Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2023 results about "Circular saw" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A circular saw is a power-saw using a toothed or abrasive disc or blade to cut different materials using a rotary motion spinning around an arbor. A hole saw and ring saw also use a rotary motion but are different from a circular saw. Circular saws may also be loosely used for the blade itself. Circular saws were invented in the late 18th century and were in common use in sawmills in the United States by the middle of the 19th century.

Circular saw

InactiveUS8739417B2Add settingsGuaranteed uptimeMetal sawing devicesToothed gearingsGear wheelCircular saw

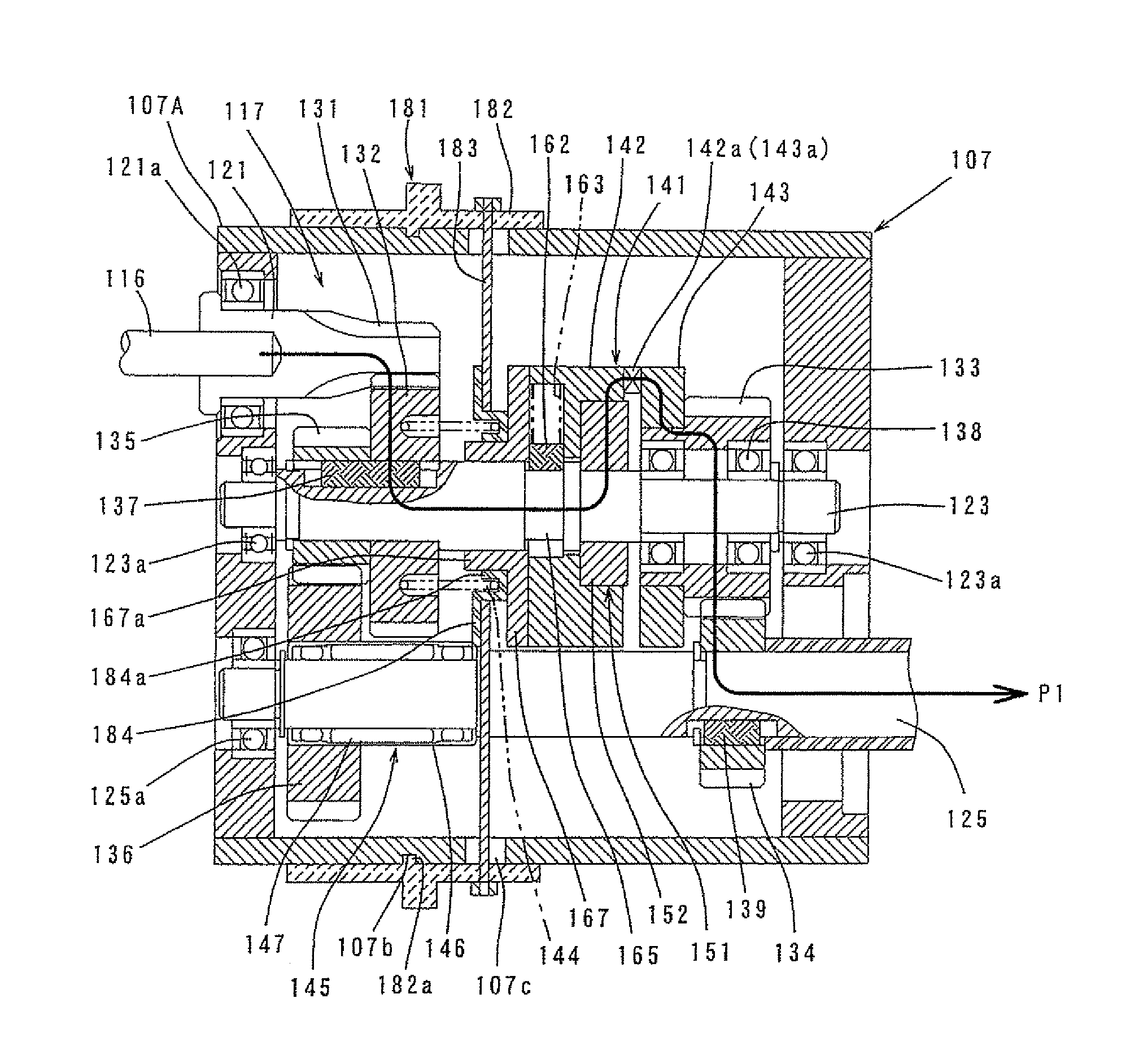

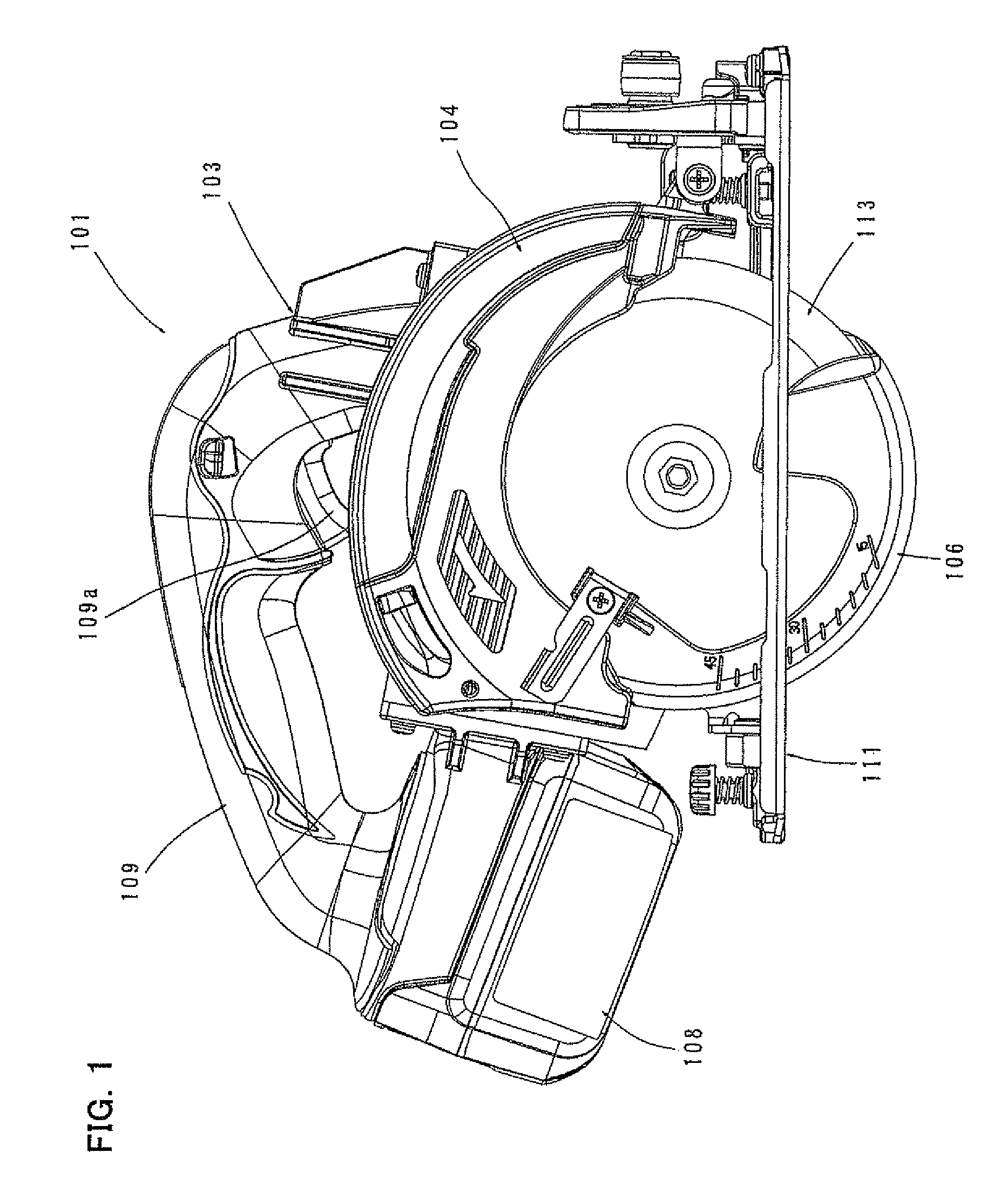

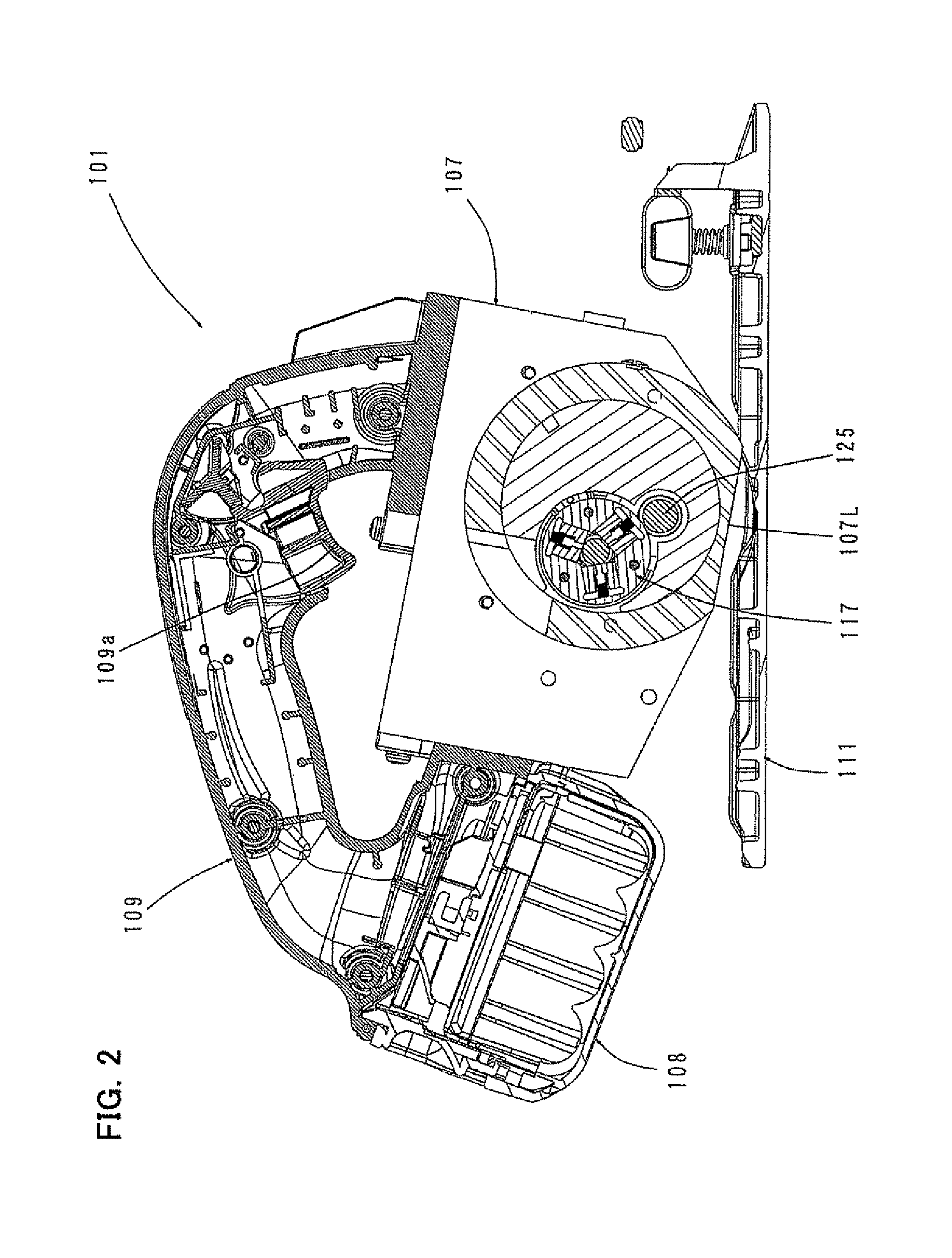

A circular saw in which cutting speed of a saw blade is smoothly controlled. A speed change mechanism of a circular saw includes first and second rotating shafts disposed parallel to each other, and first and second gear trains having different gear ratios and each having a combination of a drive gear and a driven gear as one unit which are engaged with each other and transmit torque of the first rotating shaft to the second rotating shaft. A torque transmission path via the first gear train is defined as a first power transmission path and a torque transmission path via the second gear train is defined as a second power transmission path, and the transmission path is switched between the first power transmission path and the second power transmission path.

Owner:MAKITA CORP

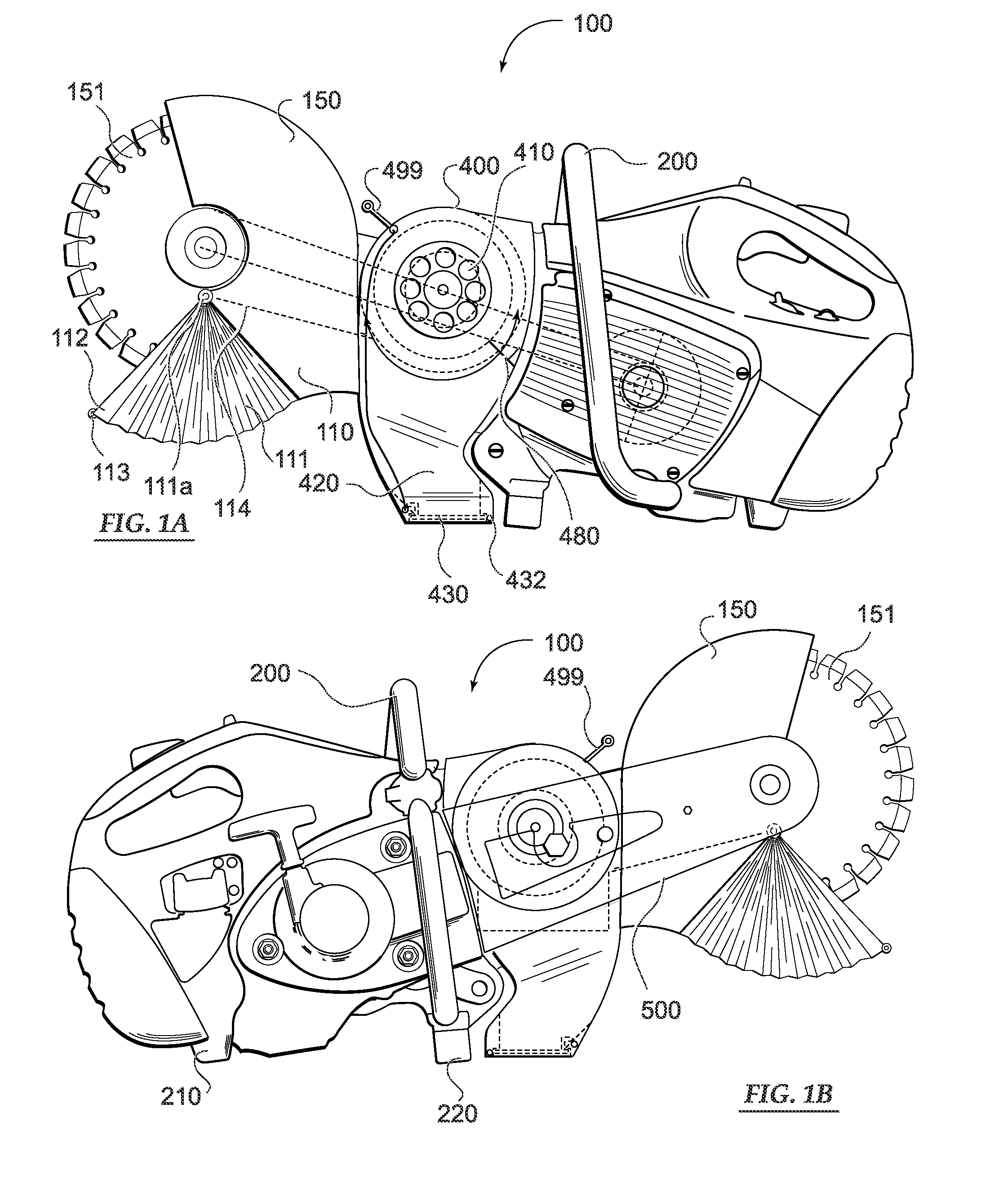

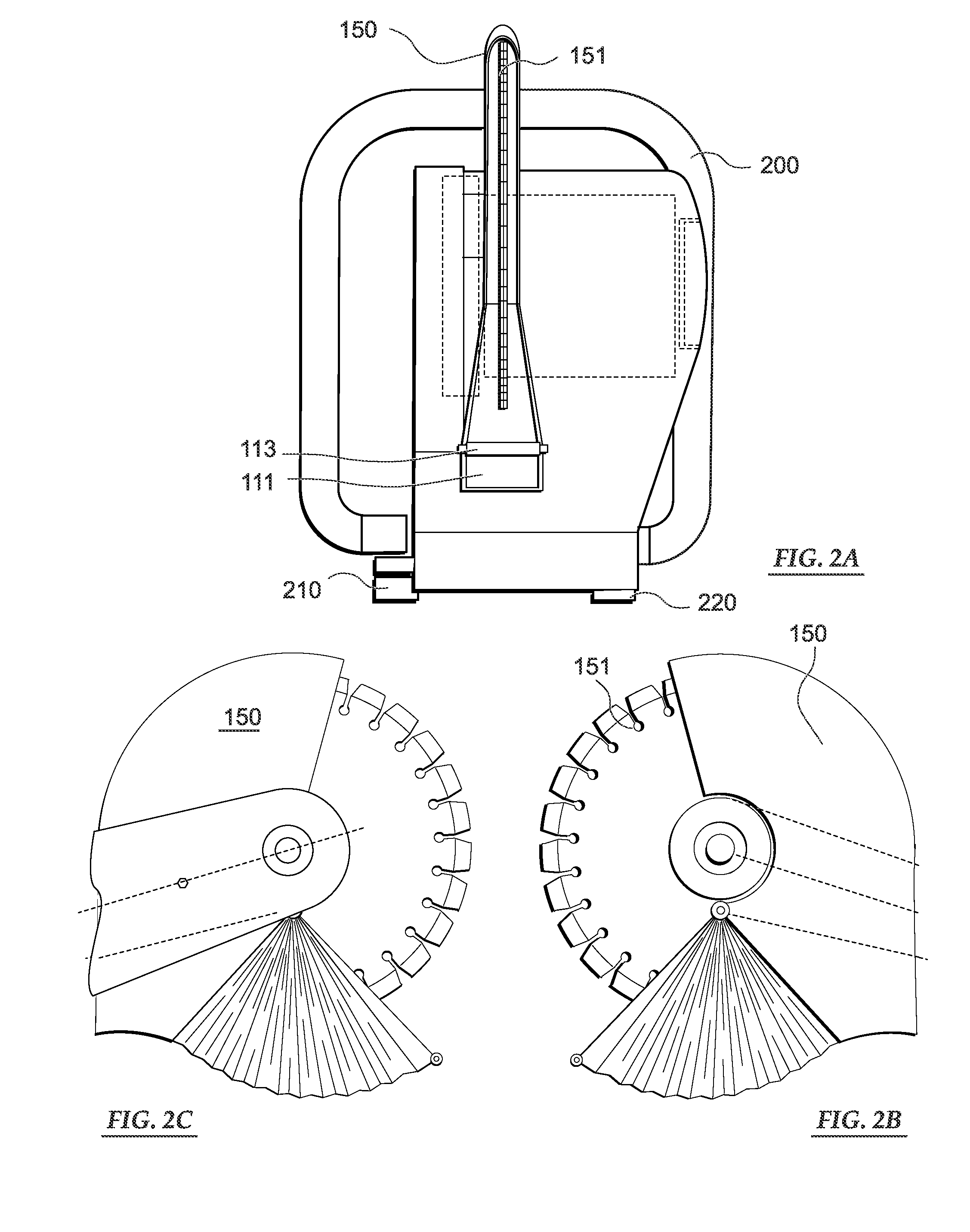

Safety systems for power equipment

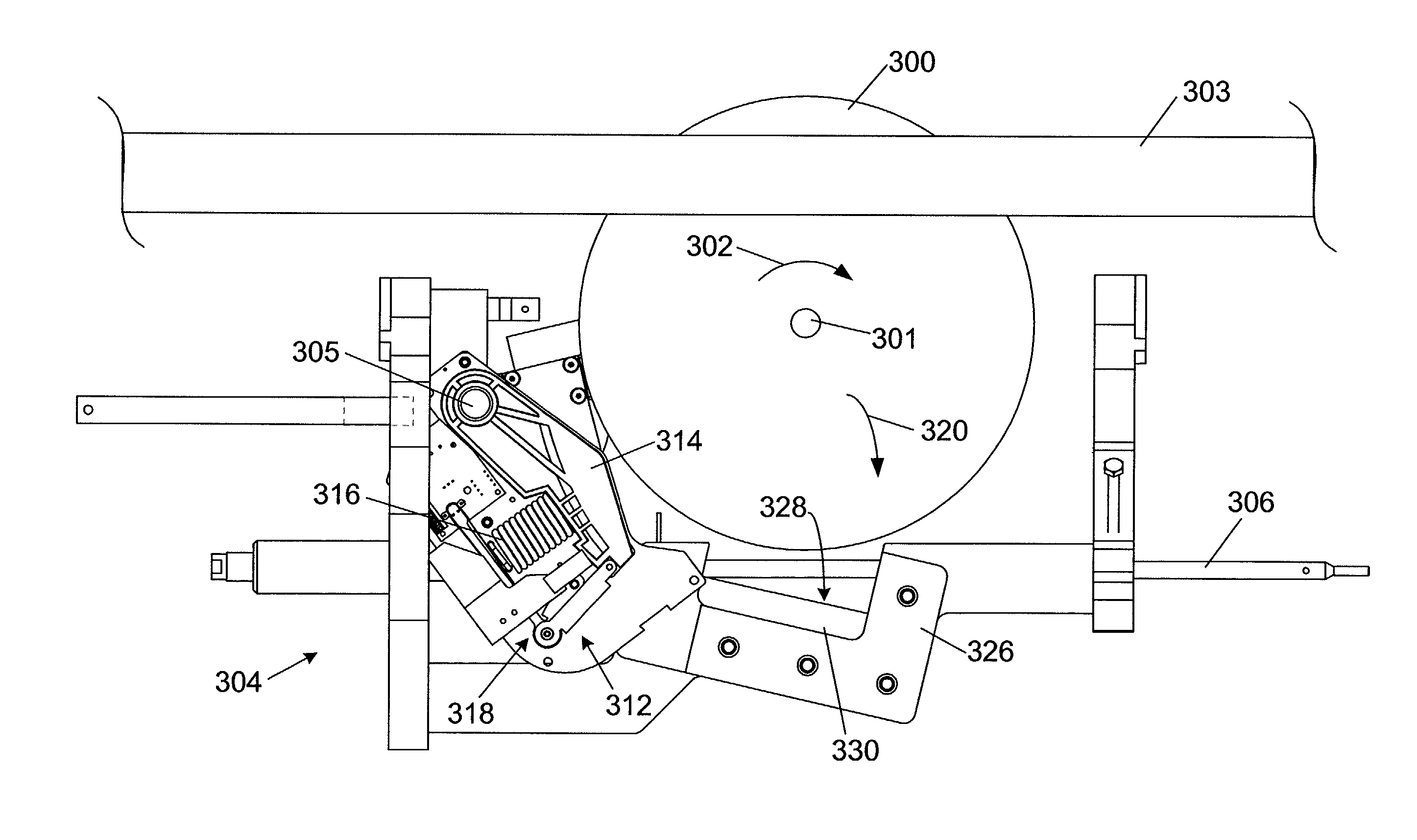

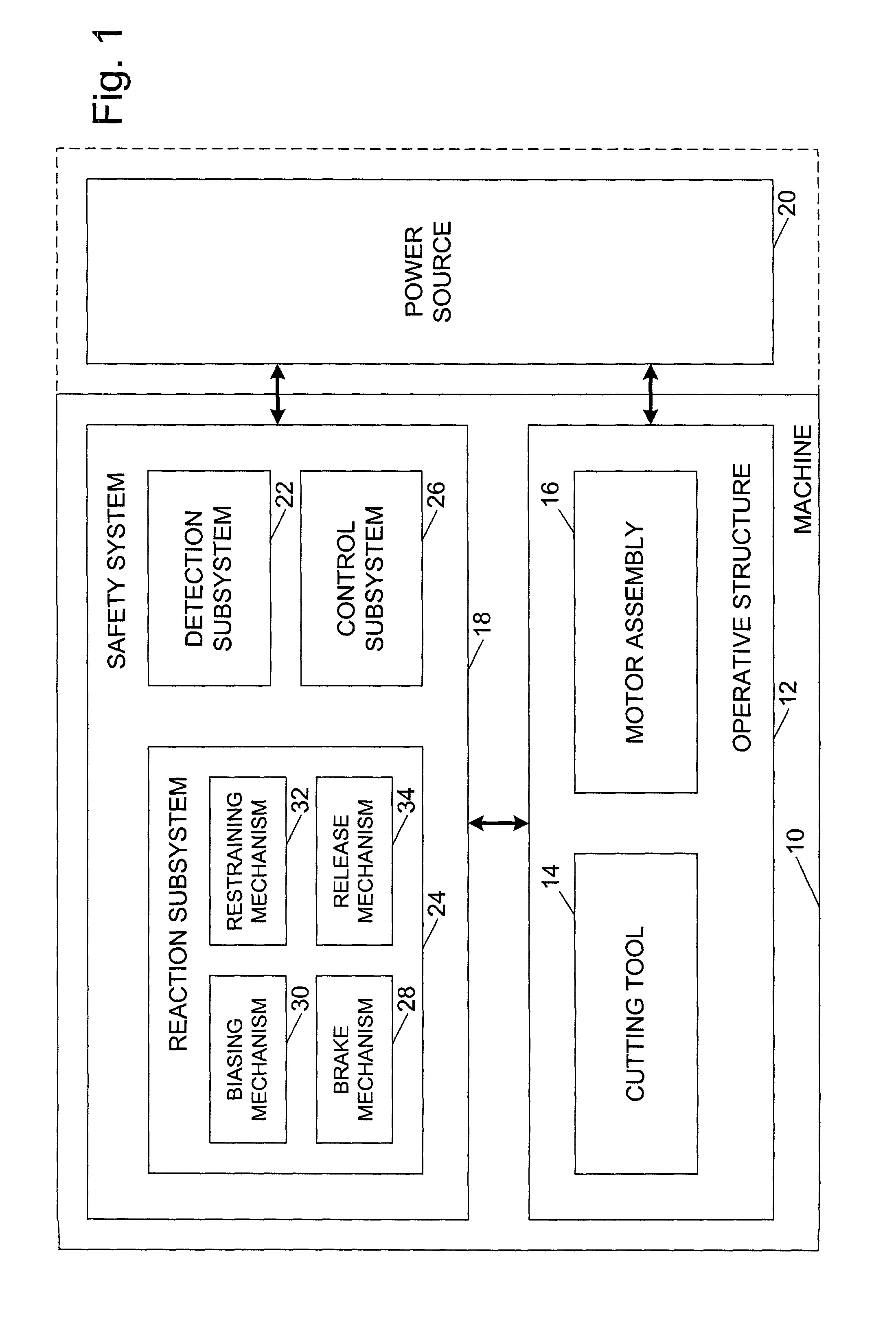

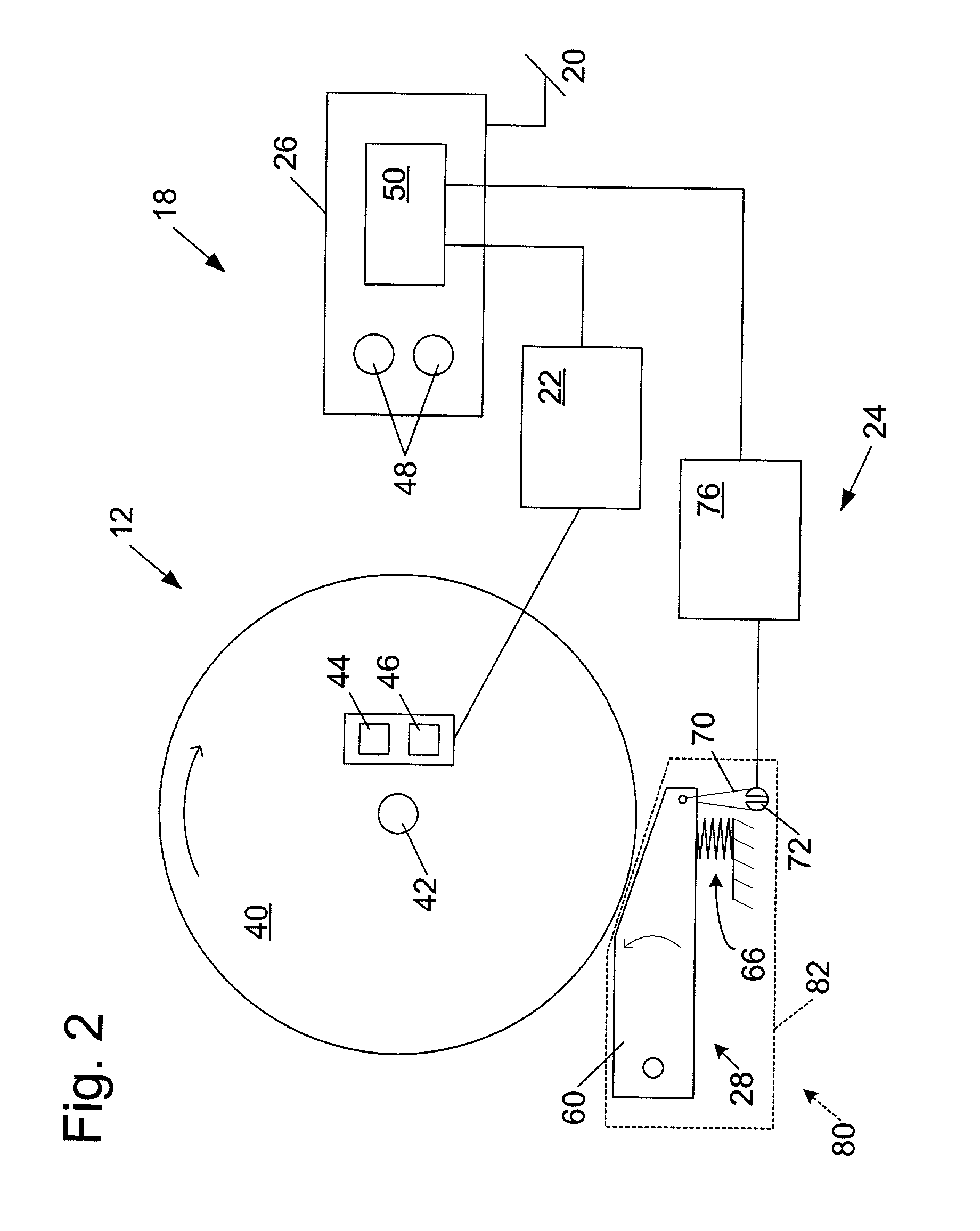

Machines with safety systems are disclosed. The machine may take the form of woodworking machines including table saws, band saws, miter saws, hand-held circular saws, pneumatic chop saws, radial-arm saws, jointers, planars, routers and shapers. The machines may include an operative structure configured to perform a task, where the operative structure includes a cutting tool adapted to move in at least one motion, and a safety system adapted to detect the occurrence of an unsafe condition between a person and the cutting tool and for mitigating the unsafe condition. The safety system may include a detection subsystem and a reaction subsystem.

