Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

219 results about "Casing hanger" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In petroleum production, the casing hanger is that portion of a wellhead assembly which provides support for the casing string when it is lowered into the wellbore. It serves to ensure that the casing is properly located. When the casing string has been run into the wellbore it is hung off, or suspended, by a casing hanger, which rests on a landing shoulder inside the casing spool. Casing hangers must be designed to take the full weight of the casing, and provide a seal between the casing hanger and the spool.

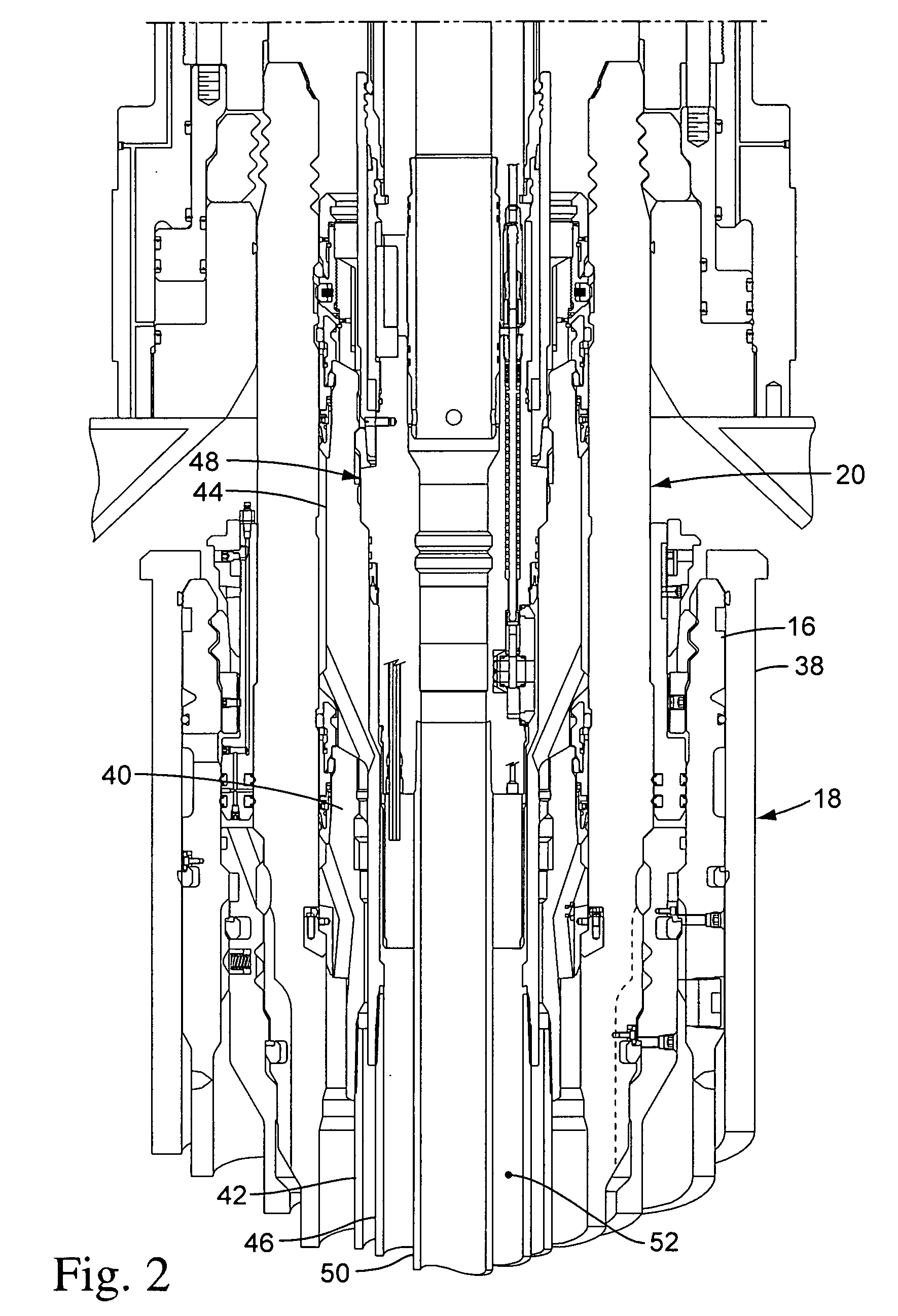

Apparatus and method for establishing branch wells from a parent well

InactiveUS6056059AOptimized areaFluid communicationDrilling rodsFluid removalCasing hangerCasing string

