Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3338results about "Metal sawing accessories" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

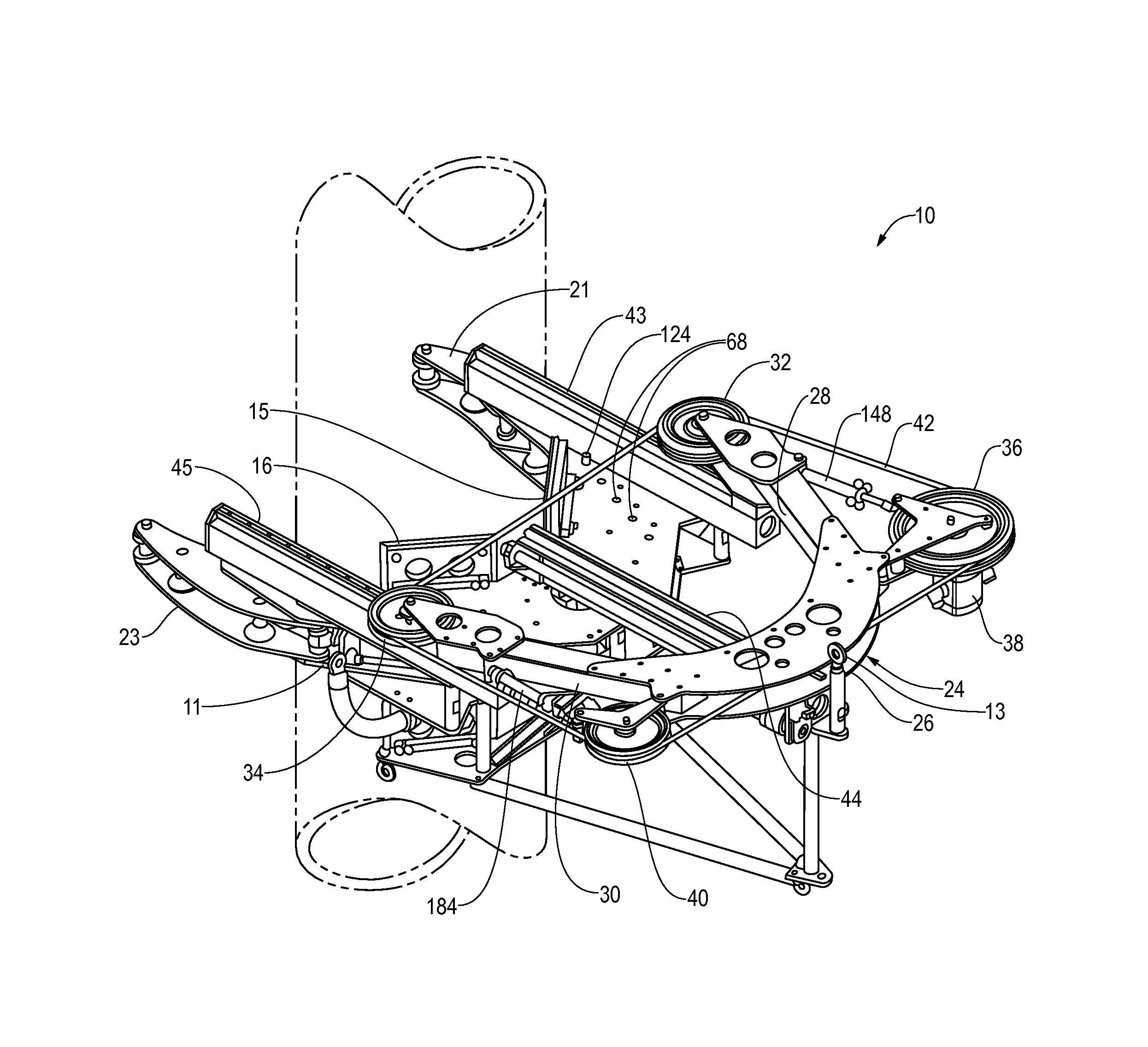

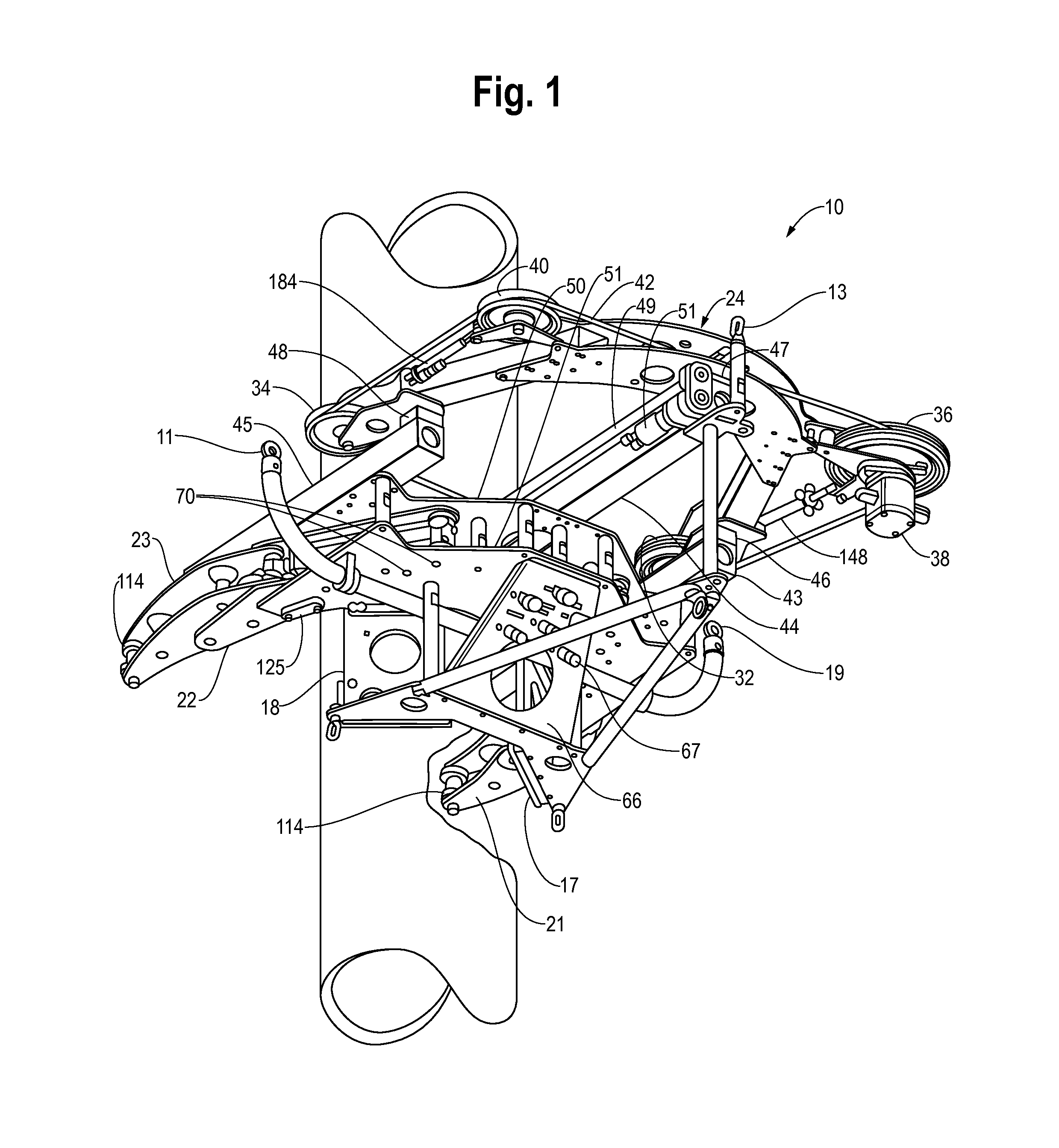

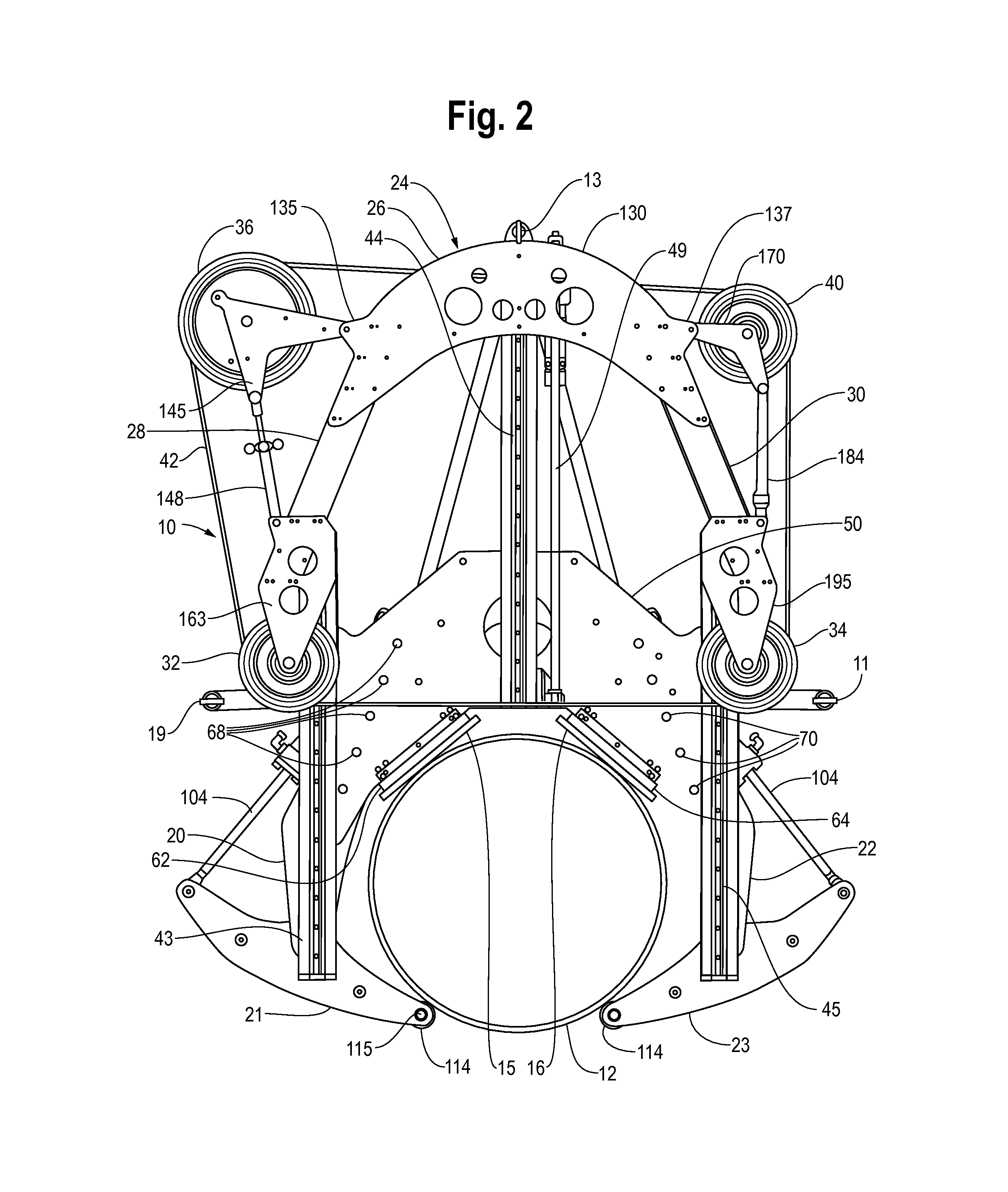

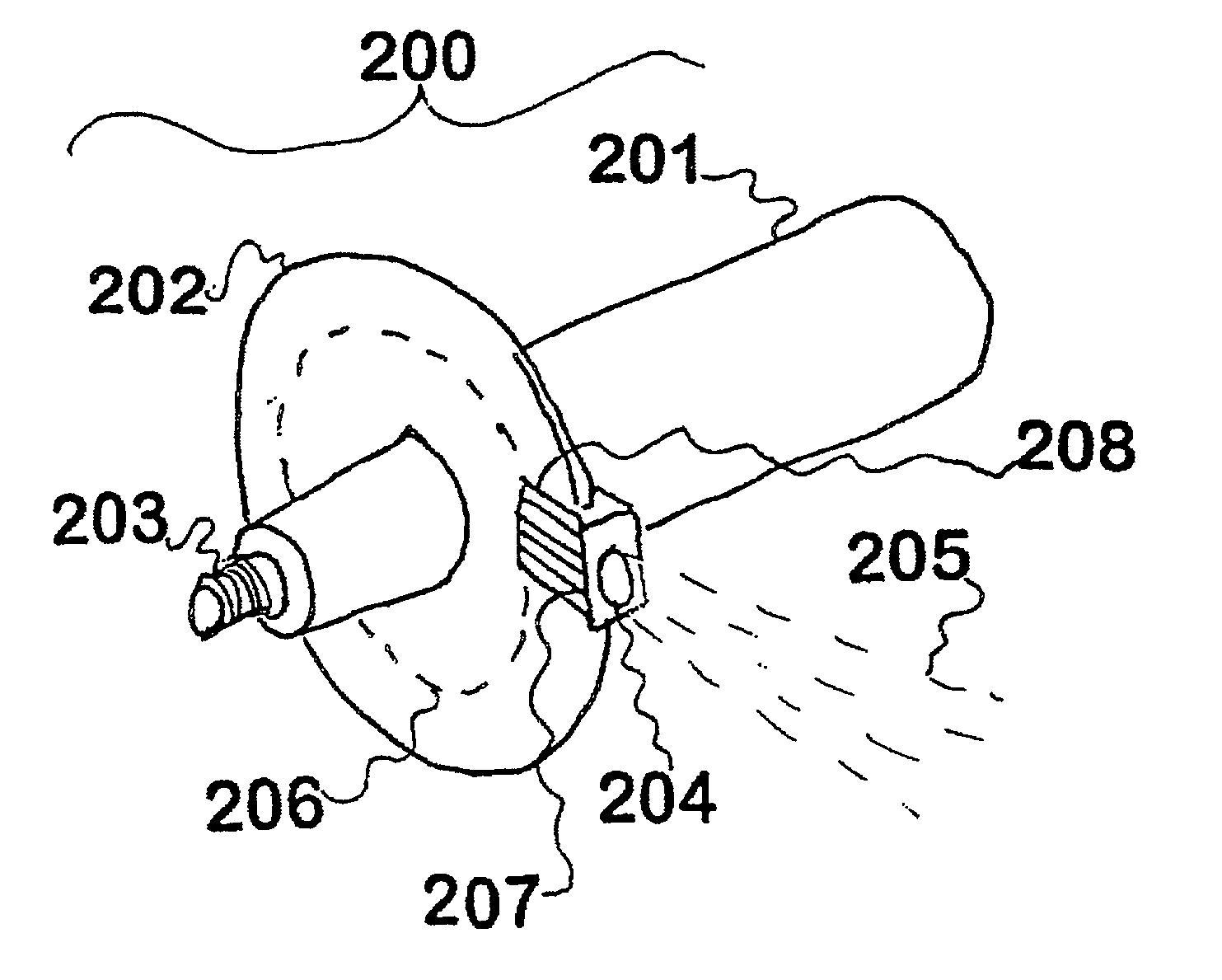

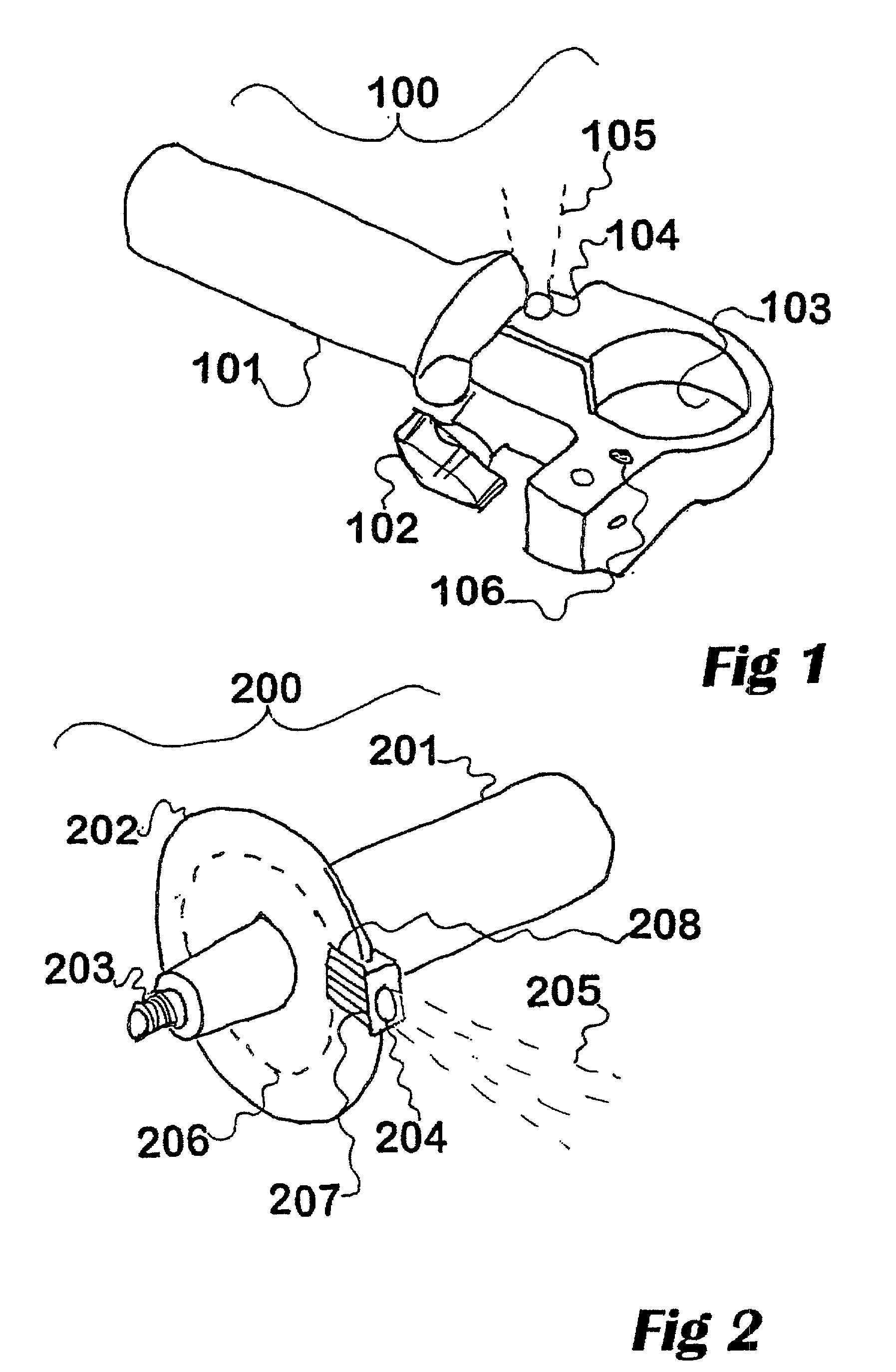

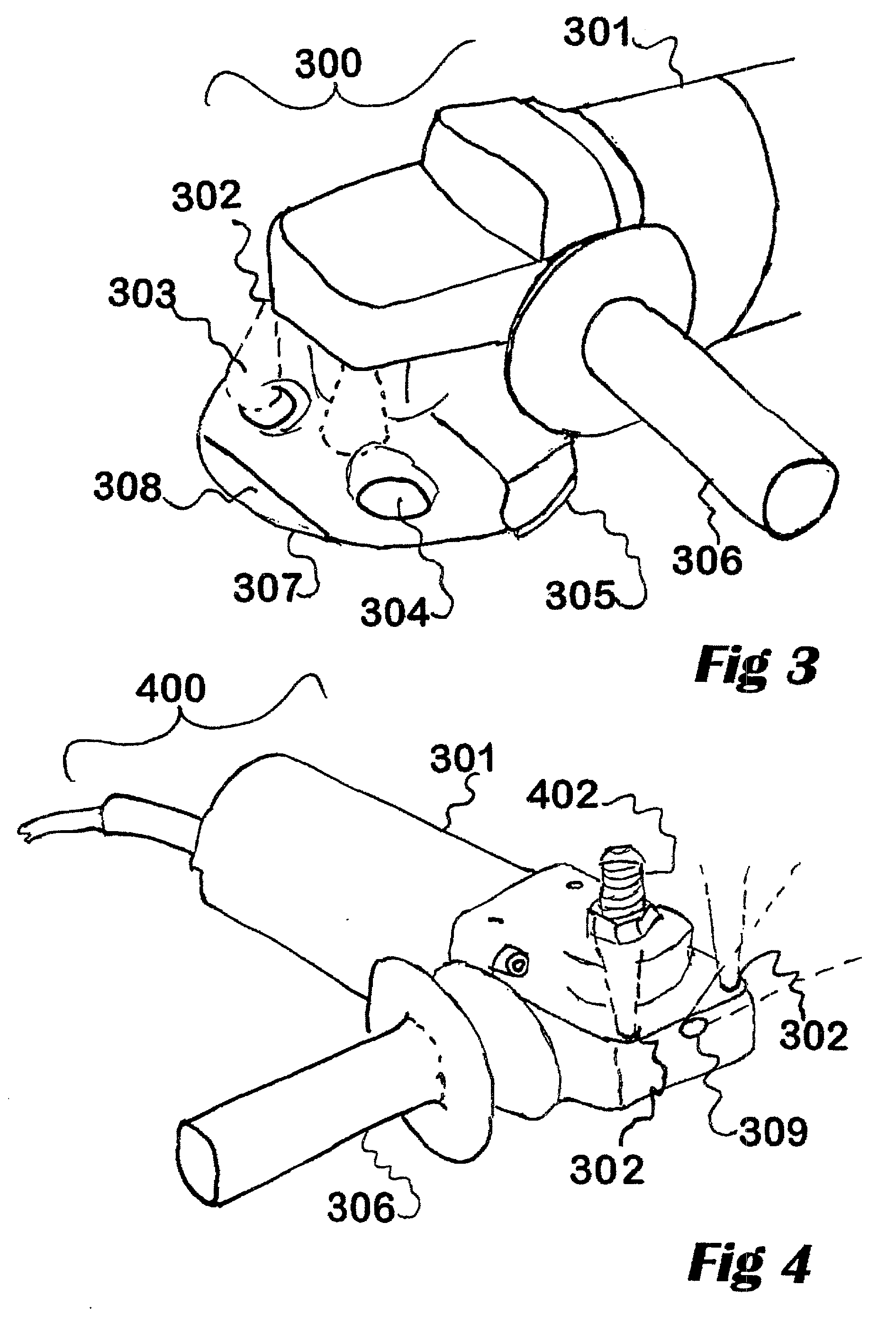

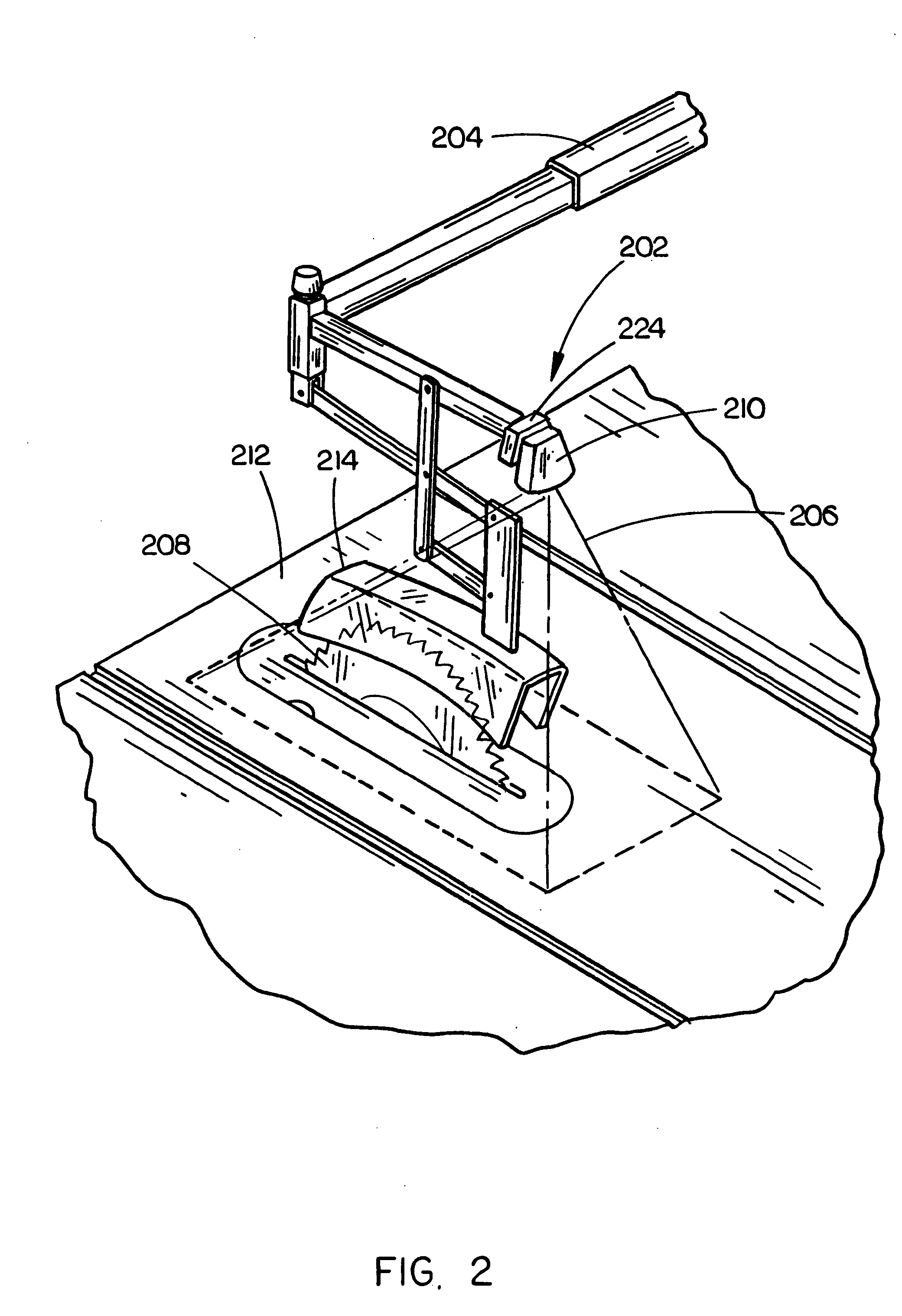

Wire saw

A device for cutting a length of pipe includes a clamp portion for clamping around a length of pipe and a bow moveable with respect to the clamp portion that retains a loop of diamond embedded wire. The device further includes a feed for driving the bow with respect to the clamp portion and a detector for detecting bending of the wire and a control responsive to the detector for controlling feed rates. The device is made of modular parts and has synchronizing arms for clamping around a length of pipe. In one embodiment, the wheels are retained in enclosures with slots through which the cutting wire passes.