Owner:SAWSTOP HLDG LLC

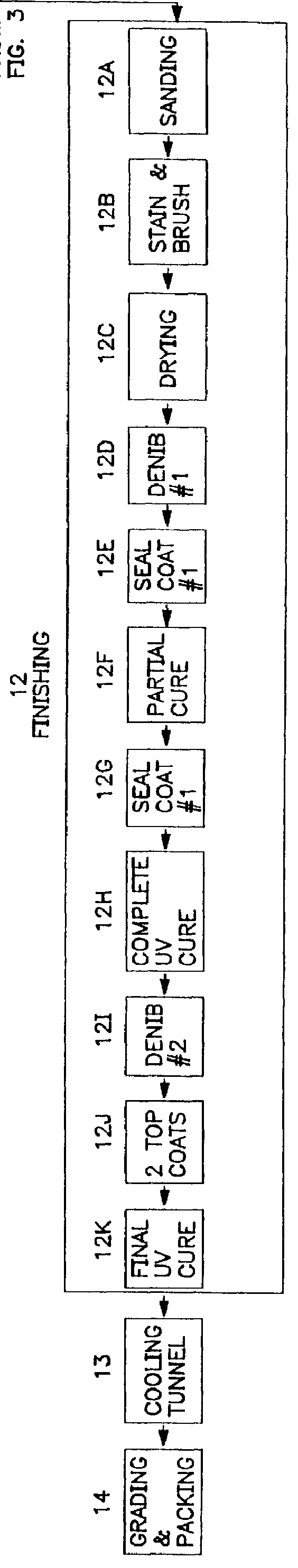

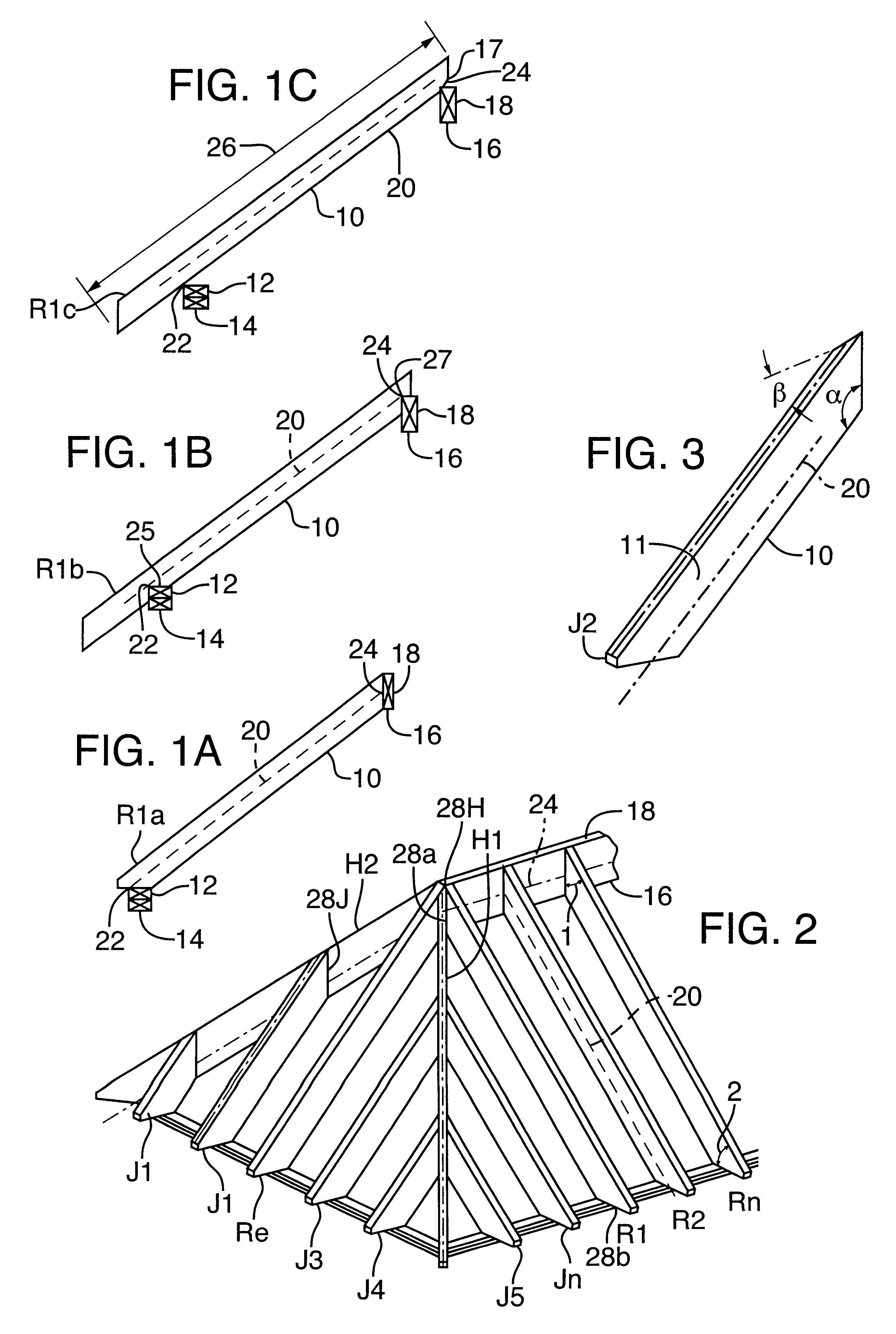

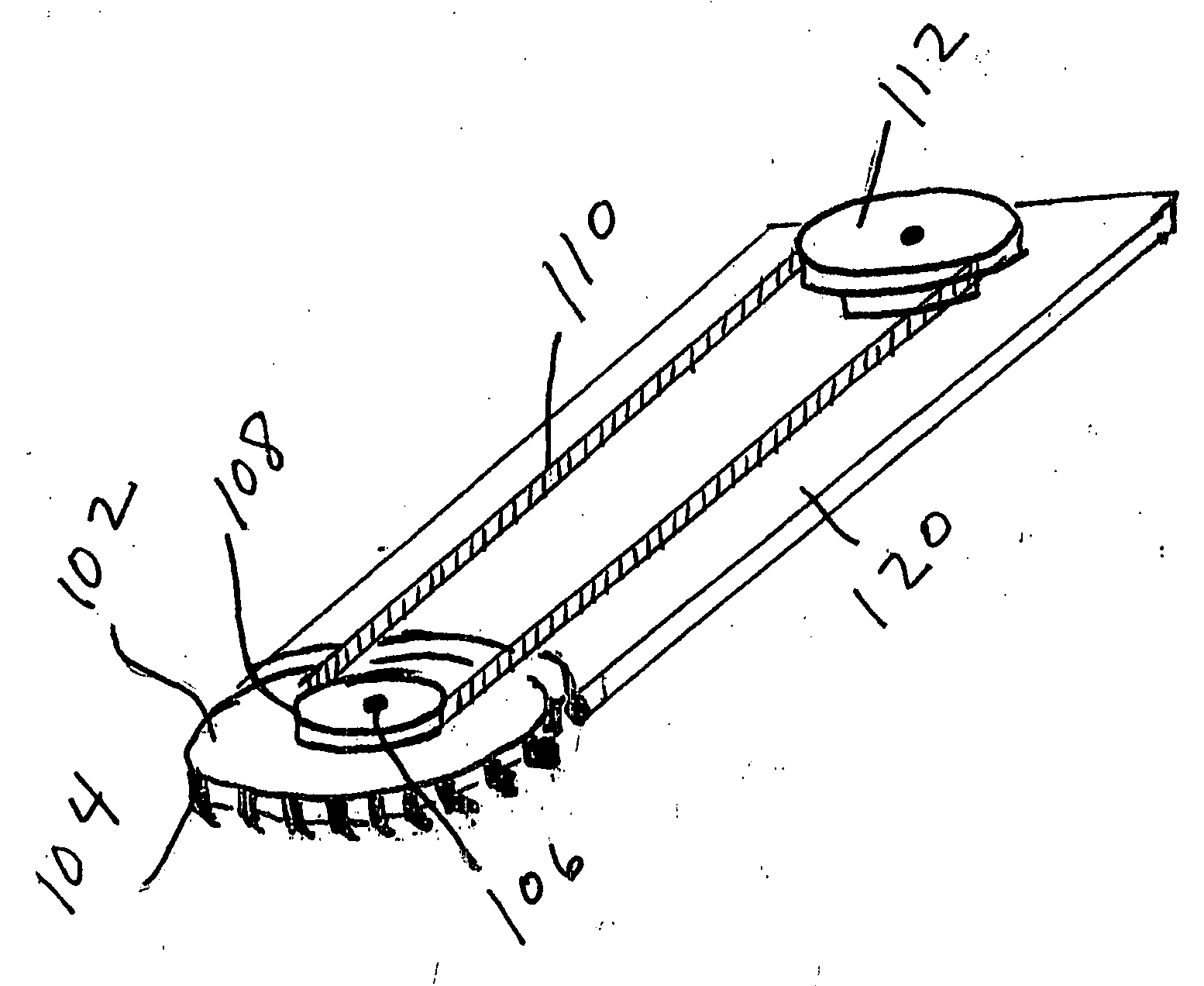

Low profile hardwood flooring strip and method of manufacture

InactiveUS6148884AConsiderable quantityImprove rigidityDovetailed workMulti-purpose machinesCircular sawTongue and groove

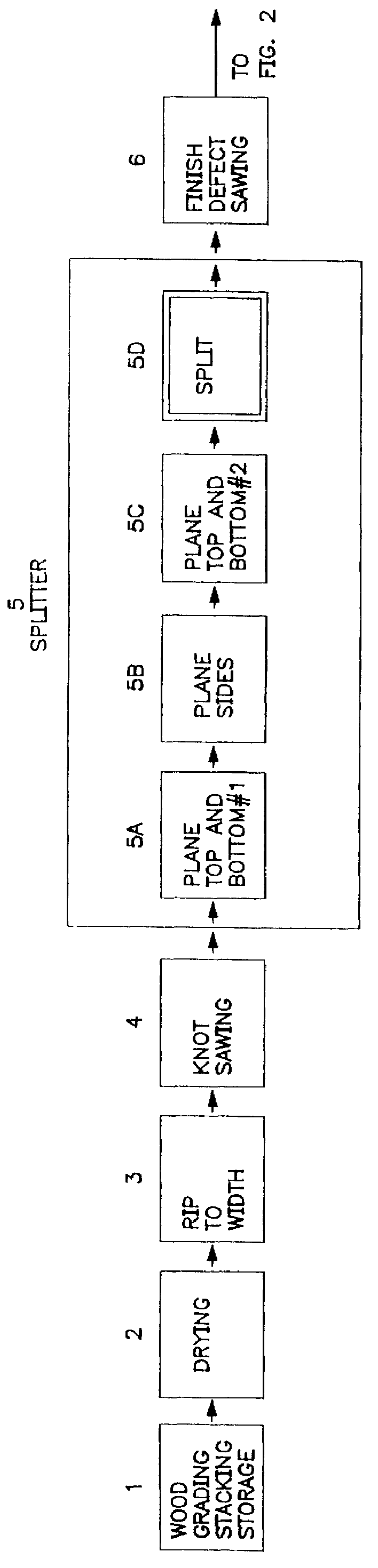

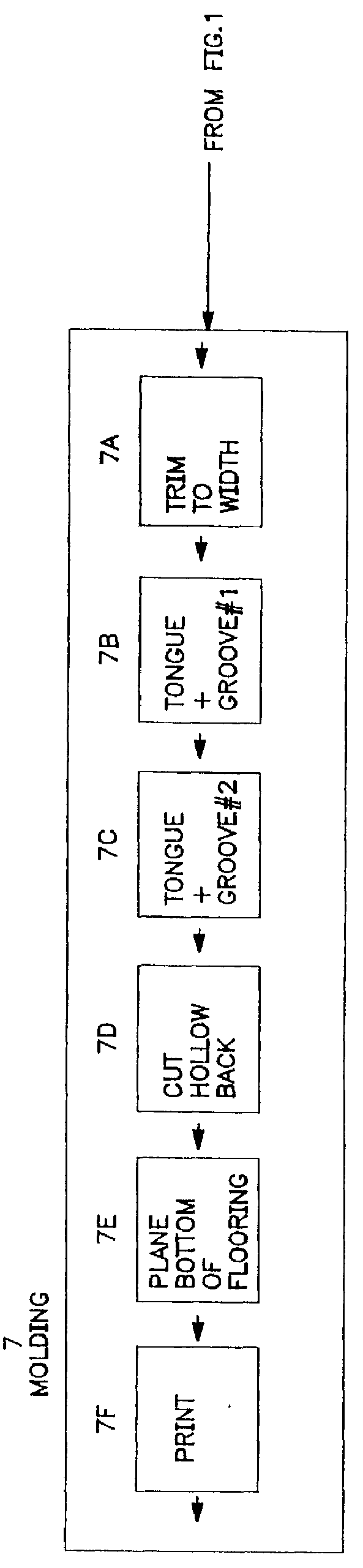

A method of producing a hardwood flooring product, including the steps of processing a strip of raw wood into a blank having a predetermined thickness and width, and top and bottom surfaces defining parallel planes relative to each other, and splitting the blank along the width of the blank from one side to the other to form two low profile flooring strips having the same width as the blank and a thickness less than one-half the thickness of the blank. The splitting step includes the steps of providing first and second circular saw blades mounted on spaced-apart vertical axes for rotation in a single plane intermediate and parallel to the planes of the top and bottom surfaces of the blank and positioning the blank on conveying means upstream from the saw blades with the plane of rotation of the saw blades intermediate and parallel to the planes of the top and bottom surfaces of the blank for movement of the blank from an upstream position to a downstream position relative to the saw blades. The blank is moved downstream into the plane of rotation of the saw blades during rotation of the saw blades thereby horizontally splitting the blank to form first and second low-profile flooring strips. Interlocking members, such as molded, mating tongue and groove members, are molded into first and second longitudinally-extending side edges of the flooring strips for securing together the flooring strips when placed side-to-side to form a floor.

Owner:ARMSTRONG HARDWOOD FLOORING CO +2

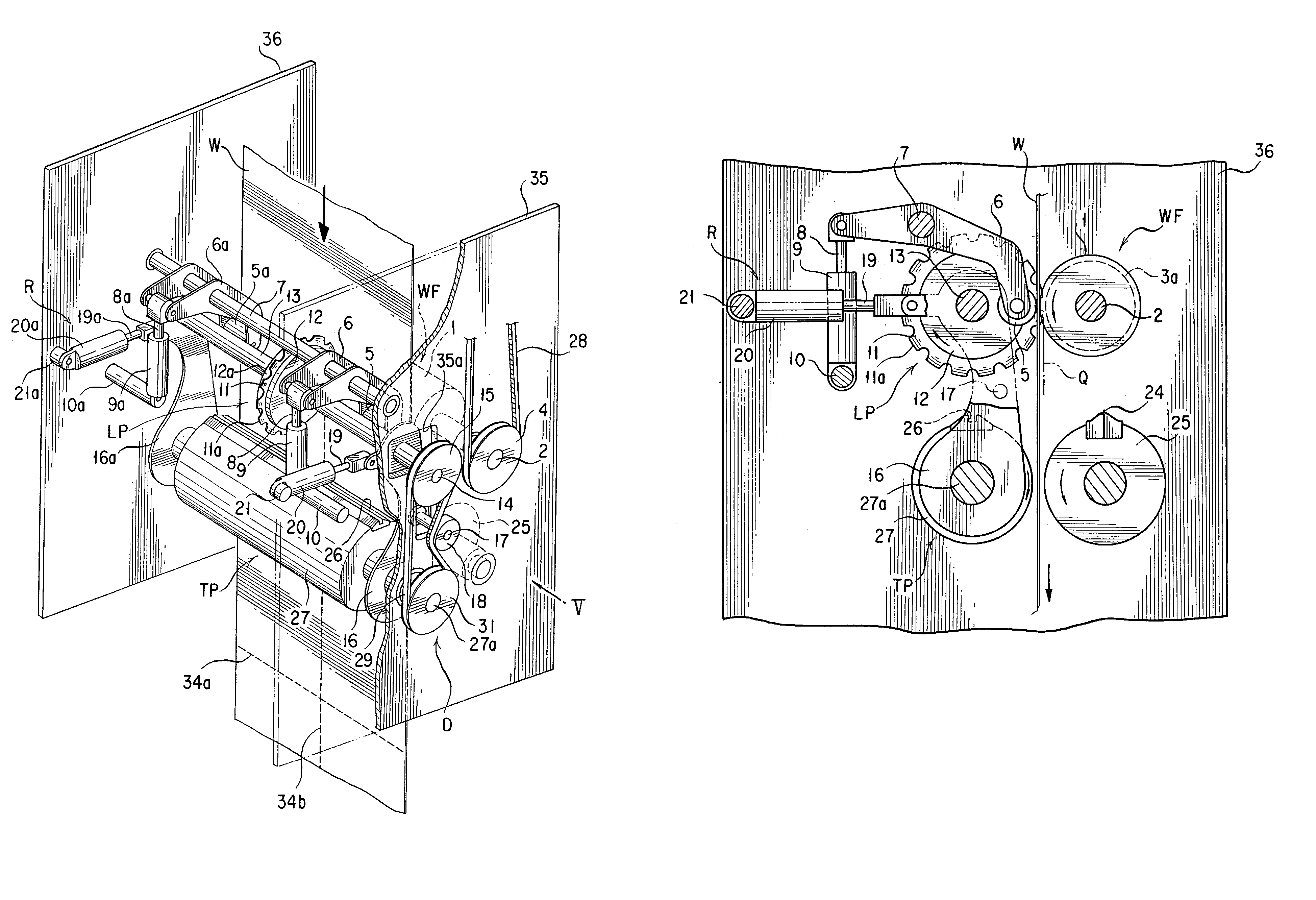

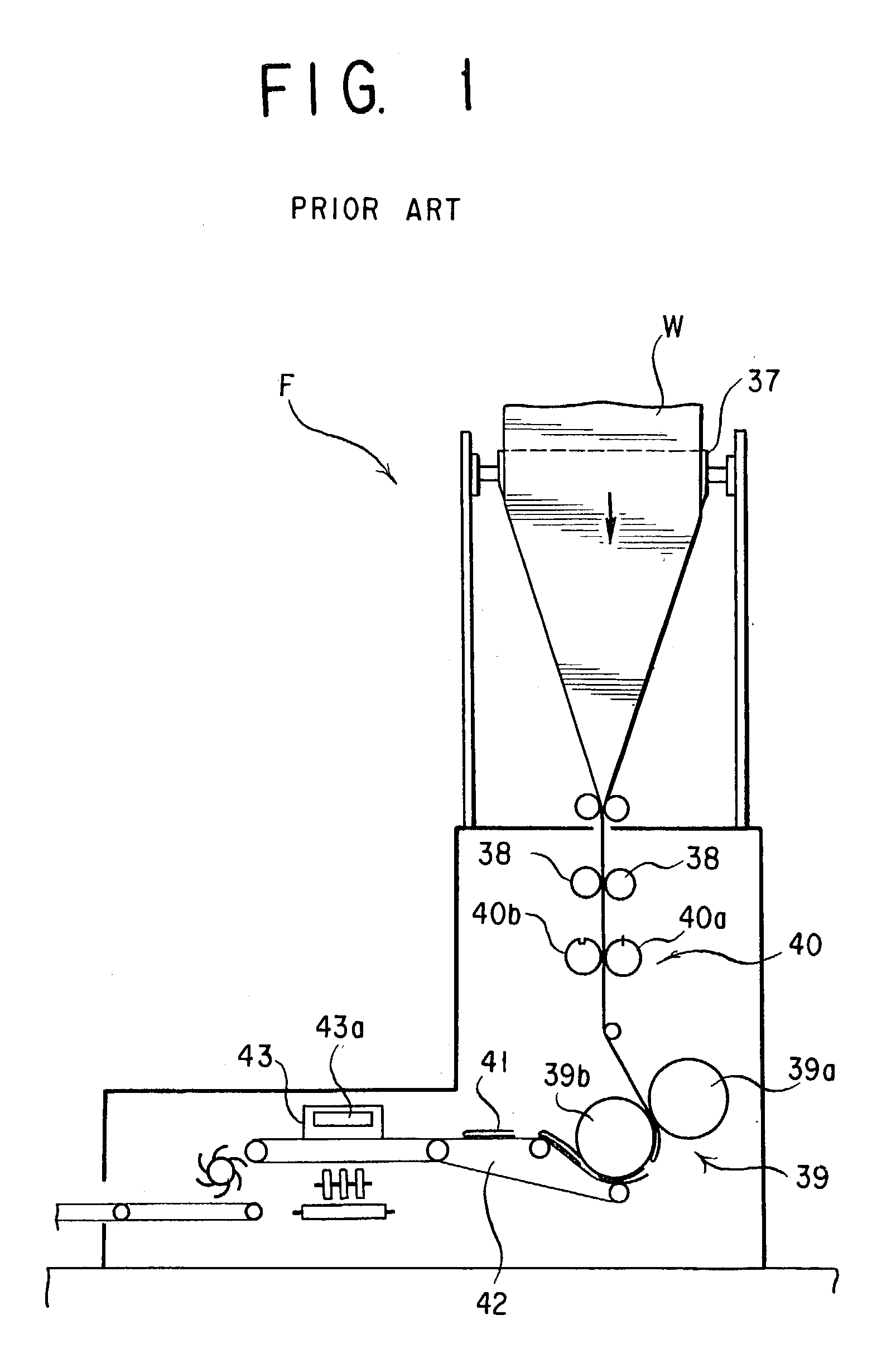

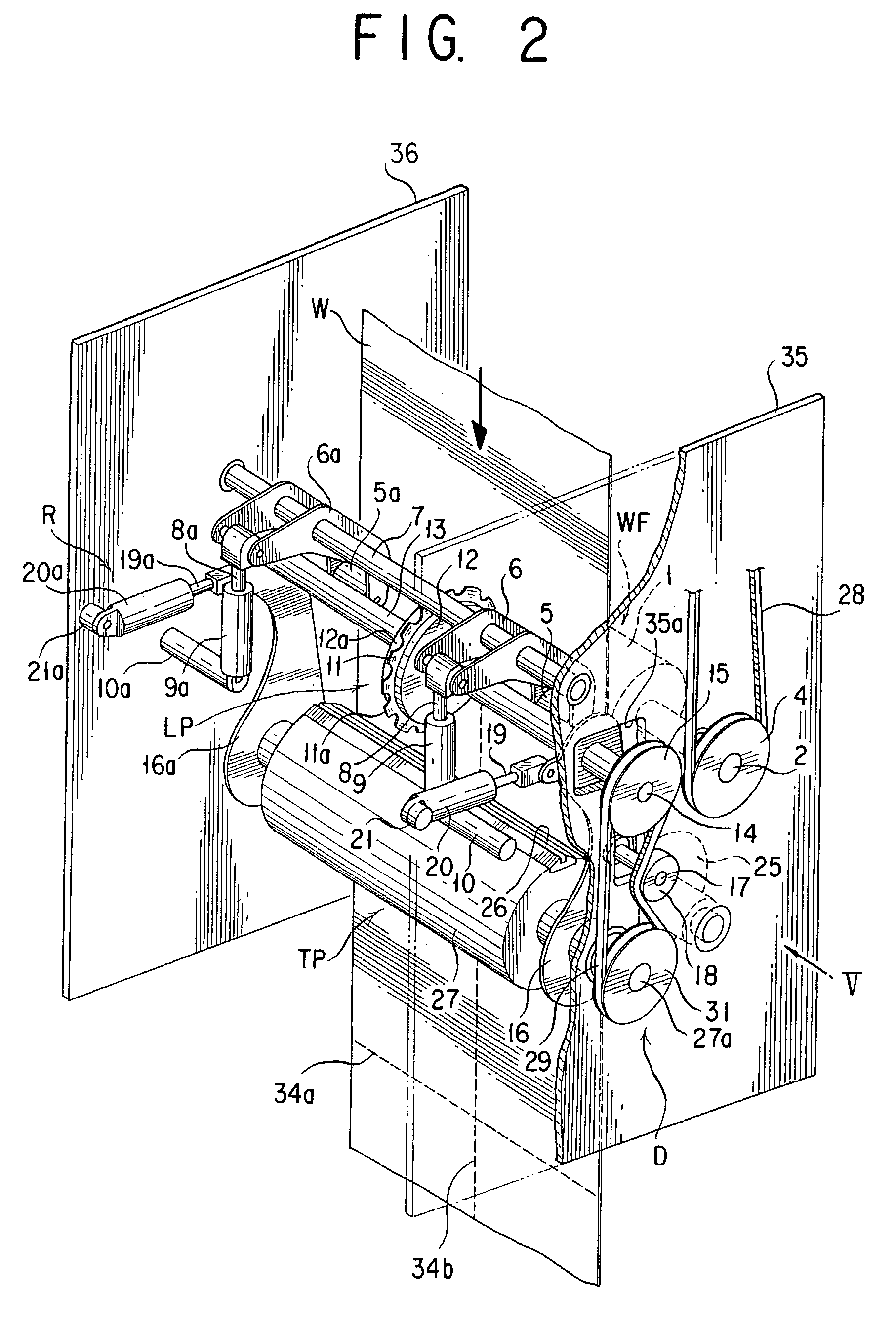

Apparatus for longitudinally perforating a web of paper in a rotary printing press

A rotary printing press has a folding station where the printed web is perforated both transversely and longitudinally in order to expedite subsequent folding thereof into signatures. In order to incorporate a longitudinal perforator into the folding station without adding to its size, a longitudinally perforating blade similar to a circular saw is mounted to a blade carrier shaft which is rotatably supported opposite a feed roller by which the web is frictionally fed into and through the folding station. An annular, longitudinally grooved anvil is formed circumferentially on the feed roller for engaging the longitudinally perforating blade via the web being thereby perforated. The longitudinally perforating blade is movable with the blade carrier shaft into and out of perforating engagement with the anvil on the feed roller.

Owner:TOKYO KIKAI SEISAKUCHI LTD

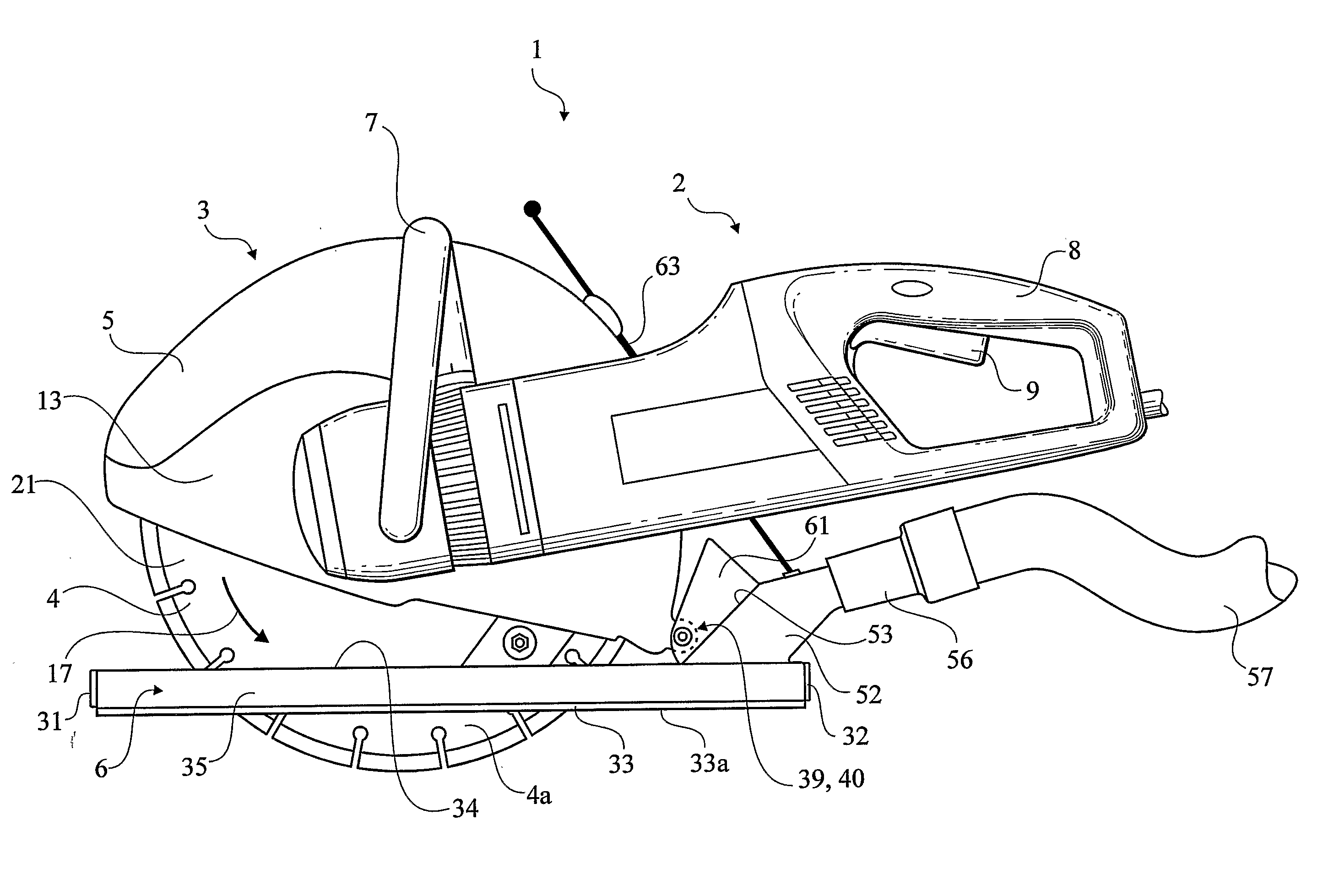

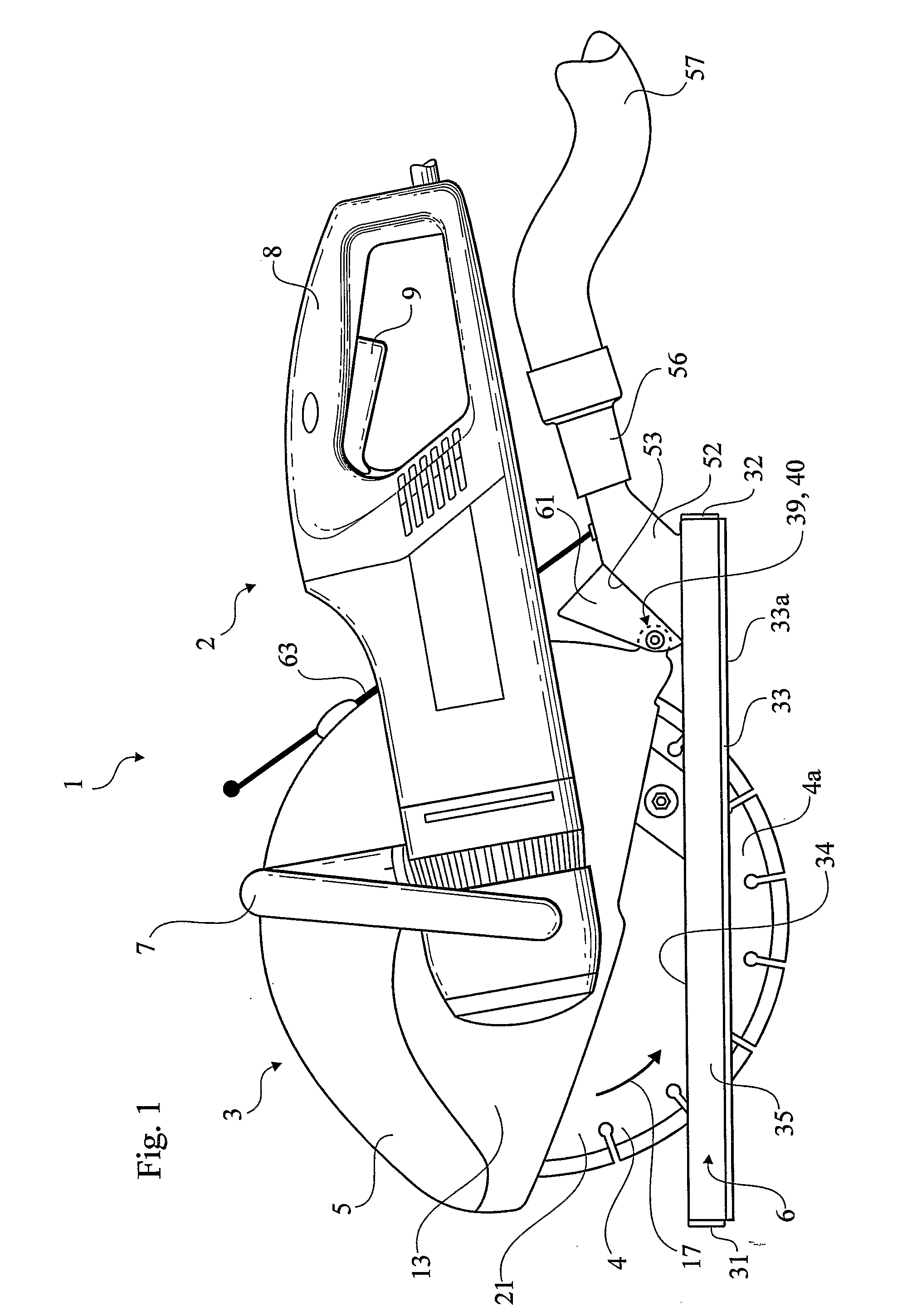

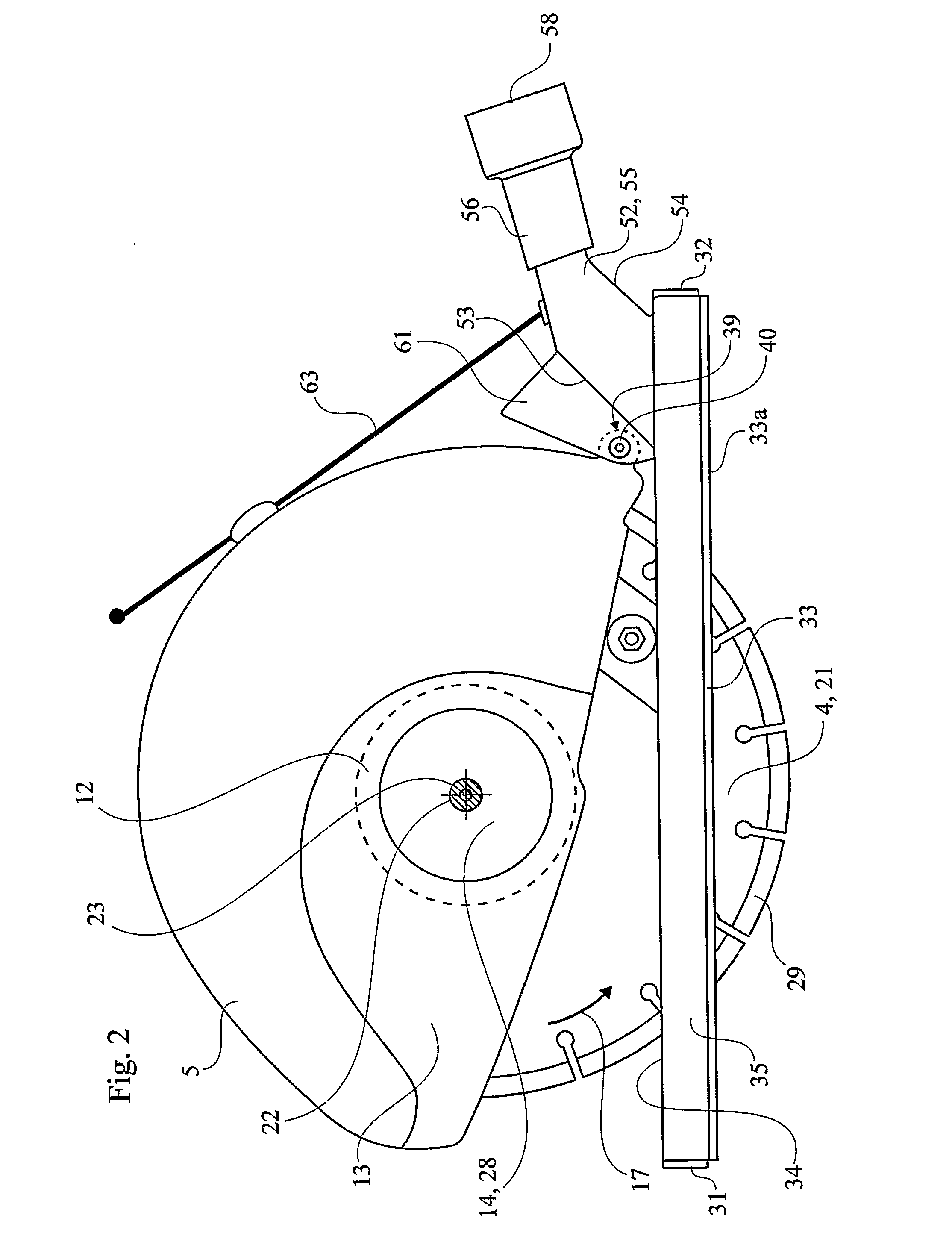

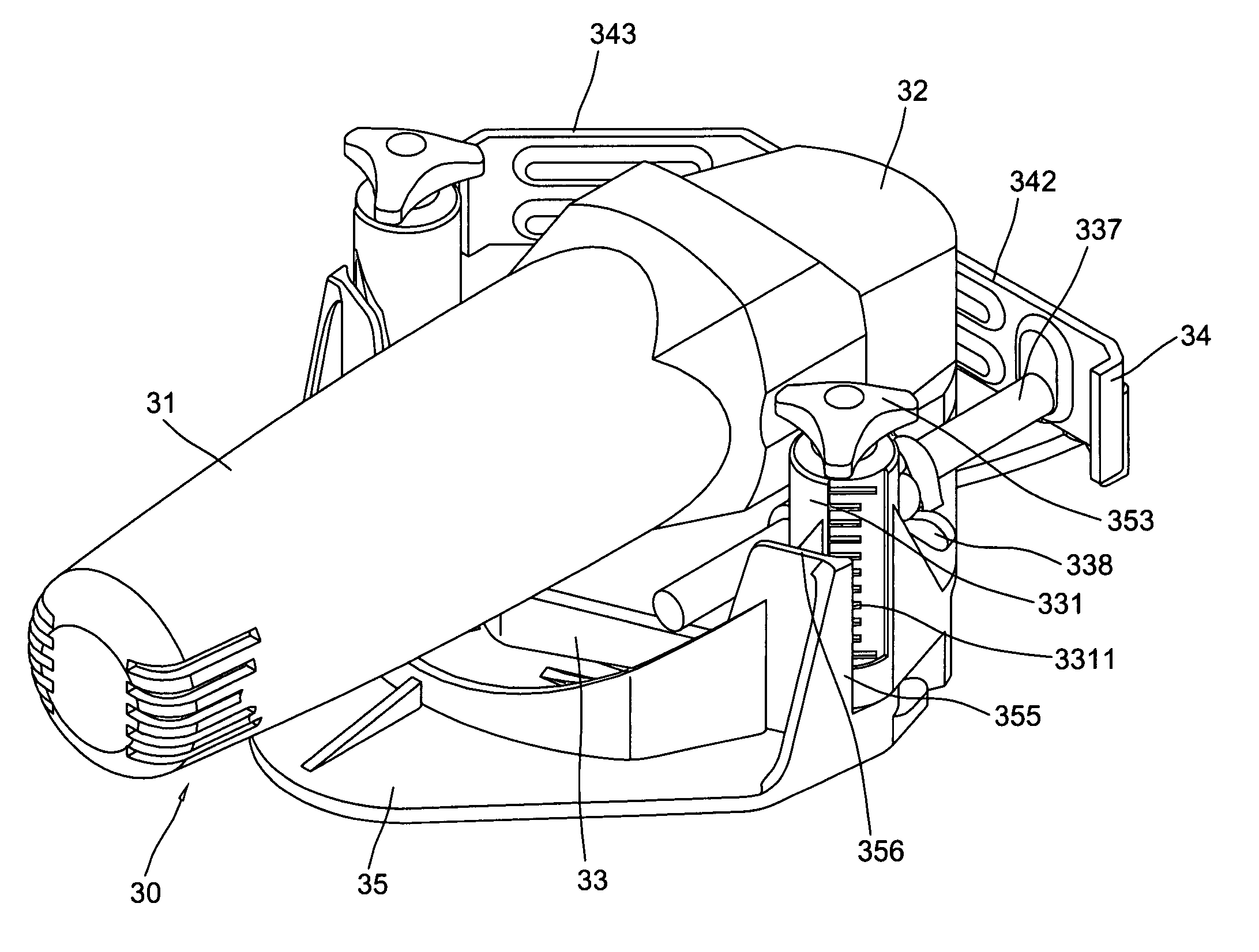

Cutting and Dust Collecting Assembly and Working Machine with Such Assembly

ActiveUS20080163492A1Avoid flyingEfficient collectionMetal sawing devicesMetal sawing accessoriesCircular sawDust control

A cutting and dust collecting assembly comprises a rotatable, circular saw blade (4) having a first side (20), a second side (21), and a cover device (6) with a terminal member (52). The bottom surface (36) of the cover device extends in a plane. A longitudinal passage (45, 46) for the saw blade extends through the cover device from its top surface to its bottom surface. The terminal member comprises a terminal chamber (60) having an inlet (45a), the mouth of which coincides with the plane of said bottom surface. An outlet (58) can be connected to a vacuum source. The direction of rotation of the operating blade is such that the rear part (4a) of the saw blade which has passed beyond the bottom surface of the cover device will move in a direction upwards-rearwards towards the bottom surface. The invention also concerns the cover device, a sealing body belonging to the cover device and a working machine which is provided with the cutting and dust collecting assembly.

