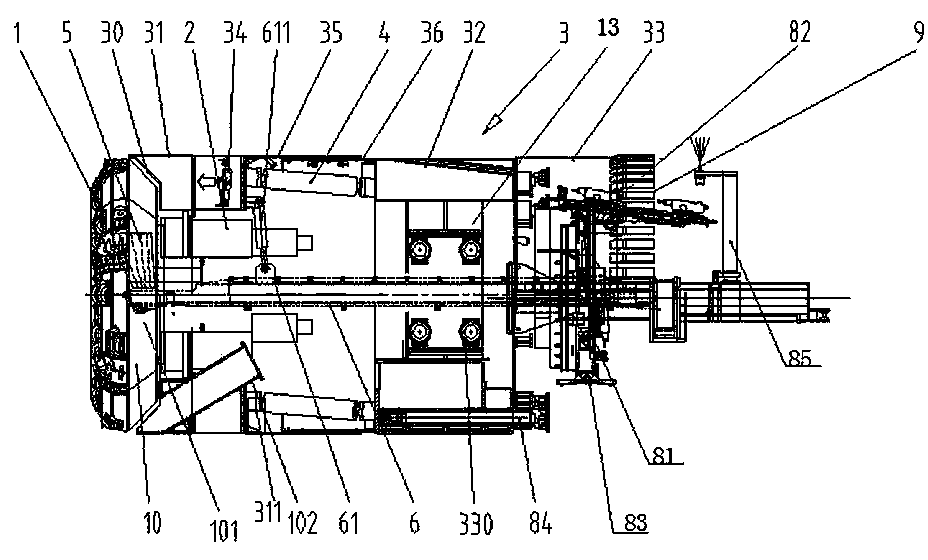

Auxiliary tool changing device of slurry balance shield tunneling machine and application method of auxiliary tool changing device

InactiveCN105781563AIncrease the level of automationEnsure safetyProgramme-controlled manipulatorTunnelsSpatial structureSlurry

The invention discloses an auxiliary tool changing device of a slurry balance shield tunneling machine and an application method of the auxiliary tool changing device. A tool disc is arranged at the foremost end of the slurry balance shield tunneling machine. An excavation cabin, an air cushion cabin and an entry gate cabin are sequentially arranged behind the tool disc. The auxiliary tool changing device comprises a first sliding rail fixedly connected to the upper portion of the air cushion cabin and a moving sliding table embedded in the first sliding rail. A robot is fixedly connected to the moving sliding table, a second sliding rail is arranged at the lower portion of the entry gate cabin, and a conveying frame is erected on the second sliding rail. A second installing base is arranged at the upper end of the conveying frame. A tool changing mechanical arm is arranged on the second installing base, and a lighting and camera shooting device is arranged at the front end of the tool changing mechanical arm. On the basis that an original shield tunneling machine cabinet door and a space structure are not changed, the auxiliary tool changing device is additionally arranged, the tool changing efficiency can be effectively improved, the tool changing cost is reduced, the safety of operators is guaranteed, and the tool abrasion detecting and replacing are finished. The automation level of the tool changing work of the slurry balance shield tunneling machine is improved, and reasonable, safe and efficient tool changing work is achieved.

Owner:NORTHEASTERN UNIV

Box-raft pressure-bearing type foundation underpinning and construction reinforcing method for tunnel across pile foundation of bridge above river

InactiveCN101761068AReduce the impactImprove construction levelFoundation repairBulkheads/pilesCofferdamAbutment

The invention relates to a geotechnical and underground engineering technology field, particularly to a box-raft pressure-bearing type foundation underpinning and construction reinforcing method for tunnels across pile foundations of a bridge above a river. The method of the invention comprises: reinforcing abutment foundation of both sides of the bridge, reinforcing the riverbed outside the cofferdam construction and abutment, strengthening bridge supports, excavating pits under cofferdam bridges, strengthening expanding plate-type foundations inside the pits and ground base under the plates, as well as shield tunneling and removing obstructive file base. The method can smoothly complete construction and guarantee smooth shield tunneling while ensuring normal passage of existing bridge structure, further can effectively reduce construction risk, accelerate construction process, reduce cost and reduce influence to environment to a maximal extent.

Owner:TONGJI UNIV +1

Double-mode shield tunneling machine

The invention belongs to the field of shield construction, and discloses a double-mode shield tunneling machine. The double-mode shield tunneling machine comprises a shield tunneling main engine, a cutterhead arranged on the front portion of the shield tunneling main engine, an earth bin, an air cushion bin, an earth pressure balancing system and a slurry balancing system, wherein the earth bin, the air cushion bin are sequentially formed in the rear portion of the cutterhead. When the shield tunneling machine works, the shield tunneling machine can be switched between an earth pressure balancing tunneling mode and a slurry balancing tunneling mode according to the strata of practical tunnels, so that the shield tunneling machine is adaptive to tunneling under different geological conditions, and the adaptability to complex strata and the shield construction efficiency are improved. Meanwhile, a dilution tank and a breaker are mounted on the tail of a spiral conveyer to break large rocks to the grain size which can be conveyed by a slurry pump, and the broken large rocks are then discharged through a slurry pipeline, and in this way, the situation that large rocks cannot be discharged smoothly in a slurry mode can be prevented effectively.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

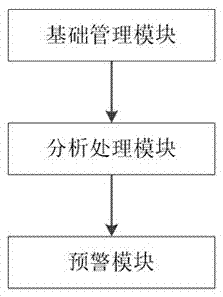

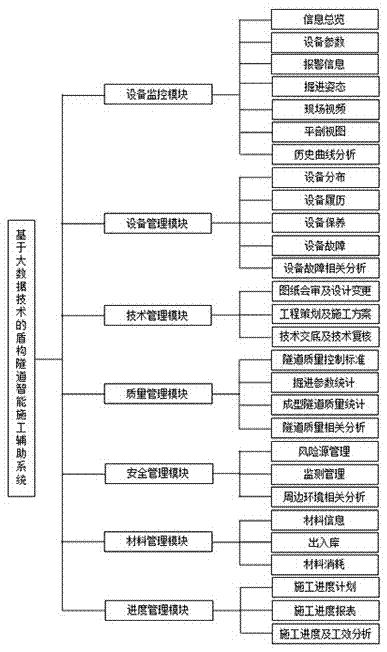

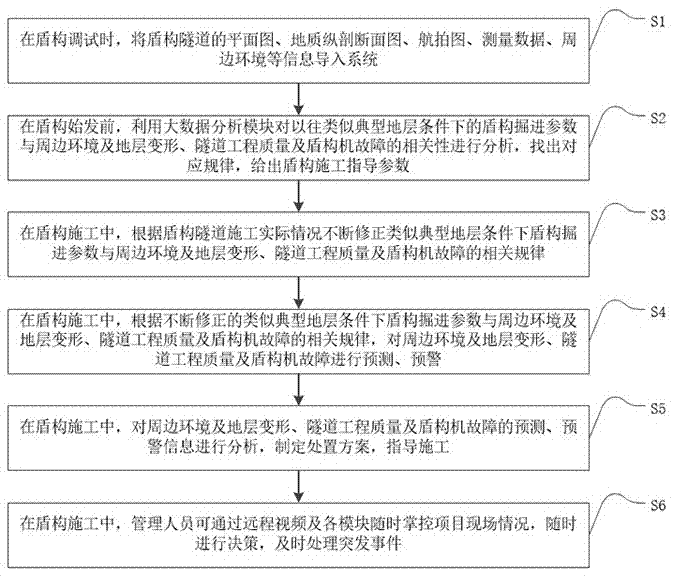

Shield tunnel intelligent construction auxiliary system based on big data technology and application method

ActiveCN107503757ATimely processingReduce unsafe behaviorTunnelsWireless networkEquipment monitoring

The invention discloses a shield tunnel intelligent construction auxiliary system based on the big data technology and an application method. The intelligent construction auxiliary system comprises a basic management module, an analyzing and processing module and a pre-warning module, wherein the basic management module is connected with the analyzing and processing module through a wireless network, and the analyzing and processing module is provided with a database, compares on-site basic management data with the database, performs analysis and outputs corresponding parameter control or performs pre-warning through the pre-warning module; the basic management module comprises an equipment monitoring module, an equipment management module, a technology management module, a quality management module, a safety management module, a material management module and a progress management module. The intelligent construction auxiliary system has the advantages that ambient environment and ground deformation, tunnel project quality and shield tunneling machine faults are predicted and pre-warned, unsafe behaviors during construction are reduced, the operation efficiency of shield tunneling equipment, the safety of tunnel construction and tunnel engineering quality are increased, and the construction cost of tunnel engineering is lowered.