Owner:ILLINOIS TOOL WORKS INC

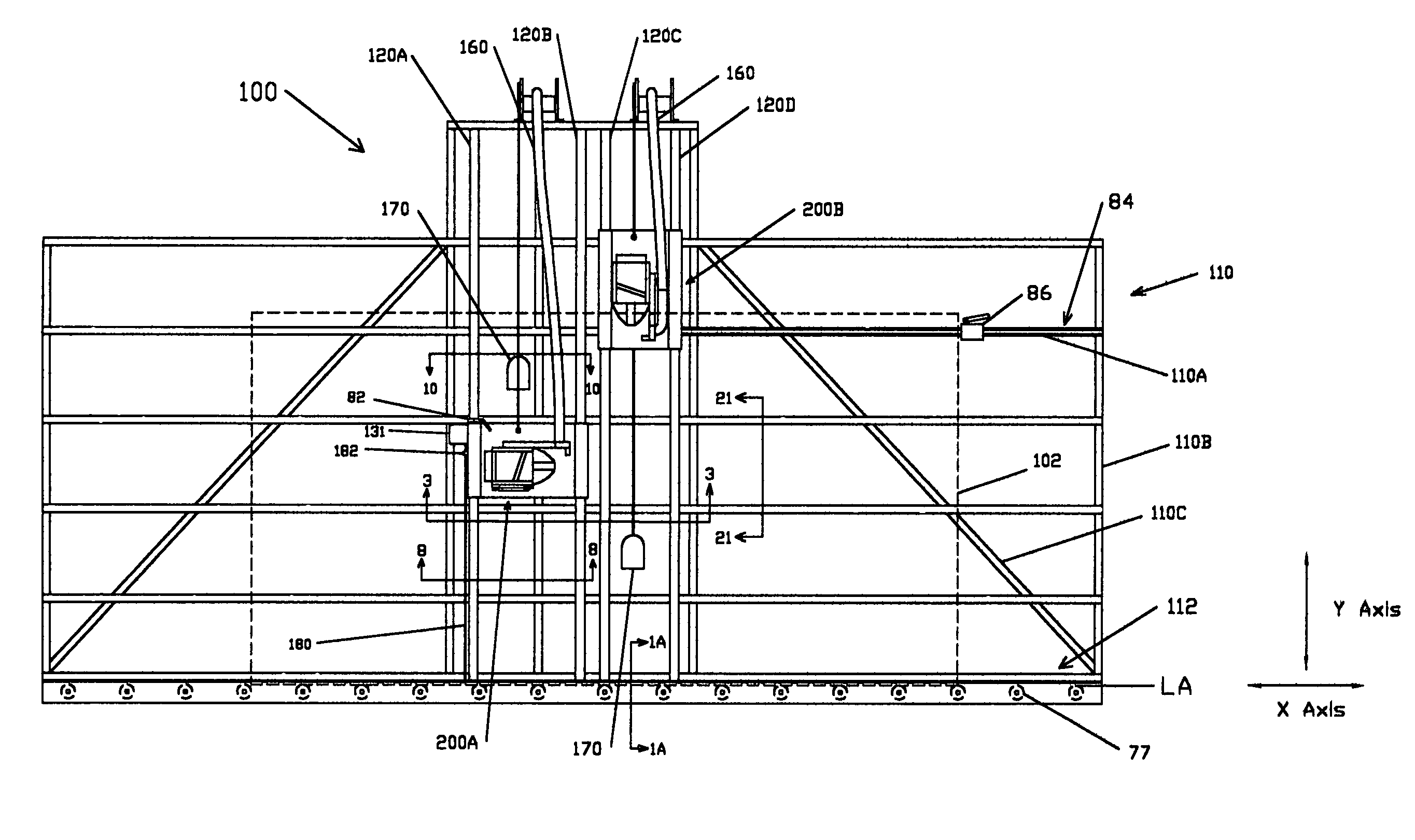

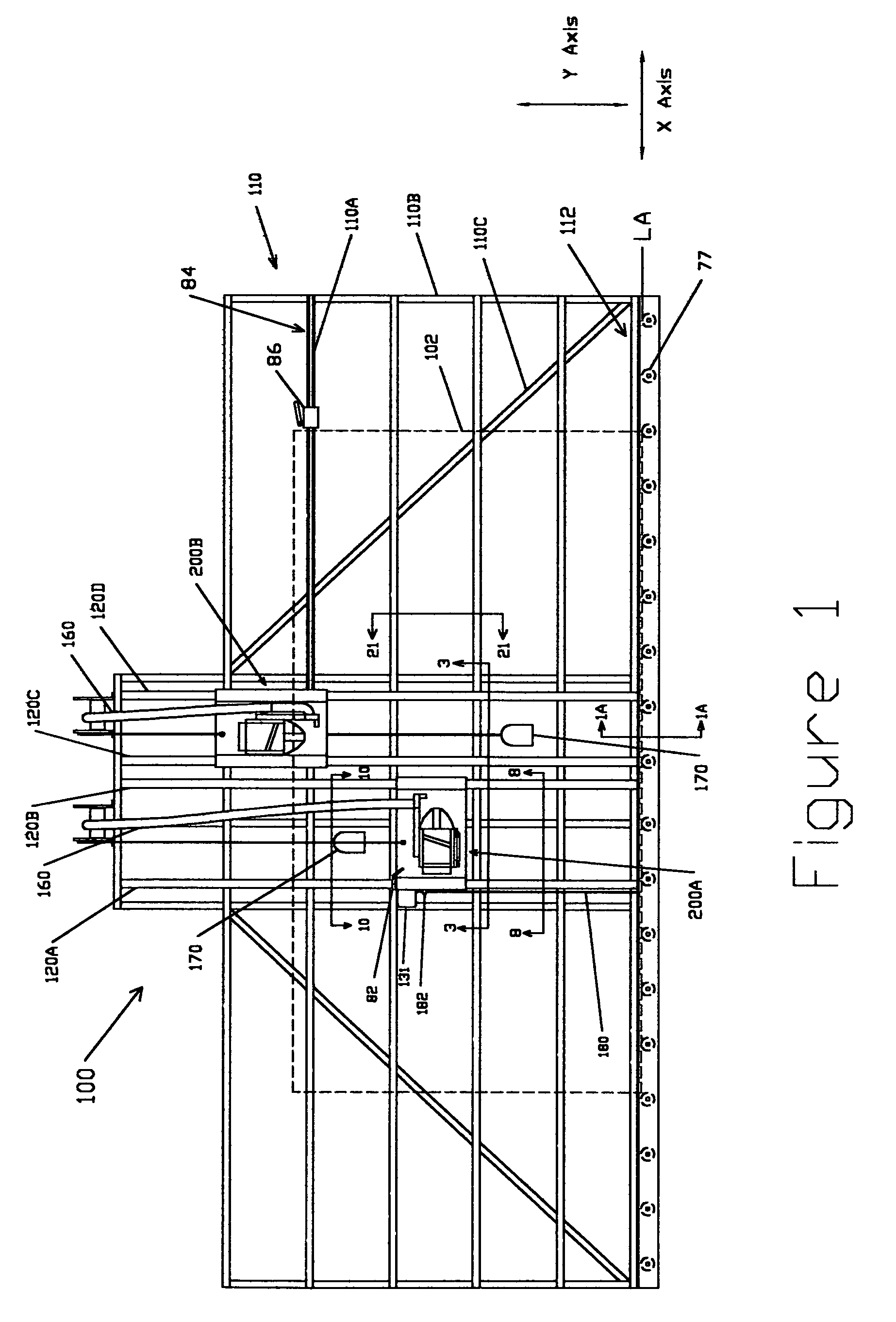

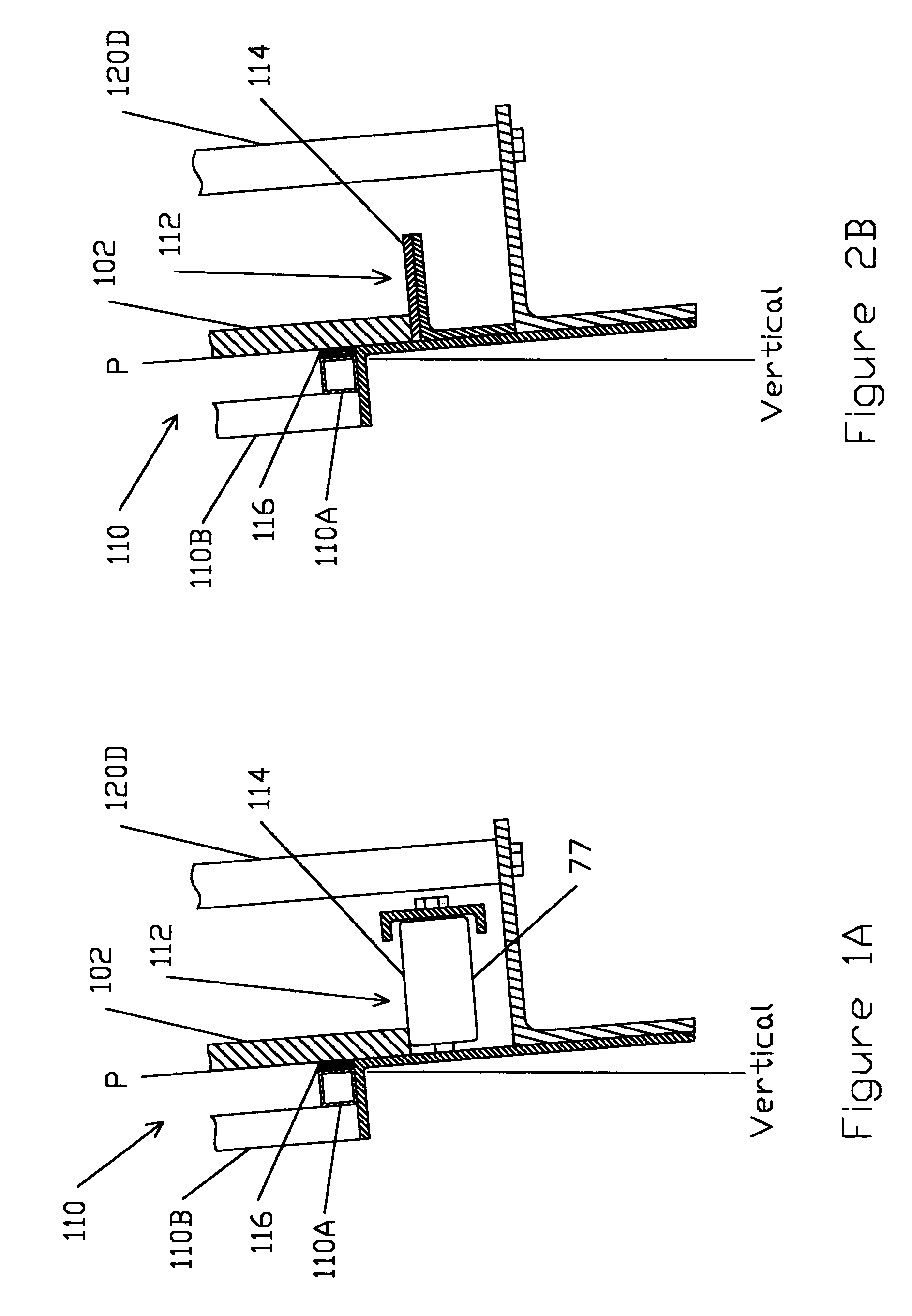

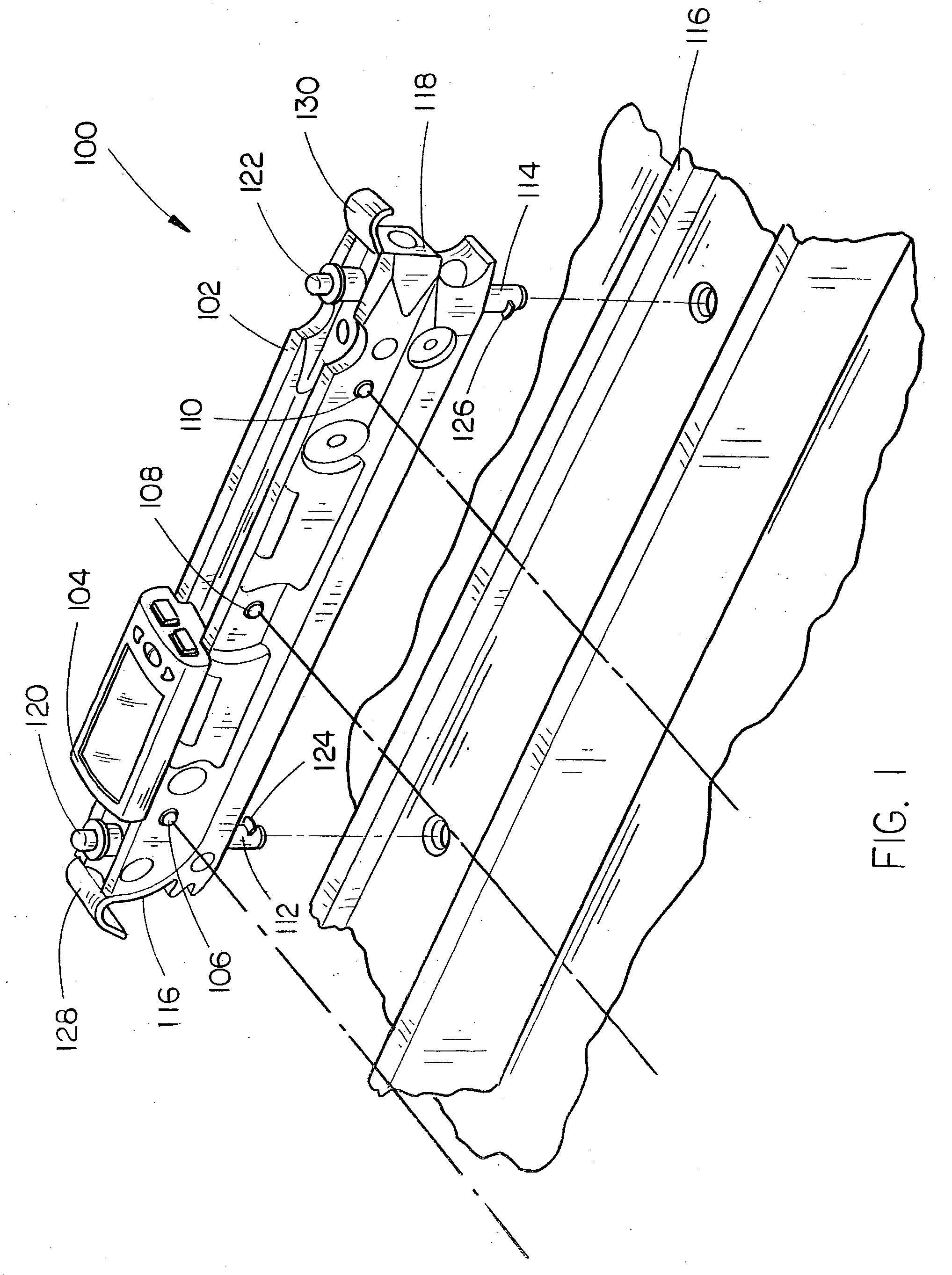

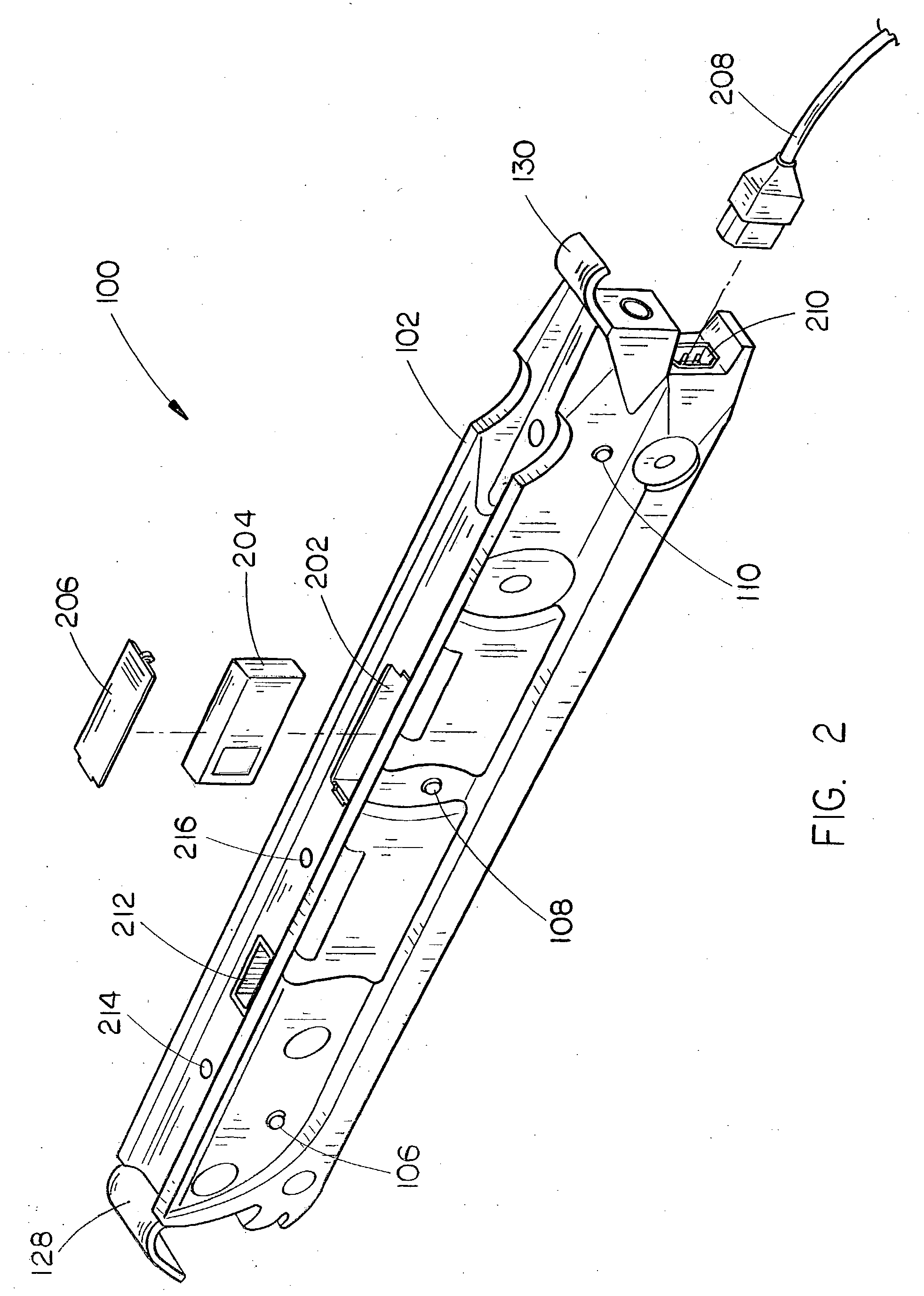

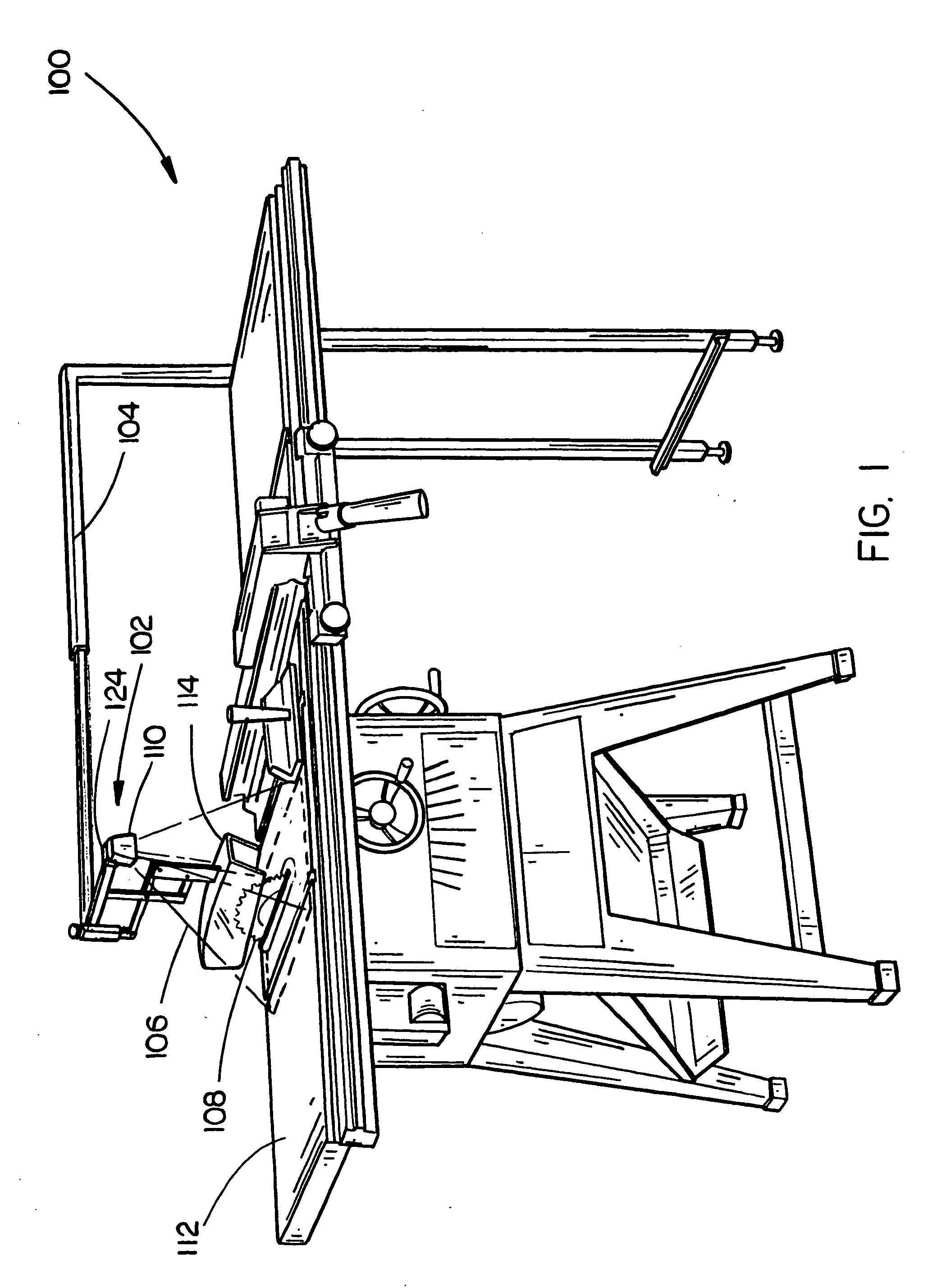

Multi-axis panel saw

A panel saw has a first cutting blade for cutting stock in a first axis and a second cutting blade for cutting the stock in a second axis. The first blade moveable from a cutting position to a position in which stock can be slid between the cutting blade and a supporting frame of the panel saw. The panel saw allows repeated cross cuts and rip cuts without changing the cutting location of the first cutting blade. A control system is configured to retract the first cutting blade from contact with the stock if the current draw exceeds a value. The control system may also retract a cutting blade when it senses the end of a panel being cut.

Owner:CHISEL WORKS L L C THE

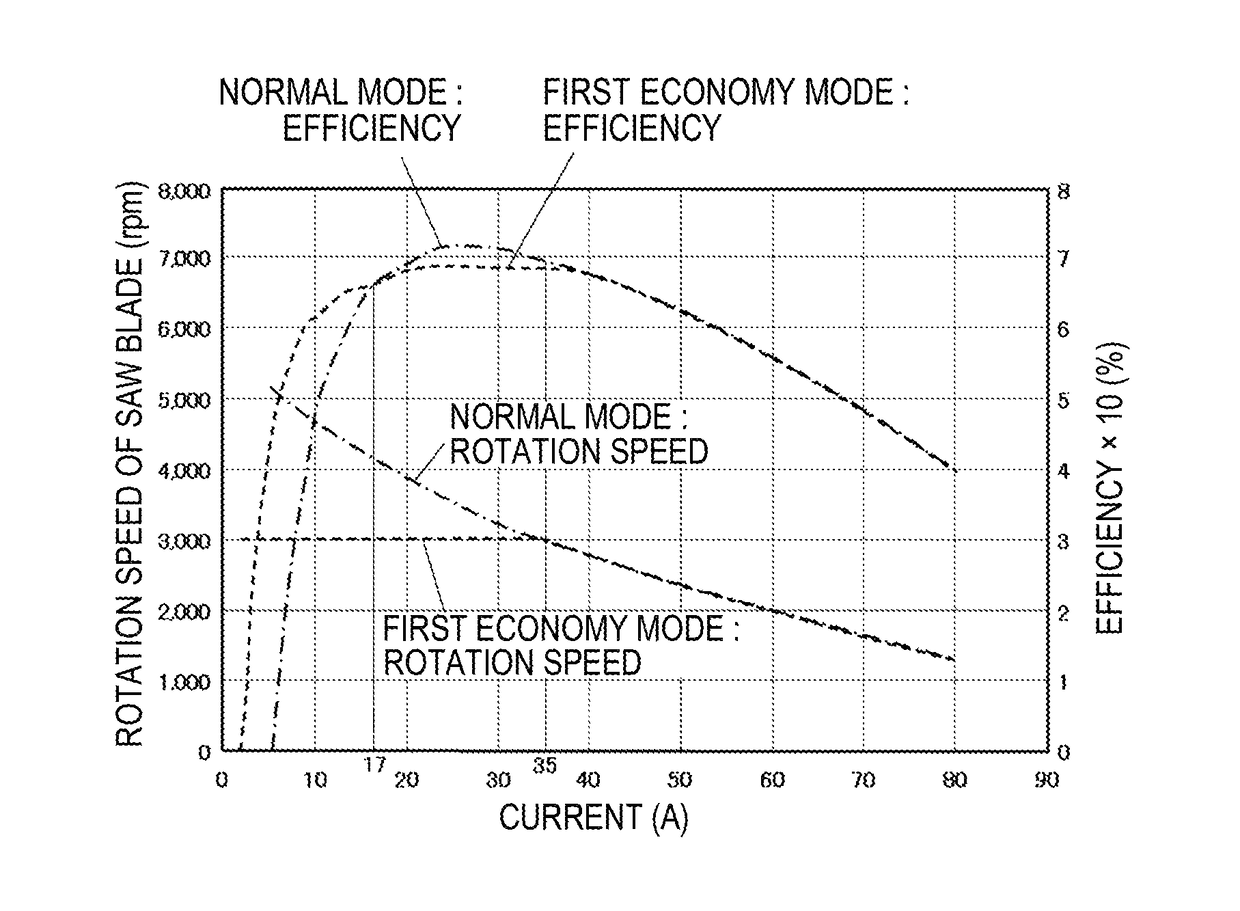

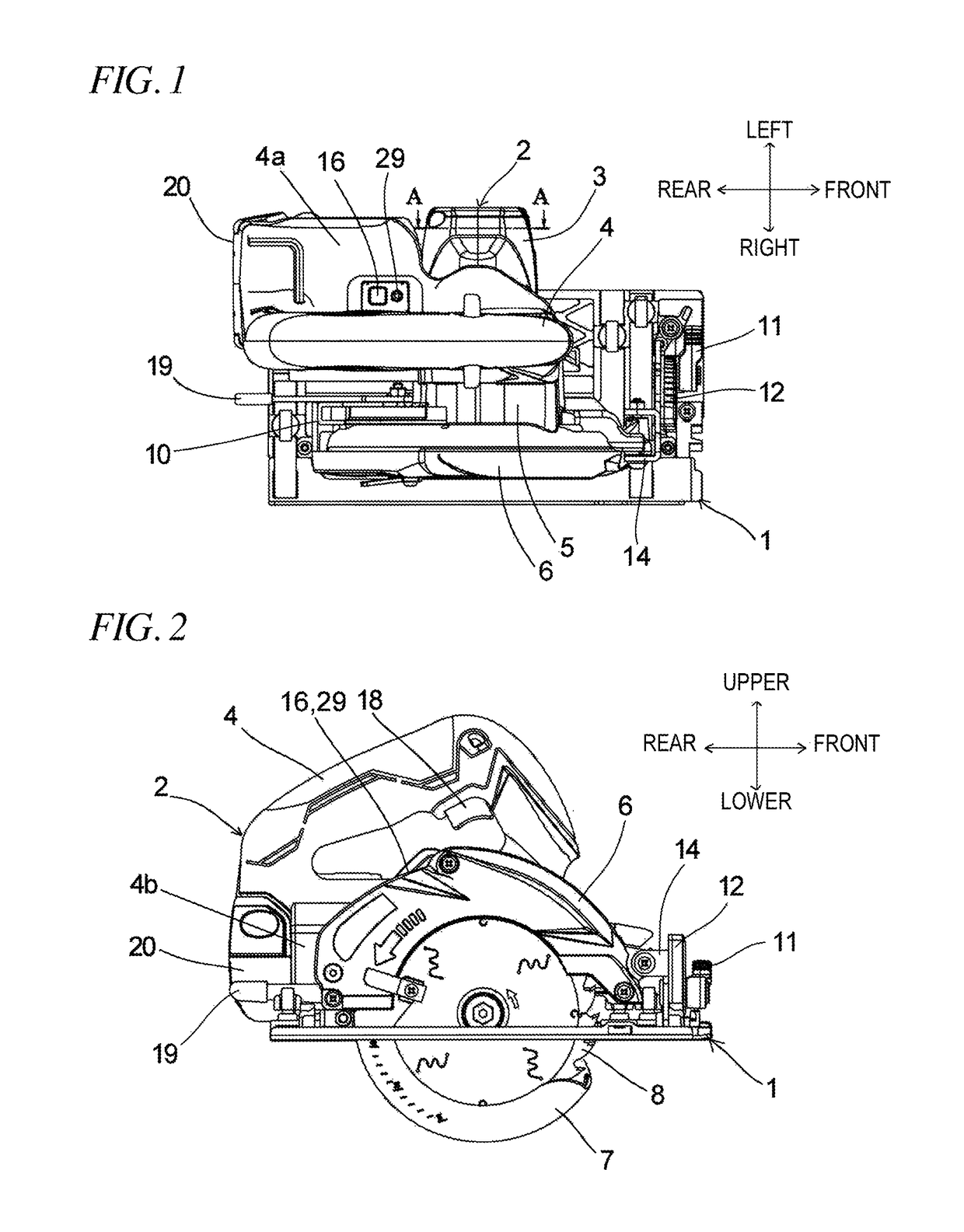

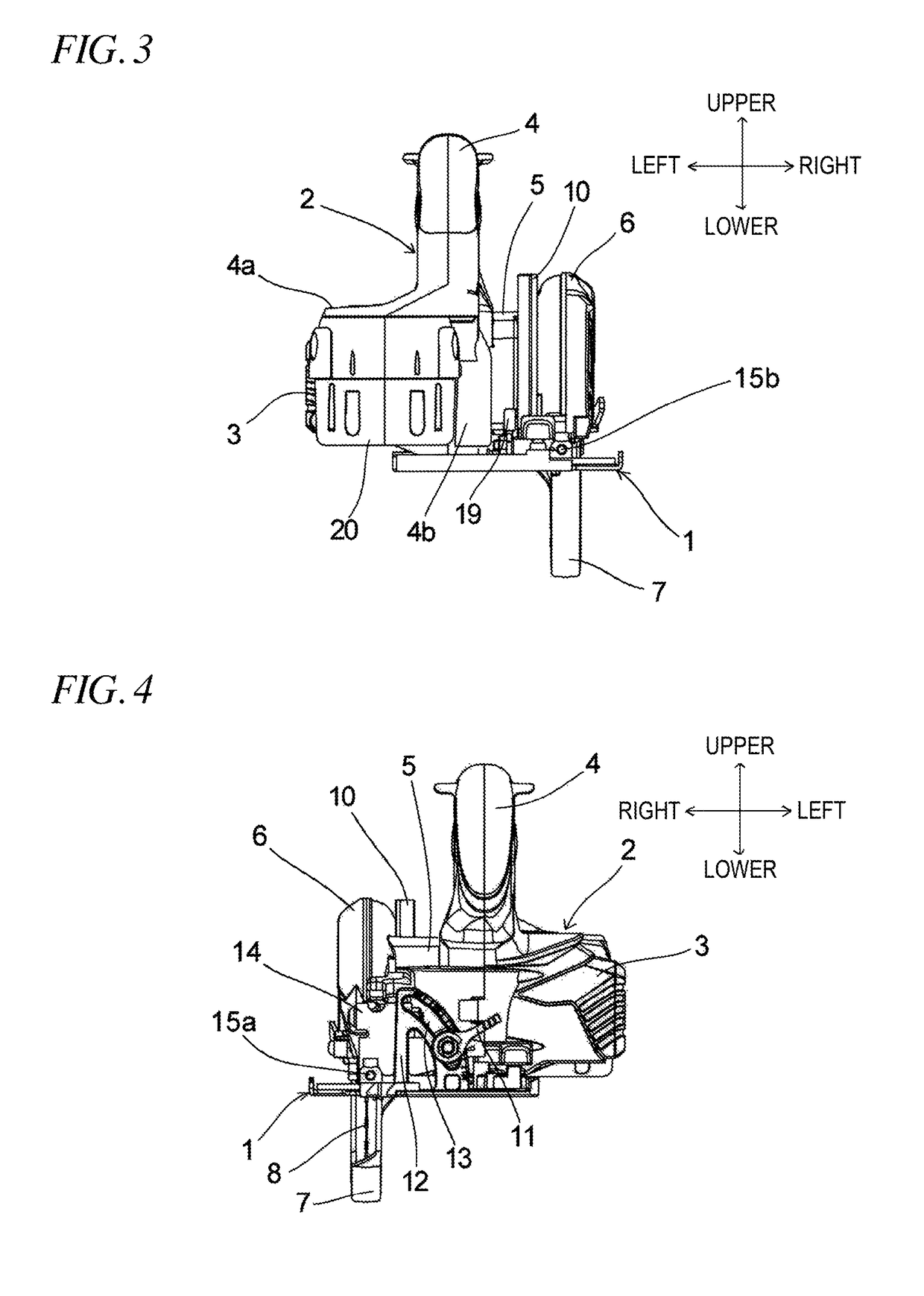

Electric power tool

ActiveUS10099303B2Improve work efficiencyConvenience to workMetal sawing devicesMetal sawing accessoriesBrushless motorsLow speed

