Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1807 results about "Food waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Food waste or food loss is food that is wasted, lost or uneaten. The causes of food waste or loss are numerous and occur at the stages of producing, processing, retailing and consuming. Global food loss and waste amount to between one-third and one-half of all food produced. Loss and wastage occur at all stages of the food supply chain or value chain. In low-income countries, most loss occurs during production, while in developed countries much food – about 100 kilograms (220 lb) per person per year – is wasted at the consumption stage.

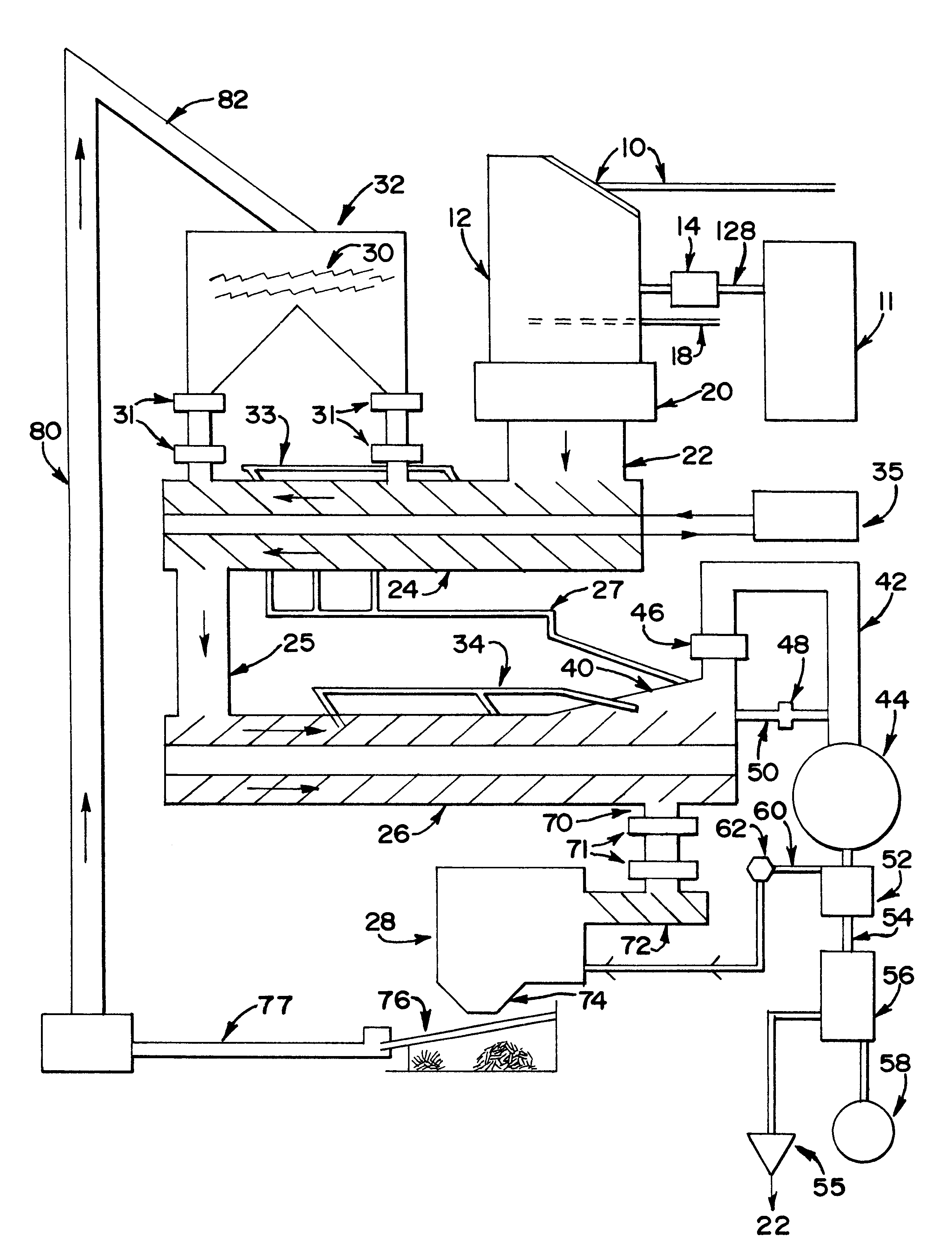

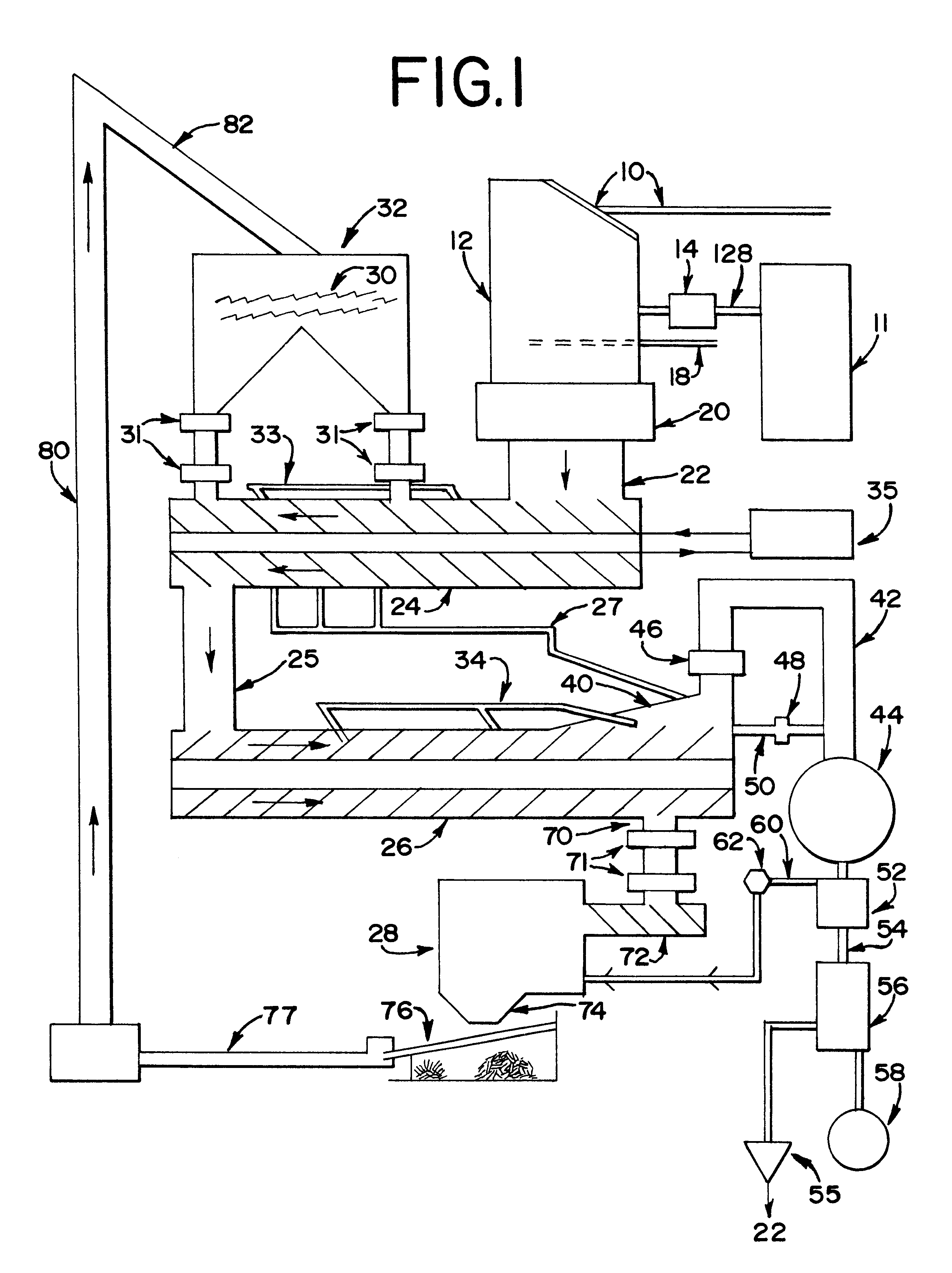

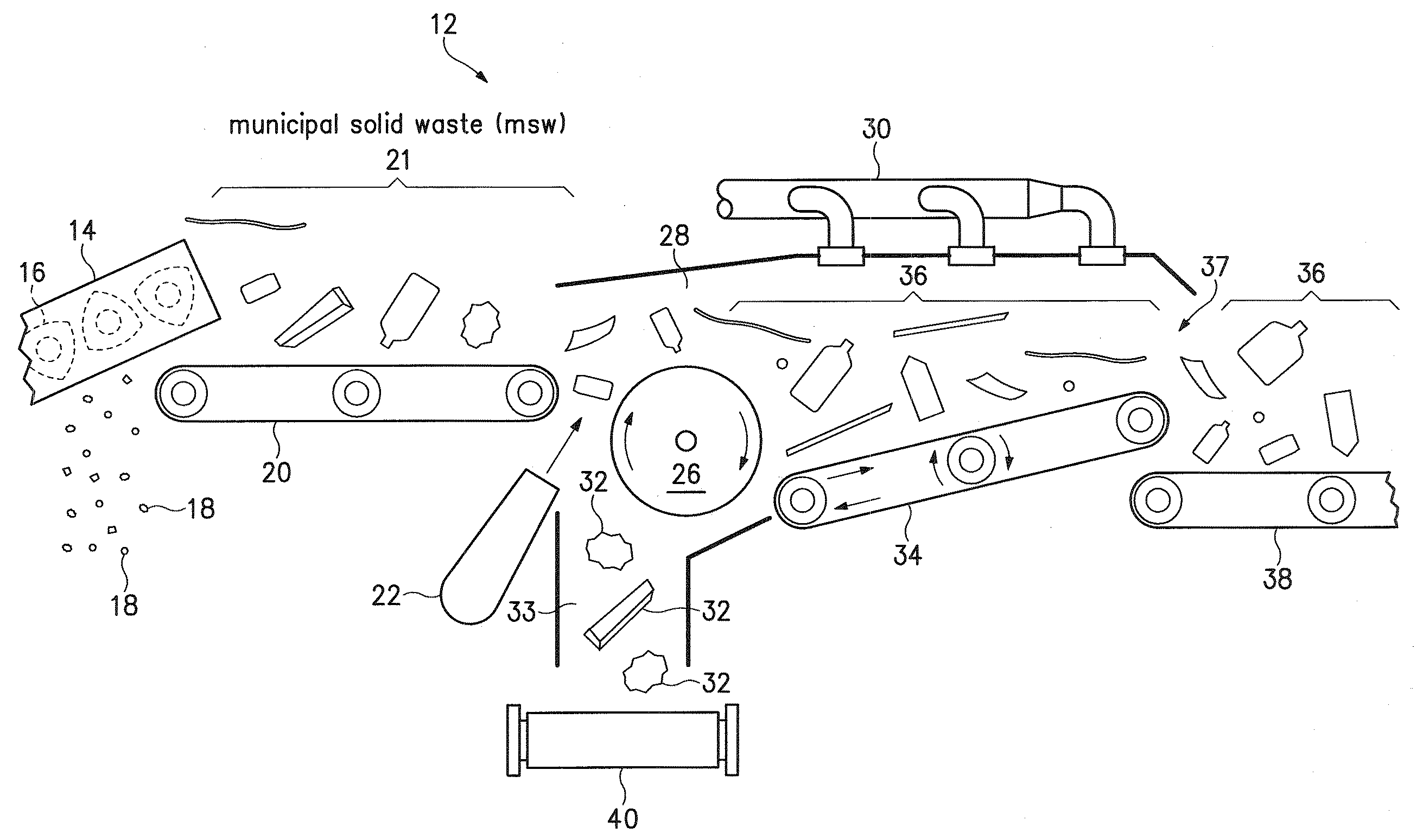

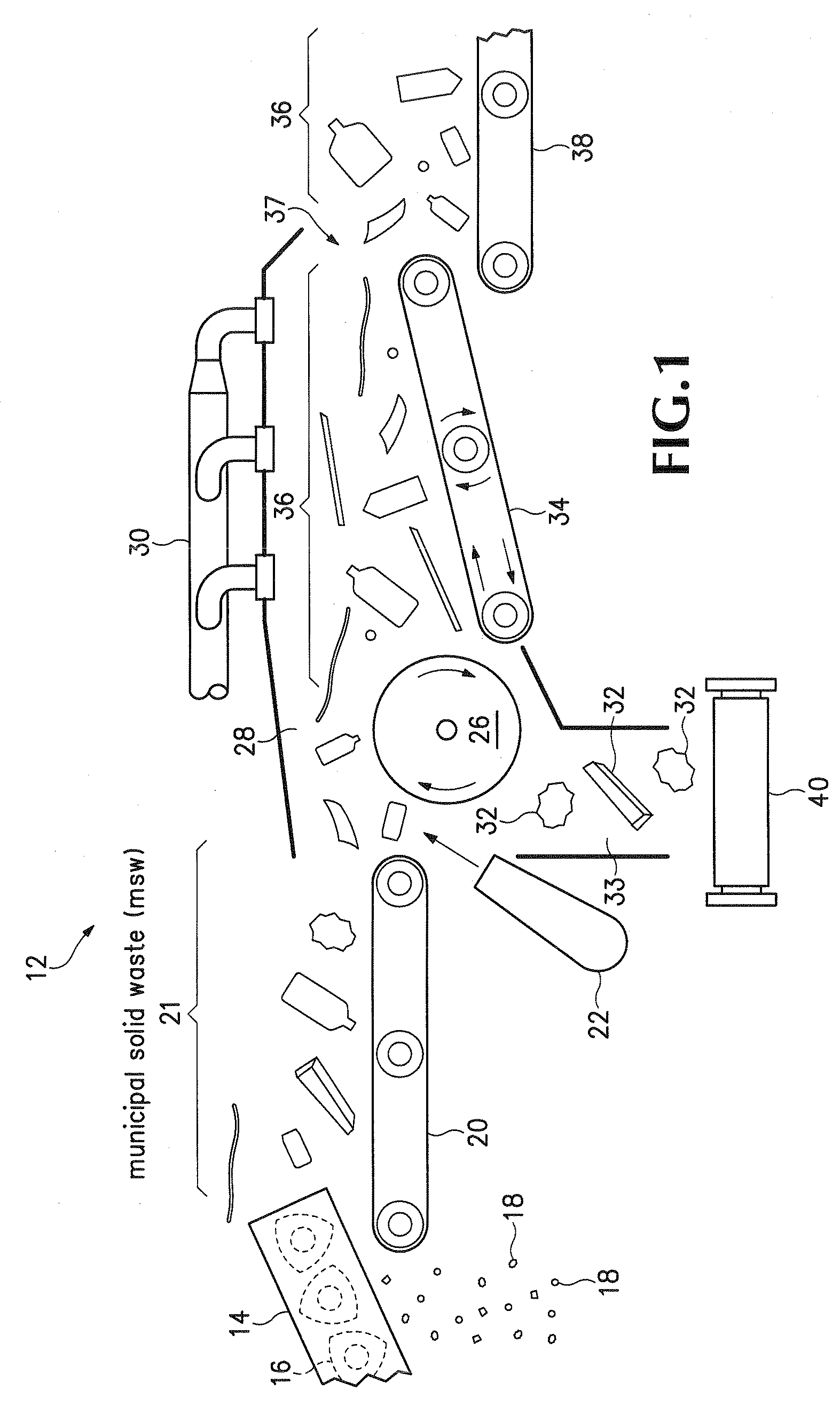

Systems and methods for converting organic waste materials into useful products

ActiveUS20080020456A1Bioreactor/fermenter combinationsBio-organic fraction processingOrganic fractionProduct system