Owner:CHINA CONSTR COMM ENG GRP UNITED

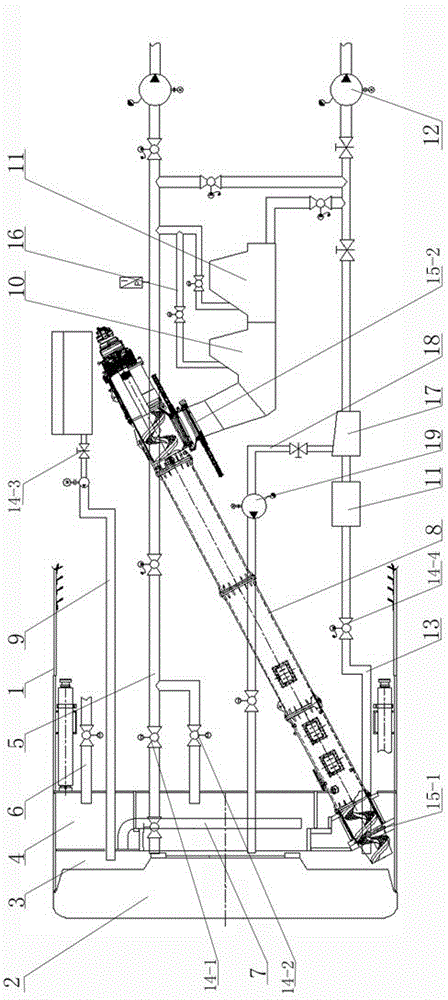

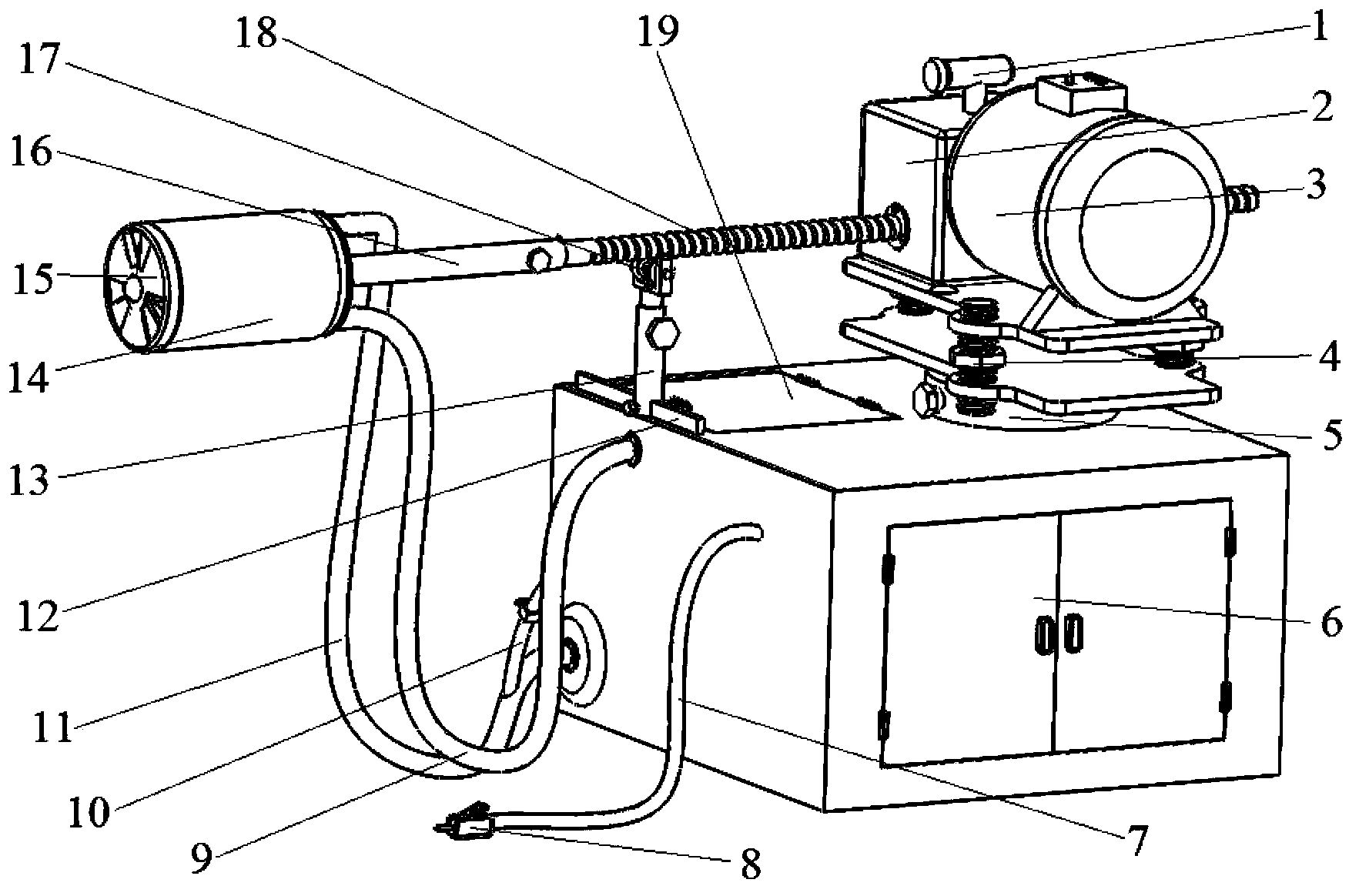

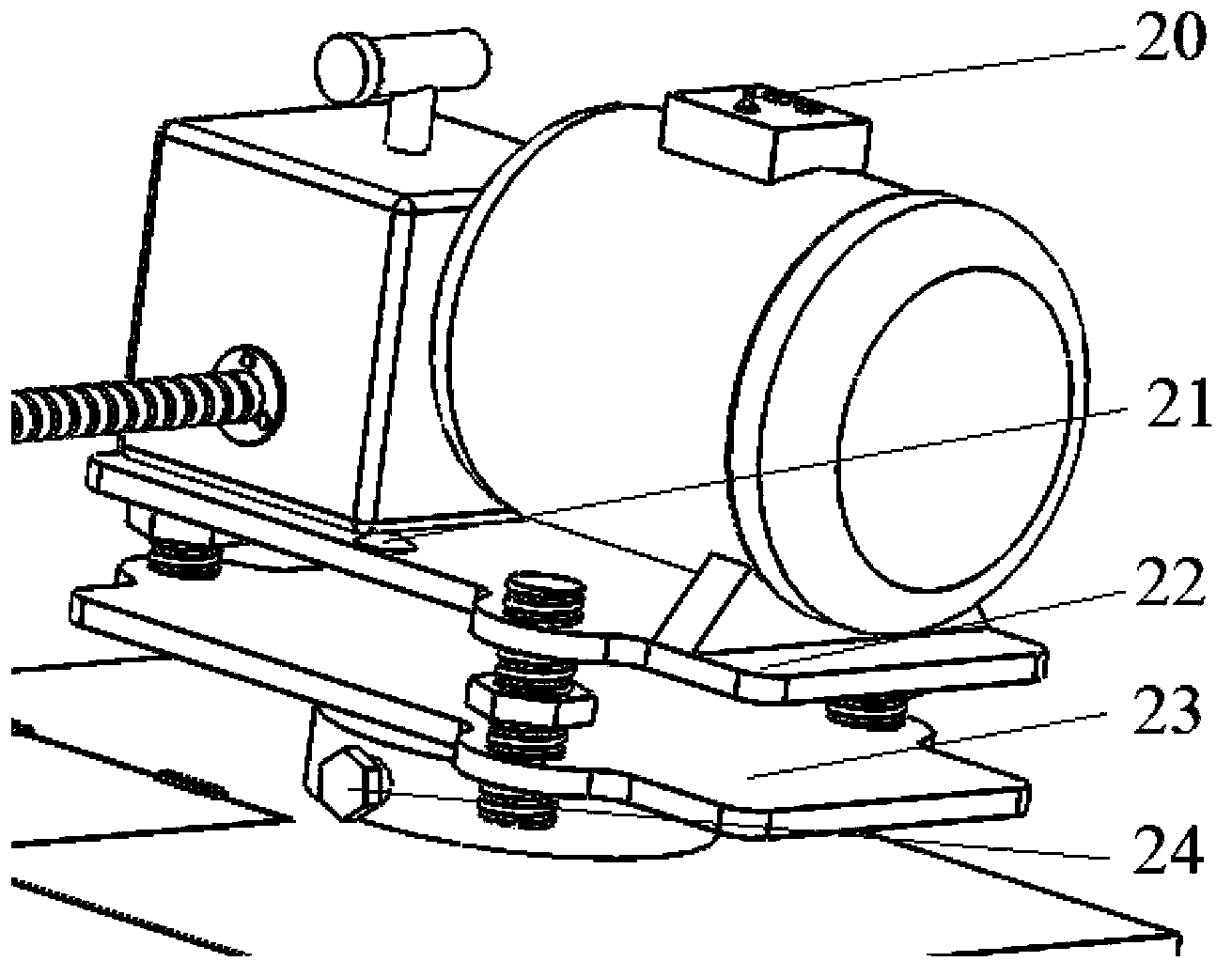

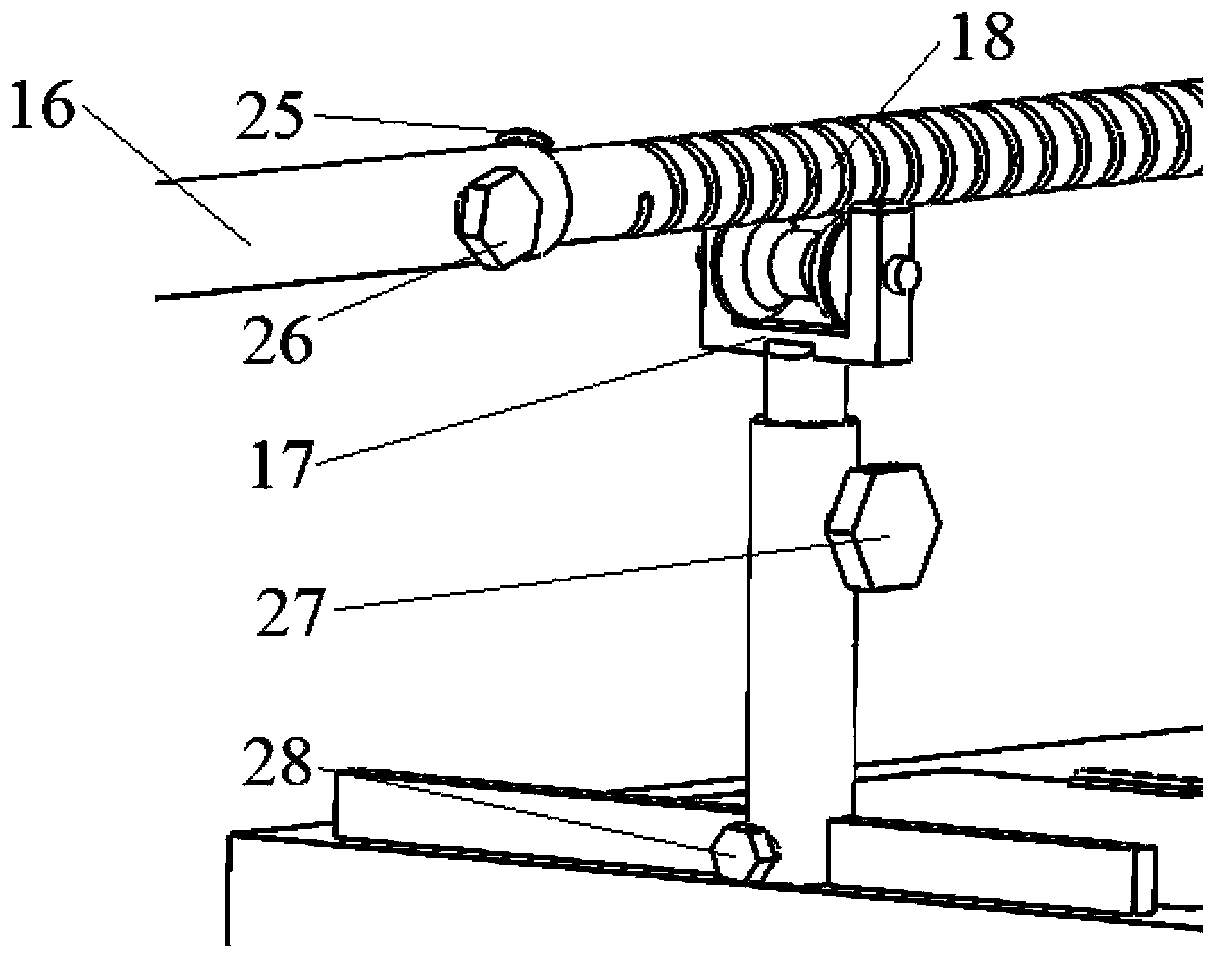

Indoor model test device capable of simulating slurry balance shield construction and use method thereof

InactiveCN103437771AComplete simulationReduce testing costsUnderground chambersTunnel liningSlurryEngineering

The invention relates to an indoor model test device capable of simulating slurry balance shield construction and a use method thereof. The indoor model test device comprises a digging propulsion mechanism, a circulation mechanism and a slurry injection mechanism, wherein the digging propulsion mechanism comprises an electric motor, a speed reducer, a shield shell, a main shaft and a rotary pipe, the circulation mechanism comprises a circulation tank, a micro water pump, a water inlet pipe, a mud outlet pipe and a pressure regulating pipe, and the slurry injection mechanism comprises a slurry injection tank, a slurry tank, a mini compressor, a pneumatic pressure tube, a slurry injection pipe and a slurry injection head. Compared with the prior art, the indoor model test device has the advantages that a whole construction process, such as dynamic digging propulsion, pipe sheet assembly and wall back grouting, of a slurry balance shield construction machine can be simulated, more accurate and real experimental data can be provided for the design of all parameters for actual shield tunneling construction, and the safety during actual construction is guaranteed.

Owner:TONGJI UNIV

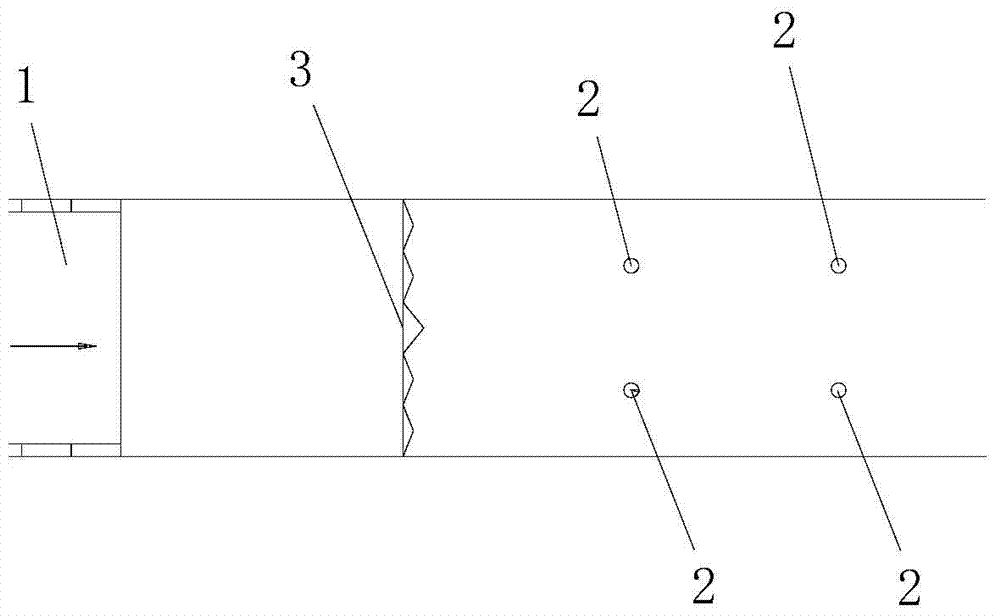

Synchronous grouting simulation test platform of shield tunneling machine

InactiveCN101881173AObserve flow phenomenaUnderground chambersTunnel liningHydraulic cylinderReciprocating motion

The invention relates to a synchronous grouting simulation test platform of a shield tunneling machine, comprising a soil tank, a simulation tube piece, a simulation shield tail, a propelling hydraulic cylinder, a guiding barrel, a transparent outer barrel, a soil pressure sensor, a camera and a grouting pump, wherein the axis of the guiding barrel is horizontally and fixedly connected to the left side wall of the soil tank, one end of the transparent outer barrel is coaxially and fixedly connected with the guiding barrel, the other end is fixedly connected with the right side wall of the soil tank, the transparent simulation tube piece is coaxially sleeved in the transparent outer barrel and is fixedly connected with the right side wall of the soil tank, the camera is arranged in an inner cavity of the simulation tube piece, the soil pressure sensor is arranged on the barrel wall of the simulation tube piece, the simulation shield tail is coaxially sleeved in the periphery of the simulation tube piece and can axially slide along the inner barrel wall of the guiding barrel and the outer barrel wall of the simulation tube piece, a grouting hole is arranged in the barrel wall of the simulation shield tail and is communicated with the grouting pump, and the propelling hydraulic cylinder can drive the simulation shield tail to do reciprocating motion. The invention can dynamically simulate and directly observe the whole process of synchronous grouting of the shield tunneling machine under different working conditions, thereby providing conditions for the test and the theoretical study of a synchronous grouting technique of the tunneling machine.