Owner:HUSQVARNA AB

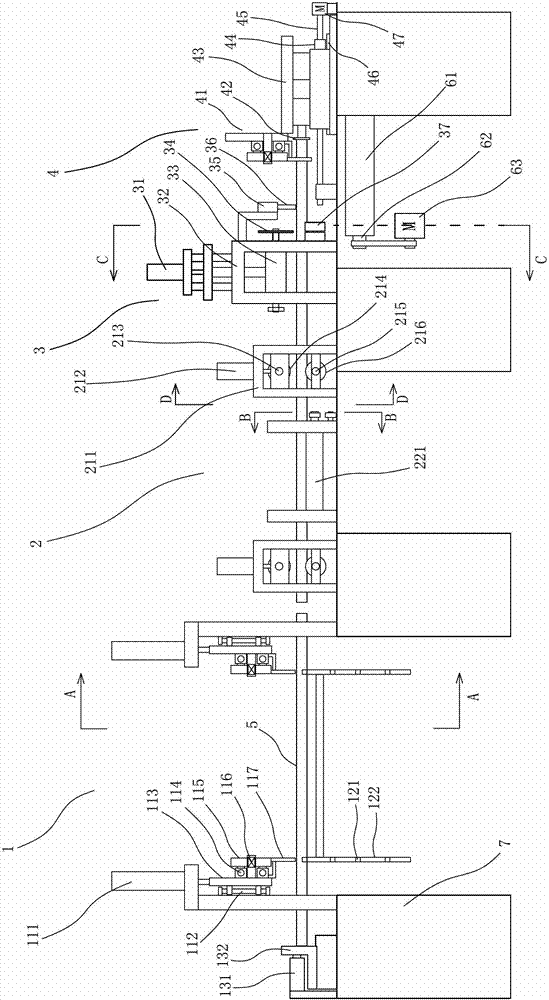

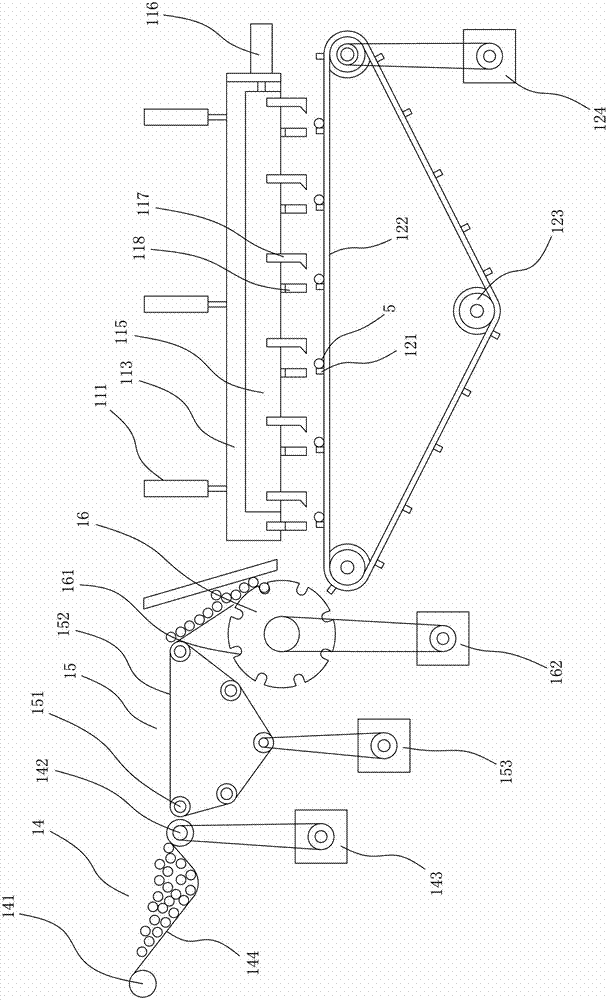

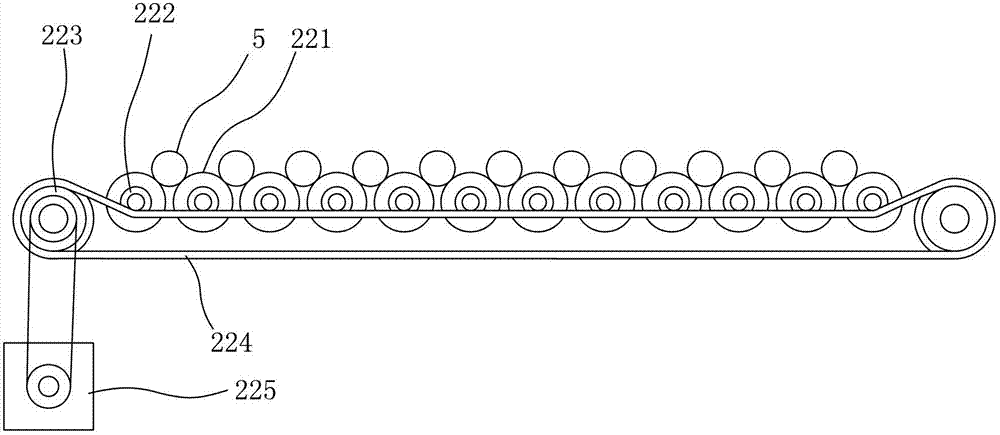

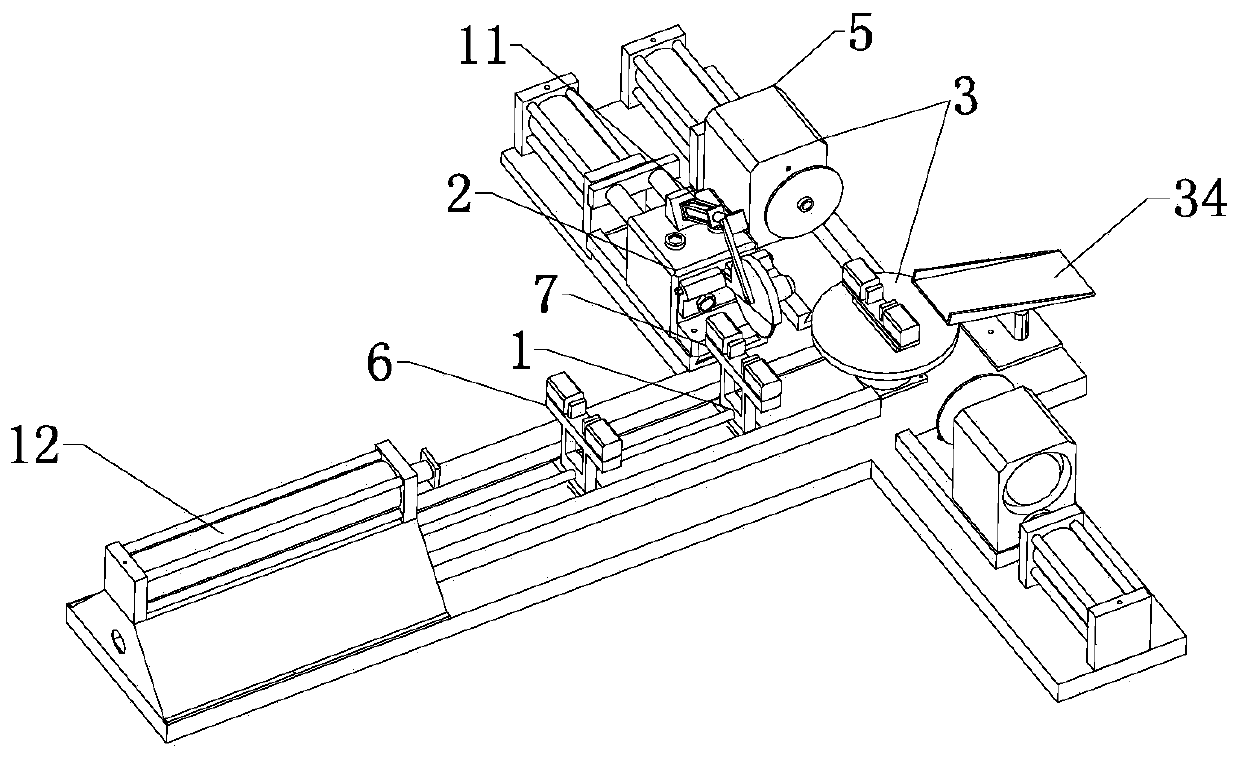

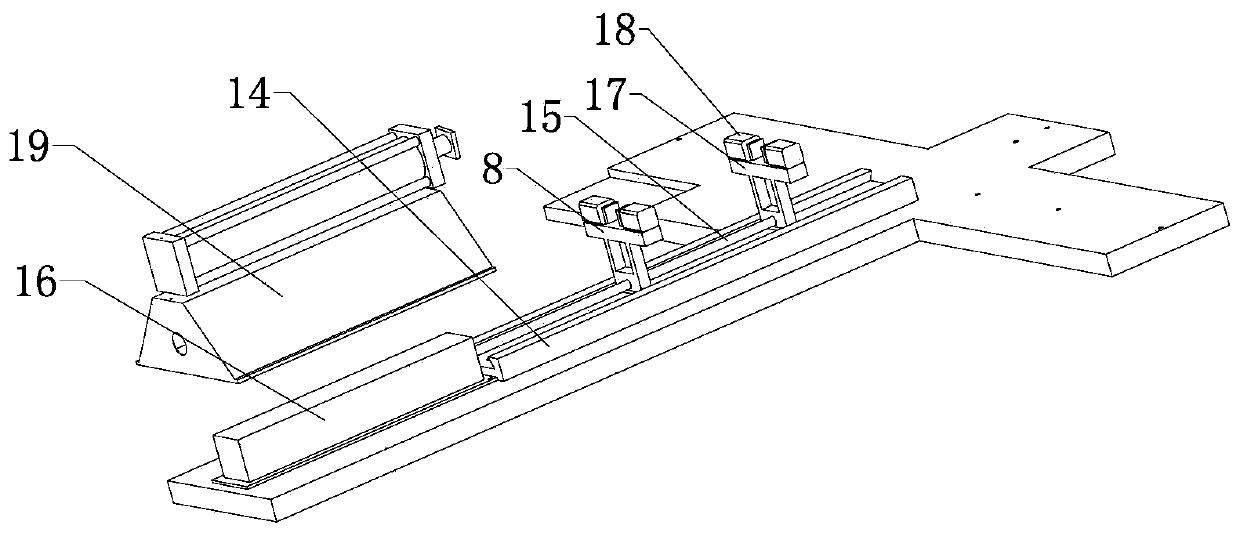

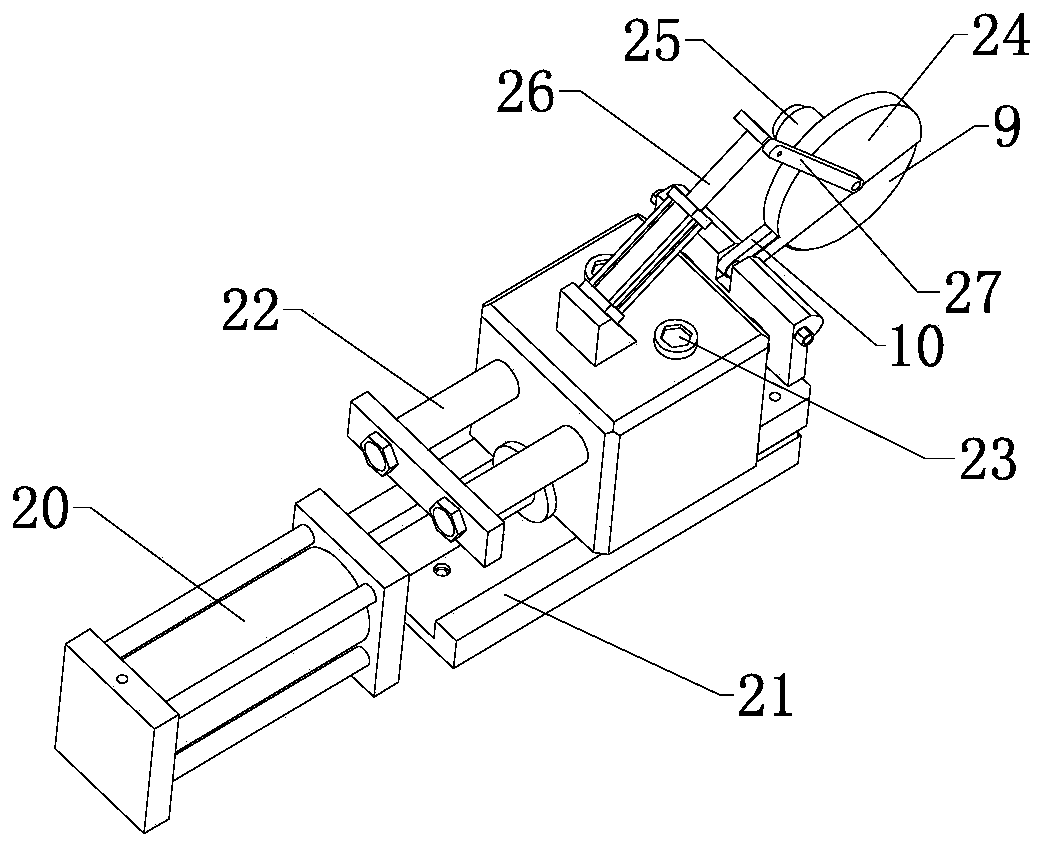

Full-automatic pipe cutting machine

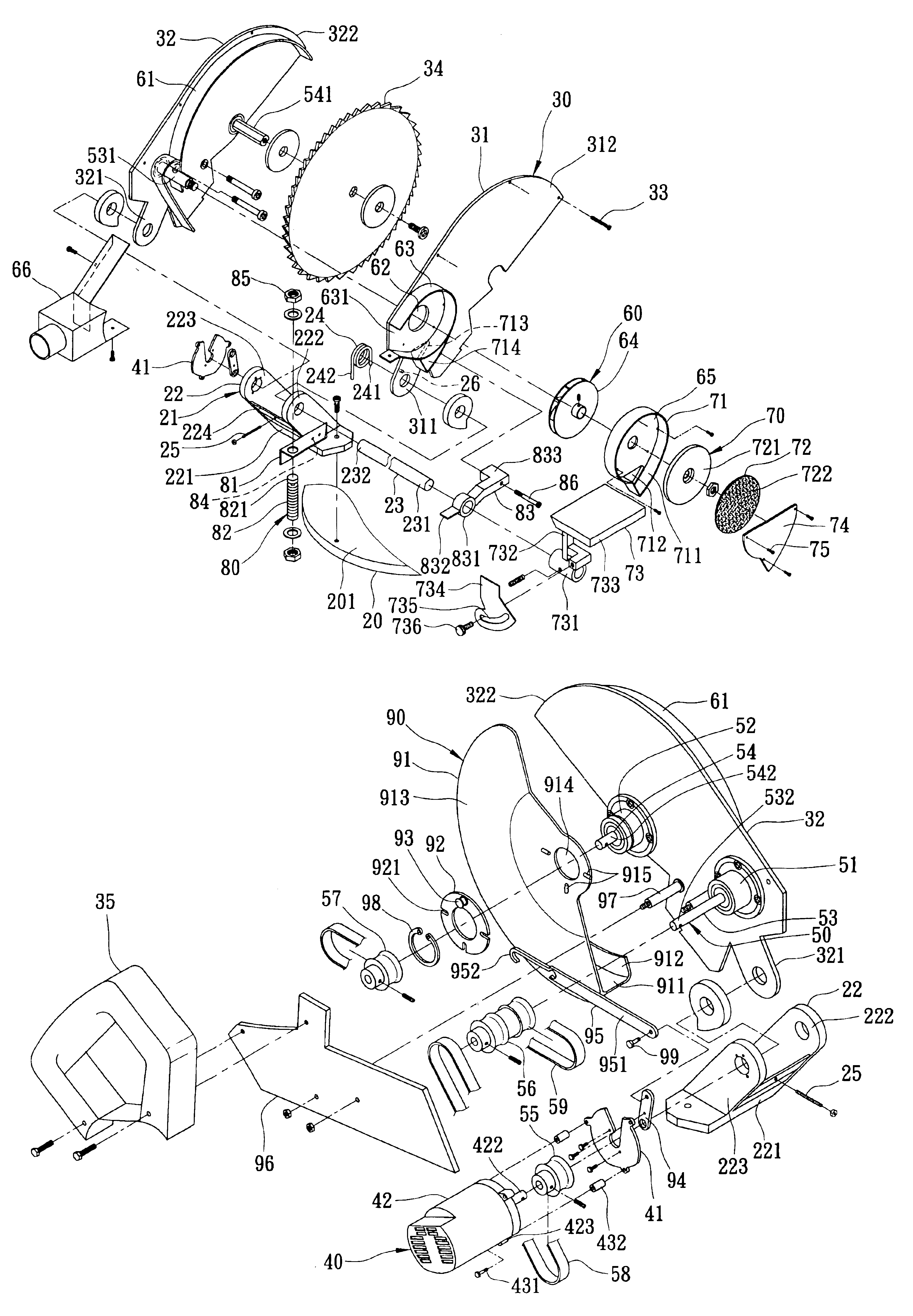

ActiveCN102814547ARealize automatic controlPrecise deliveryMetal sawing devicesCircular sawEngineering

The invention provides a full-automatic pipe cutting machine comprising a frame, and a charging device, a feeding device, a cutting device, a measuring device and a control device which are sequentially arranged on the frame horizontally; the cutting device comprises a cutter holder which is arranged on the frame, a plurality of first motors which are lined horizontally along a longitudinal direction and can be arranged on the cutter holder by moving up and down, a first cylinder which is connected with and drives each first motor to move up and down synchronously, a circular saw blade which is arranged on the output shaft of each first motor, a second motor which is in transmission connection with the input shaft of each first motor through a first transmission mechanism, and a bearing piece which is arranged on the tool rest below each circular saw blade and is used for bearing a pipe at a cut part; and the measuring device comprises a guide rail which is horizontally arranged on the frame, a slide frame which is movably arranged on the guide rail, a driving mechanism which is connected with and drives the slide frame to move along the guide rail, a pipe baffle which is arranged on the slide frame and a first pipe clamping mechanism which is horizontally arranged on the slide frame along the longitudinal direction. According to the full-automatic pipe cutting machine, more than one pipe can be cut at one time, and the machine has the advantages of high cutting efficiency, good cutting quality and the like.

Owner:冠达星股份有限公司

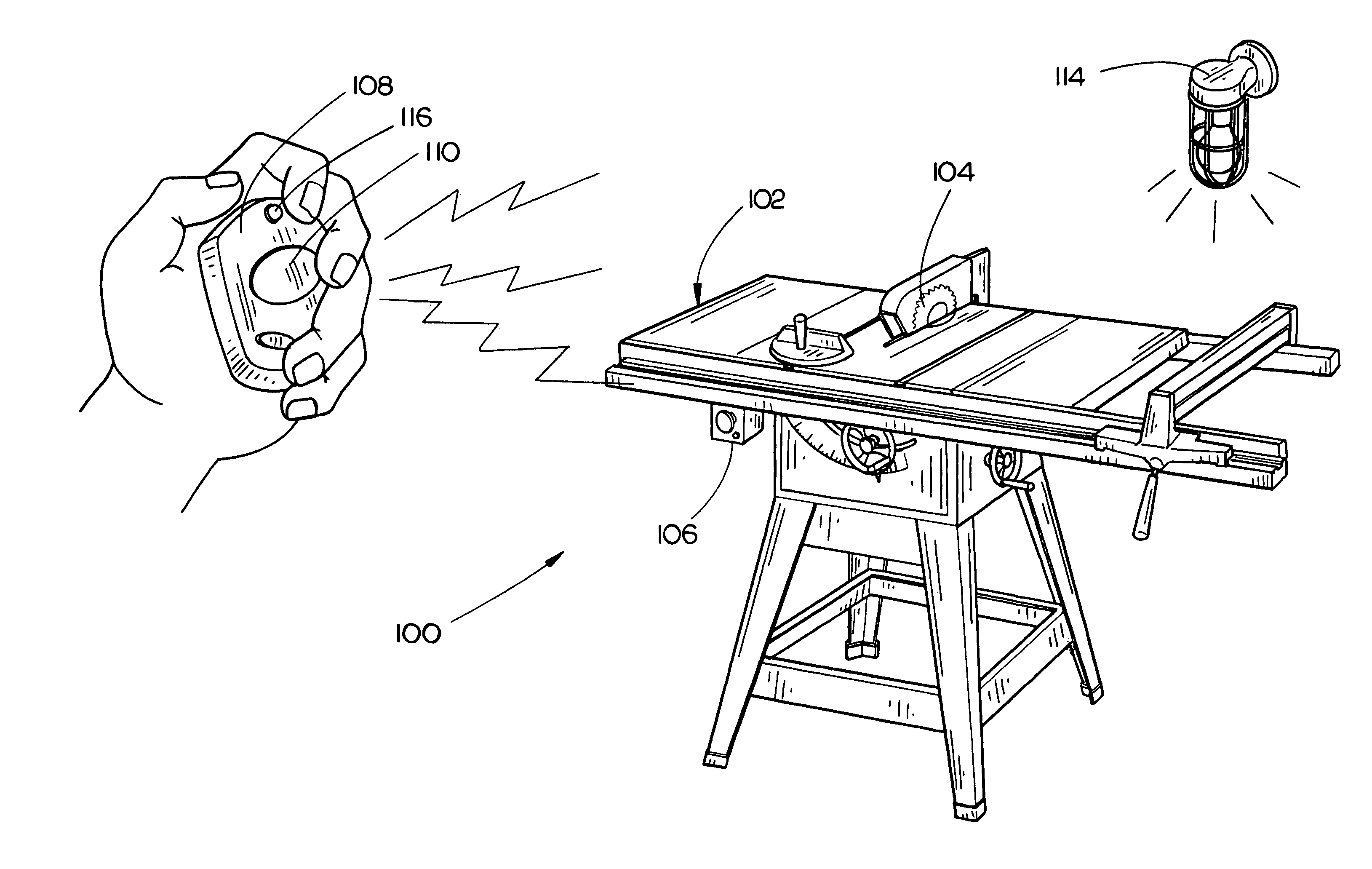

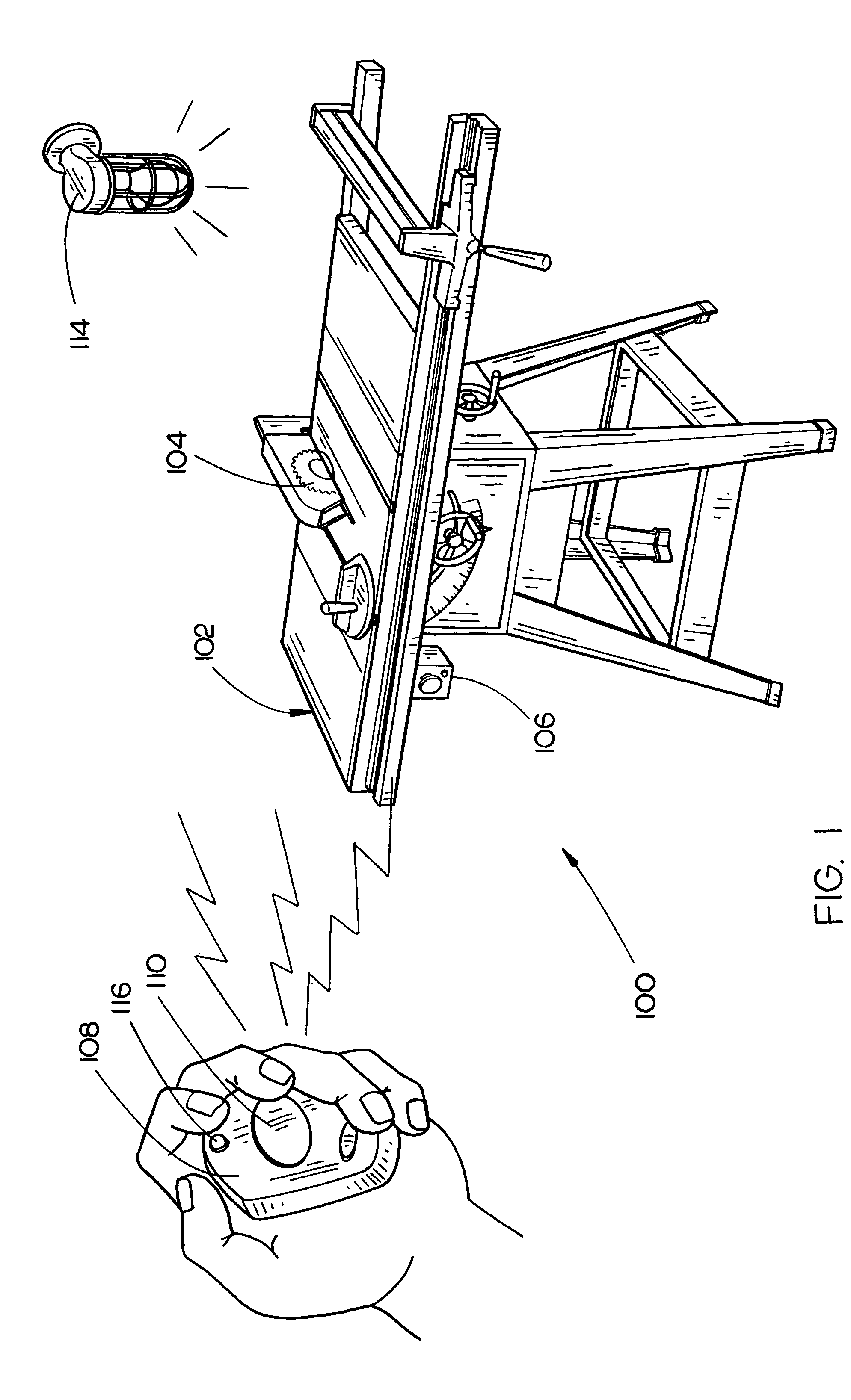

Power tool with remote stop

InactiveUS7064502B2DC motor speed/torque controlNon-electrical signal transmission systemsElectricityHand held

The present invention is directed to a power tool including a wireless remote stop for terminating the flow of electricity to an electric motor. The electric motor is configured for operating a working element assembly of a power tool, such as an arbor / circular saw blade included a table saw. In an embodiment, a remote stop is a hand-held fob, having a housing and a button. Alternatively, the remote stop may be implemented as a foot pedal apparatus, for being disposed on a shop floor.

