Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2773results about "Engineering safety devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

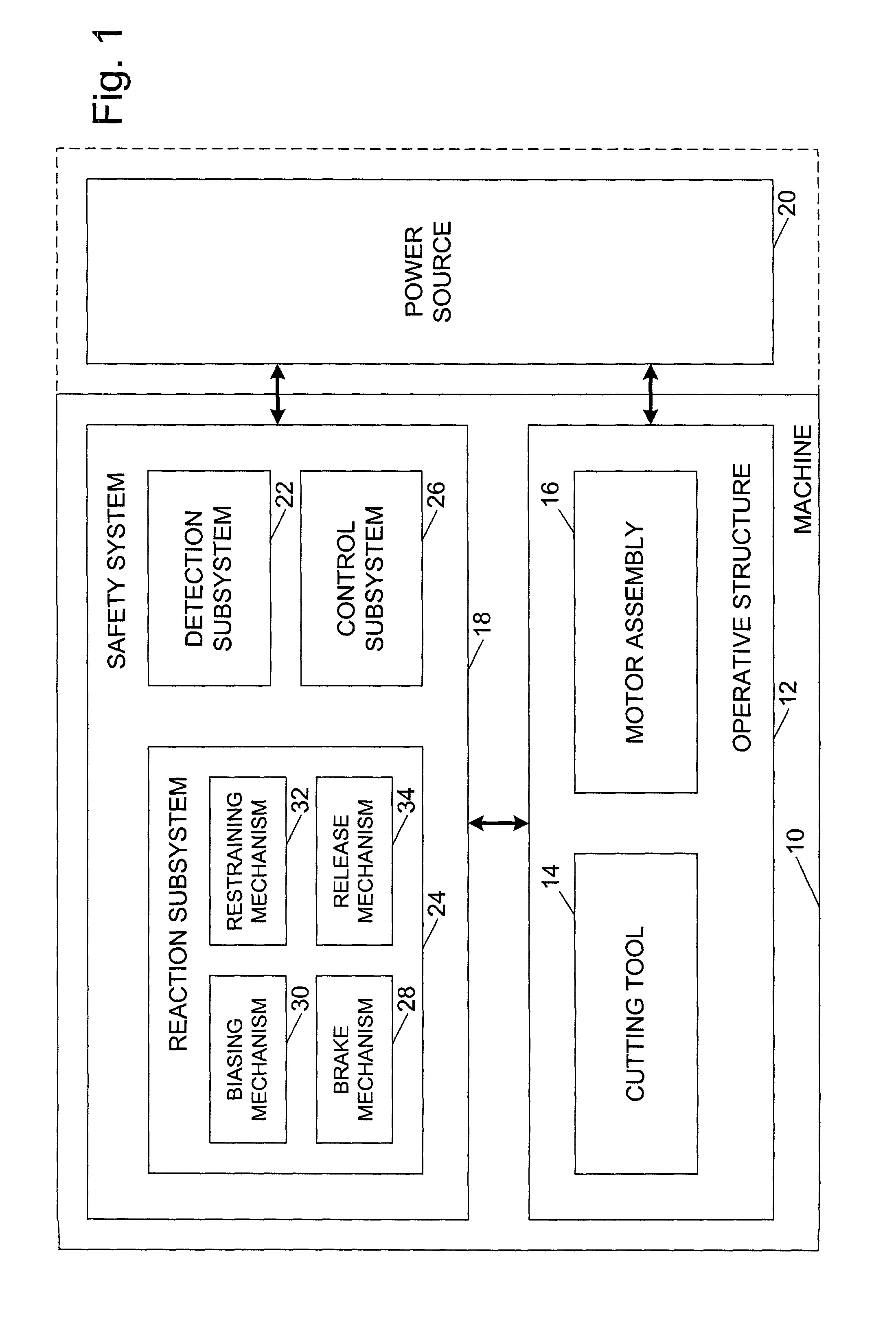

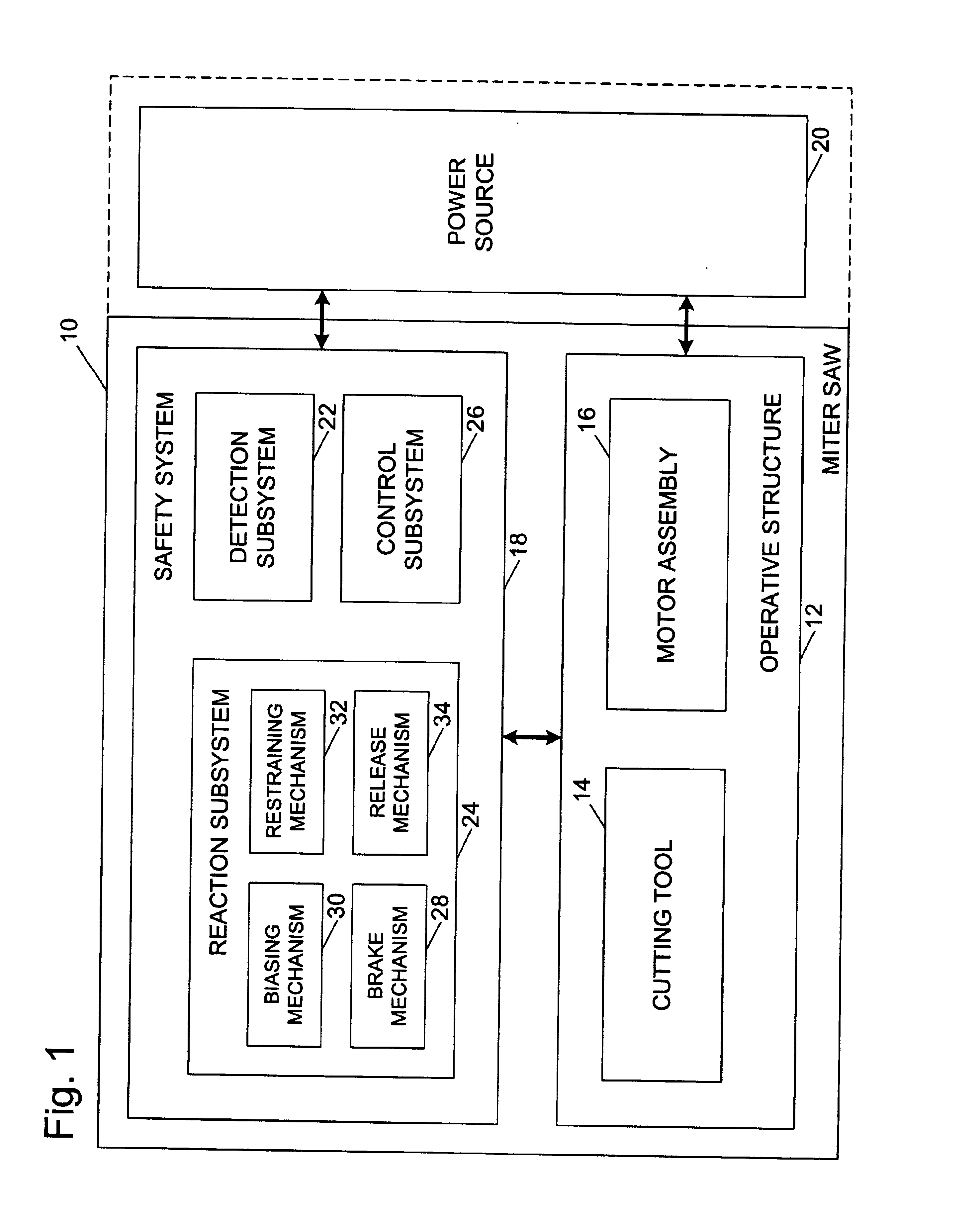

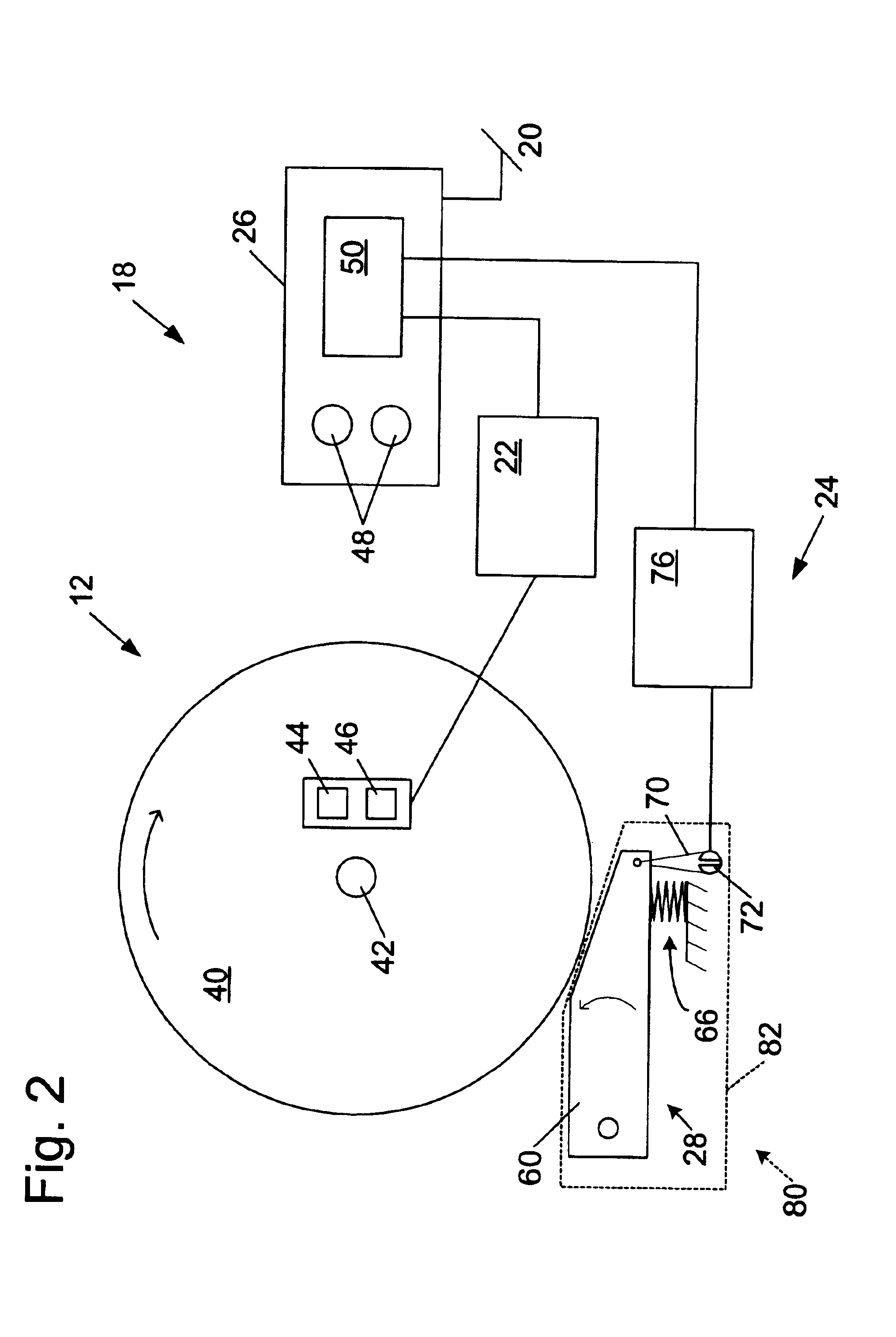

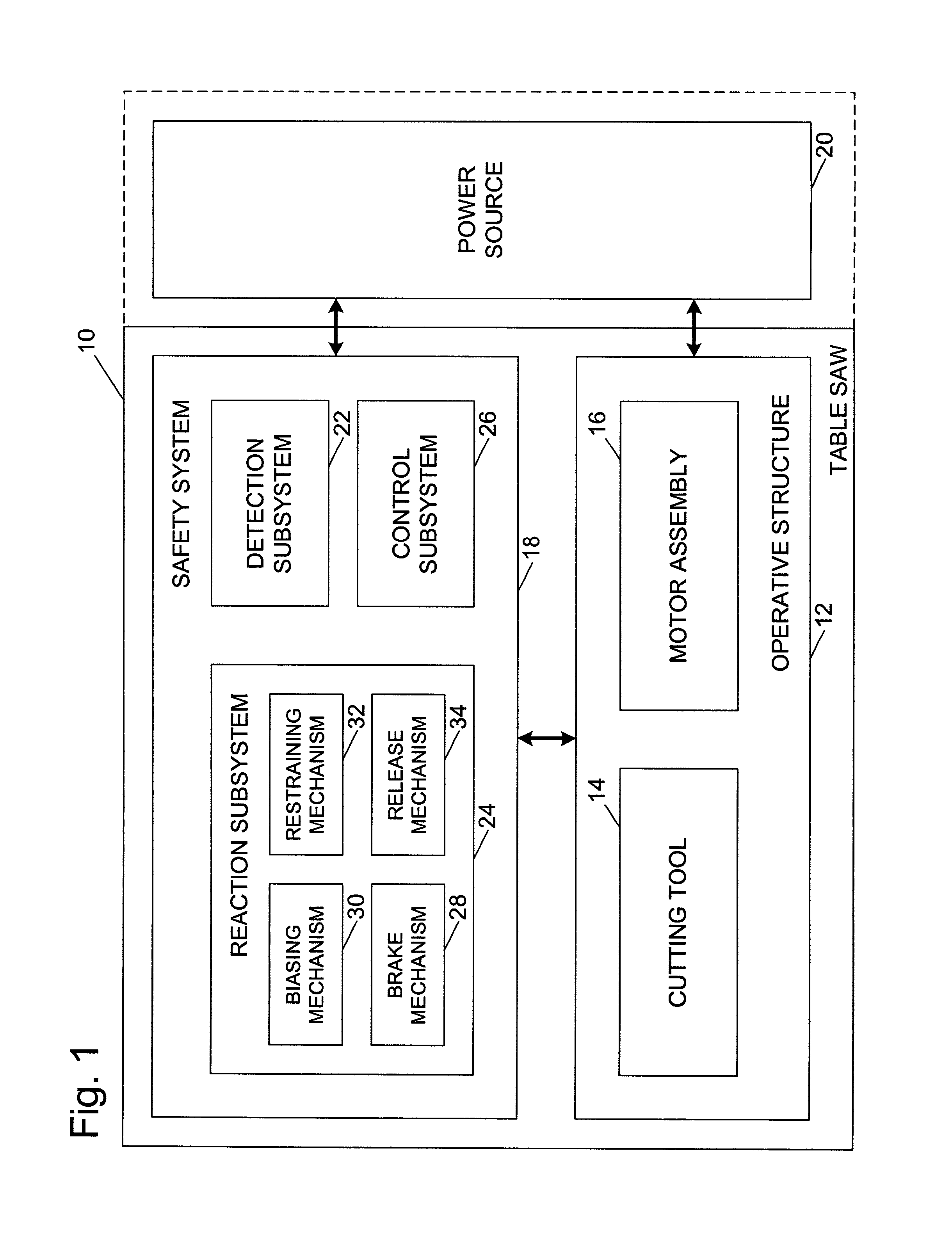

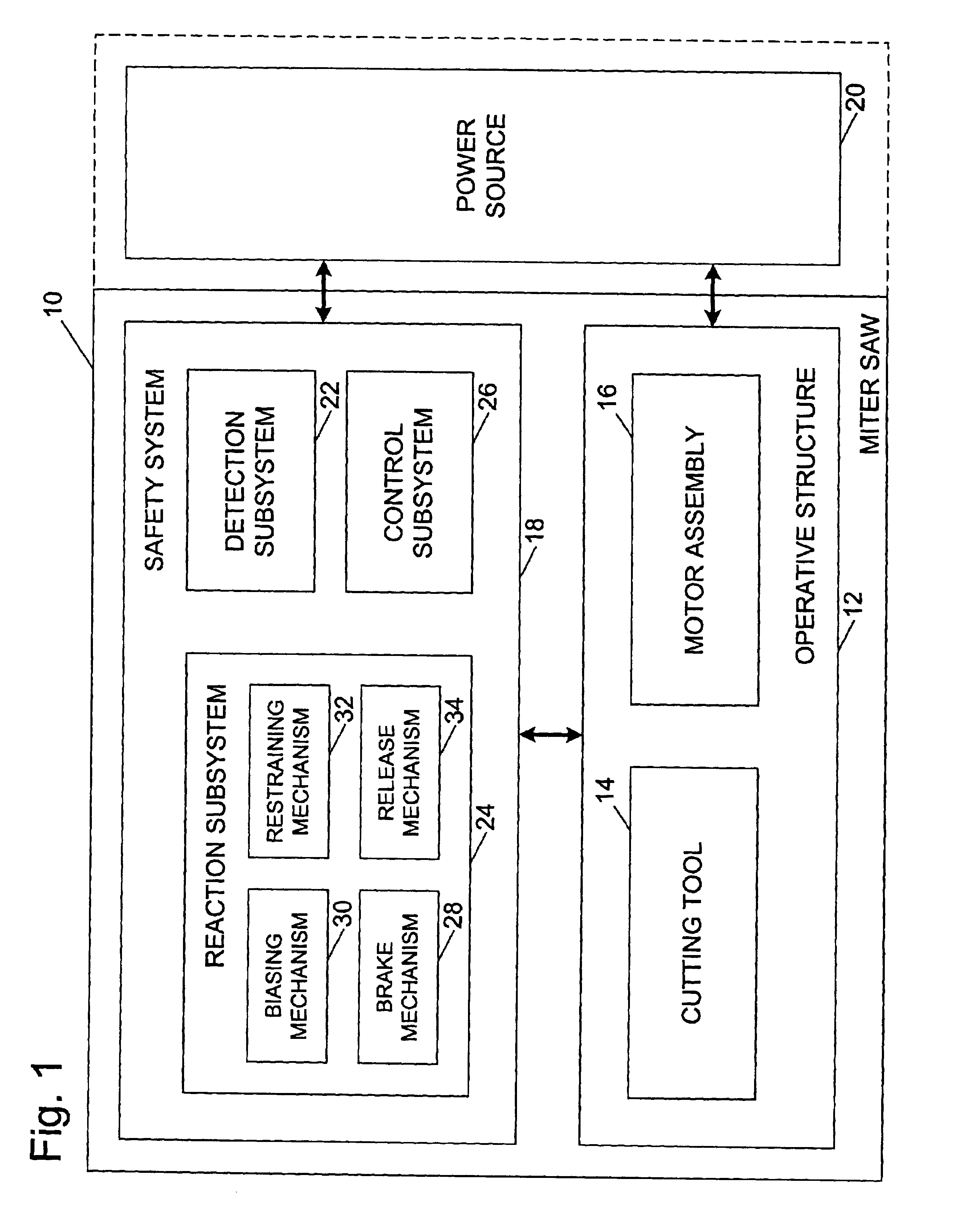

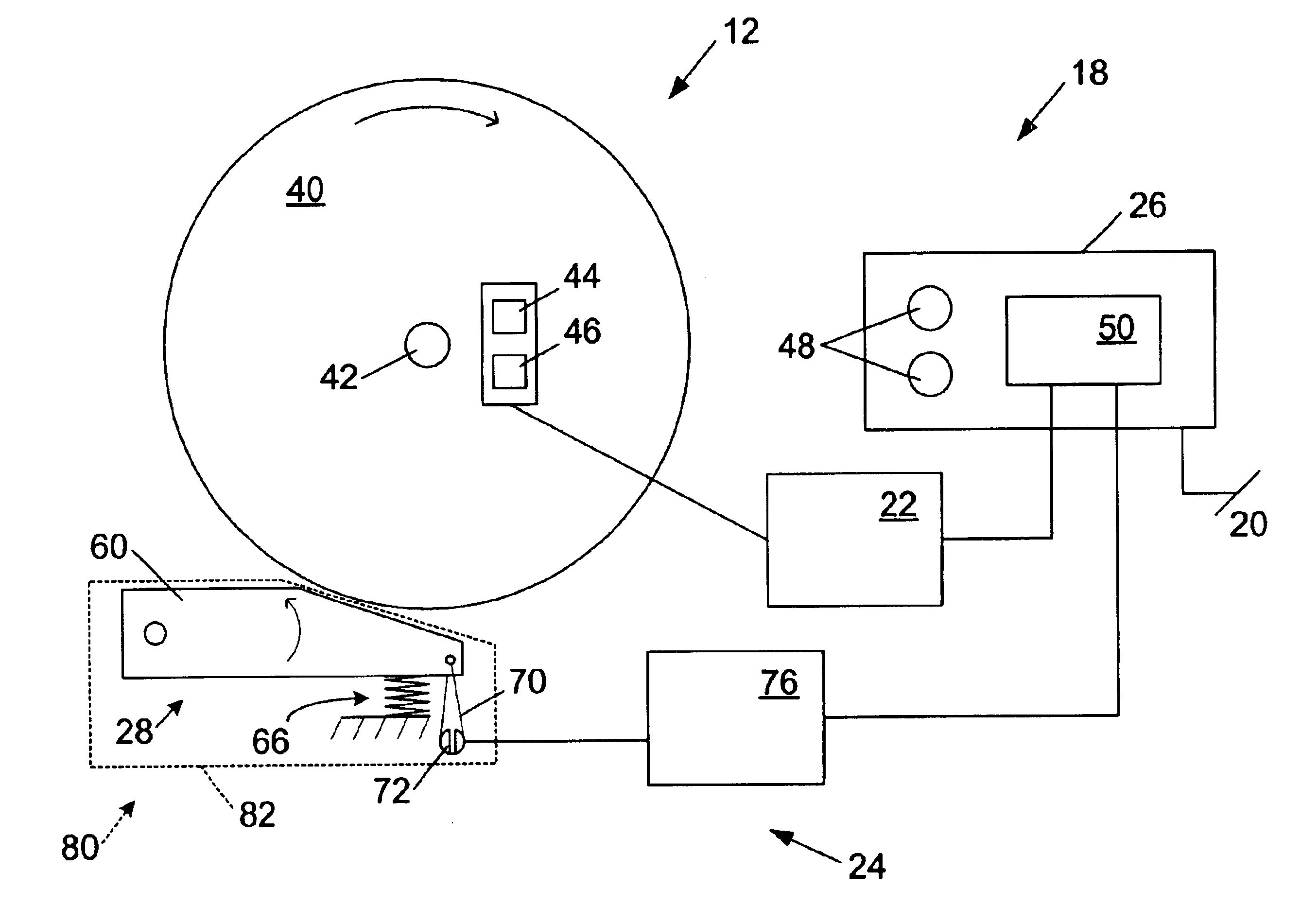

Safety systems for power equipment

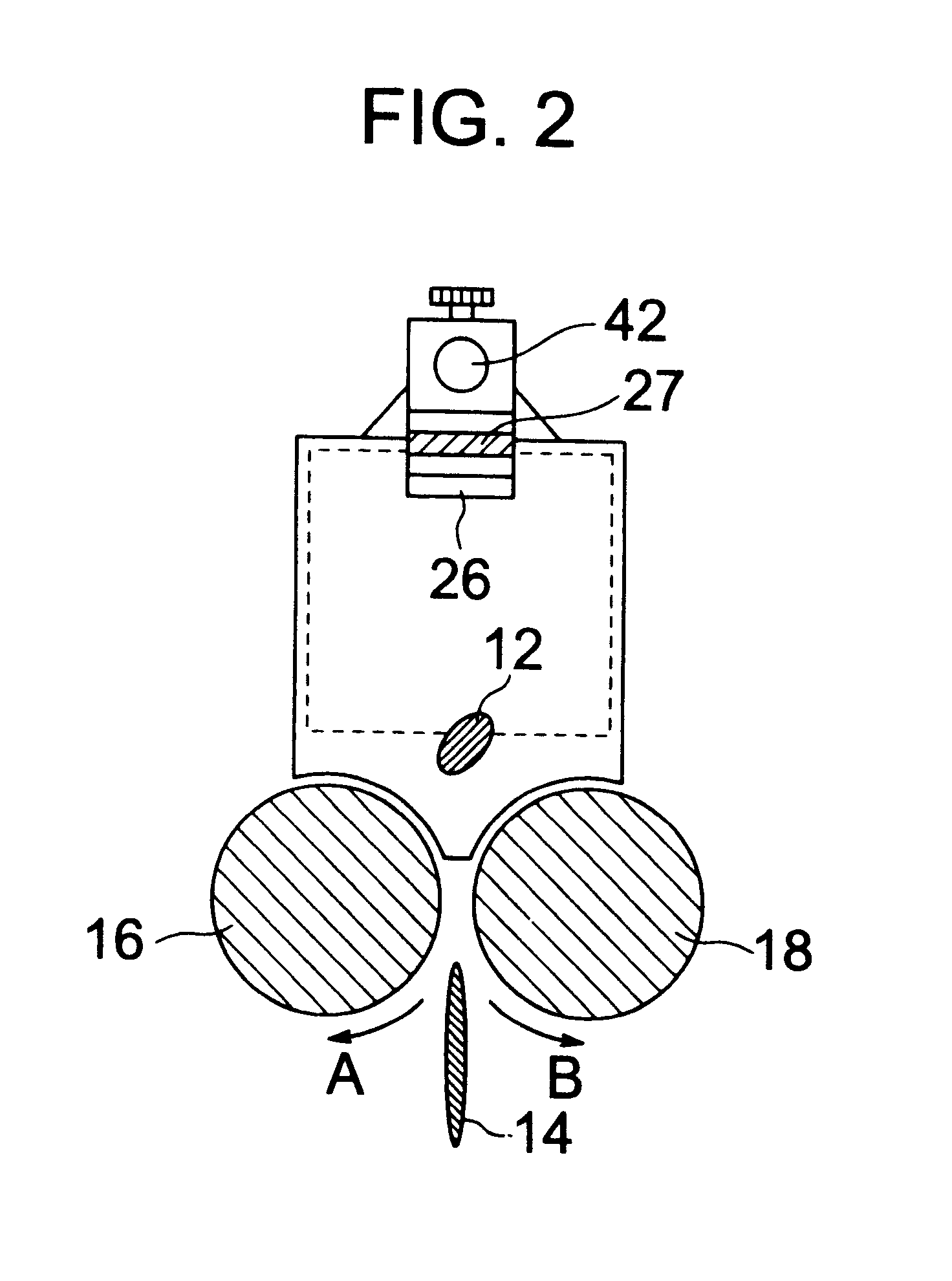

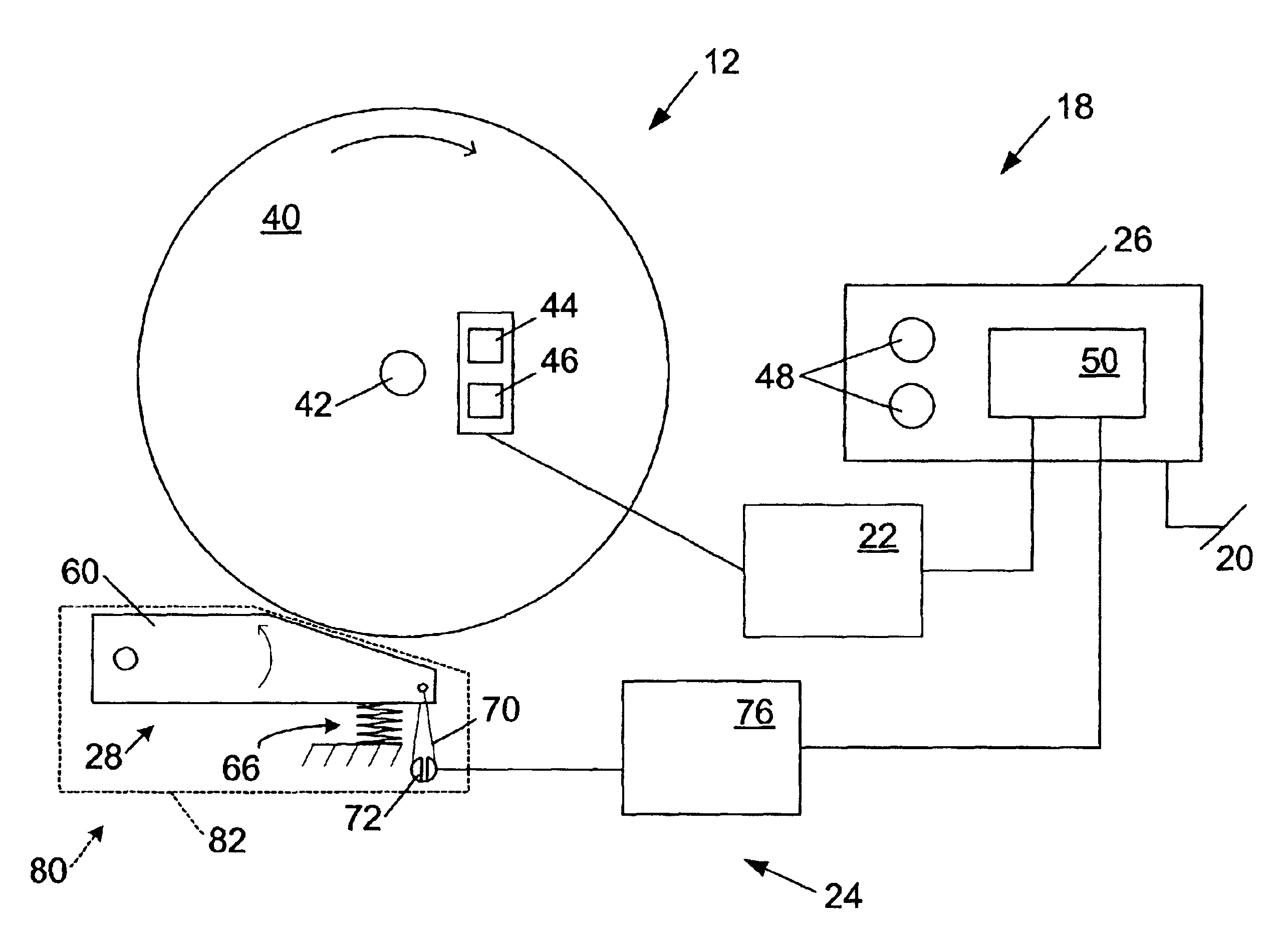

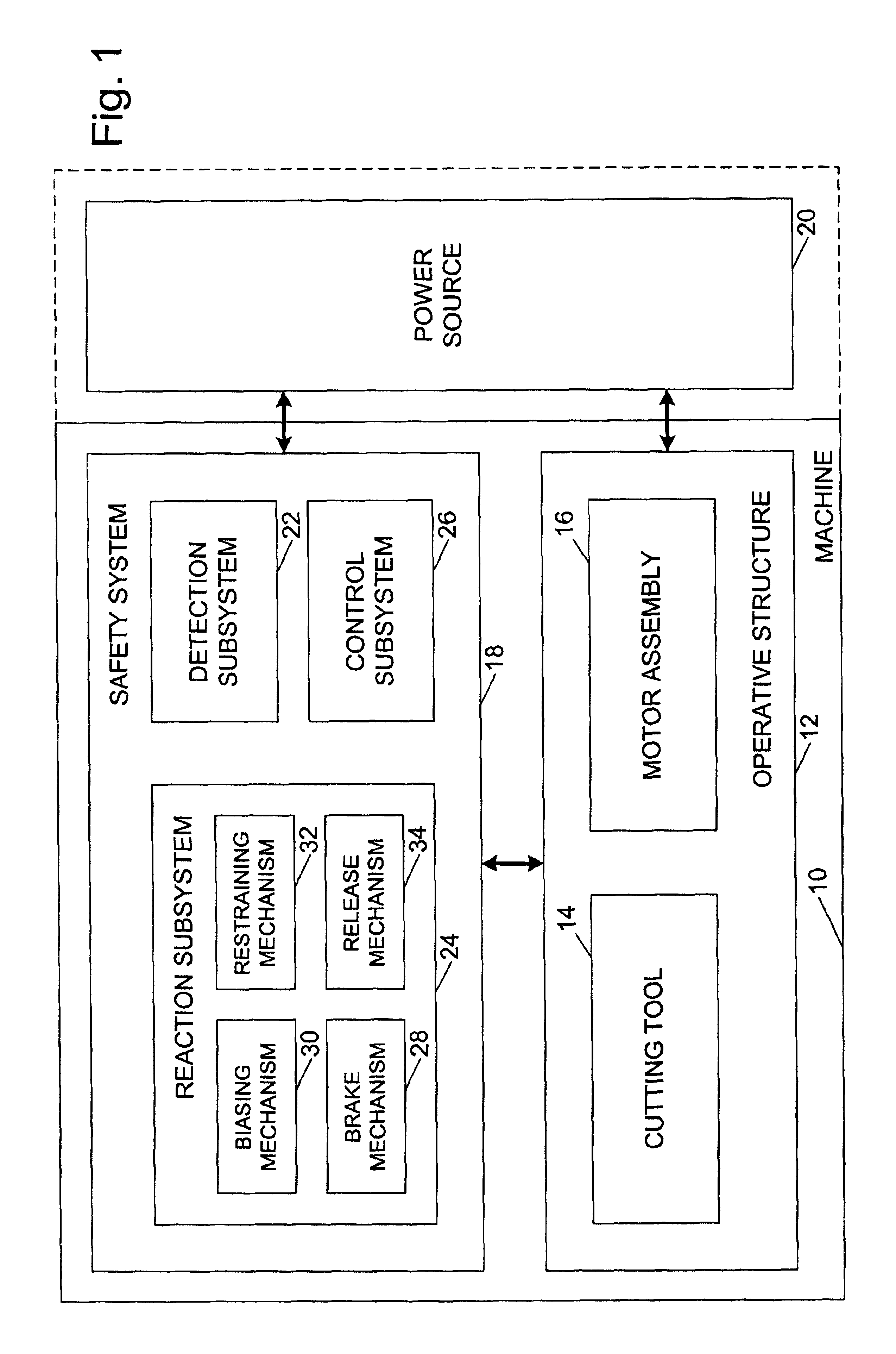

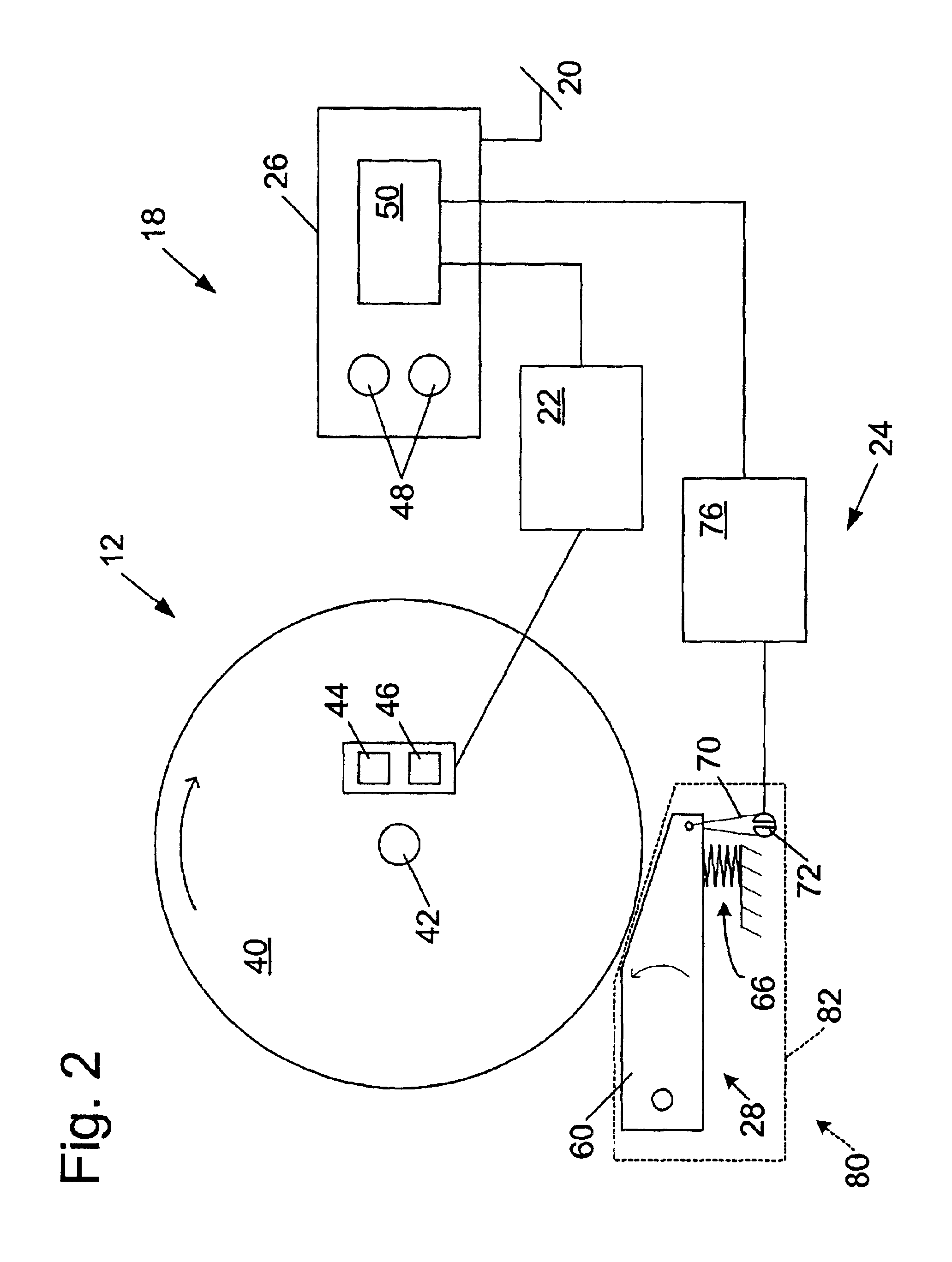

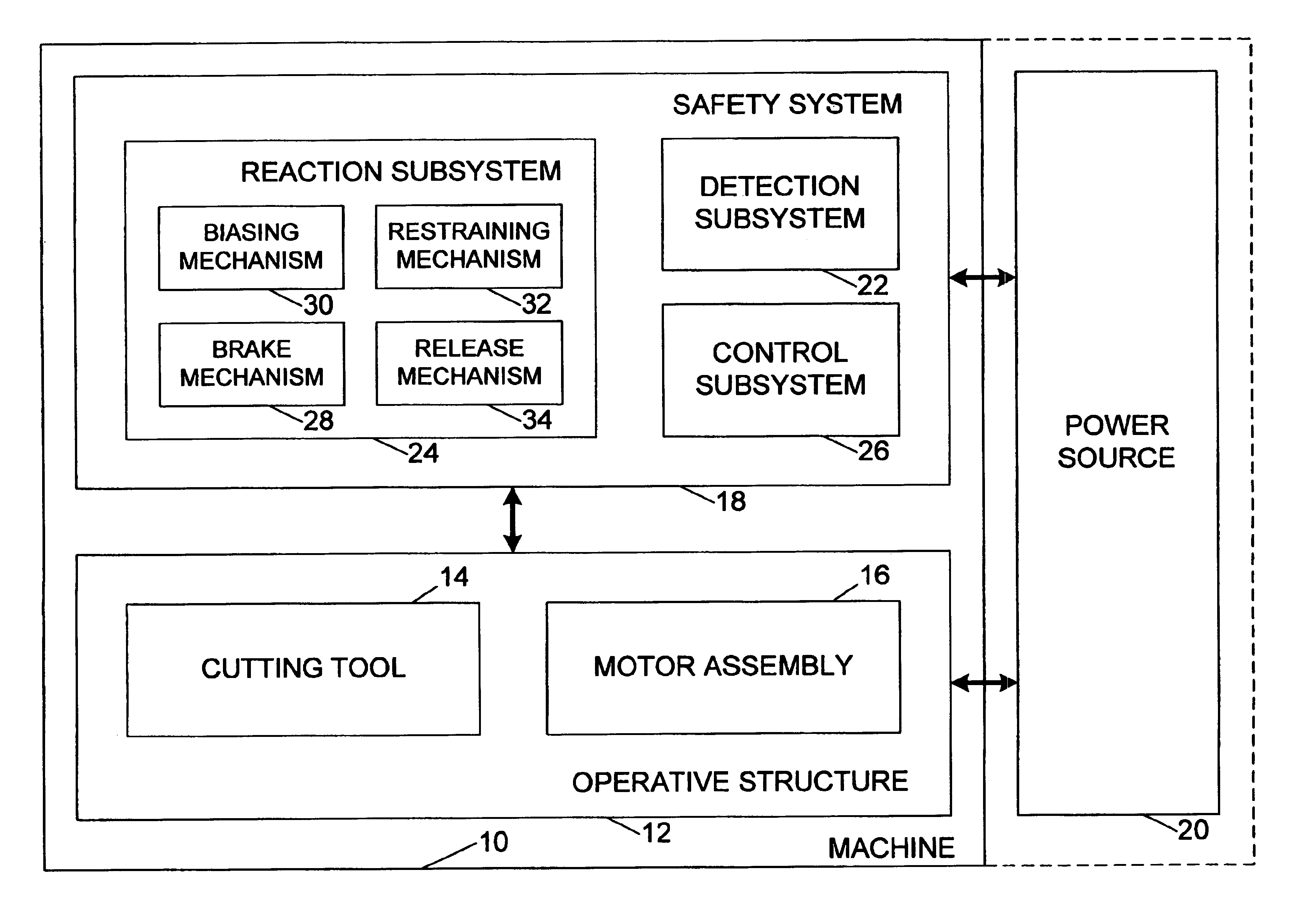

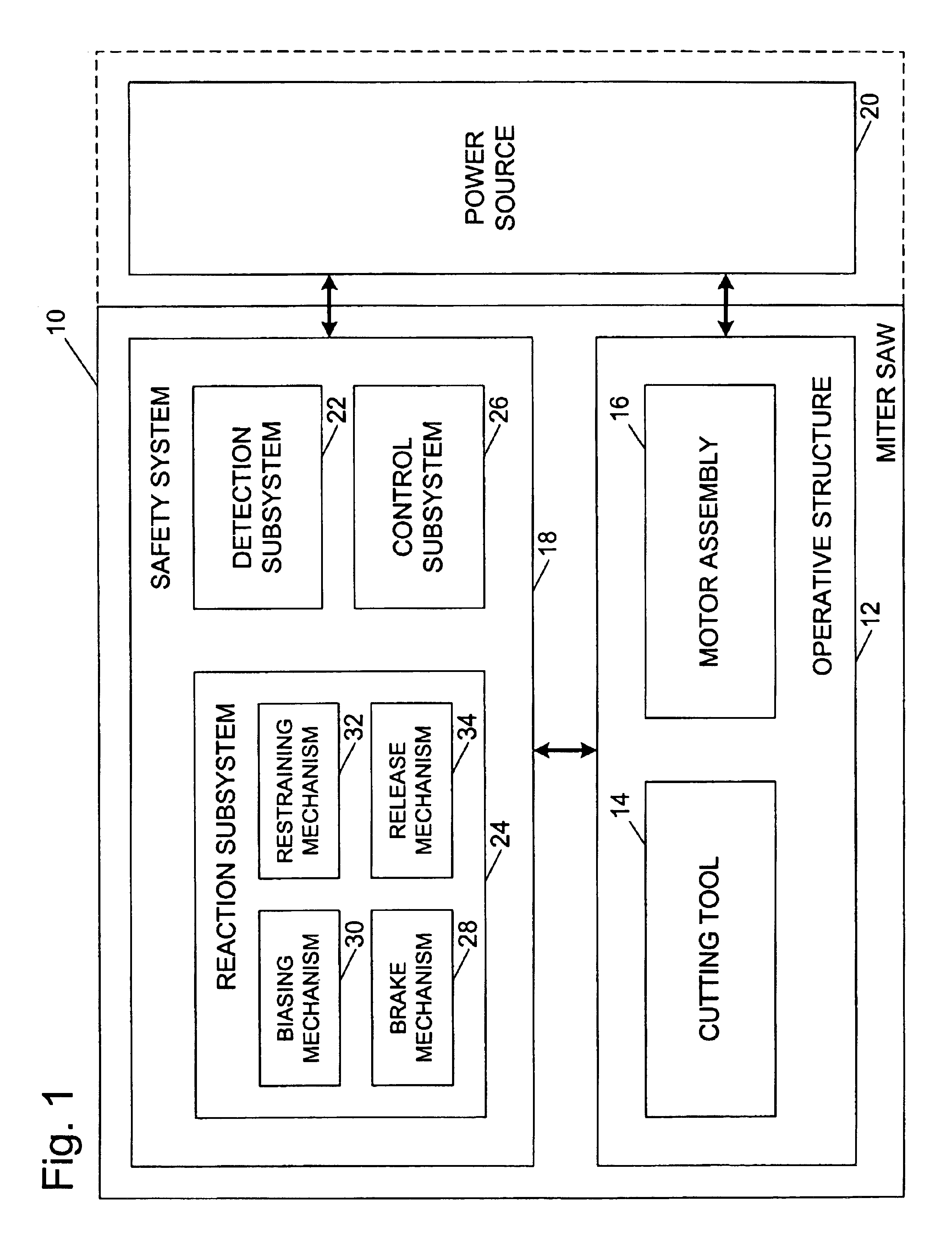

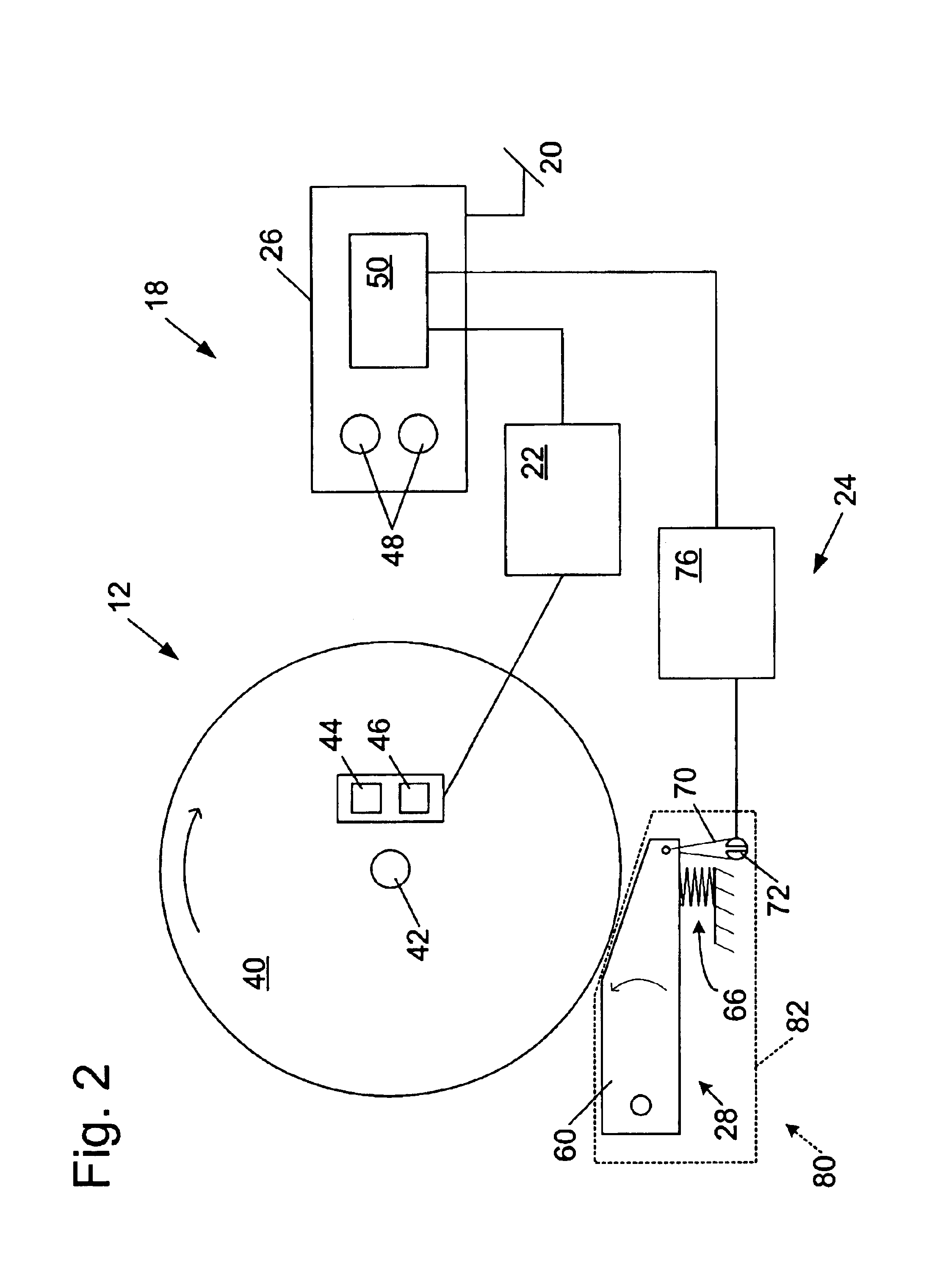

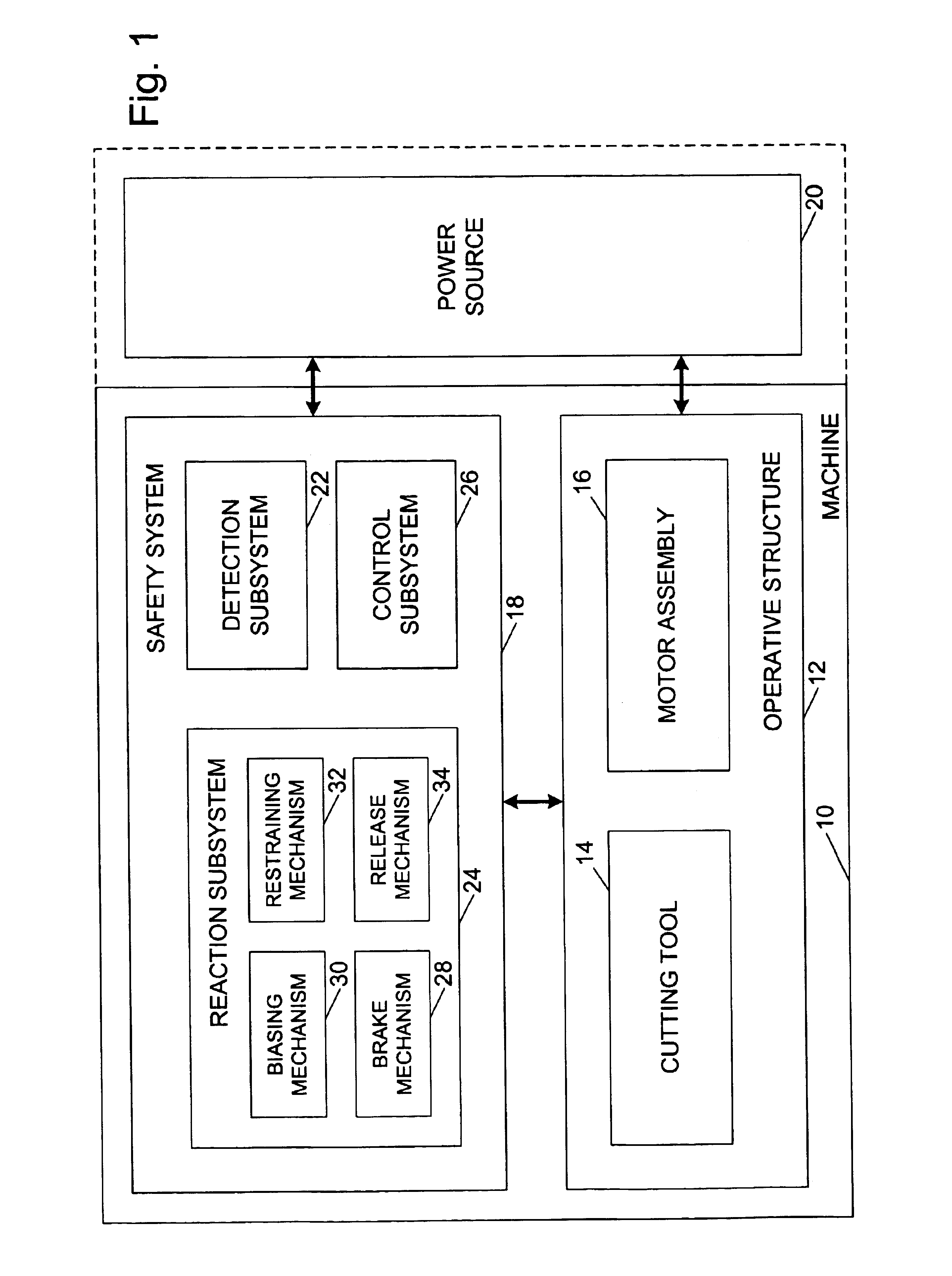

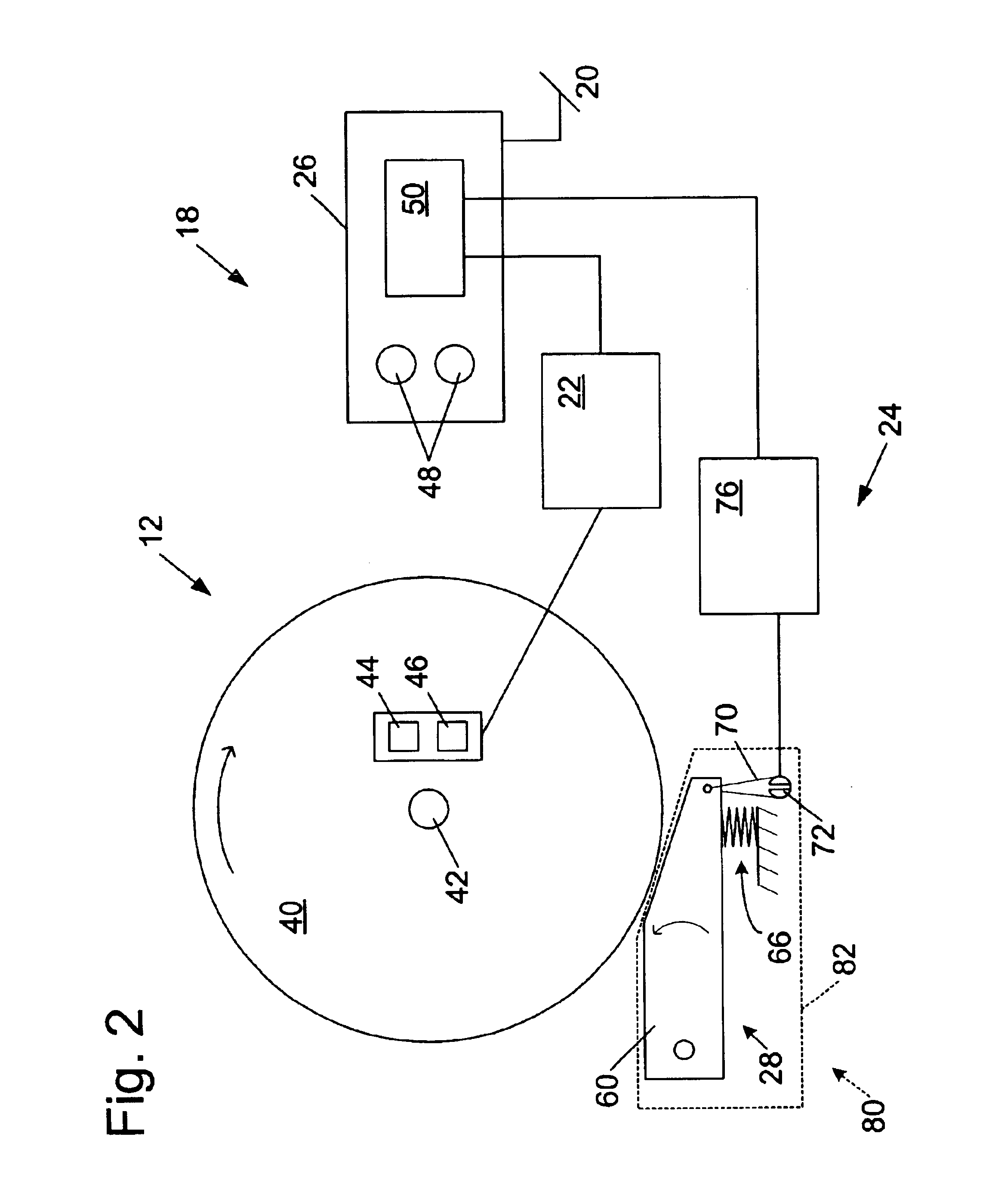

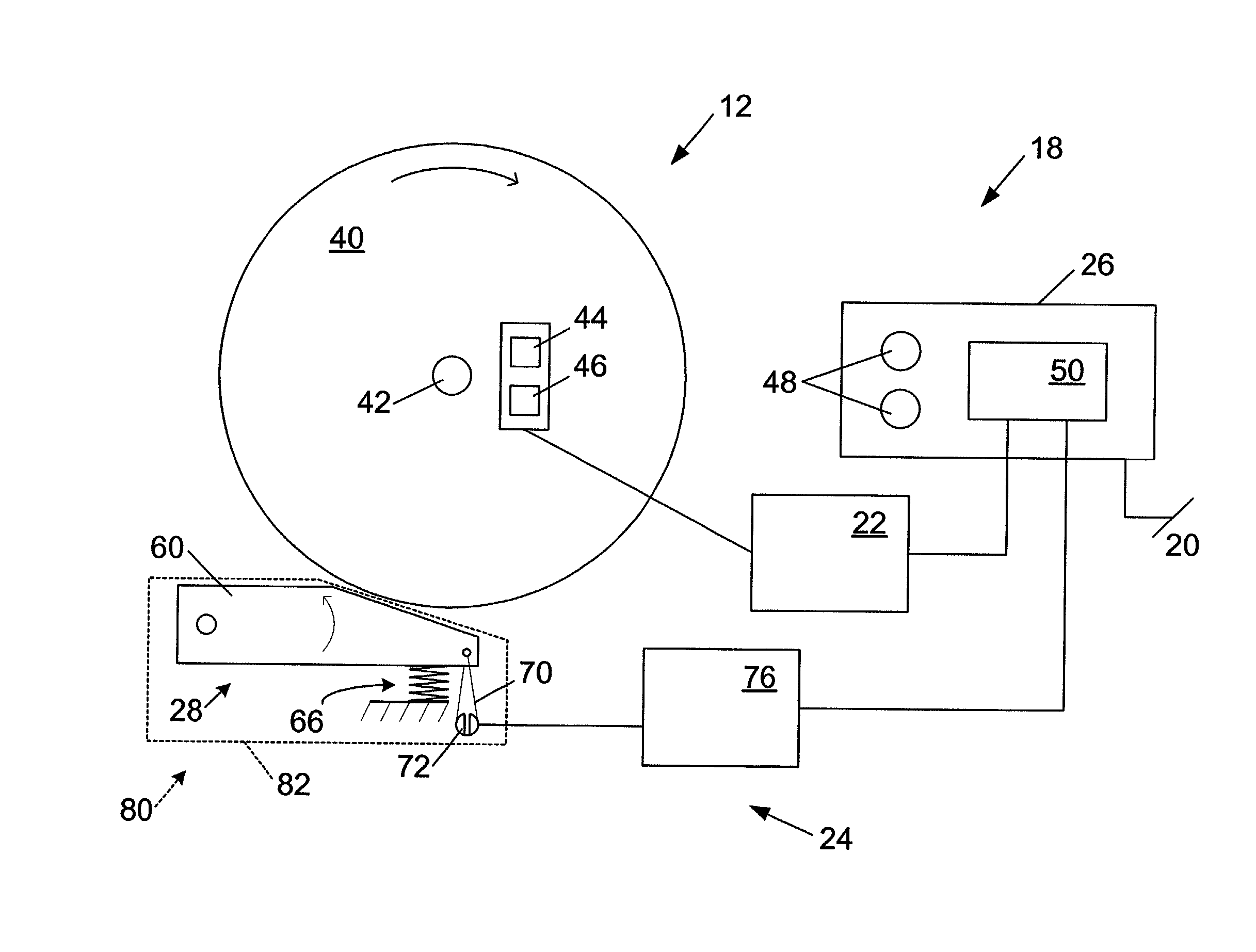

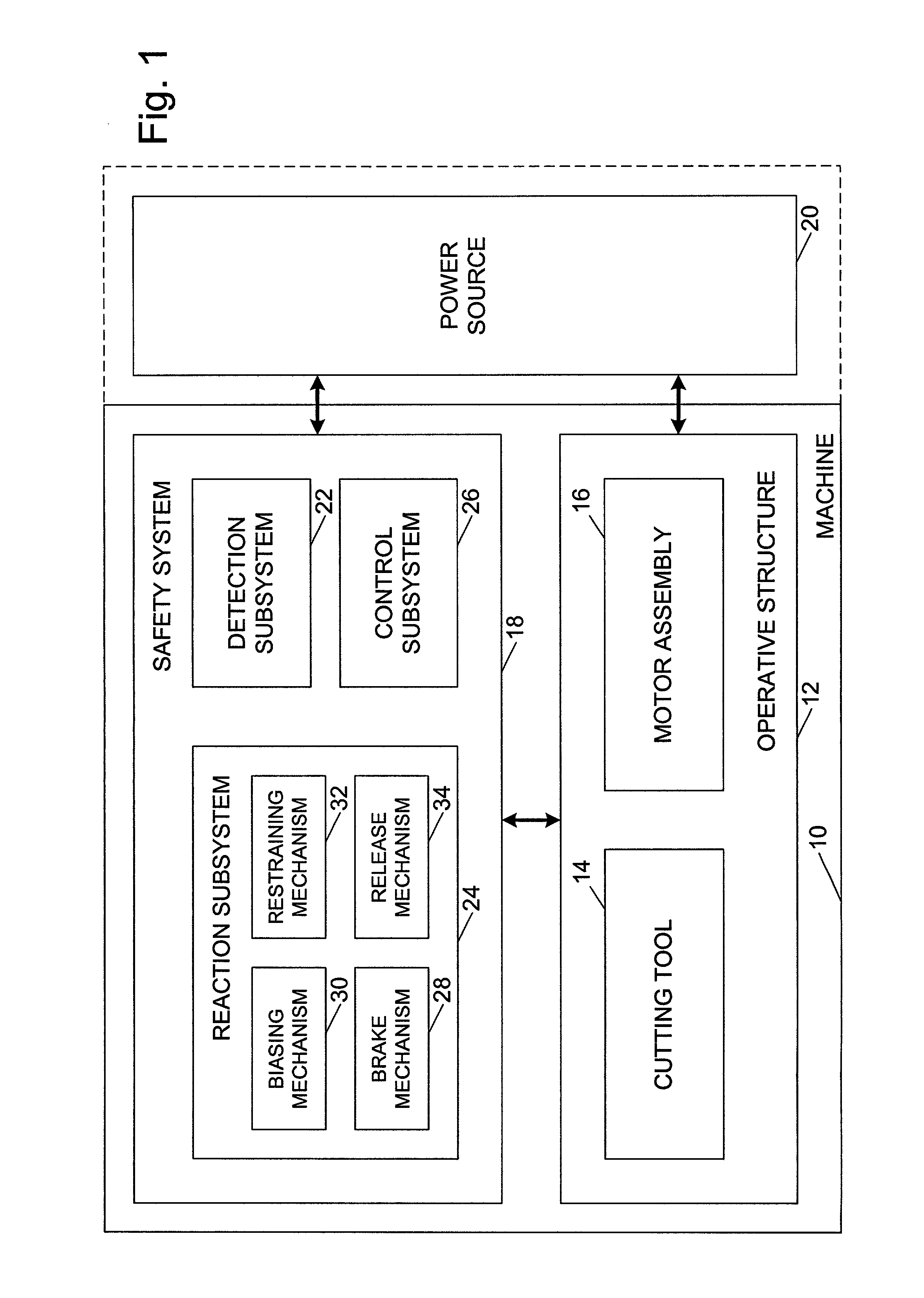

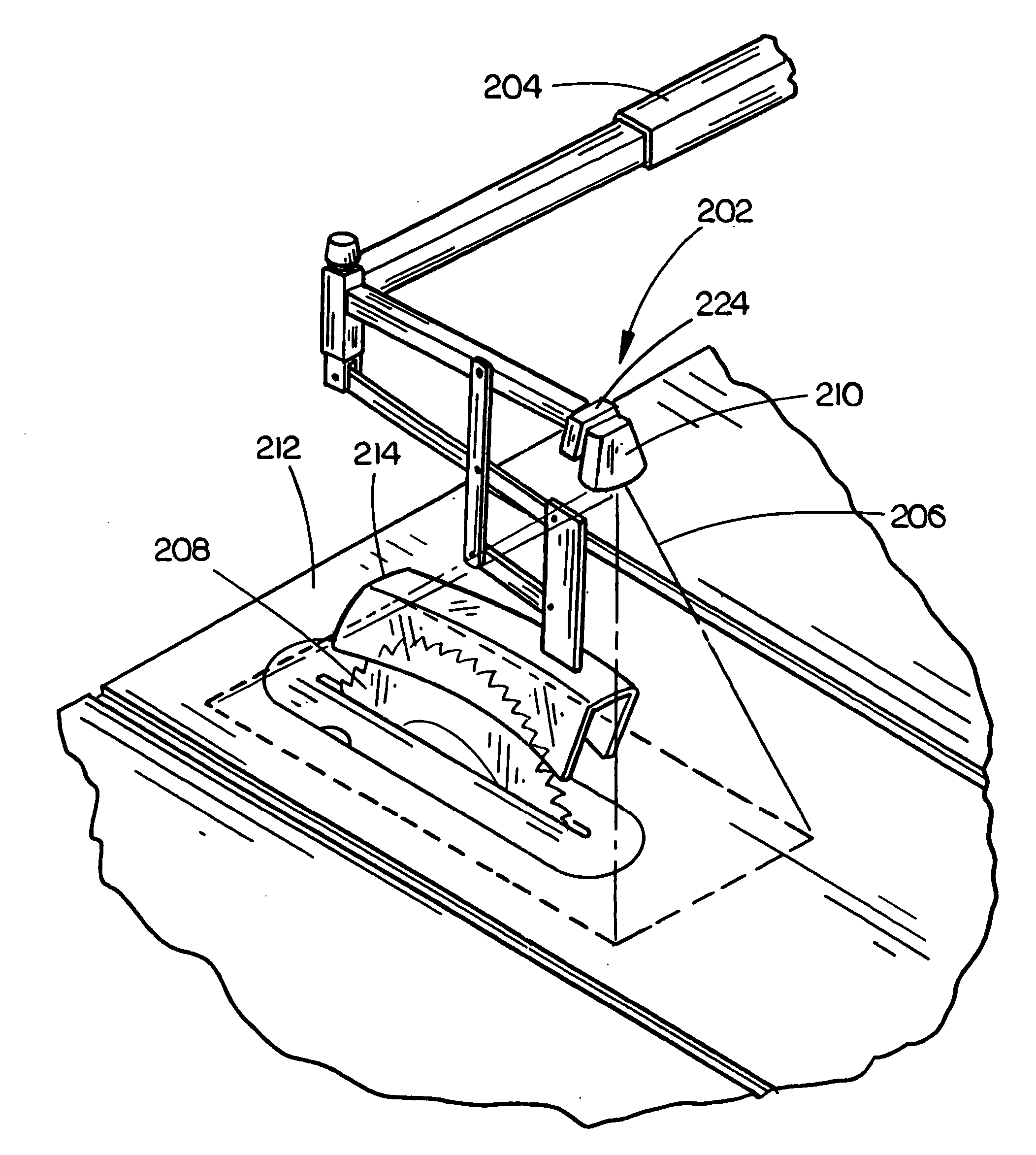

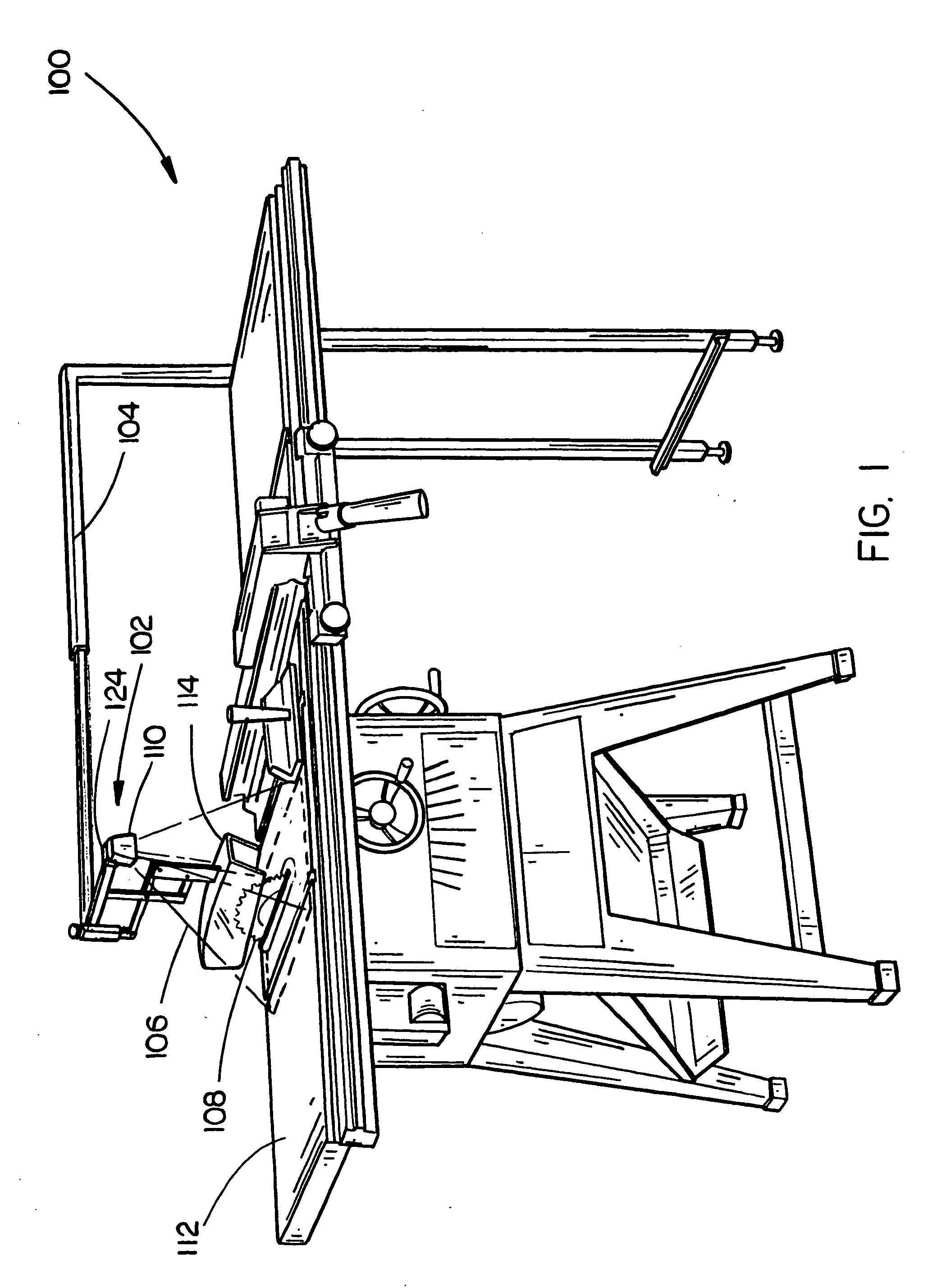

Machines with safety systems are disclosed. The machine may take the form of woodworking machines including table saws, band saws, miter saws, hand-held circular saws, pneumatic chop saws, radial-arm saws, jointers, planars, routers and shapers. The machines may include an operative structure configured