Shield tunneling machine split starting construction method

A technology of split origination and construction method, which is applied in earthwork drilling, mining equipment, tunnels, etc., can solve problems such as inoperability, save construction costs, improve construction efficiency, and reduce construction difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present invention will be further described below in conjunction with accompanying drawing:

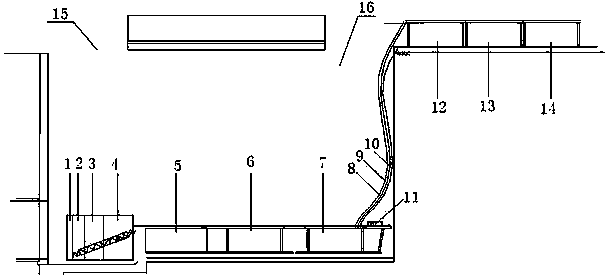

[0032] As shown in the figure, 1 is the cutter head, 2 is the front shield, 3 is the middle shield, 4 is the back shield, 5 is the connecting bridge, 6 is 1 # Trolley, 7 is 2 # trolley, 8 is gas pipeline, 9 is water pipeline, 10 is wire harness, 11 is 5 # Cable host on the trolley, 12 is 3 # Trolley, 13 is 4 # Trolley, 14 is 5 # Trolley, 15 are hoisting wellheads, and 16 are unearthed mouths.

[0033] Detailed construction method of the present invention is:

[0034] ① Underground cleaning site

[0035] ②The starting base is assembled in the well and the track is laid

[0036] Install the starting bracket before laying the track. After installing the bracket, place the waste segment on it, and then lay two left and right rails of 2080mm and 900mm gauge on the segment according to the center line of the tunnel to the bottom of the portal.

[0037] A winch is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com