Owner:KOKI HLDG CO LTD

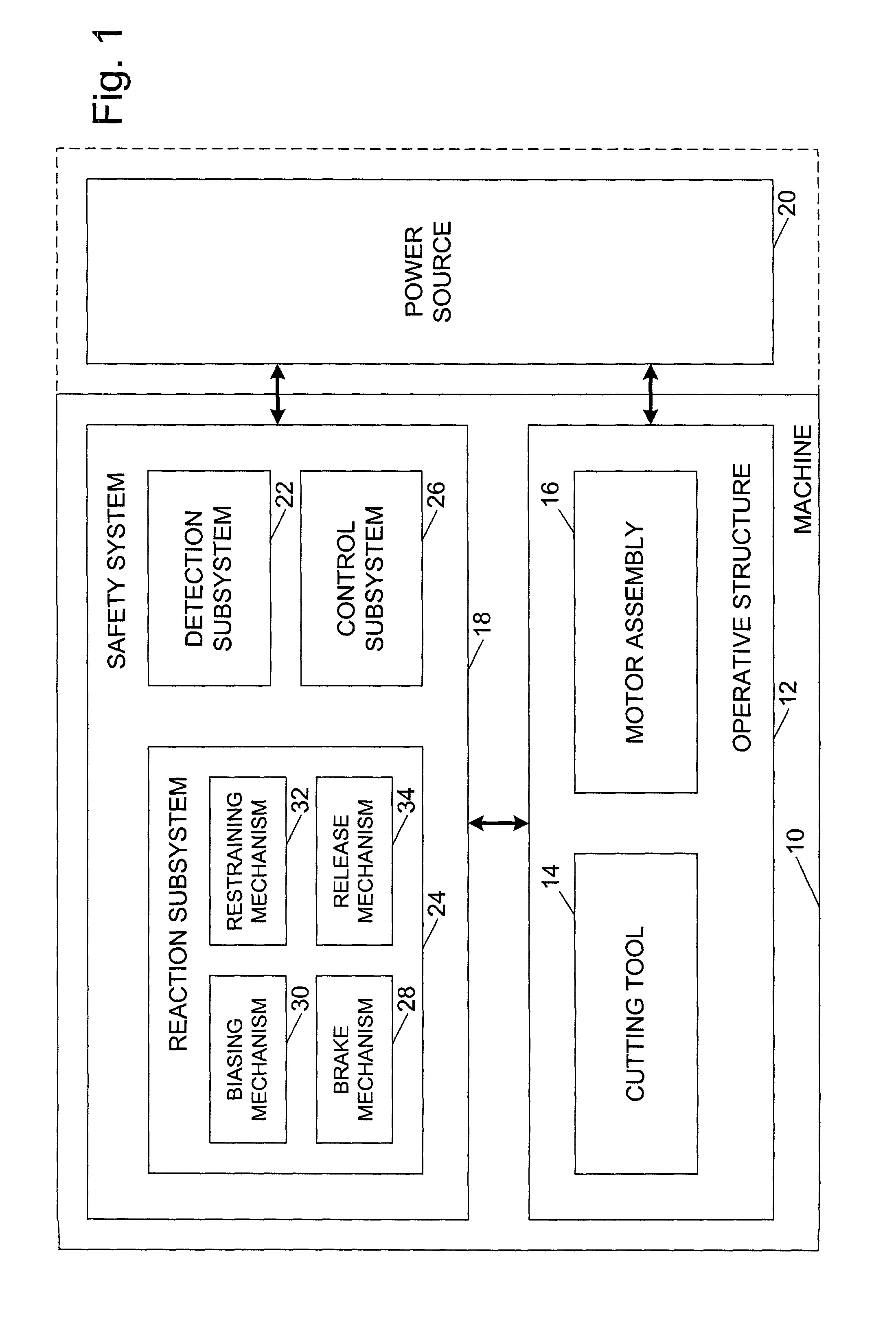

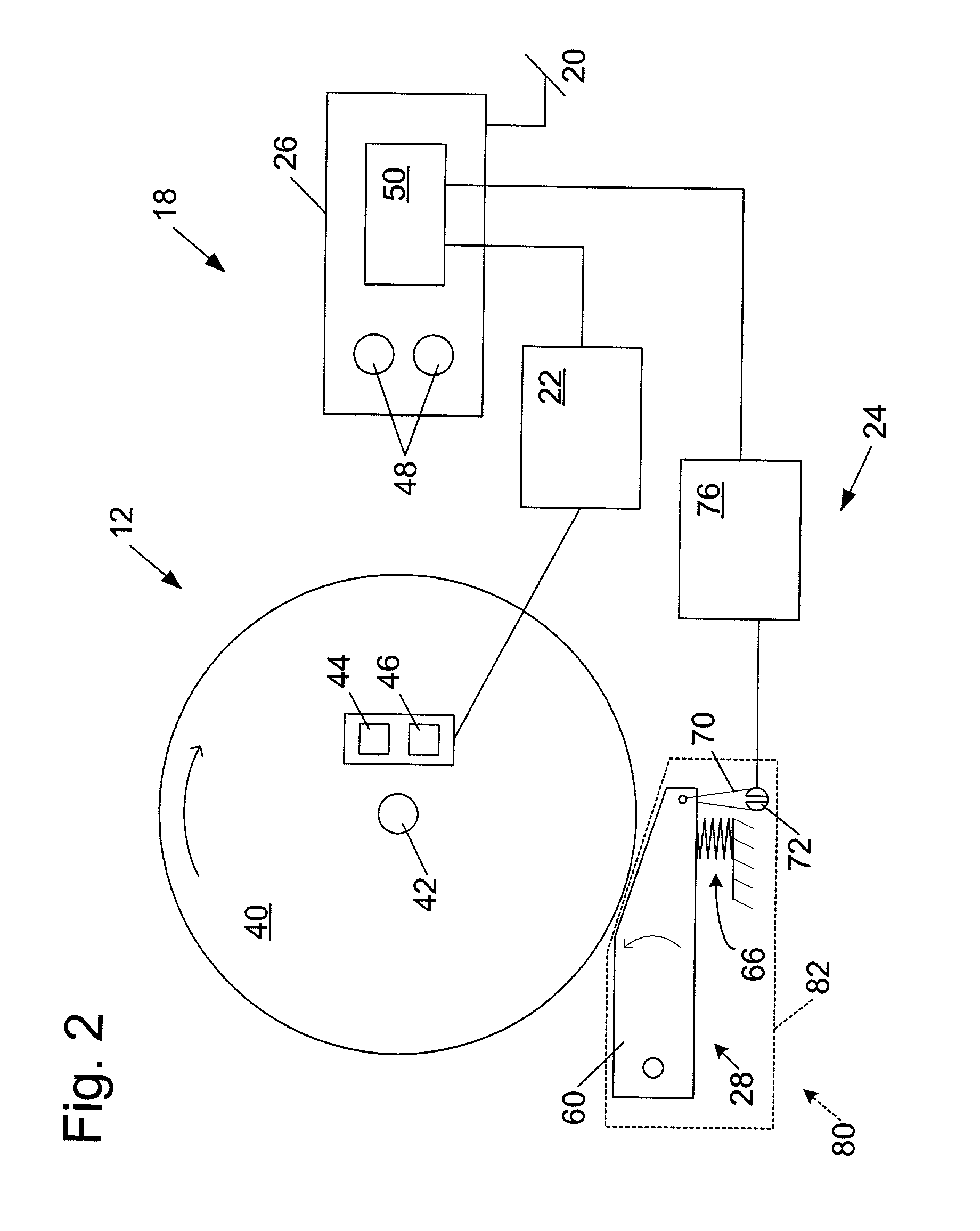

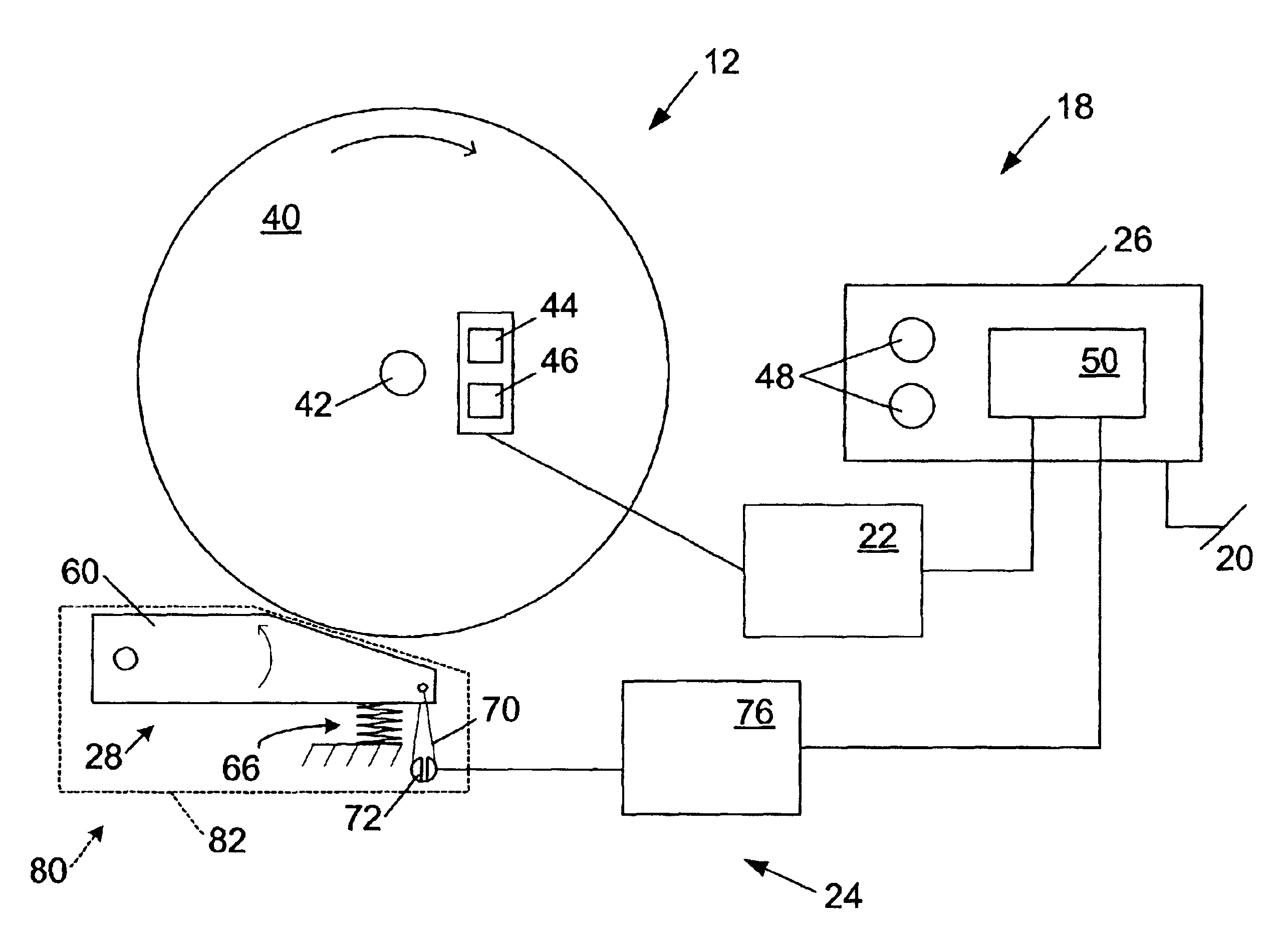

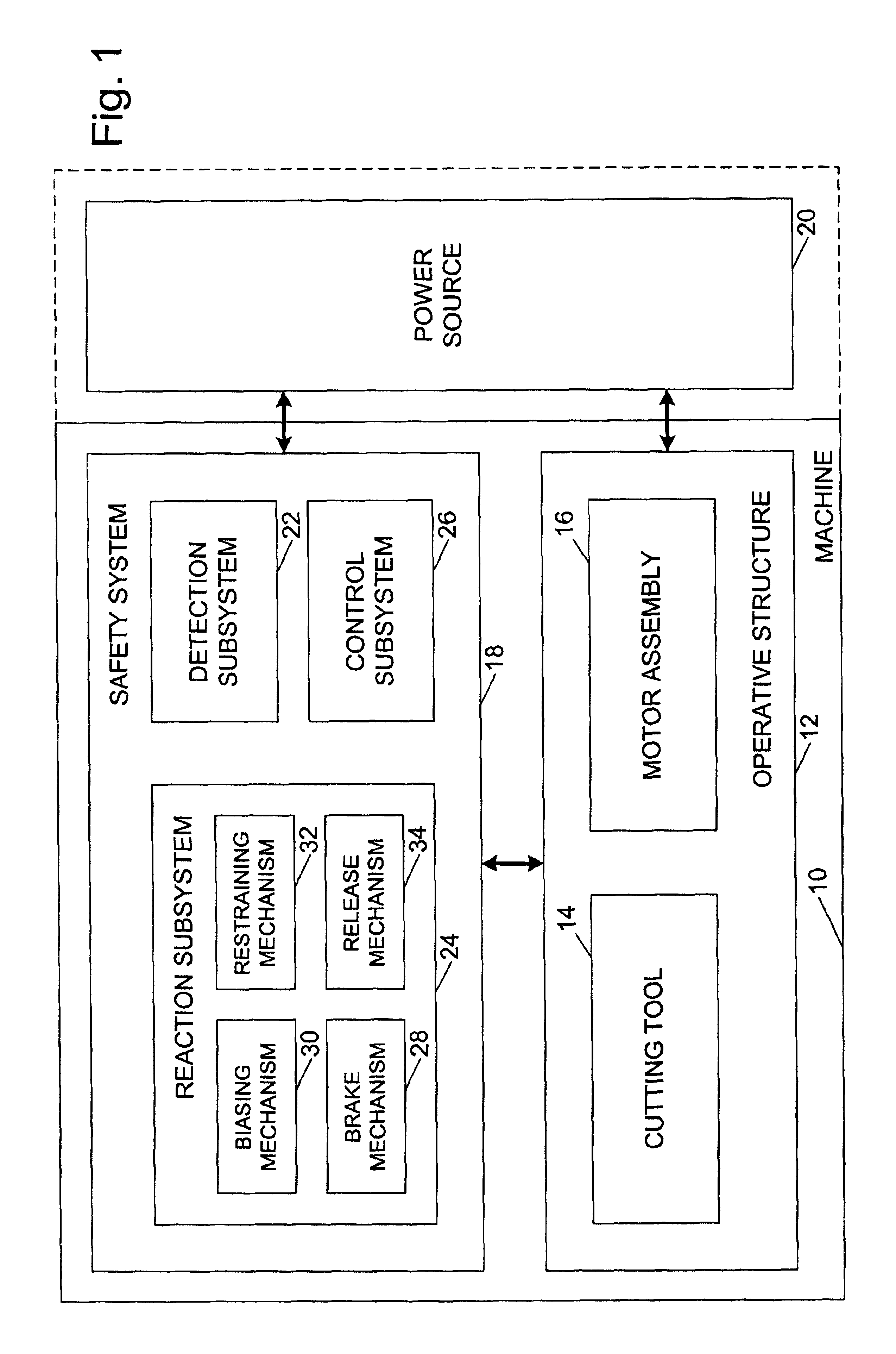

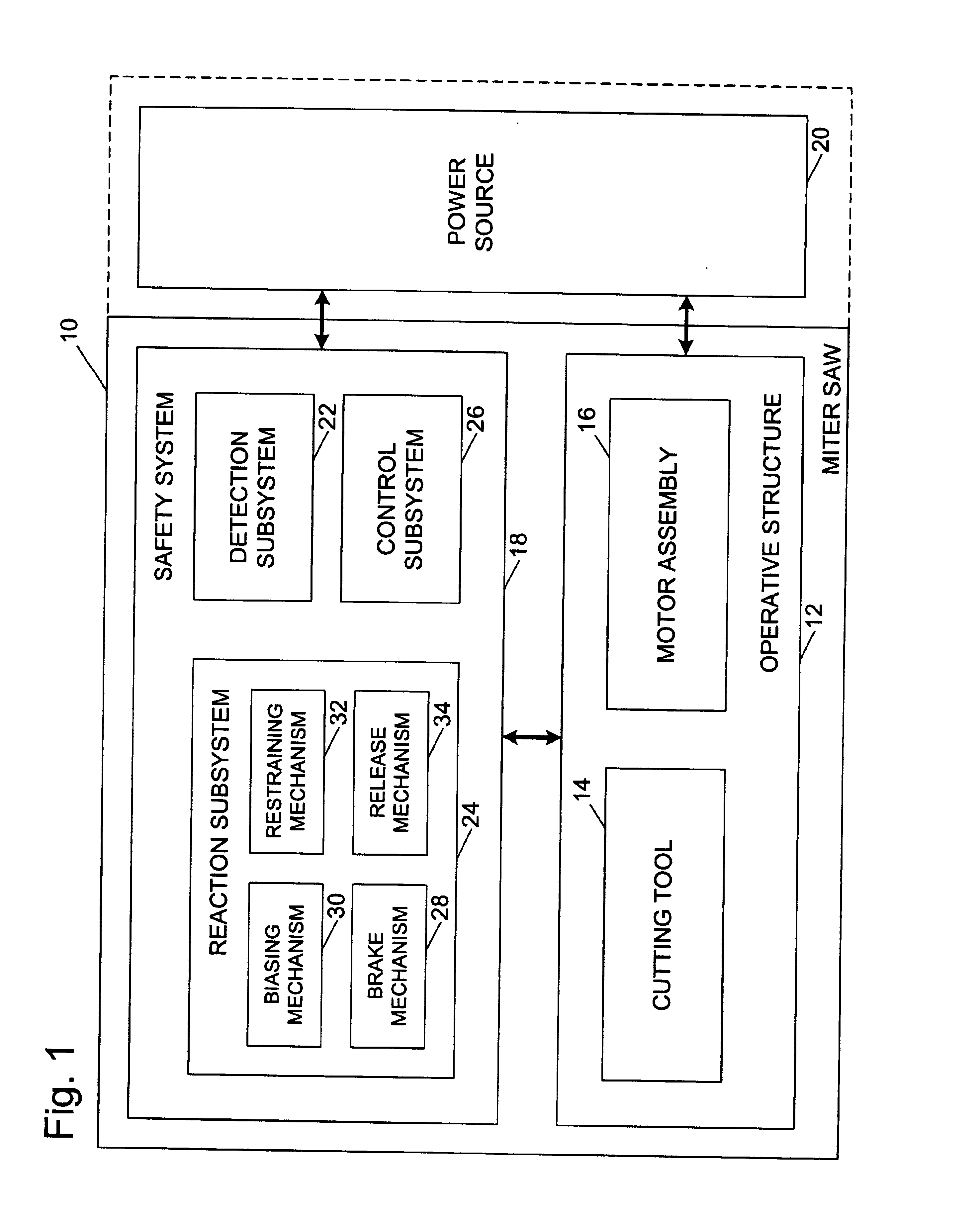

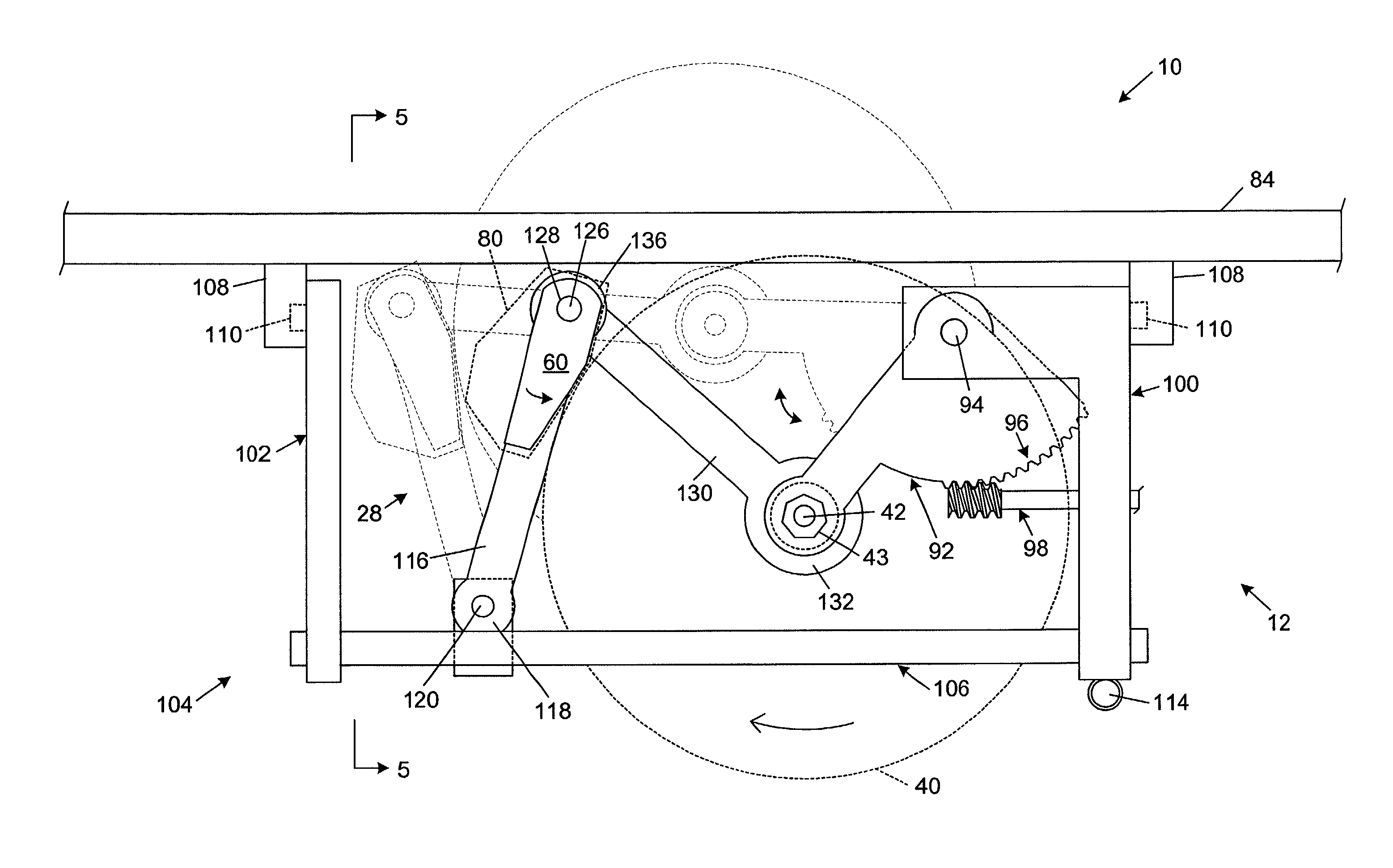

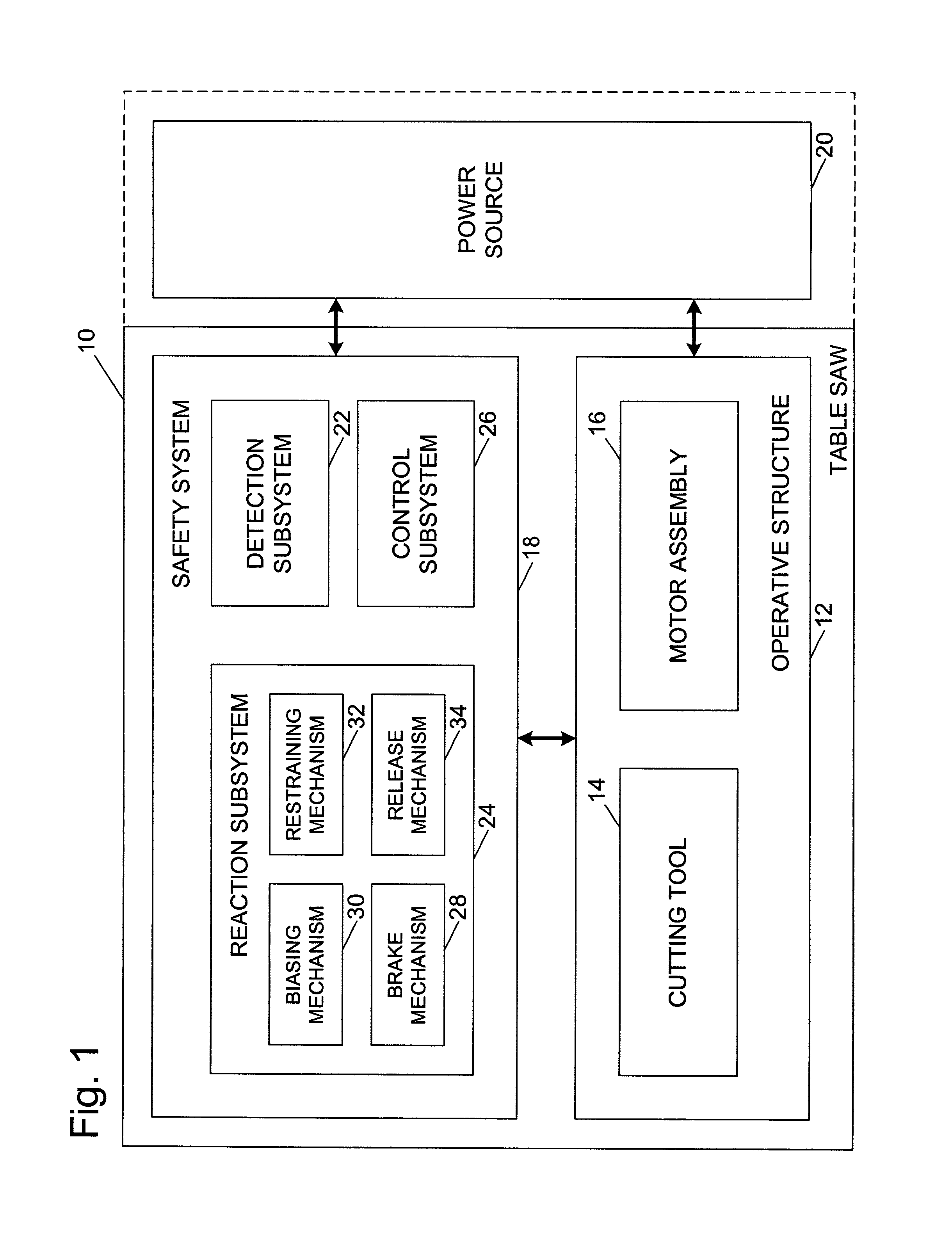

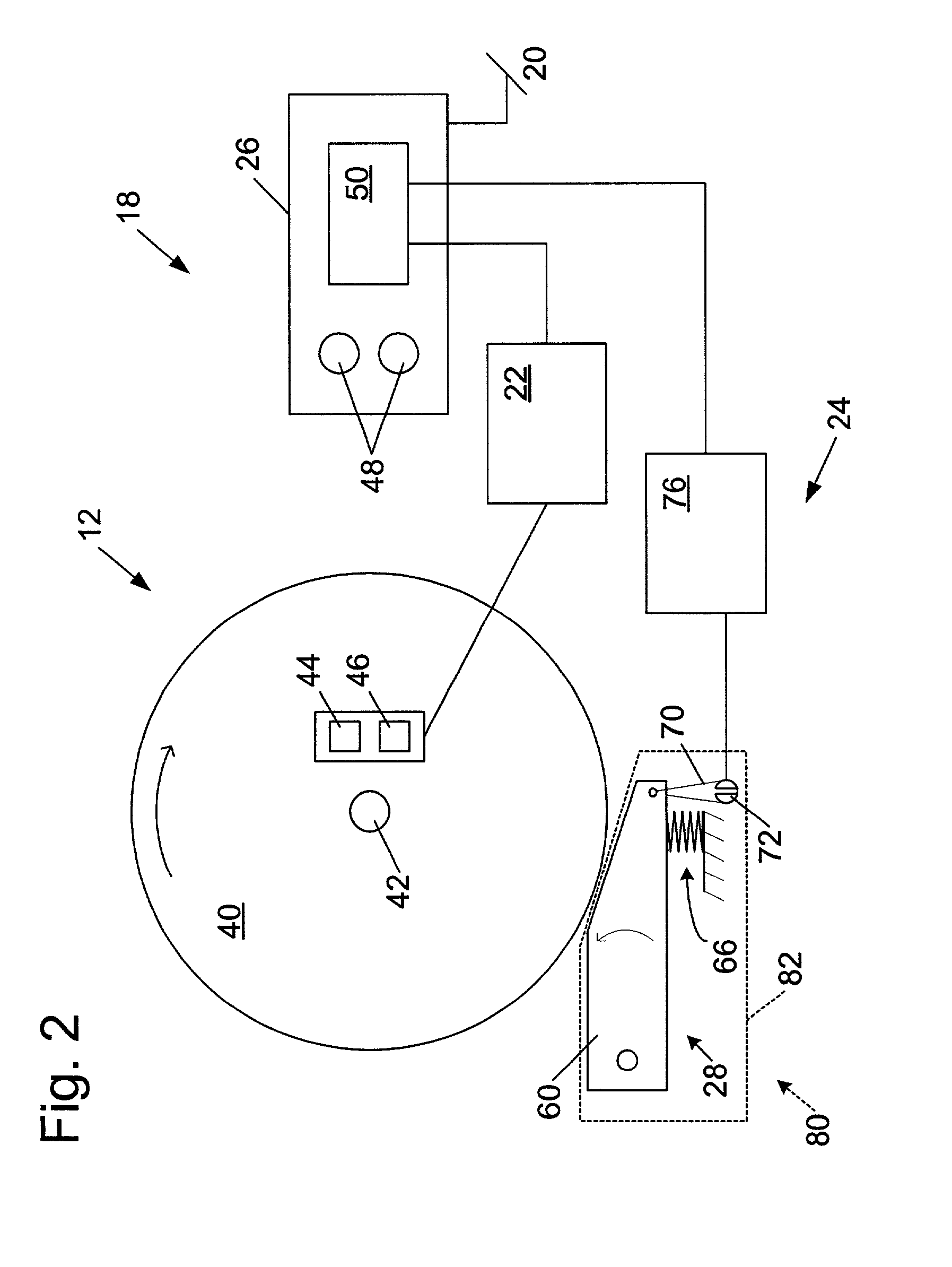

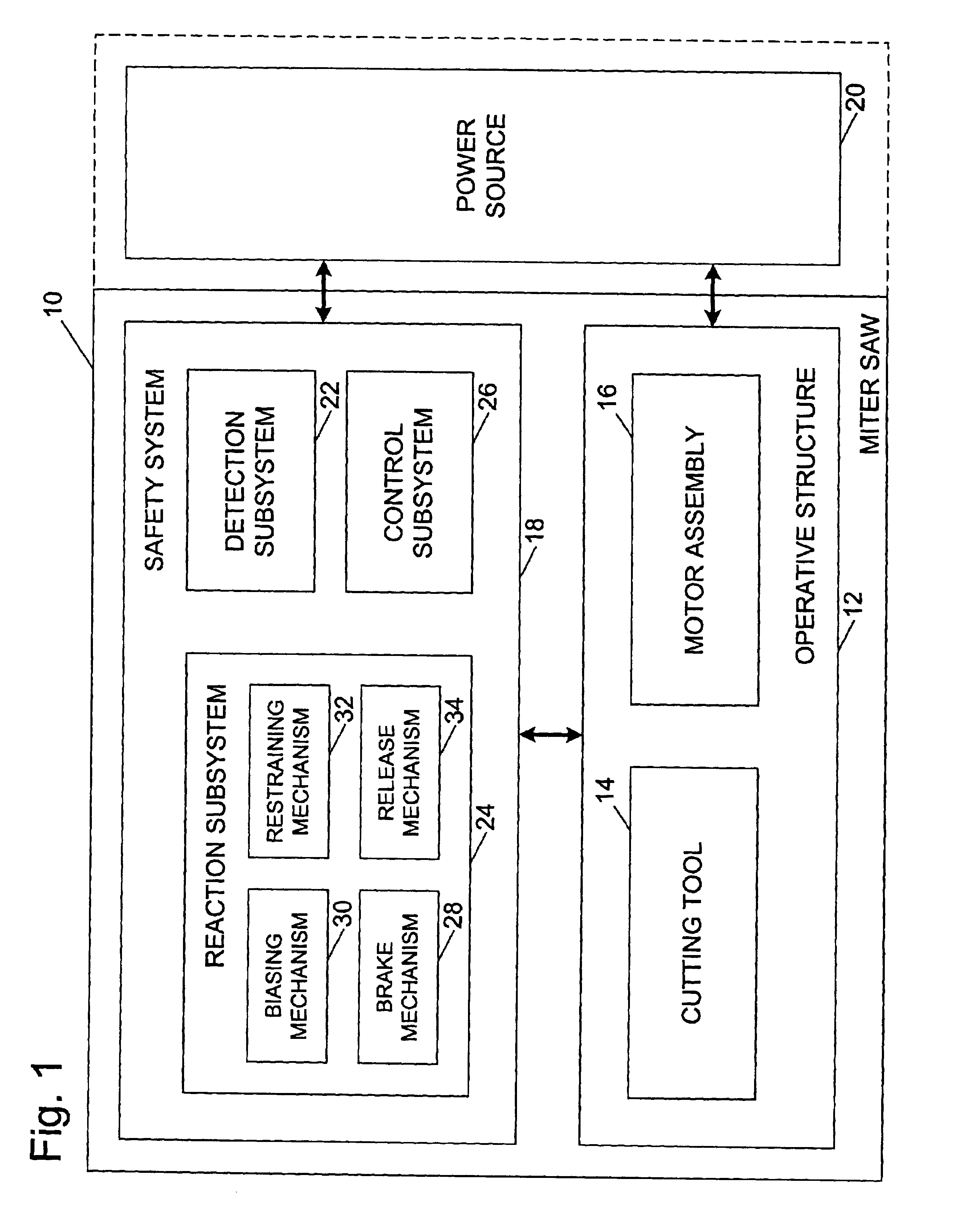

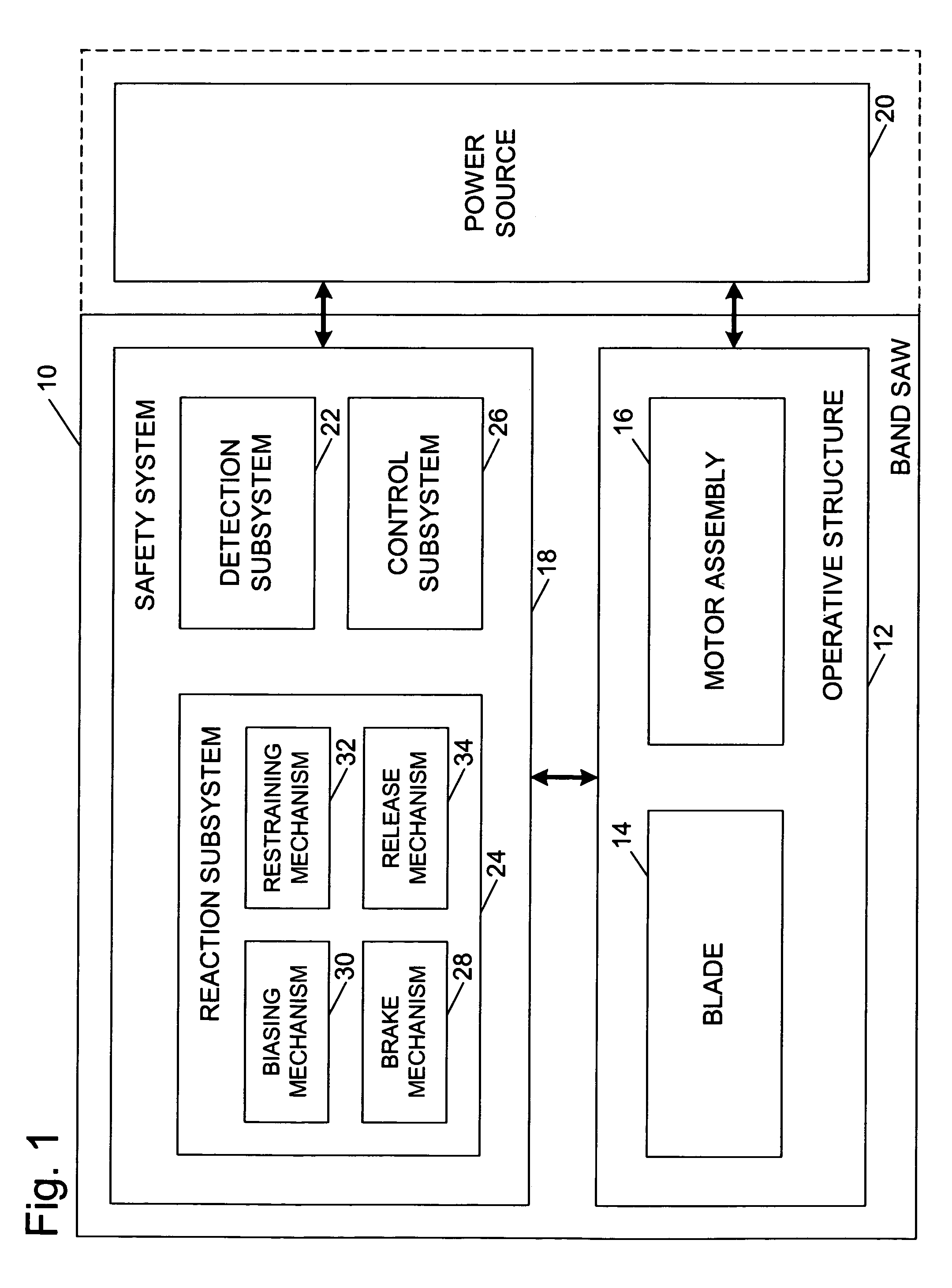

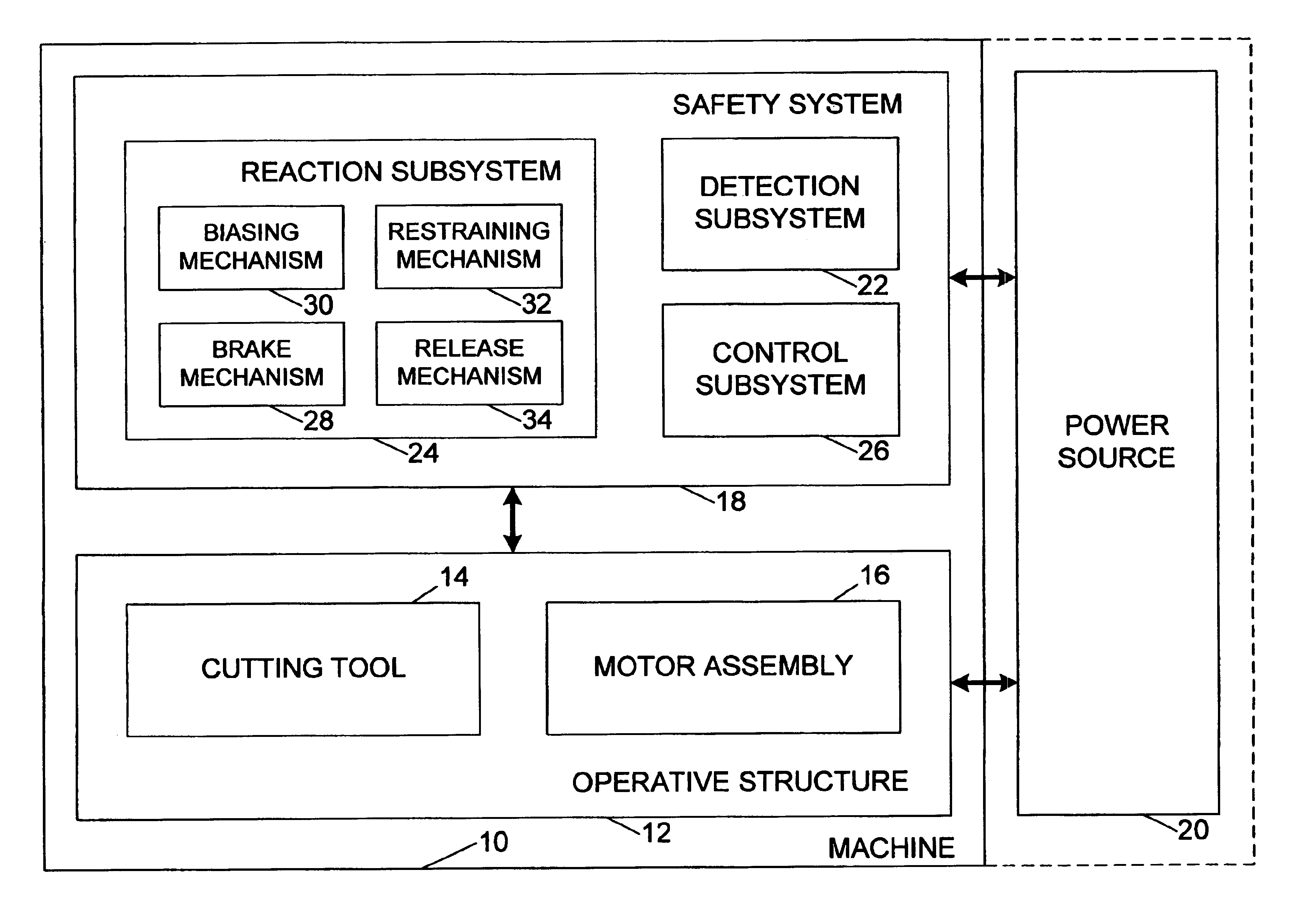

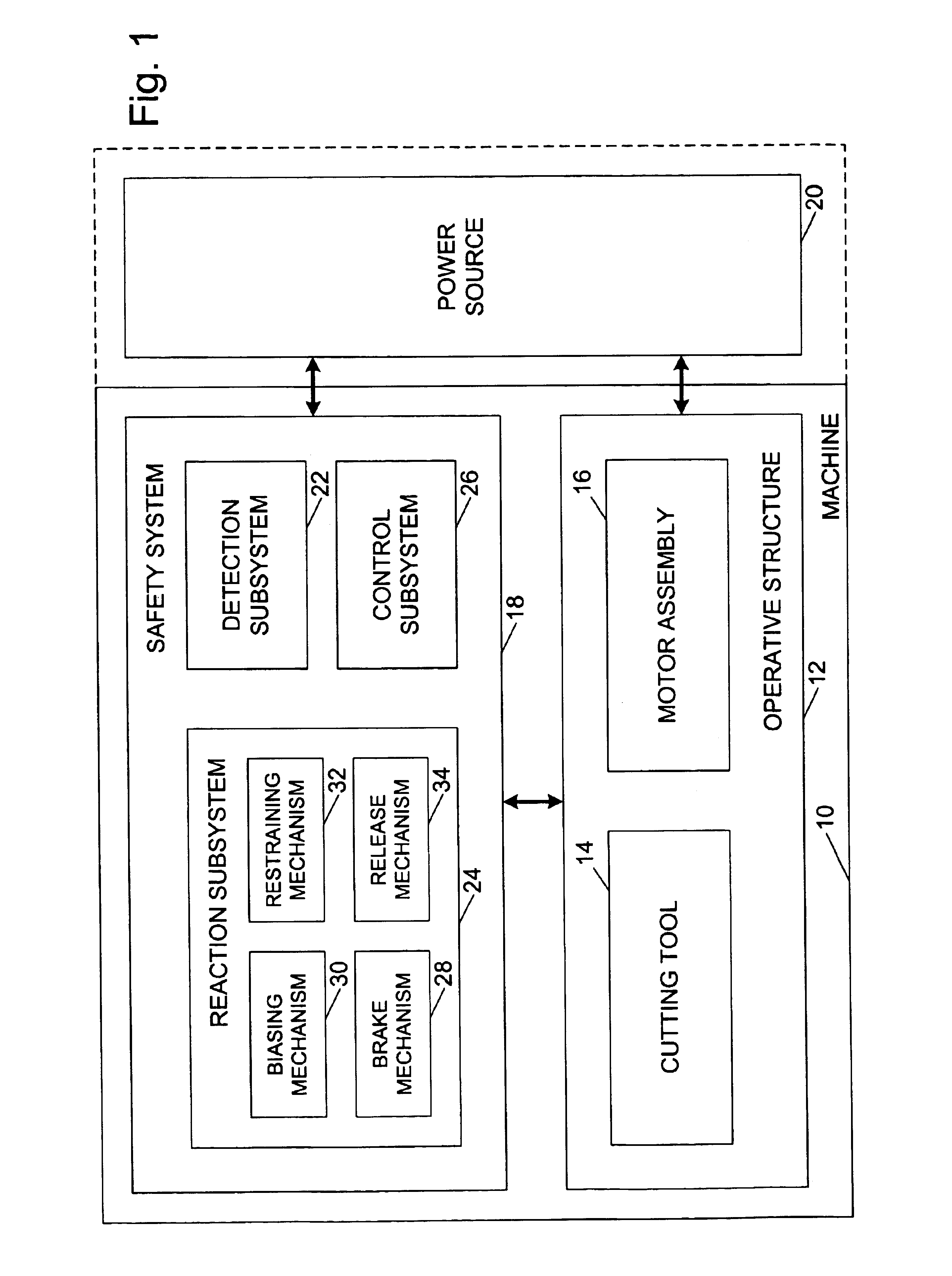

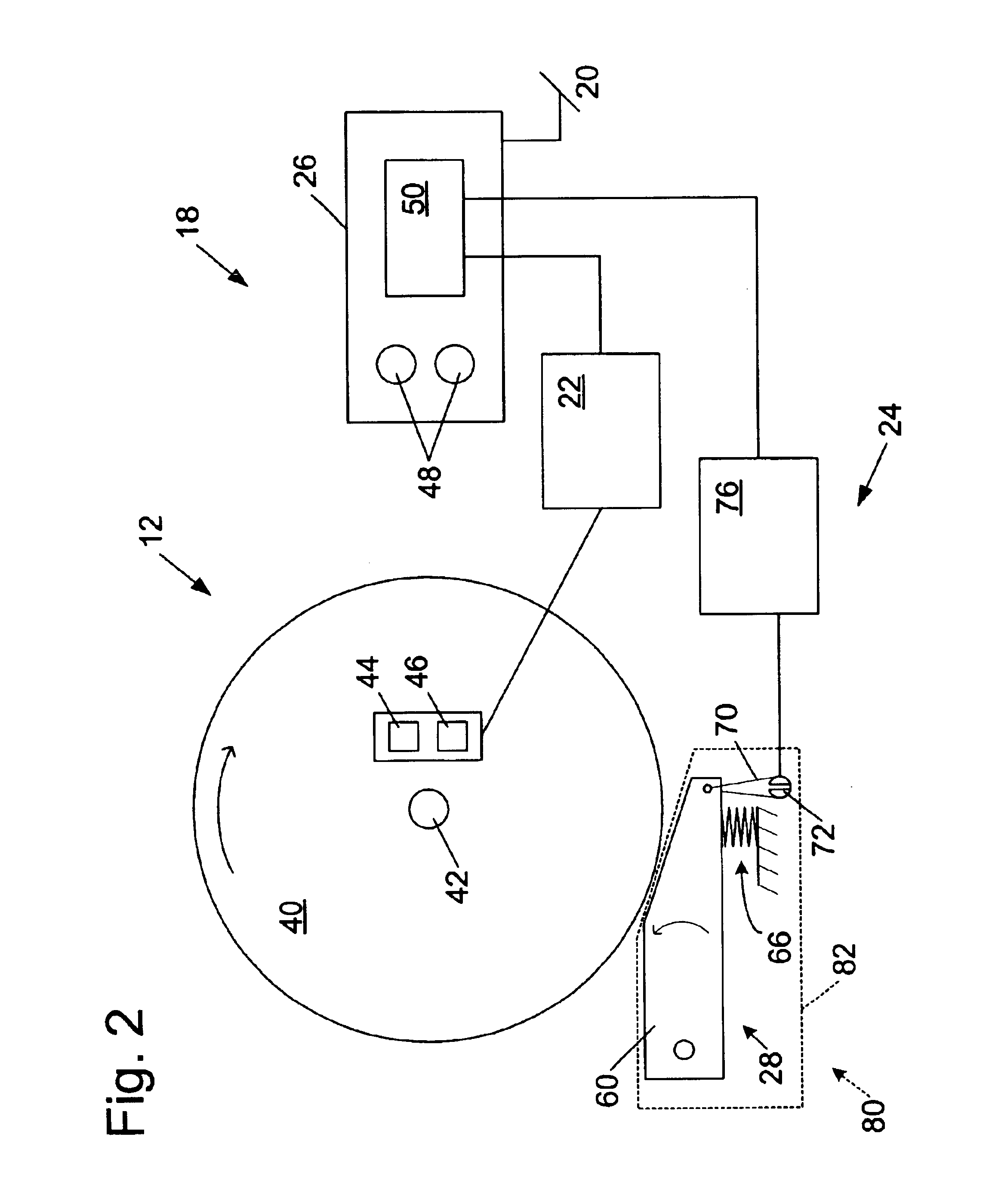

Safety systems for power equipment

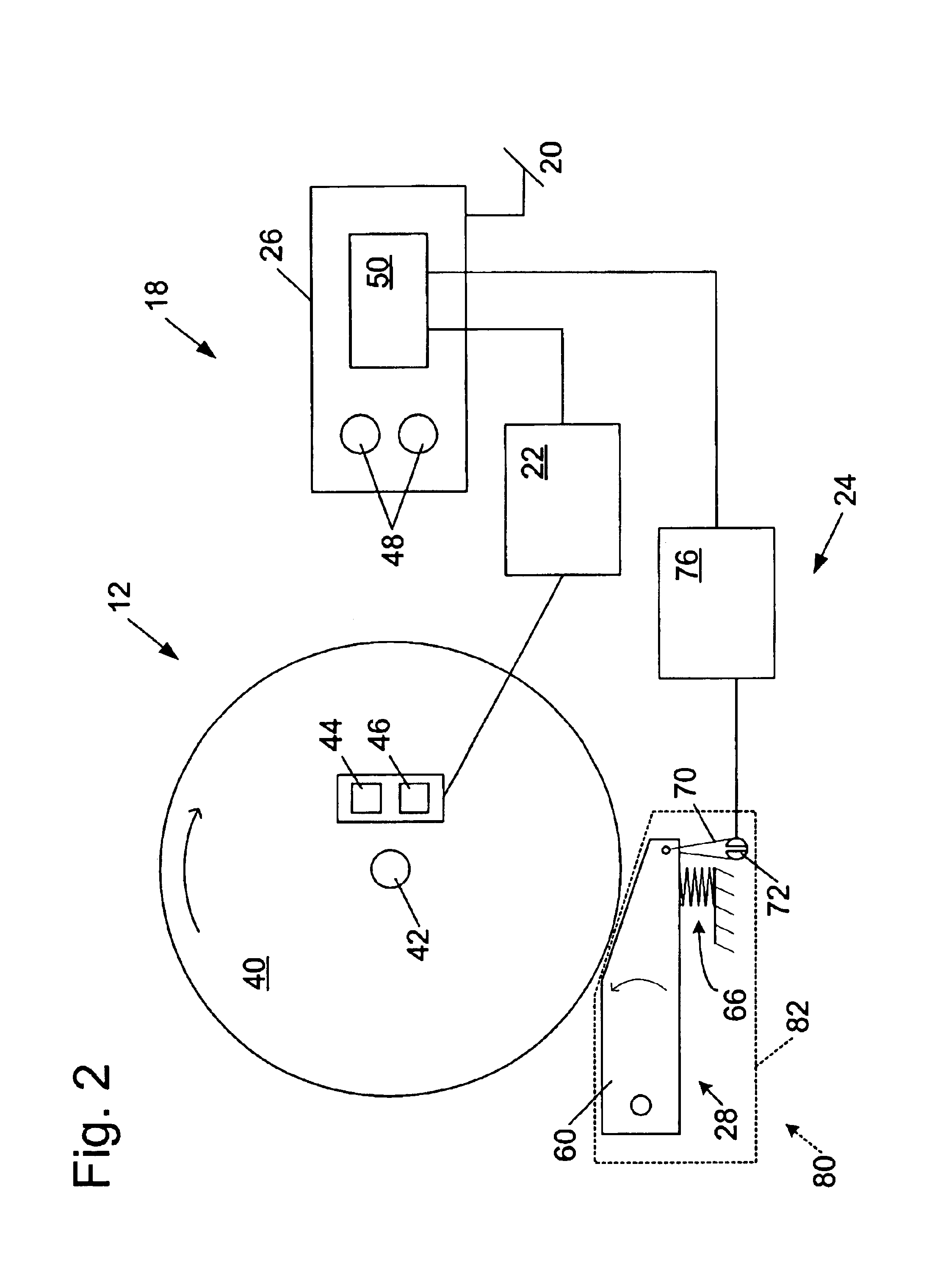

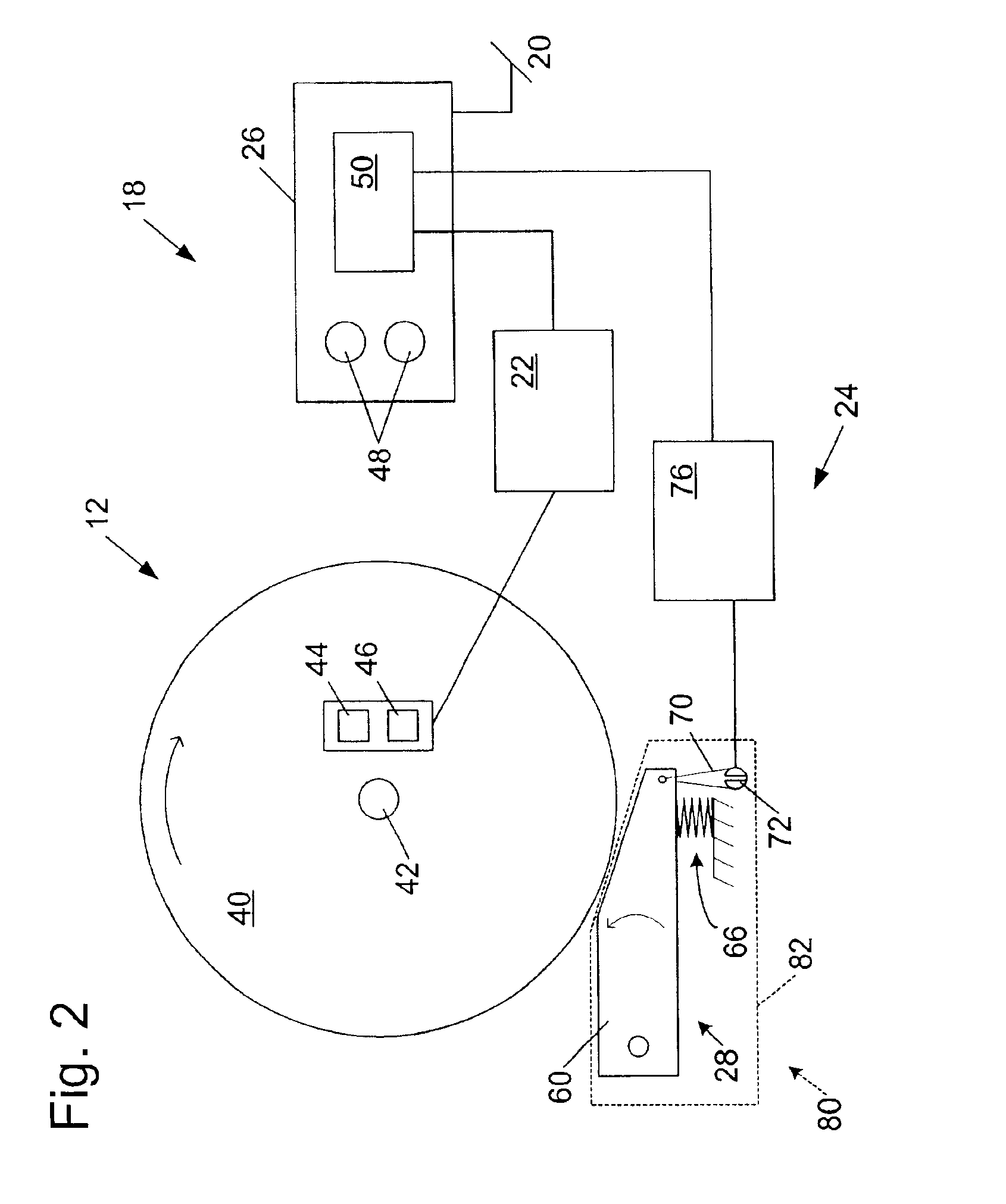

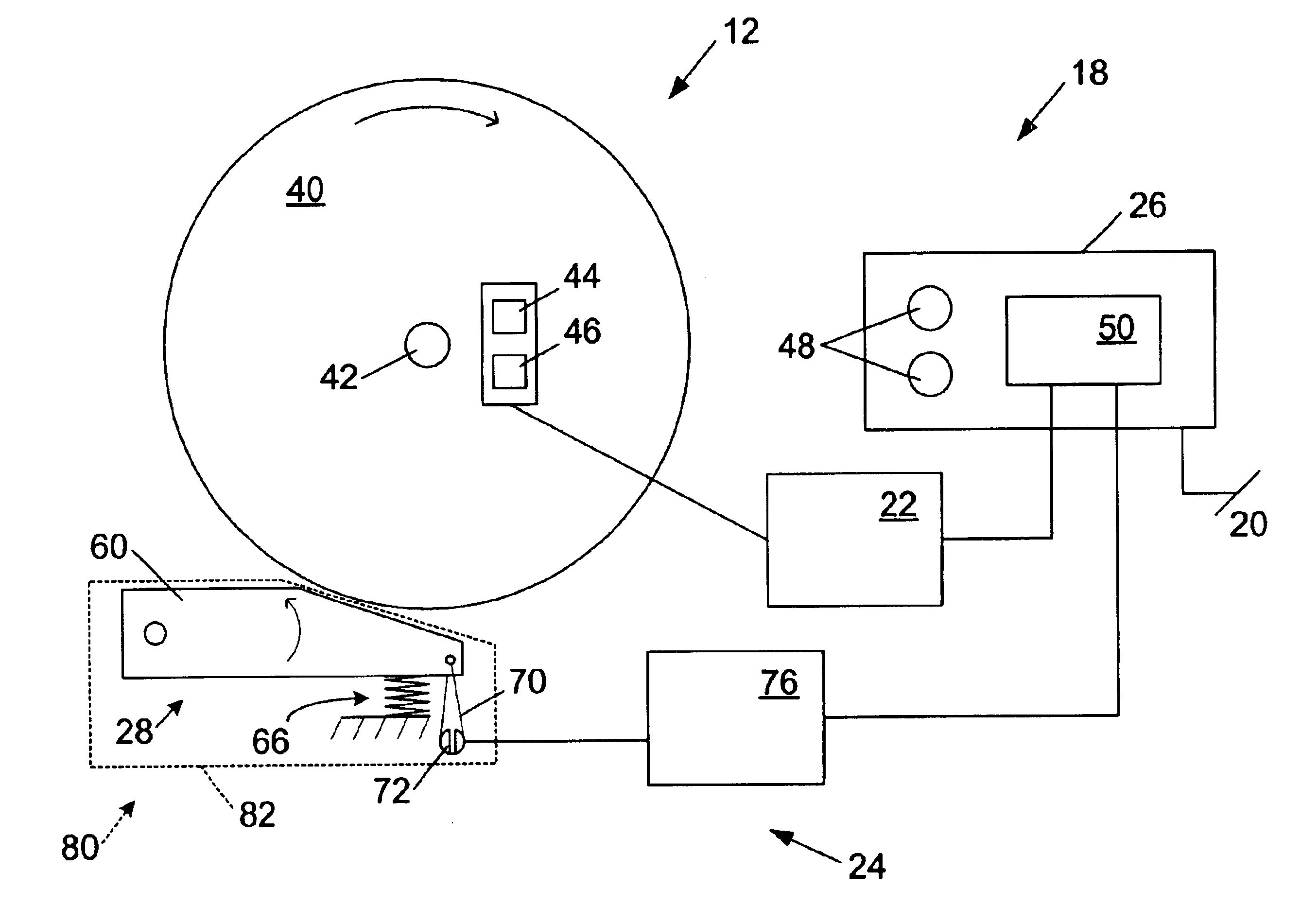

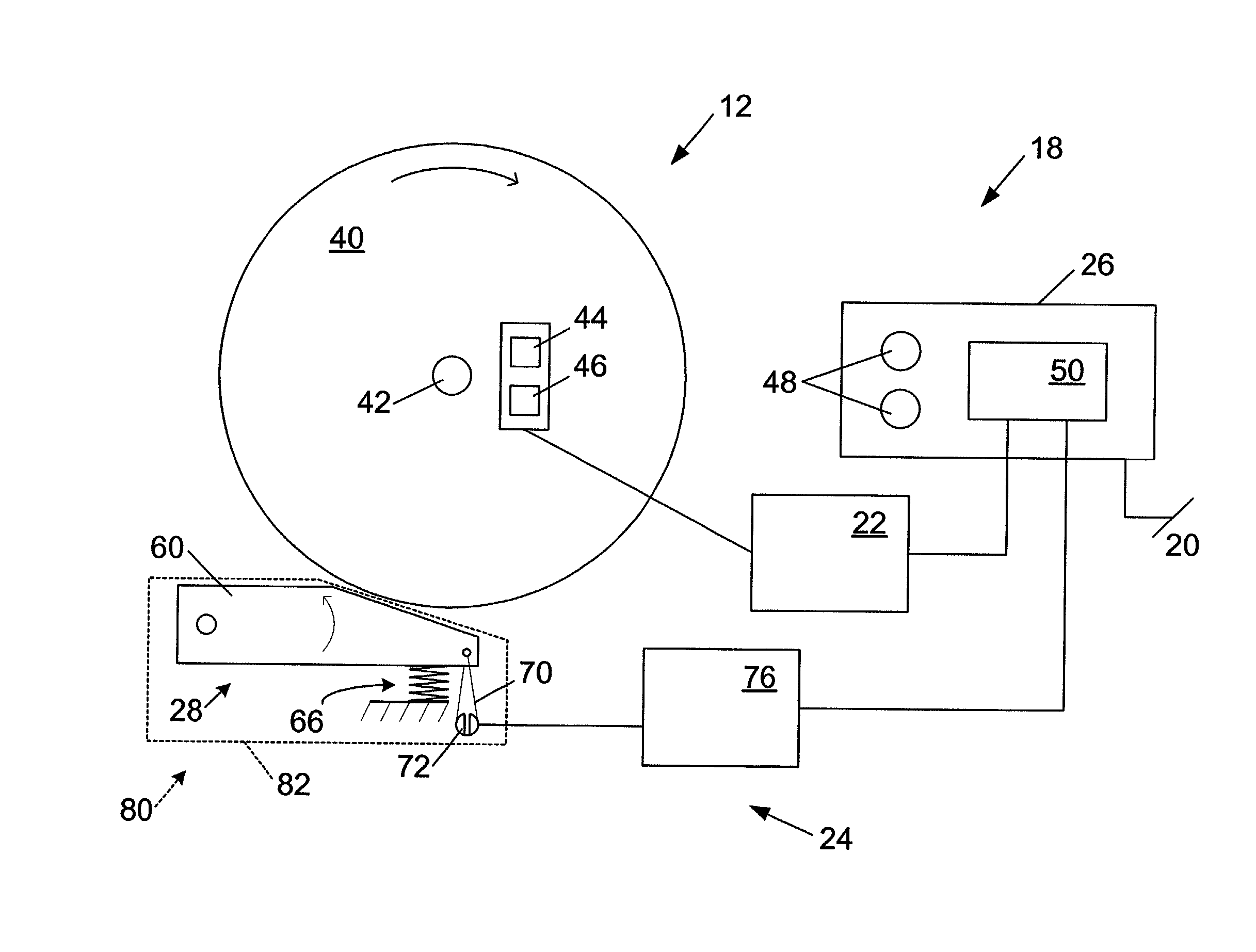

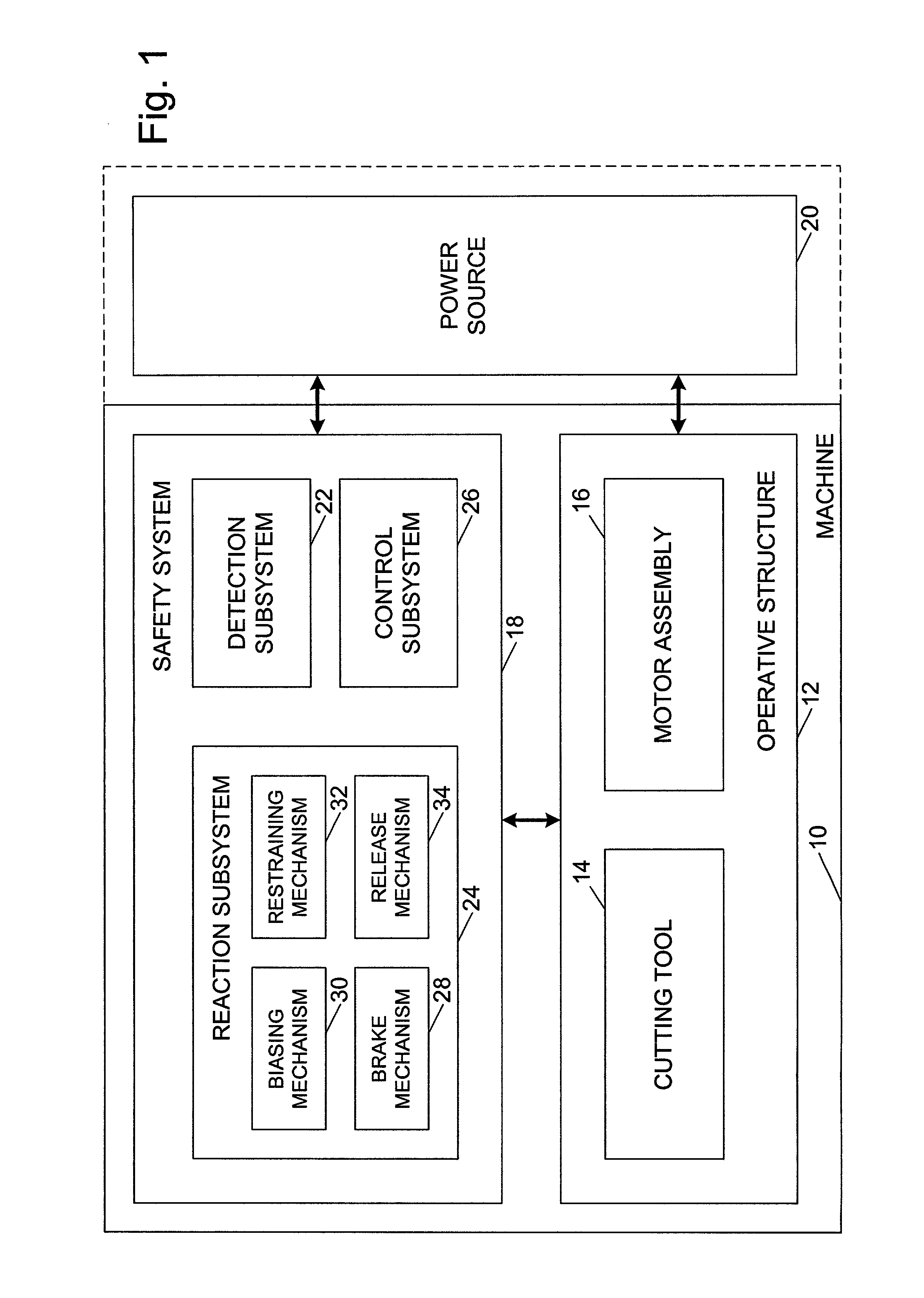

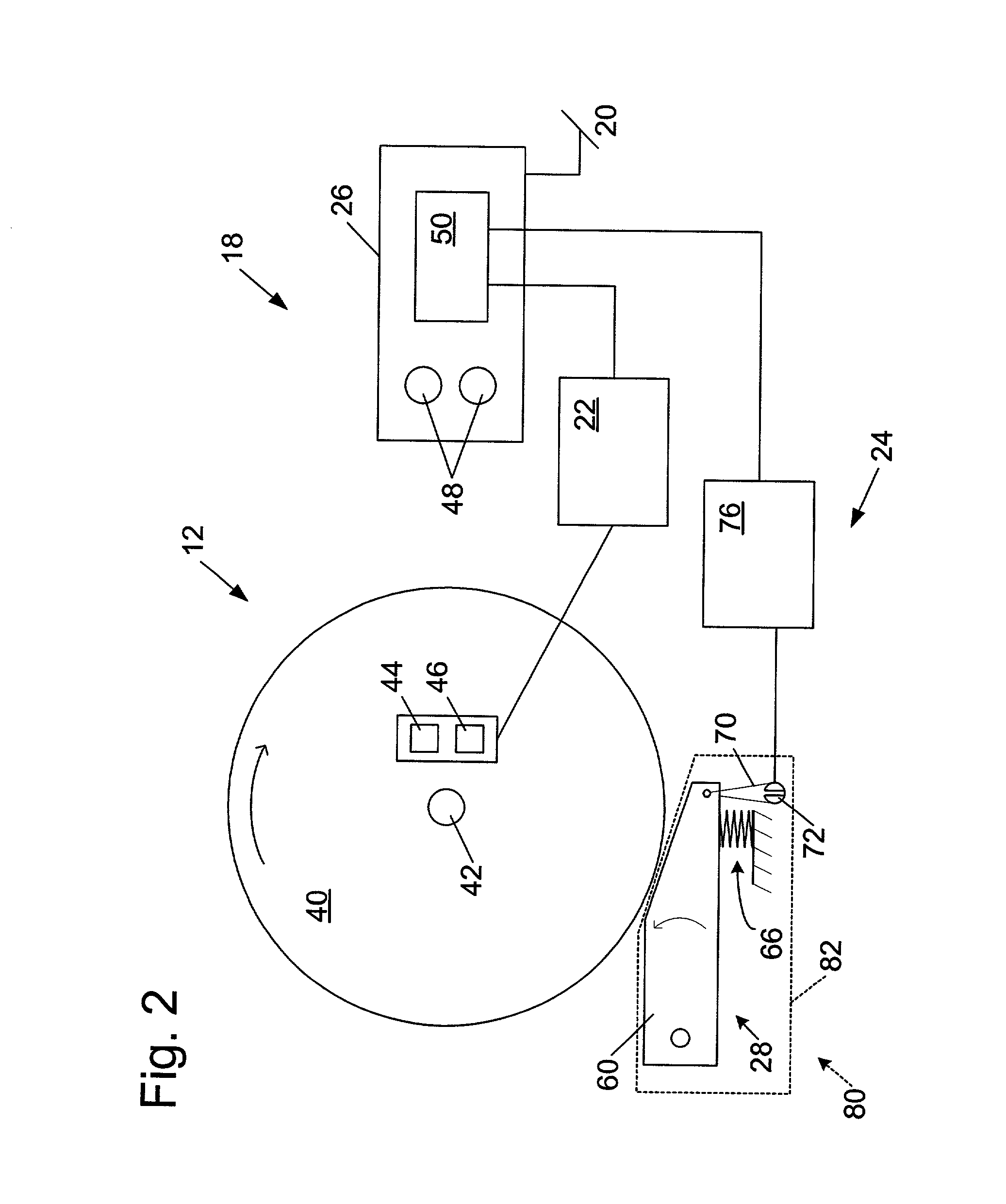

Machines with safety systems are disclosed. The machine may take the form of woodworking machines including table saws, band saws, miter saws, hand-held circular saws, pneumatic chop saws, radial-arm saws, jointers, planars, routers and shapers. The machines may include an operative structure configured to perform a task, where the operative structure includes a cutting tool adapted to move in at least one motion, and a safety system adapted to detect the occurrence of an unsafe condition between a person and the cutting tool and for mitigating the unsafe condition. The safety system may include a detection subsystem and a reaction subsystem.

Owner:SAWSTOP HLDG LLC

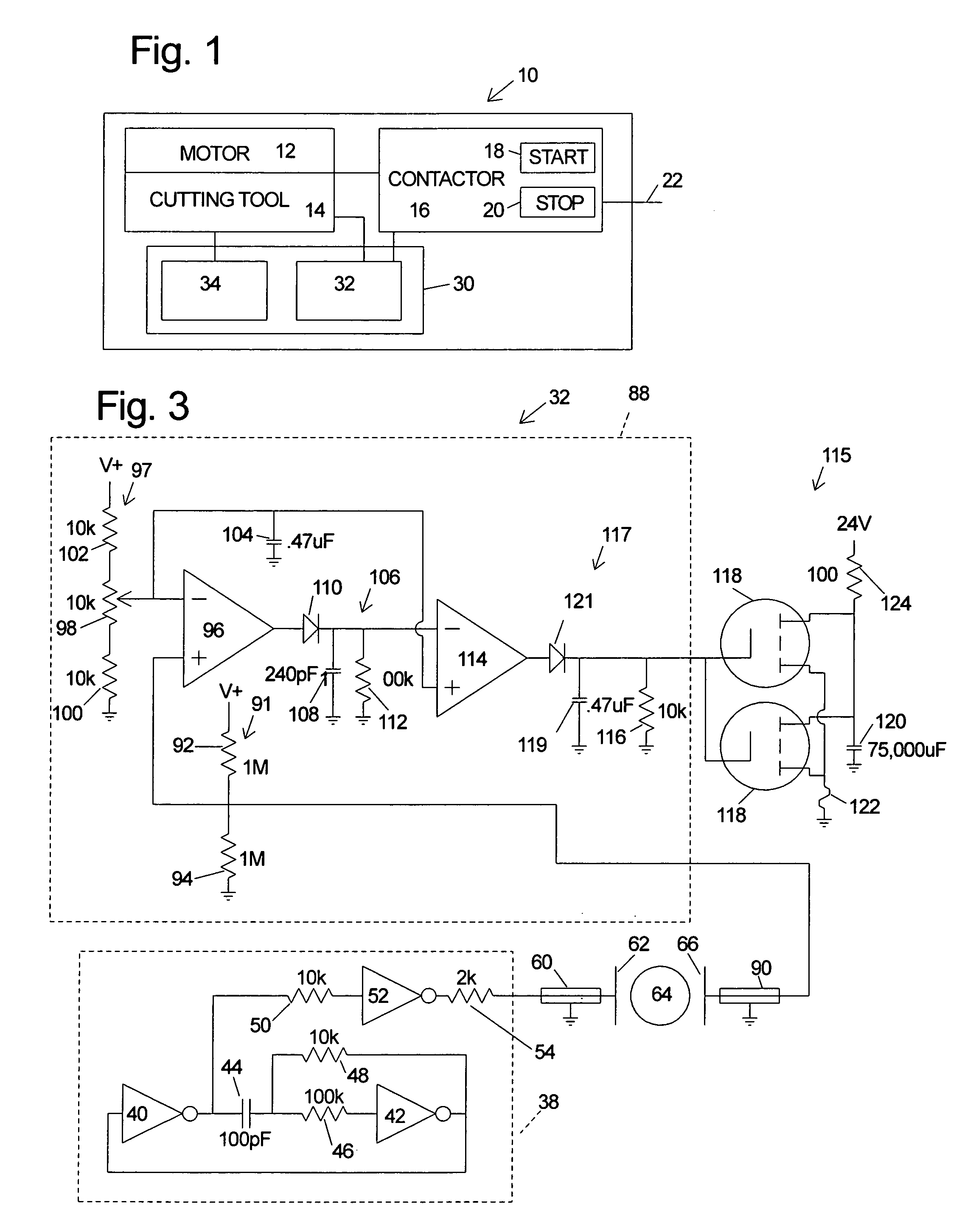

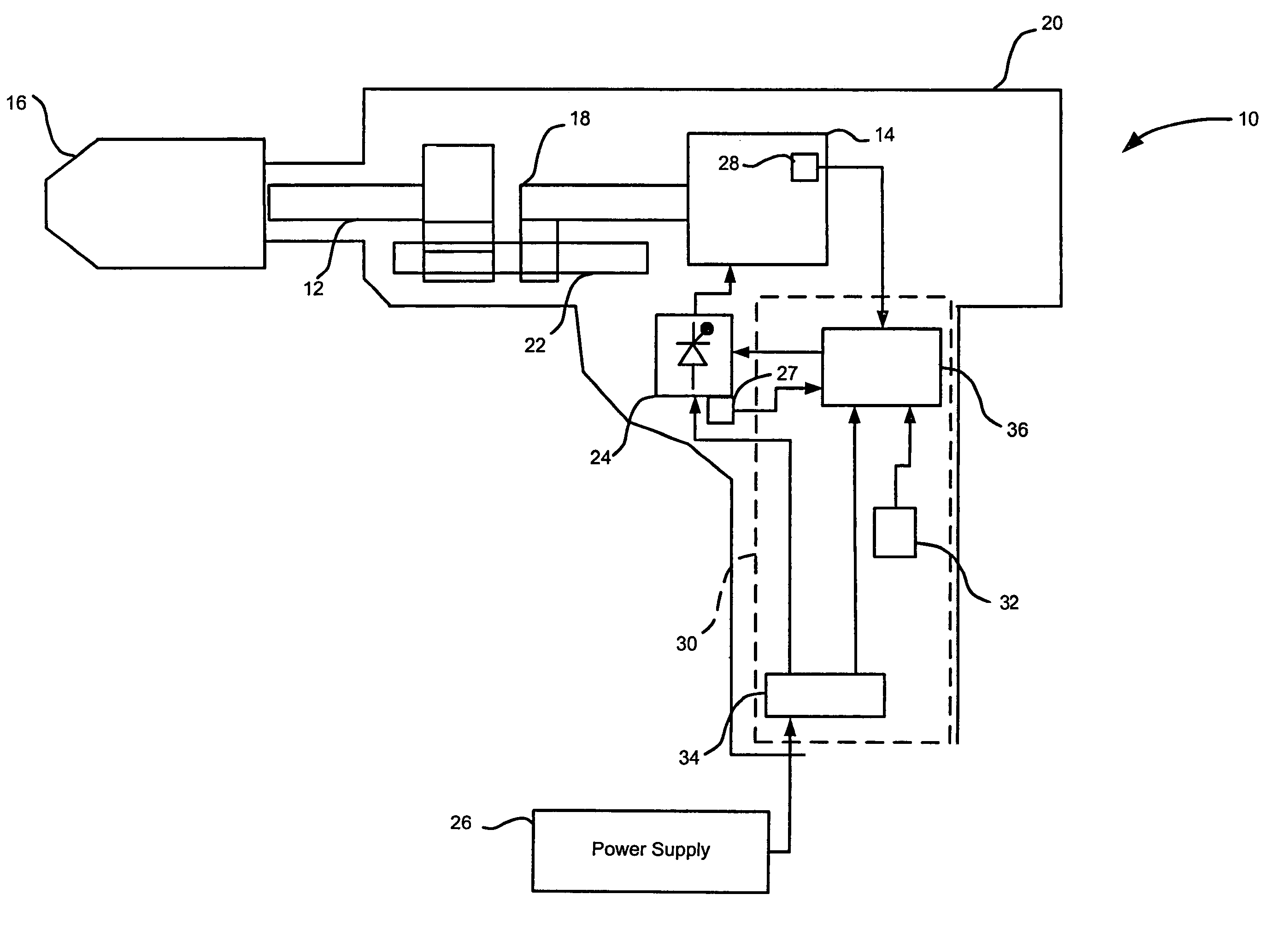

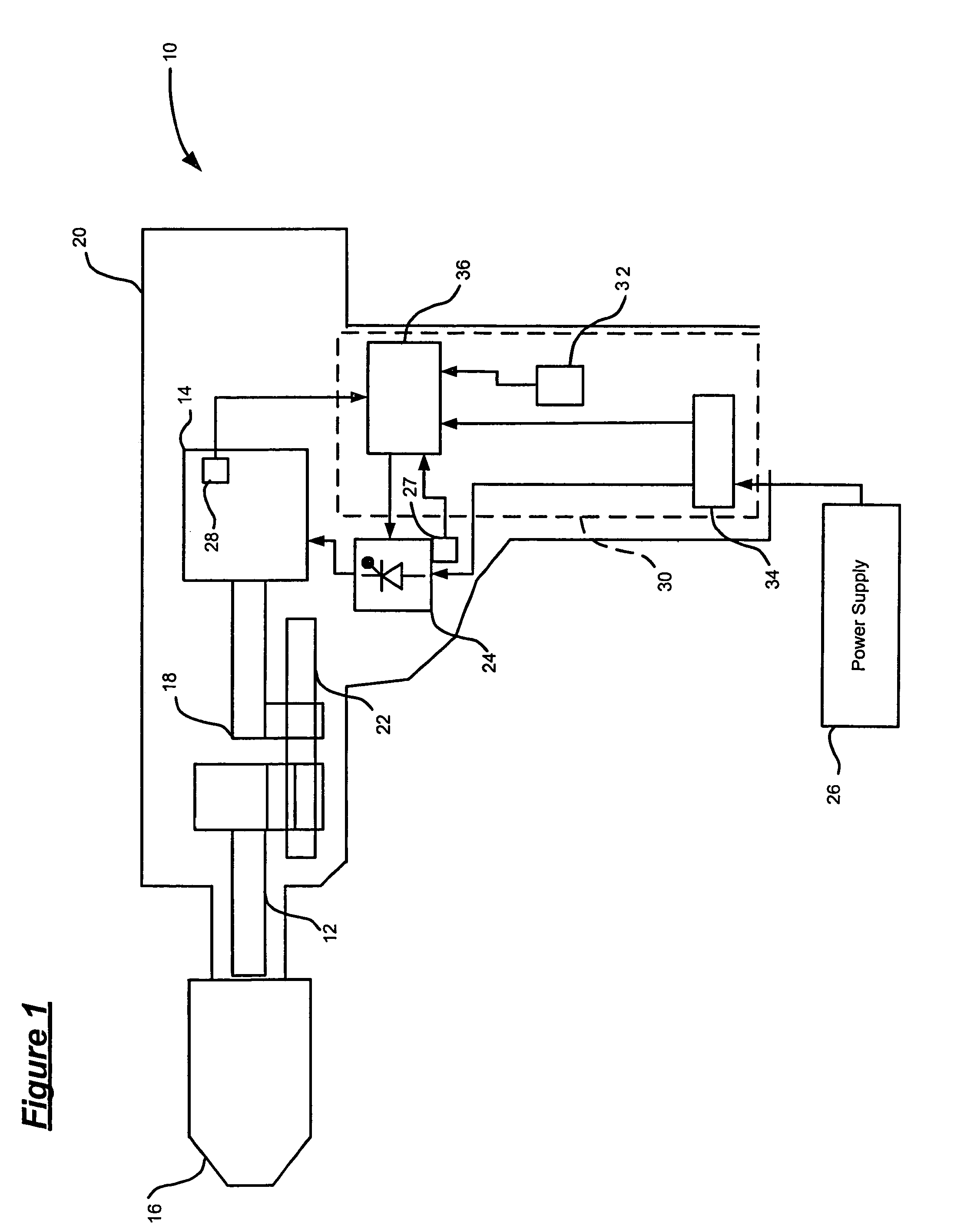

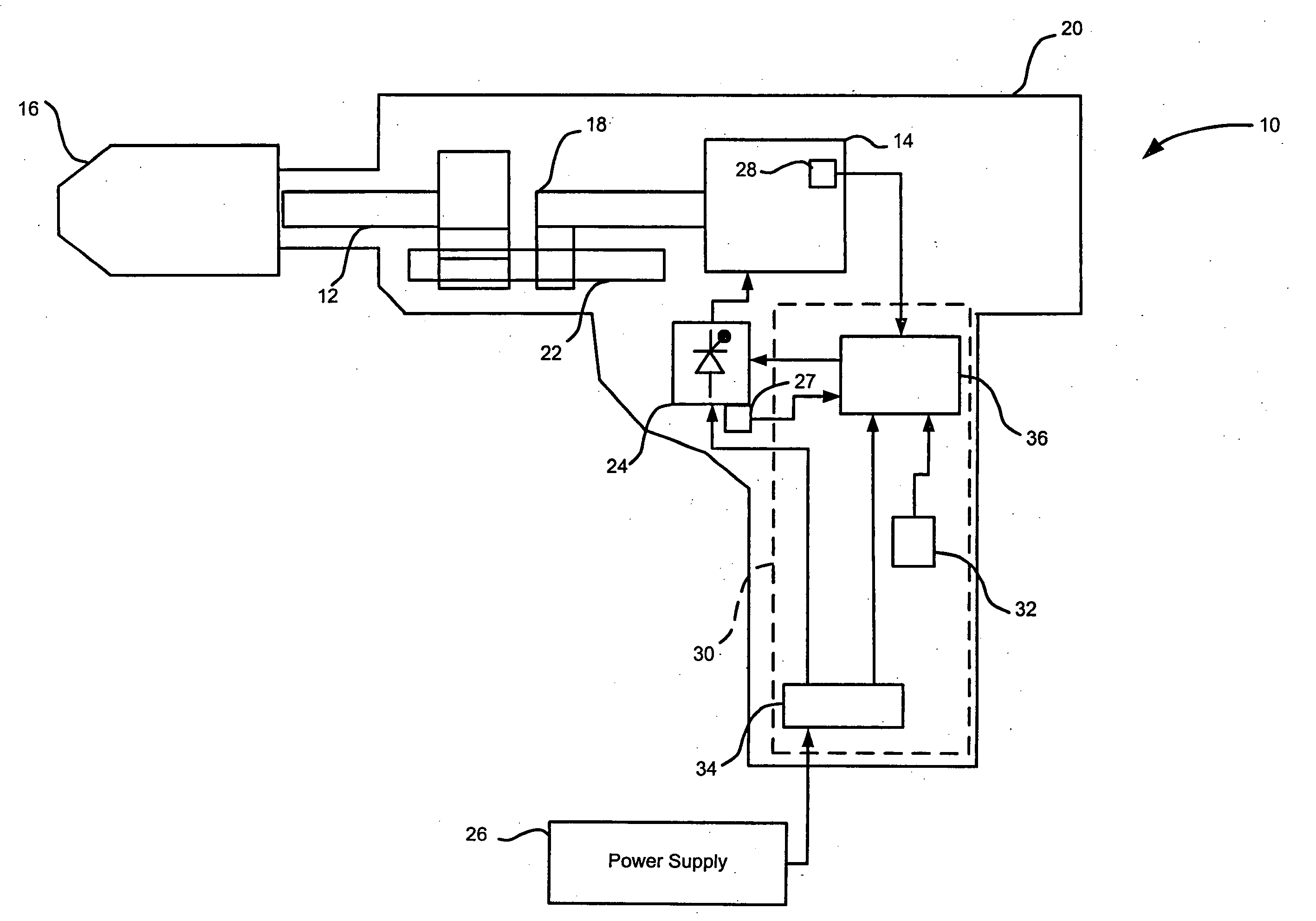

Safety detection and protection system for power tools

InactiveUS6922153B2Quick stopRule out the possibilityDC motor speed/torque controlEmergency protective circuit arrangementsPower toolProtection system

