Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

311 results about "Crop residue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

There are two types of agricultural crop residues. Field residues are materials left in an agricultural field or orchard after the crop has been harvested. These residues include stalks and stubble (stems), leaves, and seed pods. The residue can be ploughed directly into the ground, or burned first. In contrast, no-till, strip-till or reduced till agriculture practices are carried out to maximize crop residue cover. Good management of field residues can increase efficiency of irrigation and control of erosion. Simple line transect measurements can be used to estimate residue coverage. Process residues are materials left after the crop is processed into a usable resource. These residues include husks, seeds, bagasse, molasses and roots. They can be used as animal fodder and soil amendment, fertilizers and in manufacturing.

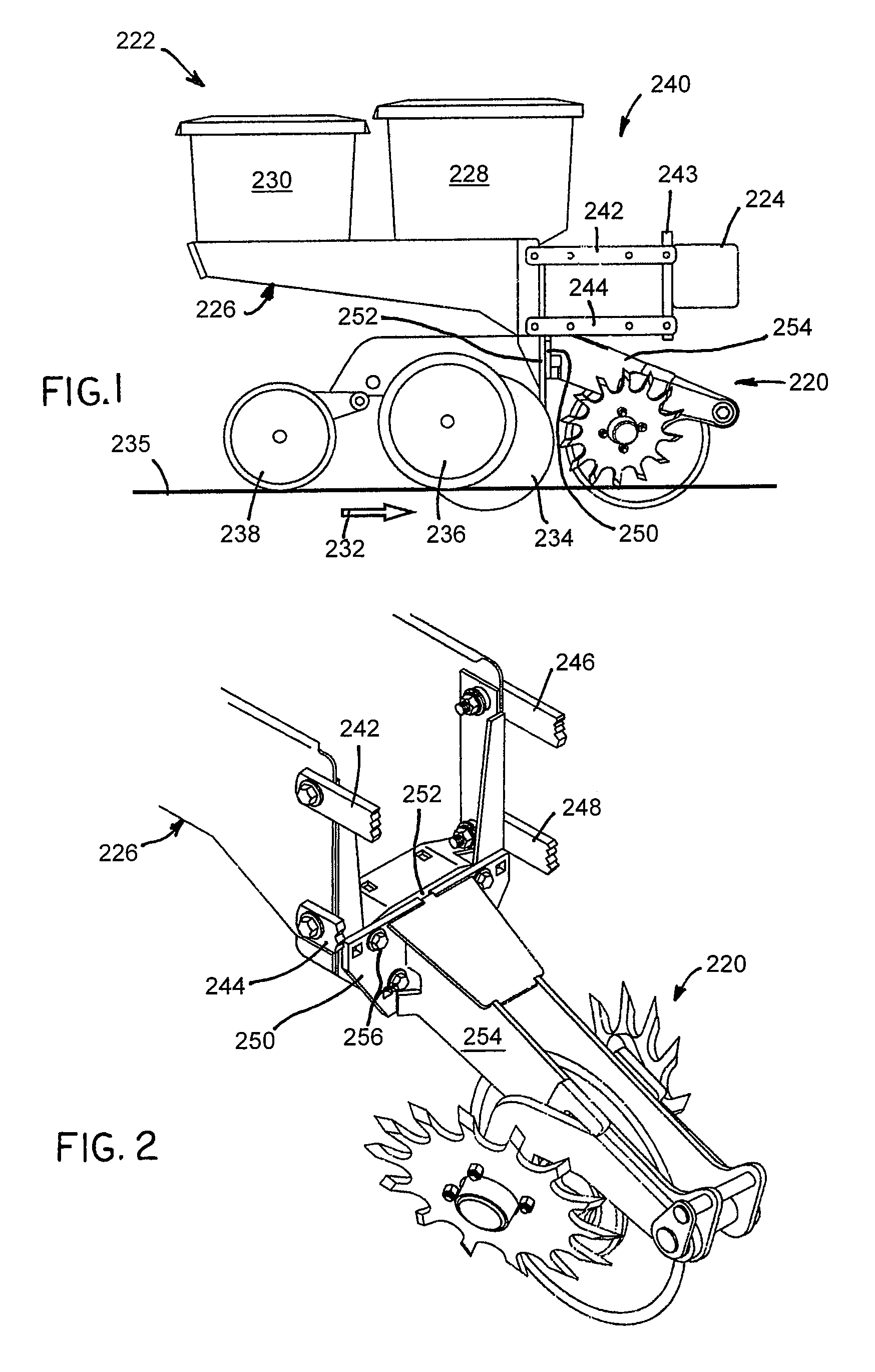

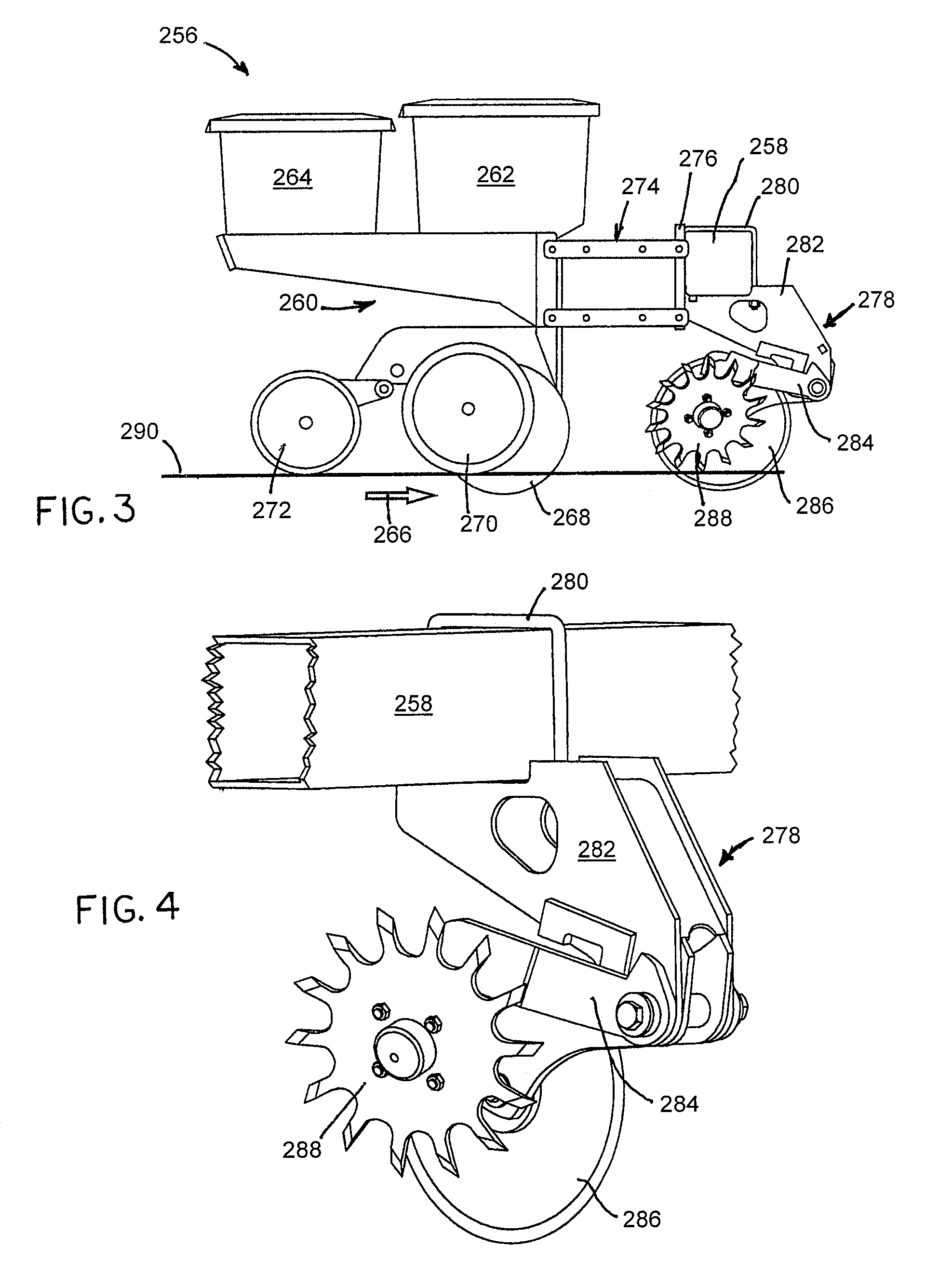

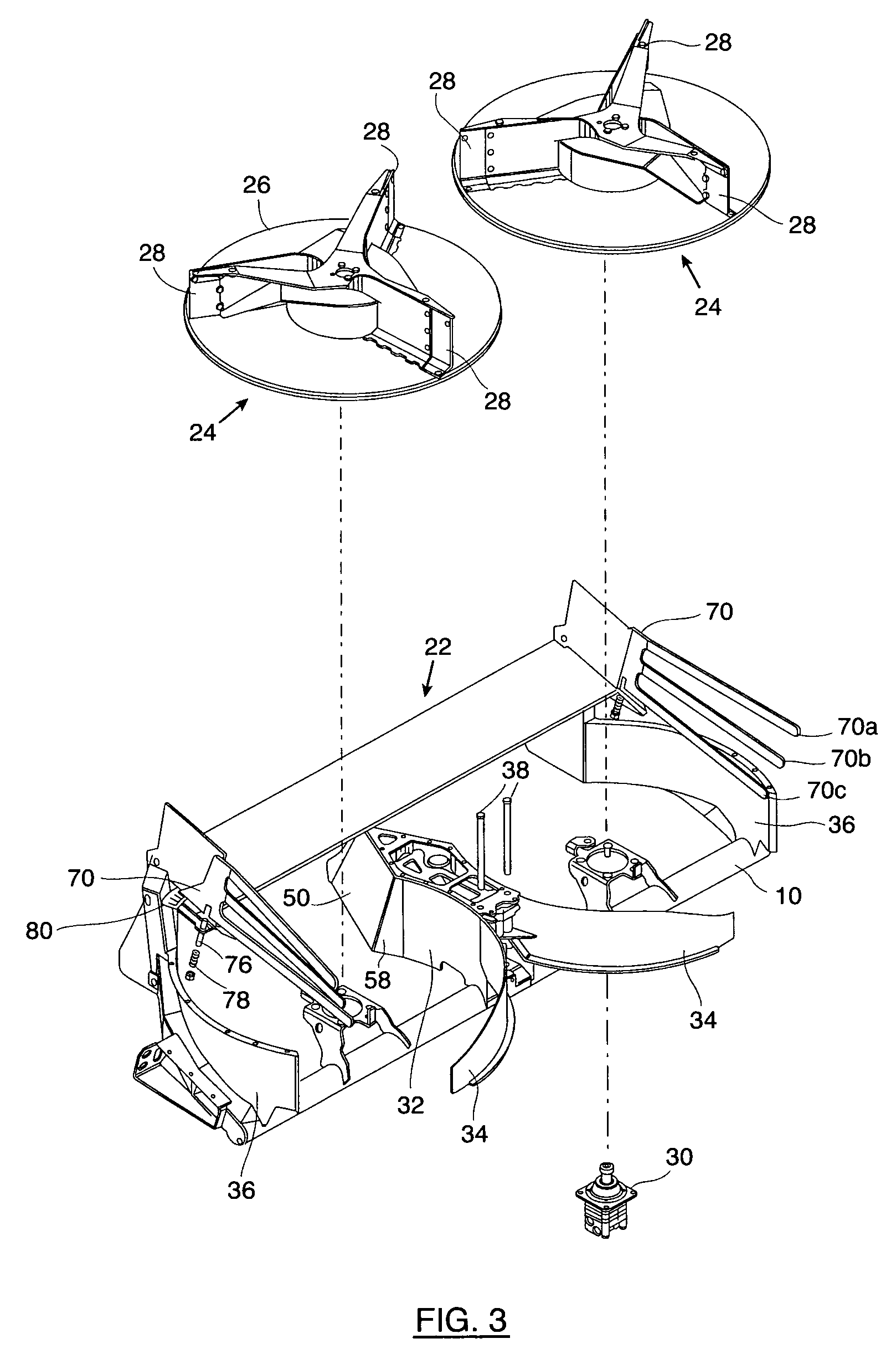

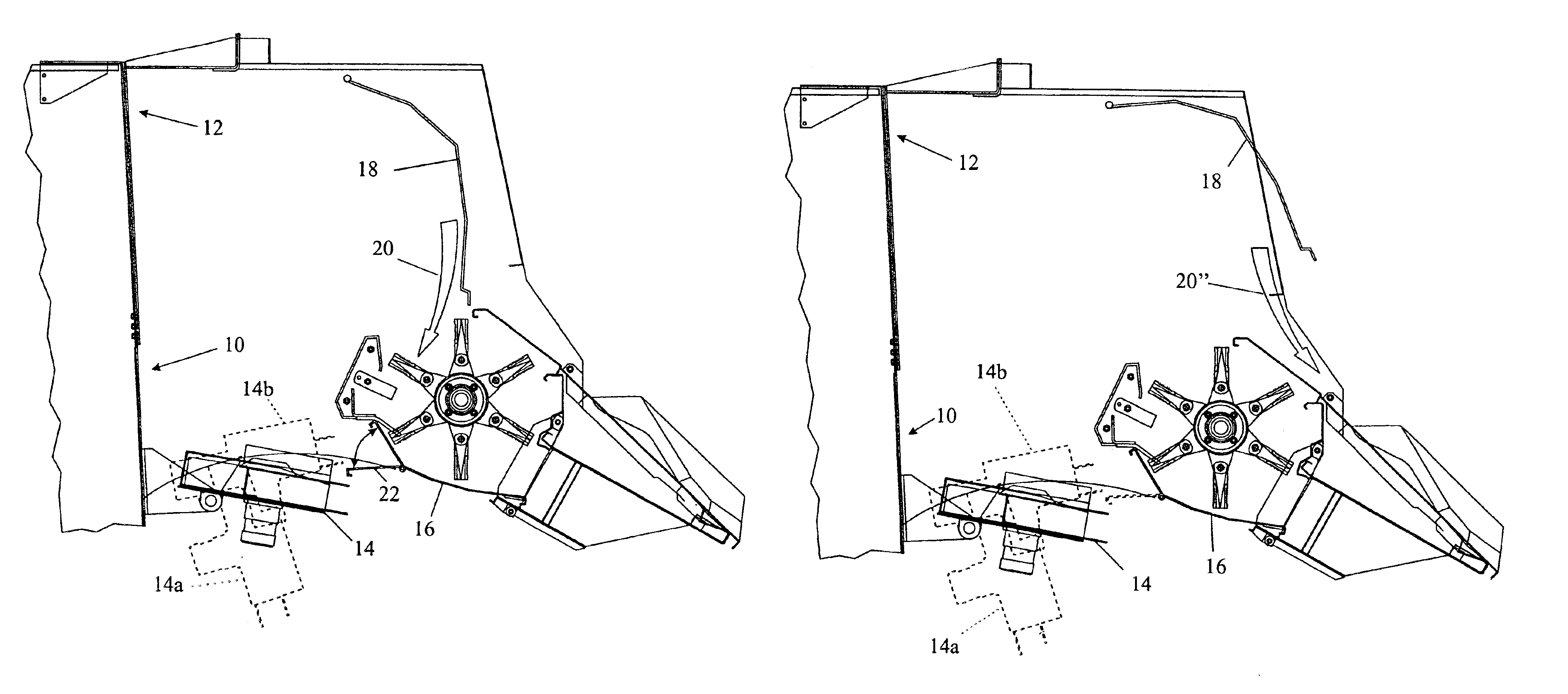

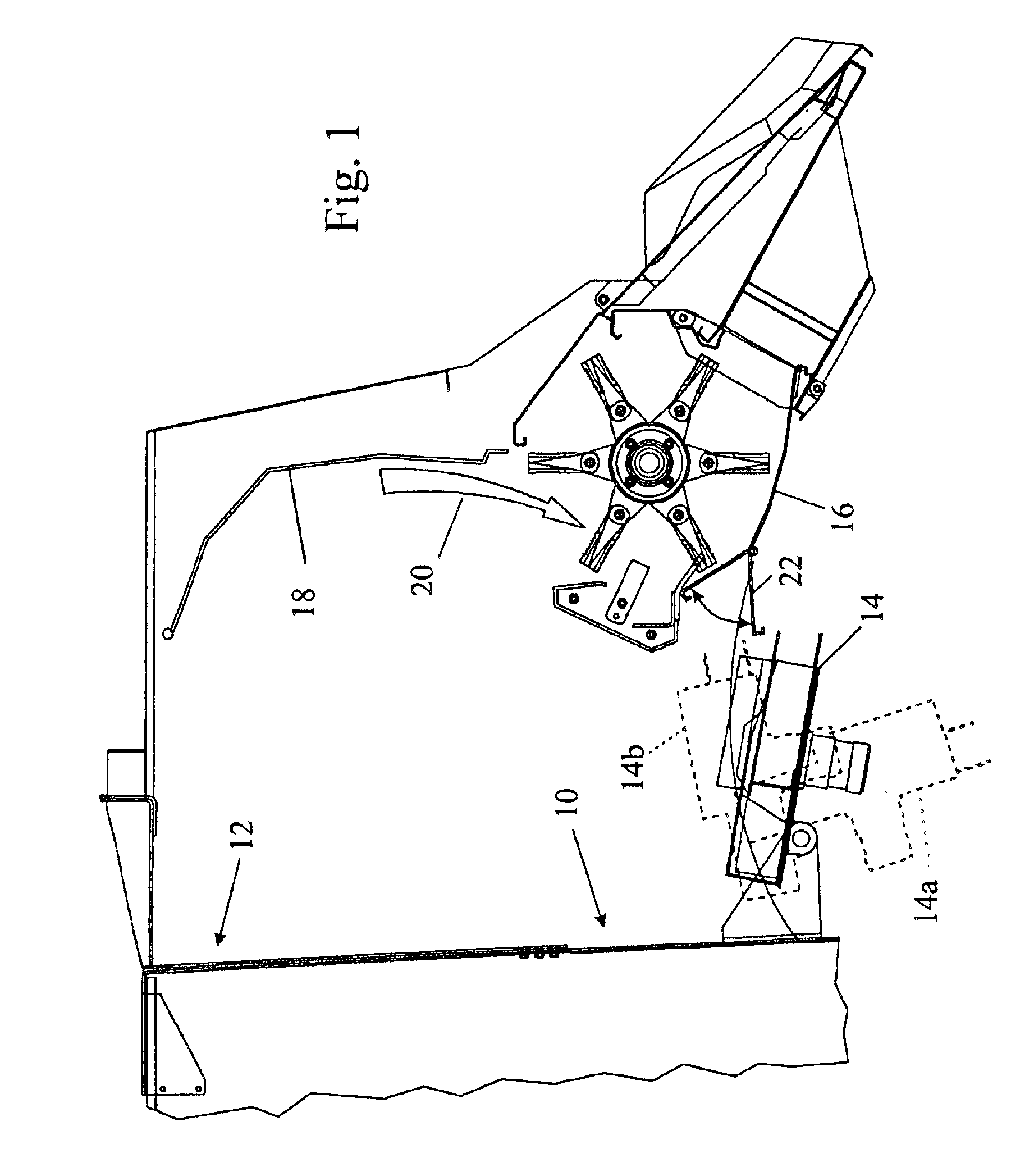

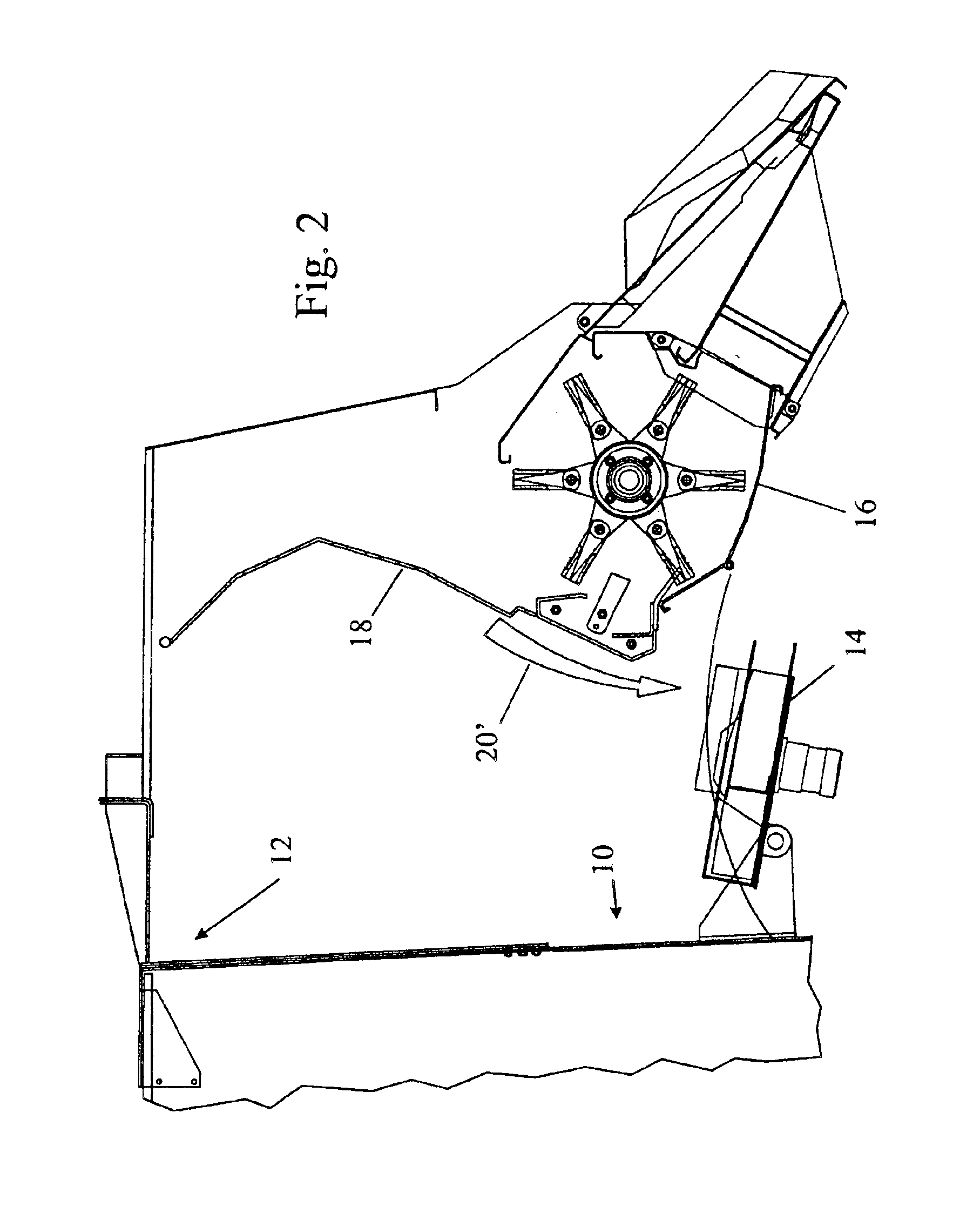

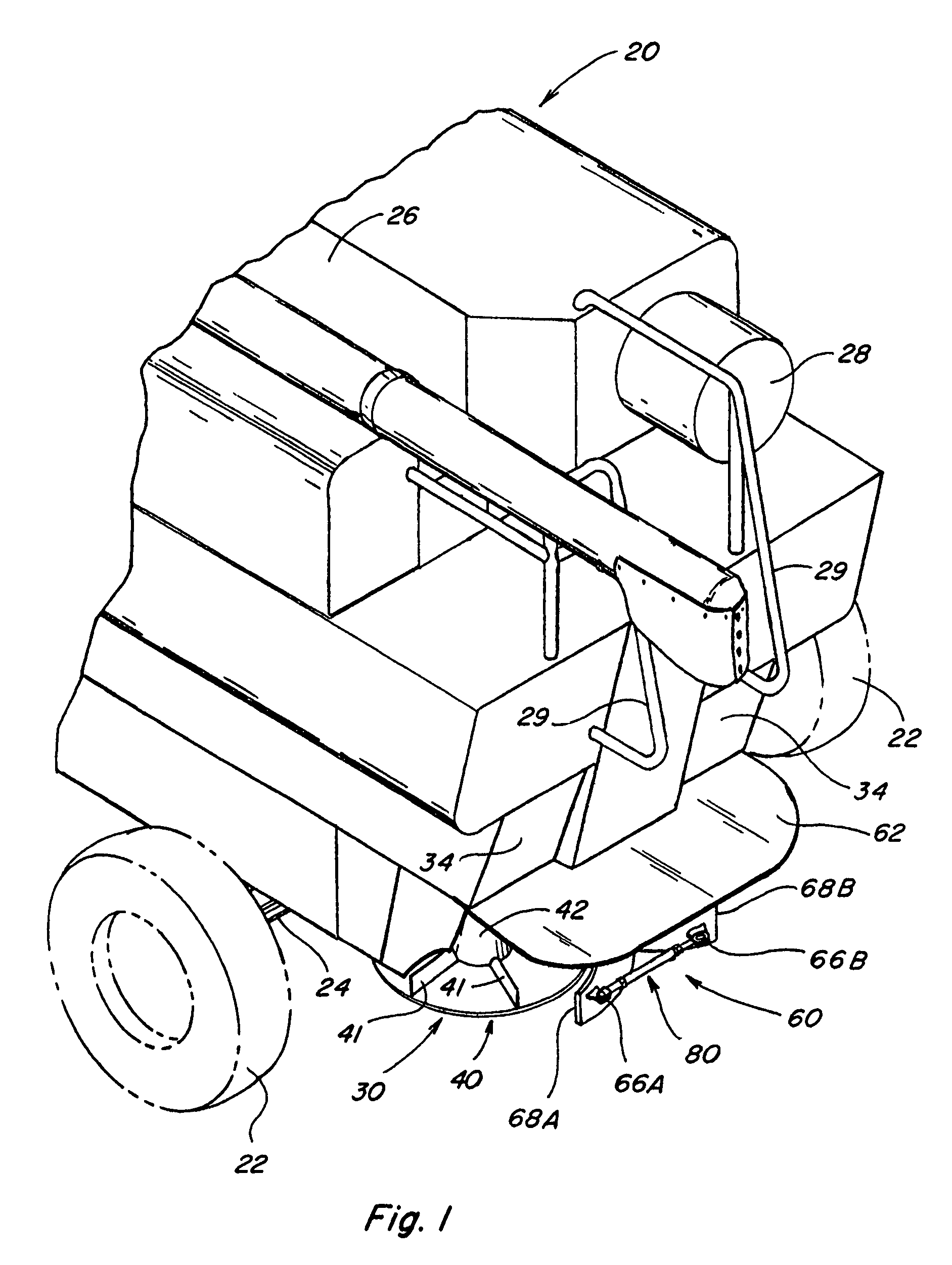

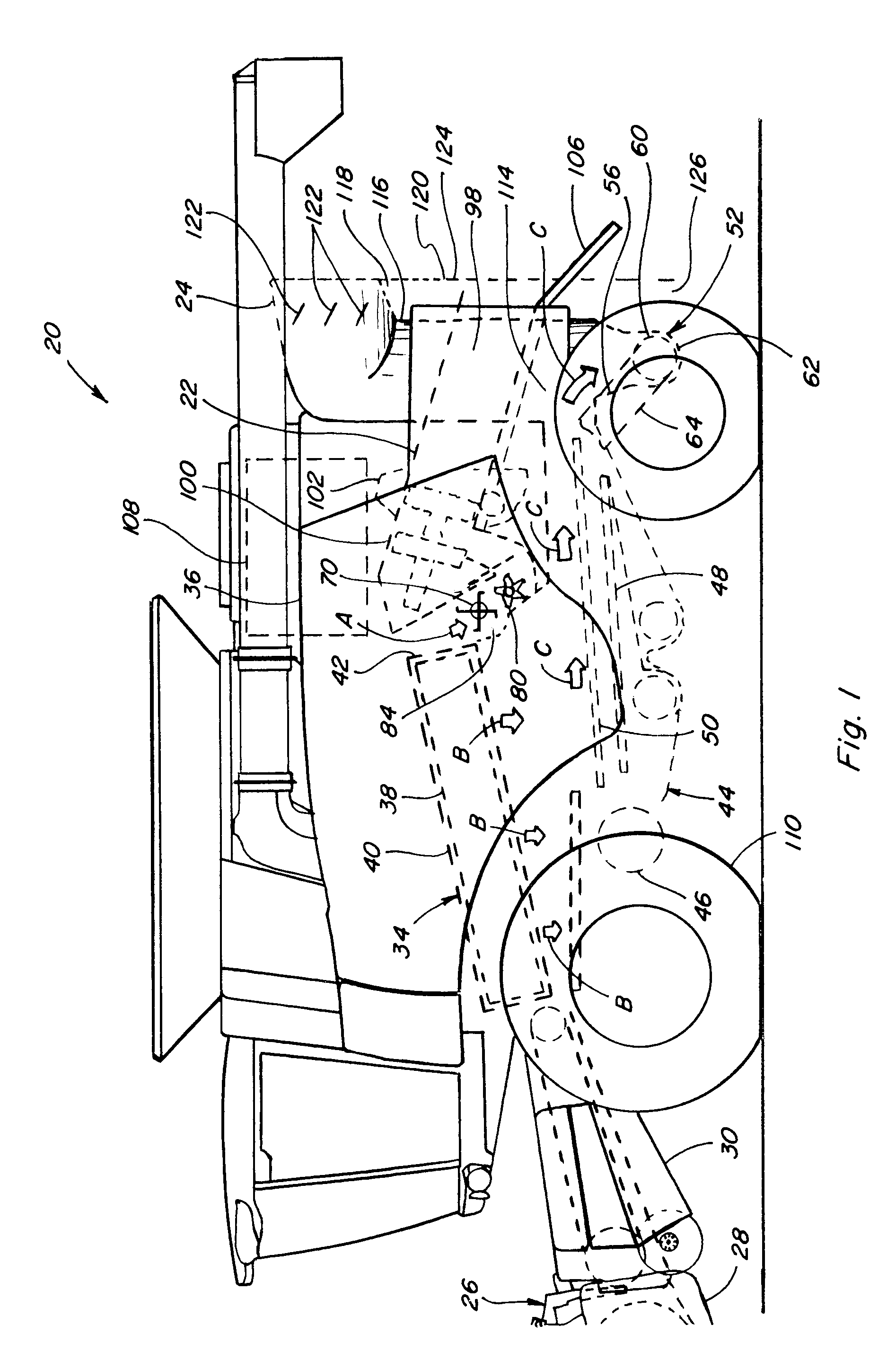

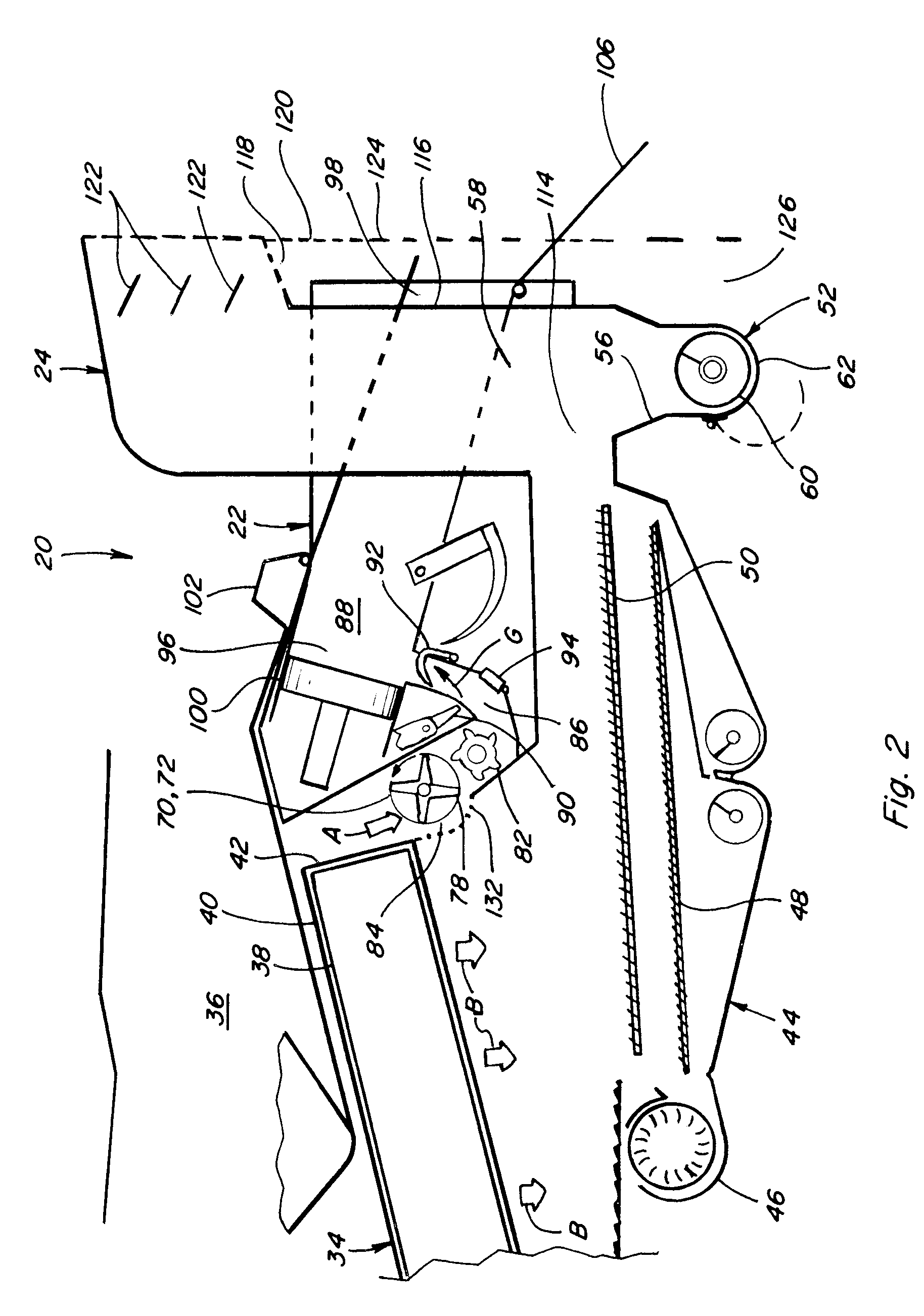

Crop residue clearing device

ActiveUS8393407B2Less susceptible to damage and destructionReduce penetrationSpadesTill seedingGear wheelCrop residue

