Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "High order aberration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

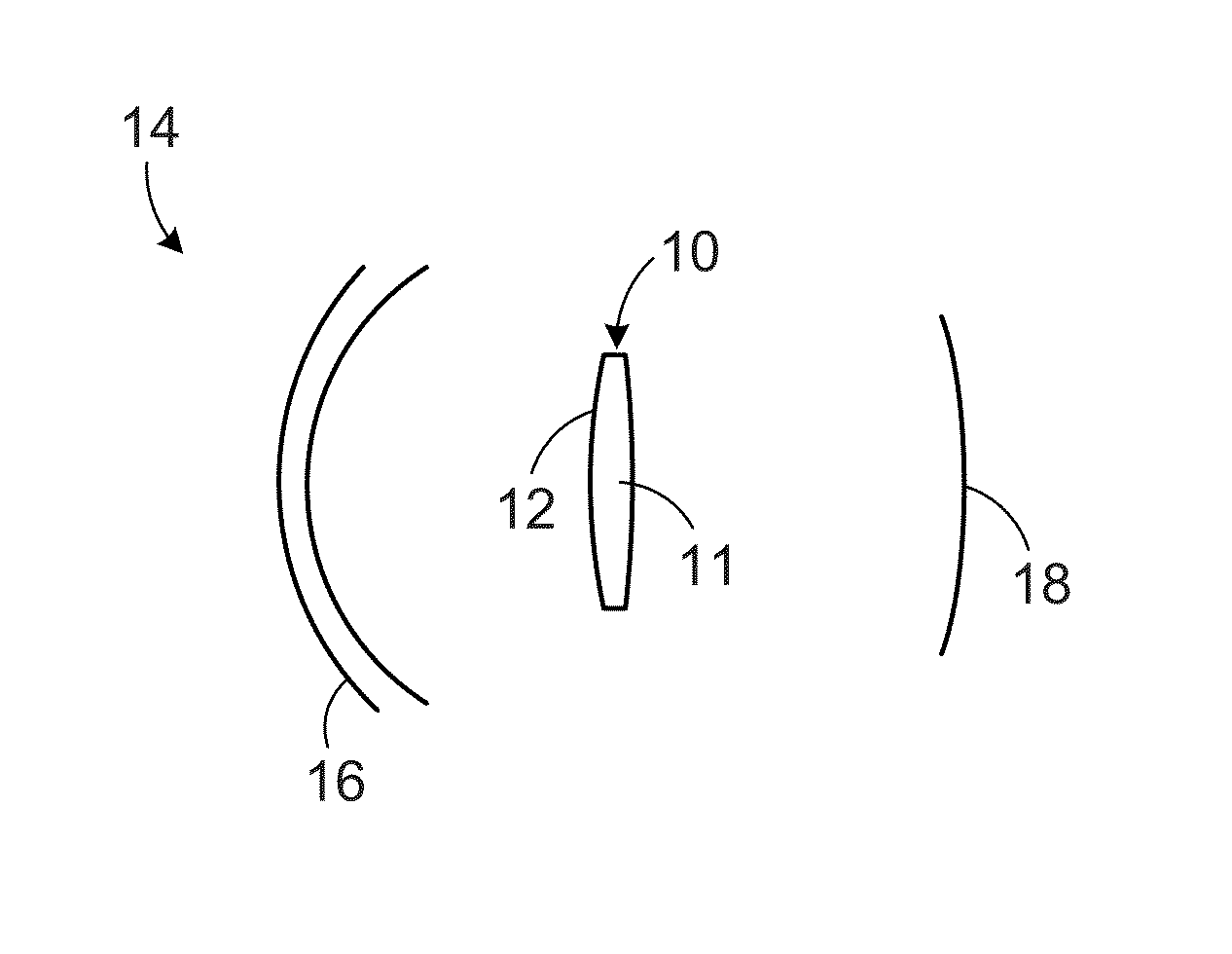

Advanced Electro-Active Optic Device

Optical devices having a dynamic aperture and / or an apodization mask are provided. The aperture and / or mask may be provided by one or more electro-active elements, and may be used in an ophthalmic device that that is spaced apart from but in optical communication with an intraocular lens, a corneal inlay, a corneal onlay, or a spectacle lens that provide an optical power.