A detection system for detecting a dangerous condition for an operator using a power tool of the type which has an exposed blade relative to a work surface and a protection system for minimizing, if not eliminating the possibility of a user being injured by contacting the blade. In one preferred embodiment of the present invention, a proximity detection system is capable of detecting the presence of a user near the blade of a table saw and a protection system that can either retract the blade below the work surface of the table saw or terminate the drive torque to the blade which can result in rapid stopping of the saw blade by a work piece that is being cut.

Owner:CREDO TECH CORP +1

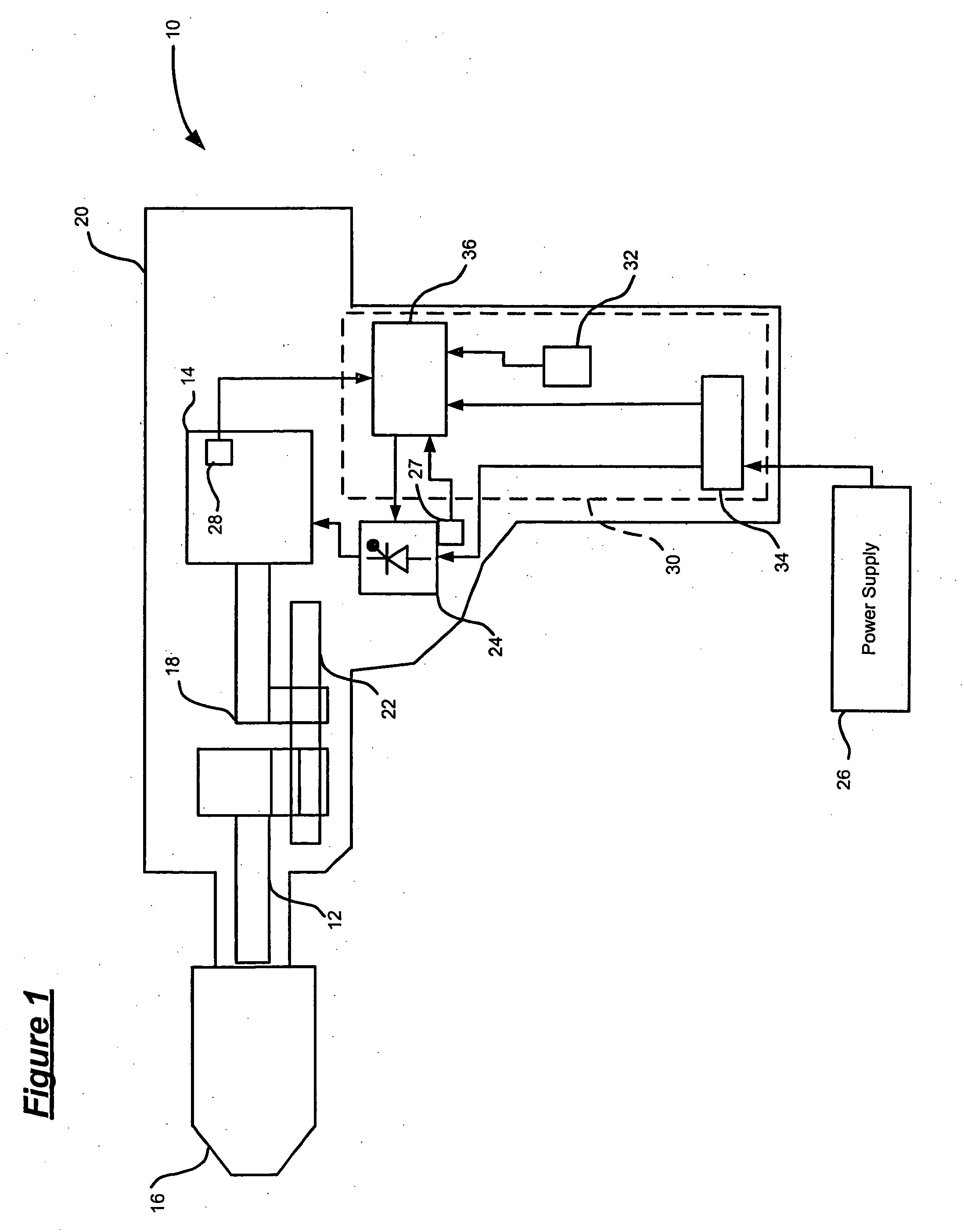

Safety detection and protection system for power tools

InactiveUS20040226800A1Quick stopQuick pullDC motor speed/torque controlEmergency protective circuit arrangementsPower toolProtection system

A detection system for detecting a dangerous condition for an operator using a power tool of the type which has an exposed blade relative to a work surface and a protection system for minimizing, if not eliminating the possibility of a user being injured by contacting the blade. In one preferred embodiment of the present invention, a proximity detection system is capable of detecting the presence of a user near the blade of a table saw and a protection system that can either retract the blade below the work surface of the table saw or terminate the drive torque to the blade which can result in rapid stopping of the saw blade by a work piece that is being cut.

Owner:CREDO TECH CORP +1

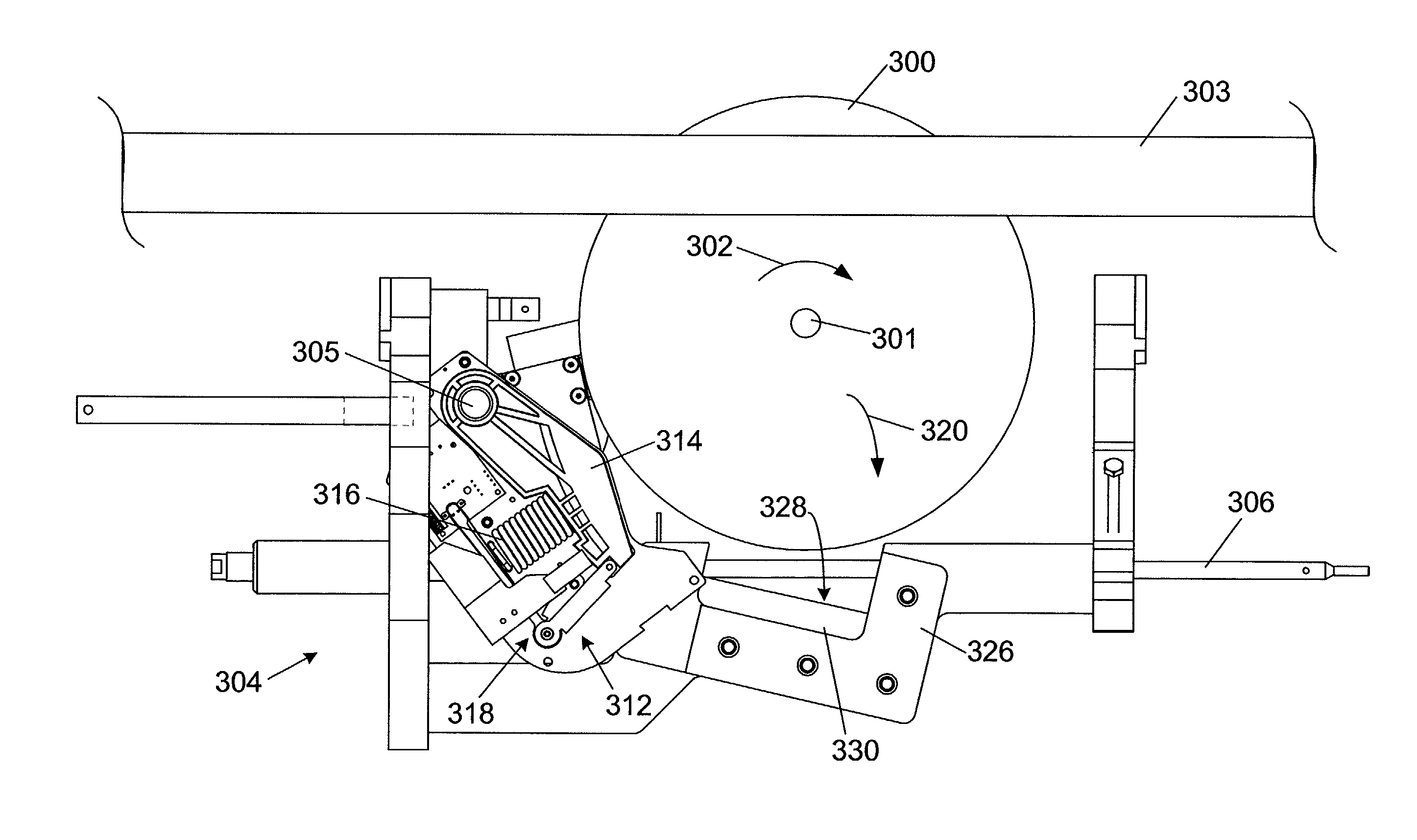

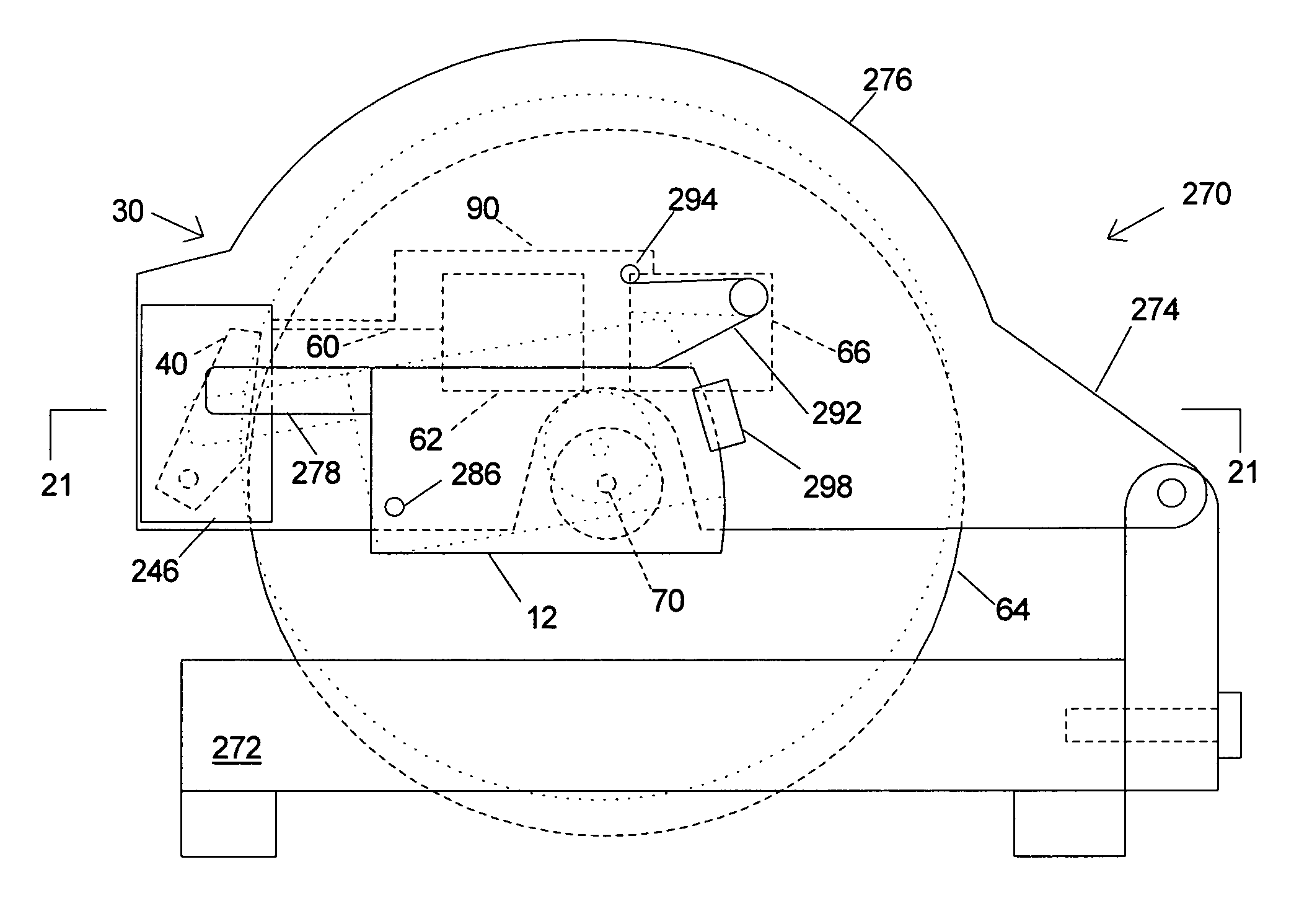

Brake positioning system

InactiveUS6857345B2Multi-purpose machinesEngineering safety devicesEngineeringMechanical engineering

A saw is disclosed having a detection system adapted to detect a dangerous condition between a person and a saw blade, and a brake adapted to stop the saw blade in response to detection of the dangerous condition. The saw further includes a brake positioning system that allows the brake to be positioned in at least two different operable positions to accommodate at least two different blade diameters. The saw may include a system to detect brake-to-blade spacing.