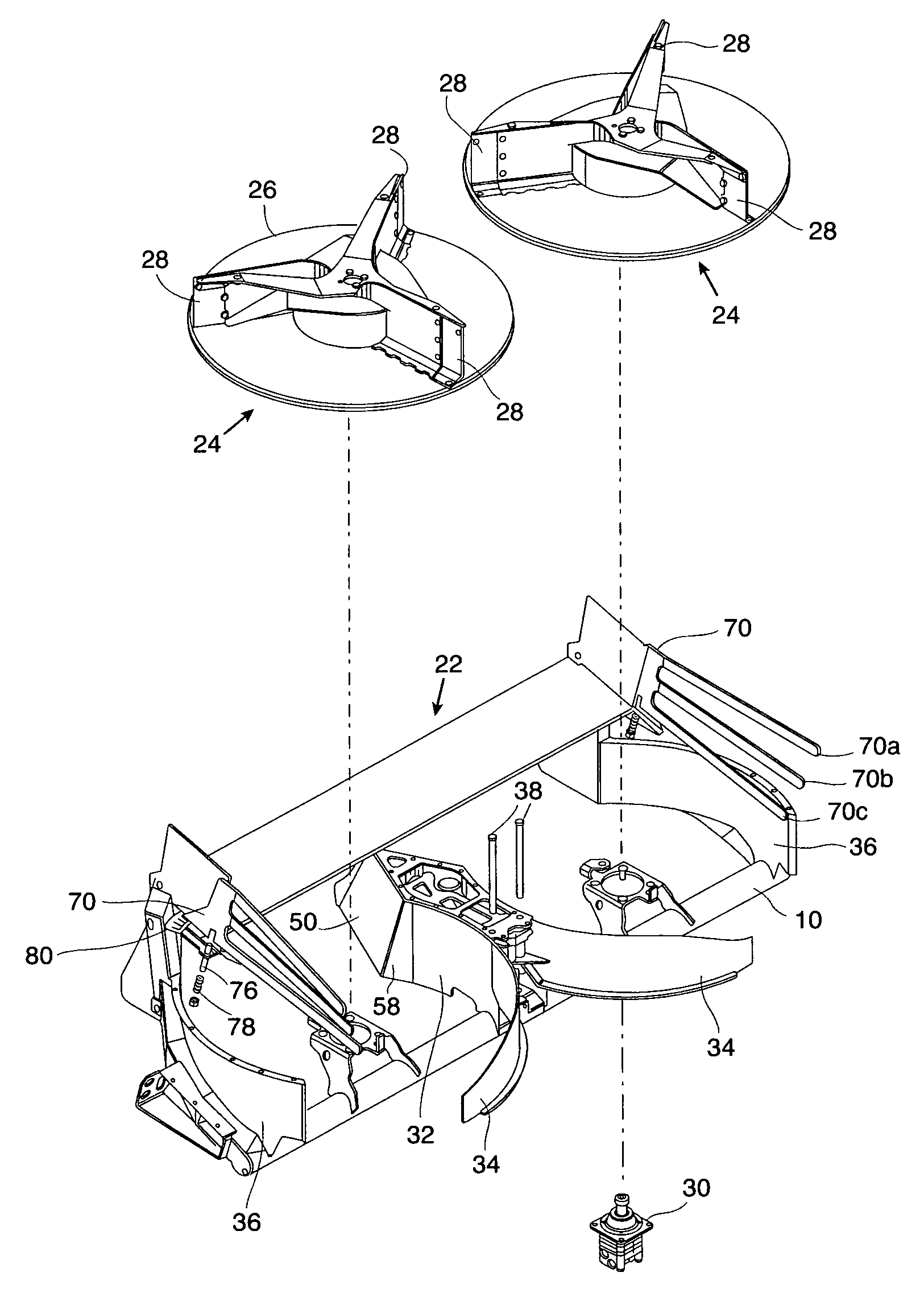

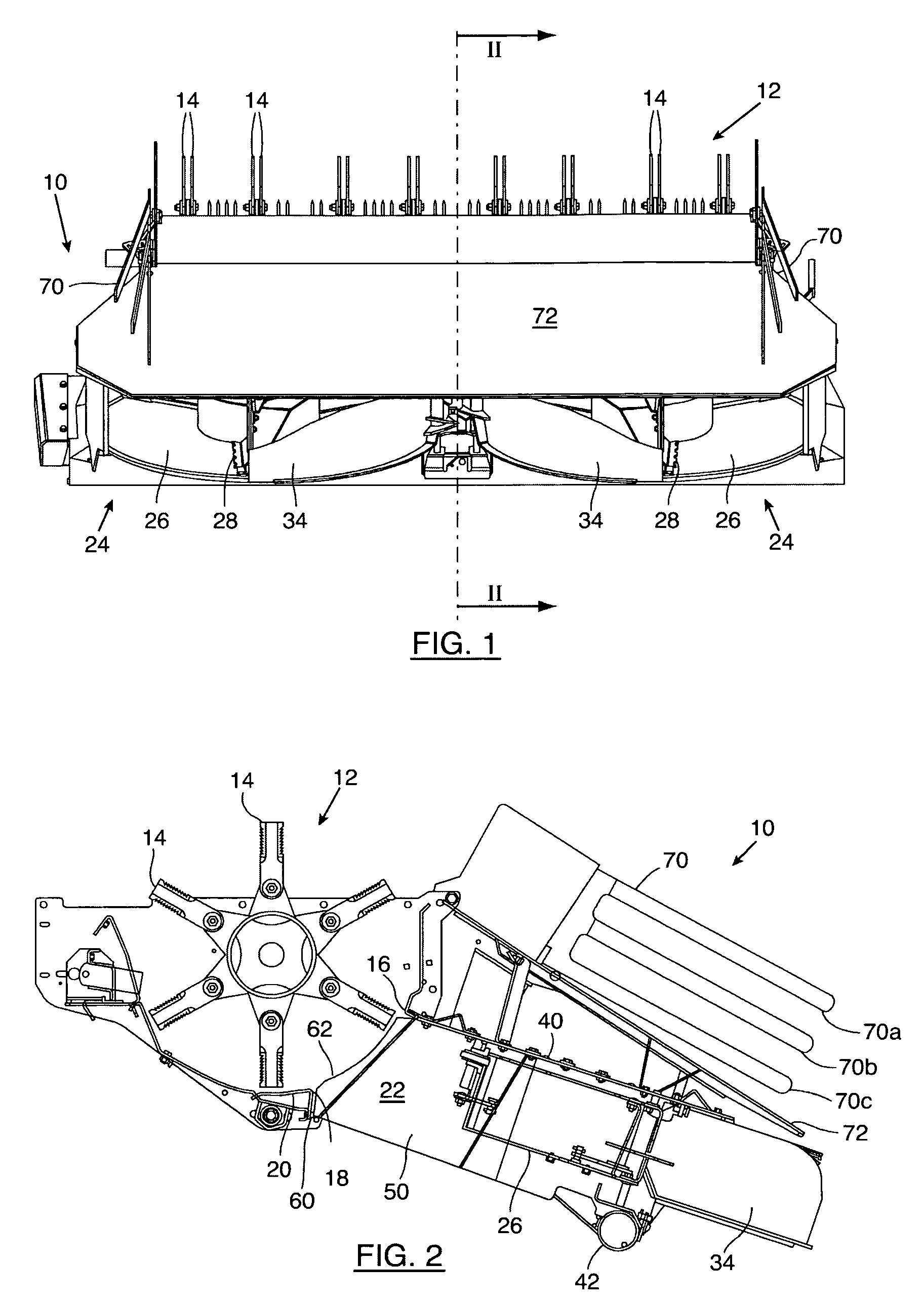

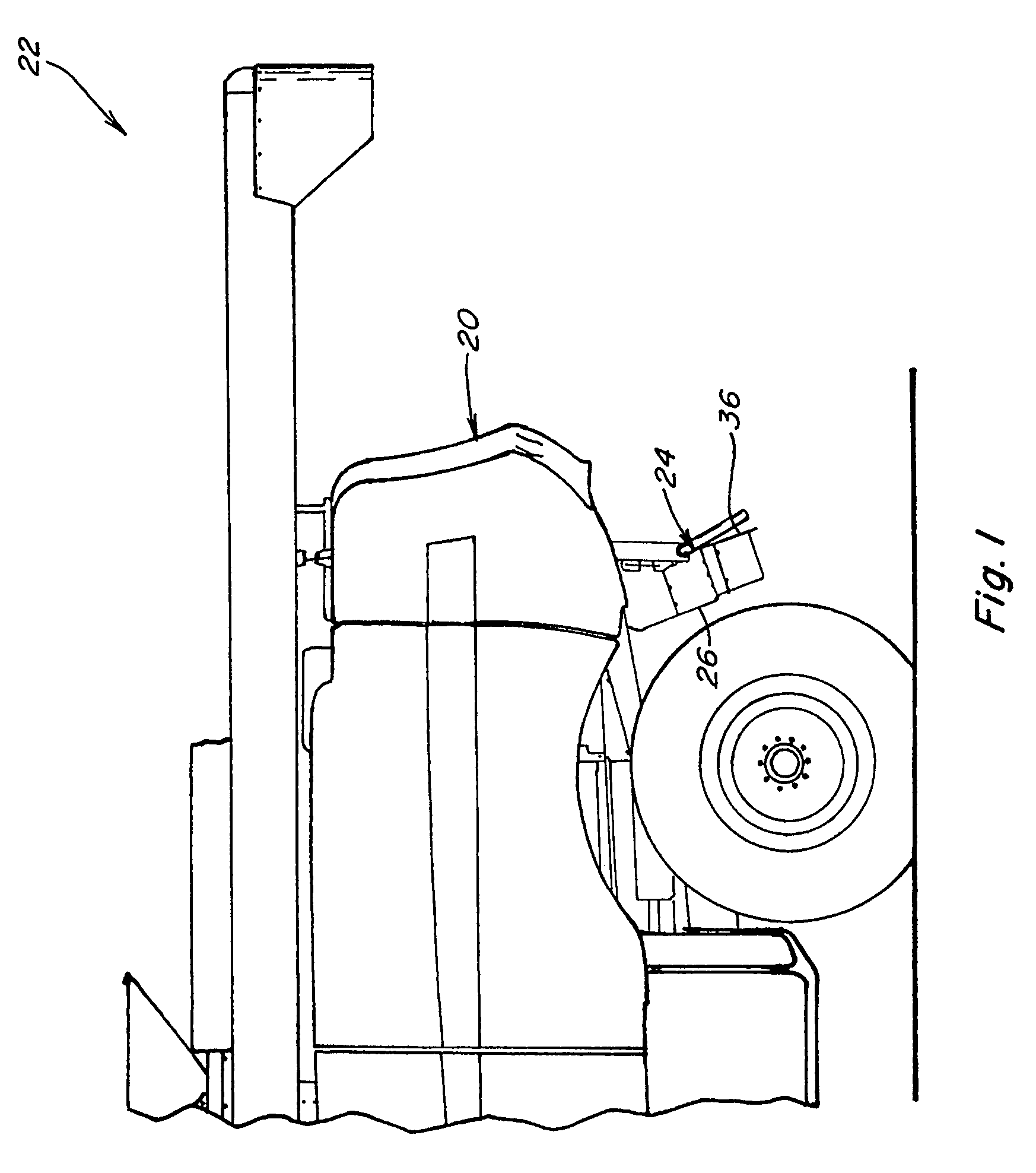

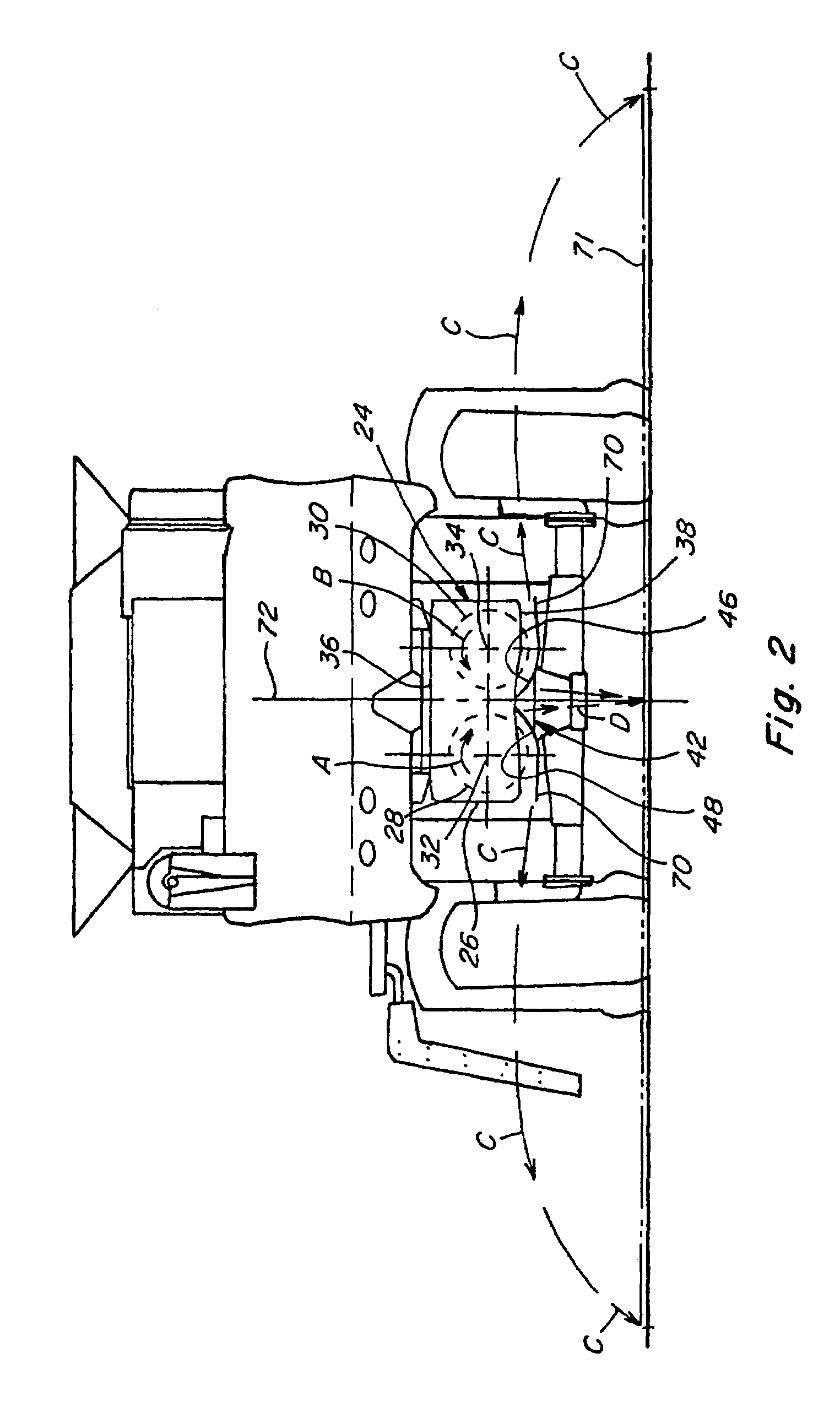

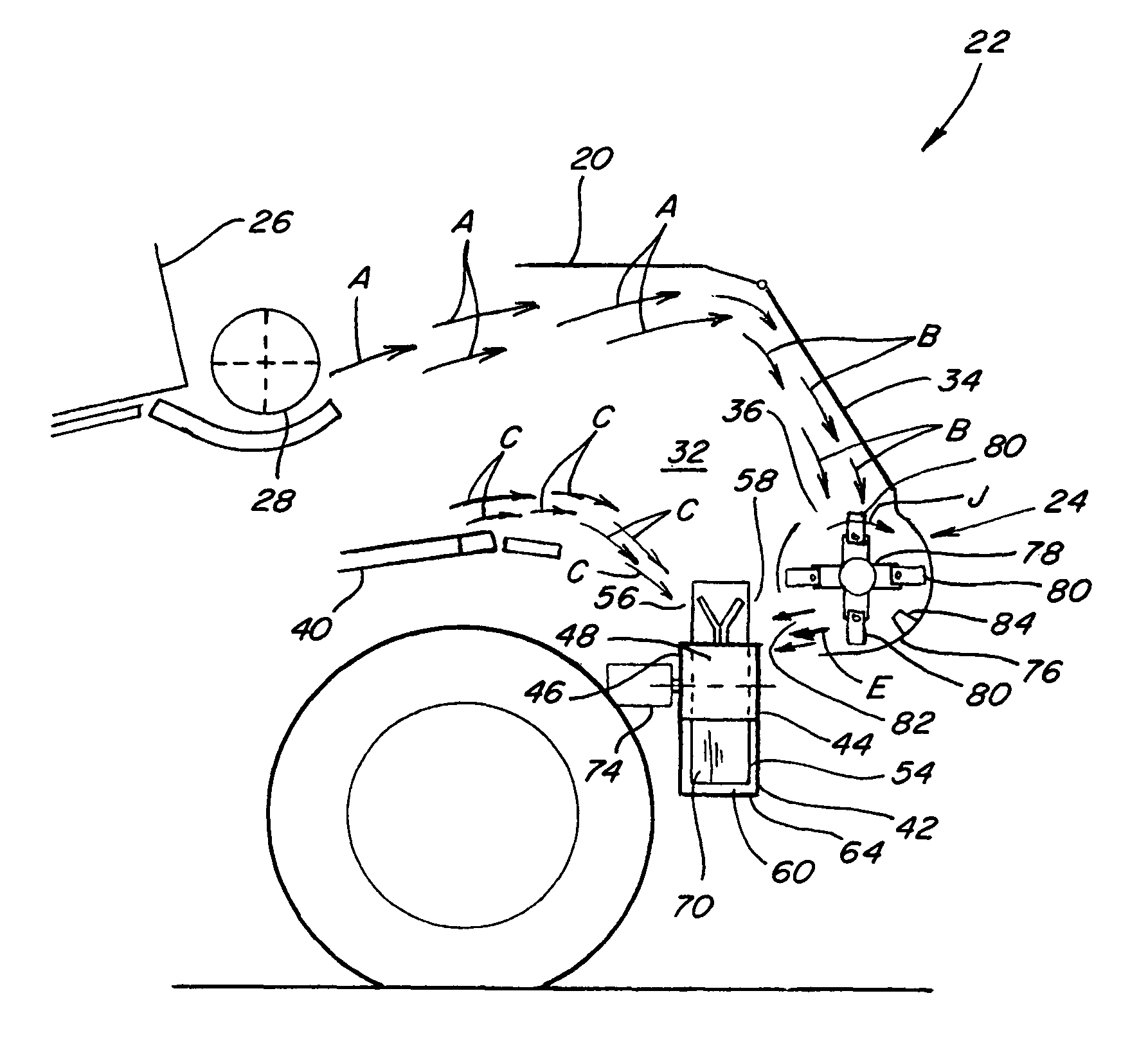

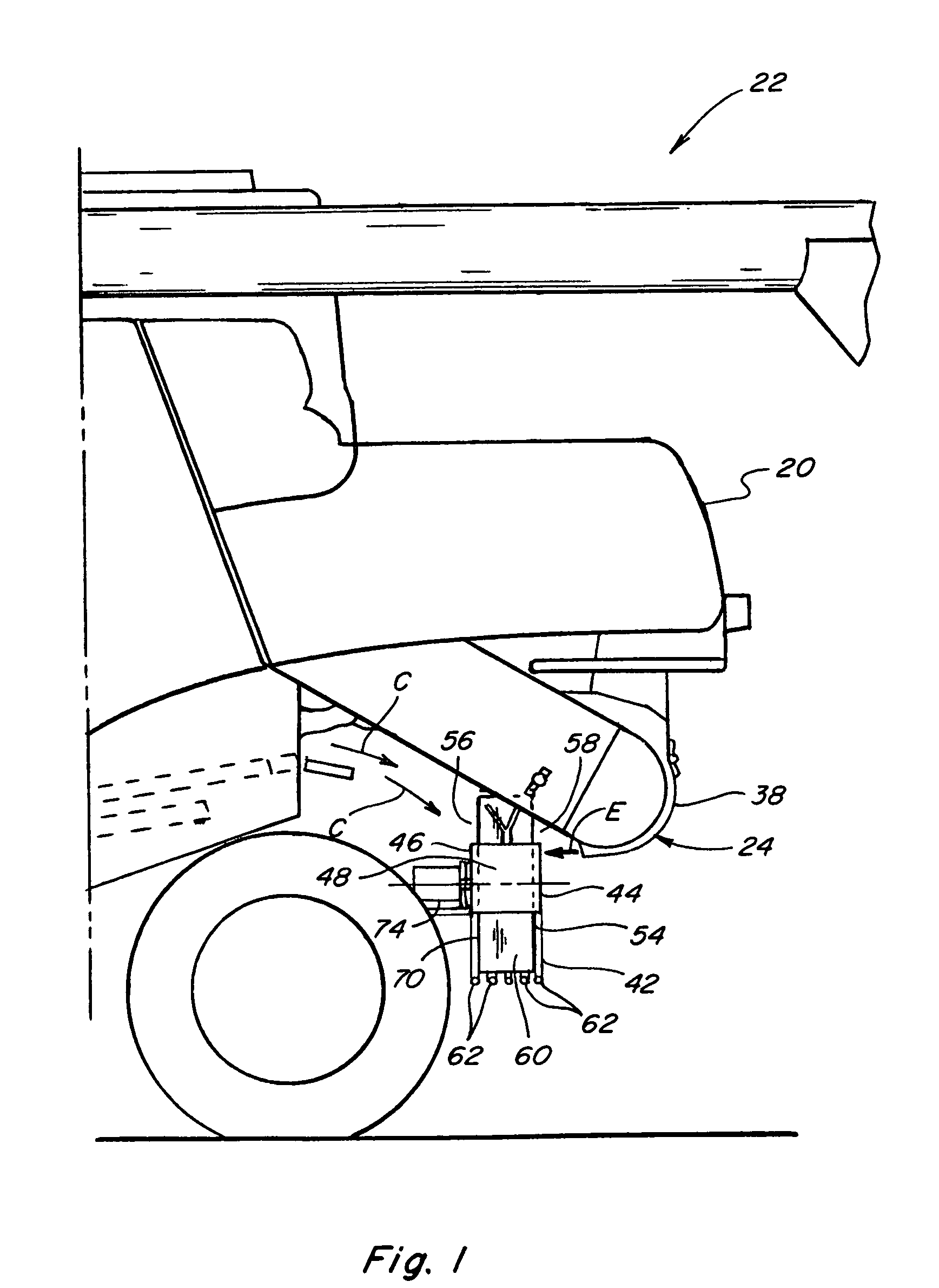

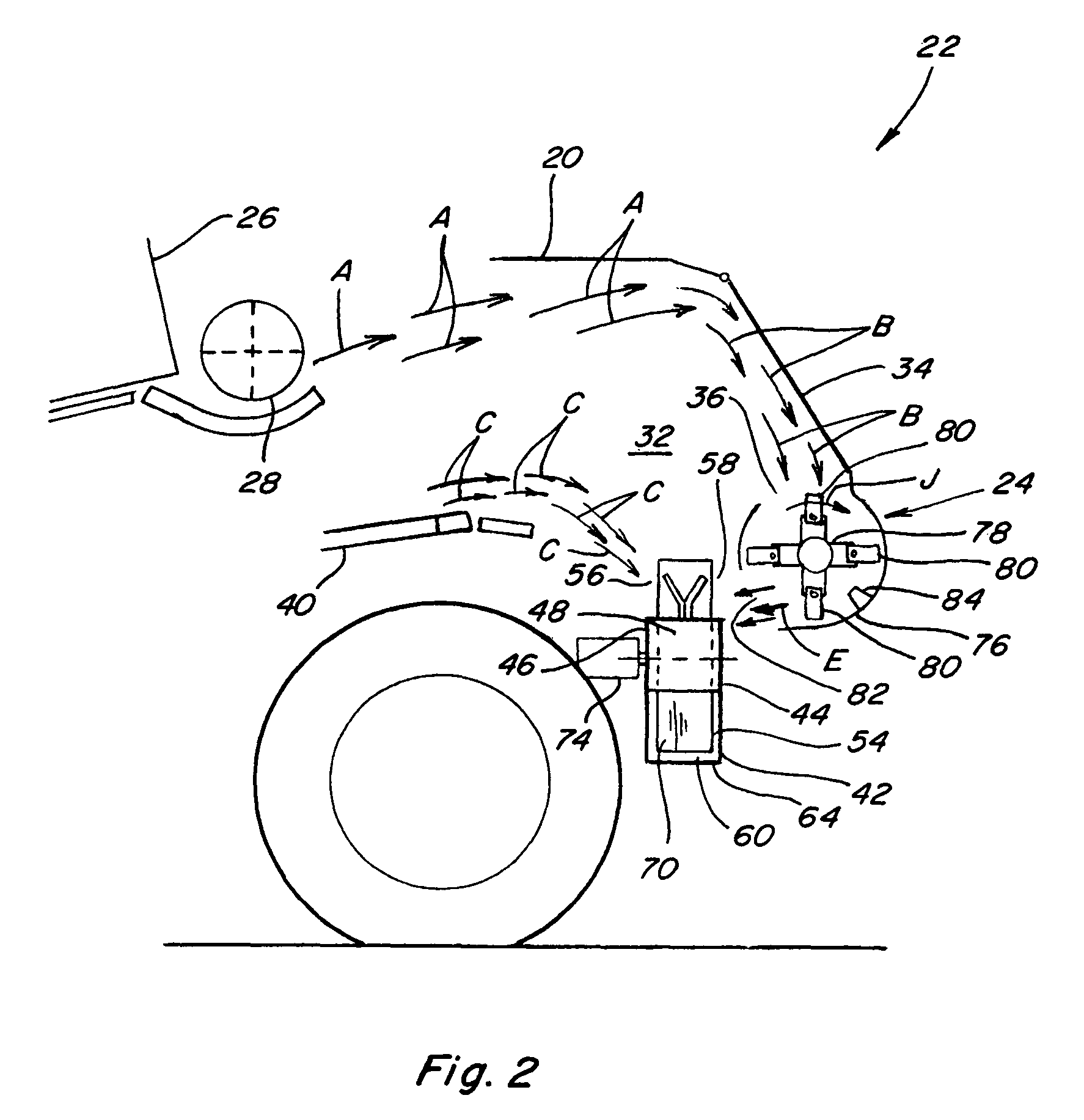

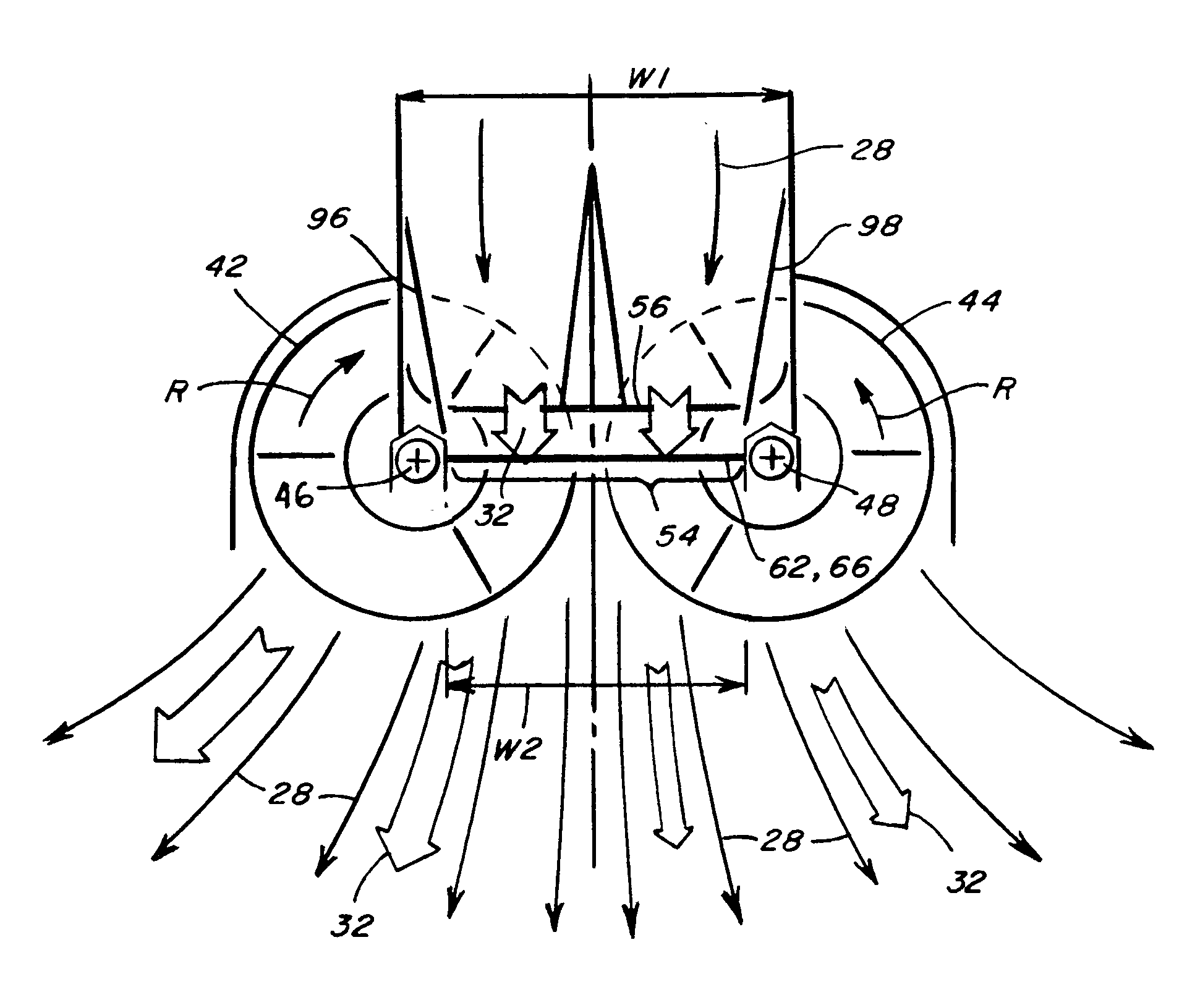

Apparatus for clearing crop residue from a field is adapted for attachment to a tool bar of an agricultural implement or to a planter unit such that the apparatus is pulled through a field by the implement. The apparatus includes a support structure extending forward of the tool bar and at least one and preferably a pair of floating arms pivotally attached to a forward portion of the support structure and extending rearwardly, with a toothed wheel rotationally attached to an aft end of the arm(s). A coulter attached to the support structure is disposed between and extends forward of the soil-engaging toothed wheel(s) and in combination with the wheel(s) severs and removes residue in the seeding pathway. An adjustable biasing arrangement urges the toothed wheels, either in unison or independently, downwardly into engagement with the soil. Upper and lower stop limits are provided to limit vertical positioning of the toothed wheel(s).

Owner:AG FOCUS LLC

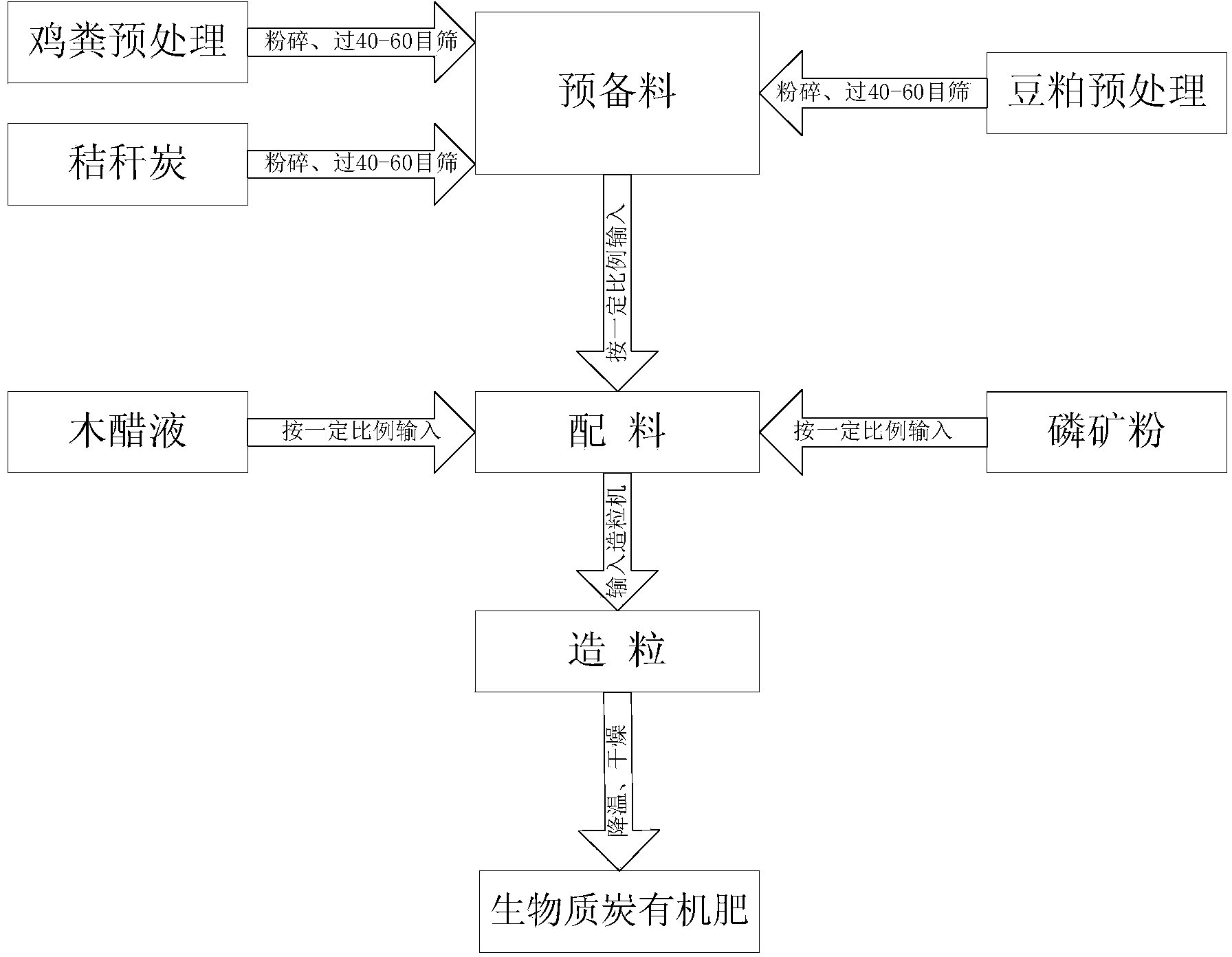

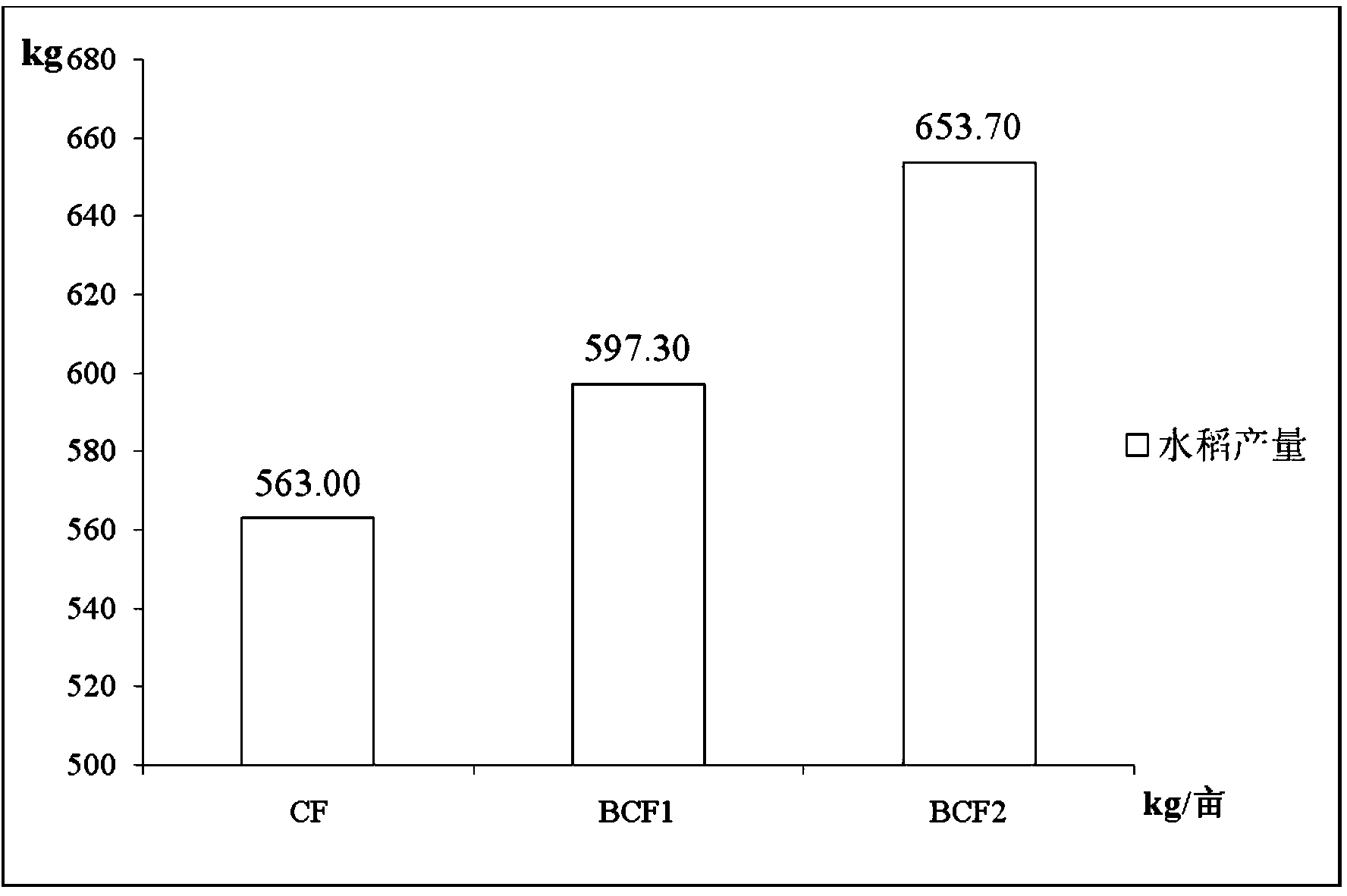

Charcoal-based organic fertilizer and preparation method thereof

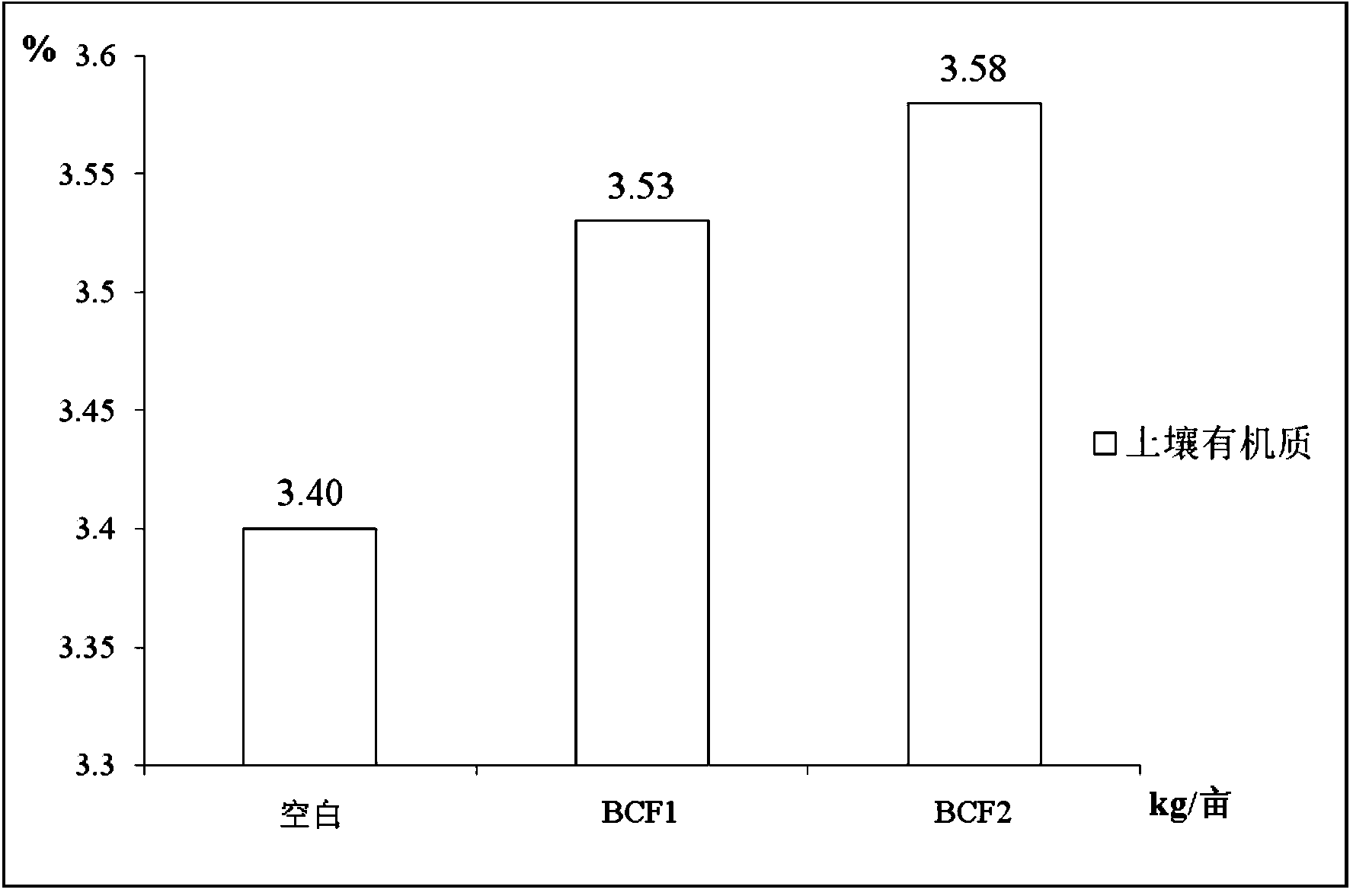

The invention relates to a charcoal-based organic fertilizer and a preparation method thereof. The charcoal-based organic fertilizer has the advantages of low cost, environment friendliness, good fertilizer efficiency, wide application range, high fertilizer efficiency utilization rate and pest prevention. The preparation method comprises the steps as follows: adding starter cultures to chicken manure and soybean meal respectively for fermentation, after drying, crushing and mixing crop-residue-derived carbon, the treated chicken manure and soybean meal with ground phosphate rock, adding wood vinegar to the mixture with stirring, performing granulation, and obtaining the charcoal-based organic fertilizer after cooling and drying.

Owner:五常市科发瑞扬农业有限公司

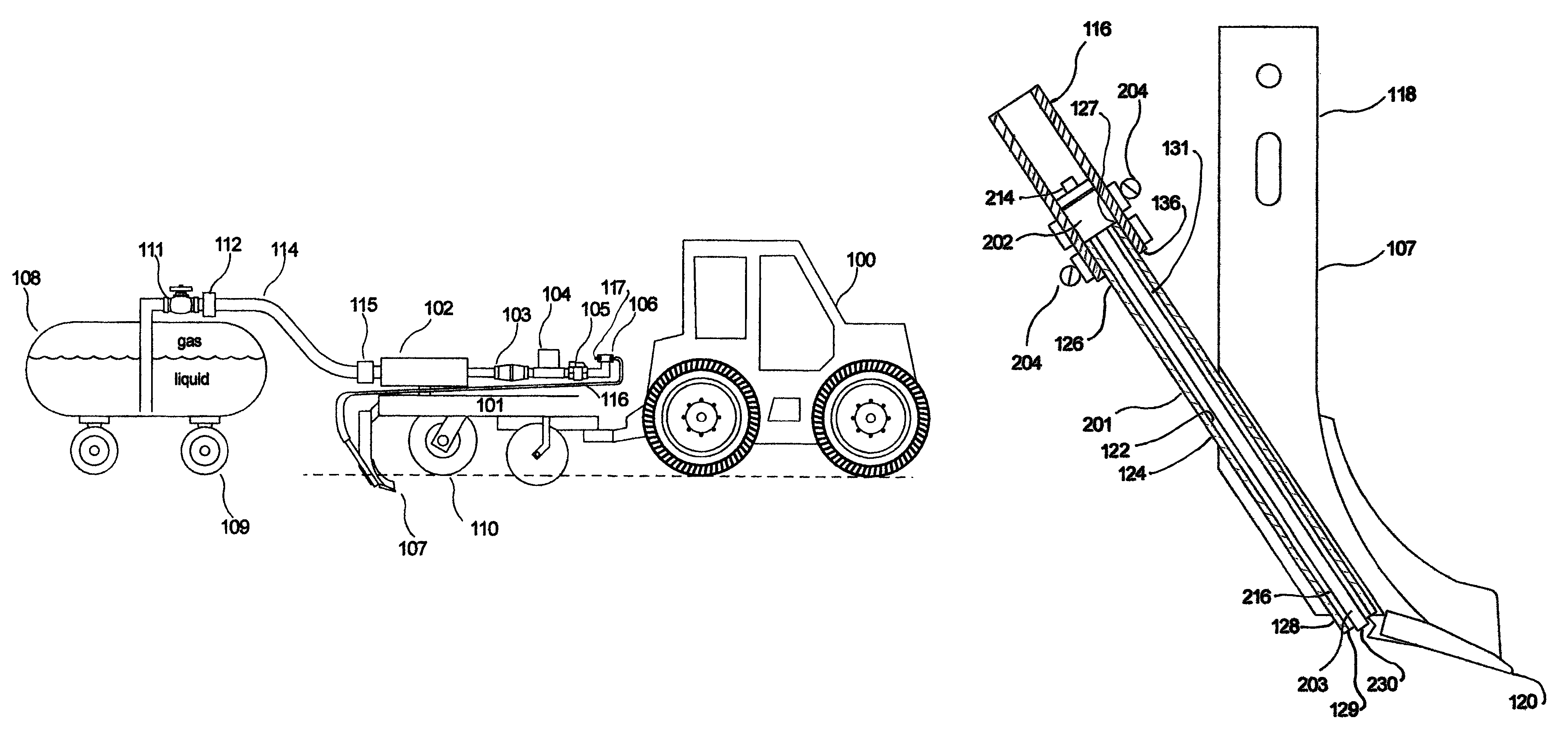

Apparatus for prevention of freezing of soil and crop residue to knife applying liquid anhydrous ammonia to the ground

InactiveUS7523709B1Reduce heat transferLow thermal conductivityPlantingLiquid fertiliser distributionCrop residueEngineering

A plastic discharge tube extends through a swaged cap bore through a metal swaged cap. A conical cap portion of the metal swaged cap is pressed into a retainer ring passage through a metal retainer ring. A swage surface in the retainer ring passage swages the conical portion of the metal swaged cap thereby fixing the position of the plastic discharge tube in the swaged cap bore and locking the swaged cap in the retainer ring passage. The plastic discharge tube is inserted into a steel injection tube fixed to a soil cutting knife. A ring bottom positioning surface contacts and injection tube upper end of the injection tube. A delivery hose is telescopically received on a plastic discharge tube retainer assembly and the steel injection tube. Hose clamps clamp the delivery hose to the retainer assembly and the injection tube.