Owner:EA3TECH LLC +1

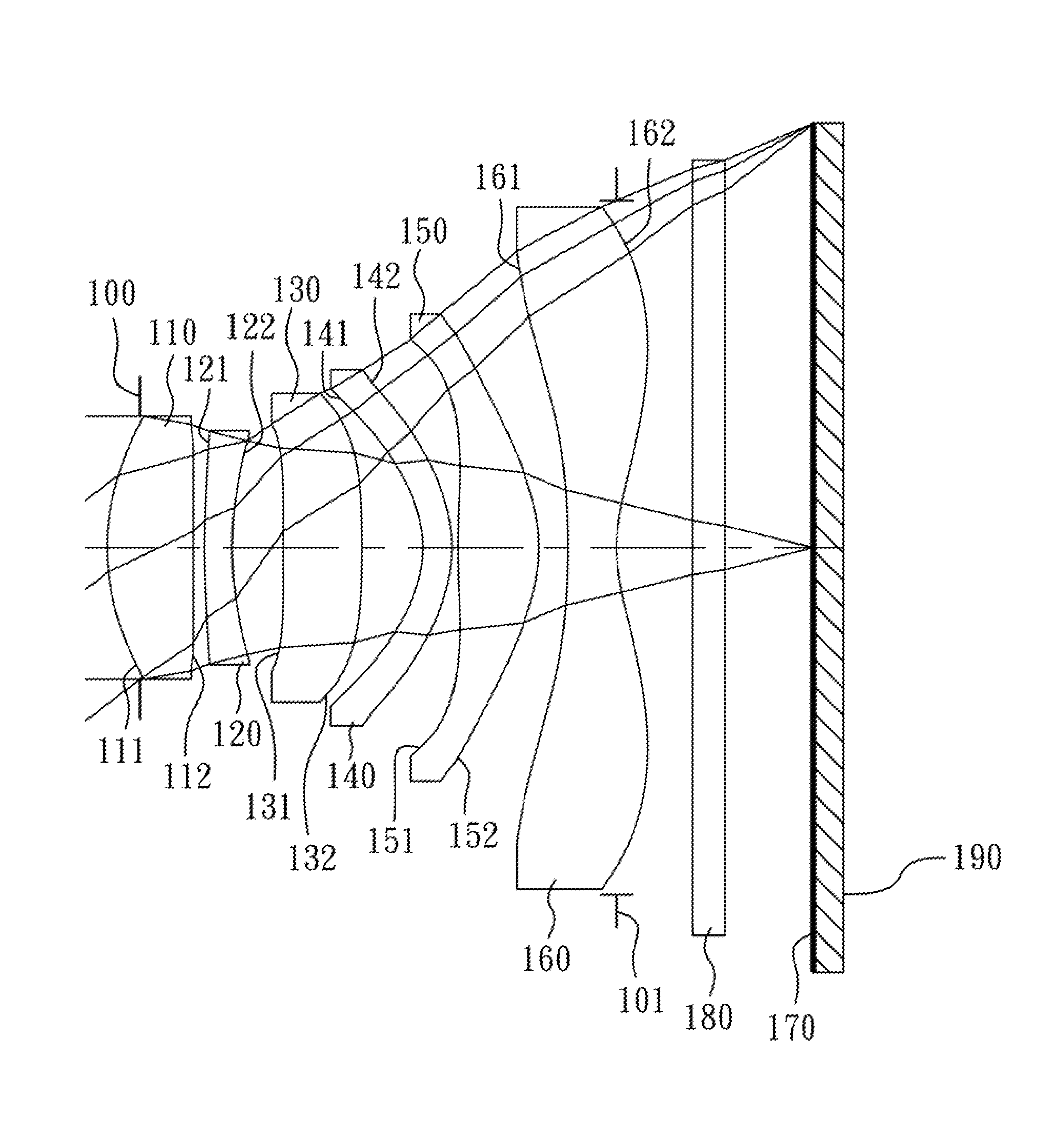

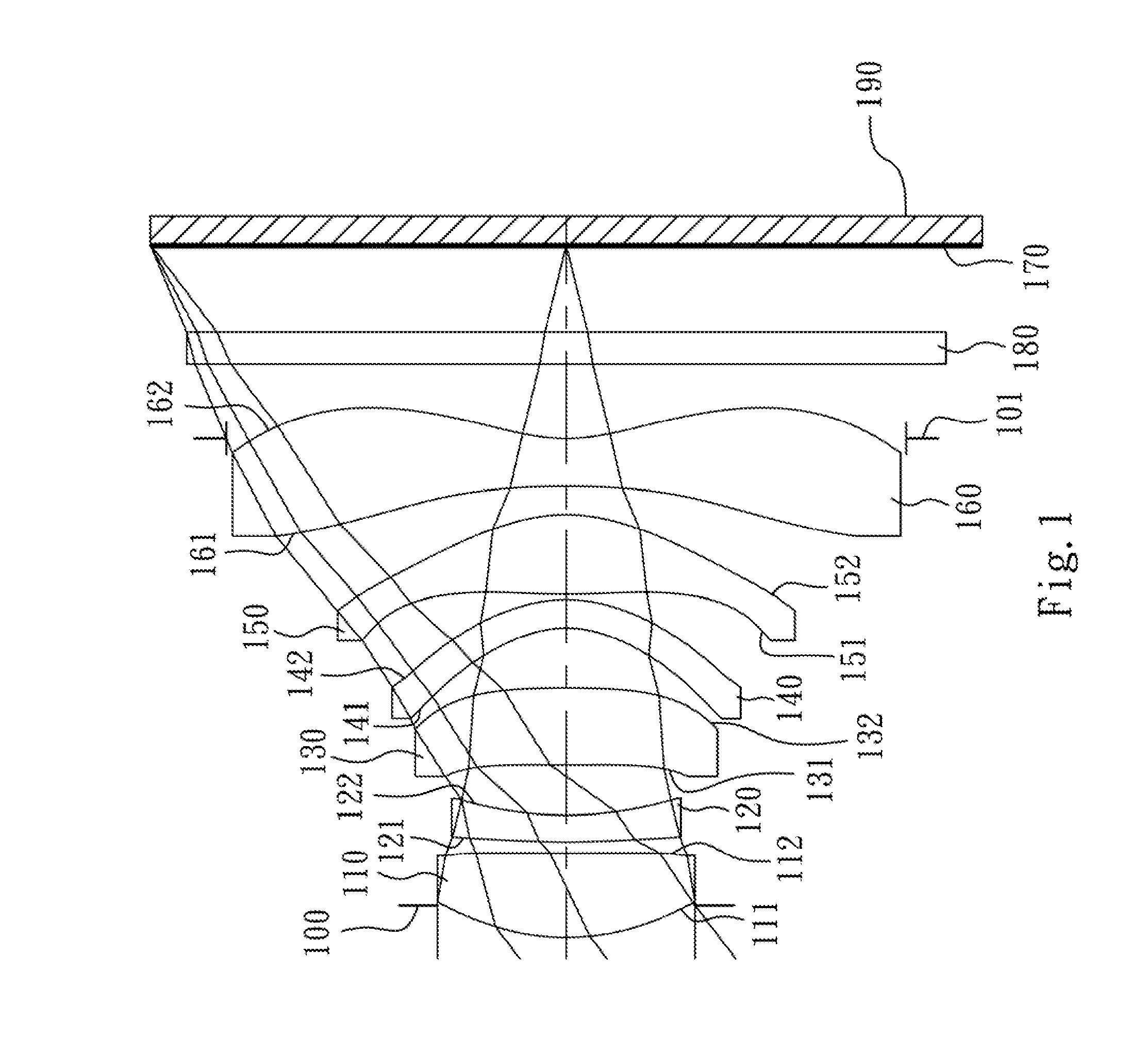

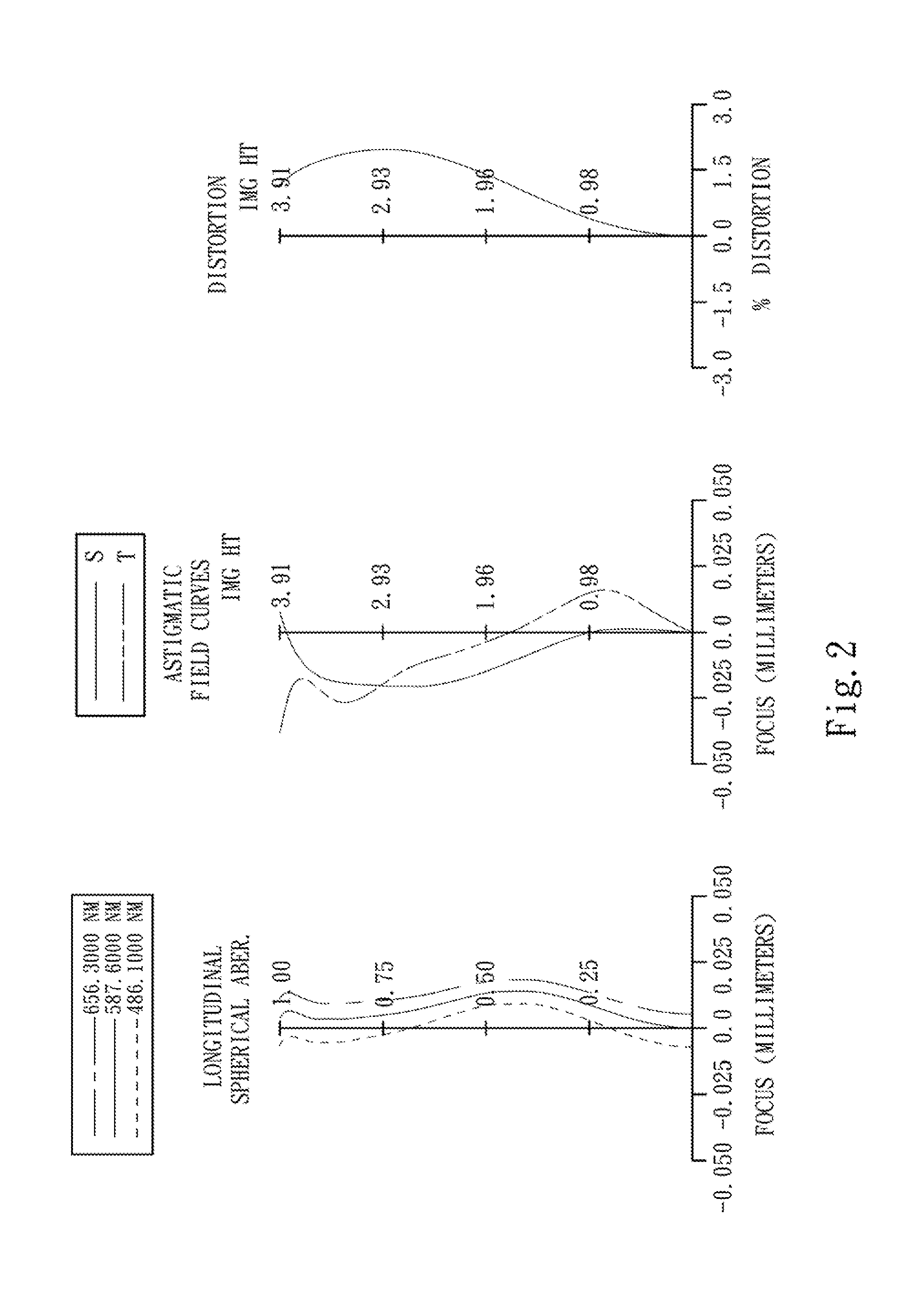

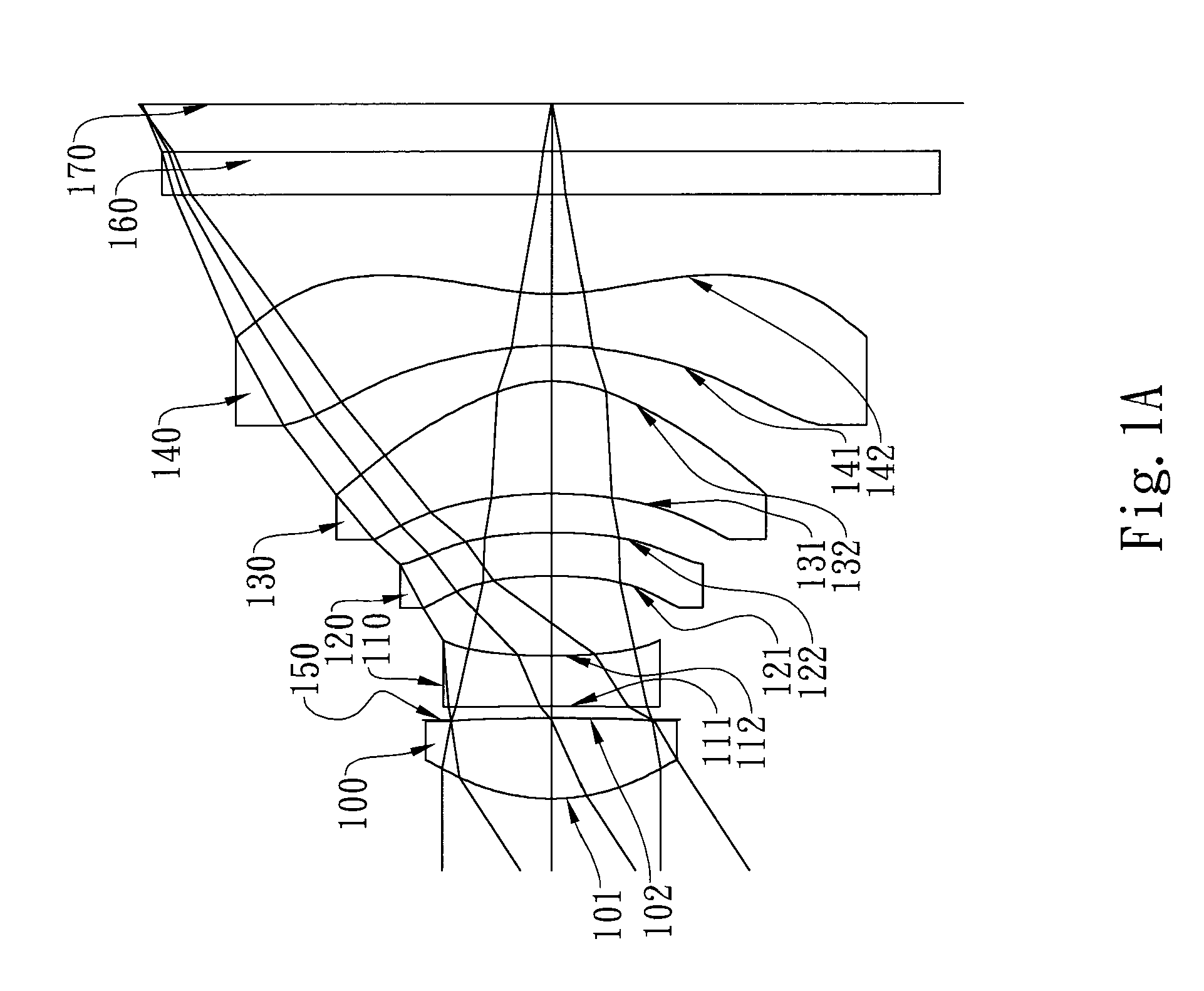

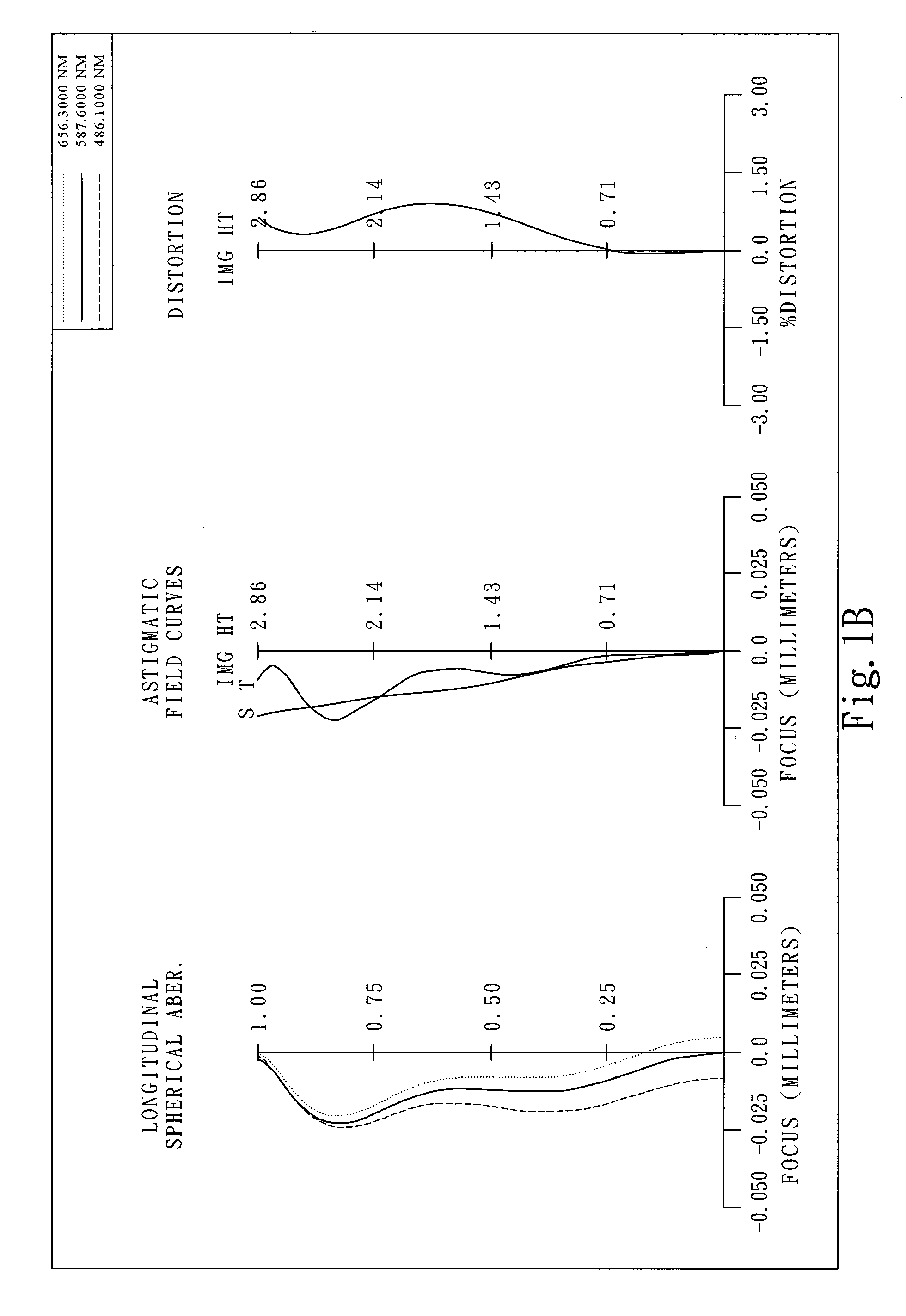

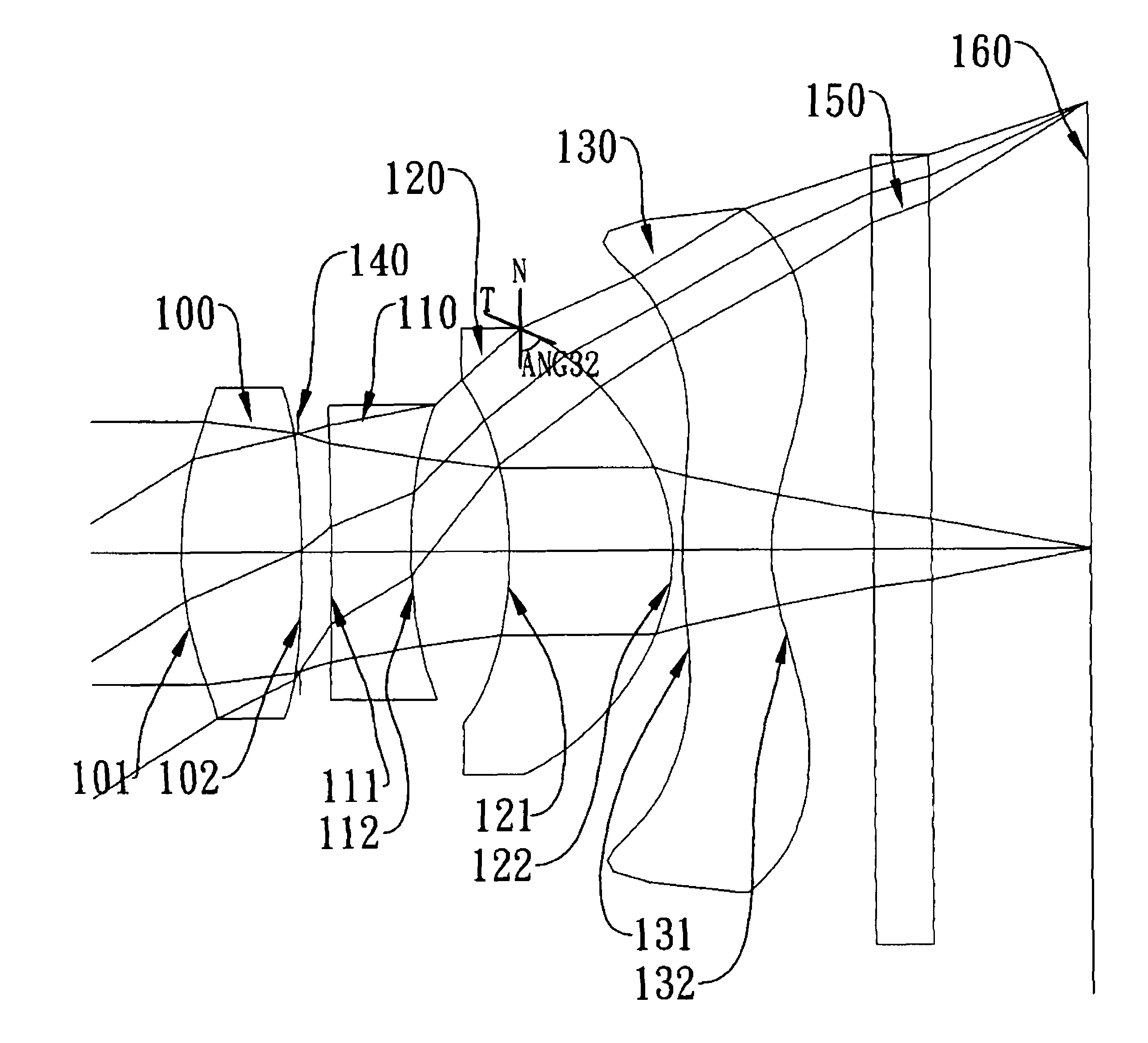

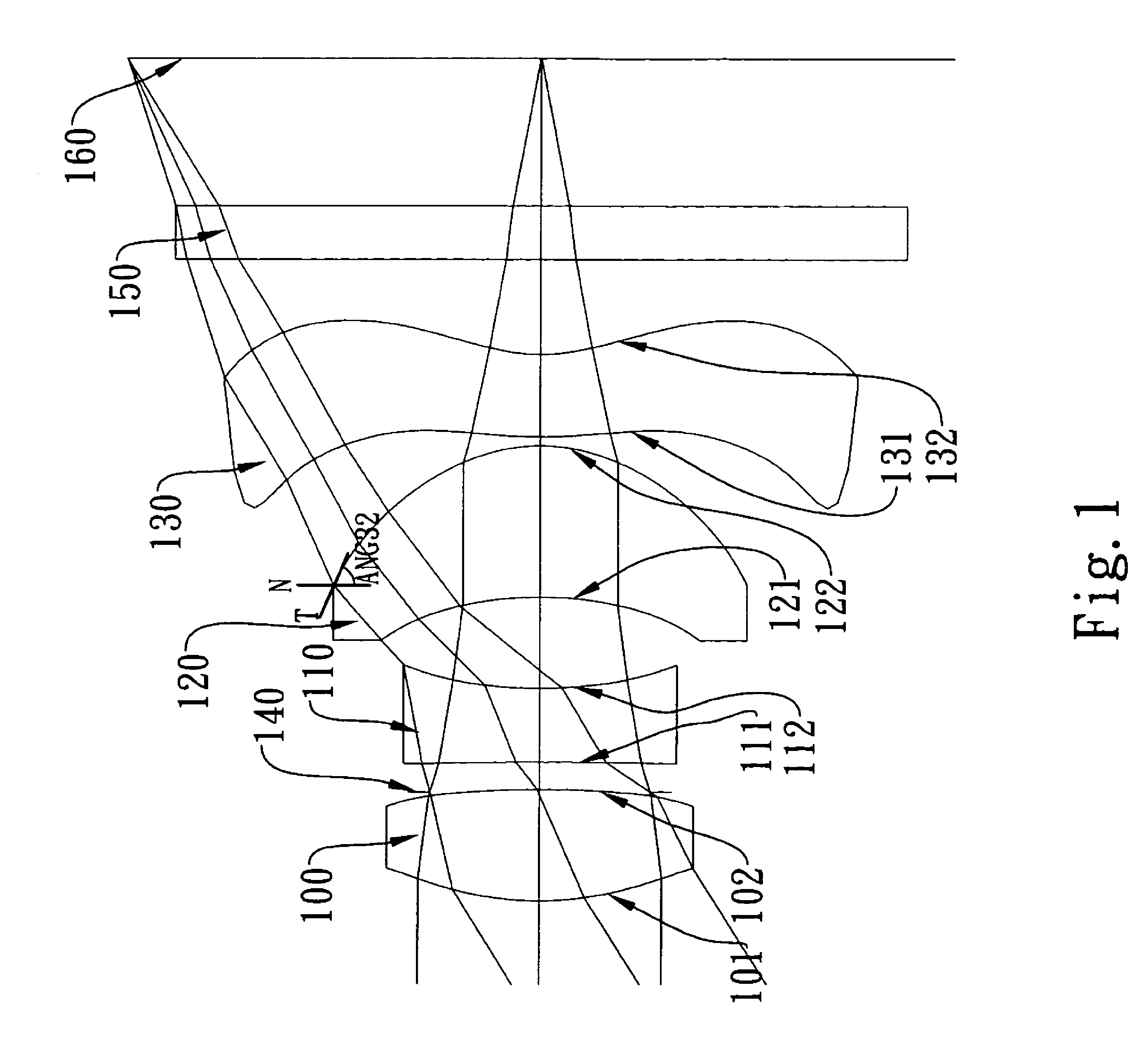

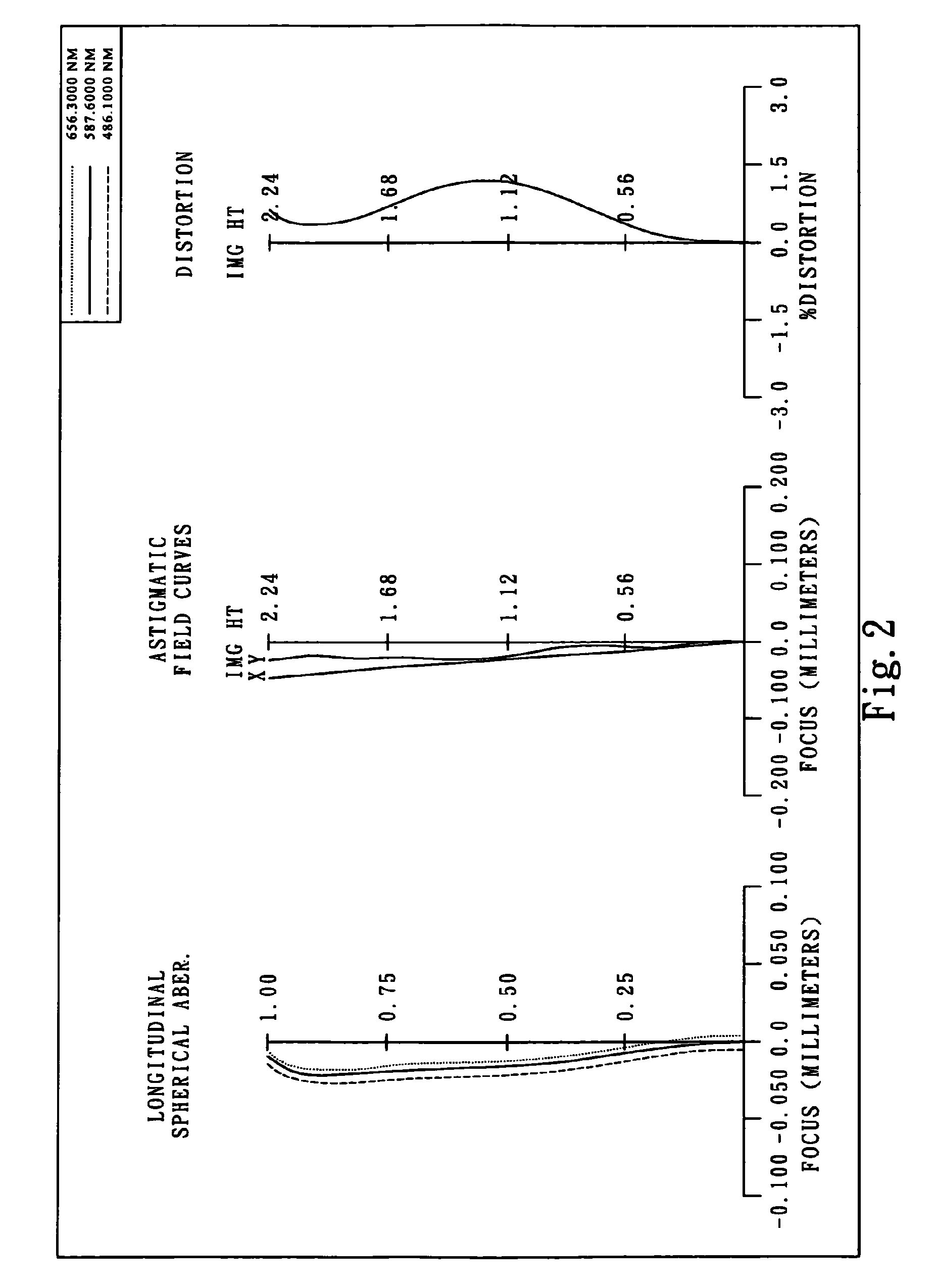

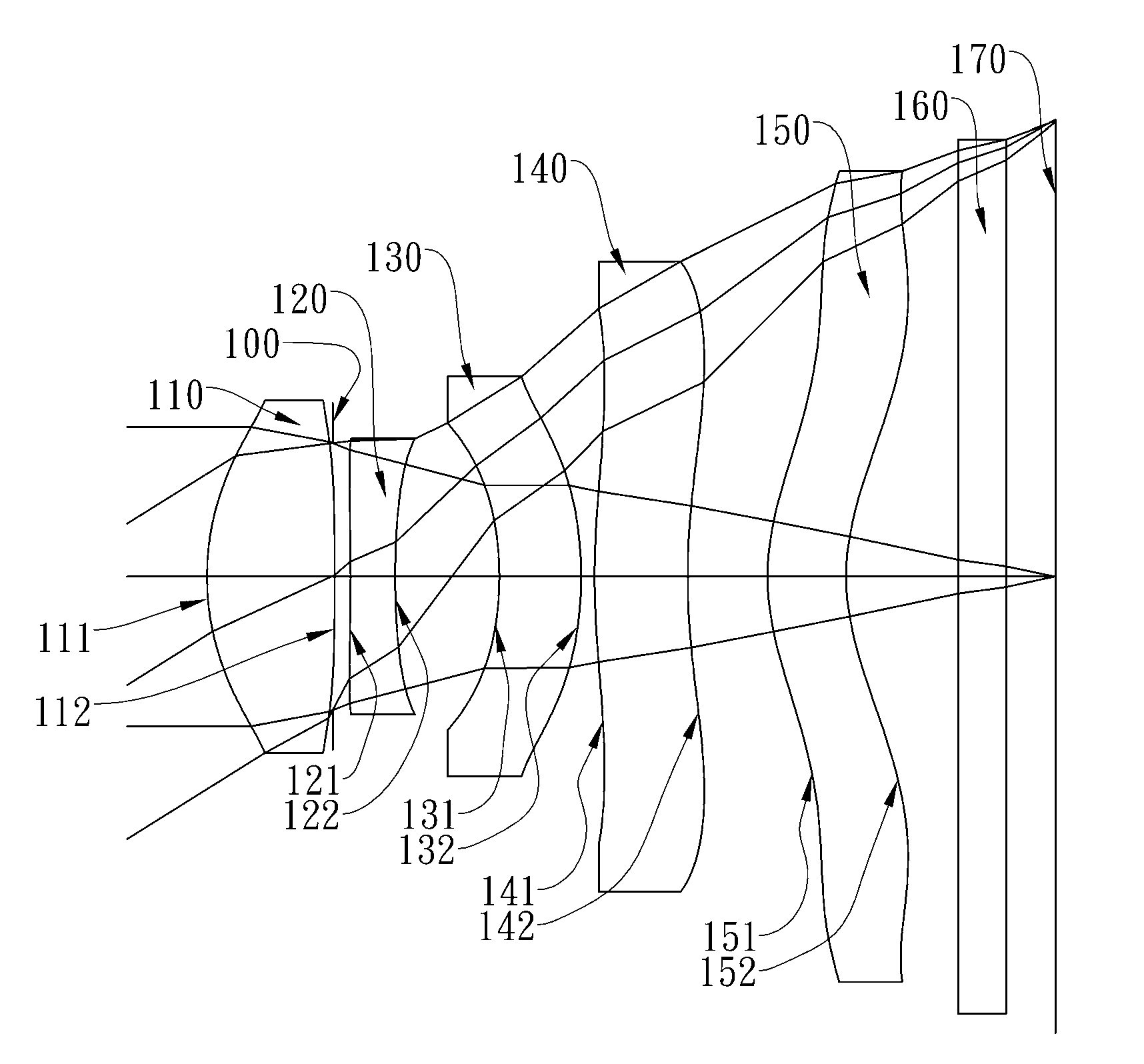

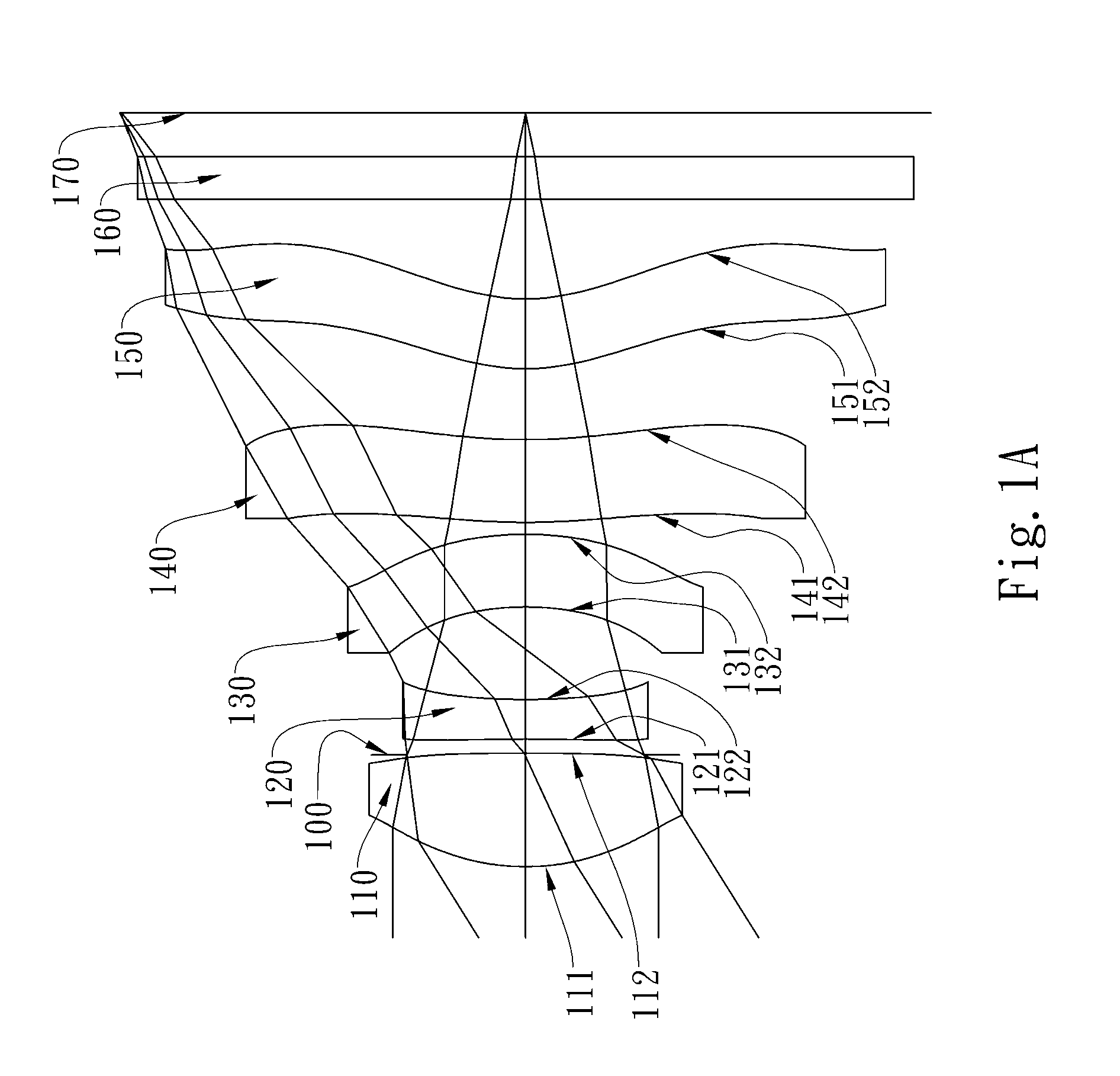

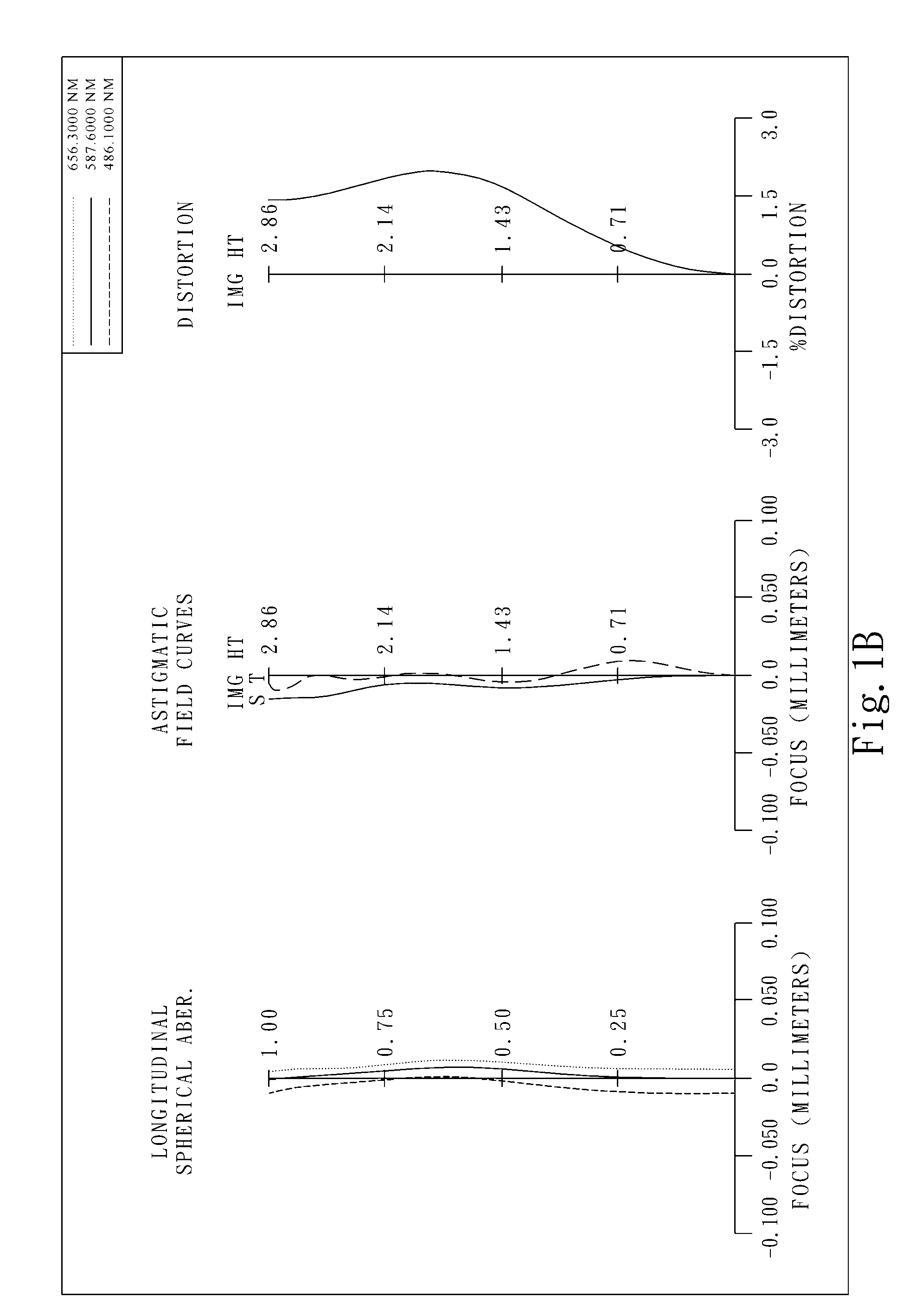

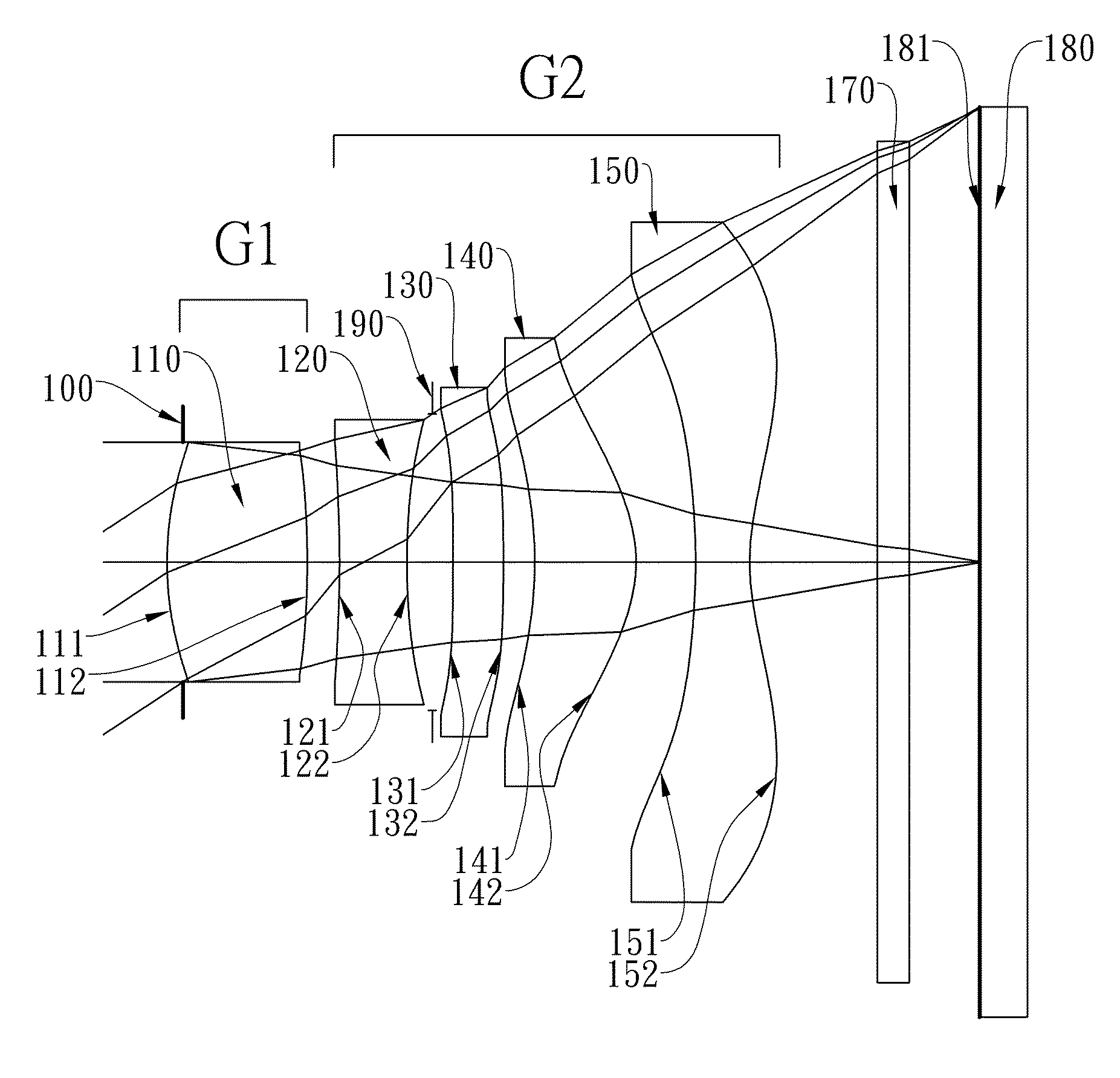

