Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3021results about "Soil-working equipments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

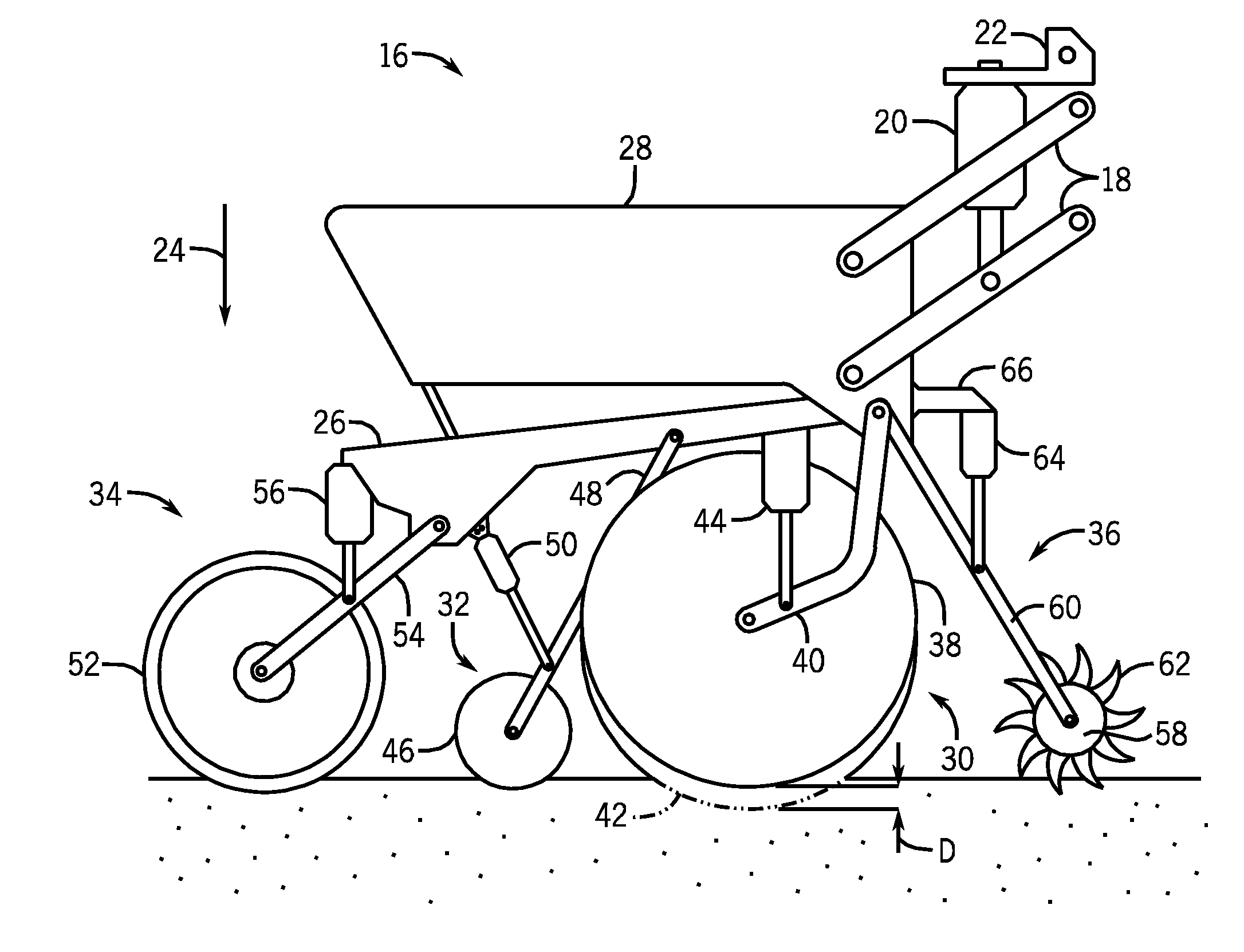

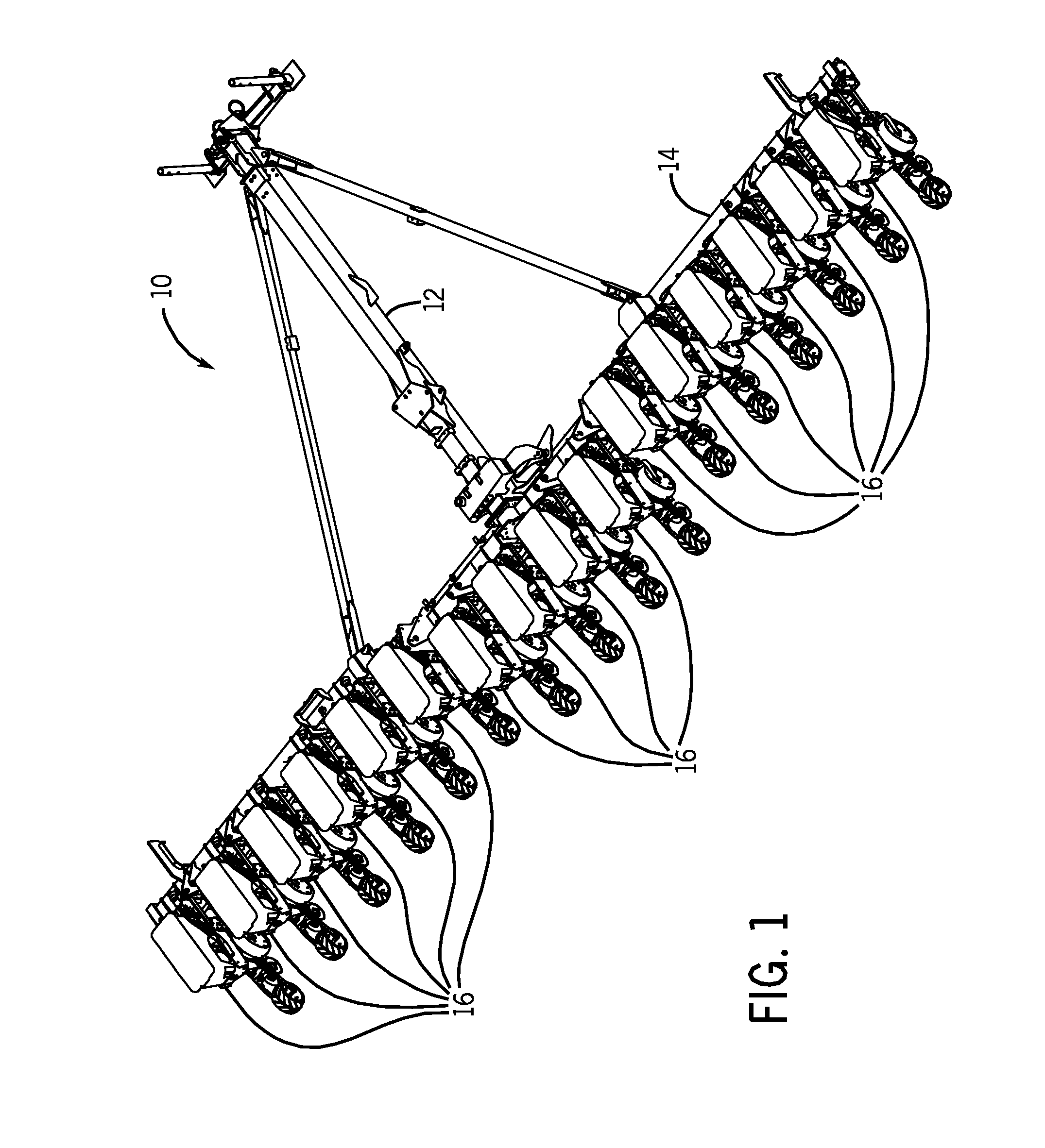

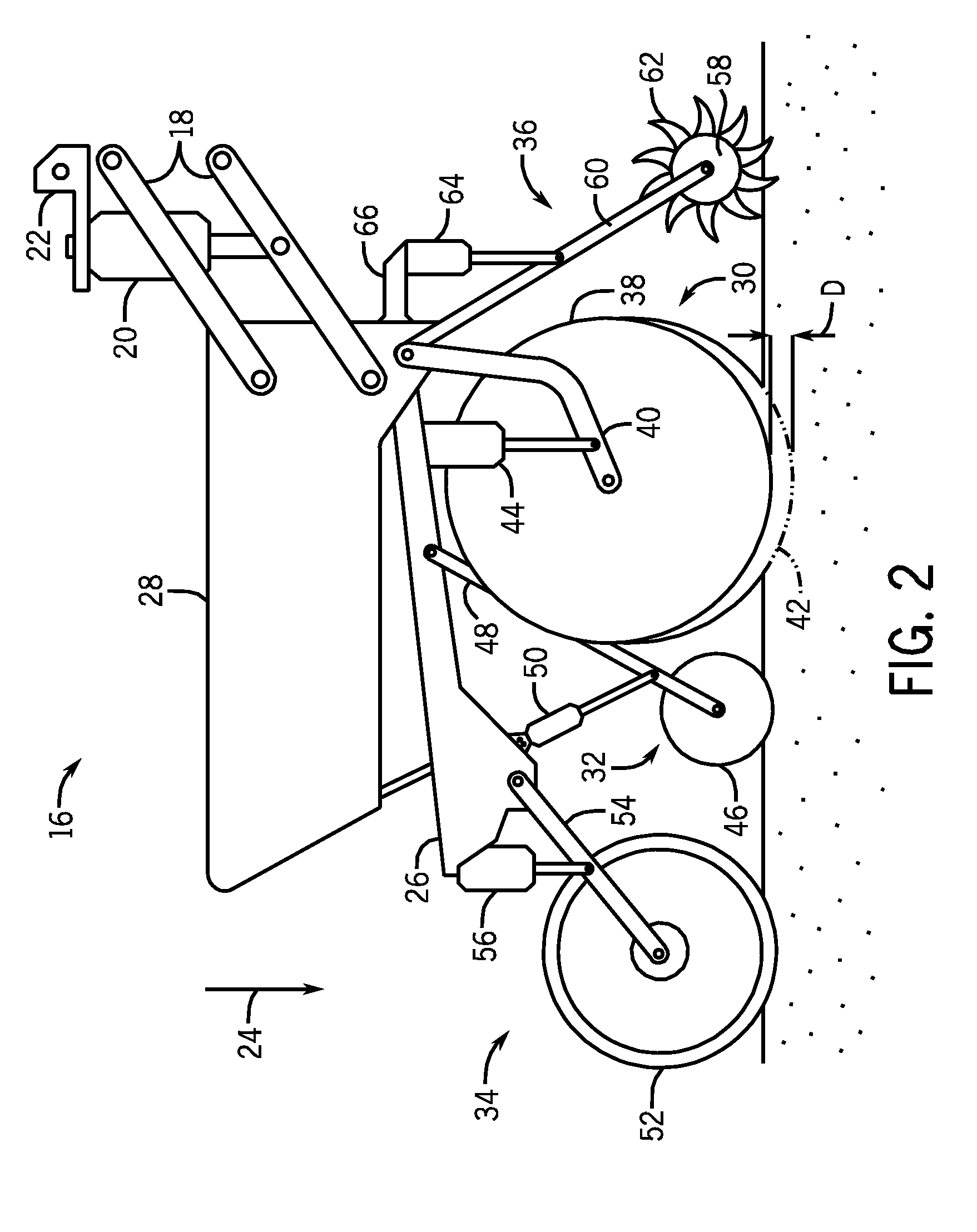

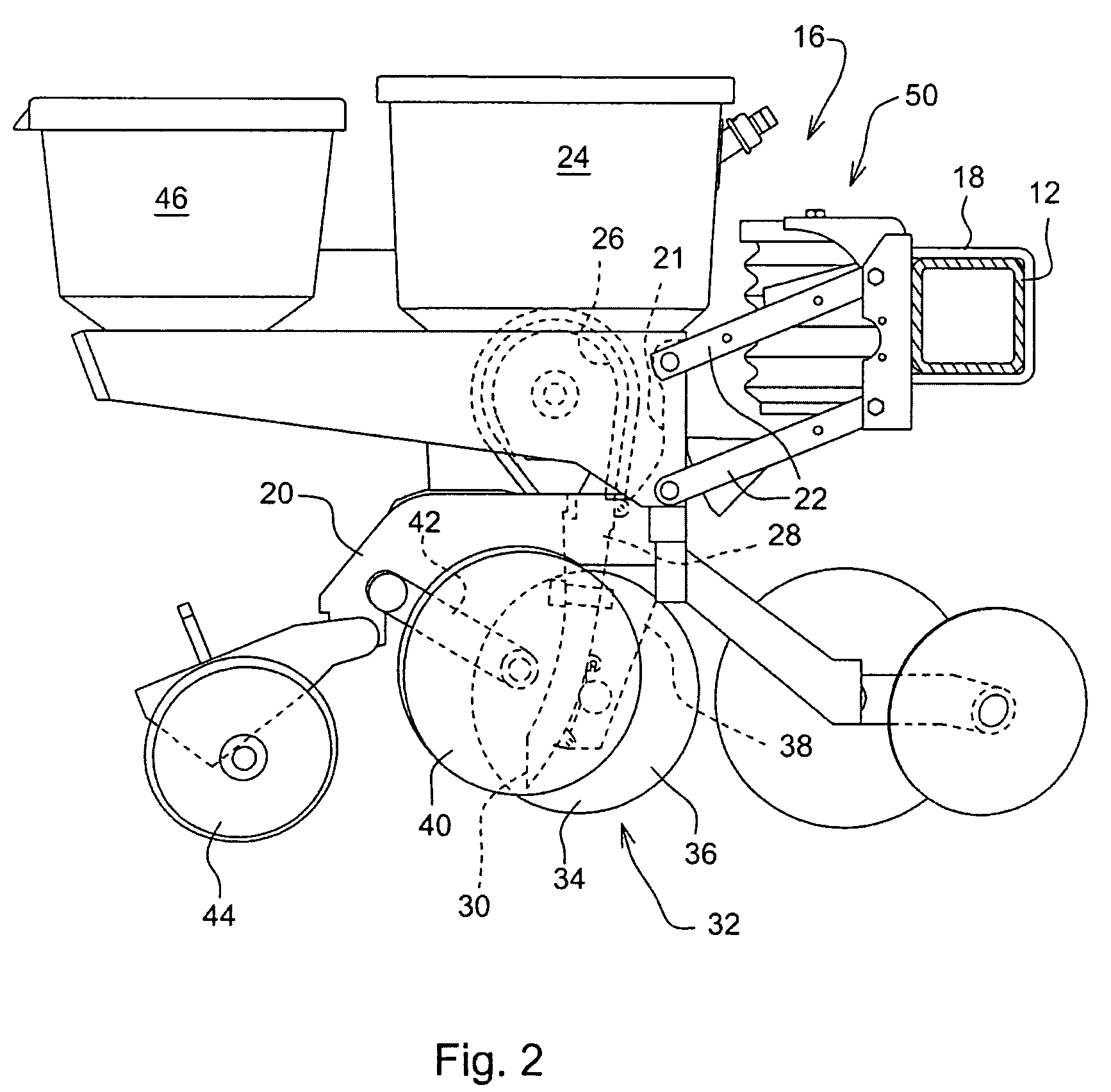

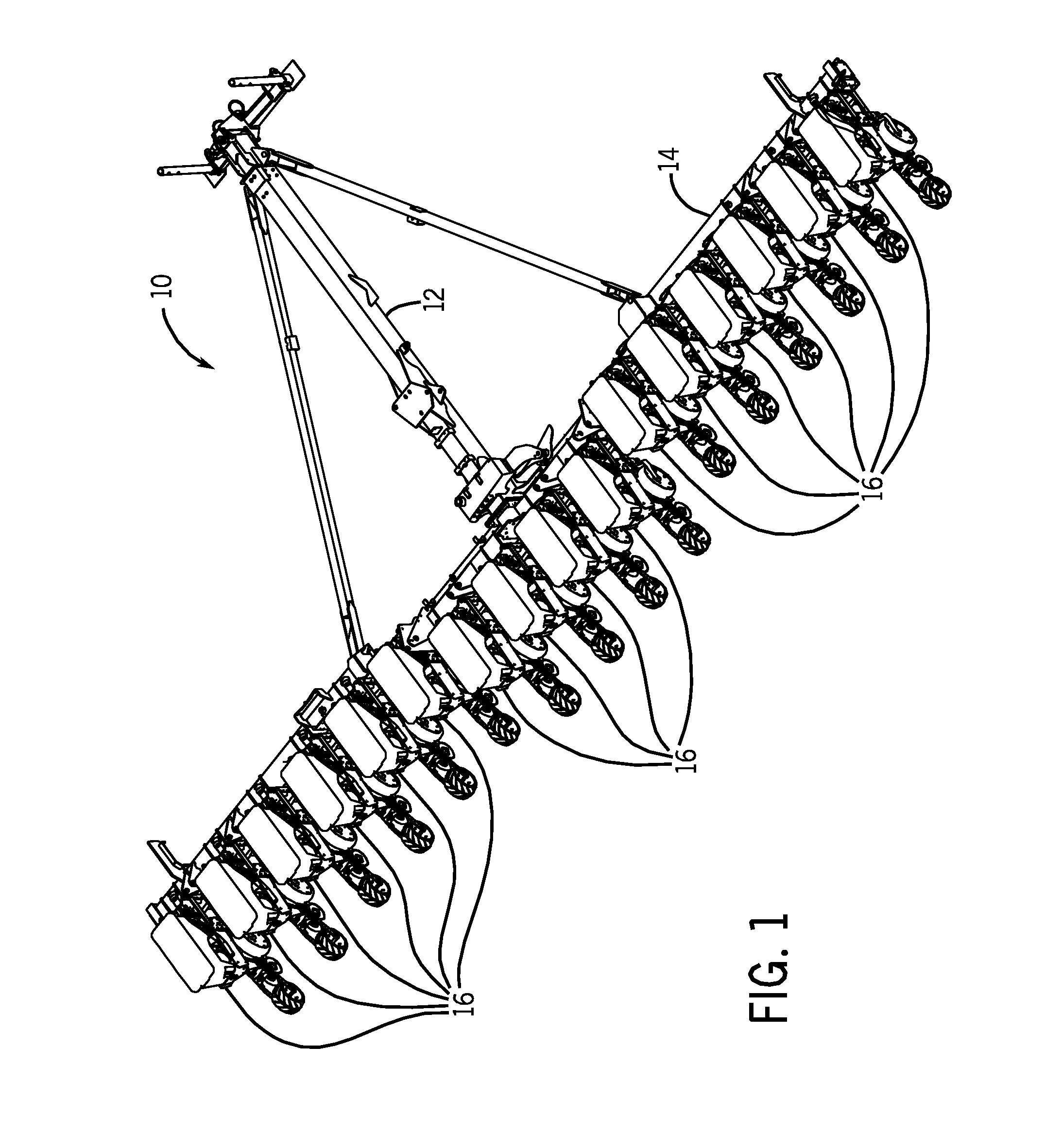

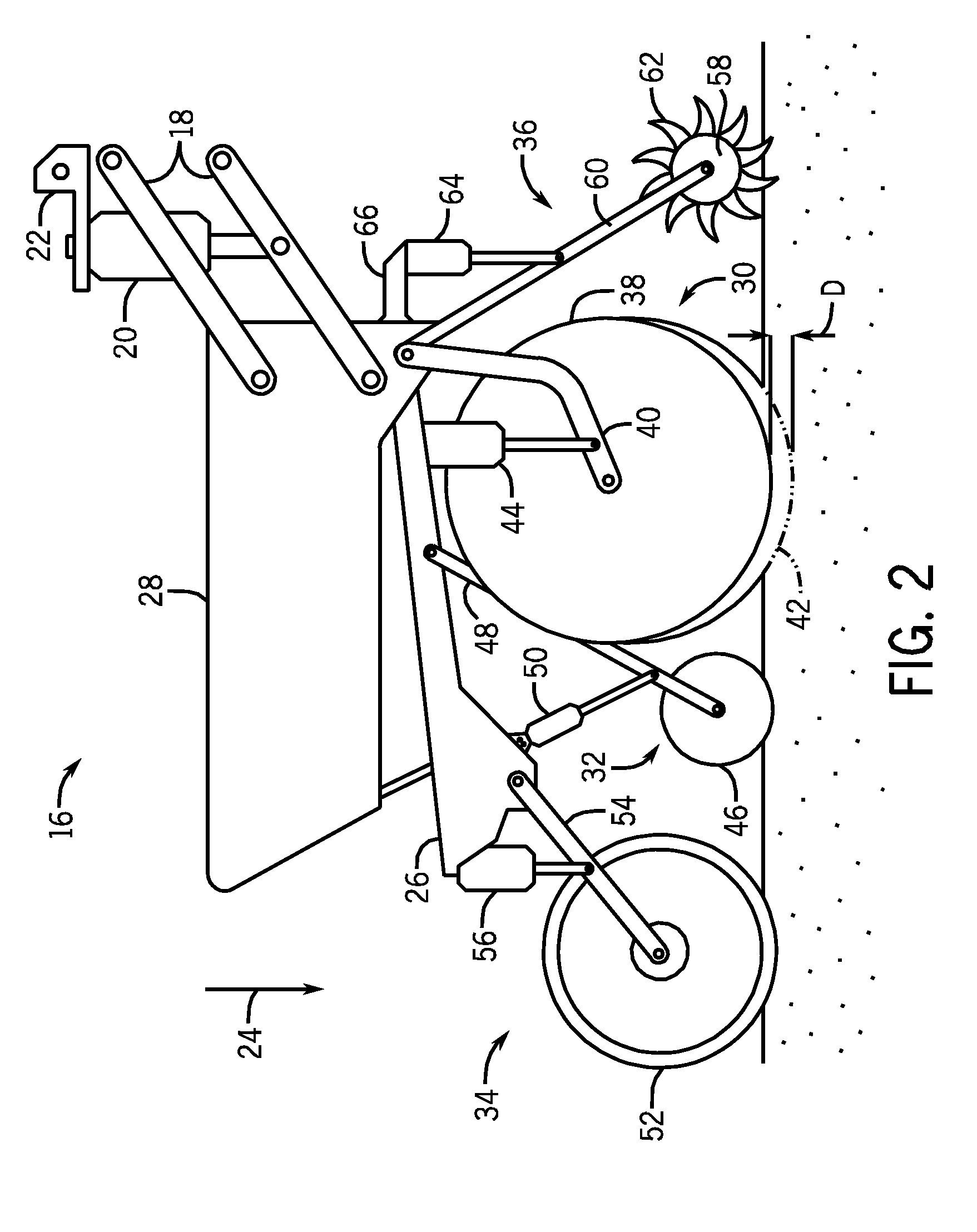

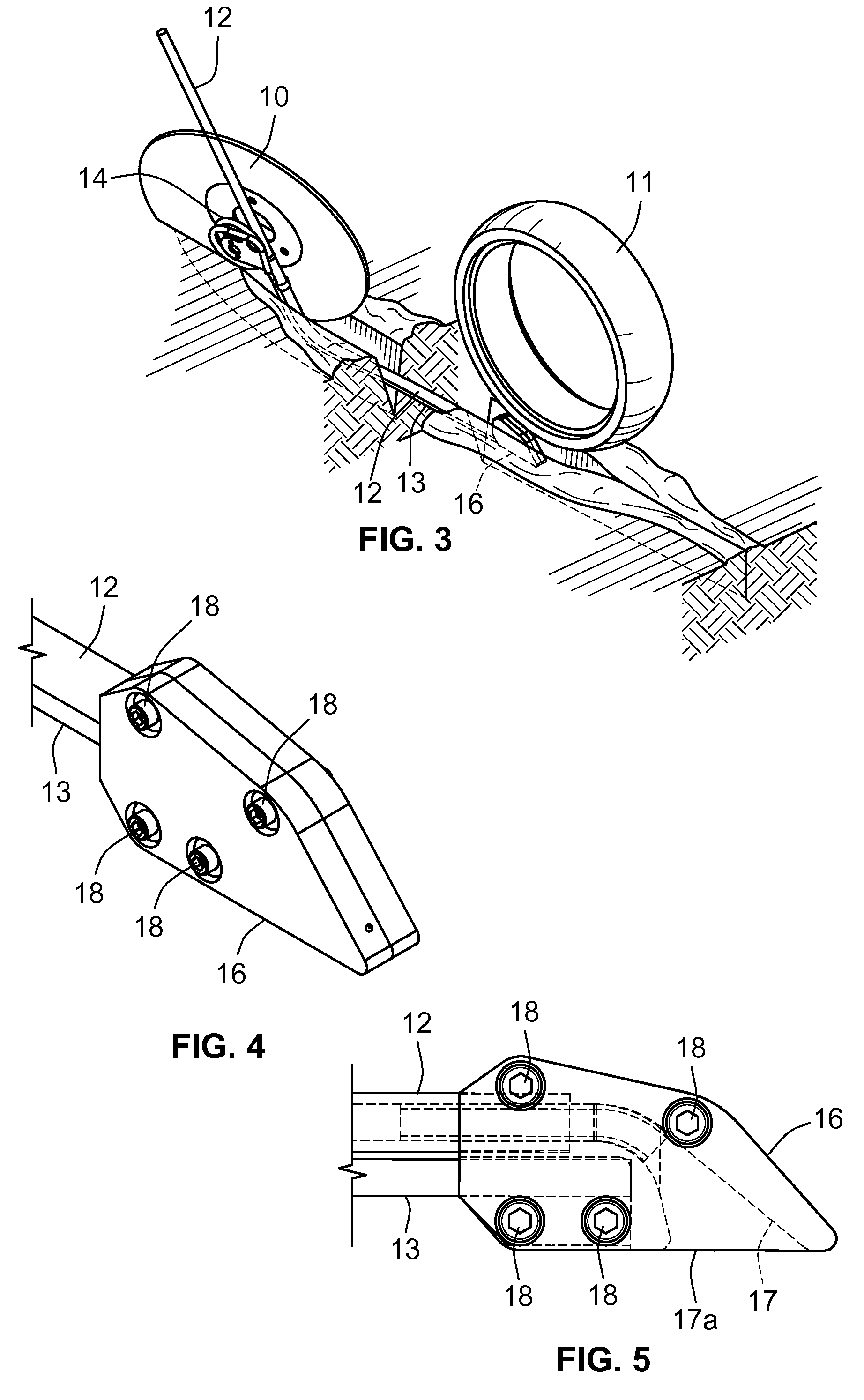

Agricultural implement with combined down force and depth control

An agricultural implement system is provided that includes a down force cylinder configured to apply a downward force to a row unit, and a depth control cylinder configured to vary a penetration depth of a ground engaging tool of the row unit. The agricultural implement system also includes a valve assembly in fluid communication with the down force cylinder and the depth control cylinder. The valve assembly is configured to automatically adjust the downward force by varying fluid pressure within the down force cylinder based on fluid pressure within the depth control cylinder.

