Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4315 results about "Dolomite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dolomite ( /ˈdɒləmaɪt/) is an anhydrous carbonate mineral composed of calcium magnesium carbonate, ideally CaMg(CO₃)₂. The term is also used for a sedimentary carbonate rock composed mostly of the mineral dolomite. An alternative name sometimes used for the dolomitic rock type is dolostone.

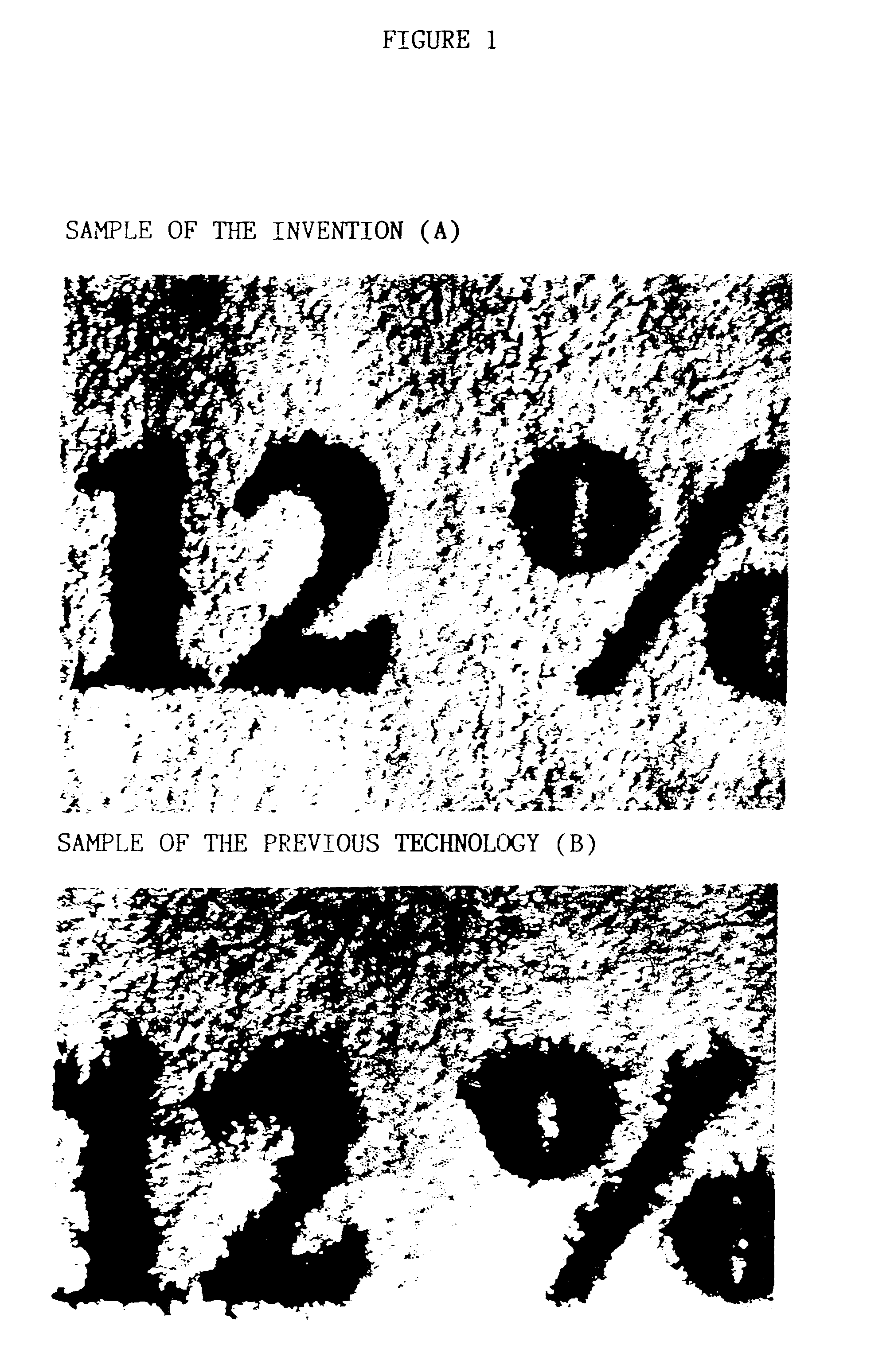

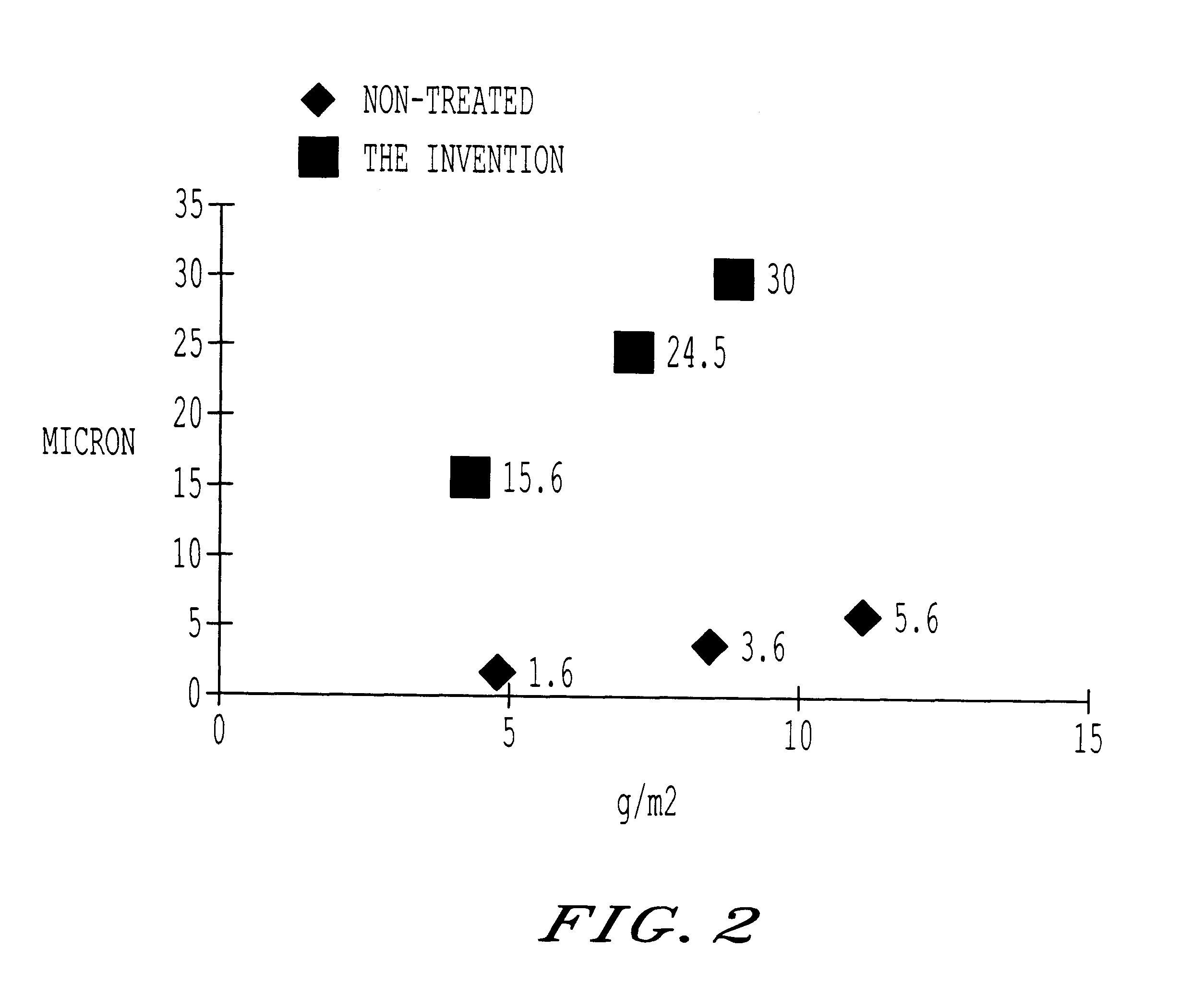

Treated filler or pigment containing natural carbonate

InactiveUS6666953B1Reduce weightReduce wearNatural cellulose pulp/paperSpecial paperPhysical chemistryKaolin clay

The invention concerns a pigment, filler or mineral containing a natural calcium carbonate, treated with one of more providers of H3O<+> ions and gaseous CO2, allowing a reduction in the weight of paper for a constant surface area without loss of physical properties when it is used as a pigment or coating filler for the said paper. In particular, the invention concerns a pigment, filler or mineral containing a natural calcium carbonate or dolomite or mixtures of talc and calcium carbonate, of kaolin and carbonate or carbonate alone or in combination with natural and / or synthetic fibers or similar, treated with one or more medium-strong or strong providers of H3O<+> ions in the presence of gaseous CO2. Applications are particularly in the paper industry, obtaining in particular good sheet properties i.e. a reduction its weight for a given surface area.

Owner:OMYA DEV AG

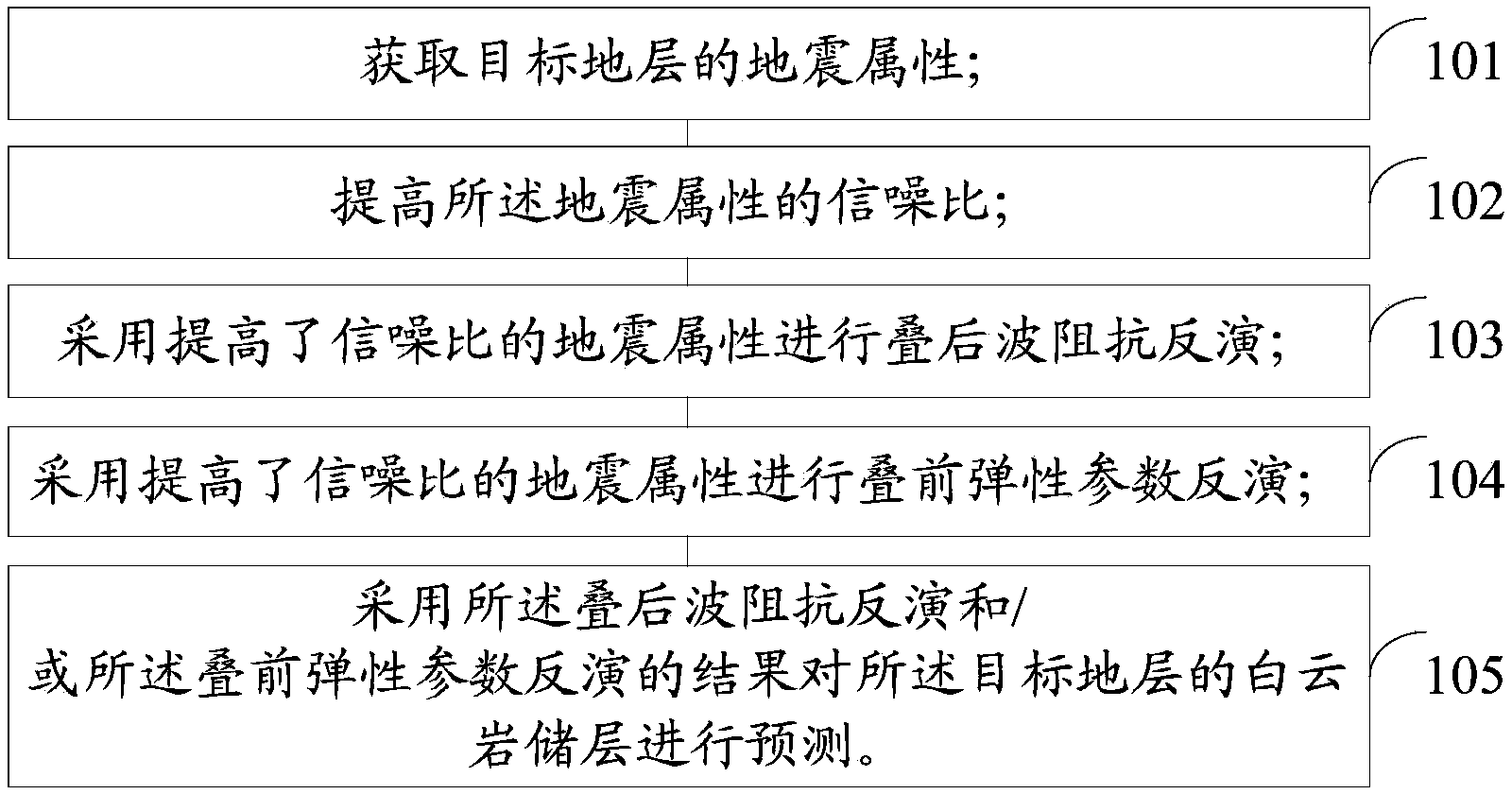

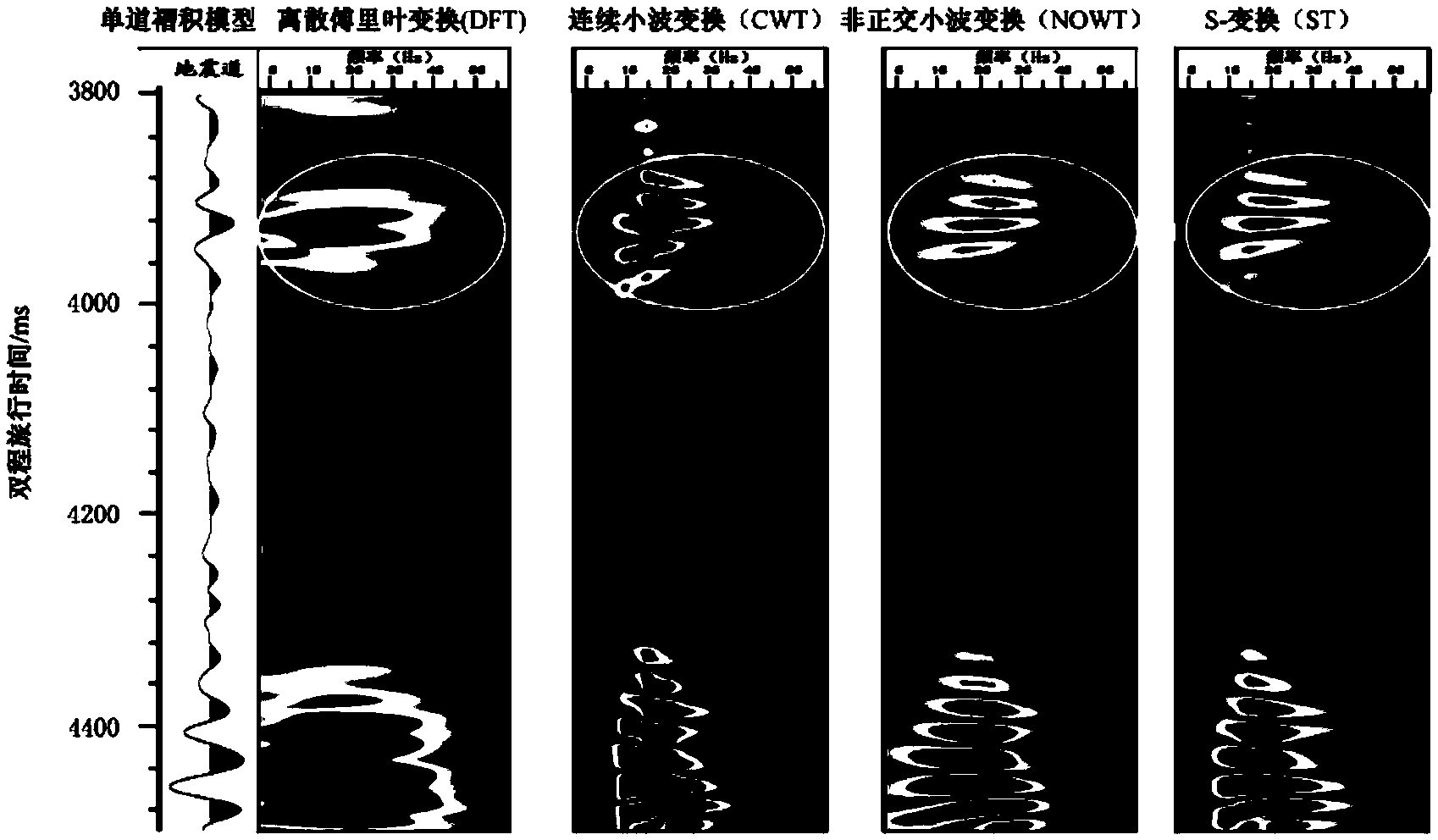

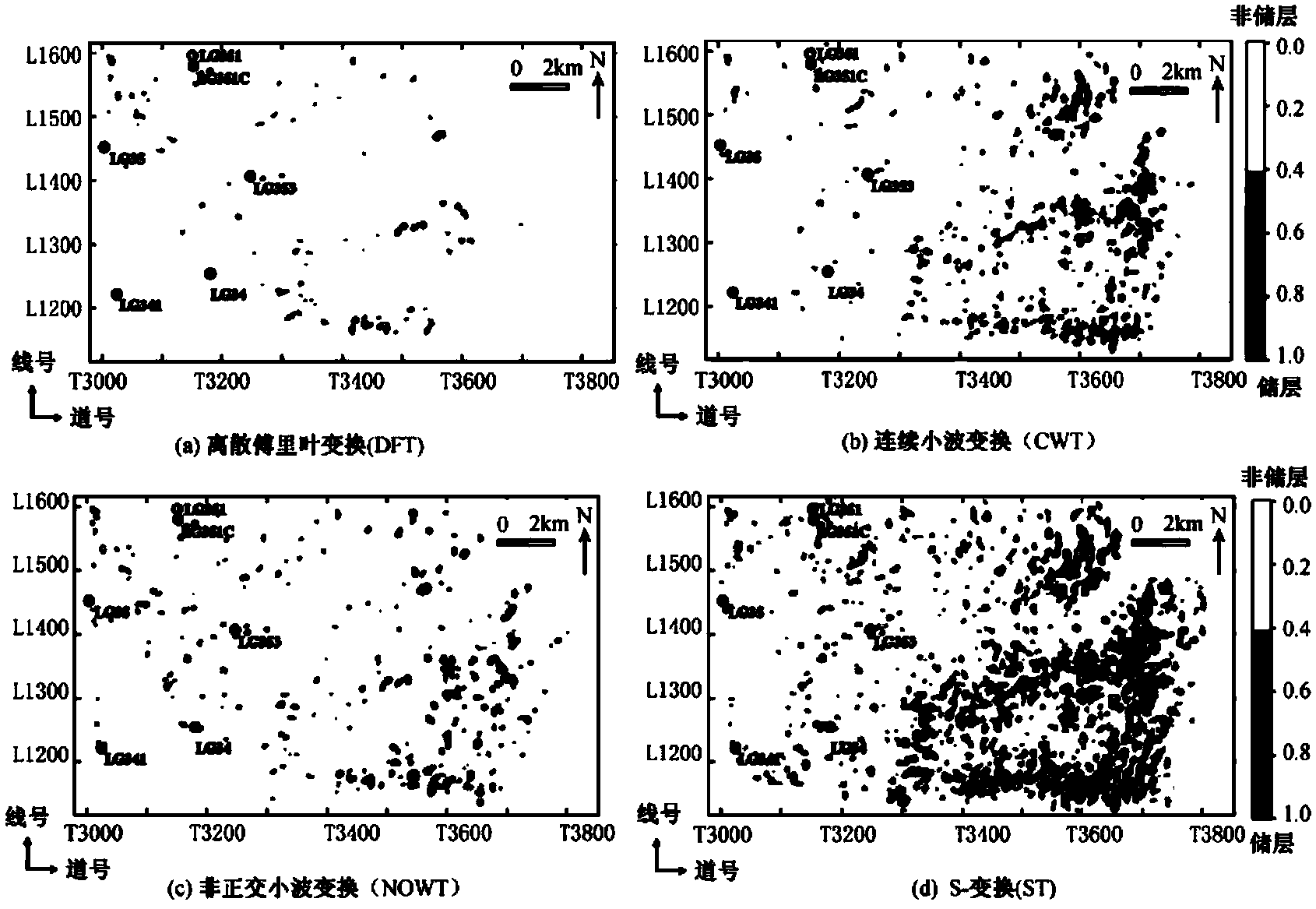

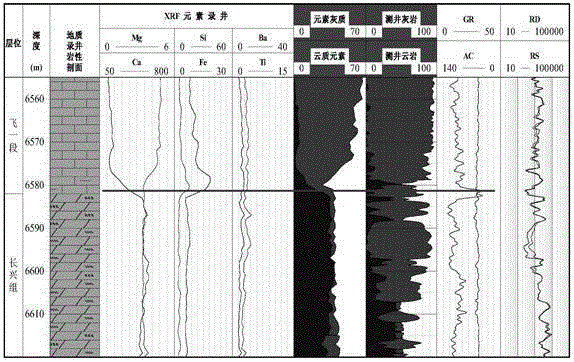

Method and system for predicting dolomite reservoir

InactiveCN103527184AEffective predictionSeismic signal processingBorehole/well accessoriesSignal-to-noise ratio (imaging)Seismic attribute

The invention provides a method for predicting a dolomite reservoir. The method includes acquiring seismic attributes of a target stratum, increasing the signal-to-noise ratio of the seismic attributes, adopting the seismic attributes with the signal-to-noise ratio increased to perform post-stack wave impedance inversion; adopting the seismic attributes with the signal-to-noise ratio increased to perform pre-stack elastic parameter inversion; adopting the results of the post-stack wave impedance inversion and / or the pre-stack elastic parameter inversion to predict the dolomite reservoir of the target stratum. By an effective predicting method technical system of seismic data quality evaluation, pre-stack depth processing, post-stack attribute analysis and post-stack wave impedance inversion lithologic identification, pre-stack attribute analysis and pre-stack elastic parameter inversion of a high-quality reservoir and hydrocarbon detection of the dolomite reservoir, the dolomite reservoir can be effectively predicted.