to perform a task, where the operative structure includes a cutting tool adapted to move in at least one motion, and a safety system adapted to detect the occurrence of an unsafe condition between a person and the cutting tool and for mitigating the unsafe condition. The safety system may include a detection subsystem and a reaction subsystem.

Owner:SAWSTOP HLDG LLC

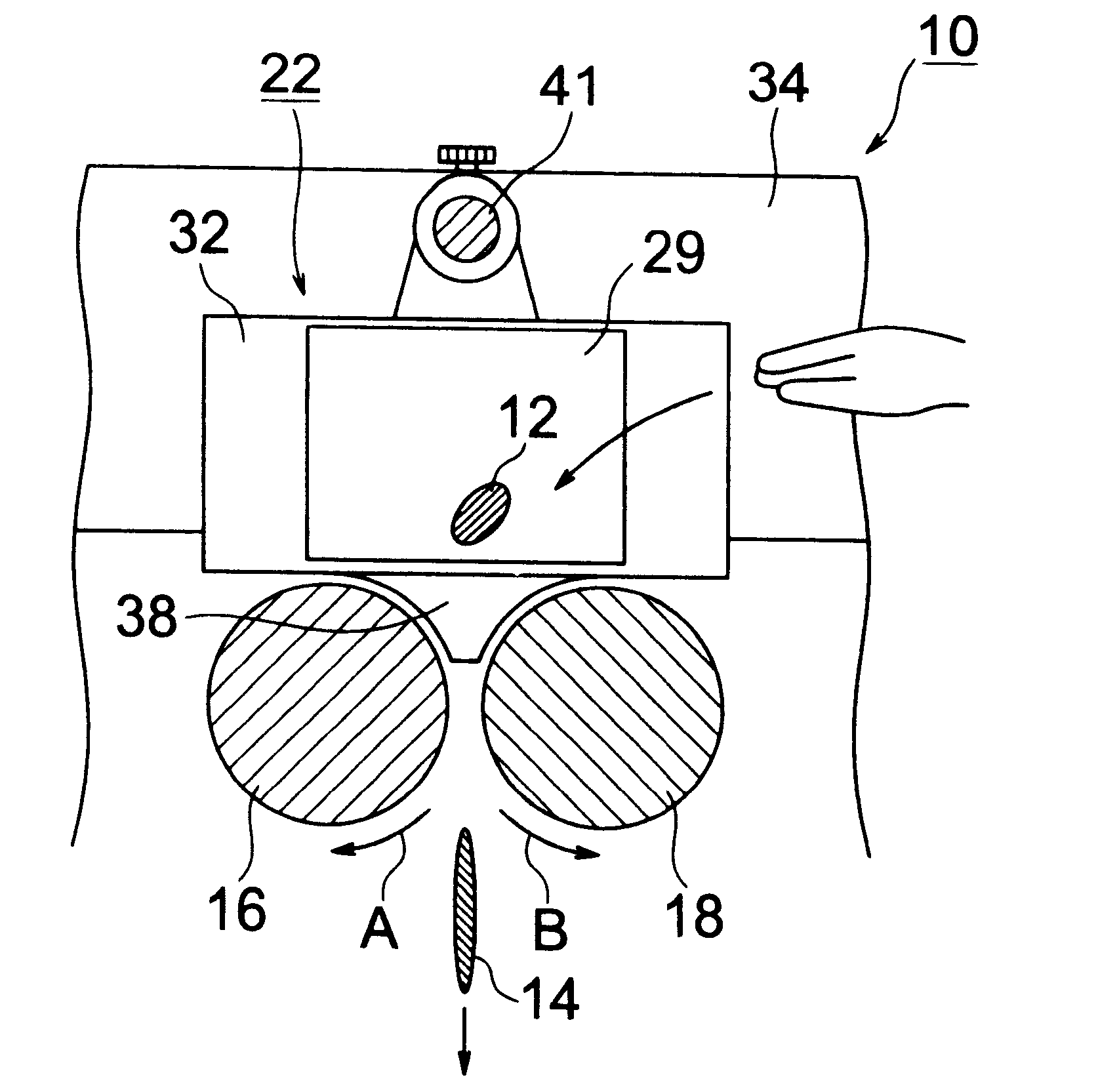

Safety detection and protection system for power tools

InactiveUS6922153B2Quick stopRule out the possibilityDC motor speed/torque controlEmergency protective circuit arrangementsPower toolProtection system

A detection system for detecting a dangerous condition for an operator using a power tool of the type which has an exposed blade relative to a work surface and a protection system for minimizing, if not eliminating the possibility of a user being injured by contacting the blade. In one preferred embodiment of the present invention, a proximity detection system is capable of detecting the presence of a user near the blade of a table saw and a protection system that can either retract the blade below the work surface of the table saw or terminate the drive torque to the blade which can result in rapid stopping of the saw blade by a work piece that is being cut.