Owner:上海盾构设计试验研究中心有限公司 +1

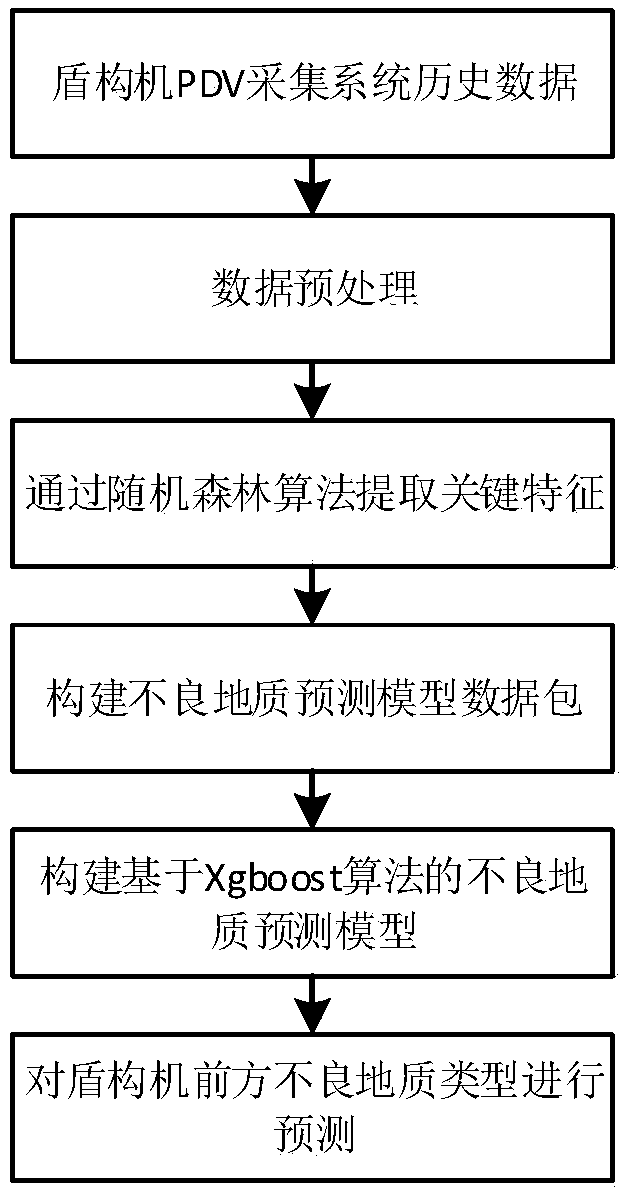

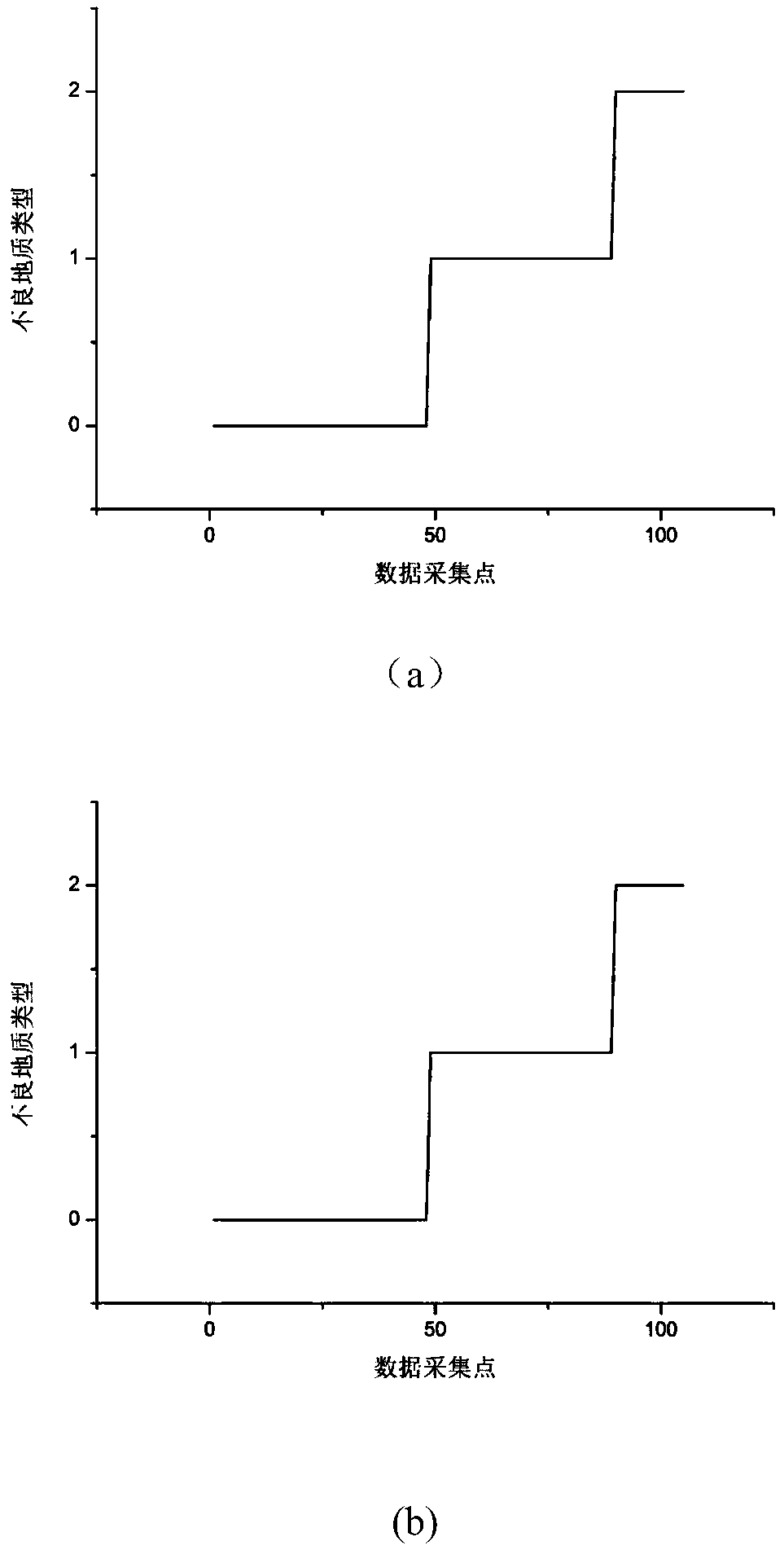

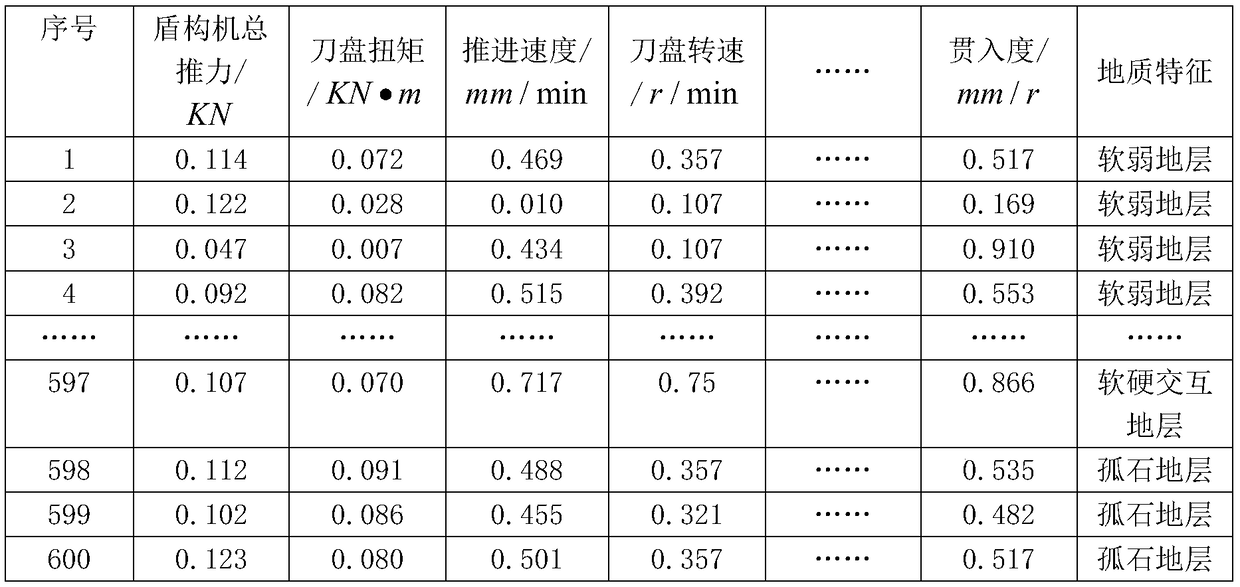

Prediction method for bad geological type of shield tunneling based on Xgboost

InactiveCN108846521AImprove forecast accuracyAvoid problems prone to local minimaForecastingCharacter and pattern recognitionFeature setNetwork packet

The invention provides a prediction method for bad geological type of shield tunneling based on Xgboost, which is used for solving the technical problems of low prediction accuracy and low timelinessexisting in the prior art. The realization steps are as follows: preprocessing the PDV historical data of a shield tunneling machine; acquiring the key features of multiple pieces of tunneling parameter data after preprocessing; constructing a bad geological prediction data package; establishing a bad geological prediction model of an Xgboost algorithm; evaluating the bad geological prediction model of the Xgboost algorithm; and predicting the bad geological types in shield tunneling. The invention extracts the key data feature set of tunneling parameters which can characterize the stratum change through a random forest algorithm feature extraction model, and predicts The bad the bad geological types through the bad geological prediction model of the Xgboost algorithm, thus improving the accuracy and timeliness of bad geological prediction. The method can be used to monitor and analyze the geological conditions of surrounding rock in the shield tunneling process in real time.