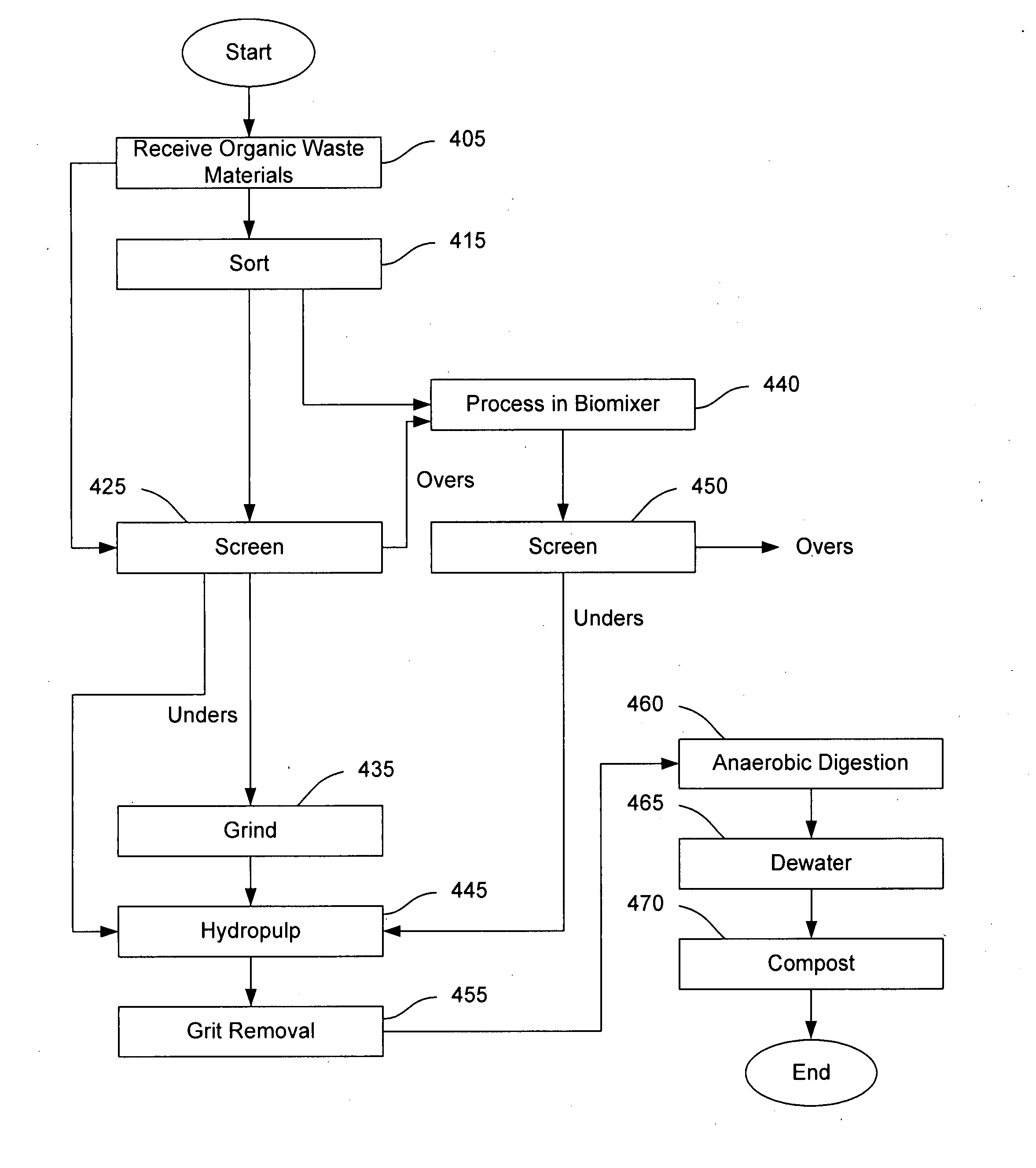

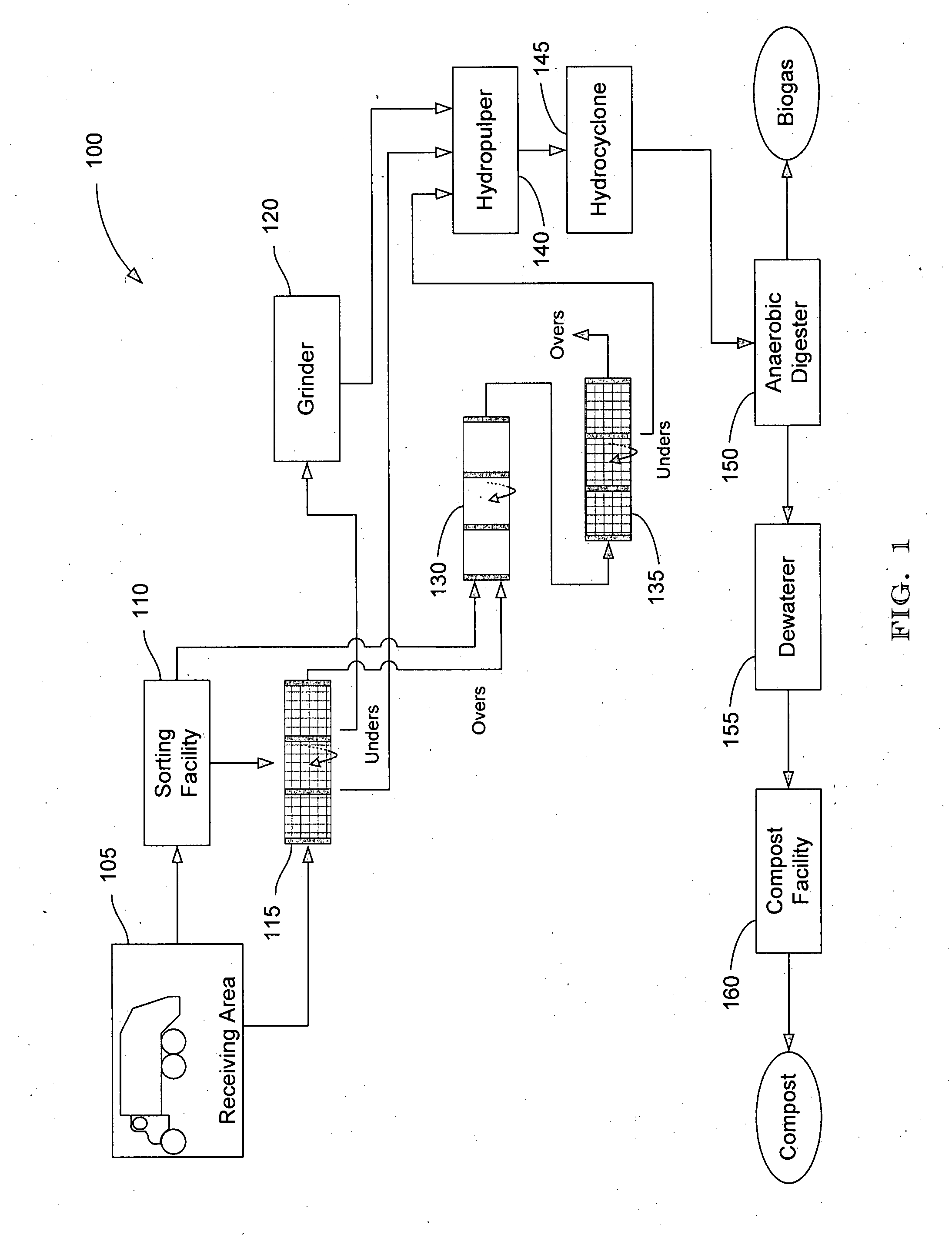

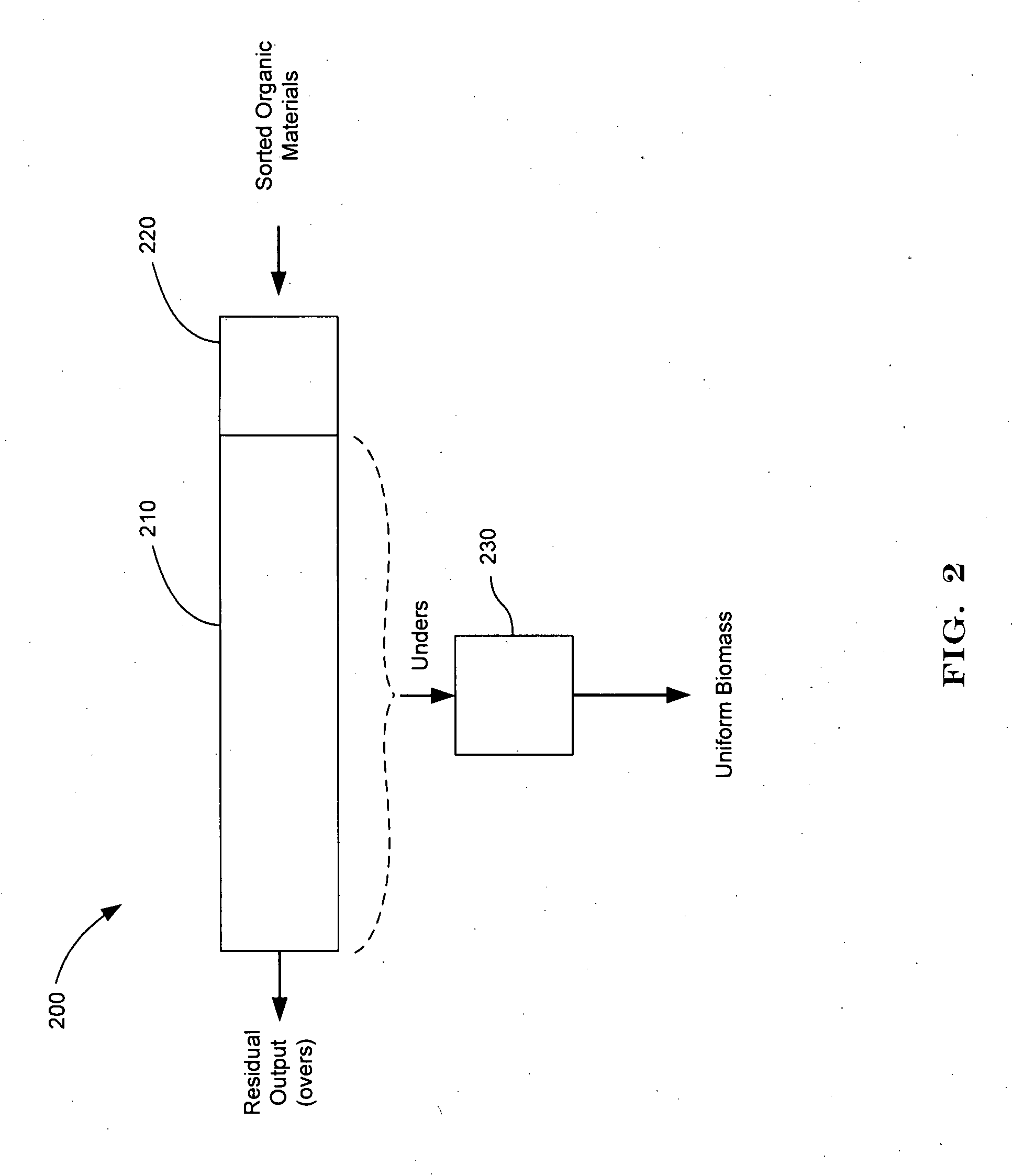

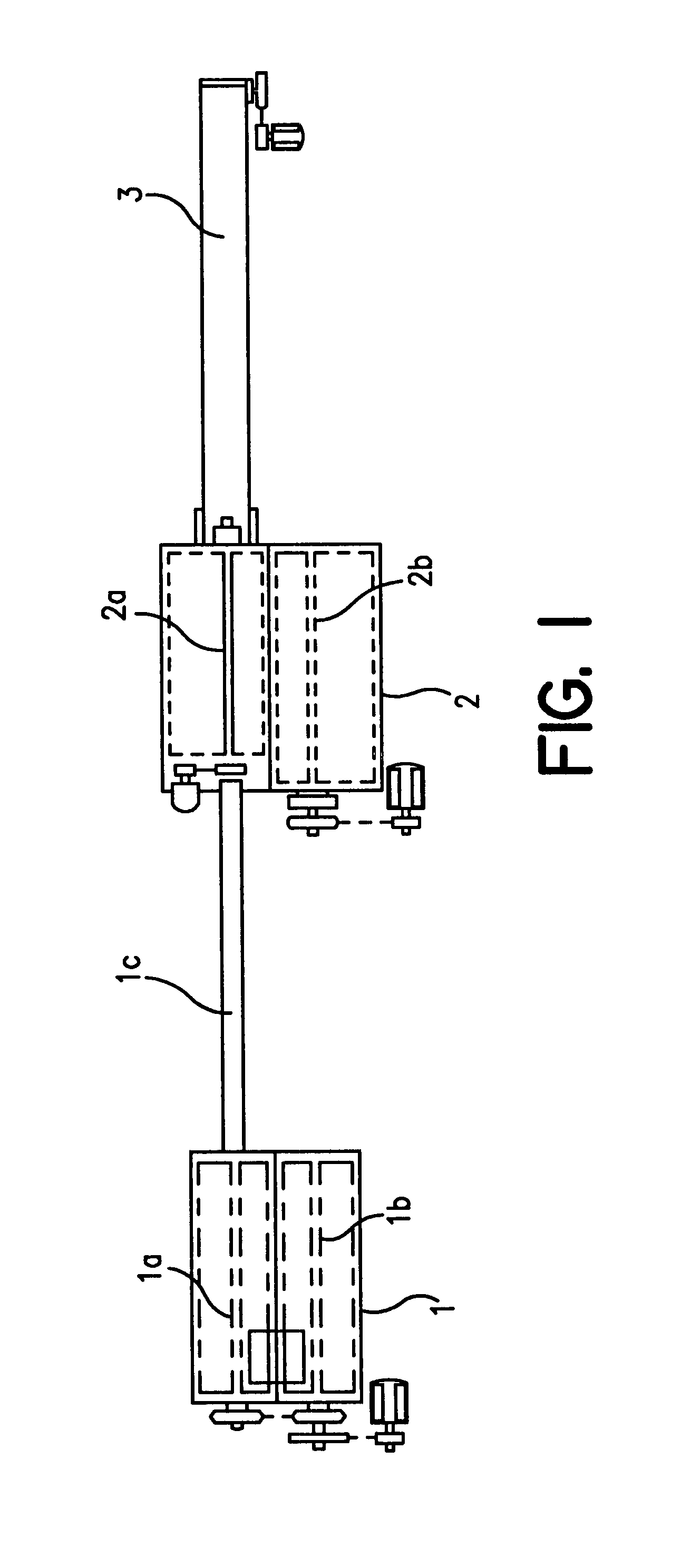

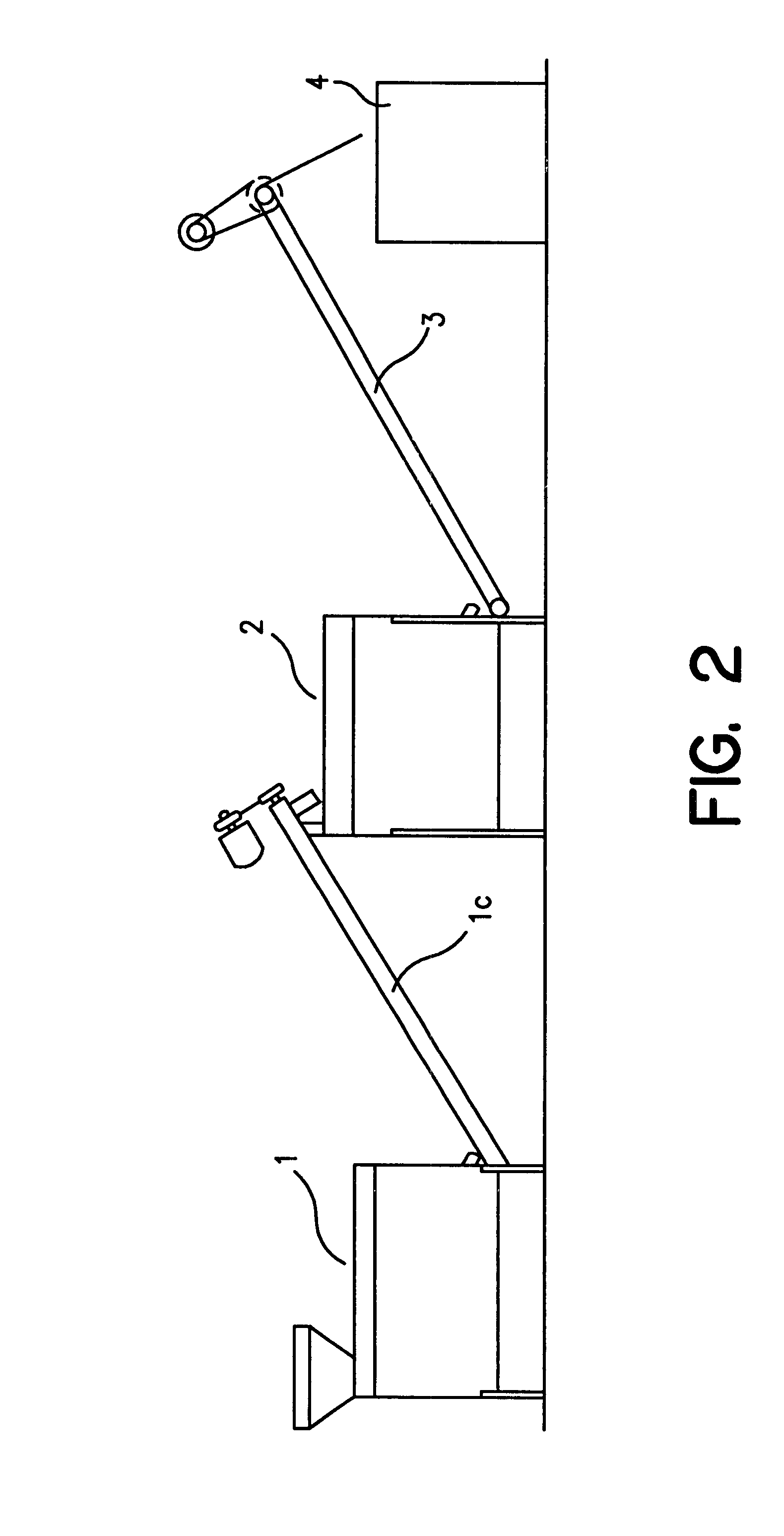

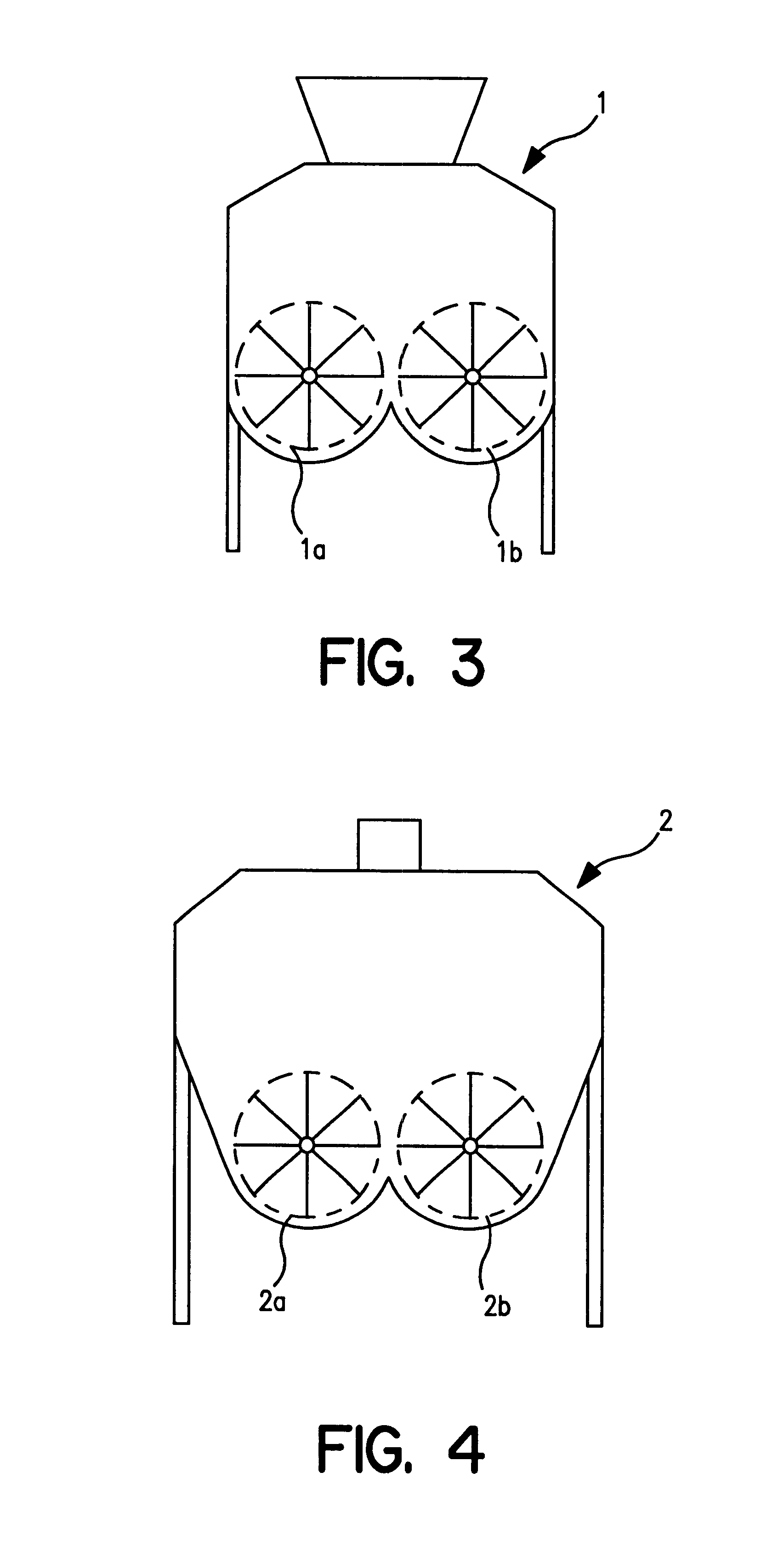

Systems and methods are provided for converting organic waste materials from a municipal waste stream to useful products. Organic waste materials having a wide range of compositions such as, for example, yard waste, food waste, paper, and the organic fraction of municipal solid waste are converted into a uniform biomass that is suitable for conversion to useful products, such as fuels. Through the use of a biomixer and a hydropulper, as well as through sorting and screening, the organic waste materials are progressively reduced in size and cleaned of contamination. The resulting uniform biomass is suitable for anaerobic digestion to produce biogas and a residual solid that is suitable for producing a high quality compost.

Owner:RECOLOGY

Method for processing food waste by using black soldier fly larvae and material formula

InactiveCN101889629AReduce capacityReduce odorBio-organic fraction processingClimate change adaptationLitterRapid processing

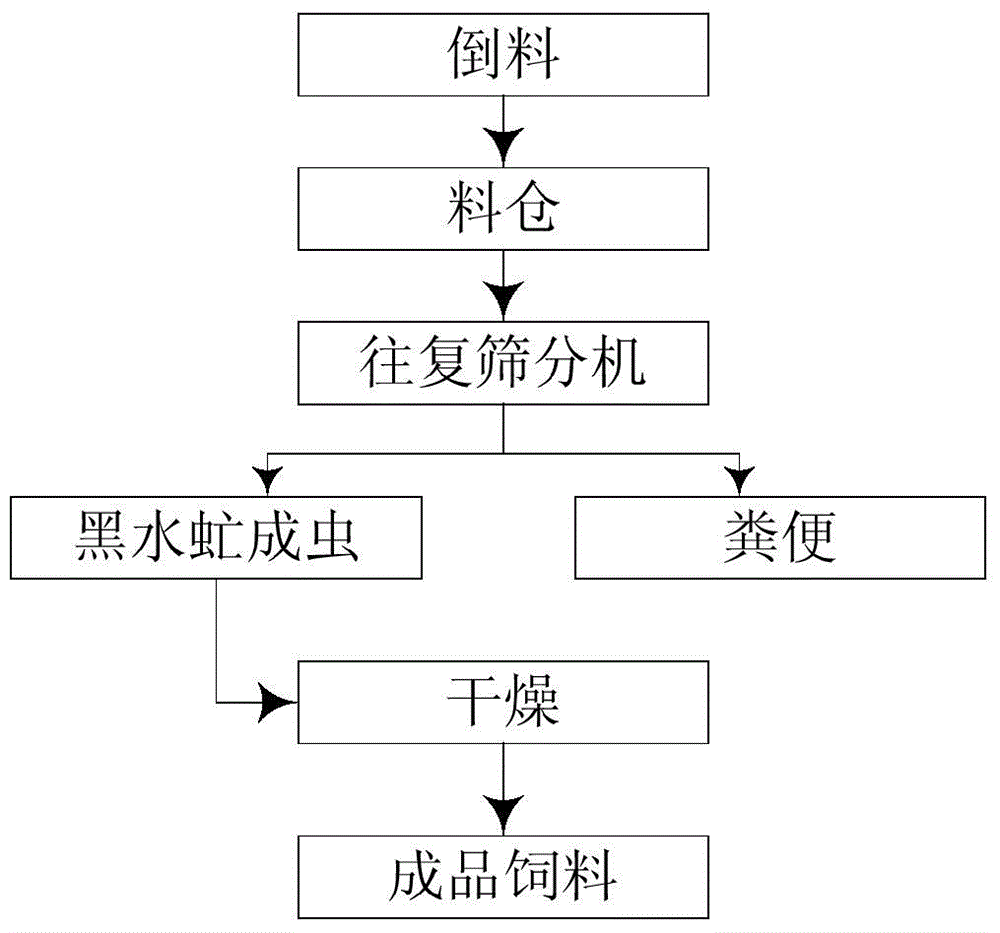

The invention belongs to the field of environmental protection, relating to a method for processing food waste by using black soldier fly larvae and comprising the following steps: coarse crushing the food waste and then adding auxiliary materials to obtain culture materials for the black soldier fly larvae; and grafting black soldier fly spawn on the surface of the culture materials for the black soldier fly larvae so that the larvae hatched by the black soldier fly spawn acquires the culture materials for the black soldier fly larvae, thereby processing and cleaning the food waste. Before the black soldier fly larvae ages, a polypide collecting container is externally connected to the area for piling up the culture materials for the black soldier fly larvae and is filled with dry rice bran powder so as to guide to collect the aged black soldier fly larvae; and the rest of the processed culture materials for the black solider fly larvae is dried and then prepared into microbial organic fertilizer. The invention has strong processing capability, rapid processing speed compared with the common compost, the processing period is 4-5 days; after being processed, the volume of the food waste is reduced by 10-30%, the peculiar smell of the waste is lightened; and the invention can obtain excellent microbial organic fertilizer and insect bioprotein at the same time.

Owner:SUN YAT SEN UNIV

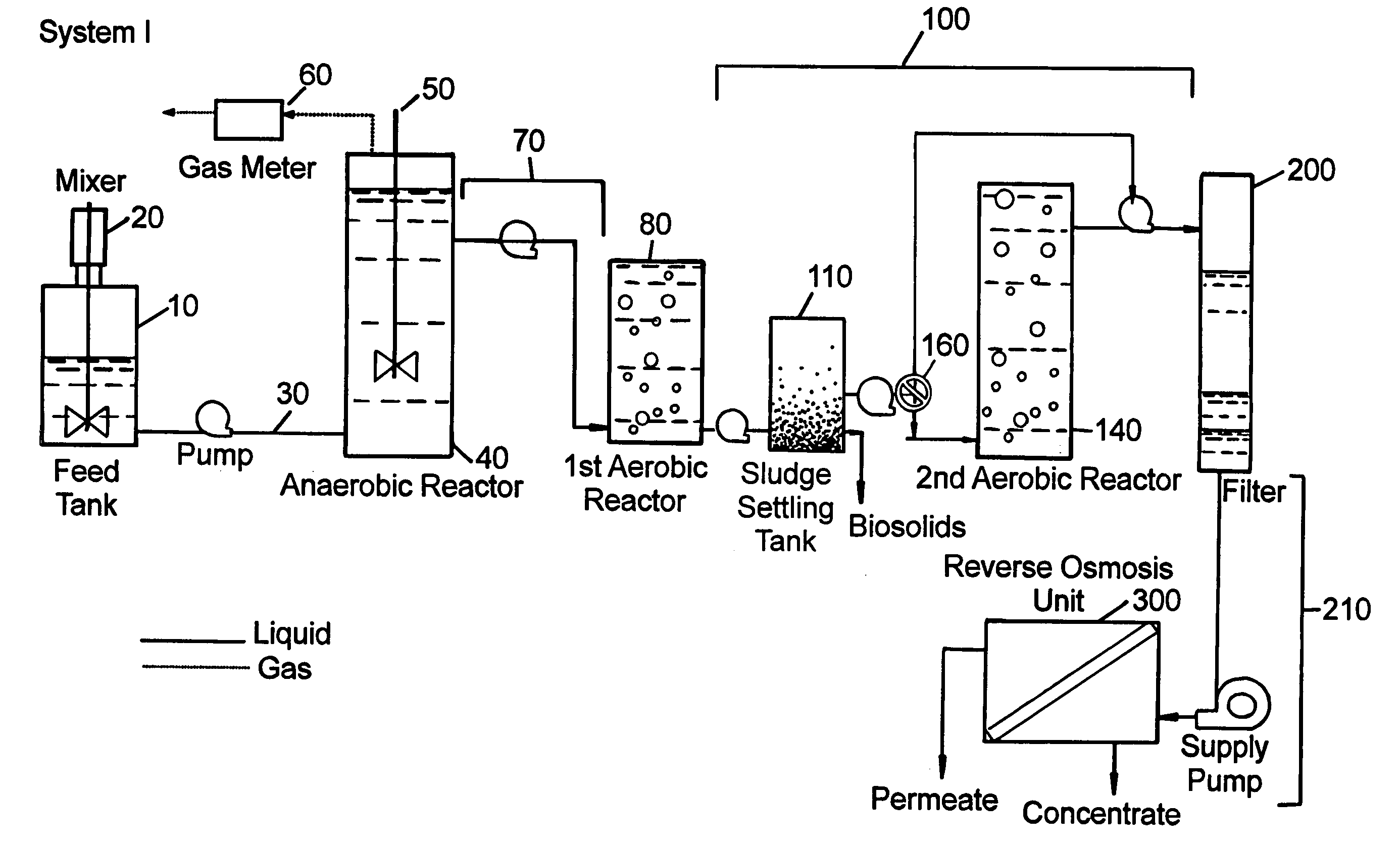

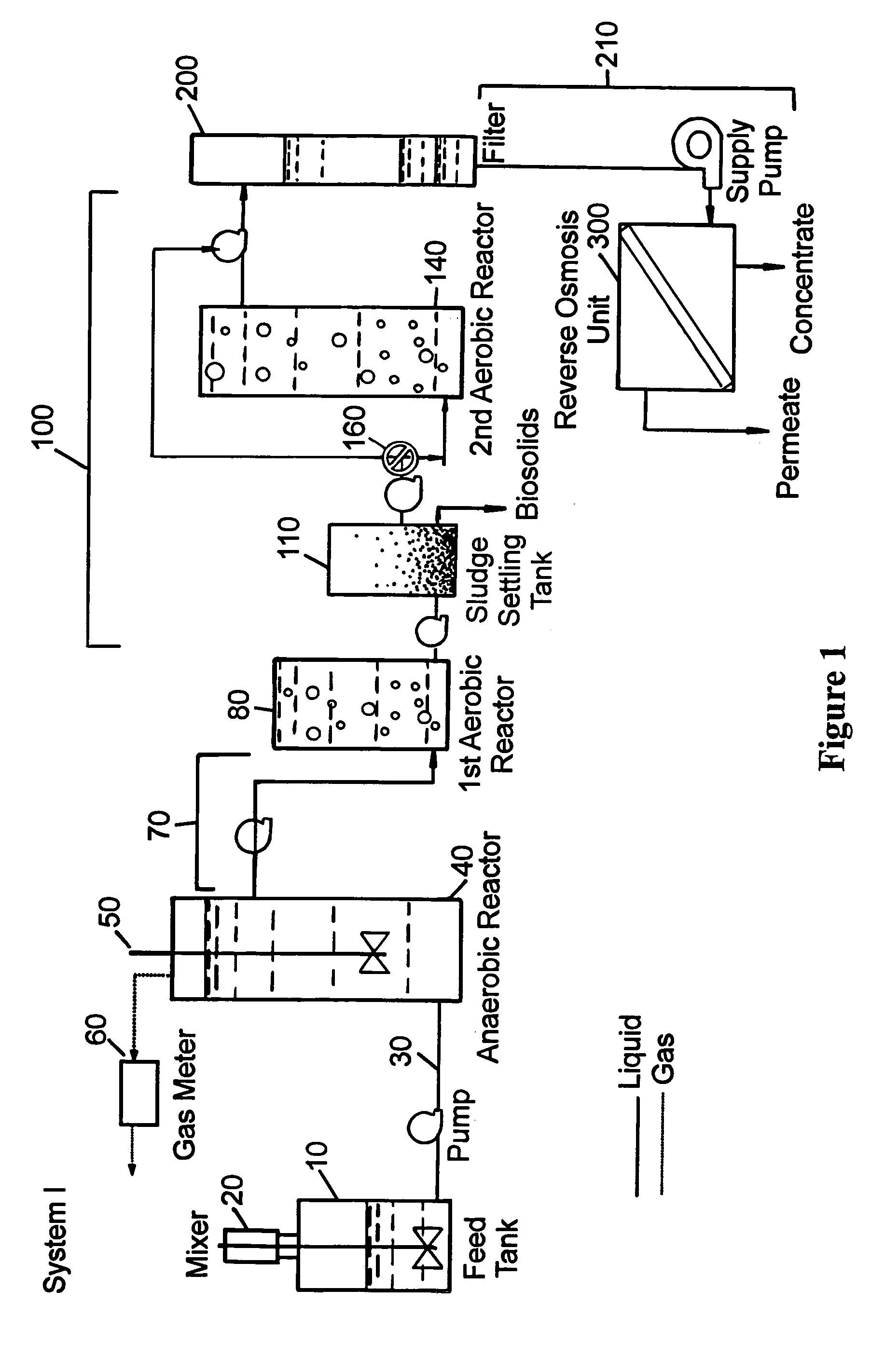

Treatment of swine wastewater by biological and membrane separation technologies

InactiveUS20050035059A1Bio-organic fraction processingWaste water treatment from animal husbandryFiltrationSeparation technology

