Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9614 results about "Elastic modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An elastic modulus (also known as modulus of elasticity) is a quantity that measures an object or substance's resistance to being deformed elastically (i.e., non-permanently) when a stress is applied to it. The elastic modulus of an object is defined as the slope of its stress–strain curve in the elastic deformation region: A stiffer material will have a higher elastic modulus. An elastic modulus has the form...

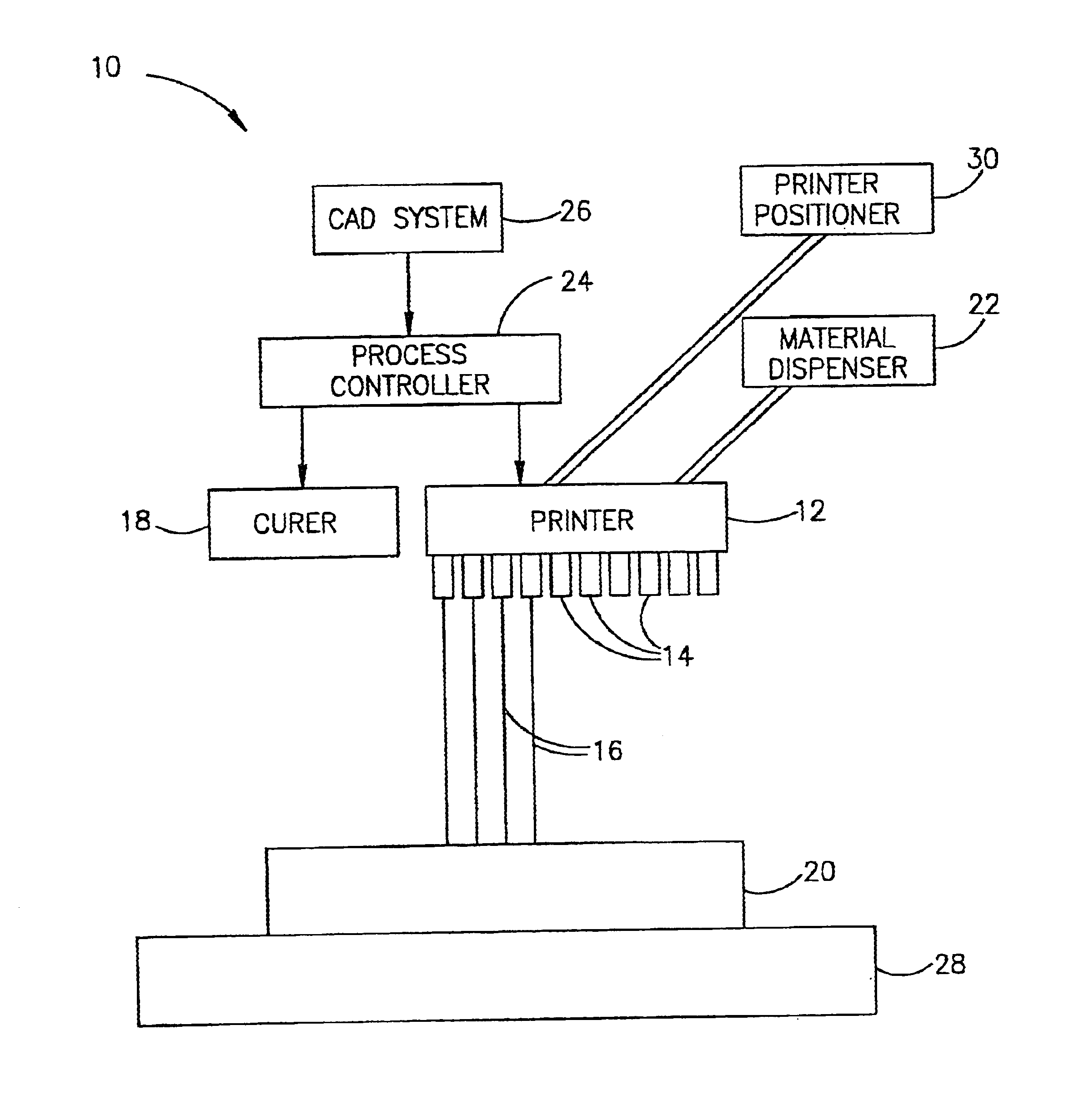

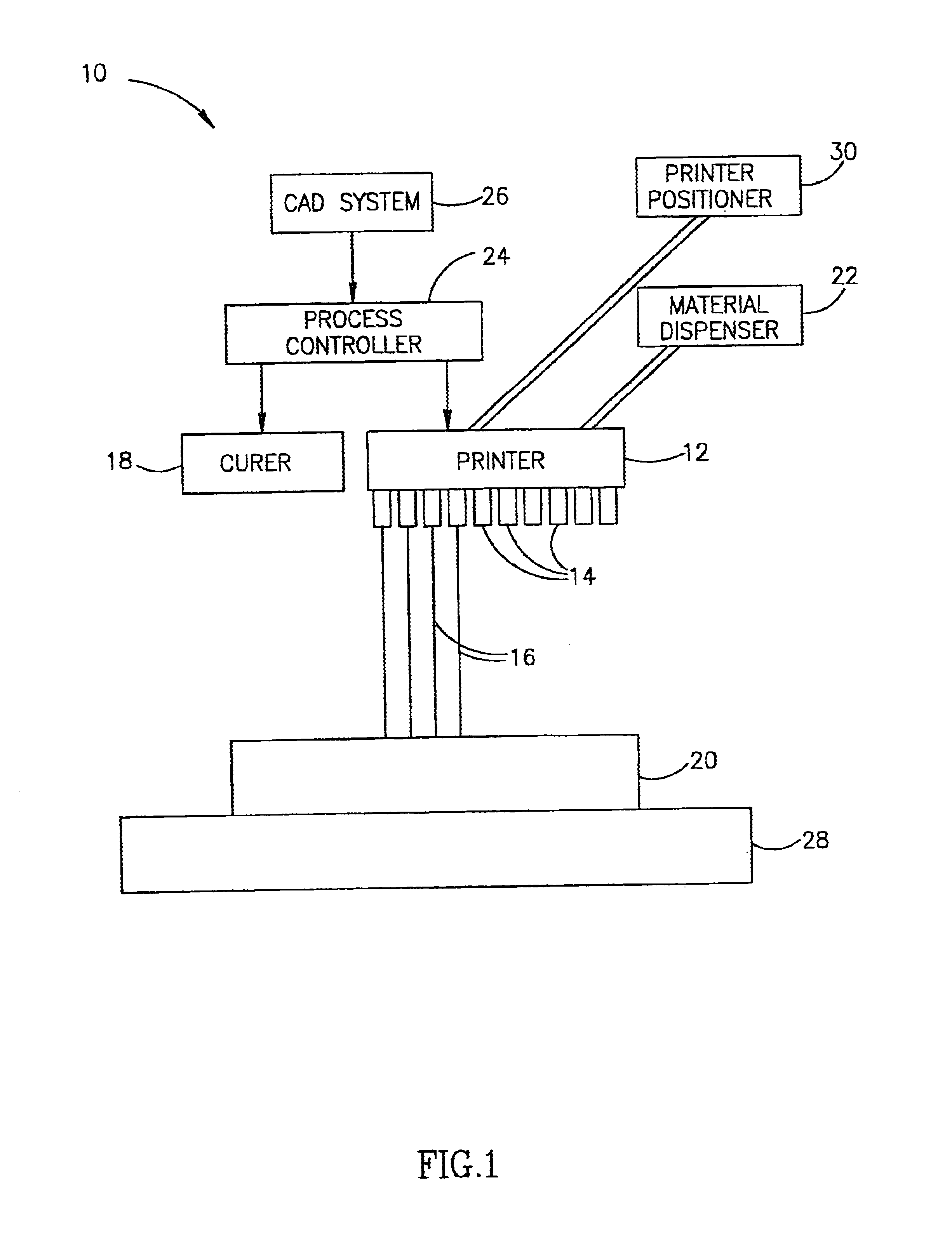

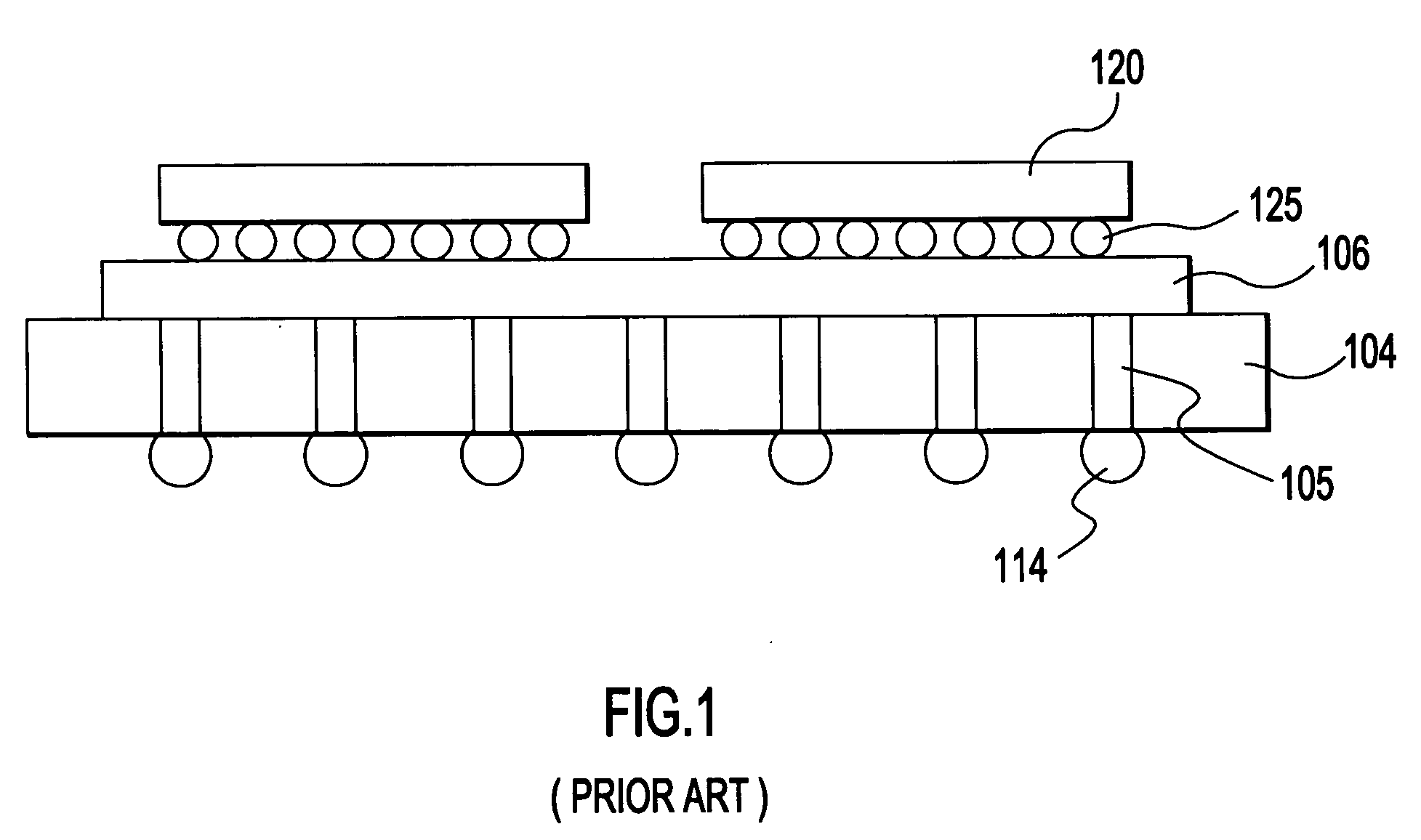

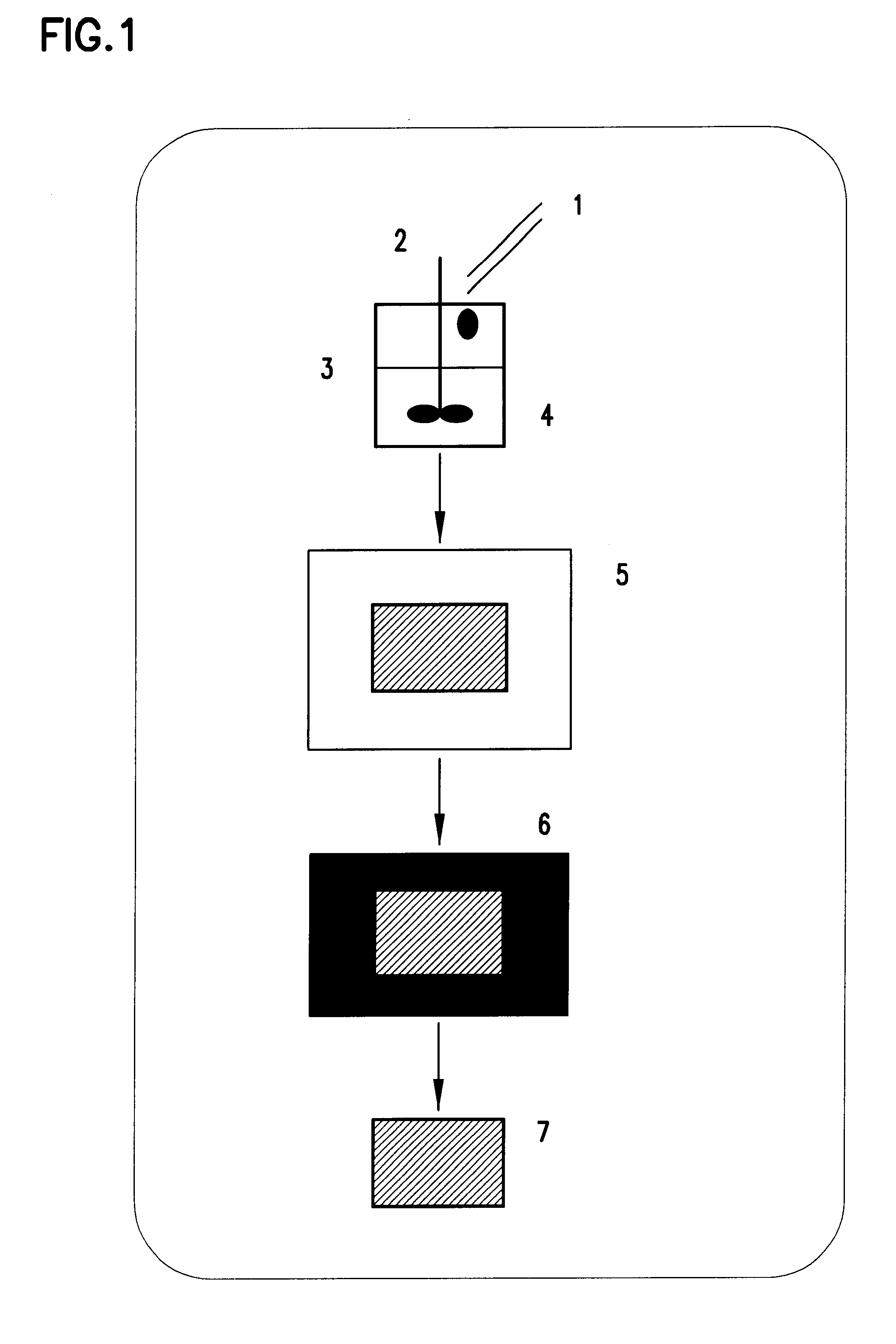

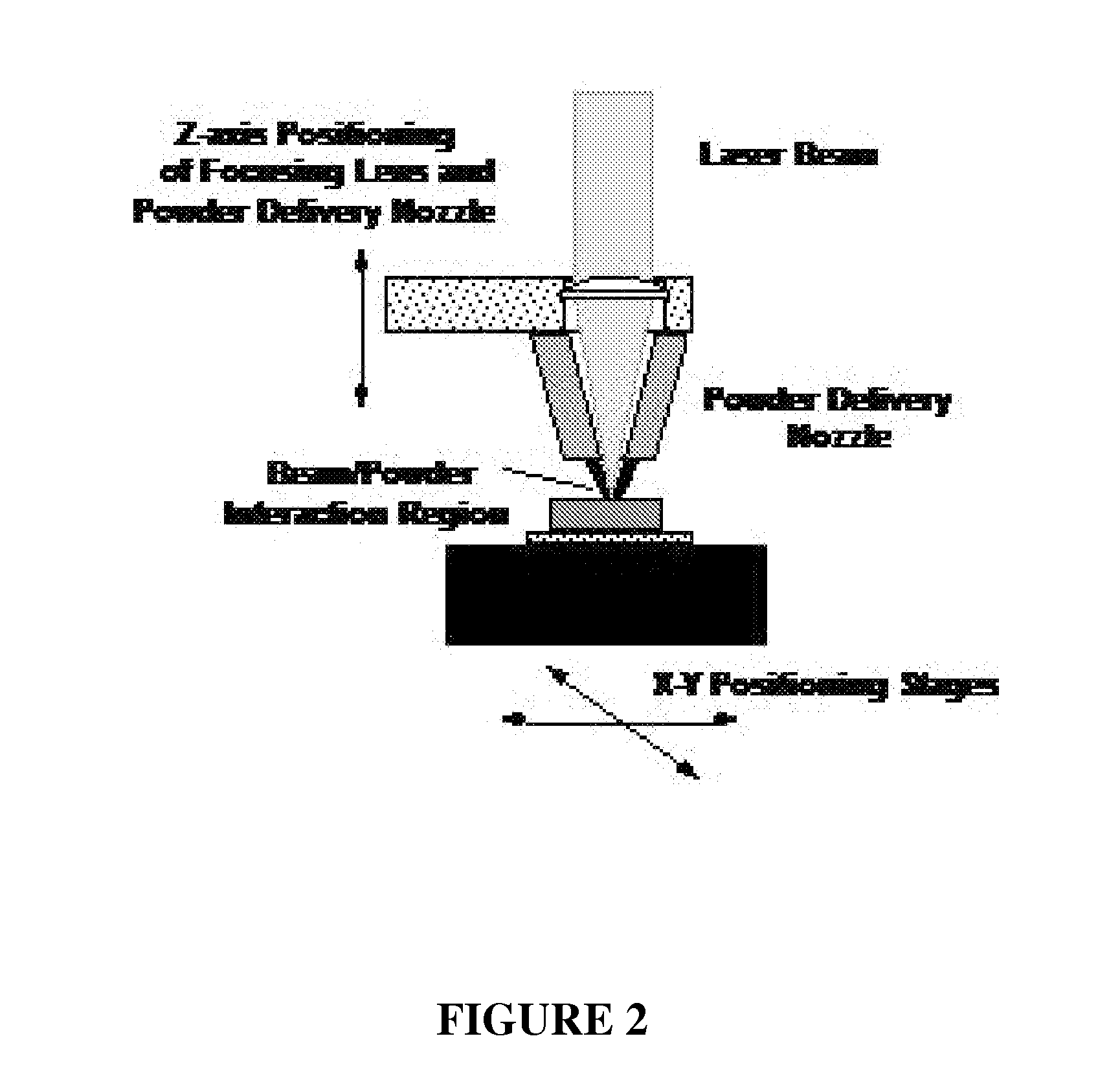

System and method for three dimensional model printing

InactiveUS6658314B1Limited hardnessAdditive manufacturing apparatusPhotomechanical treatmentThree dimensional shapeEngineering

A method and a system for three-dimensional printing of a three-dimensional model is provided. The method includes dispensing a first interface material from a printing head, dispensing at least a second interface material from the printing head and combining the first and second interface material in pre-determined proportions to produce layers for forming the three-dimensional model. In one embodiment, the layers forming the construction layers of the model are formed from interface material having a harder modulus of elasticity from the layers forming the release layers, thereby allowing for the forming complex three-dimensional shapes.

