Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

391 results about "Tubing hanger" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tubing hanger is a component used in the completion of oil and gas production wells. It is set in the tree or the wellhead and suspends the production tubing and/or casing. Sometimes it provides porting to allow the communication of hydraulic, electric and other downhole functions, as well as chemical injection. It also serves to seal-in the annulus and production areas.

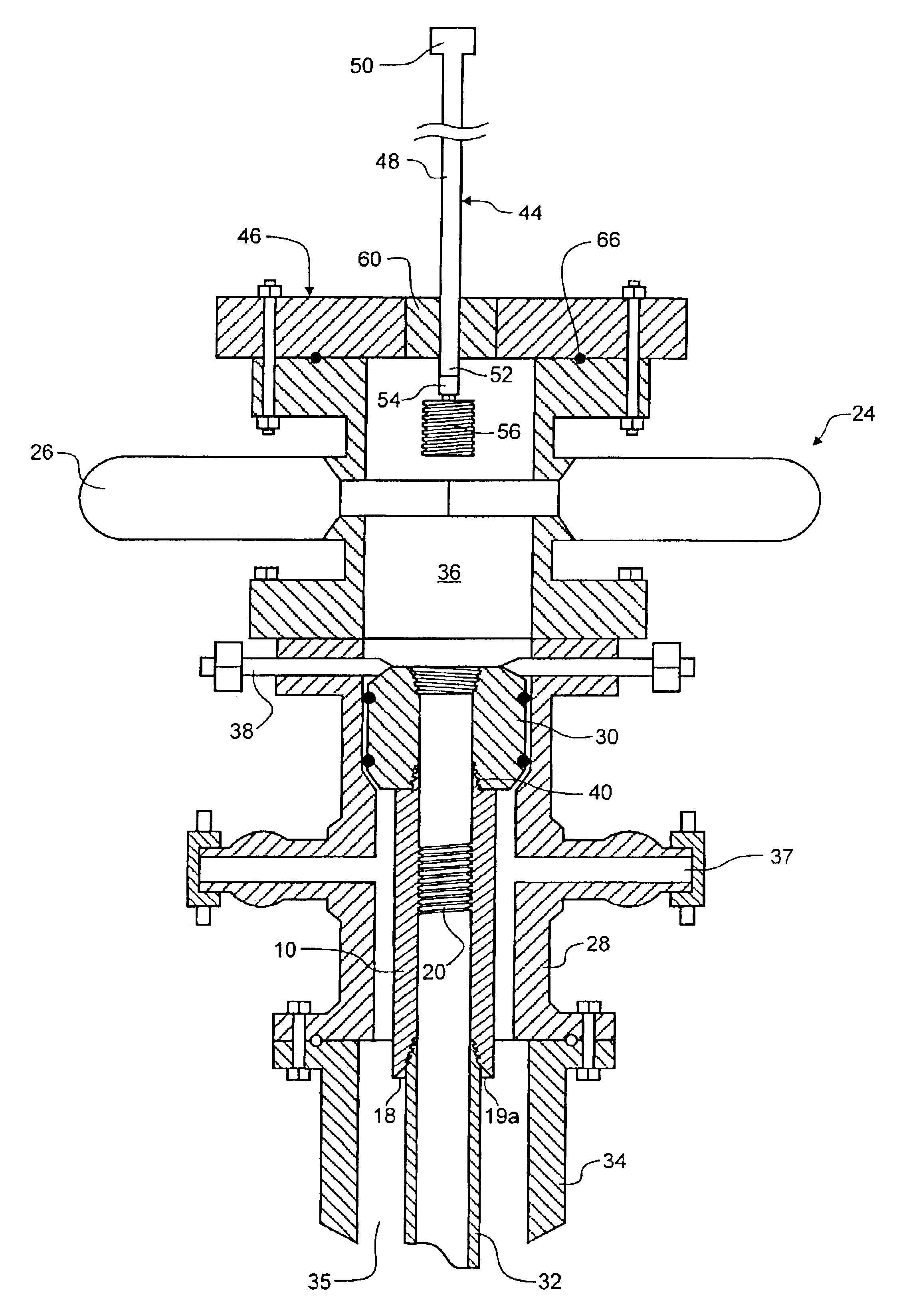

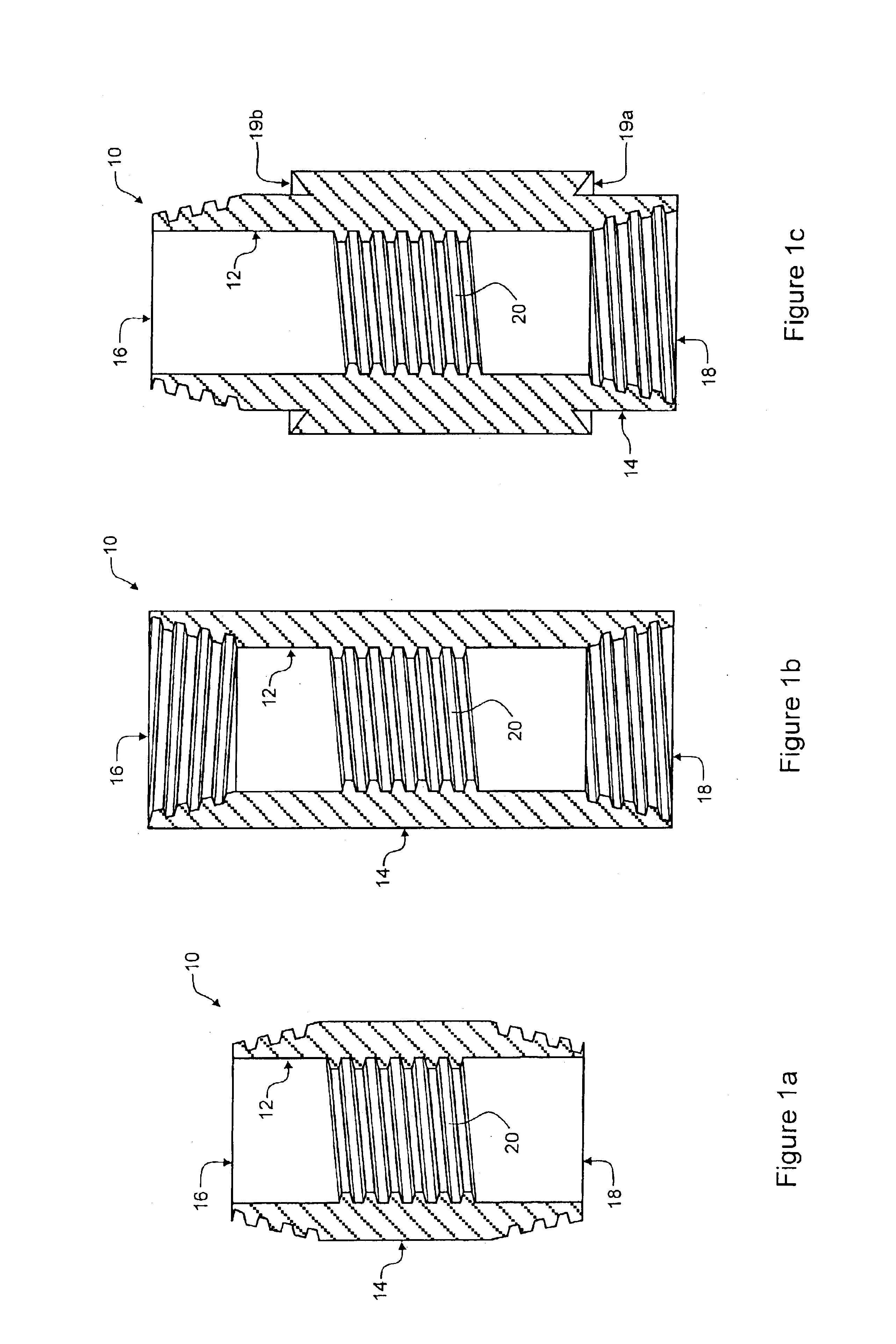

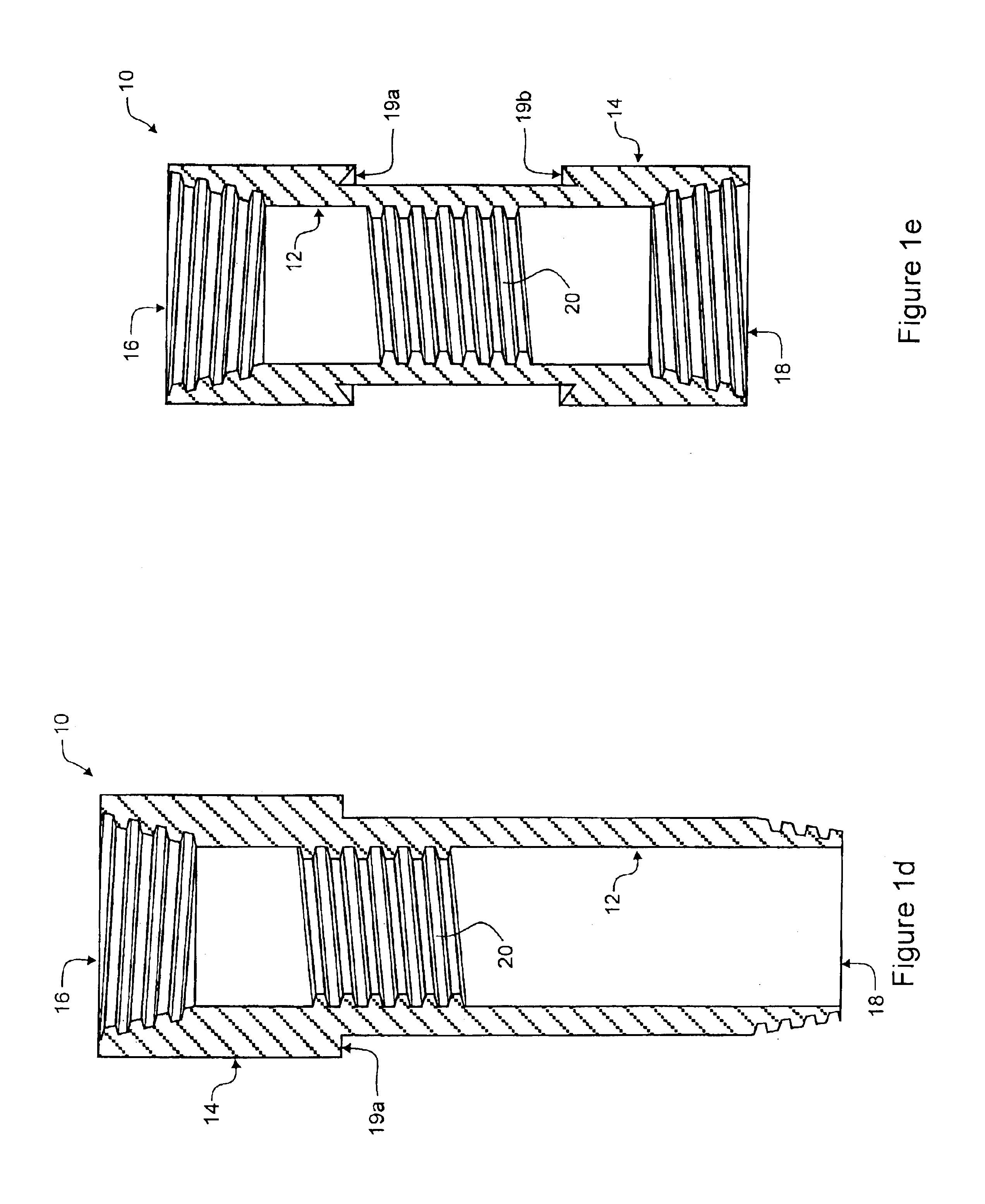

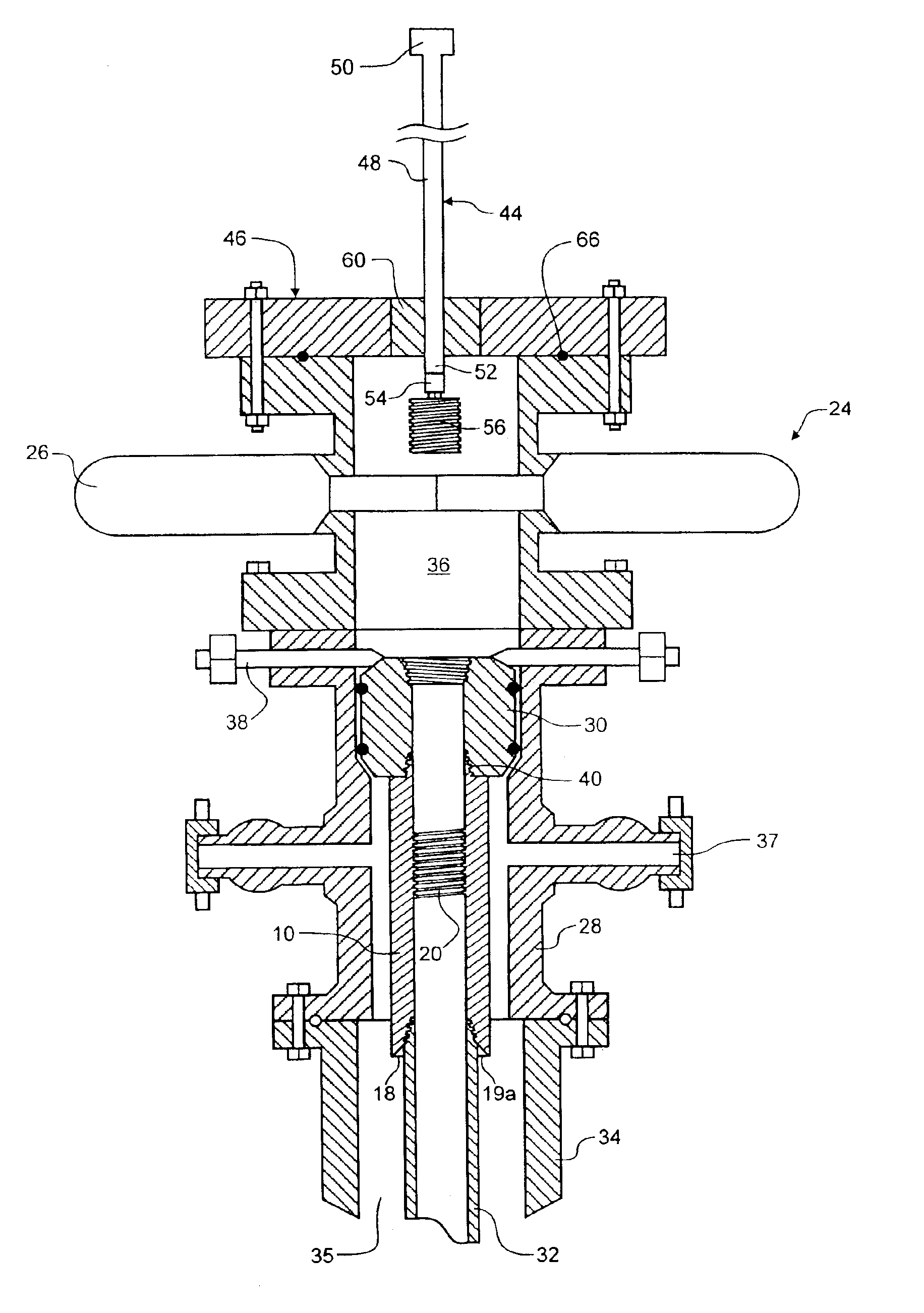

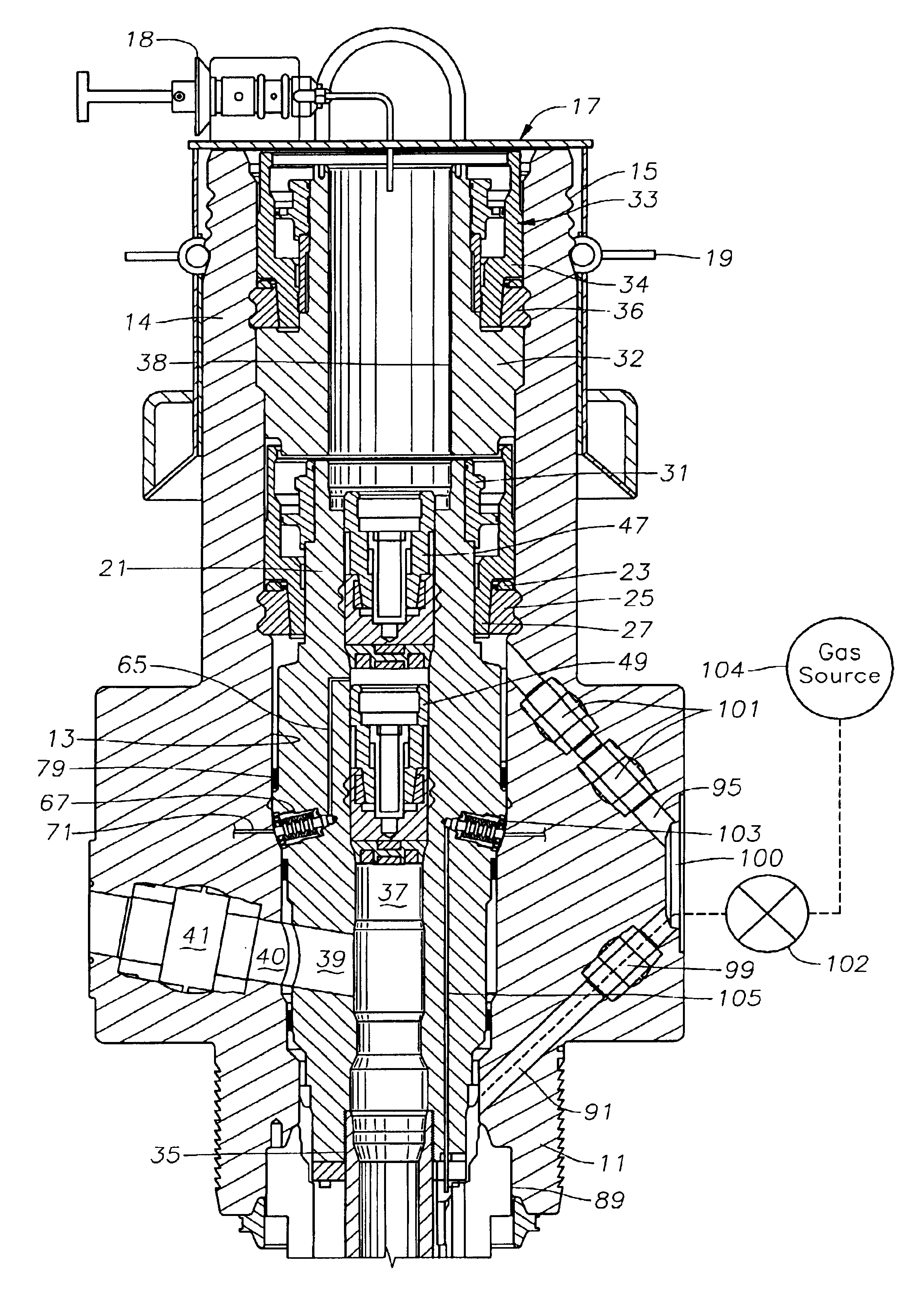

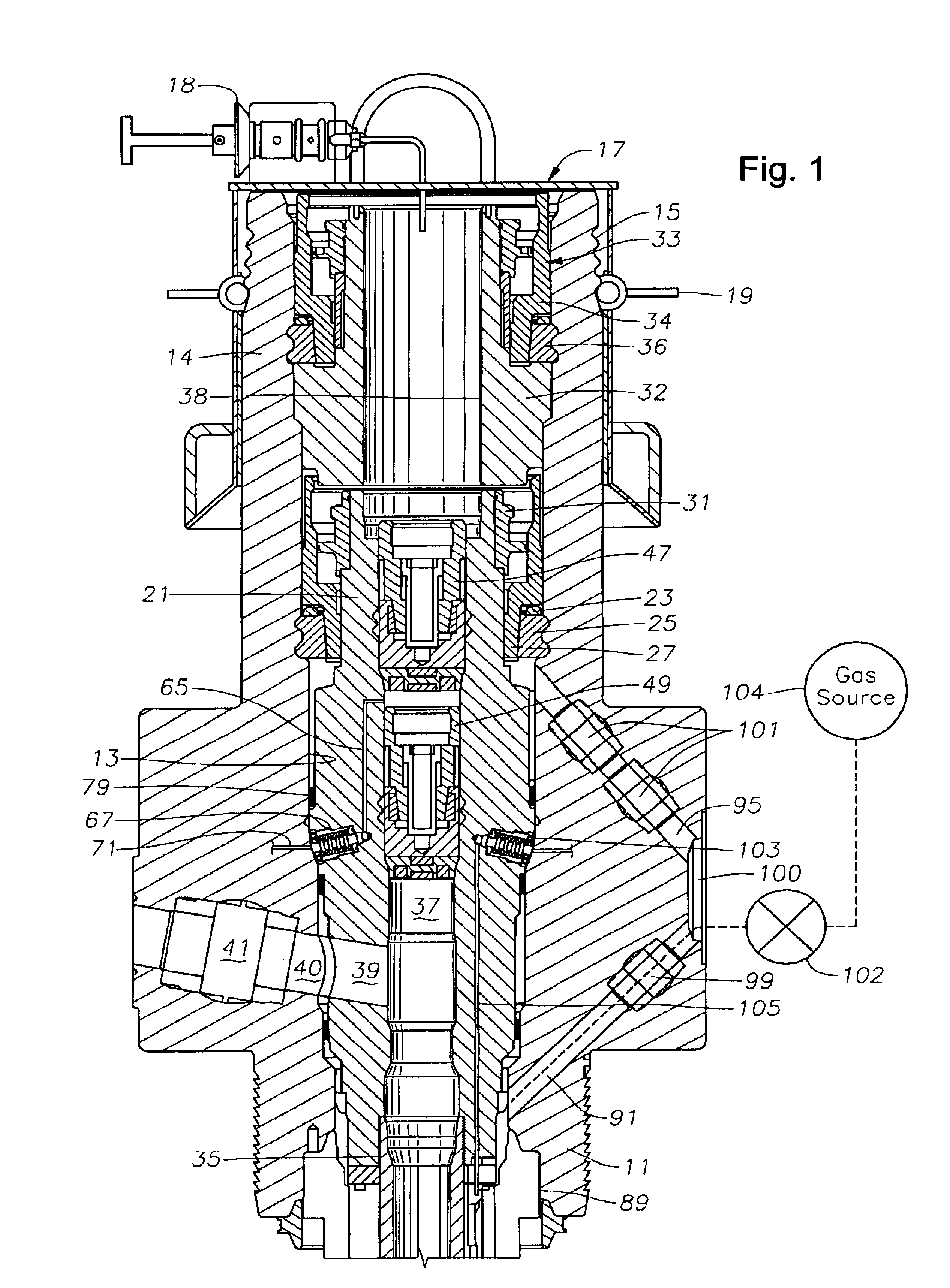

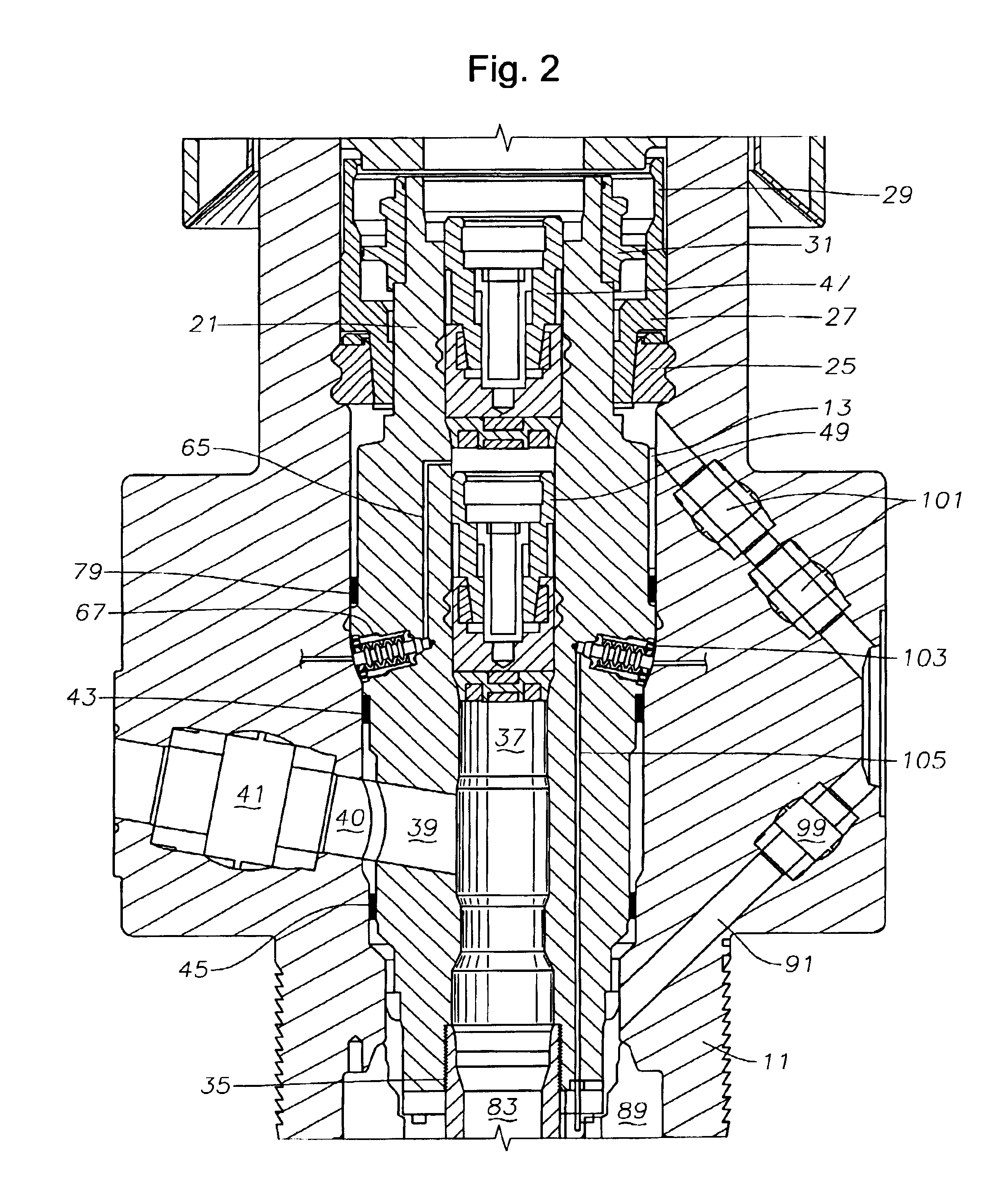

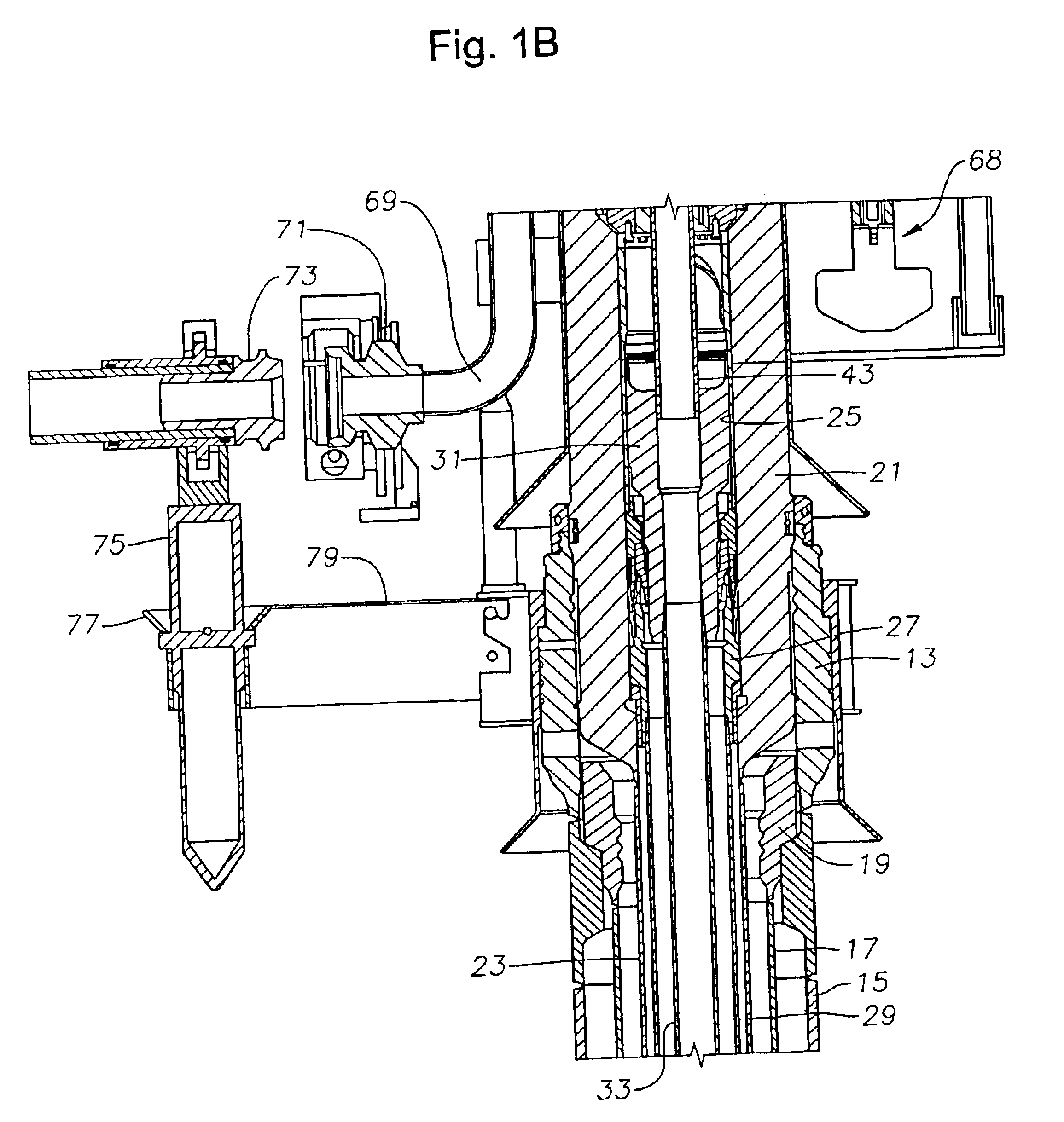

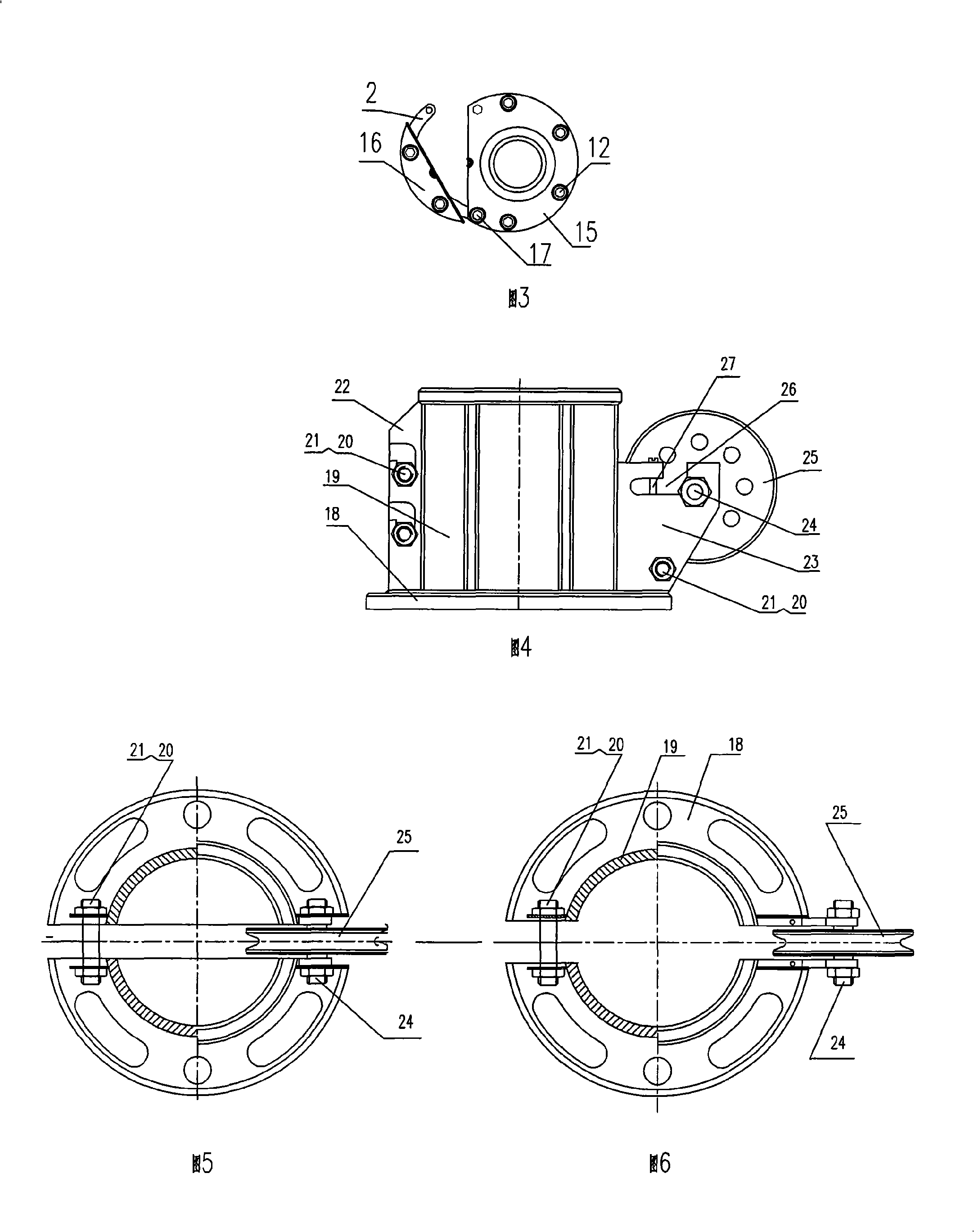

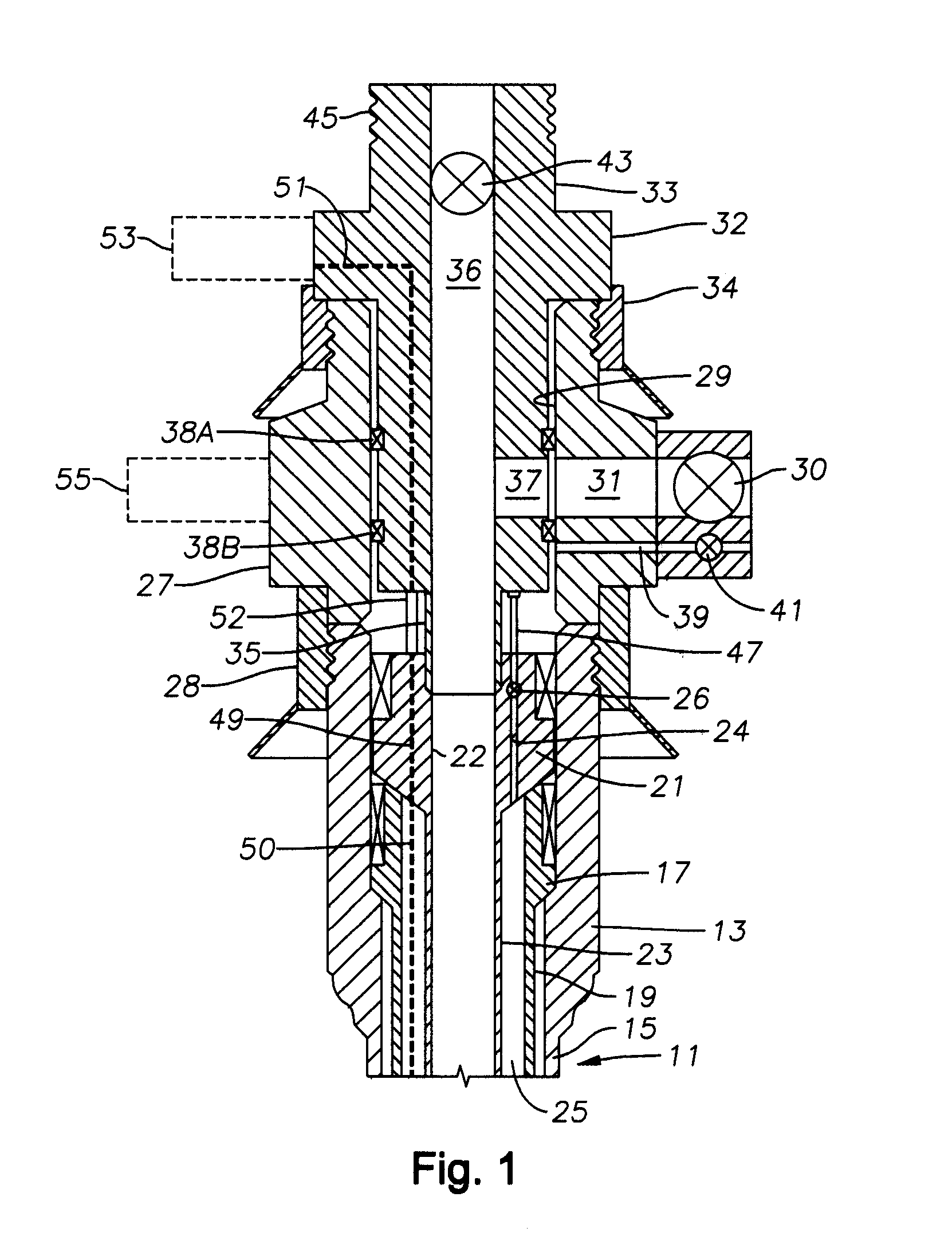

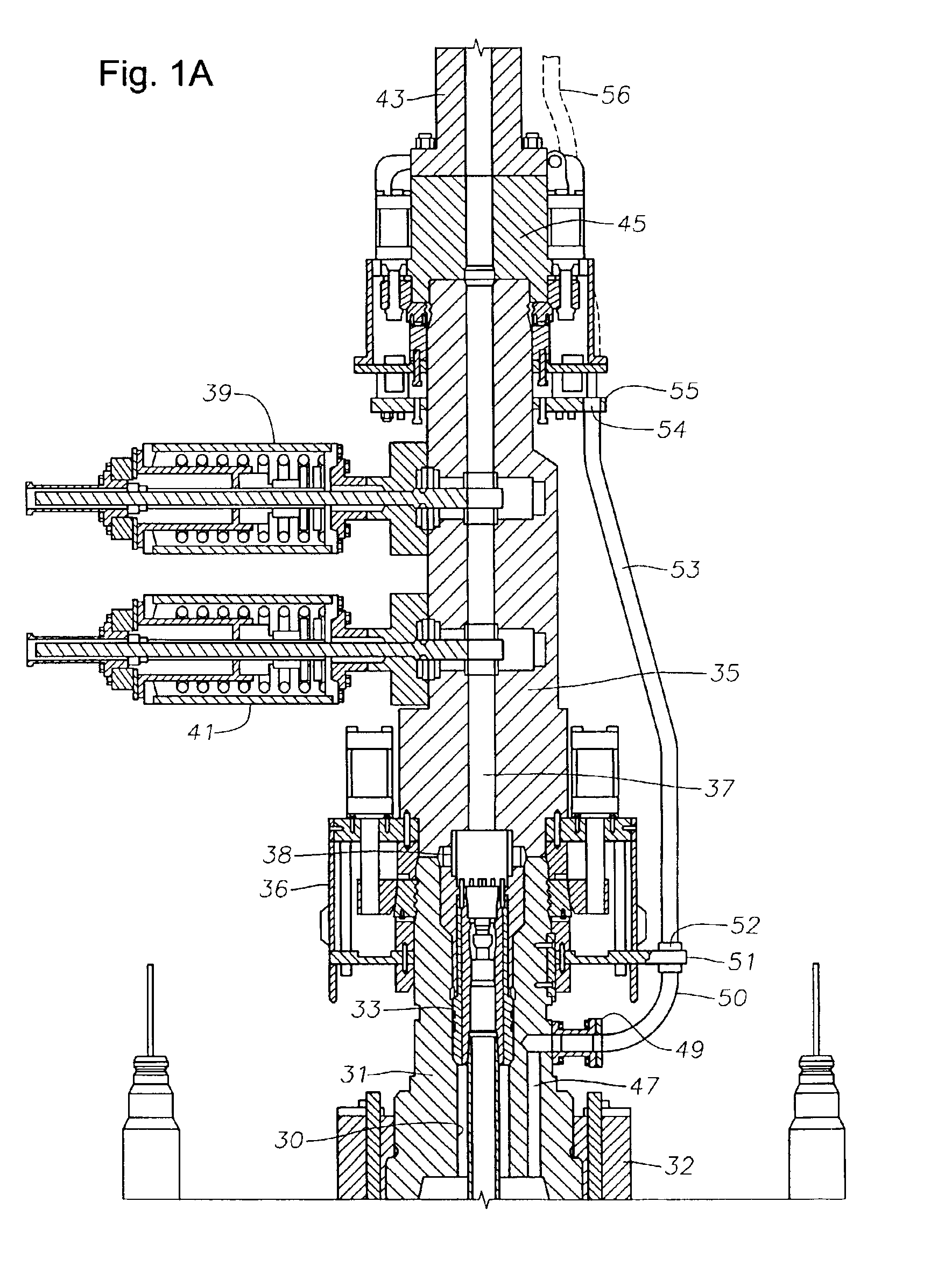

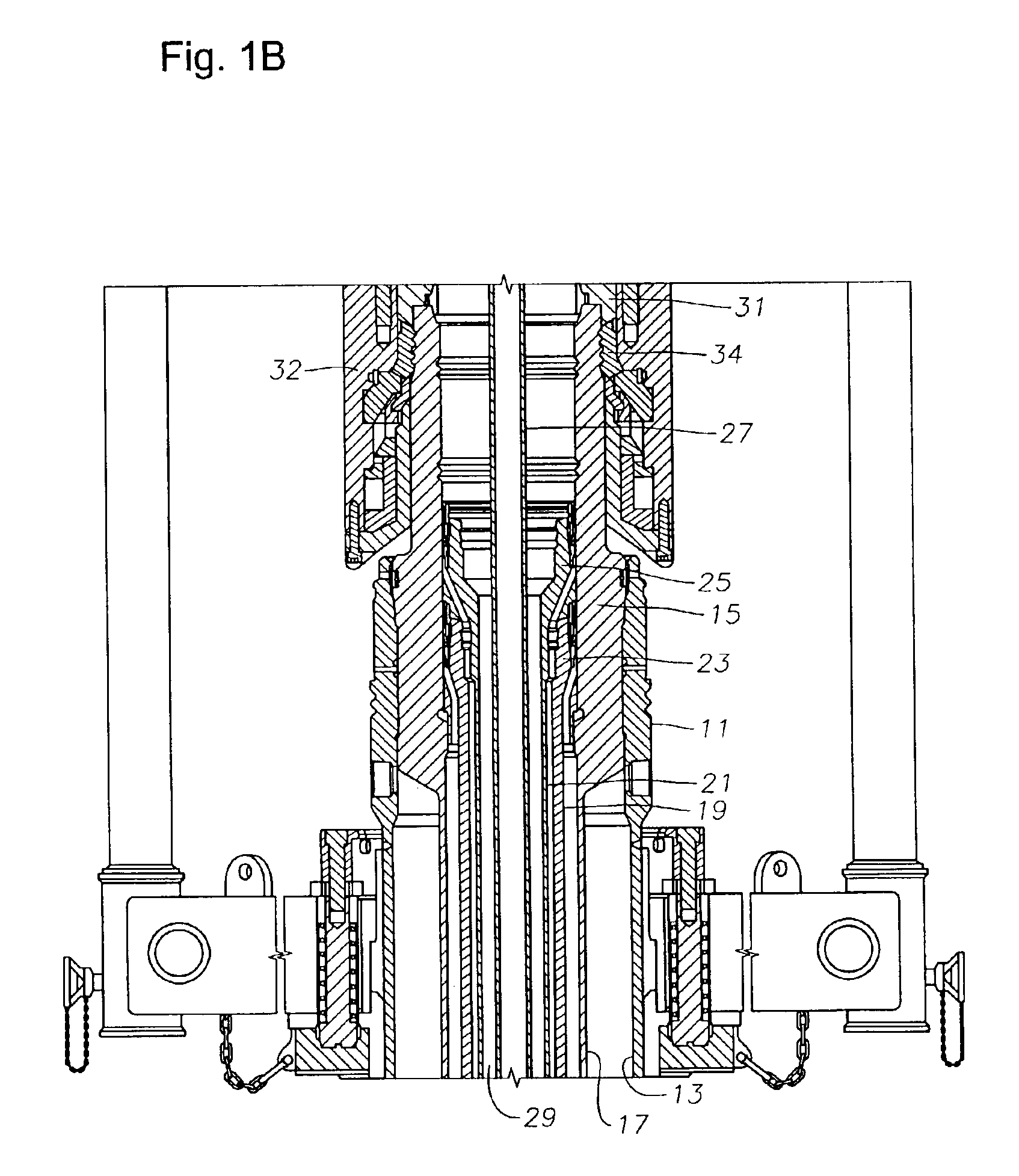

Backpressure adaptor pin and methods of use

A tubing assembly including a tubing string and tubing hanger provides a fluid passage with backpressure threads for securing a backpressure plug in a fluid-tight seal below the tubing hanger, so that the tubing hanger can be removed from the tubing string. The back pressure threads are preferably incorporated in a backpressure adapter pin connected between the tubing string and the tubing hanger. The adapter pin may also incorporate external weight-bearing shoulders for snubbing and / or suspending the tubing assembly. The backpressure plug is inserted or removed using a backpressure plug tool that slides through a packing in a pressurized casement that maintains pressure in an axial passage through a control stack of the wellhead.