Owner:BLACK & DECKER INC

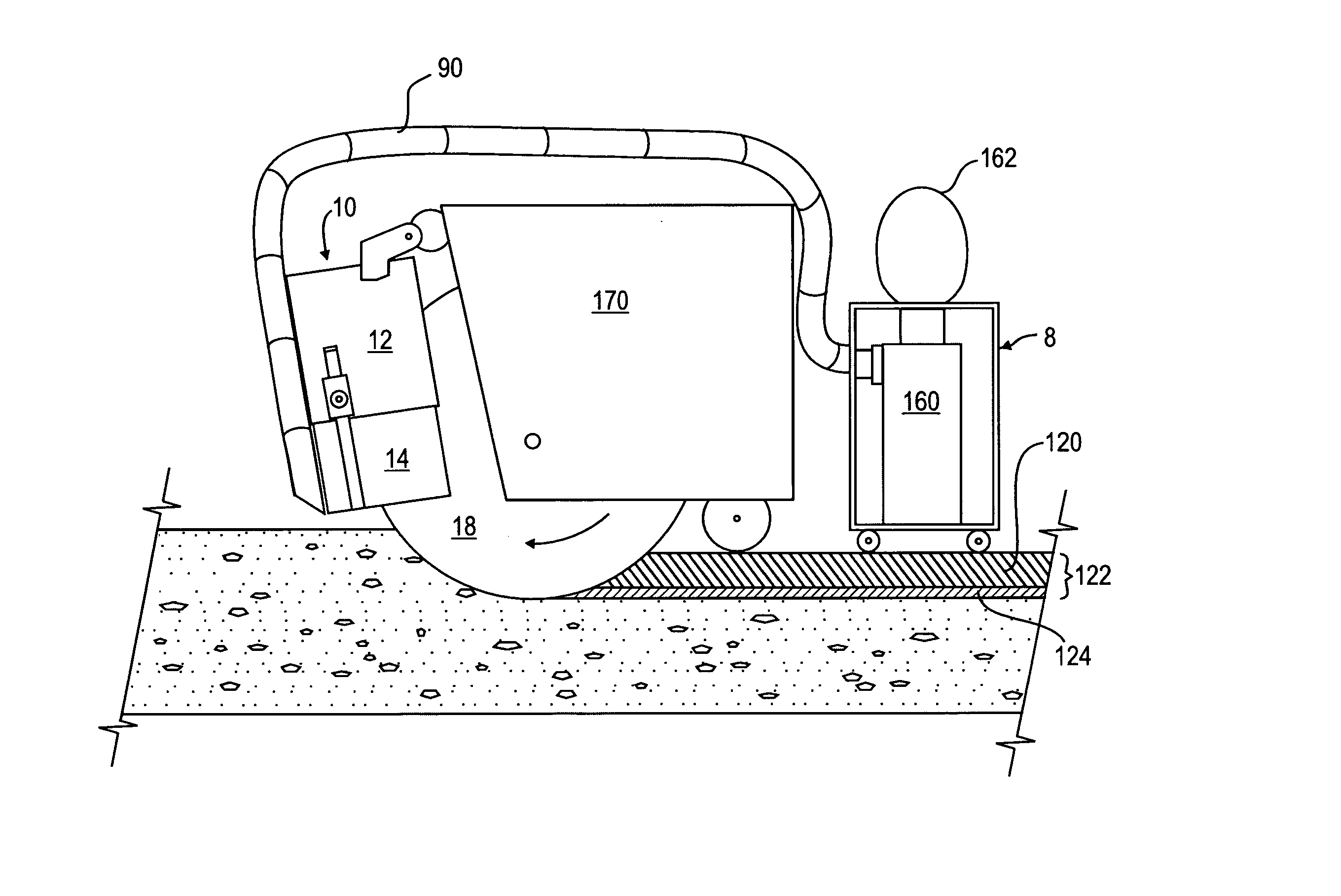

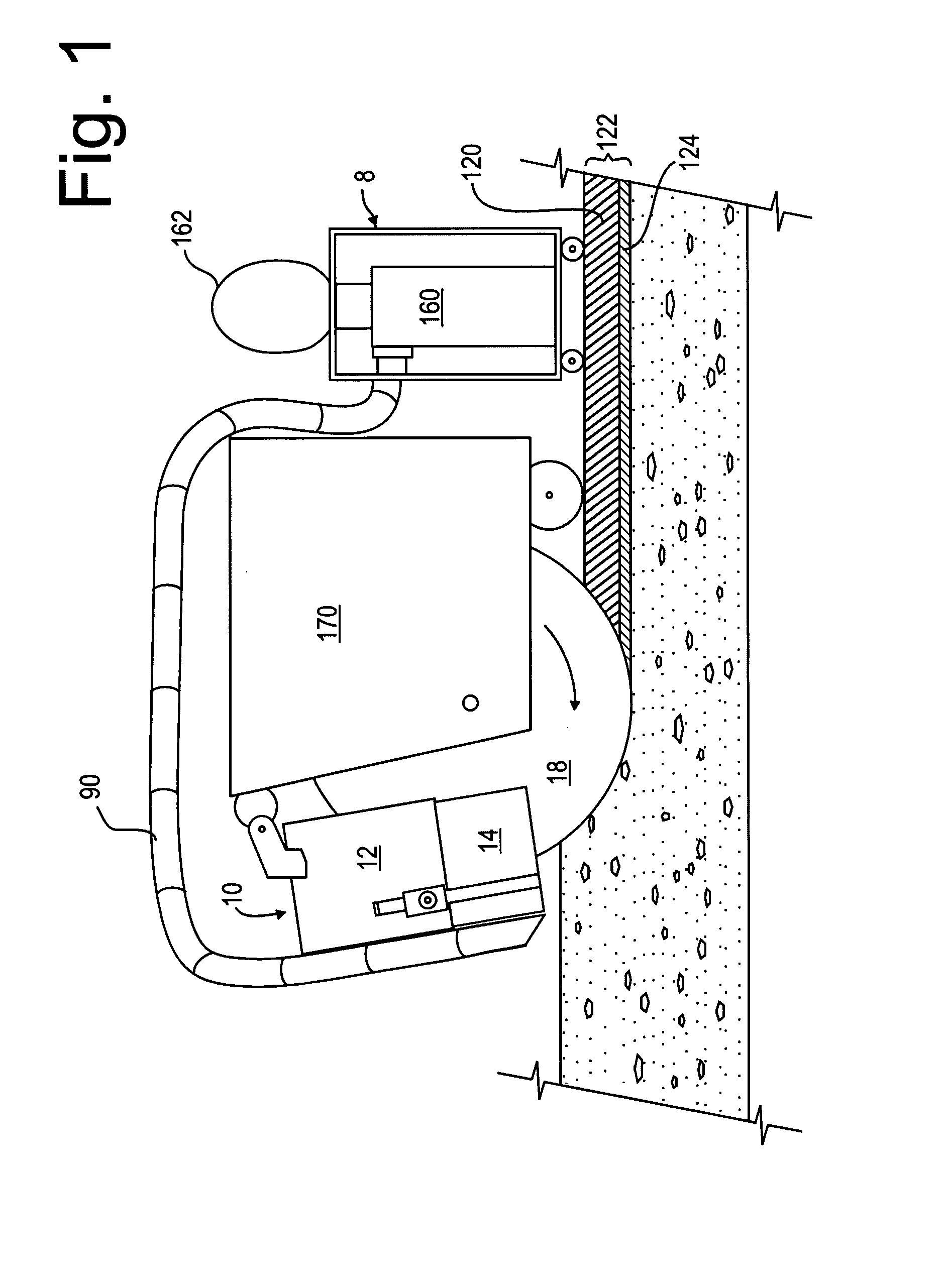

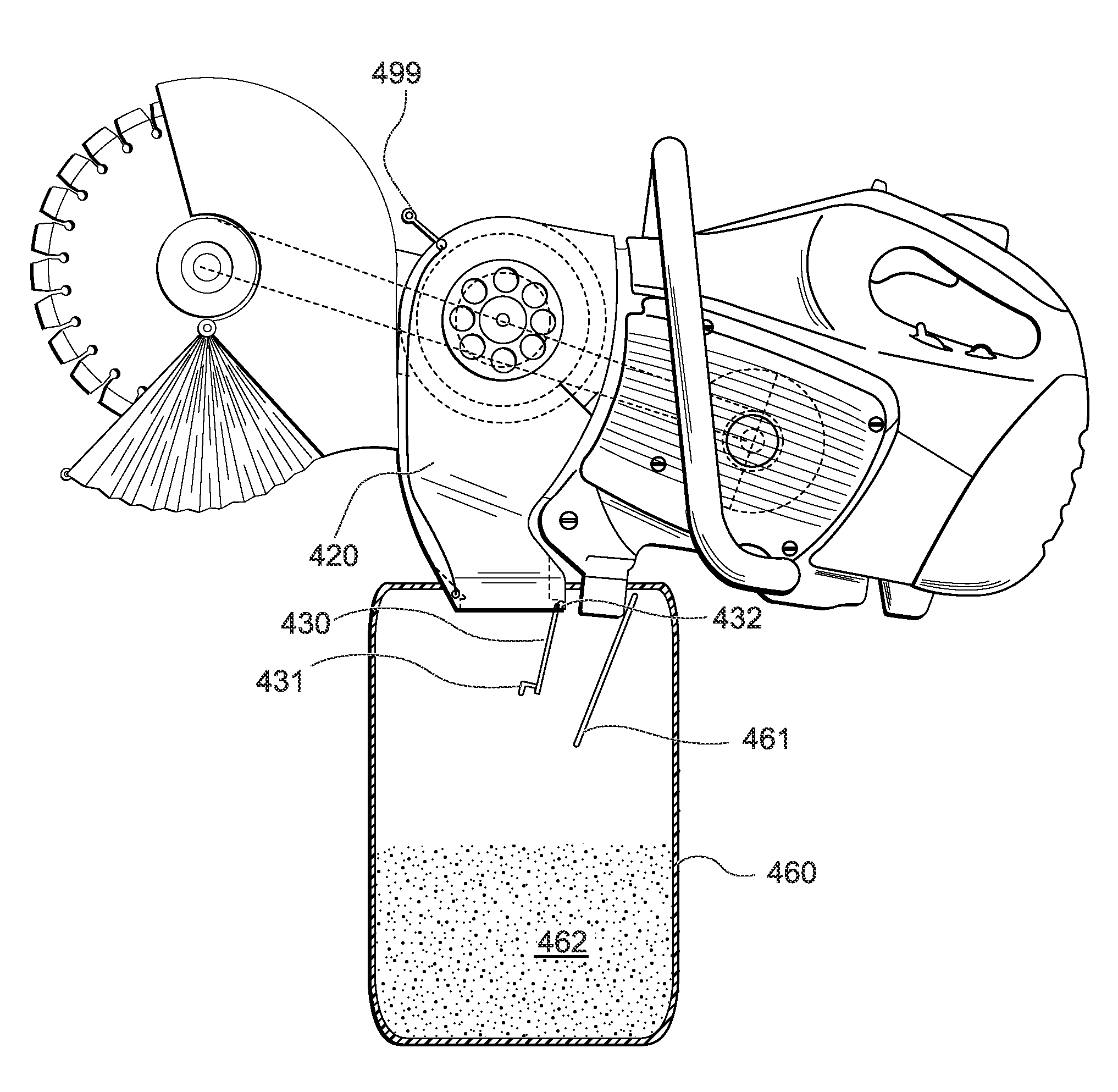

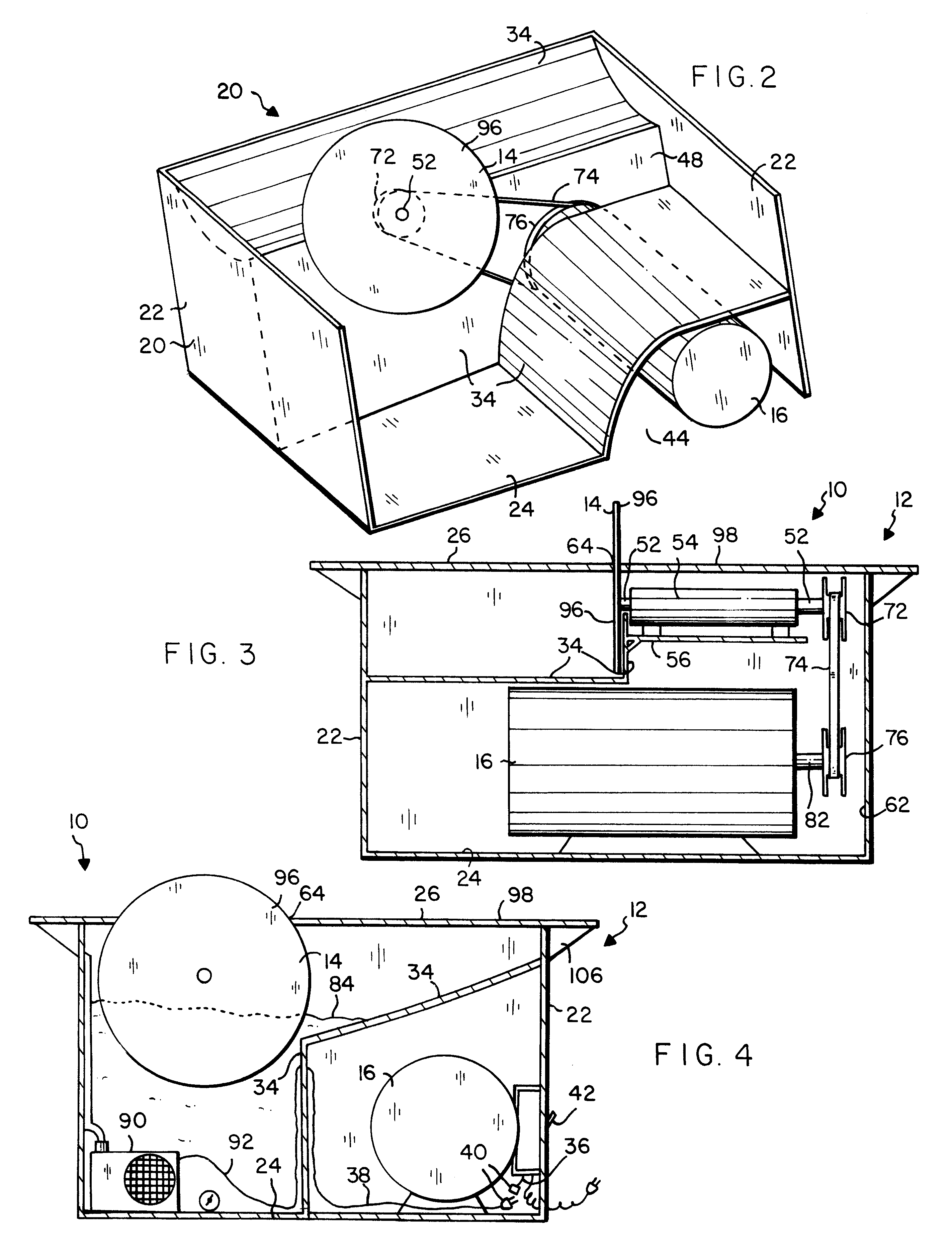

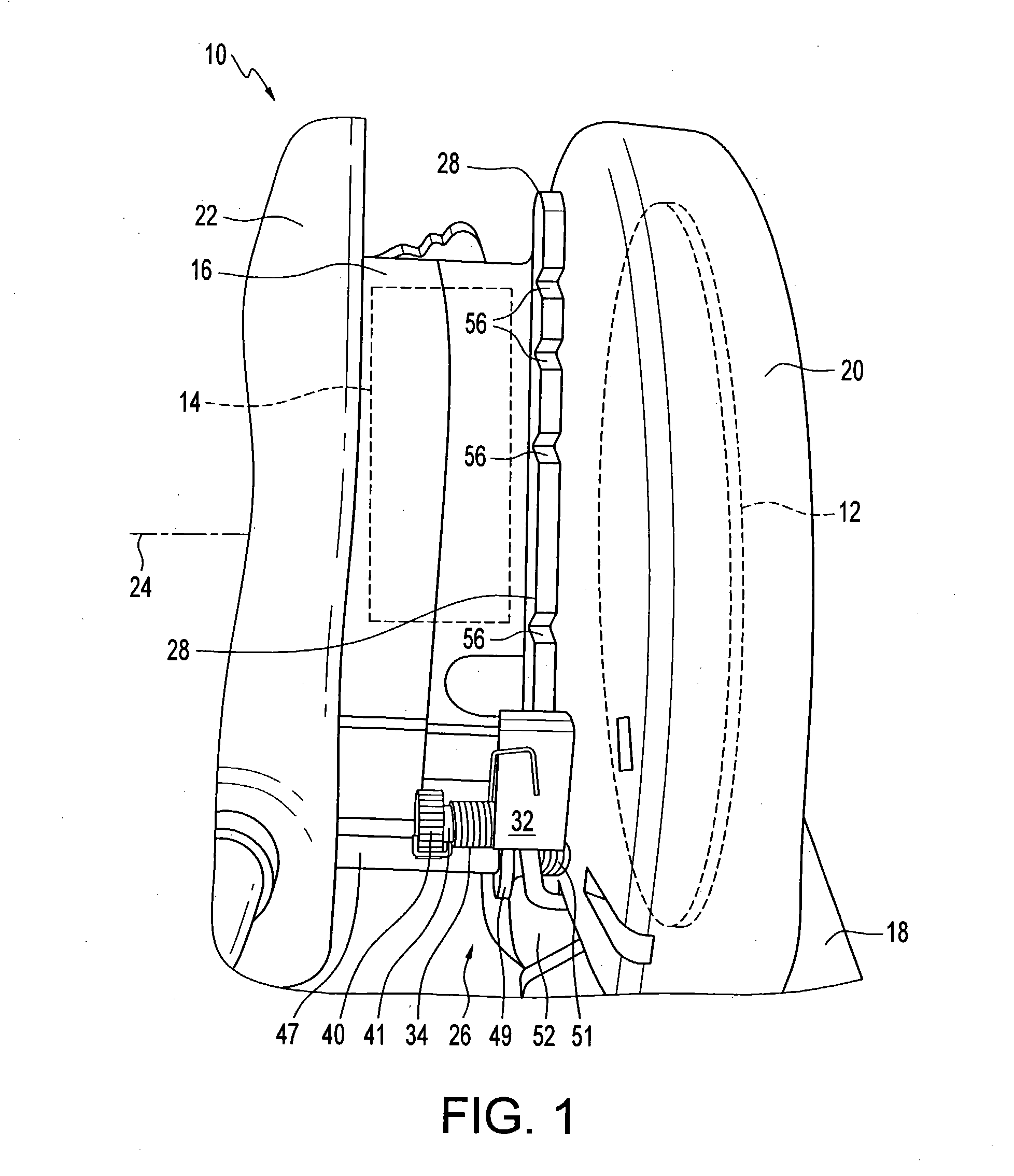

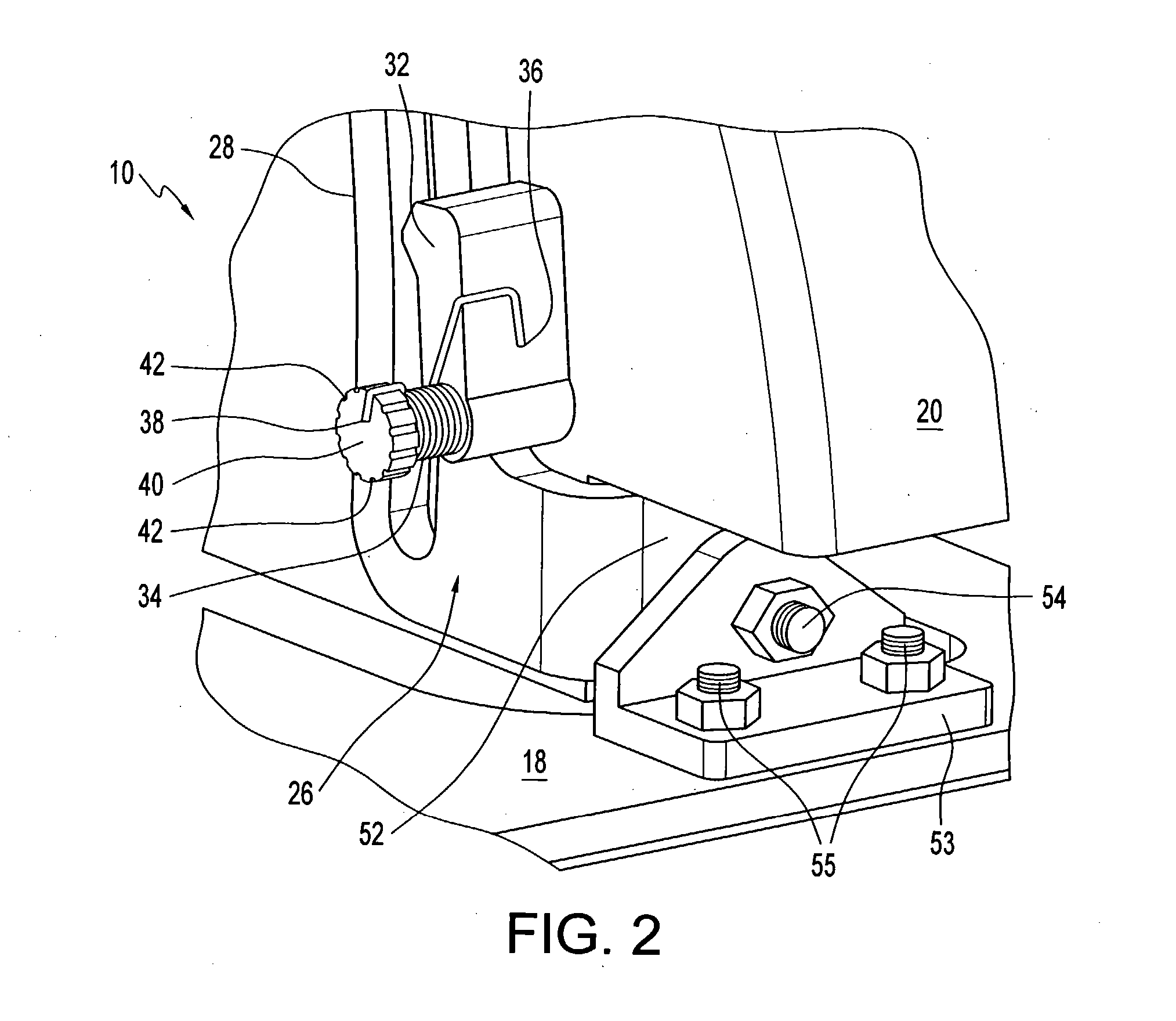

Slab saw with dust collector and method of dry-cutting pavement

A dust collector is provided for use with a SLAB saw, especially suited for dry-cutting a channel within pavement or similar exterior surface. The collector includes telescoping upper and lower housings, an open front and lower base to receive a portion of a circular saw into the interior of the housing, and an exhaust outlet, for attaching to a vacuum duct, so as to exhaust dust-laden air from the interior of the housing. The housing includes a pivot mount, pivotally mounting the unit to a slab saw. Also provided is a system, including the dust collector with a circular saw and optionally a vacuum source and dust filter unit or units. Also provided is a method for dry-cutting a trench or channel within pavement or similar hard outside surface, which is particularly suitable for laying of cable such as fiber optic cable. The method may include the step of cutting through the pavement into the underlying hard-packed substrate.

Owner:TERASPAN NETWORKS

Variable dust chute for circular saws

The present invention is directed to a hand-held circular saw with an integrated dust collection system. Such saw may include an upper blade guard for protecting the user from a saw blade, the upper blade guard configured with a front region and a back region, the front region including a hollow channel to control the pathway of dust and debris and a dust collection system incorporated within the front region of the upper blade guard allowing dust and debris to be directed away from the user.

Owner:BLACK & DECKER INC

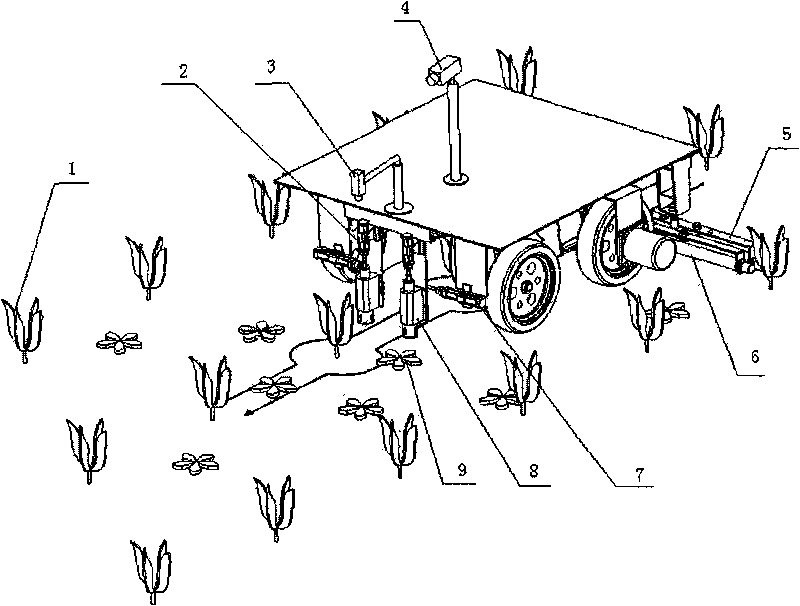

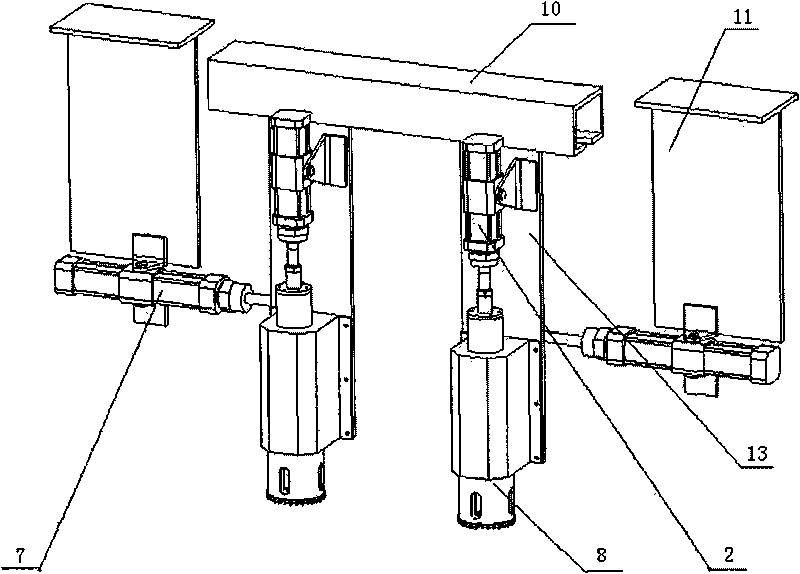

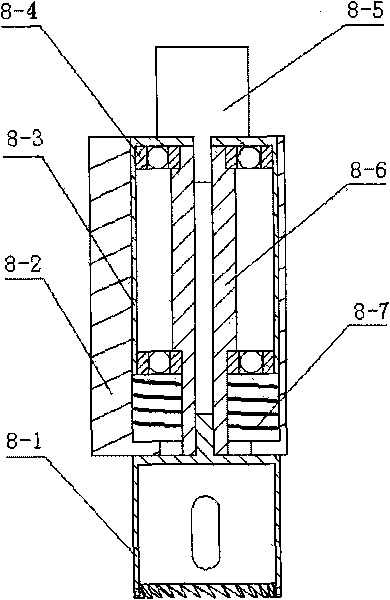

High-efficiency weeding robot

InactiveCN101707992AAchieve clearingSolve Clearing PuzzlesSoil-working equipmentsGuiding agricultural machinesCircular discControl system

The invention relates to a high-efficiency weeding robot which belongs to the technical field of agricultural machinery application. The robot comprises an automatic navigation and weed identification camera head and a control system, wherein a weeding device comprises an interline cutting and smearing weeding mechanism arranged below a trolley, and an inline weeding mechanism; the cylinder bodies of a left horizontal cylinder and a right horizontal cylinder of the inline weeding mechanism are respectively arranged at the bottom of the trolley; horizontal piston rods of the left horizontal cylinder and the right horizontal cylinder are respectively and fixedly connected with installment frames of a left vertical cylinder and a right vertical cylinder; the upper ends of the installment frames of the left vertical cylinder and the right vertical cylinder are installed in horizontal rails on the trolley to form a moving pair; the cylinders of the left vertical cylinder and the right vertical cylinder are respectively installed on the installment frames of the left vertical cylinder and the right vertical cylinder; and the lower ends of vertical pistons of the left vertical cylinder and the right vertical cylinder are respectively connected with a left end effector and a right end effector the bottoms of which are provided with electric circular saws. The invention can remove weeds in lines and among lines with high working speed and high weeding efficiency, thereby radically solving the difficulty of removing weeds in lines.

Owner:NANJING FORESTRY UNIV

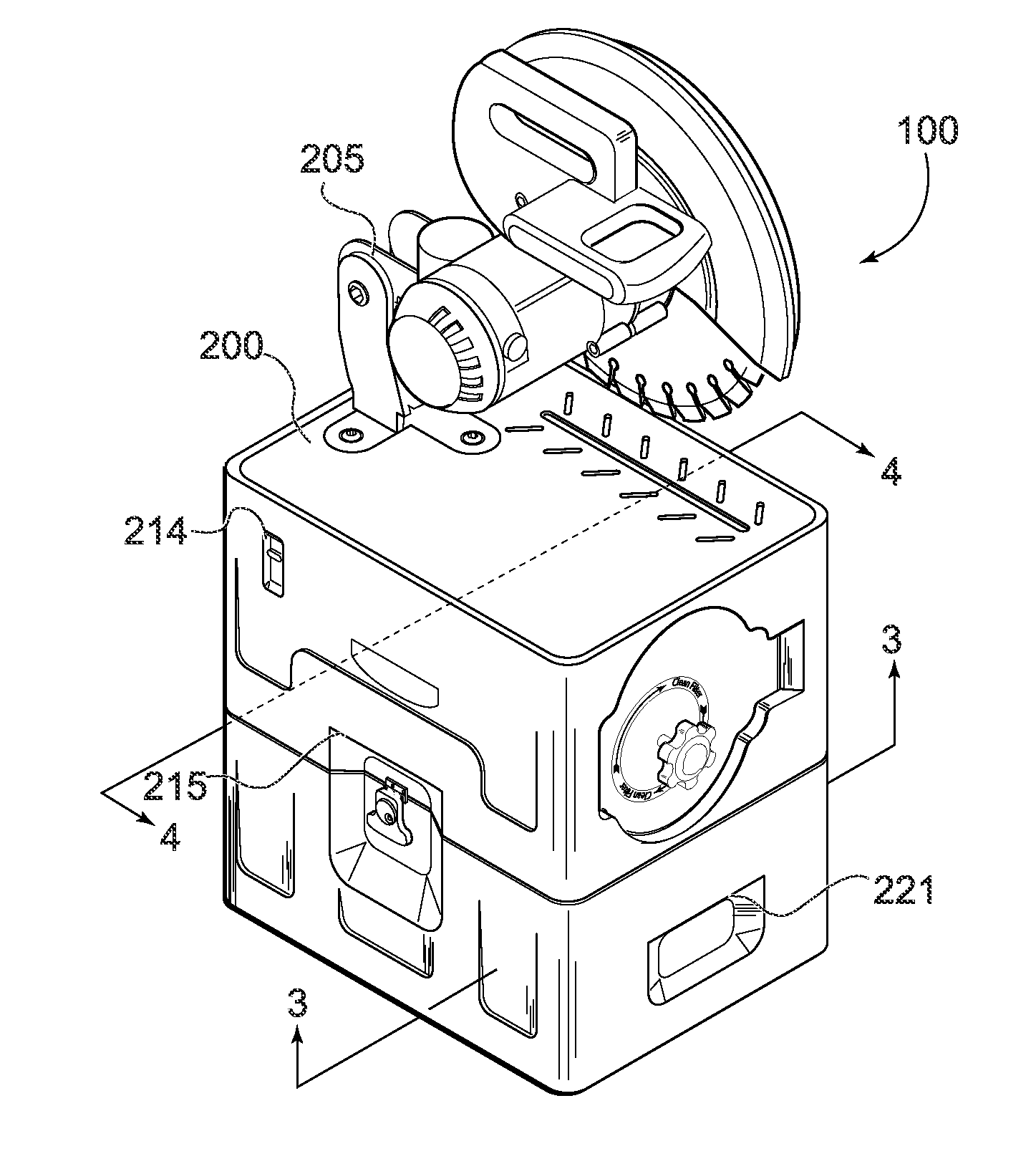

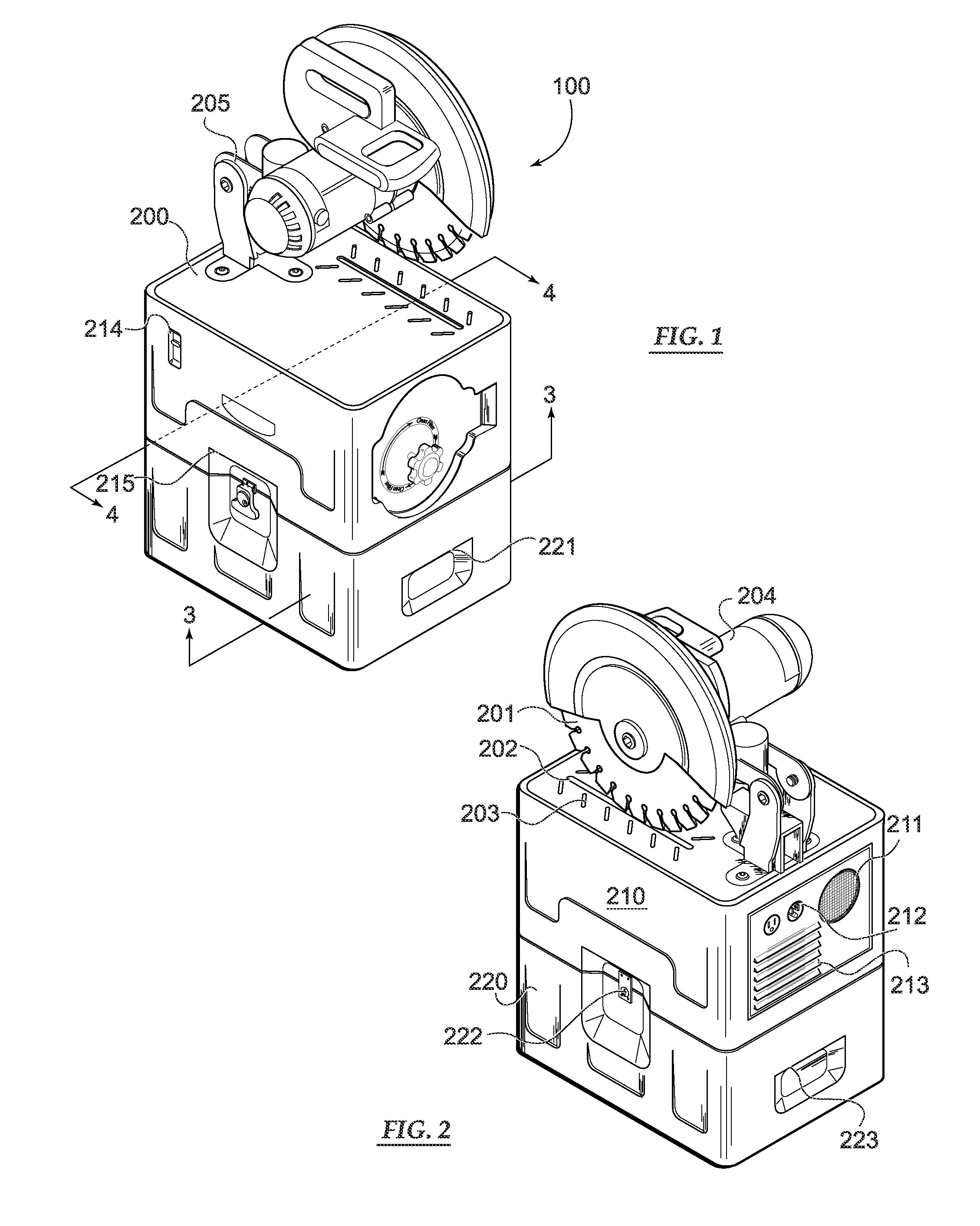

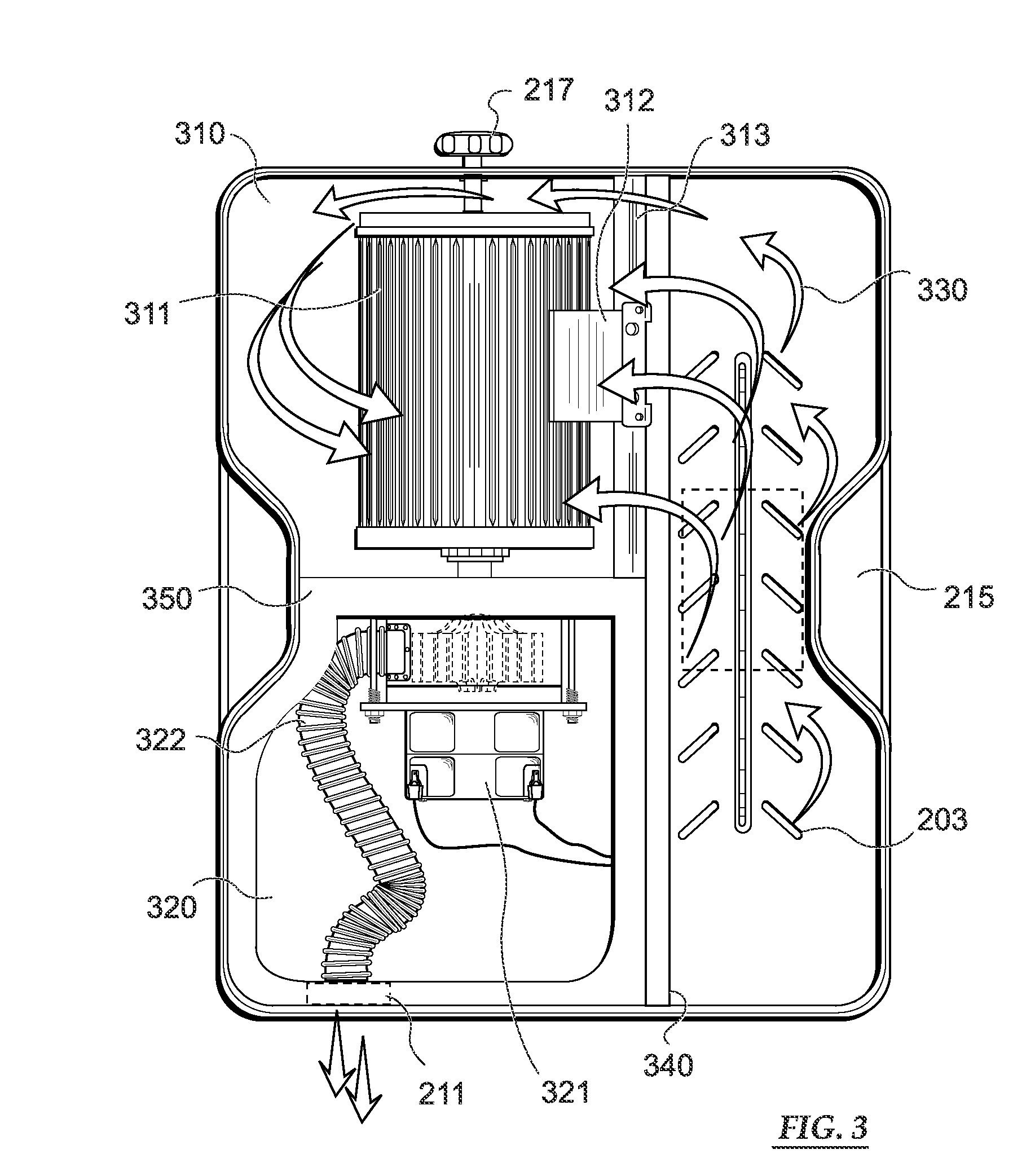

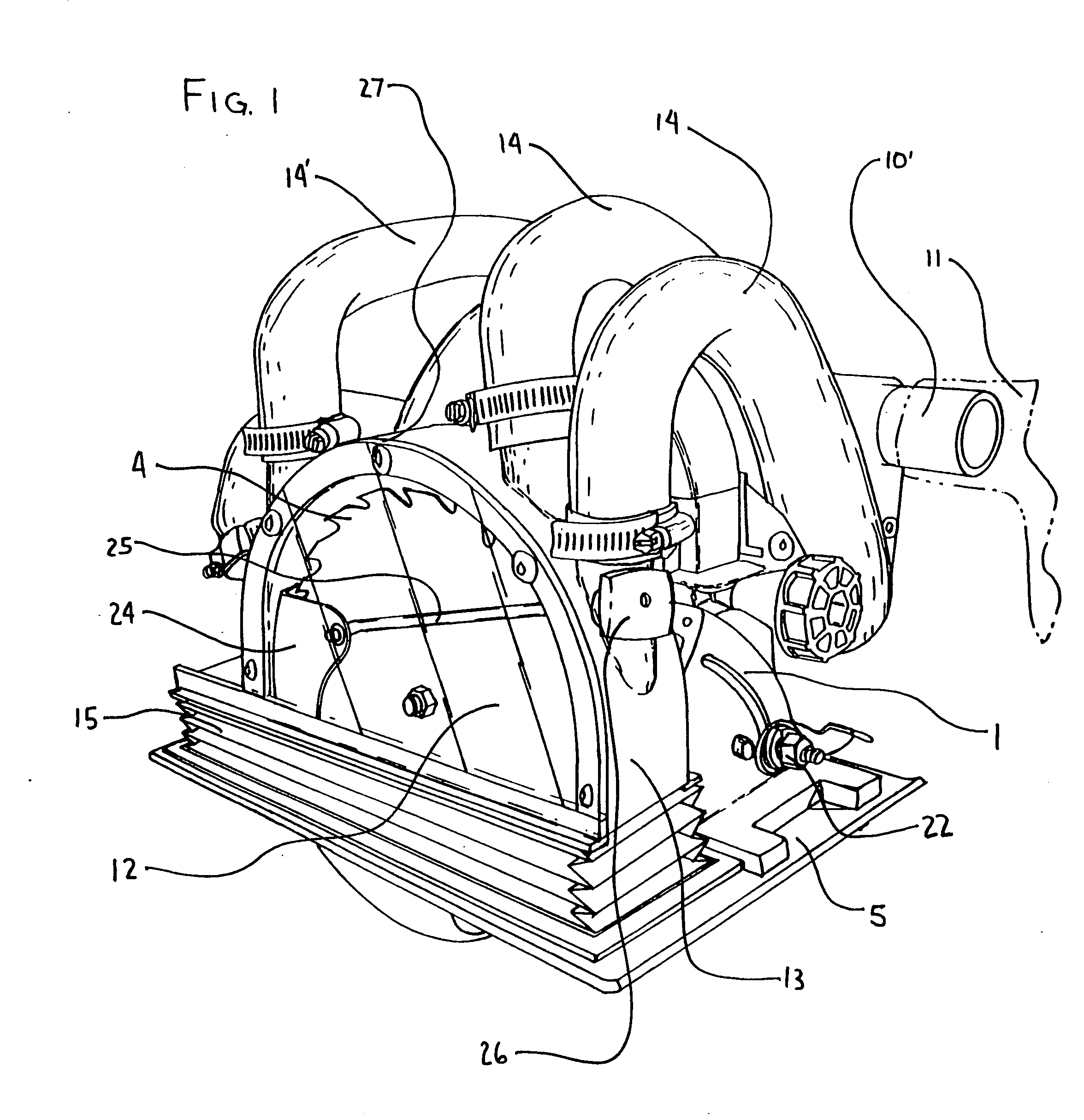

Chop Saw with Dust Collection System

ActiveUS20100116261A1Minimize undesirable current surgeIncrease usable surface areaMetal sawing devicesMetal sawing accessoriesParticulatesCircular saw

A chop saw, grinding wheel, or like apparatus is disclosed herein also incorporated to an easily portable dust collection system. In a preferred embodiment, a worktable is provided with a center slot for receiving a circular saw blade. A negative pressure and resulting air flow is provided at the center slot to capture particulate matter as a byproduct of cutting the workpiece. Side slots are also disclosed to assist in particulate collection. A unique filter chamber having a cylindrical filter is additionally provided to remove dust from air and discharge the filtered air at a lateral side of the apparatus. A filter cleaning knob is additionally disclosed to assist in cleaning the filter. Of the beneficial aspects of the chop saw with dust collection system is its portability being one integral unit and the dust filter being easily cleaned and maintained.