Owner:BLUE LEAF I P INC

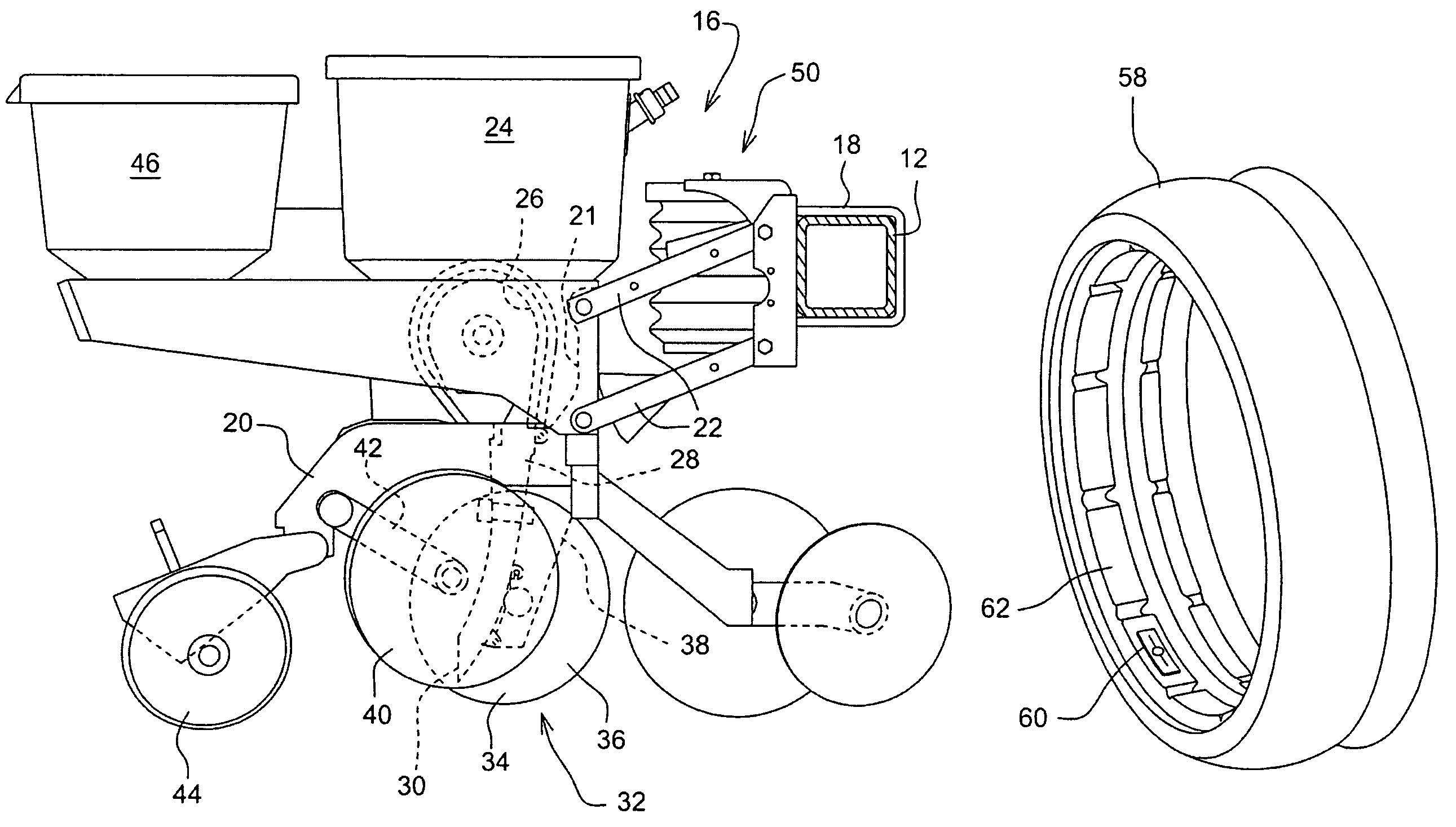

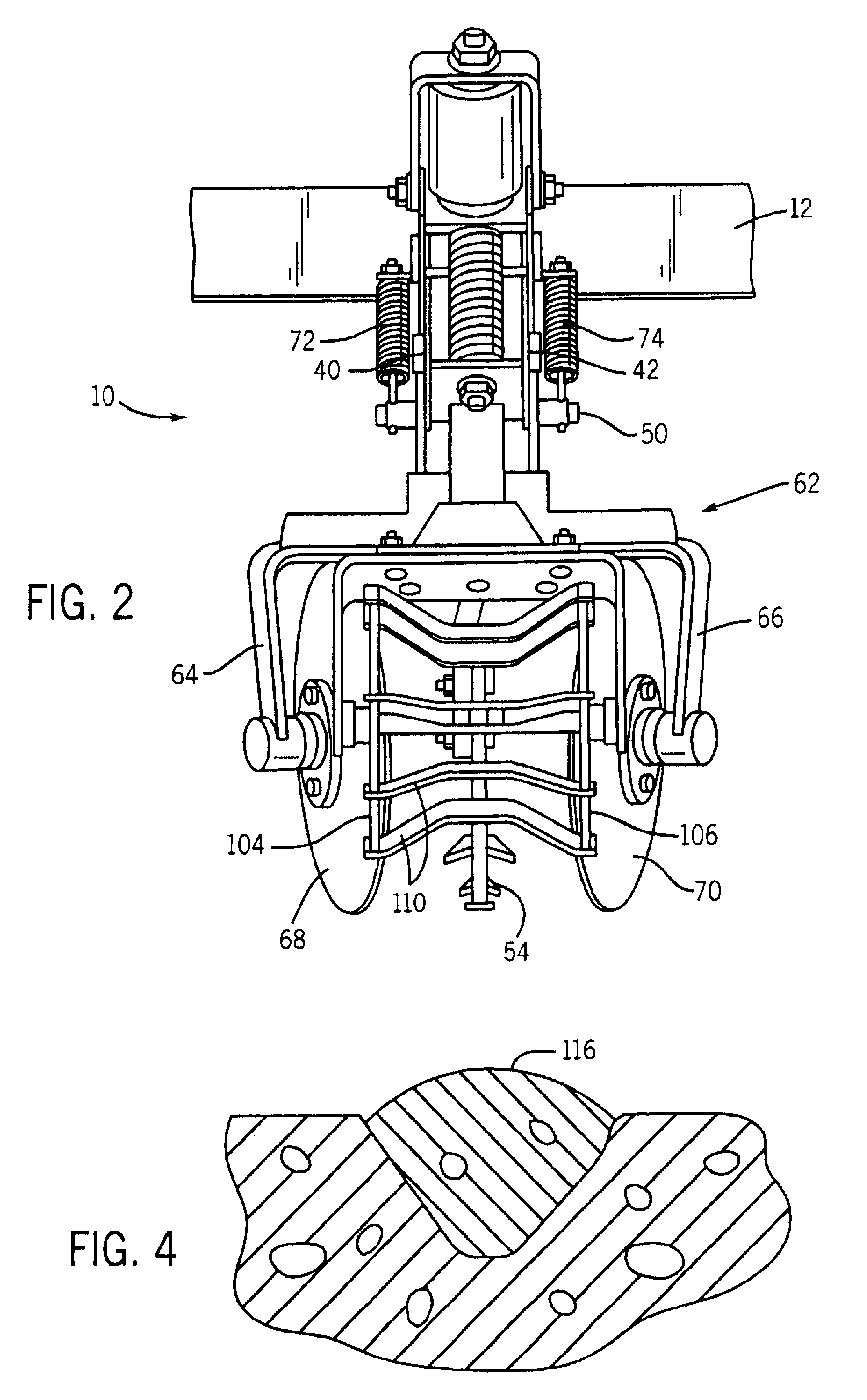

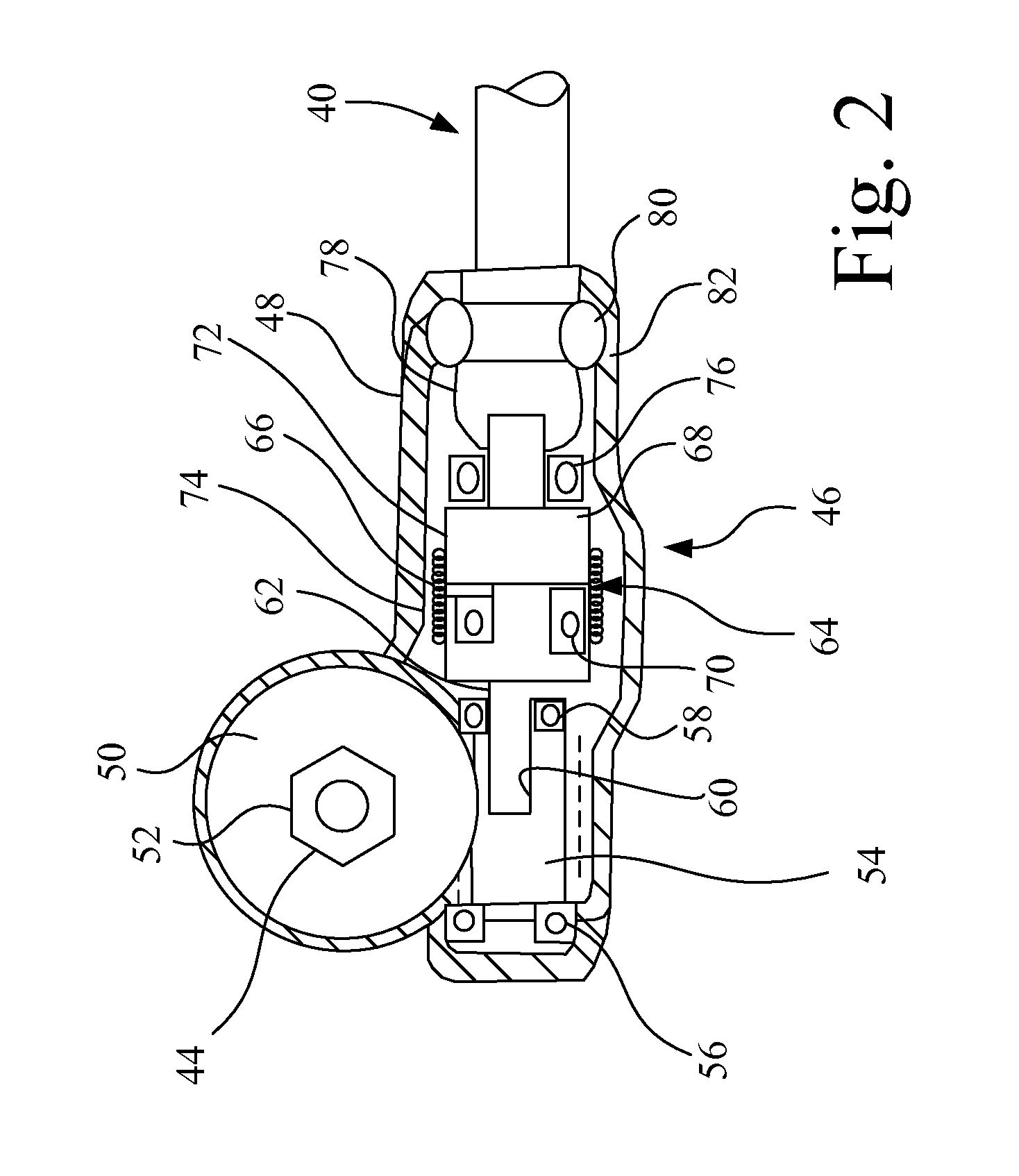

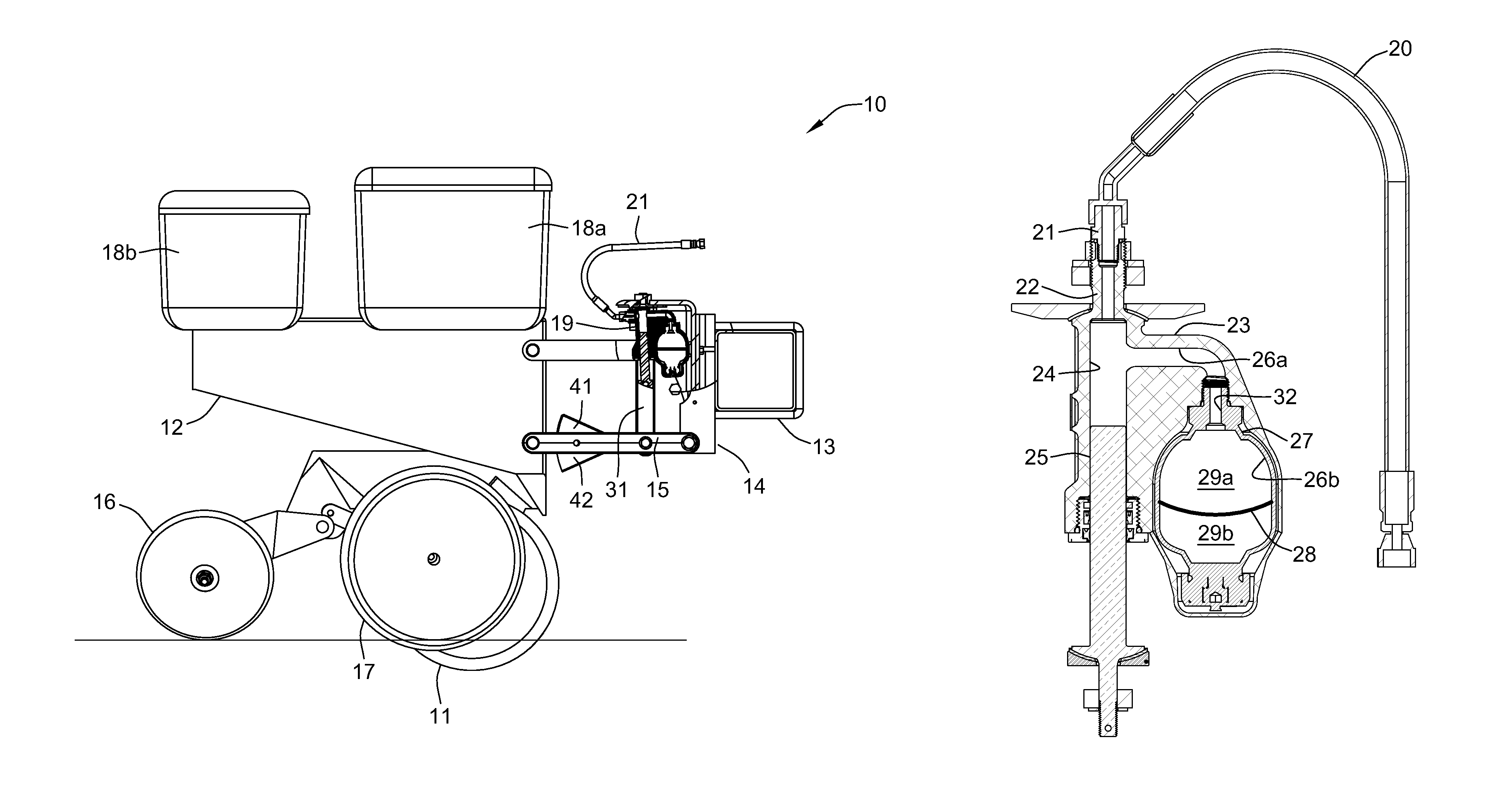

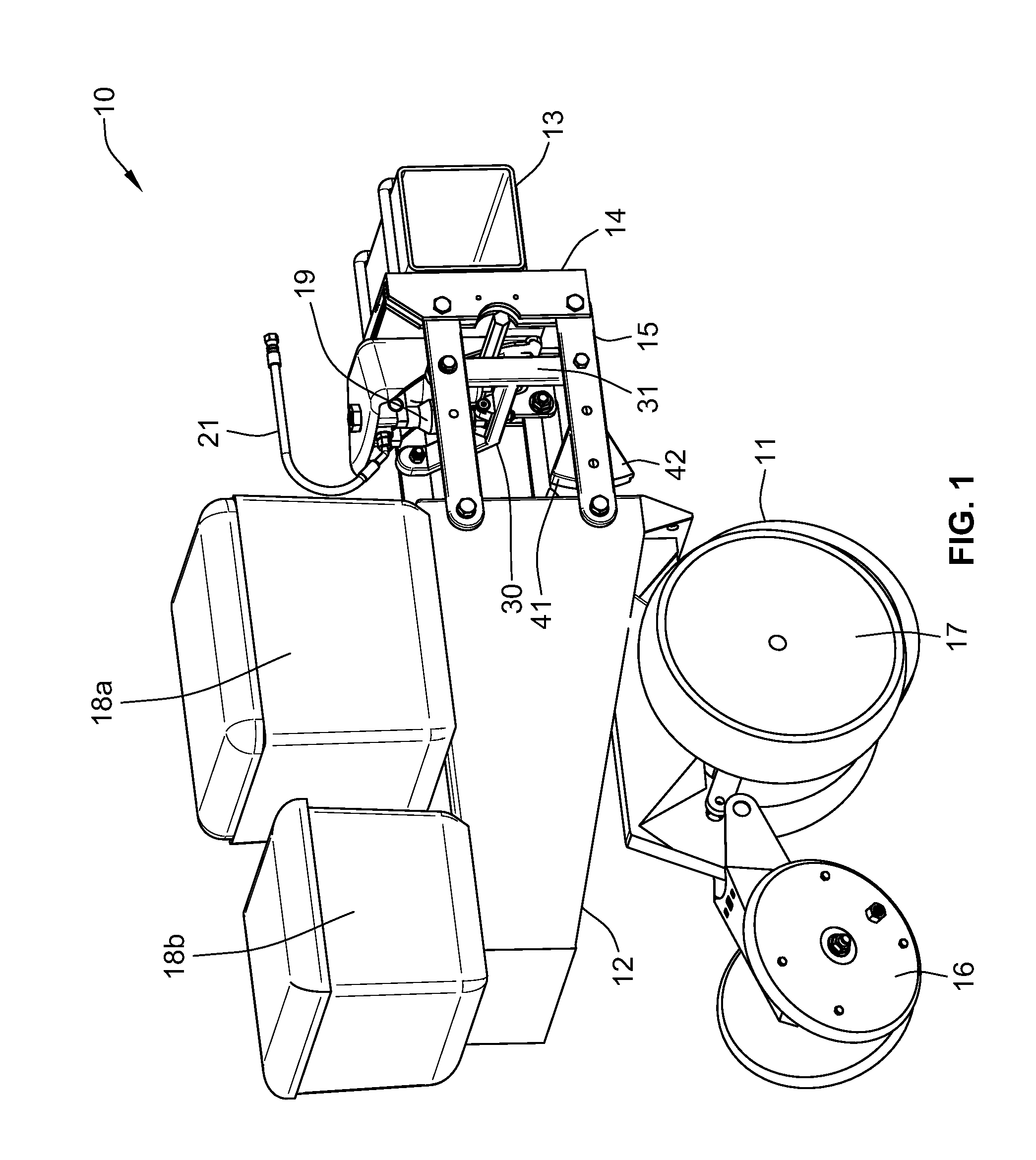

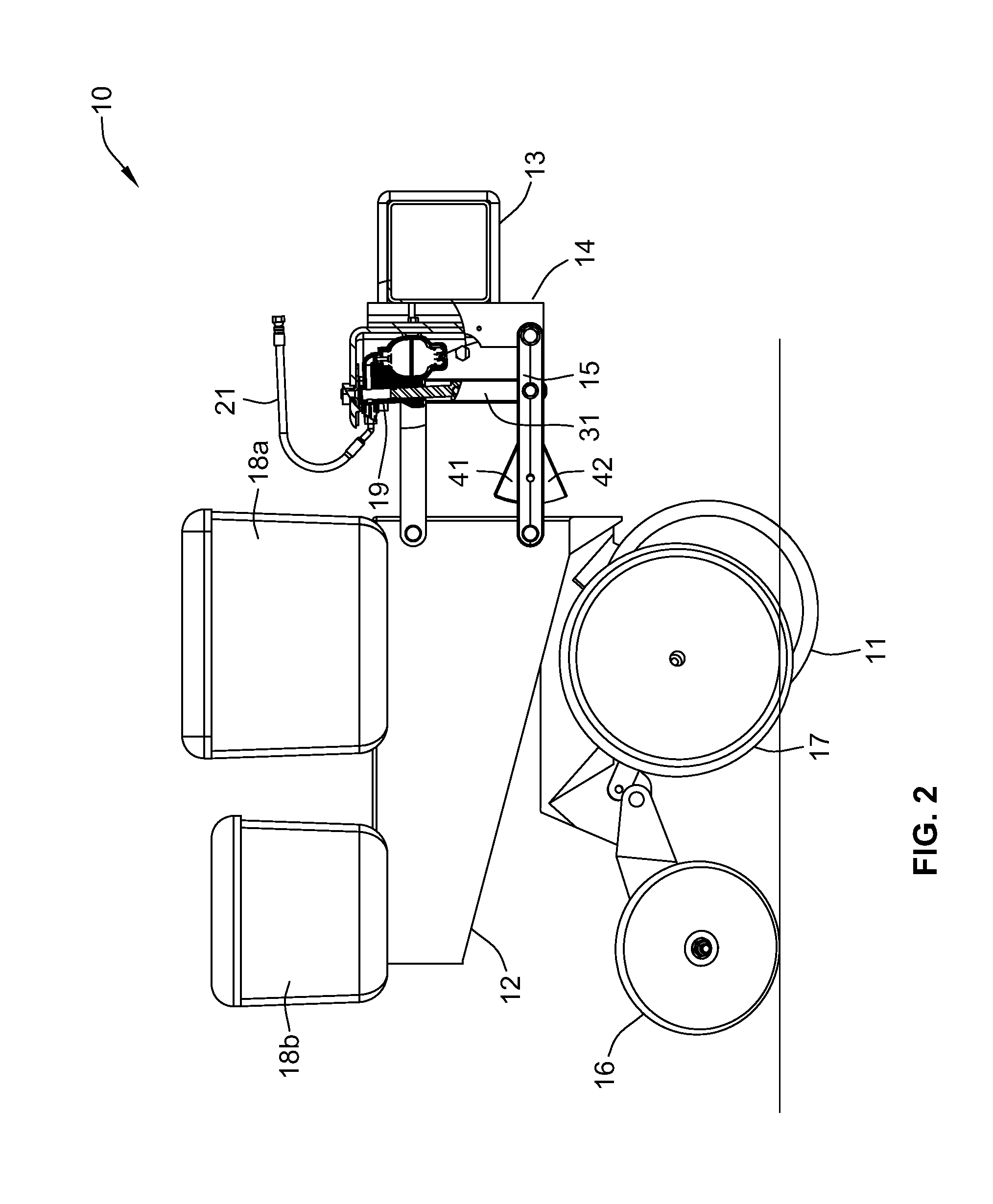

Pressure sensing system for a planter

A pressure sensing system for a seeding machine such as a planter to measure the down force on a planter row unit uses a wireless pressure sensor embedded in a load carrying wheel of the row unit. In a preferred embodiment, the pressure sensor is a passive piezoelectric pressure sensor that is a transmitter only, transmitting both pressure and RFID the information that identifies the particular sensor. Multiple sensors may be employed in each wheel and sensors may be employed in more than one wheel of the row unit, such as the gauge wheels on opposite sides of the trench opening disks. The sensors may be made of a PVDF, a known piezoelectric material. A wireless receiver is located on the planter frame or could be located elsewhere to receive the signals from the pressure sensor. A controller determines from the signal, any change in down force and commands the change to a down force generator on the row unit.

Owner:DEERE & CO

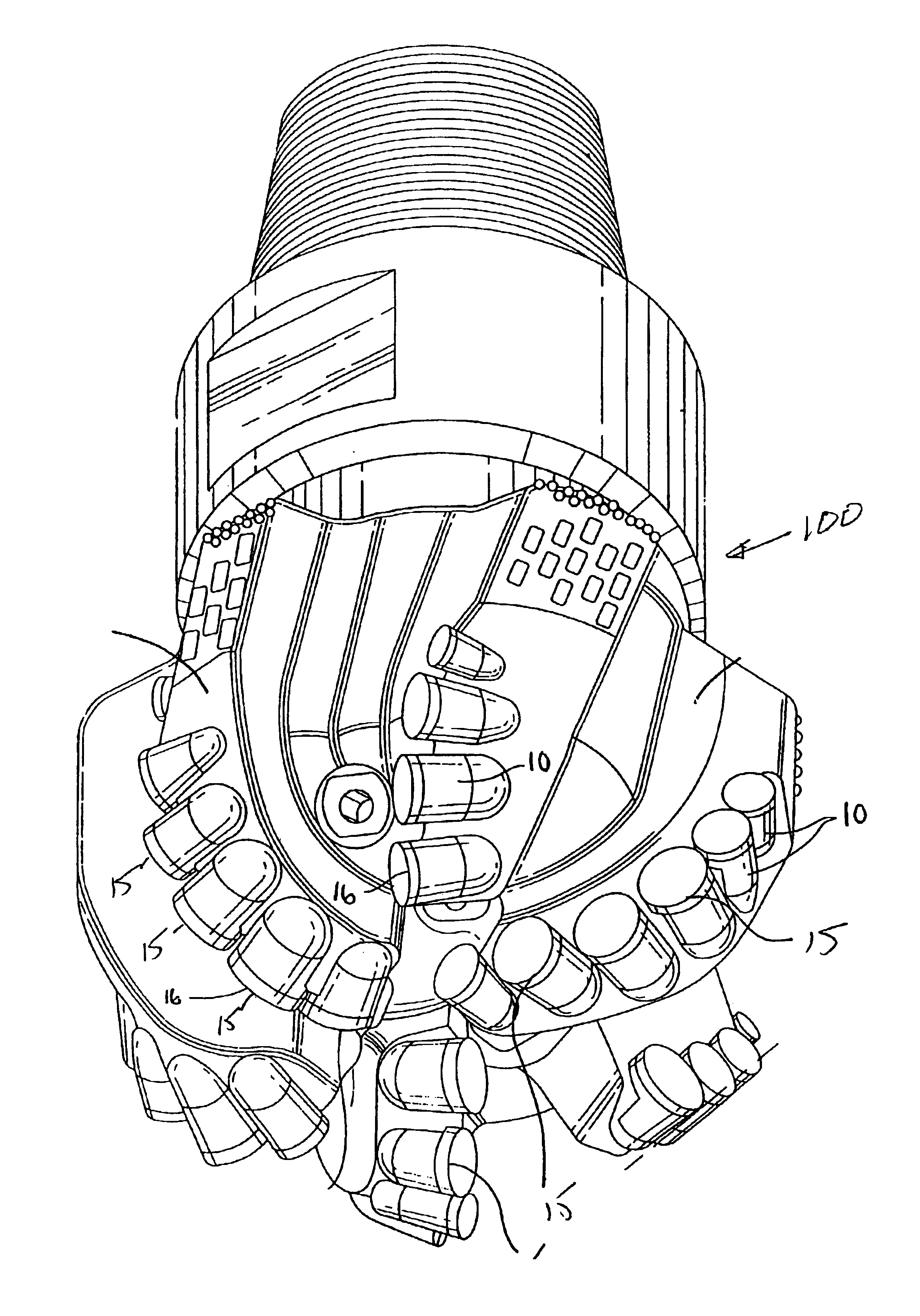

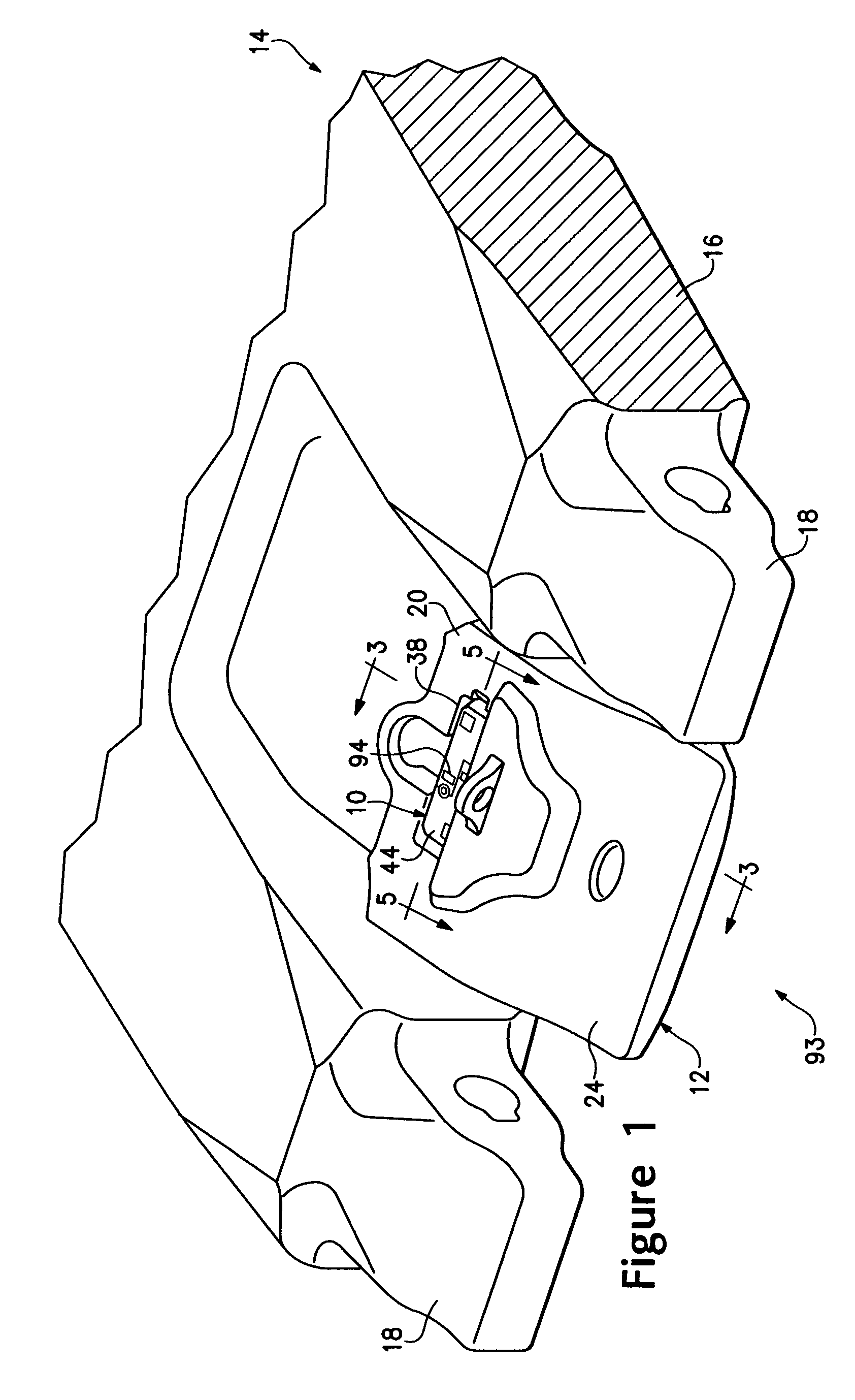

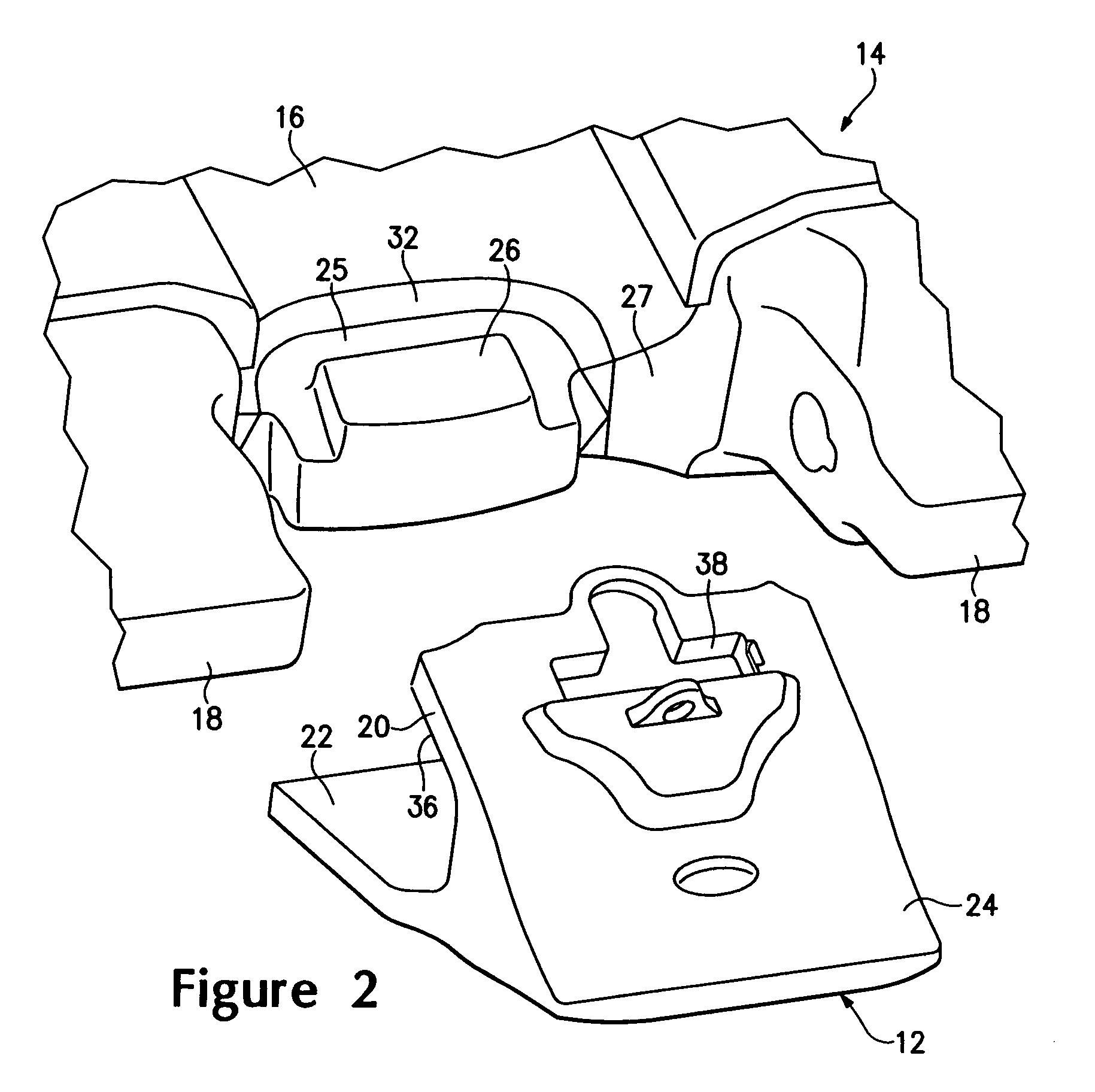

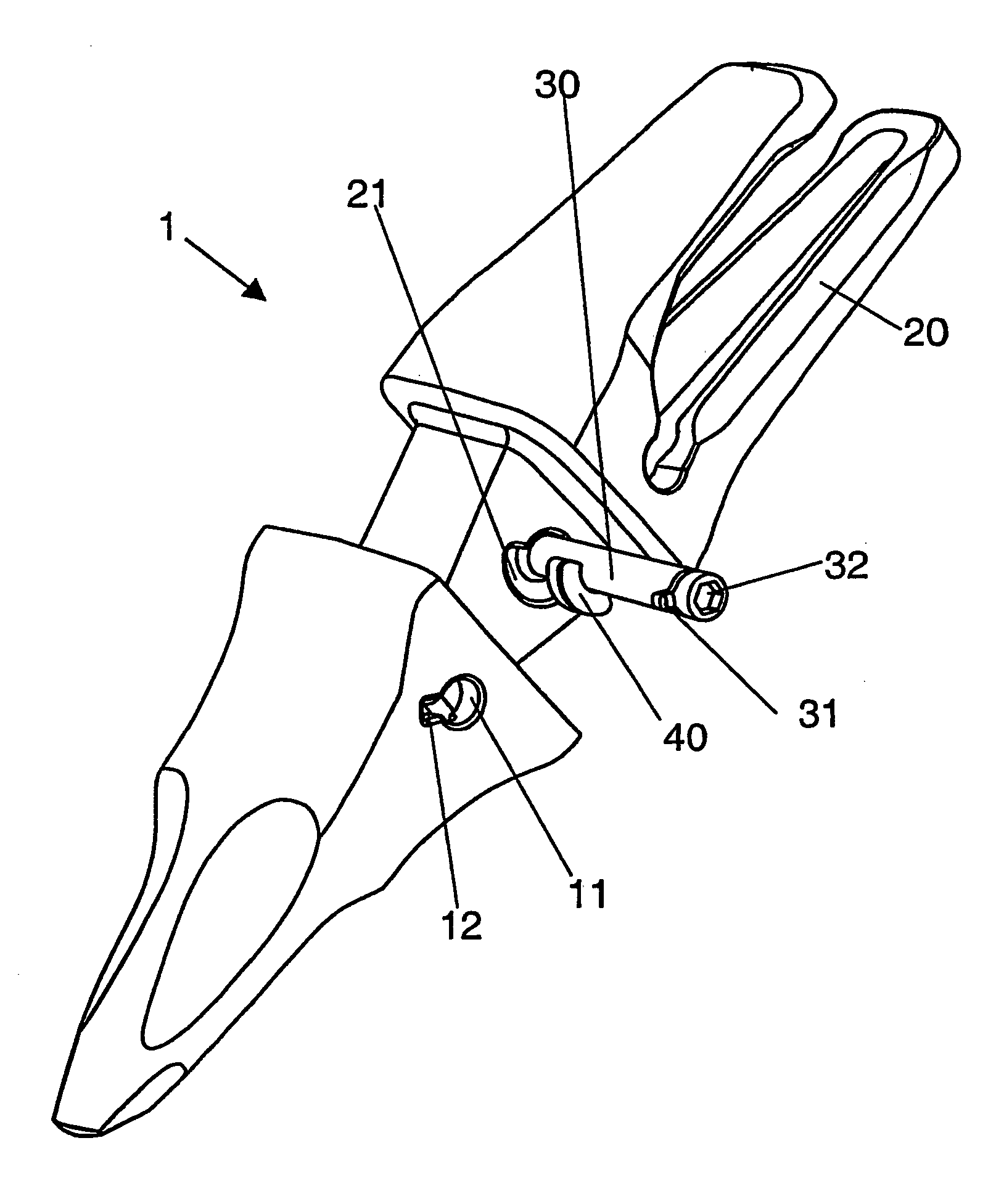

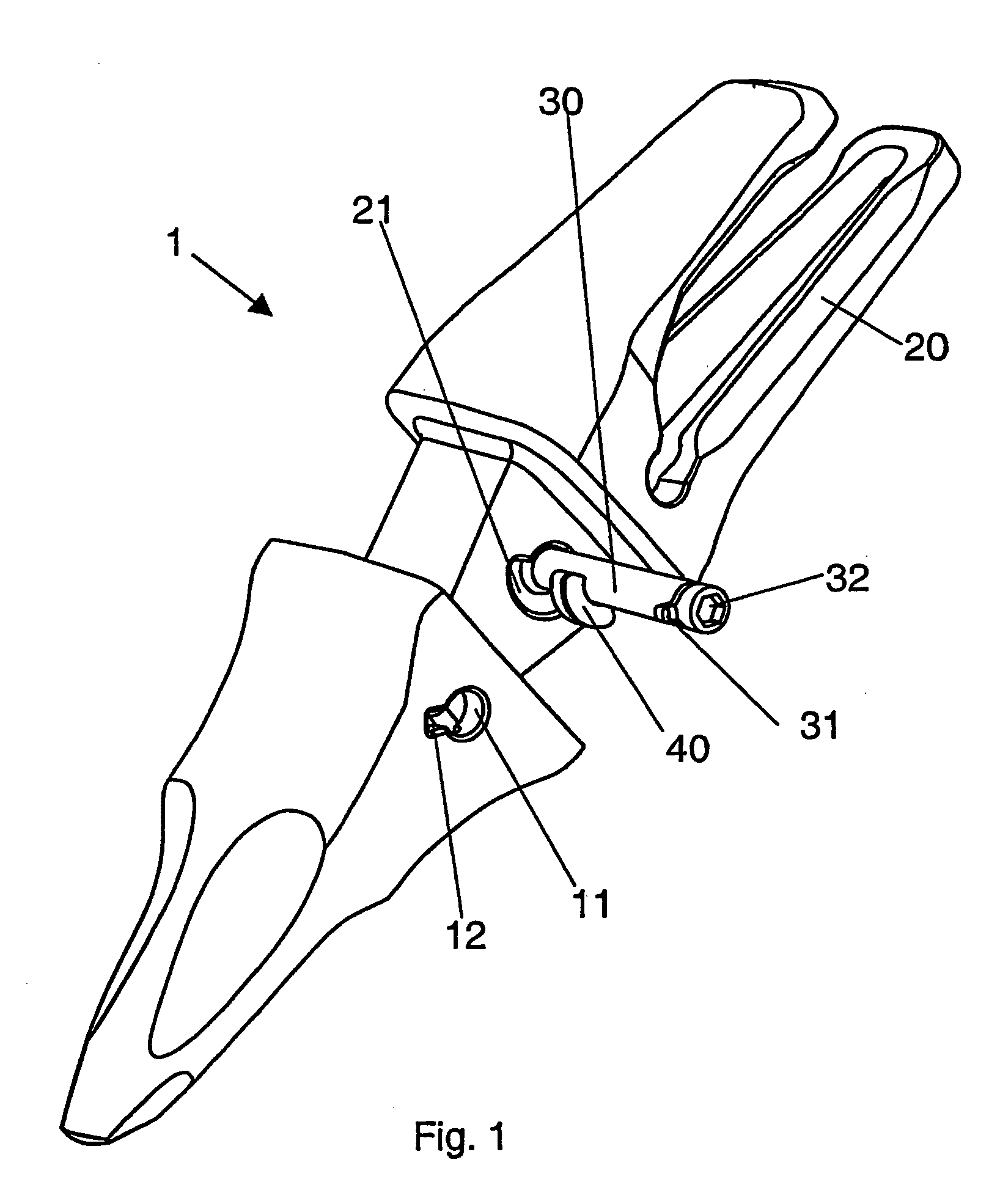

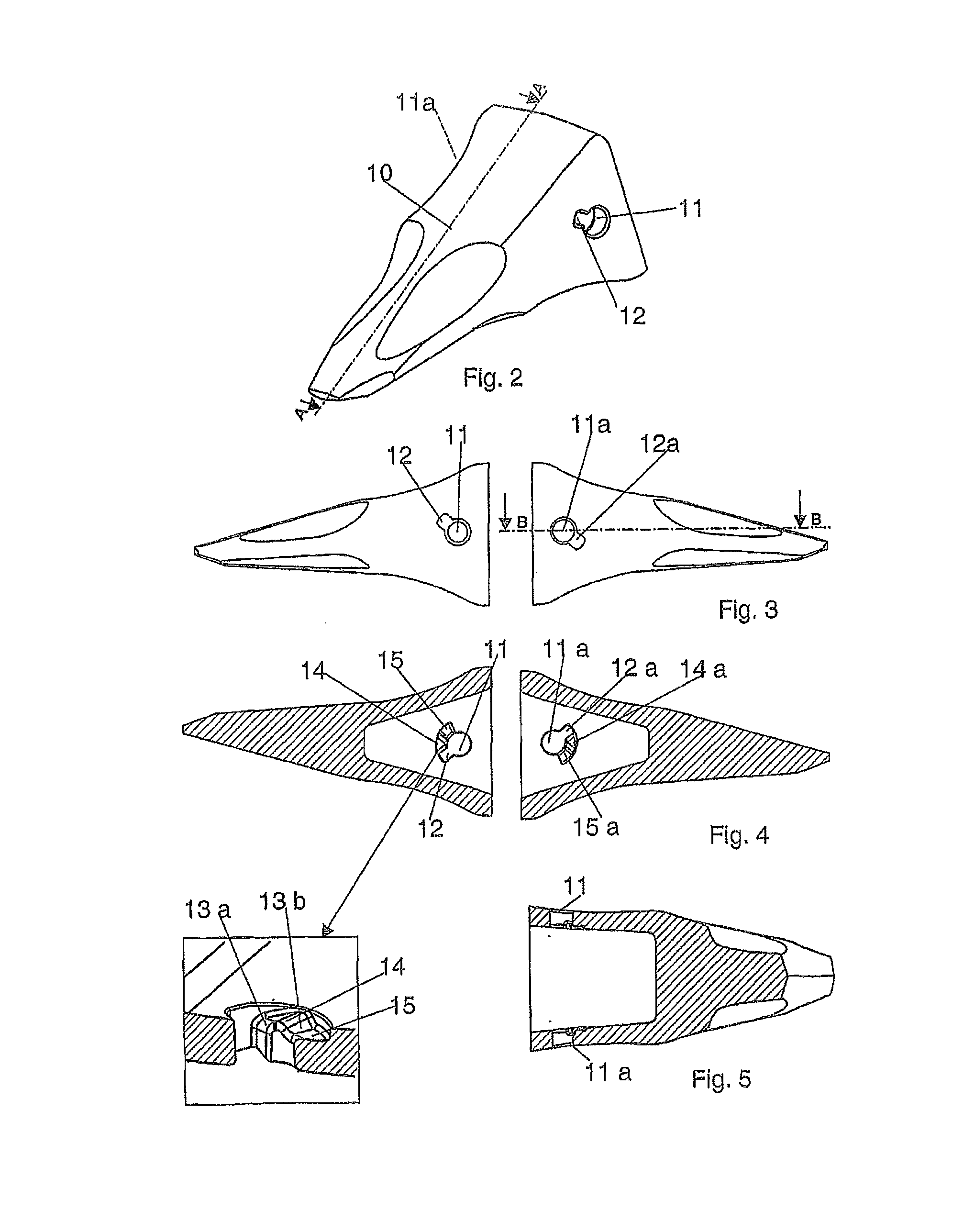

Wear Assembly and Components Thereof, Which is Intended for Machines That Are Used to Move Mateials Such as Earth and Stones

ActiveUS20080028644A1Reduce usageEasy to operateSoil-working equipmentsDragsCoupling systemExcavator

The present invention relates to a wear assembly, as well as to the different components thereof, which comprises a wear member or tooth and an adaptor member or tooth bar for wear applications in a machine for moving materials such as earth and stones.The invention contemplates a wear assembly and particularly a coupling system between the different components to one another by means of a characteristic coupling system and at least one retention system assuring the coupling and anchor between the different components, specifically between the wear member and adaptor, the latter in turn being joined to the blade of a bucket or scoop of a machine for moving materials, such as an excavator or the like.