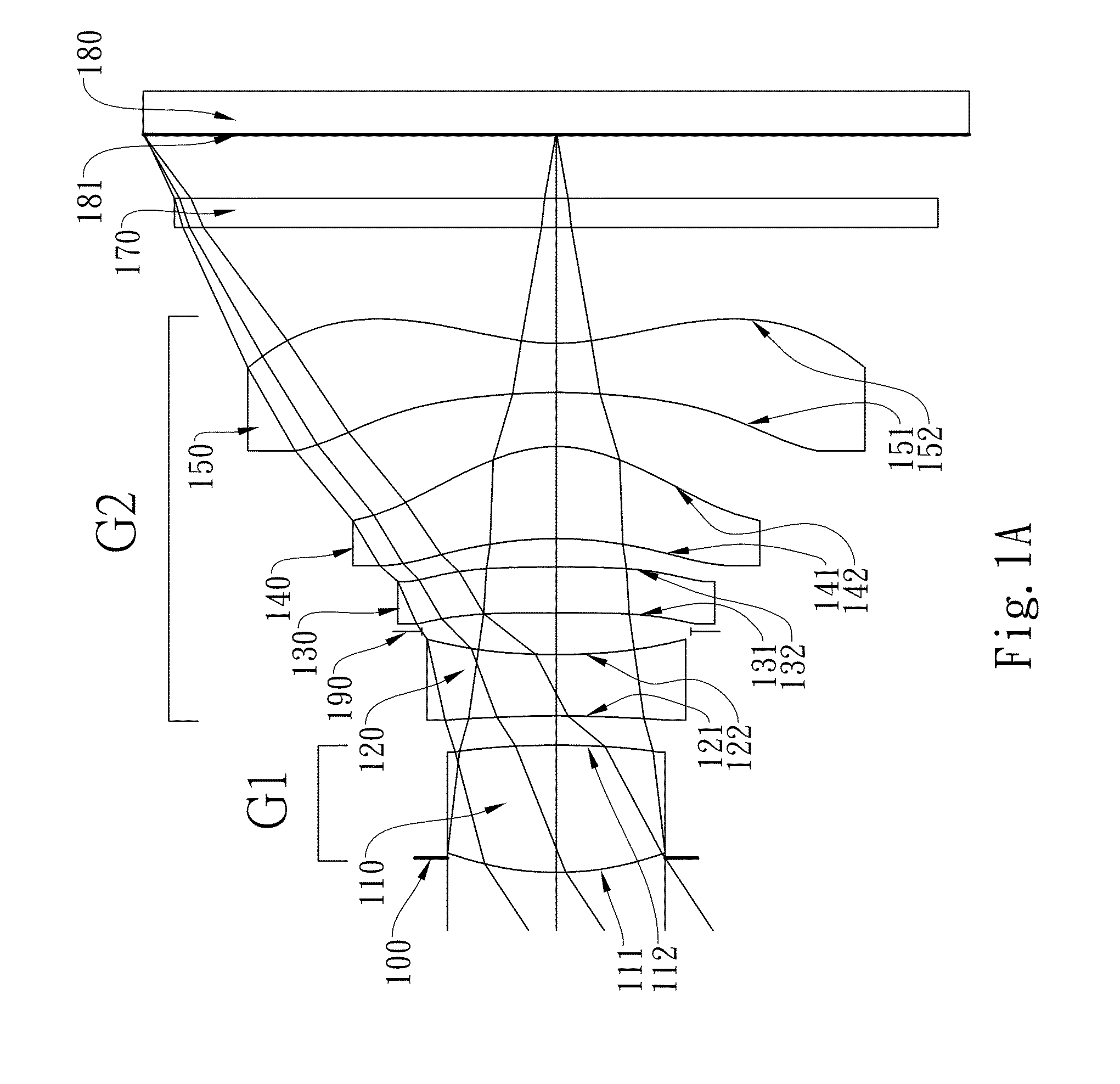

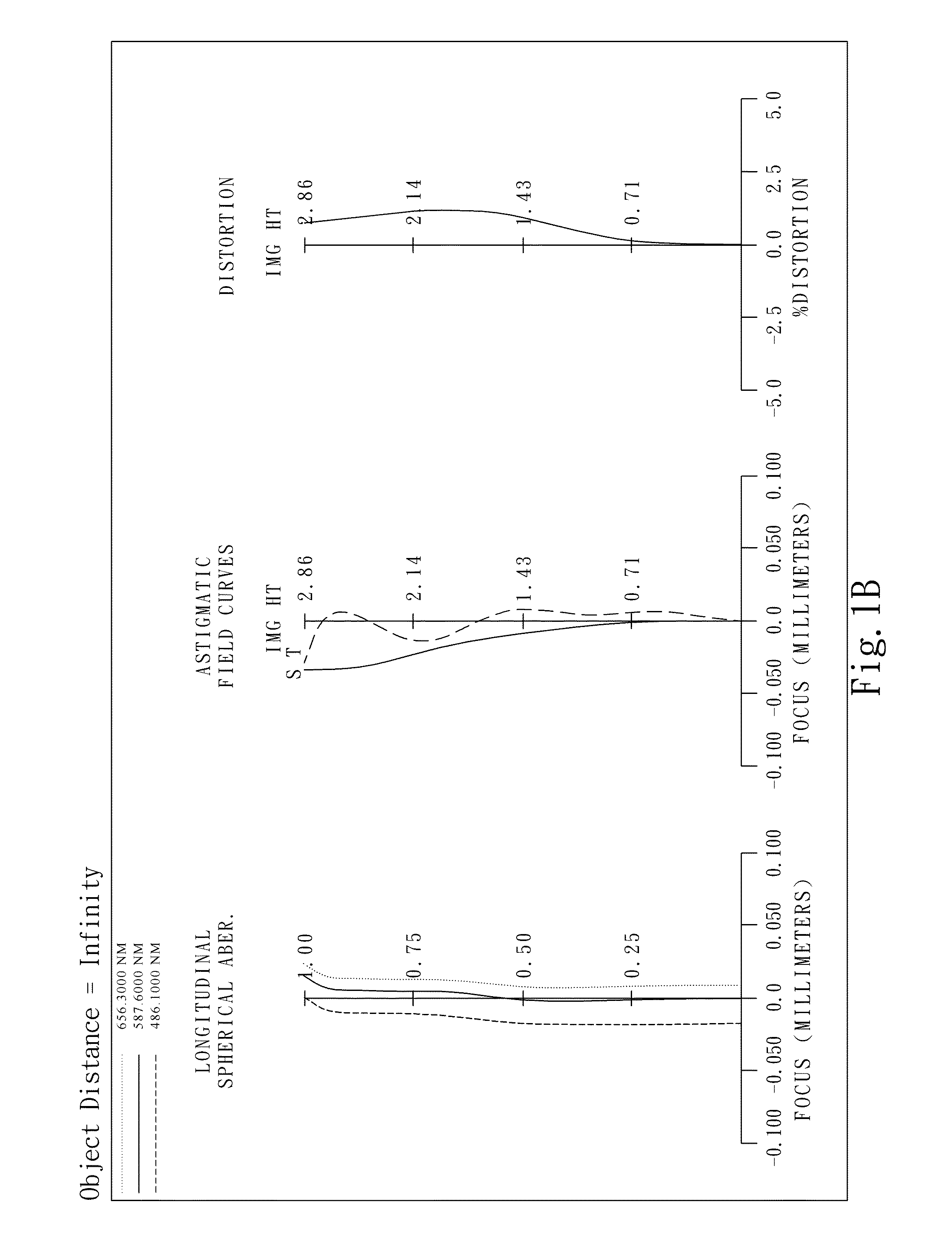

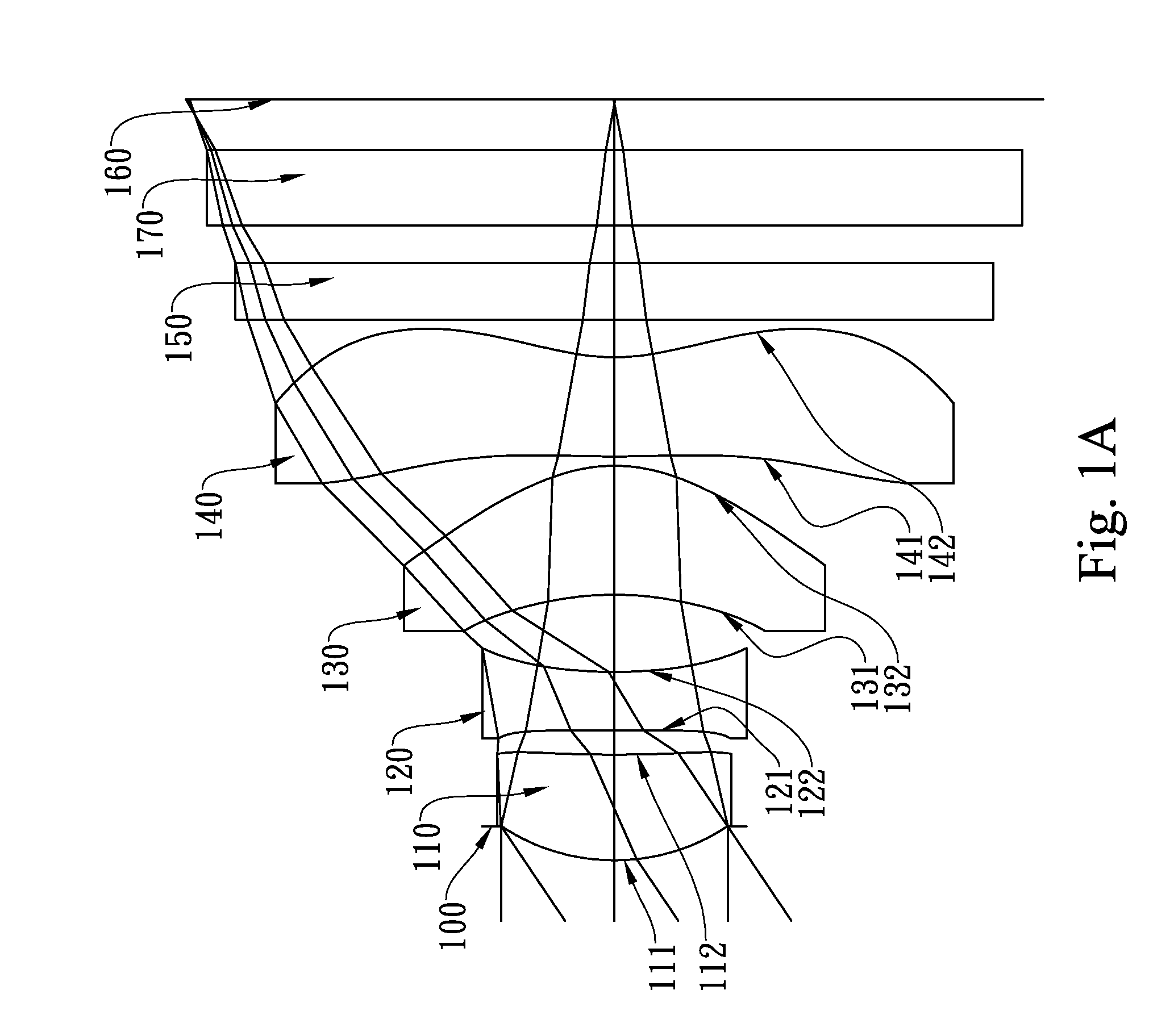

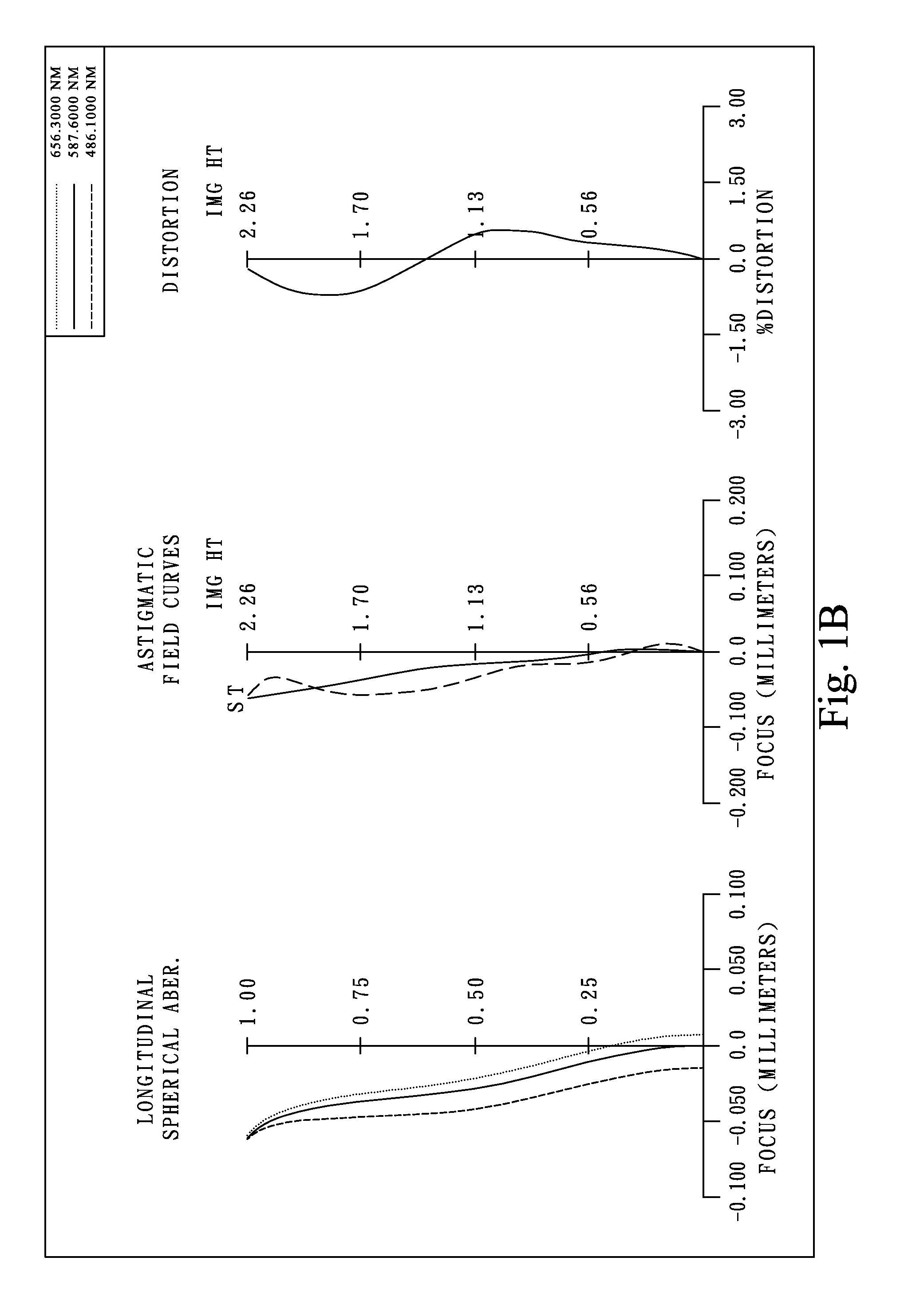

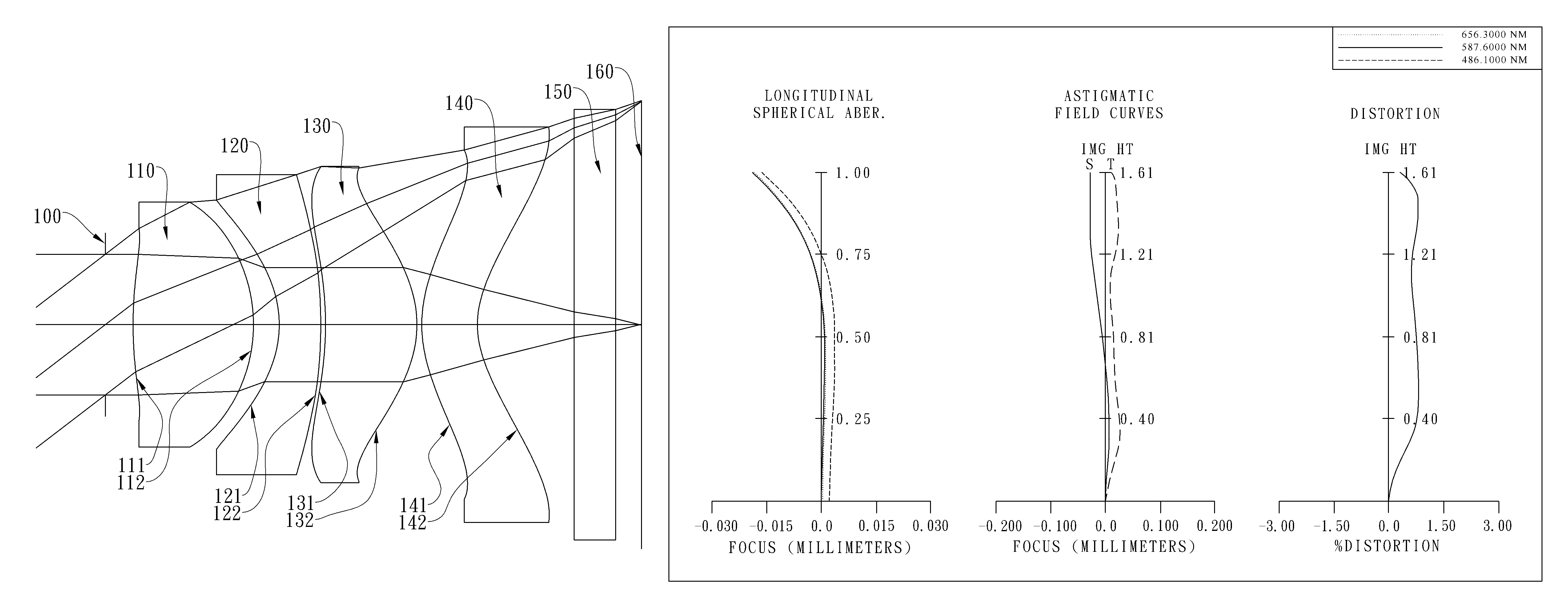

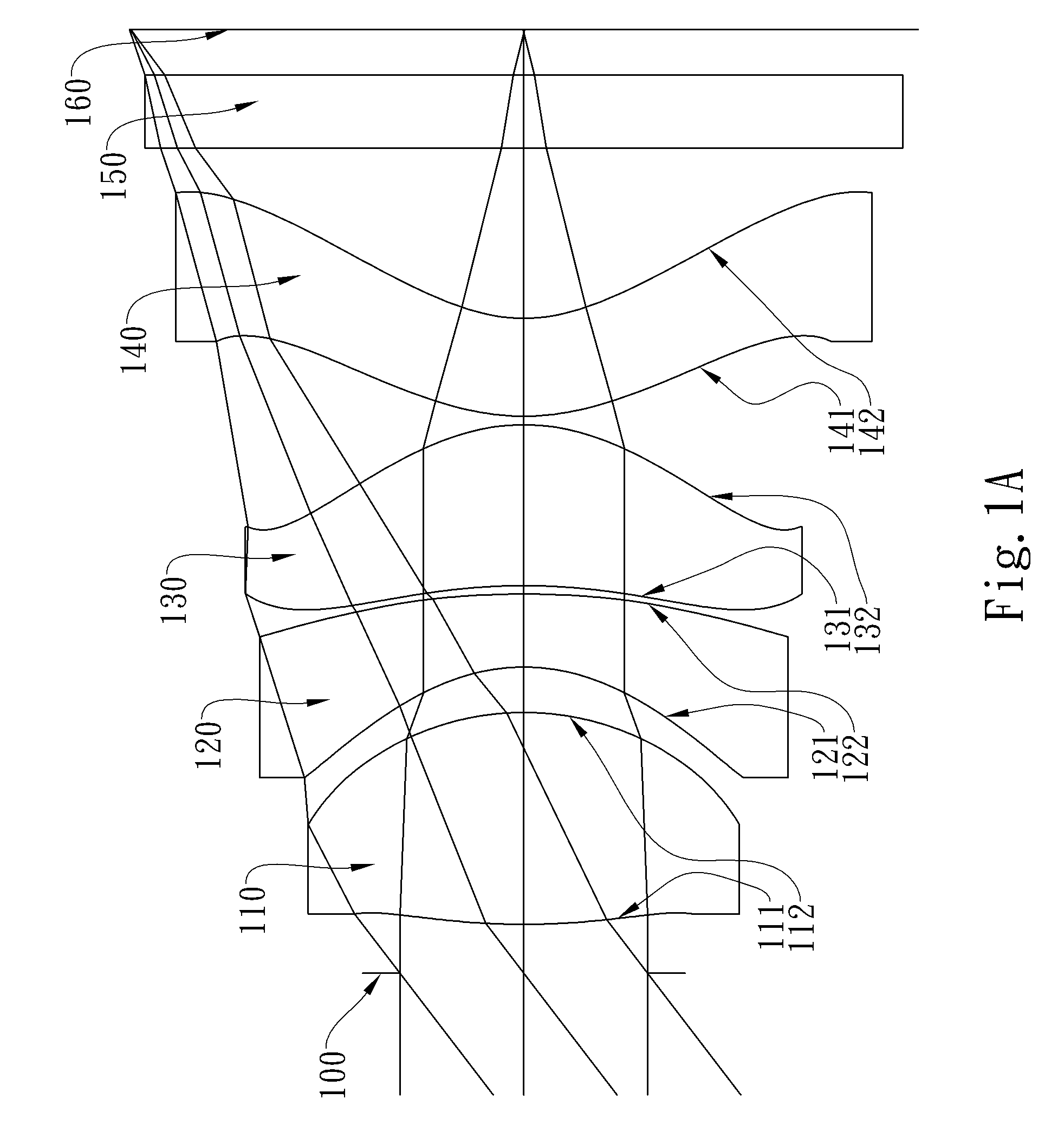

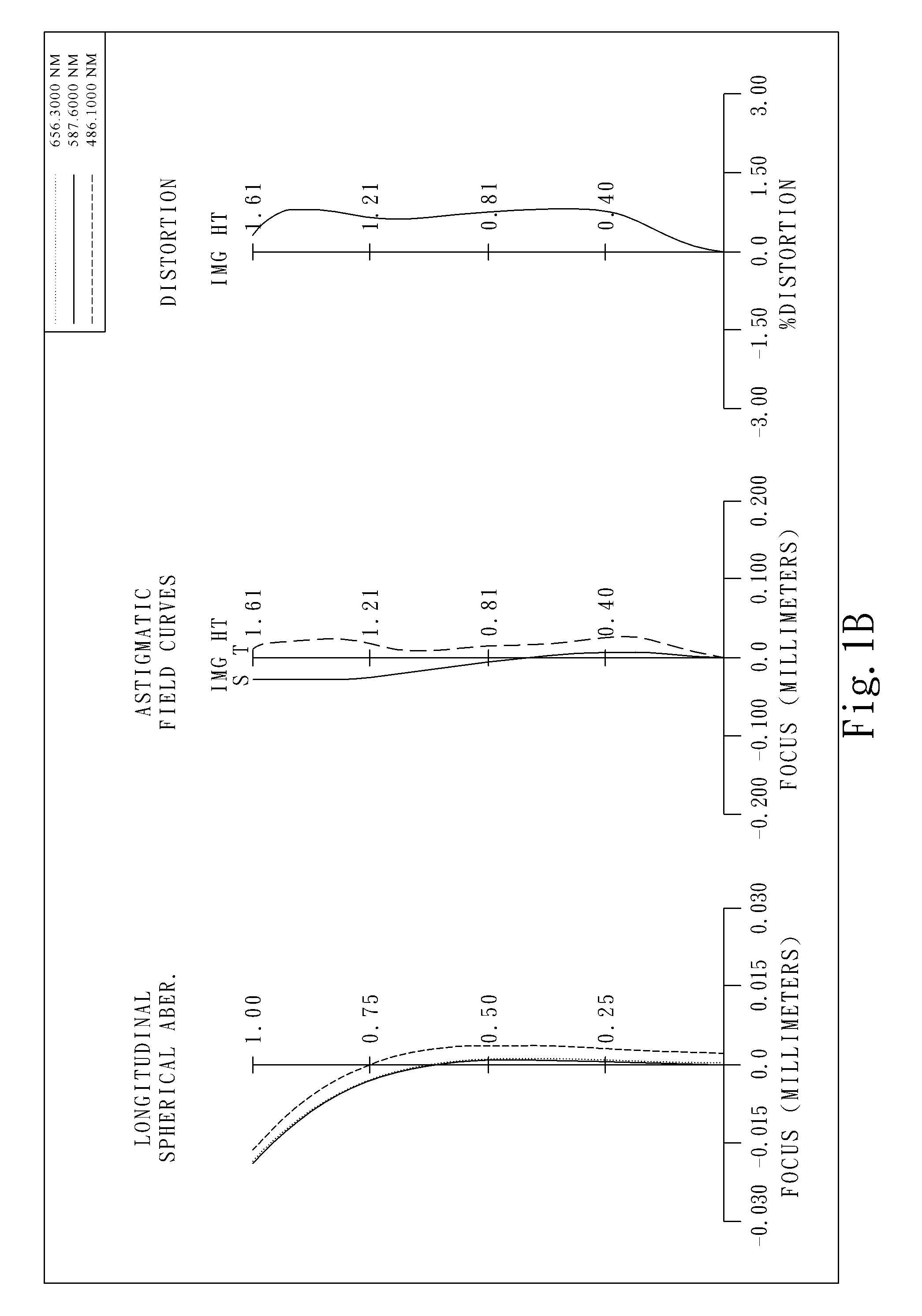

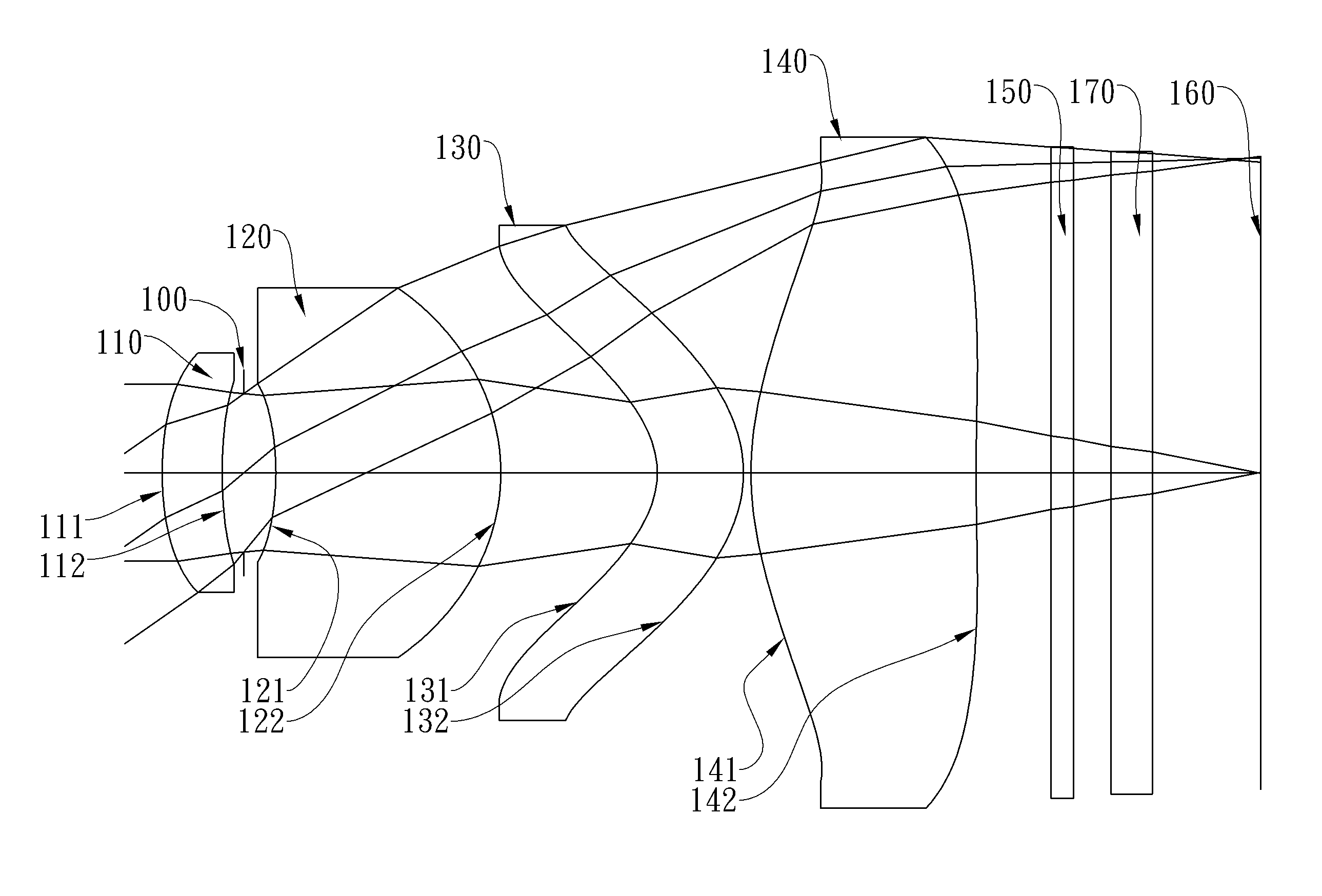

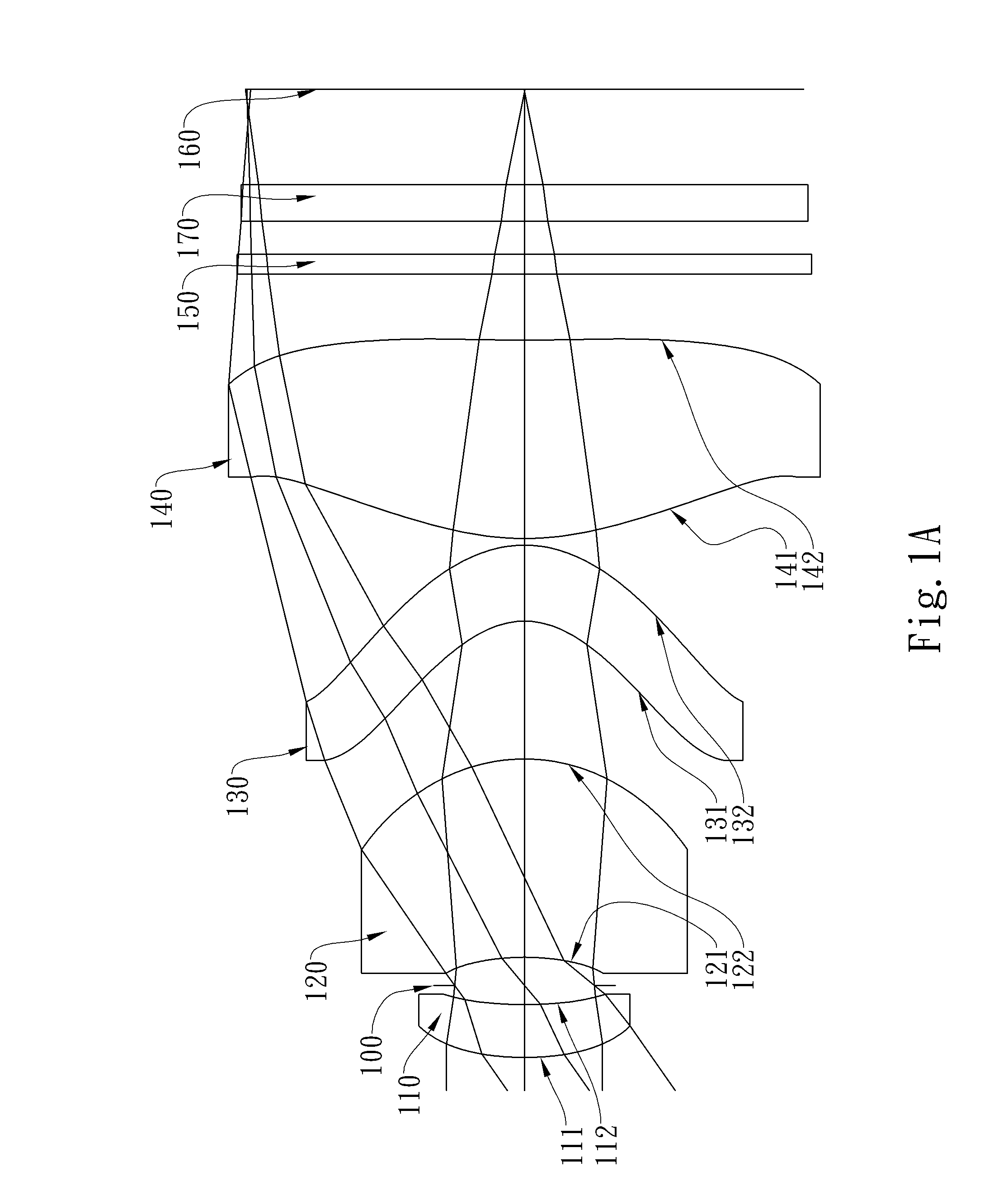

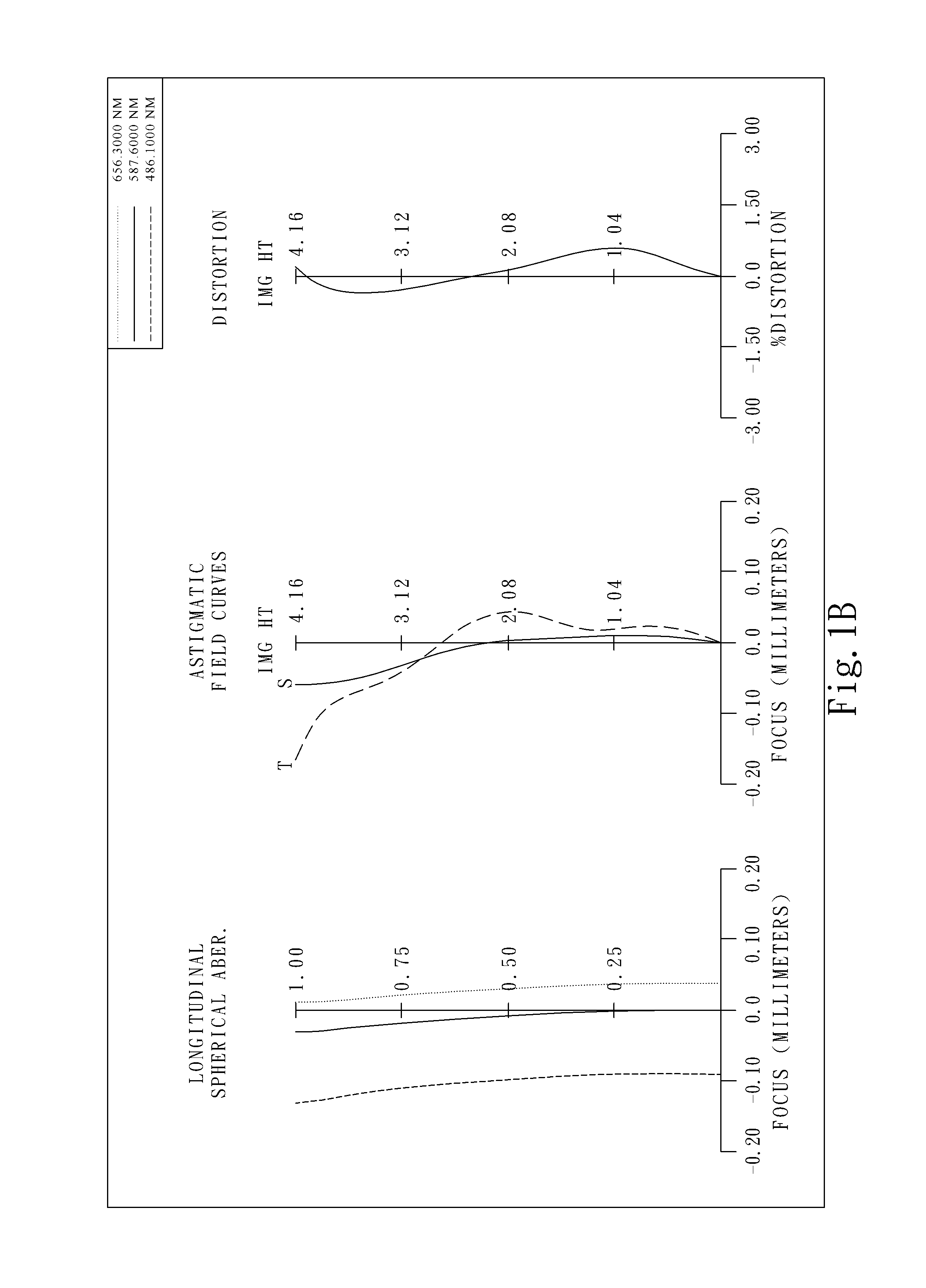

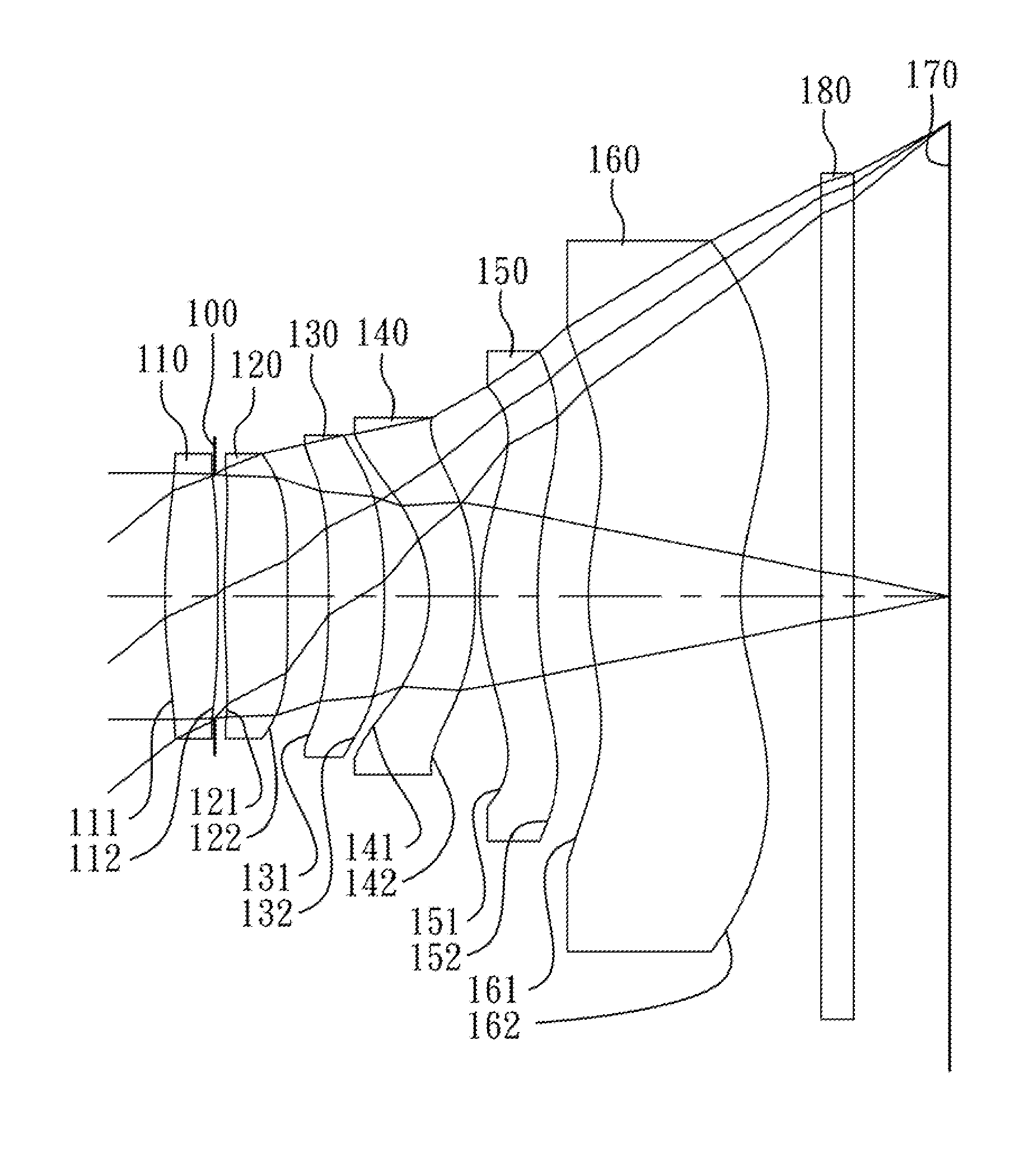

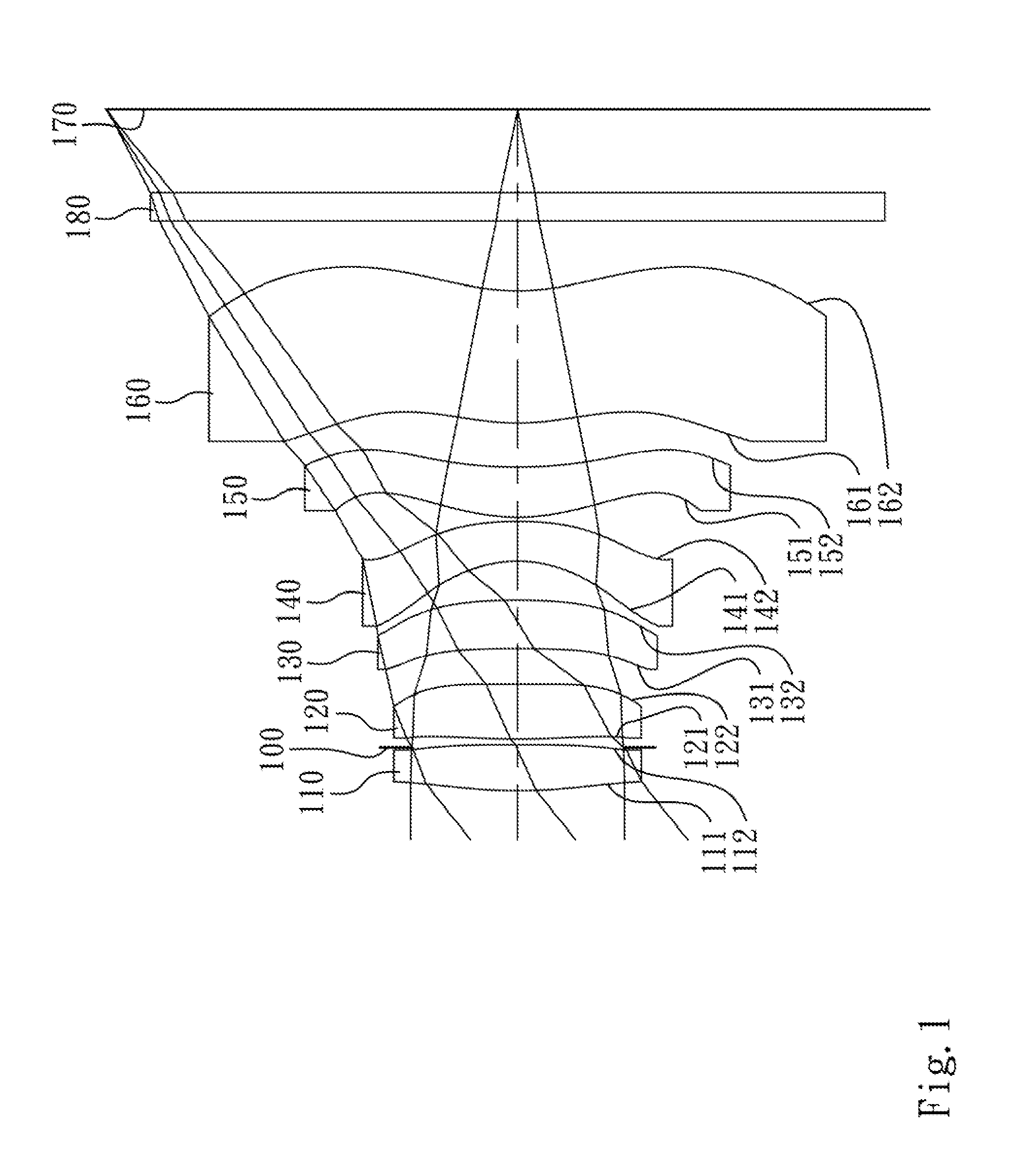

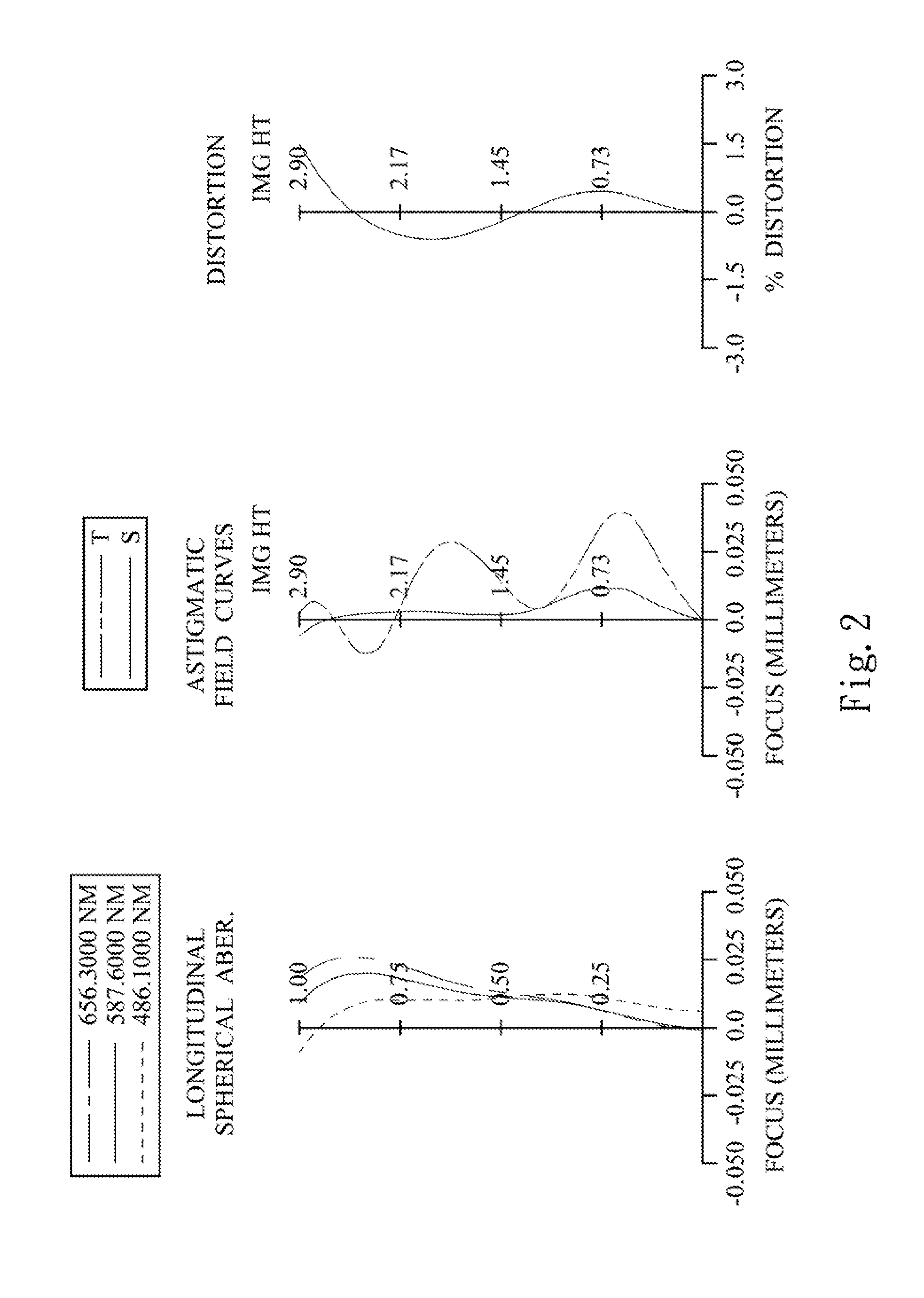