Owner:360 YIELD CENT

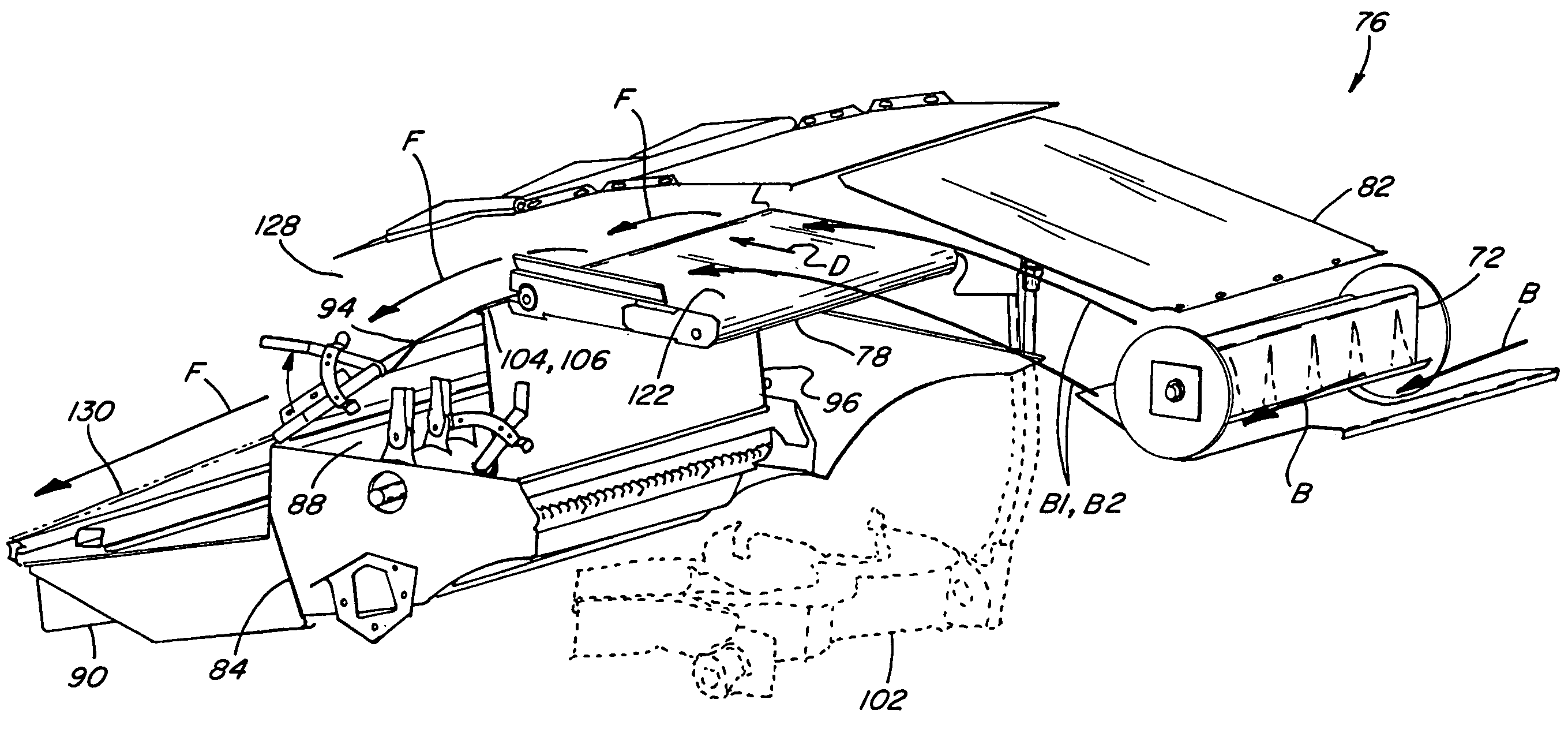

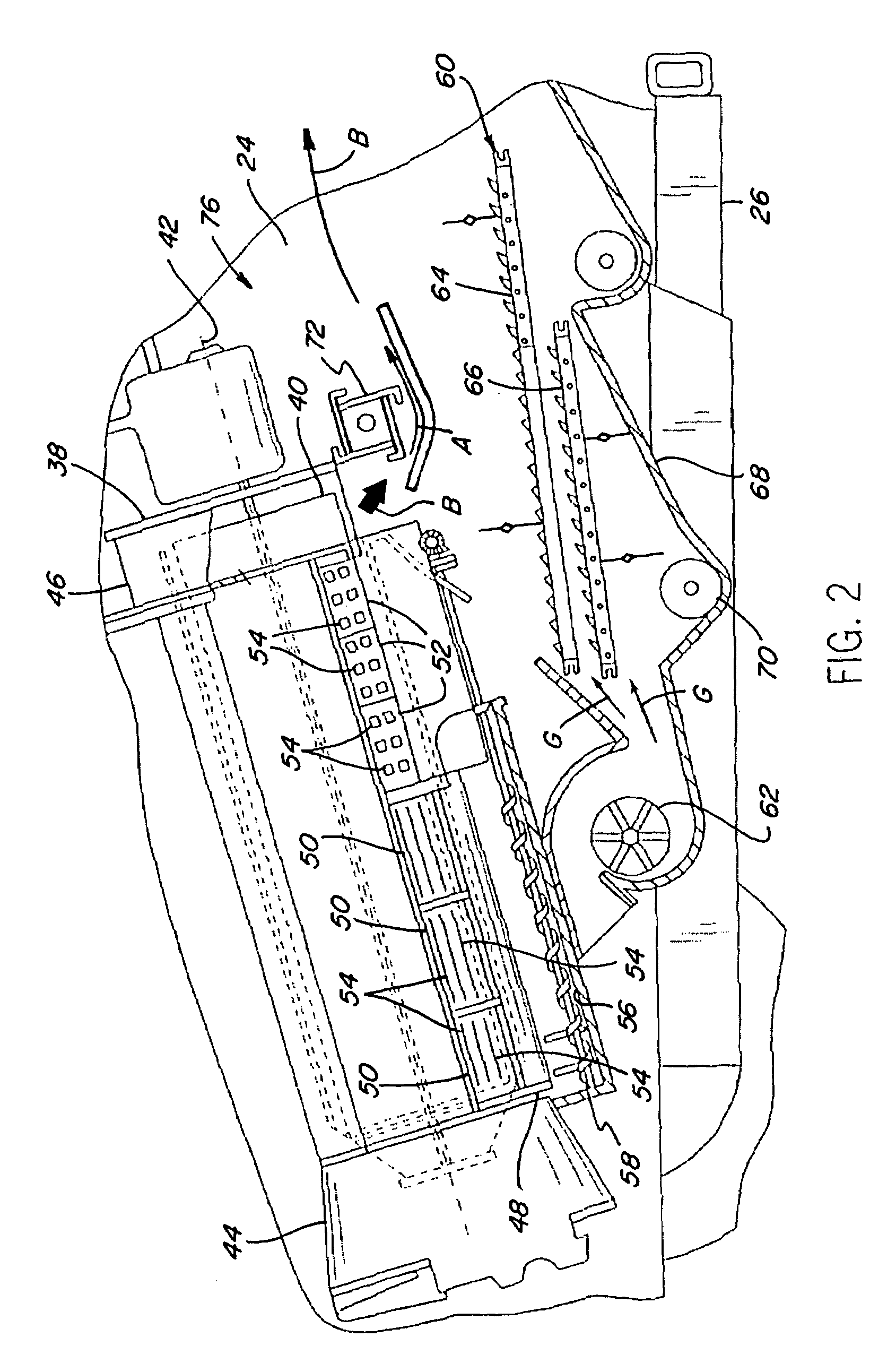

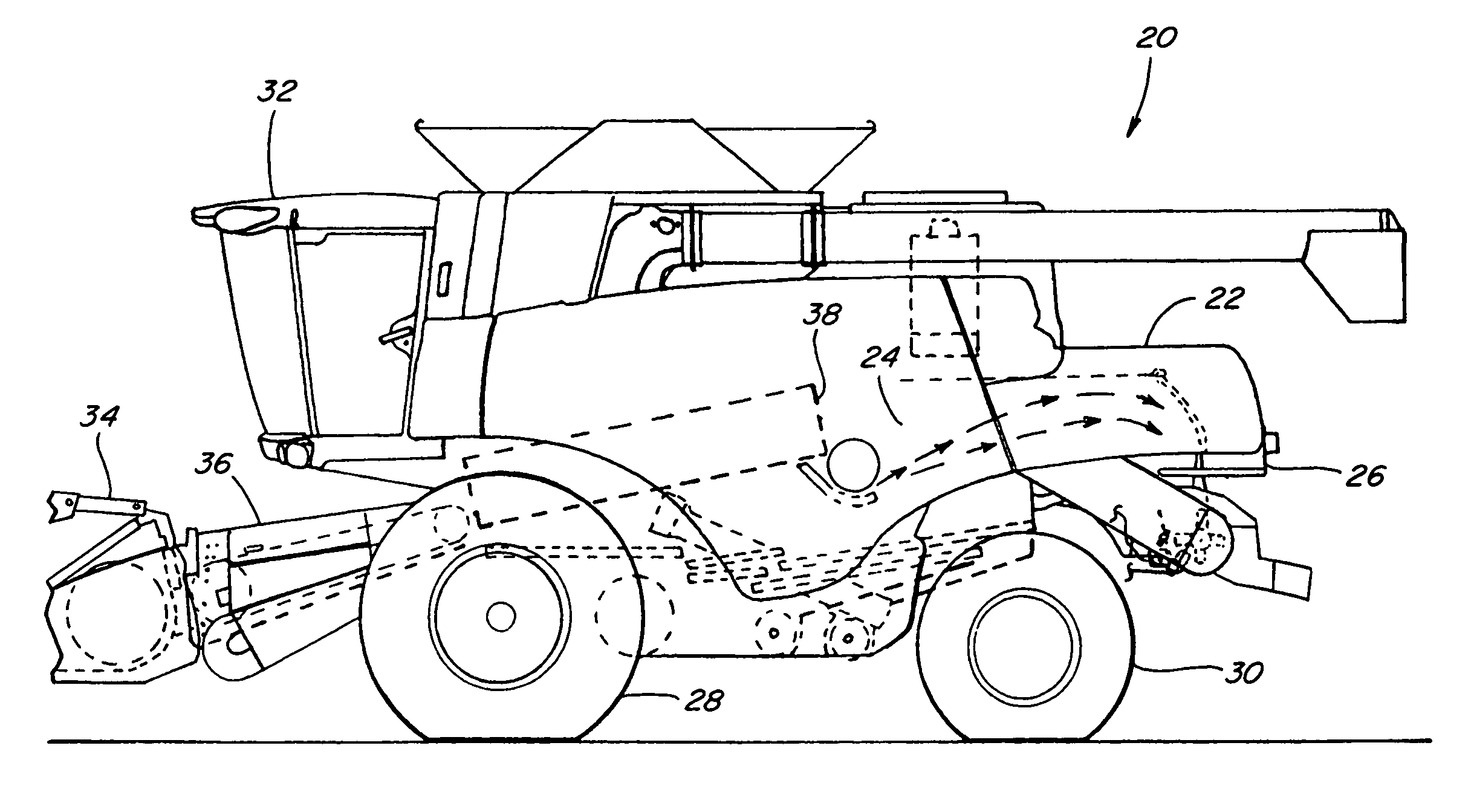

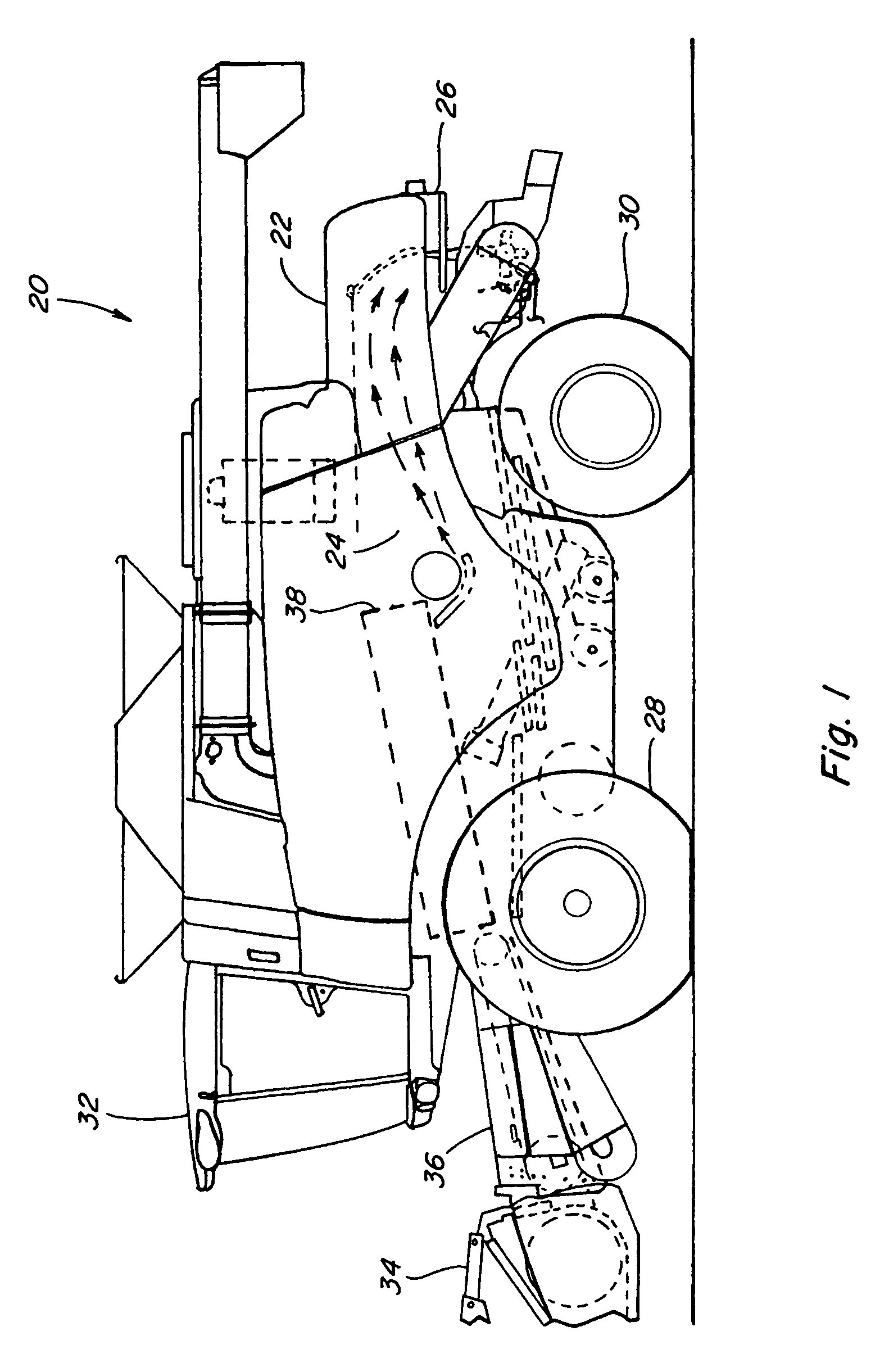

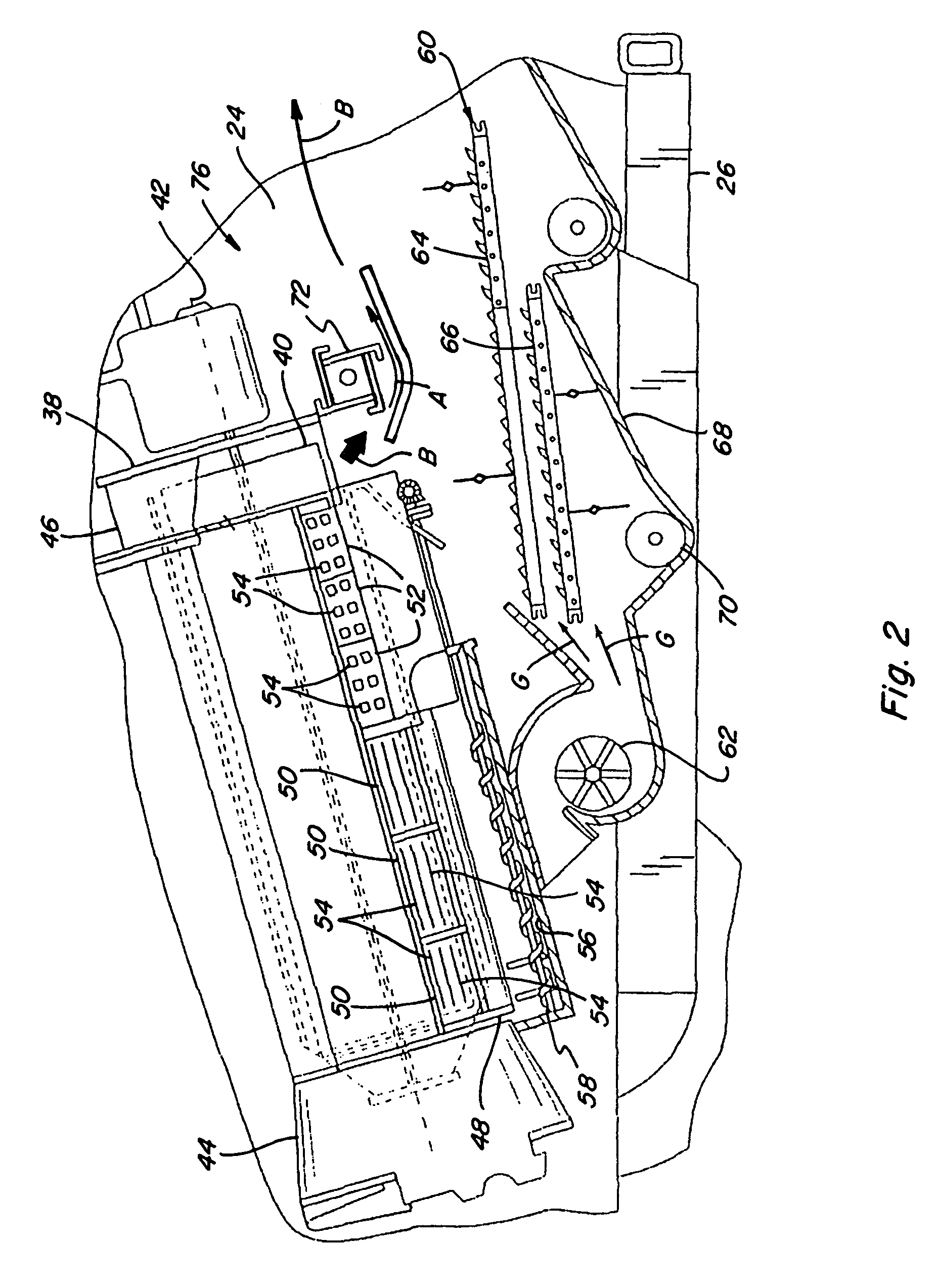

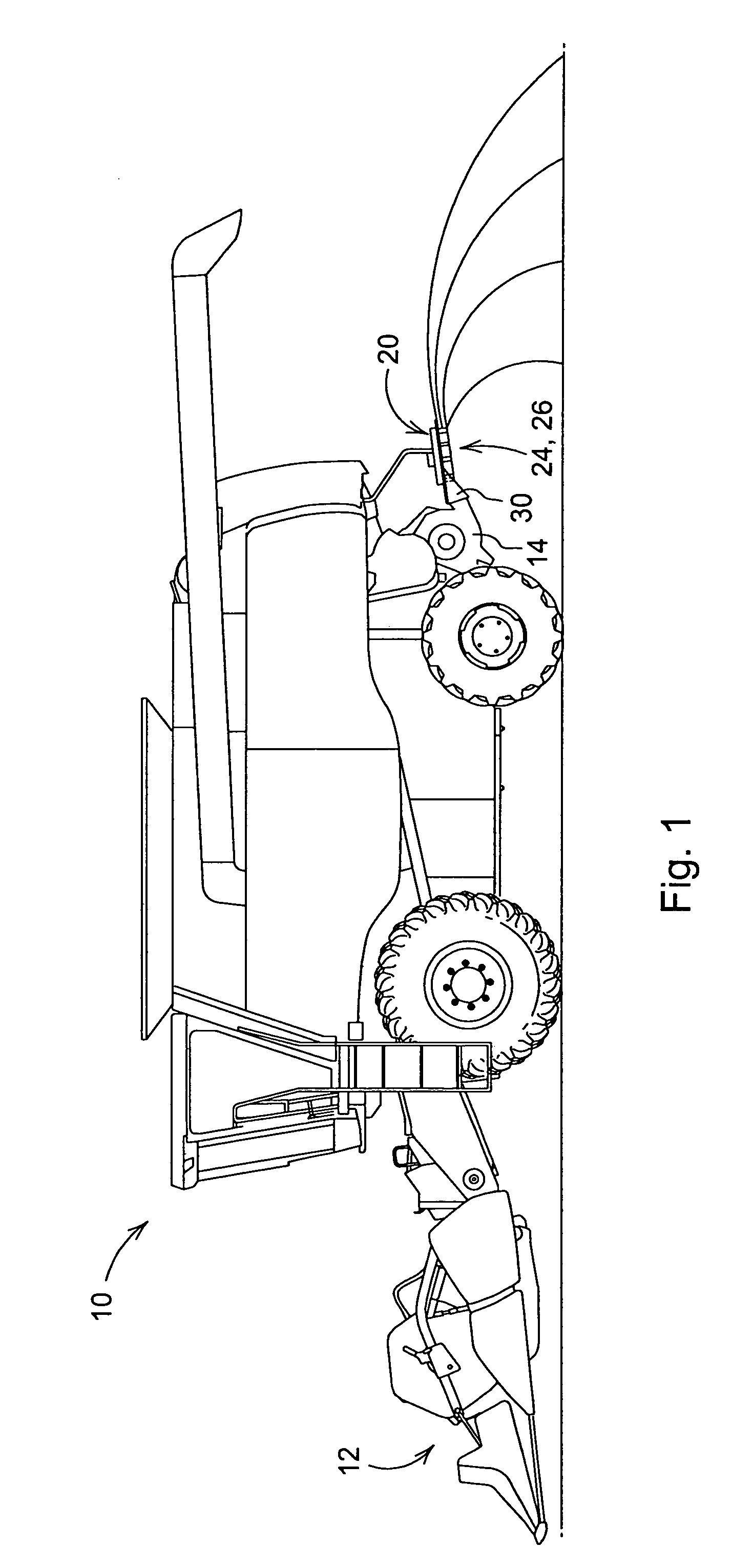

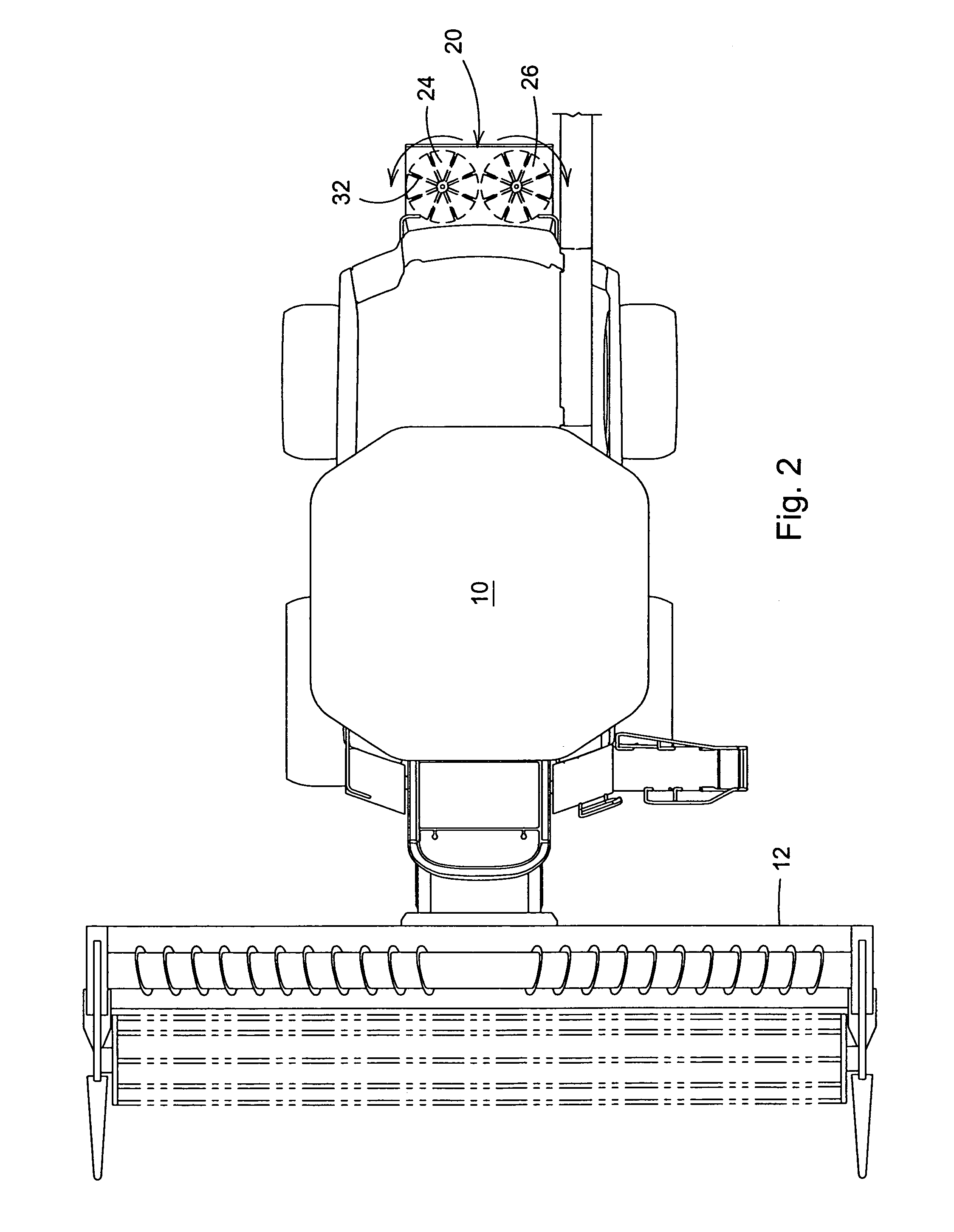

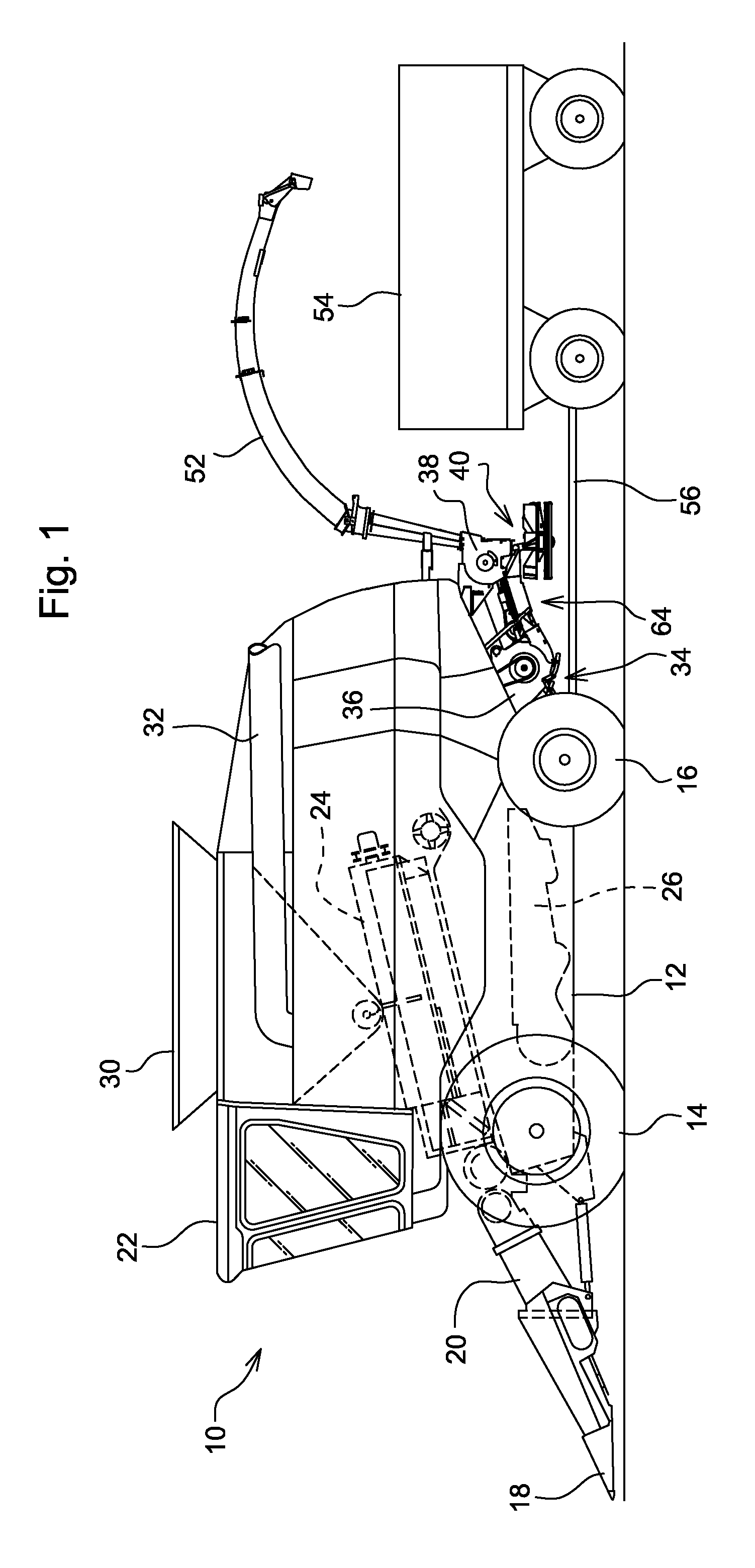

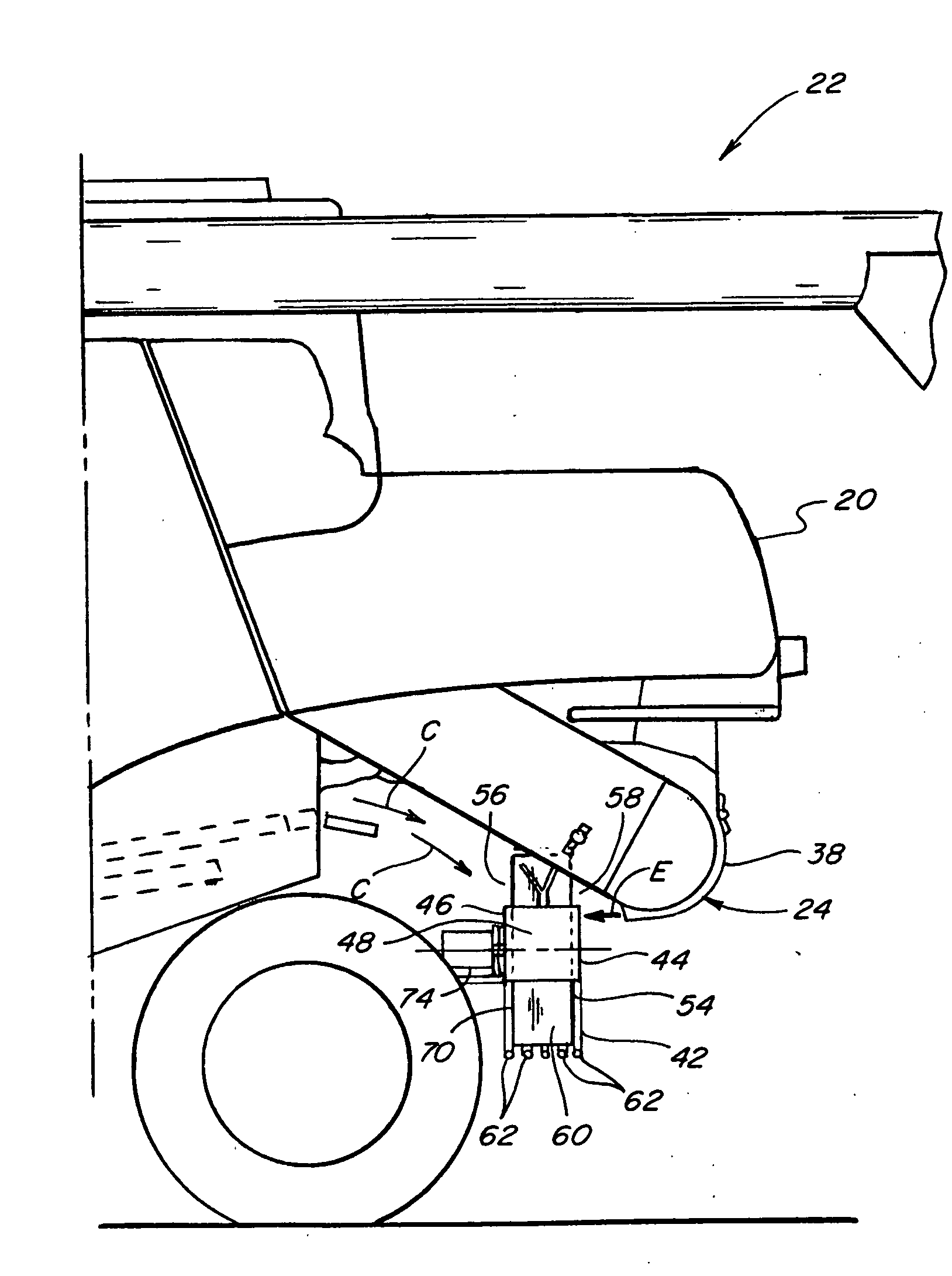

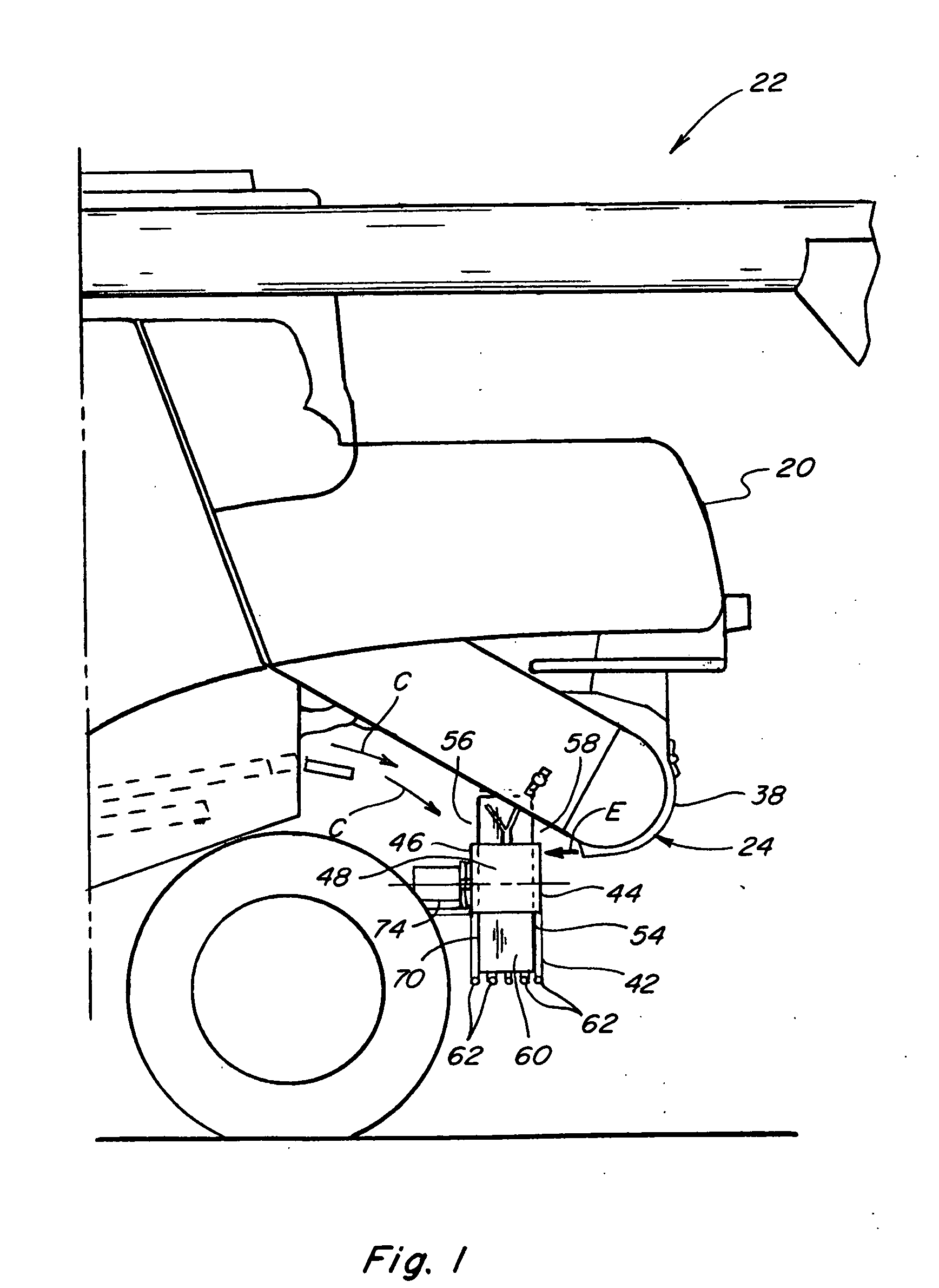

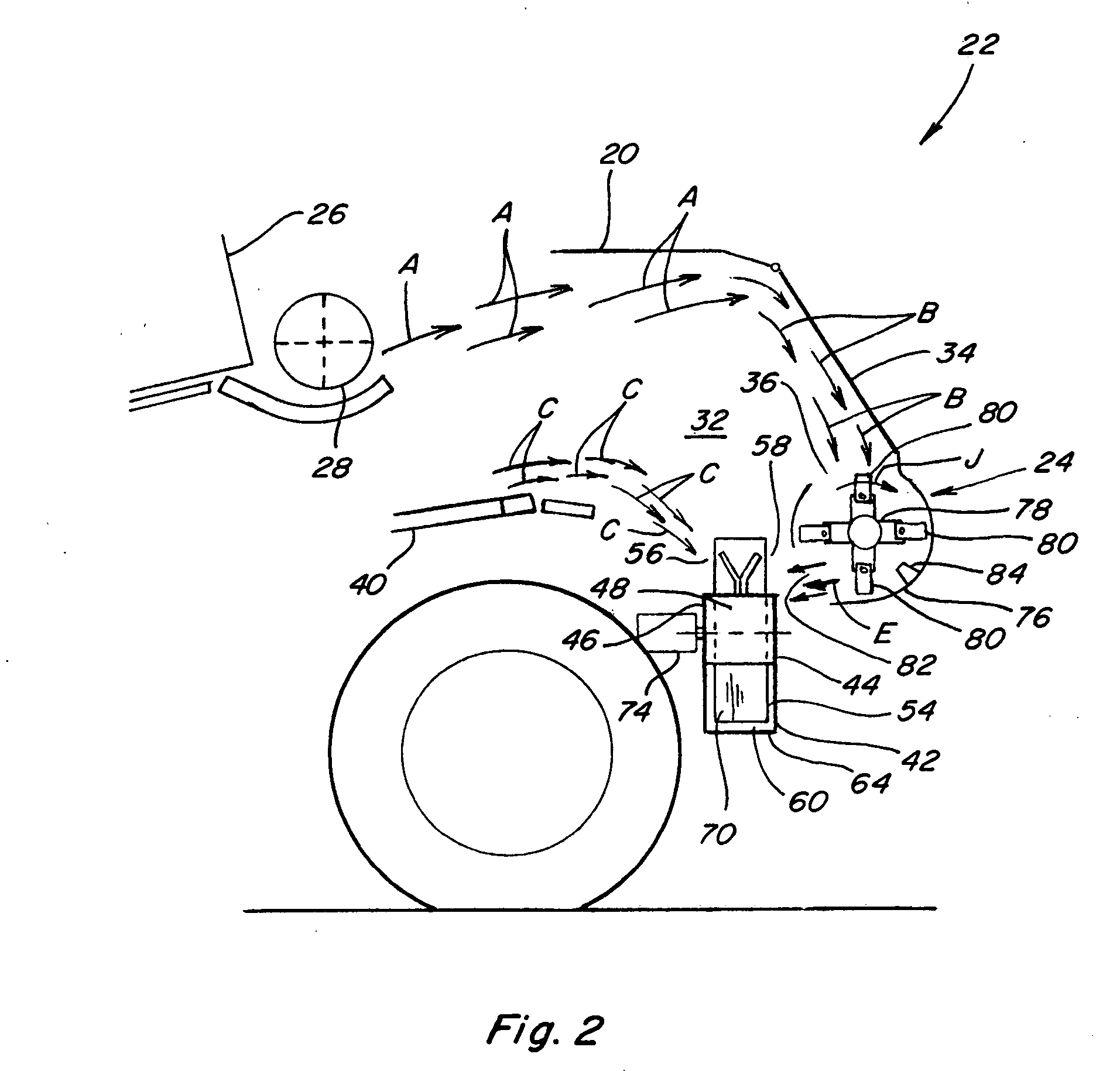

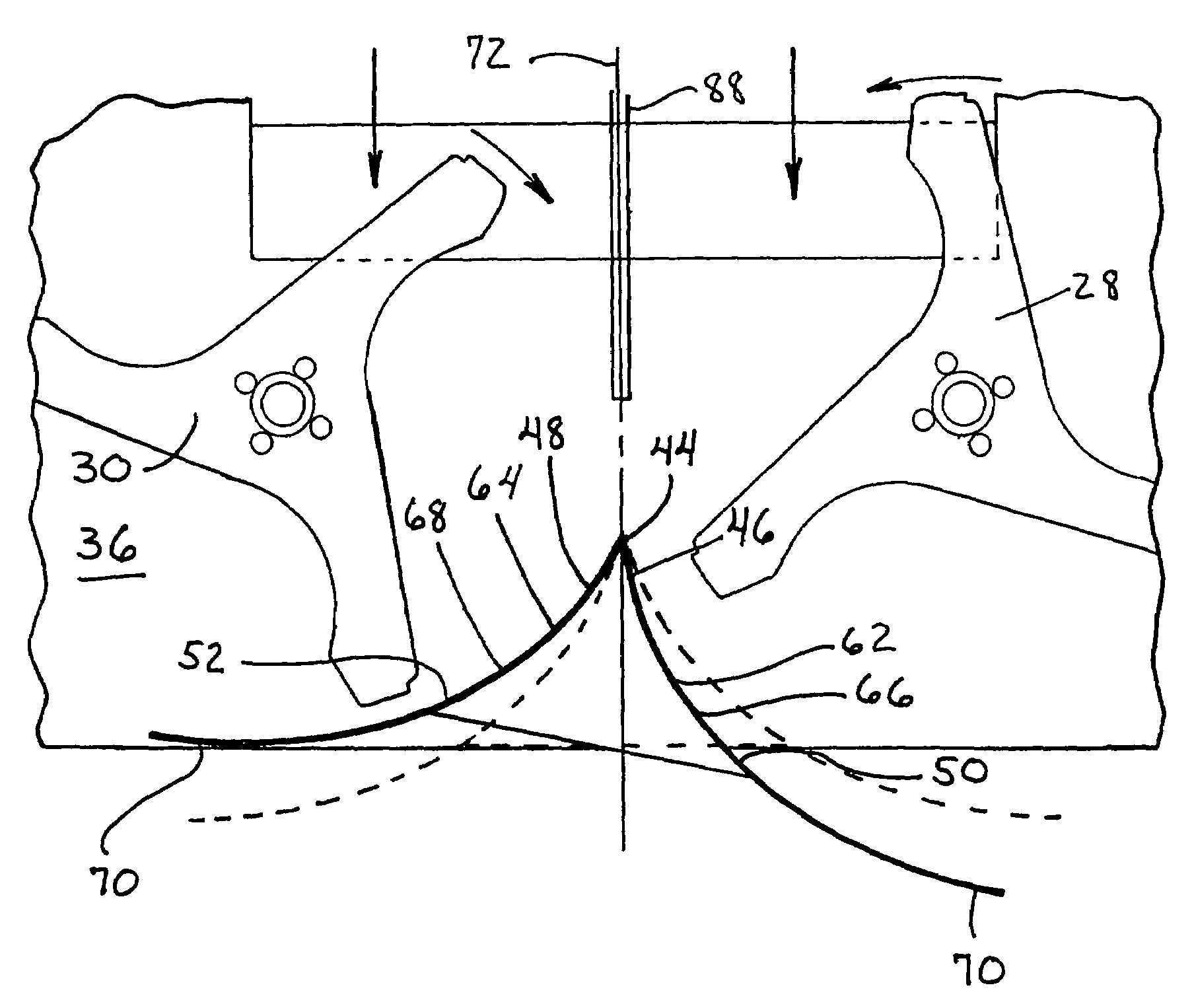

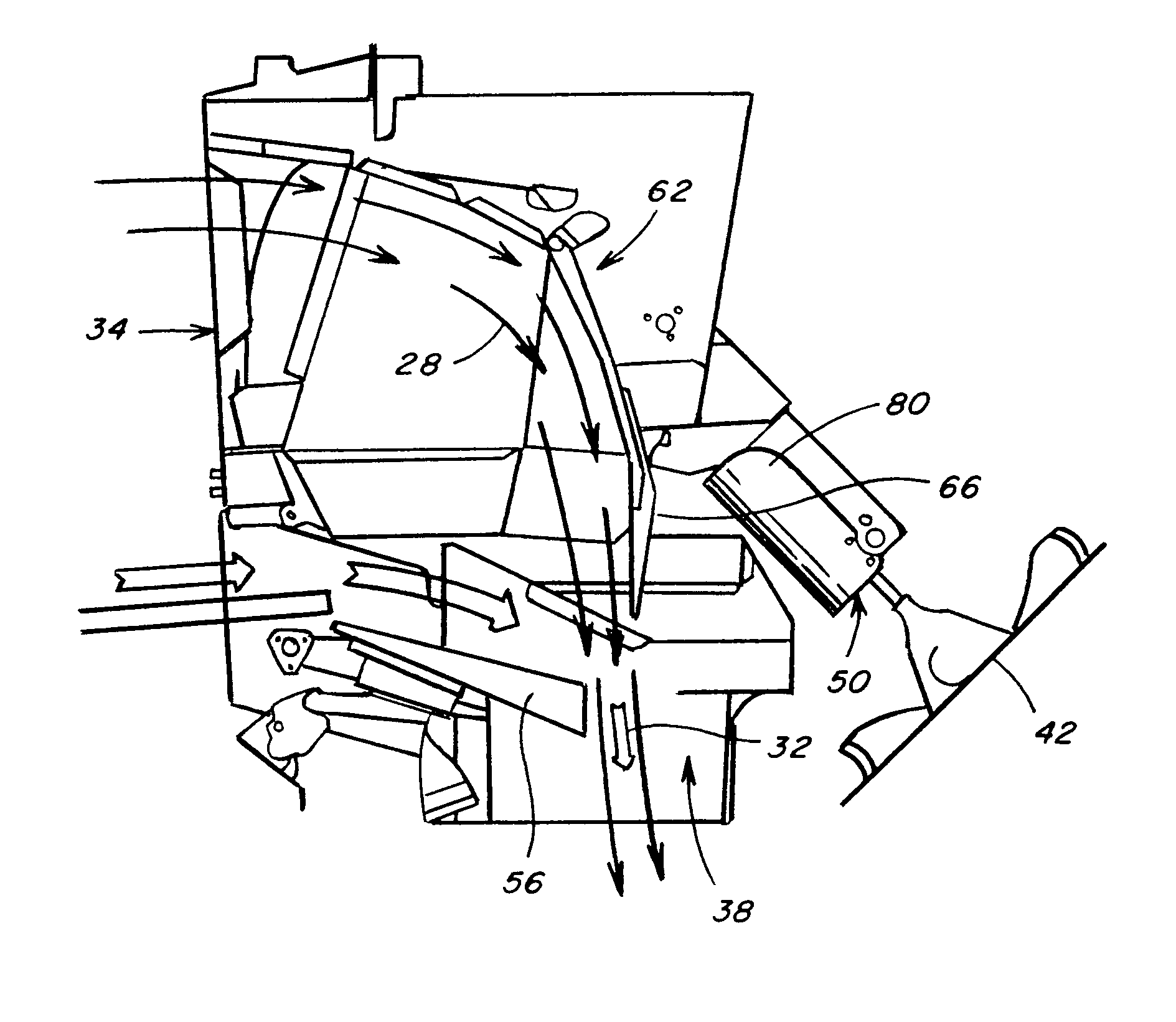

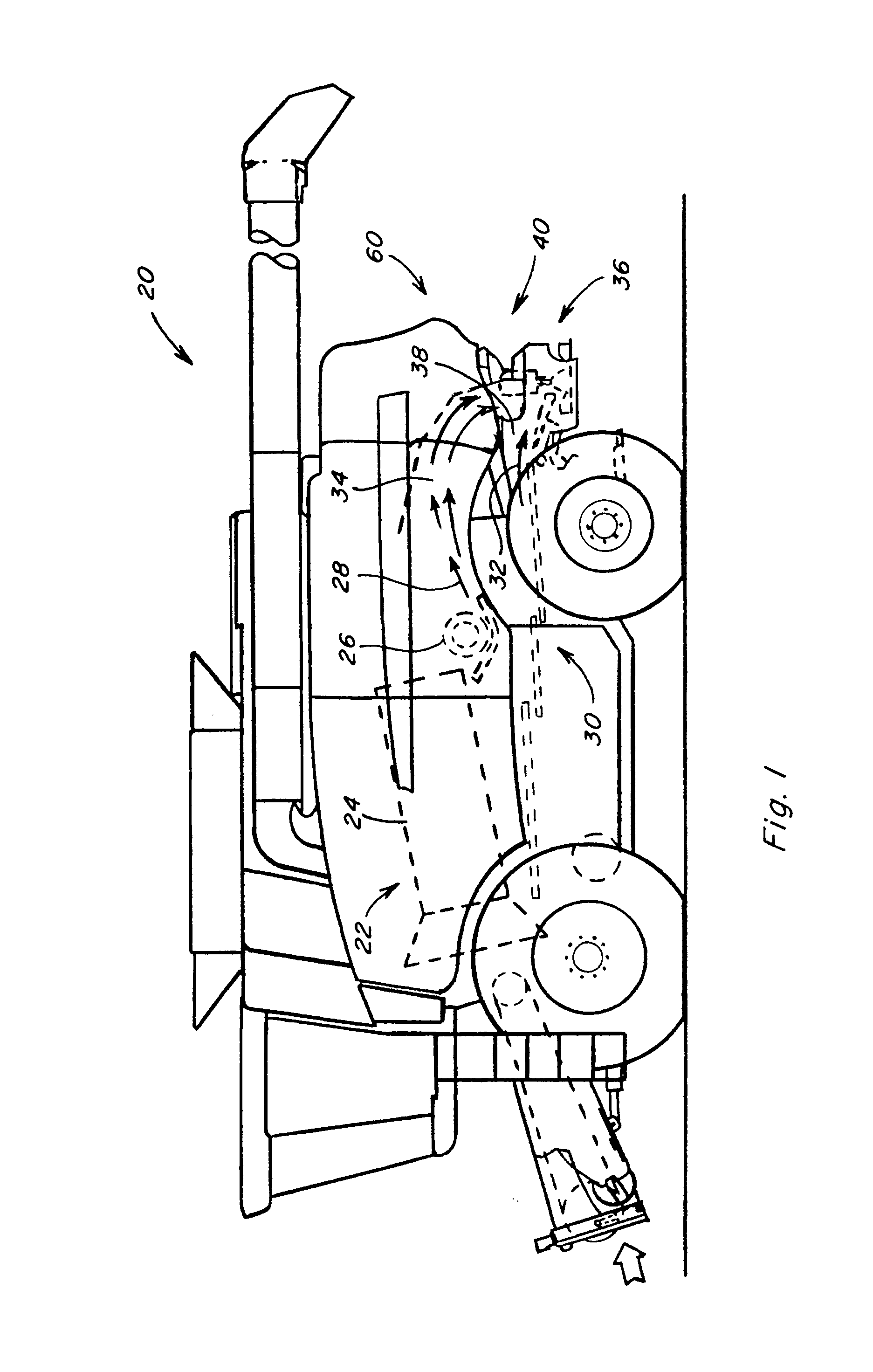

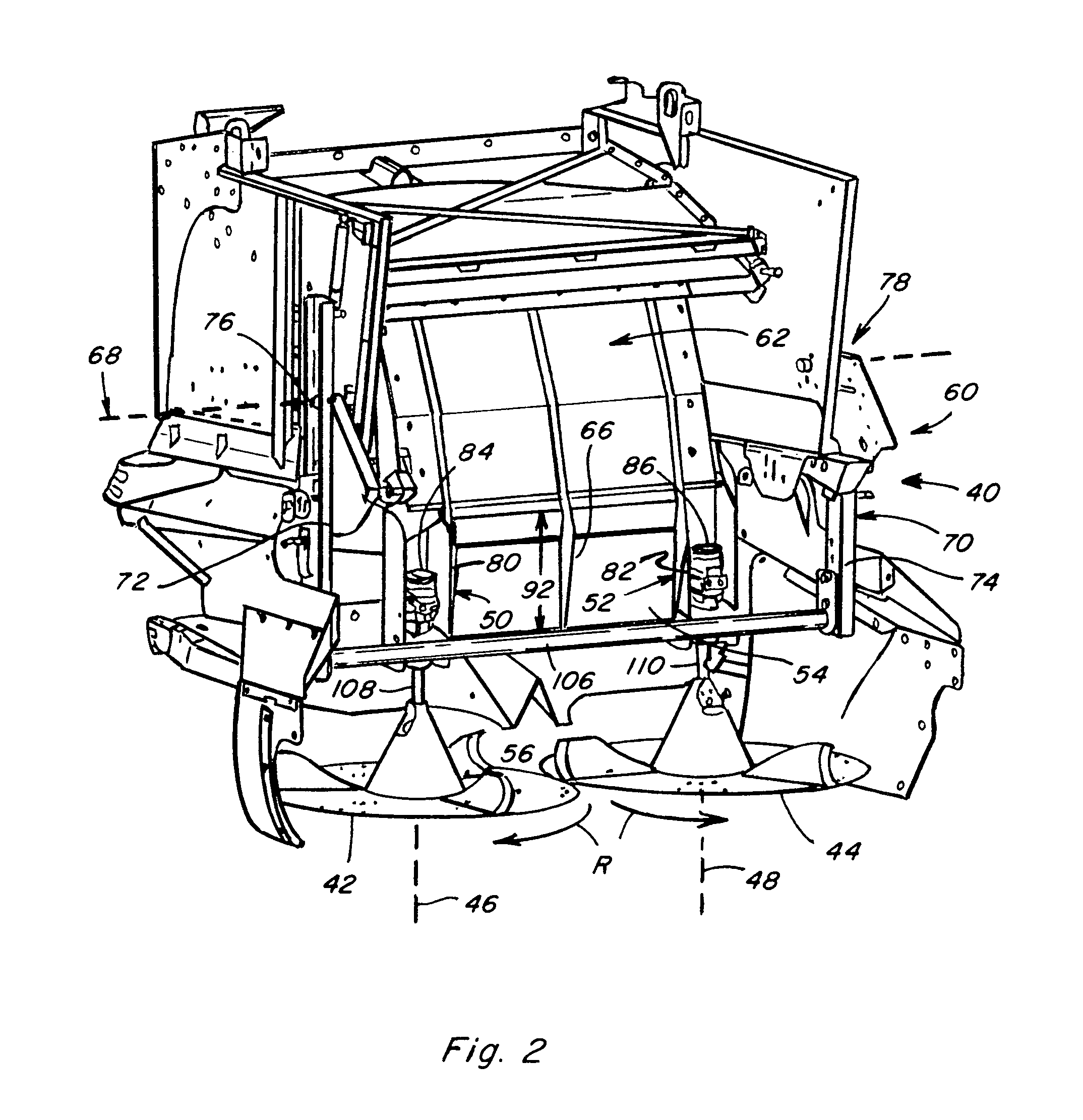

System and method for positively discharging crop residue from a combine

ActiveUS7066810B2Precise, efficient, and consistent crop residue dischargeDifferent typeMowersThreshersChaffEngineering

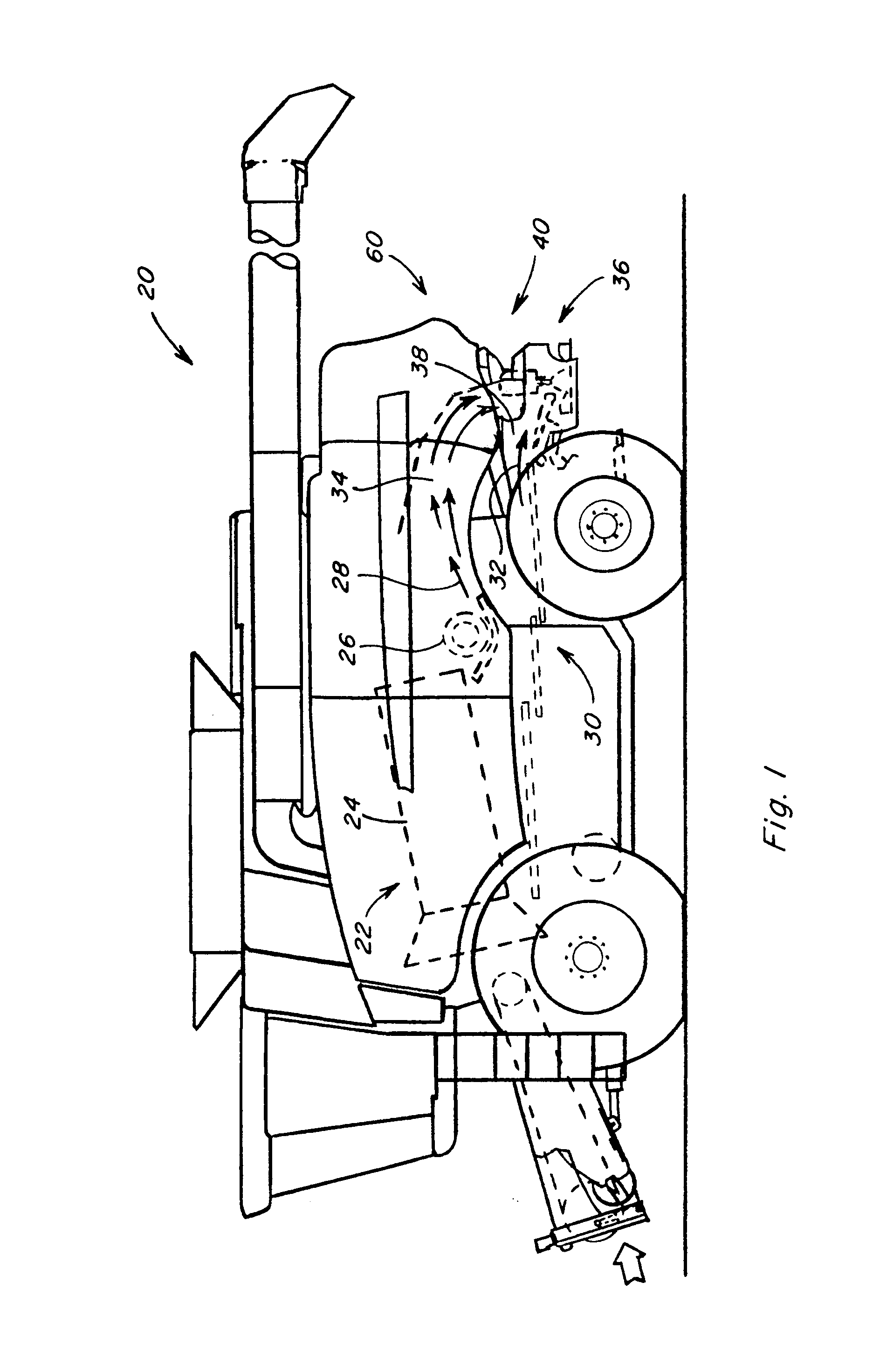

A system and method for positively discharging crop residue from a combine for precisely and consistently delivering crop residue from the threshing and separating area of a combine to the combine's residue handling system or outwardly from the rear of the combine and onto the harvested field below as a windrow. The present invention can include, or operate in cooperation with, a discharge mechanism, such as a conventional discharge beater, which delivers at least some of the crop residue to a conveying mechanism of the system. The system also includes a guide mechanism including a door arrangement configurable in several alternative configurations for receiving and merging and regulating crop residue flow from the discharge mechanism and the conveying mechanism, and directing the merged flow to a desired processing mechanism, such as, but not limited to, a chaff spreader, a straw chopper and / or spreader, etc.

Owner:BLUE LEAF I P INC

Combine harvester power management control

ActiveUS7648413B2Reduce total powerNeed for powerAnalogue computers for trafficMowersEngineeringCrop residue