Owner:METALOGENIA SA

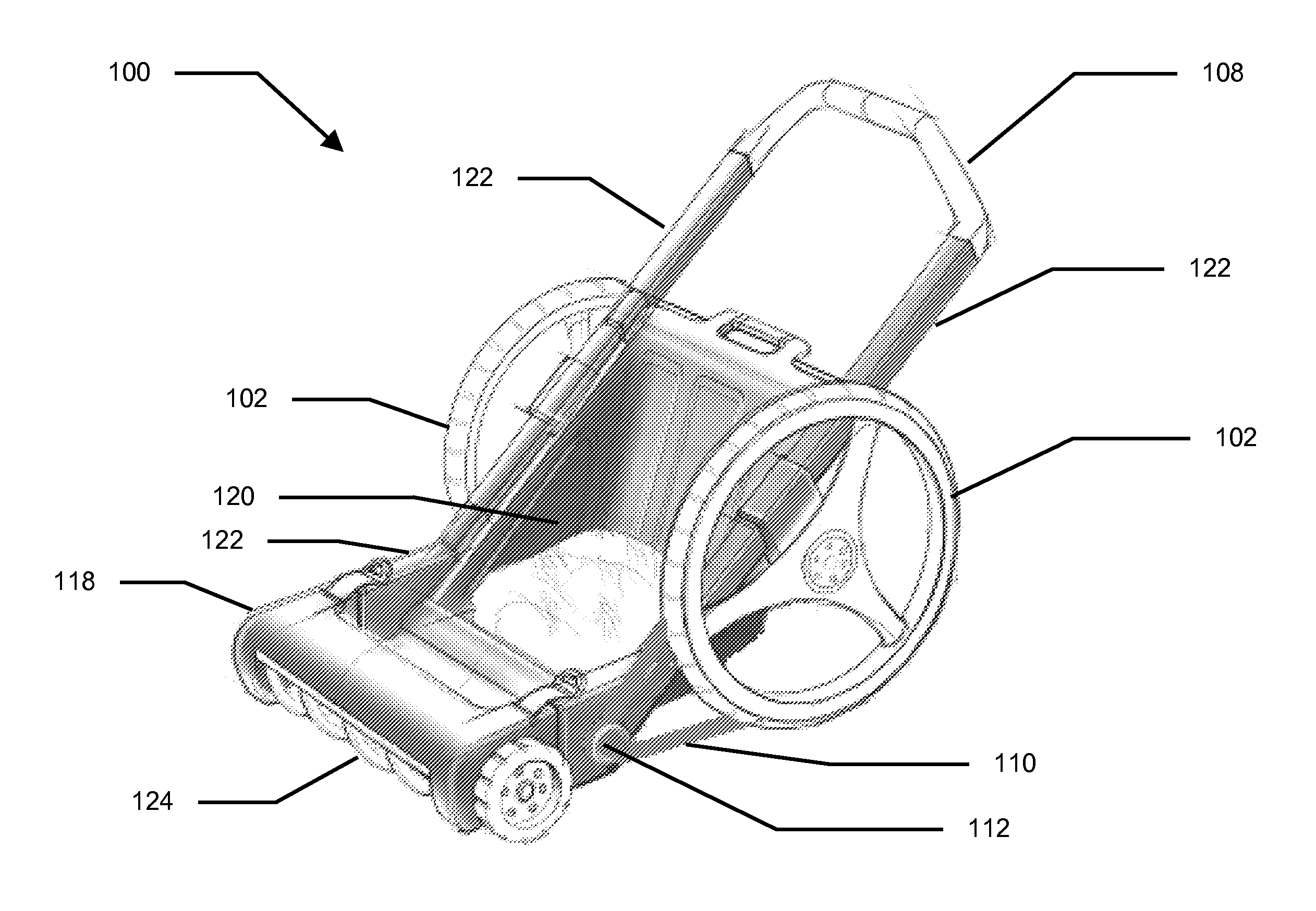

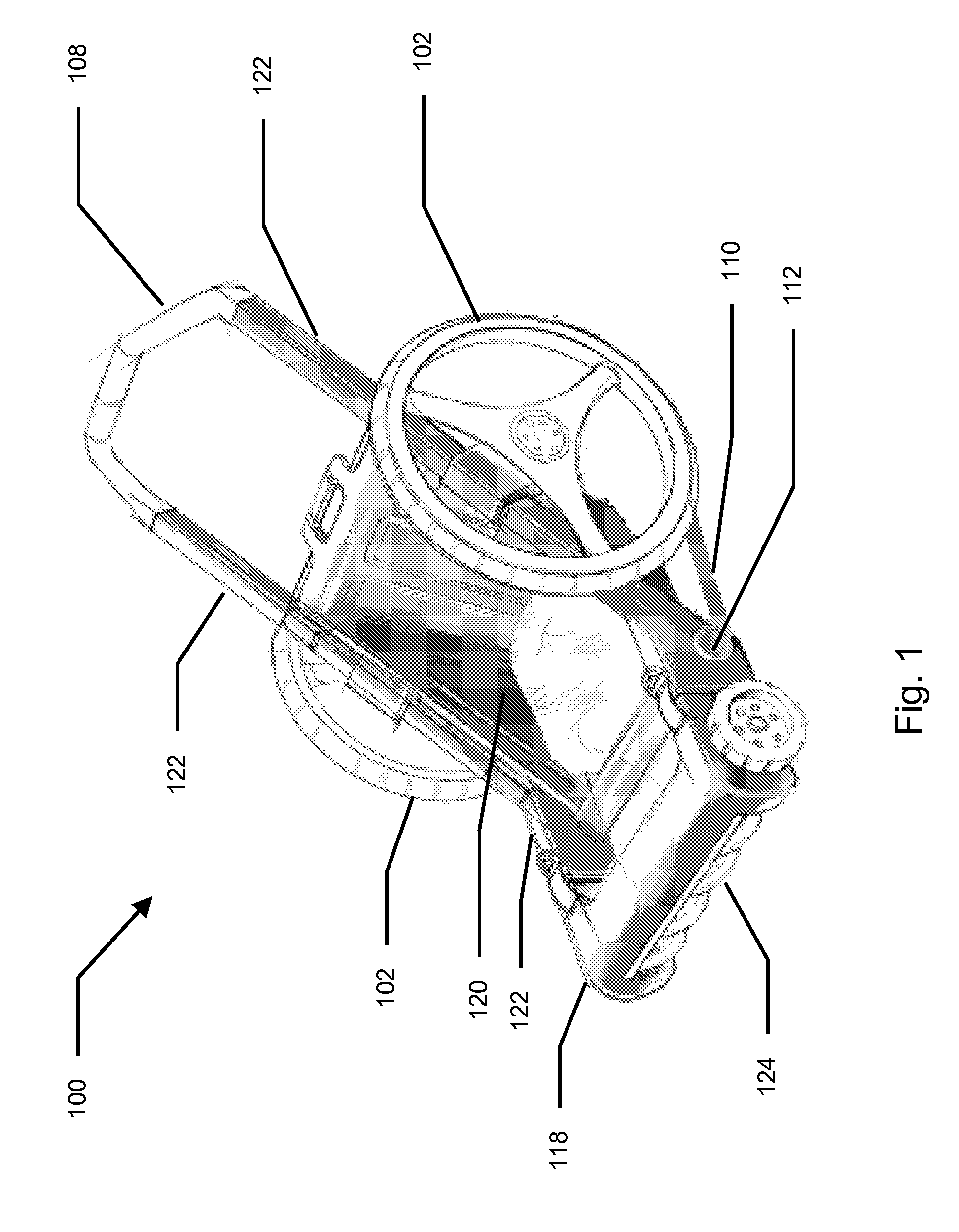

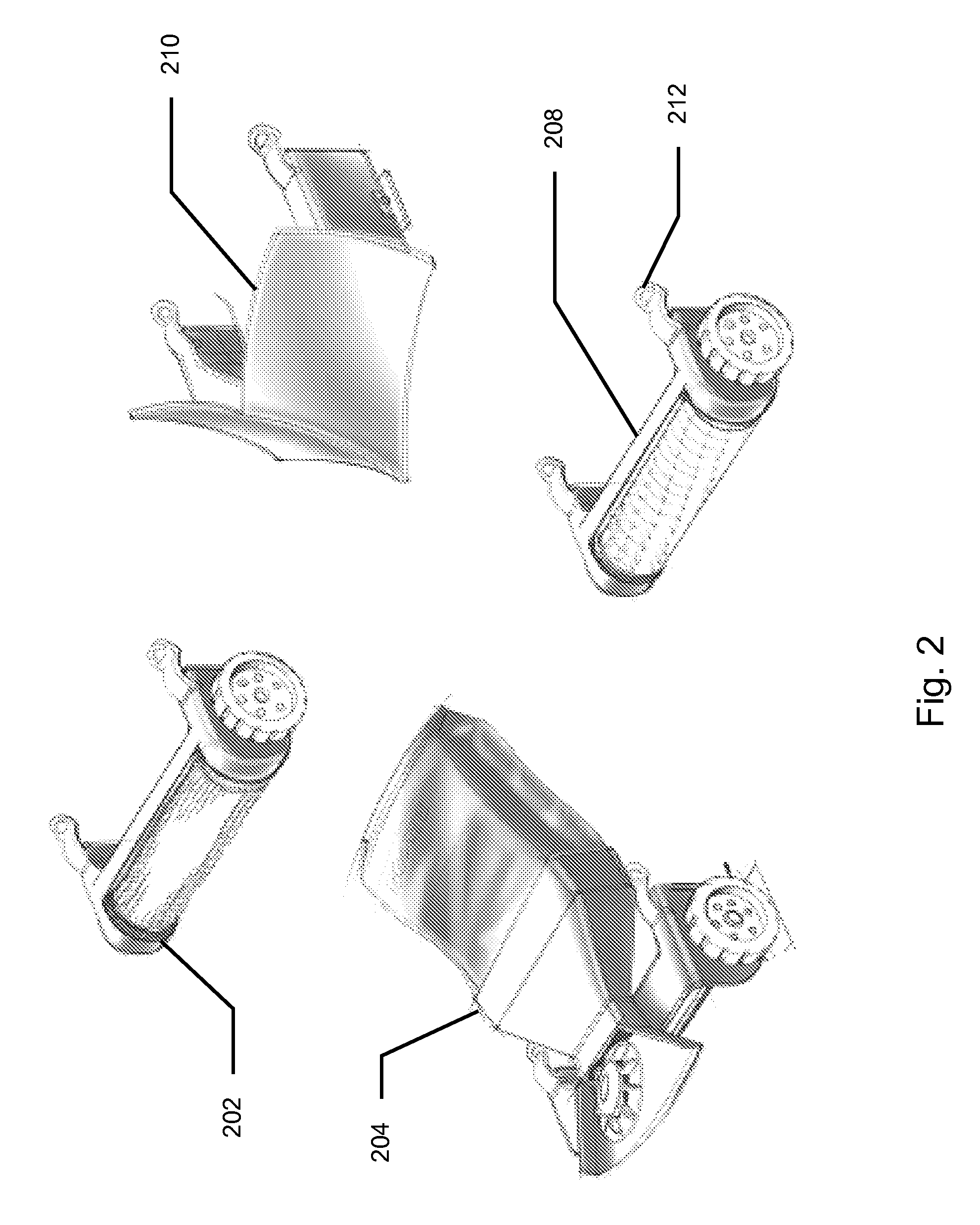

Modular landscaper

InactiveUS20080105445A1Fast spinReduce exerciseAgricultural machinesHops/wine cultivationModularityRotational energy

A modular landscaper uses oversized wheels to generate torque for turning one or more of several interchangeable modular landscape maintenance attachments. The landscaper provides a handle configured in relationship to the landscaper frame to allow an adult to normally walk behind the landscaper while applying a forward force by pushing on the handle that results in the wheels of the landscaper rolling along a landscape maintenance surface and generating torque that is transferred through a drive train to the one or more attached landscaping maintenance attachments. A drive train uses the rotational energy of the wheels to increase the operator pushing force to operate the maintenance attachment. Interchangeable attachments facilitate using the landscaper for a wide variety of landscaping maintenance tasks.