Owner:STRATASYS LTD

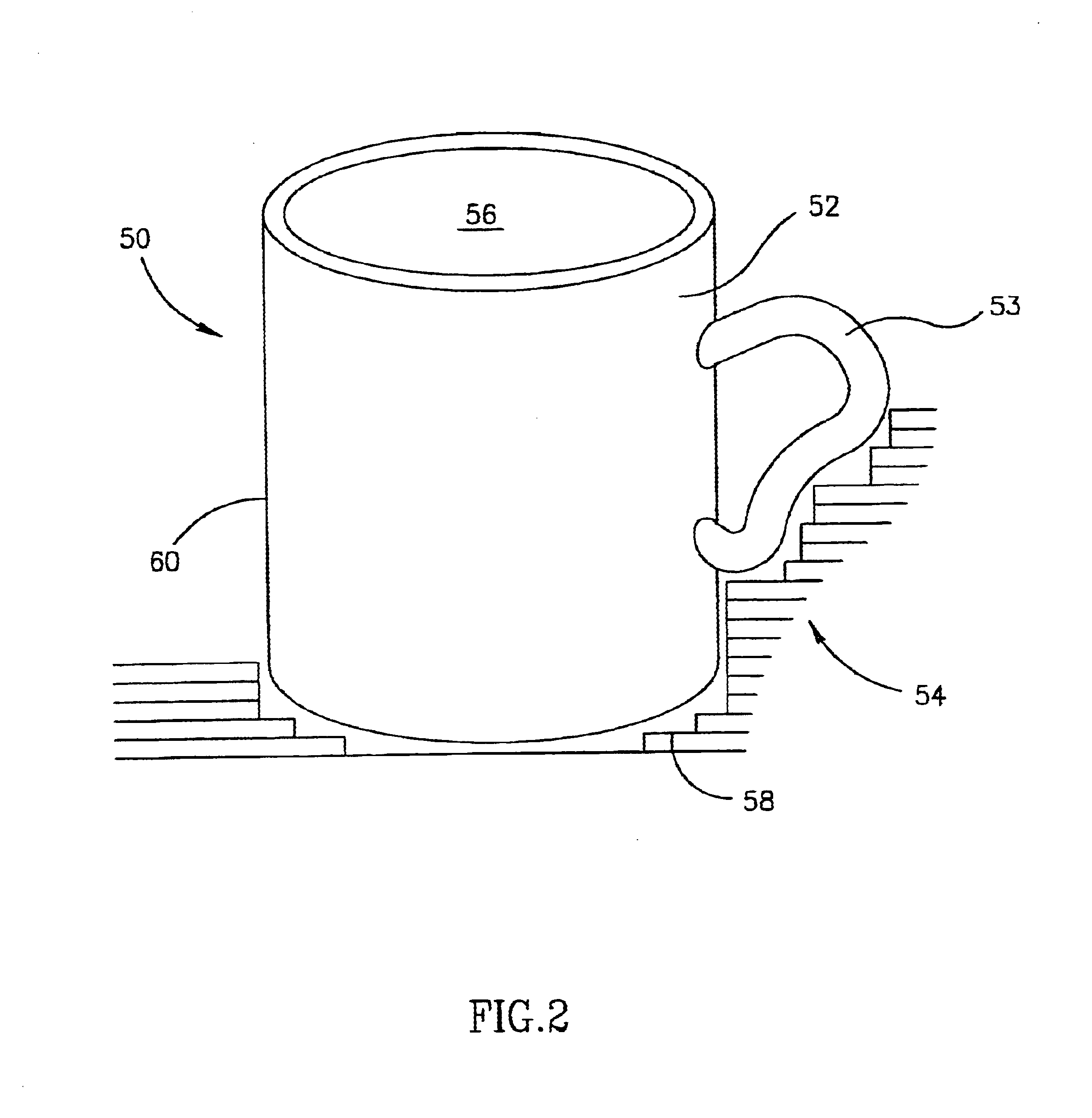

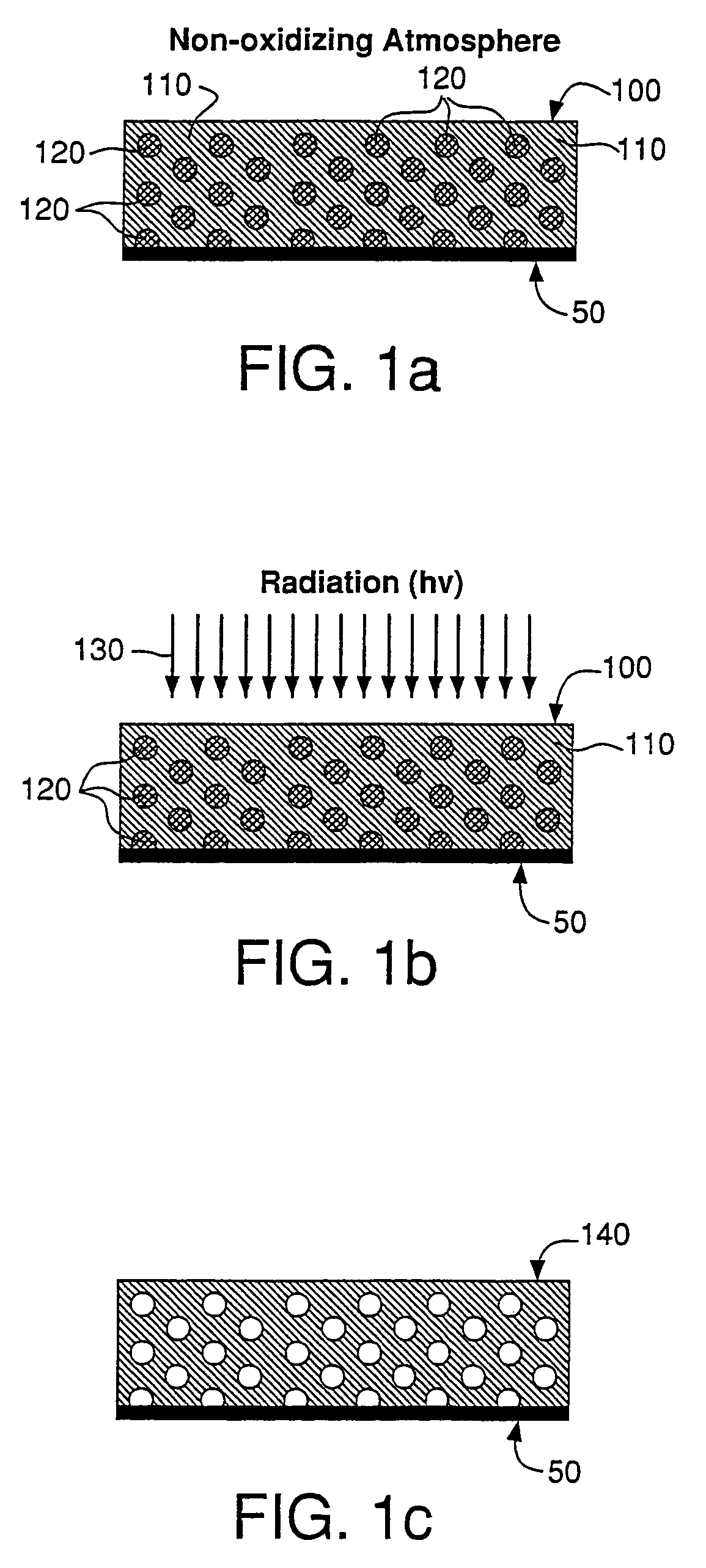

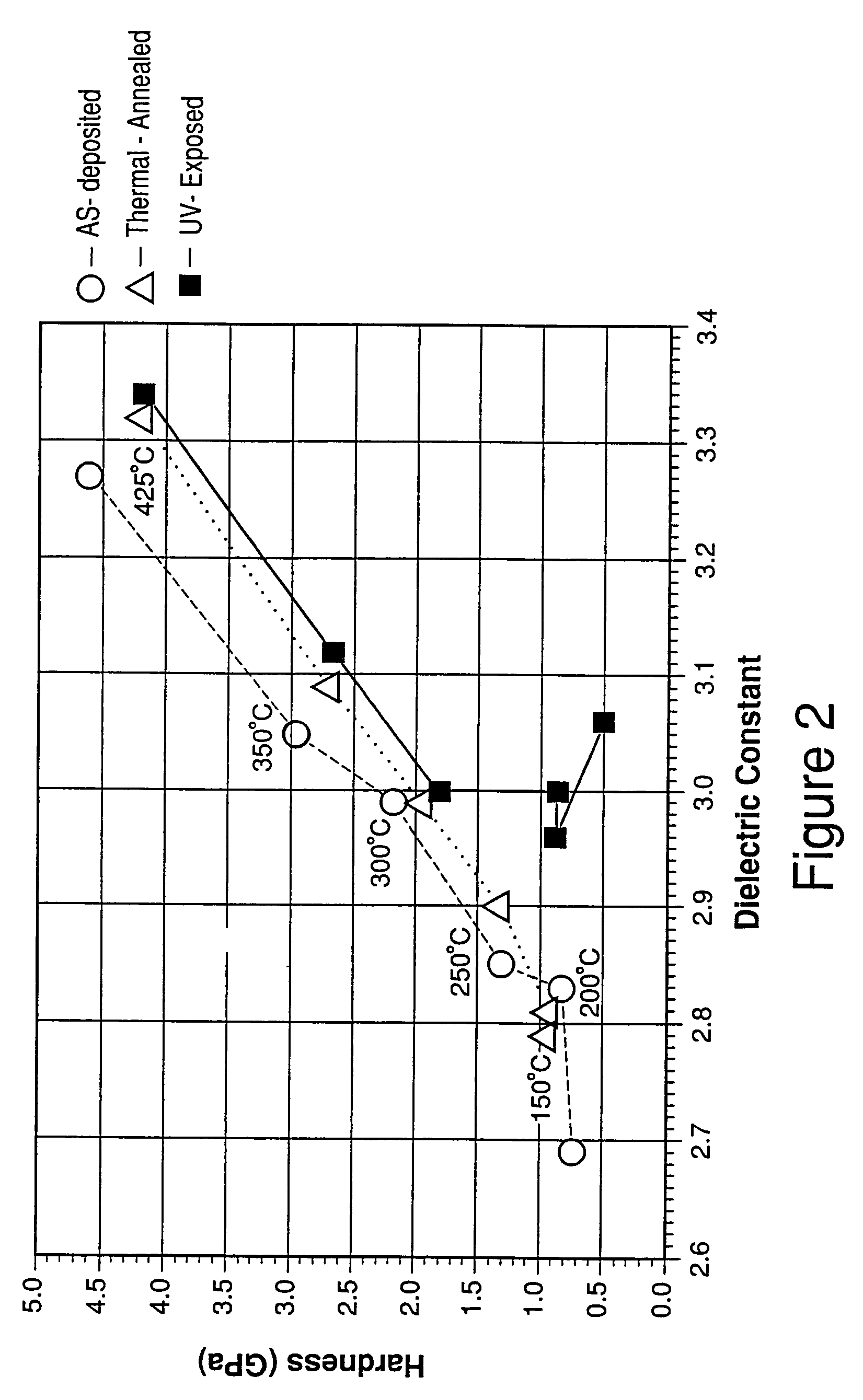

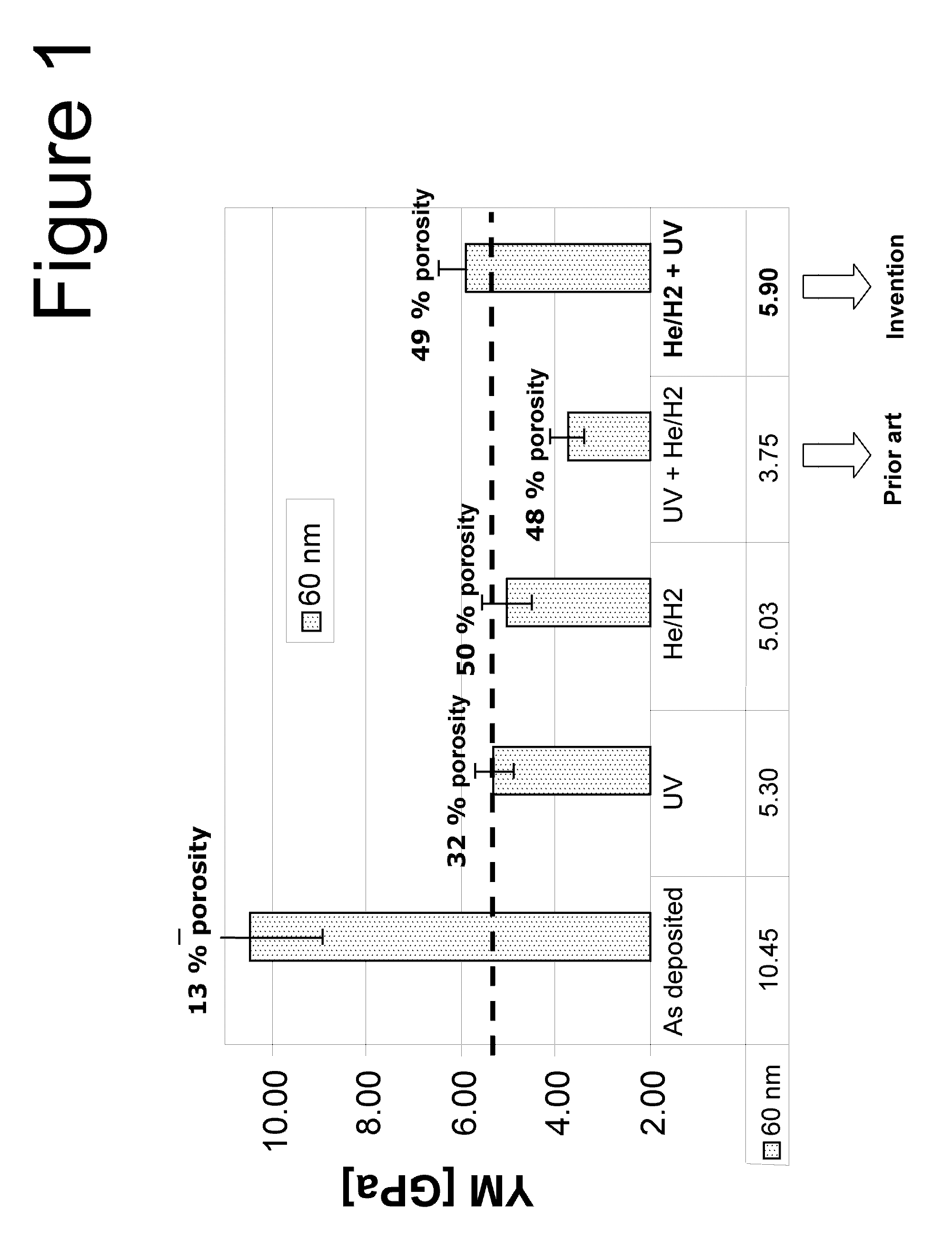

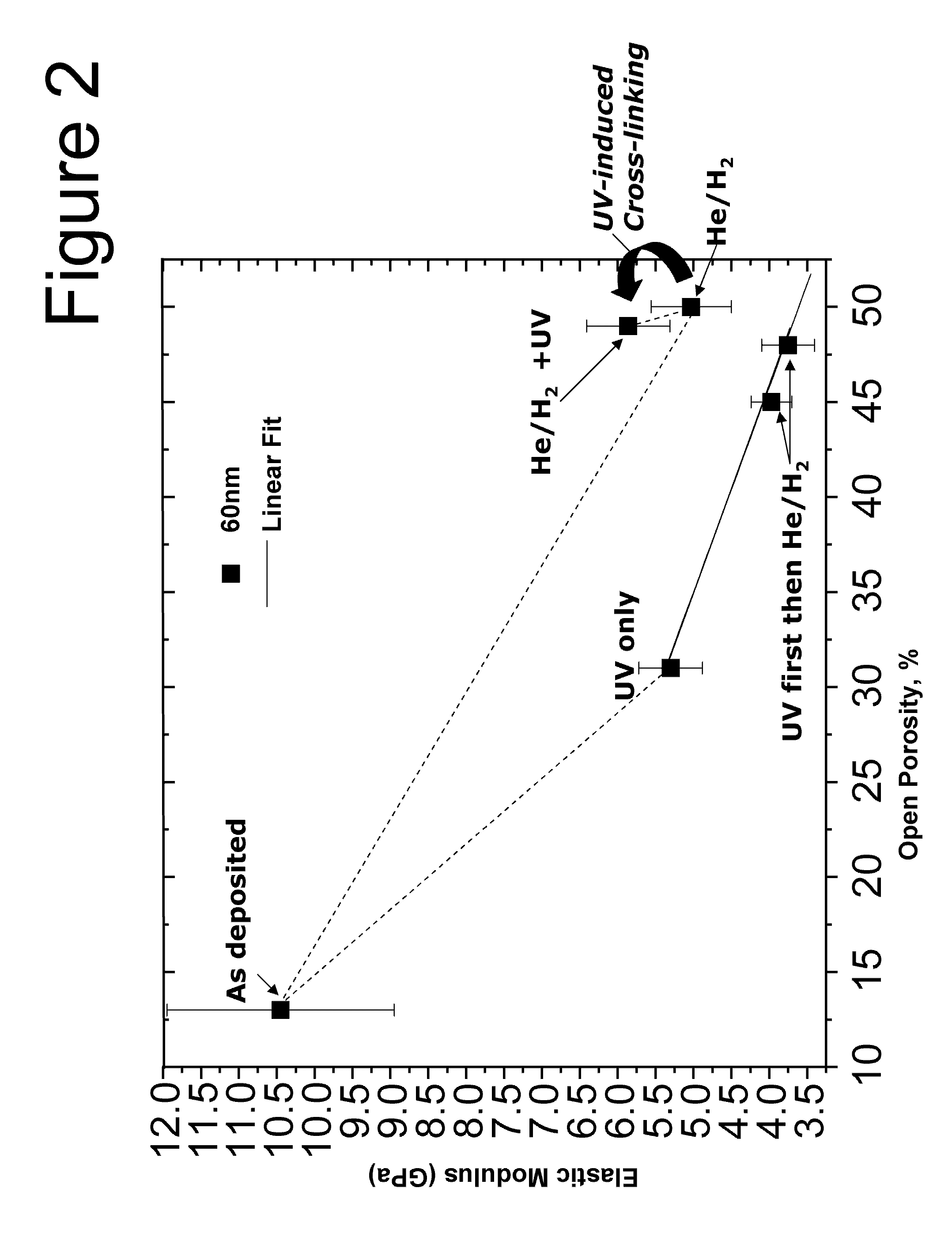

Mechanical enhancement of dense and porous organosilicate materials by UV exposure

InactiveUS7098149B2Low dielectric constantIncrease modulusSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricUltraviolet lights

Low dielectric materials and films comprising same have been identified for improved performance when used as interlevel dielectrics in integrated circuits as well as methods for making same. In one aspect of the present invention, an organosilicate glass film is exposed to an ultraviolet light source wherein the film after exposure has an at least 10% or greater improvement in its mechanical properties (i.e., material hardness and elastic modulus) compared to the as-deposited film.

Owner:VERSUM MATERIALS US LLC

Plasma curing process for porous silica thin film

InactiveUS6558755B2Low dielectric constantHigh elastic modulusSilicaSemiconductor/solid-state device manufacturingSilicon dioxideHeat treated

Low dielectric constant films with improved elastic modulus. The method of making such coatings involves providing a porous network coating produced from a resin containing at least 2 Si-H groups and plasma curing the coating to convert the coating into porous silica. Plasma curing of the network coating yields a coating with improved modulus, but with a higher dielectric constant. The costing is plasma cured for between about 15 and about 120 seconds at a temperature less than or about 350° C. The plasma cured coating can optionally be annealed. Rapid thermal processing (RTP) of the plasma cured coating reduces the dielectric constant of the coating while maintaining an improved elastic modulus as compared to the plasma cured porous network coating. The annealing temperature is typically loss than or about 475° C., and the annealing time is typically no more than or about 180 seconds. The annealed, plasma cured coating has a dielectric constant in the range of from about 1.1 to about 2.4 and an improved elastic modulus.

Owner:AXCELIS TECHNOLOGIES +1

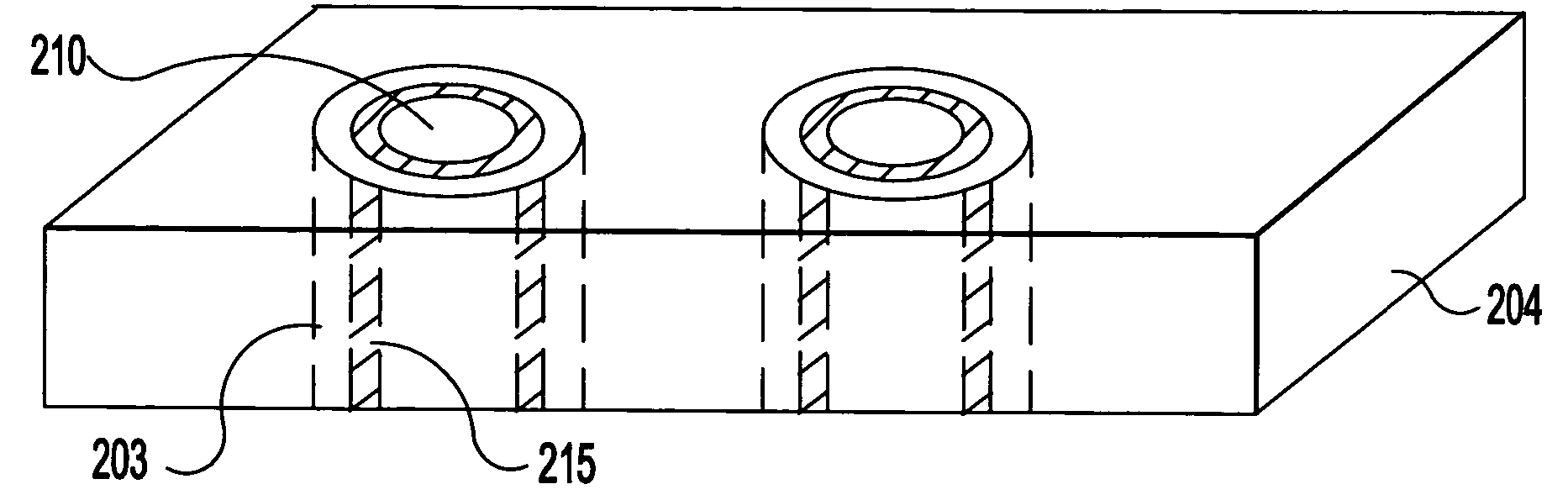

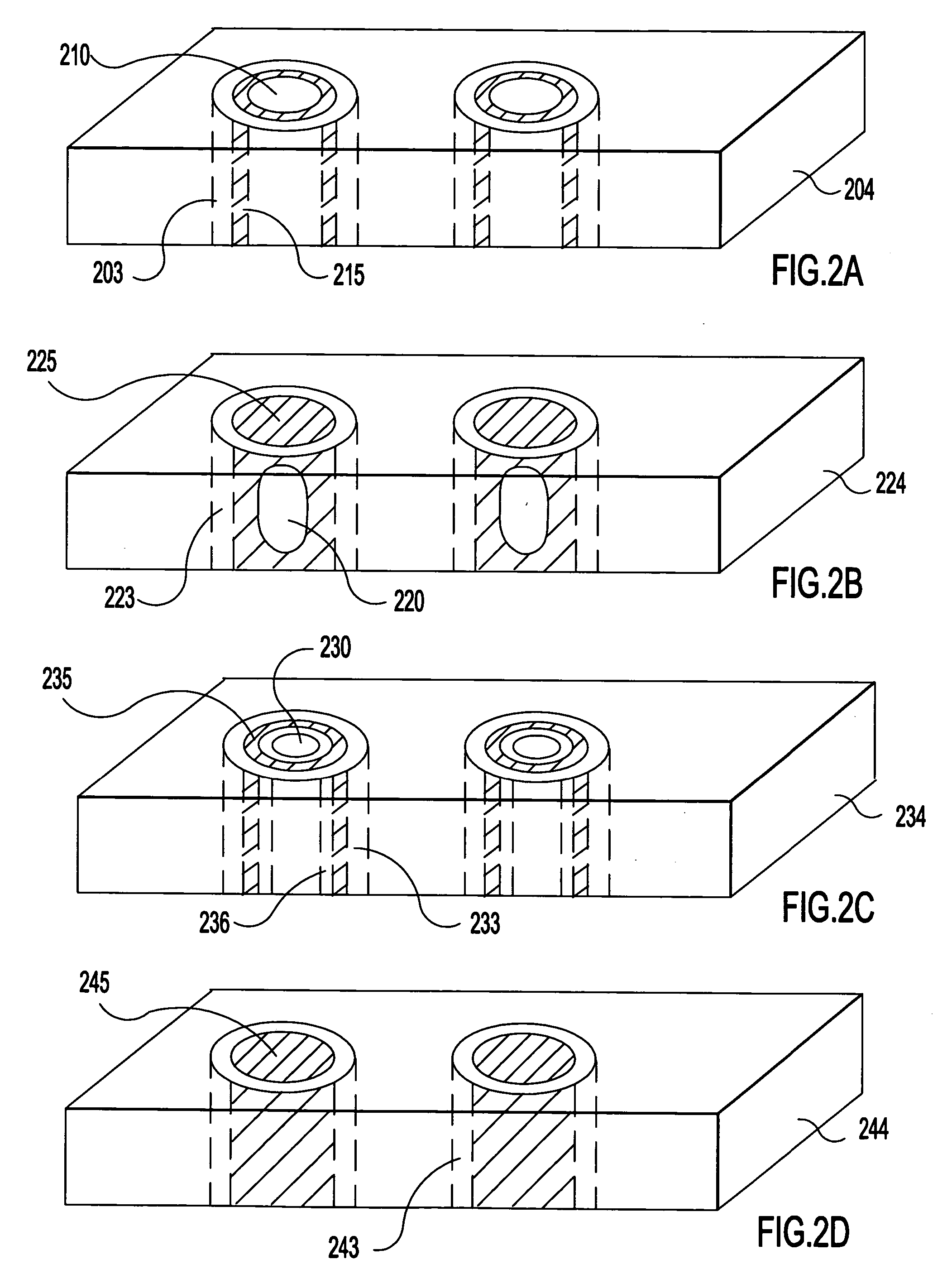

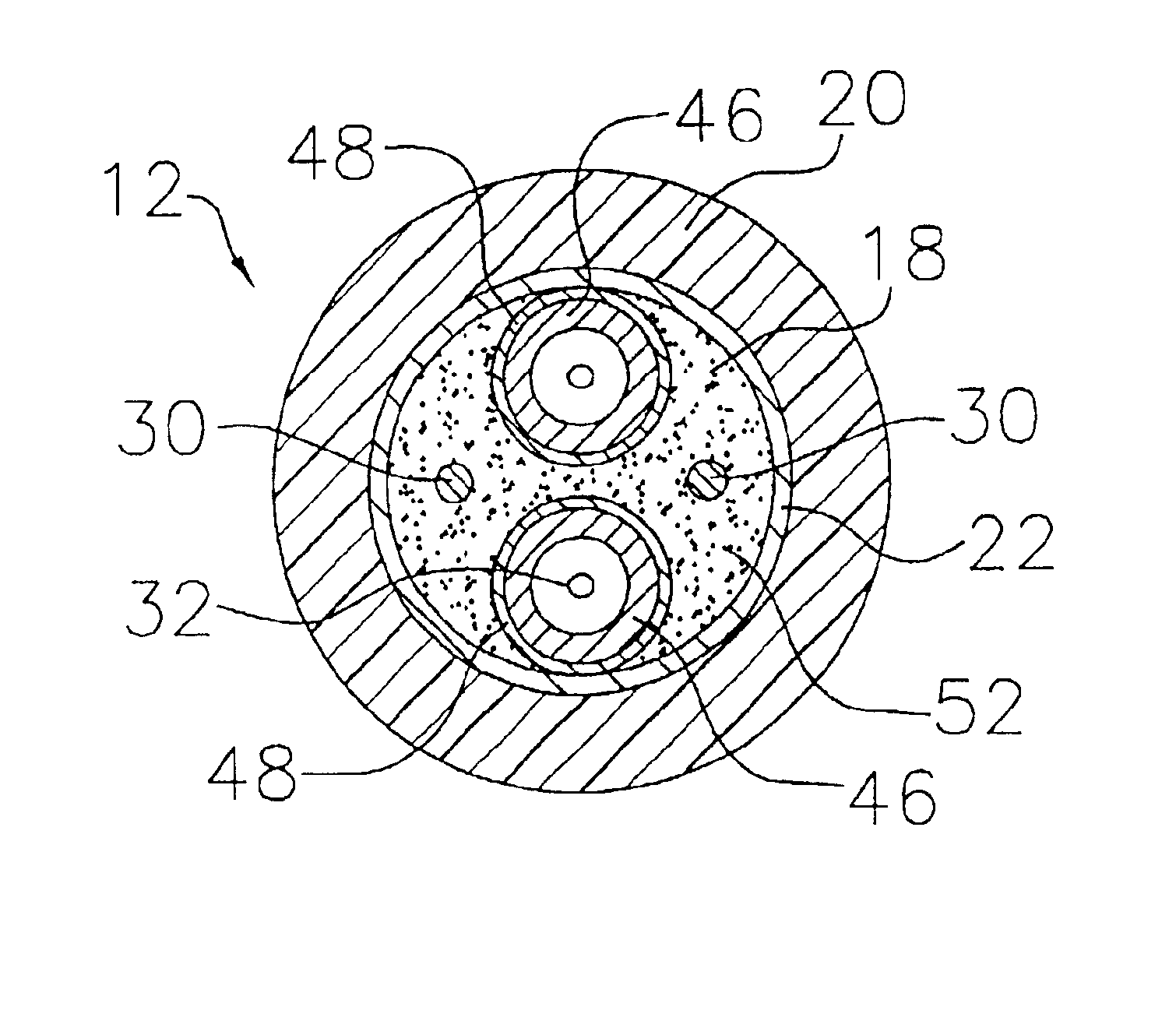

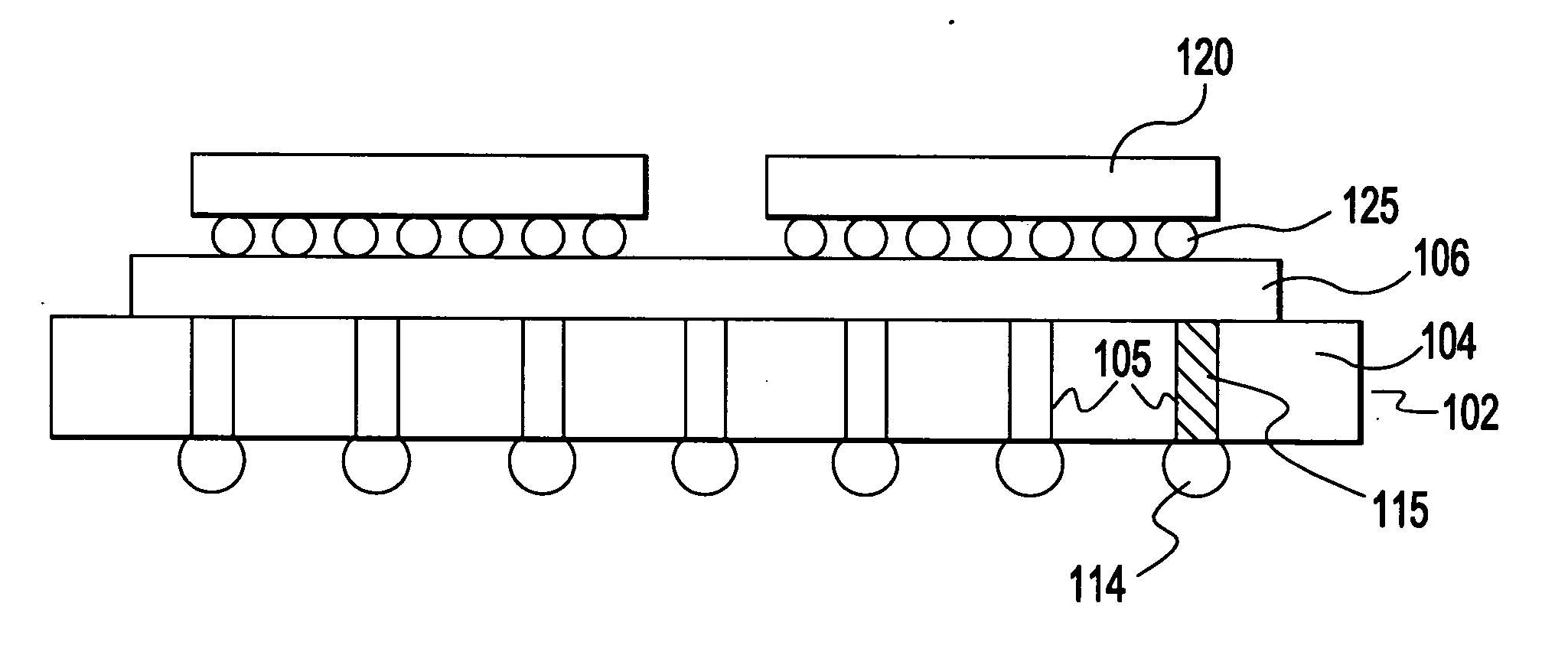

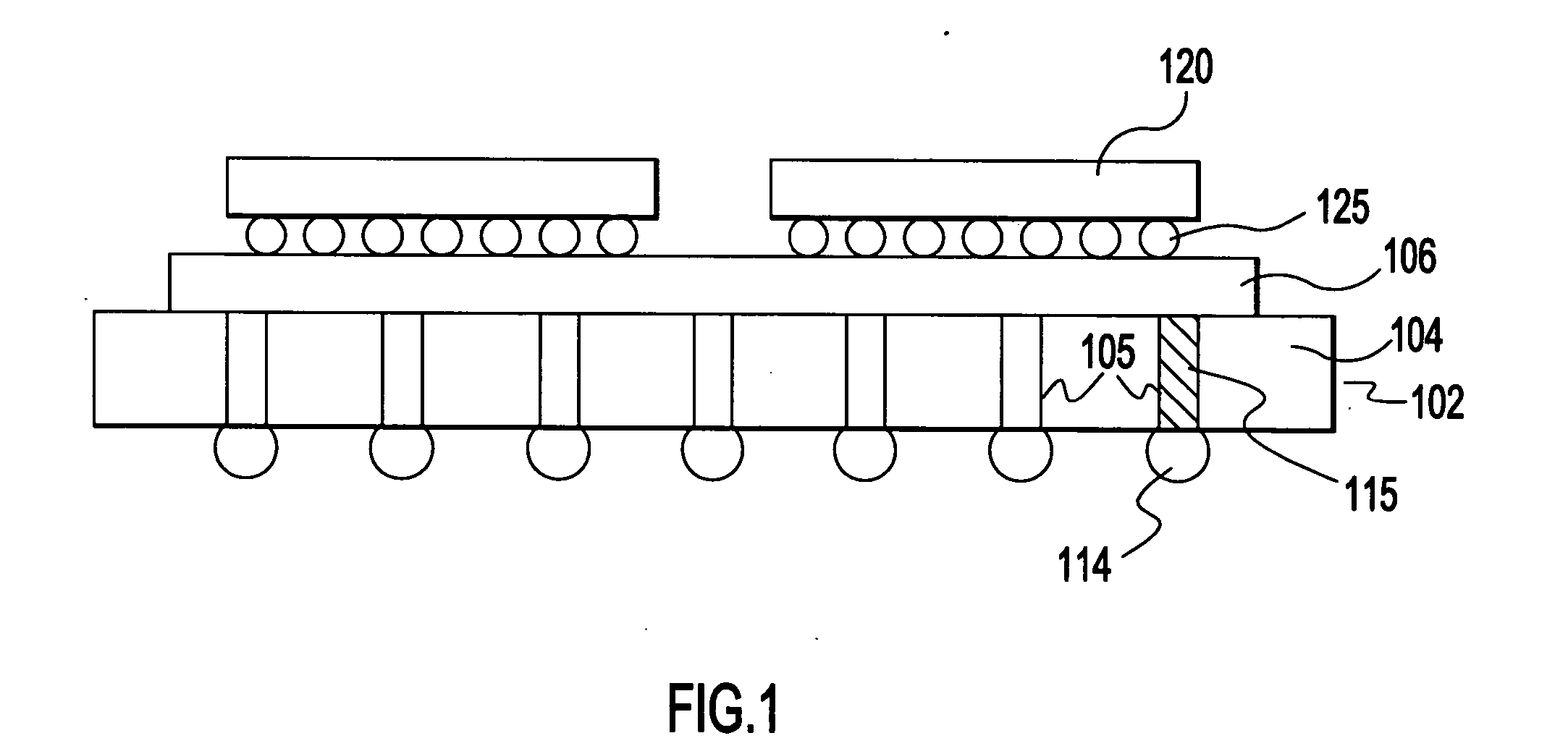

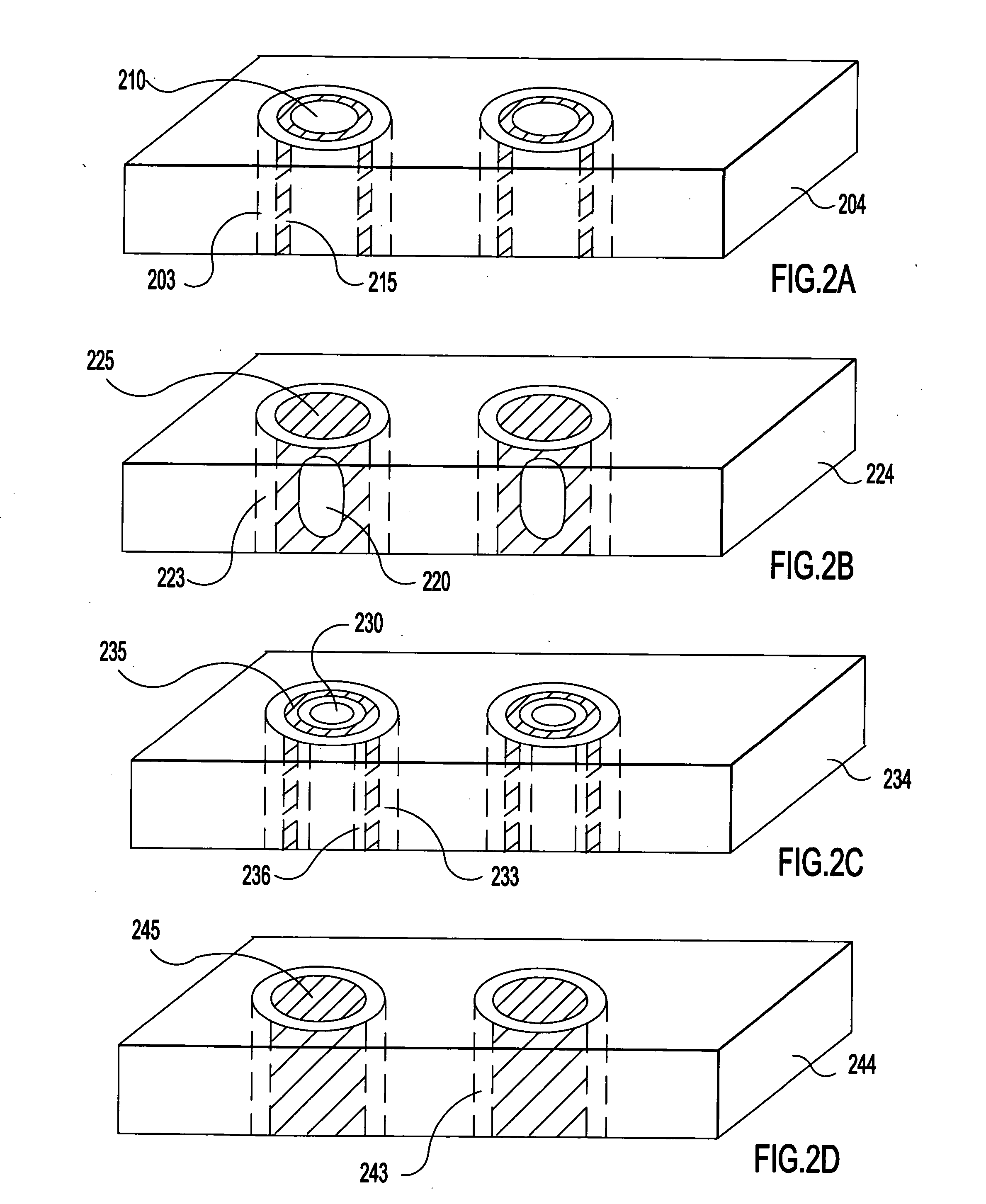

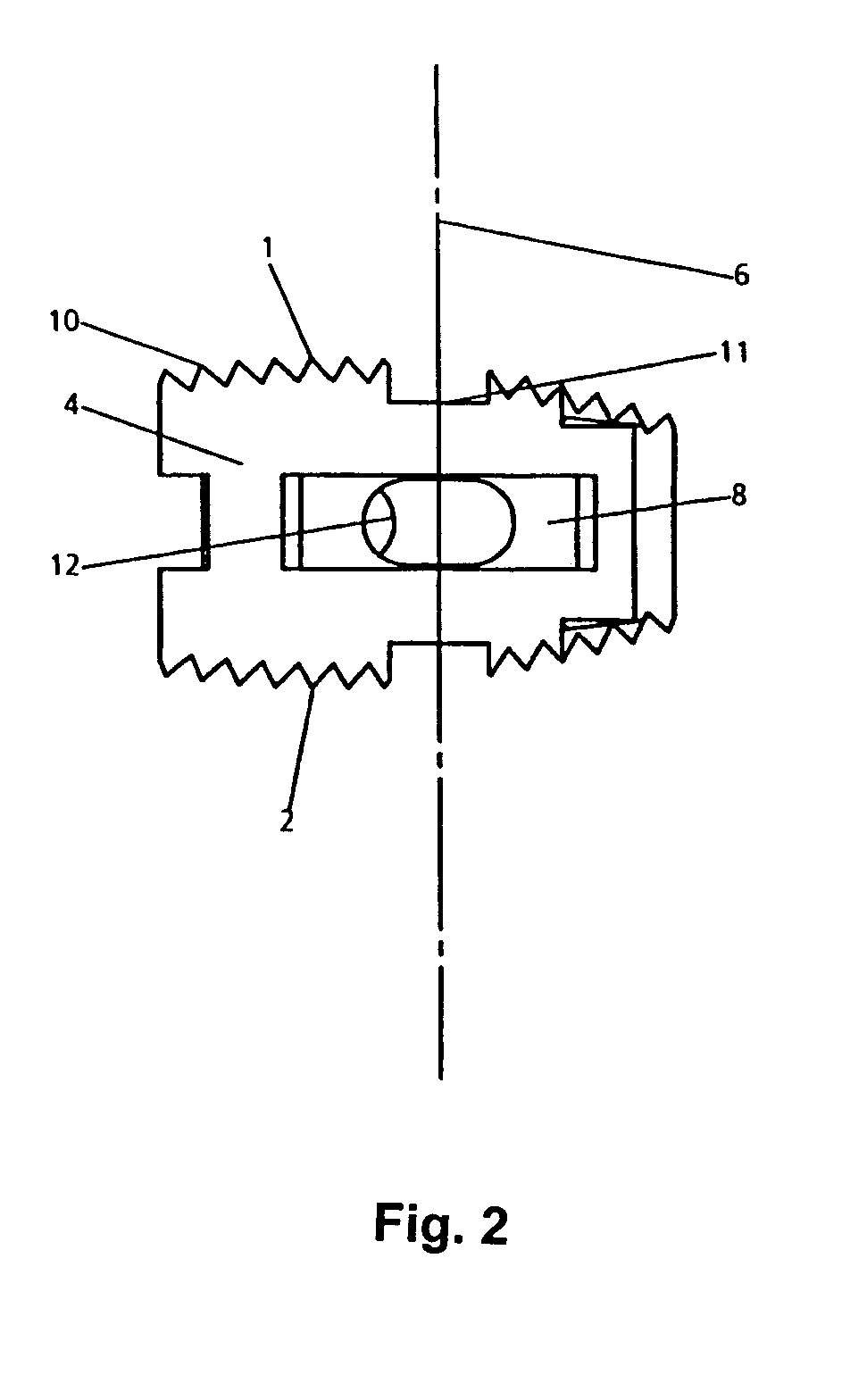

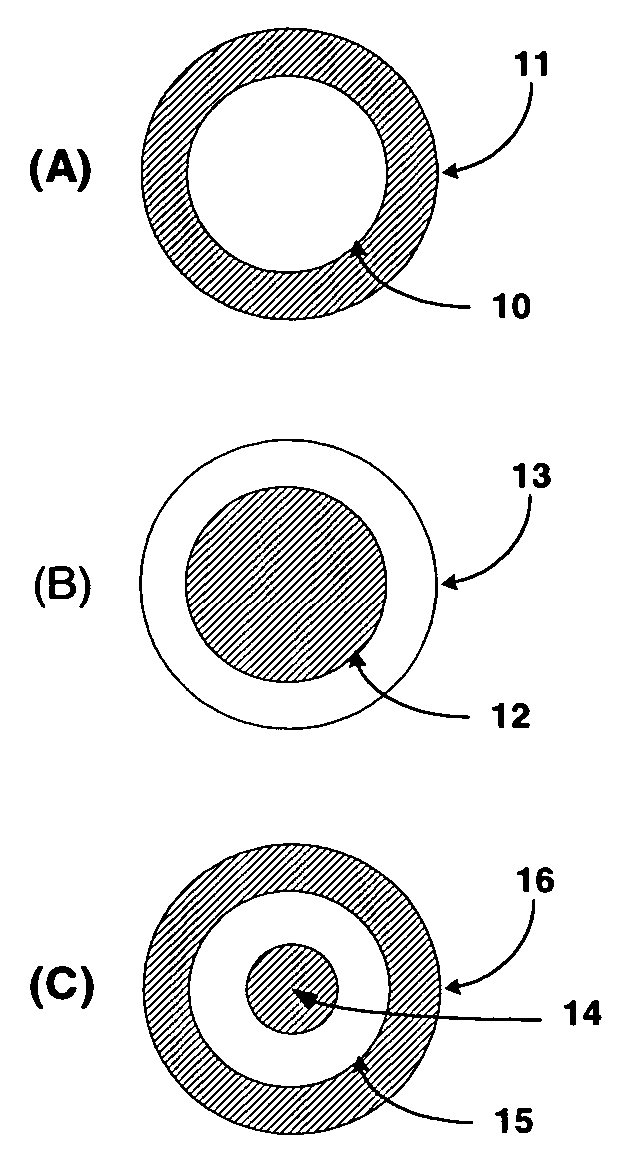

Silicon chip carrier with conductive through-vias and method for fabricating same

InactiveUS20050121768A1Effective modulusSemiconductor/solid-state device detailsSolid-state devicesSilicon chipElastic modulus

A carrier structure and method for fabricating a carrier structure with through-vias each having a conductive structure with an effective coefficient of thermal expansion which is less than or closely matched to that of the substrate, and having an effective elastic modulus value which is less than or closely matches that of the substrate. The conductive structure may include concentric via fill areas having differing materials disposed concentrically therein, a core of the substrate material surrounded by an annular ring of conductive material, a core of CTE-matched non-conductive material surrounded by an annular ring of conductive material, a conductive via having an inner void with low CTE, or a full fill of a conductive composite material such as a metal-ceramic paste which has been sintered or fused.