Owner:JPL GLOBAL

Slab saw with dust collector and method of dry-cutting pavement

A dust collector is provided for use with a SLAB saw, especially suited for dry-cutting a channel within pavement or similar exterior surface. The collector includes telescoping upper and lower housings, an open front and lower base to receive a portion of a circular saw into the interior of the housing, and an exhaust outlet, for attaching to a vacuum duct, so as to exhaust dust-laden air from the interior of the housing. The housing includes a pivot mount, pivotally mounting the unit to a slab saw. Also provided is a system, including the dust collector with a circular saw and optionally a vacuum source and dust filter unit or units. Also provided is a method for dry-cutting a trench or channel within pavement or similar hard outside surface, which is particularly suitable for laying of cable such as fiber optic cable. The method may include the step of cutting through the pavement into the underlying hard-packed substrate.

Owner:TERASPAN NETWORKS

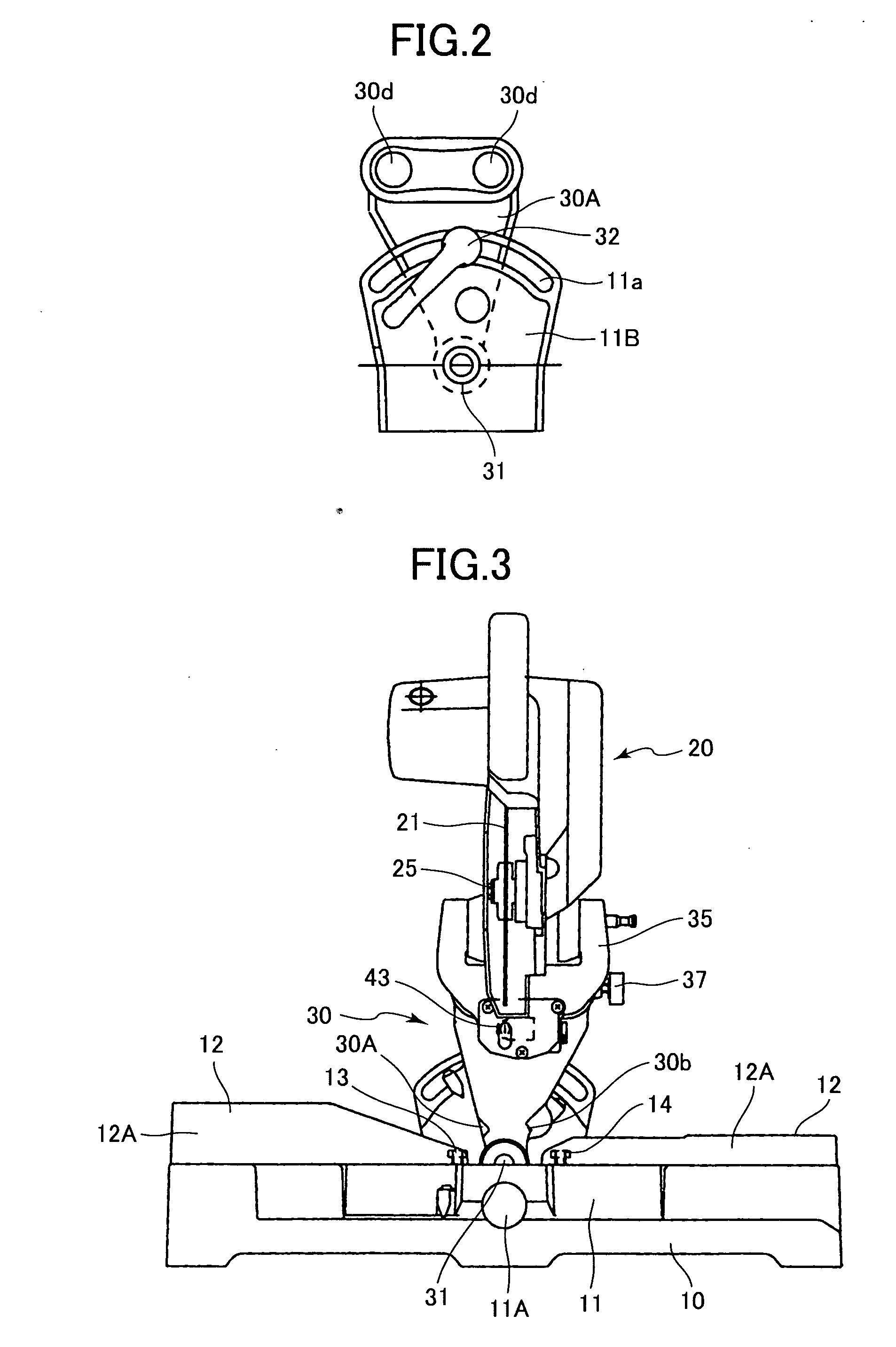

Miter saw having two laser oscillators

InactiveUS20060042444A1Clear projectionMetal sawing accessoriesMetal working apparatusCircular sawEngineering

A miter saw having first and second laser oscillators. A base is provided for mounting a worpiece. A fence extends in a lateral direction and is fixed to the base and has a front surface to which the workpiece is to be abutted. A cutting unit rotatably supports a circular saw blade. A support section is supported on the base and is pivotably supports the cutting unit movable toward and away from the base. The first laser oscillator is provided at the base for irradiating a first laser beam to the front side of the workpiece. The second laser oscillator is provided at the support section for irradiating a second laser beam to a rear side of the workpiece.

Owner:HITACHI KOKI CO LTD

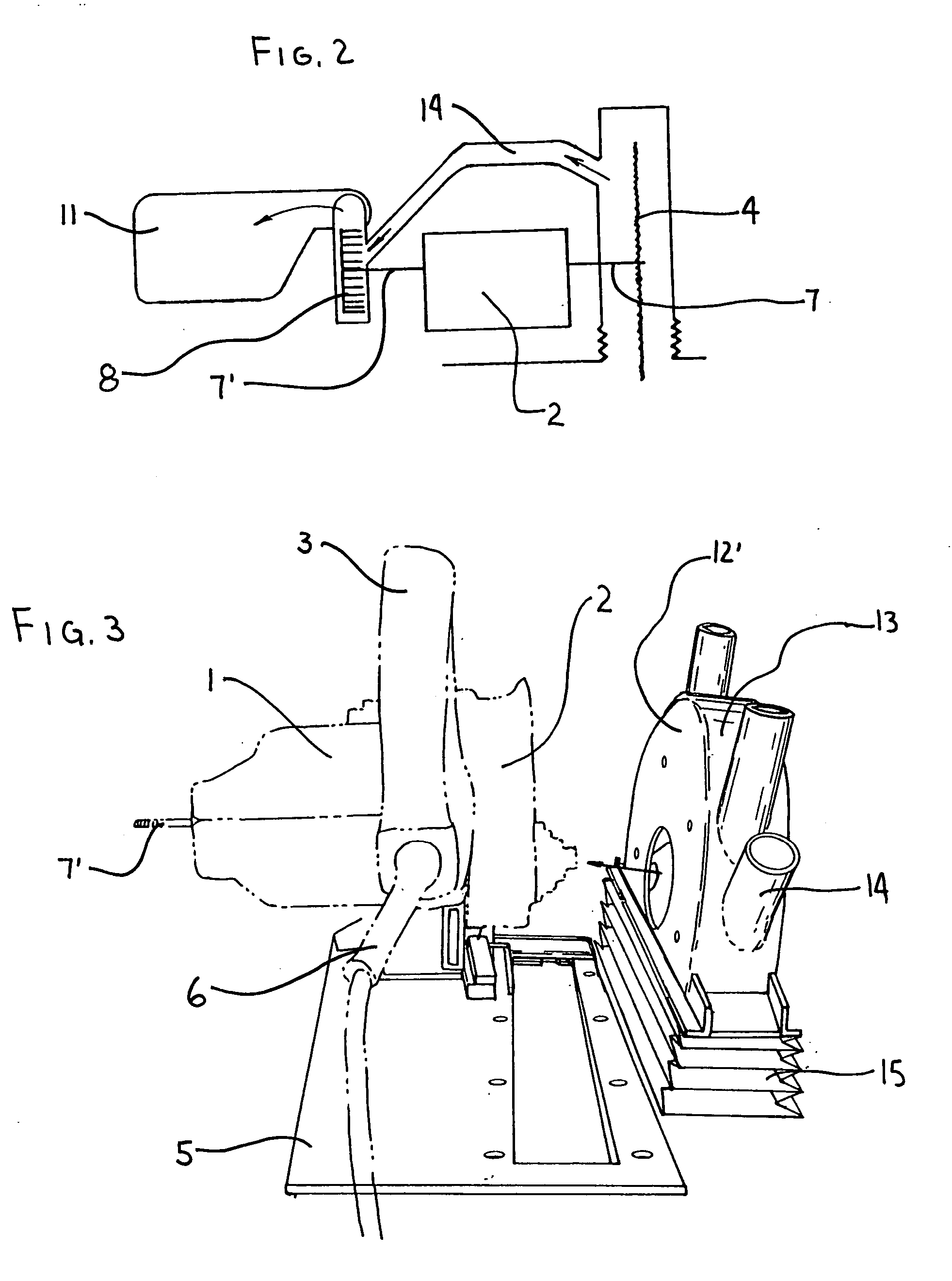

Power saw apparatus with integrated dust collector

ActiveUS20110079207A1Reduce frictionUseful surface areaMetal sawing devicesMetal sawing accessoriesParticulatesSpins

A power saw having a circular saw blade or, grinding wheel incorporated to a dust collection system that is easily portable is disclosed herein. In a preferred embodiment, negative pressure and resulting air flow is provided at a lower blade guard to capture particulate matter as a byproduct of cutting a work piece. A unique dust collection housing is additionally provided having a filter to remove dust from air and exhaust the filtered air at a lateral side of the saw. A spin handle is additionally disclosed to increase the usable surface of the filter and to work in conjunction with a filter cleaning flap. A drive belt according to a preferred embodiment, drives the circular saw and a vacuum fan. Among the beneficial aspects of the power saw is its portability by obviating a need for a dust collection bag and / or a separate vacuum unit.

Owner:JPL GLOBAL

Stone and tile table saw apparatus

InactiveUS6253757B1Maximizes workProlong lifeMetal sawing devicesMetal sawing accessoriesCircular sawEngineering

A saw apparatus for cutting a work piece includes a circular saw blade, a saw blade drive mechanism including a motor drivably connected to the saw blade and having a motor pulley, and including a blade mounting structure, a saw table including a housing with a housing side wall, and a housing top wall having a blade passing opening and being hingedly secured to and resting on the housing side wall, a housing partition defining a drive mechanism chamber and a blade mounting chamber within the housing having a drive mechanism chamber bottom wall sealingly joined to the housing side wall, and a cooling liquid contained within the blade mounting chamber, so that the blade mounting mechanism includes a blade axle extending through the housing partition between the blade mounting chamber and the drive mechanism chamber, and the blade protrudes up through the blade passing opening and down into the cooling liquid, and a blade axle pulley is secured to the blade axle, passes through the housing partition, and a belt extends from the blade axle pulley to the motor pulley.

Owner:BENSON WALTER J

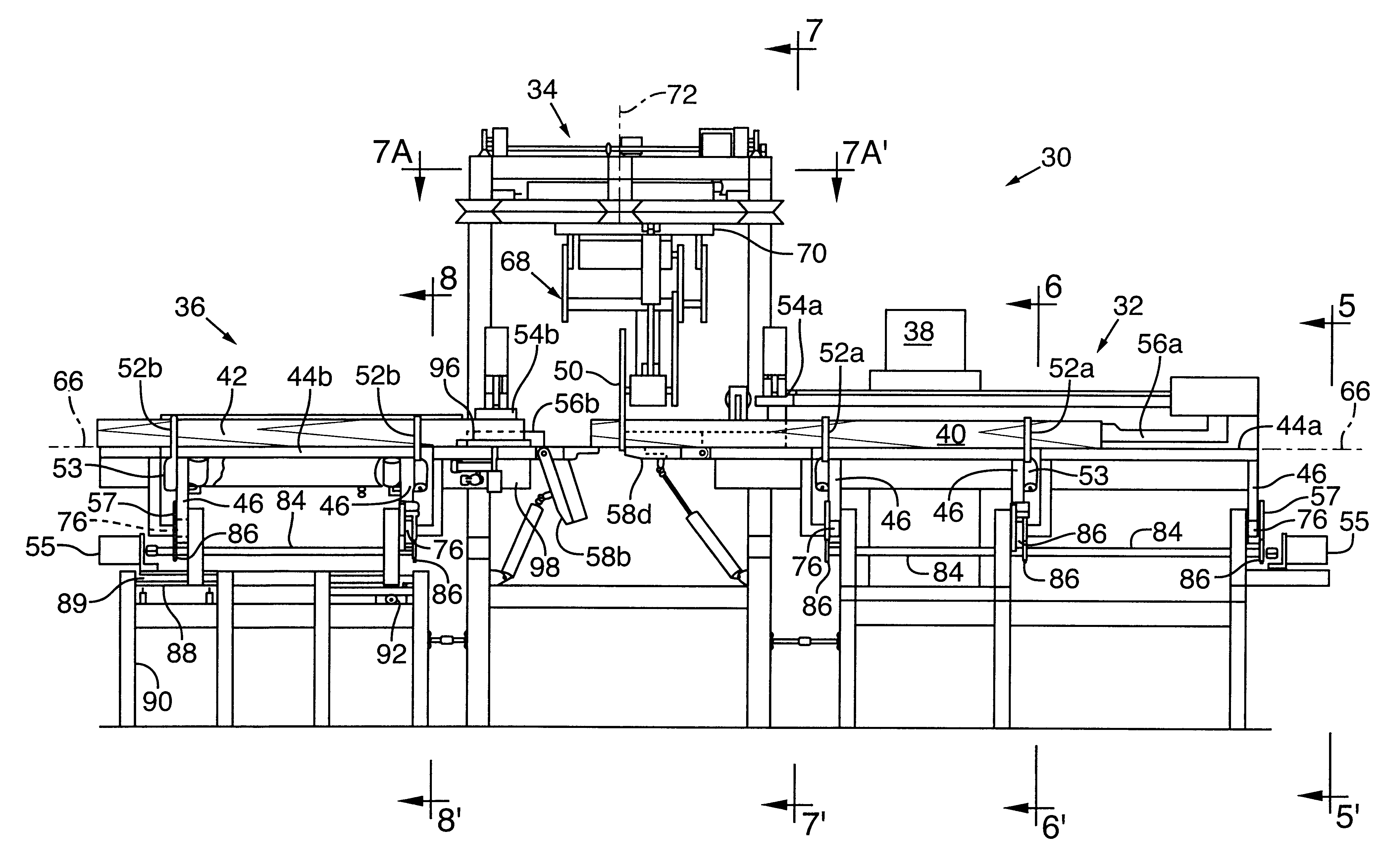

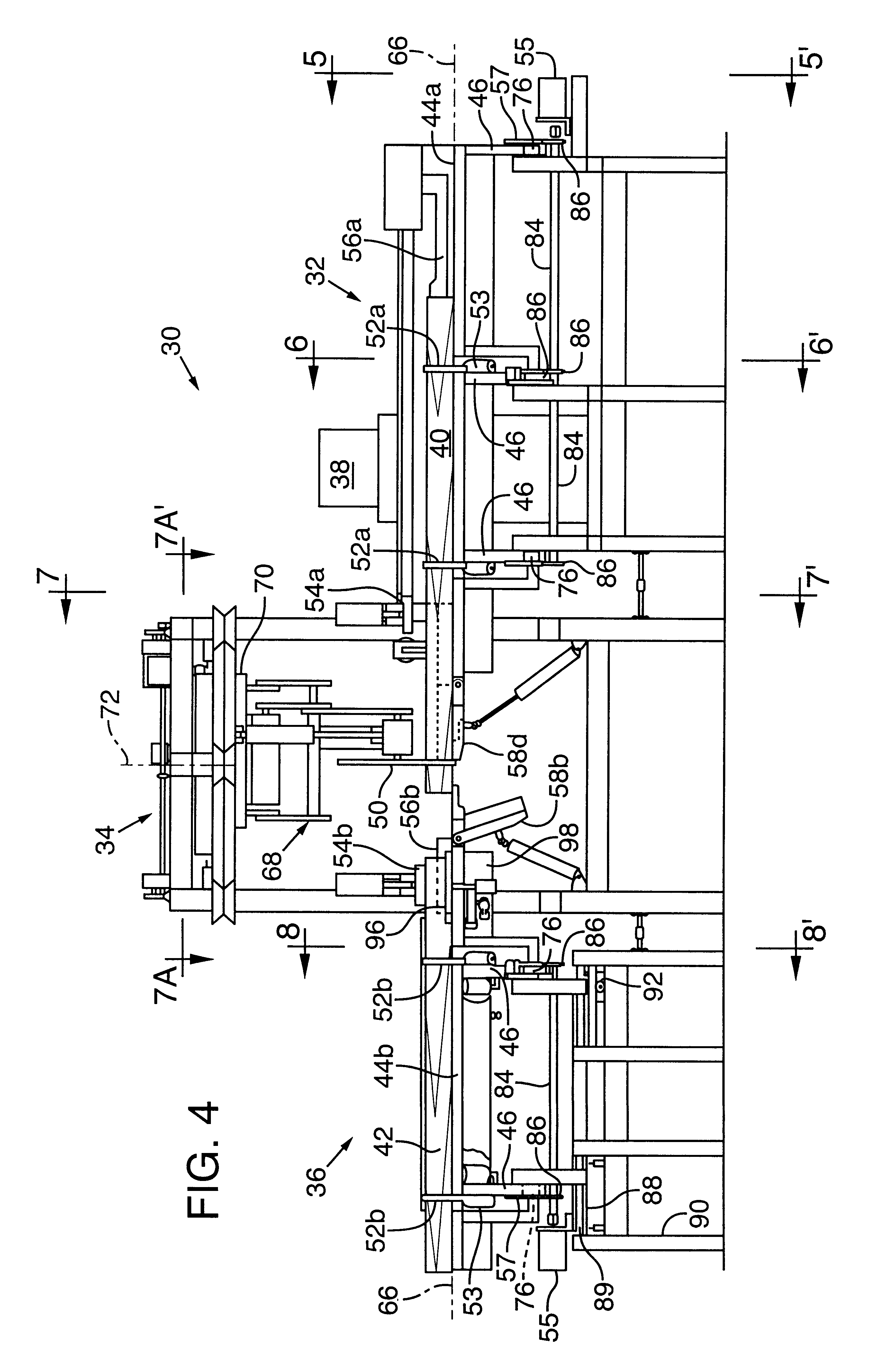

Tiltable infeed and outfeed saw table

InactiveUS6212983B1Precise positioningMinimum elapsed timeMetal sawing devicesAutomatic control devicesCircular sawEngineering

An apparatus for sequentially and automatically cutting a piece of dimension lumber at a number of predetermined angles to produce a building component, such as a rafter or truss web or chord, with composite or compound angles, is disclosed. The apparatus includes infeed and outfeed tables tiltable about a longitudinal axis and equipped with fences along which a workpiece moves longitudinally via moving devices. Clamps hold the workpiece at different positions relative to a cutting station during a cutting operation. A cutter, which for example includes a circular saw blade, is mounted for a positioning movement about a vertical axis at the cutting station, as well as for vertical movement to cut a workpiece at a predetermined composite or compound angle. The entire lumber cutting process at both ends of the workpiece, including lumber movement on the table past the cutting station, angular cutter and table adjustment, cutter movement, and clamping and unclamping, is under the control of a programmable computer operating in conjunction with appropriate sensors and pulse counters on the equipment.

Owner:STODDARD H PYLE REVOCABLE LIVING TRUST DATED JULY 17 1991

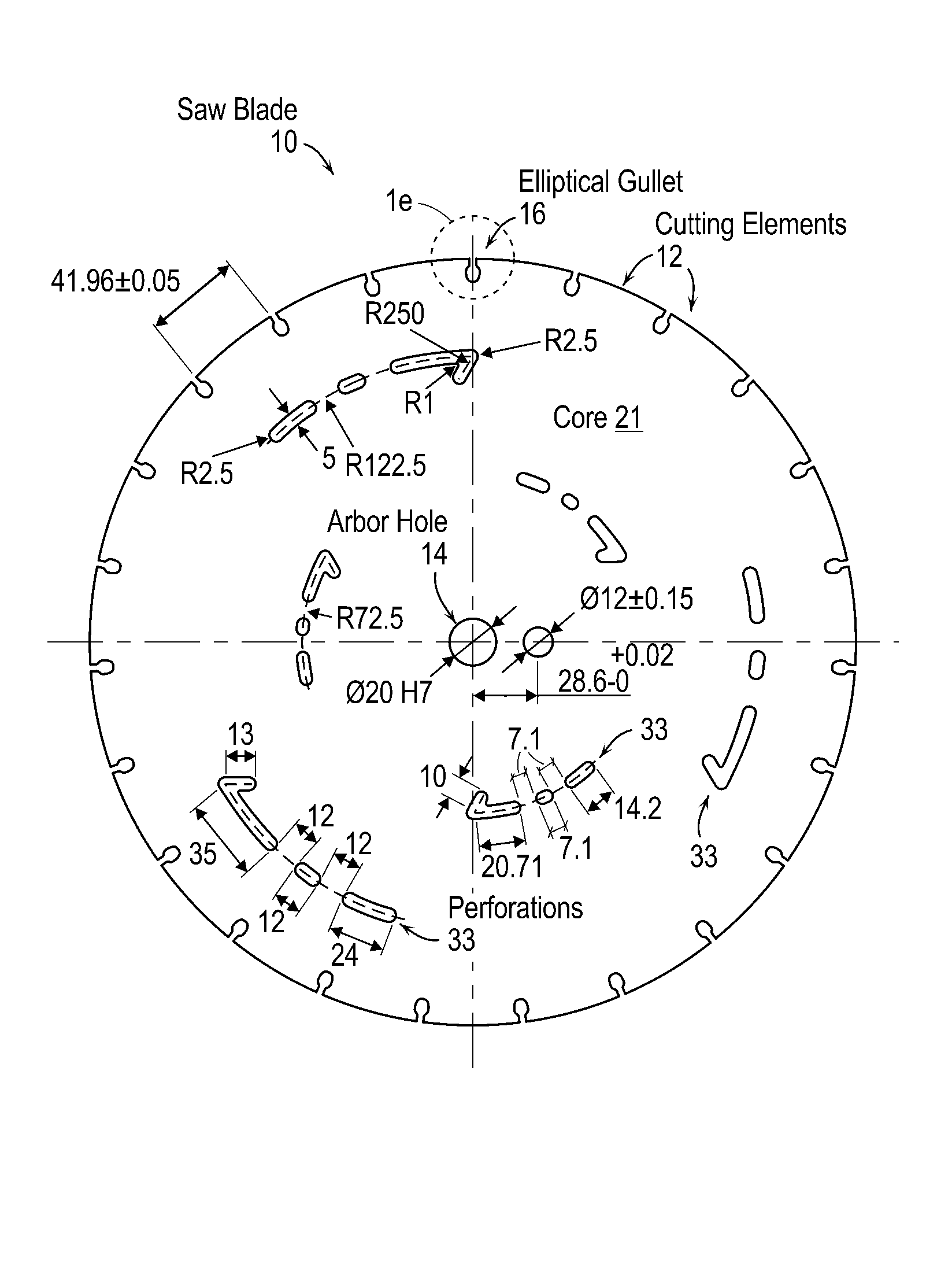

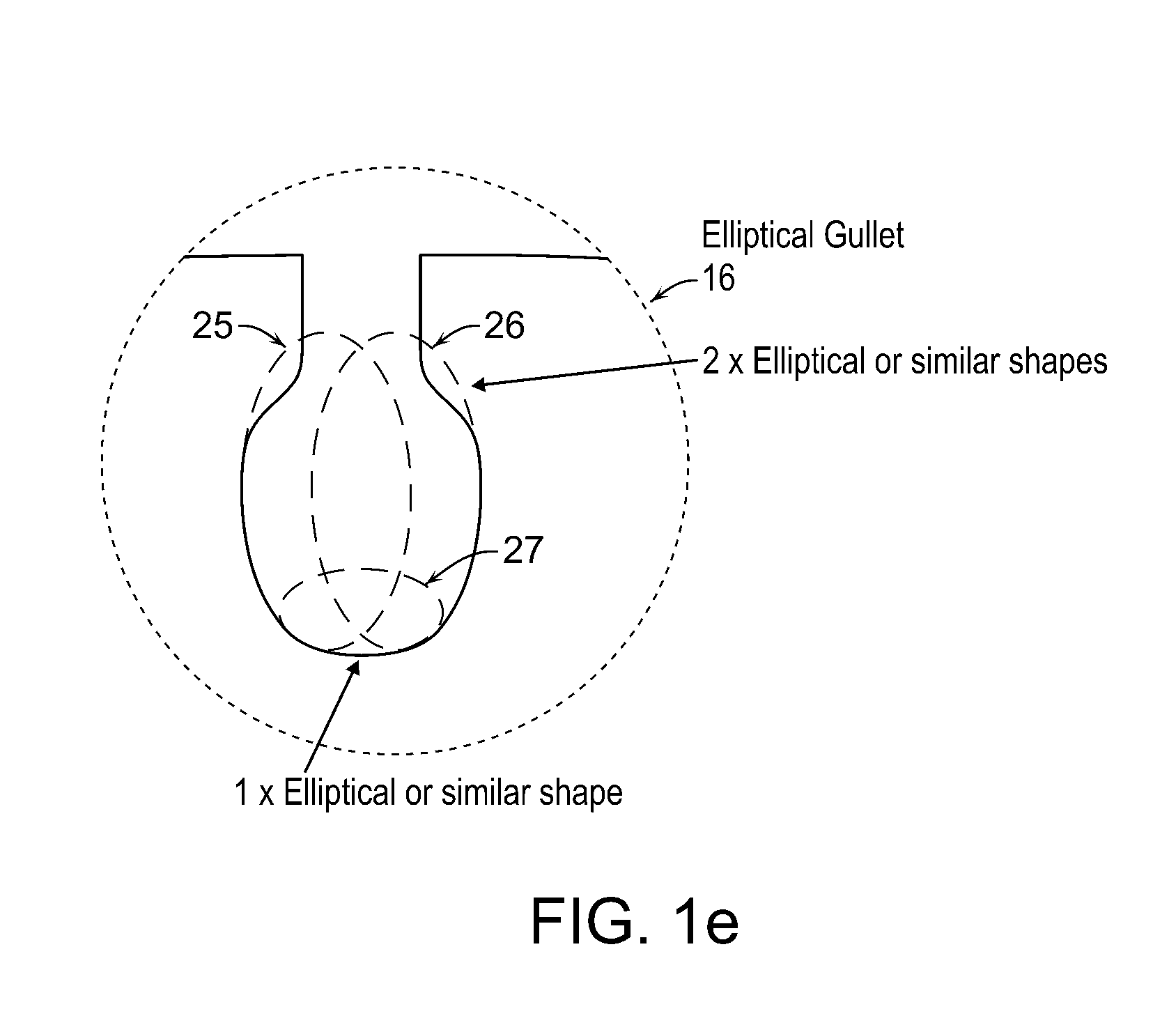

Circular Saw Blade With Elliptical Gullets

A saw blade includes a circular core having a plurality of cutting elements along its periphery, and a central arbor hole. One or more gullets extend radially inward from the perimeter of the core. Each gullet includes a shape that includes at least one elongated curve that enlarges radii in gullet areas prone to cracking, relative to other gullet areas.