Owner:STINGER WELLHEAD PROTECTION

Backpressure adapter pin and methods of use

A tubing assembly including a tubing string and tubing hanger provides a fluid passage with backpressure threads for securing a backpressure plug in a fluid-tight seal below the tubing hanger, so that the tubing hanger can be removed from the tubing string. The back pressure threads are preferably incorporated in a backpressure adapter pin connected between the tubing string and the tubing hanger. The adapter pin may also incorporate external weight-bearing shoulders for snubbing and / or suspending the tubing assembly. The backpressure plug is inserted or removed using a backpressure plug tool that slides through a packing in a pressurized casement that maintains pressure in an axial passage through a control stack of the wellhead.

Owner:STINGER WELLHEAD PROTECTION

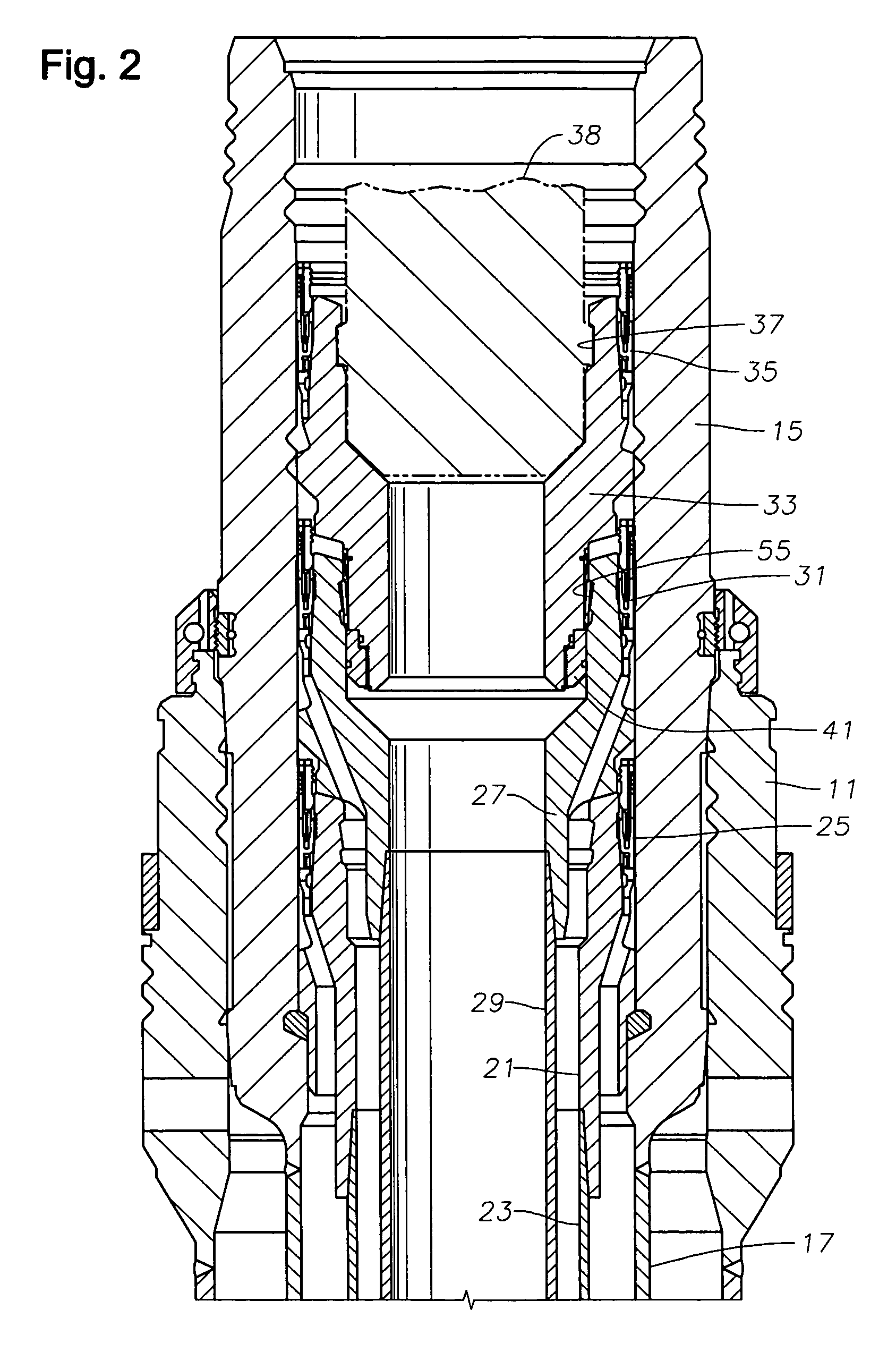

Production tree with multiple safety barriers

The wellhead assembly has a production tree with multiple safety barriers. A tubing hanger lands and seals in the bore of the tree. The tubing hanger has a lateral production flow passage that registers with a lateral passage in the tree. A tubing annulus passage extends upward from the tubing annulus to an exterior port. A second portion of the tubing annulus passage extends upward from the exterior port into the bore above the tubing hanger seal. The external port may be used for gas injection. If so, two closure members are located in the upper portion of the tubing annulus above the seal. The upper closure member may be either a check valve or a removable plug.