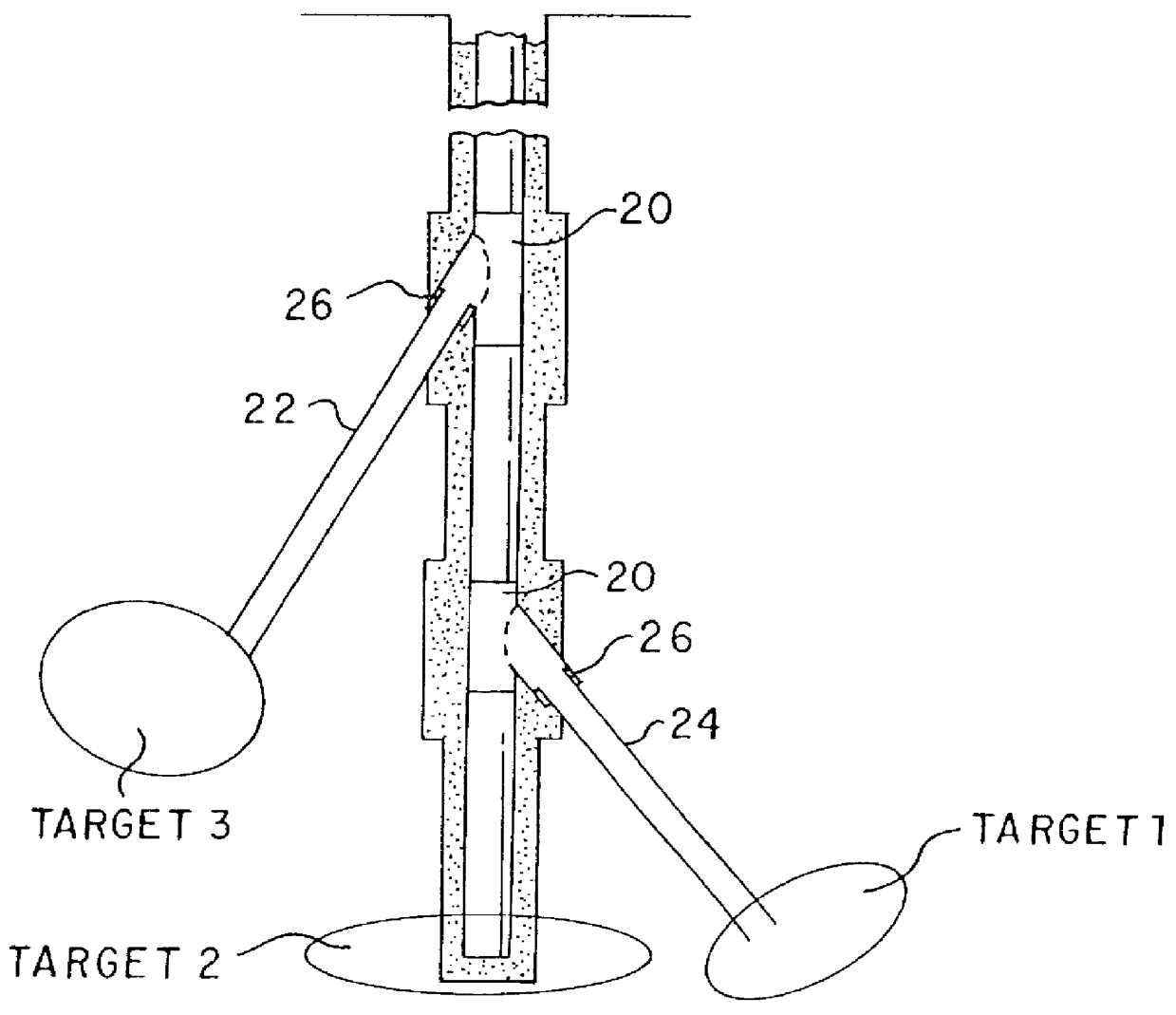

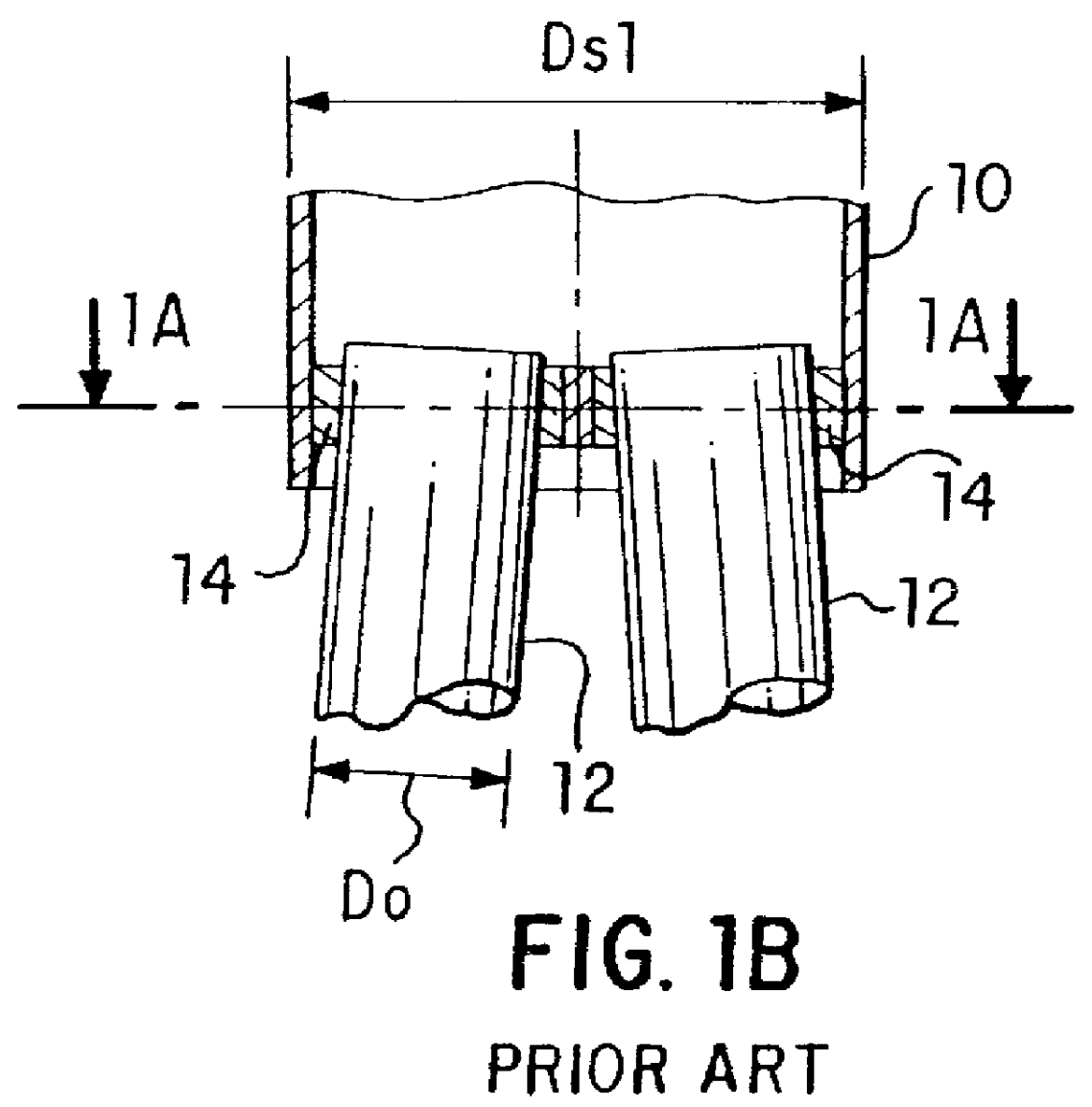

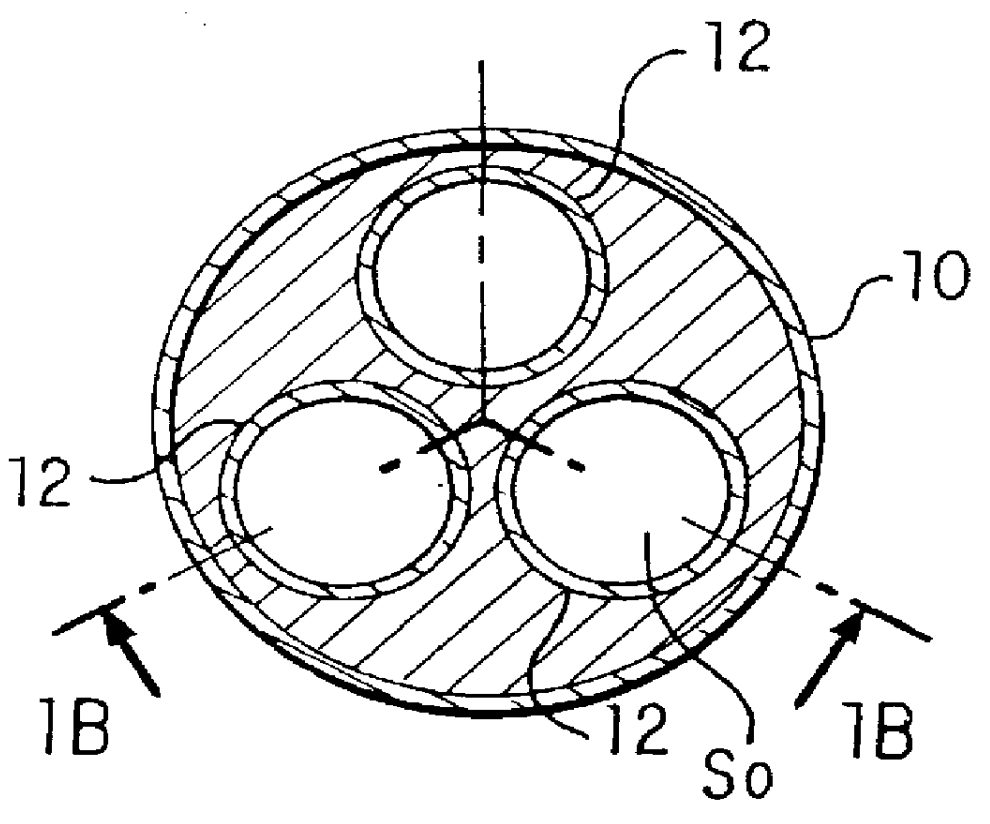

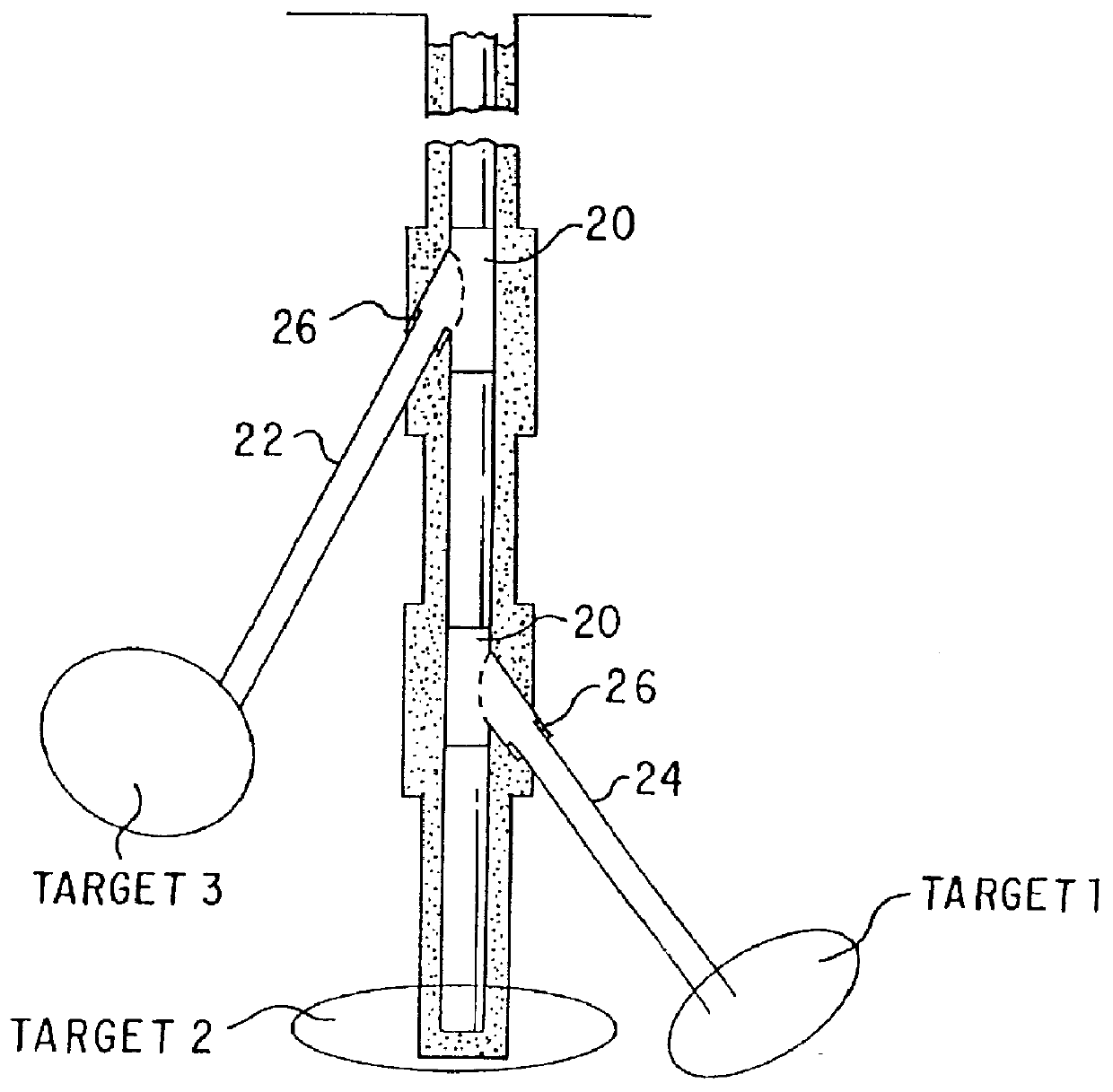

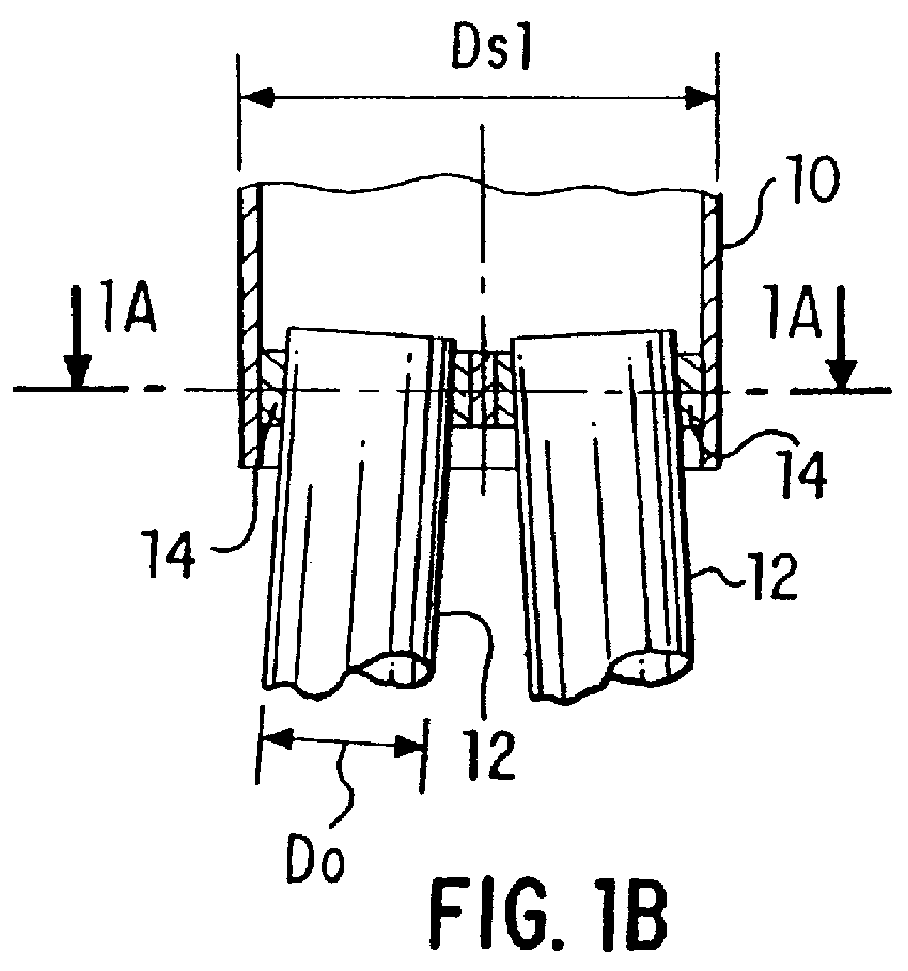

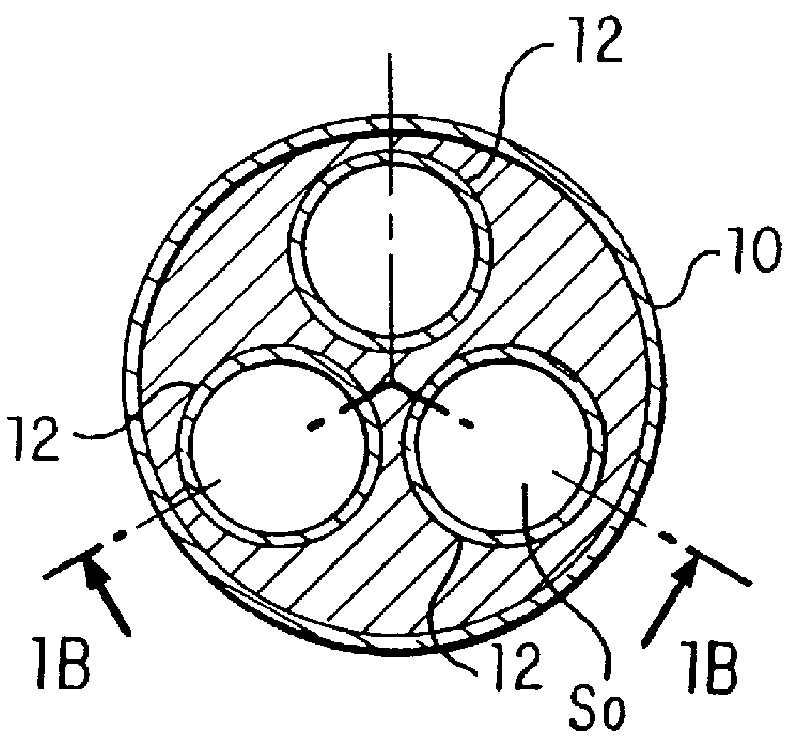

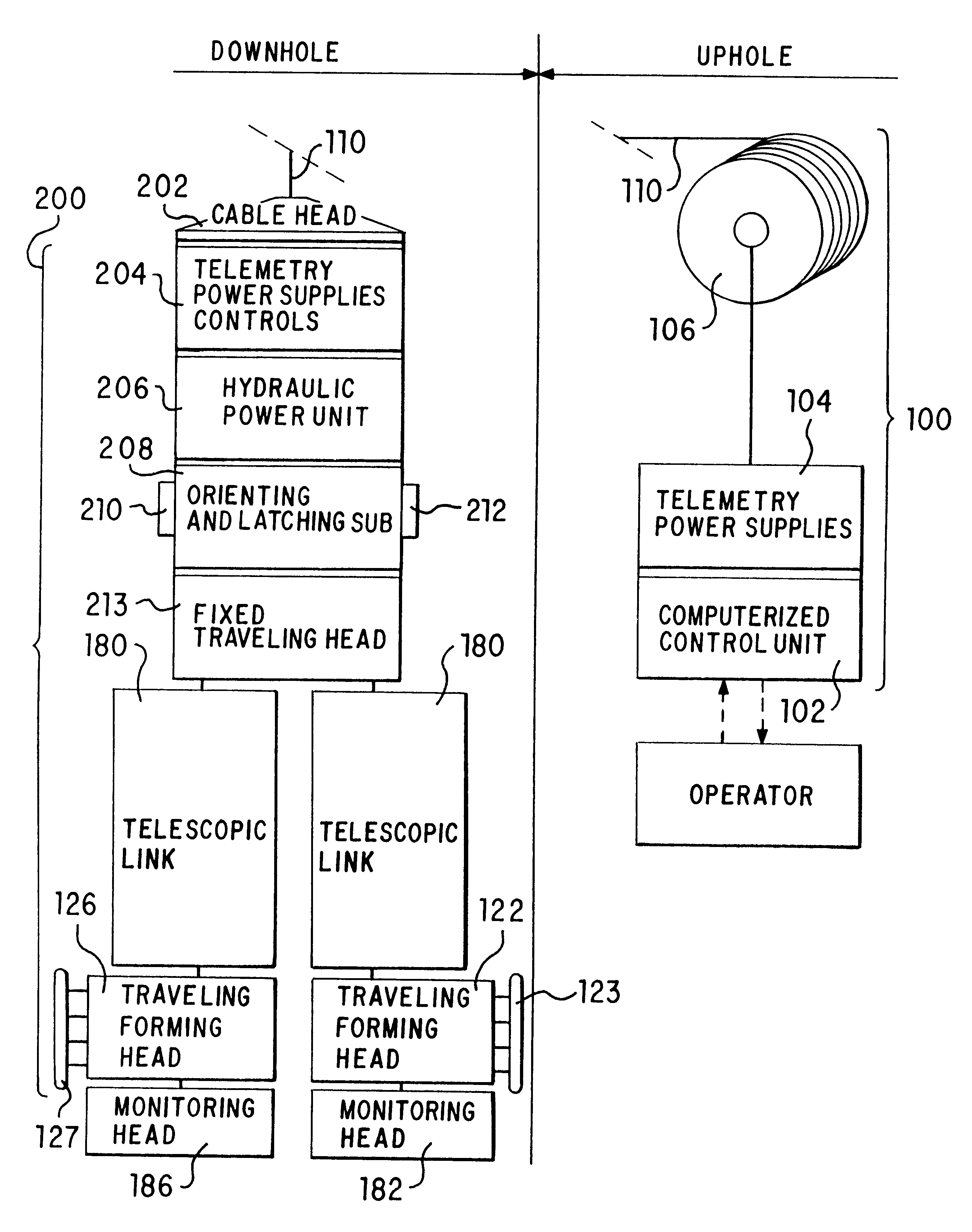

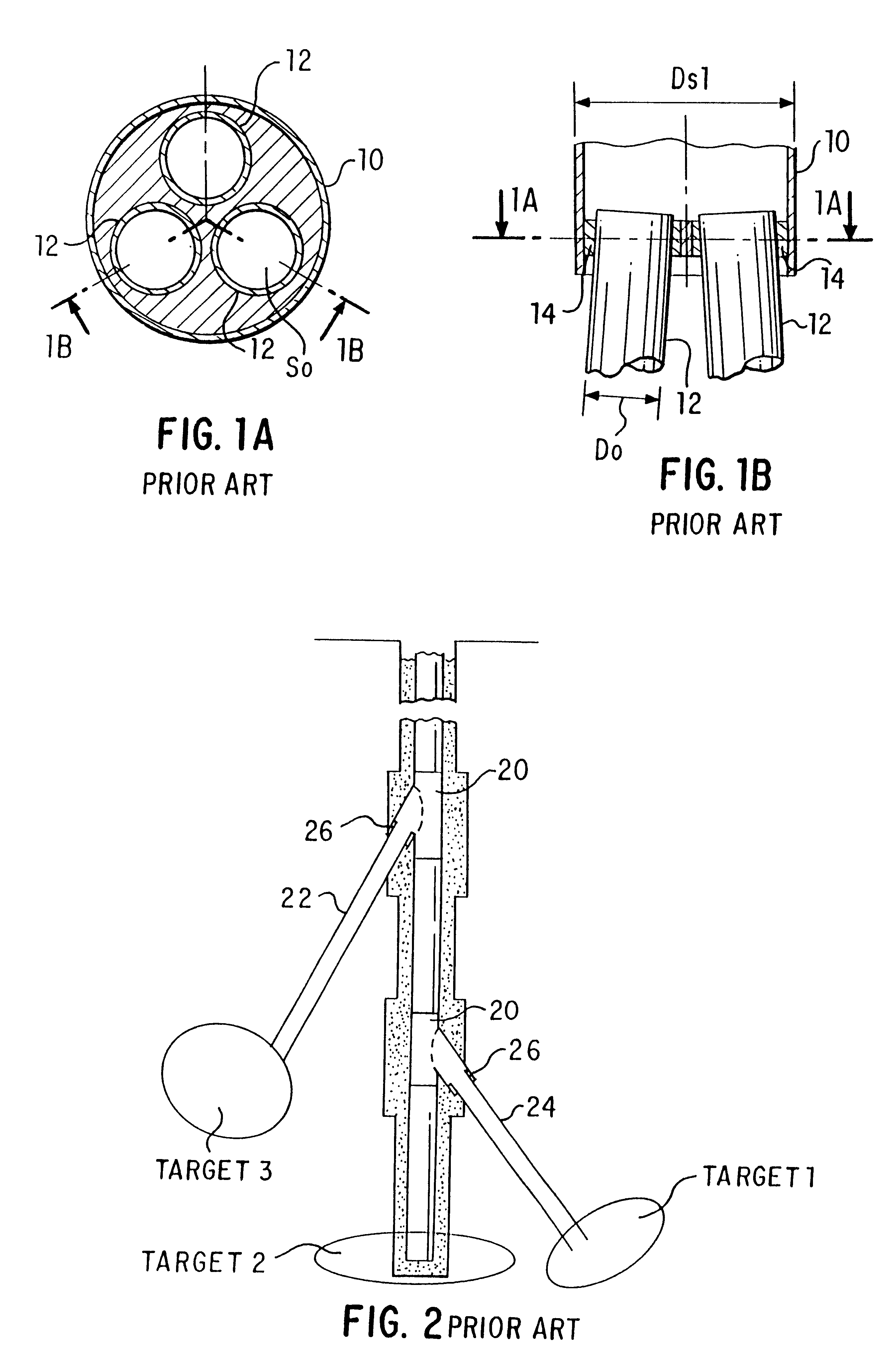

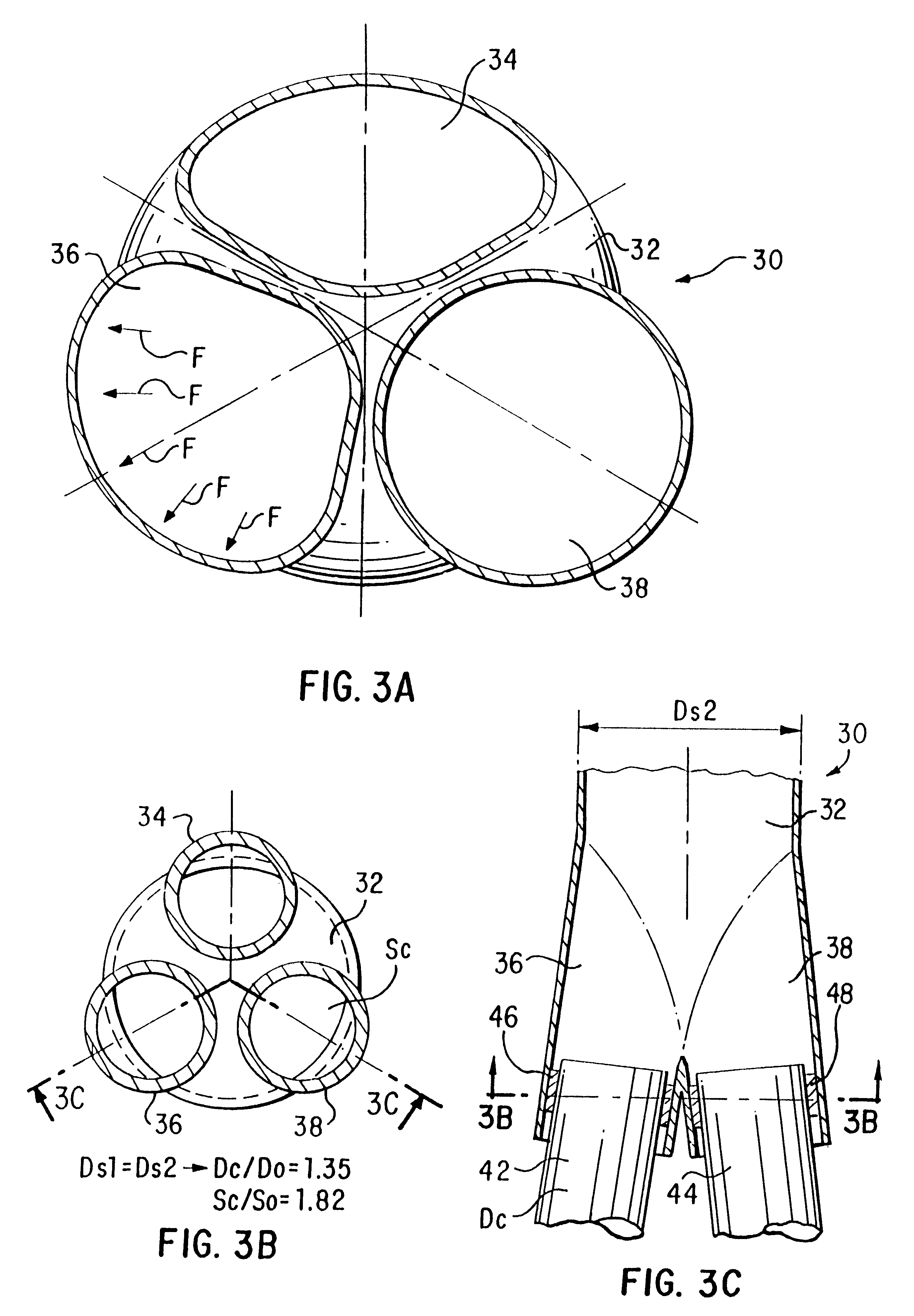

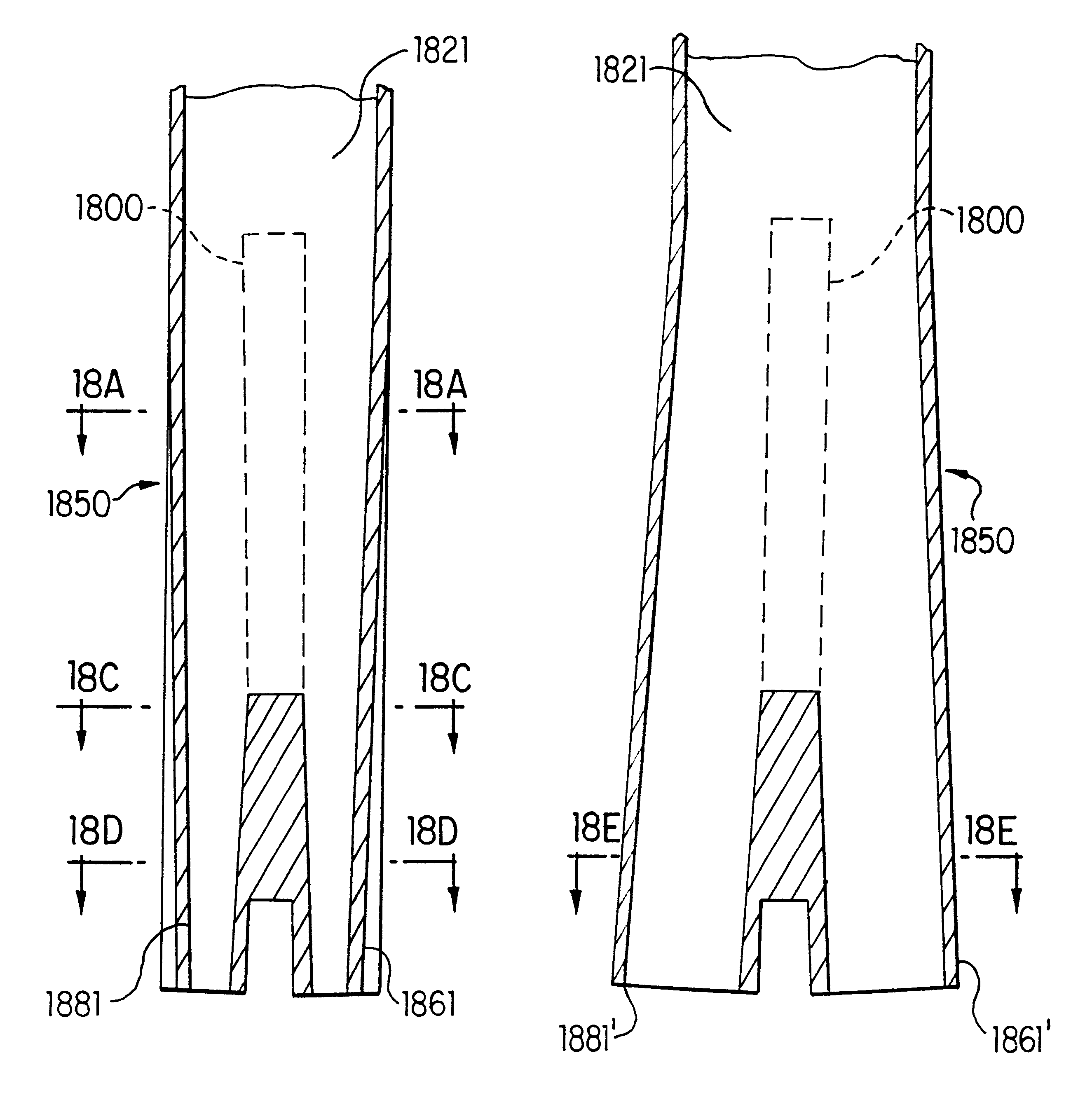

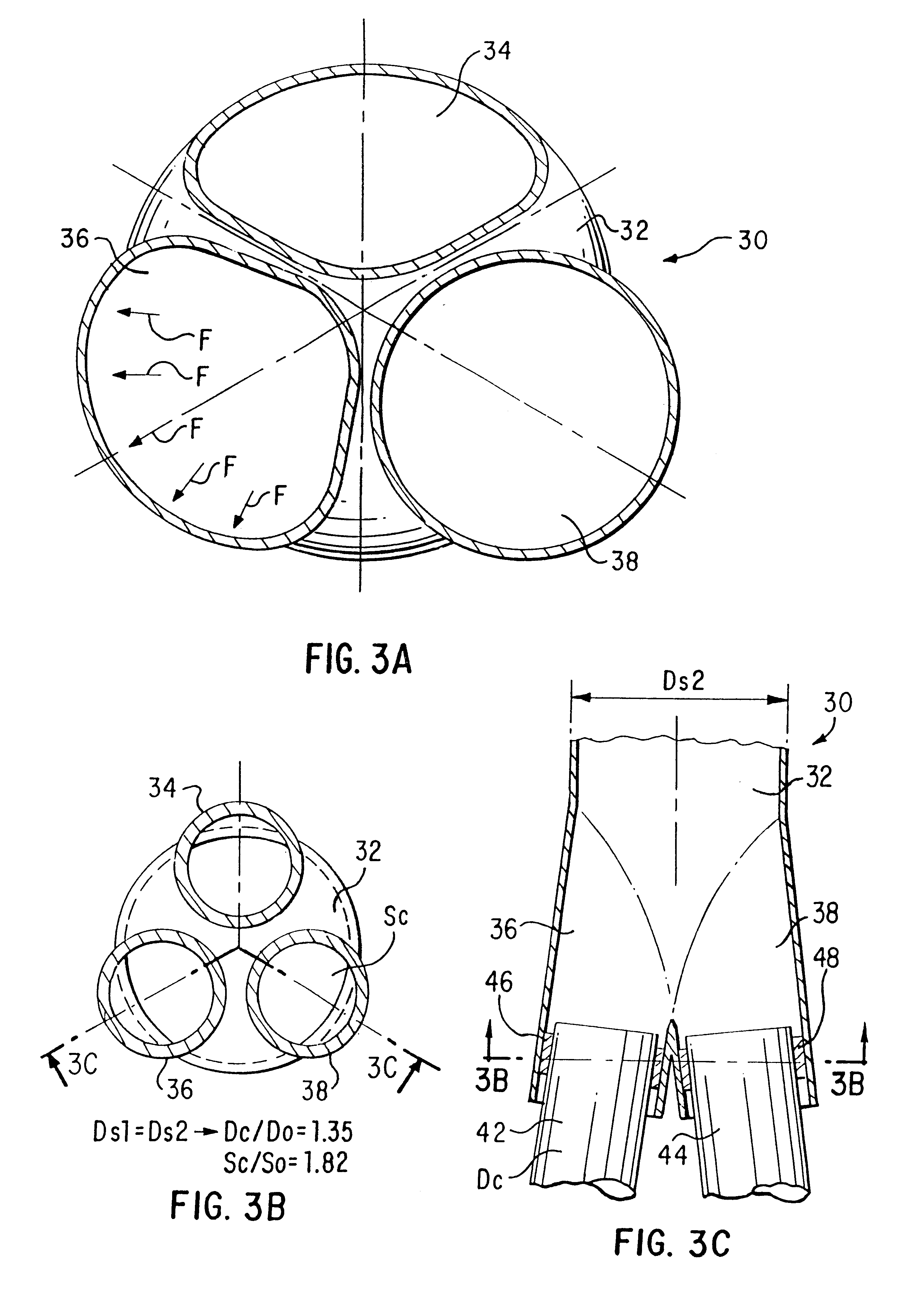

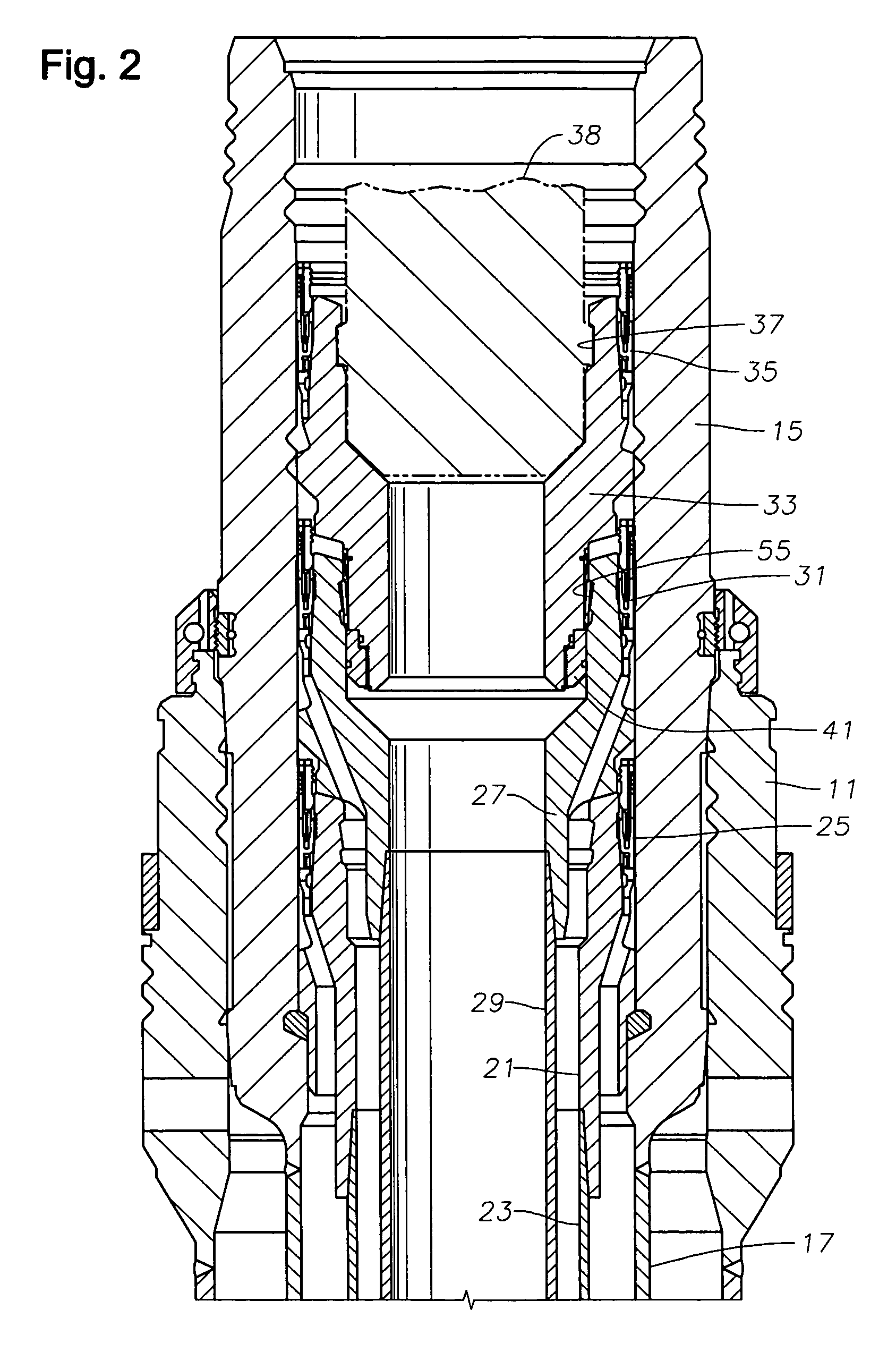

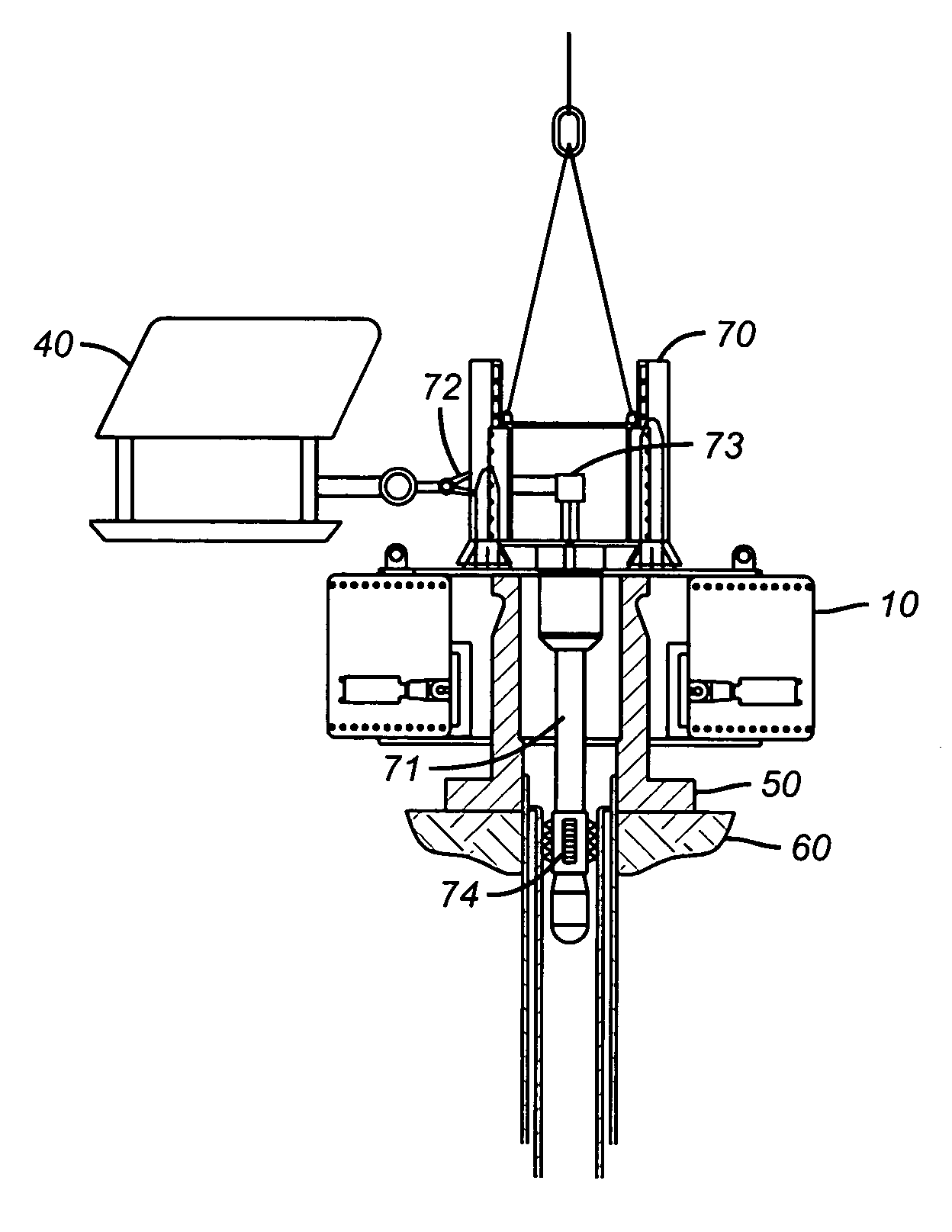

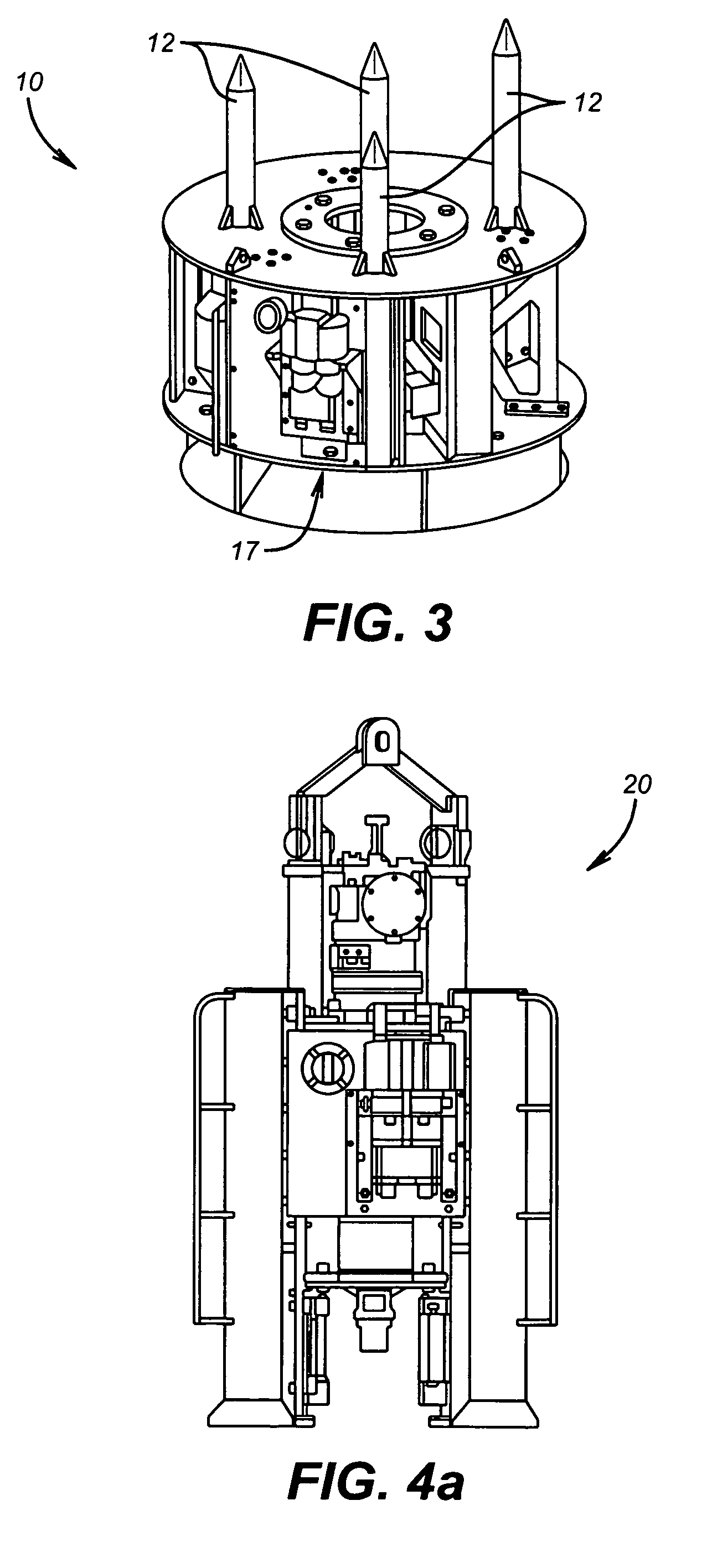

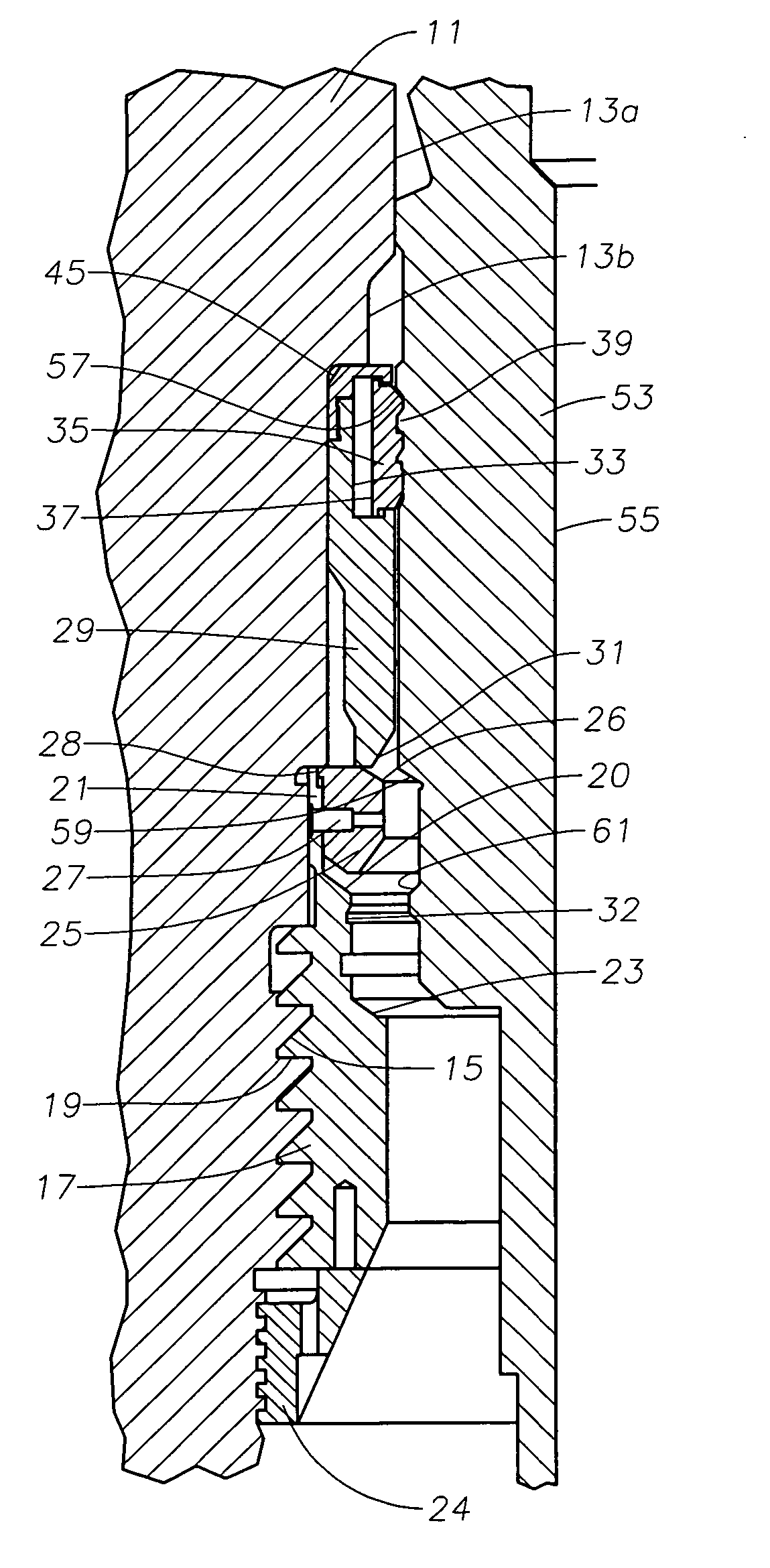

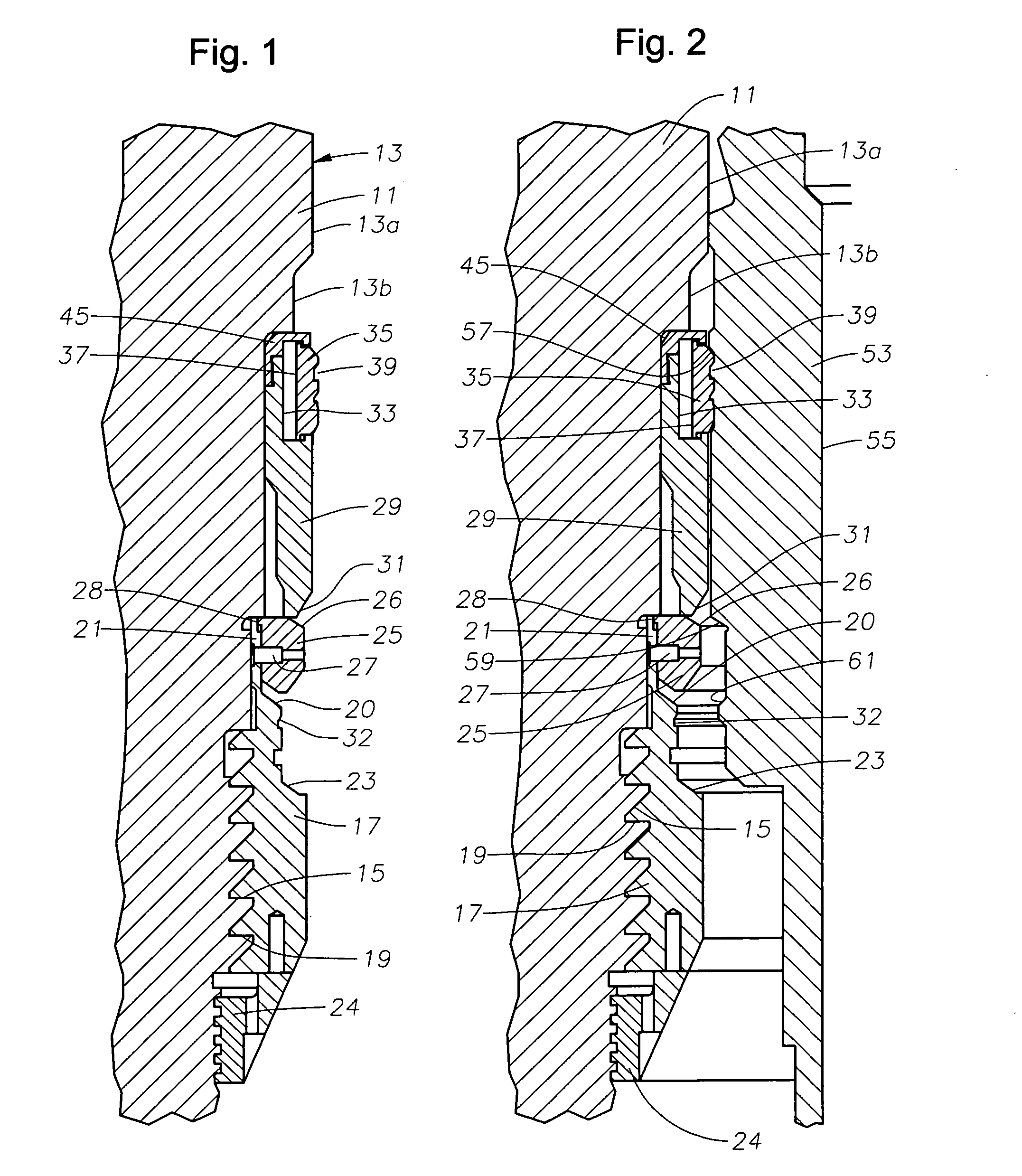

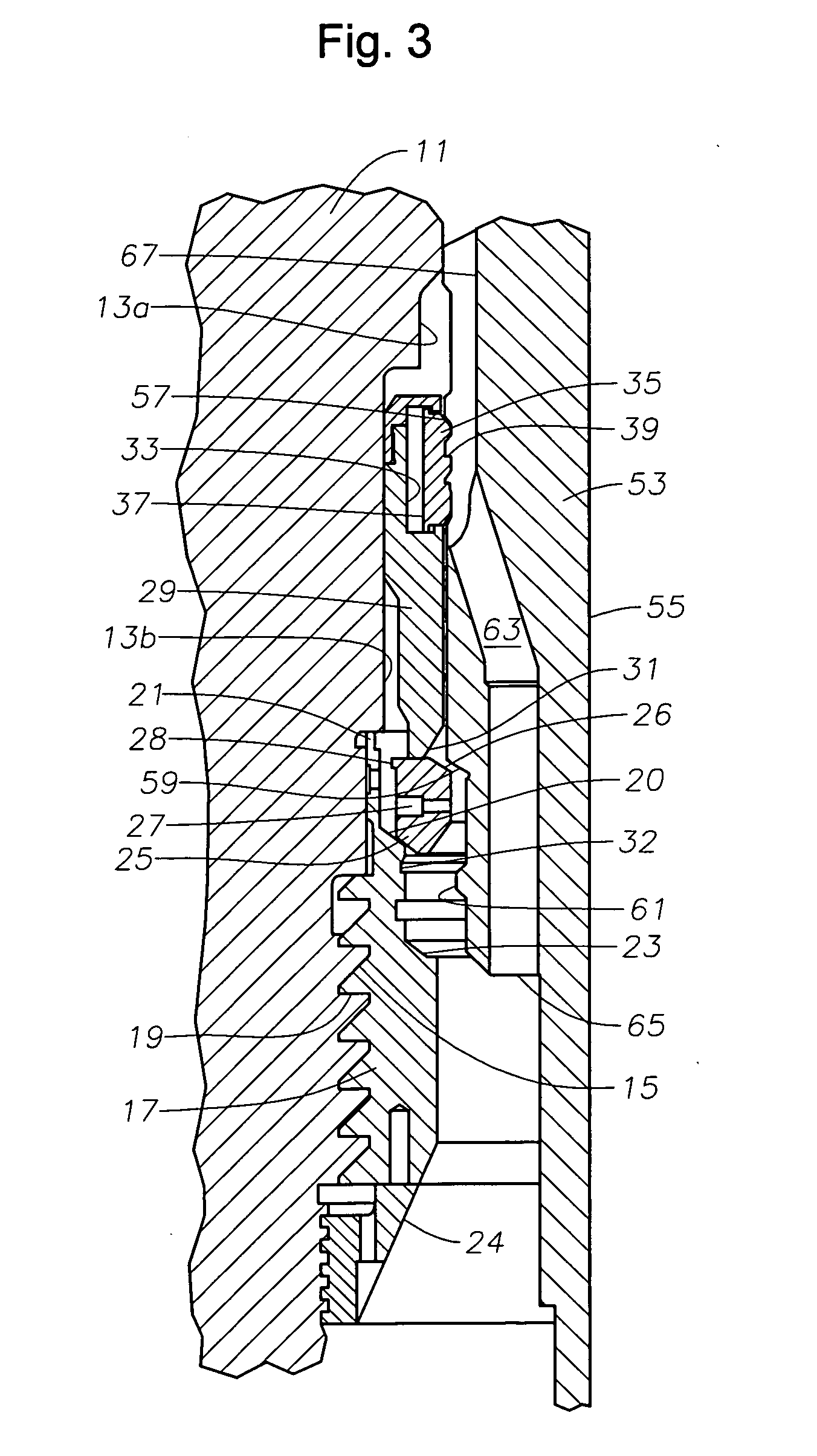

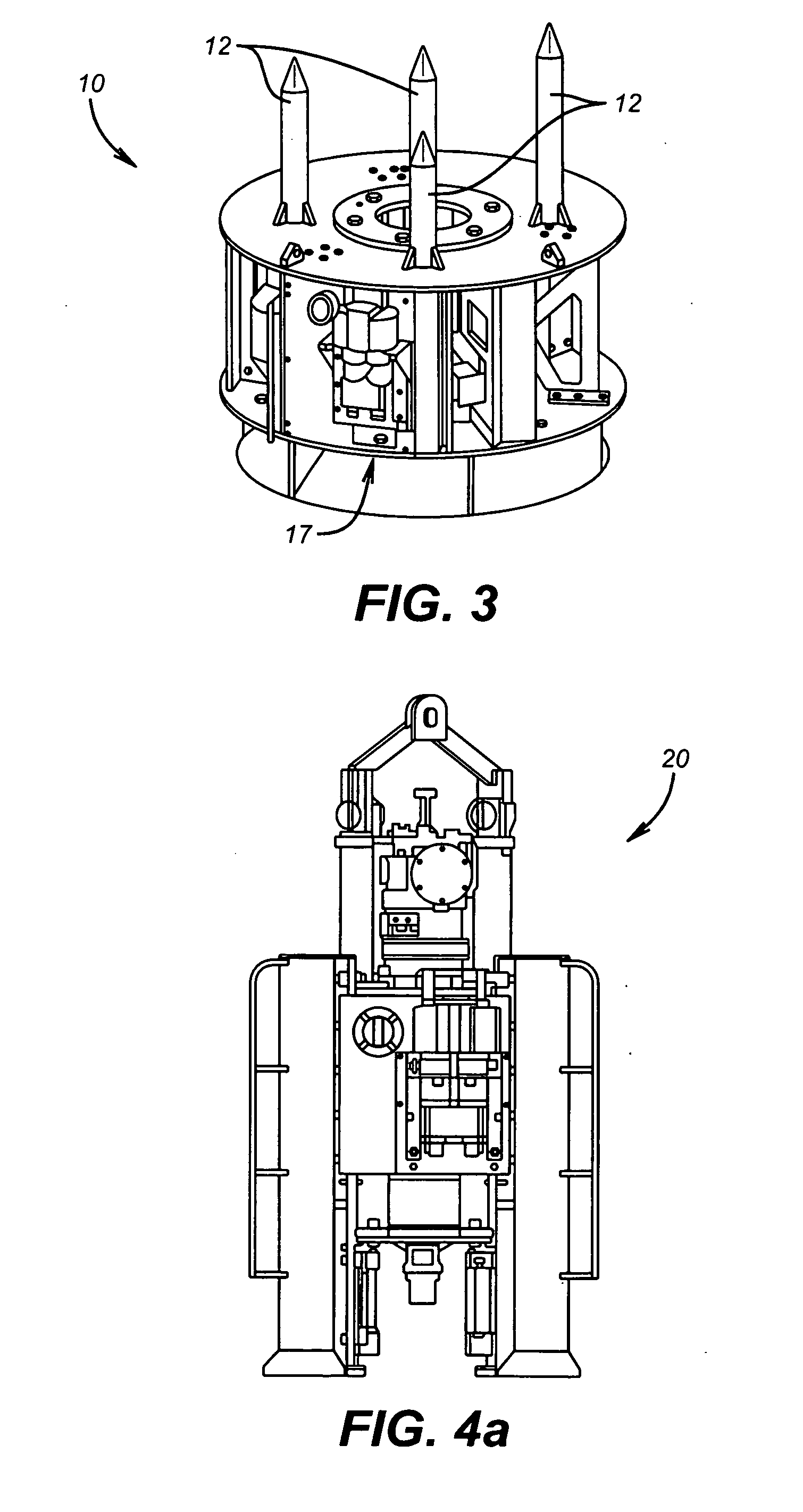

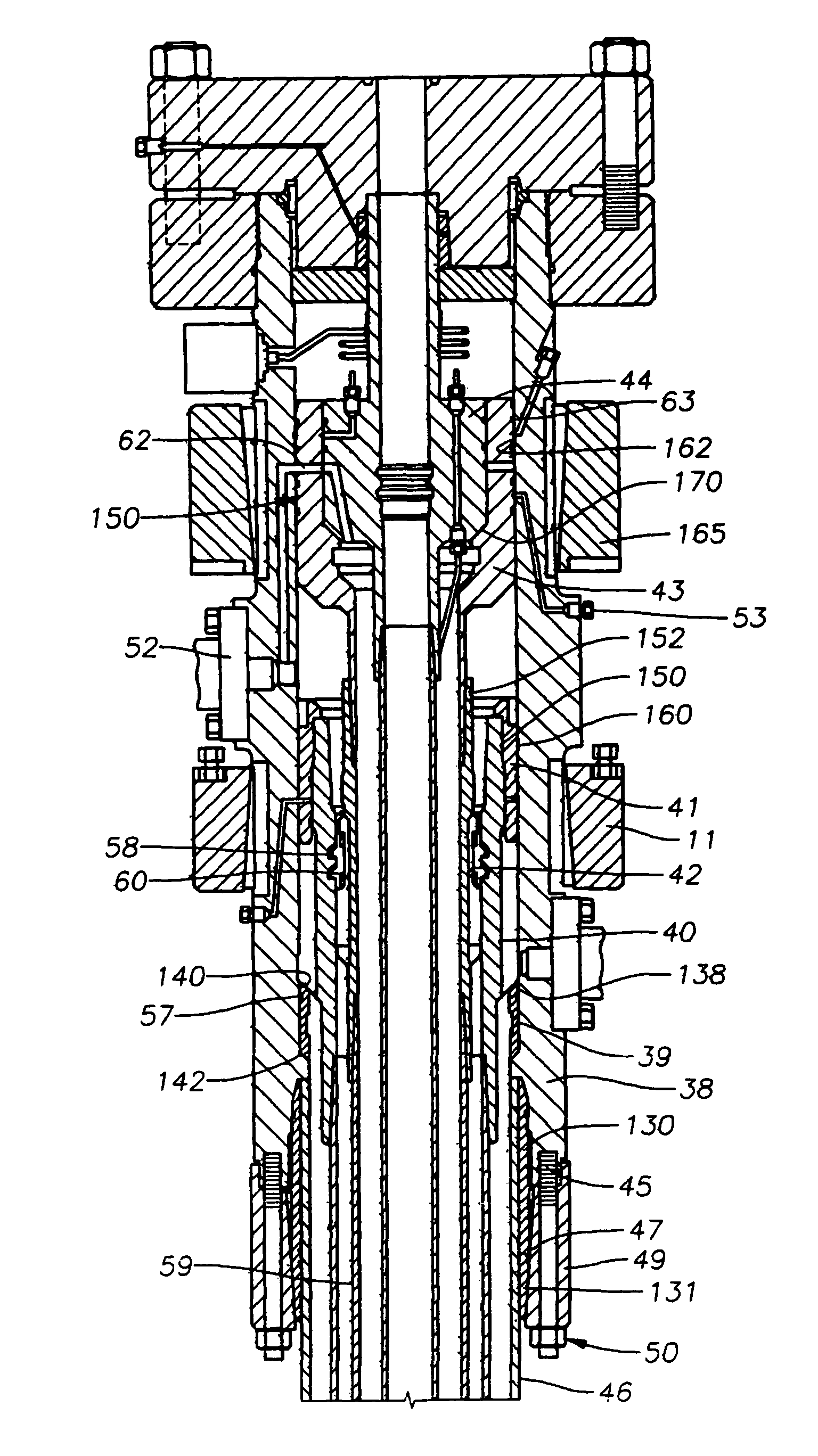

A method and apparatus for creating multiple branch wells from a parent well is disclosed. According to a first embodiment of the invention a multiple branching sub is provided for placement at a branching node of a well. Such sub includes a branching chamber and a plurality of branching outlet members. The outlet members, during construction of the branching sub, have previously been distorted into oblong shapes so that all of the branching outlet members fit within an imaginary cylinder which is coaxial with and substantially the same radius as the branching chamber. According to one embodiment, the distorted outlet members are characterized by an outer convex shape. In another embodiment, the distorted outlet members are characterized by an outer concave shape when in a retracted state. After deployment of the branching sub via a parent casing in the well, a forming tool is lowered to the interior of the sub. The outlet members are extended outwardly by the forming tool and simultaneously formed into substantially round tubes. Next, each outlet member is plugged with cement, after which each branch well is drilled through a respective outlet member. If desired, each branch may be lined with casing and sealed to a branching outlet by means of a casing hanger. A manifold placed in the branching chamber controls the production of each branch well to the parent well. According to a second embodiment of the invention, a pressure resistant branching sub is provided which may be installed in series with a casing string, and the associated equipment used for the installation operation and intervention of a well. The branching sub includes a main pipe and a lateral outlet.

Owner:SCHLUMBERGER TECH CORP

Method for establishing branch wells at a node of a parent well

InactiveUS6079495AOptimized areaFluid communicationDrilling rodsConstructionsEngineeringMechanical engineering

A method for creating multiple branch wells from a parent well is disclosed. A multiple branching sub is provided for placement at a branching node of a well. Such sub includes a branching chamber and a plurality of branching outlet members. The outlet members during construction of the branching sub, have previously been distorted into oblong shapes so that all of the branching outlet members fit within an imaginary cylinder which is coaxial with and substantially the same radius as the branching chamber. After deployment of the branching sub via a parent casing in the well, a forming tool is lowered to the interior of the sub. The outlet members are extended outwardly by the forming tool and simultaneously formed into substantially round tubes. Next, each outlet member is plugged with cement, after which each branch well is drilled through a respective outlet member. If desired, each branch may be lined with casing and sealed to a branching outlet by means of a casing hanger. A manifold placed in the branching chamber controls the production of each branch well to the parent well.

