Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6219results about "Directional drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Actively controlled rotary steerable system and method for drilling wells

InactiveUS6092610AEfficient rotary speedPromote productionDrilling rodsConstructionsAccelerometerDirectional drilling

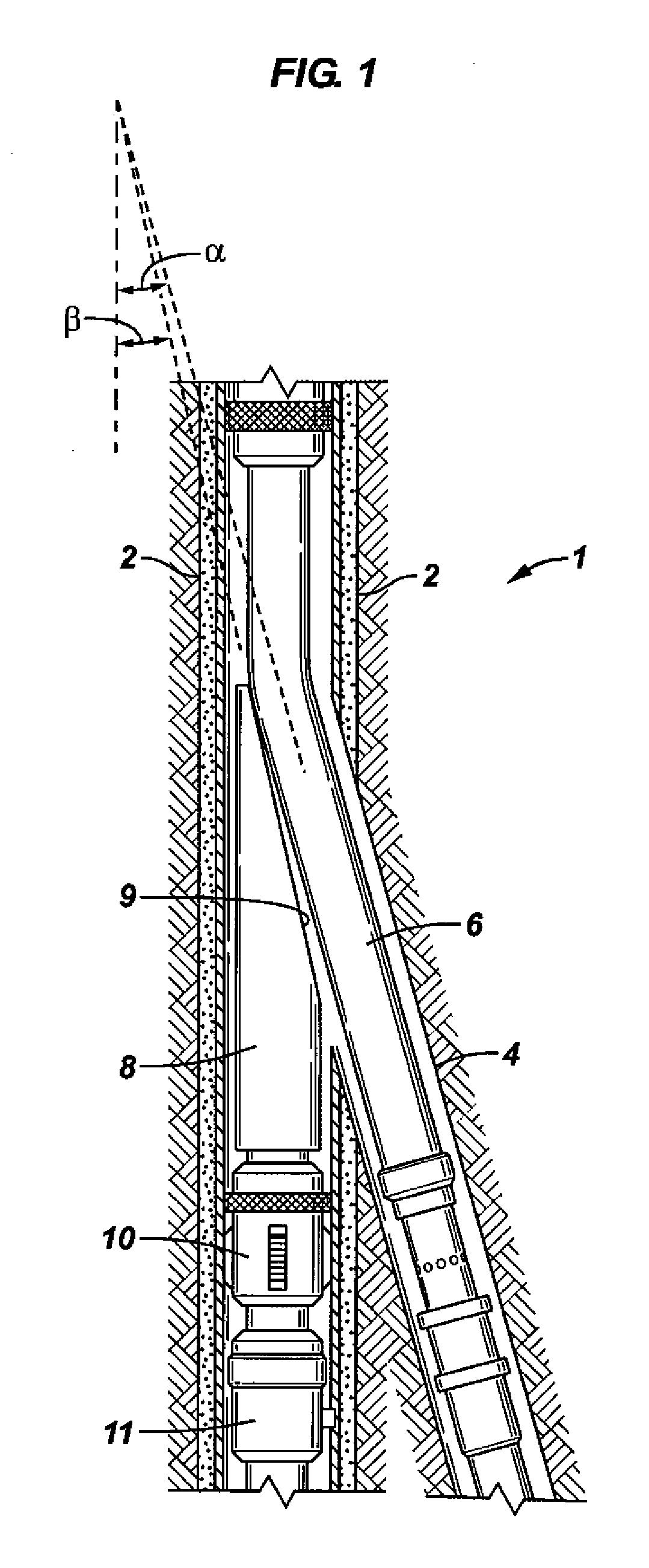

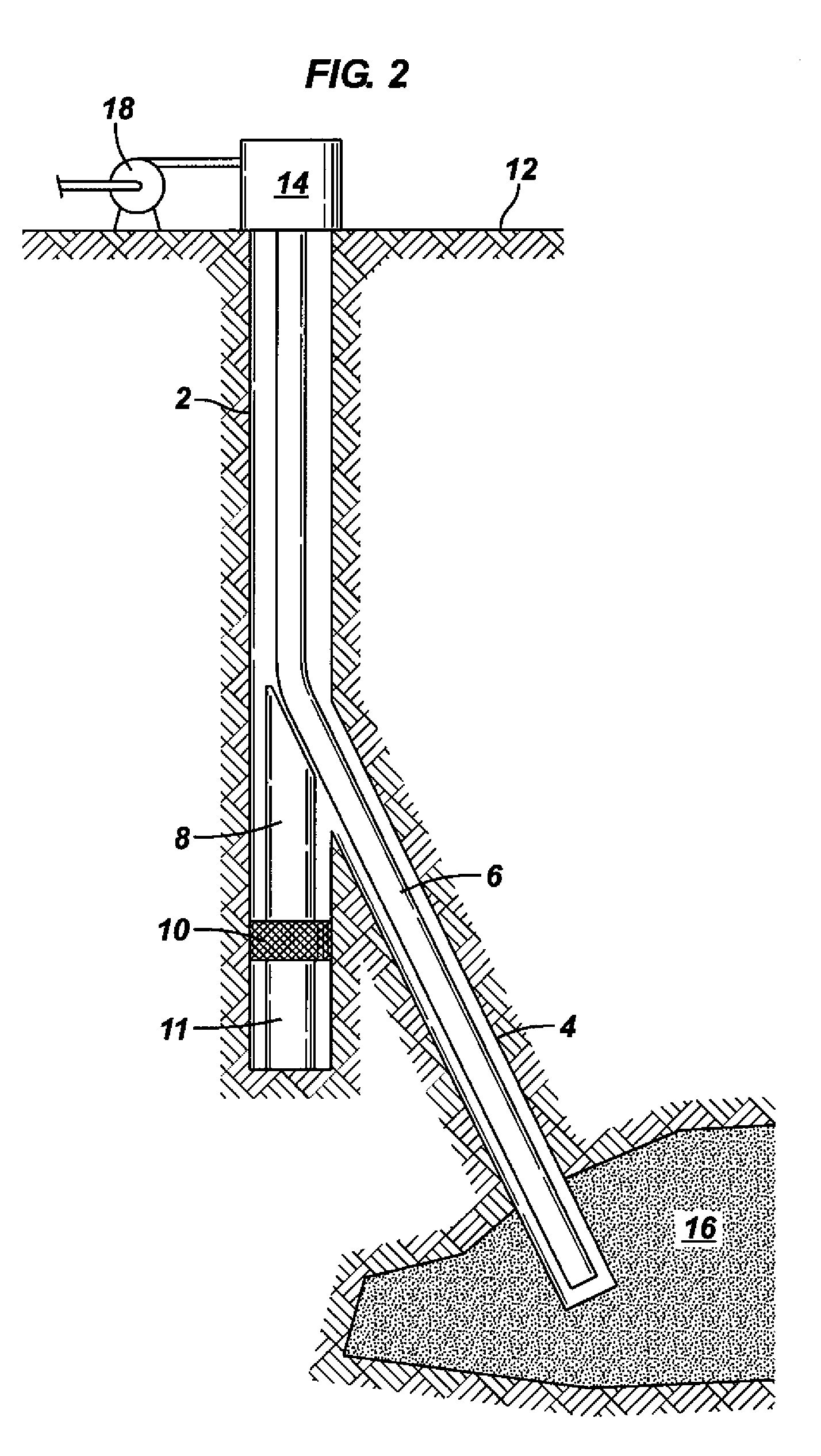

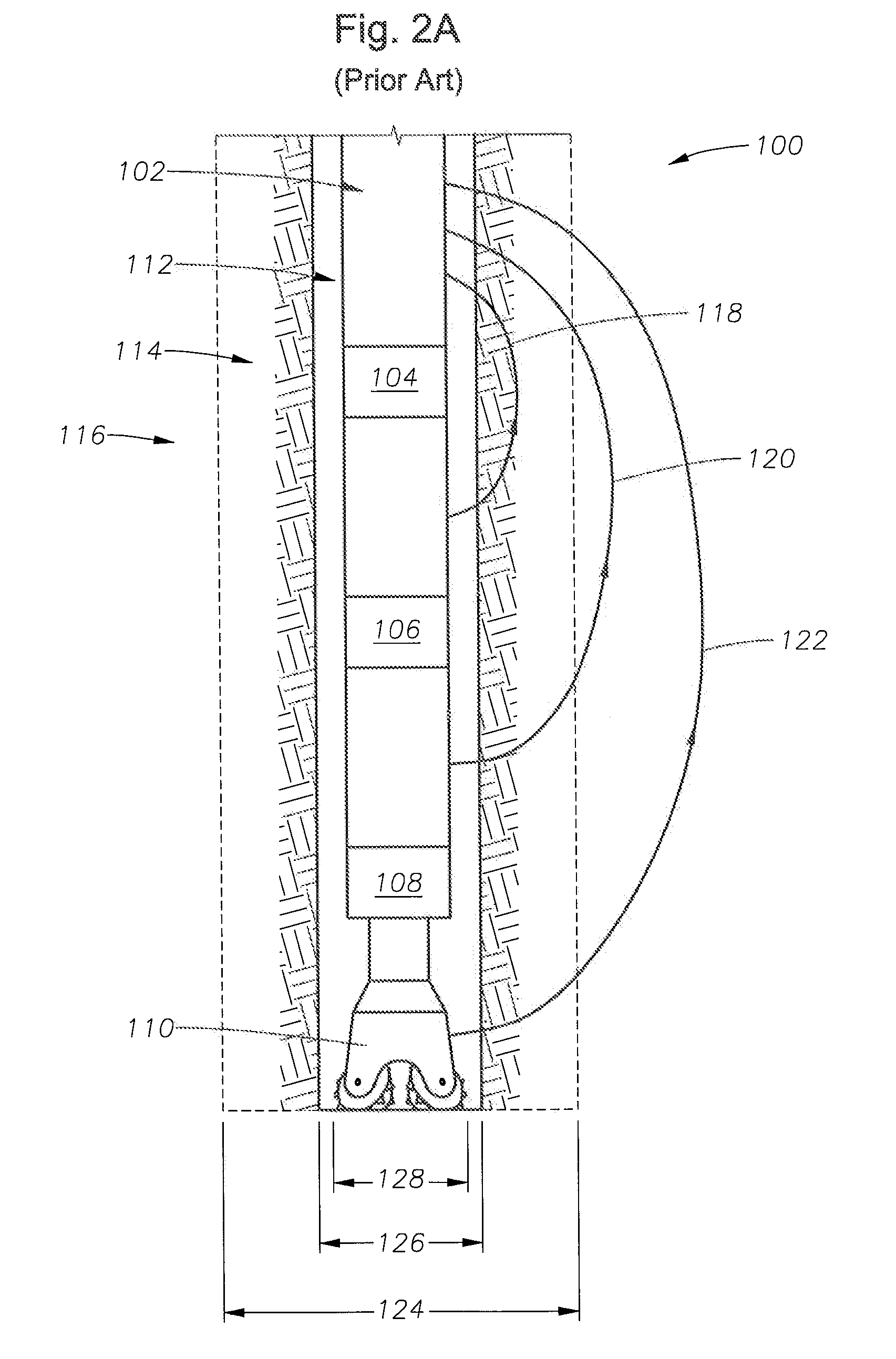

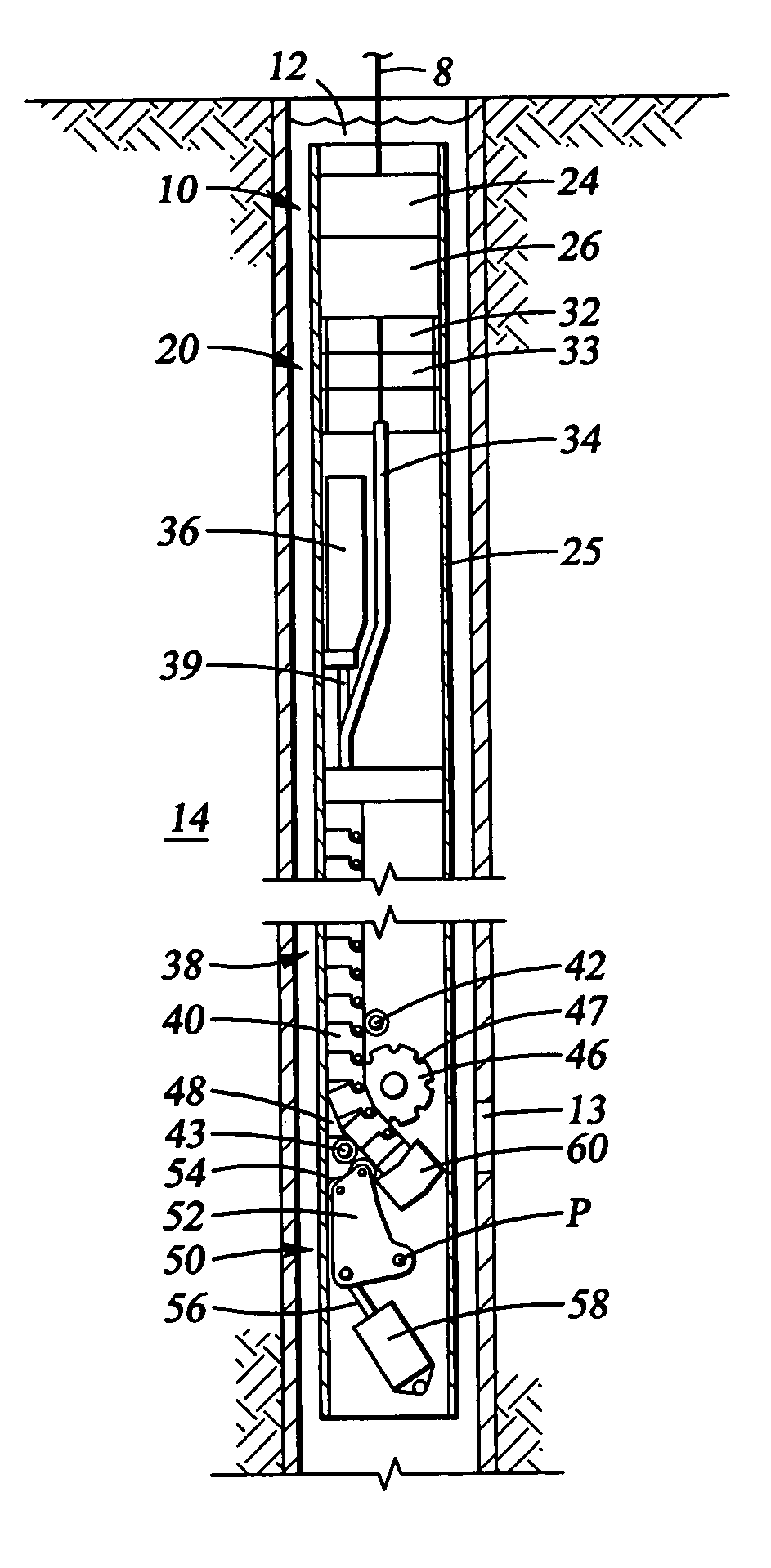

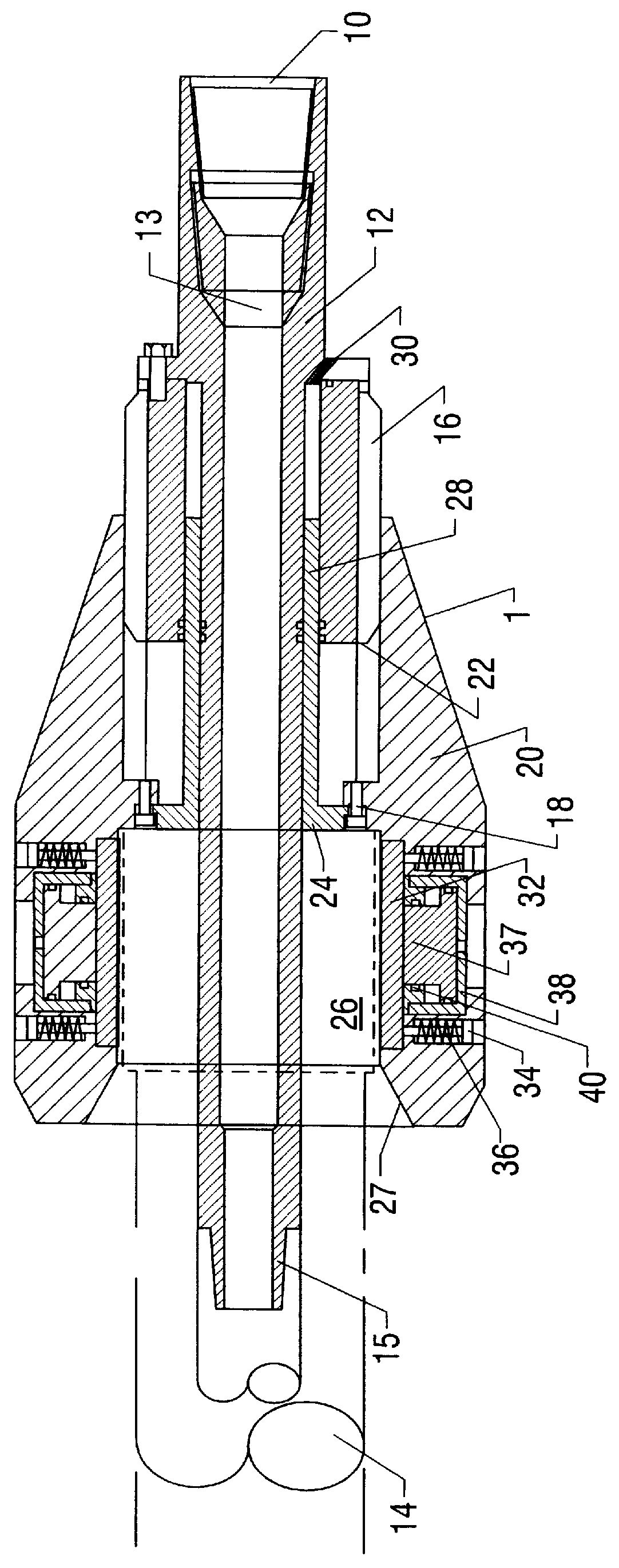

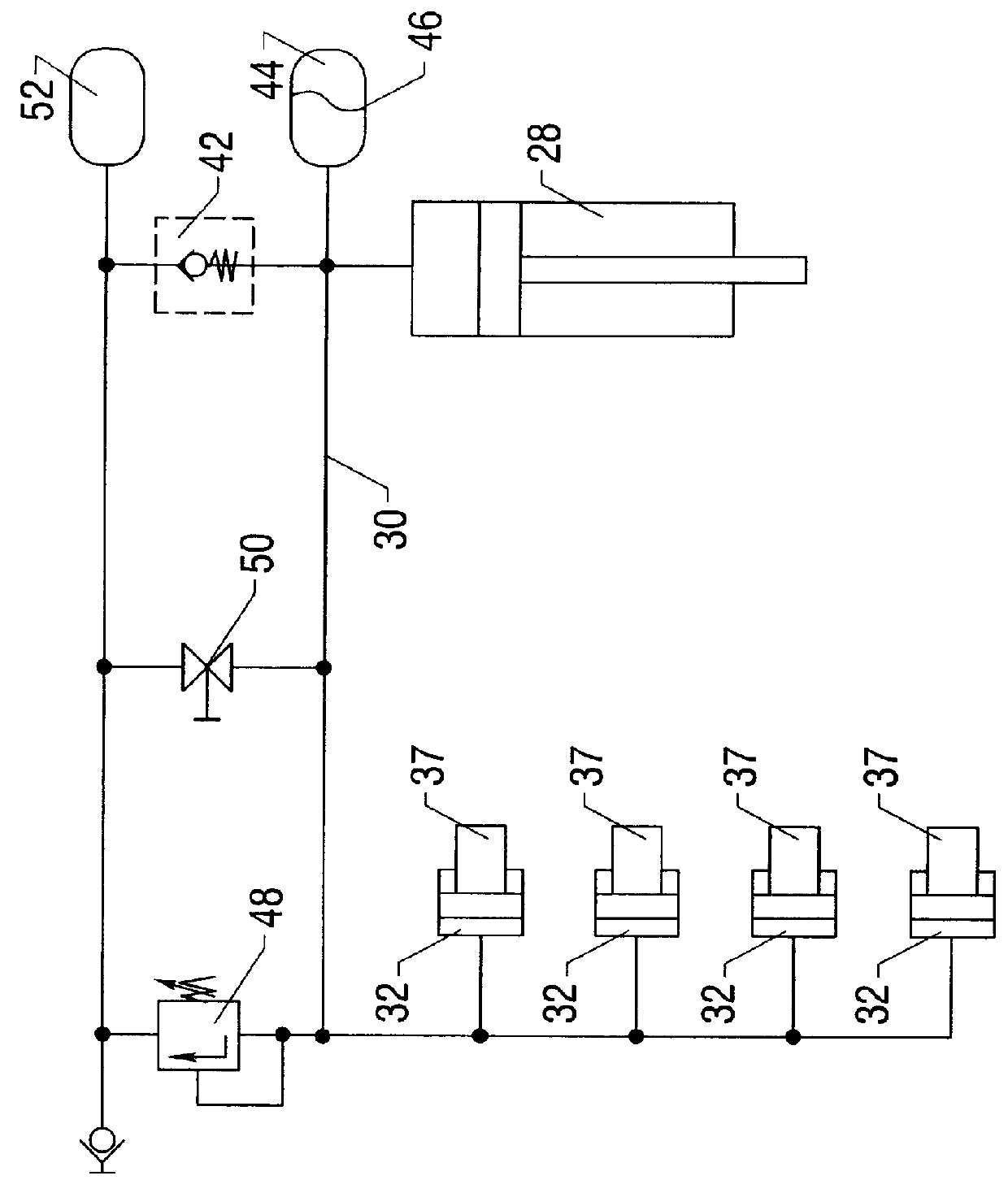

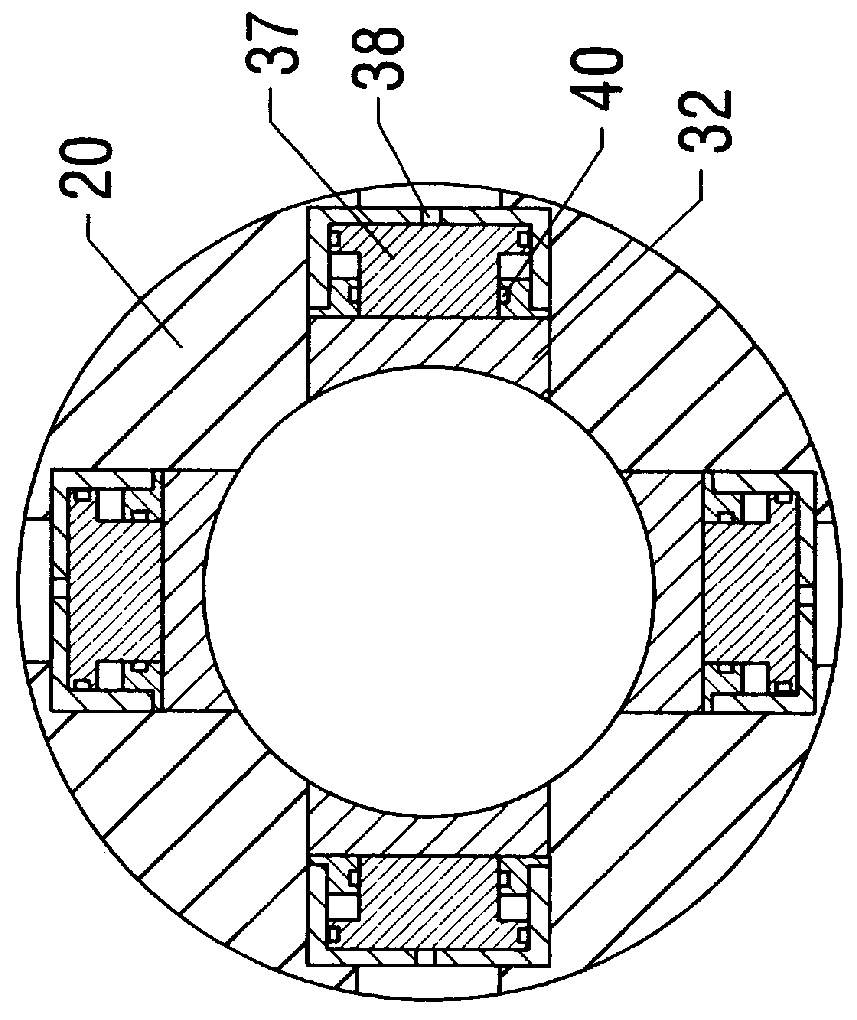

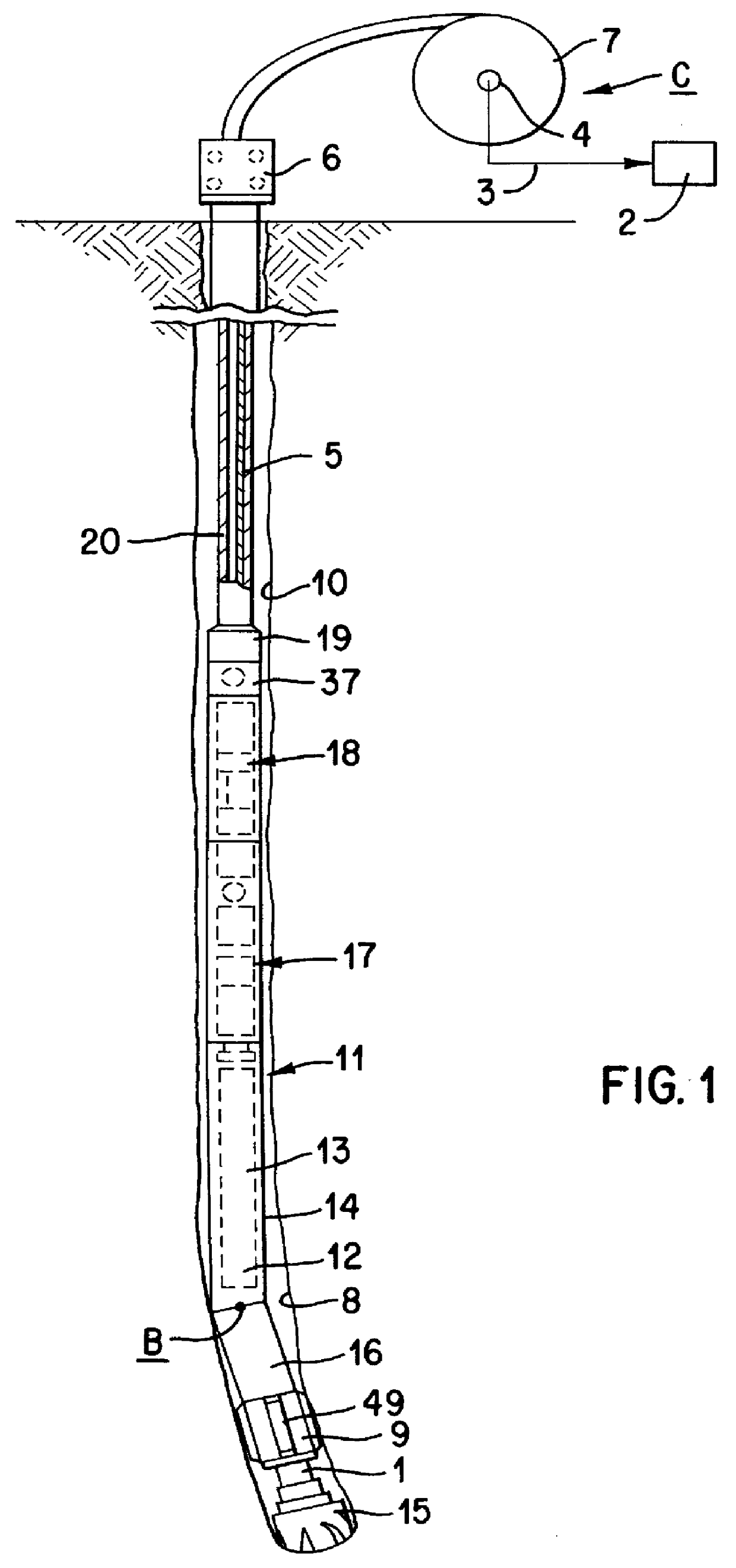

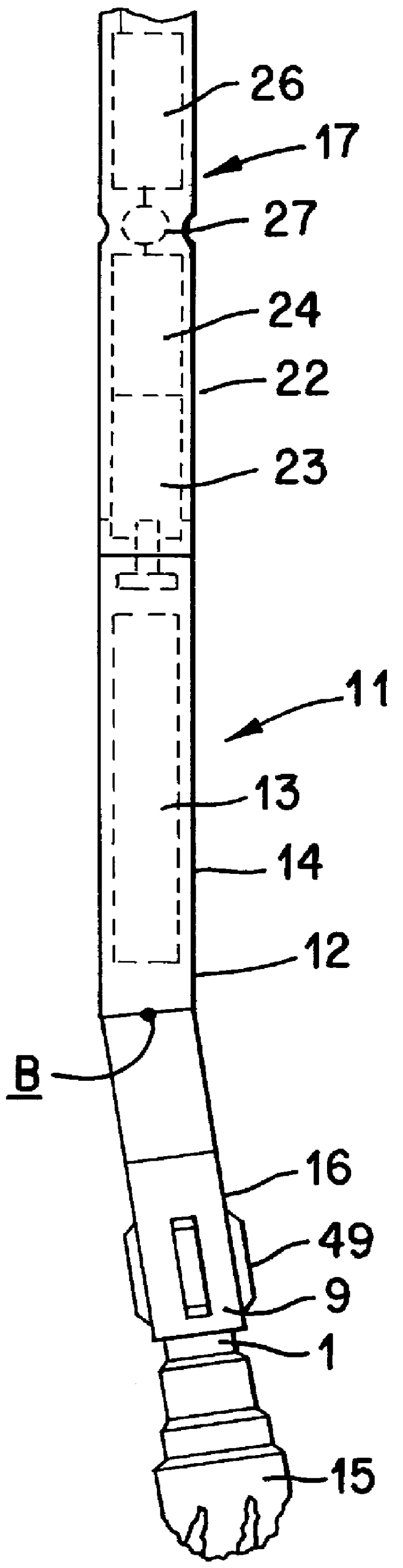

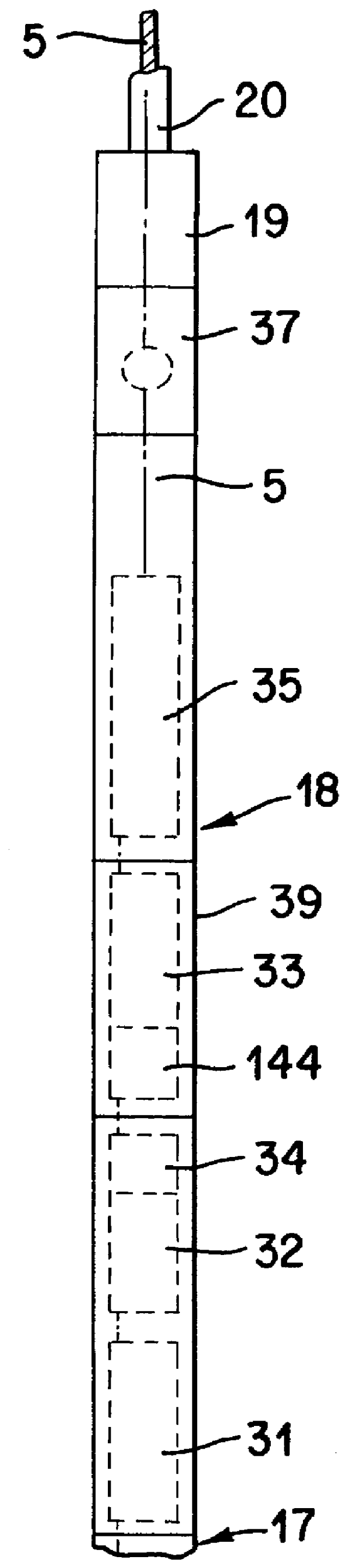

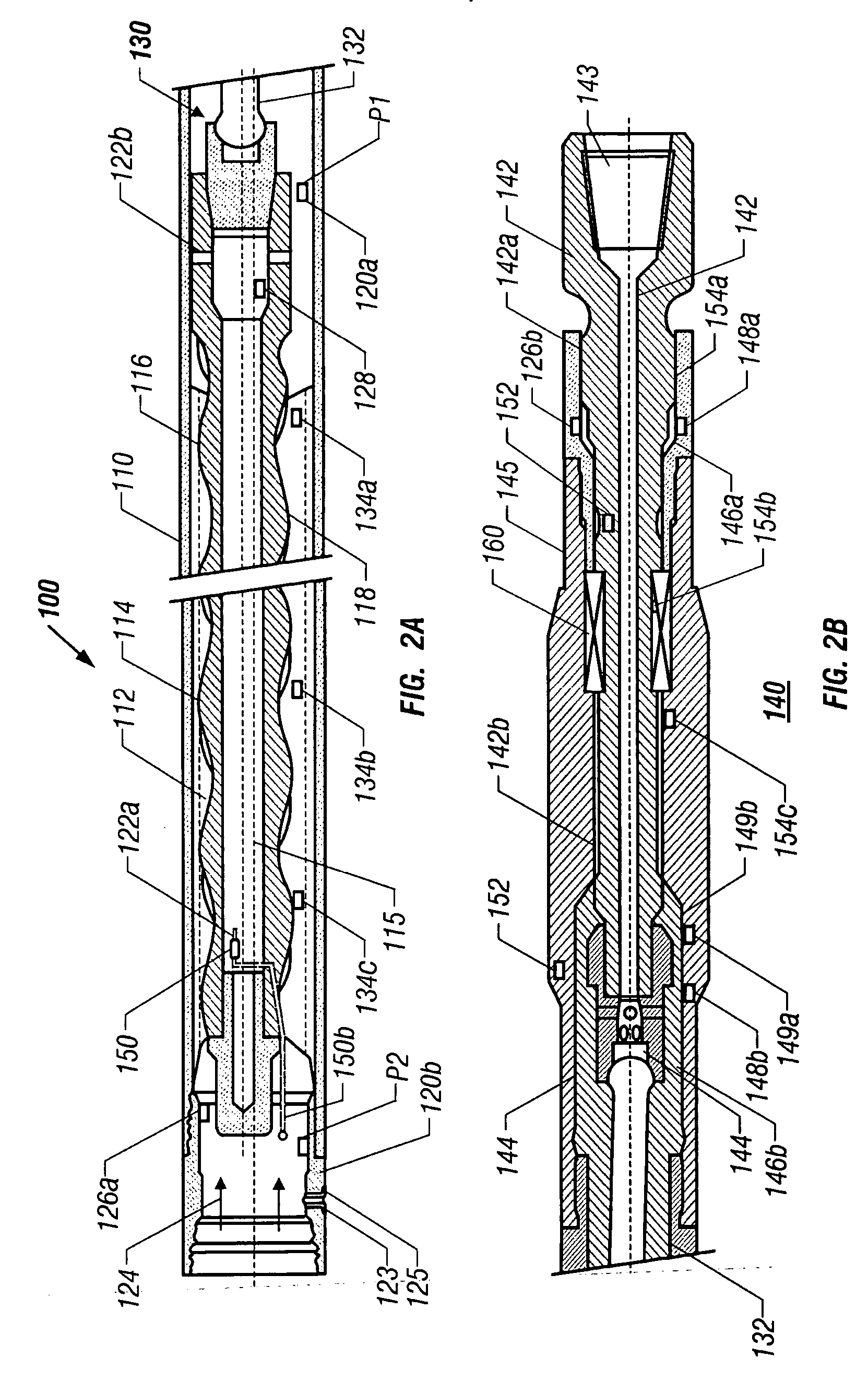

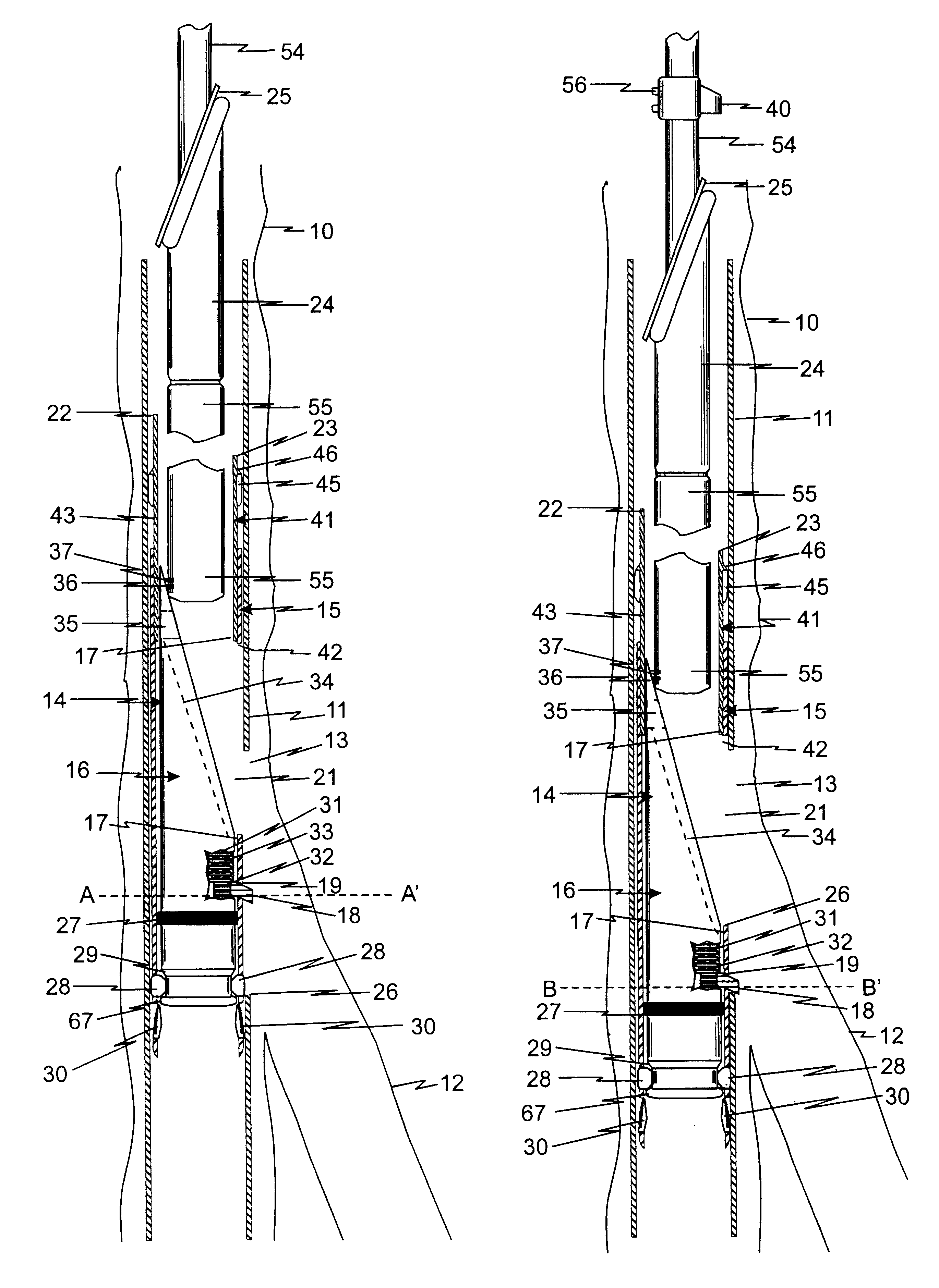

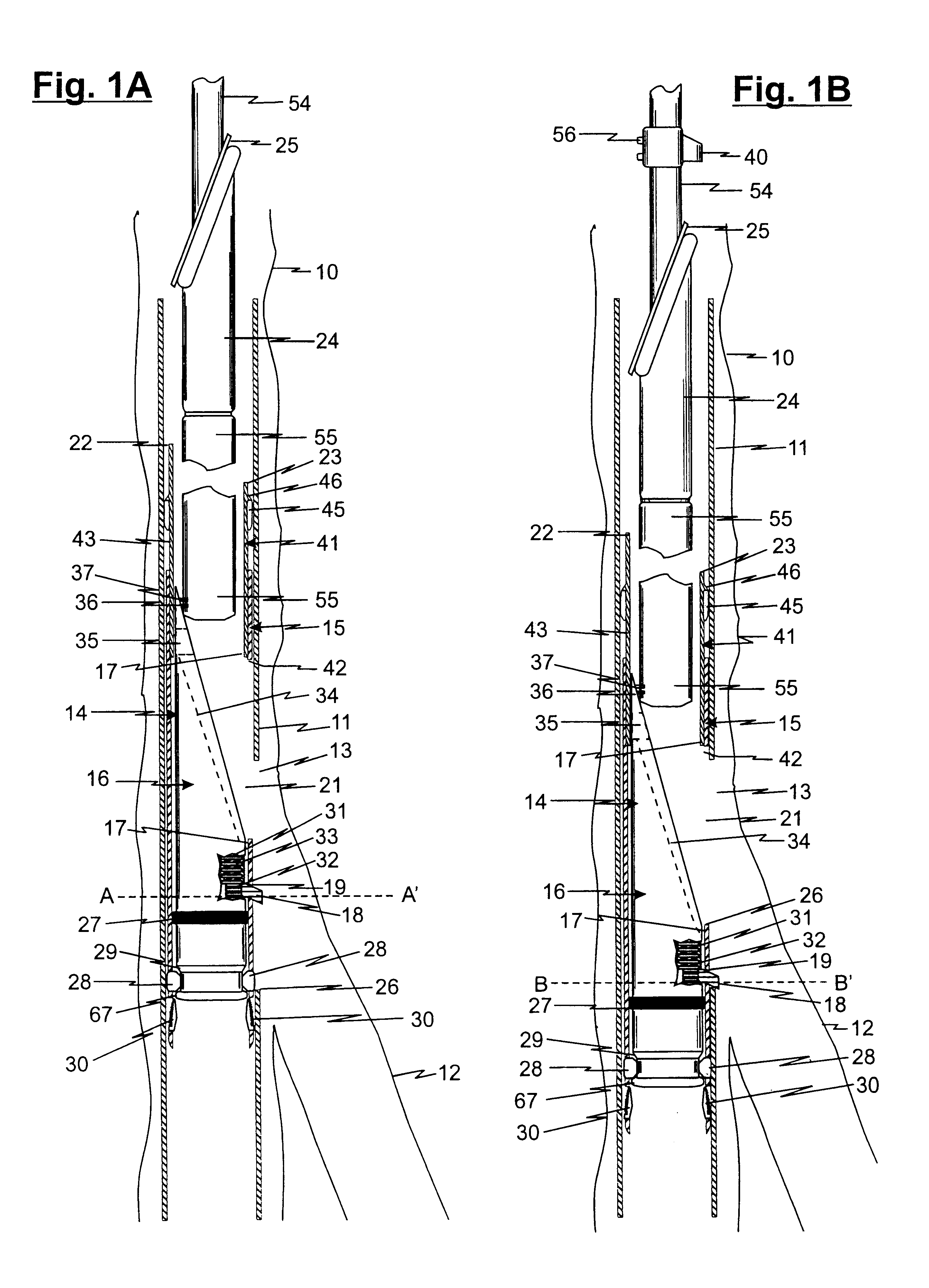

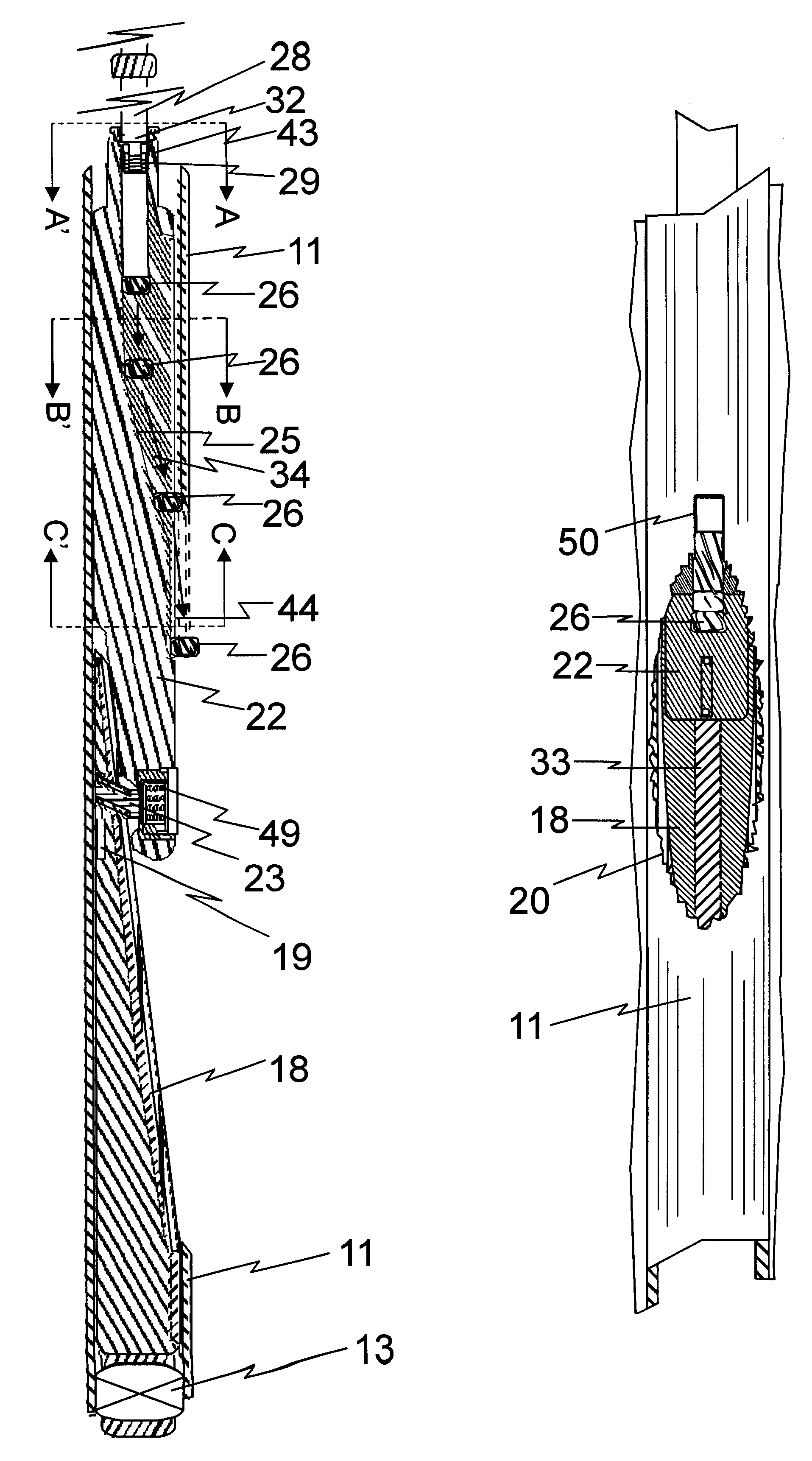

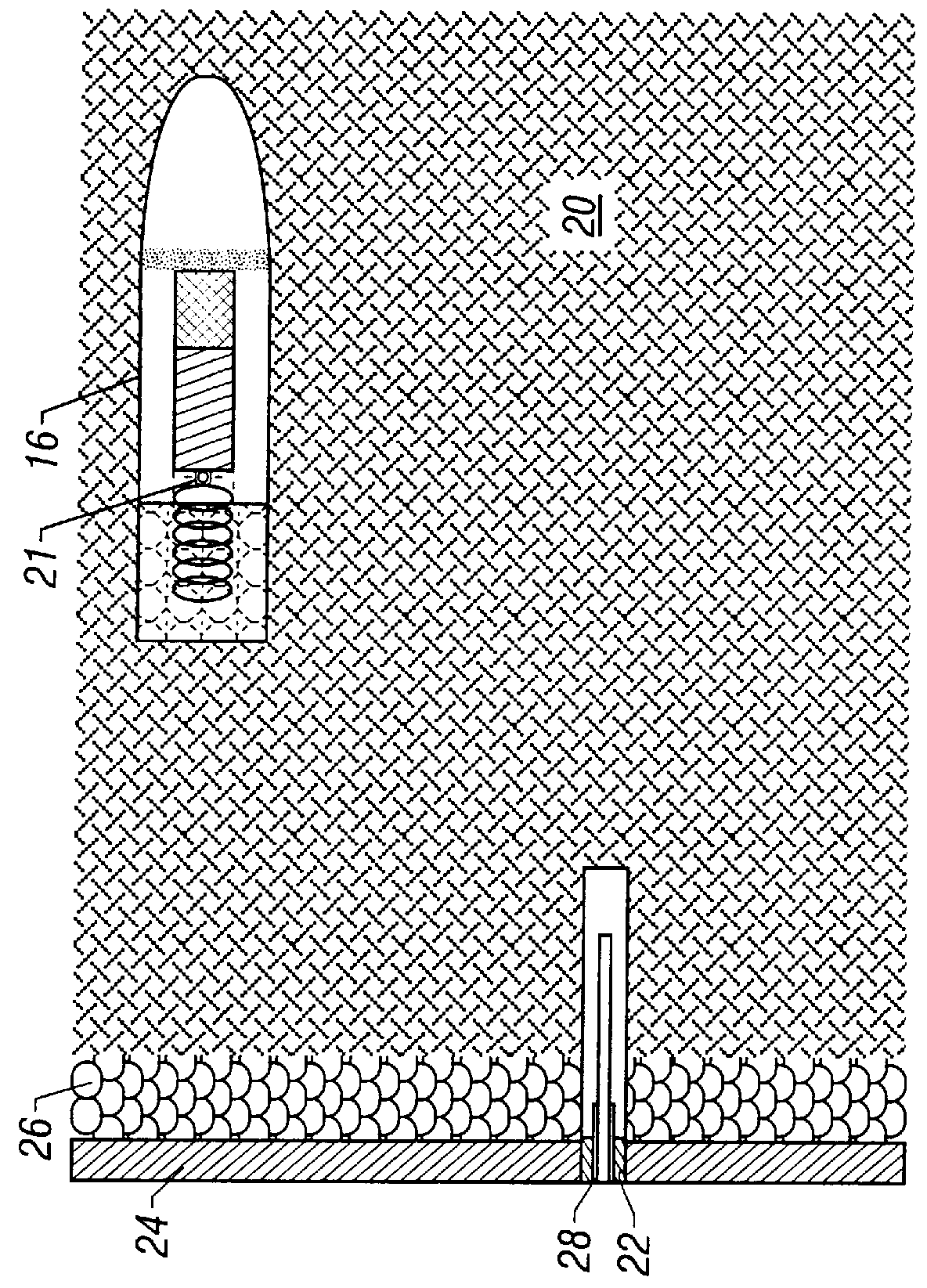

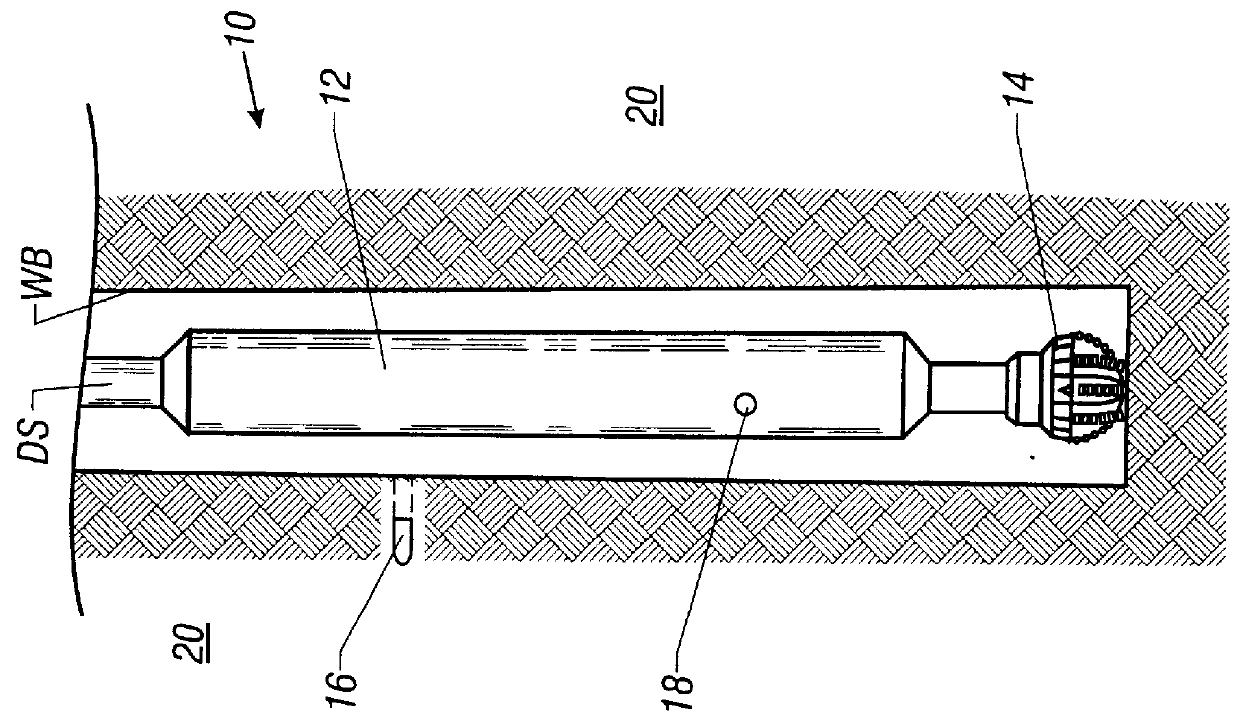

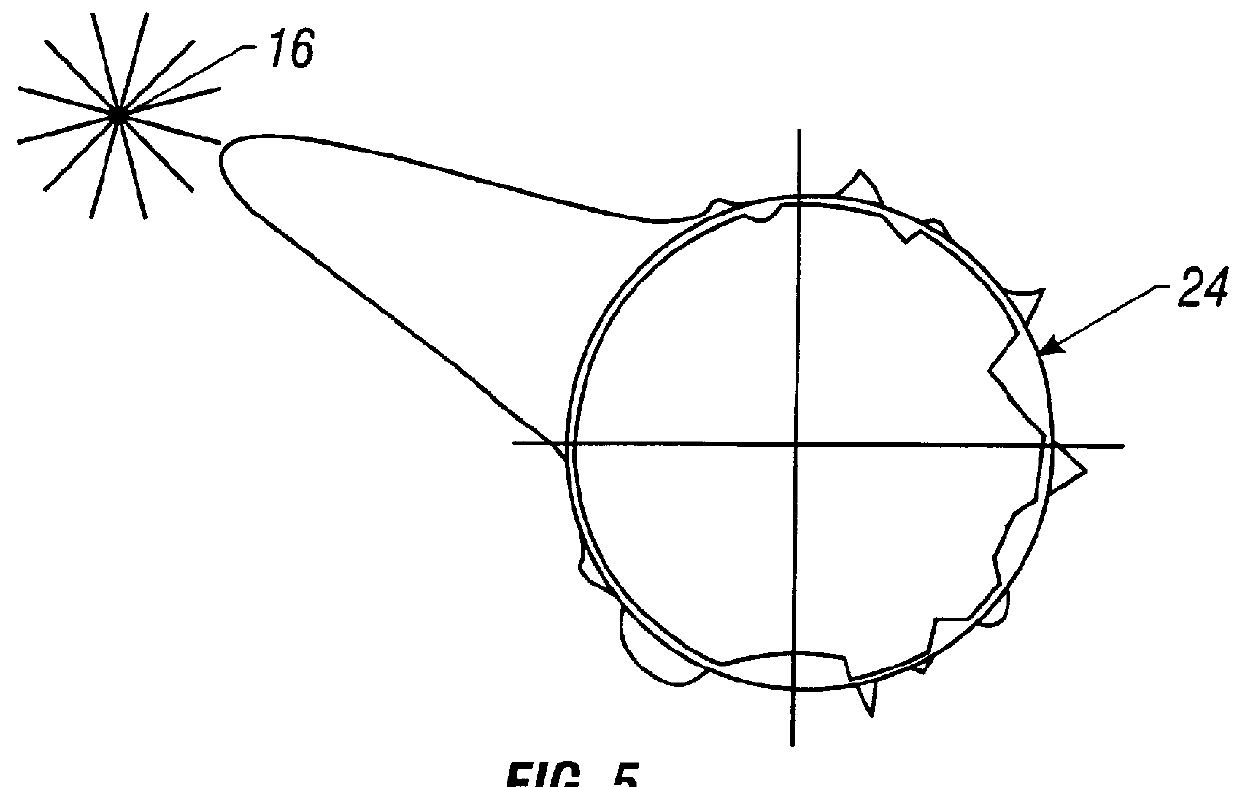

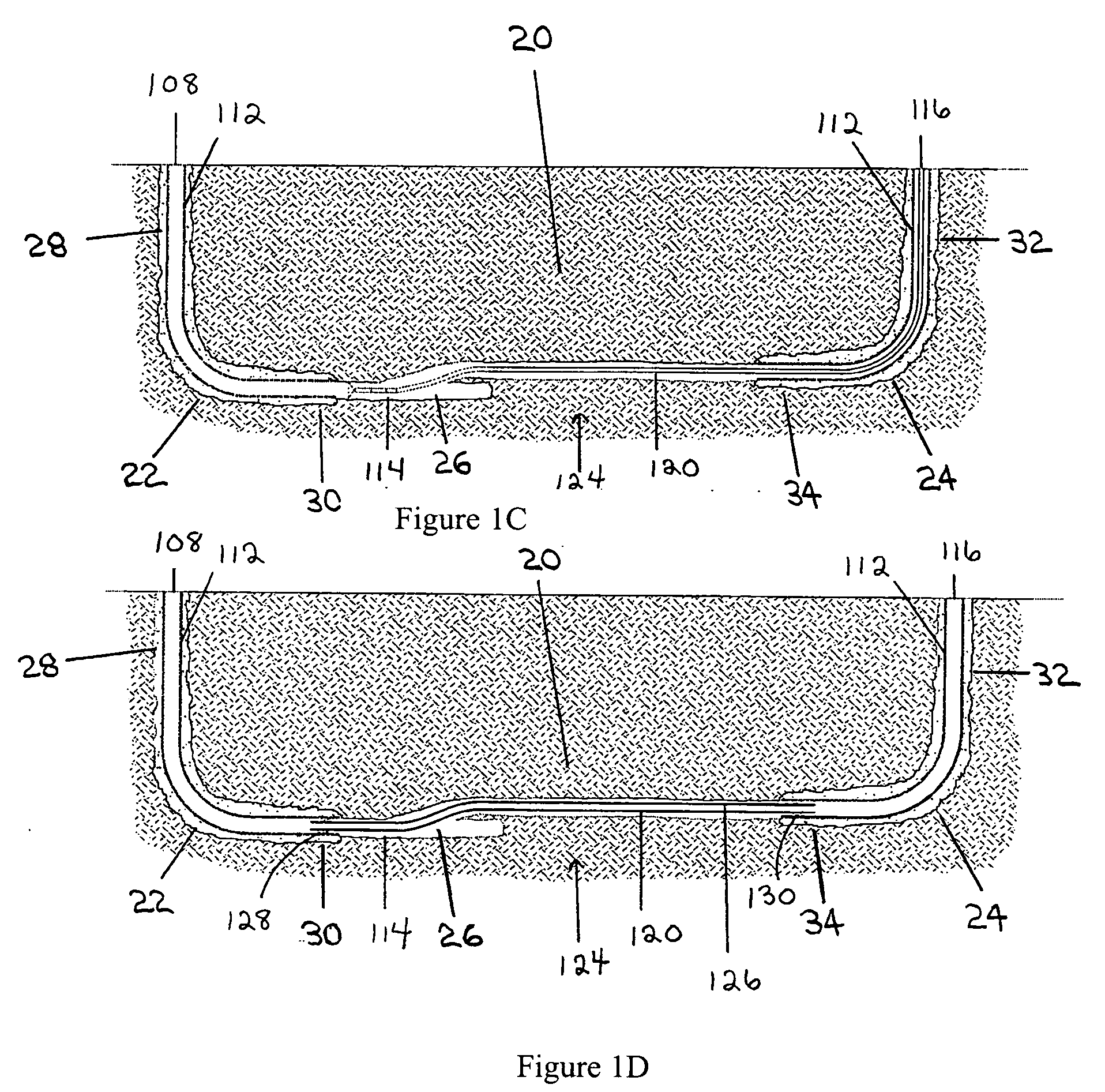

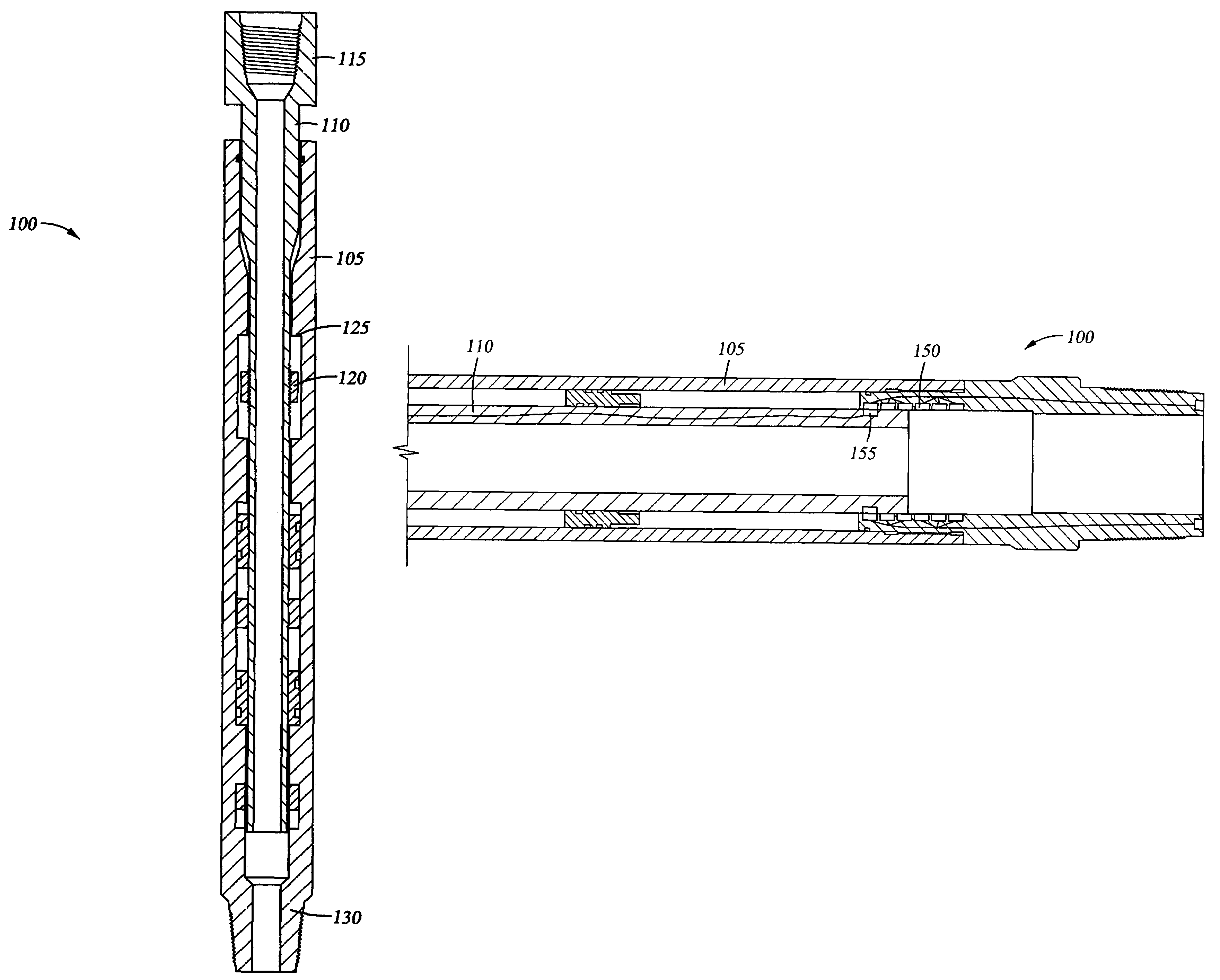

An actively controlled rotary steerable drilling system for directional drilling of wells having a tool collar rotated by a drill string during well drilling. A bit shaft has an upper portion within the tool collar and a lower end extending from the collar and supporting a drill bit. The bit shaft is omni-directionally pivotally supported intermediate its upper and lower ends by a universal joint within the collar and is rotatably driven by the collar. To achieve controlled steering of the rotating drill bit, orientation of the bit shaft relative to the tool collar is sensed and the bit shaft is maintained geostationary and selectively axially inclined relative to the tool collar during drill string rotation by rotating it about the universal joint by an offsetting mandrel that is rotated counter to collar rotation and at the same frequency of rotation. An electric motor provides rotation to the offsetting mandrel with respect to the tool collar and is servo-controlled by signal input from position sensing elements such as magnetometers, gyroscopic sensors, and accelerometers which provide real time position signals to the motor control. In addition, when necessary, a brake is used to maintain the offsetting mandrel and the bit shaft axis geostationary. Alternatively, a turbine is connected to the offsetting mandrel to provide rotation to the offsetting mandrel with respect to the tool collar and a brake is used to servo-control the turbine by signal input from position sensors.