Owner:ABB VETCOGRAY

Crossover tree system

A subterranean oil or gas well apparatus is provided. The apparatus includes a single-bore production tubing hanger arranged concentric with a wellhead. The tubing hanger includes a plurality of ports and channels arranged about the tubing hanger to give operators access to the production tubing annulus and provide chemical injection capability. The ports are closable by a sliding valve. The apparatus also includes annulus and production radial-bore stab assemblies between a christmas tree and an internal crossover assembly. The stab assemblies are extendable and retractable between the chirstmas tree and the crossover assembly to allow the retrieval and installation of each independently.

Owner:AKER SOLUTIONS AS

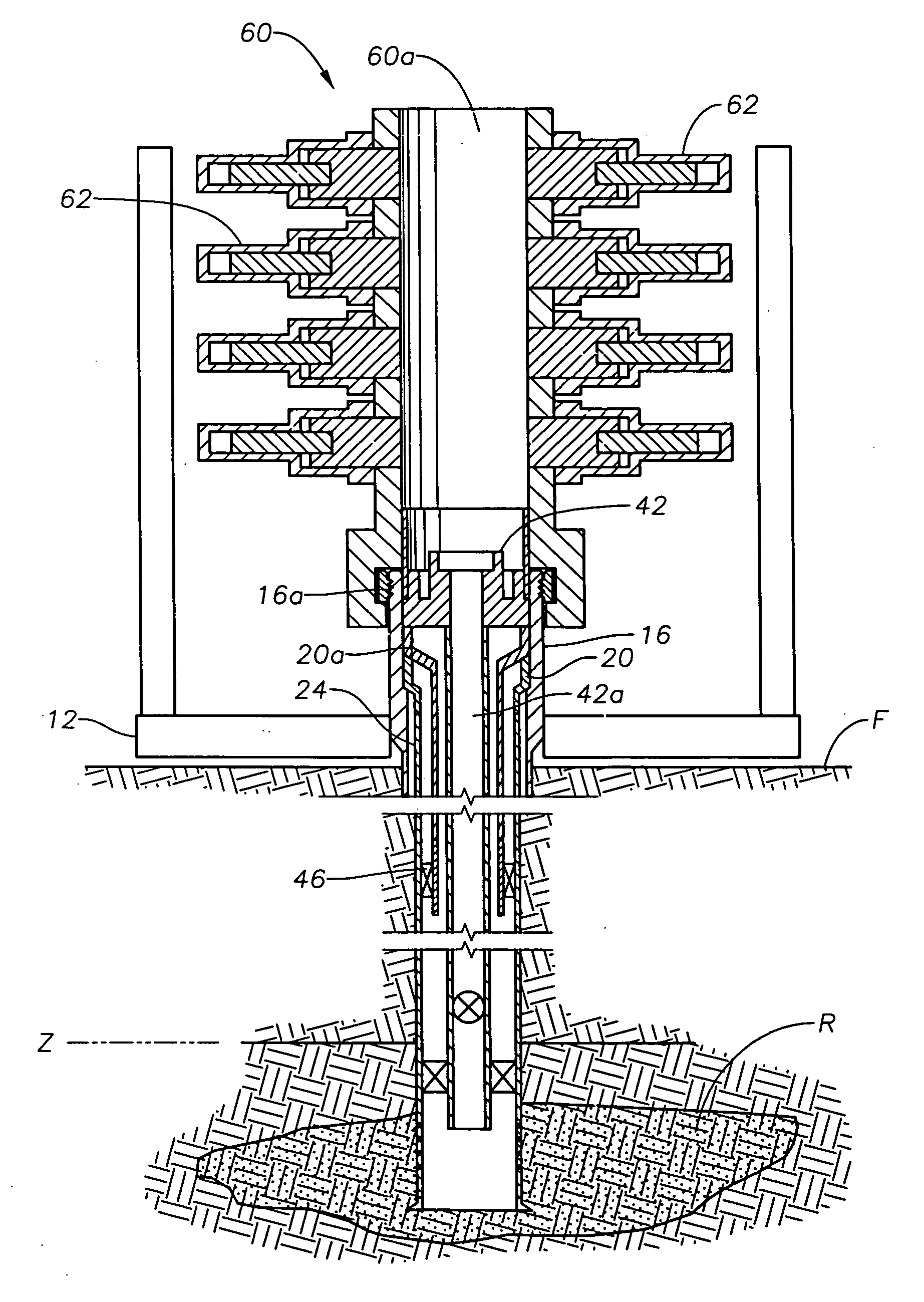

Device for installation and flow test of subsea completions

InactiveUS7114571B2Simpler and reliable and rapid disconnectionDrilling rodsFluid removalLine tubingTubing hanger

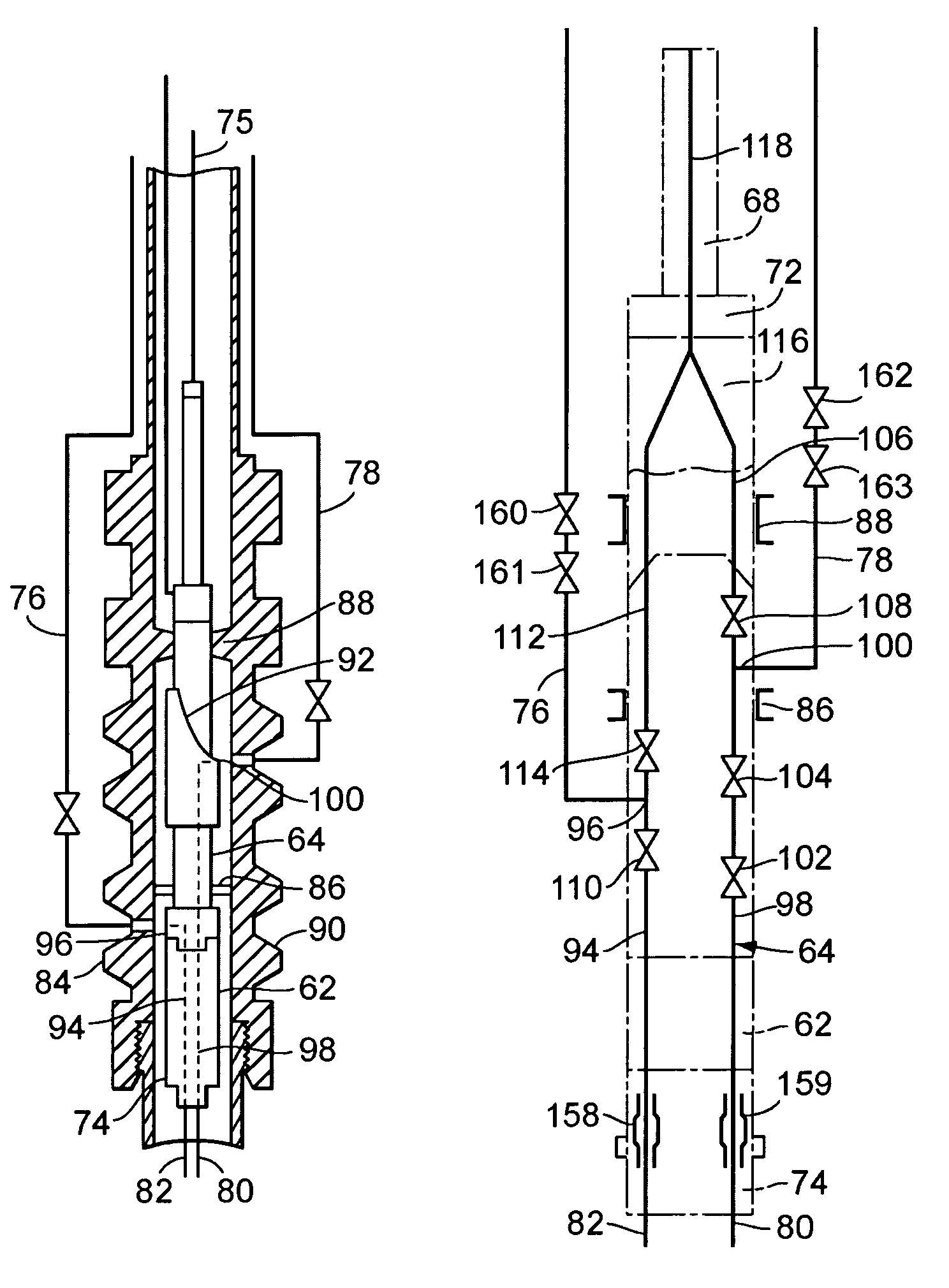

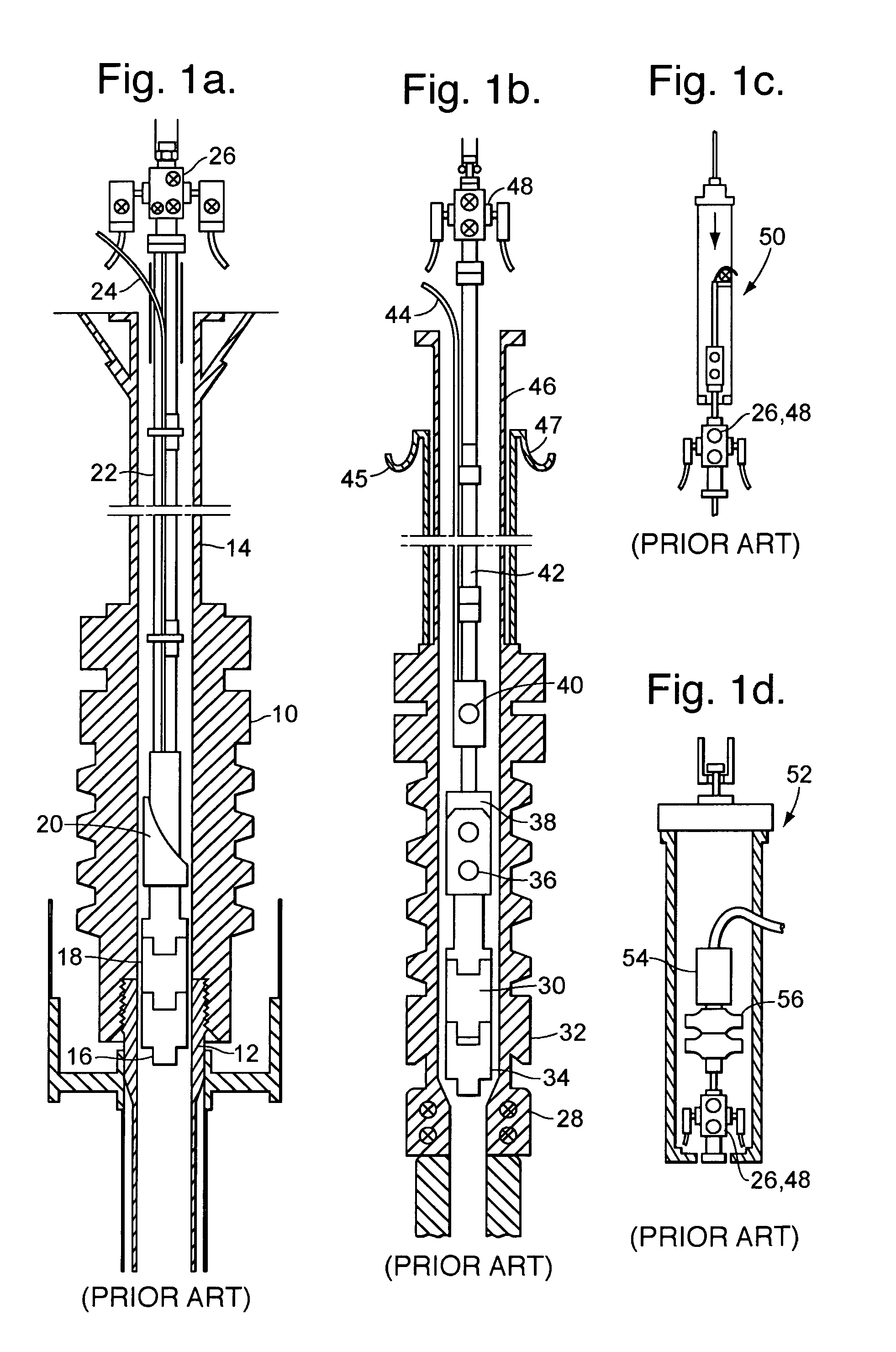

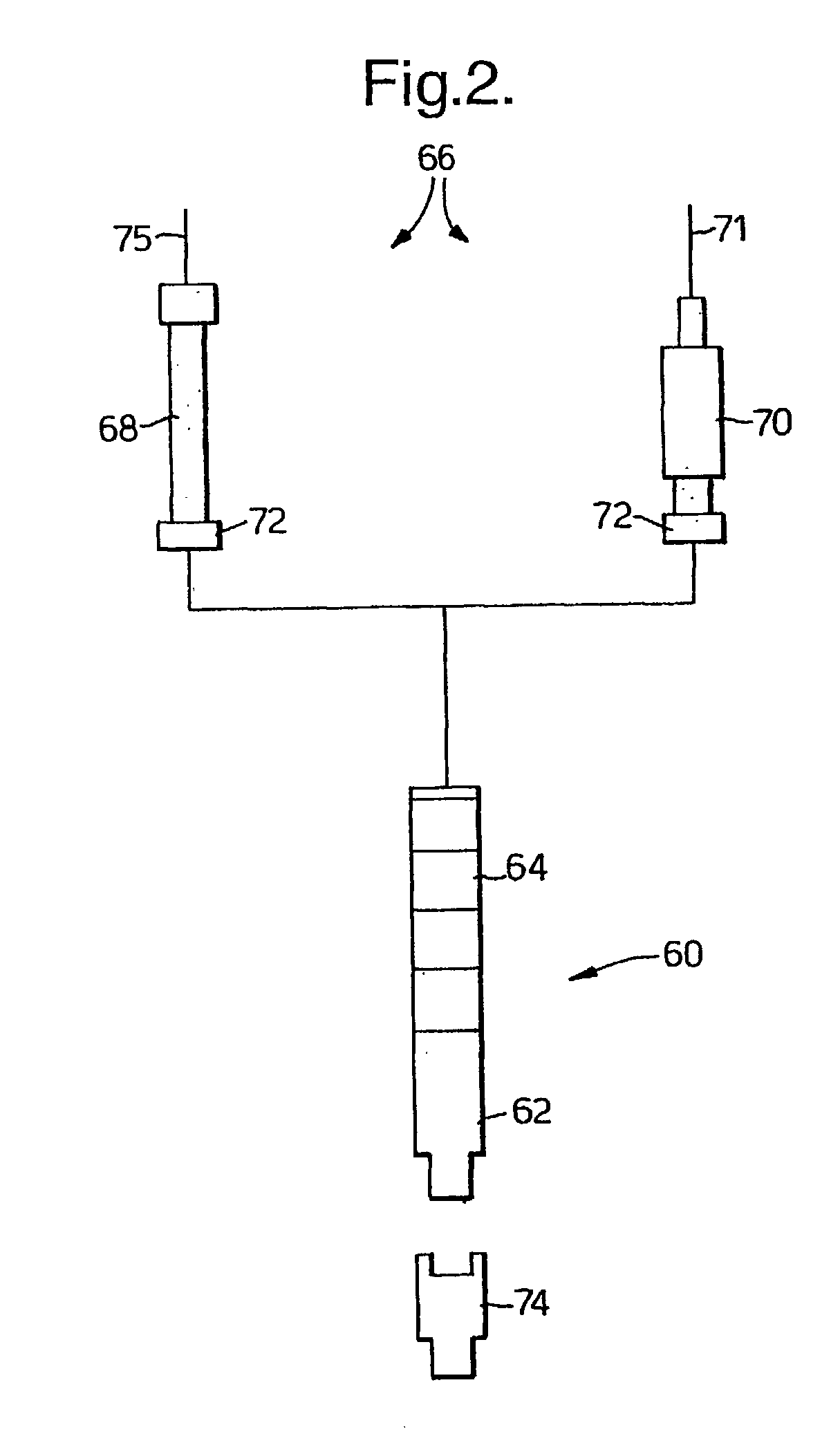

A running string for a subsea completion comprises an upper section (70) which may be a coiled tubing (CT) injector unit as shown, or a wireline lubricator (FIG. 8). A lower section (60) provides wireline / CT access to production / annulus bores of a tubing hanger (not shown) attached to tubing hanger running tool (62). A flow package (64) in the lower section (60), together with BOP pipe rams (86) and annular seal (88), directs production and annulus fluid flows / pressures to the BOP choke / kill lines (78 / 76). The upper and lower sections allow installation and pressure / circulation testing of, and wireline / CT access to, a subsea completion, without the use of a high pressure riser.