Owner:SAWSTOP HLDG LLC

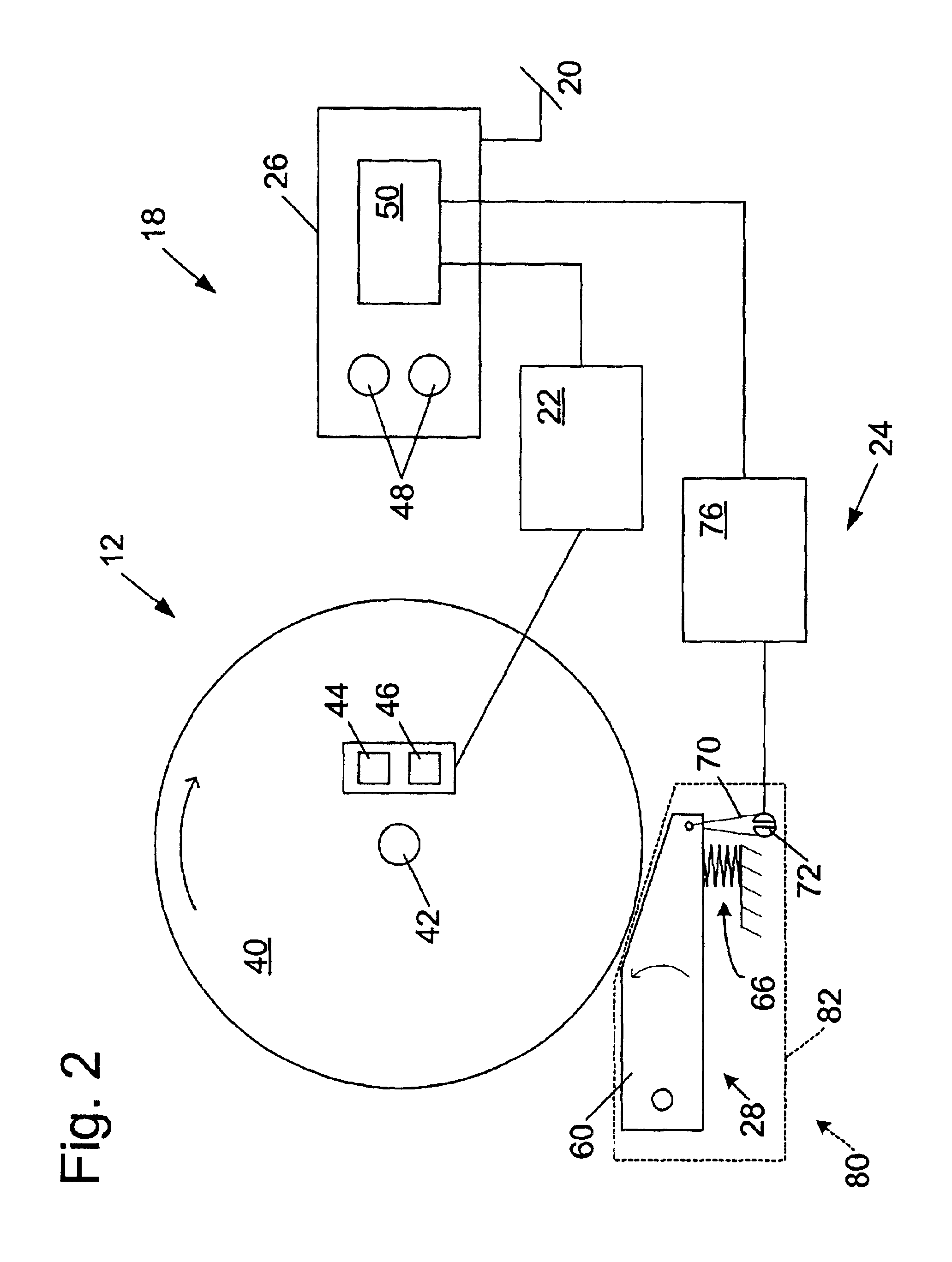

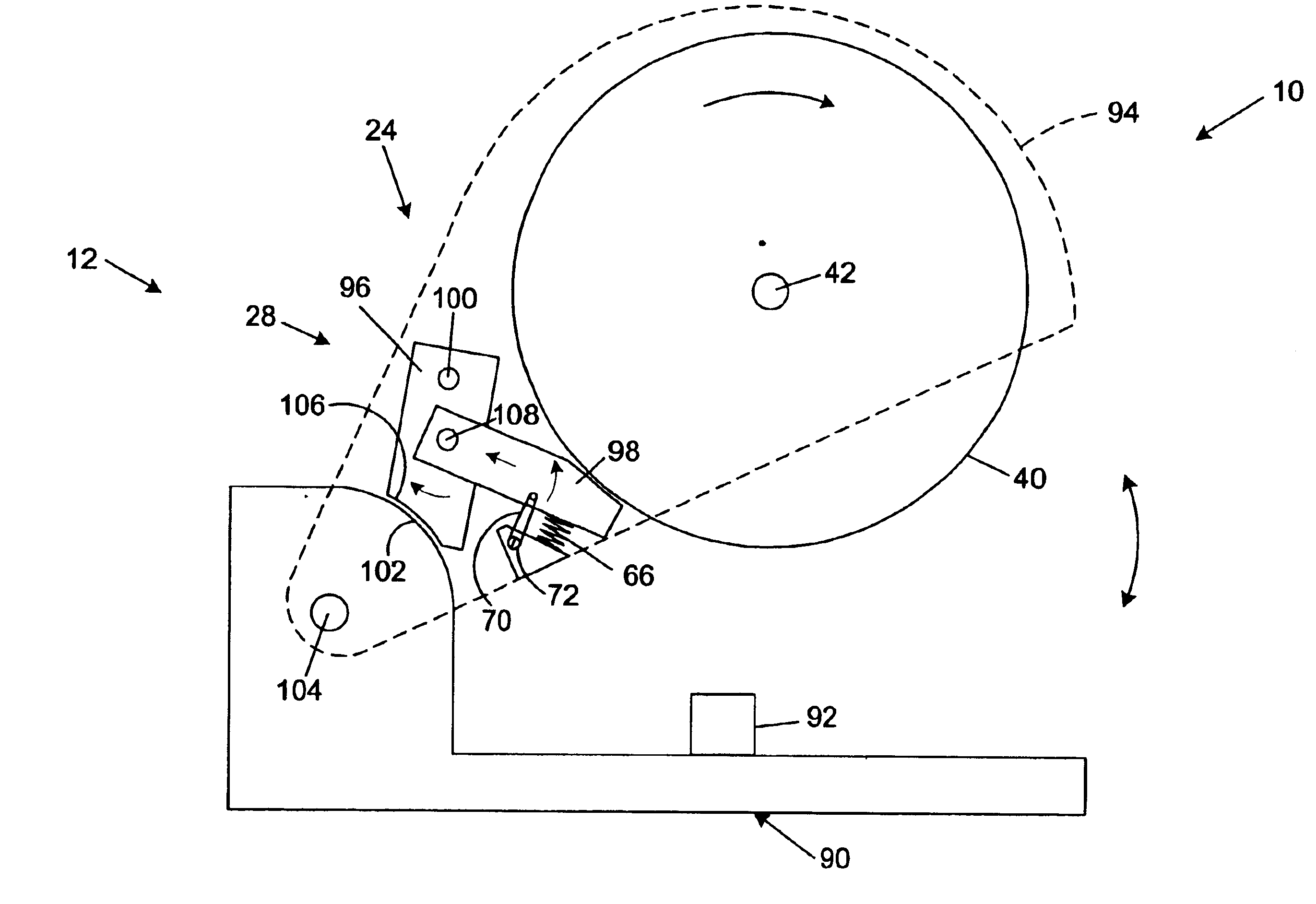

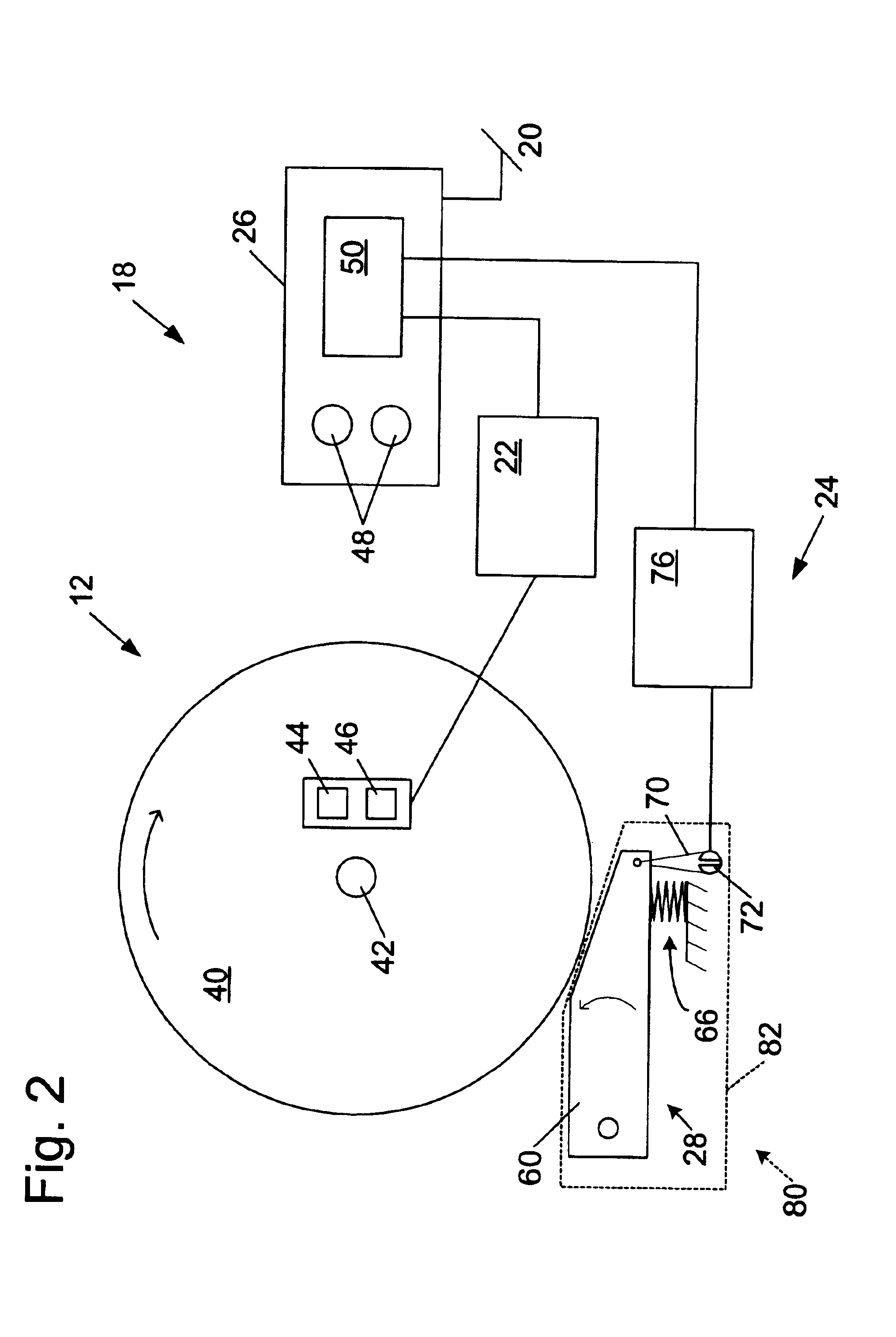

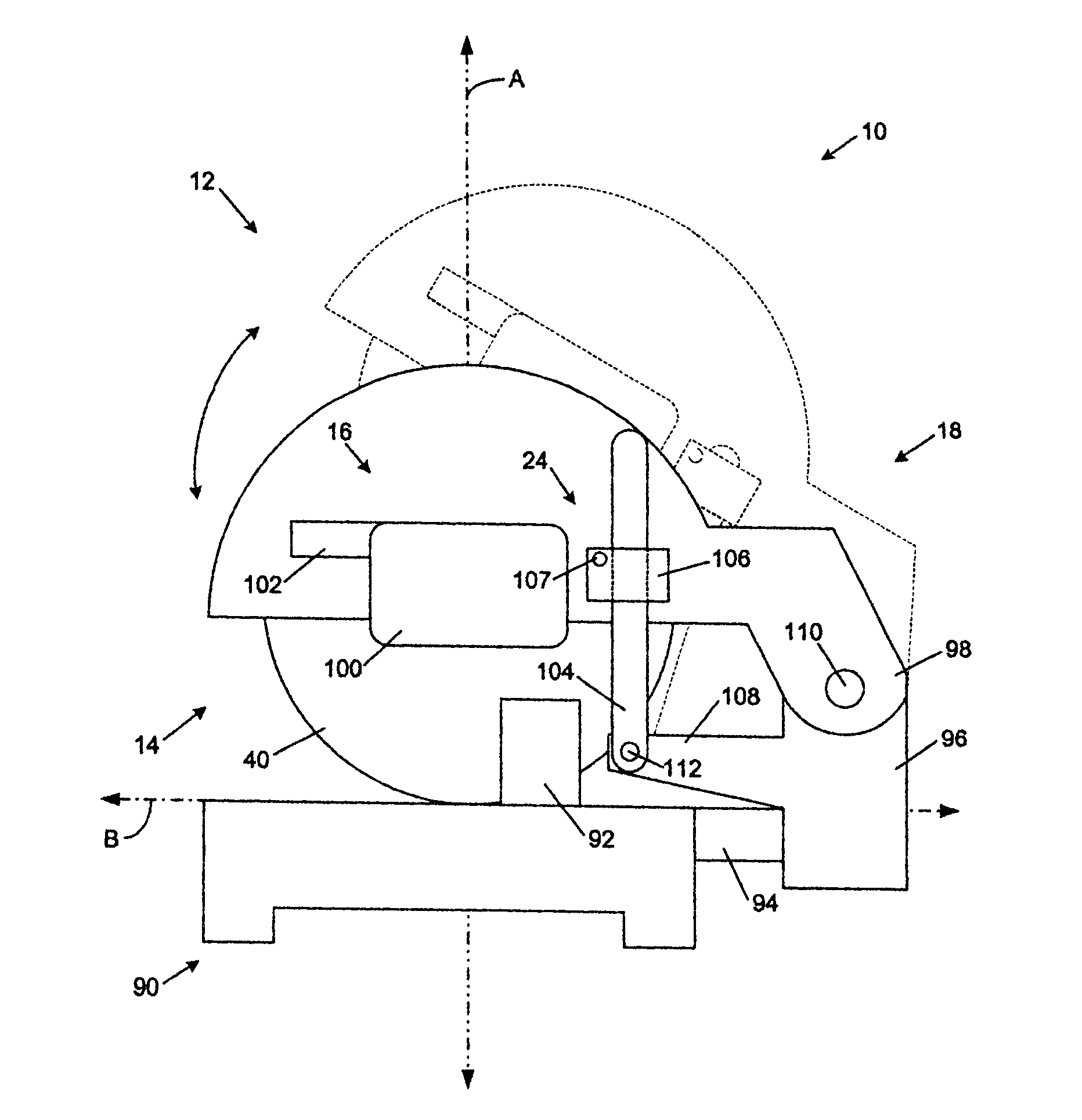

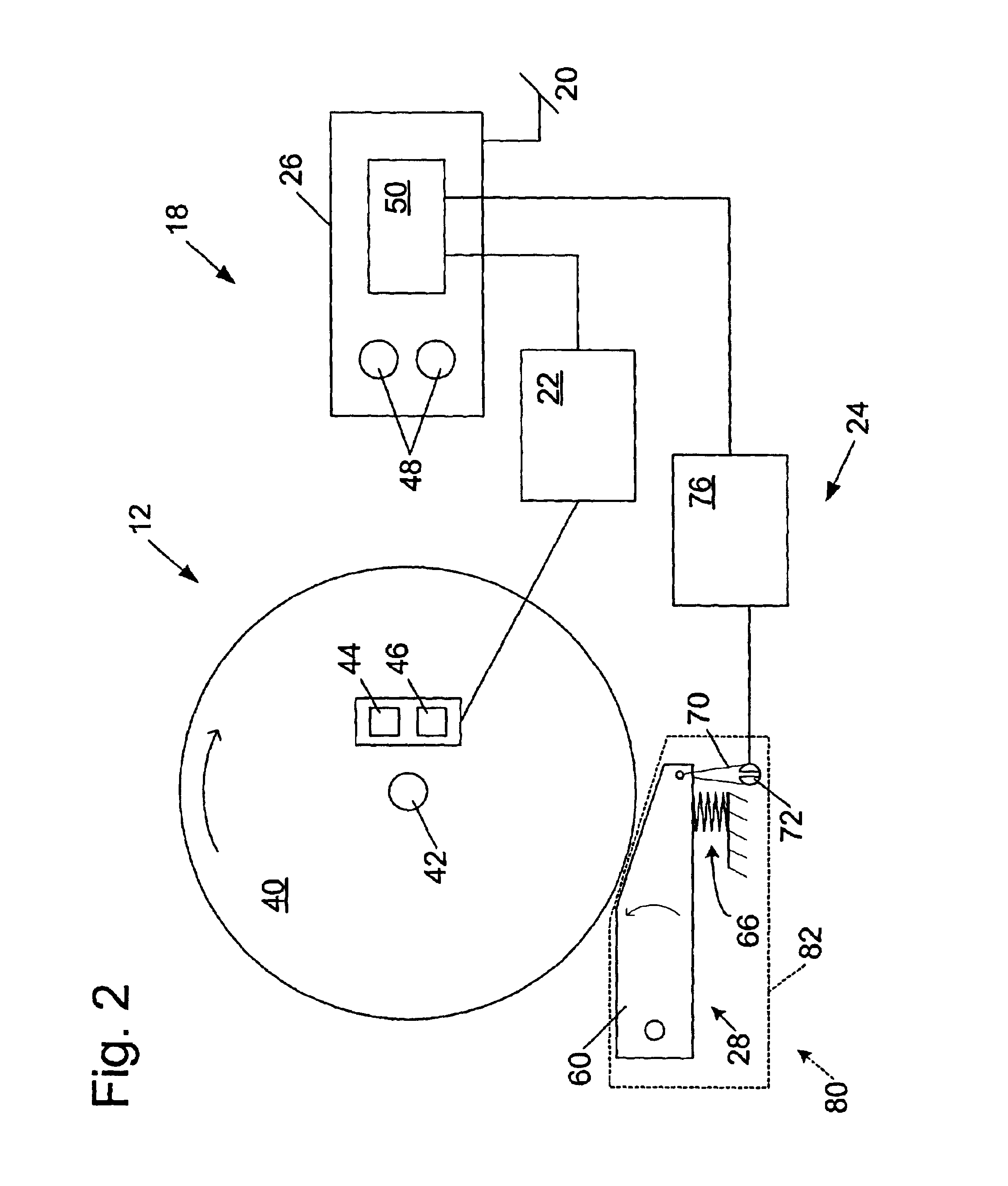

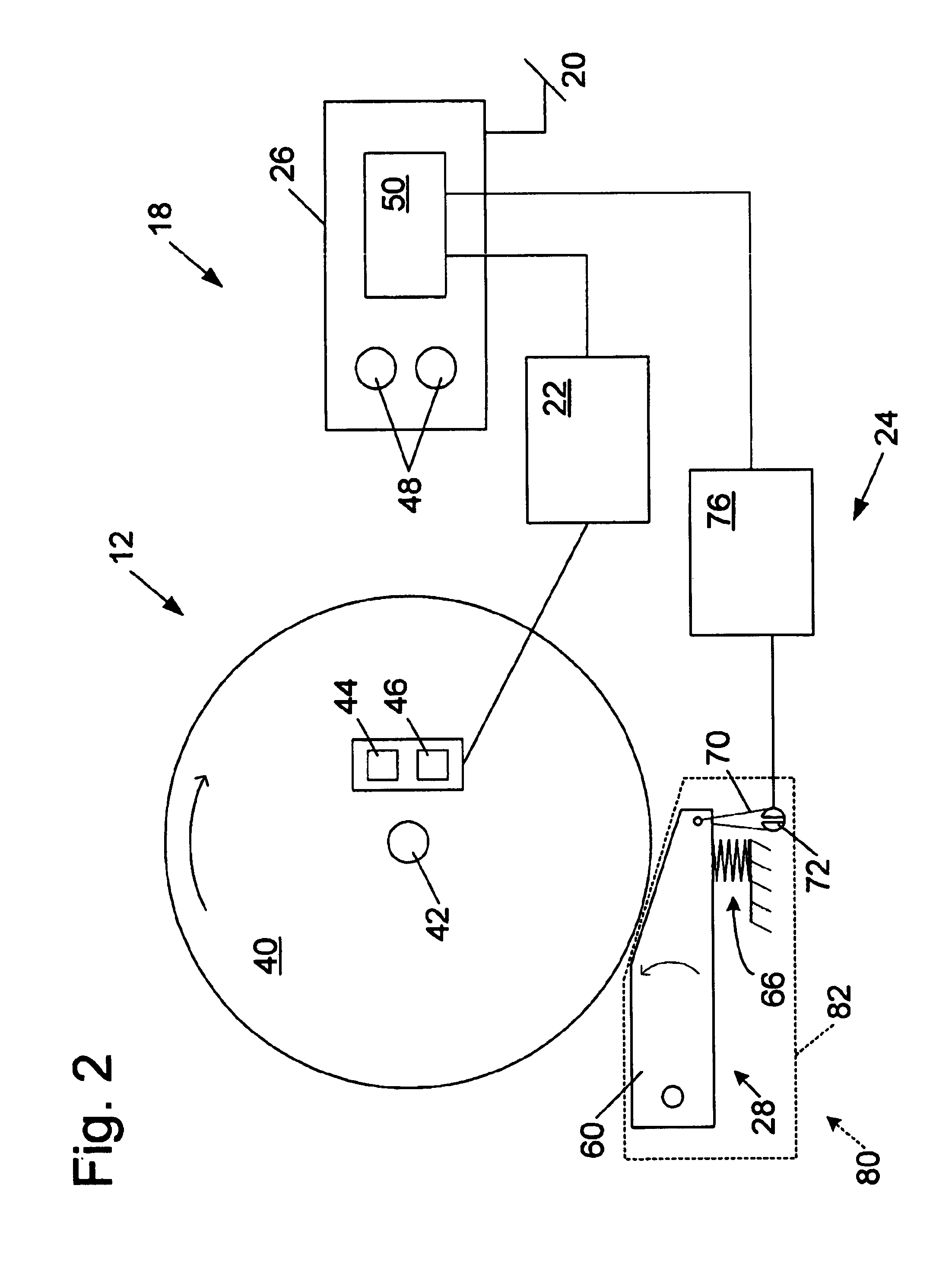

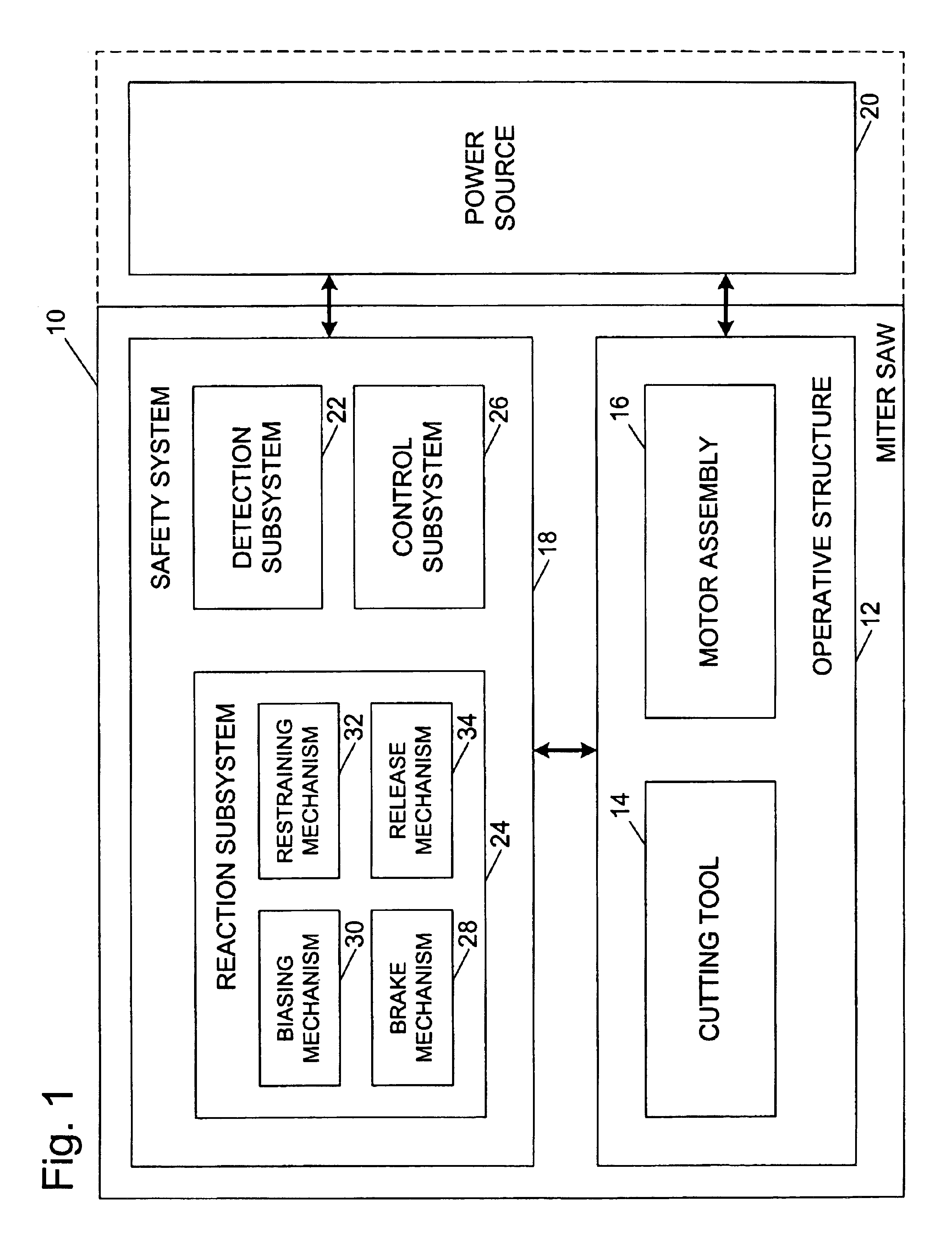

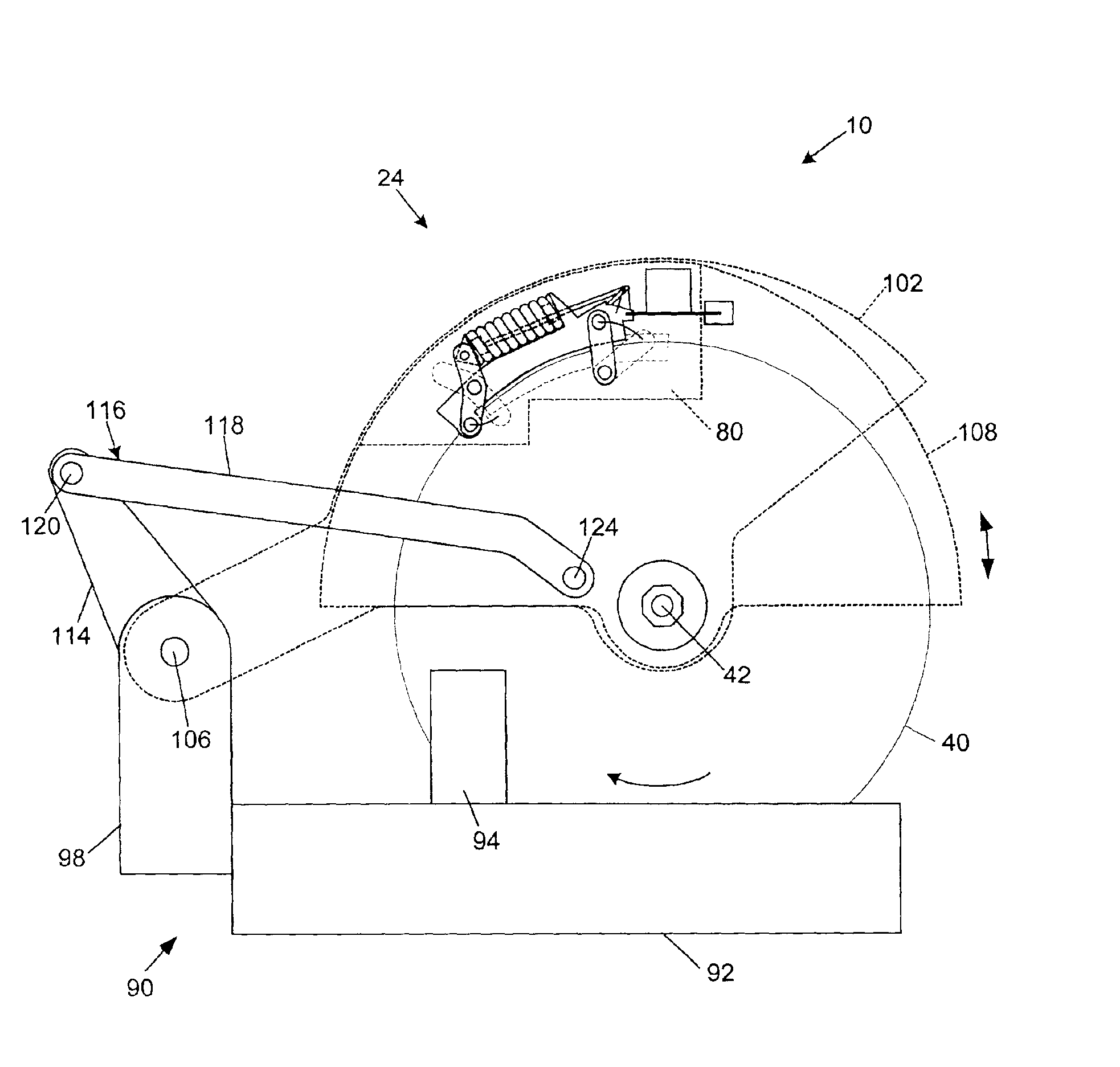

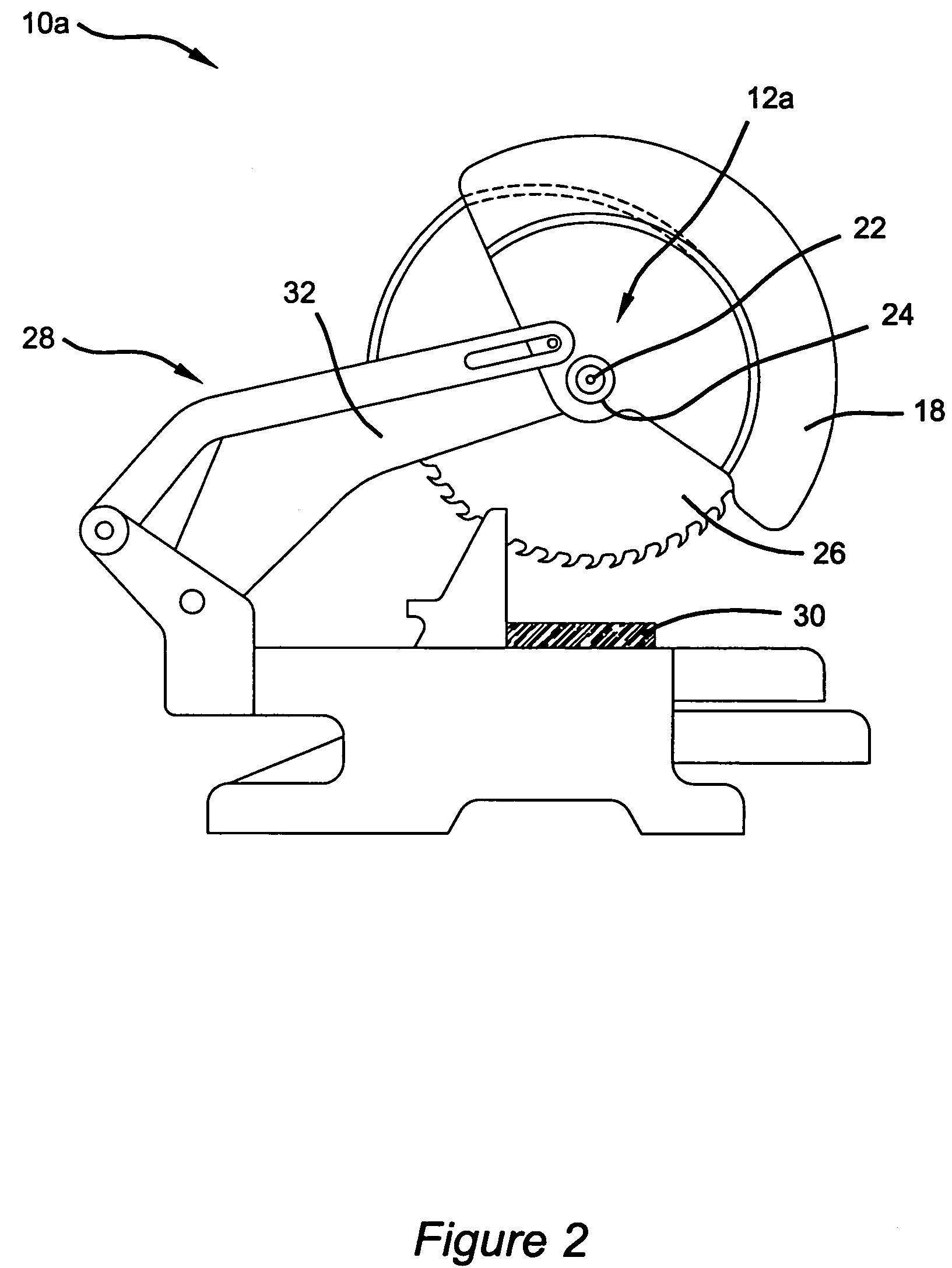

Miter saw with improved safety system

InactiveUS6826988B2Increase opportunitiesLimit and even prevent injuryEmergency protective circuit arrangementsEngineering safety devicesEngineeringWoodworking machine

A woodworking machine is disclosed having a base, a blade, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating and / or to stop movement of the blade toward the cutting zone.

Owner:SAWSTOP HLDG LLC

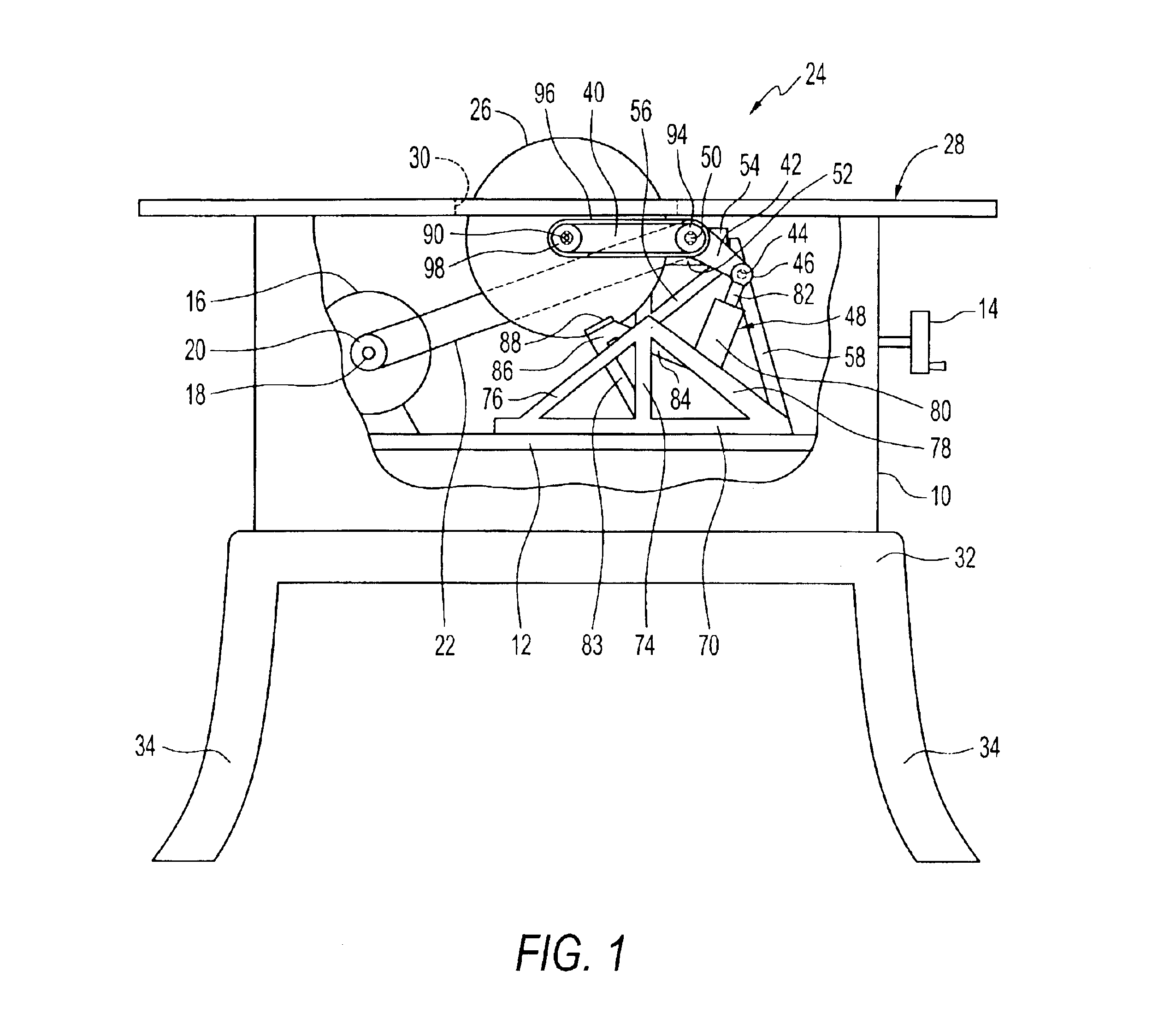

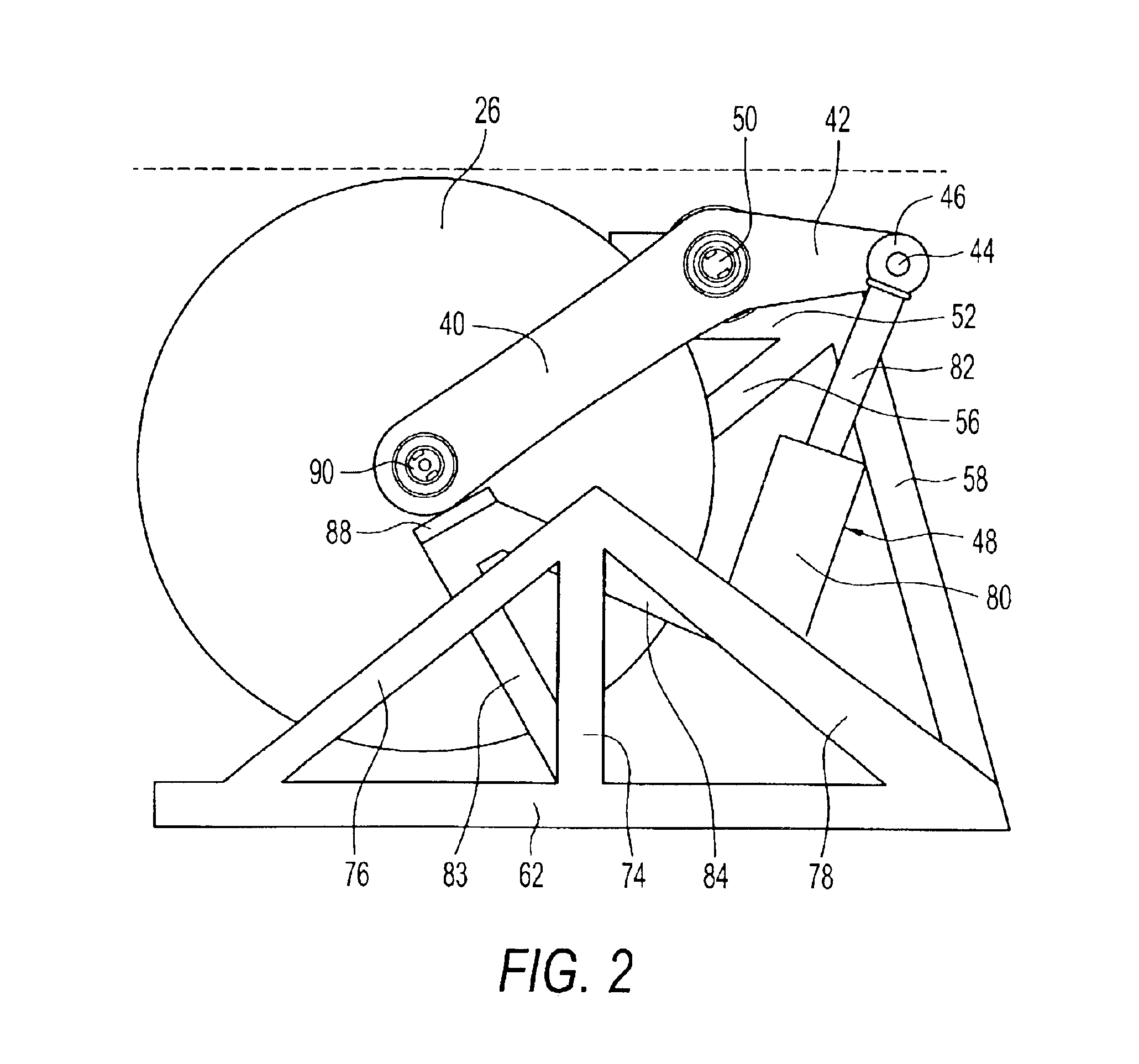

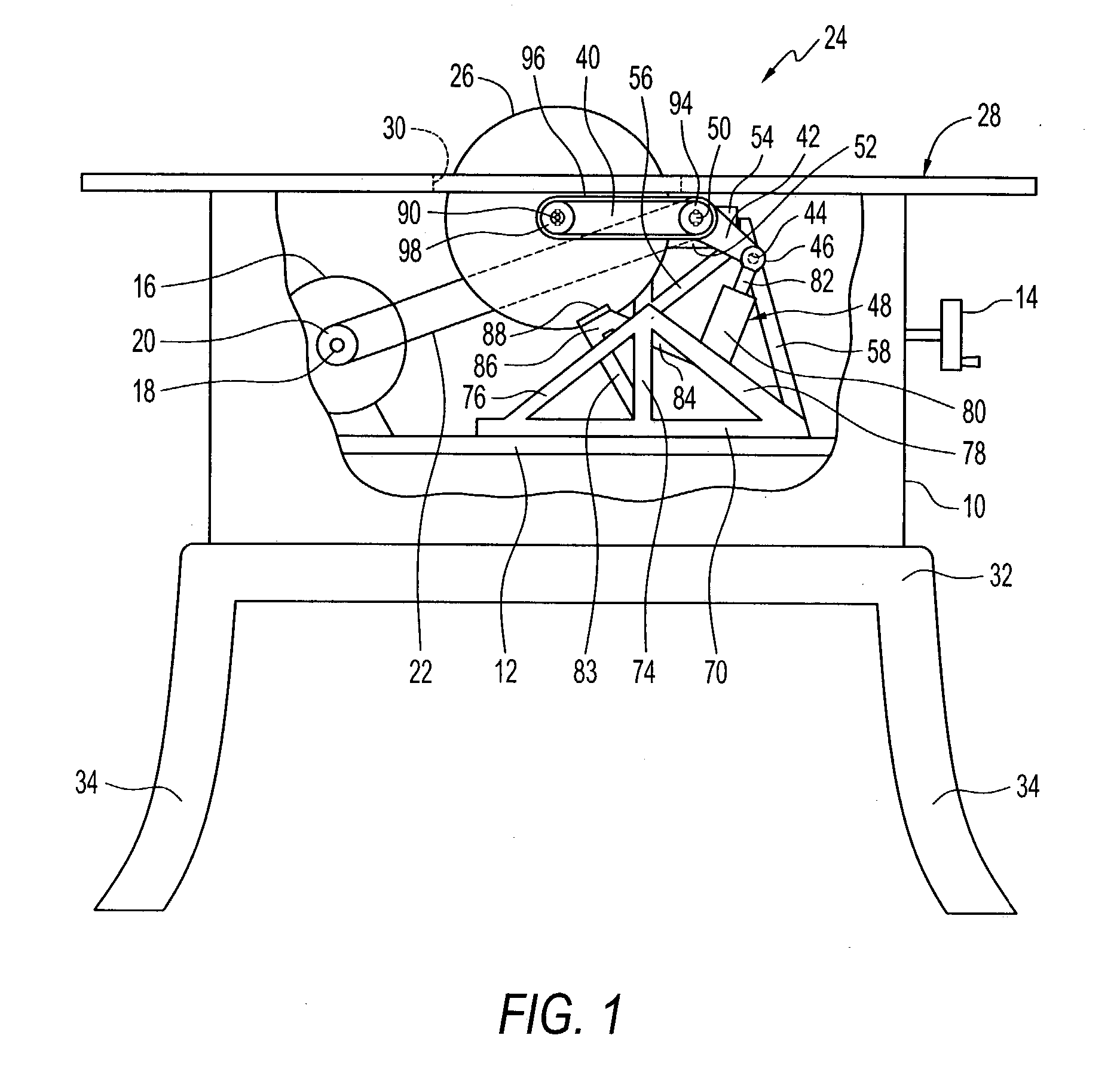

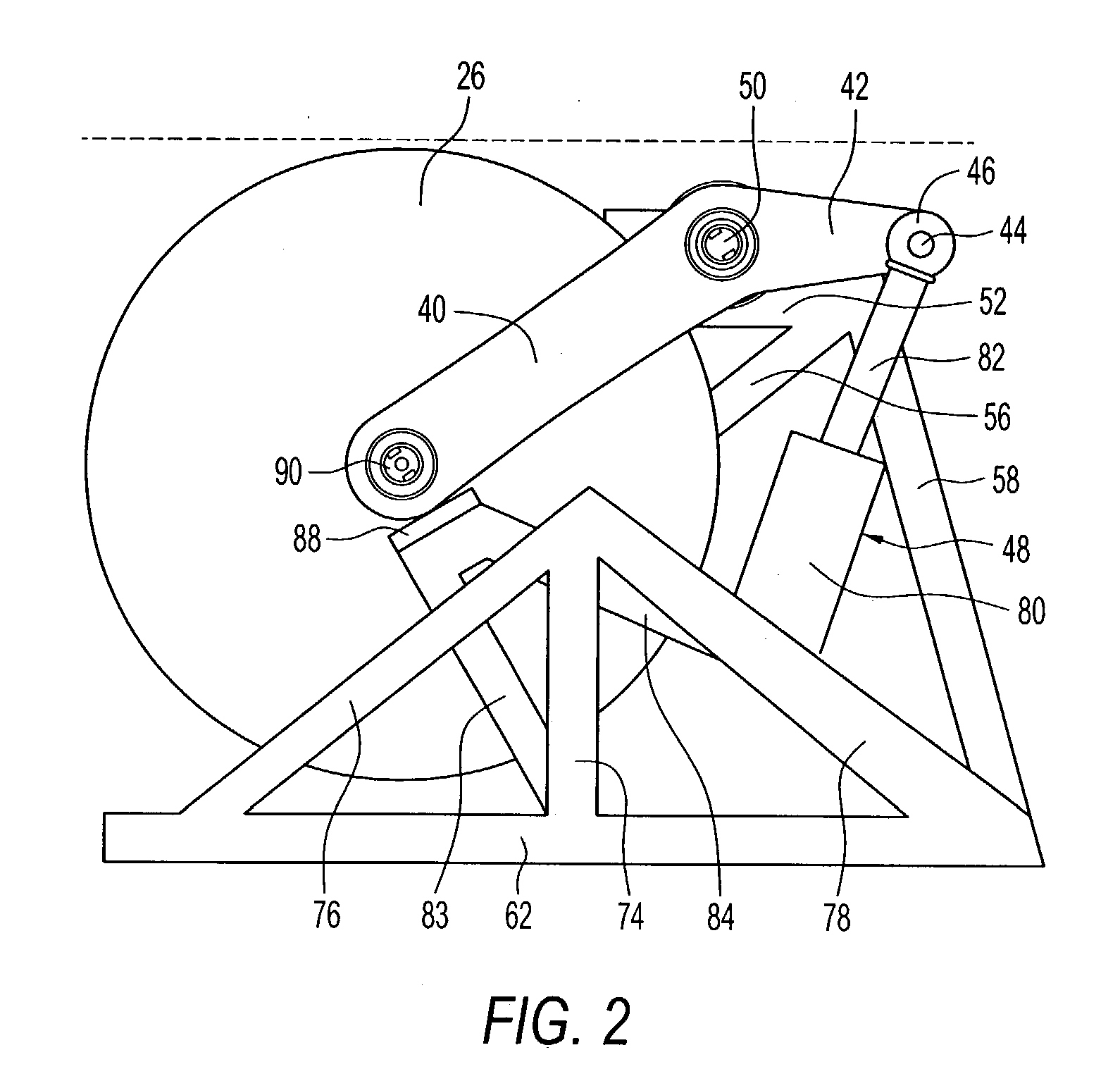

Table saw with improved safety system

InactiveUS6994004B2Metal sawing devicesMetal sawing accessoriesMechanical engineeringPositioning system

A table saw having a brake mechanism configured to engage and stop a blade is disclosed. The table saw includes a brake positioning system configured to adjust the position of the brake mechanism to maintain the brake mechanism in an operative position relative to the blade as the blade is raised and lowered.