Owner:GLOBALFOUNDRIES INC

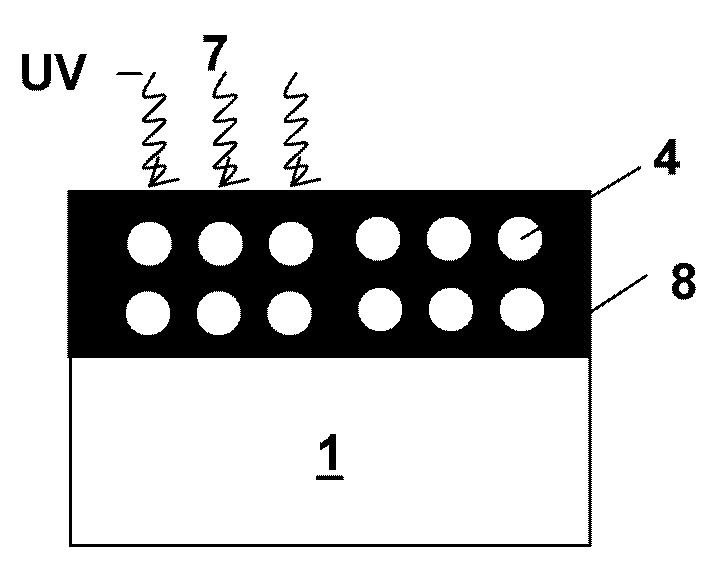

Fabrication of porogen residues free and mechanically robust low-k materials

InactiveUS20110006406A1Improve H radical concentrationHigh elastic modulusSemiconductor/solid-state device detailsSolid-state devicesPorosityHydrogen treatment

A method is provided for producing a porogen-residue-free ultra low-k film with porosity higher than 50% and a high elastic modulus above 5 GPa. The method starts with depositing a SiCOH film using Plasma Enhanced Chemical Vapor Deposition (PE-CVD) or Chemical Vapor Deposition (CVD) onto a substrate and then first Performing an atomic hydrogen treatment at elevated wafer temperature in the range of 200° C. up to 350° C. to remove all the porogens and then performing a UV assisted thermal curing step.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

Plasma curing process for porous low-k materials

InactiveUS6913796B2Improving elastic modulusImproving material hardnessSilicaLayered productsHardnessMaterials science

Low dielectric constant porous materials with improved elastic modulus and hardness. The process of making such porous materials involves providing a porous dielectric material and plasma curing the porous dielectric material to produce a plasma cured porous dielectric material. Plasma curing of the porous dielectric material yields a material with improved modulus and hardness. The improvement in elastic modulus is typically greater than or about 50%, more typically greater than or about 100%, and more typically greater than or about 200%. The improvement in hardness is typically greater than or about 50%. The plasma cured porous dielectric material can optionally be post-plasma treated. The post-plasma treatment of the plasma cured porous dielectric material reduces the dielectric constant of the material while maintaining an improved elastic modulus and hardness as compared to the plasma cured porous dielectric material. The post-plasma treated, plasma cured porous dielectric material has a dielectric constant between about 1.1 and about 3.5 and an improved elastic modulus and hardness.

Owner:DOW CORNING CORP

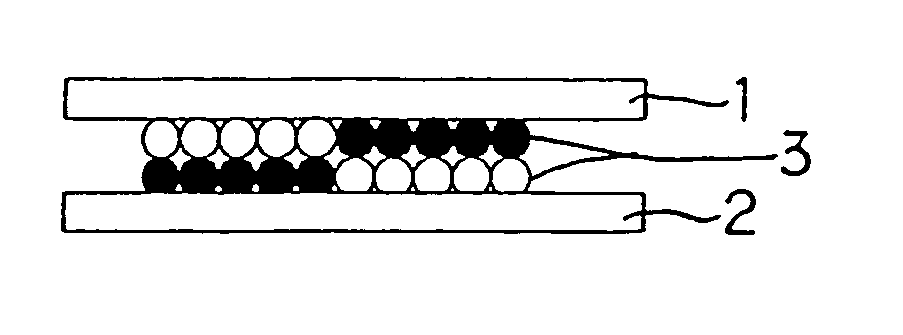

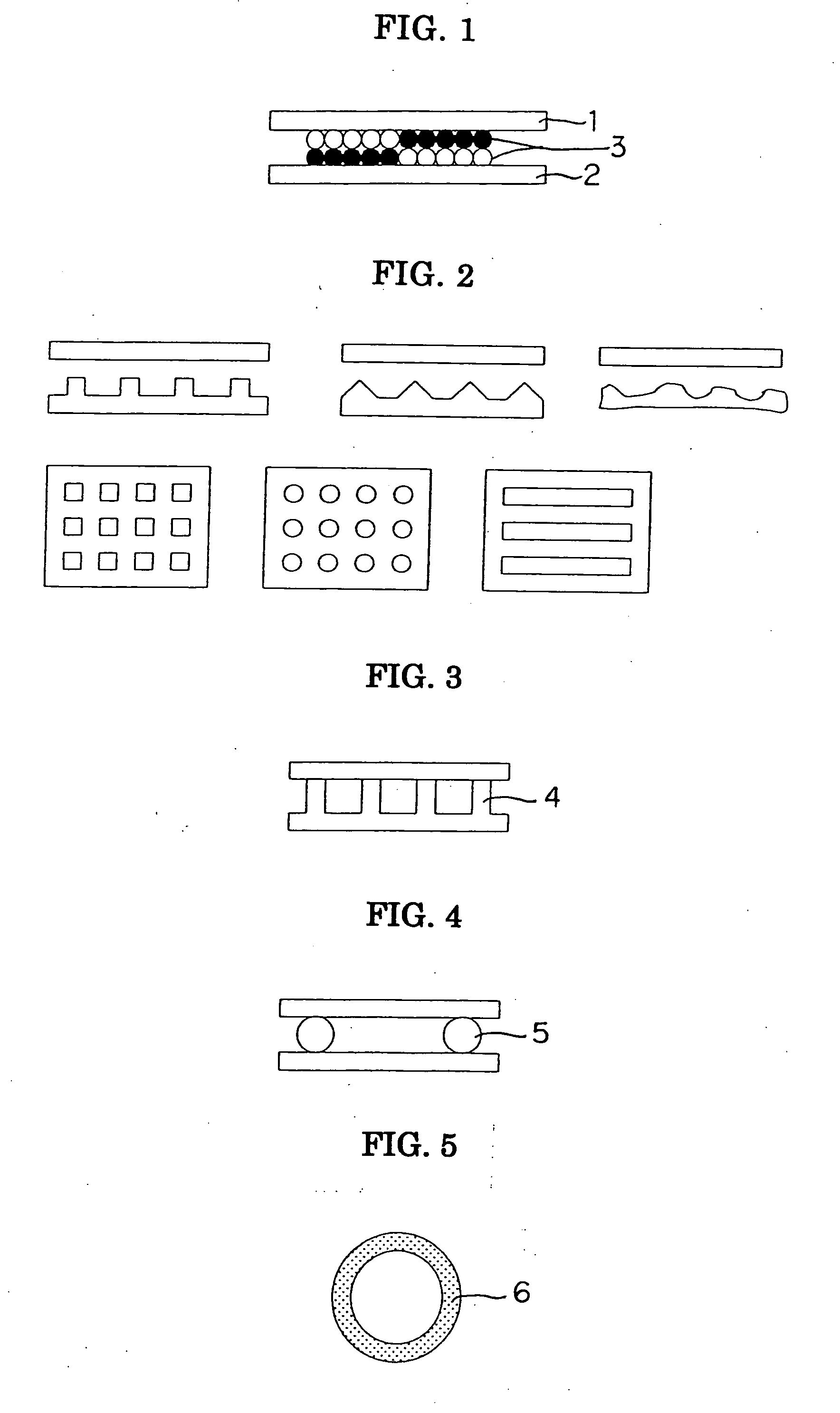

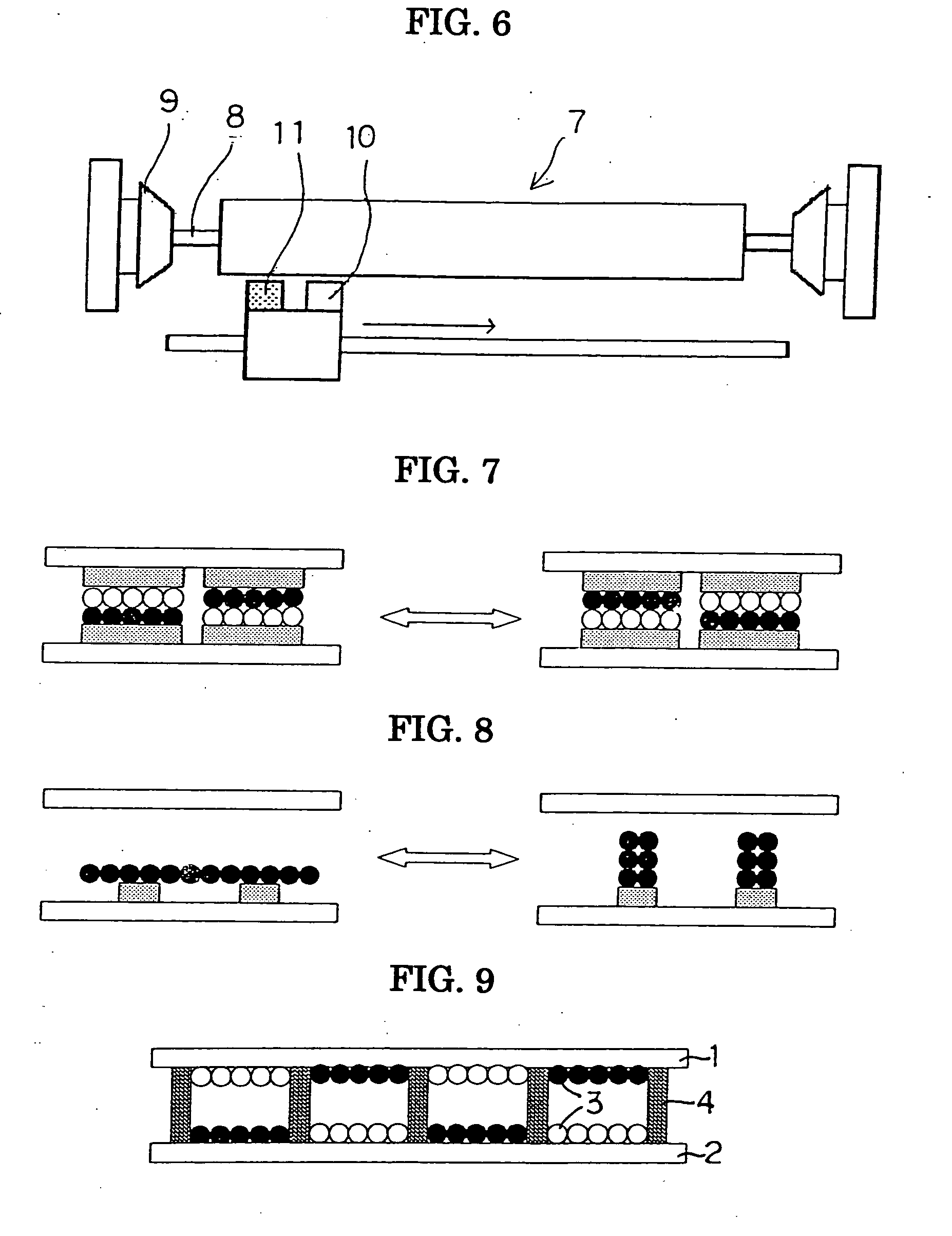

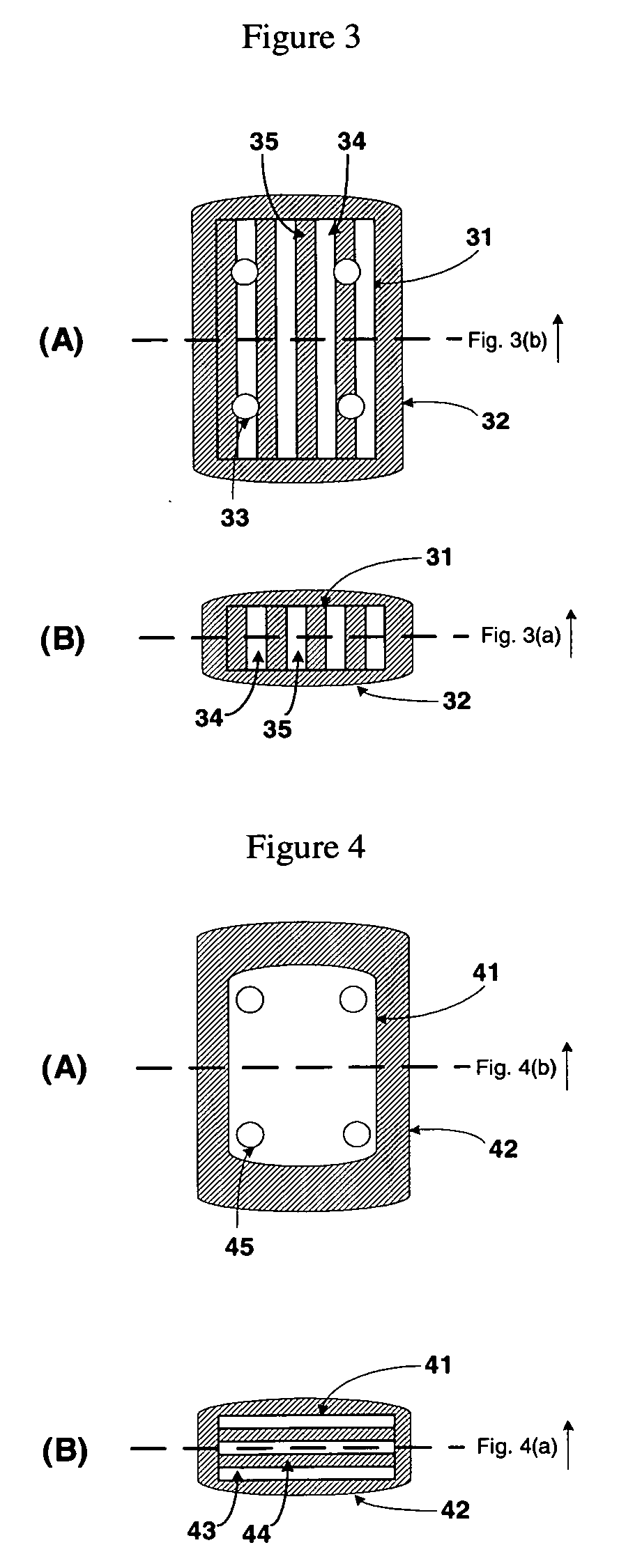

Particles and device for displaying image

InactiveUS20050001810A1Improve stabilityEnhance the imageStatic indicating devicesNon-linear opticsBreaking strengthUltrasound attenuation

The present invention intends to provide particles for displaying images used in an image display device capable of displaying and eliminating repeatedly accompanied by flight and movement of particles utilizing Coulomb force, being superior in stability, particularly in repetition durability, memory characteristic stability, adaptability for temperature change, having capability of regulating charge amount, and accordingly, favorable images with sufficient contrast should be stably obtained. The present invention provides particles coated with a resin; specifying Span of particle diameter distribution, charge attenuation property, thermal change of the surface hardness, tensile break strength, Izod impact strength (with a notch), abrasion loss (Taber), tensile elastic modulus, flexural elastic modulus, or tear strength. The present invention also proposes about the structure of the particles.

Owner:BRIDGESTONE CORP

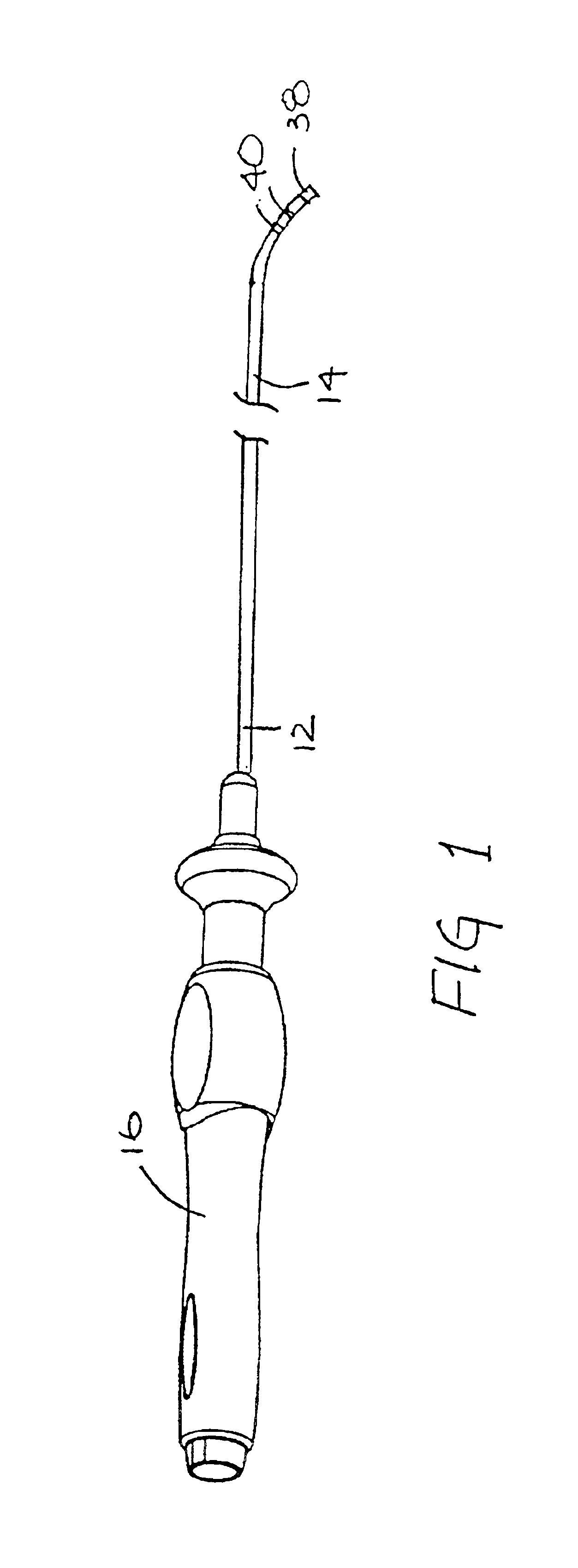

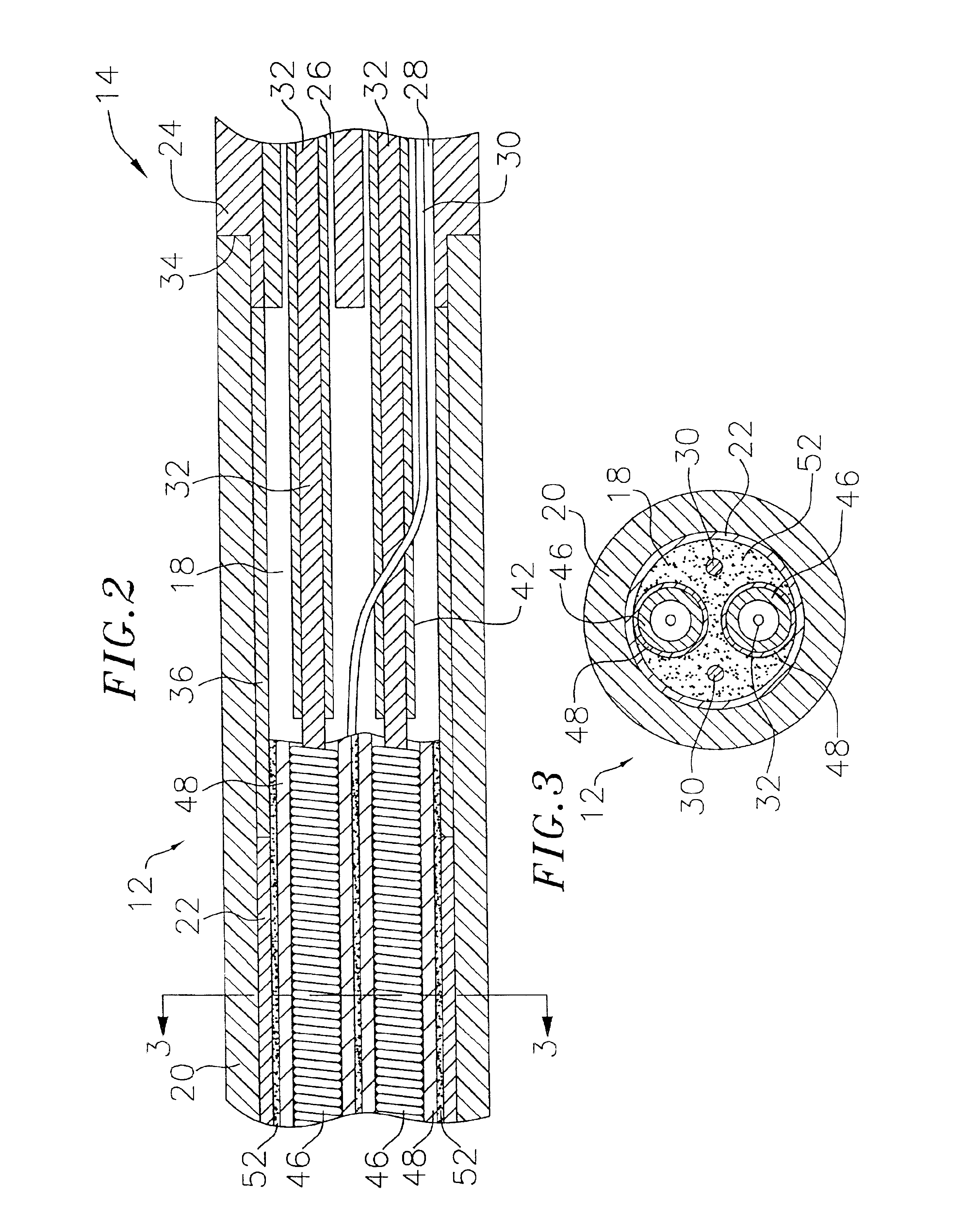

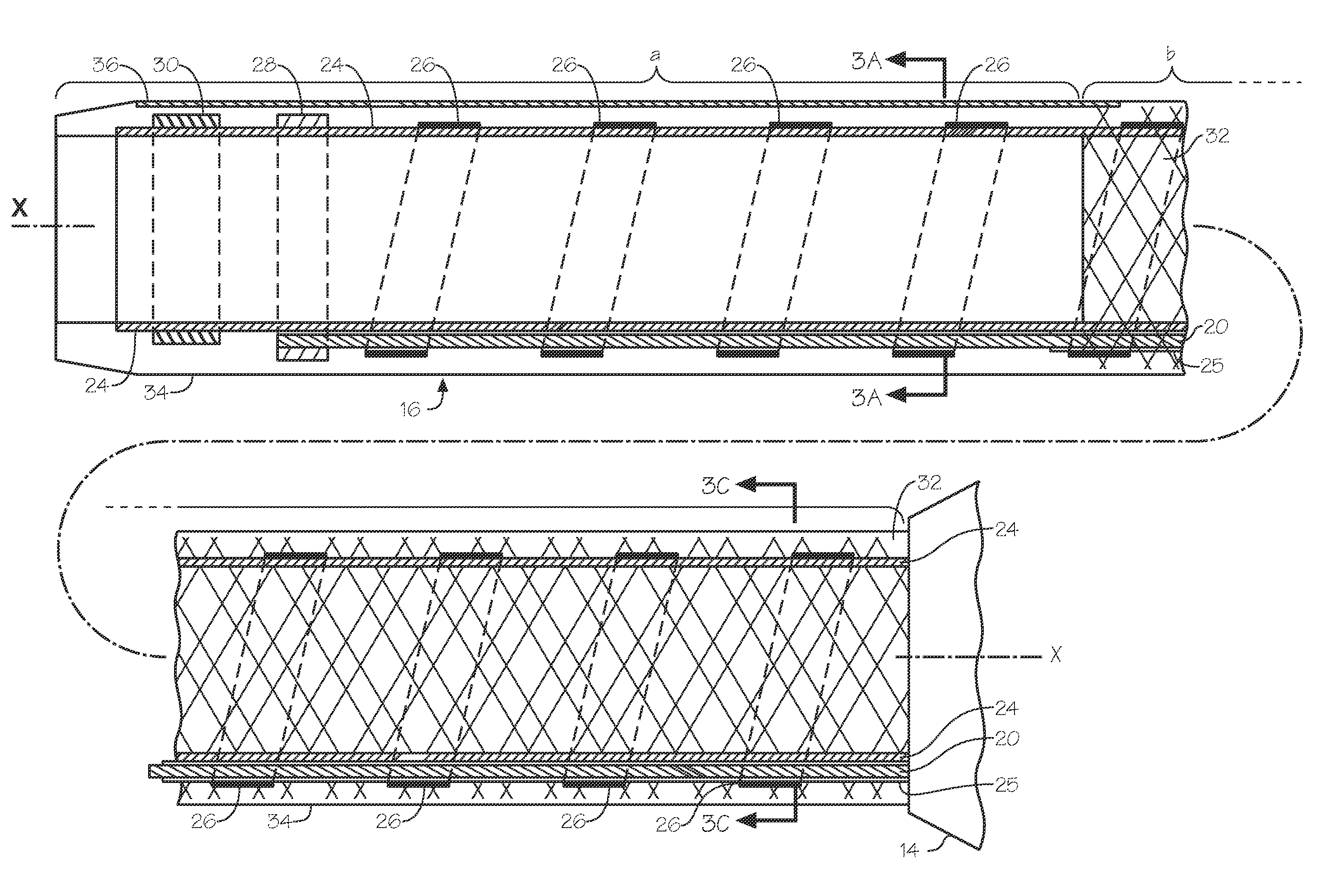

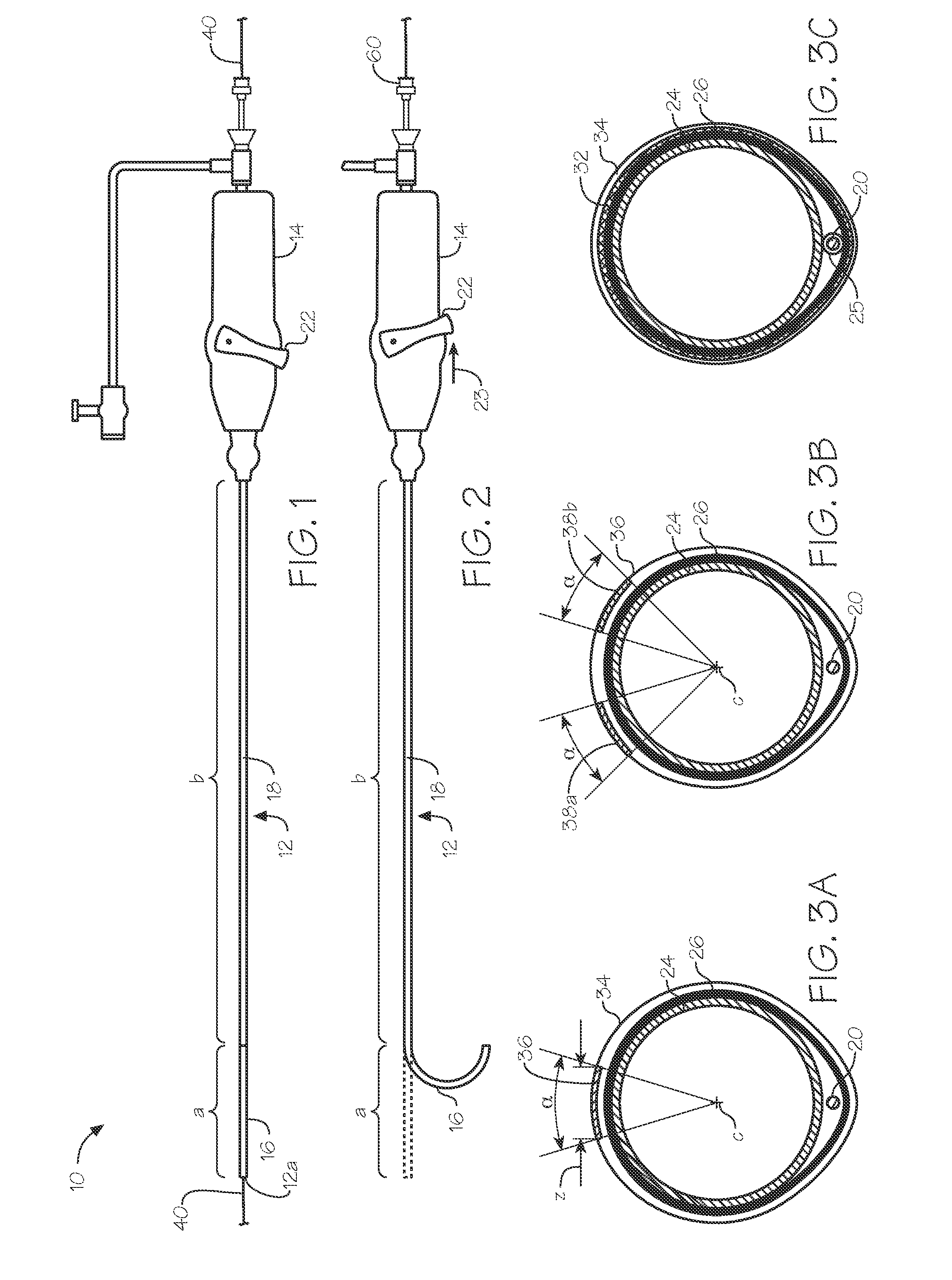

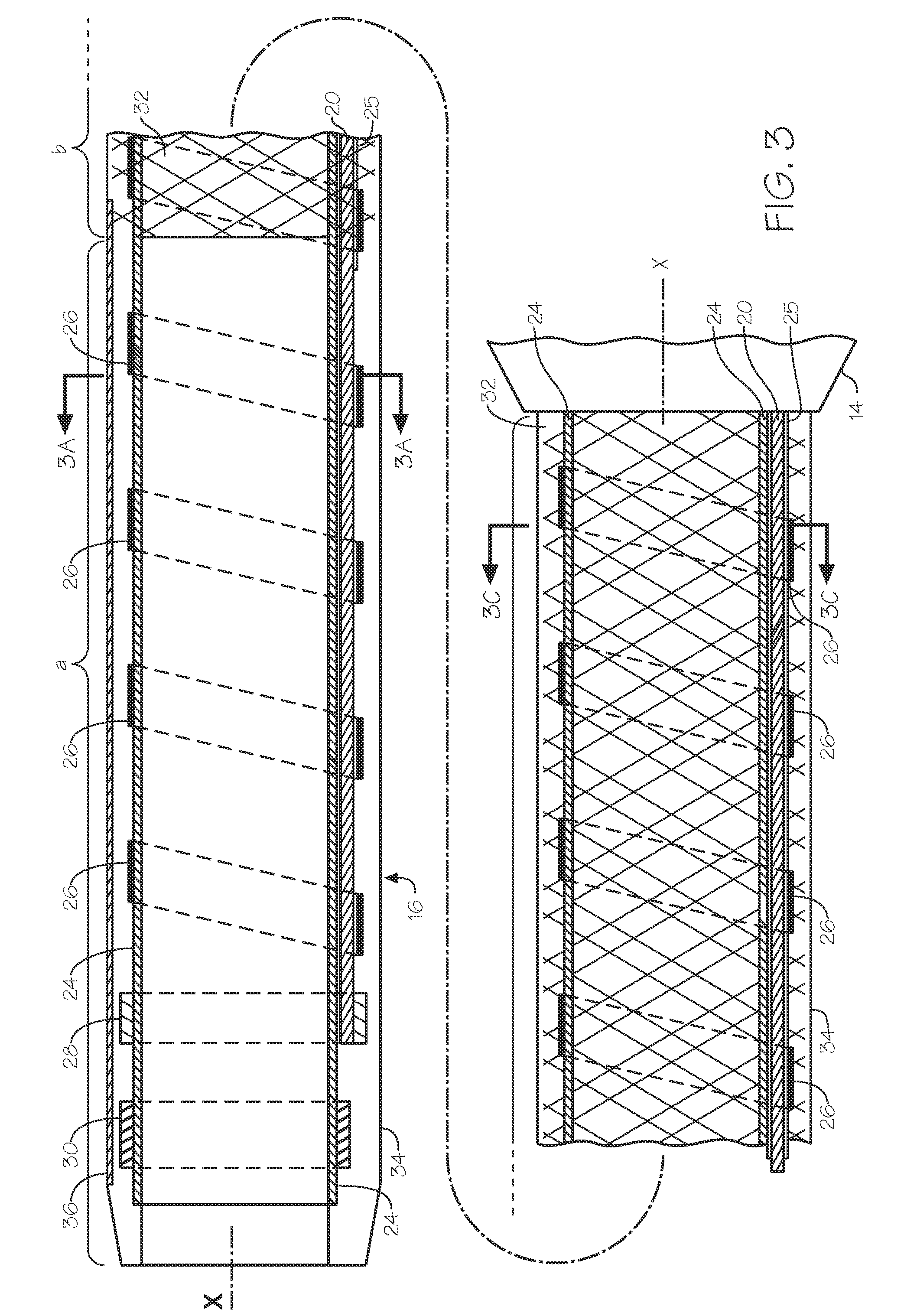

Steerable catheter with reinforced tip

A steerable catheter having a reinforced distal end for improved deflection is provided. The catheter comprises an elongated, flexible tubular catheter body having proximal and distal ends and a lumen extending therethrough. A tip section is provided at the distal end of the catheter body. The tip section comprises a flexible plastic tubing having at least one off-axis lumen extending therethrough. A control handle is provided at the proximal end of the catheter body. At least one puller wire extends through the off-axis lumen of the tip section and lumen of the catheter body. The puller wire has a proximal end anchored to the control handle and a distal end anchored to the tip section. The puller wire is longitudinally moveable relative to the catheter body to cause deflection of the tip section in a plane in a first direction. The catheter further comprises one or more stabilizing features extending longitudinally along at least a portion of the length of the tip section and positioned generally symmetrically about a diameter of the tip section corresponding to the plane in which the tip section is deflectable. The one or more stabilizing features comprise a material that has a higher modulus of elasticity than the plastic of the tip section.