Owner:FMC TECH INC

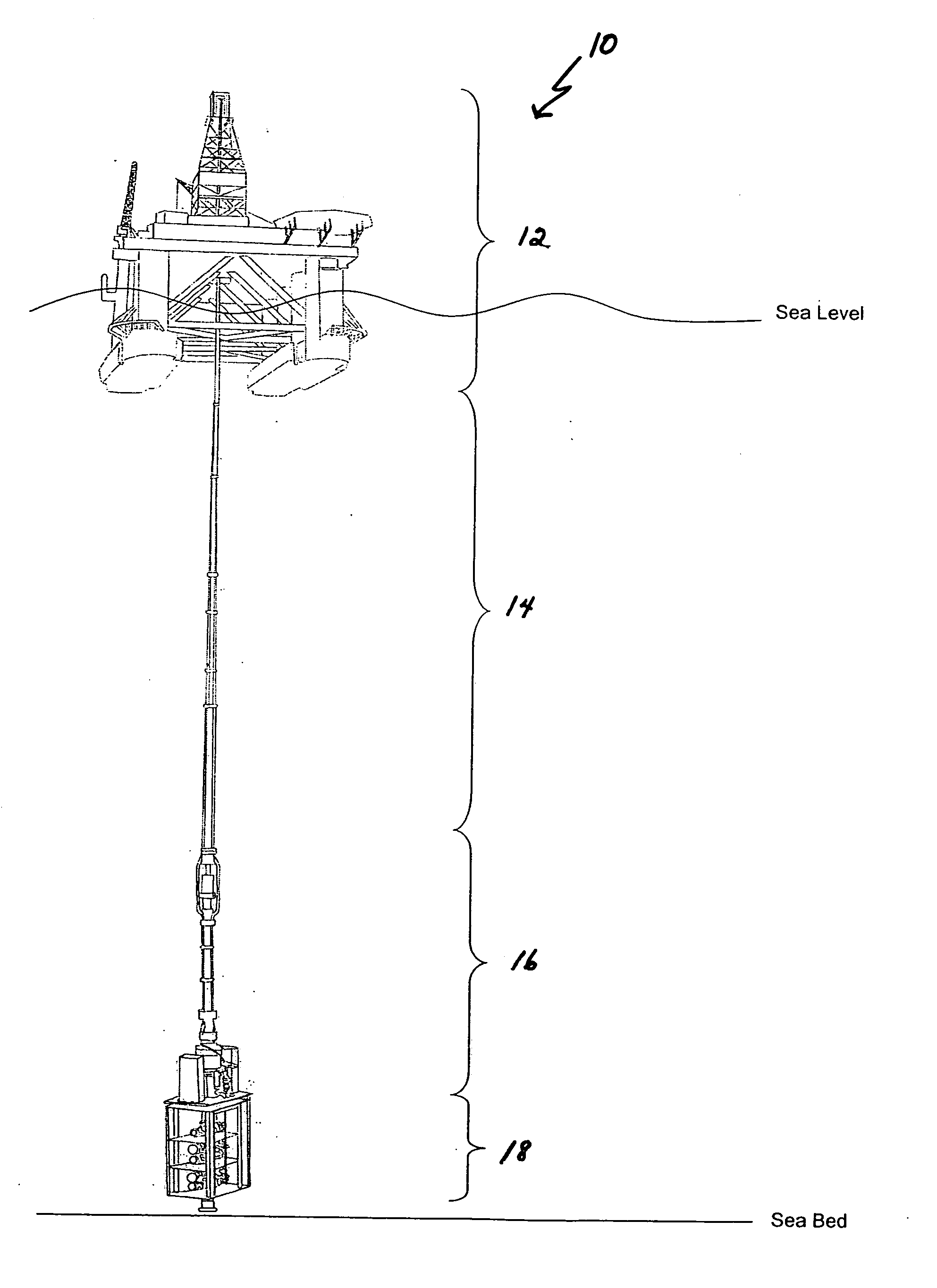

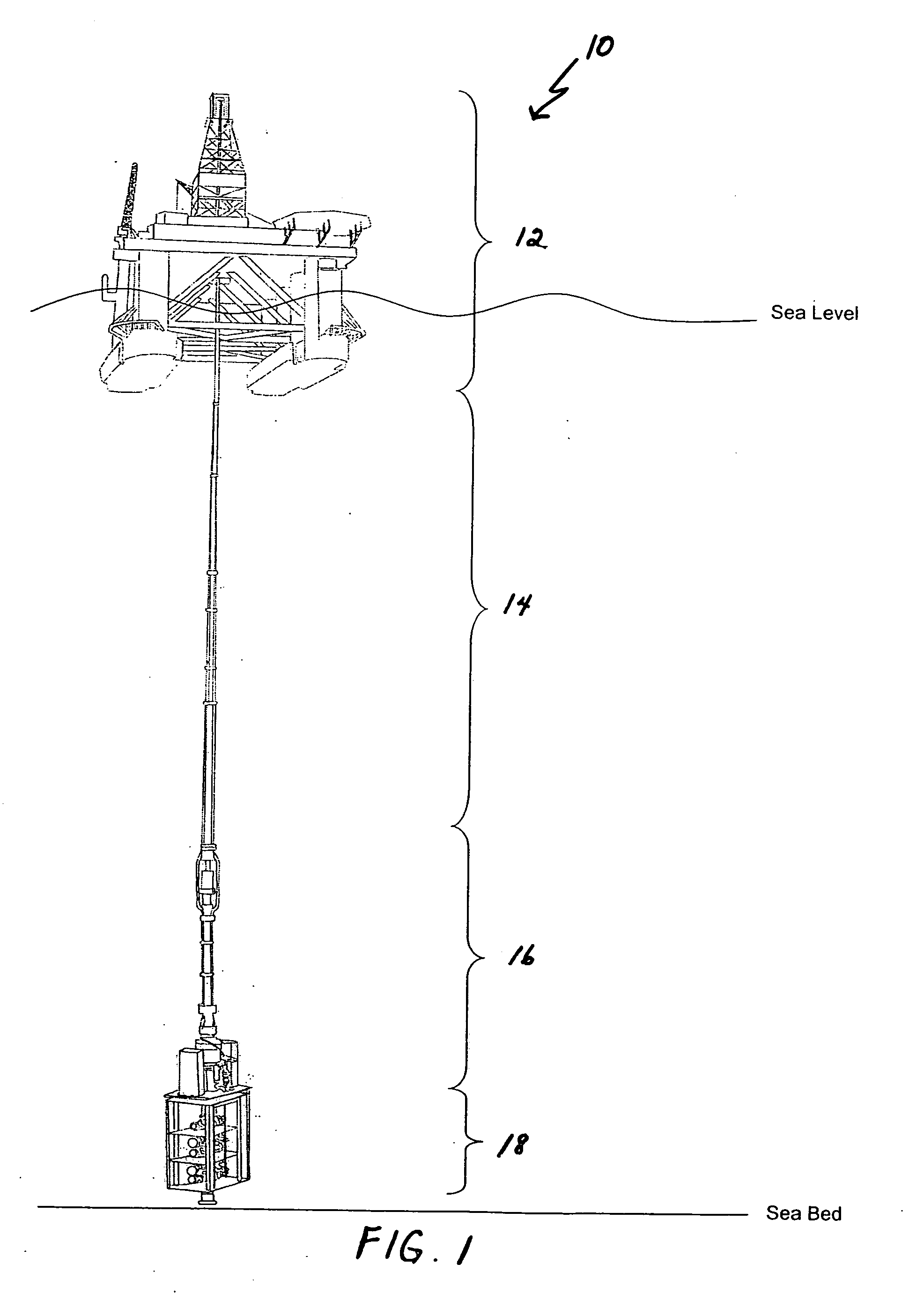

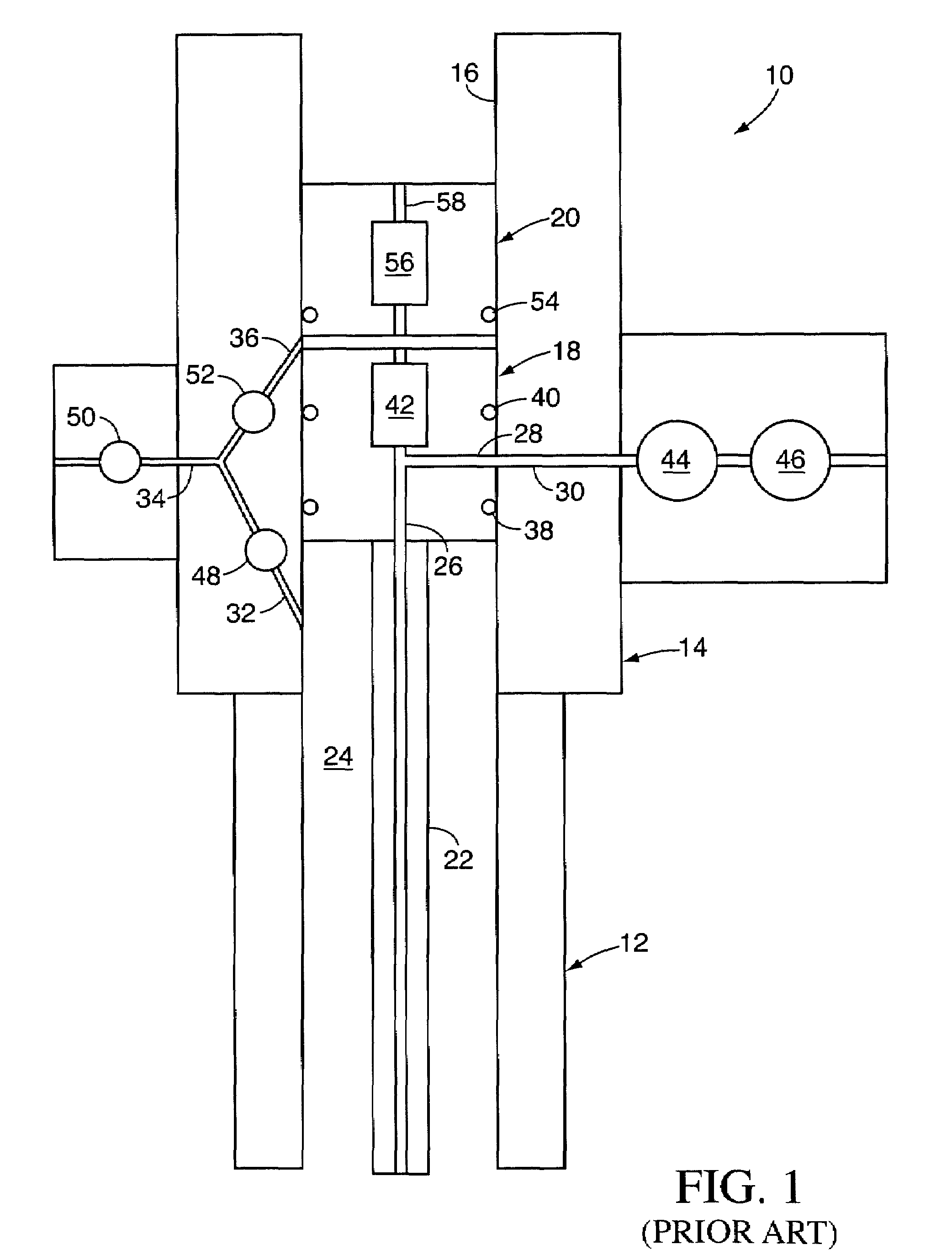

Drilling and producing deep water subsea wells

InactiveUS6968902B2Efficient separationMinimize flow disturbanceWaste water treatment from quariesLiquid separation auxillary apparatusOcean bottomWell drilling

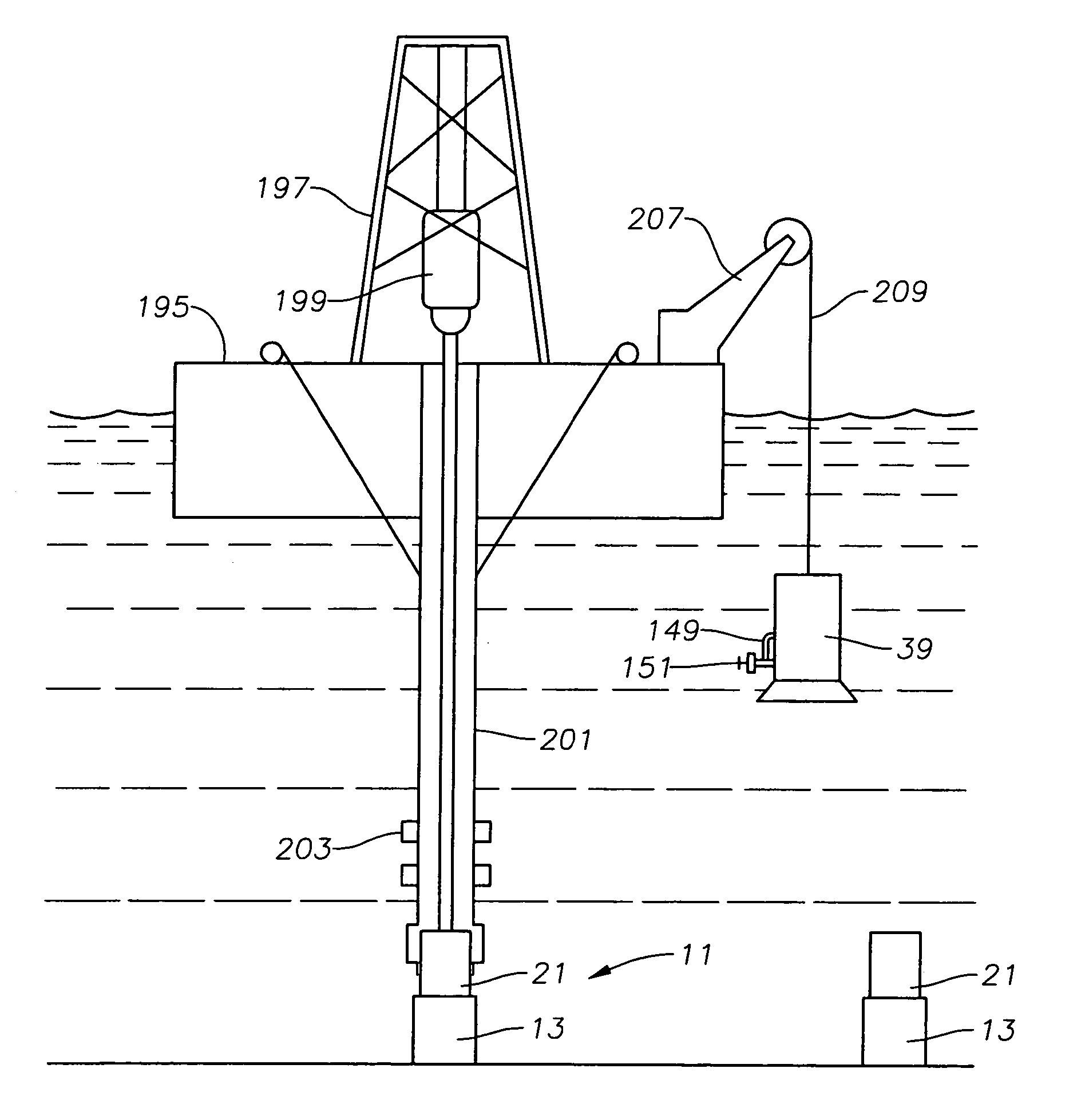

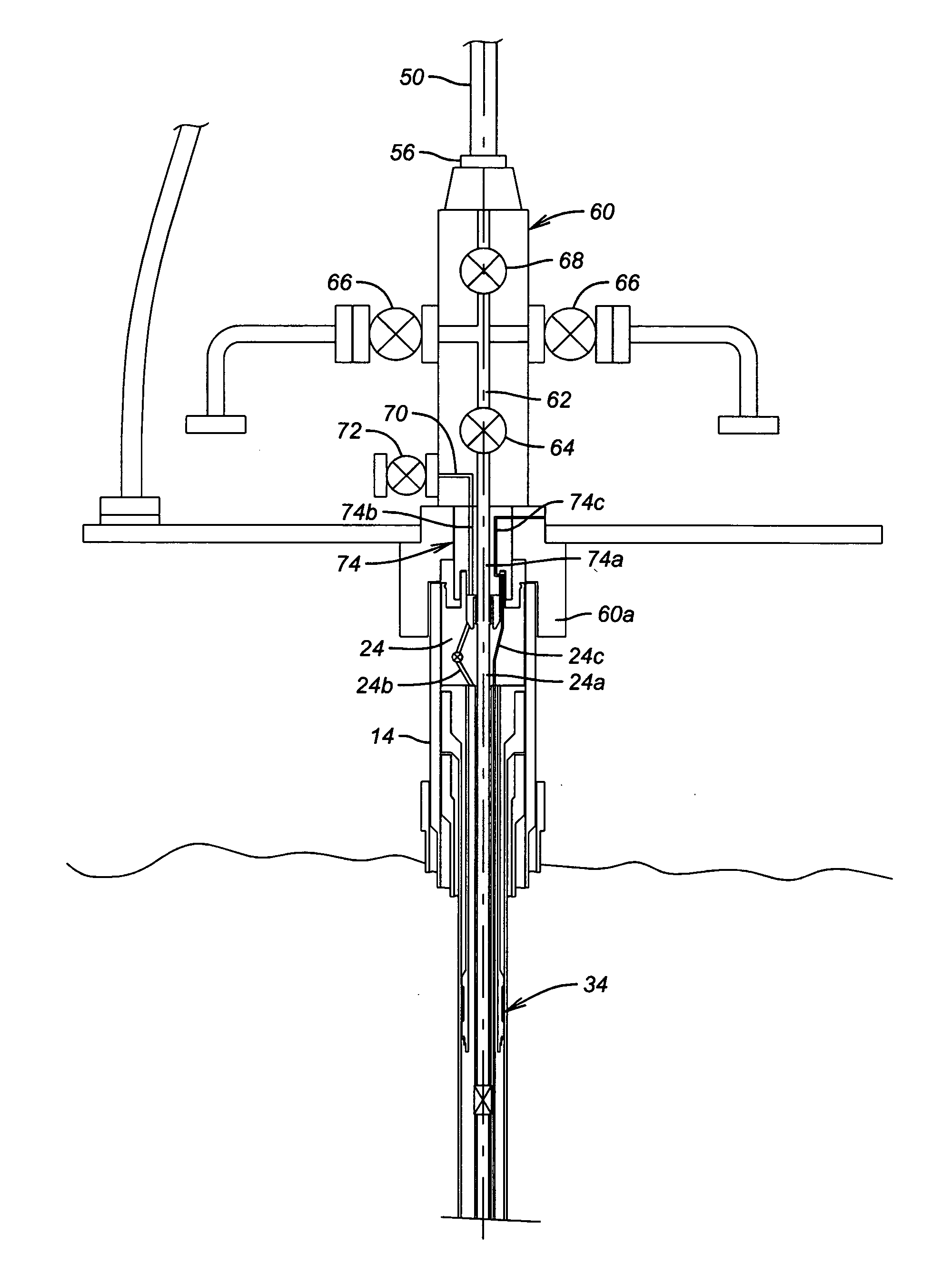

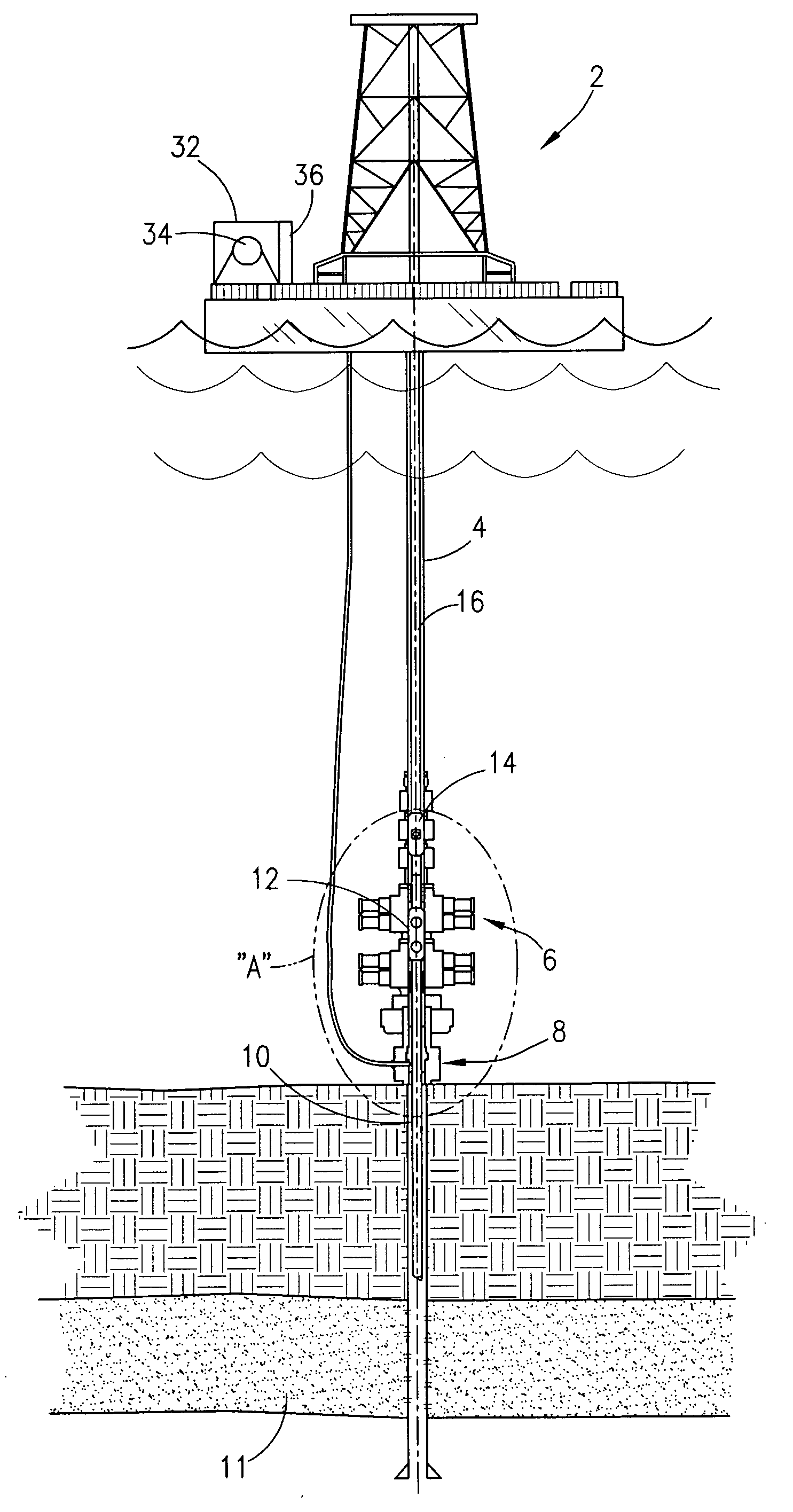

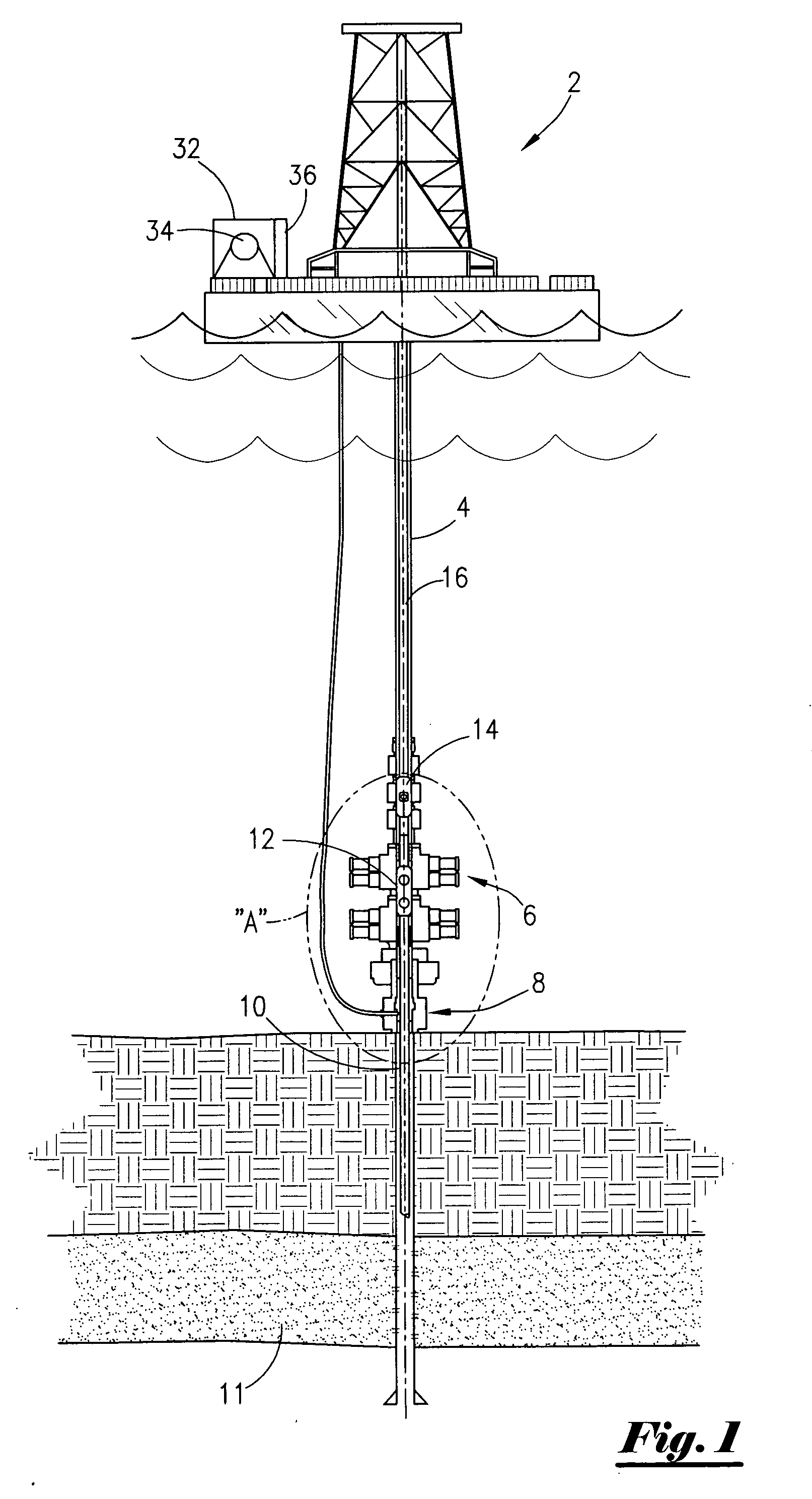

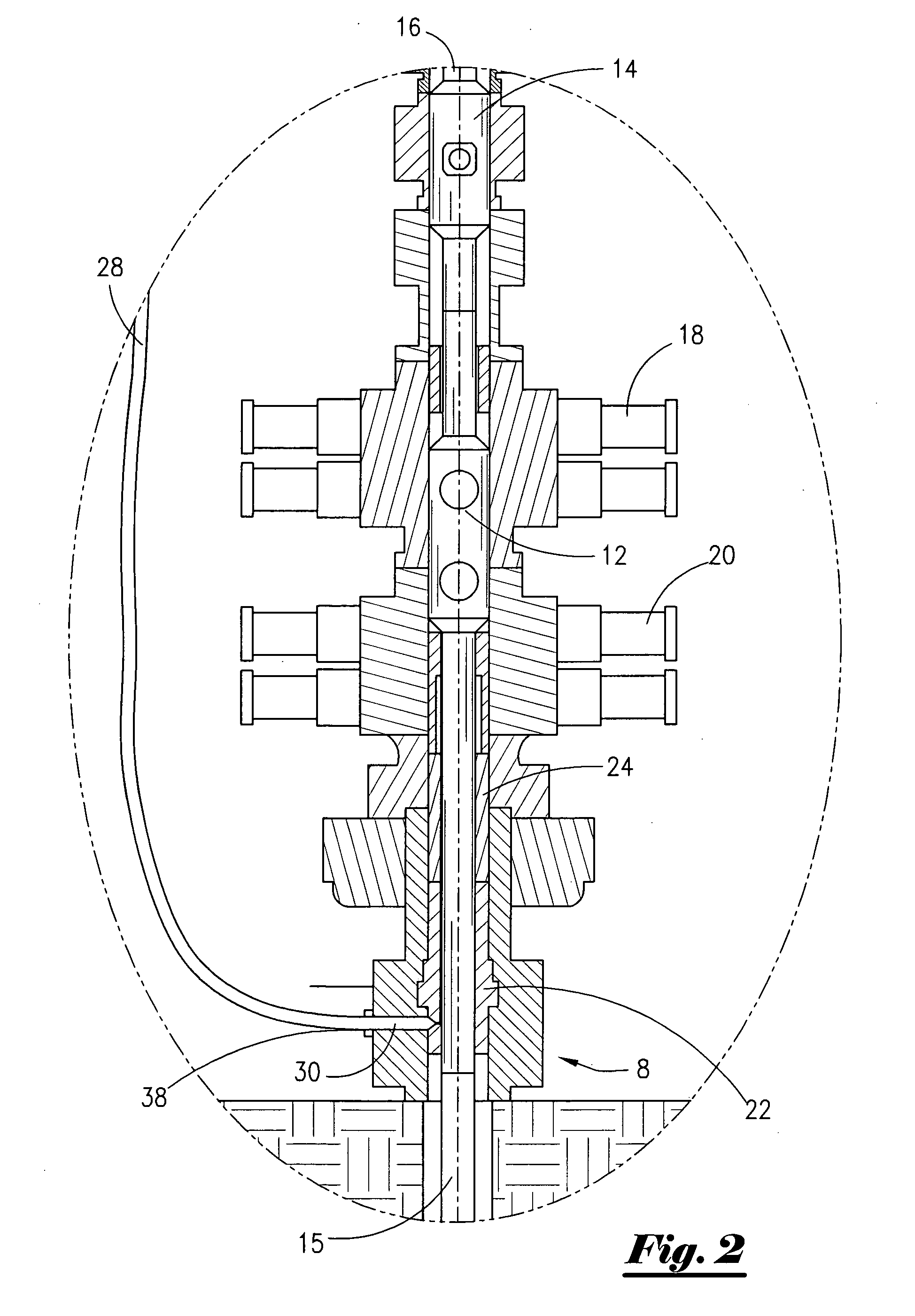

Subsea wells are drilled and completed with an offshore floating platform in a manner that allows simultaneous work on more than one well. A first well is drilled and cased. Then a tubing hanger is run through a drilling riser and landed in the wellhead housing. Then, with the same floating platform, the drilling riser is disconnected and moved to a second well. While performing operations on the second well, the operator lowers a production tree from the floating platform on a lift line, and connects it to the first wellhead housing. An ROV assisted subsea plug removal tool is used for plug removal and setting operations. Seabed separation is configured upstream of a production choke valve.

Owner:VETCO GRAY

Tubing annulus valve

InactiveUS6840323B2Increased durabilityGuaranteed uptimeWaste water treatment from quariesDrilling rodsOcean bottomTubing hanger

A subsea wellhead assembly has a tubing hanger with a tubing annulus passage and a production passage. A metal-sealing shuttle valve is mounted in the tubing hanger for blocking upward flow through the tubing annulus passage. The shuttle valve has a retention mechanism that prevents the shuttle from moving to the open position when fluid pressure is applied from above. The retention mechanism is released by the running tool after testing has been completed, causing the shuttle to close. The tree has an engaging member that can be stroked downward into the tubing hanger annulus passage to move the shuttle valve to the open position for communicating with the annulus.