Owner:SCHLUMBERGER TECH CORP

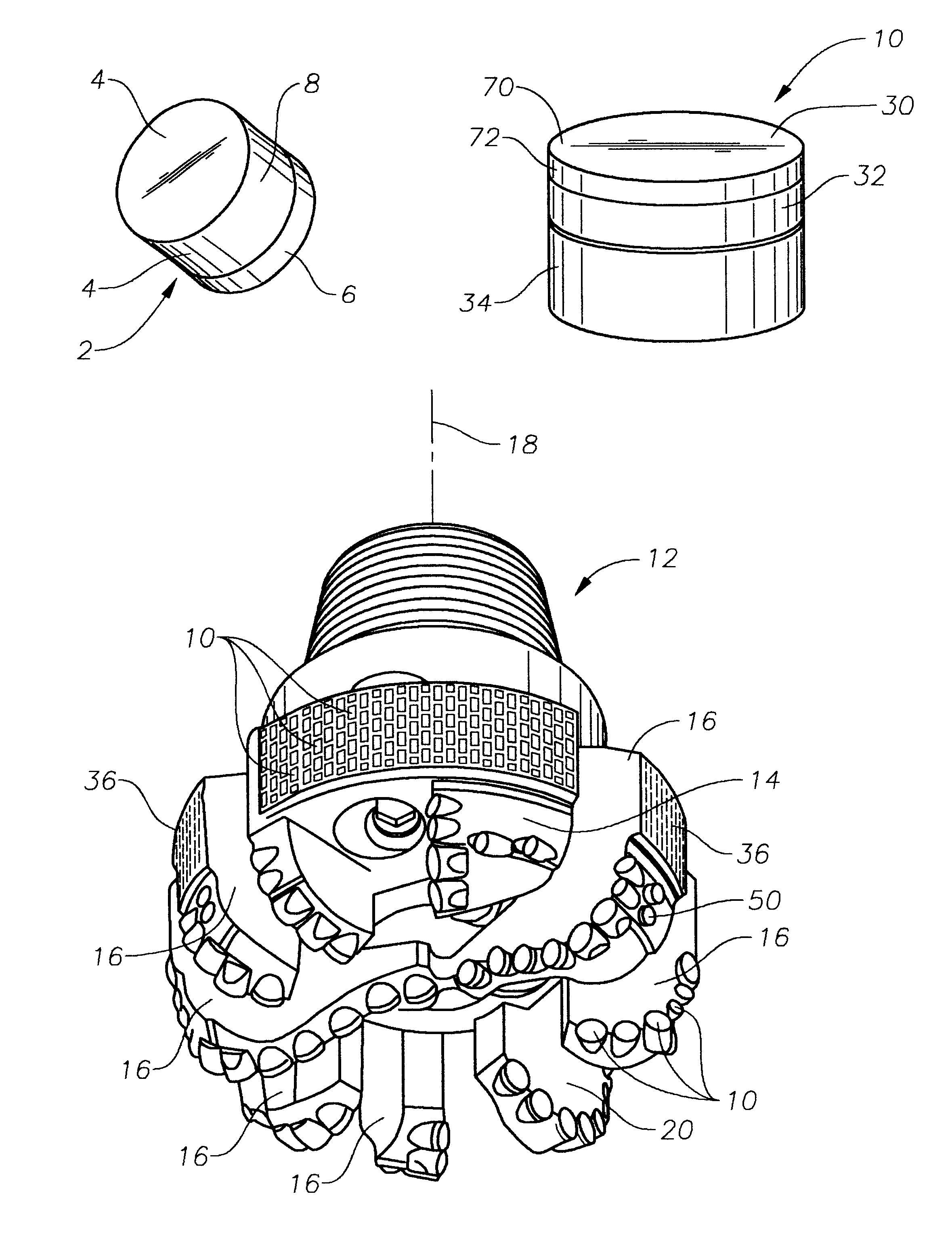

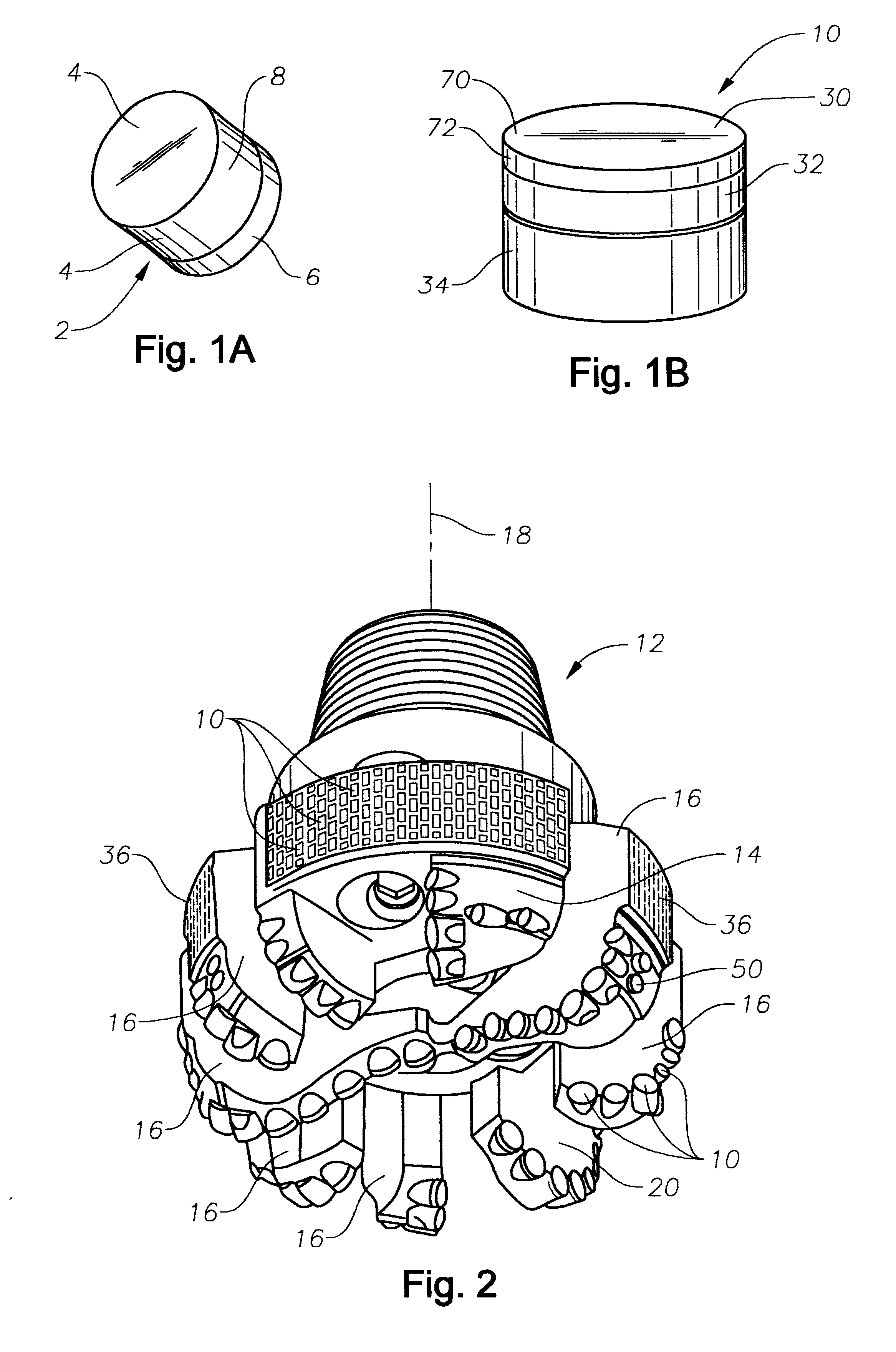

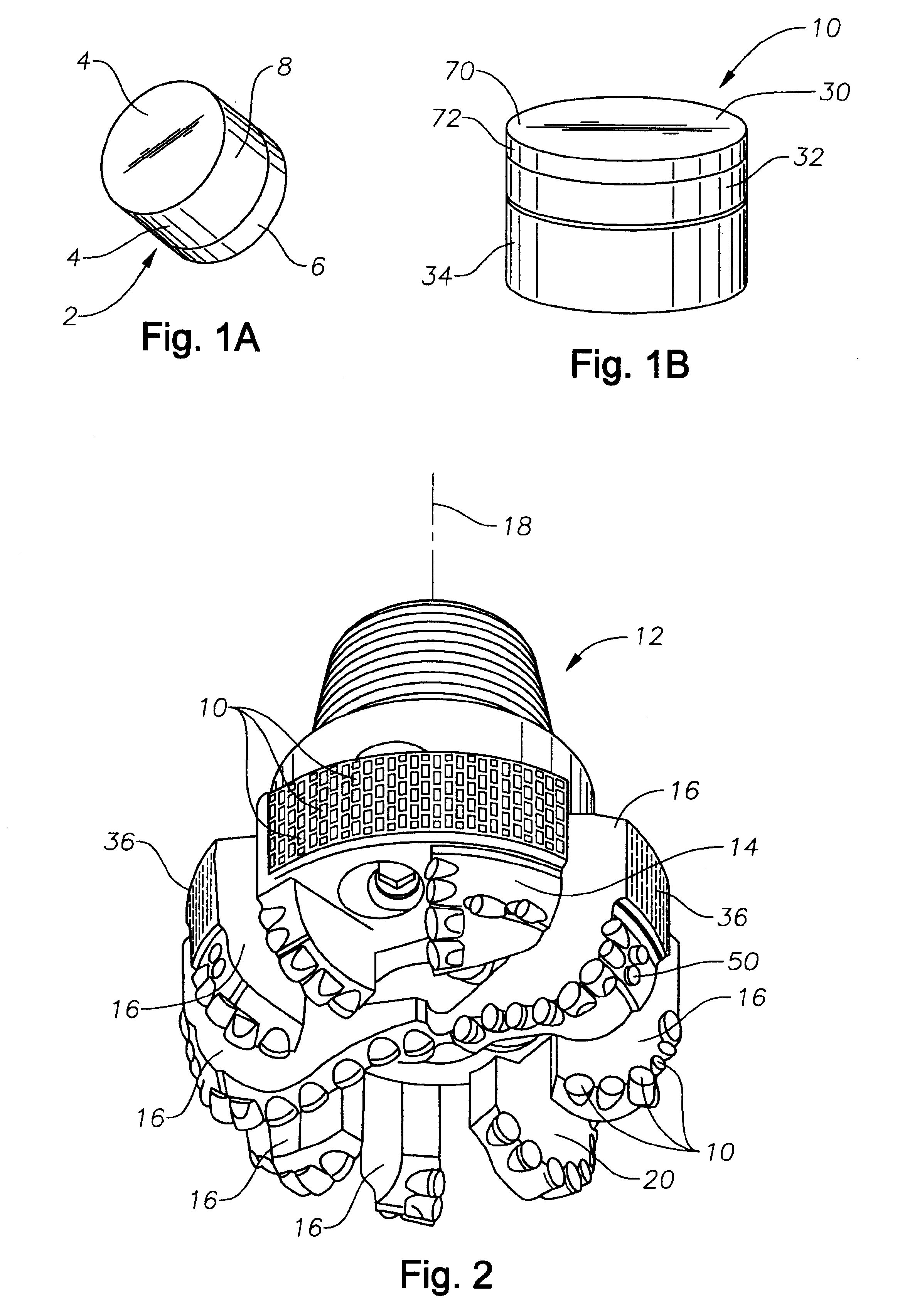

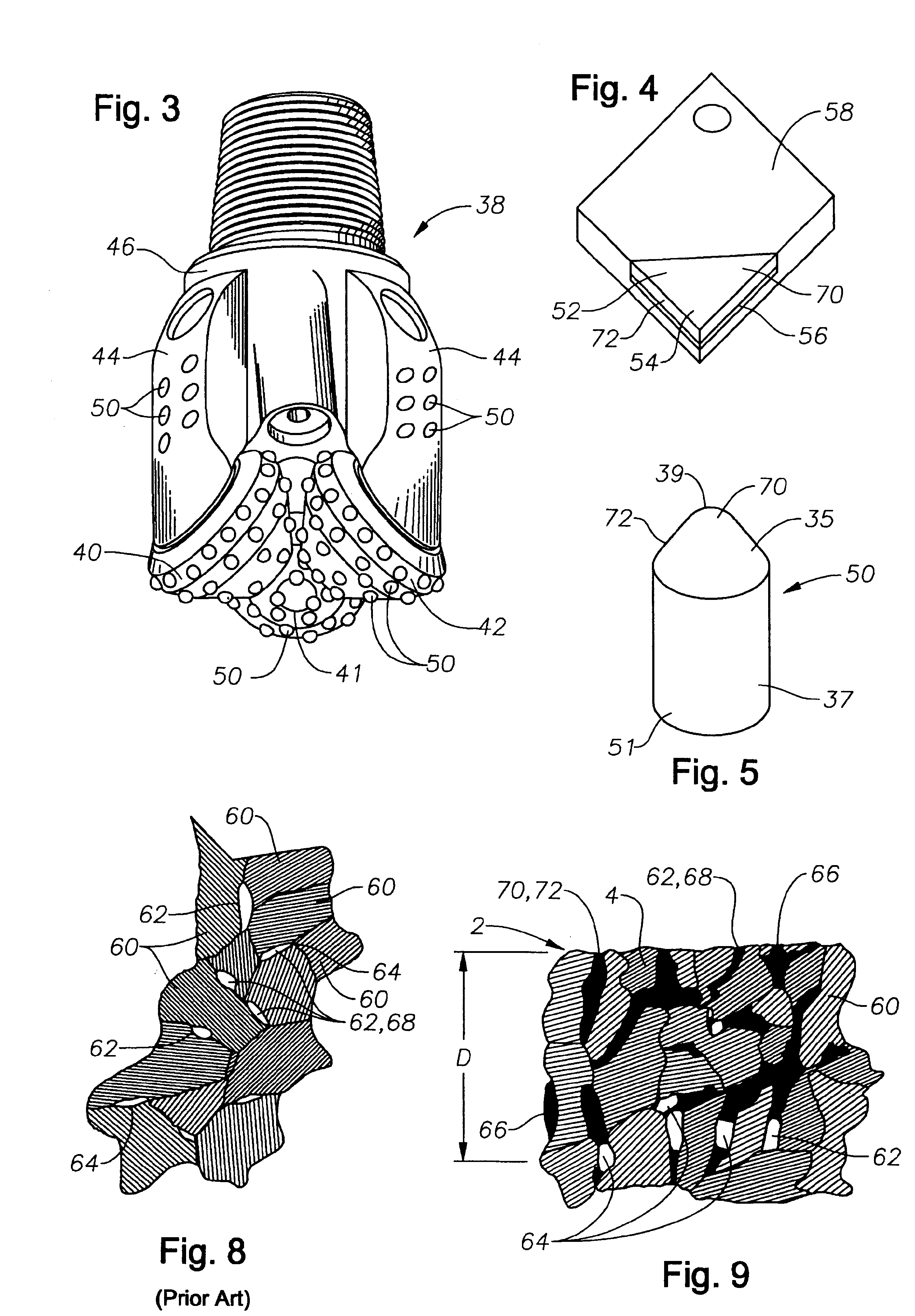

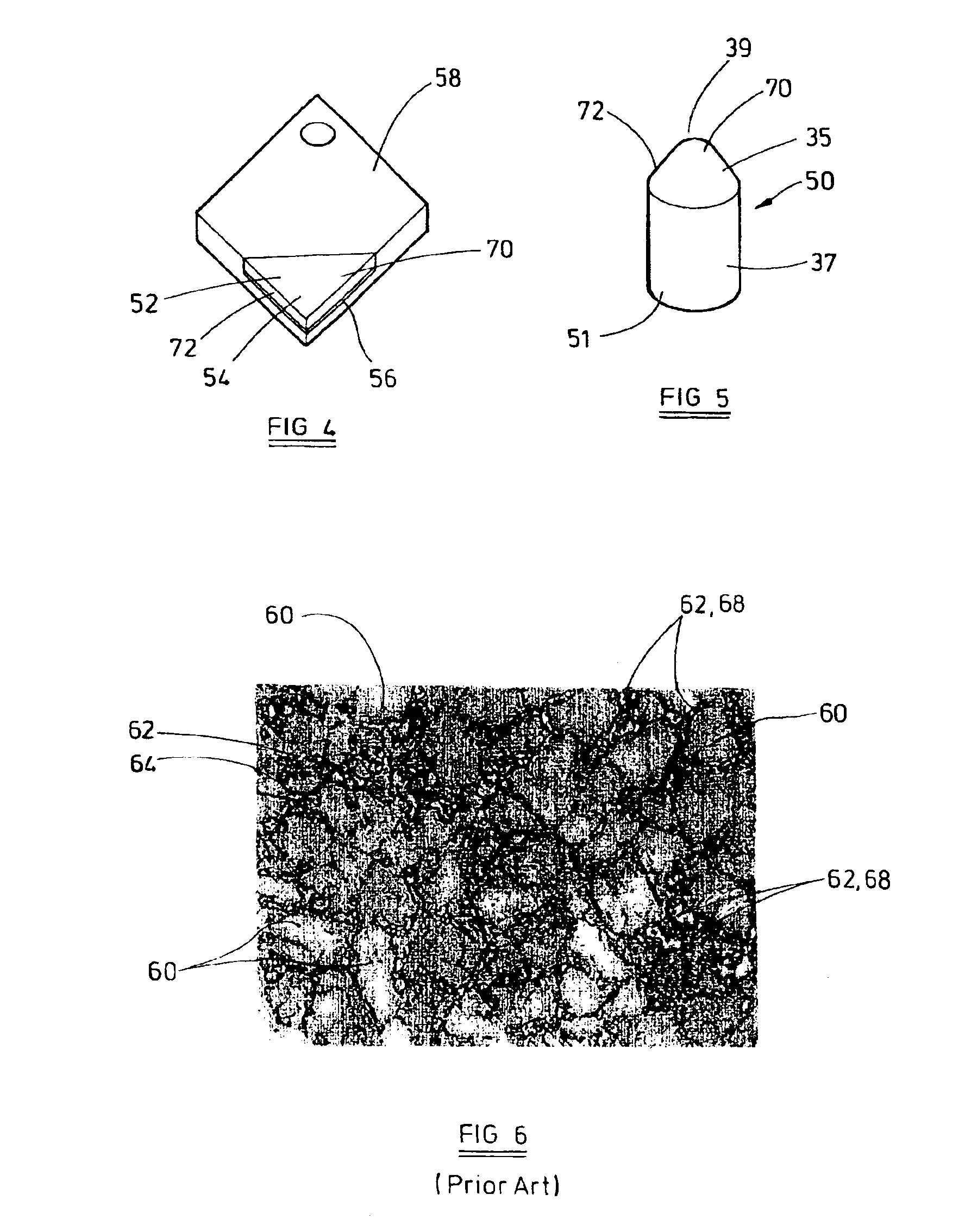

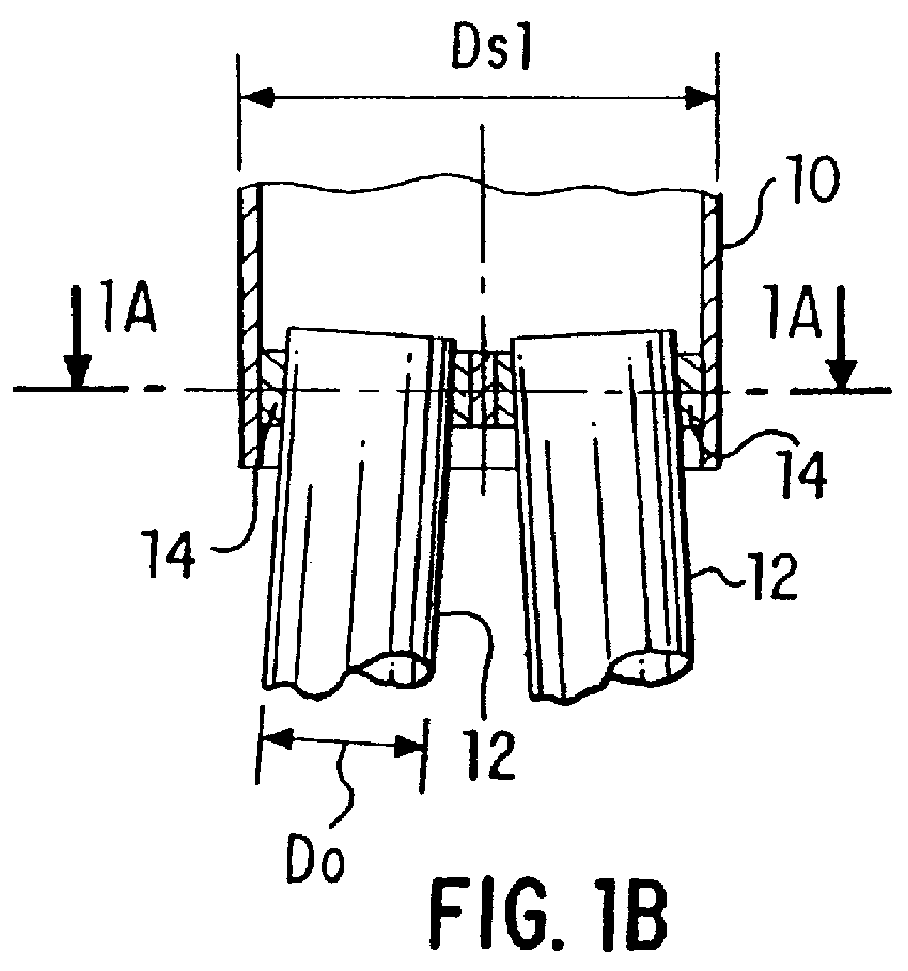

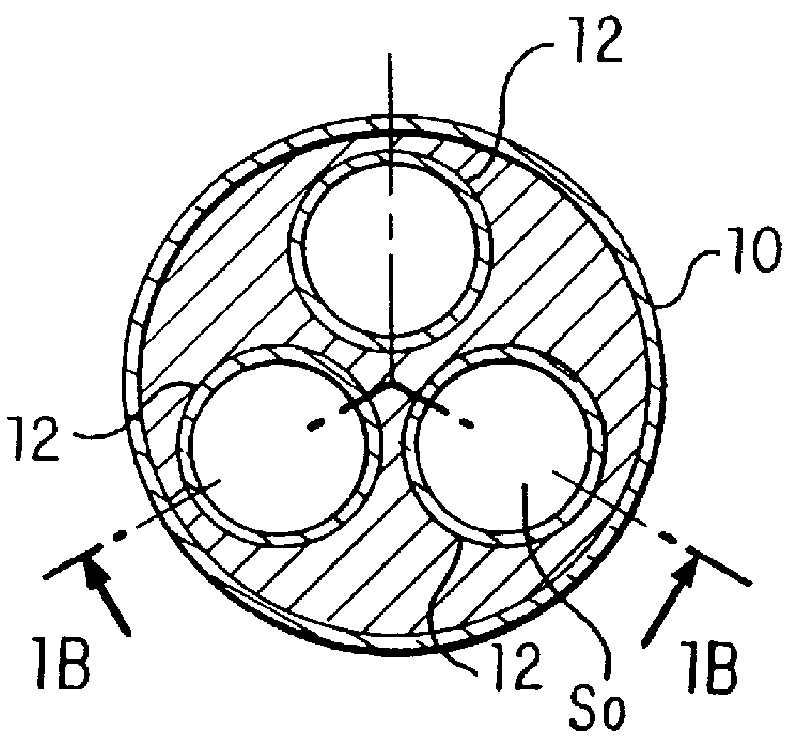

Polycrystalline diamond cutters with working surfaces having varied wear resistance while maintaining impact strength

InactiveUS6601662B2Improve wear resistanceMaintain strengthDrill bitsConstructionsDiamond crystalPolycrystalline diamond

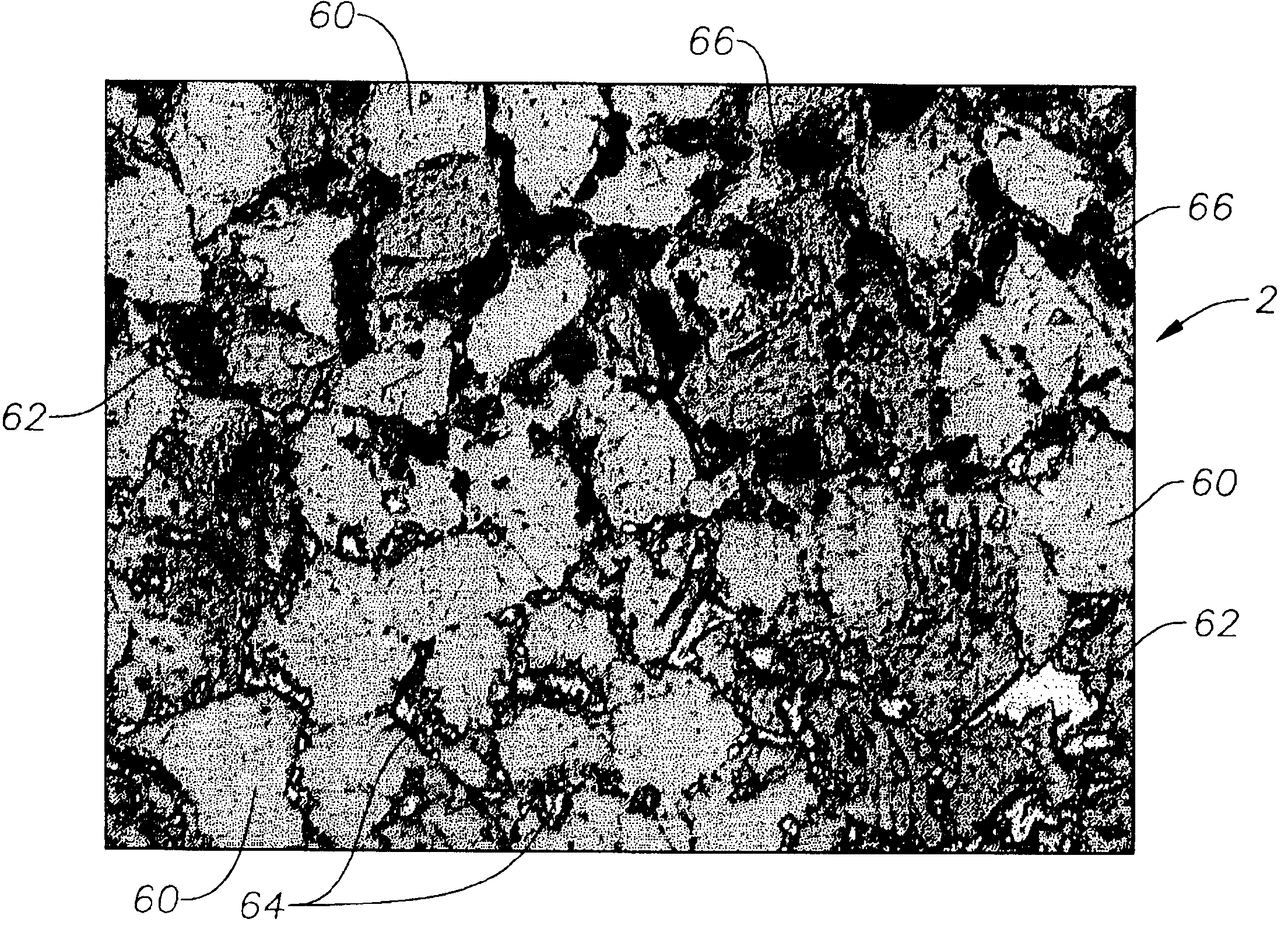

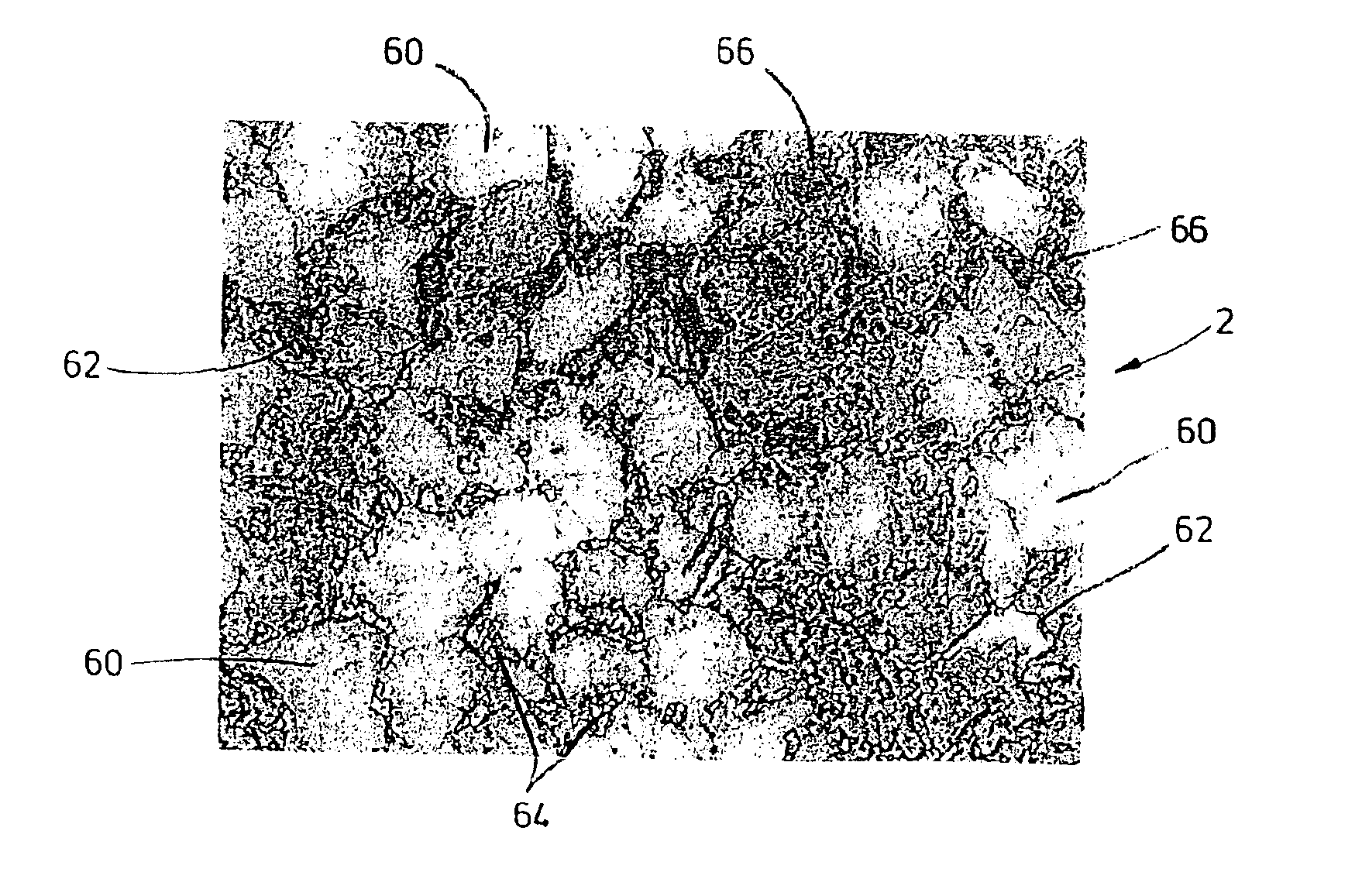

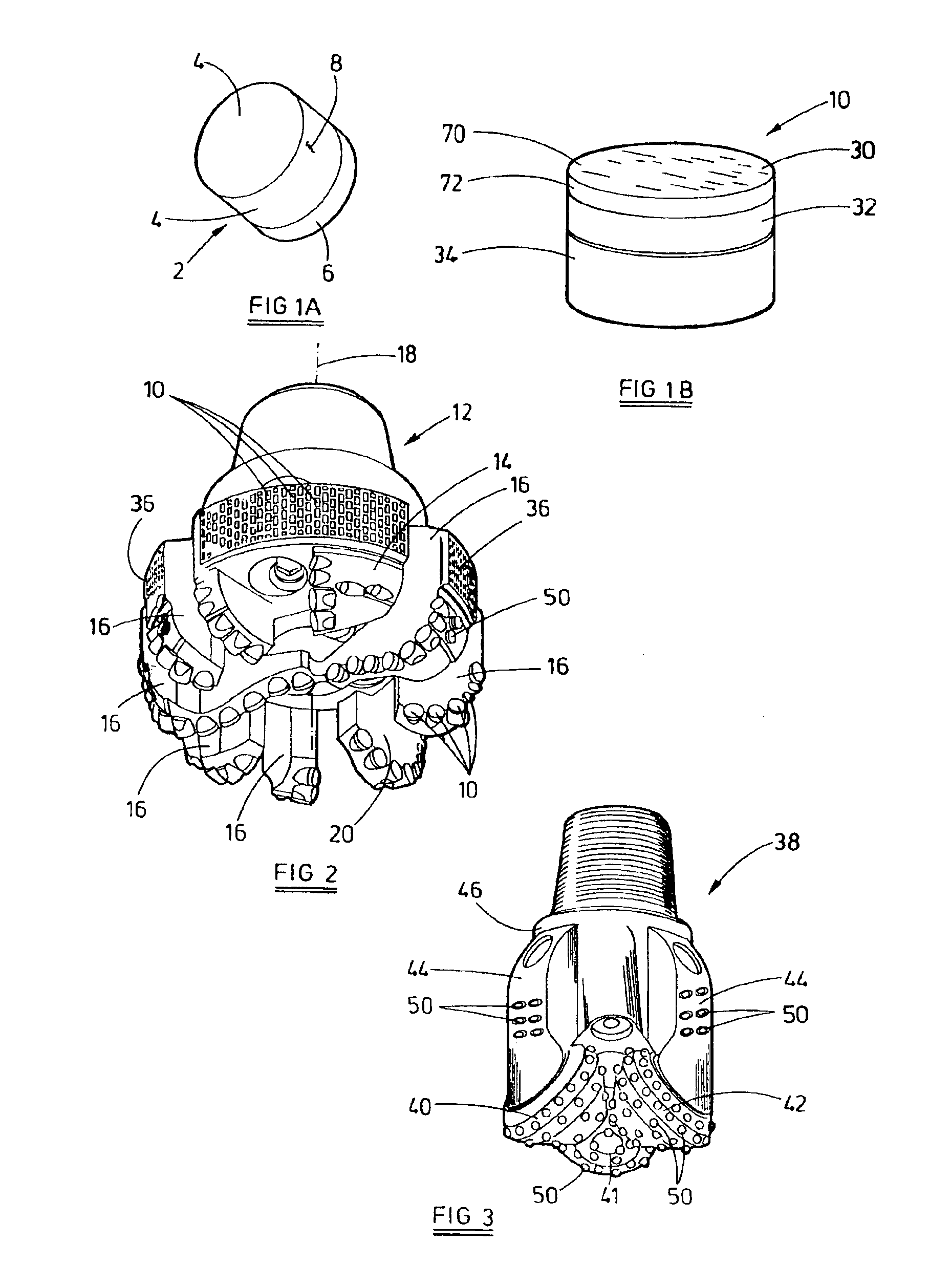

Disclosed is a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a first portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and a second portion of the interstitial matrix in the body adjacent to the working surface contains the catalyzing material. The first portion of the interstitial matrix and the second portion of the interstitial matrix have substantially the same impact strength.

Owner:REEDHYCALOG UK

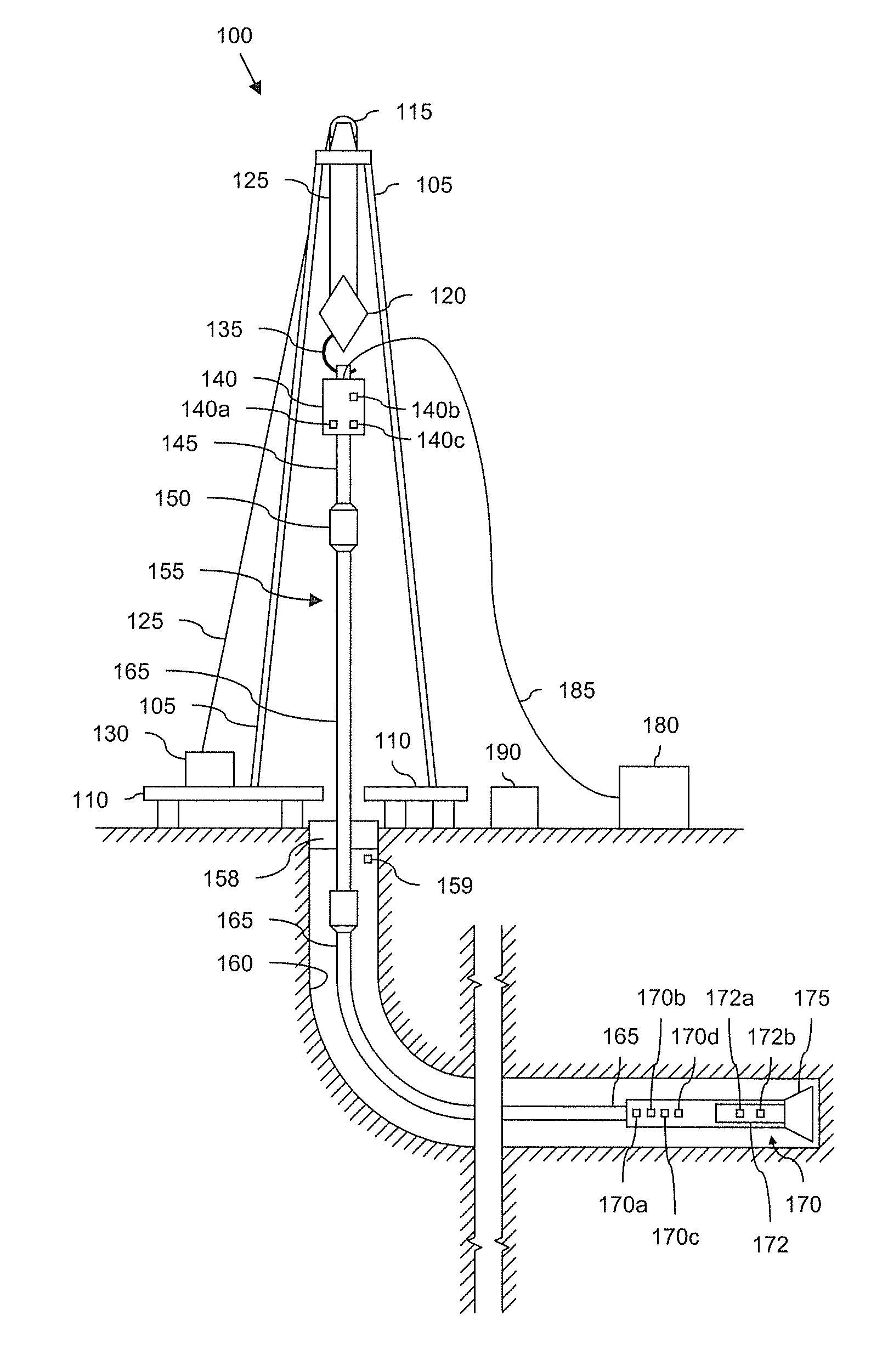

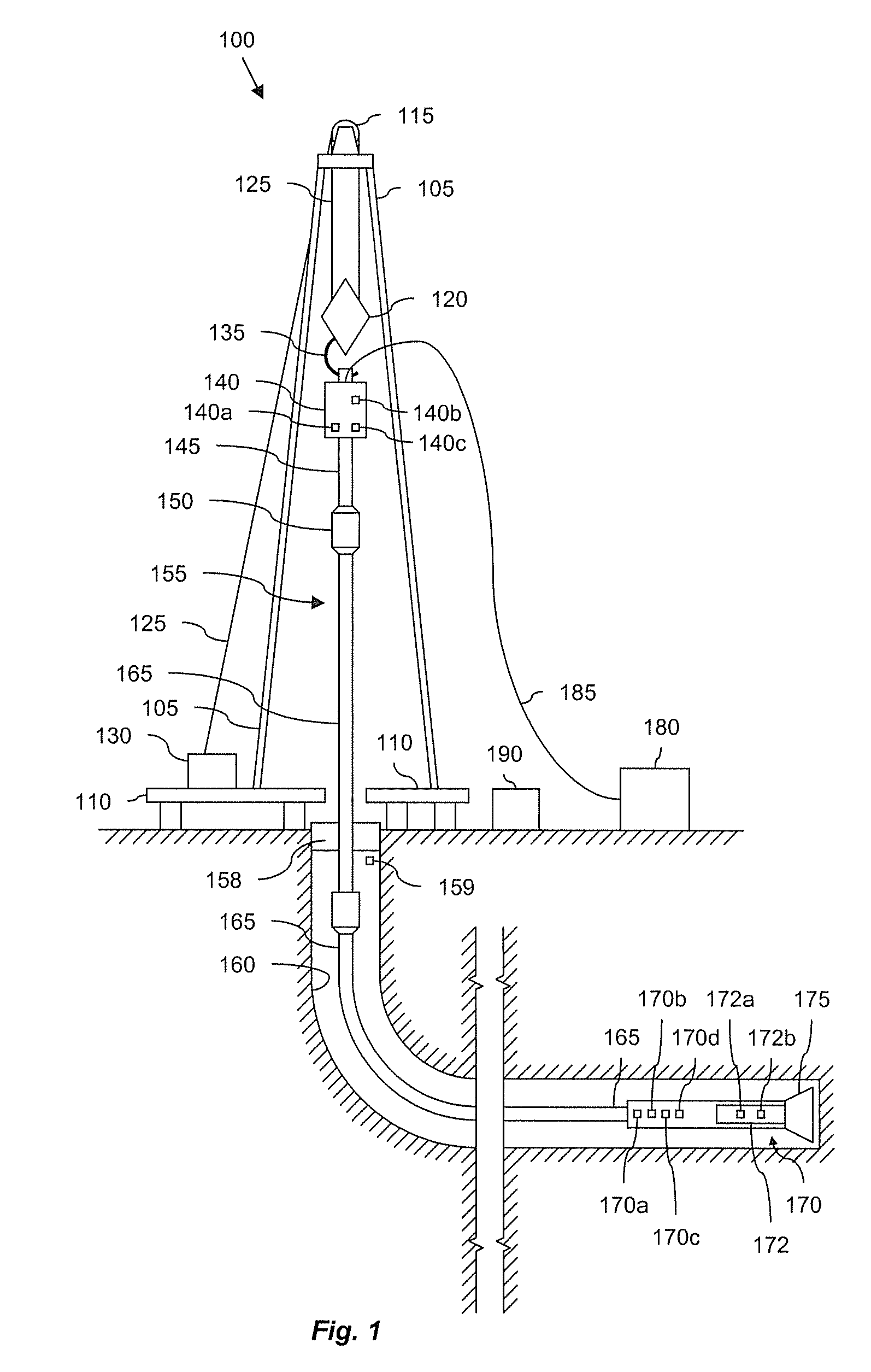

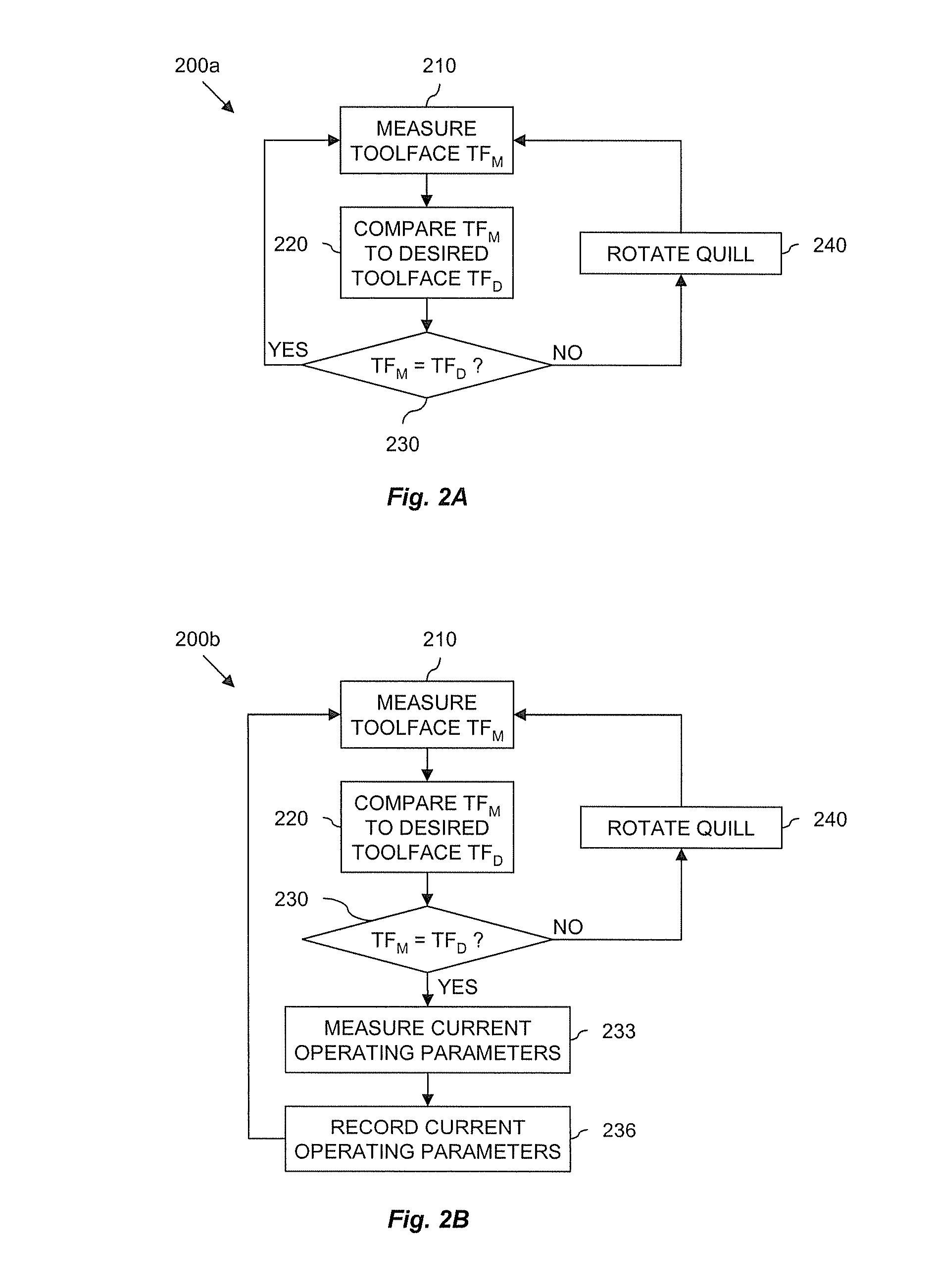

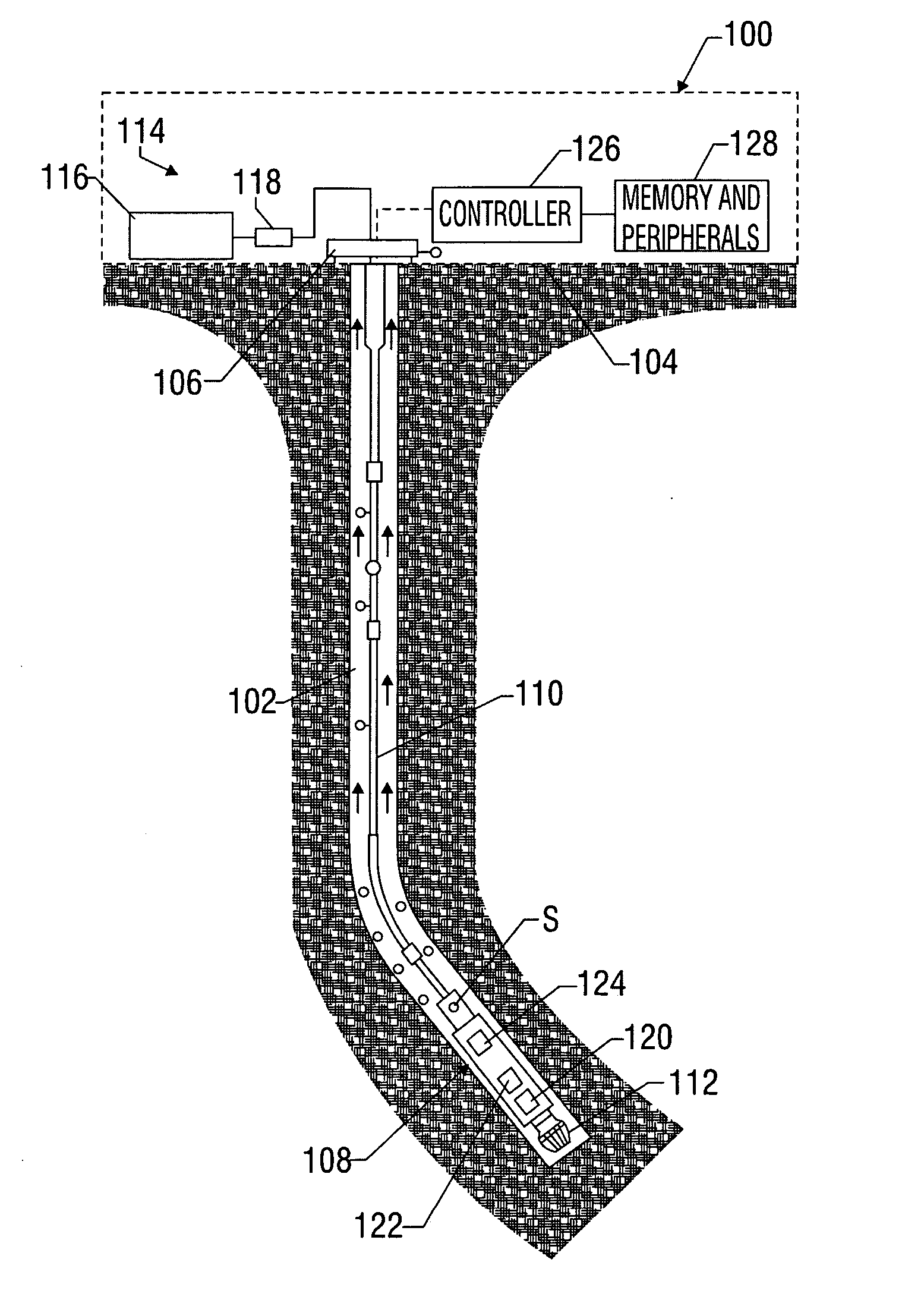

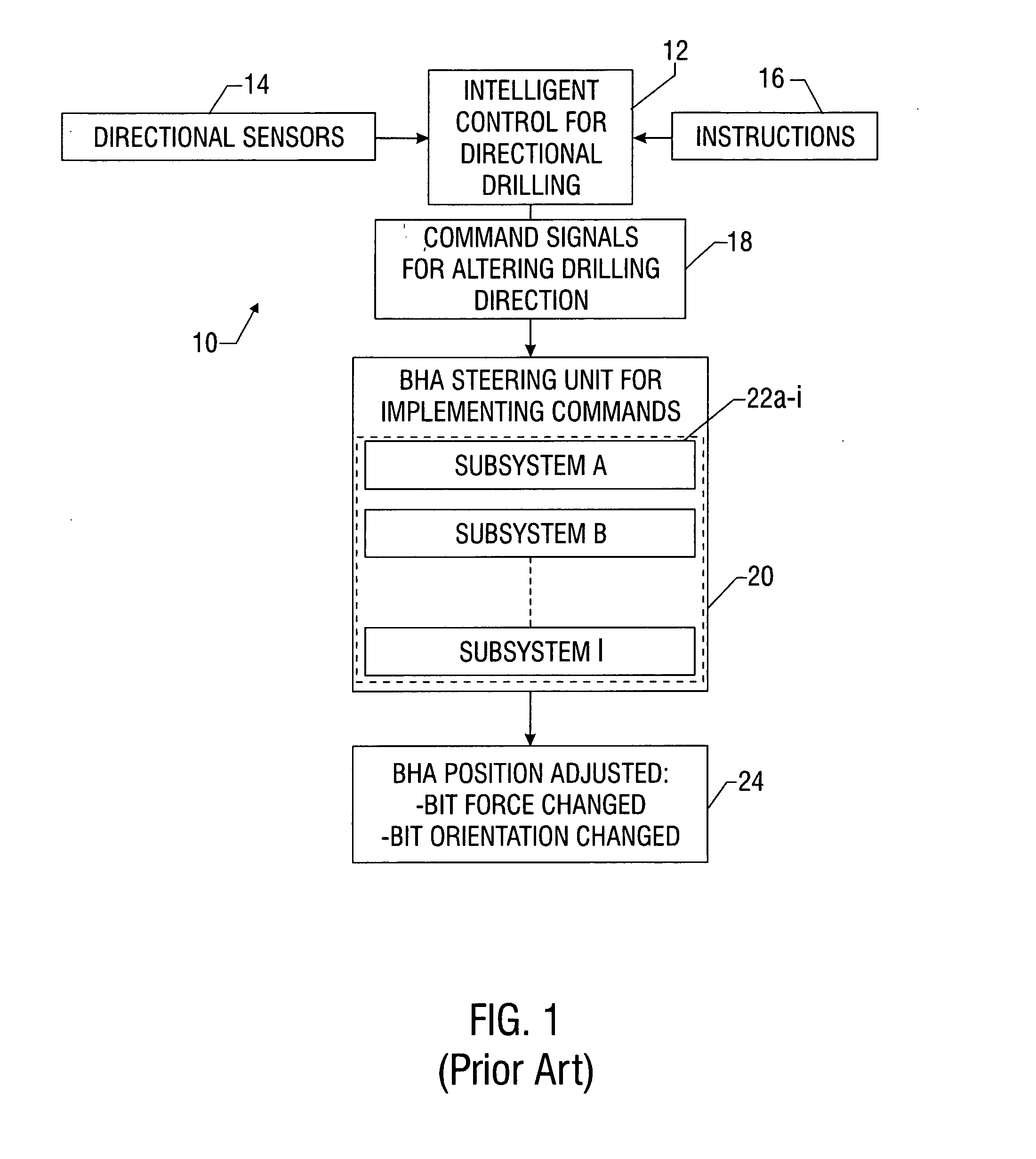

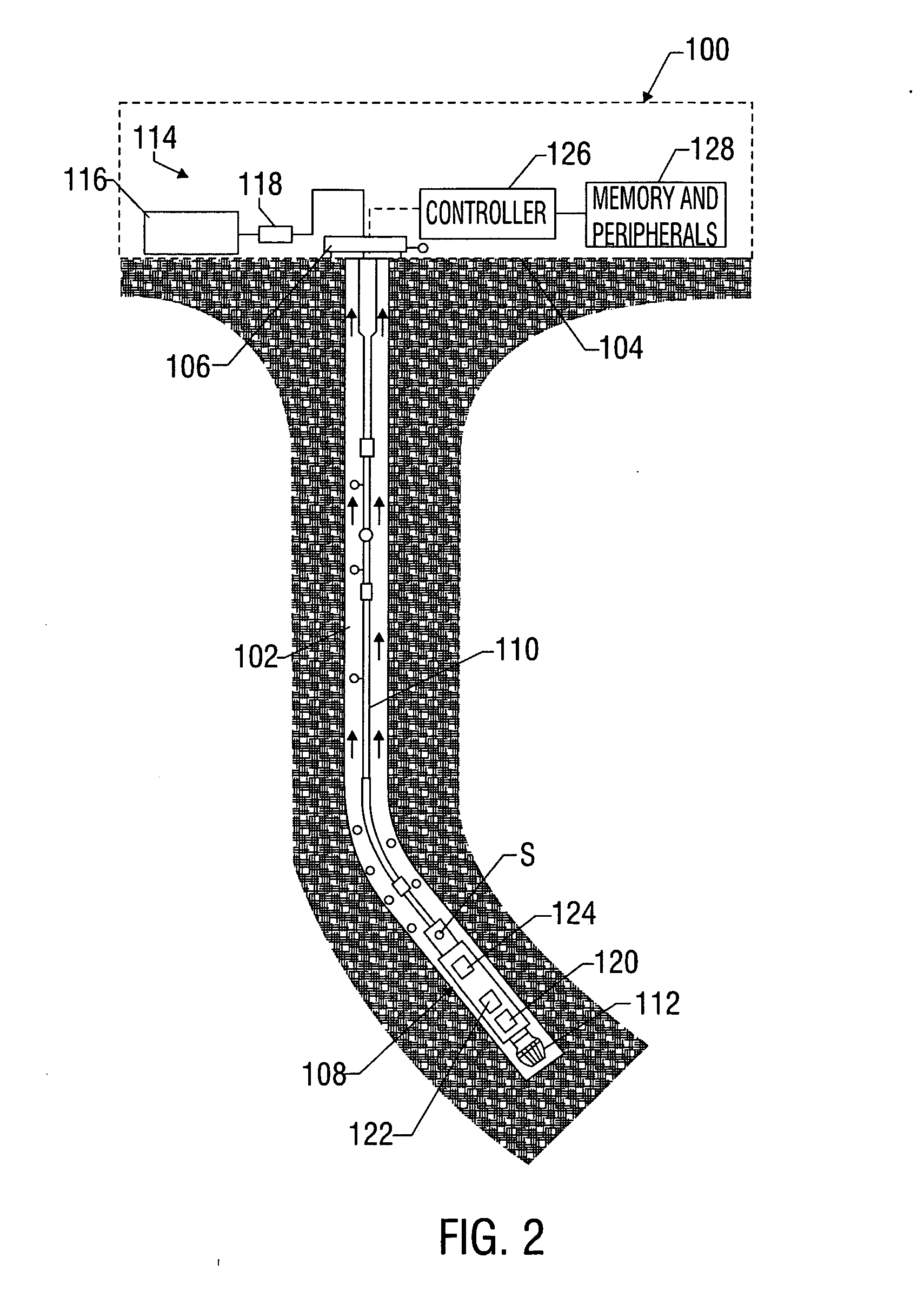

Automated directional drilling apparatus and methods

Methods and systems for drilling to a target location include a control system that receives an input comprising a planned drilling path to a target location and determines a projected location of a bottom hole assembly of a drilling system. The projected location of the bottom hole assembly is compared to the planned drilling path to determine a deviation amount. A modified drilling path is created to the target location as selected based on the amount of deviation from the planned drilling path, and drilling rig control signals that steer the bottom hole assembly of the drilling system to the target location along the modified drilling path are generated.