Owner:UMAGINATION LABS

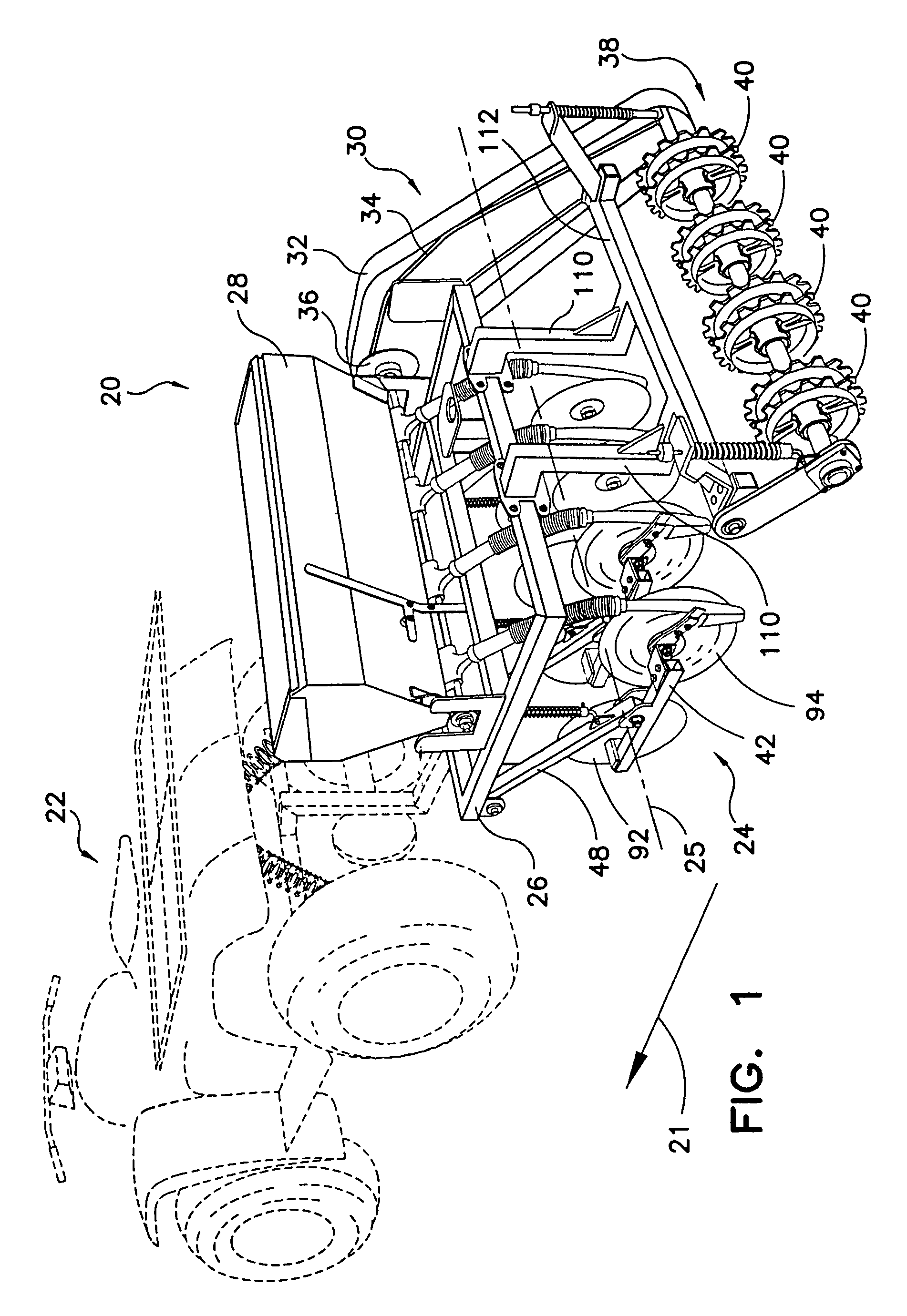

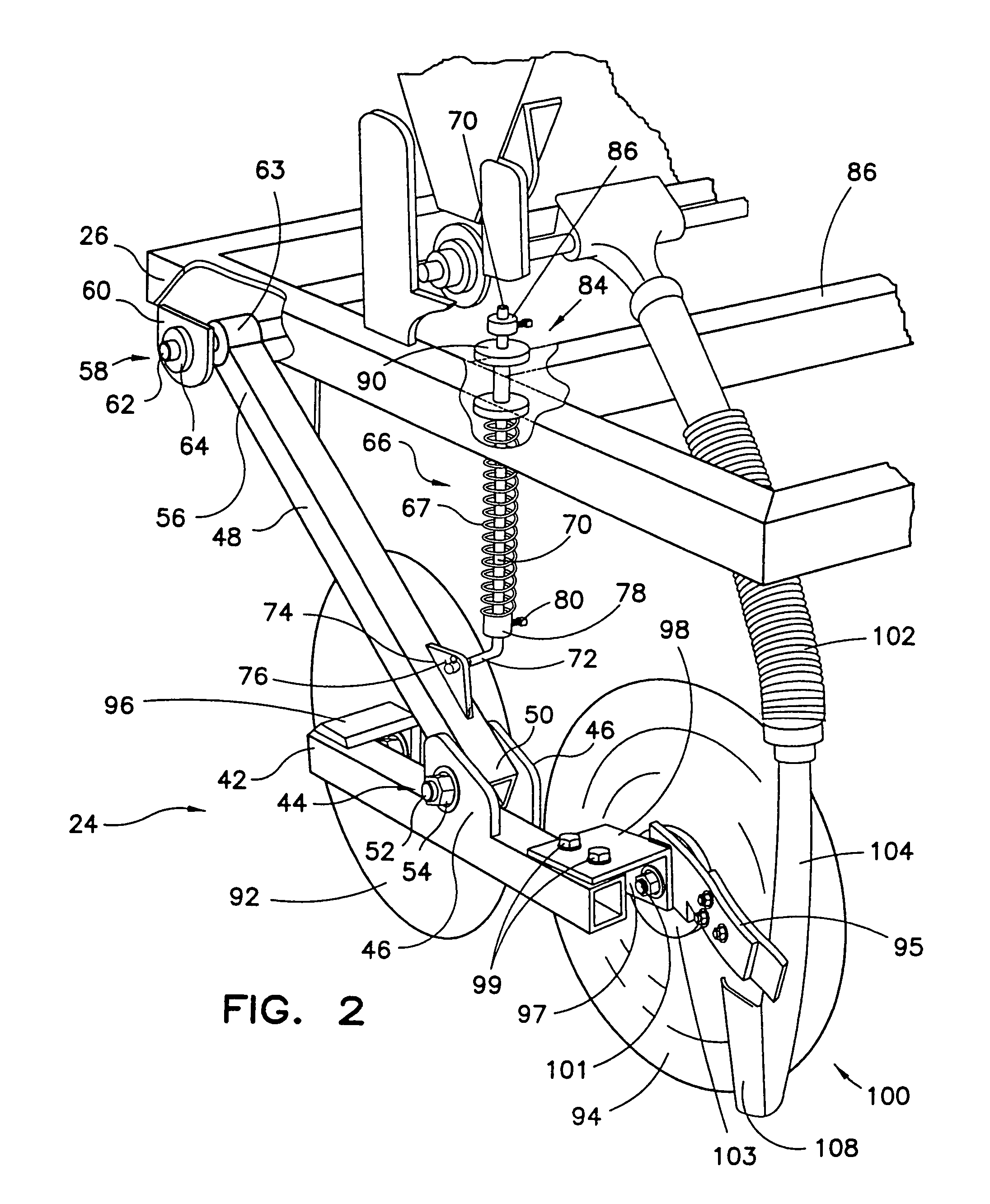

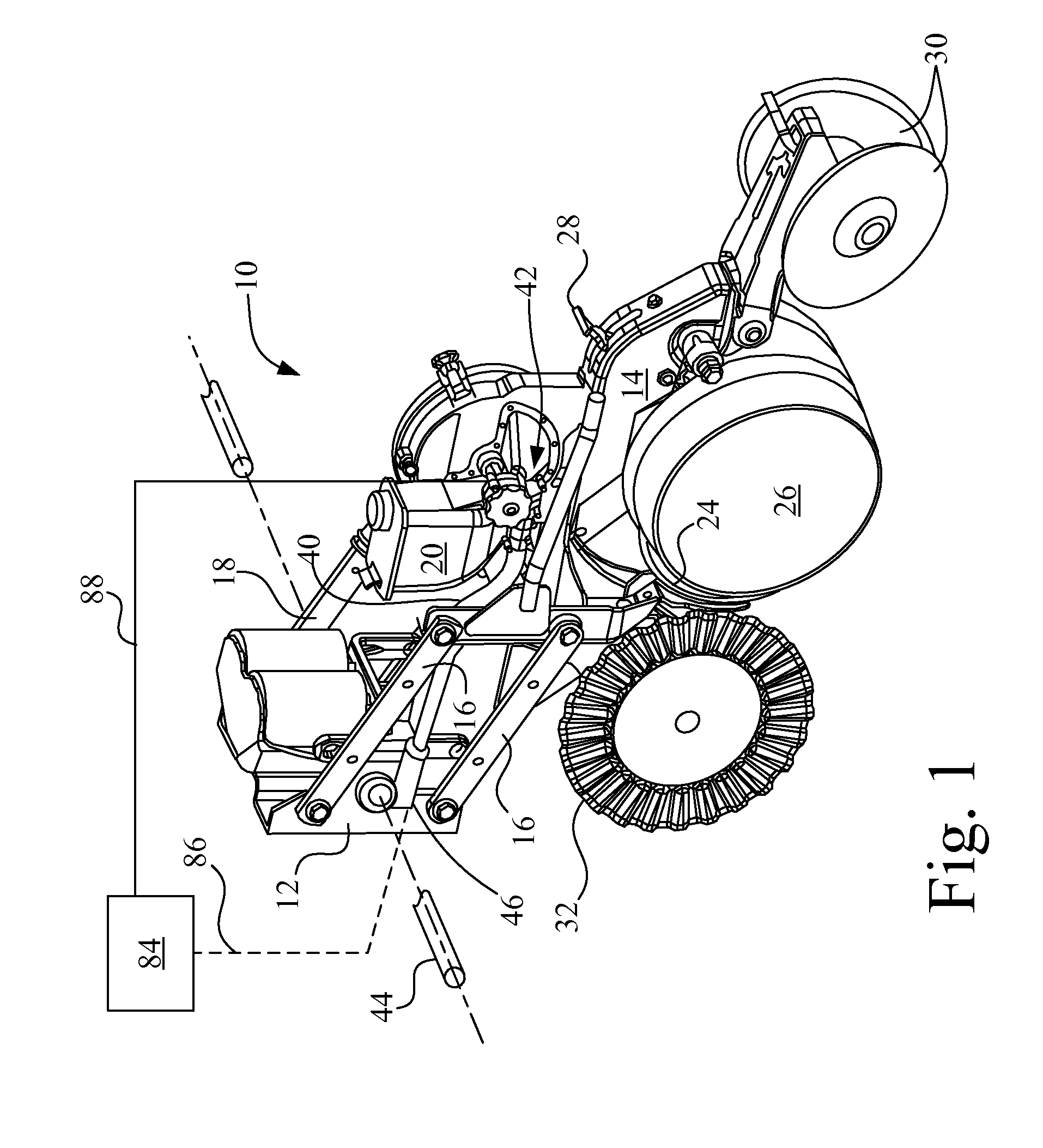

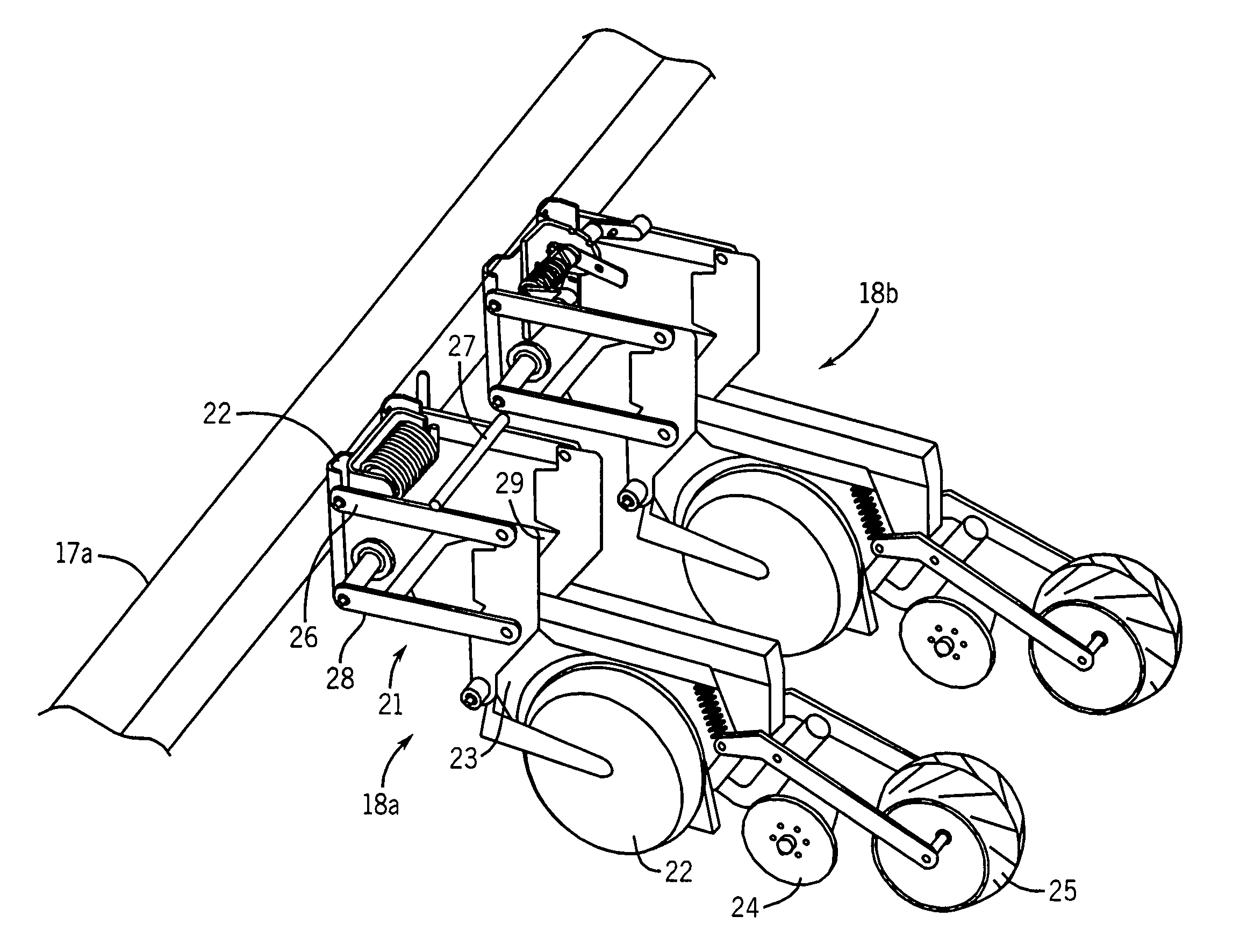

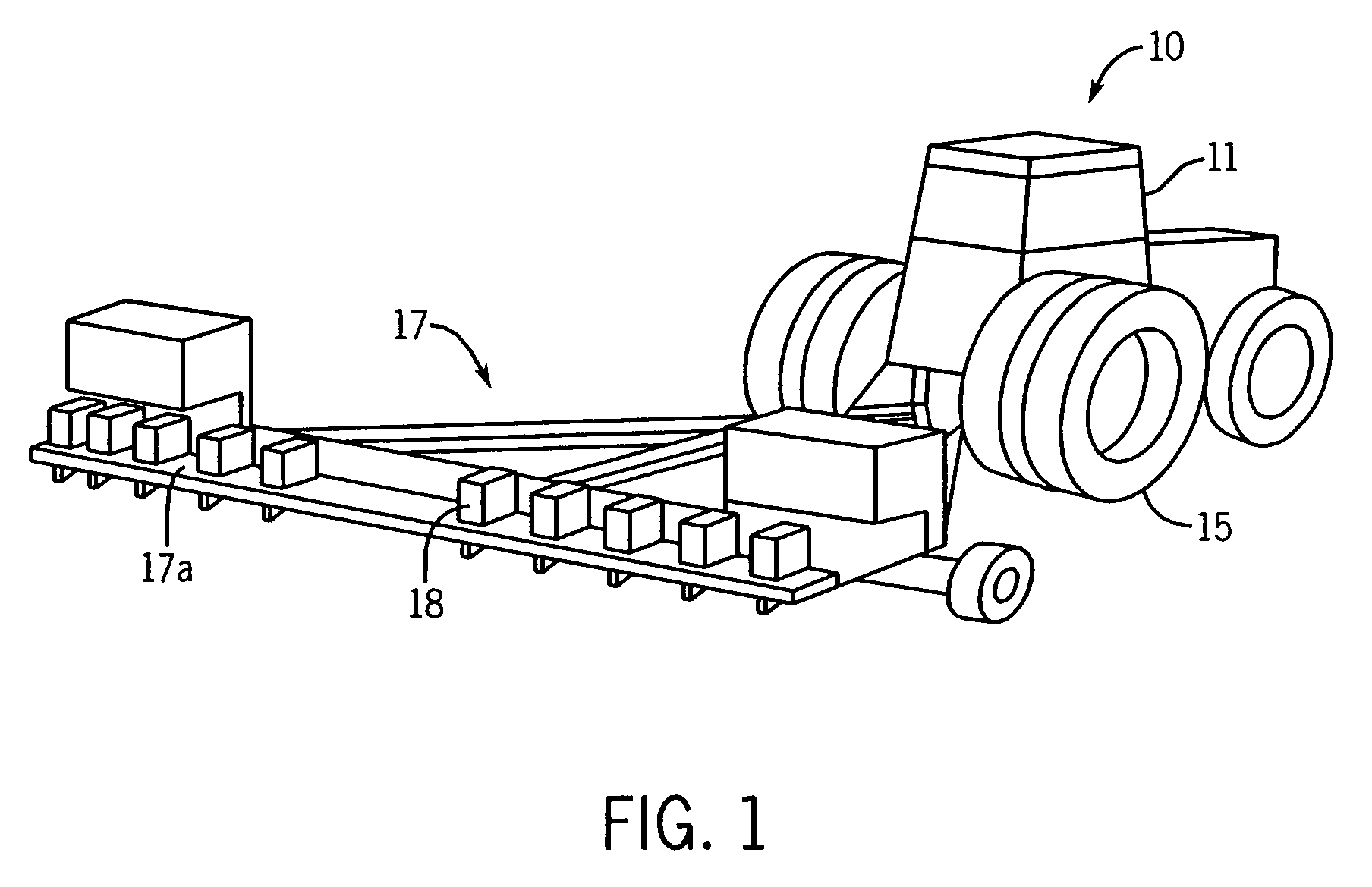

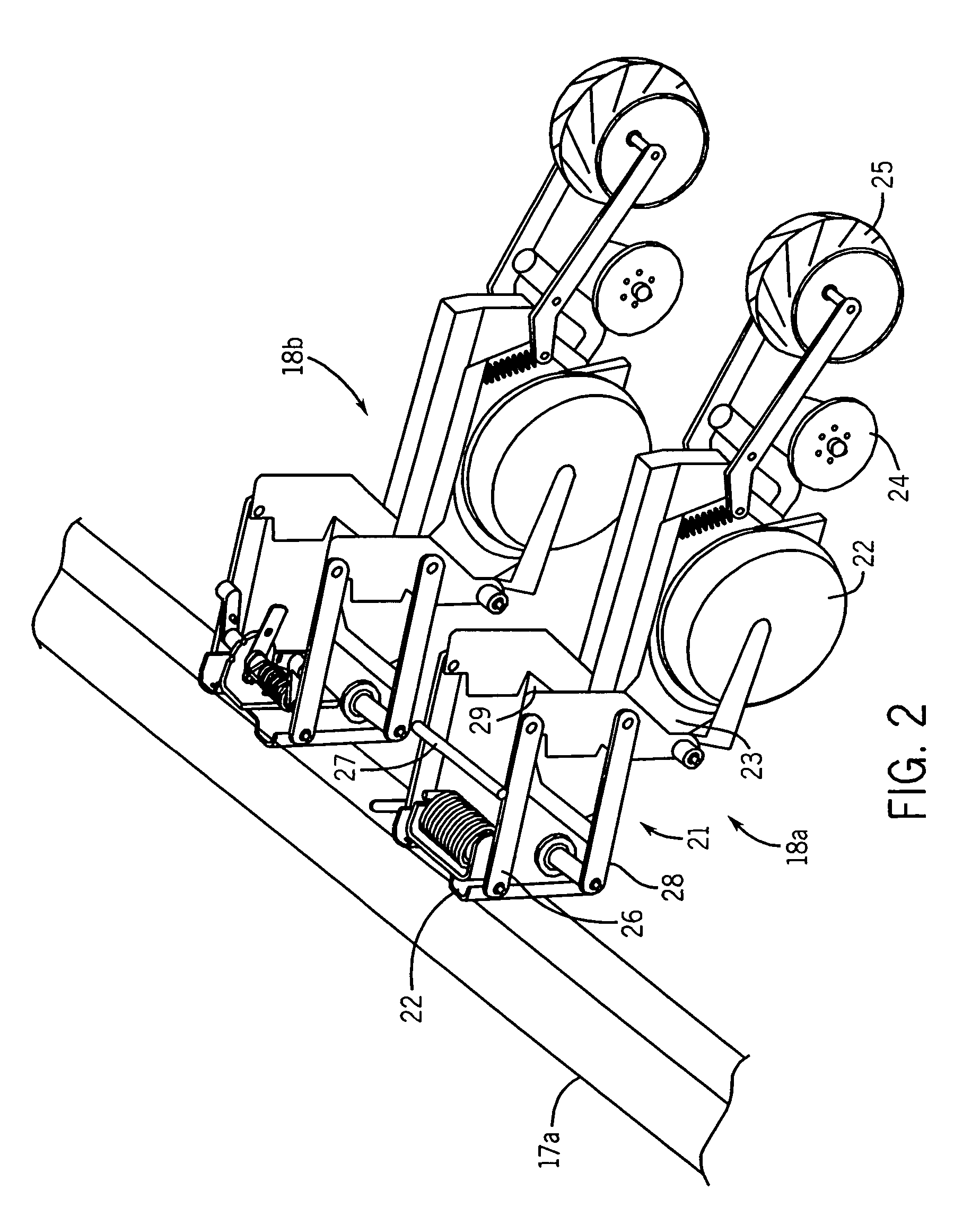

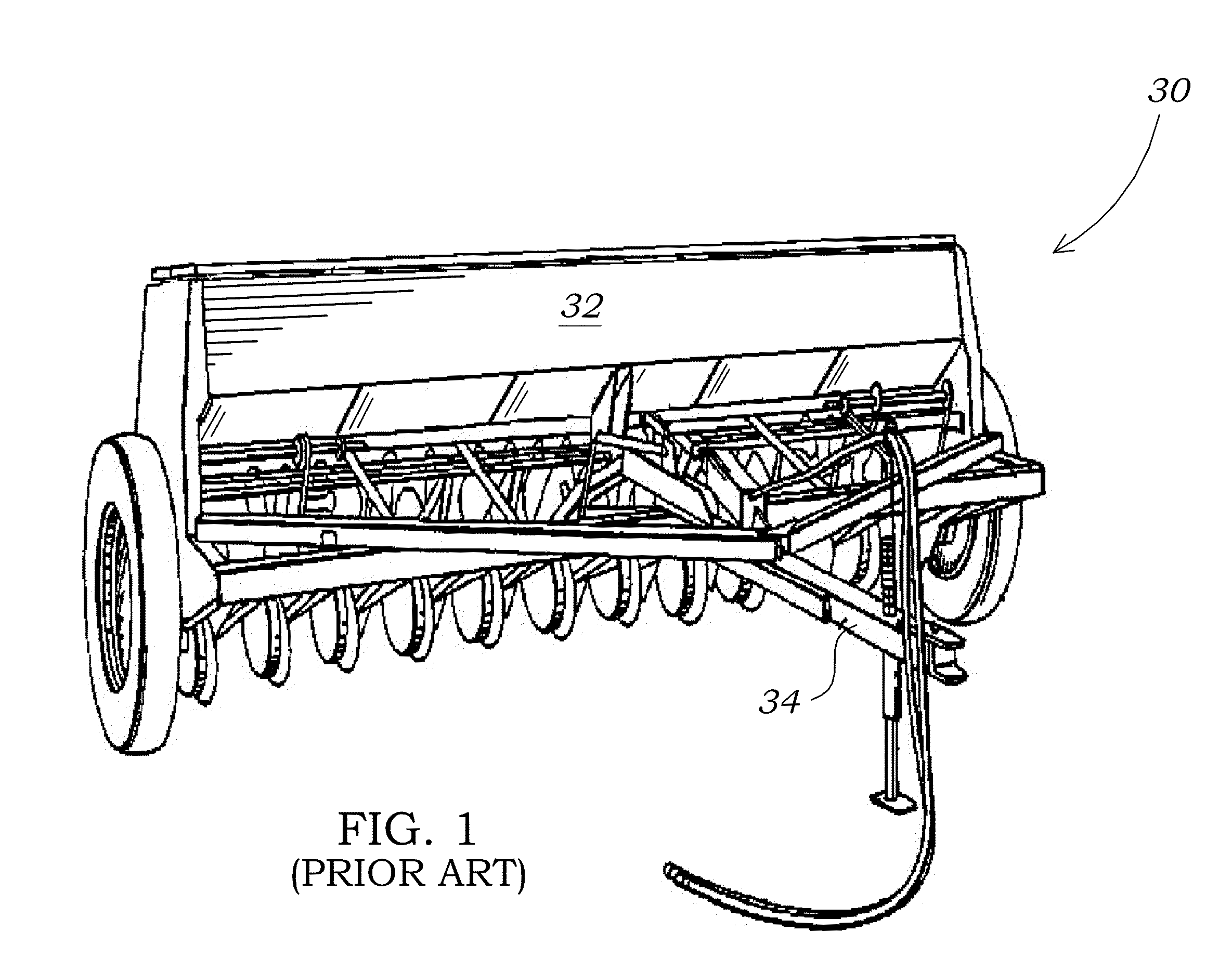

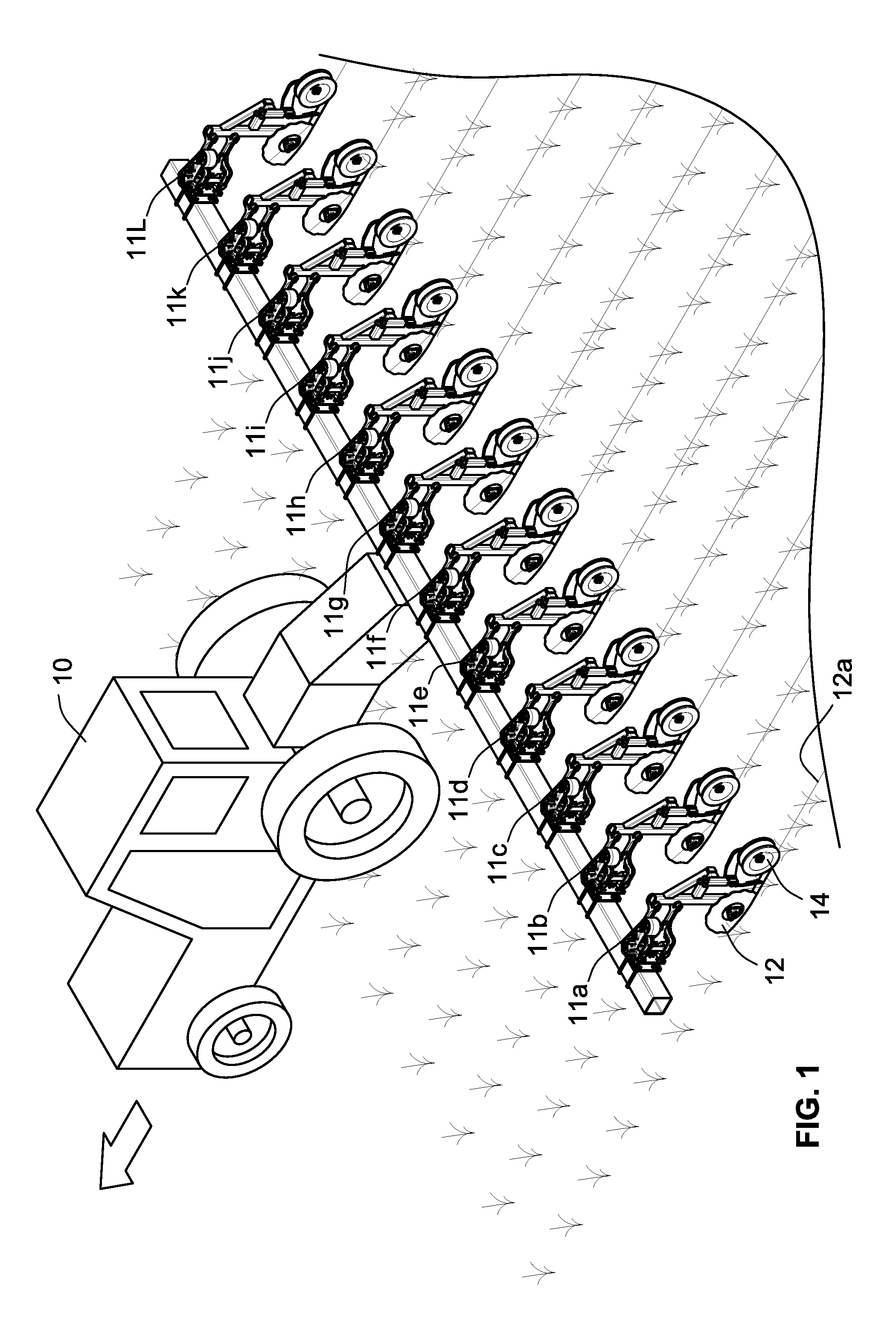

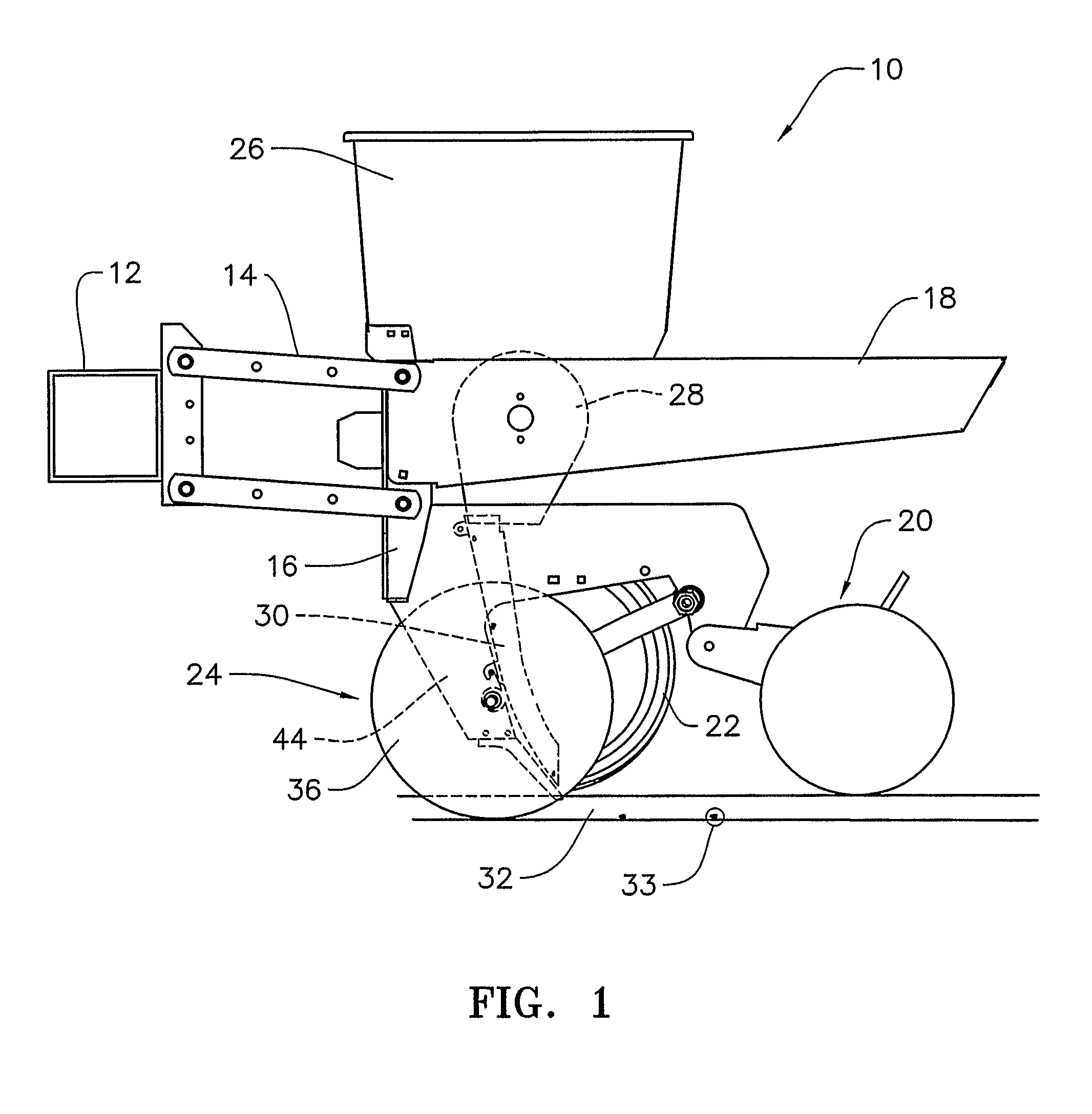

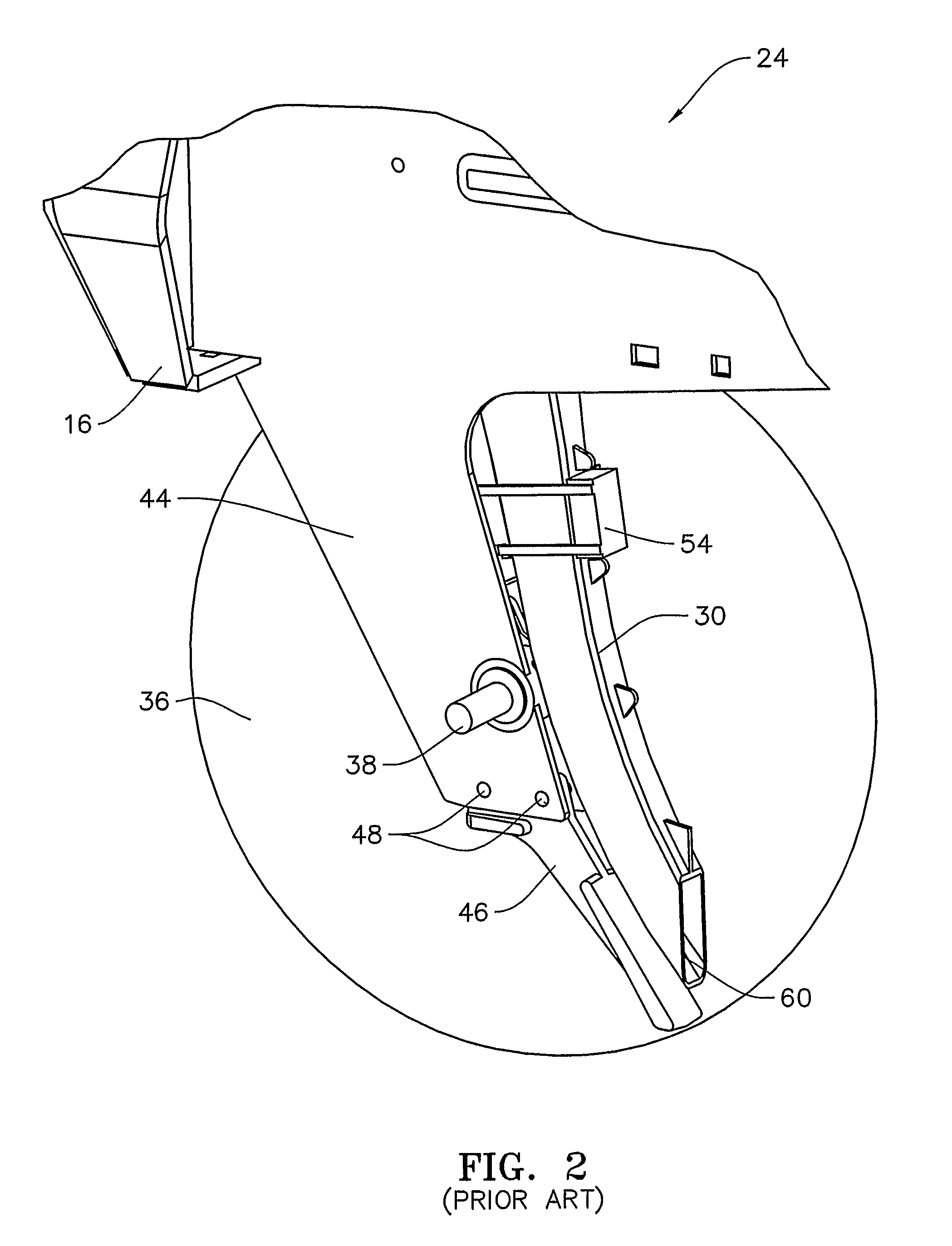

Seed drill with walking beam assembly

A no-till drill with a novel walking beam assembly that allows the drill to be pulled over severe terrain conditions that include large rocks, fallen limbs and other large obstructions. The inventive walking beam assembly includes two independent pivot points that allow the cutting and opening disks to maintain substantially constant or continuous contact with the ground, such that the length of the furrow formed and seed deposited therein are maximized. A closing disk assembly is suspended from the rear of the drill independently from the walking beam assembly. This independent suspension allows the walking beam assembly to function without interference from the closing disks.

Owner:KASCO MFG

Agricultural seeding machine with compact furrow opener/closer

Owner:DEERE & CO

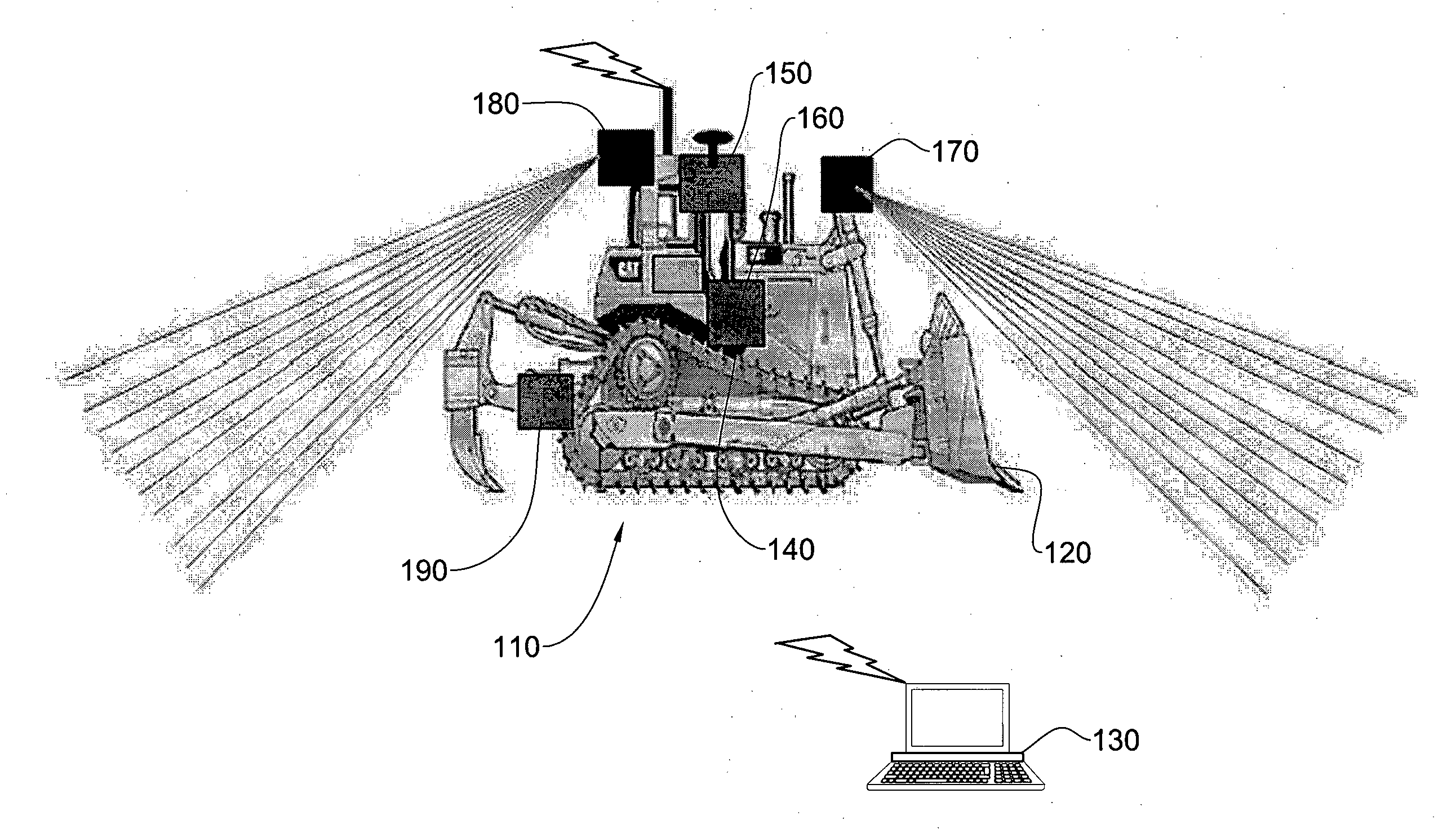

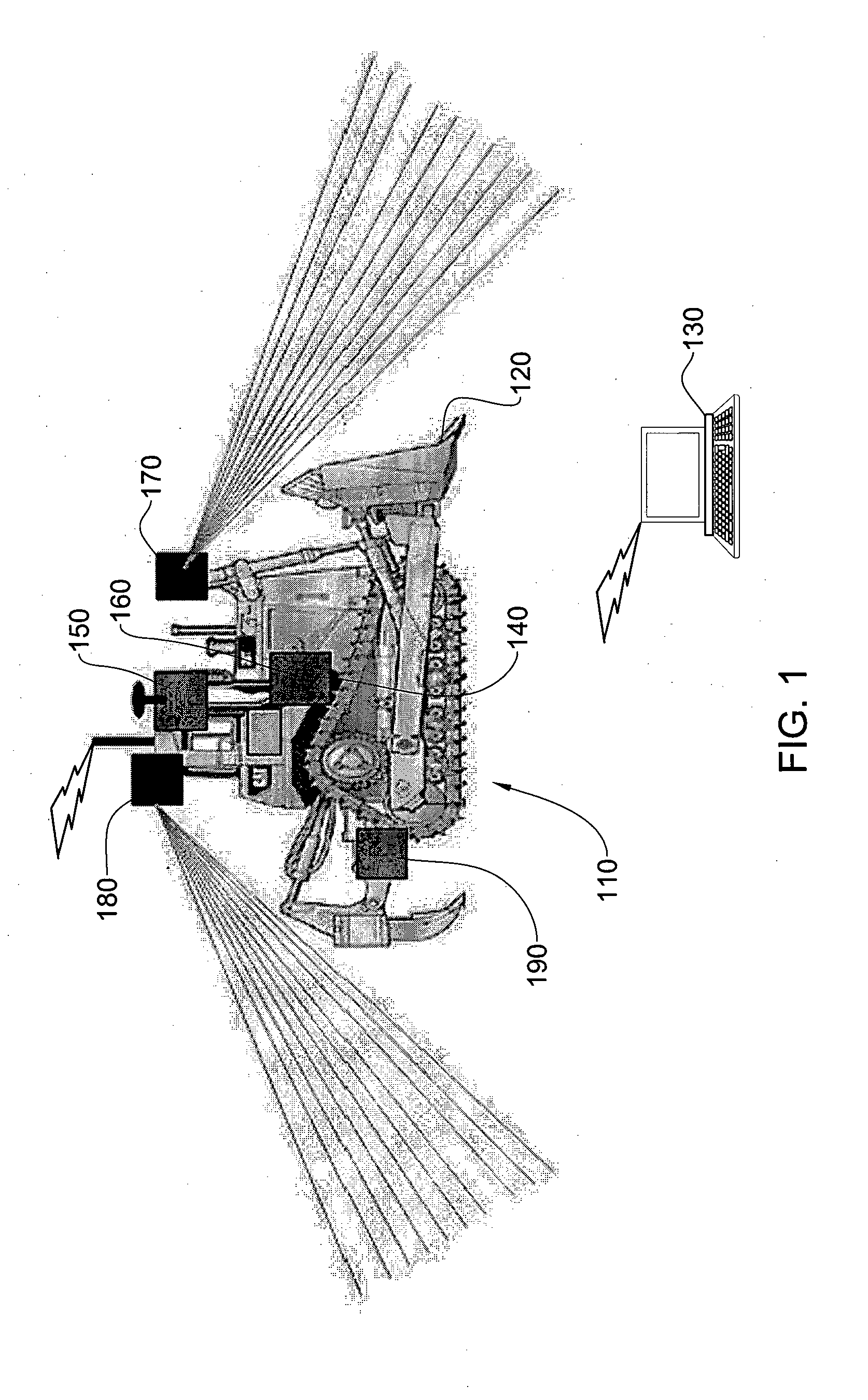

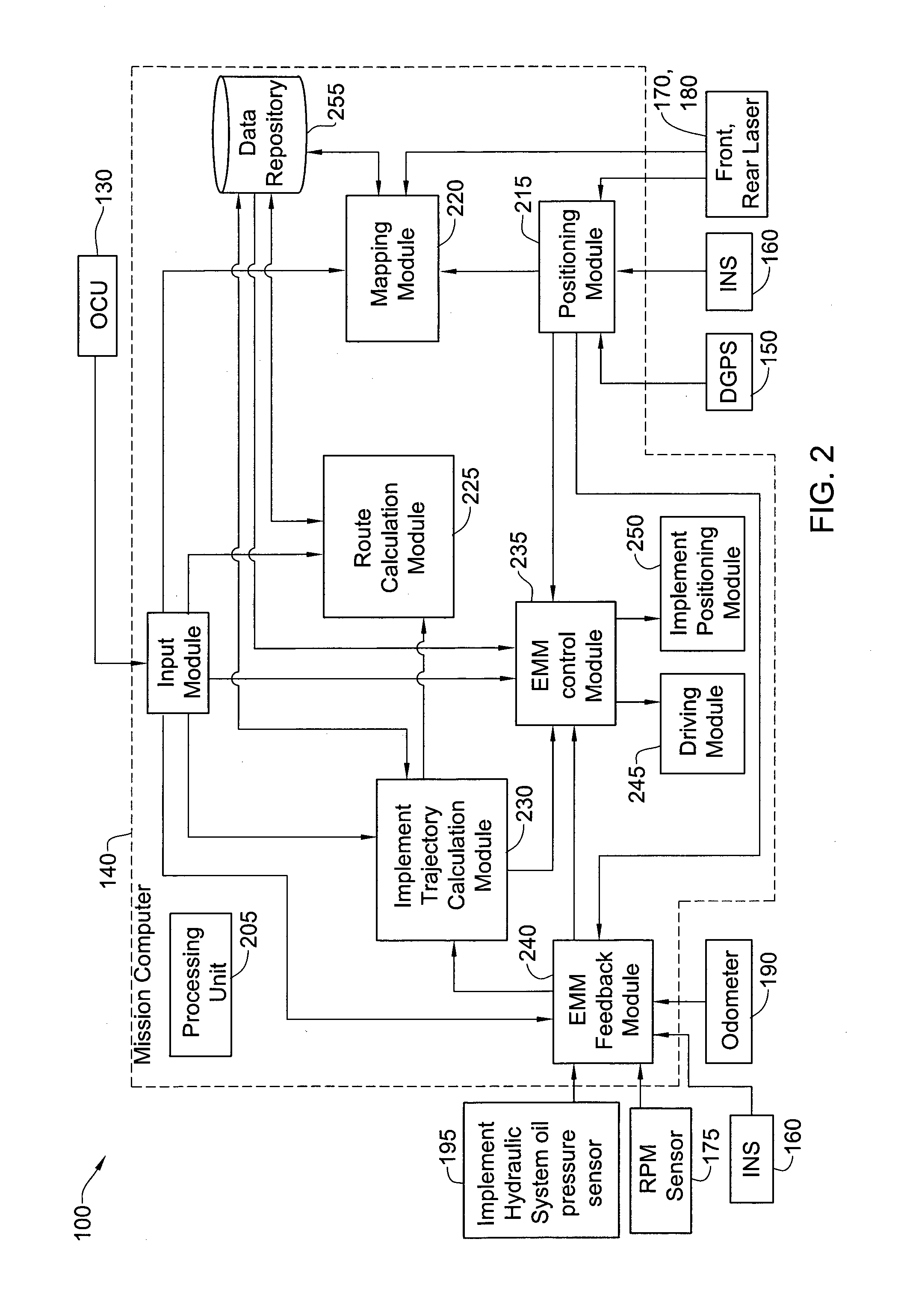

System and method of autonomous operation of multi-tasking earth moving machinery

ActiveUS20130006484A1Analogue computers for trafficSoil-working equipmentsPhysicsReal-time computing

According to certain aspects of the invention there is provided a method and system for autonomous operation of an earth moving machine (EMM), configured for shoving matter, the EMM comprising at least one implement. Based on at least the mission objective and the mapping data of the mission area, the mission area is divided into segments, each segment being associated with a disposal point. An implement trajectory is calculated in respect of each of the segments such that matter is accumulated by the at least one implement along the segment as the EMM progresses and the accumulated matter is disposed upon arrival at the disposal point, without exhausting the EMM shoving capabilities.

