Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6055results about "Pipe laying and repair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

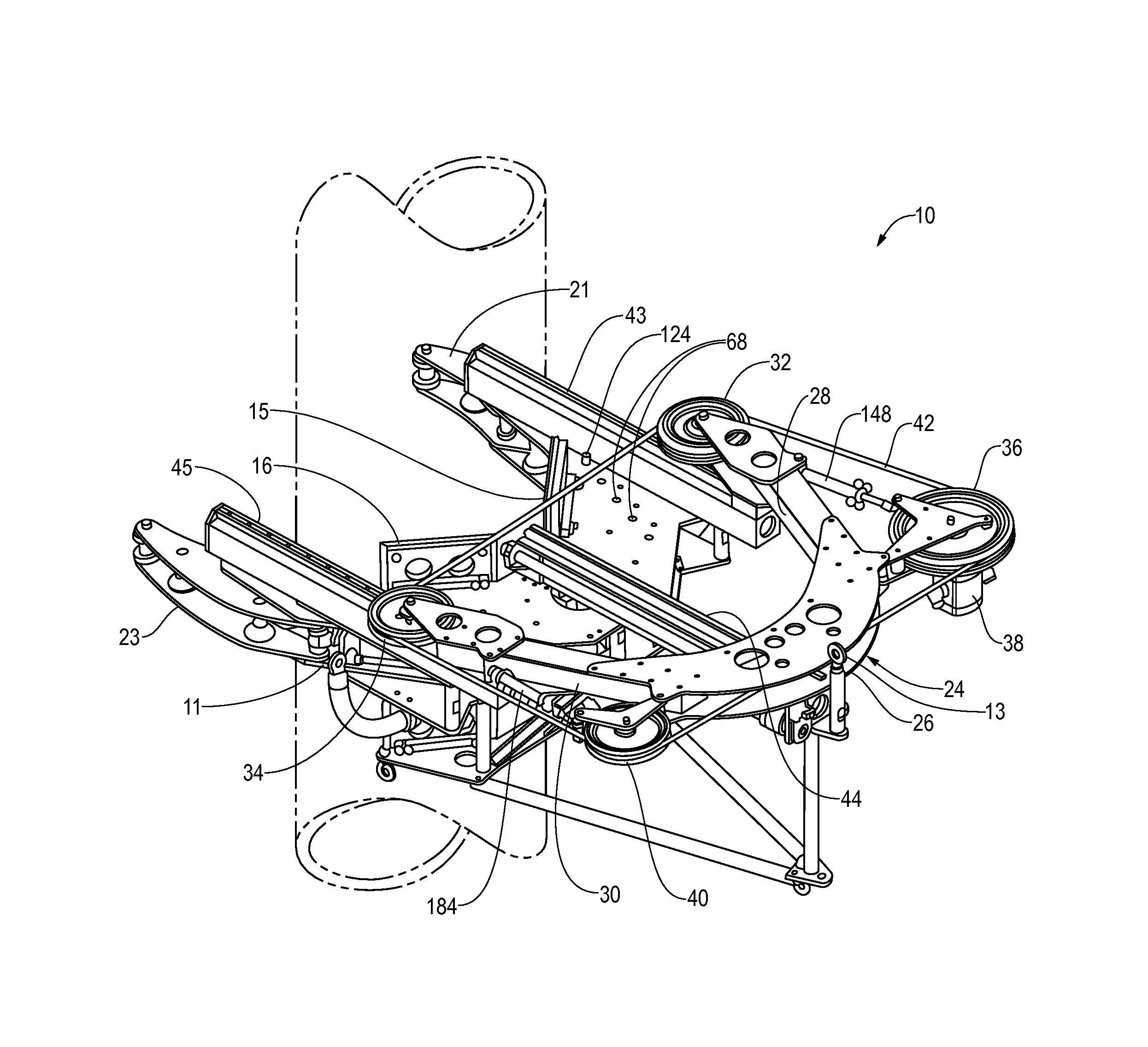

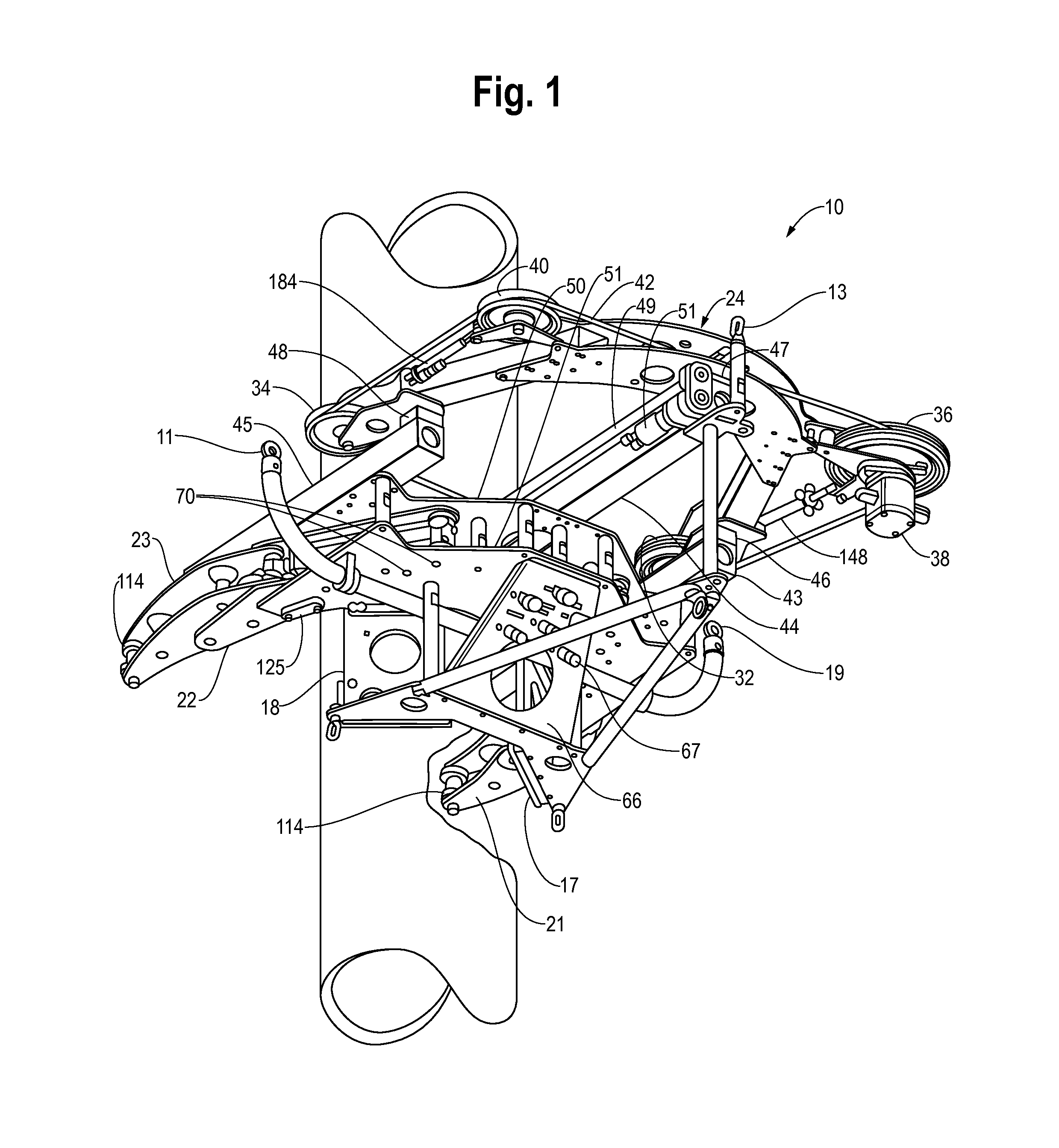

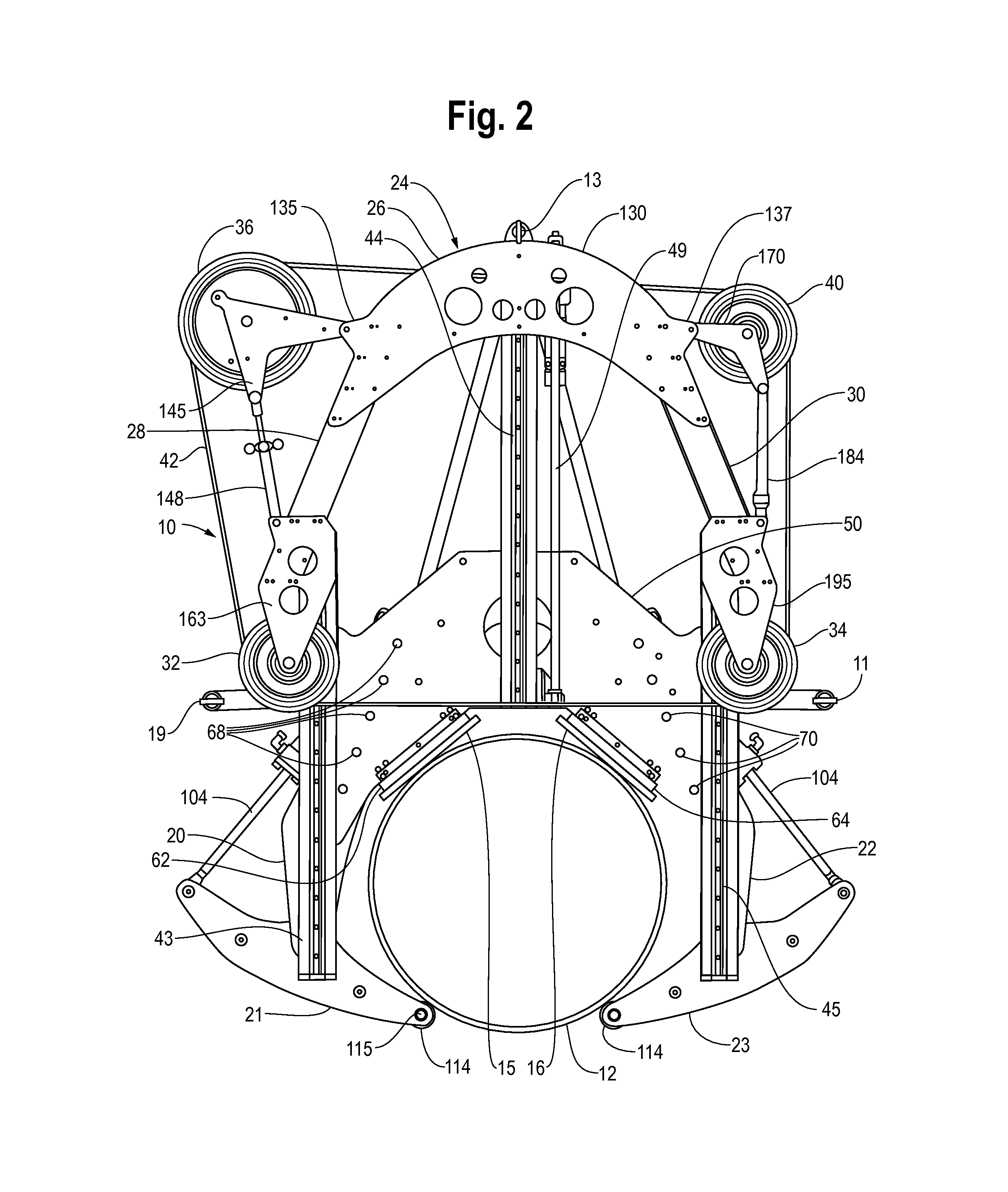

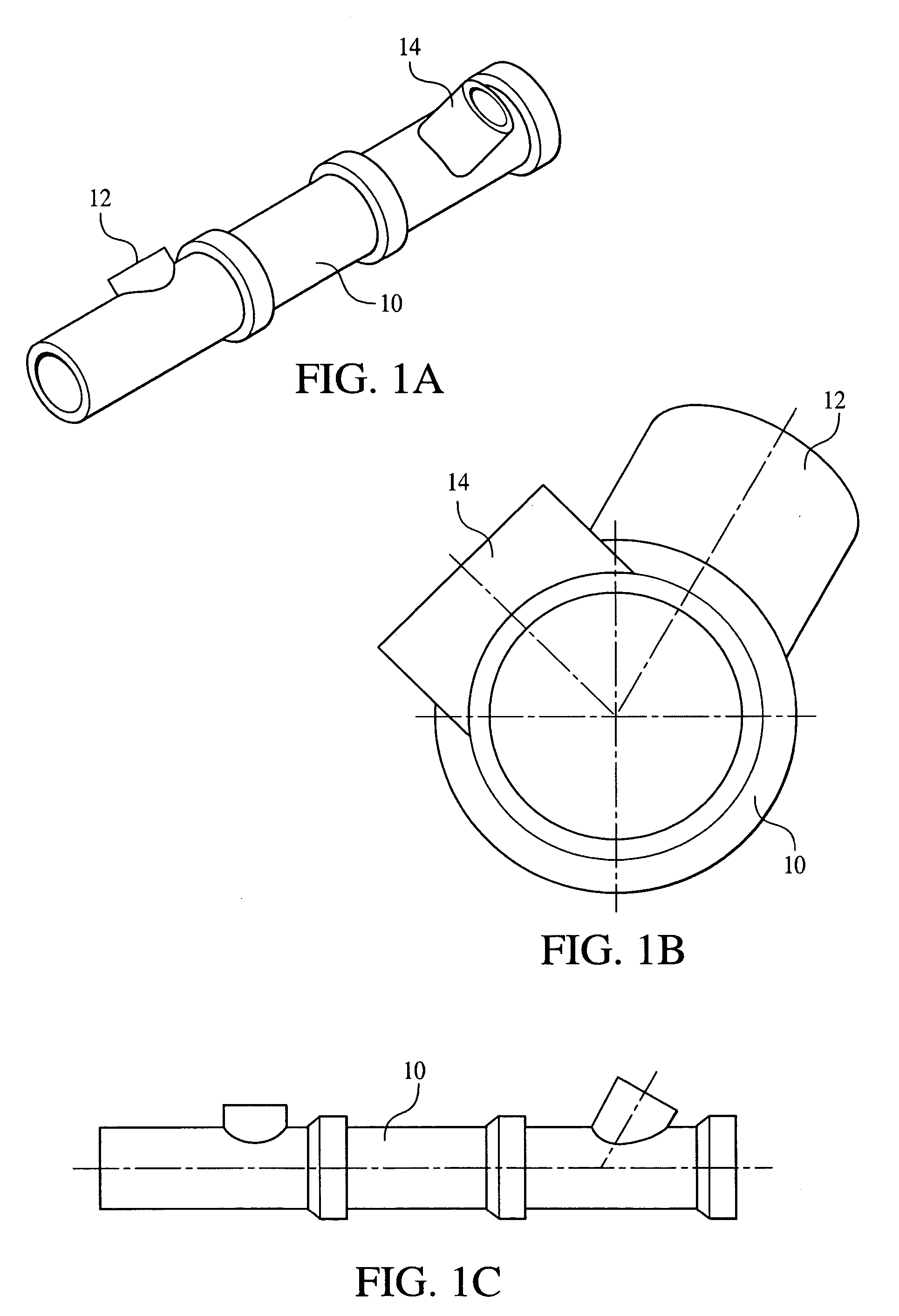

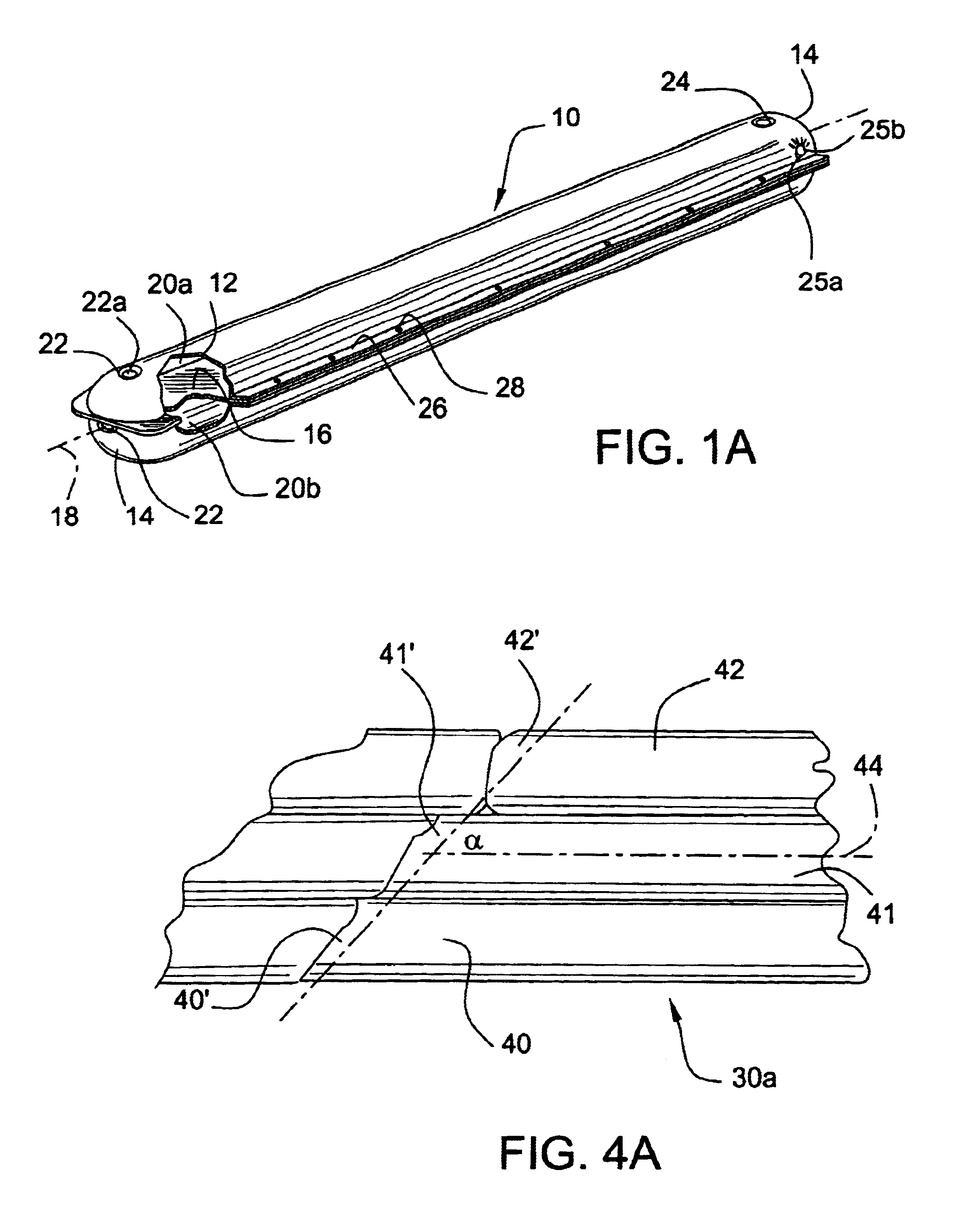

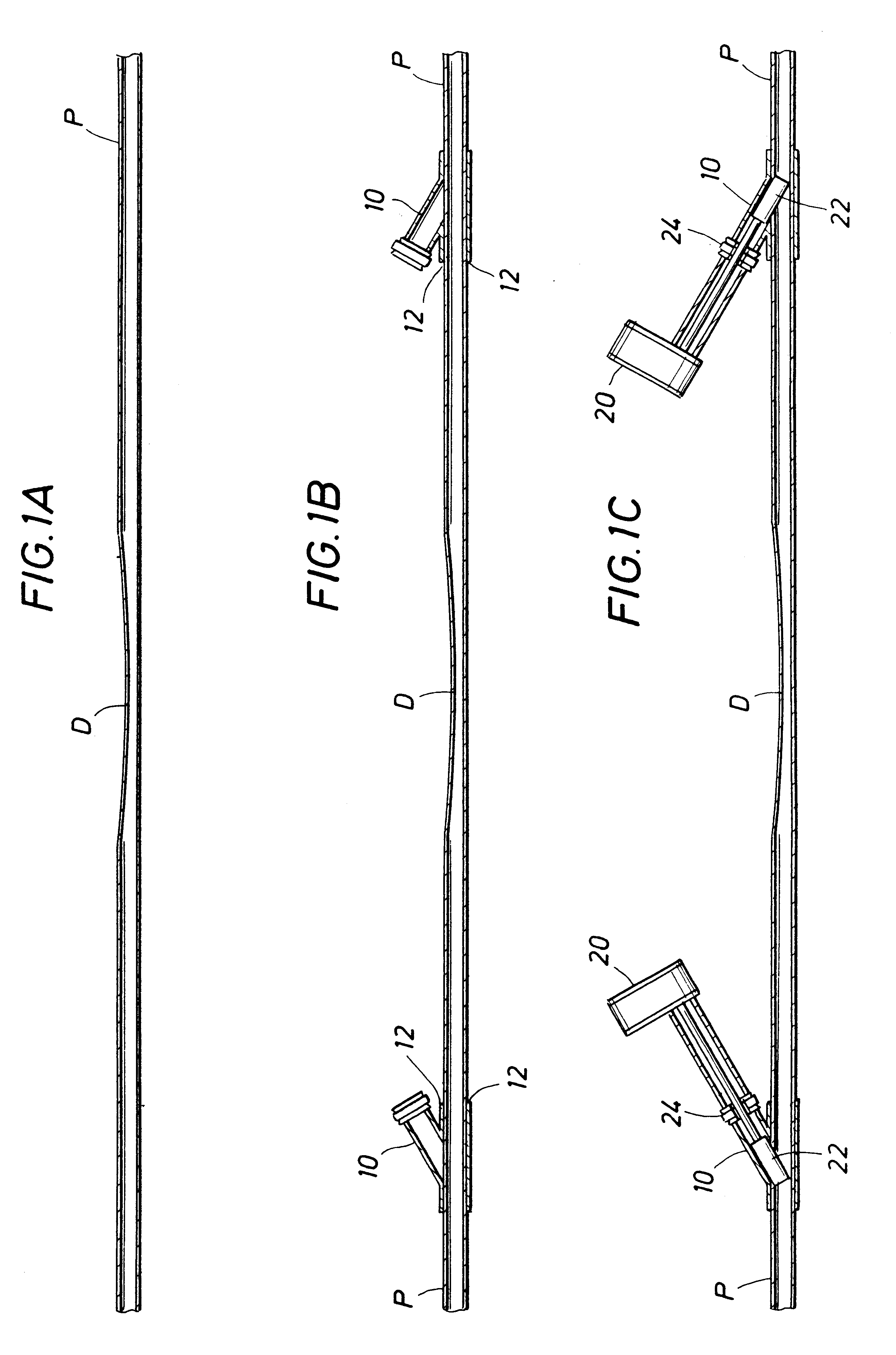

Wire saw

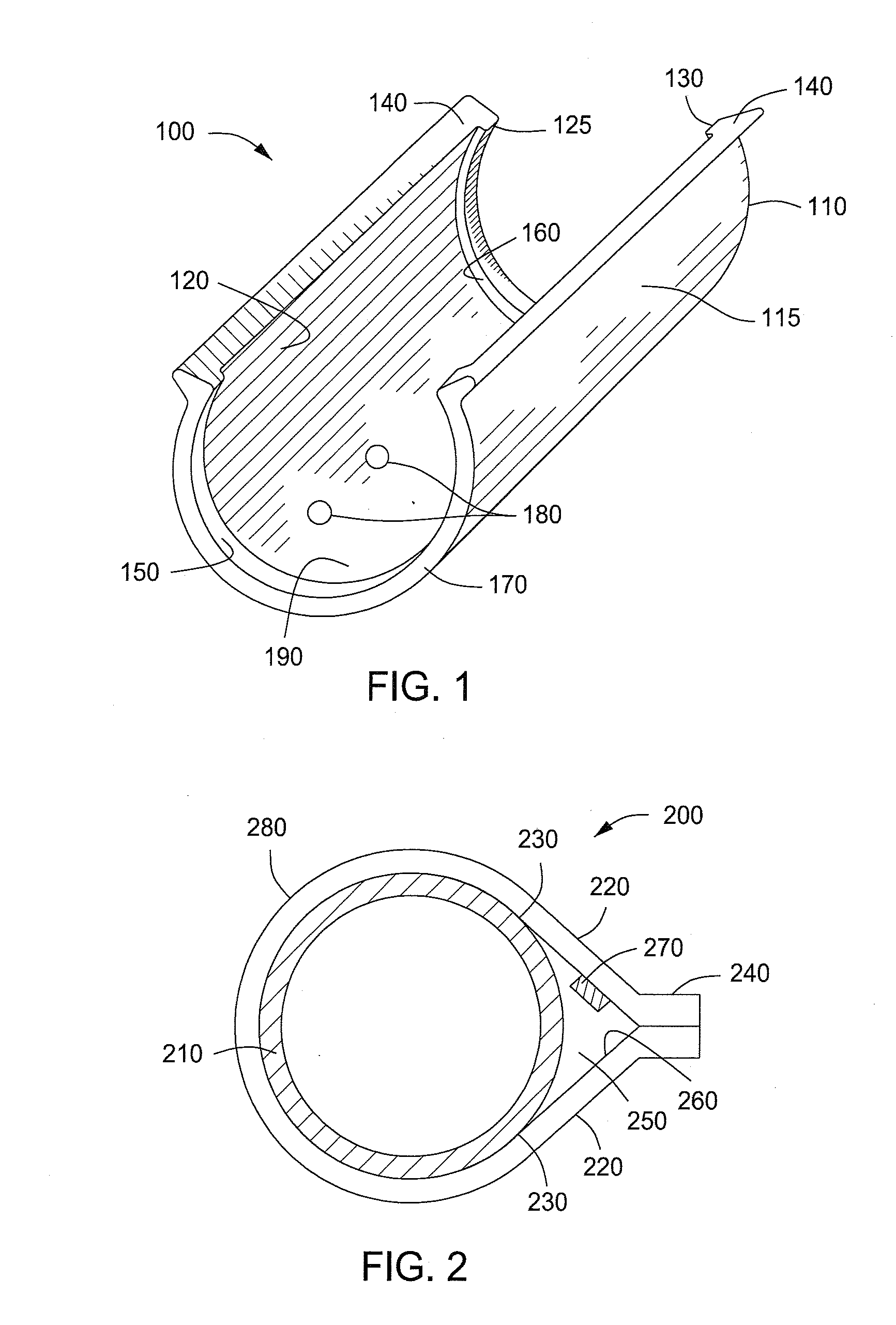

A device for cutting a length of pipe includes a clamp portion for clamping around a length of pipe and a bow moveable with respect to the clamp portion that retains a loop of diamond embedded wire. The device further includes a feed for driving the bow with respect to the clamp portion and a detector for detecting bending of the wire and a control responsive to the detector for controlling feed rates. The device is made of modular parts and has synchronizing arms for clamping around a length of pipe. In one embodiment, the wheels are retained in enclosures with slots through which the cutting wire passes.

Owner:ILLINOIS TOOL WORKS INC

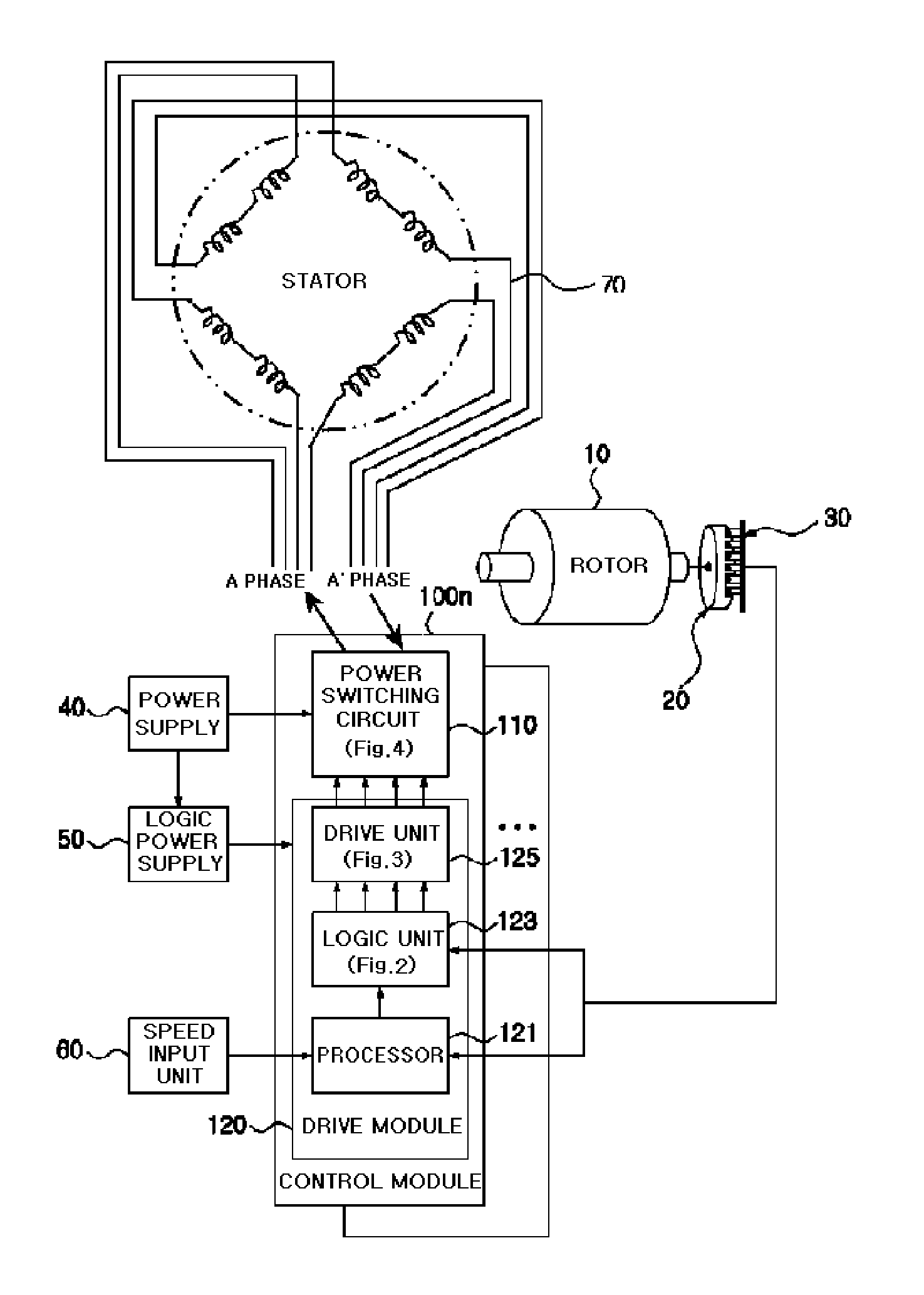

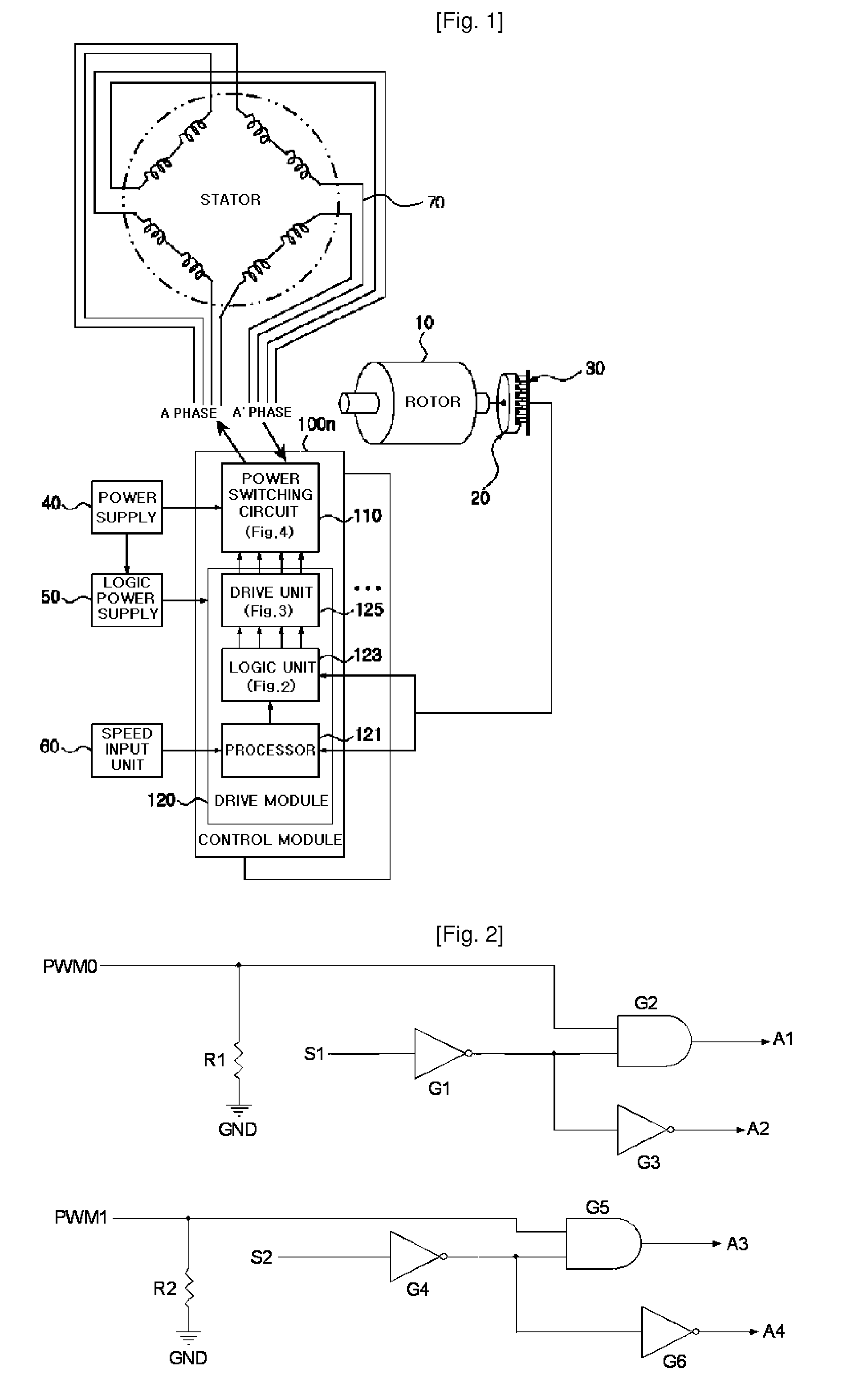

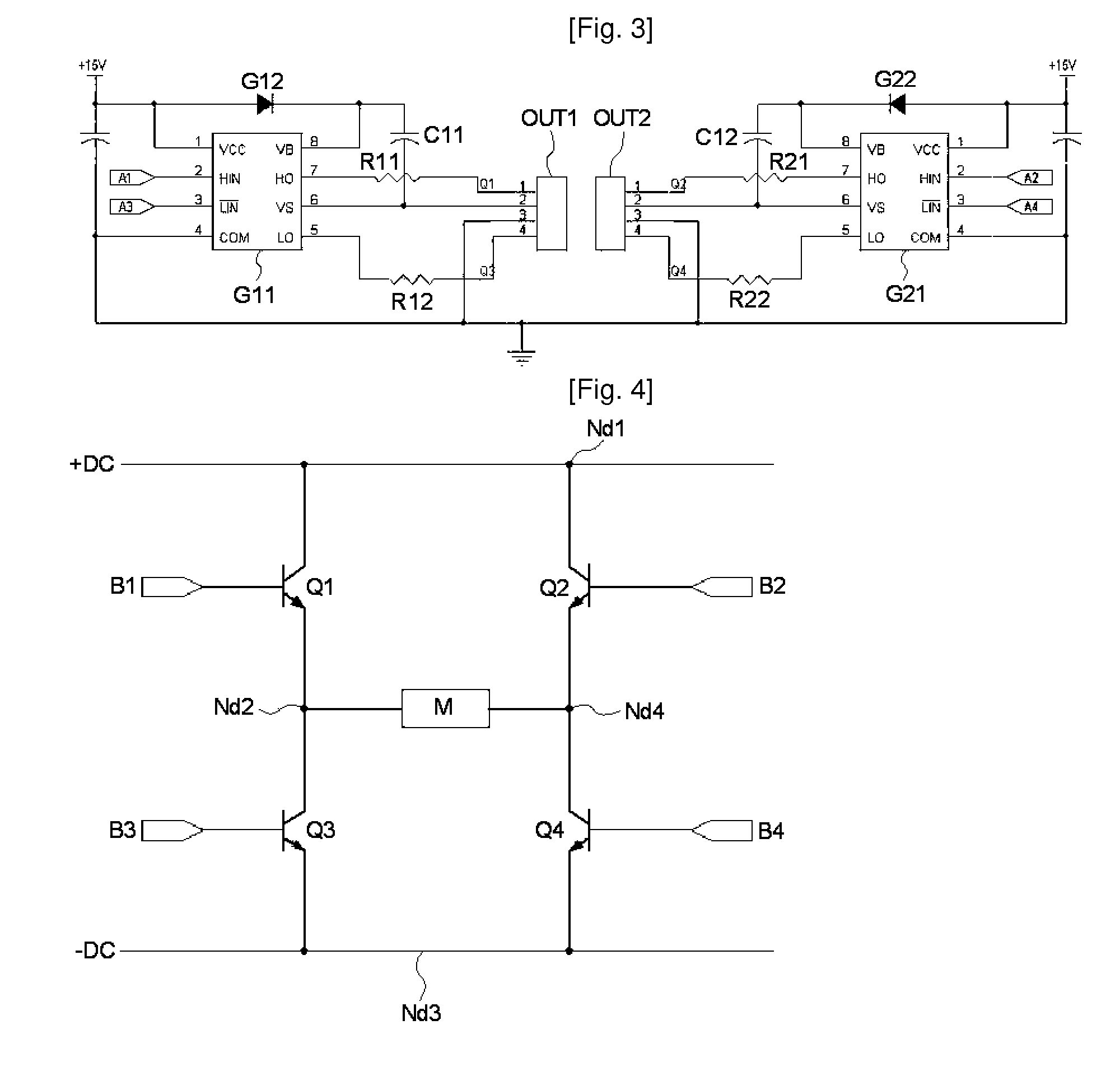

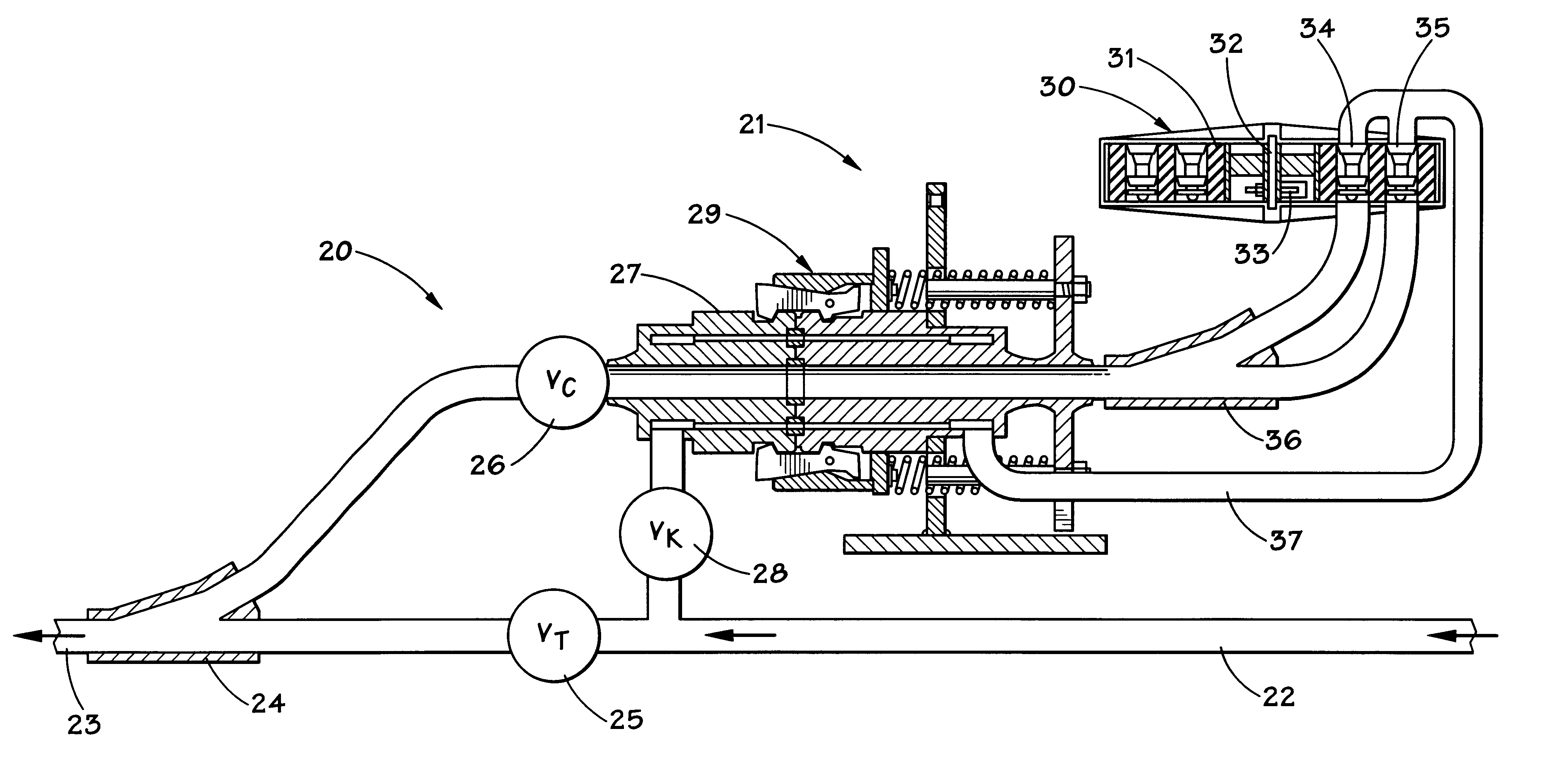

Apparatus and method for controlling hybrid motor

ActiveUS8228020B2Reduce capacityReduce electricity loadSingle-phase induction motor startersWindingsDriver circuitPower switching

An apparatus and method for controlling a hybrid motor, The hybrid motor, uses a permanent magnet instead of a field coil for a rotor, winds a coil round a stator in a multi-phase independent parallel manner, fixes a rectifying type encoder to the rotor and connects a sensor to a driving circuit. The apparatus comprises: an encoder attached to a rotor in cooperation with a pole sensor a speed input unit for generating a speed instruction signal a power switching circuit to generate motor driving signals; a drive module receiving the speed instruction signal and the sensor signal and outputting the speed instruction signal synchronized with the sensor signal as a driving motor signal; a power supply for applying a DC voltage to the power switching circuit; A logic power supply for converting the DC voltage into a logic voltage, and applying logic voltage to the drive module. The motor has n phases, n power switching circuits and n drive modules.