Owner:PEKING UNIV

Compositions and methods for inhibiting lost circulation during well operations

InactiveUS20100230169A1Reducing lost circulationReduce circulationLiquid/gas jet drillingFlushingDolomiteEnvironmental geology

Drilling fluid additive compositions are provided for use with synthetic, oil based, or water based drilling fluids. The combined additive and drilling fluid are effective for reducing lost circulation, seepage loss as well as wellbore strengthening and / or wellbore lining. The method includes injecting the drilling fluid and 0.01 or more pounds per barrel of a loss control additive including ground and sized pumice, barite or dolomite.

Owner:POMERLEAU DANIEL GUY

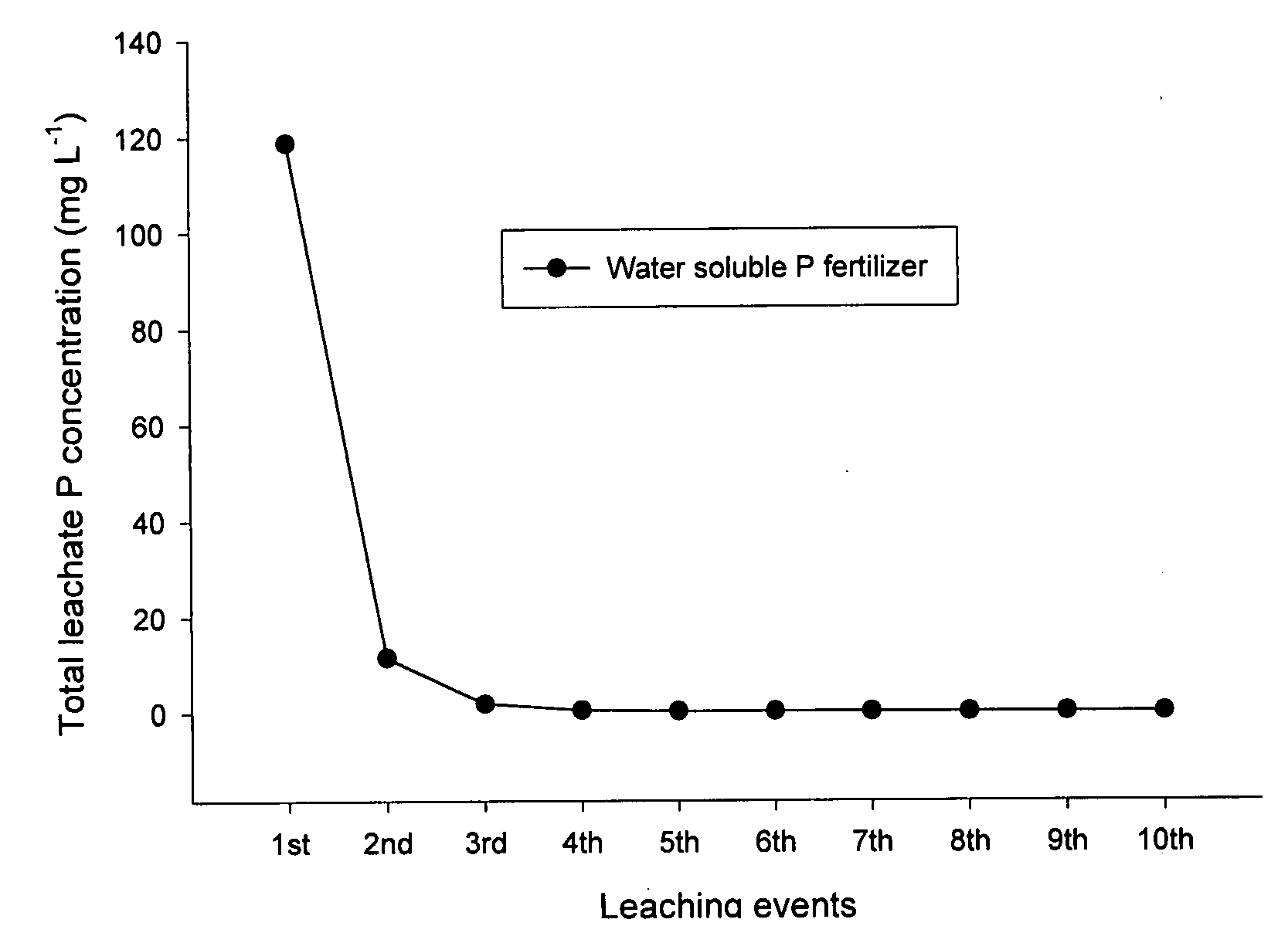

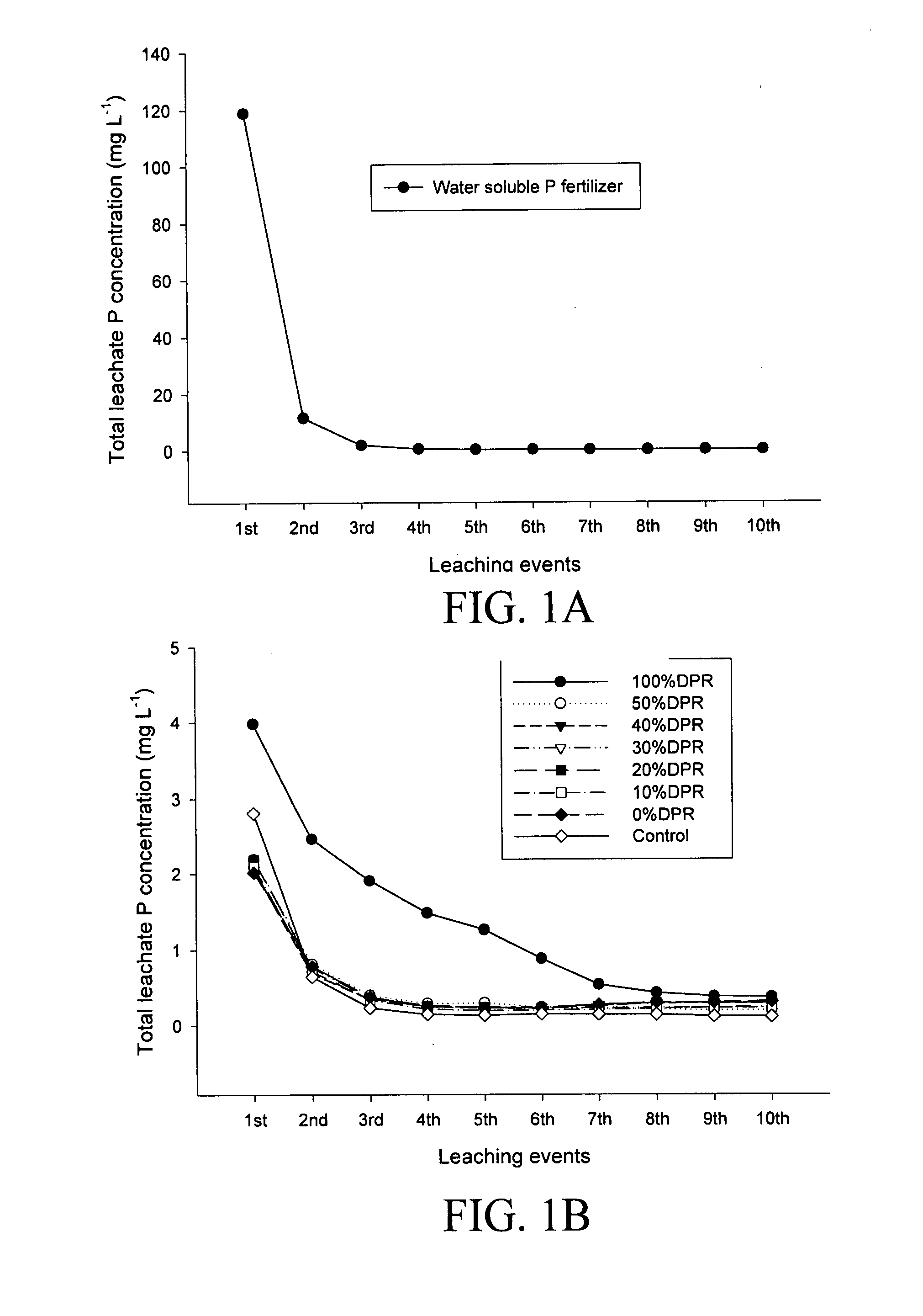

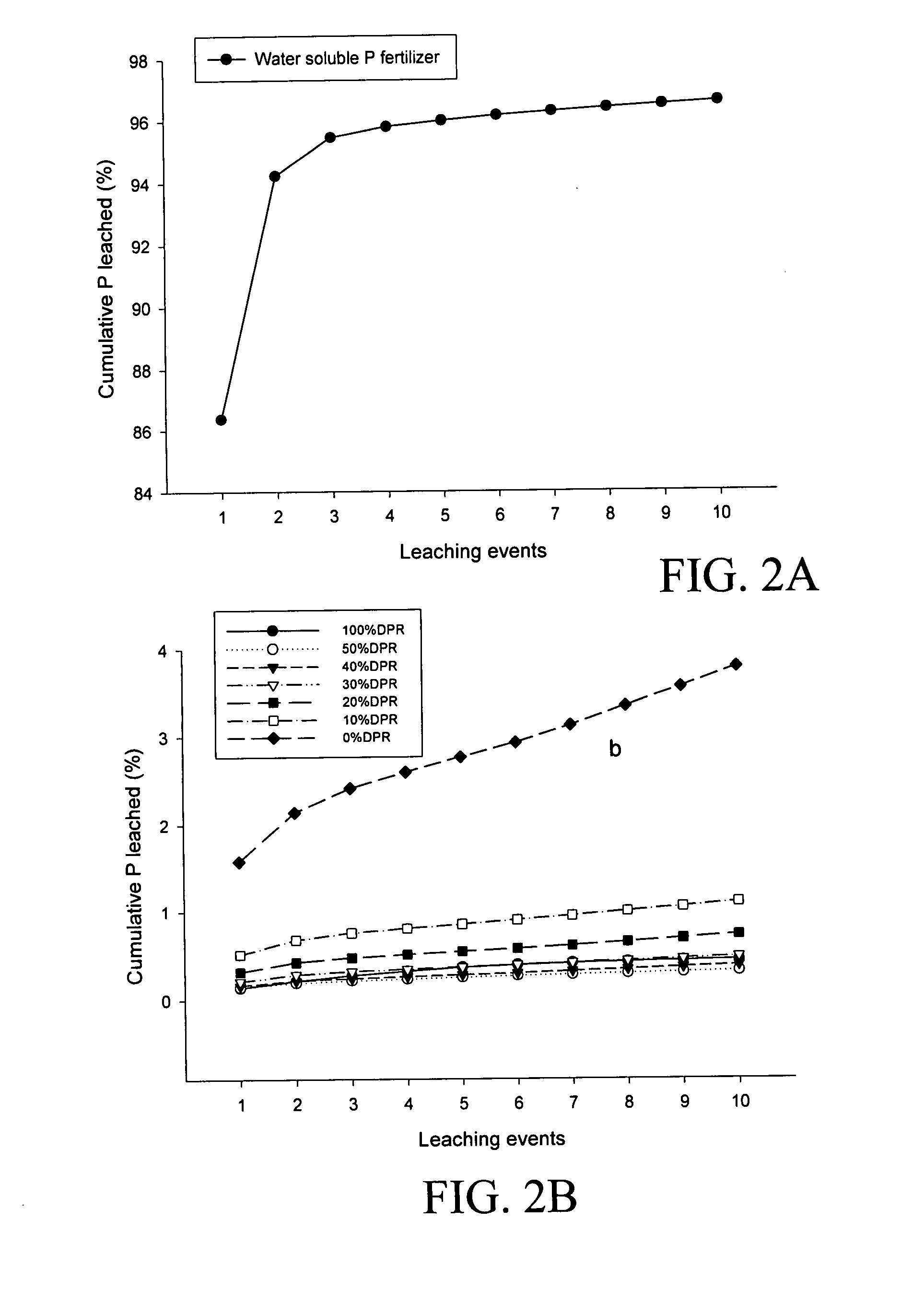

Materials and methods for preparing dolomite phosphate rock-based soil amendments and fertilizers

InactiveUS20070227212A1Neutralizing soil acidityImprove soil qualityCalcareous fertilisersMagnesium fertilisersGrowth plantPhosphate

The present invention provides compositions and methods for amending the availability of phosphate and other nutrient supplies in soil, especially acidic sandy soils, while ensuring reduced leaching and / or surface runoff of phosphorous and other nutrients. Compositions of the invention comprise granulated dolomite phosphate rock in combination with organic materials, wherein the level and rate of phosphorous and other nutrients released from the composition is controlled. Use of the compositions of the invention increases the availability of phosphorous and other nutrients while eliminating soil acidity, and also stimulates plant growth, enhances plant vigor, and / or improves crop yield.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