A system and method of controlling maximum available engine power of a combine harvester wherein the engine drives the harvester and additionally powers a threshing mechanism for separating harvested crop into grain and crop residue and at least one further crop processing subsystem that may be selectively configured and disengaged, including a straw chopper engageable for chopping the crop residue and propelling the chopped residue from the harvester, structure configurable for directing the crop residue into the chopper or to bypass the chopper, utilizing a controller for automatically reducing the maximum available engine power as a function of the status of the engagement of the subsystems, particularly the chopper and the configuration of the associated structure.

Owner:BLUE LEAF I P INC

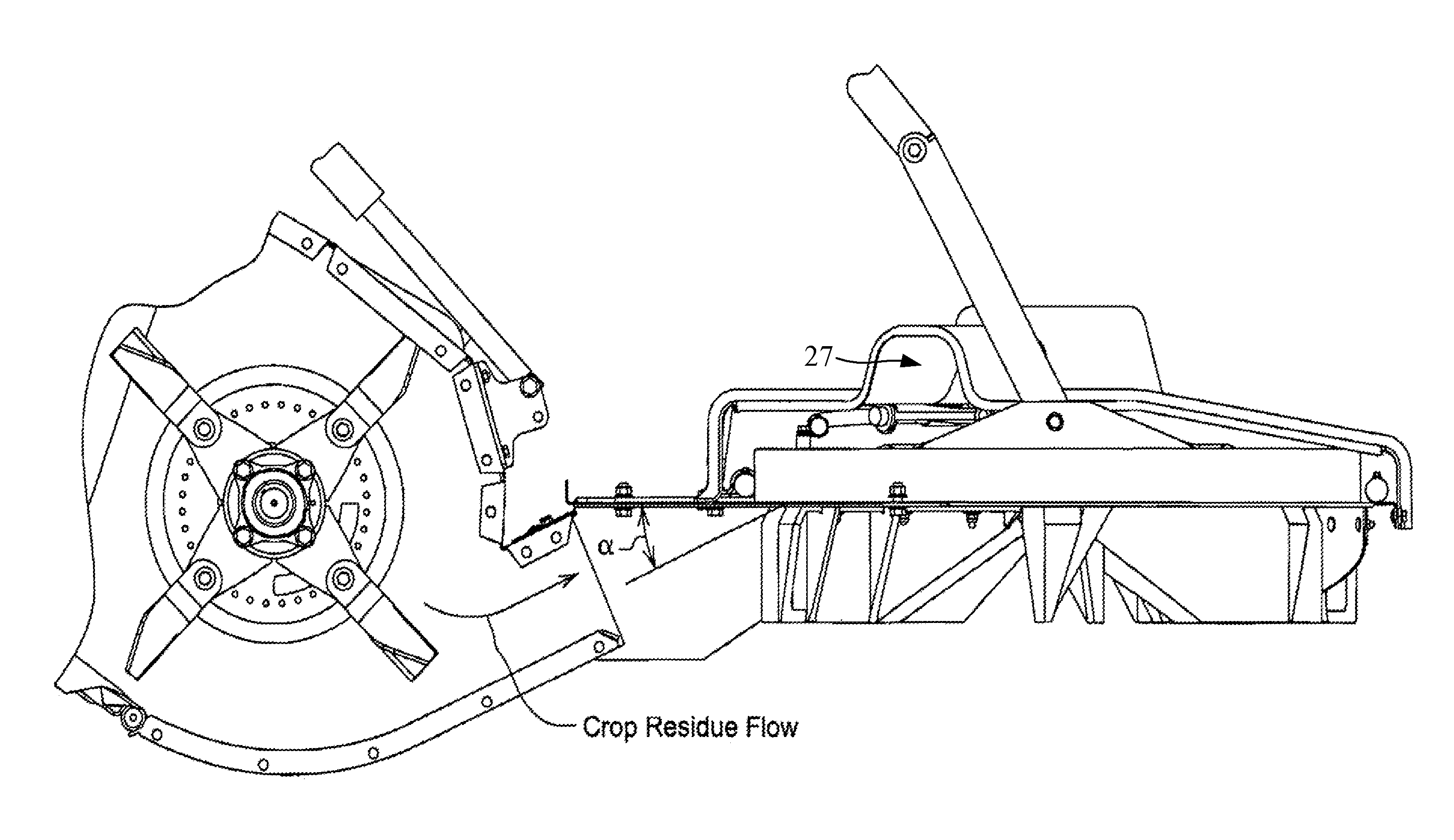

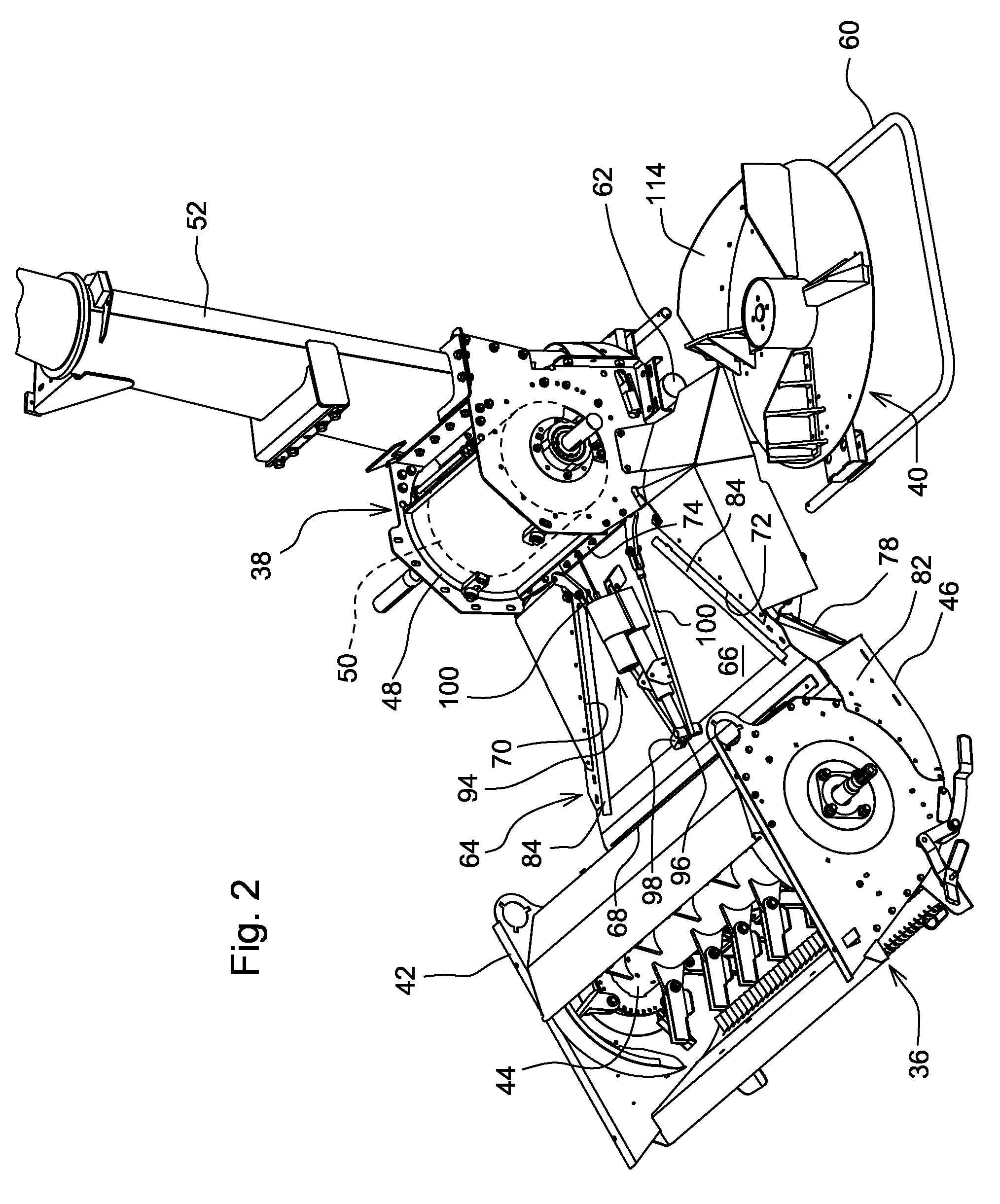

Wide-spread impeller spreader for harvesting combine

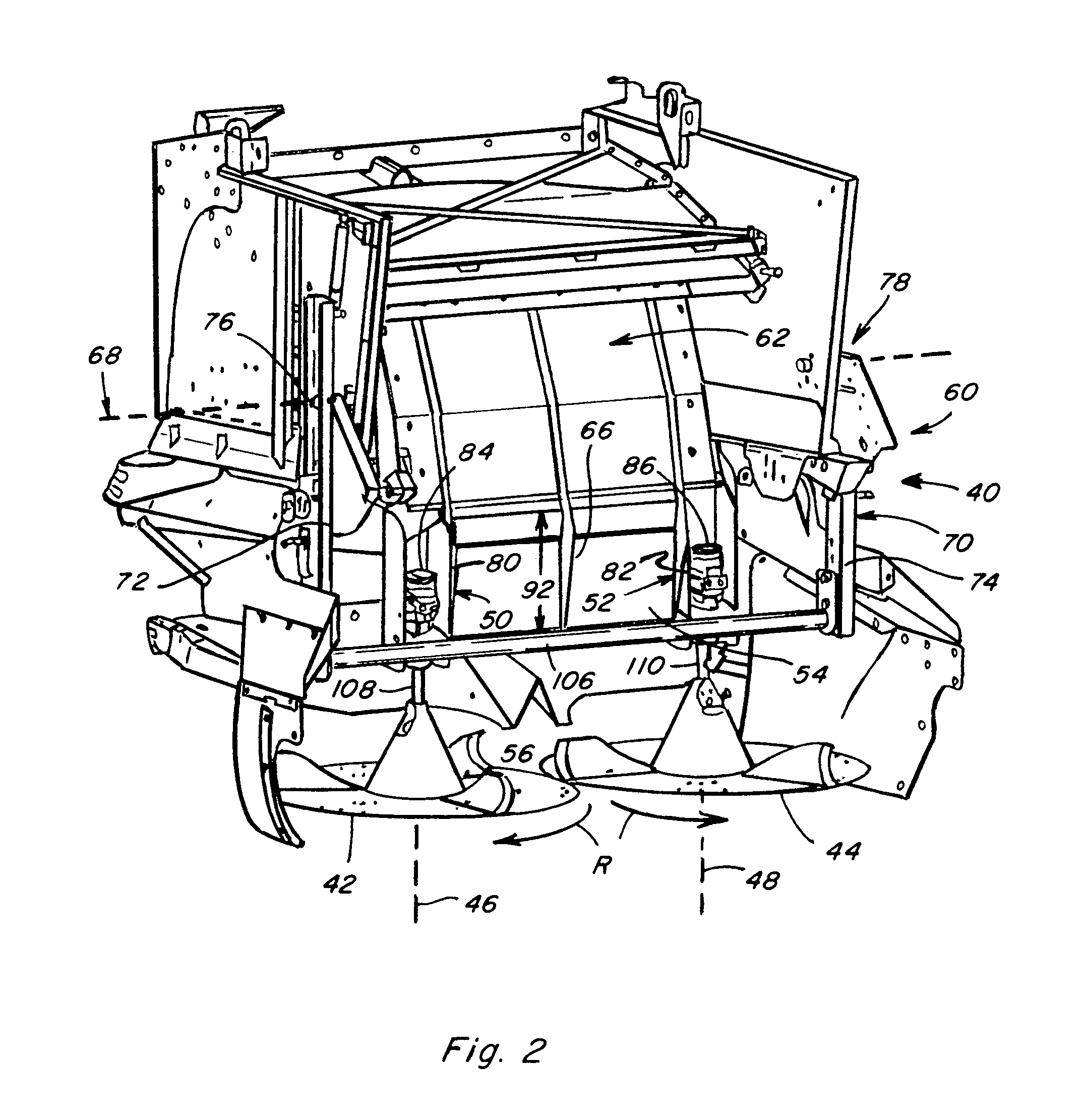

A chopper and wide-spread impeller spreader that feeds crop residue from the chopper into the spreader at a specific upward angle to more fully utilize the momentum the crop residue achieves in the chopper. The spreader incorporates air intake holes and air fins above the impellers to keep crop residue moving through the impellers without plugging of discharge material. The chopper propels the residue upwardly into the spreader resulting in a wide-spread broadcast, while preventing crop residue from plugging the spreader.

Owner:DEERE & CO

Plant biomass solid fuel

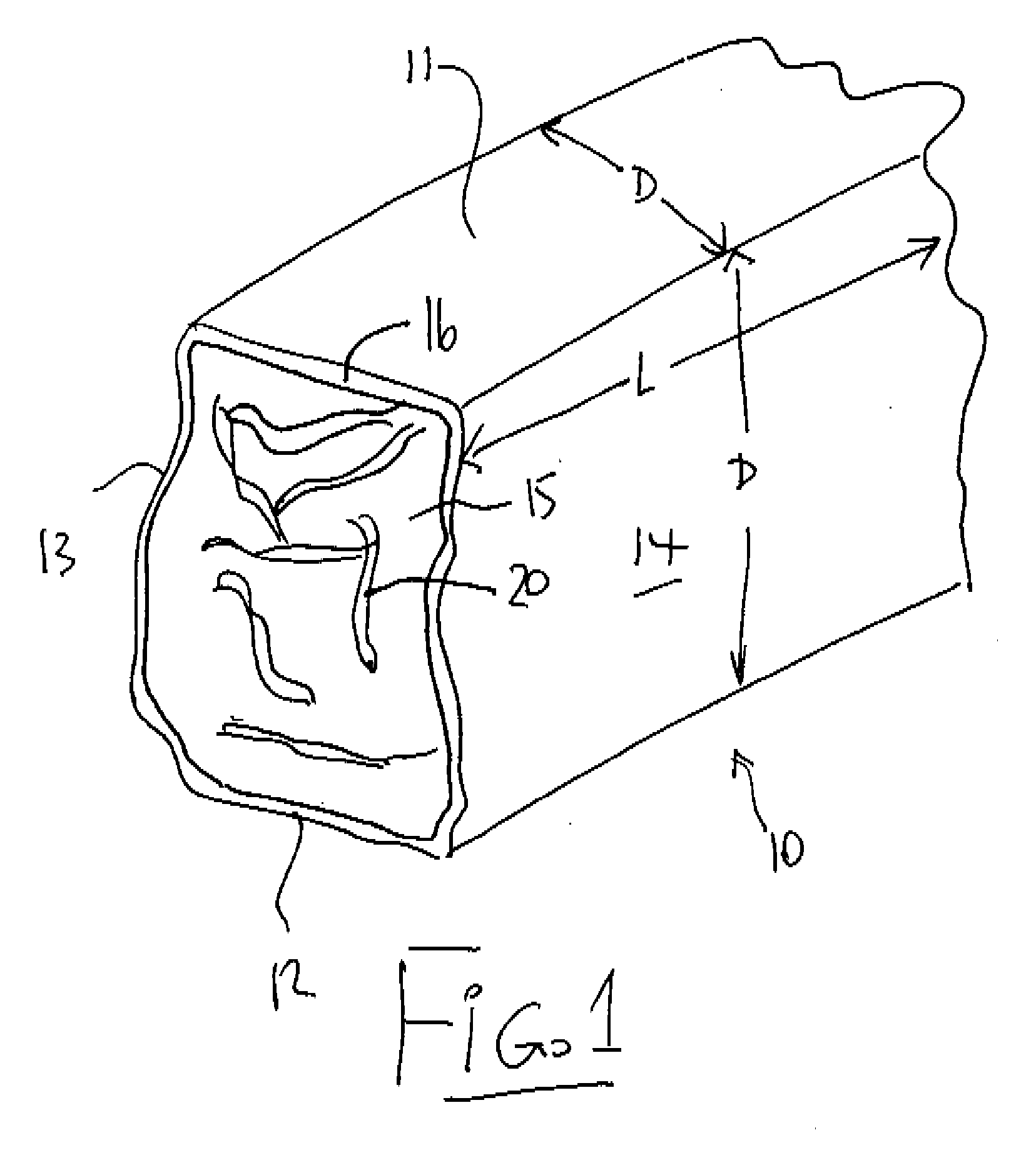

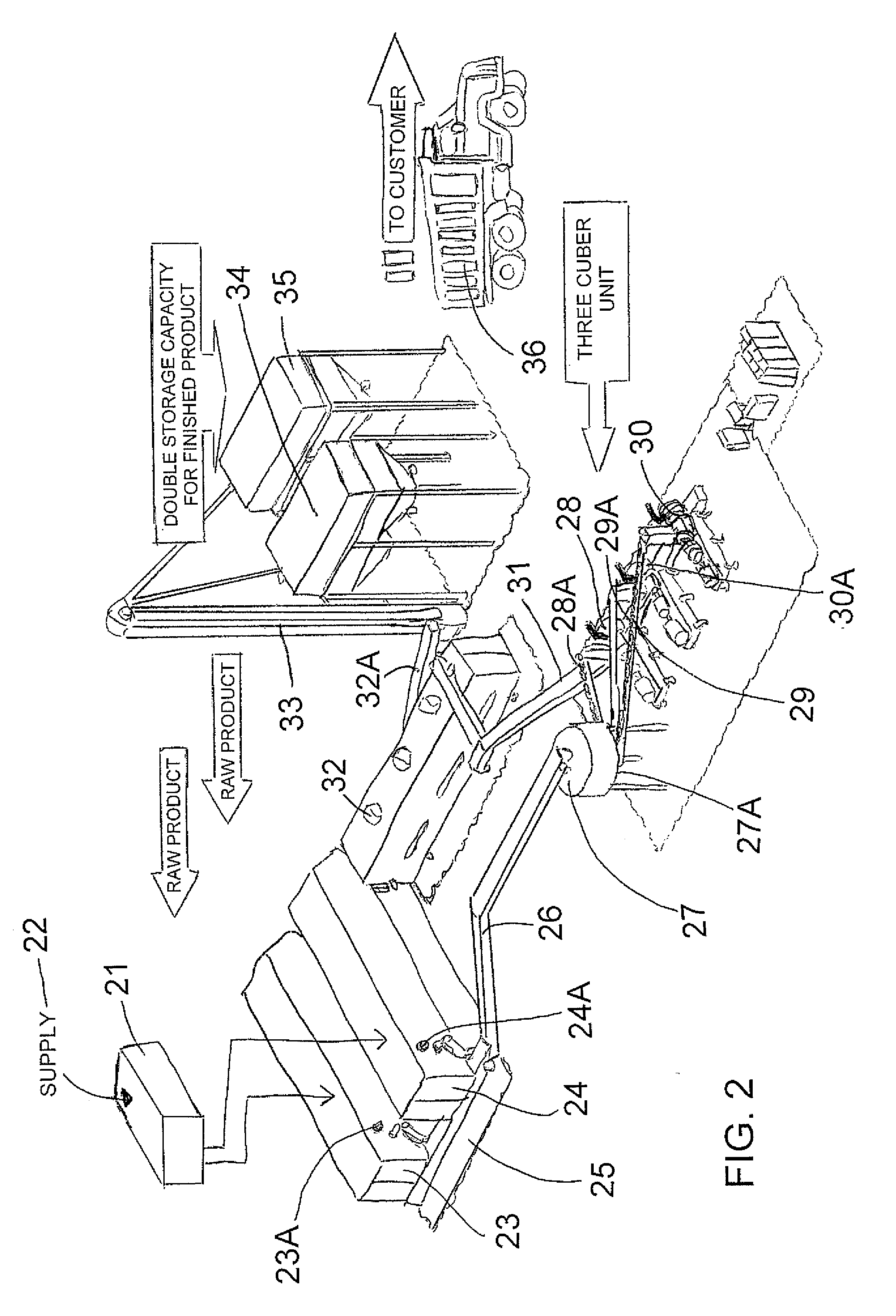

A solid fuel is formed in a cuber to form body pieces formed of materials extruded through a die with a density greater than 35 lbs / cu ft; an energy content greater than 6500 BTU / lb; transverse dimensions less than 1.5 inches; and a length less than 4 inches; from plant biomass material which contains components when extended of greater than 1.0 inch. Primarily the materials are paper or other cellulose product and crop residue such as wheat straw. The cellulose and lignin from these materials act without additional binders as binders and encasing materials. The moisture content is maintained at a target value by mixing selected quantities of the materials without drying. The cubing machine has a feeding system where the space between the inner rotor and outer casing is smaller than 4 inches and the height of the outer flight is less than 1 inch.