Owner:SAINT GOBAIN ABRASIVES INC +1

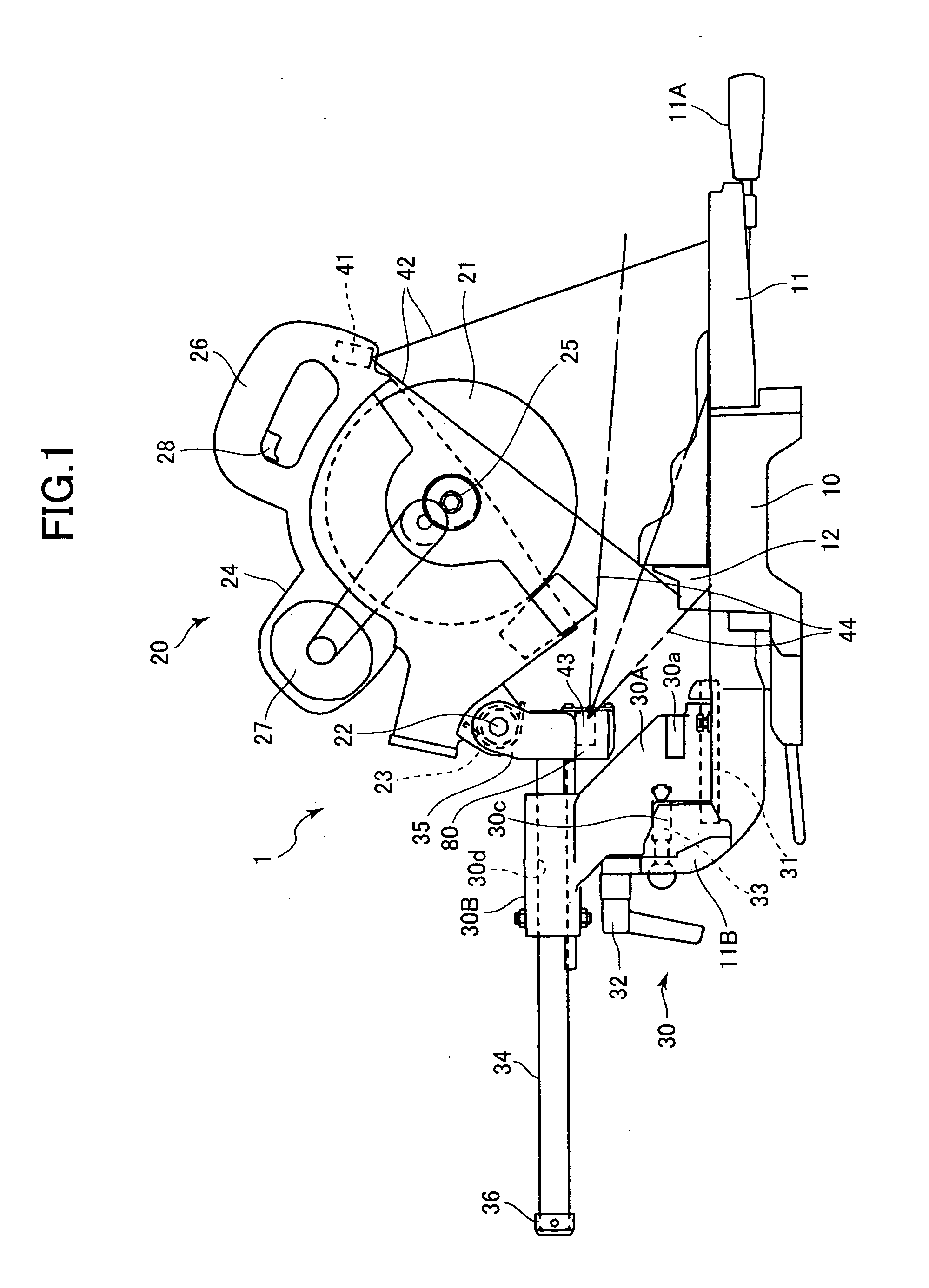

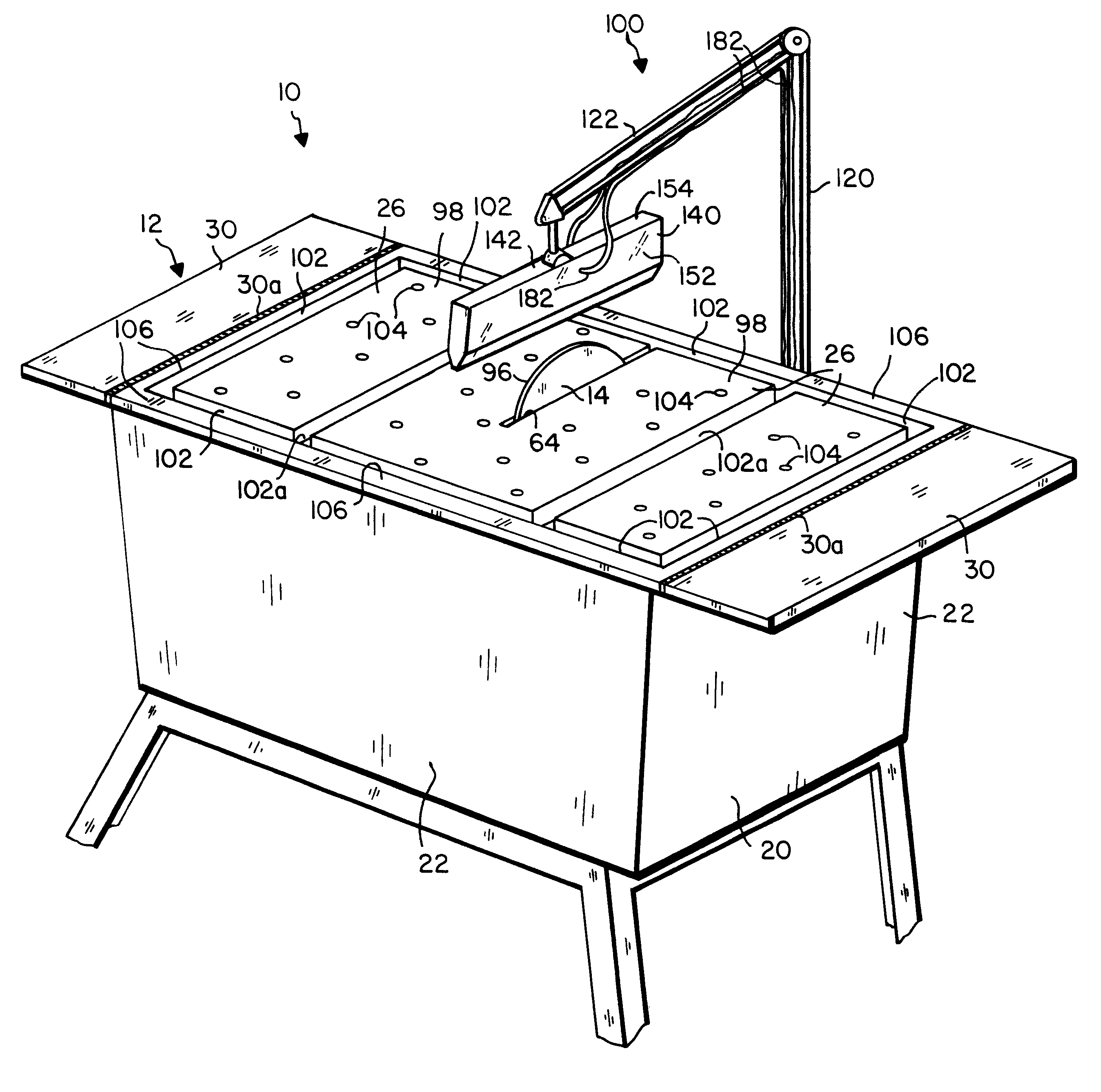

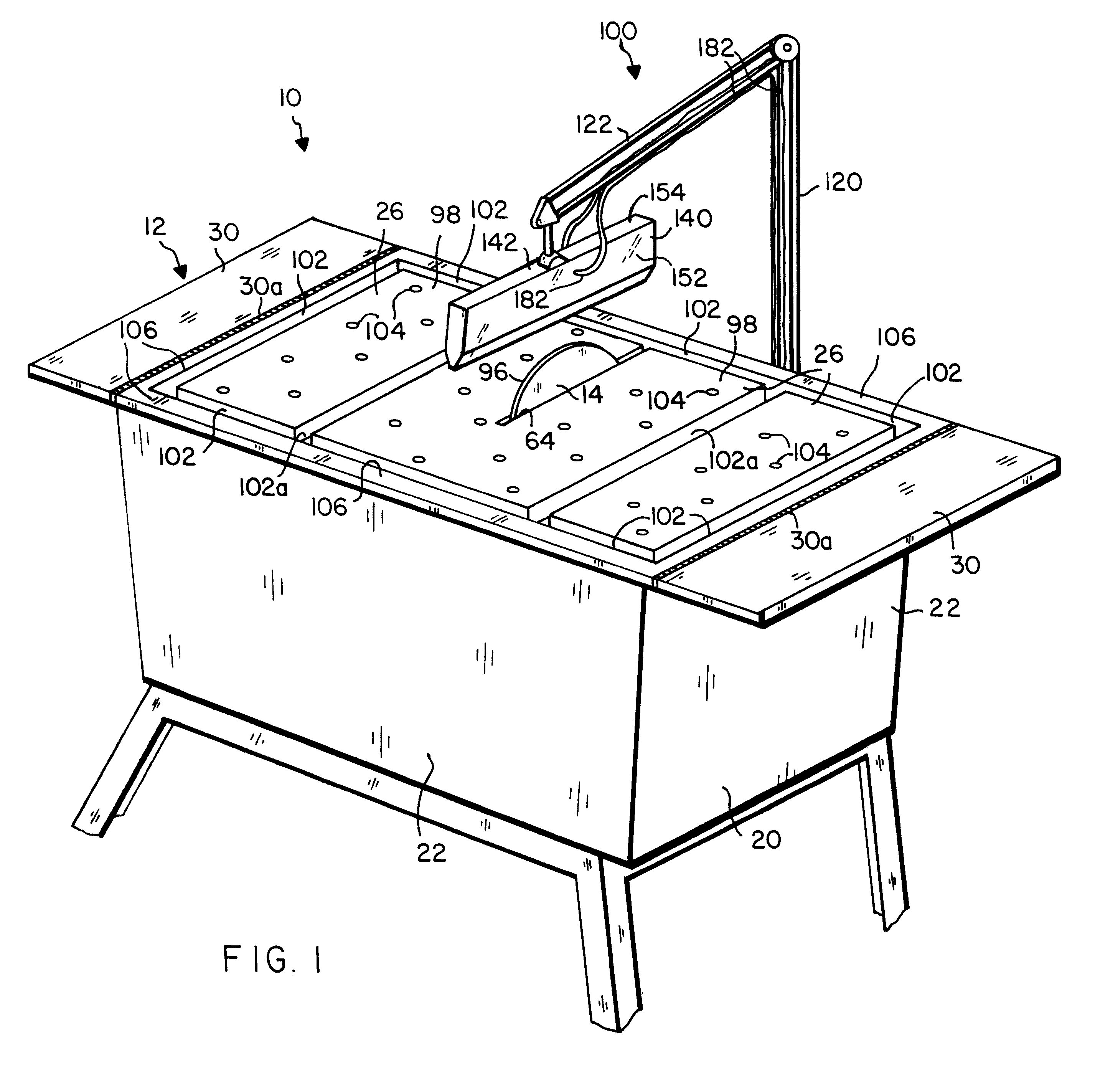

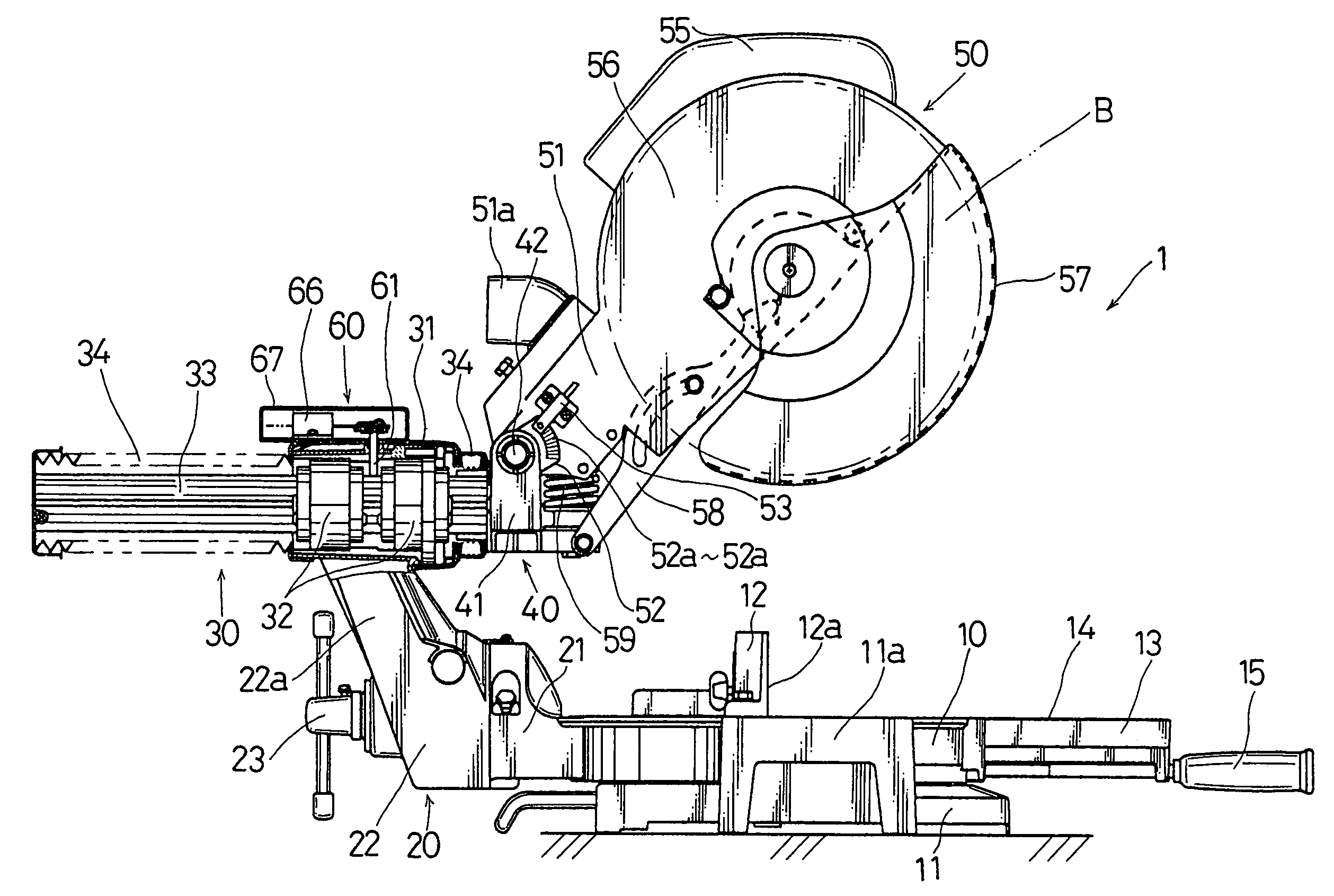

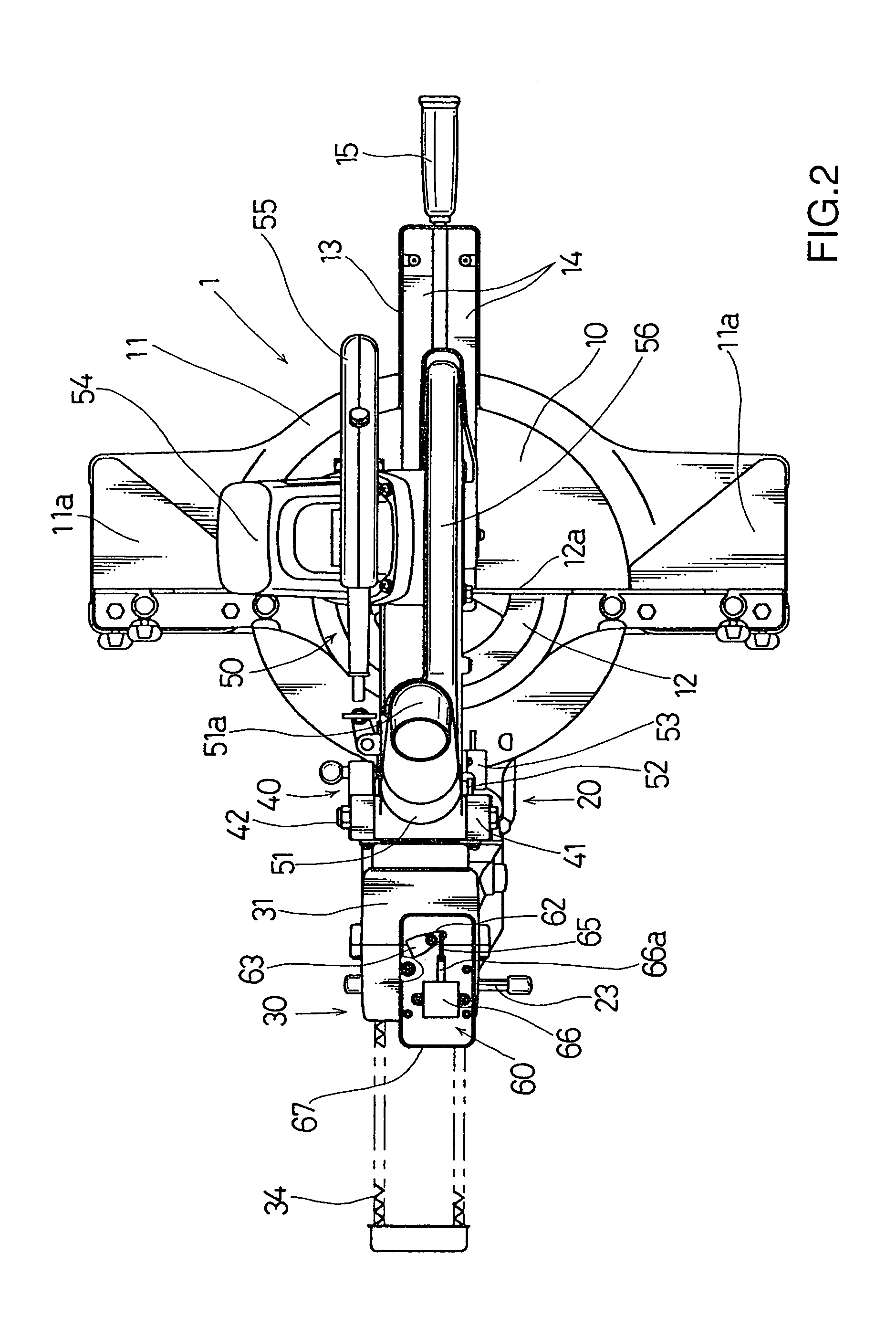

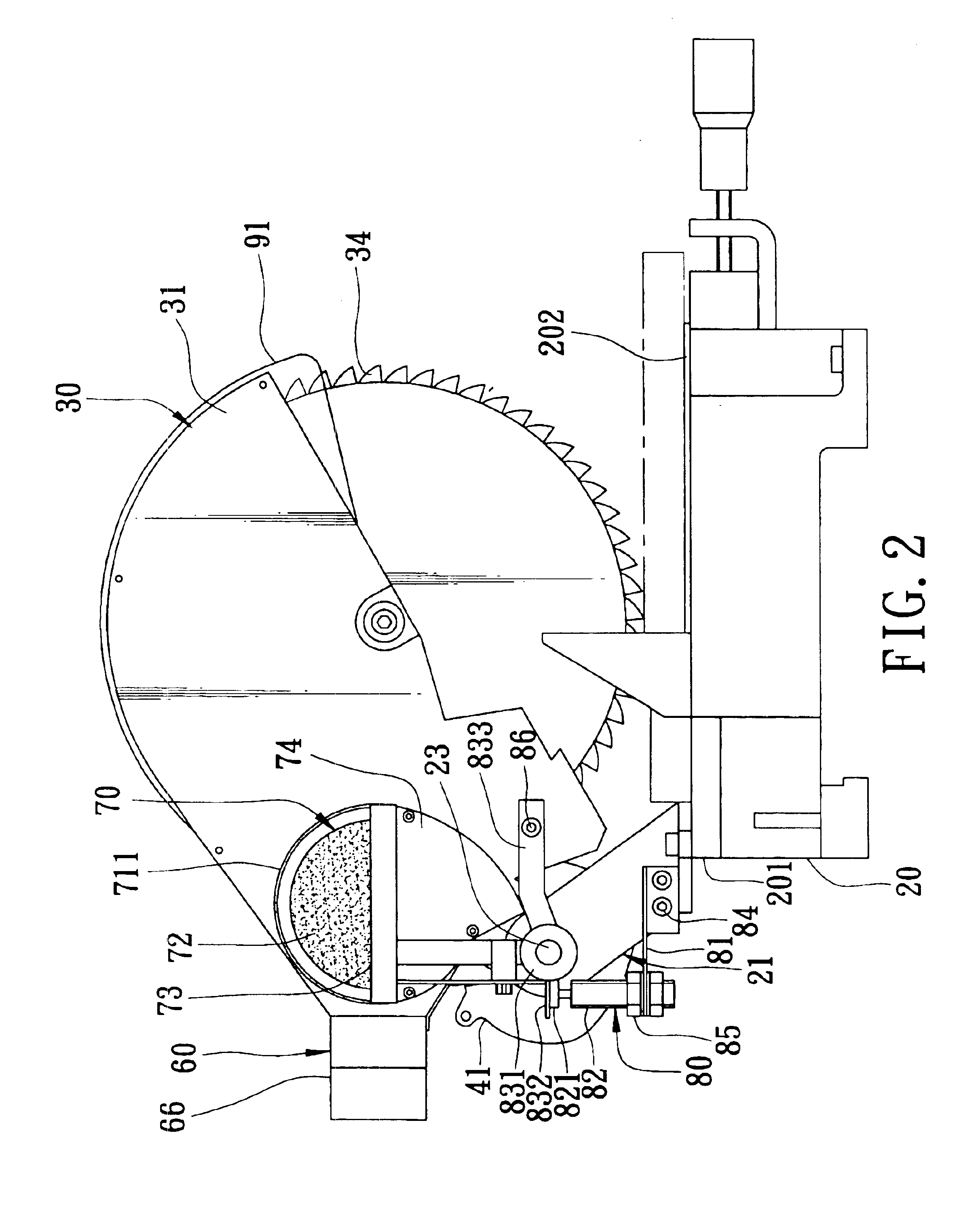

Circular saw

InactiveUS6997091B1Simple and smooth operationEasy to operateMetal sawing devicesMetal sawing accessoriesCircular sawEngineering

A circular saw includes a table having an upper surface for placing a workpiece thereon. A saw unit has a saw blade mounted thereon and is supported on the table such that the saw unit is movable in a horizontal direction parallel to the upper surface of the table and is movable in a vertical direction perpendicular to the upper surface of the table. At least one of a first lock device and a second lock device is provided. The first lock device is operable to prevent the saw unit from moving in the horizontal direction in response to the movement of the saw unit in the vertical direction. The second lock device is operable to prevent the saw unit from moving in the vertical direction in response to the movement of the saw unit in the horizontal direction.

Owner:MAKITA CORP

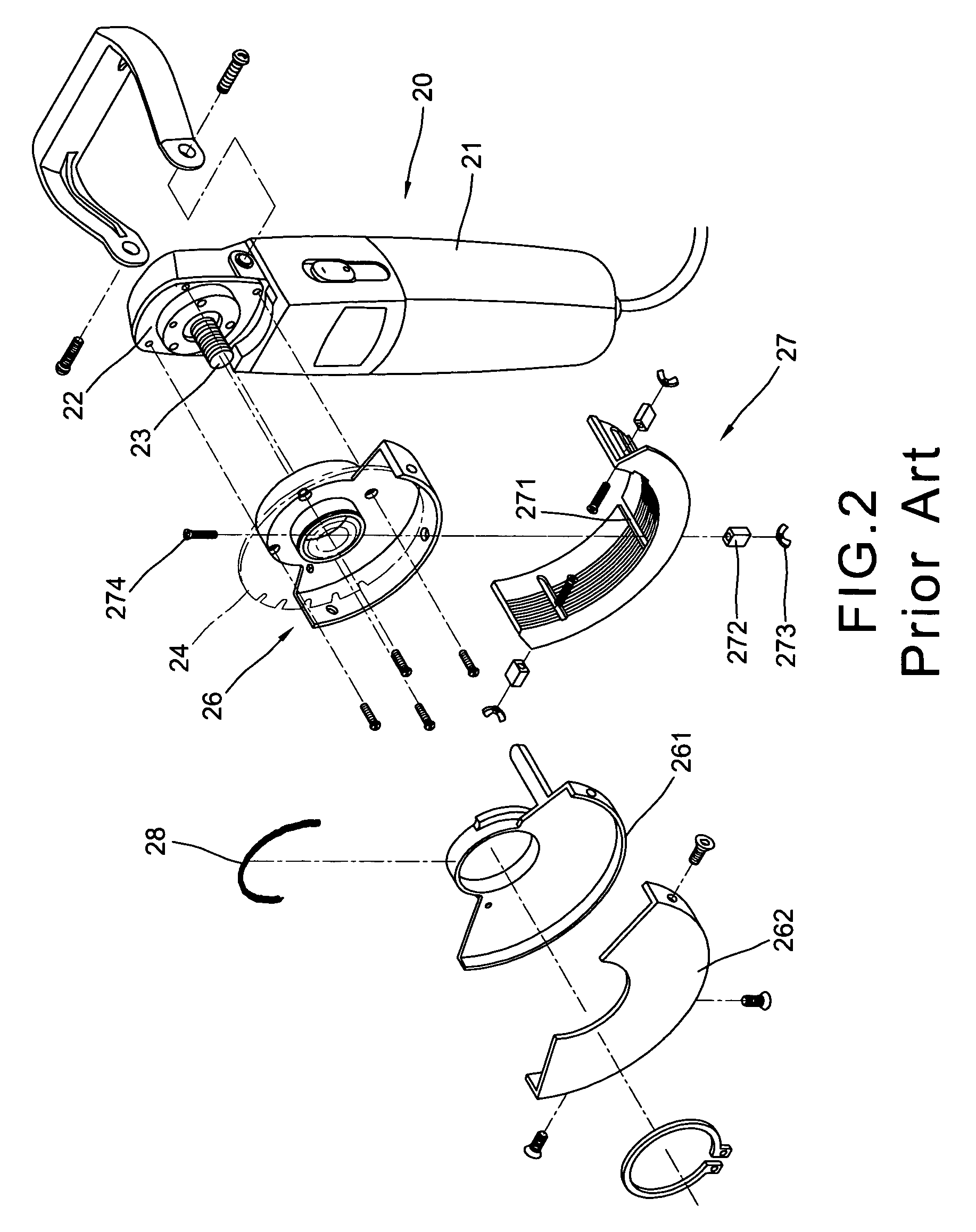

Power tool with spindle lock

InactiveUS20080014844A1Prevent rotationPortable grinding machinesPortable power-driven toolsHand heldCircular saw

A spindle lock equipped hand-held power tool, such as a grinder or circular saw, includes a housing assembly, a motor including a rotating armature shaft, a spindle carried externally of the housing adapted for selectively affixing and releasing a rotating cutting tool and a drive train which drivingly interconnects the motor armature shaft and spindle for the application of torque to the tool upon electrical energization of the motor. A lock member carried in the housing is selectively displaceable along a fixed axis between a locked position wherein it engages a rotating element of the drive train to prevent rotation of the spindle, and a released position. A spring continuously urges the lock member toward the released position. A manually operable lever selectively displaces the lock member between the released and locked positions.

Owner:PONTIERI JAMES MATTHEW

Self-contained vacuum saw

A self-contained vacuum circular saw is presented. The vacuum saw has a casing around the saw blade that includes an accordion type lower section attached to the lower platform of the saw. A number of vacuum tubes, preferably four, are attached to the side of the circular saw opposite the blade. The armature of the circular saw that turns the blade also turns the vacuum impeller on the side opposite the blade. An impeller vacuum chamber pulls in the dust and debris created by the saw blade and discharges the dust and debris into a disposable and removable vacuum bag. An important aspect of this device is that the motor that turns the saw blade also turns the impeller, thus making the self-contained vacuum Saw moveable from site to site.