Owner:NAMYANG NEXMO CO LTD

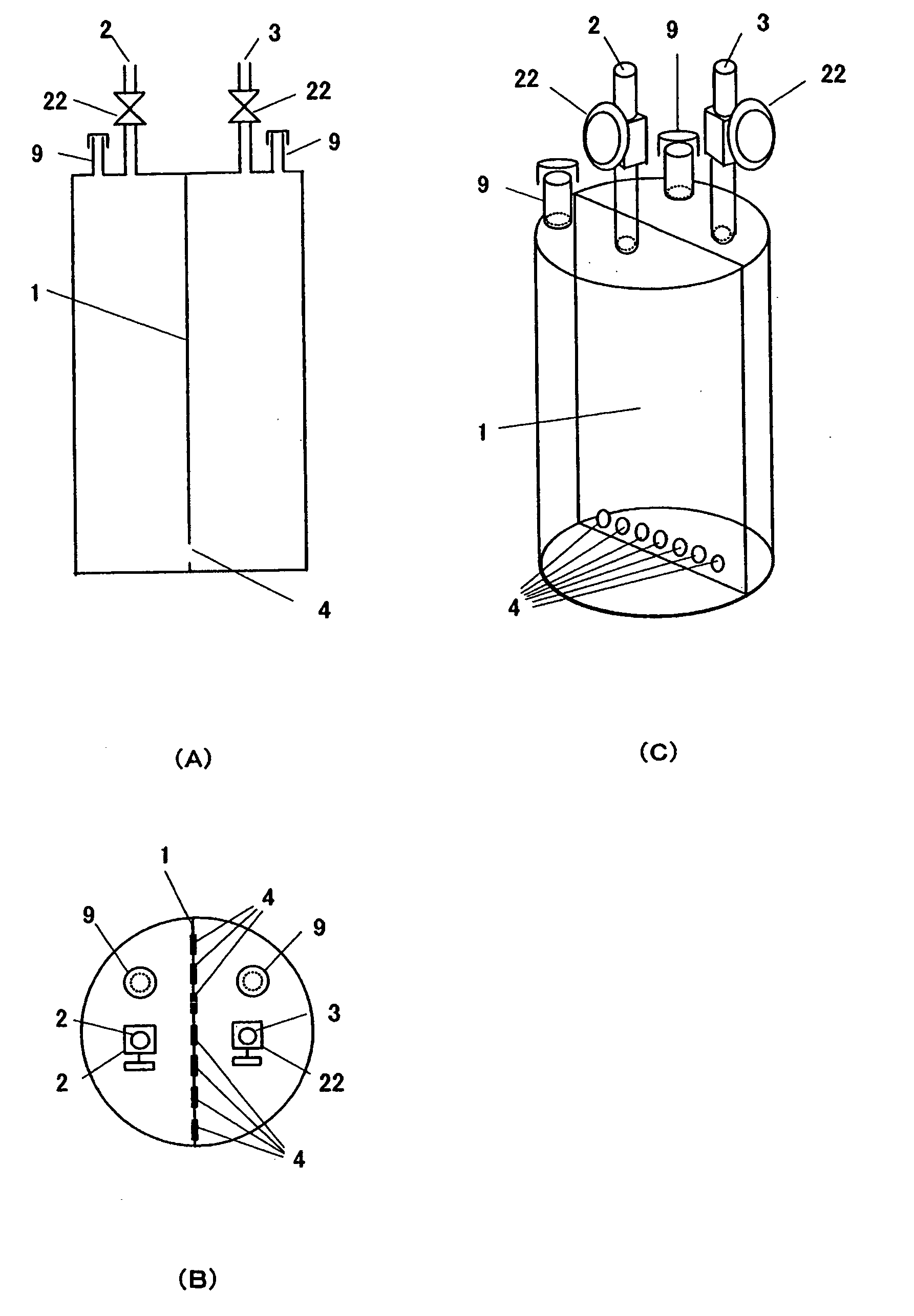

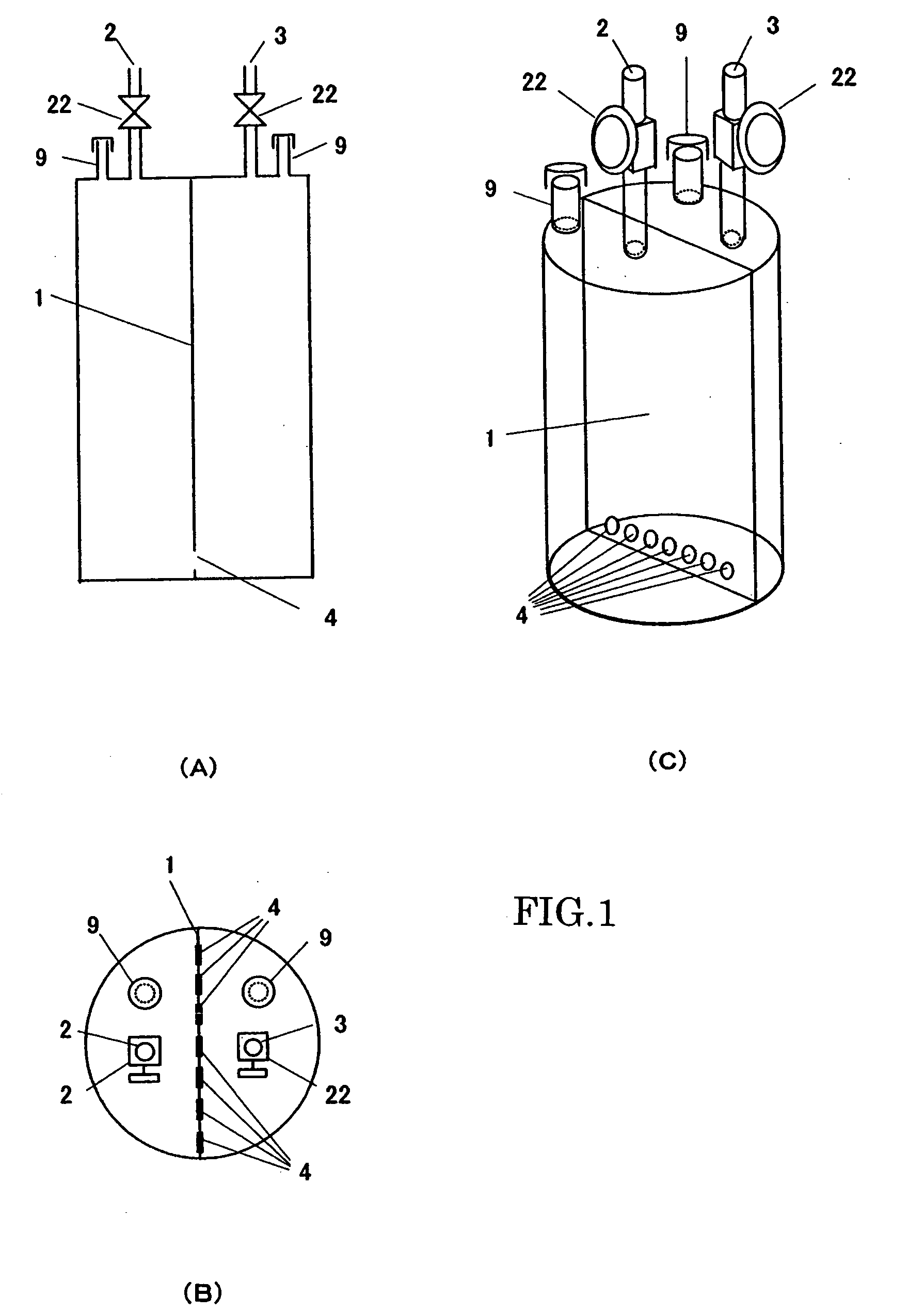

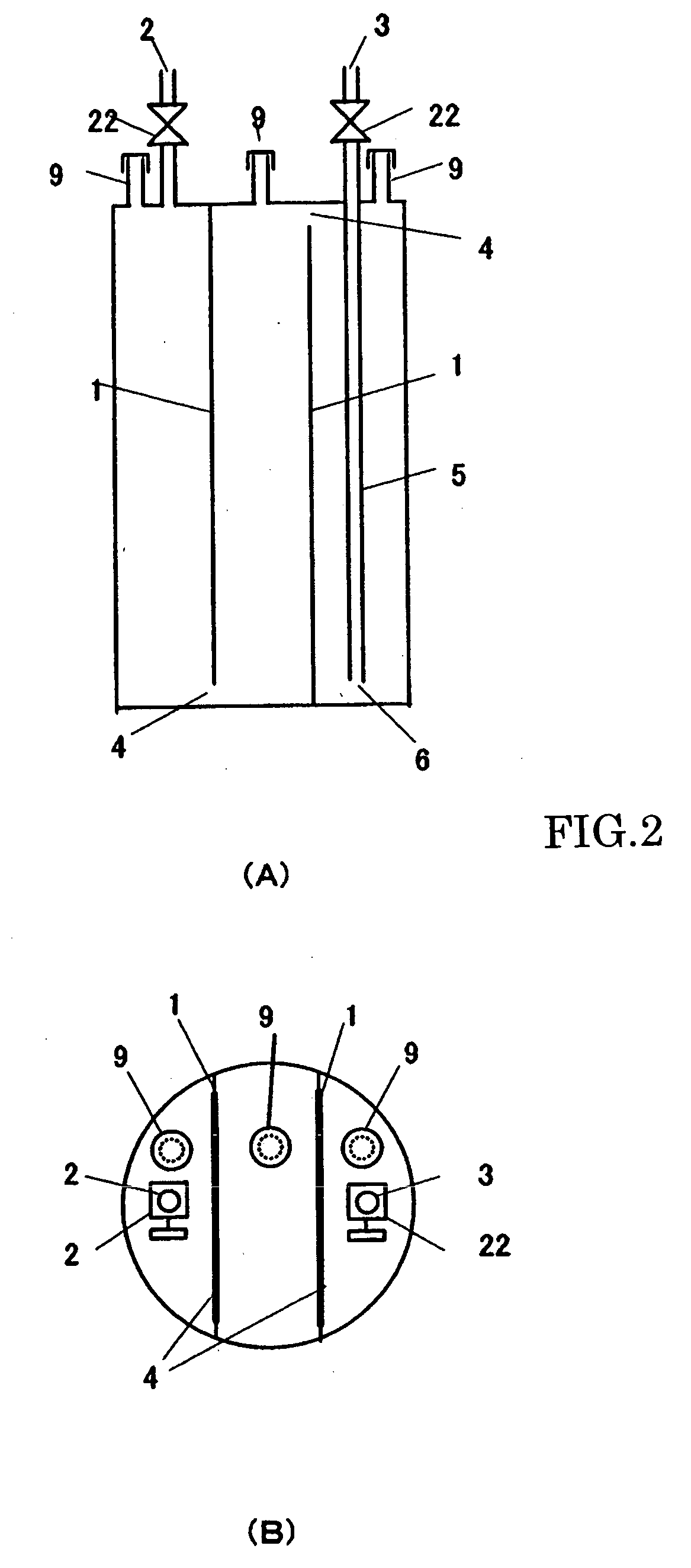

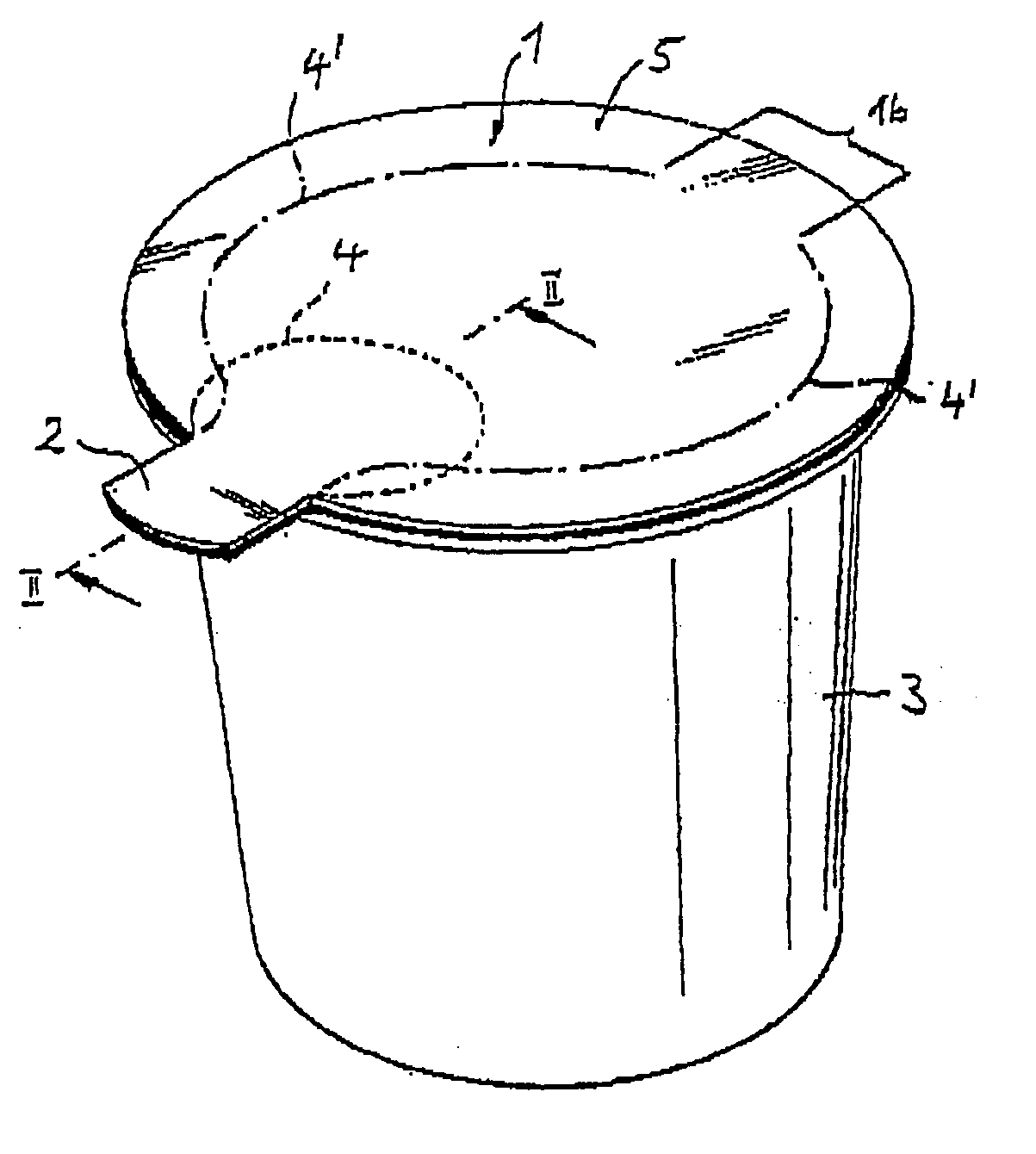

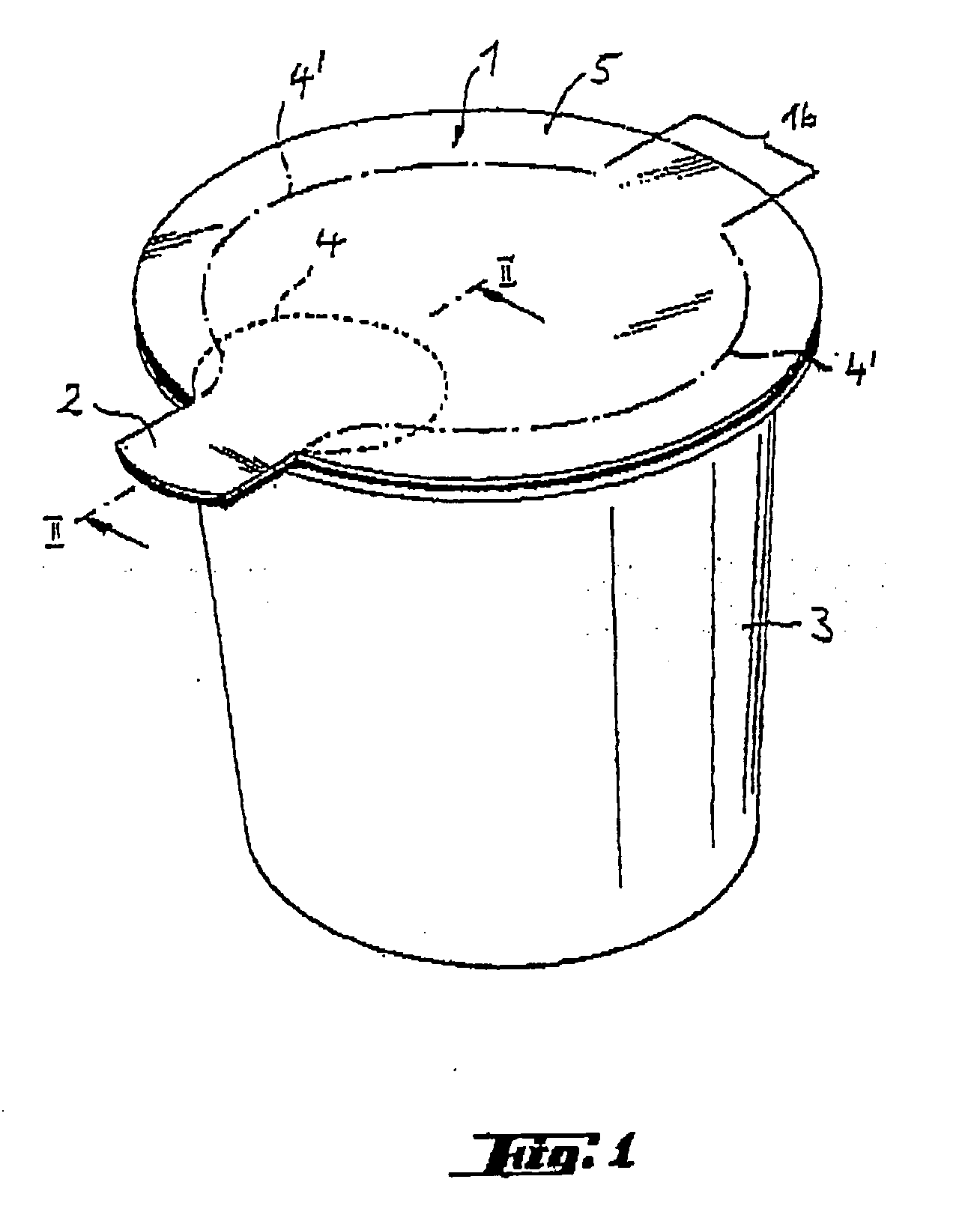

Solid organometallic compound-filled container and filling method thereof

InactiveUS20050008799A1Increasing outer sizeStable supplyEnvelopes/bags making machineryPipe laying and repairEngineeringVapor phase

A novel filled container is provided, which can stably supply an apparatus for vapor phase epitaxial growth such as an MOCVD apparatus with a solid organometallic compound over a long term. The solid organometallic compound-filled container has a carrier gas inlet and a carrier gas outlet. The interior of the filled container is separated into a plurality of vertical compartments. A carrier gas introduced via the carrier gas inlet flows through each of the vertical compartments and is then discharged via the carrier gas outlet.

Owner:TOSOH FINECHEM CORP

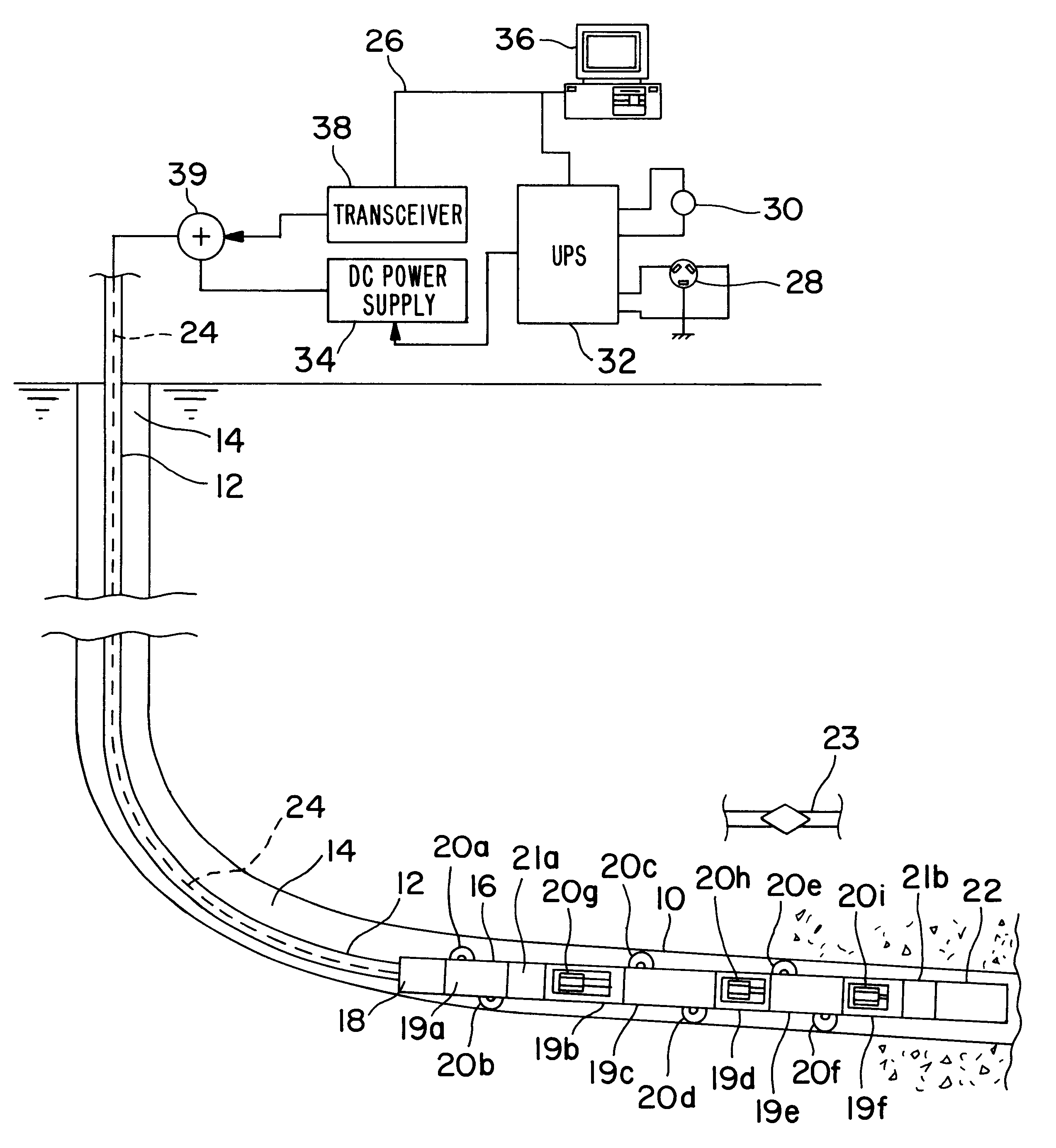

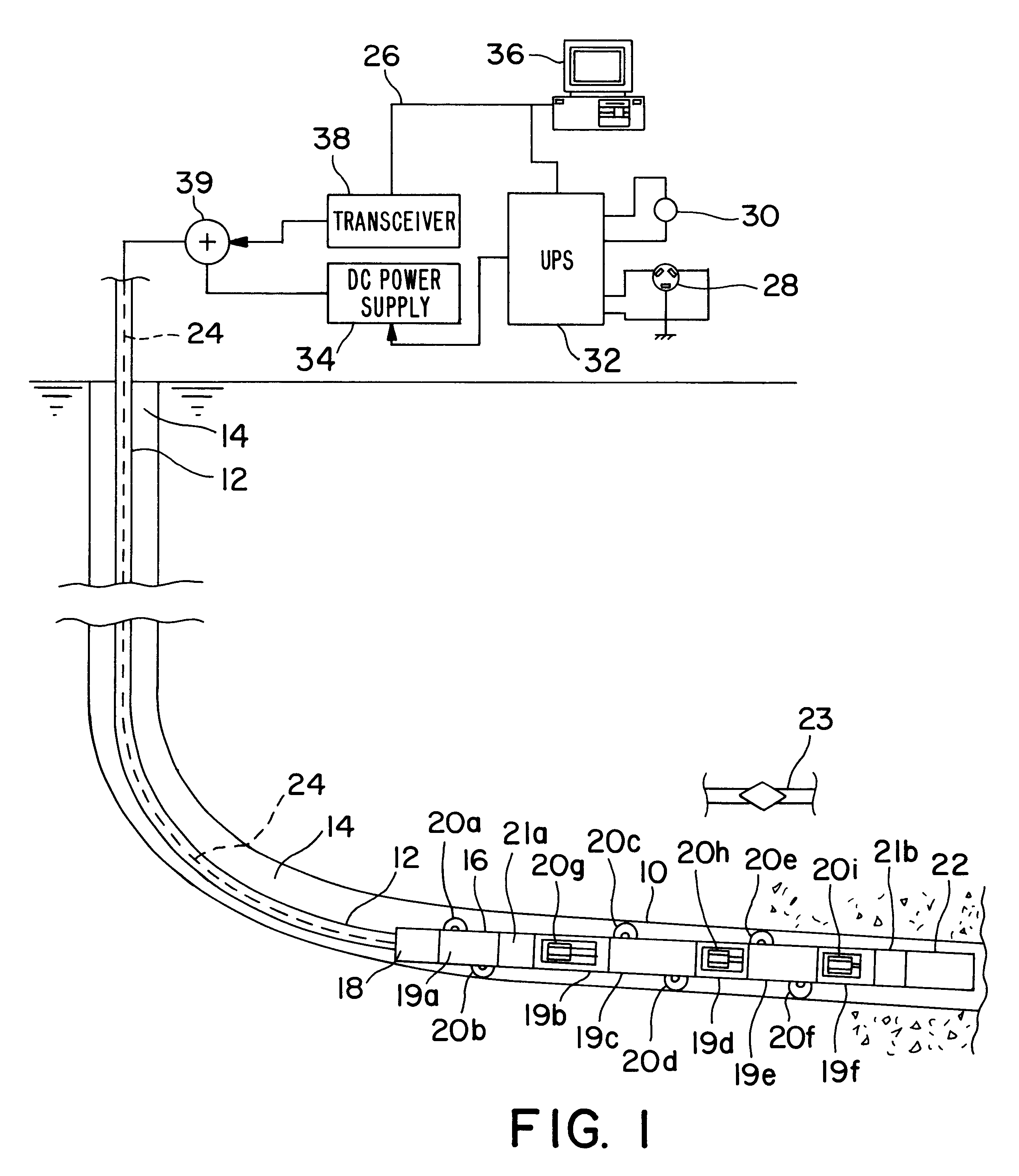

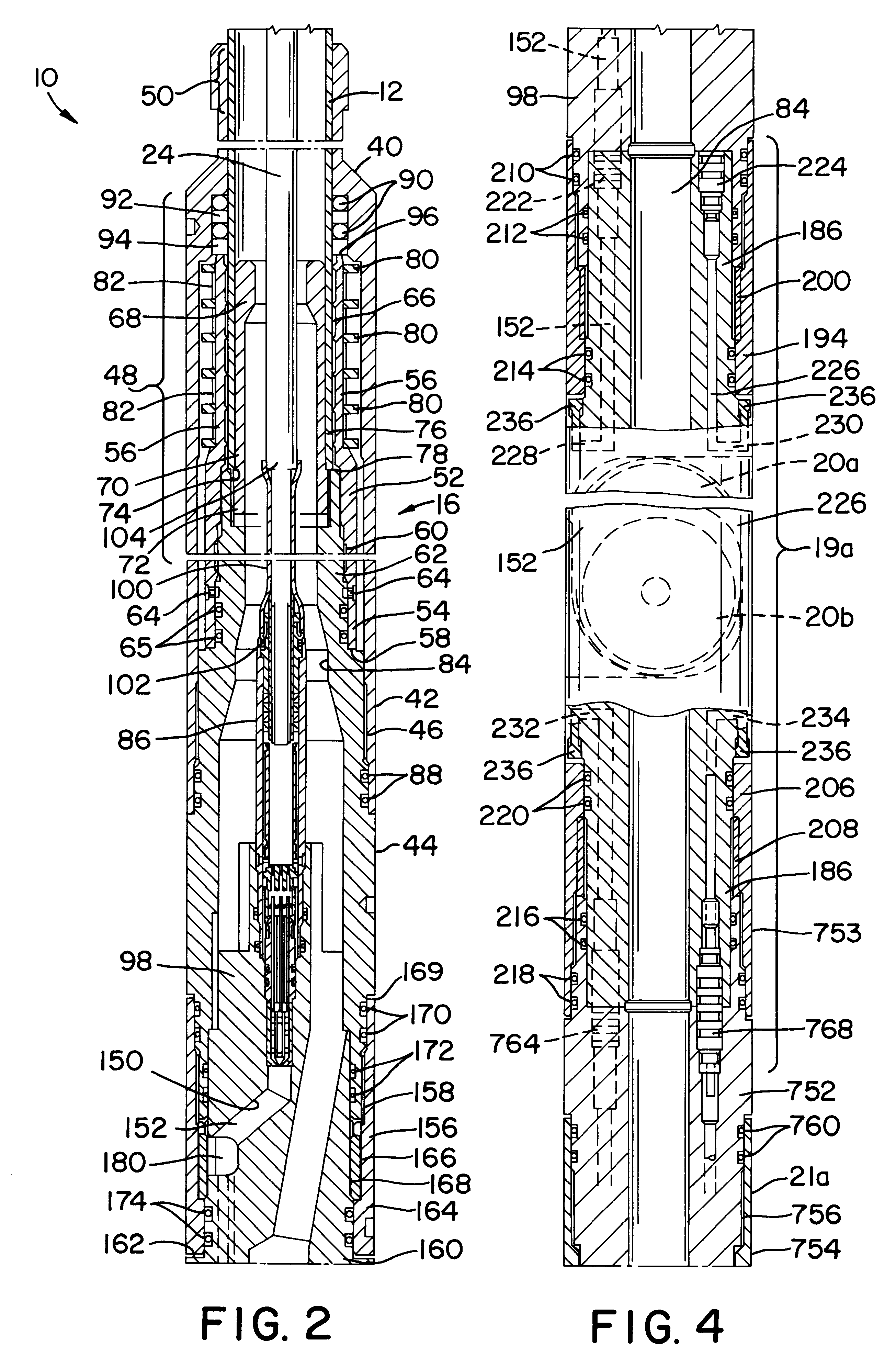

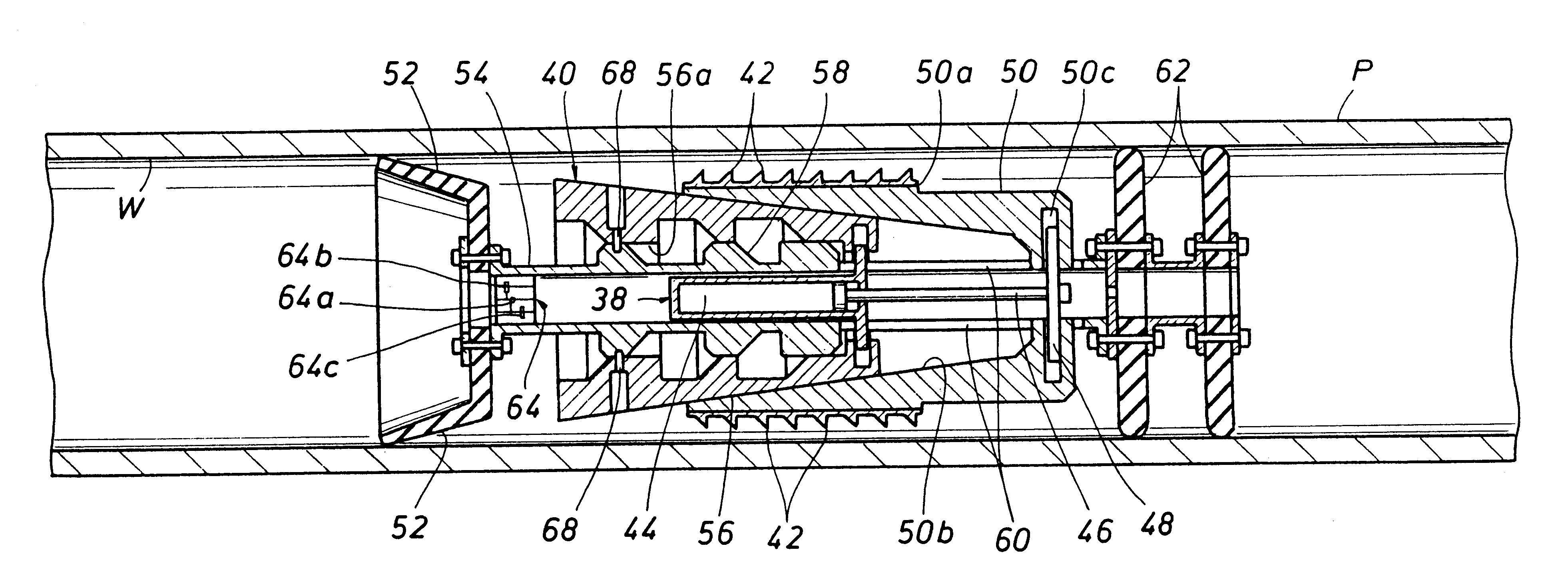

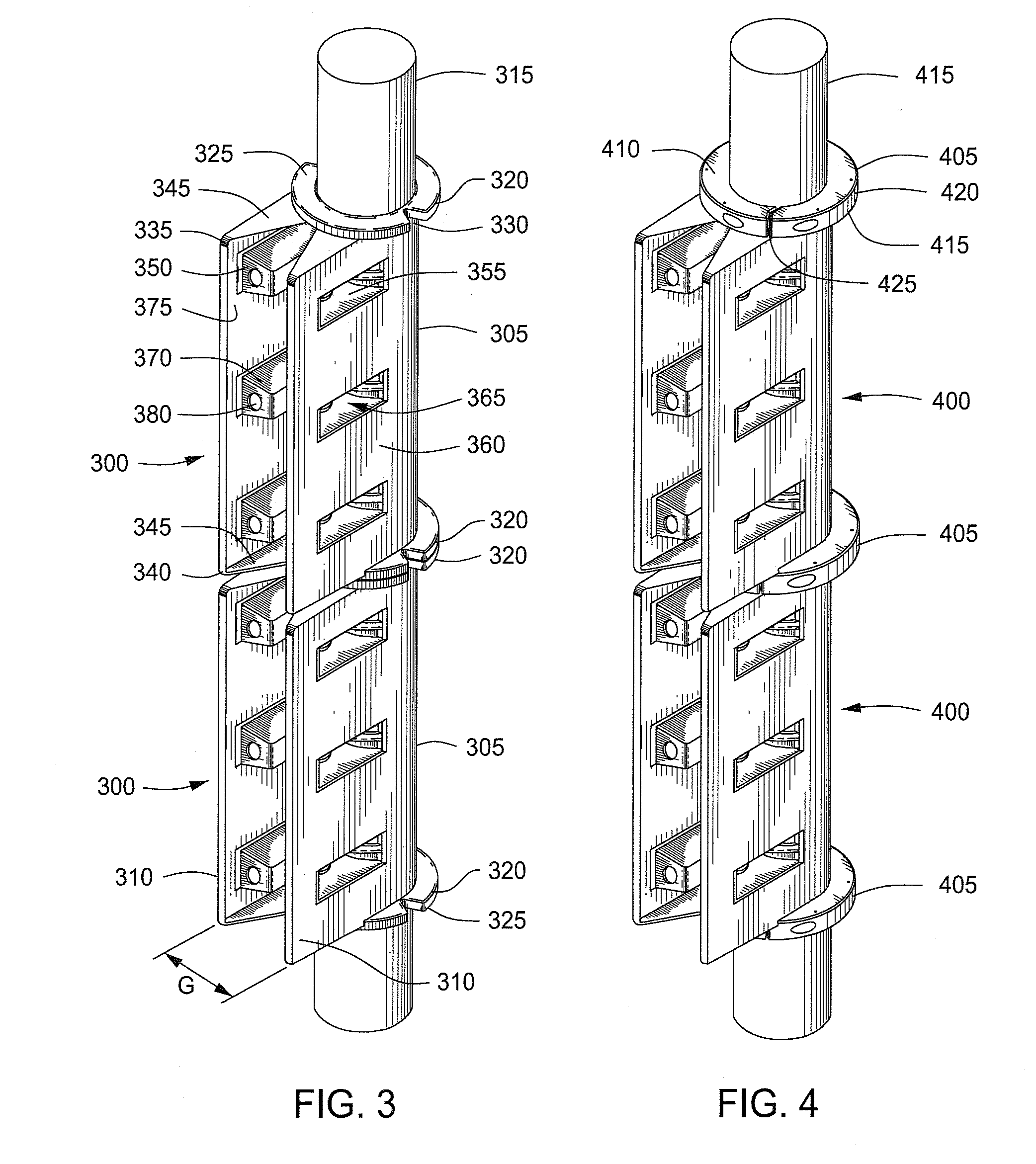

Downhole tractor

A downhole tractor is provided that includes a housing and a first wheel assembly coupled to the housing that is operable to translate away from the housing in a first direction. The first wheel assembly has a first electric motor, a first wheel, and a first reduction gear assembly coupled between the first electric motor and the first wheel. A second wheel assembly is coupled to the housing and is operable to translate away from the housing in a second direction that is opposite to the first direction. The second wheel assembly has a second electric motor, a second wheel, and a second reduction gear assembly coupled between the second electric motor and the second wheel. A fluid ram is coupled to the first and second wheel assemblies for selectively translating the first and second wheel assemblies toward and away from the housing. A first controller is provided for controlling the flow of current to the first and second electric motors. On-board and surface control systems may be incorporated to permit selective active of the wheels assemblies. In addition, couplings and connectors employing shape-memory materials may be included to secure the tractor to coiled tubing or a wireline.