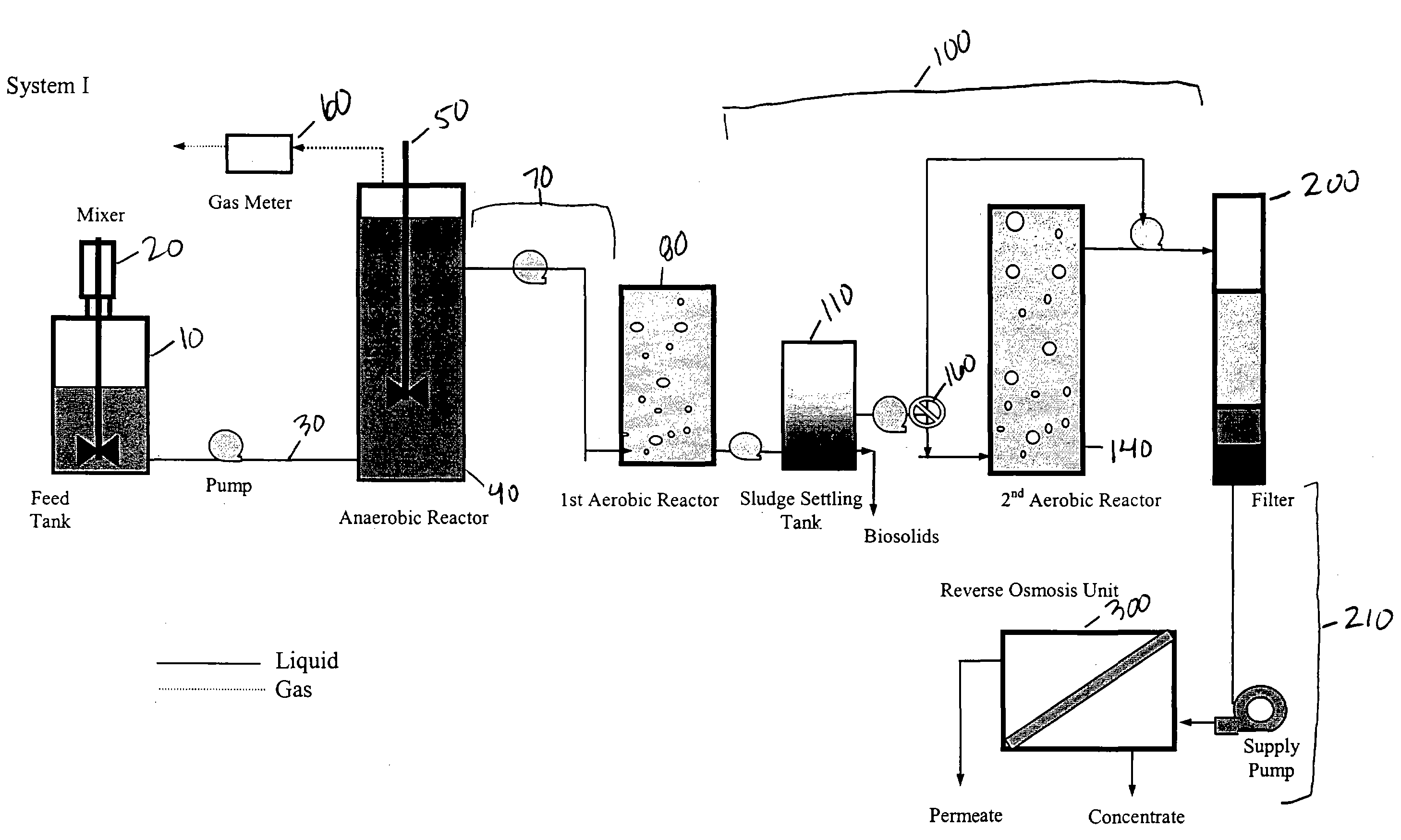

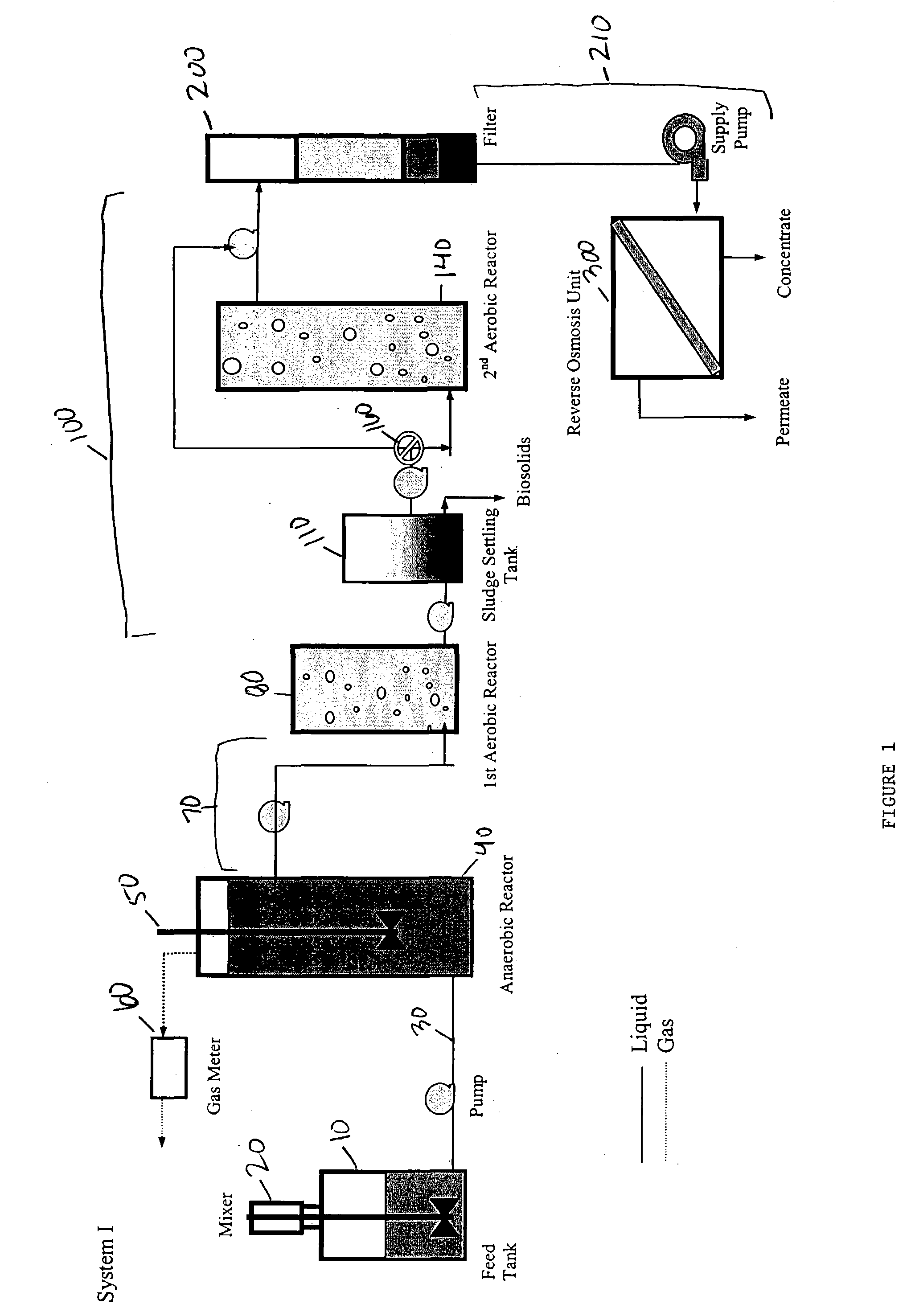

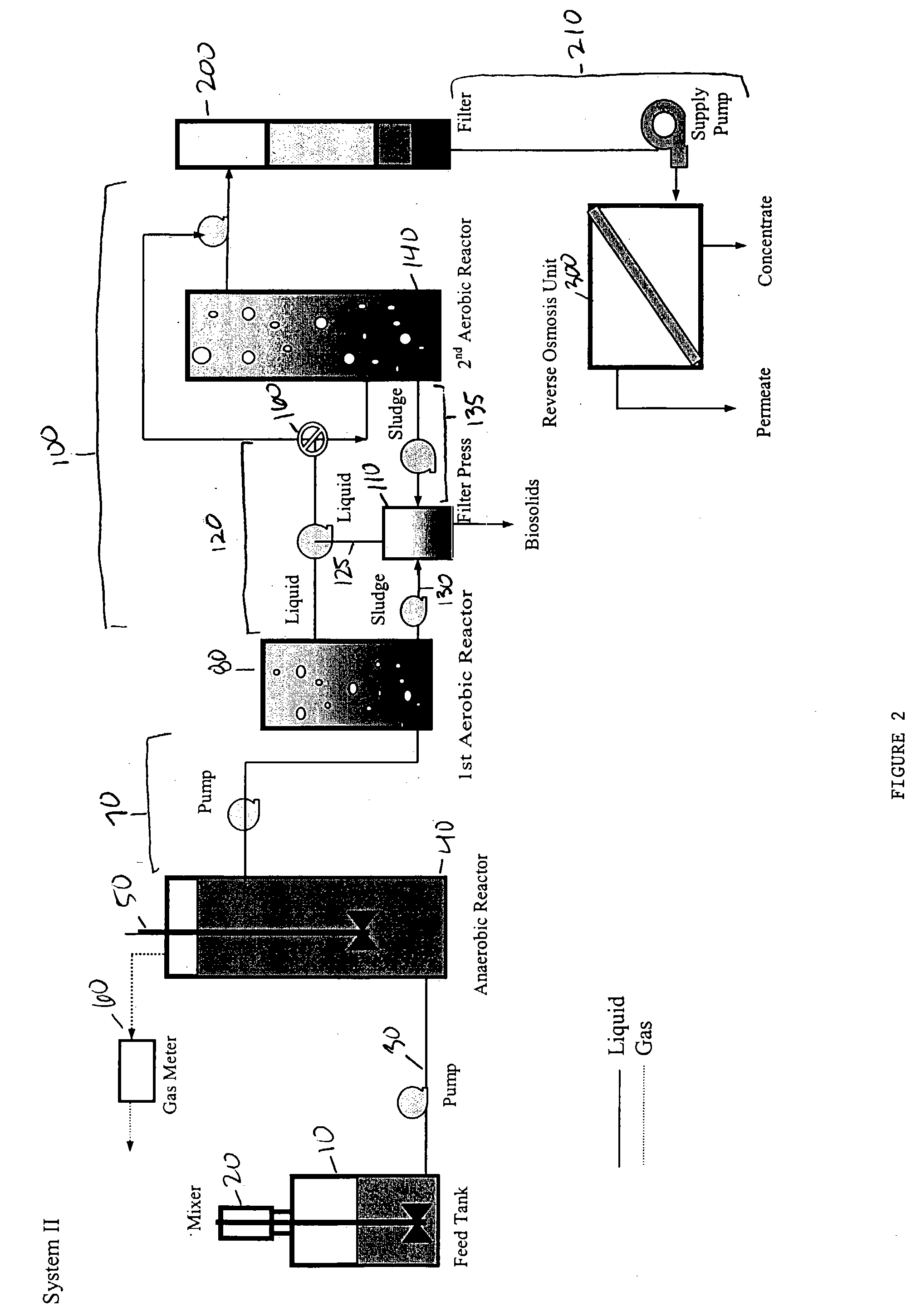

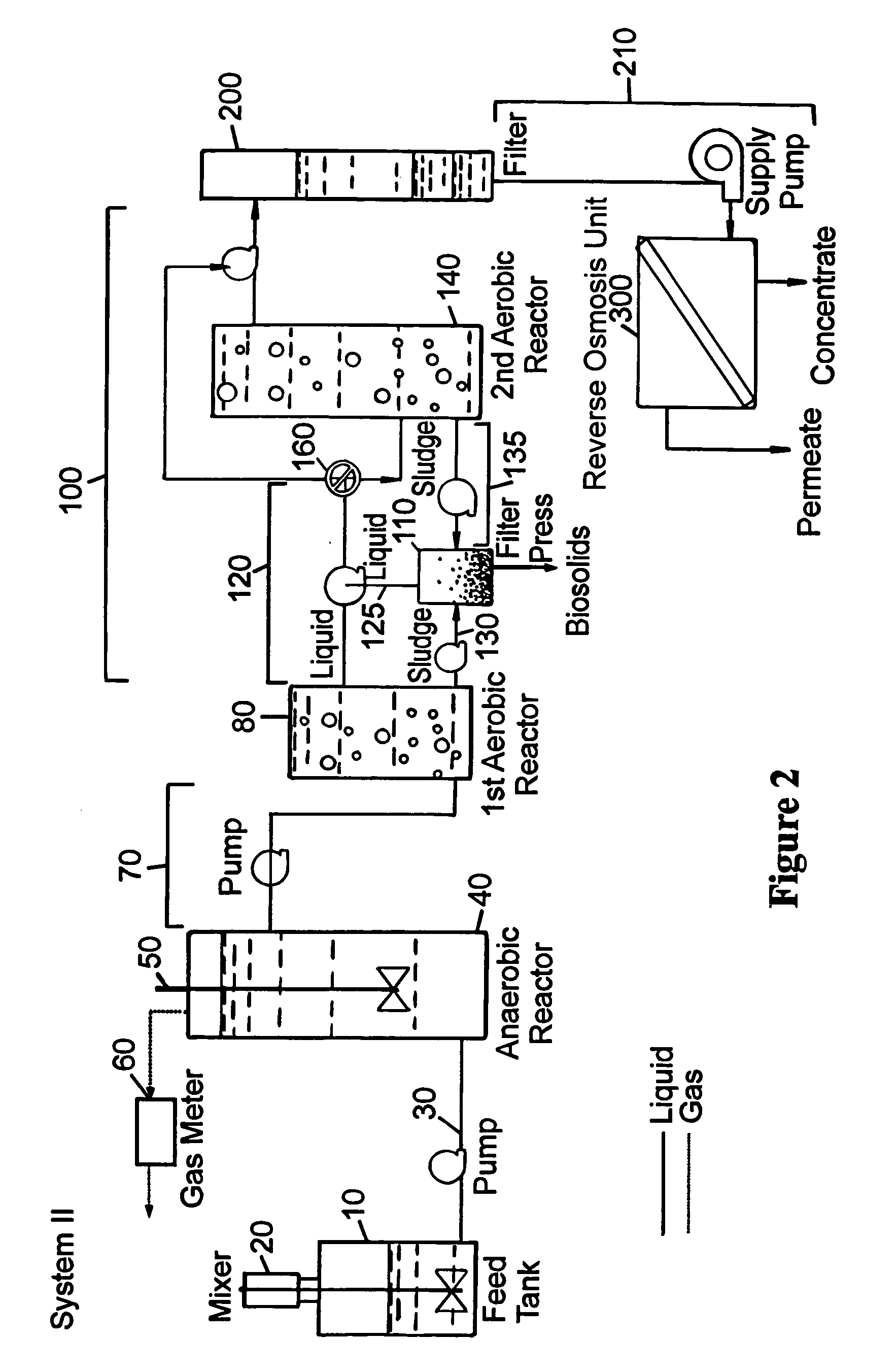

The present invention provides an integrated system for treatment of biodegradable waste, including sewage sludge, forestry waste, food waste, agricultural waste, municipal waste, and the like. The integrated system comprises an anaerobic reactor, at least one aerobic reactor, a filtration device, and a desalinization device.

Owner:RGT UNIV OF CALIFORNIA

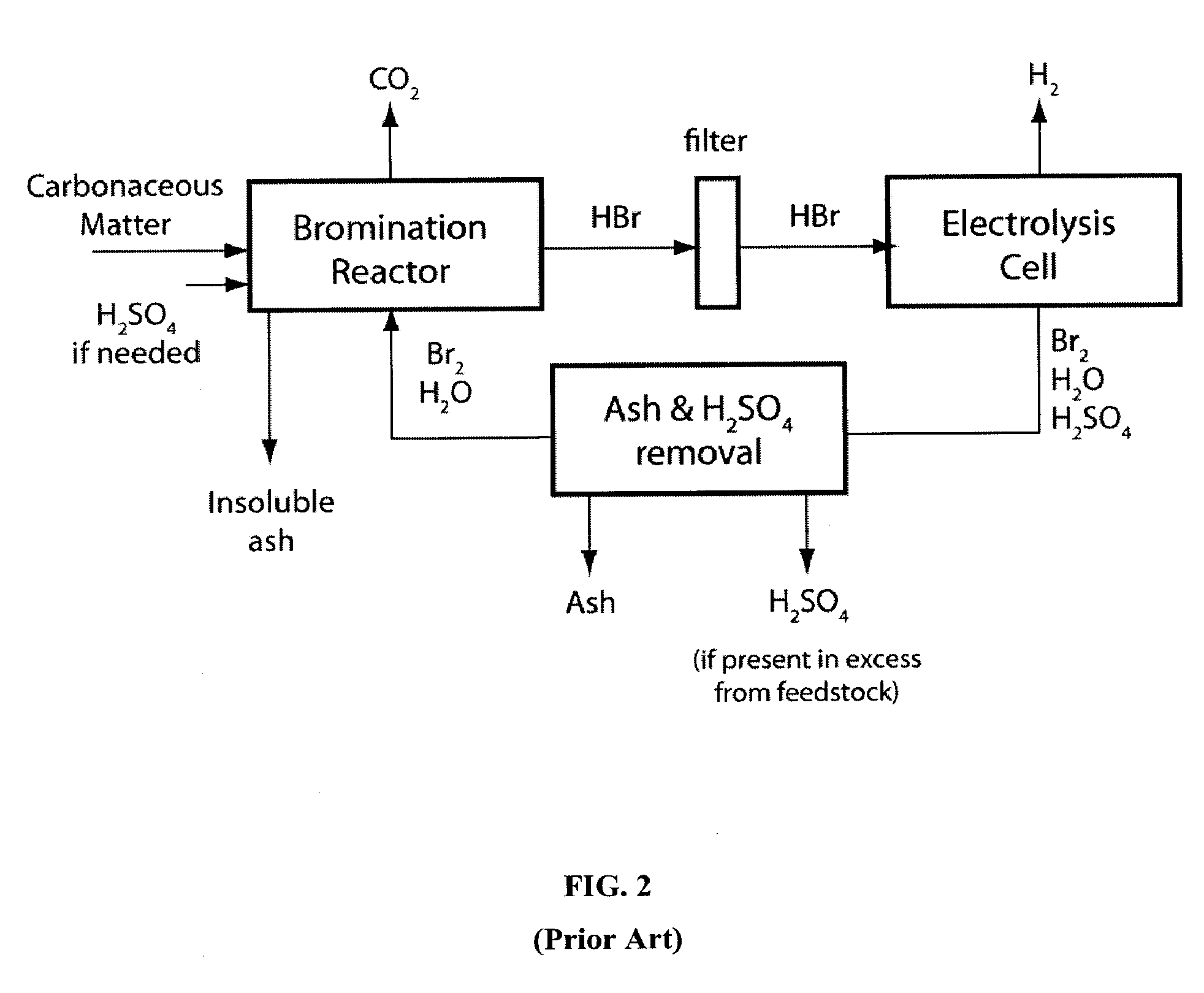

Waste Treatment and Energy Production Utilizing Halogenation Processes

InactiveUS20090028767A1Reduce needEfficient processingPhotography auxillary processesElectrolysis componentsCelluloseEngineering

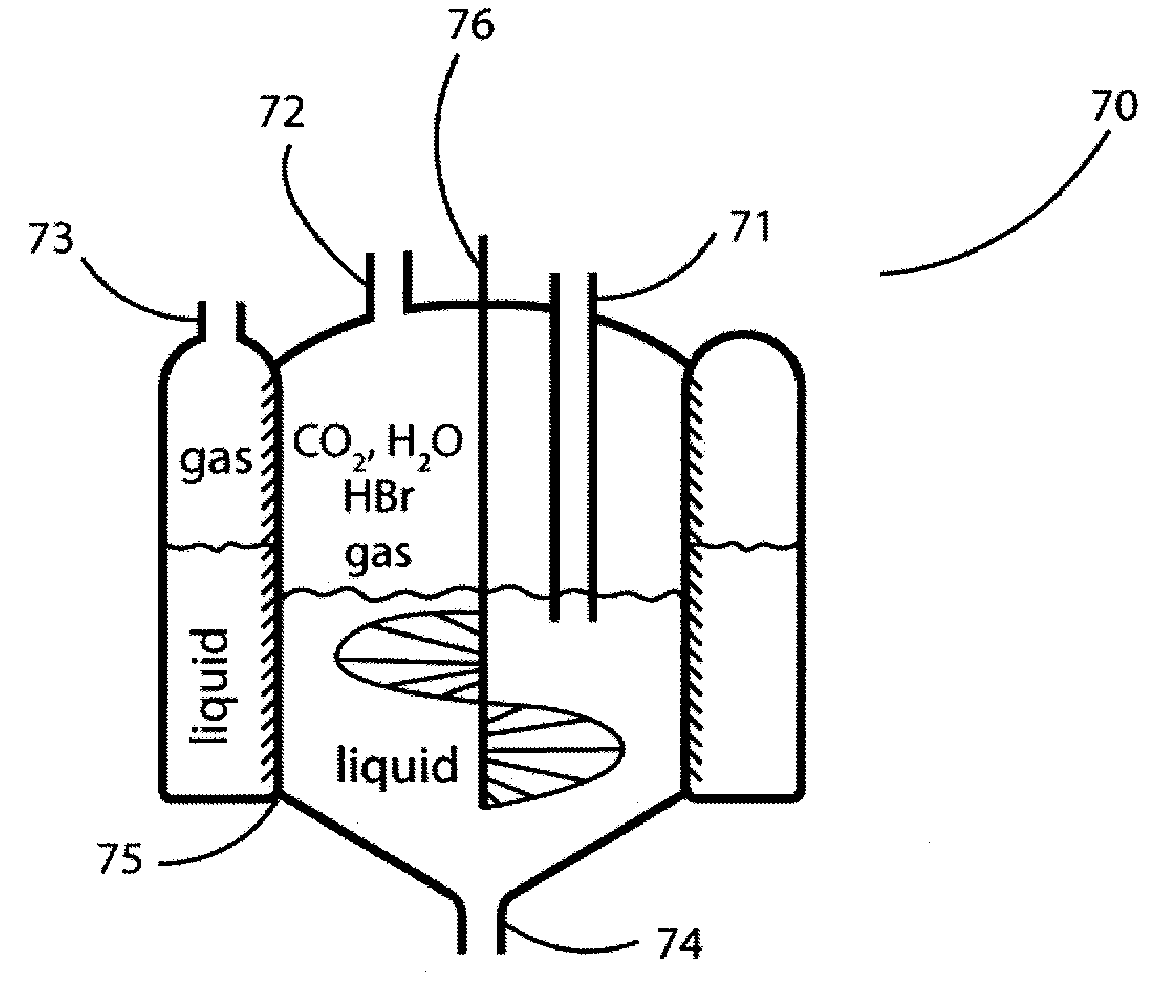

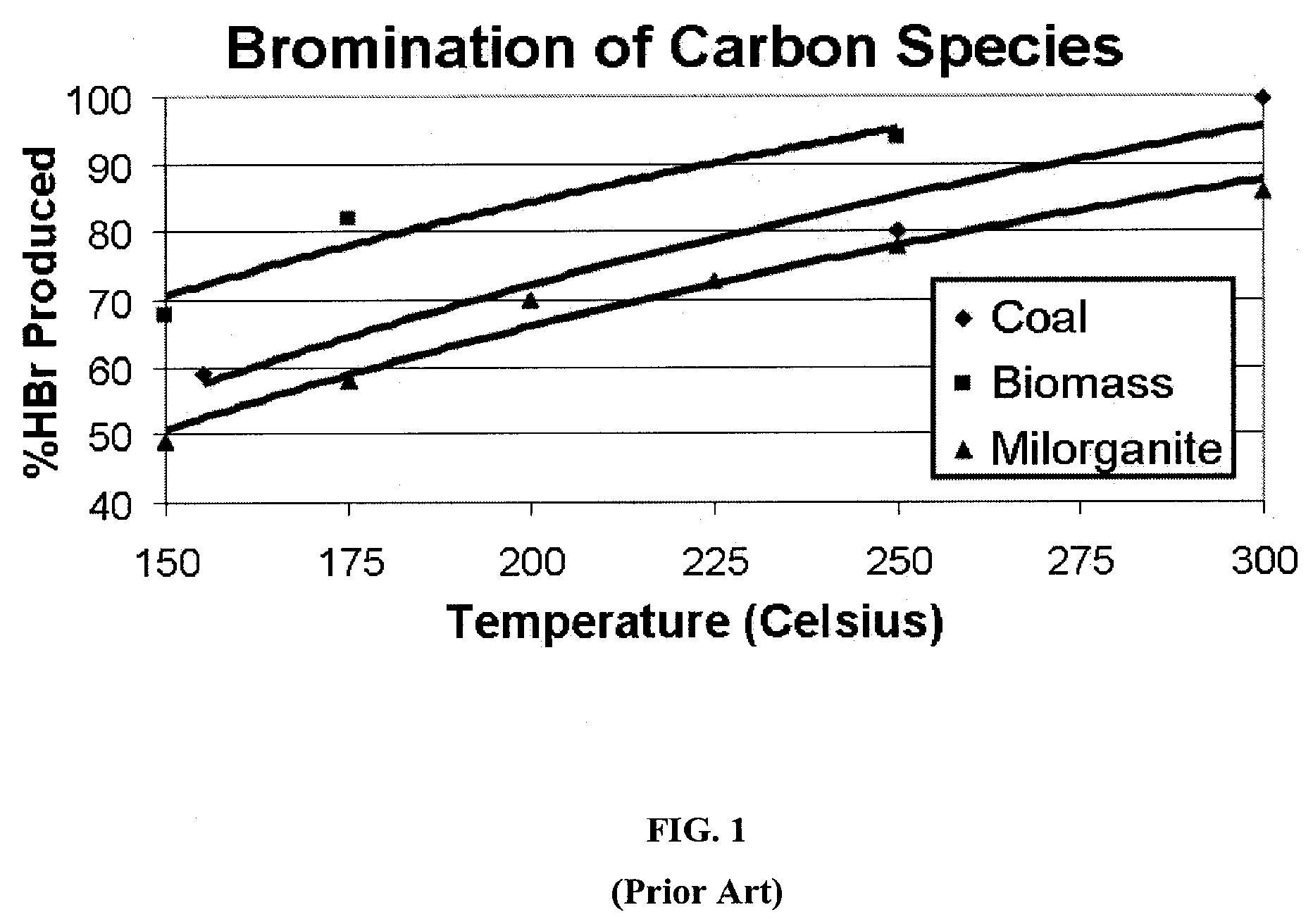

A method for generating energy and / or fuel from the halogenation of a carbon-containing material and / or a sulfur-containing chemical comprises supplying the carbon-containing material (e.g., coal, lignite, biomass, cellulose, milorganite, methane, sewage, animal manure, municipal solid waste, pulp, paper products, food waste) and / or the sulfur-containing chemical (e.g., H2S, SO2, SO3, elemental sulfur) and a first halogen-containing chemical to a reactor. The carbon-containing material and / or the sulfur-containing chemical and the halogen-containing chemical are reacted in the reactor to form a second halogen-containing chemical and carbon dioxide, sulfur and / or sulfuric acid. The second halogen-containing chemical is dissociated (e.g., electrolyzed) to form the first halogen-containing chemical and hydrogen gas (H2). The first halogen-containing chemical can be Br2 and the second halogen-containing chemical can be HBr. Any carbon dioxide formed during reaction can be directed to a prime mover (e.g., turbine) to generate electricity. Any ash and / or sulfur formed can be removed. In some cases a sulfur-containing chemical can be supplied to the reactor with the carbon-containing material.