Owner:MARTIN CHARLES B

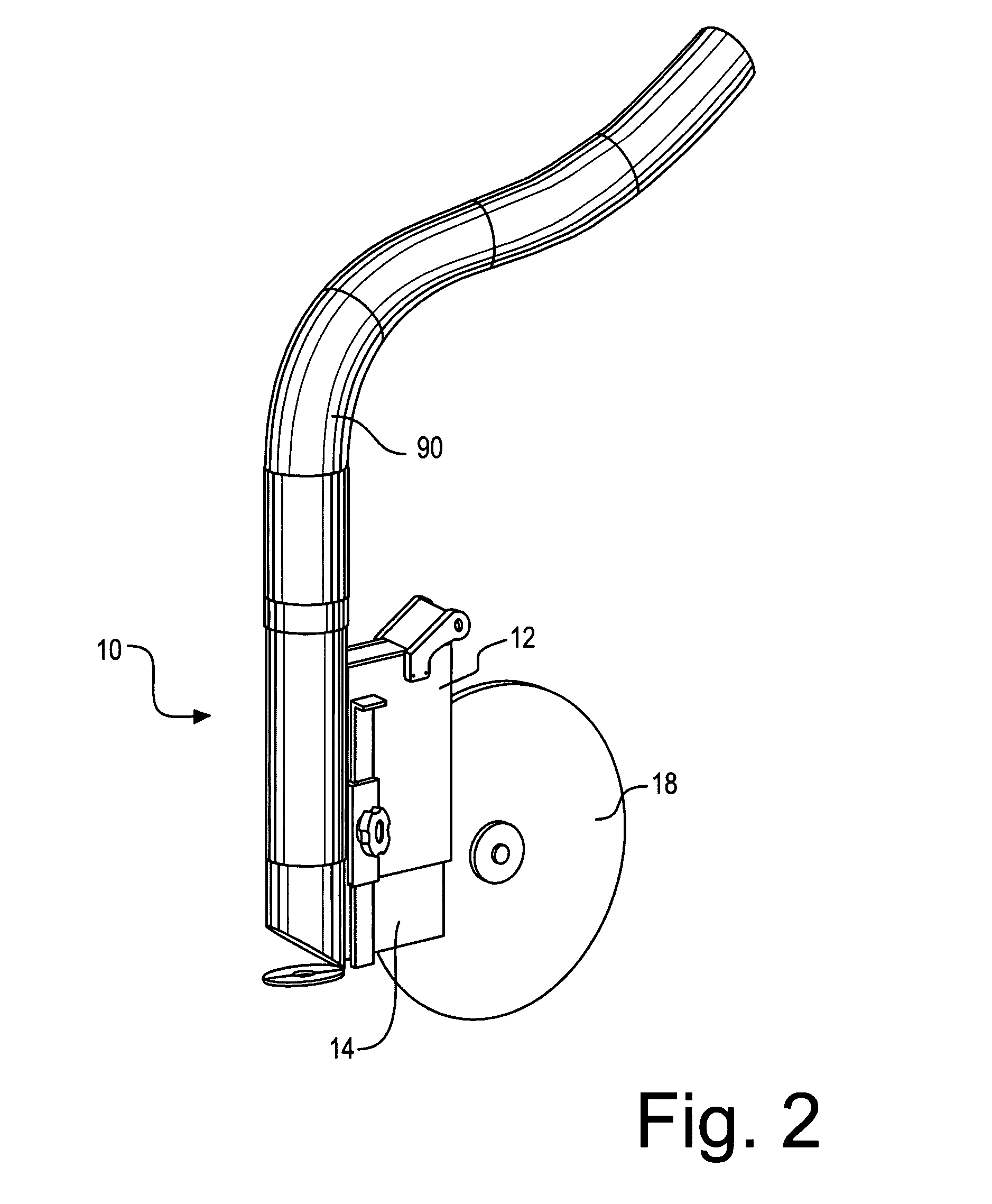

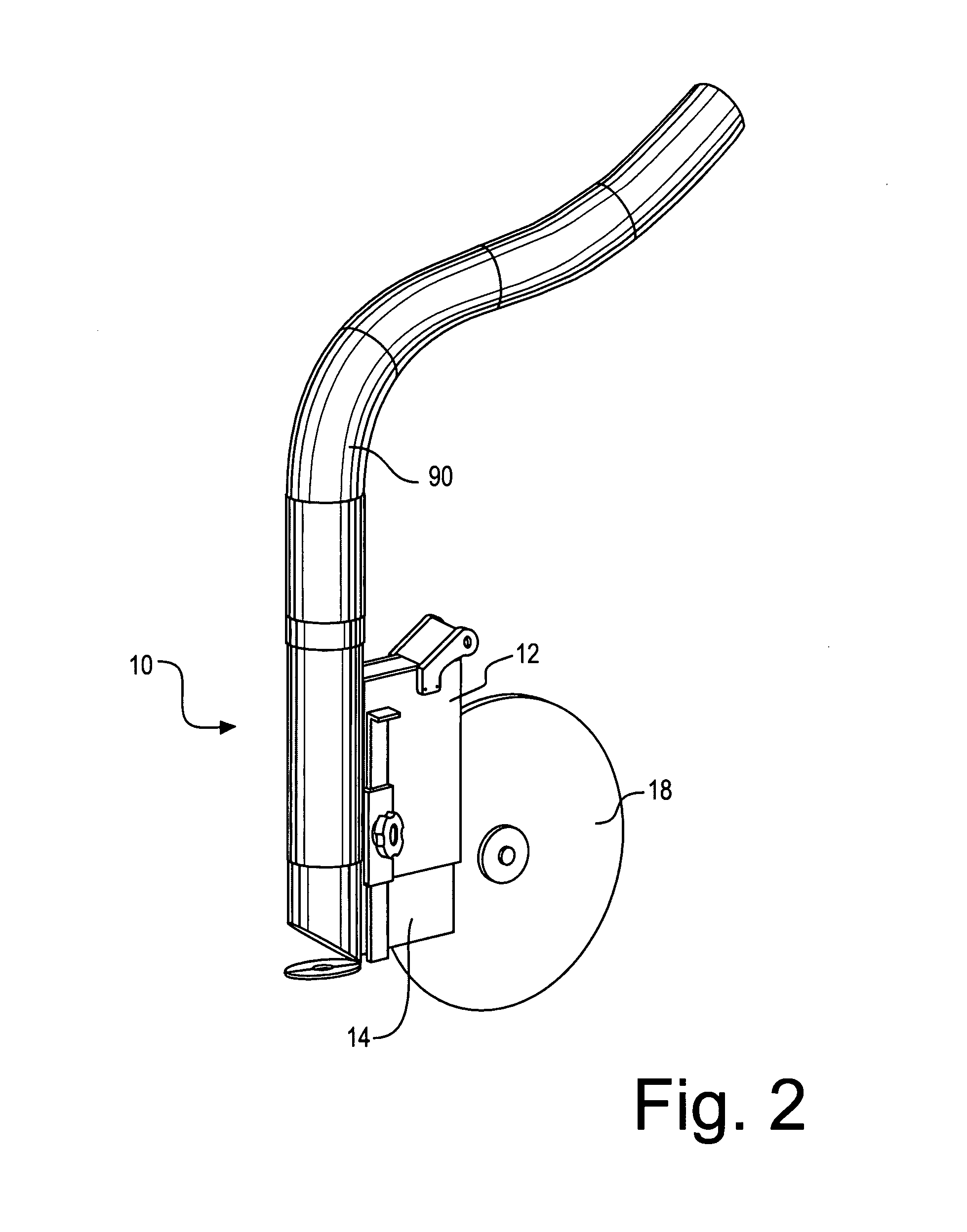

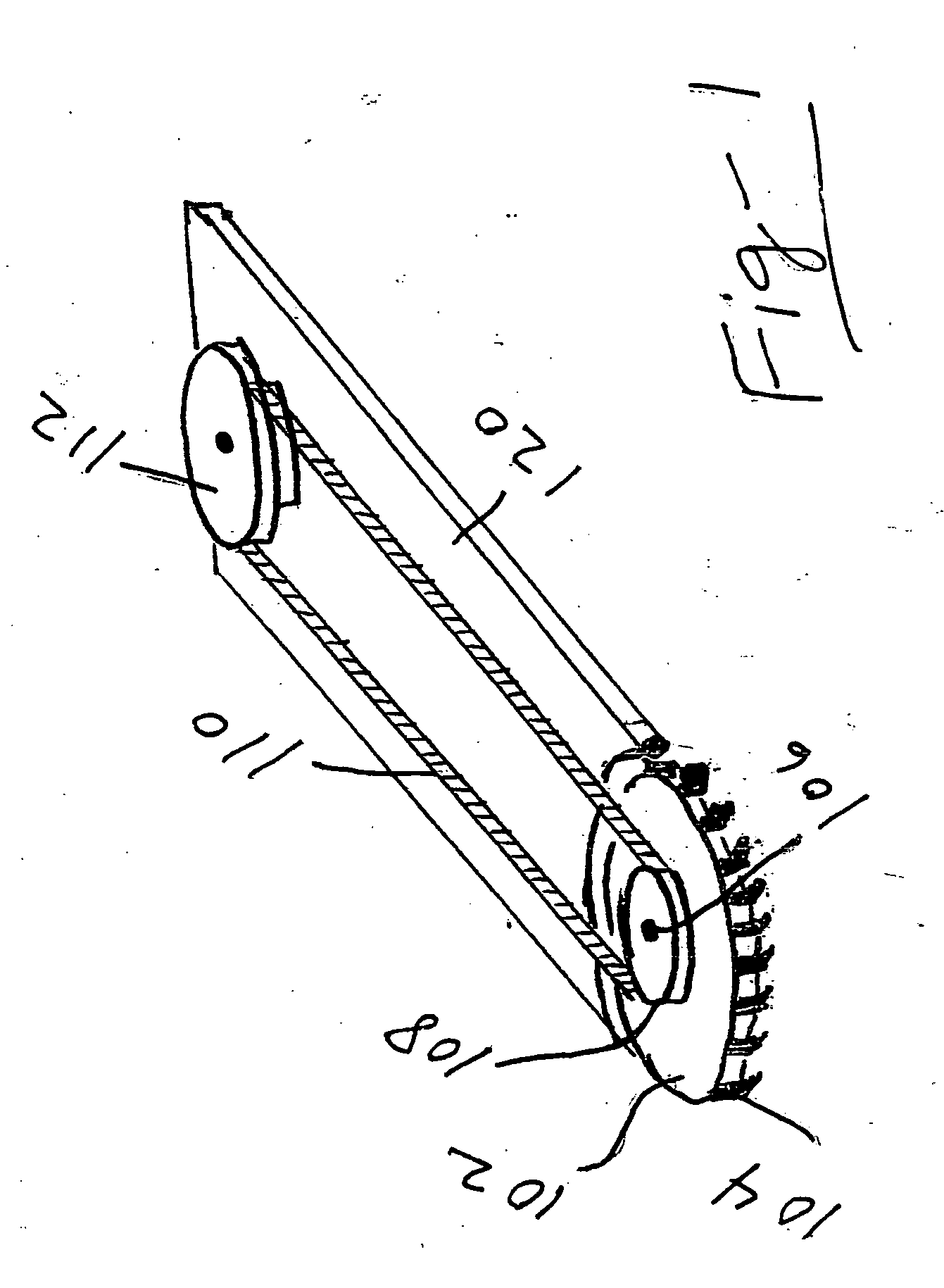

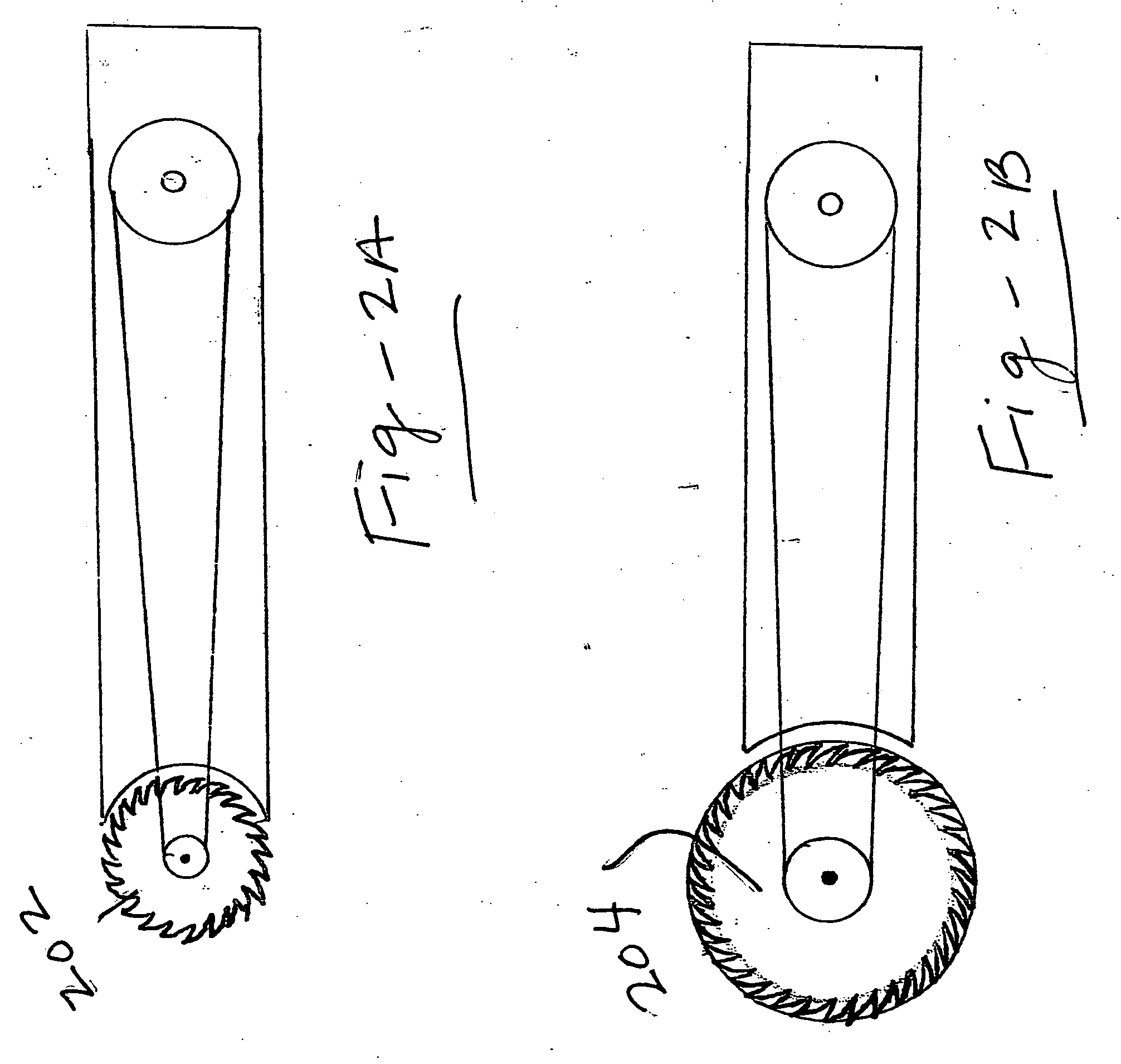

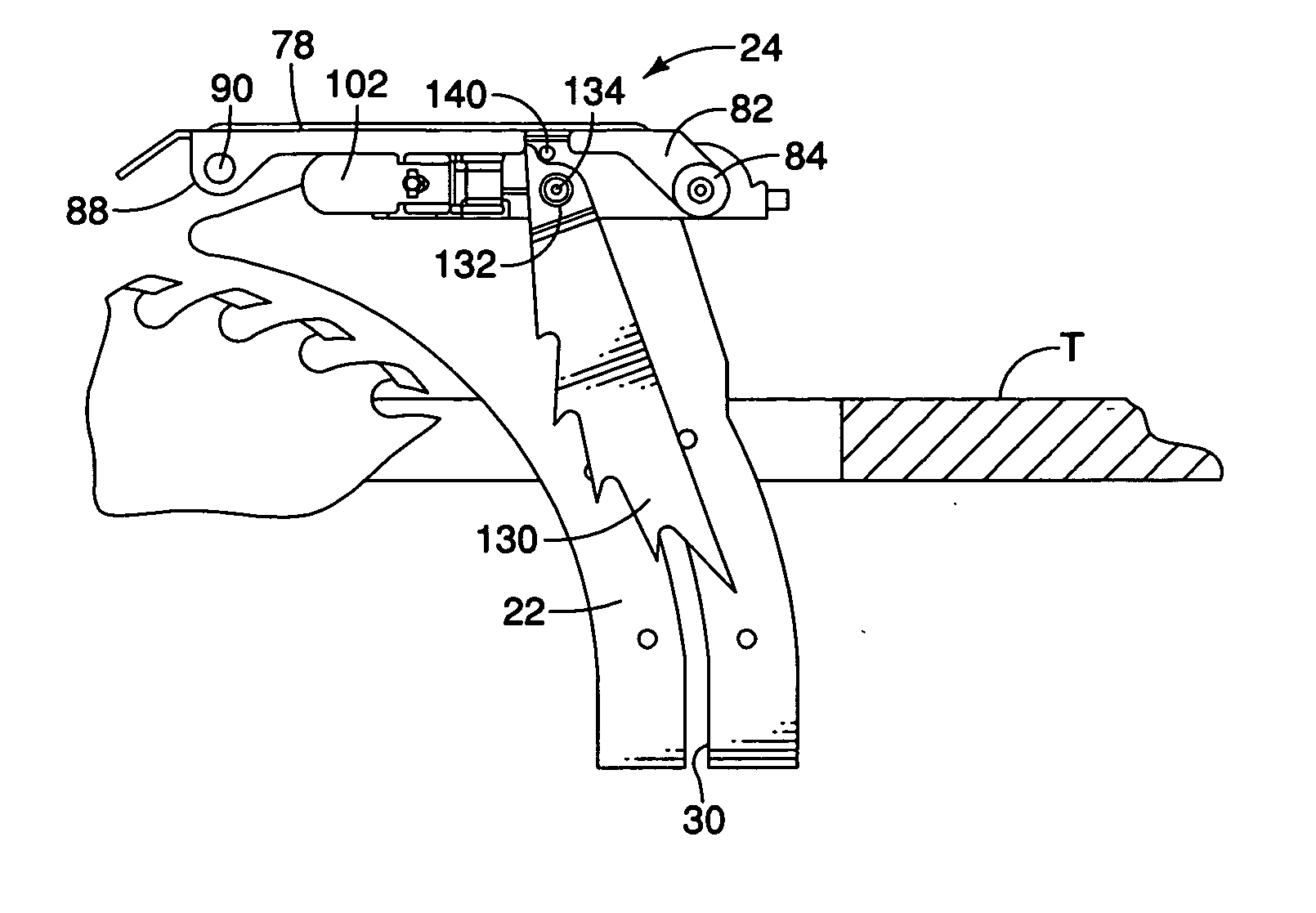

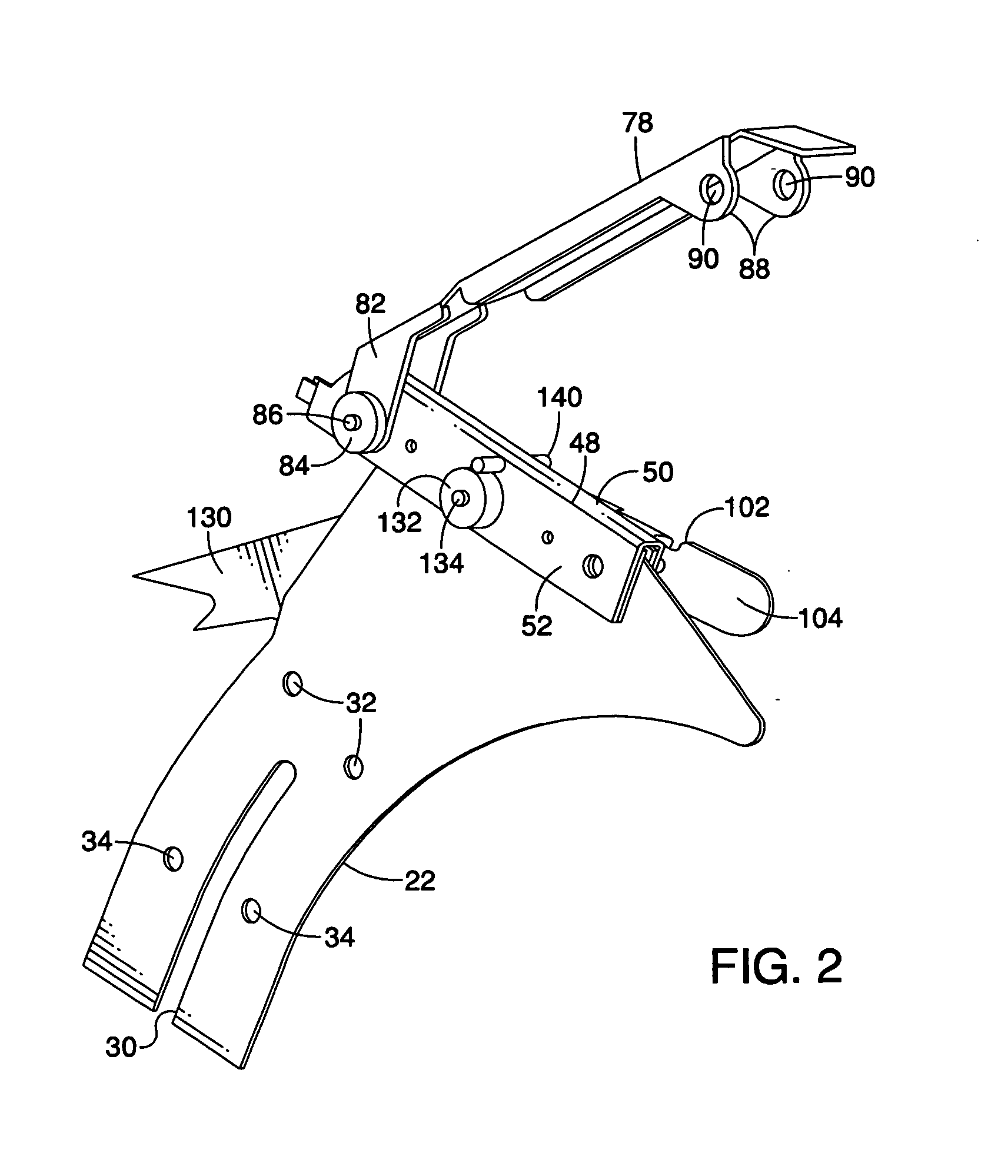

Bone-cutting circular saw

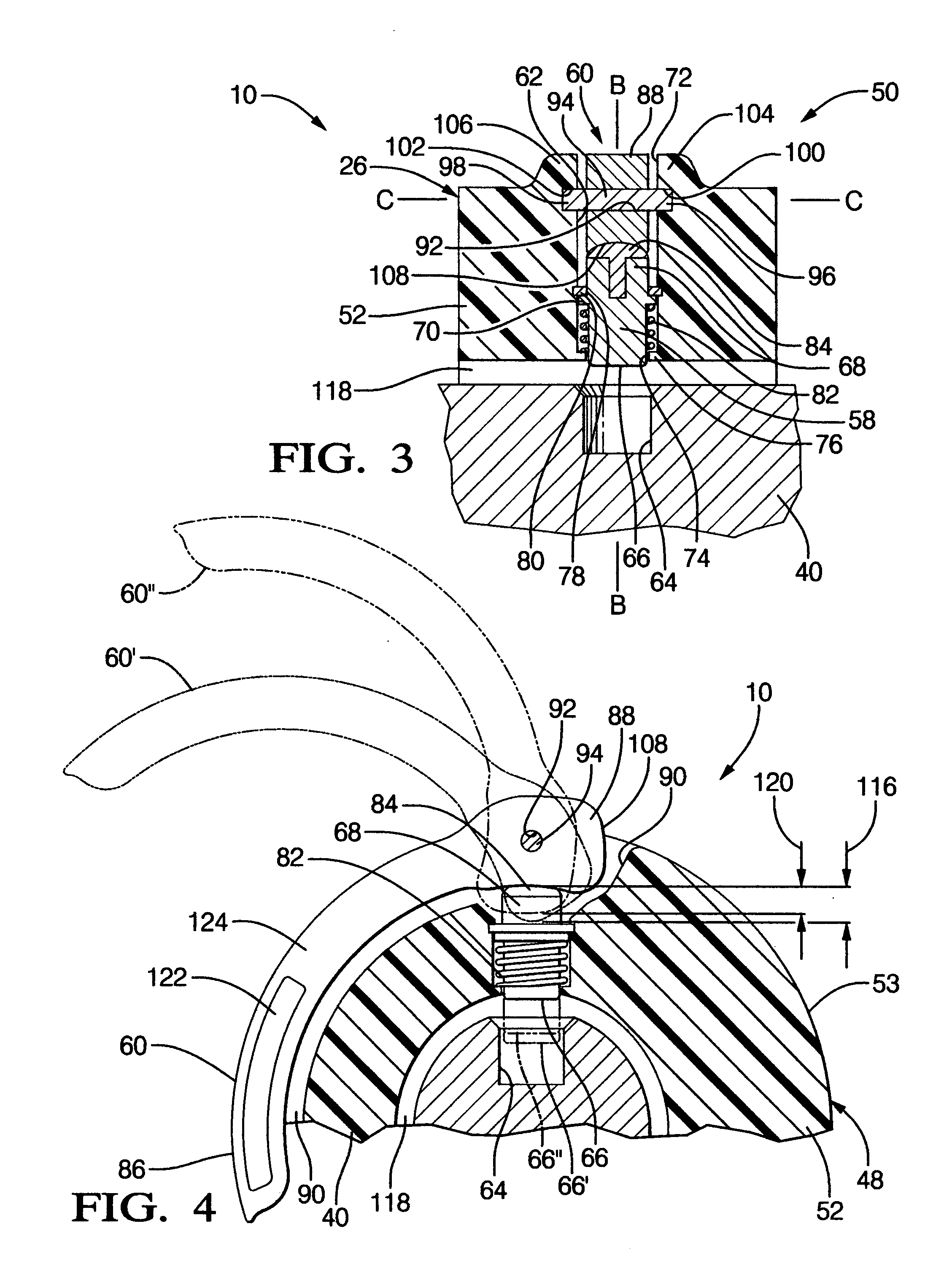

A power bone-cutting saw system exhibits the cutting efficiency of a circular saw, but retains the practical dimensions of an oscillating saw blade. A circular saw blade, available in a variety of diameters, is positioned at the end of a narrow, low-profile elongated support. The support houses a drive assembly that efficiently transmits power from a standard hand-held portable saw to the blade. The support can rest on modified saw guides for total joint procedures, providing the surgeon with a compact, efficient and precise bone-cutting tool. In the preferred embodiment the circular saw and support are single-use disposable units, available in a variety of lengths and widths. In an alternative embodiment, twin blades are used to eliminate changes in height between the blades and the support.

Owner:NAMBA ROBERT S

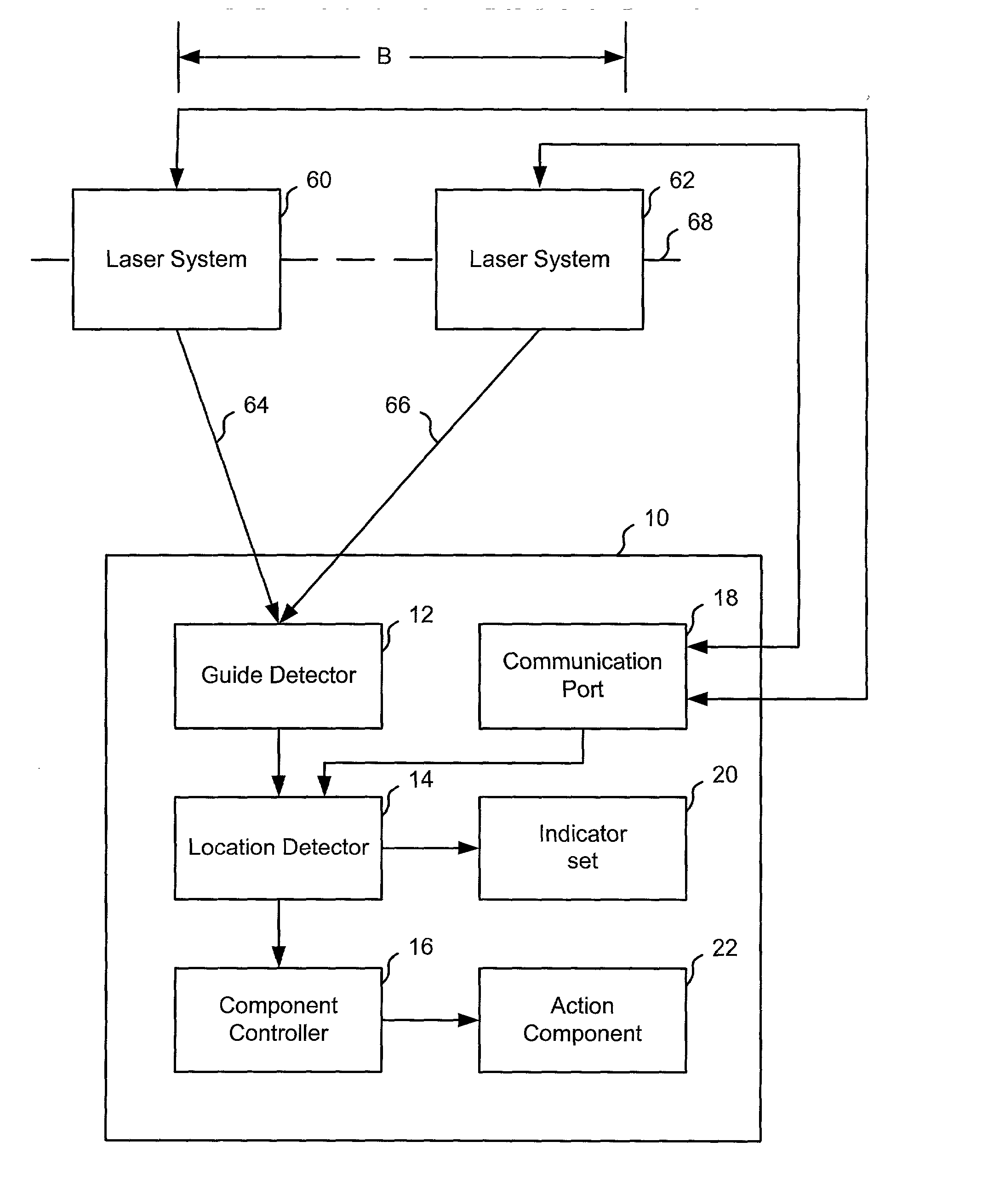

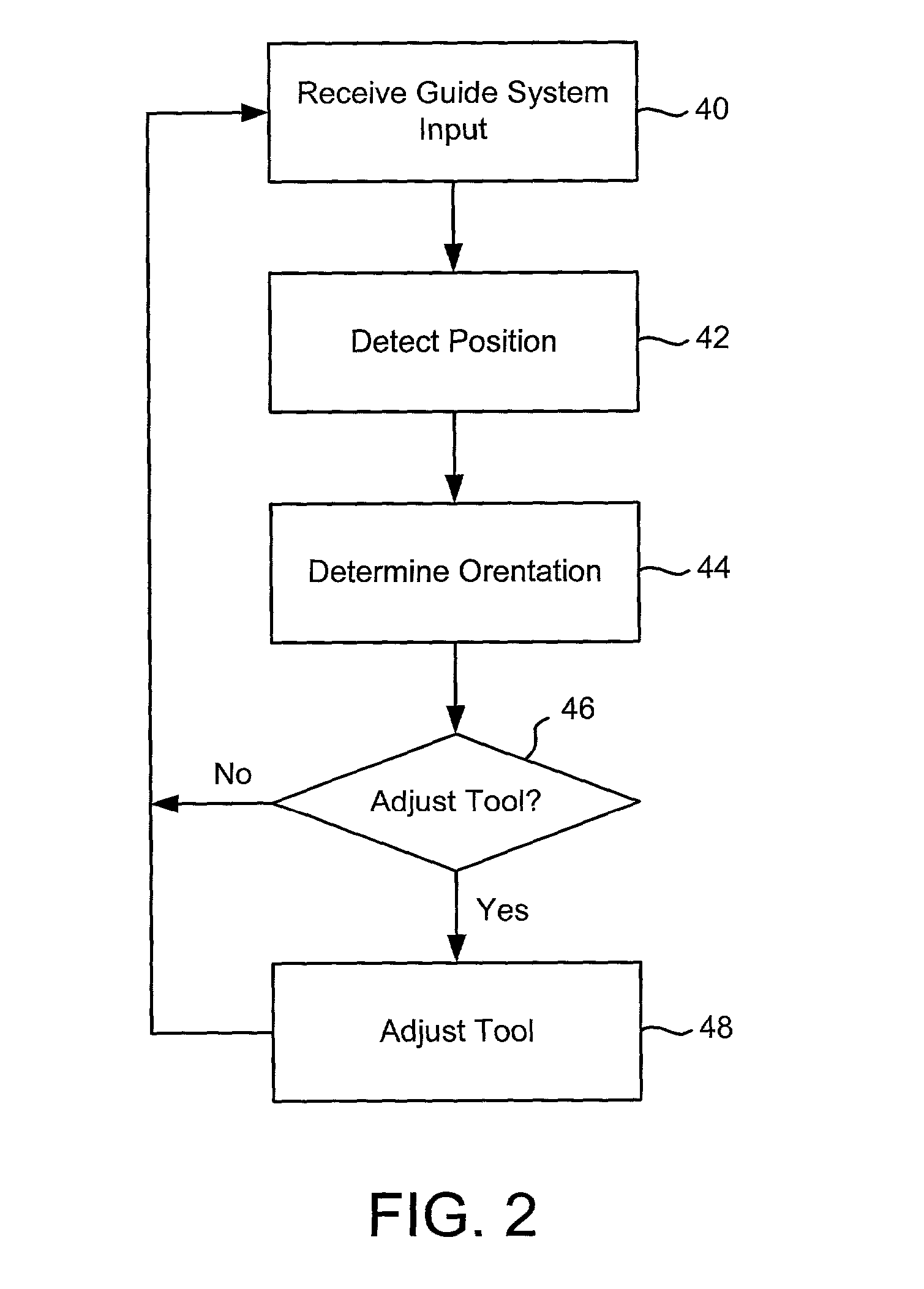

Detecting tool orientation, alignment, depth, and leveling

A tool is employed in conjunction with alignment, depth, and level detectors. The tool can use all or some of these detectors. The alignment detector provides an orthogonal laser line grid on an incident surface when the detector has a predefined relationship with the surface. The depth detector emits two sets of parallel laser planes that converge with each other. When the laser planes impact on an incident surface two sets of lines are formed. The laser lines from one laser plane set move closer to the lines from the other laser plane set as the depth detector moves closer to the surface-showing changes in depth or distance. The level detector employs two converging laser planes. An operator positions the level detector above an incident surface, so the laser planes' line of intersection appears on the surface if the surface is level. If the surface is not level, lines separate from each laser plane appear on the surface-signaling the need for a level adjustment. Some versions of the tool have the ability to detect their own orientation and make adjustments based on the orientation. Example tools include nail guns, jigsaws, circular saws, routers, and drills.

Owner:ROBERT BOSCH CO LTD

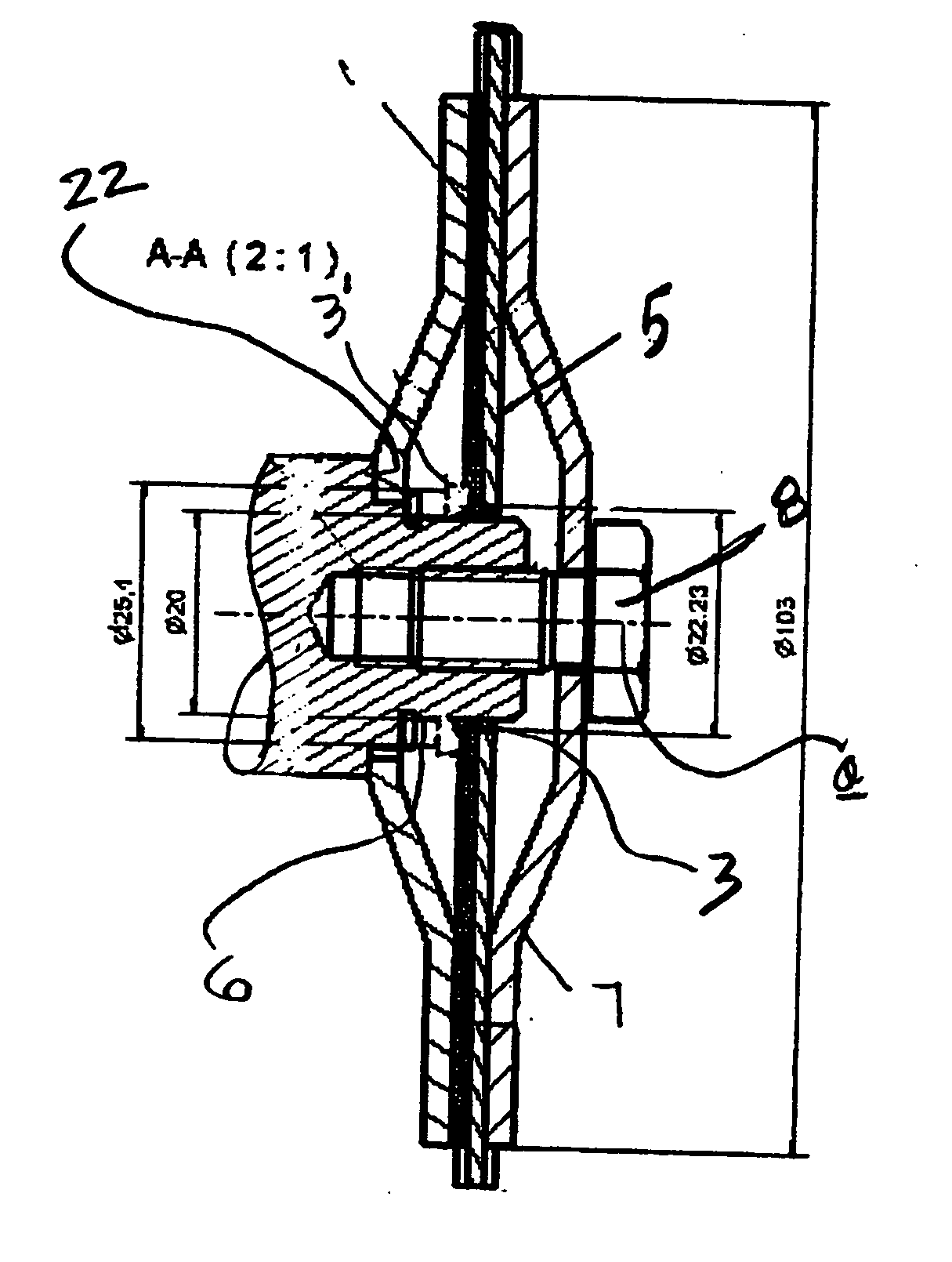

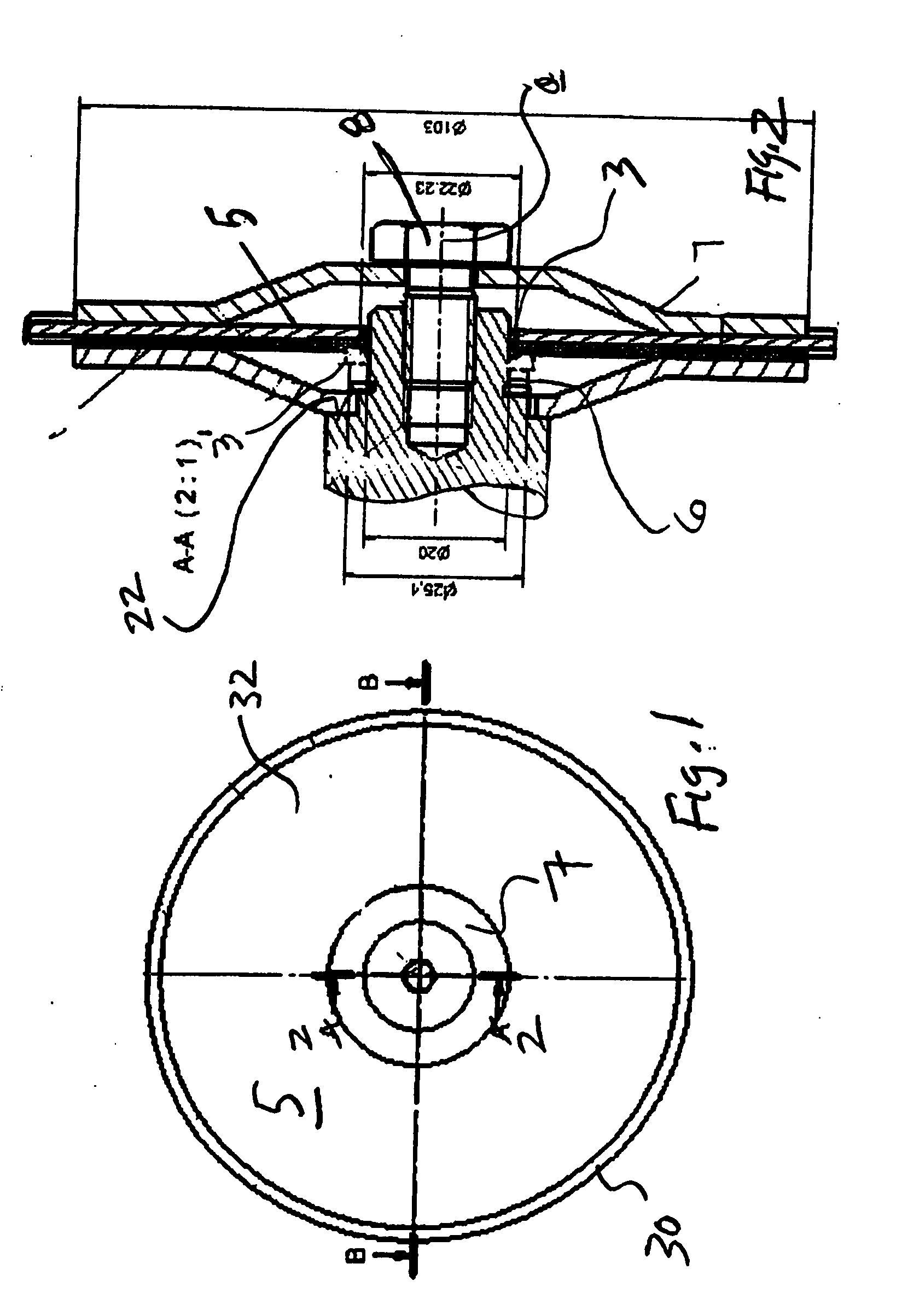

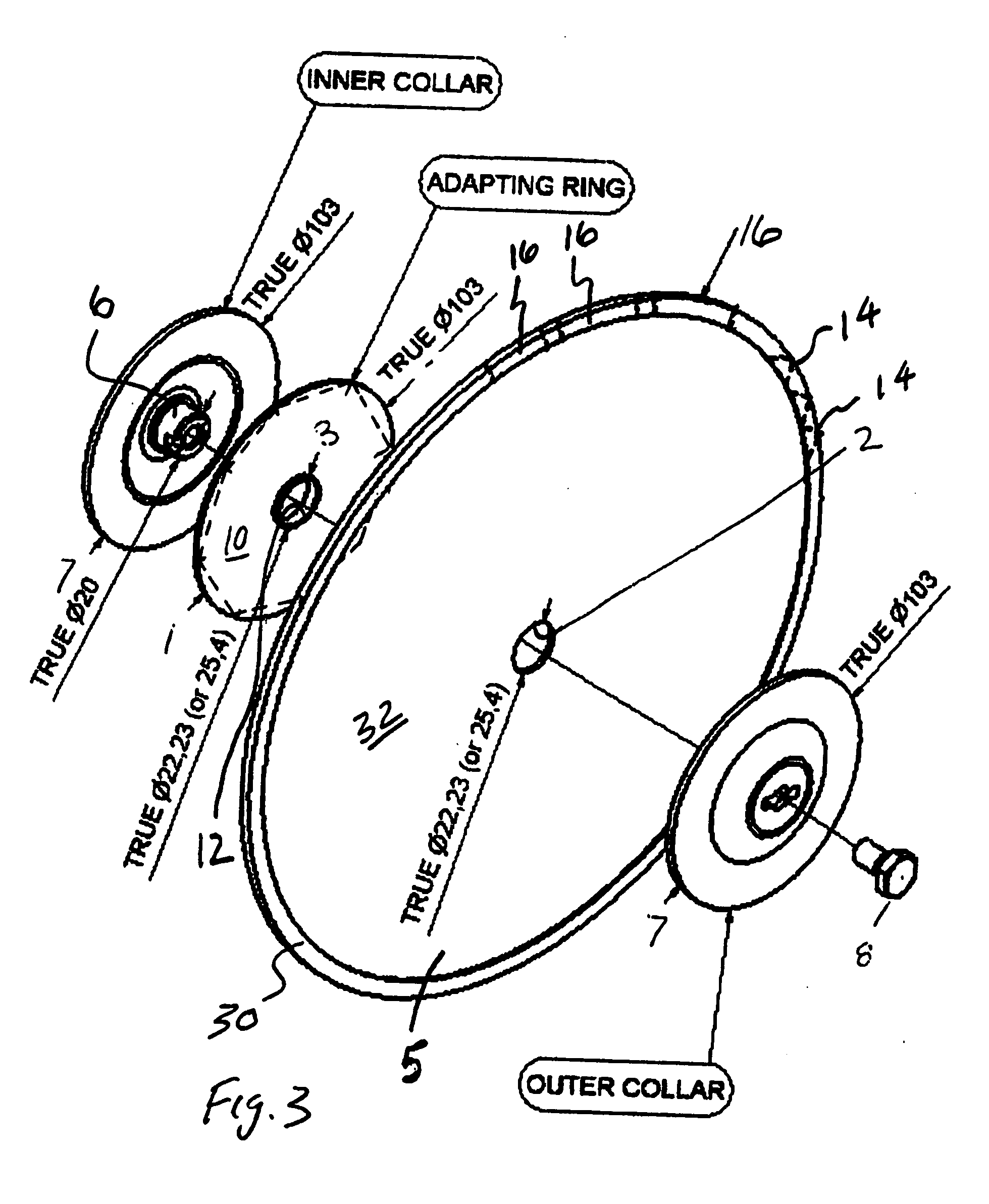

Shoulder bushing for saw blades

A shoulder bushing is provided for concentrically fastening a circular saw blade having an oversized mounting aperture, to a spindle of a rotary power tool. The bushing includes a disk having a central bore sized and shaped for concentric engagement with the spindle. An annular shoulder located on one side of the disk has an outer diameter sized for receipt within the oversized central aperture of the saw blade. The disk is provided with an outer diameter large enough to be engaged by a concave flange disposed on the spindle, by which the disk is clamped to the spindle in superposed orientation with the saw blade.