Owner:SCHLUMBERGER TECH CORP

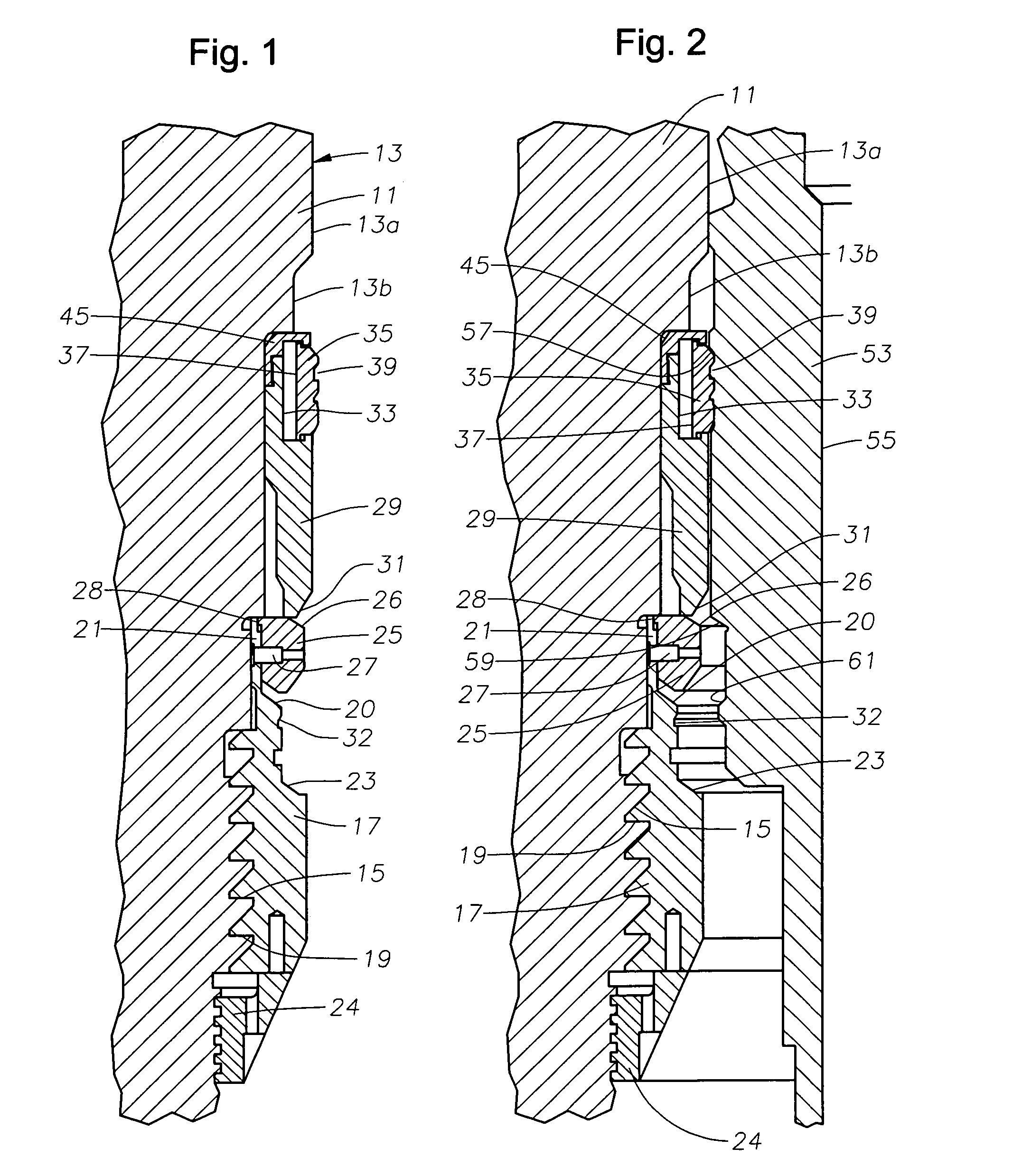

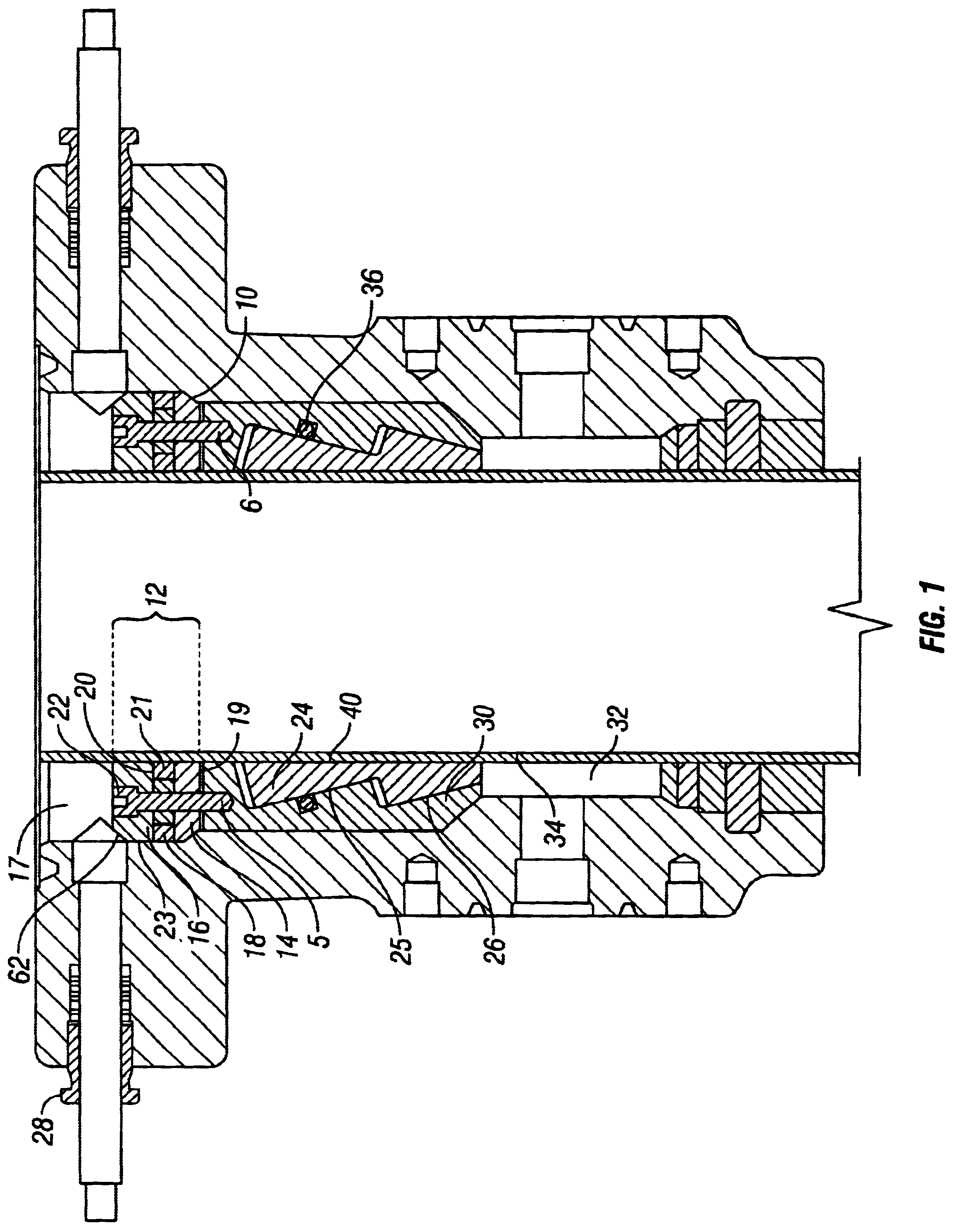

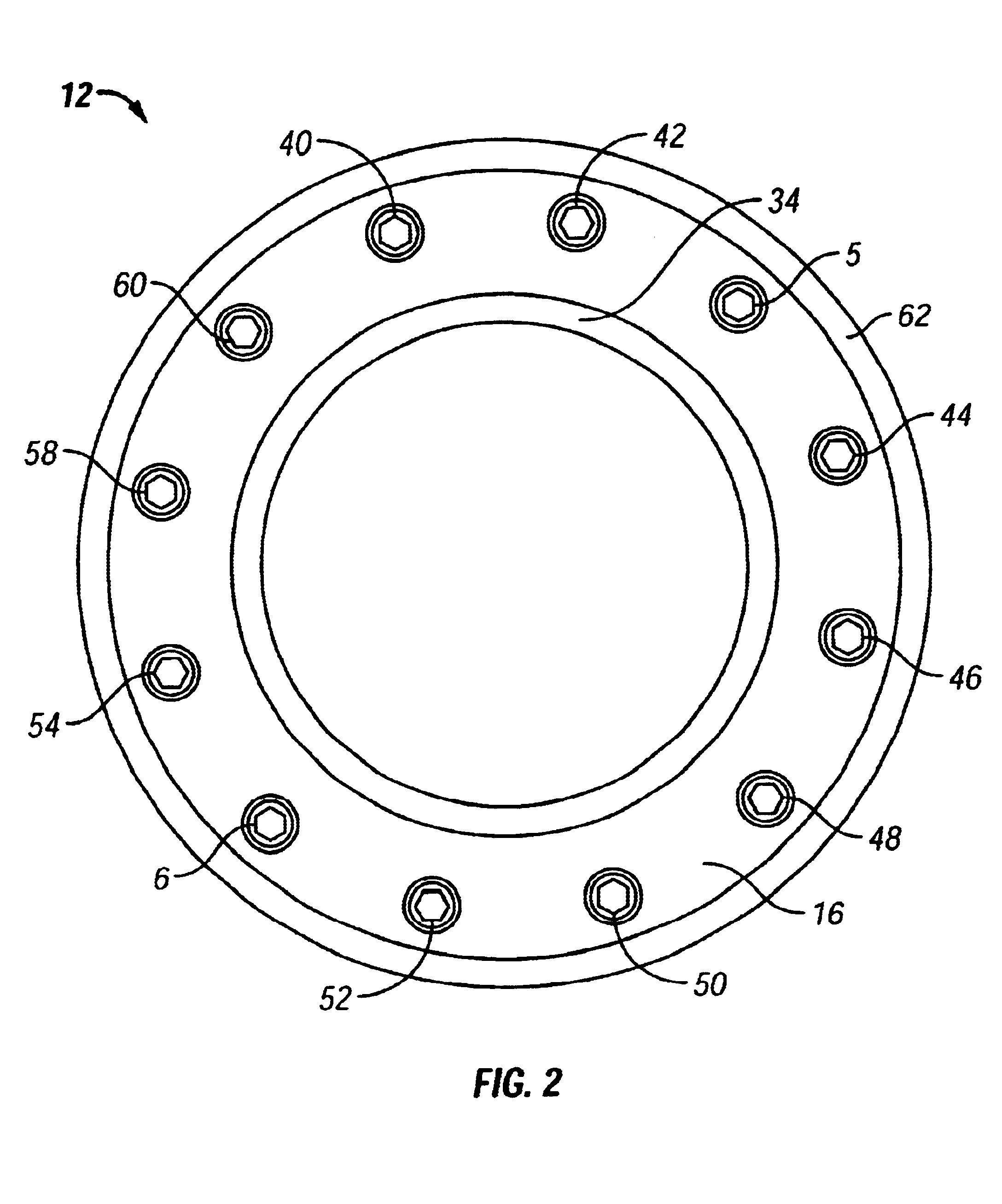

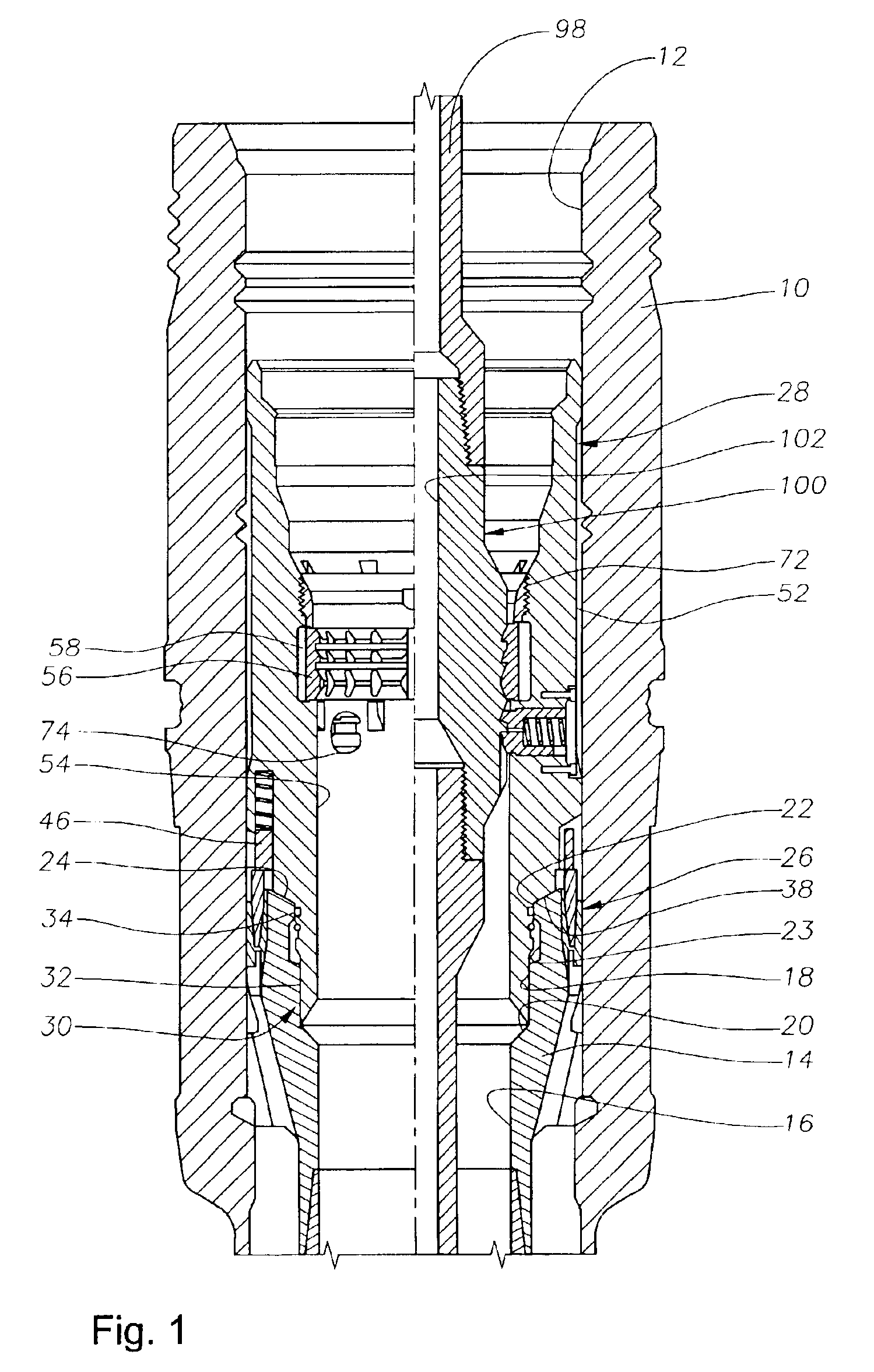

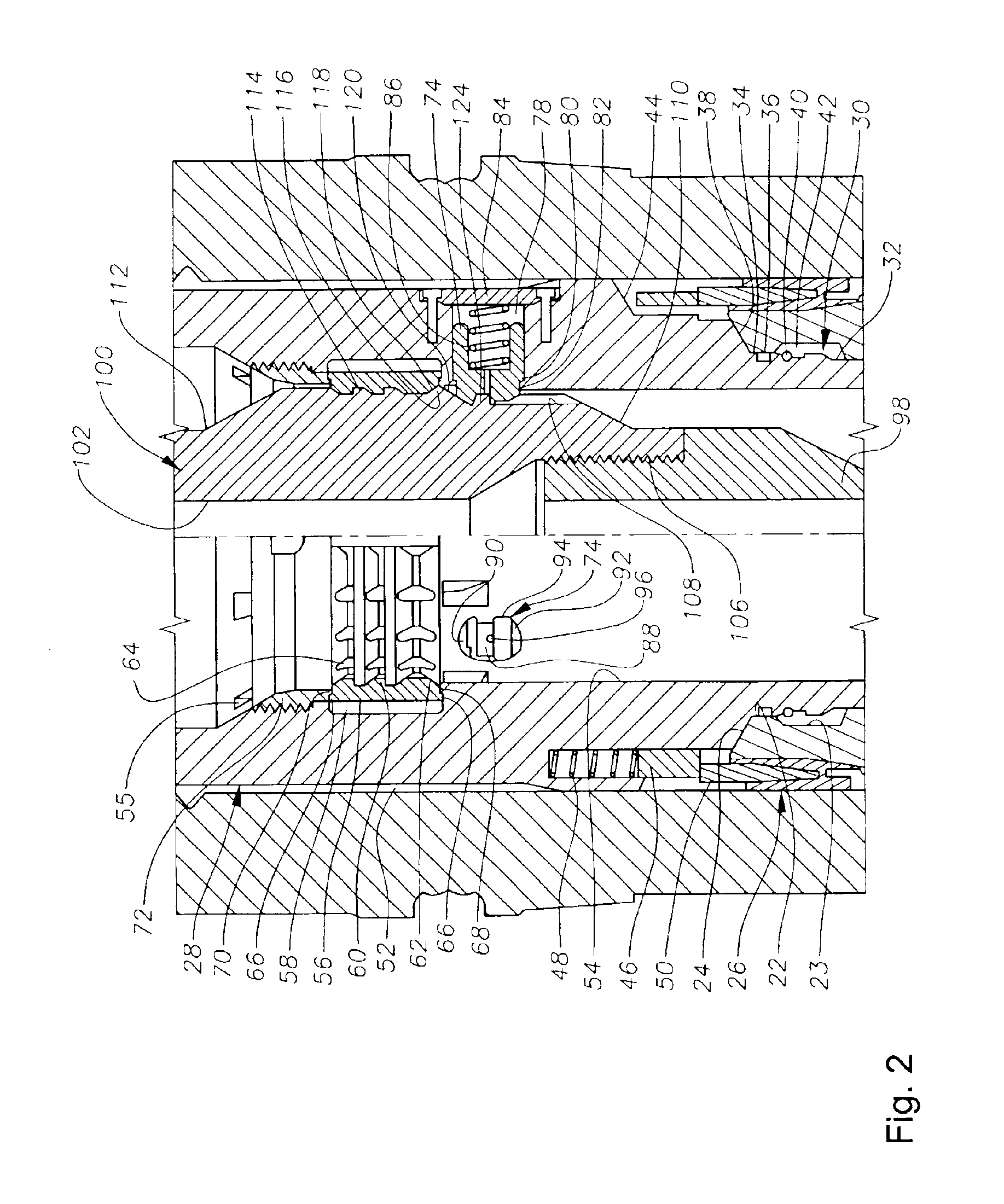

Casing hanger assembly with rupture disk in support housing and method

A casing hanger support assembly supports an inner casing string within a well containing an outer casing string and a production tubing string. The casing hanger support housing supports the casing hanger in the well, with a casing hanger being secured to an upper end of the inner casing string. One or more of a rupture disk and a blowout plug are provided in a wall of the casing hanger support housing for maintaining the desired pressure differential between an annulus within the outer casing string and an annulus exterior of the outer casing string, thereby preventing casing collapse or burst.

Owner:DRIL QUIP

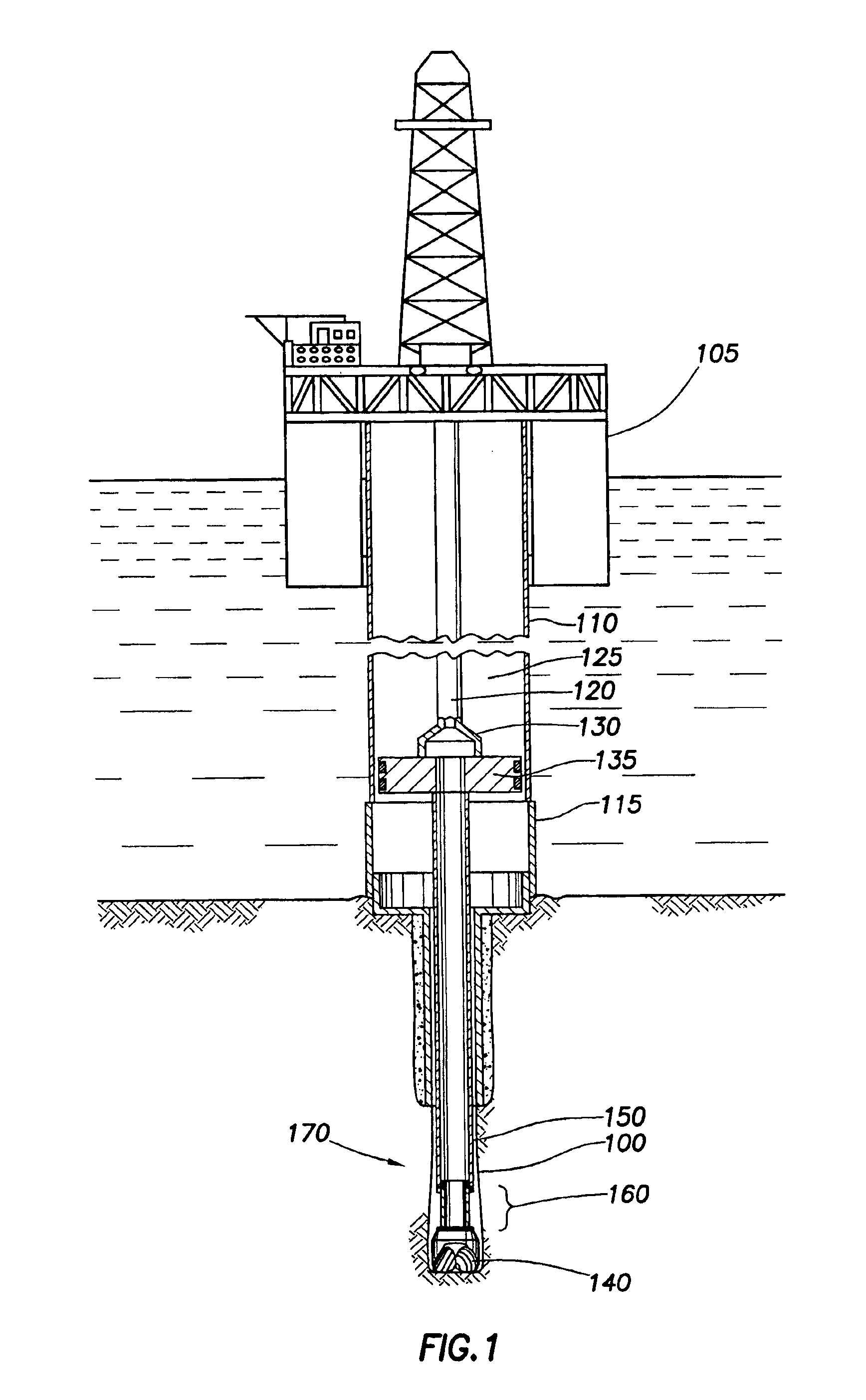

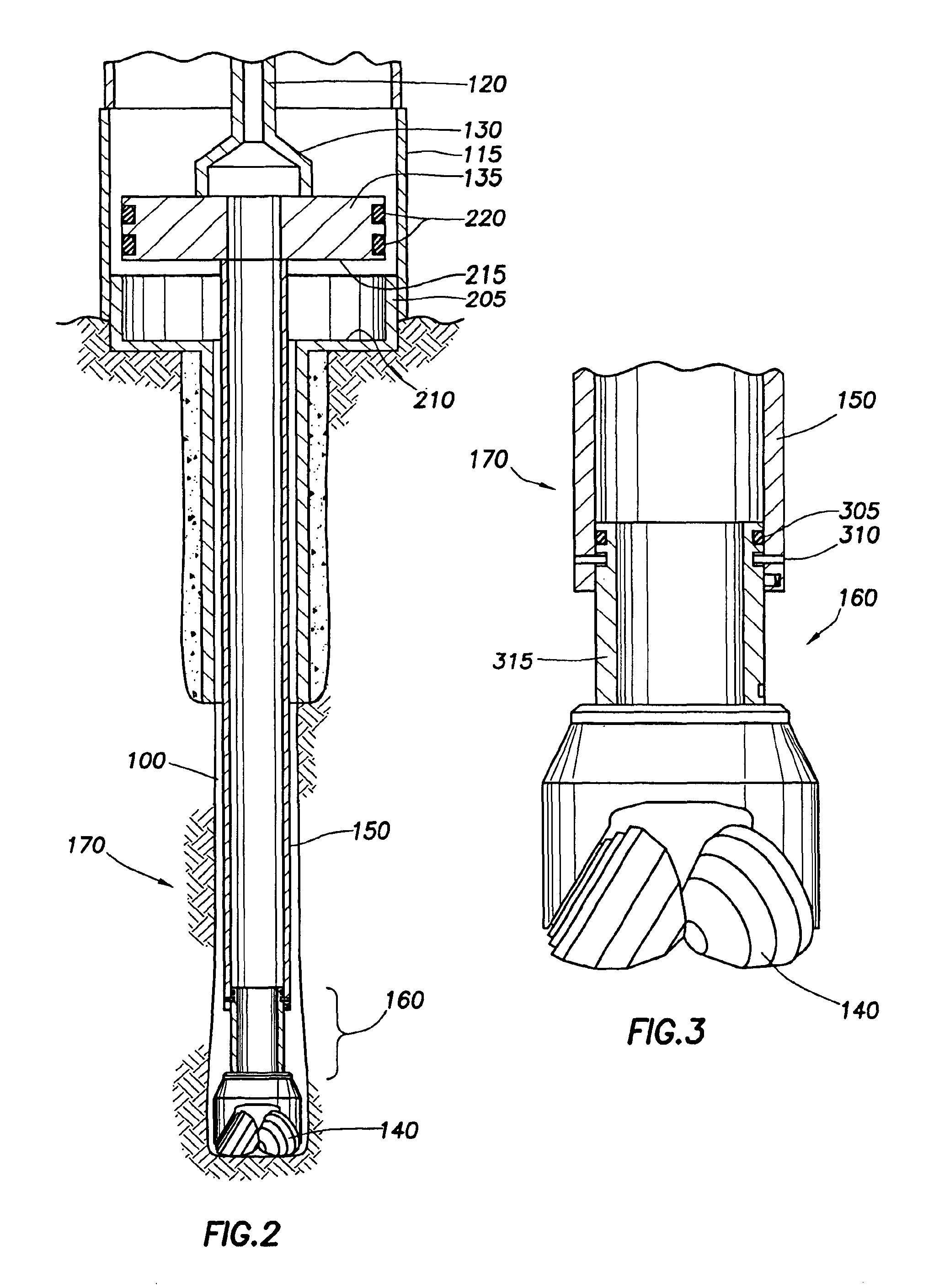

Apparatus and method of drilling with casing

InactiveUS6899186B2Shorten the lengthShorten the axial lengthDrilling rodsConstructionsCasing hangerCasing string

The present invention generally relates to methods for drilling a subsea wellbore and landing a casing mandrel in a subsea wellhead. In one aspect, a method of drilling a subsea wellbore with casing is provided. The method includes placing a string of casing with a drill bit at the lower end thereof in a riser system and urging the string of casing axially downward. The method further includes reducing the axial length of the string of casing to land a wellbore component in a subsea wellhead. In this manner, the wellbore is formed and lined with the string of casing in a single run. In another aspect, a method of forming and lining a subsea wellbore is provided. In yet another aspect, a method of landing a casing mandrel in a casing hanger disposed in a subsea wellhead is provided.

Owner:WEATHERFORD TECH HLDG LLC

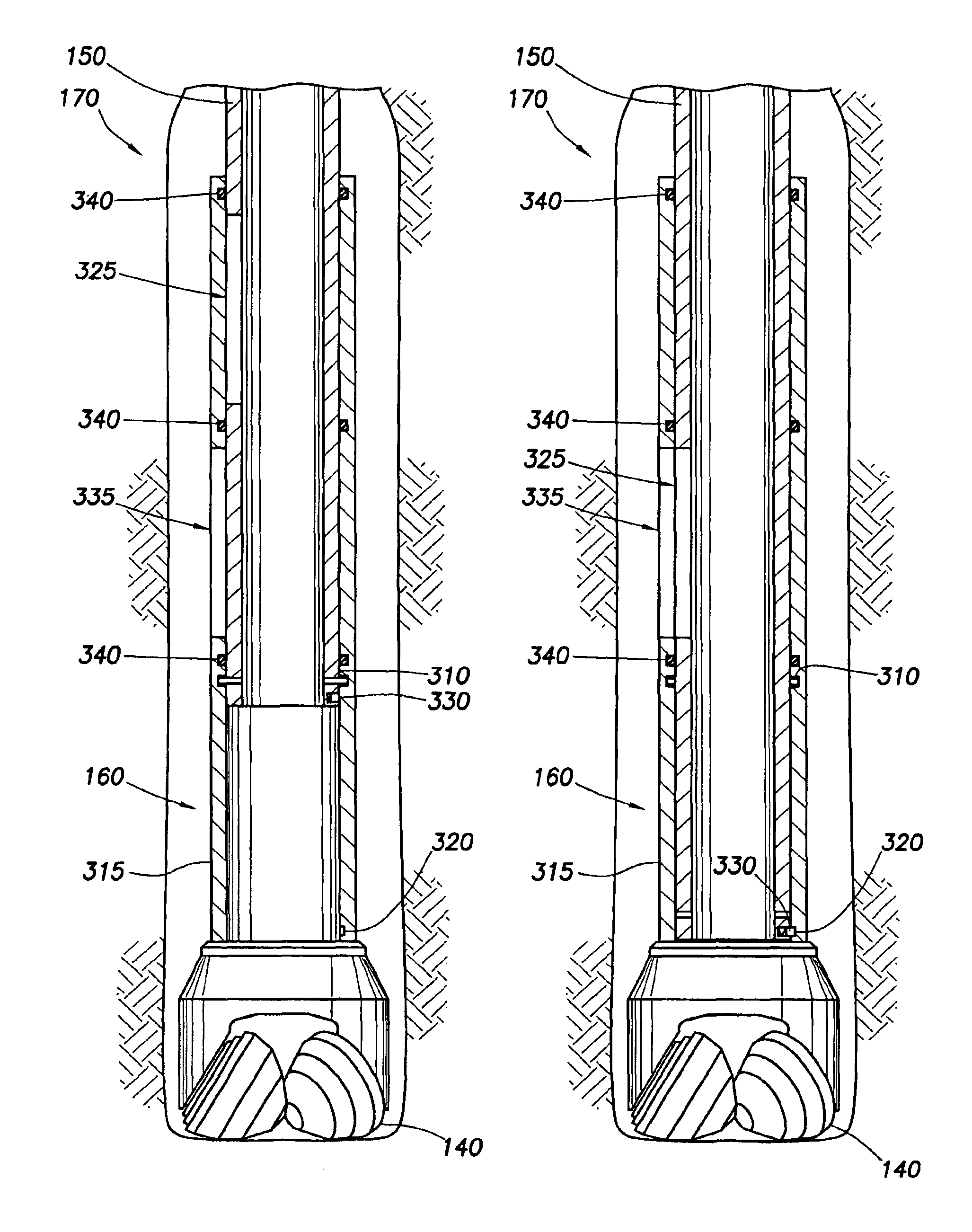

Apparatus for establishing branch wells at a node of a parent well

InactiveUS6170571B1Optimized areaFluid communicationDrilling rodsConstructionsEngineeringMechanical engineering

A method and apparatus for creating multiple branch wells from a parent well is disclosed. A multiple branching sub is provided for placement at a branching node of a well. Such sub includes a branching chamber and a plurality of branching outlet members. The outlet members during construction of the branching sub, have previously been distorted into oblong shapes so that all of the branching outlet members fit within an imaginary cylinder which is coaxial with and substantially the same radius as the branching chamber. After deployment of the branching sub via a parent casing in the well, a forming tool is lowered to the interior of the sub. The outlet members are extended outwardly by the forming tool and simultaneously formed into substantially round tubes. Next, each outlet member is plugged with cement, after which each branch well is drilled through a respective outlet member. If desired, each branch may be lined with casing and sealed to a branching outlet by means of a casing hanger. A manifold placed in the branching chamber controls the production of each branch well to the parent well.

Owner:SCHLUMBERGER TECH CORP

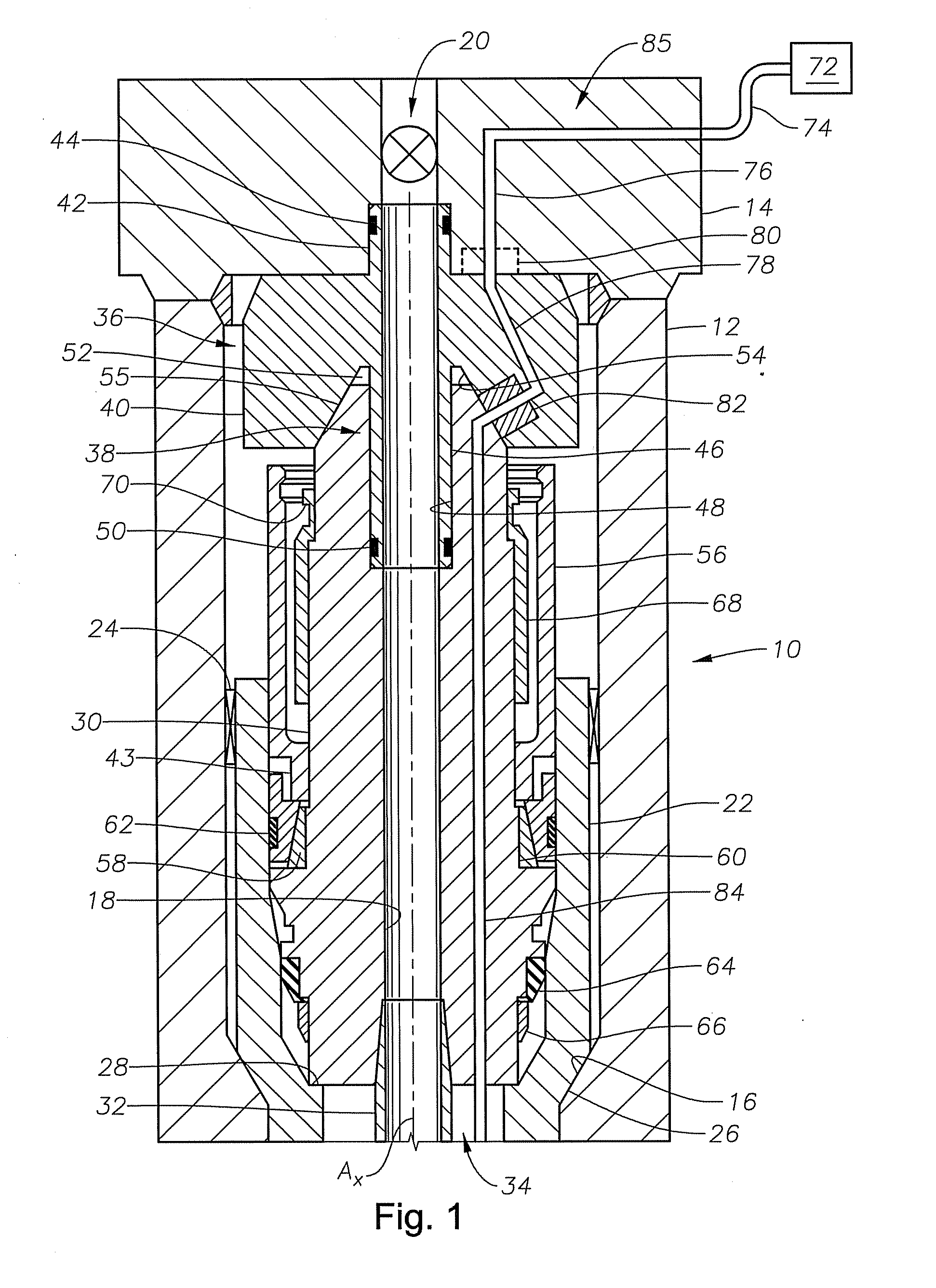

Casing hanger annulus monitoring system

A subsea wellhead assembly has the capabilities of communicating from a tree assembly mounted on an inner wellhead housing to a casing annulus. A passage in the wellhead assembly extends within the bore of the wellhead housing from the casing annulus to the tree assembly. A portion of the passage is located within a casing hanger. The passage is opened and closed by a valve. The valve does not open the passage until the tree assembly is connected to the wellhead housing and a tubing hanger orientation sleeve lands in the wellhead assembly. The tubing hanger orientation sleeve actuates the valve when it lands to open the passage. When the passage is opened, the casing annulus is in fluid communication with the interior surface of the wellhead housing, which is in communication with the tree assembly. The valve can be located in the casing hanger, or in a bridging hanger

Owner:ABB VETCOGRAY

Apparatus for establishing branch wells from a parent well

InactiveUS6247532B1Optimized areaFluid communicationDrilling rodsFluid removalCasing stringEquipment use

A method and apparatus for creating multiple branch wells from a parent well is disclosed. According to a first embodiment of the invention a multiple branching sub is provided for placement at a branching node of a well. Such sub includes a branching chamber and a plurality of branching outlet members. The outlet members, during construction of the branching sub, have previously been distorted into oblong shapes so that all of the branching outlet members fit within an imaginary cylinder which is coaxial with and substantially the same radius as the branching chamber. According to one embodiment, the distorted outlet members are characterized by an outer convex shape. In another embodiment, the distorted outlet members are characterized by an outer concave shape when in a retracted state. After deployment of the branching sub via a parent casing in the well, a forming tool is lowered to the interior of the sub. The outlet members are extended outwardly by the forming tool and simultaneously formed into substantially round tubes. Next, each outlet member is plugged with cement, after which each branch well is drilled through a respective outlet member. If desired, each branch may be lined with casing and sealed to a branching outlet by means of a casing hanger. A manifold placed in the branching chamber controls the production of each branch well to the parent well. According to a second embodiment of the invention, a pressure resistant branching sub is provided which may be installed in series with a casing string, and the associated equipment used for the installation operation and intervention of a well. The branching sub includes a main pipe and a lateral outlet.