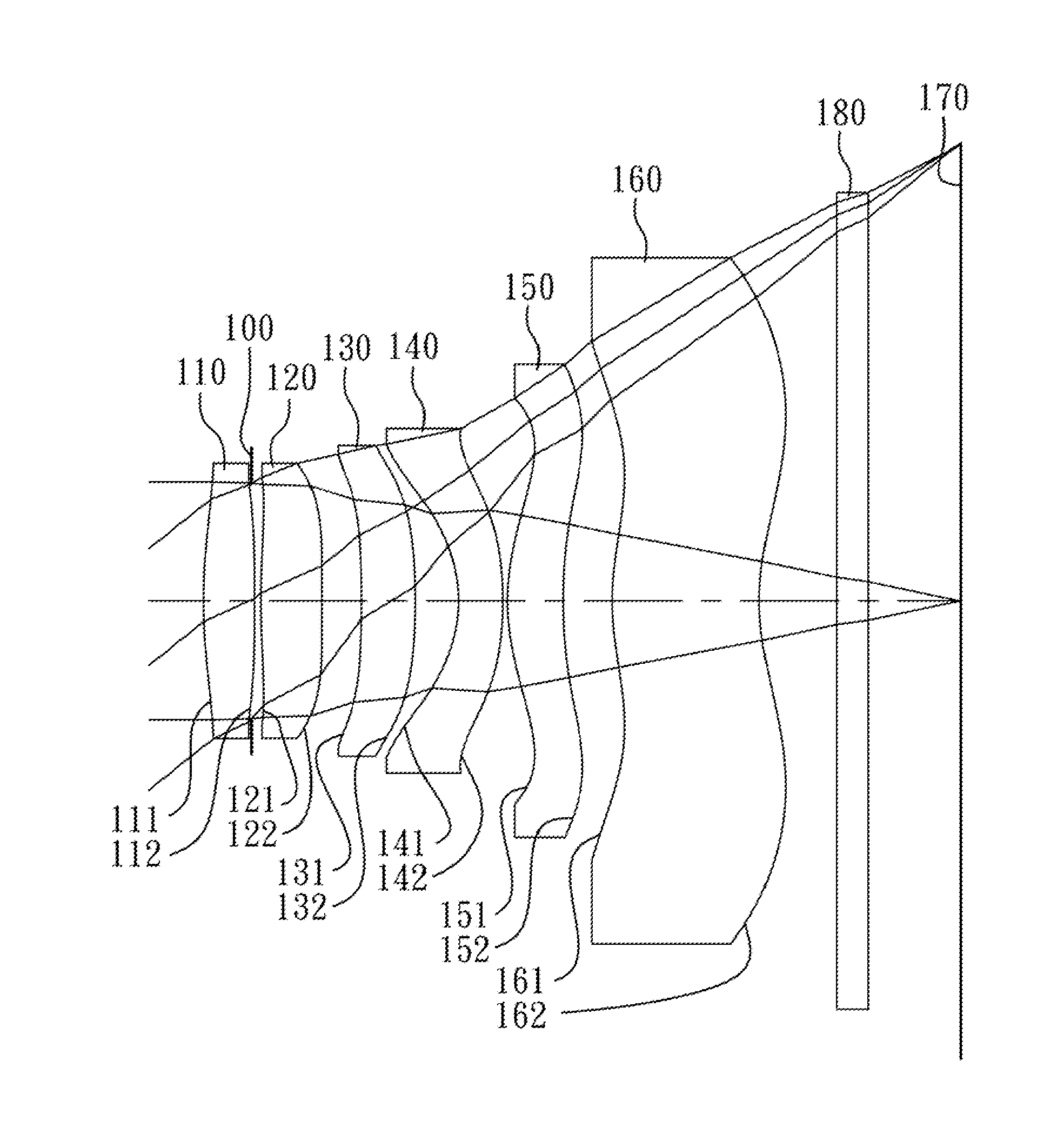

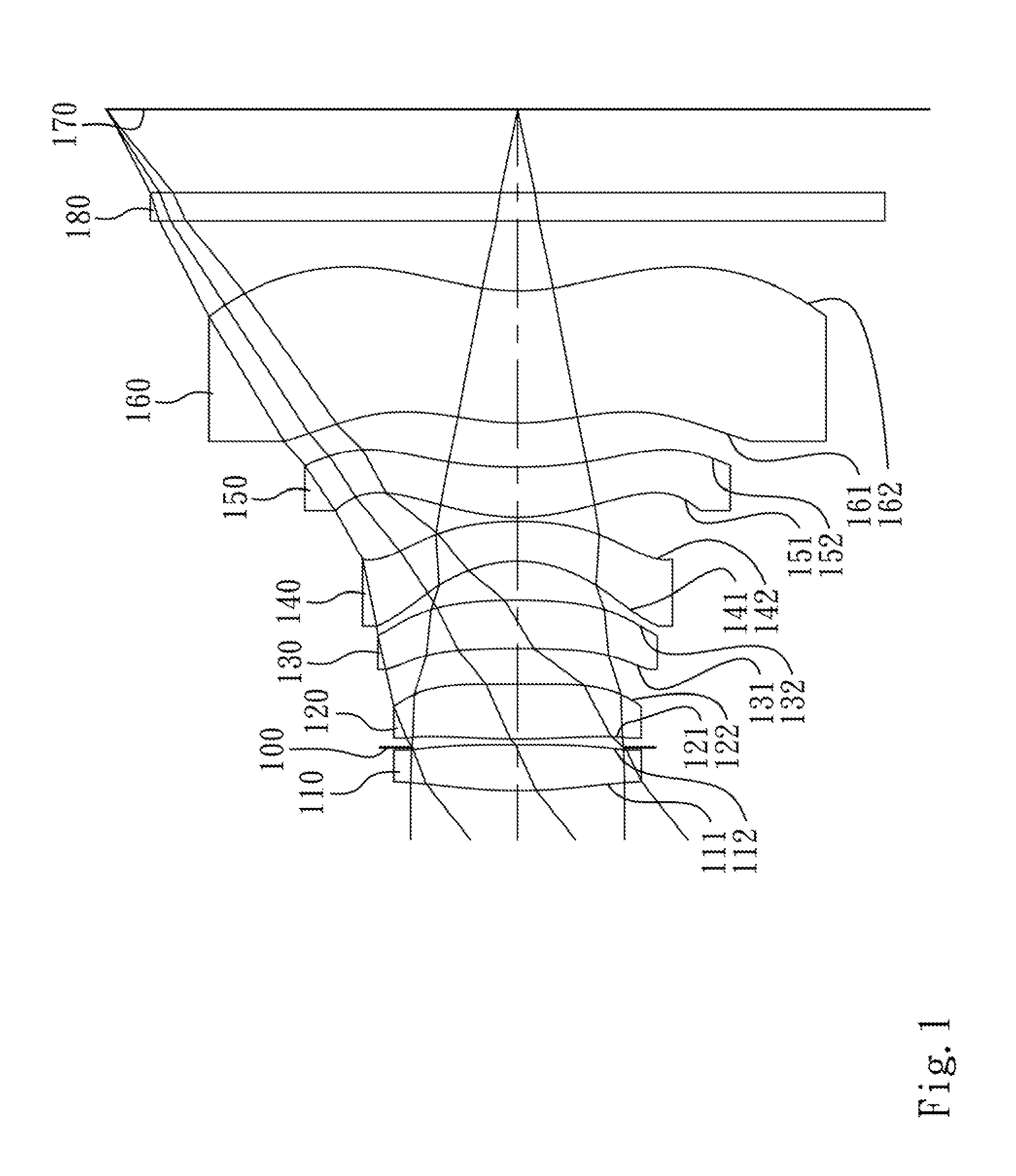

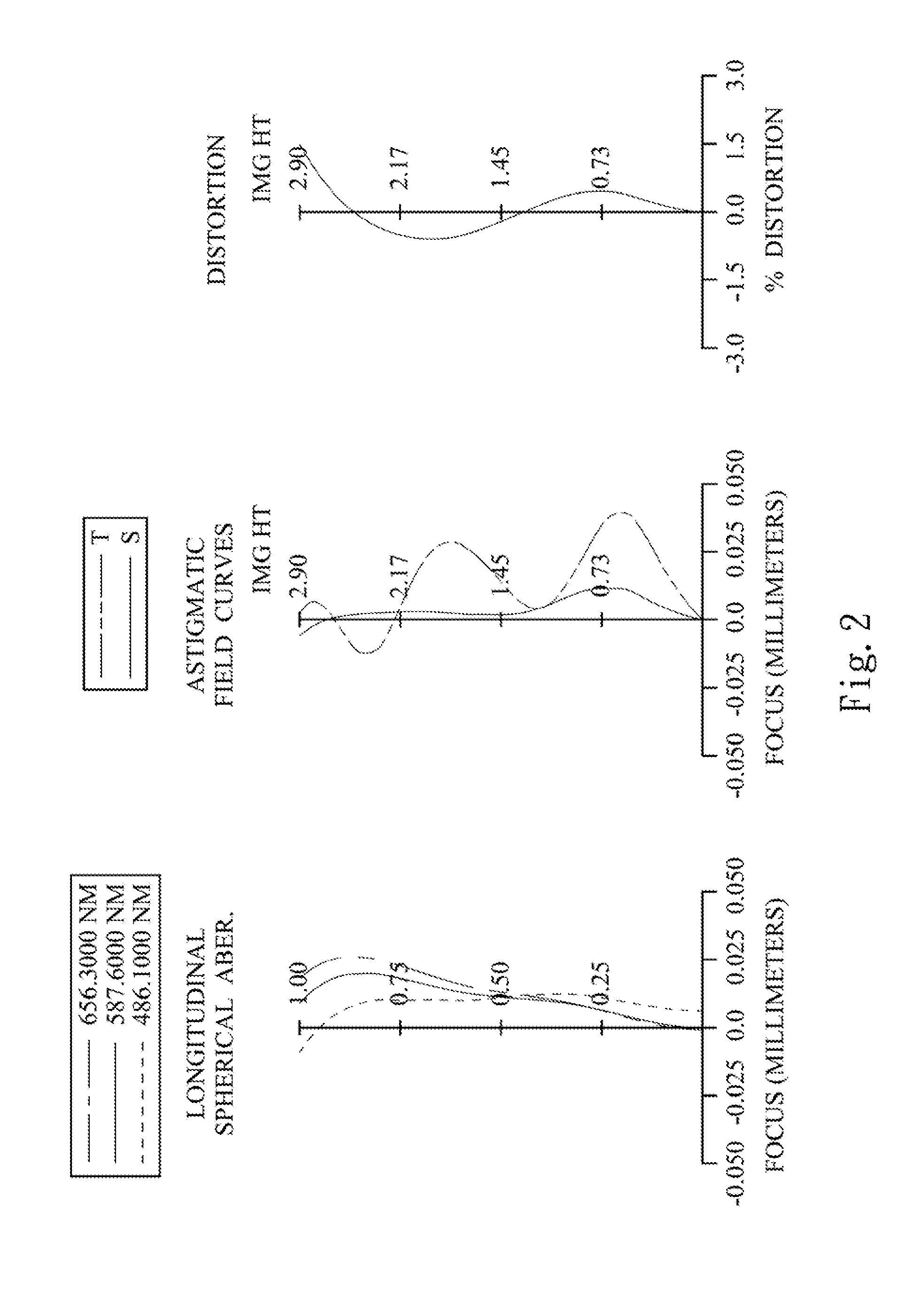

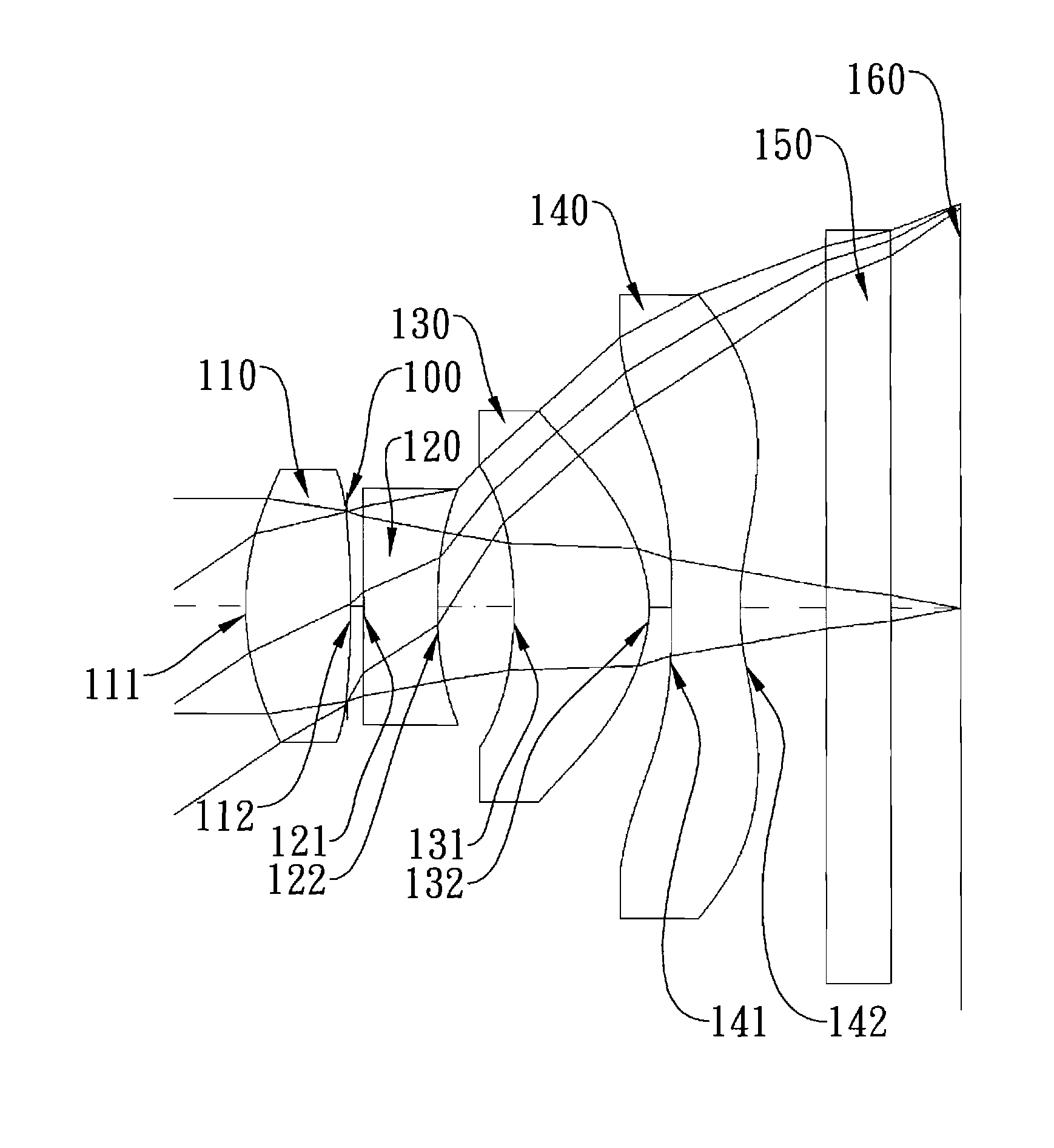

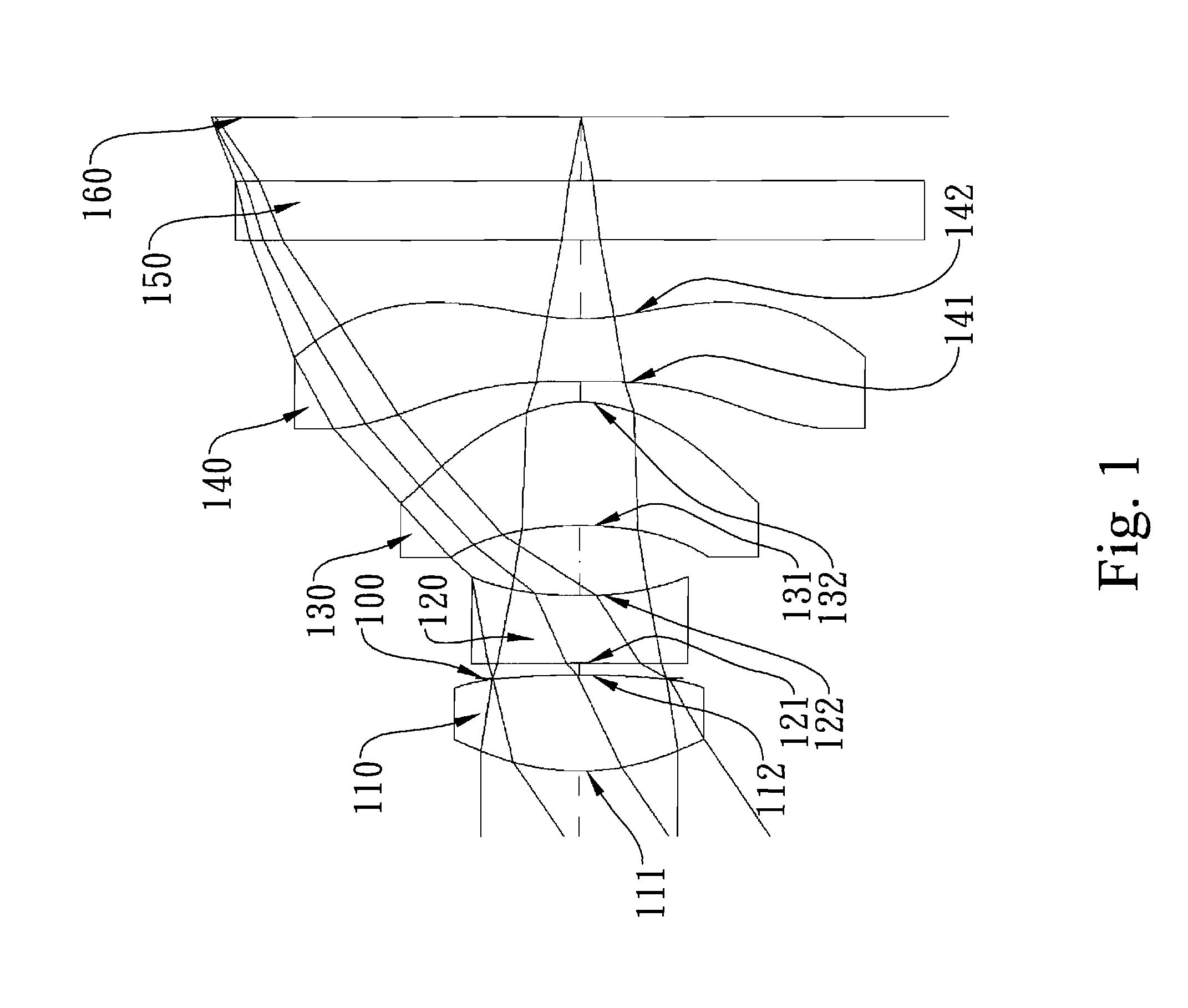

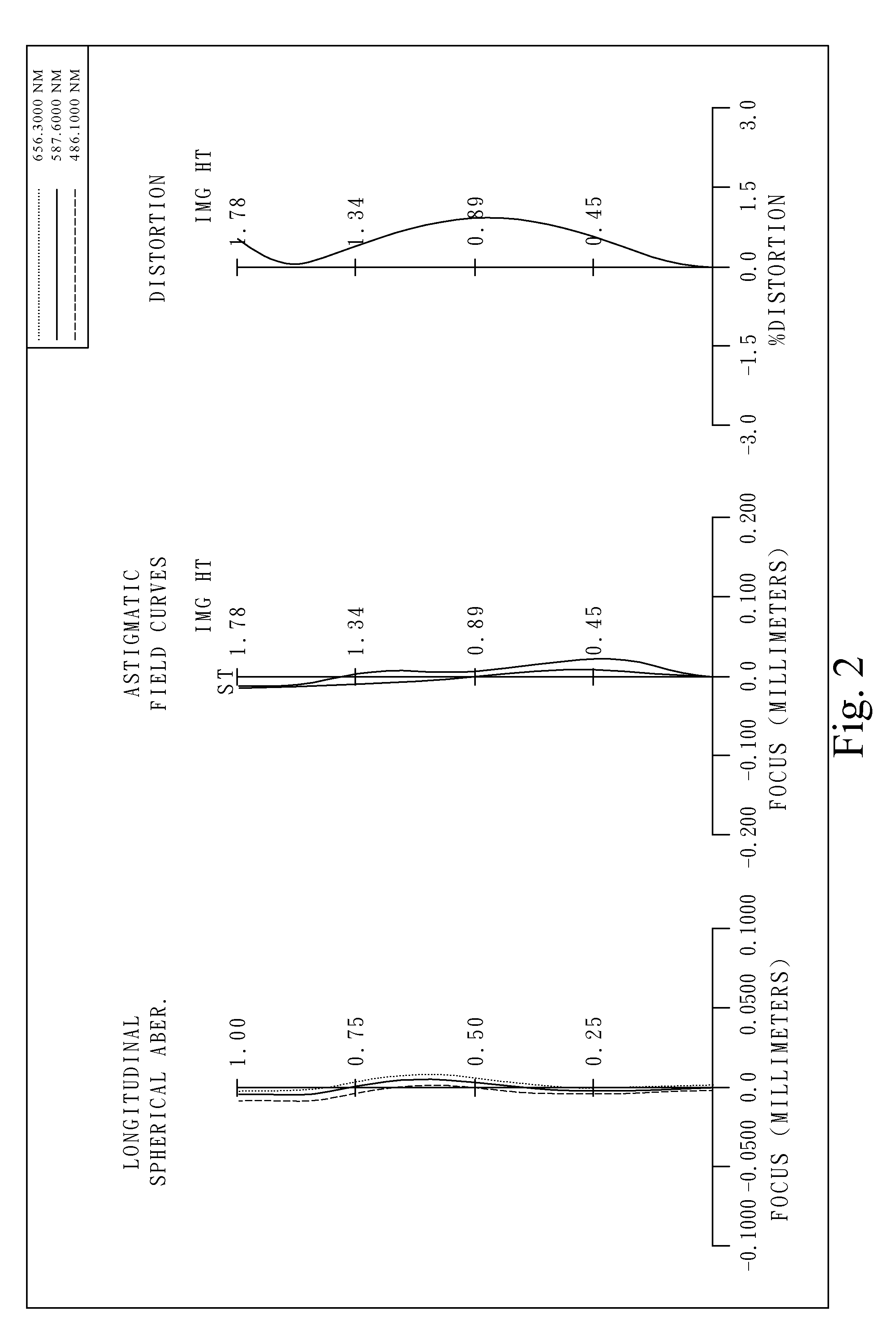

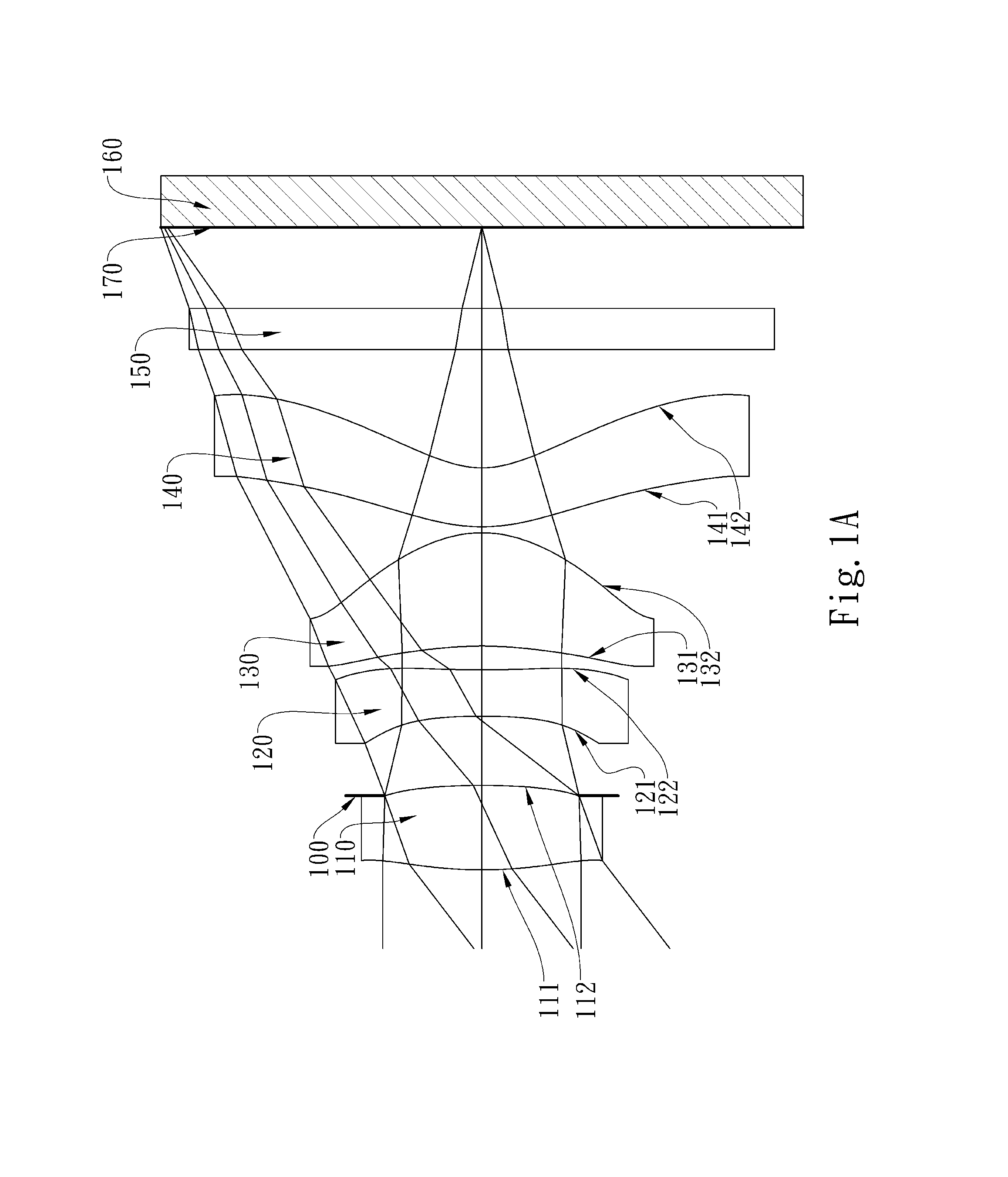

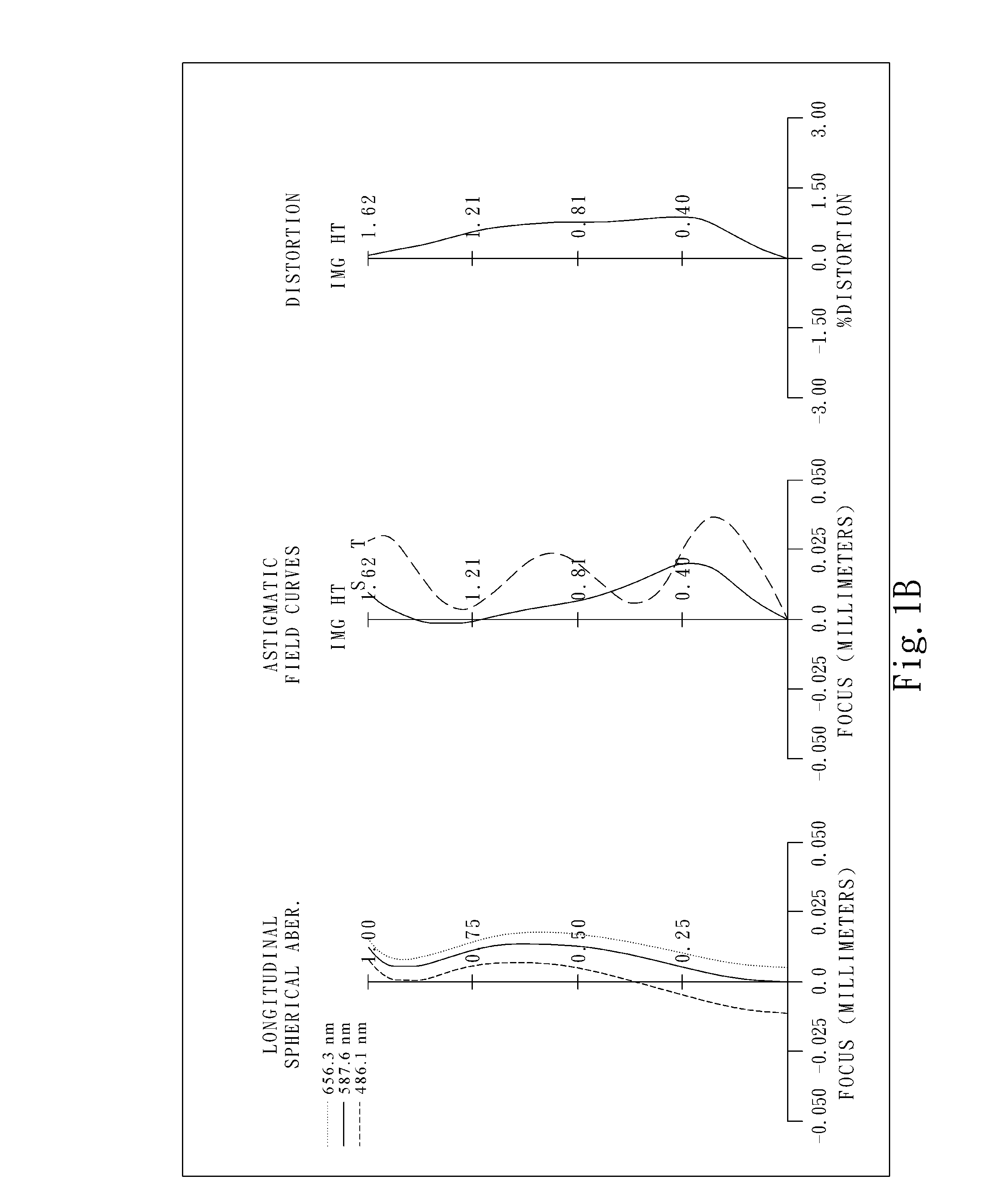

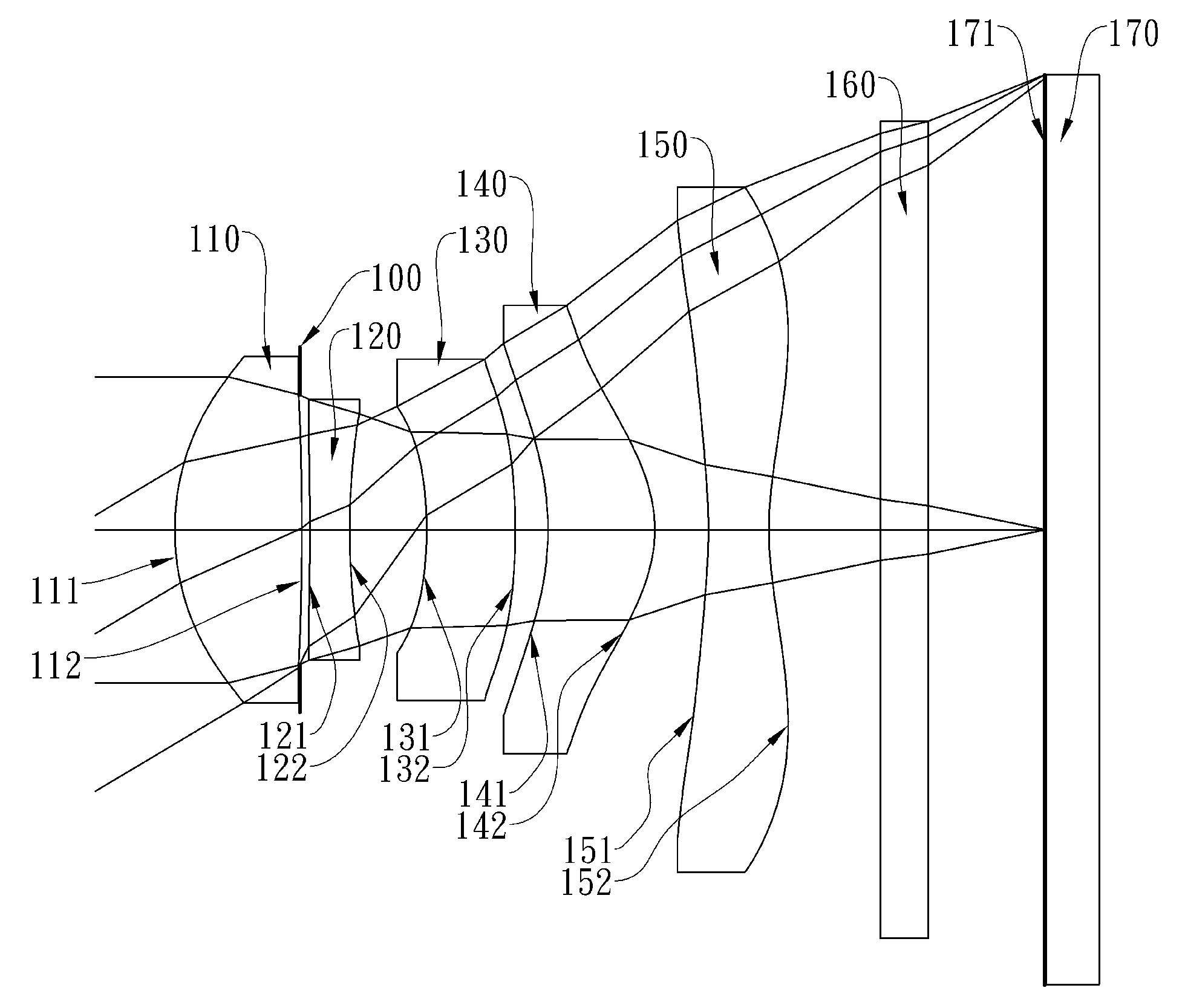

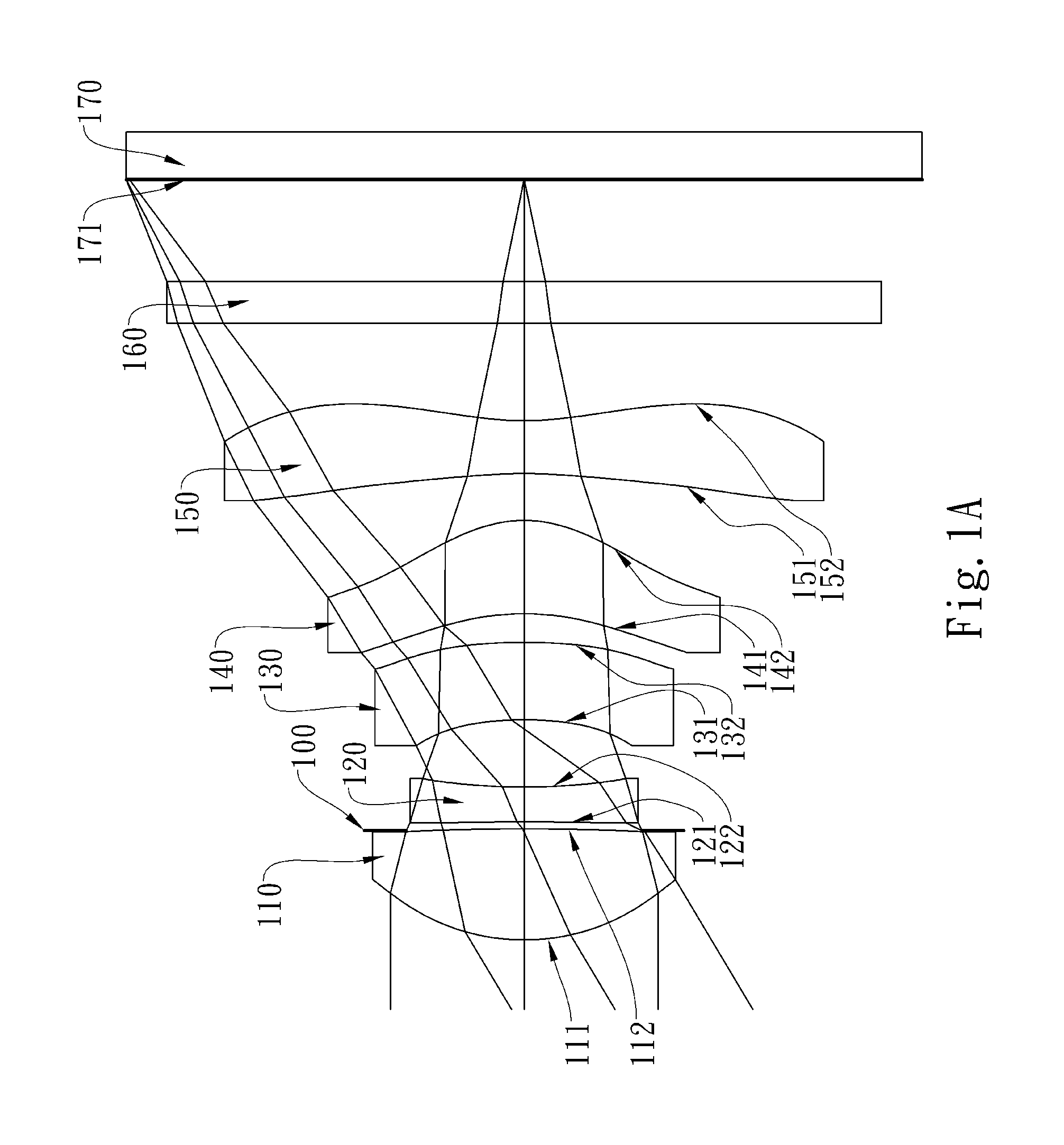

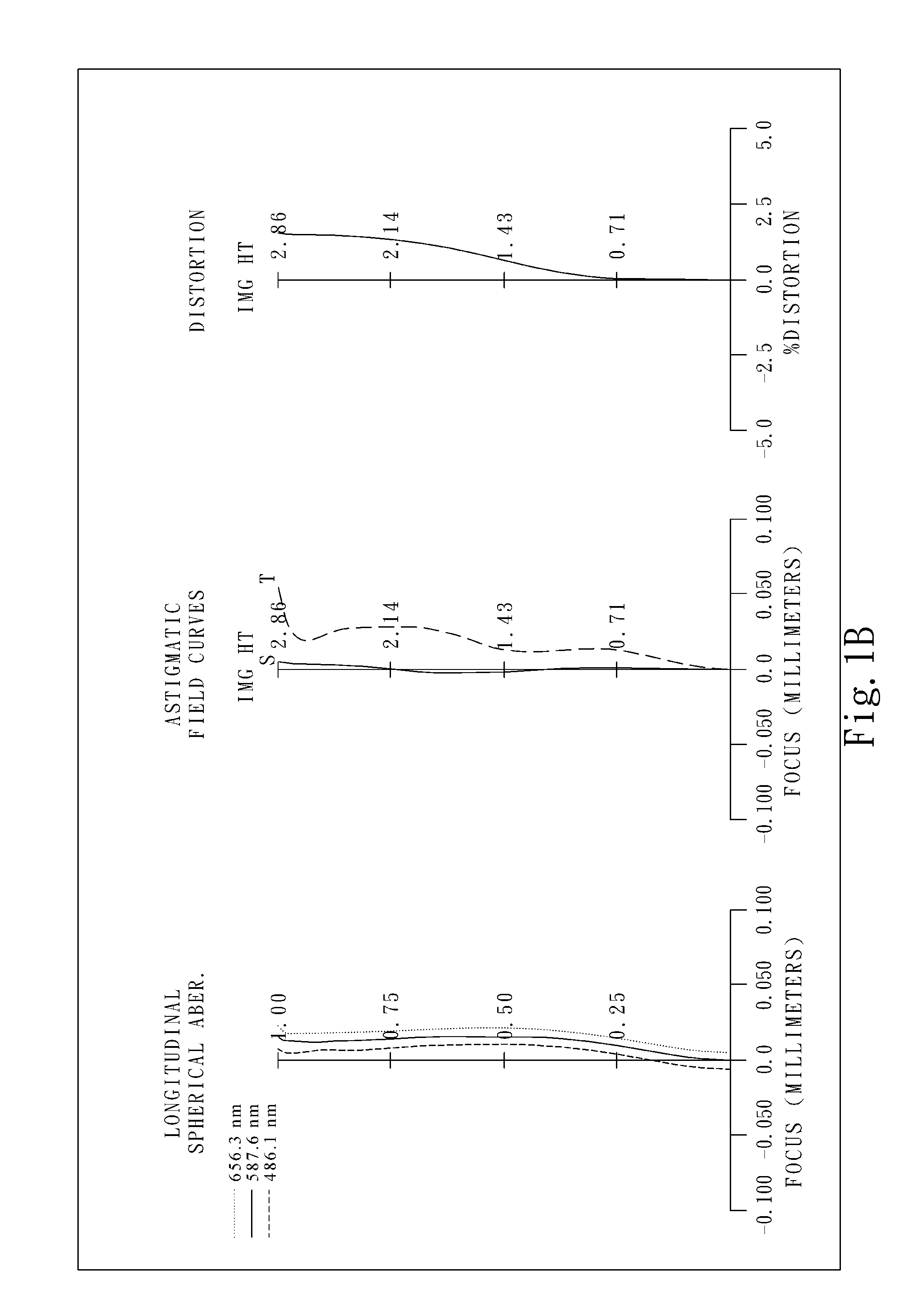

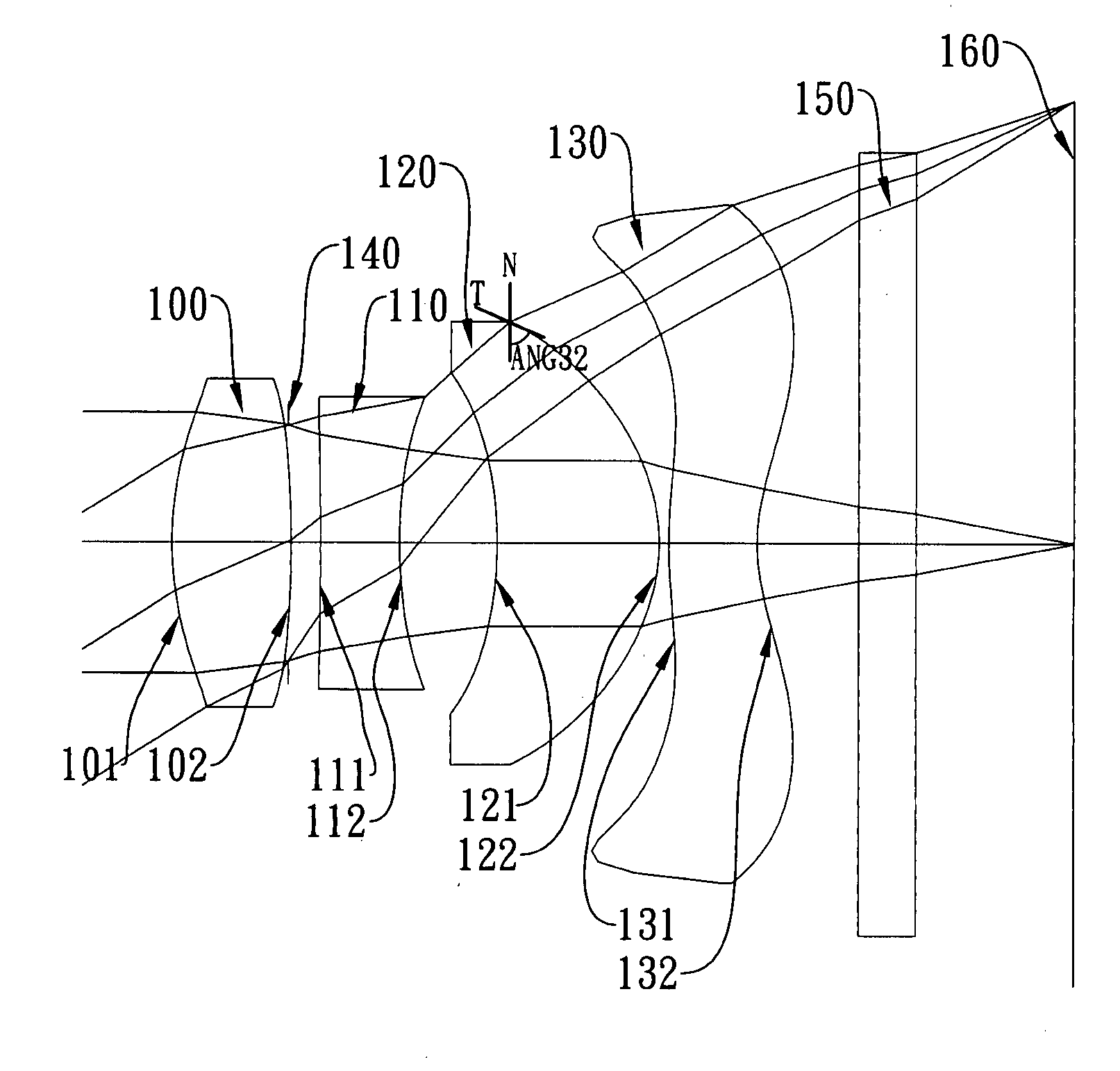

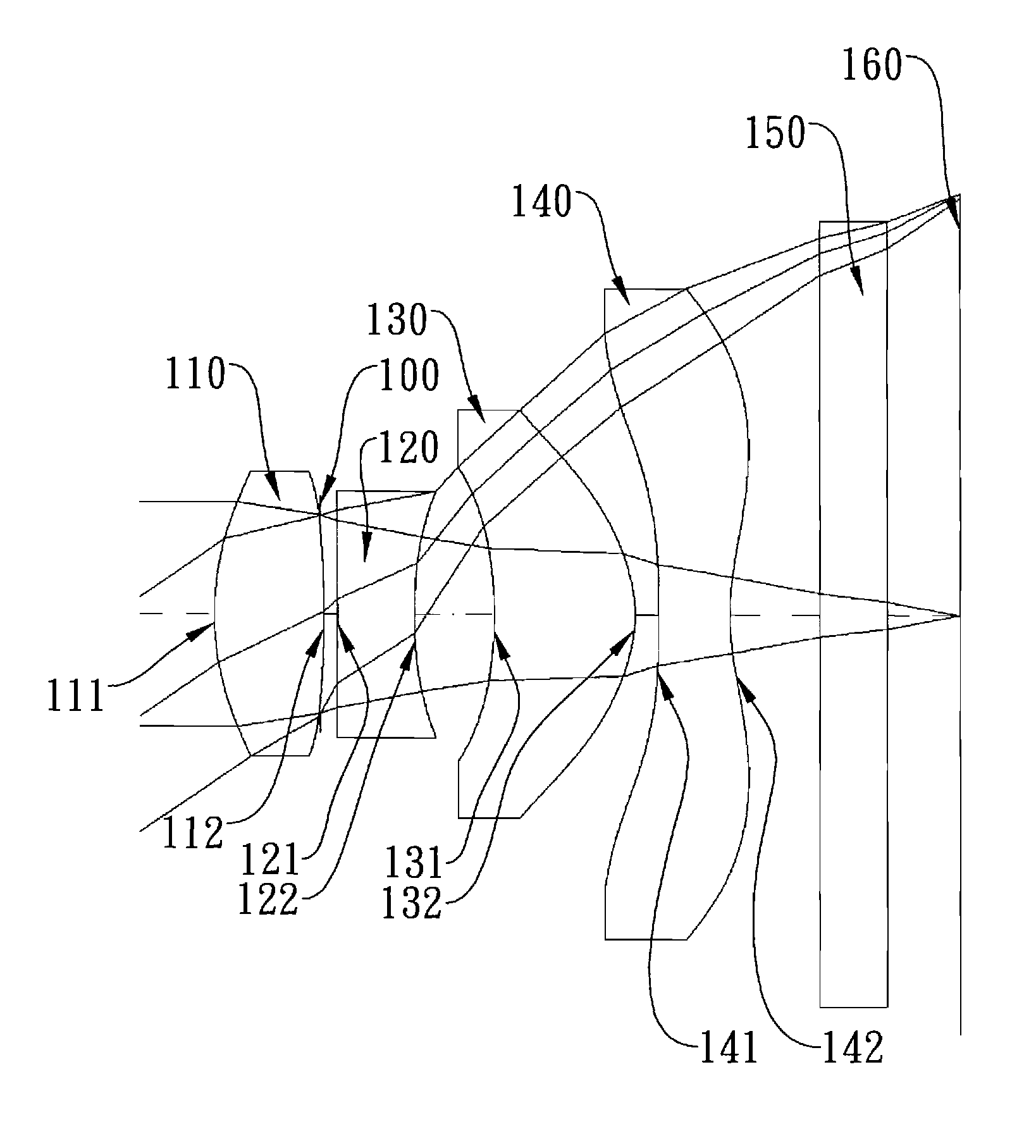