Owner:HALLIBURTON ENERGY SERVICES INC

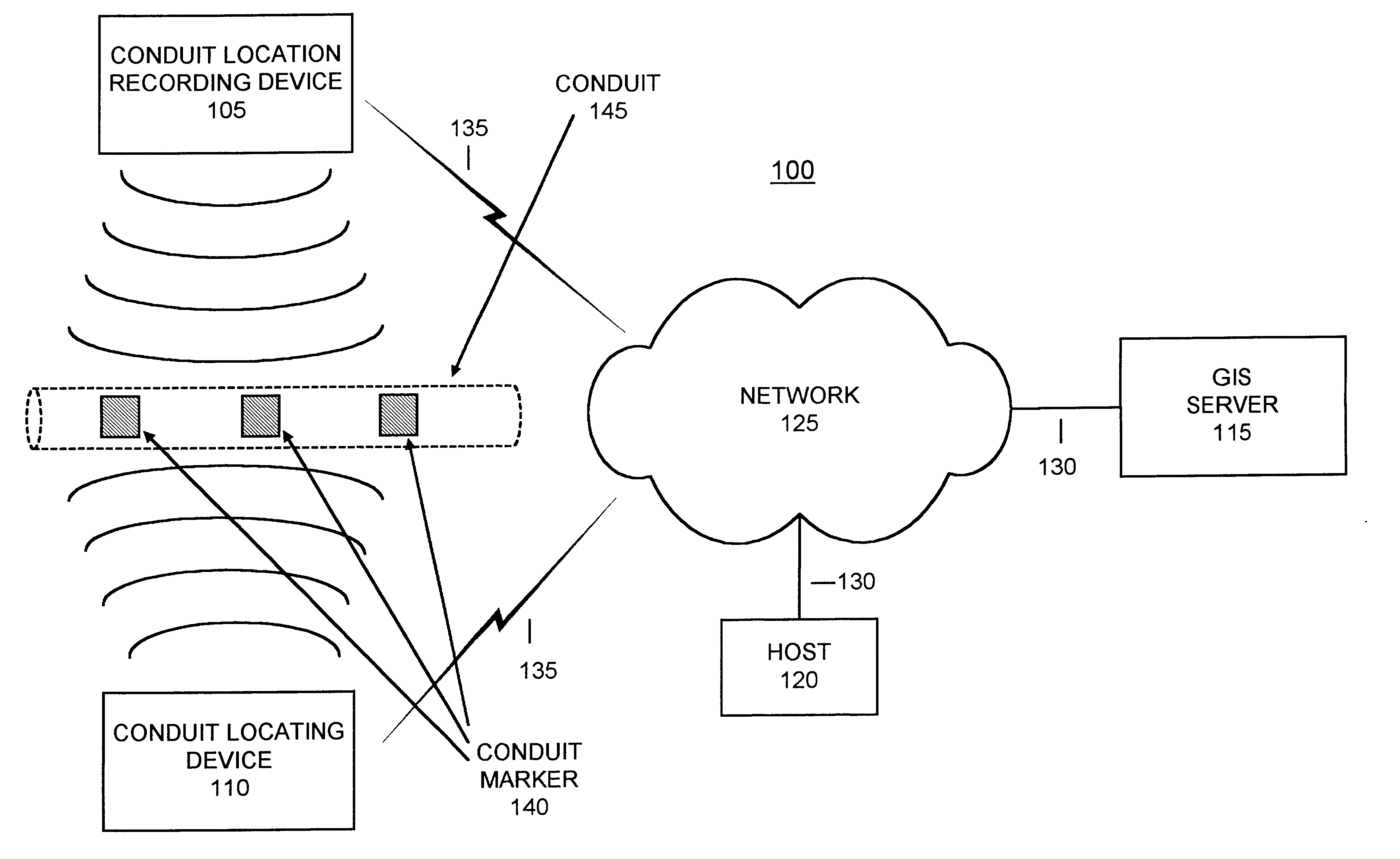

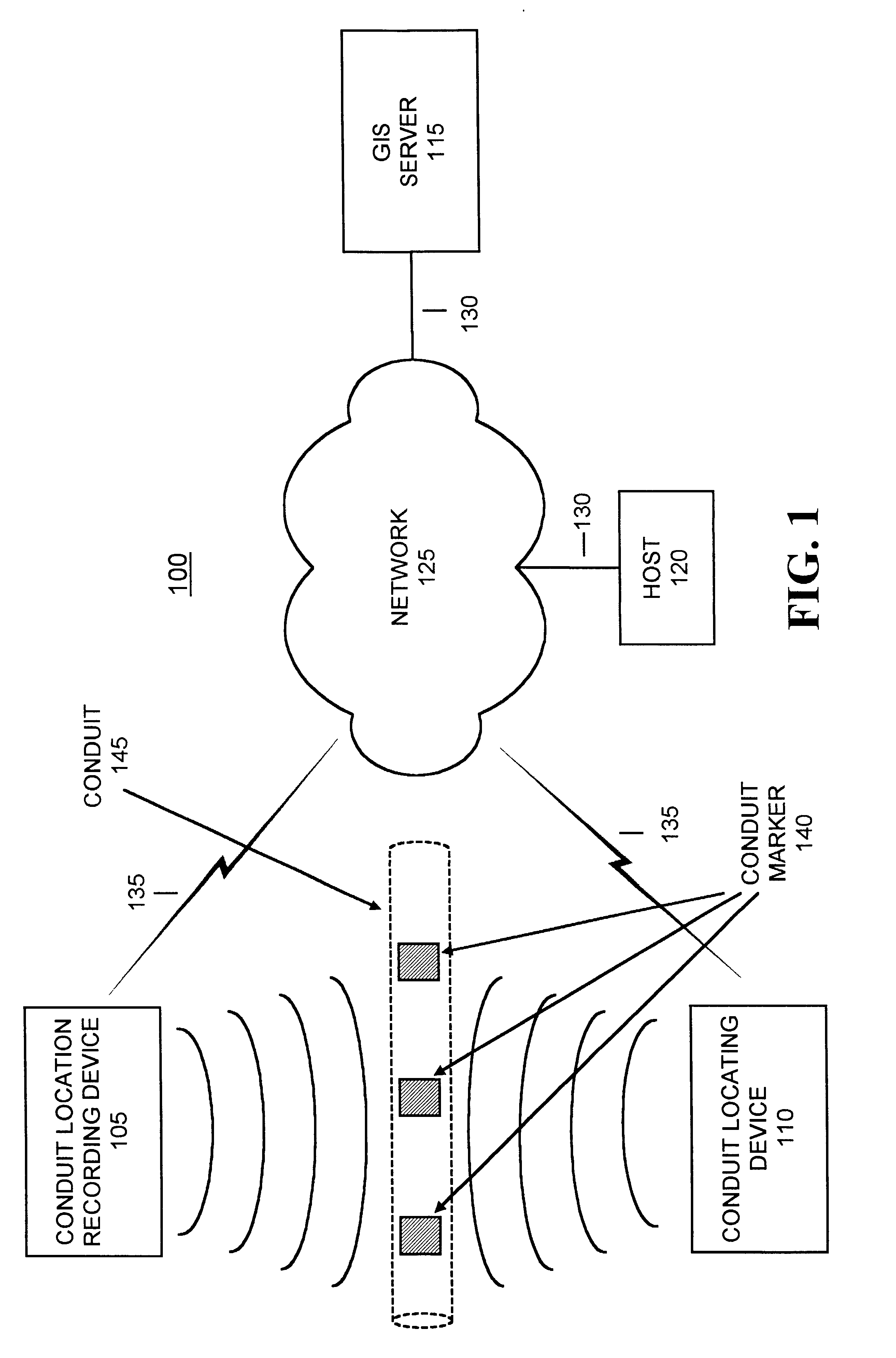

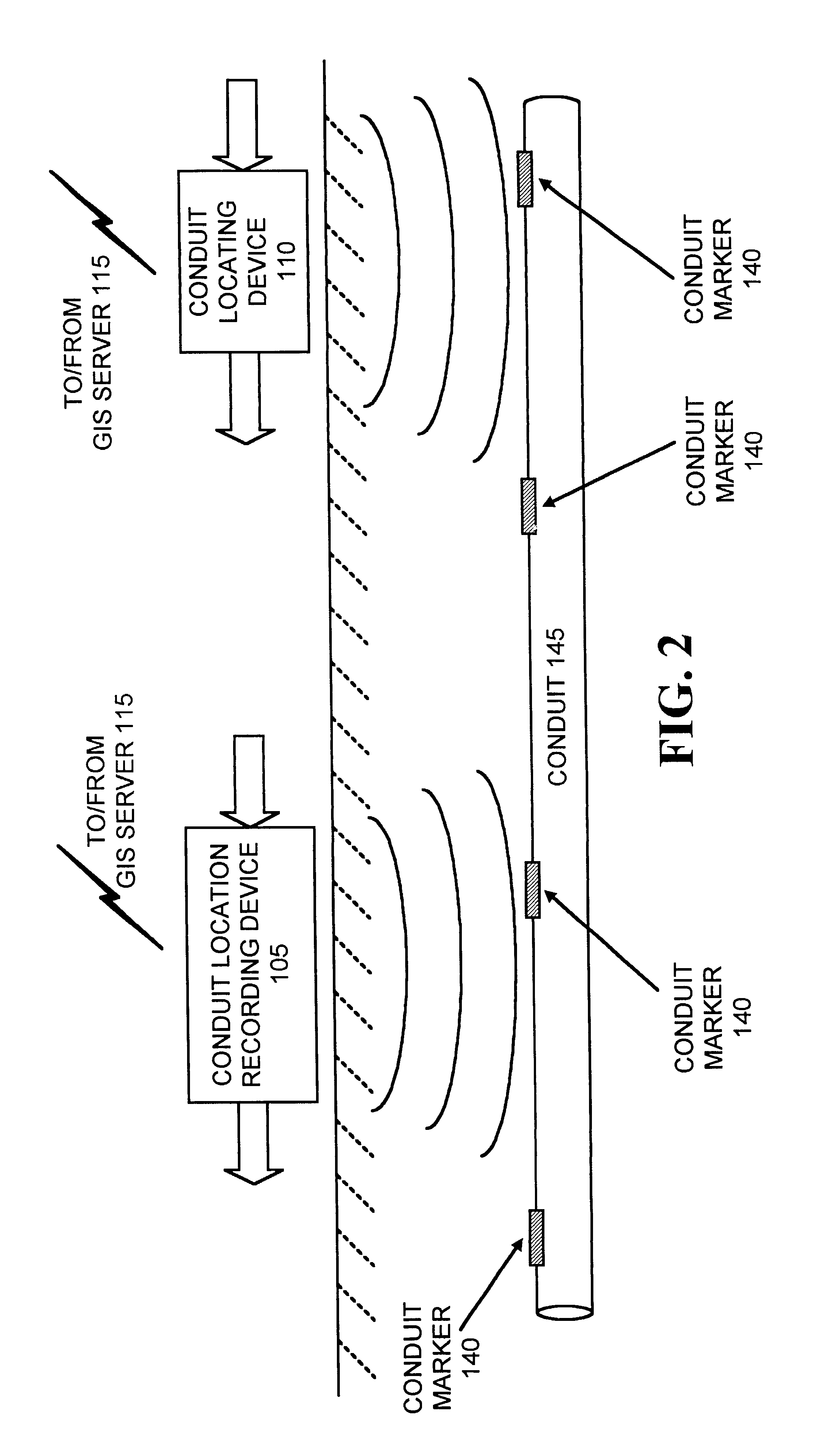

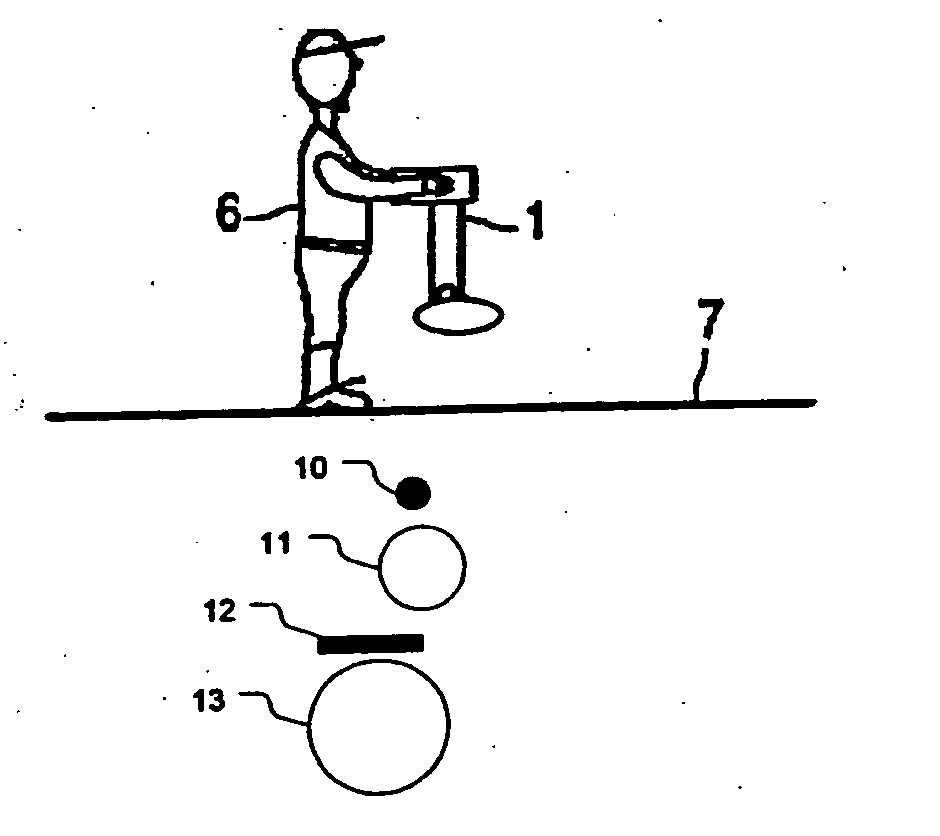

Systems and methods for identifying and mapping conduit location

InactiveUS6850161B1Efficient and less laborSurveyPipe laying and repairUnique identifierComputer science

A system (100) for mapping an underground object (145) includes a conduit location recording device 105 and a server (115). The conduit location recording device (105) senses an underground object (145), a unique identifier being associated with the sensed underground object (145), and determines a location of the underground object (145). The conduit location recording device (105) transmits, via a communications network (125), the unique identifier and determined location to the server (115) for storage in a database.