Owner:SCHLUMBERGER TECH CORP

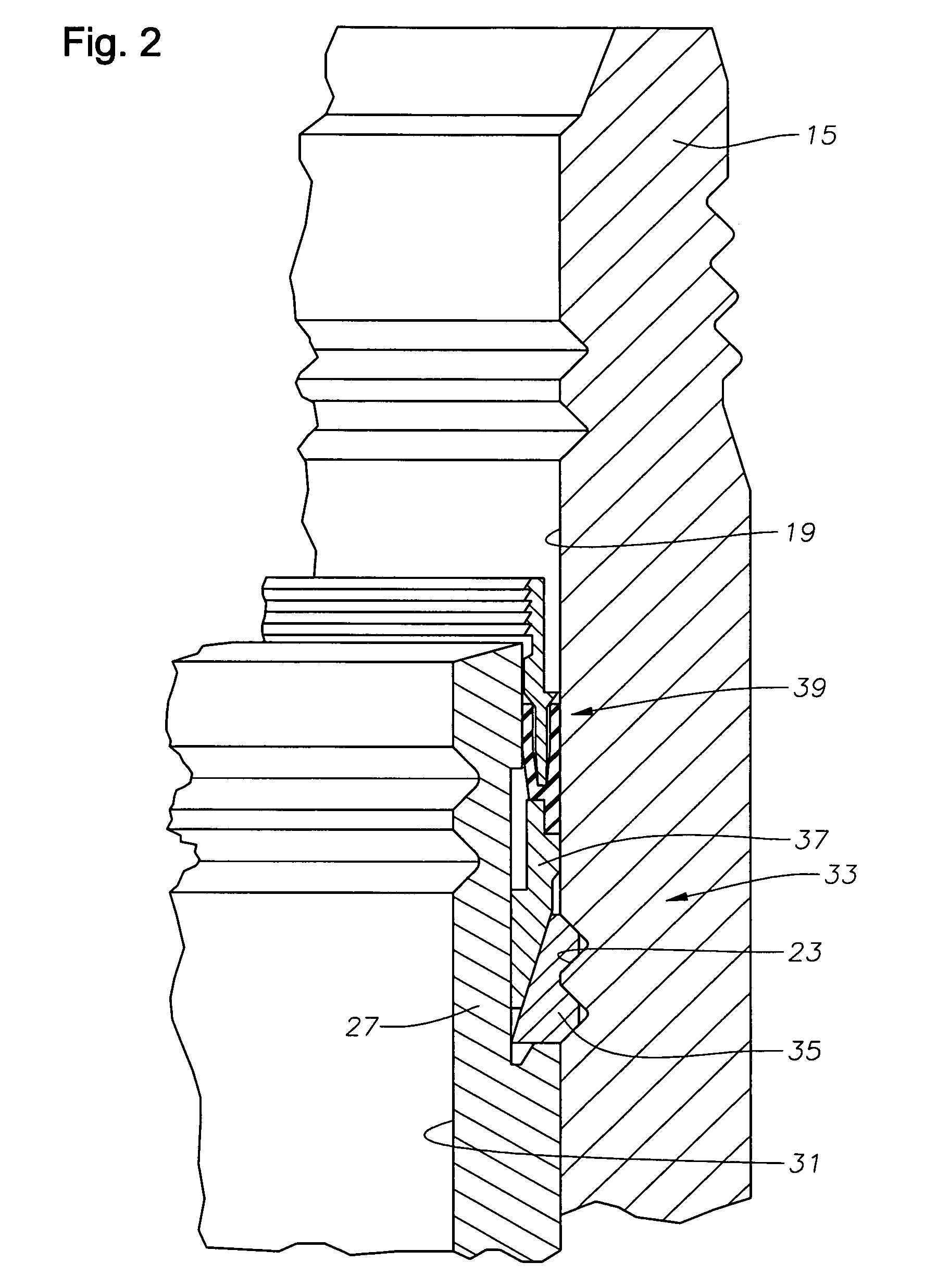

Metal-to-metal seal for bridging hanger or tieback connection

A method of completing a well having a casing hanger set in a subsea wellhead housing includes attaching a running tool to a tubular bridging hanger. A metal-to-metal inner seal is attached to a lower exterior portion of the bridging hanger and a metal-to-metal outer seal is located on an upper exterior portion of the bridging hanger. The assembly is lowered into the well and the lower exterior portion of the bridging hanger is inserted into the casing hanger. The inner seal is wedged between the casing hanger and the bridging hanger in response to weight of the running string. The running tool is actuated to set the outer seal between the upper exterior portion of the bridging hanger and the wellhead housing. Then, a tubing hanger is landed and sealed in the interior of the bridging hanger.

Owner:VETCO GRAY

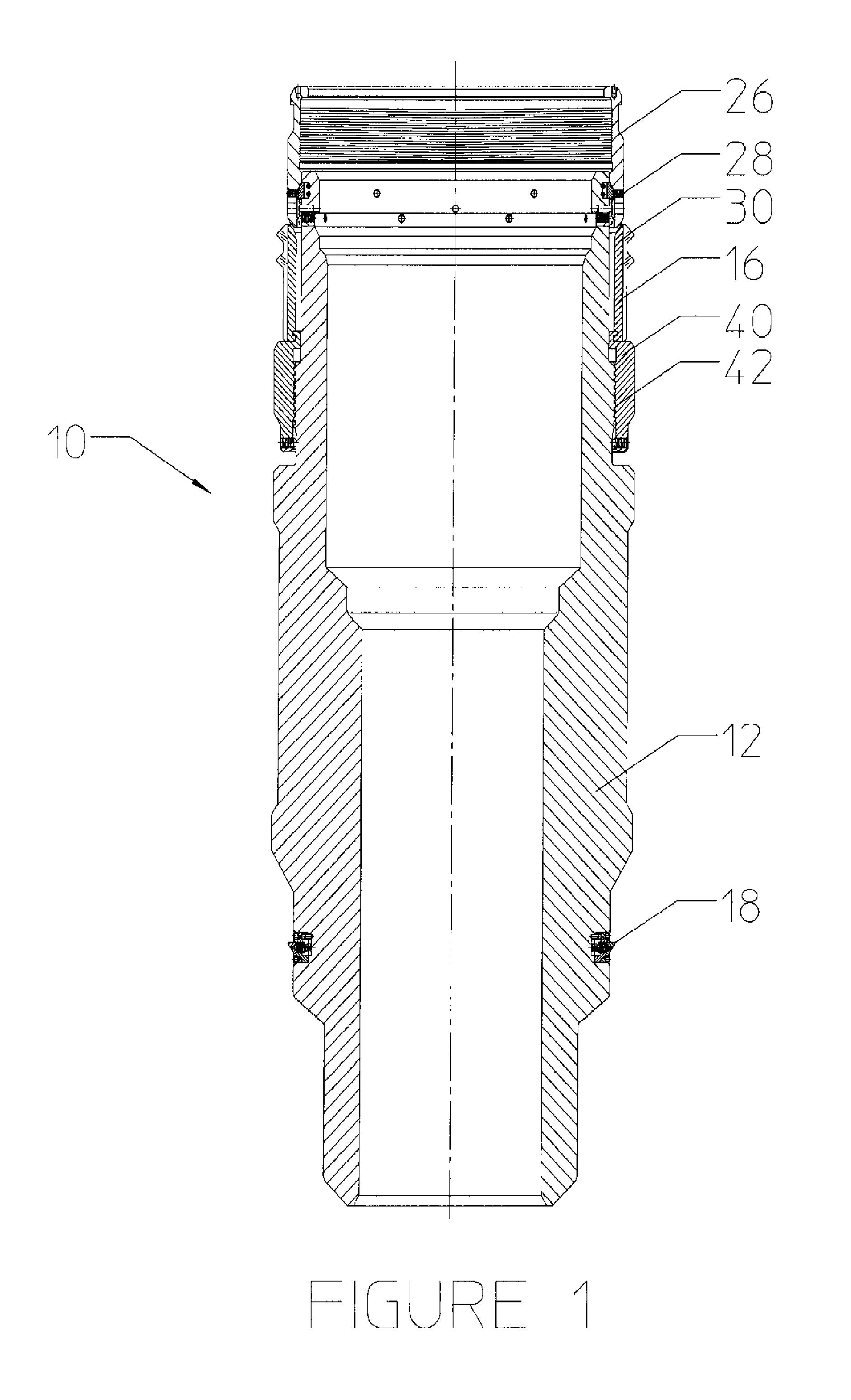

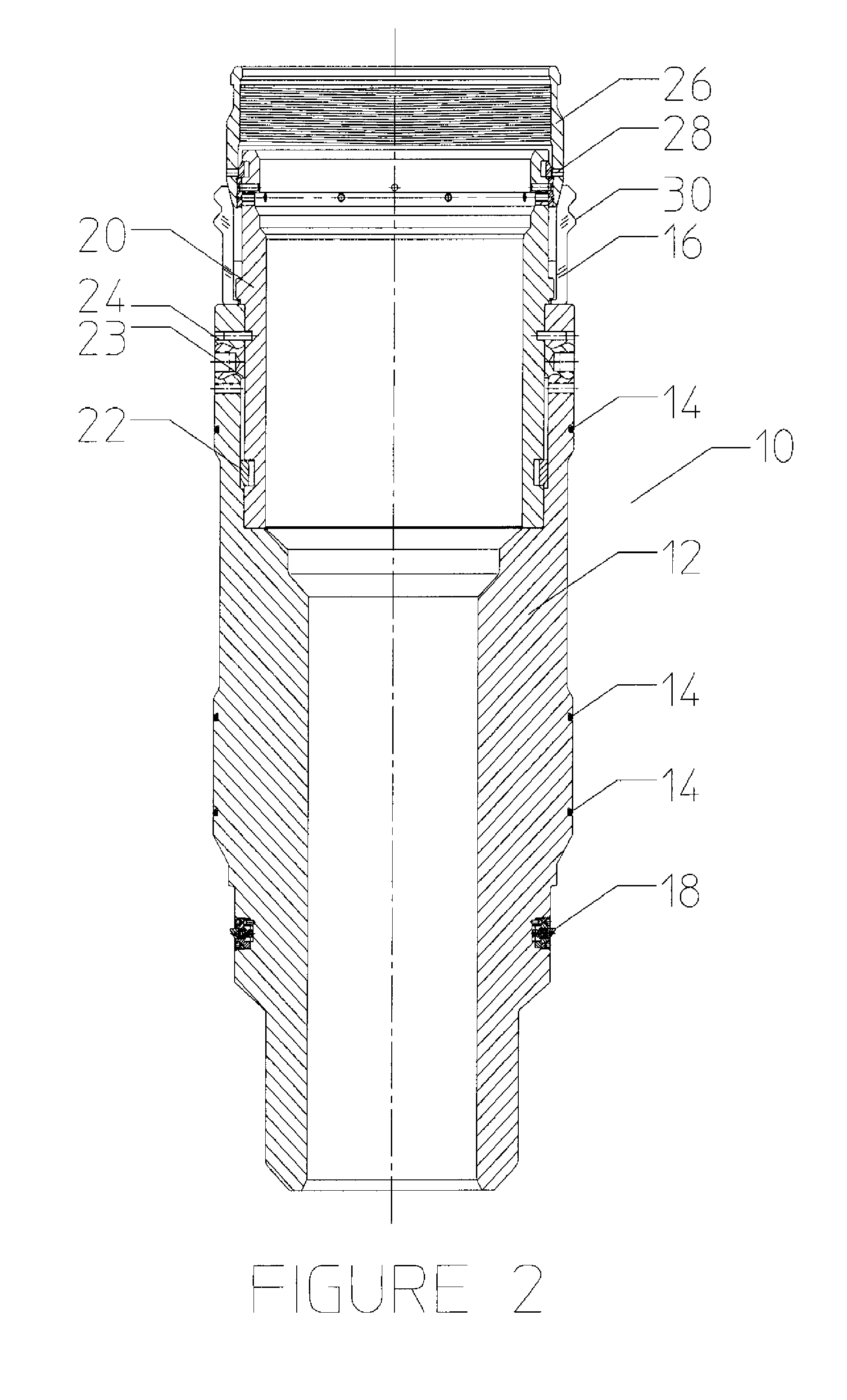

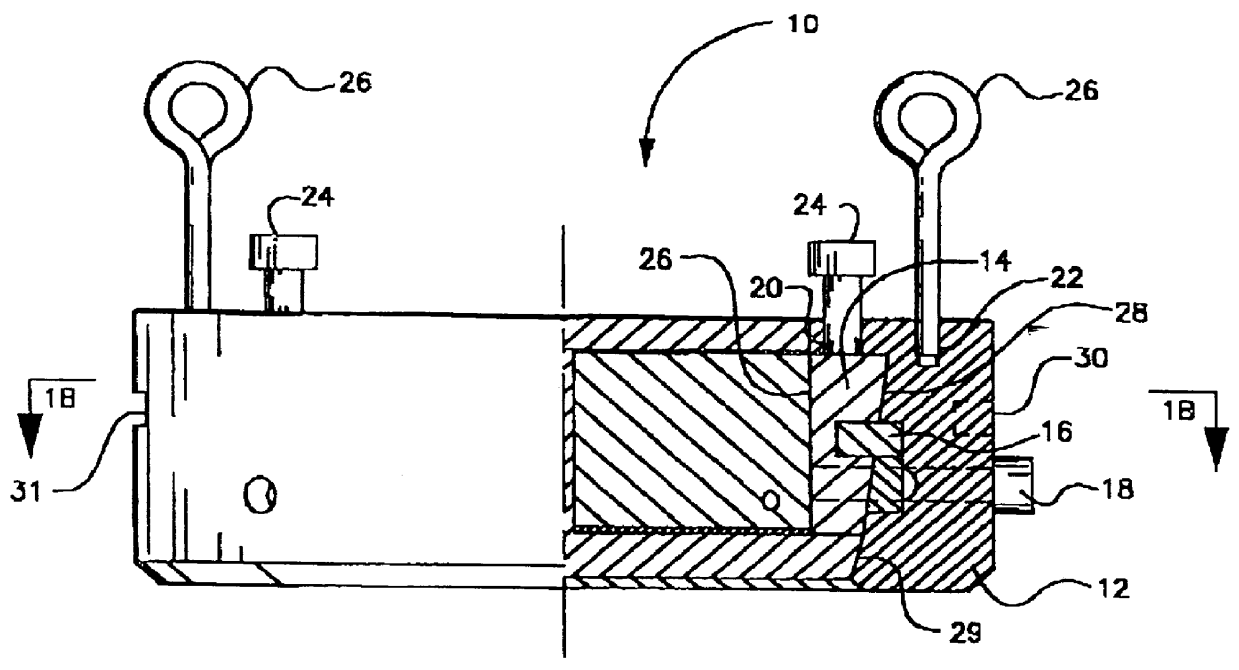

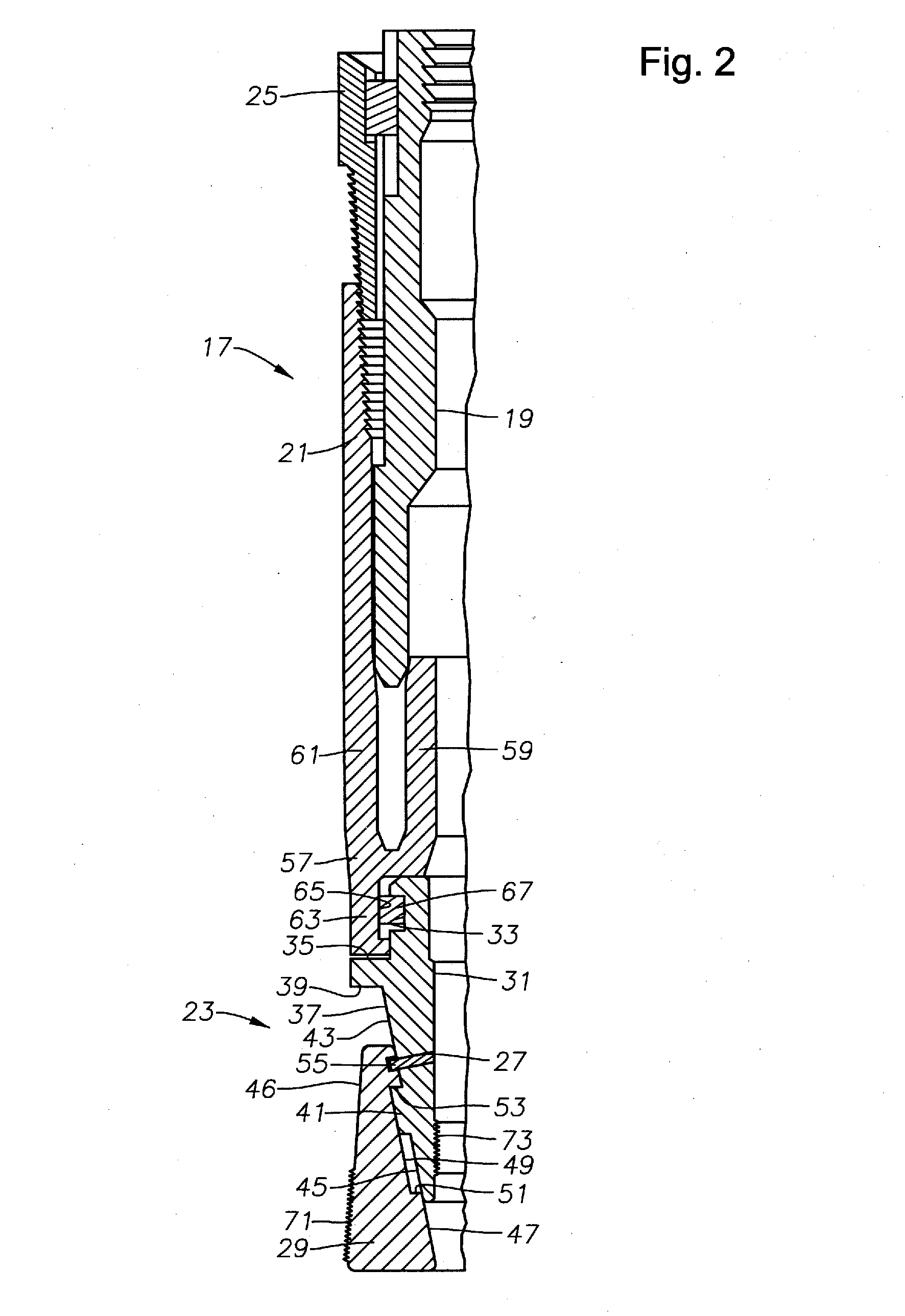

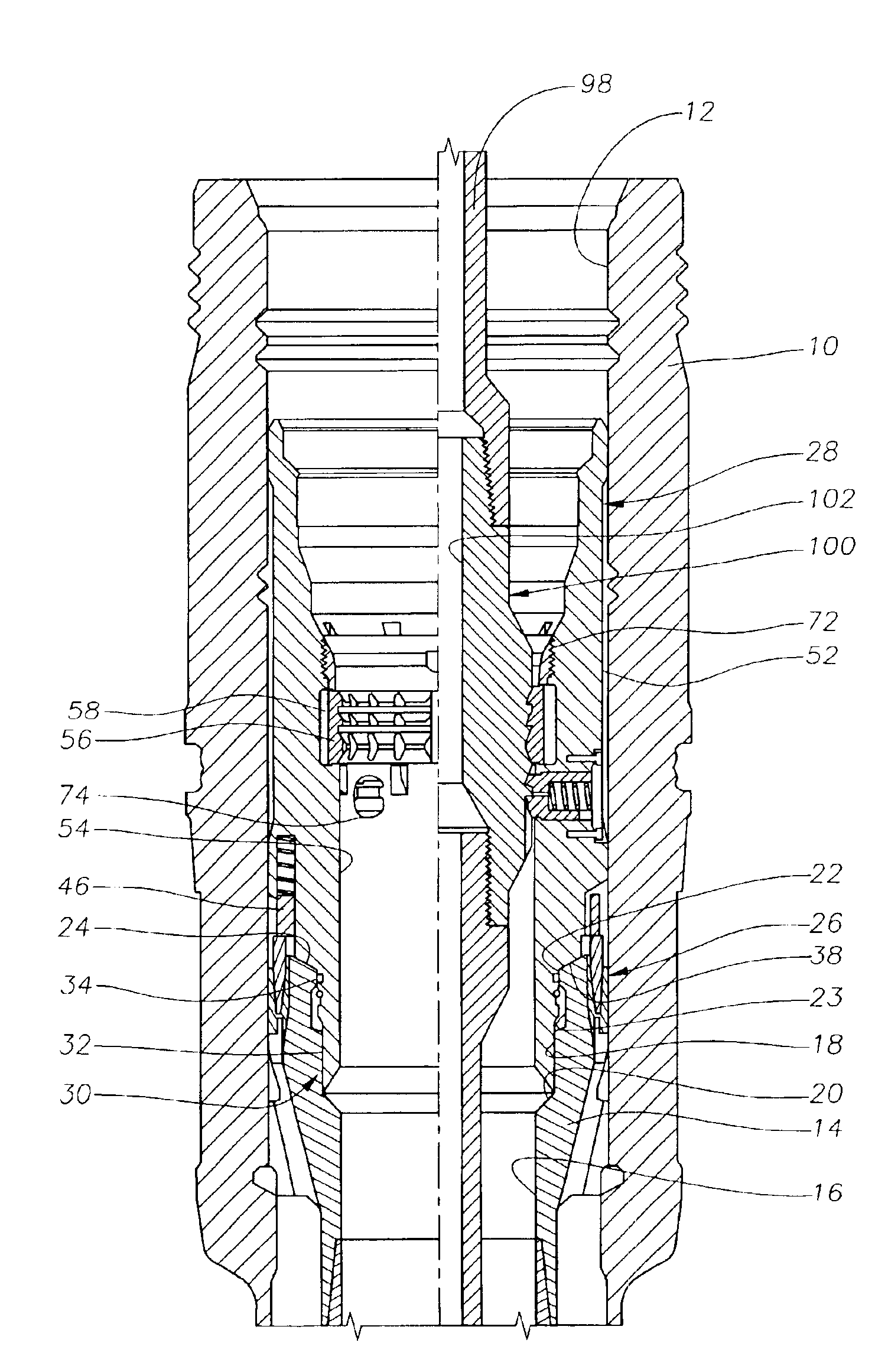

Externally activated seal system for wellhead

ActiveUS7128143B2Minimized in sizeSimple procedureDrilling rodsFluid removalTubing hangerCombined use

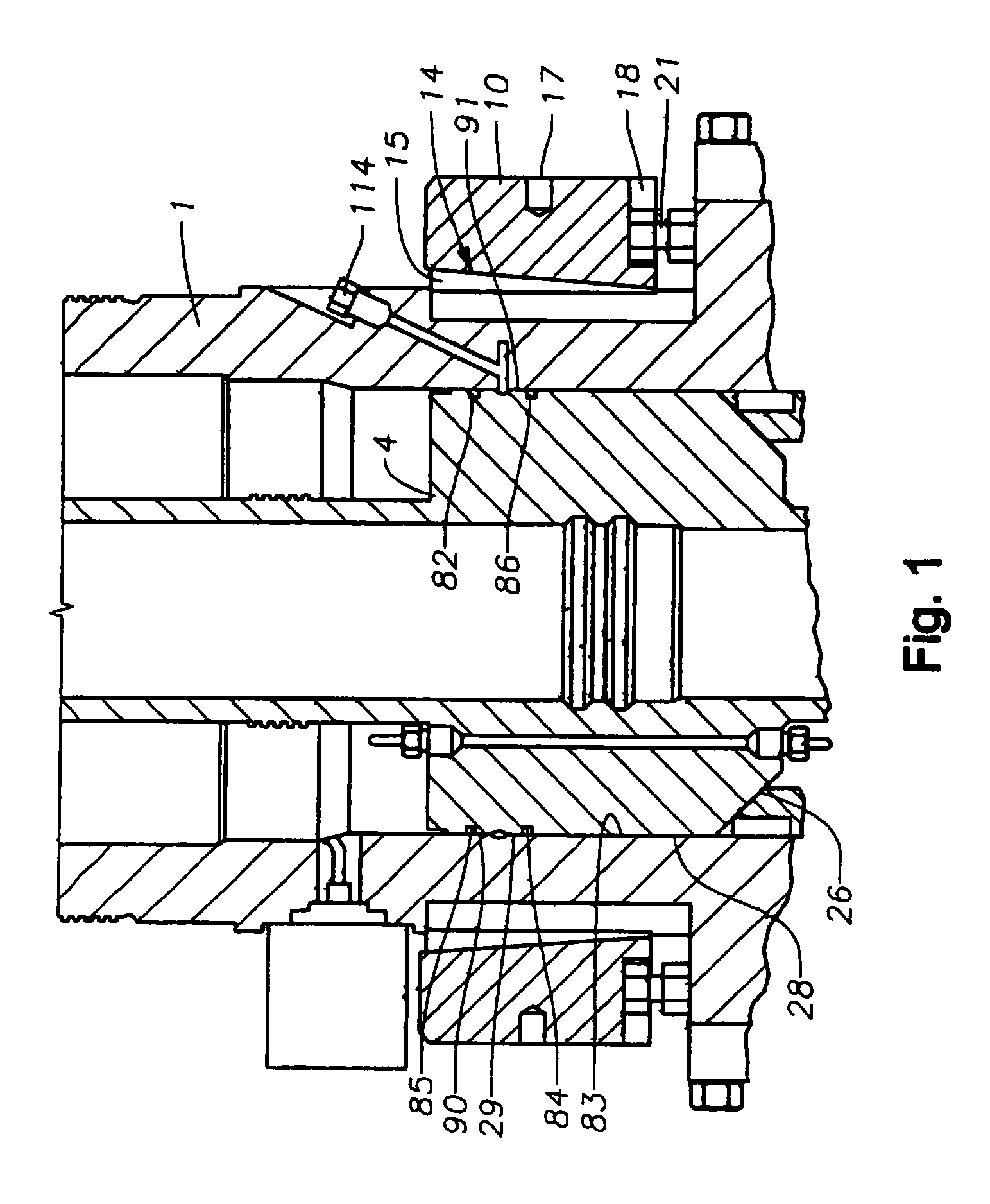

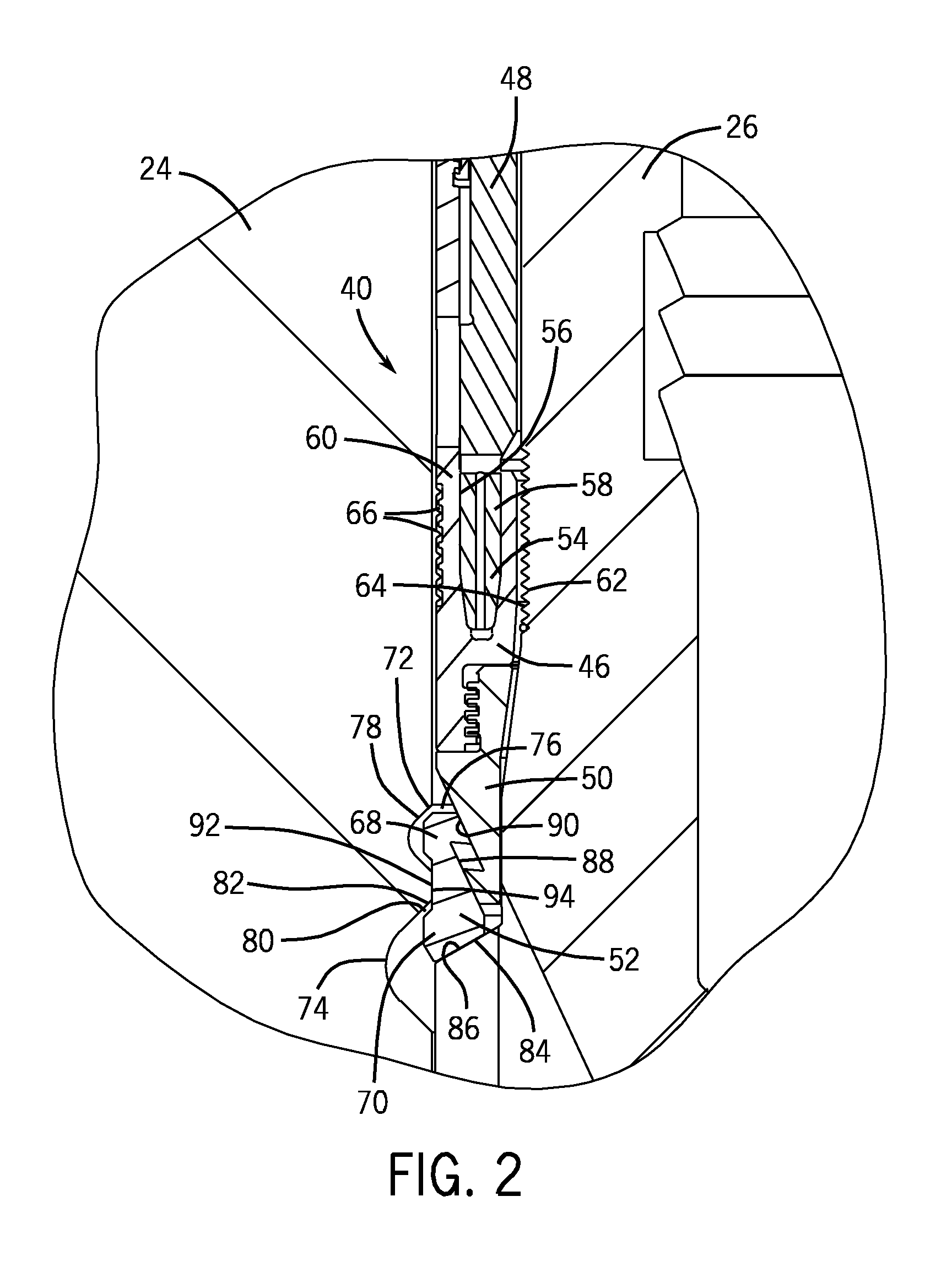

A method and apparatus for a seal assembly for a unitized wellhead system for land or platform applications utilizes a friction grip technology to create maintainable metal-to-metal seals with finely-controlled contact stresses, lock-down casing and tubing hangers, support test loads to minimize the size of landing shoulders required, and to rotationally lock casing hangers to provide simplified running procedures. The system can be used in combination with a friction grip clamping assembly to greatly streamline the wellhead design.

Owner:PLEXUS HOLDINGS PLC

Casing cutter

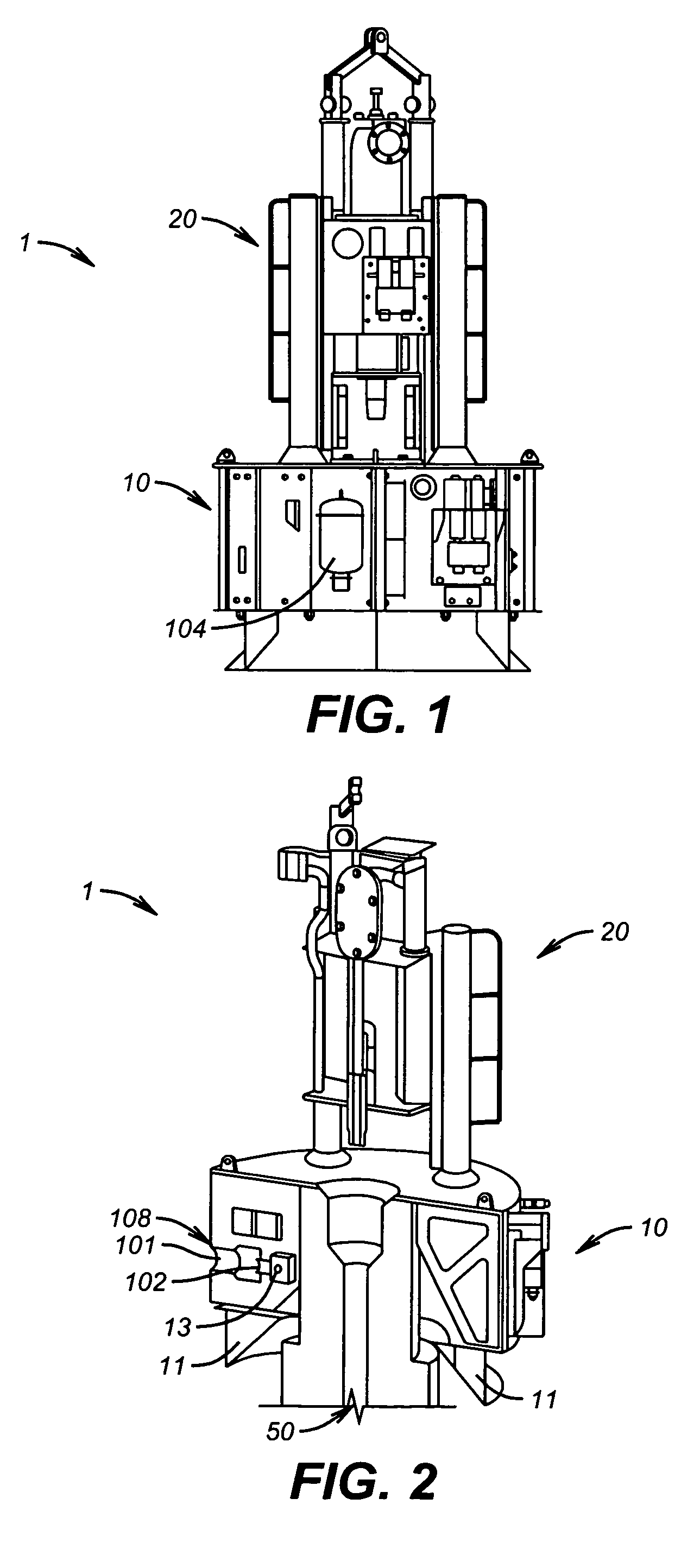

A subsea well casing cutting tool for use as part of a well abandonment procedure, the casing cutting tool deployable from a vessel located at a water surface, where in certain embodiments the casing cutting tool comprises a casing gripper; a rotary cutter drive assembly; a rotary cutter; a rotating fluid union that allows high volume water to be fed to the rotating cutting assembly below the drive motor for purposes of extending the cutting blades; and a third party casing hanger removal tool wherein the casing cutting drive assembly forms an interface between the third party rotary casing cutter, an existing subsea casing, and a work class ROV. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope of meaning of the claims.