Owner:SRT GROUP

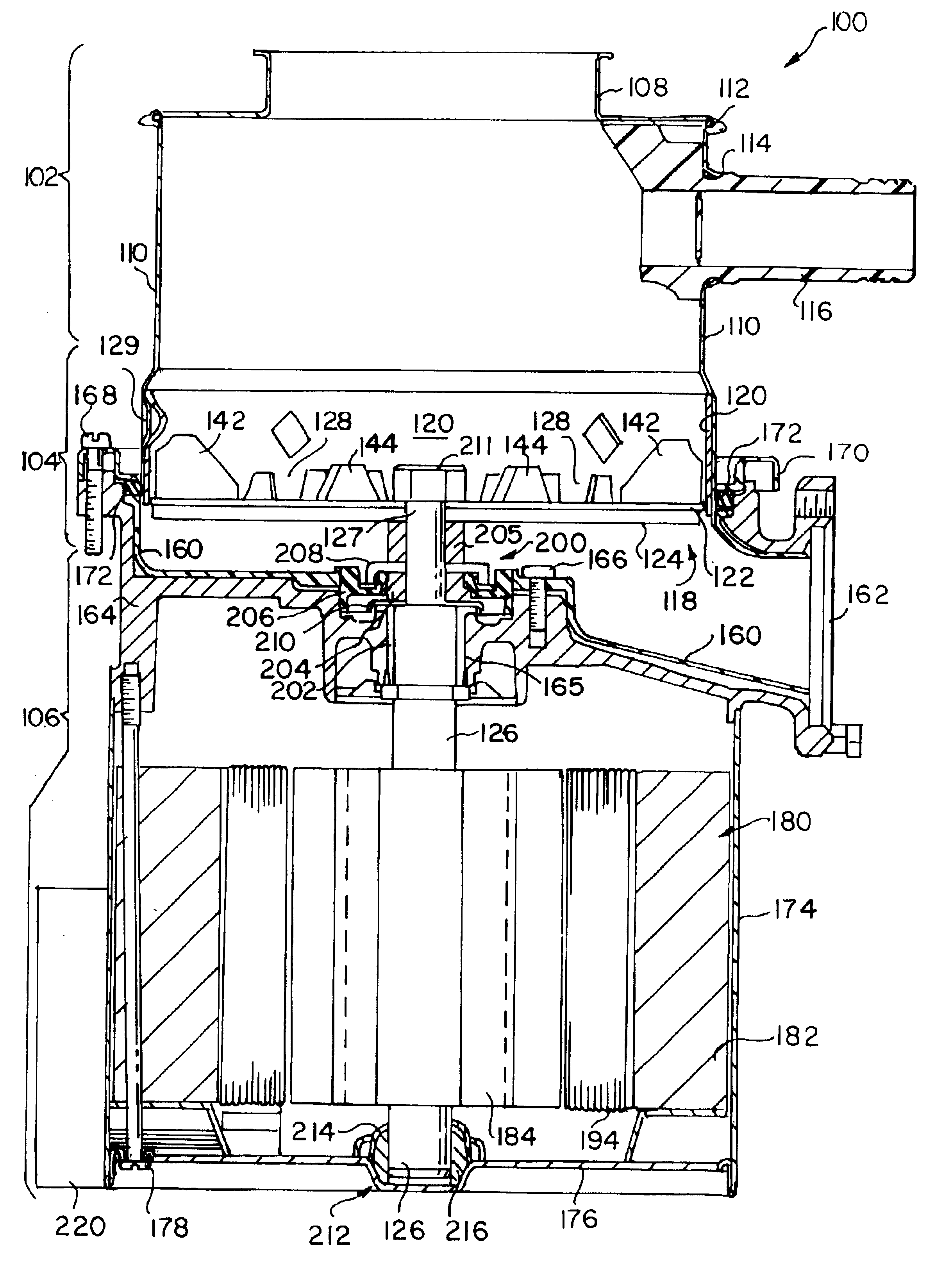

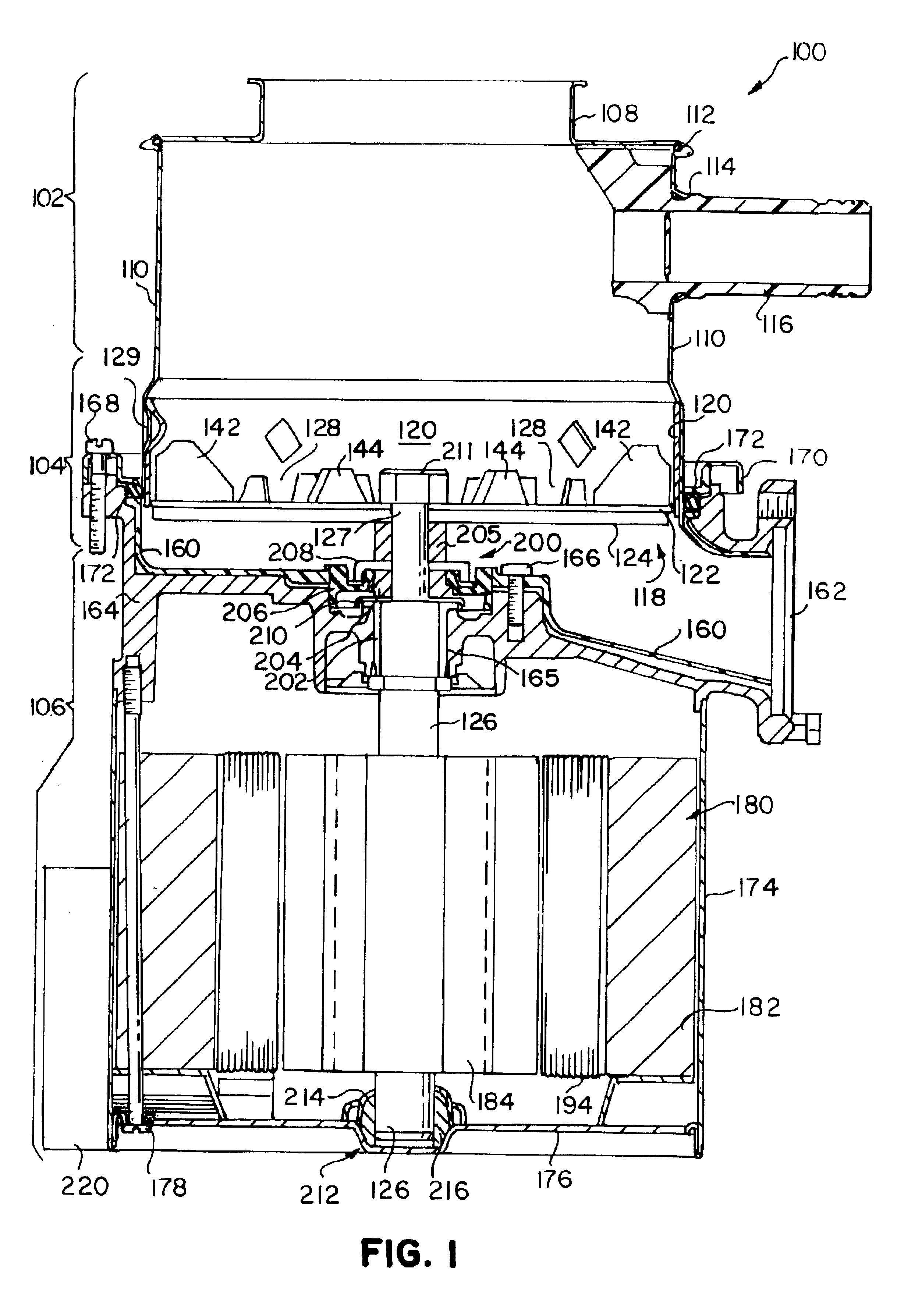

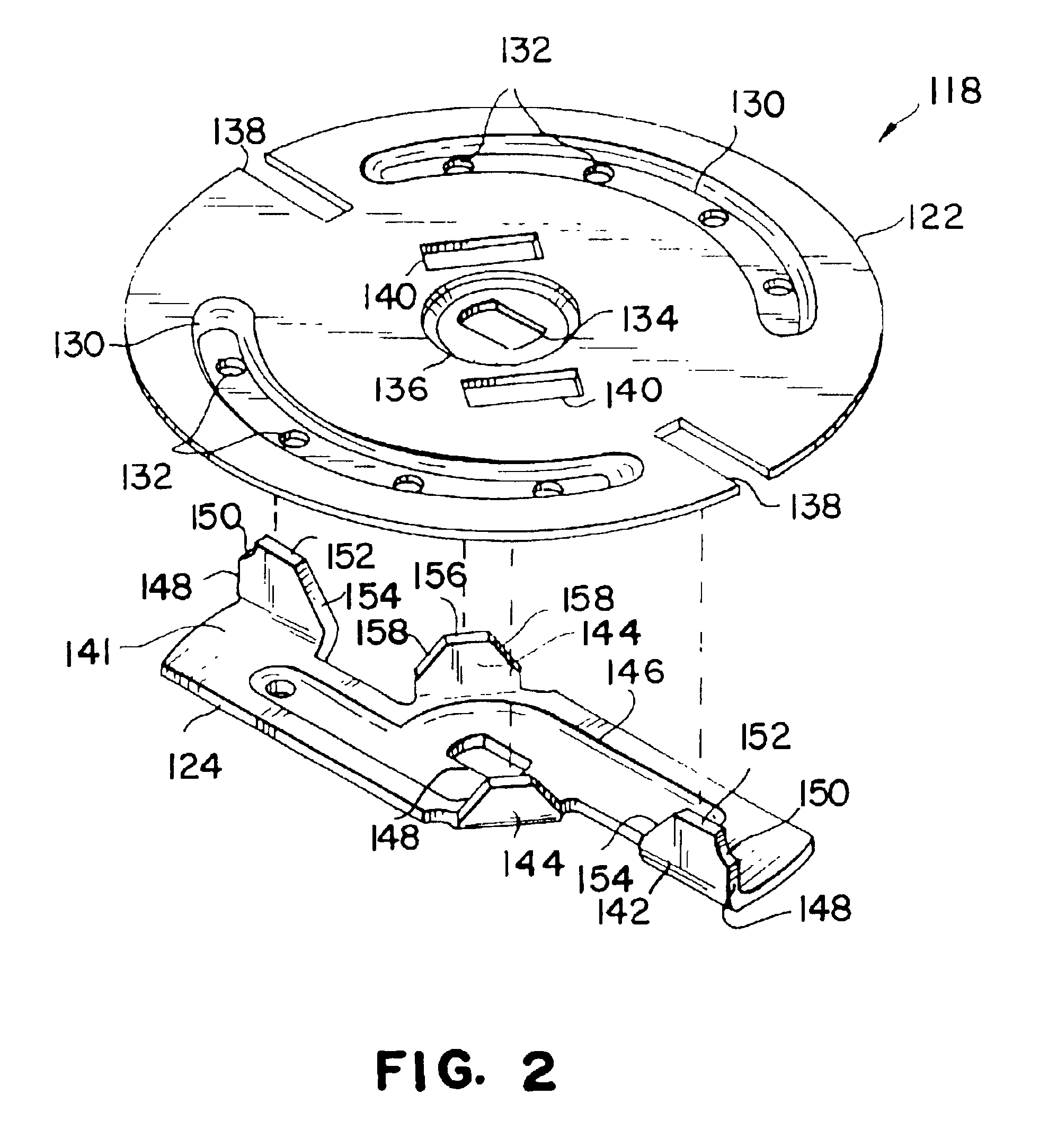

Food waste disposer having a variable speed motor

The present invention provides a food waste disposer having an upper food conveying section, a motor section, a central grinding section and a controller. The upper food conveying section includes a housing forming an inlet to receive food waste. The motor section includes a switched reluctance machine having a rotor and a stator. The rotor imparts rotational movement to a rotatable shaft. The central grinding section is disposed between the food conveying section and the motor section. The food conveying section conveys food waste to the grinding section. The grinding section includes a grinding mechanism where a portion of the grinding mechanism is mounted to the rotatable shaft. The controller is electrically connected to the stator to control the switched reluctance machine. The controller is capable of directing rotational movement to the rotatable shaft and the portion of the grinding mechanism mounted to the rotatable shaft. The controller is further capable of maintaining the rotational movement of the rotatable shaft at more than one rotational speed. The present invention also includes methods of operating a variable speed motor in different operational modes such as idle mode and anti-jamming mode.

Owner:EMERSON ELECTRIC CO

Processing method and system to convert garbage to oil

InactiveUS6387221B1Improve rendering capabilitiesIncrease speedCombustible gas coke oven heatingDirect heating destructive distillationPetroleum productHydrocotyle bowlesioides

Garbage and waste of all types that includes or comprises organic matter, particularly including medical waste, plastics, paper, food waste, animal by-products, and the like, can be economically recycled into petroleum products, including oil. Machinery performs a method that mimics natural processes but accomplishes the task in minutes, at rates of about 15 tons per day in a typical processing machine, rather than taking hundreds of thousands of years in nature. The process and apparatus of the invention may chop the waste into small pieces, under negative pressure if appropriate, and then pass the waste into first and then second augers for compression and heating. Destructive distillation occurs, in which large molecular weight hydrocarbons and petrochemicals are heated by hot oil passing through the hollow shaft and by circulating hot, dense, hard material, such as steel balls or fragments or hard rock pieces and such, under pressure with steam, to produce low molecular weight hydrocarbons. The volatile hydrocarbons are released through a pressure relief valve, into a column of catalyst material, and then to a heat exchanger, which cools the gases to condensation temperatures of water and oil. Gases remaining, such as methane, are passed to a furnace or other use, and the water and oil are separated. The hot items used to put heat into the compressed material in the first stage auger are retrieved after processing is completed and then reheated and cycled back into the first stage auger.

Owner:WASTE PROCESSORS INC TOM BECVAR TRACEY MUSGROVE & HIMSELF

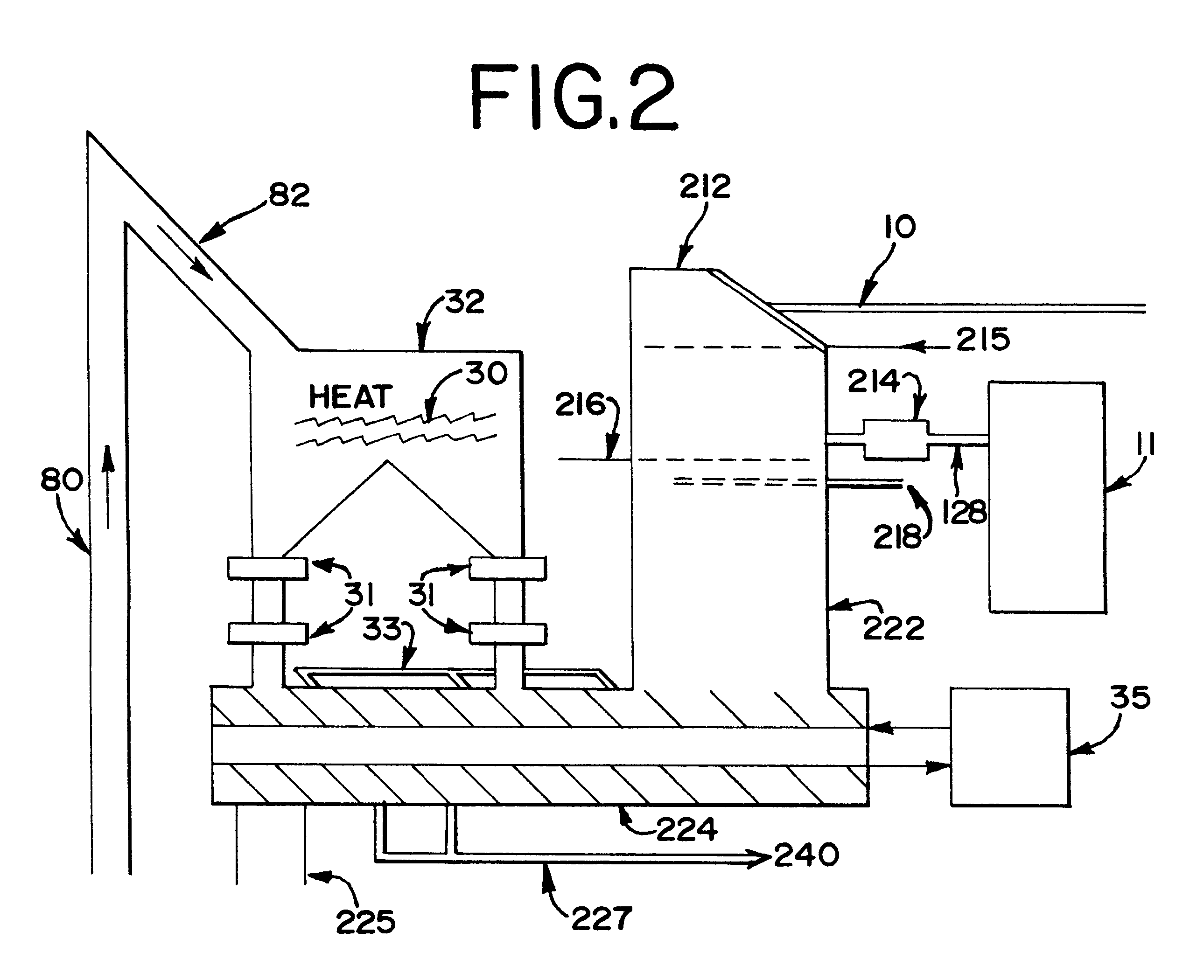

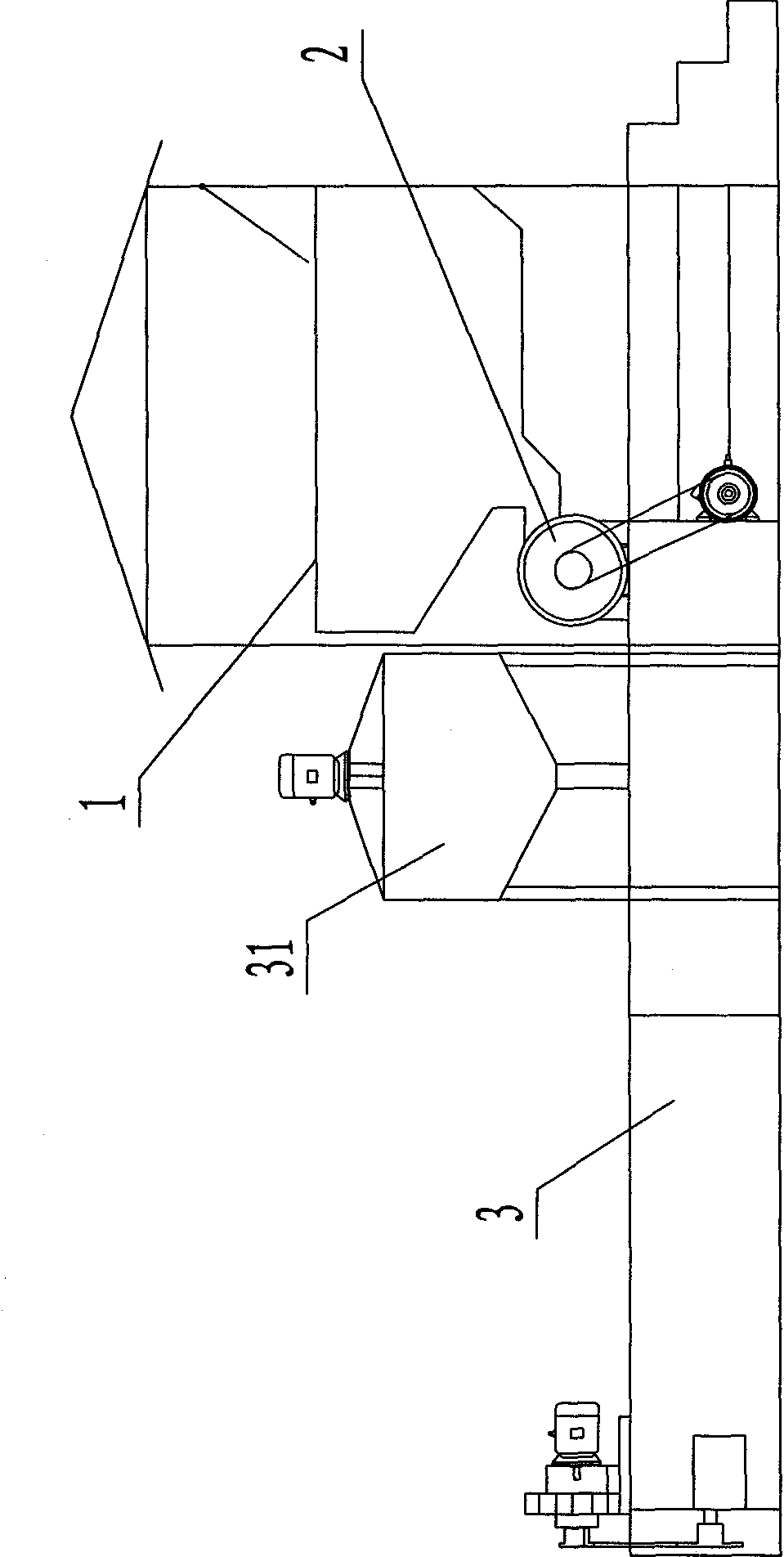

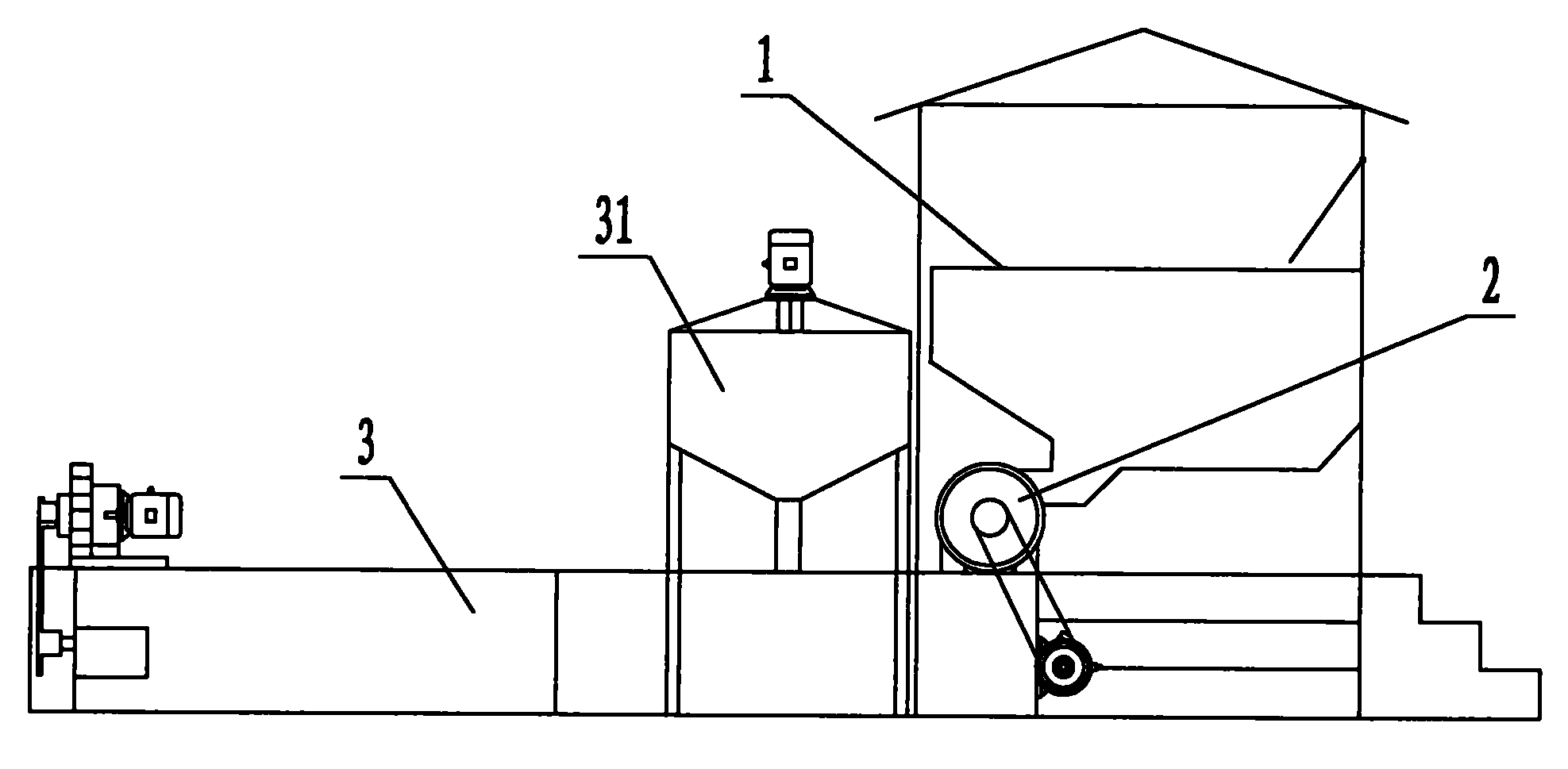

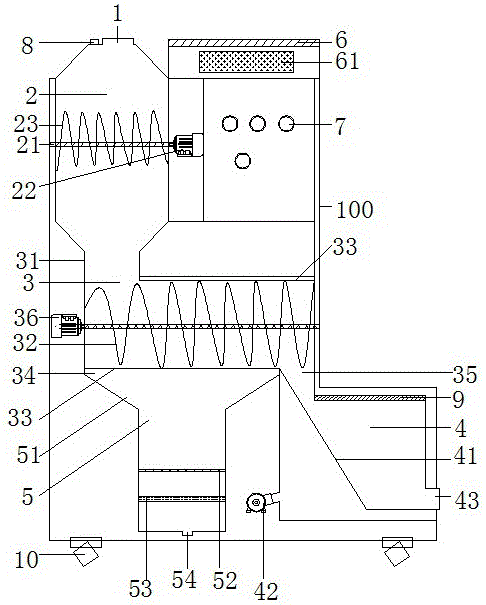

Resource using method for food and drink garbage

InactiveCN101058097AImprove conversion rateImprove efficiencyFood processingSolid waste disposalEngineeringWaste oil

The invention relates to a catering garbage reutilization method. It separates the liquid and the solid garbage and acidify them, then separate oil and water to get waste oil grease and sewage, using the waste grease synthesizing into biological diesel, processing the sewage to the required standard, crushing and grinding the solid, which are mixed with water to generate alcohol, batching, sterilizing, fermenting and drying the animal fodder. In this way, it can realize harmless processing of food waste, with zero discharge and enclosed green production.