Owner:CREDO TECH CORP +1

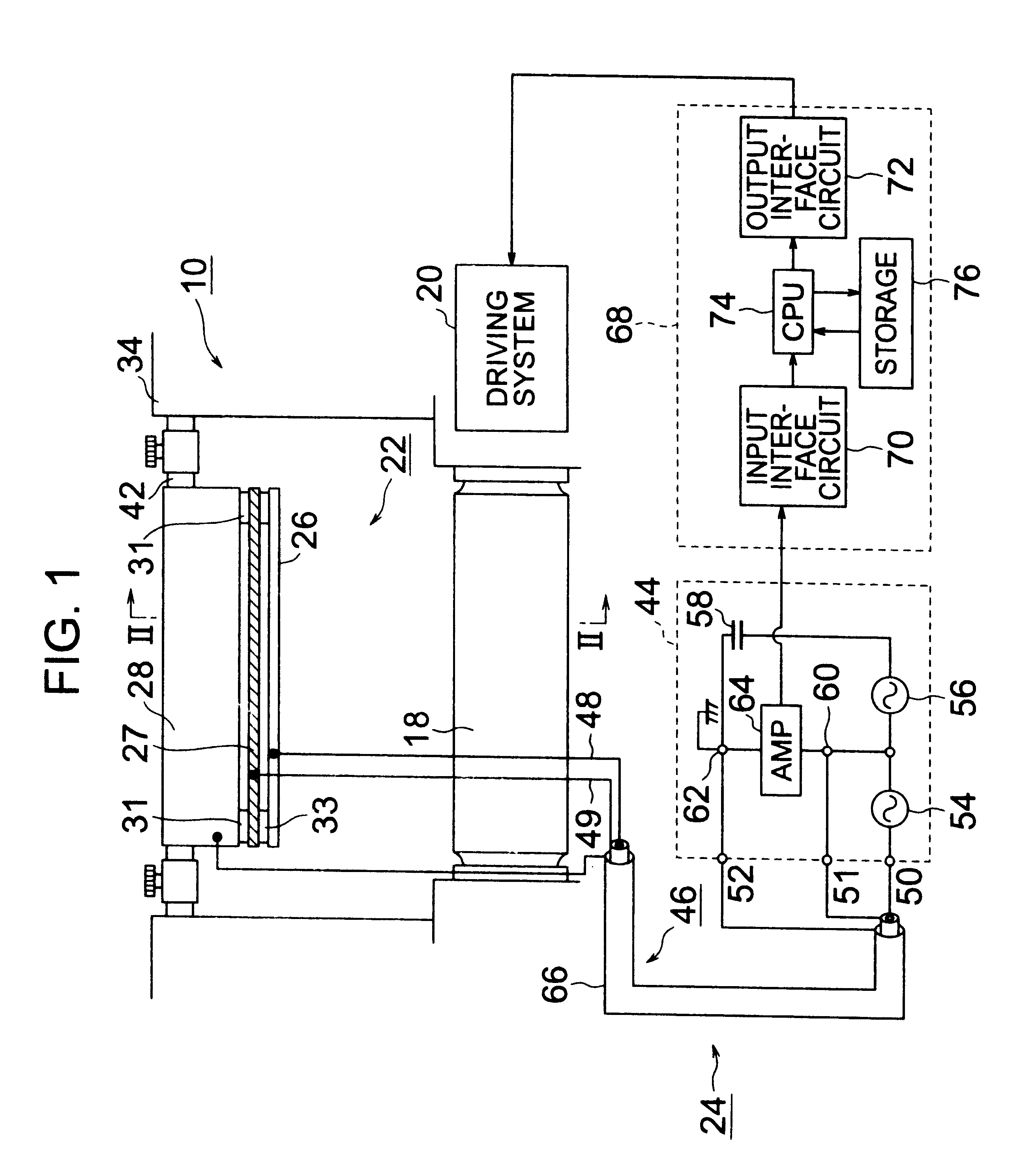

Sensor apparatus and safety apparatus for protecting approach to machines

InactiveUS6376939B1Improve securityPossibility is mitigated and suppressedBoards/switchyards circuit arrangementsEmergency protective arrangement detailsCapacitanceElectricity

A sensor apparatus and a safety apparatus which can ensure significantly enhanced safety by monitoring constantly whether the sensor apparatus is operating normally. An auxiliary electrode plate of a small area is disposed in parallel and in opposition to an electrode plate with a short distance therefrom. A switching element is turned on every second for a period of milliseconds repetitively. When the switching element is turned on under the control of a central processing unit, the auxiliary electrode plate is connected to the ground potential, as a result of which a capacitance DELTAC effective between the auxiliary electrode plate and the electrode plate is electrically connected in parallel with a capacitor C0 effective between the electrode plate and a machine component, resulting in that the capacitance C0 is increased by a proportion corresponding to the capacitance DELTAC. Consequently, change of the capacitance C0 comparable to that brought about upon detection of the human body takes place, whereby a substantially similar detection signal as the human body detection signal is made available. On the basis of this detection signal, it is possible to monitor whether or not the sensor apparatus is operating normally.

Owner:SUMITOMO CHEM CO LTD

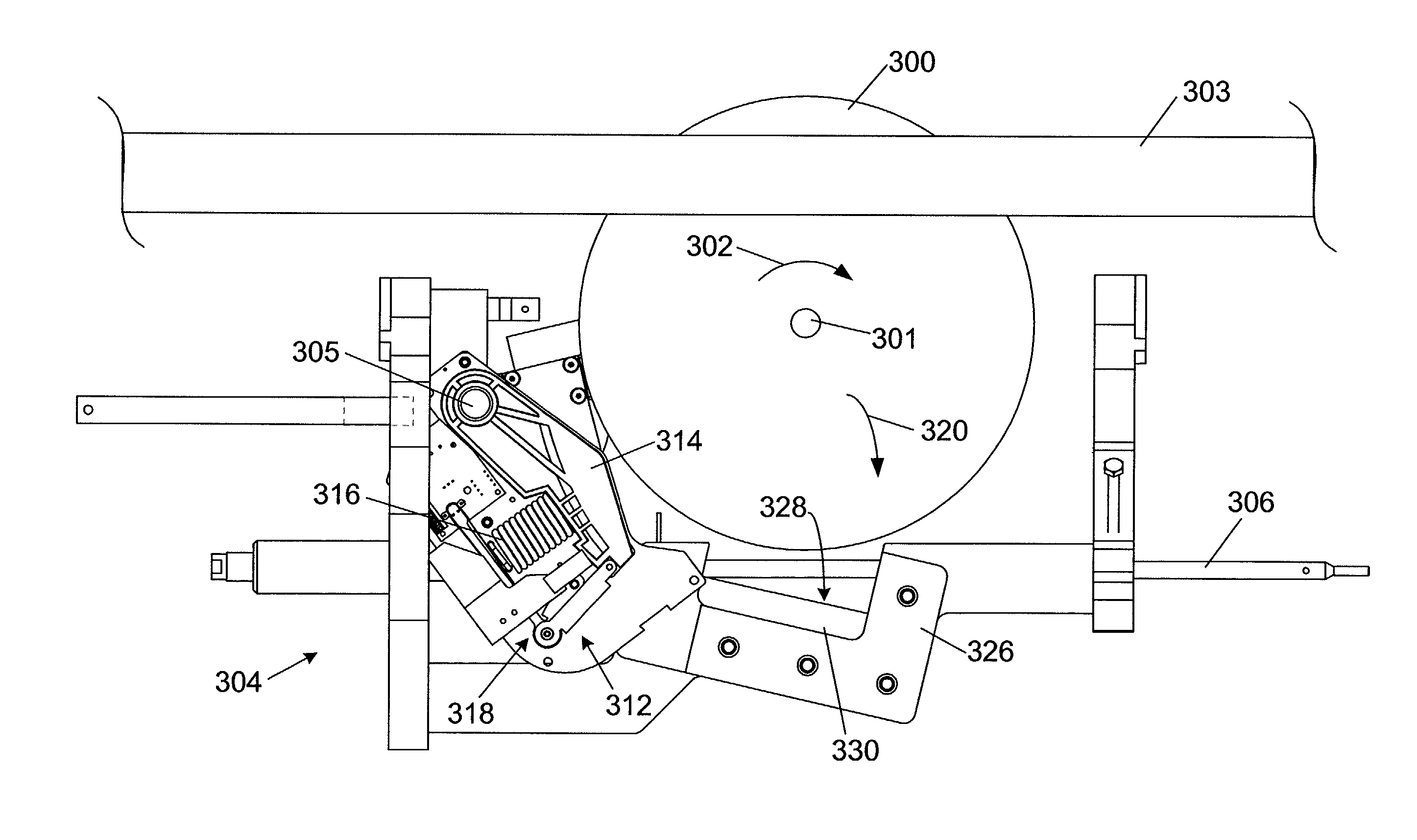

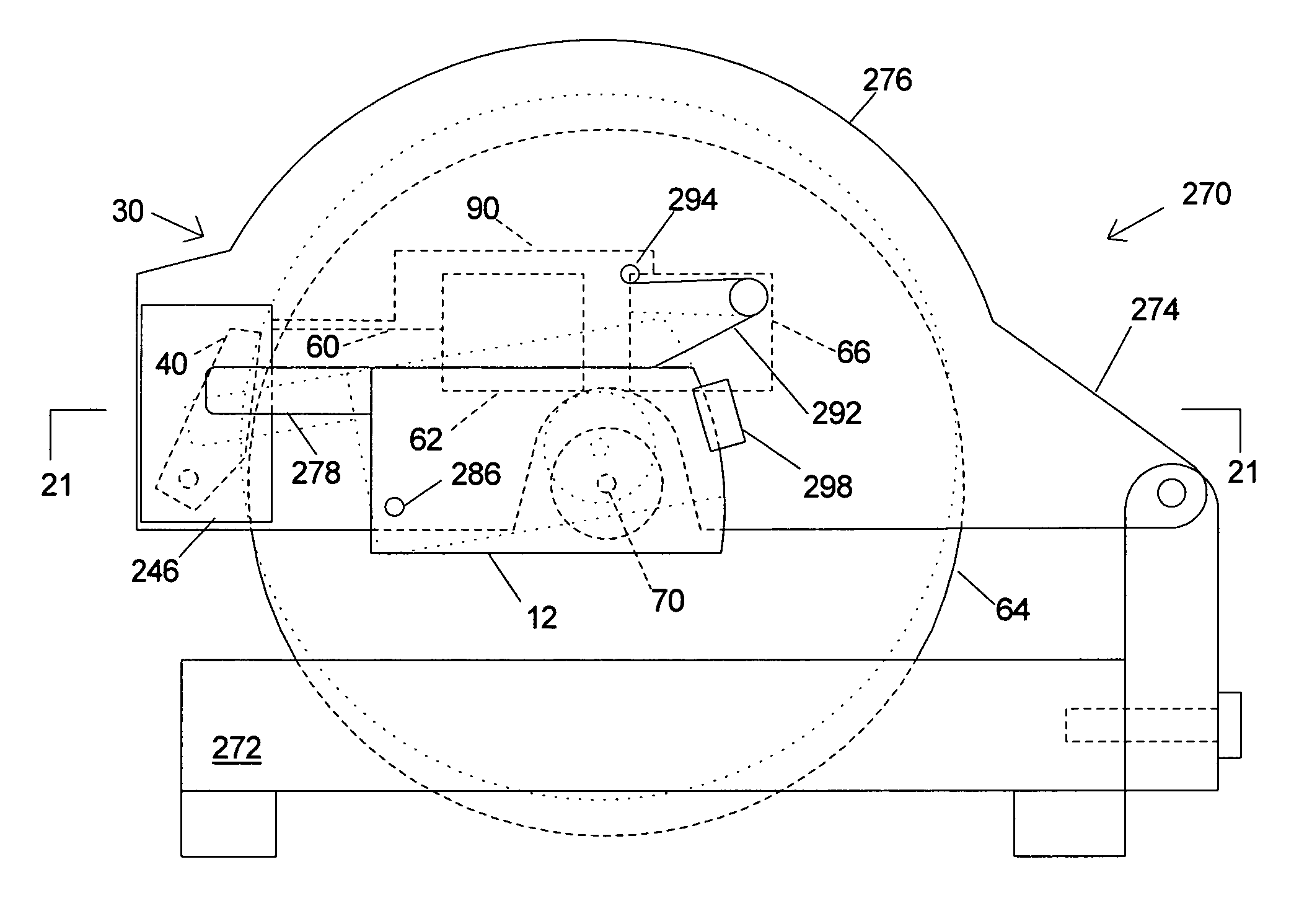

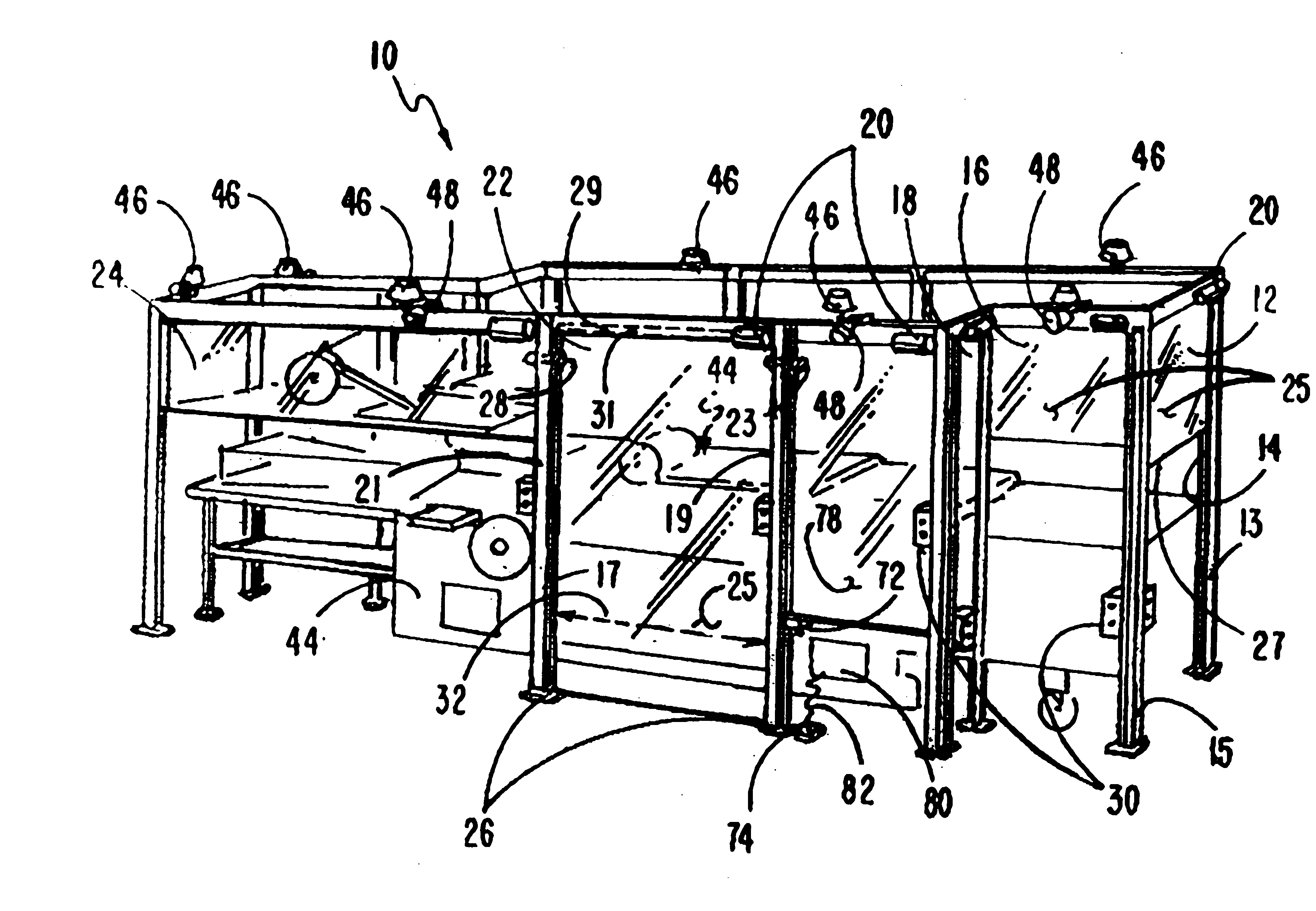

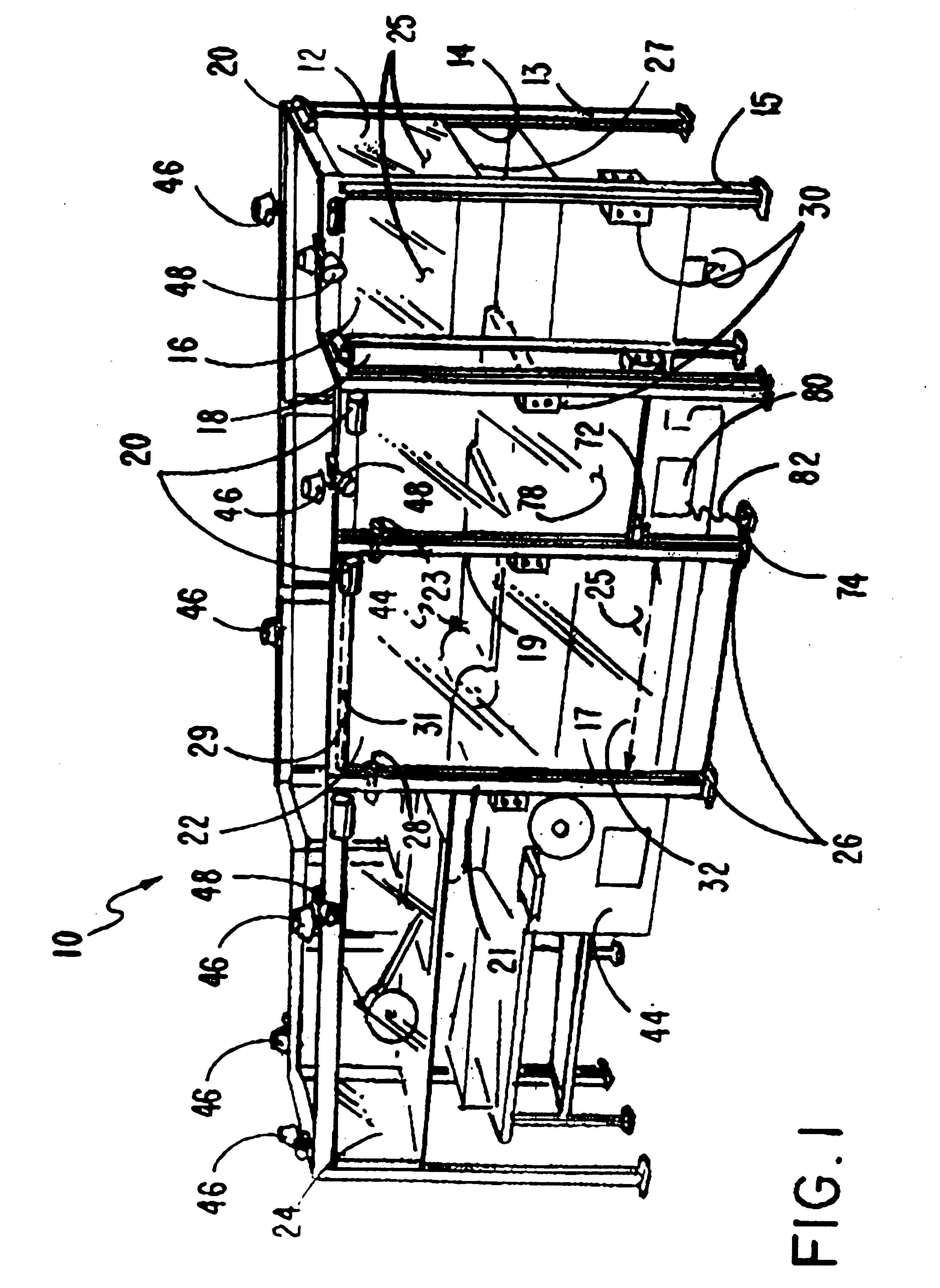

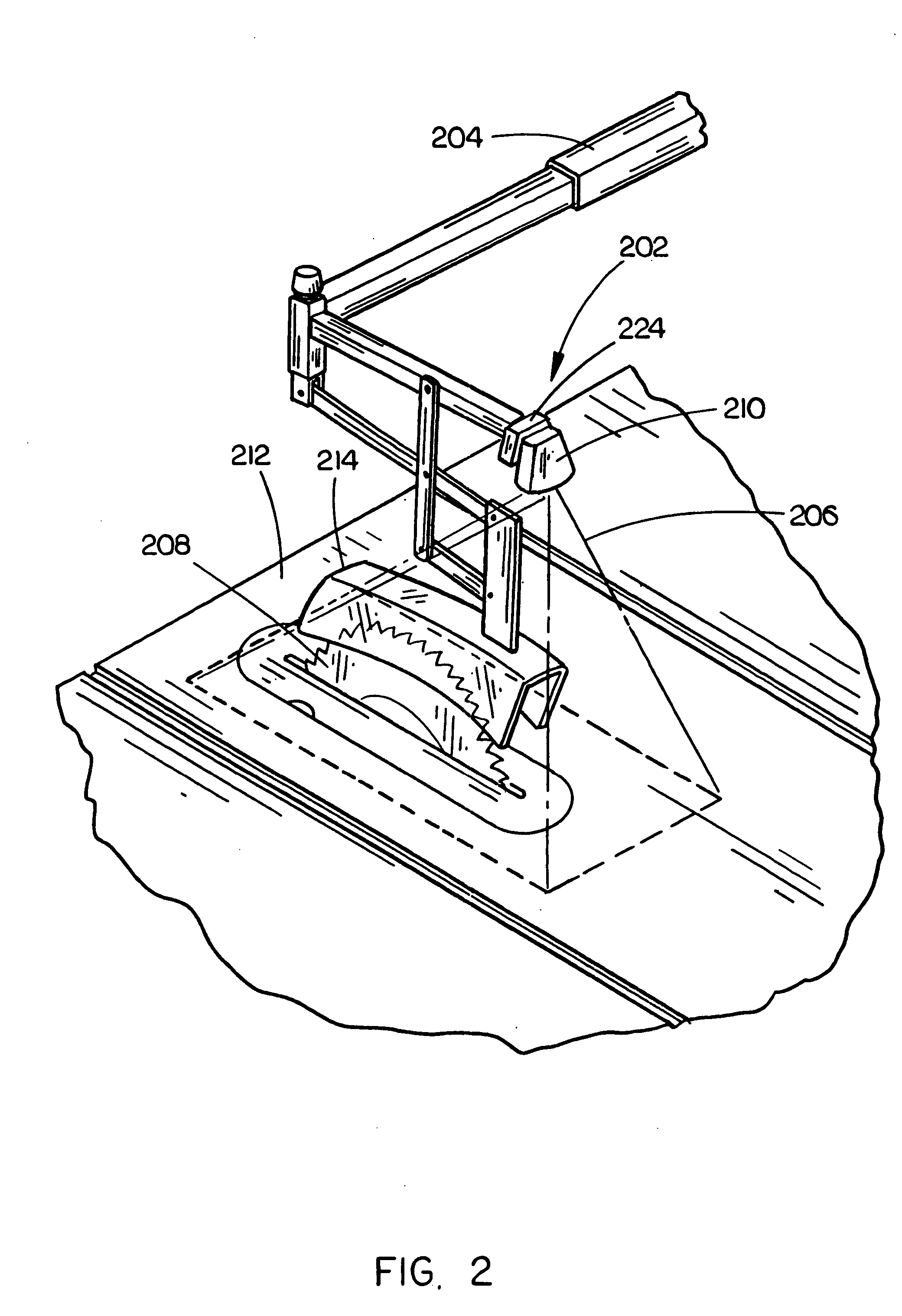

Brake positioning system

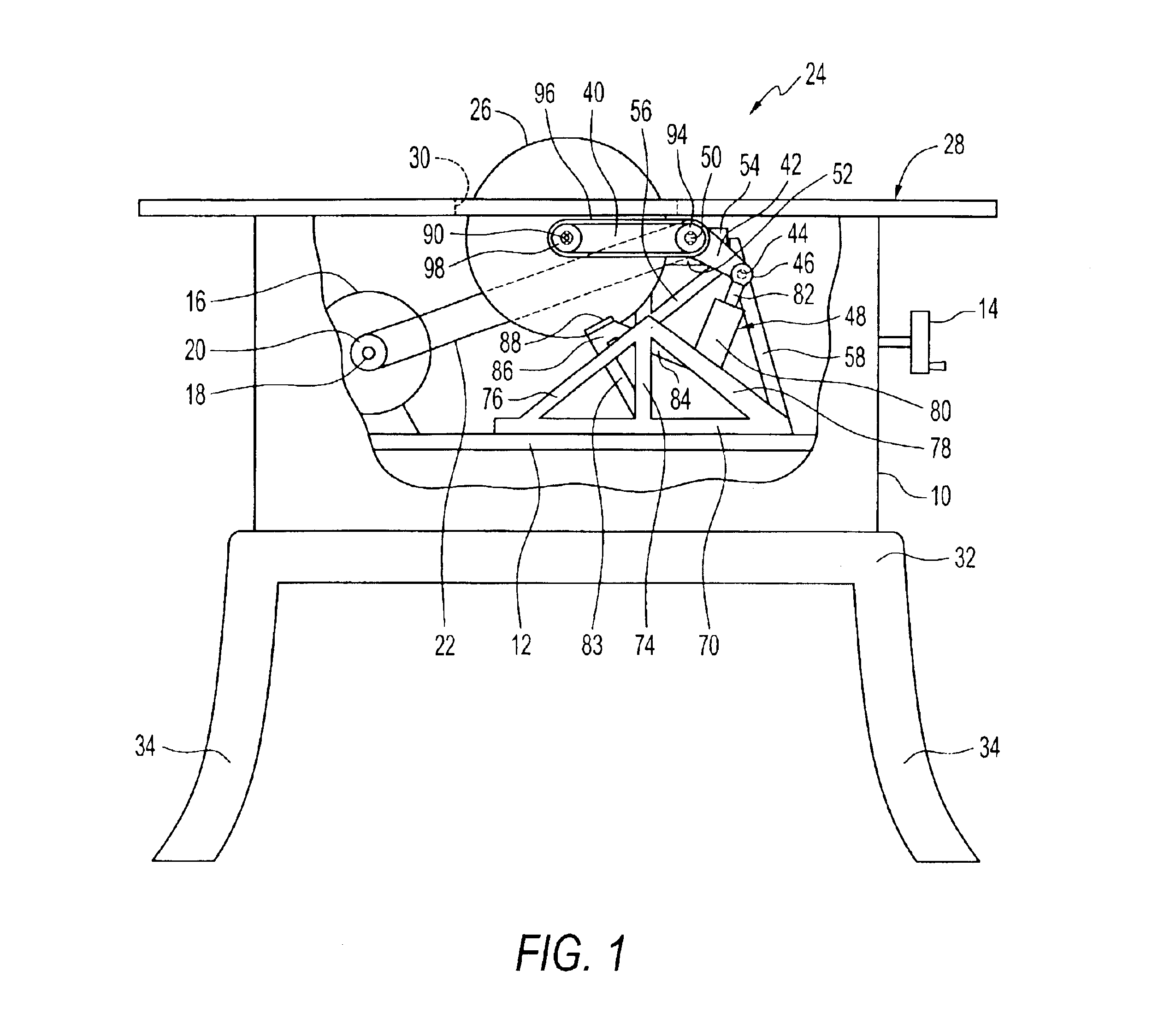

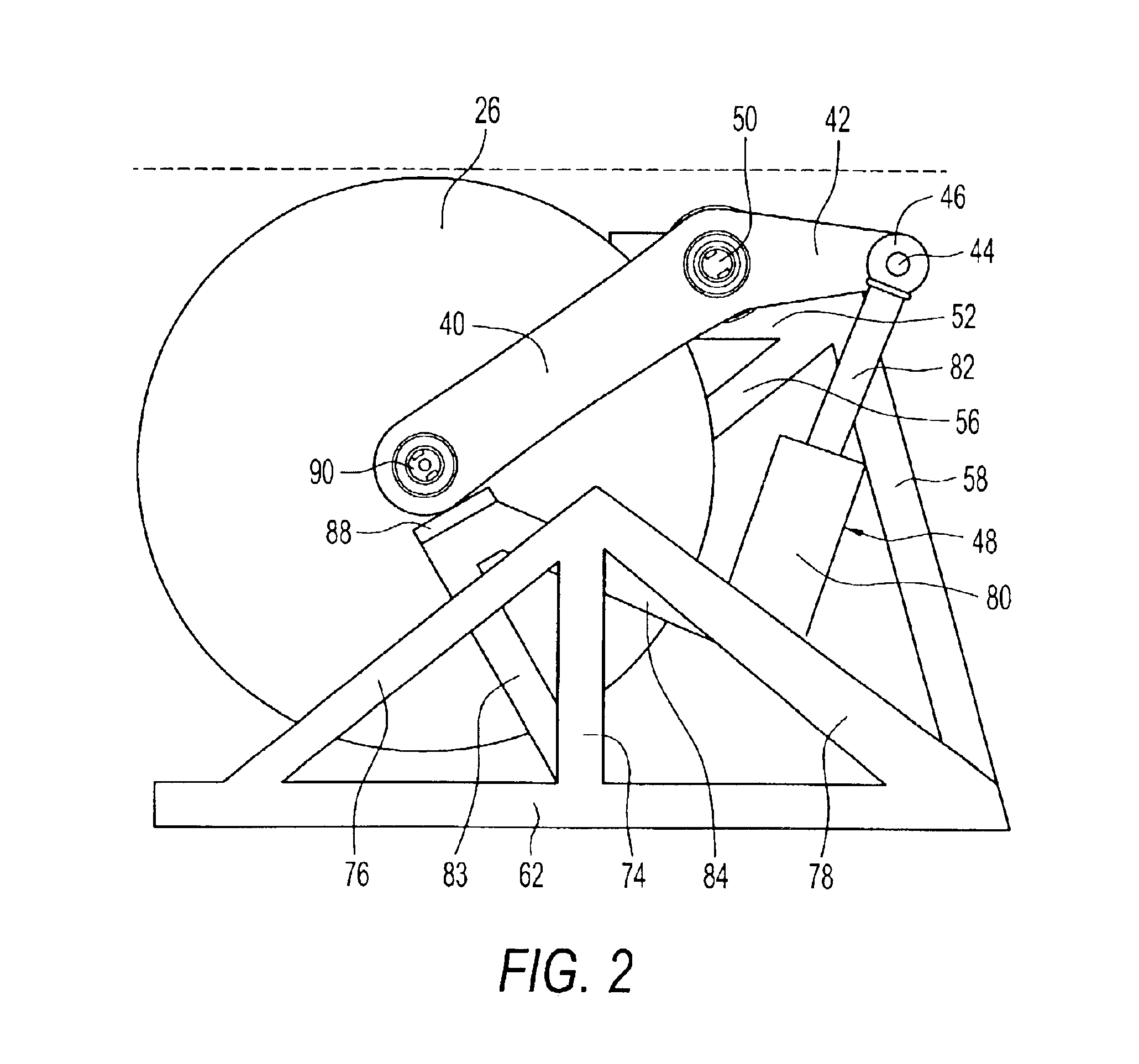

InactiveUS6857345B2Multi-purpose machinesEngineering safety devicesEngineeringMechanical engineering

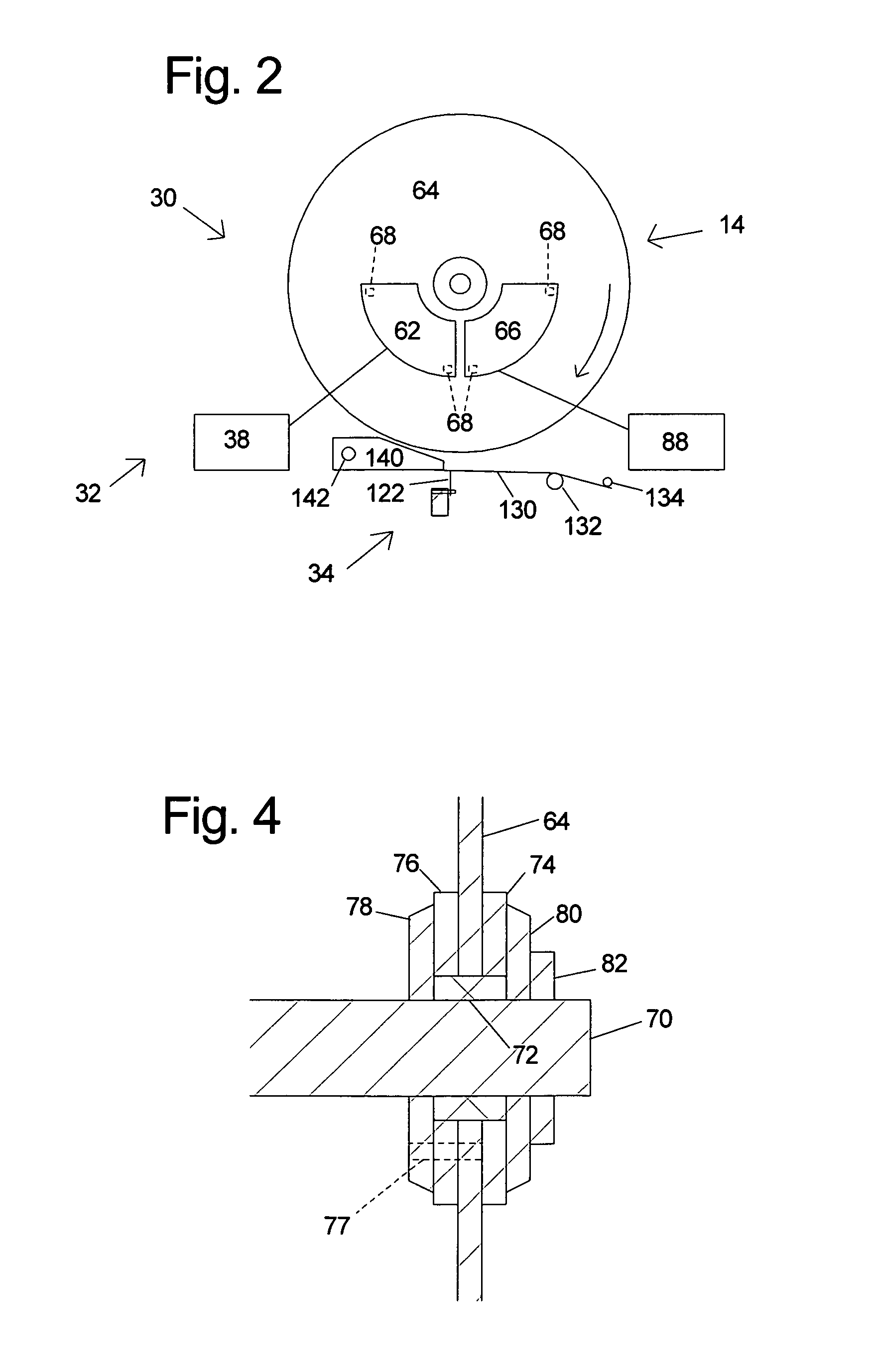

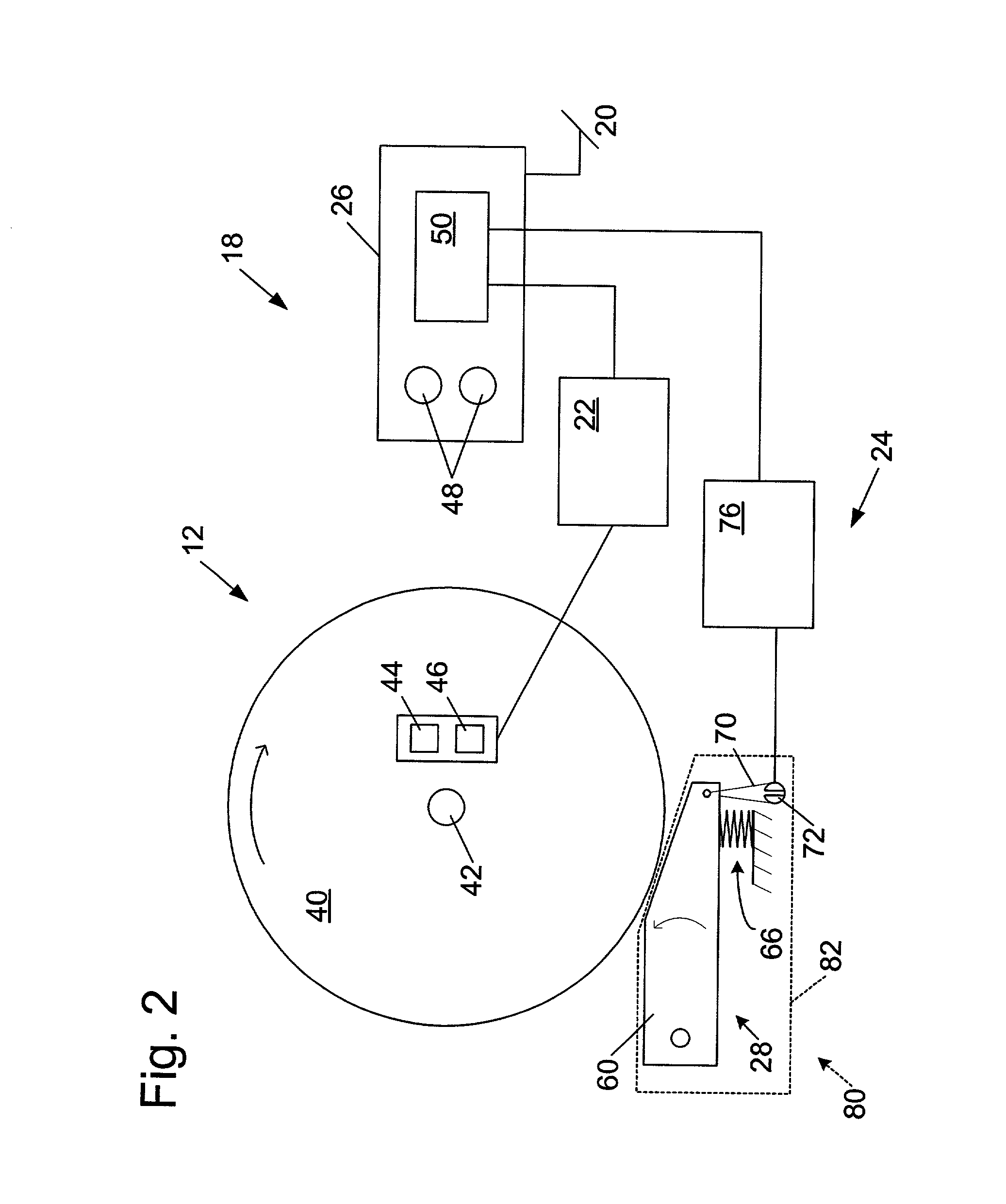

A saw is disclosed having a detection system adapted to detect a dangerous condition between a person and a saw blade, and a brake adapted to stop the saw blade in response to detection of the dangerous condition. The saw further includes a brake positioning system that allows the brake to be positioned in at least two different operable positions to accommodate at least two different blade diameters. The saw may include a system to detect brake-to-blade spacing.