Owner:VETCO GRAY

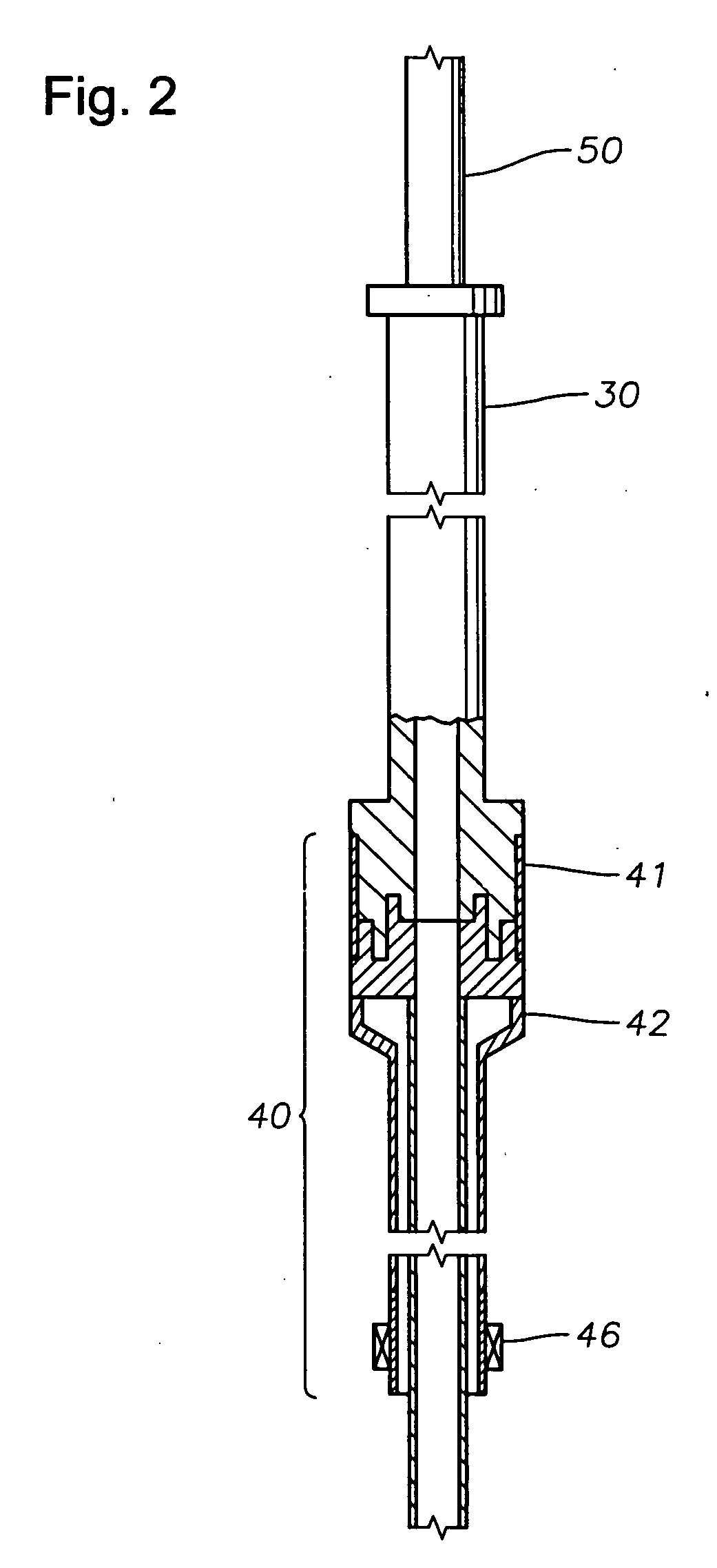

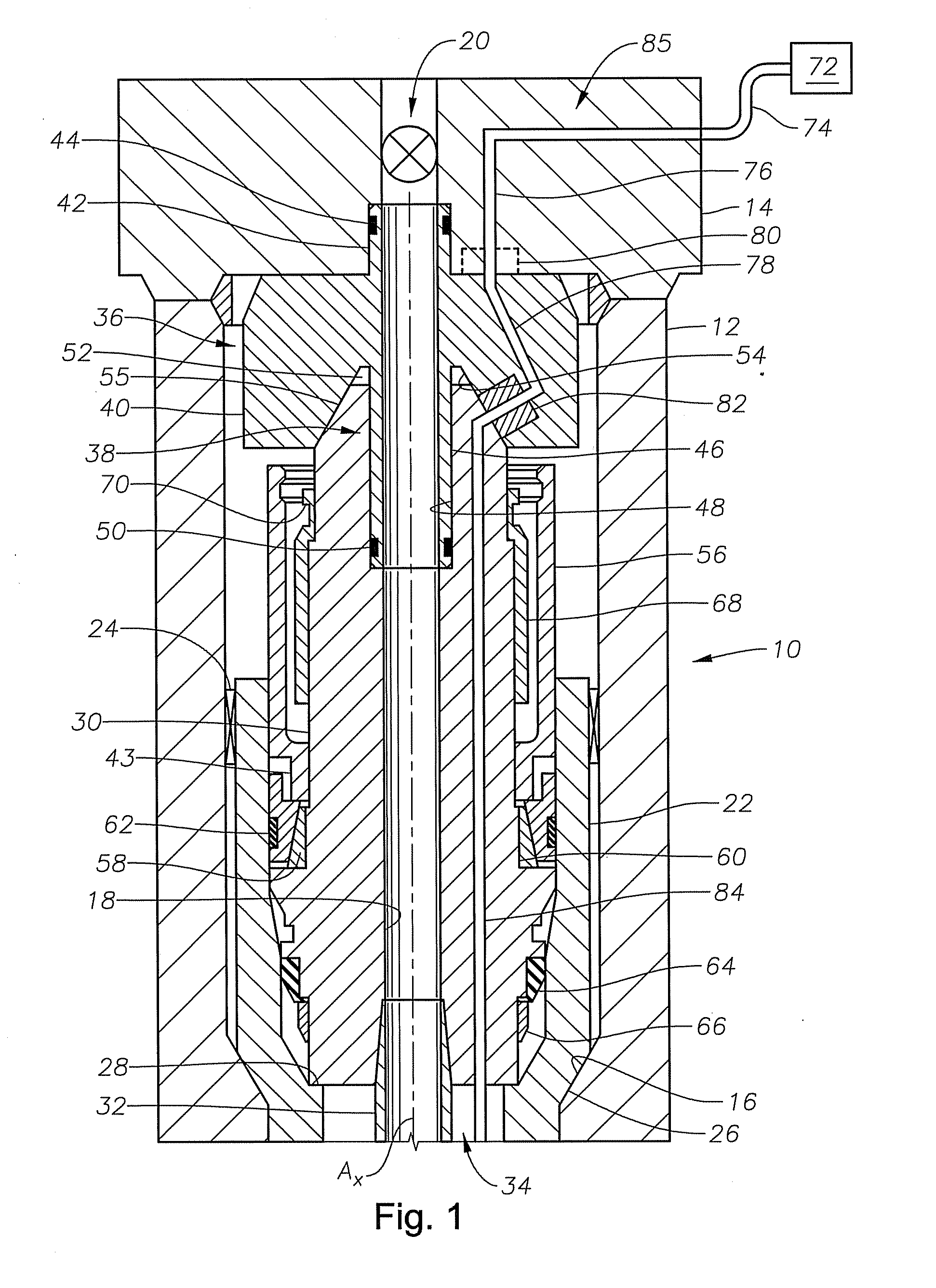

Universal tubing hanger suspension assembly and well completion system and method of using same

The present invention includes a tubing hanger suspension assembly for an oil and gas well completion system and a method of installing same. The tubing hanger suspension assembly includes a tubing hanger housing which is positioned in the wellhead housing. The tubing hanger assembly includes a sealing and lockdown mechanism capable of providing sealing and load support of the production tubing in the production casing string. A stab sub assembly connected to the upper end of the tubing hanger suspension assembly and lower end of the Christmas tree assembly provides downhole hydraulic and electric functionality and annulus access to the production tubing.

Owner:DRIL QUIP +1

Well stimulation tool and method for inserting a backpressure plug through a mandrel of the tool

A well stimulation tool includes a well stimulation tool mandrel with an axial bore having an internal diameter large enough to permit a backpressure plug to be run through the mandrel into a tubing mandrel, such as a tubing hanger or a casing mandrel, to which the well stimulation tool mandrel is secured. This permits well stimulation to be performed through a tubing string suspended in the well by the tubing mandrel, without requiring wireline services.

Owner:OIL STATES ENERGY SERVICES +1

Method of controlling landing strings in offshore operations

InactiveUS20080110633A1Meet the regulationReduce riskFluid removalUnderwater drillingElectricityTubing hanger

A method and system of operating a landing string utilized on a floating platform. The landing string is disposed within a marine riser, with the marine riser being connected to a subsea production tree, and wherein the subsea production tree contains internal conduits communicating controls through a series of stab passageways. The method comprises providing a tubing hanger operatively connected to the landing string, delivering hydraulic or electrical controls from the floating platform through a control system umbilical to a junction plate operatively attached to the subsea production tree. The method further comprises landing the tubing hanger into the subsea production tree, establishing control of the tubing hanger by providing the hydraulic controls to the tubing hanger with the series of stab passageways through the subsea production tree, and establishing control of the completion bottom hole assembly with the stab passageways. In the preferred embodiment, the landing string has attached thereto a completion bottom hole assembly that will be placed in the well.

Owner:DEEPBLUE TECH L L C

Casing hanger annulus monitoring system

A subsea wellhead assembly has the capabilities of communicating from a tree assembly mounted on an inner wellhead housing to a casing annulus. A passage in the wellhead assembly extends within the bore of the wellhead housing from the casing annulus to the tree assembly. A portion of the passage is located within a casing hanger. The passage is opened and closed by a valve. The valve does not open the passage until the tree assembly is connected to the wellhead housing and a tubing hanger orientation sleeve lands in the wellhead assembly. The tubing hanger orientation sleeve actuates the valve when it lands to open the passage. When the passage is opened, the casing annulus is in fluid communication with the interior surface of the wellhead housing, which is in communication with the tree assembly. The valve can be located in the casing hanger, or in a bridging hanger

Owner:ABB VETCOGRAY

Production tree with multiple safety barriers

The wellhead assembly has a production tree with multiple safety barriers. A tubing hanger lands and seals in the bore of the tree. The tubing hanger has a lateral production flow passage that registers with a lateral passage in the tree. A tubing annulus passage extends upward from the tubing annulus to an exterior port. A second portion of the tubing annulus passage extends upward from the exterior port into the bore above the tubing hanger seal. The external port may be used for gas injection. If so, two closure members are located in the upper portion of the tubing annulus above the seal. The upper closure member may be either a check valve or a removable plug.

Owner:ABB VETCOGRAY

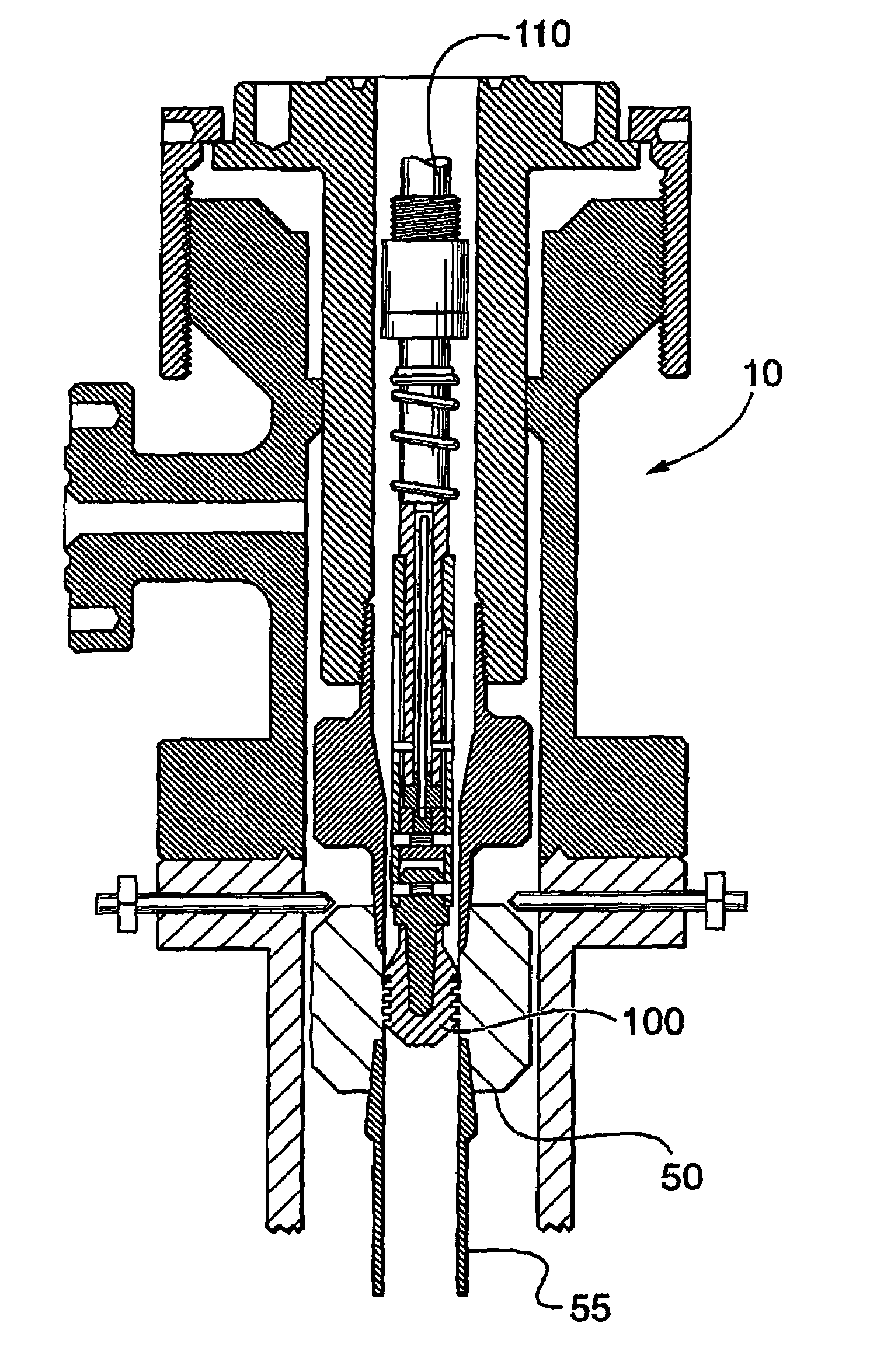

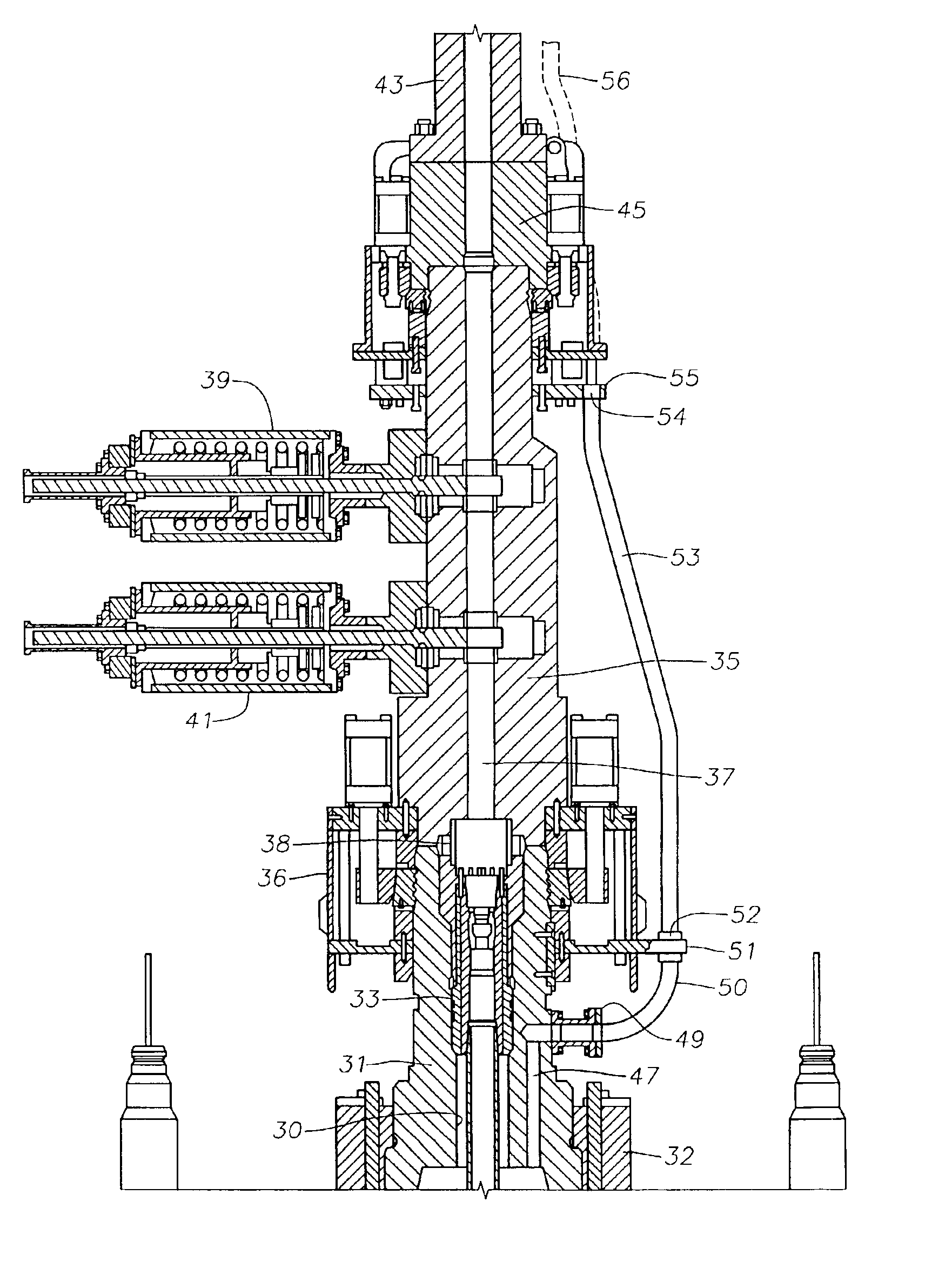

Plug installation system for deep water subsea wells

A plug retrieval and installation tool is used with a subsea well having a production tree, a tubing hanger, a passage that extends vertically through the tubing hanger and the tree, and a plug located within a plug profile in the passage within the tubing hanger. The plug retrieval device has a housing and connector that is lowered on a lift line onto the upper end of the tree. An axially extendible stem in the housing is moved with hydraulic fluid controlled by an ROV into the production passage of the tubing hanger. An installation and retrieval member mounted to the stem engages the plug and pulls it upwardly in the passage while the stem is being moved upward, and pushes the plug downward to install the plug while the stem is being moved downward. The connector, drive mechanism and retrieval member are powered by an ROV.

Owner:VETCO GRAY

Tubing hanger running tool and subsea test tree control system

InactiveUS20050217845A1Reduced rig timeImprove securityFluid removalWell/borehole valve arrangementsControl systemTubing hanger

A system for providing power to elements down-hole in a subsea well includes a control pod having at least one shuttle valve, a down-hole hydraulically-actuated device having at least one internal porting mechanism in fluid communication with the at least one shuttle valve, a blowout preventer stack connected to the down-hole device, the blowout preventer stack including a first ram and a second ram, and a choke line in fluid communication with an area between the first ram and the second ram. The at least one shuttle valve controls distribution of hydraulic pressure applied through the choke line to the internal porting mechanism for selective distribution of power to the hydraulically-actuated device.