Owner:SAWSTOP HLDG LLC

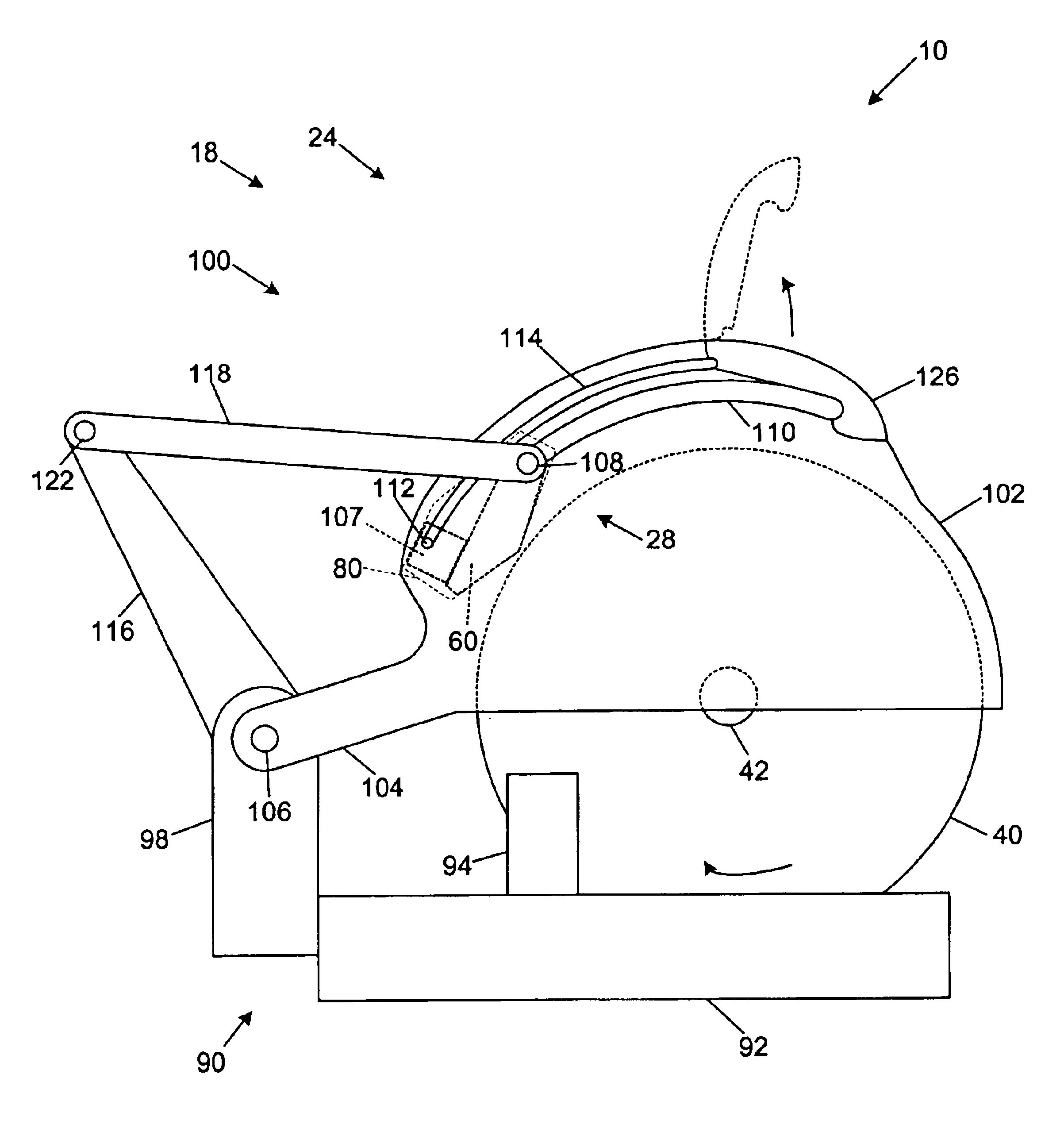

Miter saw with improved safety system

InactiveUS6880440B2Limit and even prevent injuryImprove the security systemEmergency protective circuit arrangementsEngineering safety devicesEngineeringMechanical engineering

A miter saw having a base and an arm that pivots toward the base is disclosed. A blade is supported by the arm, and is designed to cut workpieces resting on the base when the arm and blade pivot downward. The saw includes a detection system configured to detect one or more dangerous conditions between a person and the blade, such as when a person accidentally touches the spinning blade, and the saw includes a reaction system to stop the downward movement of the blade and arm when the dangerous condition is detected.

Owner:SAWSTOP HLDG LLC

Safety system for power equipment

Safety systems for power equipment are disclosed. The safety systems include a detection system adapted to detect contact between a person and a working portion of a machine, where the detection system is adapted to capacitively impart an electric charge on the working portion and to detect when that charge drops; and a reaction system associated with the detection system to cause a predetermined action to take place relative to the working portion upon detection of contact between the person and the working portion by the detection system. Machines equipped with safety systems are also disclosed, such as saws, jointers, etc. The machines include a working portion, such as a cutter or blade, a detection system adapted to detect a dangerous condition between a person and the working portion, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition, such as a brake system to stop the working portion, a retraction system to retract the working portion, or a system to cover the working portion. The machines may include a control system adapted to control the operability of one or more of the working portion, the detection system and the reaction system.

Owner:SAWSTOP HLDG LLC

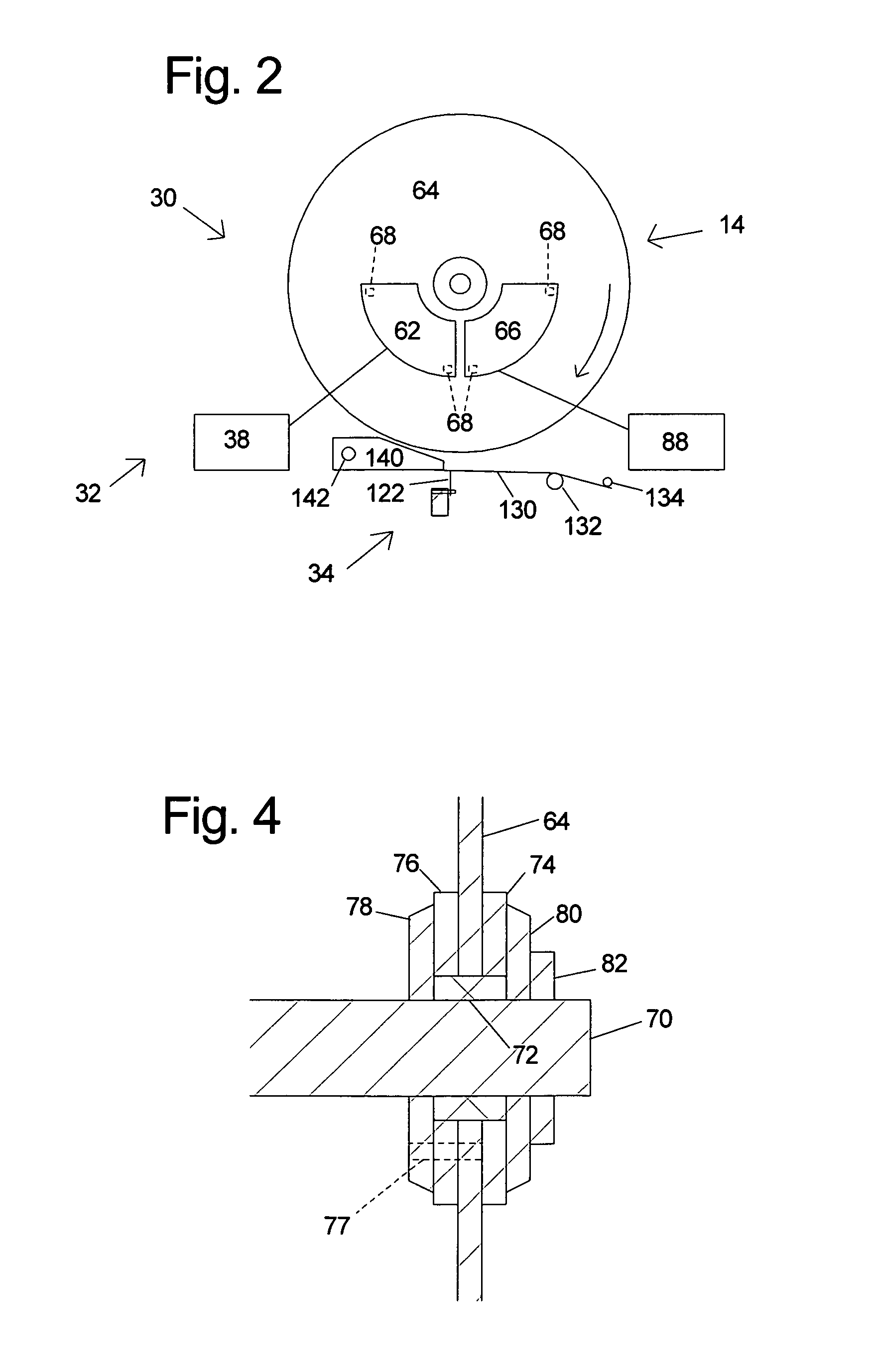

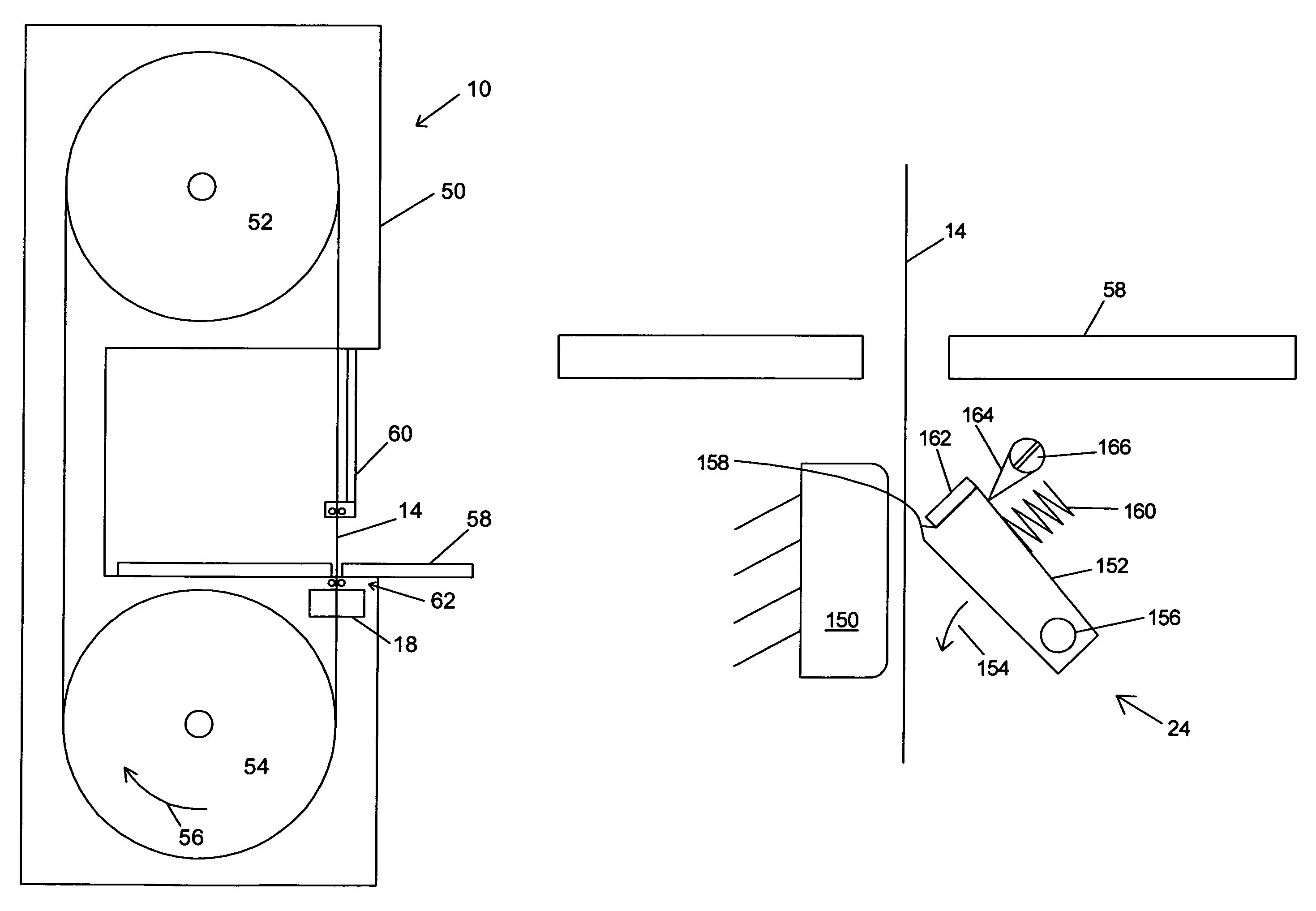

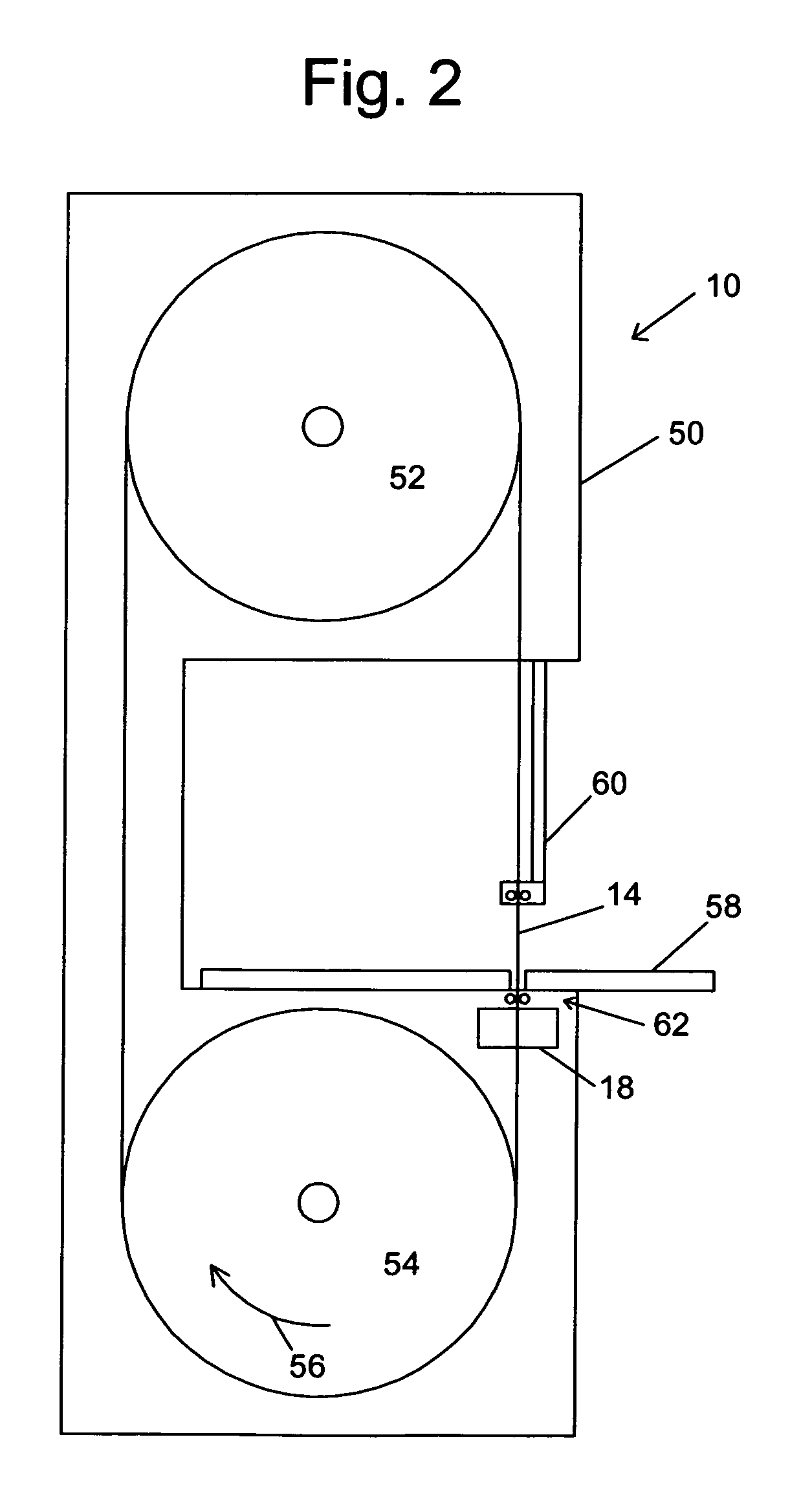

Safety systems for band saws

Owner:SAWSTOP HLDG LLC

Actuators for use in fast-acting safety systems

Cutting machines with high-speed safety systems, and actuators used in high-speed safety systems, are disclosed. The cutting machines may include a detection system adapted to detect a dangerous condition between a cutting tool and a person. A reaction system performs a specified action, such as stopping the cutting tool, upon detection of the dangerous condition. An actuator may be used to trigger the reaction system to perform the specified action.

Owner:SAWSTOP HLDG LLC

Miter saw with improved safety system

InactiveUS6945148B2Increase opportunitiesLimit and even prevent injuryOther plywood/veneer working apparatusMechanically actuated brakesEngineeringMechanical engineering

A miter saw is disclosed having a base, a blade supported by the base, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating, to create an impulse against movement of the blade into the cutting zone, or to cause the blade to move away from the cutting zone.

Owner:SAWSTOP HLDG LLC

Miter saw with improved safety system

InactiveUS6877410B2Increase opportunitiesLimit and even prevent injuryOther plywood/veneer working apparatusMetal sawing devicesMechanical engineeringReaction system

A miter saw is disclosed having a base, a blade supported by the base, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating, to create an impulse against movement of the blade into the cutting zone, or to cause the blade to move away from the cutting zone.

Owner:SAWSTOP HLDG LLC

Safety systems for power equipment

A saw with a safety system is disclosed. The safety system includes a detection system adapted to detect contact between a person and a blade while the blade is moving. The safety system further includes a brake system adapted to engage the blade and to stop the blade when the detection system detects contact between the person and the blade.

Owner:SAWSTOP HLDG LLC

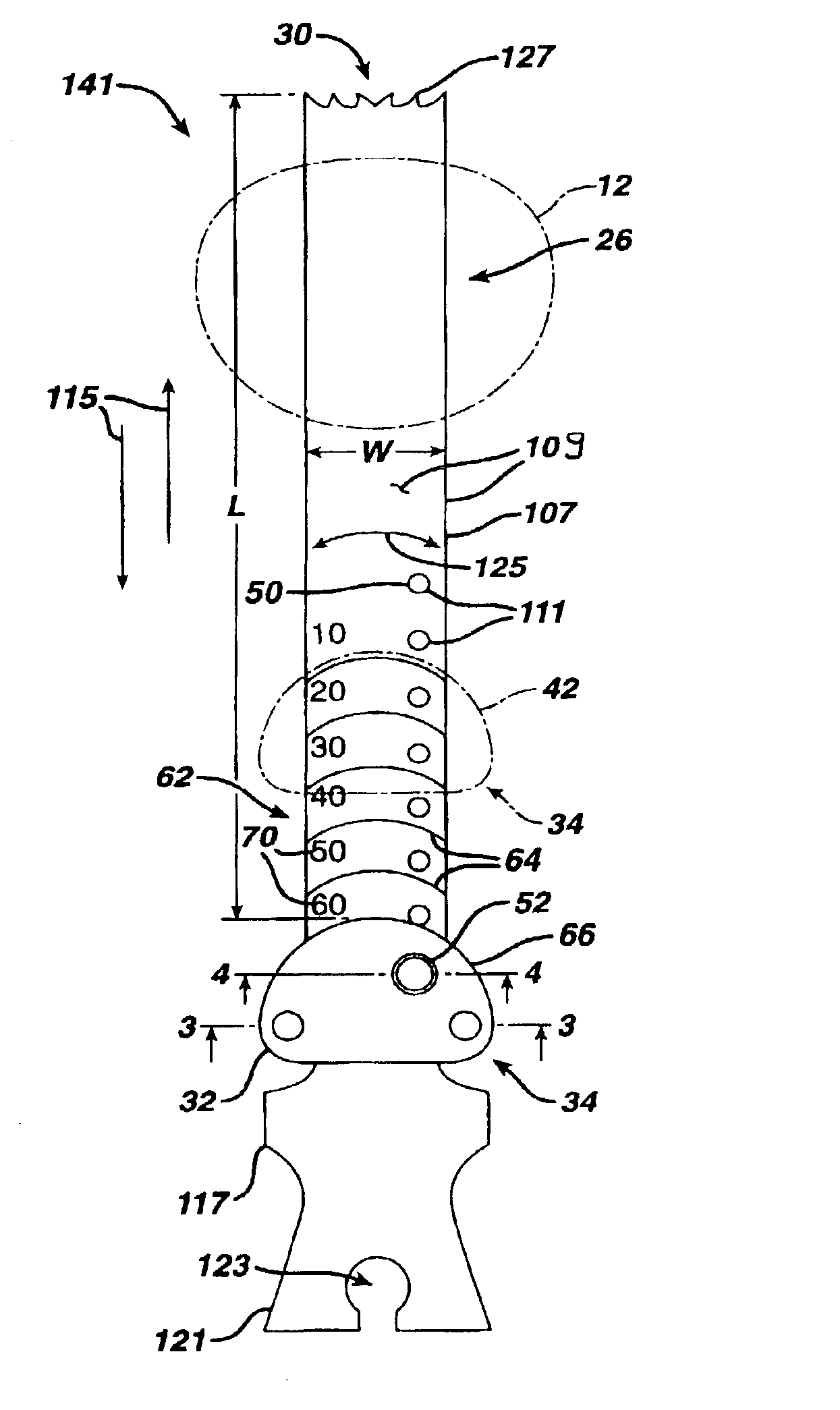

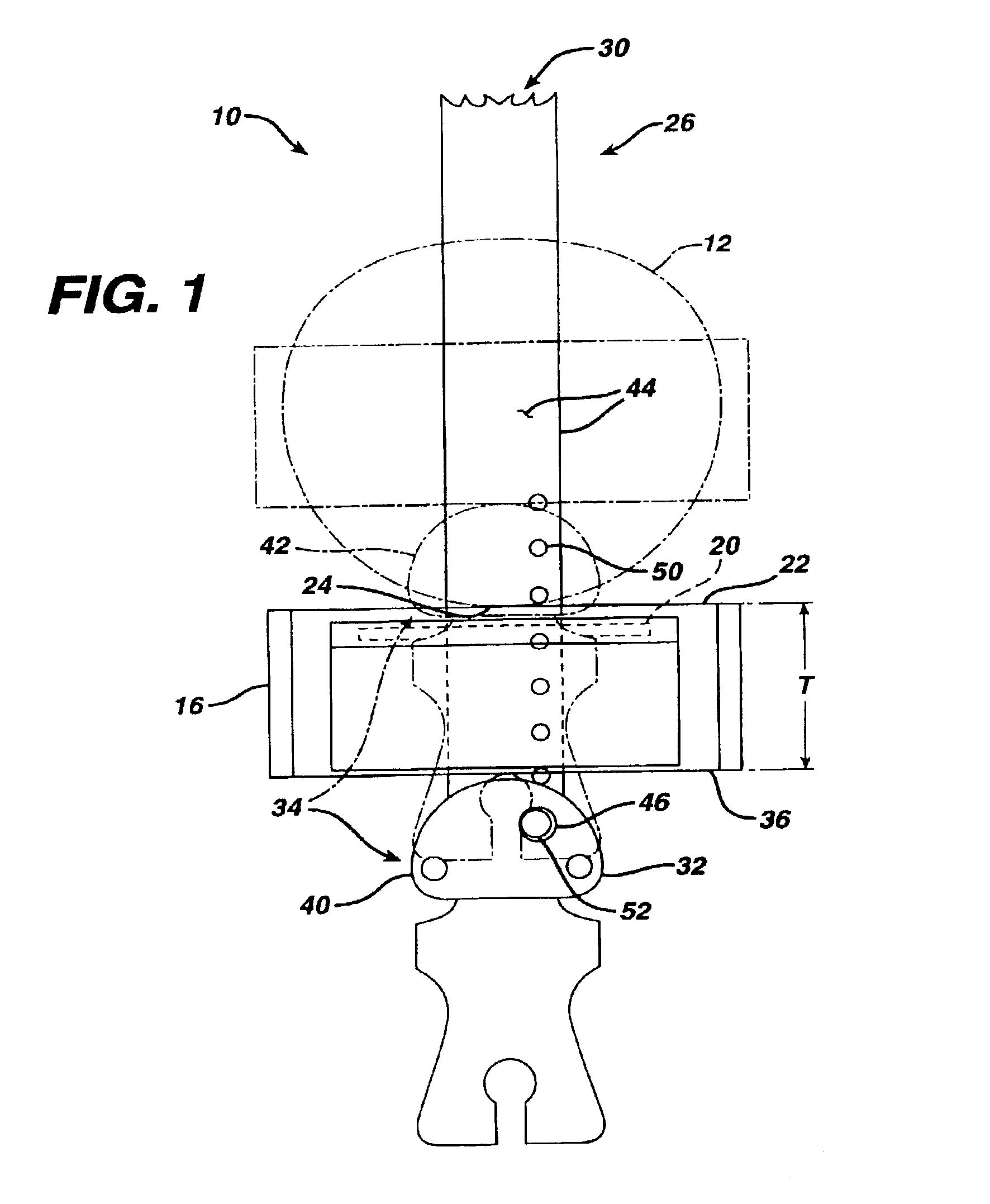

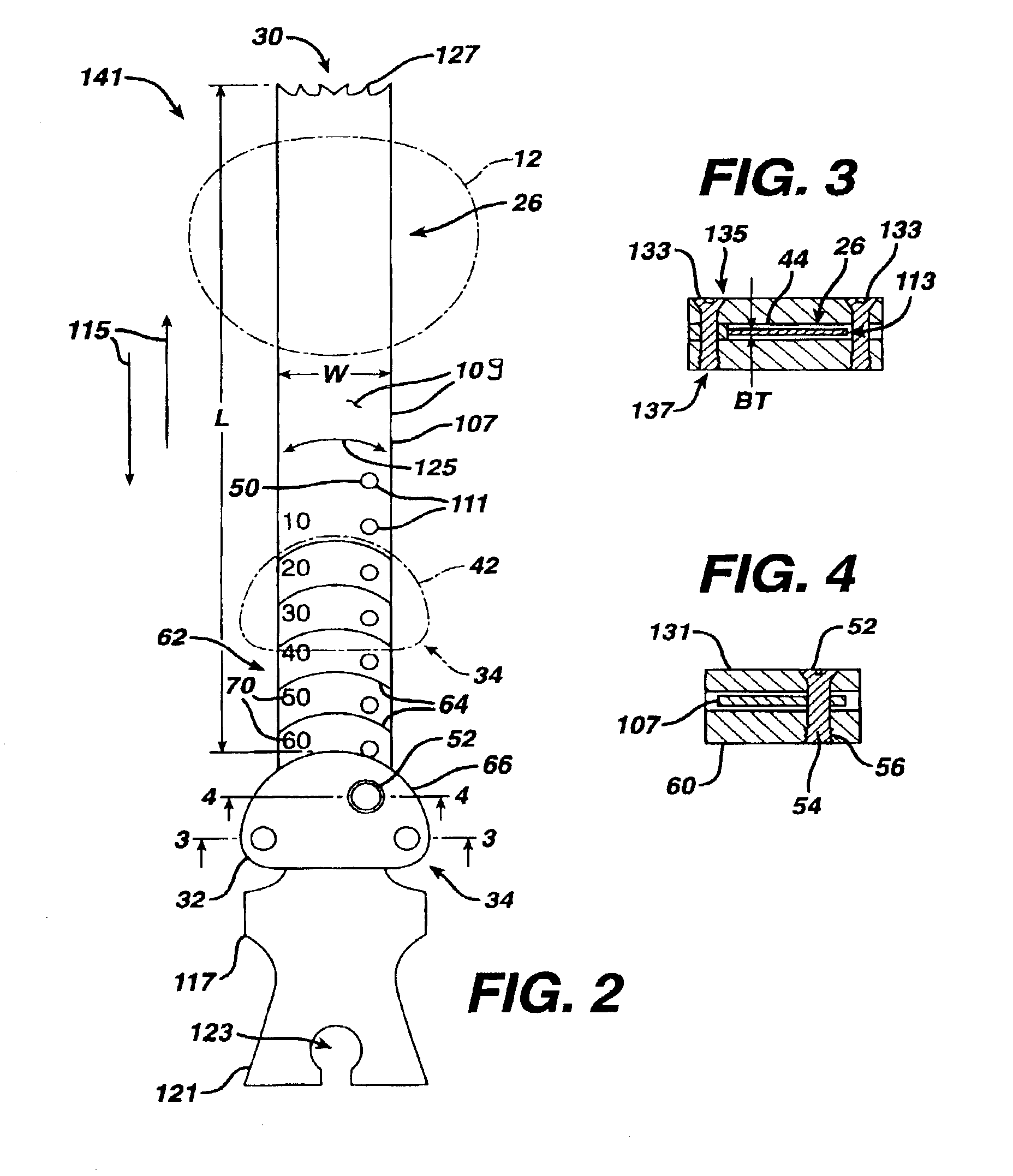

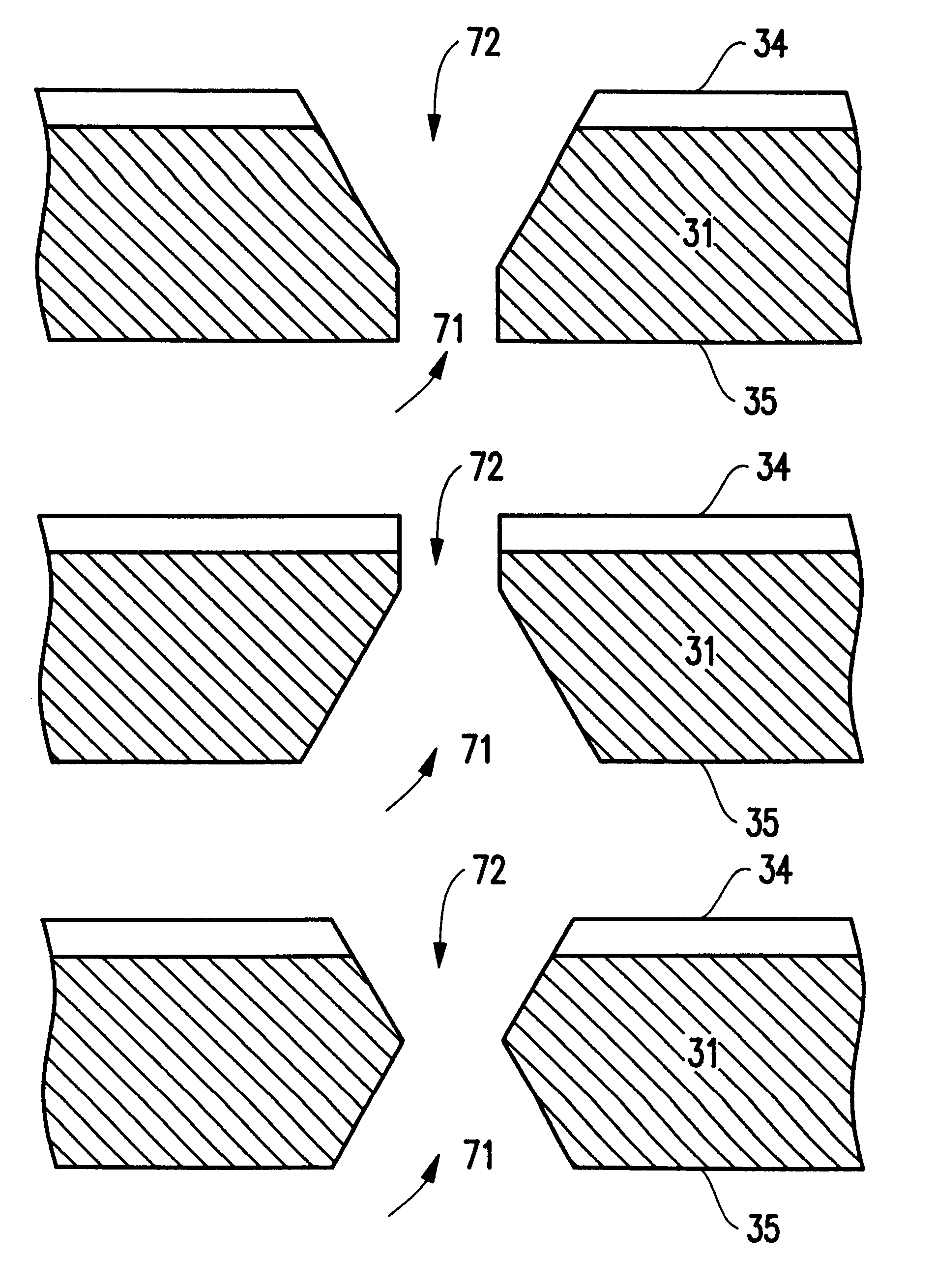

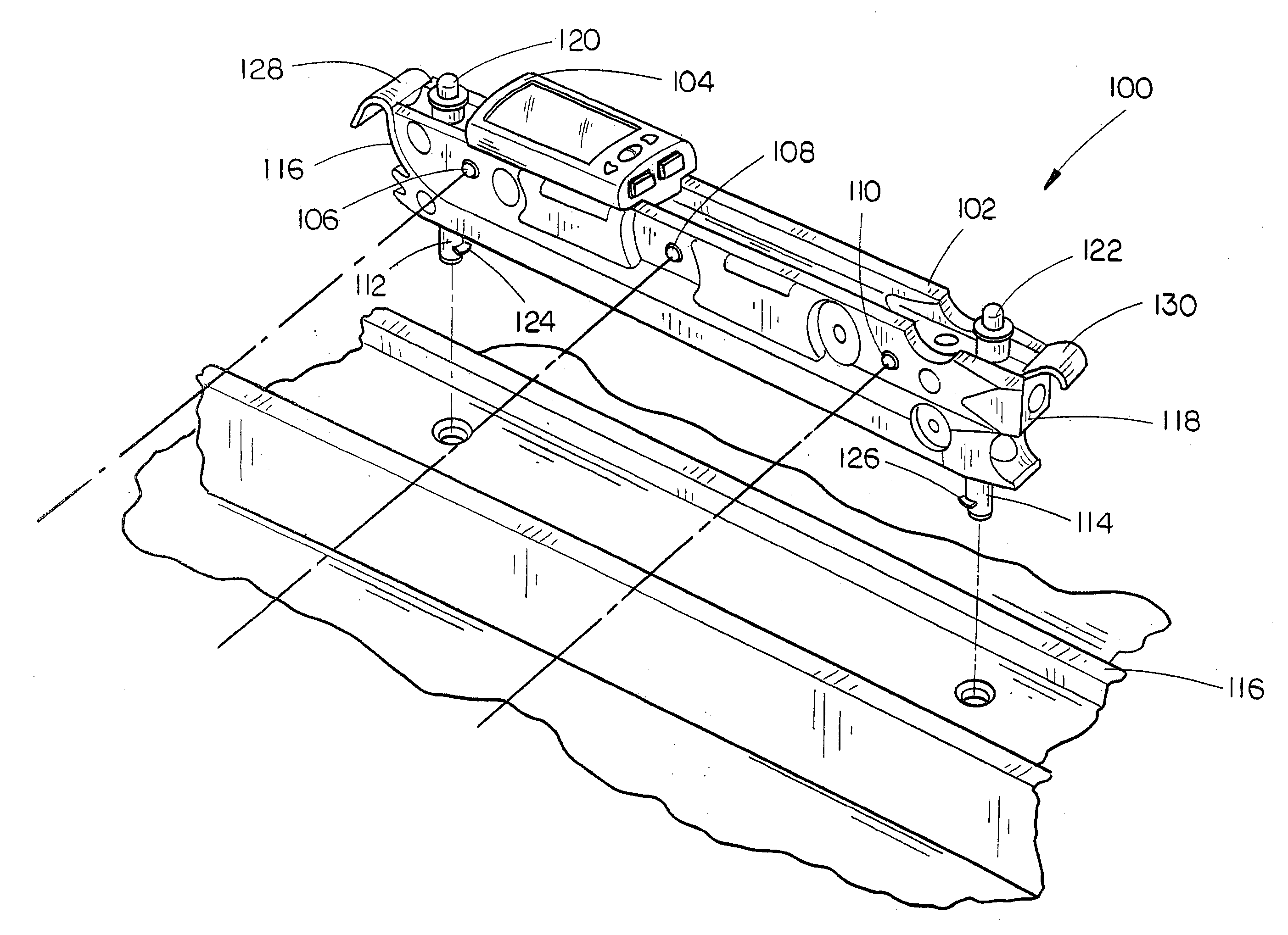

Blade for resection of bone for prosthesis implantation, blade stop and method

InactiveUS6875222B2Few instrumentsReduce in quantityMetal sawing devicesMetal sawing accessoriesProsthesis ImplantationSacroiliac joint

A kit (10) for resection of bone (12) for use in implantation of a joint prosthesis (14) is provided. The kit (10) includes a guide (16), a tool (26) and a stop (32). The guide (16) defines an opening (20) through the guide (16). The guide (16) is in cooperation with the bone (12). The tool (26) may be constrained within the opening (20) of the guide (16). The tool (26) includes a cutting edge (30) for resection of bone (12). The stop (32) cooperates with the guide (16) and the tool (26) to limit the movement of the tool (26) within the guide (16) so that the position of the cutting edge (30) with respect to the bone (12)m may be controlled. The stop (32) includes a plurality of positions (34) with respect to the tool (26) and the guide (16).