Owner:SAWSTOP HLDG LLC

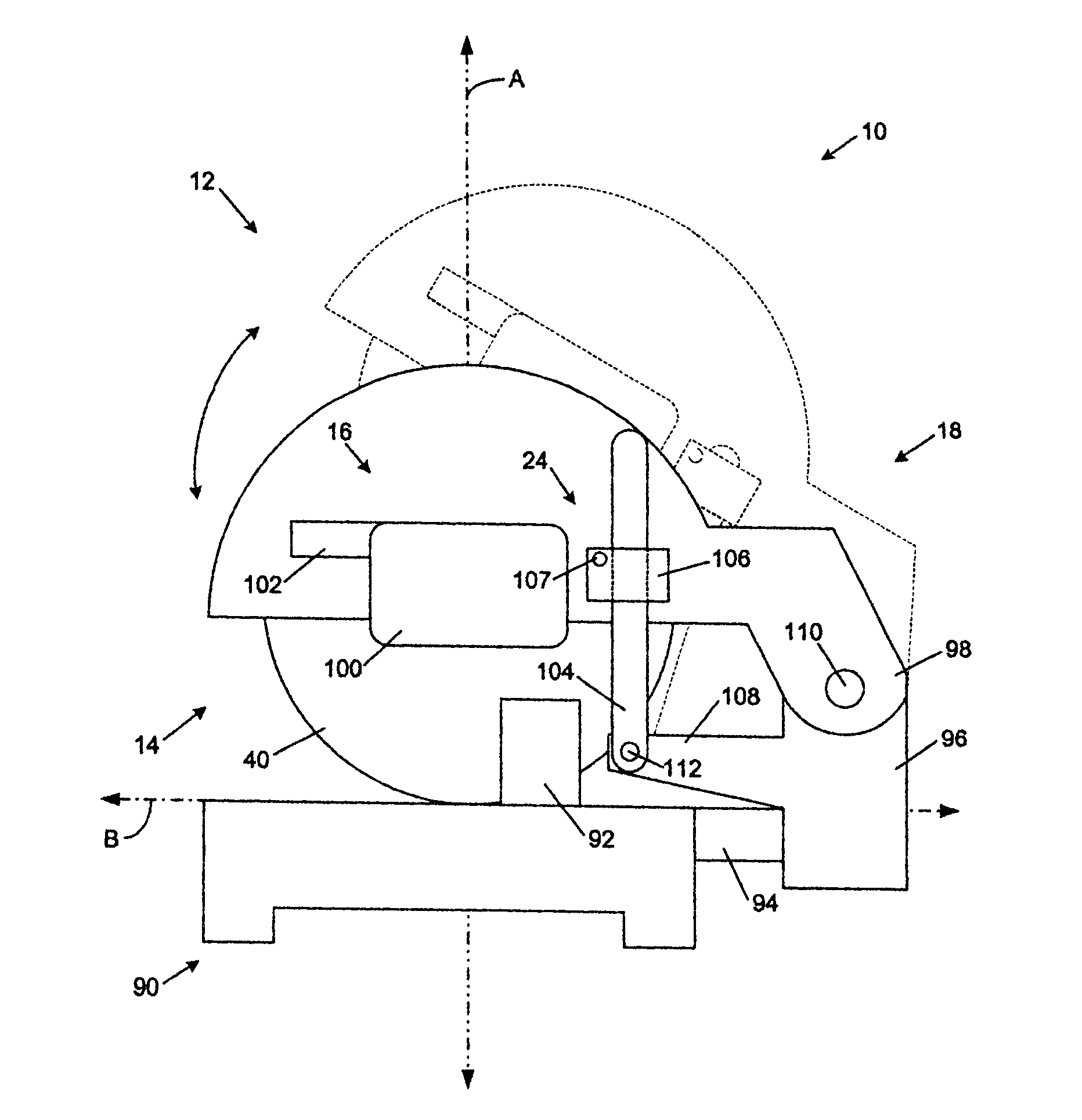

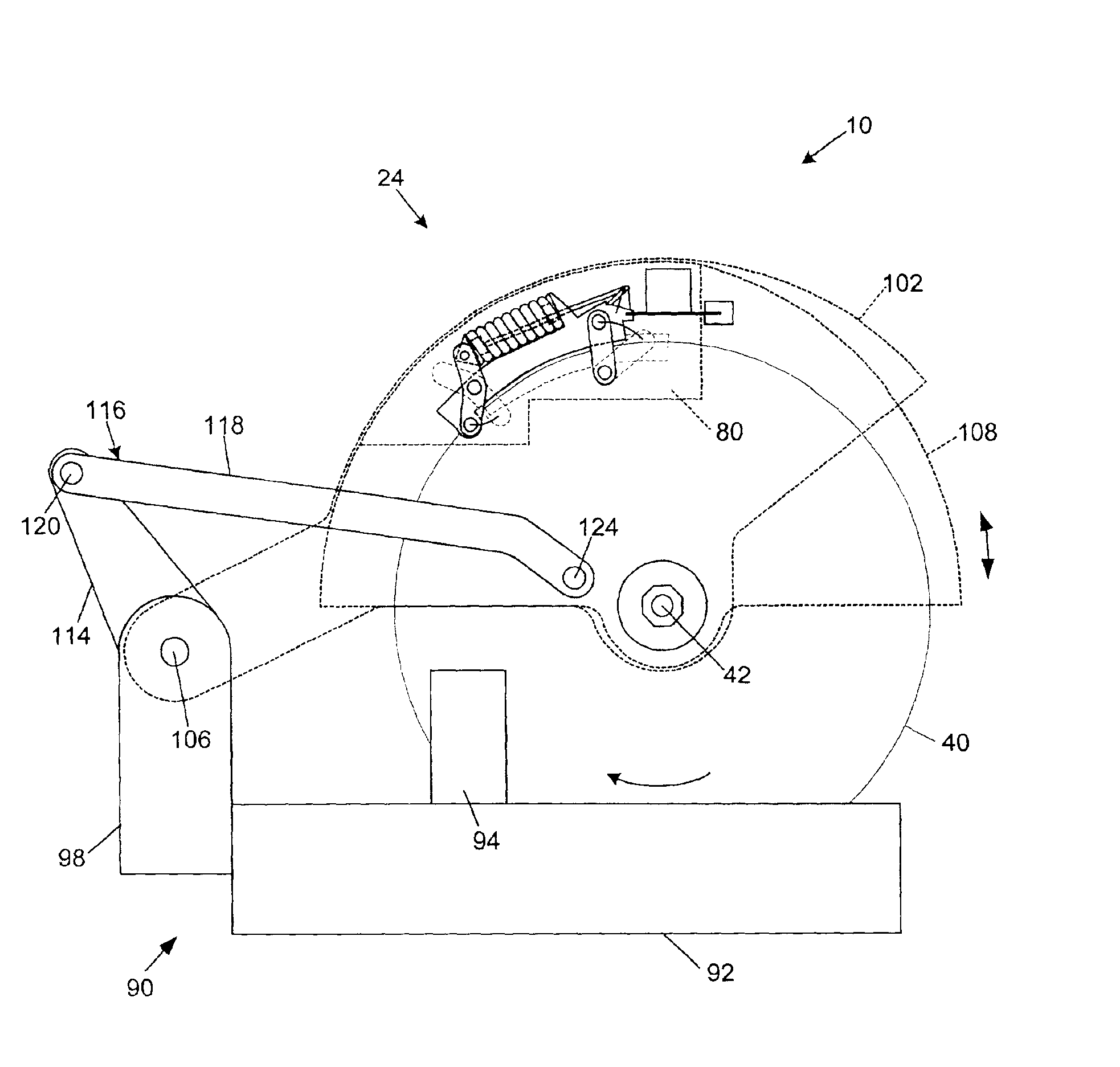

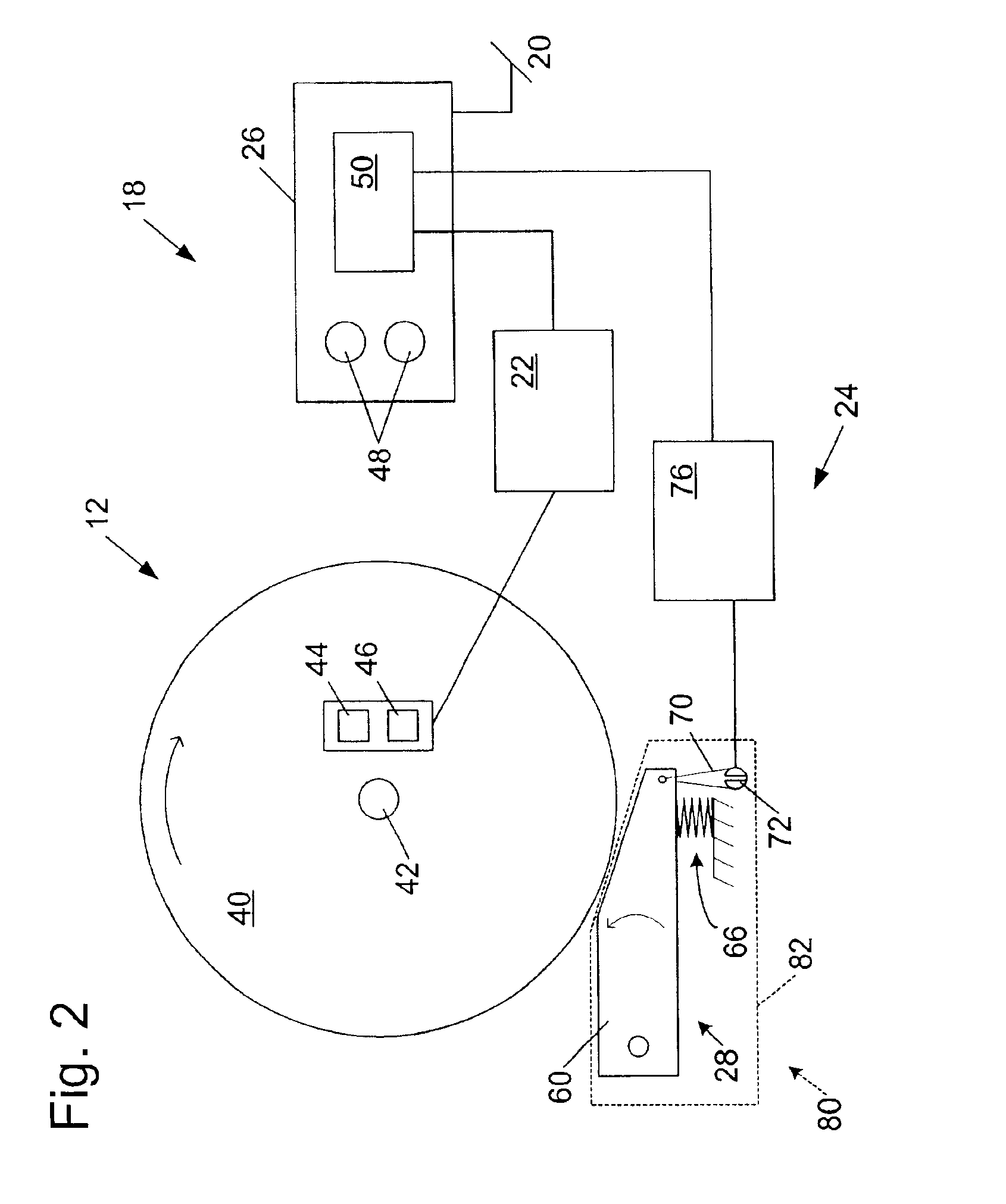

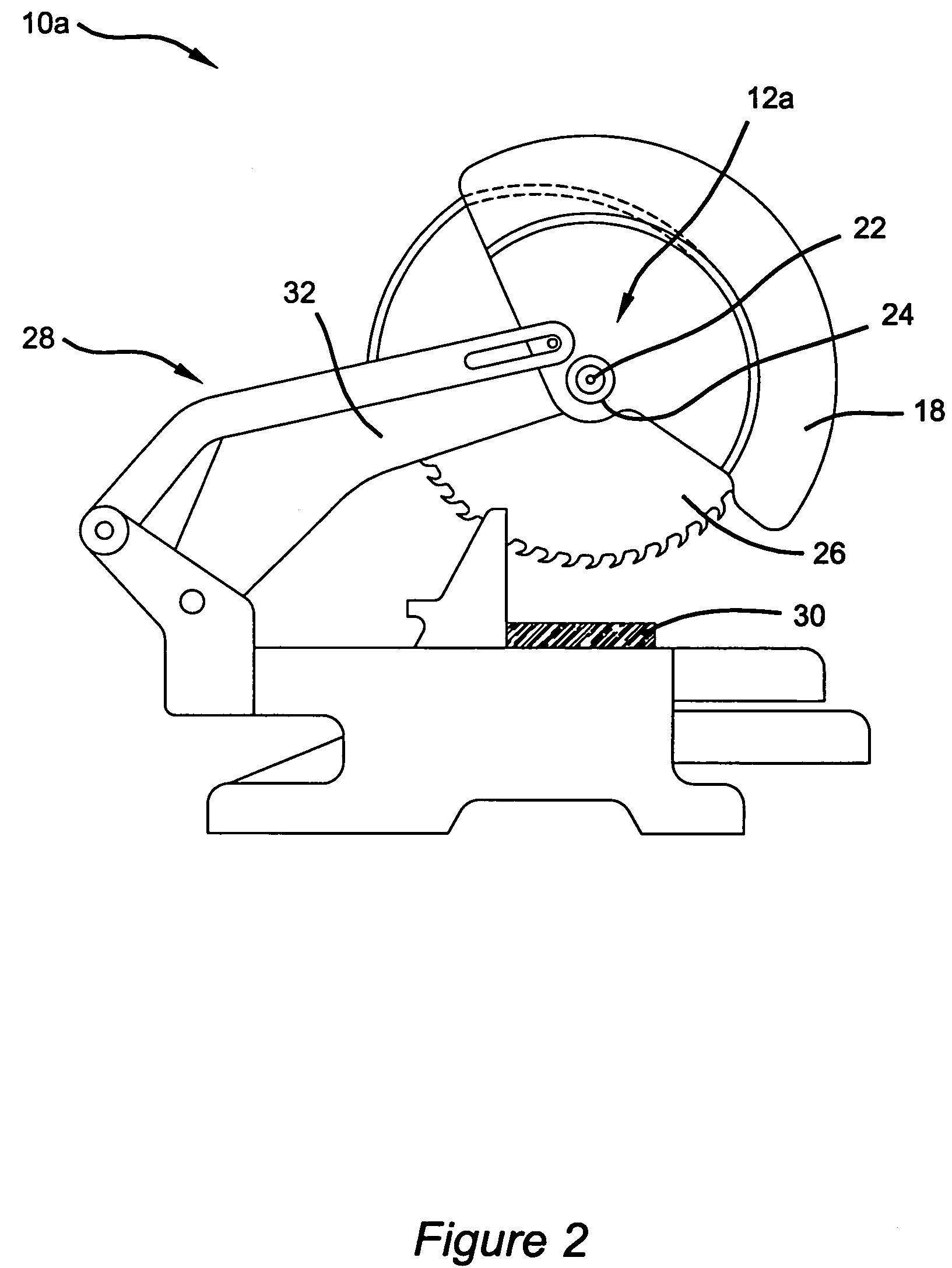

Miter saw with improved safety system

InactiveUS6826988B2Increase opportunitiesLimit and even prevent injuryEmergency protective circuit arrangementsEngineering safety devicesEngineeringWoodworking machine

A woodworking machine is disclosed having a base, a blade, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating and / or to stop movement of the blade toward the cutting zone.

Owner:SAWSTOP HLDG LLC

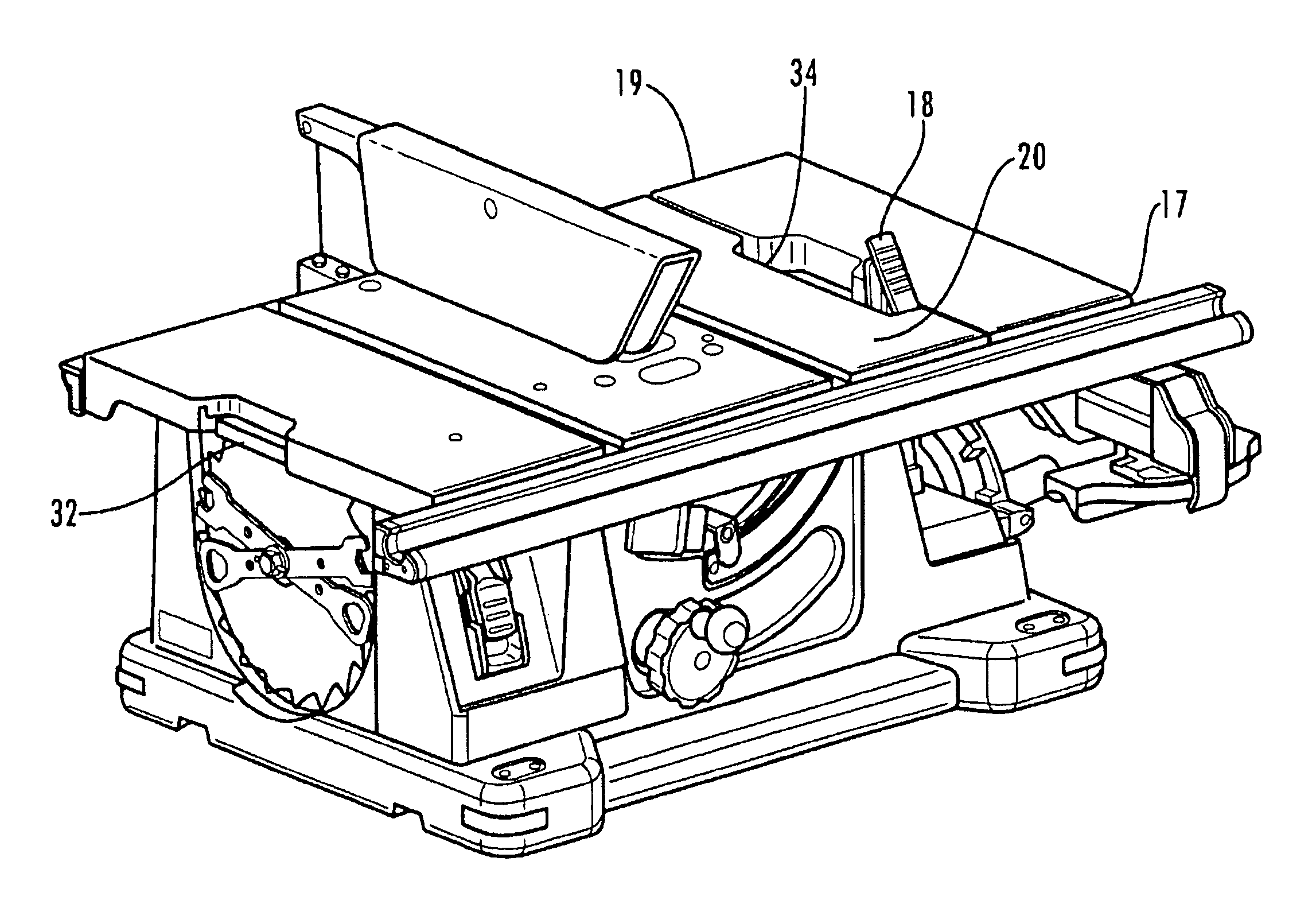

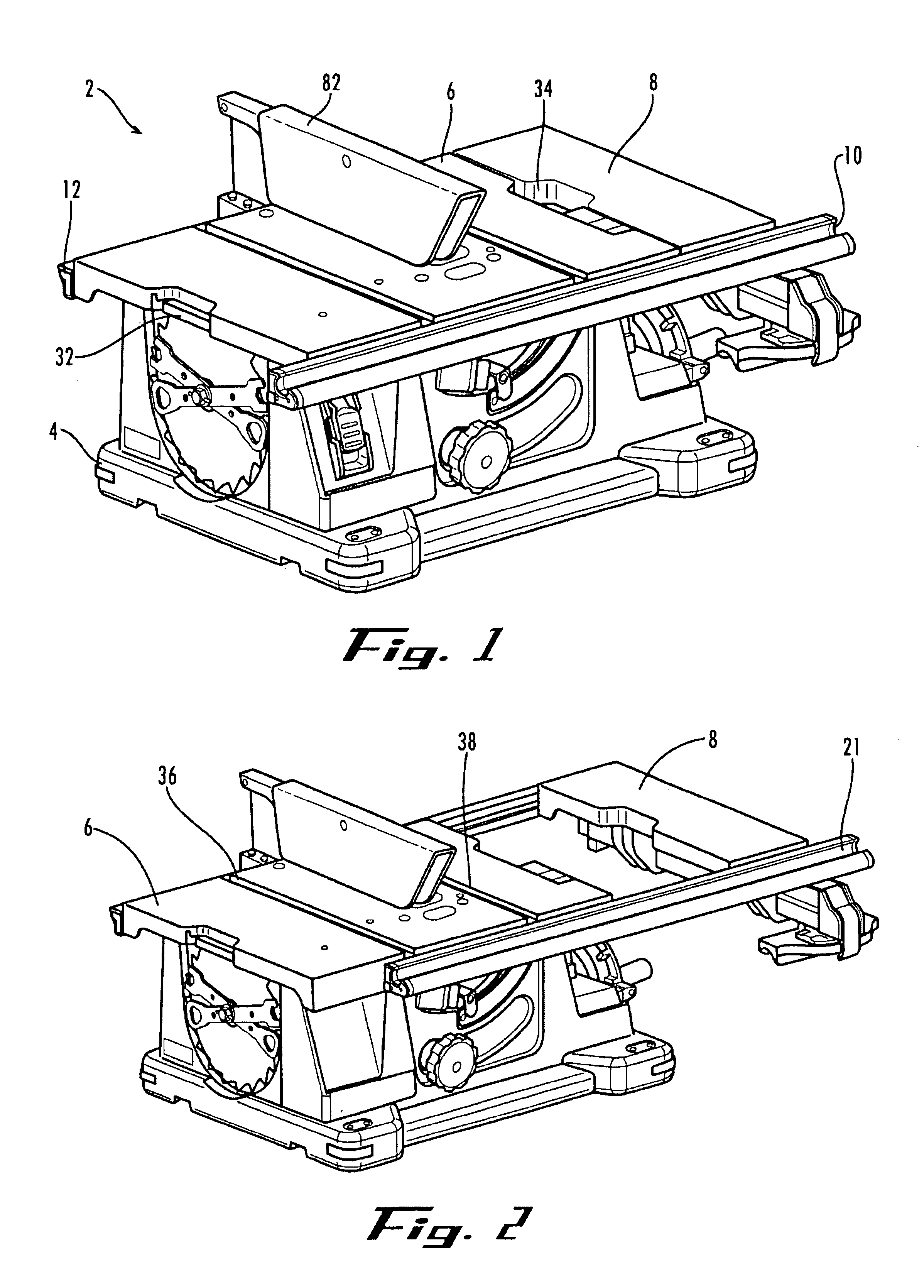

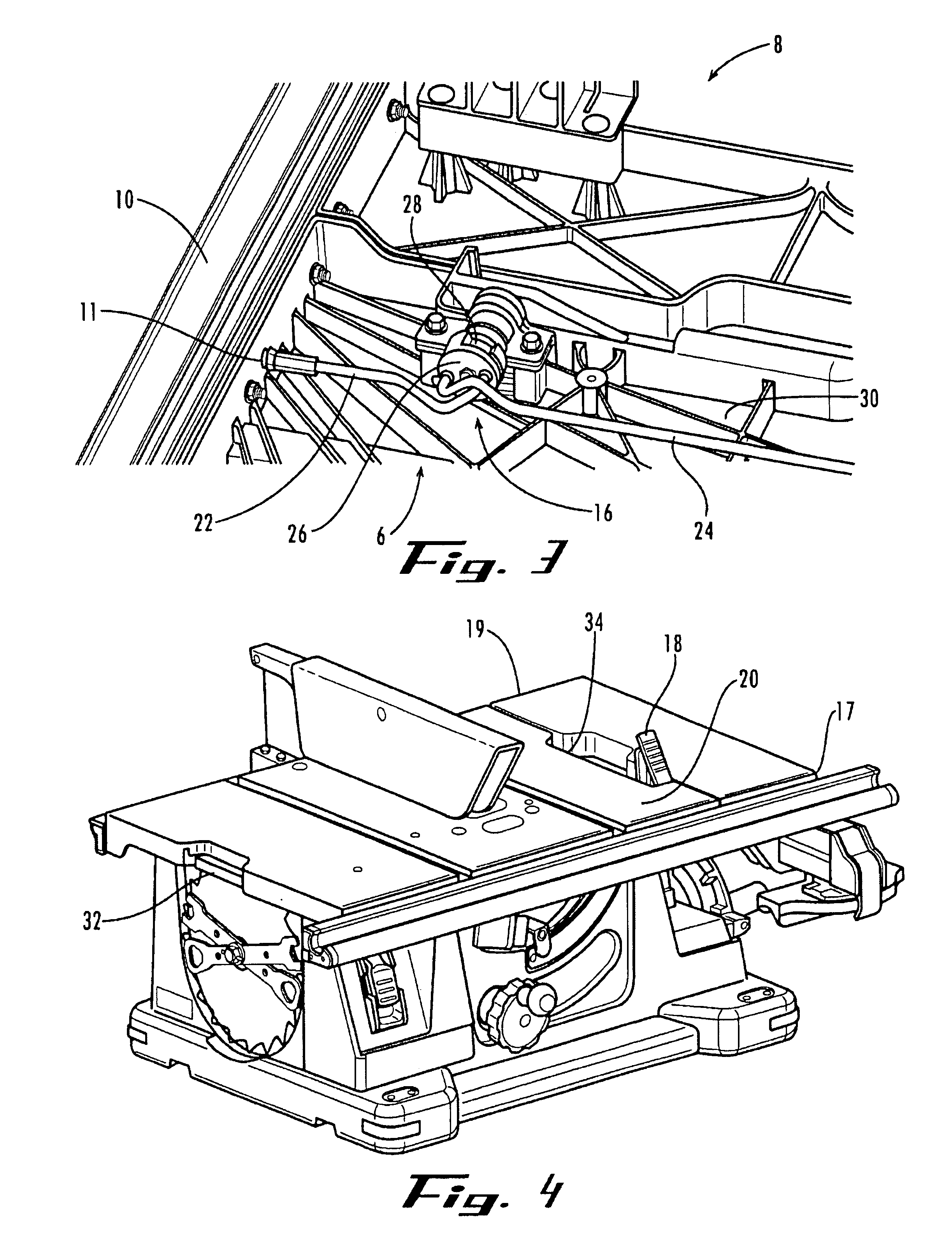

Table saw

A table saw apparatus including an extendable table. The table saw also includes a rip fence with a constant alignment spring finger to ensure alignment at all times between the rip fence and the table saw blade. The table saw further includes a self-adjusting rip fence scale associated with the extending portion of the table. The table saw further includes a self-aligning blade guard that, once adjusted a first time, ensures alignment between the blade guard and the blade on any subsequent installations of the guard. The table saw also includes a novel cradle assembly for elevating and beveling the blade.

Owner:HOME DEPOT PROD AUTHORITY

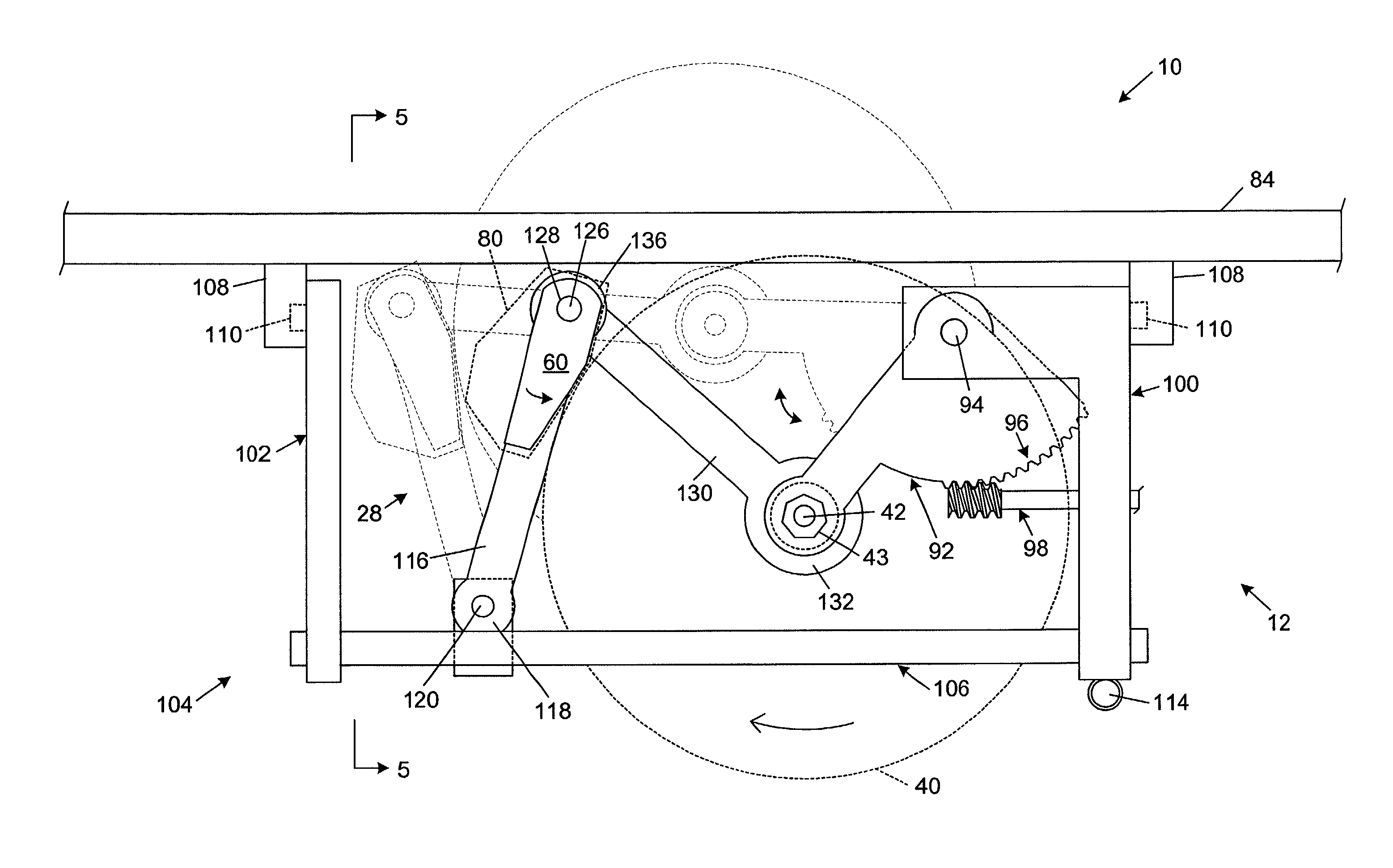

Table saw with improved safety system

InactiveUS6994004B2Metal sawing devicesMetal sawing accessoriesMechanical engineeringPositioning system

A table saw having a brake mechanism configured to engage and stop a blade is disclosed. The table saw includes a brake positioning system configured to adjust the position of the brake mechanism to maintain the brake mechanism in an operative position relative to the blade as the blade is raised and lowered.