Owner:BIOSENSE WEBSTER INC

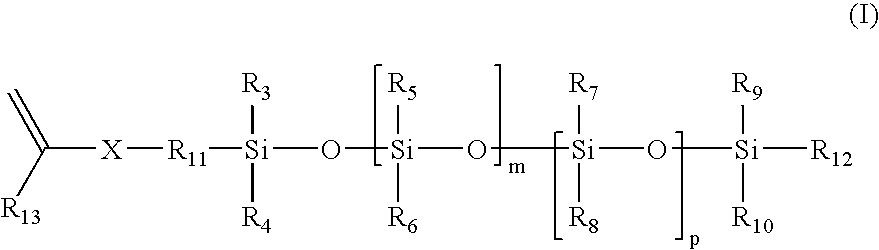

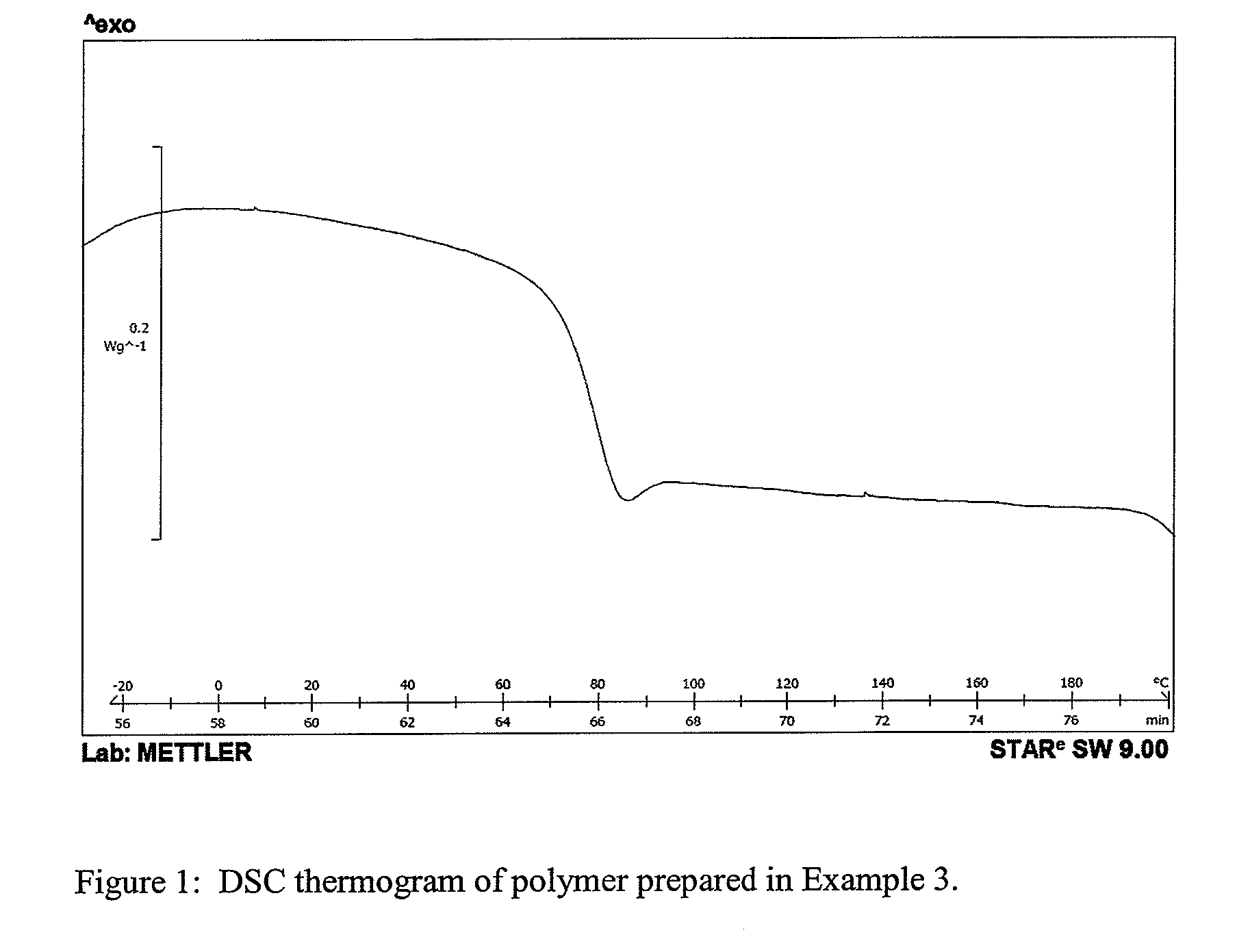

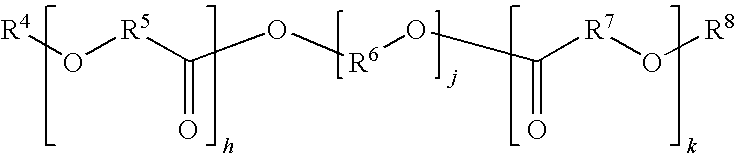

Prepolymers with dangling polysiloxane-containing polymer chains

The invention provide a new class of silicone-containing prepolymers containing dangling polysiloxane-containing polymer chains. This class of silicone-containing prepolymer is capable of being actinically crosslinked to form a silicone hydrogel material with a relatively high oxygen permeability, a reduced elastic modulus, and a relatively high ion permeability. The present invention is also related to silicone hydrogel contact lenses made from this class of silicone-containing prepolymers and to methods for making the silicone hydrogel contact lenses.

Owner:ALCON INC

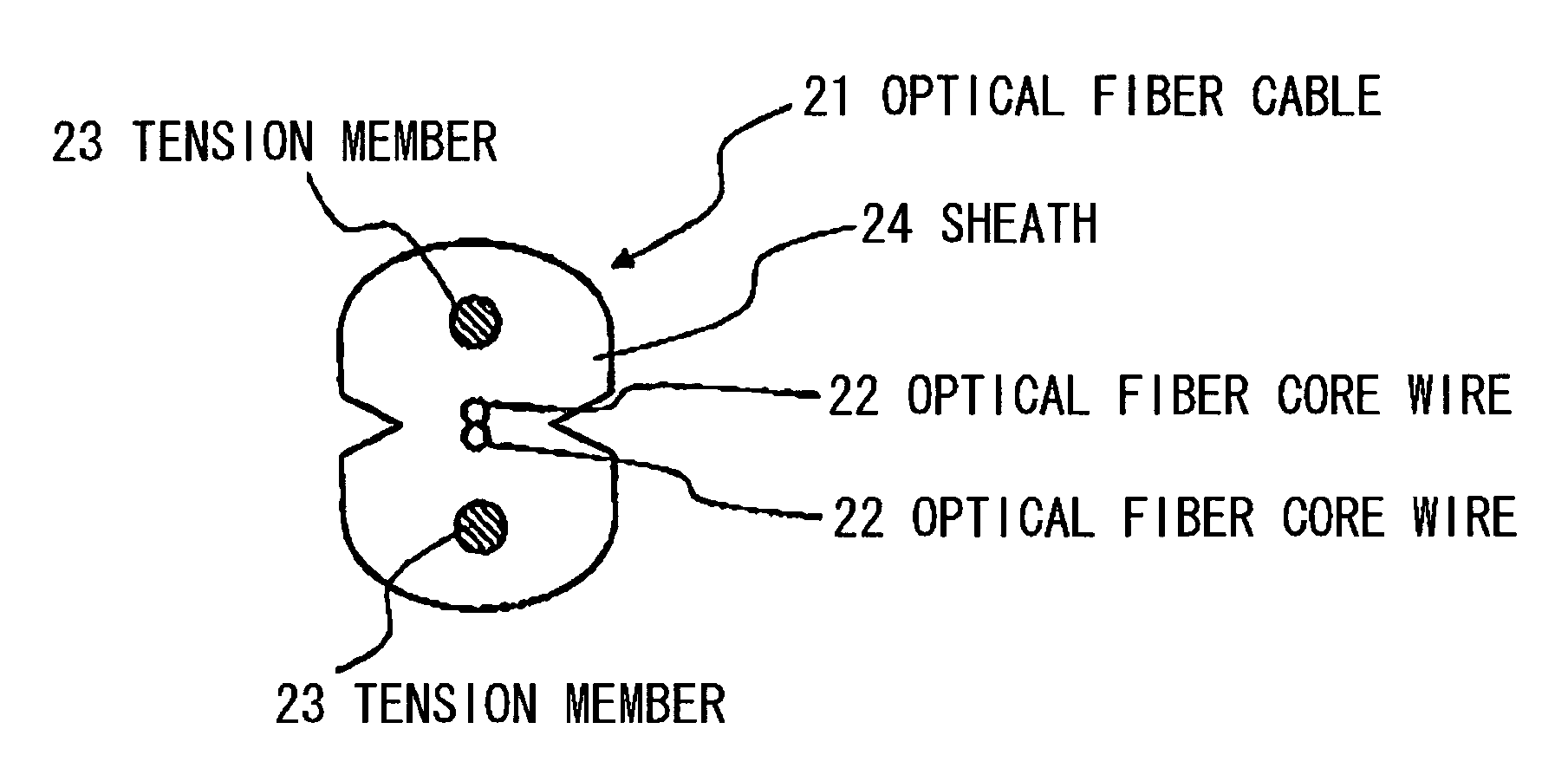

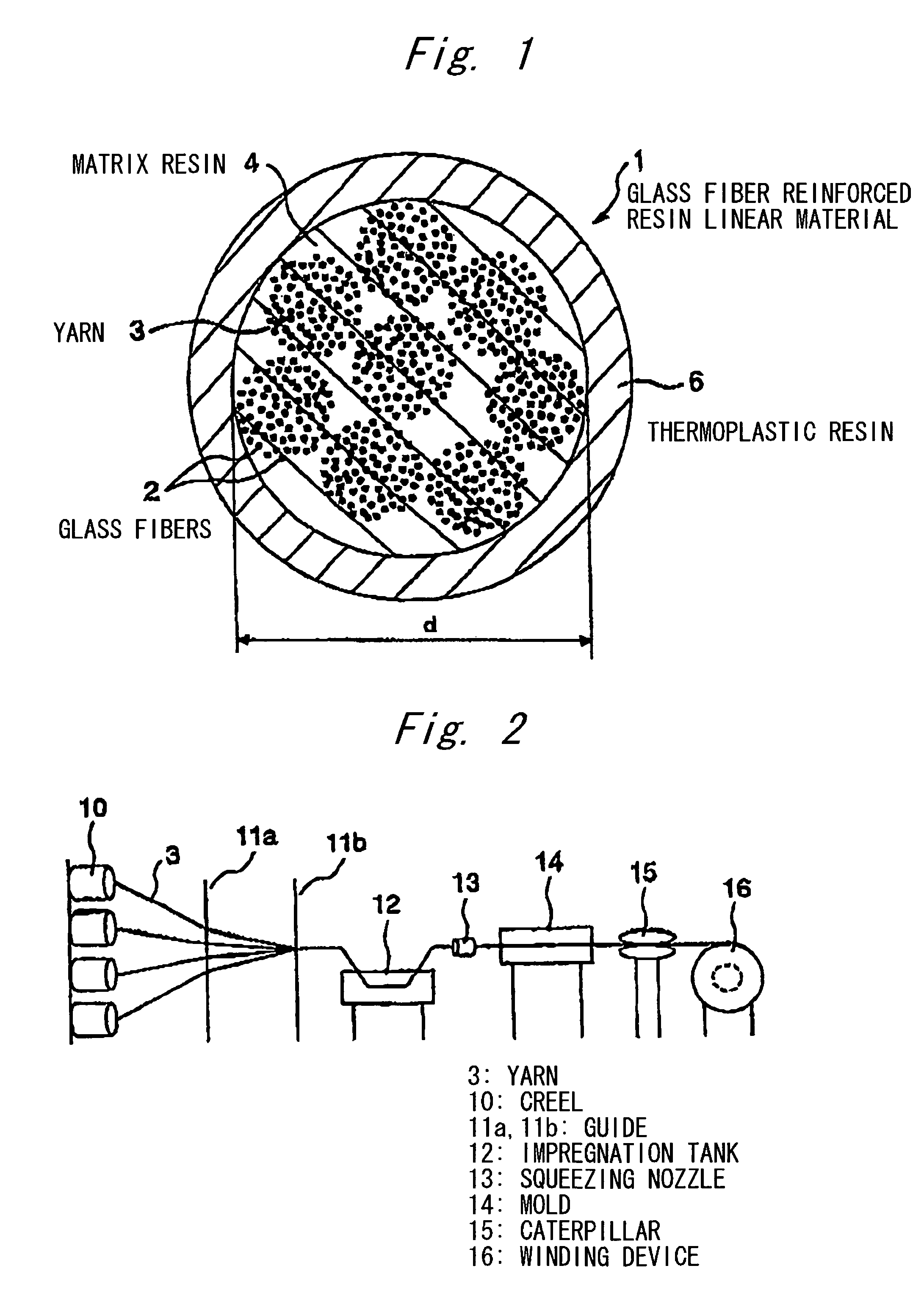

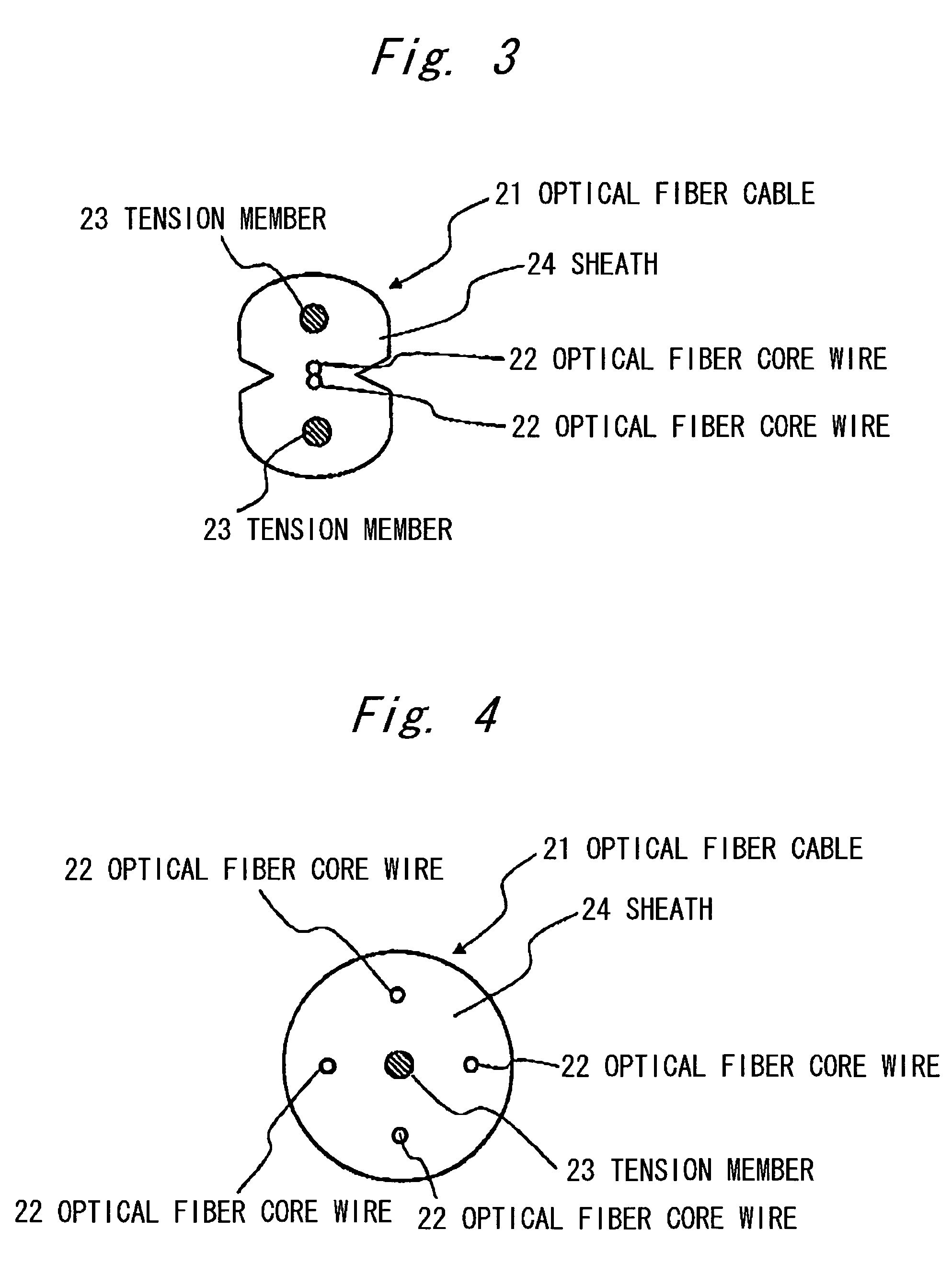

Optical fiber cable

InactiveUS7171087B2Improve the level ofImprove bending performanceCladded optical fibreFibre mechanical structuresGlass fiberTension member

An optical fiber cable has an optical fiber core wire and a tension member. The tension member is formed of a glass fiber reinforced resin linear material with glass fibers and a matrix resin, and satisfies the following requirements: (1) (EfVf+EmVm)d2≧8.3 / n wherein Ef represents the modulus of elasticity of glass fibers, GPa; Vf represents the content of glass fibers, % / 100; Em represents the modulus of elasticity of matrix resin, GPa; Vm represents the content of matrix resin, % / 100; d represents the diameter of tension member, mm; and n represents the number of tension members used in optical fiber cable; (2) (Ef / Em)≧22; (3) Vf=0.6 to 0.88; and (4) an elongation at break of glass fibers of not less than 5% and an elongation at break of matrix resin of not less than 5%.