Owner:NABORS DRILLING TECH USA INC

High volume density polycrystalline diamond with working surfaces depleted of catalyzing material

InactiveUS6861137B2Improve wear resistancePigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

Disclosed is a method for manufacturing a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and the remaining interstitial matrix contains the catalyzing material. Typically, less than about 70% of the body of the diamond matrix table is free of the catalyzing material.

Owner:REEDHYCALOG UK

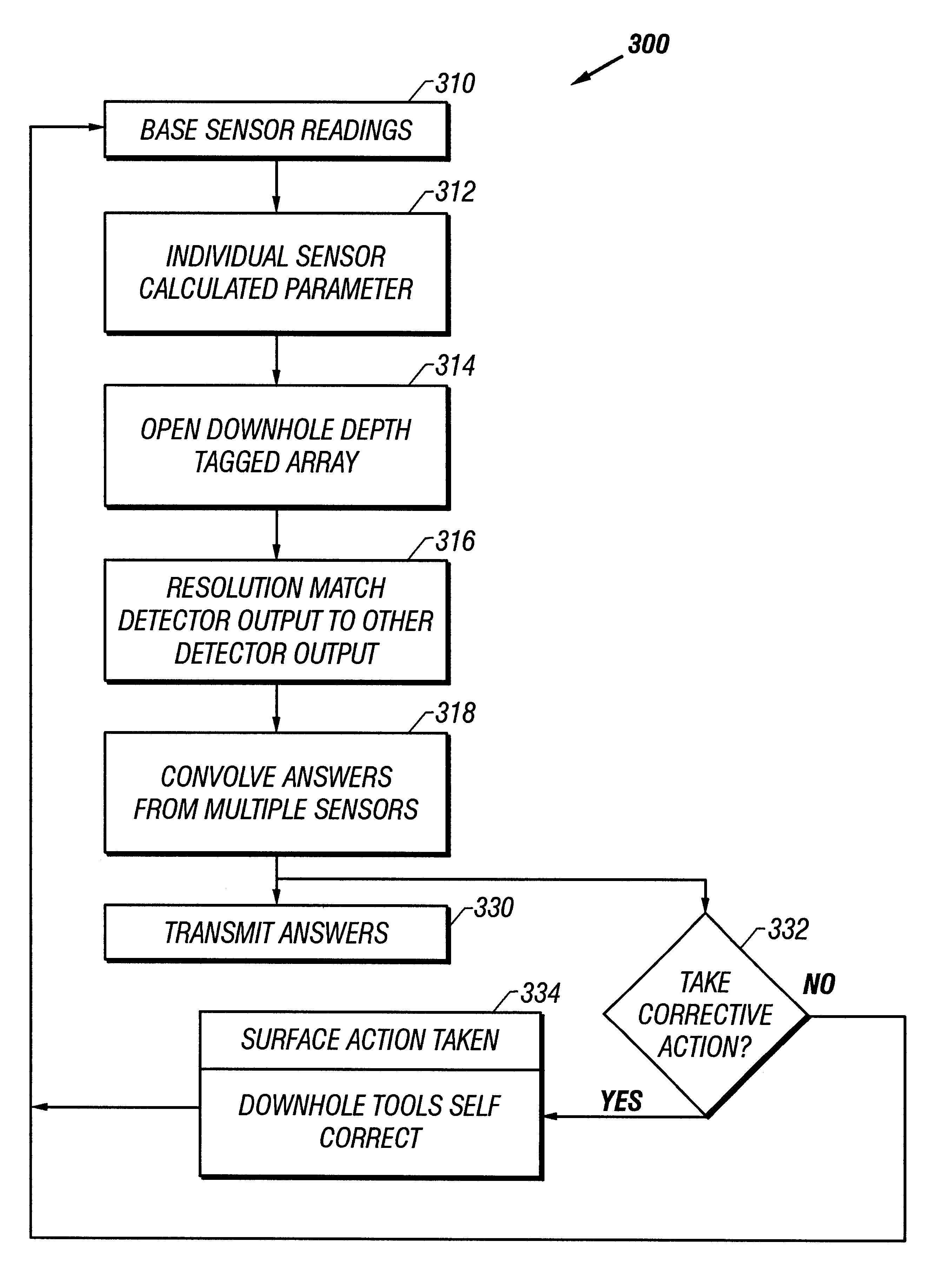

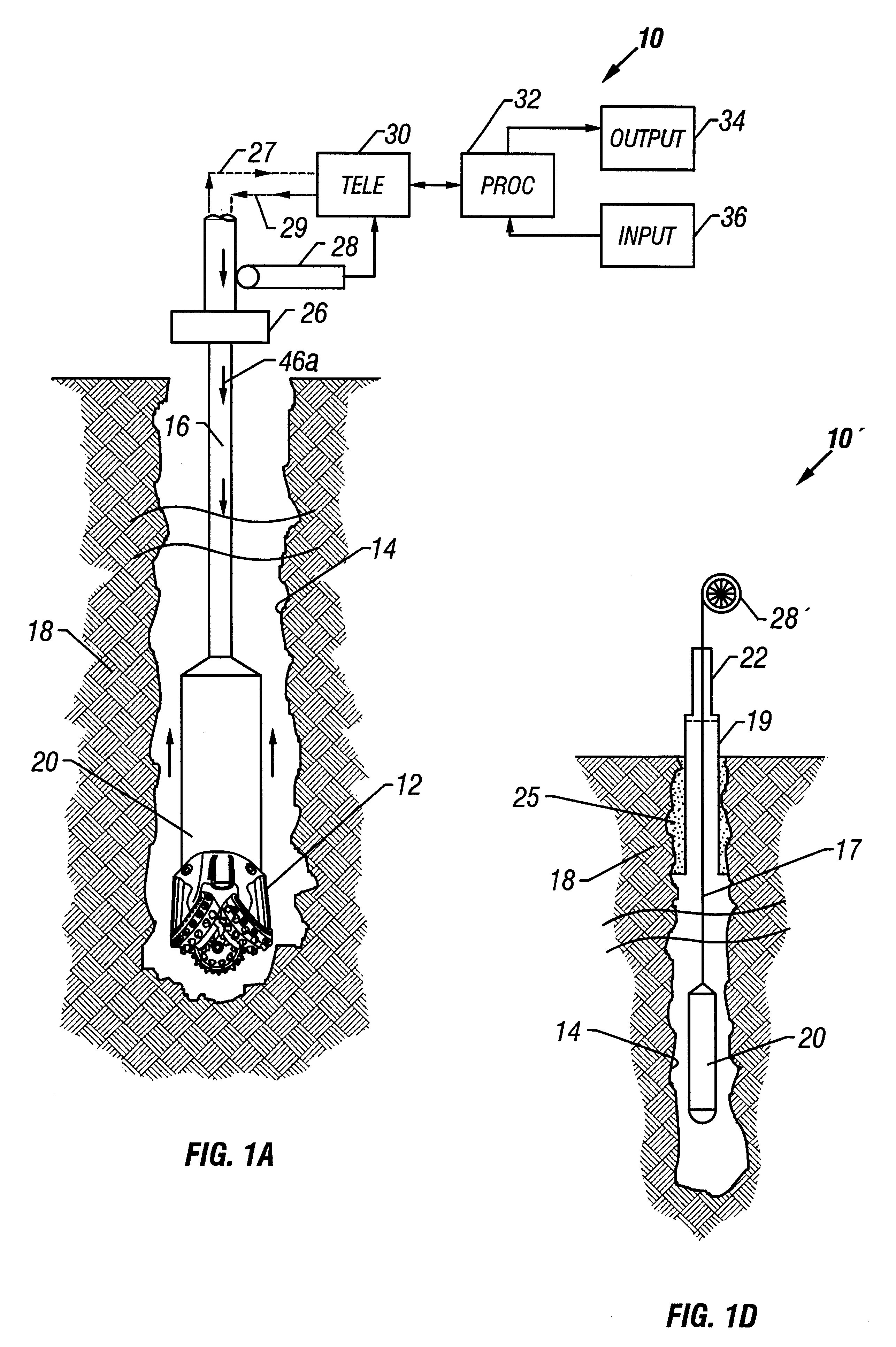

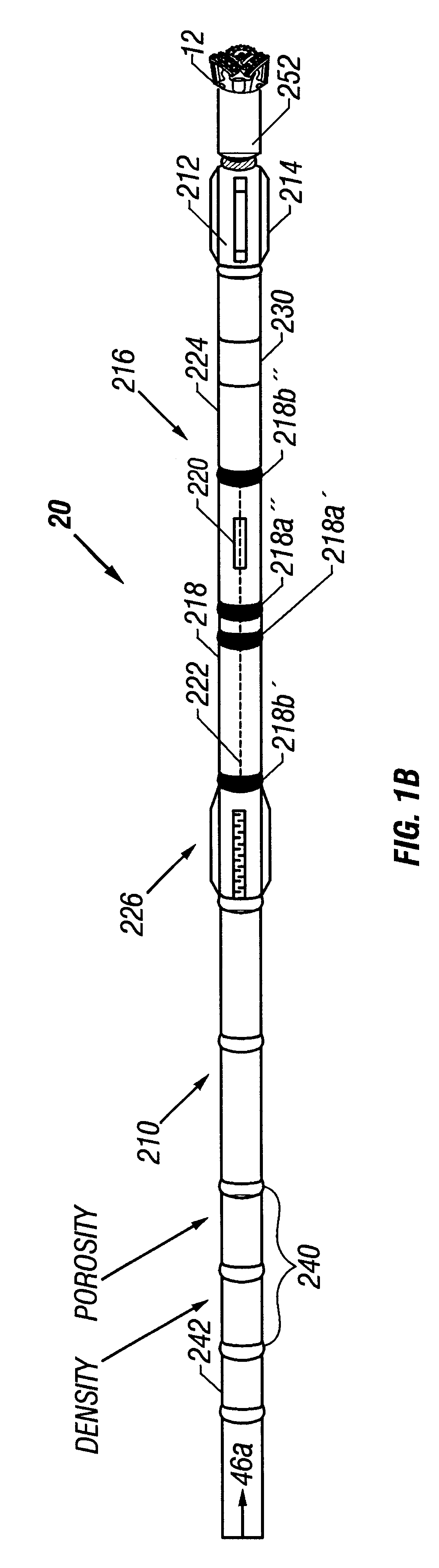

Drilling system with downhole apparatus for determining parameters of interest and for adjusting drilling direction in response thereto

The present invention provides a measurement-while-drilling (MWD) system having a downhole computer and multiple downhole sensors. Relatively large amounts of basic or "raw" data are measured by downhole sensors, and these data are processed within a downhole computer to be reduced to parameters of interest, which may be utilized to control the drilling operation by downhole devices, stored downhole, telemetered to the surface, or both. The measurements may be correlated downhole with stored reference data thereby providing additional information pertaining to the drilling operation. Downhole depth correlation between downhole measured parameters may be made by utilizing surface determined or downhole determined borehole depth.

Owner:BAKER HUGHES INC

Degradable whipstock apparatus and method of use

InactiveUS20080105438A1Improve responseSafe handlingFluid removalDirectional drillingSubject matterHigh intensity

Whipstocks and deflectors comprising a degradable composition, and methods of using same are described. In one embodiment the degradable composition consists essentially of one or more reactive metals in major proportion, and one or more alloying elements in minor proportion, with the provisos that the composition is high-strength, controllably reactive, and degradable under defined conditions. Methods of using degradable whipstocks in oilfield operations are also described. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims. 37 C.F.R. 1.72(b).

Owner:SCHLUMBERGER TECH CORP

Polycrystalline diamond partially depleted of catalyzing material

Owner:REEDHYCALOG UK

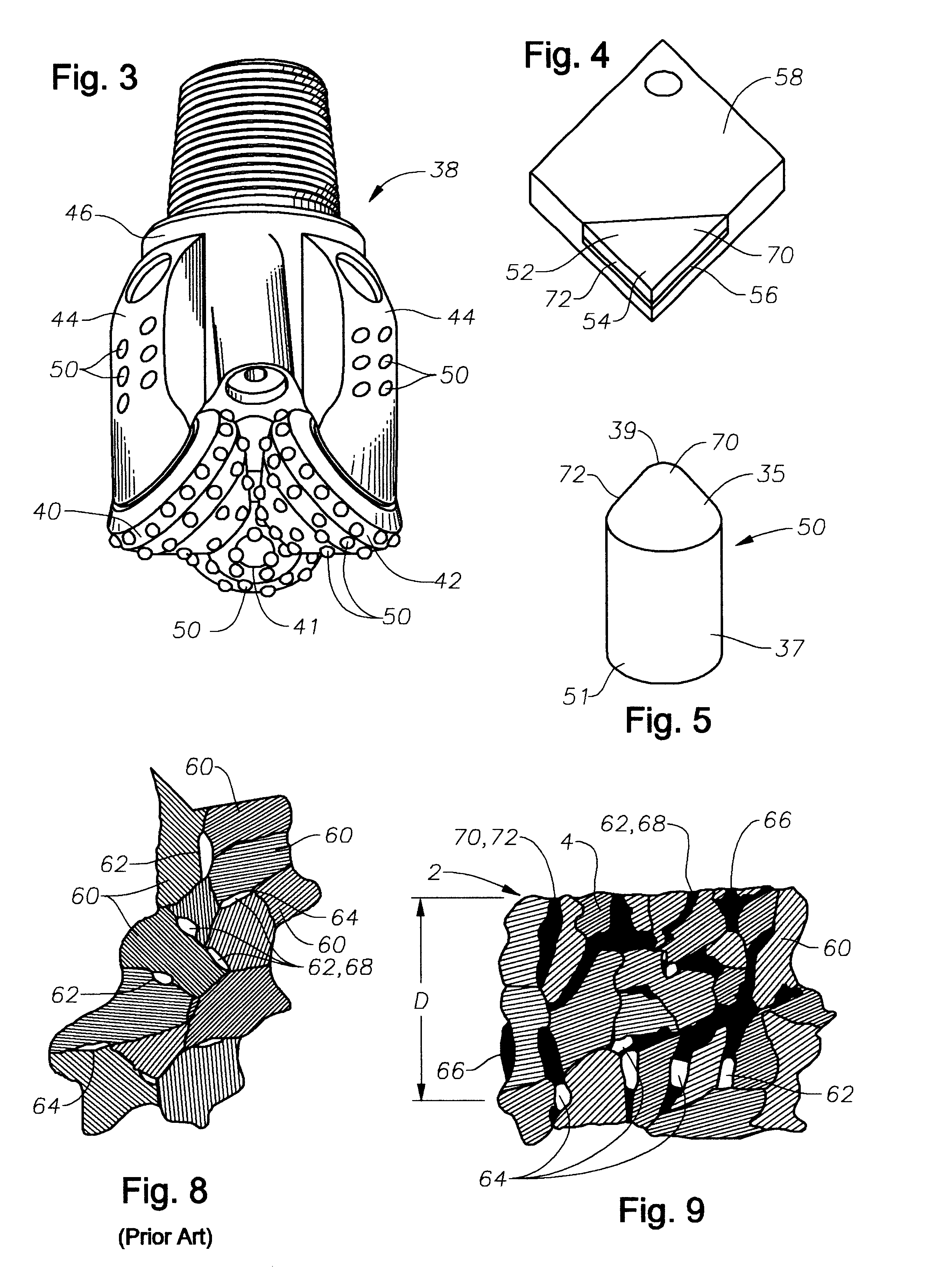

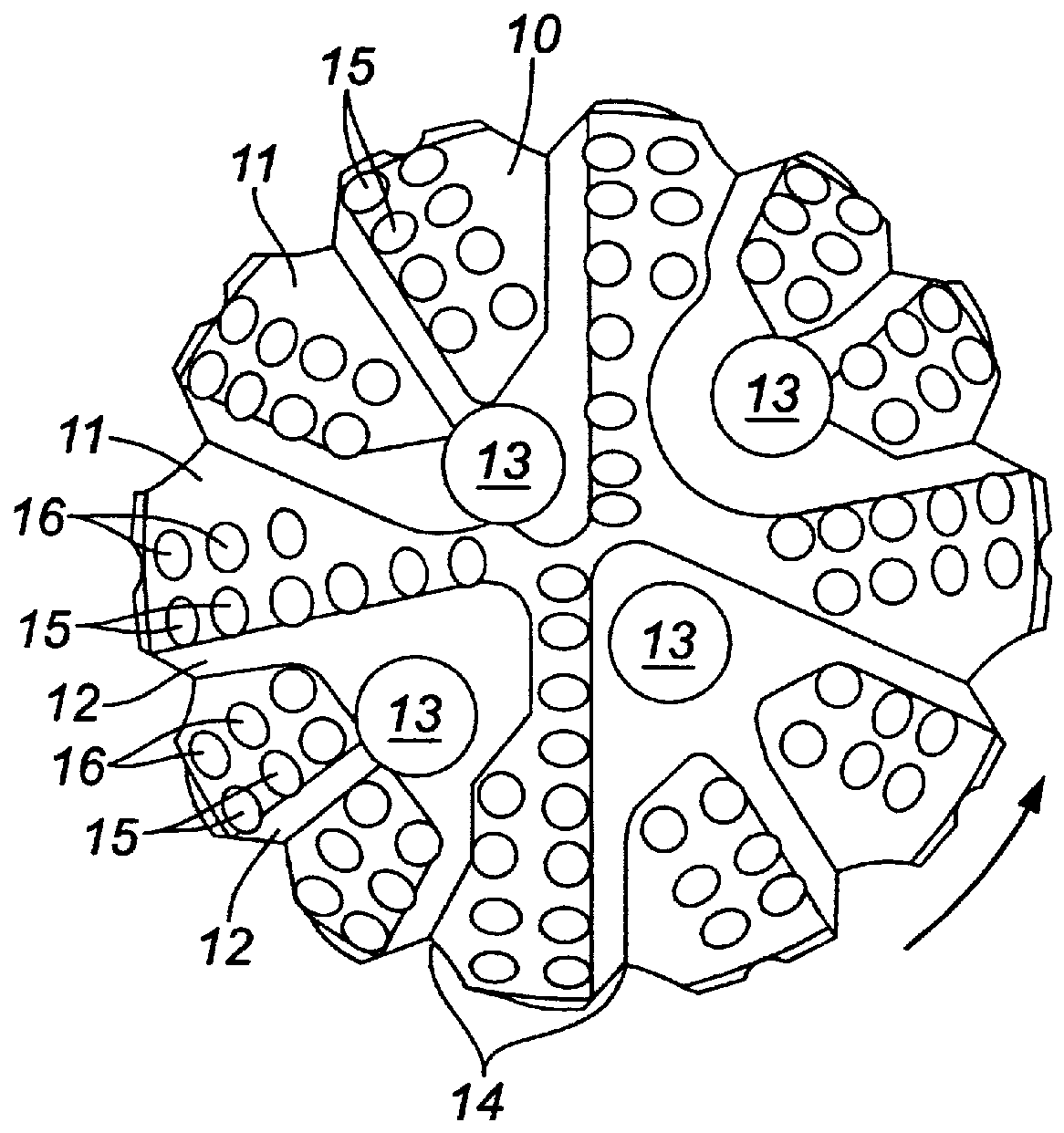

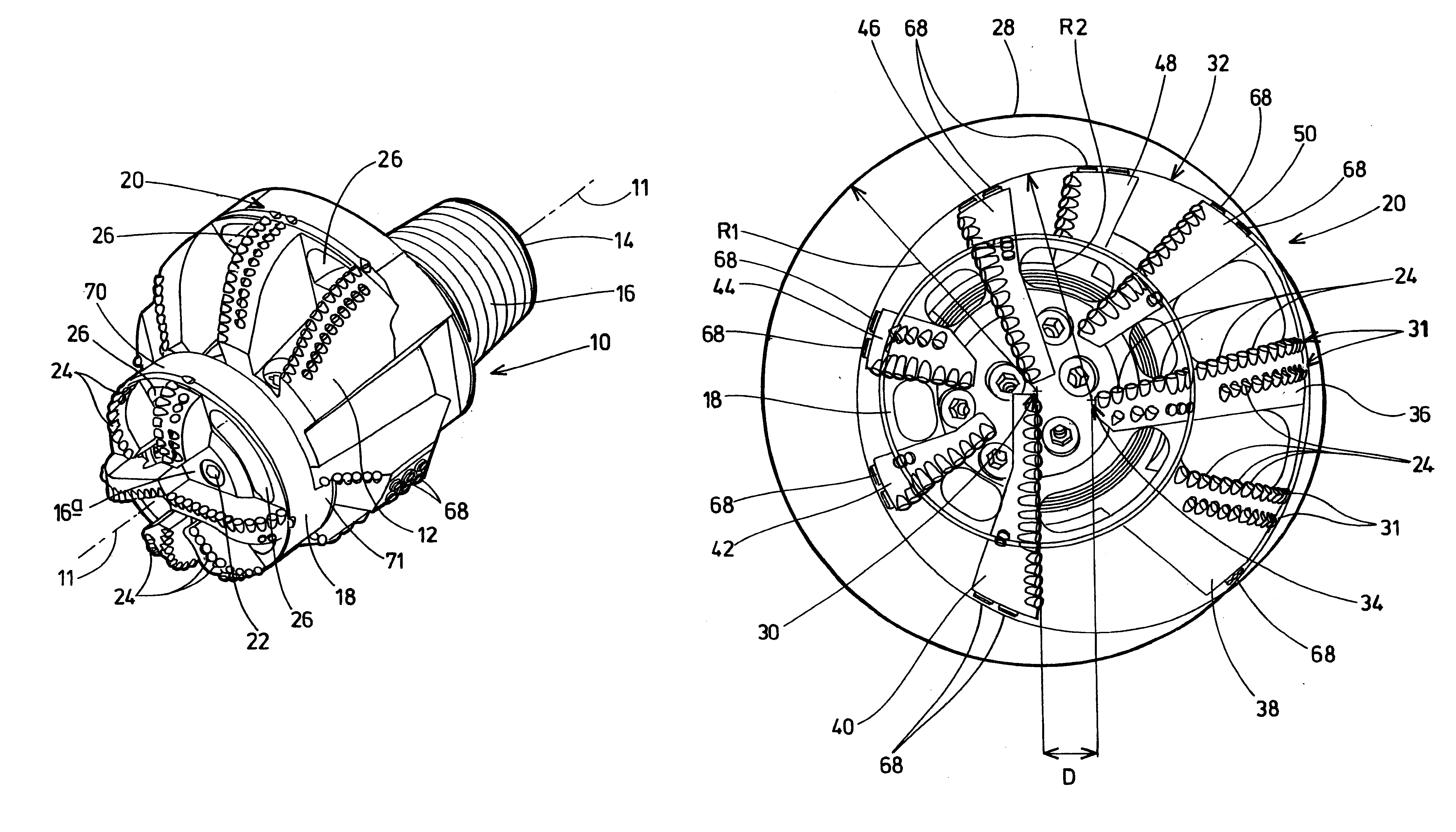

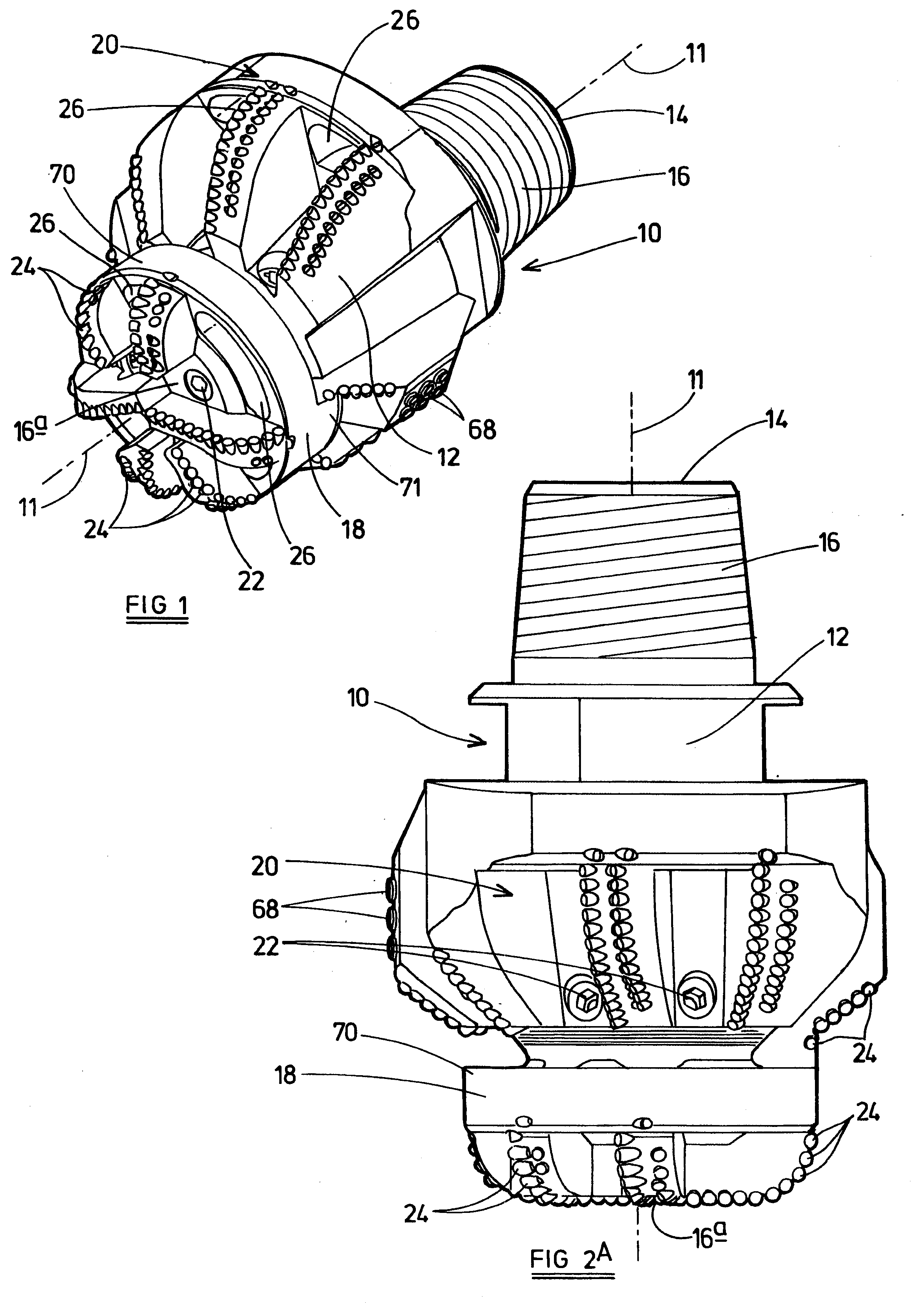

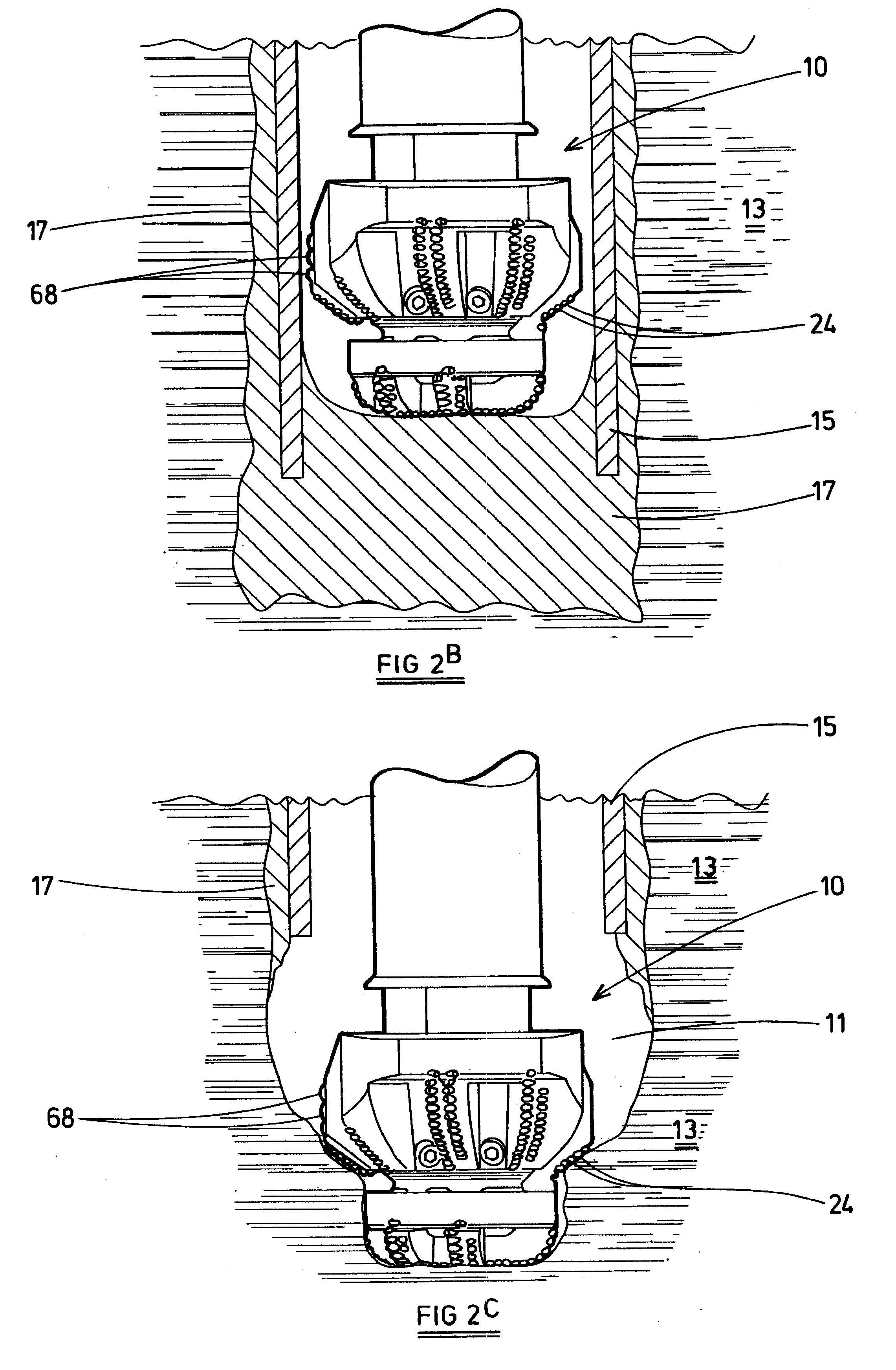

Rotary drill bit having moveable formation-engaging members

Formation engaging elements are moveably mounted onto a drill bit. Such elements may be used to protect other rigidly mounted formation engaging elements from impacts that occur during use of the drill bit, or they may be used to alter the aggressiveness of the drill bit when used in directional drilling operations.

Owner:REEDHYCALOG UK

Integrated directional under-reamer and stabilizer

The present invention is an apparatus for use in drilling operations. It uses an under-reamer having a plurality of elongated arms with cutting elements at the ends of the arms for enlarging a previously drilled borehole drilled by a drill bit. One or more stabilizers in close proximity to the under-reamer provide stability to the under-reamer and the drill bit. The stabilizer could be rotating or non-rotating; and could be positioned between the under-reamer and the drill bit, or above the under reamer or above a directional device on the drillstring. The cutting arms are selectively operable to perform the enlargement. The stabilizer may be provided with members that closely fit the size of the borehole.