Owner:DEPUY PROD INC

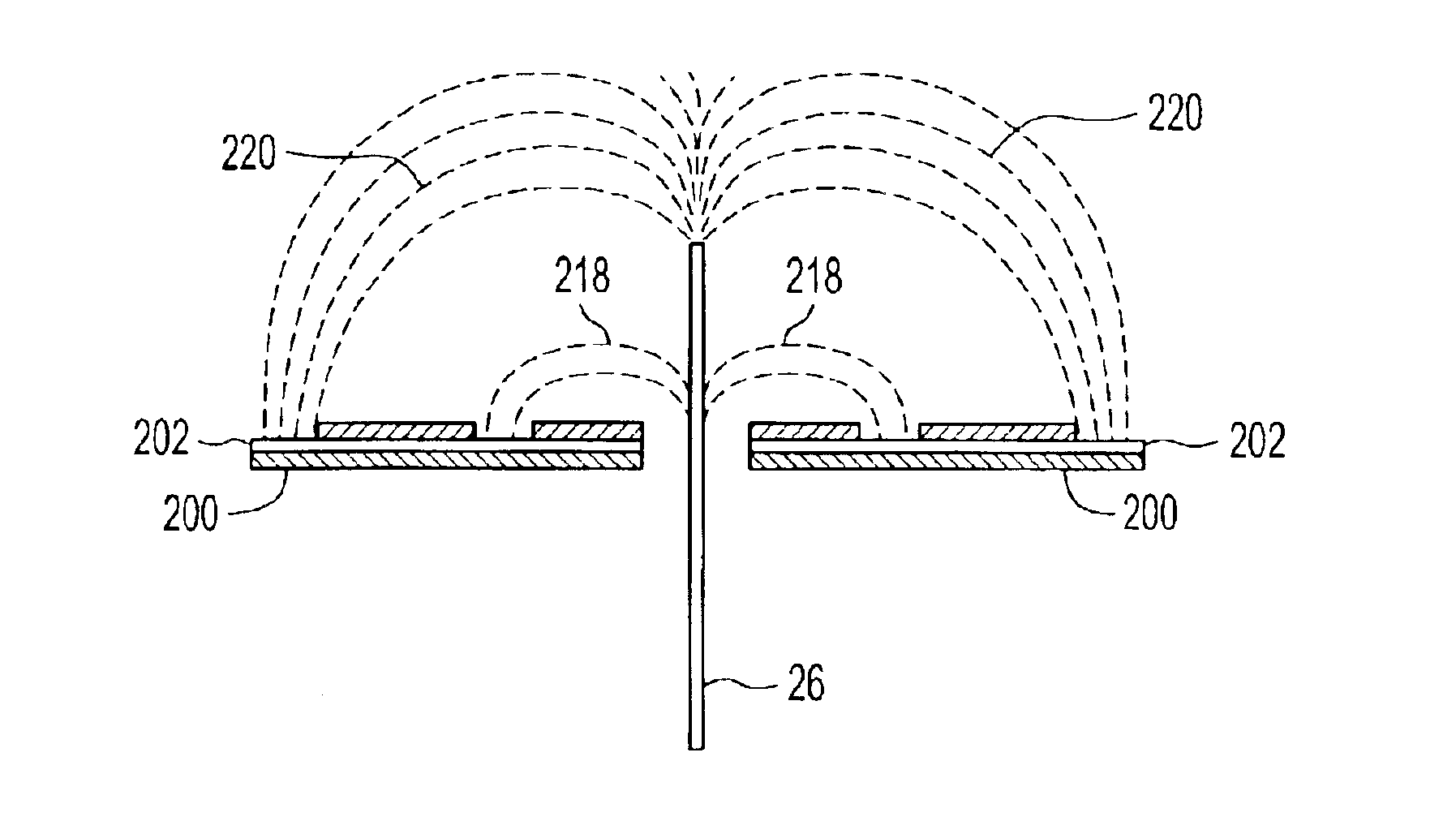

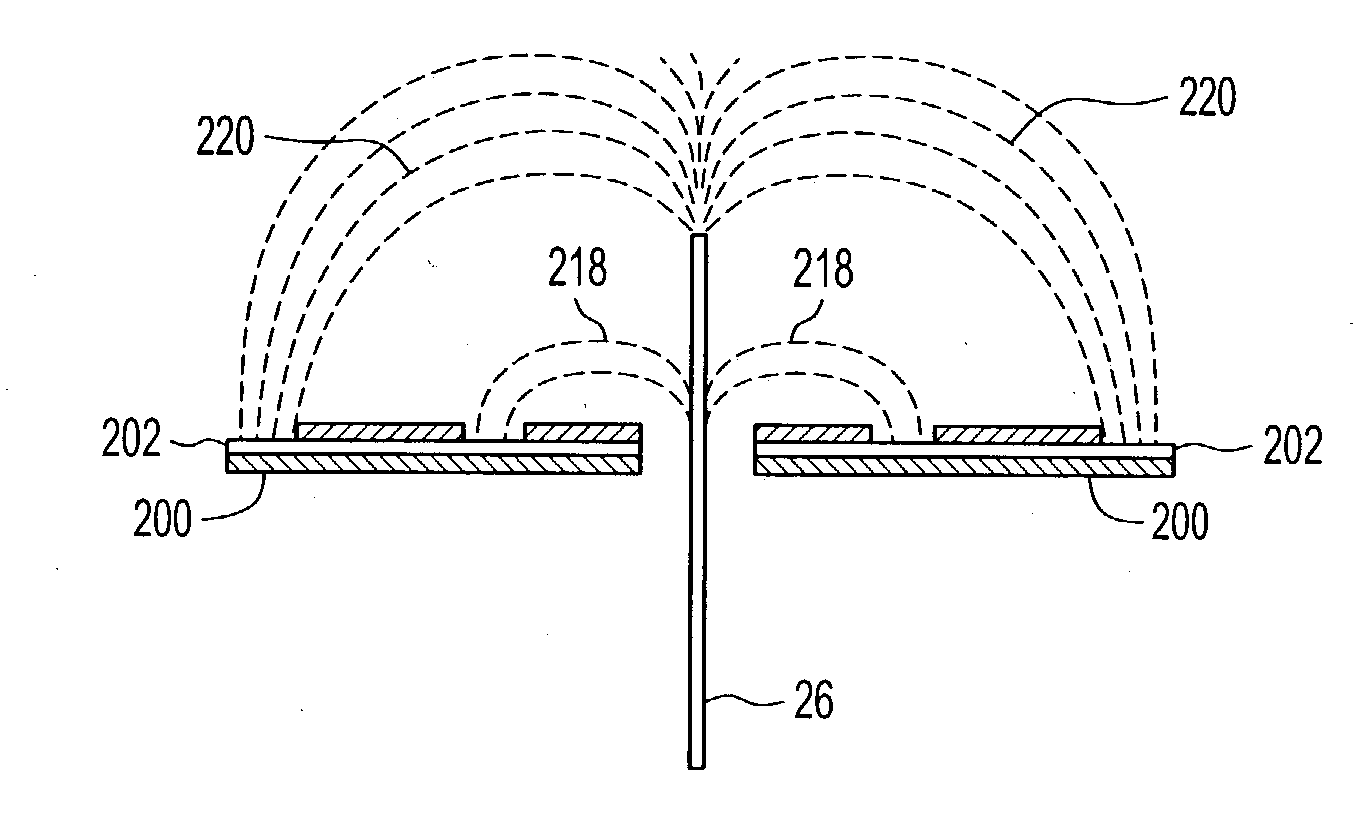

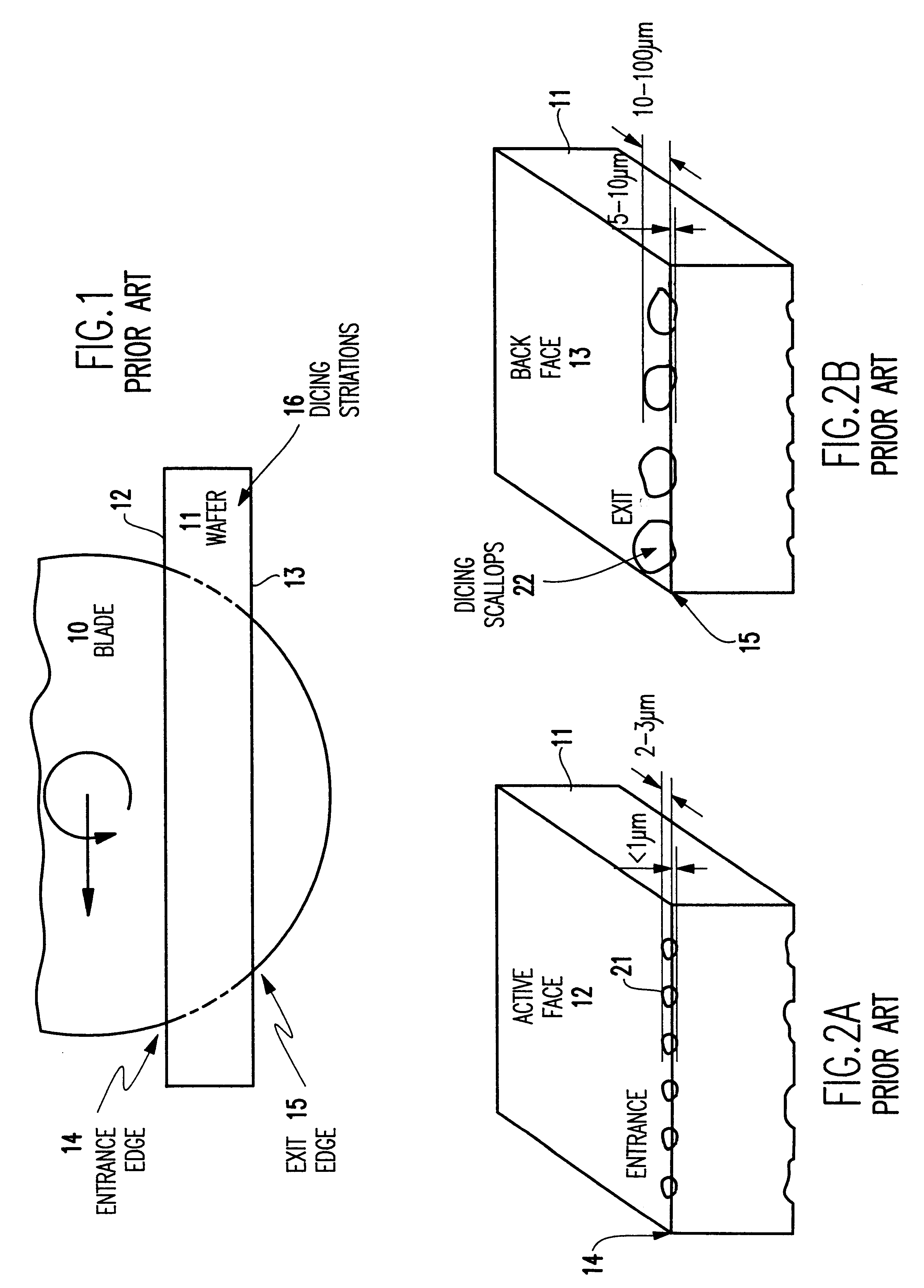

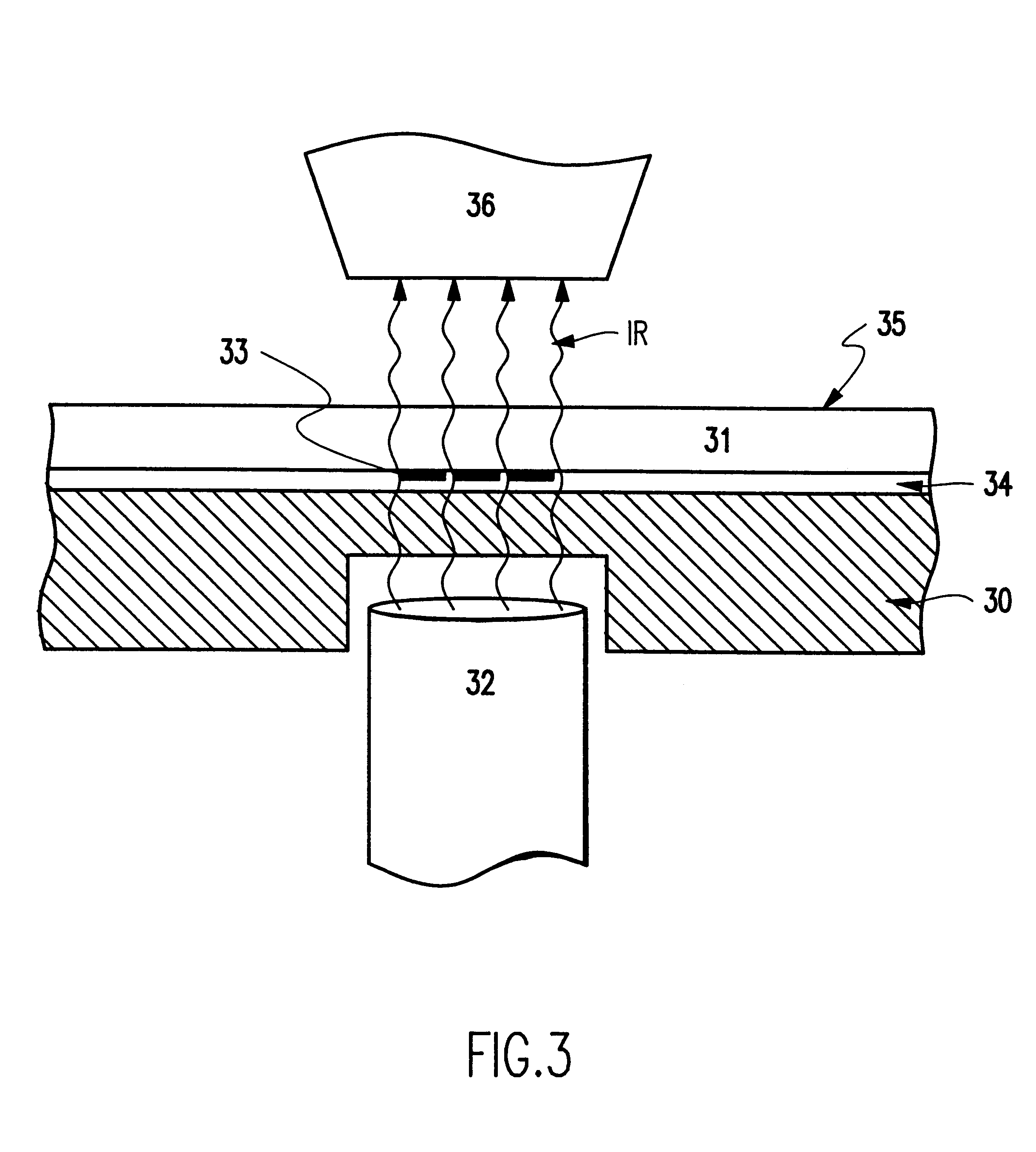

Method and system for dicing wafers, and semiconductor structures incorporating the products thereof

A method and system for dicing a semiconductor wafer providing a structure with greatly reduced backside chipping and cracking, as well as increased die strength. Semiconductor chip structures obtained from wafers diced according to this invention are also encompassed.

Owner:IBM CORP

Detection system for power equipment

Woodworking machines including conductive cutters adapted to cut workpieces, and motors adapted to drive the cutters are disclosed. The machines also include a contact detection system adapted to detect contact between a person and the cutter, and to distinguish contact between the person and the cutter from contact between the workpiece and the cutter. The machines further include a reaction system adapted to cause a predetermined action to take place upon detection of contact between the person and the cutter by the contact detection system.

Owner:SAWSTOP HLDG LLC

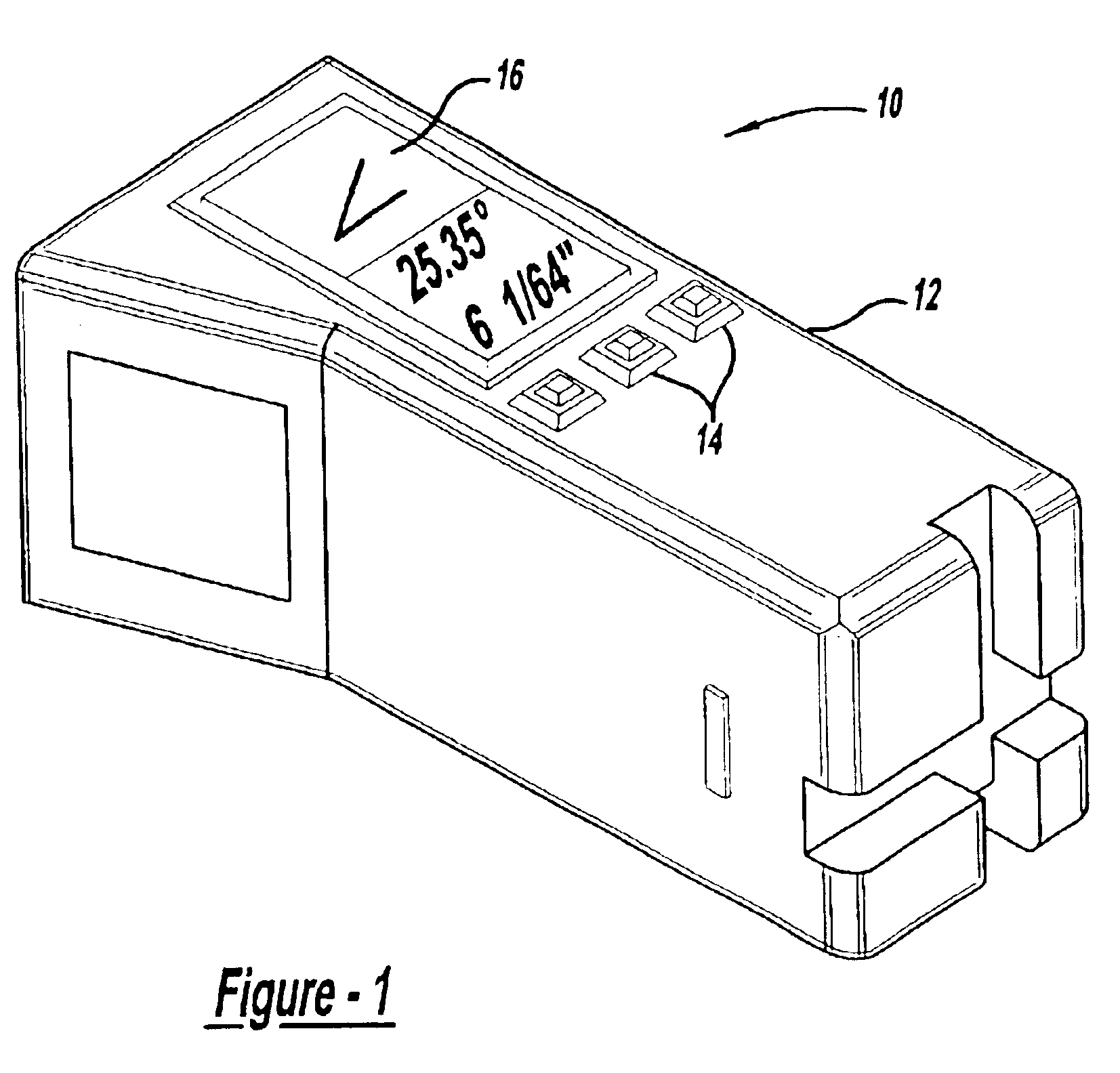

Power tool control system

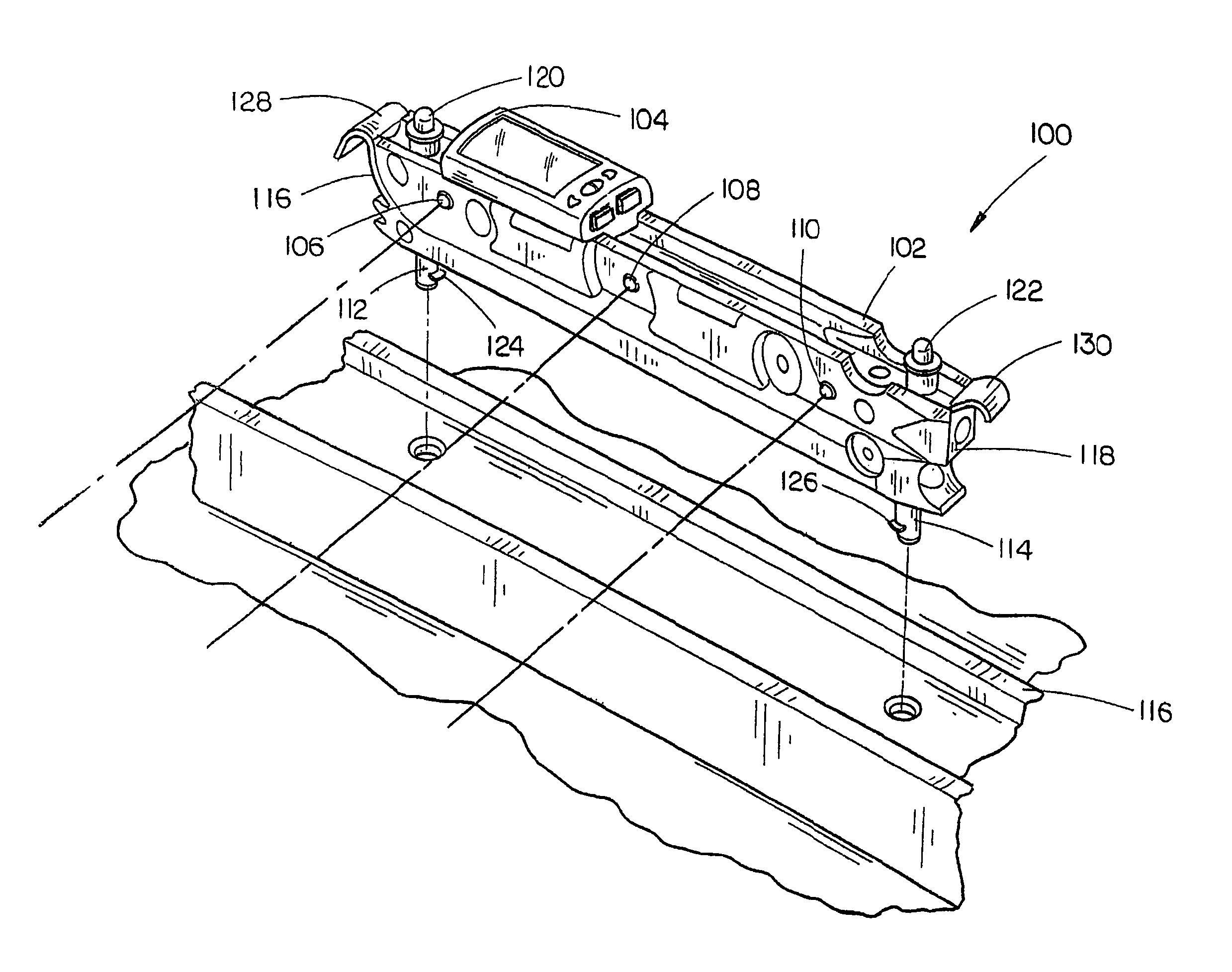

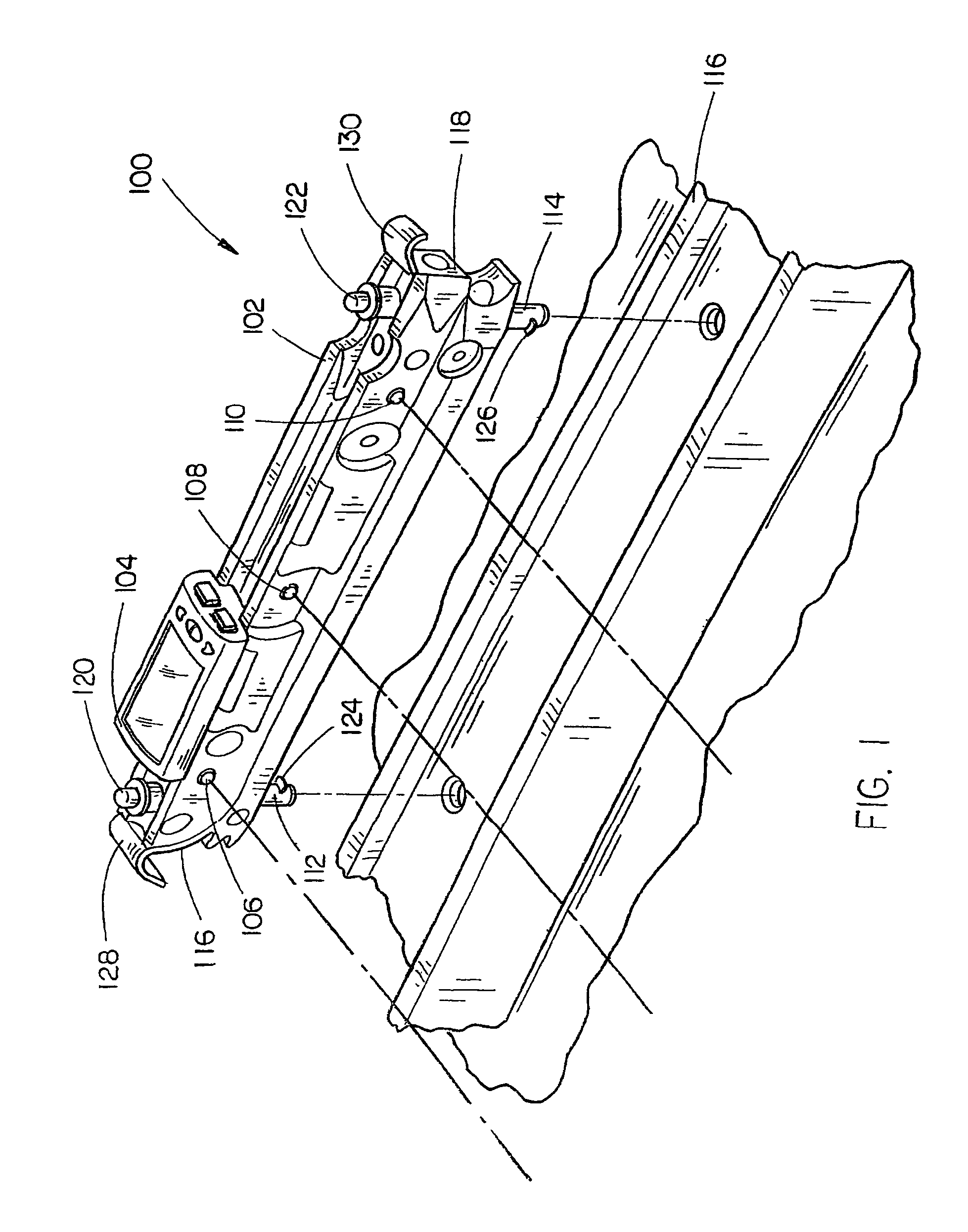

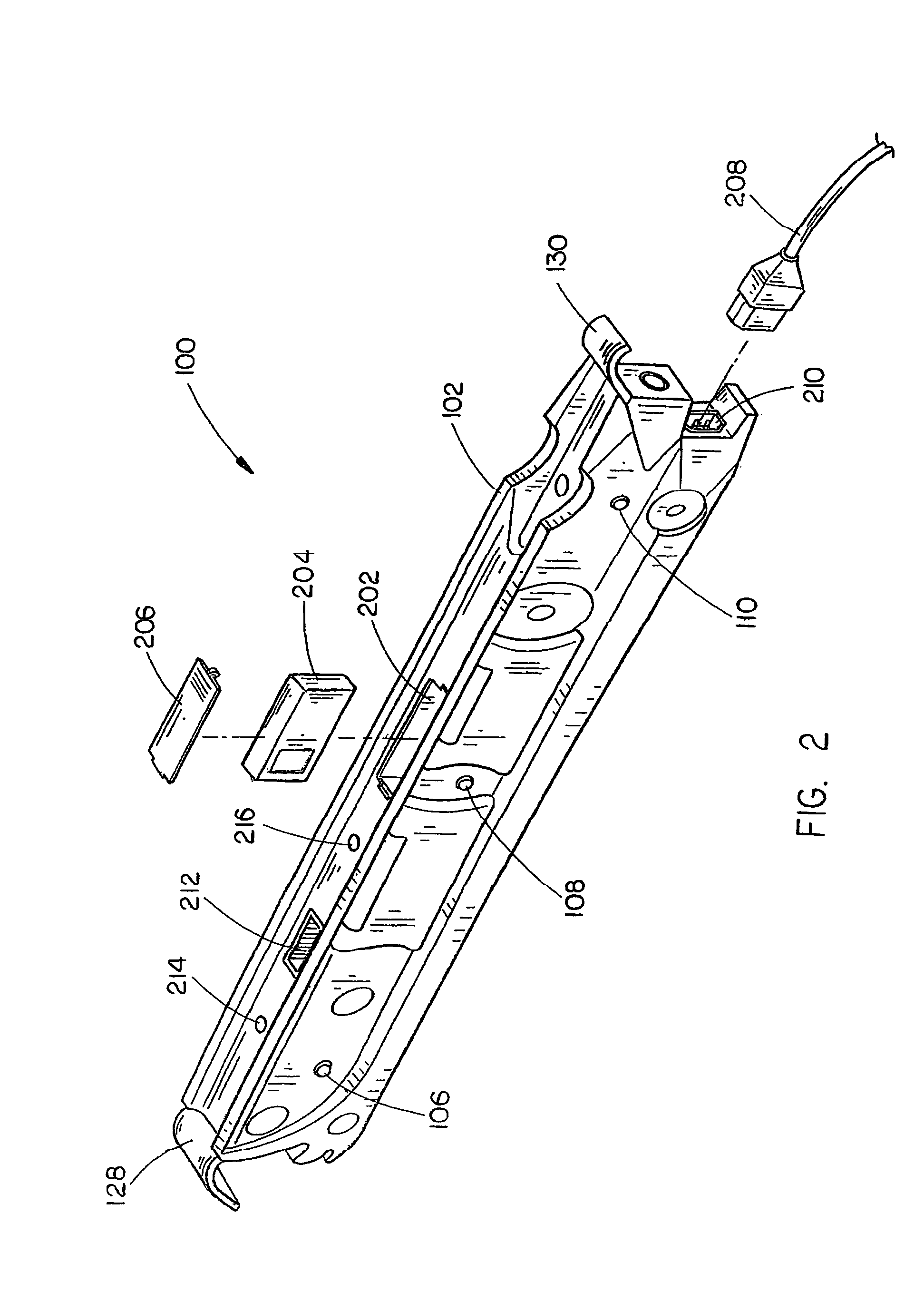

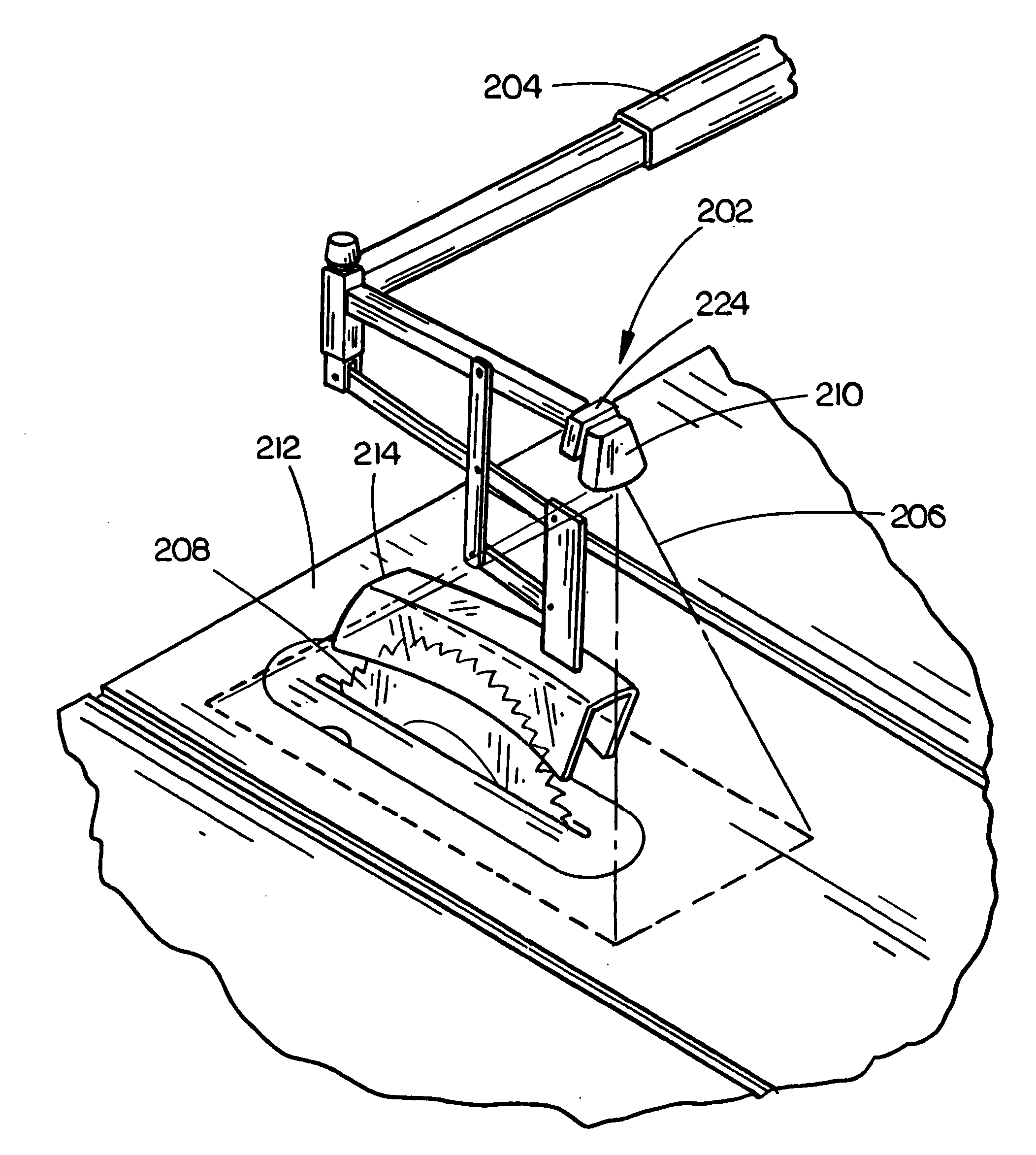

InactiveUS20060076385A1Quality improvementWell formedStapling toolsDrilling/boring measurement devicesUser needsGraphics

A power tool control system allows a user to operate a power tool through a graphical user interface communicatively coupled with a non-contact measurement and alignment device. The graphical user interface correlates user engageable selectors with a logically related menu of power tool setting options displayed on a display screen in a high quality and easily readable format. The non-contact measurement and alignment device uses one or more lasers to determine power tool settings and establish proper alignment based on user needs. The power tool control system further enables stud detection and visual indication of stud location.

Owner:BLACK & DECKER INC

Illumination by hand-operated power tools

InactiveUS20020131267A1Double battery lifeConserve battery lifeMetal sawing accessoriesLighting elementsEngineeringPower tool

An illuminator adapted for use on a hand-operated tool such as a power tool (1000) comprises a low-profile, flexible, adherent laminated housing (900), including one or more lamps (906, 907) capable of illuminating a work surface beneath the power tool. This permits a user to work with the tool in conditions of poor visibility. The housing includes connectors. A battery pack (1002) may be attached to a surface of the tool or concealed within an attachable or accessory handle (1002A). Versions including lamp control are also described.

Owner:AVOS DEV

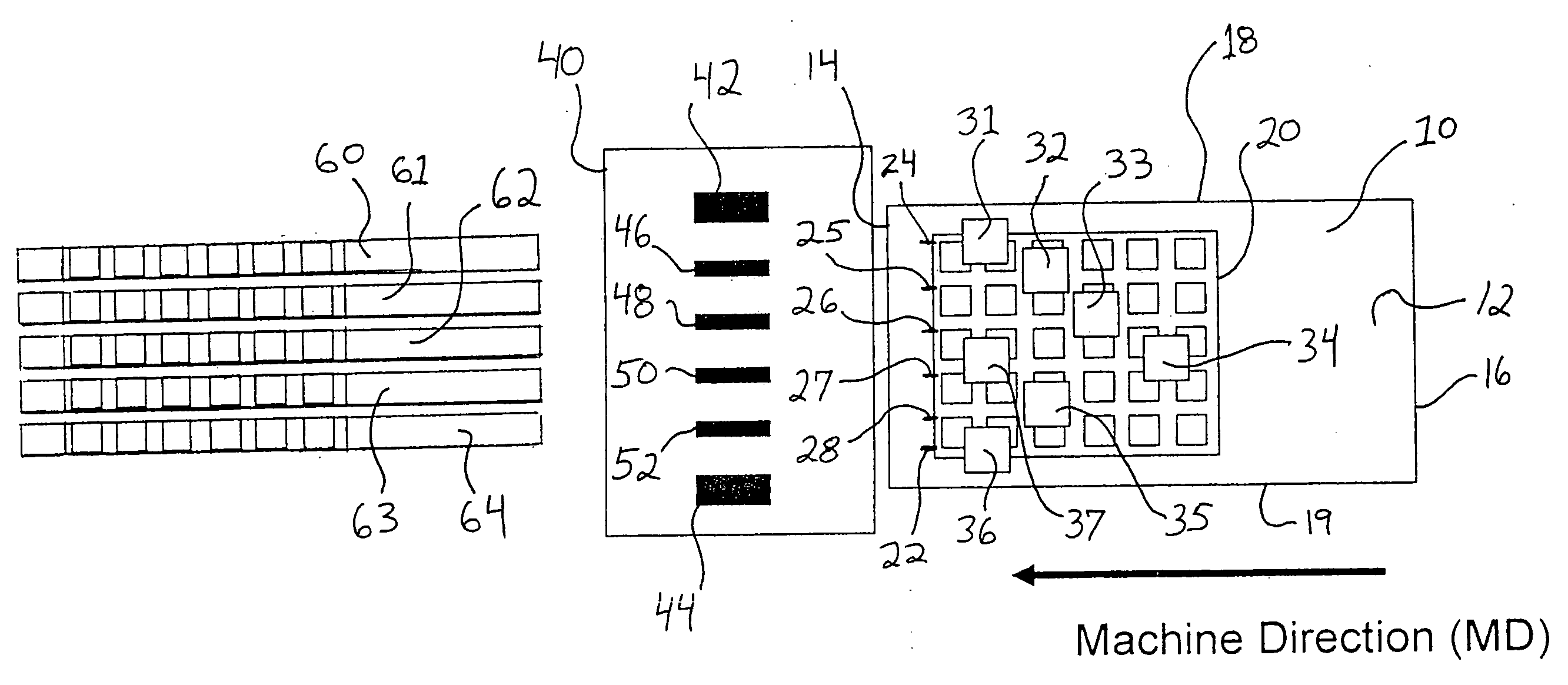

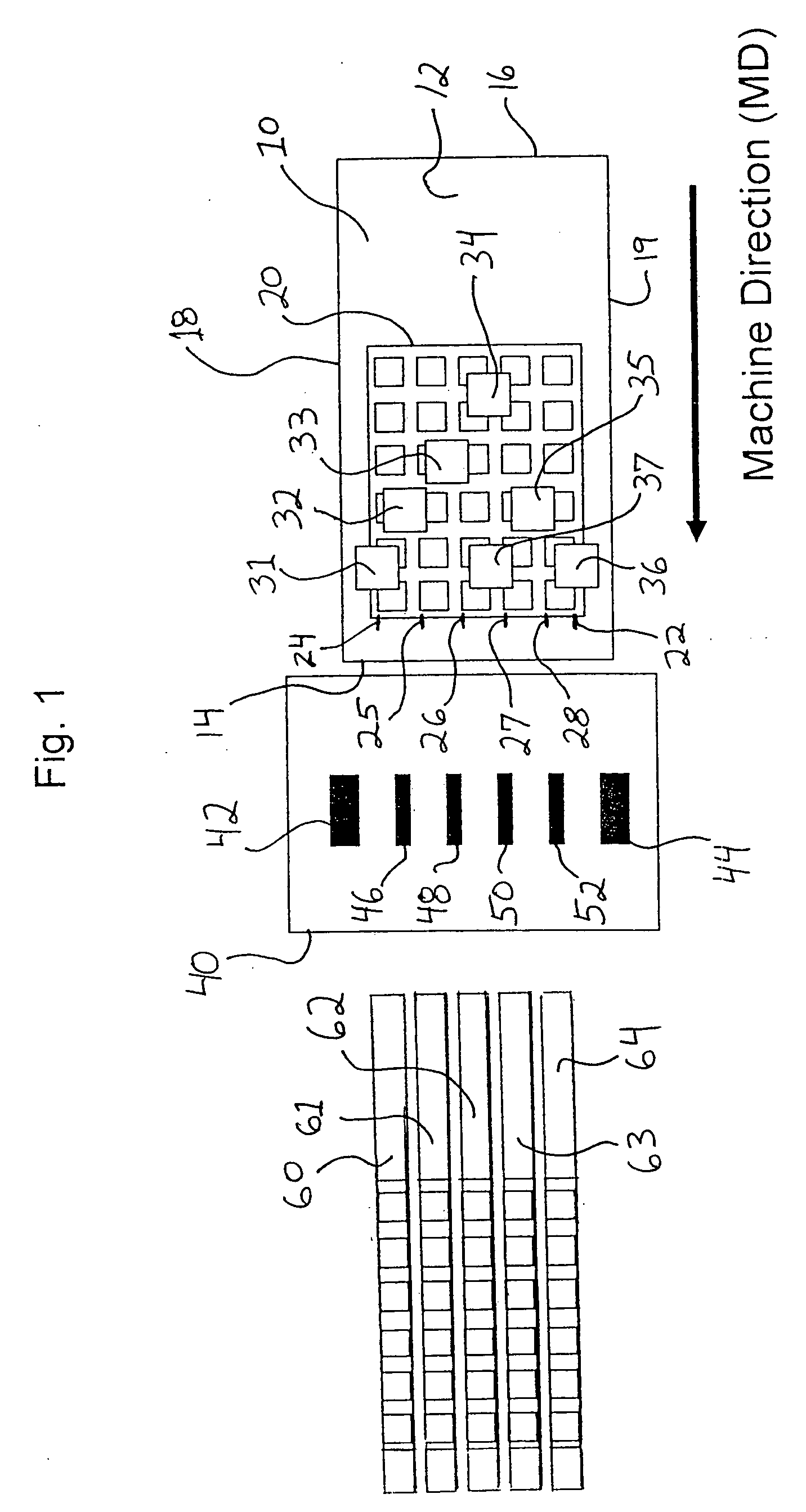

Process and system for sub-dividing a laminated flooring substrate

ActiveUS20070209736A1Good for healthAvoid mistakesMulti-purpose machinesAdjusting equipmentEngineeringControl unit

A process for sub-dividing a laminated flooring substrate into a plurality of laminated flooring planks and a system therefore are described. The process can include providing a laminated flooring substrate having a decorative pattern on a core wherein the decorative pattern can include a plurality of indicators, and independently detecting the indicators with a plurality of detecting devices, each assigned a respective indicator. The detecting devices can individually obtain the position of the detected indicators and a control unit can align a separate saw blade per each position detected. The system includes a cutting unit with individually adjustable saws or an alignment device configured to align the laminated flooring substrate with the saws, to cut the laminated flooring substrate along positions relative to the detected indicators, for example, in the center thereof or off-set therefrom.