Owner:SAWSTOP HLDG LLC

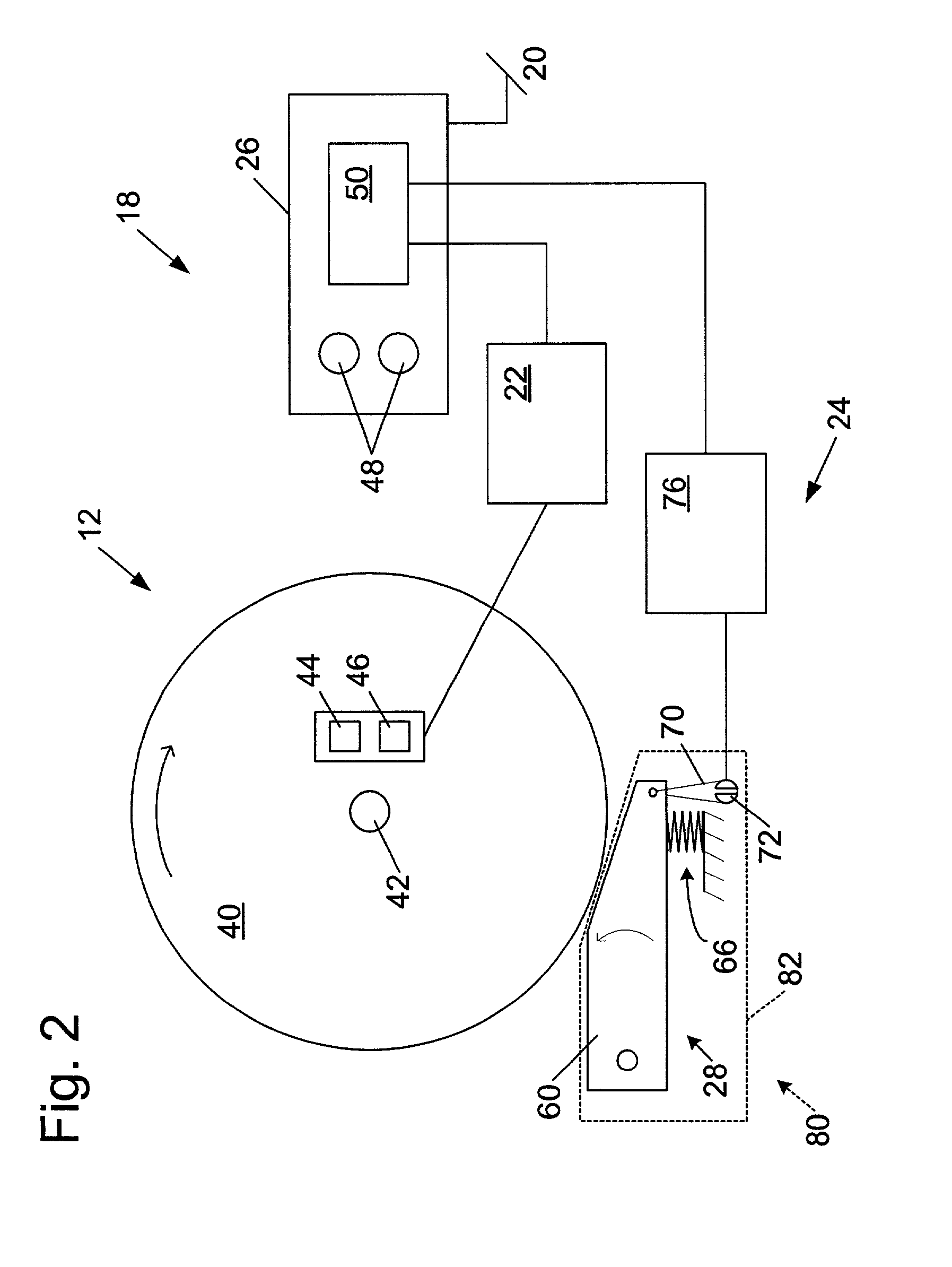

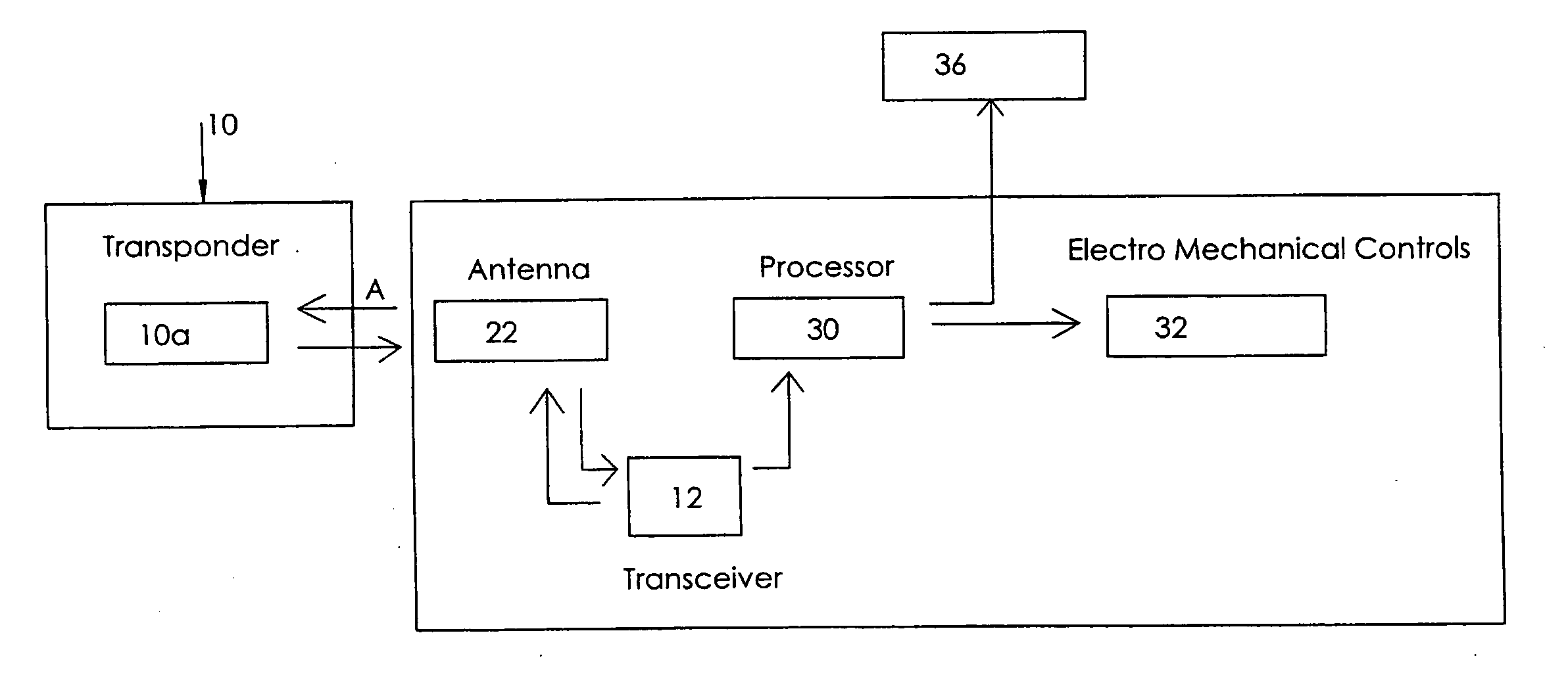

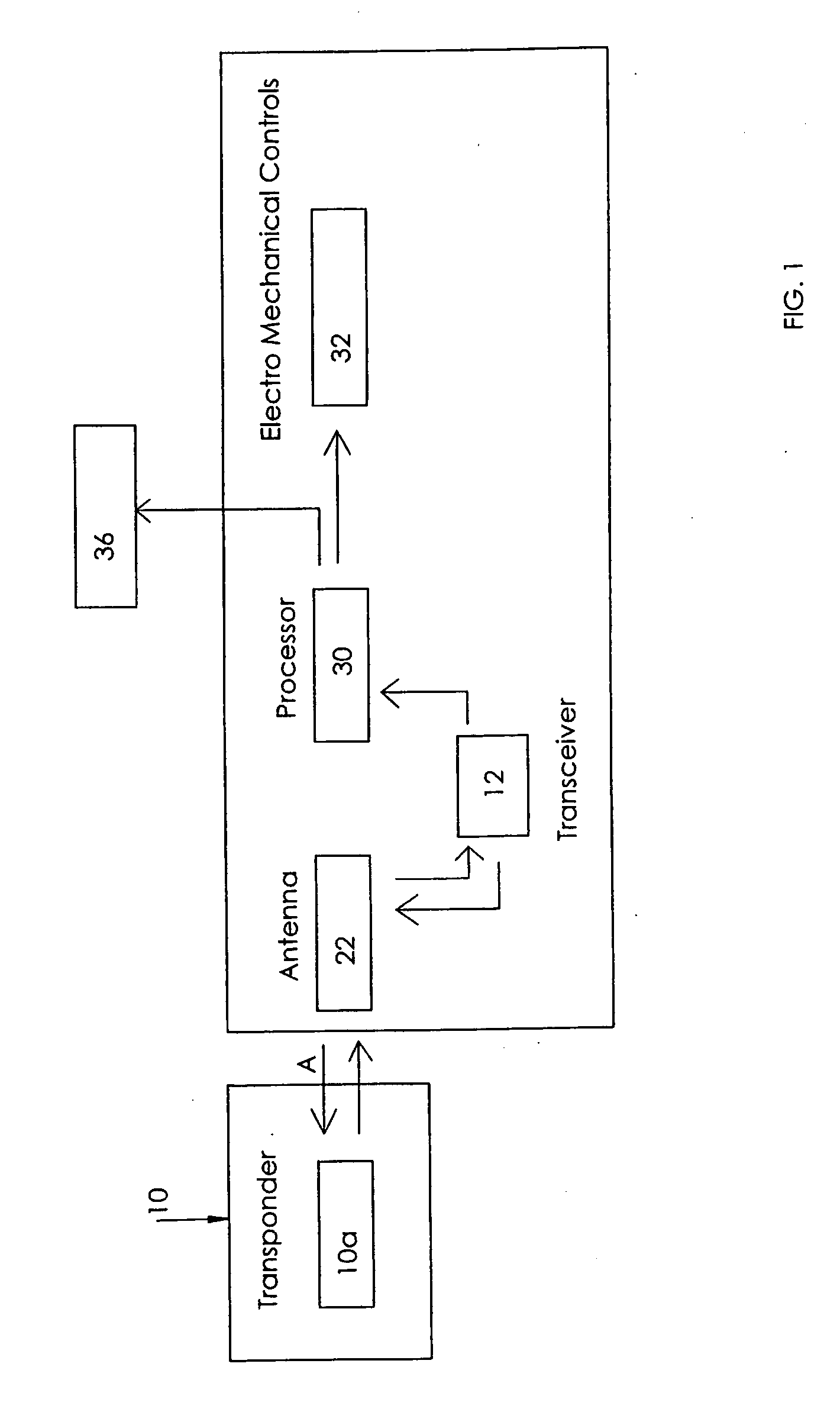

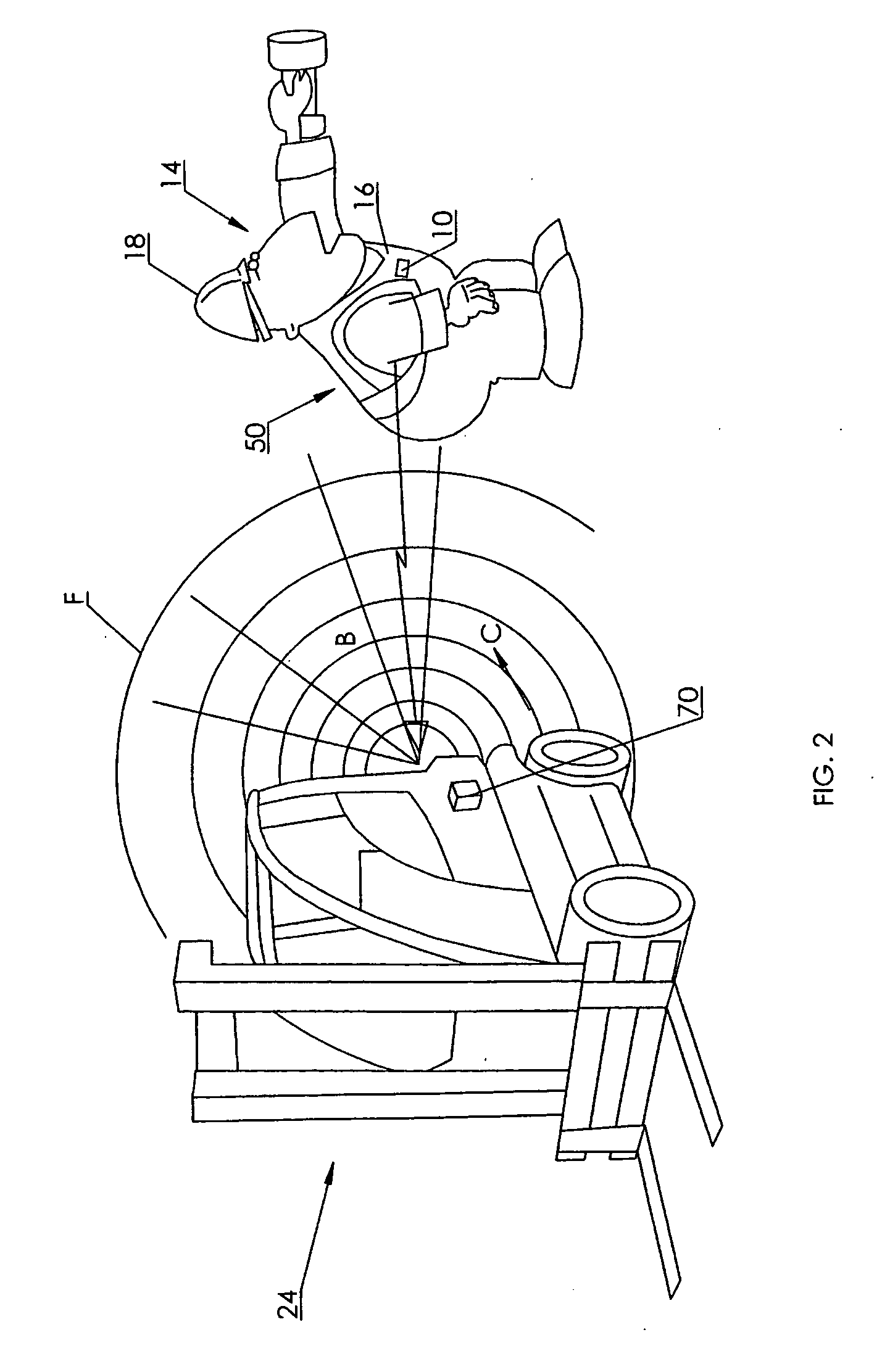

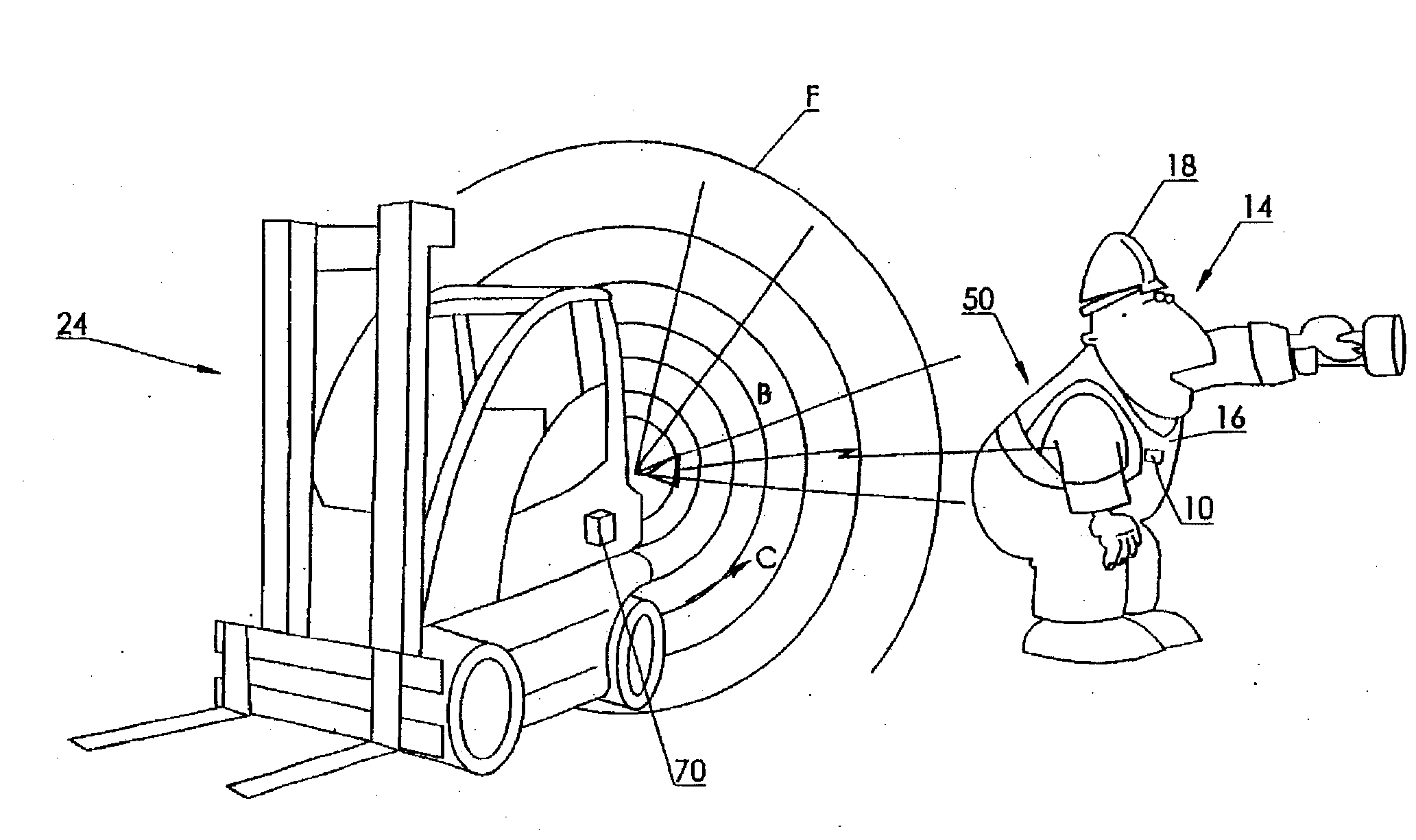

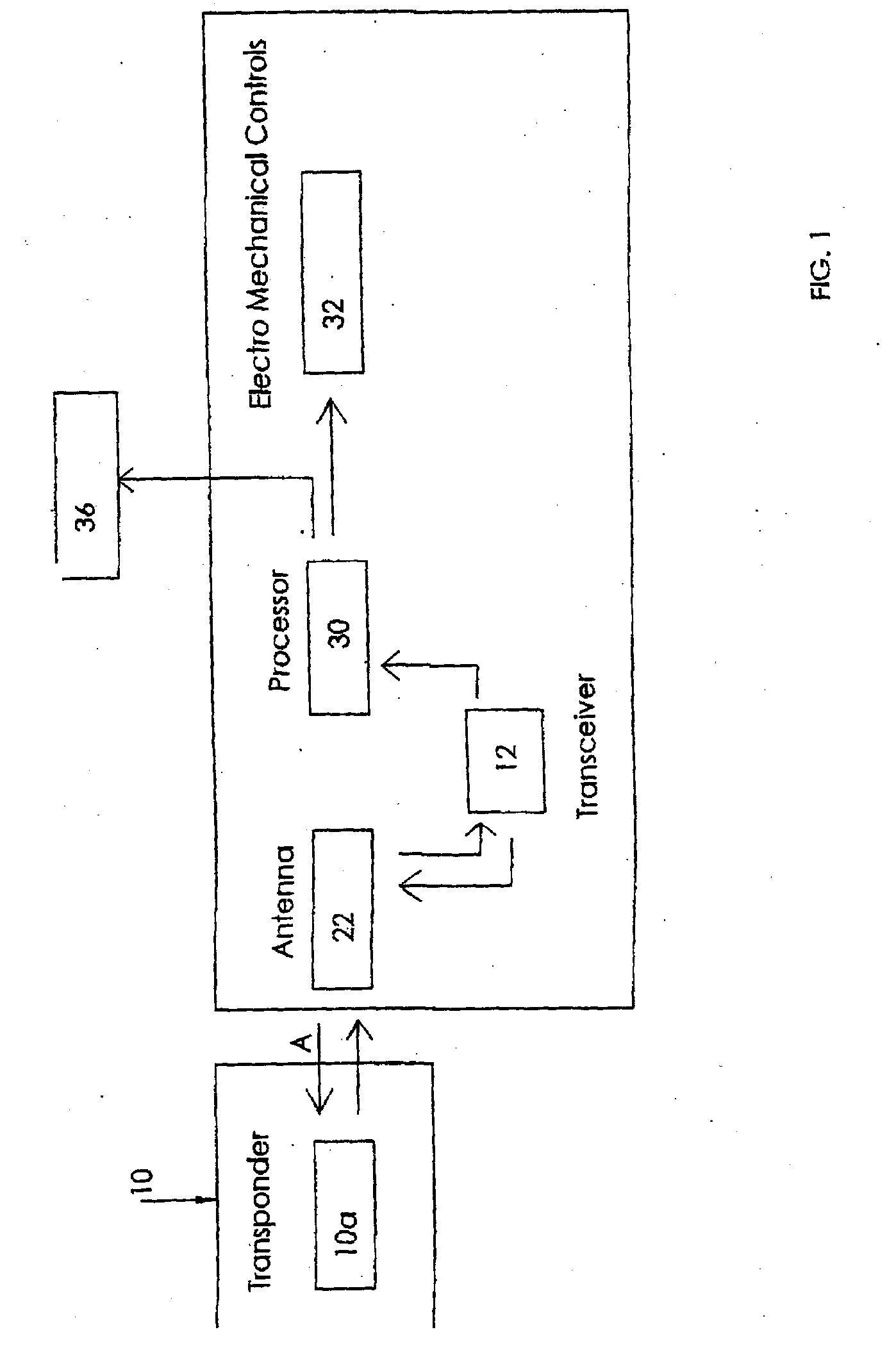

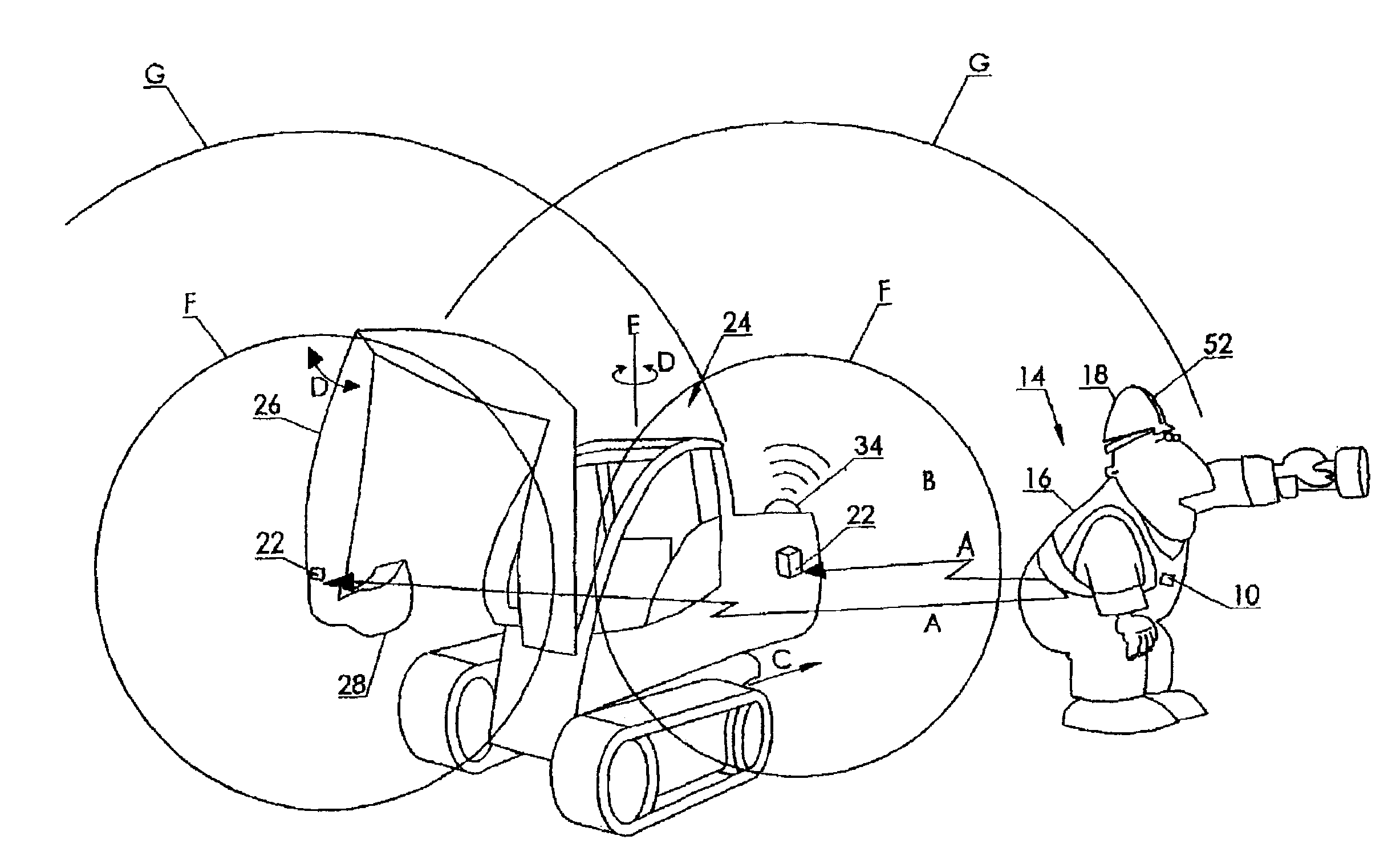

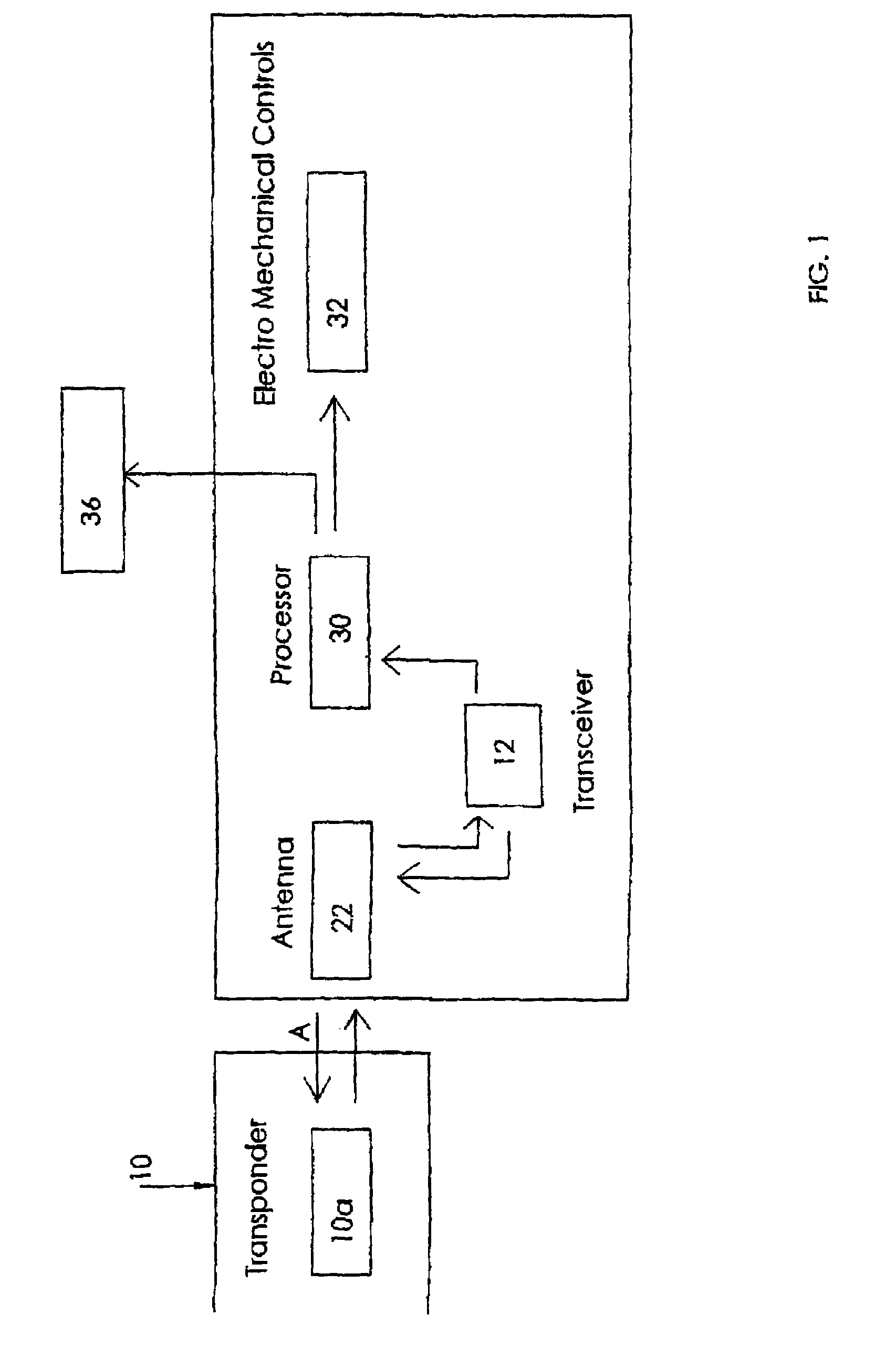

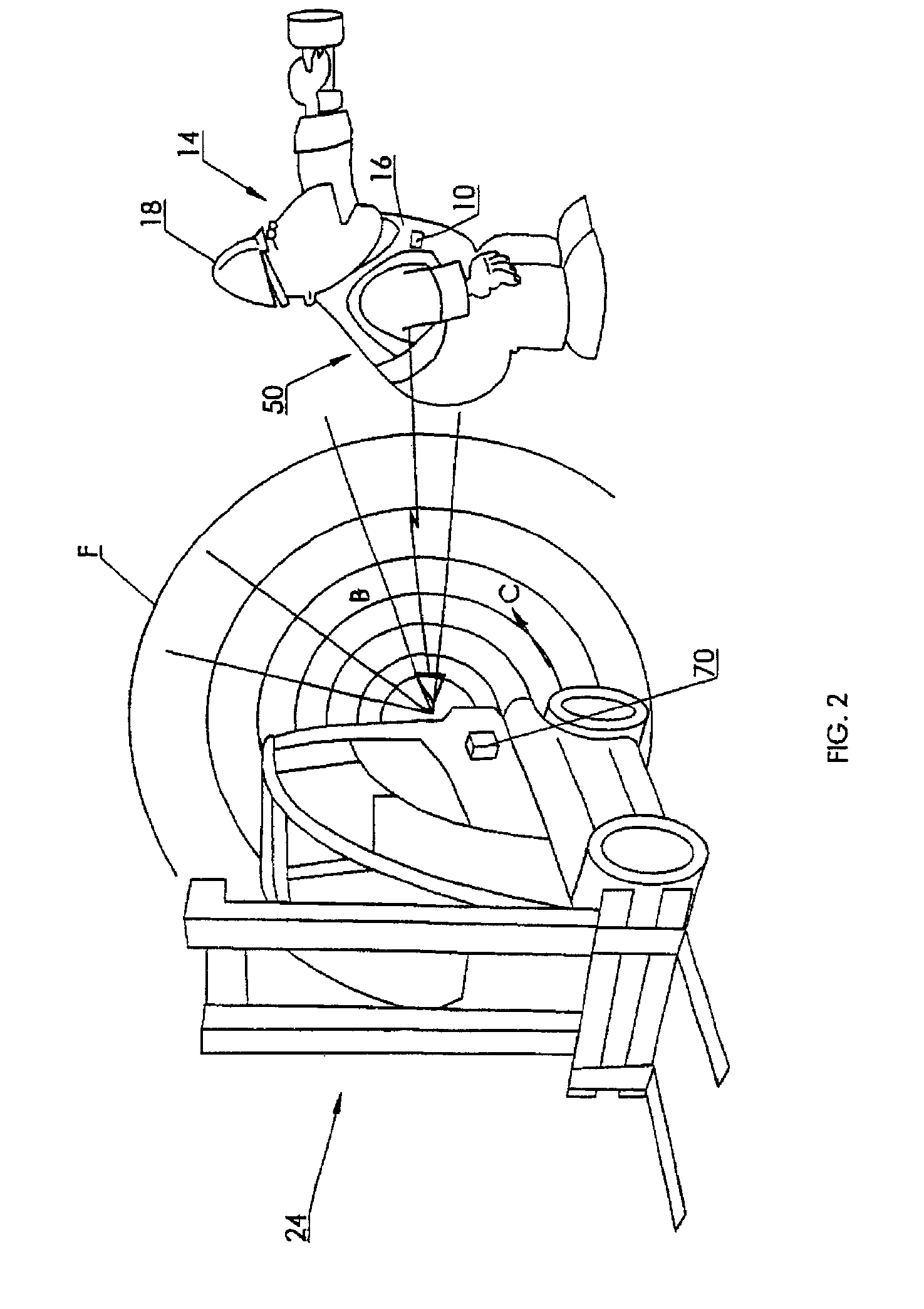

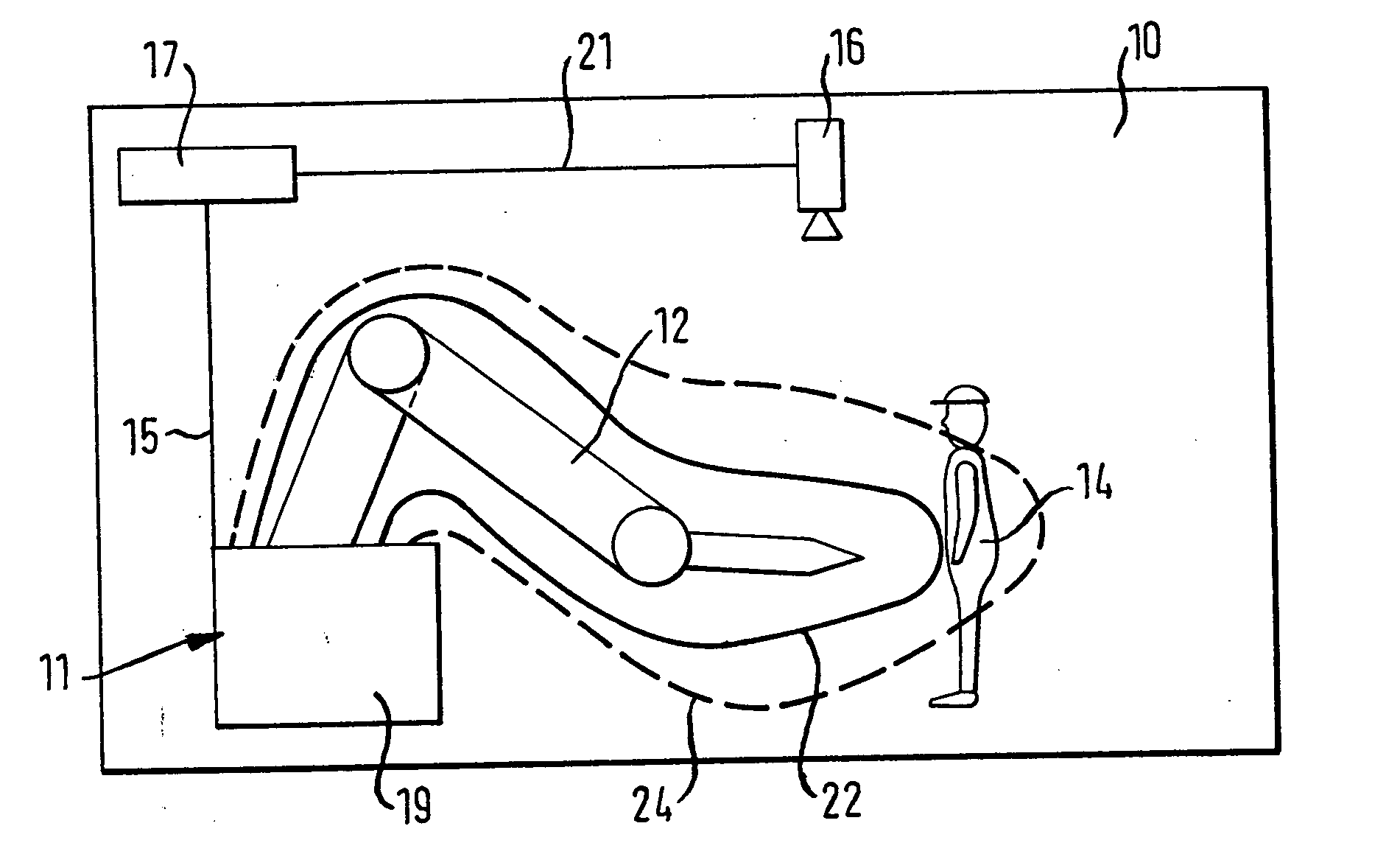

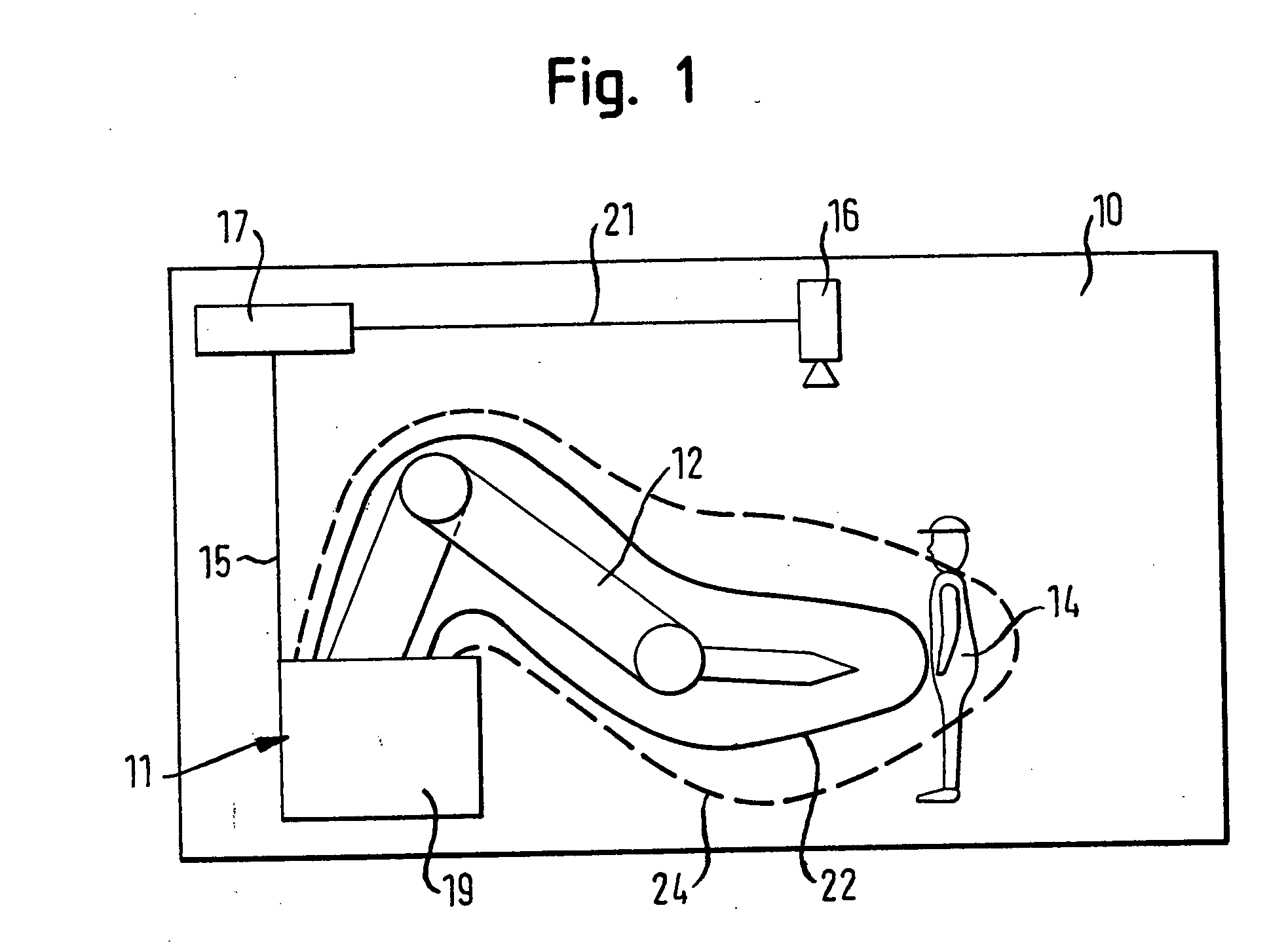

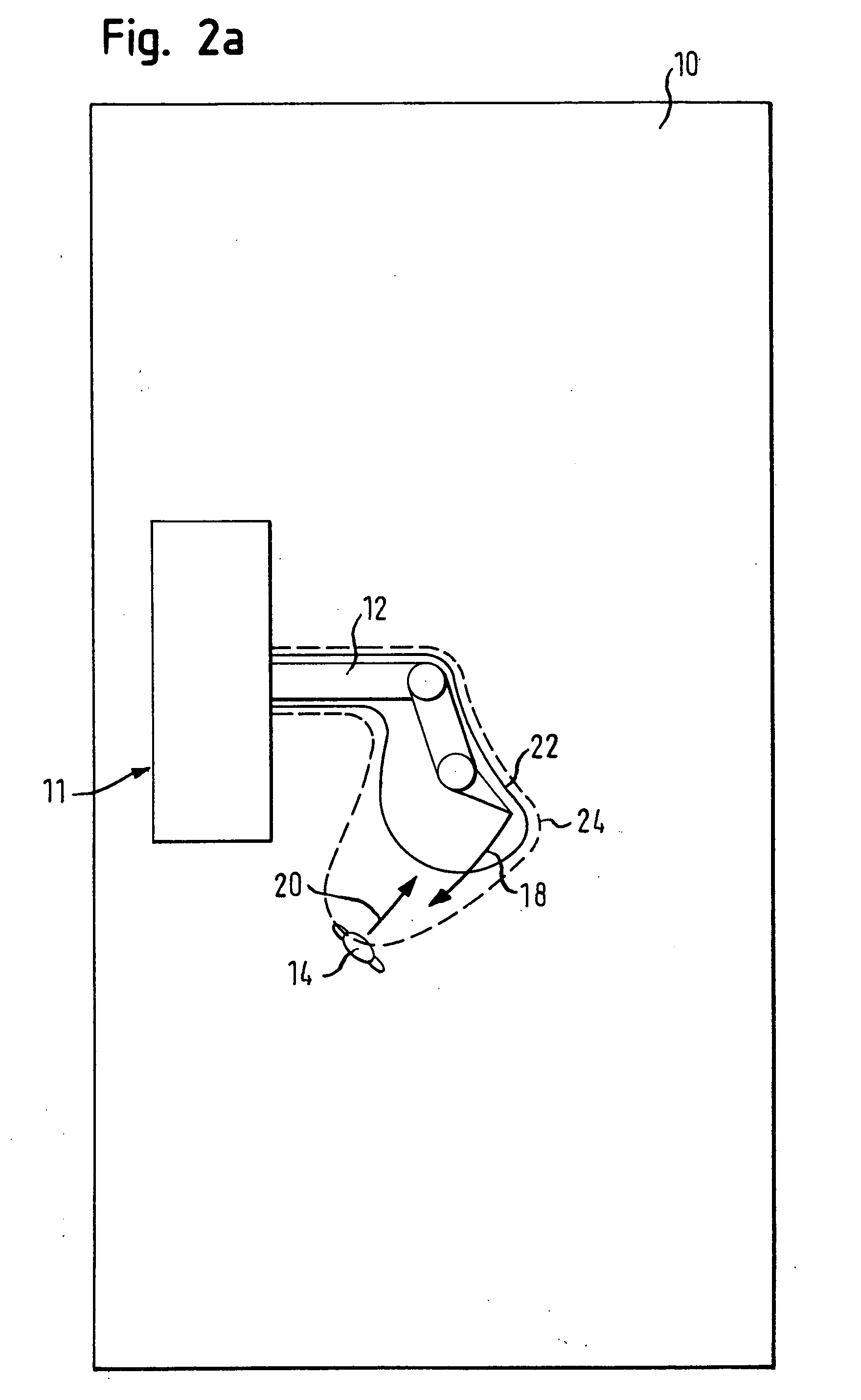

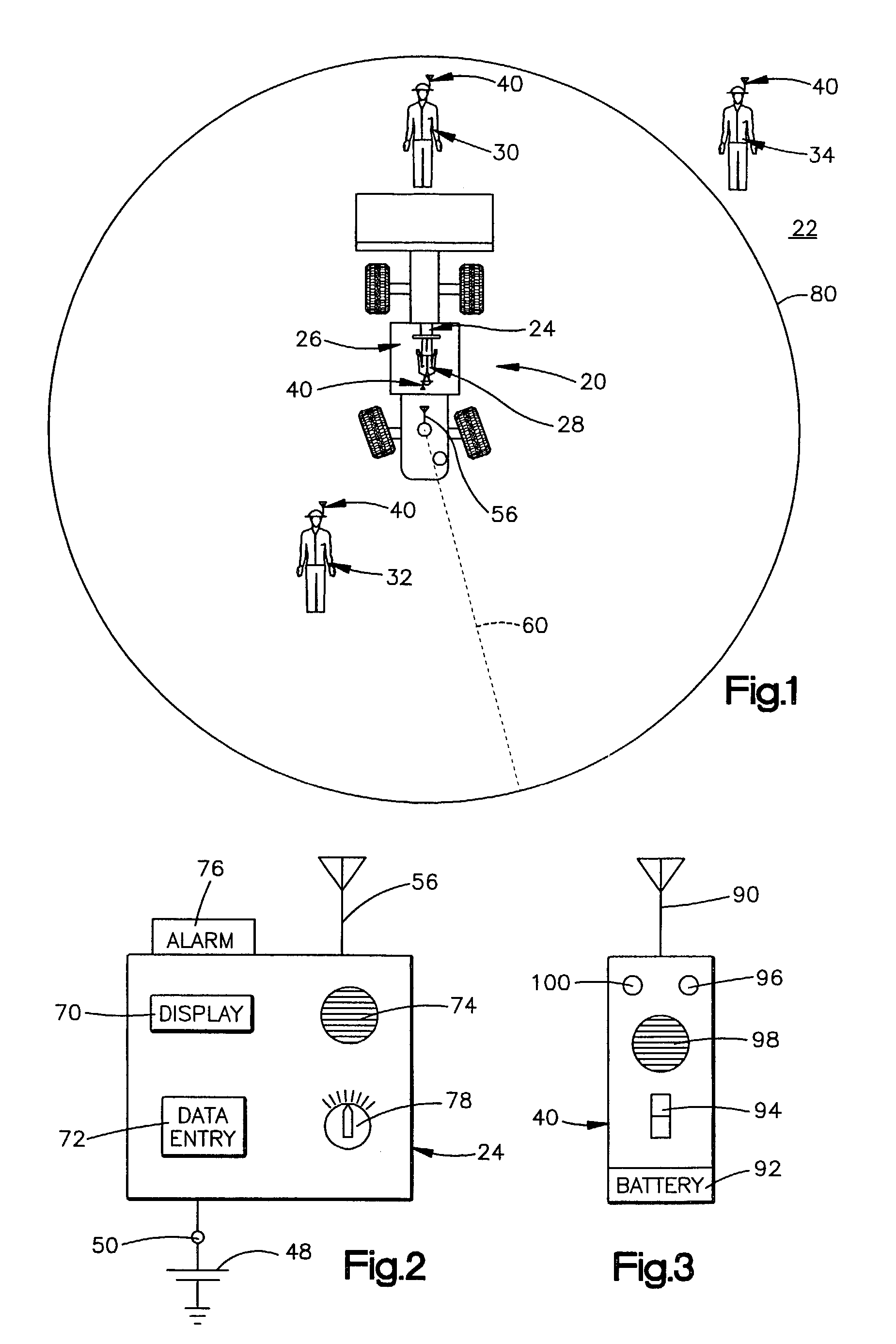

Radio frequency identification based personnel safety system

InactiveUS20080018472A1Safety devices for lifting equipmentsEngineering safety devicesEngineeringStops device

Disclosed is a method and apparatus for selectively immobilizing equipment to ensure the safety of a proximate worker. The apparatus comprises an article of clothing wearable by the proximate worker, a sensor and a stopping means for stopping the movement of a portion of the equipment in response to the sensing. The article of clothing has a RFID tag having an antenna distributed about the article so as to substantially surround a worker wearing the article of clothing. The sensor senses the proximity of the RFID tag to a portion of the equipment. The method comprises sensing the proximity of the RFID tag to a portion of the equipment and stopping the movement of a portion of the equipment in response to the sensing.