Owner:BAKER HUGHES INC

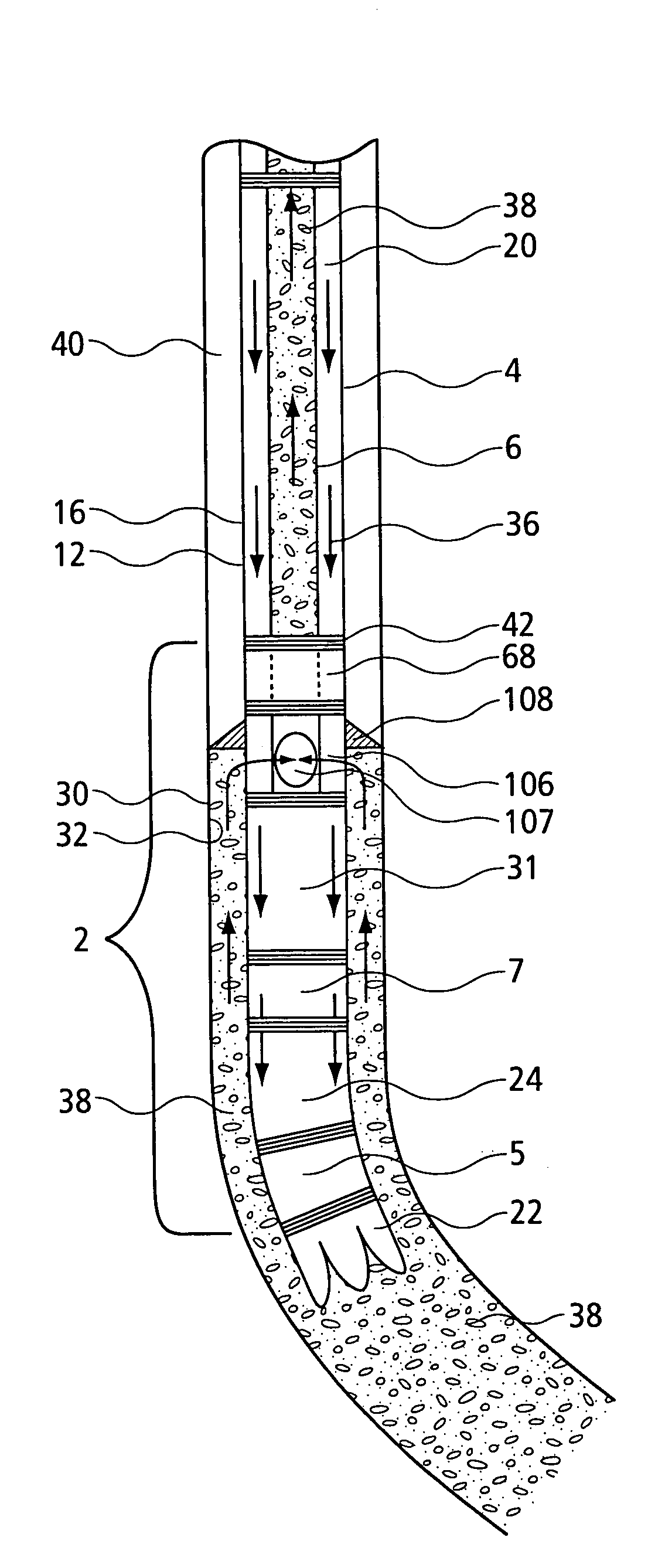

Reverse circulation directional and horizontal drilling using concentric drill string

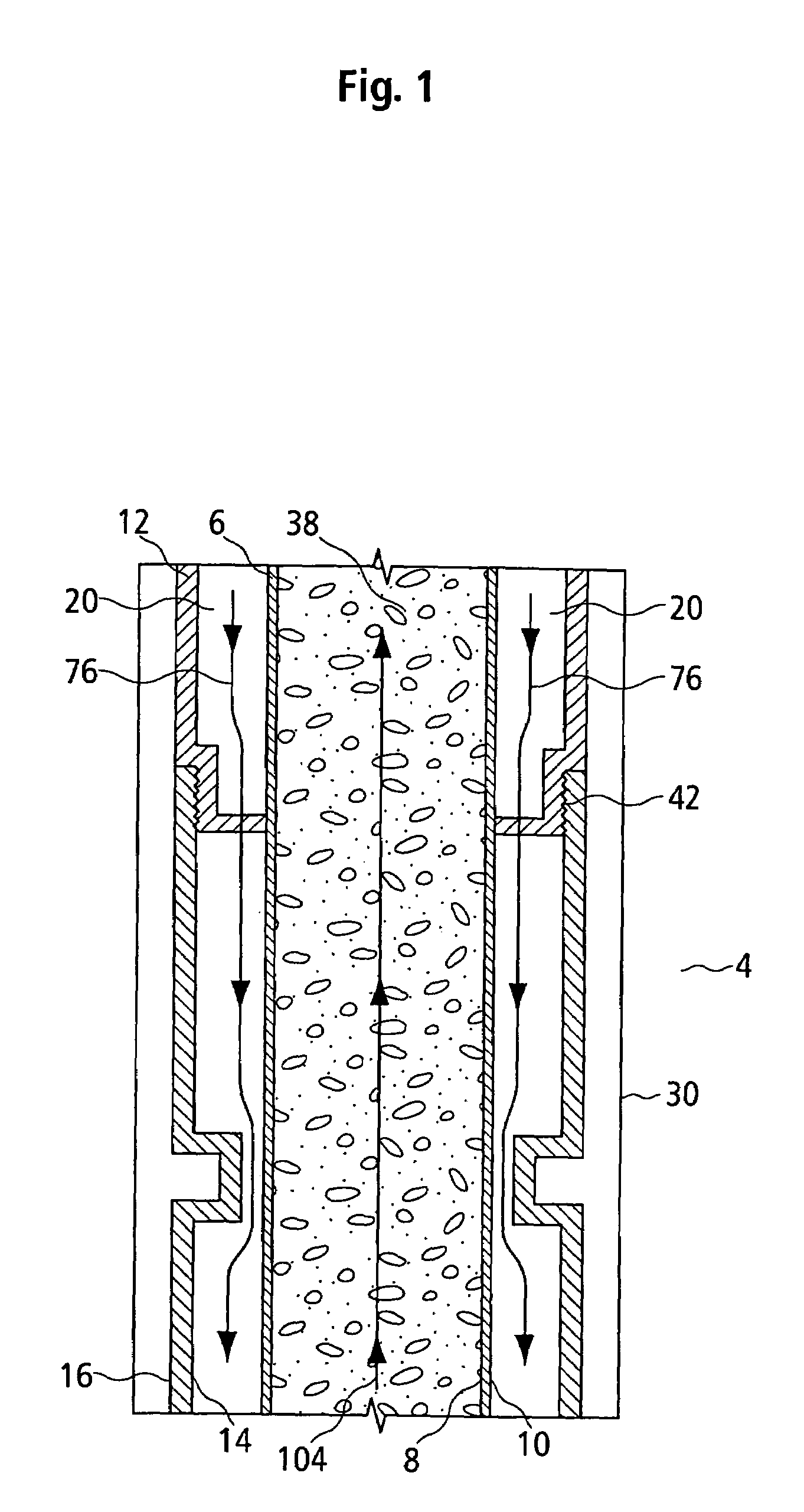

InactiveUS7204327B2Avoid damageSafe and economical mannerDrilling rodsDirectional drillingWell drillingDirectional drilling

Method and apparatus for drilling a directional or horizontal wellbore in a hydrocarbon formation using concentric drill string having an inner pipe and an outer pipe defining an annulus there between. A bottomhole assembly comprising a directional drilling means such as an air hammer or a rotary drill bit and driving system is provide at the lower end of the concentric drill string and drilling medium is delivered through the annulus or inner pipe for operating the directional drilling means to form a borehole. Exhaust drilling medium, drilling cutting and hydrocarbon are removed from the wellbore by extracting the exhaust drilling medium, drilling cutting and hydrocarbon through the other of the annulus or inner pipe.

Owner:PRESSSOL

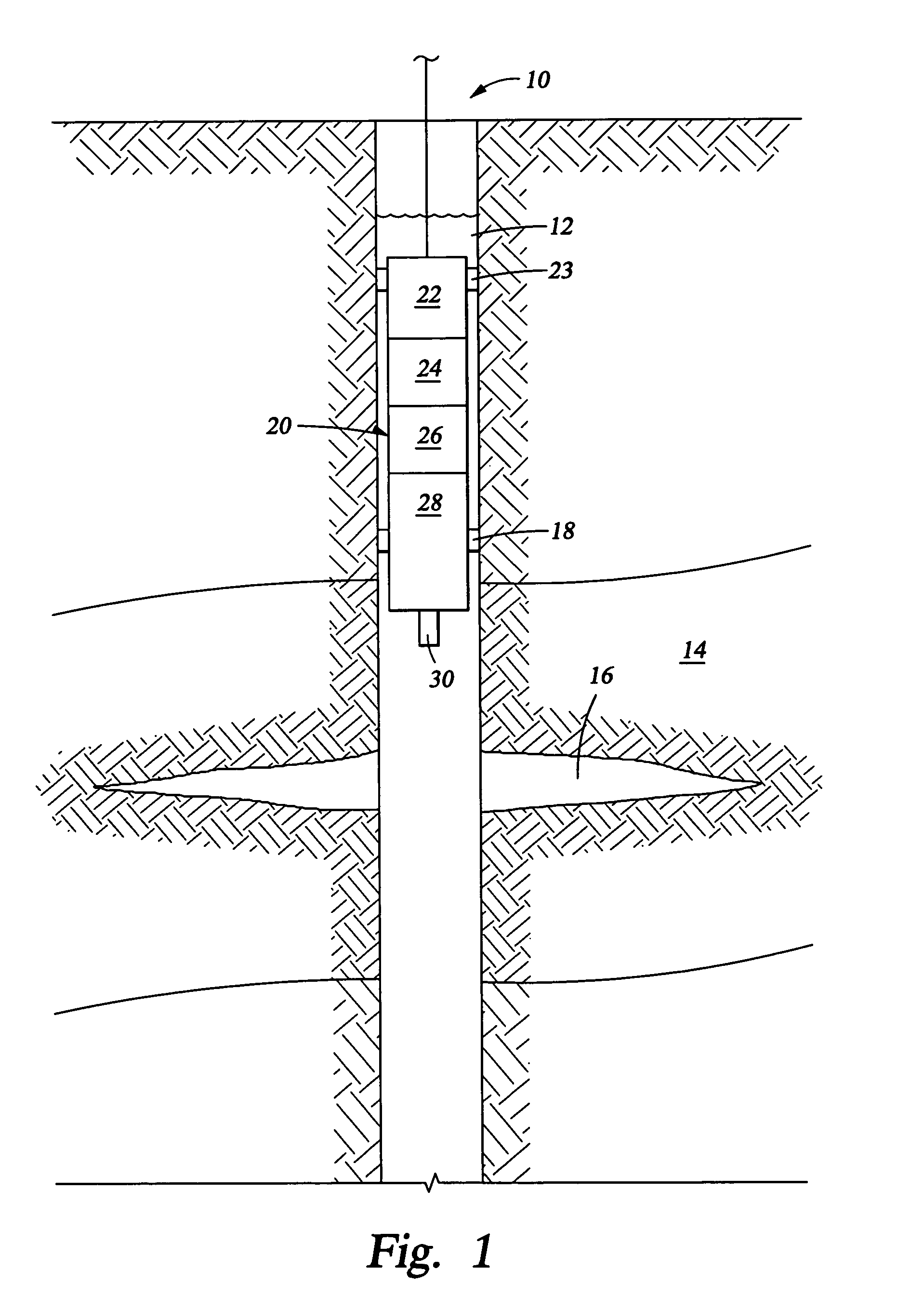

Well system

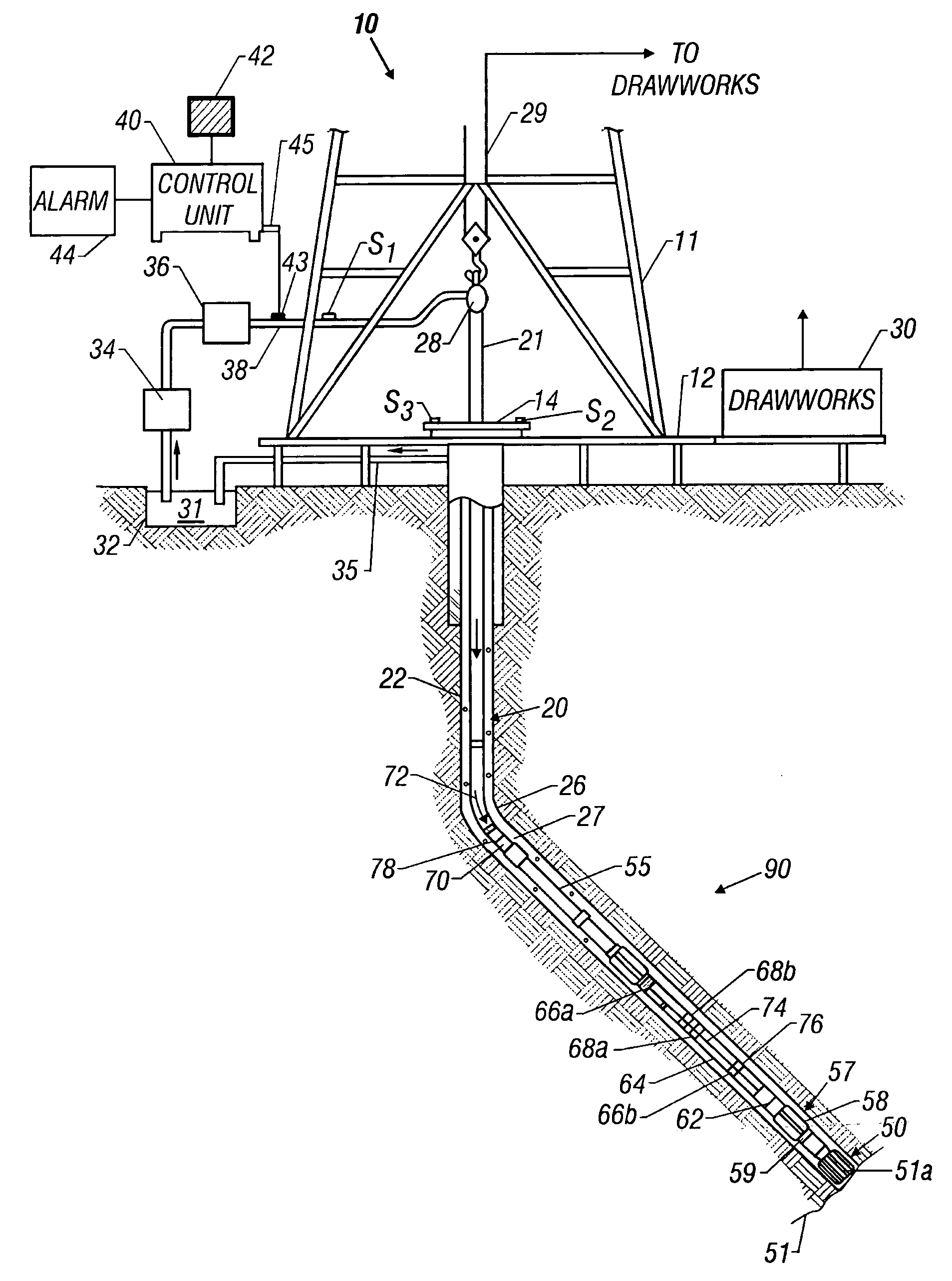

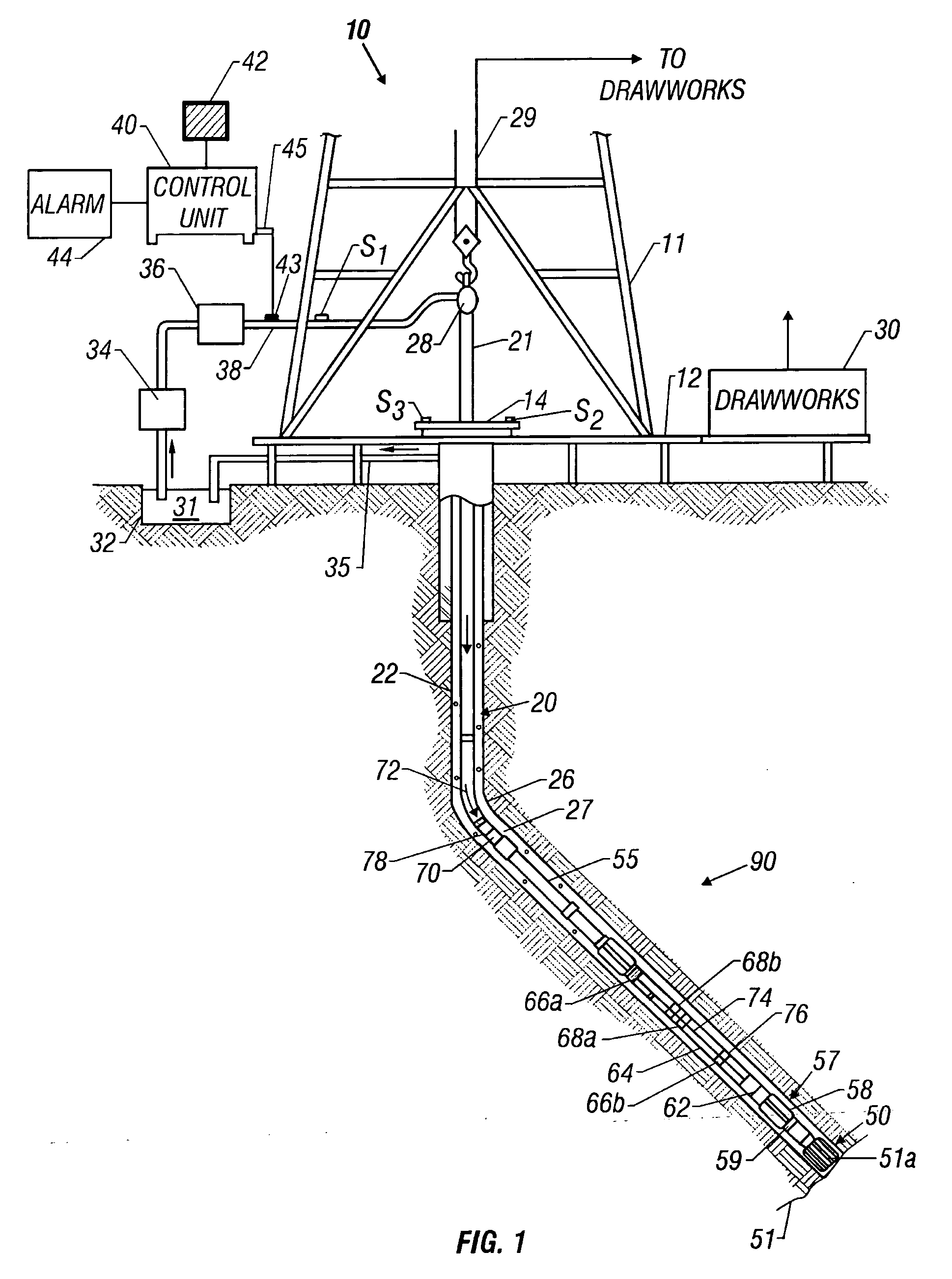

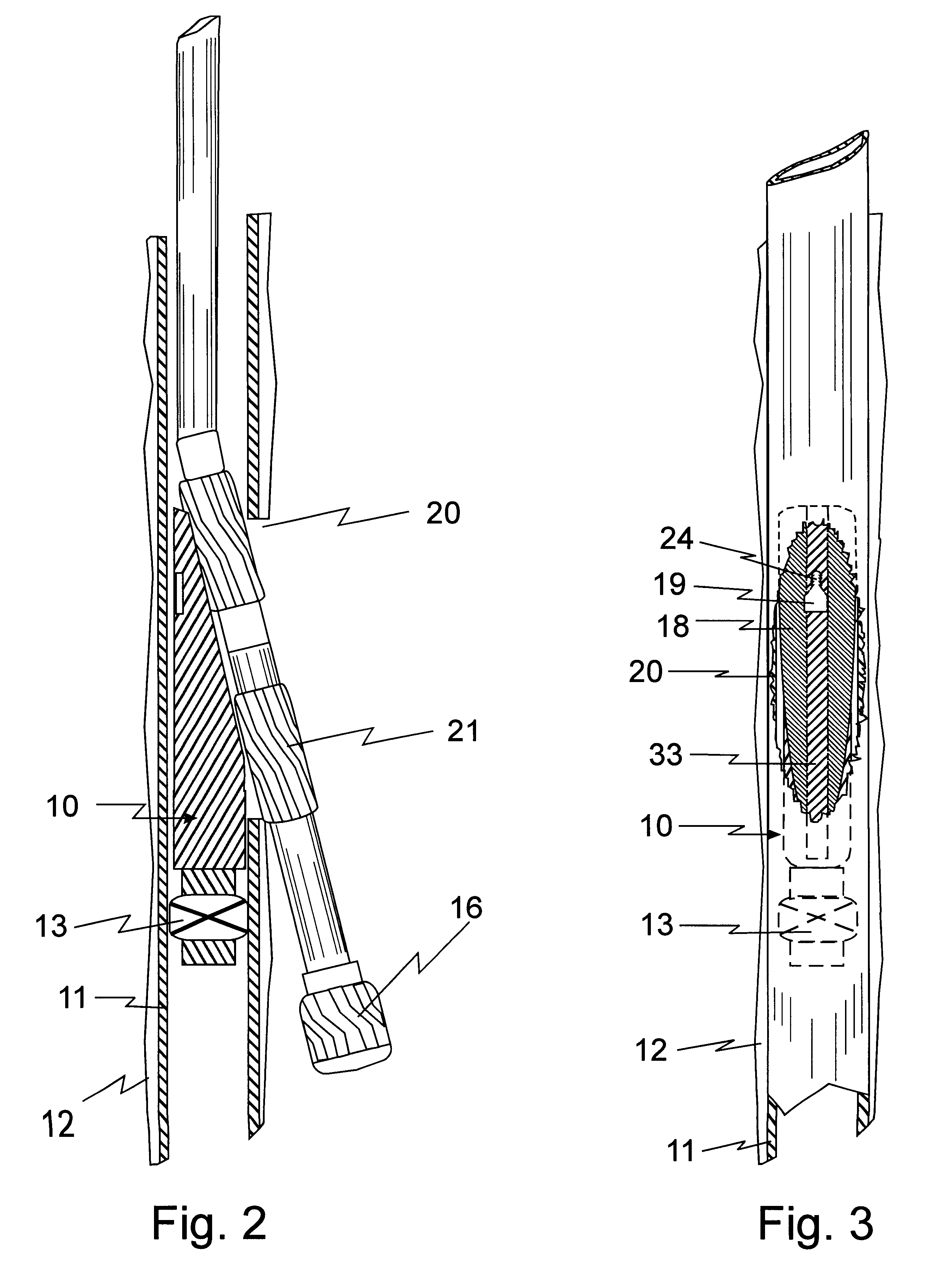

InactiveUS6923273B2Excessive vibrationLess expensiveElectric/magnetic detection for well-loggingDrilling rodsElectrical conductorEngineering

The drilling system includes a work string supporting a bottom hole assembly. The work string including lengths of pipe having a non-metallic portion. The work string preferably includes a composite coiled tubing having a fluid impermeable liner, multiple load carrying layers, and a wear layer. Multiple electrical conductors and data transmission conductors may be embedded in the load carrying layers for carrying current or transmitting data between the bottom hole assembly and the surface. The bottom hole assembly includes a bit, a gamma ray and inclinometer instrument package, a steerable assembly, an electronics section, a transmission, and a power section for rotating the bit. It may or may not include a propulsion system. The drilling system may be a gravity based drilling system that does include a propulsion system. Various motive means may be provided such as gravity, to apply weight on the bit.

Owner:HALLIBURTON ENERGY SERVICES INC

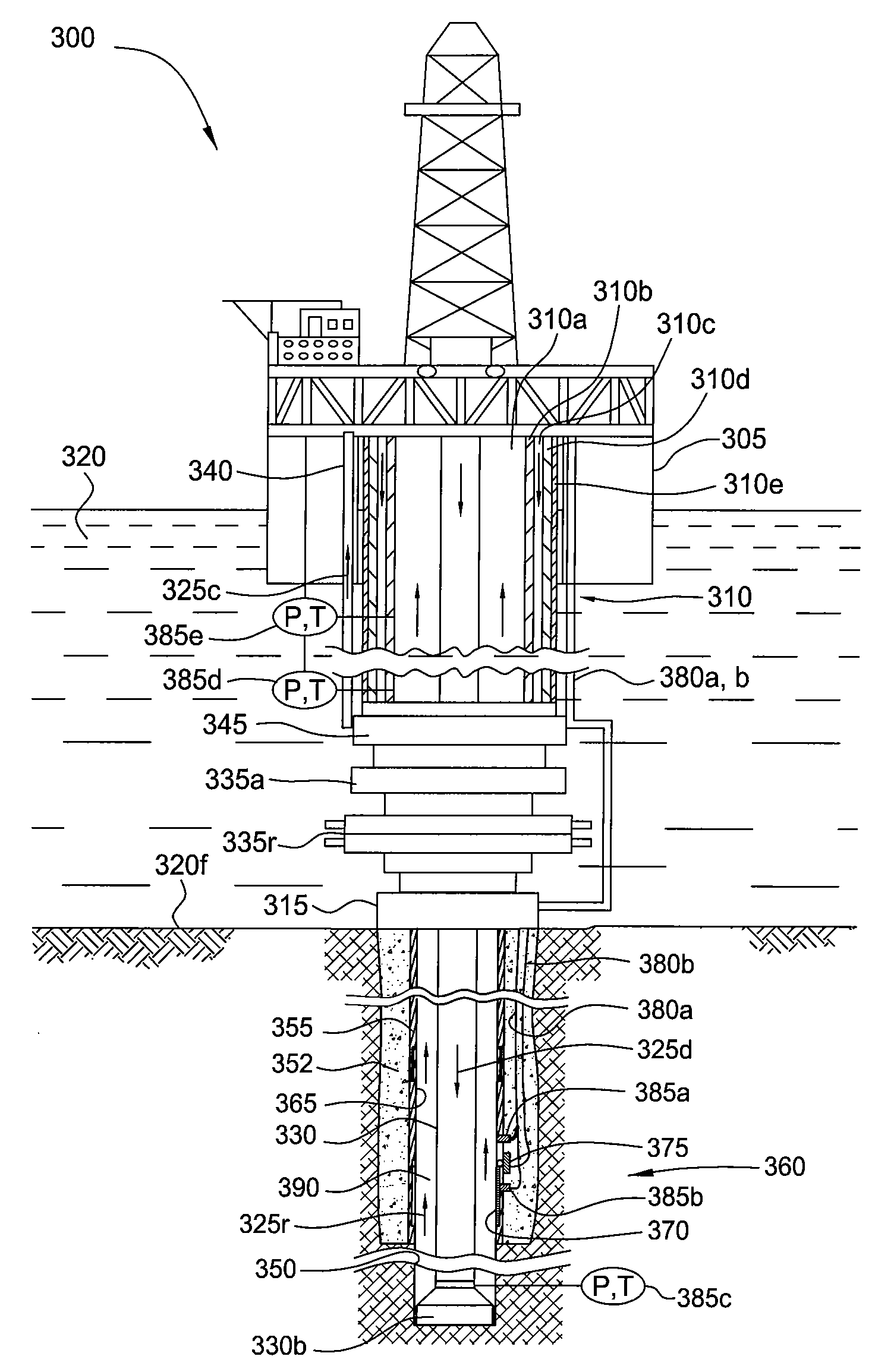

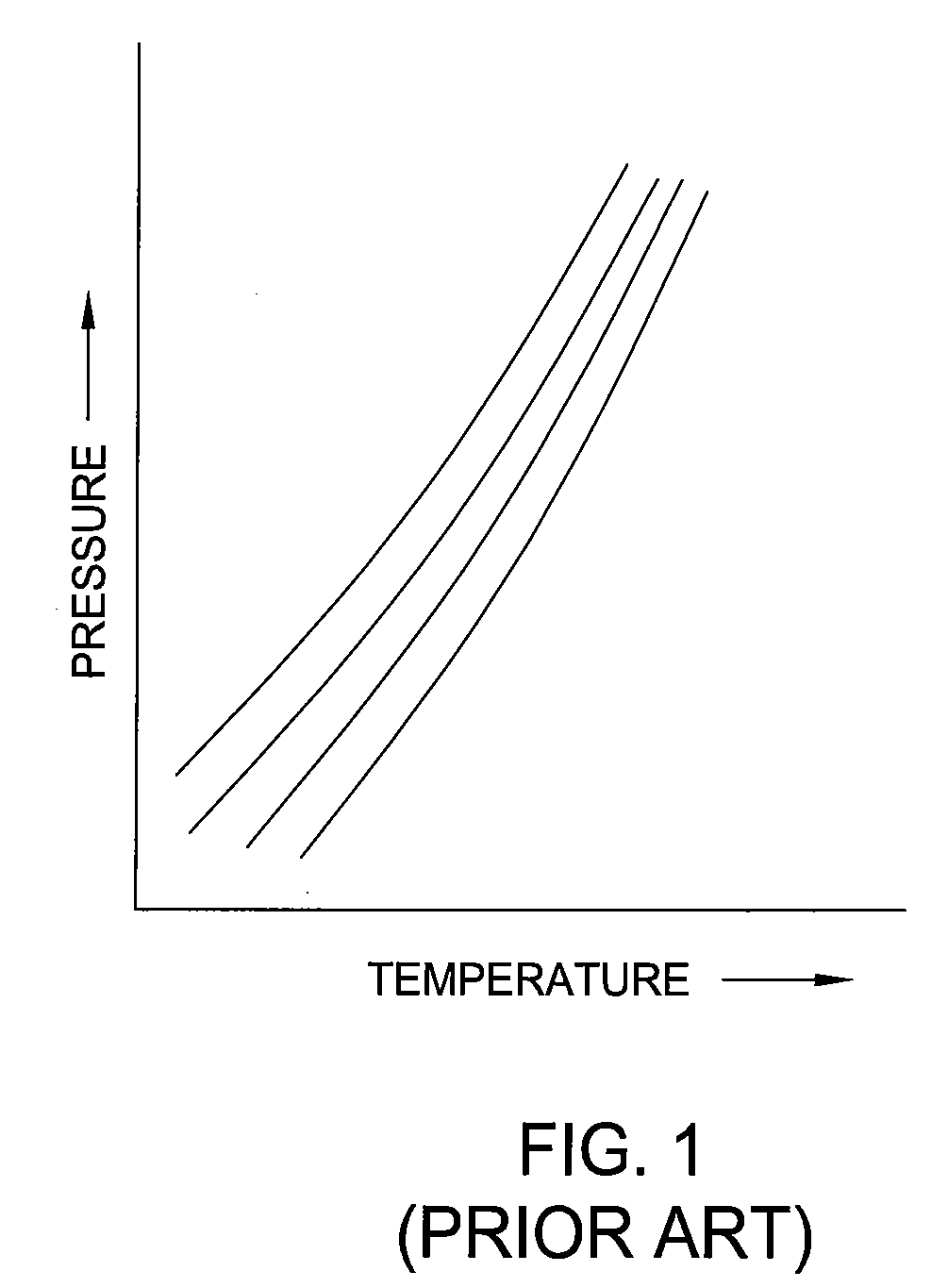

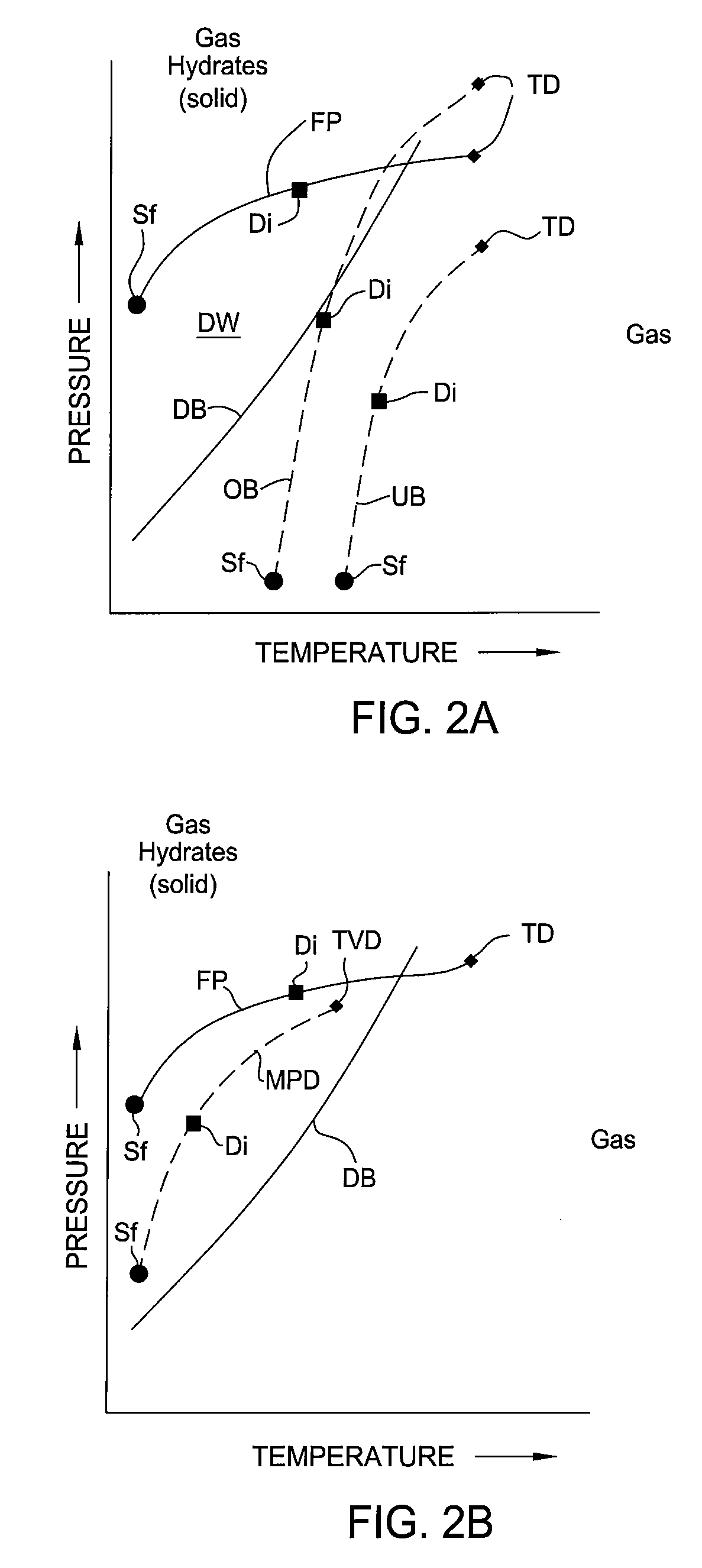

Managed pressure and/or temperature drilling system and method

The present invention relates to a managed pressure and / or temperature drilling system (300) and method. In one embodiment, a method for drilling a wellbore into a gas hydrates formation is disclosed. The method includes drilling the wellbore into the gas hydrates formation; returning gas hydrates cuttings to a surface of the wellbore and / or a drilling rig while controlling a temperature and / or a pressure of the cuttings to prevent or control disassociation of the hydrates cuttings.

Owner:WEATHERFORD TECH HLDG LLC

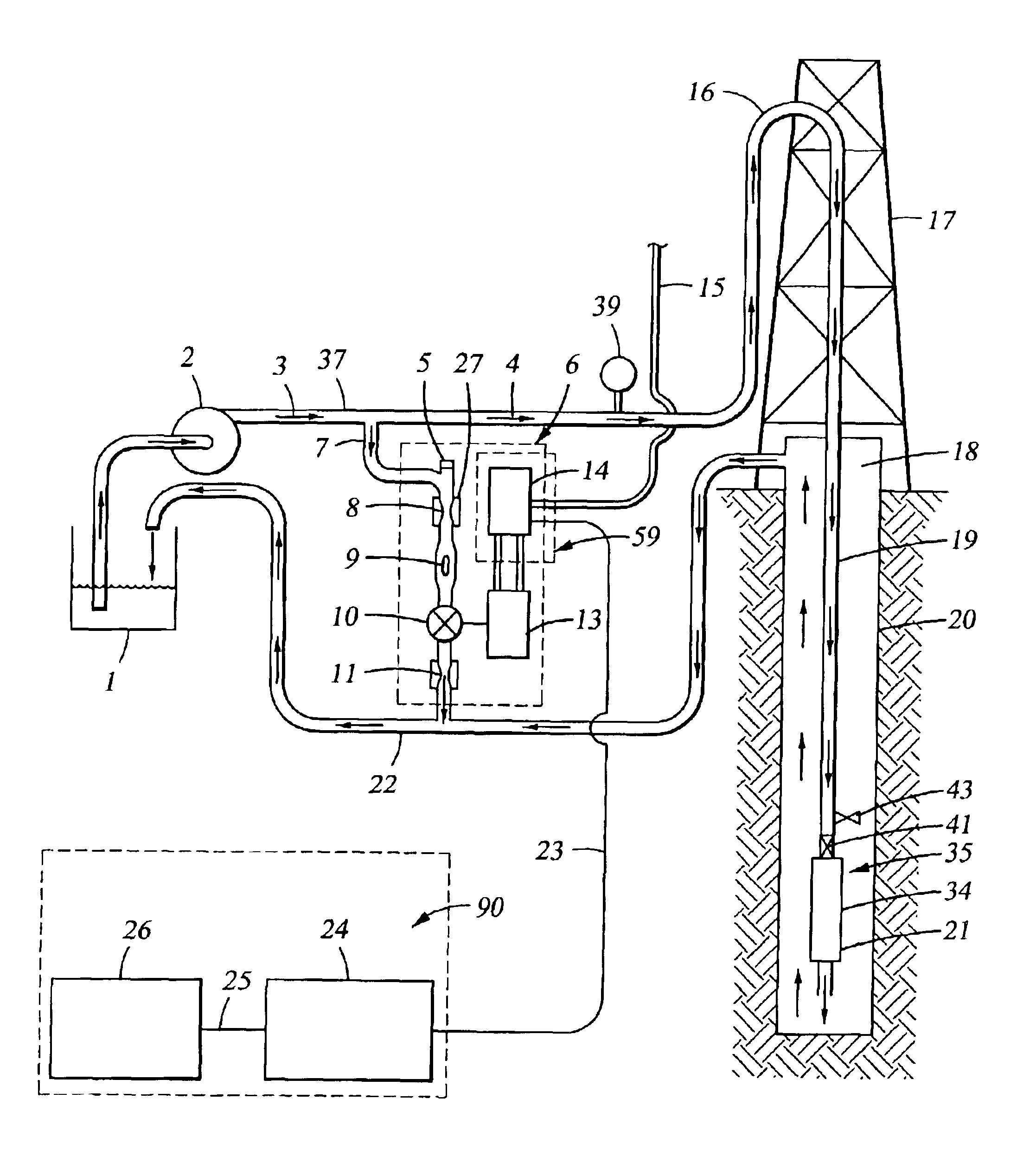

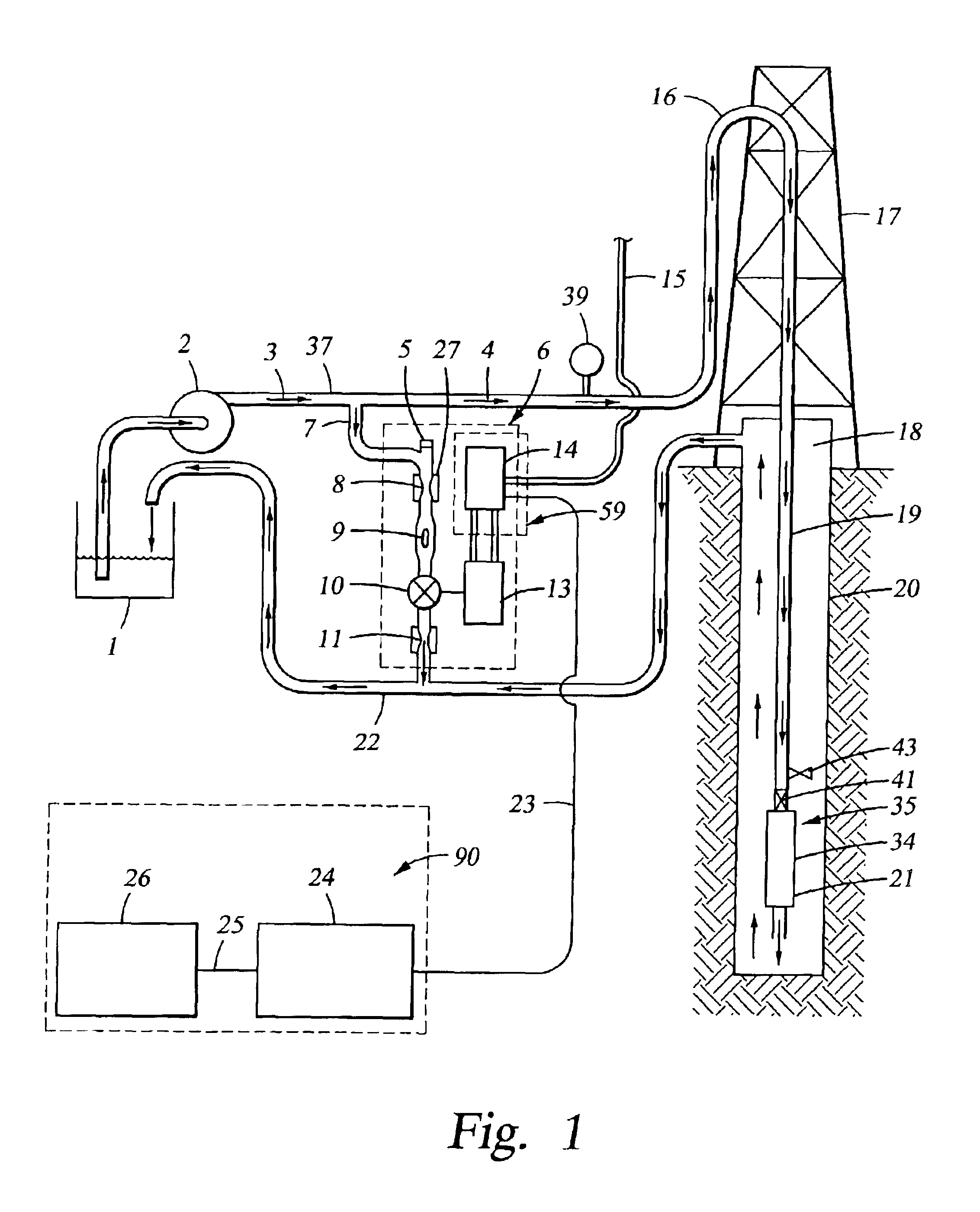

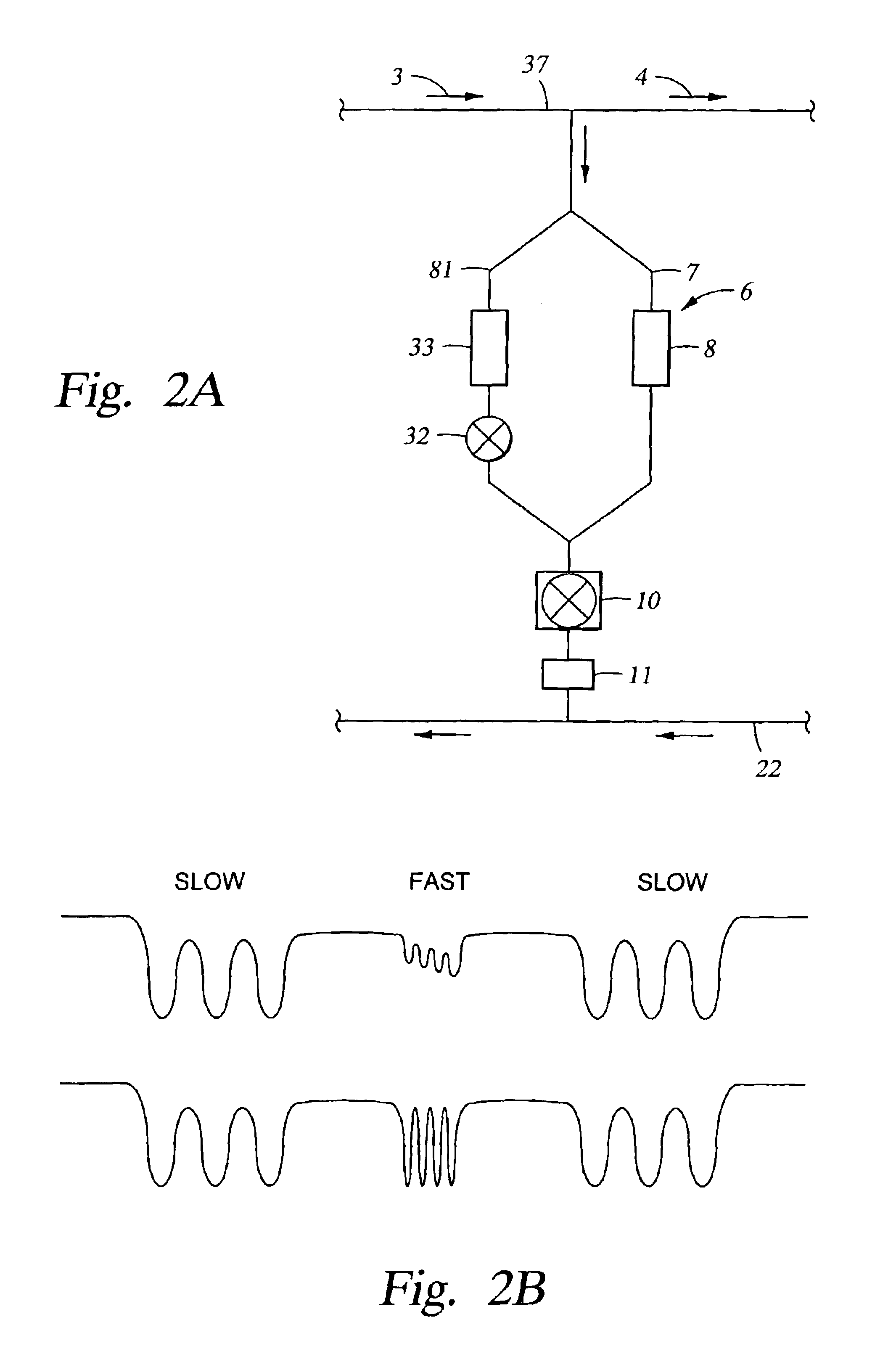

Downlink telemetry system

InactiveUS6920085B2Shorten the timeGuaranteed accuracySurveyConstructionsError checkingControl system