Owner:OCEANEERING INTERNATIONAL

Multi-purpose sleeve for tieback connector

InactiveUS20060196673A1Avoid damageFacilitate entryFluid removalUnderwater drillingOcean bottomFloating platform

A tieback connector connects a riser between a subsea wellhead housing and a floating platform. The tieback connector has a tubular body that stabs into and seals with a casing hanger. A latch member on the tieback connector engages a locking profile to secure the tieback connector to the wellhead housing. A sleeve is slidably carried on the tubular body between a running-in position and a set position. The lower end of the sleeve lands on an upper rim of the casing hanger prior to the seal engaging the seal surface. Continued downward movement of the tubular body relative to the sleeve causes the seal to engage the seal surface and the sleeve to move to the set position. The sleeve has upper end that engages a lower end of the latch member to limit any upward movement of the casing hanger in the wellhead housing.

Owner:VETCO GRAY

Metal-to-metal seal for bridging hanger or tieback connection

A method of completing a well having a casing hanger set in a subsea wellhead housing includes attaching a running tool to a tubular bridging hanger. A metal-to-metal inner seal is attached to a lower exterior portion of the bridging hanger and a metal-to-metal outer seal is located on an upper exterior portion of the bridging hanger. The assembly is lowered into the well and the lower exterior portion of the bridging hanger is inserted into the casing hanger. The inner seal is wedged between the casing hanger and the bridging hanger in response to weight of the running string. The running tool is actuated to set the outer seal between the upper exterior portion of the bridging hanger and the wellhead housing. Then, a tubing hanger is landed and sealed in the interior of the bridging hanger.

Owner:VETCO GRAY

Combined Tree Stab and Control Interface

A subsea wellhead assembly provided over a wellbore, the assembly having a wellhead housing, a tubing hanger in the housing, a production tree on the wellhead housing above the tubing hanger, and a control circuit that passes axially downward from the production tree and through the tubing hanger. A tree stab assembly may be included that is set between the tubing hanger and production tree. The wellhead assembly can also include a casing hanger landed in the housing, casing attached to the casing hanger, and tubing attached to the tubing hanger.

Owner:VETCO GRAY

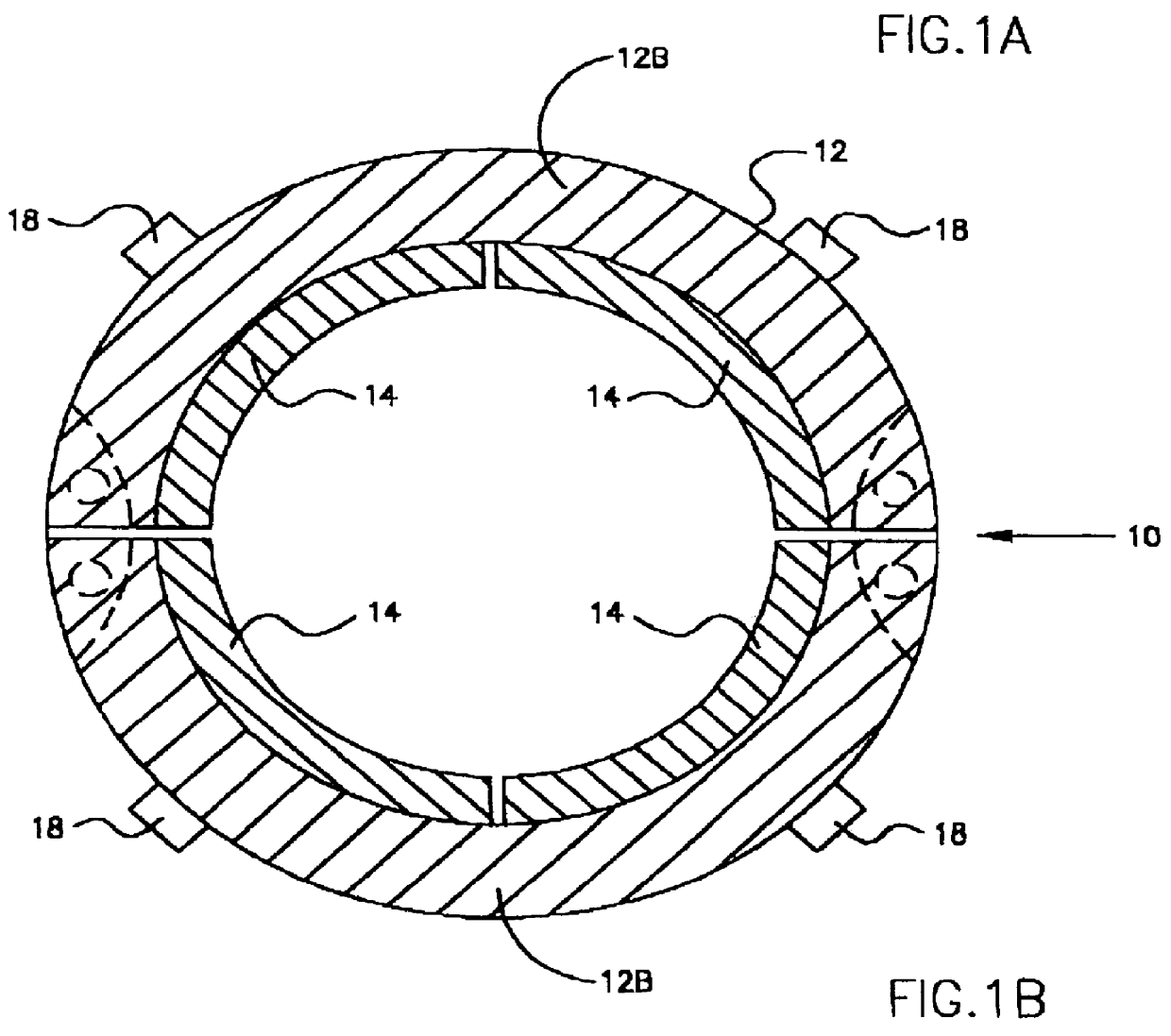

Wear bushing for locking to a wellhead

A wear bushing (10) and a running tool (32) are provided for a subsea wellhead assembly including a wellhead housing and a casing hanger. The wear bushing is landed on the casing hanger, and a connector (16) axially connects the wear bushing and the wellhead housing. The running tool is actuated to connect the wear bushing, such that at least a portion of the connector is received within a corresponding recess in an interior wall of the wellhead housing. A bushing / casing hanger latch (18) axially connects the wear bushing and the casing hanger.

Owner:DRIL QUIP

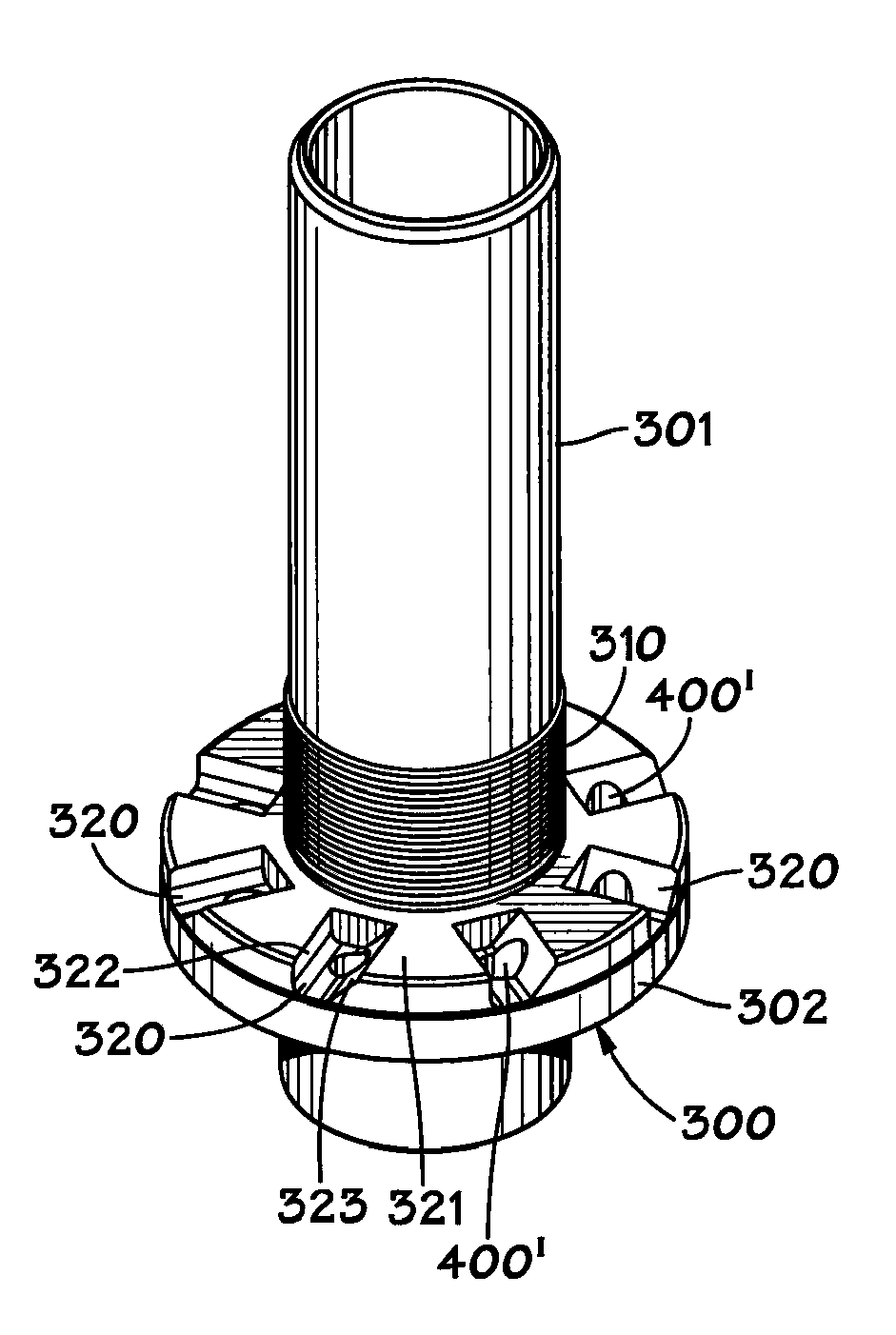

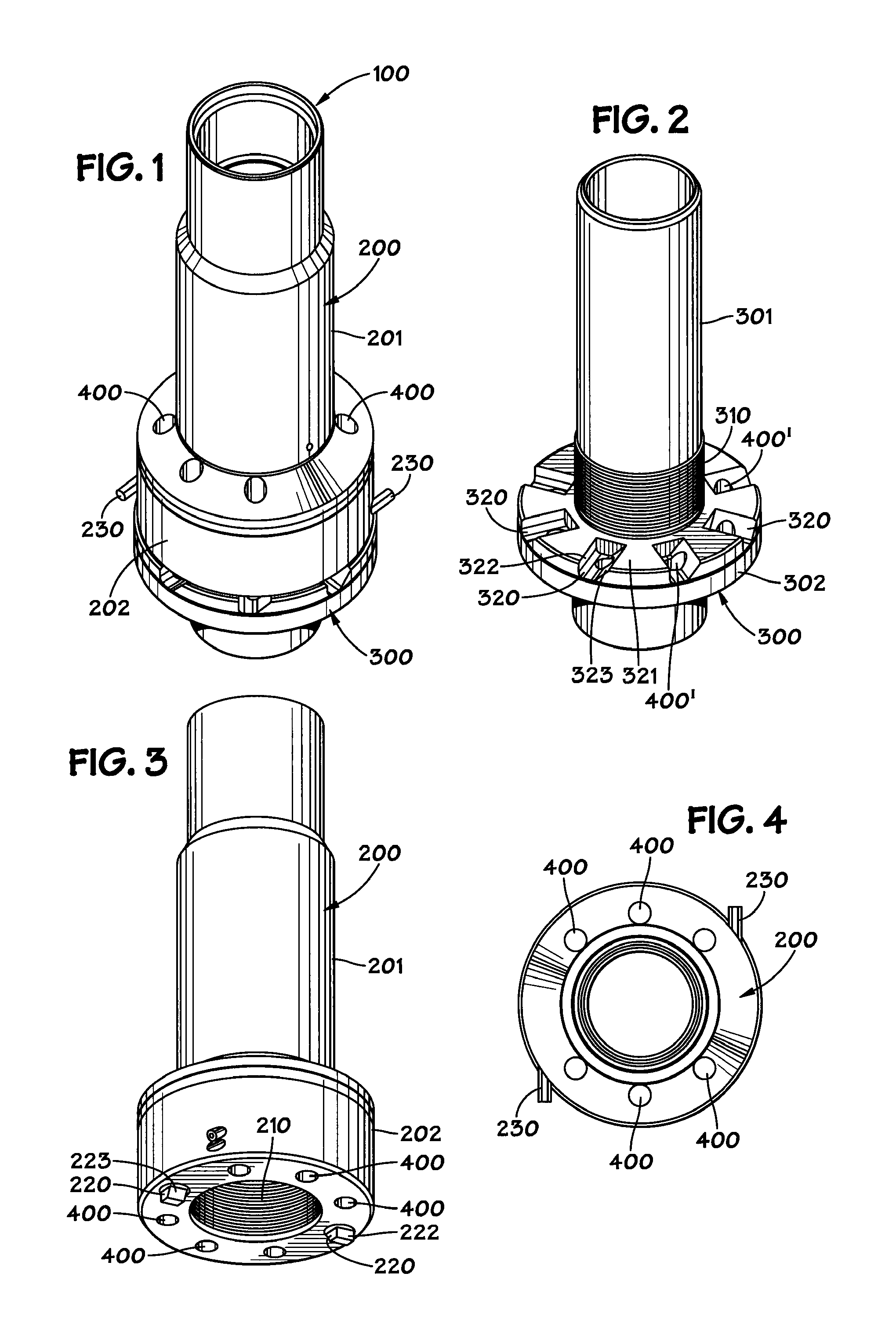

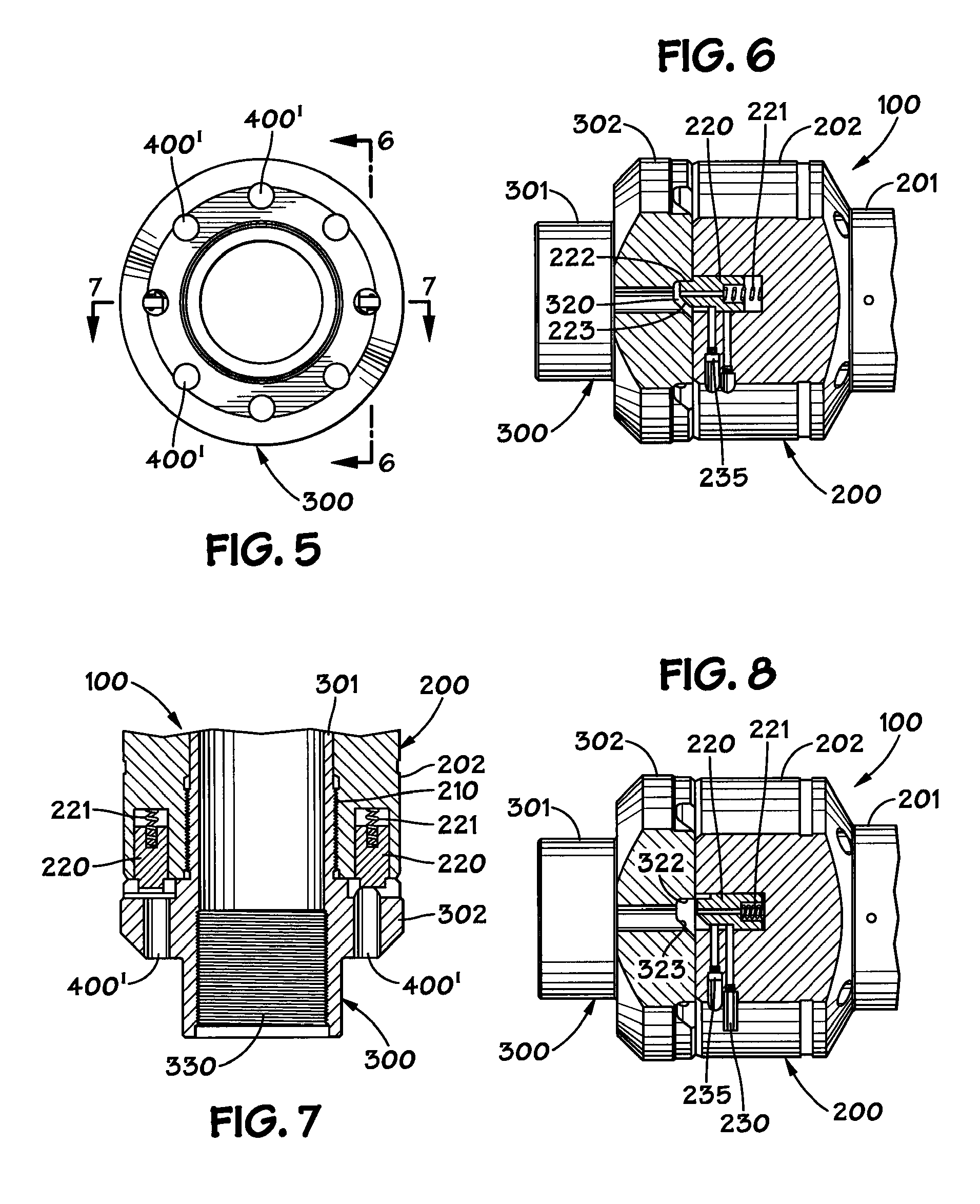

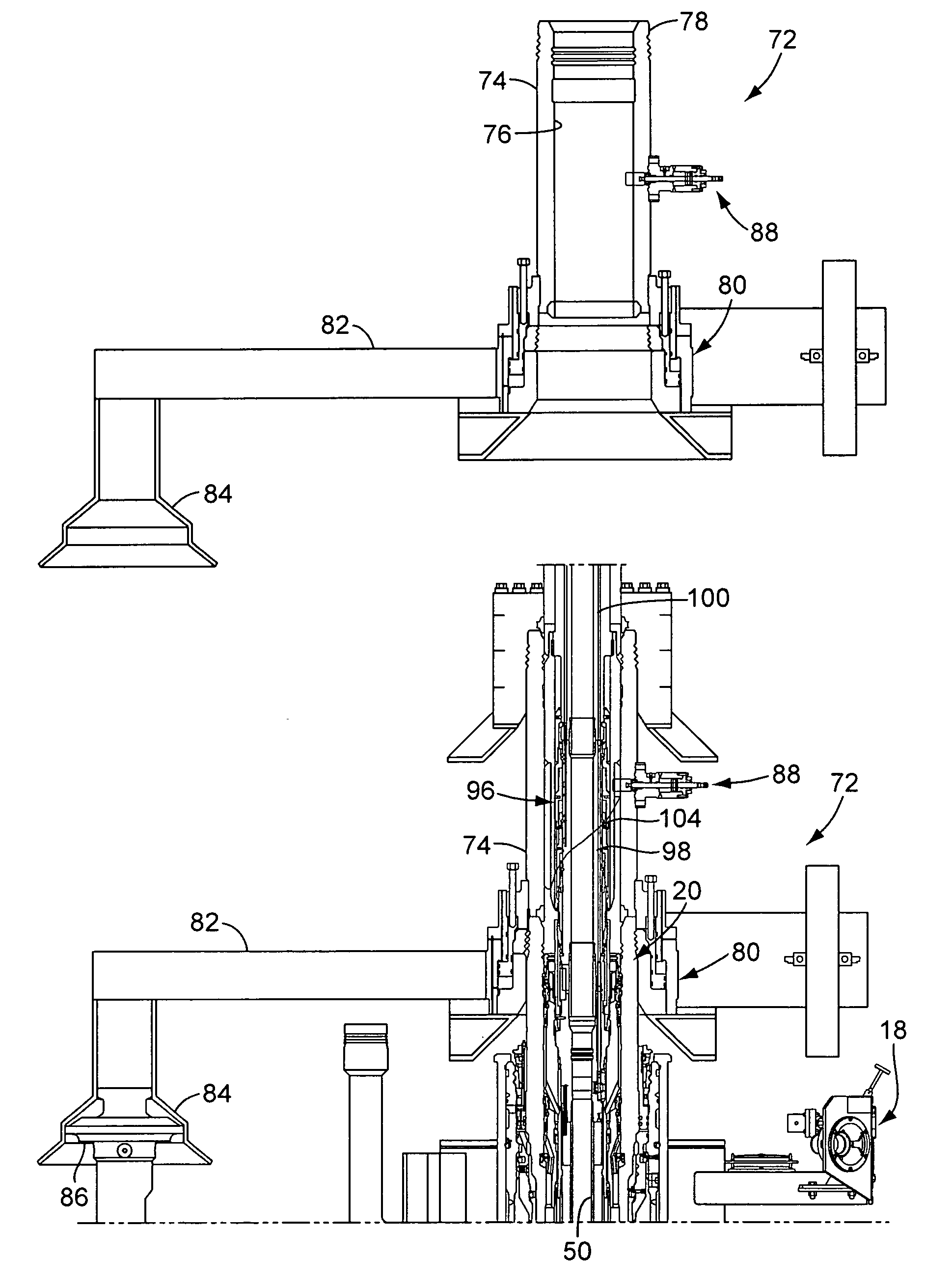

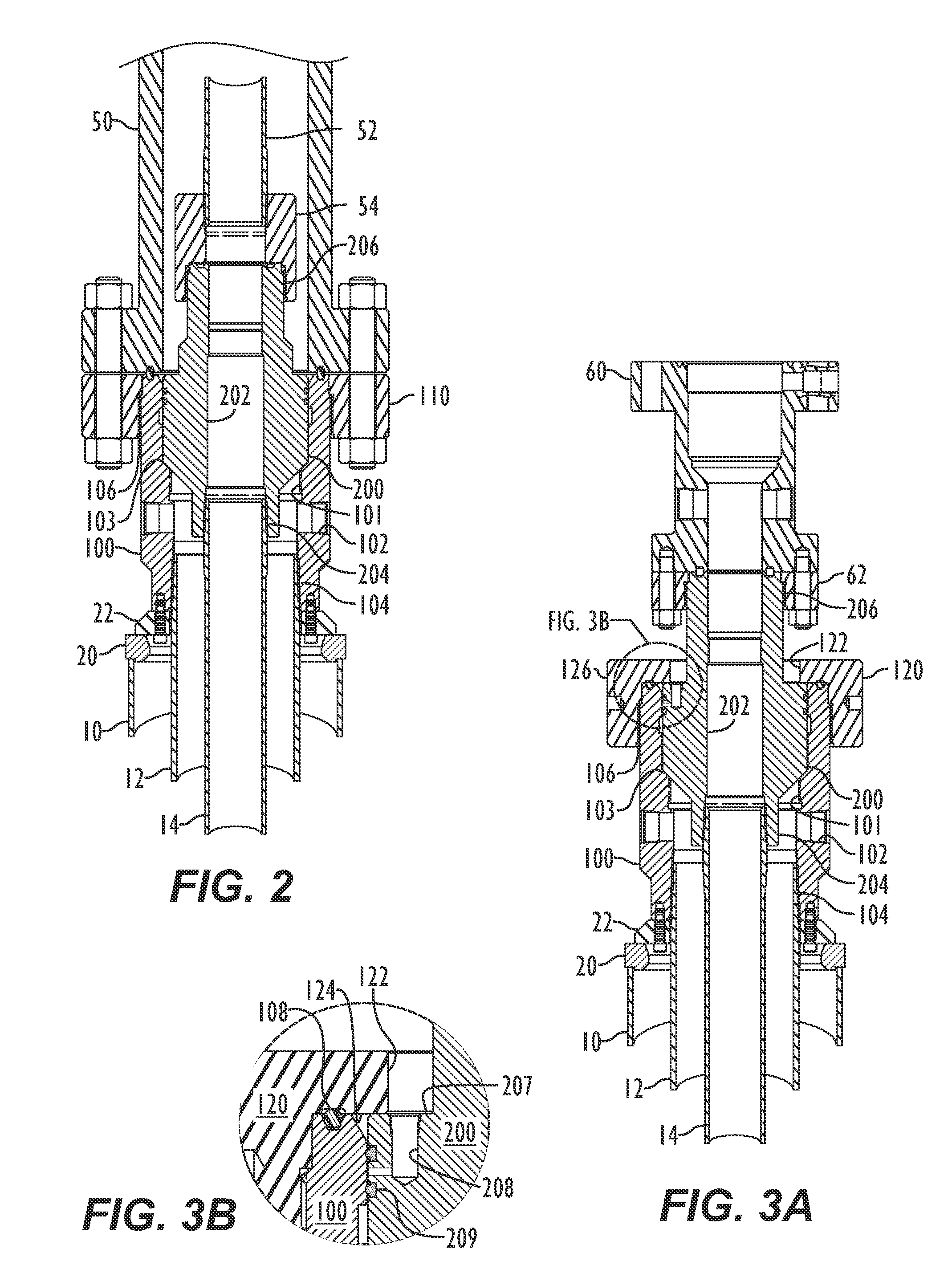

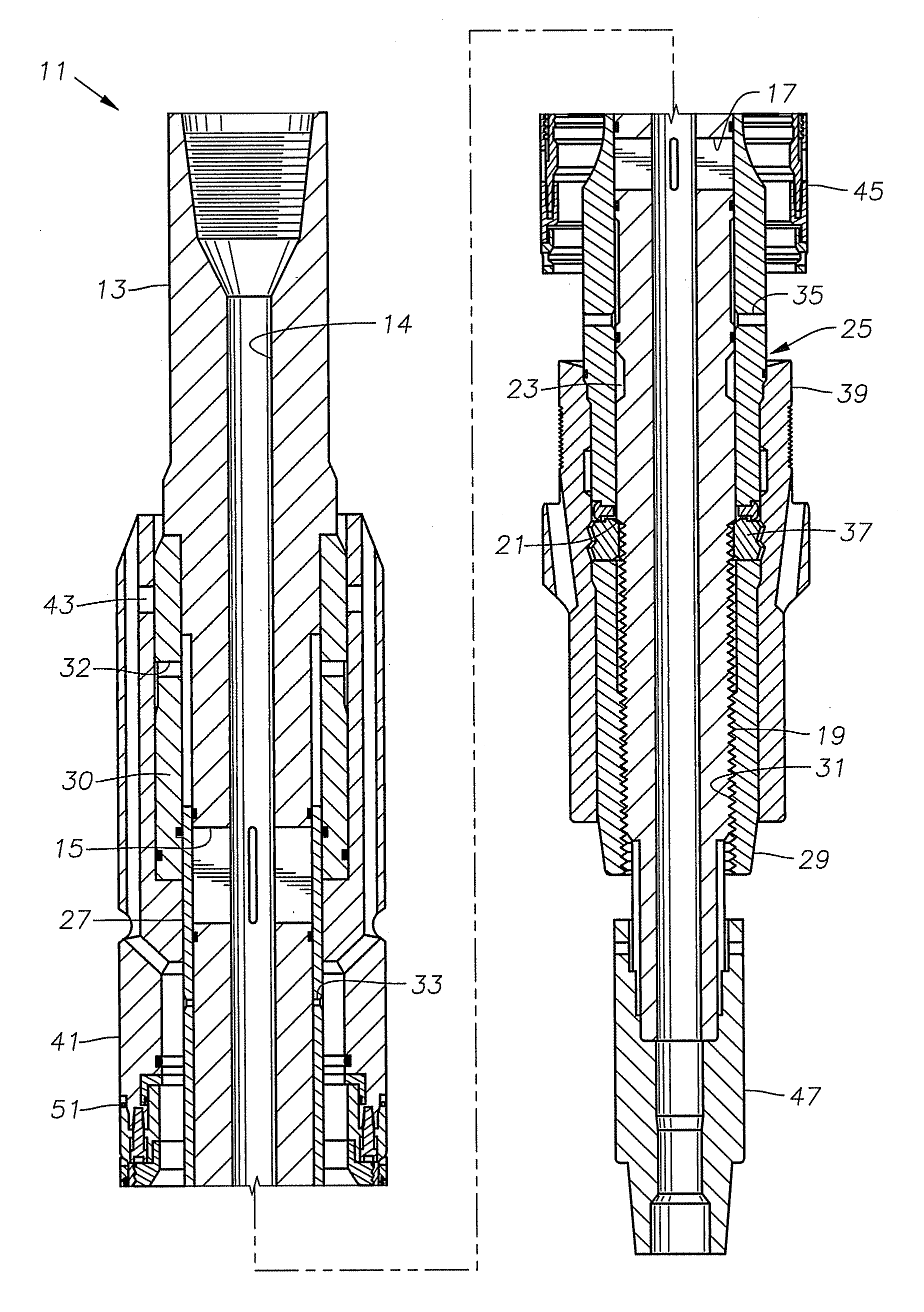

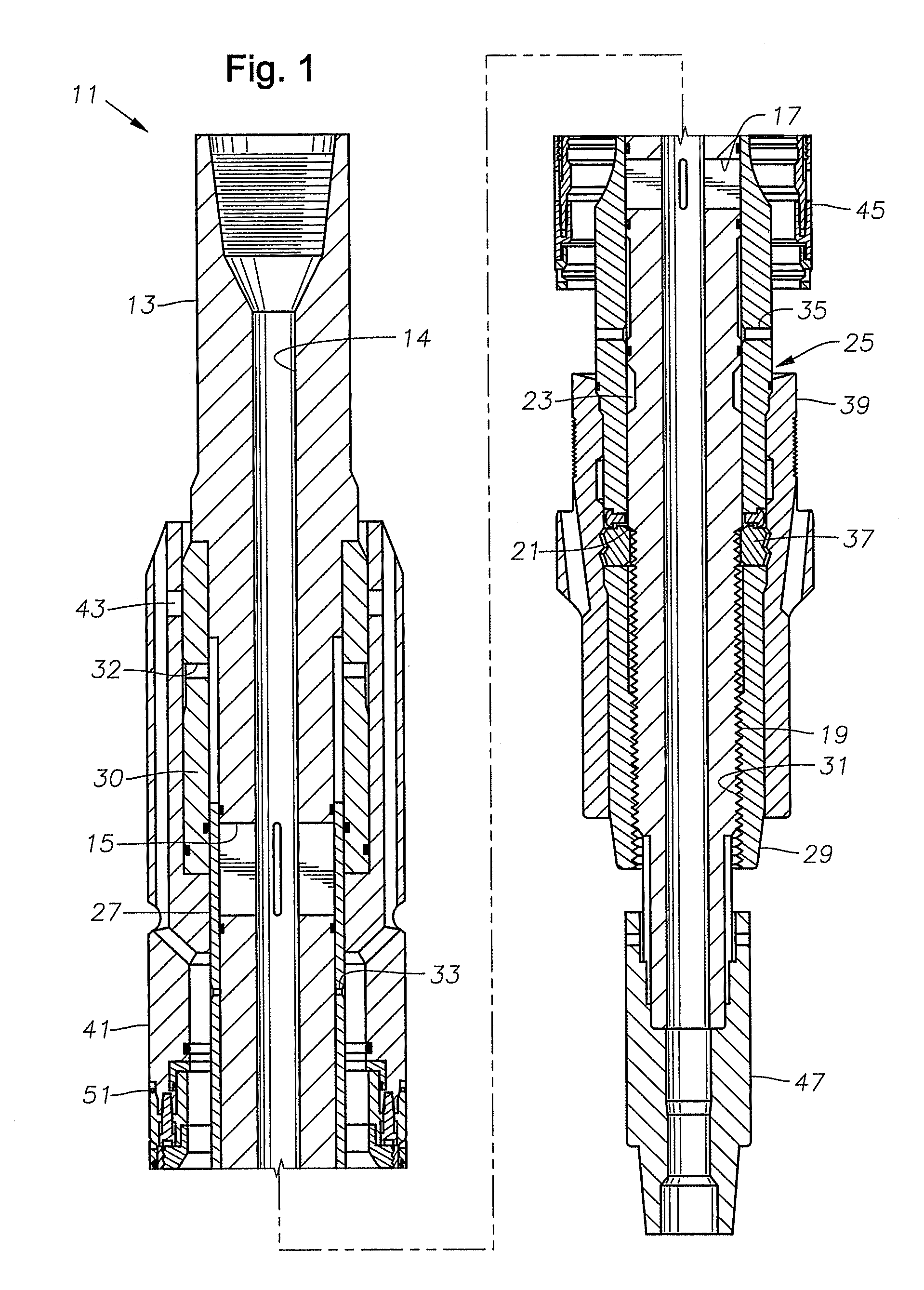

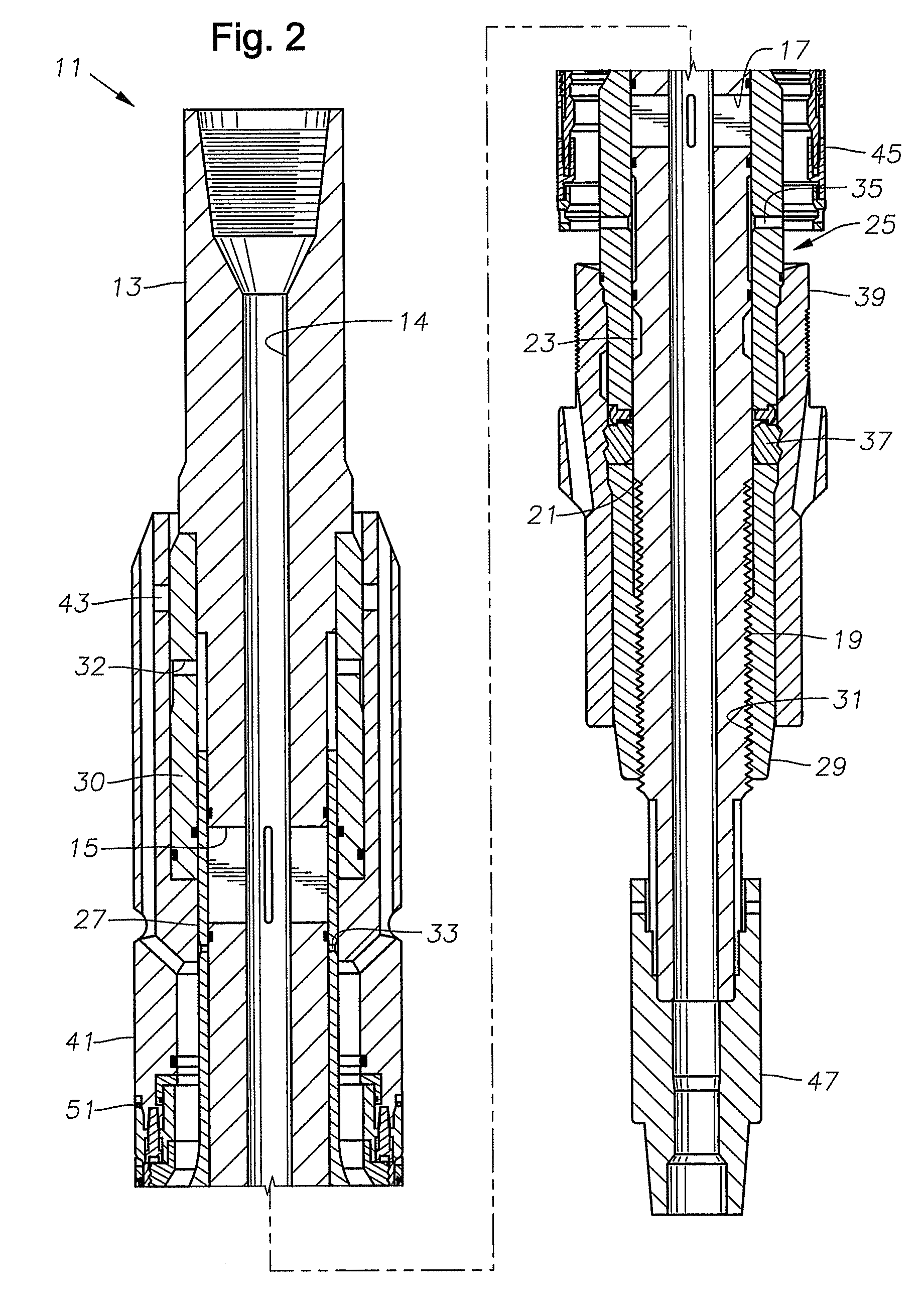

Mandrel casing hanger and running tool system

A method for rotating a casing string in a borehole and a mandrel casing hanger and running tool system, include a selectively engageable connection between a mandrel casing hanger and a running tool; and a rotational force may be applied to the mandrel casing hanger, running tool, and casing string, without substantially tightening a threaded connection between the running tool and the mandrel casing hanger, by transmitting the rotational force through the selectively engageable connection.