Owner:XIDIAN UNIV

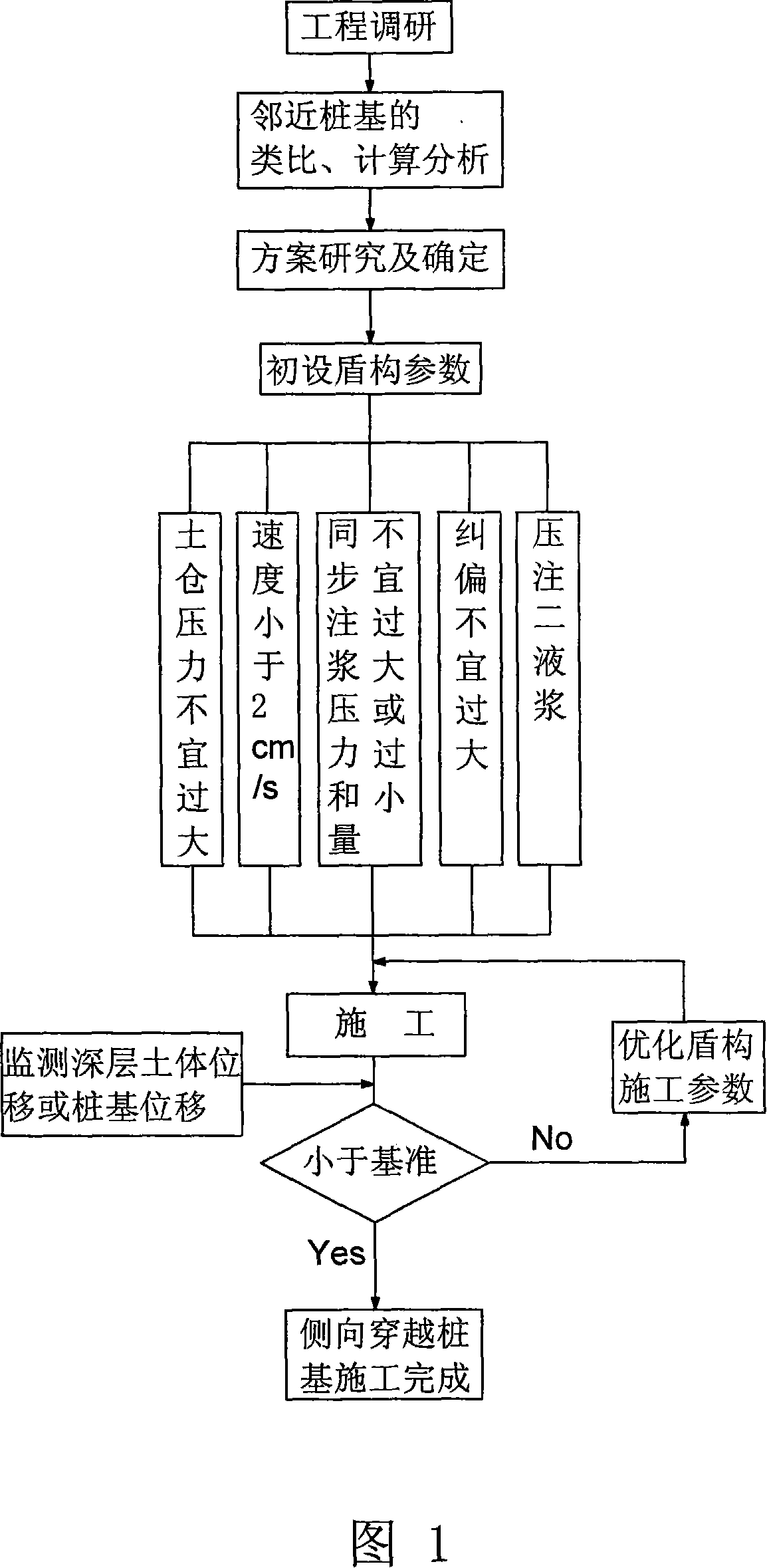

Shield tunnel lateral cross-over pile base construction method

ActiveCN101126319ASafe Approach ConstructionSmooth approach to constructionTunnelsShield tunnellingComputational analysis

The invention discloses a construction method on the side-crossing pile foundation in the shield tunnel, the main procedures comprises: the investigation and research of the project, the analogy and the computational analysis on the side-crossing pile foundation, the study and decision of the construction plan, the preliminary shield parameters for the shield construction of the side-crossing pile foundation and so on; wherein, the preliminary shield parameters mainly comprises the earth pressure, the advancing speed, the injection amount of the mortar, the rectification amount and so on; during the shield construction process of the side-crossing pile foundation, a computer is adopted to realize the real-time monitoring on the displacement of the deep soil, the displacement of the pile foundation and so on. With the method provided by the invention, the construction of the crossing pile foundation can be finished safely and smoothly without any accessory method; also, the method has no distinct influence on the existing pile foundation at the near distance and the surrounding environment.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