A downlink telemetry system providing improved apparatus and methods for communicating instructions via pressure pulses from surface equipment to a downhole assembly. The apparatus comprises a surface transmitter for generating pressure pulses, a control system, and a downhole receiver for receiving and decoding pulses.In operation, a bypass valve is opened and closed to create a series of pressure pulses received and decoded by a downhole receiver. The method significantly reduces the time required for downlink communication without interrupting drilling and without interrupting uplink communications such that simultaneous, bi-directional communication is achievable if the uplink and downlink signals are sent at different frequencies.The telemetry scheme and algorithm provide an inventive method for filtering and decoding the downlink signals. The algorithm determines the time intervals between pulse peaks and decodes the intervals into an instruction. The algorithm also includes error checking for verifying that the instruction was properly received downhole.

Owner:HALLIBURTON ENERGY SERVICES INC

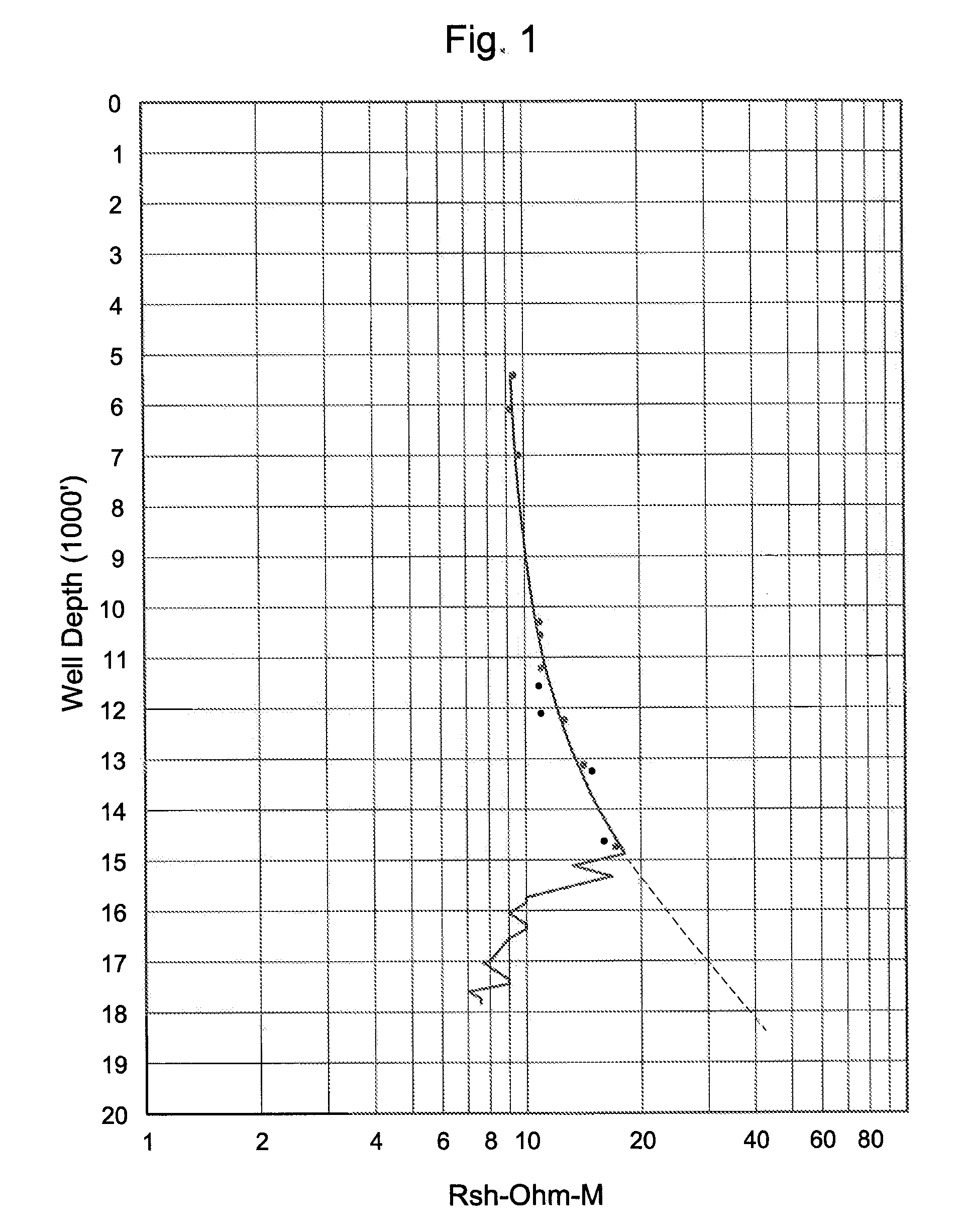

Method to detect formation pore pressure from resistivity measurements ahead of the bit during drilling of a well

ActiveUS20100000791A1Risk minimizationReduce riskElectric/magnetic detection for well-loggingSurveyWell drillingRegion of interest

Methods are described using resistivity ahead of a drill bit measurements obtained while drilling a subterranean well using a drilling mud. Resistivity data ahead of the bit is gathered during drilling and prior to penetrating a region of interest of a known subterranean formation using the drill bit and the drilling mud. The drill string progresses at known dip and azimuth angles toward the subterranean formation. The resistivity data is used to determine pore pressure ahead of the drill bit in the formation as a function of resistivity ahead of the drill bit in the formation while the drill bit advances toward but before the bit penetrates the formation while drilling. In certain embodiments, the methods include redirecting the drill bit while drilling toward locations in the formation where pore pressure is within an acceptable range. In other embodiments, a drilling mud parameter is adjusted based on the pore pressure in front of the bit.

Owner:BP CORP NORTH AMERICA INC

Zeolite-containing drilling fluids

Methods and compositions for wellbore treating fluids, especially drilling fluids, that comprise zeolite and a carrier fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

Localized fracturing system and method

A method and apparatus useful for fracturing subterranean formations with ultra high fluid pressure. The apparatus is capable of producing isolated pressure in a formation surrounding a primary wellbore, sufficient pressure is included within the formation for creating a fracture at the edge of the perforation. The apparatus is comprised of a motor, pump, and nozzle, where the entire apparatus can be disposed within the borehole. The apparatus can be conveyed within the borehole via wireline, coil tubing, slickline, or other tubing. Alternatively, a drill bit can be included for creating the perforation just prior to the fracturing procedure.

Owner:BAKER HUGHES HLDG LLC

Drillout bi-center bit

The present invention is a bi-center drill bit designed to drill out the cement and other material in the casing and then proceed to drill out the full gauge drilling diameter borehole with a diameter greater than the inside of the casing. The bi-center drill bit is configured with non-drilling bearing elements that contact with the casing when the bit is drilling the cement without allowing the gauge cutting elements of the bi-center drill bit to contact the casing. The bi-center drill bit also has a cutting element configuration which prevents reverse scraping of the cutting elements when drilling both the cement and the formation.

Owner:CAMCO INT

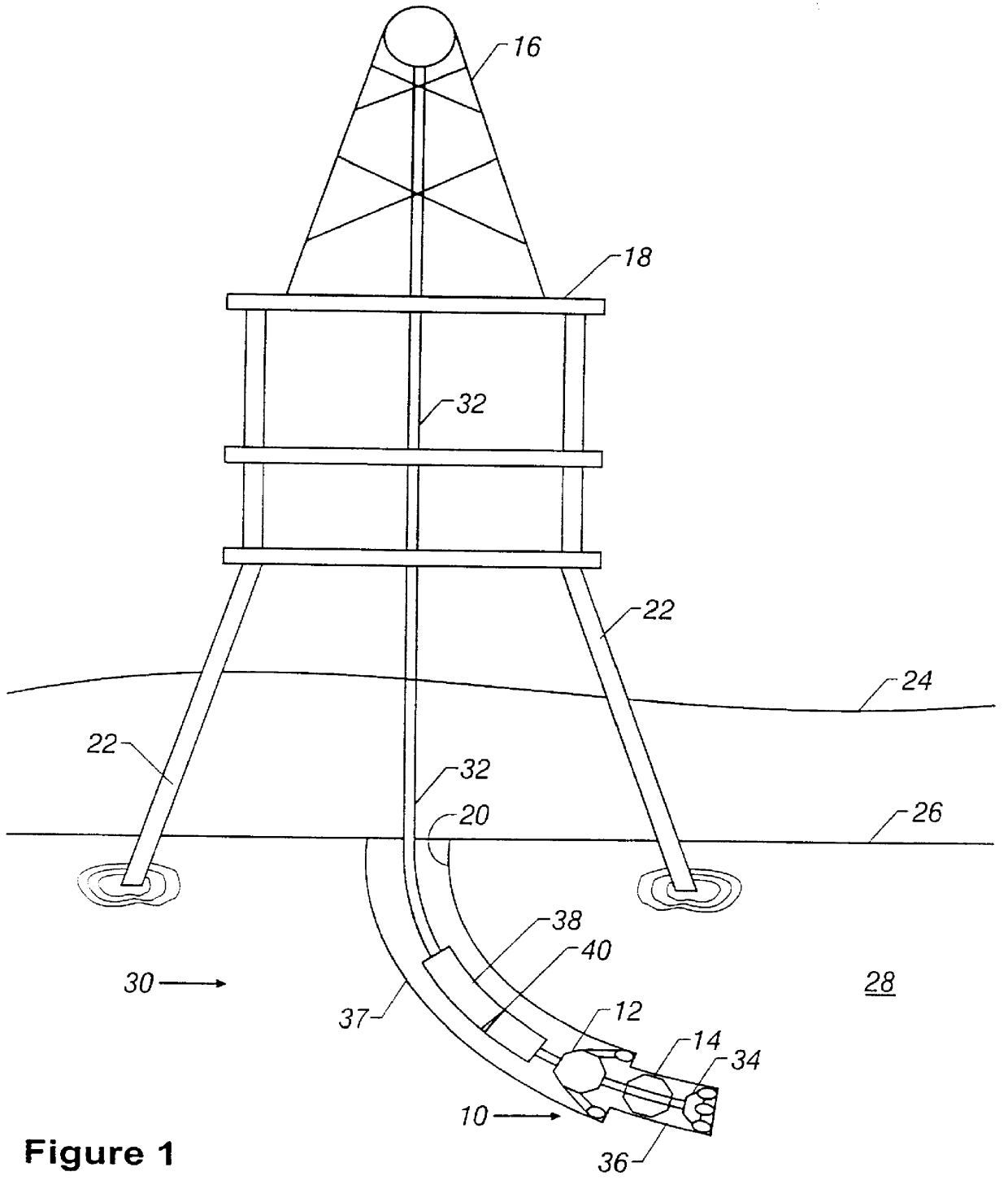

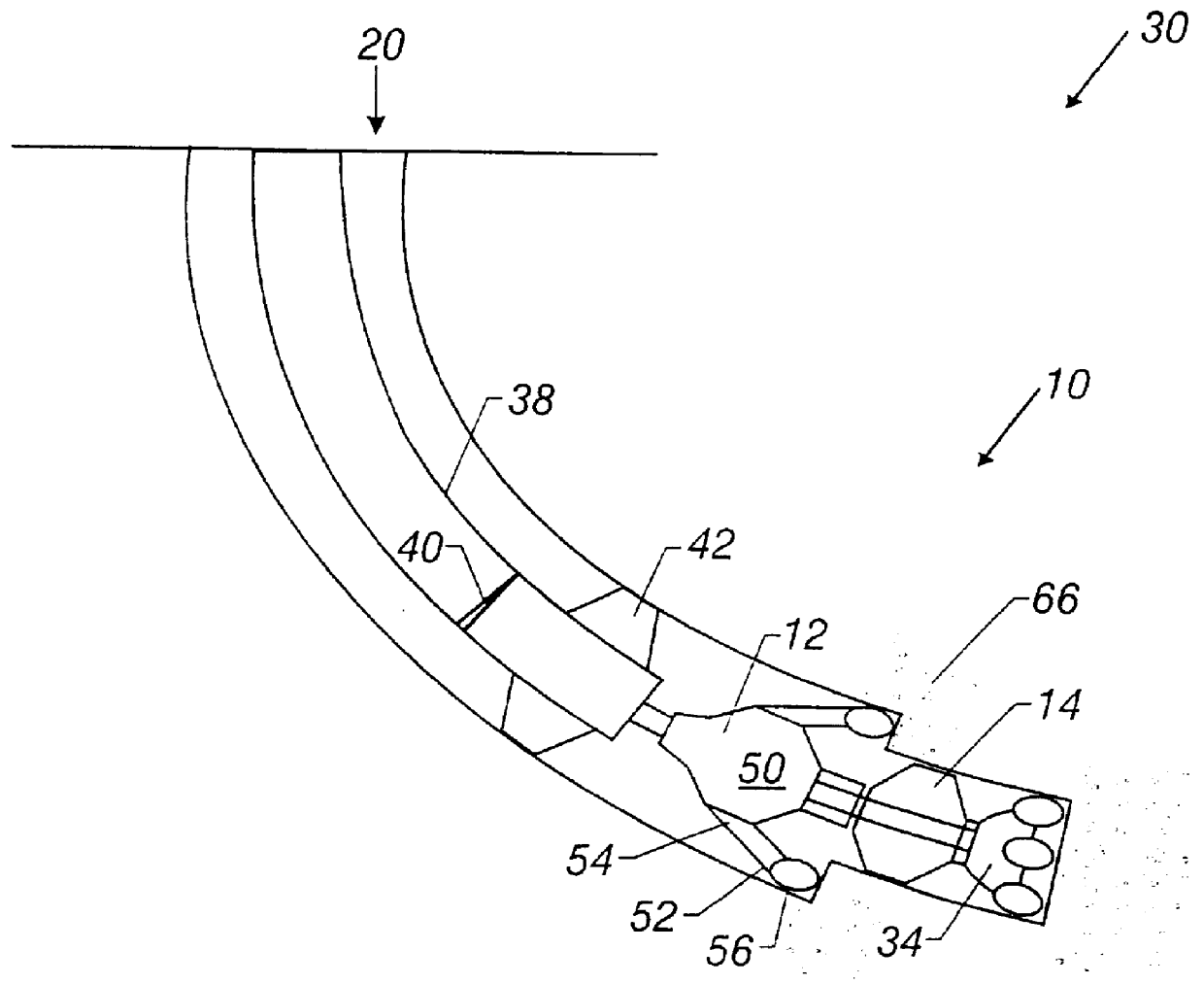

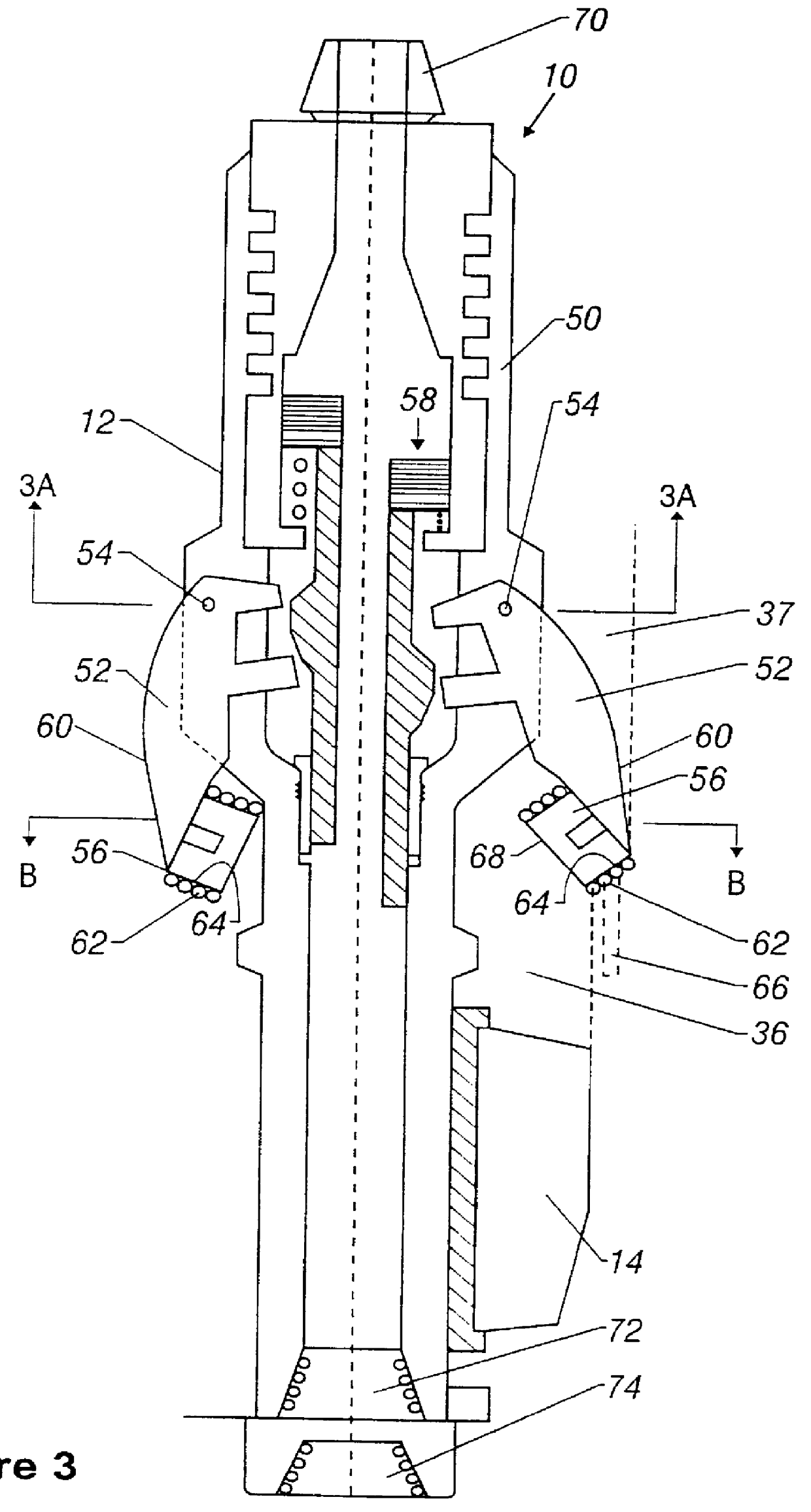

Method for establishing branch wells at a node of a parent well

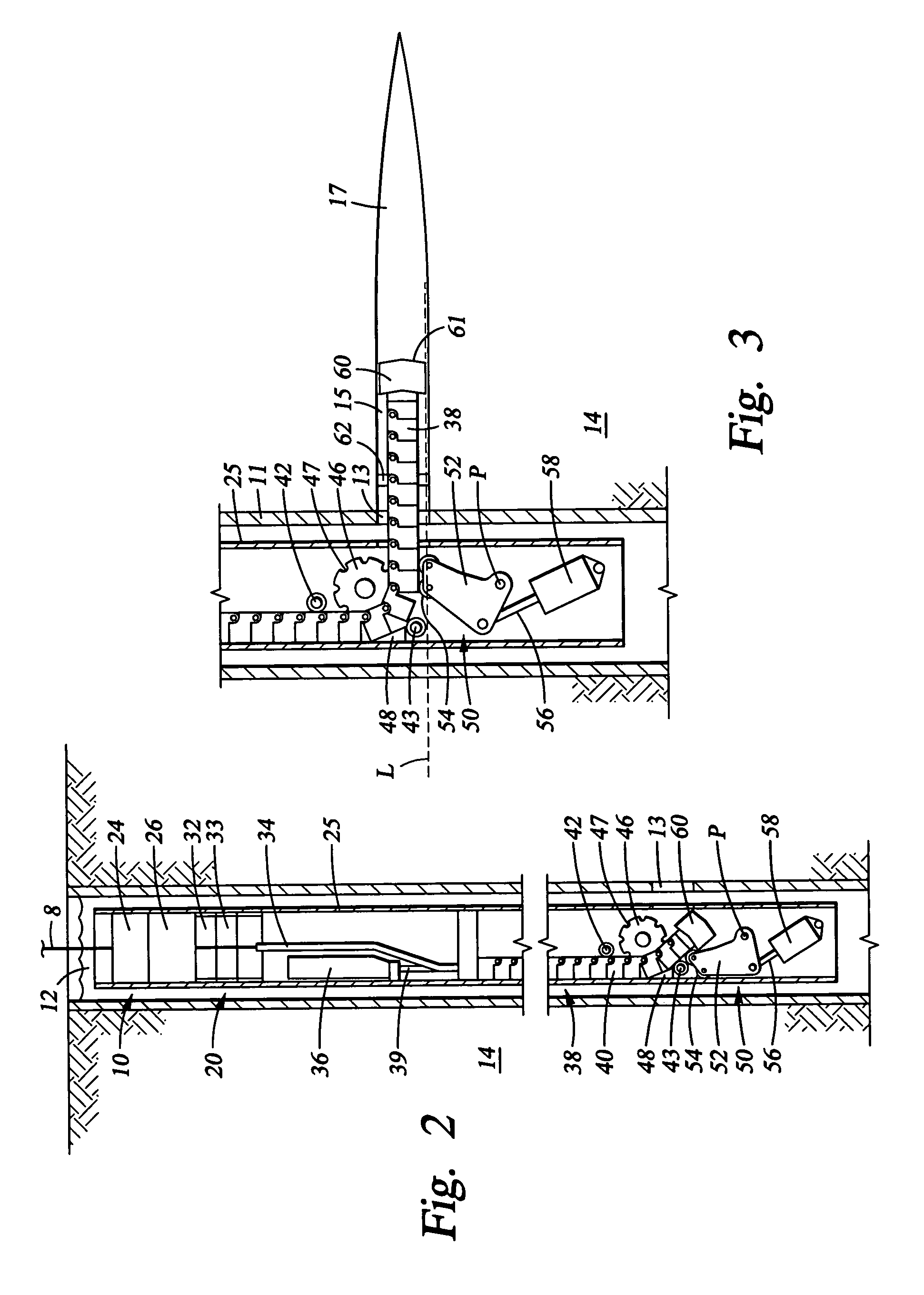

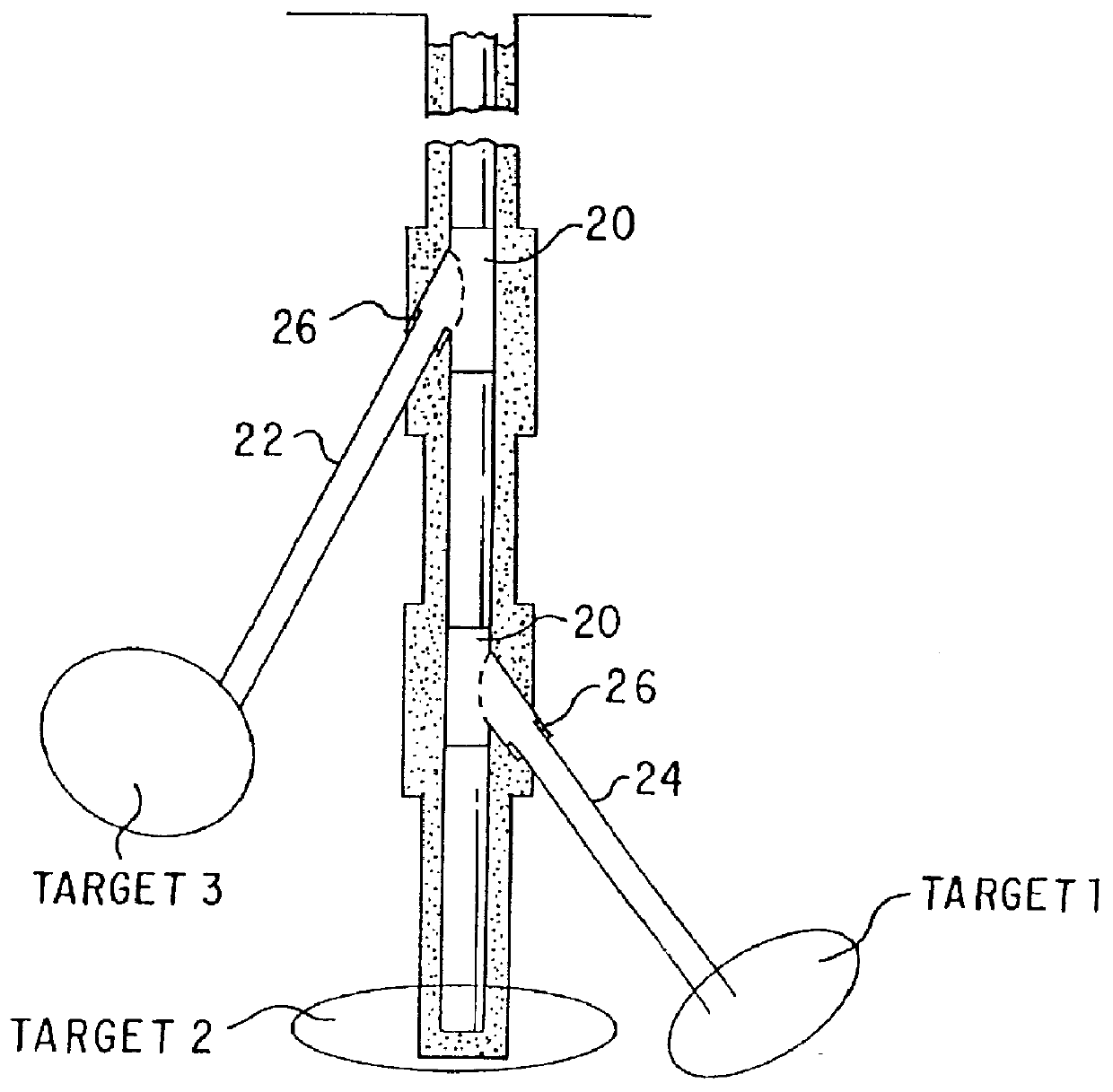

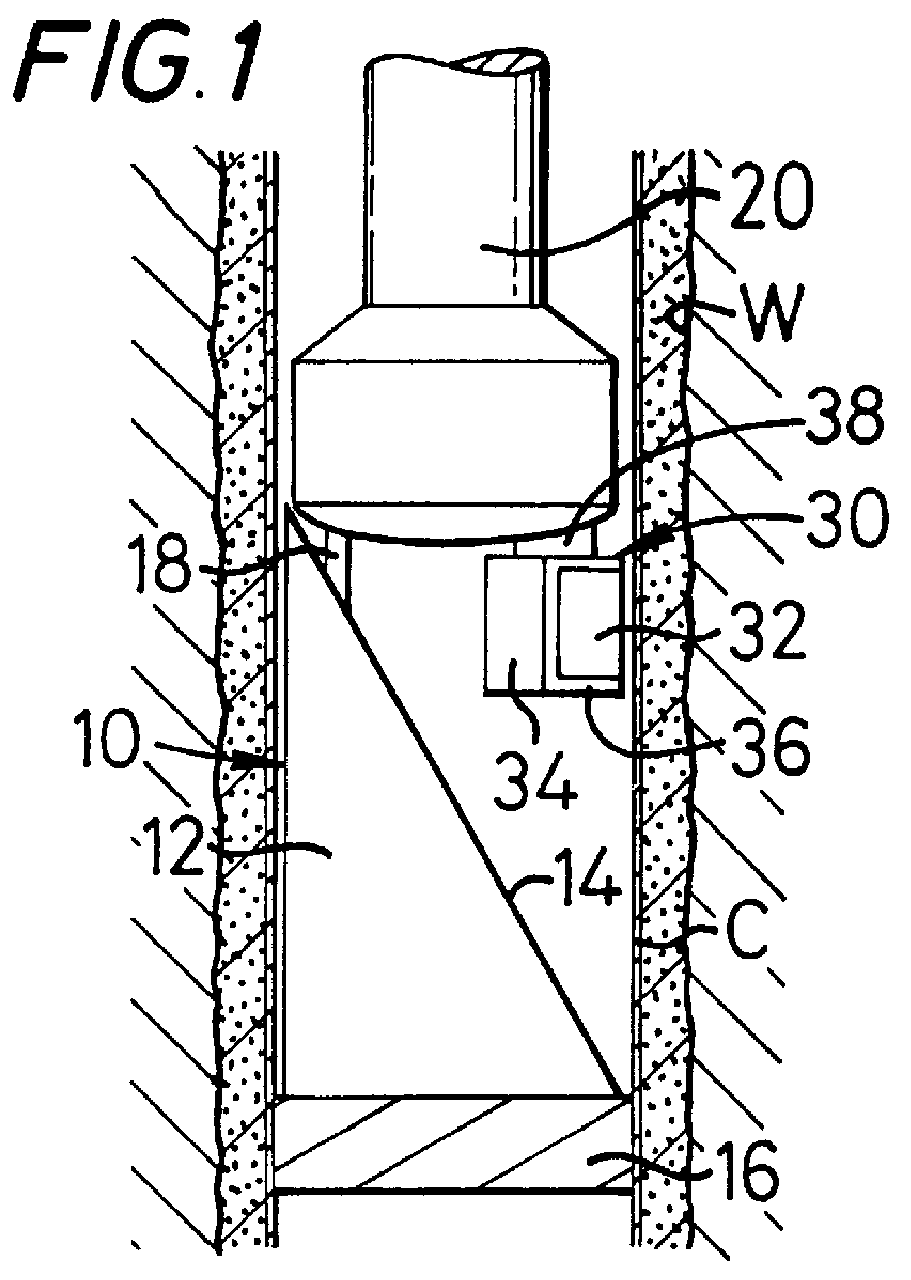

InactiveUS6079495AOptimized areaFluid communicationDrilling rodsConstructionsEngineeringMechanical engineering

A method for creating multiple branch wells from a parent well is disclosed. A multiple branching sub is provided for placement at a branching node of a well. Such sub includes a branching chamber and a plurality of branching outlet members. The outlet members during construction of the branching sub, have previously been distorted into oblong shapes so that all of the branching outlet members fit within an imaginary cylinder which is coaxial with and substantially the same radius as the branching chamber. After deployment of the branching sub via a parent casing in the well, a forming tool is lowered to the interior of the sub. The outlet members are extended outwardly by the forming tool and simultaneously formed into substantially round tubes. Next, each outlet member is plugged with cement, after which each branch well is drilled through a respective outlet member. If desired, each branch may be lined with casing and sealed to a branching outlet by means of a casing hanger. A manifold placed in the branching chamber controls the production of each branch well to the parent well.