Owner:中船重工(西安)东仪环保科技有限公司

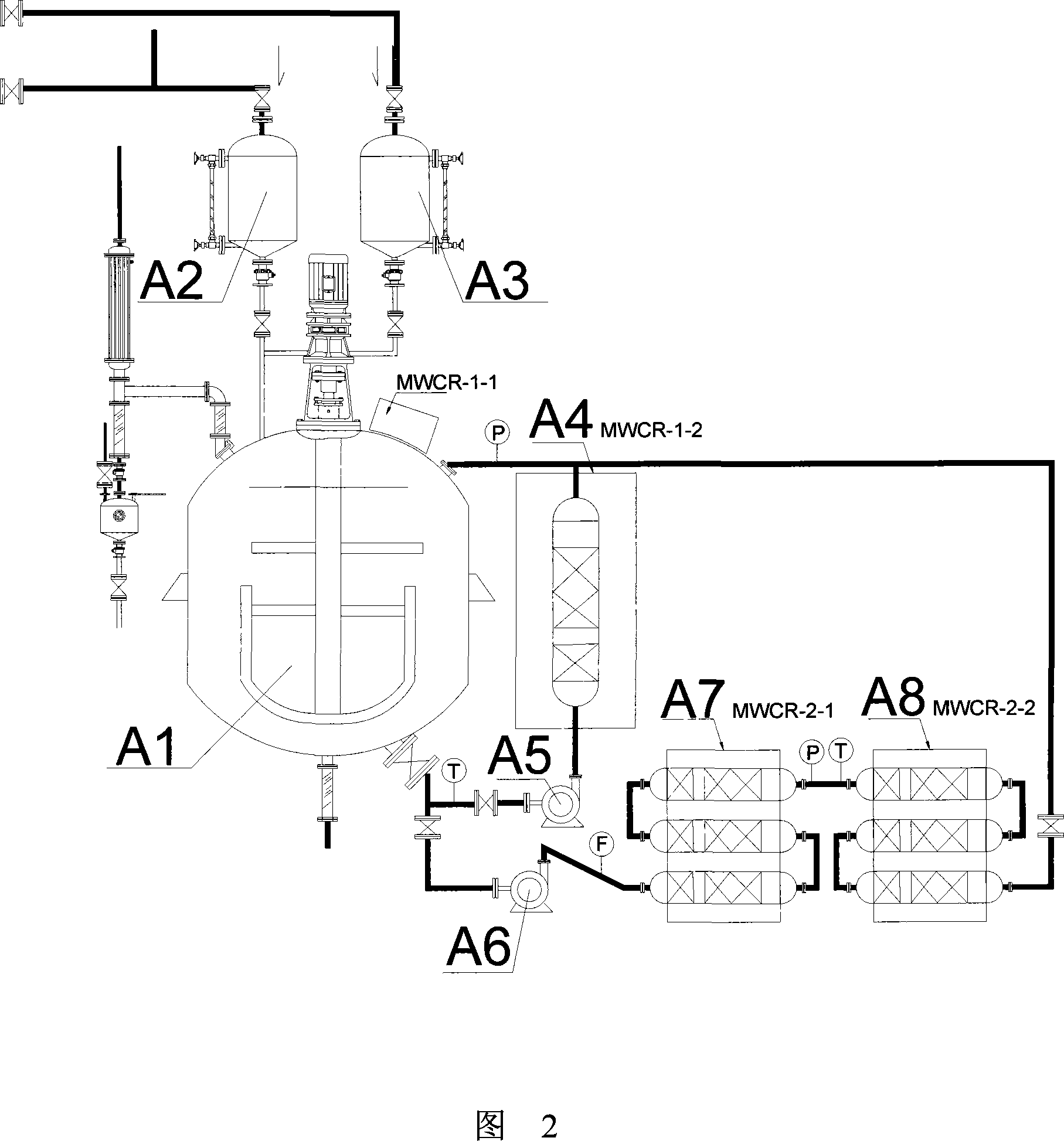

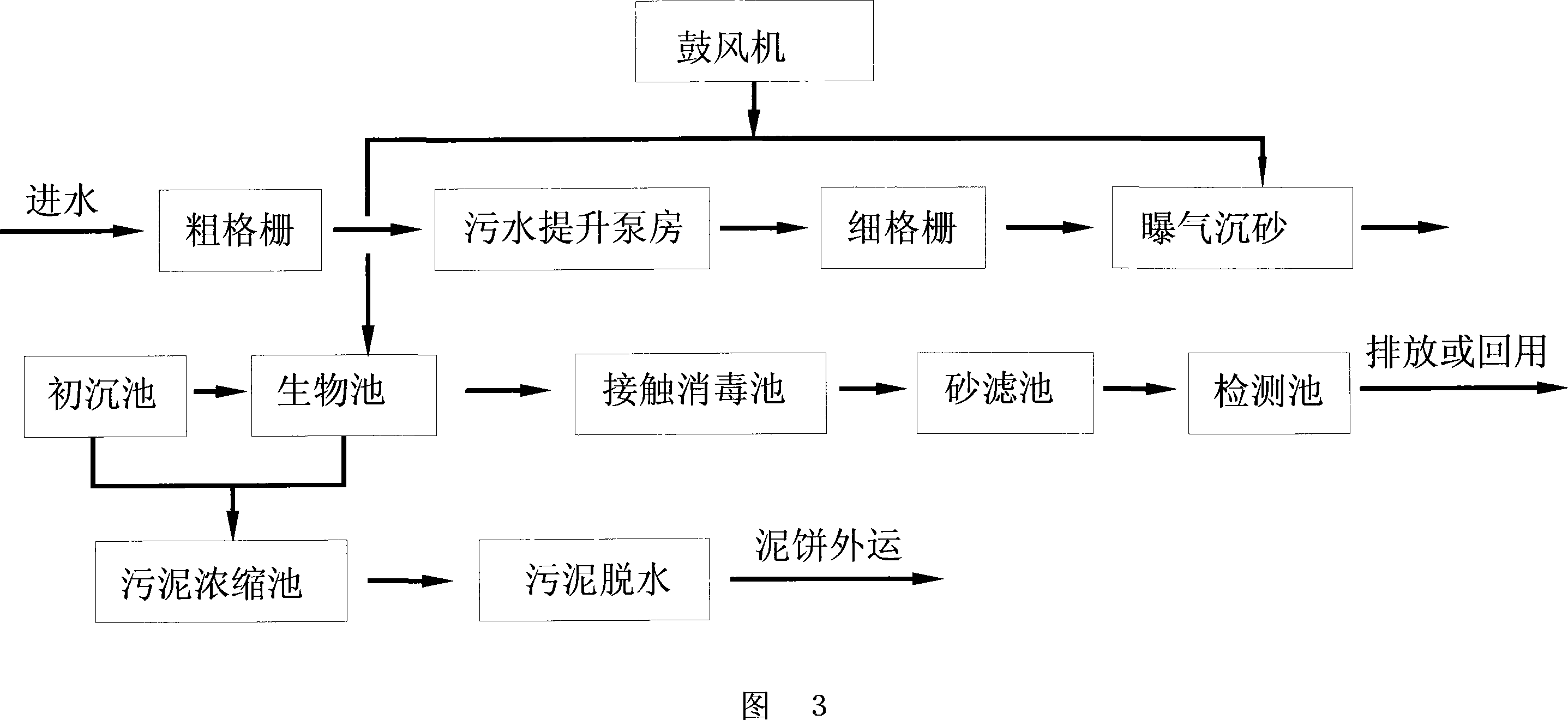

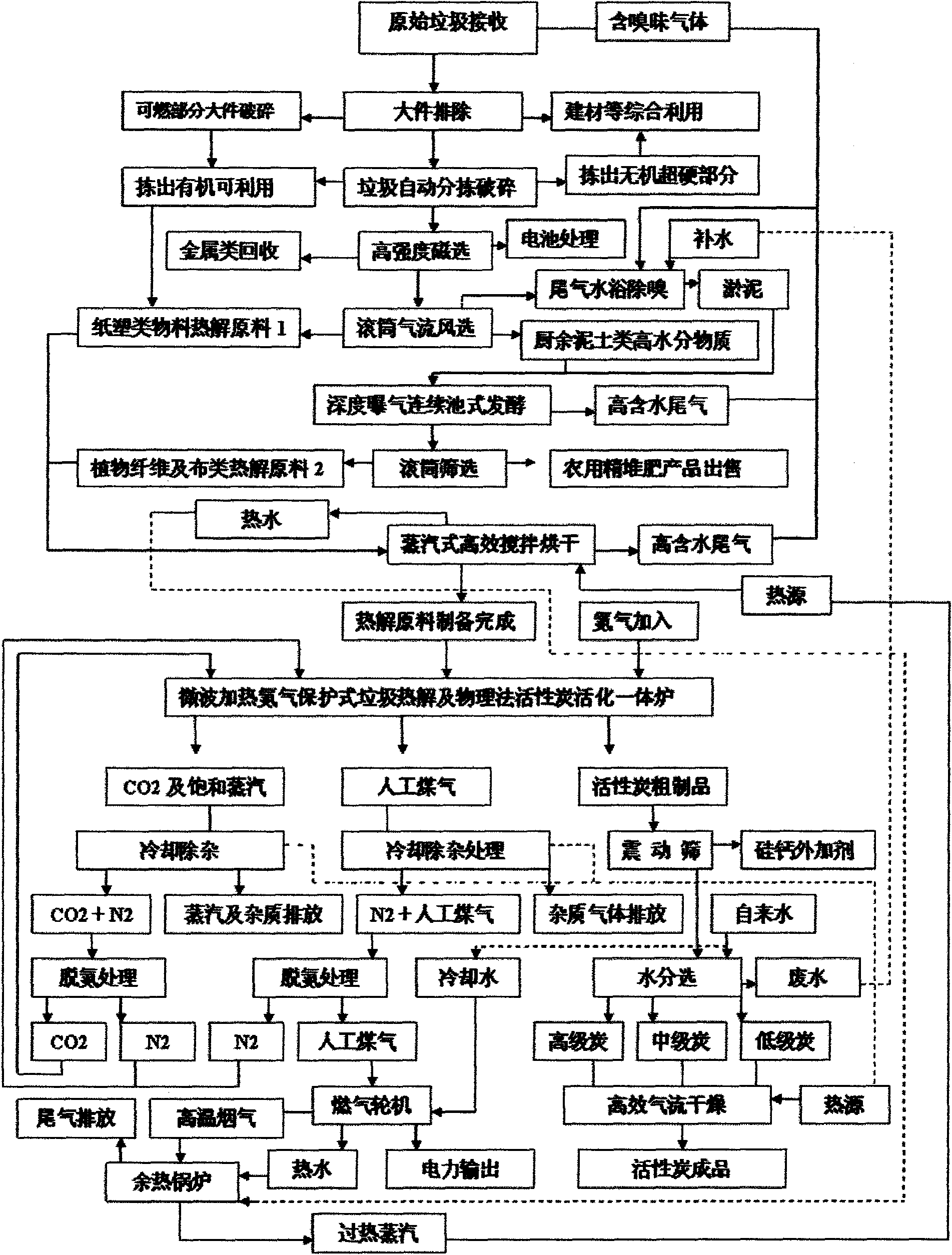

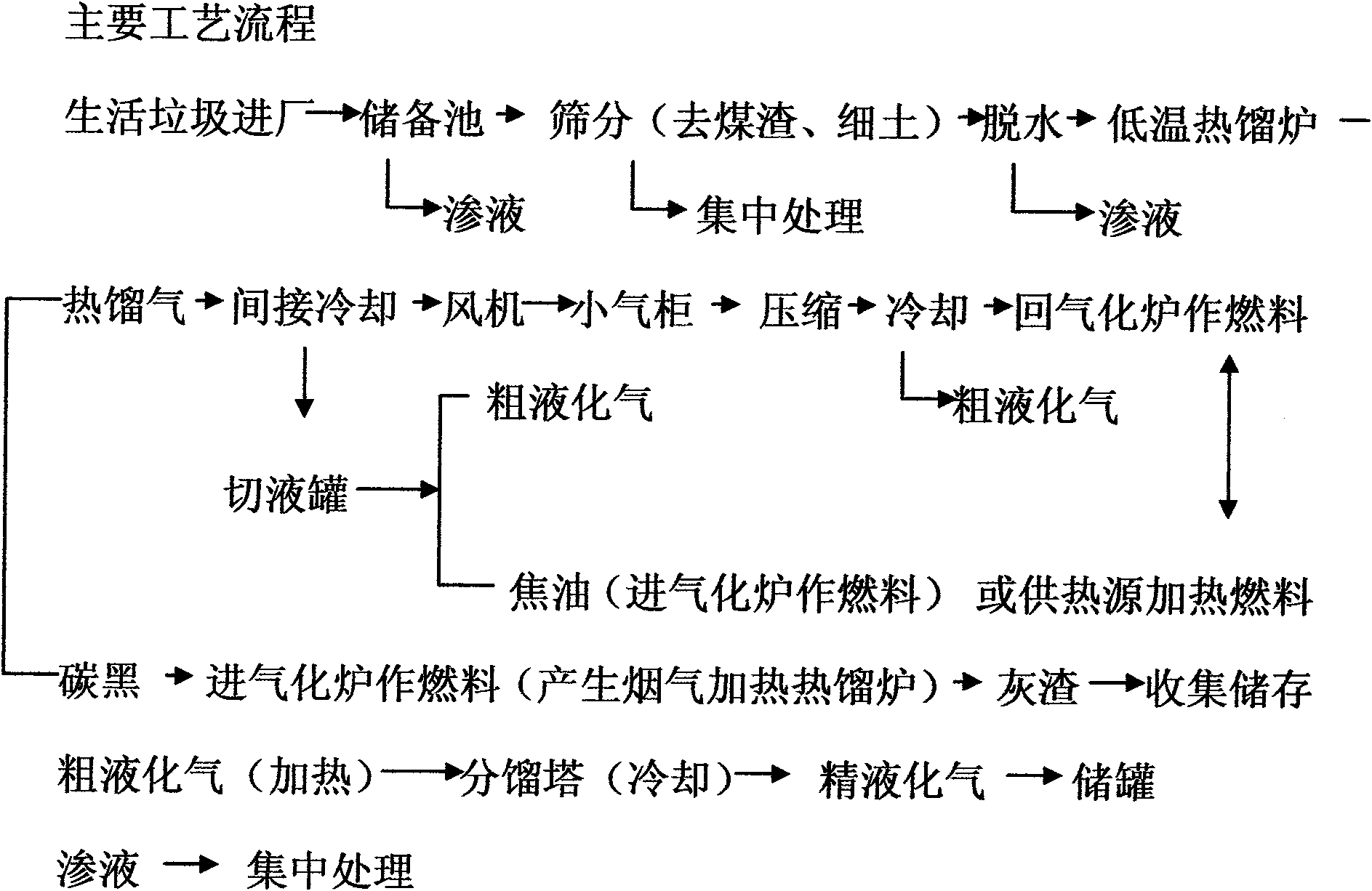

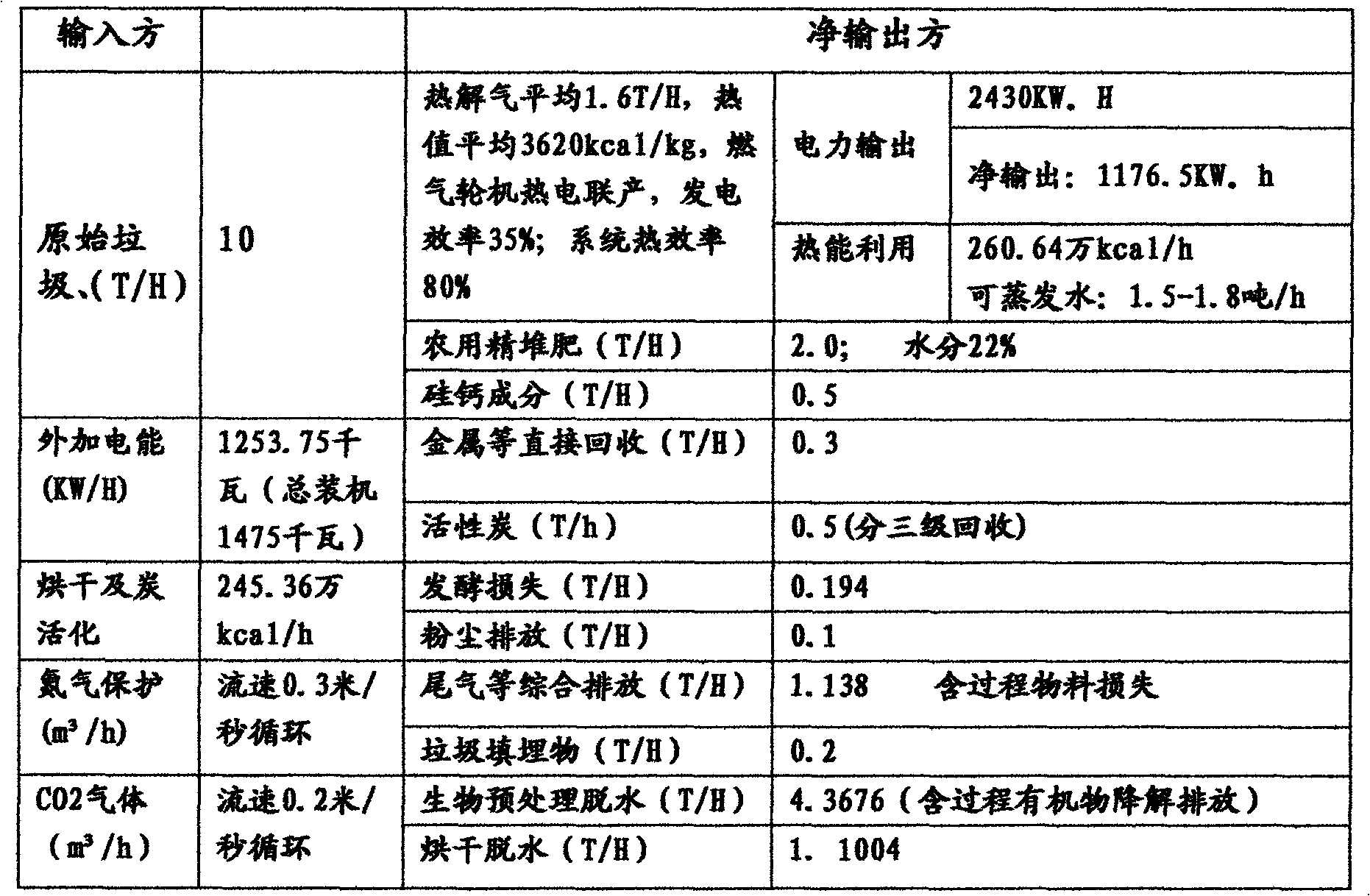

Technological method of comprehensive utilization of separation and pyrolysis treatment of garbage

InactiveCN101618392AAchieve harmless disposal rateReduce energy consumptionDrying solid materials with heatCarbon compoundsEvaporationOxygen

The invention relates to a technological method of comprehensive utilization of separation and pyrolysis treatment of garbage, which solves the problem of comprehensive utilization of separation pretreatment and pyrolysis gas in the process of separation treatment of garbage. The method comprises the following steps: separating and crushing the garbage for secondary classification; classifying the available components in the garbage into three classes, wherein the first class comprises paper, plastic and the like which are used as pyrolysis raw materials 1, the second class comprises the mixture of soil, kitchen wastes and the like, and the third class comprises the mixture of rag, fresh branches, vines and the like; chopping the mixture of the third class, and mixing the chopped mixture of the third class with the mixture of the second class; treating the mixture of the second class and the mixture of the third class by aerobic fermentation, and using penetrant for direct back-spraying and evaporation in high-temperature regions; treating the obtained product by secondary sieving to obtain pyrolysis raw materials 2; mixing and drying the pyrolysis raw materials 1 and the pyrolysis raw materials 2; condensing the generated steam to obtain hot water which back flows into a waste heat boiler of a power generating system to be used as supplemental water; commercializing and recovering the pyrolysis raw materials; and burning the obtained combustible gas for power generation. The invention has the advantages of high recovery rate, low energy consumption and no pollution caused by discharge.