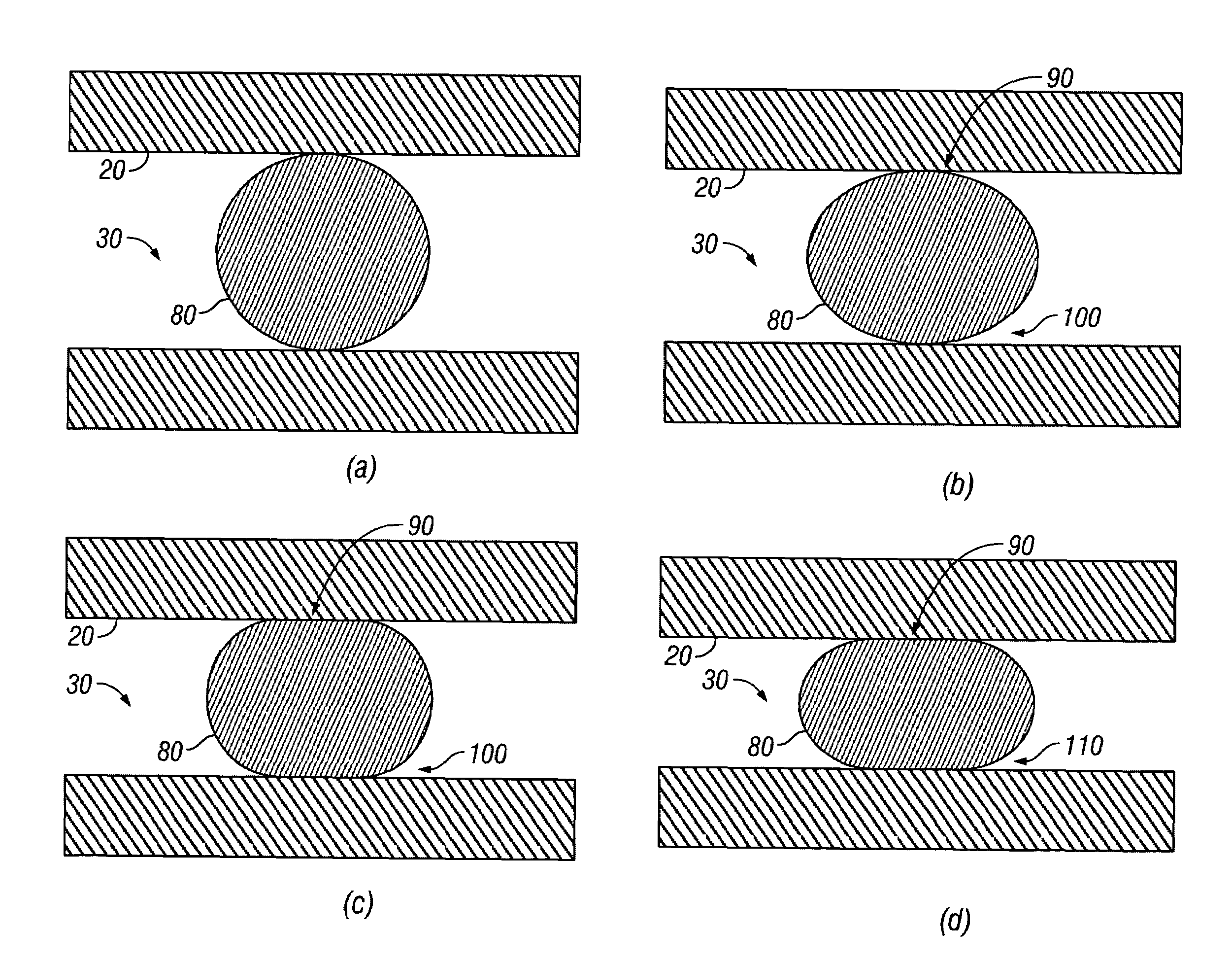

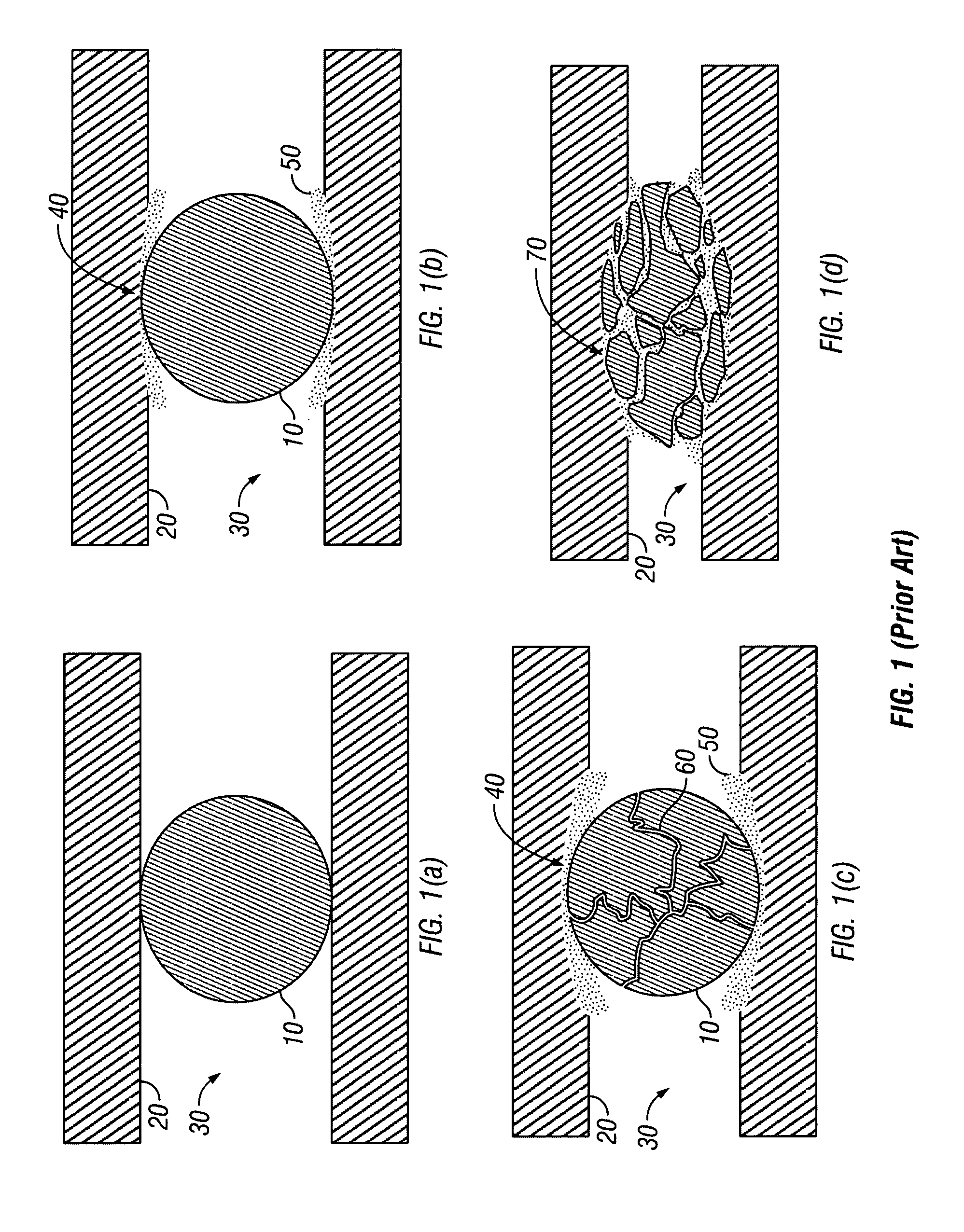

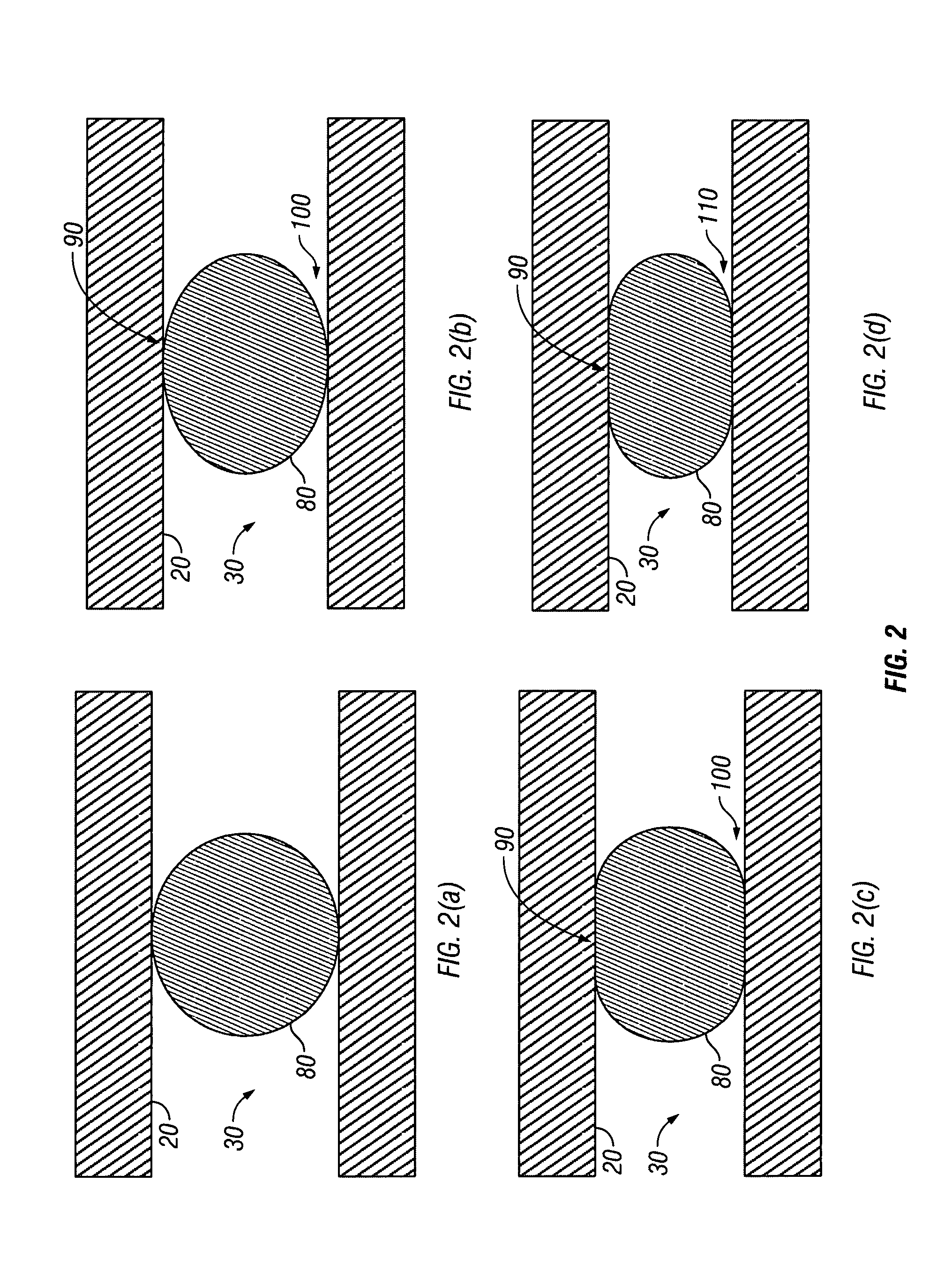

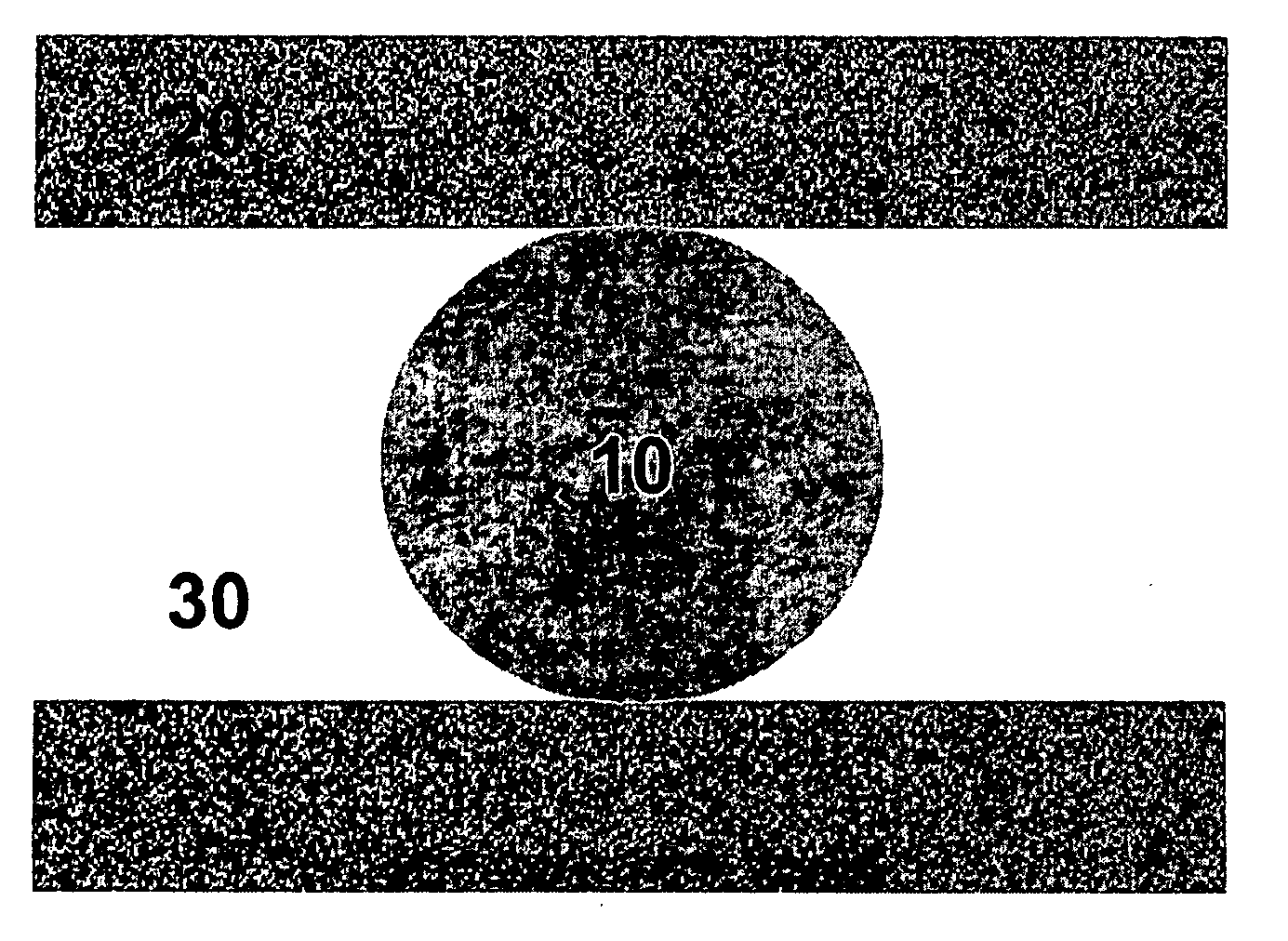

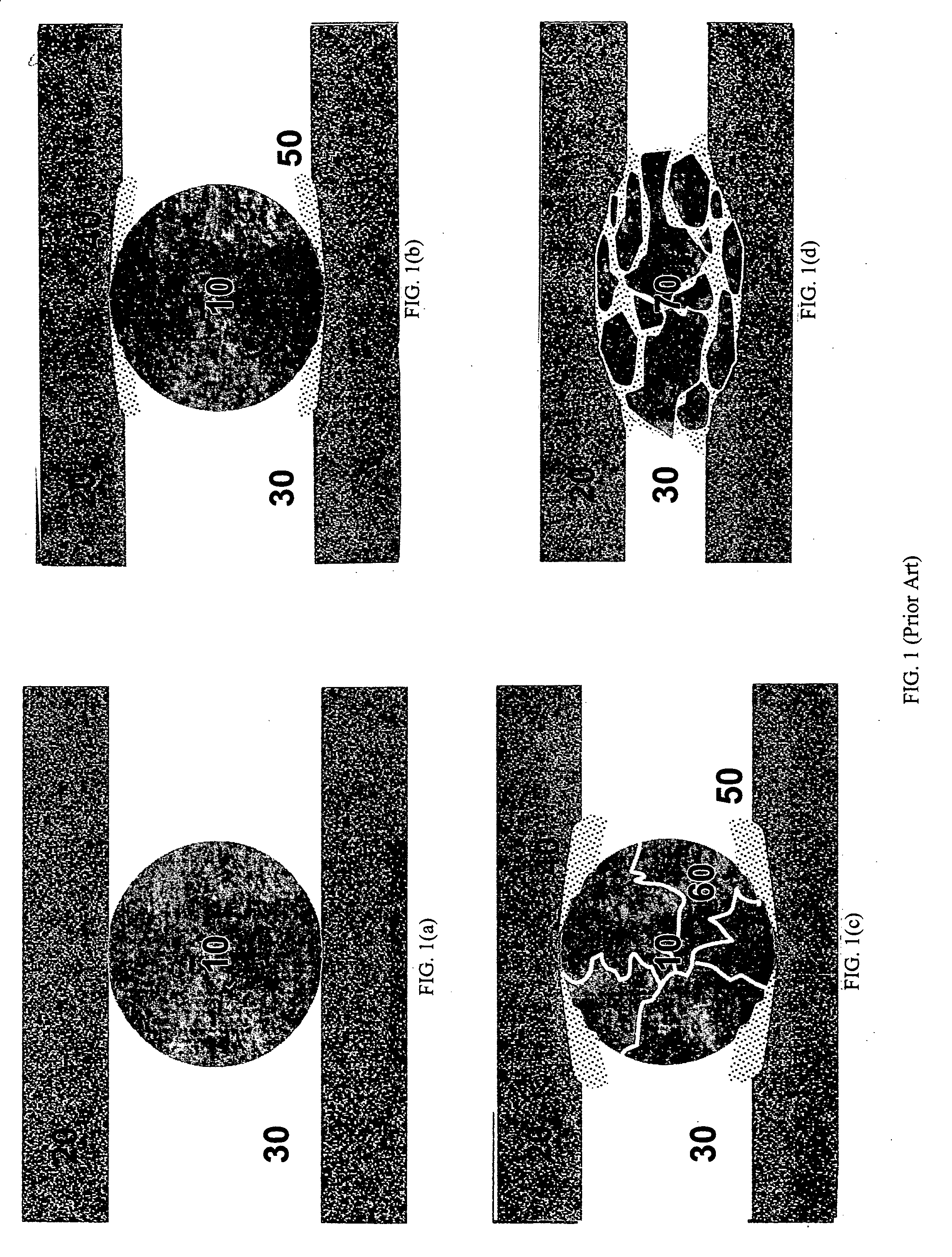

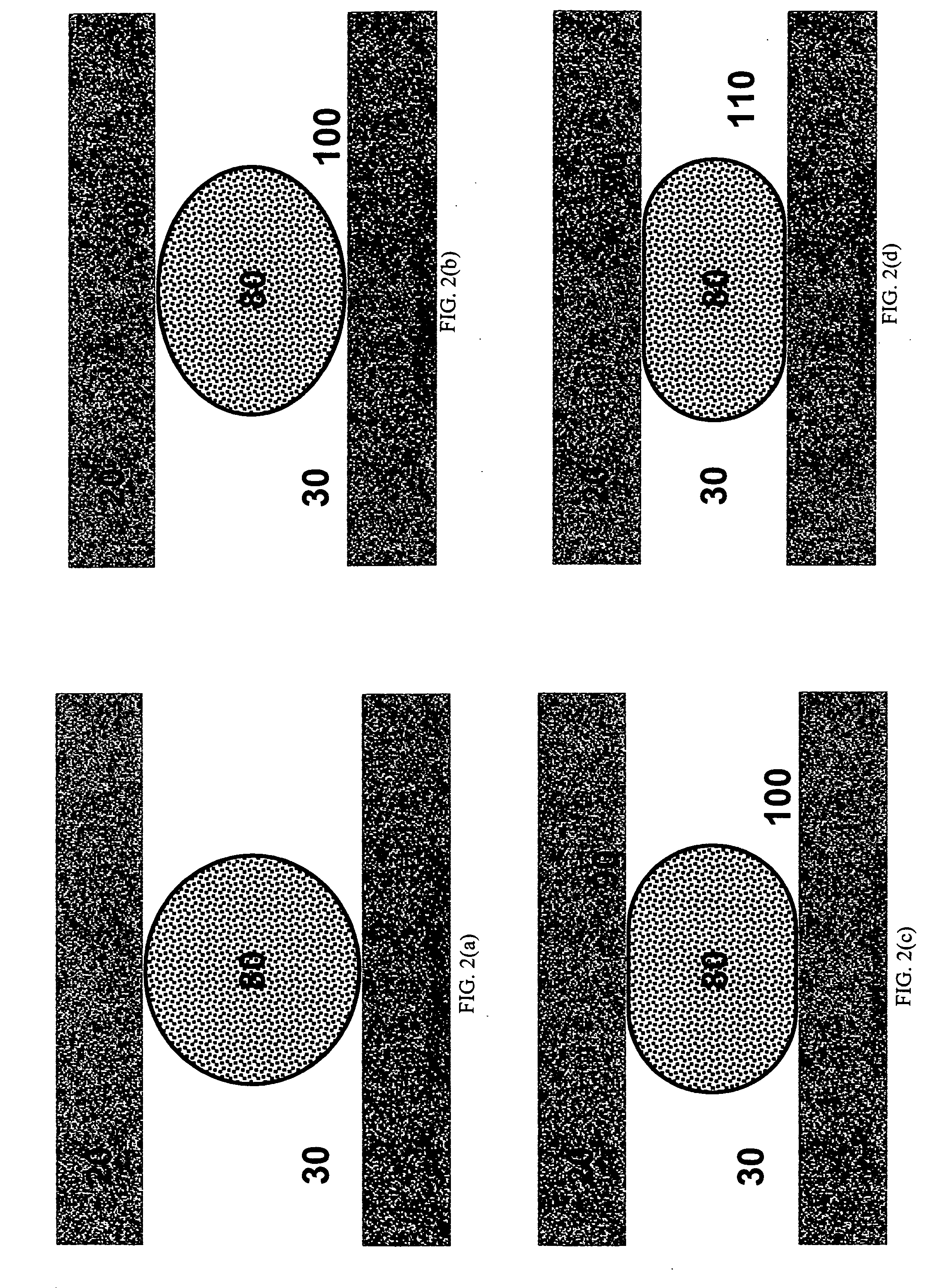

Method of stimulating oil and gas wells using deformable proppants

ActiveUS7322411B2Reduce cloggingMinimize damageFluid removalDrilling compositionFracturing fluidDolomite

A method of fracturing using deformable proppants minimizes proppant pack damage, without compromising the fracturing fluid's proppant transport properties during pumping, by use of deformable proppants. Selection of proppant is dependent upon the mechanical properties of the formation rock. The strength of the deformable proppant is dependent upon the modulus of the formation rock being treated such that the proppant is capable of providing, at the very least, a minimum level of conductivity in in-situ stress environments. The maximum elastic modulus of the deformable proppant is less than the minimum modulus of the formation rock which is being treated. The method is particularly applicable in fracturing operations of subterranean reservoirs such as those comprised primarily of coal, chalk, limestone, dolomite, shale, siltstone, diatomite, etc.

Owner:BAKER HUGHES HLDG LLC

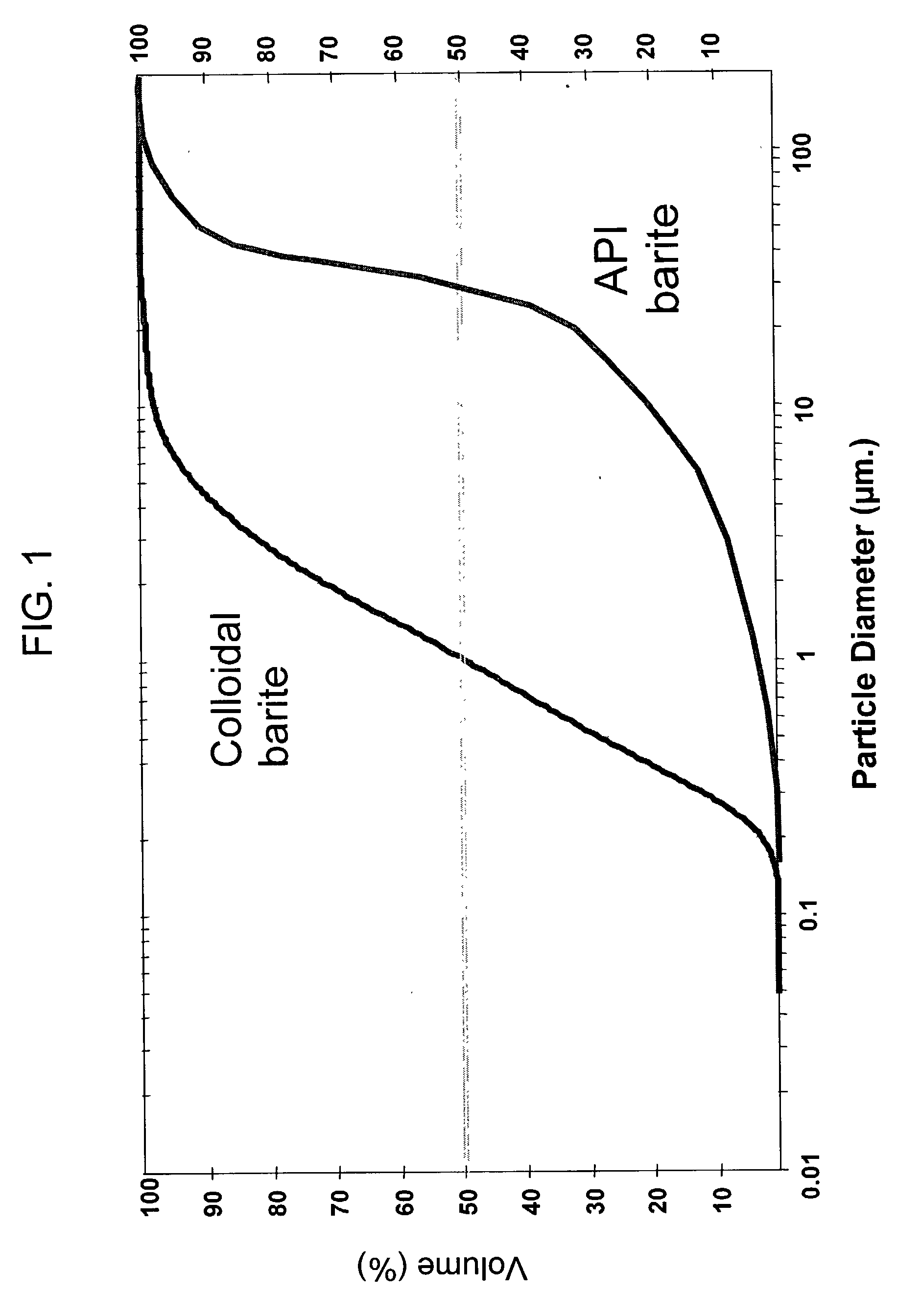

High-strength compress supporting agent for coarse oil and preparation method thereof

ActiveCN101575503AGood effectHas high strengthFluid removalDrilling compositionChemical compositionRed mud

The invention relates to a high-strength compress supporting agent for coarse oil and a preparation method thereof. The high-strength compress supporting agent for the coarse oil is prepared from the following raw materials by mass portion: 60 to 85 portions of ceramic roller waste, 1 to 20 portions of red mud, 0 to 20 portions of fly ash, 0 to 5 portions of manganese oxide or barium carbonate, 0 to 3 portions of dolomite and 5 to 10 portions of ceramic clay. The ceramic roller waste refers to corner waste or / and damaged and broken ceramic roller waste in the processing process of ceramic roller manufactures, and Al2O3 content of chemical compositions of the ceramic roller waste is not less than 68 percent. The high-strength compress supporting agent for the coarse oil prepared from the ceramic roller waste with high alumina content has the characteristics of high strength and acid resistance, and is used for oil fracturing in medium-deep wells; and the preparation method is simple and feasible, and is suitable for batch production.