Owner:MANNINGTON MILLS

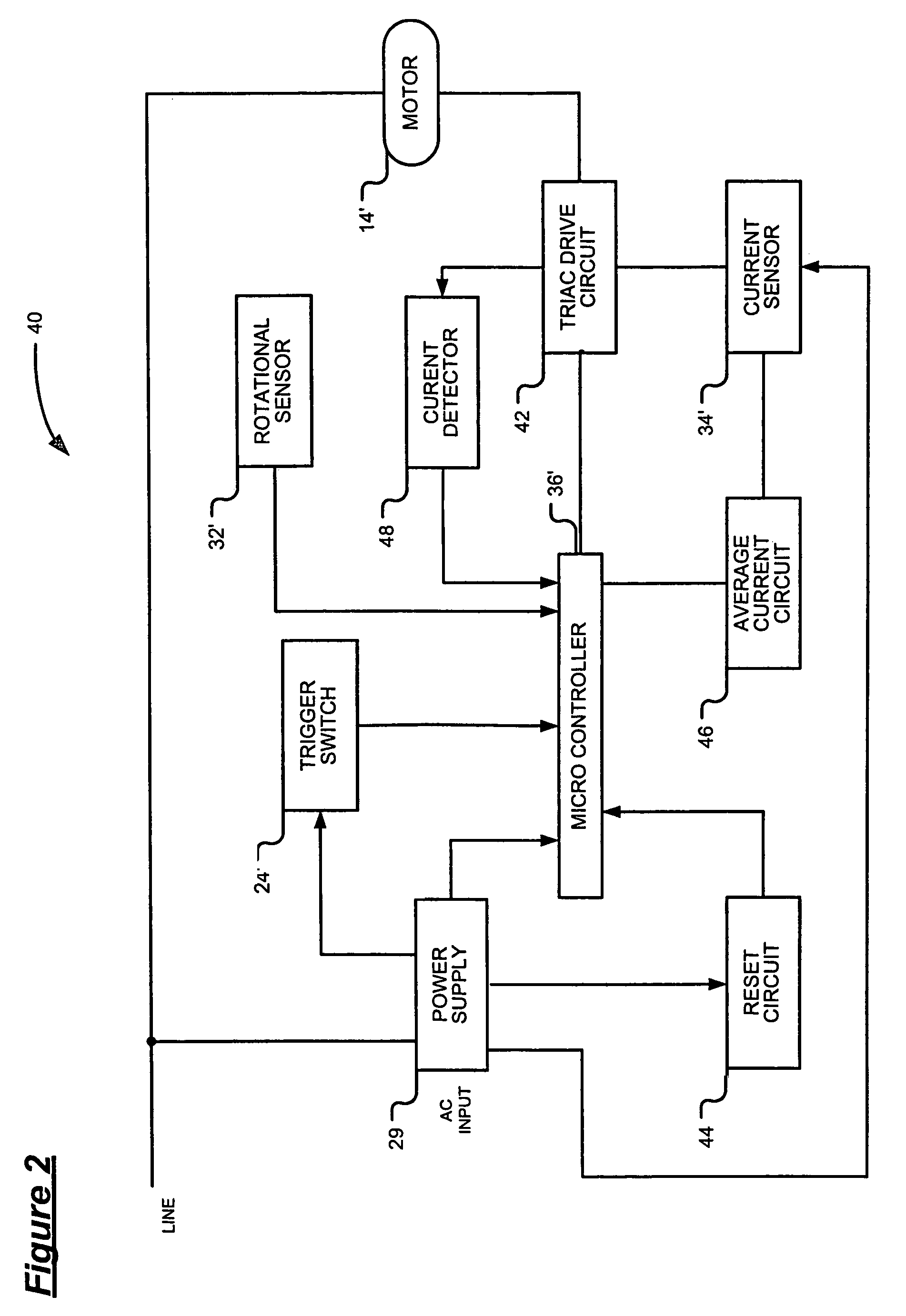

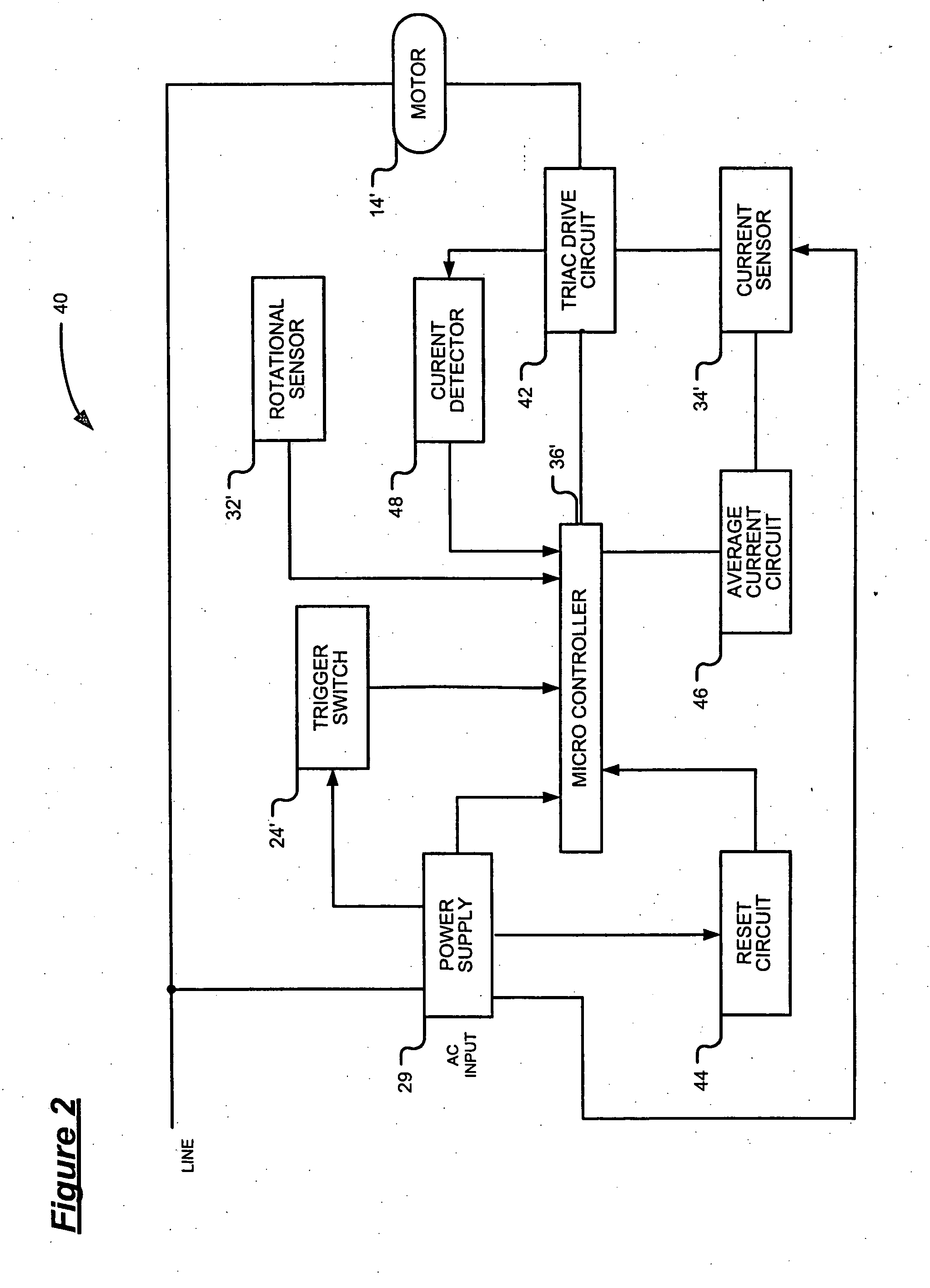

Power tool anti-kickback system with rotational rate sensor

A control system is provided for use in a power tool. The control system includes: a rotational rate sensor having a resonating mass and a controller electrically connected to the rotational rate sensor. The rotational rate sensor detects lateral displacement of the resonating mass and generates a signal indicative of the detected lateral displacement, such that the lateral displacement is directly proportional to a rotational speed at which the power tool rotates about an axis of the rotary shaft. Based on the generated signal, the controller initiates a protective operation to avoid further undesirable rotation of the power tool. The control scheme employed by the power tool may initiate different protective operations for different tool conditions.

Owner:BLACK & DECKER INC

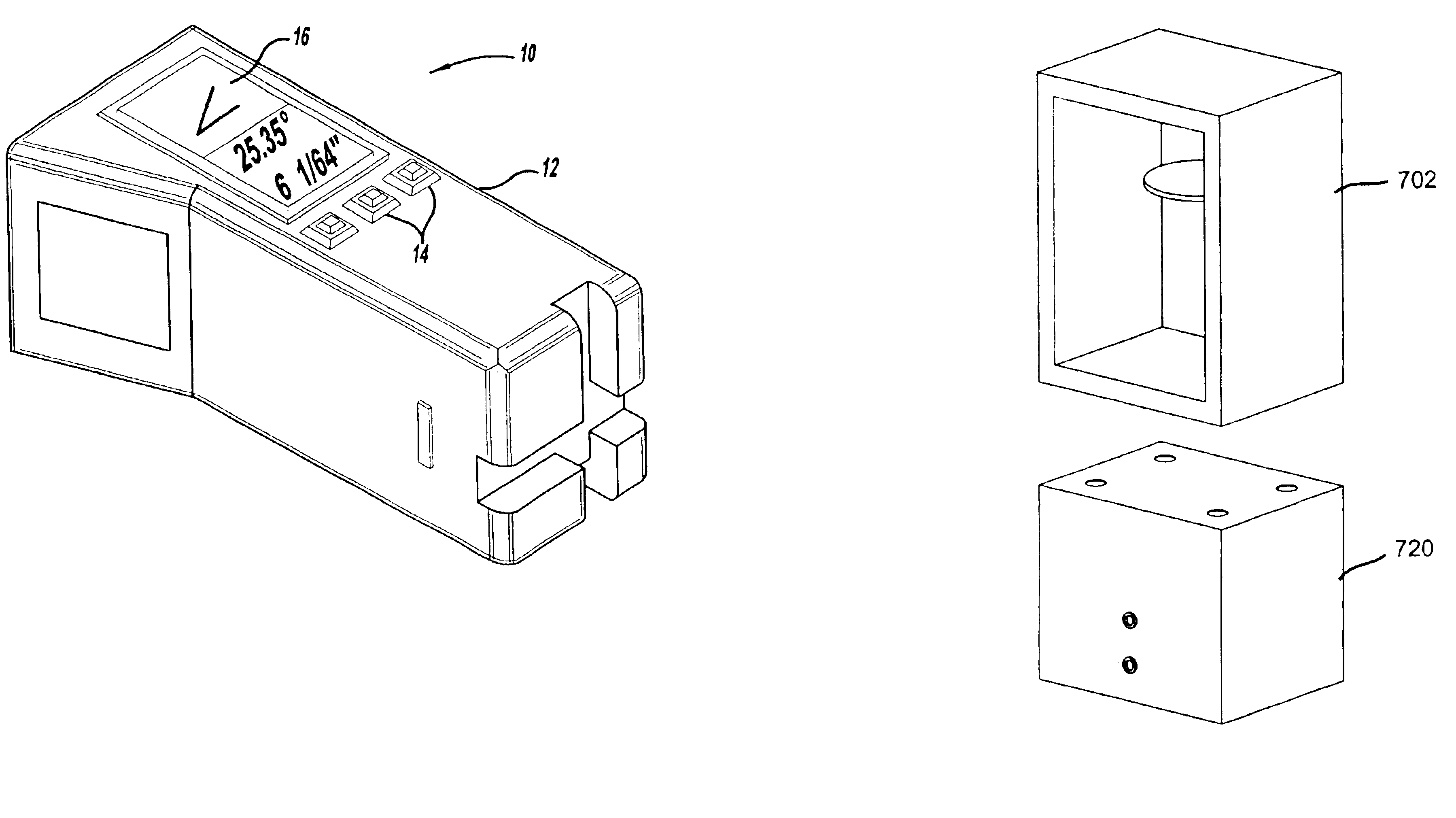

Modular non-contact measurement device for quickly and accurately obtaining dimensional measurement data

InactiveUS6858857B2Quickly and accurately performingRemove most human judgement of measurement resultsImage analysisMetal sawing accessoriesMeasurement deviceDimension measurement

A modular measurement device is provided for quickly and accurately performing non-contact measurements of various objects at different locations within a commercial or residential work area. The modular measurement device generally includes a laser base that is operable to project light onto a measured object; and a portable measurement module adapted to receive light reflected from a surface of the measured object and operable to determine dimensional measurement data for the measured object, where the portable measurement module is configured to releasably couple to the laser base. The operational components of the measurement device are partitioned between the portable measurement module and the laser base. In this way, a single portable measurement module having more expensive operational components may be used with different, less expensive laser bases, where each laser base may be adapted for a different application.

Owner:PERCEPTRON

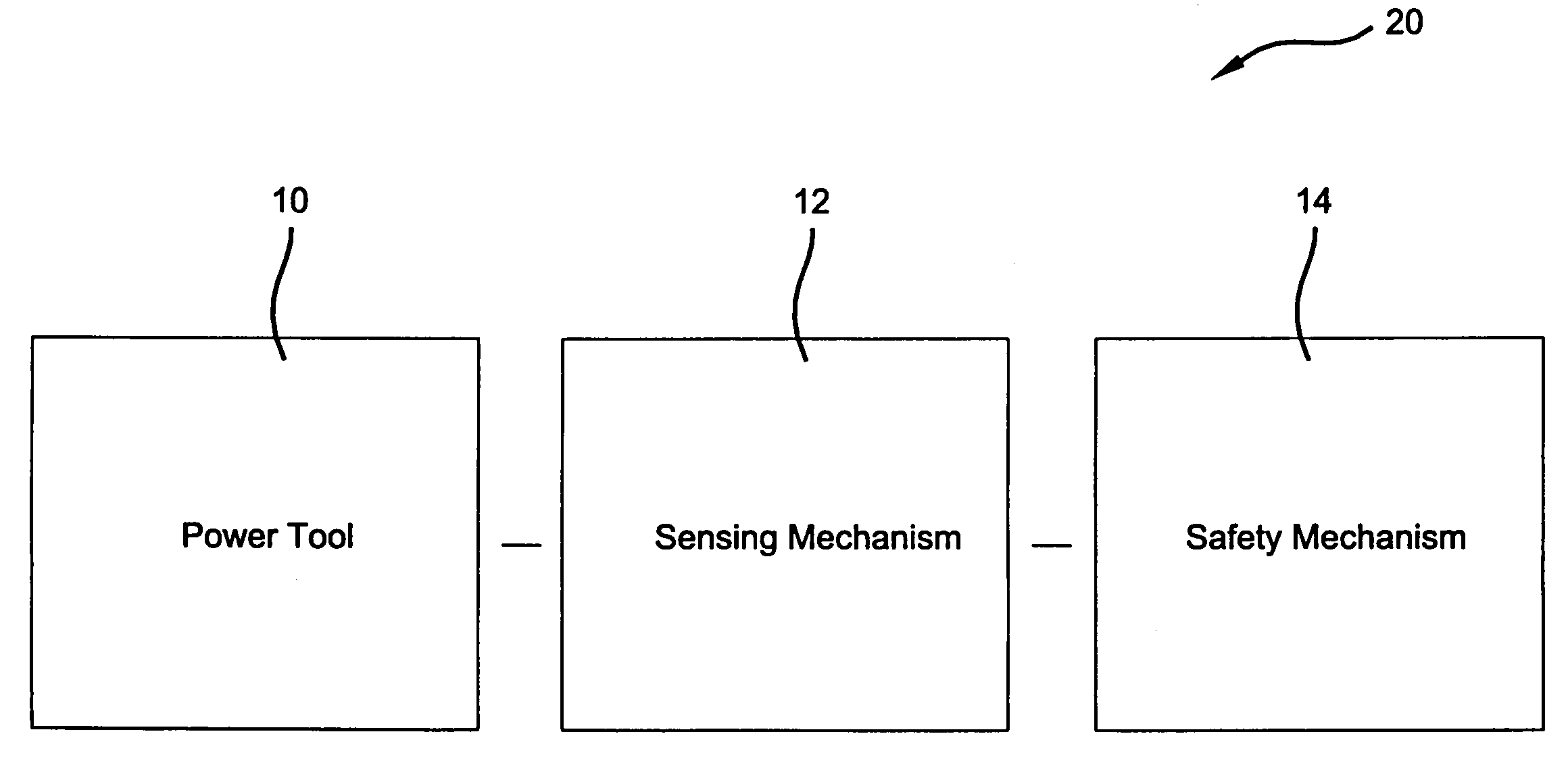

Power tool safety mechanisms

A sensing mechanism (12) for detecting user contact with an active portion (26) of the power tool (10) is provided. In addition, a safety mechanism (14) for preventing prolonged user contact with the active portion (26) of a power tool (10) is provided. The safety mechanism (14) is configured to actuate upon receipt of a signal from the sensing mechanism (12). According to a first aspect, the safety mechanism (14) is arranged to rapidly displace the active portion (26) away from a user extremity. Alternatively, according to a second aspect, the safety mechanism (14) is arranged to rapidly urge an extremity of the user away from the active portion (26) of the power tool (10).

Owner:BLACK & DECKER INC

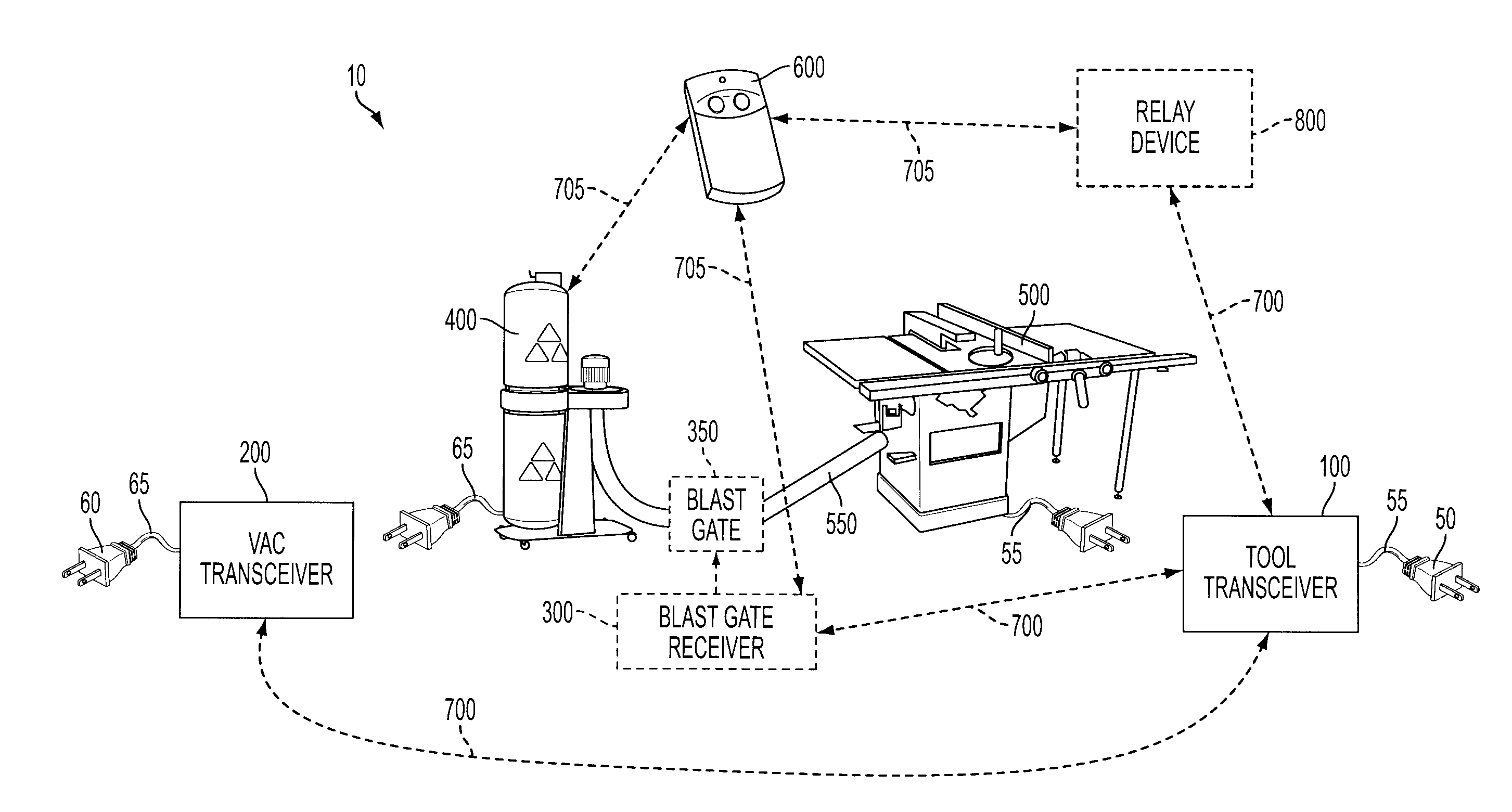

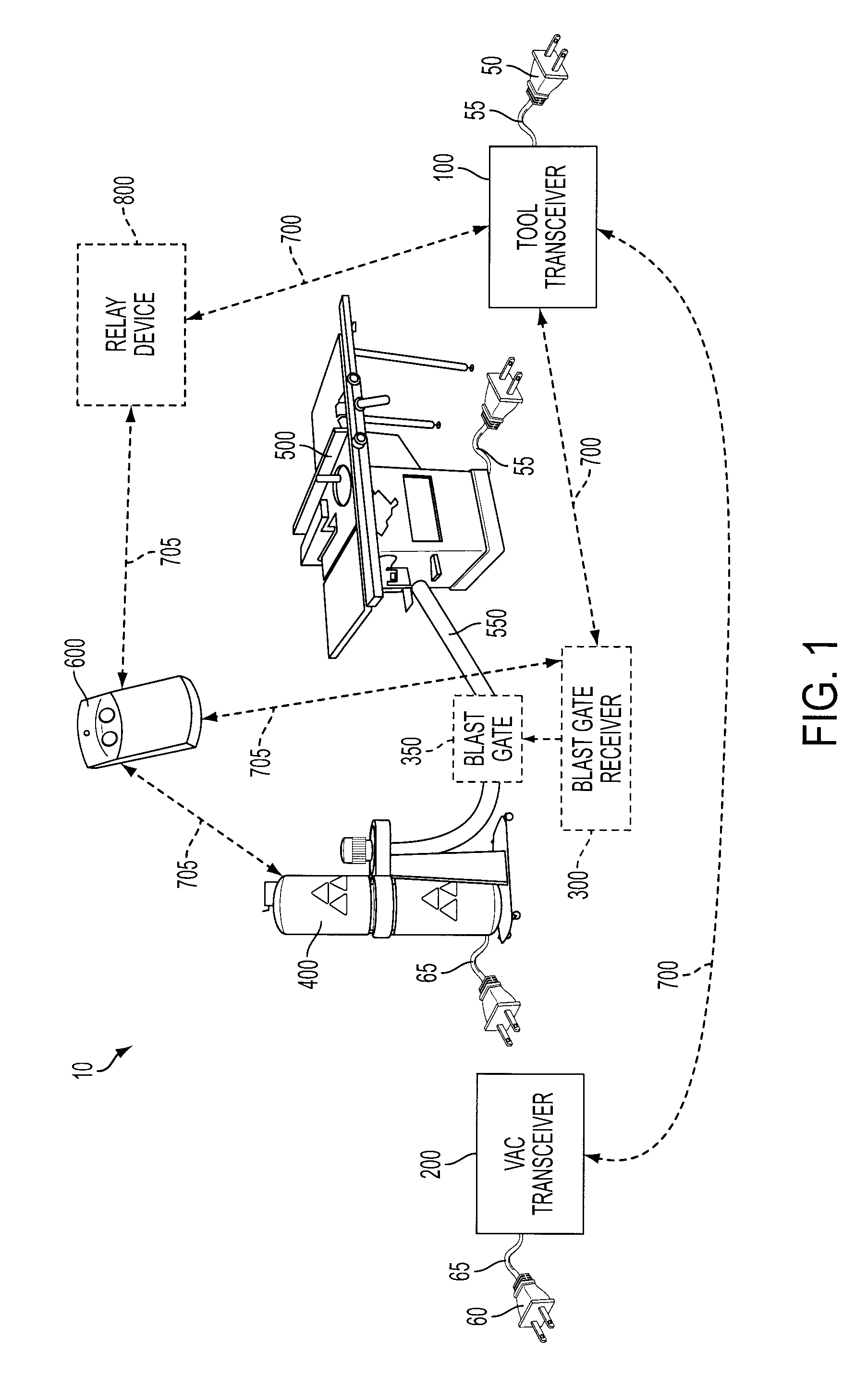

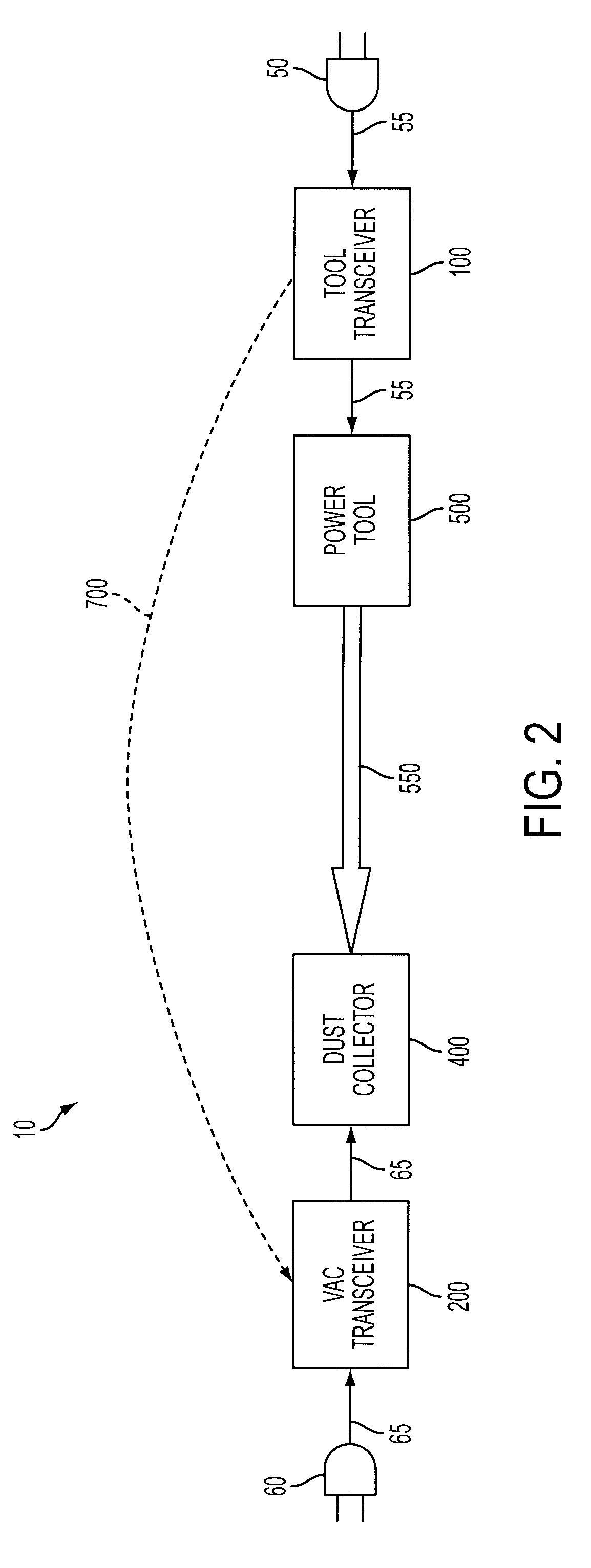

Wireless particle collection system

InactiveUS20100199453A1Metal sawing accessoriesDispersed particle filtrationCollection systemUnique identifier

A wireless particle collection system includes a dust collector and at least one power tool coupled to the dust collector. The power tool is associated with a unique identifier contained in a wireless signal transmitted from the power tool upon an activation event of the tool. The unique identifier is recognized by the dust collector, and the dust collector activates or de-activates upon receipt of the wireless signal.

Owner:CHANG TYPE INDAL

Power tool control system

InactiveUS8004664B2Quality improvementWell formedStapling toolsDrilling/boring measurement devicesGraphical user interfaceControl system

A power tool control system includes a non-contact measurement and alignment device operative with the power tool and enabled to establish various readings, such as power tool settings. A graphical user interface communicatively coupled with the non-contact measurement and alignment device enables user control over and display of the readings from the non-contact measurement and alignment device.

Owner:CHANG TYPE INDAL

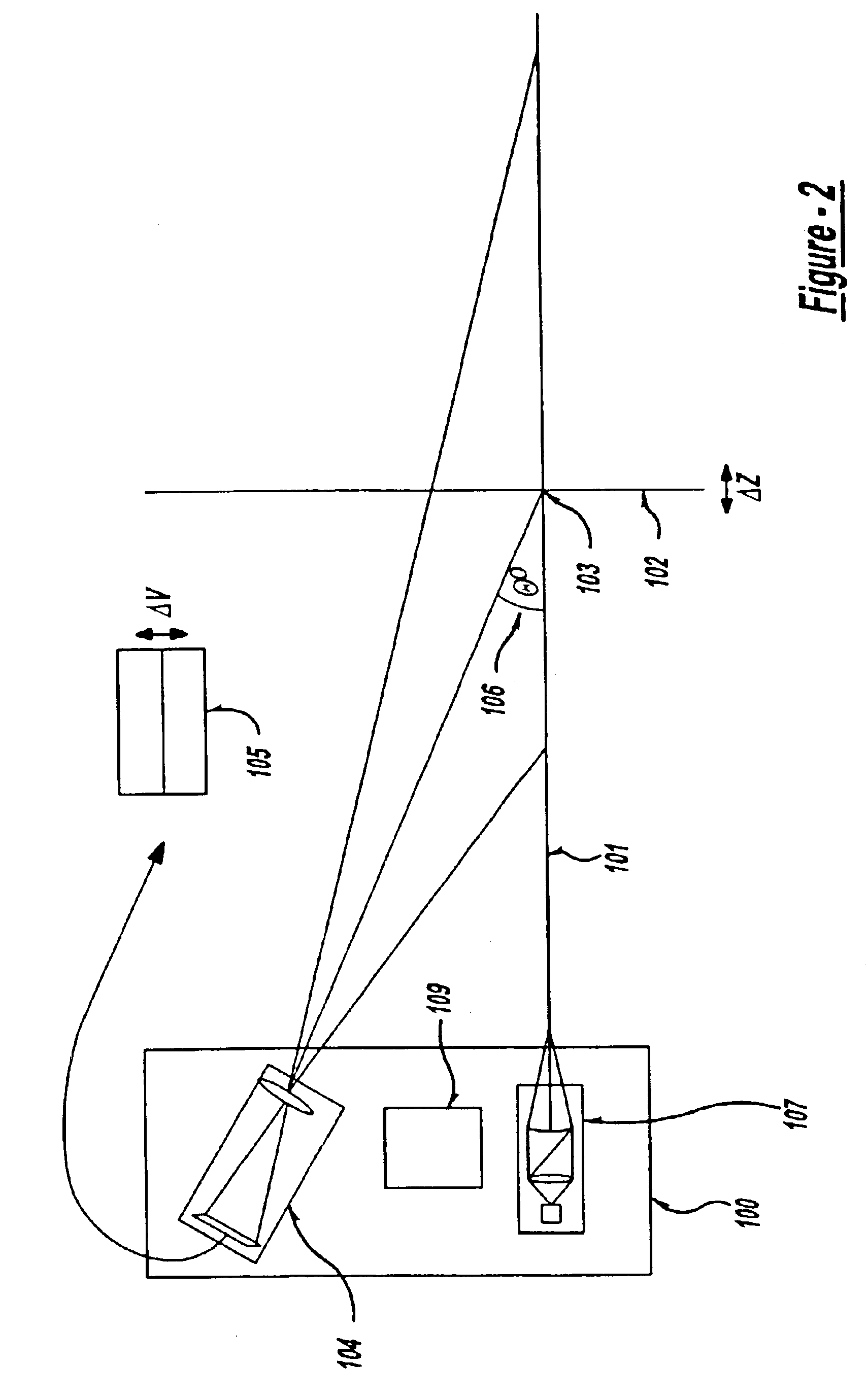

Optical proximity device for power tools

The present invention is directed to a power tool including a working element for performing a task. A light source is arranged to project a beam of light adjacent the working element. A detector, such as an electro-optic type detector, is communicatively coupled to the power tool such that the detector is capable of detecting the presence of a human body part in the beam of light. If a body part is detected, the detector may communicate to stop operation of the working element.

Owner:BLACK & DECKER INC

Power tool anti-kickback system with rotational rate sensor

A control system is provided for use in a power tool. The control system includes: a rotational rate sensor having a resonating mass and a controller electrically connected to the rotational rate sensor. The rotational rate sensor detects lateral displacement of the resonating mass and generates a signal indicative of the detected lateral displacement, such that the lateral displacement is directly proportional to a rotational speed at which the power tool rotates about an axis of the rotary shaft. Based on the generated signal, the controller initiates a protective operation to avoid further undesirable rotation of the power tool. The control scheme employed by the power tool may initiate different protective operations for different tool conditions.

Owner:BLACK & DECKER INC

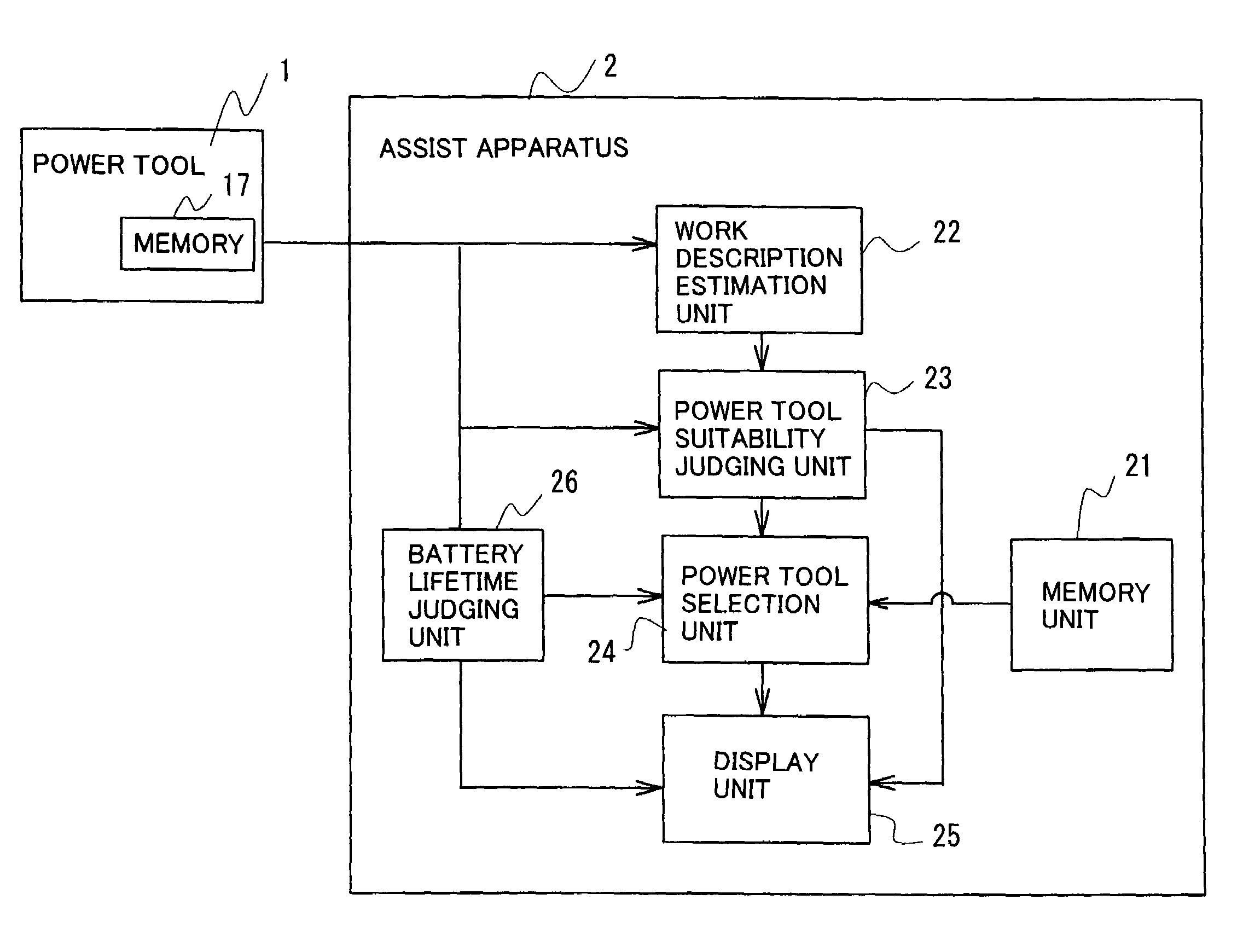

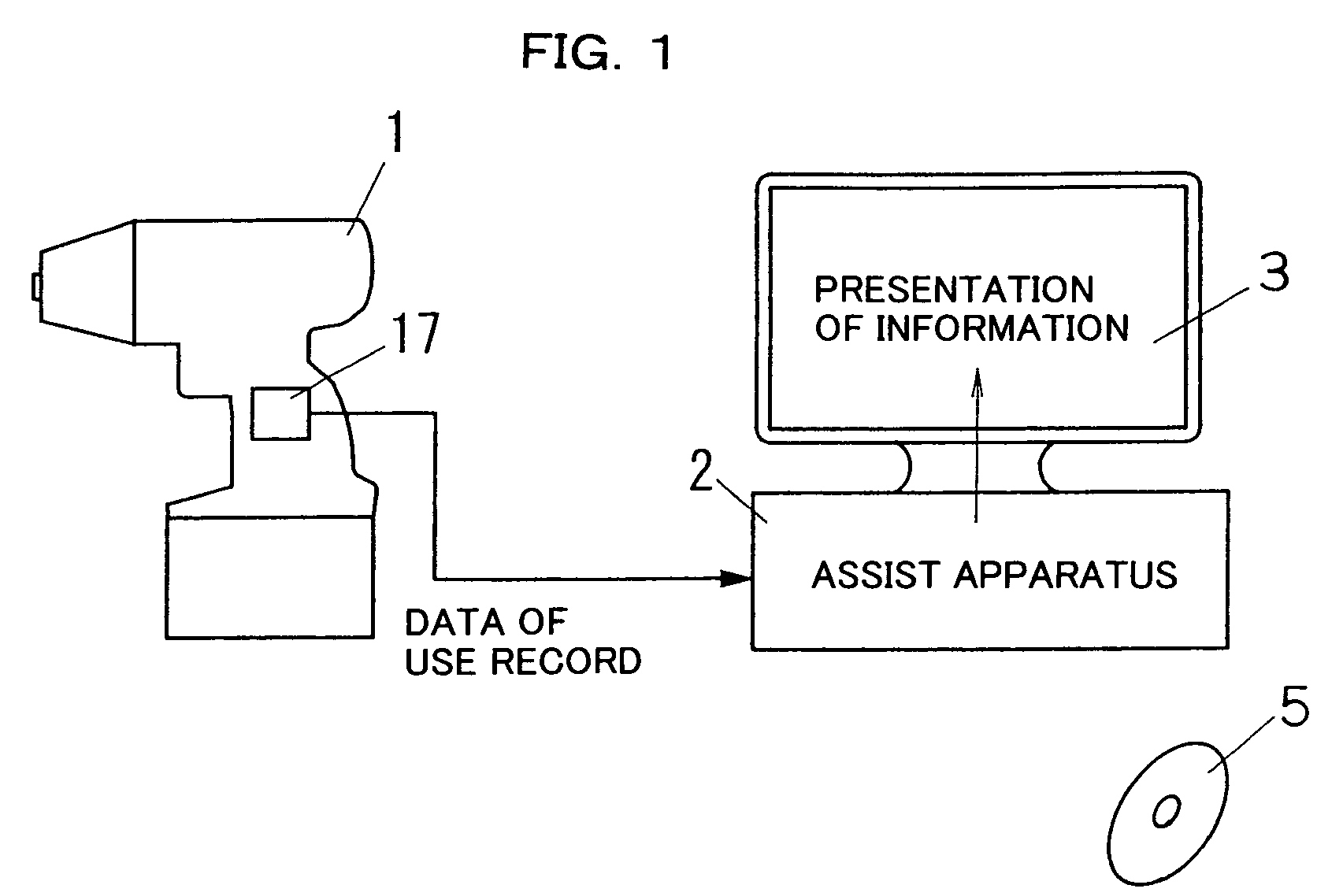

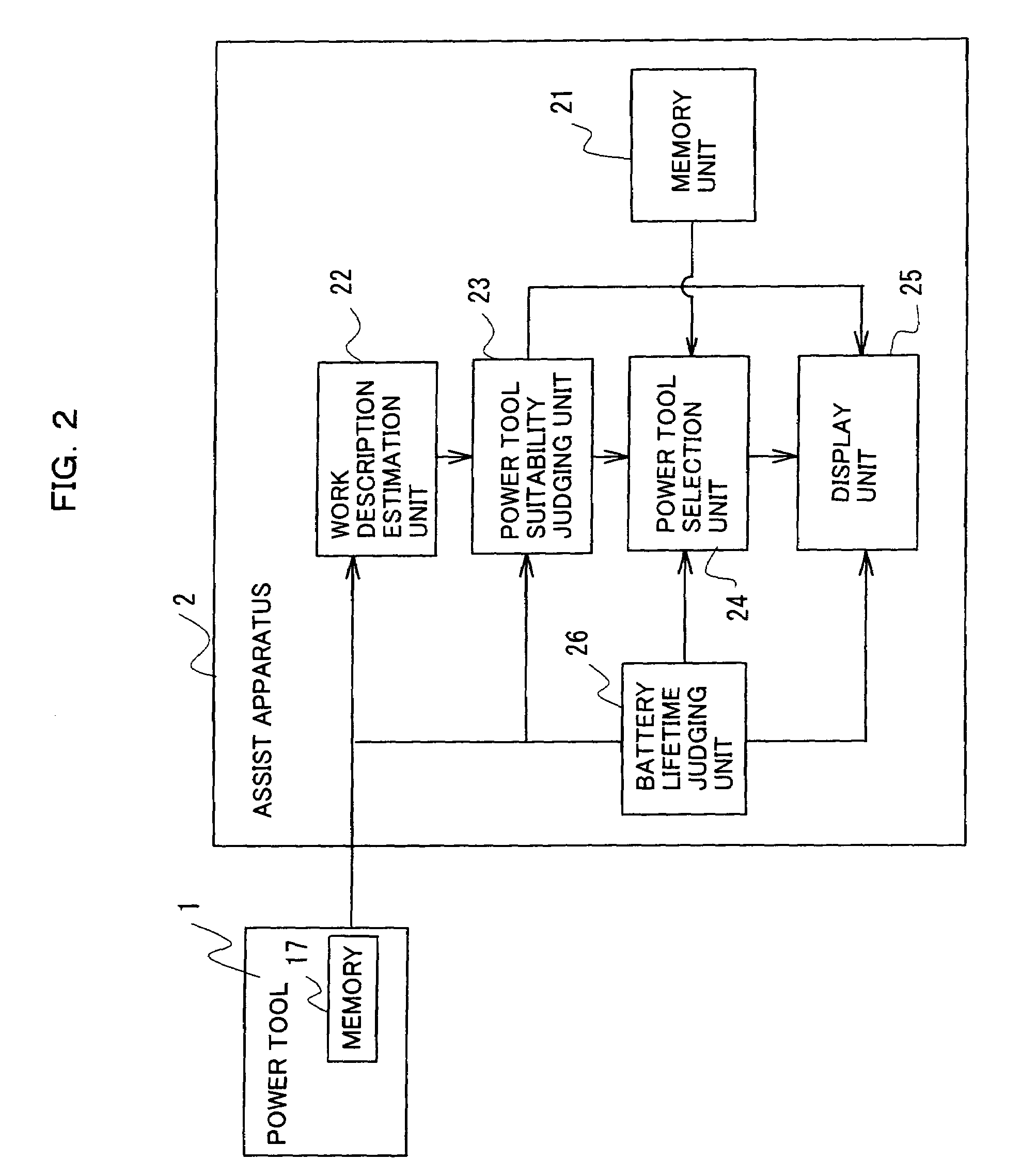

System for assisting selection of power tool

It is determined whether a power tool is suitable for a work description for which the power tool is used or not, and when it is not suitable for the work description, a suitable power tool is selected and presented to a user. The power tool has a memory, and data concerning a work record is stored in the memory. When the power tool is connected to an assist apparatus installed in a shop or the like, the data concerning the work record is read out from the memory, and the work description is estimated according to a program run in the assist apparatus. Then, it is judged whether the power tool is suitable for the estimated work description or not. When the power tool is not suitable for the work description, a power tool suitable for the work is selected from a previously stored database and presented to the user.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com