Owner:SHEN ZHEN A MART IND

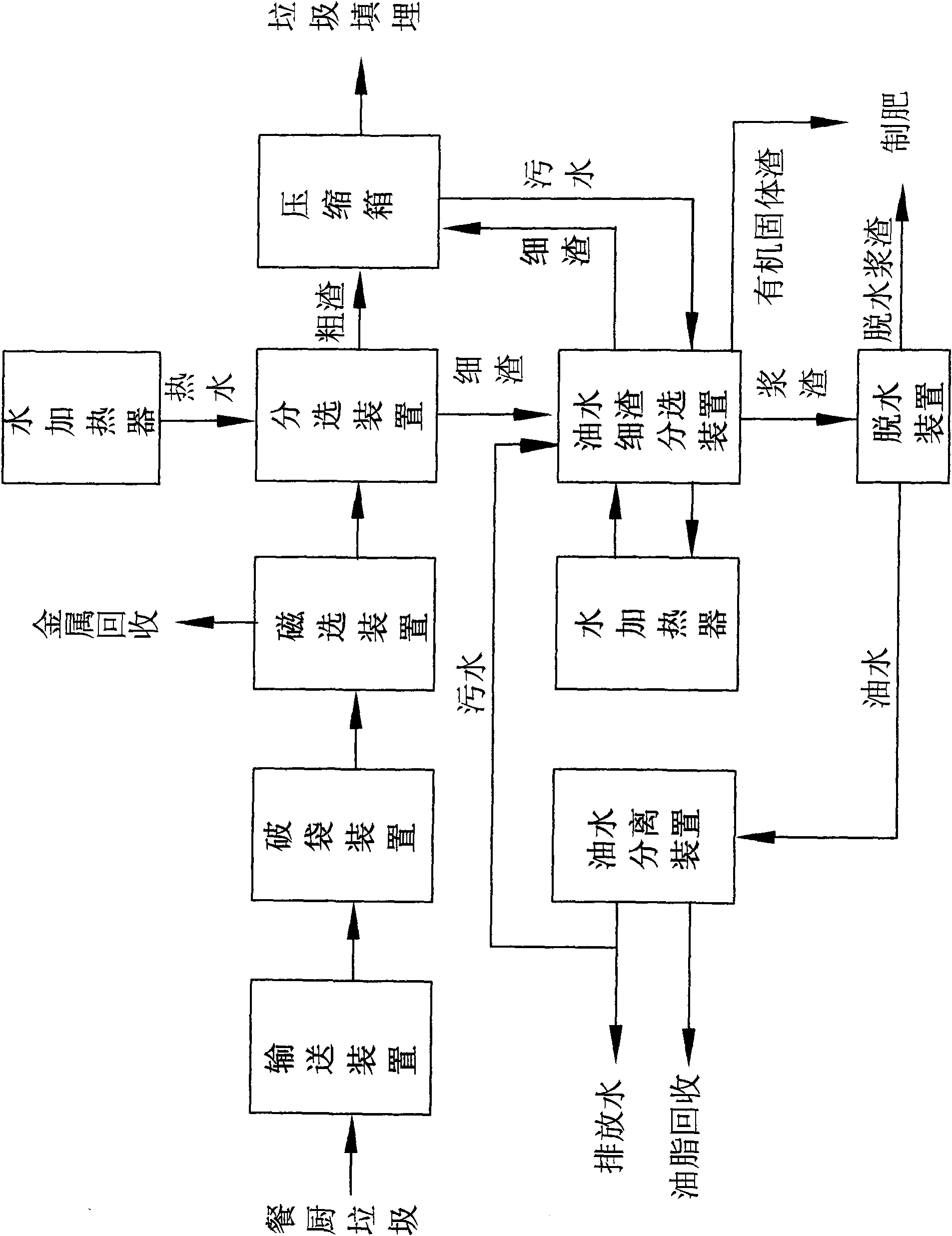

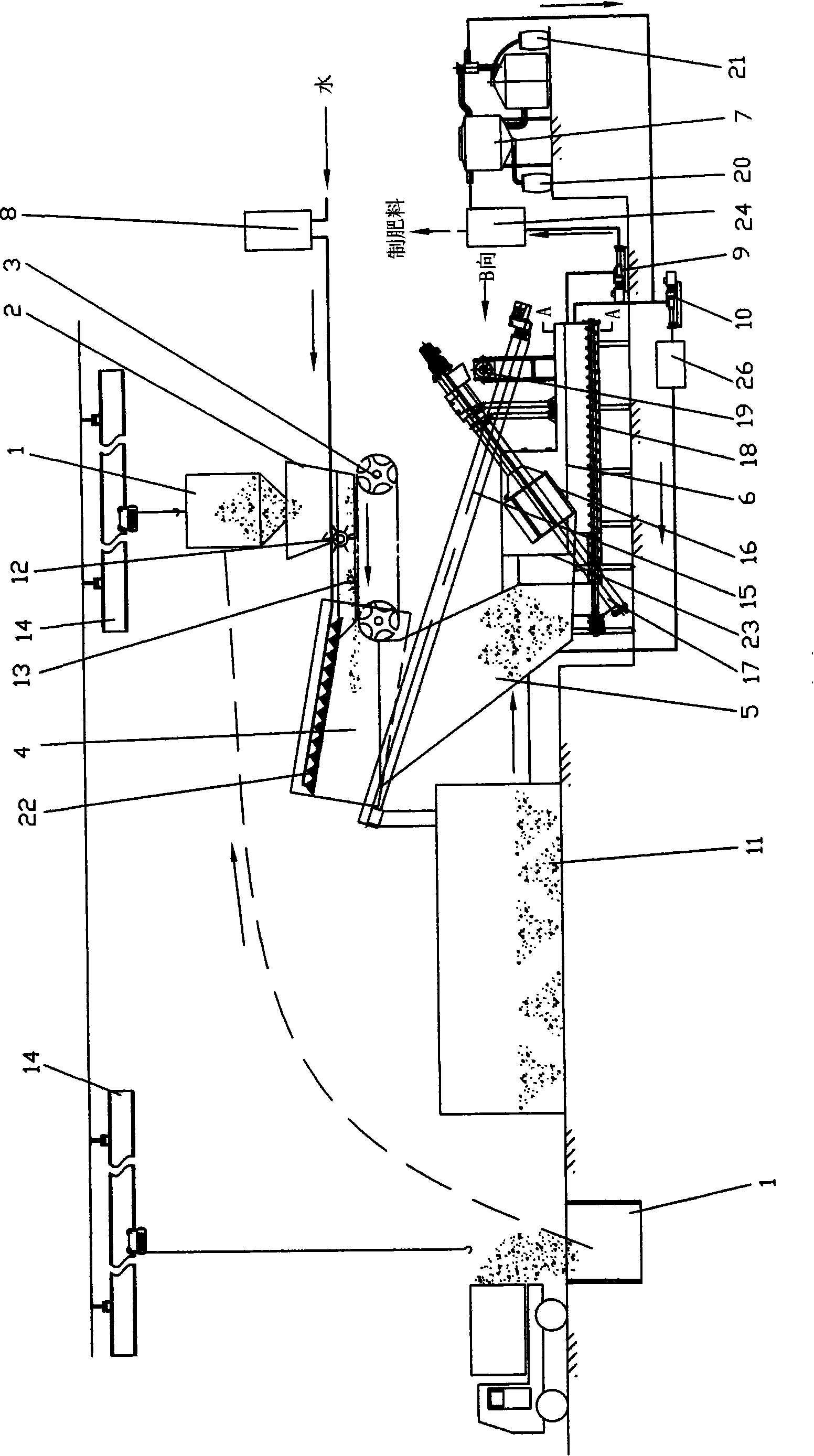

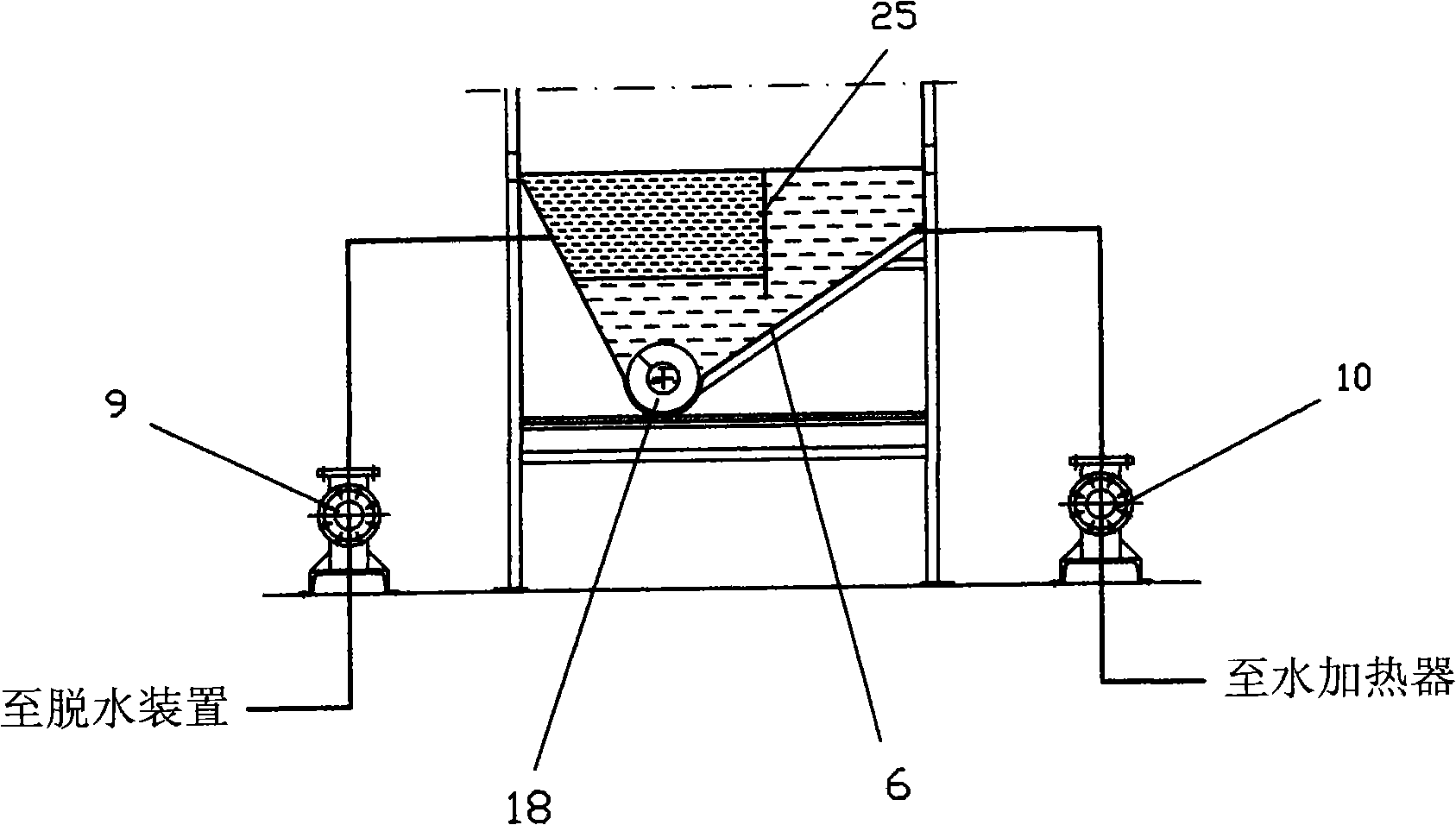

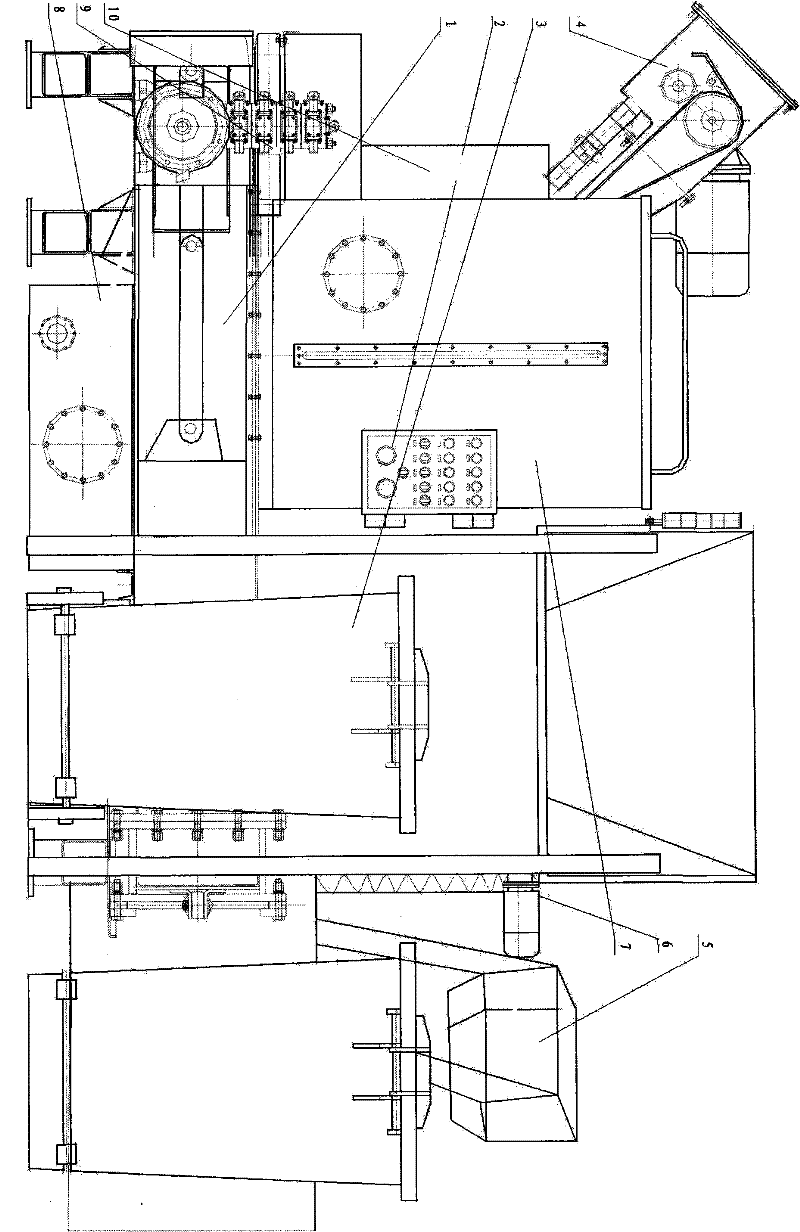

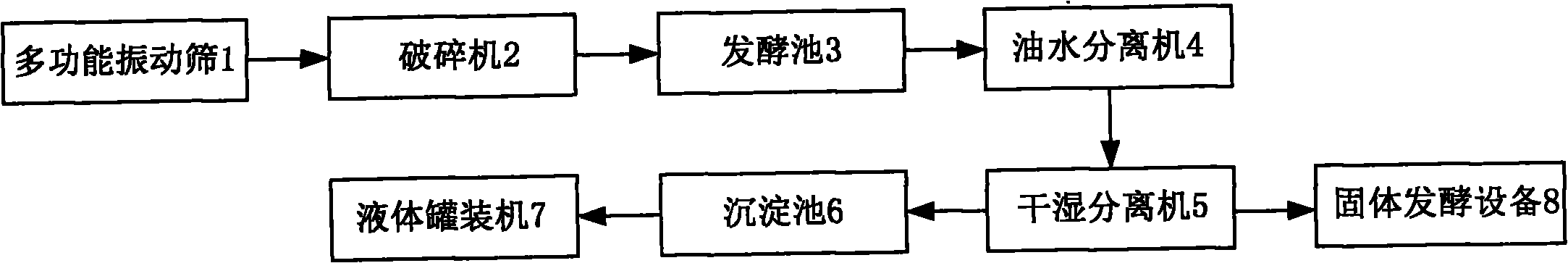

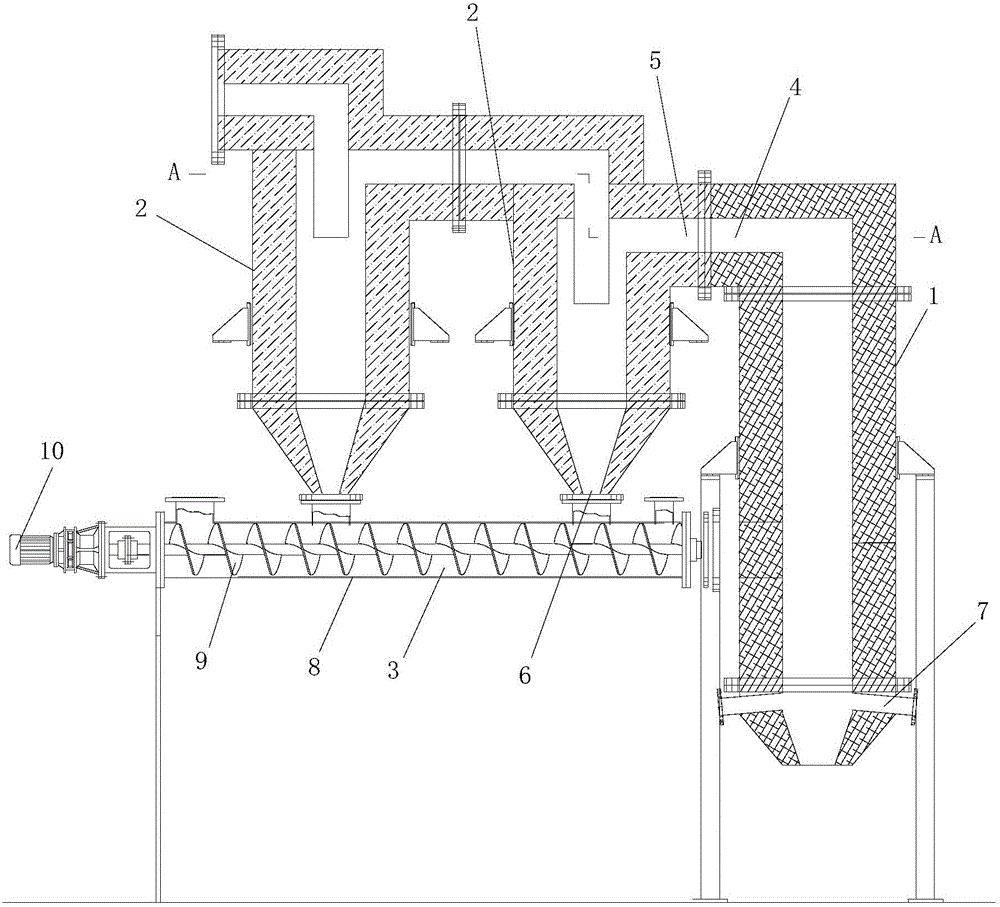

Treating technical method for food wastes and treating equipment

InactiveCN101524700AHarmlessReduce consumptionSolid waste disposalMagnetic separatorEnvironmental engineering

The invention discloses a treating technical method for food wastes and treating equipment, which relate to the technical field of screening and oil water separation in food waste treatment; the technique method comprises the following steps: the food waste is recycled by bag crushing, magnetic separation, coarse residue screening, hot water washing, solid-liquid separation of fine residue and secondary oil water separation with water in a separator of oil, water and fine residue. The treating equipment of food wastes for realizing the technique method mainly comprises a charging part, a conveying part, a bag-crushing device, a magnetic separator, a coarse residue separating part, a solid-liquid separator, a dehydrating unit, an oil water separator and the like. The invention can carry out grading screening, solid-liquid separation, oil water separation and resource recycling on food wastes, has continuous operation in use, thorough treatment and high efficiency and can protect environment.

Owner:BEIJING CENTURY GREEN ENVIRONMENTAL ENG &TECH +1

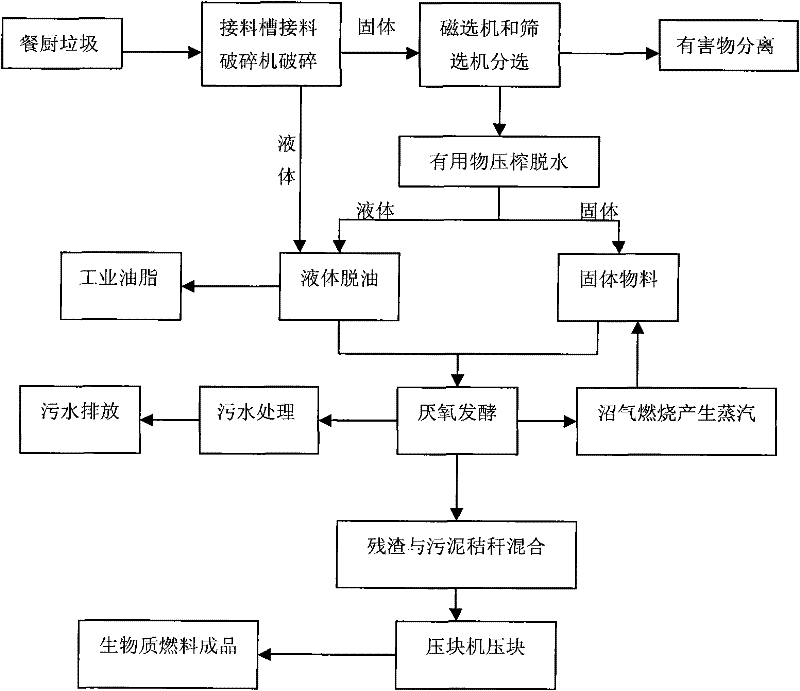

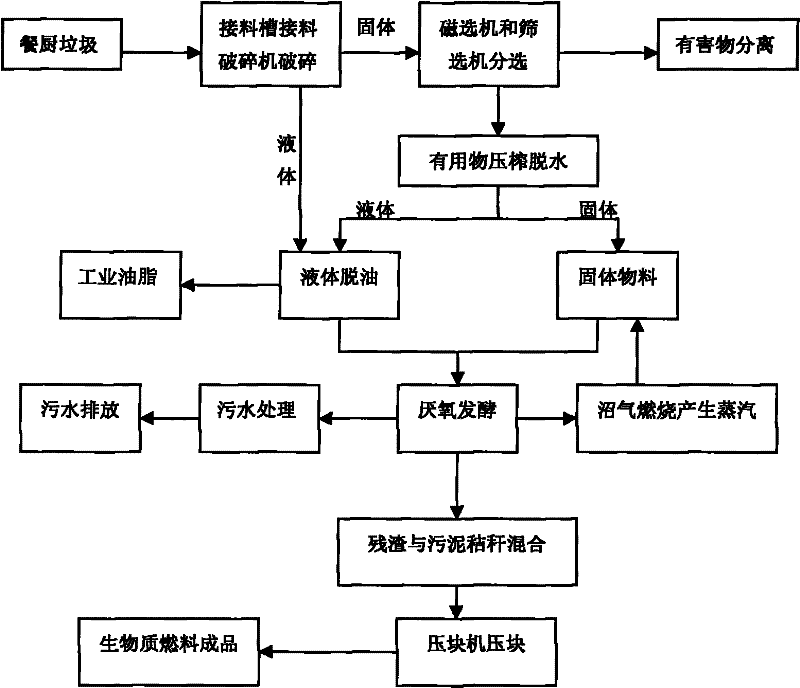

A method for preparing biomass fuel from kitchen waste

InactiveCN102268310AHarmlessAchieving processing powerFatty/oily/floating substances removal devicesSolid waste disposalSludgeSlurry

The invention relates to a method for recycling resources, in particular to a method for preparing biomass fuel from kitchen waste resources. The method for preparing biomass fuel from kitchen waste according to the present invention comprises sorting and crushing the kitchen waste, then dehydrating and deoiling, and anaerobically fermenting the solid materials in the kitchen waste after extracting the oil, and degrading the produced biogas Recycling, solid-liquid separation of the biogas slurry, the separated biogas residue is mixed with sludge, straw and other biomass materials, and dried and briquetted to make biomass fuel. The invention recycles kitchen waste and turns waste into treasure. It not only realizes the harmless and reduction treatment of kitchen waste, but also treats biomass waste such as sludge and straw, and the obtained products are completely burned without any waste. Secondary pollution, realize the comprehensive treatment of various wastes.

Owner:董雅清

Treatment of swine wastewater by biological and membrane separation technologies

InactiveUS7045063B2Bio-organic fraction processingExcrement fertilisersSeparation technologyFiltration

Owner:RGT UNIV OF CALIFORNIA

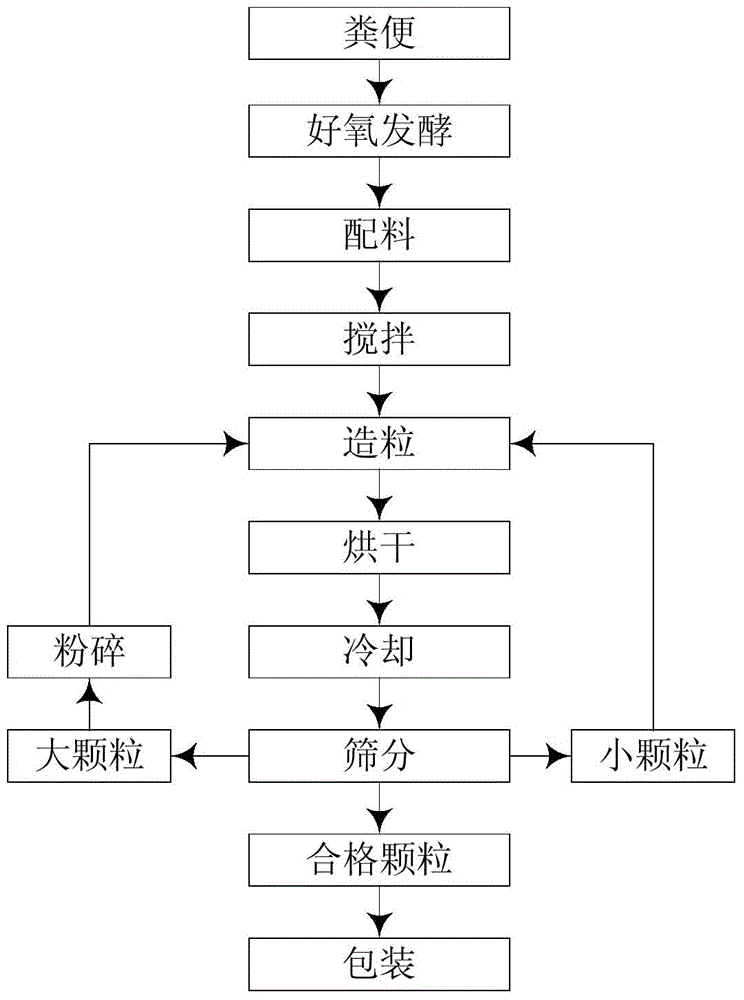

Manufacturing method of fertilizer made from organic wastes

InactiveUS6273927B1Neutralize toxicityHigh in magnesiumCalcareous fertilisersProductsHuman wasteChaff

This invention relates to a method of manufacturing the fertilizer made from organic wastes such as food wastes, human excrements, animal excrements, slaugterhouse waste, henhouse waste, fish and shellfish wastes, vegetable wastes and agricultural wastes. Various wastes are mixed and crushed into certain sizes, processes for adjusting the water content, put into the treating tank and digested by mixing a calcined lime. The present invention utilizes a dolomite or mixture of calcined lime and dolomite to provide the first treatment material. This first treatment material is mixed with the supplement material such as charcoal, saw dust, loess, zoelite, chaff, or shell powder to give compost fertilizer. It is also mixed with agricultural products such a watermelons or melons which ferment to provide a special fertilizer for the agricultural product. The treatment material can be added to water and mixed with mugwort, medicinal herb, zeolite, loess, and then extracted to provide a liquid fertilizer. As the various organic wastes are changed to organic fertilizer, the acidified soil is improved, the environmental contamination can be prevented, and the high moisturizing and the fine porous of the soil prevent drought and fertilizer loss so as to raise fertilizing efficiency.

Owner:JMBIO

Waste energy conversion system

An on-site modular method and system for processing waste typically including food from a food services facility. The waste is processed in a size reduction unit and subsequently dried in a dryer. The dried shredded waste is processed to produce densified pellets. The food binds the non-food waste in the pellets. The pellets are burned in a thermal conversion unit to produce a gas and waste heat. The waste heat is directed to the dryer for use therein. The gas is fed to a generator or turbine to produce electricity. A portion of the electricity produced is used to energize the process.

Owner:INFOSCITEX

Kitchen garbage treatment method

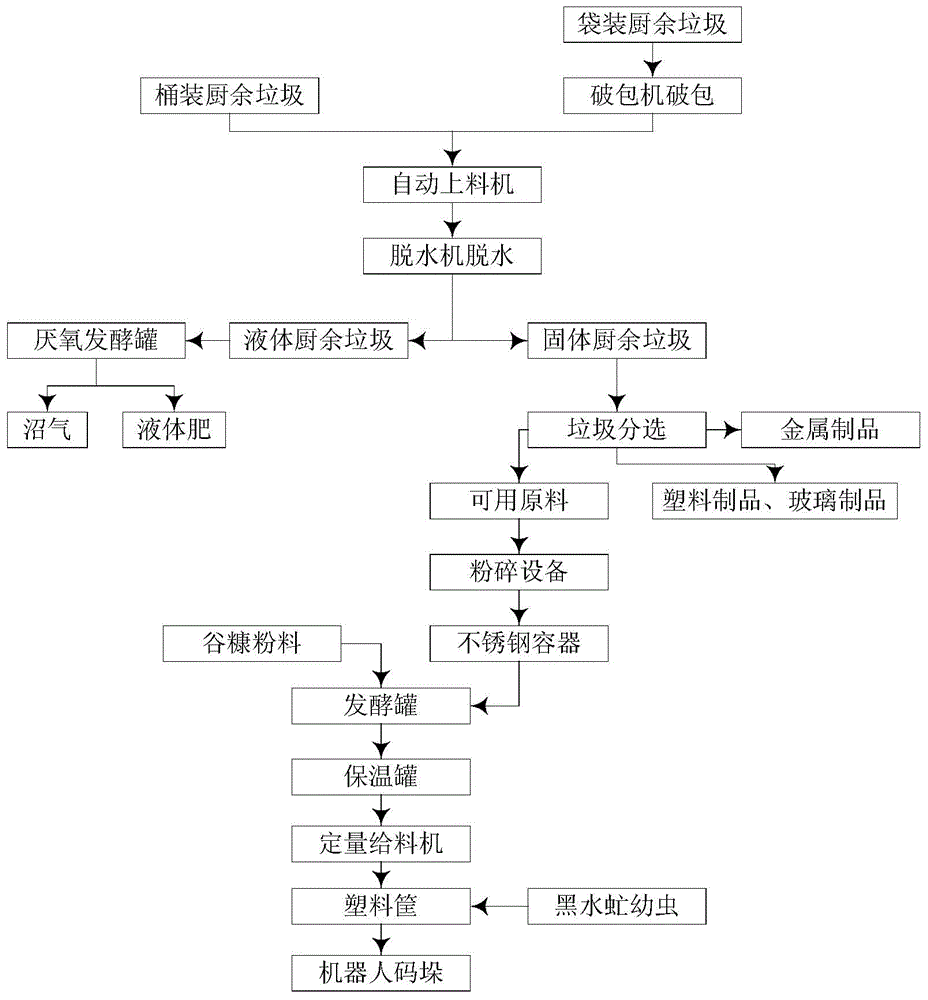

The invention provides a kitchen garbage treatment method. The kitchen garbage treatment method specifically comprises the following steps that kitchen garbage is sorted, so that metal products, plastic products, glass products and ceramic products are removed; the sorted kitchen garbage is smashed into pulp, beneficial bacteria are added for primary fermentation, and secondary fermentation is conducted after heat preservation; and after secondary fermentation is completed, young hermetia illucens is added into the pulp for reproduction, and the hermetia illucens and manure are collected. The method overcomes the defects that according to traditional landfill, incineration and compost treatment method, secondary pollution is prone to being generated and steps are complicated and has the advantages that secondary pollution is avoided, dehydration and deoiling are not needed, and terminal products with high value can be obtained. Furthermore, the temperature of primary fermentation is preferably 50-80 DEG C, the temperature of secondary fermentation is preferably 30-40 DEG C, it is guaranteed that the total time for primary fermentation and secondary fermentation is not longer than ten hours, and the treatment cycle is greatly shortened. During actual treatment, the total amount of garbage treated every day can as large as 100 tons, and kitchen garbage can be effectively treated in time.