Owner:HITACHI CABLE

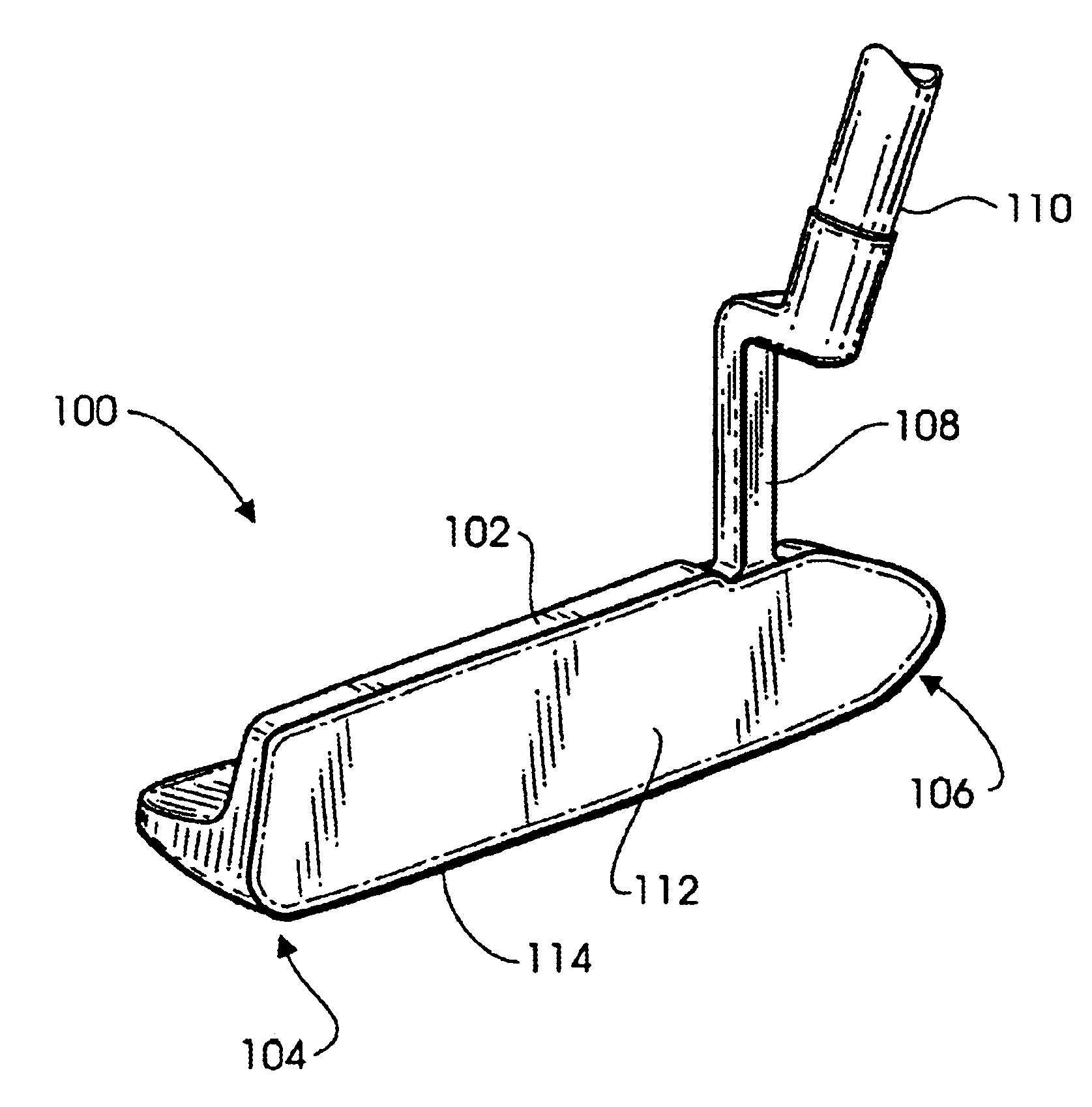

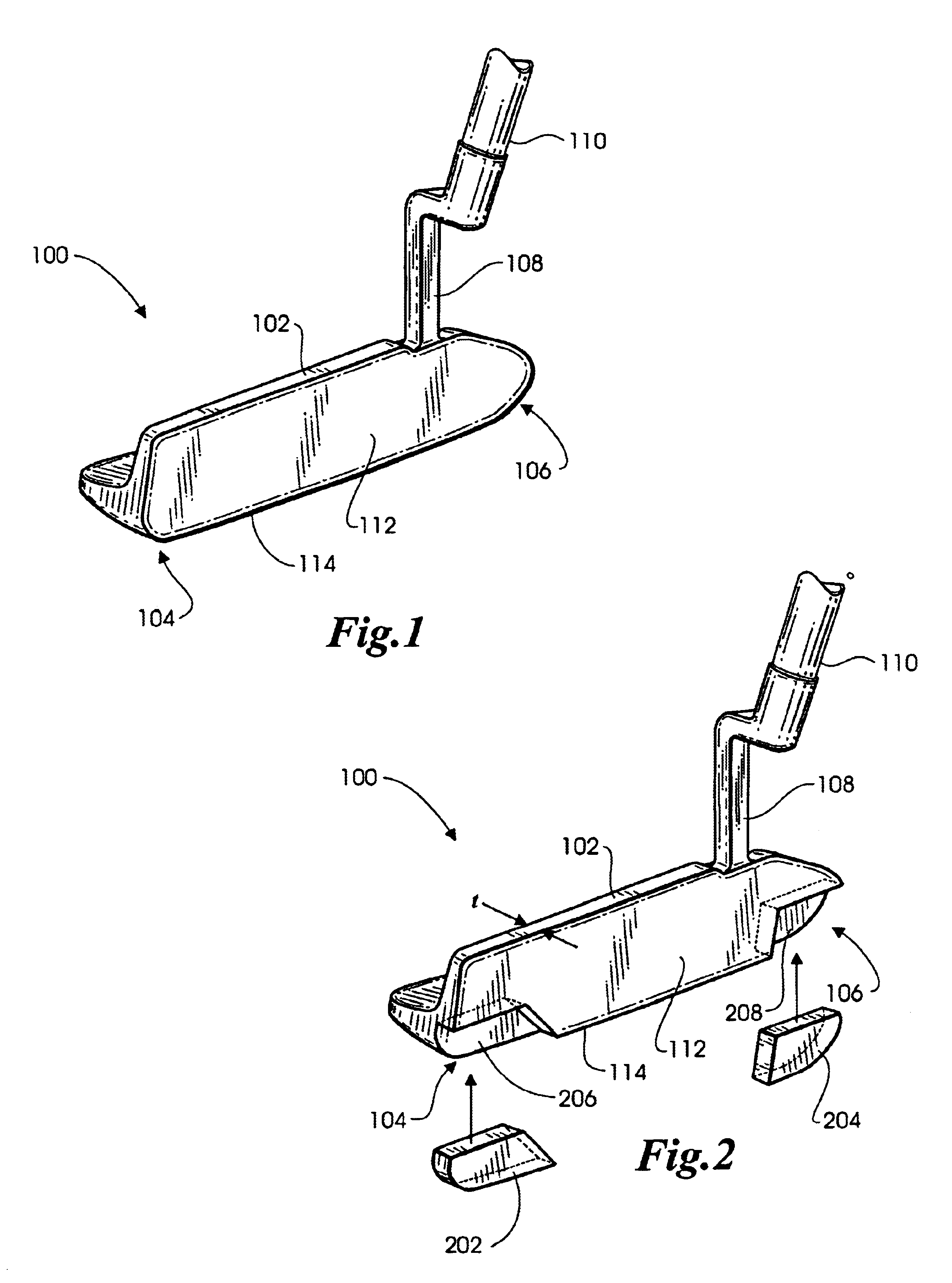

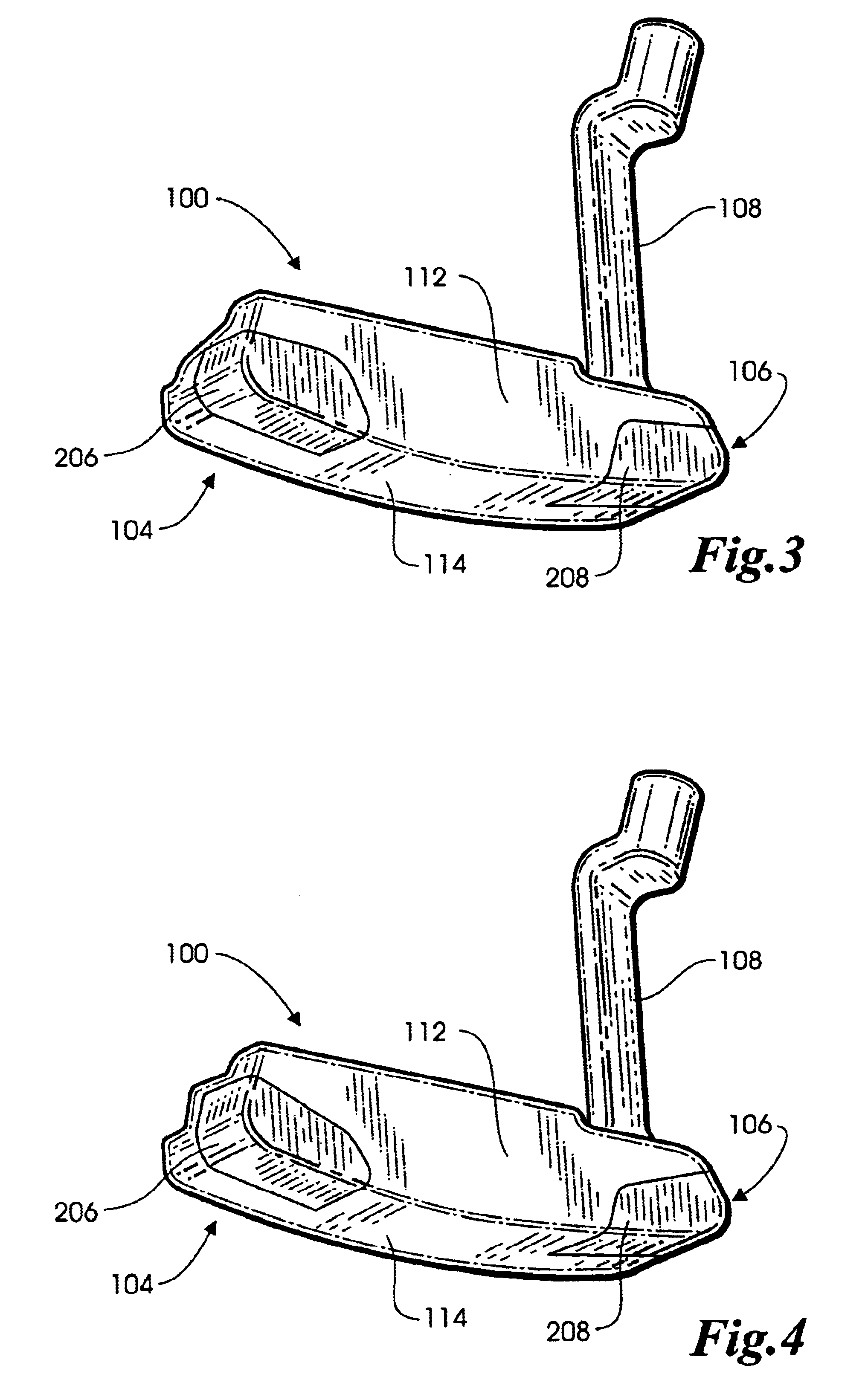

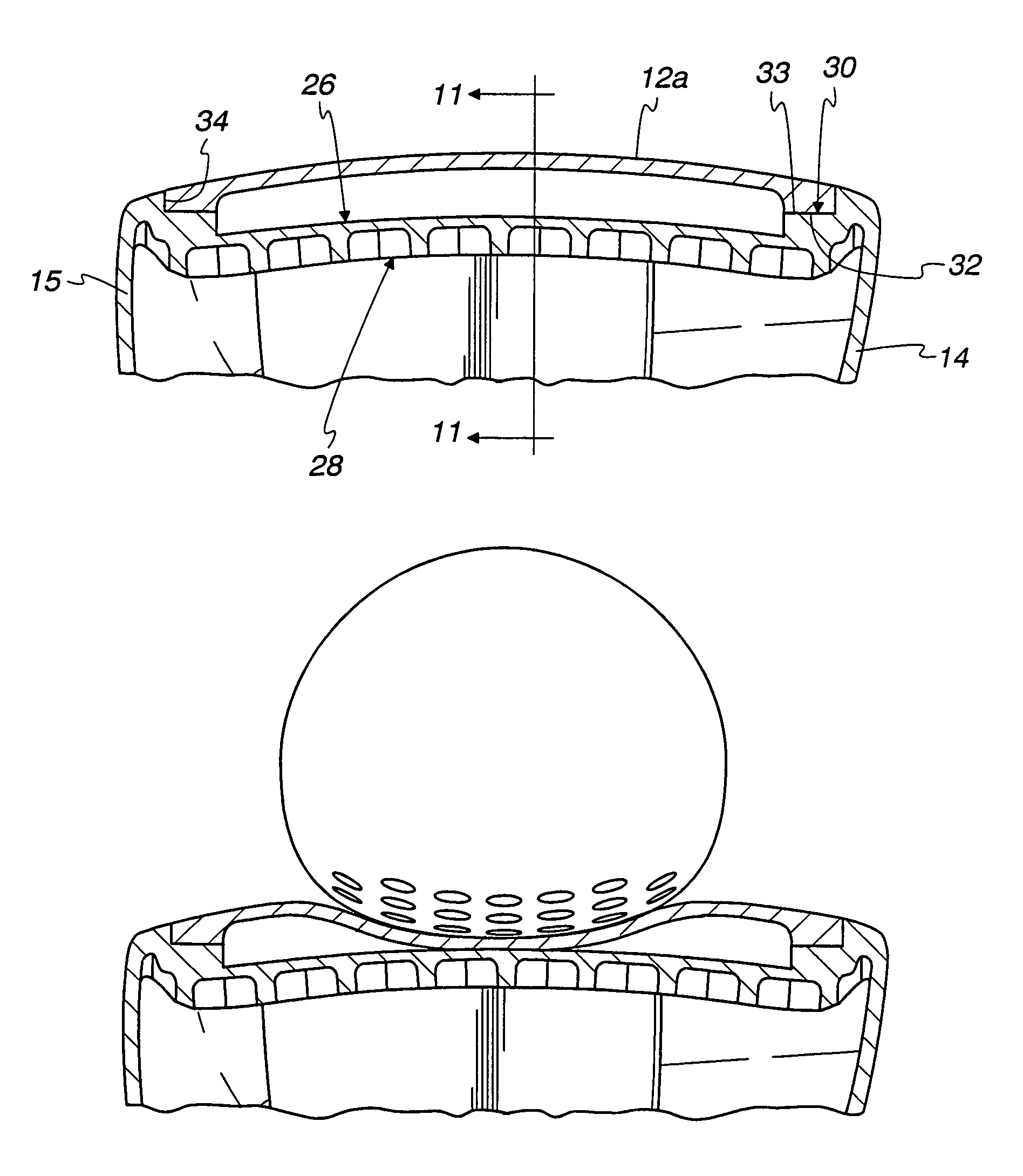

Methods and apparatus for a putter club head with high-density inserts

A putter golf club head includes a body fitted with relatively high-density heel and toe inserts. A golf putter club head includes a body formed of a first material (e.g., titanium) having a density of approximately 3.0 g / cm3 to 7.0 g / cm3. Two cavities are formed in the body, one adjacent to the heel region of the body, and another adjacent to the toe region. Inserts are provided in each of the two cavities and are formed of a second material (e.g., tungsten) having a density ranging from approximately 15.0 g / cm3 to 20.0 g / cm3. The cavities may be configured such that they extend to (or are bounded by) the bottom surface and / or the front face of the body. In one embodiment, the body of the putter club head has an elastic modulus greater than approximately 90 GPa while the density of the insert material is greater than the density of the body material by a factor of at least 3.0.

Owner:KARSTEN MFG CORP

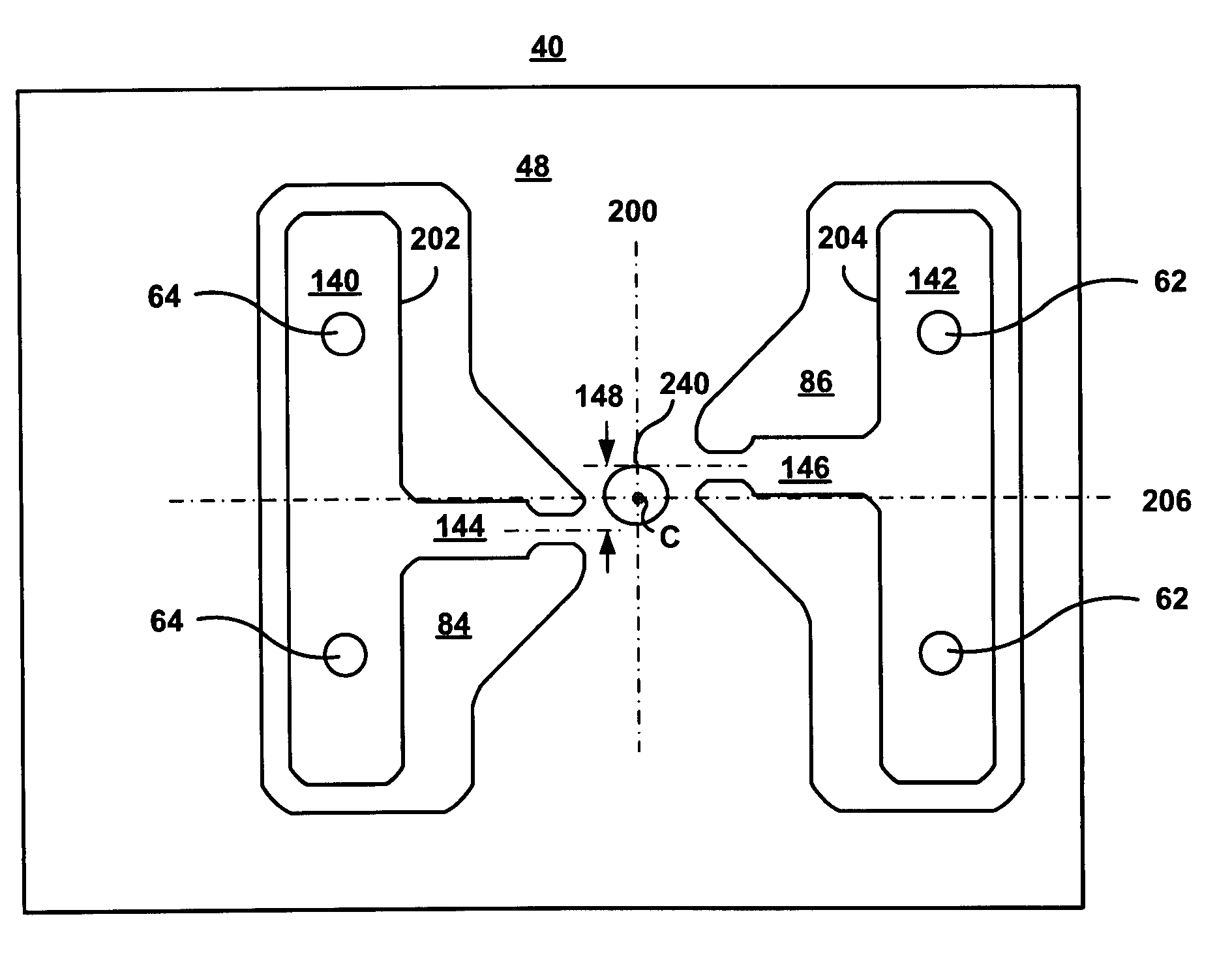

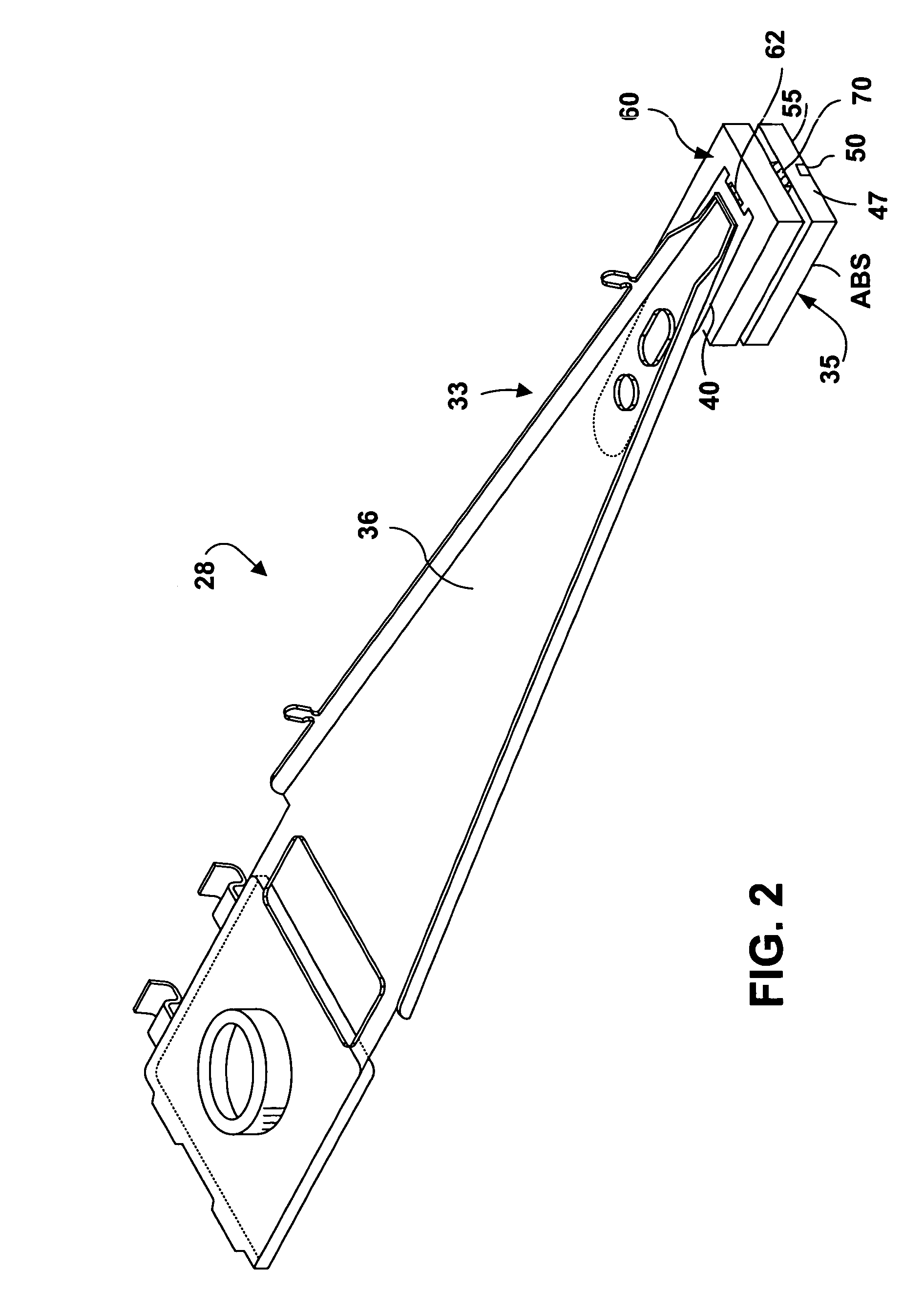

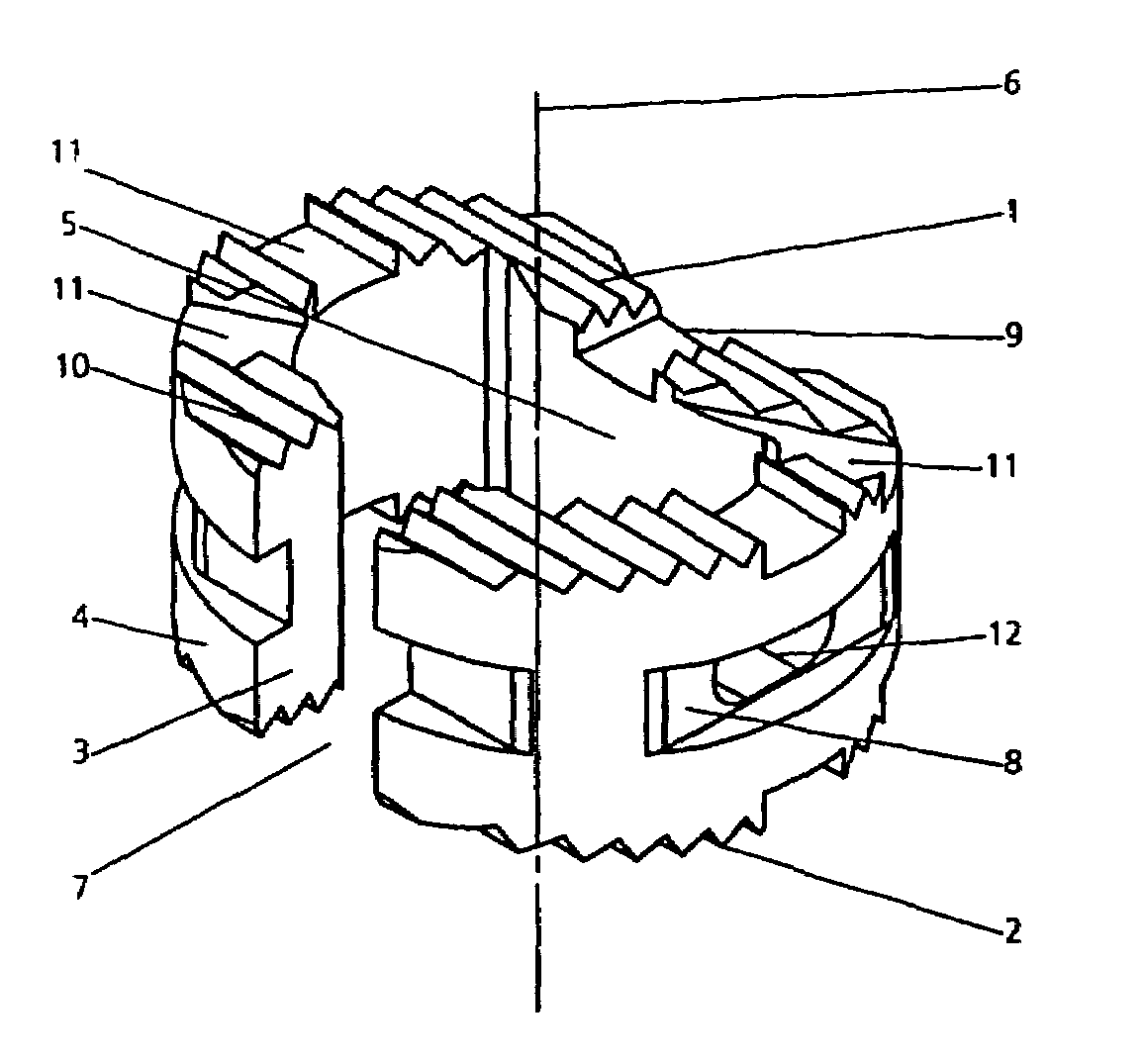

Dimple pivot post for a rotary co-located microactuator

InactiveUS7057857B1Eliminate deformationImprove performanceRecord information storageMounting/attachment of transducer headAdhesiveEngineering

A rotary microactuator-based head-gimbal assembly design controls the unwanted deflection of a flexure in a data storage device and eliminates hinge deformation. The head-gimbal assembly maintains the co-planarity of the hinged islands in the microactuator under the applied load acting on the flexure and two associated hinged islands. The dimple post is placed at the dimple loading region of the flexure tongue and has the same height as adhesive dams on paddles secured to the hinged islands. The dimple post is formed by branching one of the existing conductive traces covered by a photoresist layer to the dimple loading region on flexure tongue. In an alternative embodiment, the dimple post is secured to the dimple loading region of the flexure tongue by means of adhesives with a variety of viscosity and elastic moduli.

Owner:WESTERN DIGITAL TECH INC

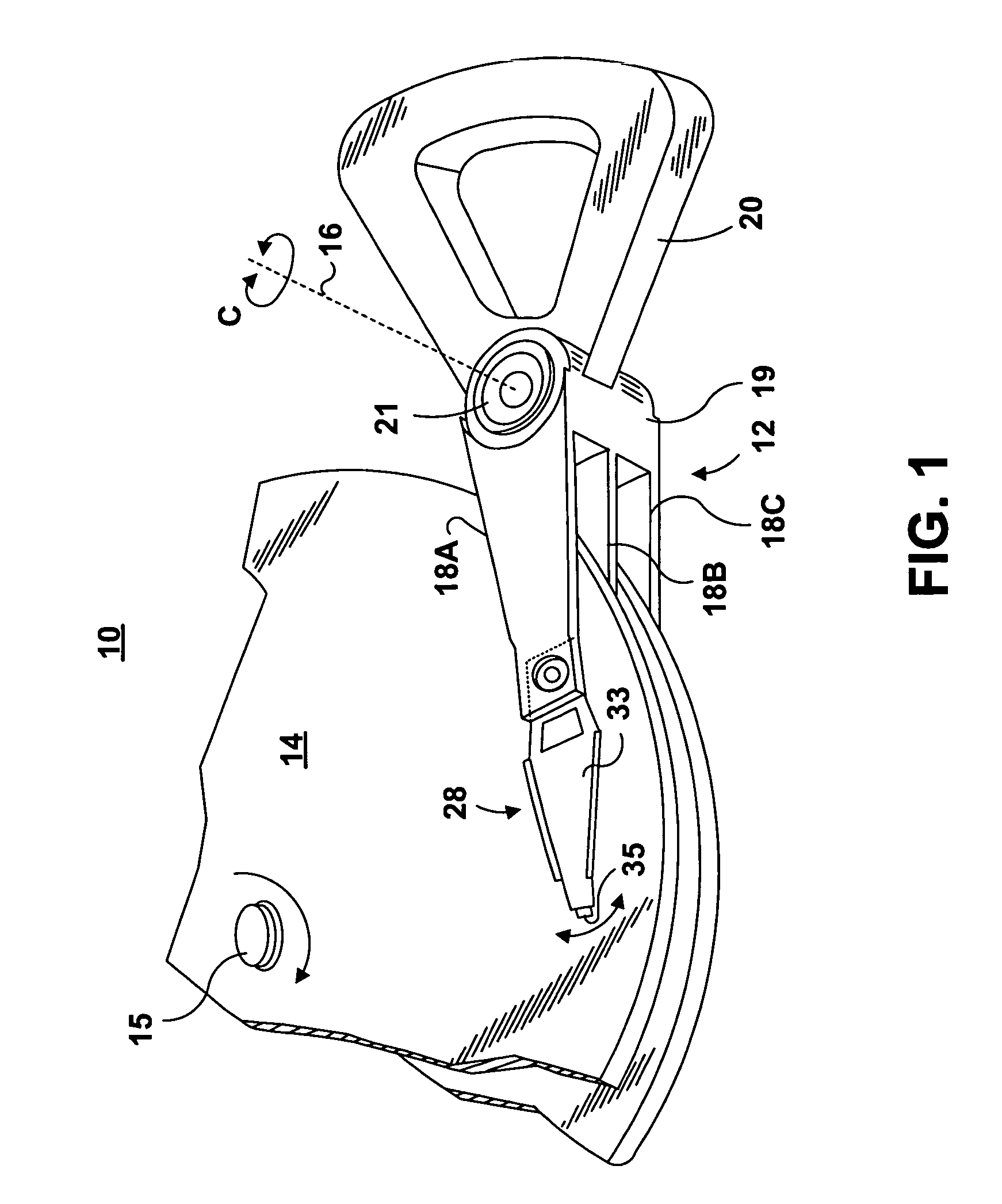

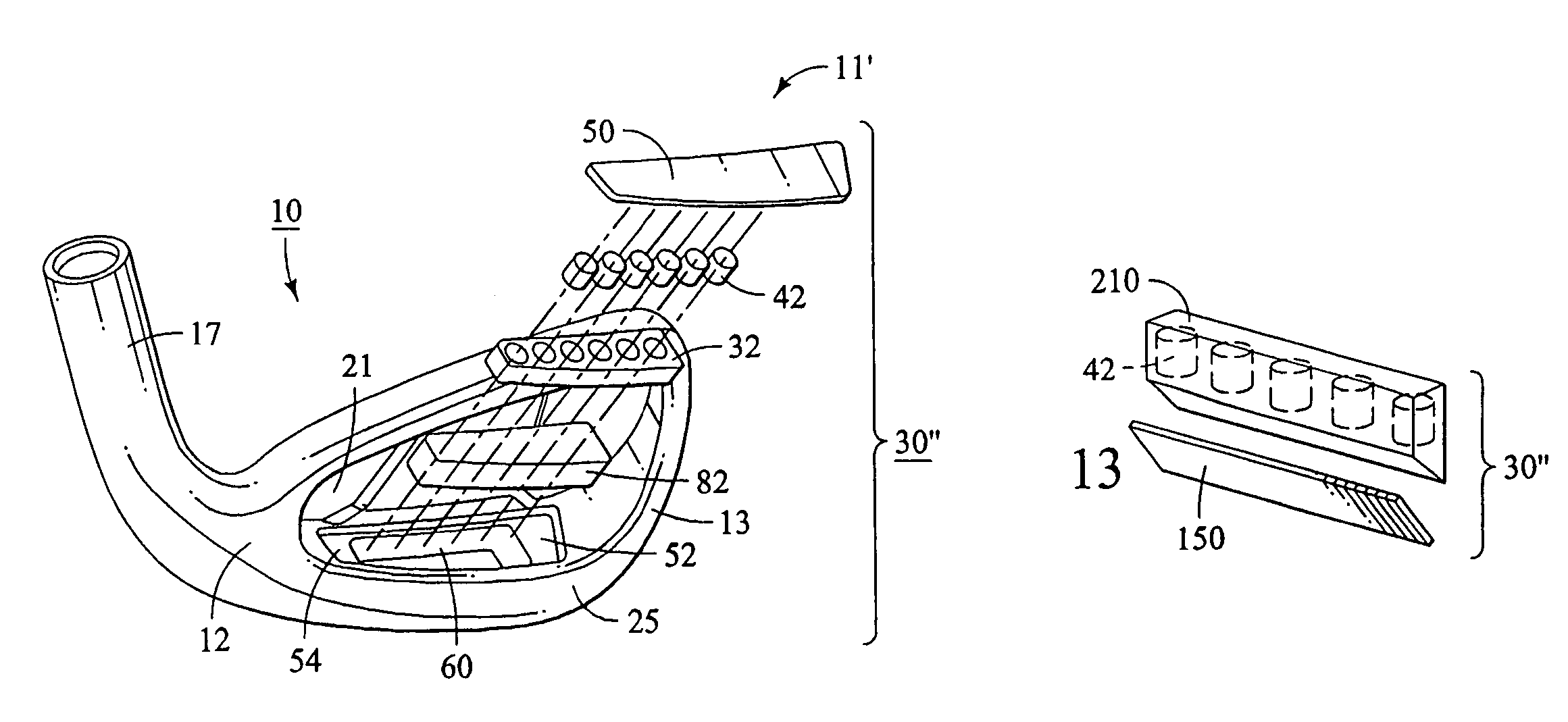

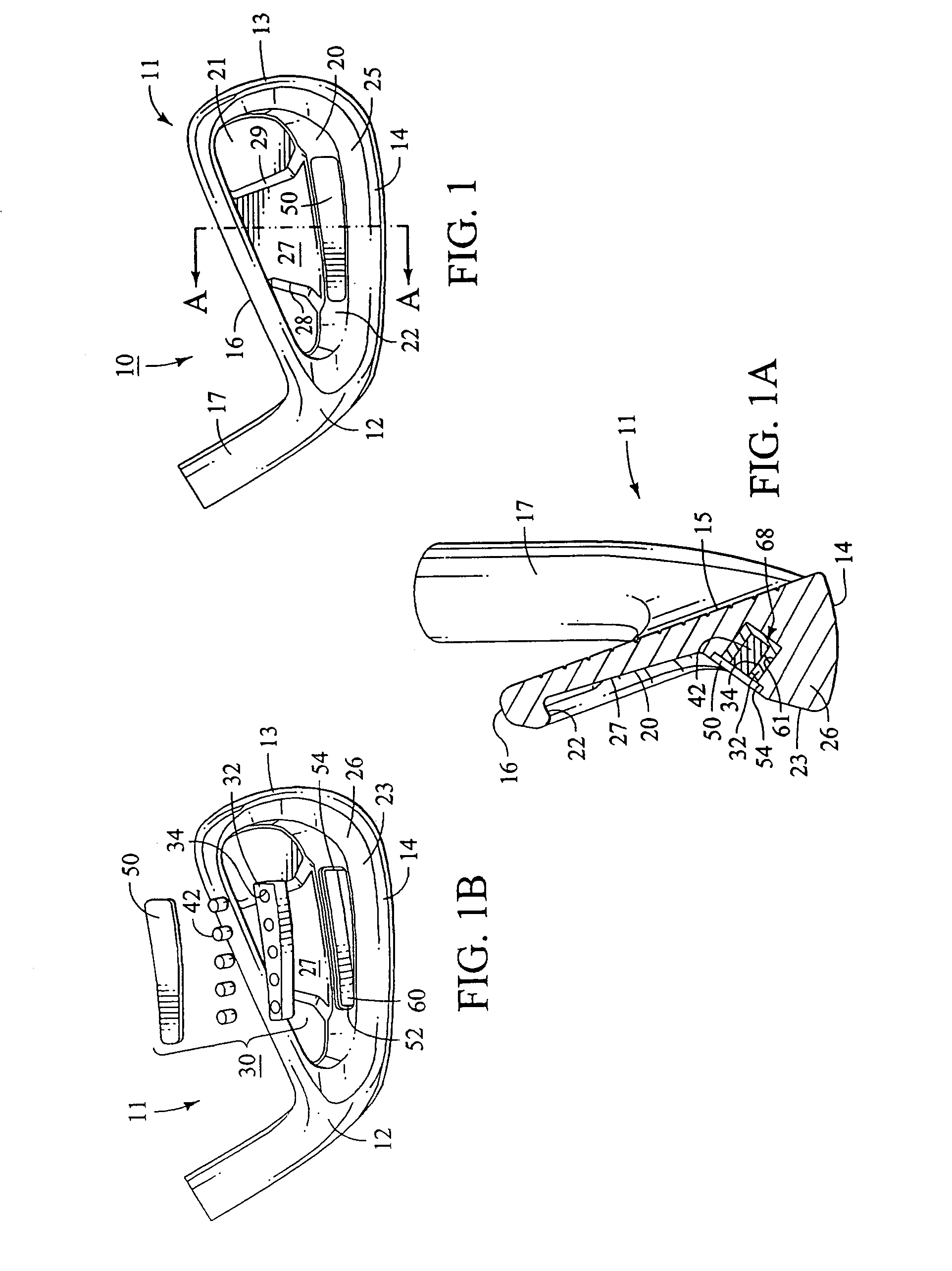

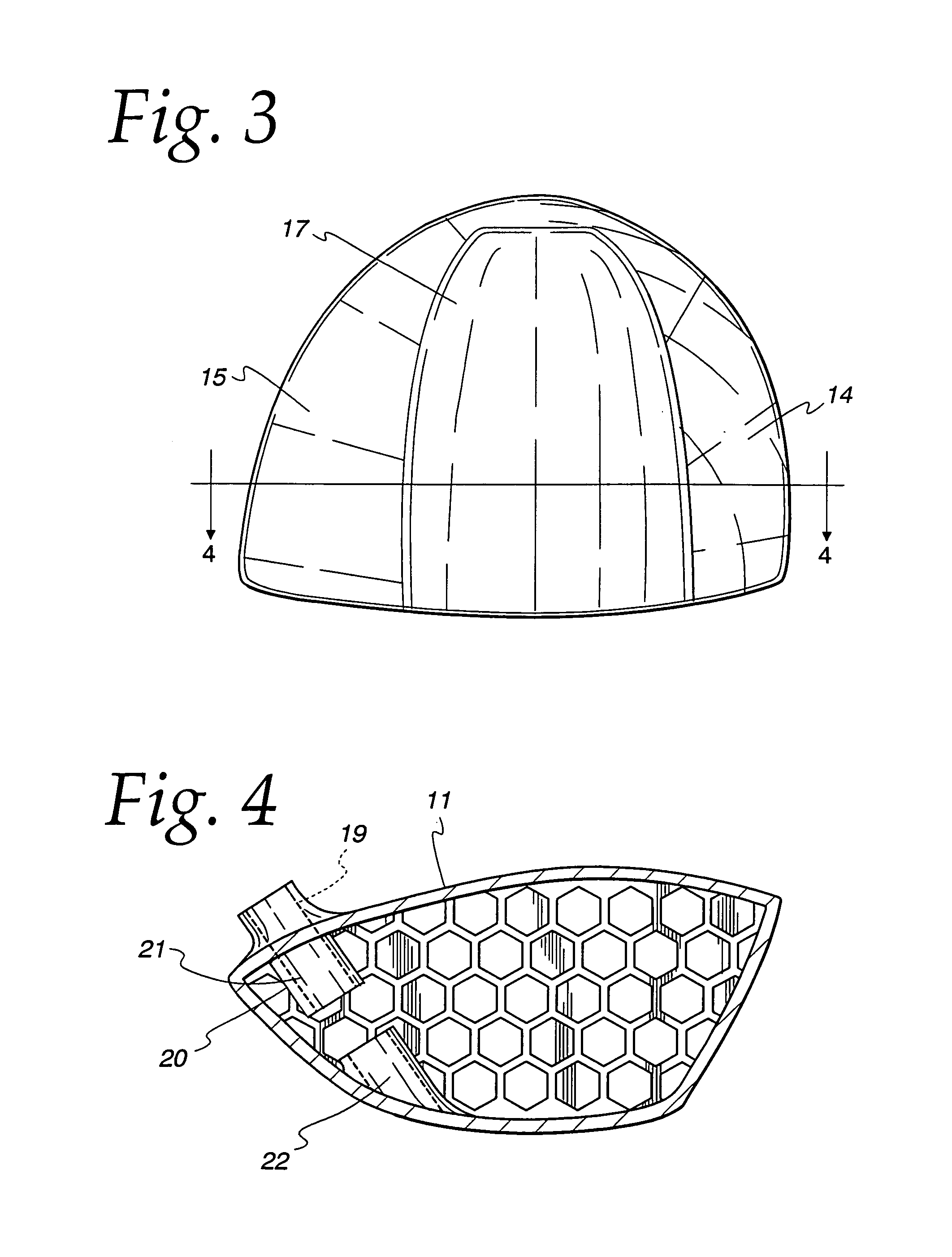

Golf club head

InactiveUS7083530B2Feel goodReduce stiffnessThermal switch detailsGolf clubsGolf BallBiomedical engineering

An iron-type golf club head is disclosed that comprises a striking face, a heel, a toe and a sole bar, wherein a recess is formed in the sole bar. A cartridge comprised of a first material at least partially disposed the sole recess, and at least one pin, comprised of a second material coupled to the cartridge. The first material has a modulus of elasticity that are less than that of the second material.