Owner:GAUTHIER STEPHANE +4

Apparatus and method for automatically setting operating parameters for a remotely adjustable spreader of an agricultural harvesting machine

ActiveUS20080268927A1Improve distributionIncrease residueAgricultural machinesAnalogue computers for trafficCrop residueEngineering

Apparatus and a method for automatically recognizing a header connected to a harvesting machine and setting operating and / or adjustment parameters of a spreader of the machine for use with the header. The apparatus includes a memory containing information representative of predetermined spreader settings for at least one header connectable to the harvesting machine, such as a grain header and a corn or maize header. A detector element is operable for automatically identifying a header connected to the machine and outputting a signal or information representative thereof, to a controller automatically operable for using that information for retrieving the stored information representative of the predetermined spreader settings for that header. Input commands and / or information, for instance, relating to crop type, and / or crop and environmental conditions, can also be inputted using either an onboard or remote input device. The controller then responsively controls a crop residue spreader connected to the machine as a function of the retrieved information and any inputted commands or information, if within predetermined permissible ranges.

Owner:BLUE LEAF I P

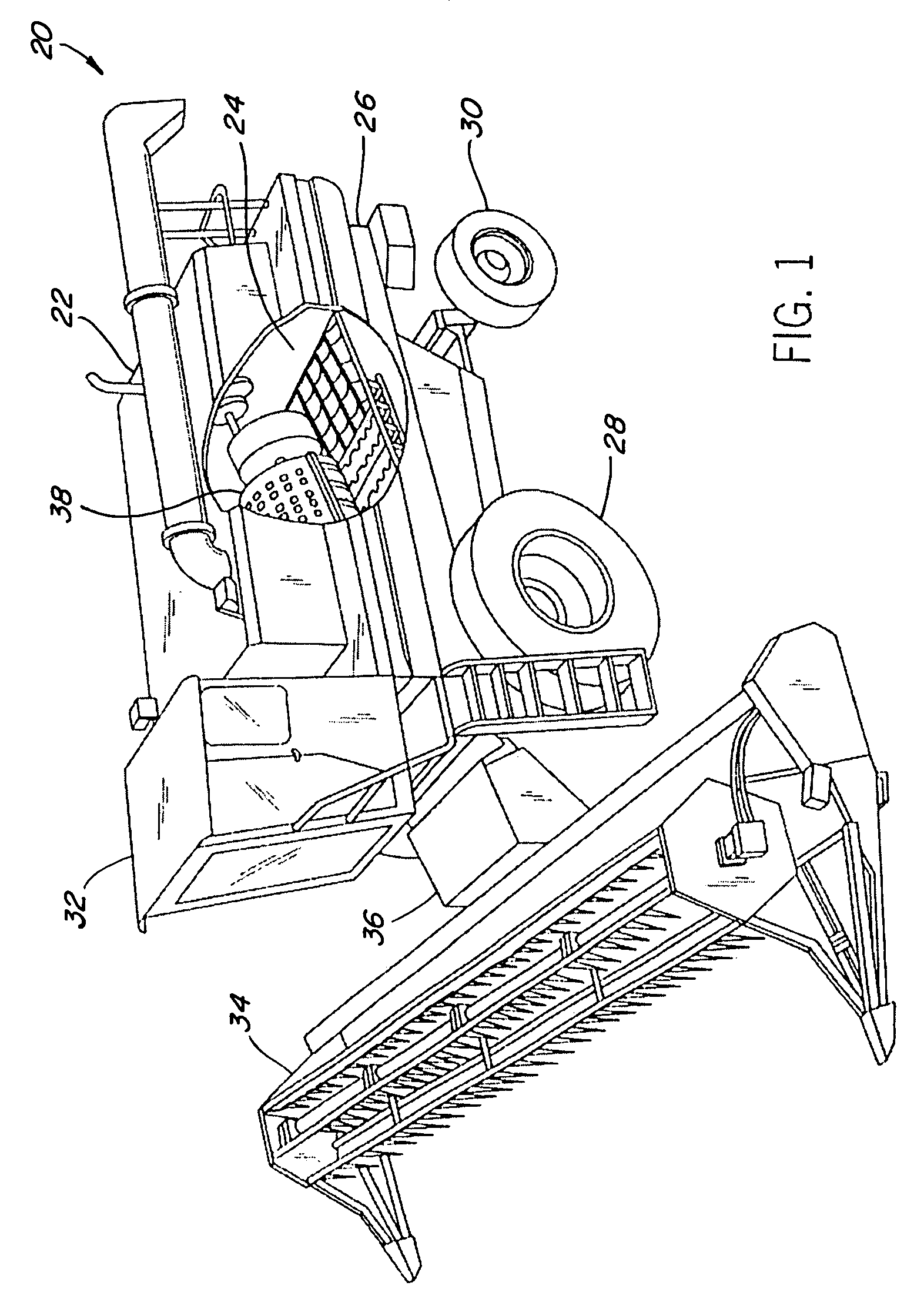

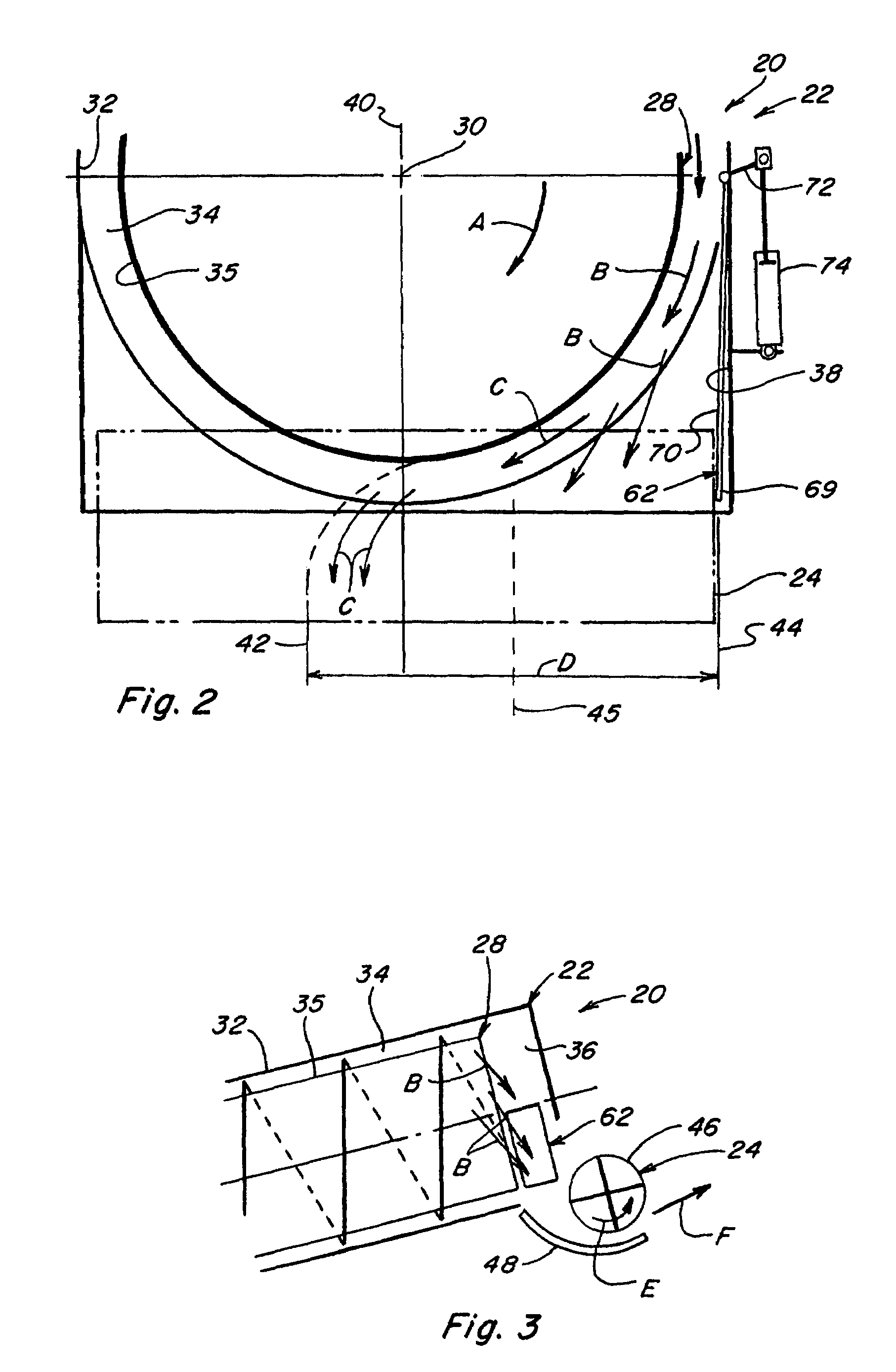

Round Baler For Baling Crop Residue

Owner:DEERE & CO

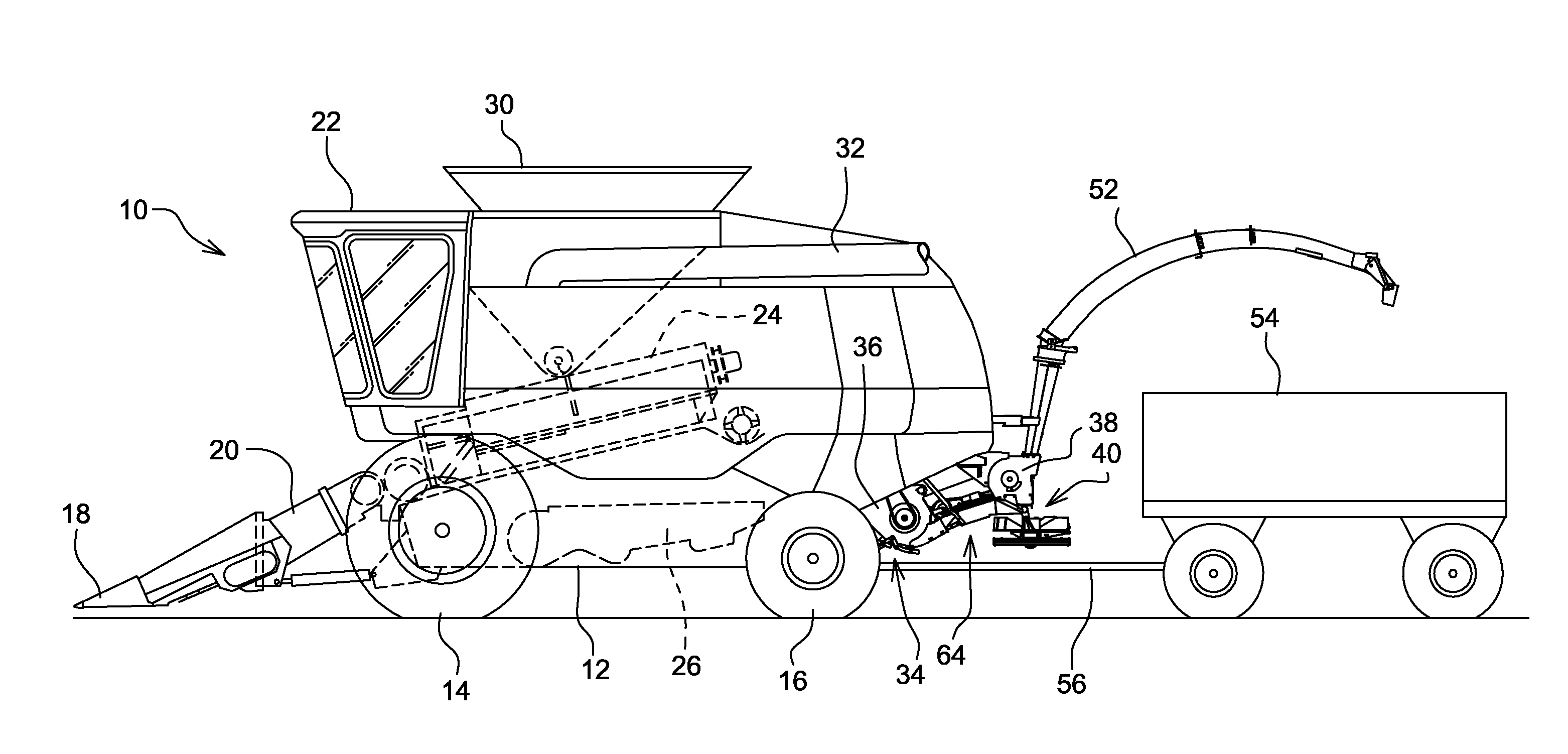

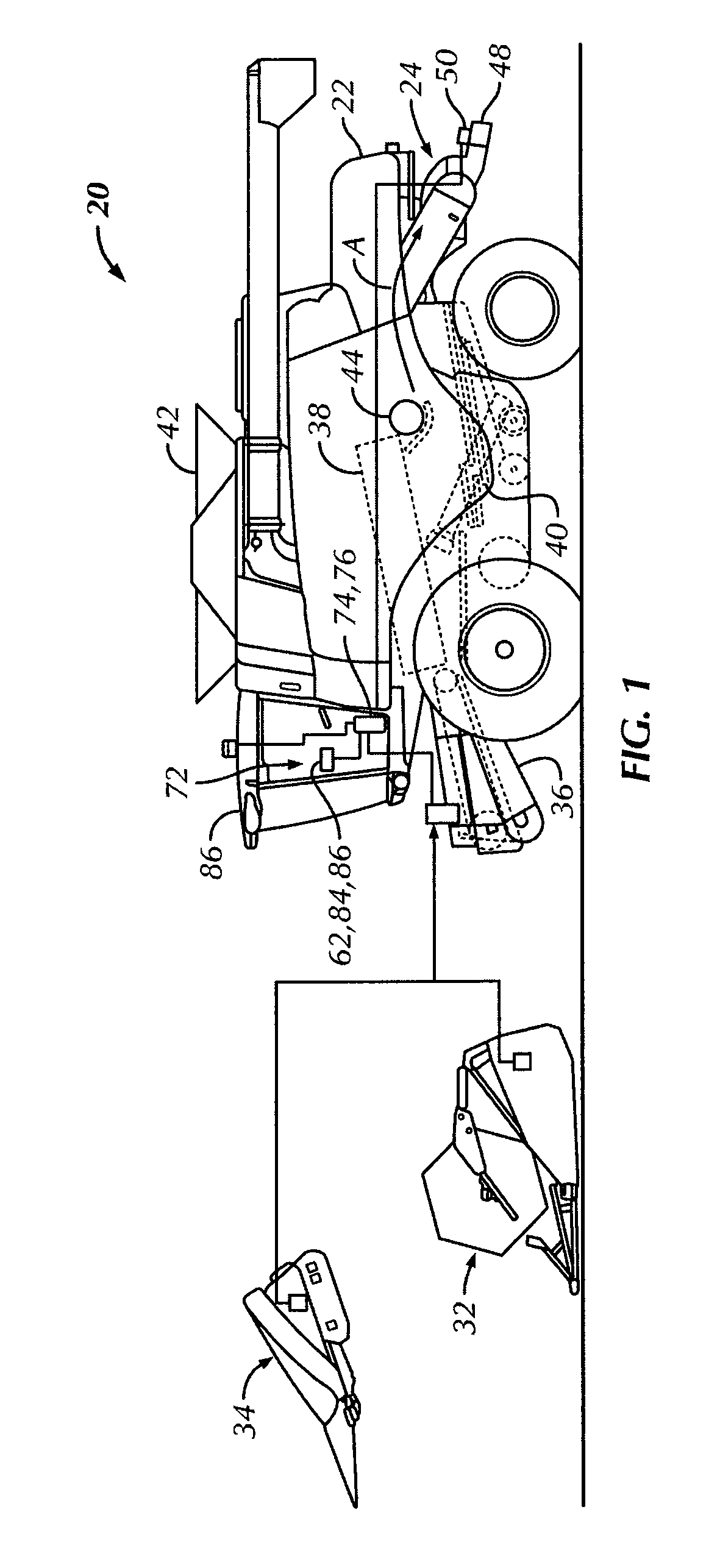

Variable rate diverter for a crop residue collecting device carried by a combine harvester

A crop residue handling device is mounted to the rear of a combine harvester for intercepting crop residue that remains after grain has been separated from the crop by the separator and cleaning arrangement of the harvester. The residue handling device includes a chopper which chops and impels the chopped residue rearwardly through a discharge duct. A transition duct receives the crop exiting from the chopper and contains upright deflector vanes mounted for pivoting and being automatically moved among desired positions, by a power actuator so as to direct desired proportions of the crop residue between a blower for receiving and accelerating the crop through a discharge chute for collection in a receptacle of a towed trailer, and a pair of spreader disks located at opposite sides of the blower for receiving and dispersing the crop residue on the ground.

Owner:DEERE & CO

Apparatus and method for automatically controlling the settings of an adjustable crop residue spreader of an agricultural combine

An apparatus and method for automatically controlling the settings of an adjustable crop residue discharge system of an agricultural combine is provided. The apparatus includes a sensor, an actuator, and a controller. The sensor detects a position of a residue deflector and / or a speed of the residue discharge system. The actuator operatively controls the residue deflector to adjustably position the residue deflector. The controller is operatively connected to the sensor and actuator. The controller includes a memory, a speed input device, a position input device, and a mode input device. The controller is configured to store in memory a plurality of positions and speeds of the residue discharge system and automatically adjust the positions and speeds of the residue discharge system upon receiving an input to change to headland mode.

Owner:BLUE LEAF I P INC

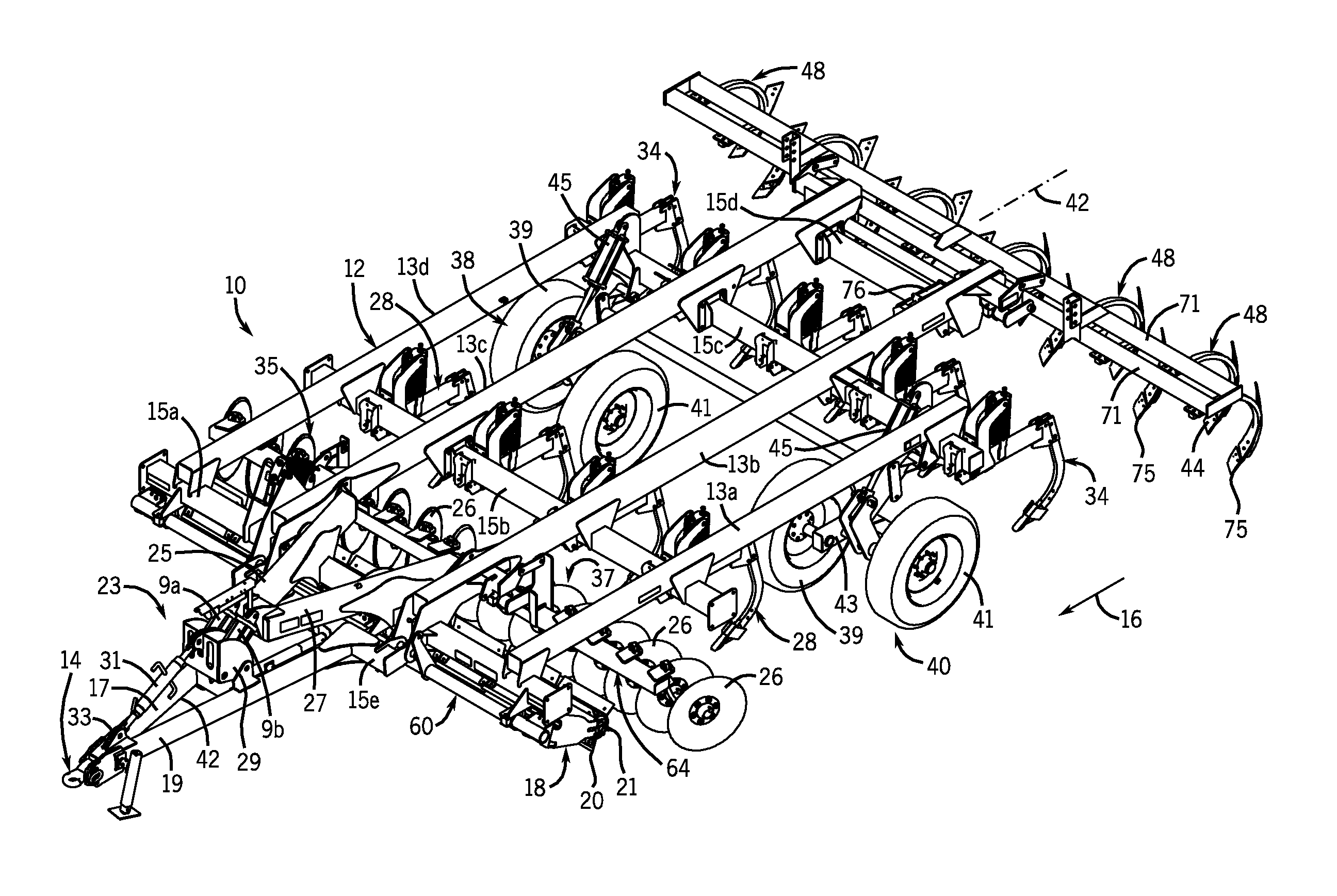

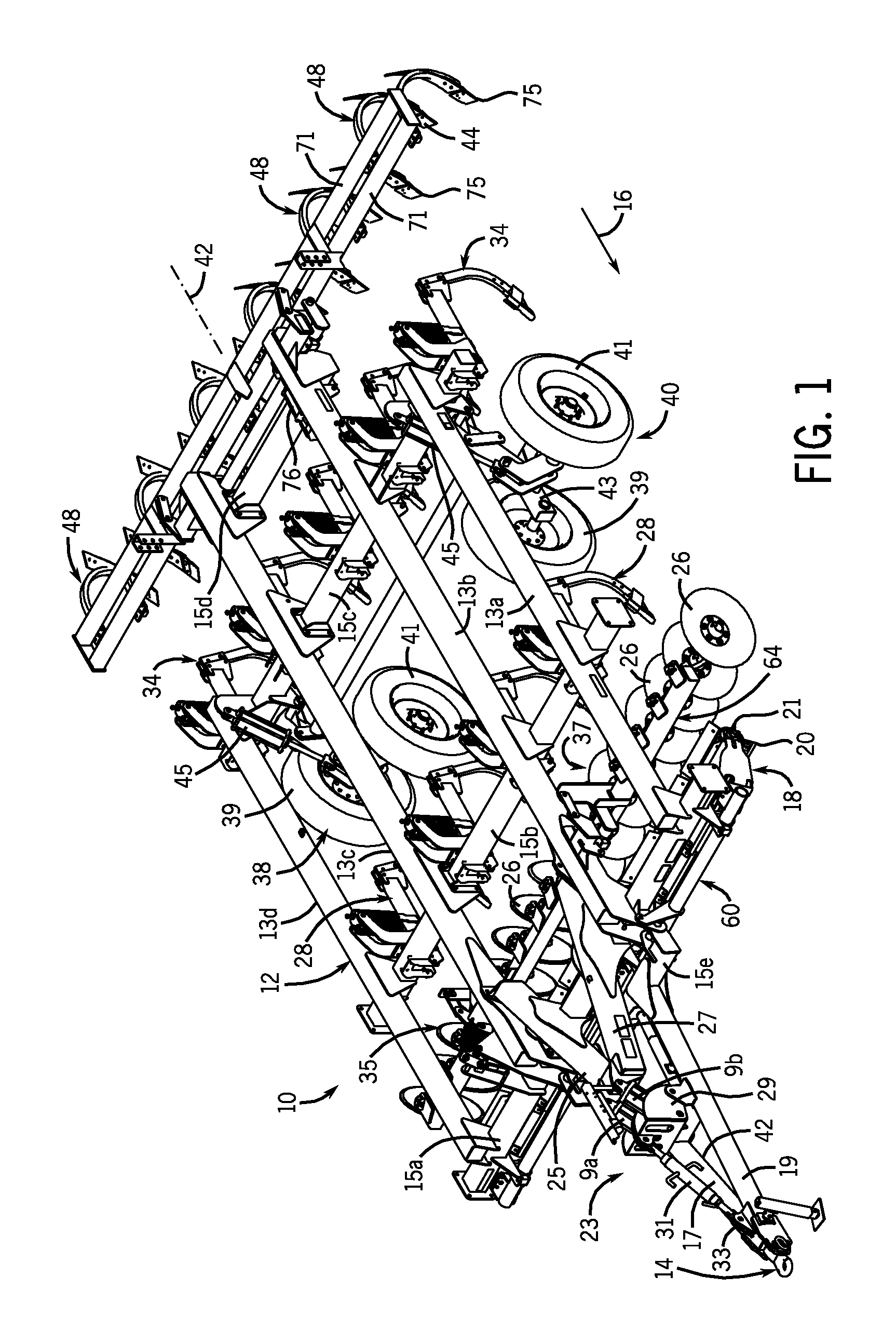

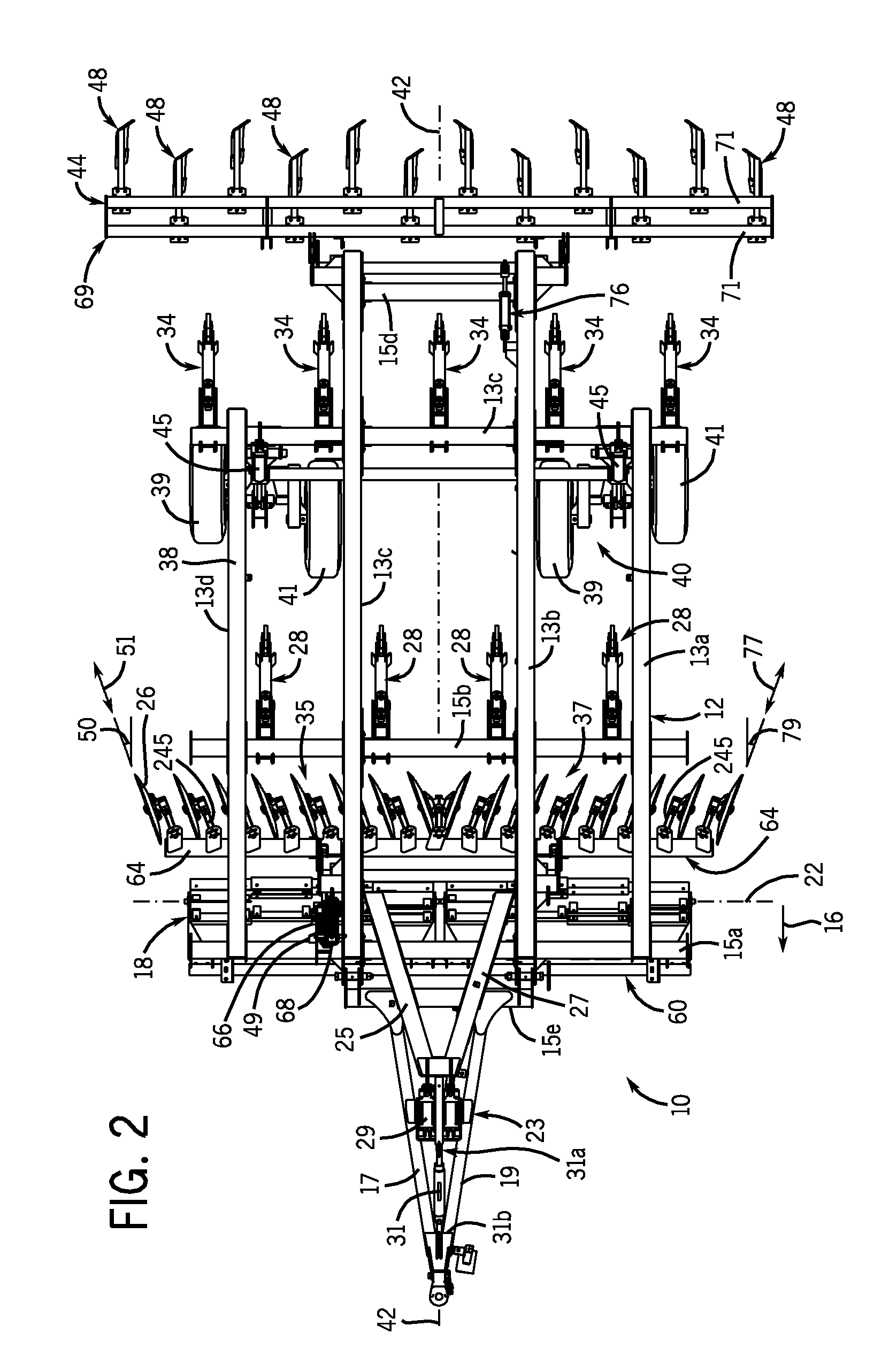

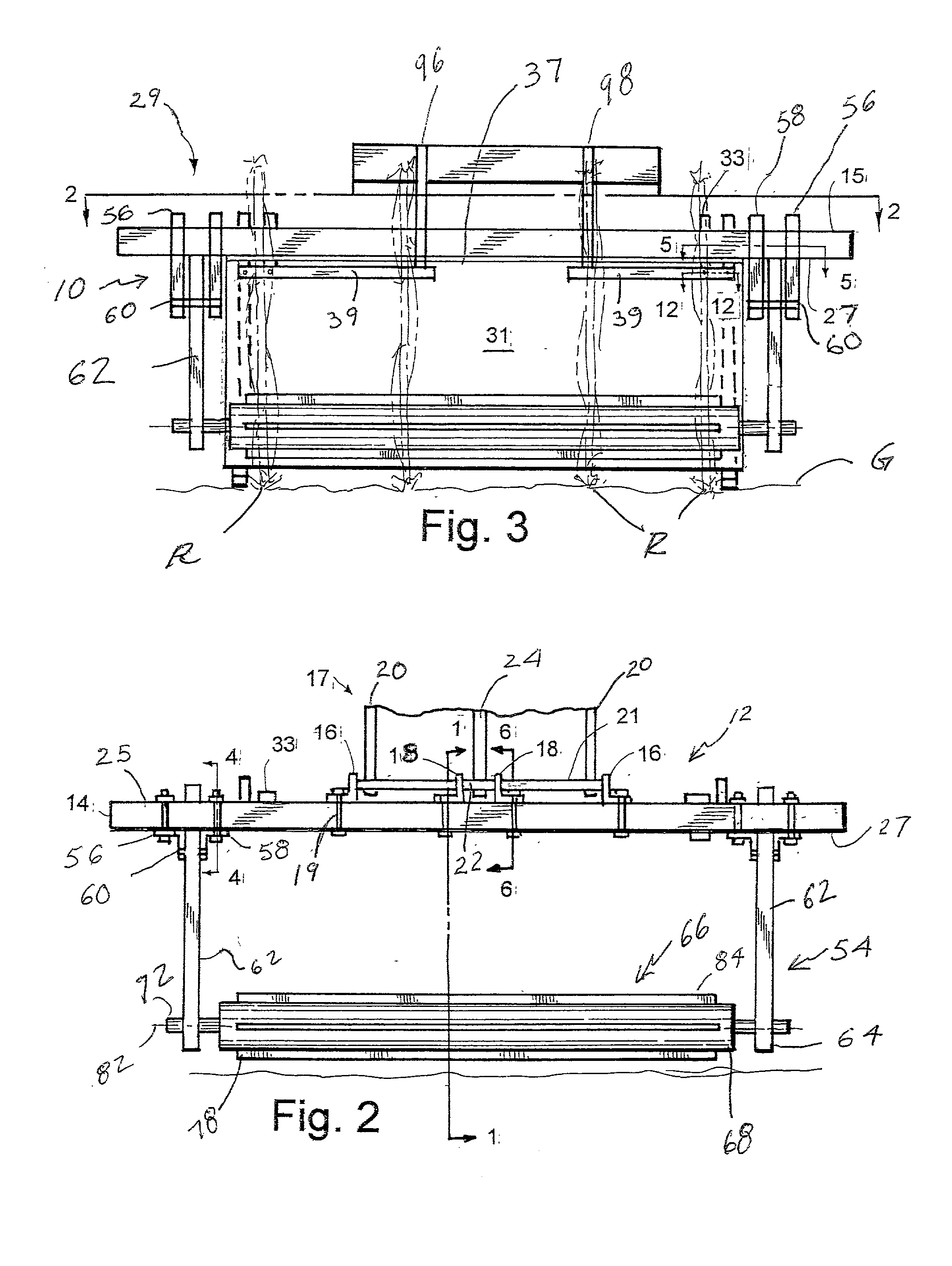

Crop residue and soil conditioning agricultural implement

ActiveUS8047299B2Efficient use ofReduce resource consumptionSpadesPloughsAgricultural engineeringCrop residue

An agricultural tillage implement constructed to condition crop residue and cultivate the conditioned crop residue. The tillage implement includes a first residue conditioner and a second residue conditioner pivotably attached to a frame of the tillage implement. The first and second conditioners are movable independent of each other and of the frame such that an operator may raise and lower the first and second conditioners relative to the frame to change the depths of the conditioners.

Owner:BLUE LEAF I P INC

Control system for an adjustable deflector

A control system, and the method of use thereof, for controlling the positioning of an adjustable deflector employed to transition or redirect a flow of crop residue from an axially arranged threshing or separating system of an agricultural combine to and through a chopper assembly and into a crop residue distribution system for distributing the residue onto a field, and more particularly, to a control system that is responsive to changes in the amounts of crop residue being distributed by side-by-side spreader assemblies of the crop residue distribution system to alter the positioning of the adjustable deflector to change the flow of crop residue and to more closely balance and equalize the amounts of crop residue being distributed by the side-by-side spreader assemblies of the crop residue distribution system.

Owner:BLUE LEAF I P INC

Crop residue chopping and spreading system for an agricultural combine

A system for chopping and spreading crop residue produced by an agricultural combine wherein the spreader is advantageously disposed directly rearwardly of a cleaning system of the combine for receiving chaff and other crop residue directly therefrom, without aid of a mechanism to convey the chaff to the spreader, and wherein the chopper is disposed just above and / or rearwardly of the spreader and is configured for discharging crop residue from the threshing system of the combine into the spreader for spreading thereby with the chaff.