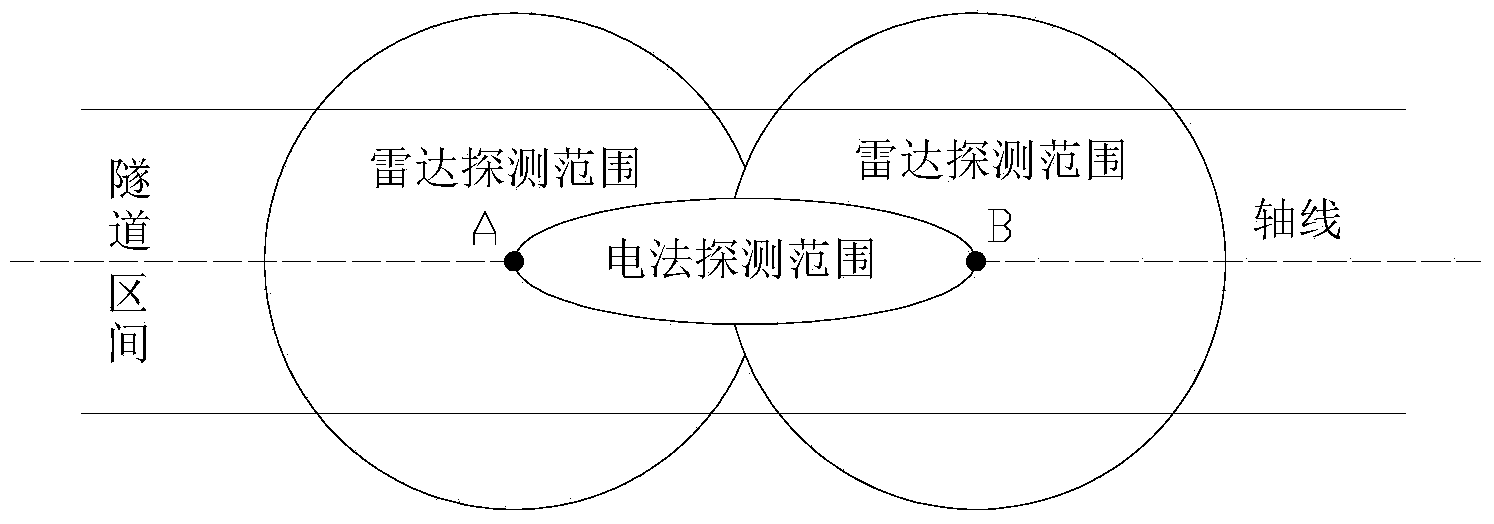

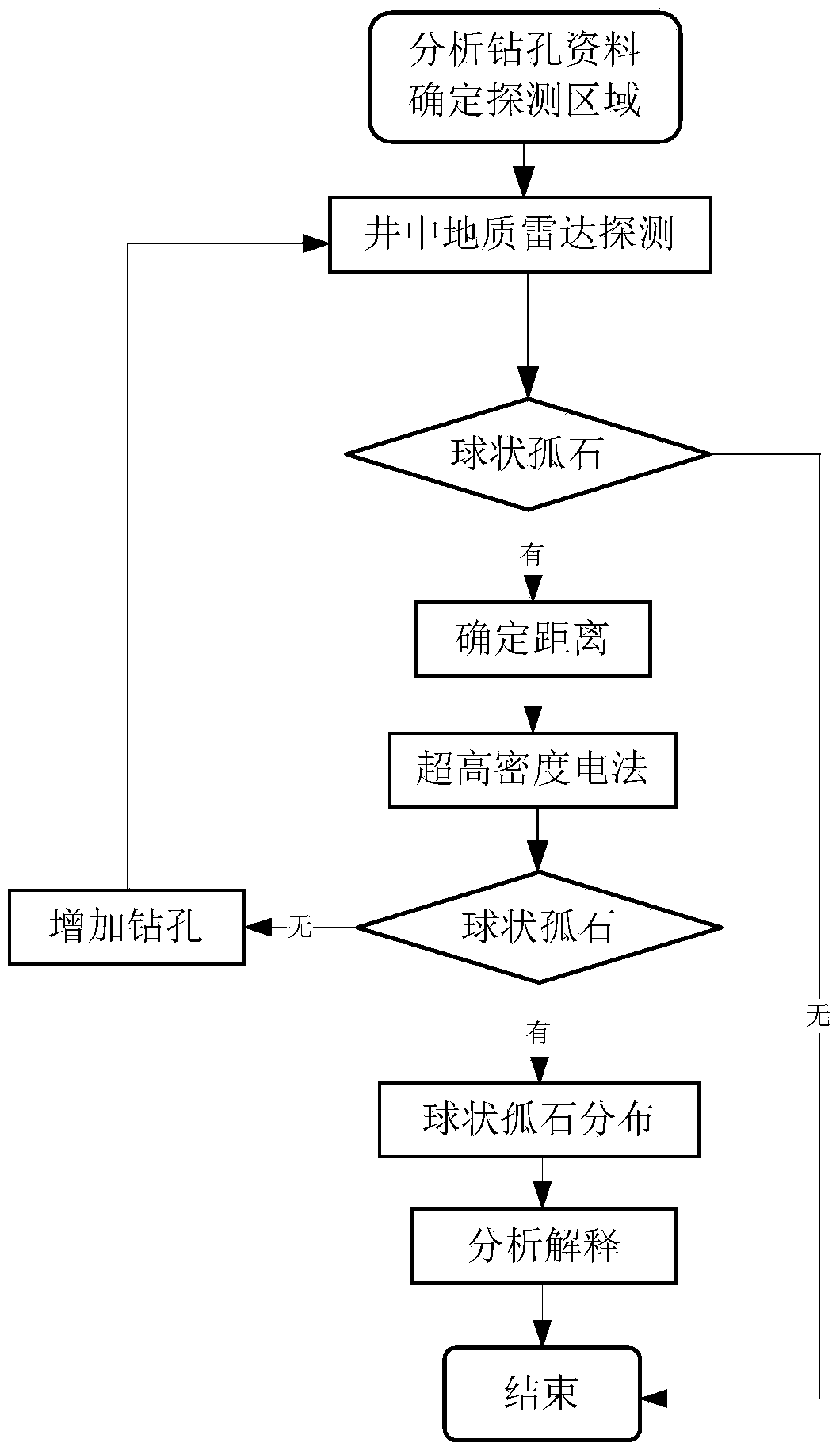

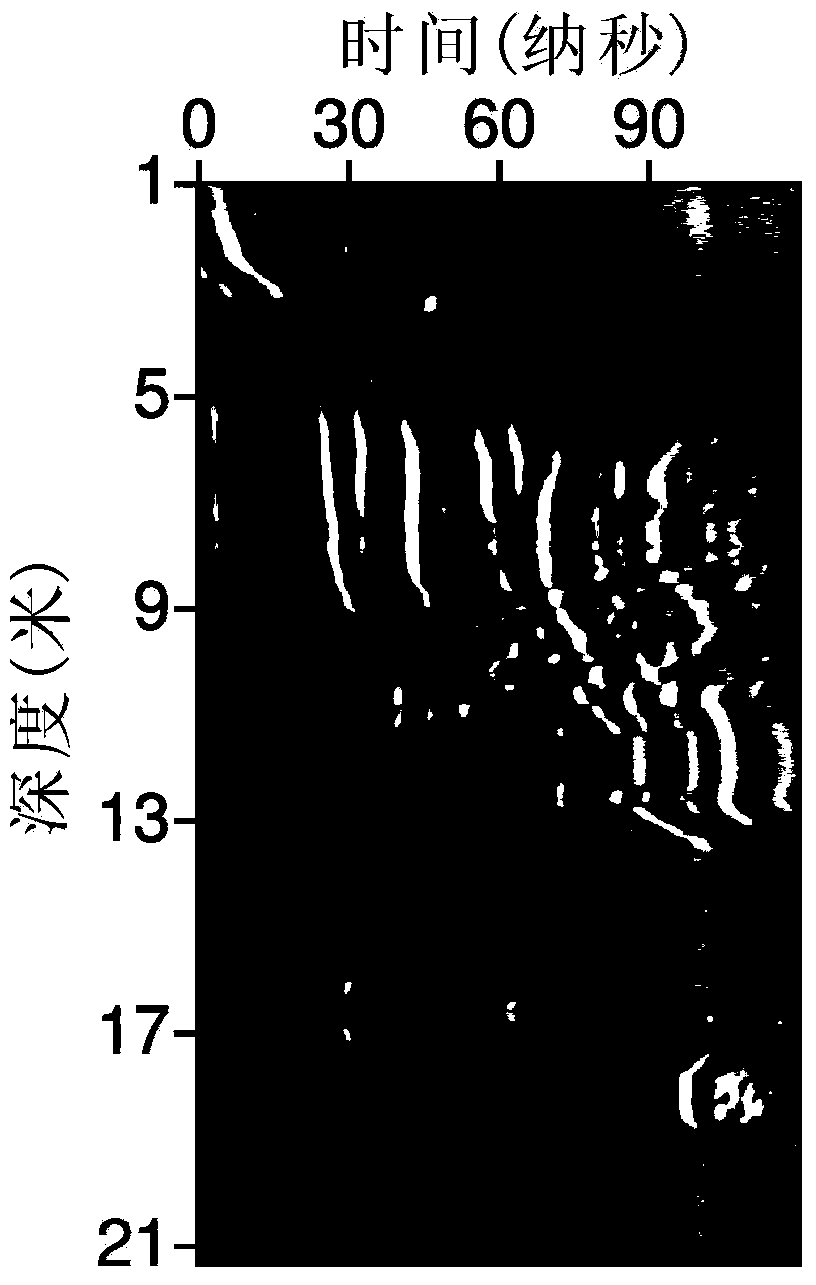

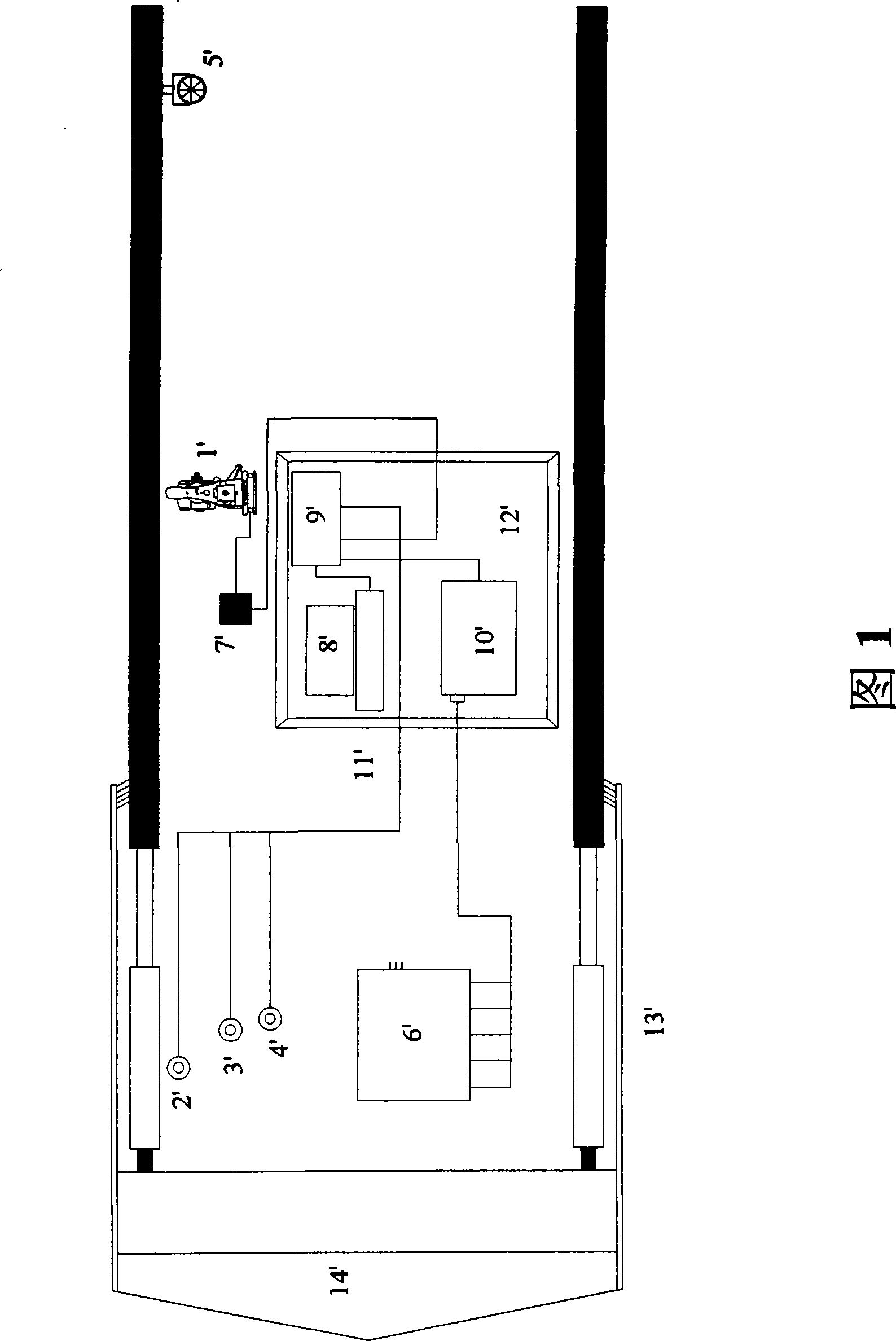

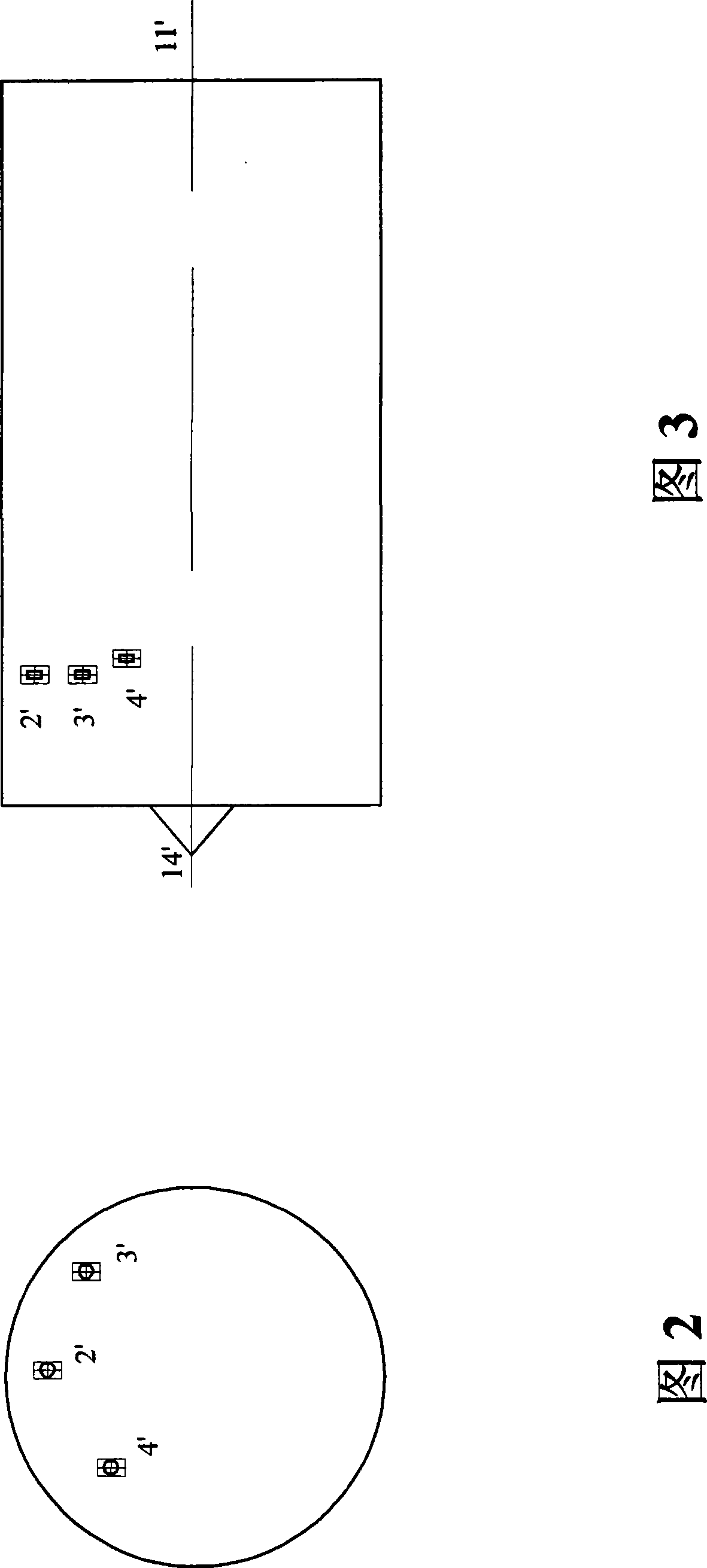

Method for detecting spherical boulders in shield construction

ActiveCN103913776AConvenient and smoothReduce the number of drilled holesDetection using electromagnetic wavesRadio wave reradiation/reflectionGeomorphologyRadar

The invention discloses a method for detecting spherical boulders in shield construction to achieve the technical purpose of improving the capability of detecting the spherical boulders in the shield district. The method comprises the step of collecting geological radar echo signals in the drilling depth direction through a well geological radar, the step of primarily defining the dimensional orientation where the spherical boulders probably exist, the step of collecting potential differences and currents between two drill holes to obtain the true resistivity of a stratum between the two holes, the step of drawing the true resistivity into a contour map to define the sizes and the distribution situation of the spherical boulders in the stratum between the two holes. Compared with the prior art, the well geological radar and the hole crossing ultrahigh precision electrical method are utilized, the spherical boulders within the shield tunnel range is detected, the distribution of the spherical boulders within the tunnel range can be detected to the maximum degree, the number of the drill holes can be reduced, the detecting cost is small, meanwhile, the probability of finding the spherical boulders in the complex stratum shield district is improved, and the smooth advancing of a shield tunneling machine is guaranteed.