Owner:JINGANG NEW MATERIALS

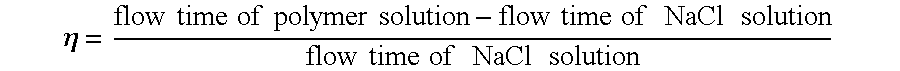

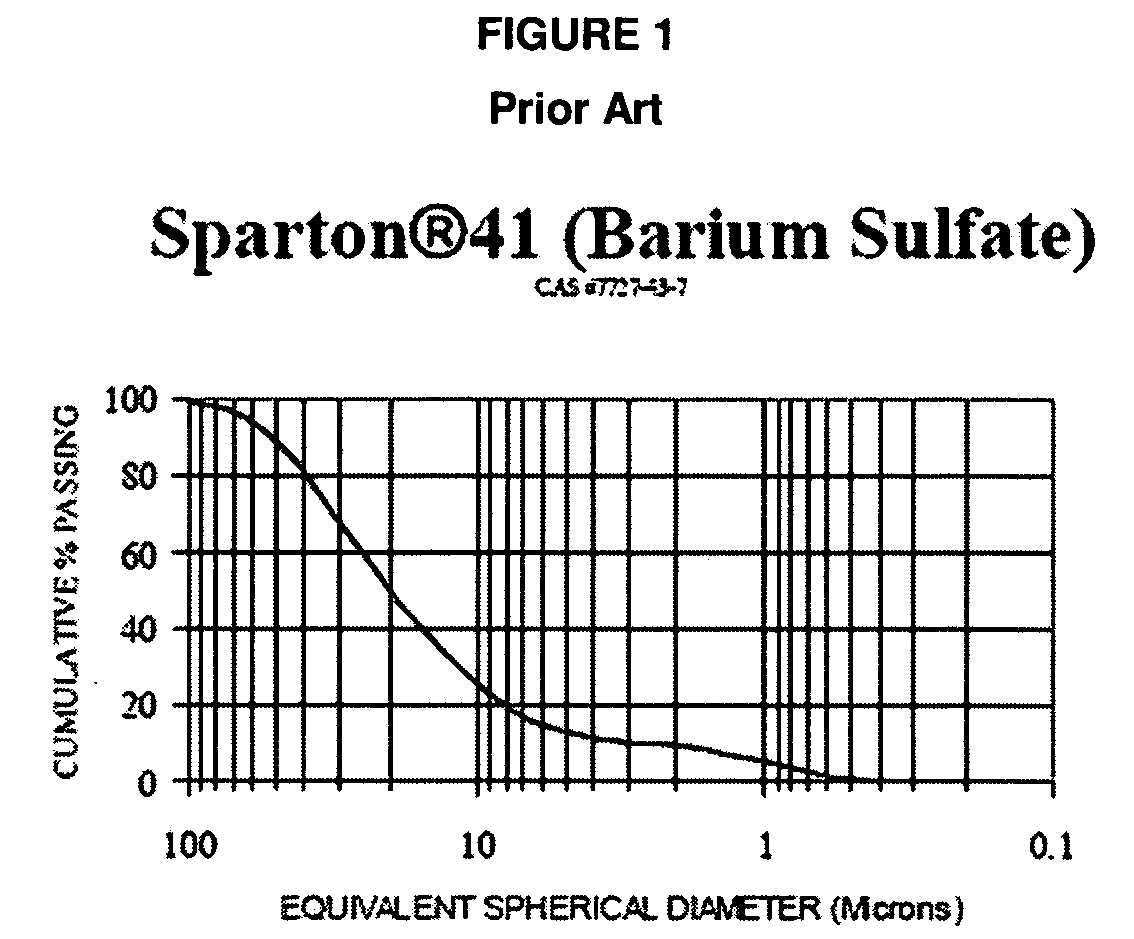

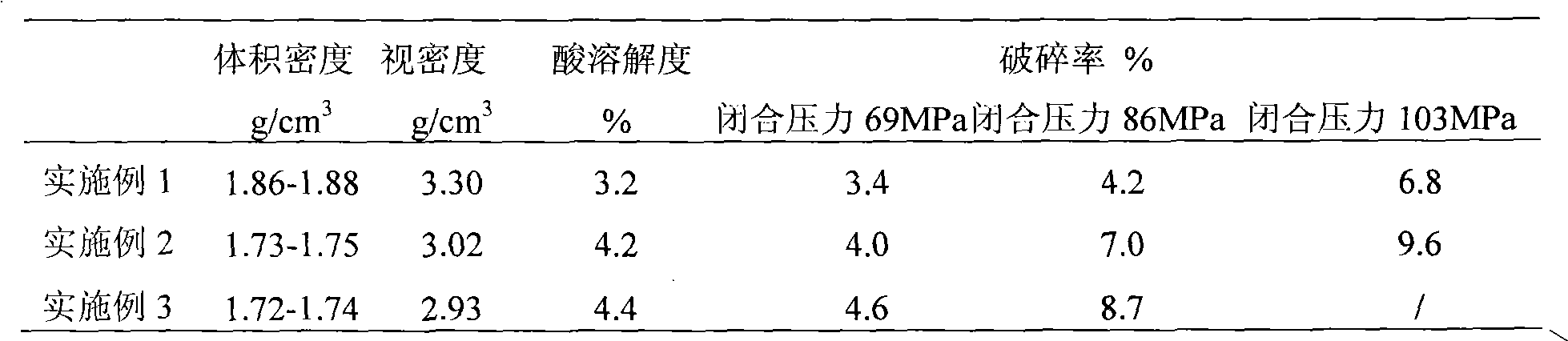

Additive for increasing the density of a fluid for casing annulus pressure control

InactiveUS20060188651A1Liquid surface applicatorsOther chemical processesVolumetric Mass DensitySolid particle

A method of controlling the pressure of a casing annulus in a subterranean well that includes injecting into the casing annulus a composition including a base fluid and a polymer coated colloidal solid material. The polymer coated colloidal solid material includes: a solid particle having an weight average particle diameter (d50) of less than two microns, and a polymeric dispersing agent coated onto the surface of the solid particle during the cominution (i.e. grinding) process utilized to make the colloidal particles. The polymeric dispersing agent may be a water soluble polymer having a molecular weight of at least 2000 Daltons. The solid particulate material may be selected from materials having of specific gravity of at least 2.68 and preferably the solid particulate material may be selected from barium sulfate (barite), calcium carbonate, dolomite, ilmenite, hematite, olivine, siderite, strontium sulfate, combinations and mixtures of these and other similar solids that should be apparent to one of skill in the art.

Owner:MI

Method of stimulating oil and gas wells using deformable proppants

ActiveUS20060151170A1Minimizing proppant pack damageImproves retained proppant pack permeabilityFluid removalDrilling compositionFracturing fluidUltimate tensile strength

A method of fracturing using deformable proppants minimizes proppant pack damage, without compromising the fracturing fluid's proppant transport properties during pumping, by use of deformable proppants. Selection of proppant is dependent upon the mechanical properties of the formation rock. The strength of the deformable proppant is dependent upon the modulus of the formation rock being treated such that the proppant is capable of providing, at the very least, a minimum level of conductivity in in-situ stress environments. The maximum elastic modulus of the deformable proppant is less than the minimum modulus of the formation rock which is being treated. The method is particularly applicable in fracturing operations of subterranean reservoirs such as those comprised primarily of coal, chalk, limestone, dolomite, shale, siltstone, diatomite, etc.

Owner:BAKER HUGHES INC

Abrasion resistant iron base sintered alloy material for valve seat and valve seat made of iron base sintered alloy

InactiveUS6139599AAbrasion resistance of the sintered alloy material is remarkably increasedIncrease resistanceMachines/enginesSlide valveCarbideHardness

A valve seat made of an iron base sintered alloy for internal combustion engines comprises of hard particles of hardness 700-1300 Hv dispersed by 3-20% by volume in a matrix phase comprising comprising of a 5-40% psarlite phase, a 20-60% fine carbide dispersed phase, and a 5-20% high alloy diffusd phase. The hard paricles are preferably selected from a group of Mo-Ni-Cr-Si-Co intermetallic compound particles, Cr-Mo-Co intermetallic compound particles, and Fe-Mo alloy particles. The iron base sinteed alloy is conpised of, by weight, C: 0.2-2.0%, Cr: 1.0-9.0%, Mo: 1.0-9.0%, Si: 0.1-1.0%, W: 1.0-50%, V: 0.2-3.0%, one or more Cu, Co and Ni of 0.5-10.0% in total, and the remainder substantial Fe.

Owner:NIPPON PISTONRING CO LTD

Additive for increasing the density of a fluid for casing annulus pressure control

InactiveUS20050101493A1Photosensitive materialsScale removal and water softeningVolumetric Mass DensitySolid particle

A method of controlling the pressure of a casing annulus in a subterranean well that includes injecting into the casing annulus a composition including a base fluid and a polymer coated colloidal solid material. The polymer coated colloidal solid material includes: a solid particle having an weight average particle diameter (d50) of less than two microns, and a polymeric dispersing agent coated onto the surface of the solid particle during the cominution (i.e. grinding) process utilized to make the colloidal particles. The polymeric dispersing agent may be a water soluble polymer having a molecular weight of at least 2000 Daltons. The solid particulate material may be selected from materials having of specific gravity of at least 2.68 and preferably the solid particulate material may be selected from barium sulfate (barite), calcium carbonate, dolomite, ilmenite, hematite, olivine, siderite, strontium sulfate, combinations and mixtures of these and other similar solids that should be apparent to one of skill in the art.

Owner:MI

Transparent lead-free fritted glaze with low expansion coefficient and preparation method thereof

The invention relates to a transparent lead-free fritted glaze with low expansion coefficient and a preparation method thereof. The fritted glaze comprises the following chemical ingredients of: 59 to 66 percent of SiO2, 10 to 15 percent of Al2O3, 5 to 10 percent of B2O3, 3 to 6 percent of CaO, 4 to 8 percent of MgO, 0 to 3 percent of K2O, 0 to 2 percent of Na2O, 0 to 1 percent of Li2O, 1 to 5 percent of ZnO and 0 to 2 percent of SrO; and the fritted glaze comprises the raw materials of: 10 to 25 percent of kaolin, 15 to 30 percent of quartz, 10 to 25 percent of potassium feldspar, 0 to 8 percent of dolomite, 2 to 6 percent of grammite, 10 to 20 percent of roasted talc, 1 to 6 percent of zinc oxide, 2 to 8 percent of boric acid, 5 to 15 percent of calcium borate, 1 to 5 percent of alumina, 0 to 2 percent of lithium carbonate and 0 to 3 percent of strontium carbonate. The expansion coefficient of the fritted glaze is 3.7-4.5*10-6 / DEG C (RT to 500 DEG C), the melted temperature is 1400 DEG C to 1500 DEG C, the glaze firing temperature is 1130 DEG C to 1230 DEG C; and the transparent lead-free fritted glaze has fine and bright glaze surface, high transparency, low expansion coefficient as well as no lead precipitation and is particularly suitable for double-fired hard porcelain body with lower expansion coefficient.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Interior wall paint composition

The invention relates to an interior wall decorating material, in particular to a building material composition consisting of natural source materials and containing diatomite. The composition comprises the following components in percentage by weight: 20 to 40 percent of diatomite, 20 to 58 percent of shell powder, 8 to 32 percent of dolomite sand, 2 to 10 percent of casein, 5 to 12 percent of 4A zeolite powder, 3 to 8 percent of seaweed gelatine powder, 0.5 to 1.5 percent of jute fiber and 2 to 5 percent of titanium white powder. The composition fully consists of natural source materials, does not contain chemical substances of synthetic resins, and really has no volatilization, emission and pollution. Because the composition does not contain the hydraulic materials such as white cement and the like, the construction opening time is long, the stirred material can be used for long term, the construction is convenient, and the material waste is avoided. The composition can be stored for long term by packing with moisture-proof paper bags, brings convenience to producers, can be mass-produced, and enables dealers not to worry about the problem of material invalidation.

Owner:深圳市汇益德环保材料有限公司

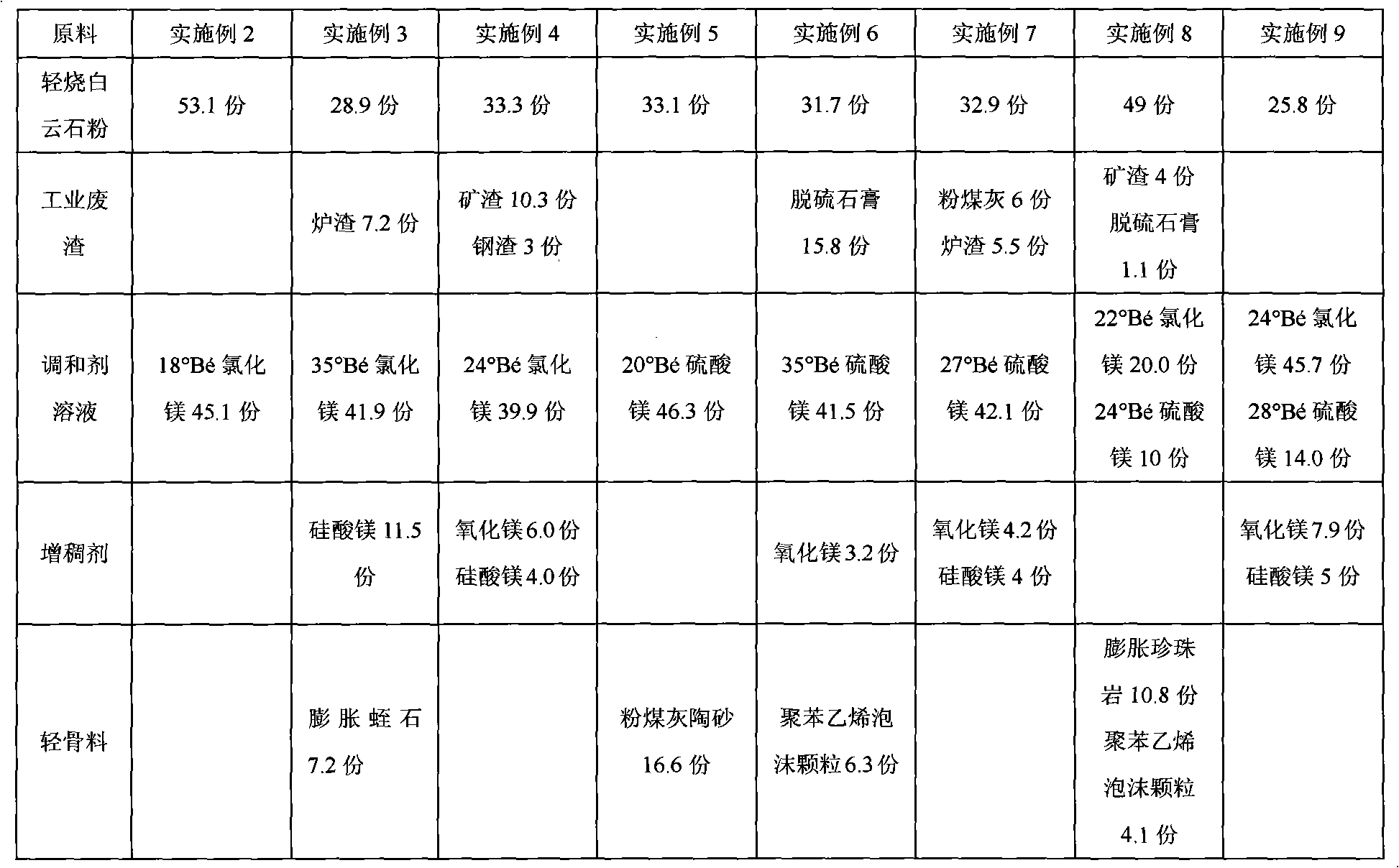

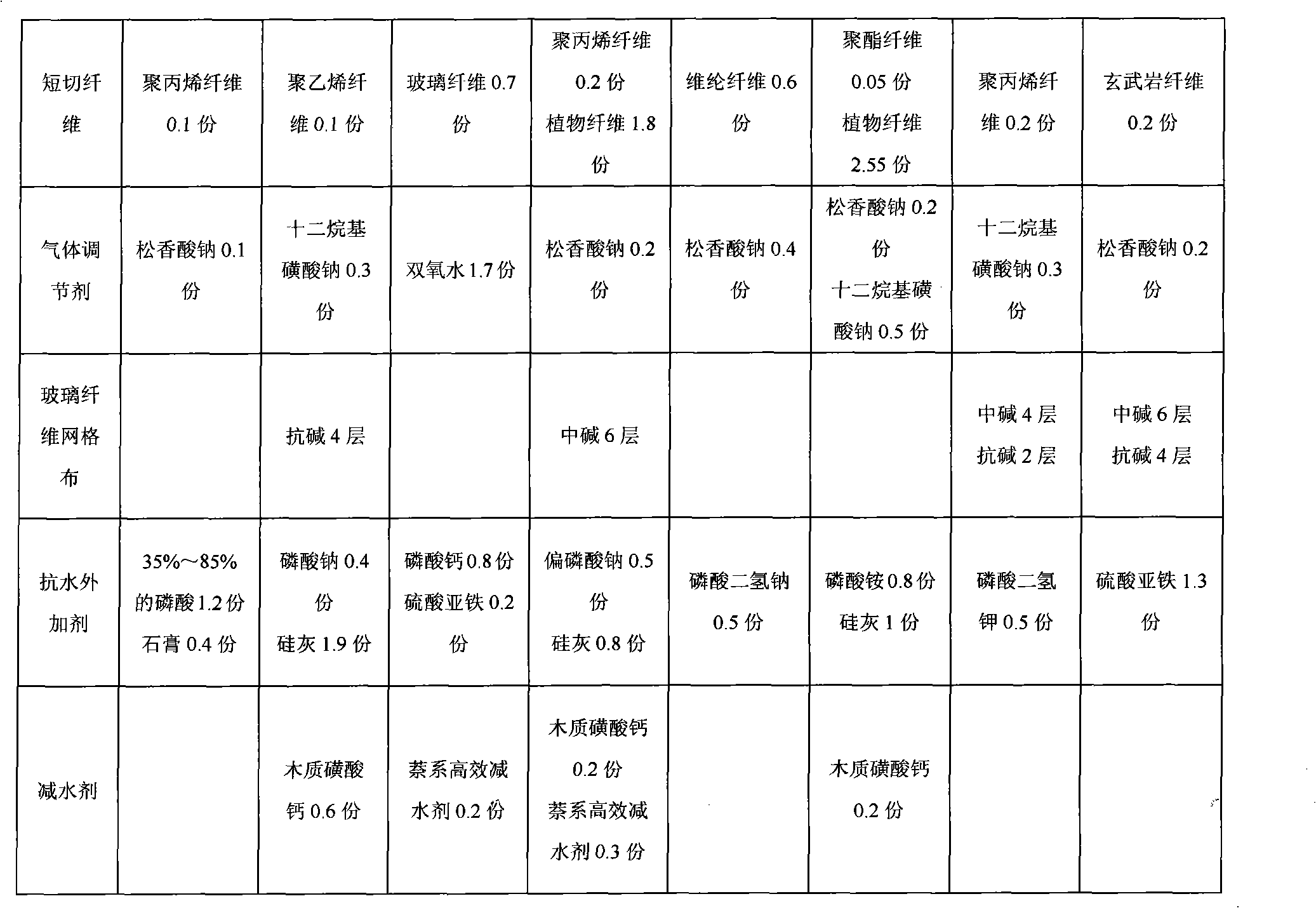

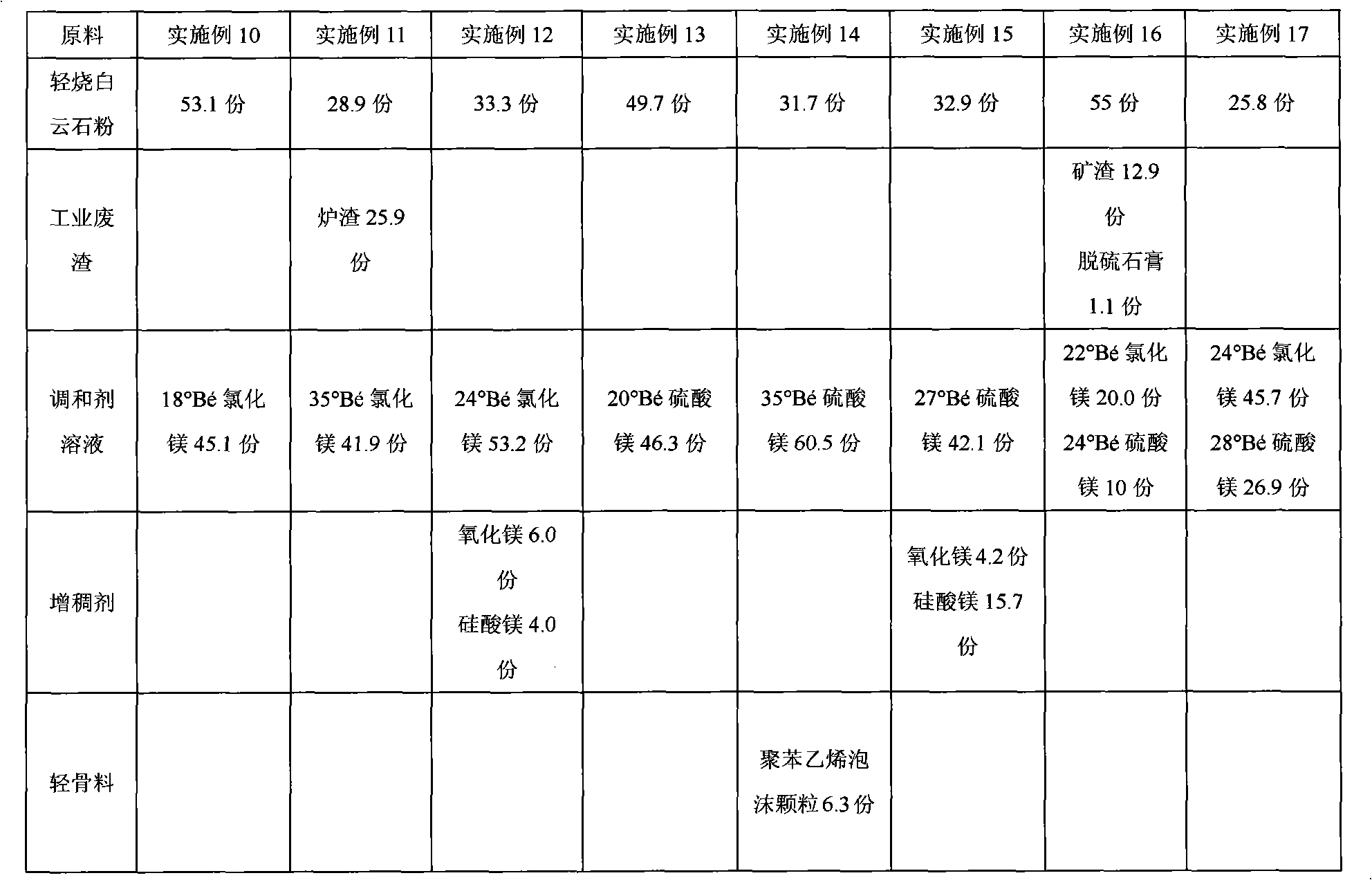

Light-burned dolomite foam light partition board

InactiveCN102070353ACuring reaction at room temperatureHarden fastSolid waste managementCeramicwareFiberMoisture absorption