Owner:SCHLUMBERGER TECH CORP

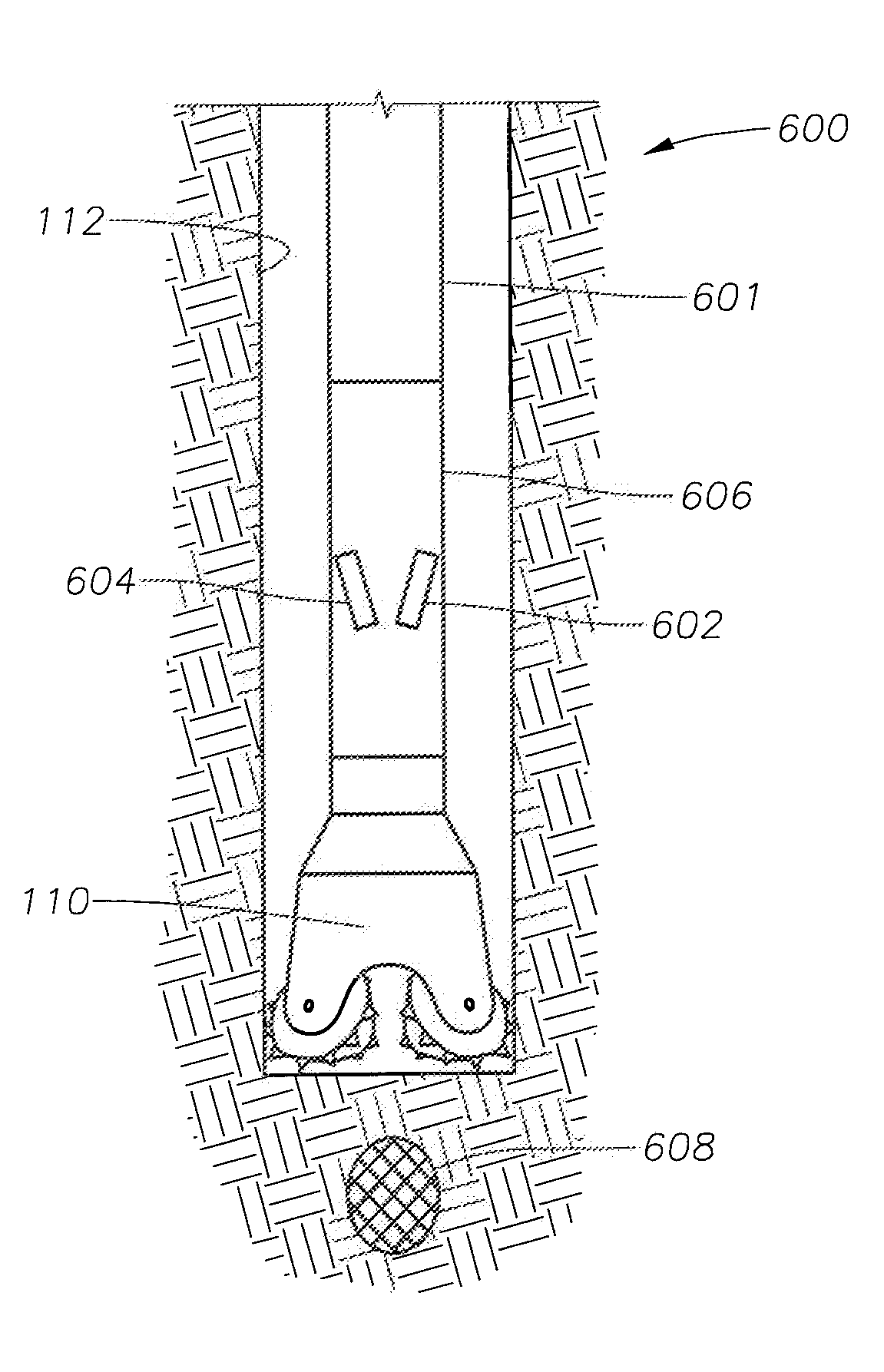

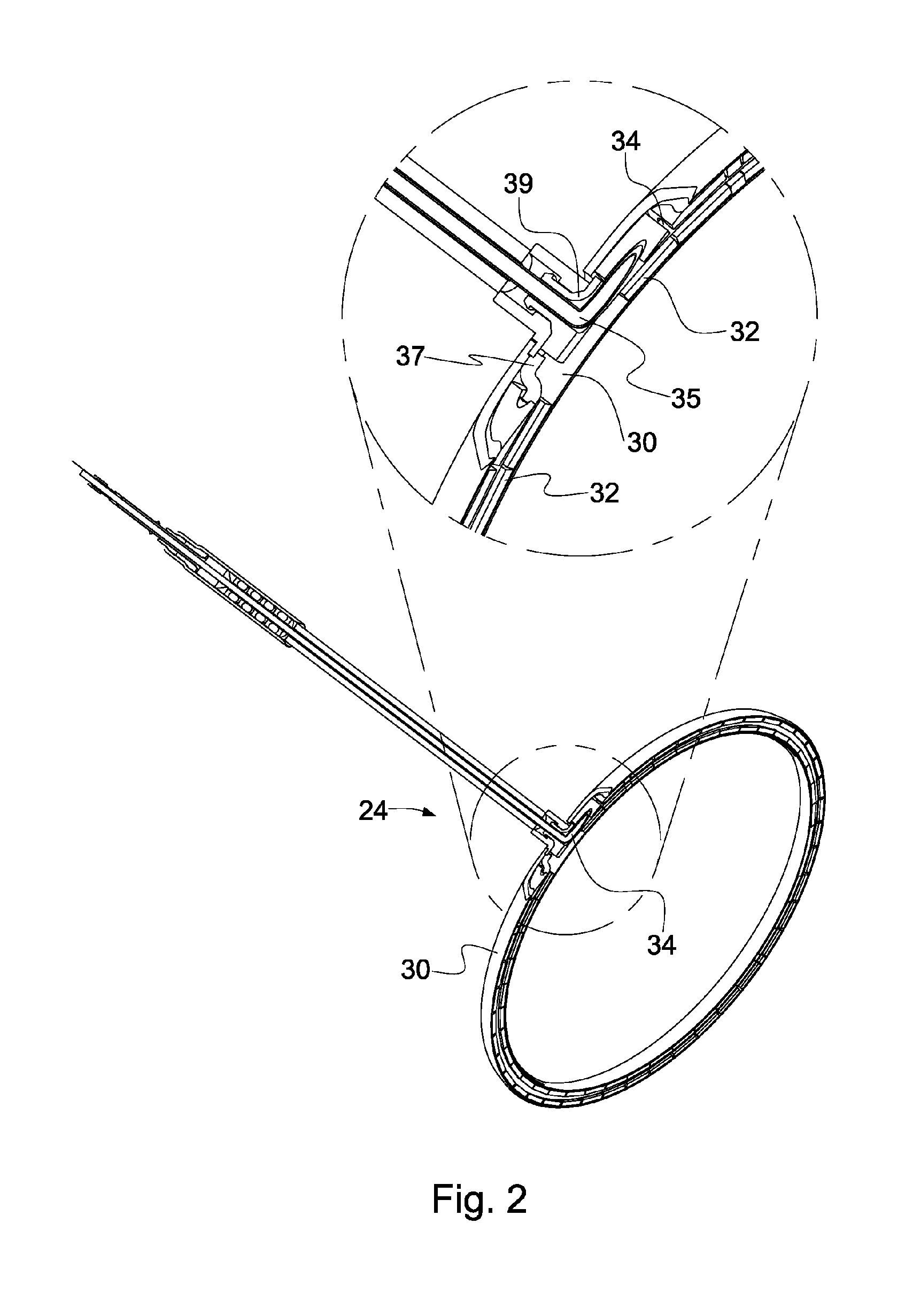

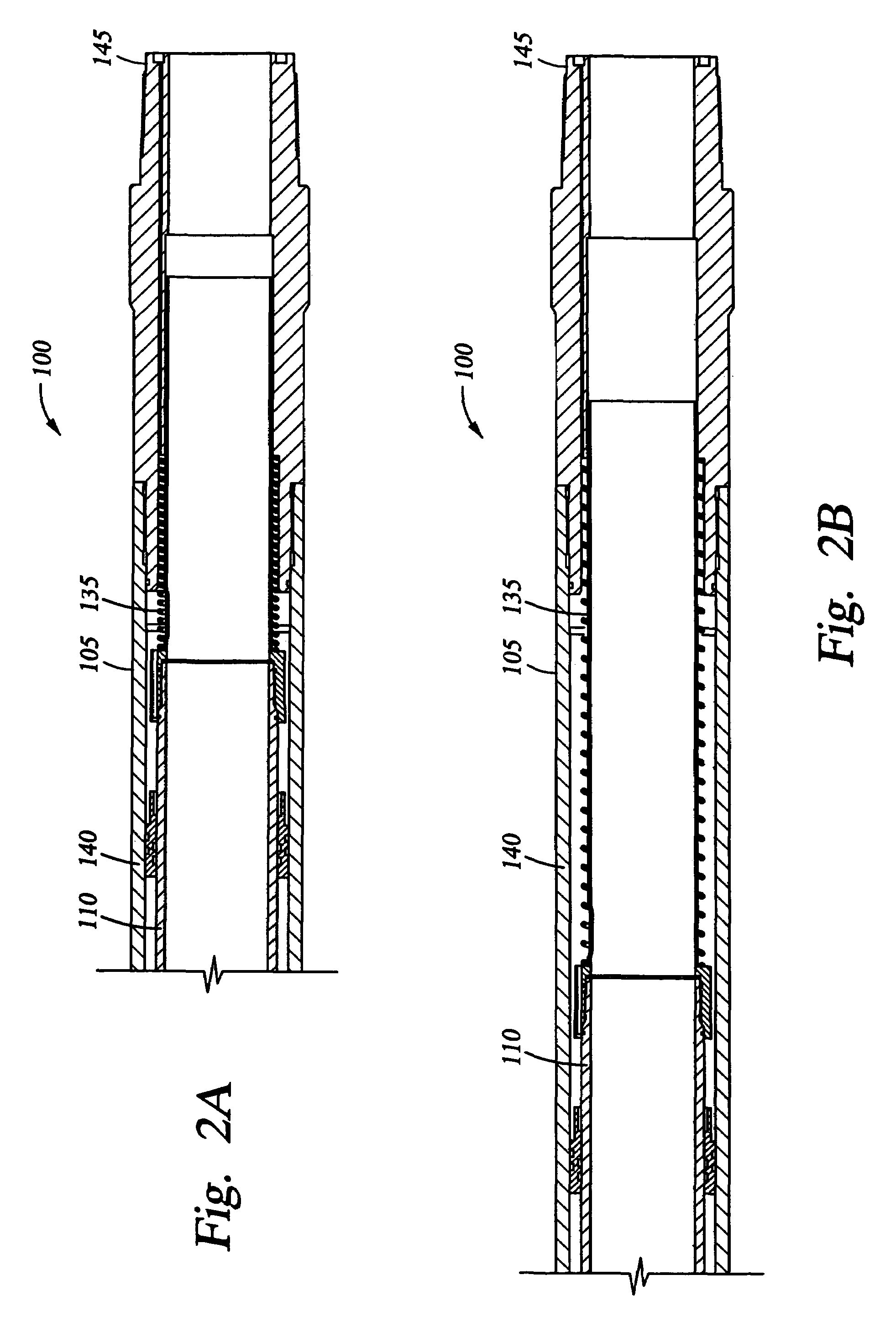

Steerable bit assembly and methods

ActiveUS20050056463A1Efficient and cost-effectiveFaster and less mechanically complexDrill bitsDrilling rodsShape changeExternal reference

A drilling system includes a steerable bottomhole assembly (BHA) having a steering unit and a control unit that provide dynamic control of drill bit orientation or tilt. Exemplary steering units can adjust bit orientation at a rate that approaches or exceeds the rotational speed of the drill string or drill bit, can include a dynamically adjustable articulated joint having a plurality of elements that deform in response to an excitation signal, can include adjustable independently rotatable rings for selectively tilting the bit, and / or can include a plurality of selectively extensible force pads. The force pads are actuated by a shape change material that deforms in response to an excitation signal. A method of directional drilling includes continuously cycling the position of the steering unit based upon the rotational speed of the drill string and / or drill bit and with reference to an external reference point.

Owner:BAKER HUGHES INC

Casing pushdown and rotating tool

A pushdown and rotating tool for holding, pushing, and rotating a floated casing string into a wellbore is provided. The tool includes a mandrel, a housing attached about the external diameter of the mandrel and shaped to receive a collared casing, a jaws assembly within the housing, and an automatic hydraulics system for actuating the jaws. The mandrel and housing are connected such that they can move telescopically relative to one another, and such motion actuates the jaws. The tool has a threaded coupling for a top drive connection, the top drive providing the pushdown and rotational forces which are transmitted to the casing by way of the tool. The mandrel also has an internal passage-way through its length and a male connection at the bottom. The tool facilitates floating a casing into a substantially horizontal wellbore when the casing becomes buoyant and tries to "kick back" out of the well, or when the floated casing becomes stuck and requires rotation to extend beyond the obstacle.

Owner:BJ SERVICES CO

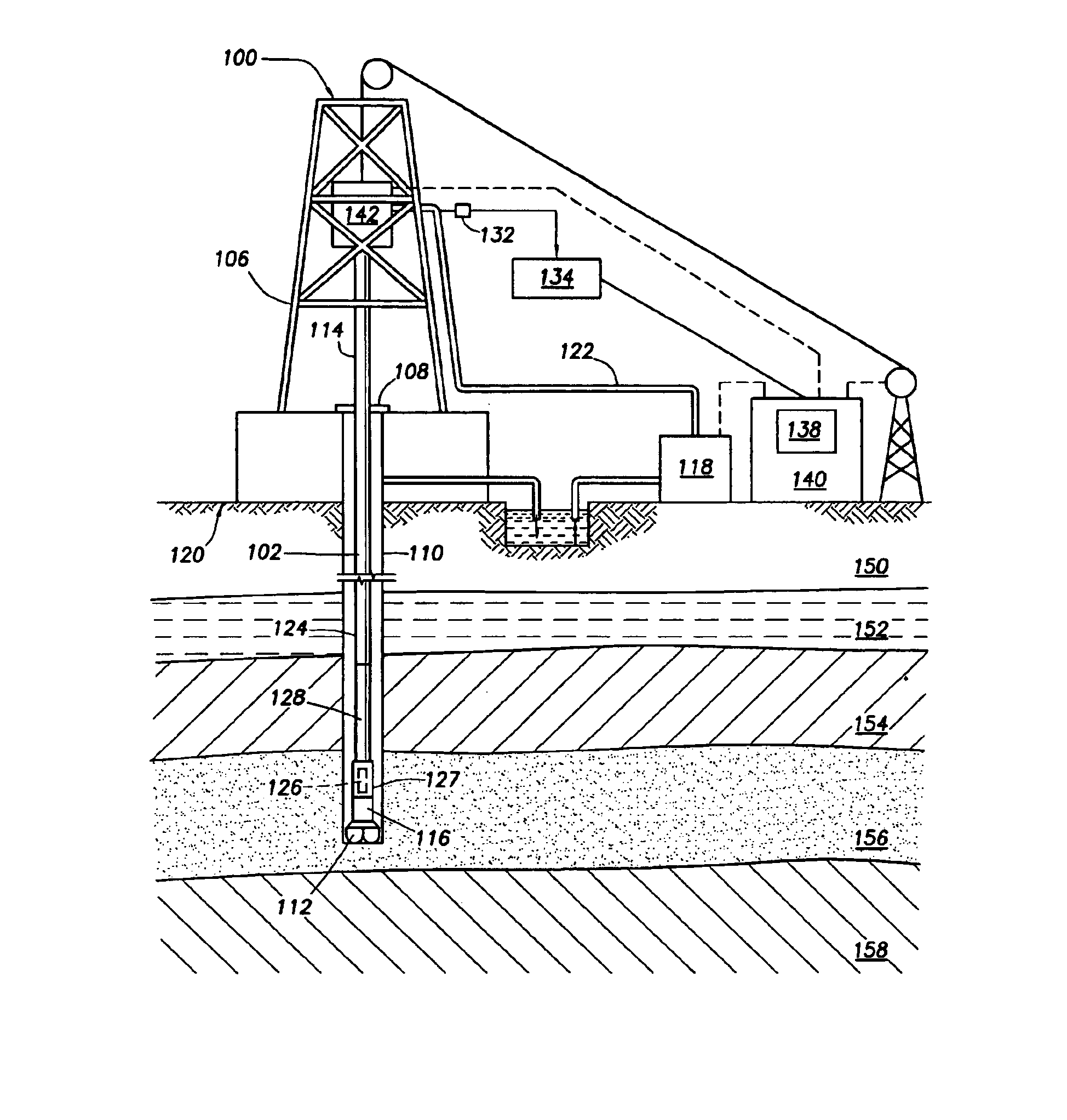

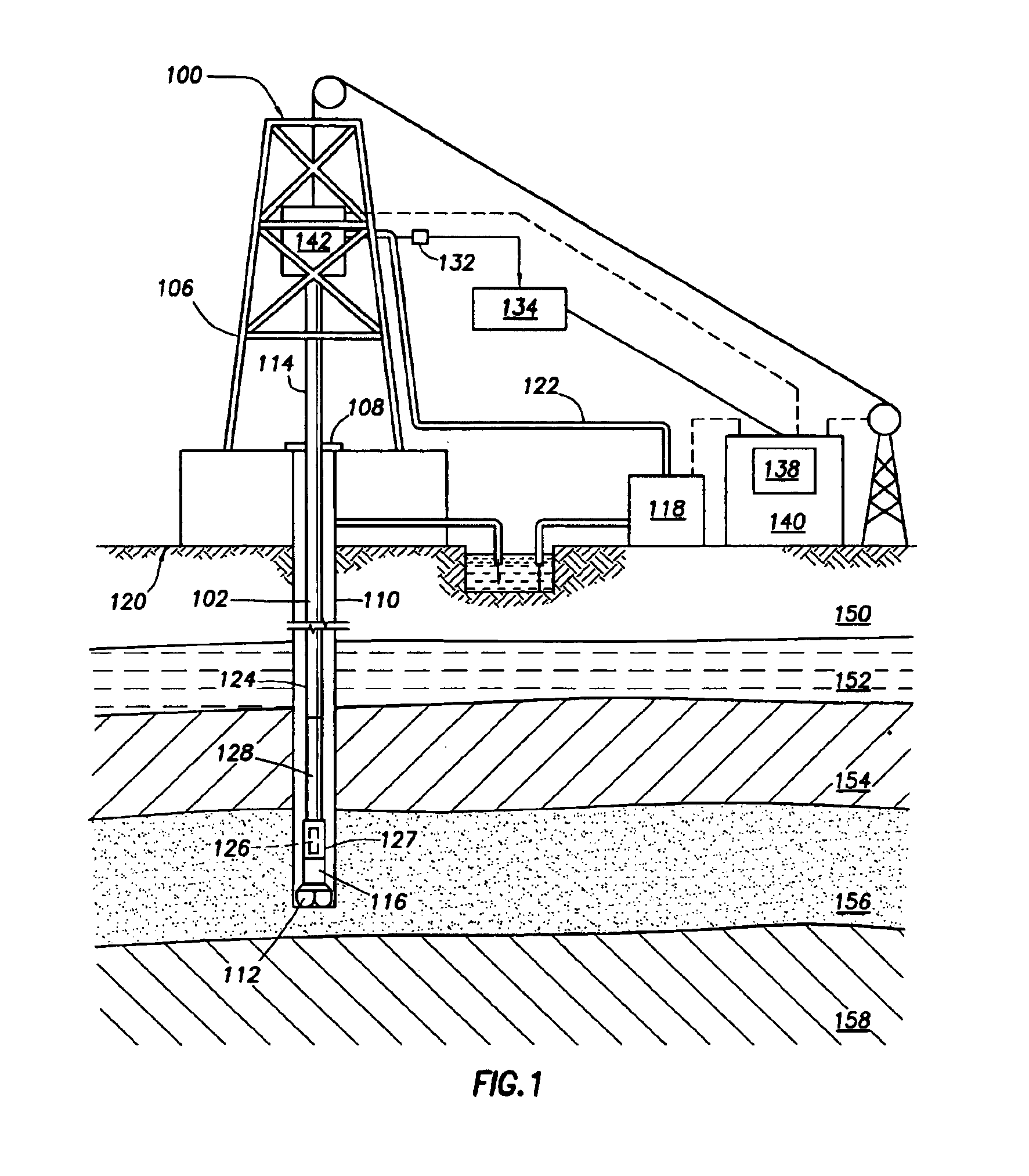

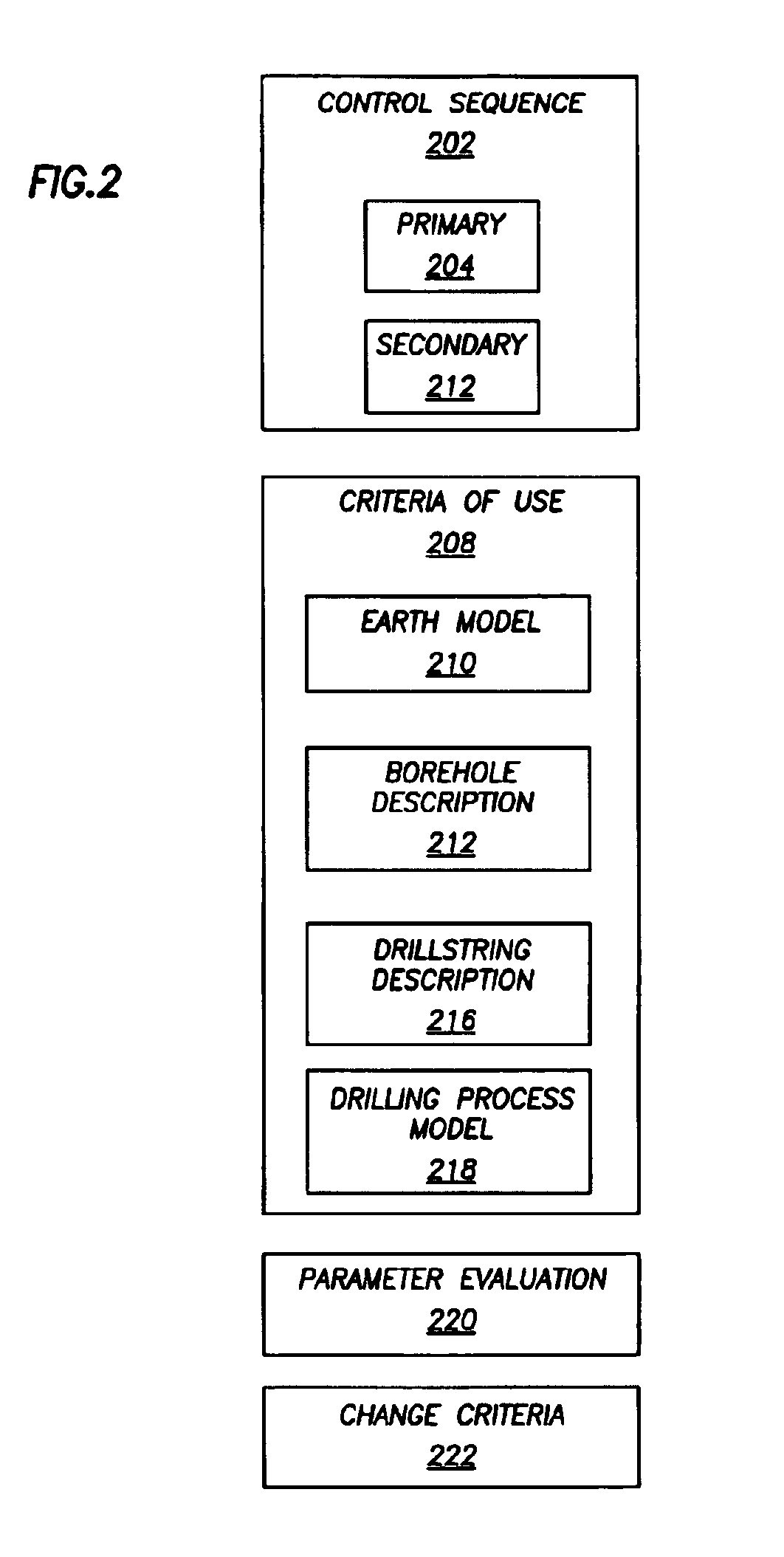

Realtime control of a drilling system using the output from combination of an earth model and a drilling process model

A system is for controlling borehole operations using a computational drilling process model representing the combined effect of downhole conditions and the operation of a drillstring. The drilling process model is continually updated with downhole measurements made during a drilling operation. From the updated drilling process model, a set of optimum drilling parameters is determined and communicated to a surface equipment control system. Further, the system allows the surface equipment control system to automatically adjust current surface equipment control settings based on the updated optimum drilling parameters. Various control scripts are generated and executed to inform the surface equipment control system based on a present drilling mode.

Owner:SCHLUMBERGER TECH CORP

Method for window formation in wellbore tubulars

InactiveUS6024169APreventing coringEasy millingFluid removalDirectional drillingStream flowEngineering

New systems and methods have been invented for explosively forming openings, ledges, windows, holes, and lateral bores through tubulars such as casing, which openings may, in cerain aspects, extend beyond the casing into a formation through which a wellbore extends. In certain aspects openings (e.g. ledges, initial, or completed windows) in wellbore tubulars (e.g. tubing or casing) are made using metal oxidizing systems, water jet systems, or mills with abrasive and / or erosive streams flowing therethrough and / or therefrom.

Owner:WEATHERFORD TECH HLDG LLC

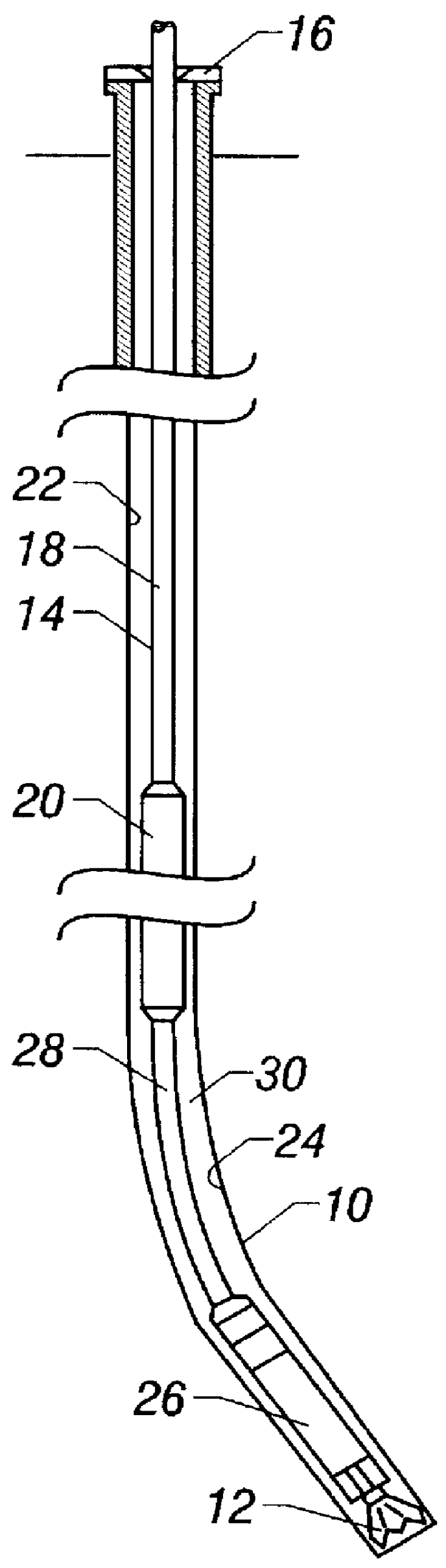

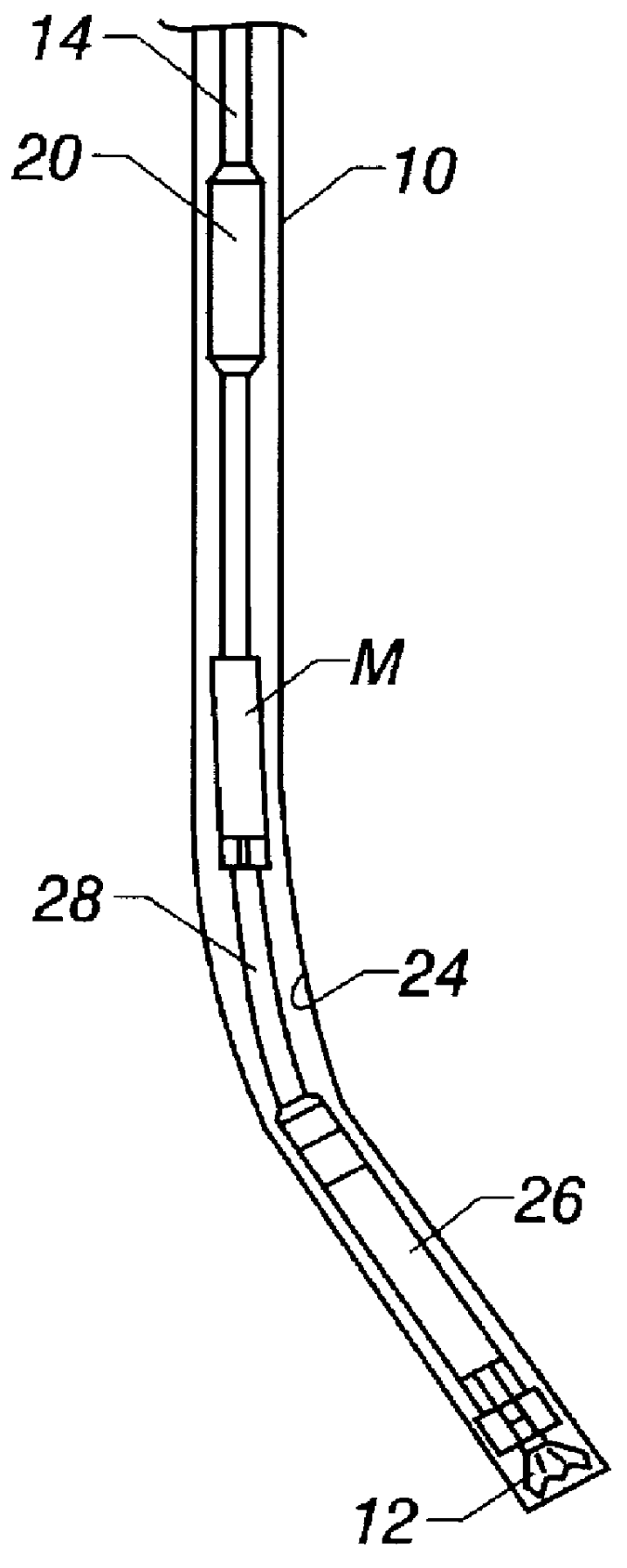

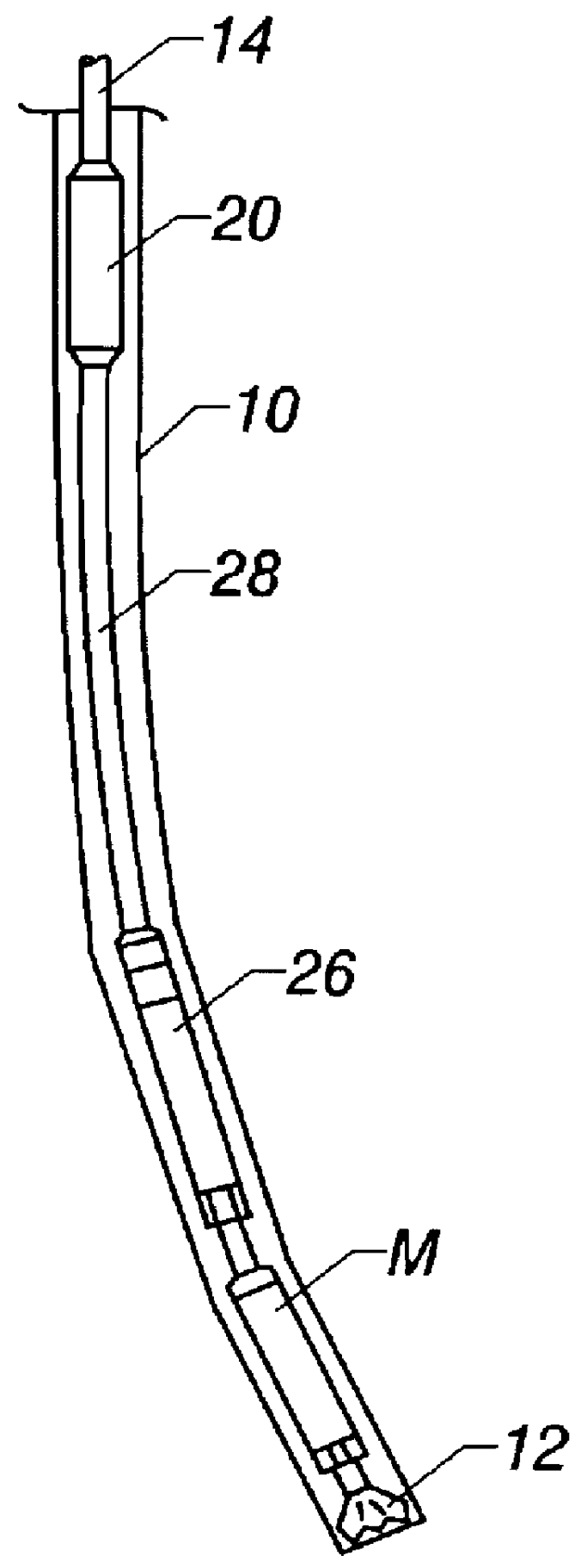

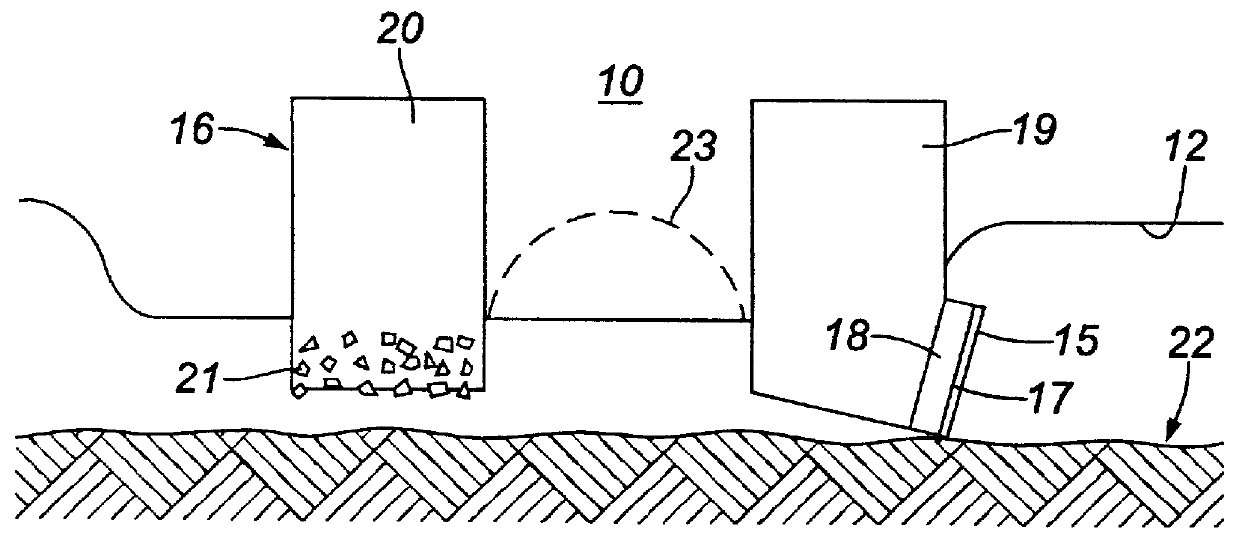

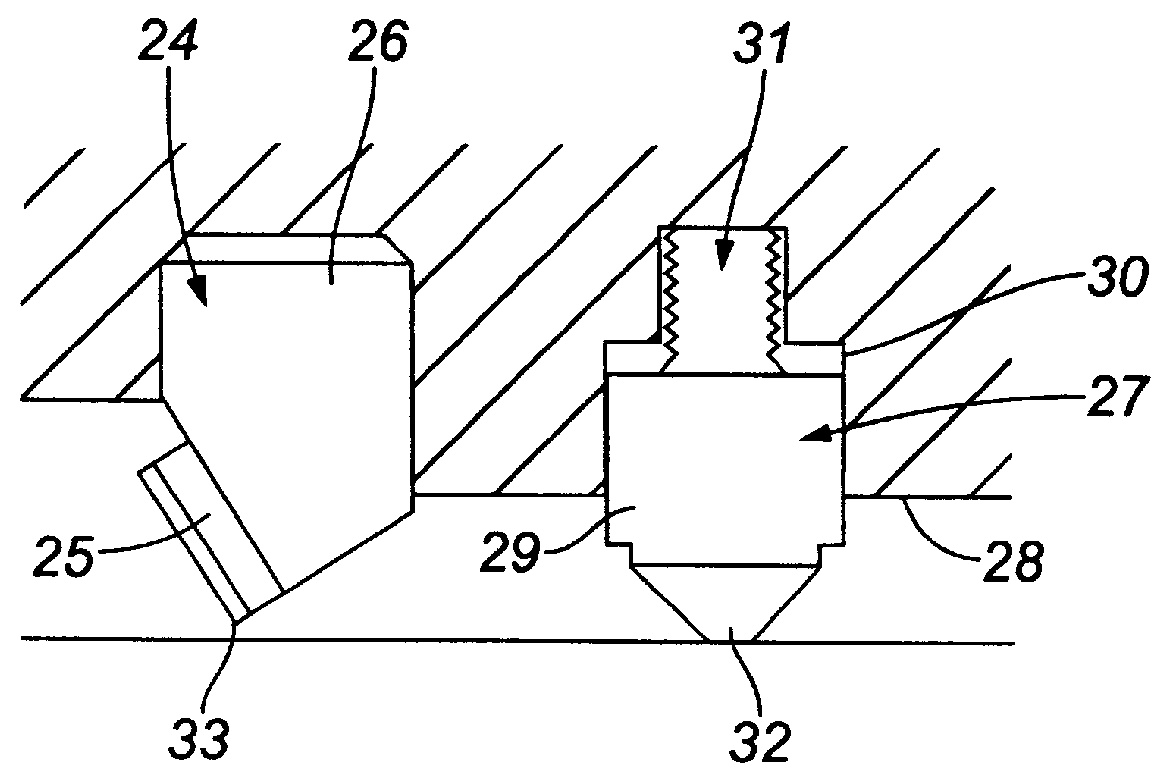

Apparatus and method for directional drilling using coiled tubing

A steerable directional drilling tool assembly includes a bent housing defining a bend angle and having a mud motor in its upper section and a drill bit below its lower section, an orienting tool rotatably coupled to such upper section and suspended on coiled tubing that extends upward to the surface, an electric motor in the orienting tool operable to rotate the bent housing in either hand direction to change or adjust the tool face angle of the bit, or continuously rotate the bent housing so that the bit drills straight-ahead, and an electric cable extending throughout the coiled tubing to furnish power from the surface to the electric motor and transmit electric signals to and from the surface. A logging tool can be included in the assembly for measuring characteristics of the formation, the borehole, and the tool assembly.

Owner:HEWLETT PACKARD CO +1

Method and apparatus for enhancing directional accuracy and control using bottomhole assembly bending measurements

A system for drilling a well comprises a tubular member having a bottomhole assembly at a bottom end thereof disposed in a wellbore. A first sensor is disposed in the bottomhole assembly at a predetermined axial location for detecting bending in a first axis and generating a first bending signal in response thereto, where the first axis is substantially orthogonal to a longitudinal axis of the bottomhole assembly. A second sensor is disposed in the bottomhole assembly at the predetermined axial location for detecting bending in a second axis and generating a second bending signal in response thereto, where the second axis is substantially orthogonal to the longitudinal axis. A processor receives the first bending signal and the second bending signal and relates the first bending signal and the second bending signal to a borehole curvature according to programmed instructions.

Owner:BAKER HUGHES INC

Assembly and method for forming a seal in a junction of a multilateral well bore

This invention relates to an assembly and method for forming a hydraulic seal at the junction of a multilateral well bore drilled through a window in at least a main well bore comprising a tubular member which is run into the well bore casing and has a sealing member positioned about the tubular member for seating, at least one orientation member being provided for orientation of the tubular member and sealing member in the main well bore casing, and having a tubular sleeve member for insertion in the well bore which has an aperture through at least one side of the tubular sleeve member for alignment of the aperture with the window and having a seating surface on the inside of the tubular sleeve member proximate the aperture, with the aperture in some embodiments being adjustable, and having a deflection member positioned and releasable sealed in the tubular sleeve member for deflecting the tubular member through the window in the well bore when the tubular member is run into contact with the deflection member, and having at least one orientation member for orientation of the deflection member relative to the window in the at least well bore casing and for aligning the aperture in the tubular sleeve with the window and a method of using the assembly to form a seal at the junction which can be executed in one run into the well bore casing in at least one embodiment.

Owner:WEATHERFORD TECH HLDG LLC

Down hole assembly and method for forming a down hole window and at least one keyway in communication with the down hole window for use in multilateral wells

Down hole assembly and method for forming a longitudinal window and a key-way in communication with the longitudinal window used in drilling multi-lateral well bores and for entry and reentry thereafter comprising, a first milling drill bit for milling the longitudinal window, a first whip stock having a guide surface, and orientation and positioning members located on the first whip stock for orienting and positioning tools to be used in forming the key-way in communication with the longitudinal window. A guide surface member is provided on the first whip stock member for guiding the first milling drill bit for milling a longitudinal window. A housing member for slidable mating with the first whip stock having a second drill bit member mounted in the housing member is provided for forming a down hole orientation key-way in communication with the longitudinally milled window. A second guide surface member positioned along the center line of the one surface guide member on the first whip stock is provided for guiding the second drill bit to drill a down hole orientation key-way in communication with the longitudinal window. A second whip stock having a forming member for forming an up hole orientation key-way in communication with the longitudinally milled window is provided with at least one guide surface member on the second whip stock member for guiding the forming member for forming the up hole orientation key-way in communication with the longitudinal window.