Owner:GE OIL & GAS PRESSURE CONTROL

Shoulder ring set on casing hanger trip

Owner:VETCO GRAY

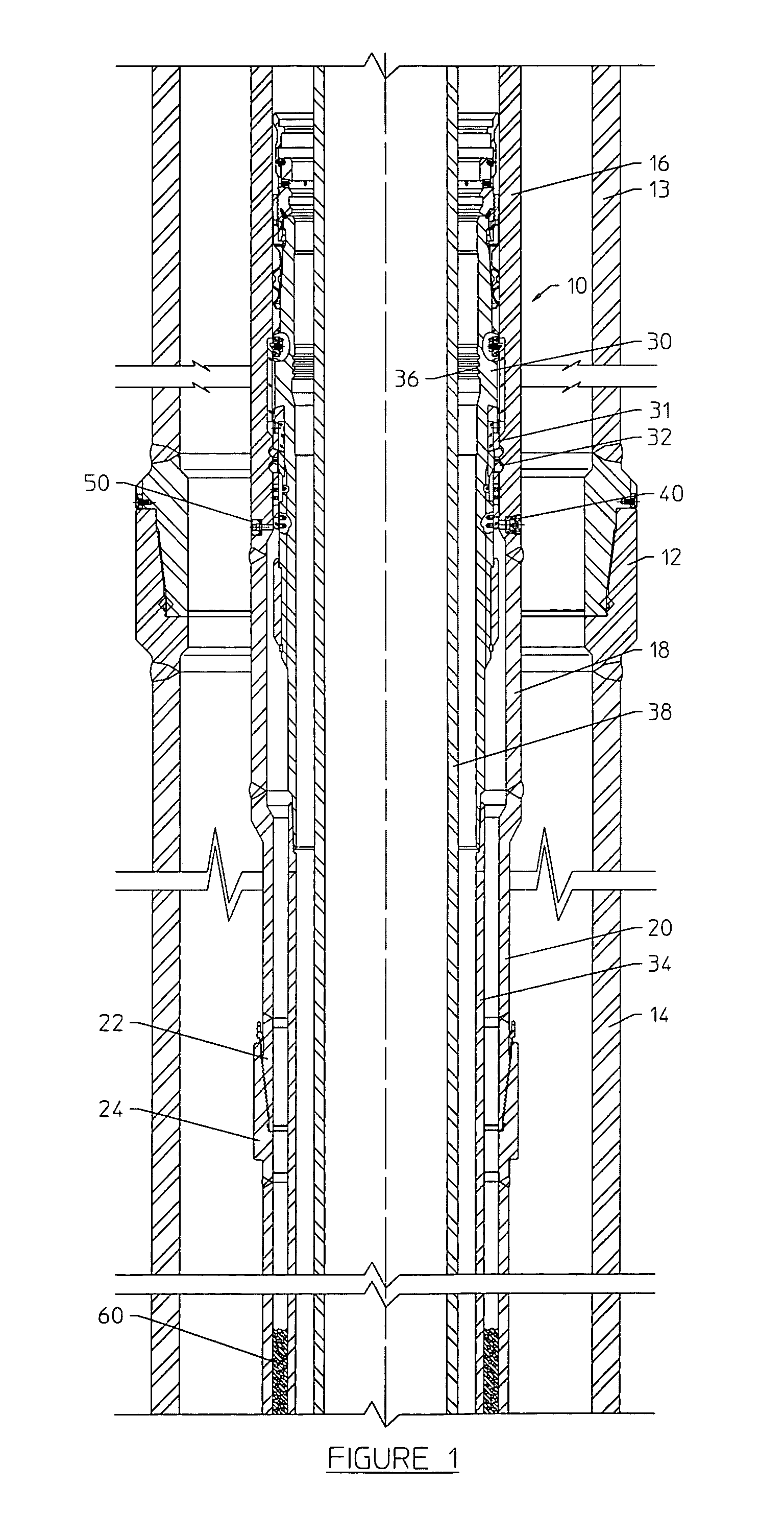

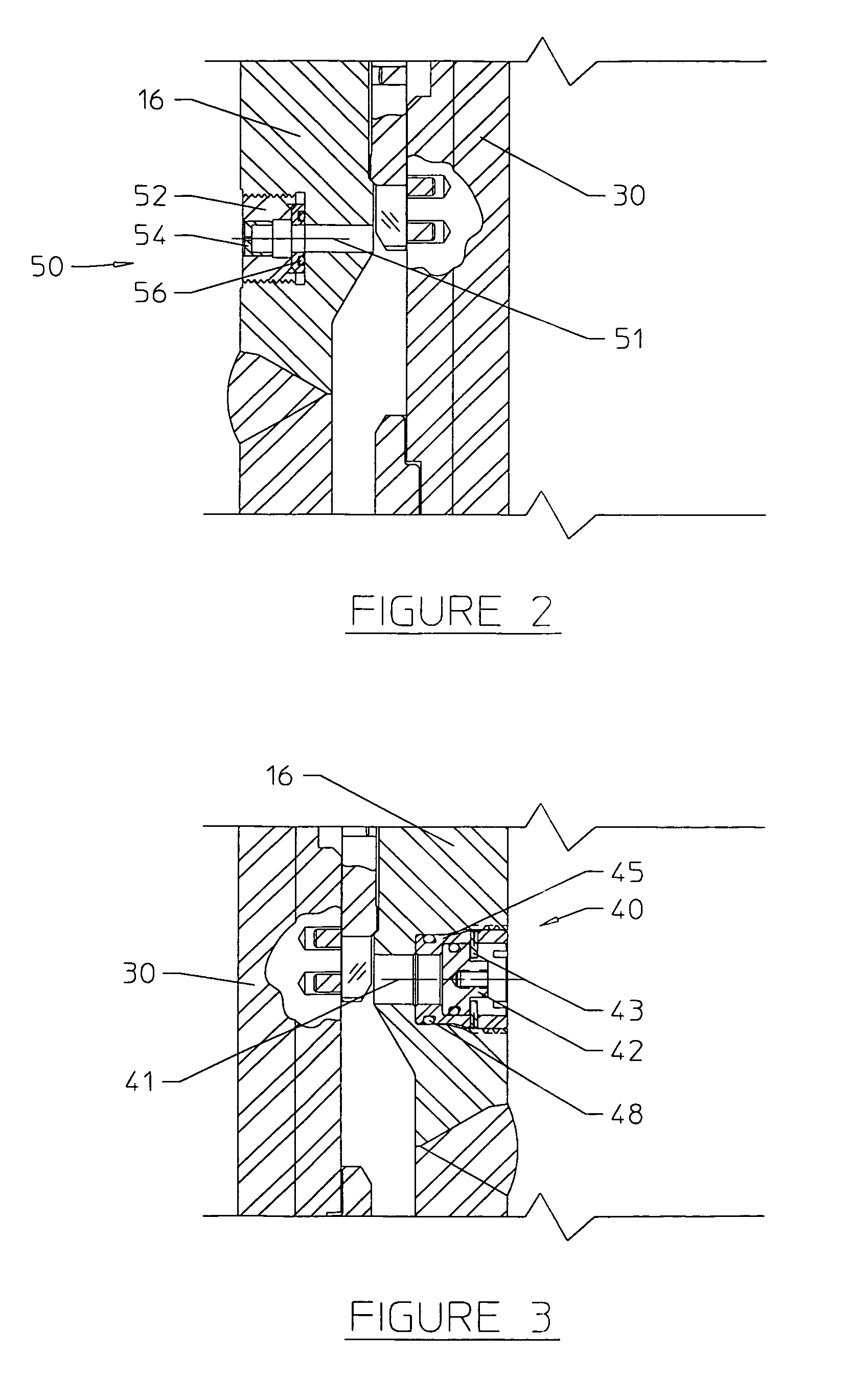

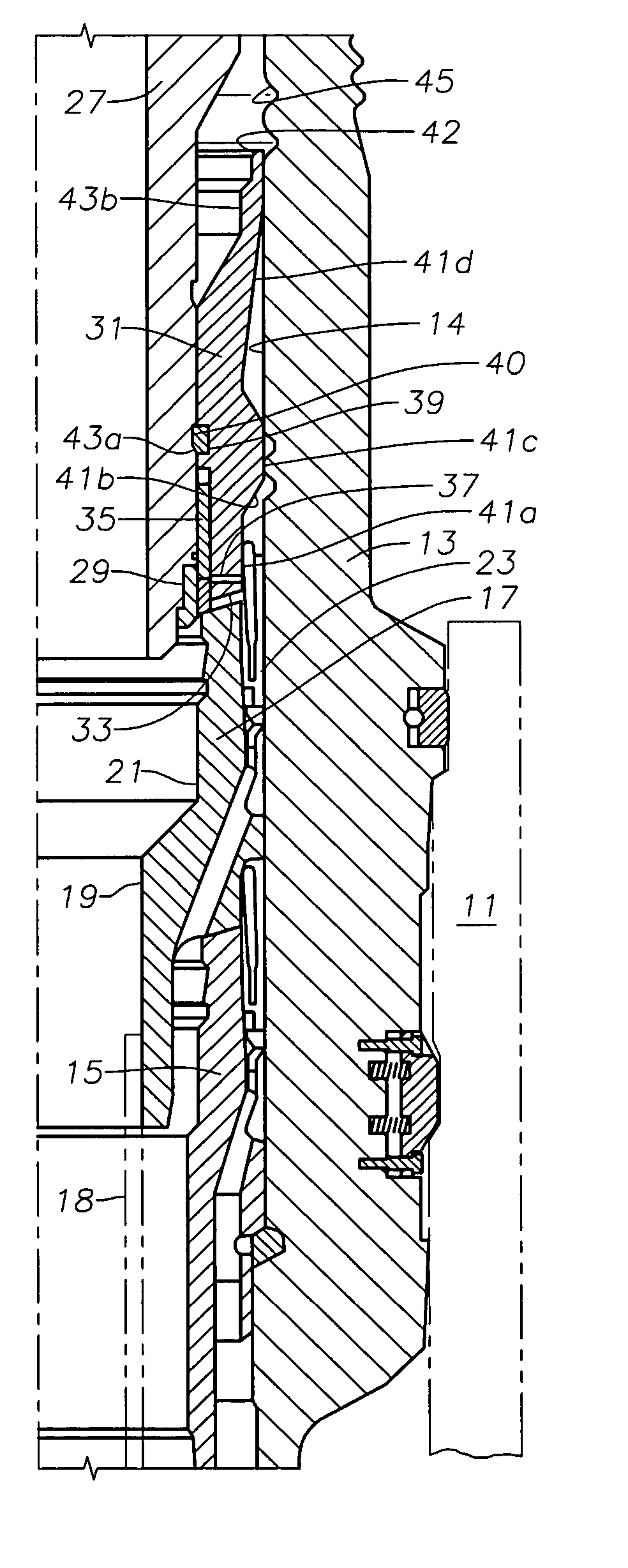

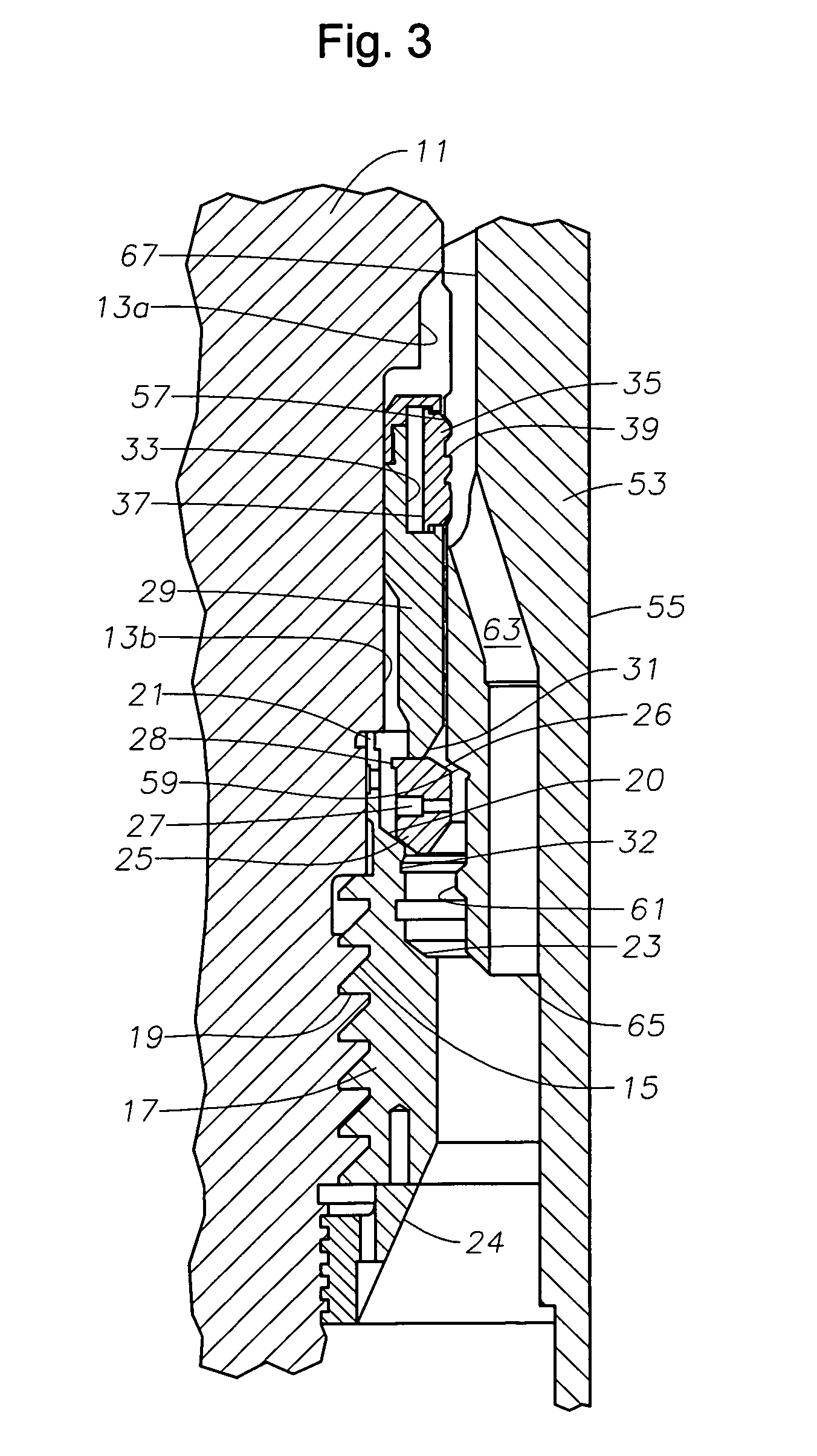

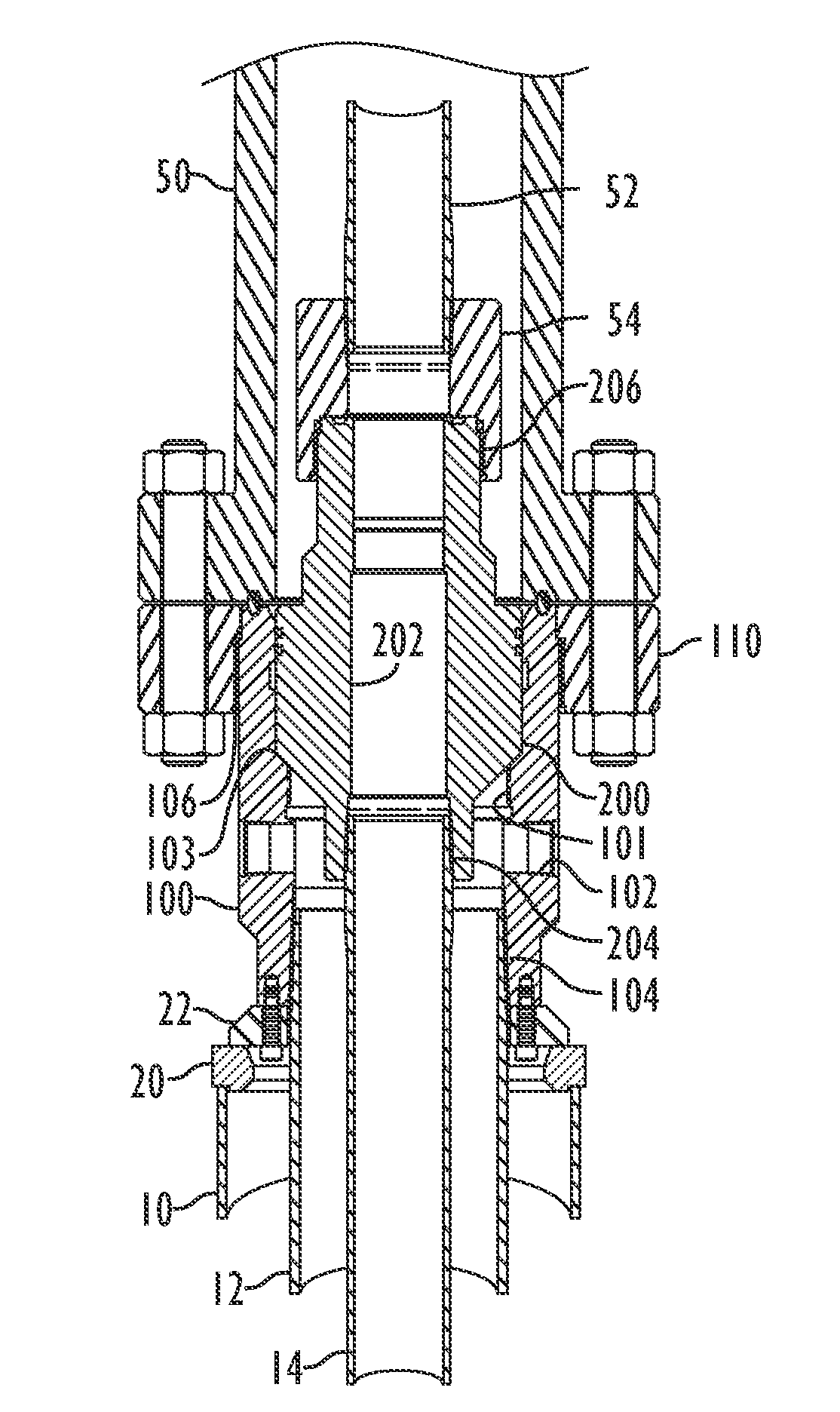

Apparatus and method for installation of subsea well completion systems

InactiveUS7143830B2Eliminate needLess expensiveFluid removalUnderwater drillingElectrical conductorTubing hanger

A method for installing a subsea completion system comprises installing a conductor housing on the sea floor, landing a wellhead in the conductor housing, securing a BOP to the wellhead, landing a casing hanger in the wellhead through the BOP, connecting a tubing hanger to a THRT, landing the tubing hanger in the wellhead or the casing hanger through the BOP, installing a wireline plug in the tubing hanger production bore through the THRT, retrieving the THRT, retrieving the BOP, securing an ROSL to the christmas tree, landing the christmas tree on the wellhead, and retrieving the wireline plug from the tubing hanger production bore using the ROSL.

Owner:FMC TECH INC

Casing hanger

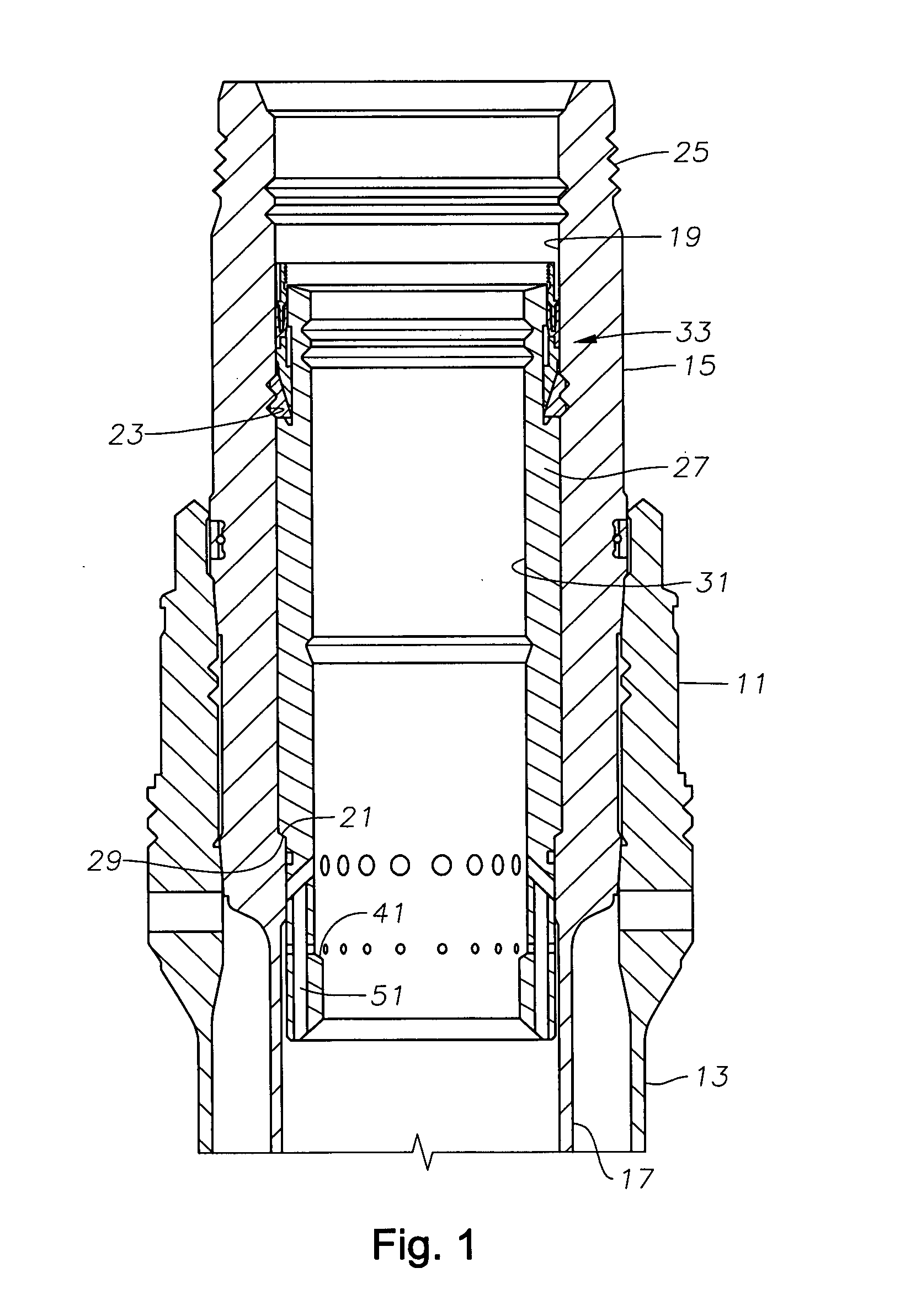

InactiveUS6095242AReduce equipmentReduce installation costsDrilling rodsFluid removalEngineeringCasing string

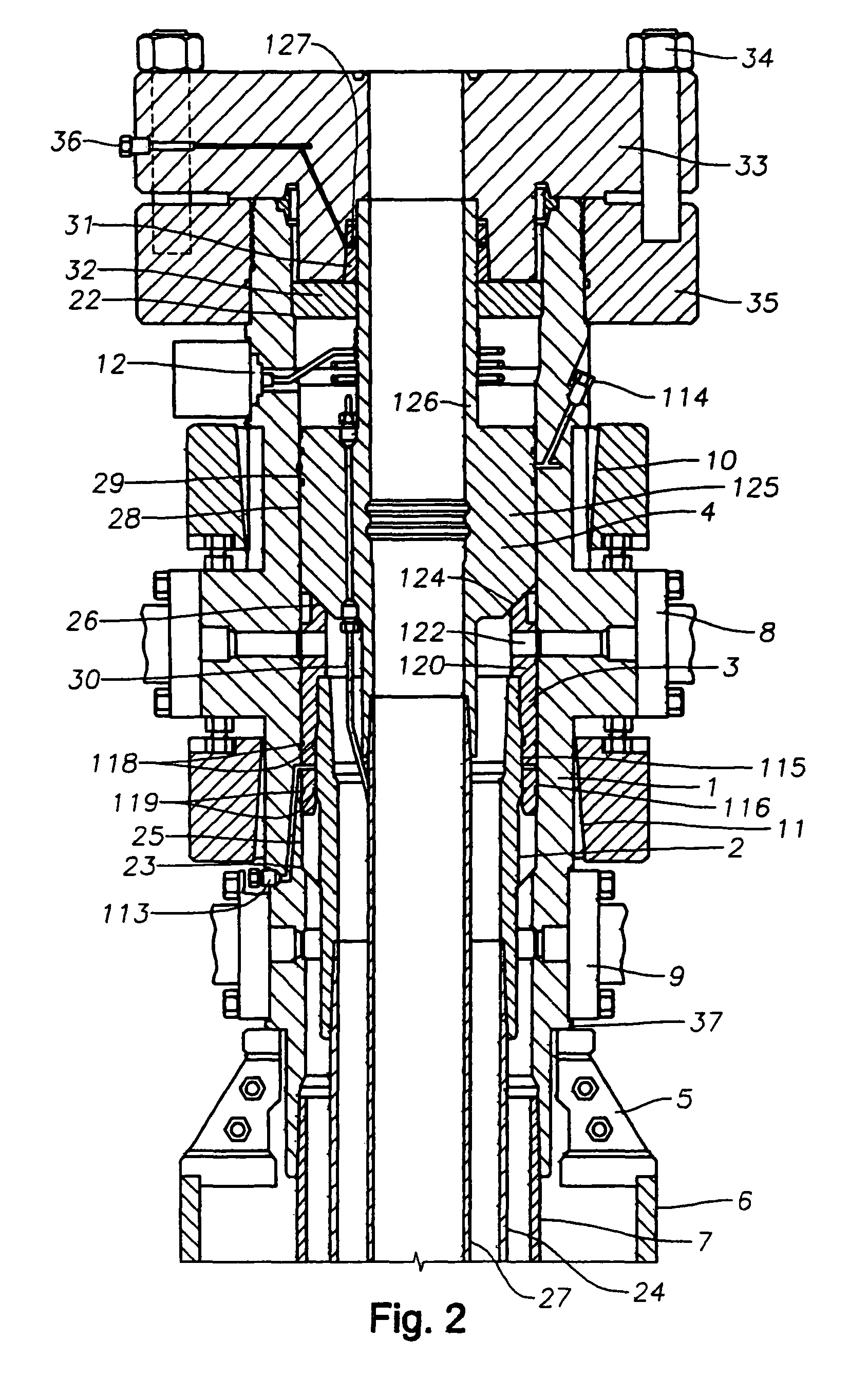

A casing hanger assembly is disclosed which includes a bottom member which centralizes a casing string within a casing head and a top member of a conventional slip-type casing hanger design. The bottom member functions to rigidly centralize the casing string inside the casing head while absorbing any side bending load induced by movements of the casing string. The top member, set on top of the bottom centralizer member, supports and transfers the weight of the casing string to the casing head.

Owner:FMC TECH INC

Shoulder ring set on casing hanger trip

InactiveUS20060016604A1Small diameterPipe supportsFluid pressure sealed jointsEngineeringMechanical engineering

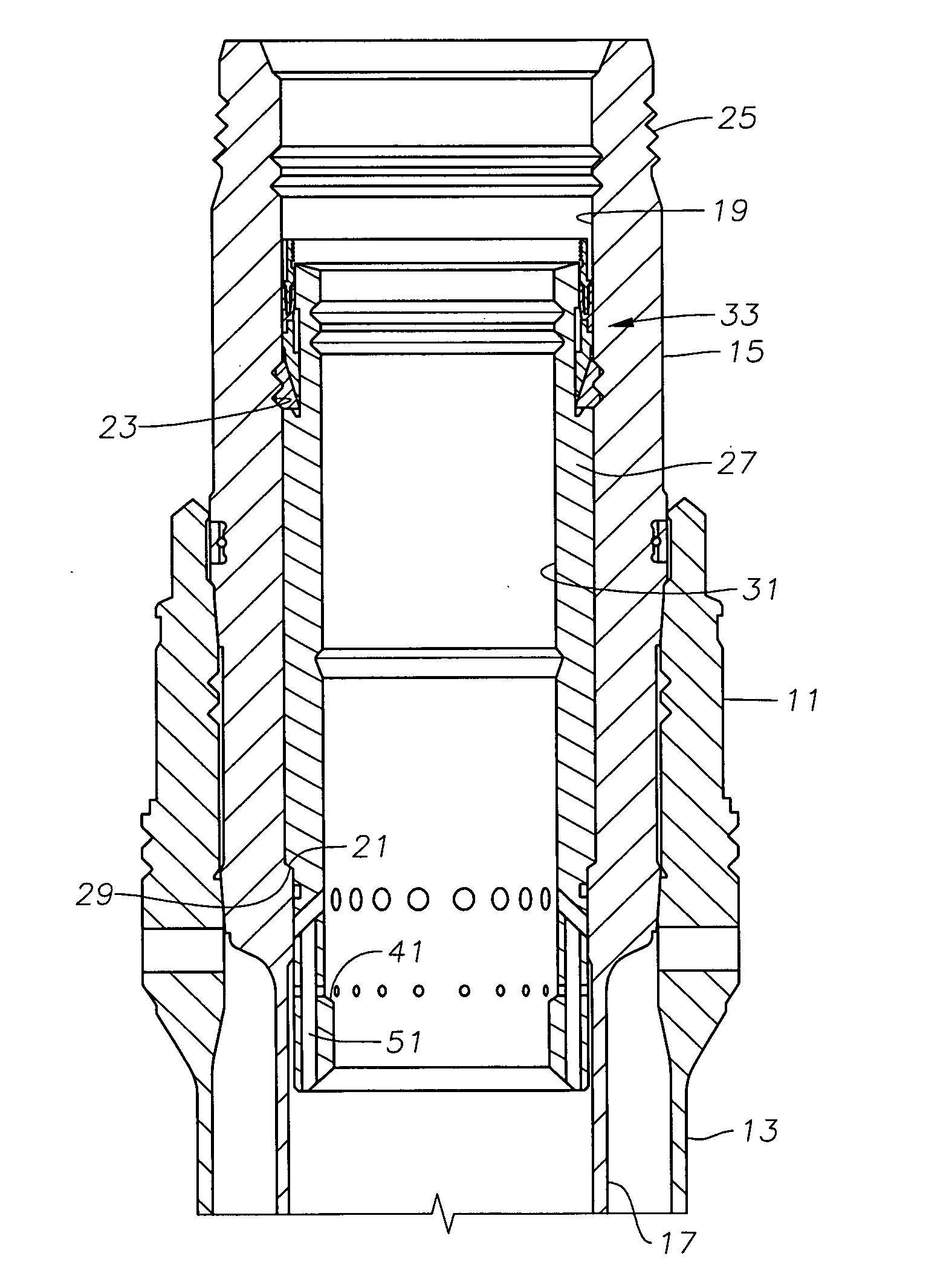

A wellhead housing has a bore with a support shoulder, a ramp surface extending upward and outward from the support shoulder, and a recess extending upward from the ramp. A split, resilient load ring is carried in an initial position in the recess. A retractable and axially movable latch ring is carried in the recess above the load ring. A casing hanger has a profile that engages the latch ring as the casing hanger moves downwardly in the bore, causing the latch ring to move downward and pushing the load ring to the set position.