The invention relates to a light-burned dolomite foam light partition board, which comprises the following components in part by weight: 20 to 55 parts of light-burned dolomite powder, 30 to 85 parts of conditioner solution, 0.1 to 5 parts of chopped fibers, 0.01 to 8 parts of gas regulator, 0.01 to 8 parts of water-resistant admixture, 1 to 60 parts of industrial waste residues, 1 to 30 parts of thickener, 1 to 35 parts of lightweight aggregate, 1 to 16 layers of glass fiber mesh fabrics and 0.1 to 1 part of water reducing agent. The foam light partition board has the advantages of no steam curing or autoclave curing, normal temperature quick reaction and curing, high strength and water resistance, no moisture absorption or halogenation, no scumming, freezing resistance, sound insulation, thermal insulation, heat preservation, flame retardance, utilization of a large number of industrial waste residues and agricultural wastes, resource and energy saving, no emission of waste gas, waste water and waste residues (three wastes), and the like, has low production cost and good social and economic benefits, and is mainly used for a non load bearing partition.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +2

Method for preparing silicon-free or low-silicon acidproof ceramic fracturing propping agent

The invention discloses a method for preparing a silicon-free or low-silicon acidproof ceramic fracturing propping agent, which comprises the following steps of: (1) preparing the following raw materials in percentage by weight: 30 to 95 percent of alumina, 5 to 70 percent of barium carbonate and 0 to 10 percent of sintering aid, wherein the sintering aid is one or more of titanium dioxide, boric acid, calcium carbonate, magnesium oxide and dolomite; (2) performing ball milling on the raw materials in the step (1) in a ball mill for 24 to 48 hours; (3) preparing the raw materials obtained in the step (2) into semi-finished product particles; and (4) sintering the semi-finished product particles obtained in the step (3) at the temperature of between 1,500 and 1,800 DEG C for 1 to 3 hours, and cooling to the room temperature. The method has simple process; the barium carbonate is decomposed at high temperature to generate barium oxide, and the barium oxide is fully reacted with alumina to generate stable barium aluminate; and the barium aluminate has strong acidproof performance and protects other components in the finished product against corrosion of acid liquor, so the acidproof performance of the finished product is greatly improved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Magnesia-calcia dry type working liner for tundish and preparation thereof

The invention relates to a magesia-calcia tundish dry working lining refractory and a method for preparing the same. The technical scheme comprises mixing 55-65wt% of particle material with a grain size of 3-0mm, 22-35wt% of powder with a grain size less than 0.088mm, 0 or 0.5-8wt% of additives and 6-12wt% of binding agent according to a theoretical content of MgO 55-85wt% and CaO 10-40wt%, baking at 200-350 DEG C after stirring and vibration molding, getting the tundish dry working lining after demoulding, wherein the particle material is one or a mixture more than one selected from the magnesia, magnesite, limestone and dolomite; the powder is one or a mixture more than one selected from the magnesia, hydrated lime, limestone, dolomite and magnestie. The invention has advantages of simple technology, convenient construction, low cost, environment friendly and saving energy, and the magesia-calcia tundish dry working lining has a good metallurgical effect and the feature of easy disintegration after use.

Owner:WUHAN UNIV OF SCI & TECH

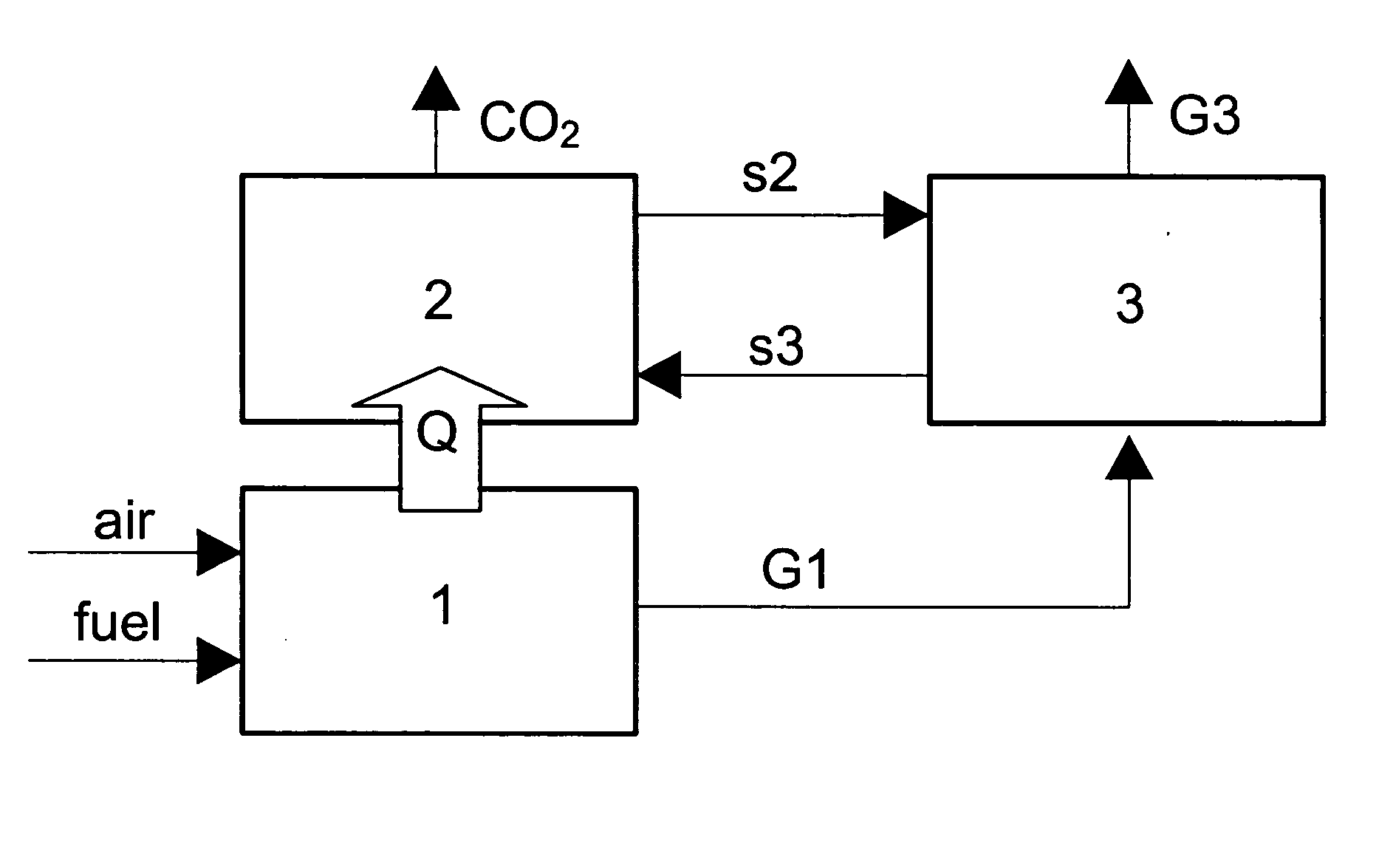

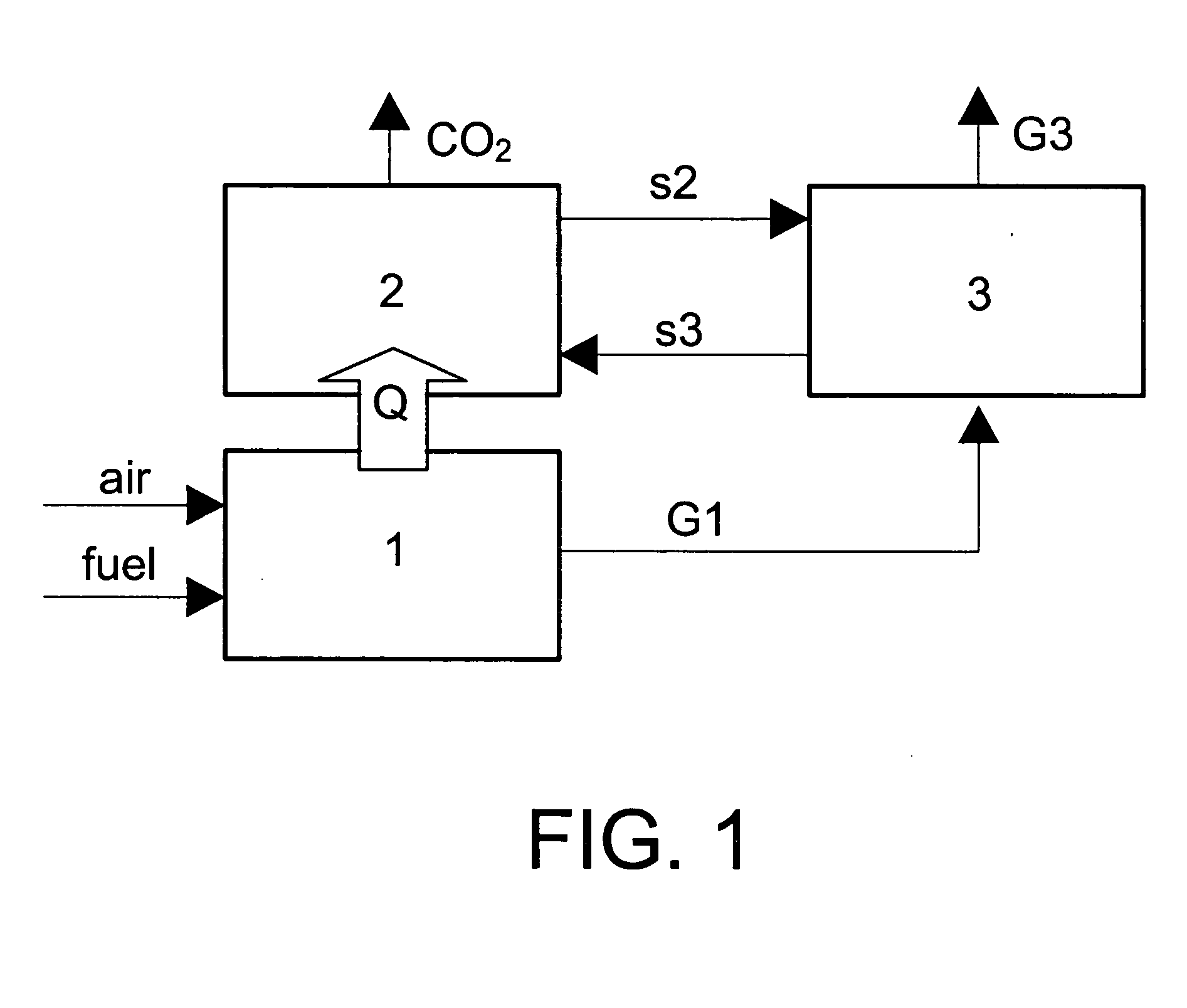

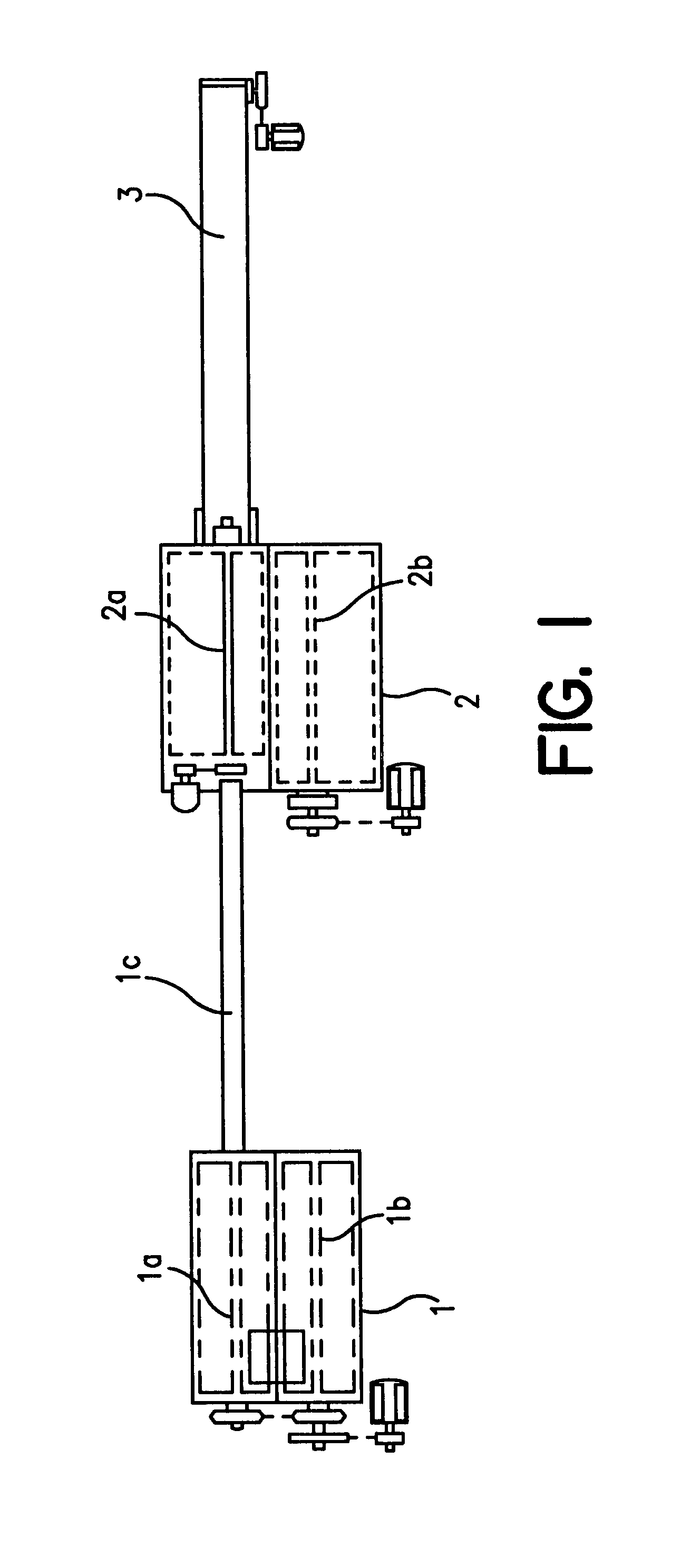

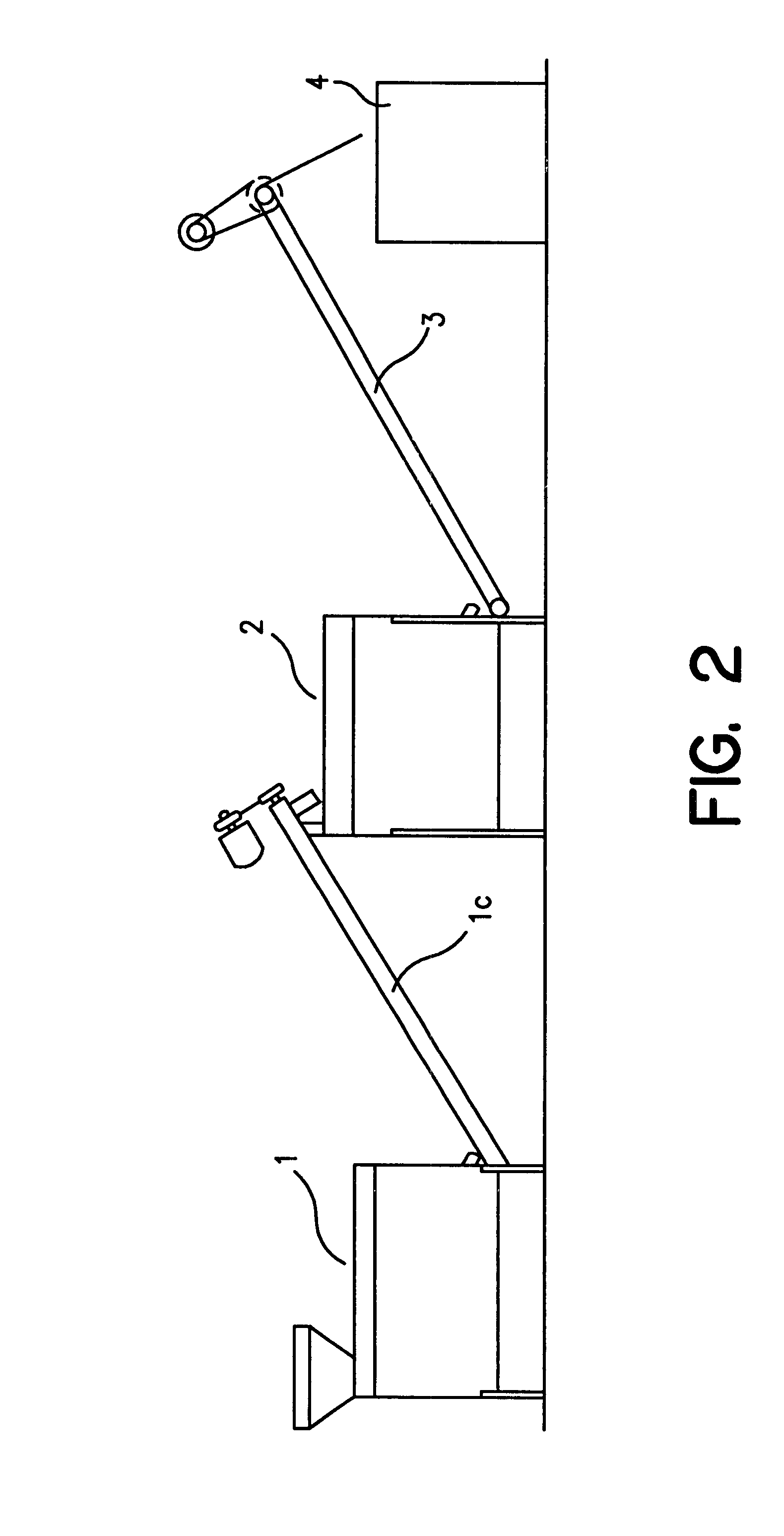

Combustion method with integrated CO2 separation by means of carbonation

InactiveUS20050060985A1Easy to separateReduce the temperatureGas treatmentOther chemical processesCalcium in biologyCombustion

The invention relates to a method for separating CO2 from combustion gases, which can be used at areas with large emissions (thermal power stations using any carbonaceous fuel). The separated CO2 stream can be used and / or contained in geological formations. The inventive method aims to reduce the high costs involved in CO2 separation which prevent large-scale use of the CO2 confinement options included in the UN's IPCC reports. Said method consists of bringing the combustion gases into contact with a calcareous sorbent (limestone, calcined dolomite) at 650-750° C., thereby producing the CO2 capture reaction by means of the rapid carbonation of the sorbent. The sorbent is regenerated in another reactor (calciner) which operates in CO2 or CO2 / H2O atmospheres.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC) +1

Biomass quick cracked oil water vapour catforming hydrogen production method

InactiveCN101318622AExtended service lifeSolve the phenomenon of carbon depositionHydrogenCatalytic reformingGas phase

The invention discloses a method by adopting biomass fast pyrolysis oil which carries out two sections of fixed bed reactors and water vapor catalytic reforming for producing hydrogen; the two sections of fixed bed reactors are connected in series, the natural dolomite which is relatively cheap and easily available is taken as catalyst in water vapor reforming reaction at the first section of fixed bed reactor, while the second fixed bed reactor adopts Ni / Mgo as catalyst to further improve the purity and yield of the target product gas. Comparatively high temperature and comparatively high S / C (more than 12) are extremely important for the effective transformation of the biomass pyrolysis oil in the first fixed bed reactor. However, for any temperature point, low mass space velocity can facilitate the increasing of the yield of any gas product and the total gas phase transformation ratio of the biomass oil is increased accordingly. The Ni / MgO catalyst is extremely effective in the purification stage, when S / CH4 is not less than 2 and the temperature is not lower than 800 DEG C, the transformation ratio of methane can reach 100 %. Low mass space velocity can facilitate effective transformation of methane; when mass space velocity is not higher than 3600h<-1>, the potential hydrogen yield can reach 81.1%.