Owner:VERIZON PATENT & LICENSING INC +1

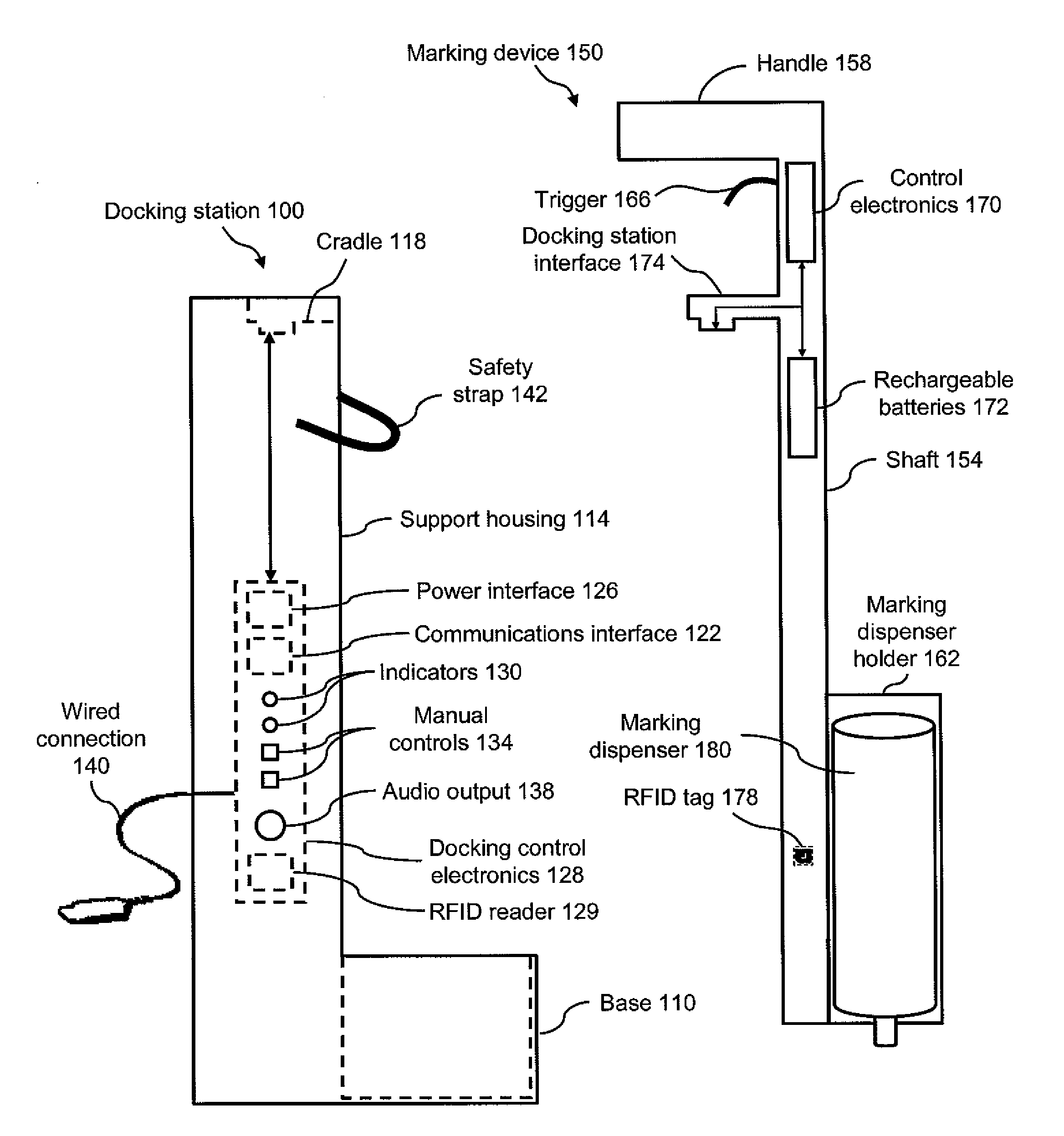

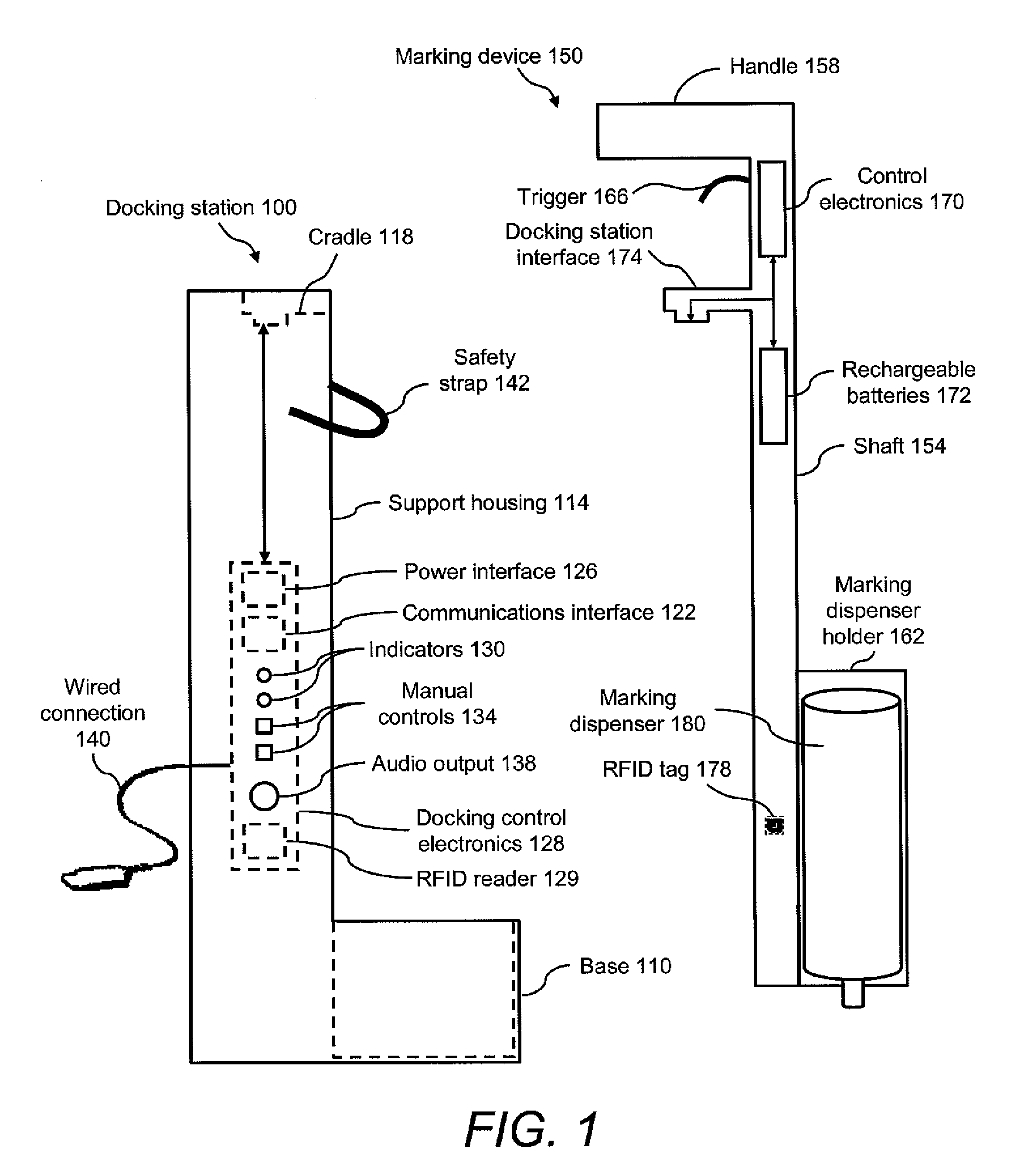

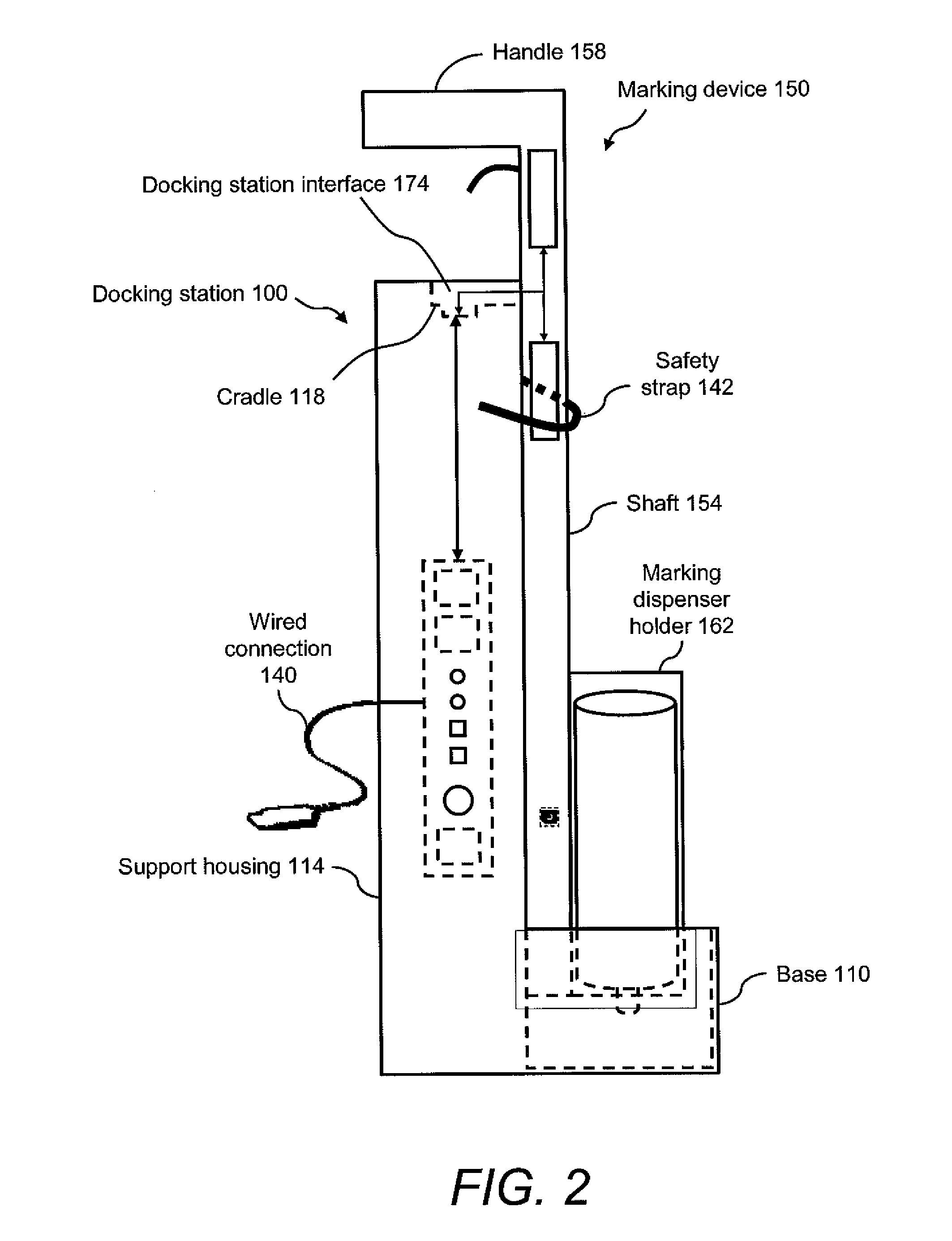

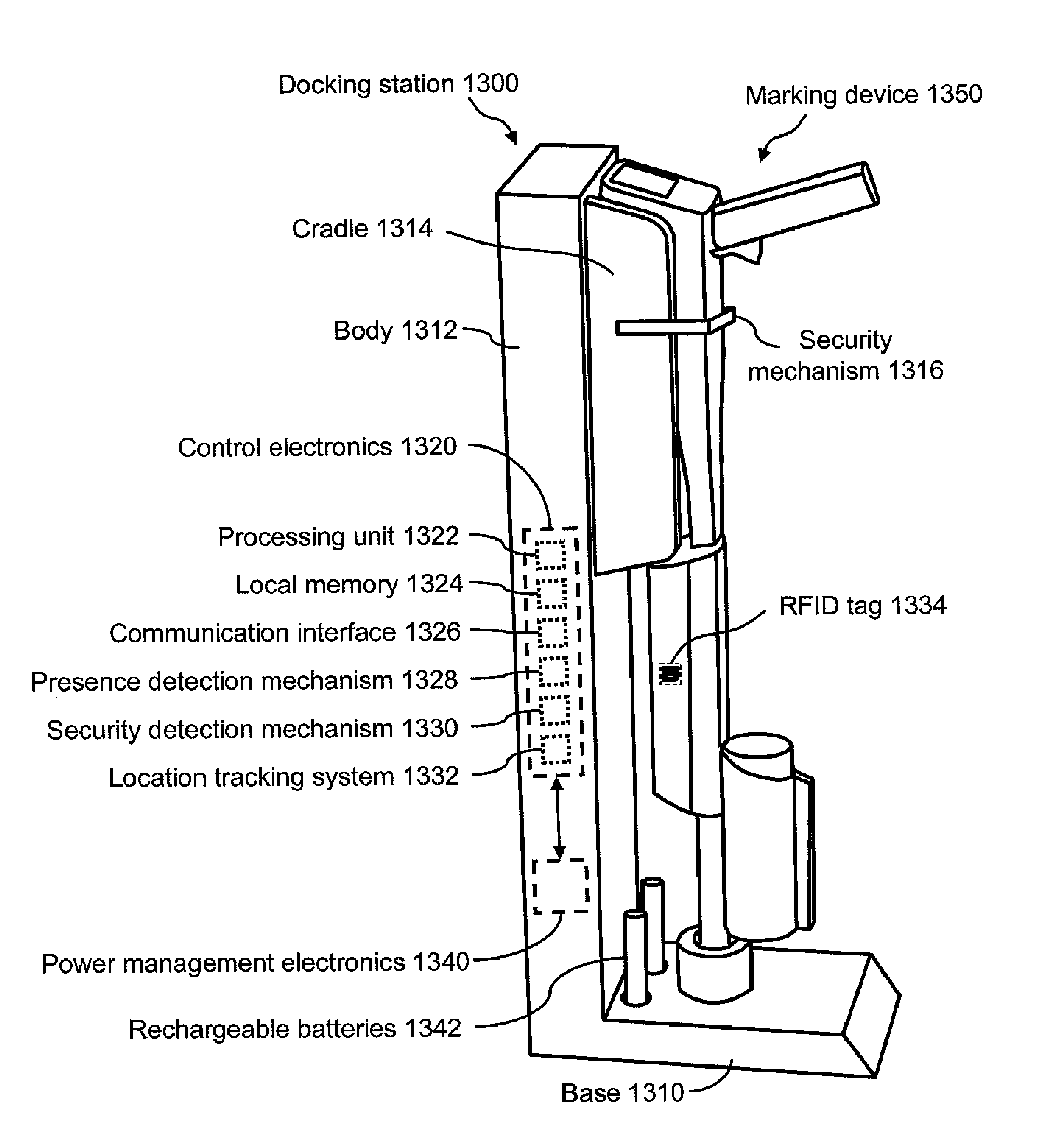

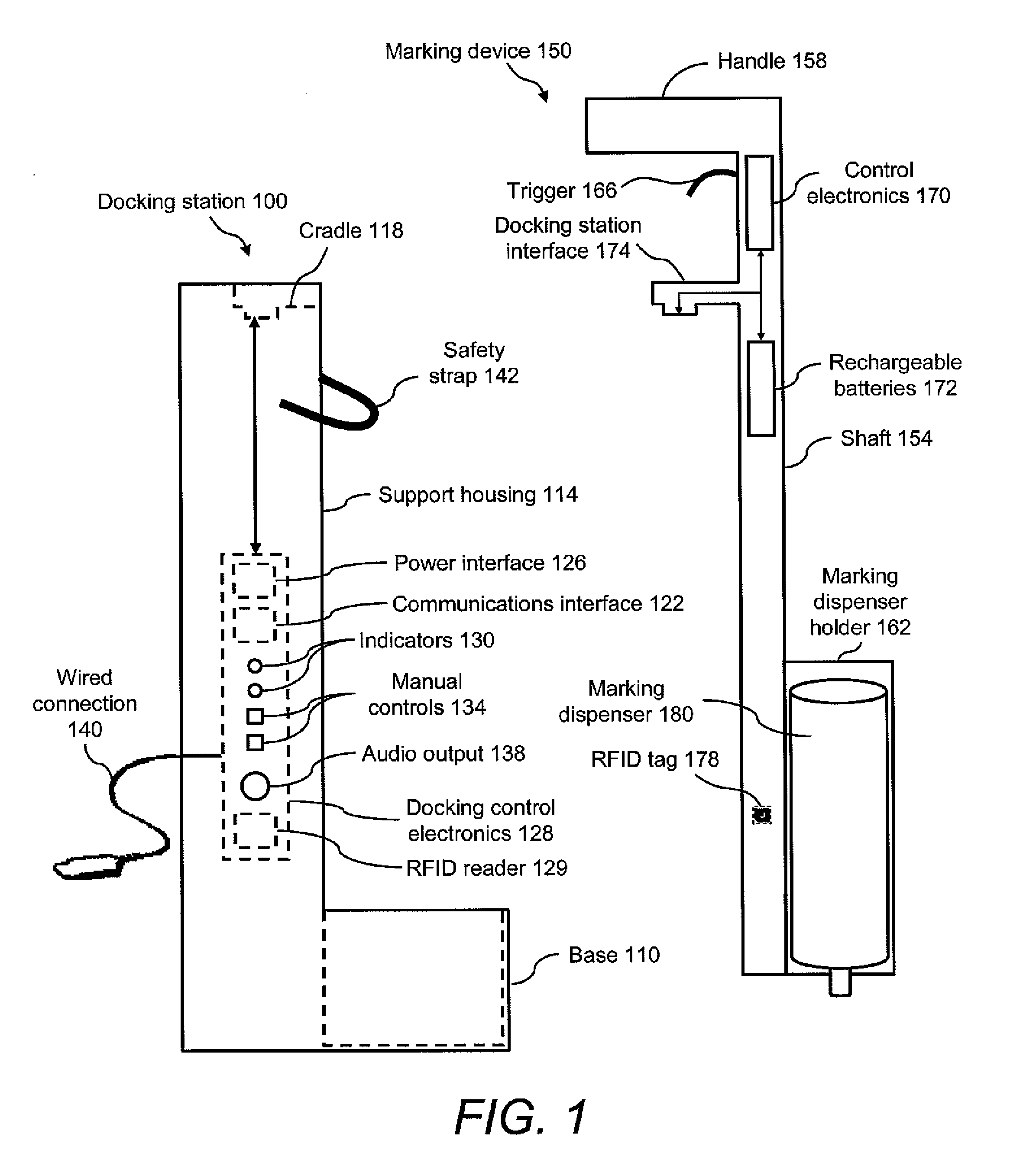

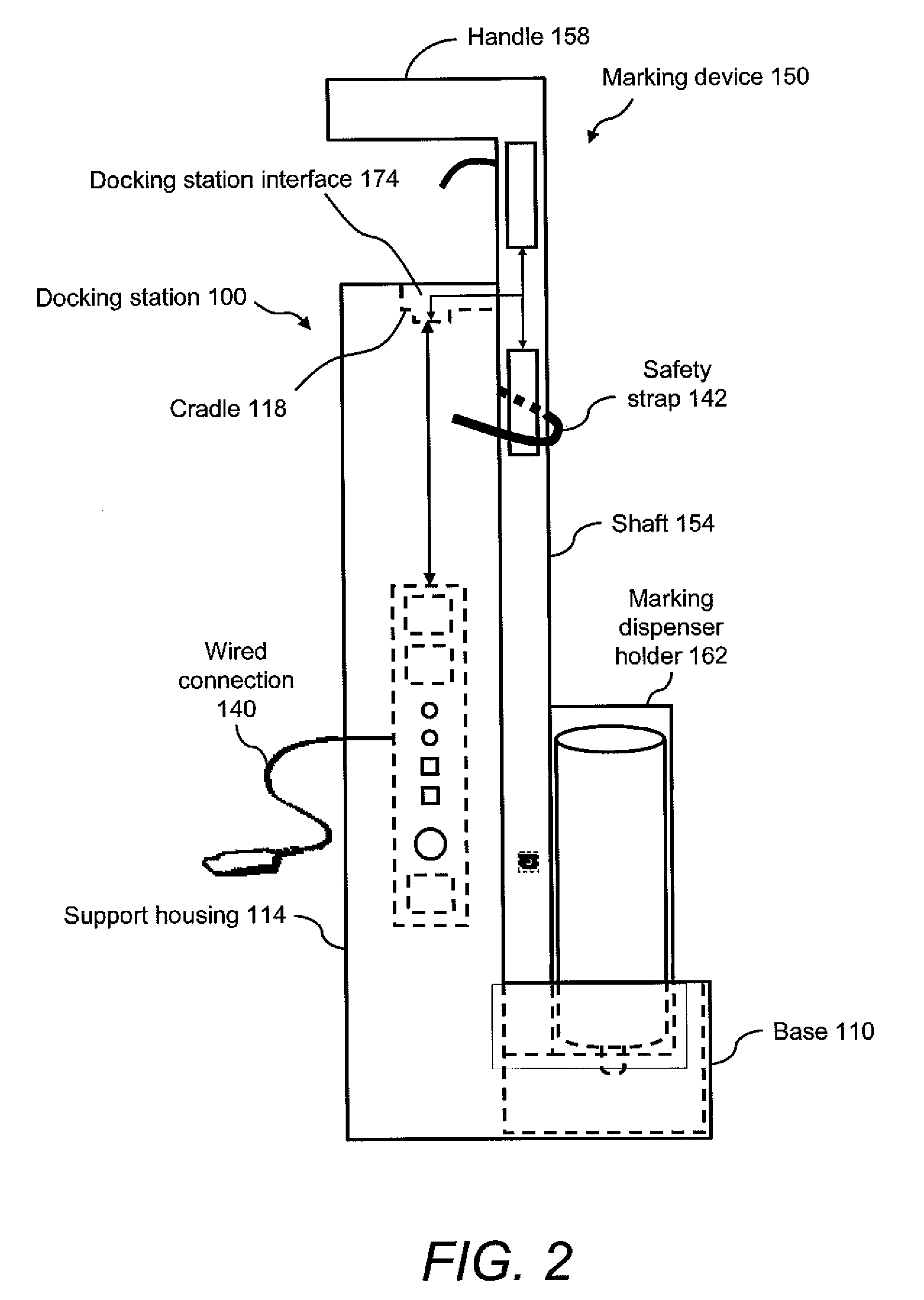

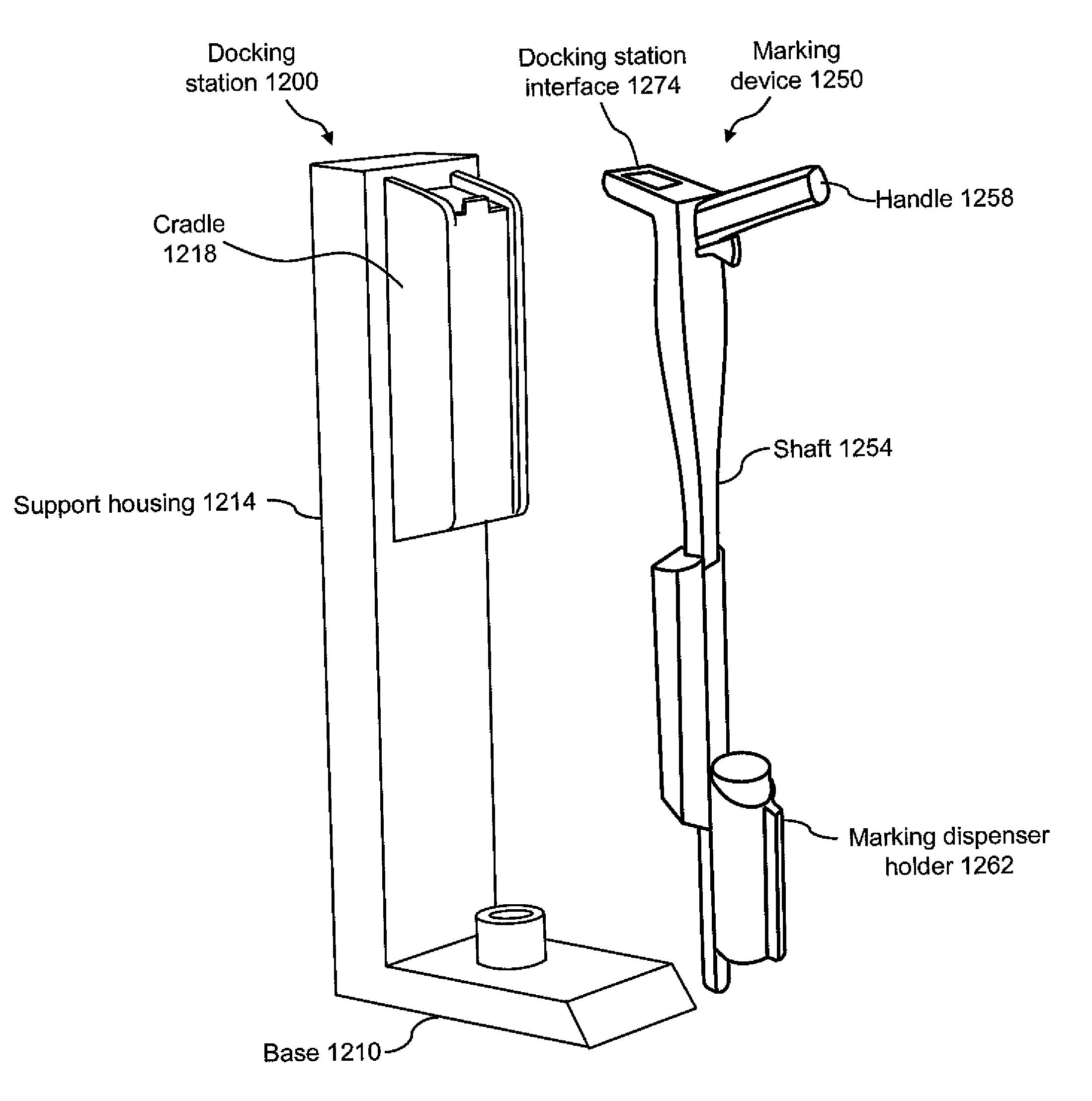

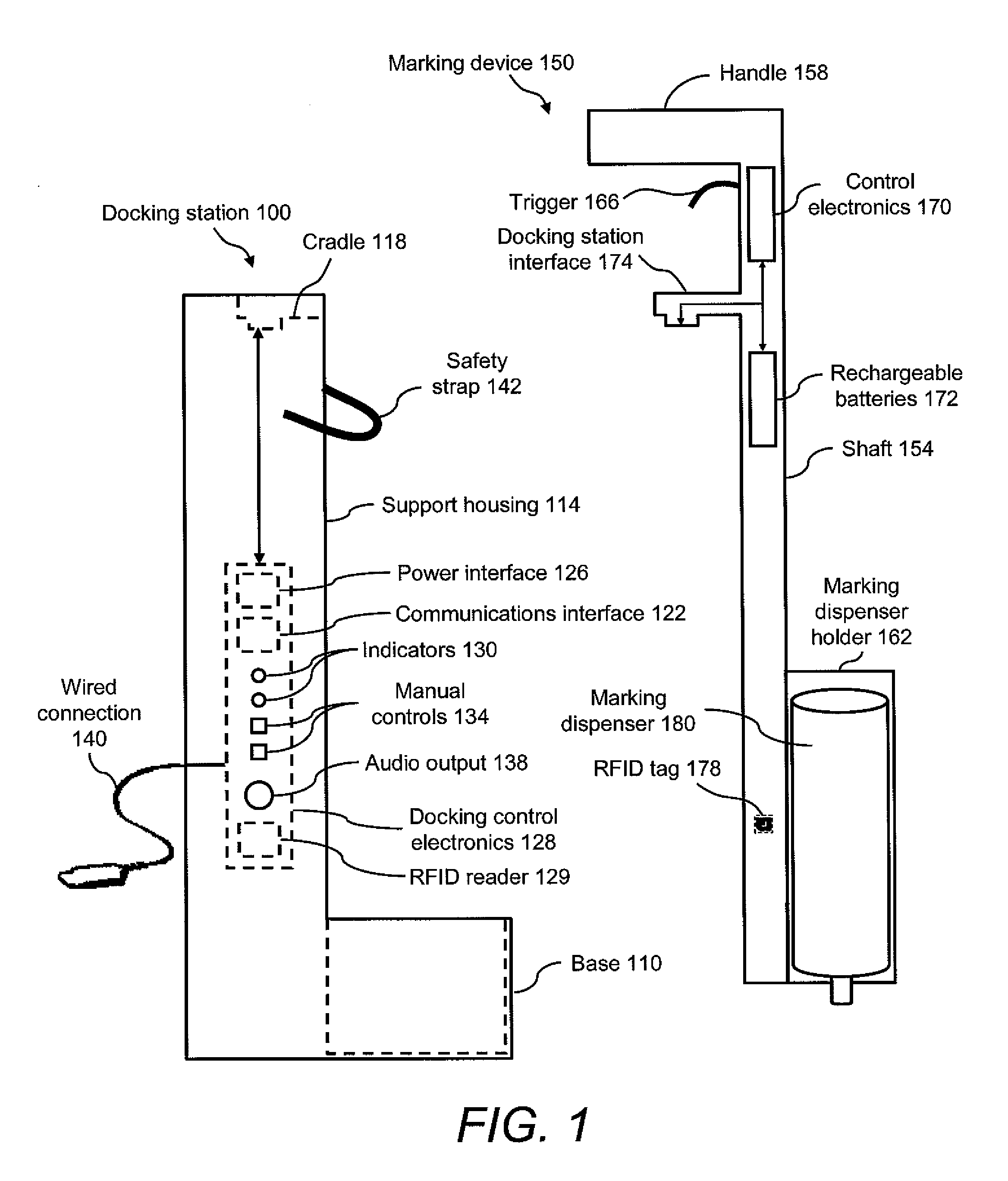

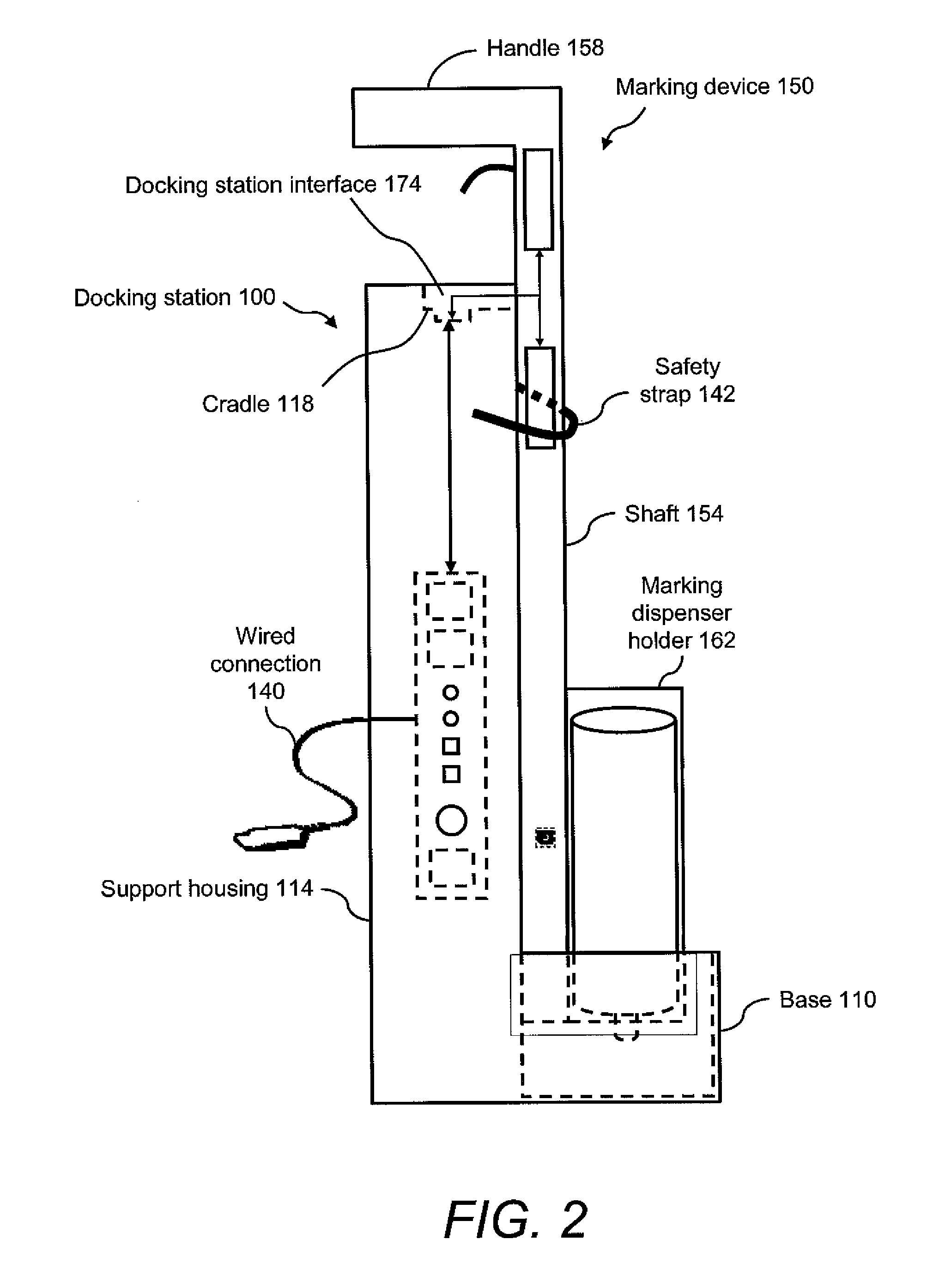

Marking device docking stations and methods of using same

ActiveUS20100085694A1Surveyor's staffsBatteries circuit arrangementsDocking stationTelecommunications

Docking stations and docking methods are provided for use with marking devices used for marking the presence or absence of an underground facility in a dig area. The docking station may serve as a home base for storage of a marking device, for charging the battery of a marking device, for transferring data to and from a marking device, and for securing a marking device against unauthorized use and / or theft. The docking station may be a mobile docking station that is installed in a vehicle or may be a fixed docking station that is installed at a central location in the field, at a central office, at a home base facility, and the like.

Owner:CERTUSVIEW TECH LLC

Marking device docking stations having security features and methods of using same

Owner:CERTUSVIEW TECH LLC

Marking device docking stations having mechanical docking and methods of using same

Docking stations and docking methods are provided for use with marking devices used for marking the presence or absence of an underground facility in a dig area. The docking station may serve as a home base for storage of a marking device, for charging the battery of a marking device, for transferring data to and from a marking device, and for securing a marking device against unauthorized use and / or theft. The docking station may be a mobile docking station that is installed in a vehicle or may be a fixed docking station that is installed at a central location in the field, at a central office, at a home base facility, and the like.

Owner:CERTUSVIEW TECH LLC

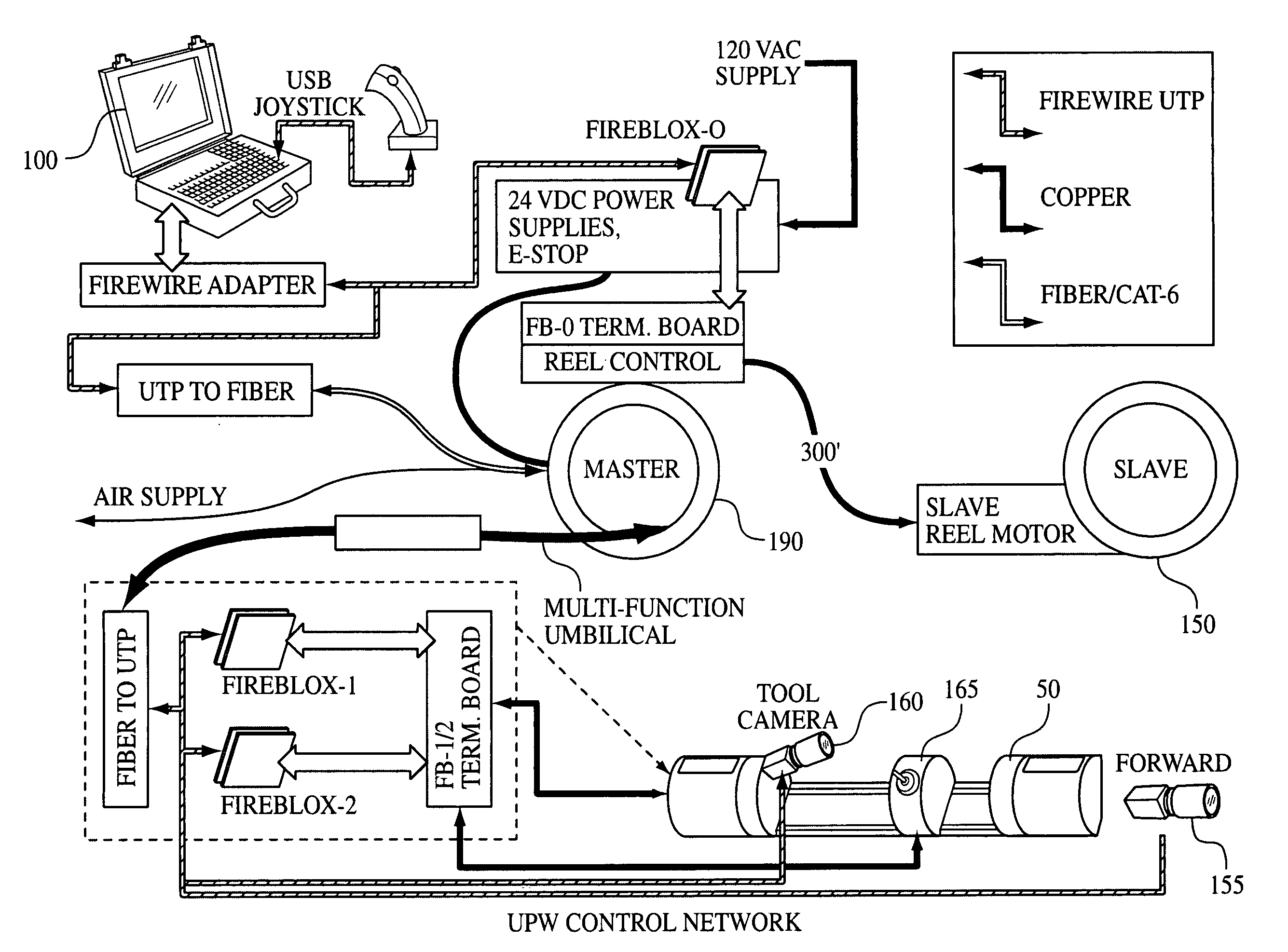

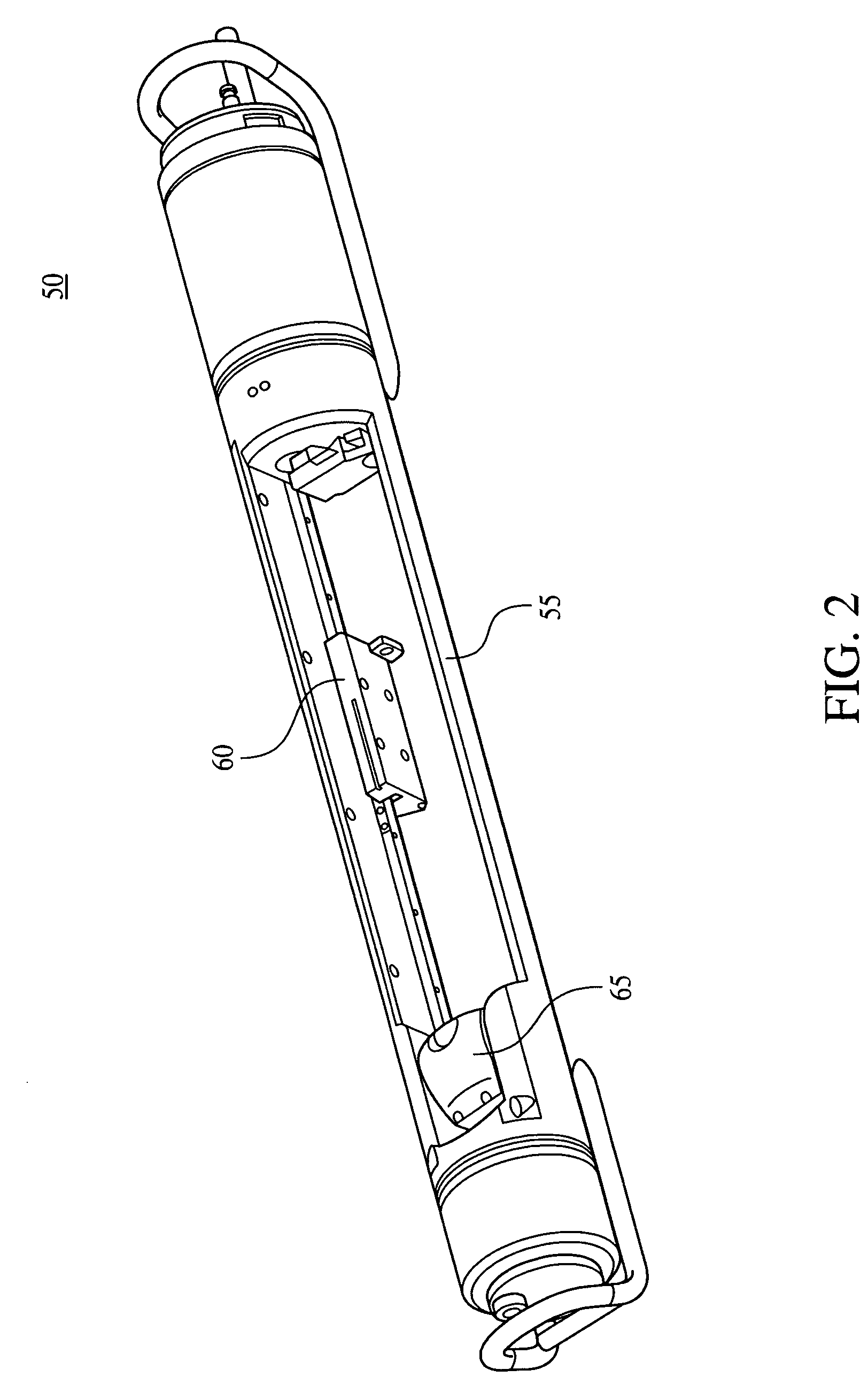

Network architecture for remote robot with interchangeable tools

ActiveUS20060074525A1Slow feedback loopLess time-critical decisionProgramme controlProgramme-controlled manipulatorDigital feedbackAuto-configuration

Systems, methods and devices for the remote control of a robot which incorporates interchangeable tool heads. Although applicable to many different industries, the core structure of the system includes a robot with a tool head interface for mechanically, electrically and operatively interconnecting a plurality of interchangeable tool heads to perform various work functions. The robot and tool head may include several levels of digital feedback (local, remote and wide area) depending on the application. The systems include a single umbilical cord to send power, air, and communications signals between the robot and a remote computer. Additionally, all communication (including video) is preferably sent in a digital format. Finally, a GUI running on the remote computer automatically queries and identifies all of the various devices on the network and automatically configures its user options to parallel the installed devices. Systems according to the preferred embodiments find particular application in the pipeline arts. For example, interchangeable tool heads may be designed to facilitate inspection, debris clearing, cleaning, relining, lateral cutting after relining, mapping, and various other common pipeline-related tasks.

Owner:REDZONE ROBOTICS

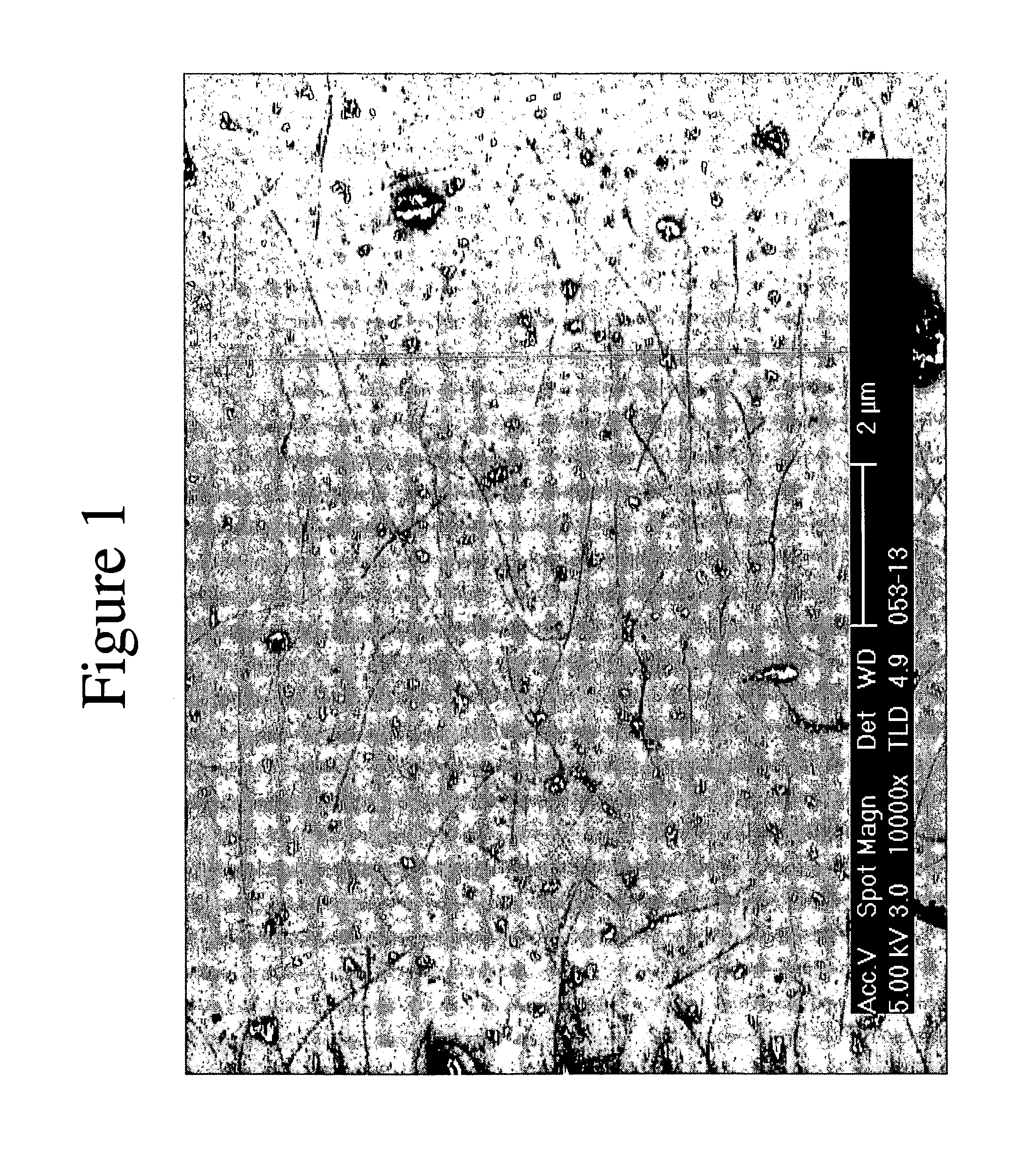

High purity nanotube fabrics and films

InactiveUS20050058797A1High standard of non-toxicity and purityMaterial nanotechnologyLayered productsLiquid mediumMetal impurities

Owner:ZEON CORP

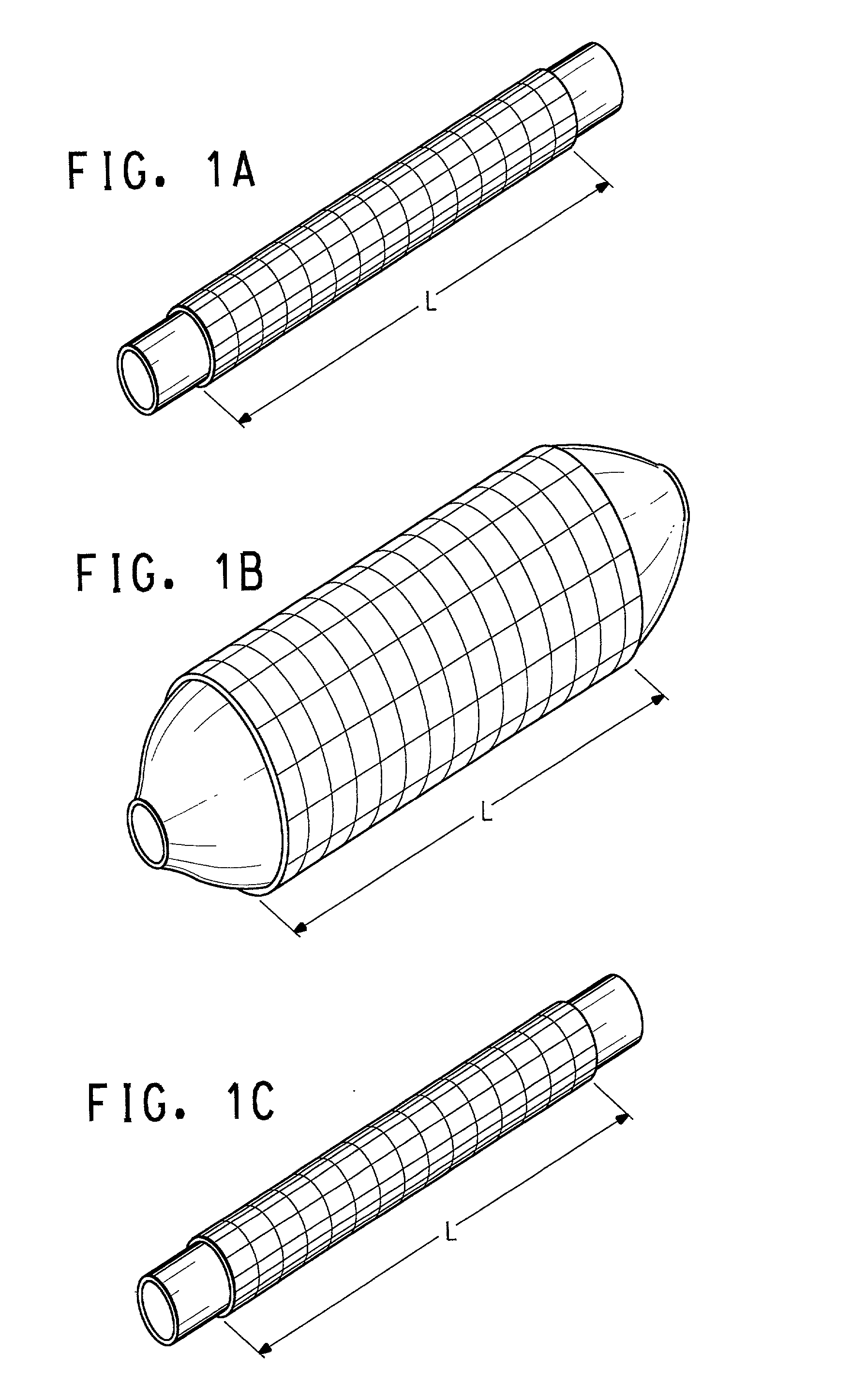

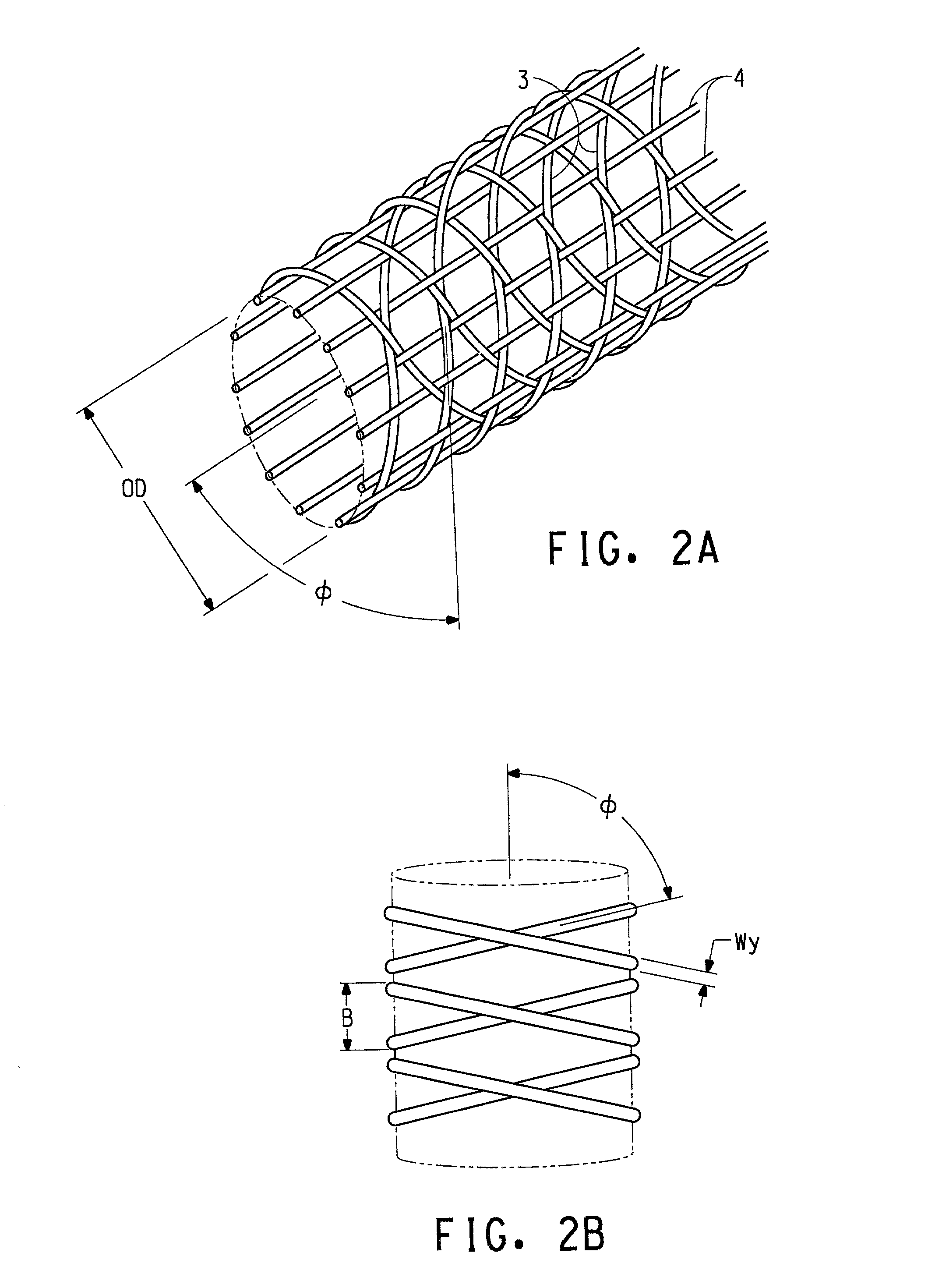

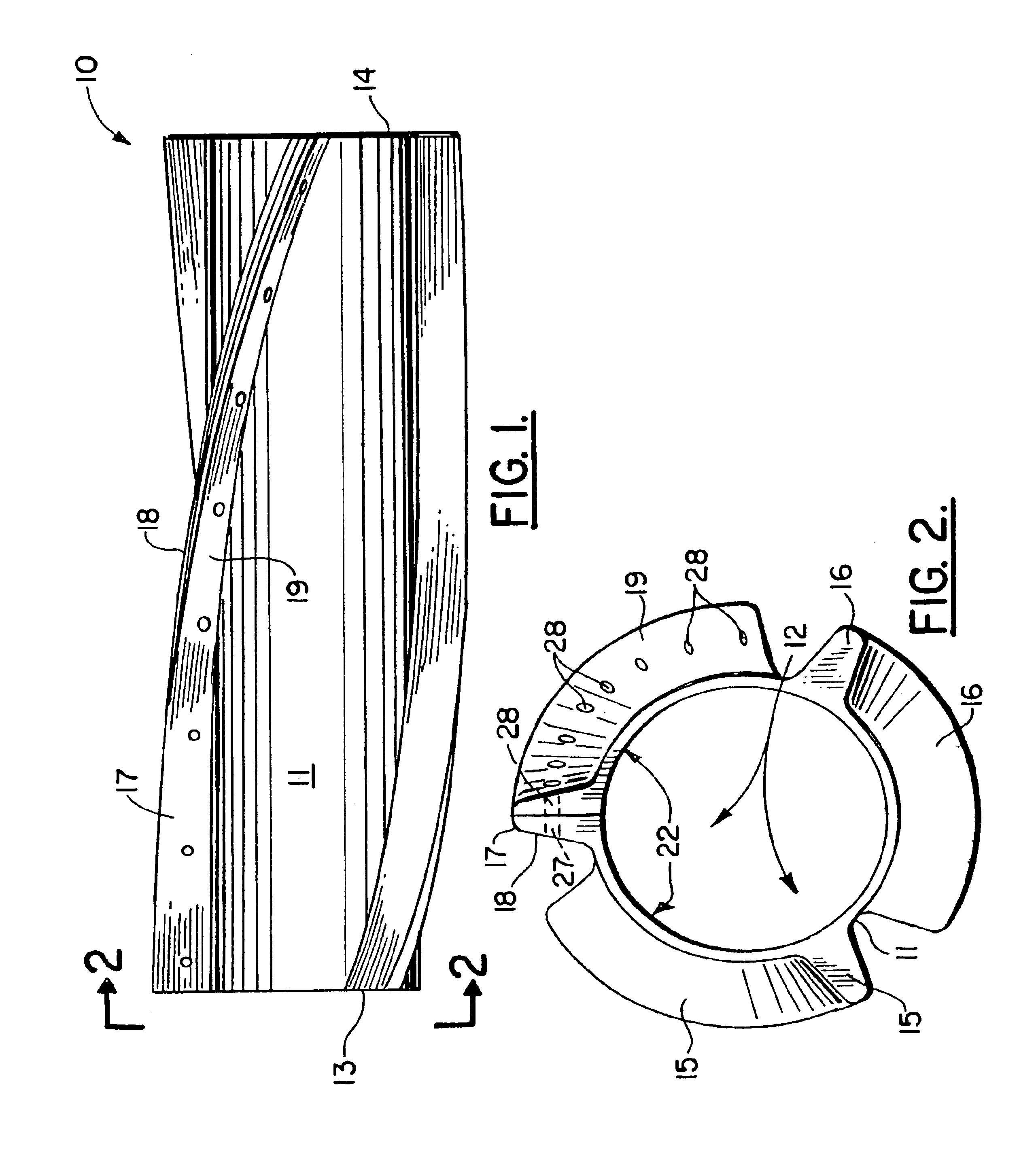

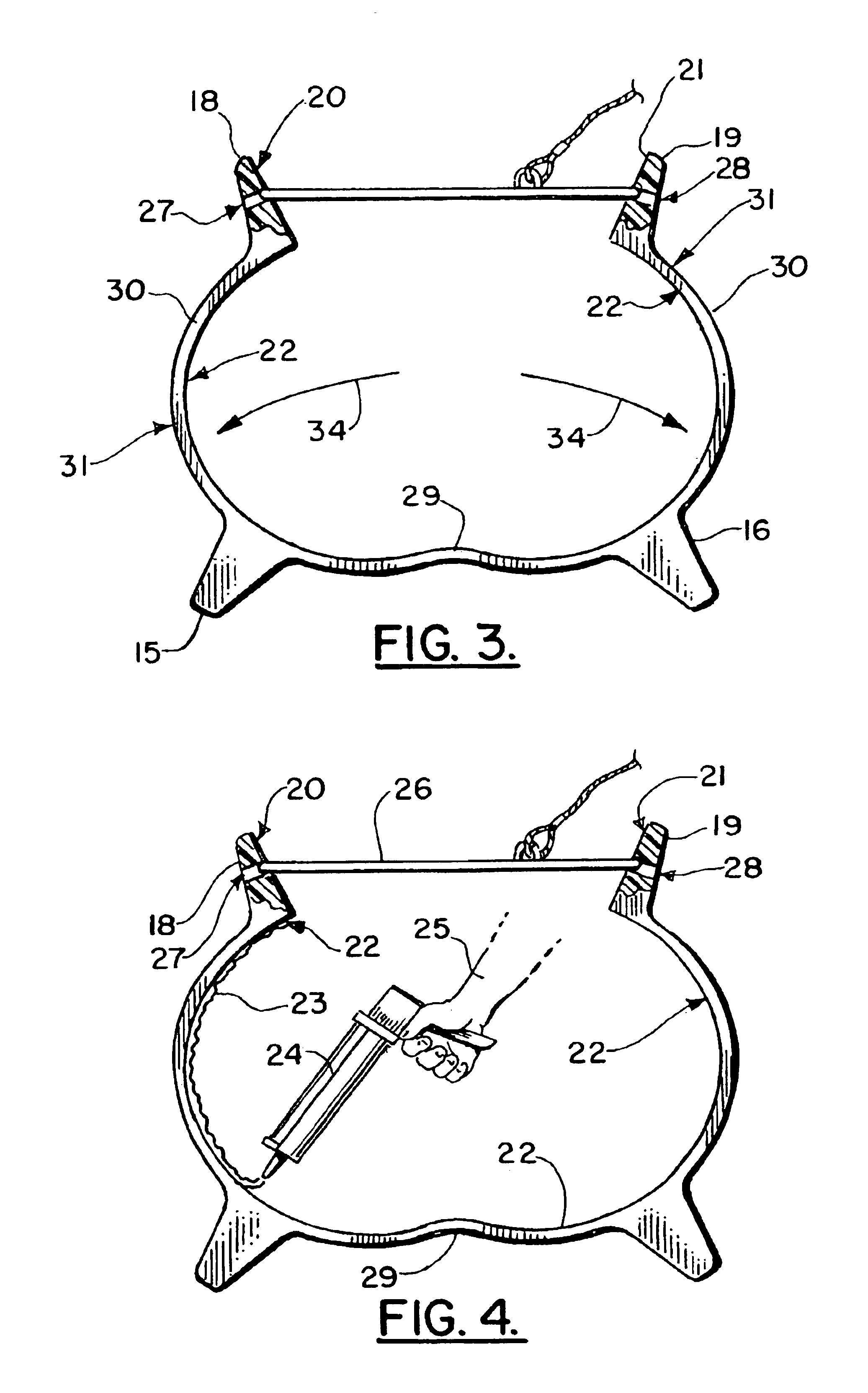

Elastomeric balloon support fabric

InactiveUS20020161388A1Promote recoveryHigh degree of stretchOrnamental textile articlesLayered productsYarnBalloon catheter

Balloon catheter covers are elastic fabric structures of interconnected yarns, the structure having a high degree of stretch and recovery in the circumferential direction with little change in dimension in the longitudinal direction during multiple pressurization cycles over full range of inflation and deflation of the balloon catheter. The covers have longitudinal yarns positioned at about zero degrees to the balloon axis and reversibly-stretchable, circumferential yarns positioned at a high angle Ø to the axis. A method for making the balloon catheter covers allowing nearly orthogonal placement of circumferential and longitudinal yarns involves triaxial braiding a minimum number of elastomeric braid yarns with multiple axial yarns to provide maximum convergence angle (approaching 90 degrees).