Owner:SHENZHEN MUNICIPAL ENG

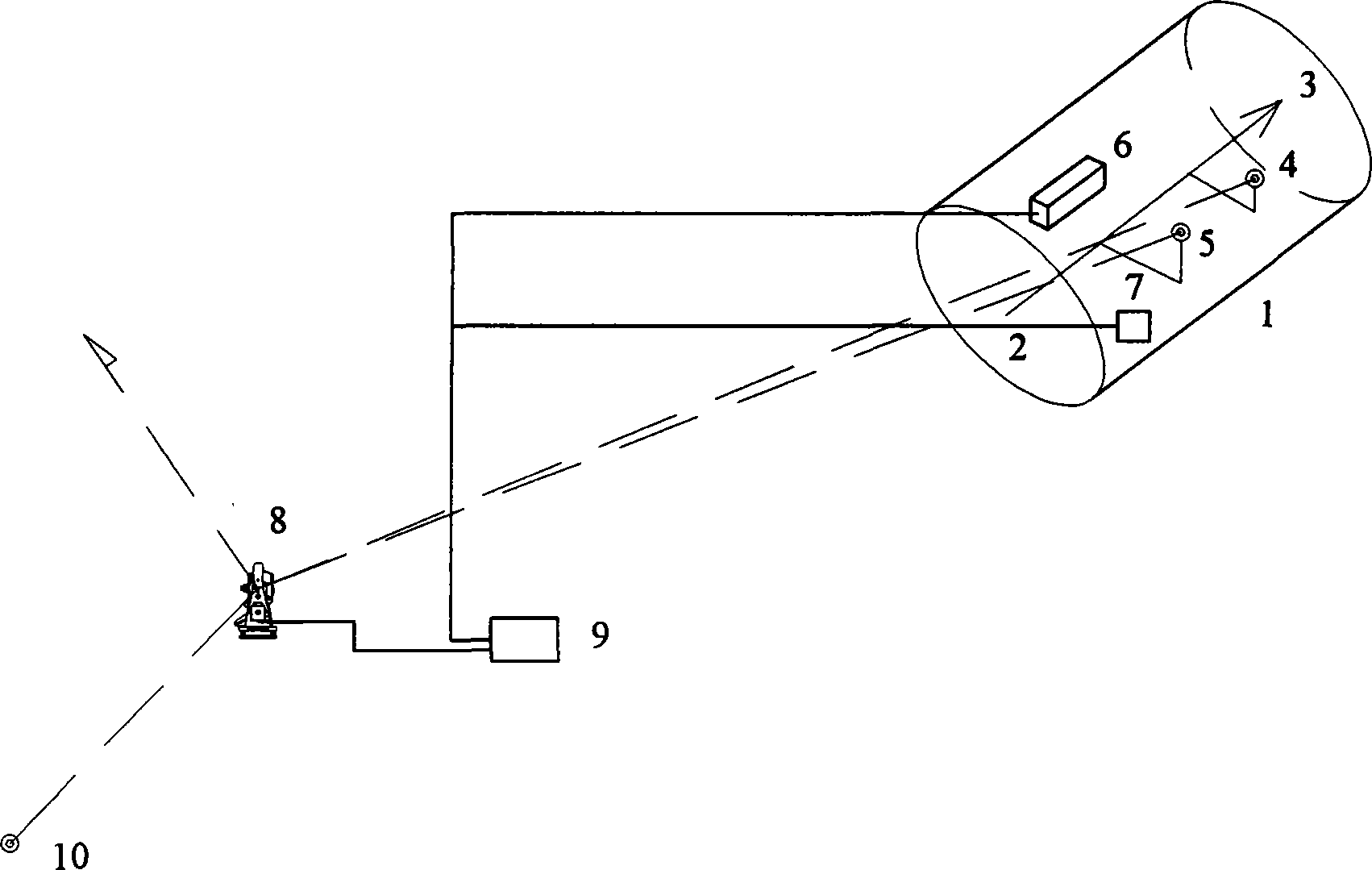

Real-time measurement system for shield excavation attitude

The invention discloses a real-time measurement system for shield tunneling posture, comprising a total station instrument which is arranged behind a shield machine and is provided with an automatic target recognition function and a plurality of target prisms fixed in the shield machine, wherein, the target prisms are arranged one by one along the longitudinal direction of the shield machine; the system also comprises a double-axis tilt sensor, and the double-axis tilt sensor is arranged on a special mounting base fixed in the shield machine. The system eliminates the contradiction between the improvement of the measurement accuracy and the extension of the continuable observation distance, particularly can adapt to the working environment with worse intervisibility conditions, has the advantages of high measurement accuracy and simple and convenient installation, can adapt to the shield tunneling construction with various conditions, and particularly adapt to the tunnel construction of small diameters and small curvature radii.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

Preparation method and application of environment-friendly type shield tail sealing grease

The invention discloses a preparation method and an application of environment-friendly type shield tail sealing grease. The shield tail sealing grease mainly comprises the following components: 14-30% of lubricating oil, 7-22% of oil plasticizer, 3-15% of thickening agent, 3-12% of lubricating grease, 3-8% of natural degradable fiber, 35-60% of filling granular material, 1-3% of coloring agent and 0.1-2% of preservative. The environment-friendly type shield tail sealing grease prepared by using the method is used for sealing a shield tail of a shield tunneling machine in tunnel engineering, and has the advantages of good water pressure sealing performance, excellent pumping performance, high adhesivity, good lubrication, stable properties, no corrosion, antioxidation, wide raw material resources, environment-friendliness and simple preparation process.

Owner:东莞市明洁隧道建设材料有限公司

Method for exploring and processing interior of boulder hole in front for shield method construction

ActiveCN103790594AThe method steps are simpleReasonable designAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansEngineeringShield tunneling

The invention discloses a method for exploring and processing the interior of a boulder hole in front for shield method construction. The method includes the following steps of advanced exploration hole drilling, boulder exploring and boulder processing. In the first step of advanced exploration hole drilling, a plurality of exploration holes are drilled in front of a cutterhead of a shield tunneling machine from back to front through a plurality of drilling channels distributed in the cutterhead of the shield tunneling machine. In the second step of boulder exploring, boulder exploring is performed through an ultrasonic detector and the multiple exploration holes with the following procedures, first, an ultrasonic transmitter and an ultrasonic receiver are installed; second, ultrasonic detection is performed, wherein the installed ultrasonic transmitter and the installed ultrasonic receiver are moved simultaneously from back to front or from front to back, and the strength of the stratum in each moving position is ultrasonically detected in the moving process. In the third step of boulder processing, boulders in front of the cutterhead of the shield tunneling machine are detonated. The method is simple in step, reasonable in design, convenient to achieve, good in using effect and capable of overcoming multiple defects existing in a boulder exploring method adopted in existing shield method construction.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Shield tunneling and shallow tunneling combined construction method for building underground station

InactiveCN101086209AImprove the quality of C&DEnsure safetyUnderground chambersTunnel liningSubway stationStructural engineering

A shield tunneling method combined with the shallow construction of the subway station construction method pertains to underground construction technology. The invention of the detailed construction methods as follows: 1) direct Shield Construction Terminal; 2) apply for soil pile around the shield tunnel lateral at a certain distance; 3) set up a temporary support columns in the shield tunnel, and apply for prestressed tightwire on the portrait of the canal slice; 4) use of shallow mining branch excavation intermediate platform / station office of the tunnel, apply for the initial support (or secondary lining); 5) grouting the soil side of the canal slice in the platform / station office of the tunnel; 6) excavate passengers evacuate horizontal channel that leading to shield tunnel, apply for the initial support; 7) remove the openings canal slice at the cross-channel, apply for secondary lining to retain the canal slice and cross-channel early support and secondary lining maintain good connection; 8) dismantle all the temporary support, apply platform board , complete the construction of the station. The invention can improve the quality of subway construction projects, reduce project costs, shorten the construction period.