Owner:VETCO GRAY

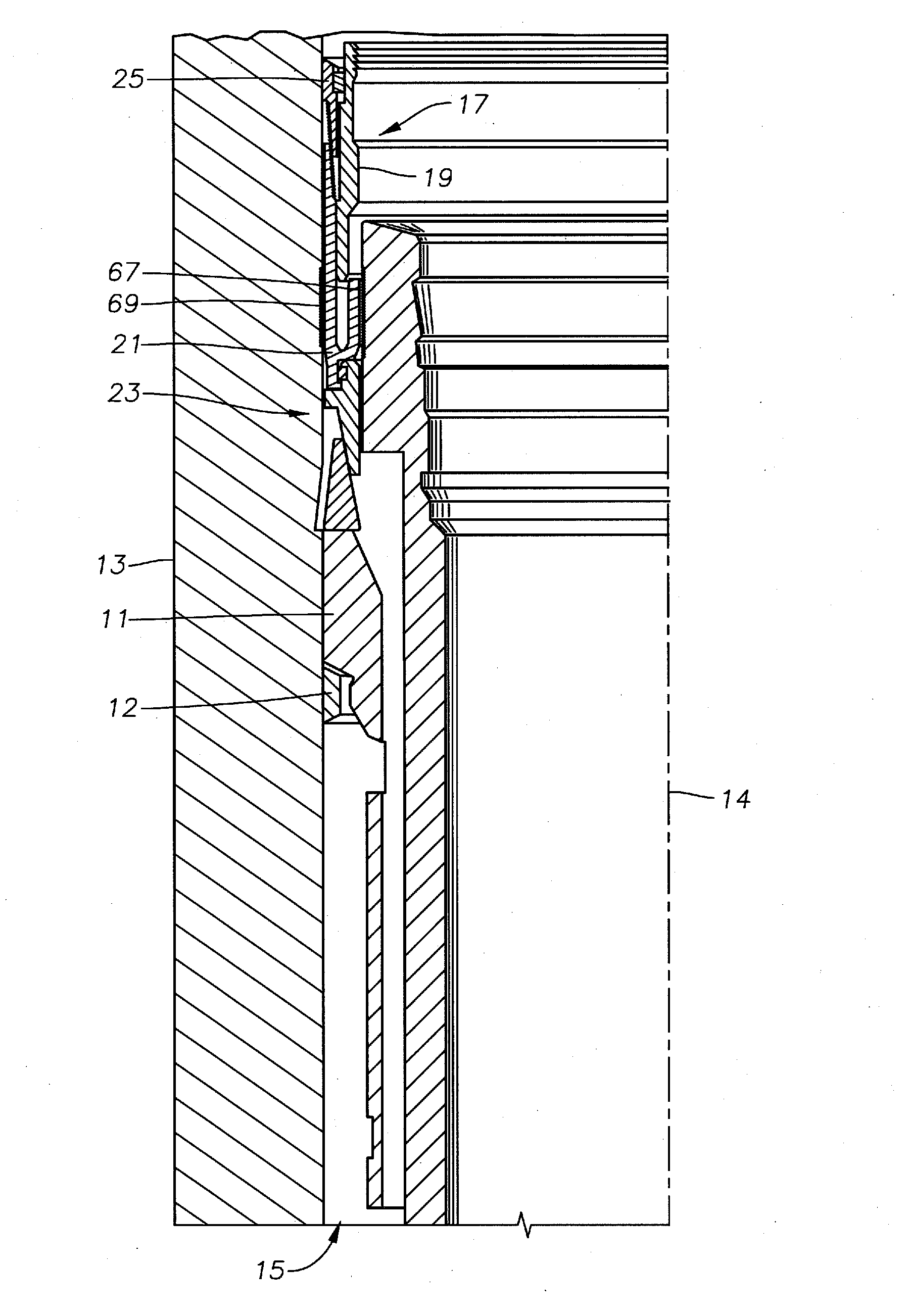

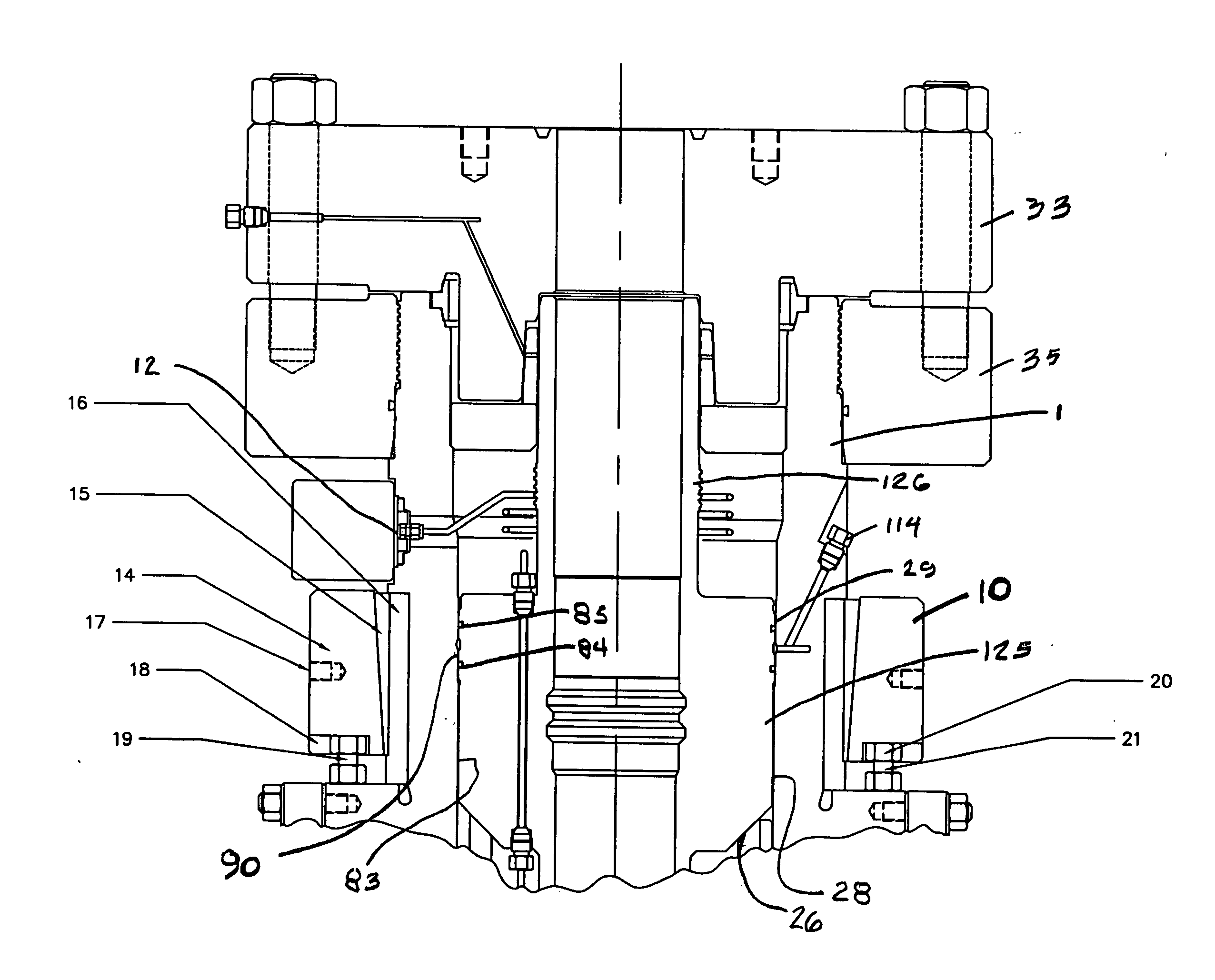

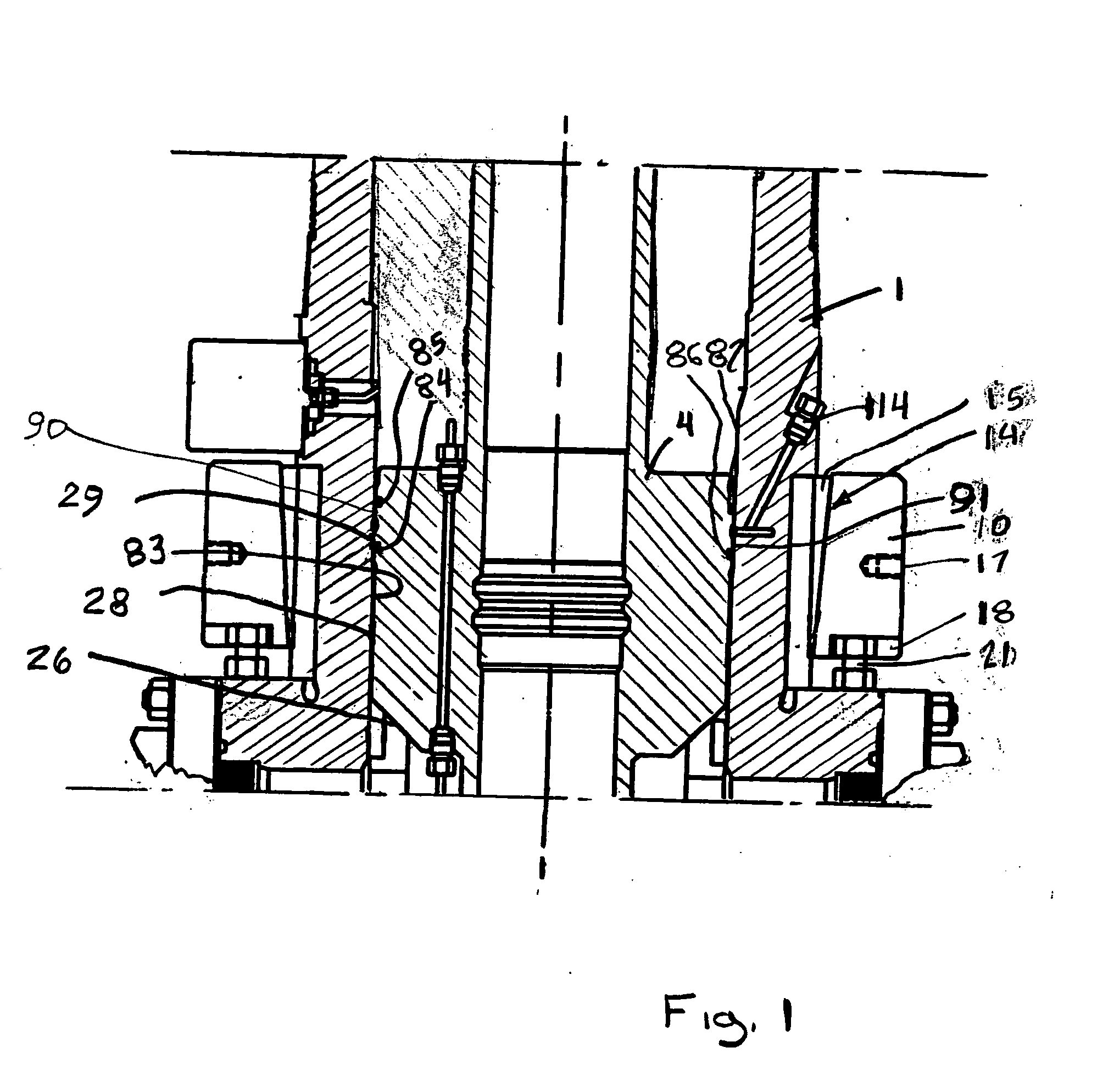

Slip type casing hanger with integral high pressure isolation plate

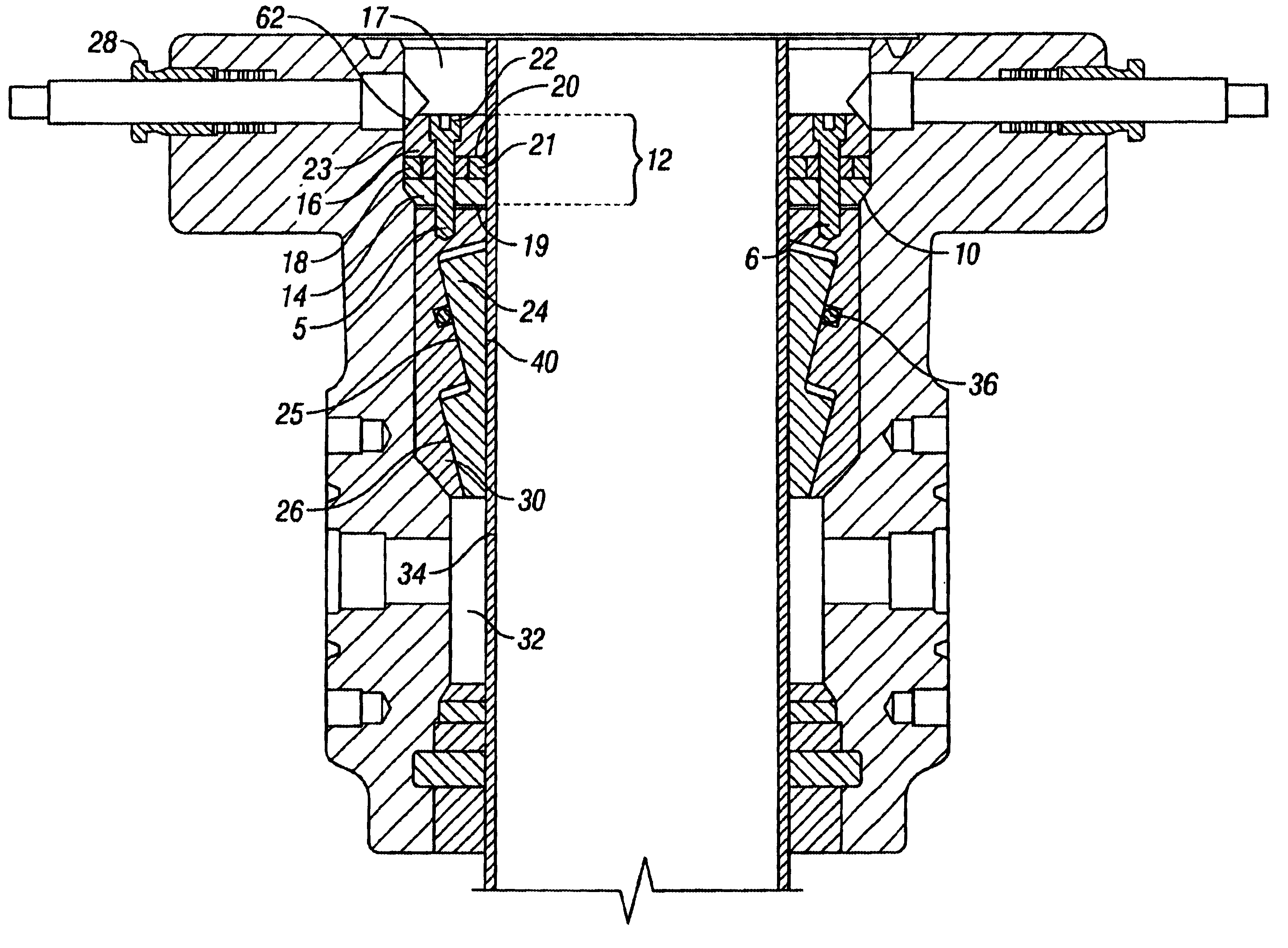

InactiveUS6644401B1Increase load capacityEasy to replacePipe supportsDrilling rodsWeight transferEngineering

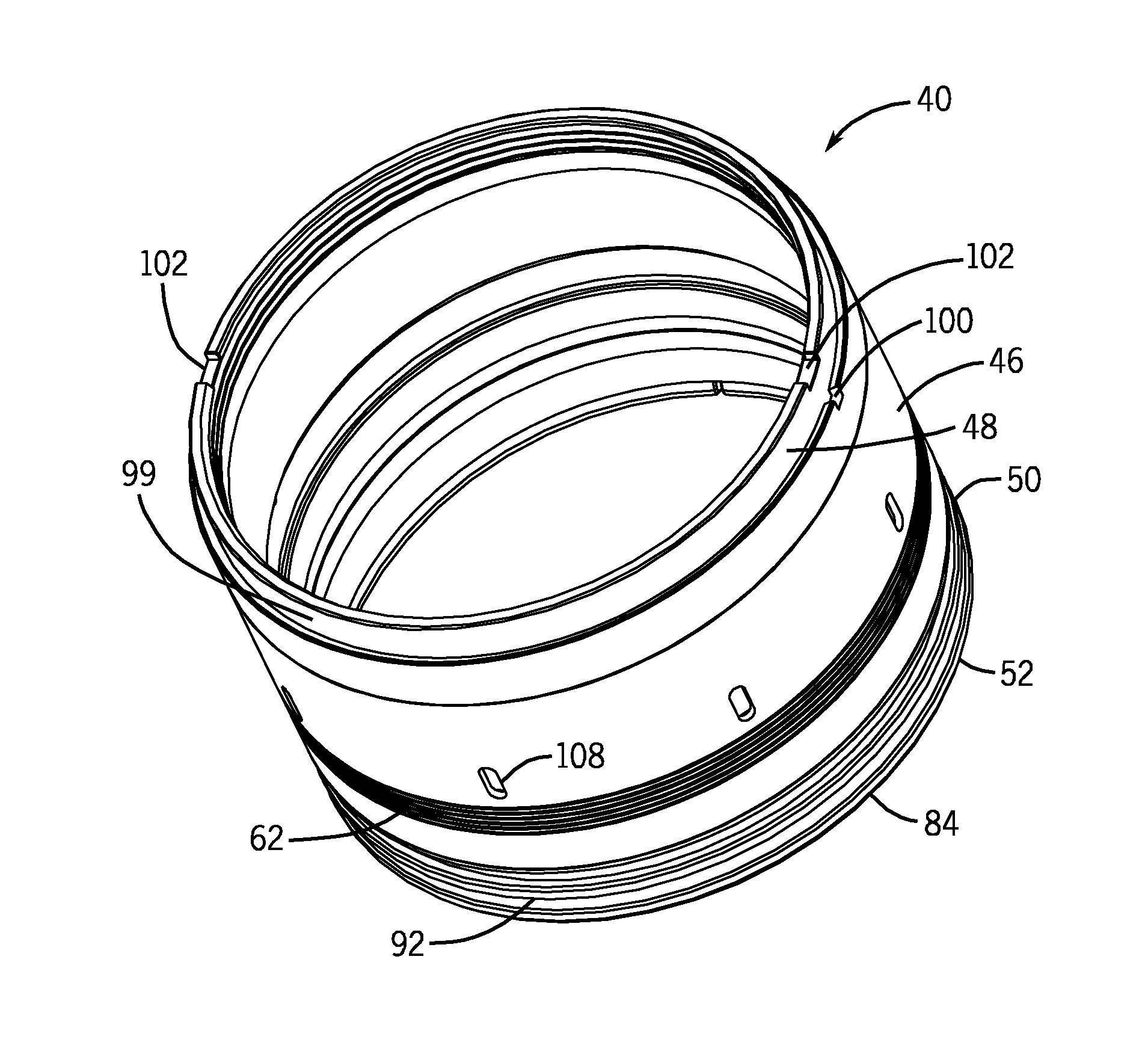

The invention relates to a slip type casing hanger assembly, having a hanger body with an annulus, a casing head disposed around casing for supporting and transferring weight of the casing string to the casing head. The slip type casing hanger assembly further includes (a) an adjustable isolation plate for sealing the annulus, further including a lower plate landing on a load shoulder, an upper plate adjoining the annulus, and a spacer separating the lower plate from the upper plates; (b) a plurality of fasteners for securing the spacer to the upper plate and the lower plate; (c) at least two slip segments, each comprising a plurality of teeth for engaging and suspend the casing string, with each slip segment having a top step and bottom step for engaging the hanger body; (d) at least one alignment ring for aligning the slip segments, and (e) locking apparatus for securing the isolation plate against the load shoulder.

Owner:KVAERNER OILFIELD PROD INC

Casing cutter

A subsea well casing cutting tool for use as part of a well abandonment procedure, the casing cutting tool deployable from a vessel located at a water surface, where in certain embodiments the casing cutting tool comprises a casing gripper; a rotary cutter drive assembly; a rotary cutter; a rotating fluid union that allows high volume water to be fed to the rotating cutting assembly below the drive motor for purposes of extending the cutting blades; and a third party casing hanger removal tool wherein the casing cutting drive assembly forms an interface between the third party rotary casing cutter, an existing subsea casing, and a work class ROV. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope of meaning of the claims.

Owner:OCEANEERING INTERNATIONAL

Externally activated seal system for wellhead

InactiveUS7740061B2Minimized in sizeSimple procedureDrilling rodsFluid removalTubing hangerWell drilling

A method and apparatus for installing casing hangers in a wellbore utilizing an externally activated gripping system to temporarily bind wearbushings secured to casing and tubing hangers in order to lock-down such hangers during various wellbore drilling activities, thereby minimizing the size of landing shoulders and eliminating additional lock down equipment and simplifying running procedures.

Owner:PLEXUS HOLDINGS PLC

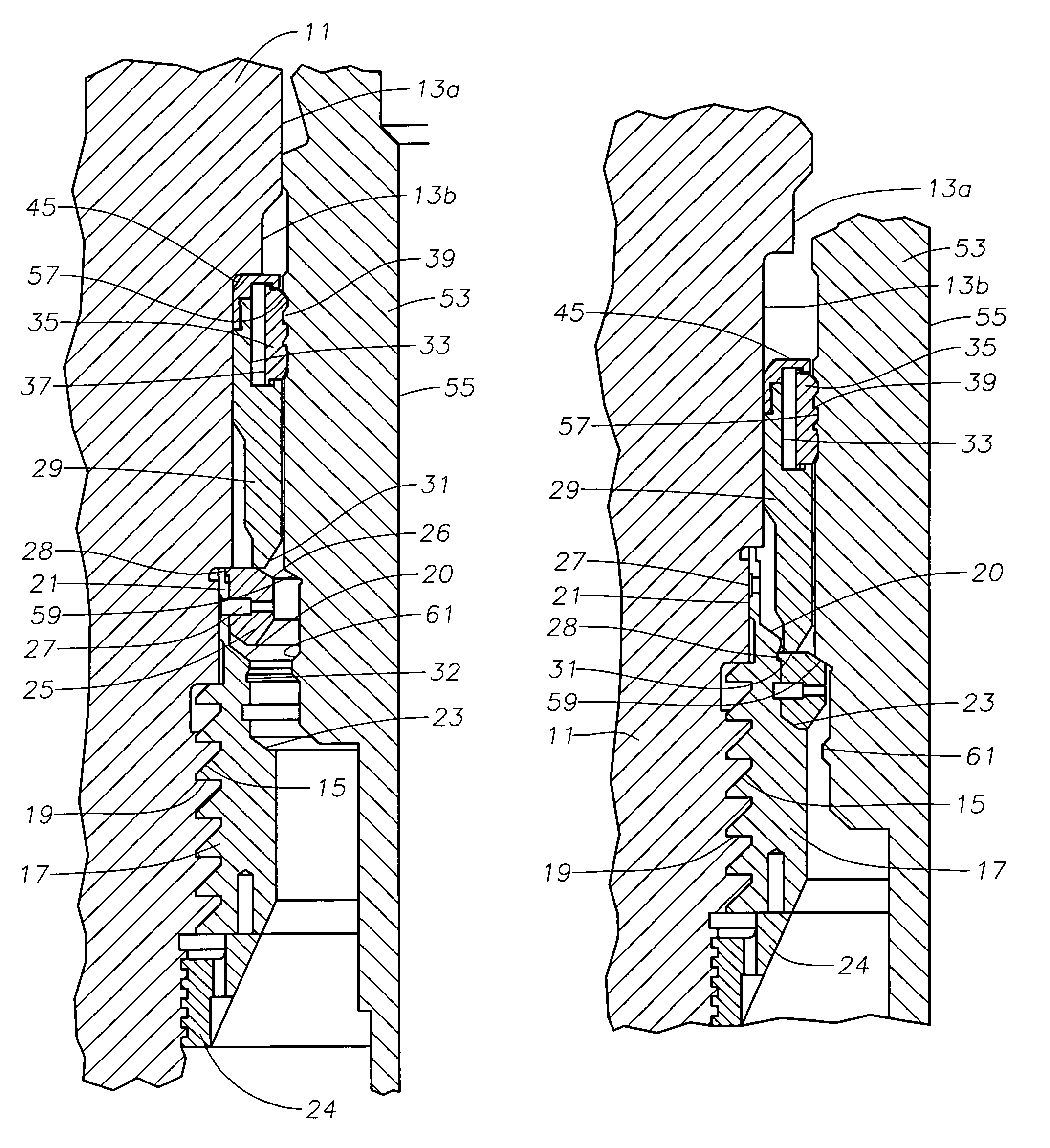

Wellhead assembly having seal assembly with axial restraint

InactiveUS20100038089A1Improve scalabilityRestrict movementDrilling rodsConstructionsEngineeringMechanical engineering

A wellhead system comprising a seal with a restraining member adapted to cooperate with a housing to restrict axial movement of the seal. The seal is adapted to form a seal between the housing, such as a wellhead, and a tubular member, such as a casing hanger. The seal has a latch ring that is expanded outward as the seal is installed within the wellhead. Axial movement of the seal is restricted by engagement between the expanded latch ring and the inner profile of the housing. The seal and housing may be adapted so that a portion of the seal is received by a recess in the inner profile of the housing.

Owner:VETCO GRAY

Adapter sleeve for wellhead housing

A subsea wellhead assembly for a subsea well including a low pressure wellhead housing having a string of conductor piping extending therefrom. A high pressure wellhead housing, having a string of outer casing suspended therefrom, lands within the low pressure wellhead housing. The high pressure wellhead housing has a housing bore. An adapter is positioned within the housing bore. The adapter has an external load shoulder that lands on a housing load shoulder of the high pressure wellhead housing. The adapter also has an adapter bore with an inner adapter load shoulder formed thereon. A casing hanger is carried in the adapter bore, and has a string of inner casing suspended therefrom and is cemented in the well. The casing hanger lands on the inner adapter load shoulder.

Owner:VETCO GRAY

Wellhead Completion Assembly Capable of Versatile Arrangements

A wellhead completion assembly has a head connected to surface casing. A rotatable flange or the like can be used to connect various components to a threaded end of the head. A casing hanger installs in the head, and the hanger's upper end extends beyond the head's top edge. This exposed end has an external threaded connection to connect to various wellhead components using a rotatable flange or the like. For example, a locking ring can threadably connect to the head's threaded end to support the hanger in the head. Then, a rotatable flange can threadably connect to the hanger's exposed end so that another component, such as a completion spool or gate valve, can nippled up directly to the hanger. When the hanger is fluted, a pack-off assembly can allow testing off inner and outer sealing integrity via a test port accessible through an opening in the locking ring.

Owner:WEATHERFORD TECH HLDG LLC

Casing hanger lockdown with conical lockdown ring

InactiveUS20130146306A1Reduce the overall diameterAvoid relative motionFluid removalSealing/packingEngineeringMechanics

A seal seals an annulus in a subsea assembly between a wellhead and a casing hanger landed on a shoulder within a bore of the wellhead. The seal includes a casing hanger seal ring disposed within the annulus. The seal ring engaged with an inner diameter surface of the wellhead, and engaged with an outer diameter surface of the casing hanger so that the seal ring prevents flow through the annulus. A nose ring is secured to a lower end of the seal ring so that, when the seal ring is energized, a conical surface of the nose ring engages a mating conical profile formed in the inner diameter surface portion of the wellhead and the nose ring engages a surface opposite the conical surface with a substantially smooth outer diameter surface portion of the casing hanger to limit upwards axial movement of the casing hanger.

Owner:VETCO GRAY

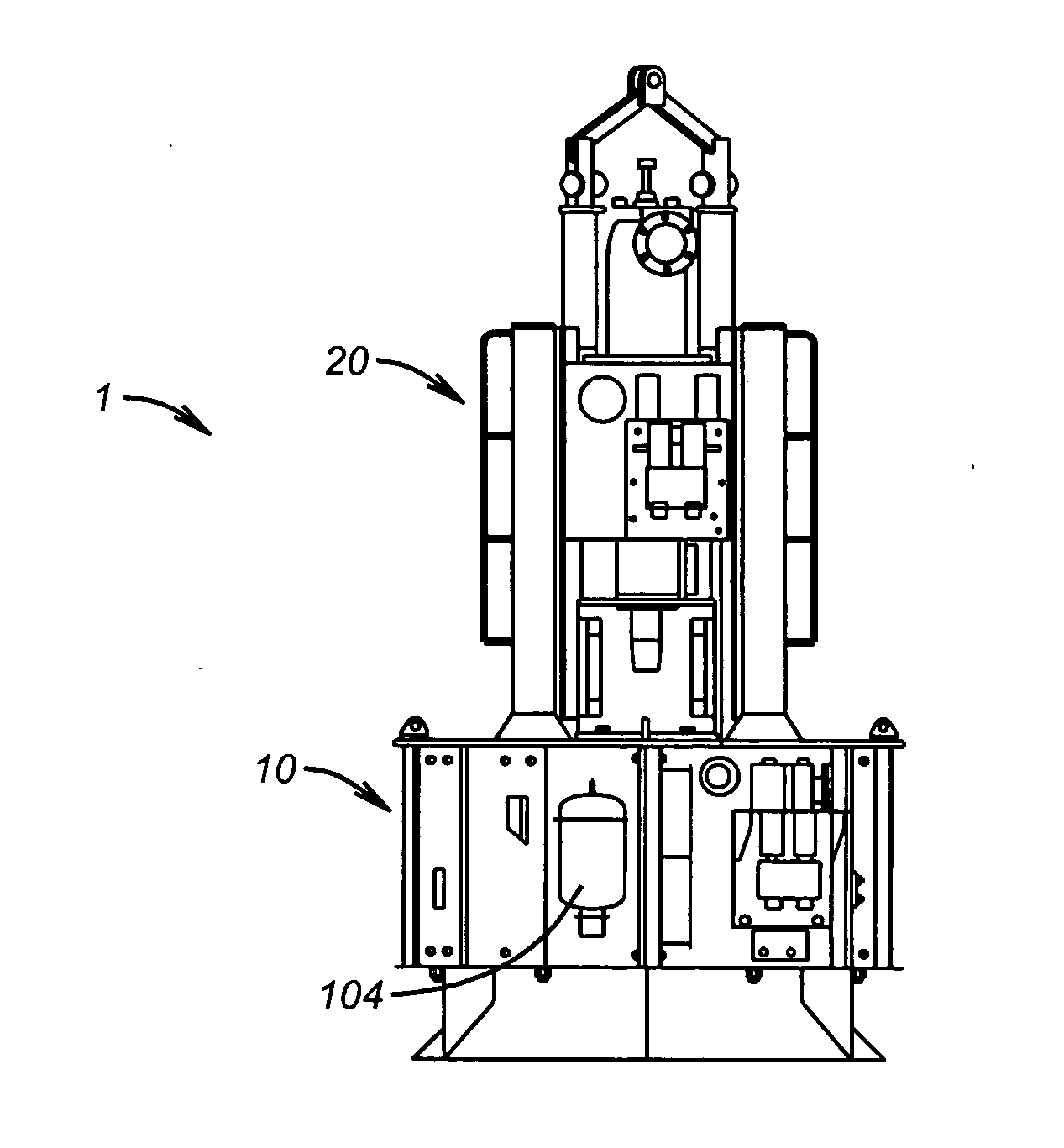

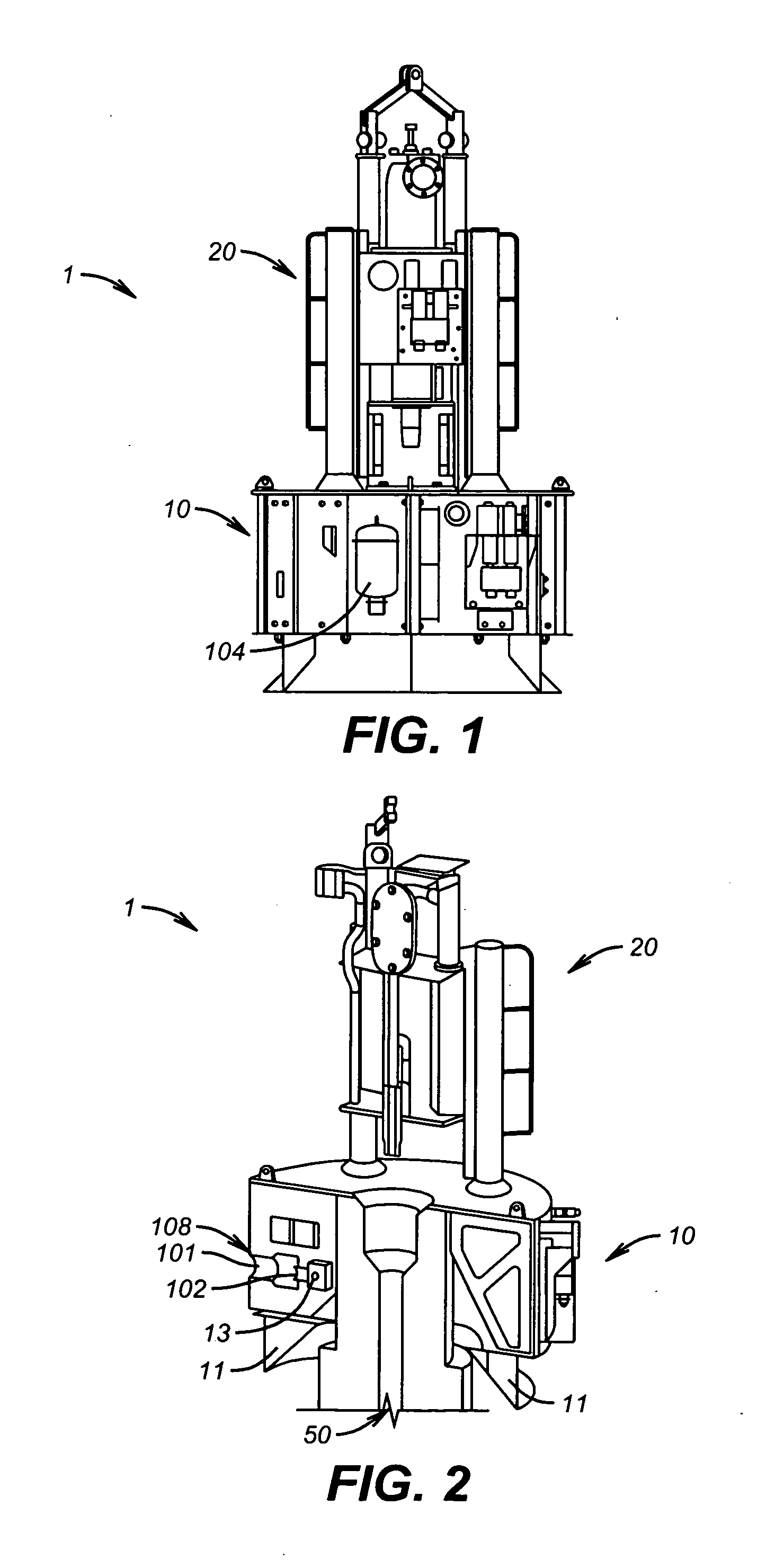

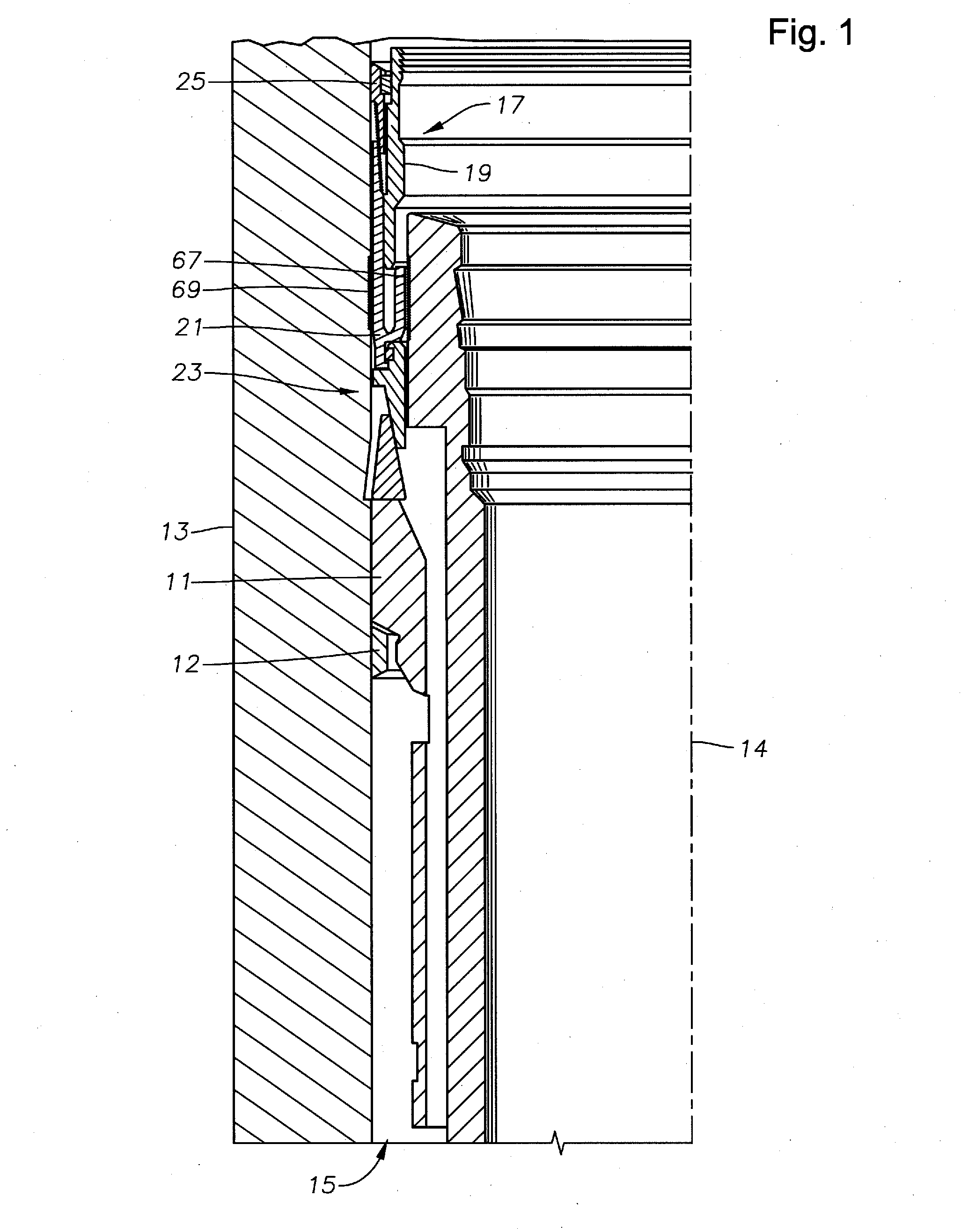

Externally activated seal system for wellhead

ActiveUS20050139360A1Improve securityMinimized in sizeDrilling rodsFluid removalCasing hangerTubing hanger

A method and apparatus for a seal assembly for a unitized wellhead system for land or platform applications utilizes a friction grip technology to create maintainable metal-to-metal seals with finely-controlled contact stresses, lock-down casing and tubing hangers, support test loads to minimize the size of landing shoulders required, and to rotationally lock casing hangers to provide simplified running procedures. The system can be used in combination with a friction grip clamping assembly to greatly streamline the wellhead design.

Owner:PLEXUS HOLDINGS PLC

Run and retrieval wear bushing and tool

A wear bushing has a lower portion that is landed on a casing hanger in a wellhead housing. The wear bushing is mounted to the running tool, which is joined to a drill string. With running-in keys locked on the tool, the wear bushing is lowered down the well into the wellhead housing. The wear bushing is landed on the casing hanger and anti-rotation pins are pressed upward as they contact a seal assembly. The wear bushing is rotated until the anti-rotation pins align and fall into slots. With the anti-rotation pins in the slots, the running tool is released from the wear bushing by opposite rotation, and the running tool may then be run deeper into the well. The wear bushing is extracted using a retrieval tool. The retrieval tool is axially positioned relative to the wear bushing such that tool retrieval teeth engage a wear bushing retrieval ring so that the wear bushing can be extracted from the casing hanger.