Owner:肖唐彦

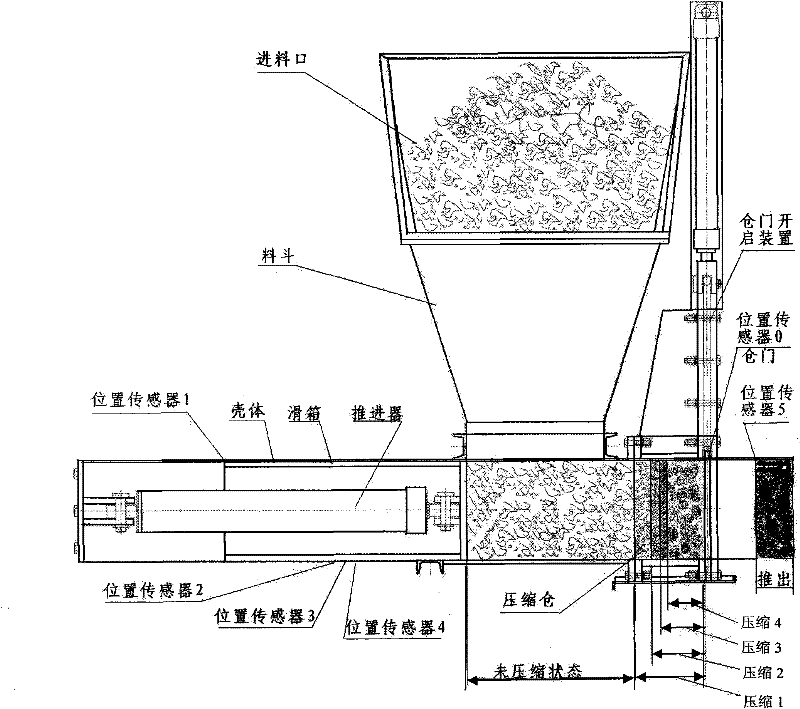

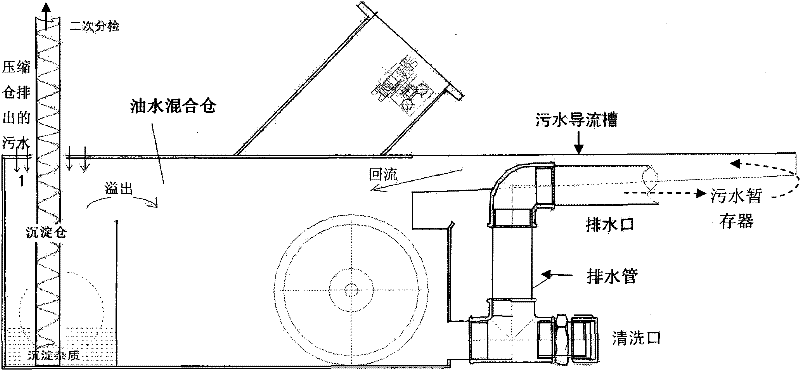

Device for reducing and sorting food waste at the source

InactiveCN102240658AEasy to handleImprove transportation capacitySolid waste disposalDrying solid materials without heatOil and greaseFailure rate

The invention discloses a device for reducing and sorting food waste at the source, and belongs to the technical field of municipal environmental protection machinery. The device is characterized in that: food waste is poured into a feed system and is conveyed into a dehydration system, a sliding box is driven to slide in a housing through a propeller of the dehydration system, a extruding way or a beating way is adopted to complete the food waste dehydrating; the resulting sewage from the dehydration step enters a sewage box from a compression bin to enable a oil and water separation system to extract greases; the solid materials after completing the dehydration are pushed out from the compression bin and enter into a material discharge system; the solid materials are output through the material discharge system and wait for centralized processing. After being processed by the device provided by the present invention, the food waste is divided into three portions comprising the water, the greases and the solid materials so as to conveniently carry out post-treatments such as reuse production of the greases and the solid materials, regeneration treatment of the water source and the like. The device has characteristics of strong processing ability, low failure rate, high automaticity, simple and easy operation and maintenance, no requirement of chemical additives, high dehydration rate, short retention time of the food waste in the device, and the like, and is benefit for improving efficiency of resource reutilization production so as to achieve effect of energy saving and emission reduction.

Owner:曹泽民

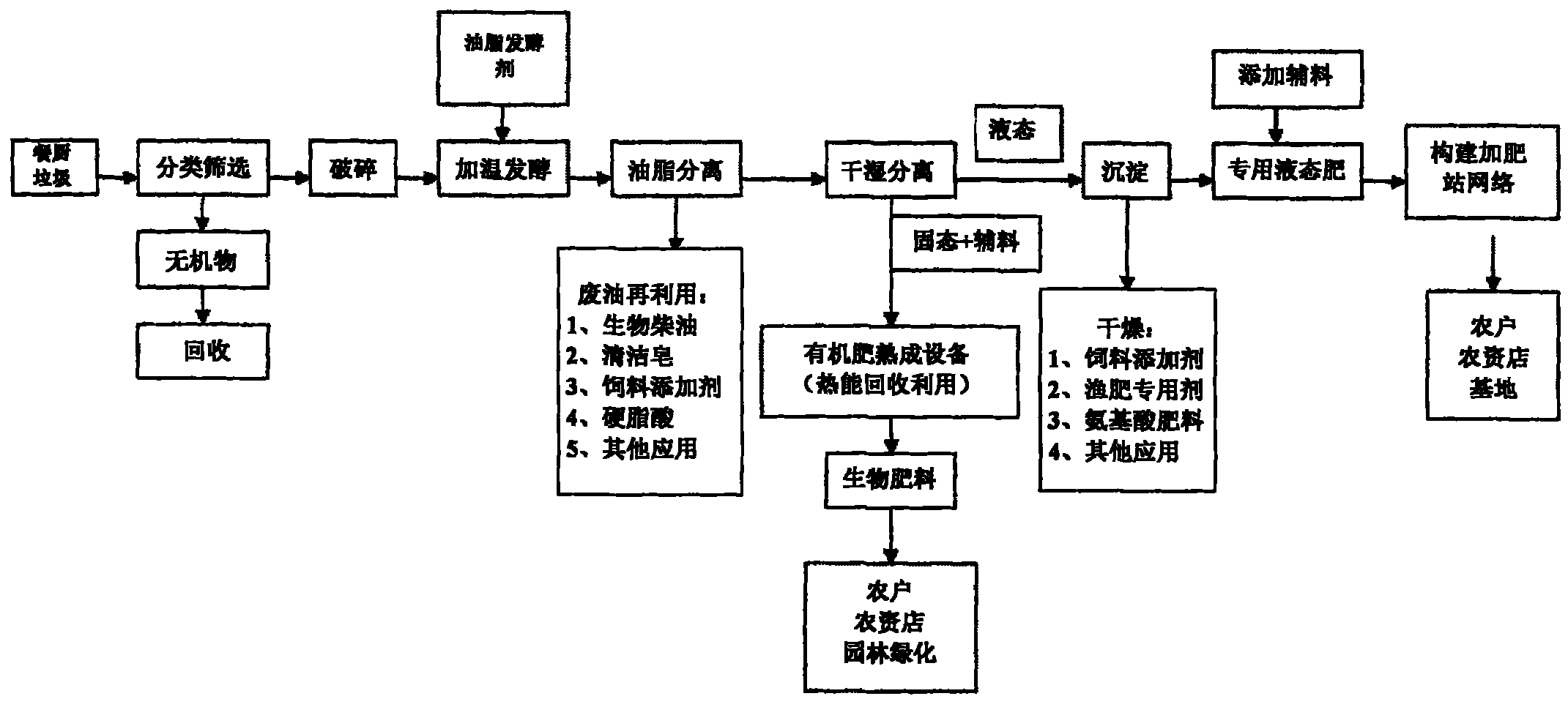

Comprehensive food waste treatment system and treatment method thereof

ActiveCN101927254AReduce pollutionReasonable designFatty oils/acids recovery from wasteSolid waste disposalProduction lineSystems design

The invention discloses a comprehensive food waste treatment system and a treatment method thereof, belonging to the technical field of environmental governance. Solids are recovered from the food waste to prepare composite protein feed, synchronously oil is recovered to prepare industrial articles, such as soap powder, bio diesel, fuel oil, and the like and the food waste water is recovered to prepare fertilizers so as to realize the aim of comprehensively utilizing the food waste. The system of the invention has reasonable design, various subsystems are mutually independent and mutually communicated to form a production line for rapidly treating the food waste; and the food waste treatment method by utilizing the production line is simple, convenient and practical, has extremely high treatment capability, turns waste into valuables and greatly solves the problem of urban environmental pollution. The production line of the invention can be used for treating 10-500 t of food waste every day, i.e. about 40 percent of the refuse quantity of a large city like Wuhan, and every 100 T of food waste can produce 8-12 t of rough protein feed, 2-4 t of refined crude oil and 50-70 t of liquid fertilizers.

Owner:武汉百信环保能源科技有限公司

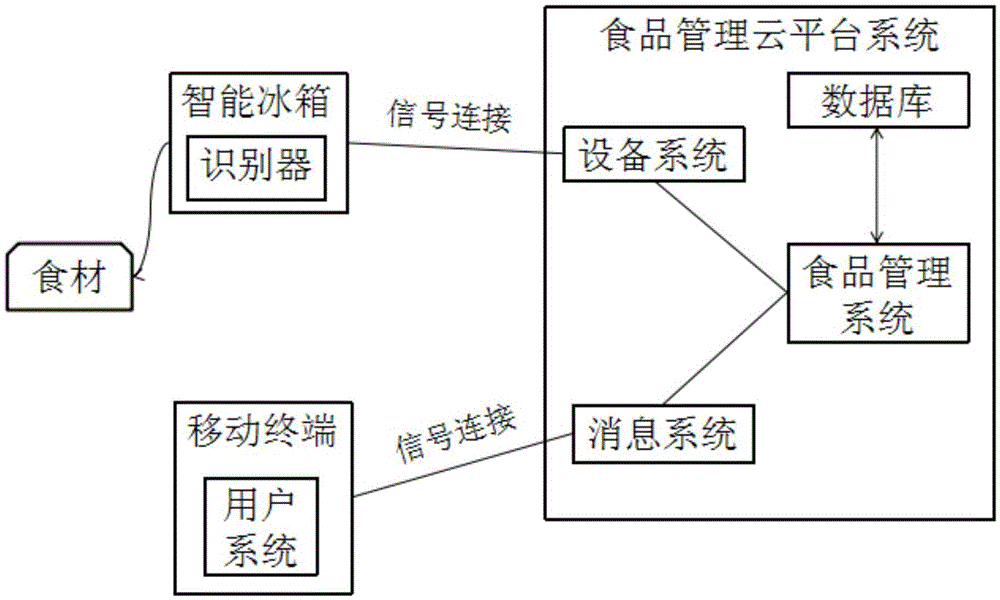

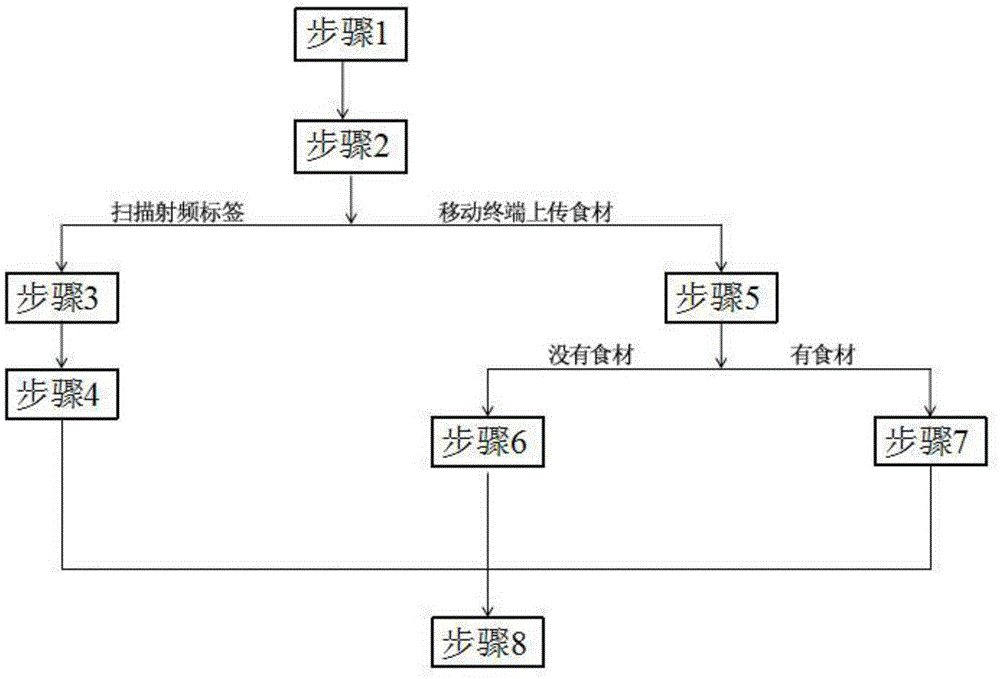

Intelligent refrigerator food management system and method based on cloud service

ActiveCN105650996AEfficient managementReduce wasteDomestic cooling apparatusLighting and heating apparatusComputer terminalFood material

The invention discloses an intelligent refrigerator food management system and method based on cloud service. The management system mainly comprises an intelligent refrigerator, a food management cloud platform system and a mobile terminal. The food management cloud platform comprises a food management system body, an equipment system, an information system and a database. The equipment system and the information system are in signal connection with the intelligent refrigerator and the mobile terminal respectively. A recognizer is installed on the intelligent refrigerator. After the recognizer scans radio frequency tags on food, according to electronic codes corresponding to the food, feature information of corresponding food materials is searched for in the database and called out; or food names are input into the mobile terminal, and according to the food names, the feature information of the corresponding food materials is searched for in the database and called out. By means of the management system and method, operation of users is reduced, a passive acceptance mode of a traditional refrigerator is converted into an active reminding mode, the food can be managed efficiently, food waste is reduced, and the purpose of cutting down expenses for the users is achieved.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

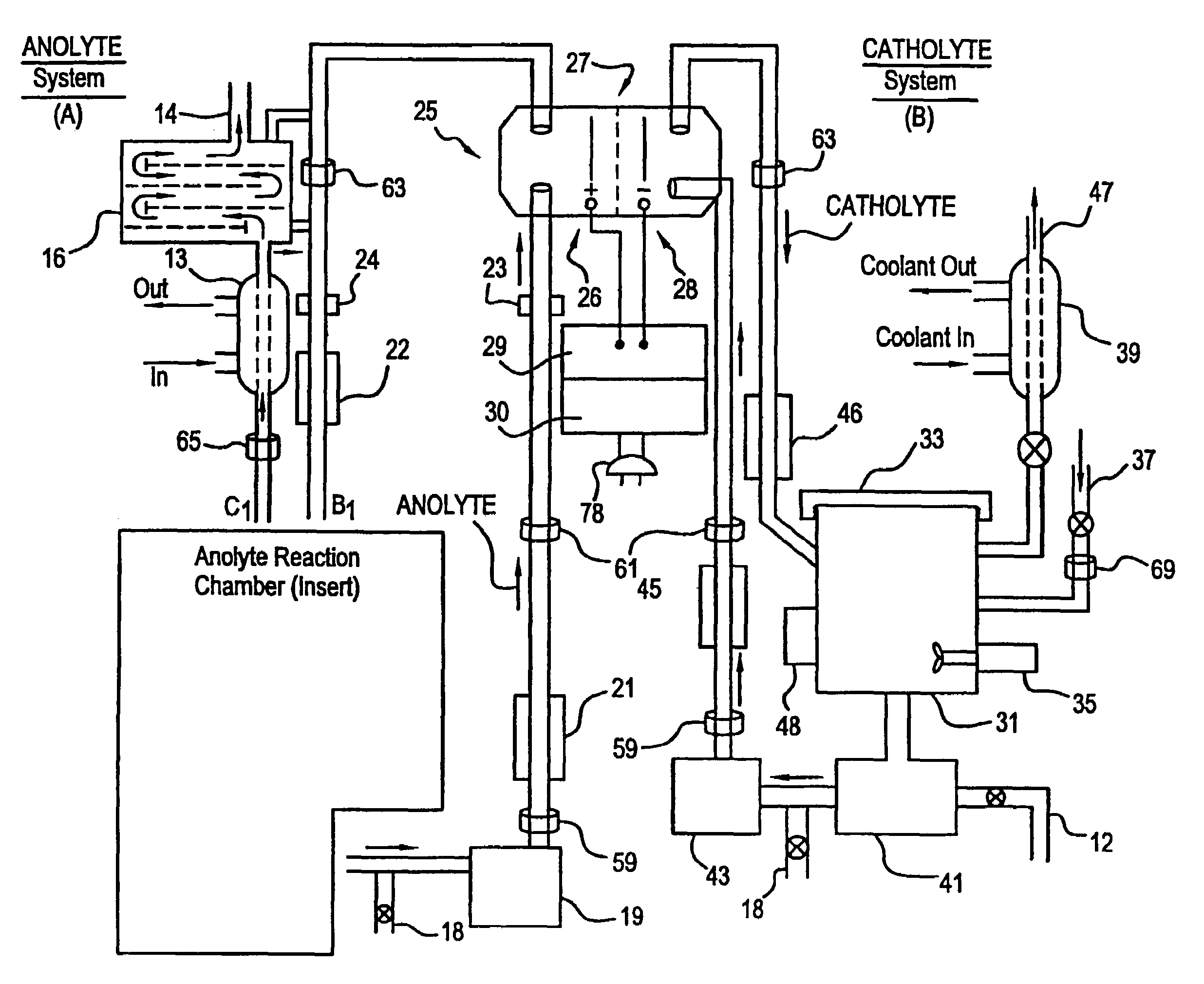

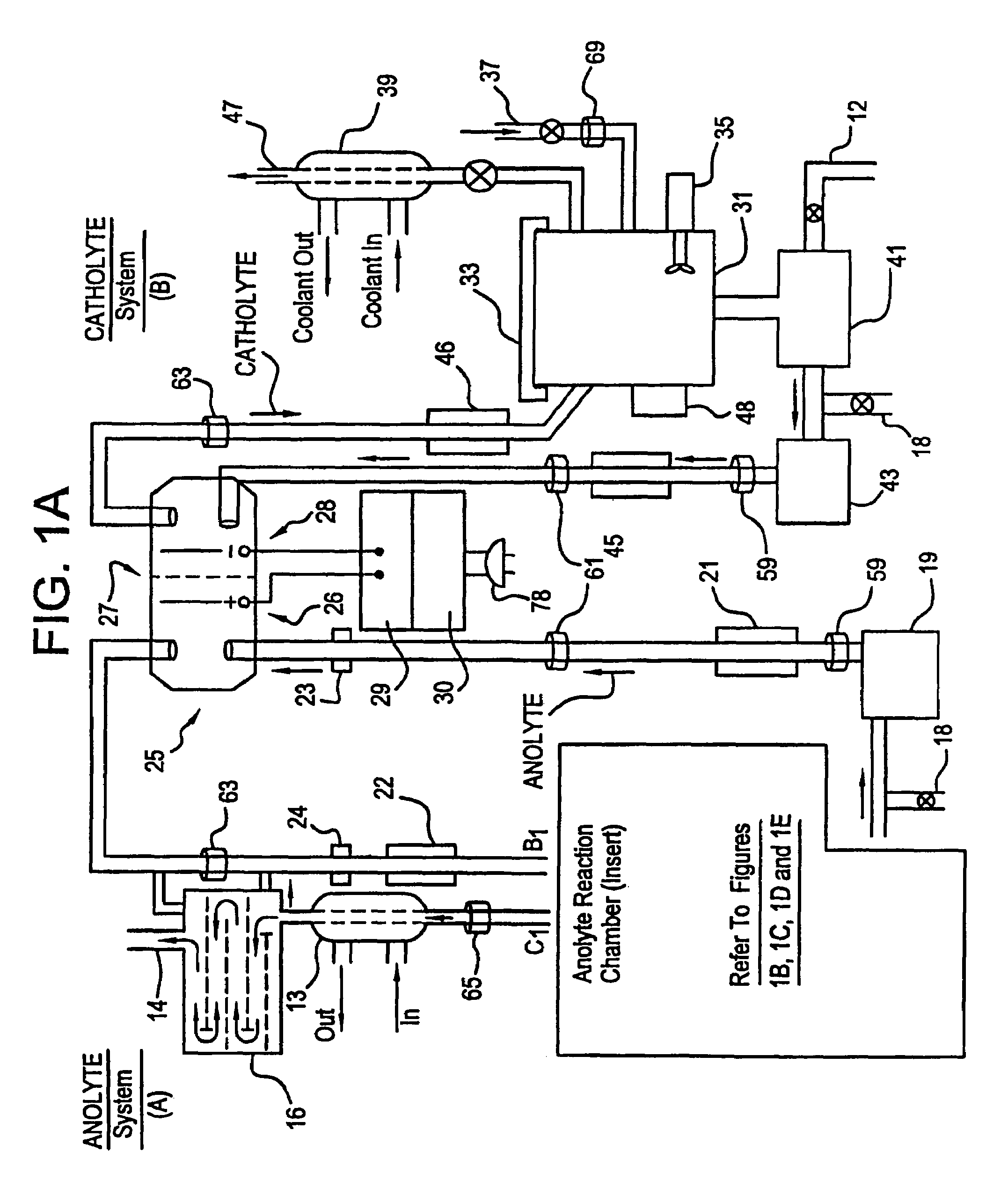

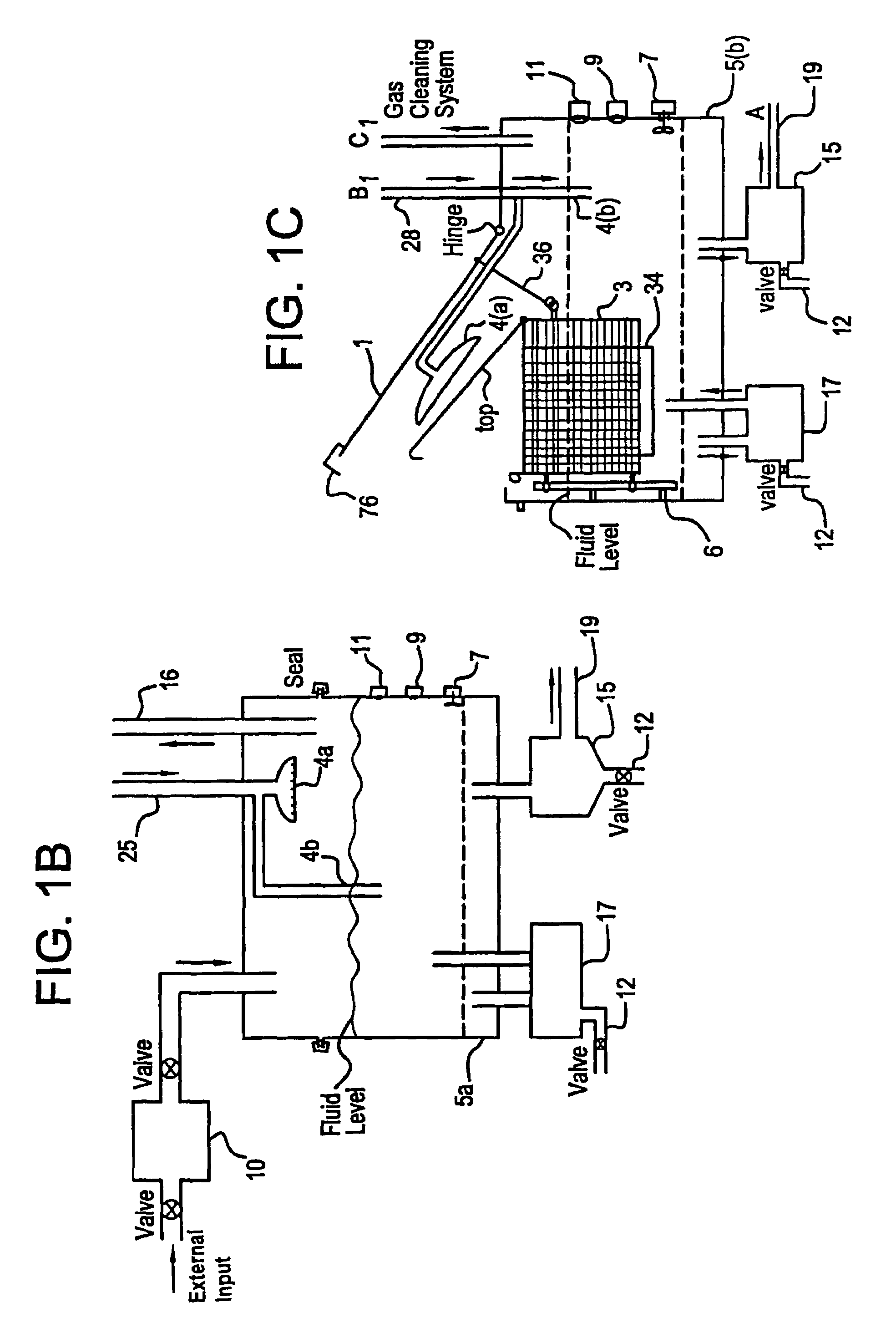

Mediated electrochemical oxidation of food waste materials

InactiveUS7517445B2Reduce the total massReduce volumeCellulosic pulp after-treatmentLiquid separation by electricityBoiling pointOxidation-Reduction Agent

A mediated electrochemical oxidation process is used to treat, oxidize and destroy food waste materials, such as manure, biological residue, hay, straw, animal byproducts, bones, horns, blood, biological items, pathological waste and combined waste. Food waste is introduced into an apparatus for contacting the waste with an electrolyte containing the oxidized form of one or more reversible redox couples, at least one of which is produced by anodic oxidation in an electrochemical cell. The oxidized species of the redox couples oxidize the organic waste molecules and are themselves converted to their reduced form, whereupon they are reoxidized by either of the aforementioned mechanisms and the redox cycle continues until all oxidizable waste species, including intermediate reaction products, have undergone the desired degree of oxidation. The process takes place at temperatures between zero degrees centigrade and below the boiling point of the electrolyte.