Owner:EI DU PONT DE NEMOURS & CO

Coupling device for security coupling first and second elements

The present invention relates generally to coupling devices for securely coupling first and second elements. The disclosed device can be used, for example, to connect different components of oral hygiene apparatuses that produce a relatively high-velocity water jet to clean a person's teeth.

Owner:HIPPENSTEEL JOSEPH B

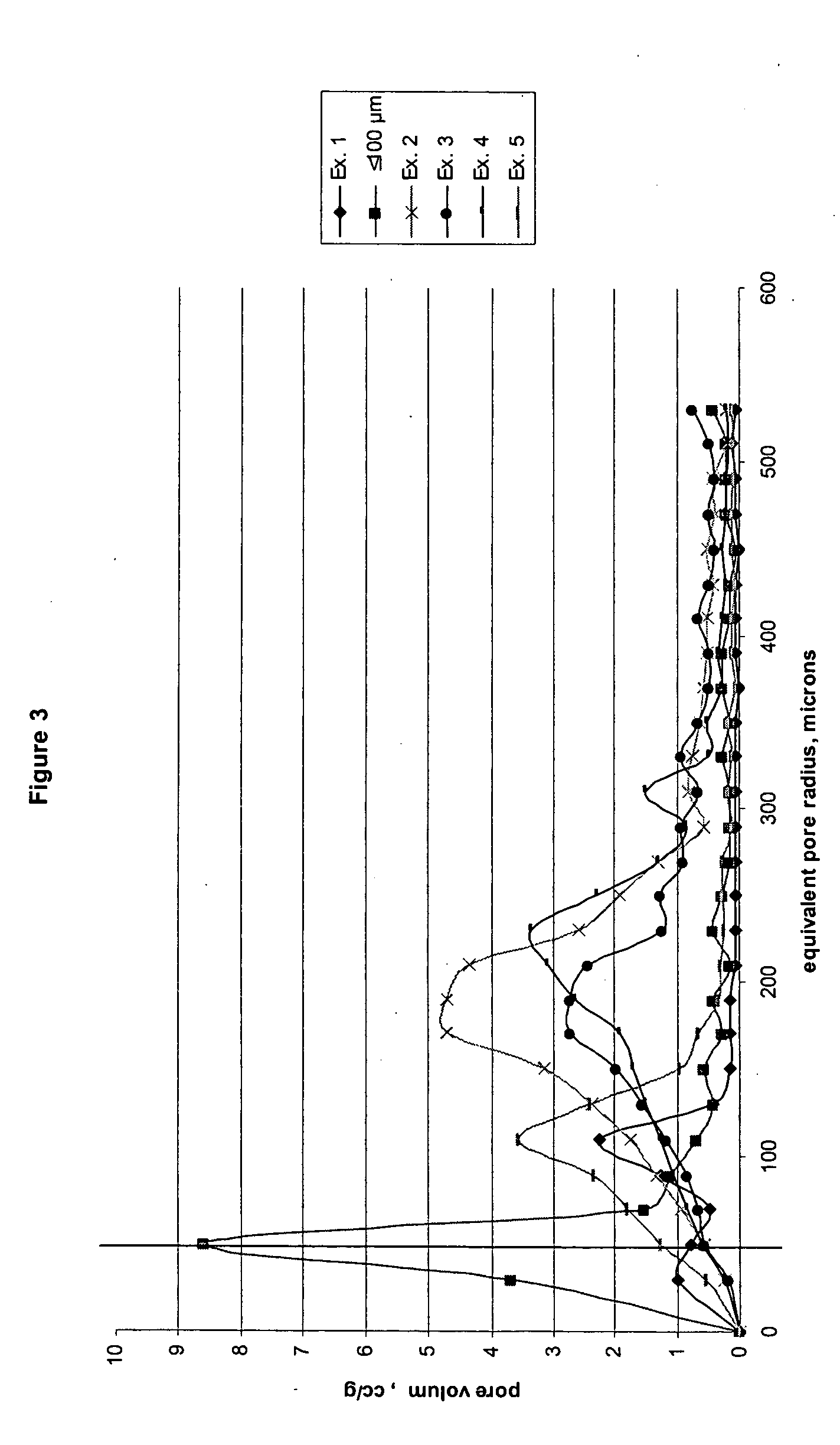

Bimodal pore size nonwoven web and wiper

InactiveUS20050148264A1Easy to cleanQuick releaseCleaning equipmentCleaning using toolsViscous liquidReservoir function

The present invention provides a nonwoven web laminate having at least a bimodal pore size distribution. The laminate has a first layer with pores having a mean equivalent pore radius greater than about 100 μm and a second layer with pores having a mean equivalent pore radius less than about 100 μm. Generally, the first layer has a mean equivalent pore size radius in the range of about 1 μm to about 100 μm and the second layer has a mean equivalent pore size radius in the range of about 100 μm to about 1000 μm. The layer having an average pore size radius greater than 100 μm provides rapid fluid release from the laminate to facilitate cleaning by providing a cleaning solution to solubilize particles or viscous liquids on the surface. In addition, the large pore size allows particles and viscous liquids to be captured and trapped within the pores of the laminate, thereby effectively cleaning the surface to be cleaned. The layer with the small pore size provides a fluid reservoir function by absorbing fluid and holding the fluid in the laminate, or by holding a cleaning fluid to be released during a cleaning operation. The nonwoven web laminate of the present invention is an effective wiper.

Owner:KIMBERLY-CLARK WORLDWIDE INC

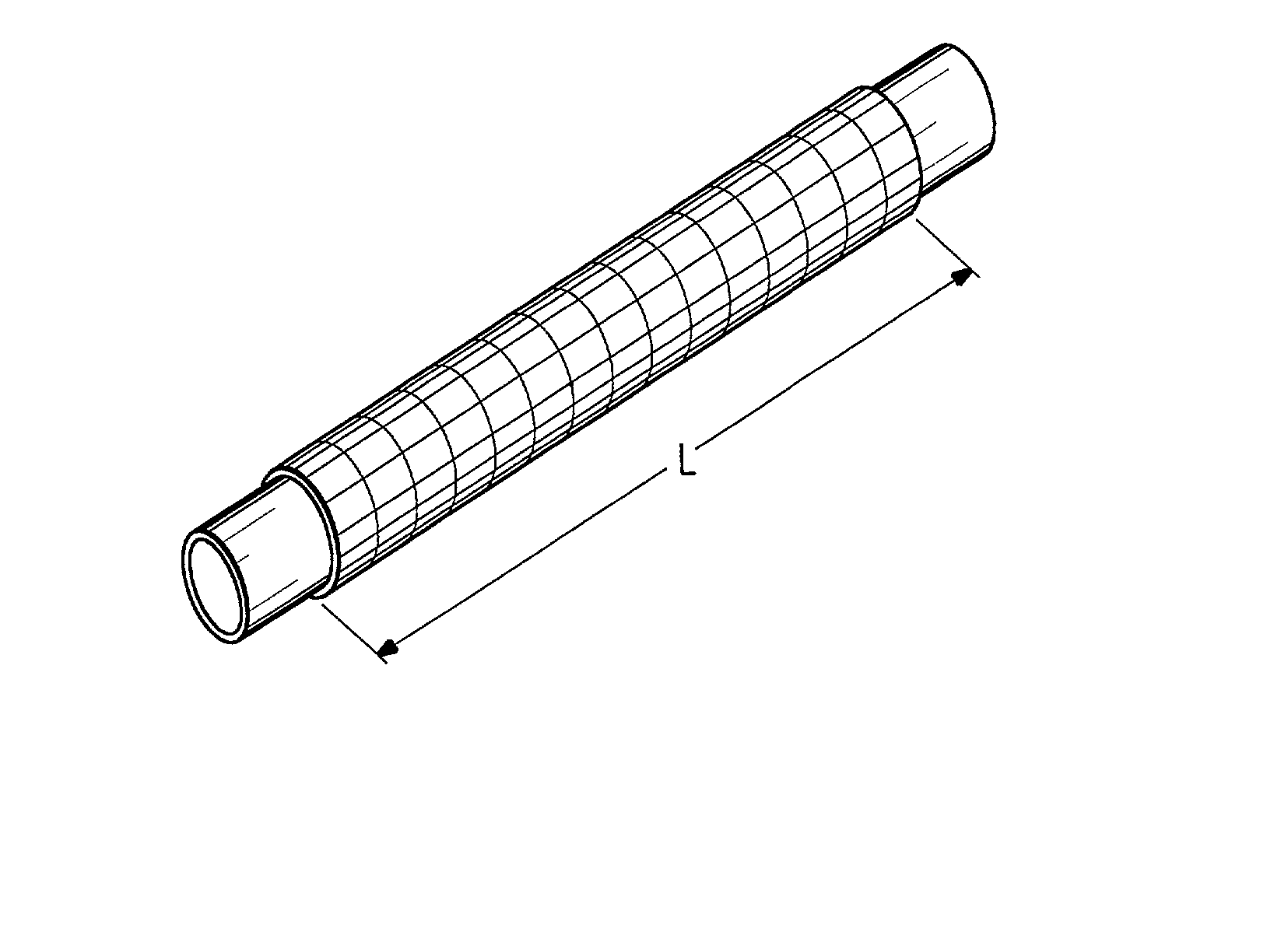

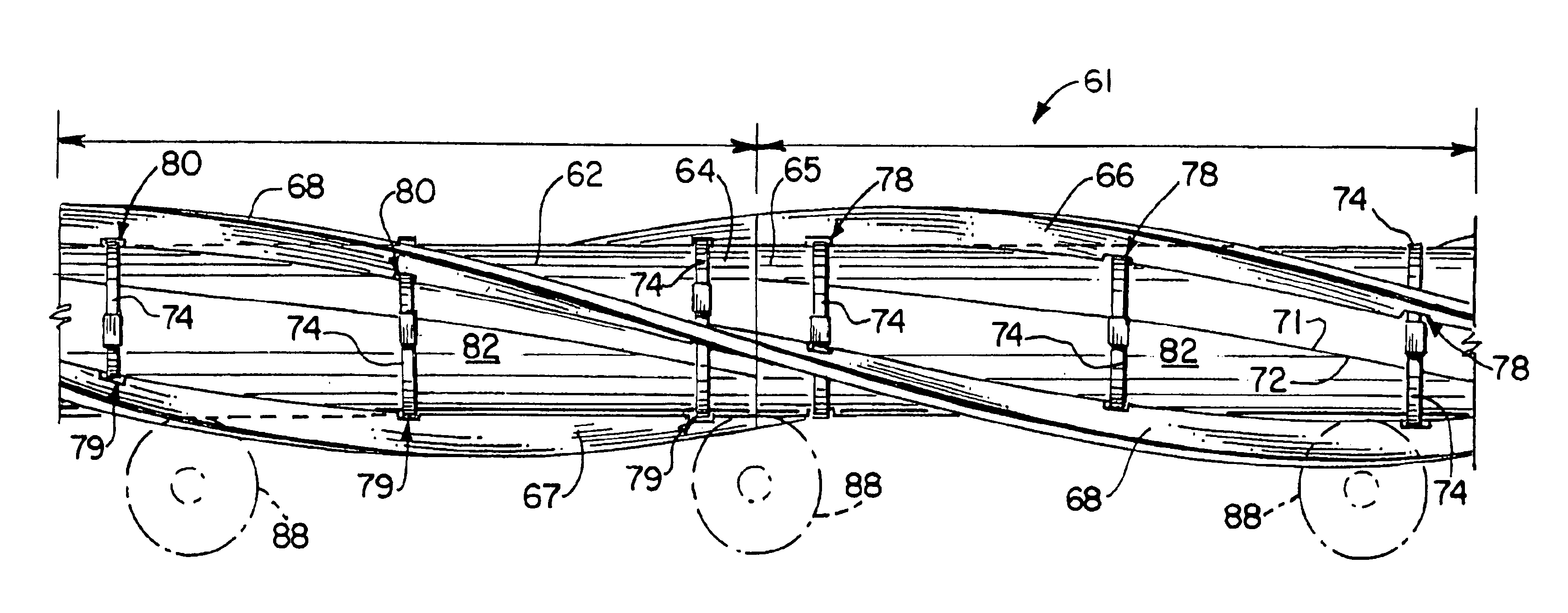

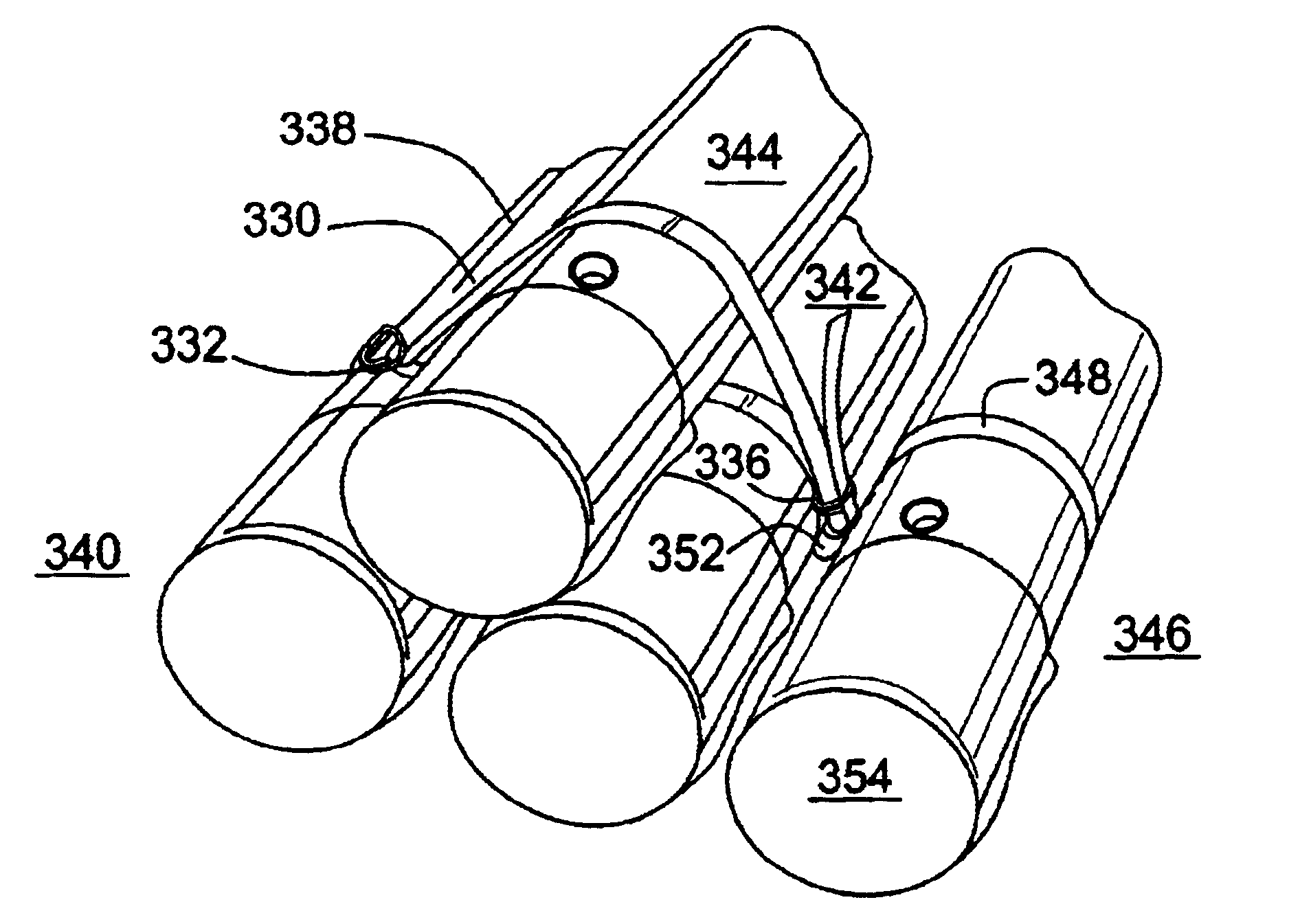

Vortex induced vibration suppression device and method

InactiveUS6896447B1Easy to installEasy constructionPipe laying and repairDrilling rodsVertical tubeHelical blade

A vortex induced vibration suppressor and method is disclosed. The apparatus includes a body that is a flexible member of a polymeric (e.g., polyurethane) construction. A plurality of helical vanes on the body extend longitudinally along and helically about the body. Each vane has one or more openings extending transversely there through. A longitudinal slot enables the body to be spread apart for placing the body upon a riser, pipe or pipeline. Tensile members that encircle the body and pass through the vane openings enable the body to be secured to the pipe, pipeline or riser.

Owner:TAQUINO WELDON

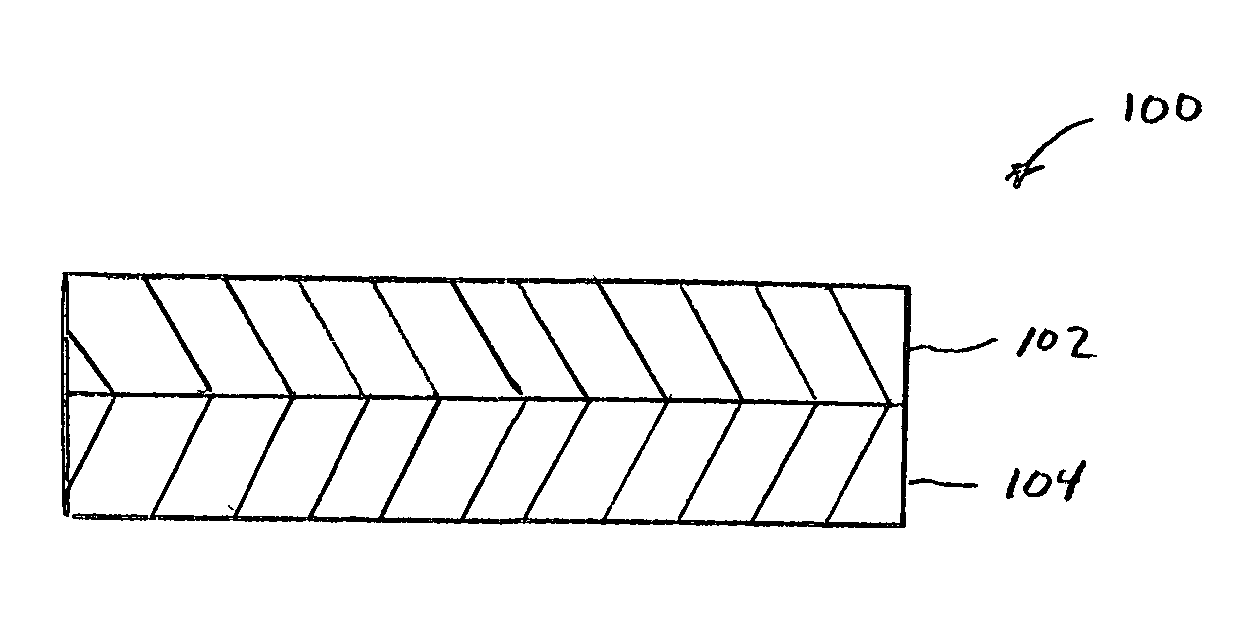

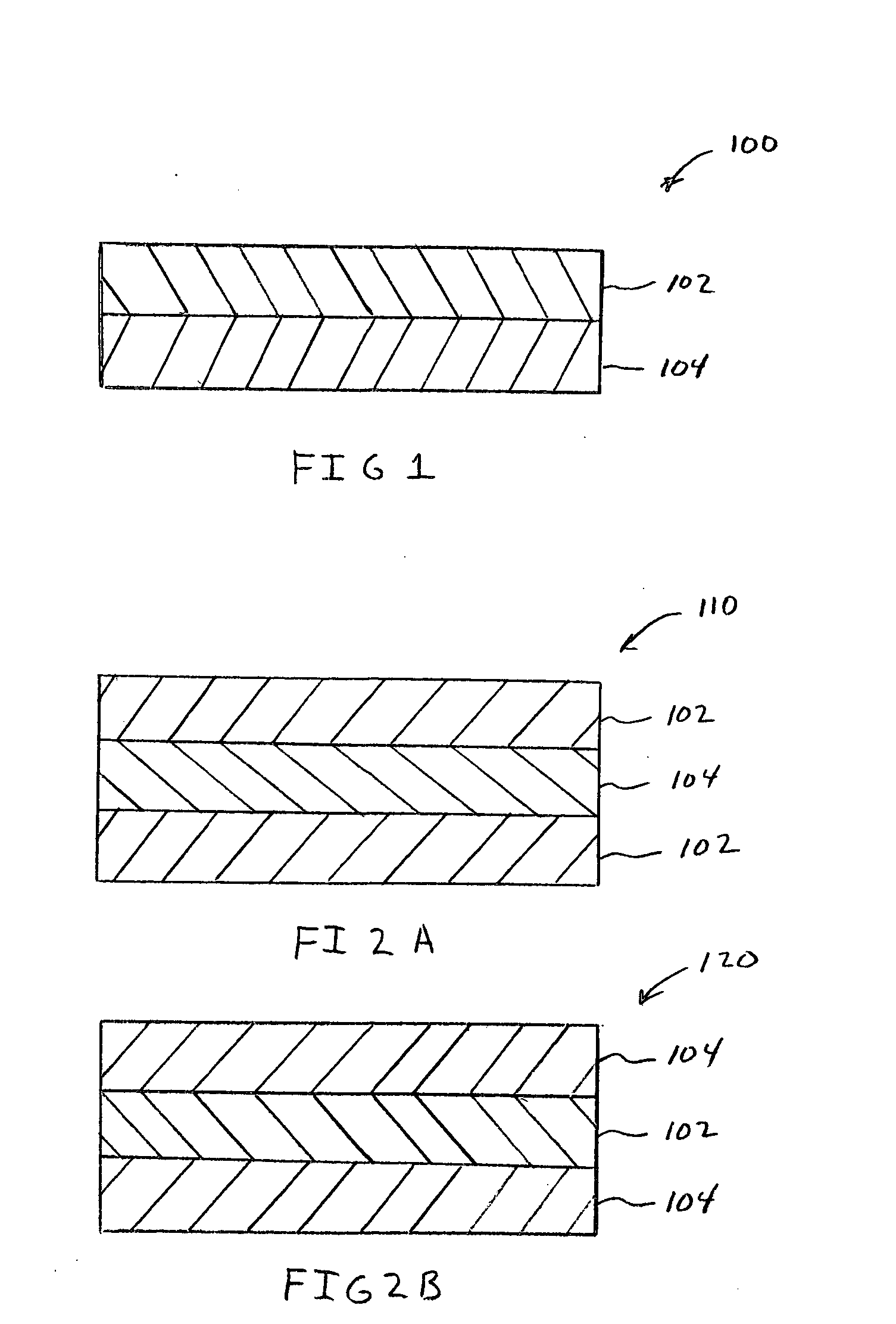

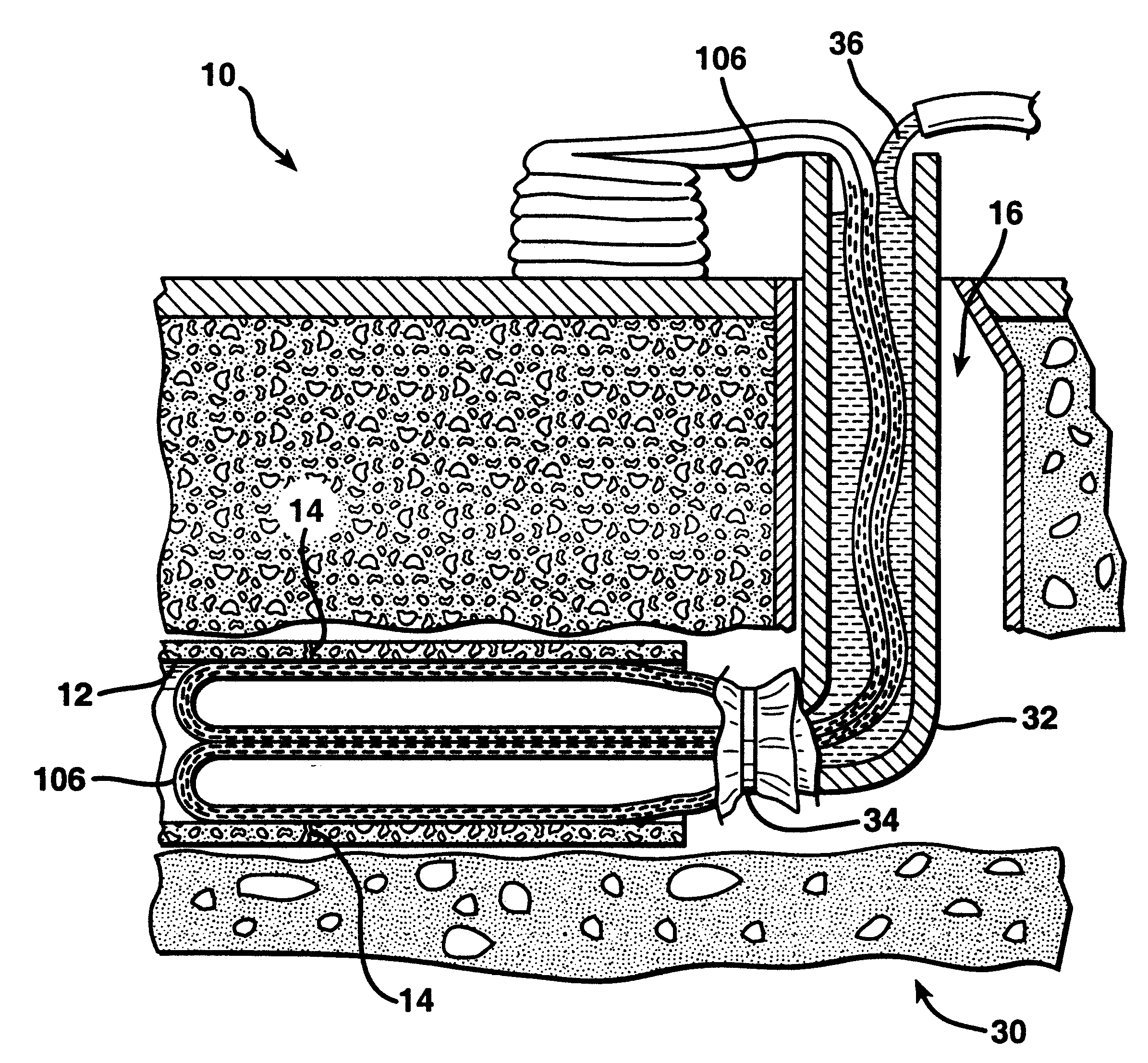

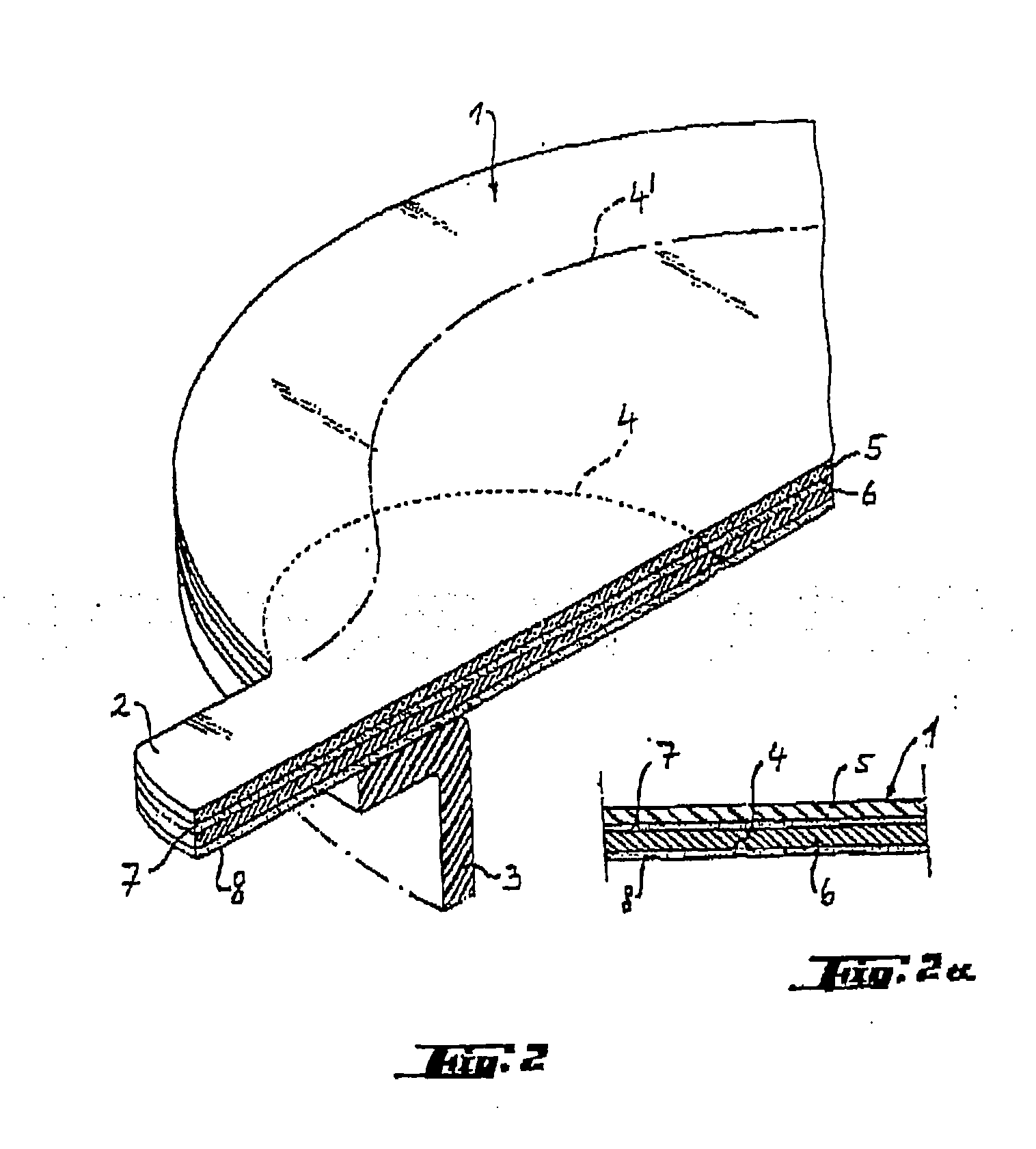

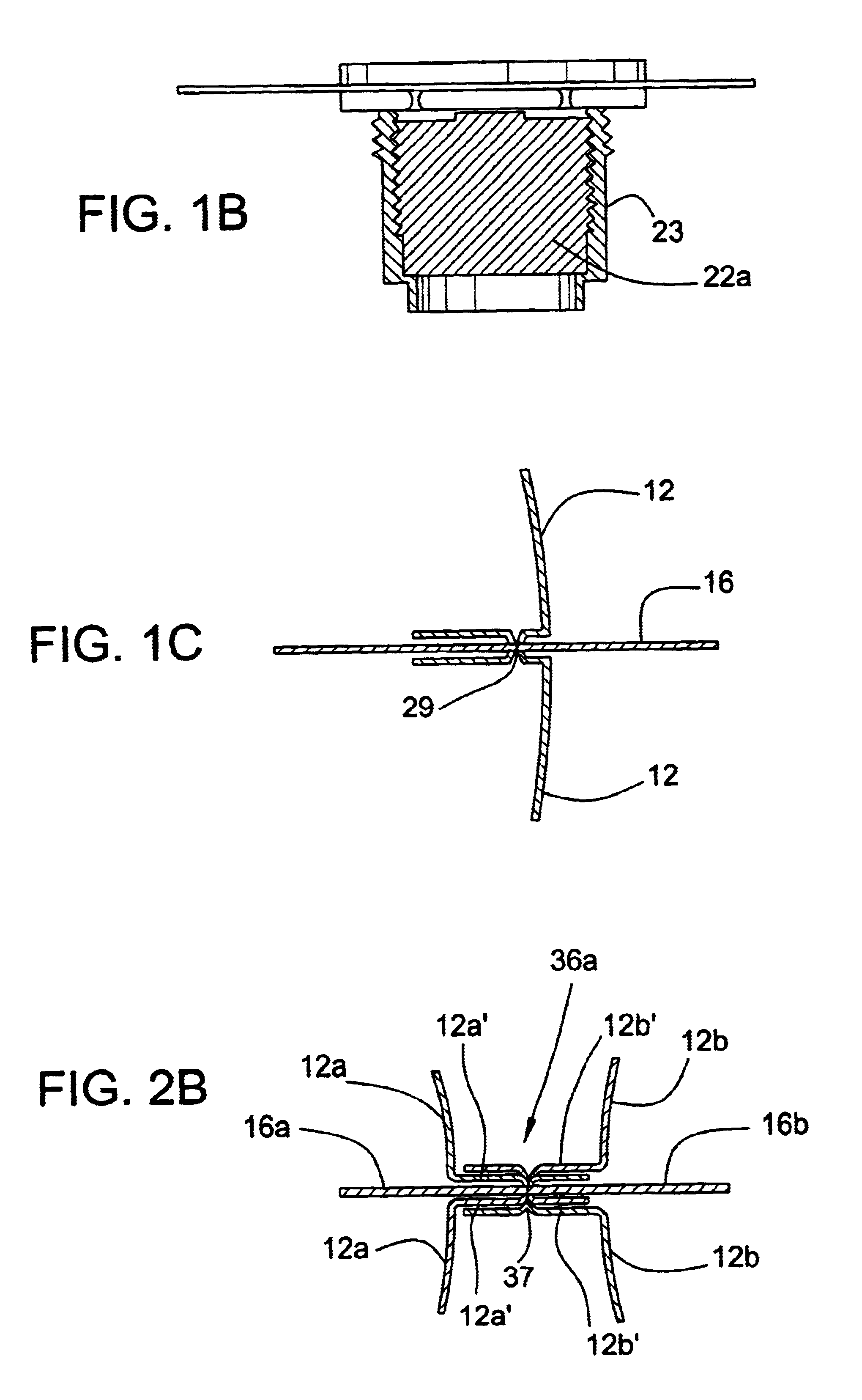

Liner for reinforcing a pipe and method of making the same

A reinforcement liner and methods of manufacturing the liner are disclosed. The liner includes a fabric material having first and second support layers. Each of the layers includes reinforcing fibers. The first and second support layers are oriented in different directions to provide support to the liner in those directions. The liner includes a stitching material that is used to couple the first and second support layers together. The stitching material is preferably an elastic yarn. One of the support layers includes long, chopped strands that are oriented parallel to each other. The long, chopped strands are directed so that they are in the peripheral direction of the finished reinforcement liner. The long, chopped fibers can be distributed continuously or only along portions of the width of the fabric. The disclosed methods of manufacturing a liner include alternative processes by which the liner can be made. The fabric is manufactured in the form of a continuous roll. One method involves winding the roll in a helical pattern about a fixed mandrel. Another method involves mounting several rolls circumferentially about a mandrel. The rolls are mounted so that strips of fabric from each roll overlap a portion of adjacent fabric strips to provide a continuous liner surface on the mandrel.