Owner:EAST CHINA UNIV OF SCI & TECH

Manufacturing method of fertilizer made from organic wastes

InactiveUS6273927B1Neutralize toxicityHigh in magnesiumCalcareous fertilisersProductsHuman wasteChaff

This invention relates to a method of manufacturing the fertilizer made from organic wastes such as food wastes, human excrements, animal excrements, slaugterhouse waste, henhouse waste, fish and shellfish wastes, vegetable wastes and agricultural wastes. Various wastes are mixed and crushed into certain sizes, processes for adjusting the water content, put into the treating tank and digested by mixing a calcined lime. The present invention utilizes a dolomite or mixture of calcined lime and dolomite to provide the first treatment material. This first treatment material is mixed with the supplement material such as charcoal, saw dust, loess, zoelite, chaff, or shell powder to give compost fertilizer. It is also mixed with agricultural products such a watermelons or melons which ferment to provide a special fertilizer for the agricultural product. The treatment material can be added to water and mixed with mugwort, medicinal herb, zeolite, loess, and then extracted to provide a liquid fertilizer. As the various organic wastes are changed to organic fertilizer, the acidified soil is improved, the environmental contamination can be prevented, and the high moisturizing and the fine porous of the soil prevent drought and fertilizer loss so as to raise fertilizing efficiency.

Owner:JMBIO

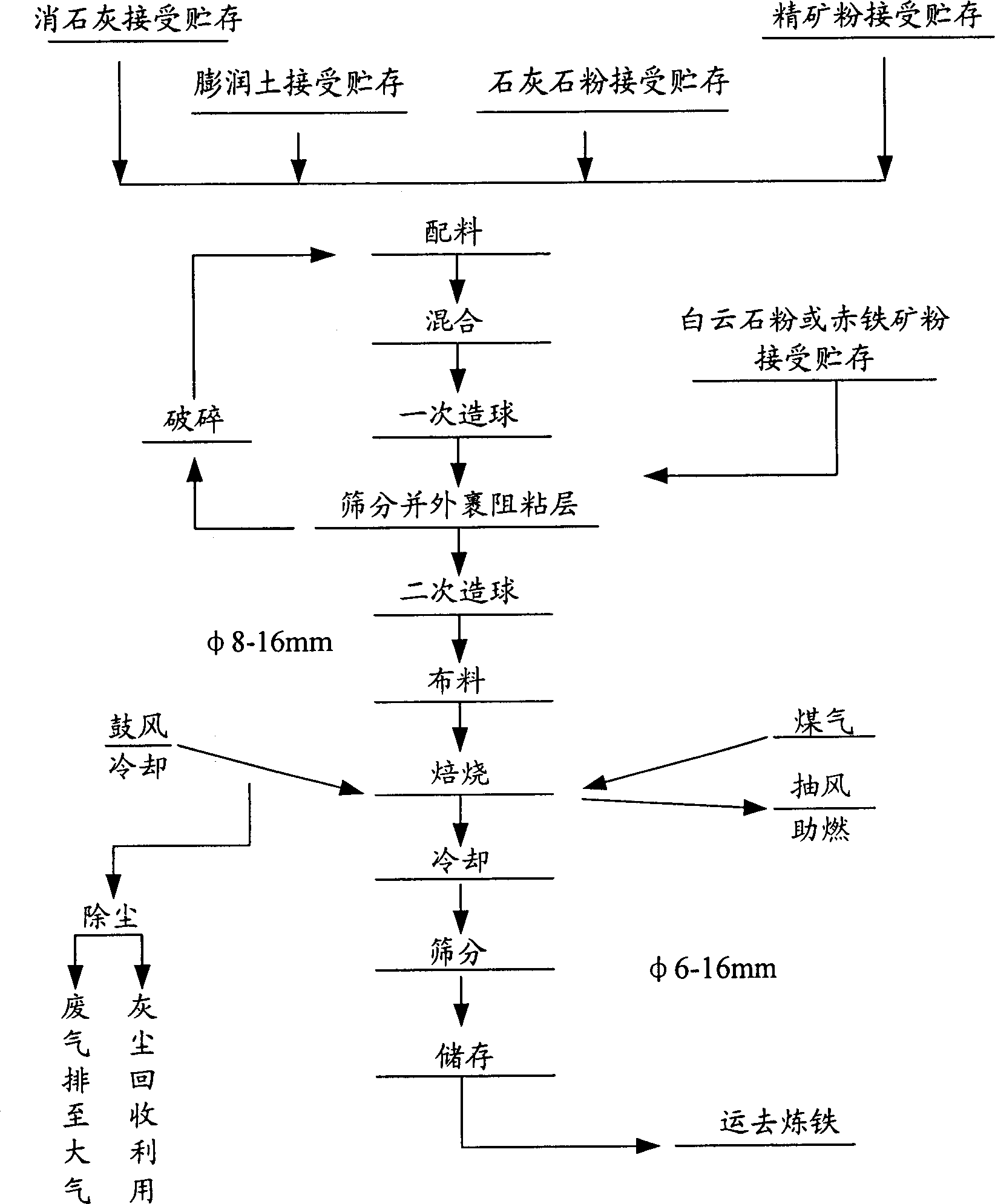

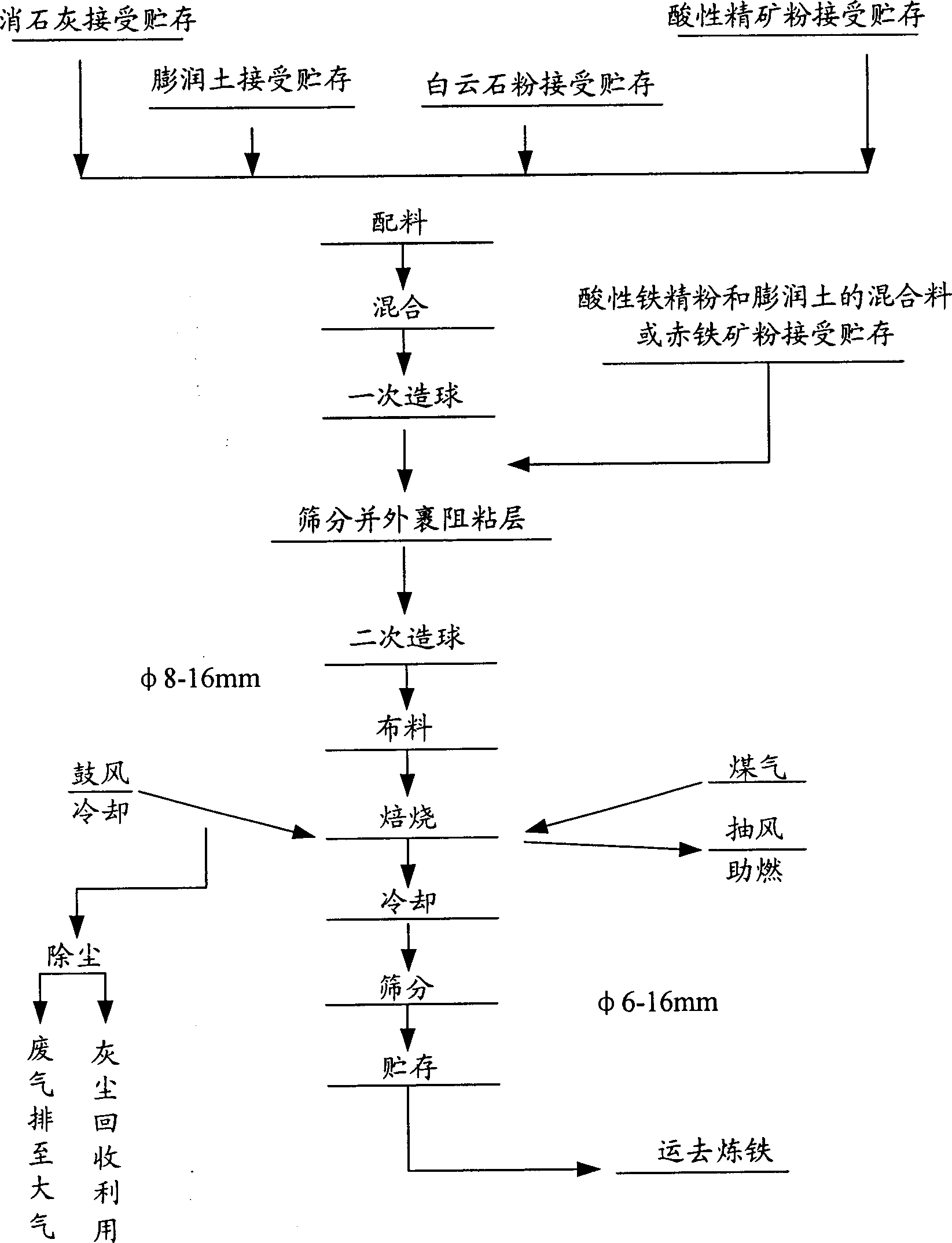

Method for making fluxed iron ore powder composite pellet

The preparation method for a solvent-type iron ore composite aggregate comprises: ensuring the proper CaO and 2-4% MgO with weight o.5-2.0 in the first process; then coming the secondary time, wrapping one block layer evenly of CaCo3 powder, dolomite powder, hematite dried powder or acidic iron concentrate ore; then, baking as the acidic aggregate baking temperature and means to ensure the ore not bond. This invention overcomes bonding problem with low cost and little pollution, and improves blast furnace yield even meets the pH balance or desulfurization request.

Owner:许贵宾

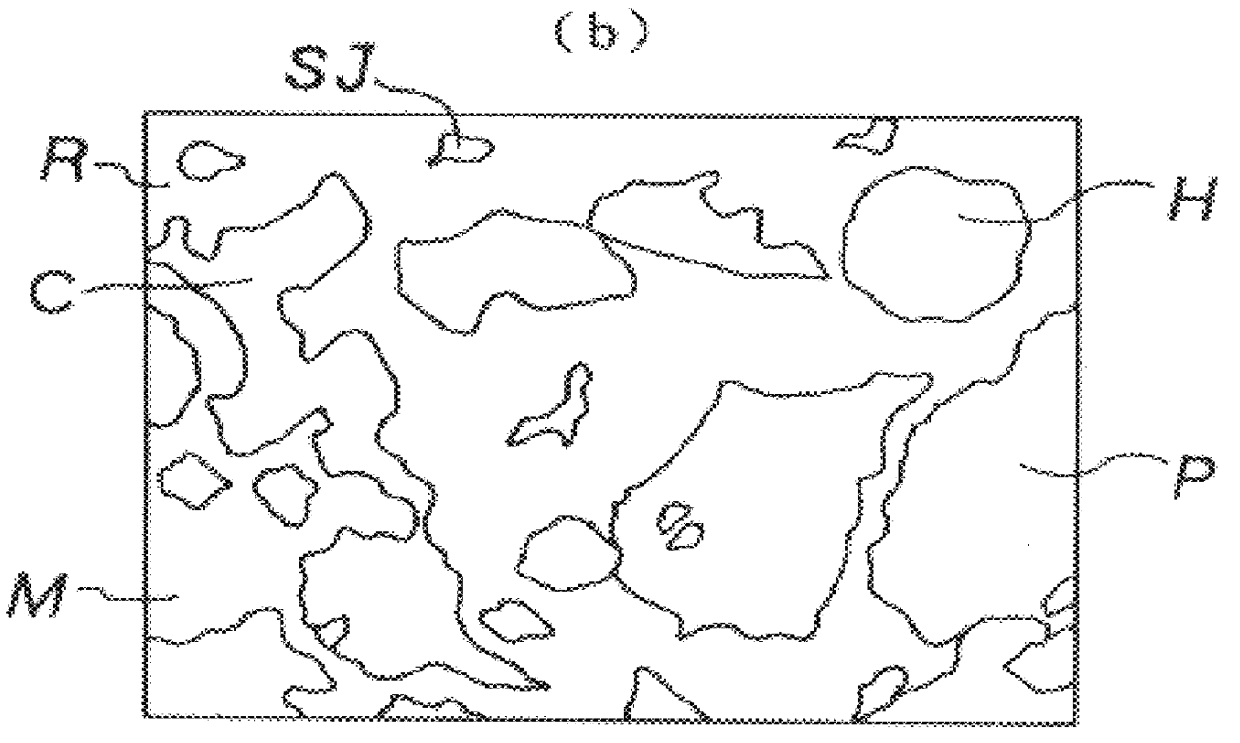

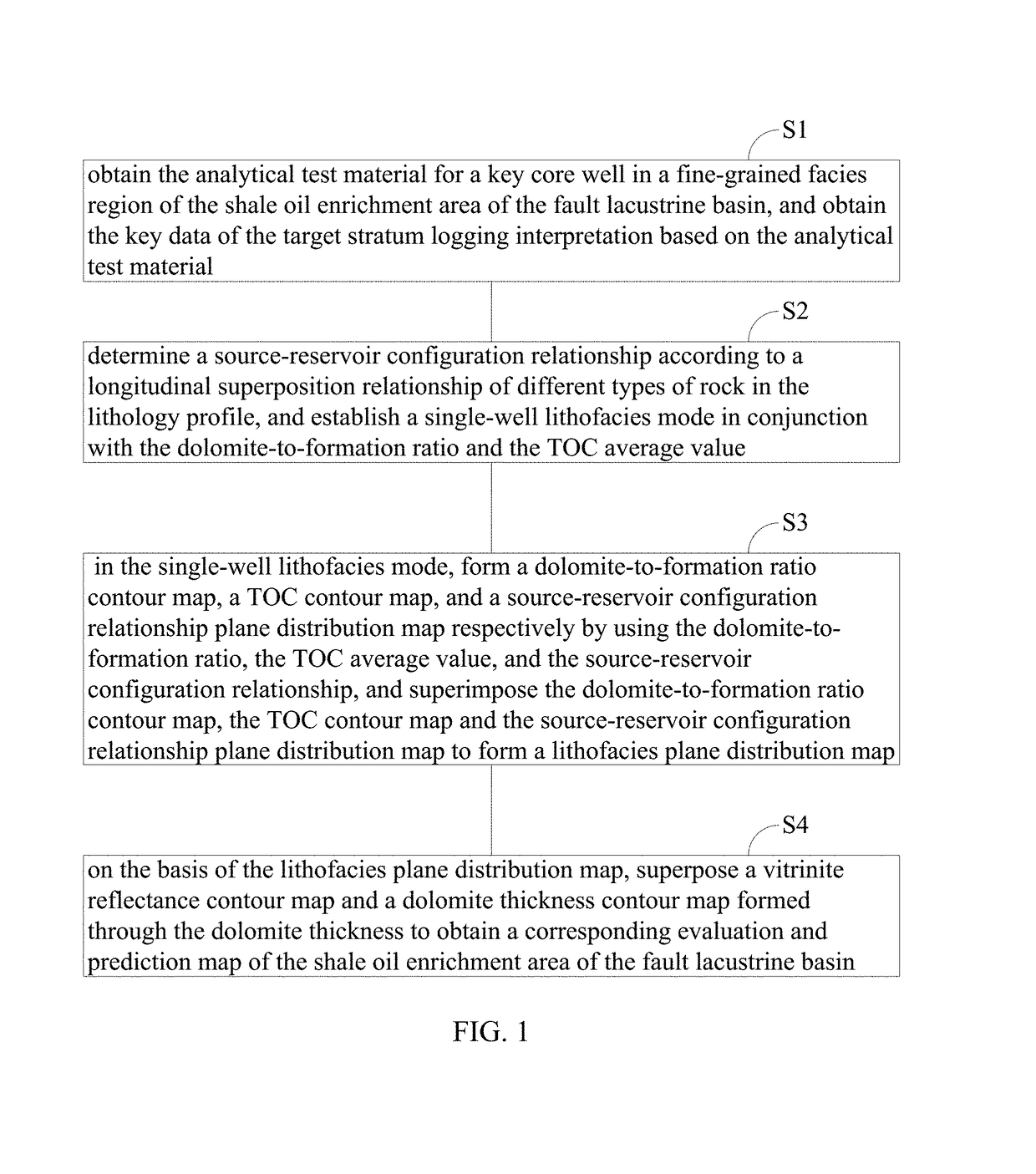

Method and device for evaluating and predicting a shale oil enrichment areas of fault lacustrine basins

ActiveUS10190998B1Reduce economic costsEasy to operateMaterial analysis using wave/particle radiationEarth material testingLithologyDolomite