Owner:BEIJING JIAOTONG UNIV +2

Combined type double-shield tunneling machine

ActiveCN104196538AIncrease the lengthShorten the lengthUnderground chambersTunnel liningSupporting systemDual mode

The invention discloses a combined type double-shield tunneling machine which comprises a cutter, an anterior shield, a cab, a main driving device, an inside-and-outside stretching shield, a V-shaped arrangement main propelling system, a hinge system, a supporting shield, a boot supporting system, a tail shield, an auxiliary propelling system, a dual-mode deslagging system, an integration supporting system and the like. Four working modes including of the double shielding modes including the support boot and segmental lining mode and the support boot and anchor-plate timbering mode, the single shielding mode and the ERB mode can be achieved, and efficient tunneling, efficient deslagging and efficient timbering are achieved under the hard rock, sandy soil and soft soil geological conditions. The combined type double-shield tunneling machine has the outstanding advantages that one device can meet various complex-geology tunneling construction requirements, the geology applicability of the tunneling machine is greatly improved, the frequency of tunneling machine replacement in tunnel construction is decreased, and production efficiency is greatly improved.

Owner:中船(青岛)轨道交通装备有限公司

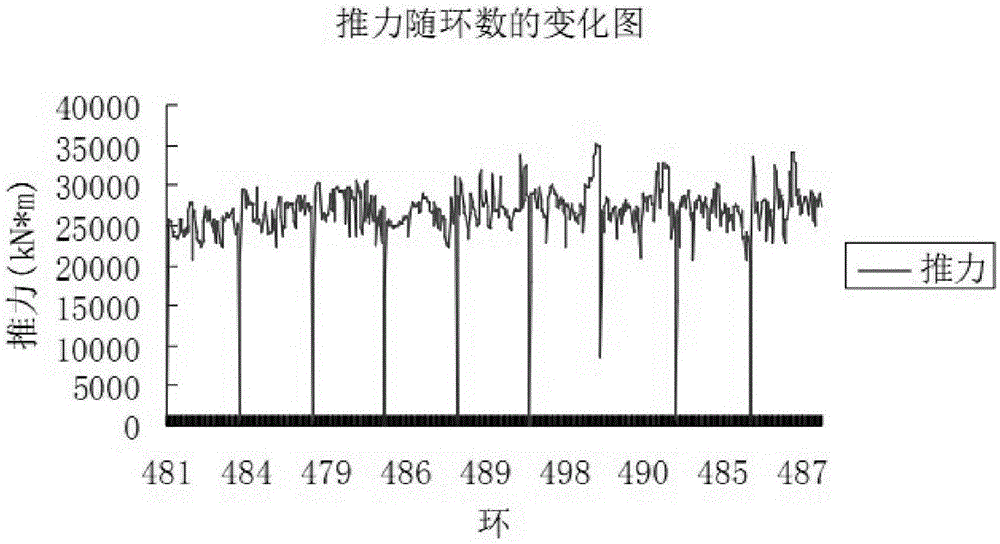

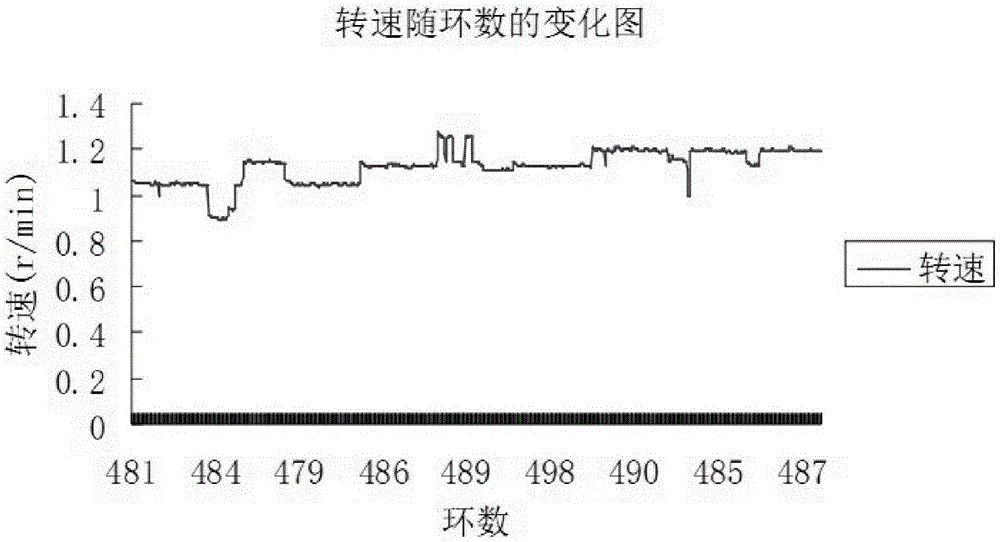

Optimization method of shield excavation parameters under condition of compound stratum

InactiveCN105631150AImprove construction safetyExtended service lifeSpecial data processing applicationsMathematical modelData acquisition

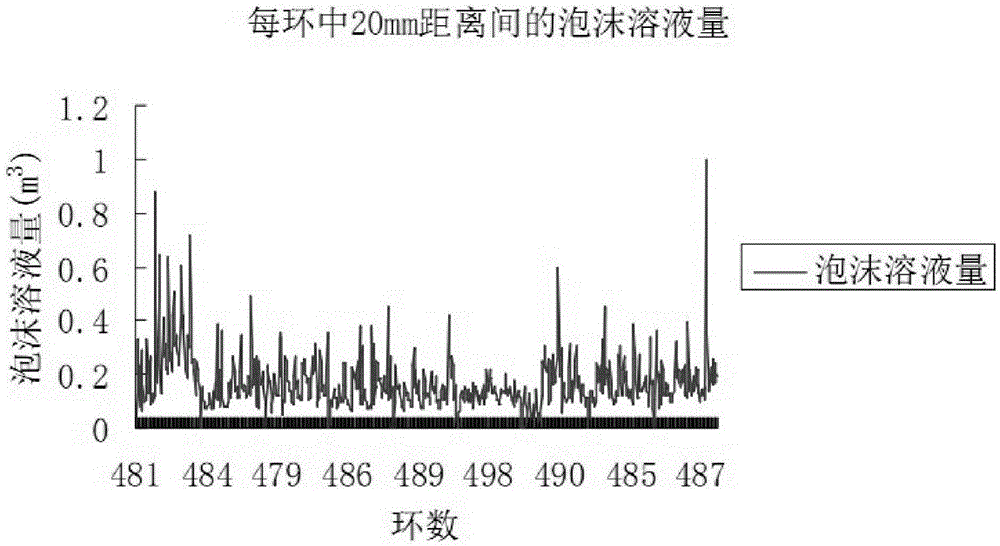

The invention discloses an optimization method of shield excavation parameters under the condition of a compound stratum. The method is characterized by comprising the following steps of (1) carrying out shield excavation orthogonal experimental design; (2) collecting excavation data; utilizing a data collection and storage system of a shield tunneling machine to collect and record experimental data; collecting the thrust, the rotating speed of a cutter, the excavation speed, the foam solution adding amount, the foam concentration and the cutter torque by the data collection system during the experiment process; collecting data at a time after excavating 20mm every time, wherein the experimental excavation length of each group is 1.6m; (3) building a shield excavation parameter mathematical model; designing an orthogonal experimental model according to the shield construction process, carrying out nonlinear regression analysis on data collected by the orthogonal experiment, respectively building an excavation speed model and a cutter torque model of earth pressure balance shield, confirming the reasonable excavation parameters under the condition of the compound stratum through resolving, and optimizing the excavation parameters, so that the safety of shield construction is improved, and the service life of the shield tunneling machine is prolonged.

Owner:SHIJIAZHUANG TIEDAO UNIV

Construction method for disassembling of shield tunneling machine in narrow and small space

The invention discloses a construction method for disassembling of a shield tunneling machine in a narrow and small space. The construction method comprises the following steps that 1, shield bodies of the shield tunneling machine are designed into assembly-type shield bodies; 2, the shield tunneling machine tunnels, arrives and receives; 3, a track beam is mounted, and an electric block is mounted on the track beam; and 4, the shield tunneling machine is disassembled. According to the construction method, ground hoisting holes do not need to be formed, after a shield cutterhead comes out of atunnel, the cutterhead is disassembled, and then a front shield and a middle shield are pushed sequentially through power of the shields to disassemble the front shield and the middle shield; and then a shield tail is pulled away from the tunnel through external arrangement of a jack to be disassembled, by pushing one of the shield bodies, one or two segments are spliced, and the disassembled components of the shield tunneling machine are transported in the mode of disassembling one of the shield bodies.

Owner:POWERCHINA RAILWAY CONSTR

Shield tunnel portal sealing device and shield tunnel portal sealing method

InactiveCN103266898APrevent gushingPrevent water seepageUnderground chambersTunnel liningEngineeringShield tunneling

The invention belongs to the technical field of shield tunnel engineering and particularly relates to a shield tunnel portal sealing device and a shield tunnel portal sealing method. The shield tunnel portal sealing device comprises a lined wall, an embedded steel ring is arranged on the lined wall, a sealing box is arranged on the embedded steel ring and comprises a sealing steel ring, a fixing plate, a fold type support plate and two waterproof structures, a plurality of grease injecting holes are evenly circumferentially reserved in the sealing steel ring between the two waterproof structures, each waterproof structure comprises a steel wire brush and a cord fabric rubber plate, the cord fabric rubber plates are arranged on one side close to the embedded steel ring, and grouting holes are reserved in the lined wall and in the sealing steel ring on the inner sides of the cord fabric rubber plates. The shield tunnel portal sealing device has the advantages that the cord fabric rubber plates are primarily used for sealing to prevent a major part of water and soil from pouring out, so that 'pouring prevention' is achieved; water penetration is prevented as the steel wire brushes secondarily achieve seamless contact with a shield tunneling machine shell or duct pieces; and the grouting holes reserved in the lined wall and the sealing steel ring can achieve grouting sealing timely in emergencies.

Owner:CCCC SECOND HARBOR ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com