Owner:OWENS CORNING COMPOSITES SPRL BELGIUM +1

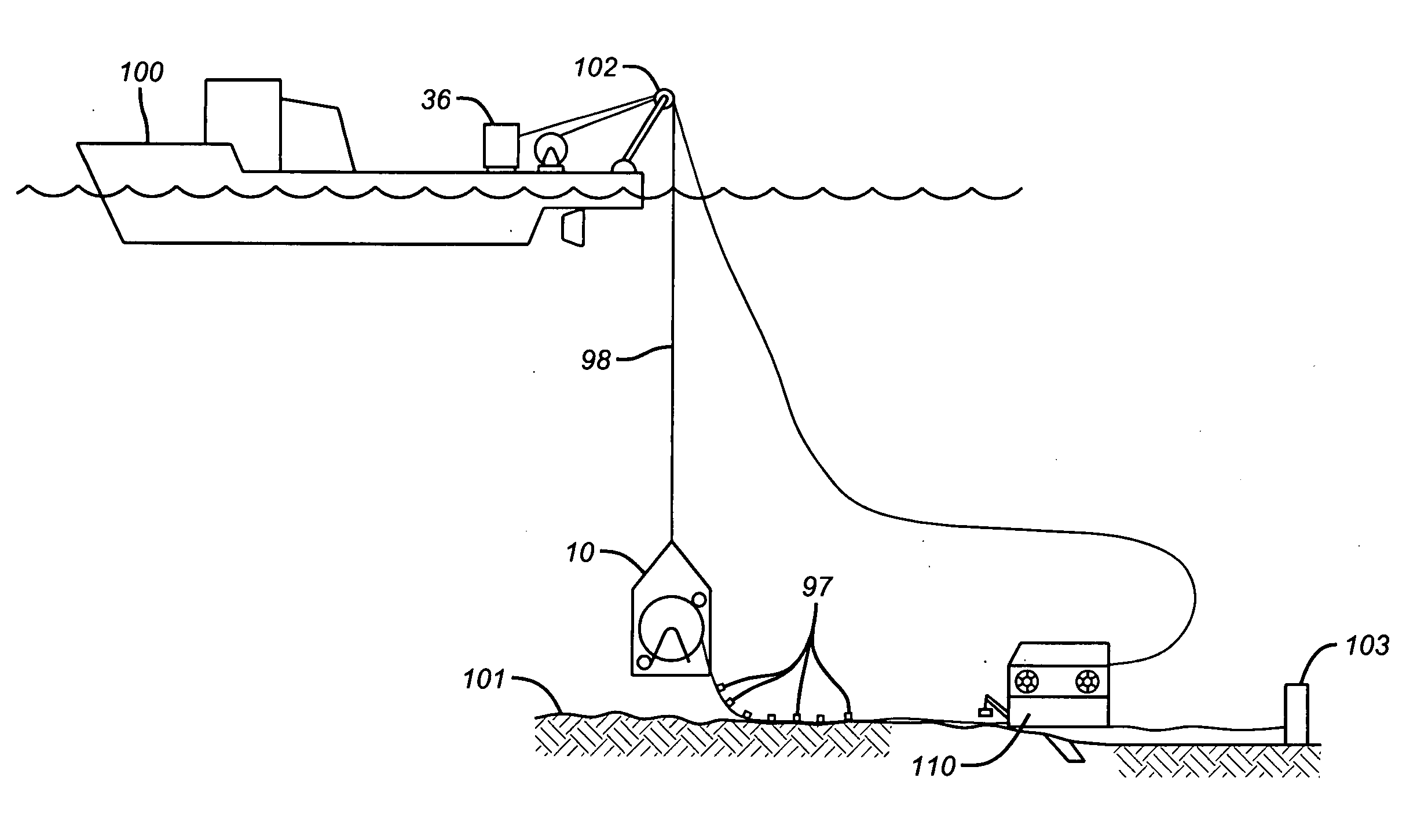

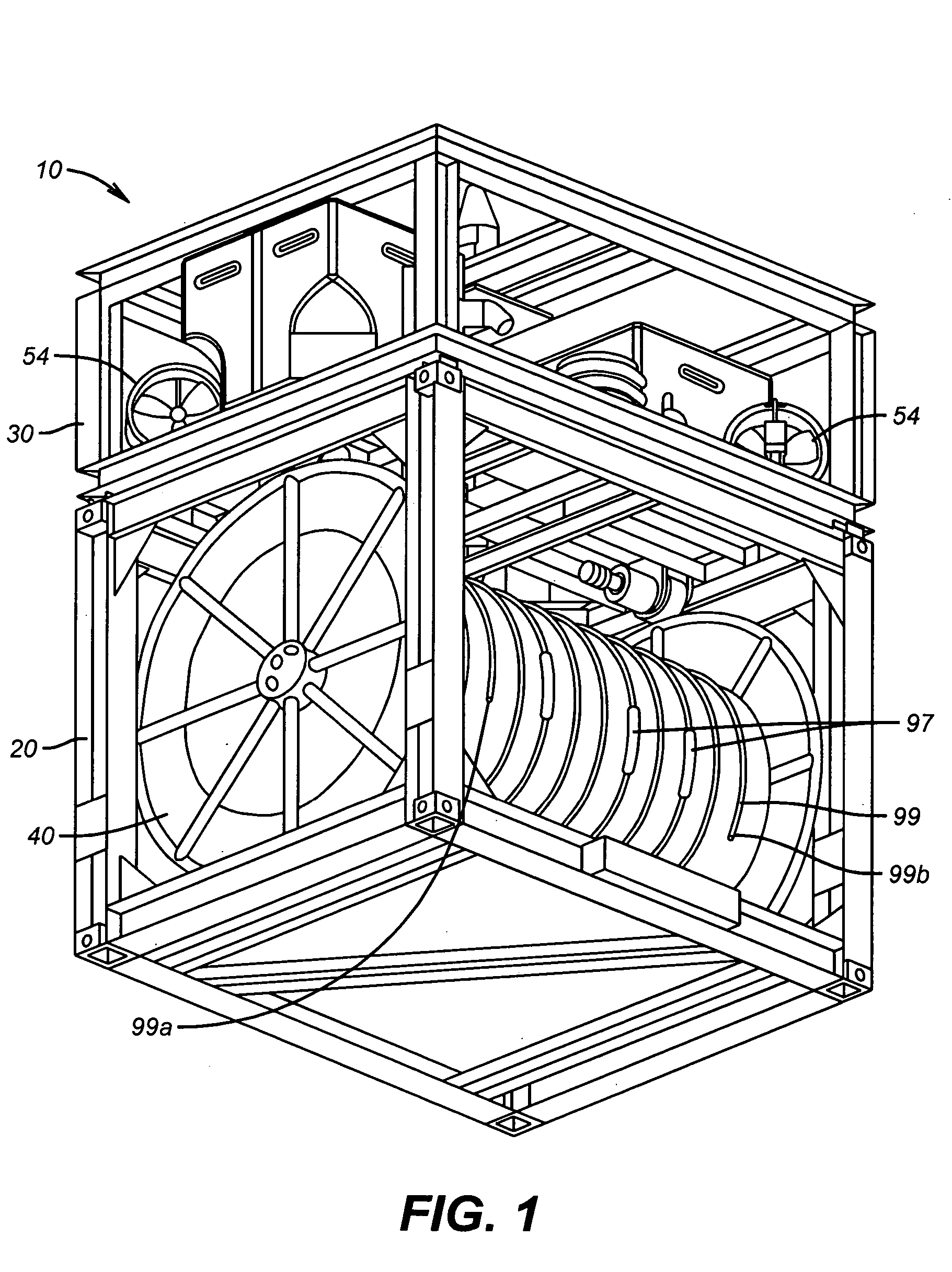

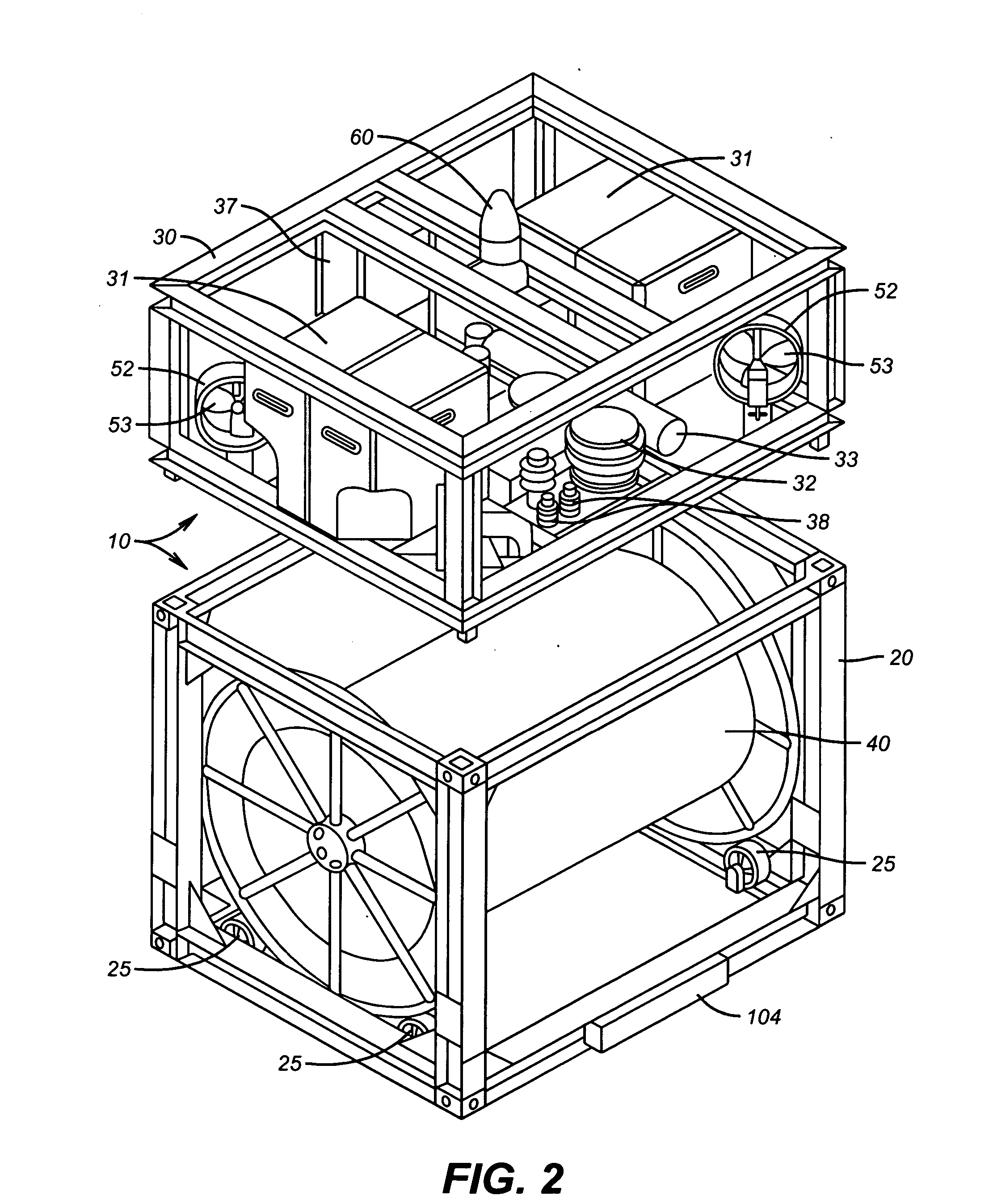

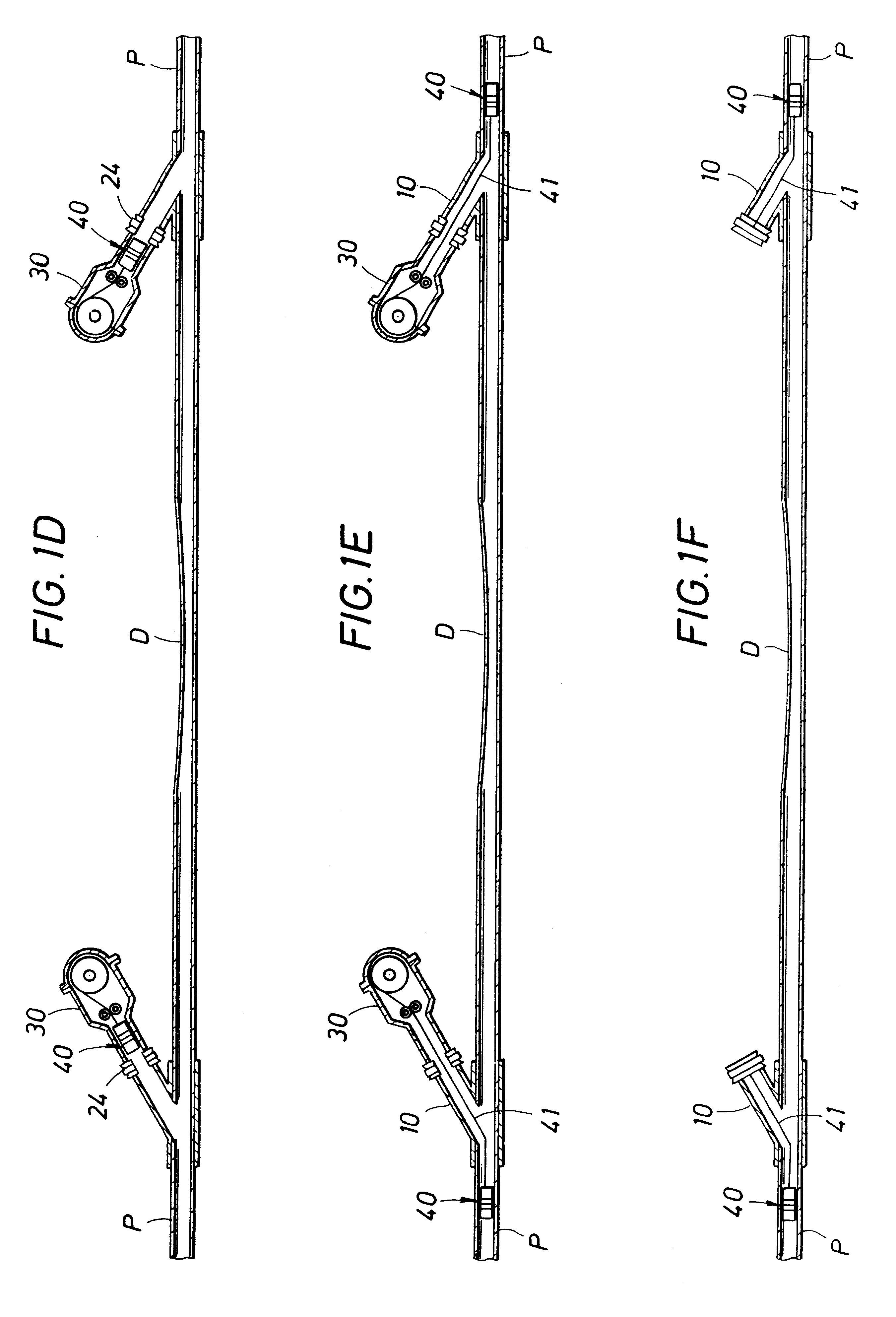

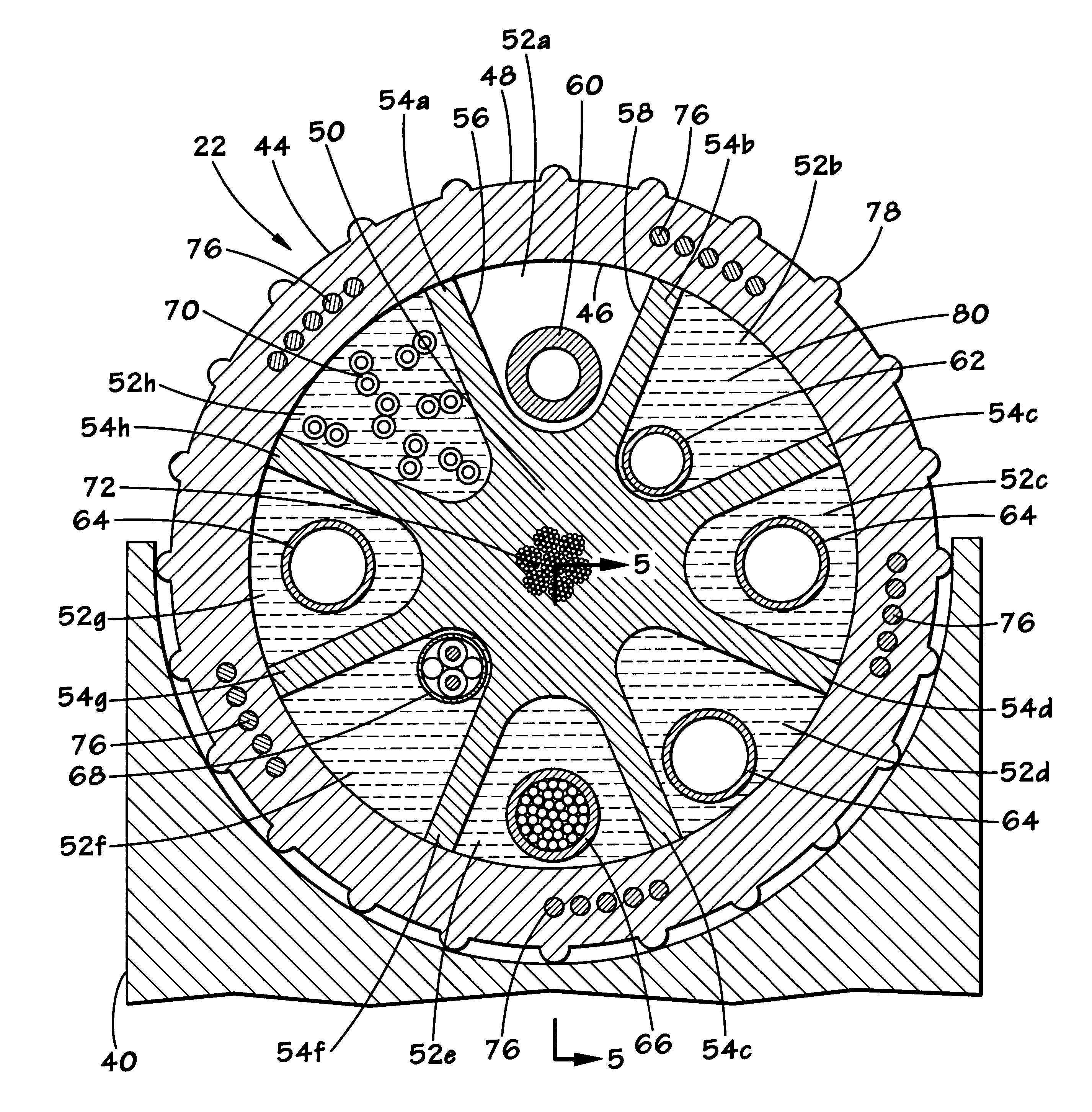

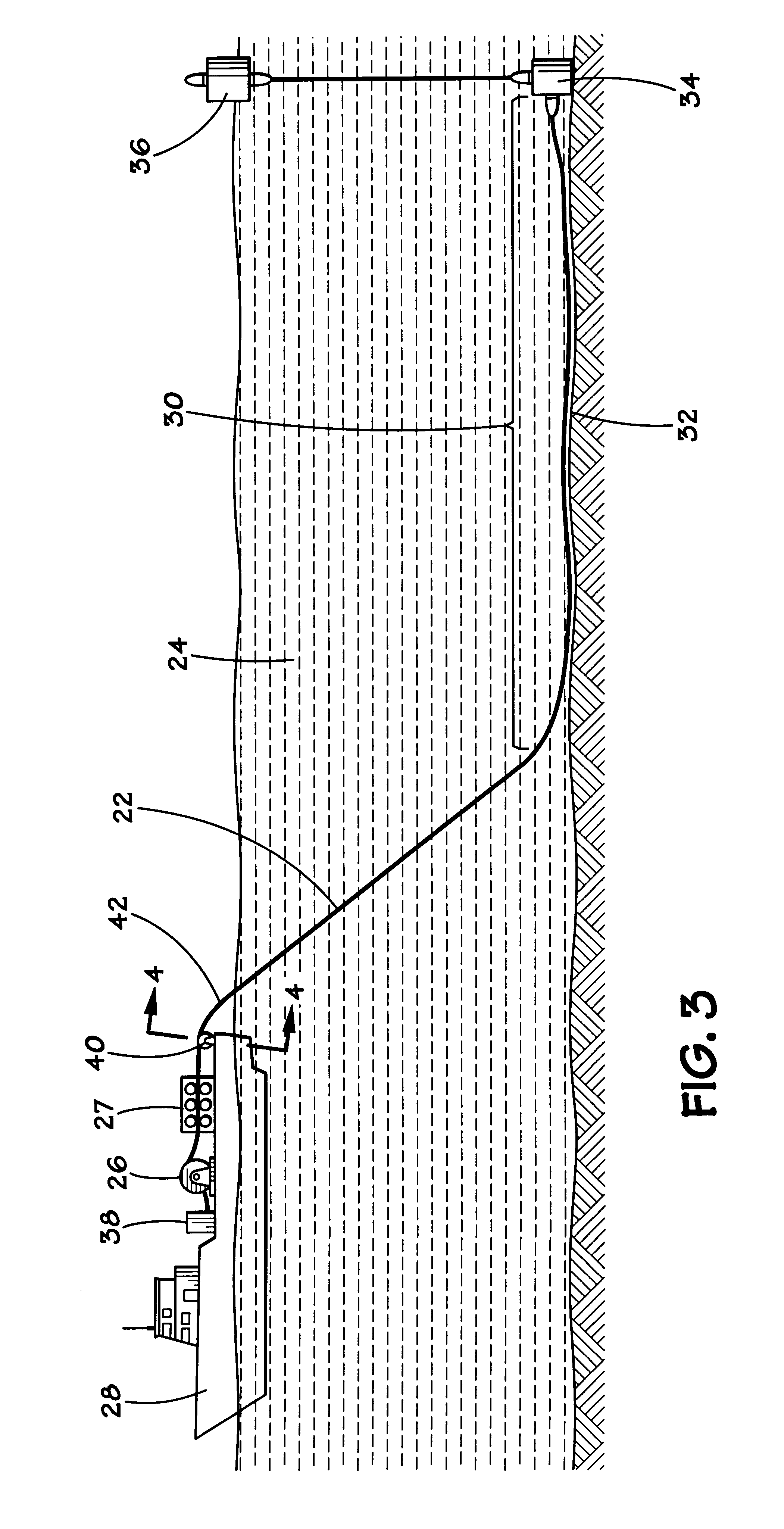

Remotely operated deployment system and method of use

A system and method for deploying and / or retrieving a cable underwater. In an embodiment, a system comprises a cage, comprising a guidance system adapted to be remotely operable subsea by a vessel; a communications link operatively linking the guidance system and the vessel; and a non-palletized reel rotatably and removably mounted within the cage, the reel adapted to receive an unspoolable length of cable, the cable comprising two fee ends. In an exemplary method, the reel, onto which cable is spooled is removably and rotatably housed in a cage adapted for remote control use underwater and the cage lowered by a vessel to a position proximate a seafloor. The cage is maneuvered along a predefined flight pattern in substantially a single plane with respect to the seafloor while selectively releasing the cable from the reel. It is emphasized that this abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope of meaning of the claims.

Owner:OCEANEERING INTERNATIONAL

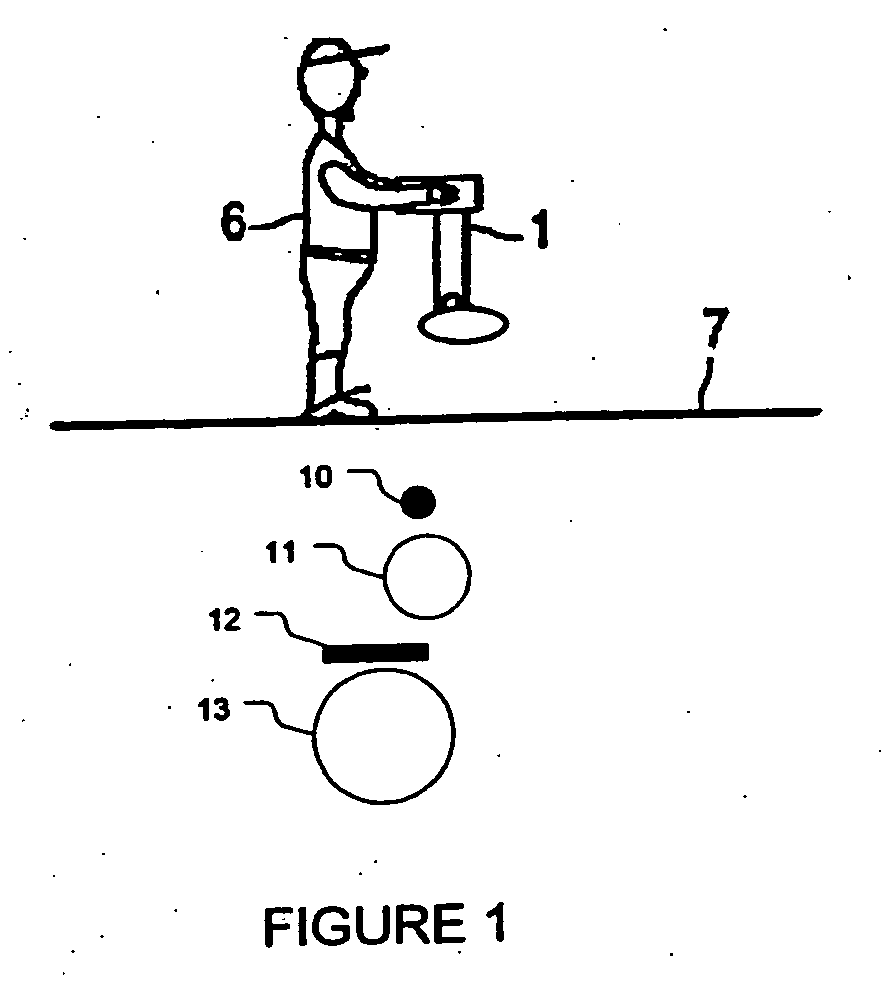

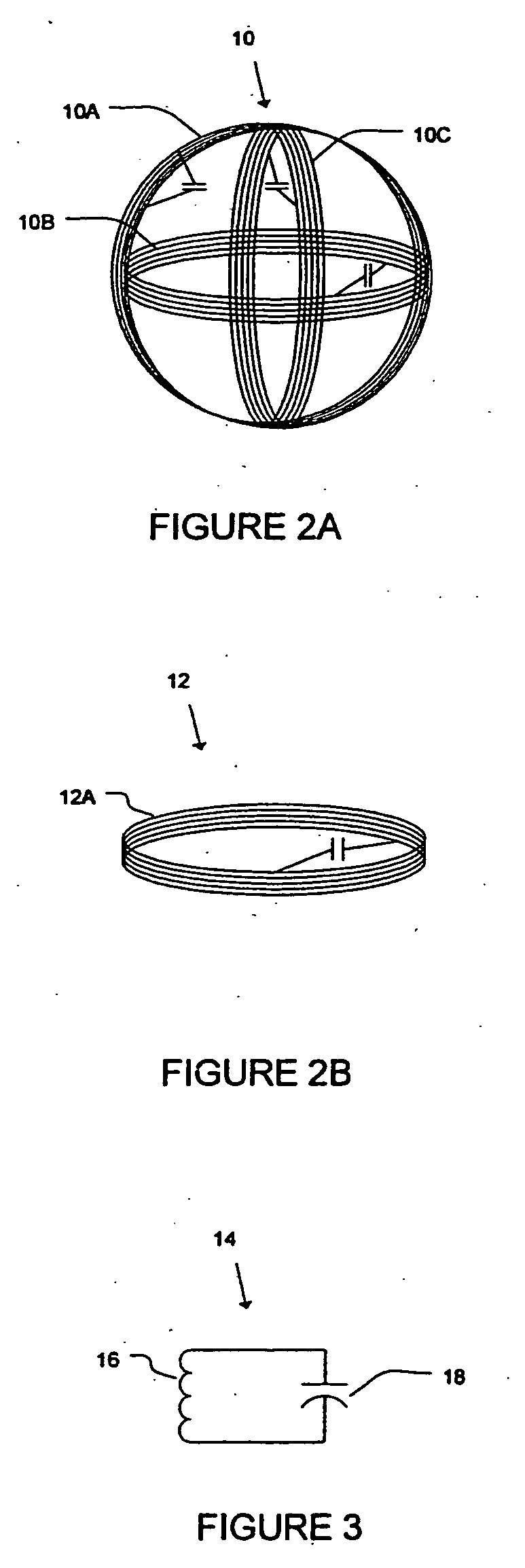

Method and apparatus for digital detection of electronic markers using frequency adaptation

ActiveUS20070040558A1High-precision identificationReliable discriminationPipe laying and repairElectric/magnetic detectionTested timeAnalog front-end

Owner:BUSAN TRANSPORTATION CORPORATION

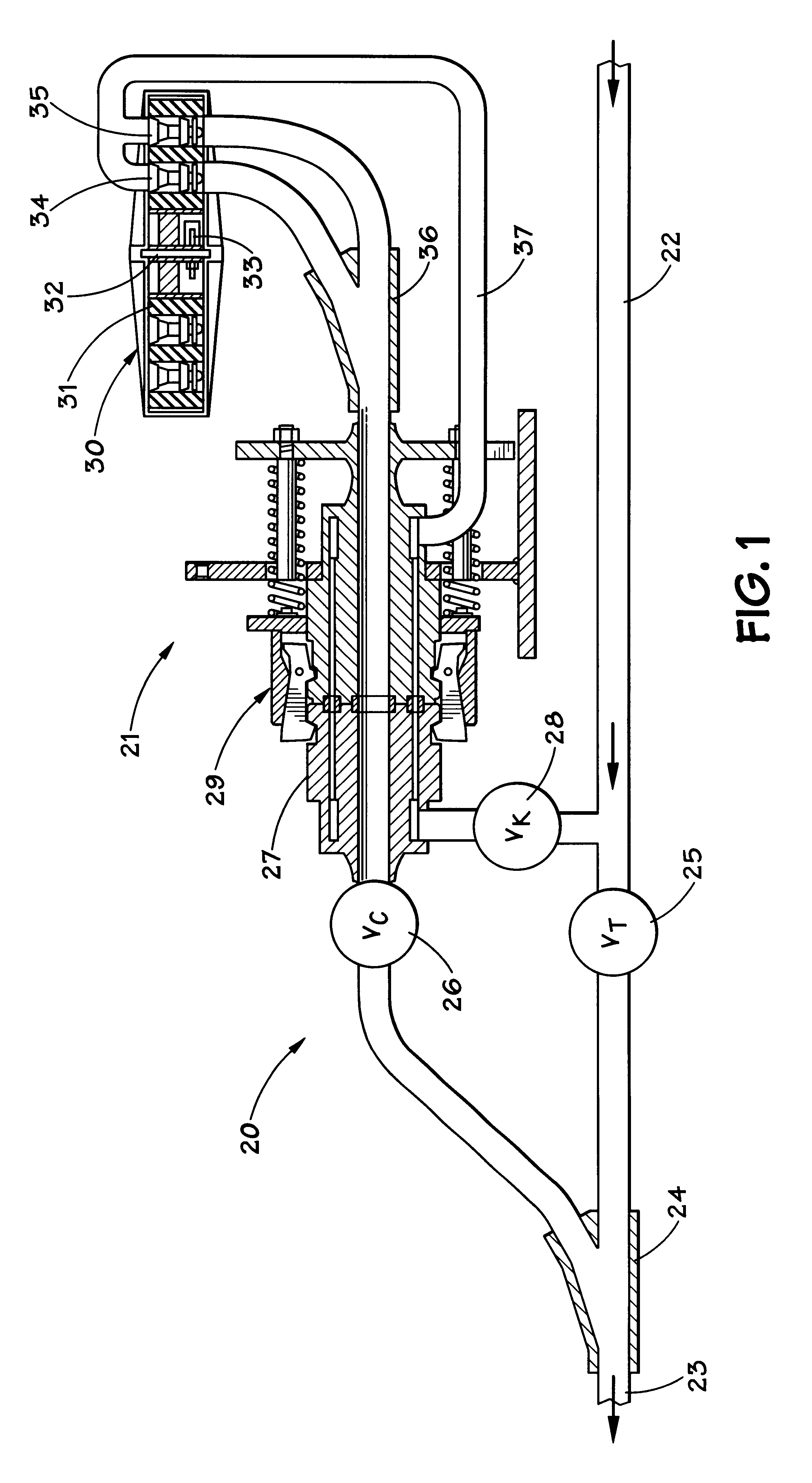

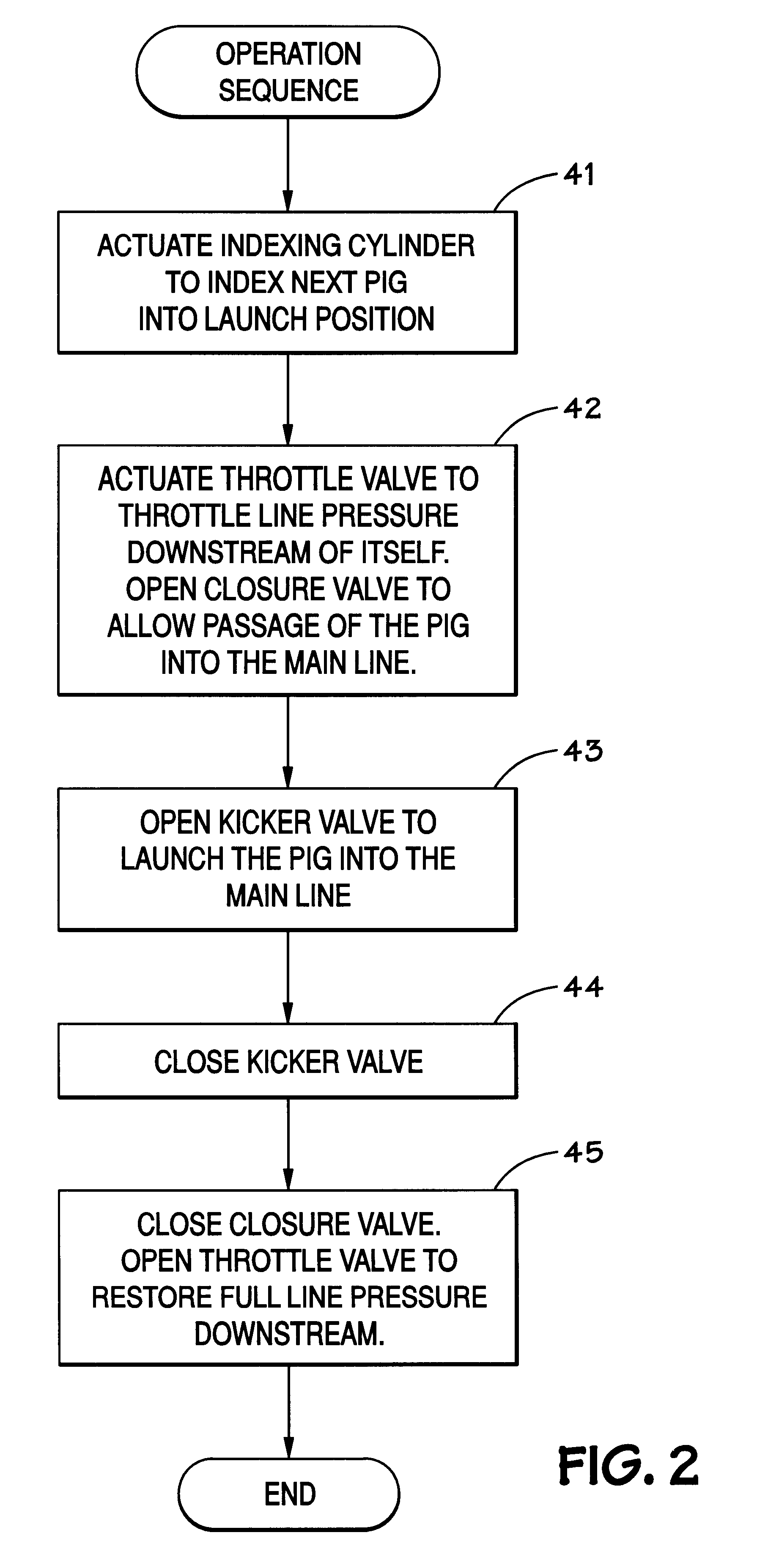

Multiple pig subsea pig launcher

The pig launcher is installed subsea by coupling it to a launcher manifold. The launcher manifold is installed substantially permanently subsea as a part of a pipeline. The pig launcher includes a dual bore collet connector for coupling to the launcher manifold, and a rotary storage magazine for storing the pigs. The launcher manifold can be manufactured, for example, as part of an inline lateral tie-in sled or as part of a pipeline end manifold (PLEM). A branch connection from the pipeline to the pig launcher is provided in the launcher manifold via a piggable Y connection to a dual bore collet connector male hub. The pig launcher is landed and latched to the launcher manifold to complete the pig launching system. A closure valve between the Y connection and the hub prevents a pressure loss when the pig launcher is not installed, and the closure valve is opened to permit passage of the pigs during launching. A throttle valve upstream of the Y connection allows the pipeline pressure to be dropped downstream so that a pig can be launched using upstream pressure. During launching, a kicker valve is opened to bypass the throttle valve and direct the higher upstream pressure through the secondary bore of the dual bore collet connector and into the rotary magazine.

Owner:OIL STATES INDS UK

Thermally-sealable multilayer film for resealable packages

InactiveUS20040013827A1Envelopes/bags making machineryPipe laying and repairEngineeringHermetic packaging

A thermally-sealable multilayer film, for packages which may be resealed after opening, includes an outer layer and a support layer, with a thermally-sealable layer on the side facing the packaged material. A self-adhesive layer made from pressure sensitive adhesive is provided between the support layer and the outer layer. The support layer has weakening lines, which define an opening for the removal of packaged material. For resealing a container, by using the thermally-sealable multilayer film, the user may simply open the defined opening for removal of the contents of the container, by application of an opening force and then reseal the container, by pressing the opened outer layer on to the self-adhesive layer. The above process may be repeated several times, until all the contents of the container are used, whereby the above are protected from possible contamination.

Owner:TEICH AGSELLSCHAFT

Liquid containment/diversion dike

A liquid filled dike is described. The dike is formed of a flexible material selected to contain water. The dike includes at least two bladders which extend at least a portion of the length of the dike. The dike can be transported in empty condition and filled on site. When it is no longer required at a particular site, the dike can be emptied and stored for later use. The dike is self-leveling and may include a leak detection system.