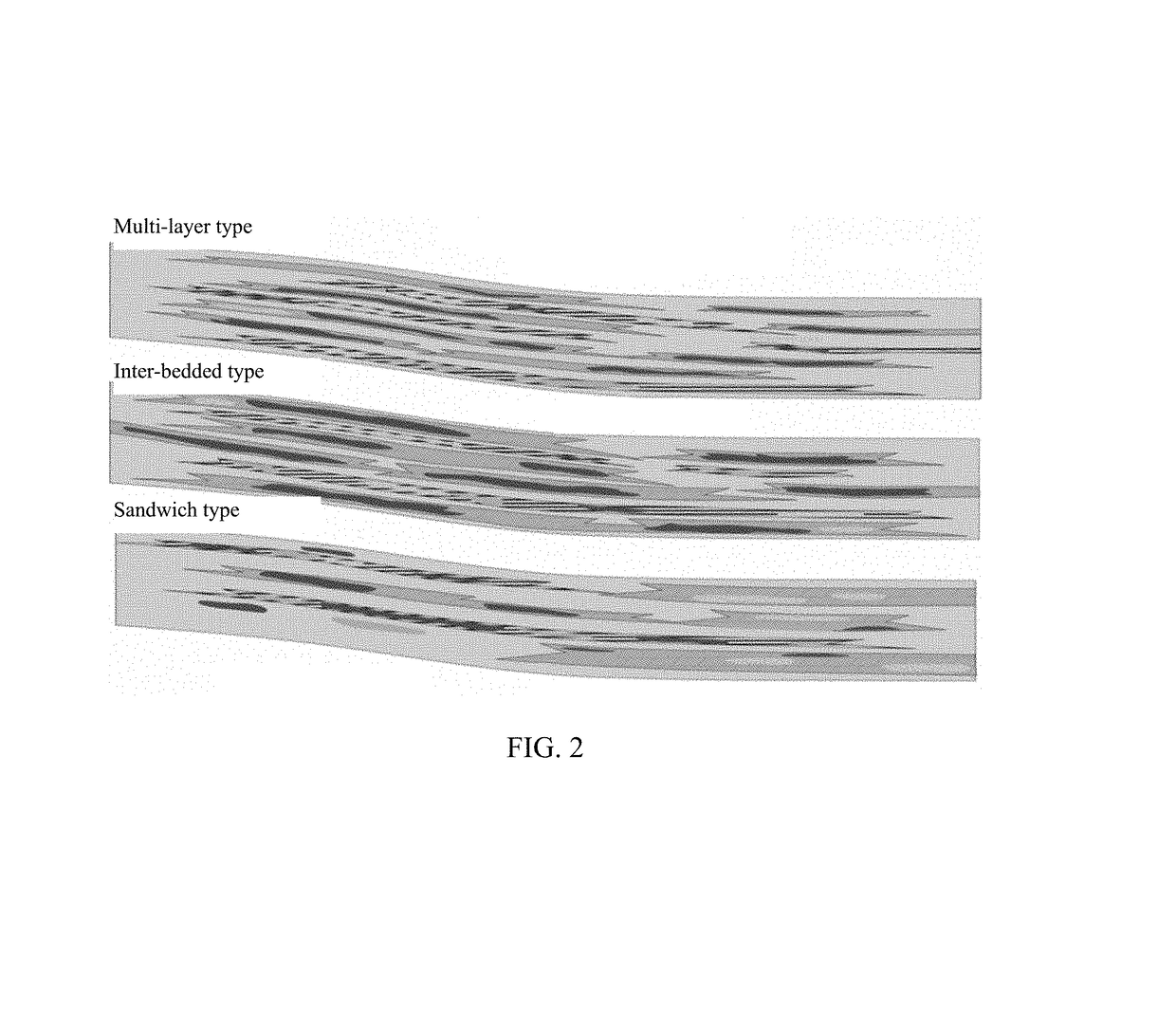

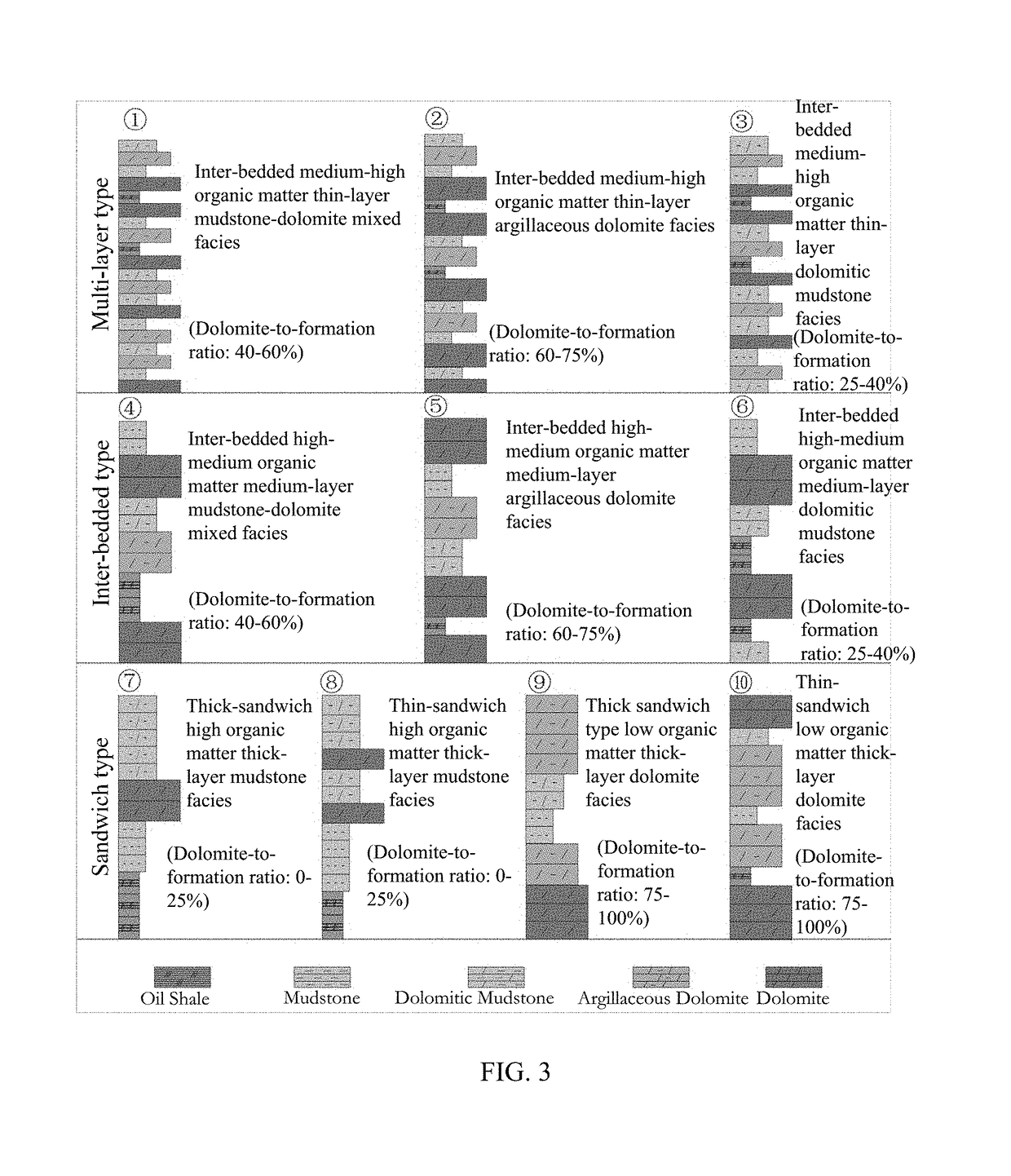

A method is disclosed for evaluating and predicting a shale oil enrichment area of a fault lacustrine basin, comprising: obtaining materials and key data; determining a source-reservoir configuration relationship according to a longitudinal superposition relationship of different types of rock in a lithology profile and establishing a single-well lithofacies model; in the single-well lithofacies model, using a dolomite-to-formation ratio and a TOC average value to form a dolomite-to-formation ratio contour map and a TOC contour map, and superposing the dolomite-to-formation ratio contour map, the TOC contour map and a source-reservoir configuration relationship plane distribution map to form a lithofacies plane distribution map; on the basis of the lithofacies plane distribution map, superposing a vitrinite reflectance contour map and a dolomite thickness contour map to obtain a corresponding evaluation and prediction map of the shale oil enrichment area of the fault lacustrine basin.

Owner:RES INST OF GASOLINEEUM EXPLORATION & DEV DAGANG OIL FIELD OF CNPC

Additive for plastic and plastic

InactiveUS20060188428A1Small amountCalcium/strontium/barium carbonatesMagnesium carbonatesCALCIUM CARBONATE/MAGNESIUM CARBONATEMagnesium carbonate / Magnesium Oxide

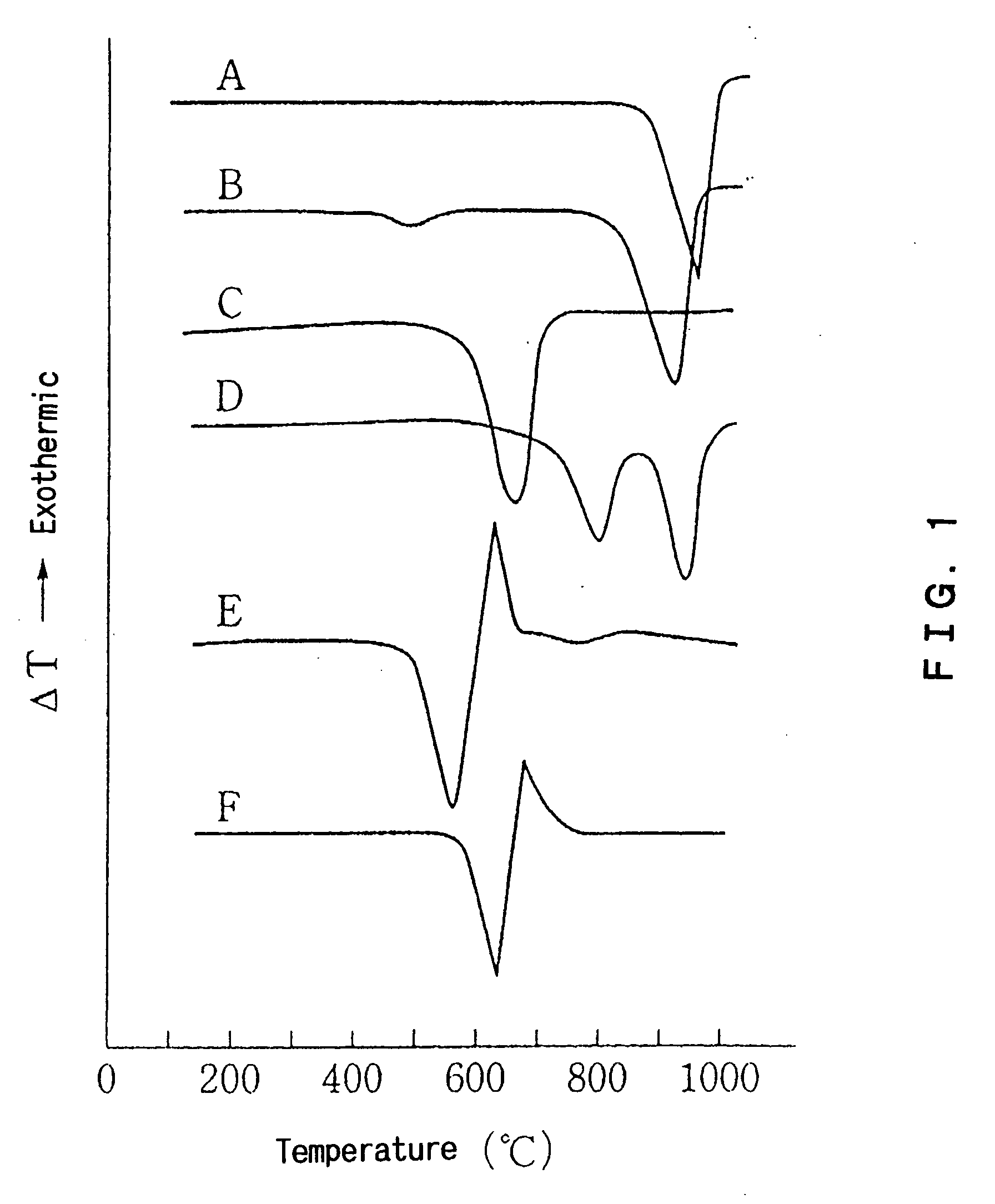

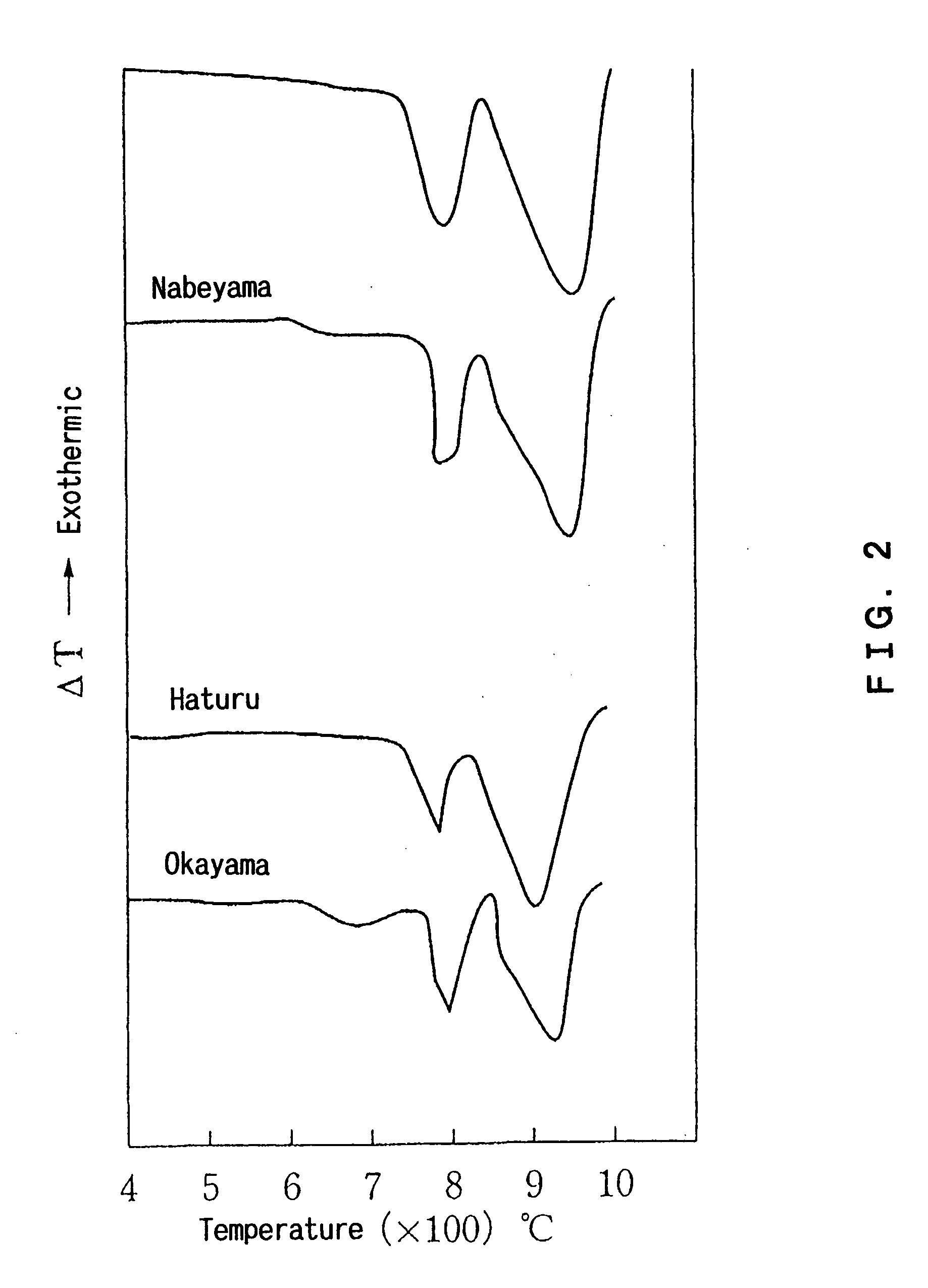

Disclosed is an additive for a plastic, comprising fine particles obtained by calcination and slaking of a dolomite which exhibits two endothermic peaks in the differential thermal analysis, said fine particles containing calcium carbonate, magnesium carbonate, magnesium oxide, calcium hydroxide and magnesium hydroxide as main chemical components and also containing an ignition loss component in an amount of 10 to 40% by weight based on the weight of said fine particles. A plastic hating hydrogen chloride scavenging properties and antimicrobial properties imparted by incorporating the additive for a plastic is also disclosed.

Owner:OSAKA MUNICIPAL TECHN RES INST +2

Valve sealing gasket sizing material and preparation method thereof

ActiveCN103012891AImprove performanceGood high and low temperature resistanceDiphenylsilanediolSolvent

The invention discloses a valve sealing gasket sizing material, which is prepared from the following raw materials in parts by weight: 20-30 parts of fluorosilicone rubber, 50-60 parts of hydrogenated nitrile-butadiene rubber, 15-25 parts of chlorosulfonated polyethylene rubber TS-320 (TOSOH, Japan), 2-3 parts of gamma-methacryloxypropyltrimethoxysilane, 1-2 parts of diphenyl silandiol, 14-16 parts of modified tree ash, 2-3 parts of ferrocene, 0.2-0.6 part of dicumyl peroxide (DCP), 20-30 parts of high-abrasion resistant carbon black N330, 20-25 parts of precipitated white carbon black, 5-7 parts of light calcium carbonate, 2-4 parts of zinc oxide, 1-3 parts of calcium stearate, 1-3 parts of aluminium oxide, 5-8 parts of dolomite, 13-15 parts of modified iron tailing powder, 0.1-0.3 part of accelerating agent MBTS, 1-2 parts of sulphur, 1-2 parts of anti-aging agent RD, 1-2 parts of anti-aging agent MB, 1-2 parts of benzimidazole-2-thiol, 1-3 parts of methyltrimethoxy silane, and 2-3 parts of paraffin. The sizing material of the rubber has excellent high and low temperature-resistant, oil-proof, solvent-resistant and chemical-resistant performance, and at the same time is good in mechanical property and low in cost.