Owner:ISRAEL AEROSPACE IND

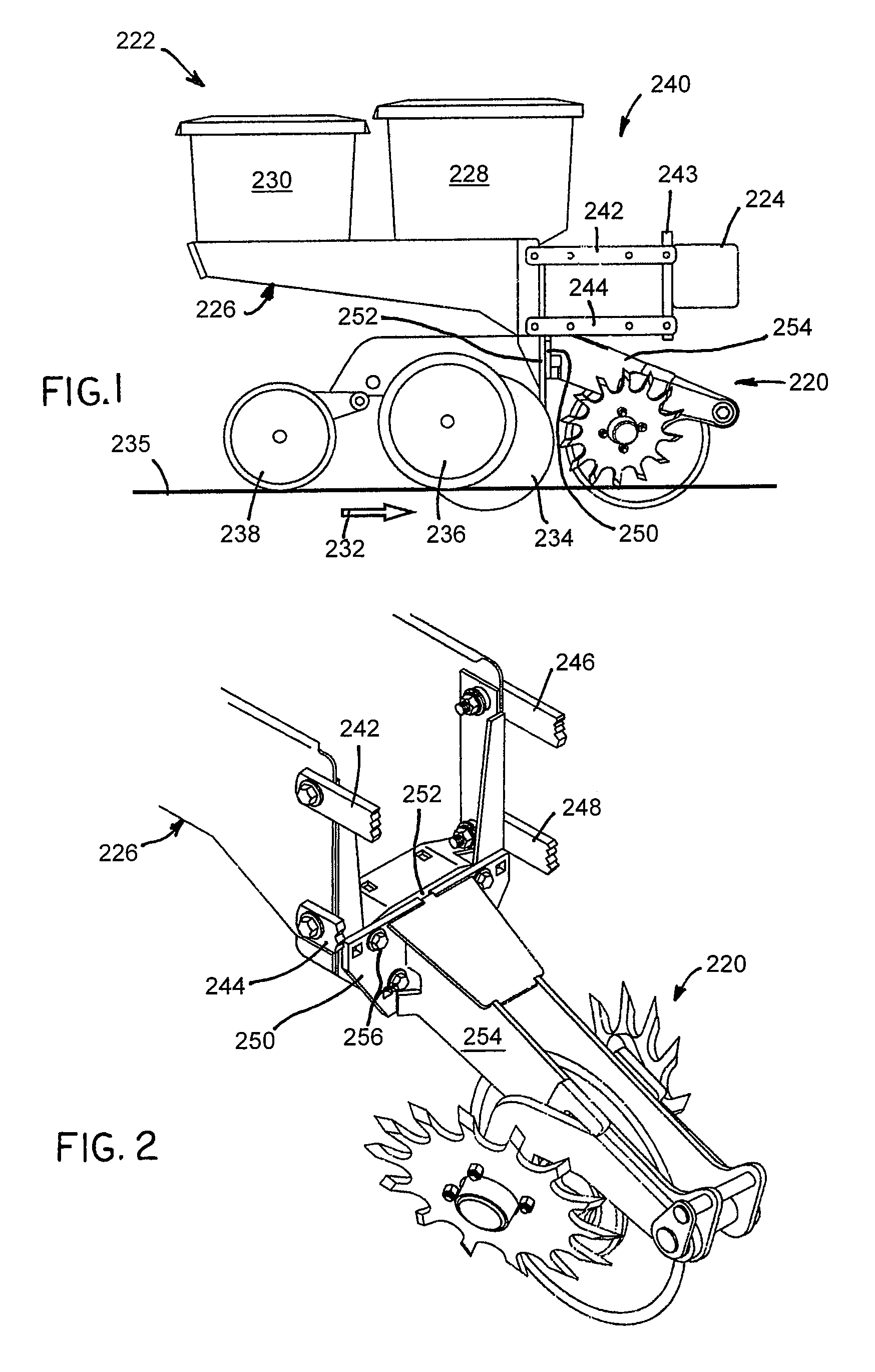

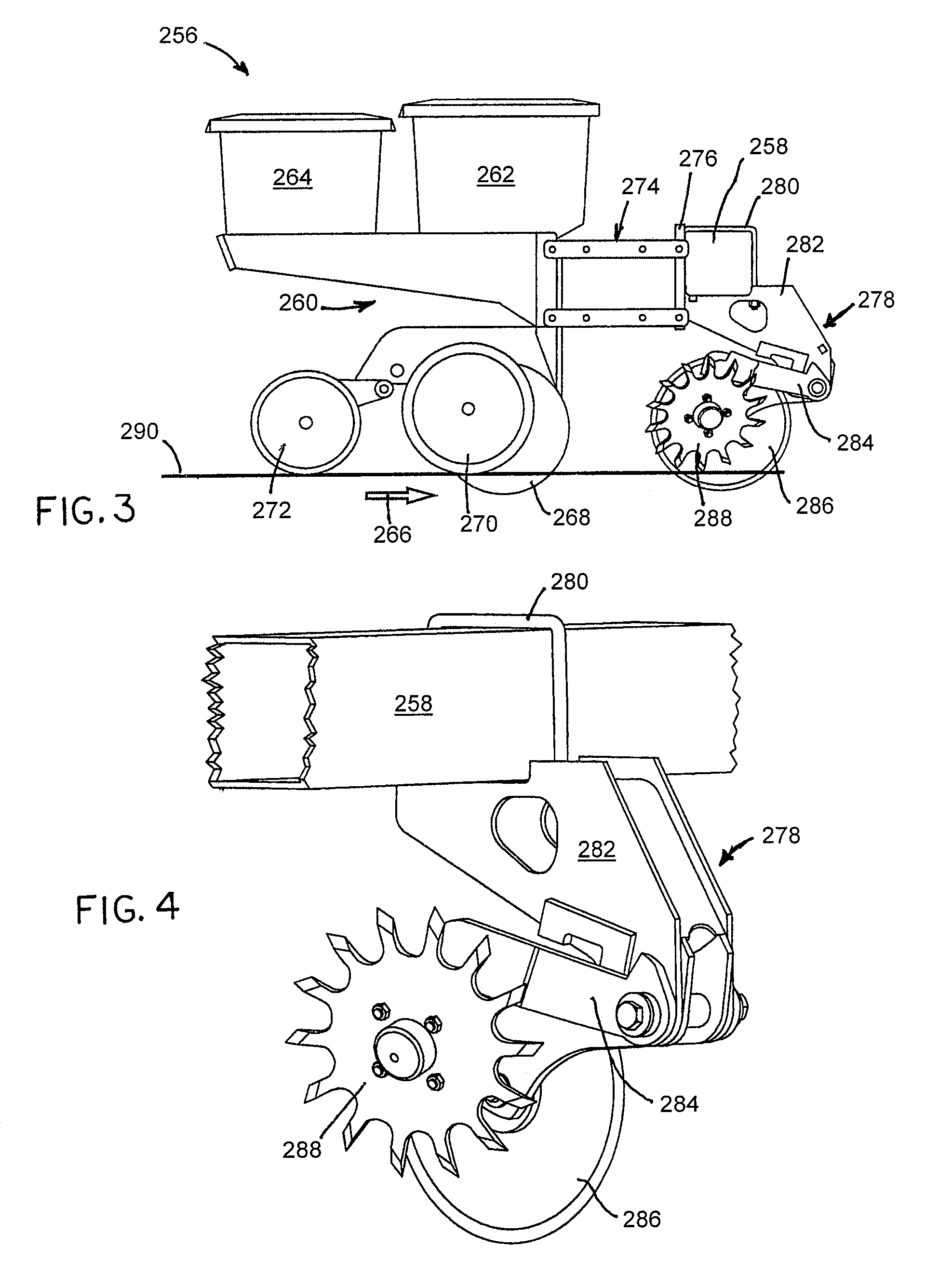

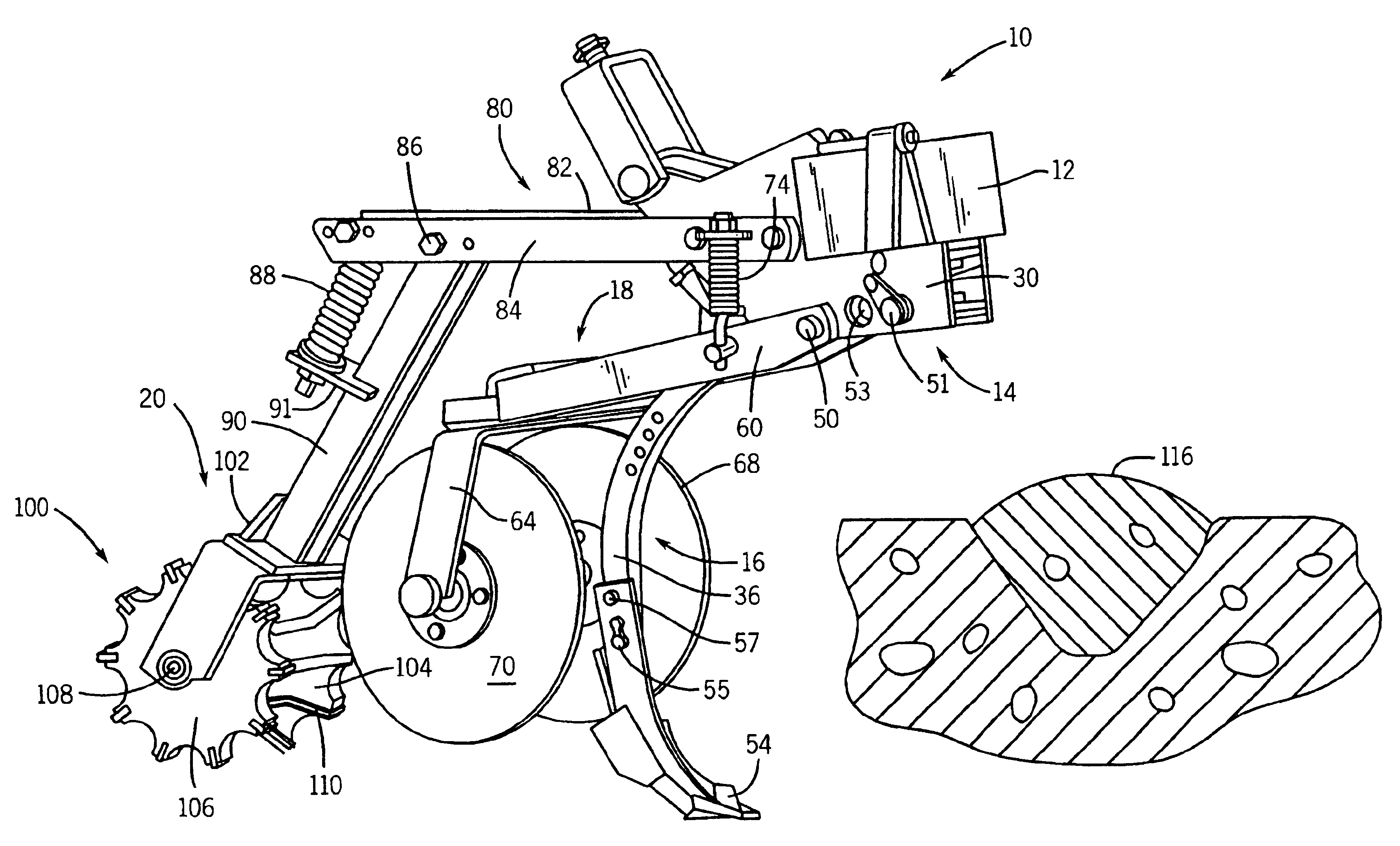

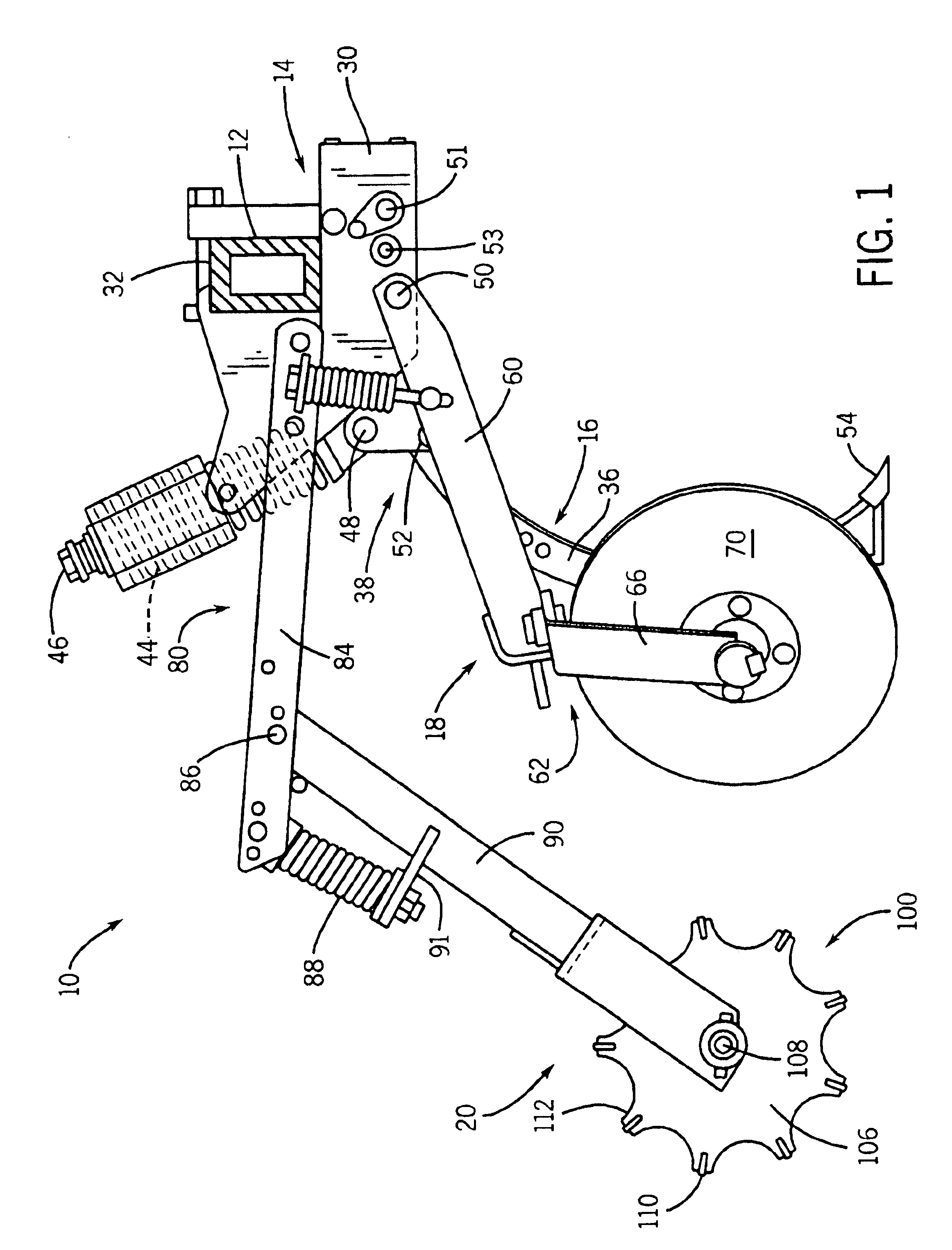

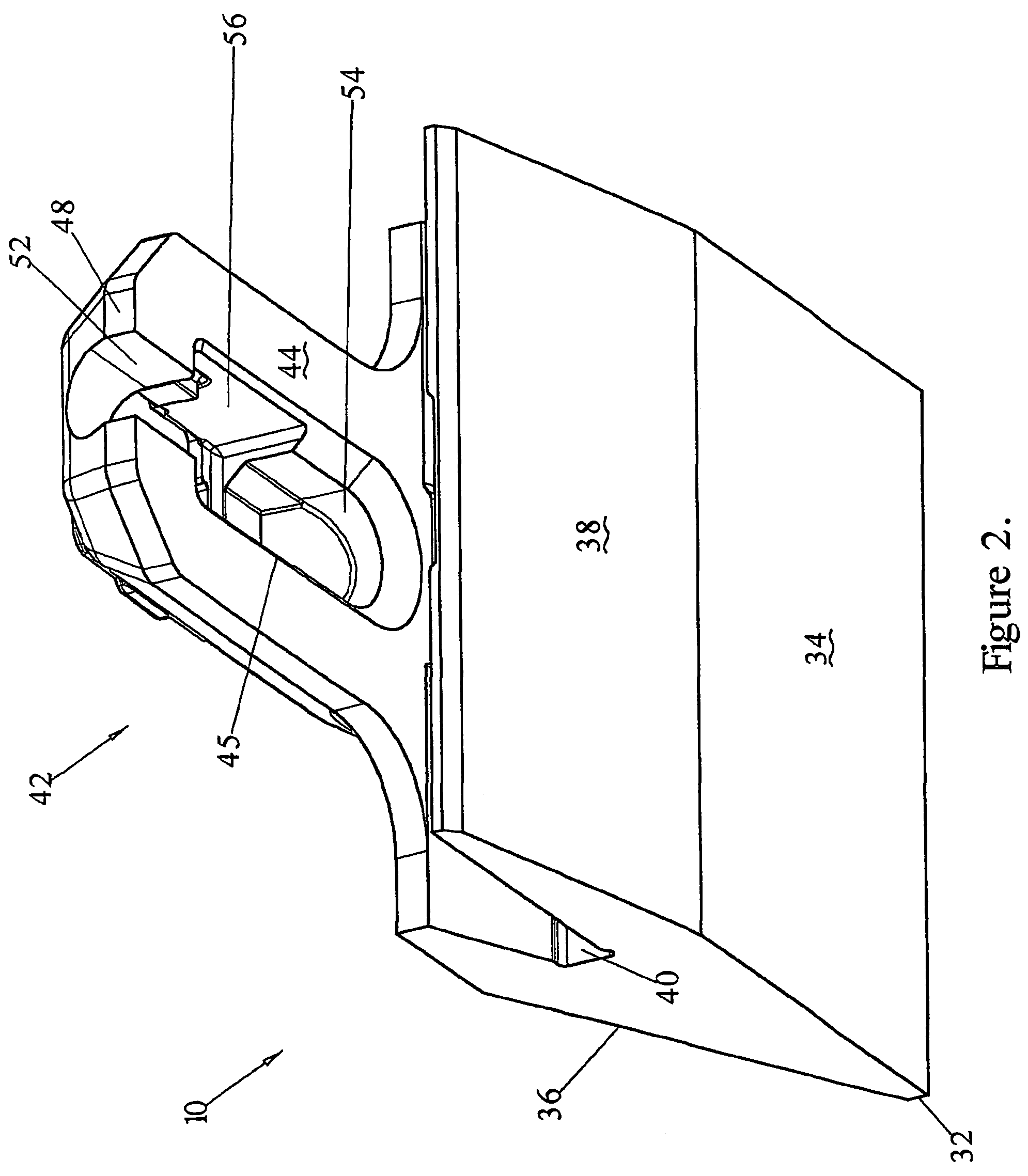

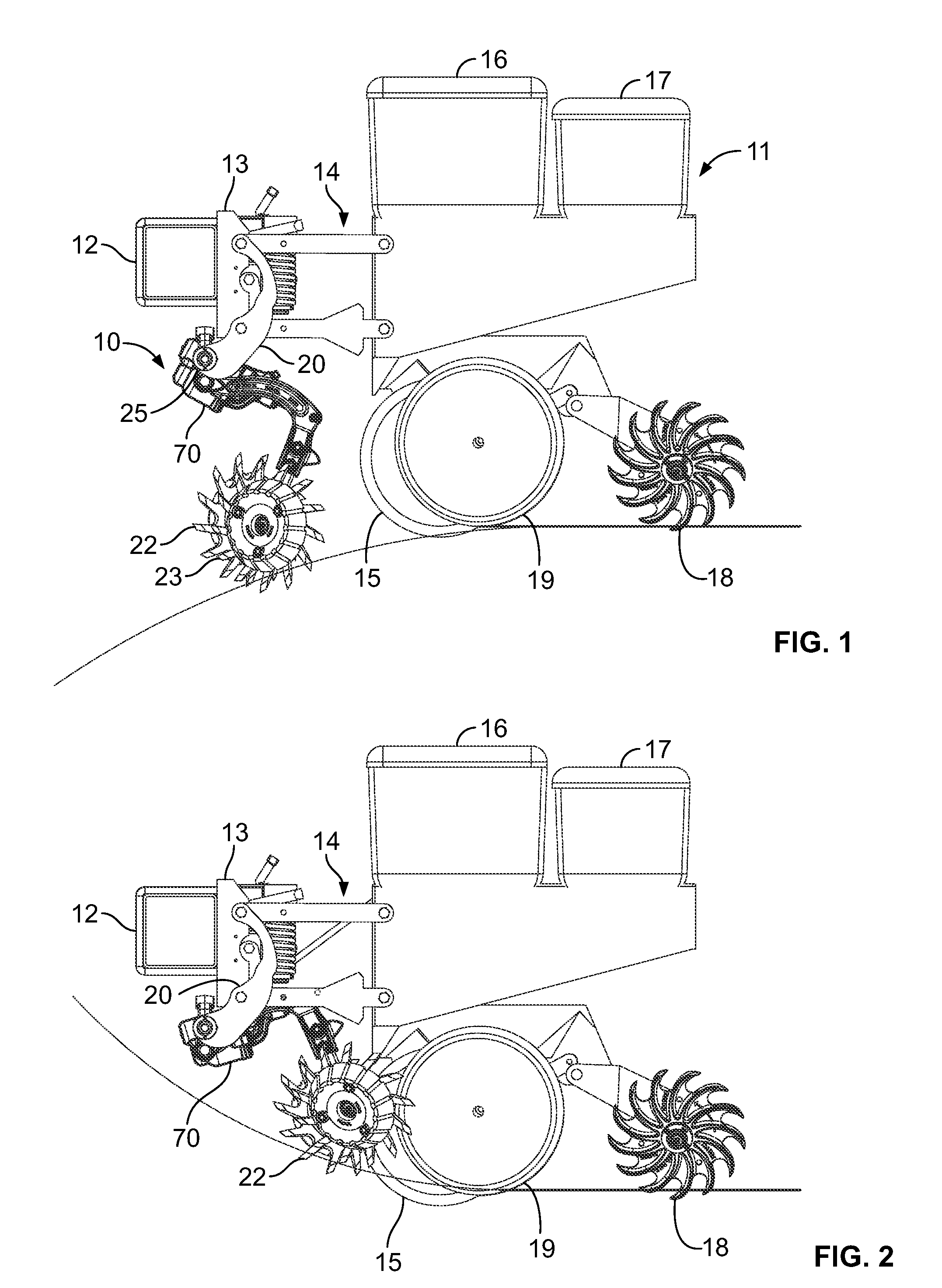

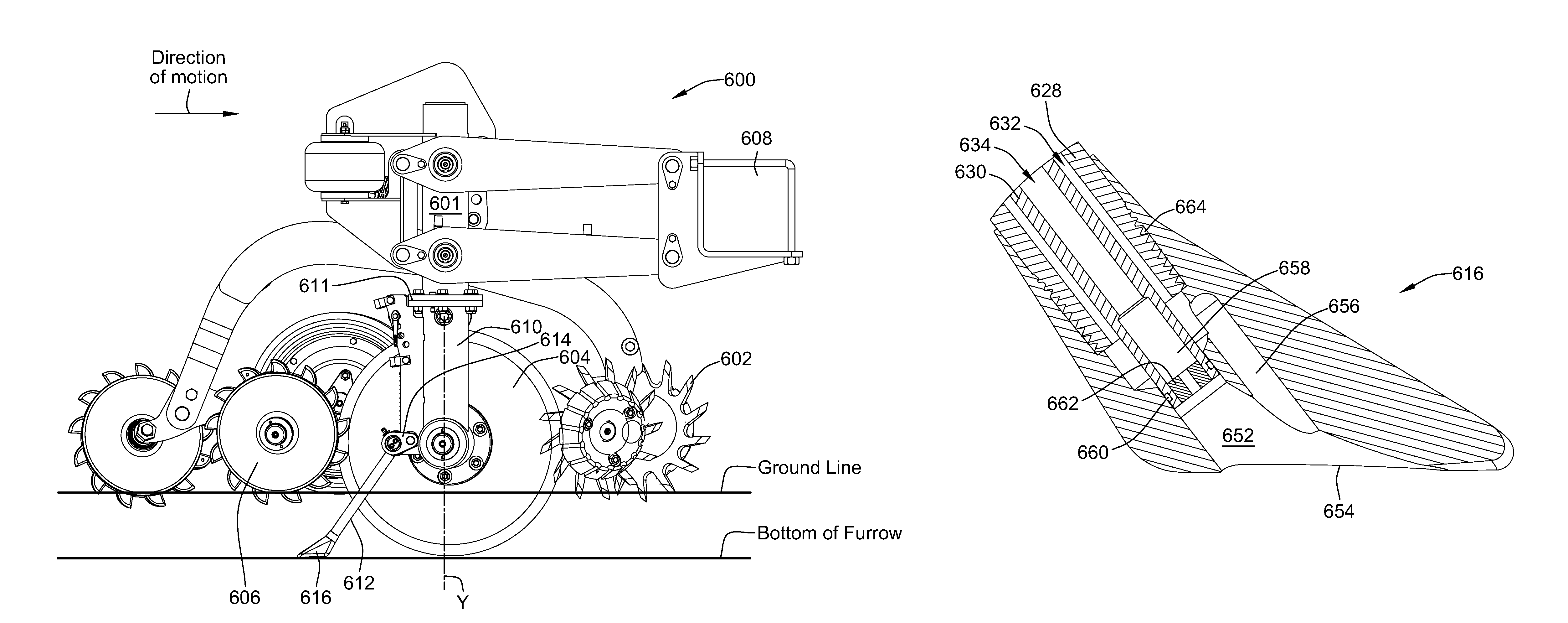

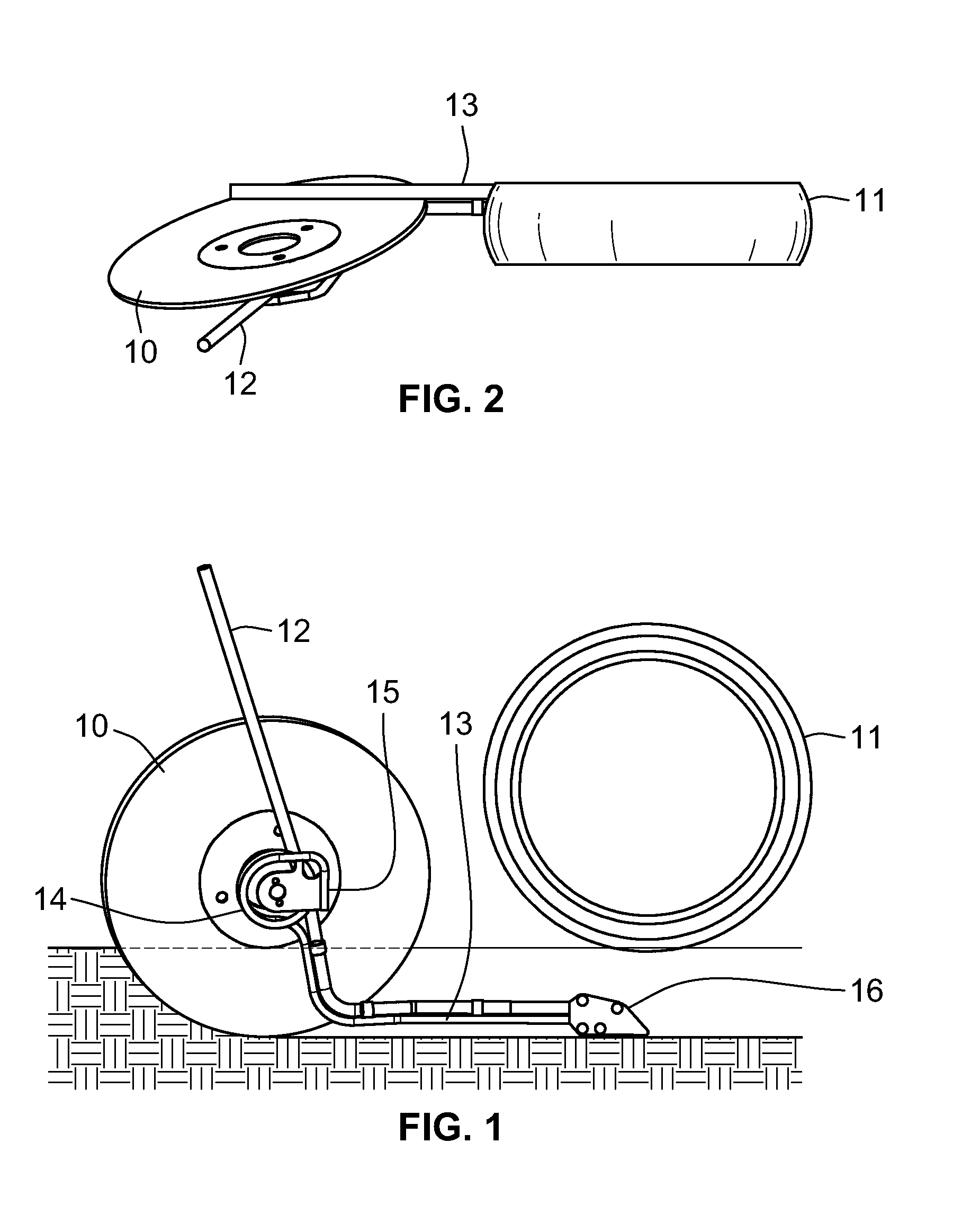

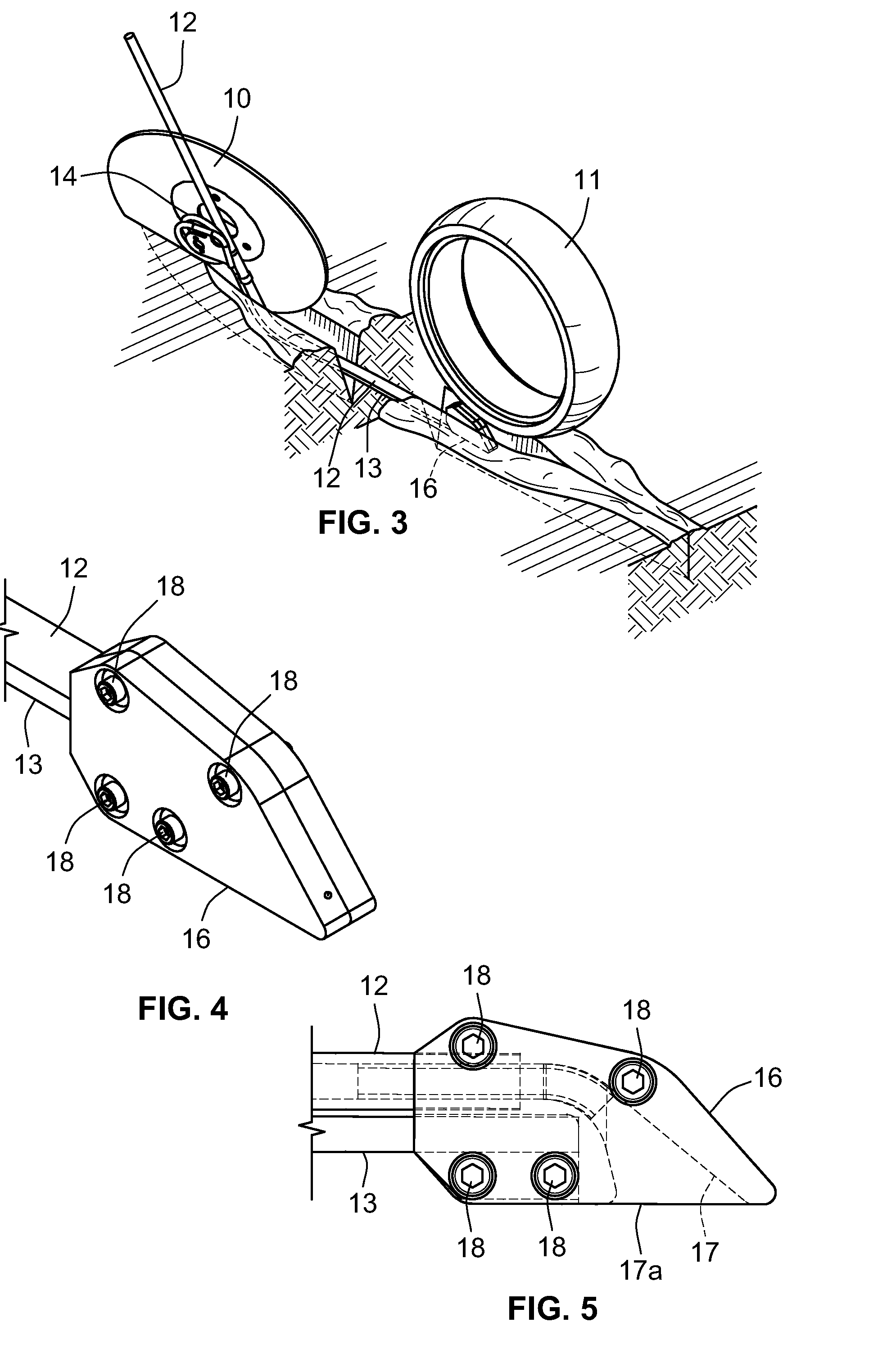

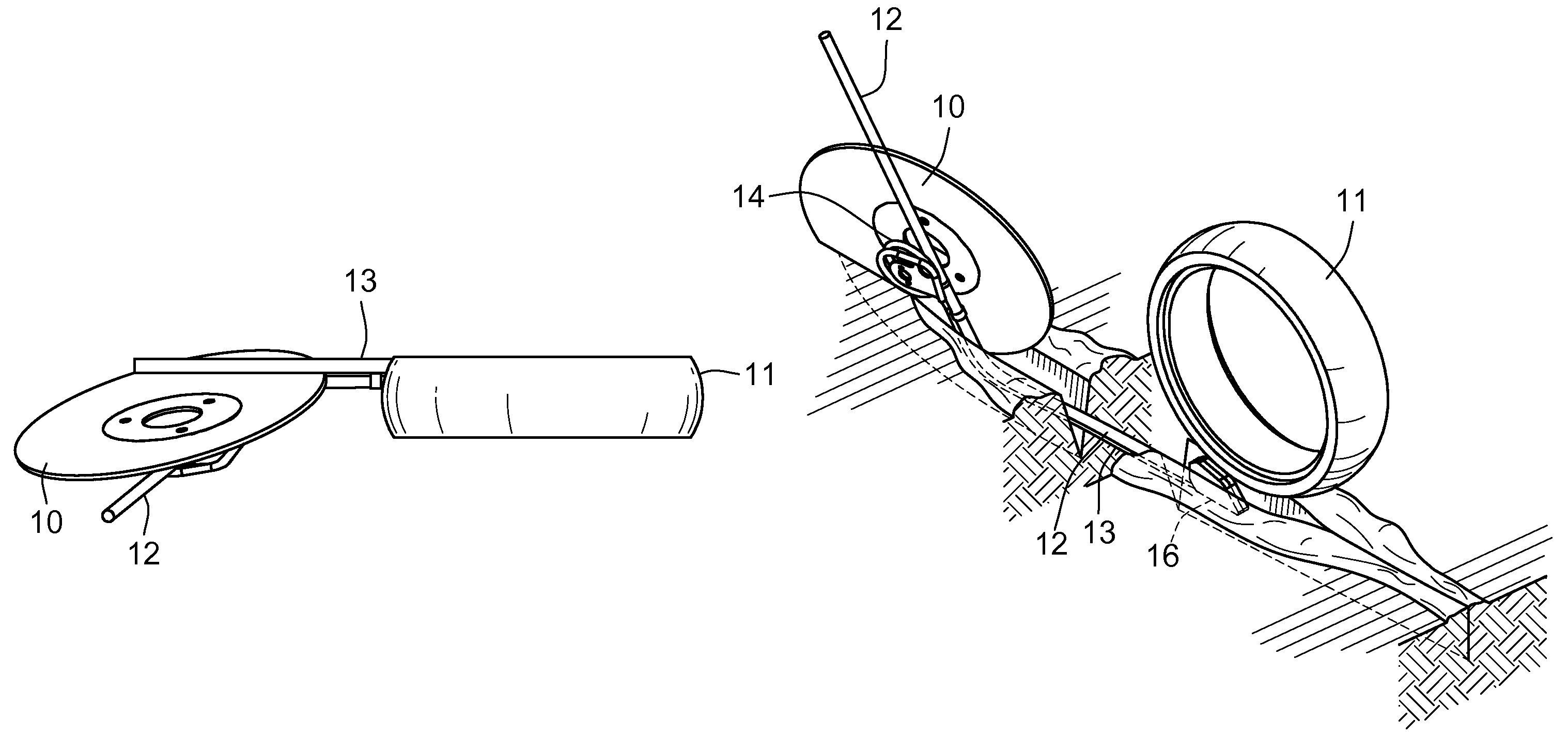

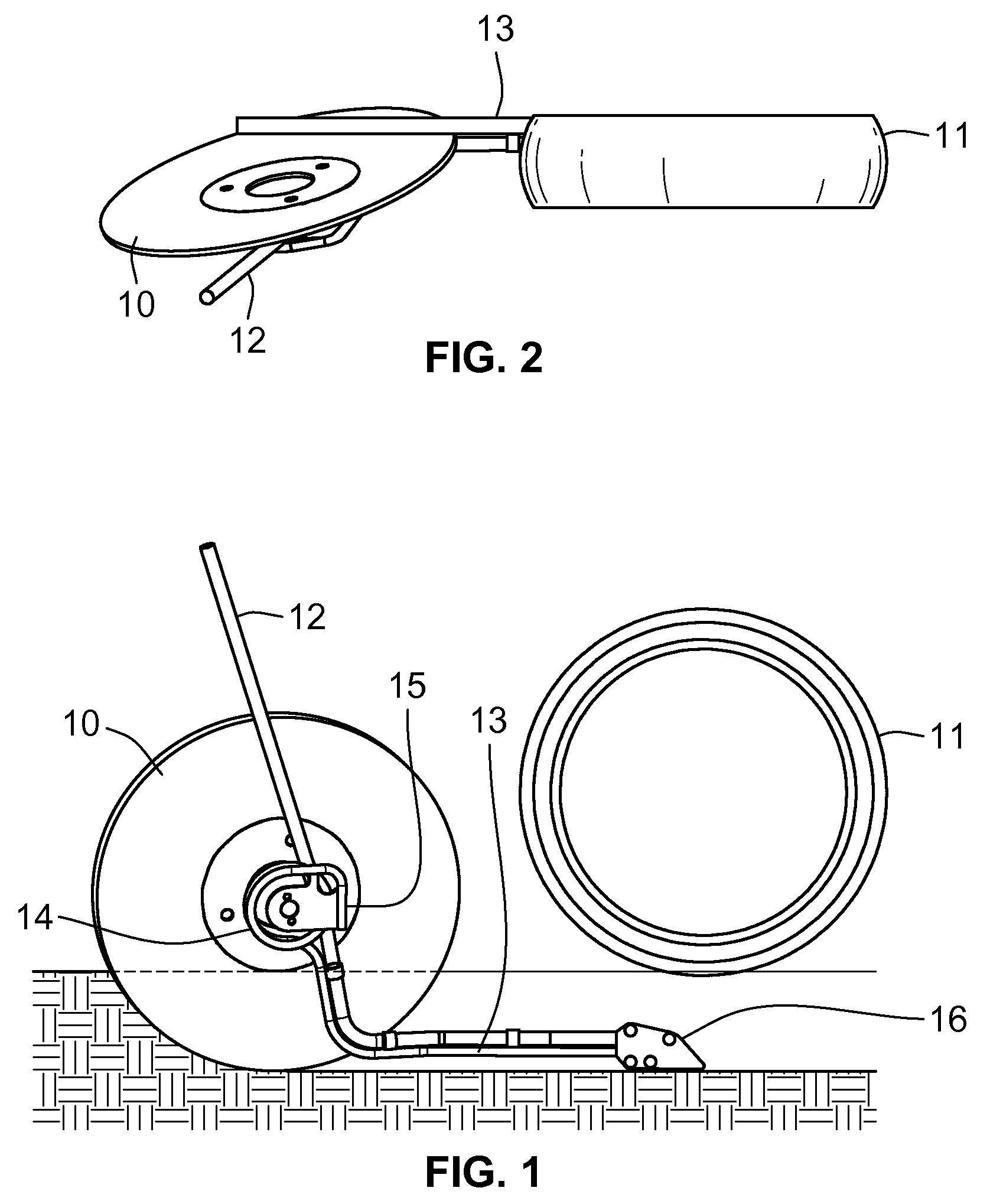

Crop residue clearing device

ActiveUS8393407B2Less susceptible to damage and destructionReduce penetrationSpadesTill seedingGear wheelCrop residue

Apparatus for clearing crop residue from a field is adapted for attachment to a tool bar of an agricultural implement or to a planter unit such that the apparatus is pulled through a field by the implement. The apparatus includes a support structure extending forward of the tool bar and at least one and preferably a pair of floating arms pivotally attached to a forward portion of the support structure and extending rearwardly, with a toothed wheel rotationally attached to an aft end of the arm(s). A coulter attached to the support structure is disposed between and extends forward of the soil-engaging toothed wheel(s) and in combination with the wheel(s) severs and removes residue in the seeding pathway. An adjustable biasing arrangement urges the toothed wheels, either in unison or independently, downwardly into engagement with the soil. Upper and lower stop limits are provided to limit vertical positioning of the toothed wheel(s).

Owner:AG FOCUS LLC

Coupling for excavating wear part

InactiveUS6993861B2Easy to replaceReduce the amount requiredSoil-working equipmentsDragsCouplingEngineering

A wear assembly provided with a tapered opening and a complementary tapered lock wherein the lock can be pried into and from the opening to thereby eliminate the need for hammering. The lock is formed with a body and a latch that is movable between a hold position where the latch is engageable with a stop in the opening to releasably retain the lock in the opening and a release position where the latch disengages the stop.

Owner:ESCO GRP LLC

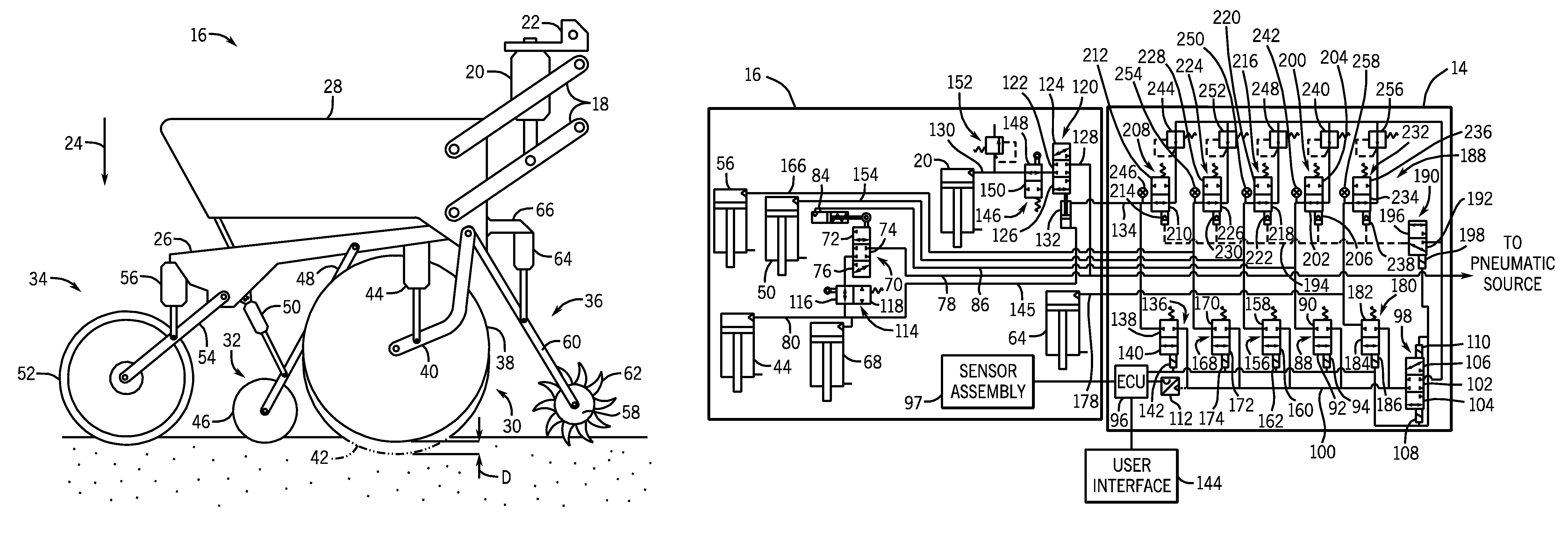

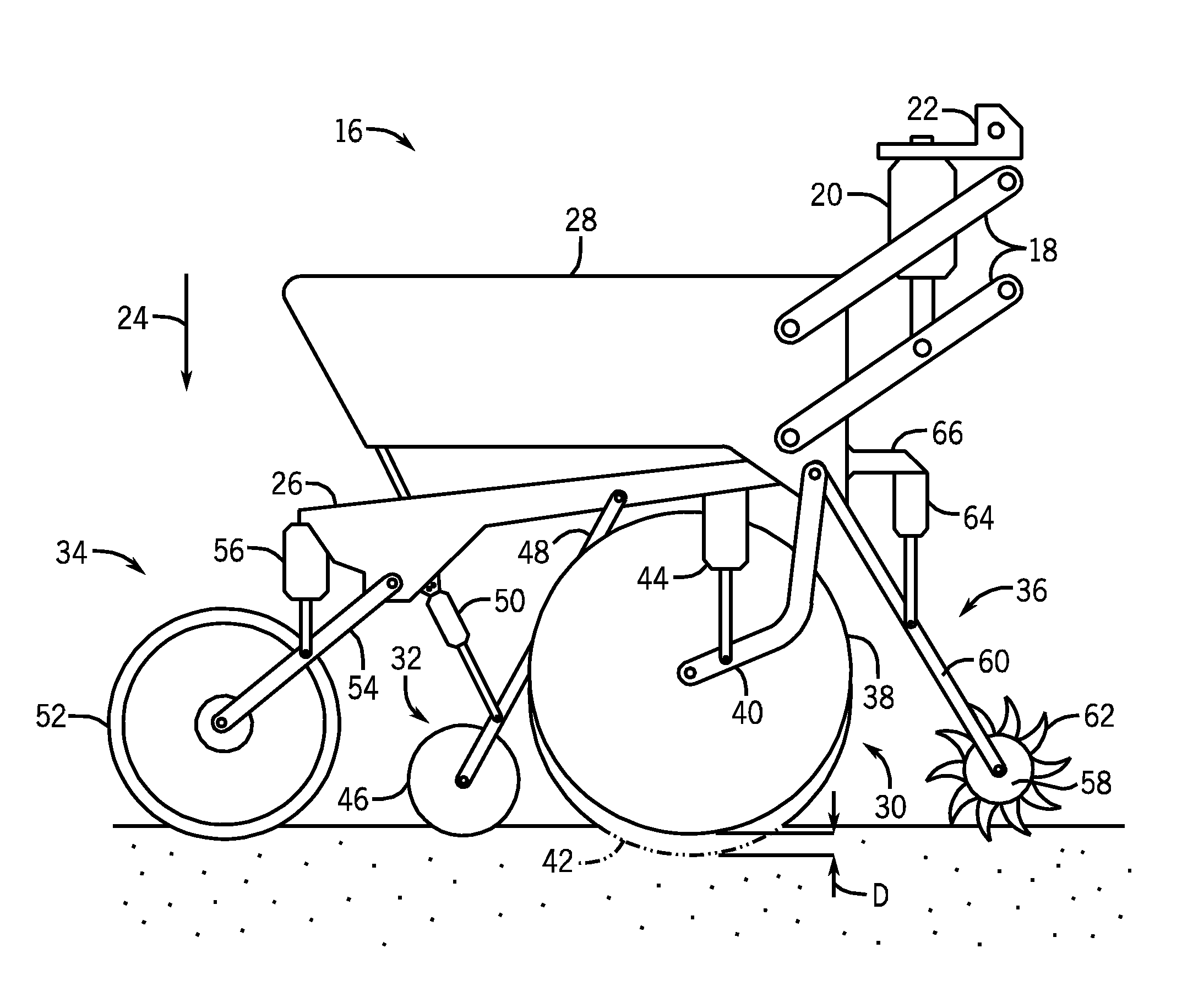

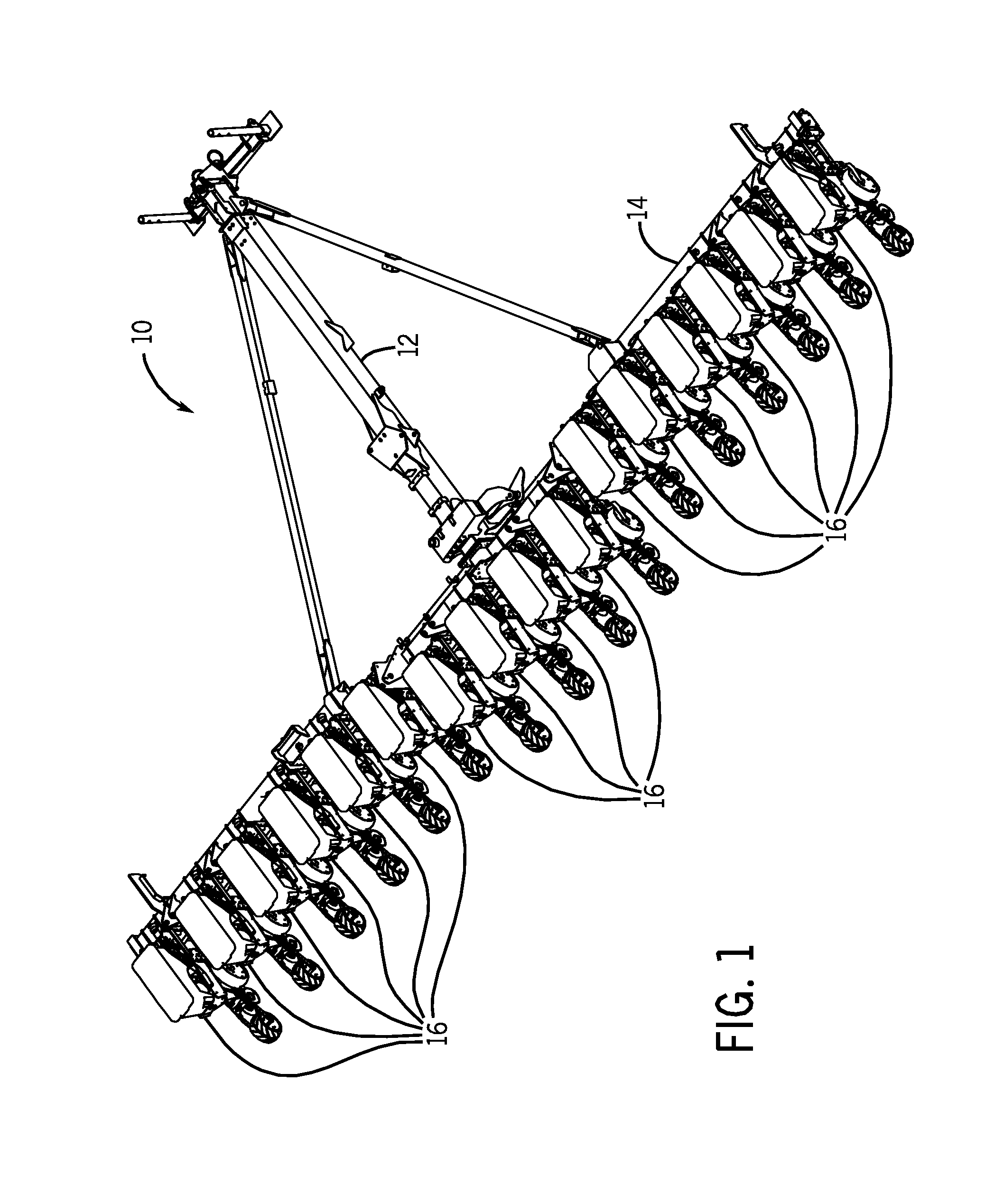

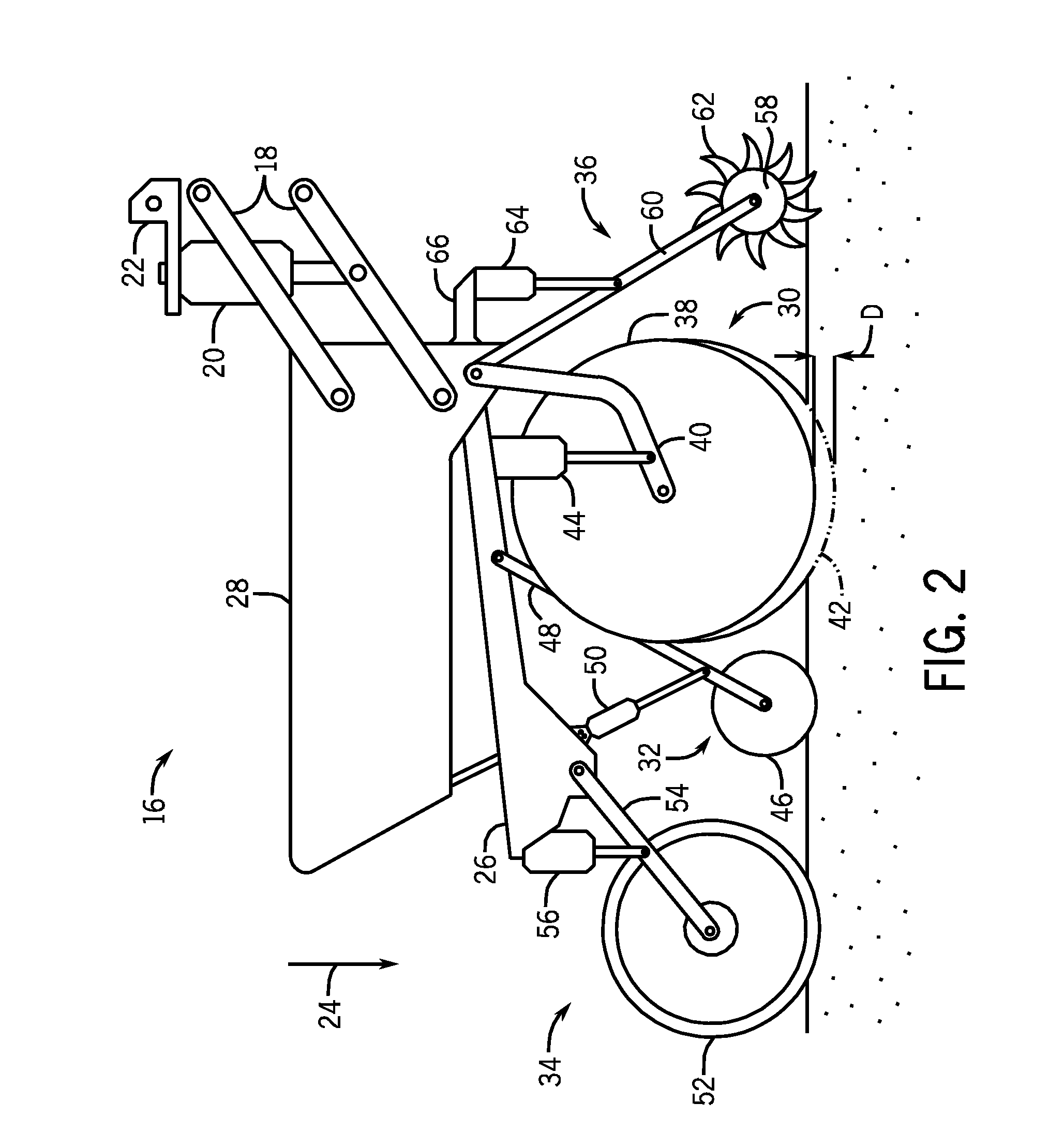

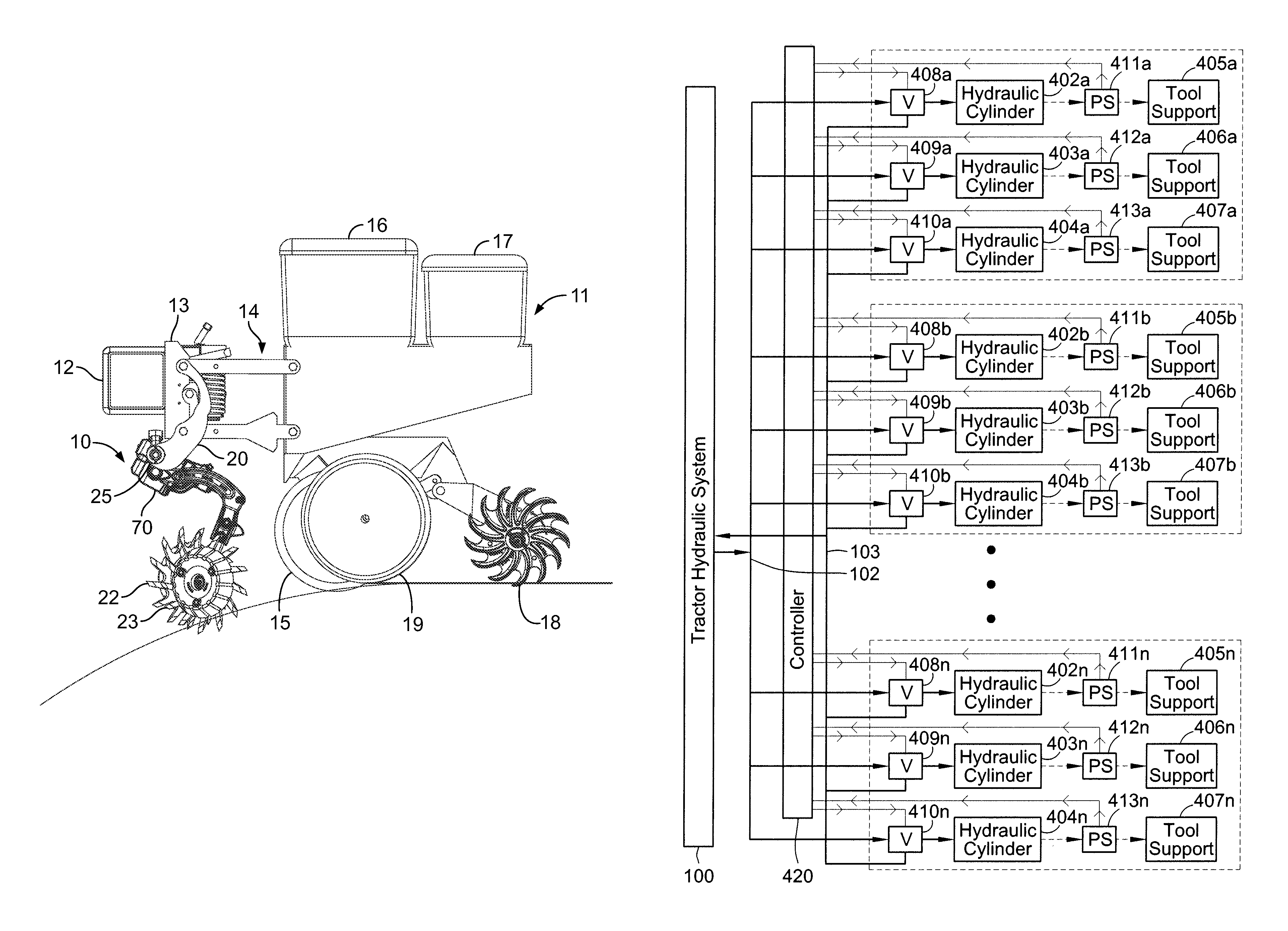

Agricultural implement with combined down force and depth control

An agricultural implement system is provided that includes a down force cylinder configured to apply a downward force to a row unit, and a depth control cylinder configured to vary a penetration depth of a ground engaging tool of the row unit. The agricultural implement system also includes a valve assembly in fluid communication with the down force cylinder and the depth control cylinder. The valve assembly is configured to automatically adjust the downward force by varying fluid pressure within the down force cylinder based on fluid pressure within the depth control cylinder.