Owner:FLOOD SERVICES +1

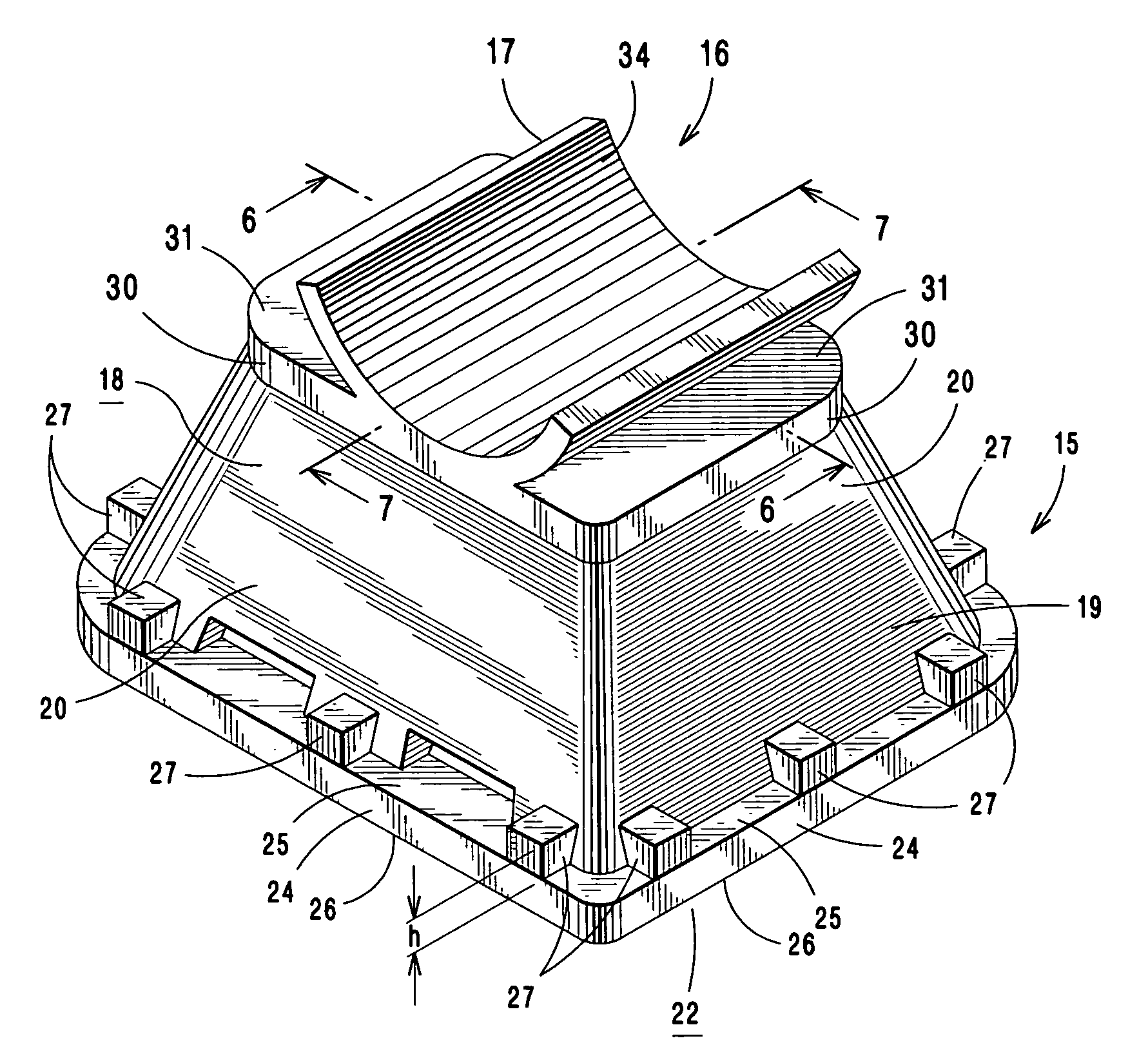

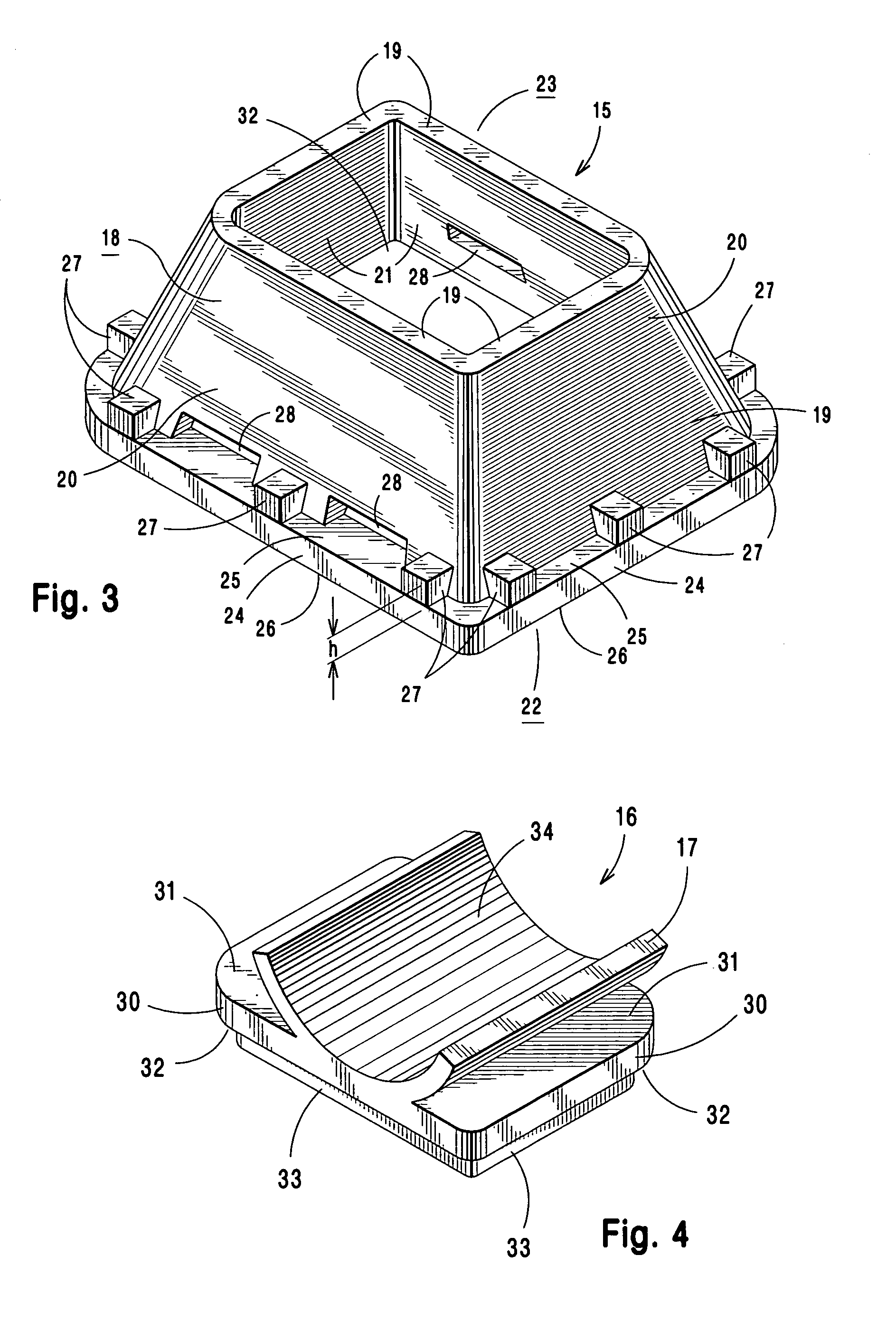

Pipeline skid and a skid system for use in pipeline construction

The present invention comprises a skid that includes at least one stackable pedestal having a continuous wall, the continuous wall enclosing an opening that extends from a first pedestal end to a second pedestal end. The stackable pedestal includes at least two support blocks, each support block having a top surface height that places a stacked pedestal at a raised position over a previously placed pedestal to prevent surface-to-surface contact between the adjacent stacked pedestal walls. A yoke is demountably coupled to the second pedestal end of a single pedestal, or to the second pedestal end of a last stacked pedestal in the skid, and the yoke includes a cradle shaped to support a pipe.

Owner:ROY DAVID E

Method and apparatus for replacing damaged section of a subsea pipeline without loss of product or entry of seawater

A method and apparatus for repairing a submerged pipeline. The method comprises installing a pair of hot tap tees on either side of the damaged section of pipeline, cutting a hole in the pipeline through each hot tap tee, inserting and securing plugging pigs into the pipeline, cutting and removing the damaged section of pipeline, and installing a new section of pipeline. The apparatus includes a plugging pig for use during repair of a damaged pipeline comprising a body shaft, a cup seal secured to the body shaft for engaging an interior wall of the pipeline, a cam attached to the exterior of the body shaft, a slip assembly for sliding on the cam and engaging a slip against the pipeline wall, and a control mechanism for engaging and releasing the slip from the wall.

Owner:VALMET OY +1

Variable buoyancy cable

A variable buoyancy cable is provided. In one aspect, the variable buoyancy cable includes a flexible sleeve that has an inner wall and an outer wall. A core is positioned in the sleeve and has a longitudinally disposed external channel with opposing first and second sidewalls. The channel and the inner wall of the flexible sleeve define a fluid passage for receiving a fluid to affect the buoyancy of the variable buoyancy cable. A slackened utility line is positioned in the channel and a fluid supply is coupled to the flexible sleeve and is operable to move fluid into and out of the fluid passage to selectively affect the buoyancy of the variable buoyancy cable. The core protects utility lines in the cable from damage due to ambient pressure and / or bending during deployment and retrieval. The buoyancy may be varied to suit various water conditions and mission requirements.

Owner:MARINE INNOVATIONS

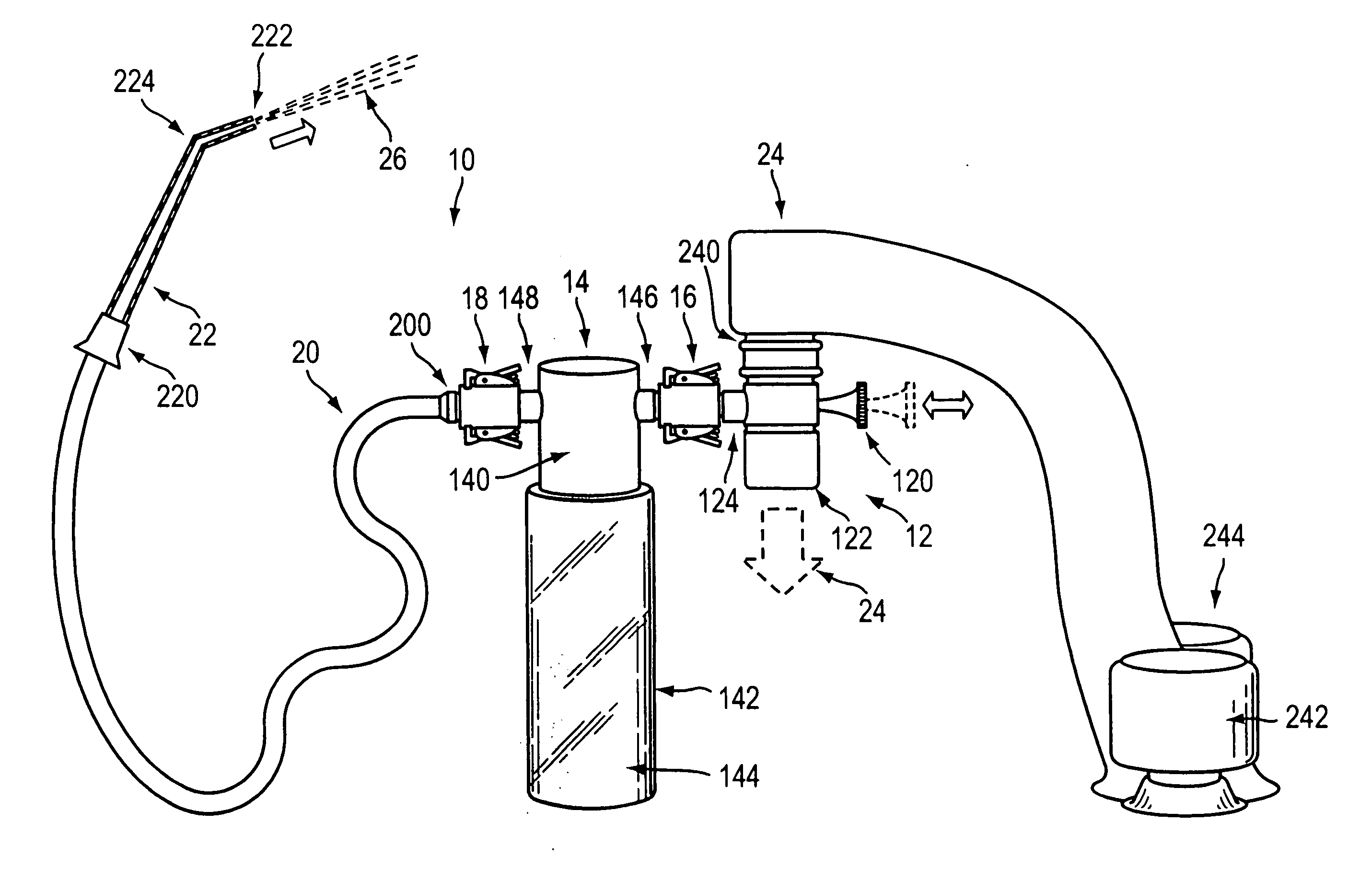

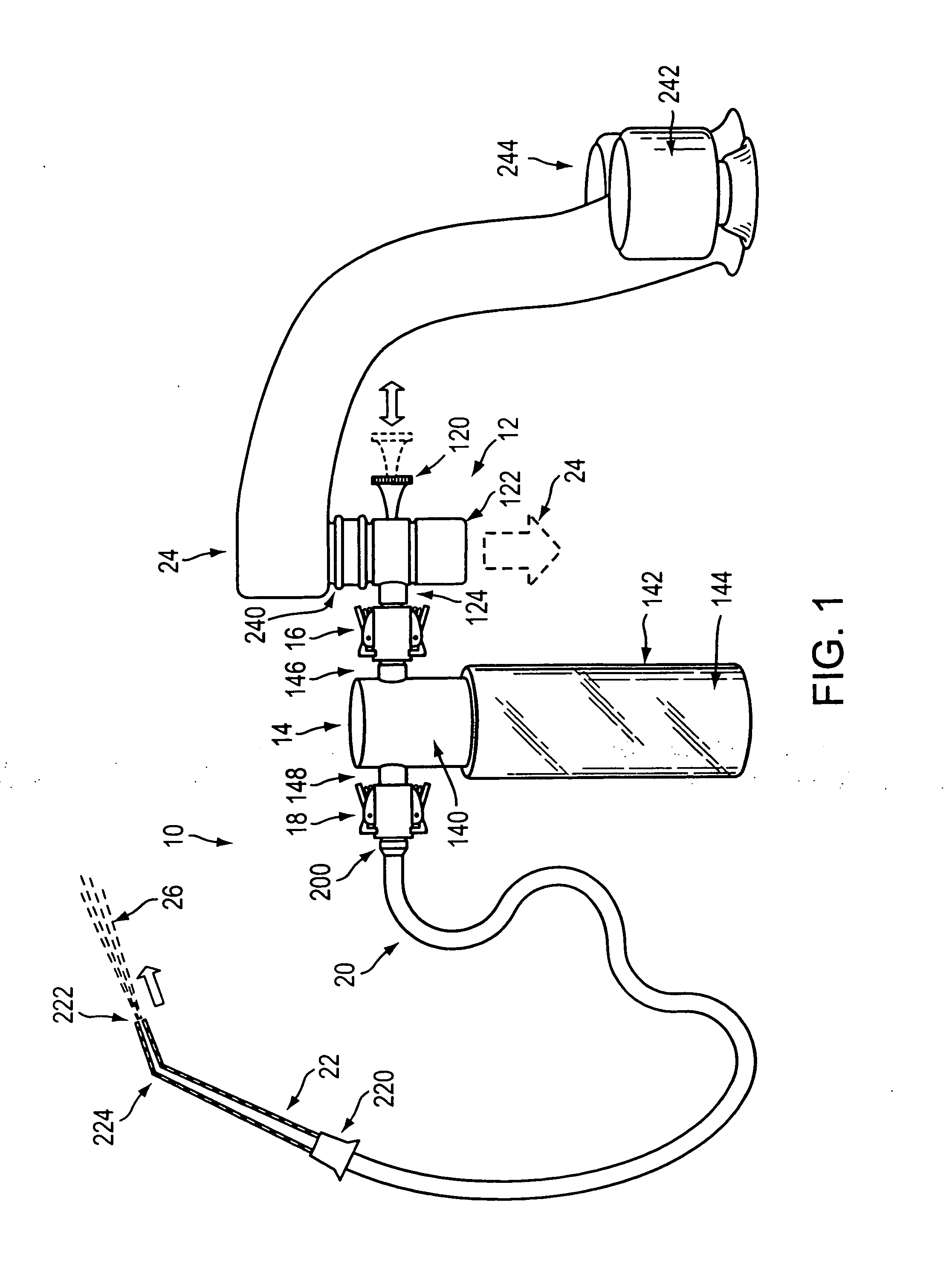

Hot tap fluid blaster apparatus and method of using same

A apparatus and method of using the apparatus for removing a blockage in a subsea pipeline without retrieval of the pipeline to the surface. The apparatus components include a hot tap saddle, a drill assembly, a fluid blaster assembly and a support frame. The hot tap saddle component has a first portion and a second portion, with the first and second portions being configured to clampingly engage in a sealing relationship to the subsea pipeline. The first portion of the saddle includes a first and second opening with the first opening extending generally upwardly and configured for connecting to a drill assembly and the second opening being positioned generally at an angle to the first opening and configured for connecting to a fluid blaster assembly. The fluid blaster assembly including a nozzle, a hose and a high pressure pump with the fluid blaster assembly being contained within a pressure vessel. The fluid blaster assembly is configured for mounting to the second opening of the hot tap saddle component. The support frame assembly is configured for gripping and supporting the subsea pipeline on the sea floor while the fluid blaster assembly operates to remove a blockage in the subsea pipeline with the pipeline being under pressure and without severing the pipeline.

Owner:SAIPEM AMERICA

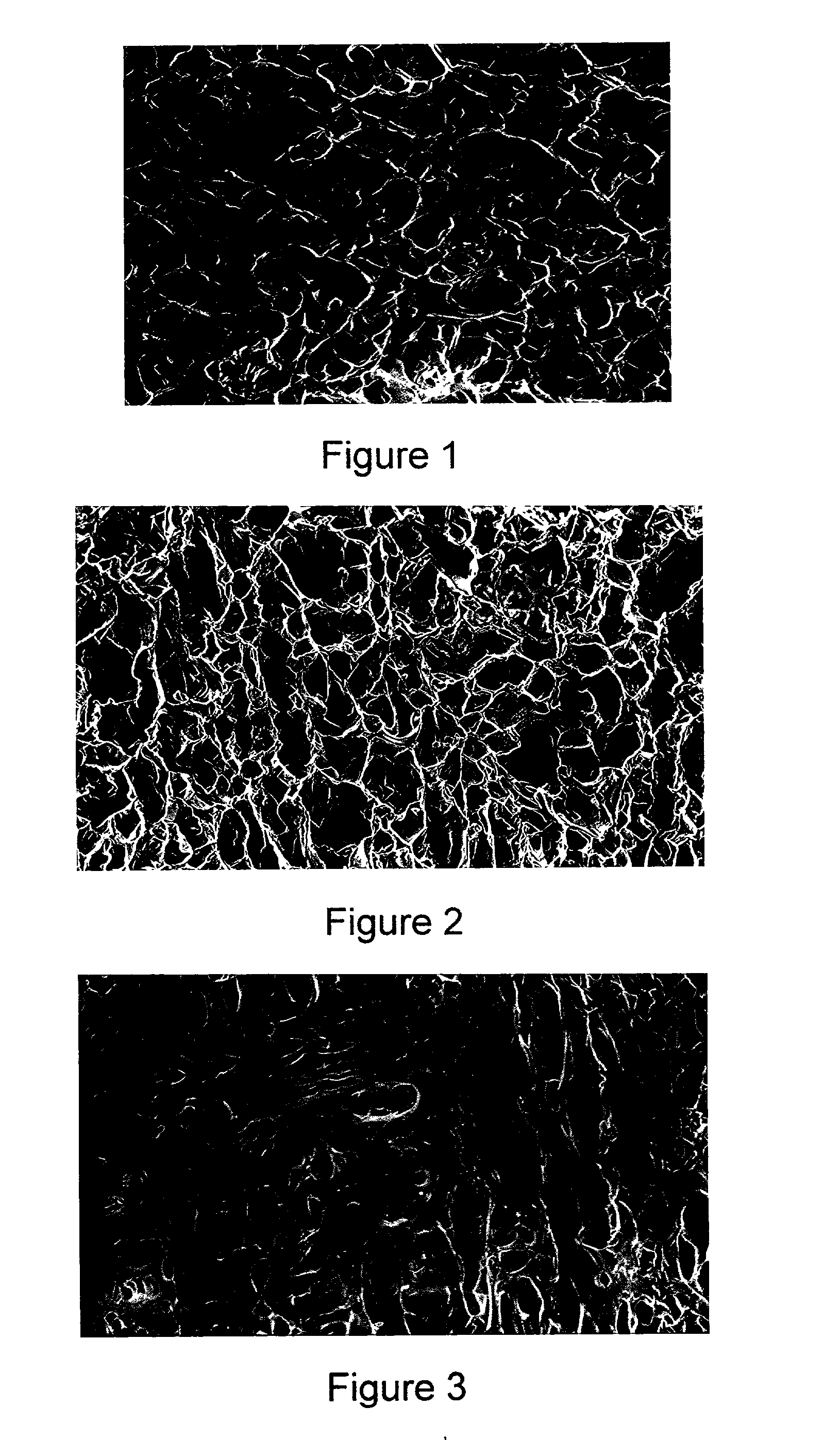

Method for making a porous Polymeric material

Porous polymers having a plurality of openings or chambers that are highly convoluted, with each chamber being defined by multiple, thin, flat partitions are produced by a new gel enhanced phase separation technique. In a preferred embodiment, a second solvent is added to a polymer solution, the second solvent causing the solution to gel. The gel can then be shaped as needed. Subsequent solvent extraction leaves the porous polymeric body of defined shape. The porous polymers have utility as medical prostheses, the porosity permitting ingrowth of neighboring tissue. The present technique also enhances shape-making capability, for example, of bifurcated vascular grafts, which feature a common entrance region but two or more exit regions.