Owner:TAYLOR MADE GOLF

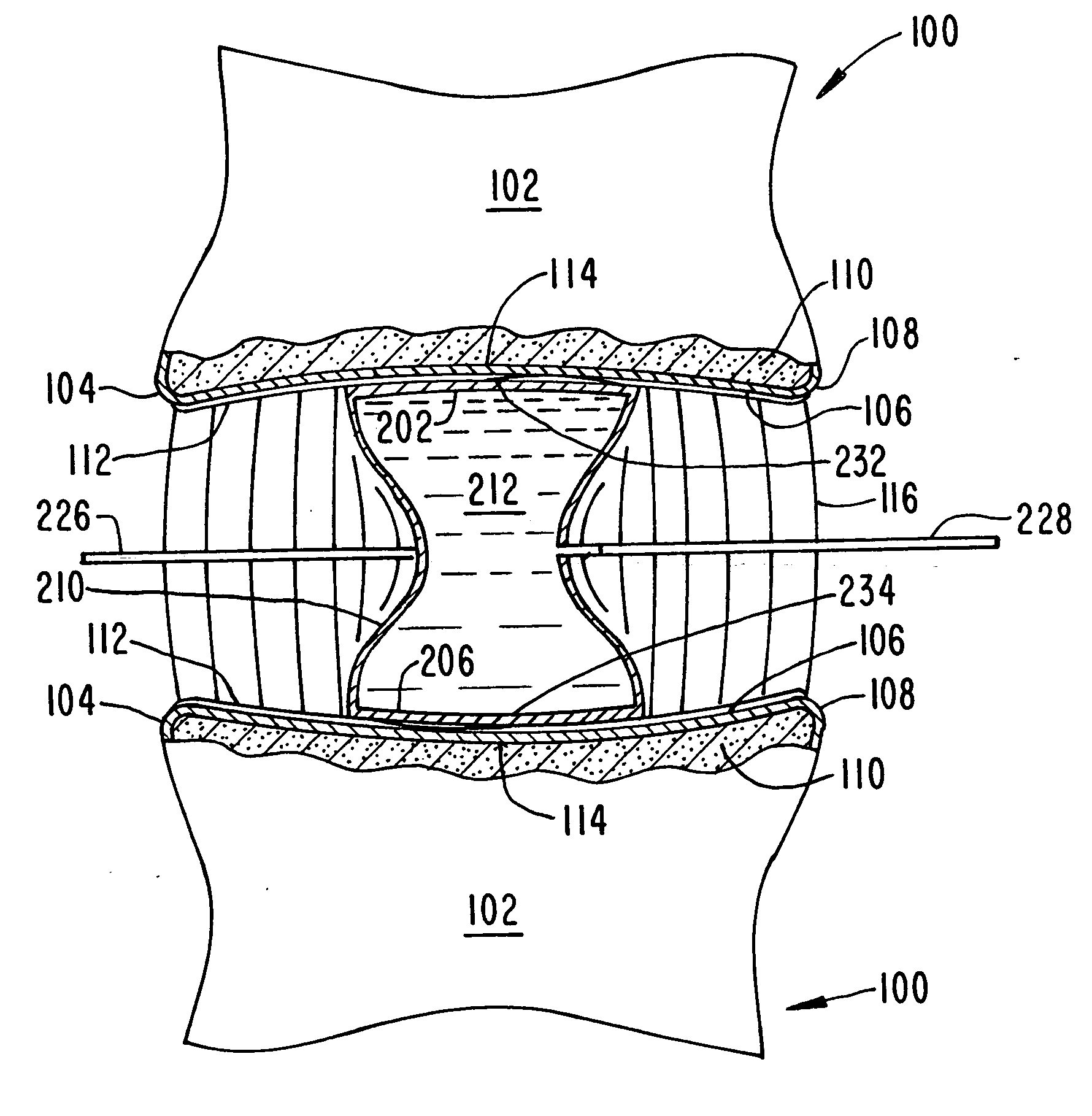

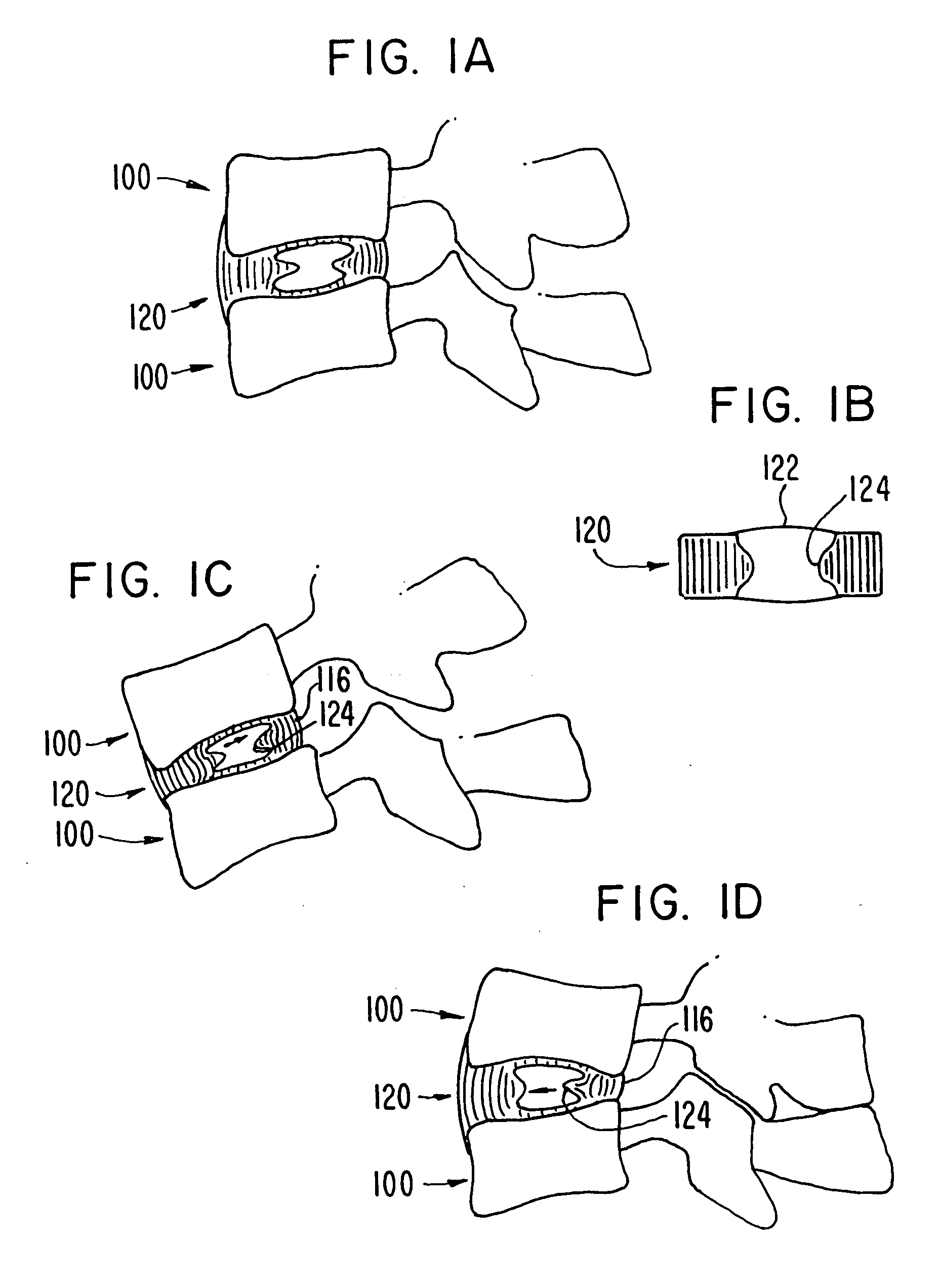

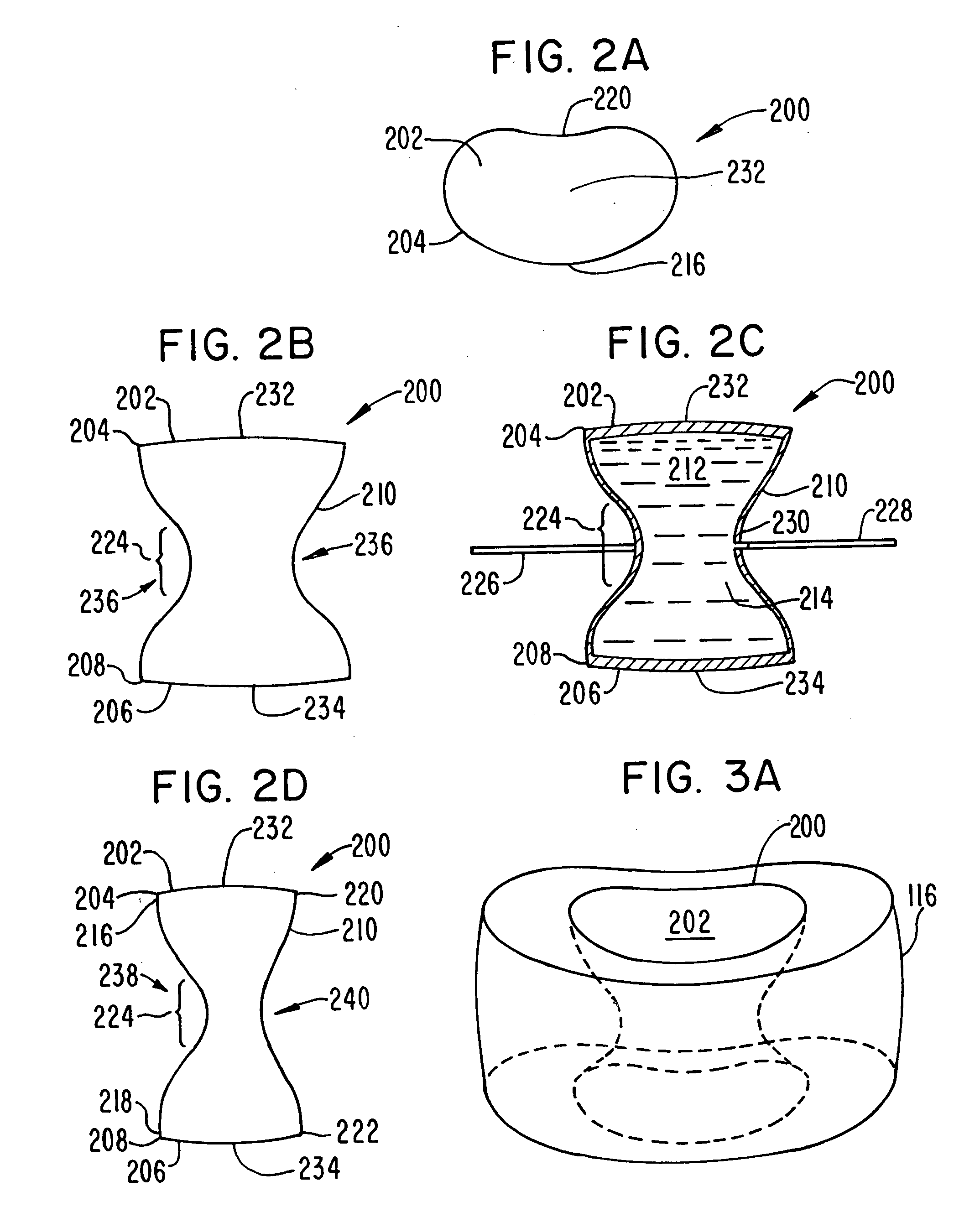

Intervertebral disk and nucleus prosthesis

A prosthetic implant for replacing a nucleus pulposus of an intervertebral disk includes upper and lower endwalls of discoid cross-section, each having an antero-posterior diameter less than its transverse diameter, and an hourglass-shaped sidewall connecting the peripheries of the upper endwall and lower endwall to enclose an interior volume filled with a substantially incompressible liquid or soft plastic material. A total prosthesis for replacing the entire human intervertebral disk has an annular core made of a first biocompatible polymer surrounding a central cavity, transitional plates affixed respectively to the upper and lower surfaces of the annular core, the upper and lower transitional plates being made of a second biocompatible material having an elastic modulus greater than that of the first biocompatible polymer, and upper and lower endplates adapted to contact adjacent vertebrae and affixed respectively to the upper and lower transitional plates.

Owner:K2M

Method of forming polysaccharide sponges for cell culture and transplantation

A polysaccharide sponge characterized by having: (i) an average pore size in the range between about 10 mum to about 300 mum; (ii) an average distance between the pores being the wall thickness of the pores in the range between about 5 mum to about 270 mum; and (iii) an E-modulus of elasticity being a measure of the rigidity of the sponge in the range of about 50 kPa to about 500 kPa.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

Silicon chip carrier with conductive through-vias and method for fabricating same

InactiveUS20060027934A1Semiconductor/solid-state device detailsSolid-state devicesOptoelectronicsThermal expansion

A carrier structure and method for fabricating a carrier structure with through-vias each having a conductive structure with an effective coefficient of thermal expansion which is less than or closely matched to that of the substrate, and having an effective elastic modulus value which is less than or closely matches that of the substrate. The conductive structure may include concentric via fill areas having differing materials disposed concentrically therein, a core of the substrate material surrounded by an annular ring of conductive material, a core of CTE-matched non-conductive material surrounded by an annular ring of conductive material, a conductive via having an inner void with low CTE, or a full fill of a conductive composite material such as a metal-ceramic paste which has been sintered or fused.

Owner:GLOBALFOUNDRIES INC

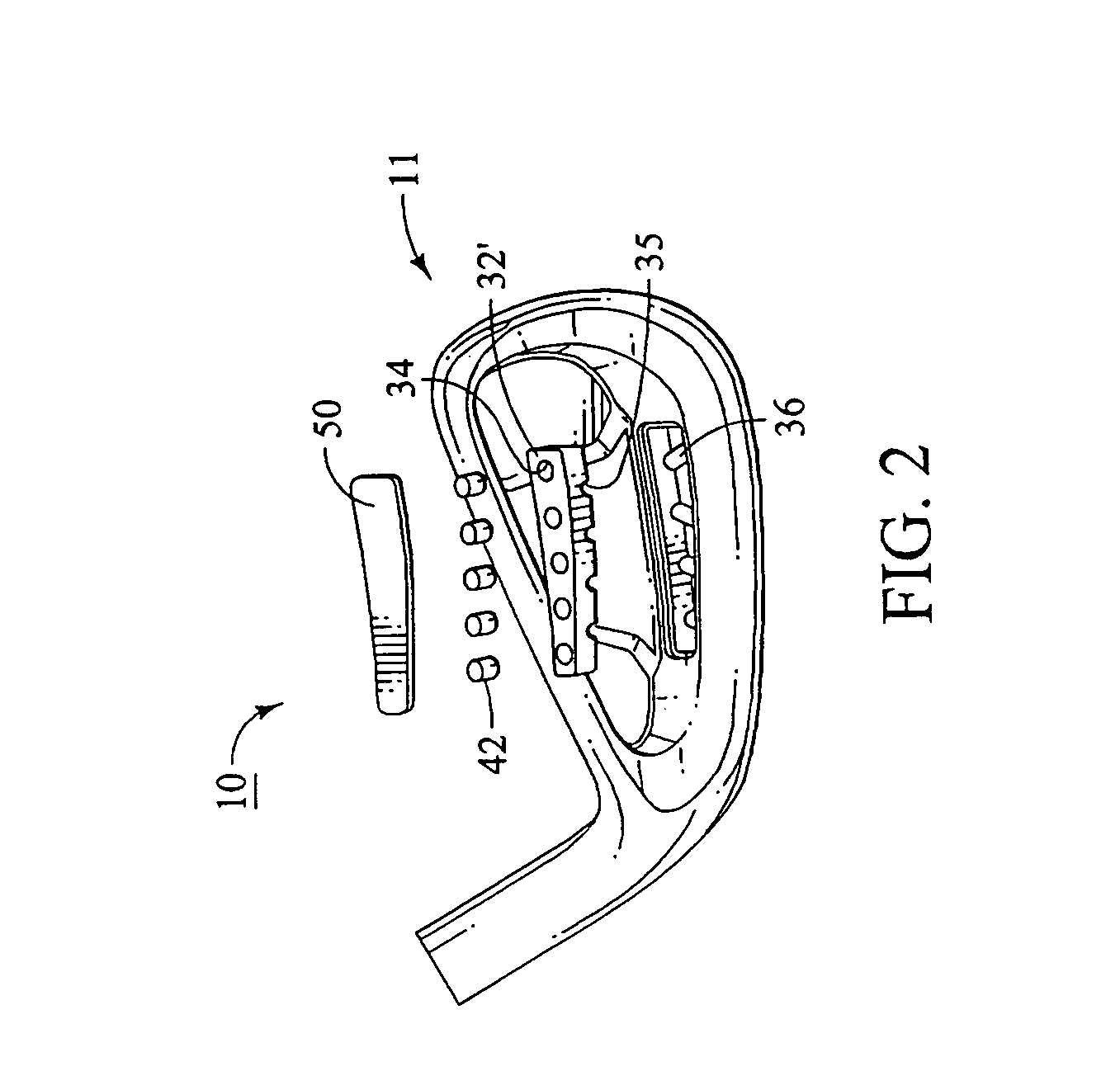

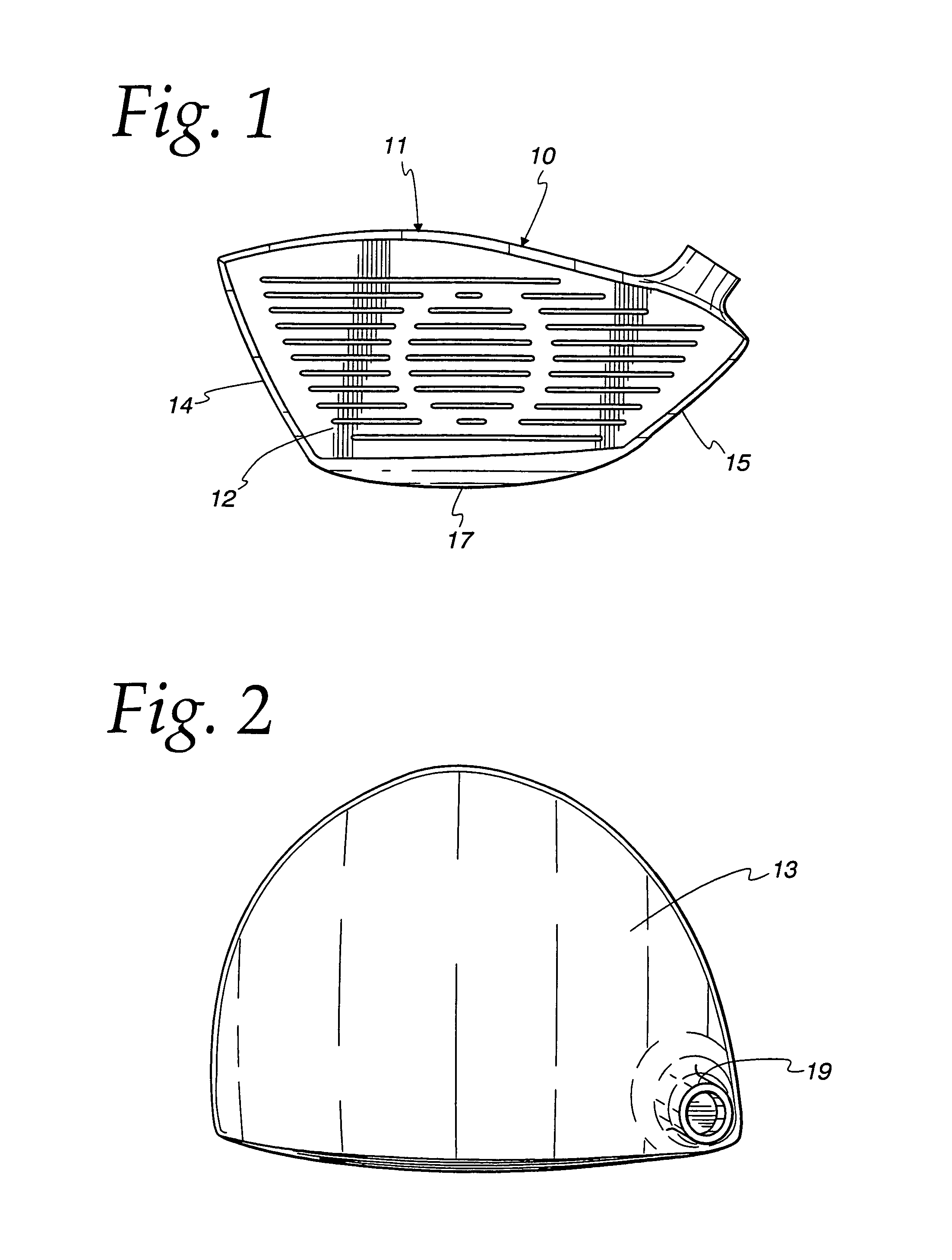

Golf club face flexure control system

InactiveUS6979270B1High modulusImprove energy transferGolf clubsRacket sportsControl systemGolf Ball

An improved line of golf clubs tailored to the golfer. The face wall firstly is designed so that the face wall modulus of elasticity increases from a low modulus for the low swing speed range to progressively higher modula for the higher swing speed ranges. Face modulus can be altered by a variety of techniques including face wall thinning, material selection and heat treatment or a combination thereof. In each of the swing speed range clubs, the face has a first modulus of elasticity determined by the face itself and after the face deflects to a predetermined value, the face modulus is significantly increased by a secondary wall parallel to and closely spaced behind the face wall.

Owner:KARSTEN MFG CORP

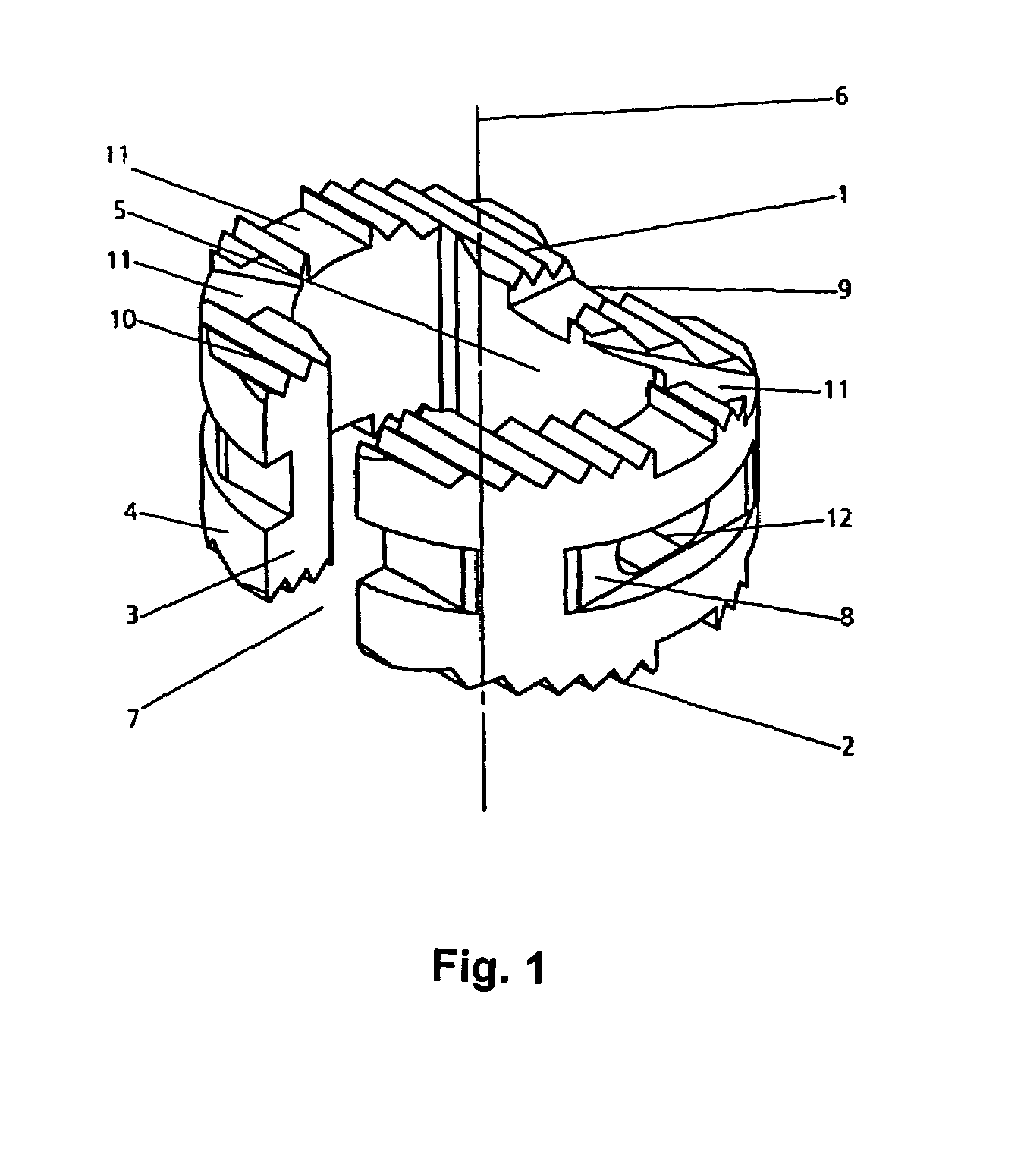

Intervertebral implant

InactiveUS7303583B1High degreePrevent implantationSurgeryDomestic plumbingLateral regionBiocompatibility Testing

Owner:SYNTHES USA

Method of making a product with improved material properties by moderate heat-treatment of a metal incorporating a dilute additive

InactiveUS6150186AStable mechanical propertiesImprove conductivitySemiconductor/solid-state device testing/measurementFinal product manufactureUltimate tensile strengthMechanical property

Deposition of metal in a preferred shape, including coatings on parts, or stand-alone materials, and subsequent heat treatment to provide improved mechanical properties. In particular, the method gives products with relatively high yield strength. The products often have relatively high elastic modulus, and are thermally stable, maintaining the high yield strength at temperatures considerably above 25 DEG C. This technique involves depositing a material in the presence of a selected additive, and then subjecting the deposited material to a moderate heat treatment. This moderate heat treatment differs from other commonly employed "stress relief" heat treatments in using lower temperatures and / or shorter times, preferably just enough to reorganize the material to the new, desired form. Coating a shape and heat treating provides a shaped deposit with improved material properties. Coating a shape with a portion connected to a base and a portion detached therefrom can provide a resilient, conductive contact useful for electronic applications.

Owner:FORMFACTOR INC

Composite spinal fixation systems

InactiveUS20060247638A1Adjustable stiffnessAdjustable flexibilityCosmetic preparationsHair cosmeticsPolyether ether ketoneMaterials science

Embodiments provide composite components for use in spinal fixation systems. The composite components may comprise polyetheretherketone (PEEK) or another non-resorbable or resorbable polymeric material and at least one metal. Incorporation of PEEK or another non-resorbable or resorbable polymeric material into the components allows average or mean physical properties (e.g., tensile strength, modulus of elasticity, etc.) of the components to be modulated. The composition and orientation of the composite components can be advantageously chosen to produce components with desired physical characteristics.

Owner:WARSAW ORTHOPEDIC INC

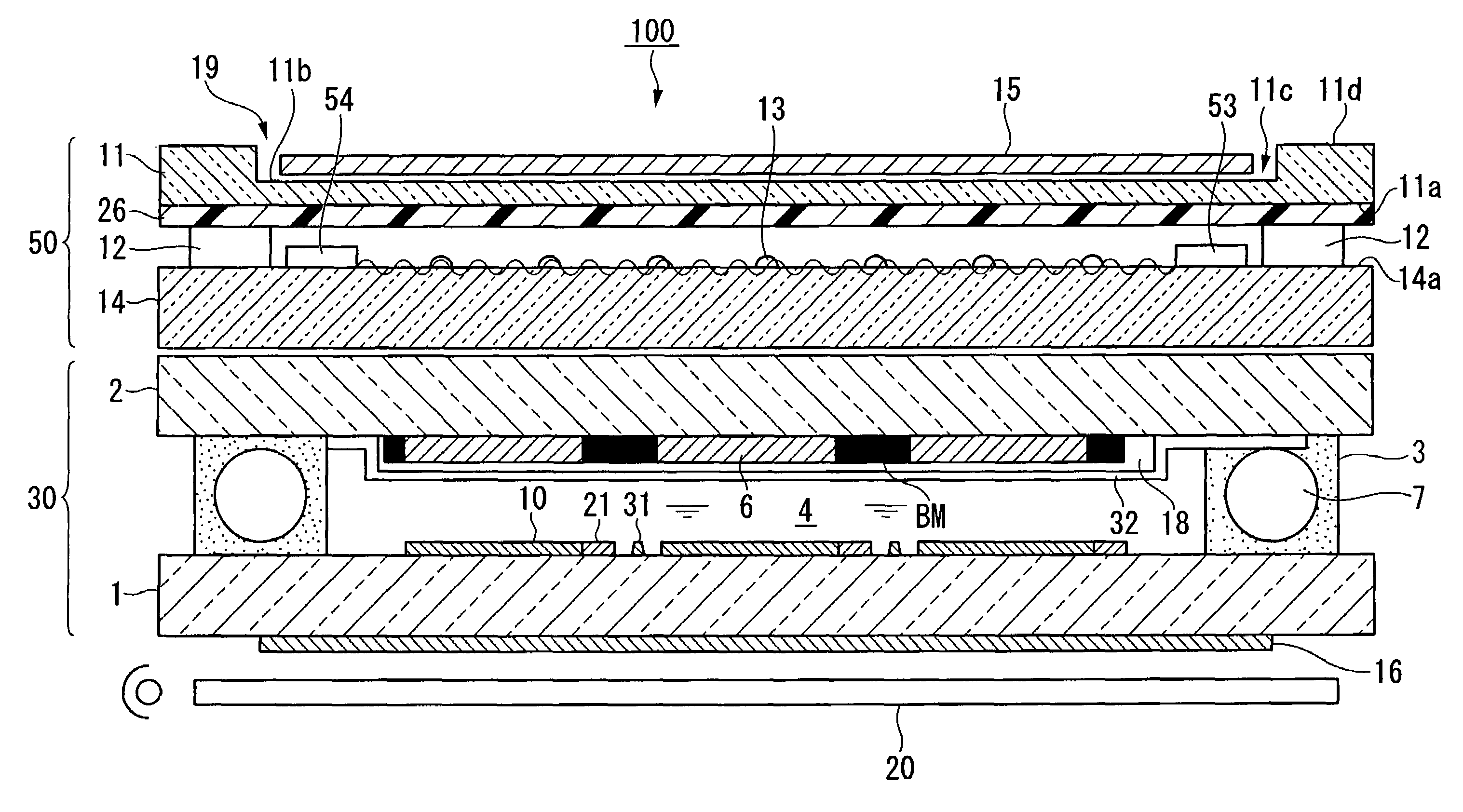

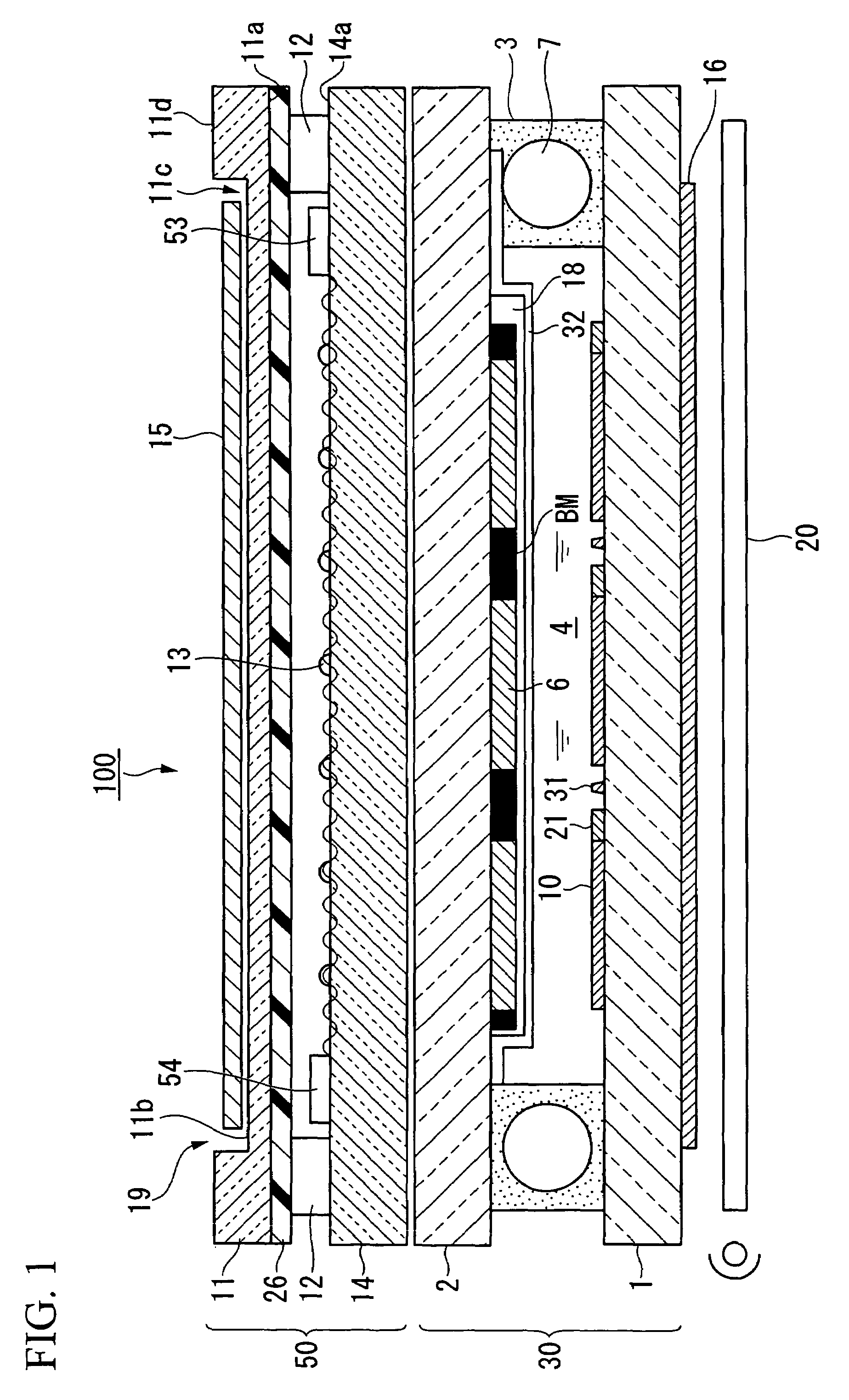

Electro-optical device and electronic equipment having touch panel with resin having particular elastic modulus

ActiveUS7593067B2The detection position is accurateAvoid failureNon-linear opticsInput/output processes for data processingEngineeringTouch panel

An electro-optical device includes: an electro-optical panel having a first substrate, a second substrate, and an electro-optical substance interposed between the first and the second substrates; a third substrate arranged on the second substrate; a fourth substrate having a flexibility and arranged on the third substrate via a spacer; a position detector provided on the third substrate and detecting a pressed position on the fourth substrate based on changes in surface waves generated on the third substrate; and a resin film provided on the fourth substrate and opposed to the third substrate.