Owner:平湖市博宏塑料制品厂

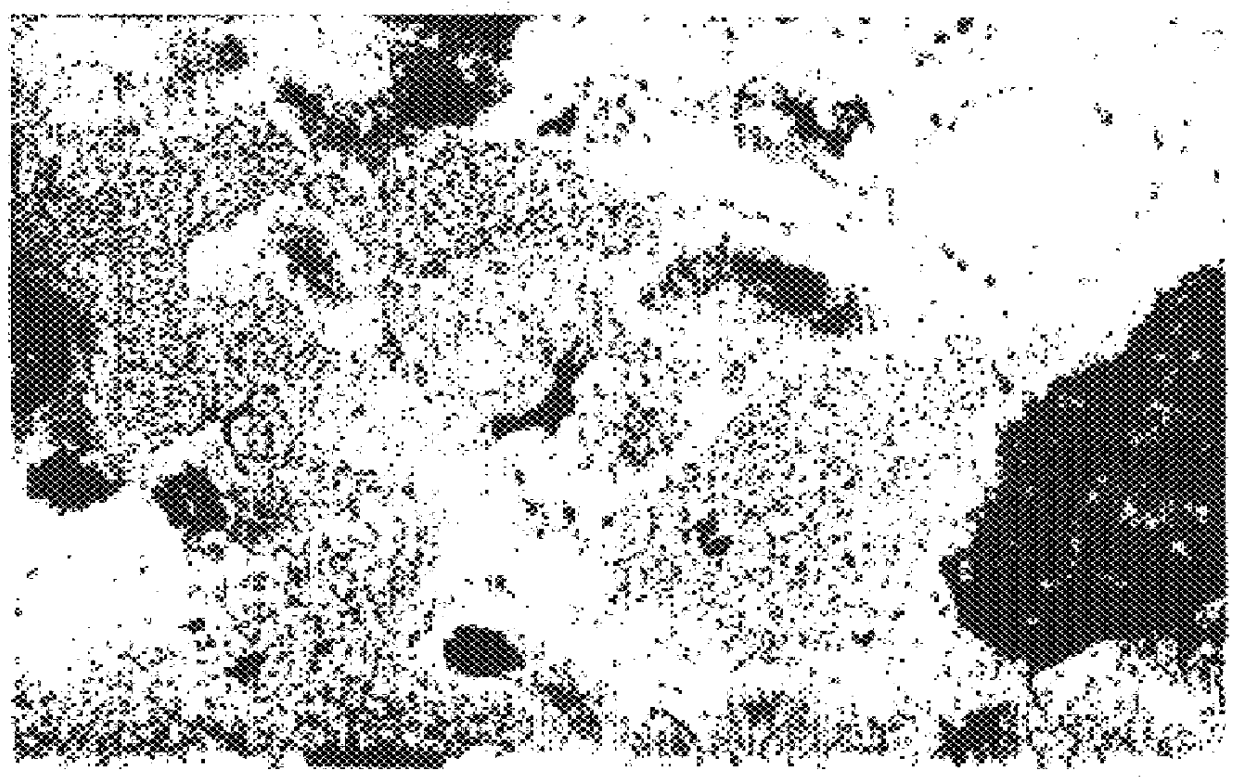

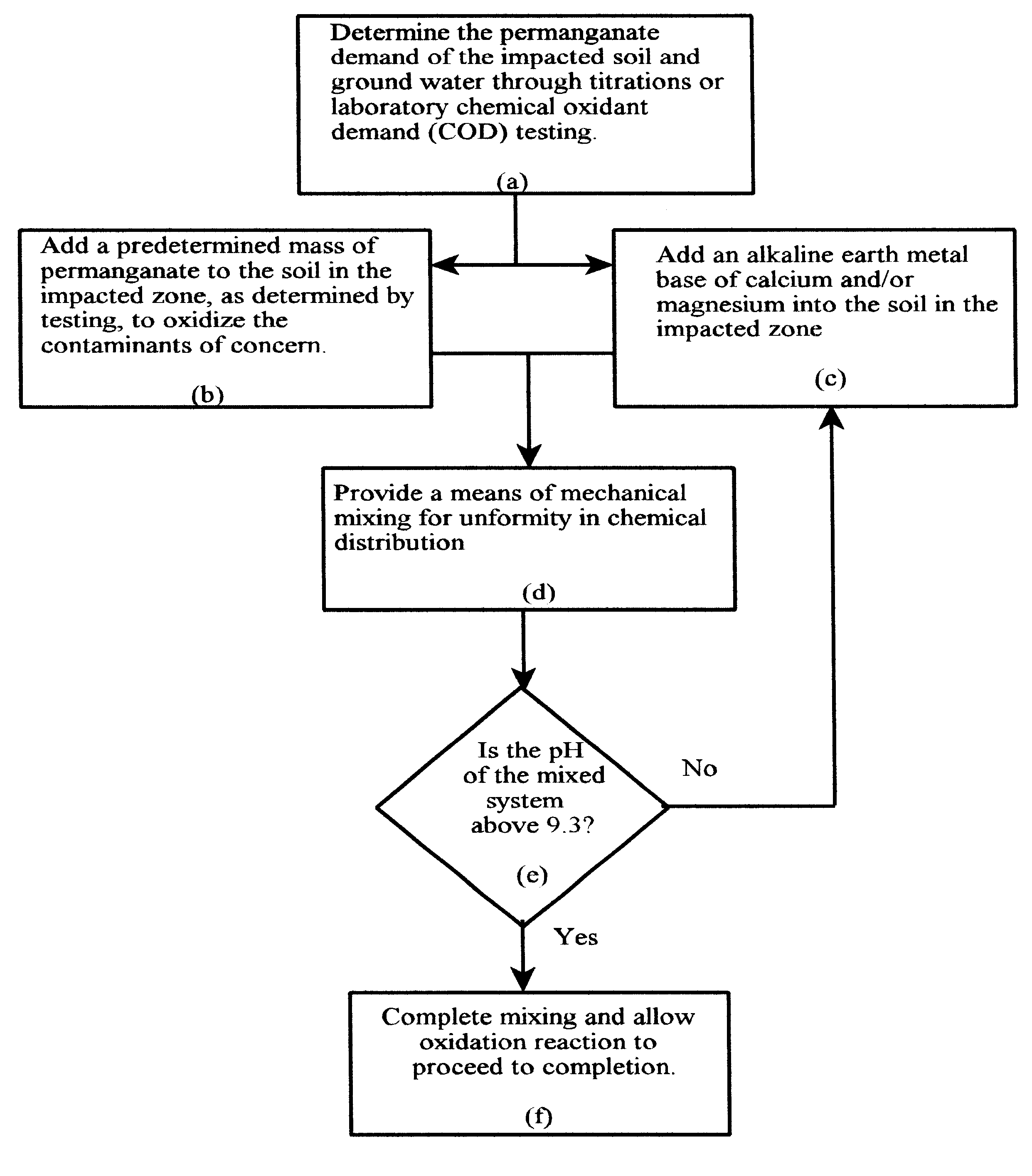

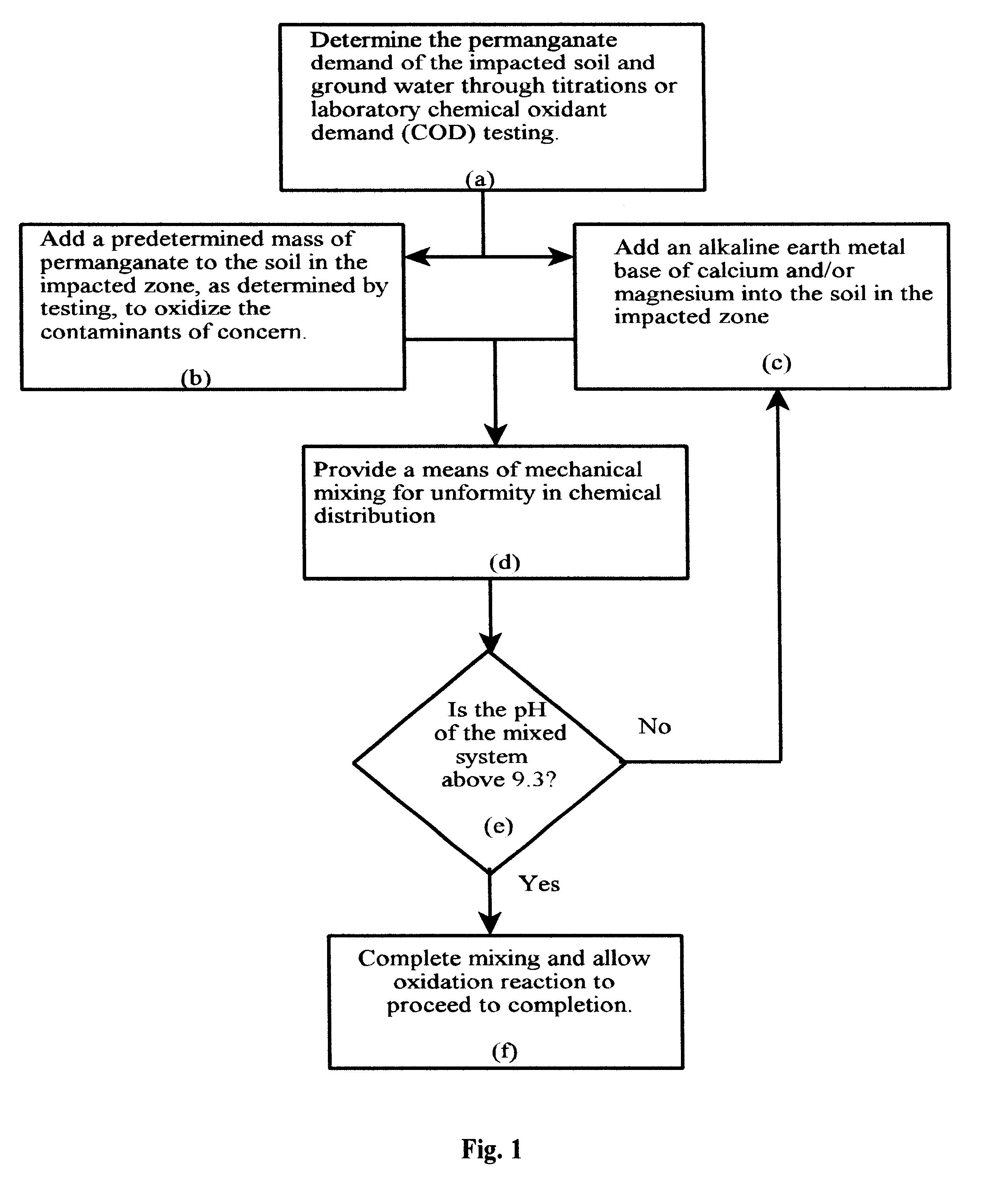

Soil remediation by permanganate oxidation

The permanganate ion and an alkaline earth metal base of calcium and / or magnesium are distributed into the soil by a means of mechanical mixing to destroy contaminants in the soil and groundwater by chemical oxidation. The disclosed method produces a stable, post-treatment, manganese dioxide precipitate that does not adversely effect the ground water with high dissolved manganese concentrations. The permanganate salts may include potassium, magnesium or sodium permanganate, and the preferred alkaline earth metal bases may include calcium oxide, calcium hydroxide, magnesium oxide and magnesium hydroxide. Dolomite quick lime may be used to supply an inexpensive source of the desired calcium and / or magnesium base. The calcium and / or magnesium base may be added before, during or after the addition of the permanganate salt.

Owner:OBERLE DANIEL W

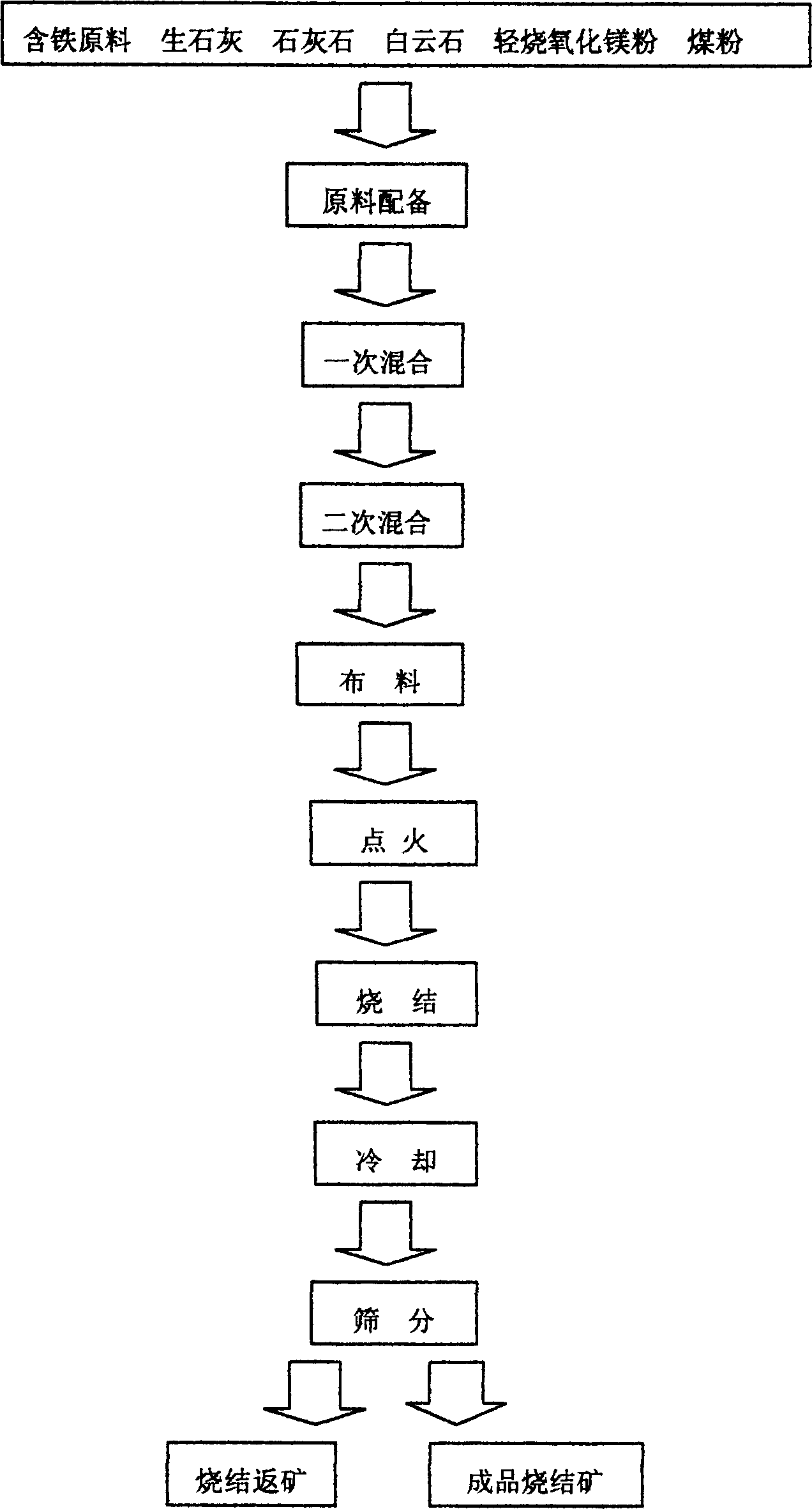

Sintered ore capable of improving viscosity of blast furnace slag and process for preparing same

The invention discloses a sintered ore and preparing method of improved blast furnace slag viscosity to solve bad fluidity of blast furnace slag with high Al2O3 in the present ferric ore, which comprises the following parts: 70-85% ferric material, 2-5% limestone, 0.2-5% light-burned magnesia powder and 3-8% coal dust or coke dust, wherein the alkalinity of CaO and SiO2 of sintering ore is 1.5-3.0 with TFe at 50-60% and MgO at 1.5-4.0%. The preparing method comprises the following steps: allocating raw materials; blending once and twice; distributing materials; igniting; sintering; cooling; sieving.

Owner:武钢集团有限公司 +1

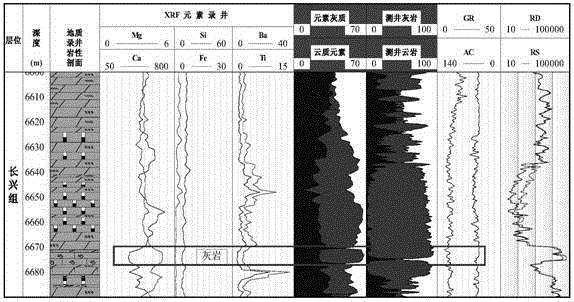

Method for quickly recognizing carbonate formation lithologies while drilling

ActiveCN104612675ASolve the problem of lithology identificationAccurate divisionBorehole/well accessoriesLithologyDolomite

The invention provides a method for quickly recognizing carbonate formation lithologies while drilling. The method includes the first step that the different lithologies are judged; the second step that rock debris of the different lithologies are sampled and are analyzed through the X-ray fluorescence element logging technology, and the Ca element pulse content and the Mg element pulse content are counted; the third step that rock debris of the different lithology centers are sampled, the Mg pulse content and the Ca pulse content of the different lithology centers are counted, and the average interval between the Mg pulse content and the Mg pulse content at the lithology center and the average interval between the Ca pulse content and the Ca pulse content at the lithology center are calculated; the fourth step that the Ca pulse content average value and the Mg pulse content average value of different lithologies are calculated respectively, then logging lithology recognition standards are obtained, and a lithology interpretation chart is established. The method achieves accurate recognition of the lithologies while drilling, judges that whether a horizontal well track passes through dolomite or not in time, and then provides a scientific basis for the necessity of adjustment of a track of an undrilled well segment and for predicament of the track of the undrilled well segment.

Owner:CHINA PETROCHEMICAL CORP +4

Glass fiber blanket and producing method thereof

ActiveCN103103695AImprove adhesionGood peeling effectGlass making apparatusNon-woven fabricsGlass fiberFlat glass

The invention discloses a glass fiber blanket and a producing method thereof. The method comprises the steps of mixing the following components , by mass, 35-40 parts of silica flour, 5-12 parts of feldspar, 9-14 parts of borax, 1-3.5 parts of calcite, 6-8 parts of dolomite, 11-14 parts of soda ash, and 15-25 parts of sheet glass to form a mixture; melting the mixture to obtain glass metal; placing the glass metal in a centrifugal machine for spinning treatment to obtain glass fiber and spraying water and binders onto the surface of the glass fiber in a vaporific mode at the same time; placing the glass fiber coated with the binders in a cotton collecting machine to enable the glass fiber to evenly fall onto the cotton collecting machine under the action of a negative-pressure fan to form a glass cotton layer; and conveying the glass cotton layer well laid to a curing oven through a conveyer to be cured to obtain the glass fiber blanket.

Owner:CHENGDU HANJIANG NEW BUILDING MATERIAL

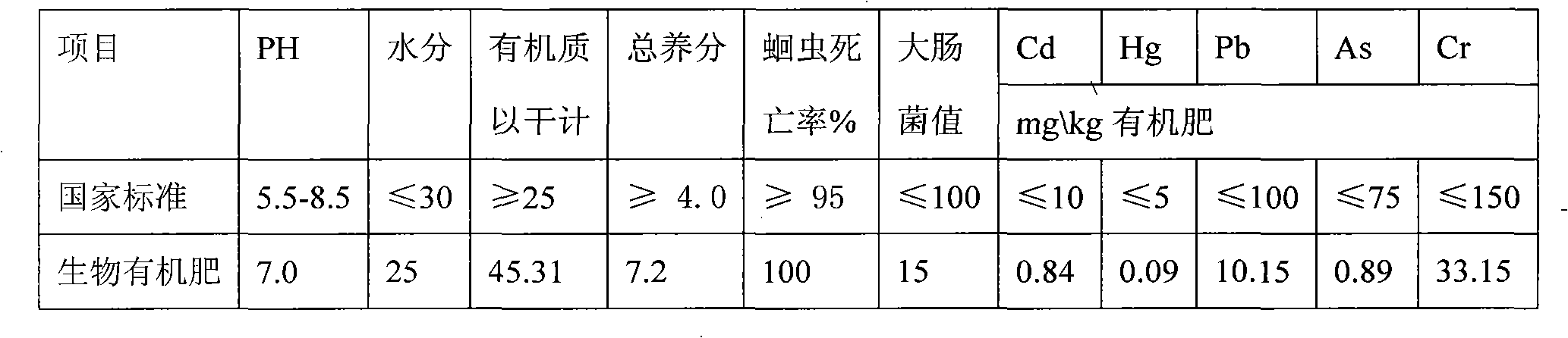

Microorganism and enzyme powder composite biological agent for microbial organic fertilizer

ActiveCN101786911AImprove decomposition effectSpeed up fermentationBio-organic fraction processingClimate change adaptationBiotechnologyNoxious weed

The invention discloses a microorganism and enzyme powder composite biological agent for a microbial organic fertilizer, which consists of 25 percent of various microbial agents, 23 percent of various bio-enzyme preparations, 30 to 35 percent of microbial nutrition agent, 5 percent of mordenite, 8 percent of dolomite, 3 percent of potassium fulvic acid, and the balance of water. The invention provides the microorganism and enzyme composite biological agent for promoting the high-quality and high-yield production of the microbial organic fertilizer, which is formed by compounding purely natural microorganism and enzyme, and integrates the advantages of the microbial agents and the enzyme preparation, and has the biocatalyst and biological degradation function; when used in a compost, the microorganism and enzyme composite biological agent accelerates the degradation speed of organic matters, makes the temperature of the composting materials rise in a short time (24 hours), eliminates the situations such as strong smelling and mosquitoes and flies breeding, and the like caused in the composting process of the biological organic raw materials, reduces the emission of massive pollution gases, and kills the noxious weeds, pathogenic bacteria and ova in the raw materials, and improves the content of organic matters of the composting product; improves the insect resistance capability of crops, and improves the soil degradation problems caused by the fertilizer.

Owner:北京微邦生物工程有限公司

High-strength ceramic brick and preparation method thereof

The invention discloses a high-strength ceramic brick and a preparation method thereof. The ceramic brick is prepared from the following raw materials in parts by weight: 40-60 parts of yellow sand, 30-50 parts of barite, 15-25 parts of dolomite, 10-20 parts of volcanic rock, 20-30 parts of zirconite, 5-15 parts of mullite, 4-12 parts of blast furnace slag, 16-28 parts of modified clay, 7-14 parts of sea mud, 11-19 parts of a silica micro-powder, 8-16 parts of a waste brick powder, 3-9 parts of tricalcium phosphate, 4-8 parts of barium carbonate, 2-5 parts of nano silicon carbide, and 3-6 parts of nano alumina. The prepared ceramic brick has high strength, has the breaking strength of not less than 1050 N and the rupture modulus of not less than 30 MPa, is anti-knock, anti-cracking and non-friable, and enables the service life to be significantly improved.

Owner:安徽省亚欧陶瓷有限责任公司

Superfine dry granular porcelain glazed tile

The invention discloses a superfine dry granular porcelain glazed tile which belongs to the field of preparation of porcelain glazed tiles. The superfine dry granular porcelain glazed tile comprises agreen body, ground glaze and surface glaze, wherein the surface glaze comprises the following raw materials in percent by weight: 22-25wt% of potassium feldspar, 6-8wt% of calcined talc, 17-20wt% ofbarium carbonate, 2-5wt% of calcined alumina, 3-5wt% of calcined zinc oxide, 3-5wt% of quartz, 5-8wt% of kaolin, 6-8wt% of dolomite and 26-30wt% of 10,139 # dry granules. The green body of the tile islow in water absorption and high in breaking strength; the green body, the bottom glaze and the surface glaze are good in combinability, and the tile in good in flatness; the superfine dry granules form a slightly rugged surface in the surface glaze, and the grain size of each of granular crystals protruding out of the glaze is 0.12-0.18mm, so that an anti-skidding and abrasion-proof effect can be achieved on the glaze, and the defect that dirt is hided and adsorbed in the glaze can be overcome.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

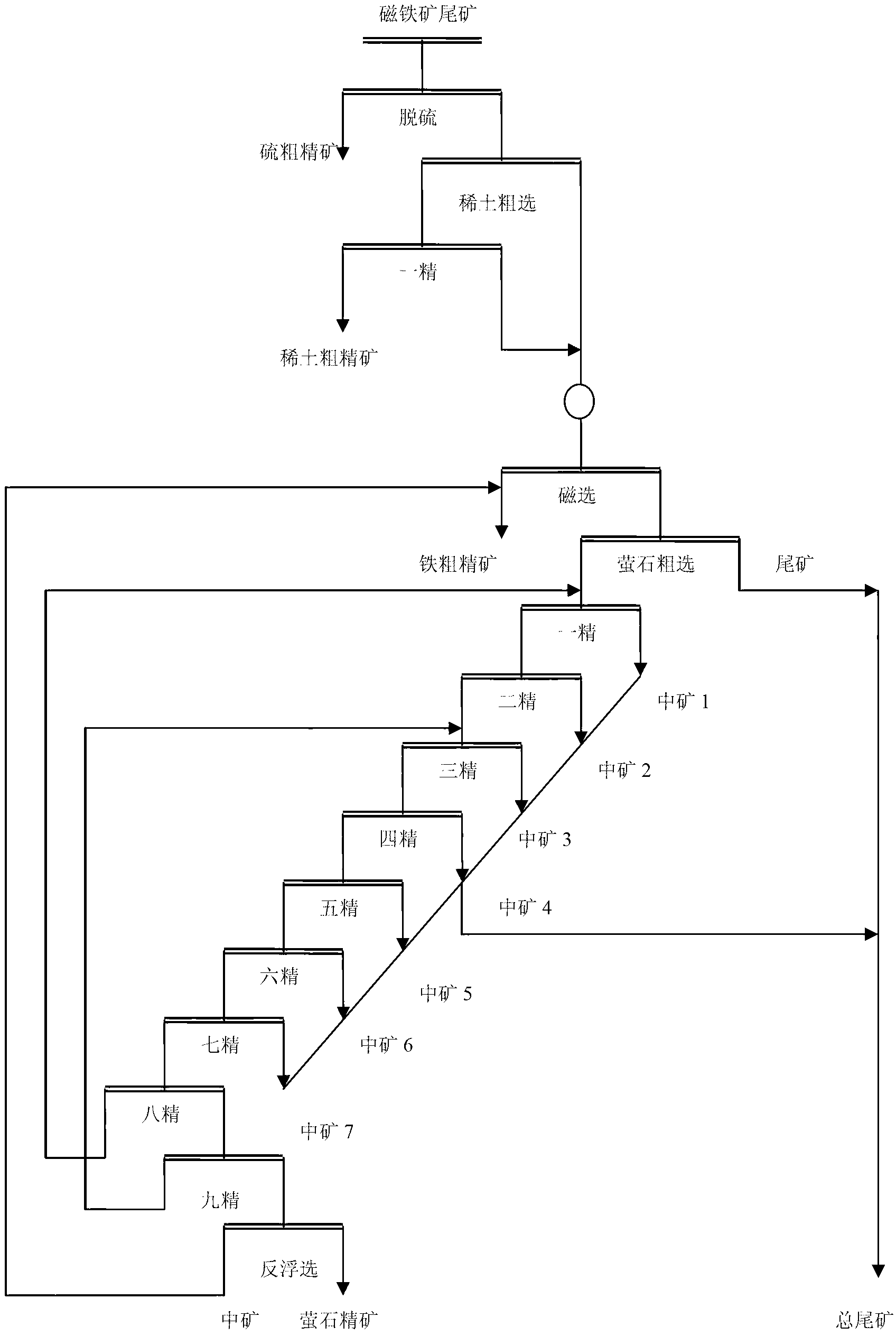

Mineral processing technology for recycling fluorite from baotite, magnetite and tailing

The invention belongs to the technical field of mineral engineering and provides a mineral processing technology for recycling fluorite from baotite, magnetite and tailing. In the tailing, mineral particle size of the fluorite is thin, iron-bearing mineral, rare-earth mineral, gangue mineral and the fluorite mineral are closely symbiotic and floatability of minerals such as rear earth, barite, apatite, calcite and dolomite is close to the fluorite mineral, so that separation of the fluorite mineral is difficult. According to the mineral processing technology for recycling the fluorite from the baotite, the magnetite and the tailing, priority desulfuration, rear earth flotation, ore grinding, iron selection through magnetic separation, fluorite selection through direct flotation and a reverse flotation sorting technology are performed on the magnetite and the tailing to enable pyrite, the rare earth, the iron-bearing mineral and the fluorite to be picked out in sections, efficient, high selective, easy-to-operate inhibitor and collecting agent combination is utilized in sorting of fluorite which is mostly performed monomer separation, so that fine fluorite of high grade and high recovery rate is obtained, a purpose of synthetically recycling valuable minerals is achieved, and effective separation of the fluorite mineral and the gangue mineral is achieved.

Owner:包钢集团矿山研究院(有限责任公司)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com