Owner:BLUE LEAF I P INC

Strip-till primary tillage system

InactiveUS6871709B2Improved seedbed preparation feature and characteristicWarm up fasterSpadesSoil-working equipmentsAgricultural engineeringTillage

An agricultural tillage implement that employs multiple apparatus to carry out a strip-till farming operation is disclosed. A tillage shank runs a point through the compaction layer to fracture and loosen the soil, forcing it upwardly and outwardly where a pair of angled soil-gathering blades, located adjacent the shank, redirect the soil into a newly created berm. A trailing conditioning rotary reel having a particular cross-sectional profile forms the soil into a uniform raised berm ideally suited for planting.

Owner:BLUE LEAF I P INC +1

Integrated clutches for a seeding machine

A seeding machine having a plurality of seed meters receiving rotary input from a common input shaft. First and second gearboxes respectively connect the common rotary input to individual seed meters. A flexible drive extends from the gearbox adjacent the common rotary input to the seed meters. Spring clutches, normally connected, are electrically actuated to disengage the drive to the individual seed meters. The clutches may be integrated in the gearbox adjacent the rotary drive or the gear box for the individual seed meters.

Owner:DEERE & CO

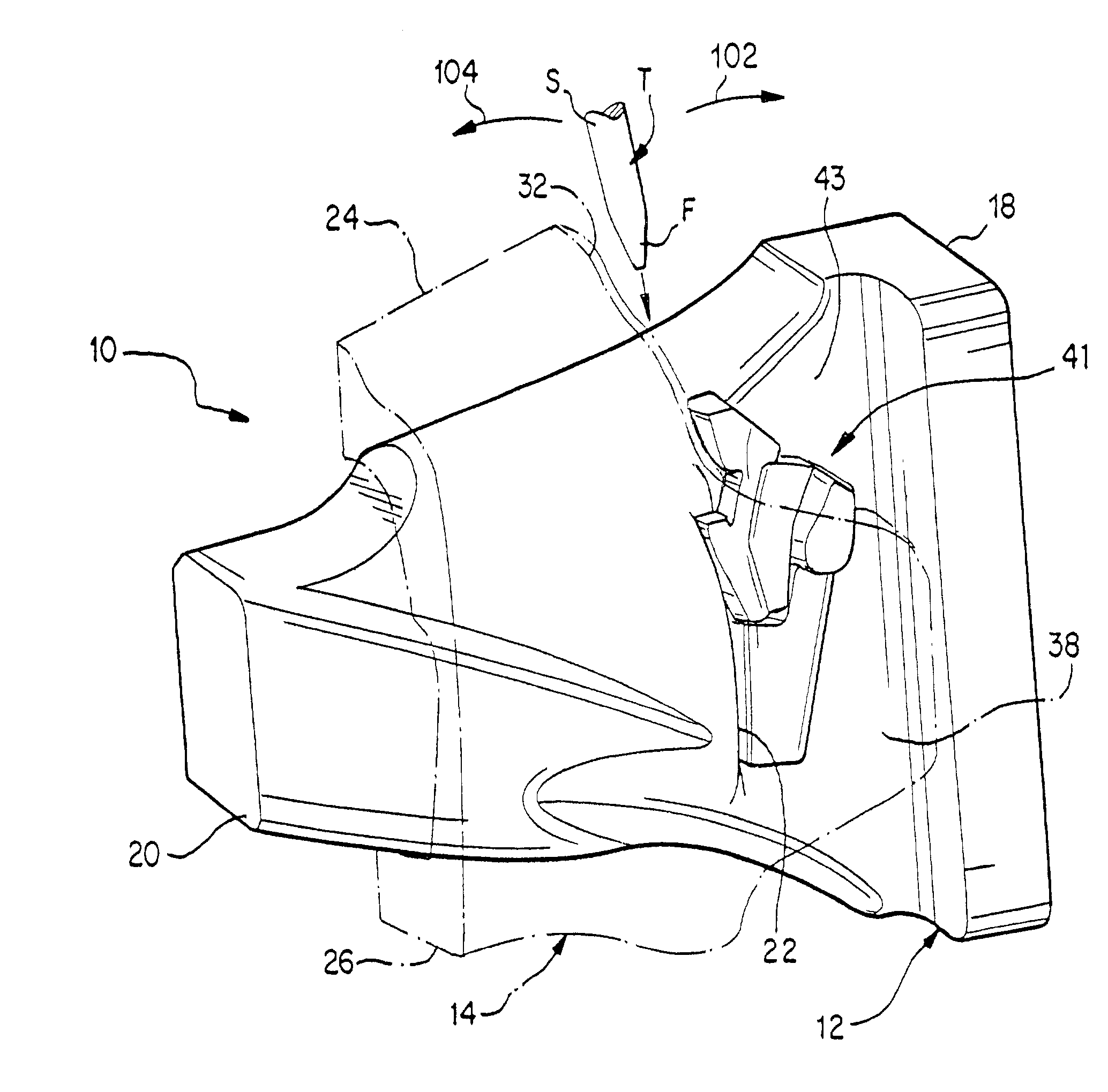

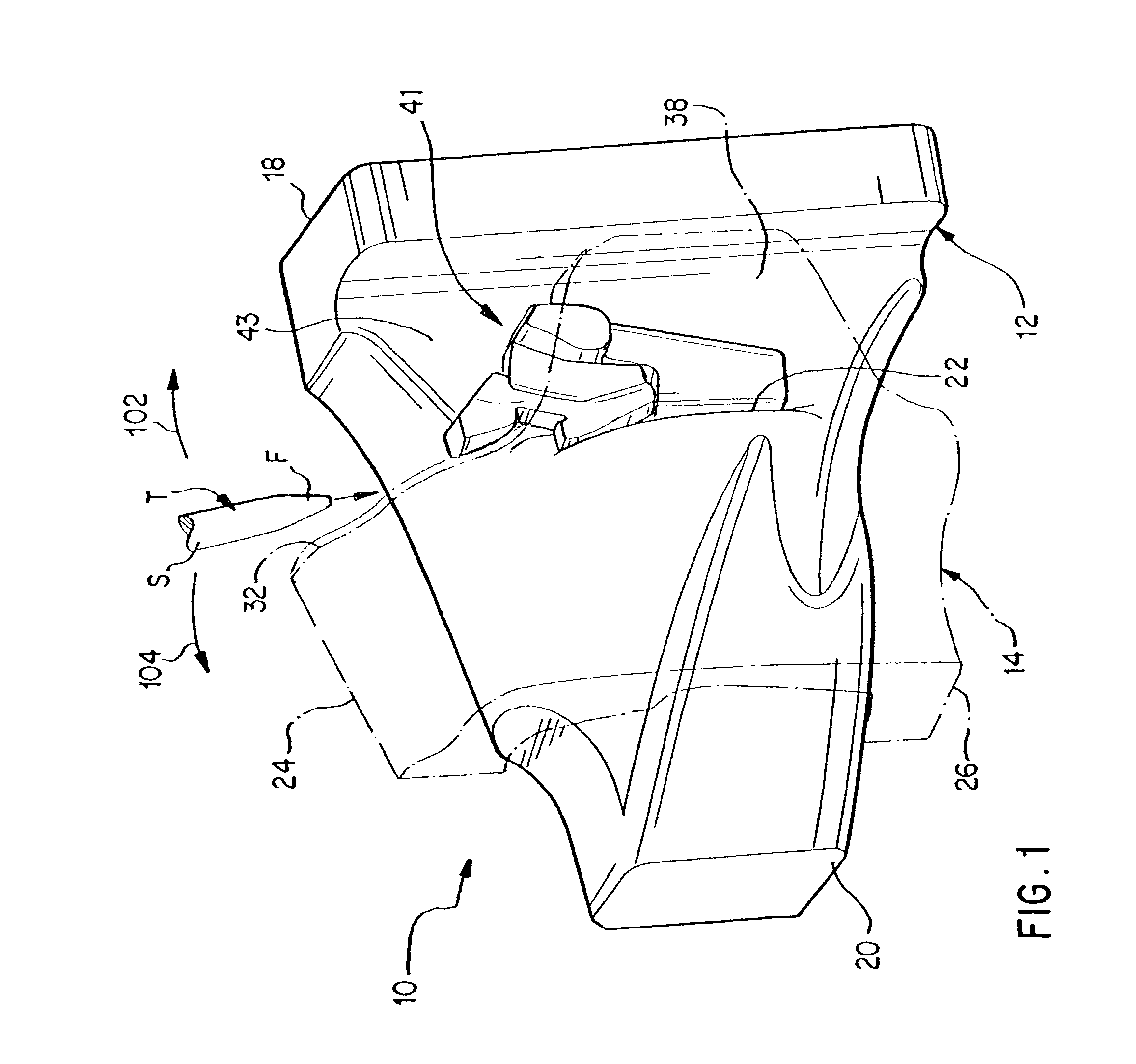

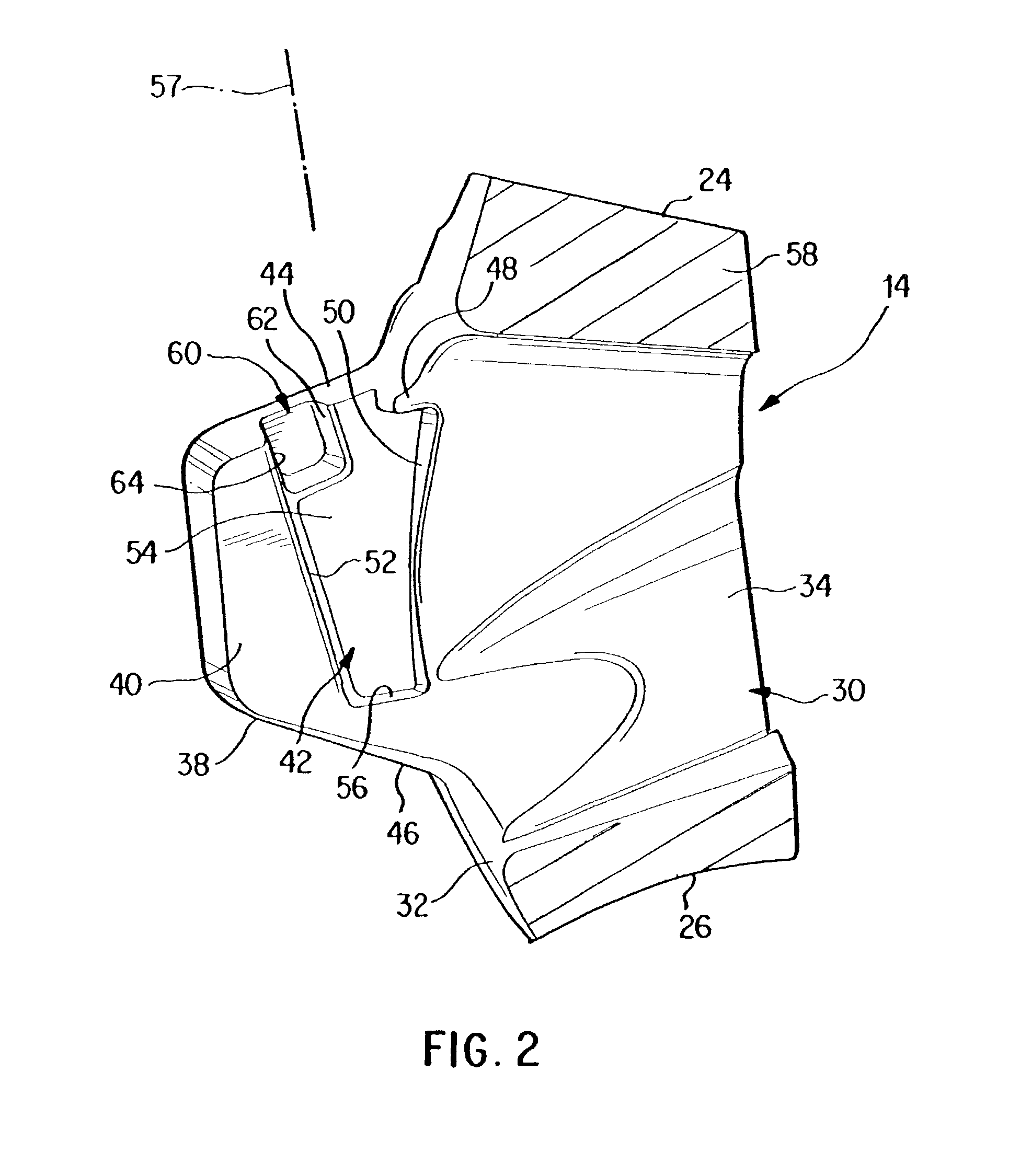

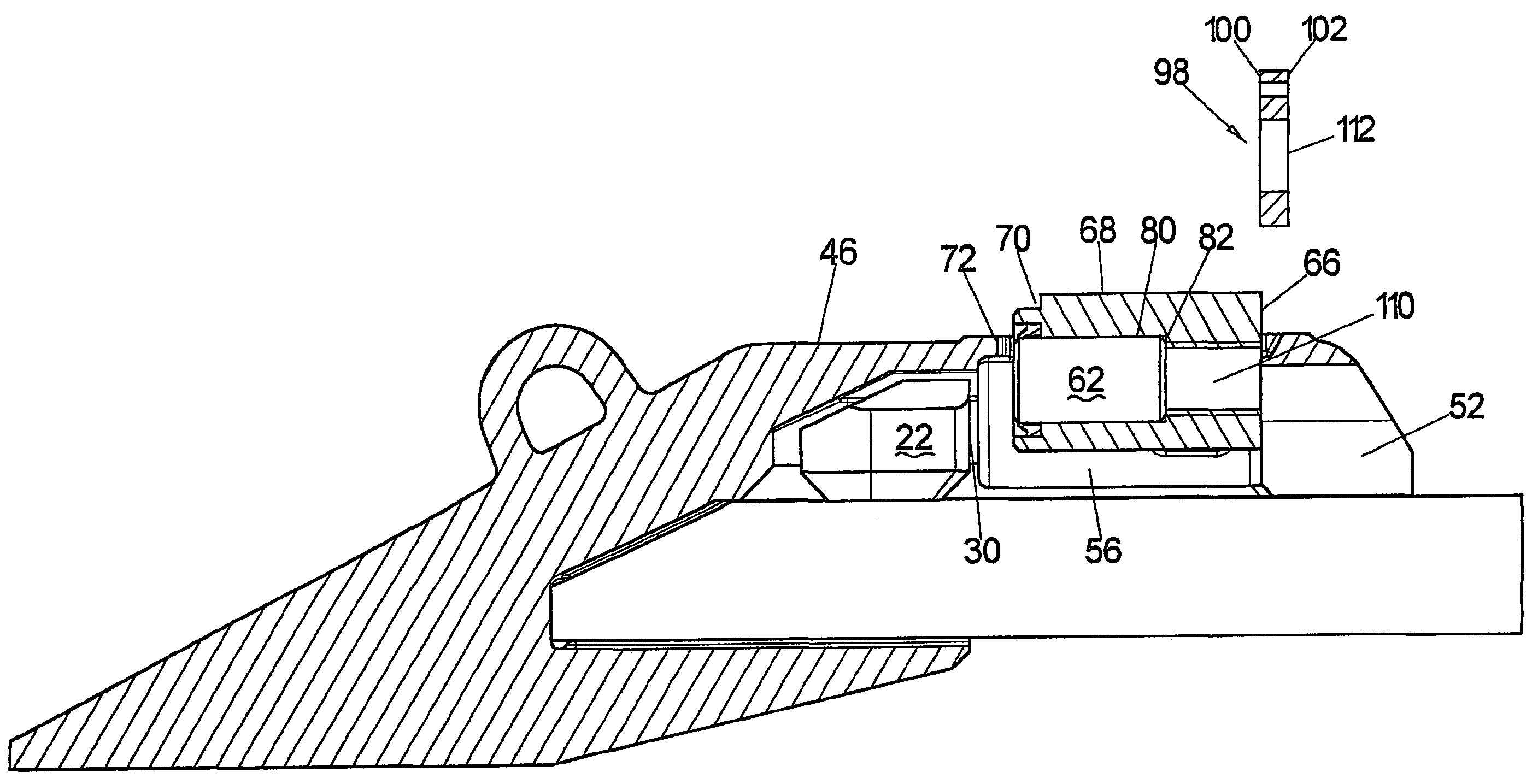

Attachment system

InactiveUS7219454B2Yielding couplingFlexible wall reciprocating enginesEngineeringMechanical engineering

An attachment system for connecting a first member such as a lip plate (12) of a mechanical digging device to a second member such as a ground engaging tool (10). The first member has a lug portion (22) attached thereto the second member has a recess (50) arranged, in use, about the lug portion. A clamping member (60) is disposed between the lug portion (22) and the second member (10) such that the supply of pressure to the clamping member (60) acts to restrain disengagement of the second member (10) from the lug portion (22).

Owner:SANDVIK SHARK

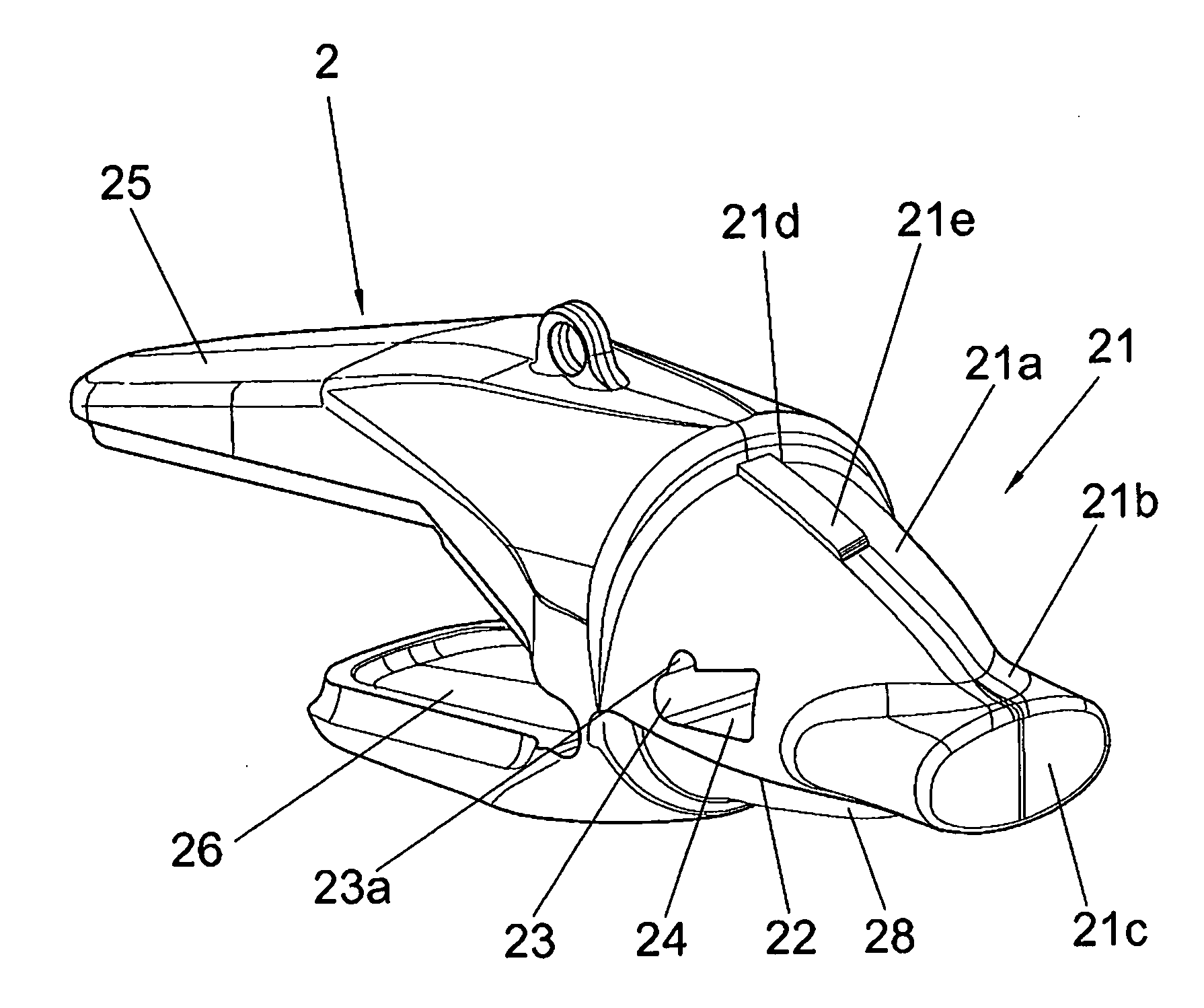

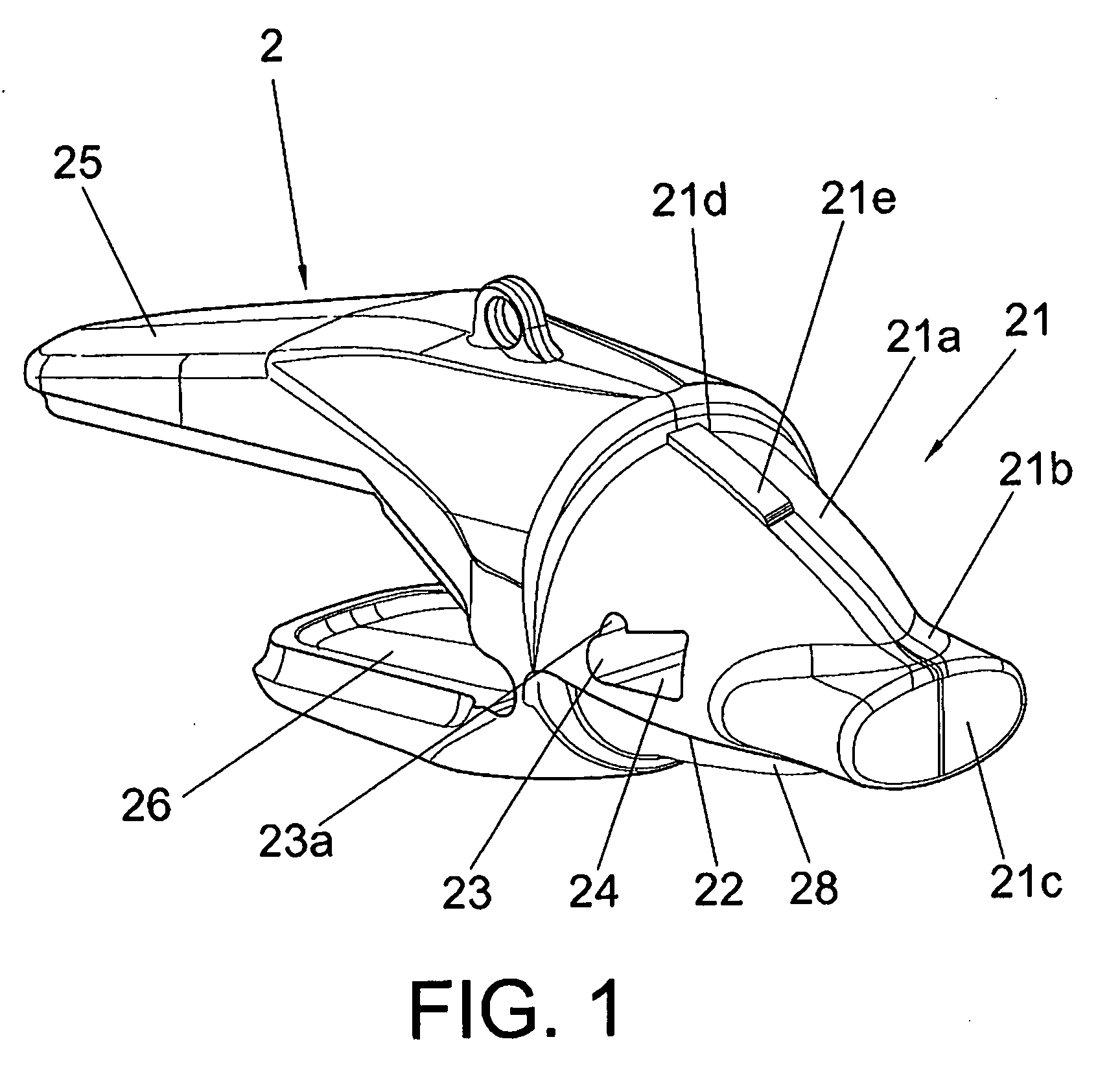

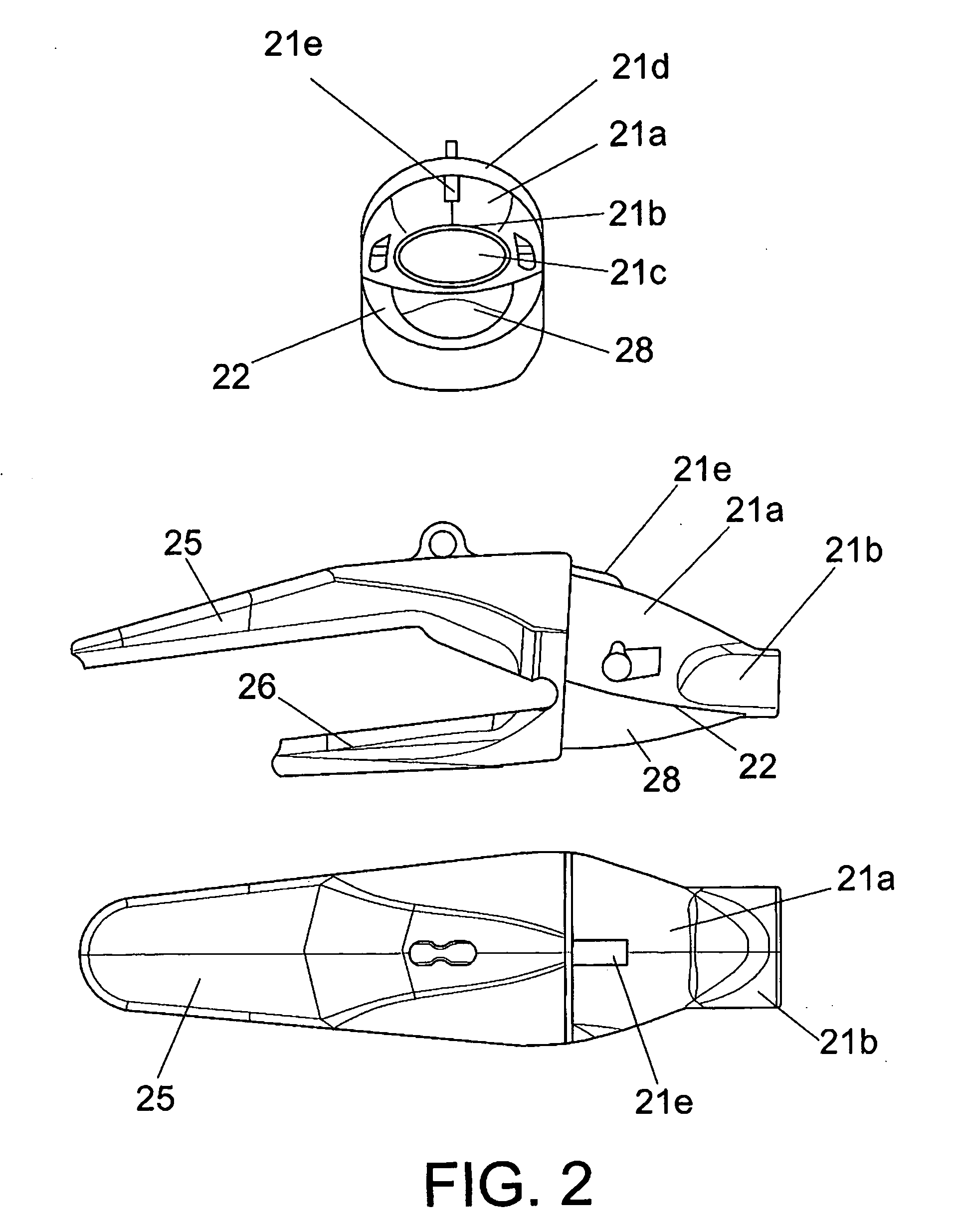

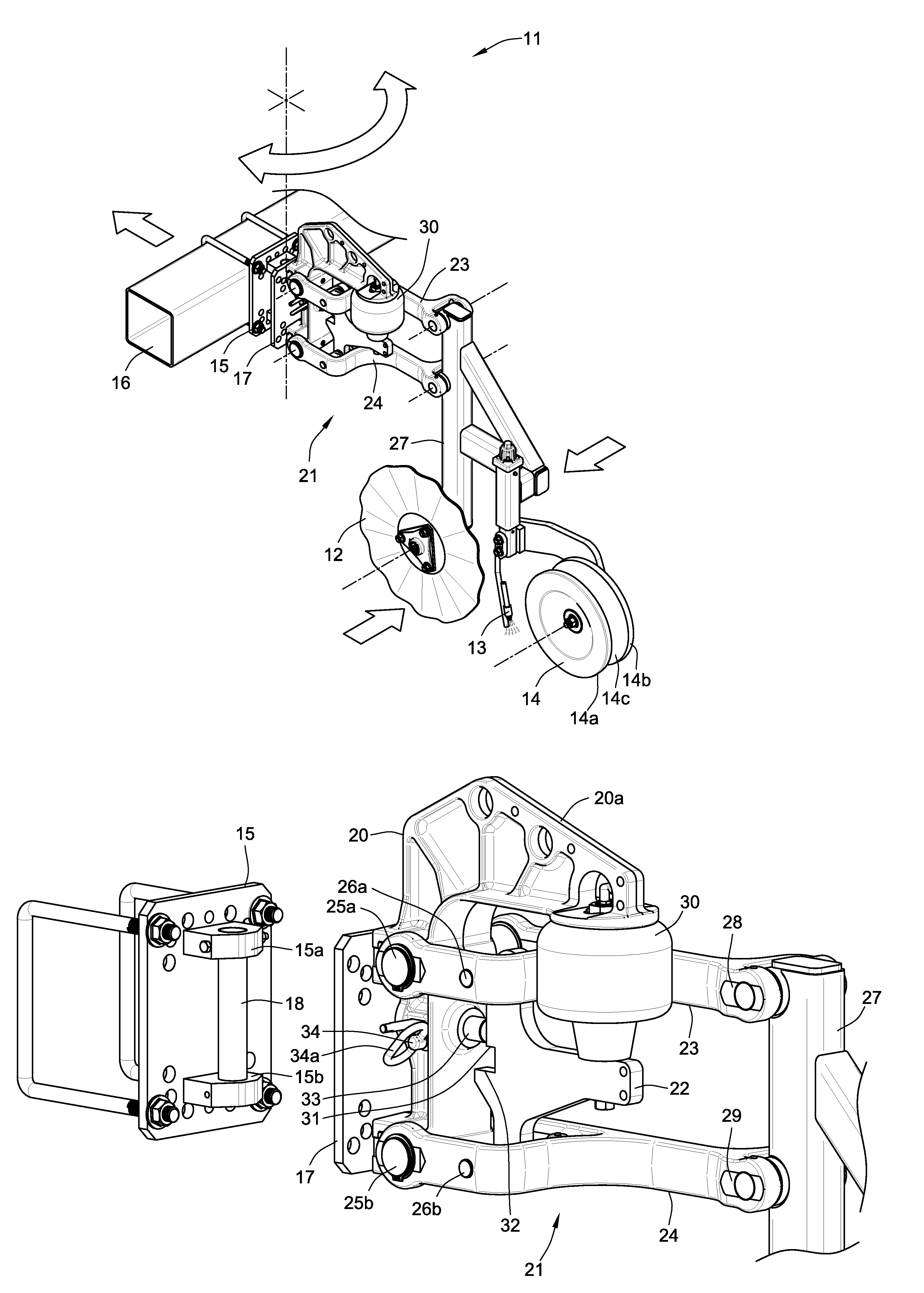

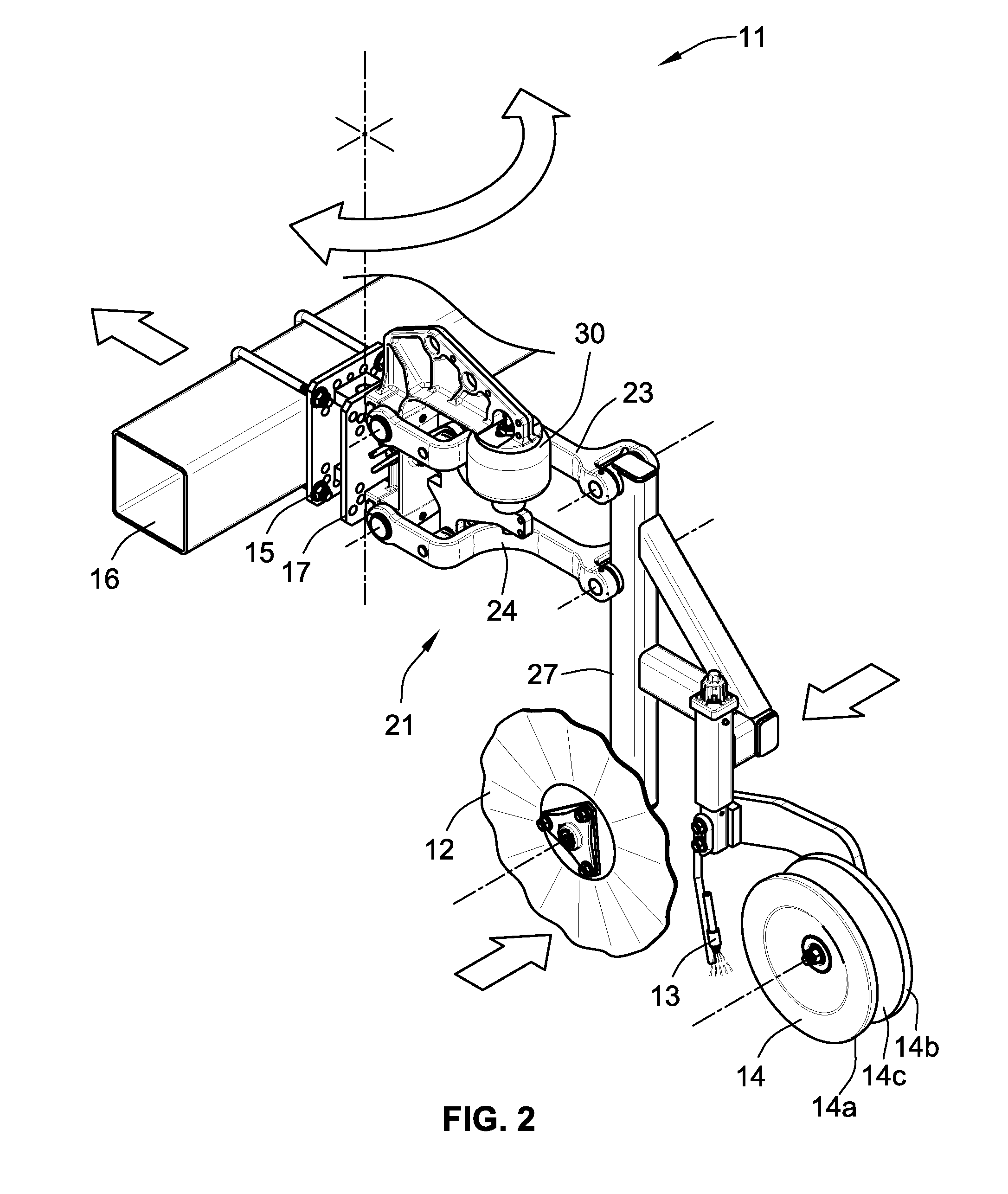

Row unit down pressure assembly

A down pressure assembly for incorporation into an agricultural implement to be pulled by a tractor (10) has an attachment frame (21) for attachment between a portion of the agricultural implement and at least two wheels (22) of a row unit (18) for traveling along the ground, the row unit (18) also having a tool (23) disposed between the two wheels (22) for engaging the ground, the down pressure assembly also having at least one torsion element (41, 50) disposed on the frame (21), with the torsion element (41, 50) having one fixed mounting to the frame (21) and one adjustable mounting to the frame (21), and the assembly further having an adjustment mechanism (37, 60) for varying the torsion of the torsion element (41, 50) at the adjustable mounting; and at least one down pressure member (36, 56, 57) for receiving a force from the torsion element to apply a downward force to the top members (26, 27) of the frame (21).

Owner:BLUE LEAF I P INC

Hydraulic down pressure control system for closing wheels of an agricultural implement

In one embodiment, an agricultural row unit for use with a towing frame hitched to a tractor includes an attachment frame adapted to be rigidly connected to the towing frame. A support member is pivotably coupled to the attachment frame to permit vertical pivoting movement of the support member relative to the attachment frame, and at least one furrow-closing device is mounted on the support member. A hydraulic cylinder is coupled to the support member for urging the row unit frame downwardly toward the soil. The hydraulic cylinder includes a movable ram extending into the cylinder, and a hydraulic-fluid cavity within the cylinder for receiving pressurized hydraulic fluid for urging the ram in a first direction that pivots the support member in a first vertical direction. An accumulator has a fluid chamber containing a pressurized gas for urging the ram in a second direction that pivots the support member in a second vertical direction.