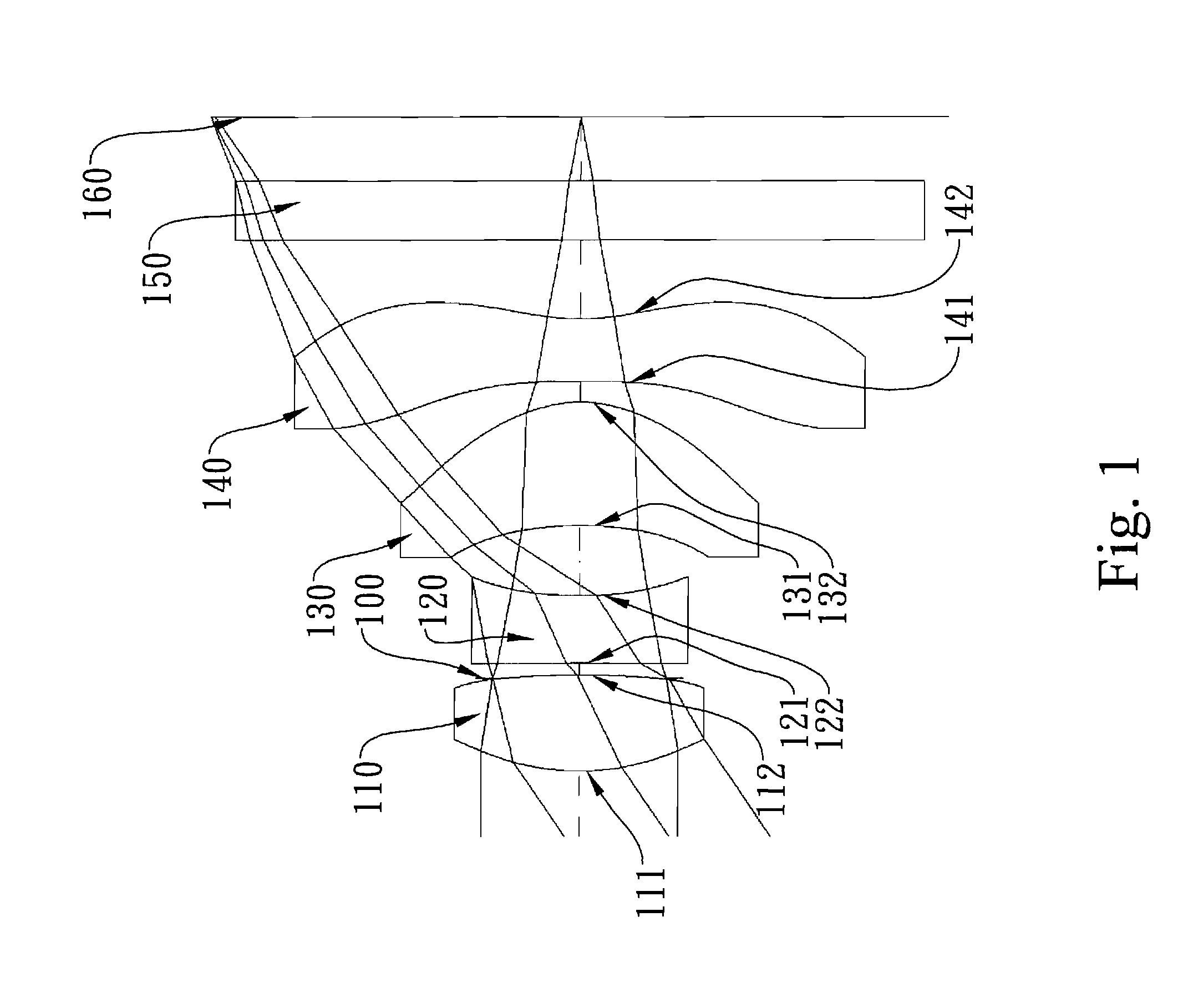

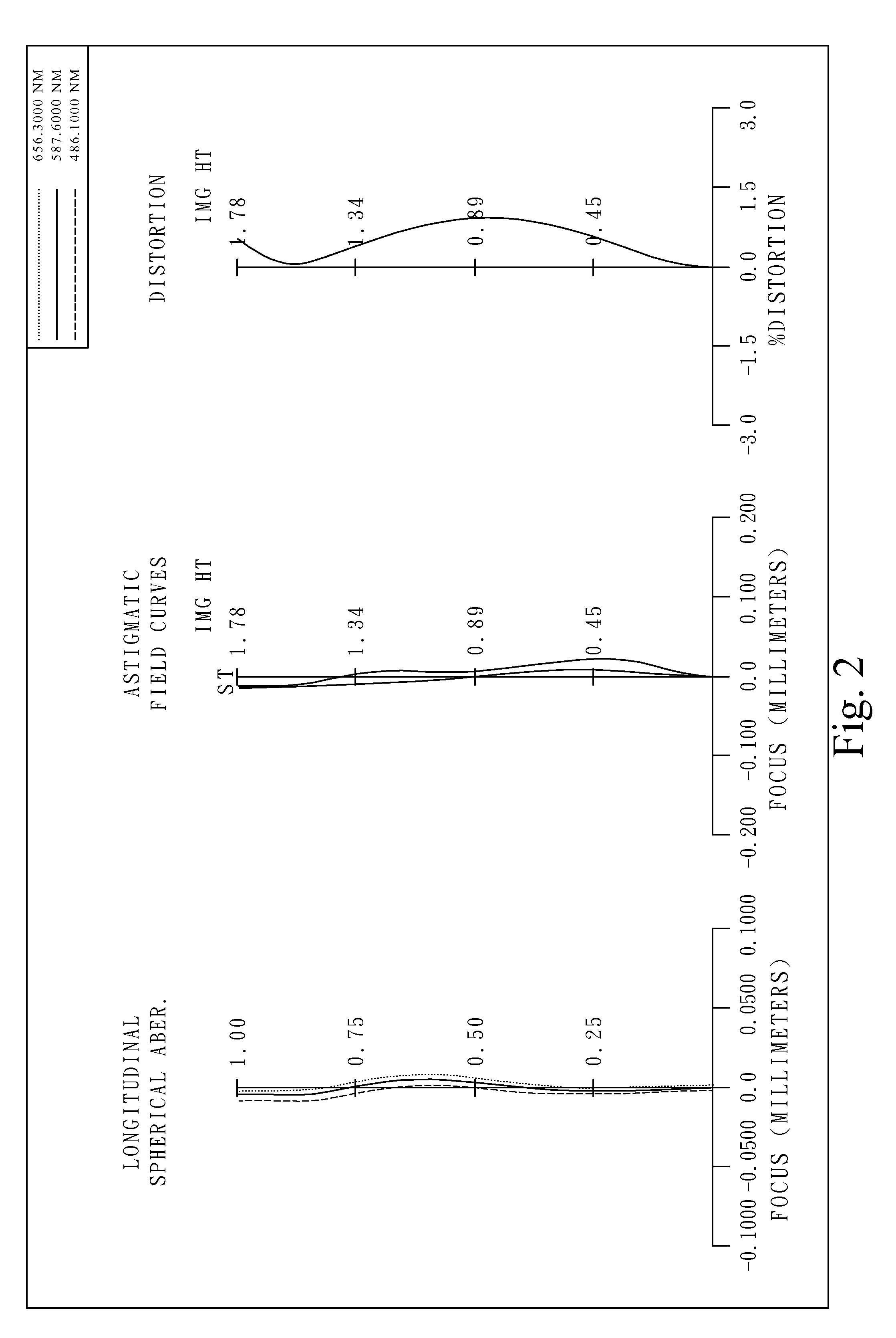

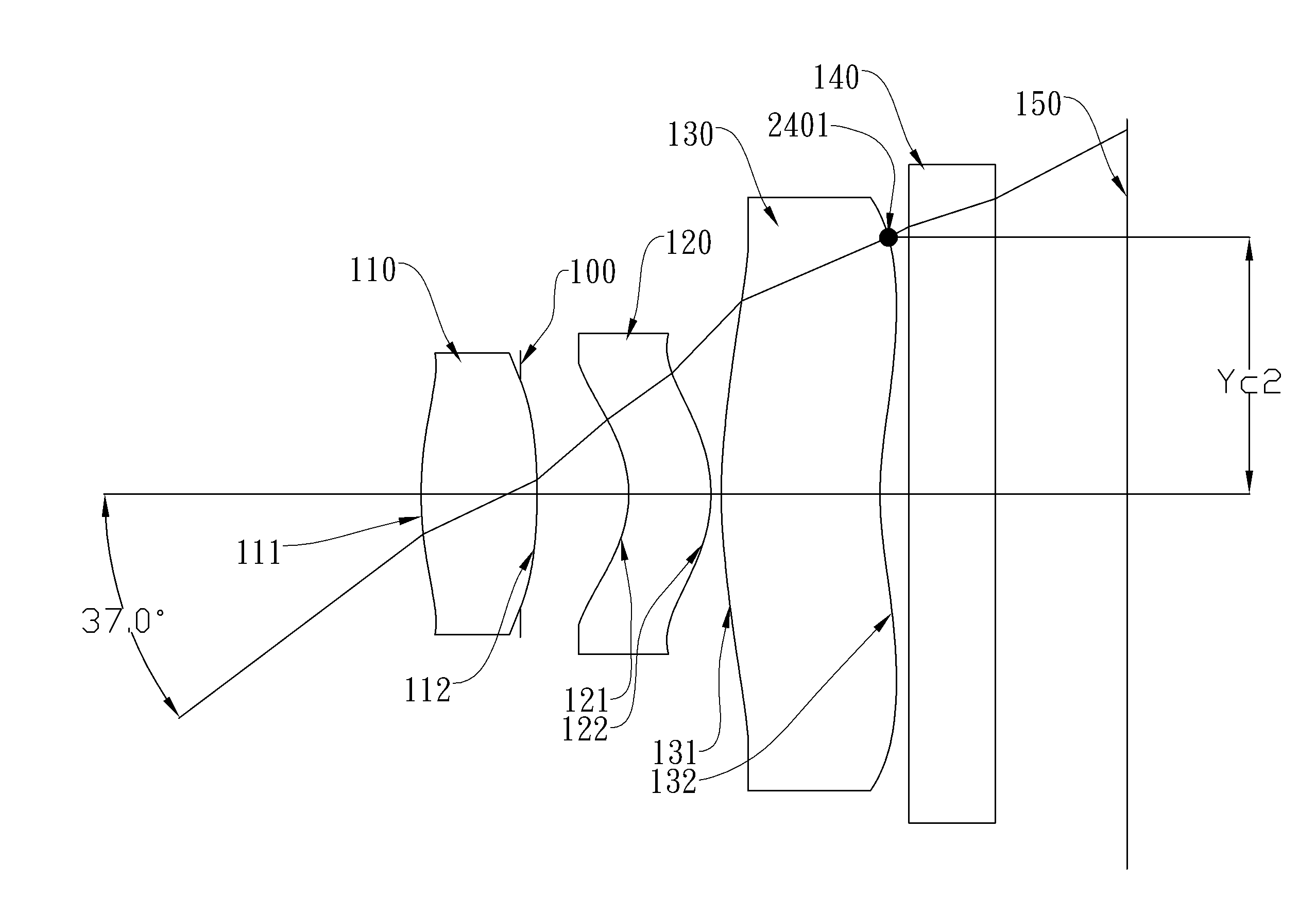

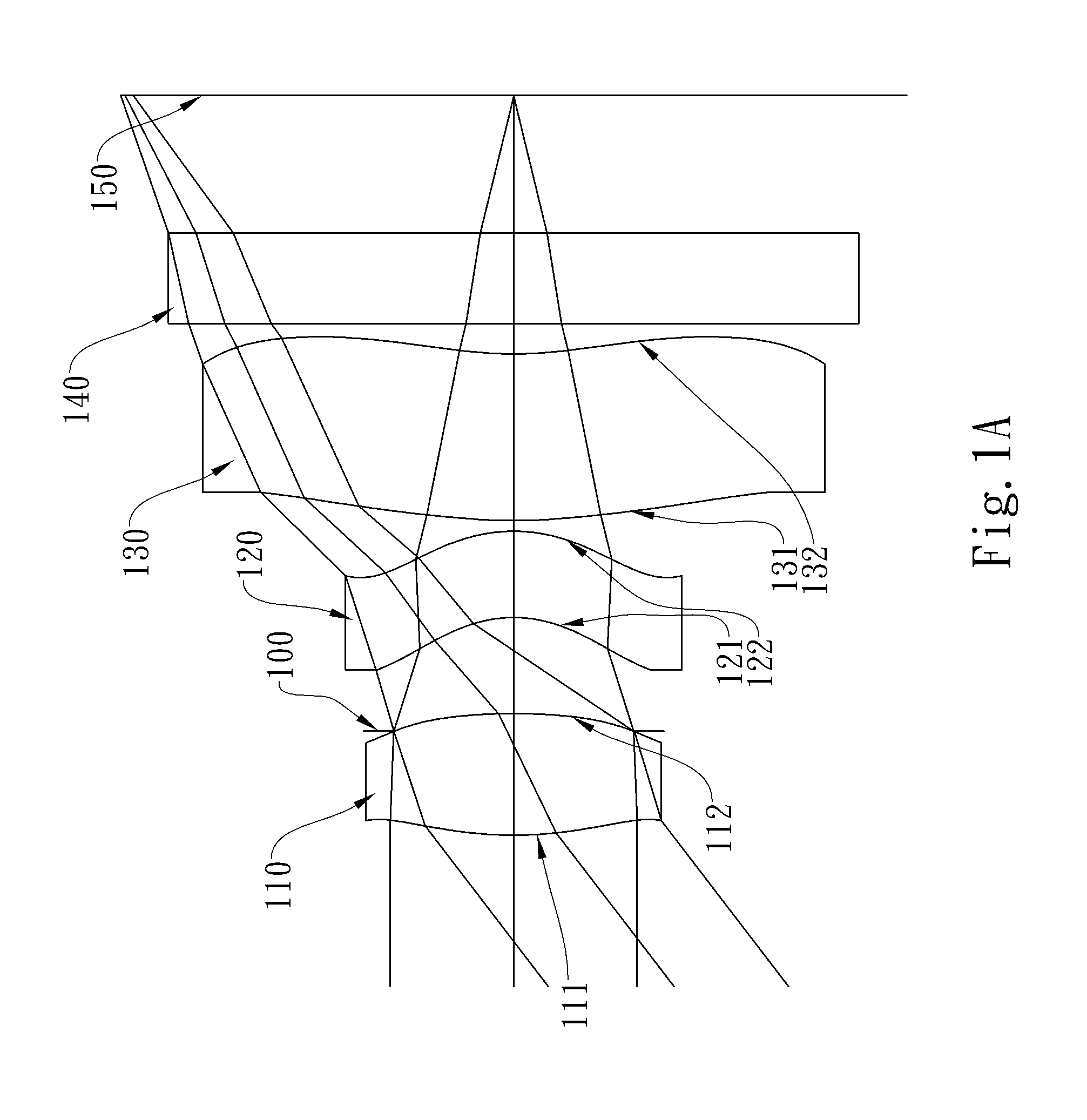

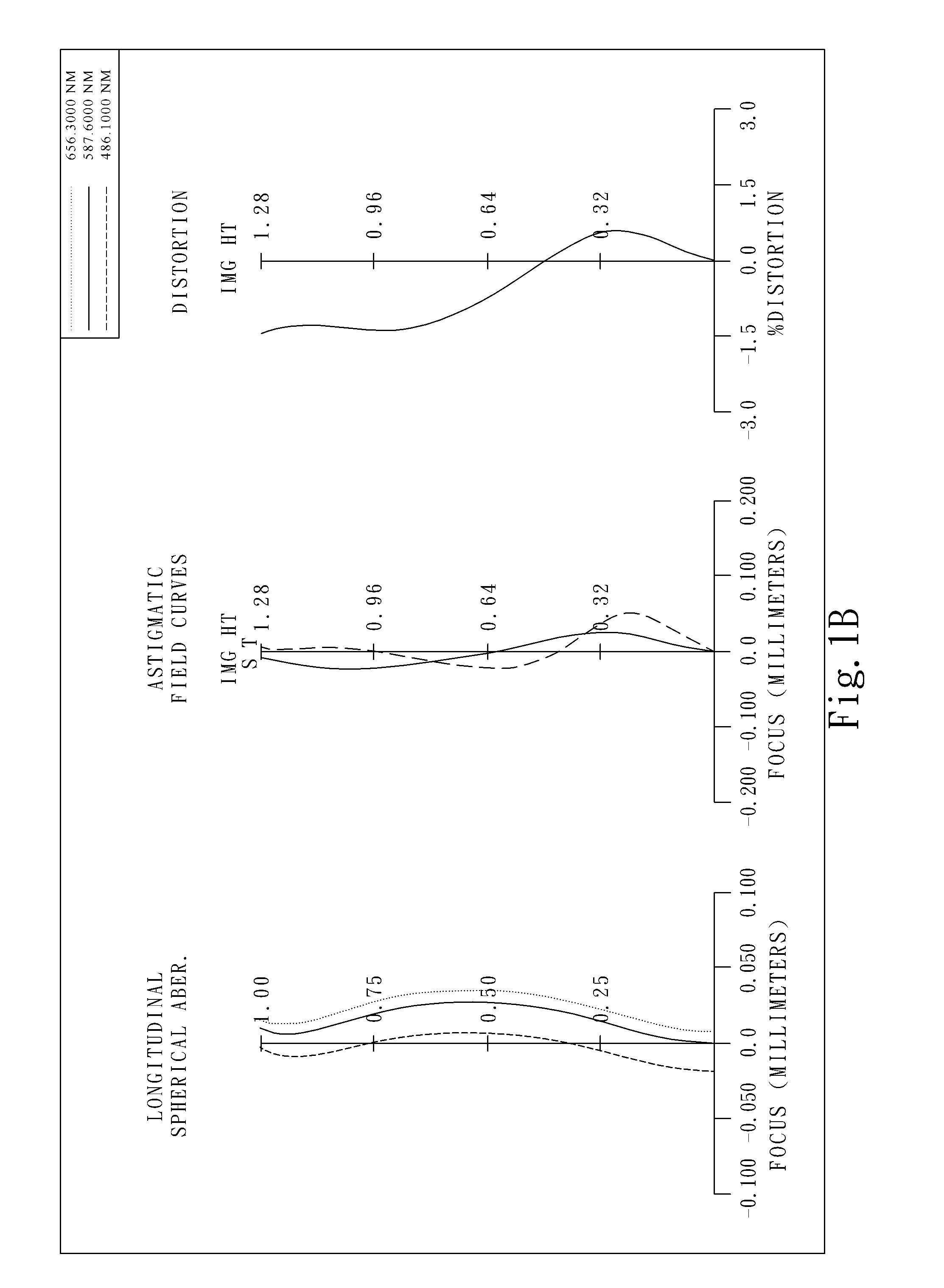

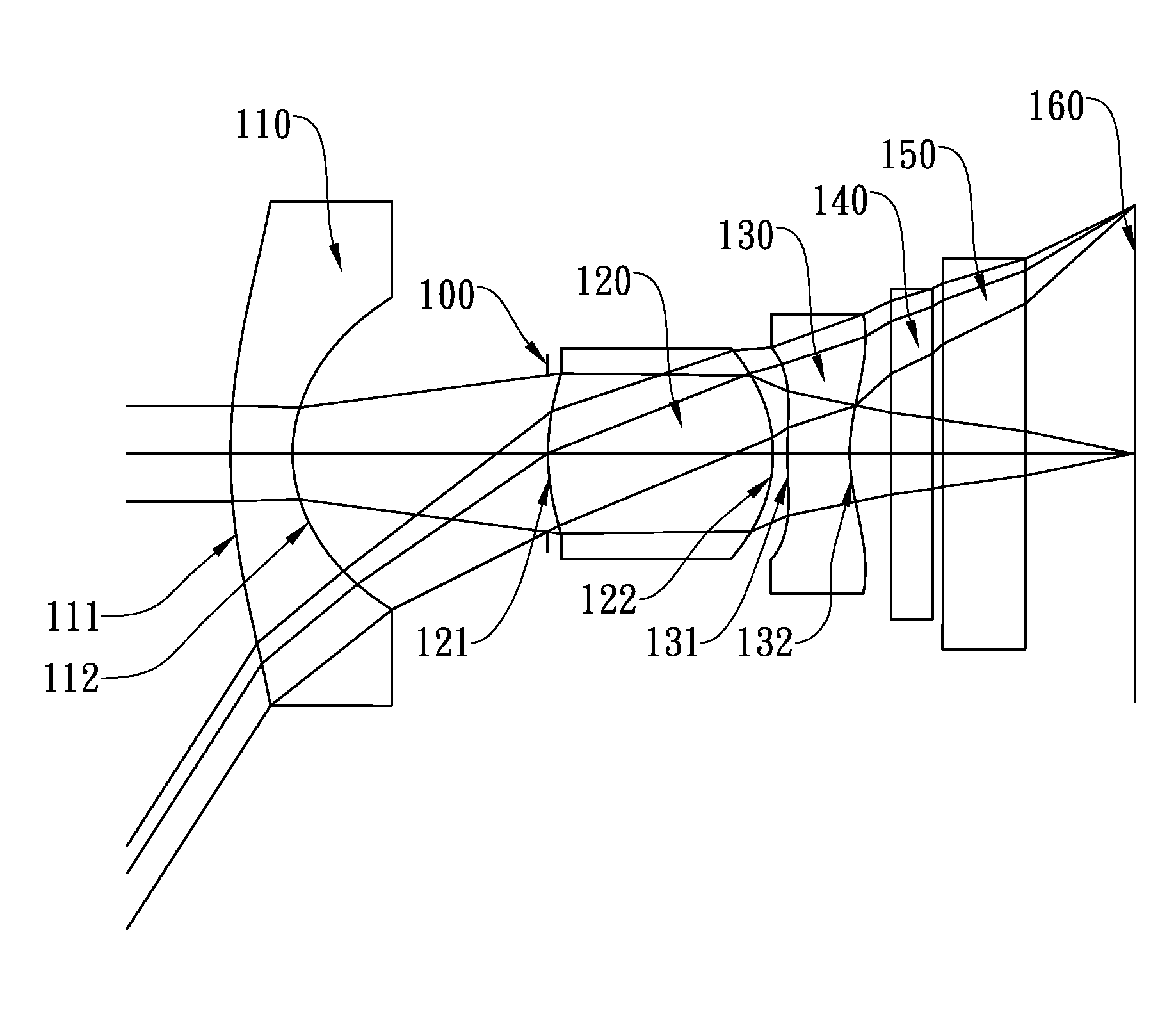

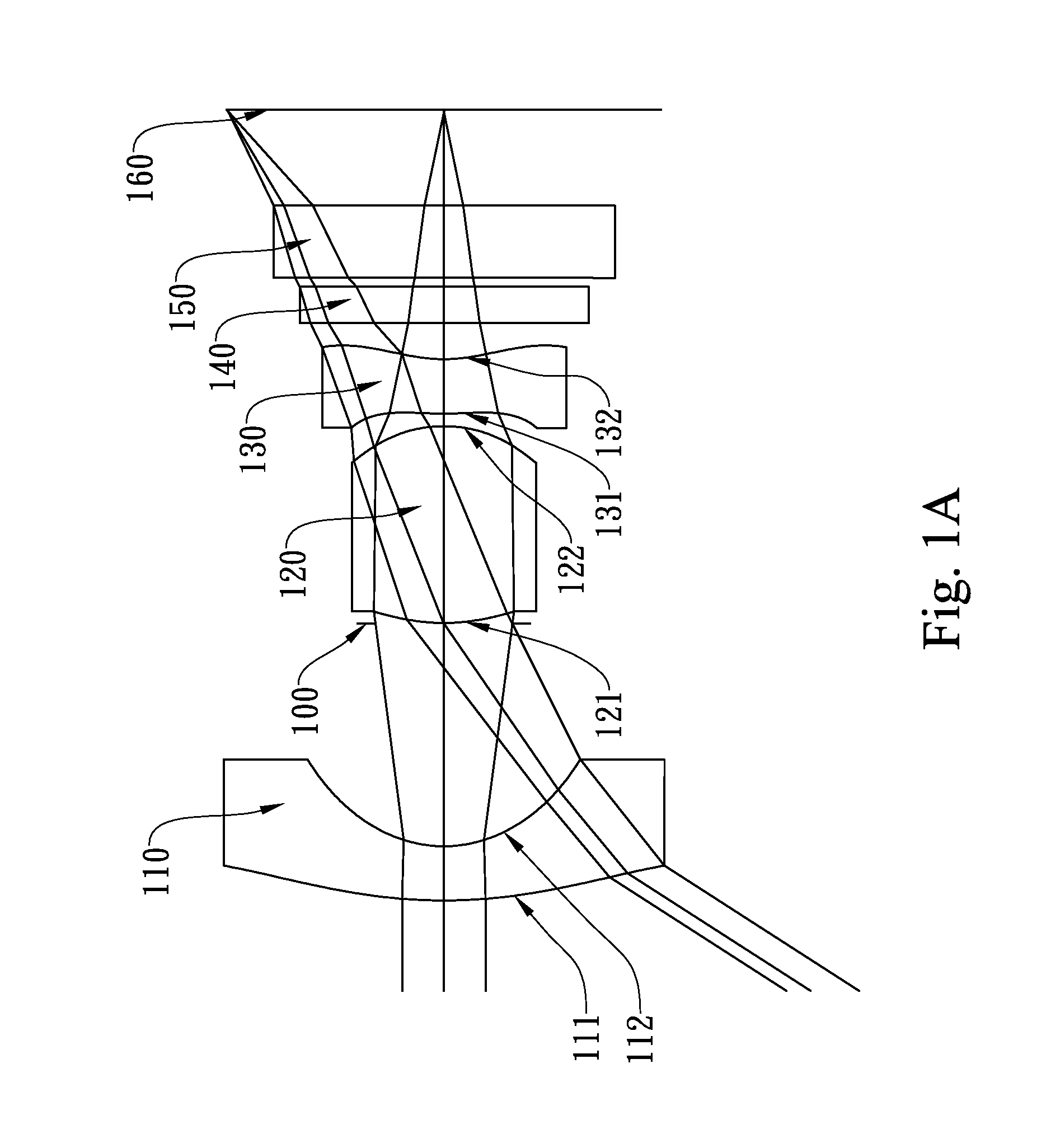

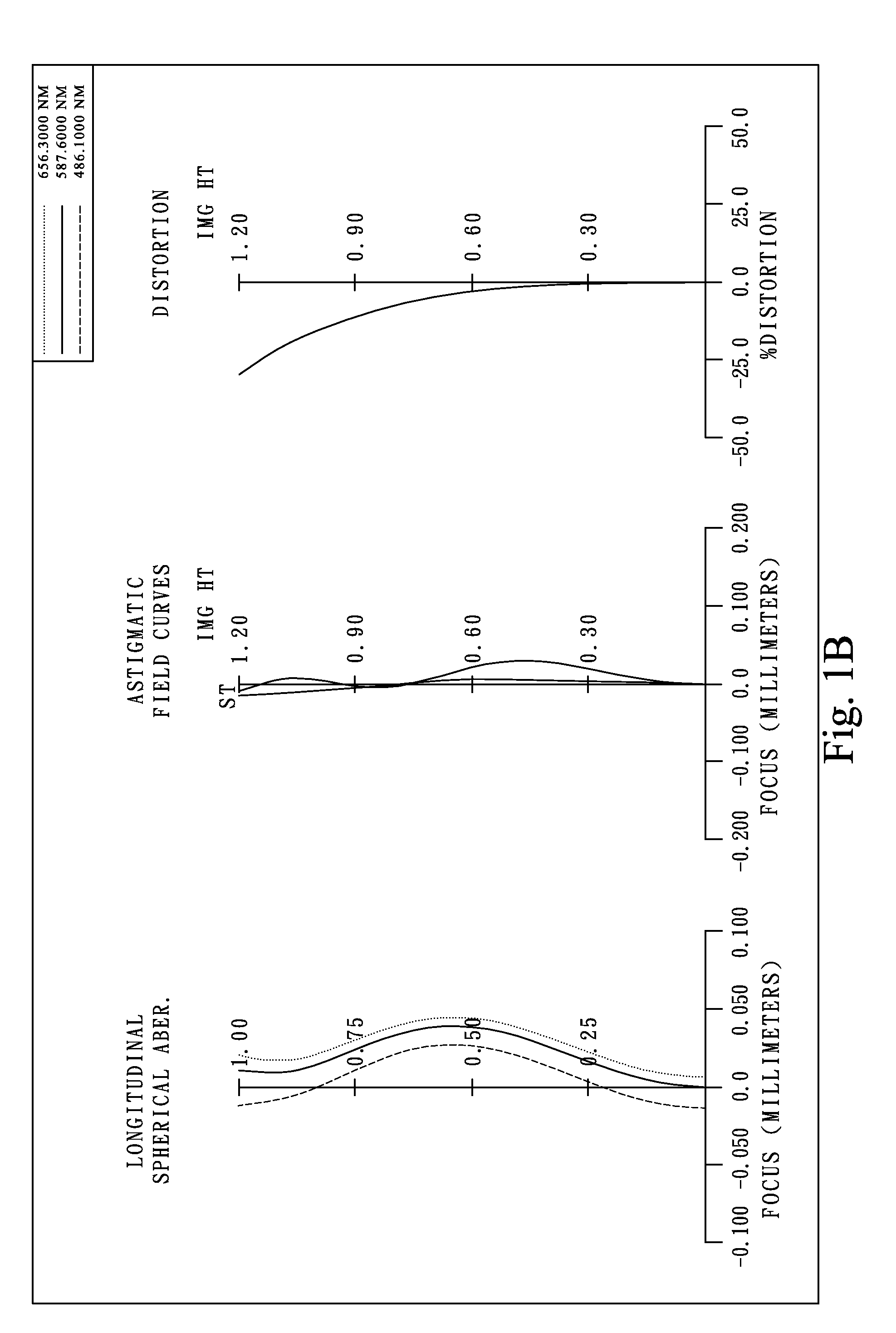

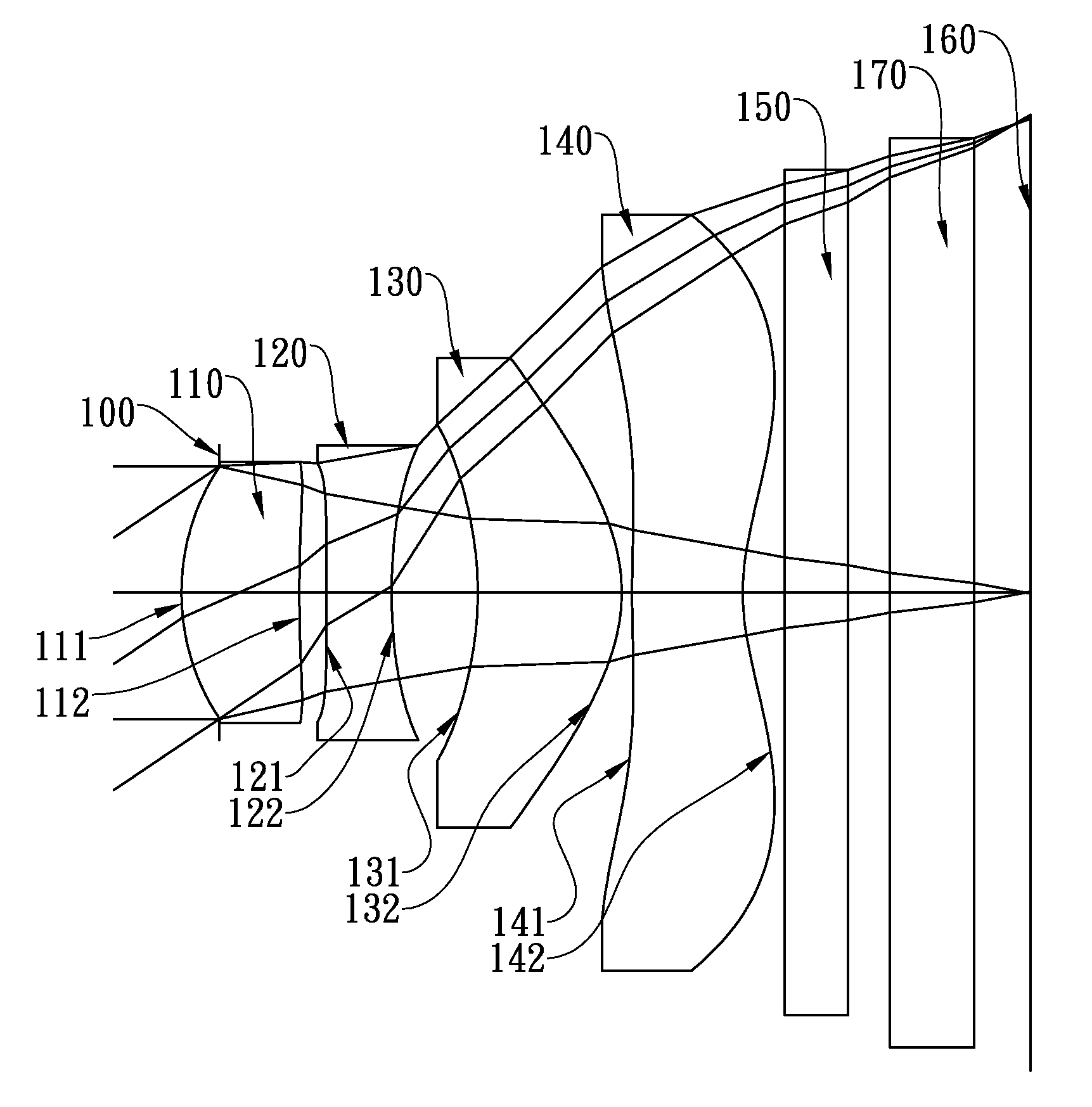

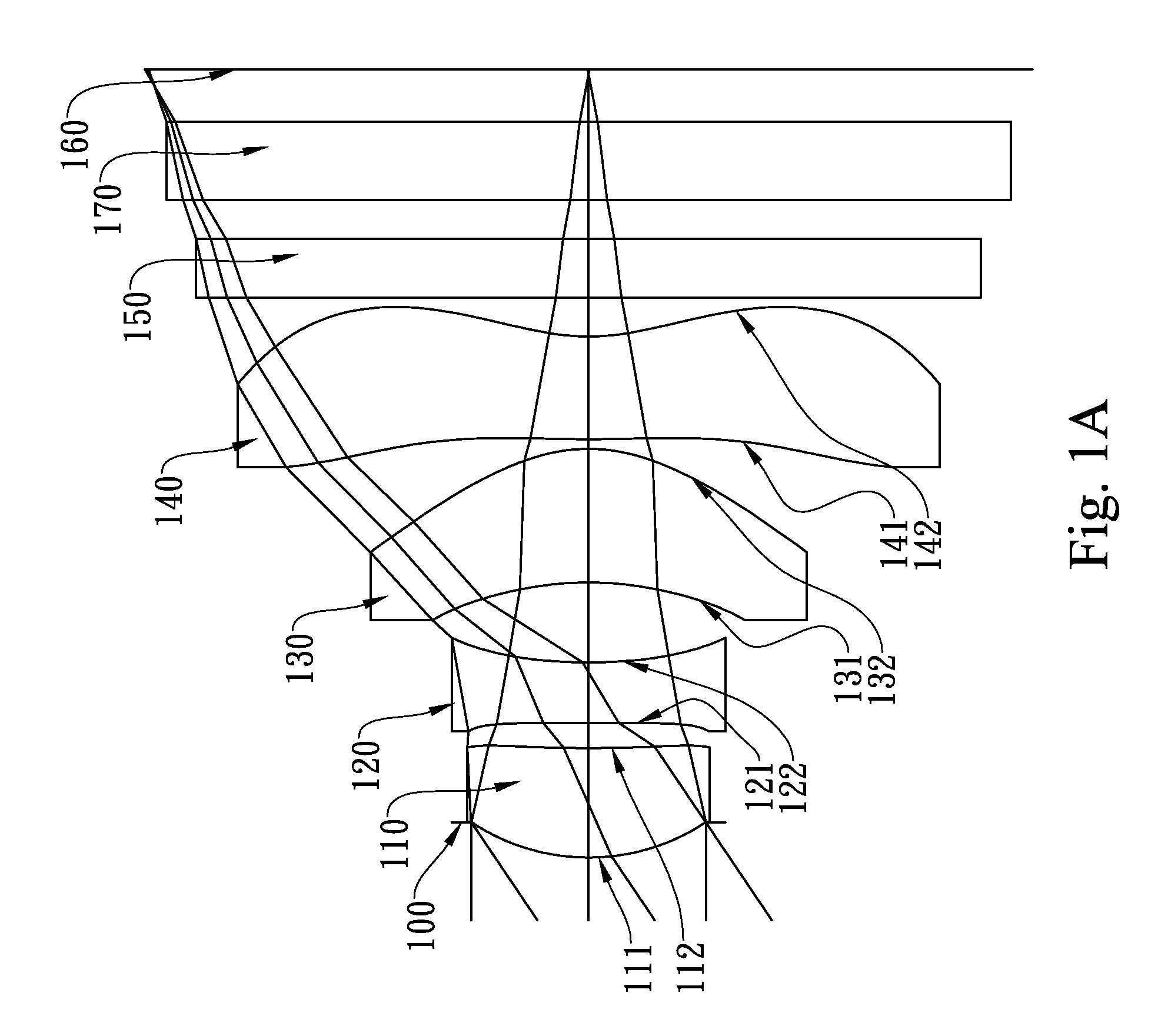

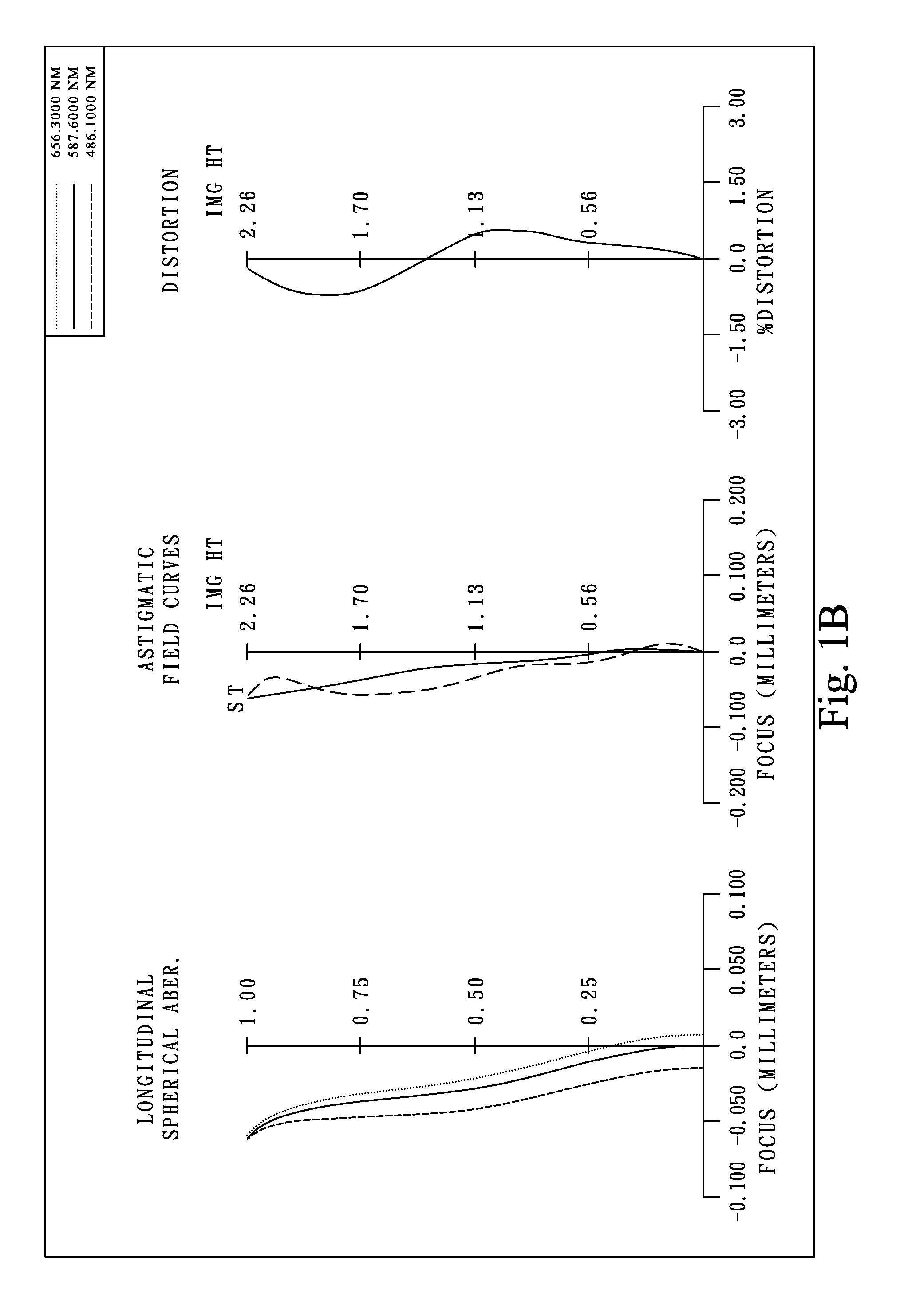

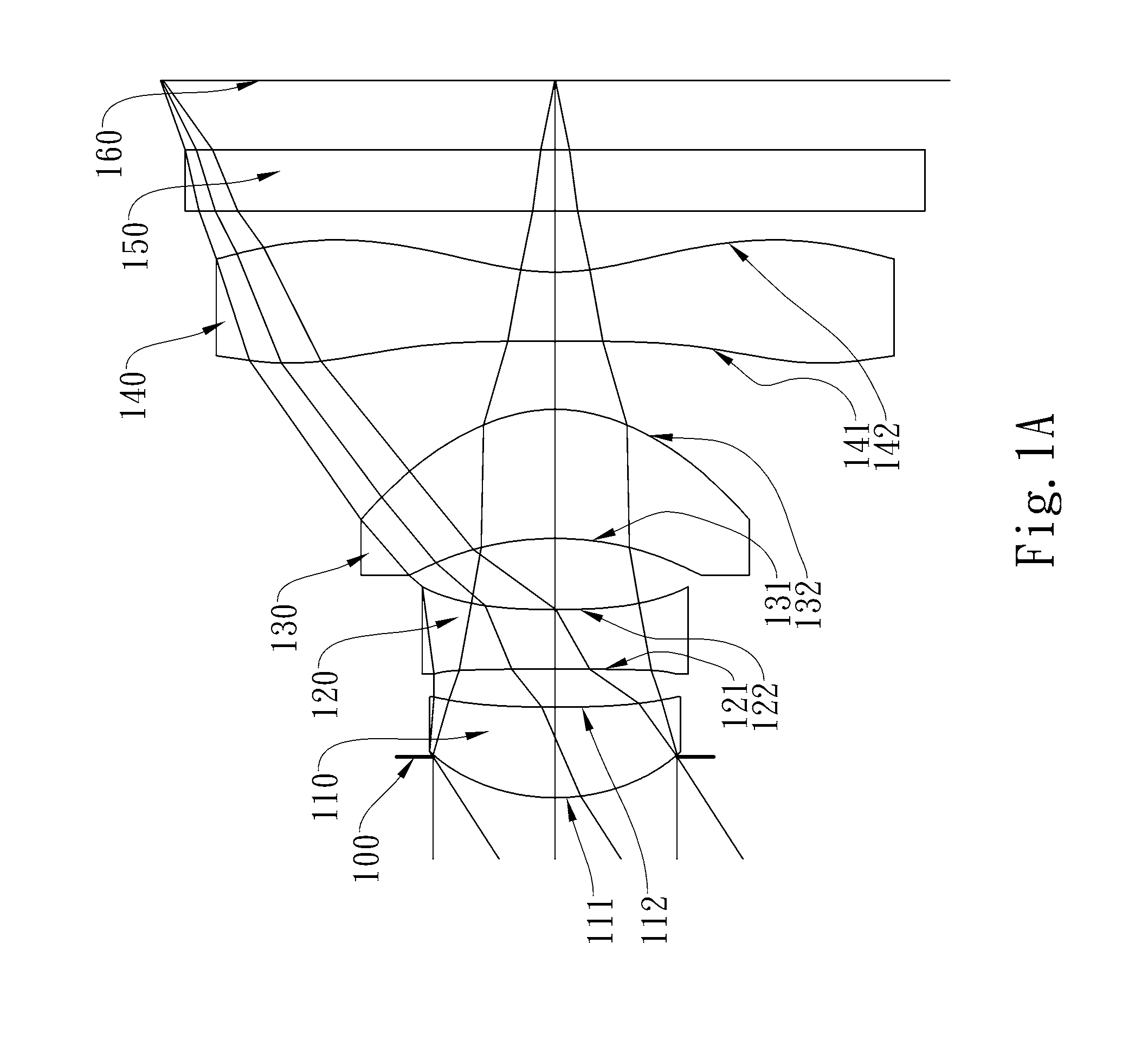

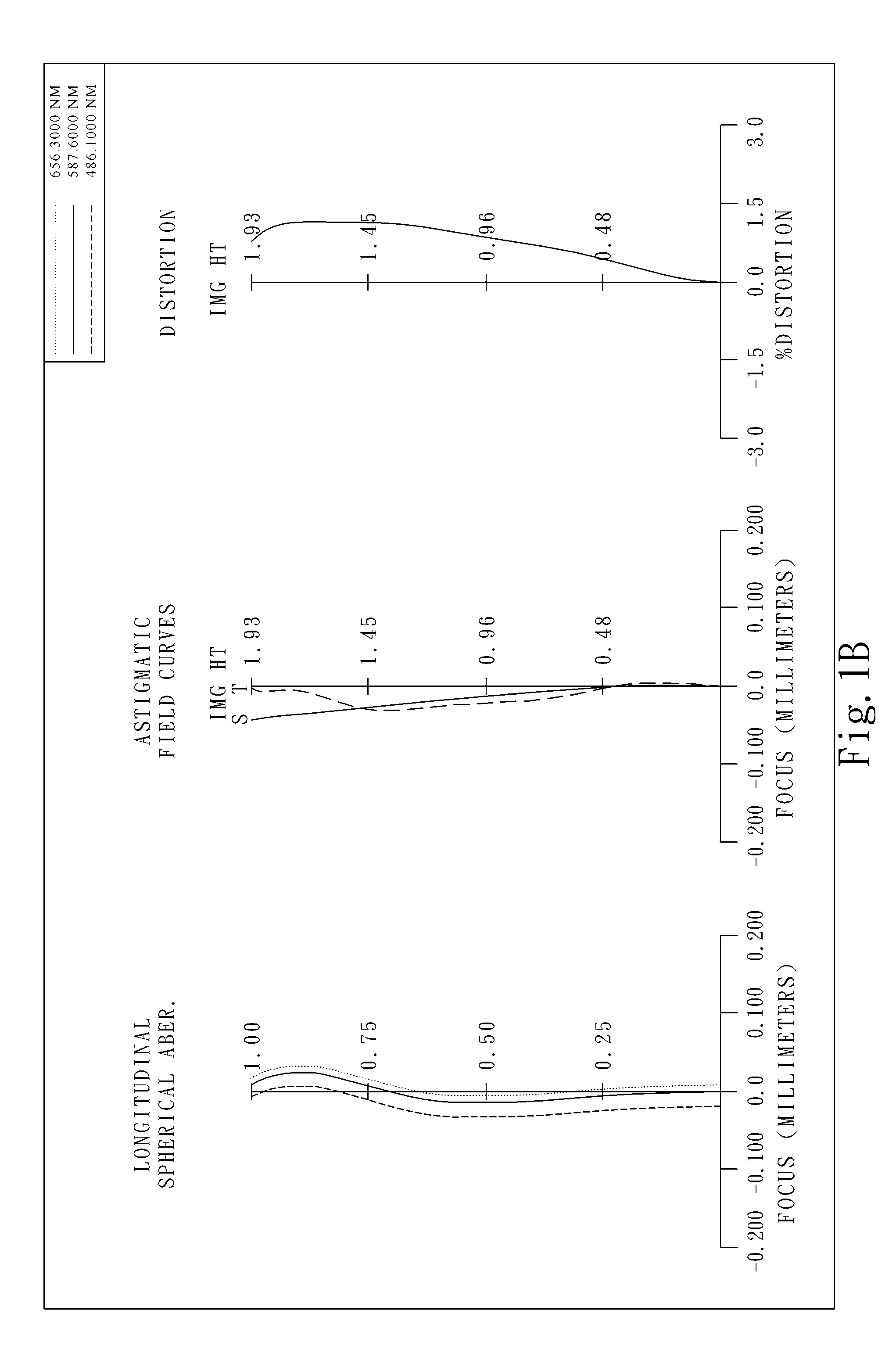