Owner:138 EAST LCD ADVANCEMENTS LTD

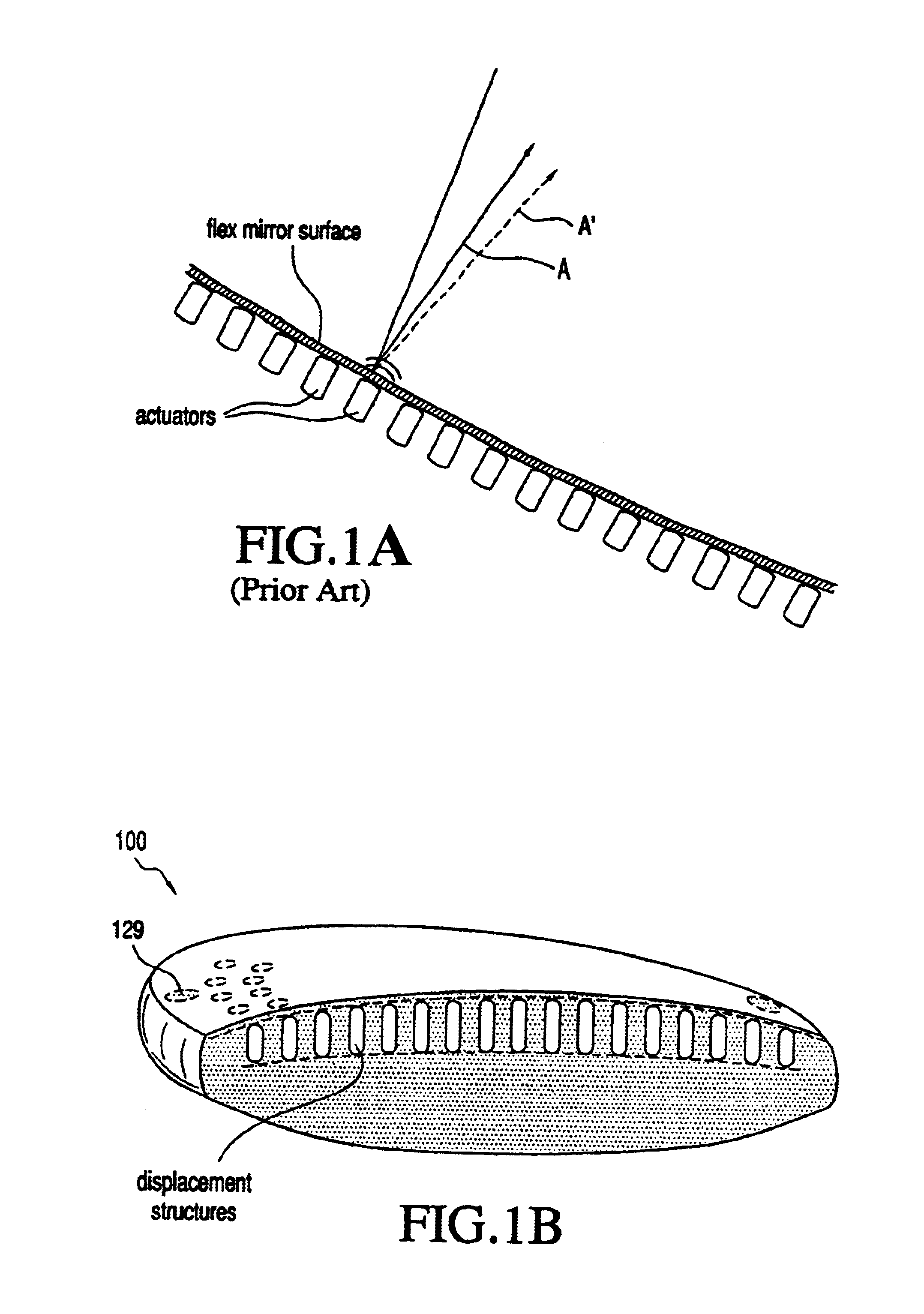

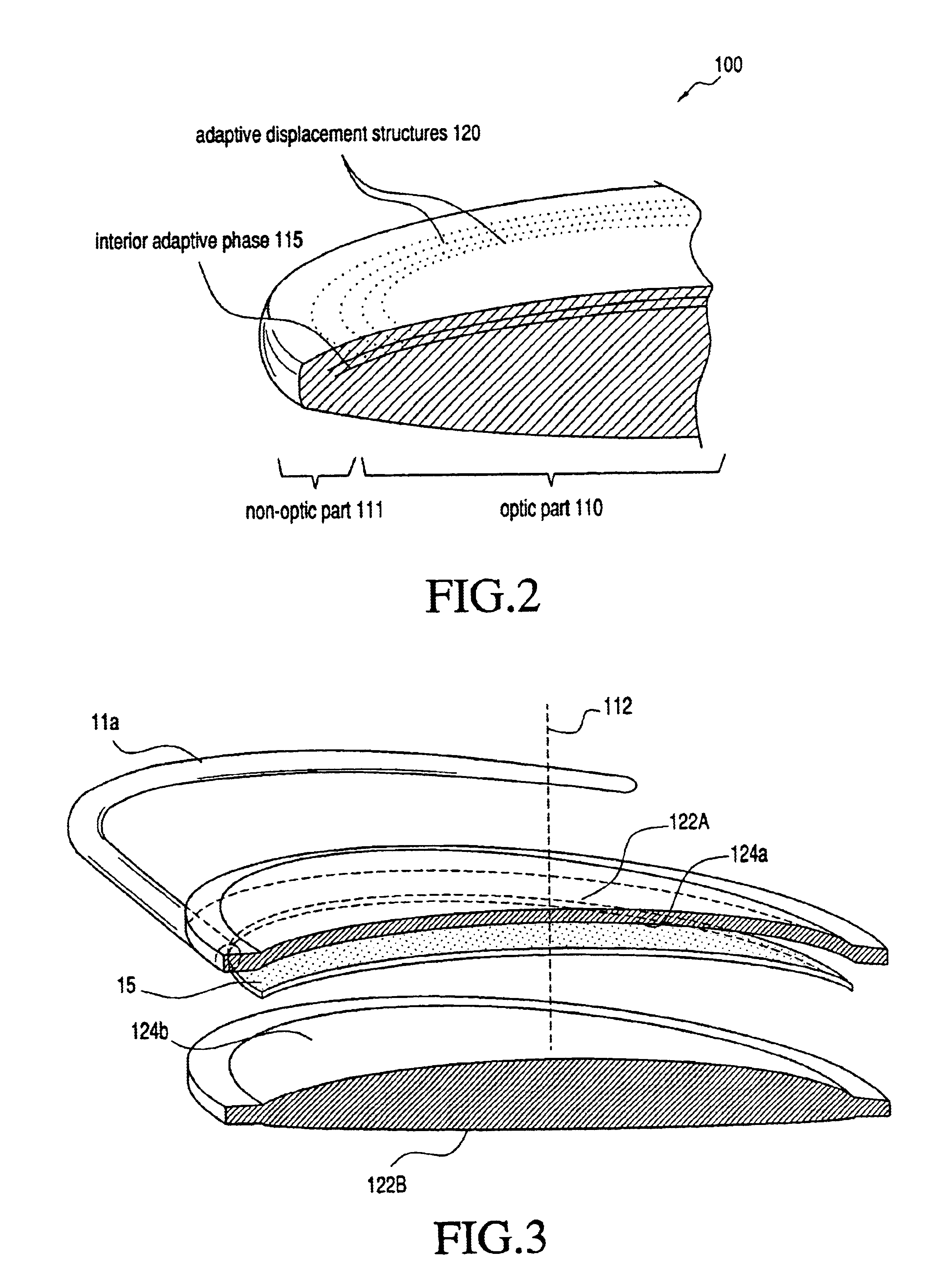

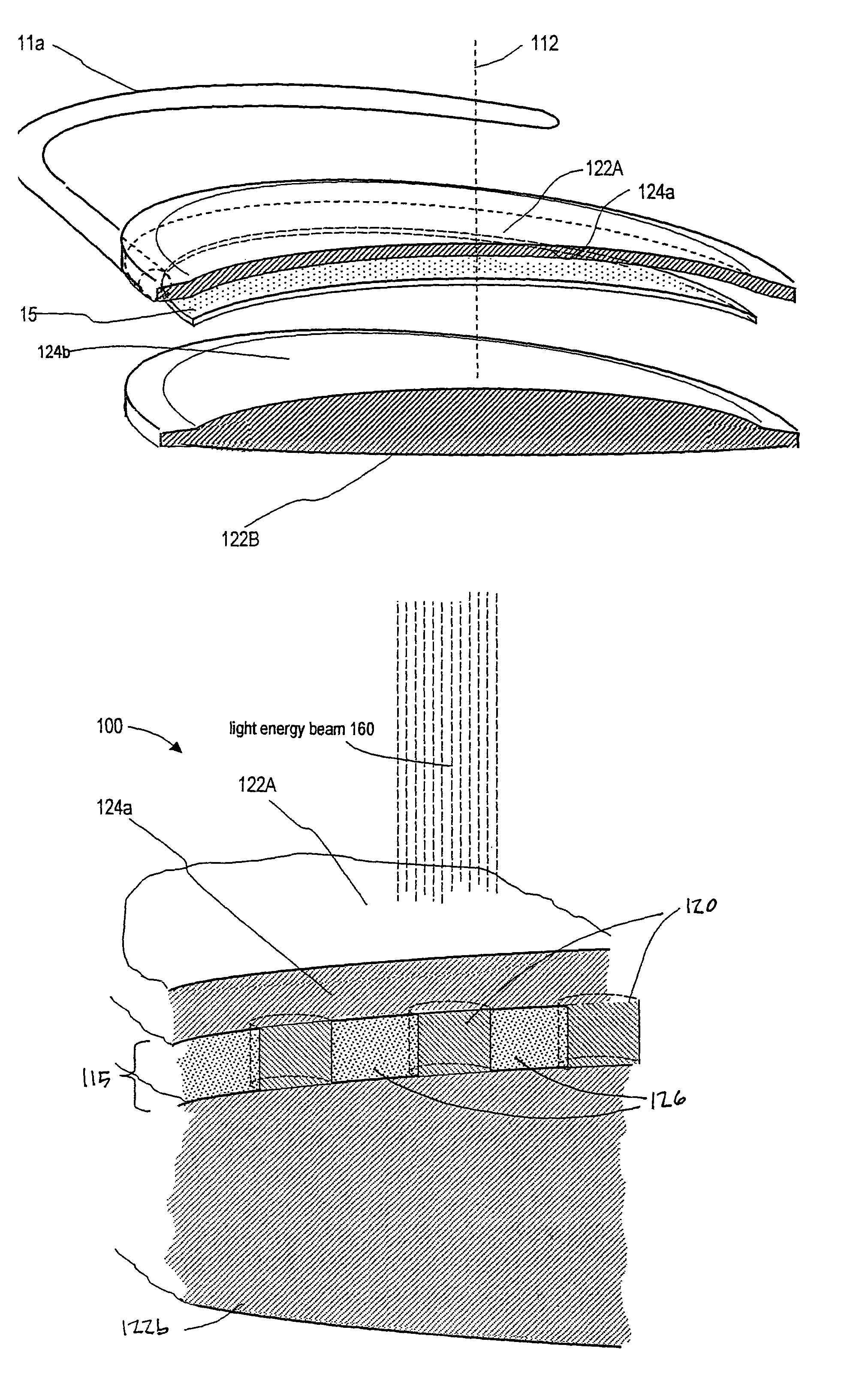

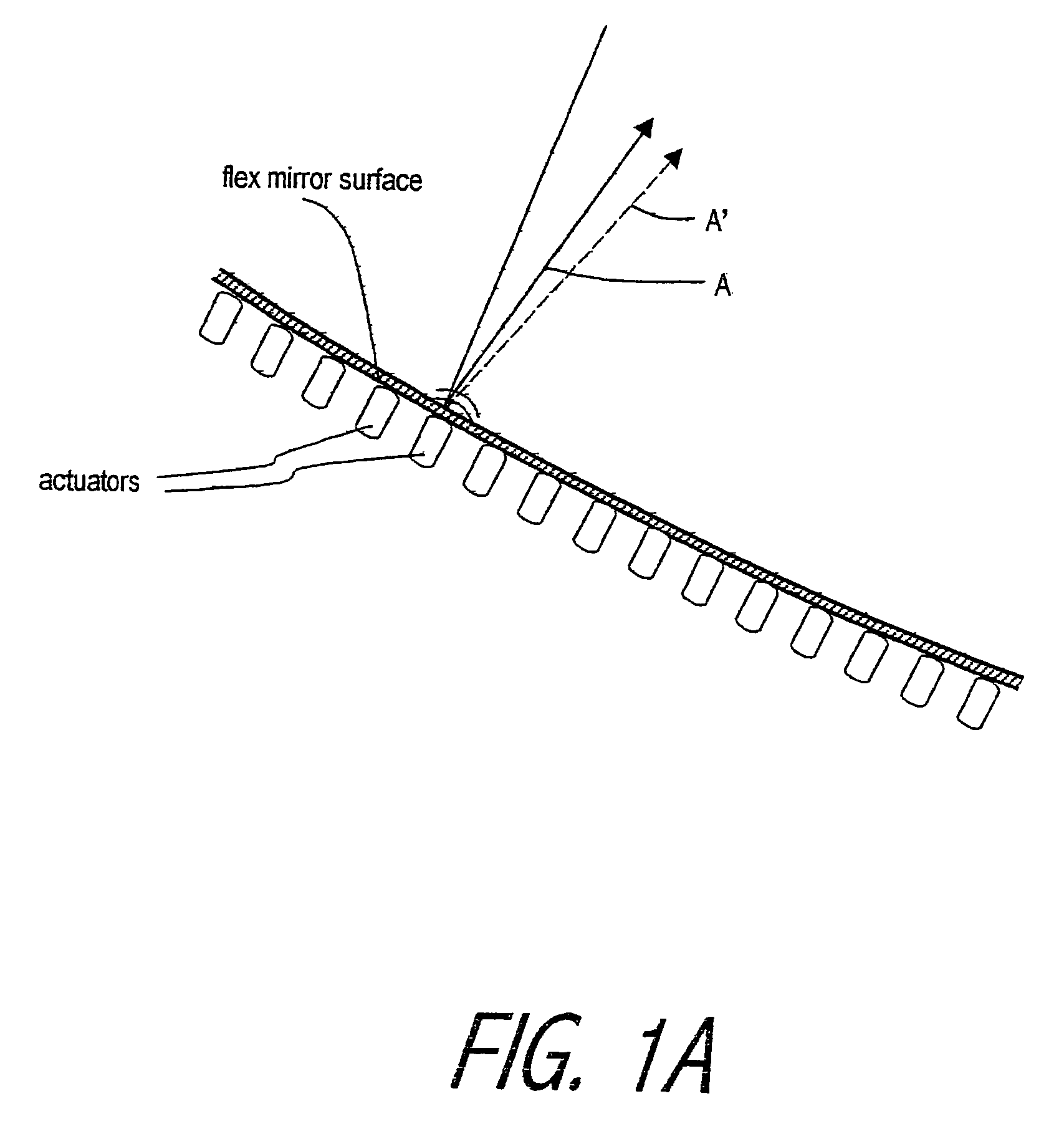

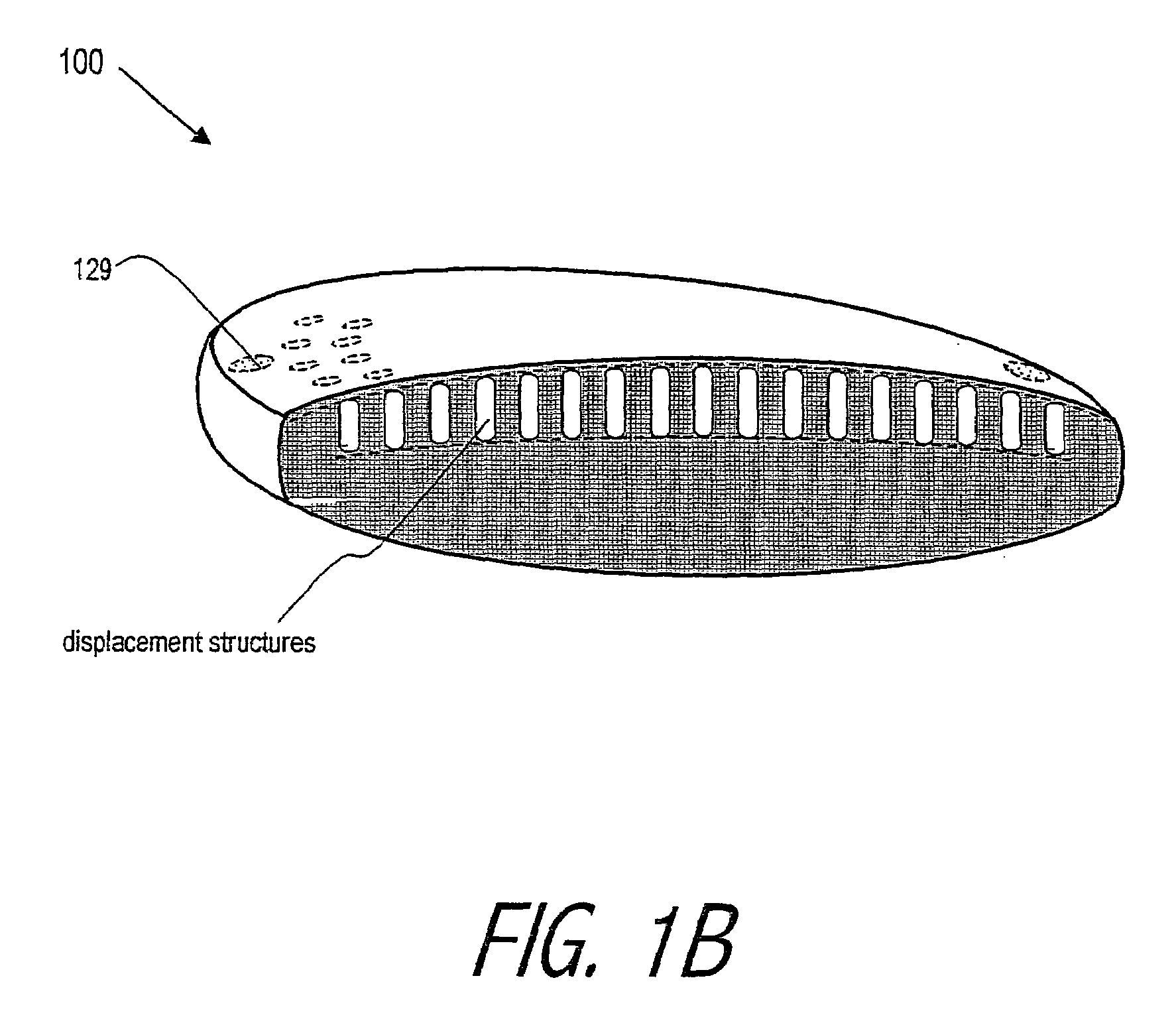

Adaptive optic lens system and method of use

InactiveUS6860601B2Reduce aberrationHigh order aberrationSpectales/gogglesEye diagnosticsCamera lensCorneal inlay

An lens for correcting human vision, for example an IOL, contact lens or corneal inlay or onlay, that carries and interior phase or layer comprising a pattern of individual transparent adaptive displacement structures. In one embodiment, the displacement structures are actuated by a shape memory polymer (SMP) material or other polymer that is adjustable in shape in response to applied energy. The SMP can be designed to be selectively adjustable in volumetric dimension, modulus of elasticity and / or permeability. The adaptive optic means of the invention can be used to create highly localized surface corrections in the lens to correct higher order aberrations-which types of surfaces cannot be fabricated into and IOL and then implanted. The system of displacement structures also can provide spherical corrections in the lens.

Owner:ALCON INC

Bone replacement materials

ActiveUS20070203584A1Easy adhesionFacilitate cell growthAdditive manufacturing apparatusBone implantBone tissueBone tissue engineering

Particular aspects provide novel devices for bone tissue engineering, comprising a metal or metal-based composite member / material comprising an interior macroporous structure in which porosity may vary from 0-90% (v), the member comprising a surface region having a surface pore size, porosity, and composition designed to encourage cell growth and adhesion thereon, to provide a device suitable for bone tissue engineering in a recipient subject. In certain aspects, the device further comprises a gradient of pore size, porosity, and material composition extending from the surface region throughout the interior of the device, wherein the gradient transition is continuous, discontinuous or seamless and the growth of cells extending from the surface region inward is promoted. Additional aspects provide a device for bone tissue engineering, comprising a metal or metal-based composite member / material comprising an interior porous structure, wherein the pore size, porosity and material composition is selected to provide a device having an optimal density and / or elastic modulus and / or compression strength for a specific recipient. Novel methods for fabricating the devices are also provided.

Owner:WASHINGTON STATE UNIVERSITY

Steerable endoluminal devices and methods

A steerable endoluminal device adapted for delivery into a patient's vasculature. The device includes a tubular member having a distal deflection portion that extends to the distal end and a main body portion that extends from the deflectable portion to the proximal end, the tubular member further including a stiff portion extending along the distal deflection portion, and being formed of polymeric material, which is disposed circumferentially adjacent to the stiff portion. The stiff portion is made of a material that has an elastic modulus greater than the elastic modulus of the polymeric material. A pull wire extends between the proximal end and the distal end of the tubular member and is attached to the distal deflection portion to control deflection of the distal deflection portion of the tubular member.

Owner:BIOCARDIA

Structures including dielectric layers and methods of forming same

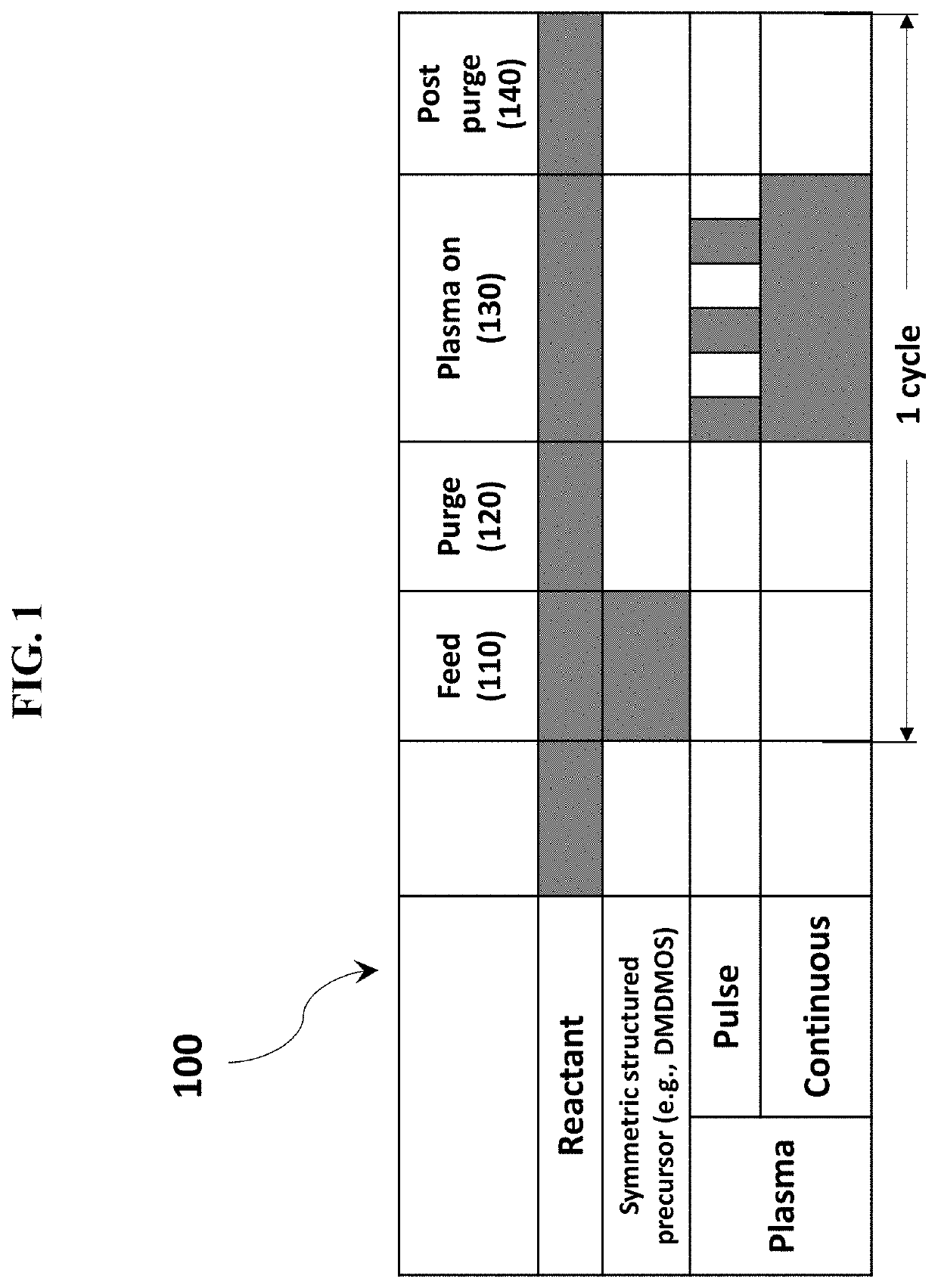

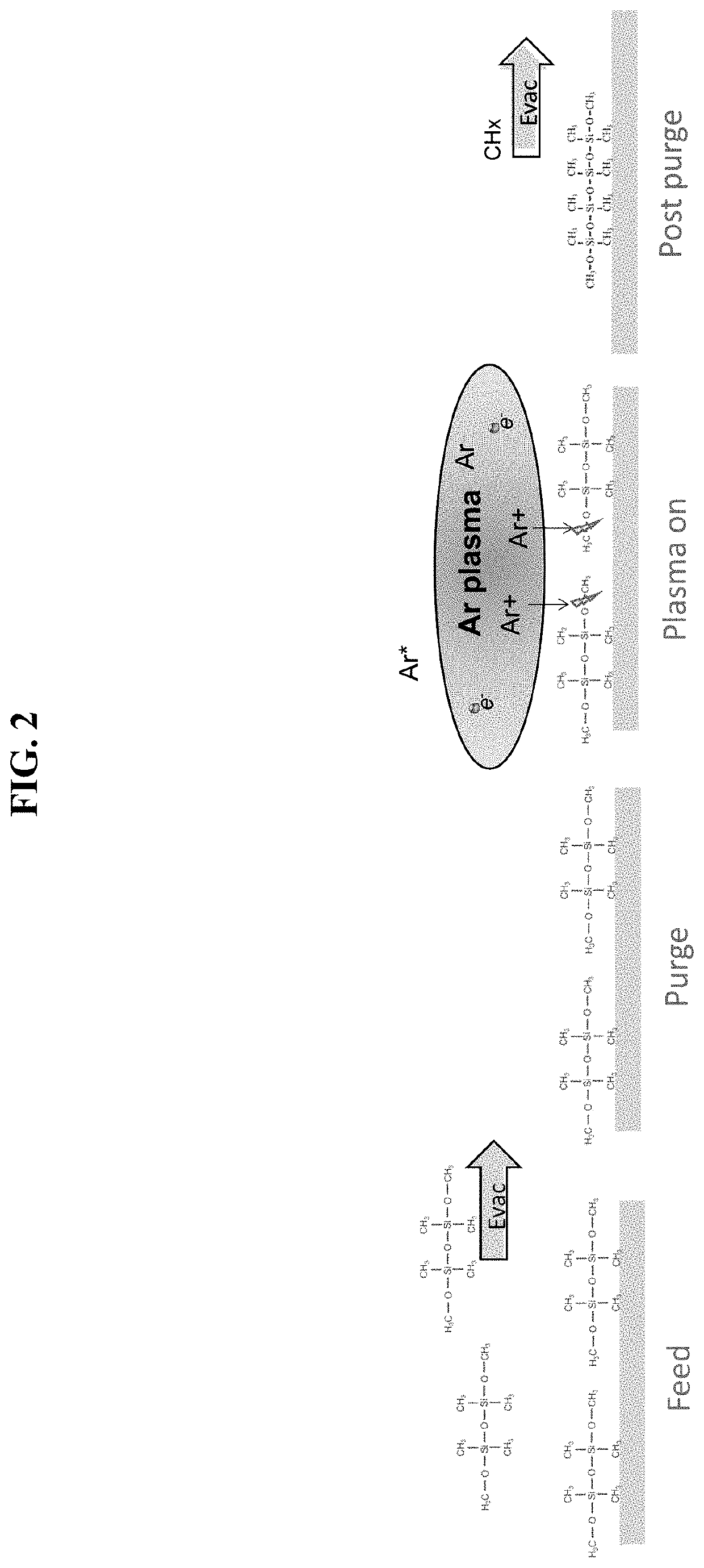

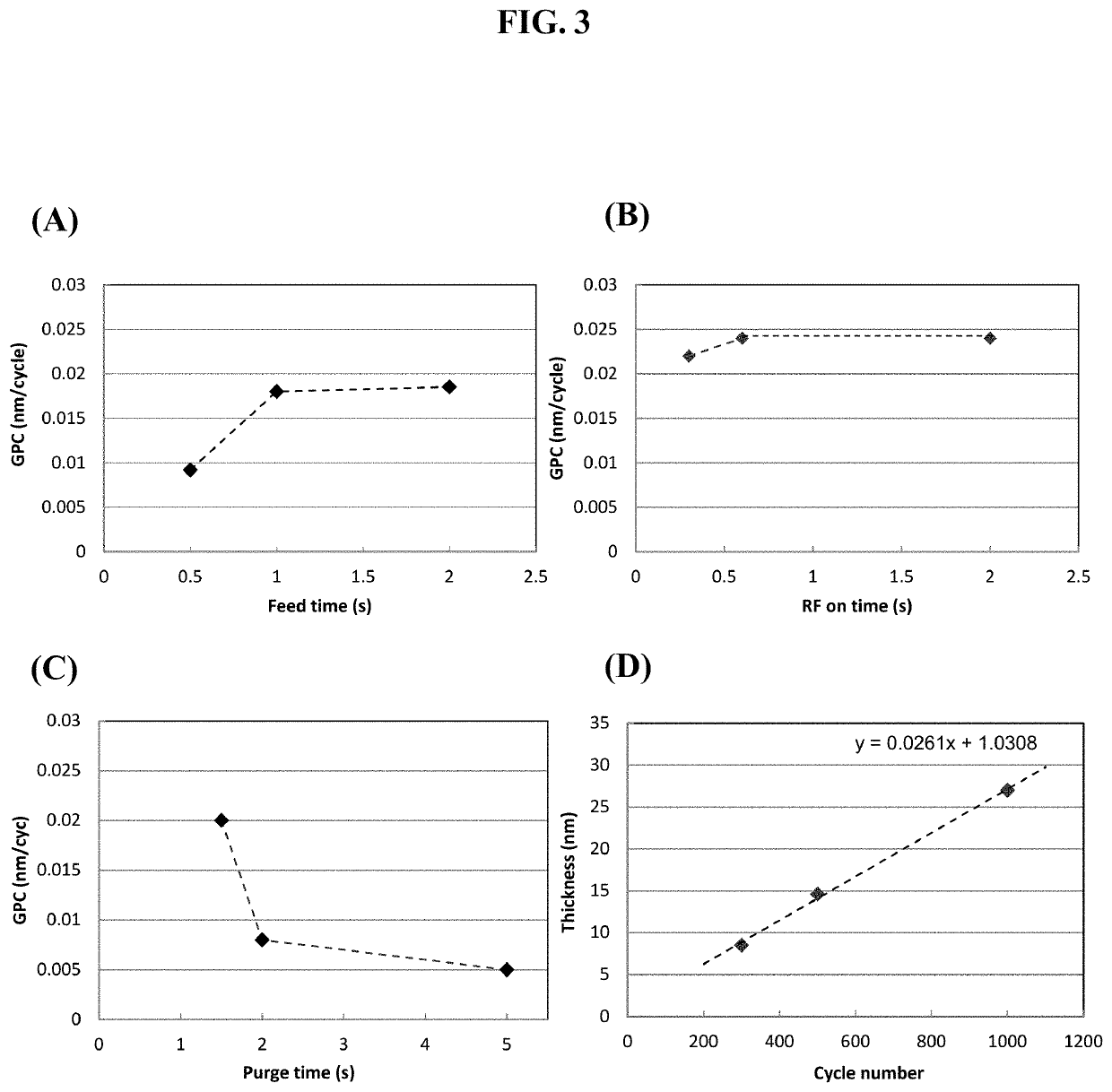

PendingUS20210066075A1Readily apparentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectric membraneDeposition process

Methods of forming structures having dielectric films with improved properties, such as, for example, improved elastic modulus and / or dielectric constant are disclosed. Exemplary films can be formed using a cyclic deposition process. Exemplary methods use activated species to cleave (e.g., symmetric-structured) precursor molecules to form the high quality dielectric layers.