Owner:BLUE LEAF I P

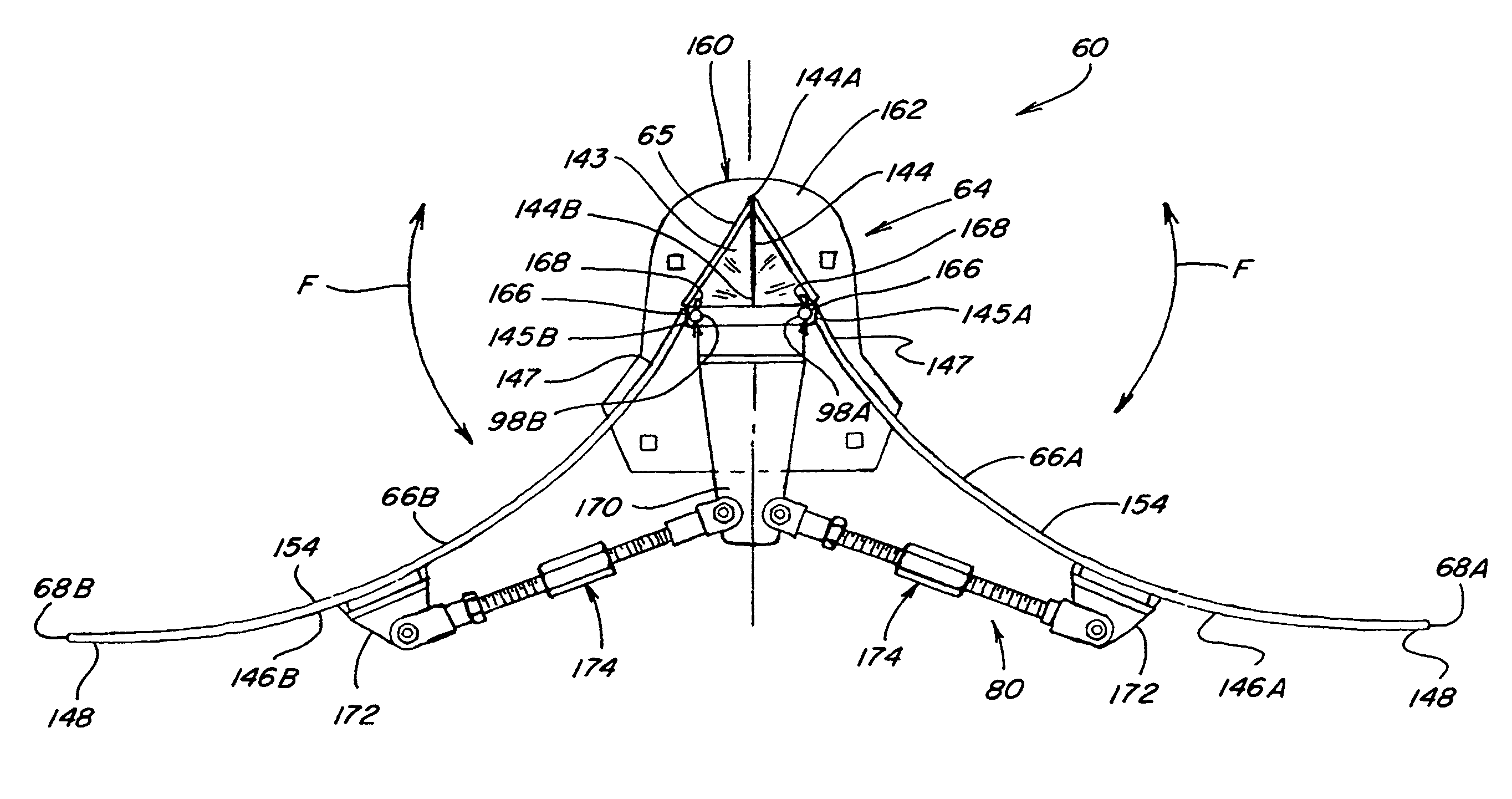

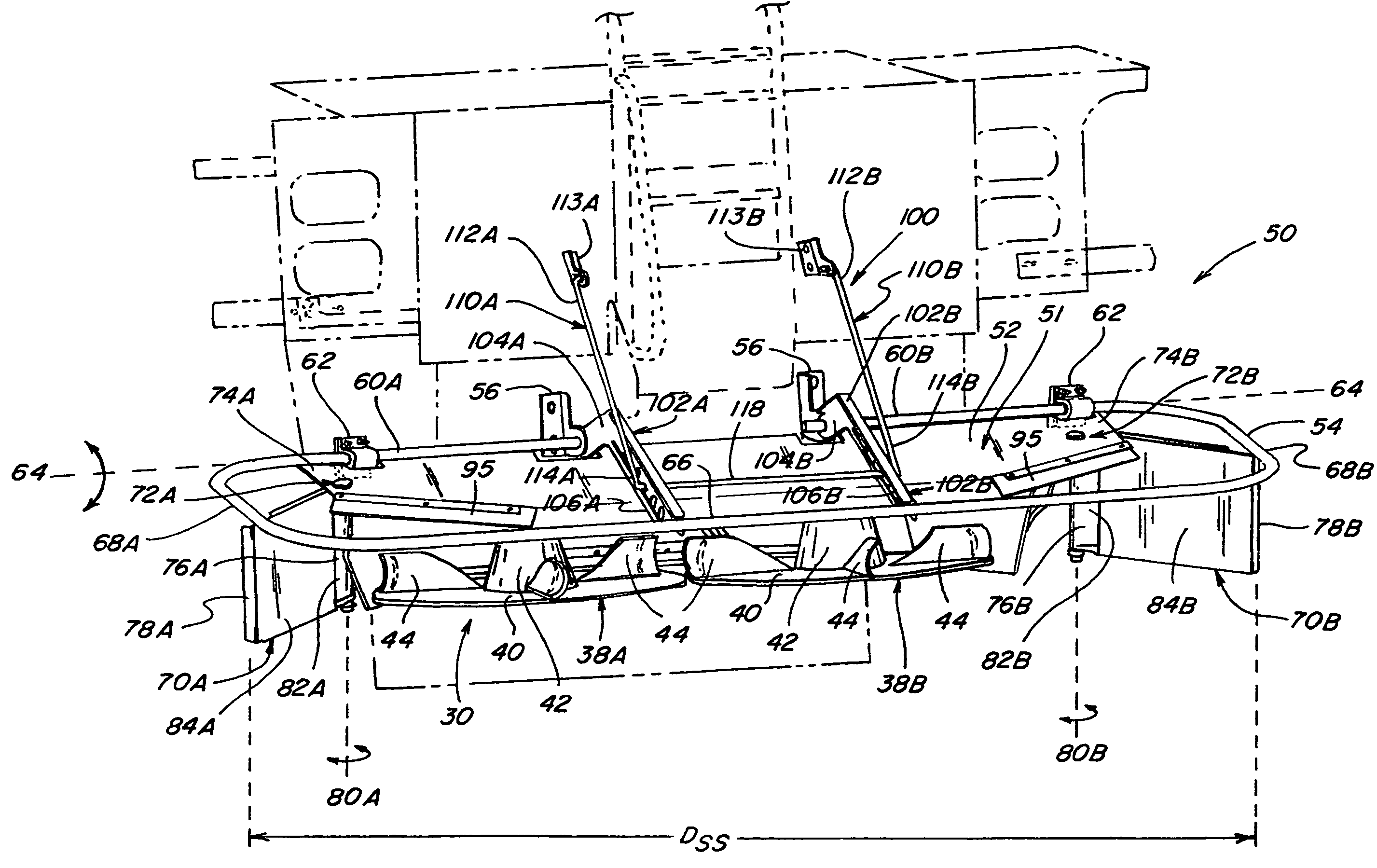

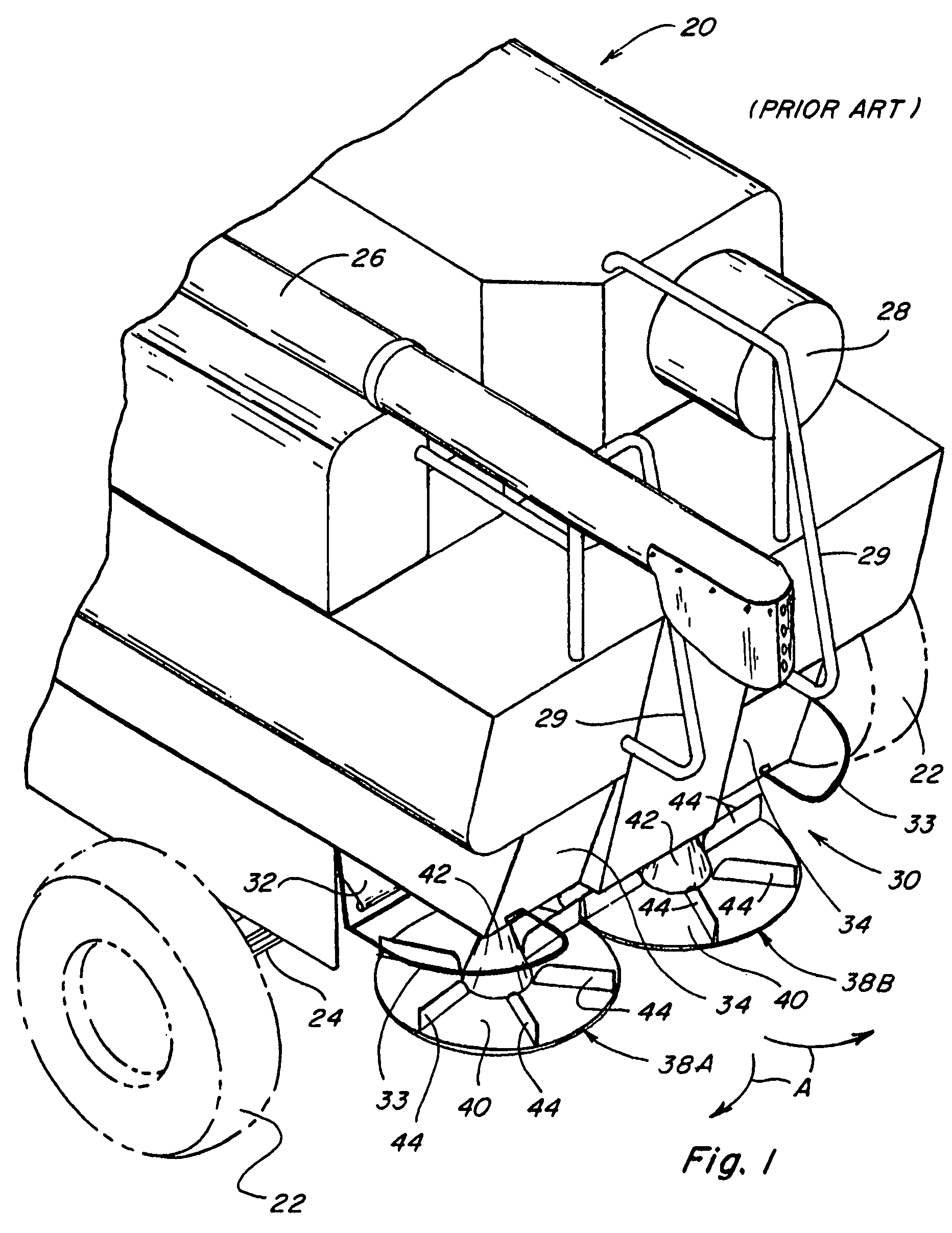

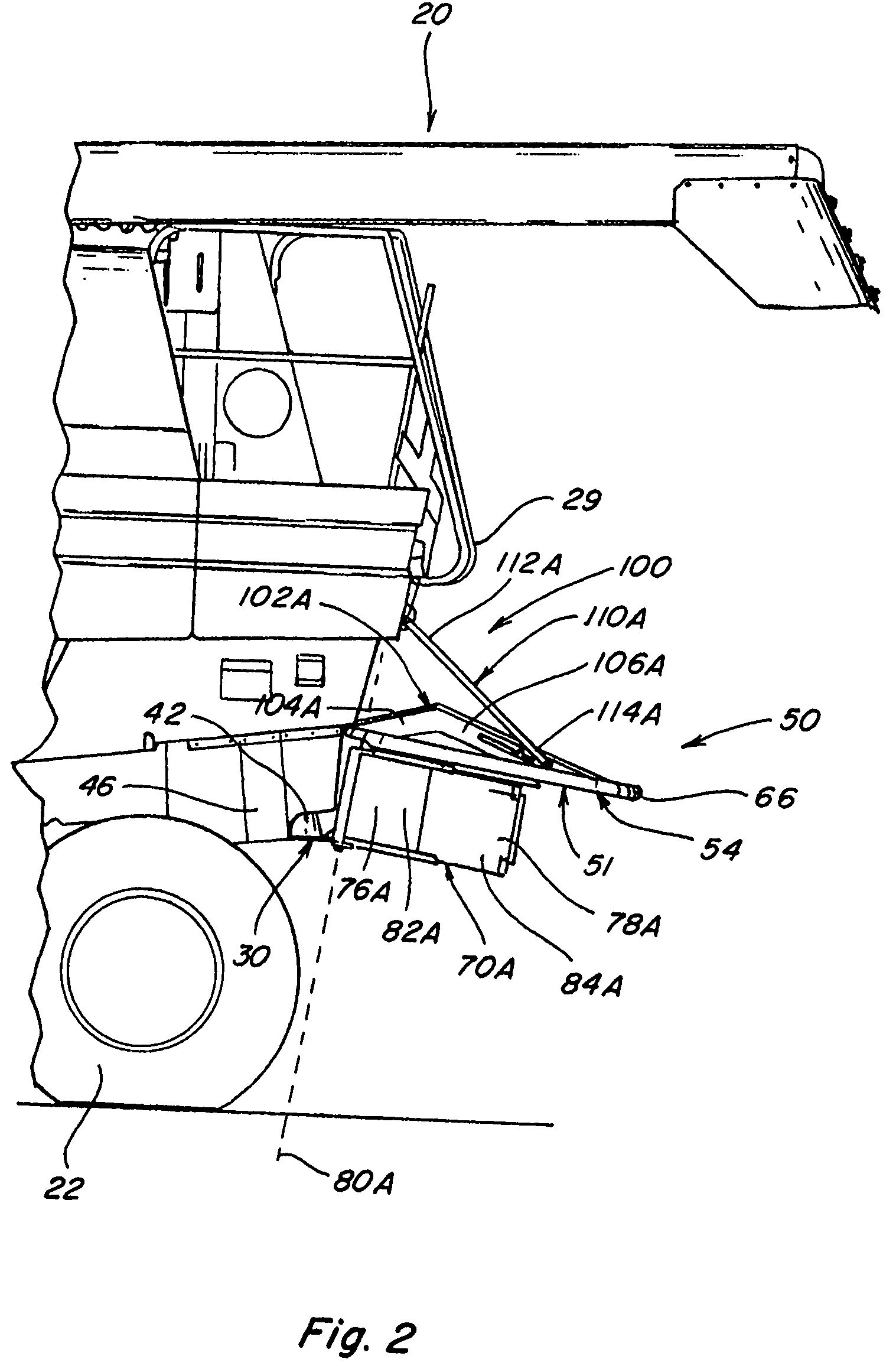

Unitary pivoting spreader apparatus

Spreader apparatus for a crop residue chopper of an agricultural harvesting machine or combine, mountable in a simple manner and quickly and precisely pivotable sidewardly, and optionally upwardly and downwardly, in a unitary manner, for adjusting or varying a direction and / or one or more characteristics of discharge of crop residue propelled from a chopper. The spreader apparatus includes a spreader board having vanes mounted thereon for guiding crop residue flow discharged from the chopper, the vanes and the spreader board being movable simultaneously and in a unitary manner, to achieve adjustments or shifts in crop residue deposition location, without altering consistency or uniformity of the crop residue distribution.

Owner:BLUE LEAF I P INC

Unitary pivoting spreader apparatus

Spreader apparatus for a crop residue chopper of an agricultural harvesting machine or combine, mountable in a simple manner and quickly and precisely pivotable sidewardly, and optionally upwardly and downwardly, in a unitary manner, for adjusting or varying a direction and / or one or more characteristics of discharge of crop residue propelled from a chopper. The spreader apparatus includes a spreader board having vanes mounted thereon for guiding crop residue flow discharged from the chopper, the vanes and the spreader board being movable simultaneously and in a unitary manner, to achieve adjustments or shifts in crop residue deposition location, without altering consistency or uniformity of the crop residue distribution.

Owner:BLUE LEAF I P INC

Agricultural combine active spreader having a triangular nose divider

An active crop residue spreader for an agricultural combine including two horizontal rotor impellers for guiding and uniformly distributing the crop residue on a field, a triangular nose divider with a pyramidal shape which is wider at the base and an extension near or into the chopper. The spreader further comprises a straw guiding plate provided with specially shaped rakes on each side of the guiding plate.

Owner:BLUE LEAF I P INC

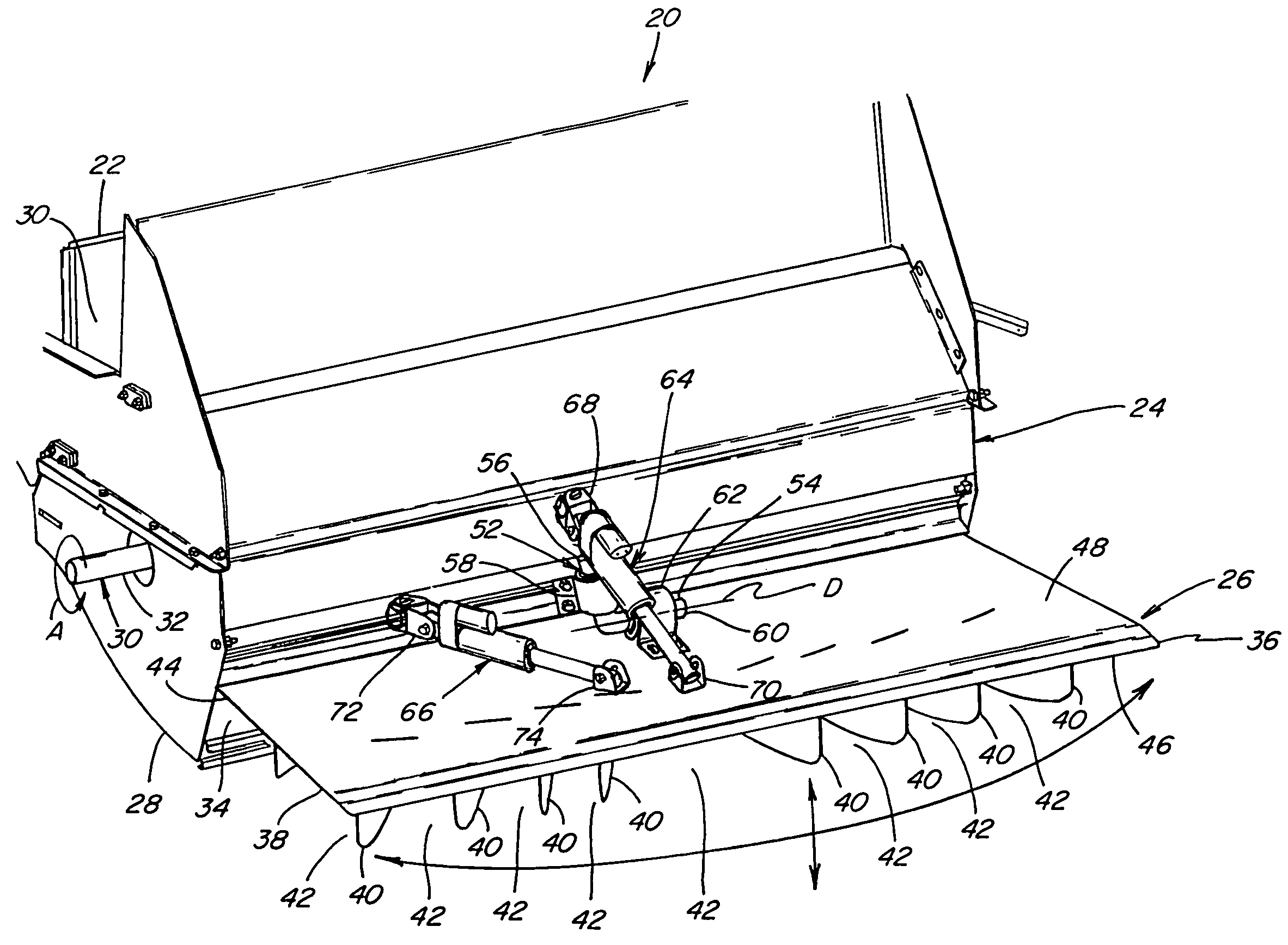

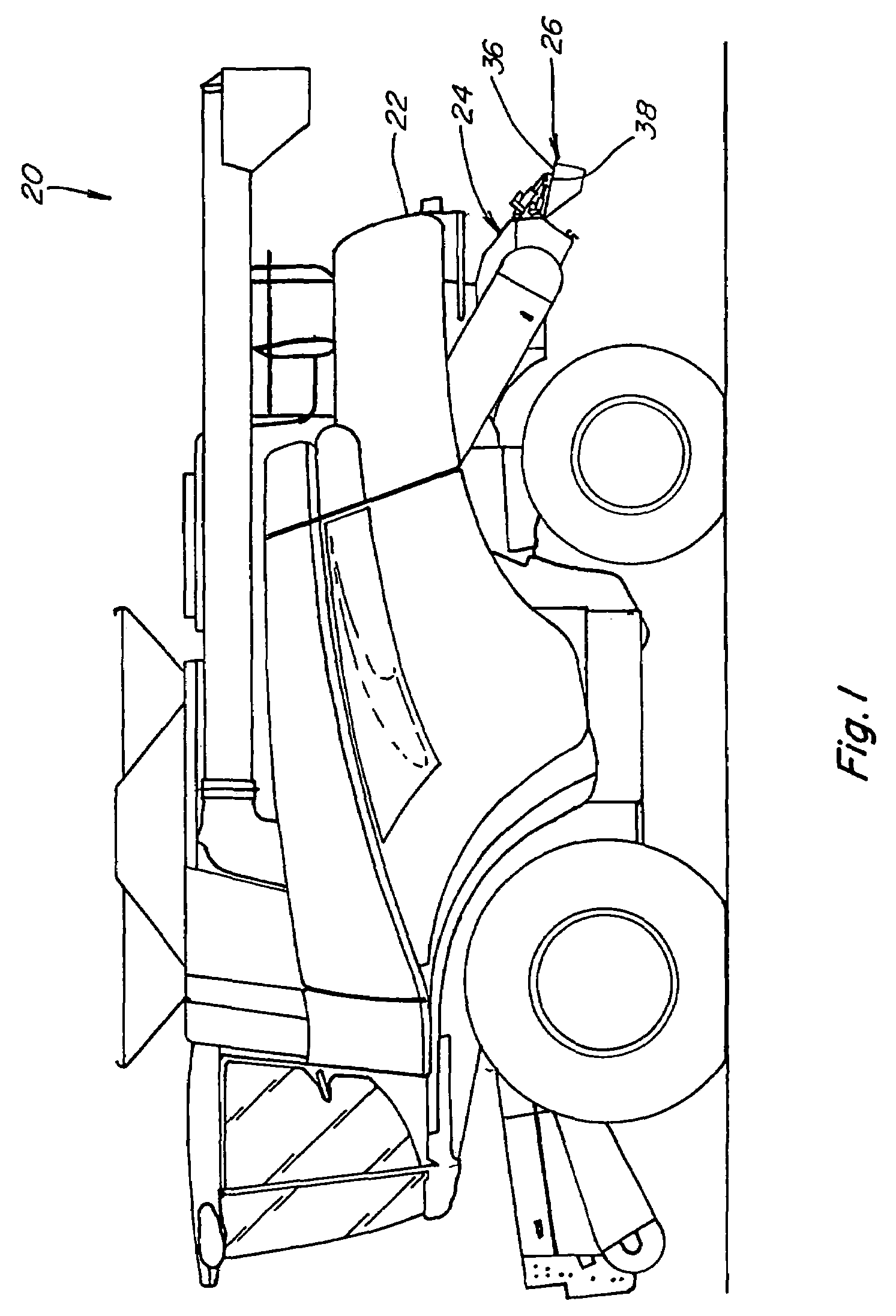

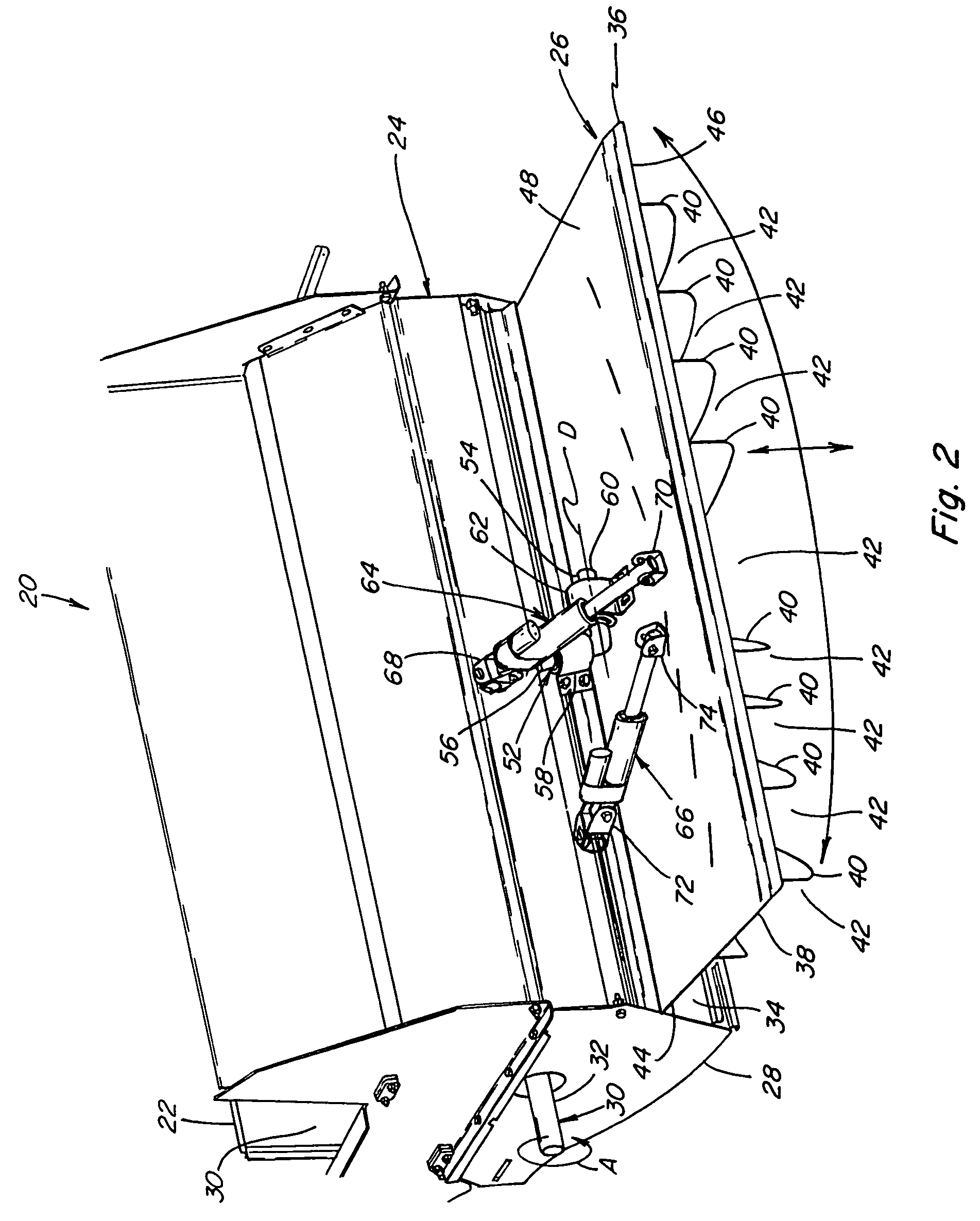

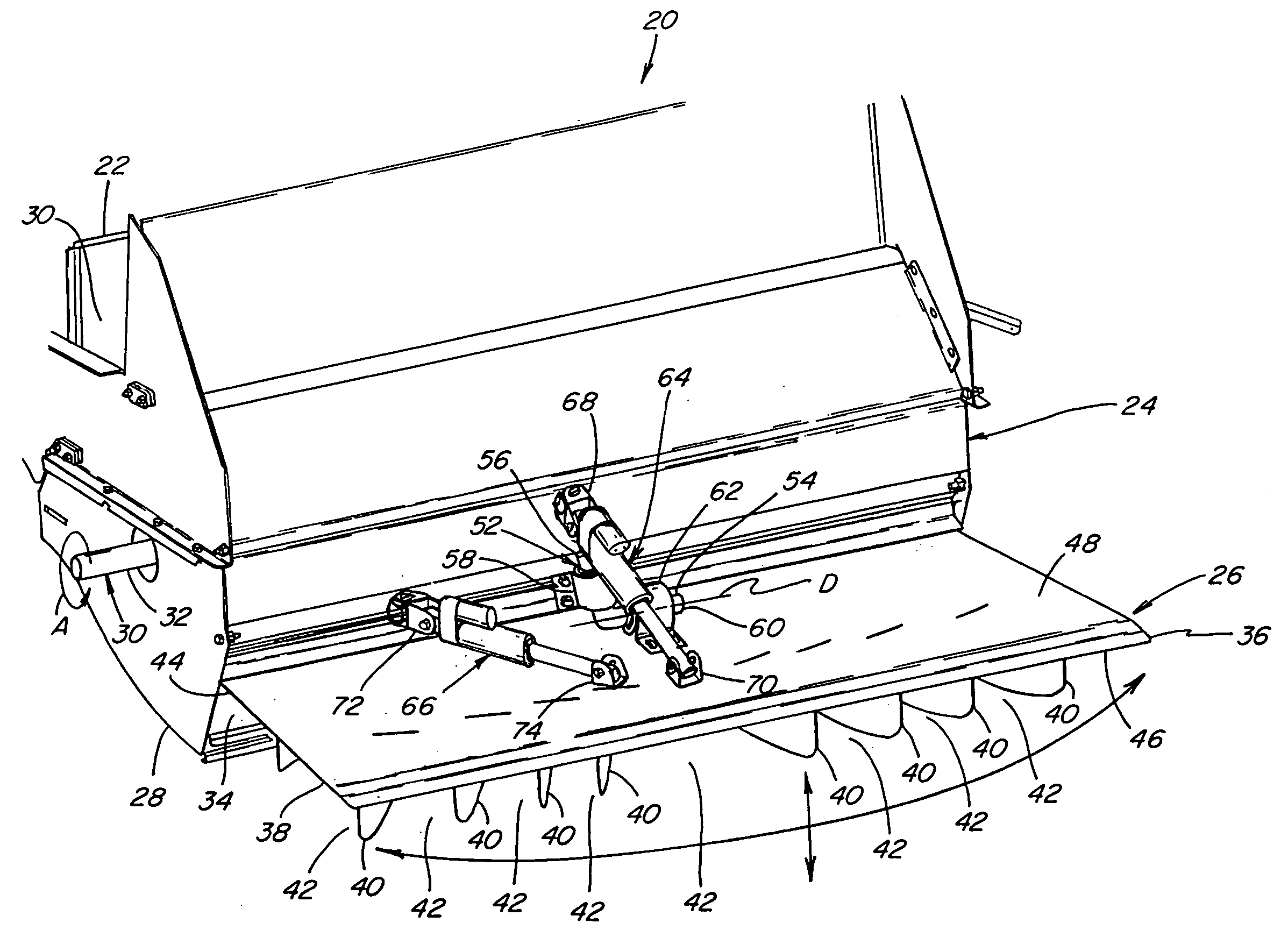

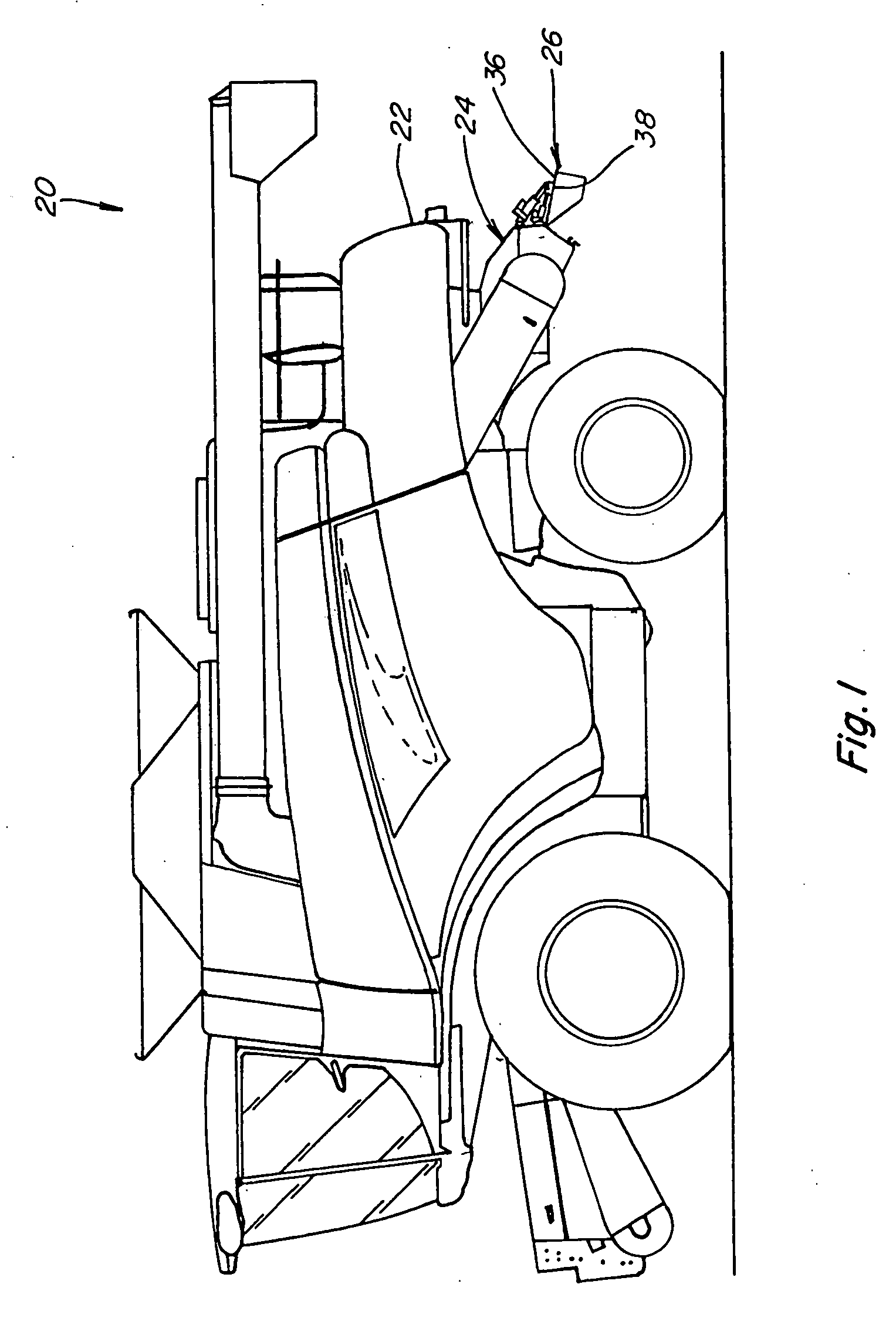

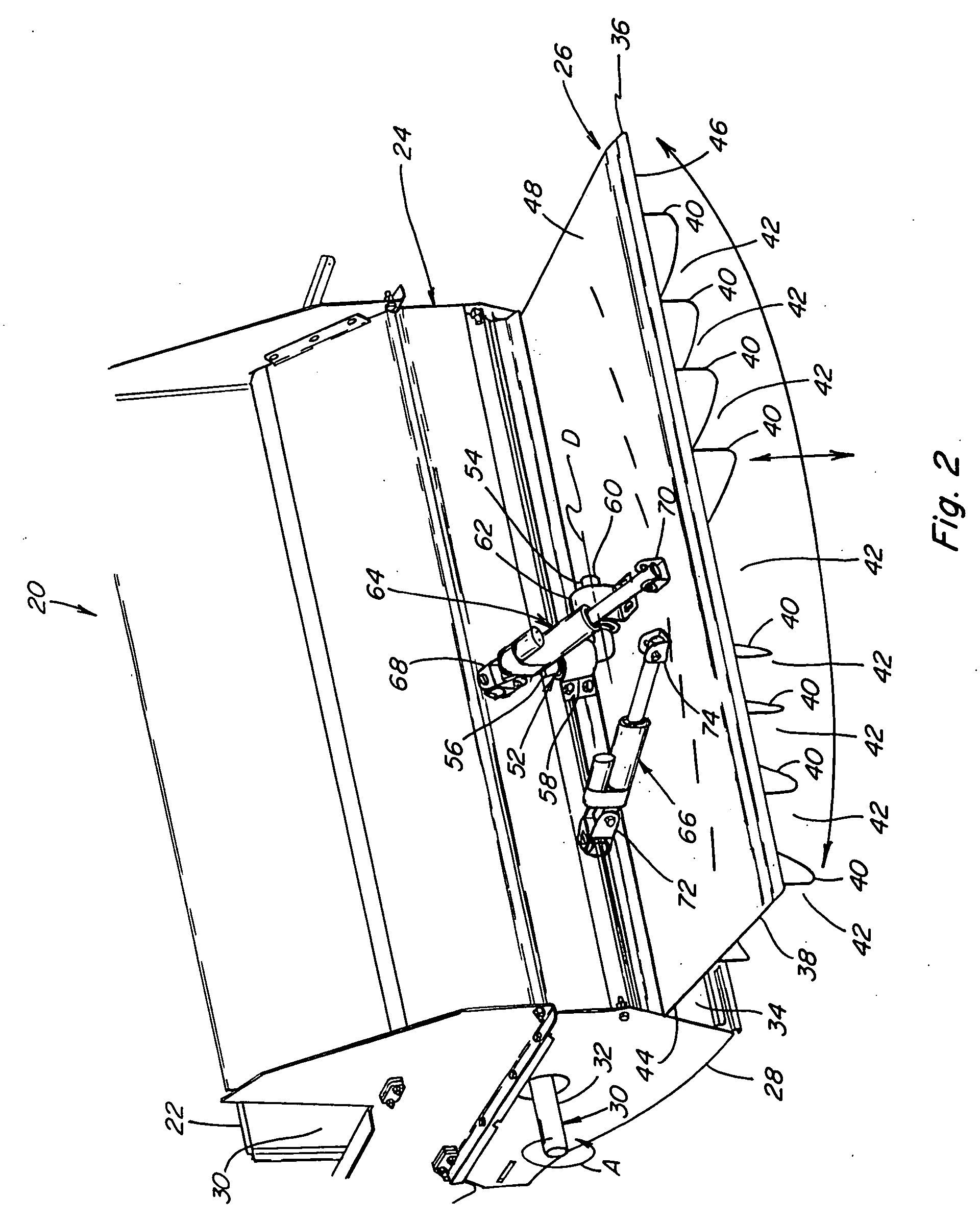

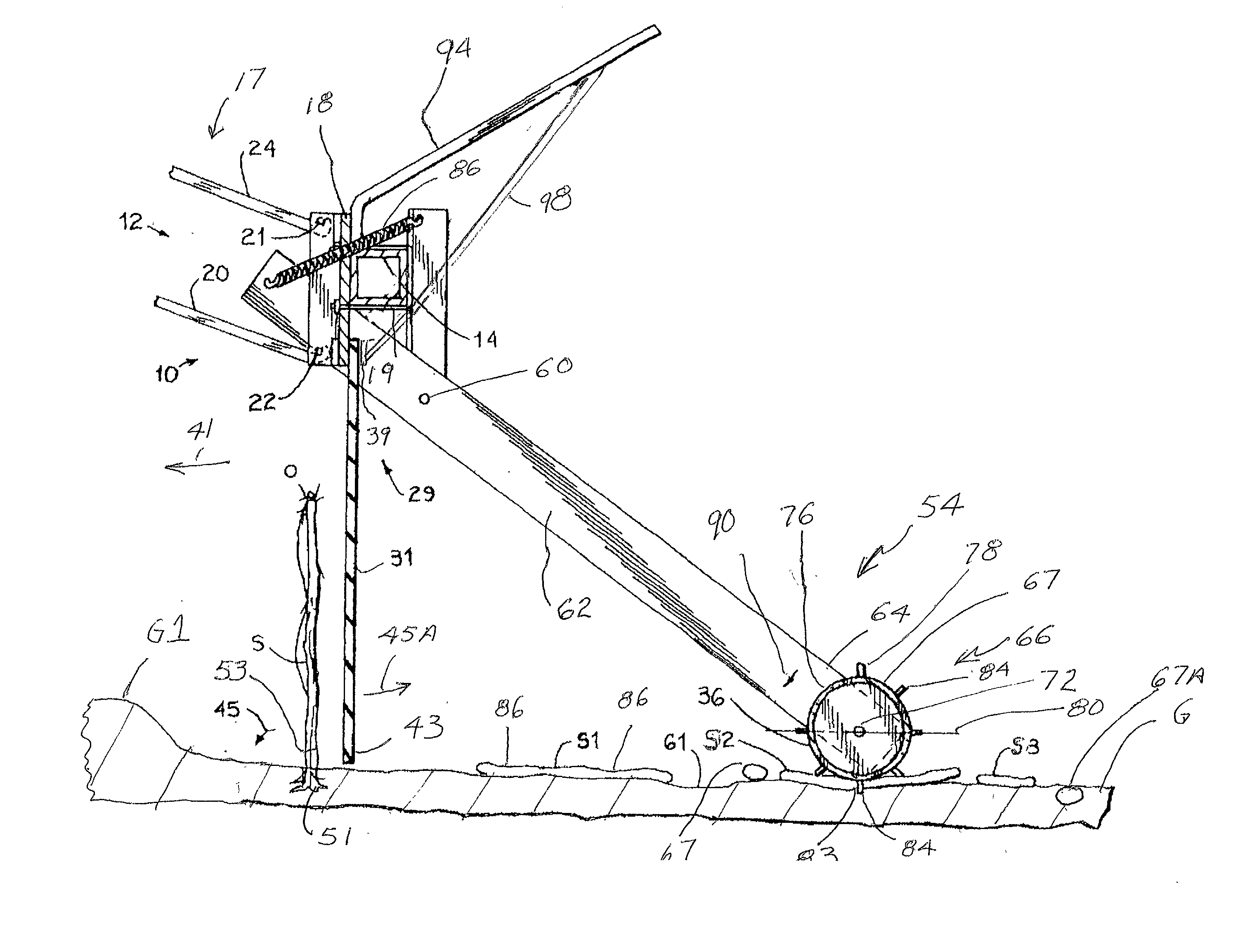

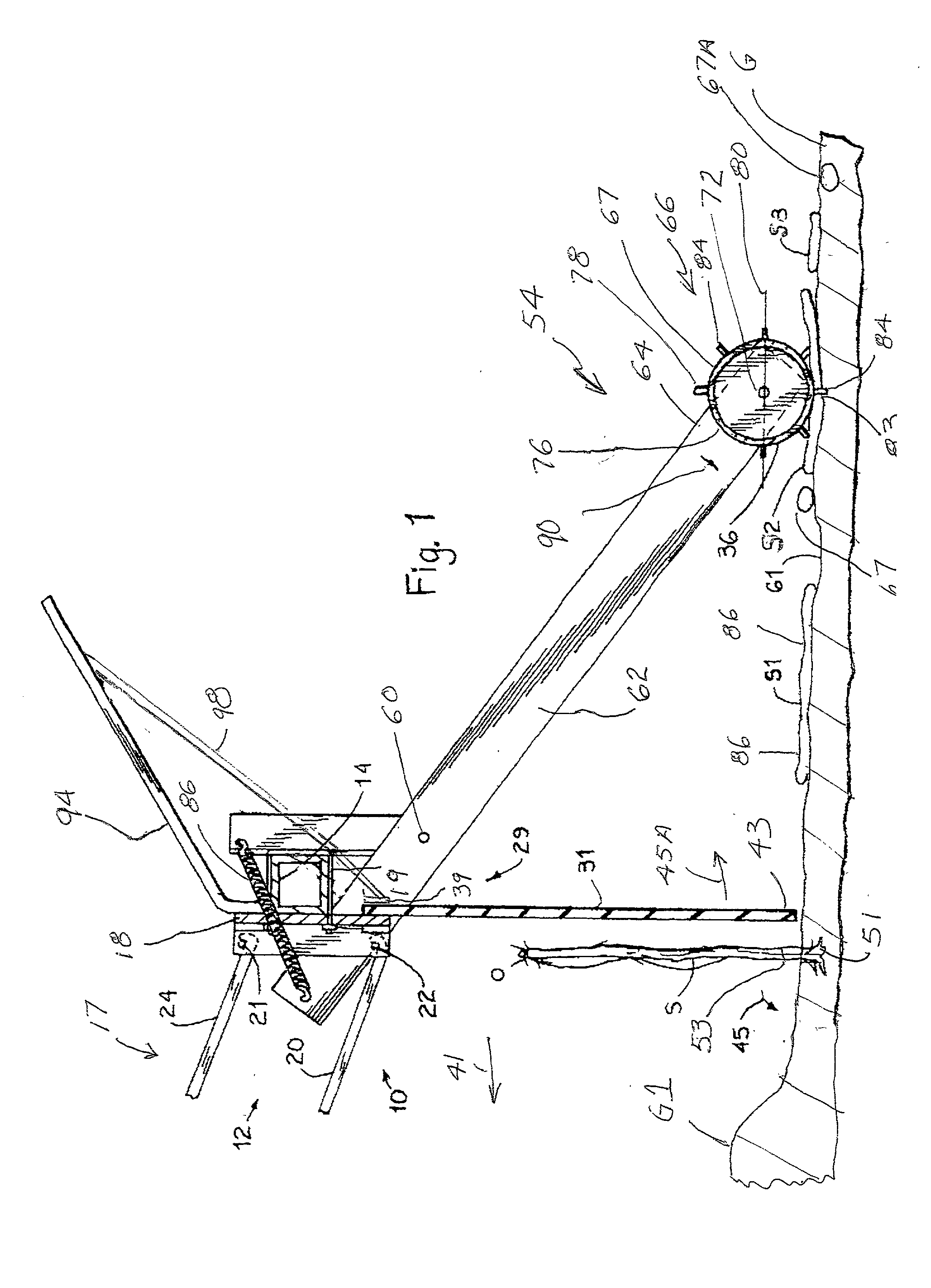

Apparatus and method for knocking down and crushing farm crop residue

Apparatus and method for crushing plant residue remaining in a farm field following the crop harvest comprising a main frame moveable in a forward path, a yieldable residue knock-down drape suspended on the frame for knocking the plant residue to the ground and breaking the upstanding plant residue apart from its underground roots as the frame forwardly moves, and a transversely disposed residue crushing roller mounted on the frame rearwardly of the knock-down drape for crushing spaced-apart portions of the knock-down residue into a plurality of smaller crop residue segments.