Owner:DAWN EQUIPMENT COMPANY

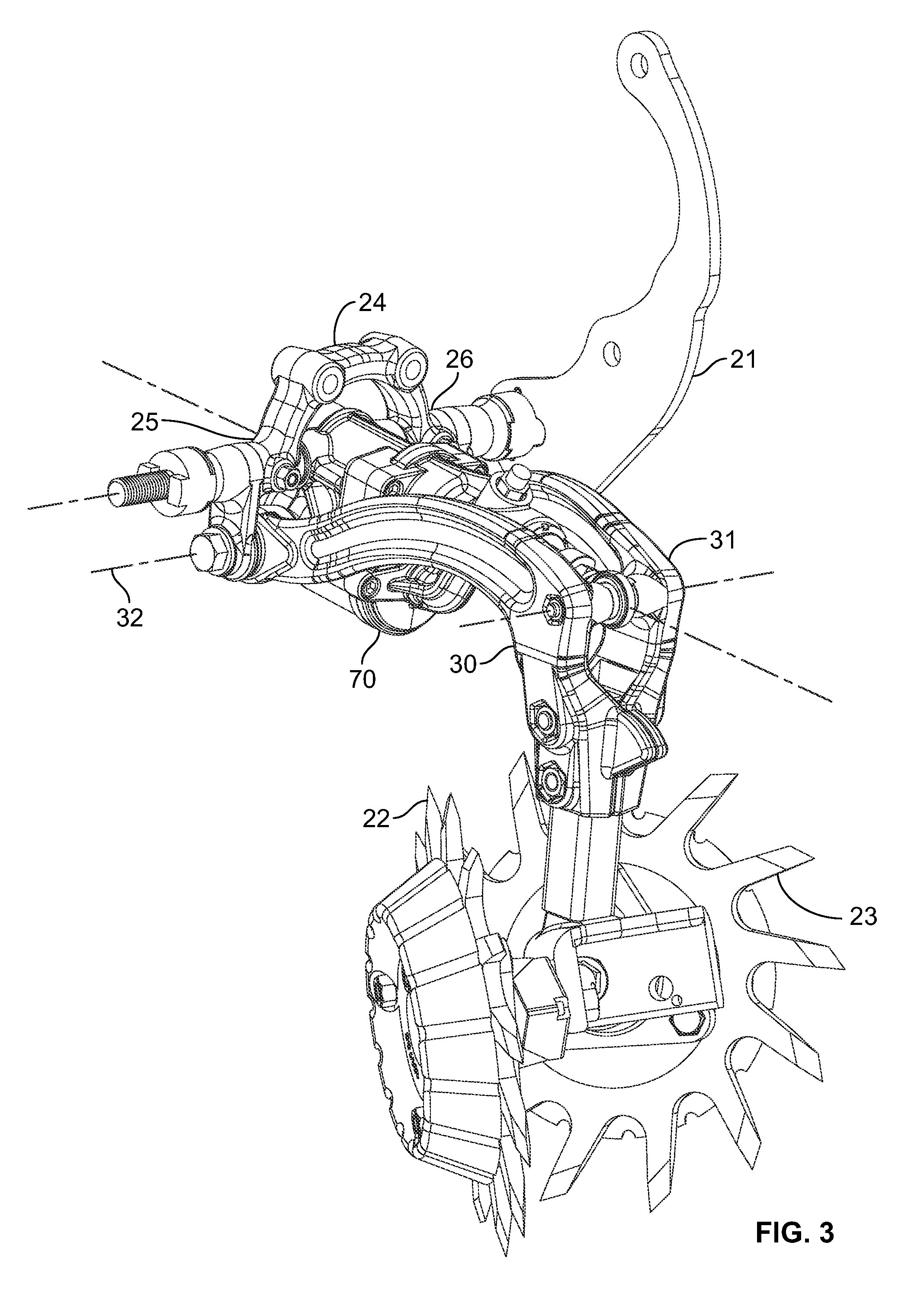

Single arm row cleaner

A single arm row cleaner unit mountable to a grain drill opener arm includes a row cleaner arm and a mounting saddle. The mounting saddle is generally configured for attachment to a main arm of a furrow forming assembly. A row cleaner arm may be pivotally attached to the mounting saddle about a mandrel, and a row cleaner wheel may be pivotally mounted to the row cleaner arm. A biasing member may be positioned adjacent the mandrel to engage the row cleaner arm and a biasing member retainer, which may be affixed to the mounting saddle. A deflector may be positioned adjacent the row cleaner wheel and biased there against. A connector and lever arm may be used to communicate forces from a closing wheel arm to the row cleaner wheel for adequate clearance of the row cleaner wheel during transport of the grain drill.

Owner:MARTIN HOWARD D +1

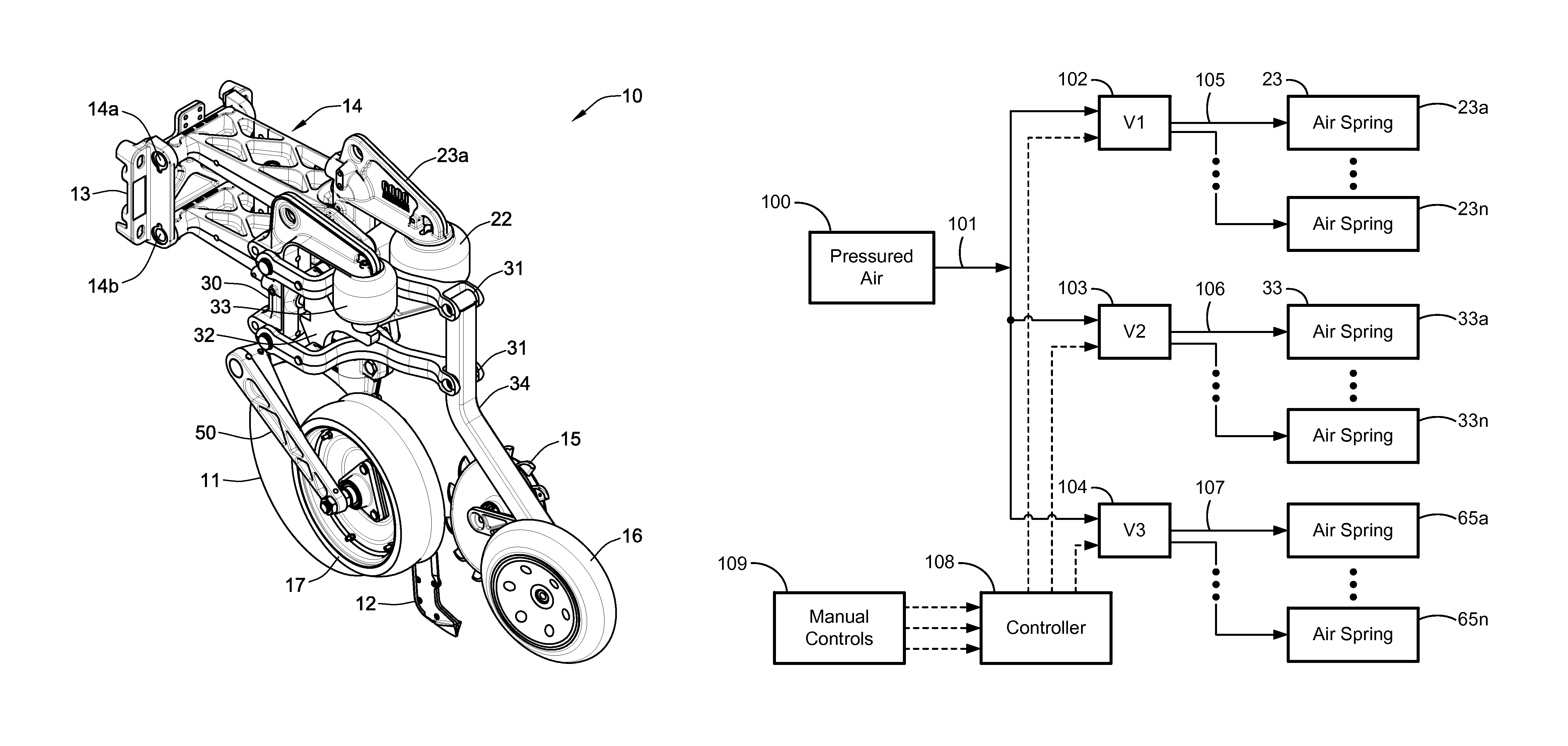

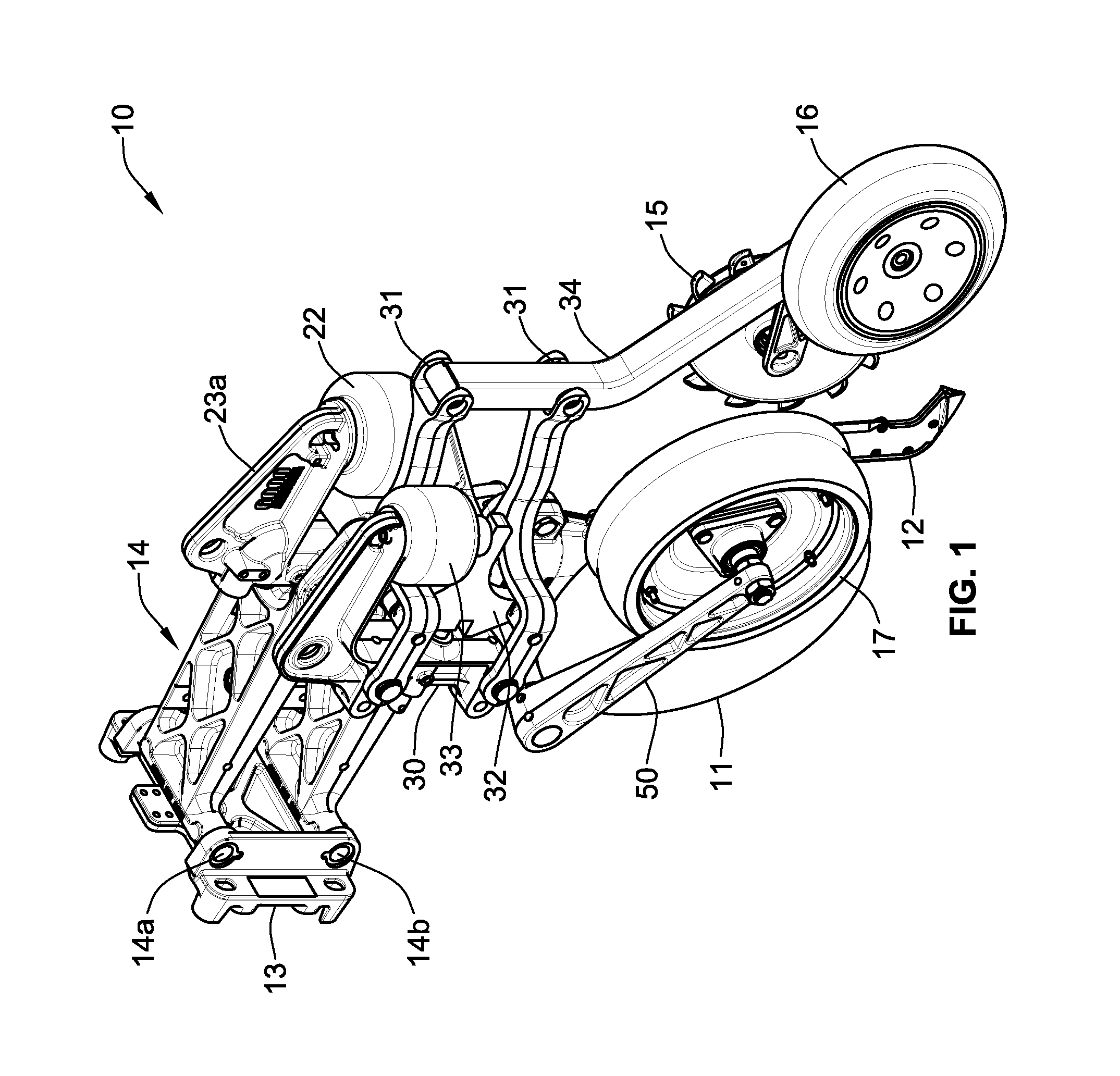

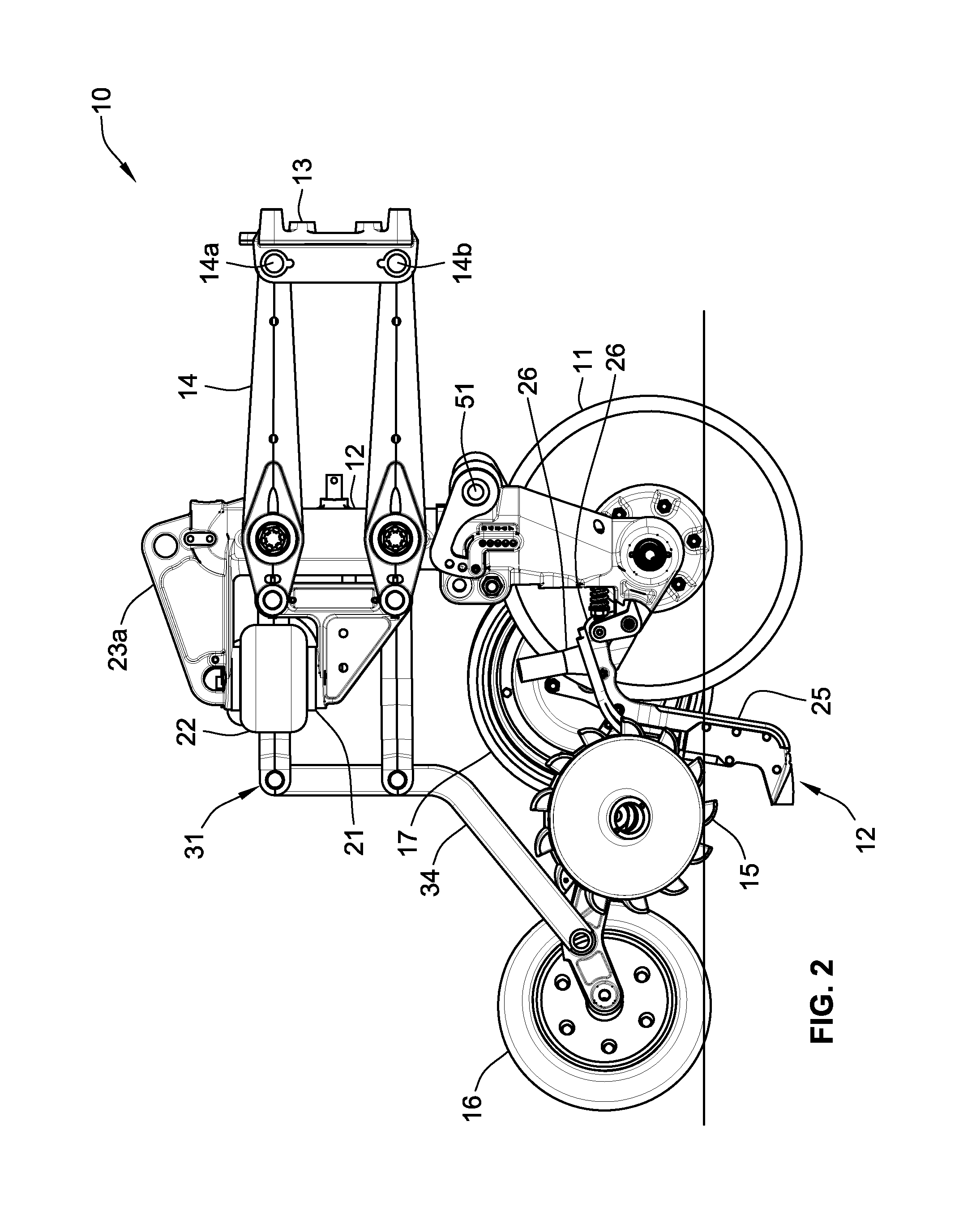

Manual backup system for controlling fluid flow to cylinders within an agricultural implement

An agricultural implement system is provided that includes a down force cylinder configured to apply a downward force to a row unit, a depth control cylinder configured to vary a penetration depth of a ground engaging tool of the row unit, a press wheel cylinder configured to vary contact force between a press wheel and a soil surface, a closing disk cylinder configured to vary contact force between a closing disk and the soil surface, a residue manager cylinder configured to vary contact force between a residue manager and the soil surface, or a combination thereof. The agricultural implement system also includes an electronic control unit configured to automatically regulate a pressure within the cylinders, and a manual backup system configured to facilitate manual pressure adjustment of the cylinders.

Owner:CNH IND AMERICA LLC

Agricultural implement with automatic down pressure control

Owner:DAWN EQUIPMENT COMPANY

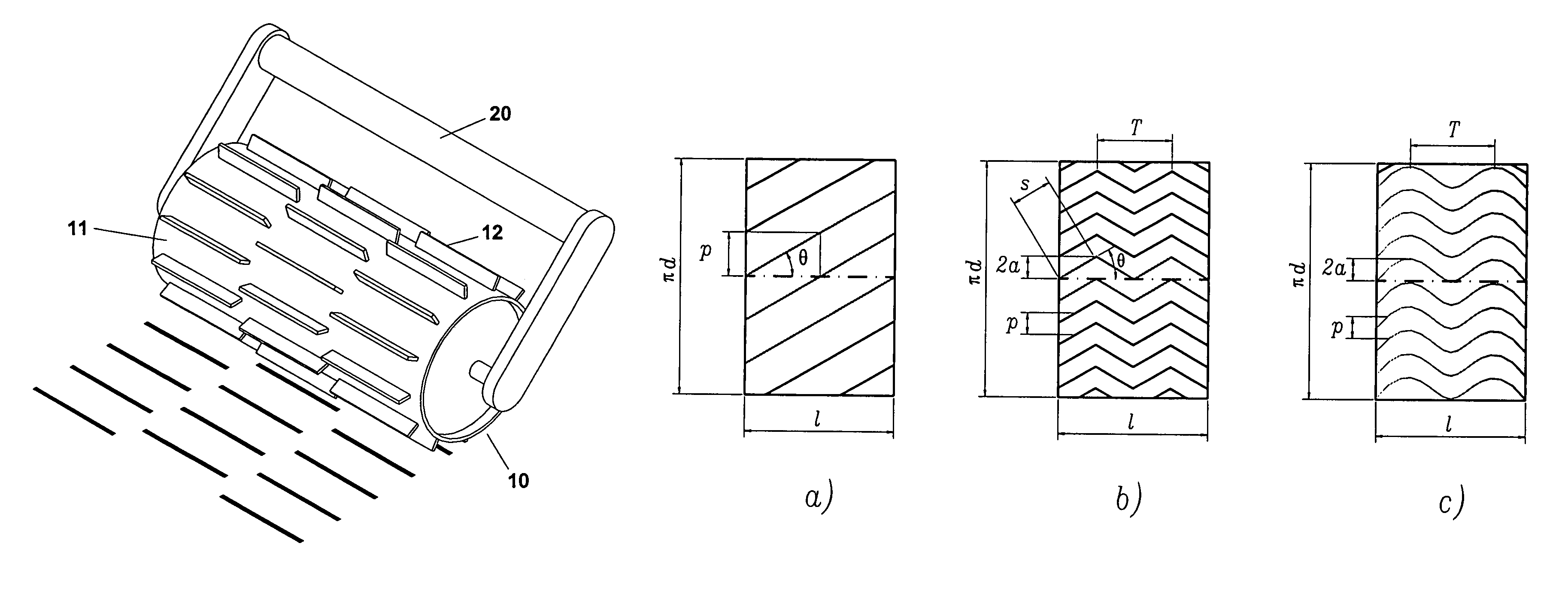

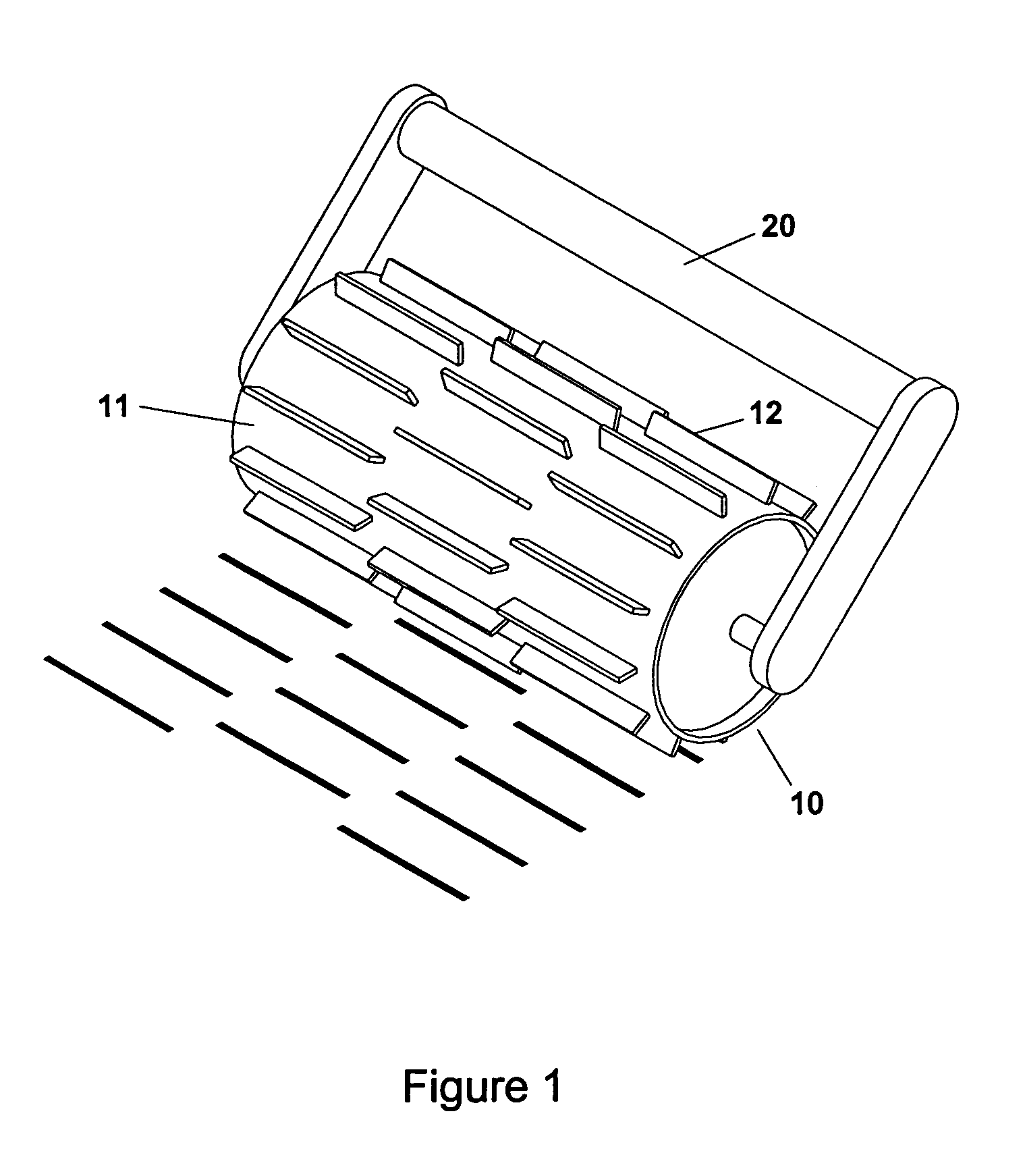

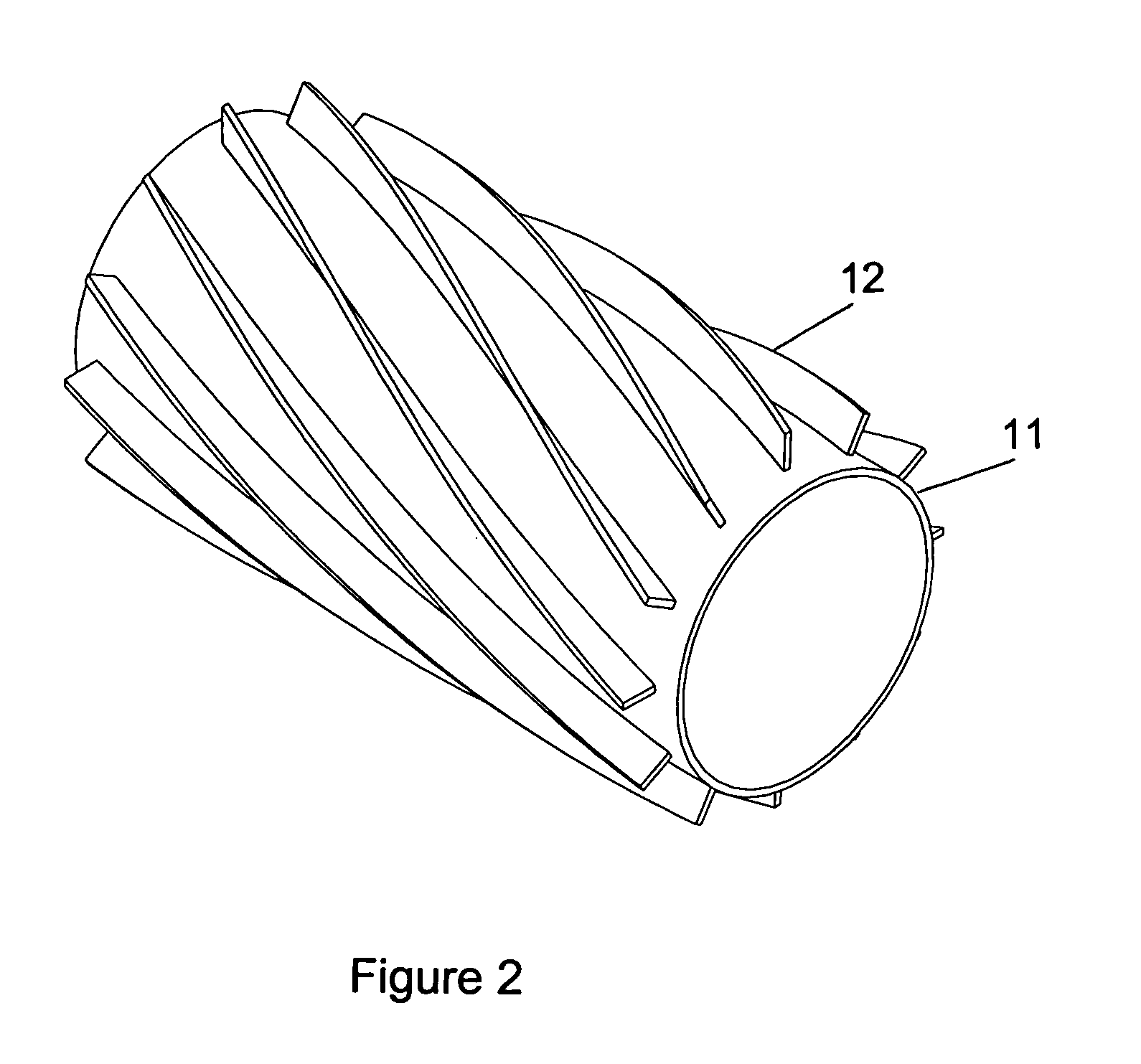

Smooth rolling cover crop roller

Cover crops may be rolled and crimped using an apparatus which may be rolled across a field at a relatively high speed without excessive vibration. The apparatus includes a substantially cylindrical drum which has a plurality of rows of outwardly extending blades projecting therefrom. The blades may be wave-shaped, curved, substantially straight and discontinuous, blades paired with a plurality of spaced apart outwardly extending rings, or combinations thereof. In use as the apparatus is rolled across a field having a crop thereon, the blades contact and crimp the stalks of the crop, effectively killing the plant.

Owner:AGRI UNITED STATES OF AMERICA REPRESENTED BY THE SEC OF THE +1

Side dressing fertilizer coulter

An agricultural side dressing fertilizer coulter row unit includes a first attachment member adapted to be rigidly connected to a towing frame, and a second attachment member pivotably coupled to the first attachment member for pivoting movement about a substantially vertical axis. A linkage is pivotably coupled to the second attachment member for pivoting movement of the trailing end of the linkage relative to the second attachment member, and a tool-carrying stem pivotably coupled to the trailing end of the linkage carries a rotatably mounted coulter wheel for forming a slit in the soil, a liquid fertilizer dispenser for dispensing fertilizer, and a rotatably mounted closing wheel for closing the slit. A biasing element is pivotably attached to the linkage and coupled to the second attachment member for urging the stem downwardly with a controllable force.

Owner:DAWN EQUIPMENT COMPANY

Row unit for agricultural implement

An agricultural row unit for use with a towing frame hitched to a tractor includes an attachment frame adapted to be rigidly connected to the towing frame, and a furrow-opening module comprising a first linkage pivotably coupled to the attachment frame, a first movable frame pivotably coupled to the linkage to permit vertical pivoting movement of the first movable frame relative to the linkage, a furrow-opening device mounted on the first movable frame, and a first biasing element pivotably attached to the linkage and coupled to the first movable frame for urging the furrow-opening device downwardly against the soil. The row unit also includes a furrow-closing module and a second biasing element for urging the at least one furrow-closing device downwardly against the soil.

Owner:DAWN EQUIPMENT COMPANY

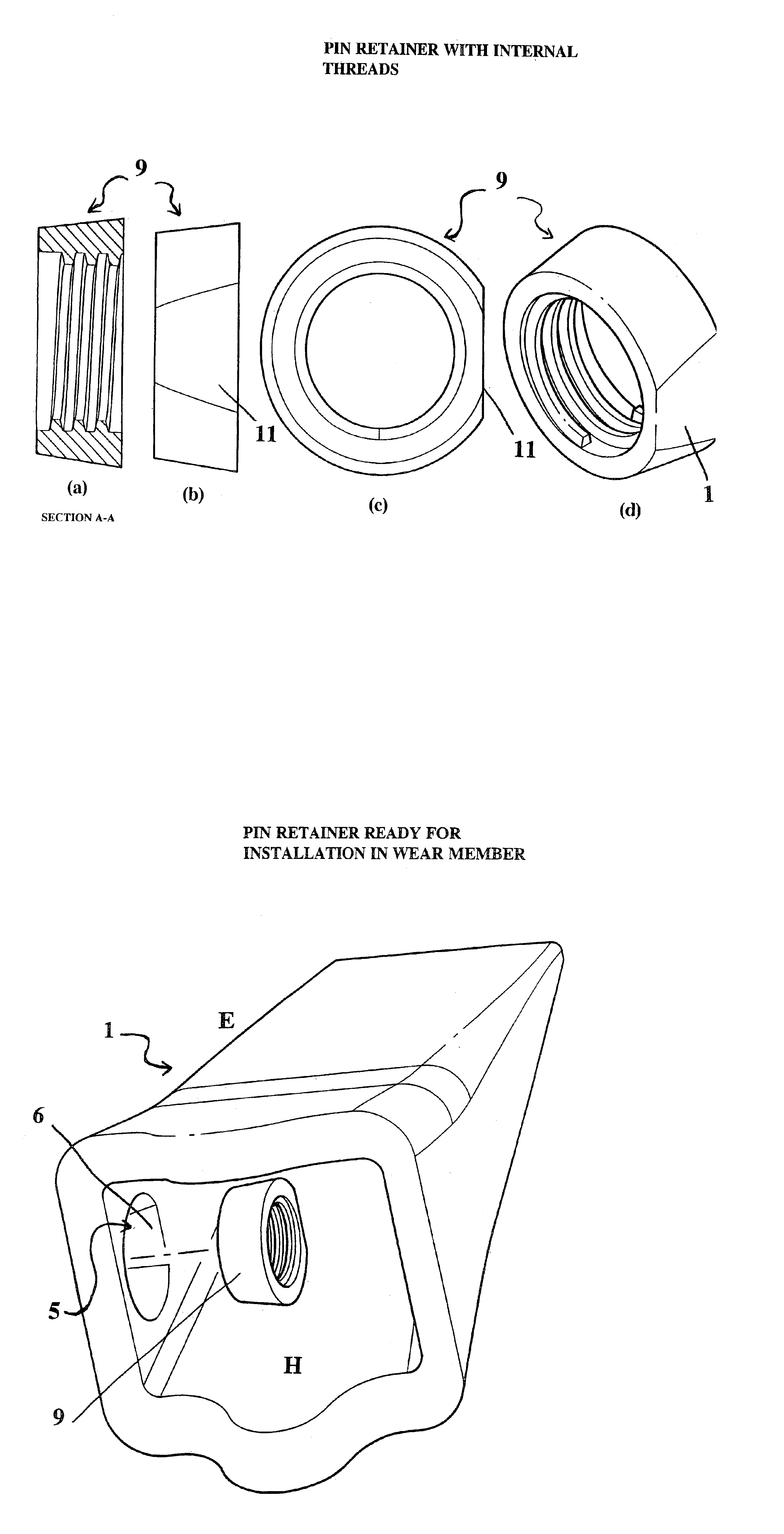

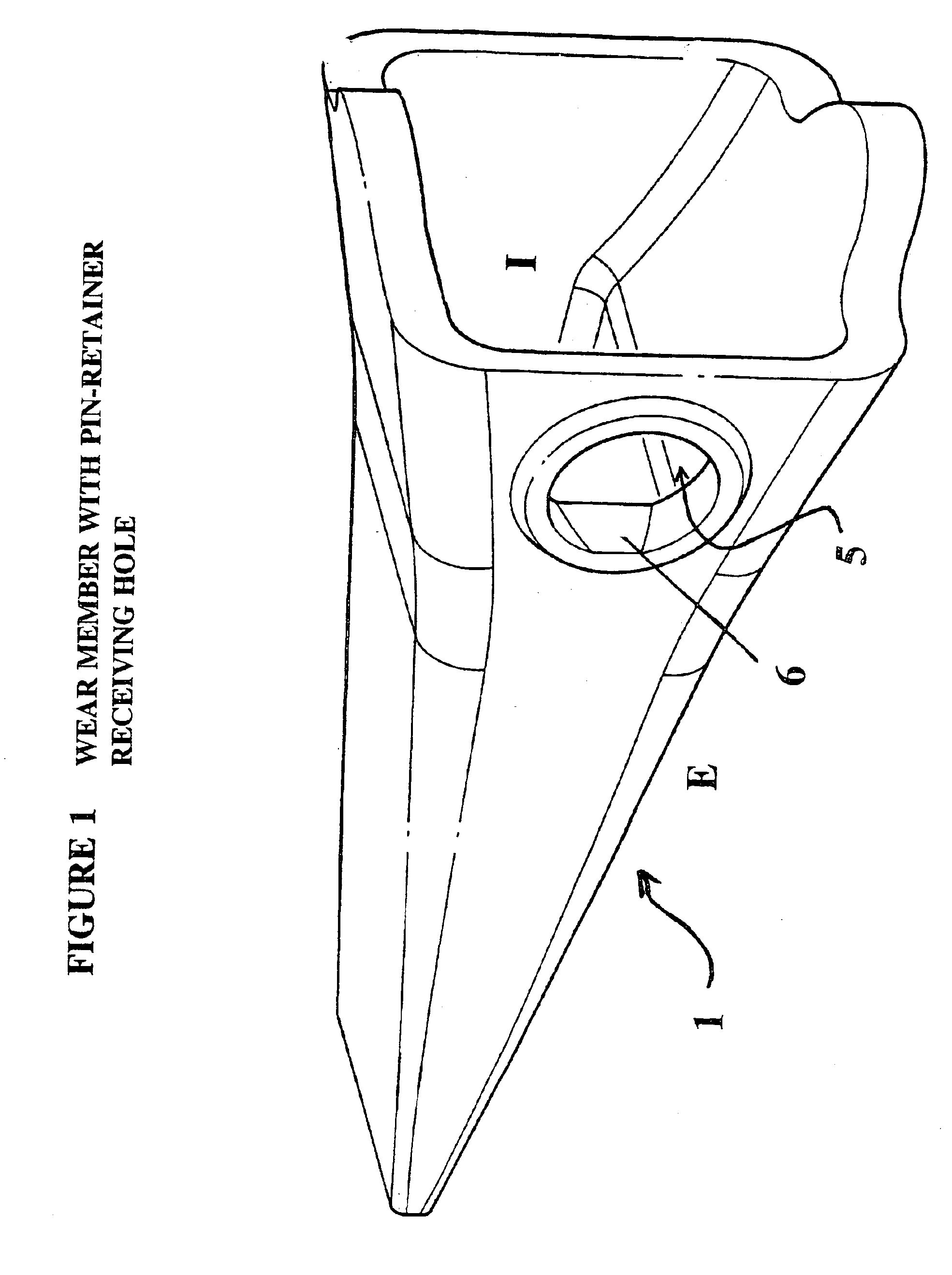

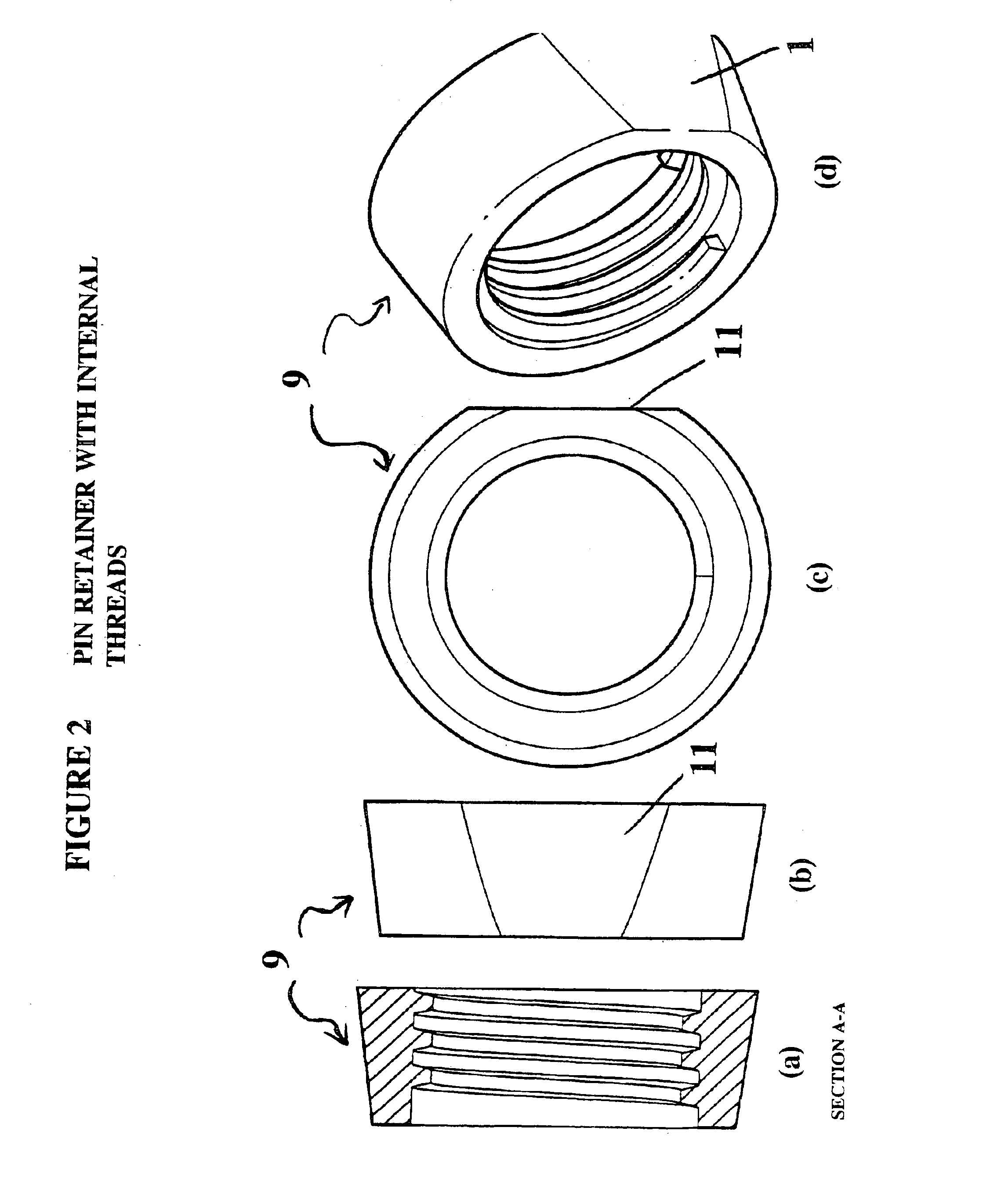

Torque locking system for fastening a wear member to a support structure

The present invention is directed to a releasable locking assembly for attaching a wear member to a support structure. It may be used with excavating equipment for attaching ground-engaging teeth to adaptors, lip shrouds to bucket lips, or other analogous uses. The wear member includes at least one pin-retainer-receiving opening in one side. The opening is tapered, being narrower at its outer surface and wider at its inner surface. The support structure includes at least one pin-receiving recess which generally aligns with the opening in the wear member when the wear member and the support structure are operatively coupled. The pin retainer is a frustoconically shaped cylinder which is threaded internally. It is inserted into the opening in the wear member. The wear member is slidably mounted onto the support structure. The pin is an elongate body which is externally threaded. It is screwed into the pin retainer by the application of torque force from a standard ratchet tool. The pin extends through the wear member and into the recess in the support structure to lock the wear member to the support structure. The pin may be released using a ratchet tool and removed from the pin retainer. The wear member may then be removed from the support structure.