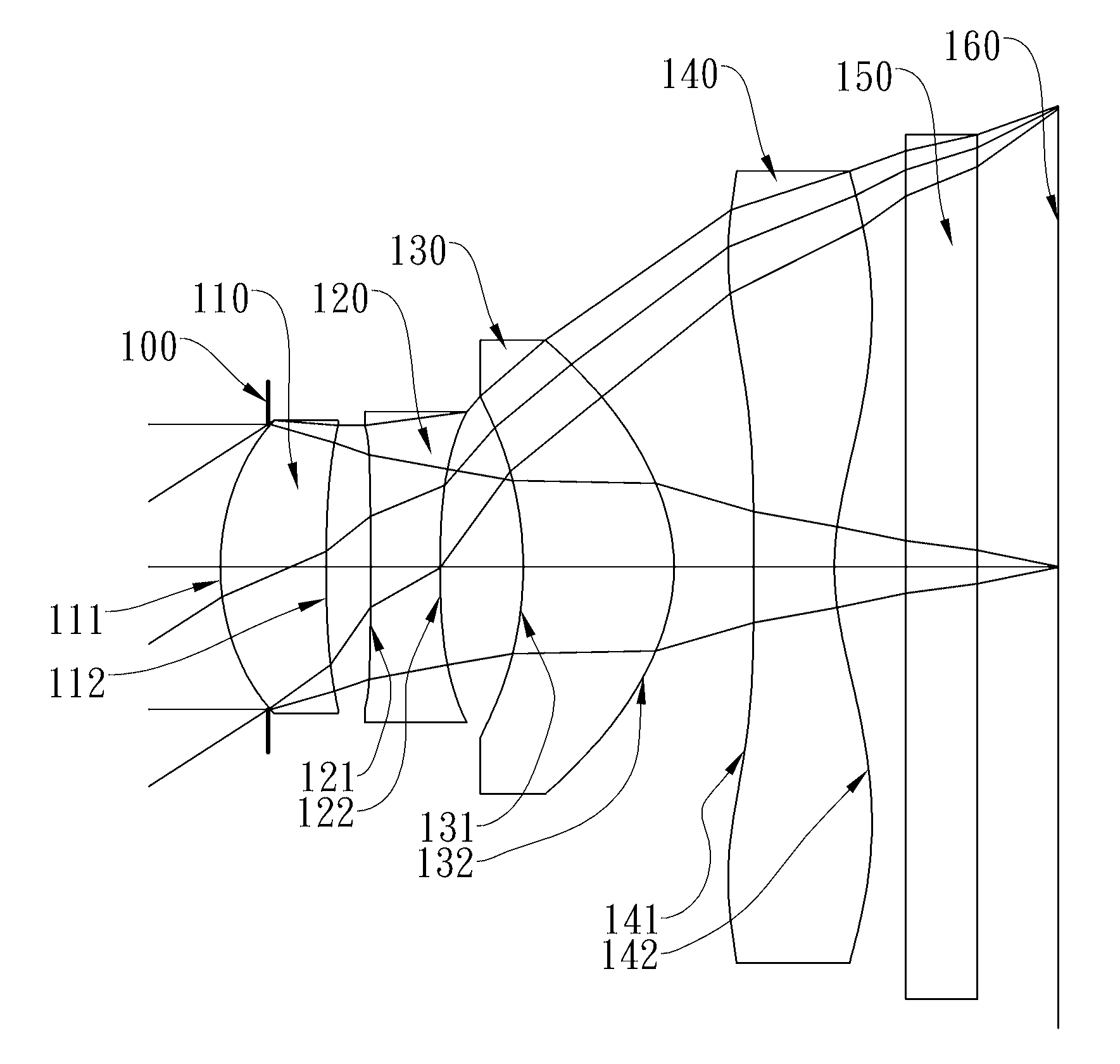

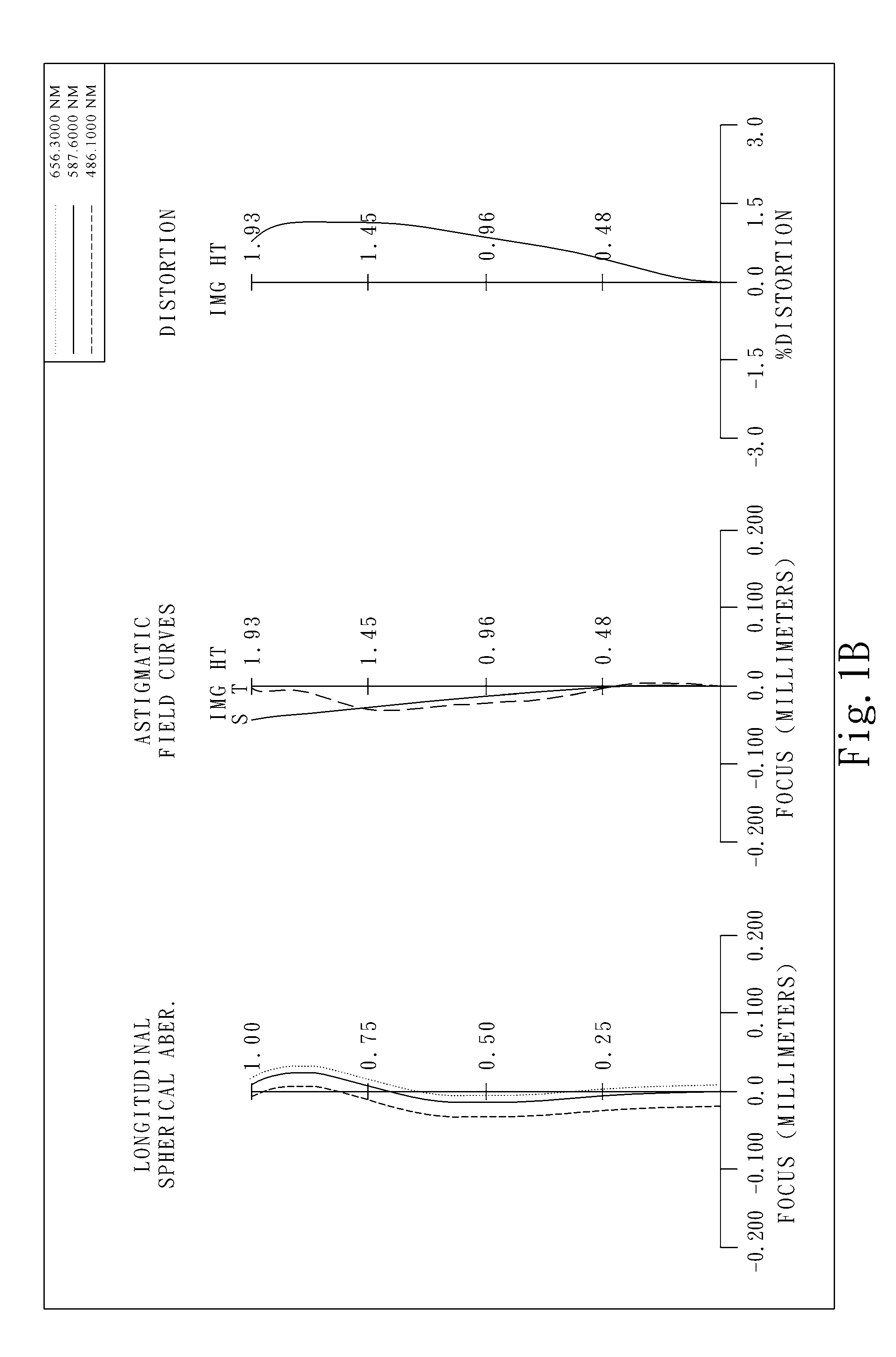

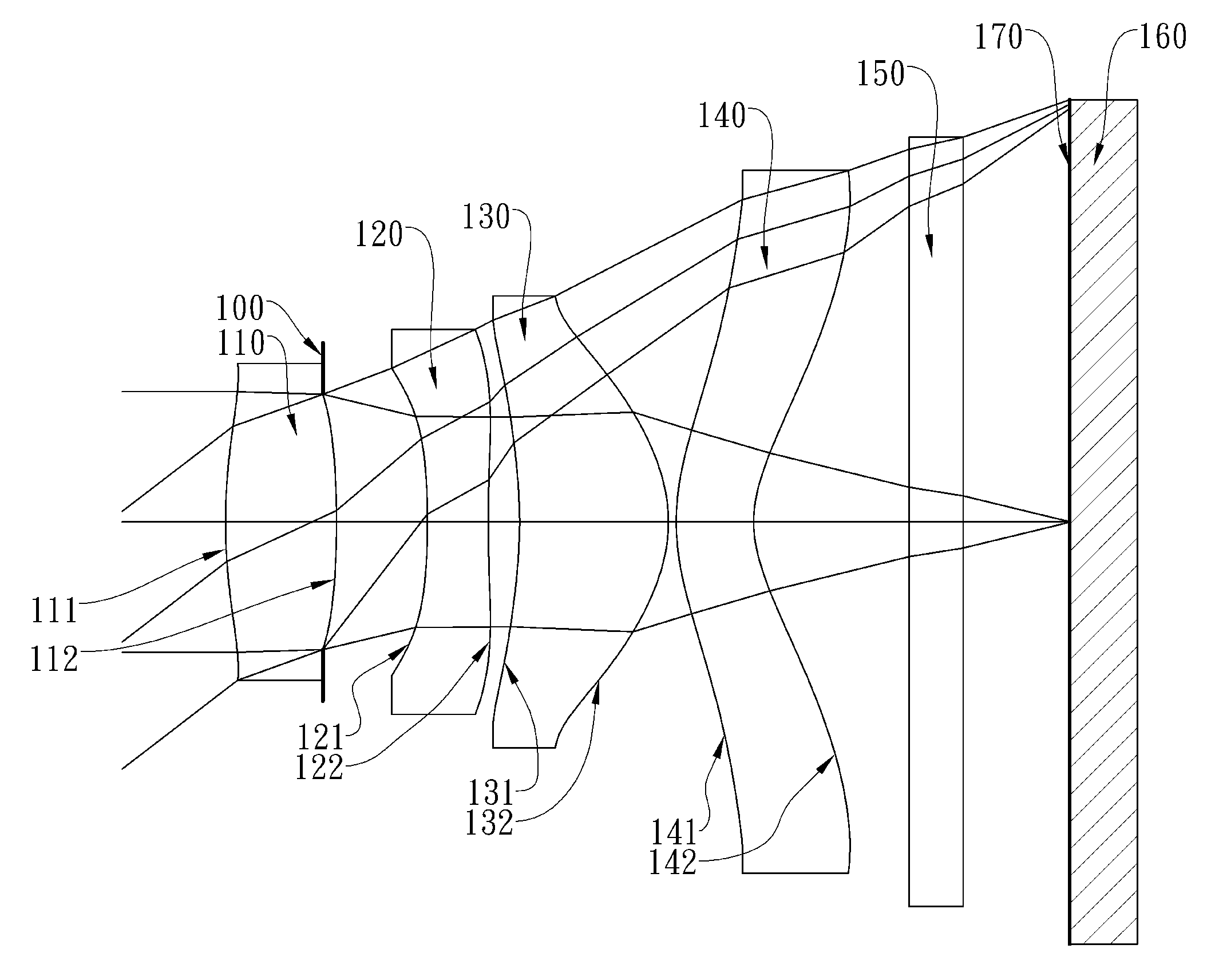

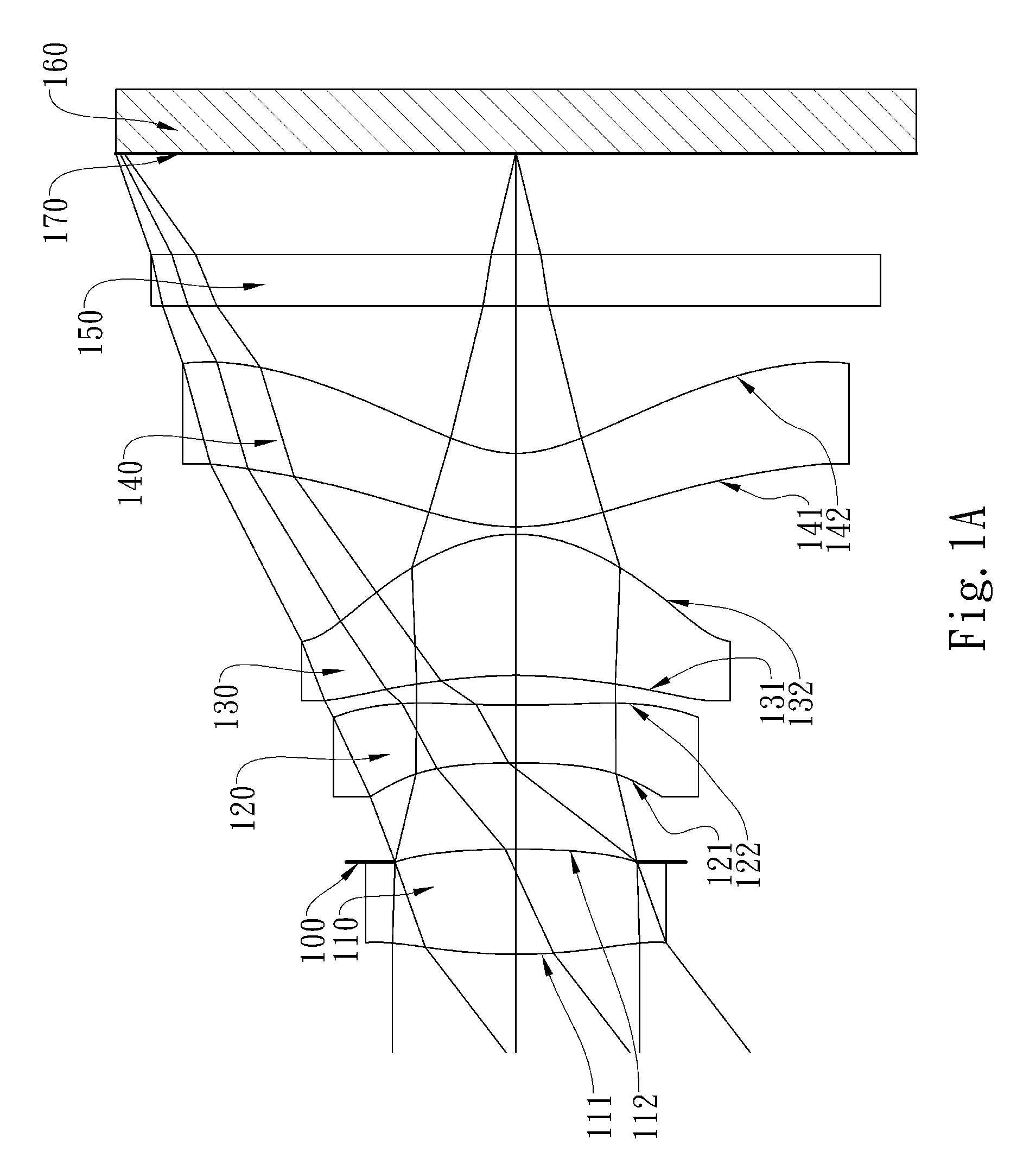

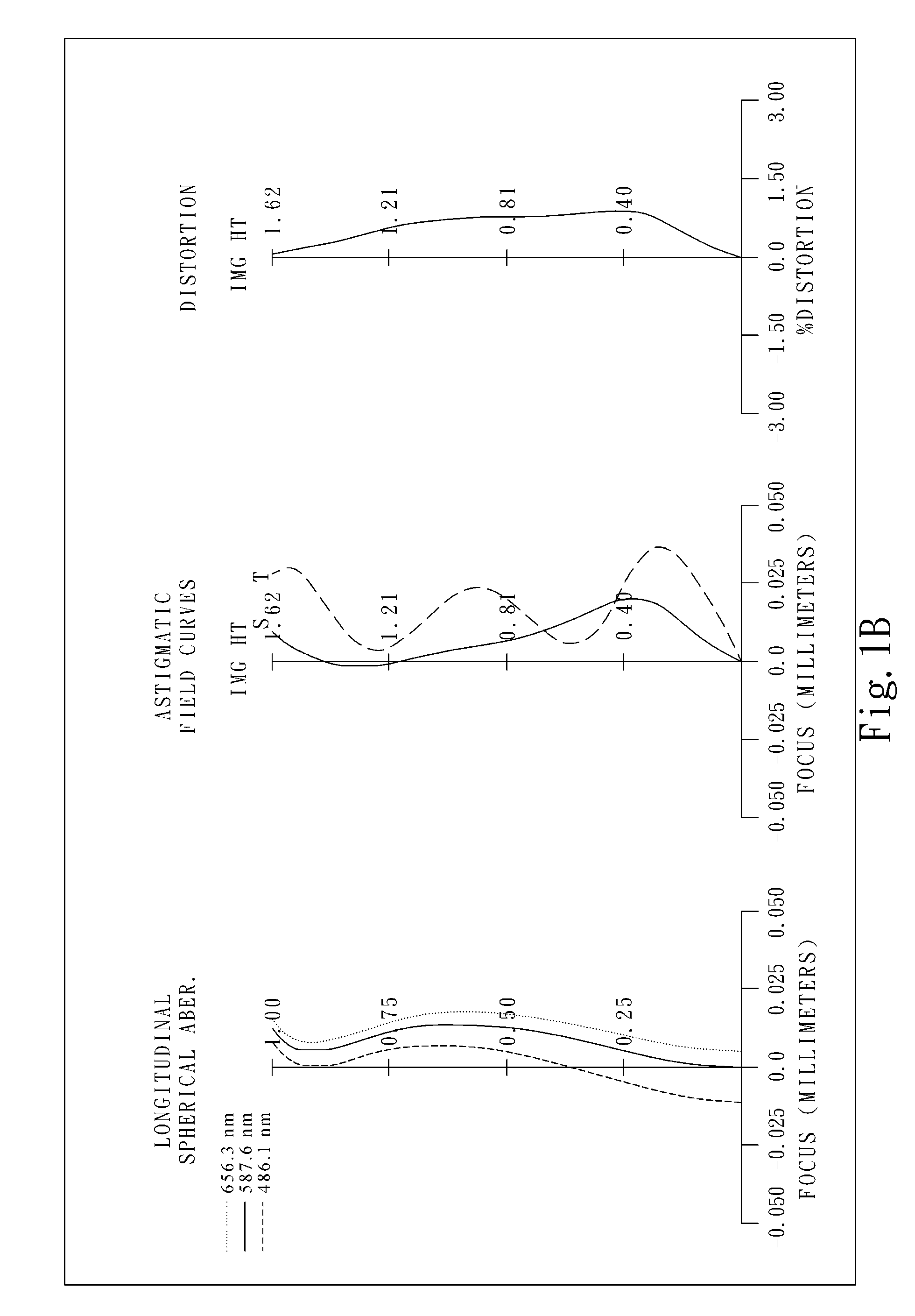

Optical image capturing lens assembly

An optical image capturing lens assembly includes, in order from an object side to an image side, the first lens element with positive refractive power having a convex object-side surface, the second lens element with refractive power, the third lens element with refractive power, the fourth lens element with refractive power having a concave object-side surface and a convex image-side surface, the fifth lens element with refractive power having a convex image-side surface, the object-side surface and the image side surface of the fifth lens element being aspheric, and the sixth lens element with negative refractive power made of plastic material and having a concave image-side surface. The object-side surface and the image-side surface of the sixth lens element are aspheric, and at least one surface thereof has at least one inflection point.