Owner:MCGUIRE LINDELL V

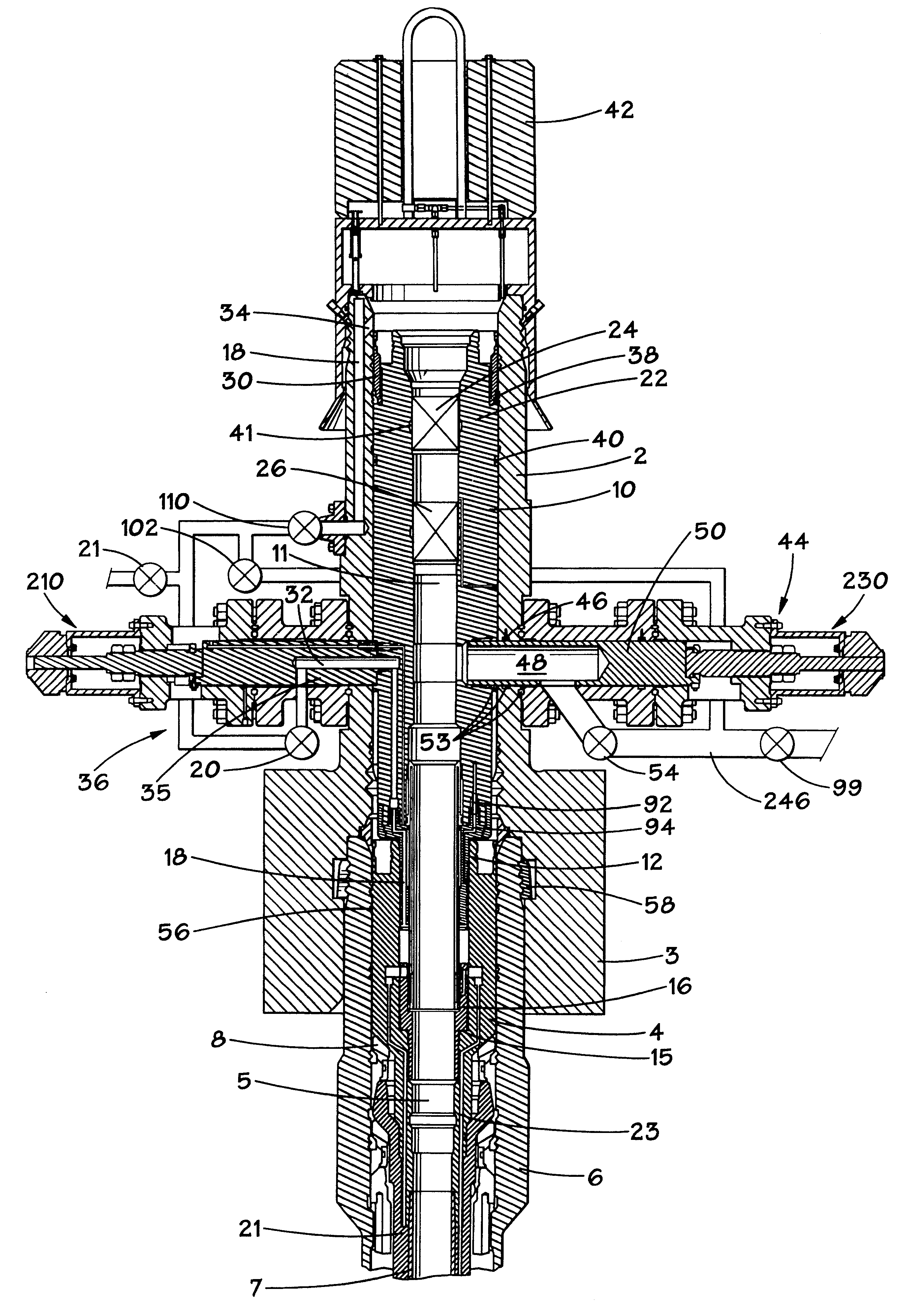

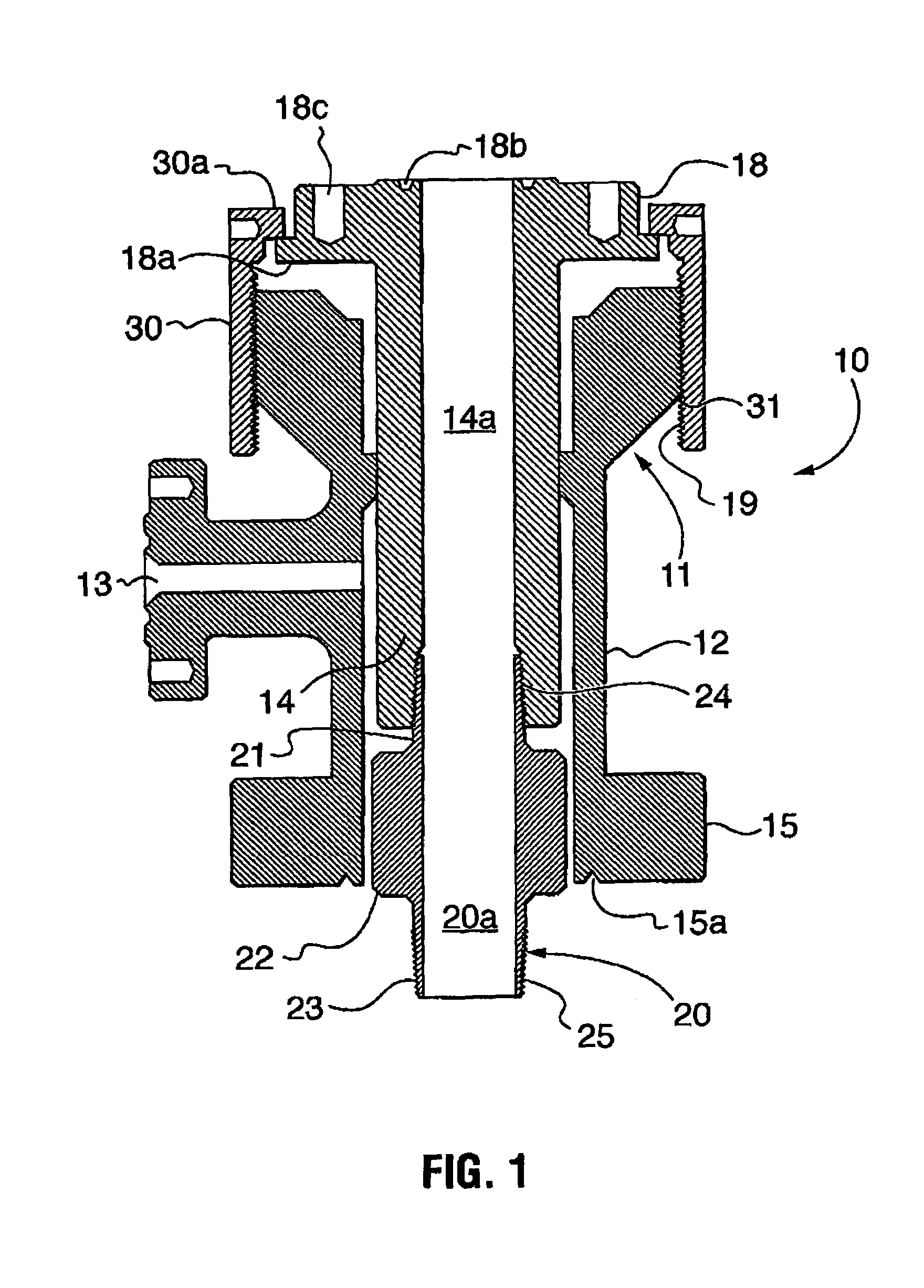

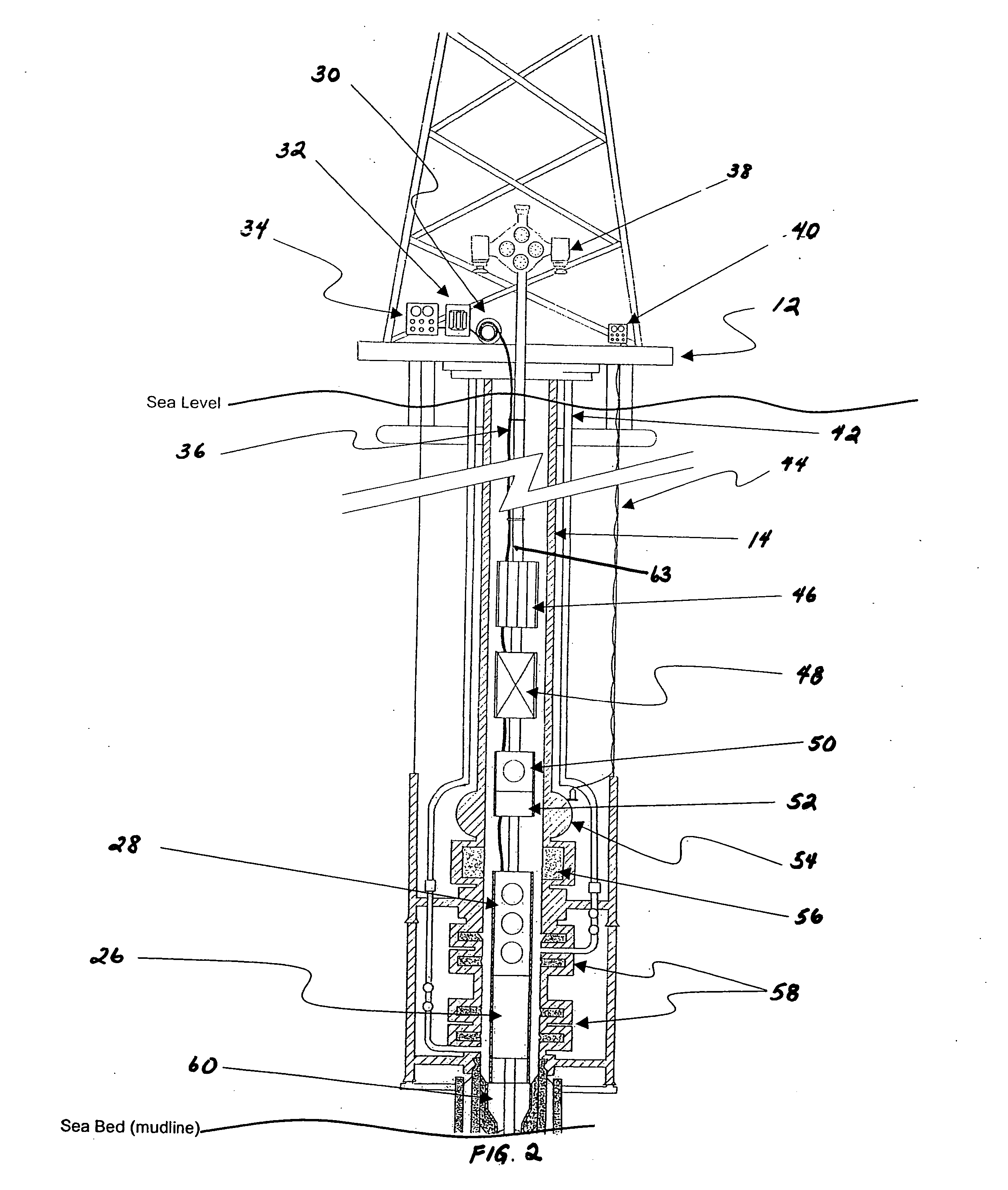

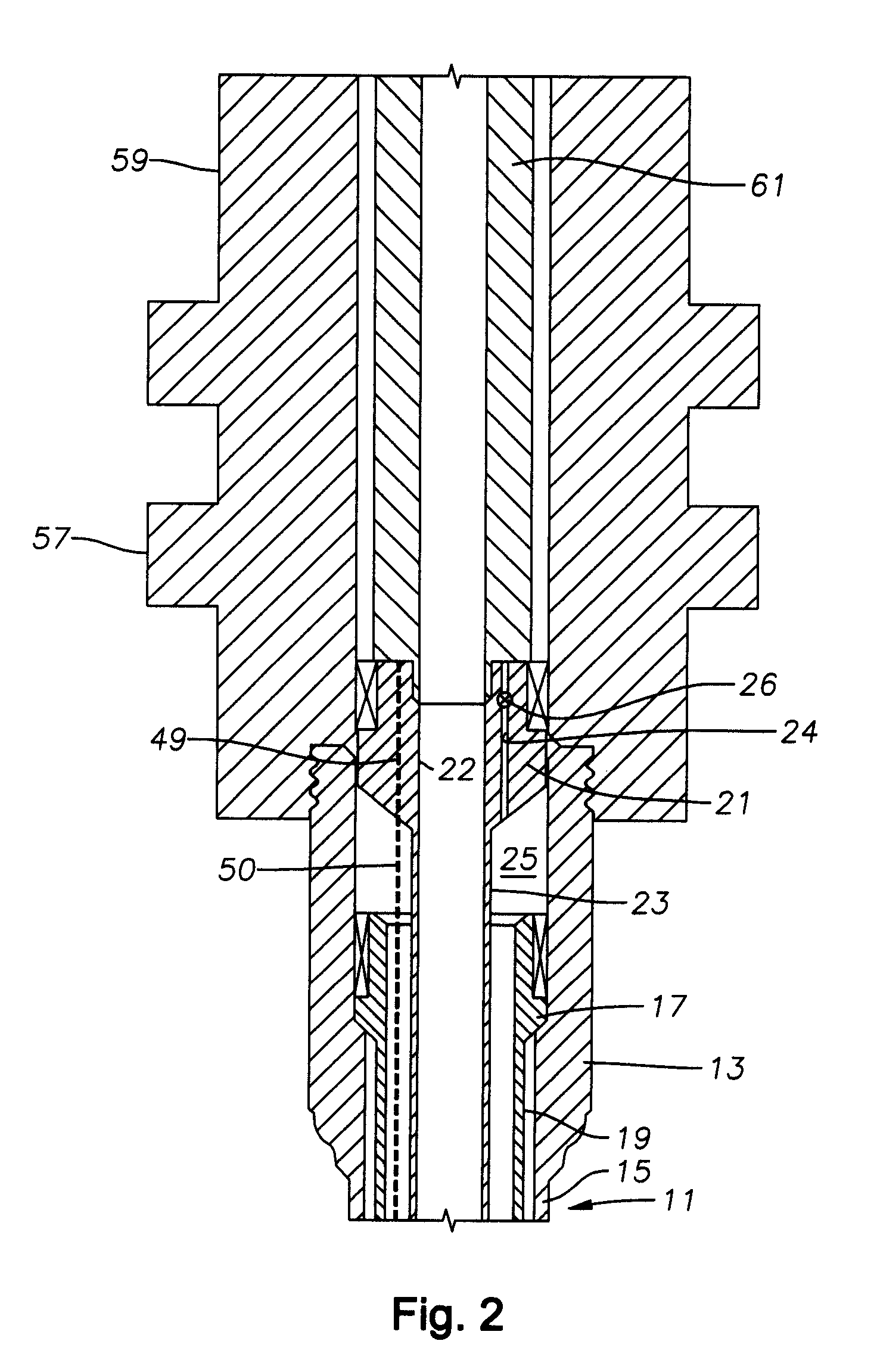

Flow completion apparatus

InactiveUS7025132B2Shorten the timeLow costOperating means/releasing devices for valvesDrilling rodsTubing hangerEngineering

A flow completion apparatus comprises a wellhead housing installed at an upper end of a well bore and a tubing spool connected over the wellhead housing. The tubing spool includes a central bore extending axially therethrough, a production outlet communicating with the central bore and an annulus passageway communicating with the tubing annulus. A tubing hanger is supported in the central bore and includes a production bore extending axially therethrough and a production passageway communicating between the production bore and the production outlet. The tubing spool comprises a workover passageway extending between the annulus passageway and a portion of the central bore located below the top of the tubing hanger. Furthermore, the tubing hanger comprises an annulus bore extending between the workover passageway and the top of the tubing hanger.

Owner:FMC TECH INC

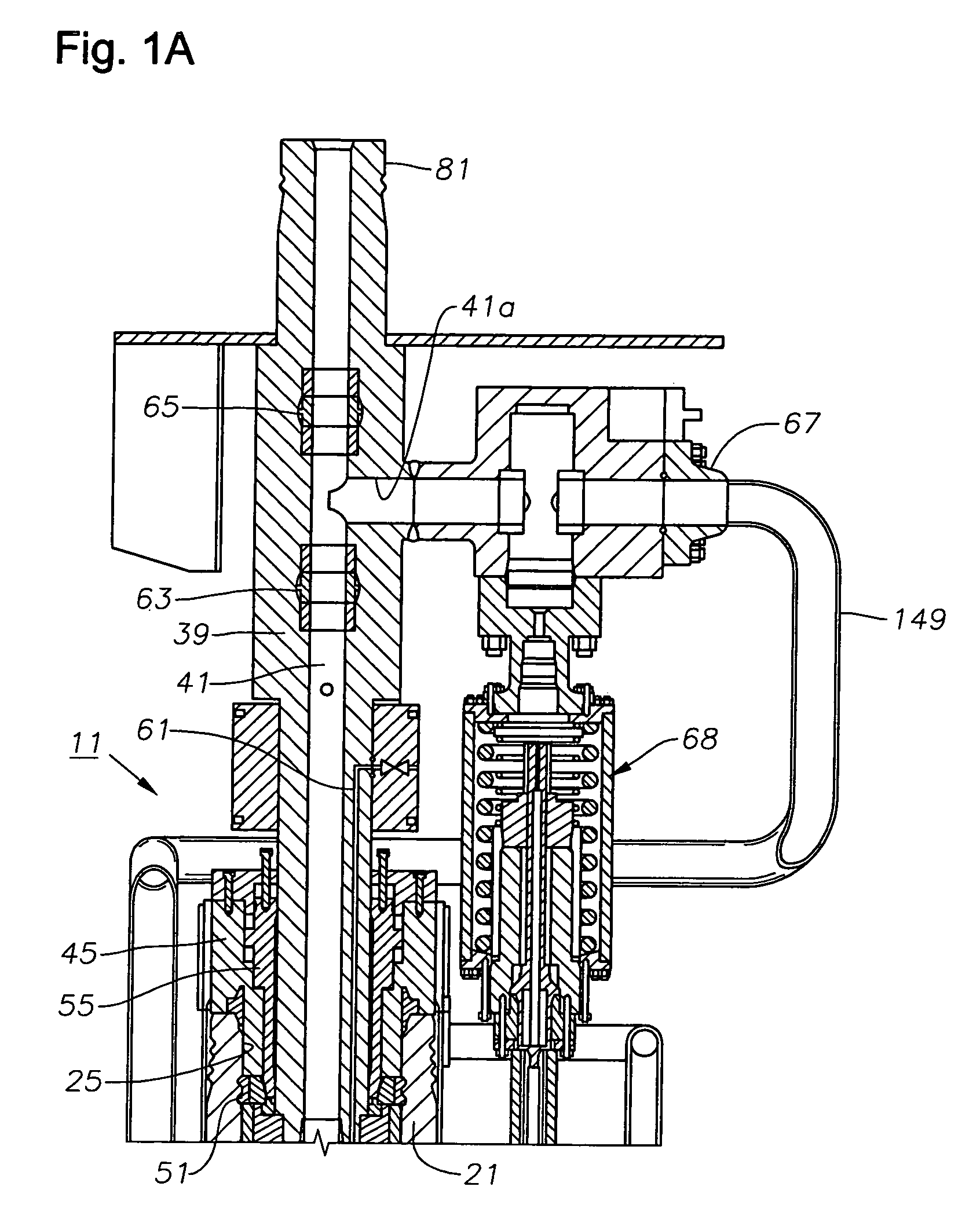

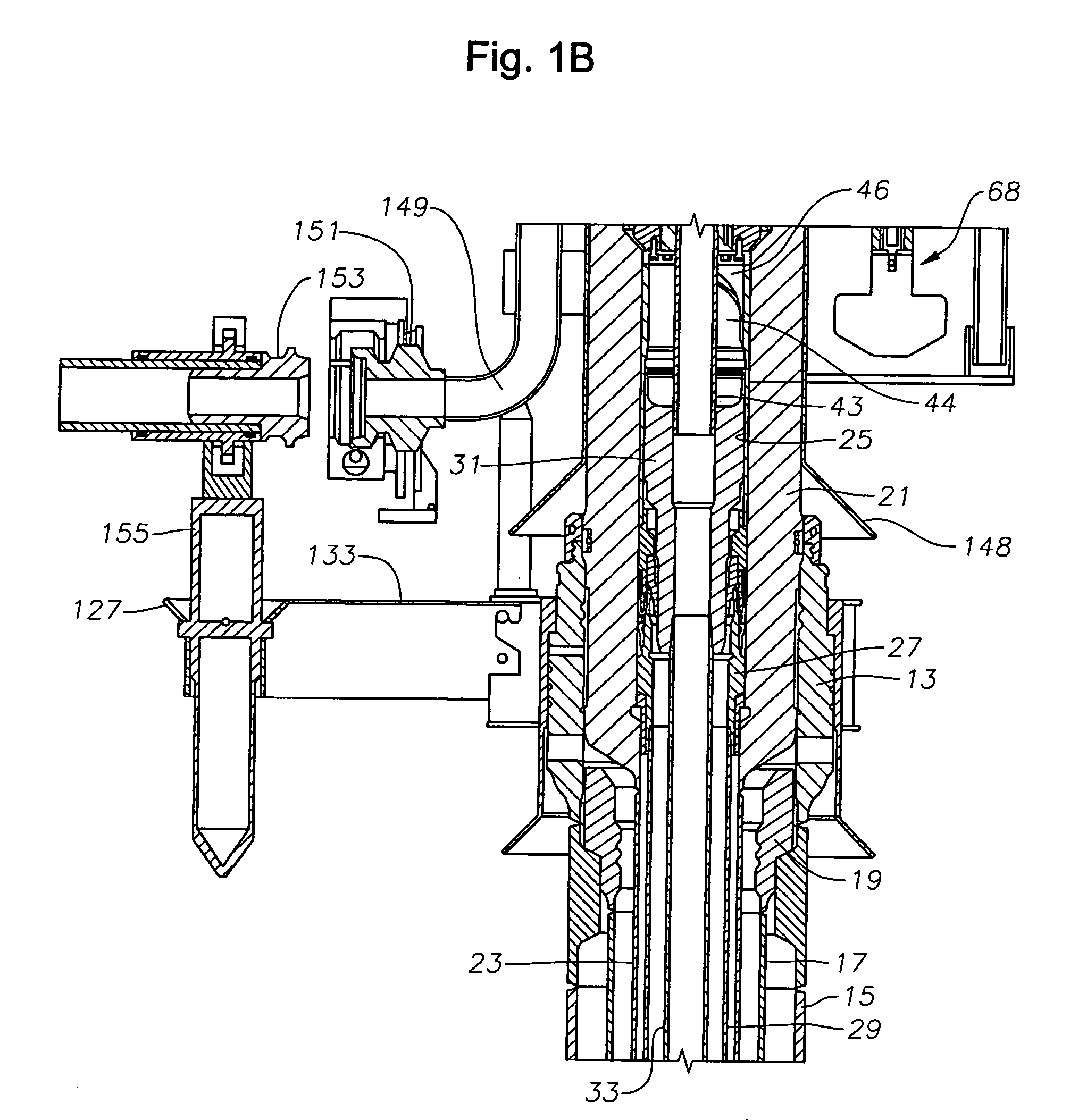

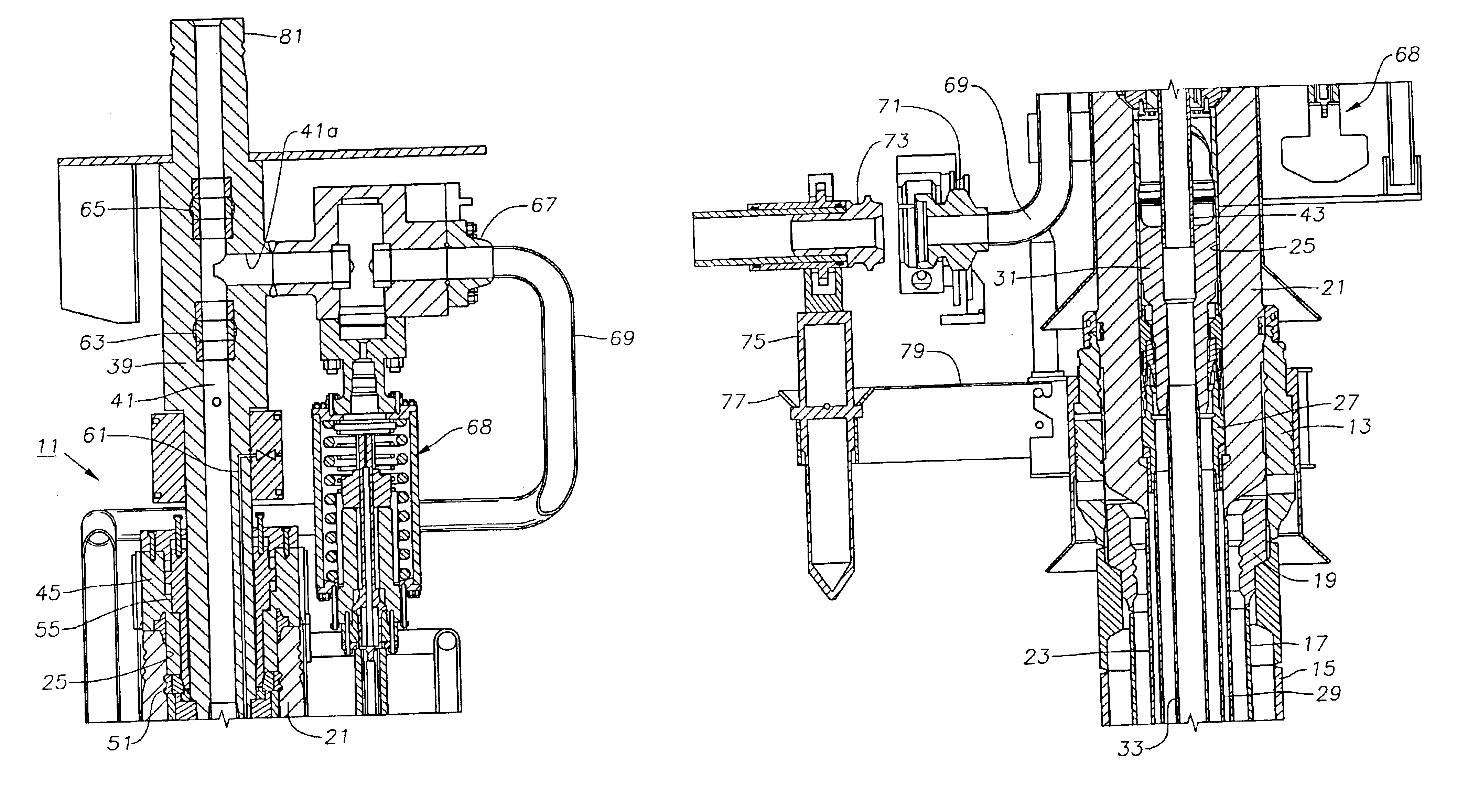

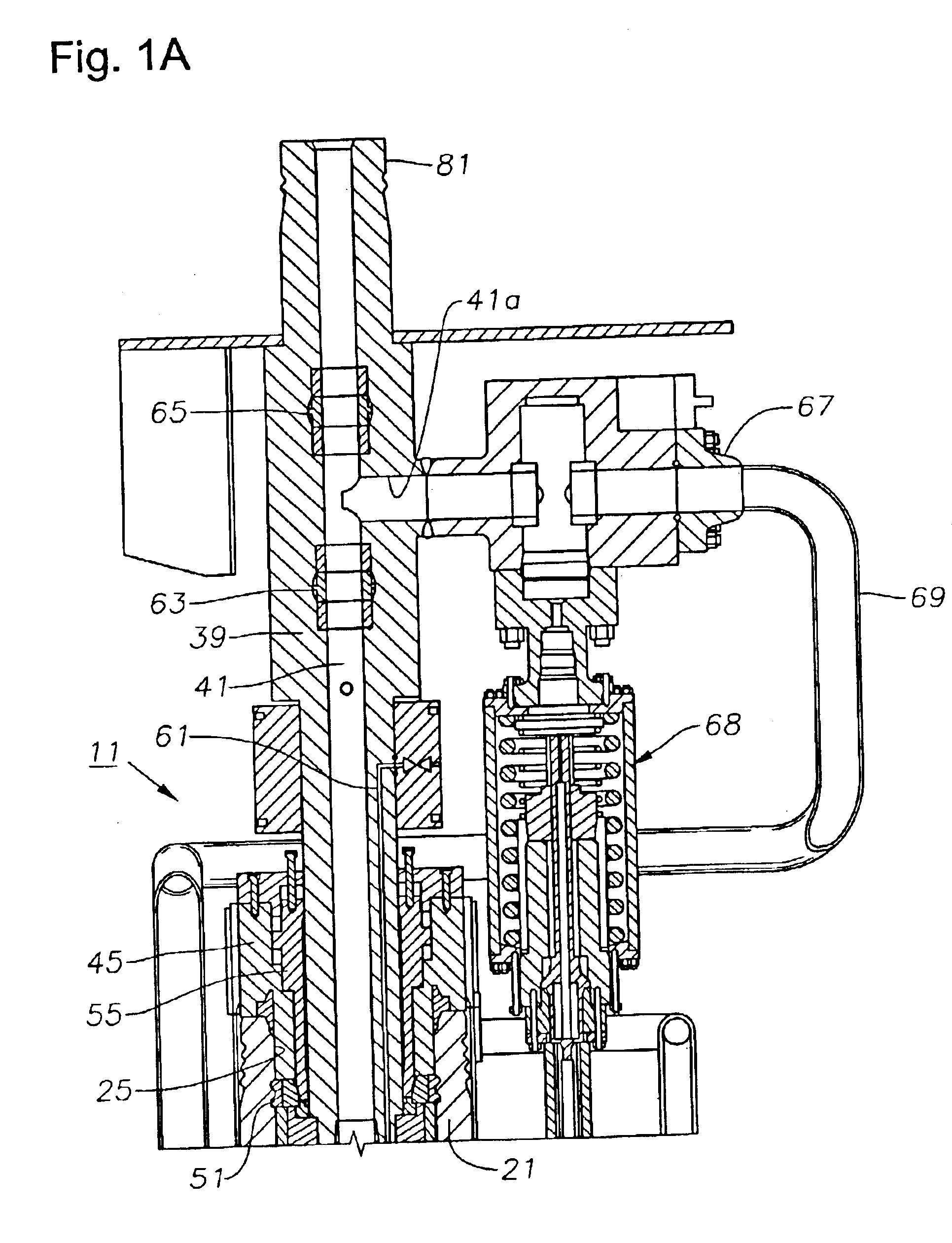

Universal tubing hanger suspension assembly and well completion system and method of using same

A tubing hanger suspension assembly for an oil and gas well completion system and a method of installing same. The tubing hanger suspension assembly includes a tubing hanger housing which is positioned in the wellhead housing. The tubing hanger assembly includes a sealing and lockdown mechanism capable of providing sealing and load support of the production tubing in the production casing string. A stab sub assembly connected to the upper end of the tubing hanger suspension assembly and lower end of the Christmas tree assembly provides downhole hydraulic and electric functionality and annulus access to the production tubing.