Owner:ESCO CANADA

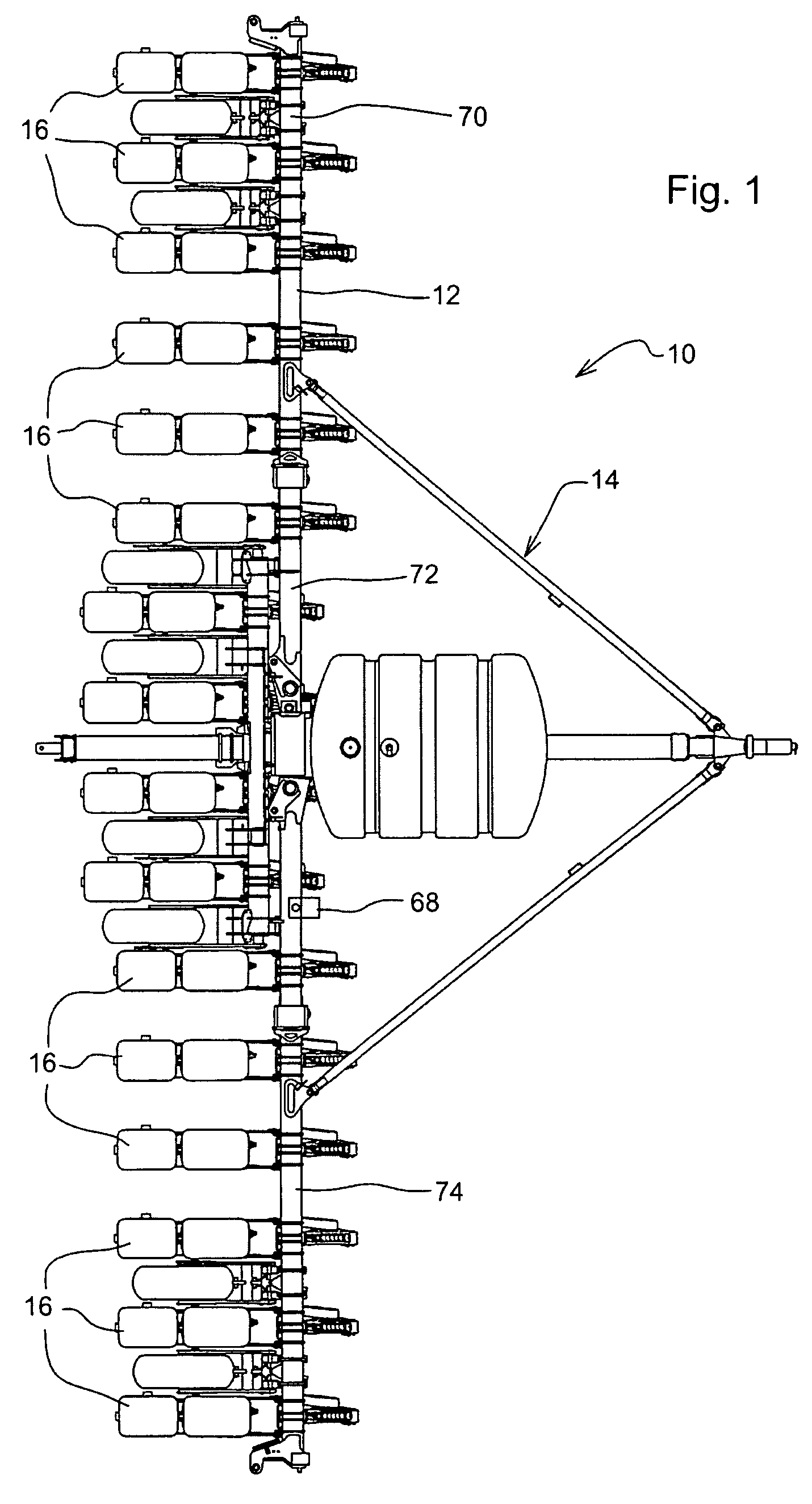

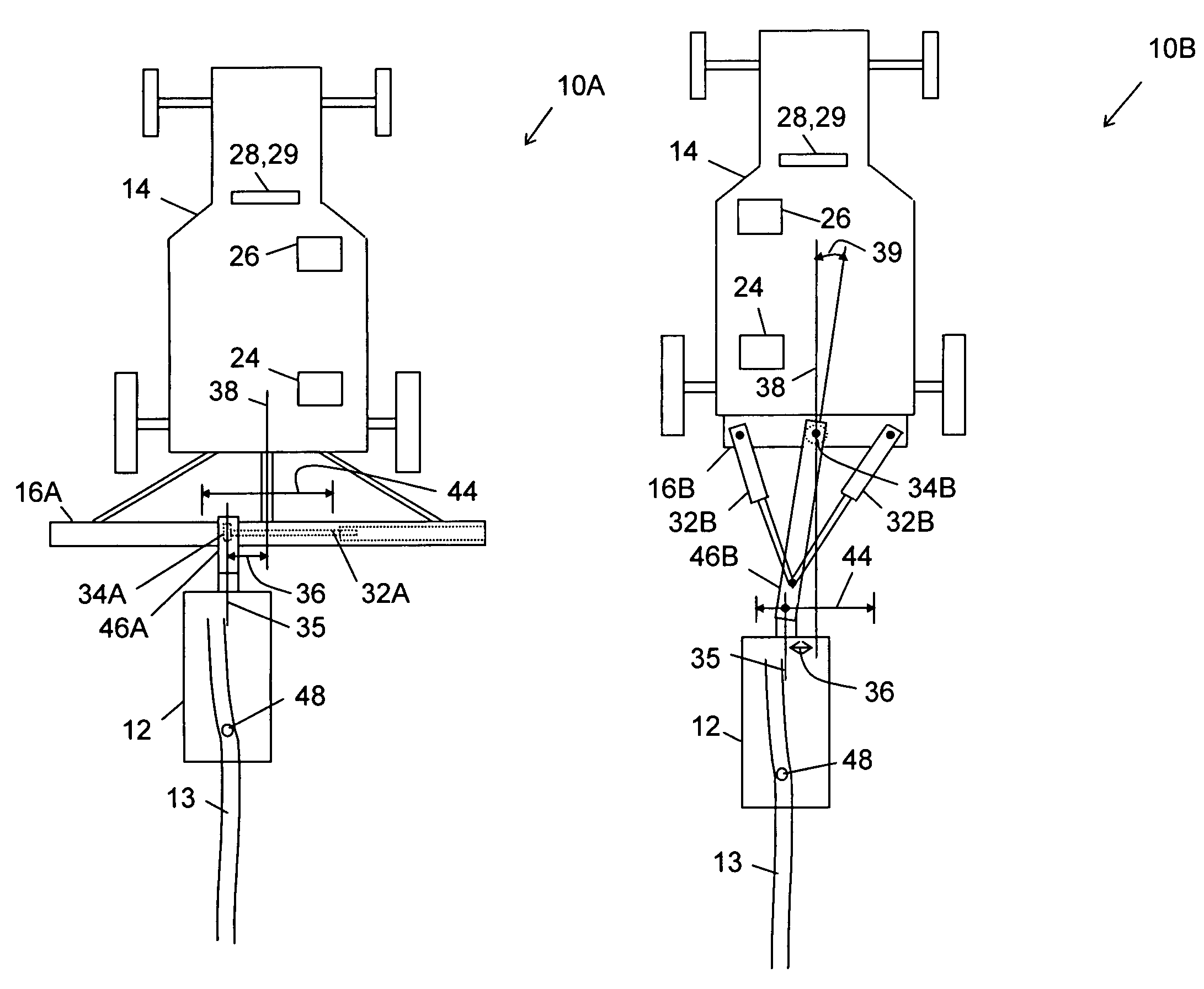

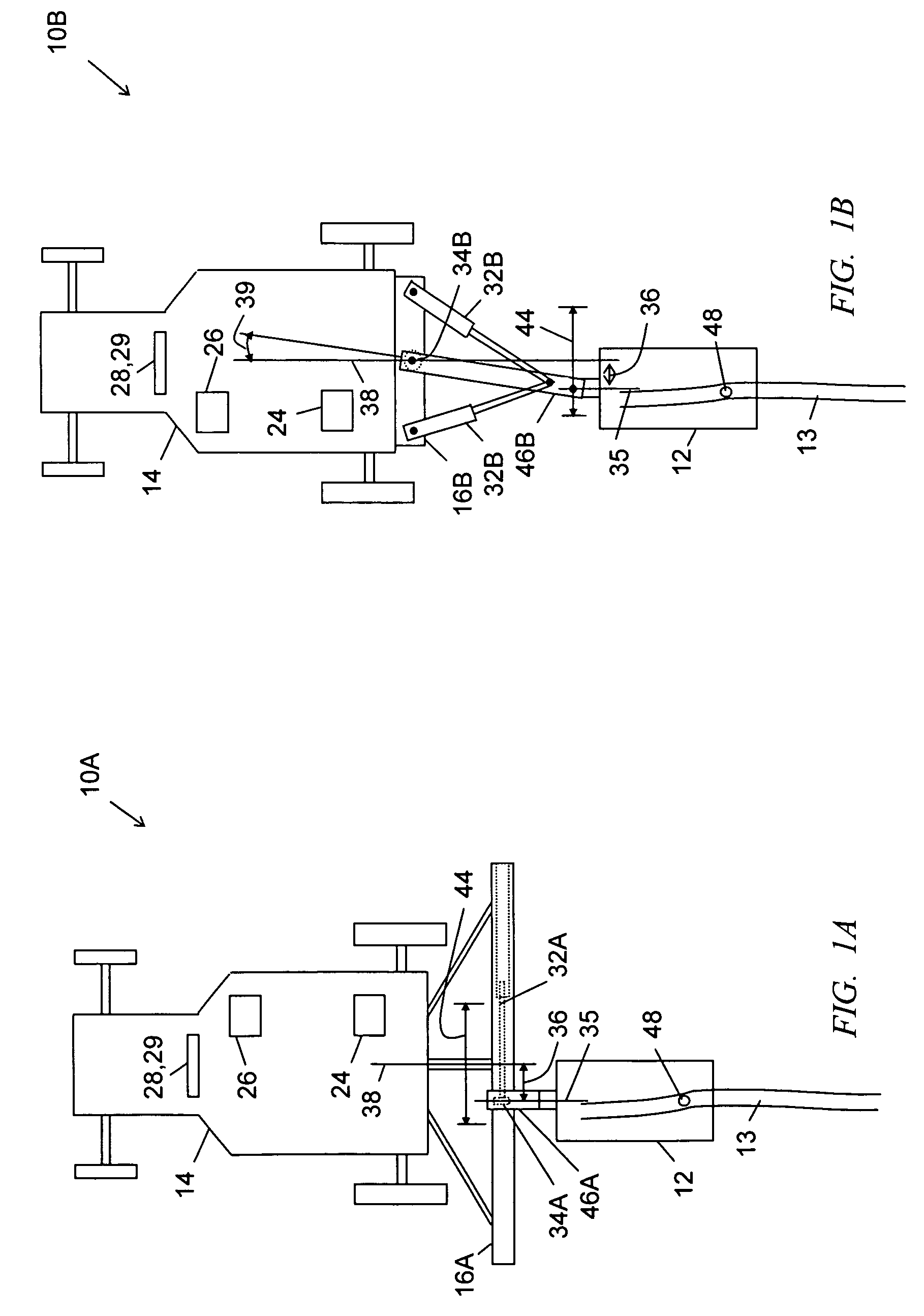

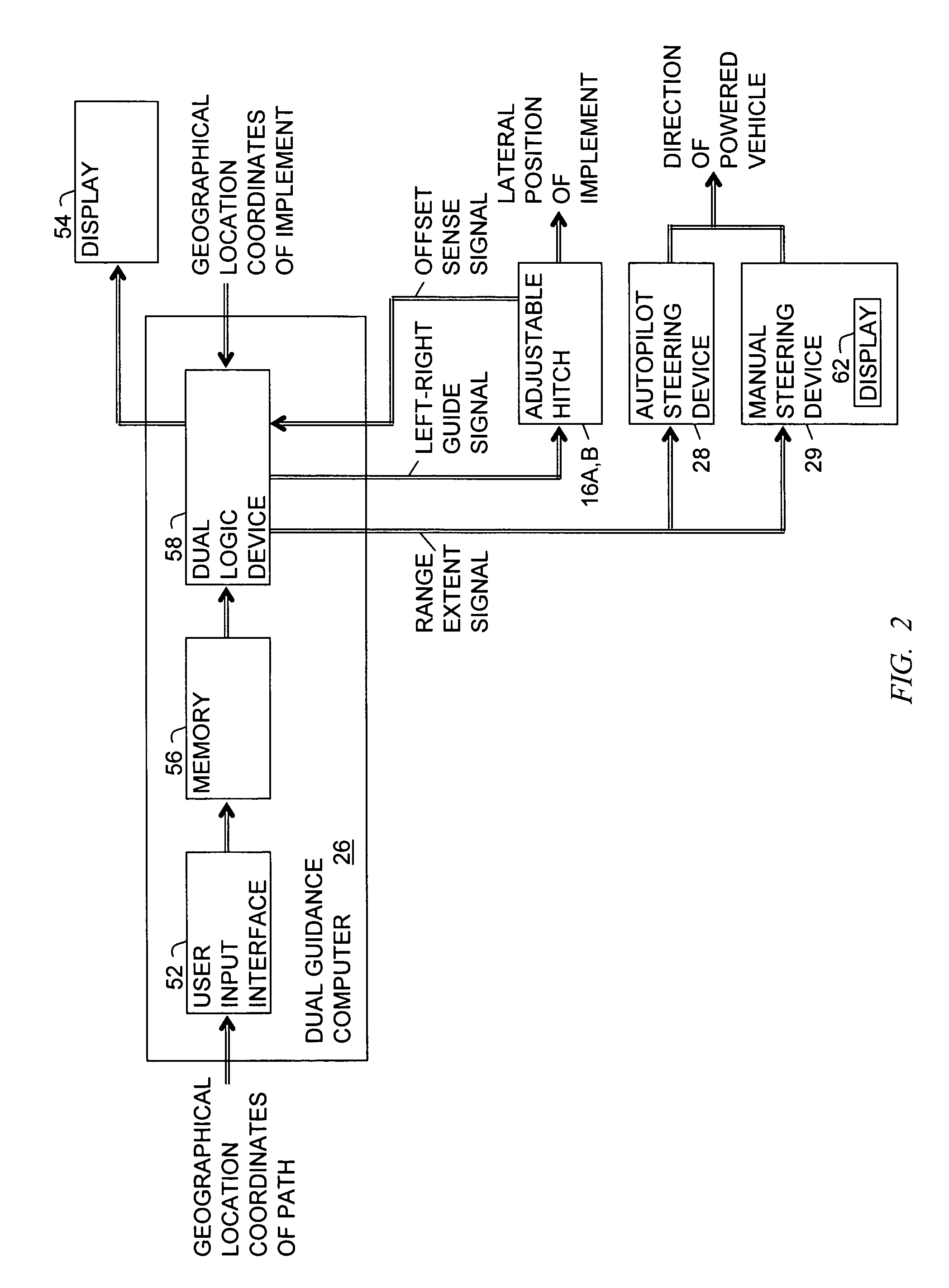

Method and apparatus for steering a farm implement to a path

ActiveUS7383114B1Quick launchOversteering of the tractorAnalogue computers for trafficSoil-working equipmentsSteering angleGps receiver

An apparatus and method using GPS for dynamically adjusting side-to-side positioning of a farm implement along a geographical path. The apparatus includes a global positioning system (GPS) antenna disposed on the farm implement, a GPS receiver coupled to the GPS antenna for determining a location of the GPS antenna, and a dual guidance computer for comparing the location to stored geographical coordinates of a desired path for providing a guide signal for offsetting the lateral position of an adjustable hitch or angling a wheel or ground rudder in a steerable implement for guiding the implement along the path; and a range extent signal for maintaining the offset of the hitch or steering angle of the implement within its dynamic range.

Owner:TRIMBLE NAVIGATION LTD

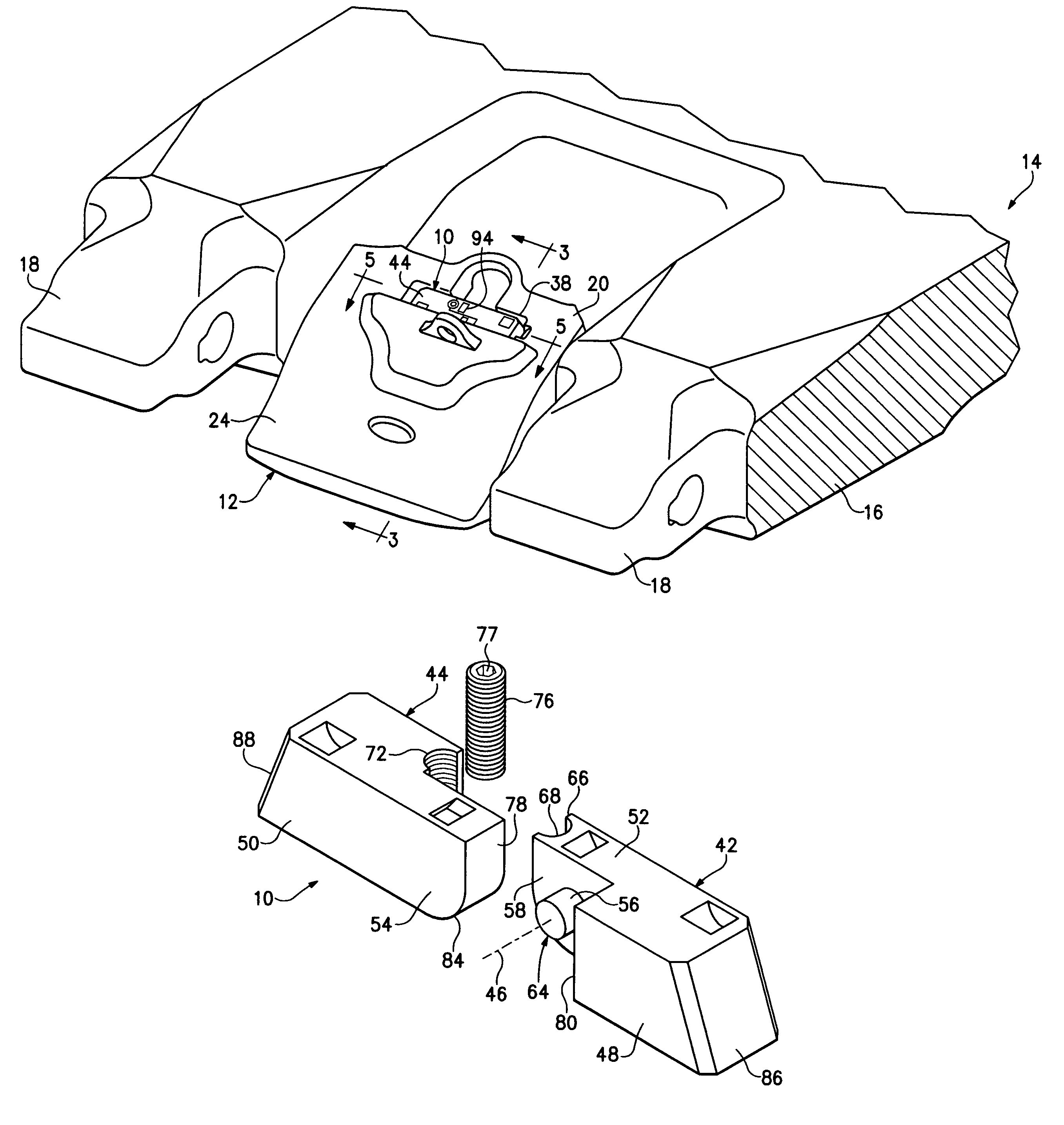

Lock for securing wear parts to earth-working equipment

ActiveUS7536811B2Resistant to ejectionEasy to manufactureMechanical machines/dredgersSoil-working equipmentsEngineeringMechanical engineering

A lock for securing a wear part to earth-working equipment that is foldable between a retaining position to hold the wear part to the equipment and a release position that permits removal of the lock and release of the wear part from the equipment. The lock includes a retainer for releasably holding the lock in the retaining position. The retainer may comprise a threaded wedge received into a complementary threaded passage.

Owner:ESCO GRP LLC

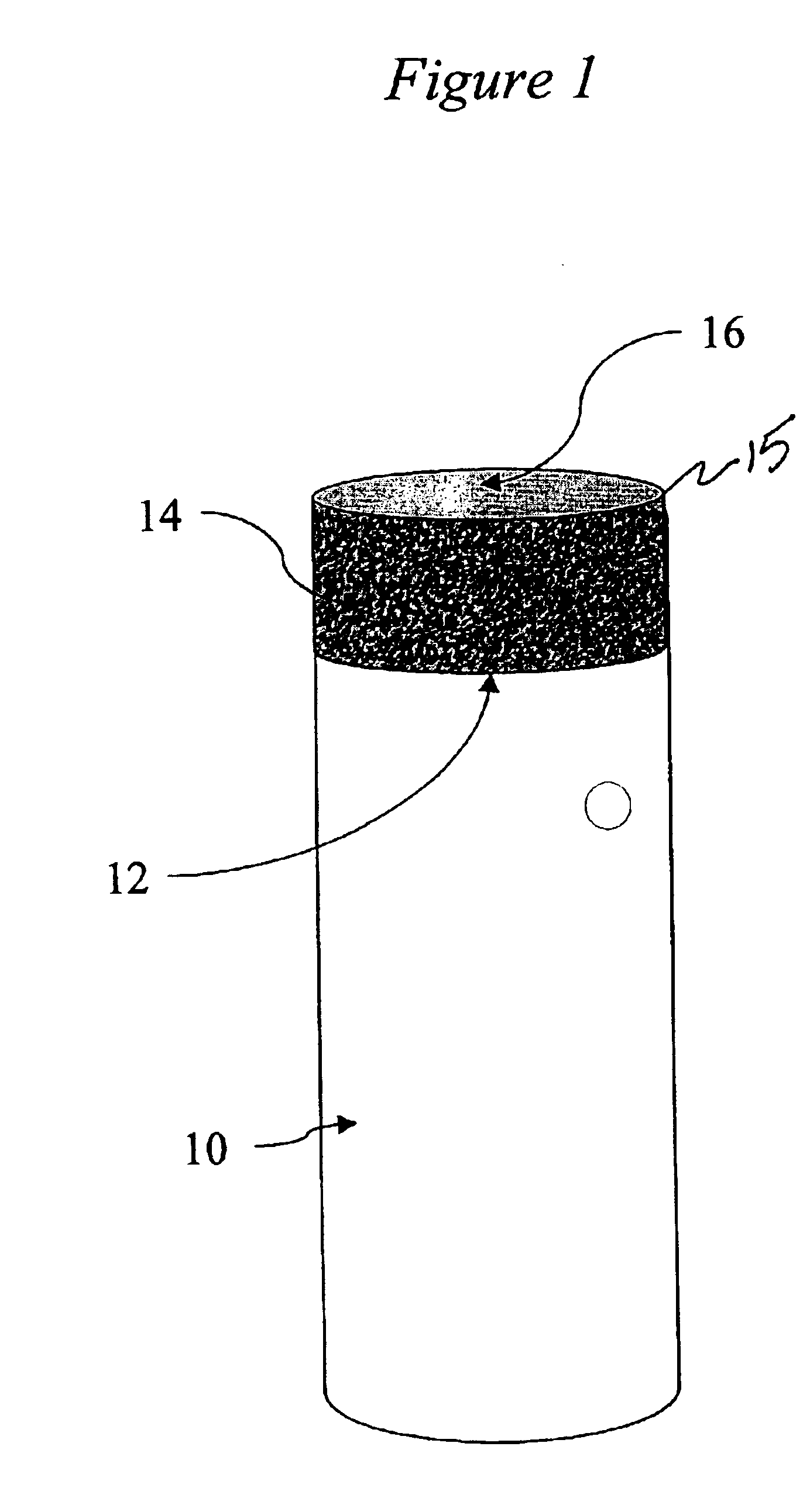

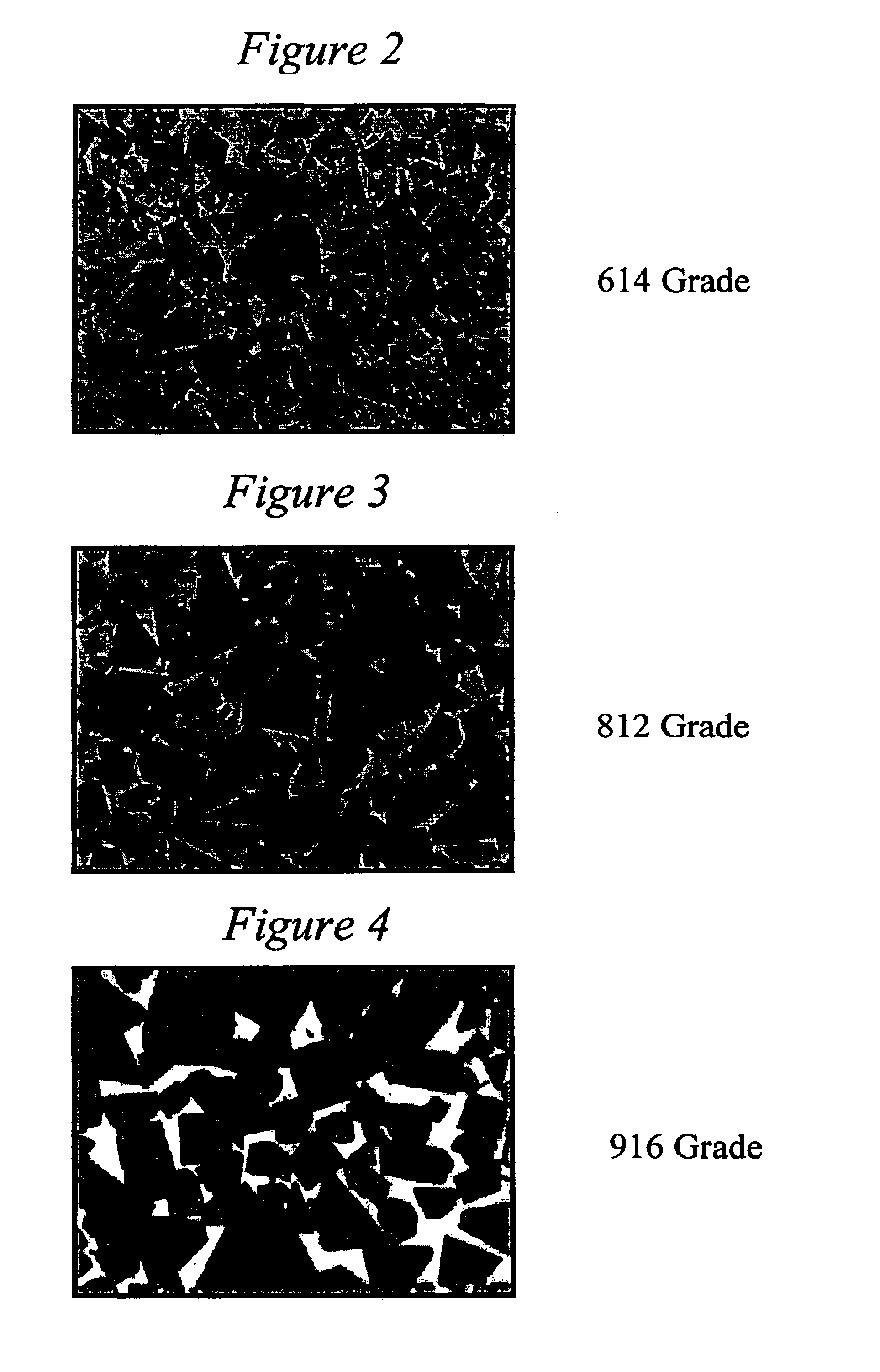

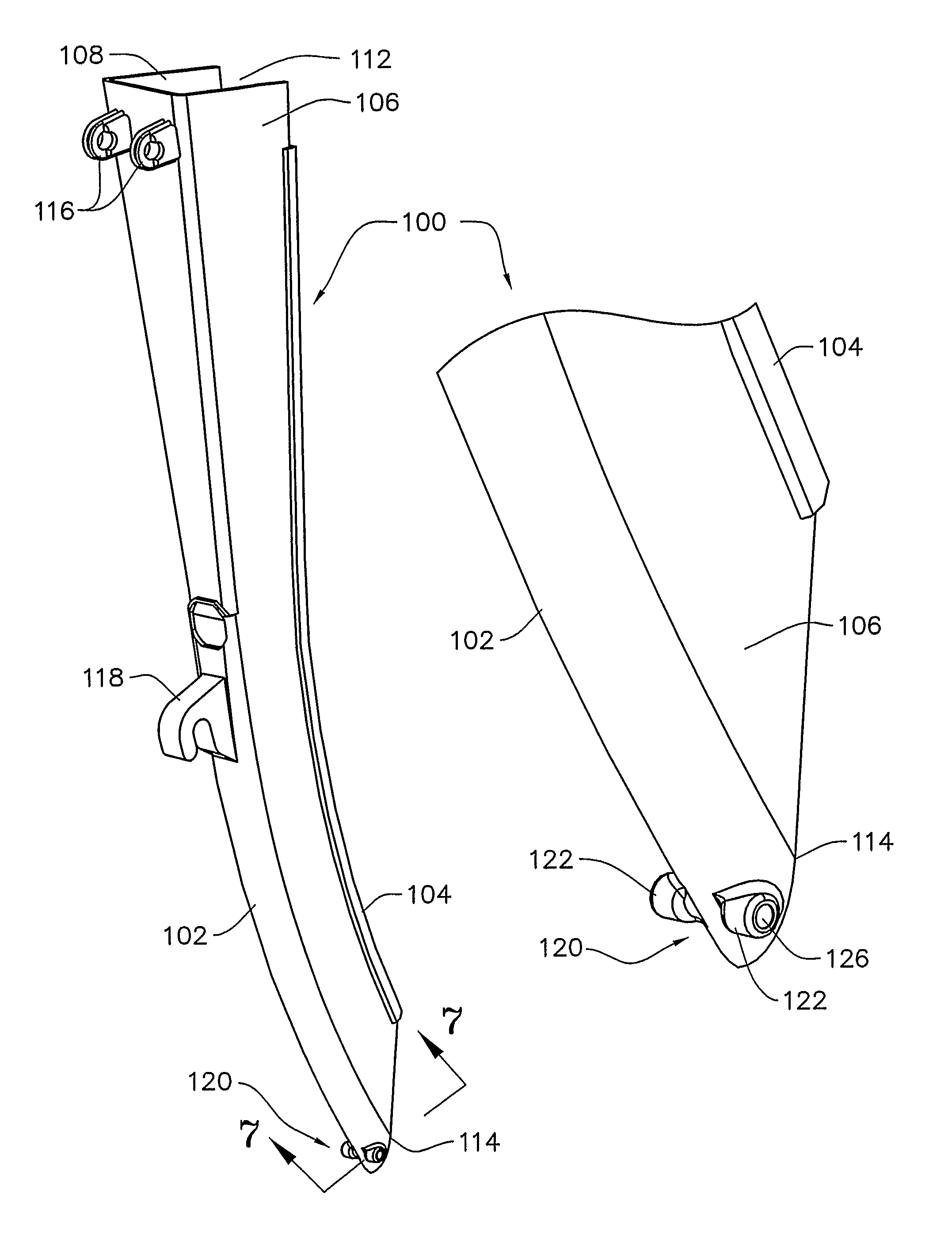

Wear resistant seed tube for an agricultural planter

ActiveUS7584707B2Avoid wear and tearSpadesSoil-working equipmentsWear resistantAgricultural engineering

A seed tube for an agricultural planter having a rearwardly curving forward wall, a rearwardly curving rearward wall and opposing sidewalls defining a seed passageway which curves rearwardly from an upper ingress end toward a lower egress end. Wear resistant material is disposed proximate the egress end which provides a point of first contact with the opener disks thereby preventing appreciable wear of the egress end of the seed tube.

Owner:PRECISION PLANTING LLC

Agricultural implement for delivering multiple media to soil

ActiveUS8146519B2Liquid fertiliser distributionSoil-working equipmentsDevice formAgricultural engineering

An agricultural implement is directed to delivering multiple fluids to the soil of an agricultural field. The implement includes a frame for carrying a soil cutting device and a closing device. The cutting device forms a furrow in the soil and the closing device, which trails the cutting device, closes the furrow. A fluid delivery tine is mounted on the frame and extends downwardly into the furrow between the cutting device and the closing device. The tine has a pair of coaxial tubes, including an outer tube and an inner tube, wherein the coaxial tubes form an outer passageway between the outer tube and the inner tube for delivering a first fluid toward the furrow. The inner tube has an internal passageway for delivering a second fluid toward the furrow.

Owner:DAWN EQUIPMENT COMPANY

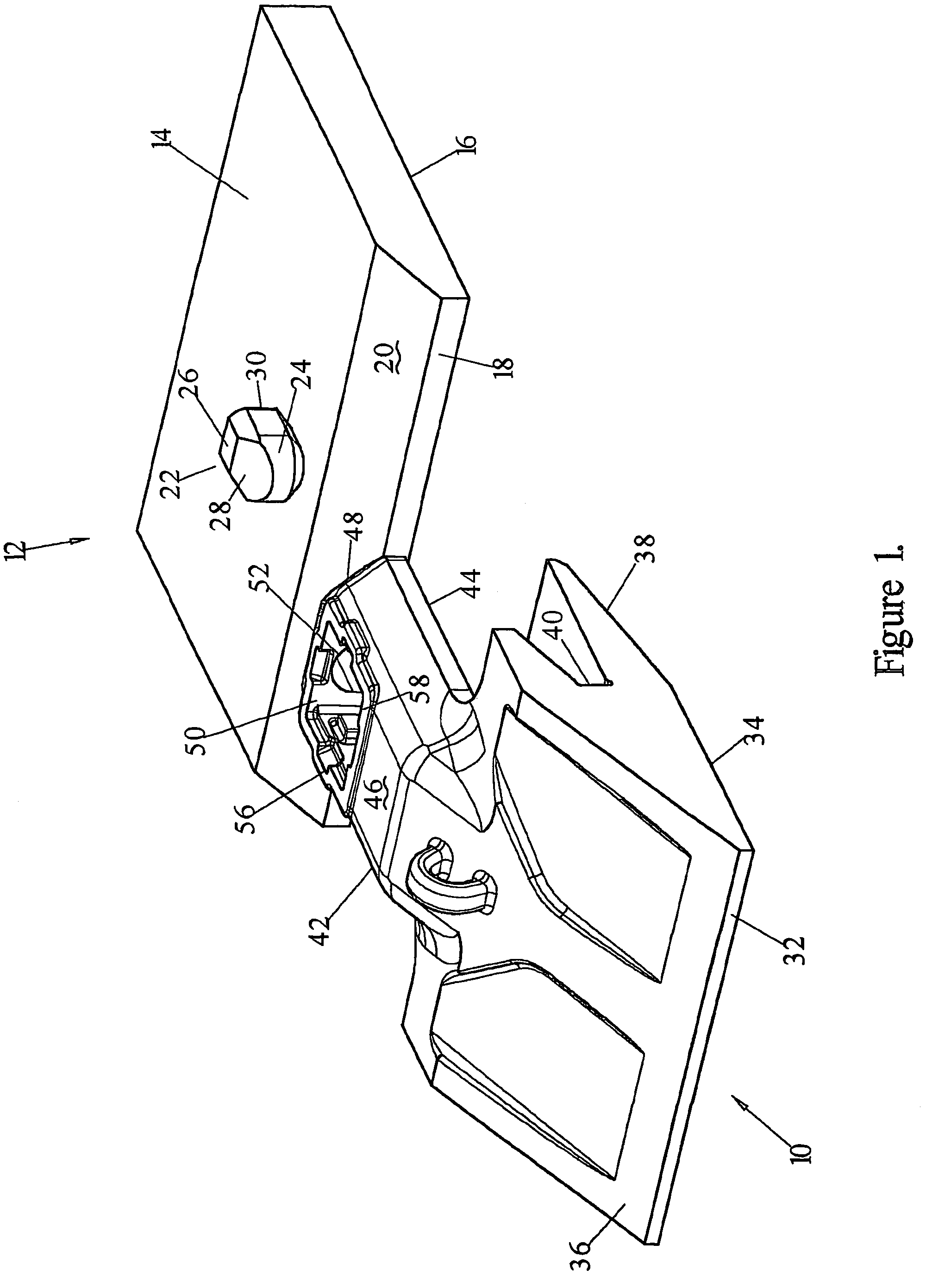

Agricultural Seeder Implement

A seeder implement (125) includes a fork (146) having a first spindle support arm (150) that supports a first spindle (164) and a second spindle support arm (152) that supports a second spindle (168). A first disk (160) is supported on the first spindle (164), wherein the first spindle (164) is oriented in a first orientation and at a first acute angle relative to a lateral line. The first disk (160) is oriented at a second acute angle relative to the ground surface. A second disk (166) is supported on the second spindle (168), wherein the second spindle (168) is oriented in a second orientation and at a third acute angle relative to the lateral line. The second disk (166) is oriented at a fourth acute angle relative to the ground surface. The first disk (160) is longitudinally offset ahead of the second disk (166), and there are no structural components between the first and second disks (160, 166) other than the first and second spindles (164, 168). In one embodiment, a packing wheel (142) is disposed to close and compact furrows opened by the disks (160, 166) and is disposed in the same orientation as one of the disks (160, 166).

Owner:VADERSTAD LLC

Agricultural implement for delivering ammonia gas to soil

An agricultural implement for delivering ammonia gas to soil includes a soil cutting device for forming a furrow in the soil to be fertilized, a closing device trailing the cutting device for closing the furrow, and an ammonia gas delivery tube extending downwardly into the furrow between the cutting device and the closing device, and then extending rearwardly along the furrow to the closing device for delivering ammonia gas onto at least one wall of the furrow rearwardly of the trailing end of the cutting device and of the leading end of the closing device. A discharge nozzle is mounted on the trailing end of the ammonia gas delivery tube for discharging ammonia gas onto the bottom and / or sides of the furrow. The ammonia gas delivery tube and the discharge nozzle may be made of non-metallic material, such as polymeric material, to reduce or avoid freezing of soil and moisture on the implement.

Owner:DAWN EQUIPMENT COMPANY

Removable device for attaching two mechanical parts

ActiveUS7707755B2Simplify assembly and removalEasy to slideSoil-working equipmentsDragsComing outTension member

Owner:METALOGENIA SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com