Owner:PSST MOBILE EQUIP - RICHARD SHERVEY

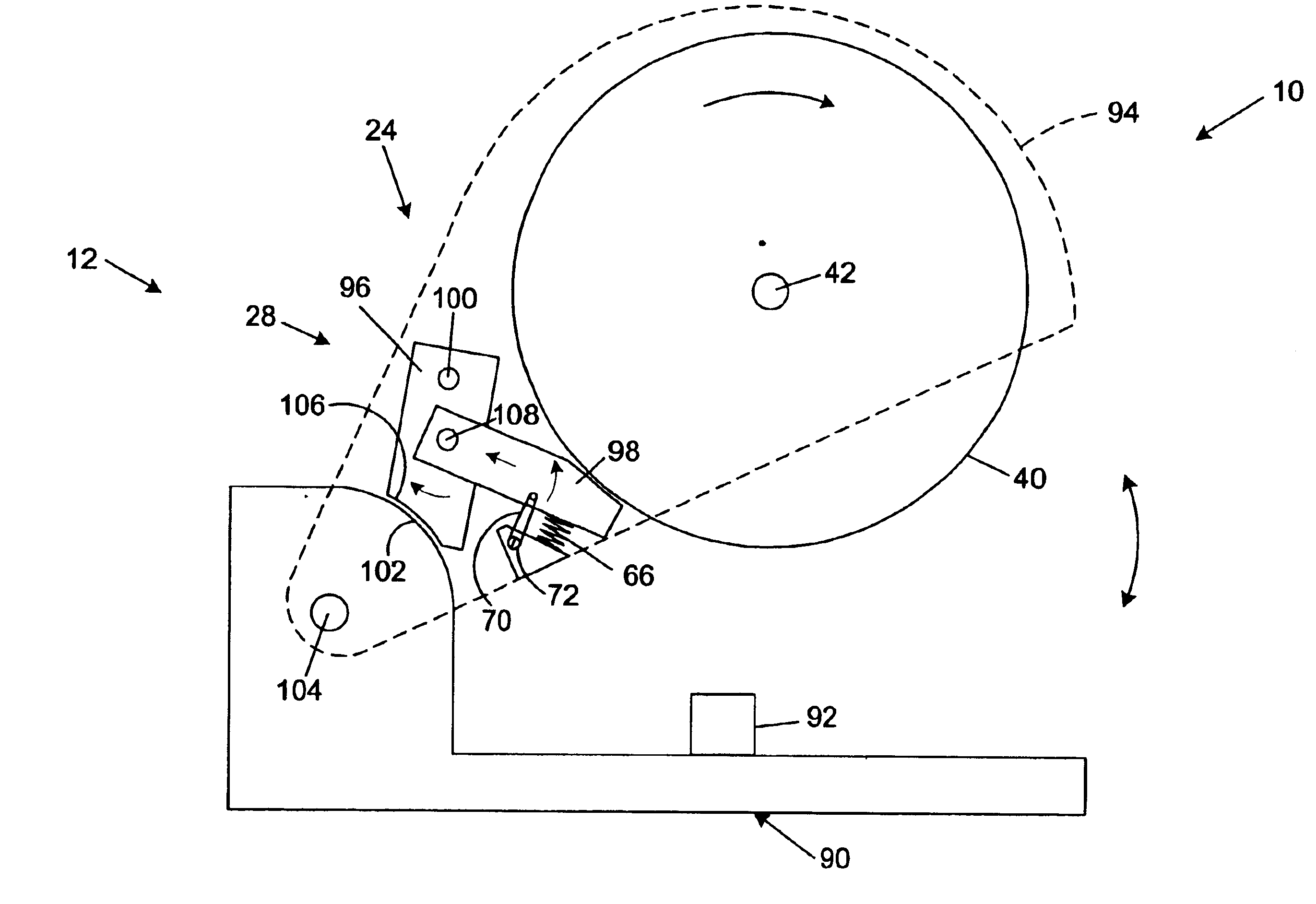

Miter saw with improved safety system

InactiveUS6880440B2Limit and even prevent injuryImprove the security systemEmergency protective circuit arrangementsEngineering safety devicesEngineeringMechanical engineering

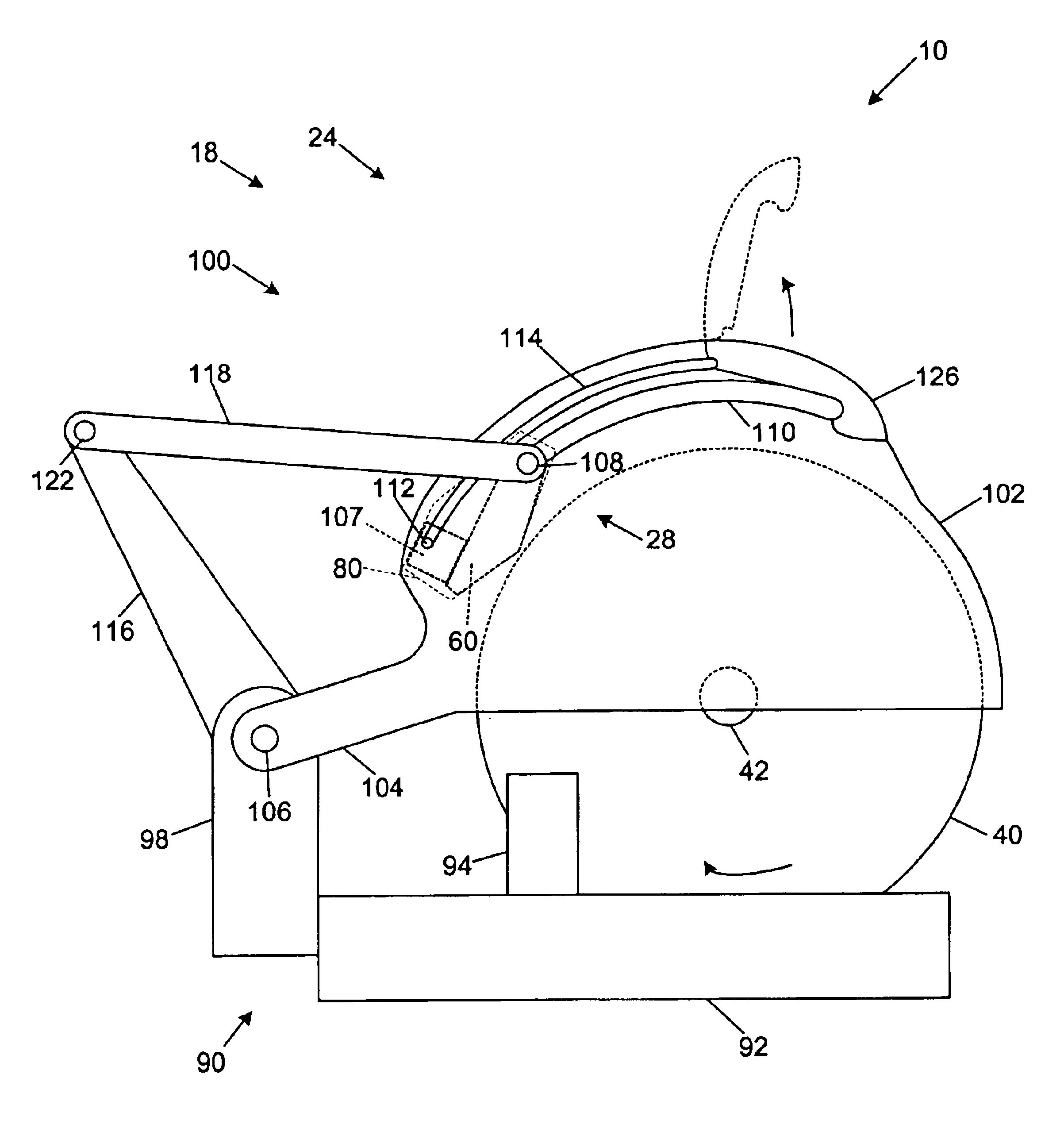

A miter saw having a base and an arm that pivots toward the base is disclosed. A blade is supported by the arm, and is designed to cut workpieces resting on the base when the arm and blade pivot downward. The saw includes a detection system configured to detect one or more dangerous conditions between a person and the blade, such as when a person accidentally touches the spinning blade, and the saw includes a reaction system to stop the downward movement of the blade and arm when the dangerous condition is detected.

Owner:SAWSTOP HLDG LLC

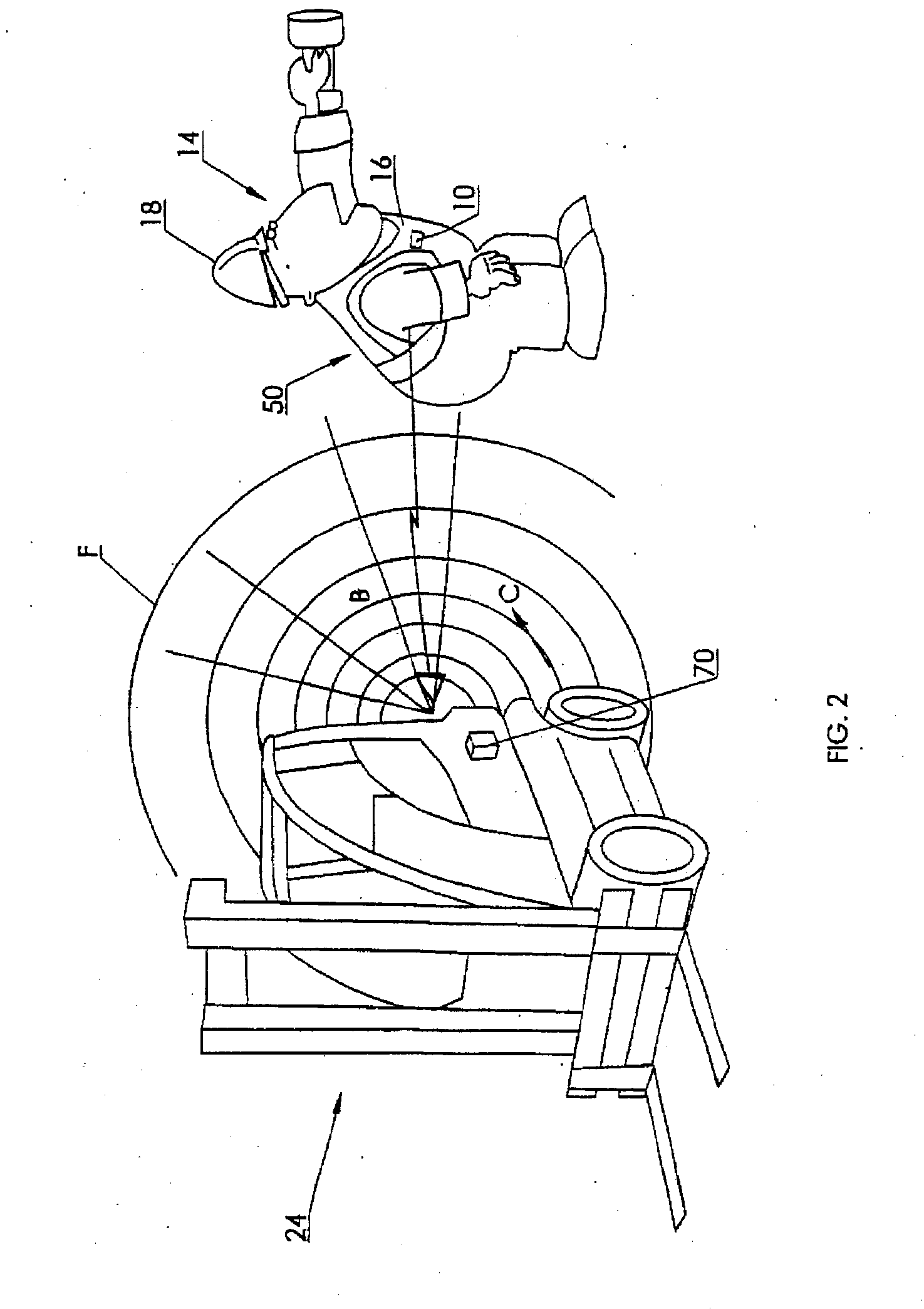

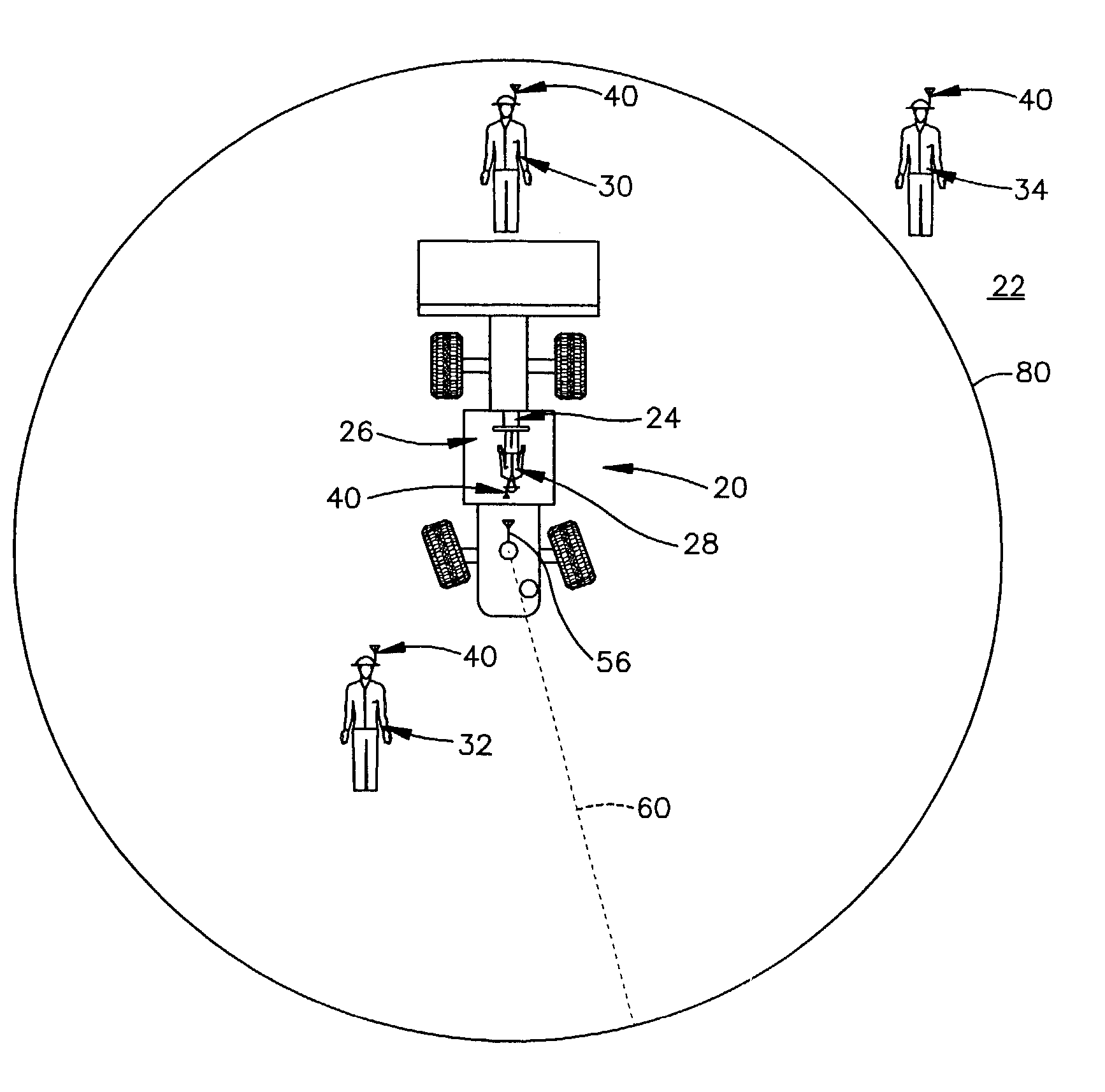

Personnel safety utilizing time variable frequencies

InactiveUS20100289662A1High noiseIncrease resistanceSafety devices for lifting equipmentsEngineering safety devicesOmnidirectional antennaDirectional antenna

A system to improve safety of workers who are in proximity to mobile machines includes a machine mountable radio-frequency identification reader that wirelessly monitors radio-frequency identification tags worn by workers moving relative to and in proximity to a mobile machine when the reader is mounted on the machine. The reader includes a processor and an antenna front-end which is switchable between an omni-directional antenna or at least one directional antenna. The omni-directional antenna is mountable so as to monitor a machine circumference completely around the mobile machine. Each directional antenna is mountable so as to monitor only either a front or a back of the mobile machine relative to the machines direction of motion.

Owner:PSST MOBILE EQUIP - RICHARD SHERVEY +1

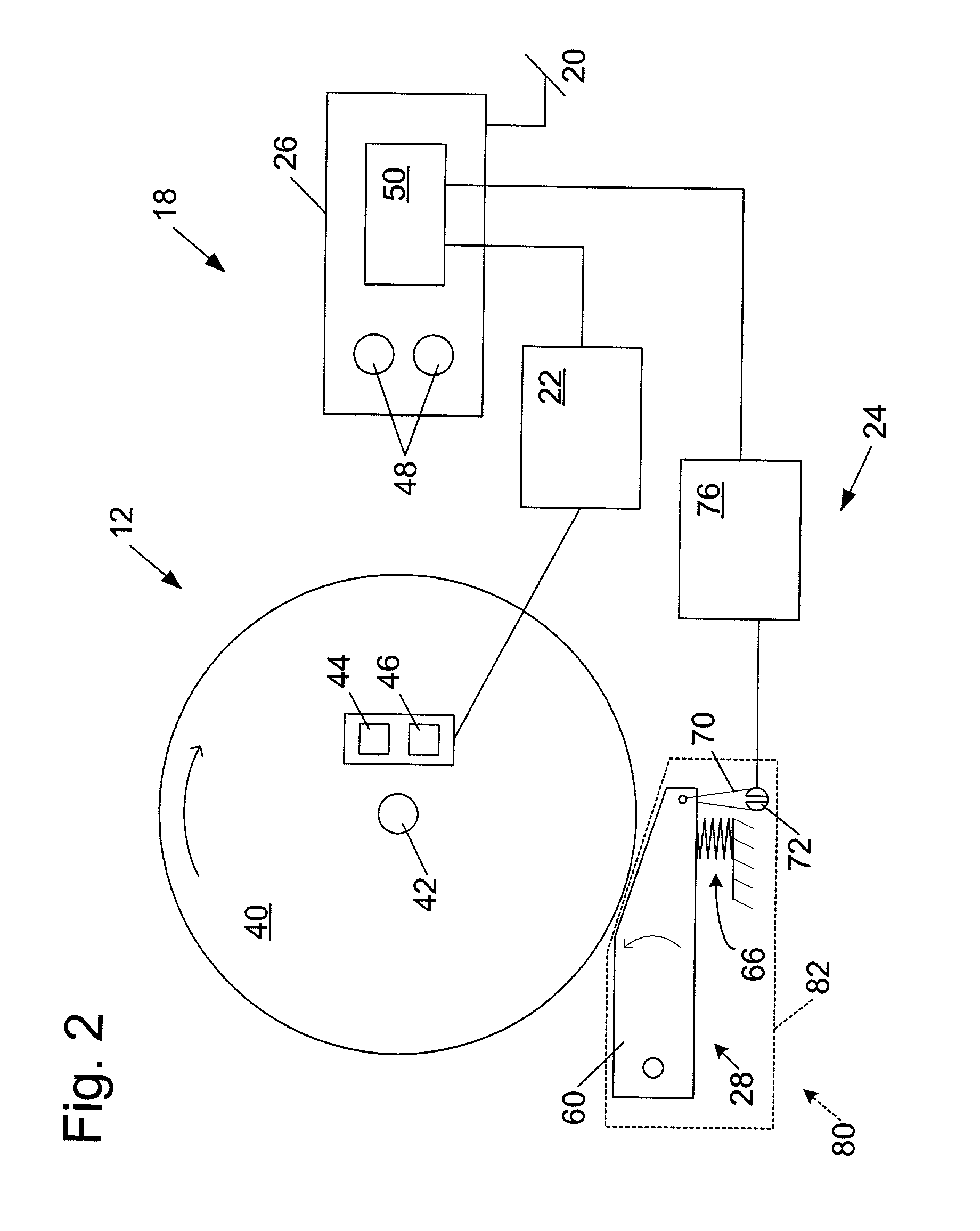

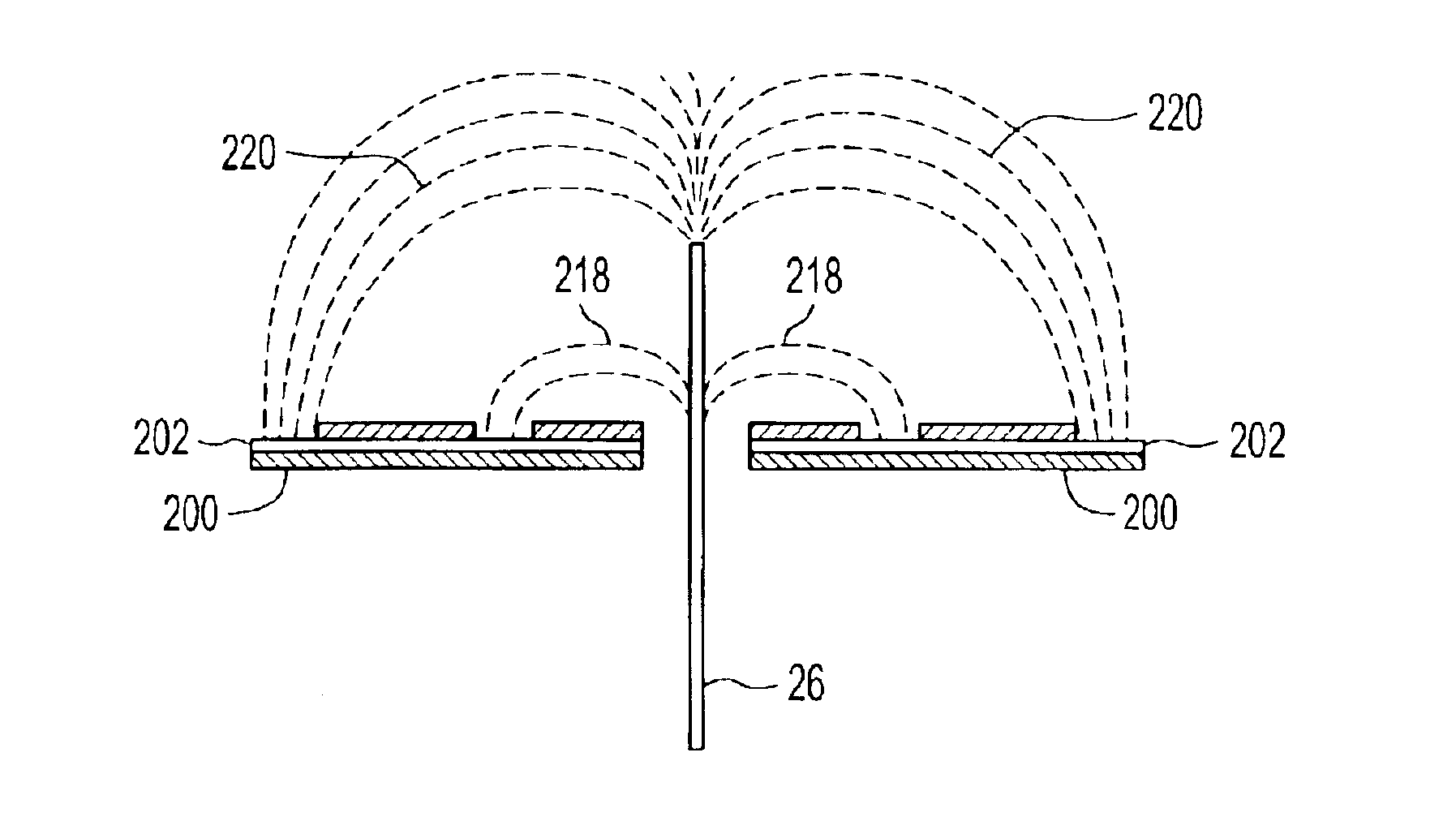

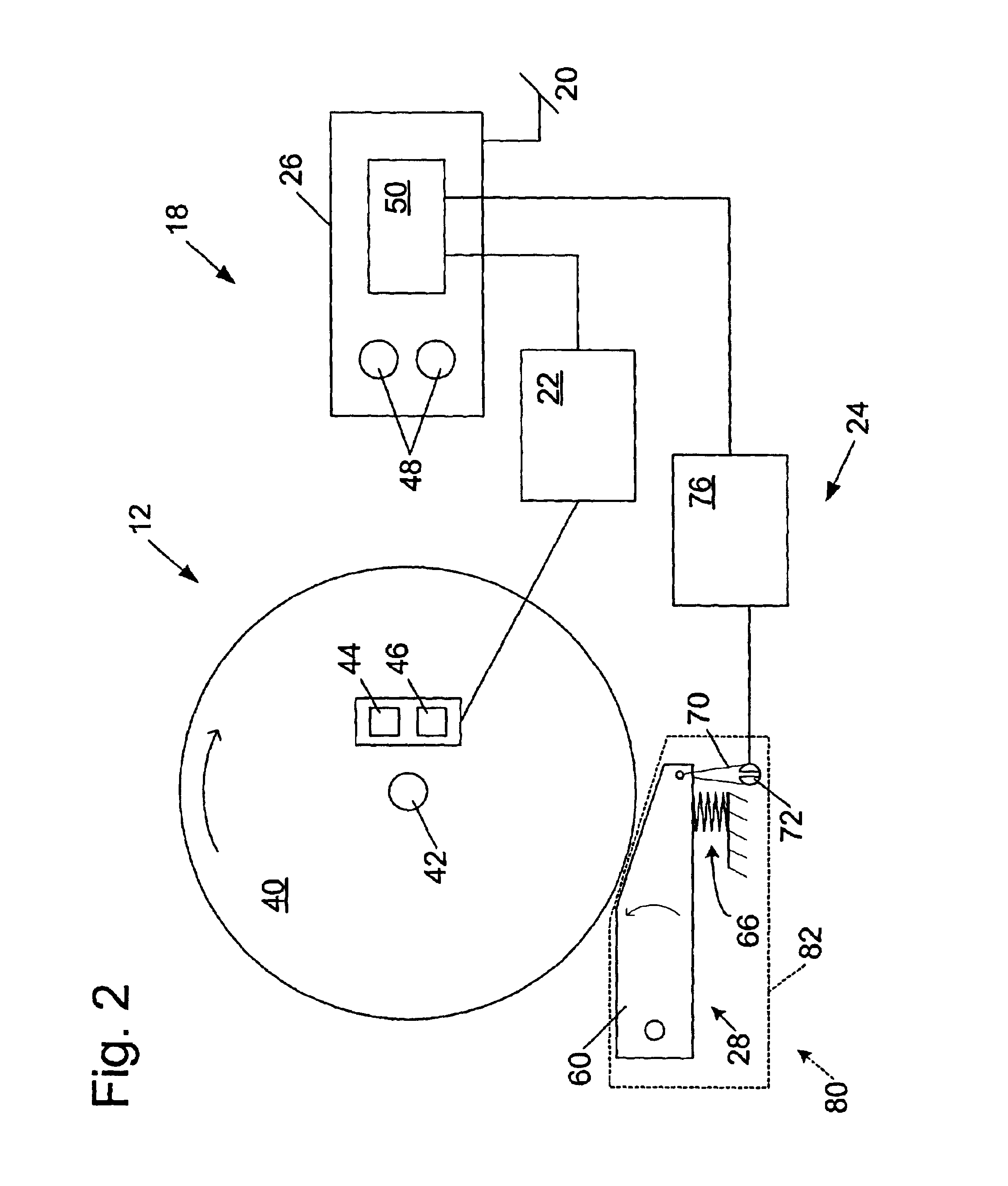

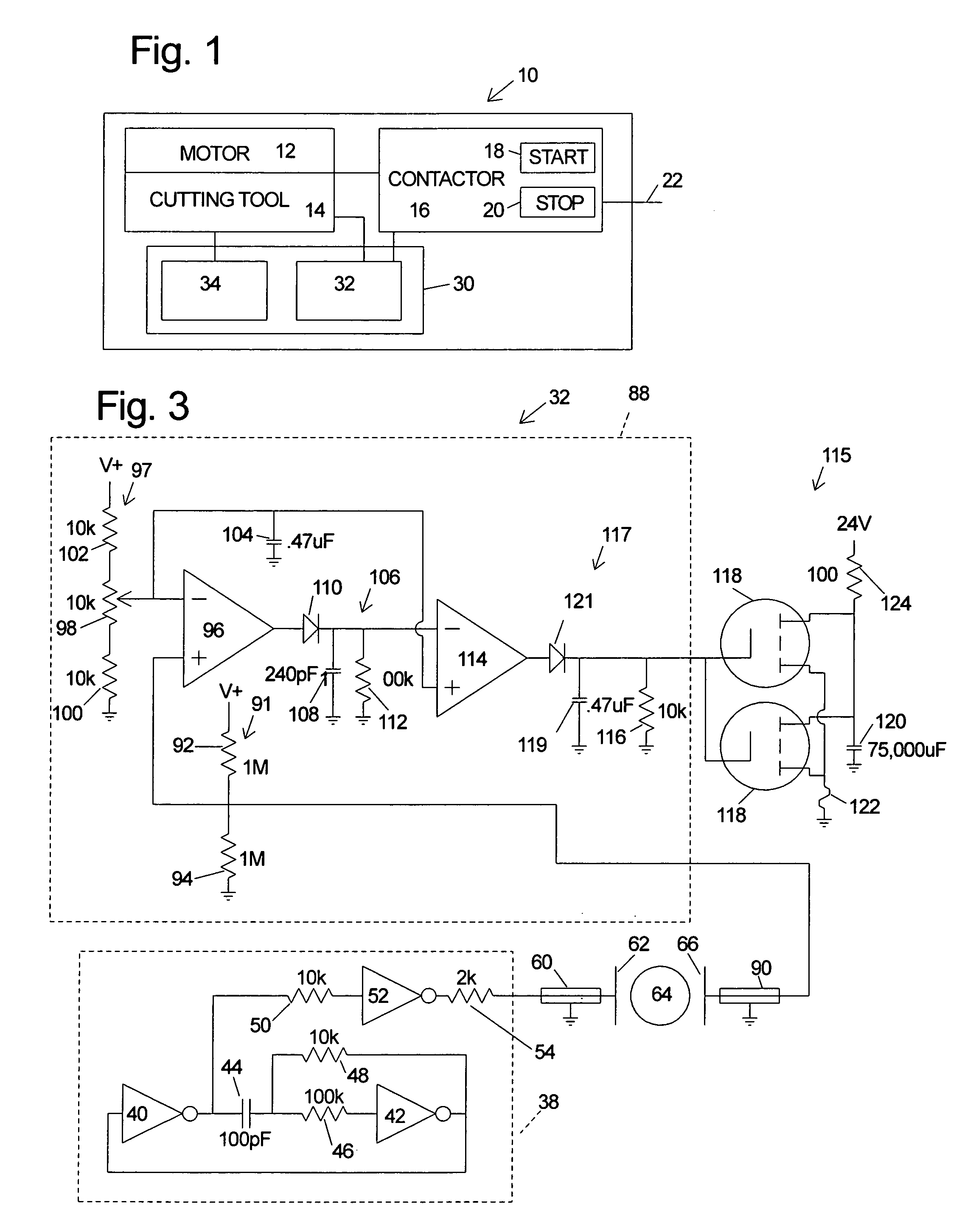

Safety system for power equipment

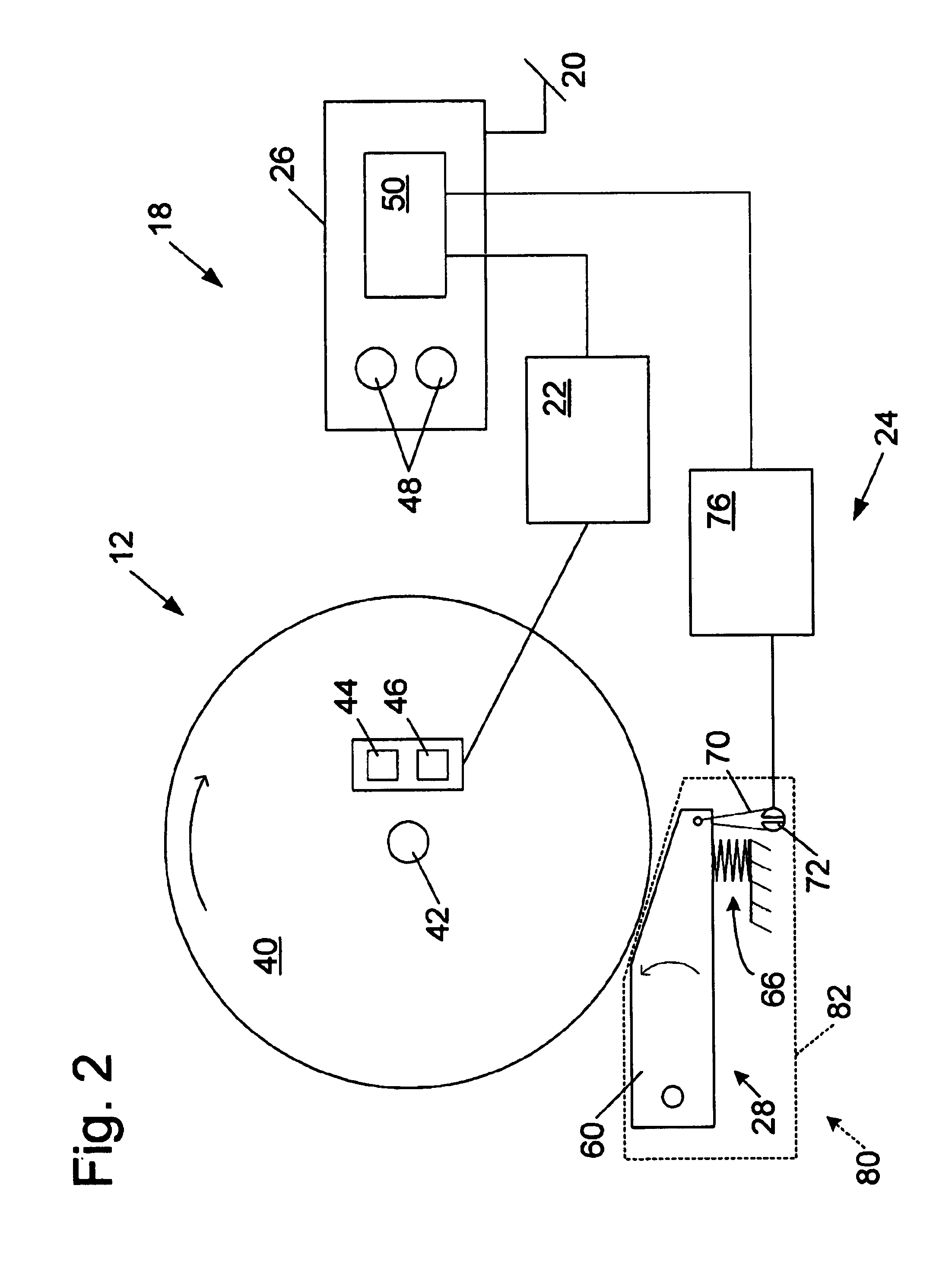

Safety systems for power equipment are disclosed. The safety systems include a detection system adapted to detect contact between a person and a working portion of a machine, where the detection system is adapted to capacitively impart an electric charge on the working portion and to detect when that charge drops; and a reaction system associated with the detection system to cause a predetermined action to take place relative to the working portion upon detection of contact between the person and the working portion by the detection system. Machines equipped with safety systems are also disclosed, such as saws, jointers, etc. The machines include a working portion, such as a cutter or blade, a detection system adapted to detect a dangerous condition between a person and the working portion, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition, such as a brake system to stop the working portion, a retraction system to retract the working portion, or a system to cover the working portion. The machines may include a control system adapted to control the operability of one or more of the working portion, the detection system and the reaction system.