Owner:WEATHERFORD TECH HLDG LLC

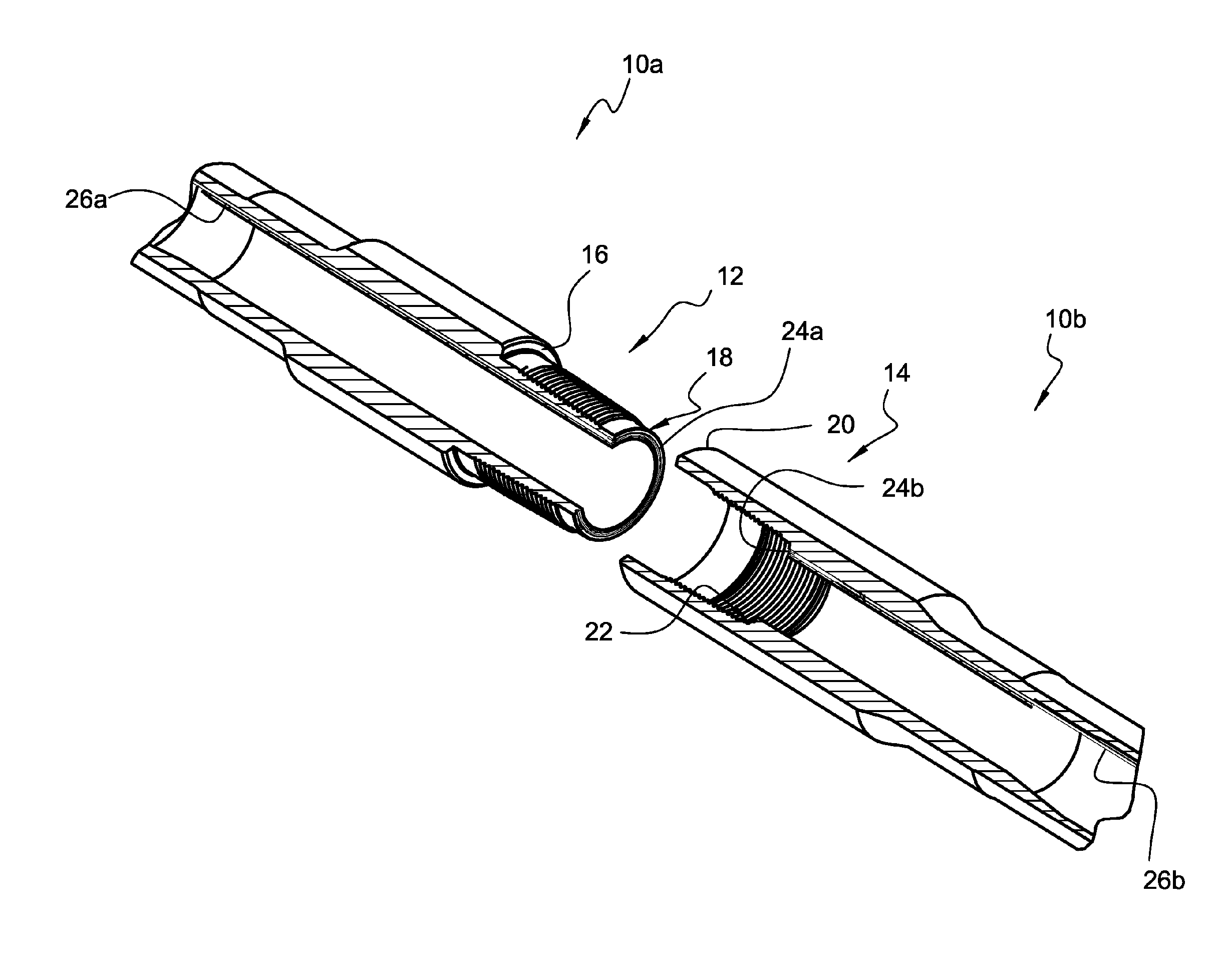

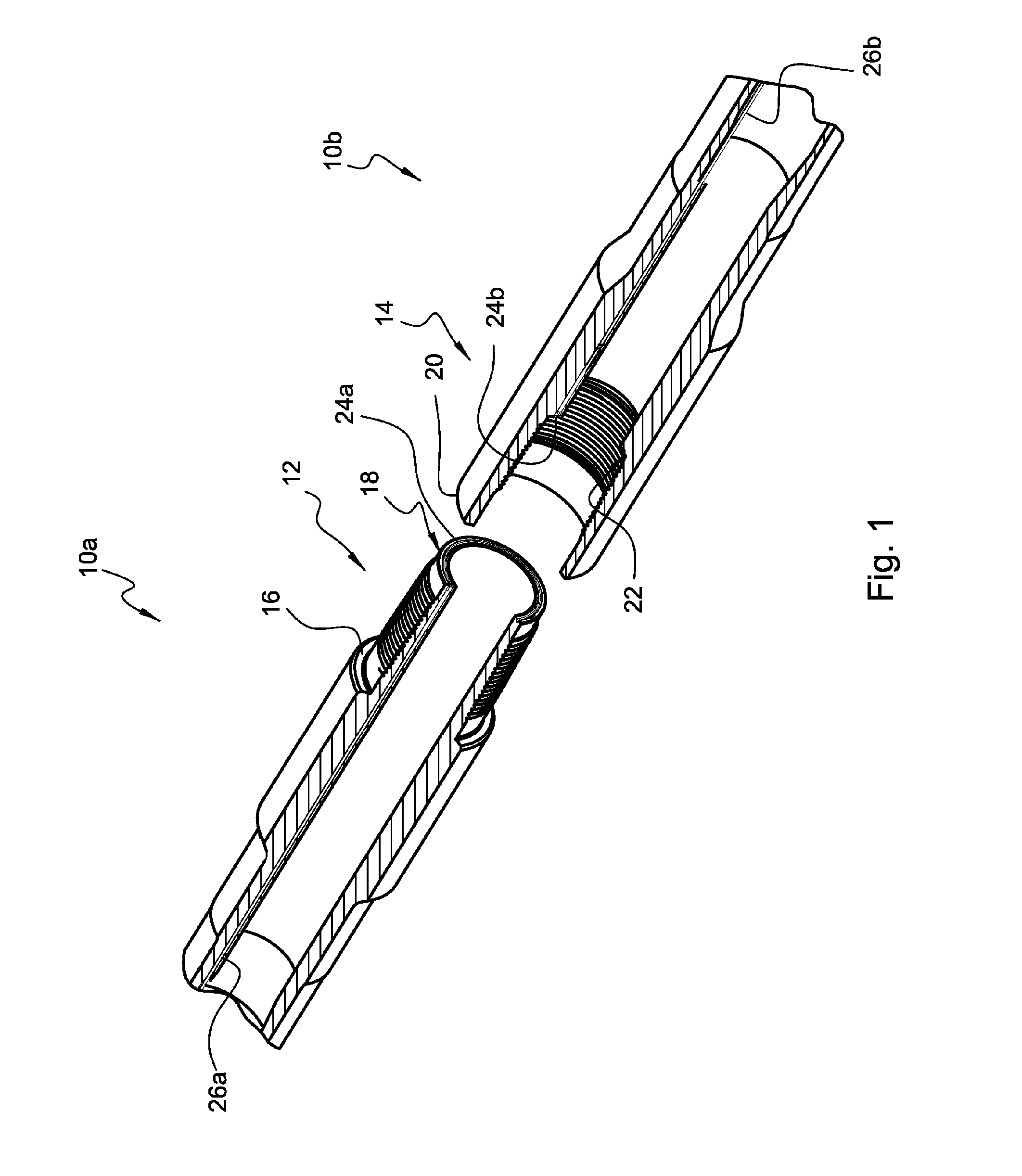

Corrosion-Resistant Downhole Transmission System

An apparatus in accordance with the invention may include a downhole tool and a data transmission path incorporated into the downhole tool. The data transmission path may include one or more contact surfaces providing electrical continuity to the data transmission path. To protect the contact surfaces from corrosion while maintaining electrical conductivity, a coating may be attached to one or more of the contact surfaces. The coating may include any of various materials that increase the corrosion-resistance of the underlying base metal, including but not limited to cobalt, nickel, tin, tin-lead, platinum, palladium, gold, silver, zinc, or combinations thereof.

Owner:INTELLISERV

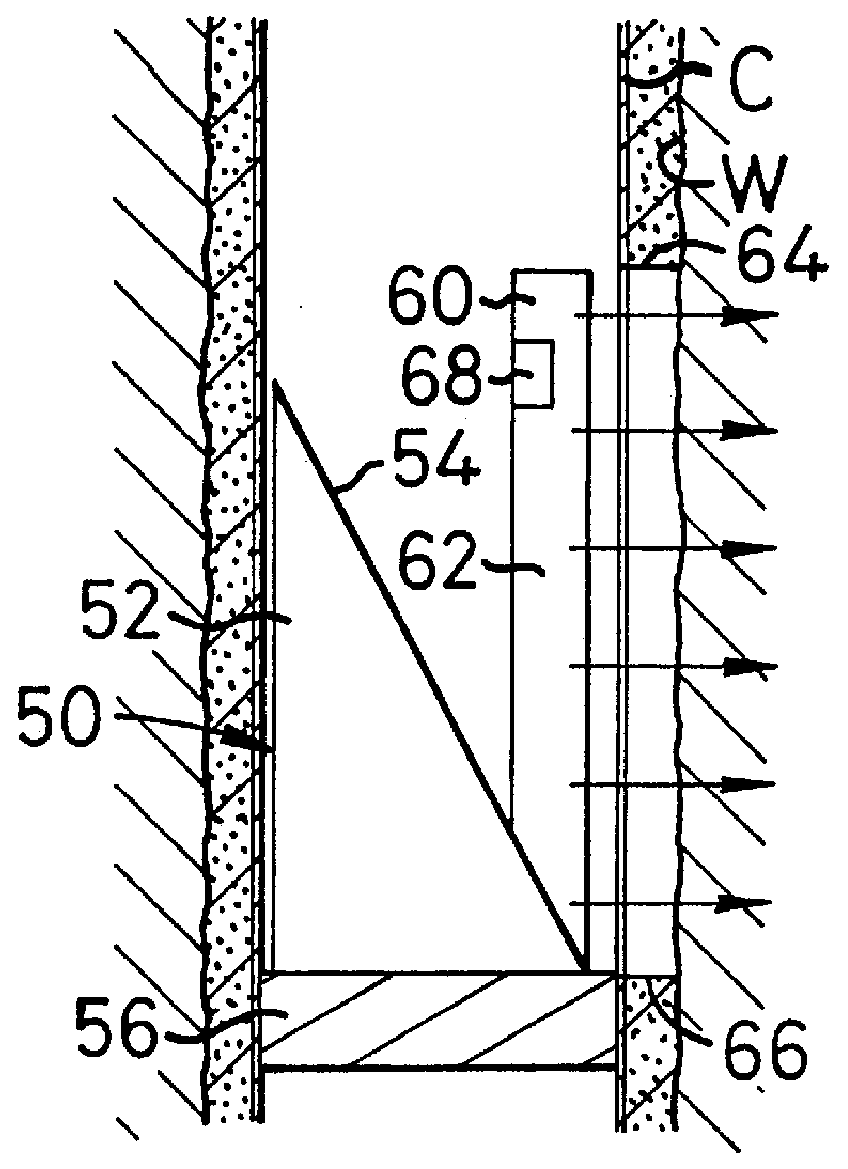

Formation pressure measurement with remote sensors in cased boreholes

The present invention relates to a method and apparatus for establishing communication in a cased wellbore with a data sensor that has been remotely deployed, prior to the installation of casing in the wellbore, into a subsurface formation penetrated by the wellbore. Communication is established by installing an antenna in an opening in the casing wall. The present invention further relates to a method and apparatus for creating the casing wall opening, and then inserting the antenna in the opening in sealed relation with the casing wall. A data receiver is inserted into the cased wellbore for communicating with the data sensor via the antenna to receive formation data signals sensed and transmitted by the data sensor. Preferably, the location of the data sensor in the subsurface formation is identified prior to the installation of the antenna, so that the opening in the casing can be created proximate the data sensor. The antenna can then be installed in the casing wall opening for optimum communication with the data sensor. It is also preferred that the data sensor be equipped with means for transmitting a signature signal, permitting the location of the data sensor to be identified by sensing the signature signal. The location of the data sensor is identified by first determining the depth of the data sensor, and then determining the azimuth of the data sensor relative to the wellbore.

Owner:SCHLUMBERGER TECH CORP

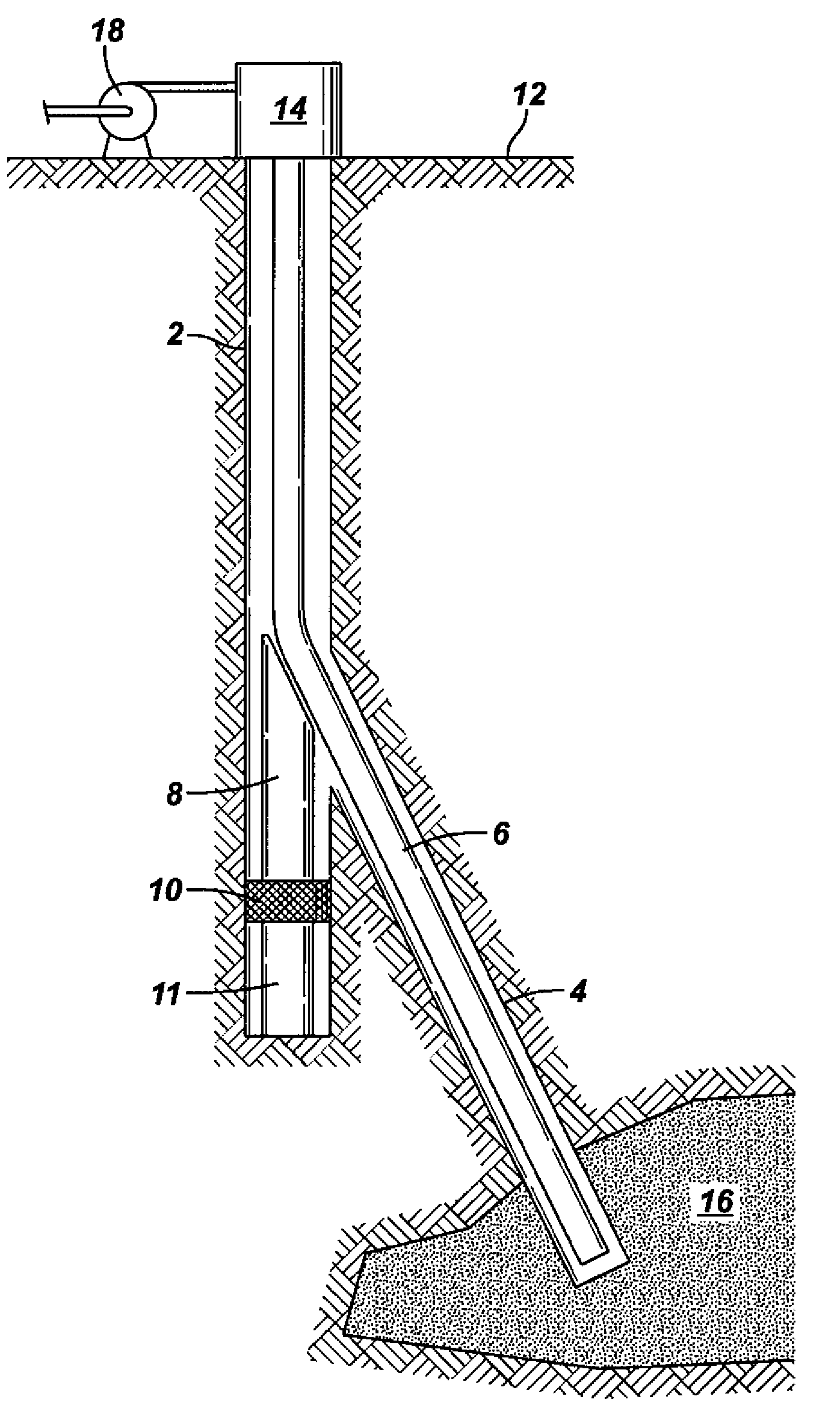

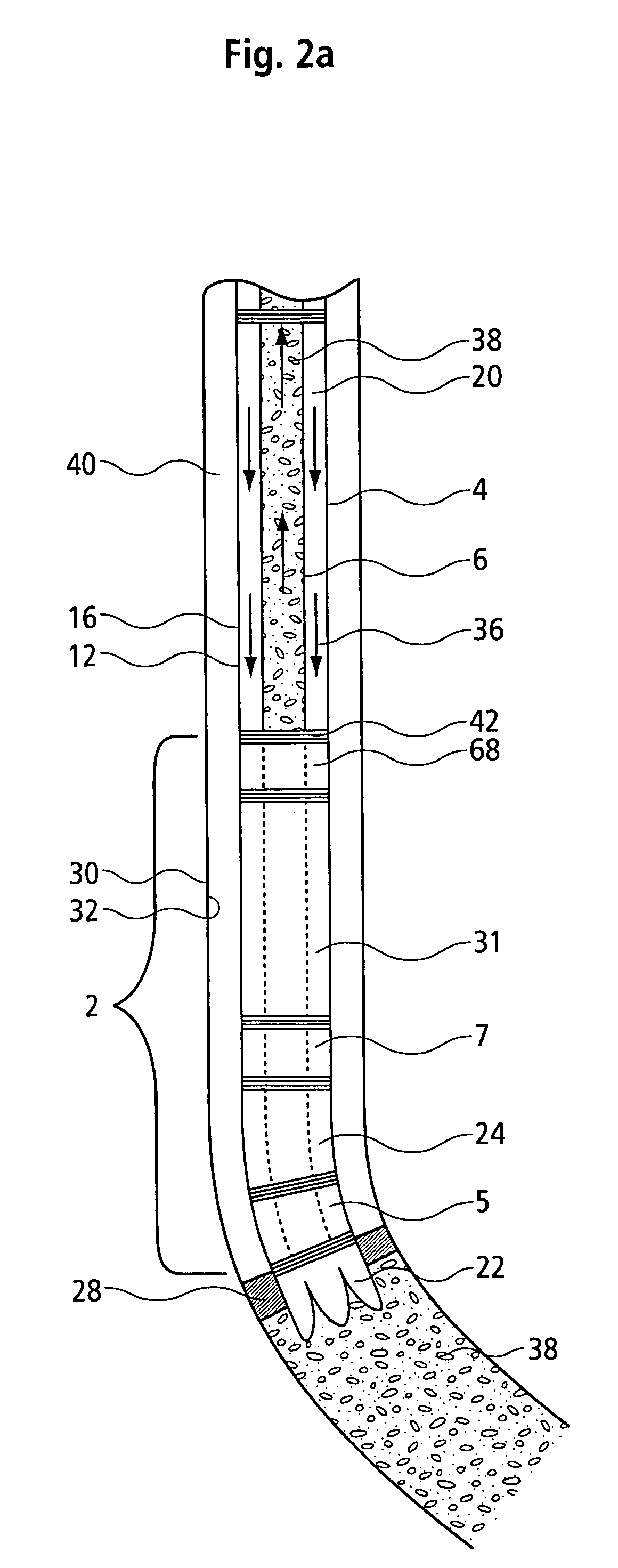

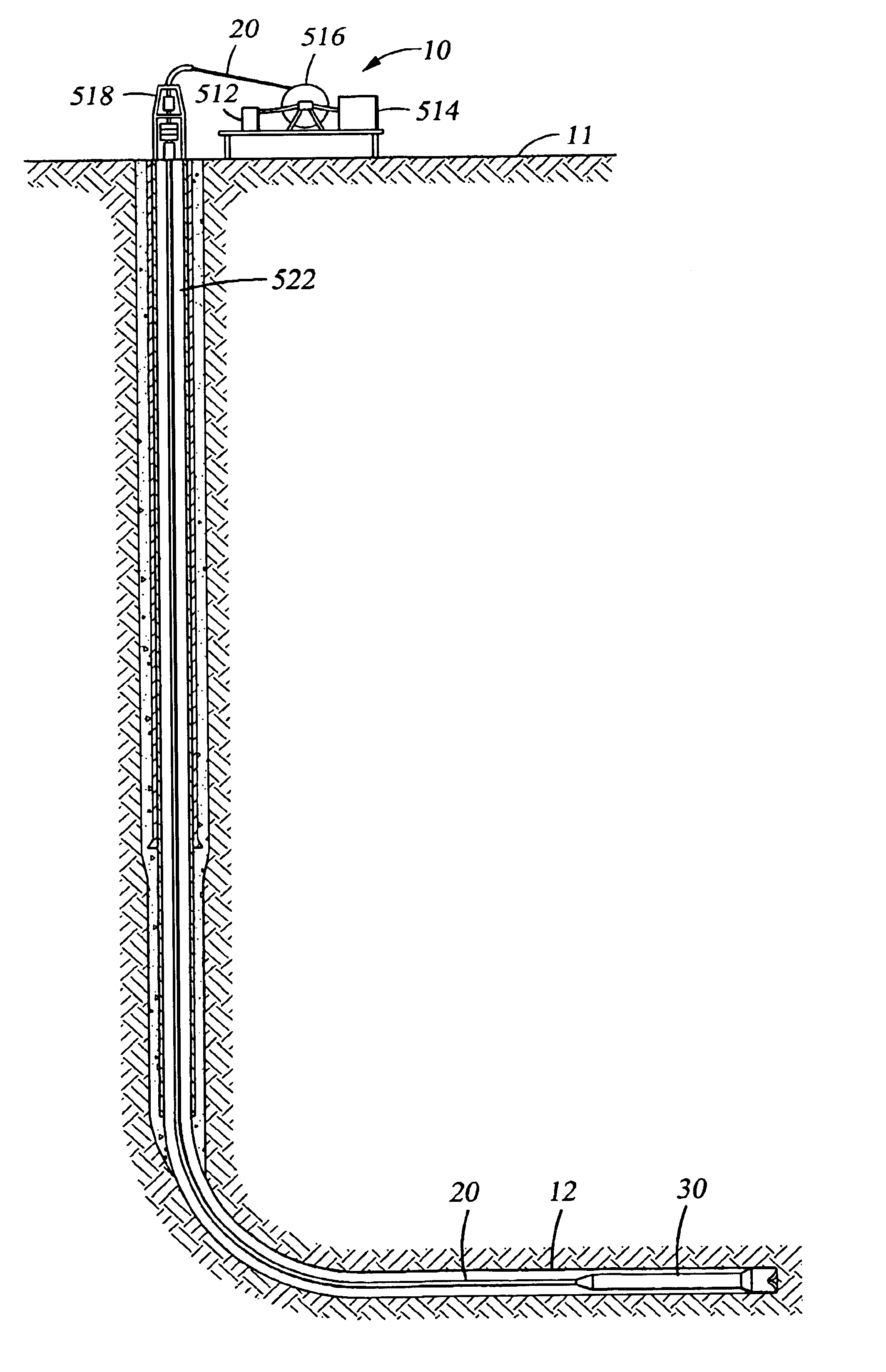

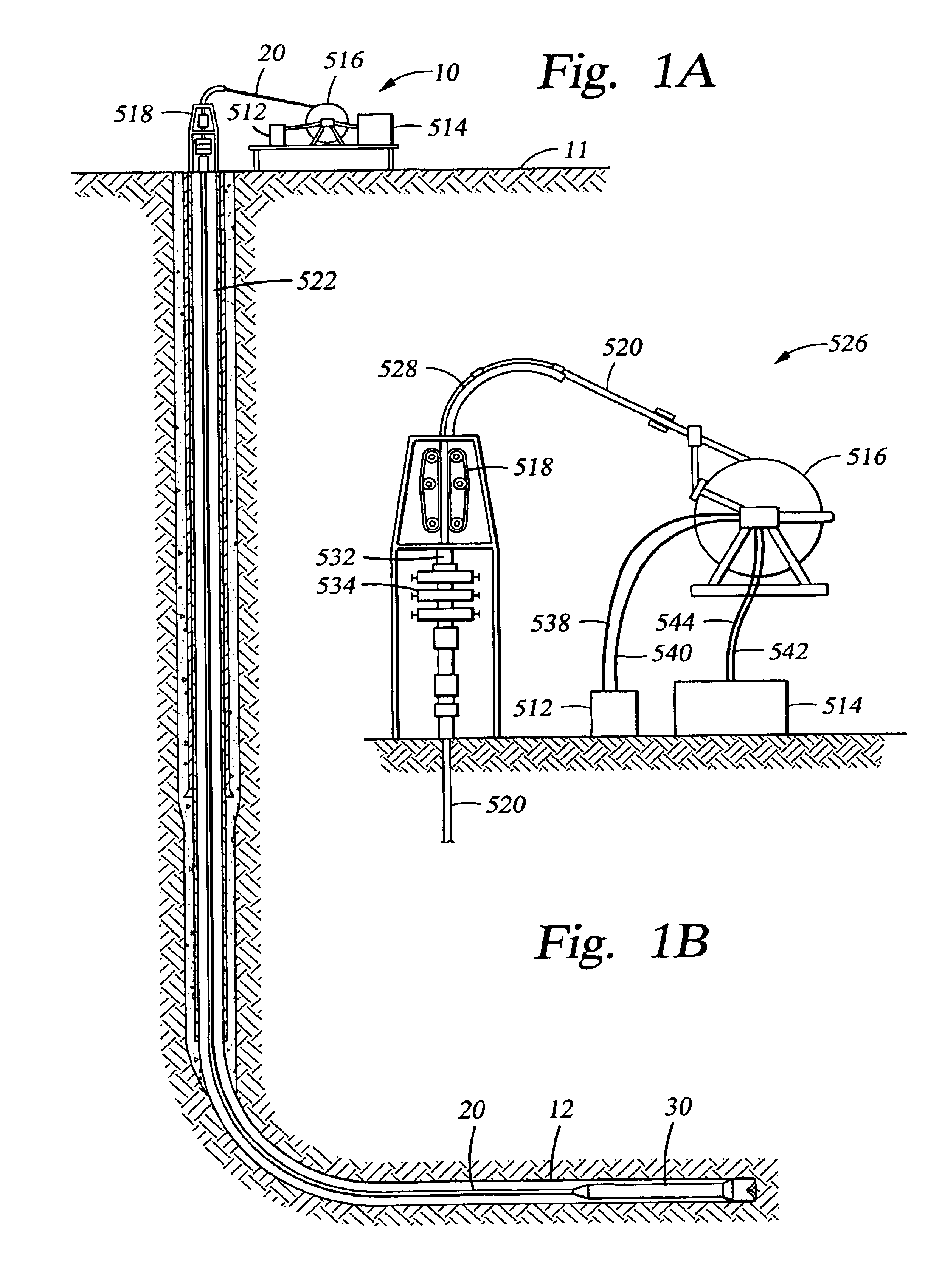

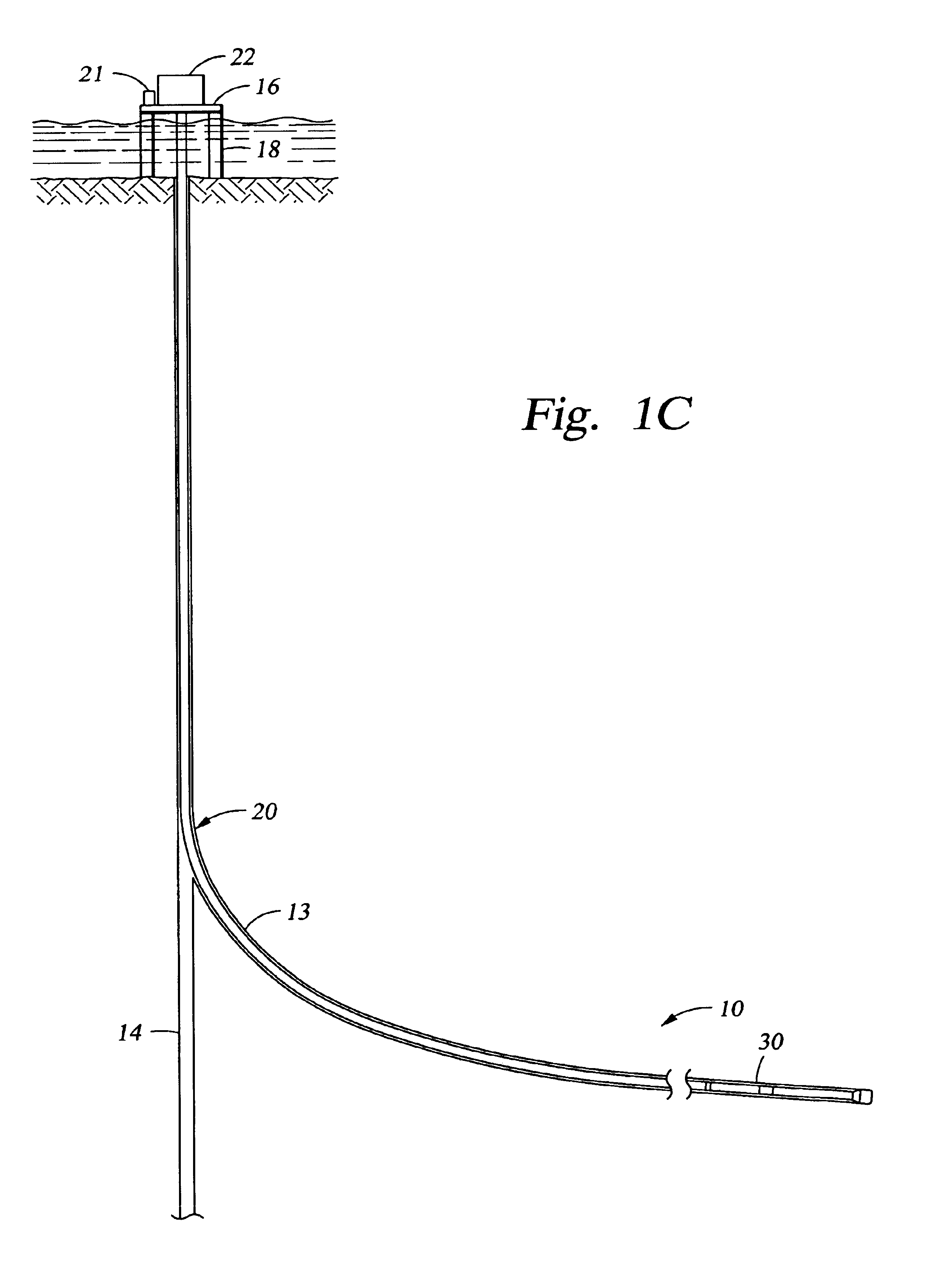

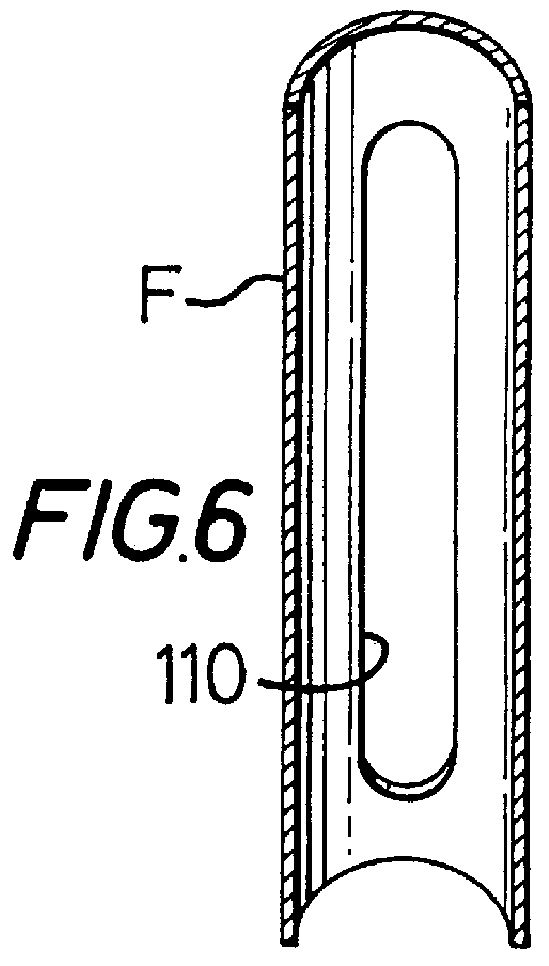

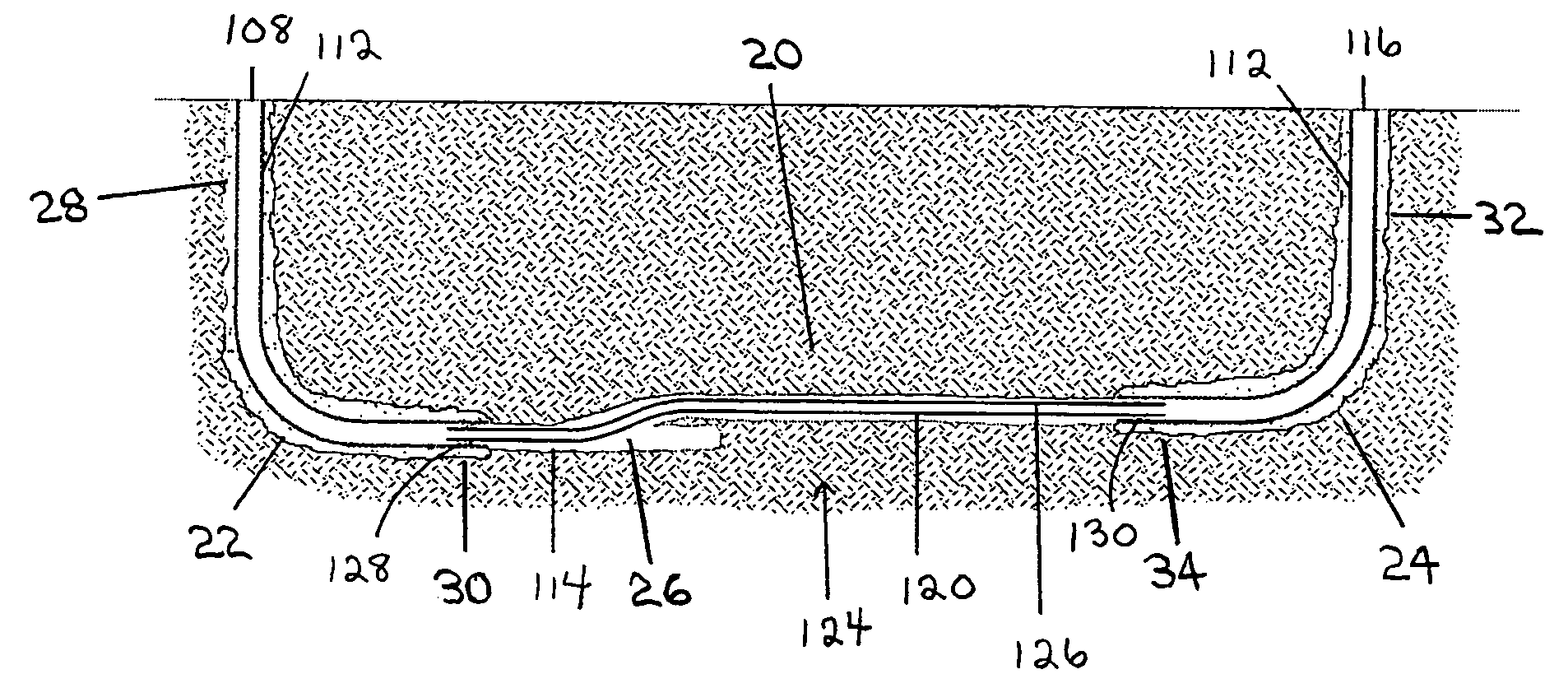

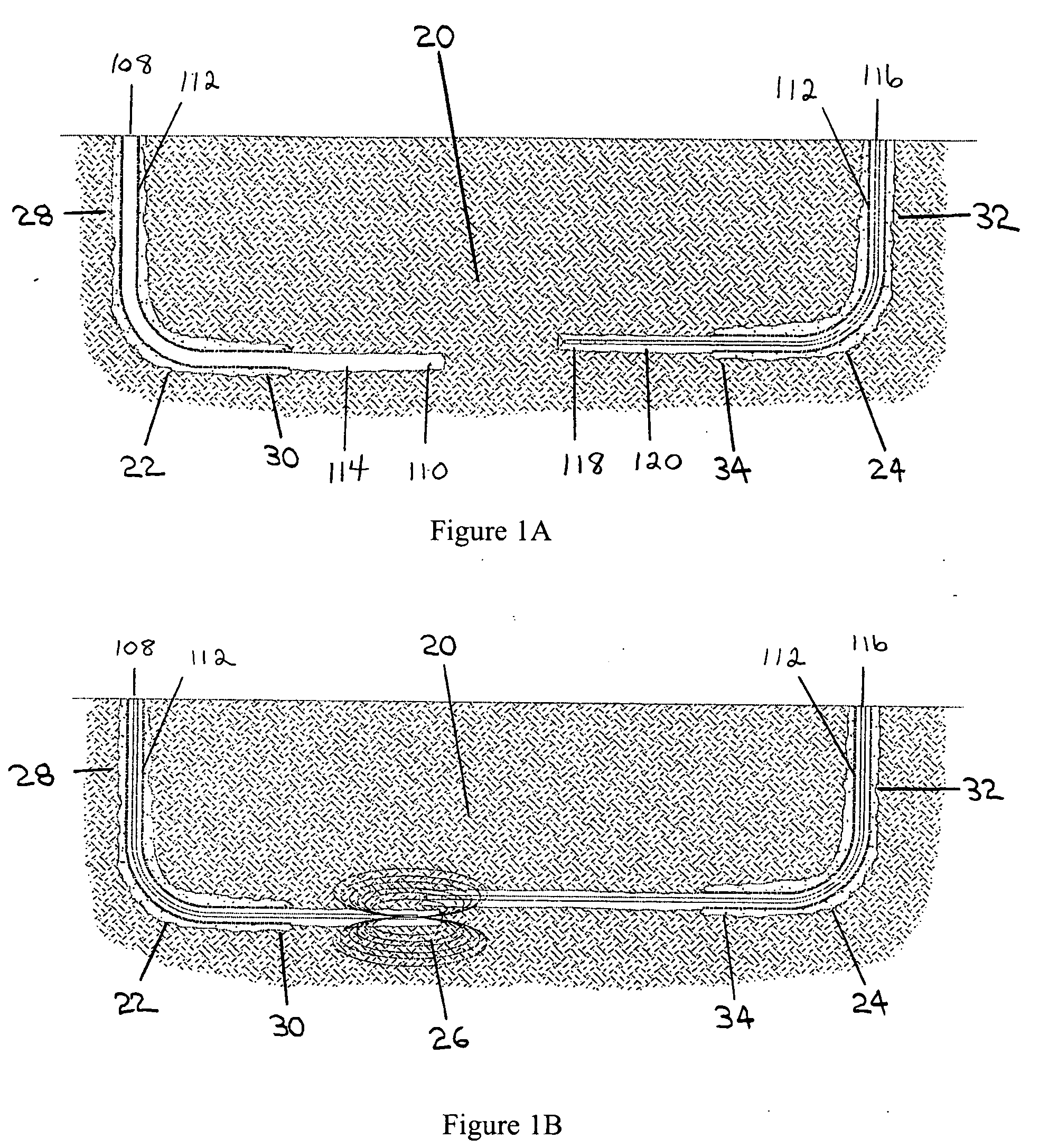

Methods and apparatus for drilling, completing and configuring U-tube boreholes

A borehole network including first and second end surface locations and at least one intermediate surface location interconnected by a subterranean path, and a method for connecting a subterranean path between a first borehole including a directional section and a second borehole including a directional section. A directional drilling component is drilled in at least one of the directional sections to obtain a required proximity between the first and second boreholes. An intersecting component is drilled, utilizing magnetic ranging techniques, from one directional section to provide a borehole intersection between the first and second boreholes, thereby connecting the subterranean path.

Owner:HALLIBURTON ENERGY SERVICES INC

Methods and apparatus to control downhole tools

The present invention generally provides a downhole tool with an improved means of transmitting data to and from the tool through the use of wired pipe capable of transmitting a signal and / or power between the surface of the well and any components in a drill string. In one aspect, a downhole tool includes a body, and a mandrel disposed in the body and movable in relation to the body. A conducive wire runs the length of the body and permits signals and / or power to be transmitted though the body as the tool changes its length.

Owner:WEATHERFORD TECH HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com