Owner:ASM IP HLDG BV

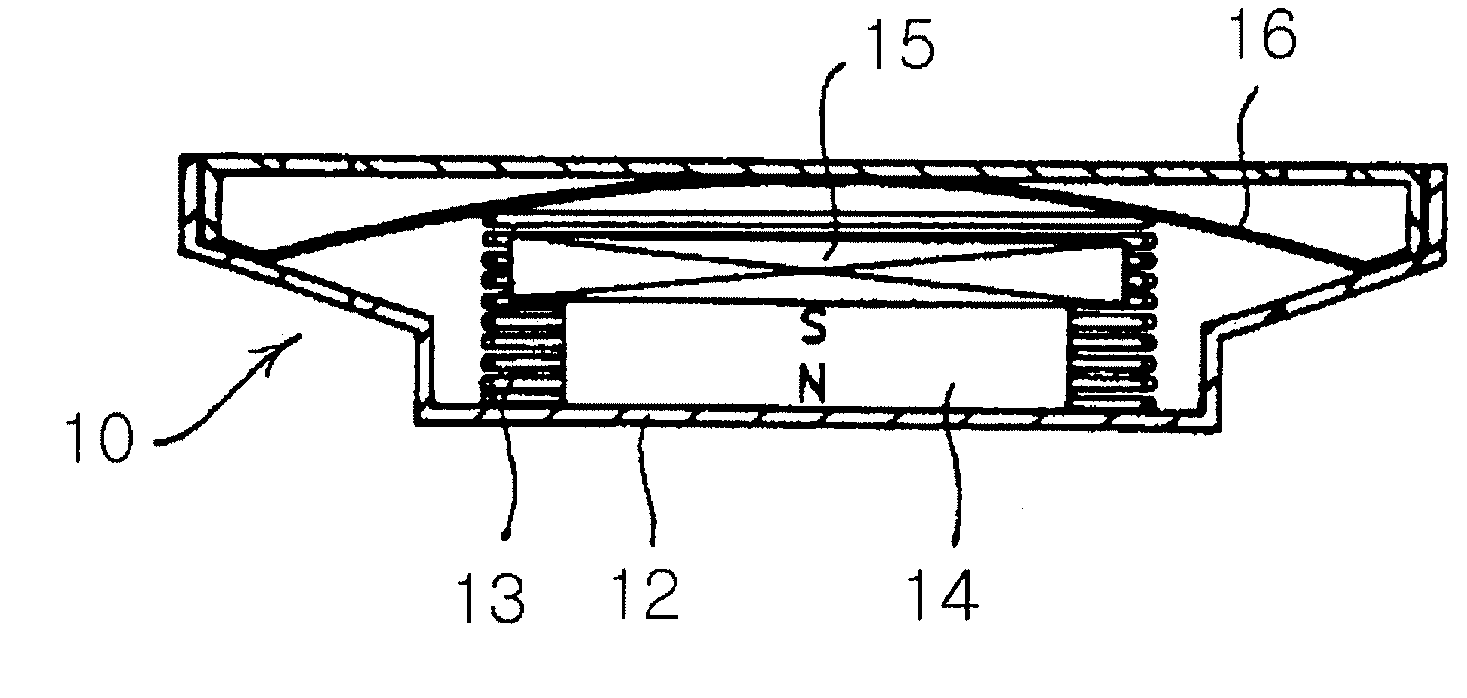

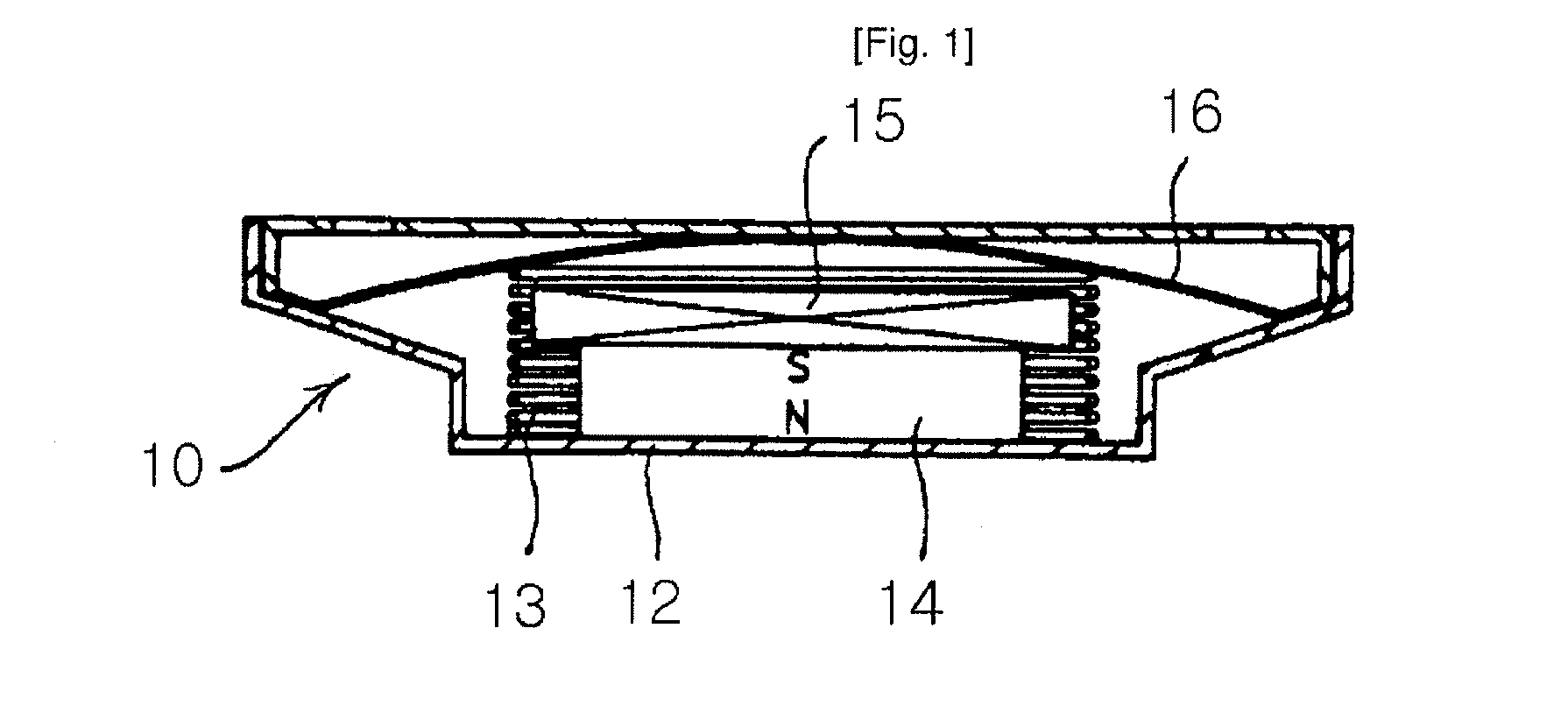

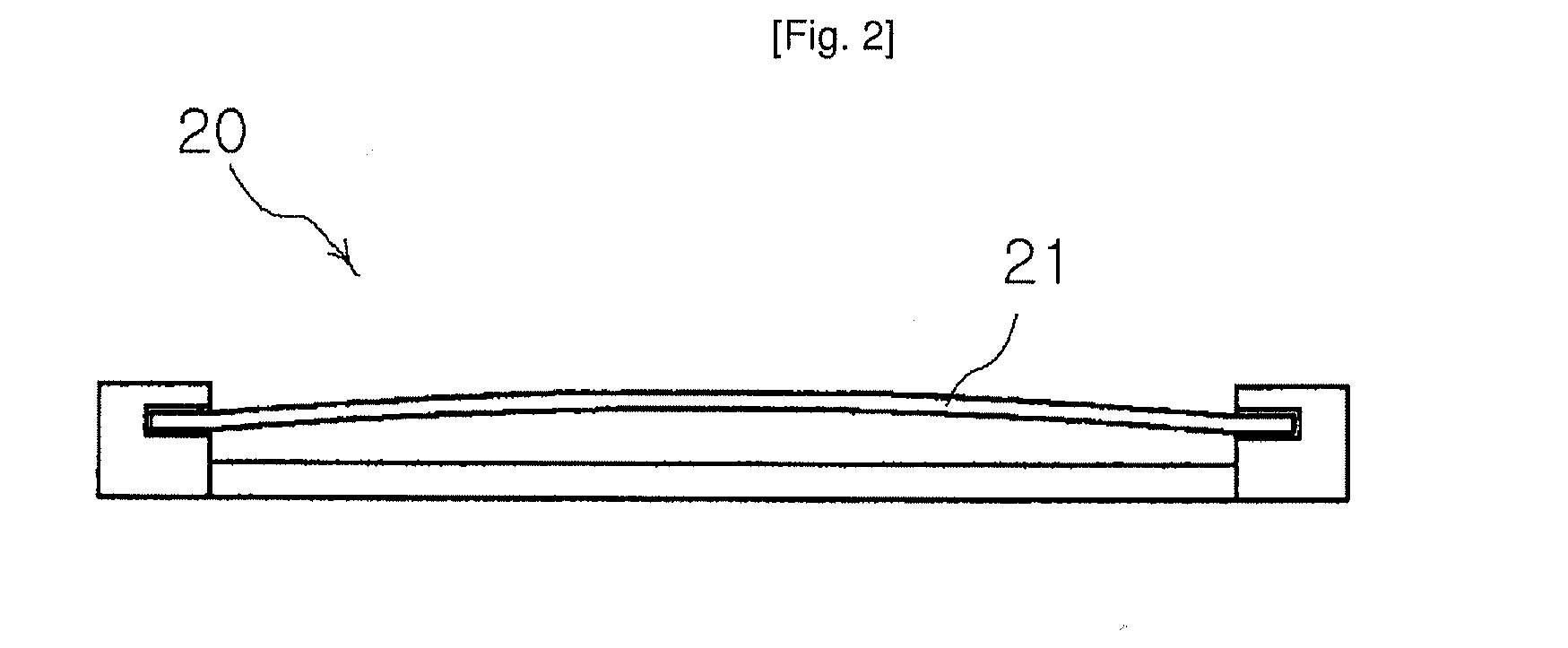

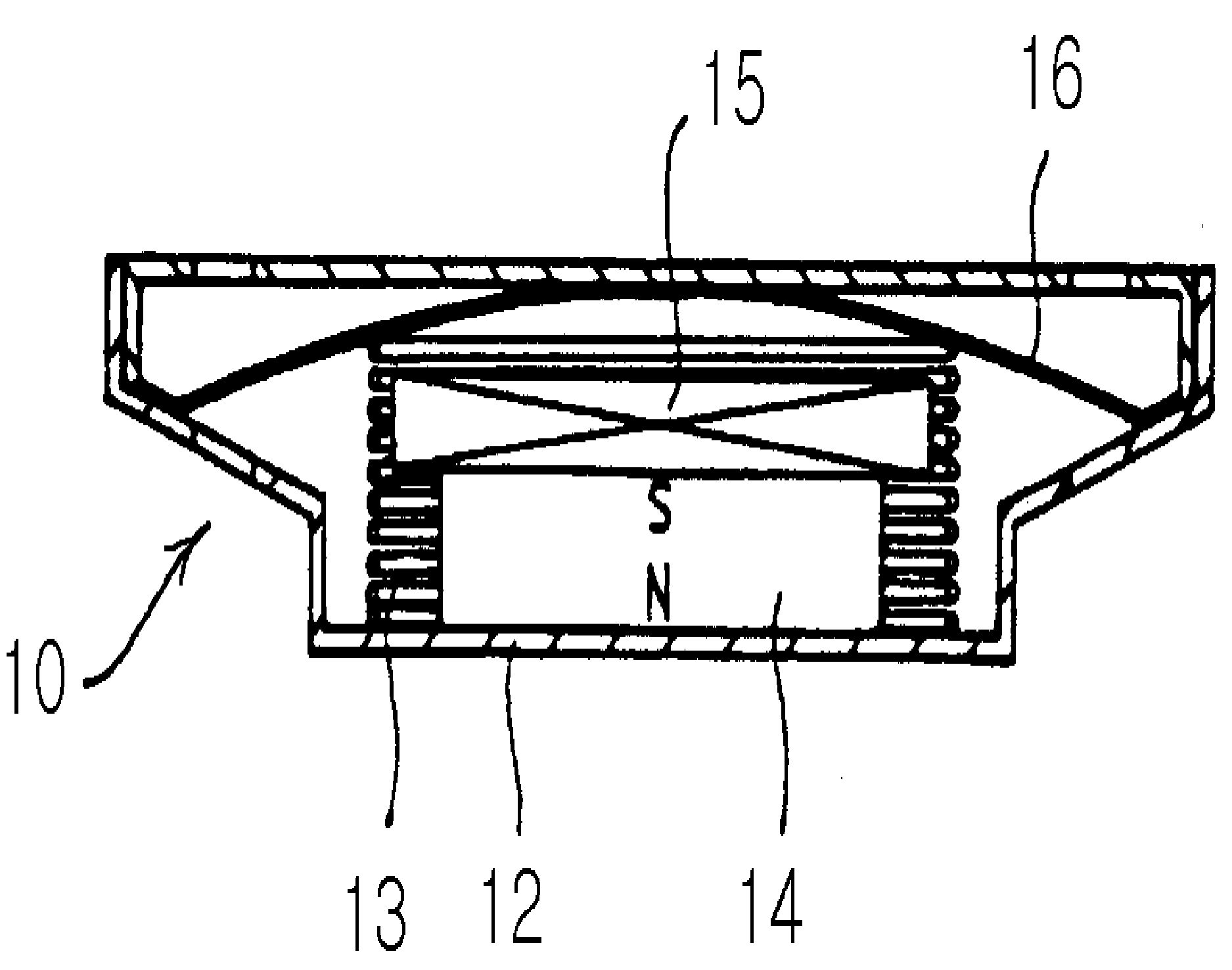

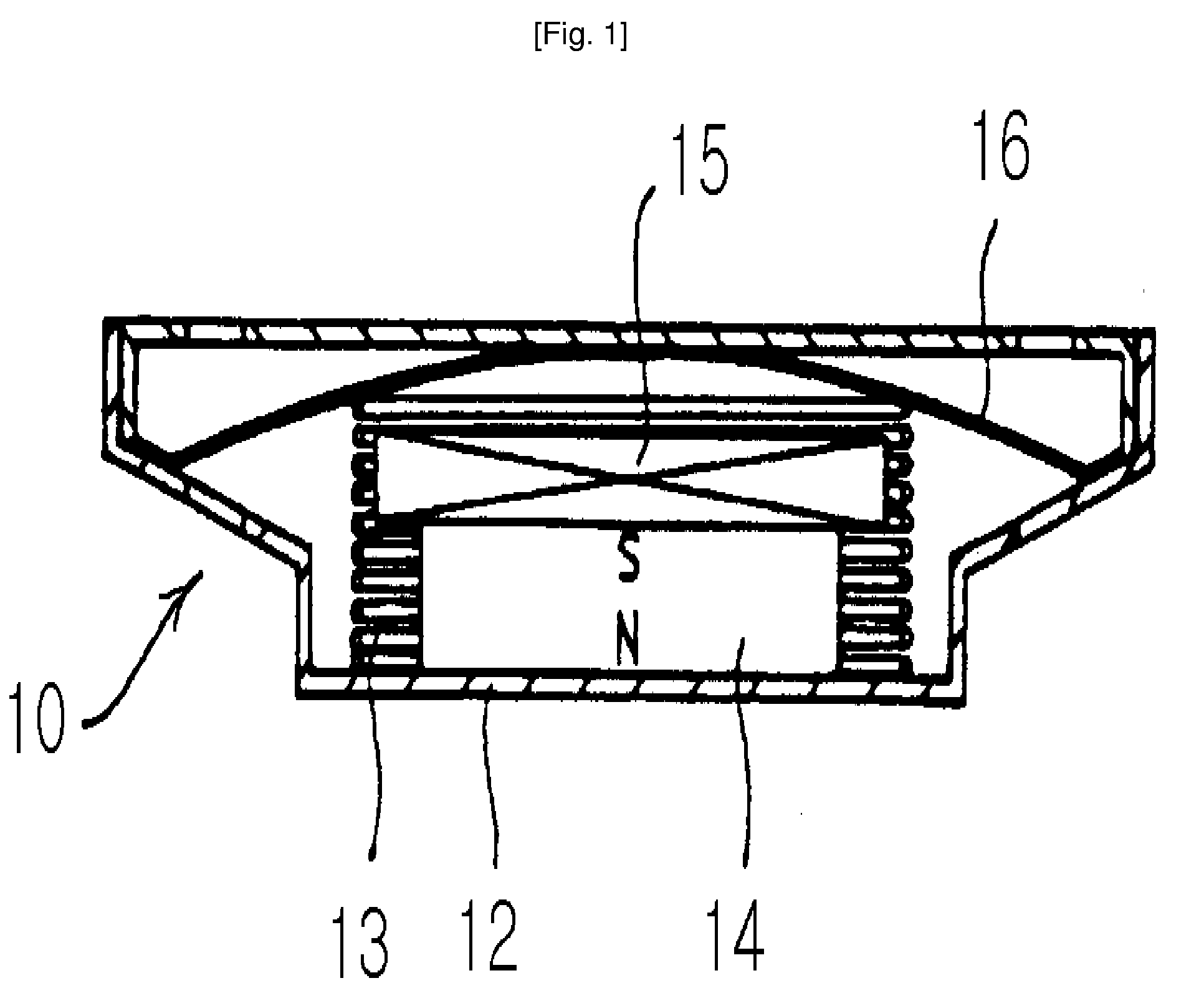

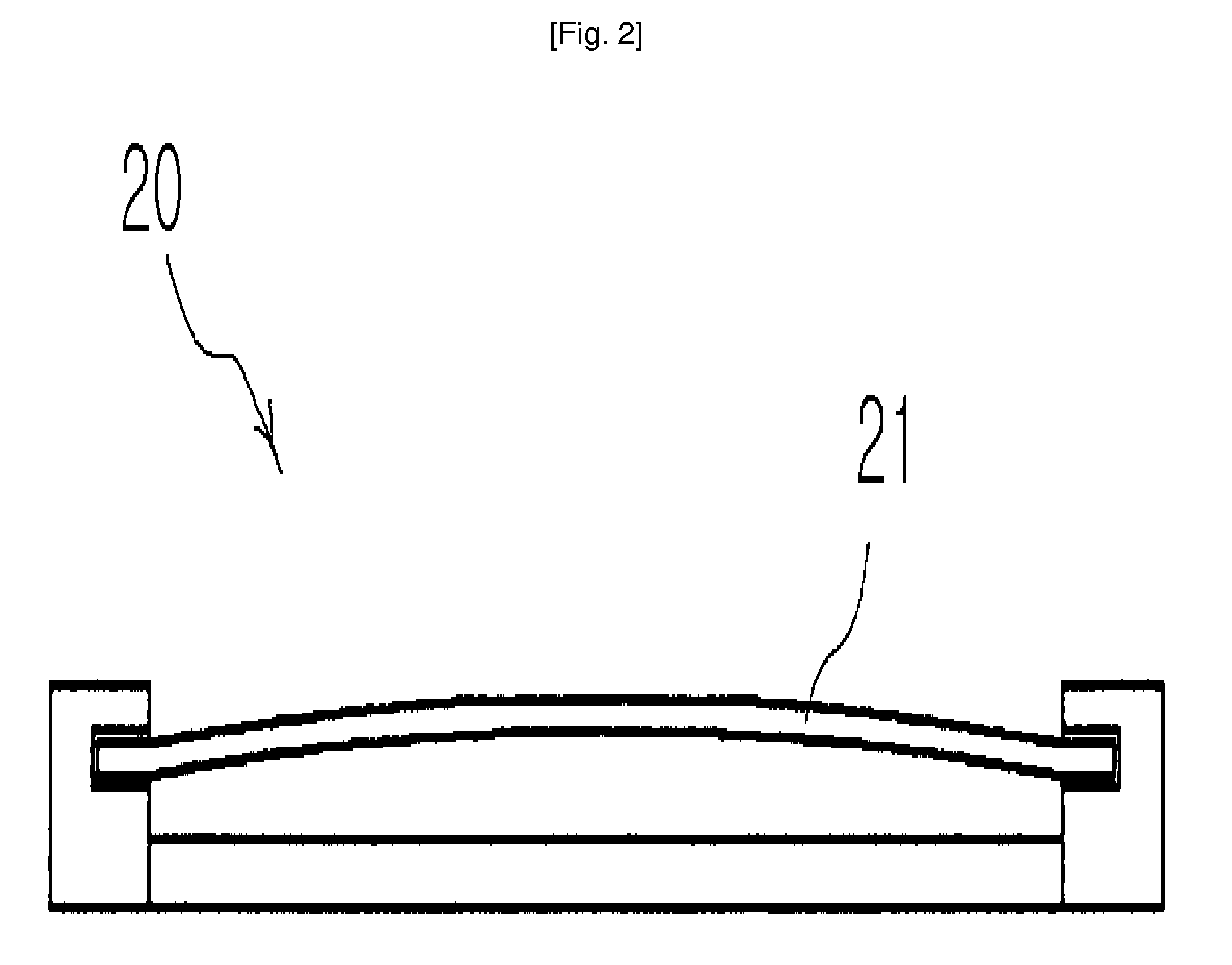

Acoustic Diaphragm and Speaker Having the Same

InactiveUS20080260188A1Good physical propertiesImprove sound qualityFibre diaphragmsPolymeric diaphragmsFiberNanofiber

Disclosed herein is an acoustic diaphragm for converting electrical signals into mechanical signals to produce sounds. The acoustic diaphragm comprises carbon nanotubes or graphite nanofibers as major materials. Preferably, the carbon nanotubes or graphite nanofibers are included or dispersed in the acoustic diaphragm. Since the acoustic diaphragm has excellent physical properties in terms of elastic modulus, internal loss and strength, it can effectively achieve superior sound quality and high output in a particular frequency band as well as in a broad frequency band.

Owner:KH CHEM CO LTD

High modulus polyurethane and polyurethane/urea compositions

ActiveUS20090099600A1High modulusHigh strengthStentsAdditive manufacturing apparatusMedicineUltimate tensile strength

The present invention provides a polyurethane or polyurethane / urea composition which has a tensile strength greater than 10 MPa, a modulus of elasticity greater than 400 MPa and an elongation at break greater than 30% at a temperature of between 0° C. and 60° C. and at a relative humidity of between 0% and 100%.The invention further provides uses of the compositions of the invention in biomedical vascular stents, an orthopaedic implant, a drug delivery coating or in tissue engineering.

Owner:POLYNOVO BIOMATERIALS PTY LTD

Magnetic tape

InactiveUS20120196156A1Good electromagnetic characteristicGood characteristic frictionMagnetic materials for record carriersRecord information storageMagnetic tapeNon magnetic

An aspect of the present invention relates to a magnetic tape comprising, on one surface of a nonmagnetic support, a nonmagnetic layer containing a nonmagnetic powder and a binder, and thereon, a magnetic layer containing a ferromagnetic powder and a binder, whereinthe magnetic layer contains a nonmagnetic filler the average particle diameter φ of which satisfies relation (I) below with a thickness t of the magnetic layer:1.0≦φ / t≦2.0 (I);the thickness t of the magnetic layer ranges from 30 to 200 nm;the nonmagnetic layer has a thickness ranging from 30 to 200 nm;a composite elastic modulus as measured on a surface of the magnetic layer ranges from 6.0 to 8.0 GPa; anda centerline average surface roughness Ra of the surface of the magnetic layer, as measured by an optical three-dimensional profilometer, ranges from 0.2 to 1.5 nm.

Owner:FUJIFILM CORP

Acoustic Diaphragm and Speakers Having the Same

InactiveUS20090045005A1Good physical propertiesImprove sound qualityPiezoelectric/electrostrictive transducersNanotechnologyFiberNanofiber

Disclosed herein is an acoustic diaphragm for converting electrical signals into mechanical signals to produce sounds. The acoustic diaphragm comprises carbon nanotubes or graphite nanofibers as reinforcing agents. Preferably, the carbon nanotubes or graphite nanofibers are included or dispersed in the acoustic diaphragm or coated on the surface of the acoustic diaphragm. Since the acoustic diaphragm has excellent physical properties in terms of elastic modulus, internal loss, strength and density, it can effectively achieve superior sound quality and a high output in a particular frequency band as well as in a broad frequency band.

Owner:KH CHEM CO LTD

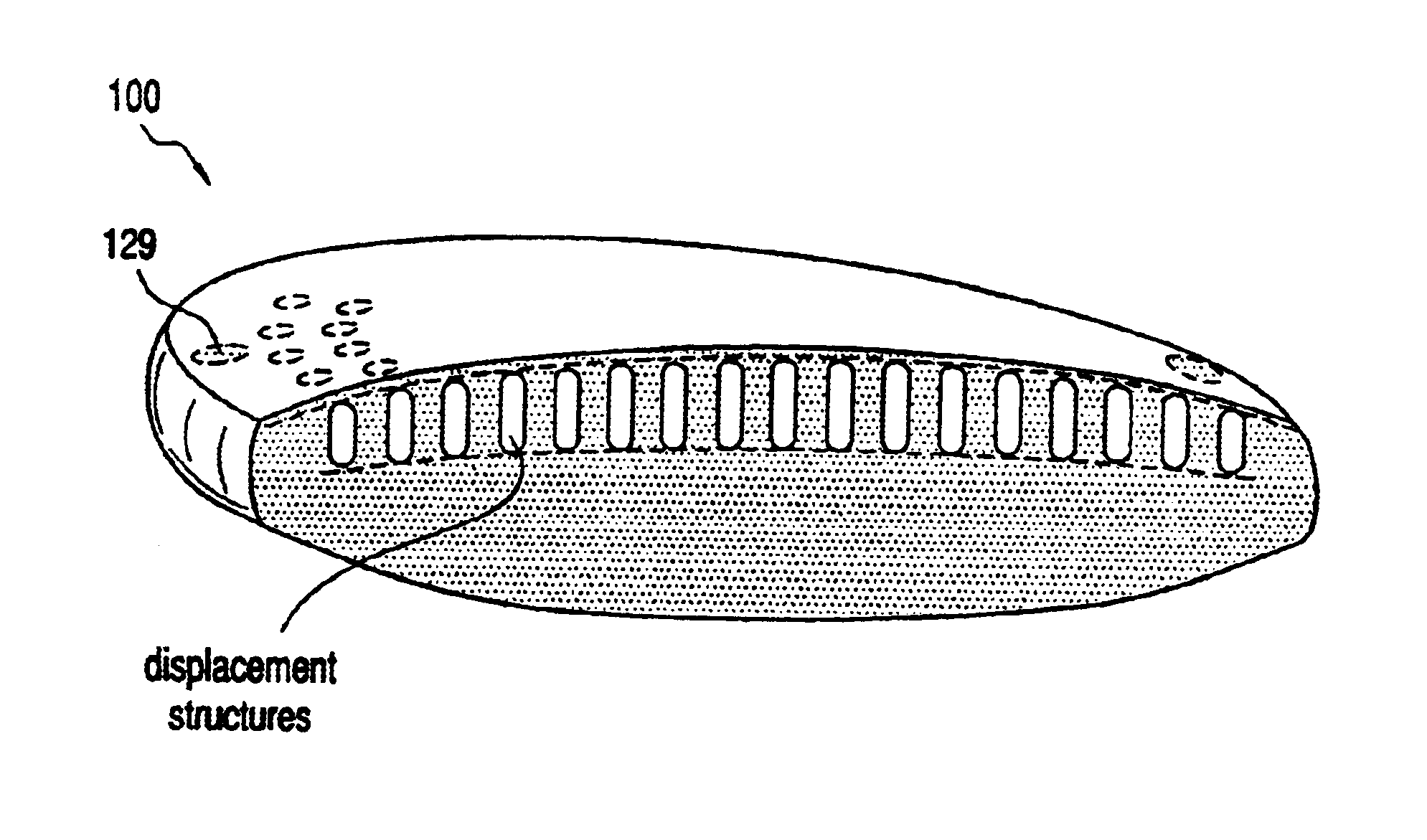

Adaptive optic lens system and method of use

InactiveUS6966649B2Reduce aberrationHigh order aberrationSpectales/gogglesEye diagnosticsCamera lensCorneal inlay

An lens for correcting human vision, for example an IOL, contact lens or corneal inlay or onlay, that carries and interior phase or layer comprising a pattern of individual transparent adaptive displacement structures. In one embodiment, the displacement structures are actuated by a shape memory polymer (SMP) material or other polymer that is adjustable in shape in response to applied energy. The SMP can be designed to be selectively adjustable in volumetric dimension, modulus of elasticity and / or permeability. The adaptive optic means of the invention can be used to create highly localized surface corrections in the lens to correct higher order aberrations—which types of surfaces cannot be fabricated into and IOL and then implanted. The system of displacement structures also can provide spherical corrections in the lens.

Owner:ALCON INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com