Owner:SAWSTOP HLDG LLC

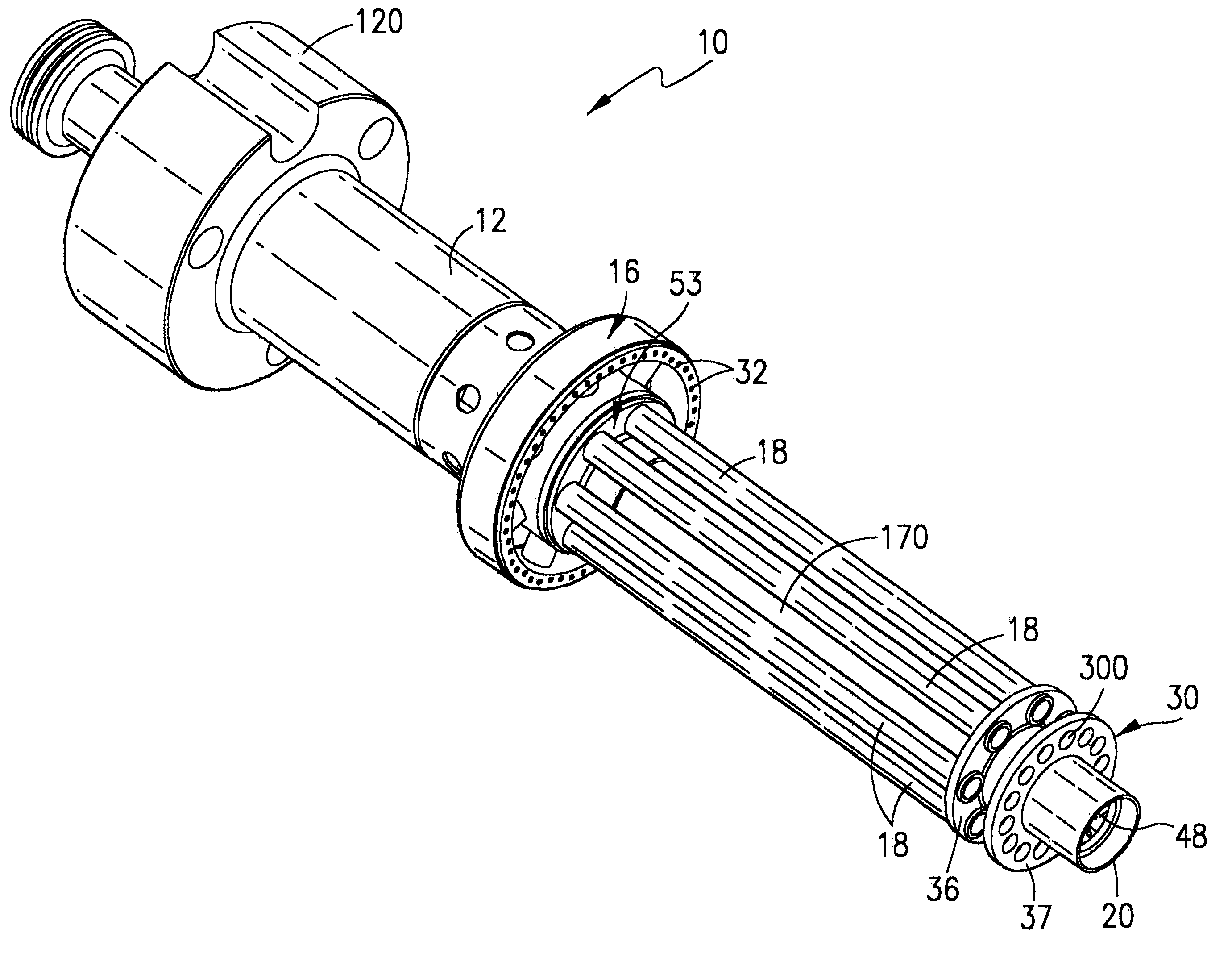

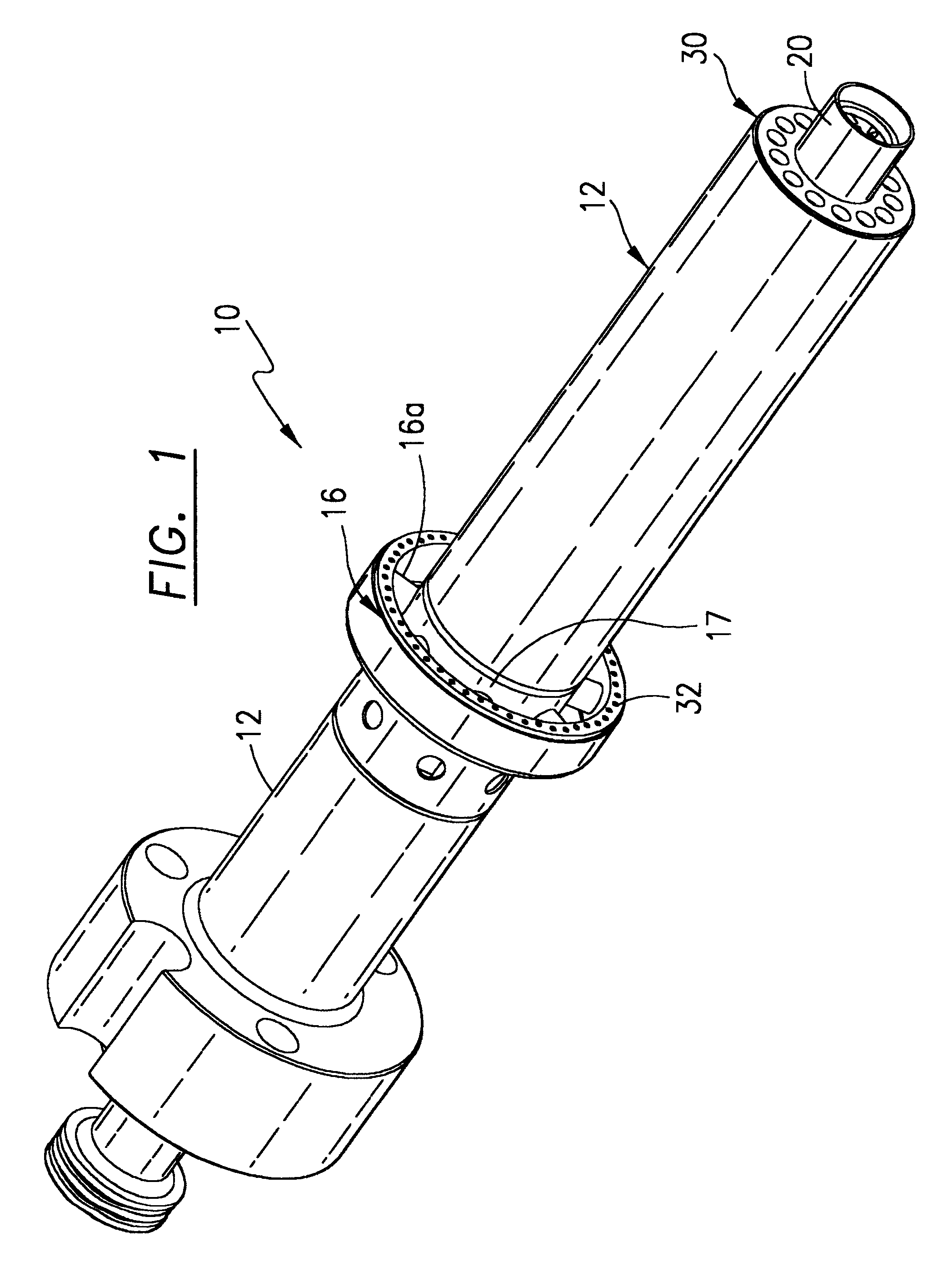

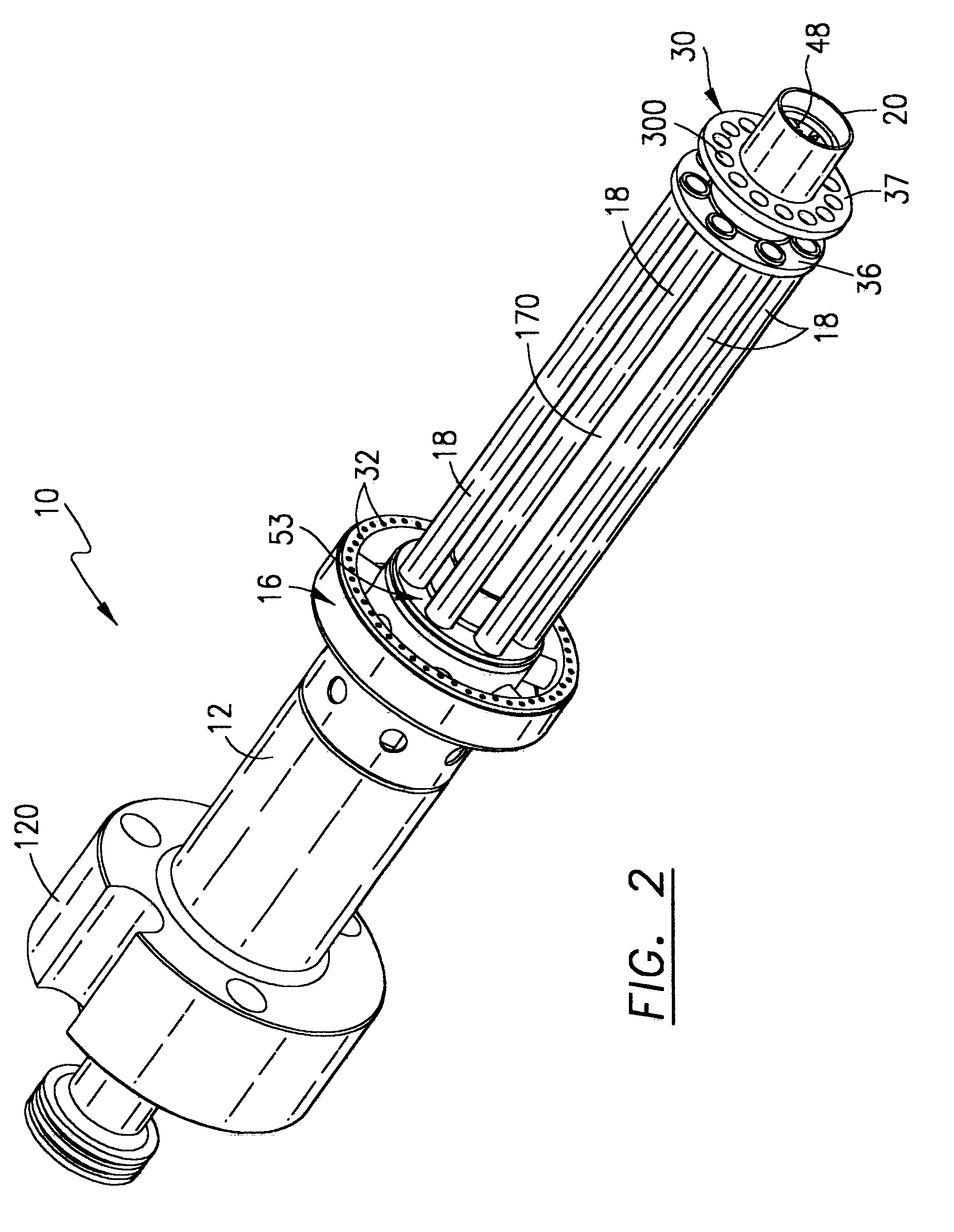

Actuators for use in fast-acting safety systems

Cutting machines with high-speed safety systems, and actuators used in high-speed safety systems, are disclosed. The cutting machines may include a detection system adapted to detect a dangerous condition between a cutting tool and a person. A reaction system performs a specified action, such as stopping the cutting tool, upon detection of the dangerous condition. An actuator may be used to trigger the reaction system to perform the specified action.

Owner:SAWSTOP HLDG LLC

Miter saw with improved safety system

InactiveUS6945148B2Increase opportunitiesLimit and even prevent injuryOther plywood/veneer working apparatusMechanically actuated brakesEngineeringMechanical engineering

A miter saw is disclosed having a base, a blade supported by the base, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating, to create an impulse against movement of the blade into the cutting zone, or to cause the blade to move away from the cutting zone.

Owner:SAWSTOP HLDG LLC

Miter saw with improved safety system

InactiveUS6877410B2Increase opportunitiesLimit and even prevent injuryOther plywood/veneer working apparatusMetal sawing devicesMechanical engineeringReaction system

A miter saw is disclosed having a base, a blade supported by the base, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating, to create an impulse against movement of the blade into the cutting zone, or to cause the blade to move away from the cutting zone.

Owner:SAWSTOP HLDG LLC

Safety systems for power equipment

A saw with a safety system is disclosed. The safety system includes a detection system adapted to detect contact between a person and a blade while the blade is moving. The safety system further includes a brake system adapted to engage the blade and to stop the blade when the detection system detects contact between the person and the blade.

Owner:SAWSTOP HLDG LLC

Detection system for power equipment

Woodworking machines including conductive cutters adapted to cut workpieces, and motors adapted to drive the cutters are disclosed. The machines also include a contact detection system adapted to detect contact between a person and the cutter, and to distinguish contact between the person and the cutter from contact between the workpiece and the cutter. The machines further include a reaction system adapted to cause a predetermined action to take place upon detection of contact between the person and the cutter by the contact detection system.

Owner:SAWSTOP HLDG LLC

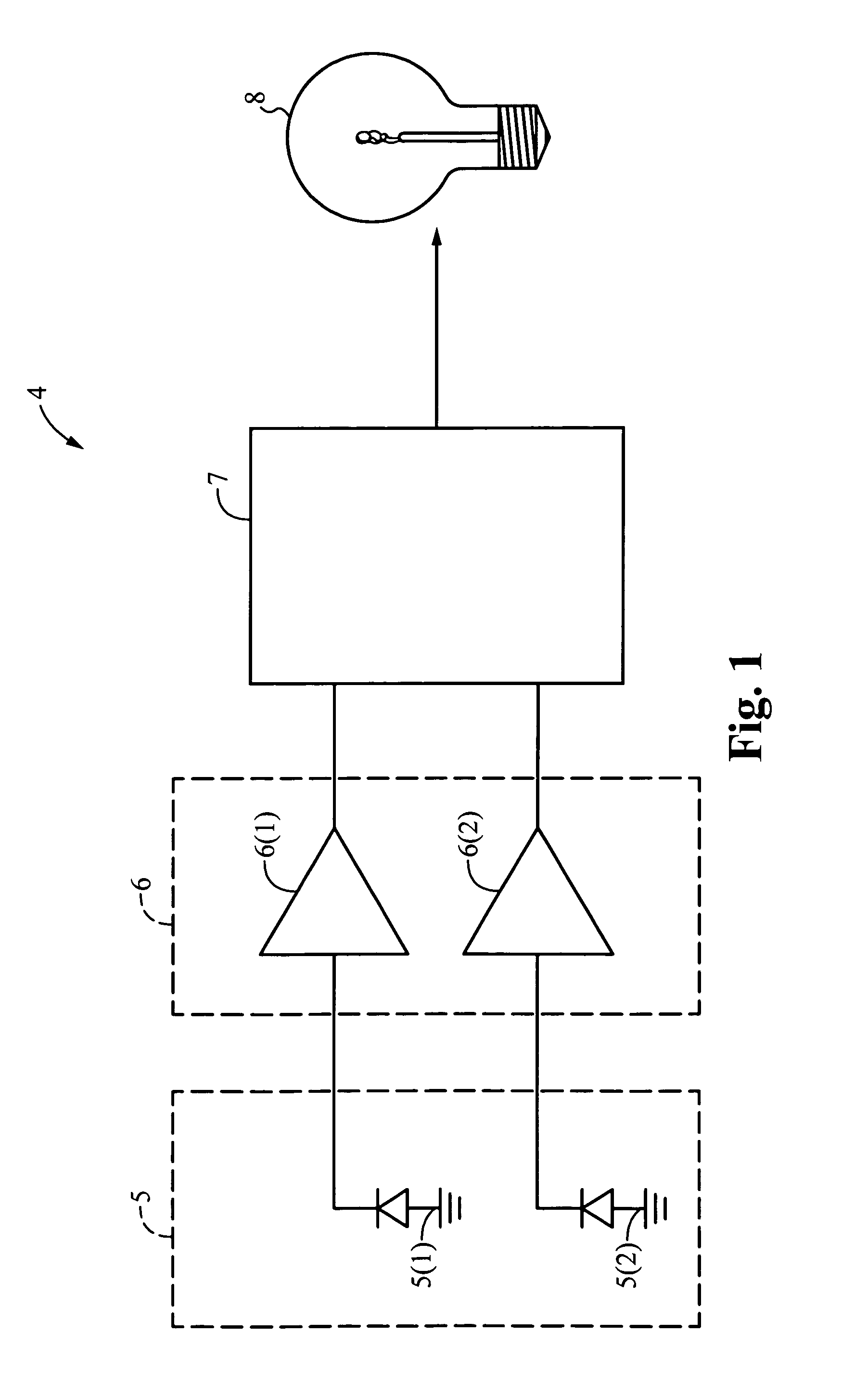

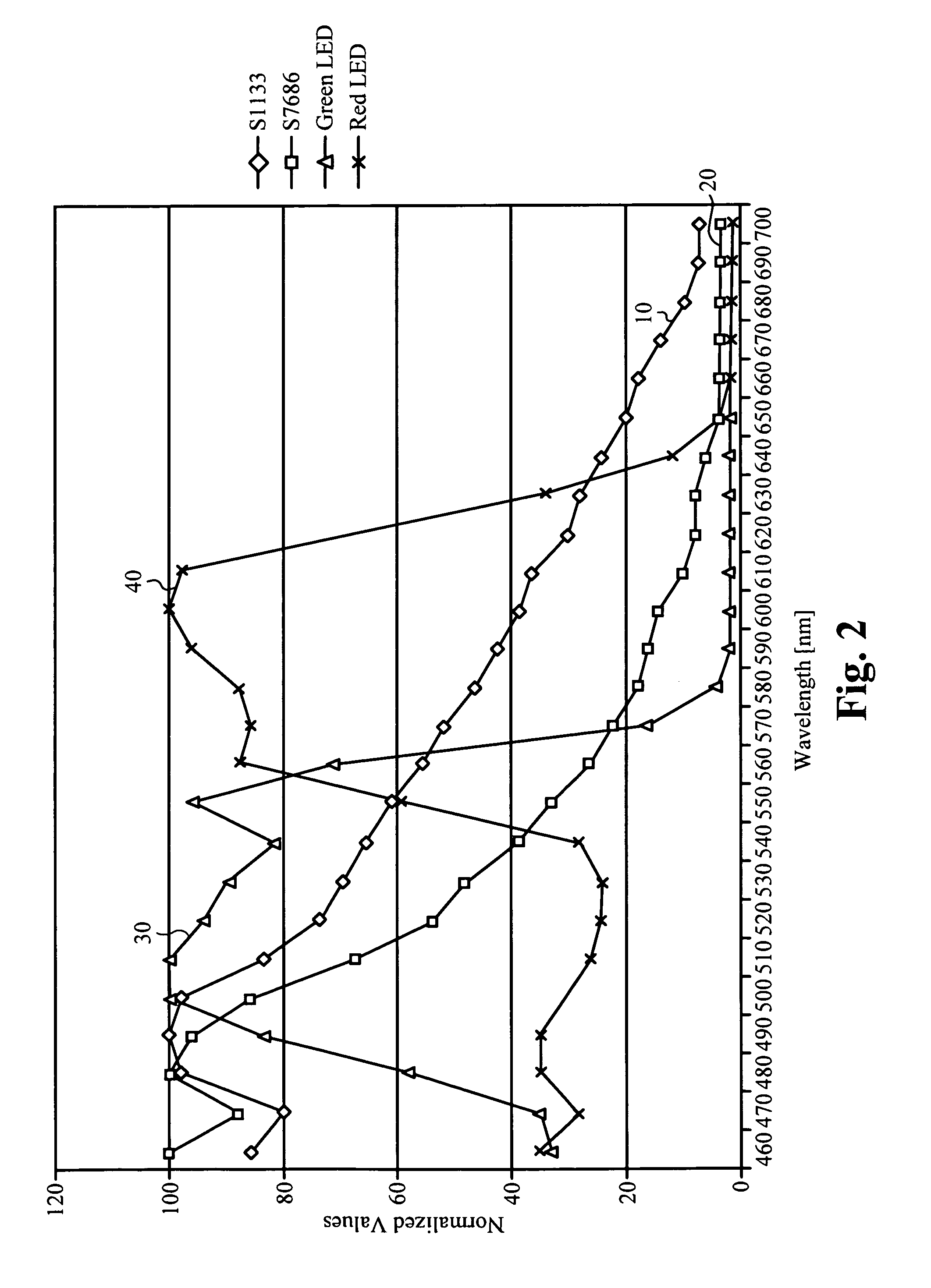

Diode-based light sensors and methods

The present invention provides an illumination management system that includes a first LED that outputs a first signal when exposed to a first spectrum of light, the first signal indicating an intensity of light from the first spectrum; a second LED that outputs a second signal when exposed to a second spectrum of light, the second signal indicating an intensity of light from the second spectrum and wherein the second spectrum includes at least some wavelengths that are not in said first spectrum. In some embodiments, more LEDs could be included in the system for associating the presence of light energy from different parts of the light spectrum. Also included is light control circuitry, coupled to the LEDs, configured to generate a lighting control signal that can be output to one or more lights to adjust the lights to a desired light level, wherein the lighting control signal varies in response to said first and second signals.

Owner:WATT STOPPER

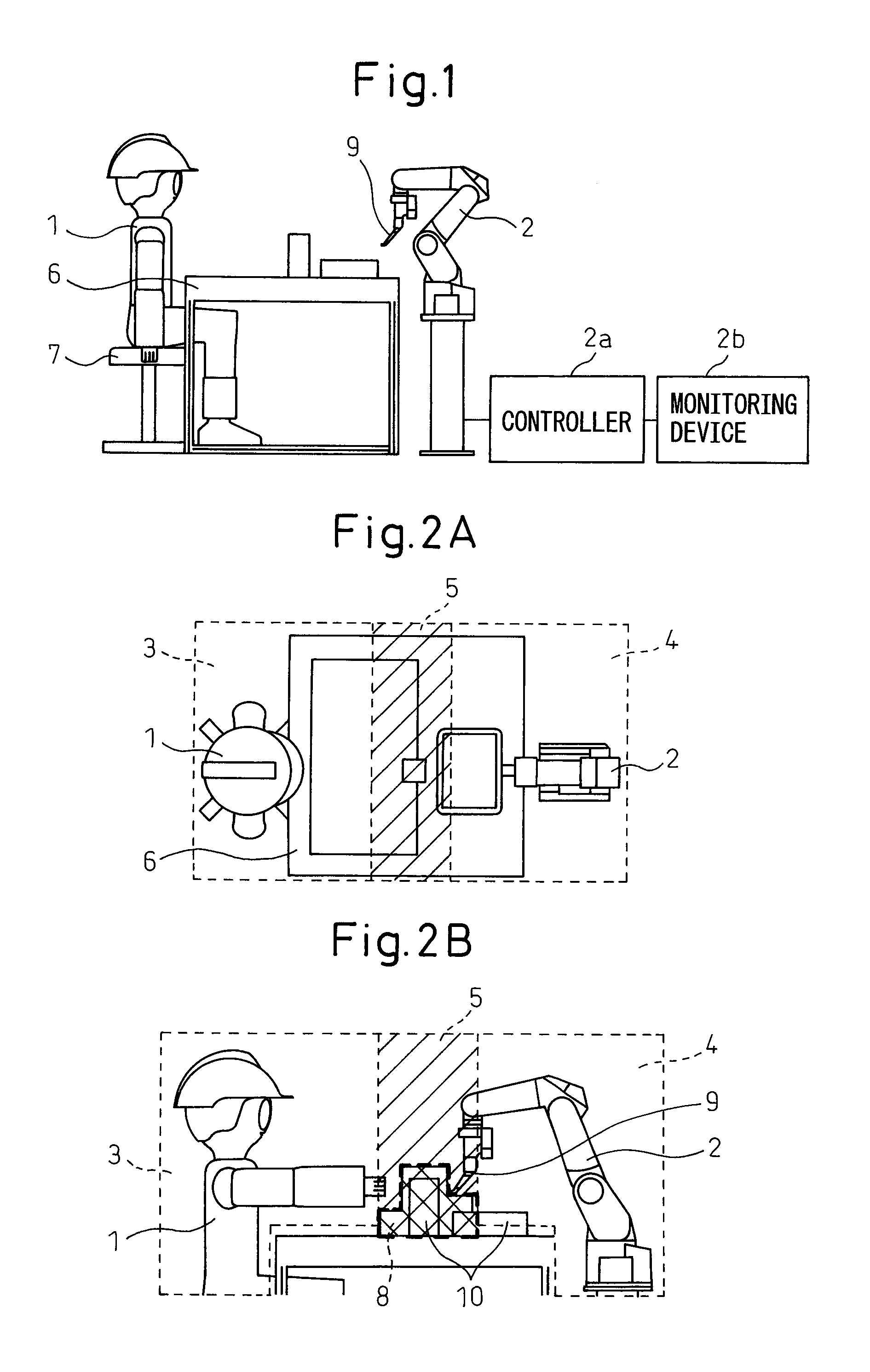

Production system having cooperating process area between human and robot

ActiveUS20100191372A1Ensure safetyImprove securityProgramme-controlled manipulatorSafety arrangmentsEngineeringRobot

A production system in which a human and a robot may simultaneously perform a cooperative task in the same area while ensuring human's safety. A robot is positioned at one side of a working table, and an operator is positioned at the other side of the working table. The reachable area of the operator is limited by the working table. An area of the working table is divided into an area where only the operator may perform a task, an area where only the robot may perform a task, and an area where both the operator and the robot may enter. In a cooperation mode, the maximum movement speed of a component of the robot is limited lower than when the component of the robot is outside the cooperative task area, and, the motion of the robot is limited so that the robot does not enter a robot entry-prohibited area.

Owner:FANUC LTD

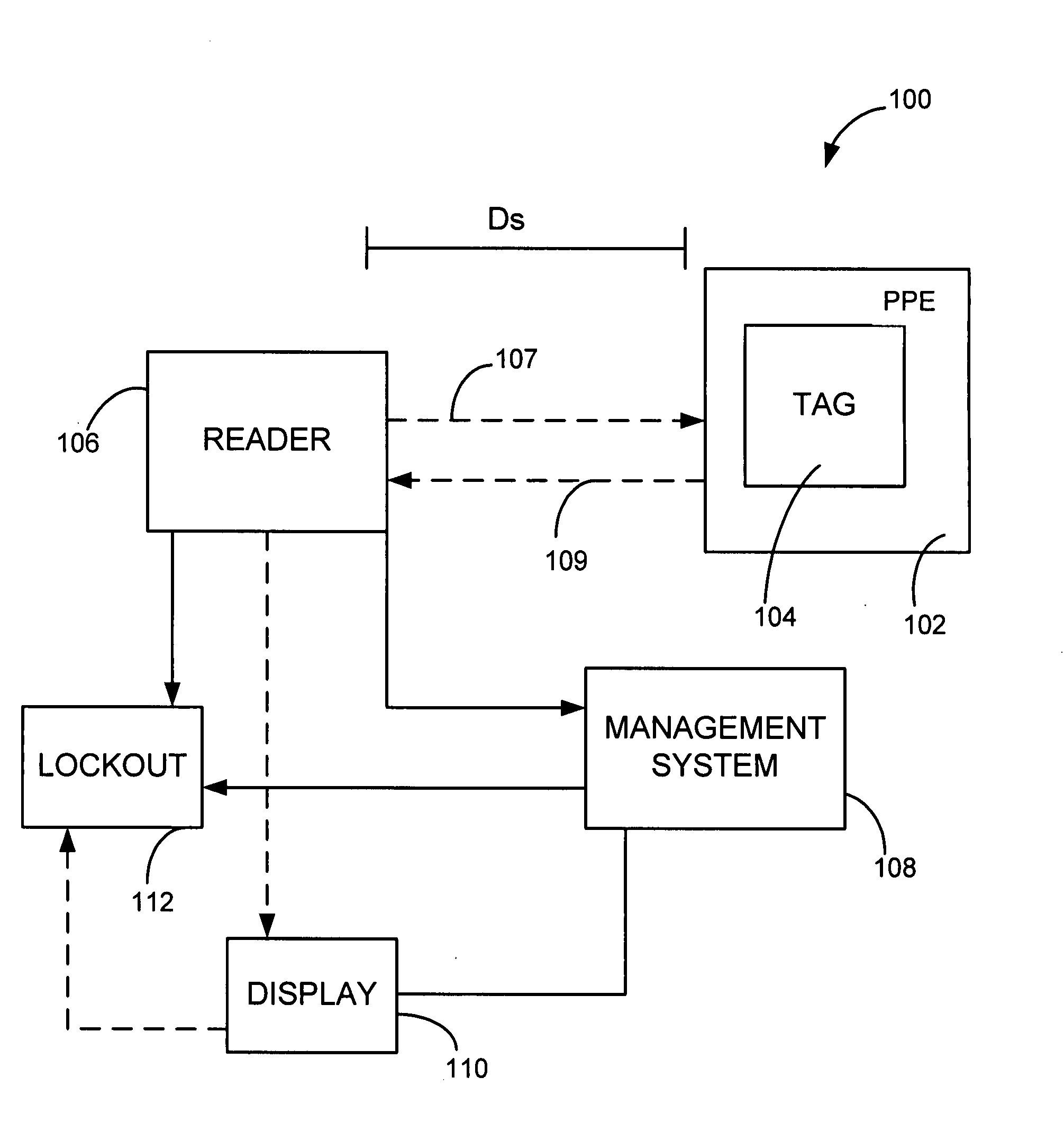

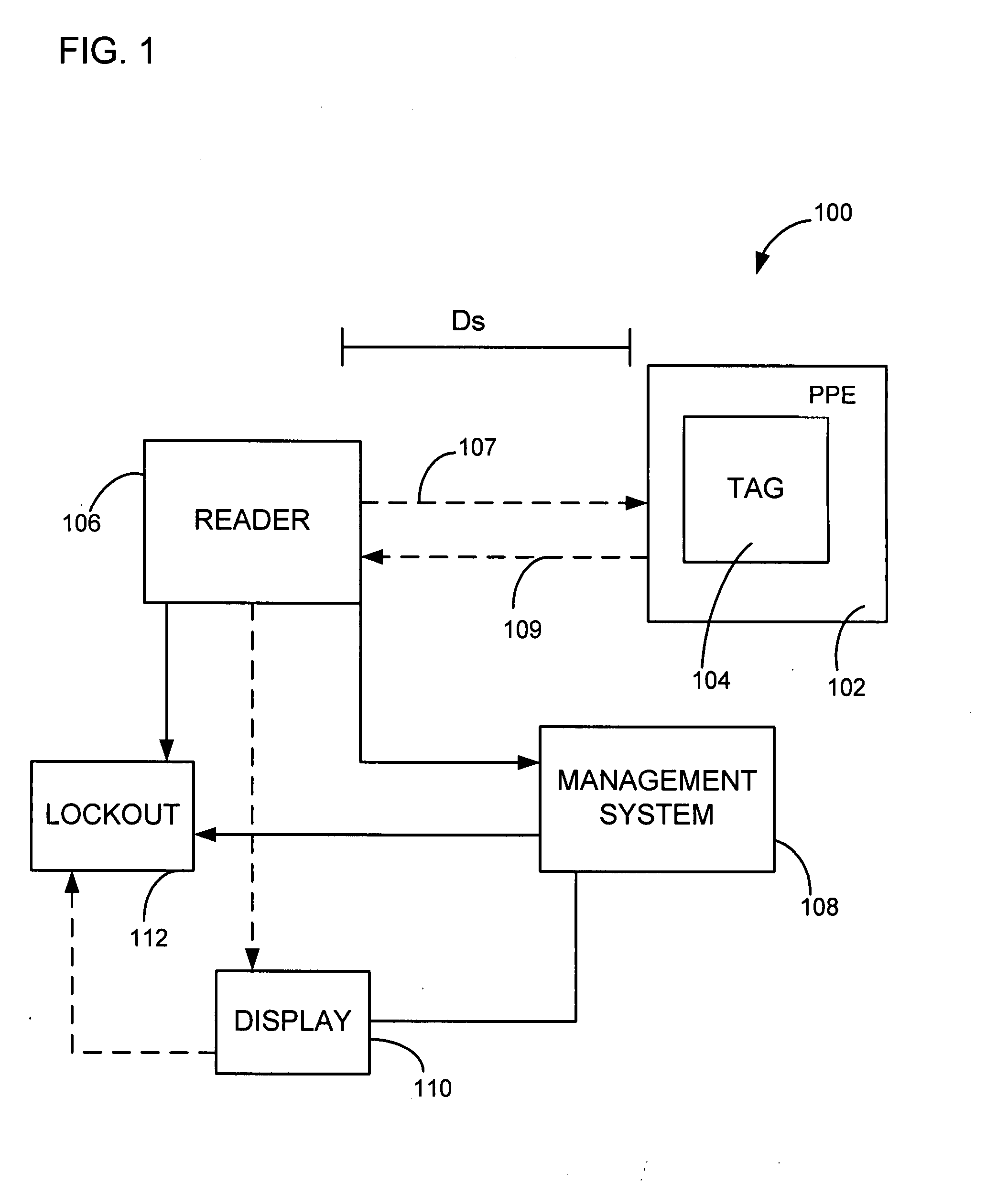

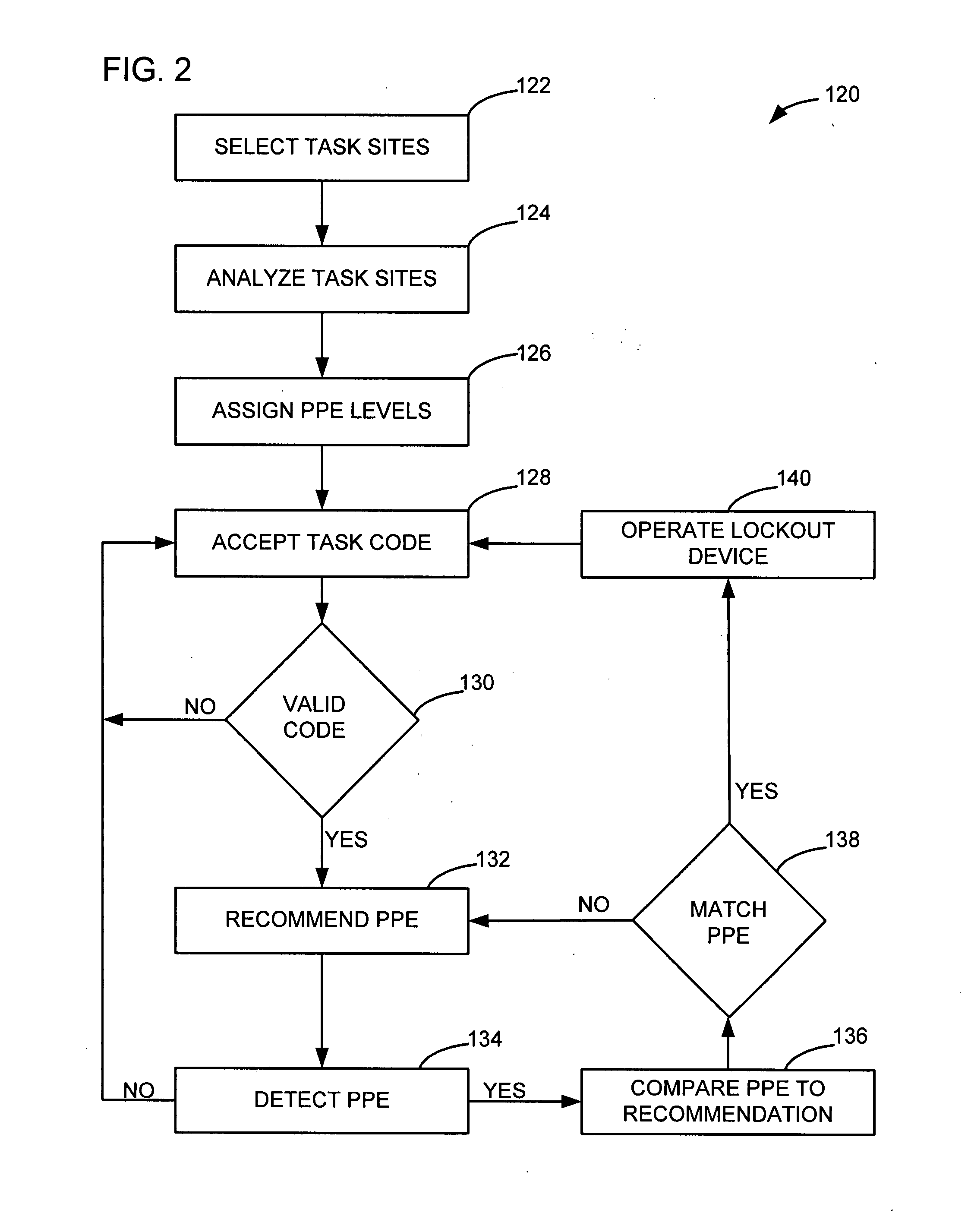

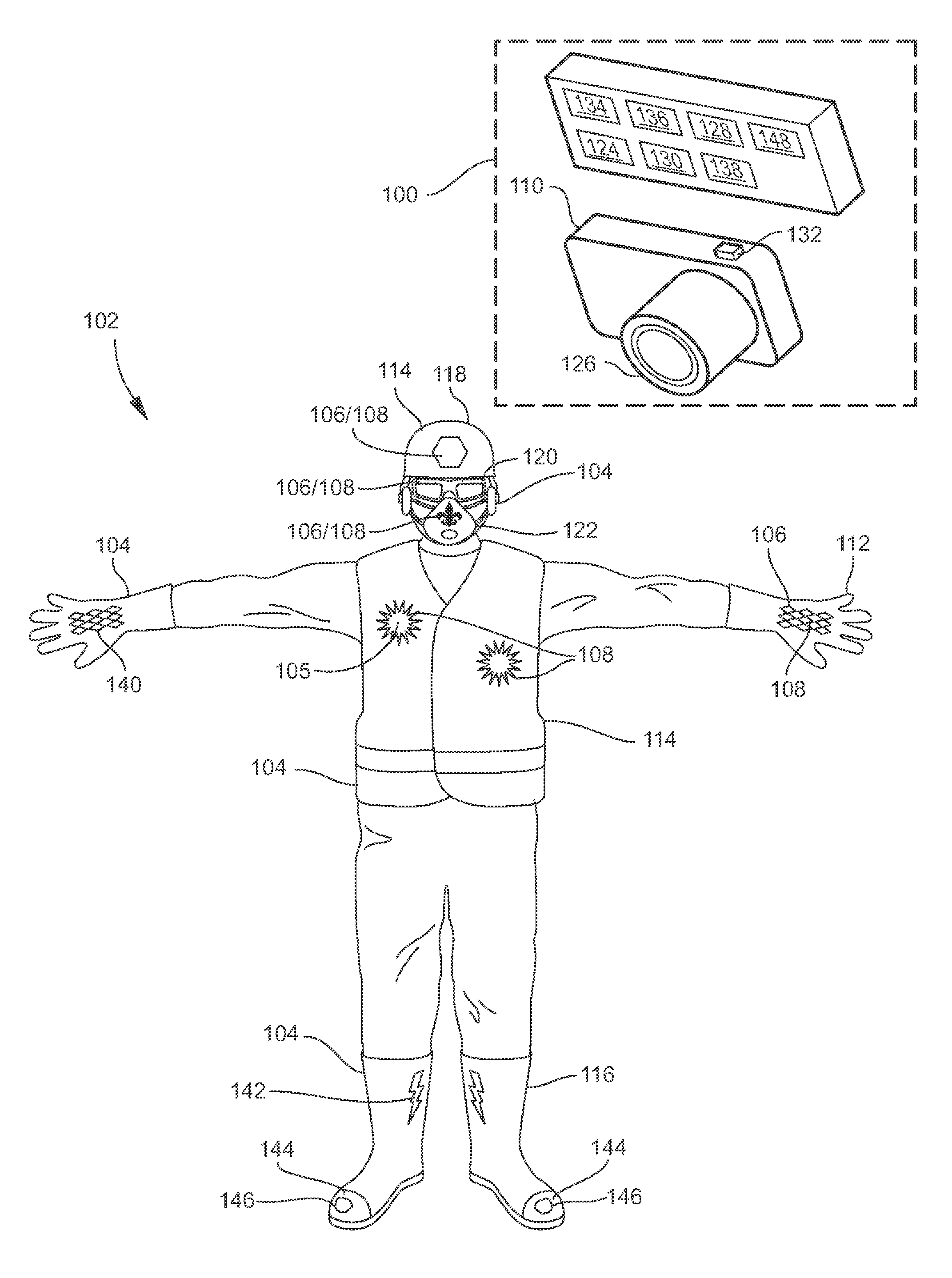

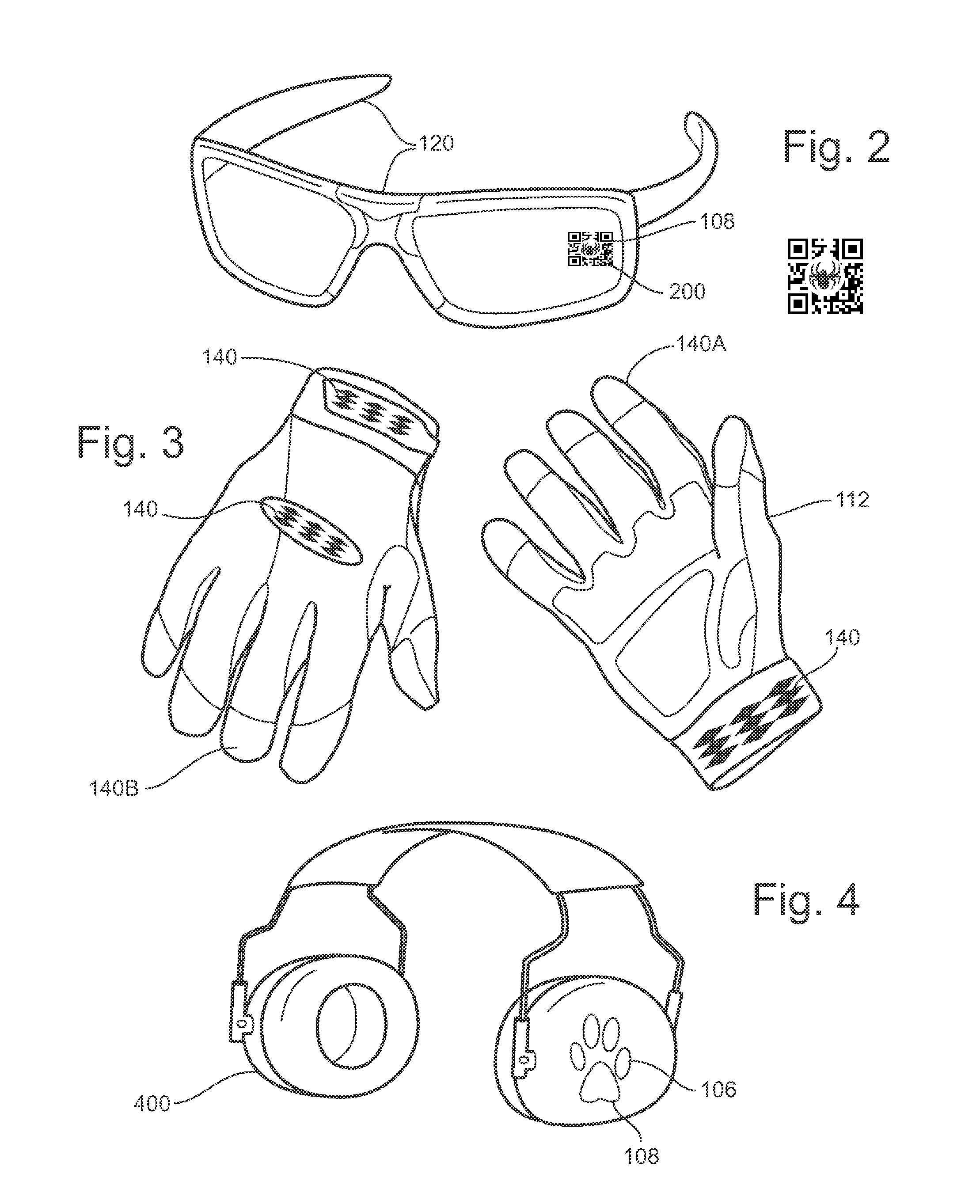

System and methods for ensuring proper use of personal protective equipment for work site hazards

ActiveUS20090040014A1Electric signal transmission systemsMultiple keys/algorithms usagePersonal protective equipmentEngineering

Systems and methods for detecting and verifying the adequacy of personal protective equipment needed by a person to complete a potentially hazardous task.