Owner:VETCO GRAY

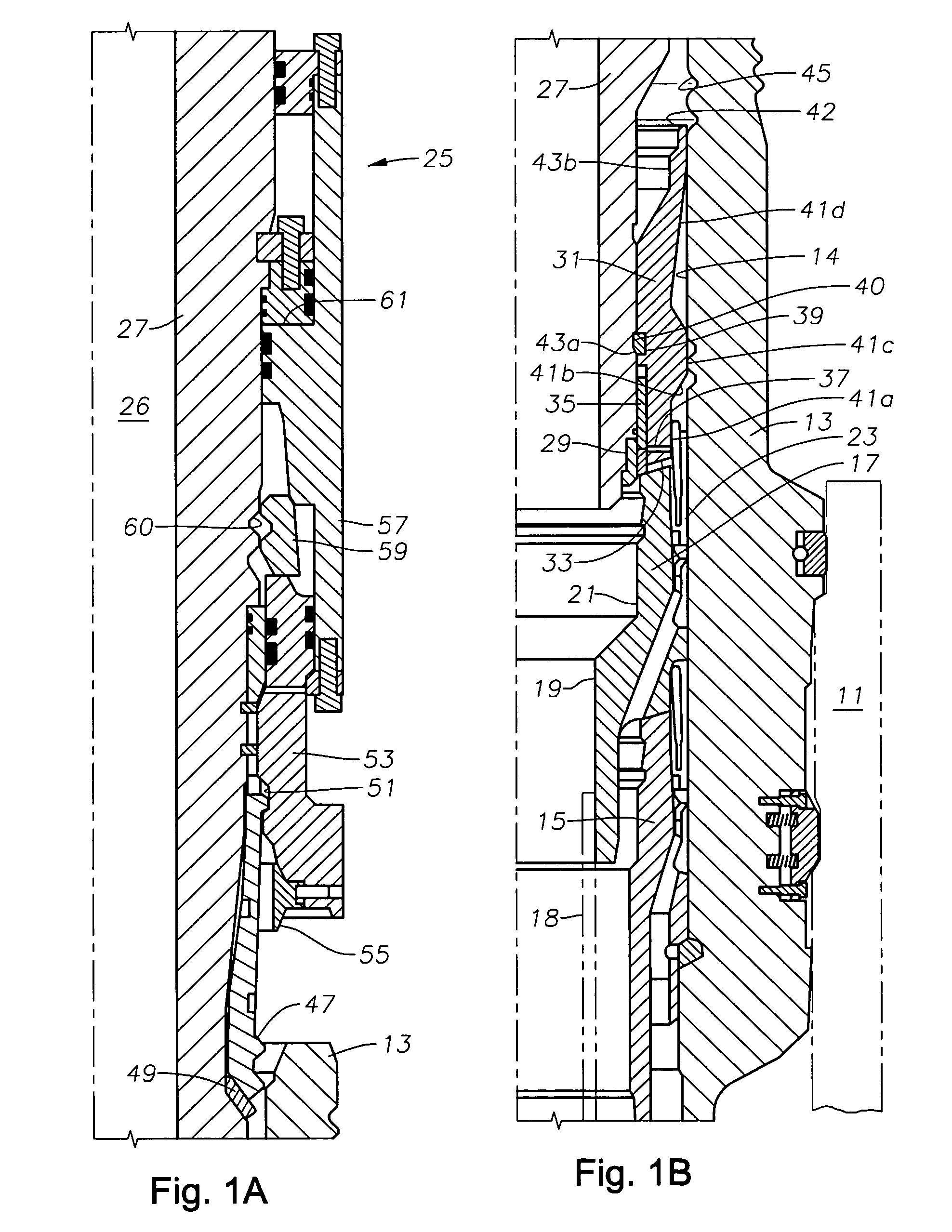

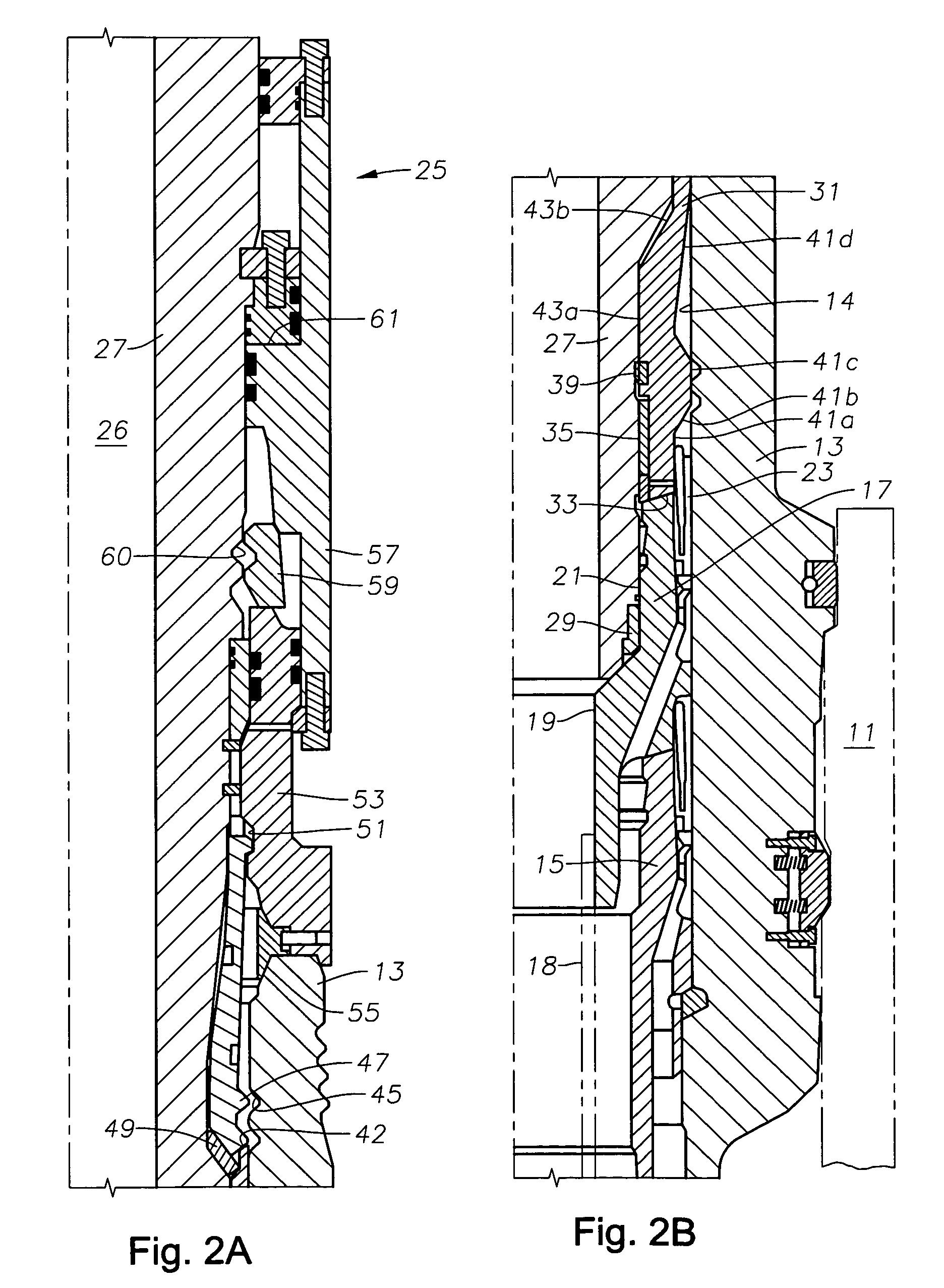

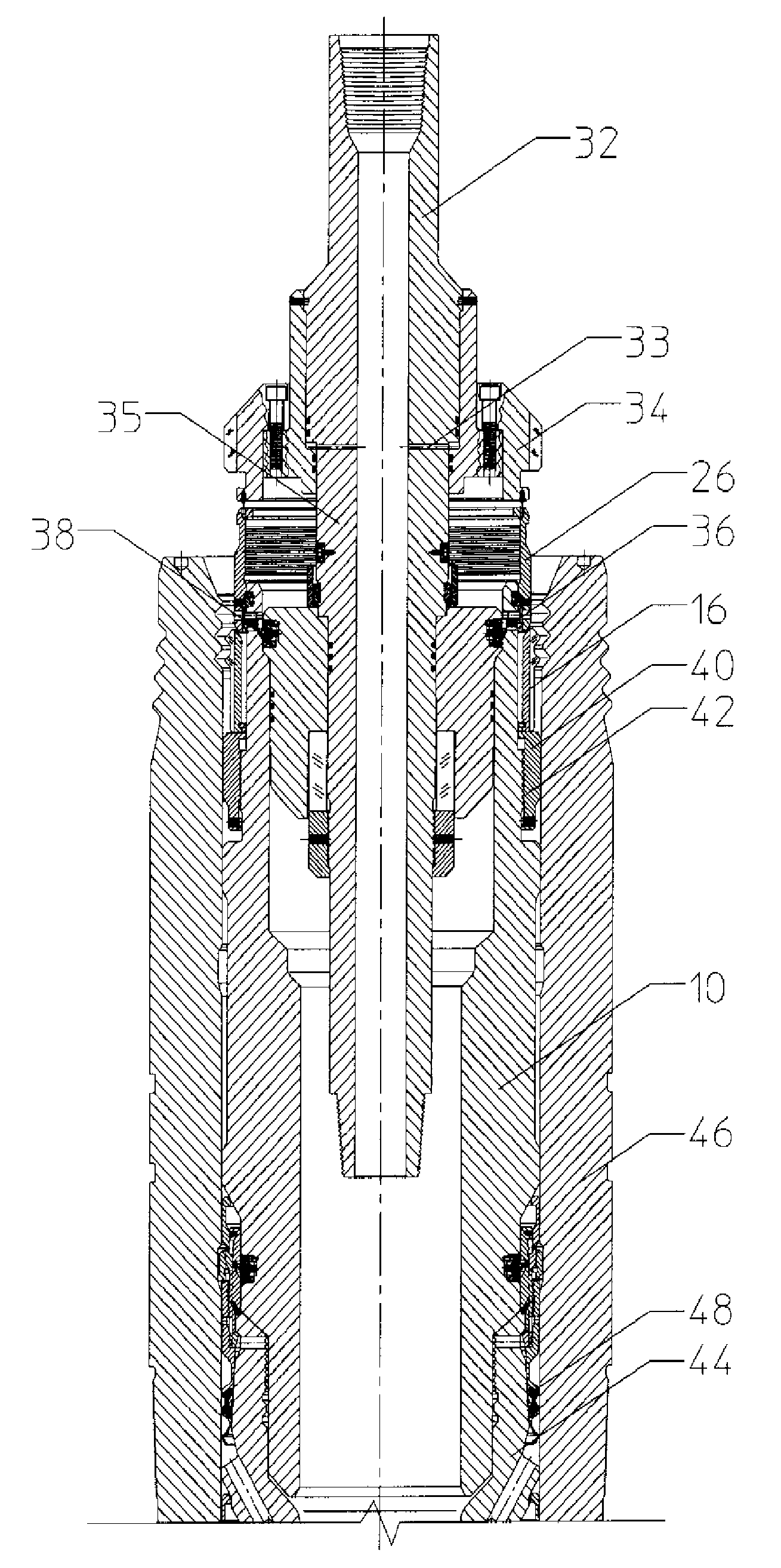

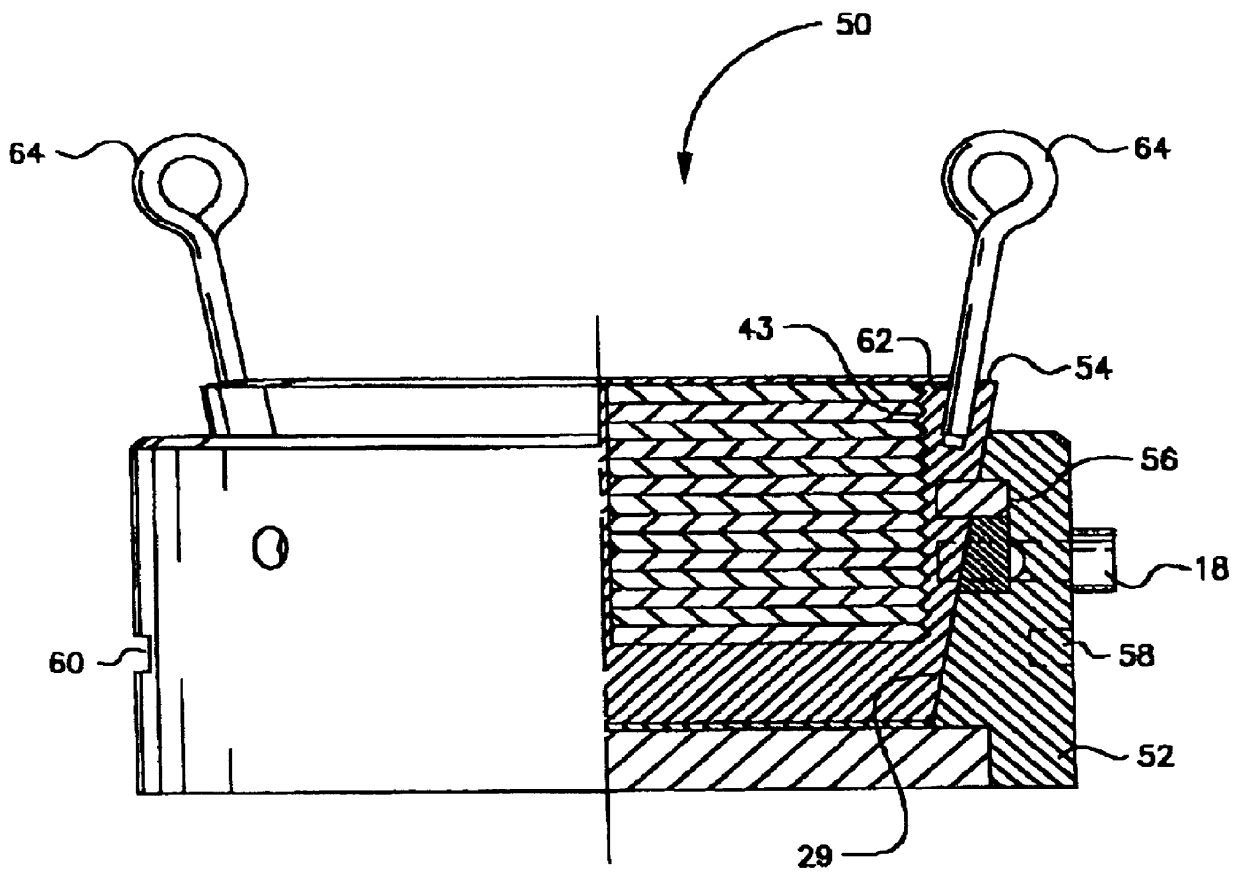

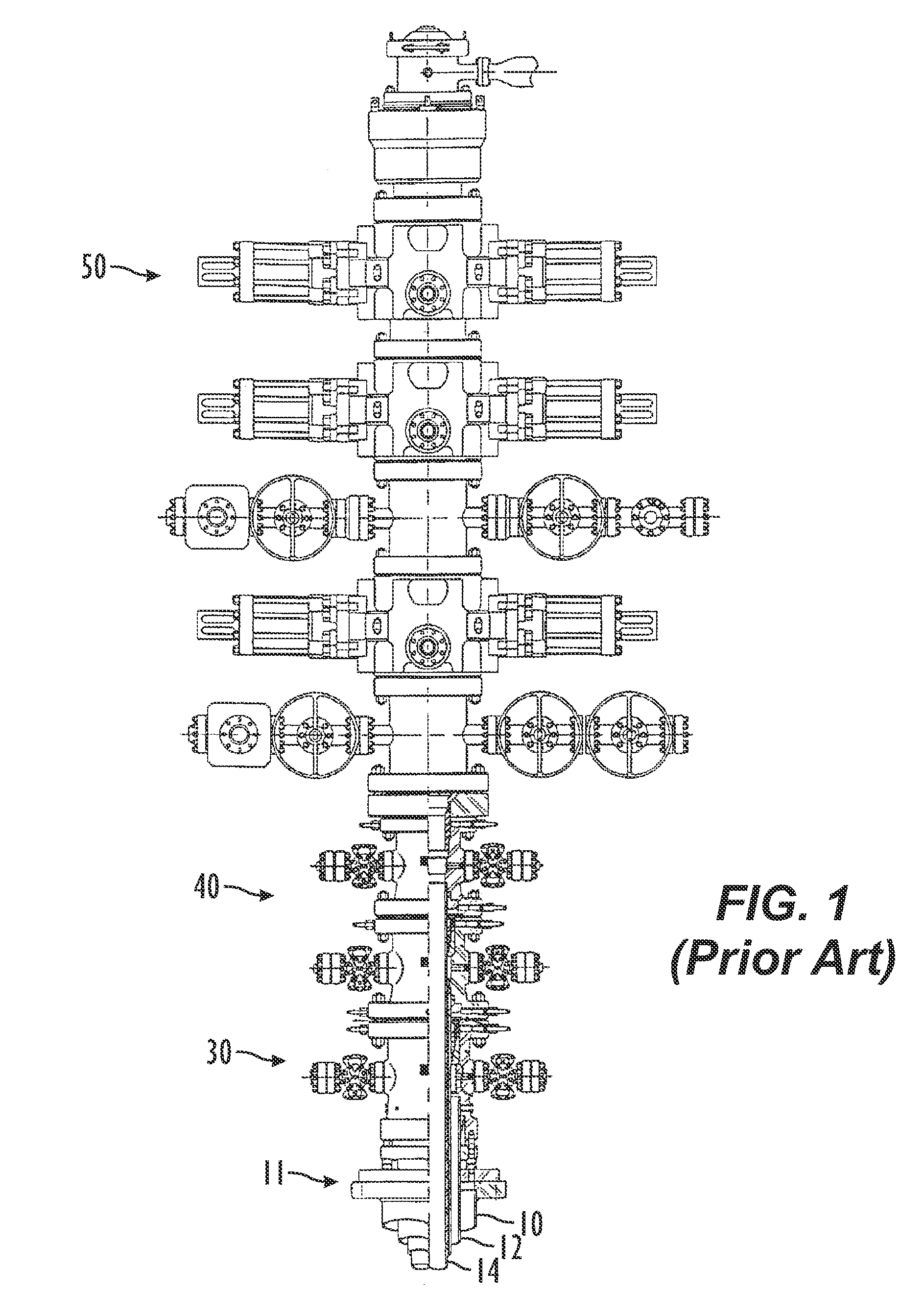

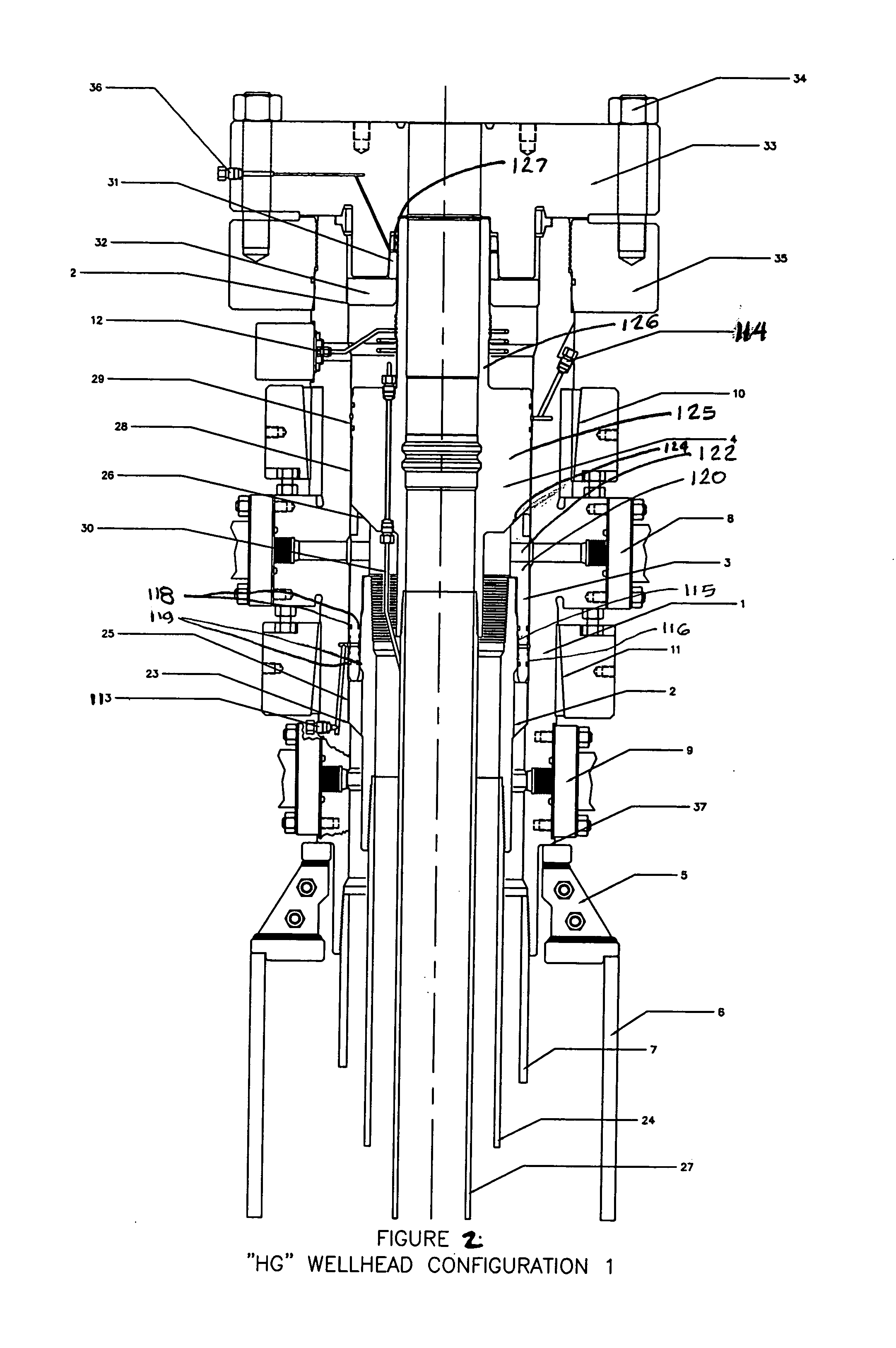

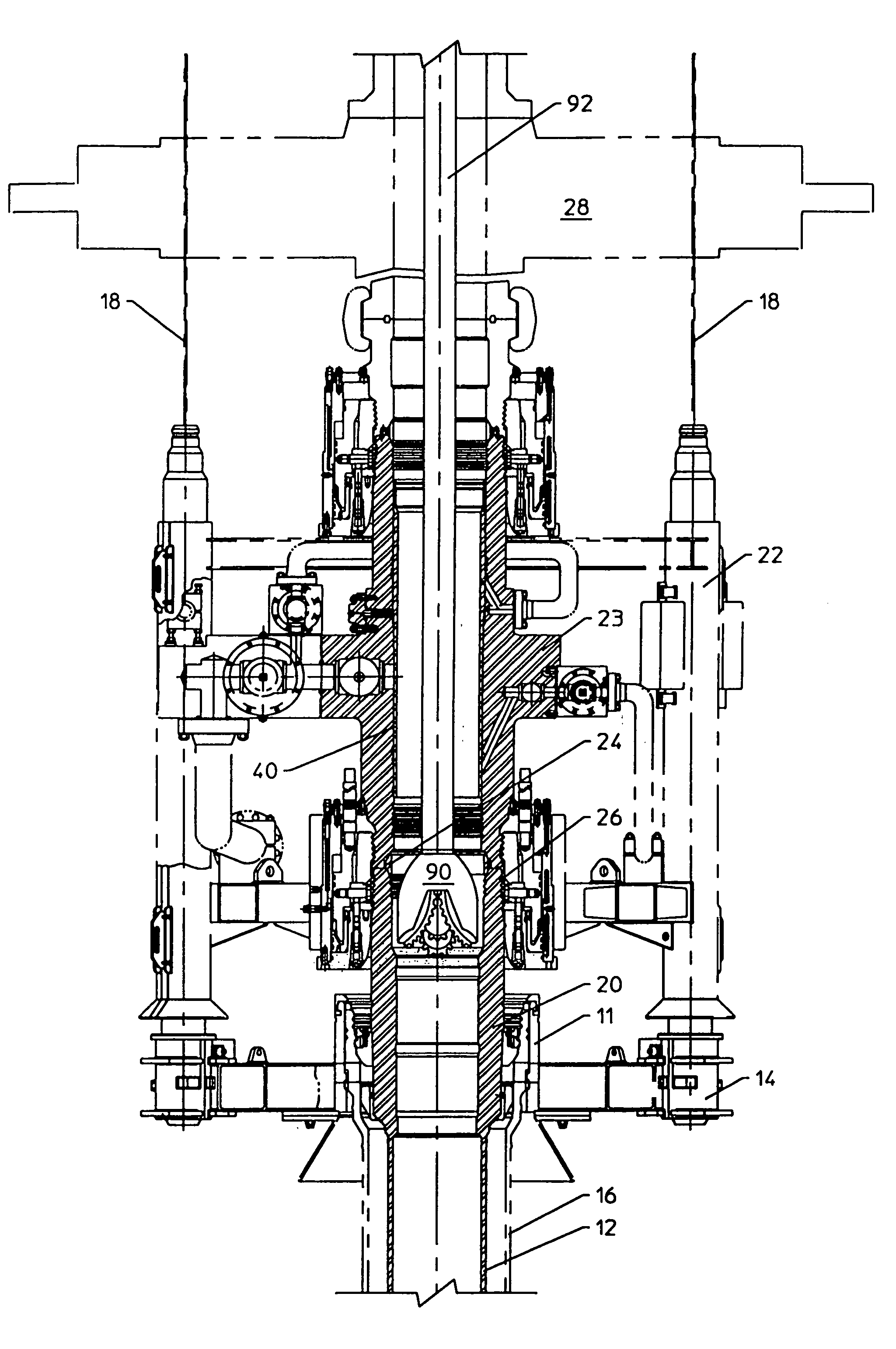

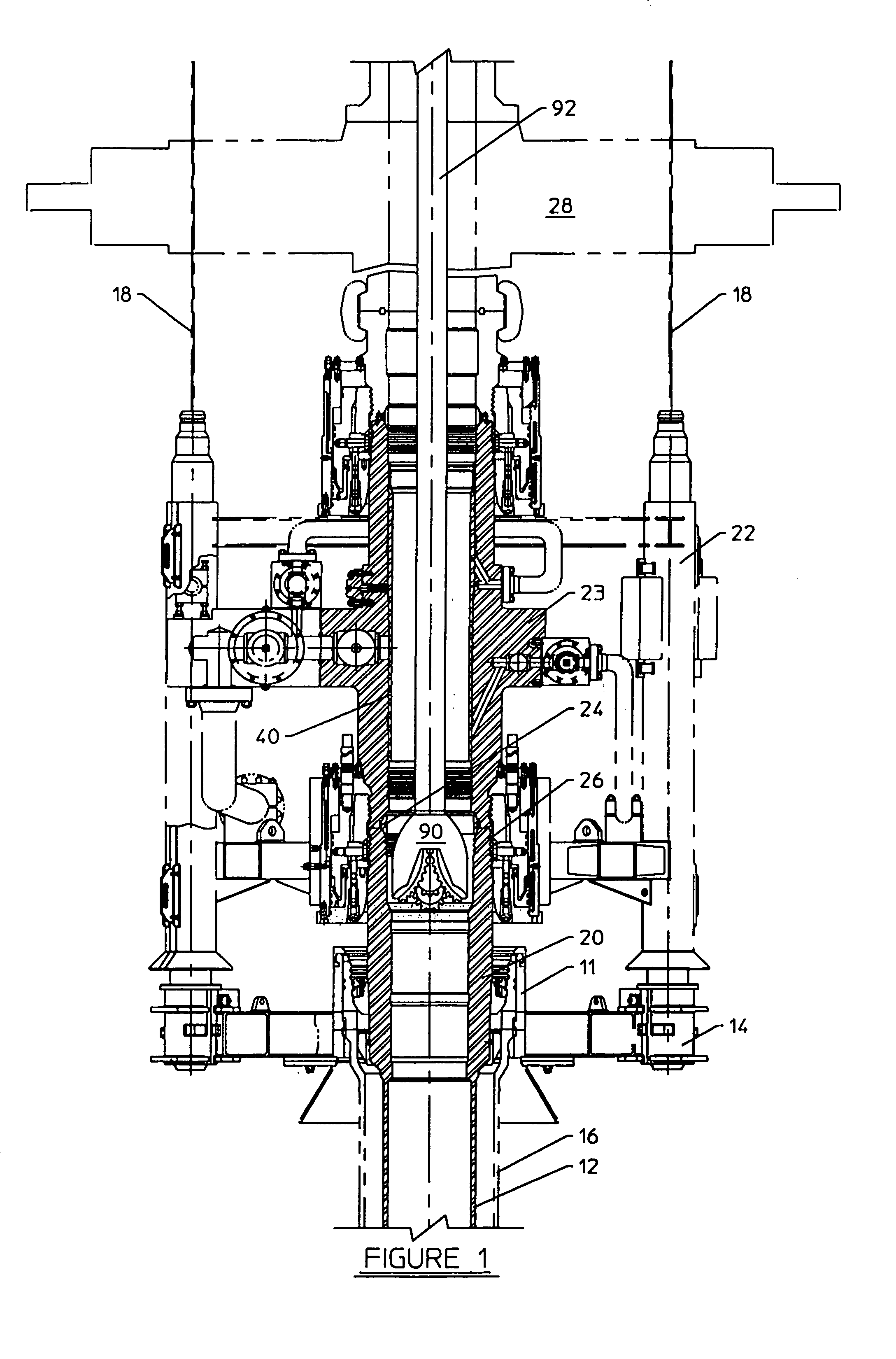

Horizontal spool tree wellhead system and method

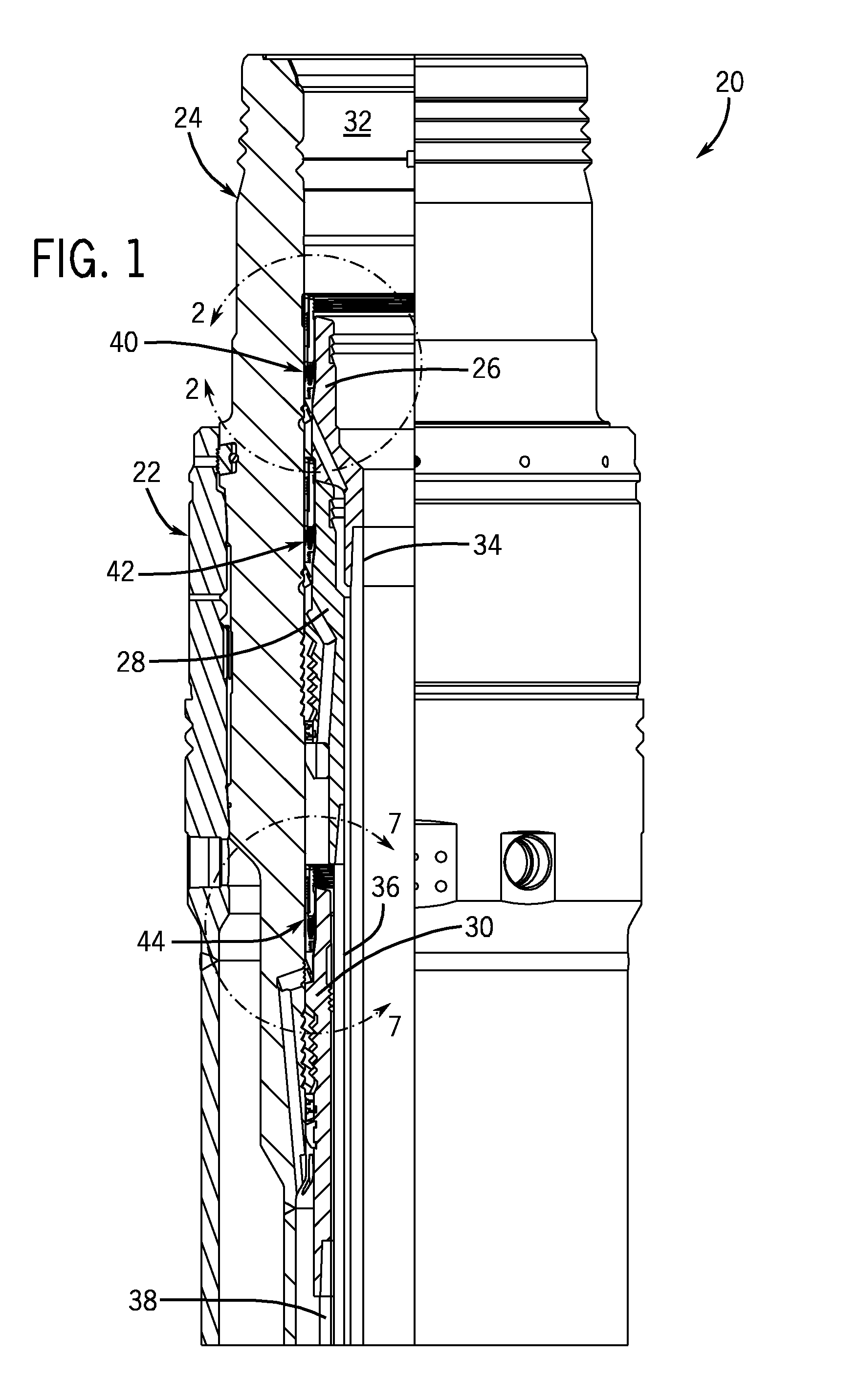

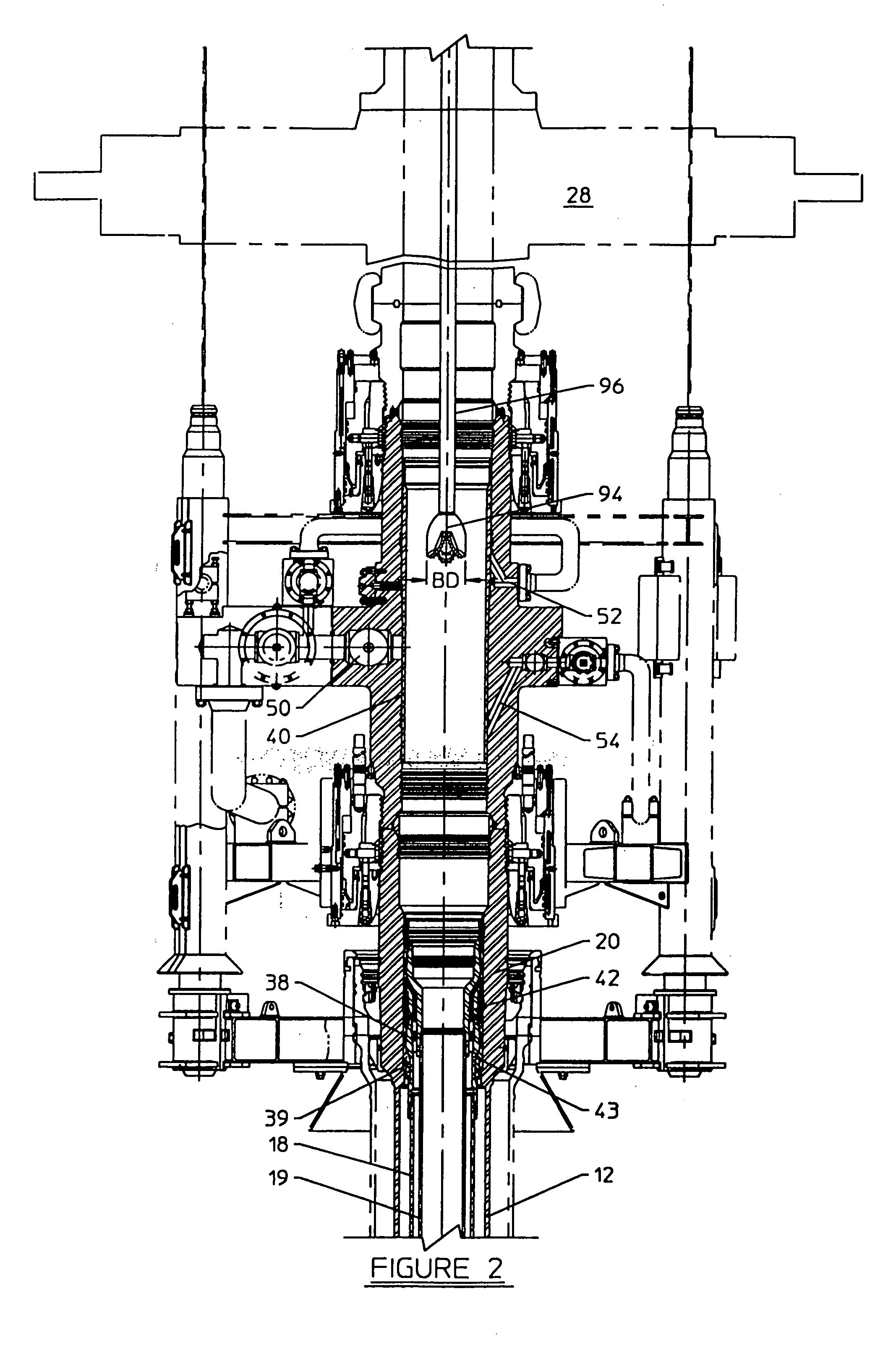

A horizontal spool tree wellhead system 10 utilizes a casing 18, 19 installed in a well bore and a wellhead housing 20 at the upper end of the casing. A spool 23 of the horizontal tree 22 is connected to the upper end of the wellhead housing, and includes at least one radially extending side port. The BOP 28 is also installed at the upper end of the housing with a bore aligned with the wellhead housing bore. After drilling the well, the casing string 19 carrying a casing hanger 42 may be lowered through the bores of the BOP, the spool tree, and the wellhead housing and into the well. An orientation / isolation sleeve 60 may be installed in a predetermined rotational orientation with the spool tree. A tubing hanger 70 having a side port is landed onto the orientation sleeve and is automatically oriented to align the tubing hanger side port with the spool side port.

Owner:DRIL QUIP

High capacity running tool and method of setting a packoff seal

A high capacity running tool sets and internally tests a casing hanger packoff during the same trip. The running tool has a stem and a body. The body is secured by threads to the stem of the running tool so that rotation of the stem relative to the body will cause the stem to move longitudinally. An engagement element connects the tool body to the casing hanger by engaging the inner surface of the casing hanger. Longitudinal movement of the stem relative to the body moves the engaging element between inner and outer positions and lines up ports in the stem and in the body for setting and testing functions.

Owner:VETCO GRAY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com