Owner:SCIMIST LNC

Separation system for recyclable material

A separation system includes an air separator that, in one embodiment, primarily receives Municipal Solid Waste (MSW) containing a mixture of relatively light MSW recyclable materials such as plastic, paper, cardboard, plastic containers, and / or metal containers and relatively heavy MSW such as textiles, food waste, yard debris, etc. The air separator blows the relatively light MSW recyclable materials up though a chamber and onto a first conveyor while the other relatively heavy MSW material drops down a chute onto a second conveyor. A separation screen receives the relatively light MSW recyclable materials from the air separator and separates the relatively flat fiber and plastic film materials from the other paper, plastic and metal containers. In another separation stage, an electrostatic emitter is positioned adjacent to a conveyor for applying an electrostatic charge to the fiber and plastic materials. The electrostatic charge causes at least some of the plastic materials to at least partially cling to the conveyor belt while being carried over an end of the conveyor so that the plastic materials do not drop out as far from the conveyor as the fiber materials.

Owner:EMERGING ACQUISITIONS

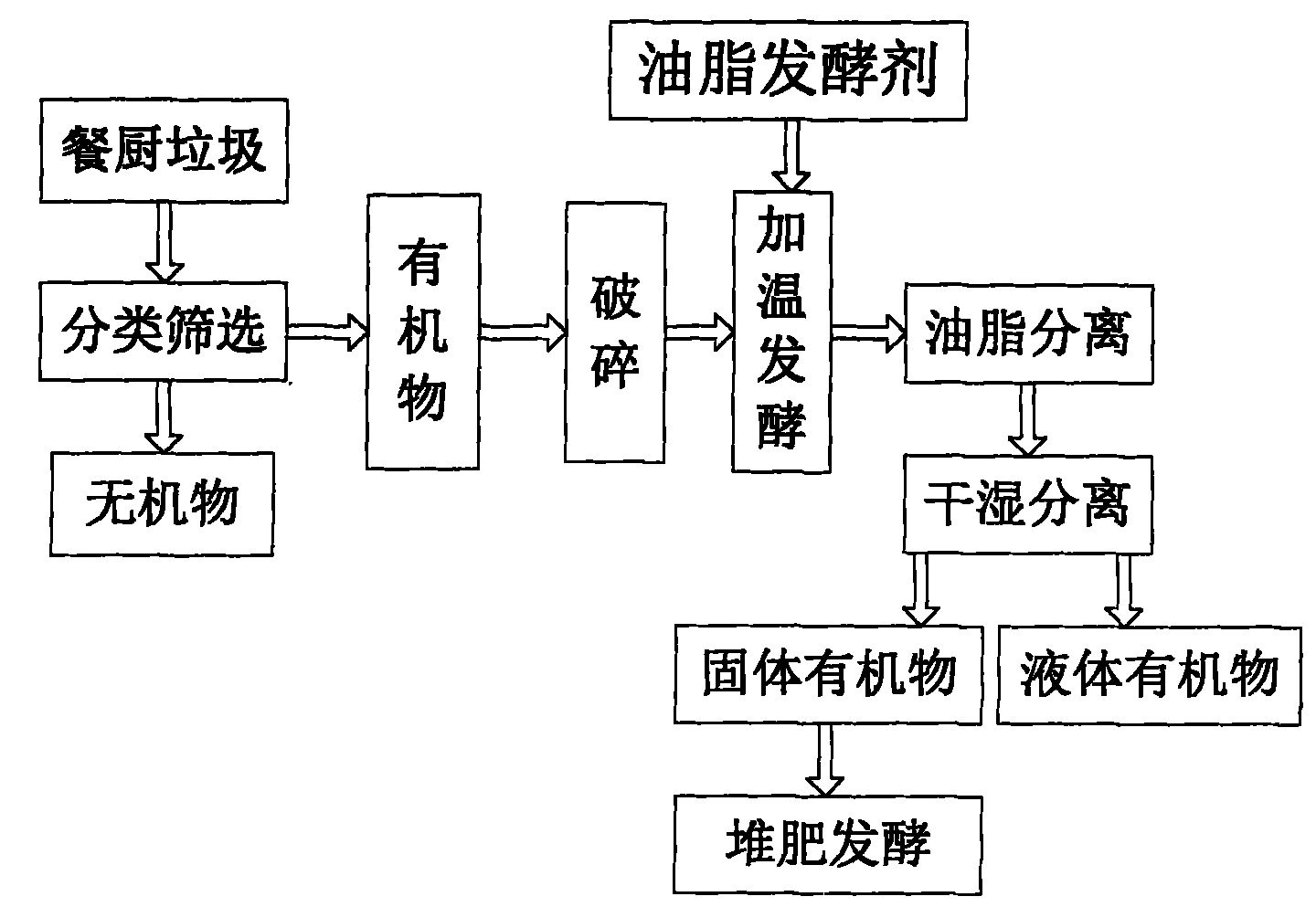

Treatment method and treatment system of food wastes

InactiveCN101955382AInhibition of regrowthGrowth inhibitionClimate change adaptationOrganic fertilisersFiltrationSoil organic matter

A treatment method of food wastes comprises the following steps: (1) sorting: classifying the collected food wastes according to organic matters and inorganic matters, wherein the inorganic matters are to be treat; (2) crushing: crushing the separated inorganic matters to obtain waste mixed particles with the uniform particle size; (3) performing fermentation treatment: adding culture starter in the crushed waste mixed particles, performing the first fermentation treatment to obtain a fermentation product; (4) perform fat separation: separating fat type materials from the fermentation solution, removing through filtration; (5) performing dry separation: performing dry separation to the fermentation product to obtain solid organic matters and liquid organic matters; (6) precipitating: precipitating the liquid organic matters to remove; and (7) preparing fertilizer: respectively using the solid organic matters and the liquid organic matters to prepare solid fertilizer and liquid fertilizer. By using the treatment method of the invention, the food wastes can be treated to prepare fertilizers, thus nutrients can be reused and the method is more environmentally friendly.

Owner:广州万吉生物科技有限公司

Domestic organic food waste treatment method and treatment equipment

InactiveCN101844940ASolve perishable deteriorationTroubleshoot technical issues that create foul odorsClimate change adaptationMultistage water/sewage treatmentLiquid wasteDecomposition

The invention relates to a domestic organic food waste treatment method and domestic organic food waste treatment equipment. The treatment method comprises the following steps of: a, performing solid-liquid separation on domestic organic food wastes on the spot; b, treating solid wastes, namely, putting the solid wastes produced in crushing into a fermentation machine and adding more than one microorganism for deodorization, fermentation and decomposition to obtain a primary bio-organic fertilizer; and c, treating waste liquor, namely, adding more than one microorganism into the waste liquor produced in dehydration and performing degreasing and purification treatment. The treatment equipment comprises a dehydration platform, a crusher, a waste liquor purification tank and the fermentation machine, wherein the crusher is positioned below the dehydration platform. Through the method and the device, before rotten, the domestic organic food wastes are treated to produce the primary bio-organic fertilizer, which reduces waste flow links, and the harmless in-place treatment of the domestic organic food wastes is realized.

Owner:张岳清

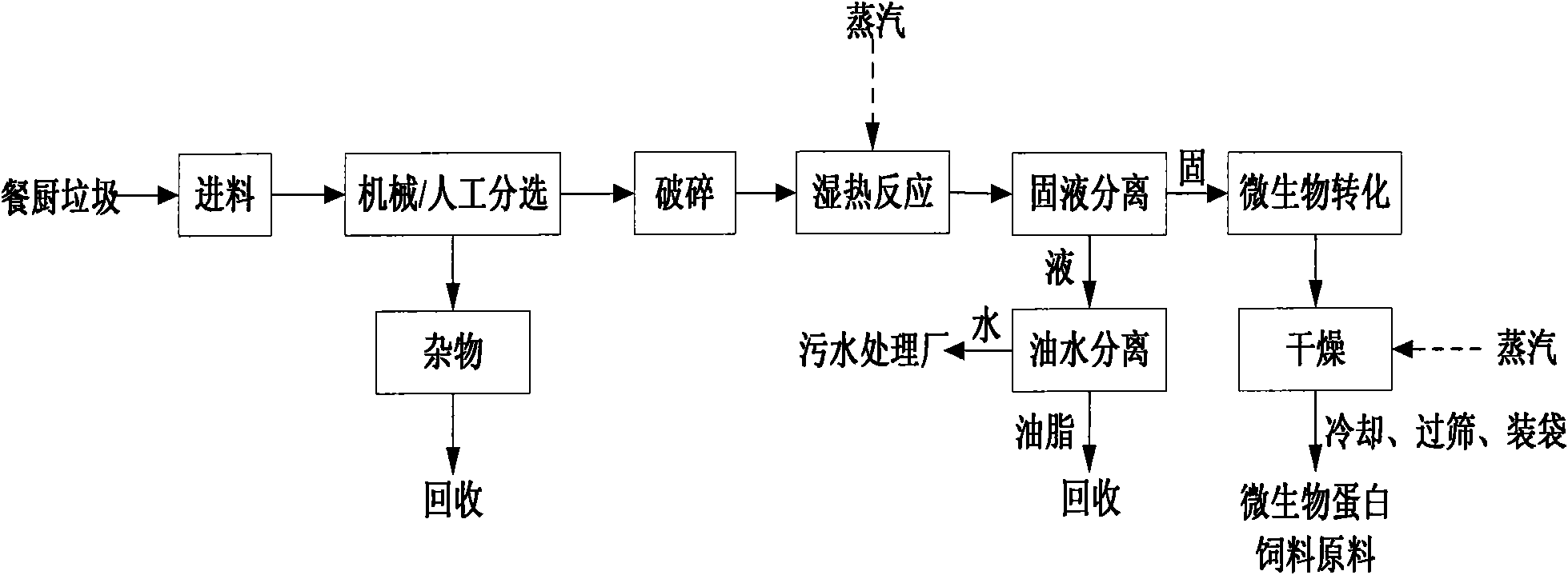

Kitchen waste and food waste treatment process and kitchen waste and food waste treatment system

The invention discloses a kitchen waste and food waste treatment process and a kitchen waste and food waste treatment system. The process comprises steps as follows: mixtures of kitchen waste and food waste are sorted by an automatic sorting table and put into a pre-treatment pulverizer for pulverizing; a liquid-phase mixture obtained through the automatic sorting table and an oil-water mixture separated from the pulverizer enter oil-water separating equipment for oil-water separation; a water phase separated from the oil-water separating equipment is filtered and is discharged as life irrigating water finally; an oil phase enters biological separating equipment for biological separation, and biological oil is prepared finally. The kitchen waste and the food waste pulverized by the pre-treatment pulverizer are taken as nutrition sources and are put into a polypide cultivation production line for saprophagous polypide cultivation, adult polypides enter a dryer for drying treatment and are processed and produced into feedstuff for poultry, fish and the like, polypide waste and residues are degraded, a part of a degraded material is used for generating electricity in a biomass fuel mode, and the other part is packed and transported outwards in an organic fertilizer mode for use.

Owner:深圳市德力骏塑胶机械有限公司

Food waste treatment device using microorganisms

InactiveUS20090042267A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyYeast

The present invention is directed to a composition for decomposing a majority of food waste into water and carbon dioxide comprising an effective combination of at least two species of microorganisms chosen from bacillus, lactobacillus, burkholderia, yeast fungus, eumycetes or any combinations thereof. A preferred embodiment comprises a combination of four different species of microbes having DNA sequences that correspond to SEQ ID Nos. 5-8 and which were deposited with the Korean Collection for Type Cultures (KCTC) on Mar. 8, 2007, and designated KCTC11085BP; KCTC11086BP; KCTC11087BP; KCTC11088BP, respectively. Also, presented by this invention is a device and methods for decomposing a majority of food waste into water and carbon dioxide using the microbial compositions presented herein.

Owner:WASTE TO WATER CORP

Kitchen waste treatment device

InactiveCN106673719AEasy to handleTurn waste into treasureWaste processingTransportation and packagingOil waterWaste treatment

The invention discloses a kitchen waste treatment device, which comprises a waste feeding hole, a crushing chamber, a solid-liquid separation chamber, a solid treatment chamber and a liquid treatment chamber, wherein the crushing chamber comprises a crushing rotating shaft and a crushing motor; a plurality of crushing knives are evenly distributed on the crushing motor; the solid-liquid separation chamber comprises a separation chamber inlet, a spiral dehydrator, a filter net, a liquid outlet, a solid outlet and a separation motor; the solid treatment chamber comprises an inclined drying net and a fan; the liquid treatment chamber comprises a liquid inlet, an oil-water separation layer, a purification layer and a water outlet; a solar panel is arranged at the top of the waste treatment device and is connected with a storage battery; and the crushing motor, the separation motor and the fan are connected with the storage battery through a wire. The kitchen waste treatment device has the beneficial effects that the structure is reasonable, the operation is convenient, the recycling of kitchen waste is facilitated and the environment is protected.

Owner:石芮巾

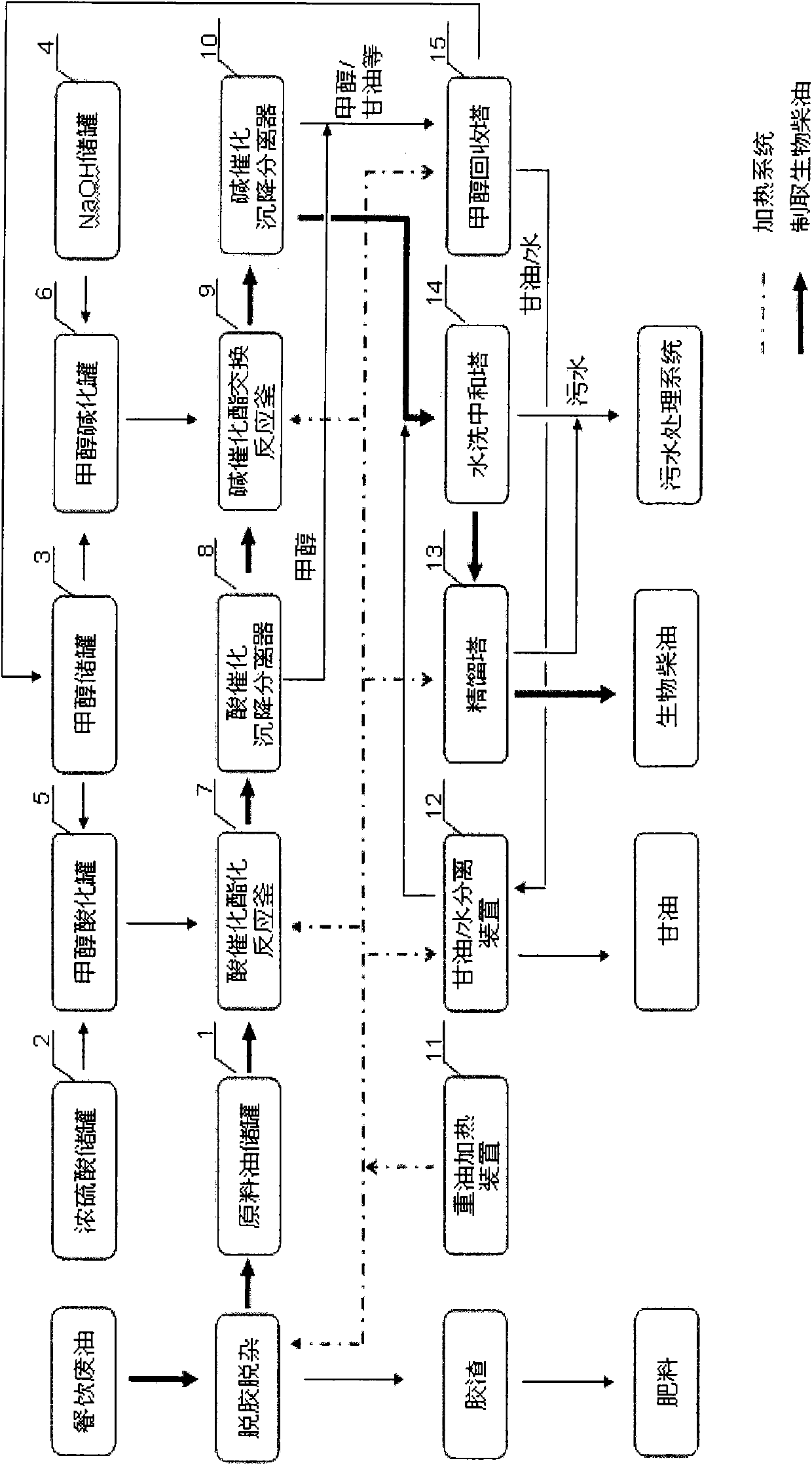

Method for preparing biodiesel by utilizing food waste recycling oil

ActiveCN101906355AReduce manufacturing costImprove pollutionFatty acid esterificationBiofuelsBiodieselGlycerol

The invention relates to a method for preparing biodiesel by utilizing food waste low-cost high-efficiency recycling oil, which is realized by four steps of dining waste oil degumming and impurity removing treatment, acid catalytic esterification reaction, base catalytic transesterification reaction and biodiesel refining. The final product is colourless biodiesel, and all performance indexes can reach the European and American biodiesel quality standard. The invention has the advantages of low production cost, high conversion rate and less pollutant discharge and overcomes the defect of preparation by a single method. When the biodiesel is produced, by-products comprise glycerol and methanol.

Owner:北京昊业怡生科技有限公司

Method and device for preparing fertilizer from kitchen garbage

ActiveCN105060946AImprove efficiencySave spaceBio-organic fraction processingClimate change adaptationLitterOrganic liquids

The invention discloses a method and device for preparing fertilizer from kitchen garbage. The method comprises crushing kitchen garbage, carrying out solid-liquid separation, carrying out pyrolysis carbonization on the separated solid kitchen garbage to obtain pyrolysis gas and carbon residue, washing the pyrolysis gas, carrying out anaerobic fermentation on the separated liquid to obtain a broth, biogas residue and biogas, carrying out aerobic fermentation on the broth, then preparing organic-inorganic composite liquid fertilizer from the obtained liquid, mixing the biogas residue and the biogas residue obtained by the pyrolysis carbonization, adding composite microbe engineering bacteria into the mixture, and carrying out solid state fermentation to obtain the organic carbon solid fertilizer. The method and device respectively carry out resourceful treatment on the solid kitchen garbage and the organic liquid, the organic liquid is treated by a biotechnology so that the organic-inorganic composite liquid fertilizer is produced, and solid kitchen garbage is subjected to pyrolysis carbonization so that energy and biochar are produced.

Owner:GUANGZHOU YINGHAO ENVIRONMENTAL PROTECTION TECH CO LTD

Food waste acidifying hydrolysis treatment method

InactiveCN101585044AHigh organic contentEasy to acidifyBio-organic fraction processingSolid waste disposalMethanationHydrolysis

The invention provides an anaerobic fermentation treatment method for food waste. The method comprises: crushing the unsorted food waste by machine, mixing with an amount of water to obtain a mixture with solid content of 6-35%; loading the mixture into a hydrolysis reactor by a pump; adding water into the hydrolysis reactor by amount of 1-5 times of the food waste mass; performing repeated cycling, flushing and acidifying to the food waste under the condition of 34-40 or 50-56 degrees centigrade for 2-10 days, while controlling the pH value of the acidification liquid between 1.5 and 6.8; filtering the hydrolyzed acidification liquid, and loading it into a methanation reactor, making into biogas by anaerobic digestion, performing desulfurization treatment, and using as energy; performing compost treatment to the hydrolyzed solid material according to the routine compost technology to obtain organic fertilizer. The invention simplifies the pretreatment process of the food wastes greatly, saves energy consumption, reduces equipment investment, realizes the recycling of food waste effectively, and meets the environmental protection idea.

Owner:宝林

Organic waste treatment device for spatial permanent base

InactiveCN101791619AIncrease concentrationGuaranteed moisture contentBio-organic fraction processingSolid waste disposalAutomatic controlTemperature control mode

The invention provides an organic waste treatment device for a spatial permanent base, which mainly aims at the recycle problem of organic wastes (inedible plant biomass, excrement, kitchen garbage and the like) in a bio-regenerative life support system of a long-time and long-distance spatial manned base (such as permanent moon base and a mars base). The device consists of a fermentation tank body, a gas inlet pretreatment system, a gas outlet condensation system, a stirring system, a percolate collecting reflux system, a heating temperature control system, a tail gas treatment system, a sensor system and an automatic control system. The device can be used for both aerobic fermentation and anaerobic fermentation, can automatically monitor and adjust main indexes of a fermentation process, improves an oxygen consumption rate monitoring method, and improves the form of a stirrer and a temperature control mode. Biogas produced by fermentation is adsorbed by a plant culture medium. The percolate is refluxed into the material for compensating moisture brought out by the emitted gas.

Owner:BEIHANG UNIV

Comprehensive resource treatment method of food waste

InactiveCN102744243AEfficient use ofRealize industrialized mass productionSolid waste disposalOil and greaseSocial benefits

The invention discloses a comprehensive resource treatment method of food waste, relating to the technical field of resource recycle treatment. The comprehensive resource treatment method comprises the technical steps of impurity separation, oil-slag separation, organic solid matter treatment, oil-water separation, liquid grease treatment, wastewater treatment, methane utilization, methane slurry and methane residue utilization, and membrane filtration wastewater treatment. Compared with the traditional treatment process, the comprehensive resource treatment method disclosed by the invention has the advantages that the treated food waste realizes real innocent treatment, the food waste is fully recycled, and organic solid matters, methane, methane residue and methane slurry generated in the treatment process are all most efficiently utilized, thus not only is the food waste hard to be treated in the prior art changed to be valuable, but also the treatment cost is low; and the industrial large-scale production can be realized, and simultaneously great economic and social benefits are also generated.

Owner:山东博洋环境资源有限公司

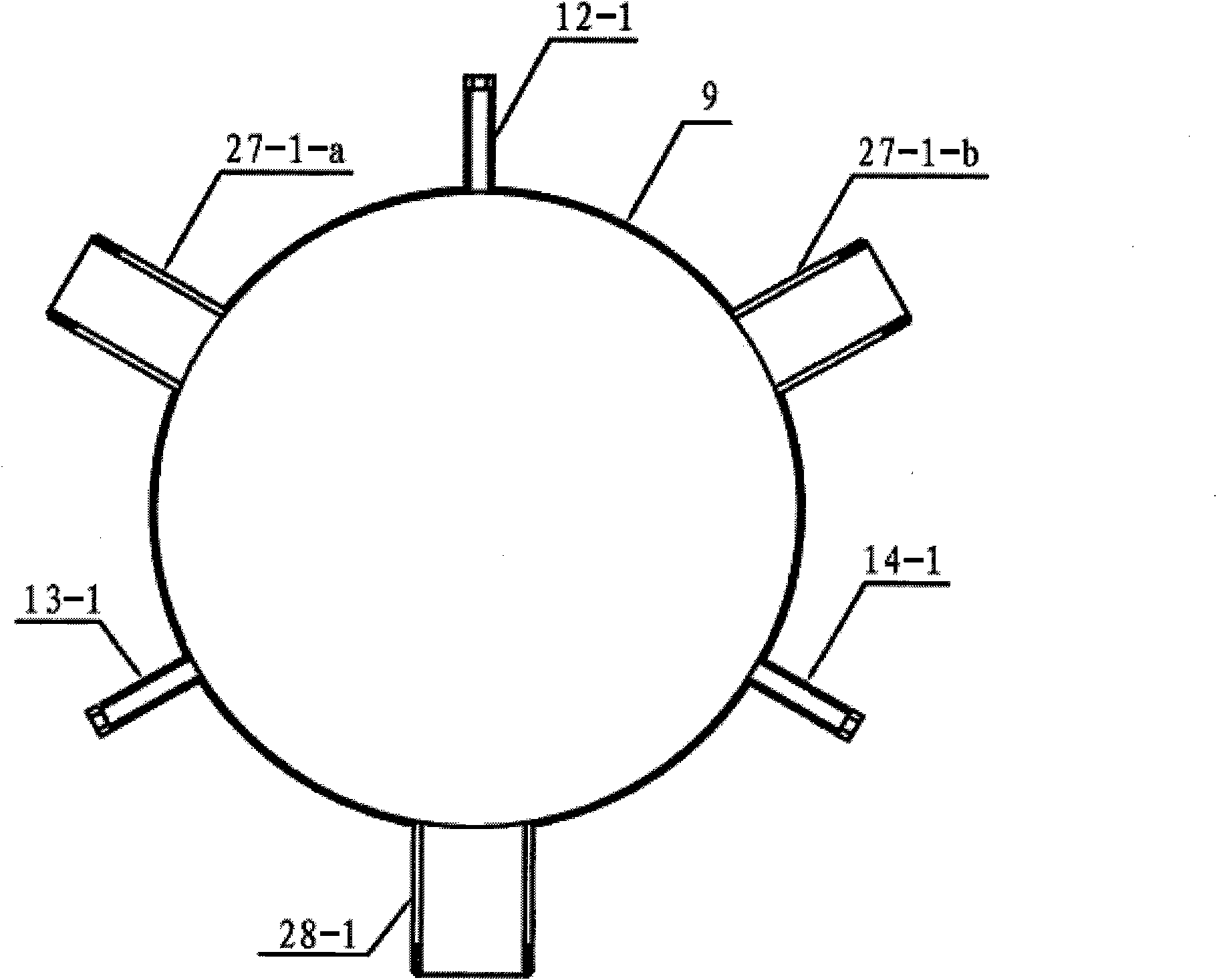

Method for producing protein feed material by utilizing food wastes

InactiveCN101642188AEfficient killingPromote digestion and absorptionAnimal feeding stuffWorking-up animal fodderAdditive ingredientMicrobial transformation

The invention relates to a method for producing protein feed material by utilizing food wastes, belonging to the field of solid waste treatment. The method comprises the following steps: separating and crashing food wastes, and then carrying out heat-moisture treatment; adding bran in solid matters after solid-liquid separation, and inoculating appropriate among of microbes for anaerobe fermentation so as to obtain the protein feed material. Microbes of the solid matters are converted by adding 10-15 percent of bran, taking aspergillus niger, candida utilis and lactobacillus as mixed fungicides according to the ratio of 1: 2: 2 with the inoculation amount of 0.5-2 percent and carrying out anaerobic fermentation for 35-55h at 30 DEG C. The treated product reaches requirements of Feed Hygiene Standard (GB13078-2001) in China, is not easy to go bad and easy to be stored, and bovine-derived and ovine-derived materials of the product are measured to be both negative. The method can effectively kill pathogenic microbes in the food wastes, converts macromolecular proteins, such as animal-based protein, and the like into micromolecular proteins that are absorbed more easily, thereby also reducing the risks caused by isogenous invitro-cannibalism of food feed products.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com