Owner:EATON INTELLIGENT POWER LIMITED

Power tool safety mechanisms

A sensing mechanism (12) for detecting user contact with an active portion (26) of the power tool (10) is provided. In addition, a safety mechanism (14) for preventing prolonged user contact with the active portion (26) of a power tool (10) is provided. The safety mechanism (14) is configured to actuate upon receipt of a signal from the sensing mechanism (12). According to a first aspect, the safety mechanism (14) is arranged to rapidly displace the active portion (26) away from a user extremity. Alternatively, according to a second aspect, the safety mechanism (14) is arranged to rapidly urge an extremity of the user away from the active portion (26) of the power tool (10).

Owner:BLACK & DECKER INC

Personnel safety utilizing time variable frequencies

InactiveUS8248263B2High noiseIncrease resistanceSafety devices for lifting equipmentsEngineering safety devicesOmnidirectional antennaDirectional antenna

A system to improve safety of workers who are in proximity to mobile machines includes a machine mountable radio-frequency identification reader that wirelessly monitors radio-frequency identification tags worn by workers moving relative to and in proximity to a mobile machine when the reader is mounted on the machine. The reader includes a processor and an antenna front-end which is switchable between an omni-directional antenna or at least one directional antenna. The omni-directional antenna is mountable so as to monitor a machine circumference completely around the mobile machine. Each directional antenna is mountable so as to monitor only either a front or a back of the mobile machine relative to the machine's direction of motion.

Owner:PSST MOBILE EQUIP - RICHARD SHERVEY +1

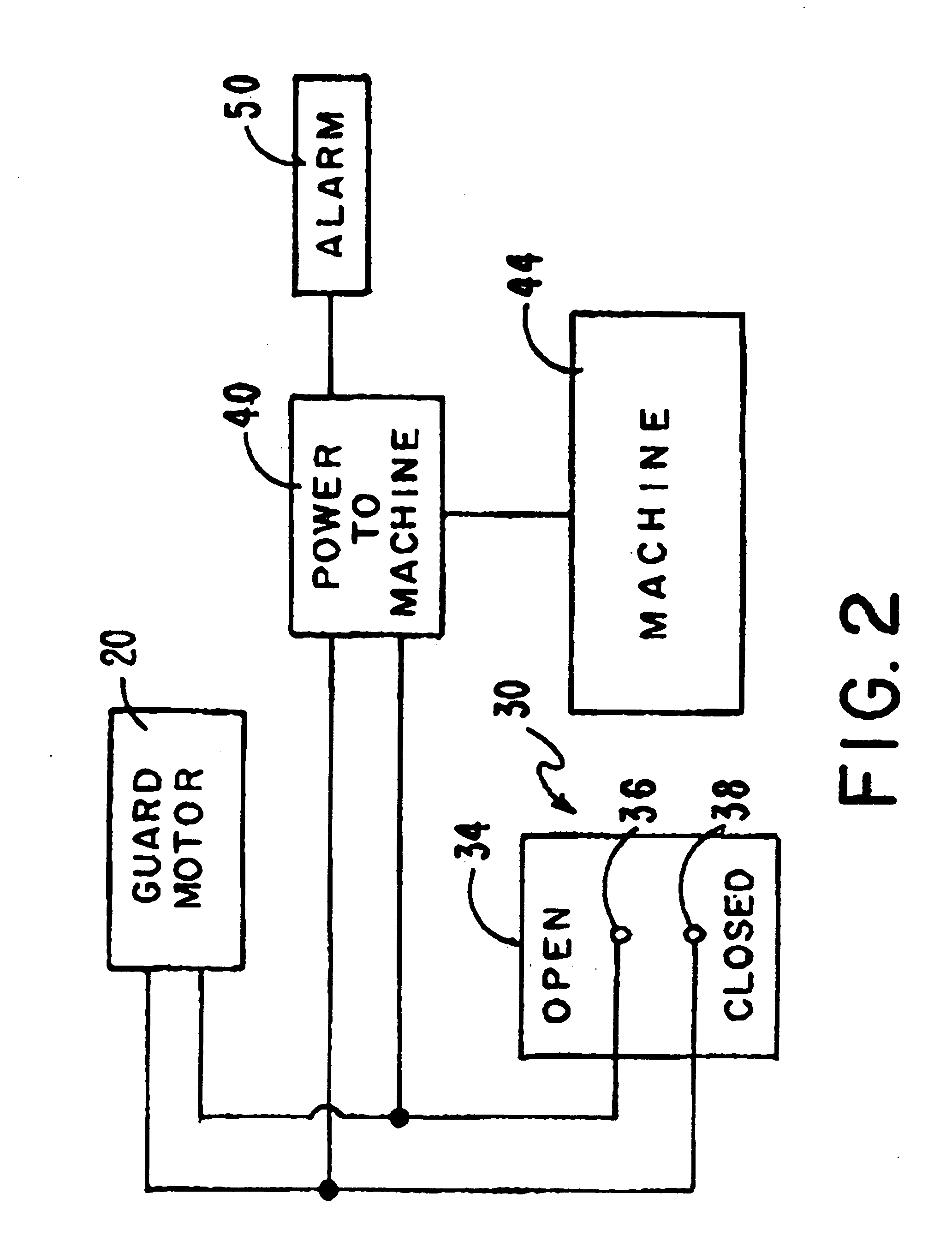

Machine safety guard

InactiveUS6325195B1Easy to operateProvide securityYielding couplingShutters/ movable grillesUnit systemEngineering

A machine safety guard unit system having a flexible panel moved upwards and downwards between track members with the system positioned between the operative parts of a machine and a machine operator, such panel when closed protecting the machine operator and when moved upwards into its open mode, allowing access to the machine and preventing the machine from operating. In some embodiments more than one of such units can be disposed around a machine with alarm means; and in yet other embodiments, with interengagement means connecting such units.

Owner:RITE HITE HLDG CORP

Optical proximity device for power tools

The present invention is directed to a power tool including a working element for performing a task. A light source is arranged to project a beam of light adjacent the working element. A detector, such as an electro-optic type detector, is communicatively coupled to the power tool such that the detector is capable of detecting the presence of a human body part in the beam of light. If a body part is detected, the detector may communicate to stop operation of the working element.

Owner:BLACK & DECKER INC

Method and apparatus for the control of a safety-relevant function of a machine

ActiveUS20060049939A1Move quicklyEngineering safety devicesBurglar alarmMovement controlMachine control

An apparatus for the control of at least one safety-relevant function of a machine is described having a machine control for the control of the movements of the machine, having at least one sensor for the sensing of an object inside a monitored zone and having an evaluation unit for the setting of a danger zone and for the triggering of the safety-relevant function on the intrusion of the sensed object into the danger zone. To set the danger zone, the evaluation unit is coupled to the machine control and the evaluation unit is designed for the derivation of the parameters required for the setting of the danger zone starting from the control signals used by the machine control for the movement control of the machine. A corresponding method is furthermore described.

Owner:SICK AG

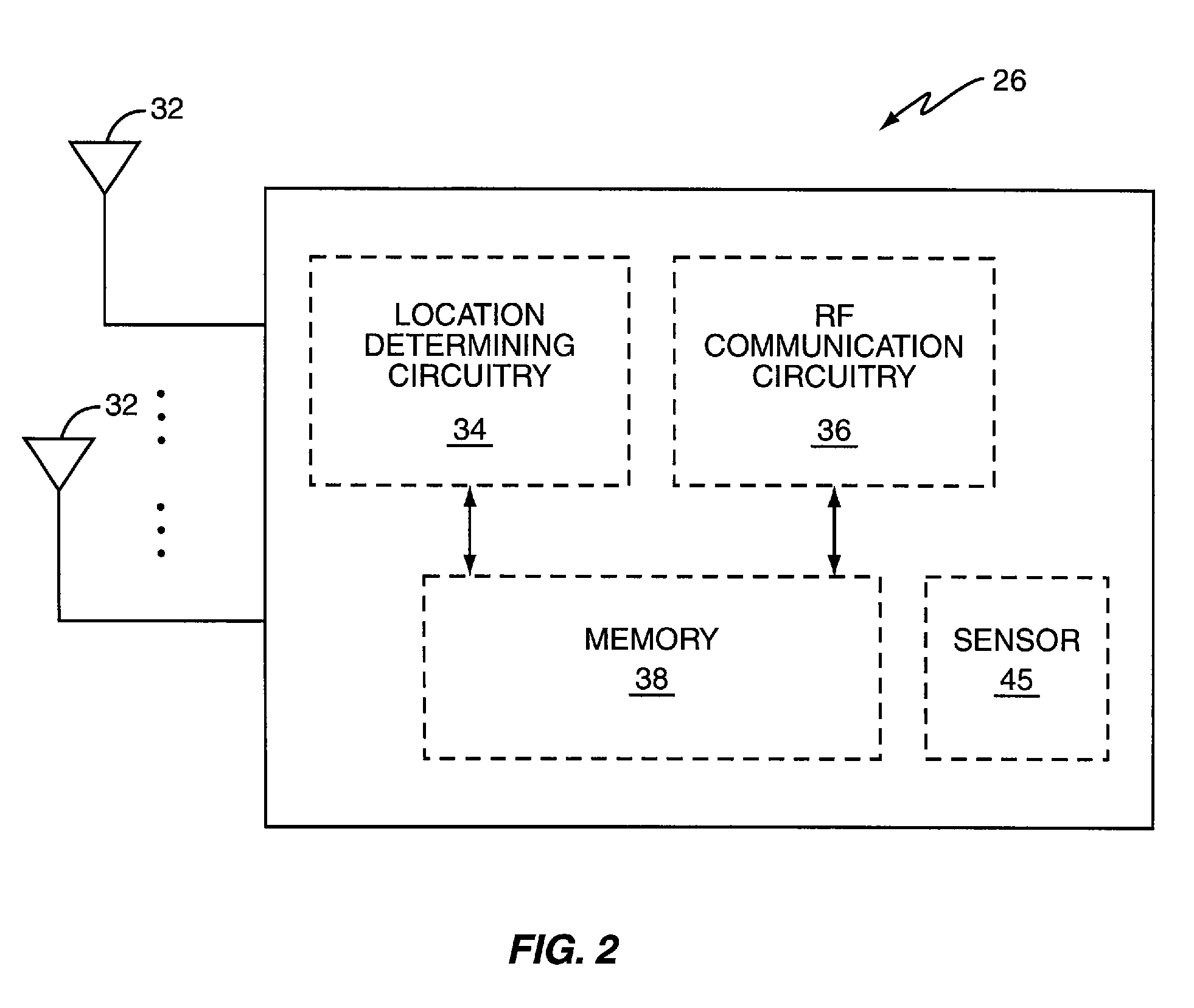

Construction hard hat having electronic circuitry

ActiveUS7298258B1Electric testing/monitoringEngineering safety devicesComputer sciencePerson location

Personnel activity at a construction site is tracked using electronic circuitry included in hard hats worn by personnel at the site. According to one embodiment, activity at a construction site is monitored by processing personal information directly or indirectly received from electronic circuitry formed as part of one or more hard hats worn by personnel located at the construction site. The personal information is uniquely associated with individual ones of the personnel. One or more messages are generated based on the personal information received from the electronic circuitry and personnel location. For example, the messages may warn particular personnel that they have entered an unauthorized area at the construction site. Optionally, personnel activity may be periodically monitored and reported.

Owner:ACCUSTIAL

Full ring fuel distribution system for a gas turbine combustor

InactiveUS6282904B1Convenient lightingEnhancing quality and integrityBurnersContinuous combustion chamberCombustion chamberCombustor

A fuel nozzle system for use in a combustor utilized in a combustion turbine for reducing nitrogen oxides and other pollutants including an annular fuel distribution manifold separately mounted away from a diffusion nozzle, said annular manifold having a plurality of fuel emitting passages or holes disposed along the downstream side of the manifold, said manifold being mounted in a position away from the diffuser nozzle body to allow air to stream around the manifold on all sides allowing for a thorough mixture of fuel and air around the annular manifold for better premixing in the combustion chamber.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Method and apparatus for enhancing safety within a work zone

ActiveUS6963278B2Improve securityEngineering safety devicesElectric/electromagnetic visible signallingWork zoneIndustrial engineering

Owner:FRAME GARY M

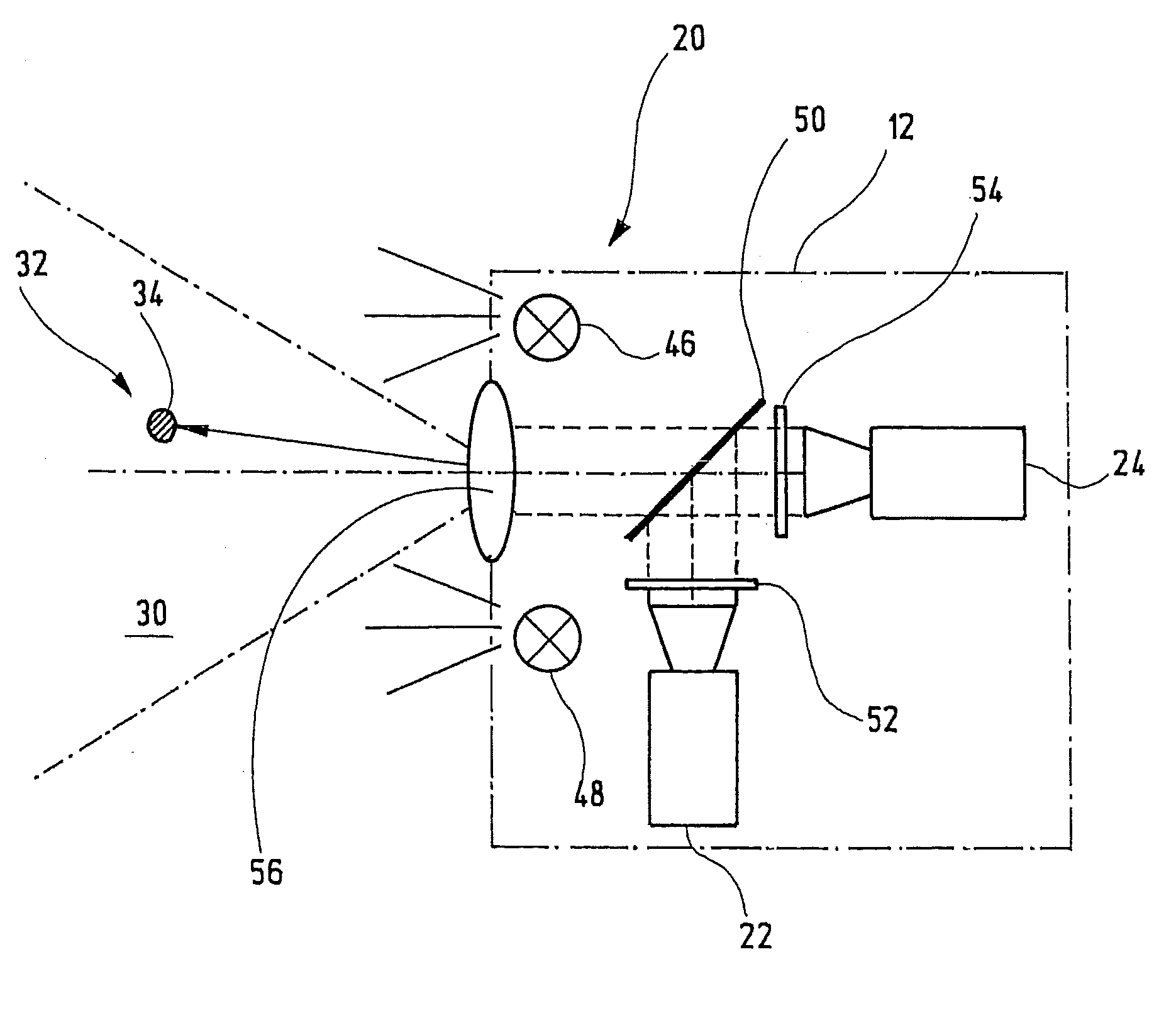

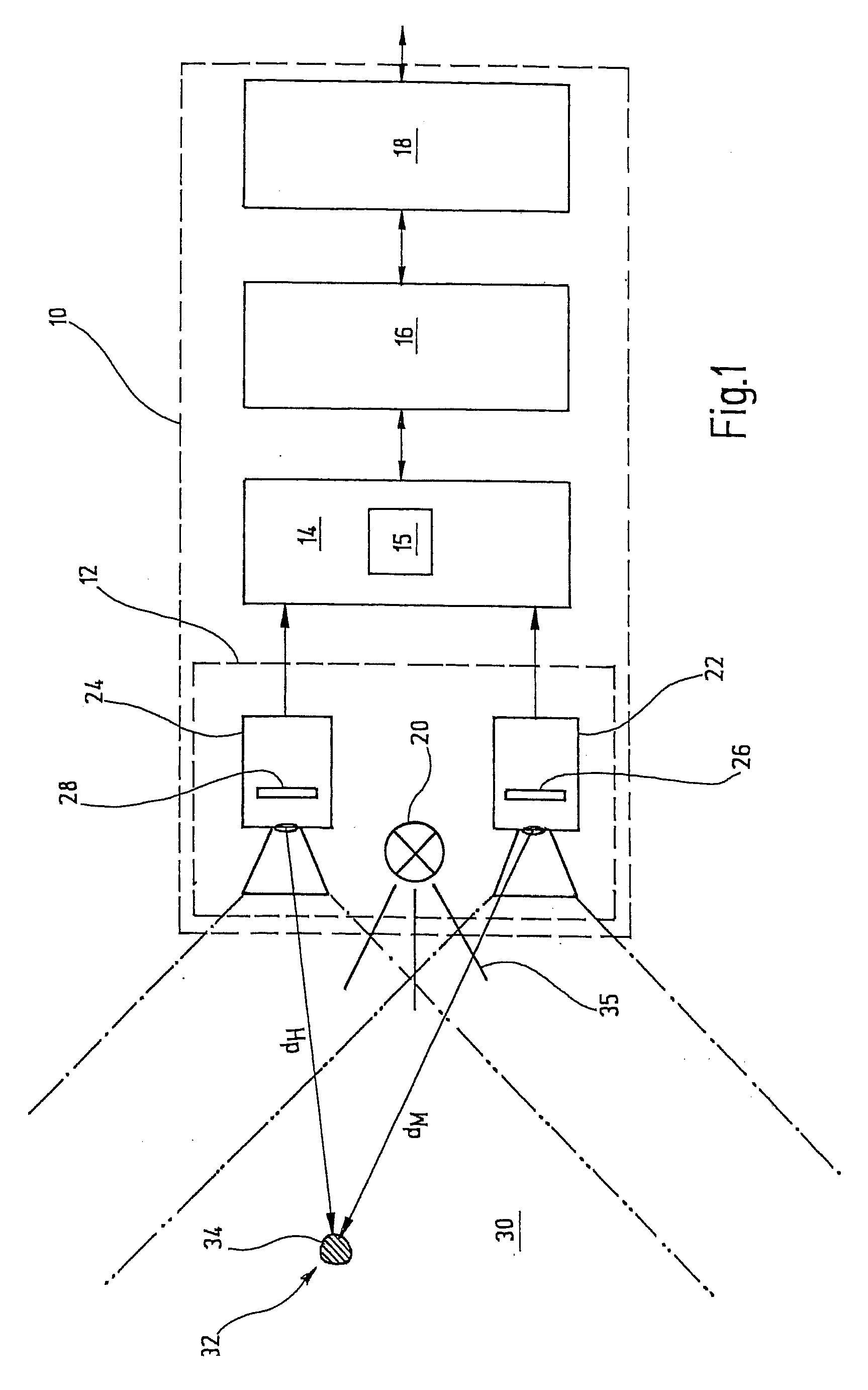

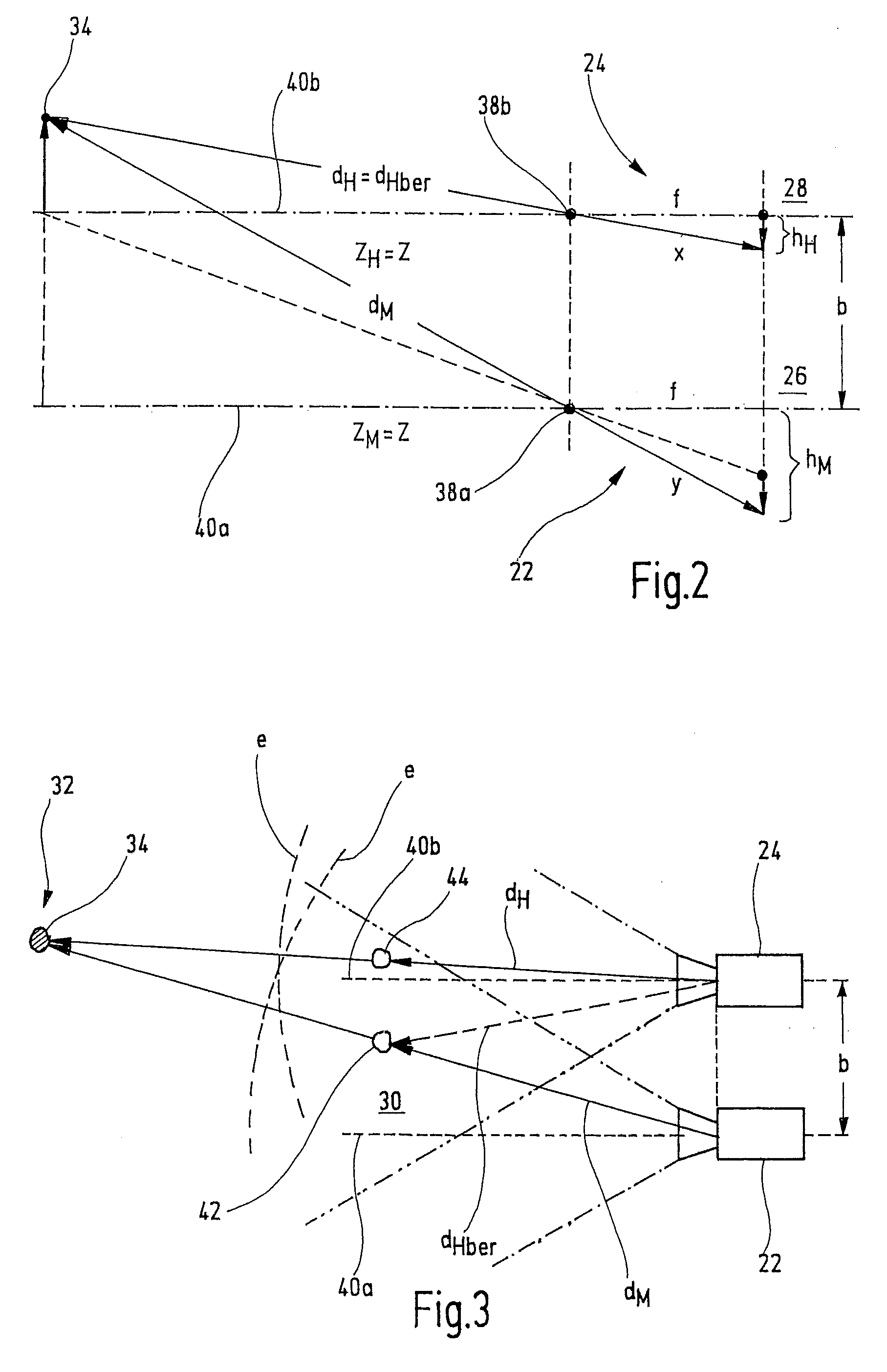

Apparatus and method for monitoring a spatial area, in particular for safeguarding a hazardous area of an automatically operated installation

ActiveUS20080273758A1Increased fail-safetySimple processOptical detectionEngineering safety devicesImage recordingLight signal

An apparatus for monitoring a spatial area, in particular for safeguarding a hazardous area of an automatically operated installation, comprises an illumination device which at least temporarily emits light signals into the spatial area. A first image recording unit records a first image of the spatial area. The first image recording unit comprises an image sensor having a plurality of pixels. An evaluation unit determines a distance value for at least one spatial area point, which is located in the spatial area and is imaged on at least one pixel, by means of a propagation type measurement. The propagation type measurement suffers from a limited unambiguity range. Therefore, a test device is designed to check the distance value by means of a reference distance value determined from a second image of said spatial area.

Owner:PILZ (COMPANY)

Systems and methods for monitoring personal protection equipment and promoting worker safety

InactiveUS20140307076A1Promotes worker safetyEasily and simply identifyEngineering safety devicesCharacter and pattern recognitionDigital imagingControl signal

Systems and methods for monitoring and personal protection equipment promoting worker safety are disclosed. According to an aspect, a system for promoting the safety of workers comprises a digital imaging device positioned to capture one or more images of a predetermined viewing area. Further, the system comprises an image processor operatively associated with the digital imaging device. The image processor is configured to determine whether a person is within the predetermined viewing area of the digital imaging device. The image processor is further configured to determine whether the person is not wearing required personal protection equipment. Additionally, the image processor is configured to generate a message or control signal in response to determining the person is within the predetermined viewing area of the digital imaging device and determining the person is not wearing the required personal protection equipment.

Owner:DEUT RICHARD

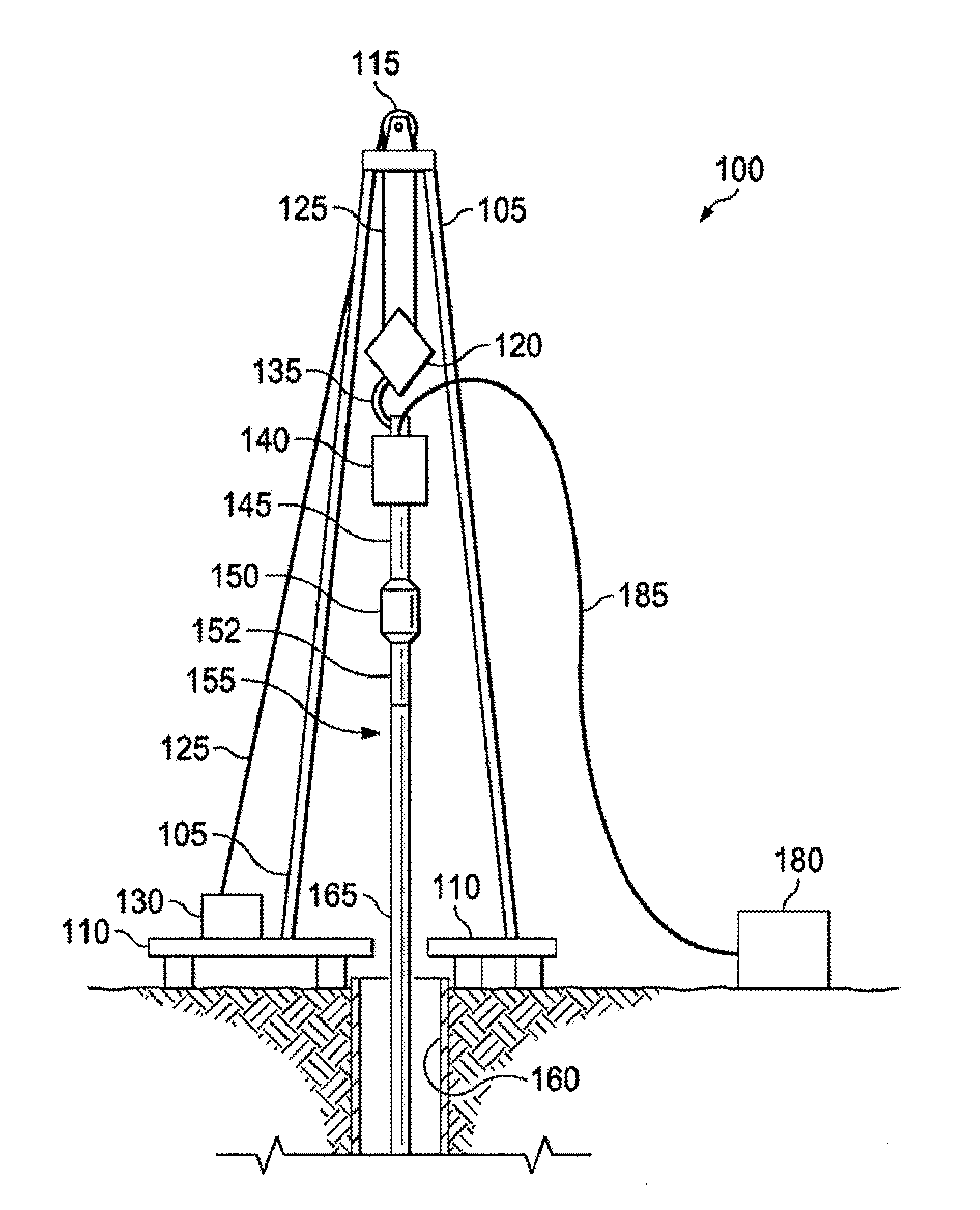

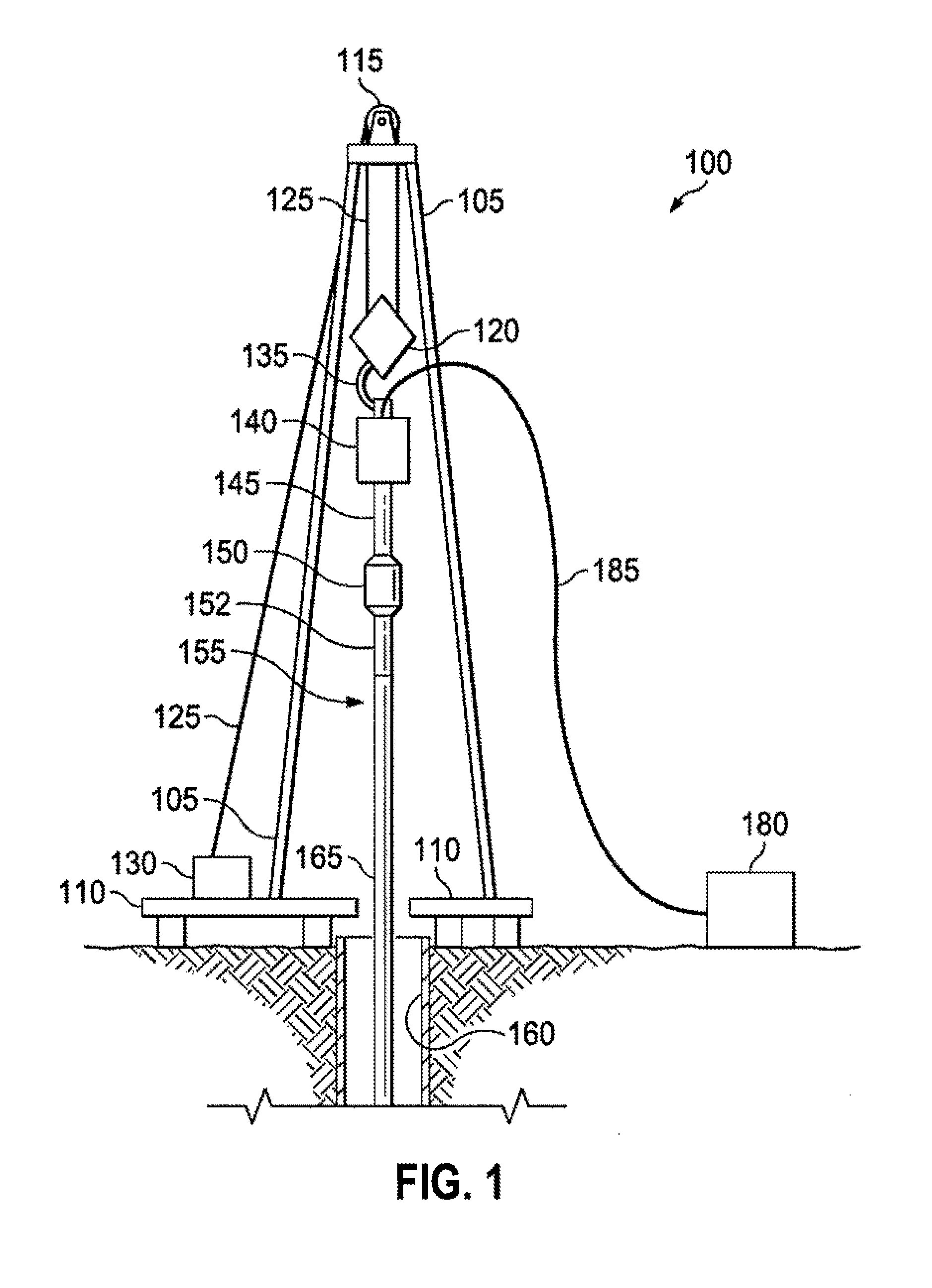

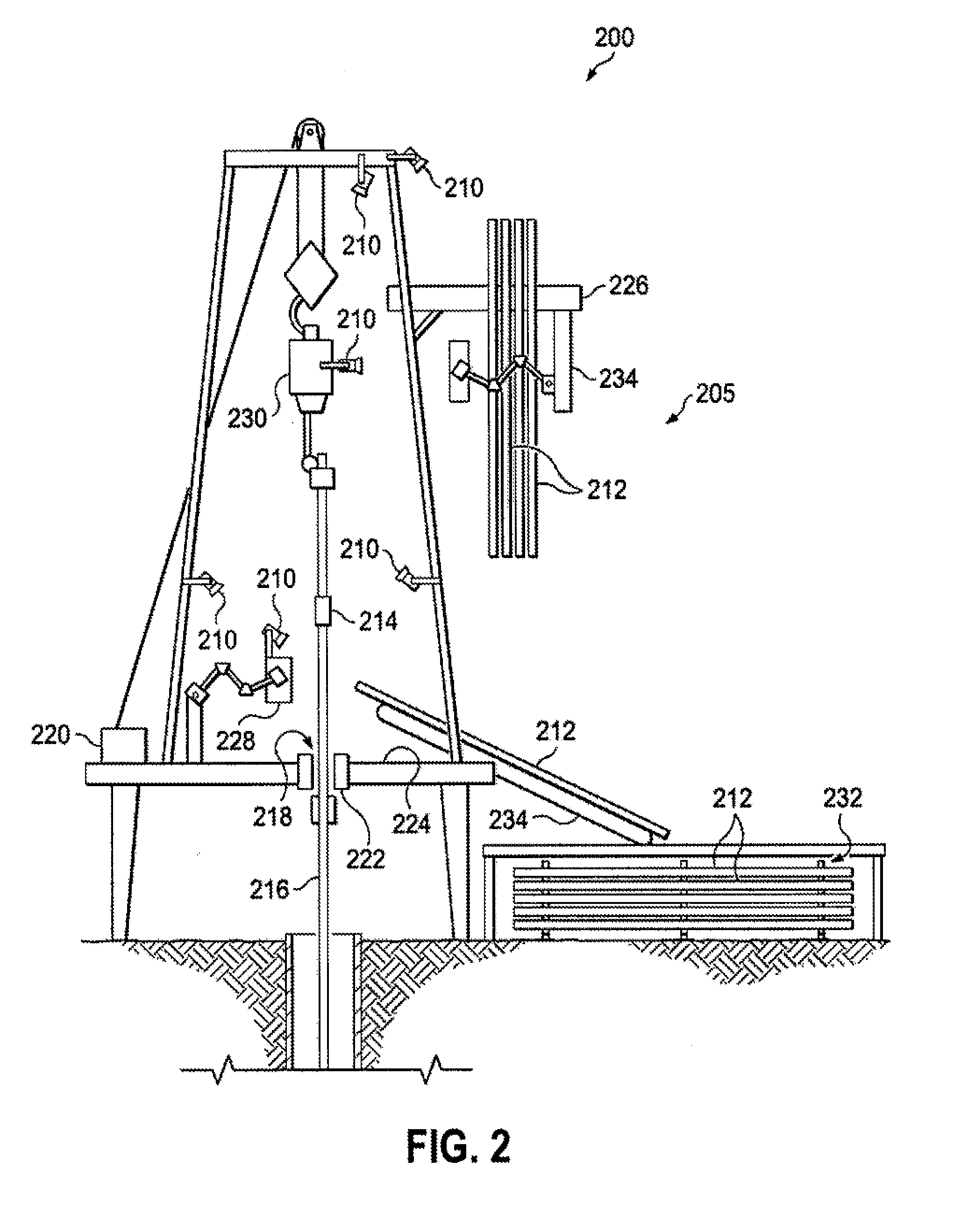

Wellsite control employing three-dimensional imaging

According to one aspect, a three-dimensional model of at least a portion of a wellsite is generated. A three-dimensional camera system is calibrated to the three-dimensional model. A draw-works encoder is calibrated. The motion of a component is monitored. The draw-works encoder is recalibrated based on the monitoring. According to another aspect, three-dimensional imaging data sets are received, the three-dimensional imaging data sets being associated with a control volume in which the portion of the wellsite is disposed. A predefined three-dimensional model is augmented with the three-dimensional imaging data sets. According to another aspect, at least one three-dimensional camera employs a first three-dimensional sensing technology that is different from a second three-dimensional sensing technology employed by at least one other three-dimensional camera. A single three-dimensional model is generated by merging respective three-dimensional imaging data sets. At least one system is controlled using the single three-dimensional model.

Owner:NABORS DRILLING TECH USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com