Owner:SAINT GOBAIN ABRASIVES INC +1

Hand-operated circular saw having blade cutting depth adjustment device

InactiveUS7047650B2Easy to operateEasy and convenient and preciseMetal sawing devicesMetal sawing accessoriesHand graspCircular saw

Owner:CHEN YUEHTING

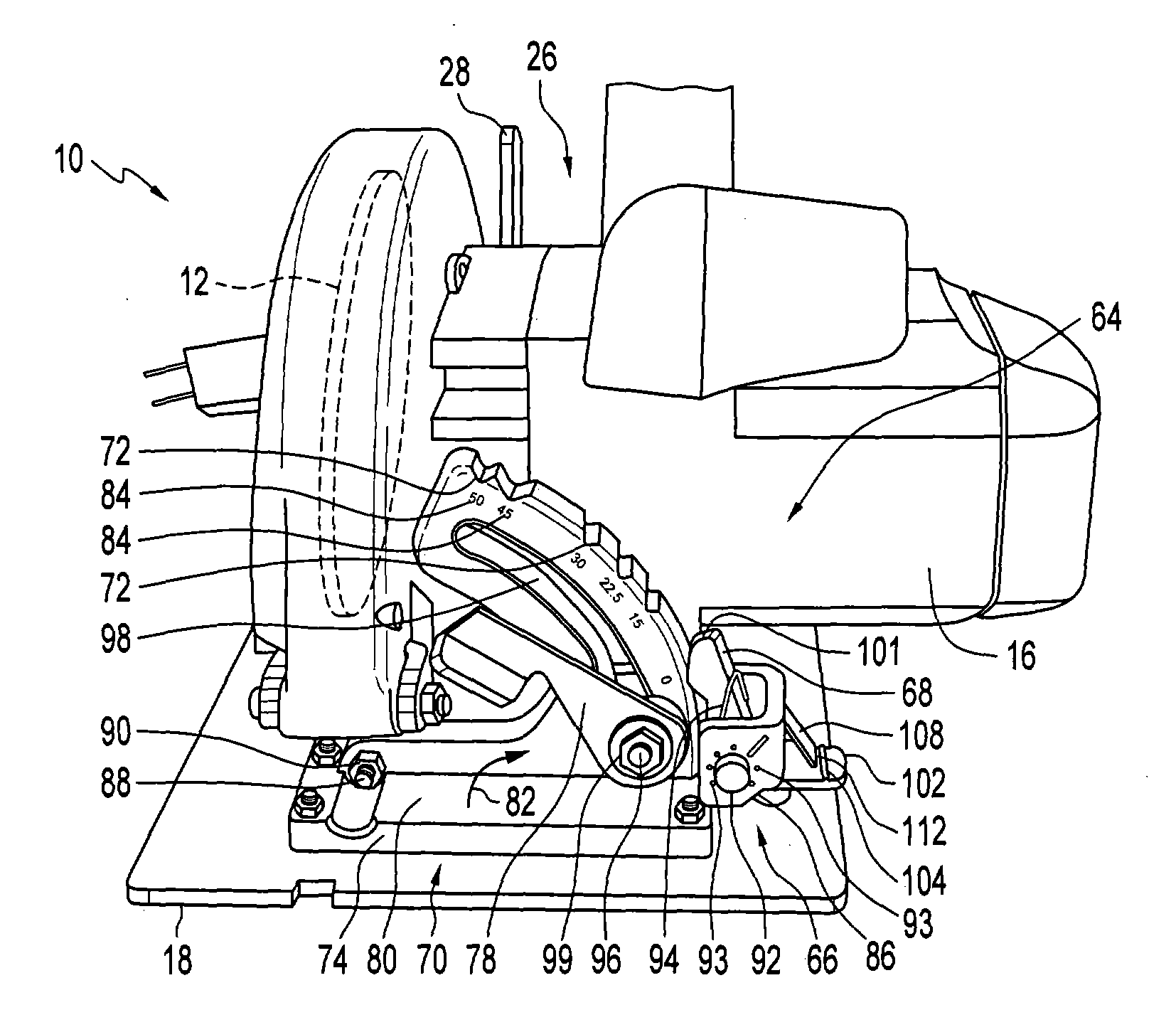

Modular guard system for a power saw

ActiveUS20070113715A1Resistance is appliedMetal sawing devicesGuide fencesCircular sawProtective system

A preferred embodiment of the present invention is directed to a modular saw guard system for a power saw of the type which has a table top, a rotatable circular saw blade, the table top having an opening through which the saw blade can extend, the system comprising a riving knife mounted to the saw rearwardly of the blade and having a top surface and at least one aperture near the top surface, a blade guard and kickback prevention mechanism that is releasably mounted to the riving knife, the mechanism comprising a mounting channel configured to fit on and be releasably attached to the riving knife, the blade guard portion being pivotally attached to the mounting channel, the kickback prevention portion being pivotally attached to the mounting channel; and a lever mechanism for holding the mounting channel to the riving knife and for releasing the mounting channel for removal therefrom, the lever mechanism including a movable pin member for engaging the aperture of the riving knife.

Owner:CREDO TECH CORP +1

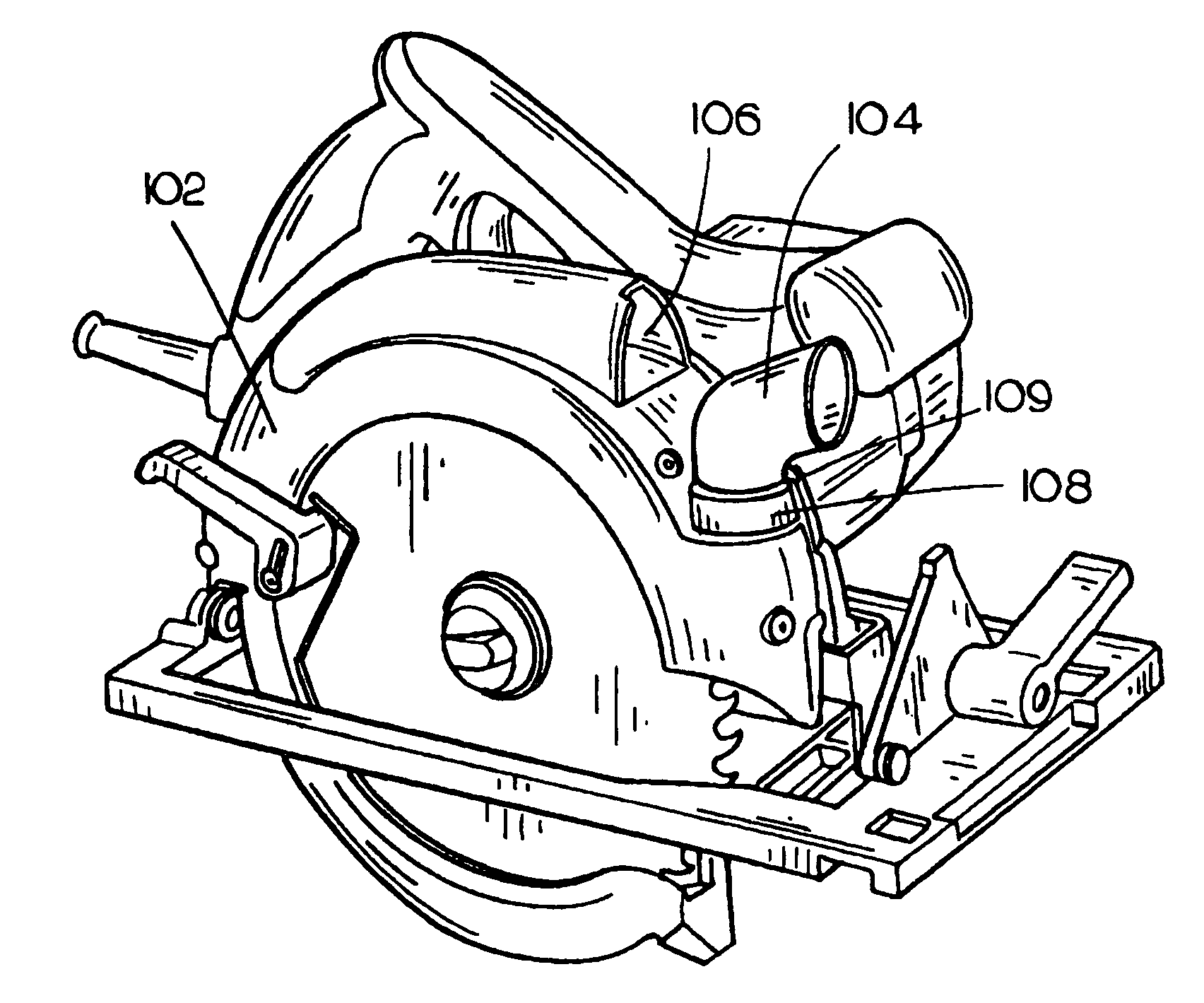

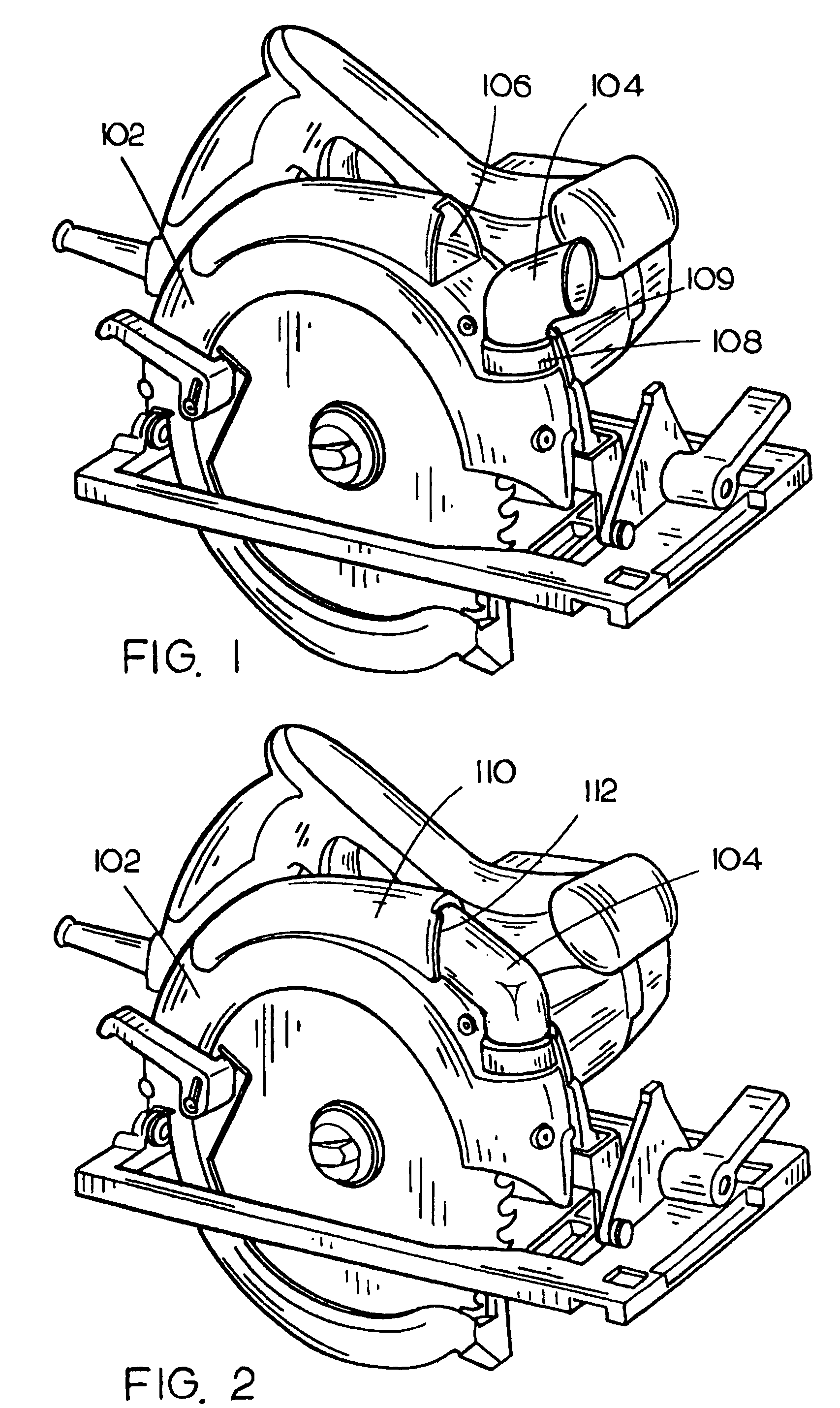

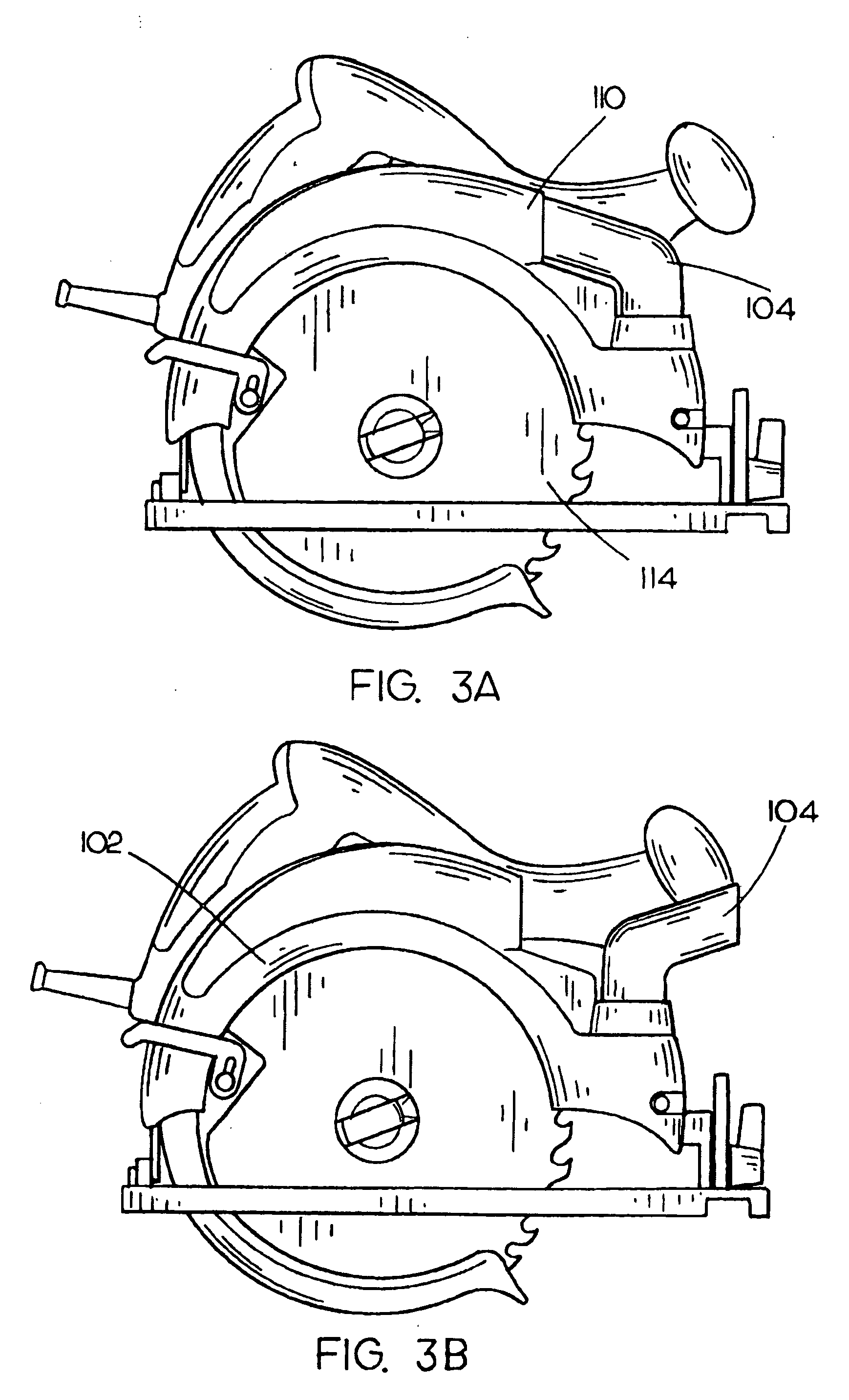

Circular saw having bevel and depth of cut detent system

A circular saw having a saw blade depth adjustment detent mechanism for facilitating rapid positioning of a saw blade at predetermined depth positions includes a housing enclosing a motor disposed therein that rotates a circular saw blade. The circular saw includes a foot which rides on a workpiece to guide the saw blade during cutting operations. The saw blade depth adjustment detent mechanism pivotally interconnects the foot to said housing such that the circular saw blade is adjustable to the foot through a number of saw blade depth settings within a range of saw blade depth of cuts relative to the foot. The saw blade depth adjustment detent mechanism includes a saw blade depth detent and a second member having a plurality of spaced saw blade depth recesses that are each matingly engageable with the saw blade depth detent to provide the range of saw blade depths.

Owner:CREDO TECH CORP

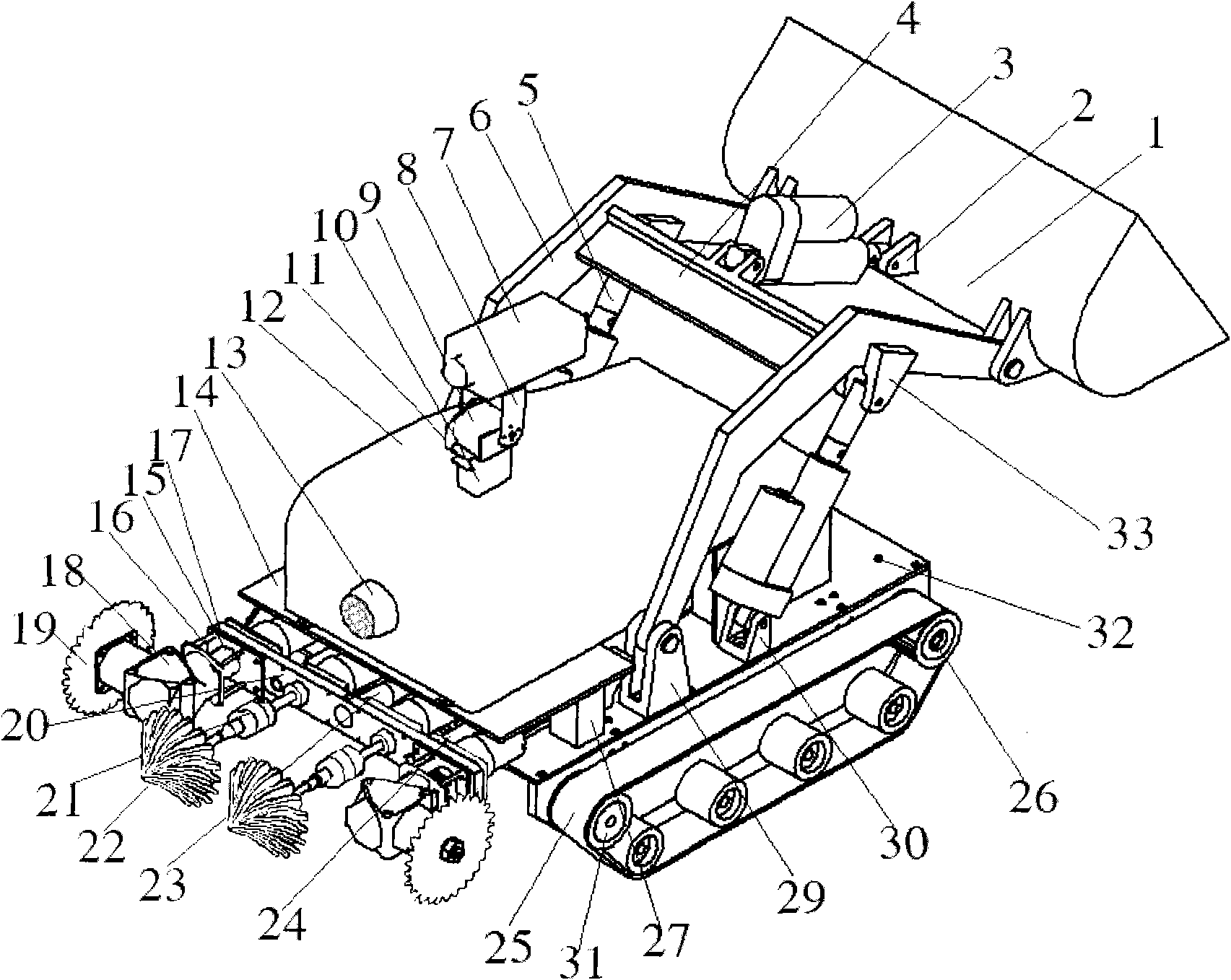

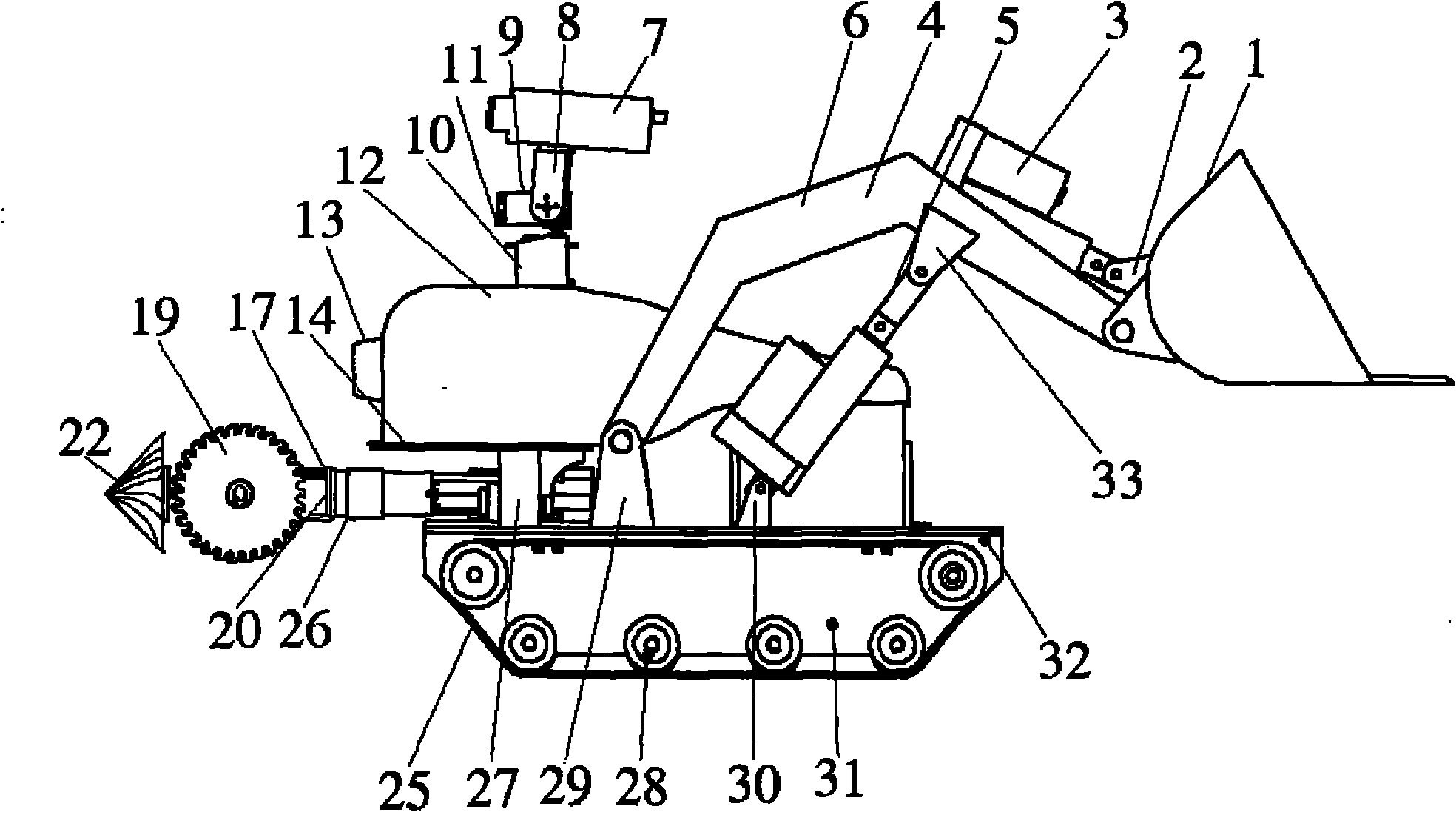

Multifunctional rescuing and barrier-breaking robot

InactiveCN101845832AReduce volumeIncrease flexibilityTelevision system detailsMechanical machines/dredgersCircular sawEngineering

The invention provides a multifunctional rescuing and barrier-breaking robot which is characterized in that a barrier breaking mechanism is arranged in front of a robot body, a shovel mechanism for breaking barriers to walk on as well as carrying and transferring articles is arranged at the rear of the robot body, crawler traveling mechanisms are arranged at two sides below a chassis (32) of the robot body, and an electric control board control unit for controlling the robot to actuate is arranged on the chassis (32); the barrier breaking mechanism is used for breaking barriers by turning the head when the robot meets barriers; the barrier breaking mechanism is provided with two circular saws (19) and two cone drills (22) which are respectively used for achieving the works of breaking barriers respectively under the driving of a motor; and the shovel mechanism is provided with a shovel with lifting and overturning function. The invention can implement functions of breaking barriers, carrying and moving, searching and rescuing, positioning at the real time, loading rescue goods, and the like under the long-distance control in a plurality of sudden disaster accidents and more hostile environments so as to realize fast rescuing and has the advantages of small size, high flexibility, more practical functions, and the like.

Owner:WUHAN UNIV OF TECH

Circular saw

InactiveUS6866568B1Save effortAvoid damageMetal sawing devicesEdge grinding machinesCircular sawKnife blades

A circular saw includes a worktable, a mounting seat extending upwardly from the worktable for mounting a motor thereon, a blade supporting unit pivotally mounted on the mounting seat at a pivot end so that an opposite free end is turnable to be close to and away from the worktable, and a saw blade shaft mounted rotatably on the blade supporting unit about a blade axis parallel to an output shaft axis of an output shaft of the motor and having a saw blade mounted thereon. The saw blade shaft is coupled to the output shaft by a drive transmitting unit which transmits driving force of the output shaft to the saw blade shaft so as to rotate the saw blade.

Owner:LIAO HUI CHUAN

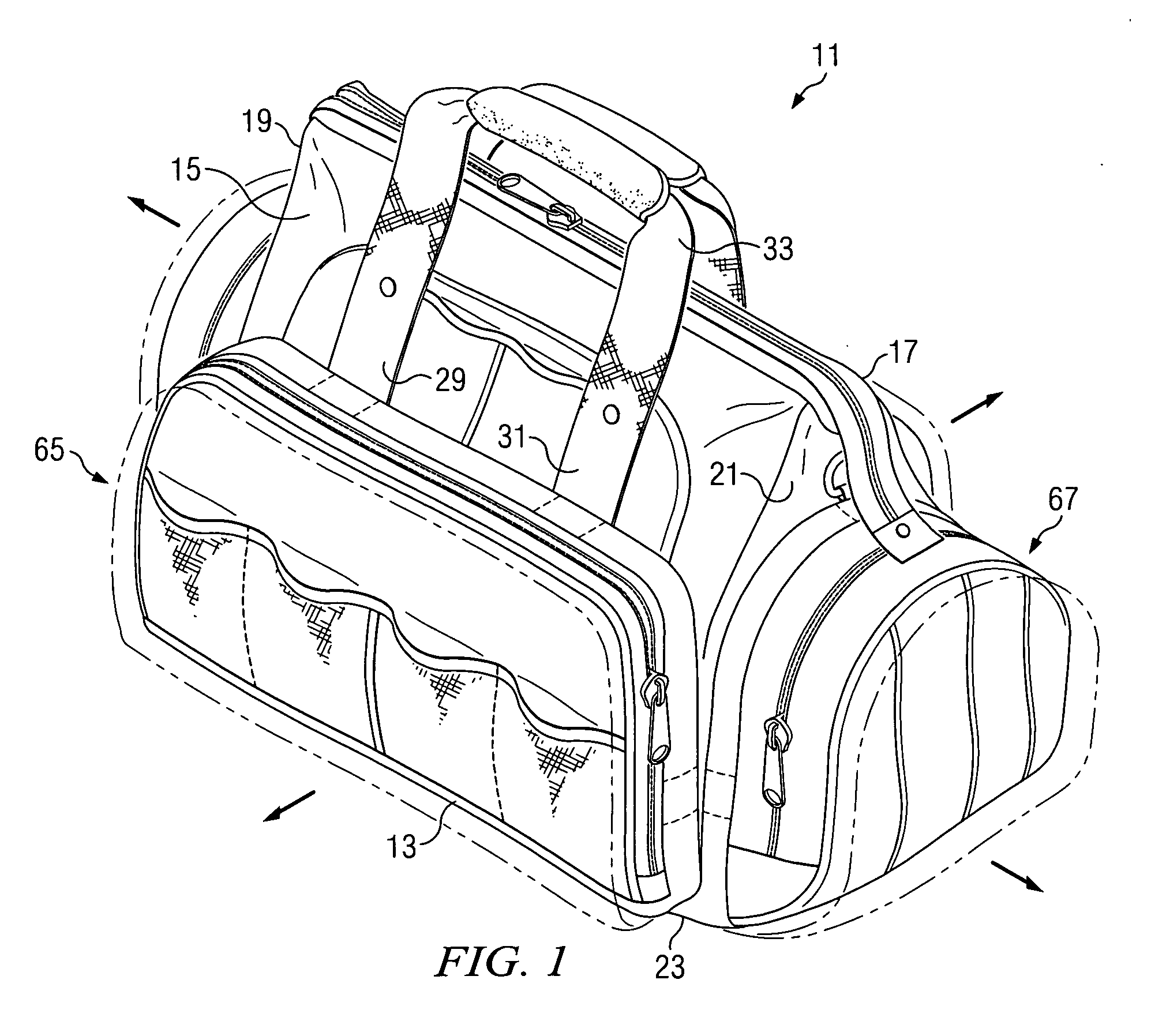

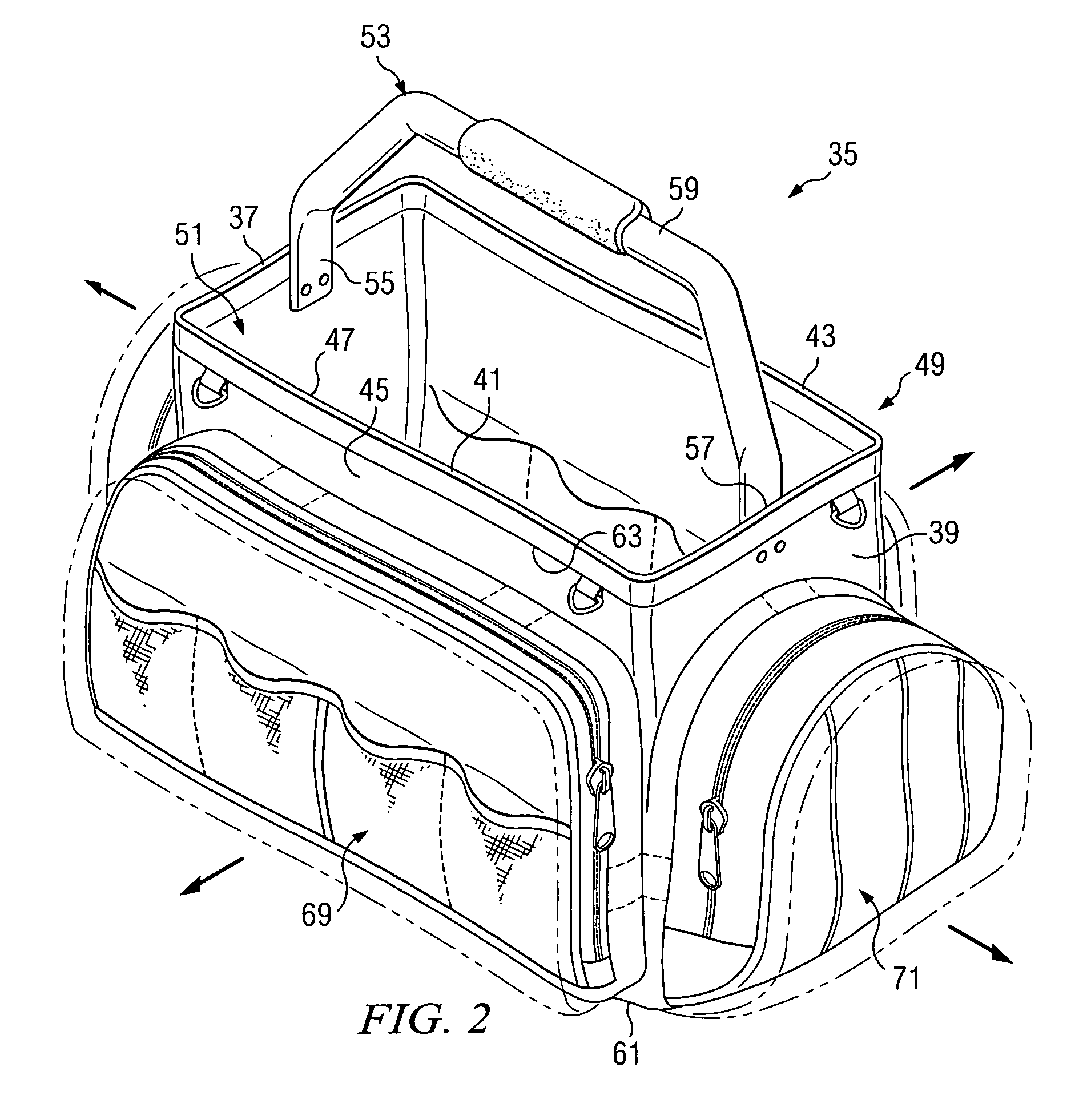

Toolbag with expandible pockets

A tool storage bag is provided for storing tools and accessories at a work site. The tool storage bag is formed with soft sides and has external expandible pockets to accept a variety of tools and accessories. In one version, the bag has an A-frame opening which presents an unobstructed opening in the open position for receiving larger tools such as a circular saw. In another version, the tool bag has a rectangular opening which is spanned by a rigid handle with end portions which are attached to selected opposing sidewalls of the bag. The rigid handle accommodates heavier loads and adds increased stability to the bag construction.

Owner:G A GOLDEN PACIFIC INT

Square tube cutting and end surface grinding integrated equipment

InactiveCN110421356ADisadvantages of realizing that it cannot be completed at one timeWork clamping meansOther manufacturing equipments/toolsCircular sawEngineering

The invention relates to the field of cutting and grinding machines, in particular to square tube cutting and end surface grinding integrated equipment. The equipment comprises a feeding component, acutting component and an end grinding component, wherein the end grinding component comprises a rotary table and two grinding mechanisms symmetrically arranged on the two sides of the rotary table, the feeding component comprises a first fixed clamp and a movable clamp, the cutting component comprises a movable base and a circular saw blade, an angle adjusting mechanism connected with a free end of a supporting arm is arranged at the top of the movable base, a horizontal pushing air cylinder is arranged at the top of the starting end of the feeding component in a horizontal state, the horizontal pushing air cylinder, the first fixed clamp, the movable clamp and the rotary table are linearly arranged in sequence, and a second fixed clamp is arranged on the top of the rotary table. Accordingto the square tube cutting and end surface grinding integrated equipment, the cutting component carries out cutting on a square tube, and the end grinding component carries out grinding on the squaretube, so that the cutting and end surface grinding integrated equipment is realized, and a large amount of manpower and financial resources are reduced.

Owner:吴丽平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com