Owner:KENSEY NASH CORP

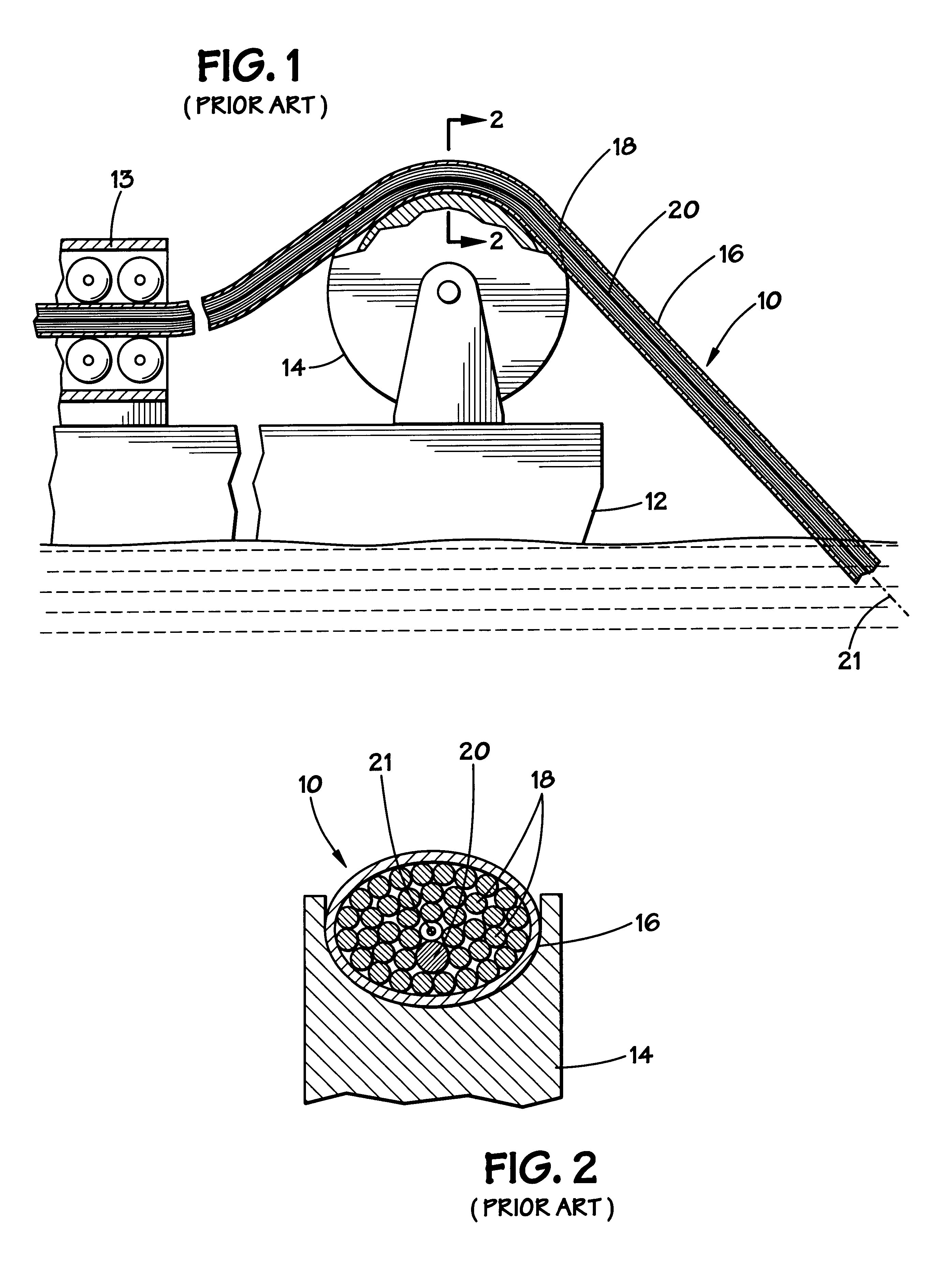

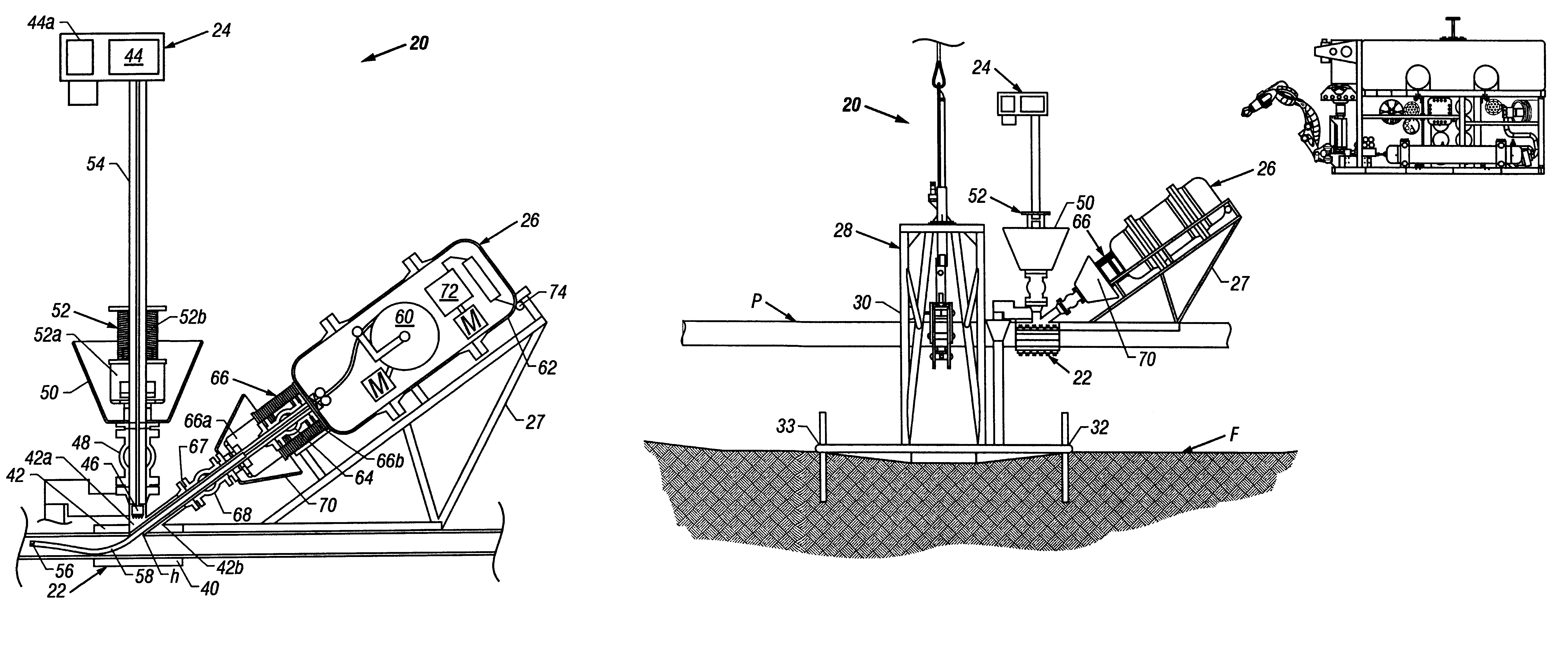

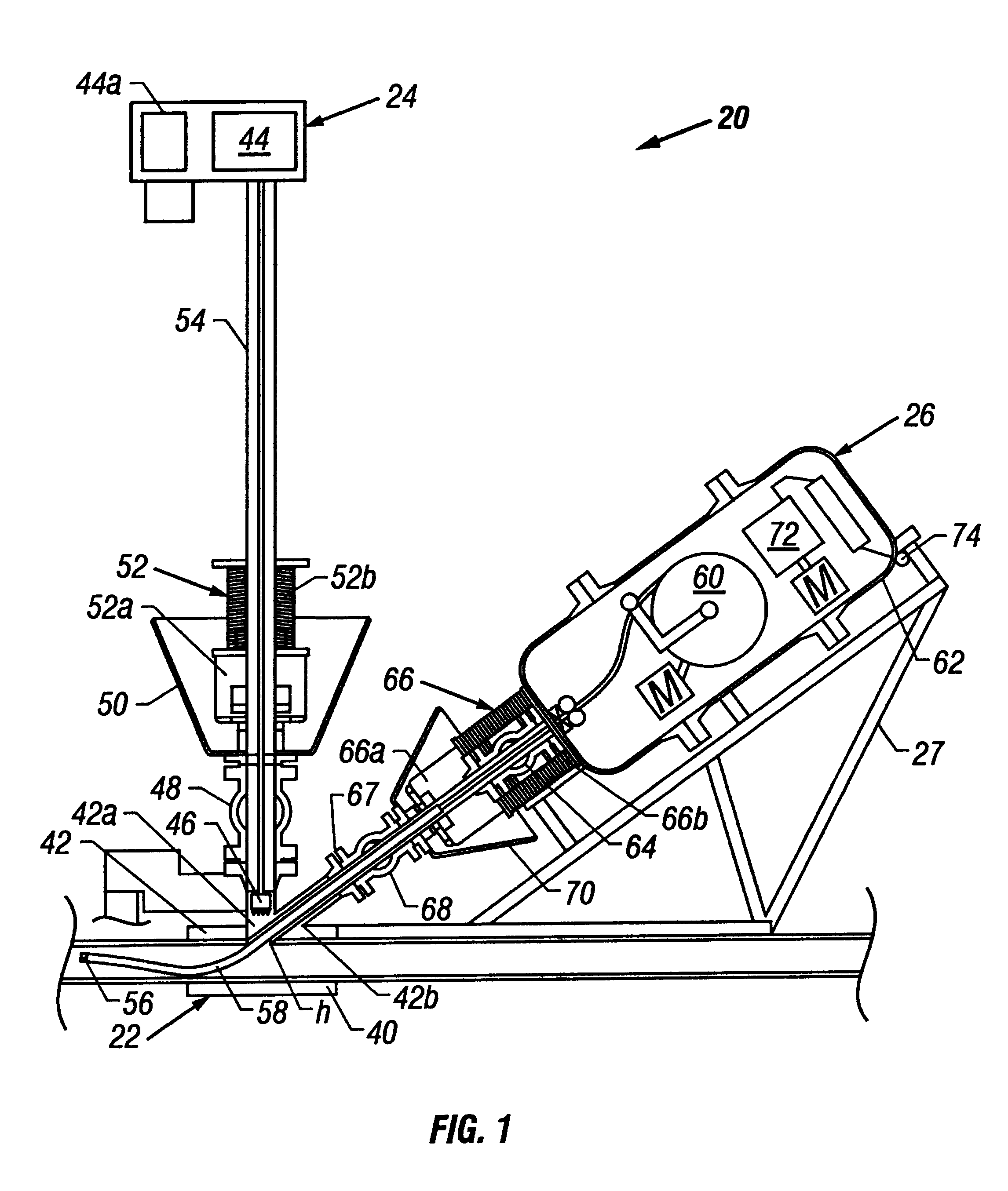

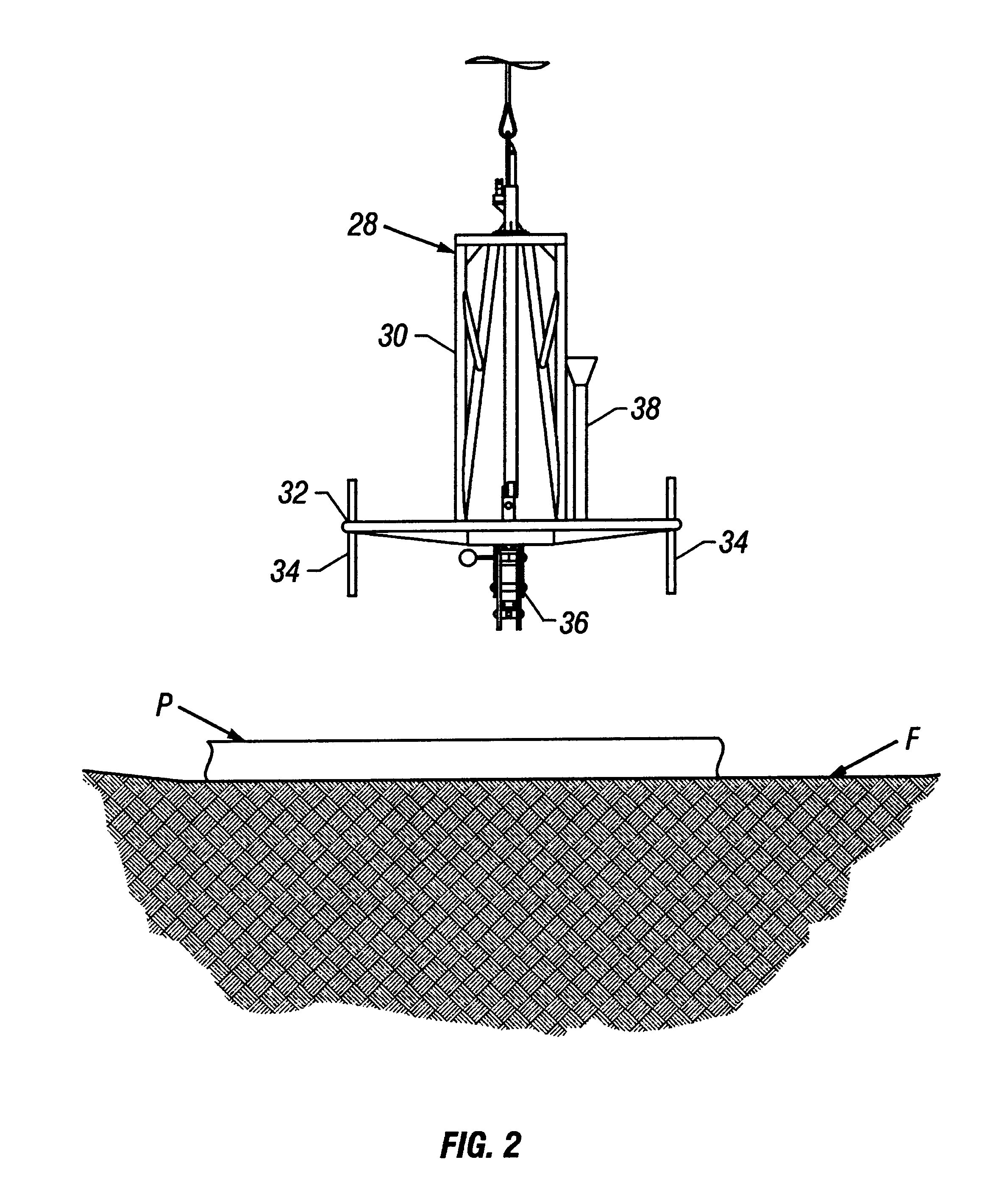

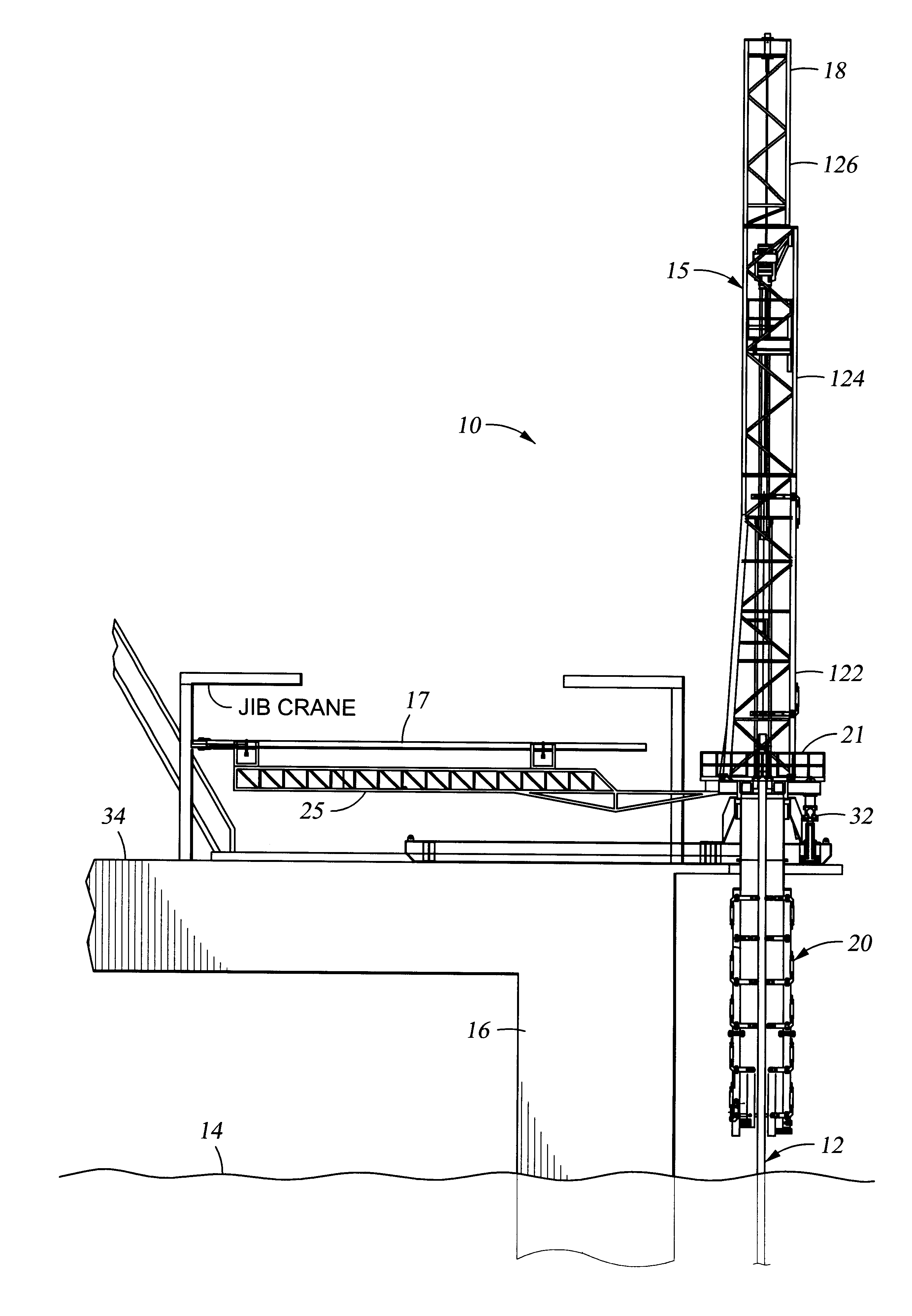

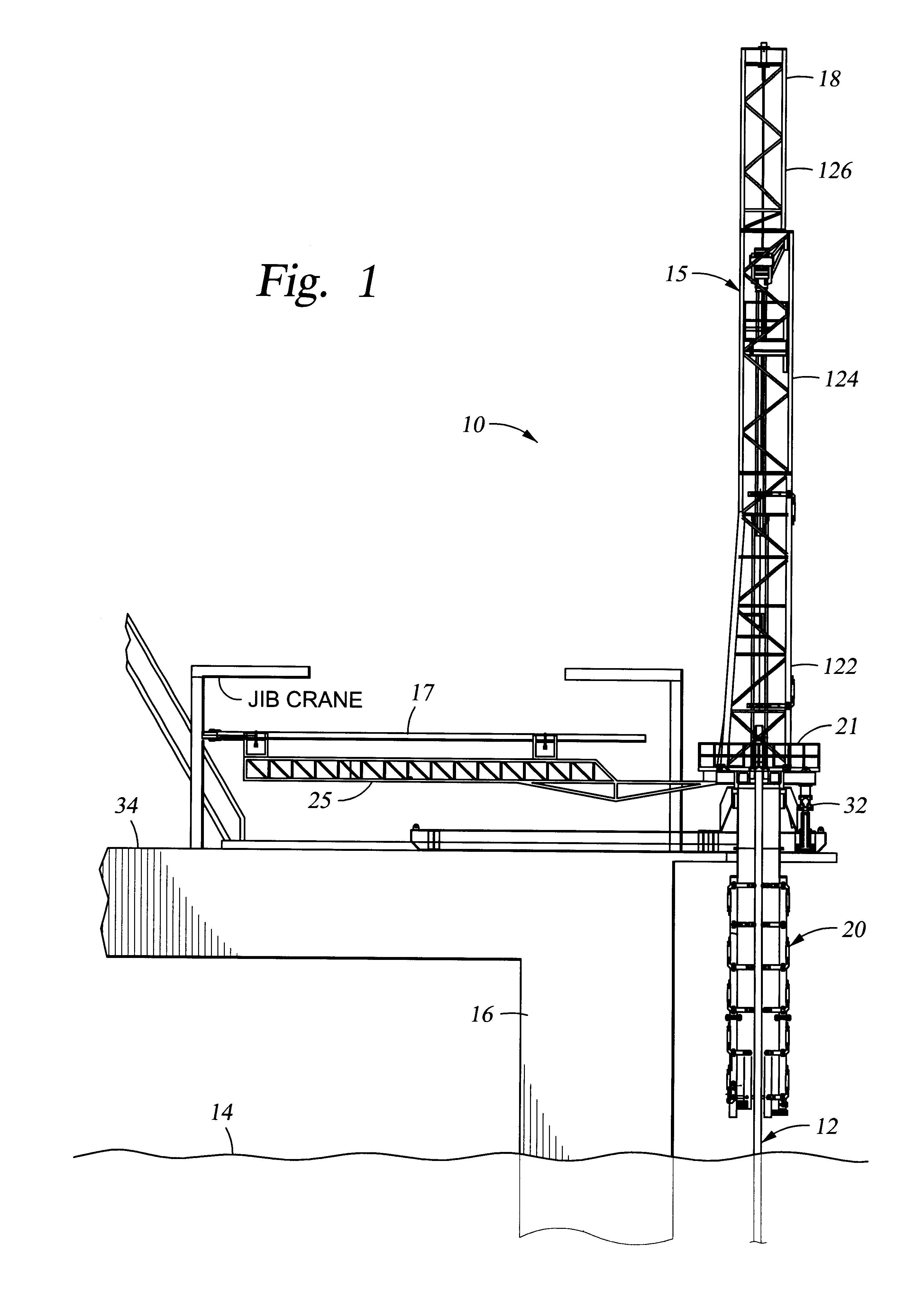

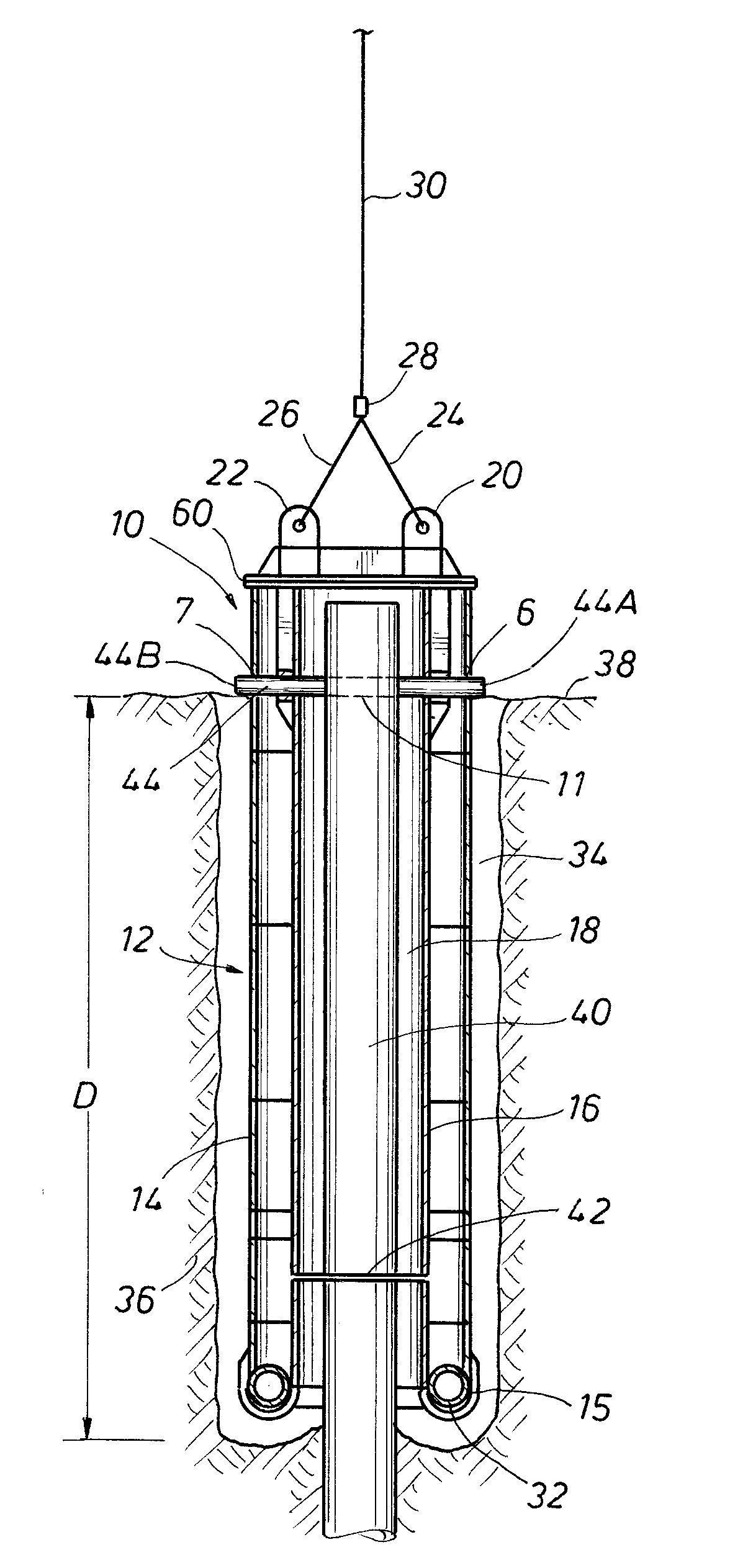

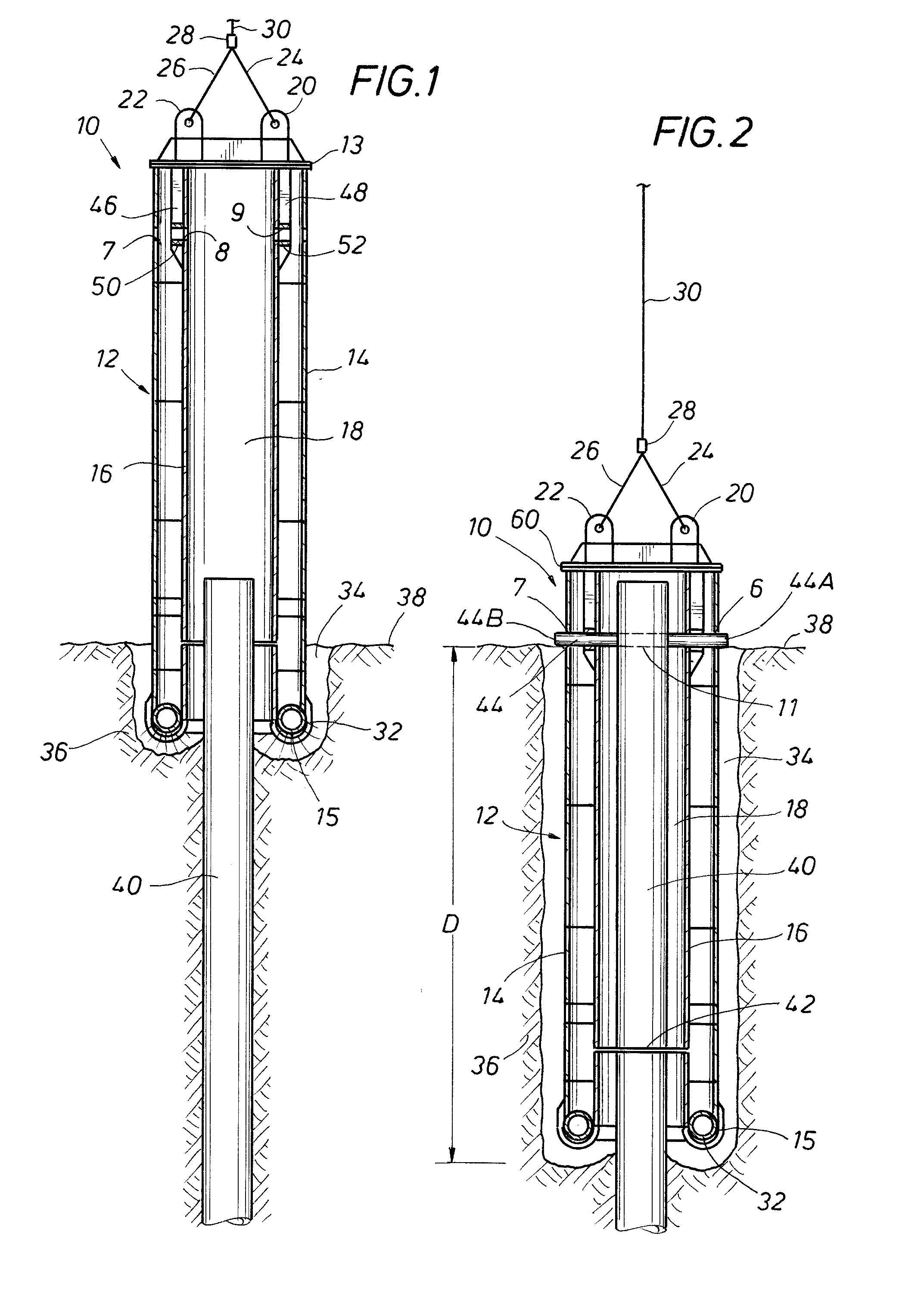

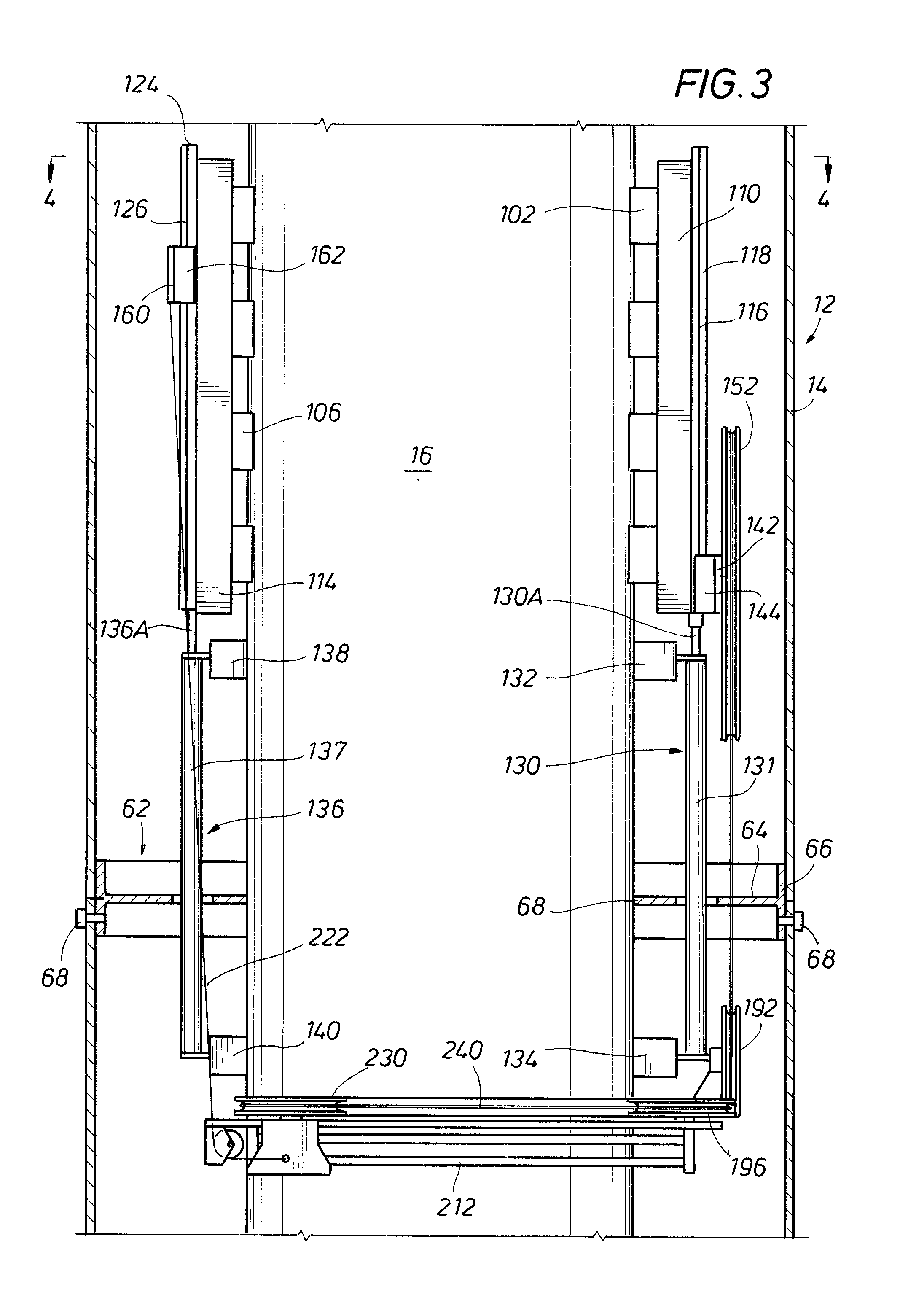

Apparatus for deploying an underwater pipe string

An apparatus for deploying an underwater pipe string includes a mast, an articulated table, a stinger, and a pipe erector. The mast is affixed to the articulated table and extends above the articulated table. The stinger is affixed to the articulated table and depends below the articulated table. The pipe erector is connected to the mast for loading pipe joints up to the mast. A pipe joint loaded in the mast is welded to the pipe string, which depends from the articulated table and through the stinger toward a seabed. The stationary table is articulated for tilting of the table, the mast, and the stinger azimuthally and angularly for a preferred direction and lay angle of the pipe string being deployed.

Owner:OIL STATES INDS UK

Apparatus and Method for Removing Subsea Structures

InactiveUS20090266552A1Fully understandEasy to appreciateMetal sawing devicesPipe laying and repairOcean bottomMarine engineering

An apparatus and method for removing a subsea structure wherein a housing defining a subsea structure receiving space and having a jetting system attached at or near the bottom of the housing is used to form an excavation around the subsea structure to the desired depth and a frame attached to or mounted in the housing carries a cutter assembly which is movable from a first position on the frame to a second position on the frame, the first position being on one side of the subsea structure, the second position being on the opposite side of the subsea structure.

Owner:BARRA MARC T +3

Marine Anti-foulant system and methods for using same

InactiveUS20090185867A1Reducing vortex-induced vibrationReduce dragPipe laying and repairWaterborne vesselsEngineering

Systems and methods for reducing vortex-induced vibration and drag about a marine element are provided. The system can include, but is not limited to, a shell rotatably mounted about the marine element, the shell having opposing edges defining a longitudinal gap configured to allow the shell to snap (be placed) around at least a portion of the marine element. A fin can be positioned along each opposing edge of the longitudinal gap, wherein each fin can extend outwardly from the shell. The fins can be positioned on the shell so as to reduce vortex-induced vibration and minimize drag on the marine element. One or more antifouling agents can be disposed on, in, or about at least a portion of the shell, the fins, or a combination thereof.

Owner:ASSET INTEGRITY MANAGEMENT SOLUTIONS L L C D B A AIMS INT

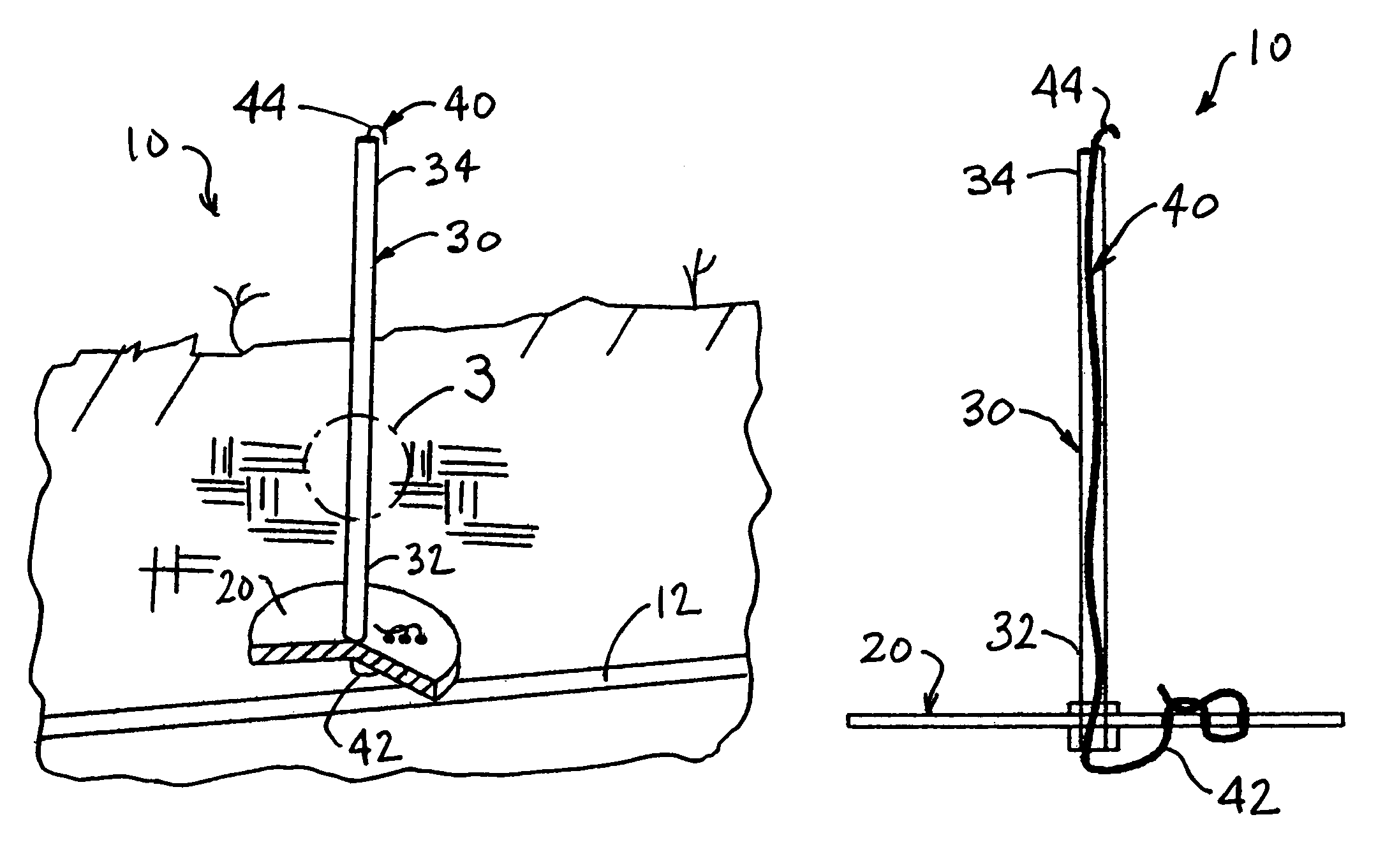

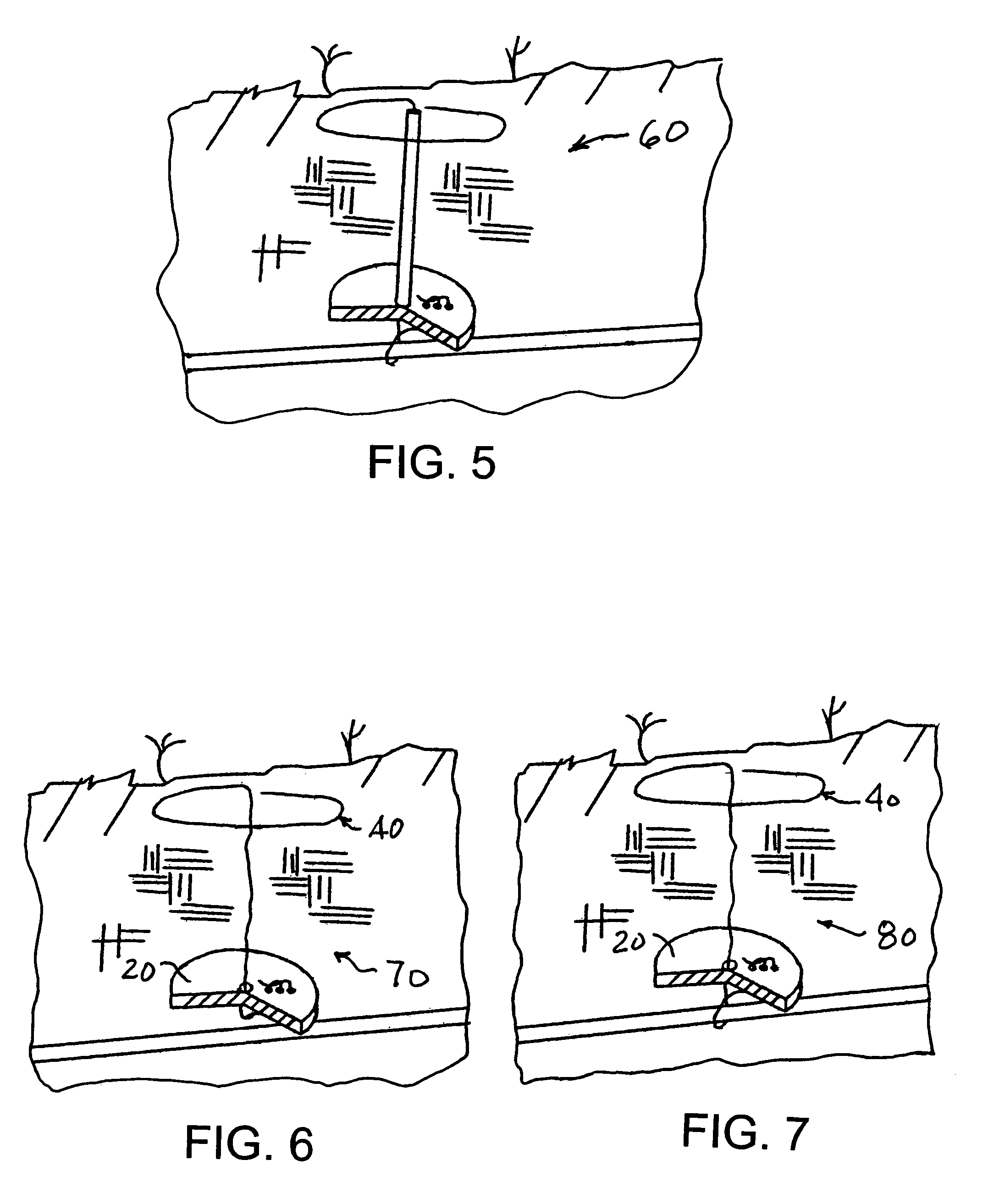

Underground marking systems and methods for identifying a location of an object underground

InactiveUS6941890B1Analysis using chemical indicatorsPipe laying and repairEngineeringHorizontal and vertical

An underground marking system for marking buried objects is constructed from synthetic, brightly colored materials, which provides redundant horizontal and vertical markers and the ability to trace back to the buried object. The system is economical and easily installed. In one embodiment, the system includes a base disposable adjacent to the object, a hollow member having a lower end attachable to the base. The upper end is disposable adjacent to the ground. A cord is disposed in the hollow member and extends from the lower end to the upper end of the hollow member. The system provides a way of easily locating the marker either above or immediately below the ground surface. The hollow member may include a calibrated marking system to identify the depth to either the base or the buried object from the point of discovery of the hollow member.

Owner:MURPHY TAYLOR ANN +2

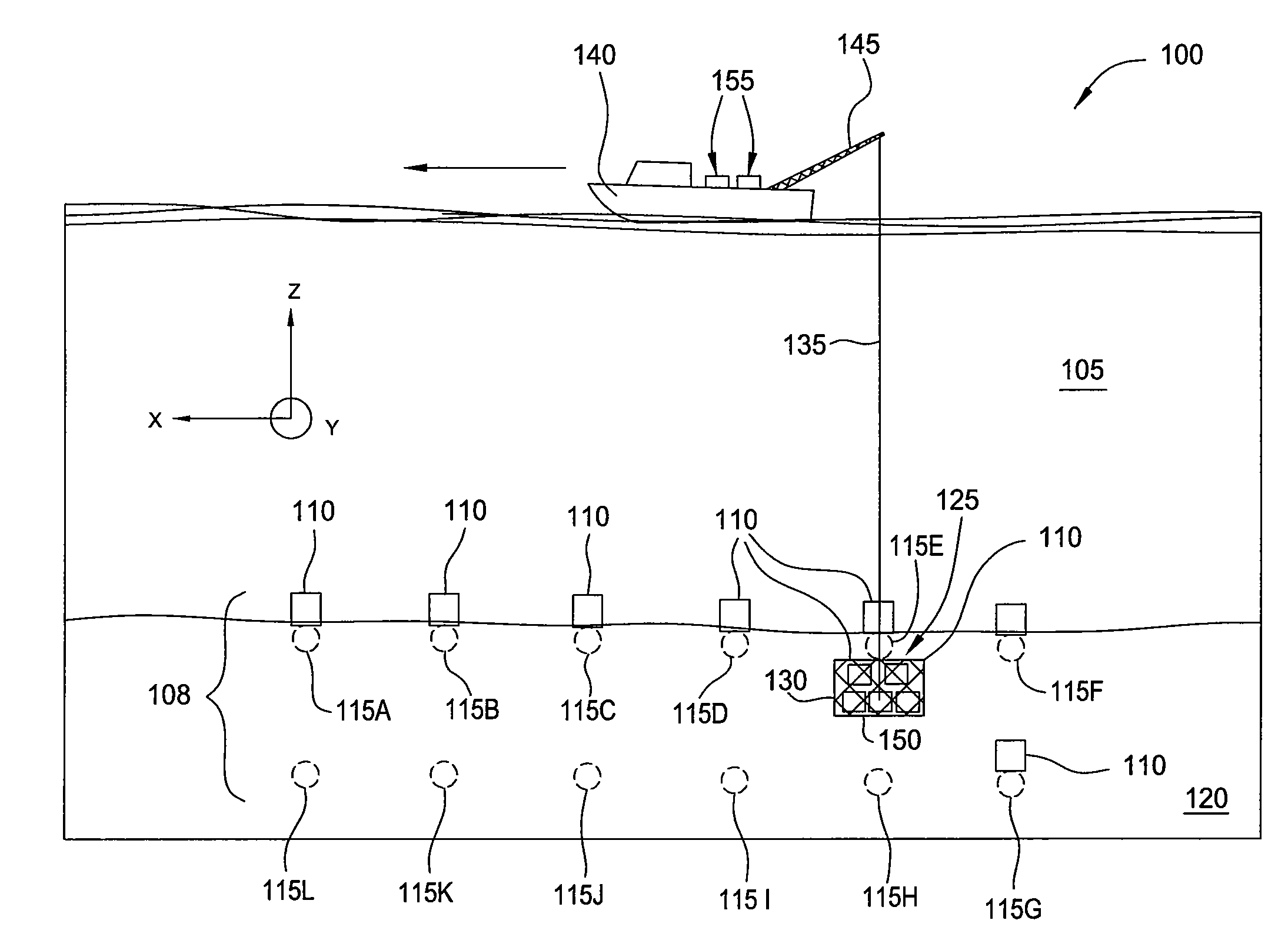

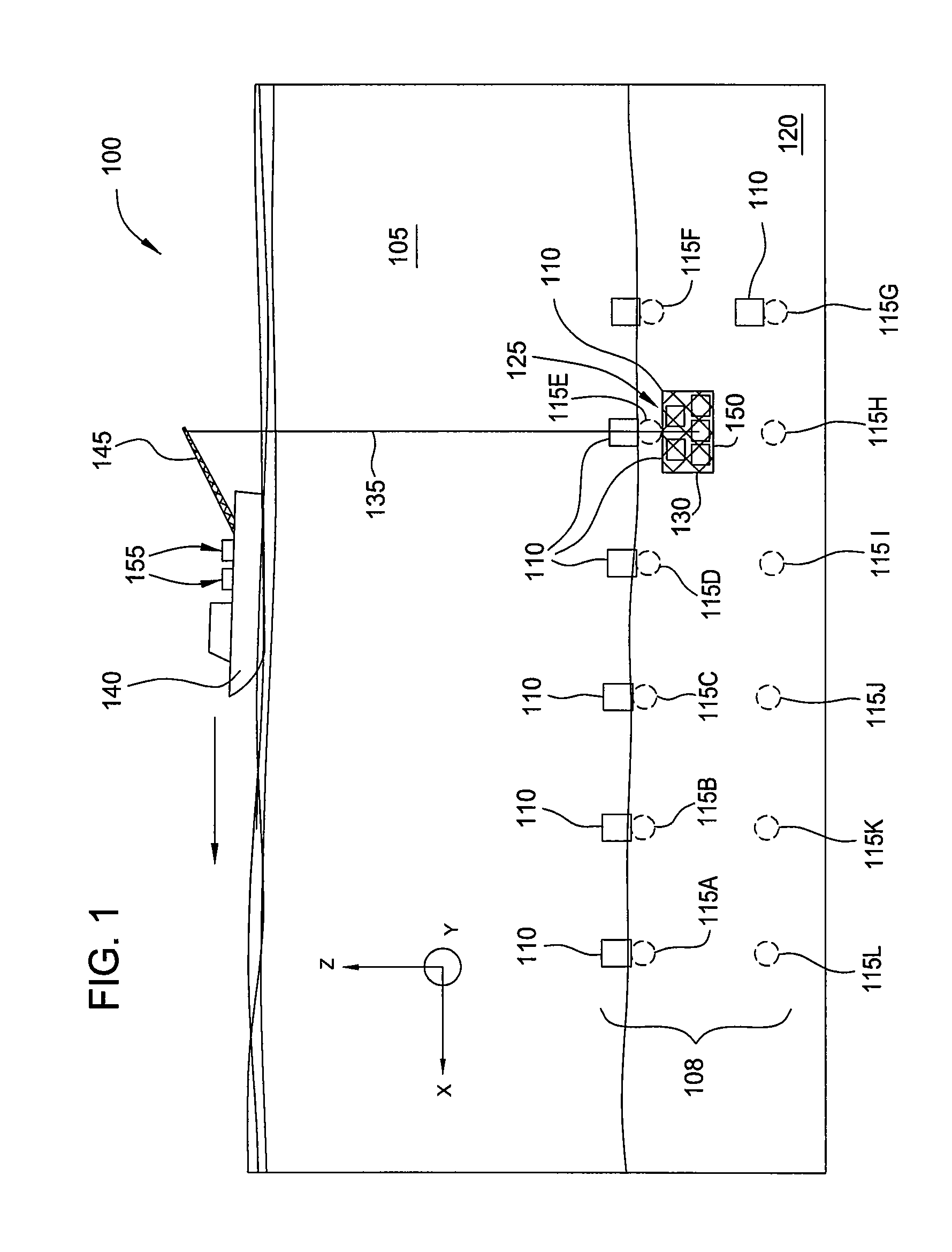

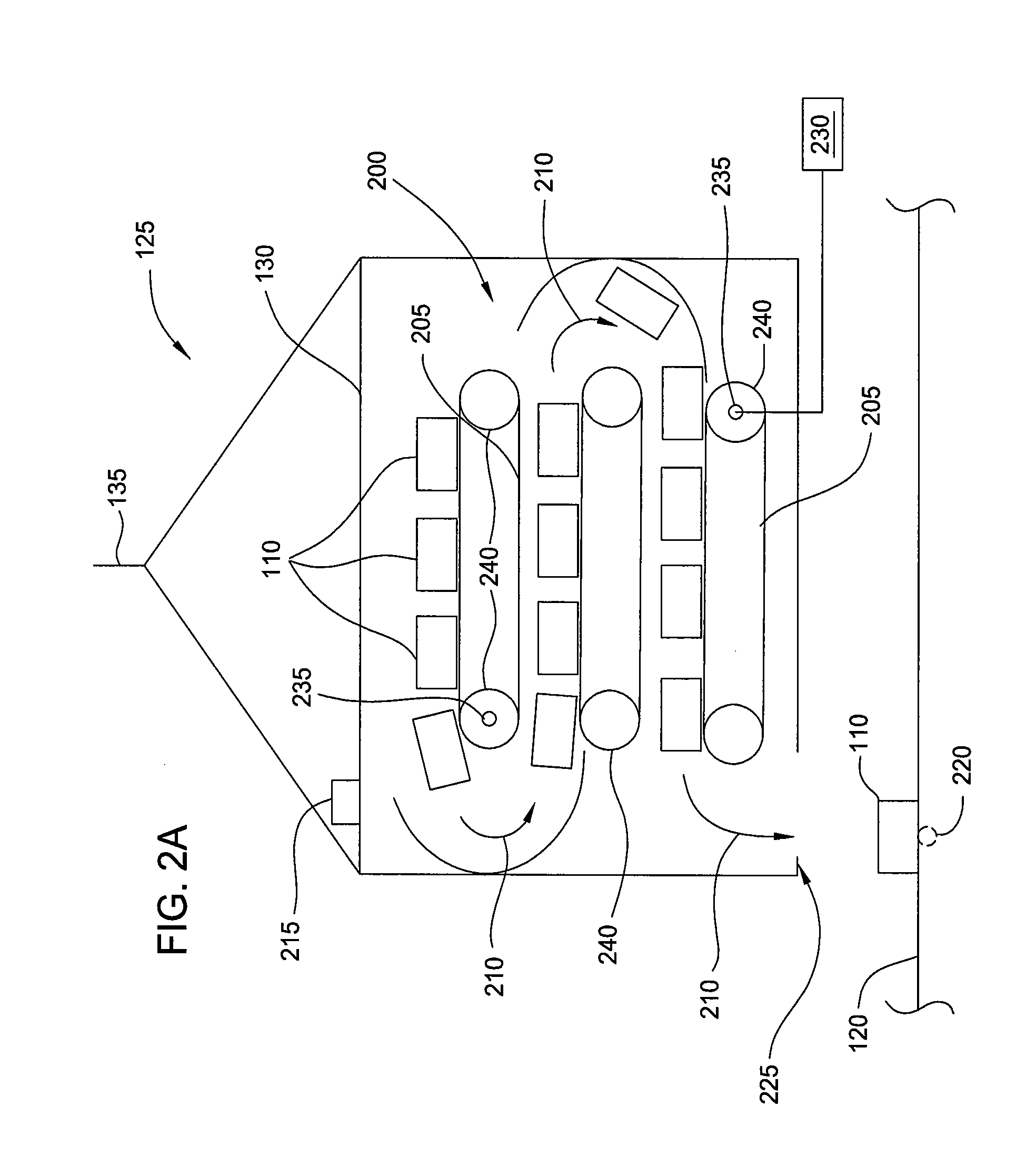

Ocean bottom seismic sensor deployment vehicle

Embodiments described herein relate to an apparatus and method for transferring one or more seismic sensor devices to or from a support vessel on or near a surface of a body of water and a subsurface marine location. In one embodiment, an apparatus for transferring seismic sensor devices is provided. The apparatus includes a frame structure having one or more rails disposed thereon, the one or more rails comprising an elevator mechanism and defining at least one exit path for one or more seismic sensor devices, and one or more motors coupled to the elevator mechanism.

Owner:MAGSEIS FF LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com