Owner:DRIL QUIP +1

Method and apparatus for blow-out prevention in subsea drilling/completion systems

A system and method for subsea drilling / completion. The system comprises a high-pressure riser extending from a semi-submersible platform to a subsea wellhead. A landing string extends along the insider of the riser, and has a surface blowout preventer and at least one subsea blowout preventer attached thereto. A tubing hanger running tool is run from the platform toward the wellhead. In one embodiment, hydraulic control for various functions of the tubing hanger running tool is communicated either through the tubing string or through the riser. In another embodiment, hydraulic control lines for the tubing hanger running tool extend from the platform to the tubing hanger running tool through an umbilical line, which may either run through the tubing string, inside the riser but outside the tubing string, or outside and alongside the riser. In an embodiment where the umbilical line runs inside the riser, a protective structure is provided to prevent damage to the umbilical line in the event that the subsea blowout preventer is deployed.

Owner:DRIL QUIP

Metal-to-metal seal for bridging hanger or tieback connection

A method of completing a well having a casing hanger set in a subsea wellhead housing includes attaching a running tool to a tubular bridging hanger. A metal-to-metal inner seal is attached to a lower exterior portion of the bridging hanger and a metal-to-metal outer seal is located on an upper exterior portion of the bridging hanger. The assembly is lowered into the well and the lower exterior portion of the bridging hanger is inserted into the casing hanger. The inner seal is wedged between the casing hanger and the bridging hanger in response to weight of the running string. The running tool is actuated to set the outer seal between the upper exterior portion of the bridging hanger and the wellhead housing. Then, a tubing hanger is landed and sealed in the interior of the bridging hanger.

Owner:VETCO GRAY

Oil and gas well completion system and method of installation

A completion system, and a corresponding method, for completing a subsea well, where the well includes a wellhead and a tubing hanger disposed in the wellhead and supports a string of production tubing, allows for angular alignment-free assembly of the subsea well. The completion system includes a series of circumferential channels formed in a well completion device at a boundary between the tubing hanger and the well completion device. The circumferential channels provide complete circular fluid paths with respect to the tubing hanger and the well completion device. At least one supply bore is in communication with each circumferential channel and is and oriented to supply a fluid to the circumferential channel, and at least one drain bore in communication with each circumferential channel and is oriented to remove fluid from the circumferential channel. Finally a circumferential electrical connector couples the tubing hanger and the completion device. The circumferential channels and bores provide fluid services between the completion device and the tubing hanger and the electrical connector provides electrical services to the tubing hanger. The completion system allows the fluid and electrical services to be provided without requiring any angular alignment between the tubing hanger and the completion device.

Owner:DRIL QUIP

Single trip, tension set, metal-to-metal sealing, internal lockdown tubing hanger

A system, apparatus, and method to apply tension to completion tubing in a wellbore. The system, apparatus, and method comprises an inner and outer tubing hanger, with the string of tubing attached to the inner tubing hanger. A running tool lands the outer tubing hanger on a landing shoulder and continues to lower the inner tubing hanger into the wellbore until the lower end of the inner tubing hanger latches into a retaining device. The running tool then sets a seal which holds the outer tubing hanger in position and causes a ratcheting mechanism to move to an engaged position. The running tool then withdraws the inner tubing hanger a predetermined distance until the inner tubing hanger engages the ratcheting mechanism.

Owner:VETCO GRAY

Externally activated seal system for wellhead

ActiveUS7128143B2Minimized in sizeSimple procedureDrilling rodsFluid removalTubing hangerCombined use

A method and apparatus for a seal assembly for a unitized wellhead system for land or platform applications utilizes a friction grip technology to create maintainable metal-to-metal seals with finely-controlled contact stresses, lock-down casing and tubing hangers, support test loads to minimize the size of landing shoulders required, and to rotationally lock casing hangers to provide simplified running procedures. The system can be used in combination with a friction grip clamping assembly to greatly streamline the wellhead design.

Owner:PLEXUS HOLDINGS PLC

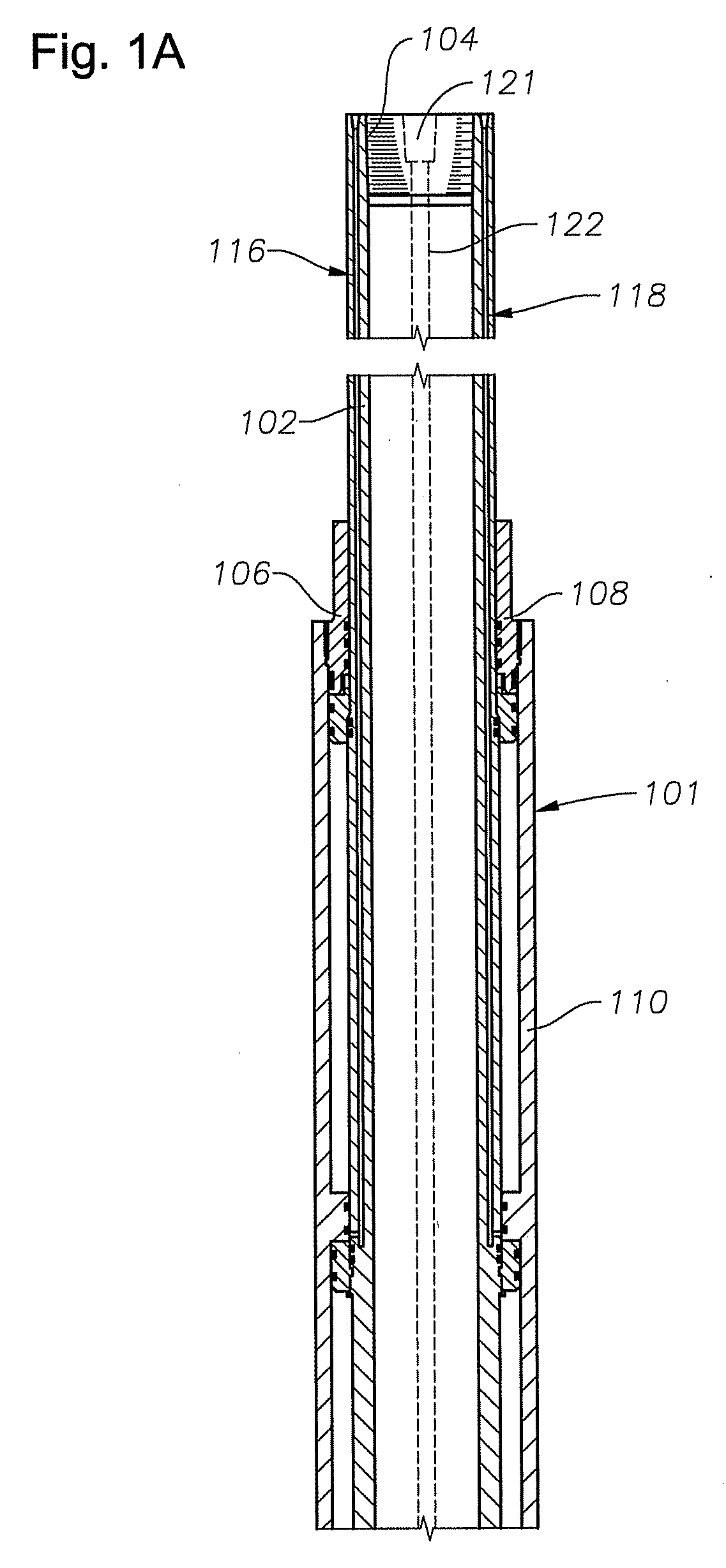

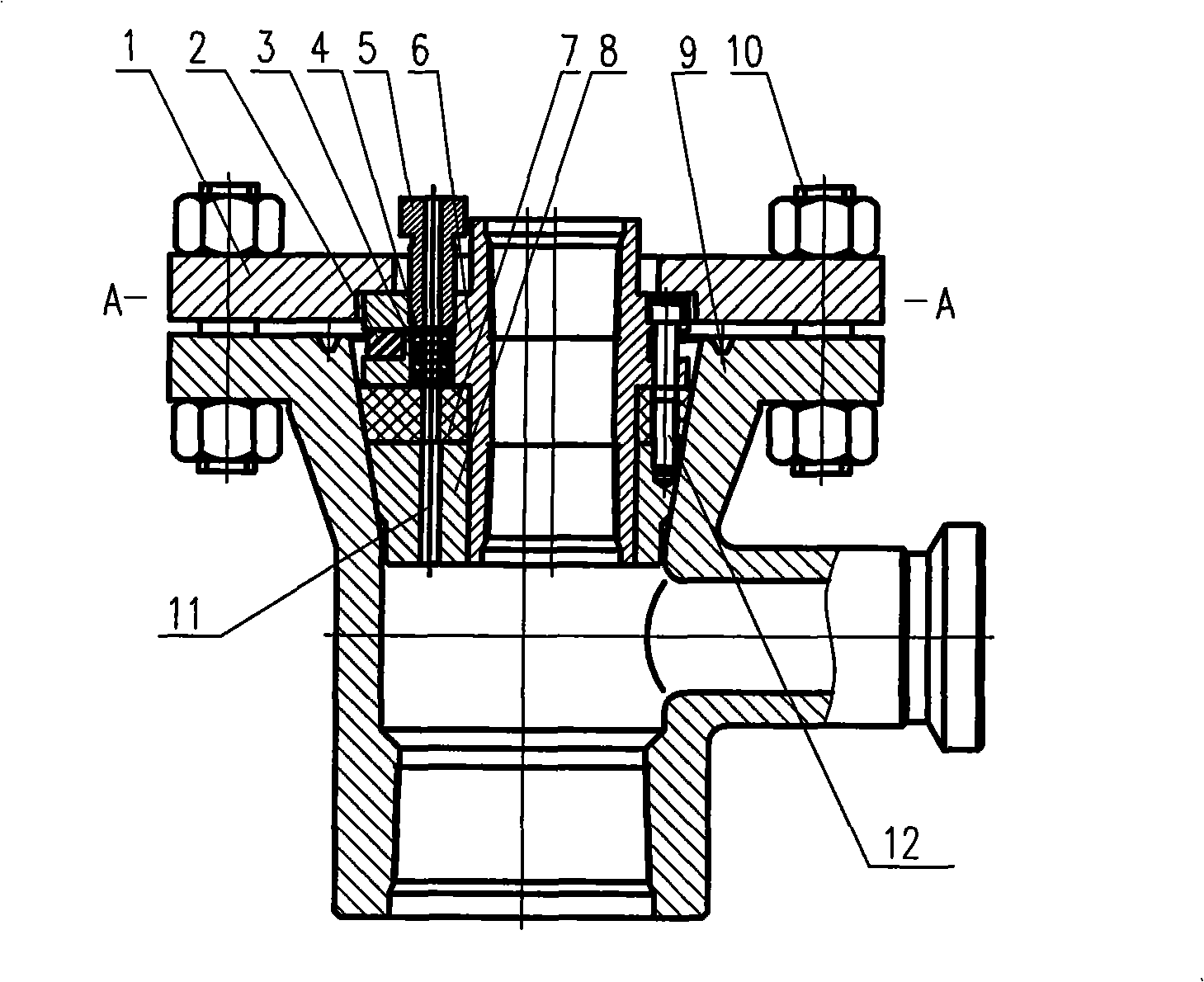

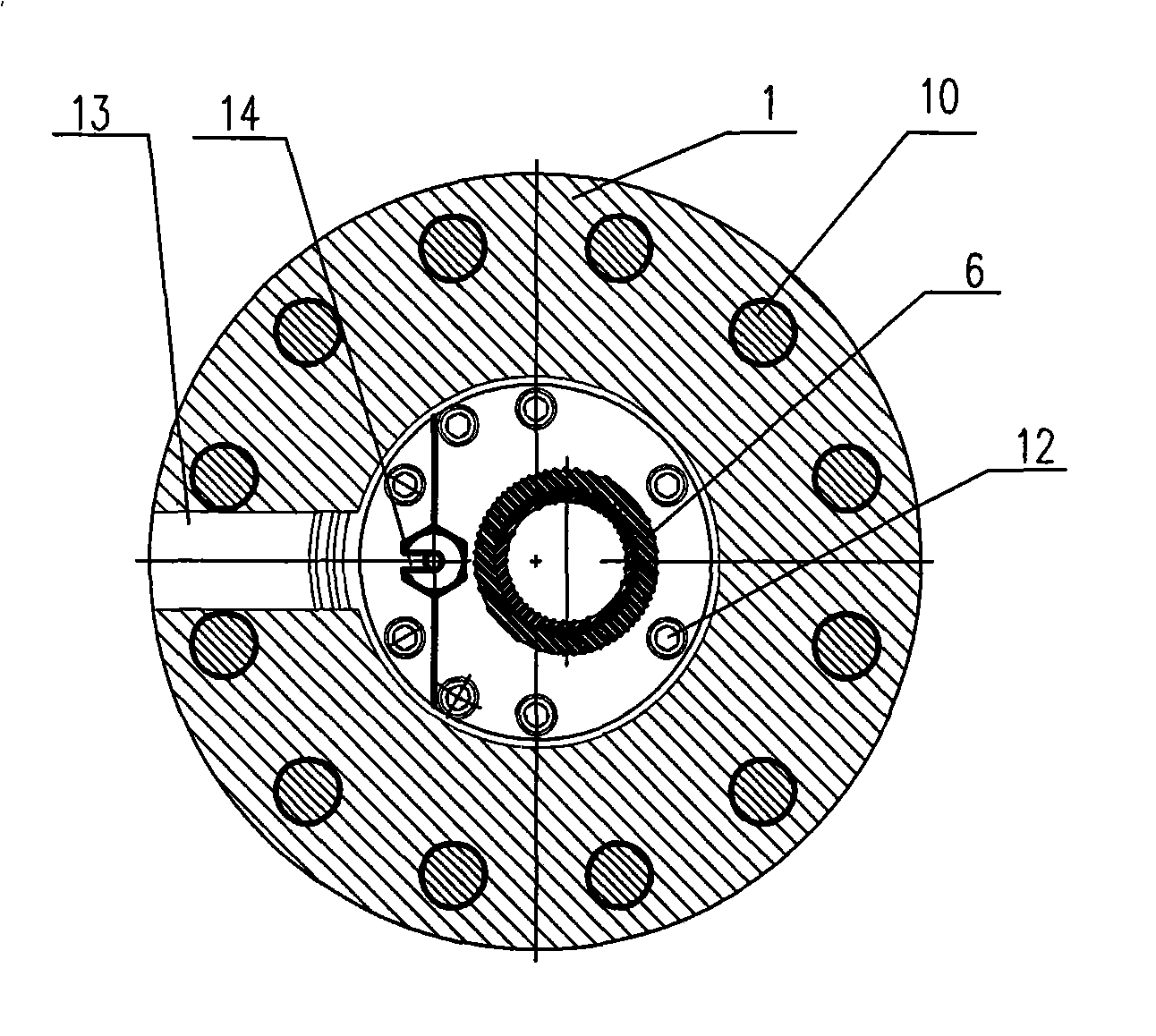

Preset production fluid section plane test method of mechanical mining horizontal well and special shaft mouth test apparatus

ActiveCN101403291AEasy to get up and downSo as not to damageSurveySealing/packingSection planeTubing hanger

The invention relates to a mechanical recovery horizontal well preset produced fluid profile testing method and a special wellhead testing device thereof, mainly aiming at solving the problem of the downhole testing of a mechanical recovery horizontal well. The invention is characterized in that: the special wellhead testing device comprises an eccentric type tubing hanger body connected with a tubing string, wherein, the side wall of the tubing hanger body is divided into a body and splits which are completely matched with each other, and the splits are fixed on a locking arm which is fixed on the body though bolts; and a corresponding matched cable penetrating a channel is arranged at the splitting seam of the body and the splits, the channel is internally provided with a cable gasket, a spacer and a pressing cap. By being matched with a special wellhead support, under the condition that a testing cable and a tester are pre-arranged in the horizontal well to test a target layer, an oil pipe does not touch the cable during the up and down process of the oil pipe. The method and the special wellhead testing device can realize the produced fluid profile testing of the mechanical recovery horizontal well, and ensure the accuracy of normal testing and data of the mechanical recovery horizontal well with simple and reliable operation method.