Owner:BURK CARL A

Combine harvester with pivoting deflector plate

A combine harvester has at its rear end a crop residue chopper and a deflector plate for defining the path followed by the crop residue discharged from the rear end of the combine harvester. The deflector plate has a first position to direct the crop residue into the chopper and a second position to direct the crop residue forward of the chopper. In the invention, the deflector plate also has a third position in which the crop residue is directed to flow over the top and to the rear of the chopper.

Owner:BLUE LEAF I P +1

Flow distributor apparatus for controlling spread width of a straw spreader

A flow distributor apparatus for a vertical spreader operable for discharging a flow of straw or other crop residue in a sideward direction over a field, the flow distributor apparatus including a flow guide element, an adjusting mechanism, and a coupling connector connecting the flow guide element to the adjusting mechanism for controllable repositioning of the flow guide element relative to the spreader paddles. The flow guide element is disposed generally adjacent to the back plate of the spreader and intermediate the spreader paddles with an apex portion, laterally extending arm portions, and longitudinally extending crop residue flow surfaces, at least portions of which crop residue flow surfaces extend beneath the spreader paddles. The adjusting mechanism is operable to effect at least either vertical, horizontal, or rotational movement of the flow guide element relative to the spreader paddles to adjustably vary the clearances between the outer swept diameters of the spreader paddles and the crop residue flow surfaces to control the sidewardly outwardly discharge of crop residue from the spreader.

Owner:BLUE LEAF I P INC

Crop residue chopping and spreading system for an agricultural combine

Owner:BLUE LEAF I P INC

Crop residue distribution apparatus and system with cooperatively movable deflector door and spreader assembly

The crop residue distribution apparatus and system use a horizontal crop spreader assembly and deflector door independently relatively positionable to be configurable in a straw windrowing and chaff spreading configuration in which straw flow is directed through an aperture between drive units of the spreader assembly while the chaff is directed to the spreader disposed in a lower opening; in a straw and chaff spreading configuration wherein the door closes the aperture and both straw and chaff are directed to the spreader; and in a straw and chaff windrowing configuration wherein the spreader is withdrawn from the lower opening such that the straw and chaff are both discharged therethrough to form a windrow without requiring removing disks of the spreader.

Owner:BLUE LEAF I P INC

Corn cob cleaning system

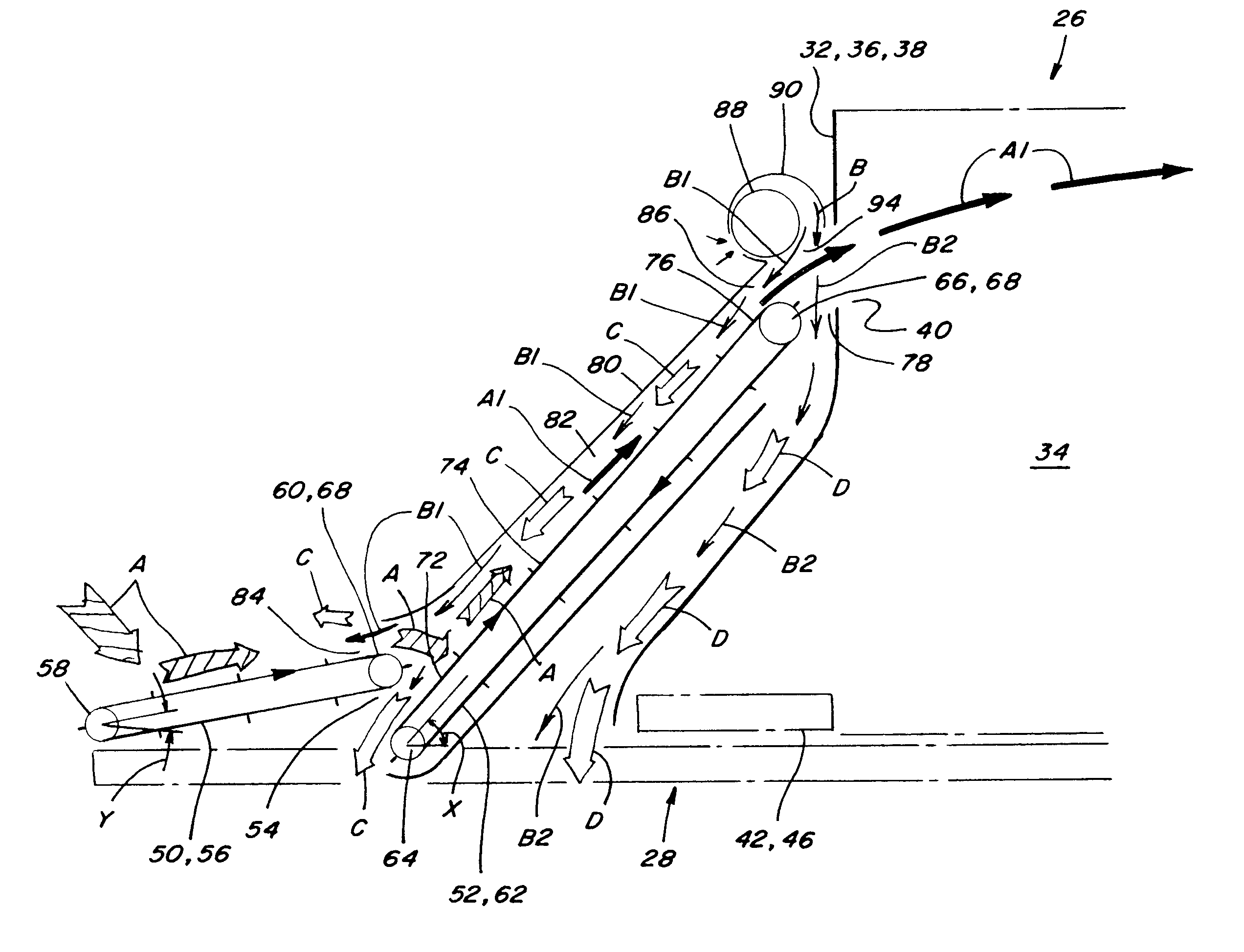

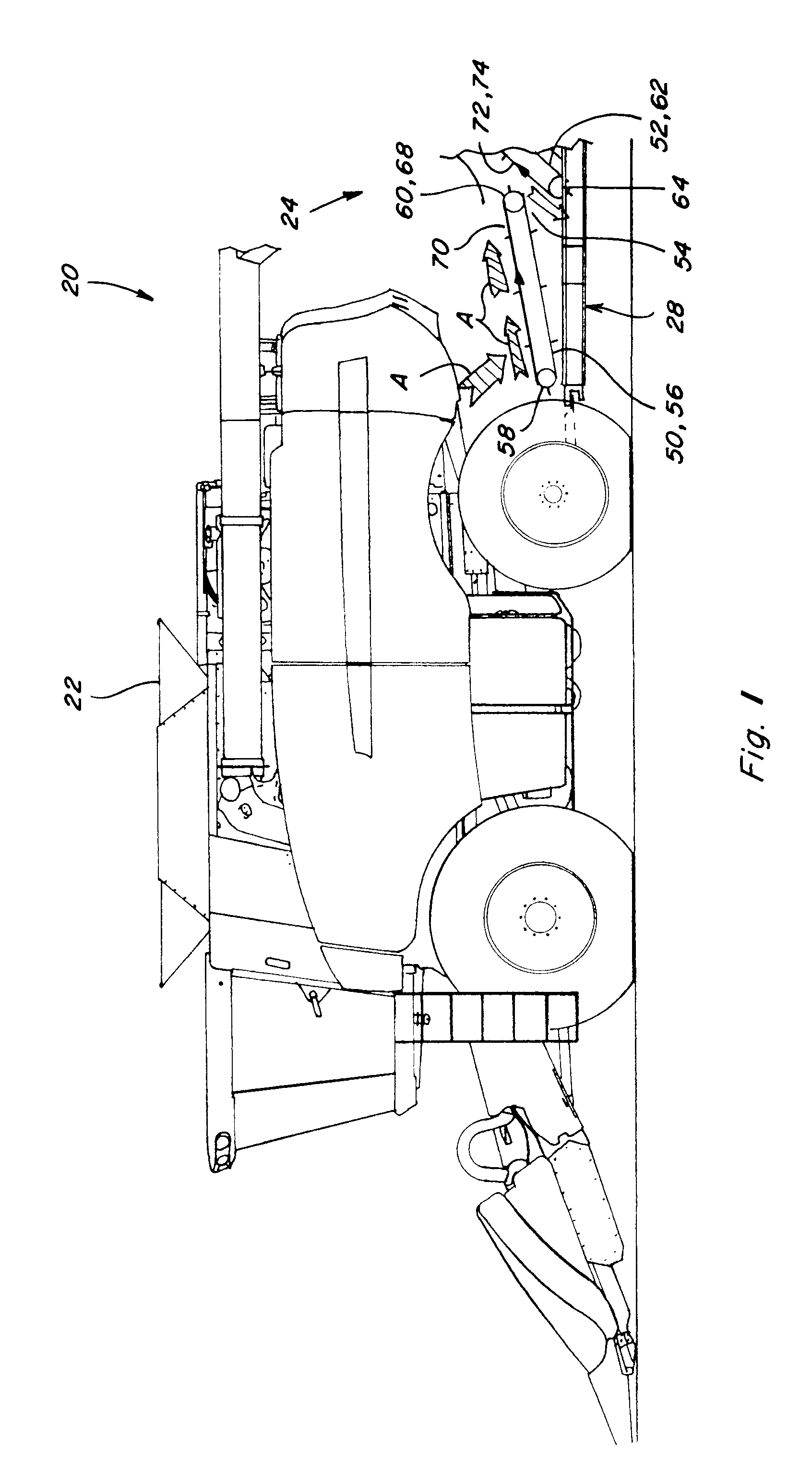

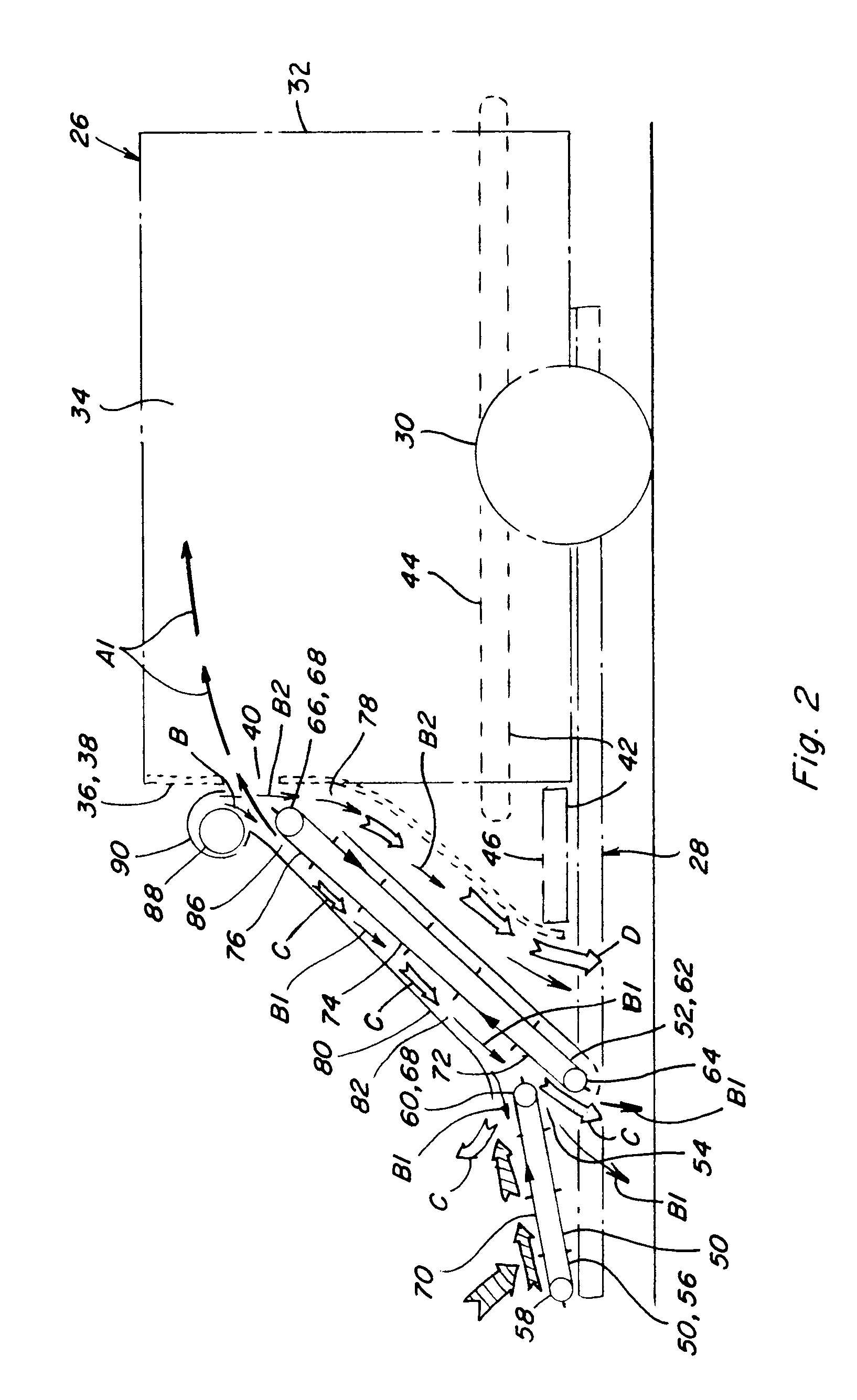

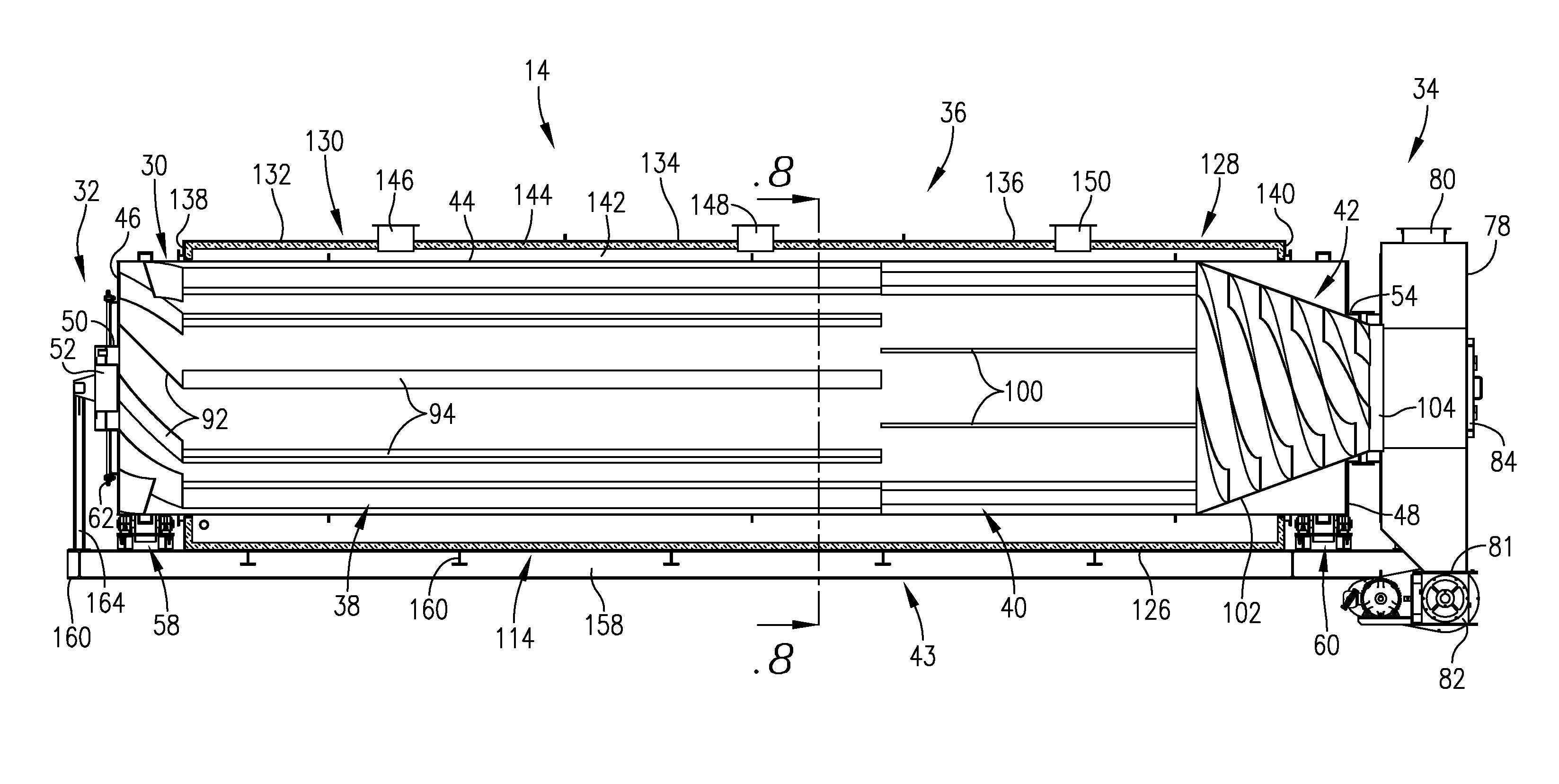

A cleaning system for corn cobs incorporating a conveyor system providing a capability for positively removing or cleaning other crop residue from the cobs, which is adapted to be towed by a harvester; to be incorporated with a cob collecting device; and which can be adjustable for varying corn varieties, conditions and the like. The conveyor system includes at least one enclosed inclined conveyor for carrying a flow of the crop residue upwardly and propelling the flow into a space, while a flow of air is directed downwardly along the conveyor to remove other residue material from the cobs. Another flow of air is optionally directed downwardly through the space for removing additional material other than cobs, and at least one aspect of the system can be adjusted for relatively varying the air flows to adapt the system for a variety of conditions.

Owner:BLUE LEAF I P INC

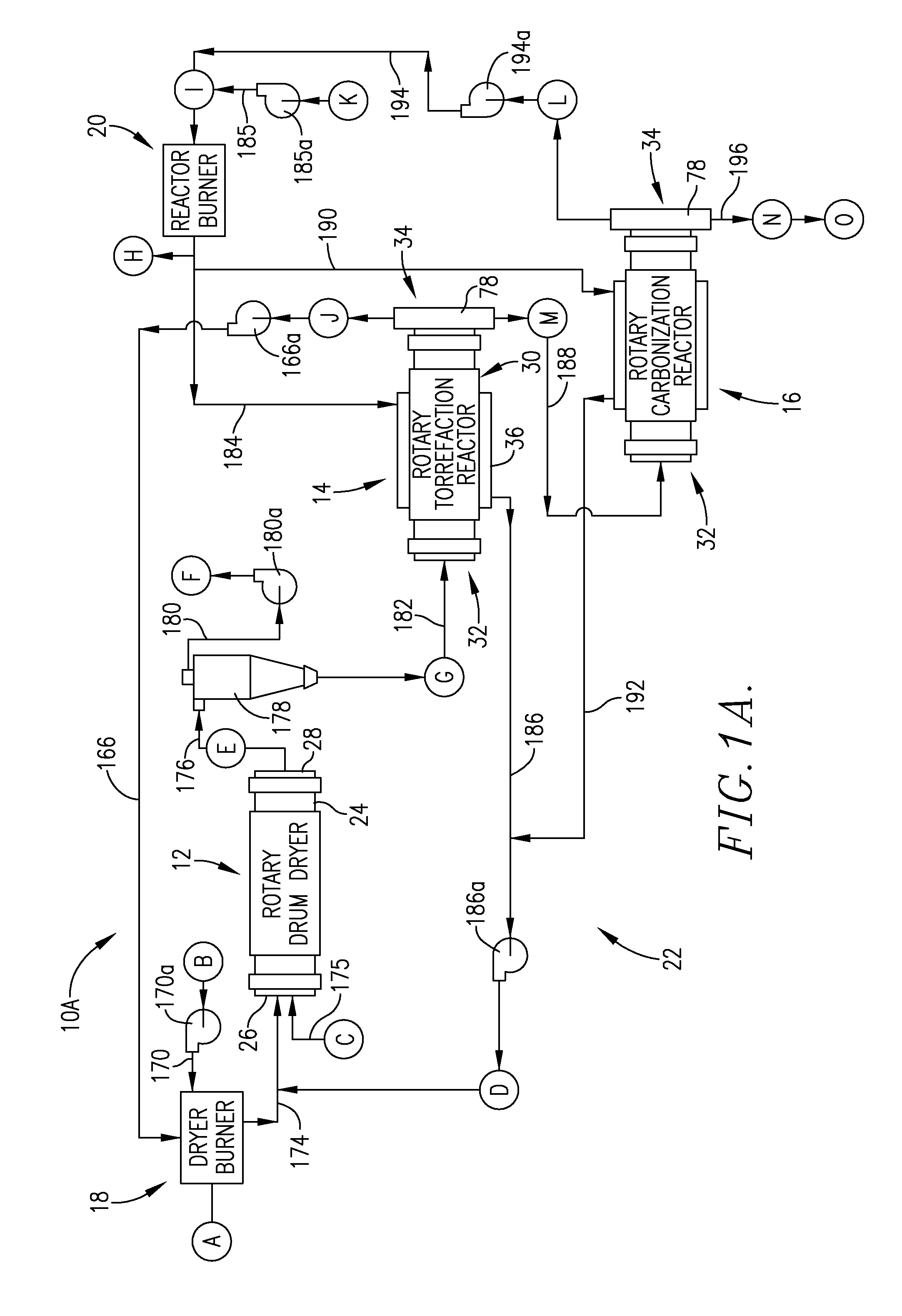

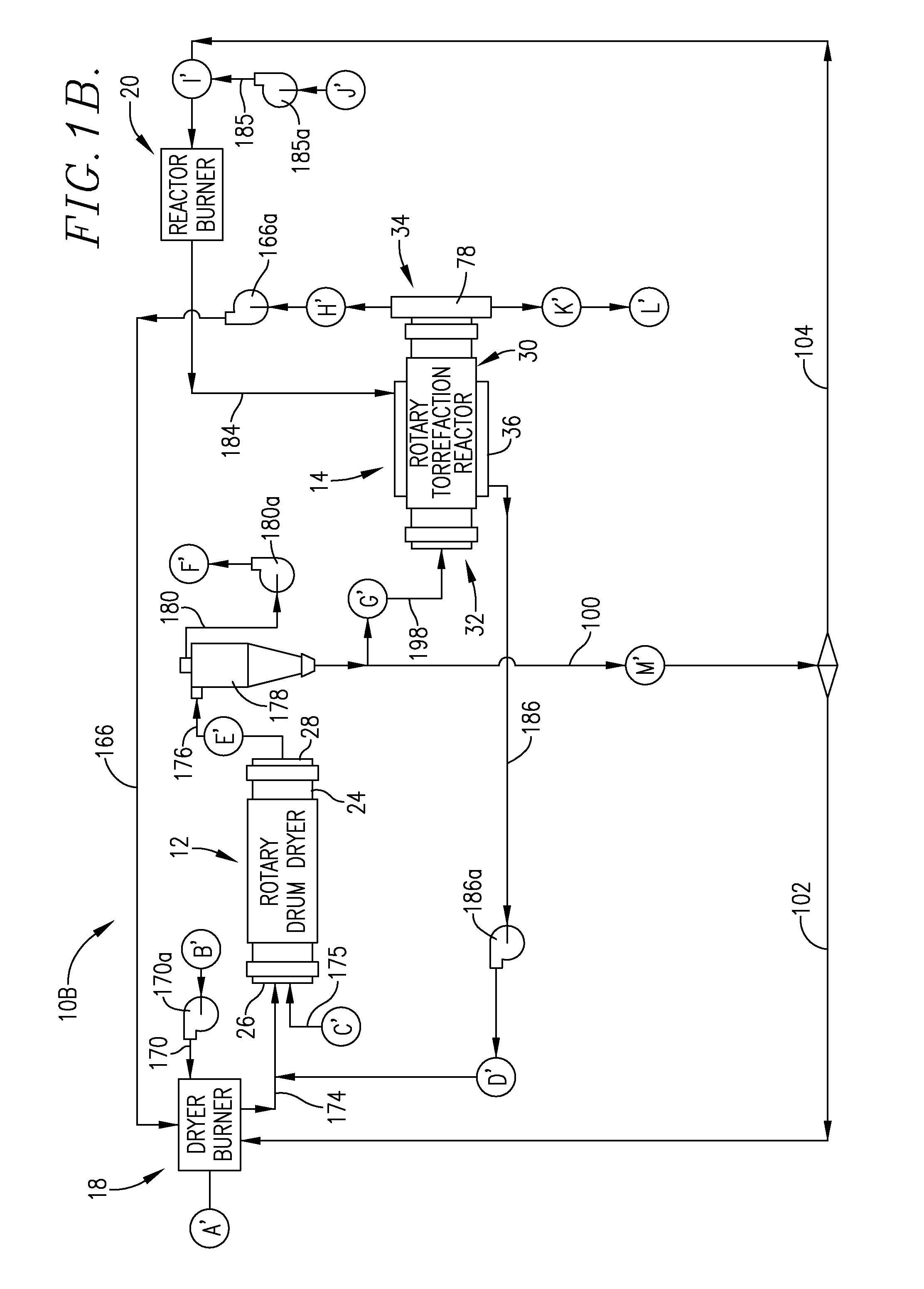

High energy efficiency biomass conversion process

Improved, fuel-efficient systems are provided for the processing of biomass, such as wood or crop residues, food waste or animal waste in order to selectively obtain torrefied and / or carbonized final products. In general, the processes involve thermally drying incoming biomass using a dryer employing the hot gas output of a fuel-operated burner. Next, the dried product is torrefied in an indirect torrefaction reactor so as to evolve light volatile organic compounds which are used as a gaseous fuel source for the burner. The torrefied product can be recovered, or some or all of the torrefied product may be directed to a carbonization reactor coupled with a reactor burner. Carbonization serves to remove most of the remaining VOCs which are used as a gaseous fuel input to the dryer. In certain instances, portions of the dried biomass are directed to the burners, as an additional source of fuel.

