Ultra-short radius radial horizontal well drilling, completion tool and technique thereof

一种水平钻井、超短半径的技术,应用在定向钻井、钻井设备、钻杆等方向,能够解决水平井钻进方位难以控制、易产生较大偏差、生产效率降低等问题,达到节省有效空间、降低施工难度、钻井精度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

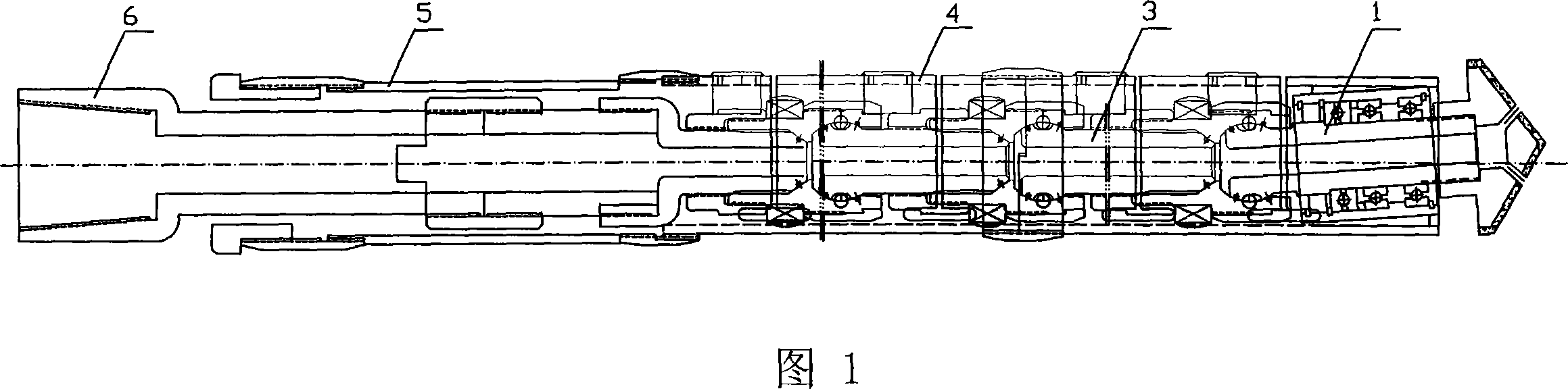

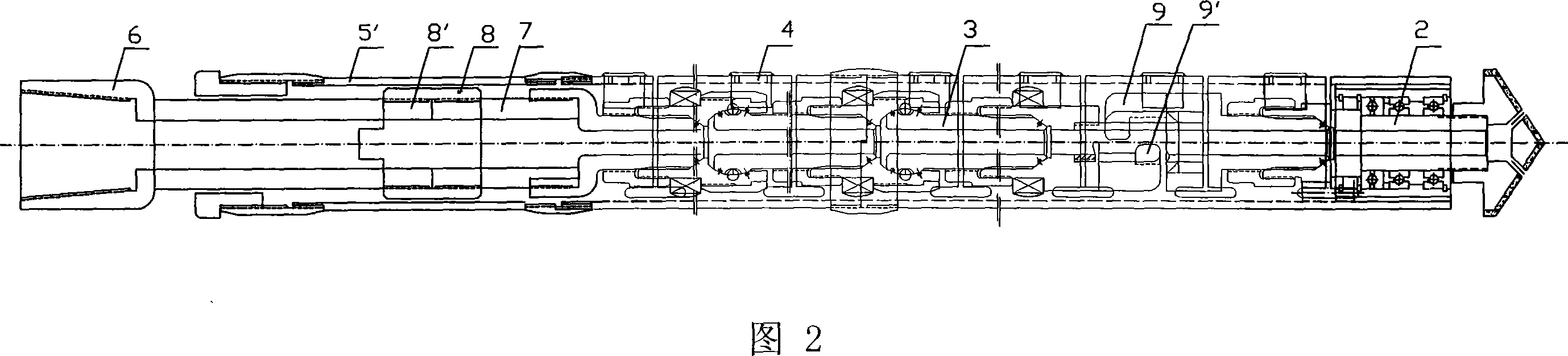

[0041] 1. Assemble various tools of the present invention:

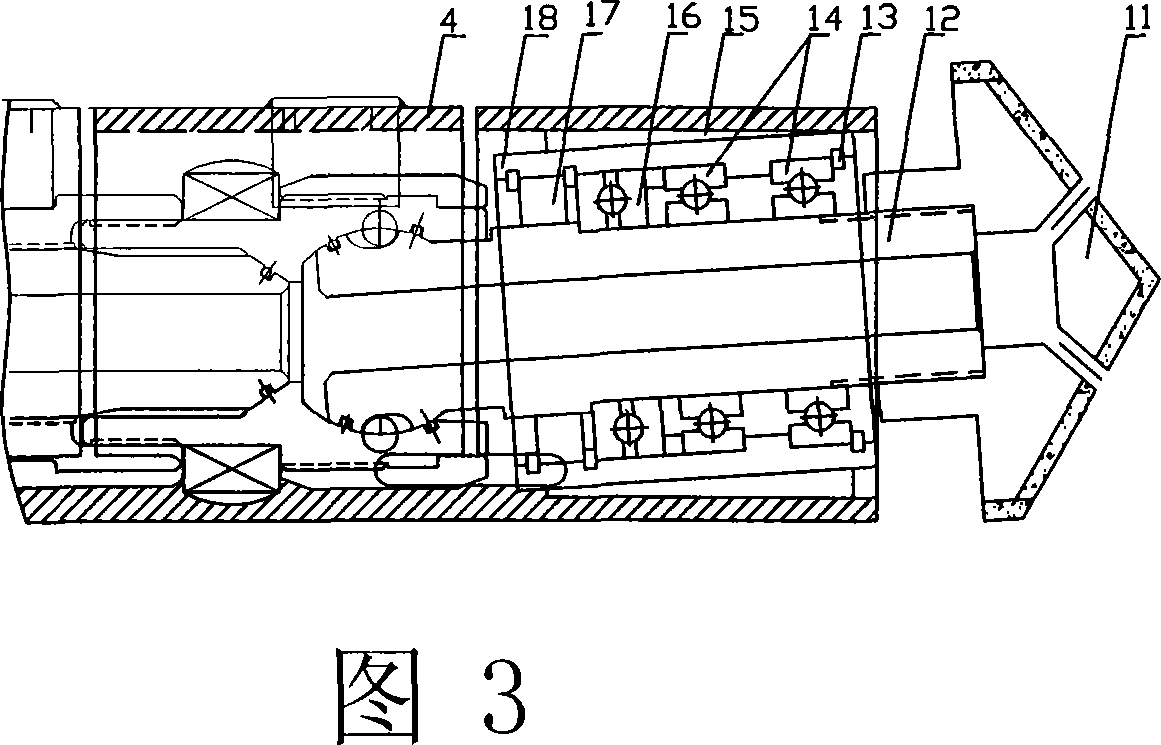

[0042] (1) First, assemble the deflection rotation assembly 1, as shown in Figure 3, put the righting bearing 14, the pressure bearing 16, the collar 13, and the oil seal 17 into the outer casing 18 in sequence, and penetrate the central shaft 12, and put the drill bit 11 is connected to the front end of the central shaft 12 by means of a screw, the triangular pad iron 15 is welded on the jacket 18, and then the deflection rotation assembly 1 is welded to the front end of the directional follow-up guide tube 4;

[0043] (2) Assemble the horizontal rotation assembly 2, as shown in Figure 4, put the righting bearing 23, the pressure bearing, the collar and the oil seal into the outer cover 25 in sequence, penetrate the central shaft 22, and connect the drill bit 21 with a screw thread. At the front end of the central shaft 22, the rectangular pad iron 24 is welded on the outer sleeve 25, and the inner spline 39' of the...

Embodiment 2

[0053] Assemble each part of the present invention.

[0054] (1) The length of the horizontal drilling footage is 45.0m, and the installation length of the flexible drill pipe 3 is 45.0m; each flexible rod is 150mm, and the inner ball 31 is made of 40 chromium nickel molybdenum material;

[0055] (2) The directional follow-up guide pipe 4 is made of a seamless steel pipe with a slit width of 4mm and a slit spacing of 110mm. A 70mm wide pipe wall is left as a rib at the lower part of the steel pipe.

[0056] Drilling process

[0057] Mill out a 1.3m window on the well casing wall at the design depth of the oil well;

[0058] The bending degree of the flexible drill pipe is 18° / m, and the deflection angle is 90°. When drilling 5.0m, the radius of curvature R=5.0×4÷2π=3.18; it also belongs to the category of ultra-short radius deflection technology.

[0059] Other parts manufacture and drilling process are all the same as embodiment 1.

Embodiment 3

[0061] Assemble each part of the present invention.

[0062] (1) The length of horizontal drilling footage is 98.0m, and the length of each flexible rod is 140mm. A 98.0m long flexible drill pipe is assembled, and the inner ball is processed by 42 chromium molybdenum;

[0063] (2) The slit width of the directional follow-up guide pipe 4 is 4 mm, and the slit spacing is 105 mm; 60 mm of the pipe wall is left as ribs at the lower part of the slotted pipe.

[0064] Drilling process

[0065] The bending degree of the flexible drill pipe is 22° / m, and the deflection angle is 90°. When drilling 4.1m, the curvature radius R=4.1×4÷2π=2.61m.

[0066] Other parts manufacture and drilling process are all the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com