Owner:DAQING OILFIELD CO LTD +1

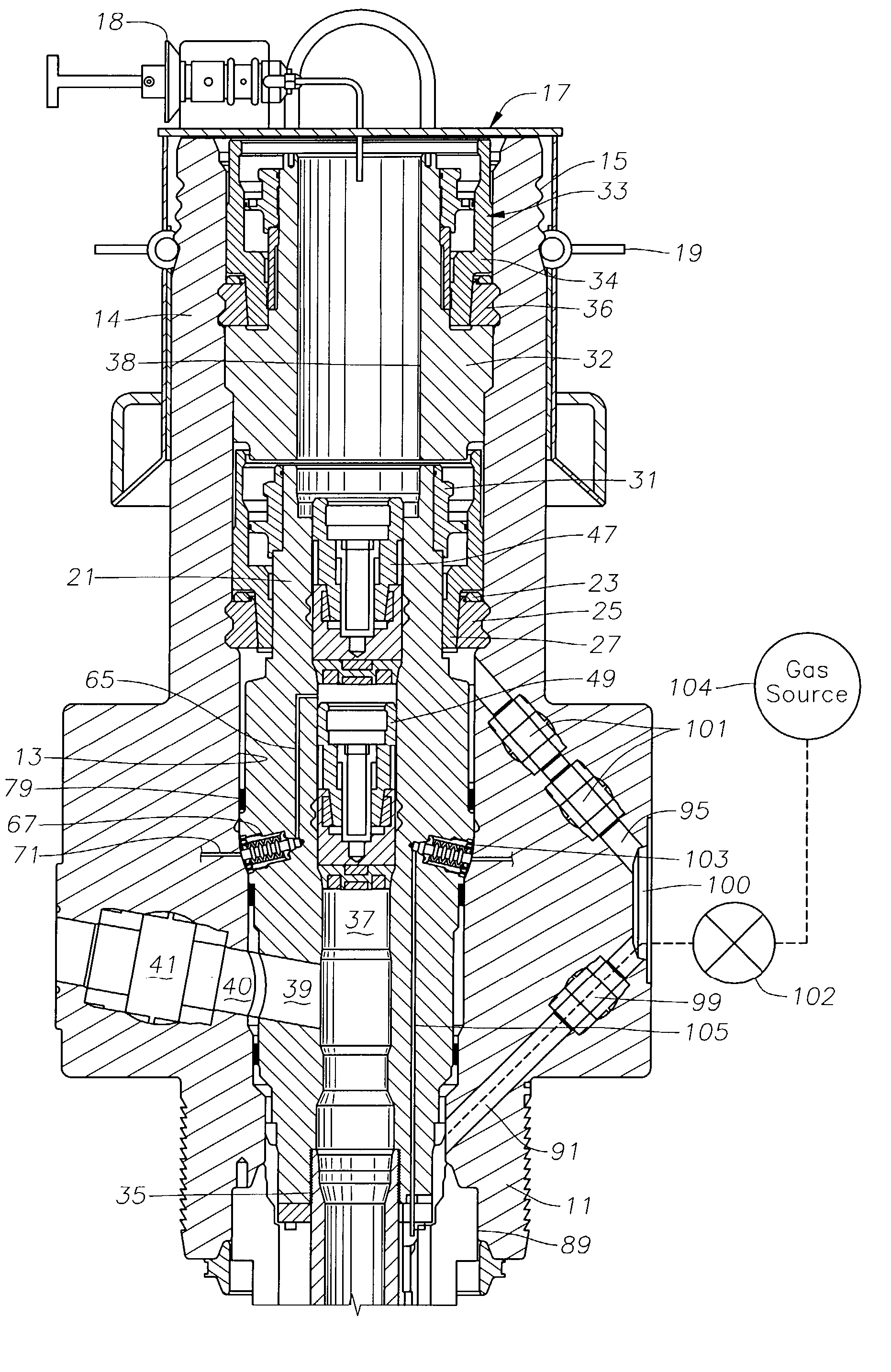

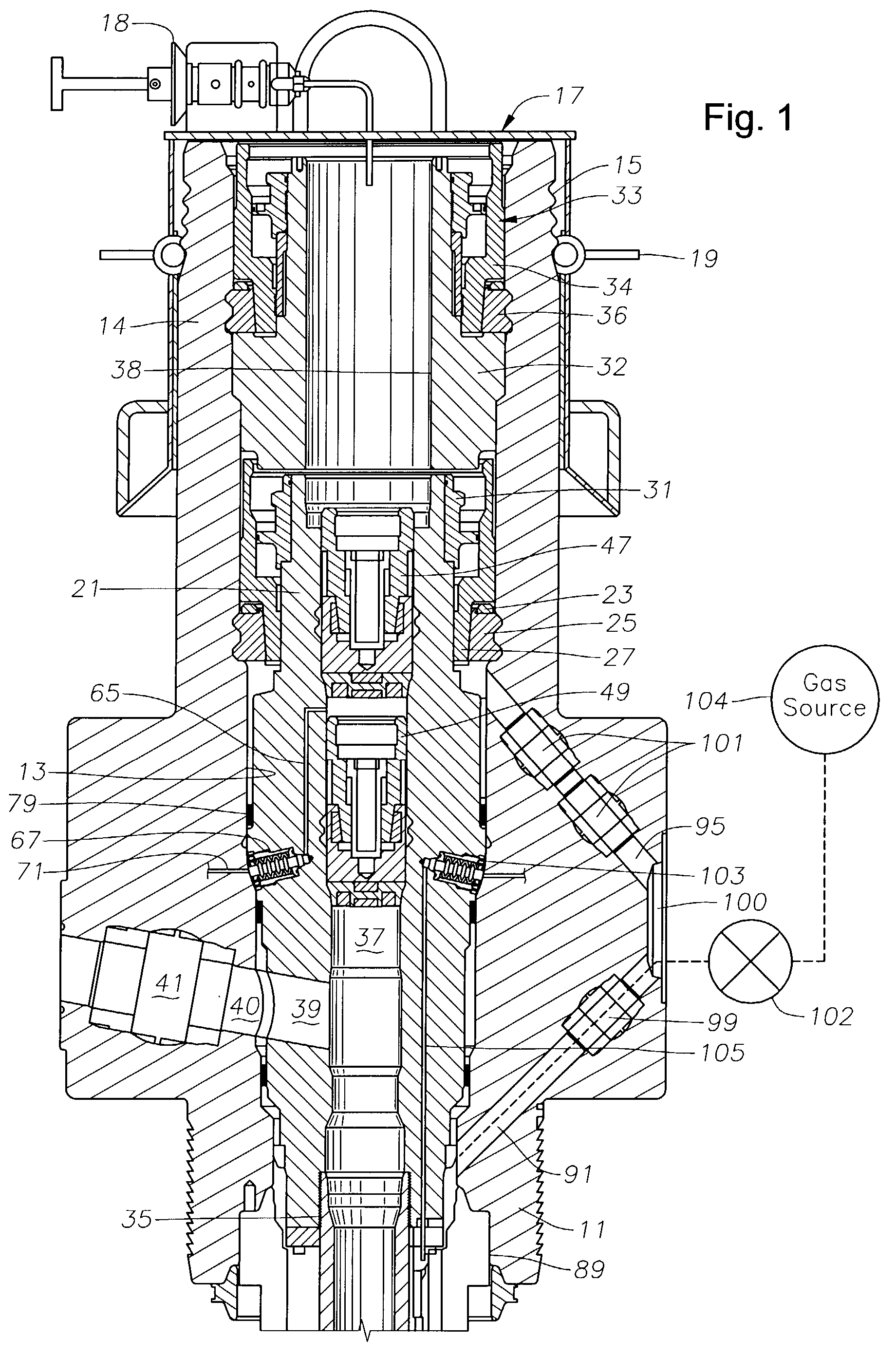

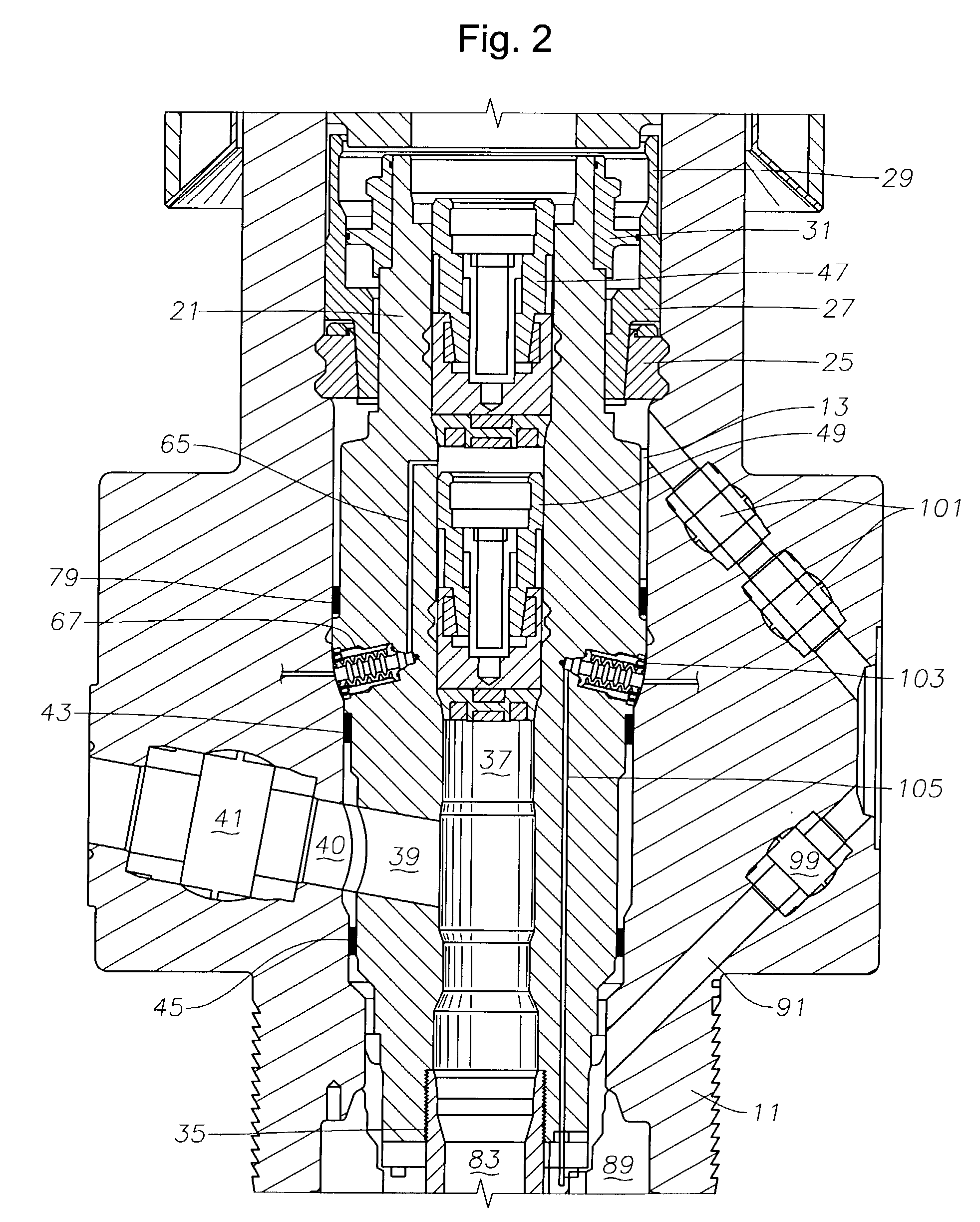

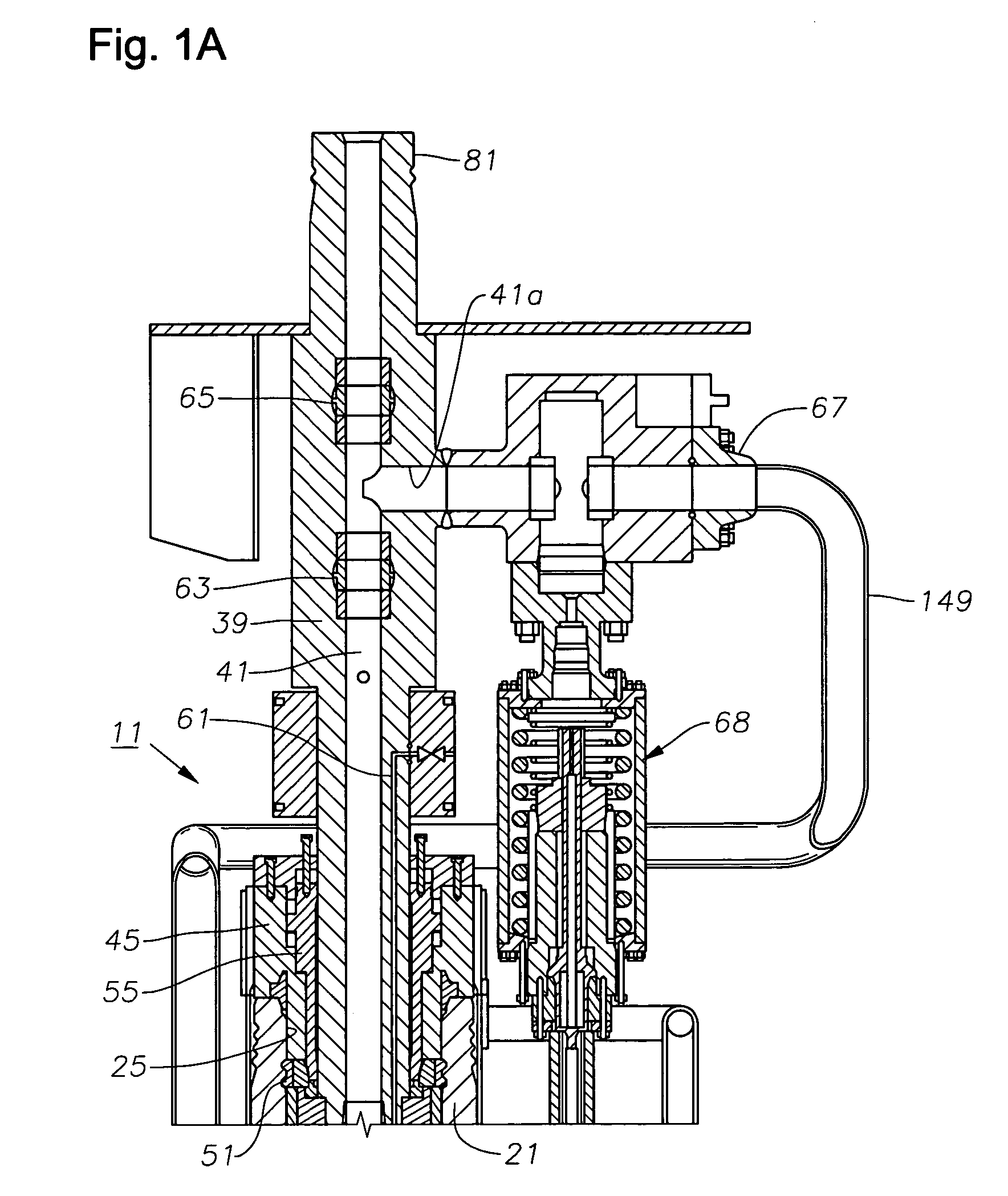

Central circulation completion system

A completion system comprises a christmas tree (10) mounted on a wellhead housing (11), a tubing hanger (12) landed in the tree or wellhead housing, the wellhead housing (11) being mounted on a casing string (100) and a tubing string (14) being suspended from the tubing hanger within the casing string; wherein, in use, the annulus defined between the tubing (14) and the casing (100) serves as a production bore. A second tubing string (98) is expanded into sealing engagement with the casing string (100) over at least a portion of their lengths. The annulus normally used to provide well service functions is thus eliminated. Well servicing is instead provided via the tubing string (14), which may be coiled tubing.

Owner:FMC TECH INC

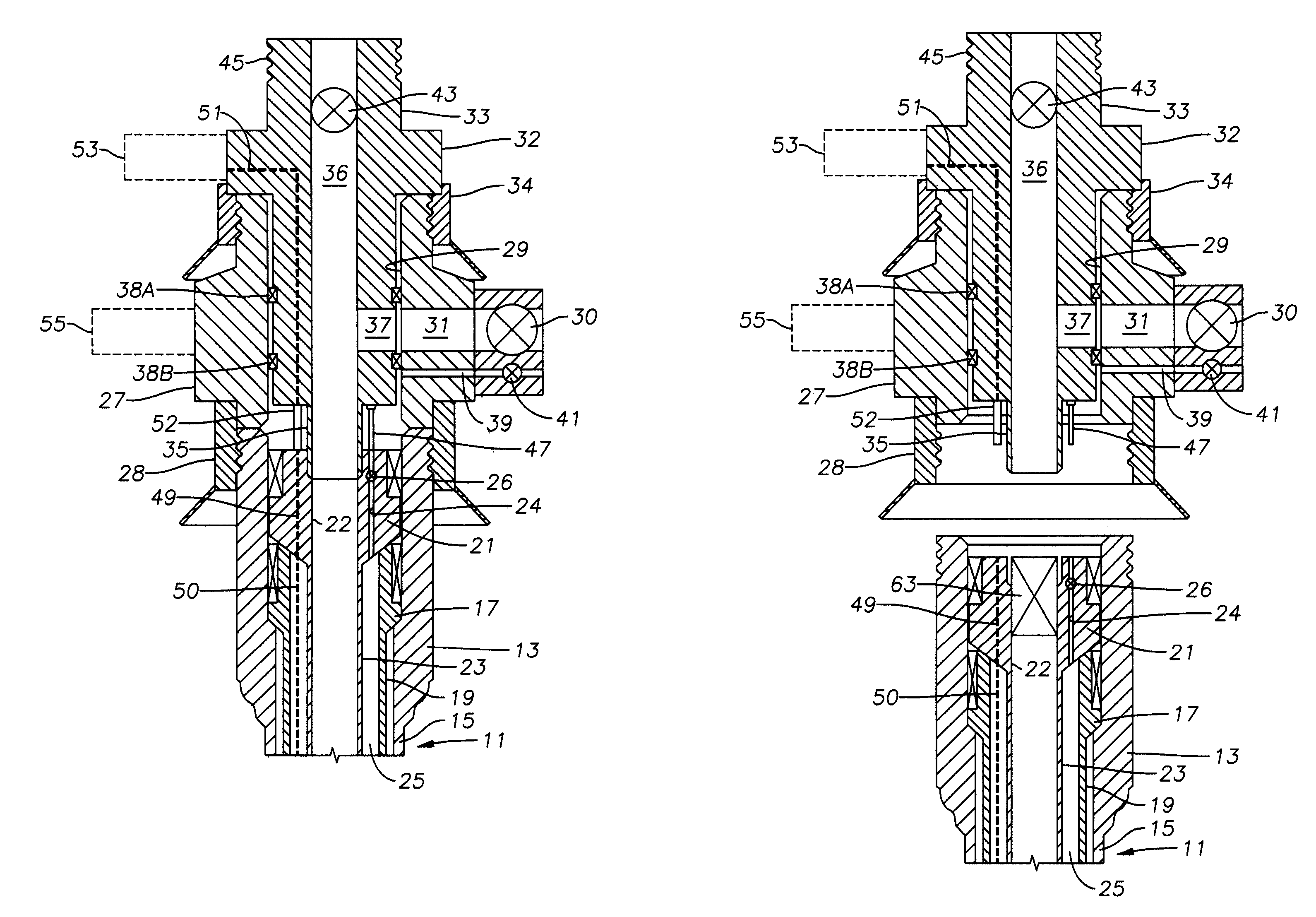

Underwater cable connector

ActiveCN102593640ASimple structureEasy to operateCoupling contact membersTwo-part coupling devicesTubing hangerEngineering

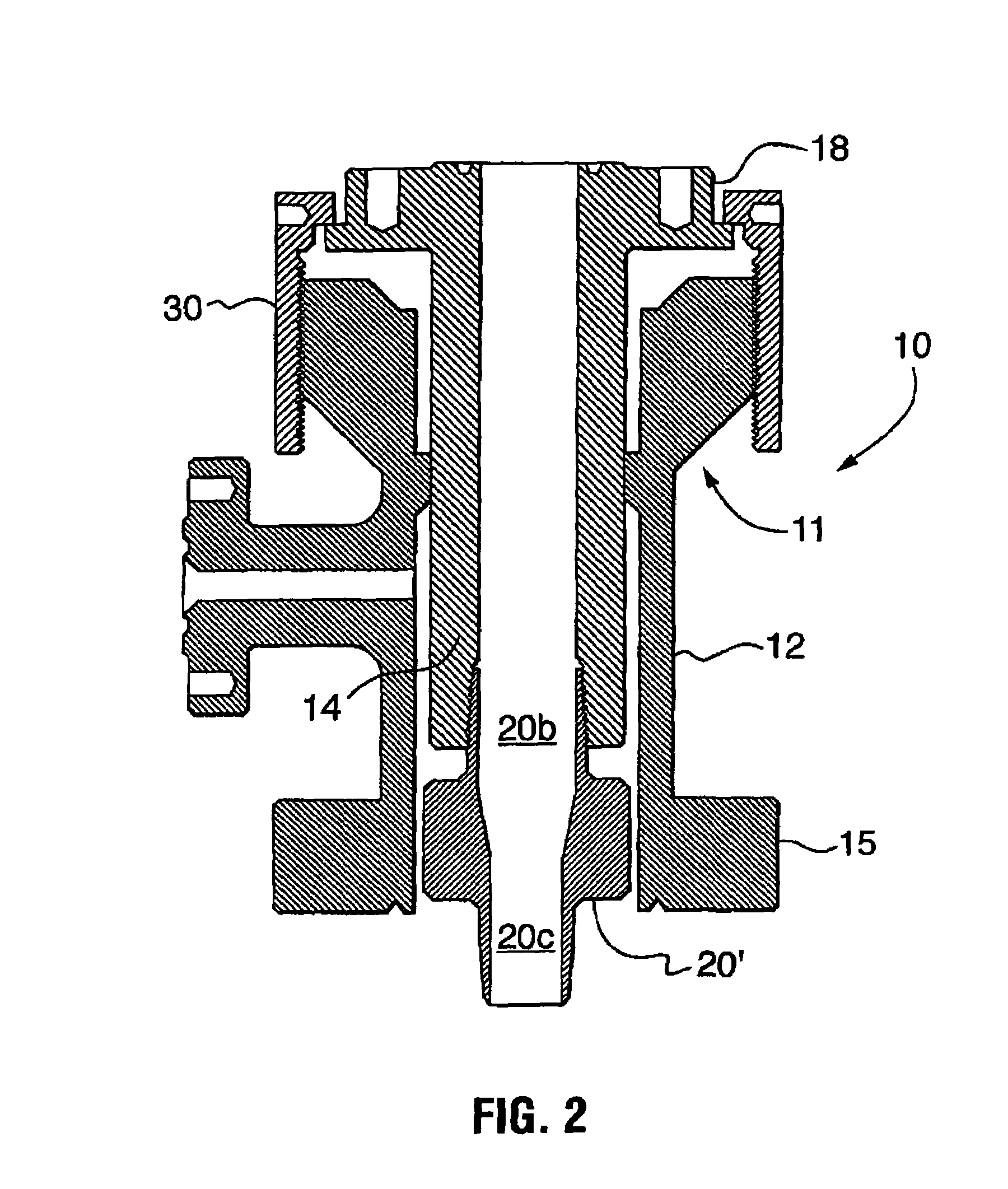

The invention relates to an underwater cable connector. An insertion head part is installed in an oil tube suspender, a piston A is arranged in an insertion head chamber in the oil tube suspender, the axle center of the piston A is sleeved on an insertion head conducting ring, two ends of the insertion head conducting ring are respectively provided with insertion head non-conductive parts, a spring A is sleeved at the periphery of a rear insertion head non-conductive part, and a cable A is connected with the insertion head conducting ring; a socket part is fixed on an underwater Christmas tree body and in a socket chamber of a socket shell, a socket body is sleeved in an internal guiding sleeve of the socket shell, a guiding column is arranged at the axle center of the socket body, and a socket conducting ring is arranged on the contact surface of the guiding column and the socket body; a spring B is arranged in a spring chamber of the socket body, and the bottom of the spring chamber is connected with a hydraulic pressure compensated cavity; a compensation liquid flow channel is additionally formed in the socket body; the socket conducting ring is connected with outside by the cable B; and the inner cavity of the compensated cavity shell is sequentially provided with the hydraulic pressure compensated cavity, and the piston B and a second spring chamber. The device realizes the underwater reliable insertion and pulling connection.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

Retrievable Tubing Hanger Installed Below Tree

A subsea wellhead assembly has a tubing hanger landed in a wellhead housing. A spool lands on the wellhead housing and has a bore with a laterally extending production flow outlet. A tree cap having an axially extending flow passage and a laterally extending production flow outlet lands within the bore of the spool. Upper and lower seals on the tree cap seal between the tree cap and the bore of the spool above and below the production flow outlet of the spool. An isolation tube on a lower end of the tree cap sealingly engages the production flow passage of the tubing hanger. The tree cap may be ran with the spool as an assembly and retrieved from the spool for workover operations.

Owner:VETCO GRAY

Retrievable tubing hanger installed below tree

Owner:VETCO GRAY

Metal-to-metal seal for bridging hanger or tieback connection

A method of completing a well having a casing hanger set in a subsea wellhead housing includes attaching a running tool to a tubular bridging hanger. A metal-to-metal inner seal is attached to a lower exterior portion of the bridging hanger and a metal-to-metal outer seal is located on an upper exterior portion of the bridging hanger. The assembly is lowered into the well and the lower exterior portion of the bridging hanger is inserted into the casing hanger. The inner seal is wedged between the casing hanger and the bridging hanger in response to weight of the running string. The running tool is actuated to set the outer seal between the upper exterior portion of the bridging hanger and the wellhead housing. Then, a tubing hanger is landed and sealed in the interior of the bridging hanger.

Owner:VETCO GRAY

Combined Tree Stab and Control Interface

A subsea wellhead assembly provided over a wellbore, the assembly having a wellhead housing, a tubing hanger in the housing, a production tree on the wellhead housing above the tubing hanger, and a control circuit that passes axially downward from the production tree and through the tubing hanger. A tree stab assembly may be included that is set between the tubing hanger and production tree. The wellhead assembly can also include a casing hanger landed in the housing, casing attached to the casing hanger, and tubing attached to the tubing hanger.

Owner:VETCO GRAY

Tubing annulus communication for vertical flow subsea well

A subsea wellhead assembly allows communication between a production tubing annulus and a conduit in fluid communication with a platform above. The wellhead assembly has a tubing hanger that is held relative to a tubular wellhead member of a subsea well by a tubing hanger support. A string of tubing extends from the tubing hanger into the well, defining an annulus around the tubing. The conduit communicates with the tubing annulus through a tubing annulus passage. The tubing annulus passage has a portion extending through the tubing hanger support. The wellhead member supports a valve block located between the tubing hanger support and the riser. The tubing annulus passage has another portion that registers with the portion of the passage in the tubing hanger support. The conduit stabs into valve block portion of the tubing annulus passage when the riser connects to the upper end of the valve block.

Owner:VETCO GRAY

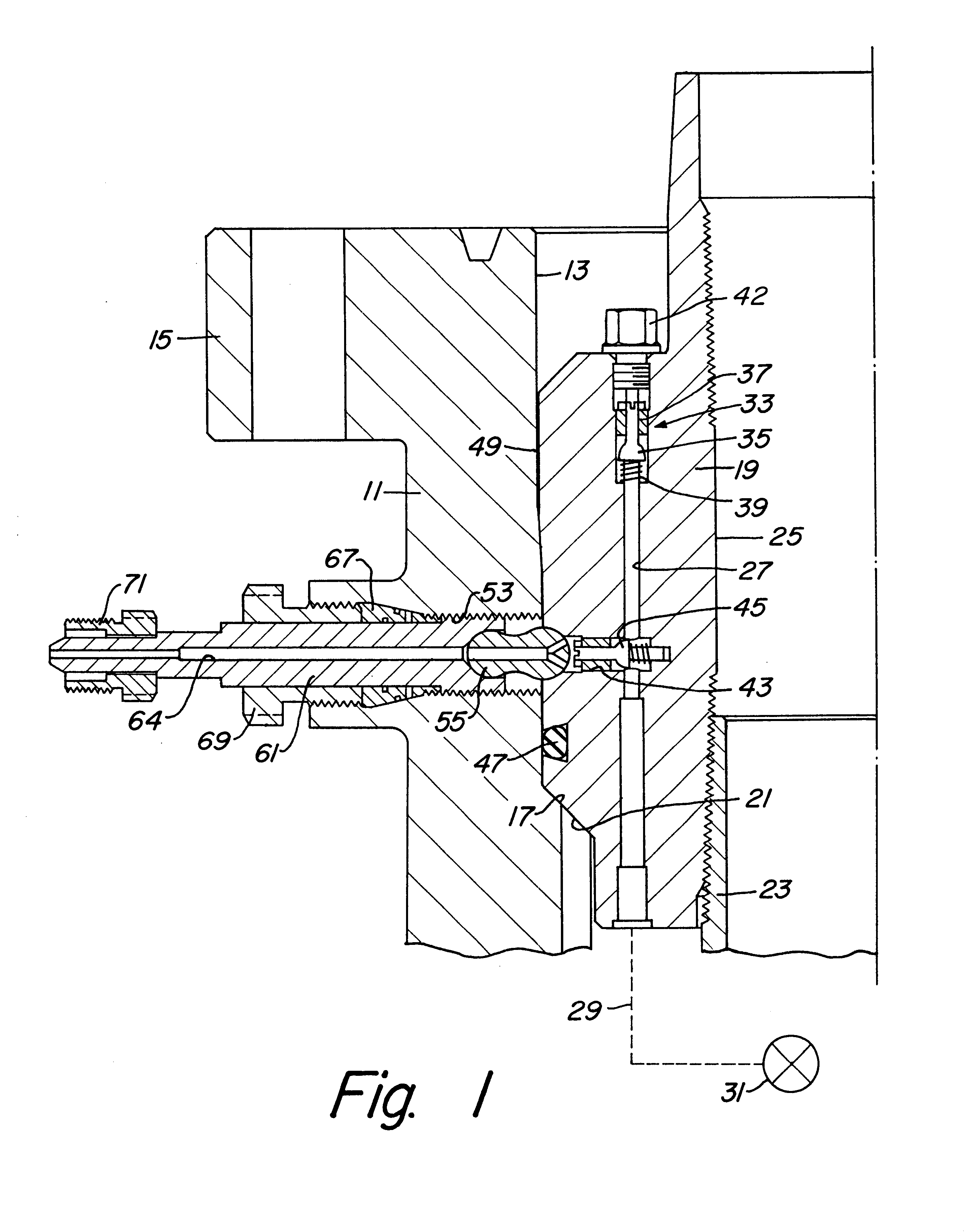

Tubing head control and pressure monitor device

A tubing hanger and wellhead have features for controlling and monitoring fluid pressure to downhole equipment. The tubing hanger has an internal vertical passage. A hydraulic line connects to the lower end of the vertical passage and runs downhole. The vertical passage communicates with a lateral passage through the outer wall of the hanger. A lateral passage through the wellhead housing is generally aligned with the lateral passage of the hanger when the hanger is installed in the wellhead housing. A pressure shaft is installed in the wellhead passage and has a passage therethrough. A seal member having spherical ends is inserted between spherical receptacles located on the inner end of the pressure shaft passage and on the outer end of the lateral passage of the hanger. The seal member has an internal passage having a flared inner end. The seal member is allowed to rotate to sealingly connect the lateral passages if some misalignment of the lateral passages exists. A gage or other pressure monitoring device or a source of hydraulic pressure can be attached to the outer end of the pressure shaft to communicate with the shaft passage.

Owner:ABB VETCOGRAY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com