Owner:SMART TERRA CARE LLC

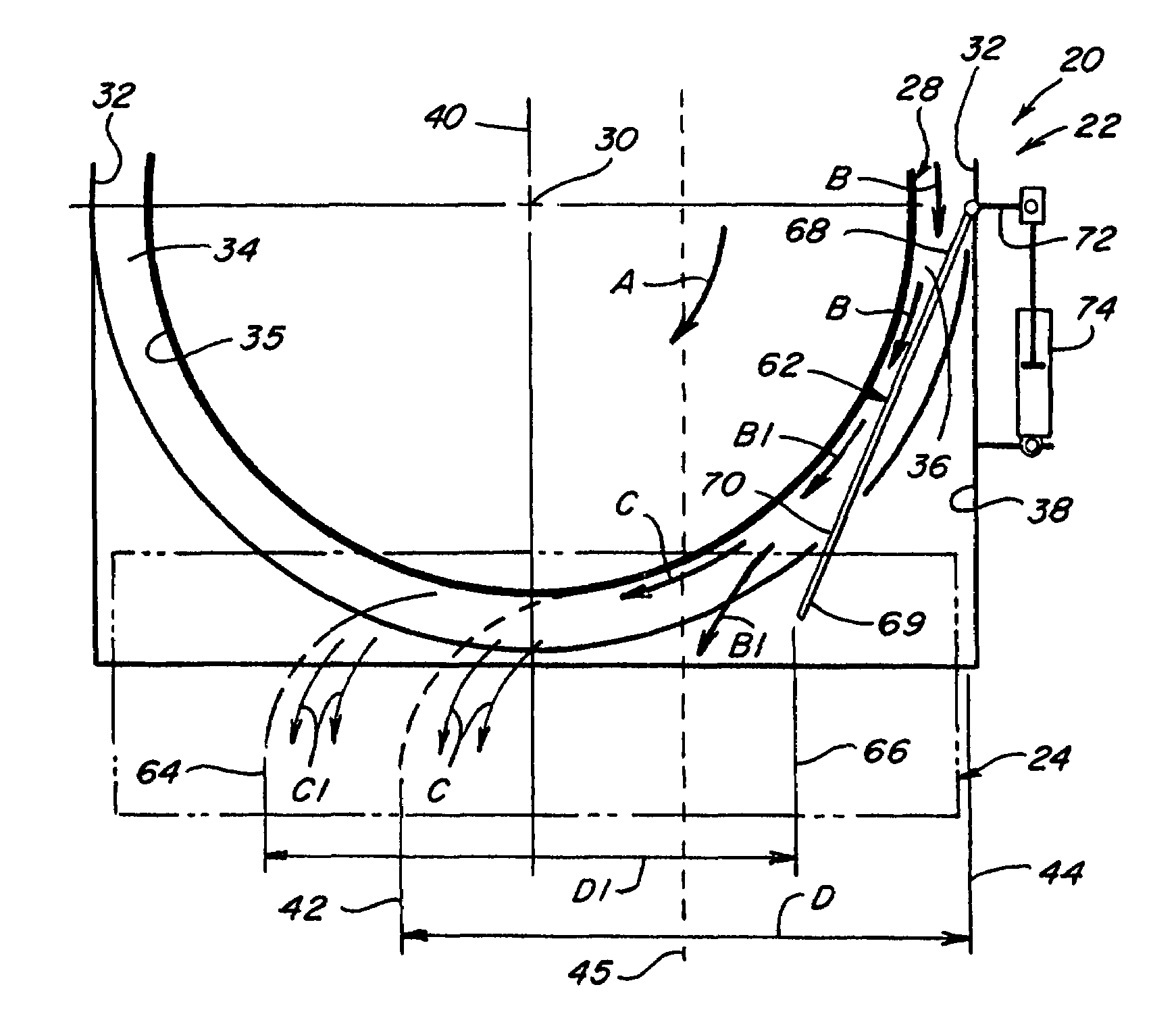

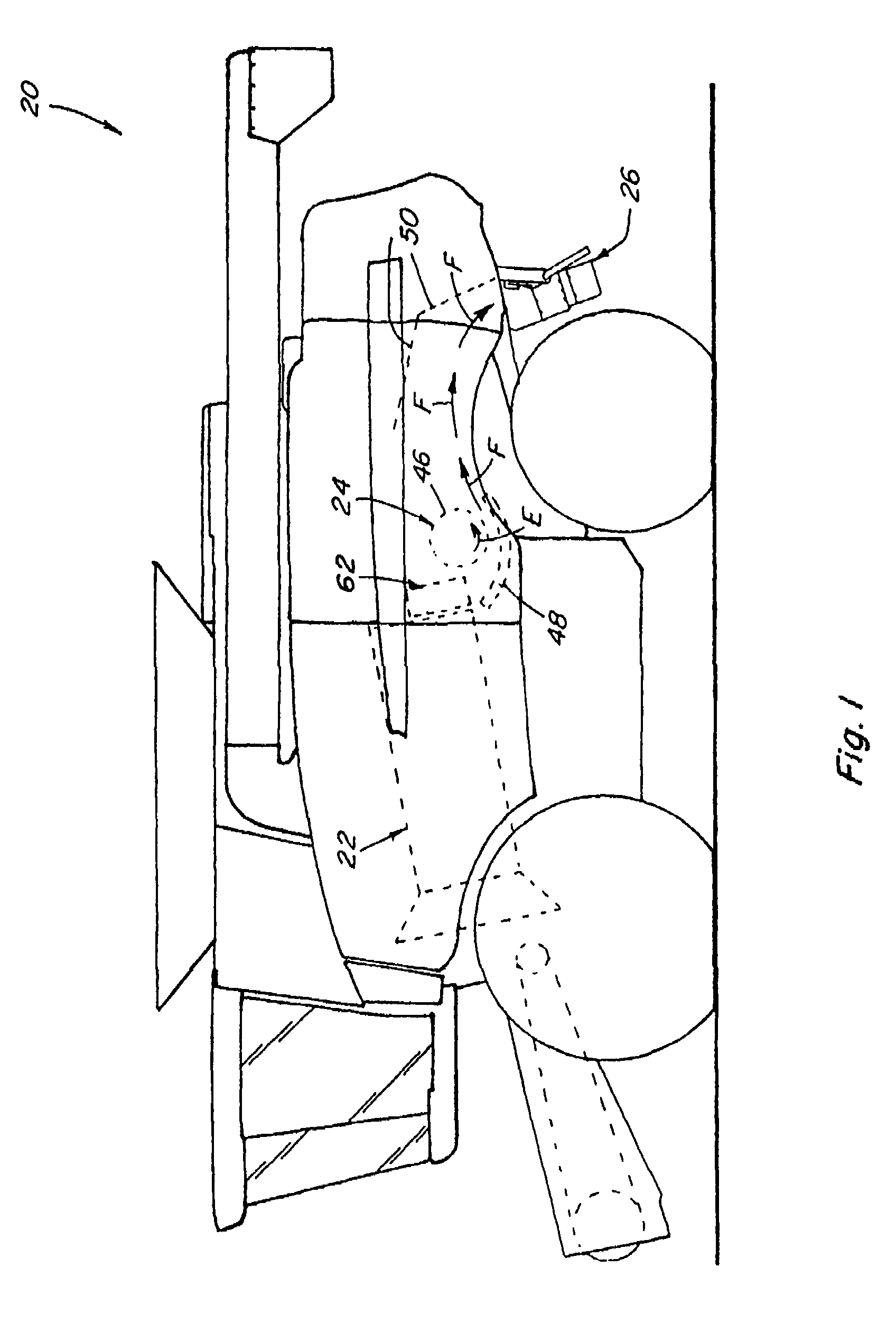

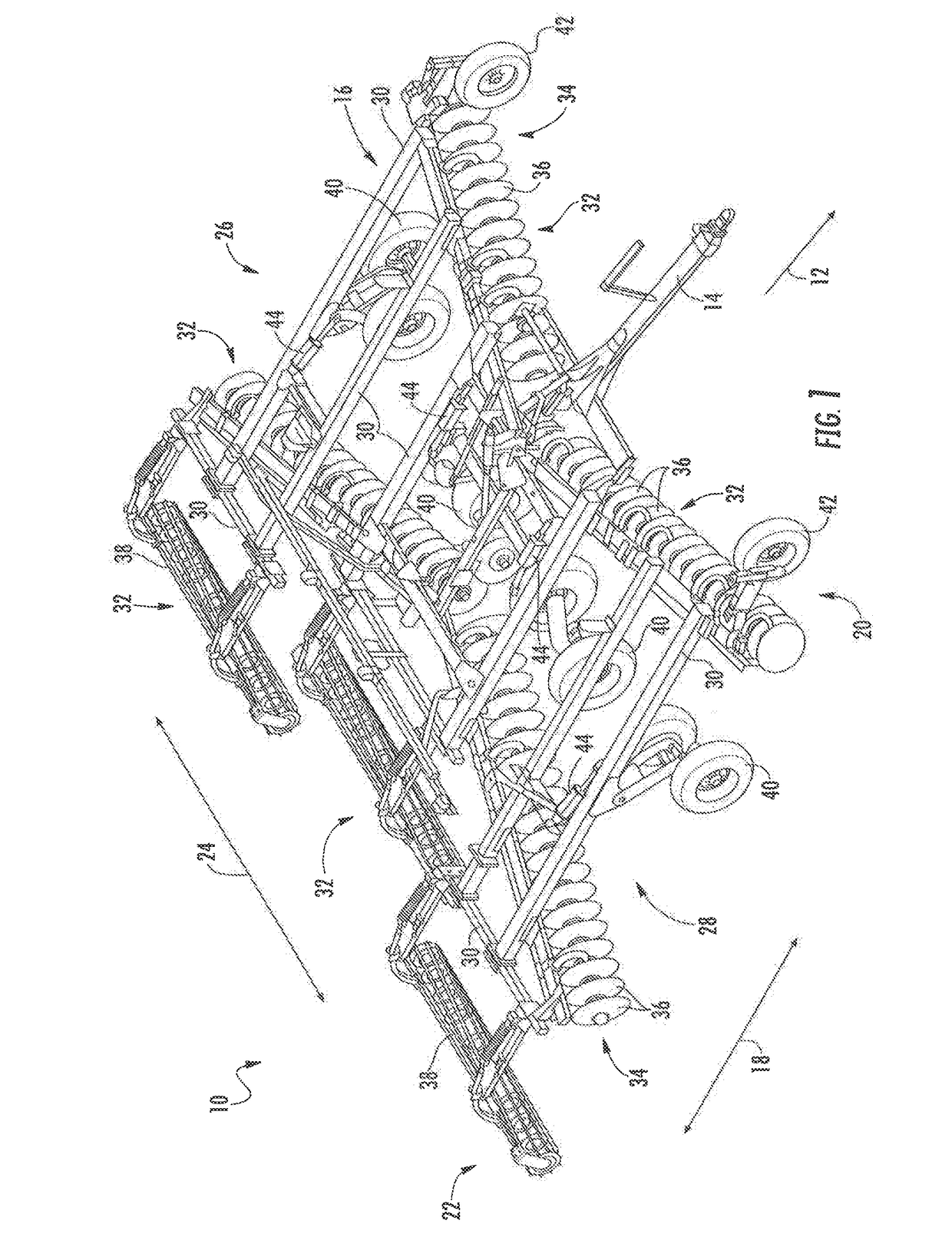

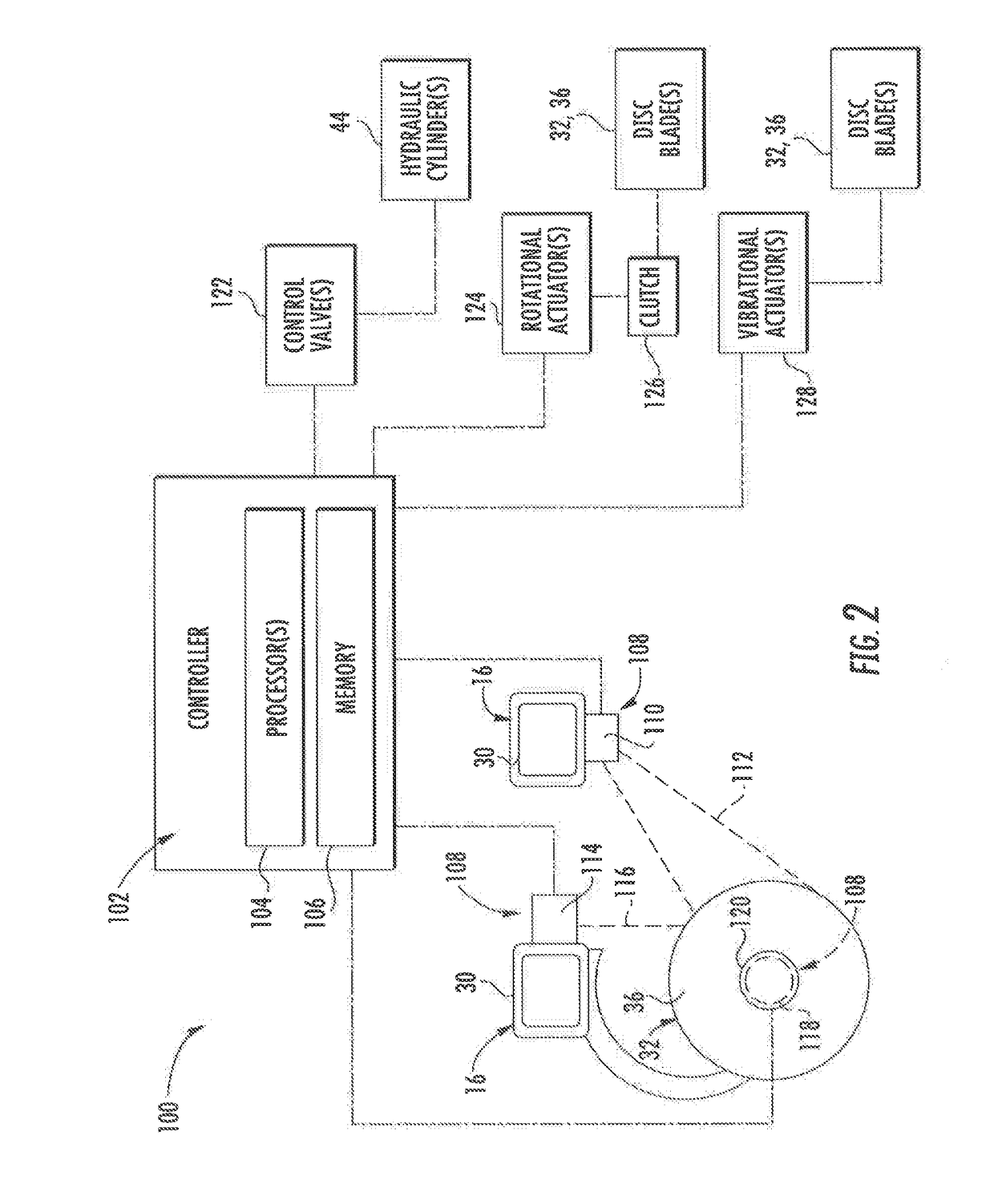

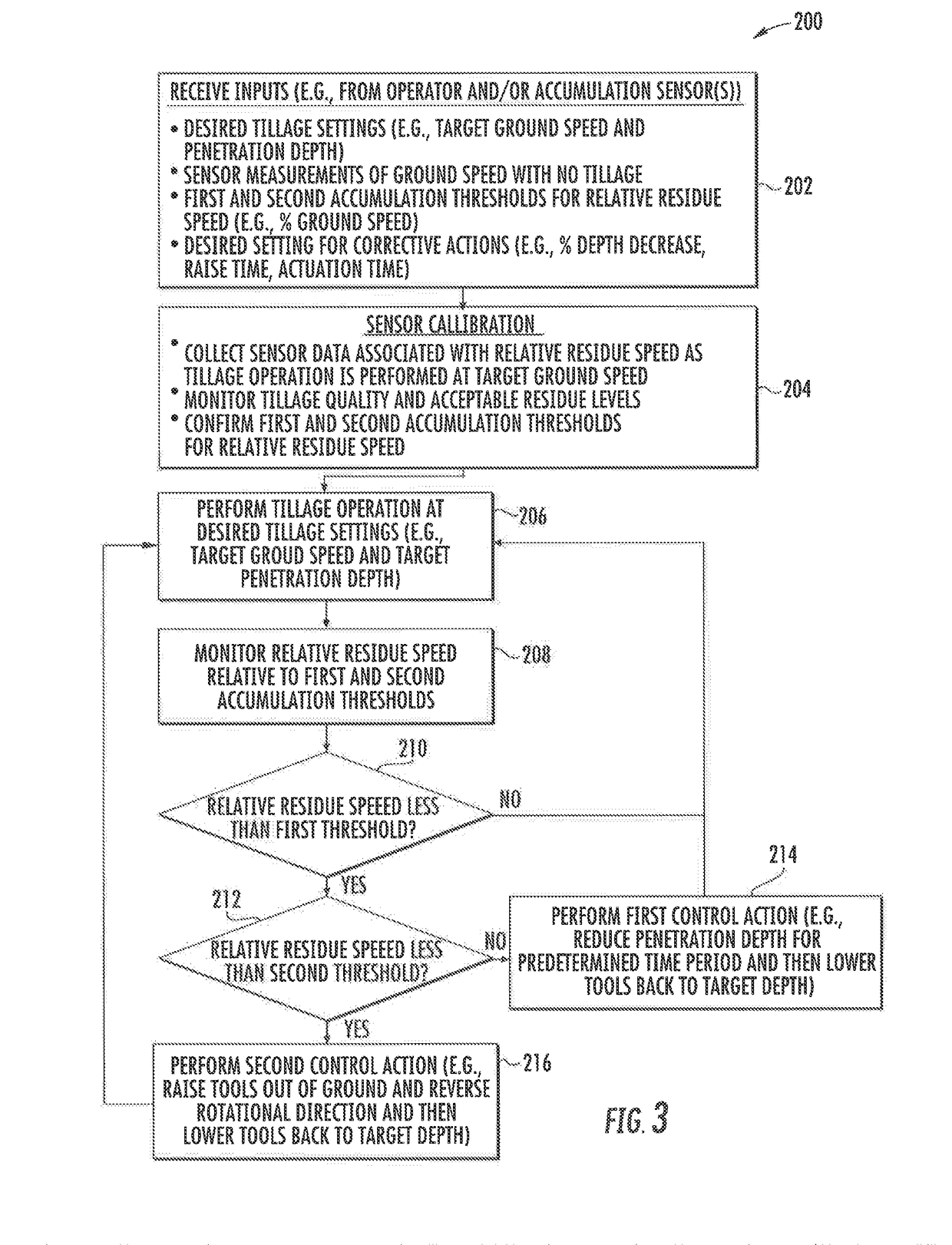

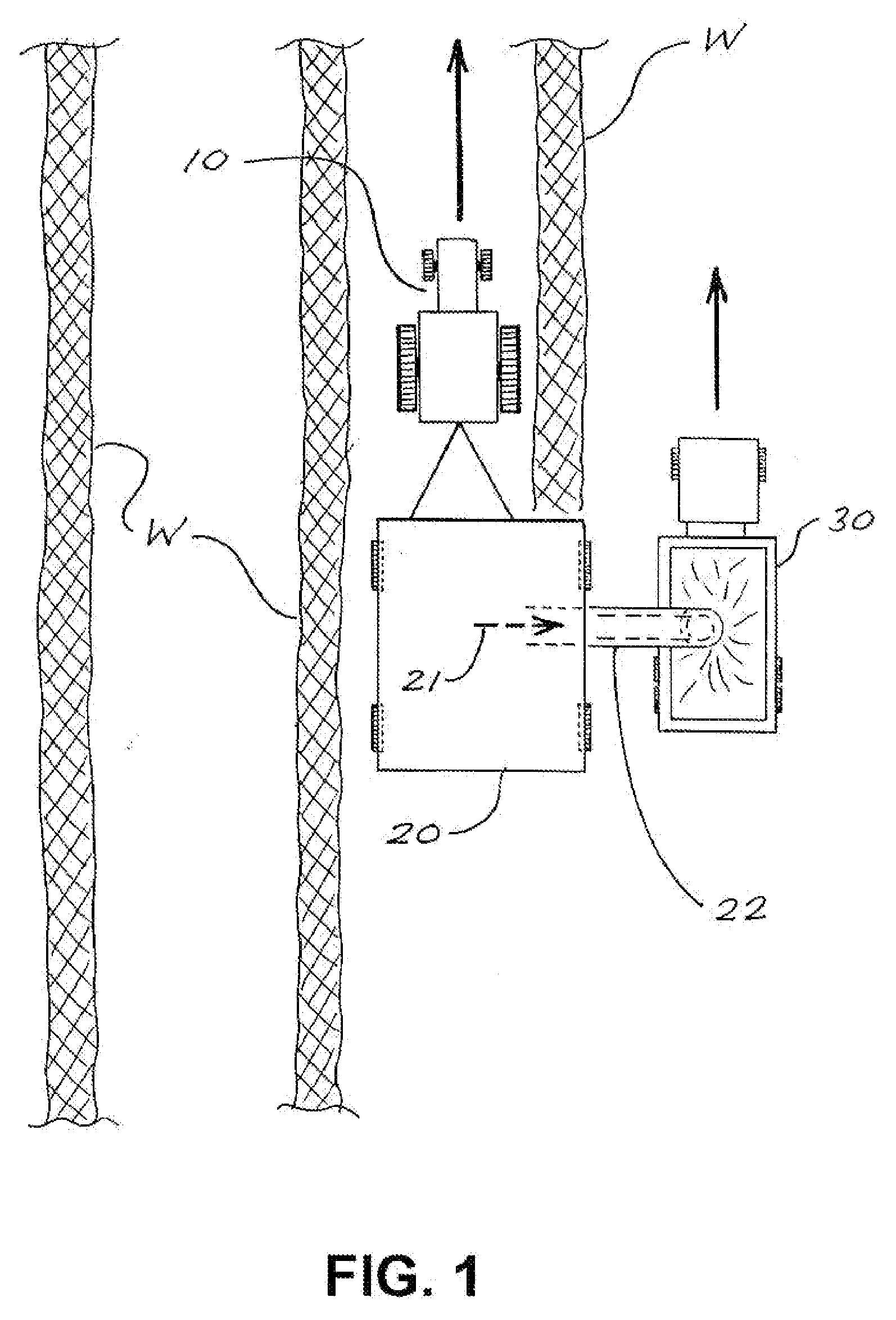

System and method for reducing soil and crop residue accumulation relative to ground-engaging tools of a tillage implement

ActiveUS20180352718A1Reduce accumulationReduce the amount requiredSpadesAgricultural machinesCrop residueEngineering

A method for reducing material accumulation relative to ground-engaging tools of a tillage implement may include monitoring, with a computing device, an accumulation parameter as a tillage operation is being performed, wherein the accumulation parameter provides an indication of material accumulation relative to a plurality of ground-engaging tools of the tillage implement. The method may also include comparing, with the computing device, the accumulation parameter to a material accumulation threshold, wherein the material accumulation threshold is indicative of a given degree of material accumulation relative to the plurality ground-engaging tools. In addition, based on the comparison between the accumulation parameter and the material accumulation threshold, the method may include controlling, with the computing device, an operation of at least one component of the tillage implement to execute a control action for reducing an amount of the material accumulation relative to the plurality of ground-engaging tools.

Owner:CNH IND CANADA

Crop residue distribution apparatus and system with cooperatively movable deflector door and spreader assembly

ActiveUS8585475B2Avoid flowSimple and economical meanMowersThreshersCrop residueMechanical engineering

The crop residue distribution apparatus and system use a horizontal crop spreader assembly and deflector door independently relatively positionable to be configurable in a straw windrowing and chaff spreading configuration in which straw flow is directed through an aperture between drive units of the spreader assembly while the chaff is directed to the spreader disposed in a lower opening; in a straw and chaff spreading configuration wherein the door closes the aperture and both straw and chaff are directed to the spreader; and in a straw and chaff windrowing configuration wherein the spreader is withdrawn from the lower opening such that the straw and chaff are both discharged therethrough to form a windrow without requiring removing disks of the spreader.

Owner:BLUE LEAF I P INC

Residue splitter

A residue splitter apparatus for use with a horizontal spreader assembly that employs a pair of spreader paddles disposed side-by-side to rotate about respective generally vertical axes for controlling the spread width distribution of crop residue on and over a field, and the method of use thereof, including a flow guide element located generally intermediate to the spreader paddles of the horizontal spreader assembly with crop residue flow surfaces that extend rearwardly from a front edge portion of the flow guide element and sidewardly to free end portions generally aft of at least portions of the spreader paddles to receive and direct the flow of crop residue from such spreader paddles. Preferably, the flow guide element is laterally expandable to permit the flow of crop residue from the spreader paddles to be adjustably varied to effect a desired pattern of crop residue flow from the spreader paddles, for instance, so as to better and more evenly distribute the flow side-to-side over a swath of an agricultural field from which the crop was harvested.

Owner:BLUE LEAF I P INC

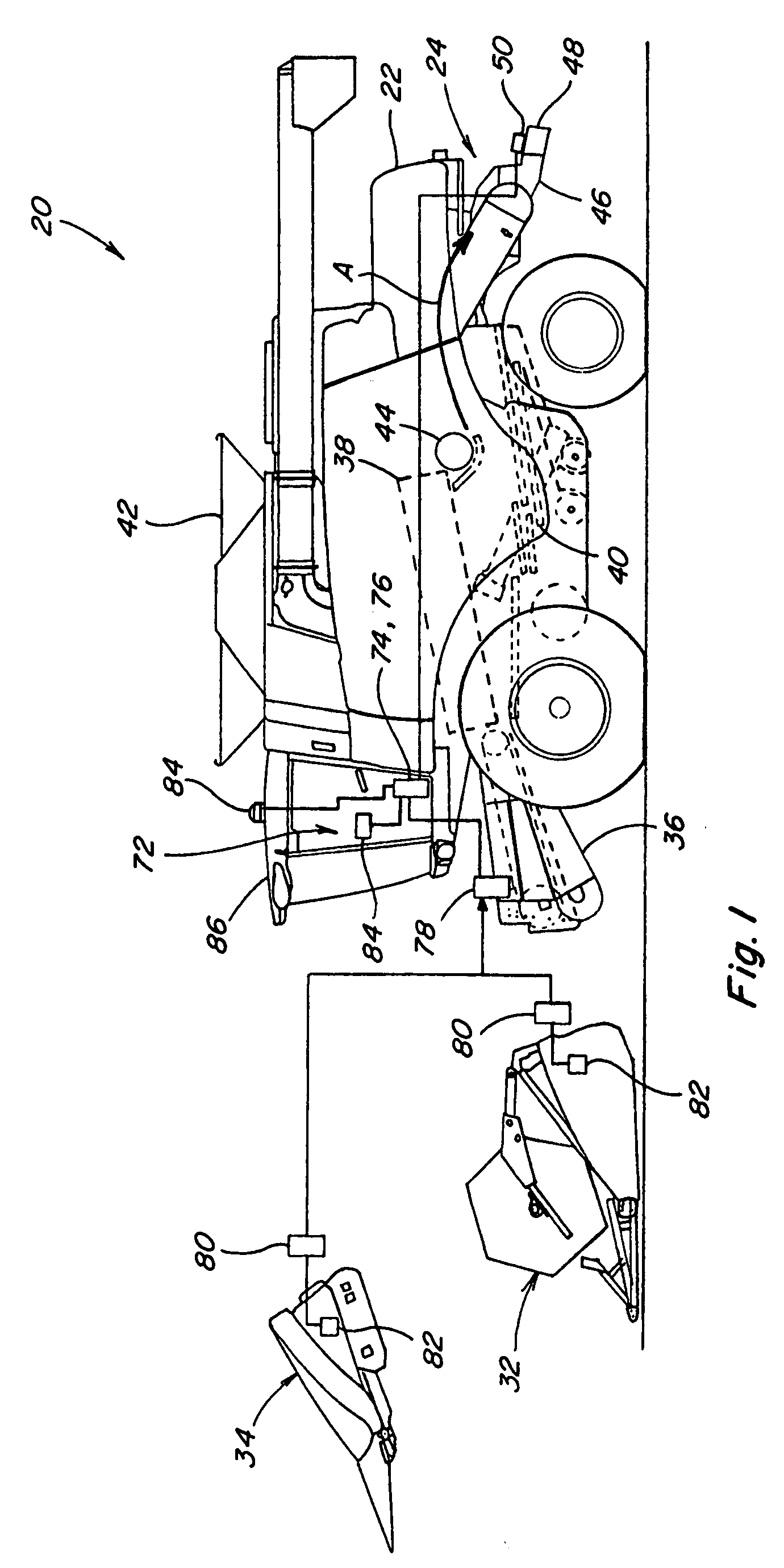

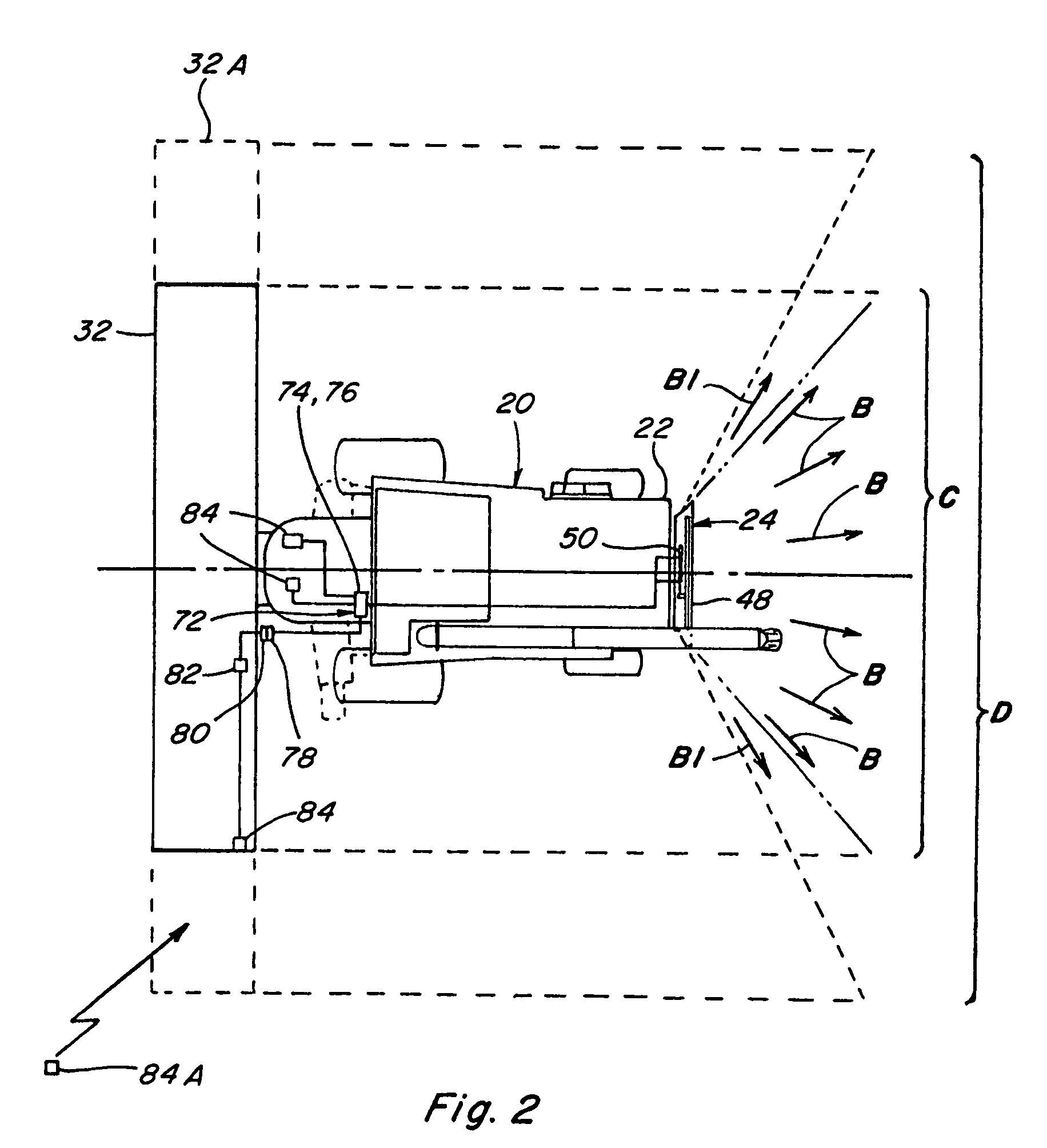

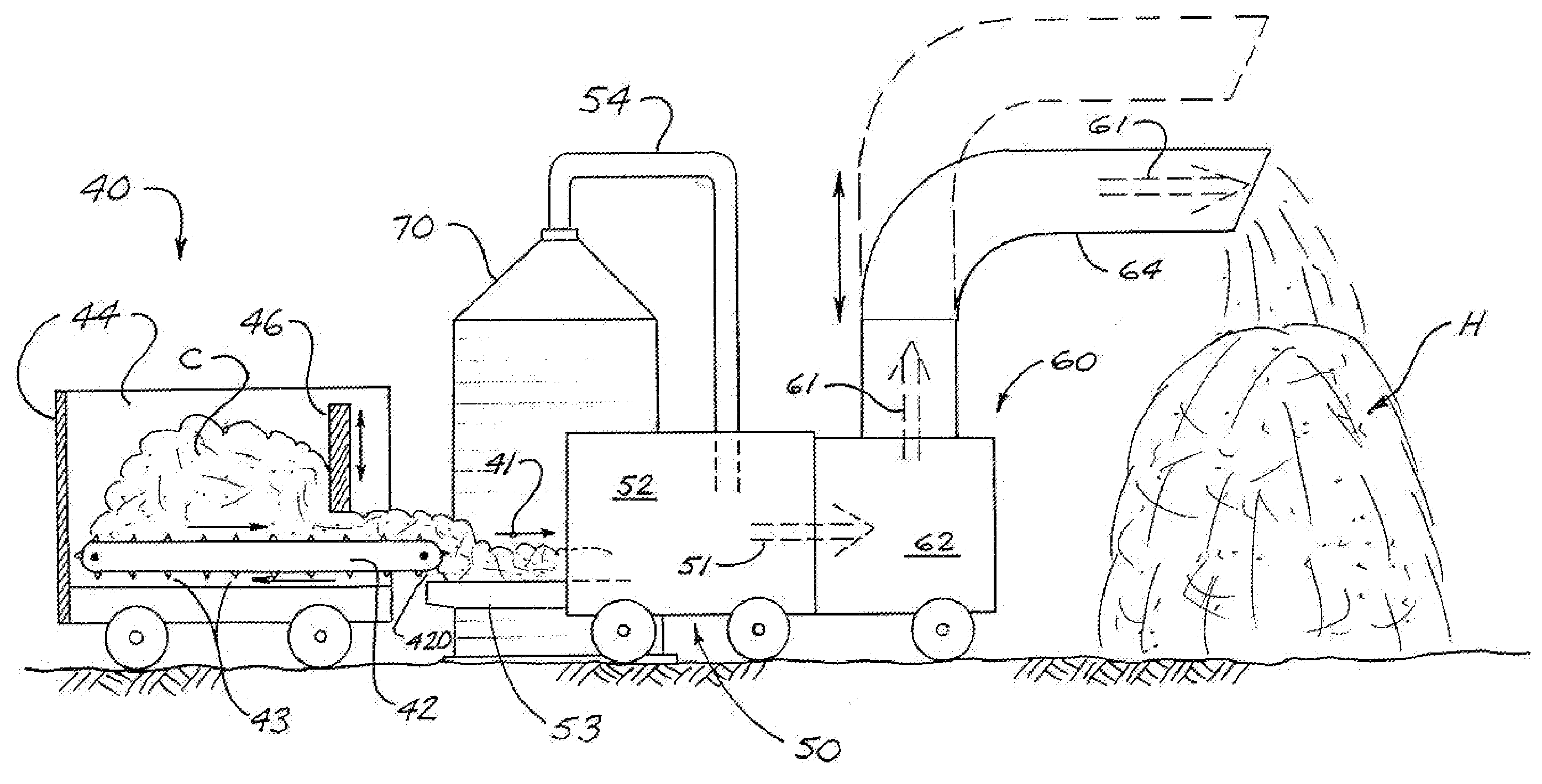

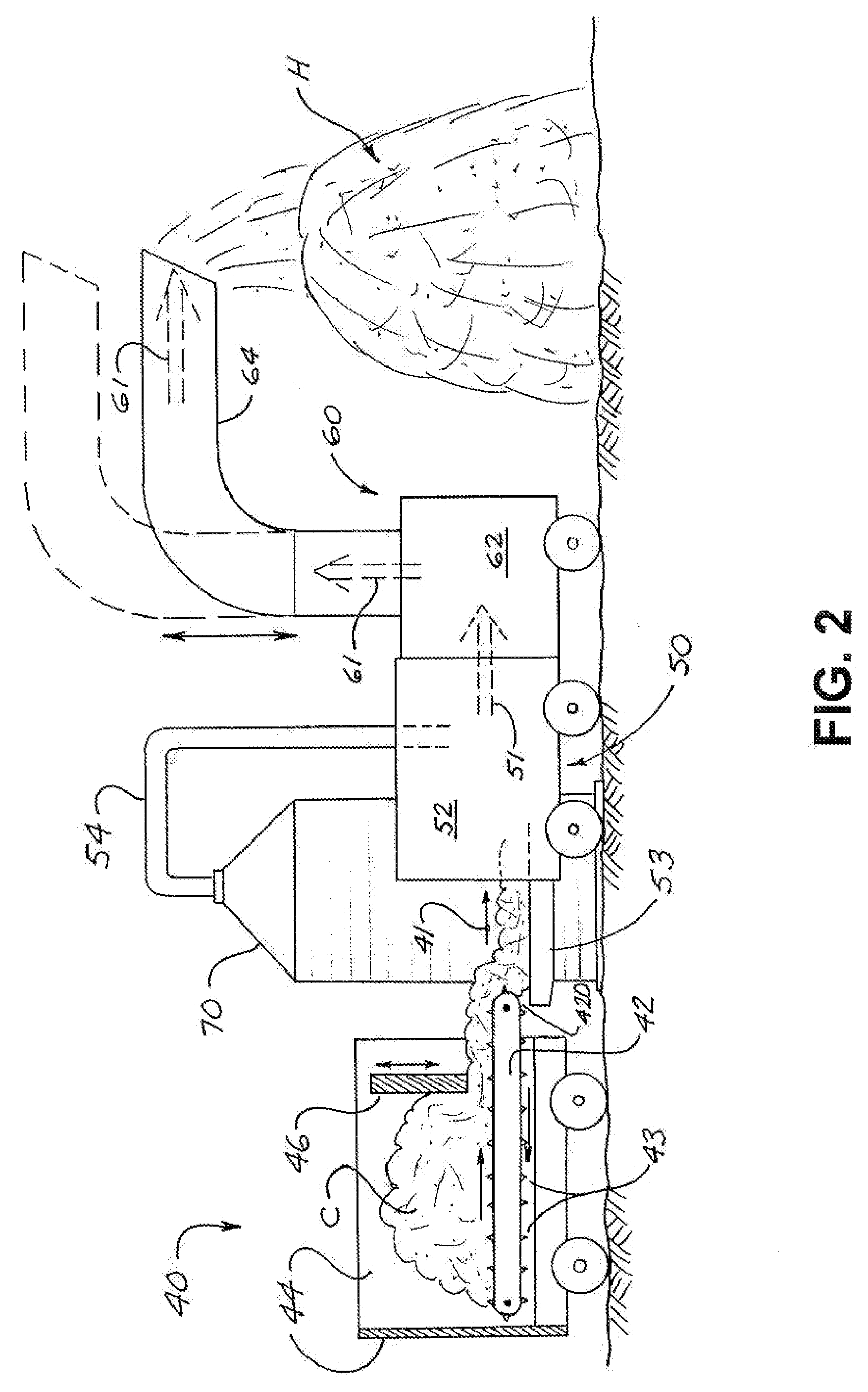

Crop processing method and apparatus

InactiveUS20090017885A1Easy constructionLower requirementHarvestersThreshersMass storageGrain storage

In a method for processing swathed crops, the entire cut crop is picked from the field and transported to a processing facility located away from the field. The processing facility has a threshing apparatus which separates grain from the cut crop, leaving a crop residue comprising plant stalks, chaff, and other constituents of the cut crop. The separated grain is conveyed from the threshing apparatus to a grain storage bin or directly to a transport truck for delivery to a grain terminal. The processing facility also includes crop residue handling means for conveying crop residue to a bulk storage pile, to a baling machine, or to some other selected location. The method makes field baling operations unnecessary, thus expediting the total removal of the crop from the field.

Owner:HALLS FLOYD W

Windrow forming construction

A windrow forming construction mountable at the rear of a combine above the level of a spreader assembly, such construction extending rearwardly from the combine to beyond the rear extent of the spreader assembly footprint and laterally across the expanse of the spreader assembly footprint and being adjustably positionable to vary the inclination thereof relative to the ground surface, the construction including side deflectors disposed at opposite sides of the construction so as to control to some extent the sidewardly distribution of the crop residue, which side deflectors are laterally pivotable about generally vertical axes to vary the spacing between the free ends thereof and are also longitudinally extendable so as to channel to some extent the crop residue towards the space between the free ends, and a positioning mechanism operable to vary the inclination of such construction relative to the ground surface so as to control to some extent the degree with which the crop residue is directed into the stubble remaining on the field and to support the construction in such position.

Owner:BLUE LEAF I P INC

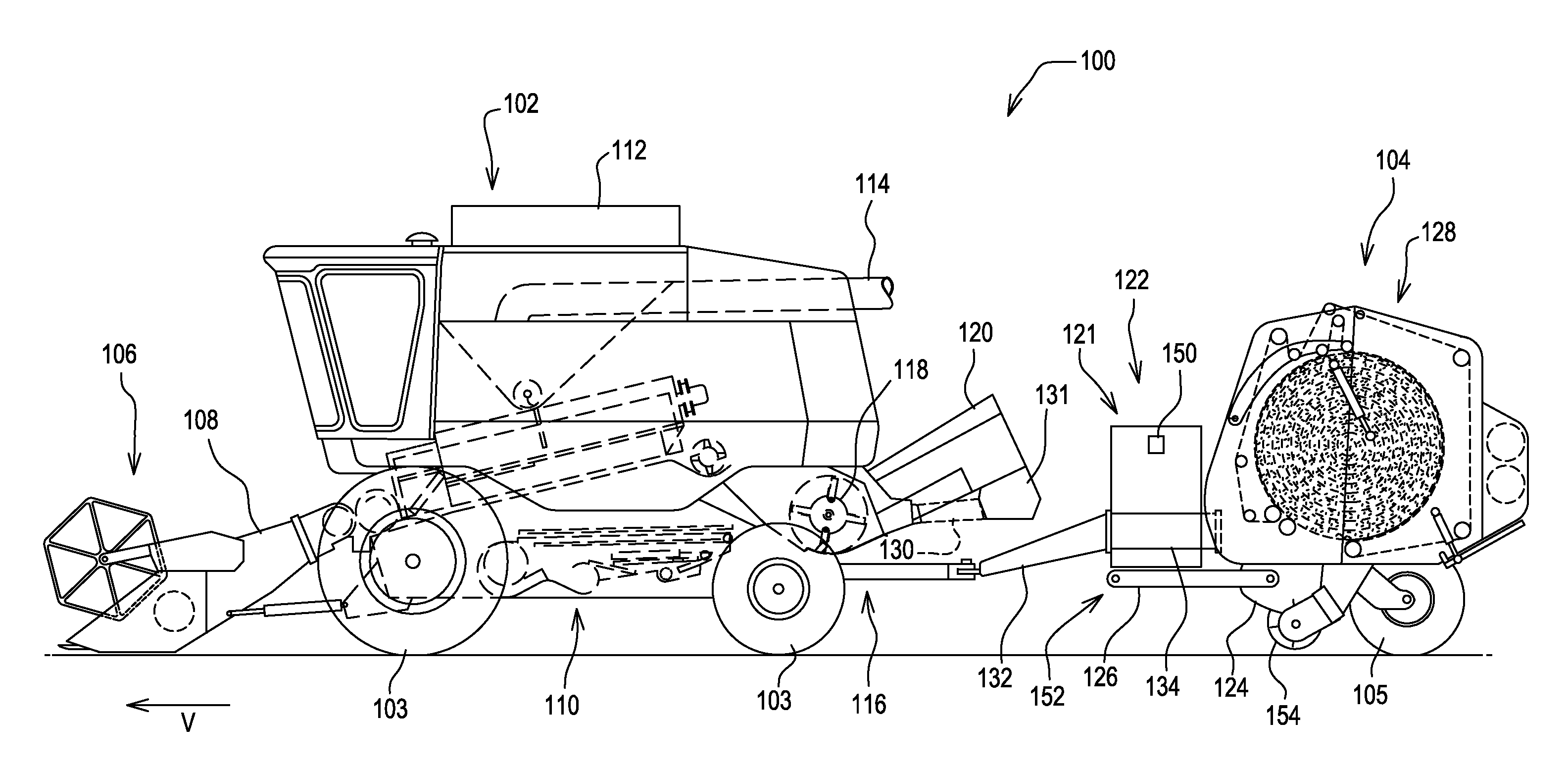

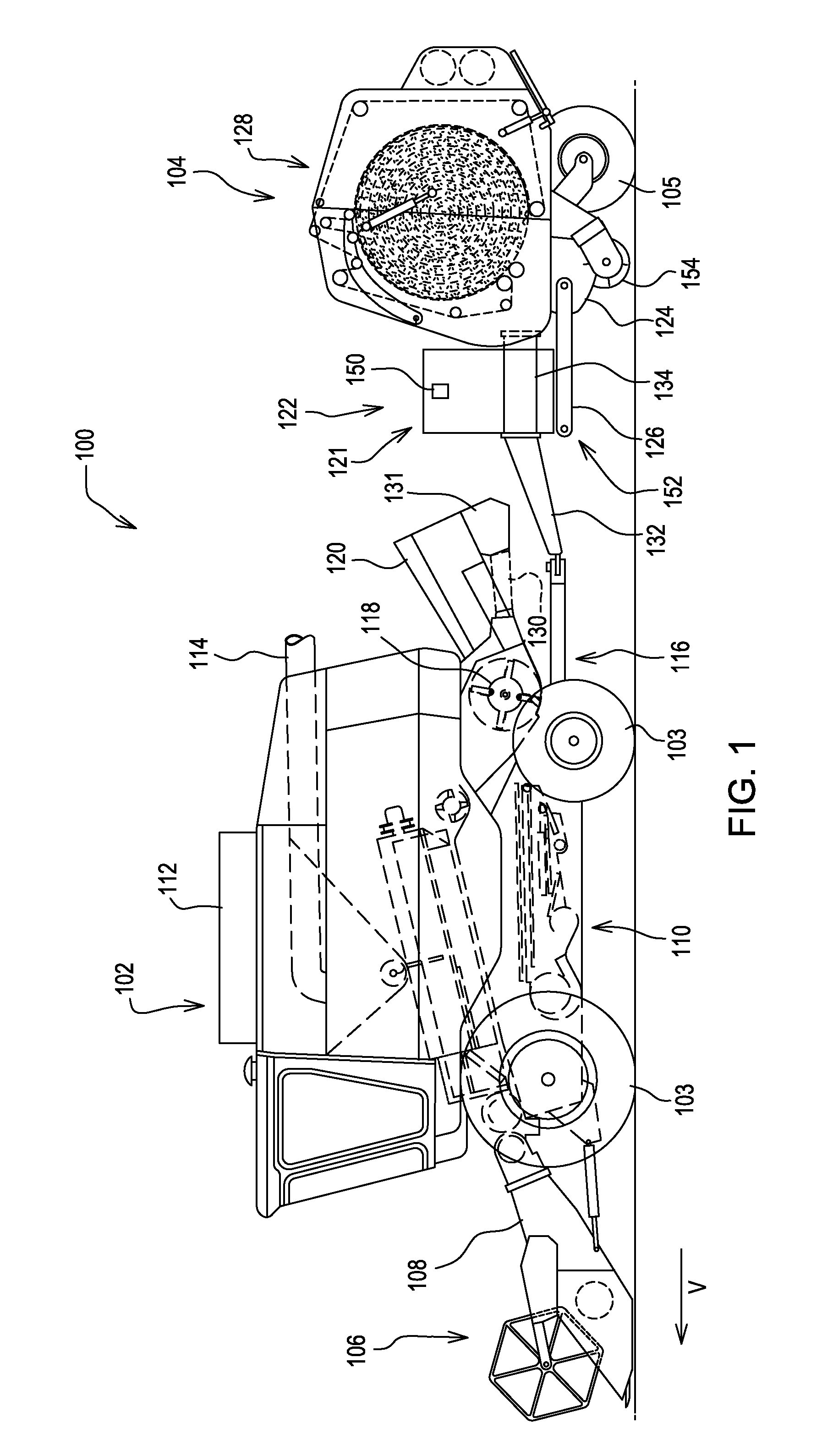

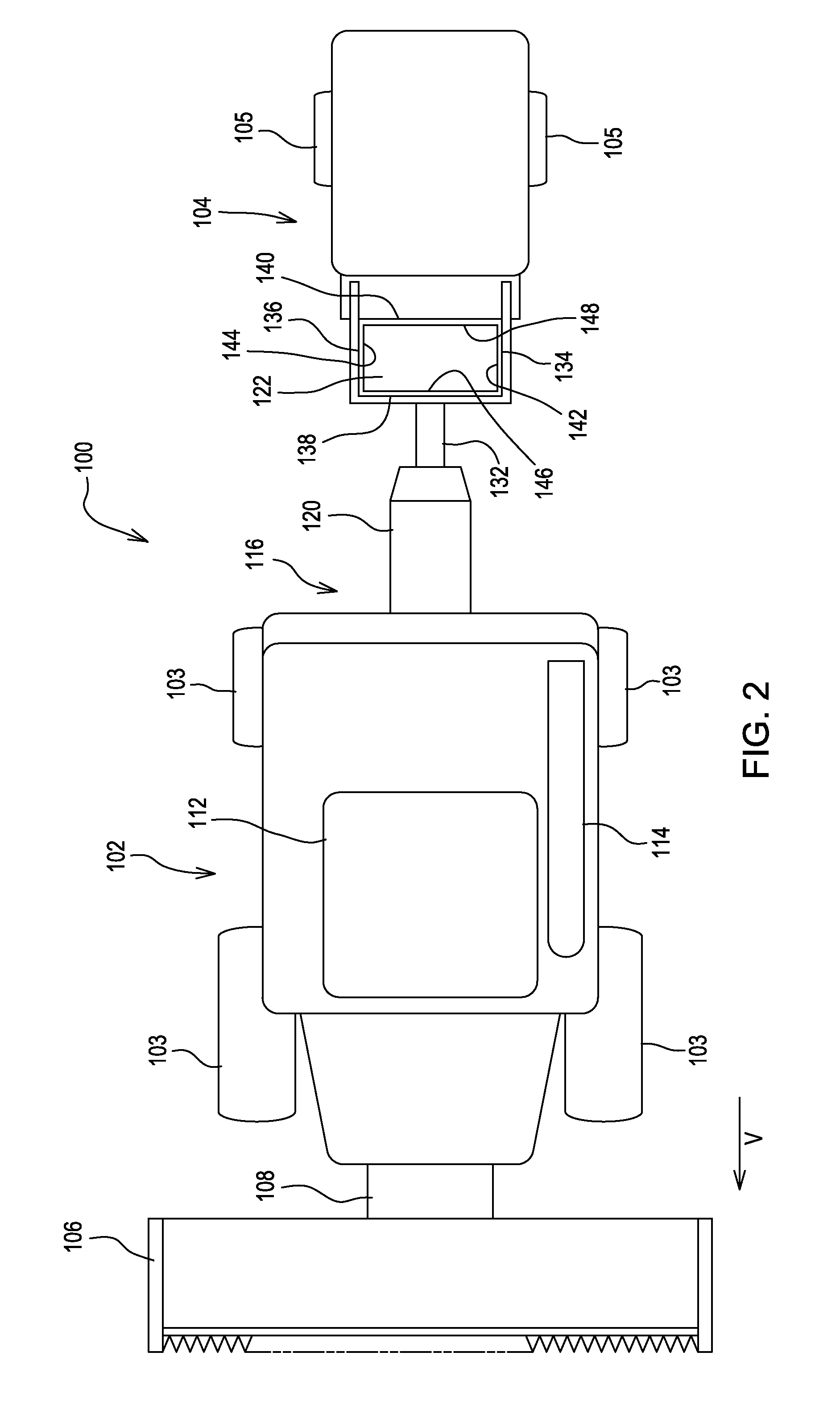

Agricultural combine with on-board baler and dust suppression capability

A self-propelled agricultural combine having a capability for baling crop residue produced by operation of the combine, including chaff from the cleaning system. The combine can also incorporate a dust suppression capability. The crop residue produced by threshing is in a compressed state, and is routed directly to a baler of the combine is essentially a continuous, compressed stream, while still in that state, and the chaff is mixed in before compaction into the bales. The dust suppression apparatus uses air flow of a cleaning system of the combine, to carry the dust and separates the air such that the dust will fall from the combine.

Owner:BLUE LEAF I P INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com