Owner:LARGAN PRECISION

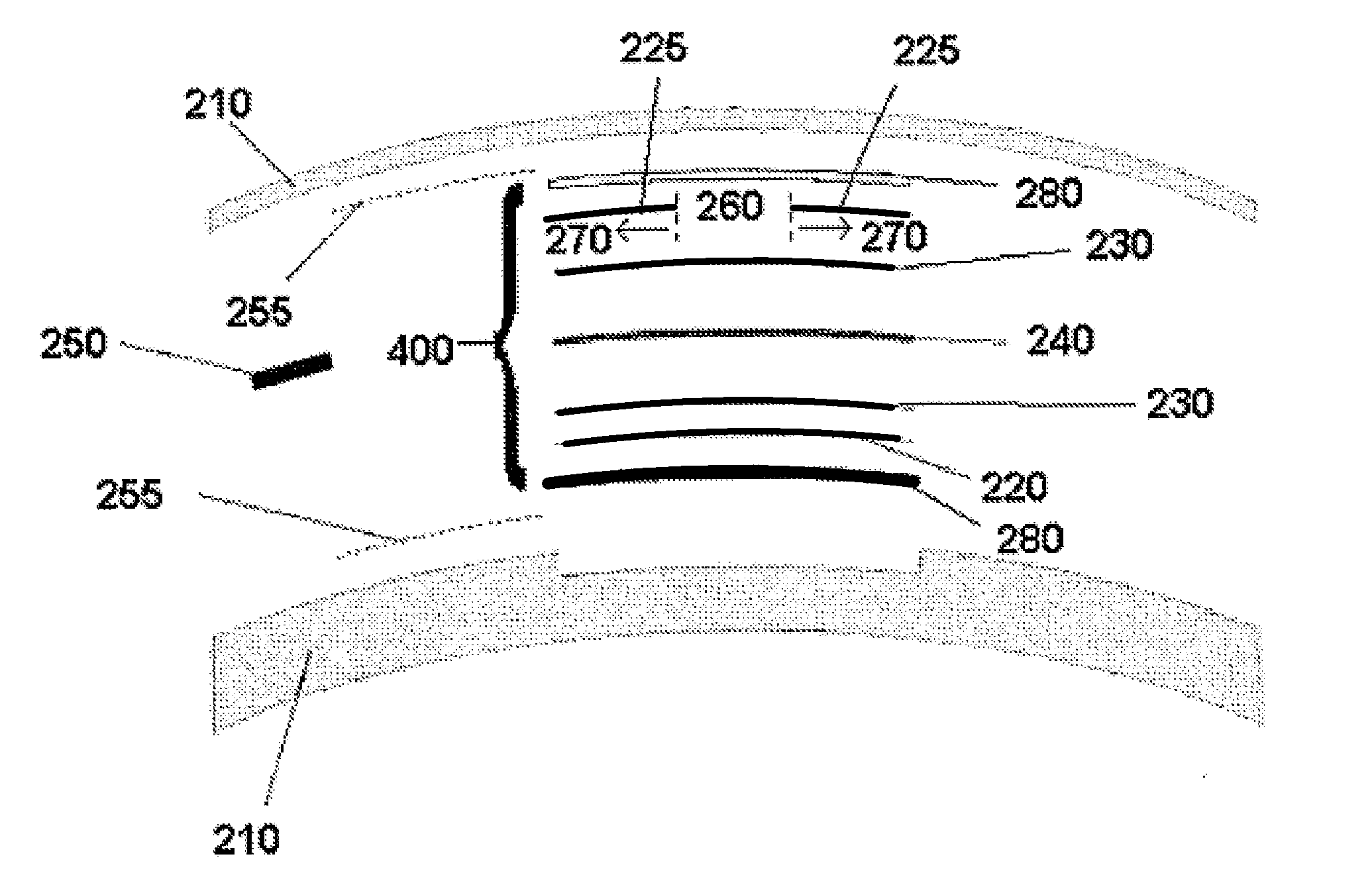

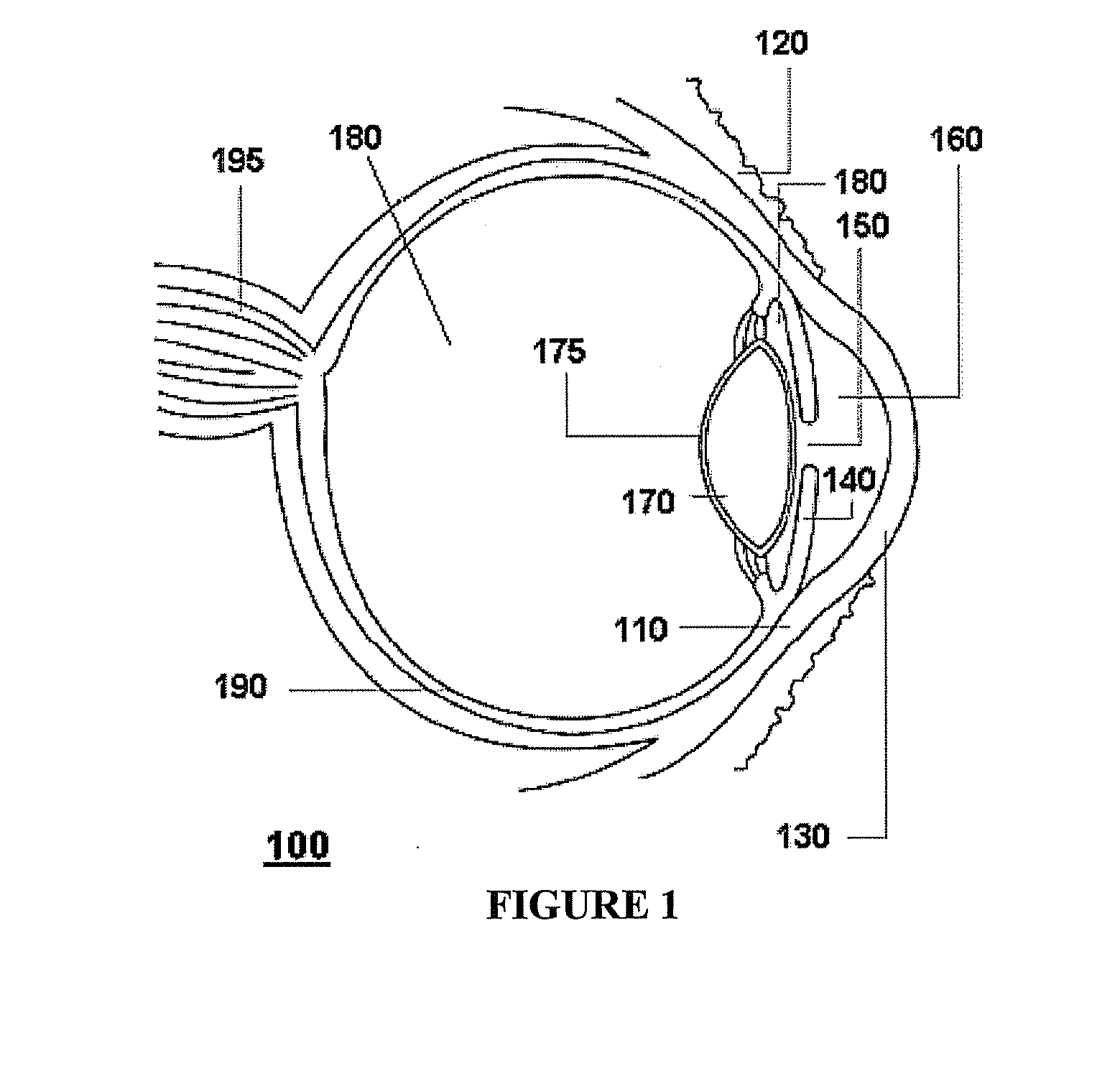

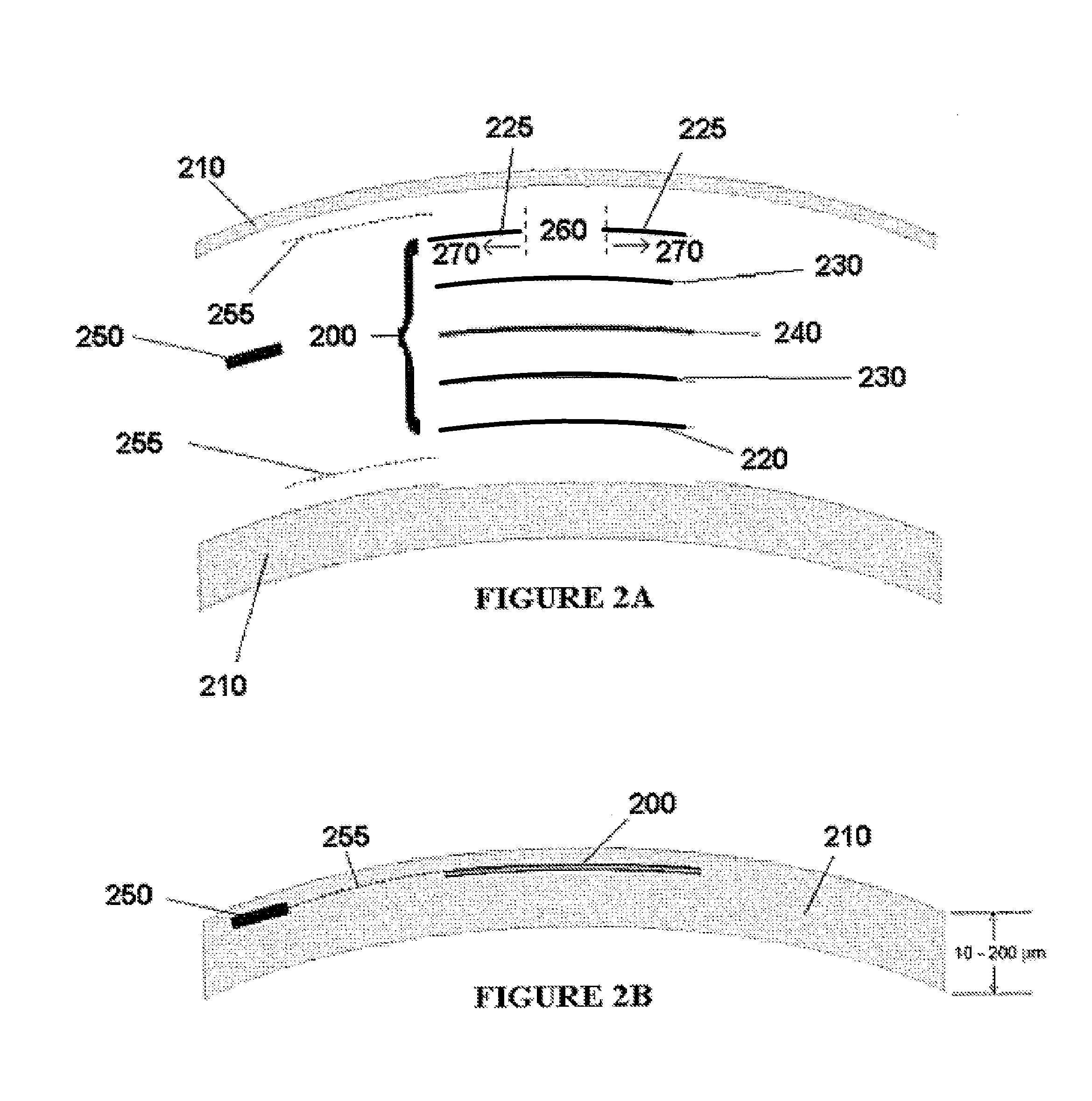

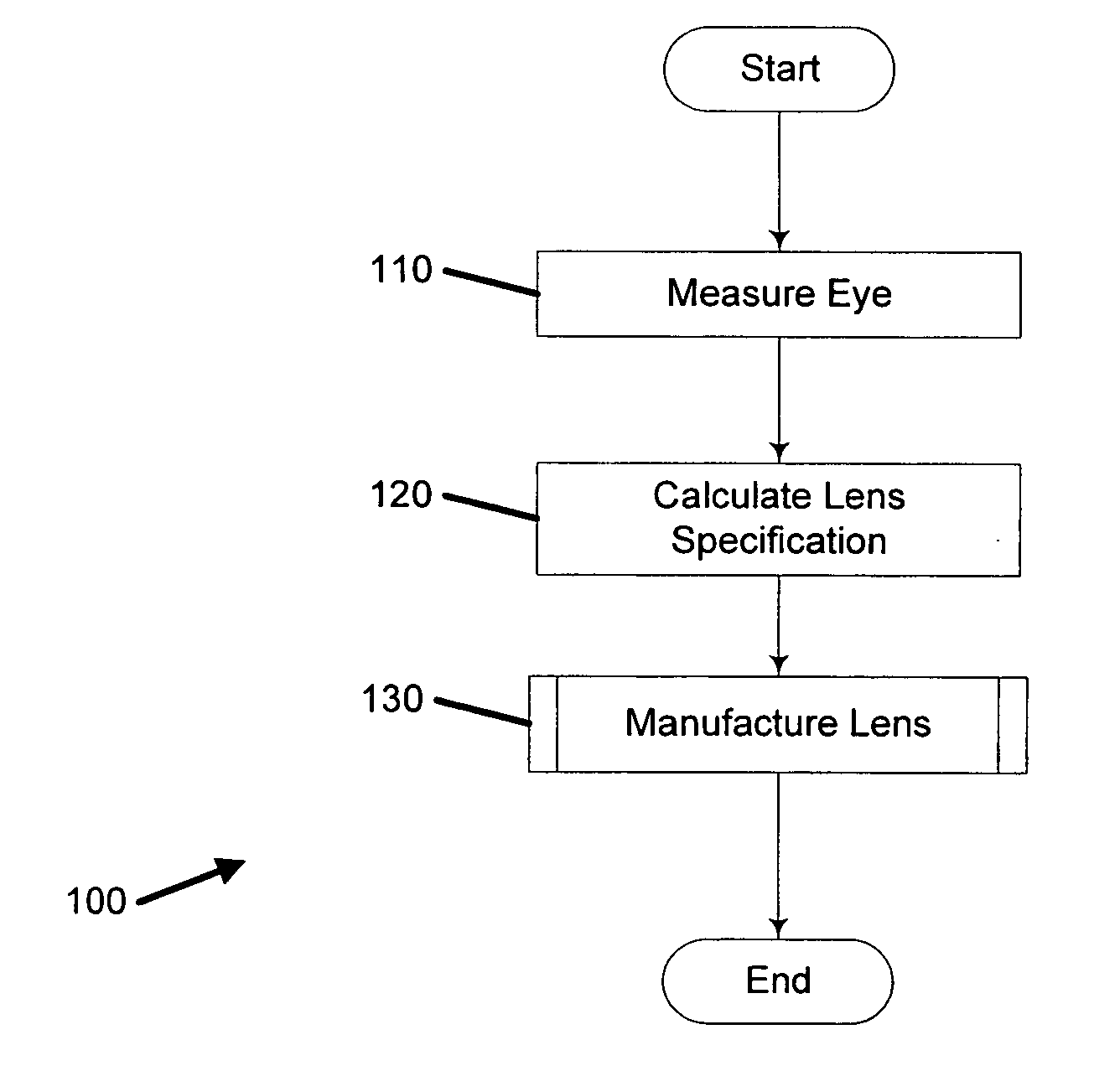

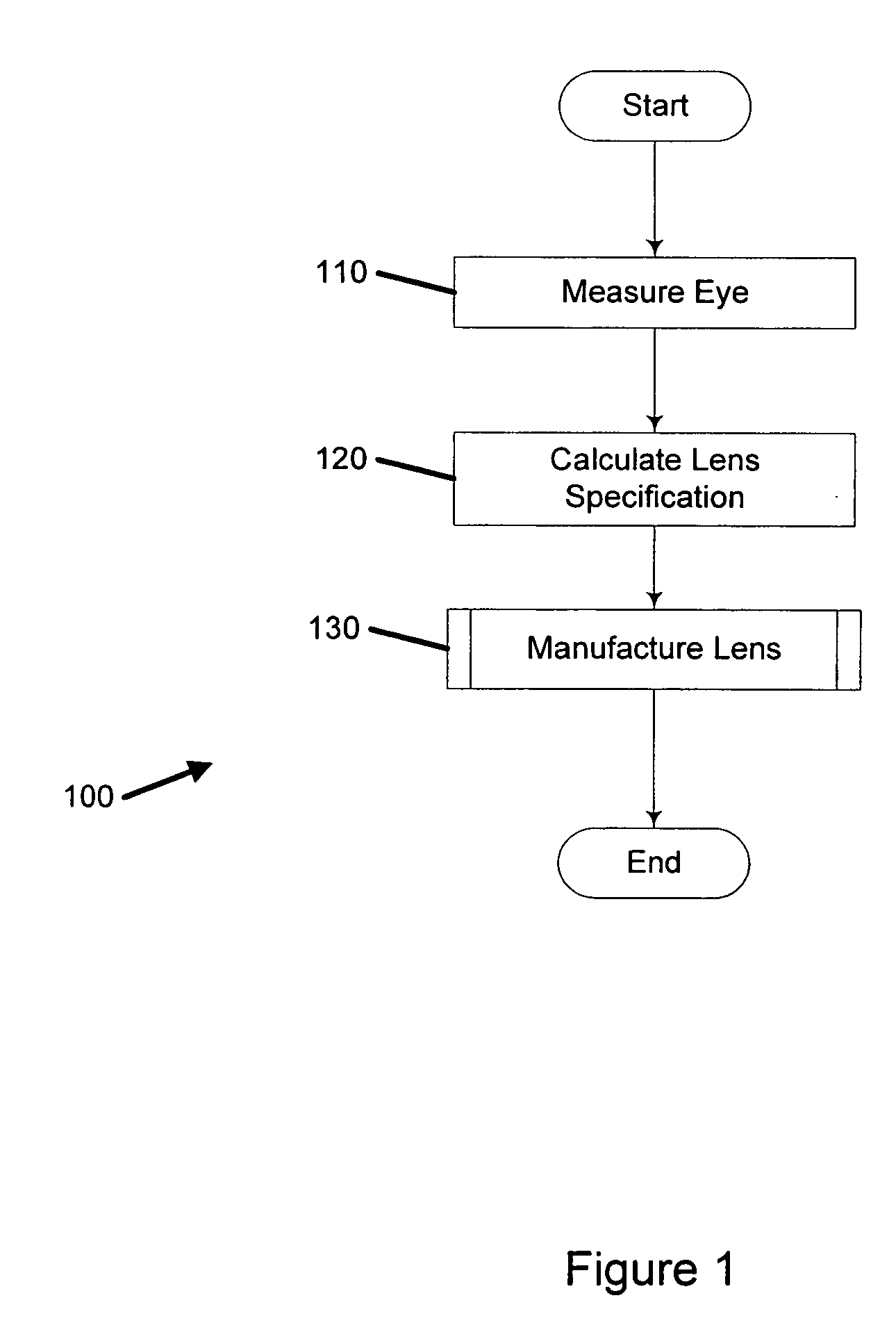

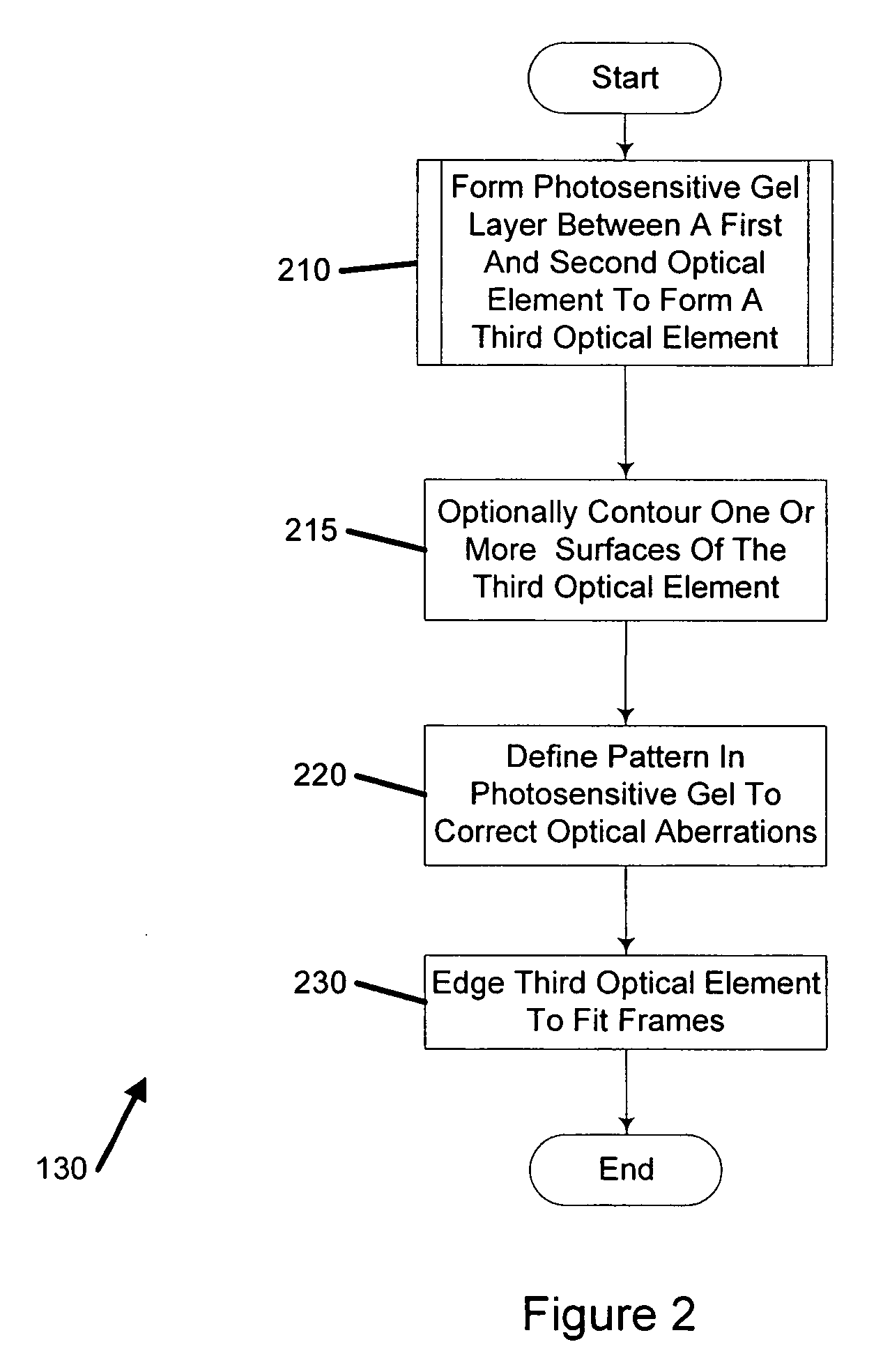

Eyeglass manufacturing method using variable index layer

An Eyeglass Manufacturing Method Using Epoxy Aberrator includes two lenses with a variable index material, such as epoxy, sandwiched in between. The epoxy is then cured to different indexes of refraction that provide precise corrections for the patient's wavefront aberrations. The present invention further provides a method to produce an eyeglass that corrects higher order aberrations, such as those that occur when retinal tissue is damaged due to glaucoma or macular degeneration. The manufacturing method allows for many different applications including, but not limited to, supervision and transition lenses.

Owner:ESSILOR INT CIE GEN DOPTIQUE +1

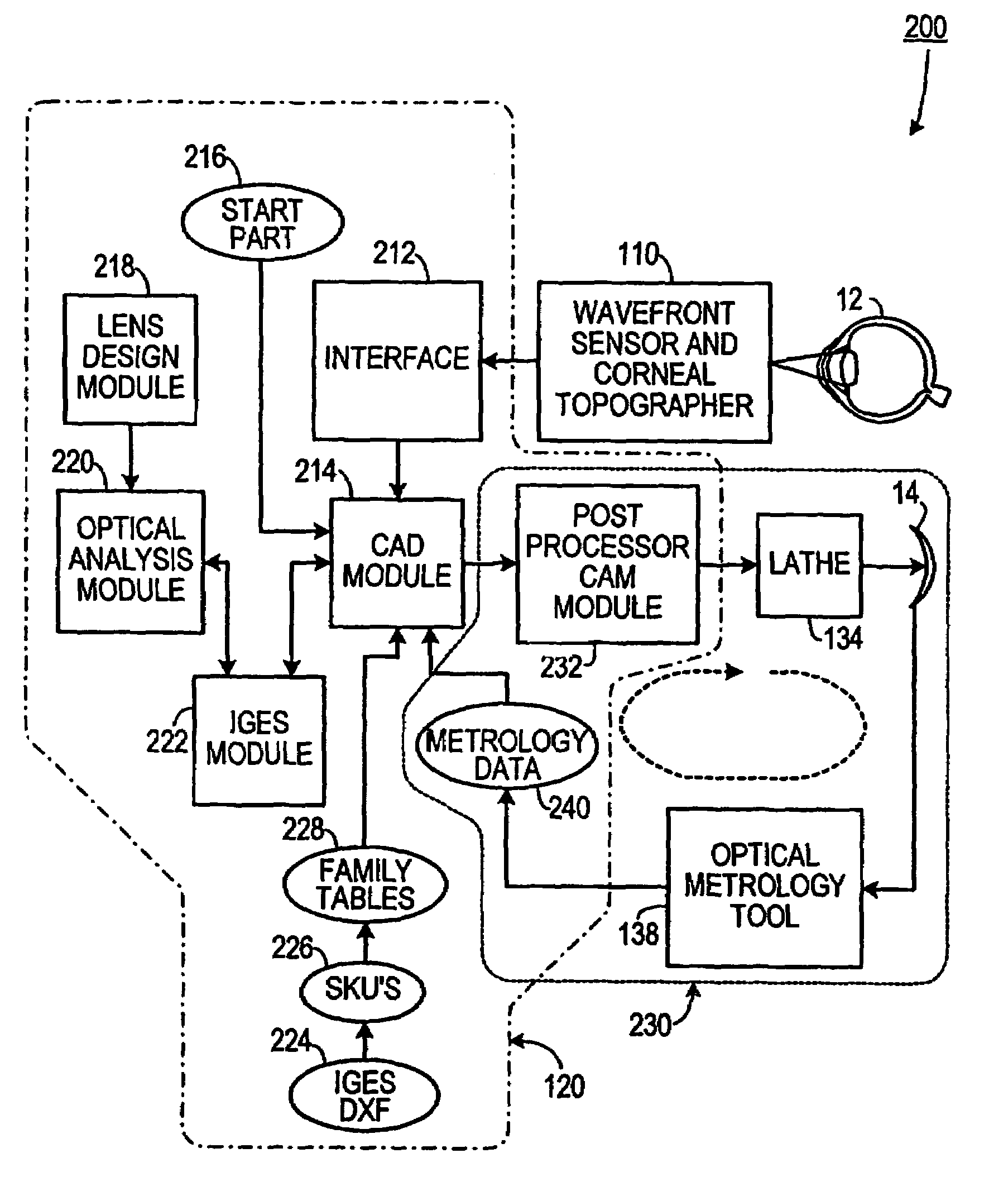

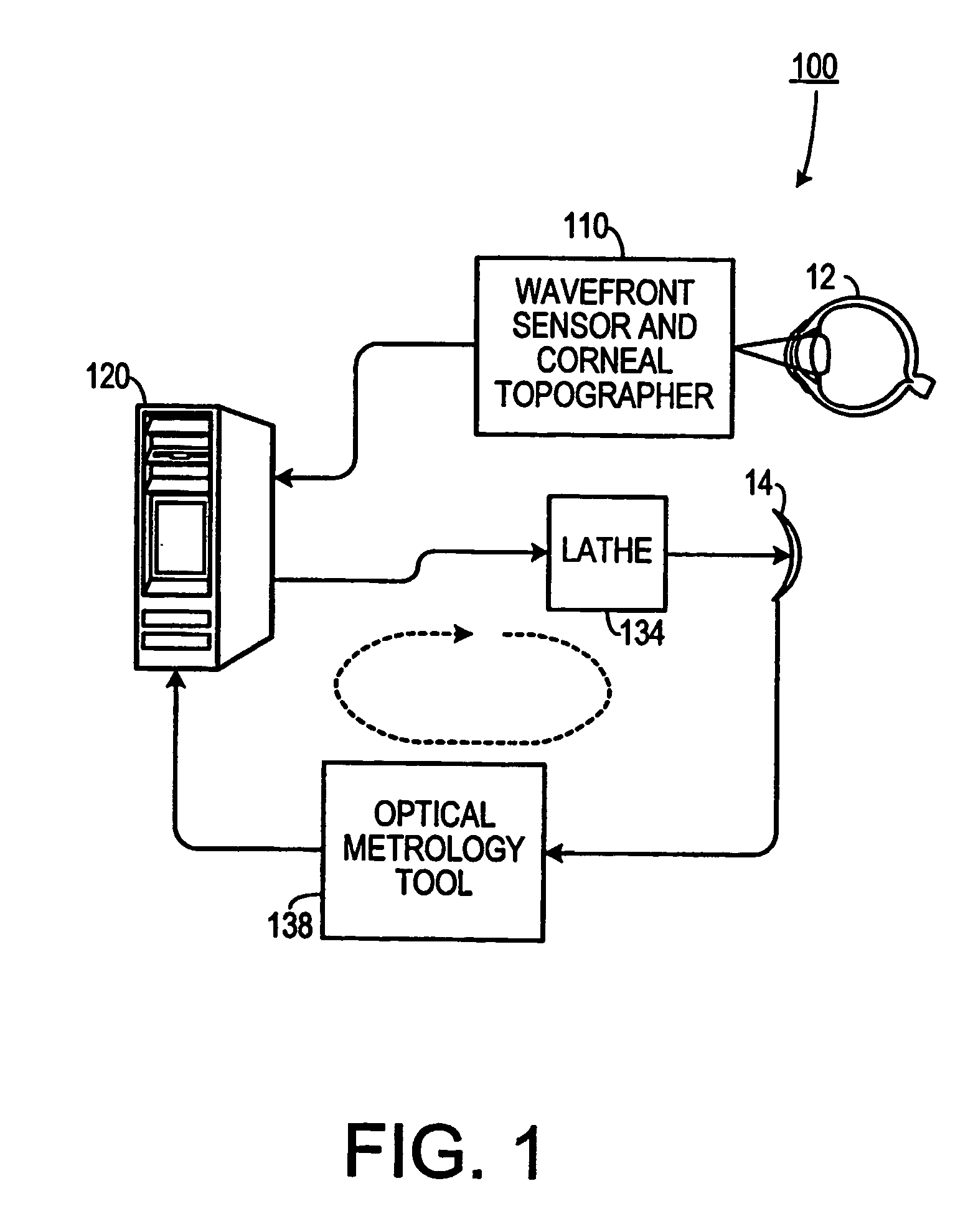

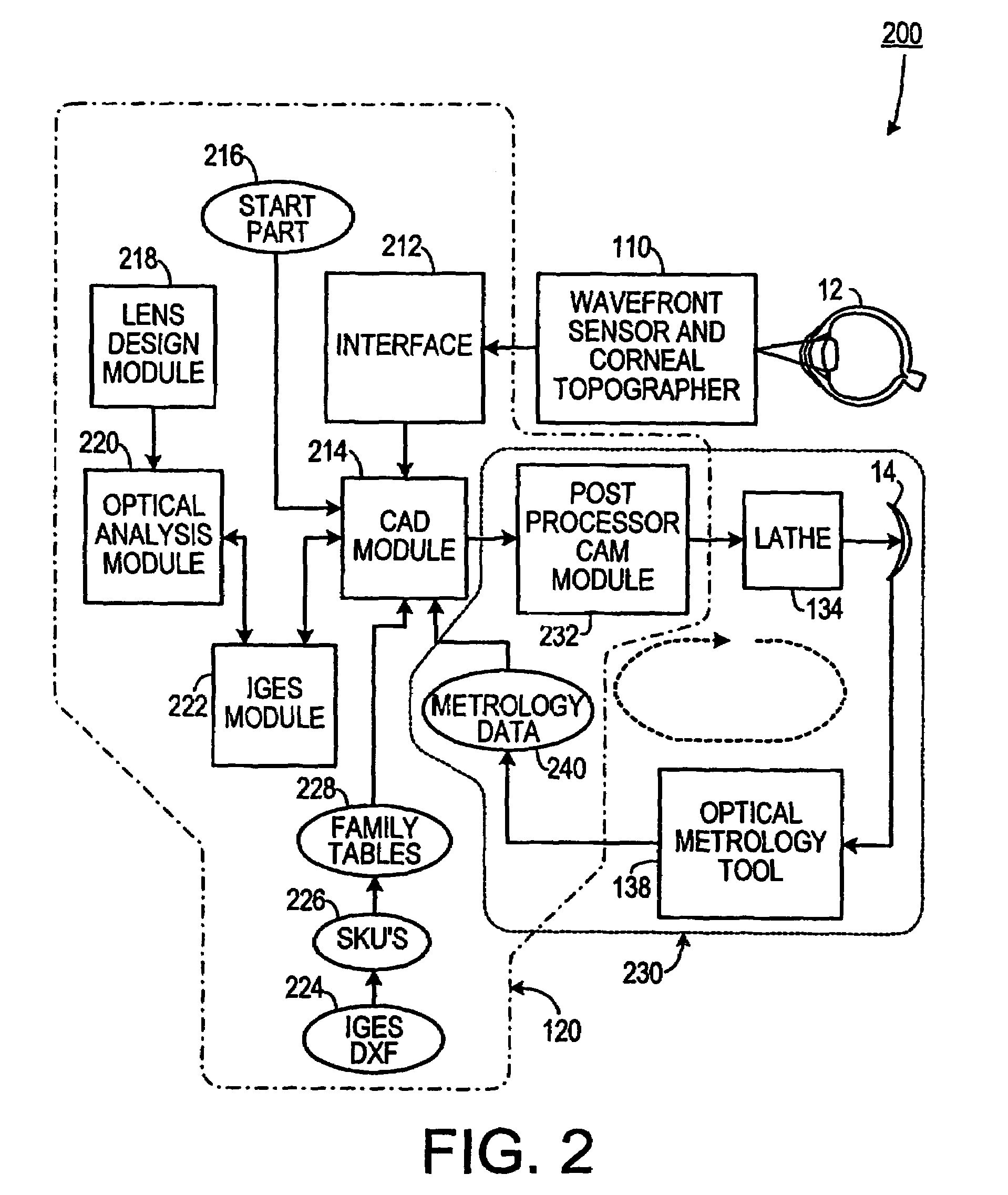

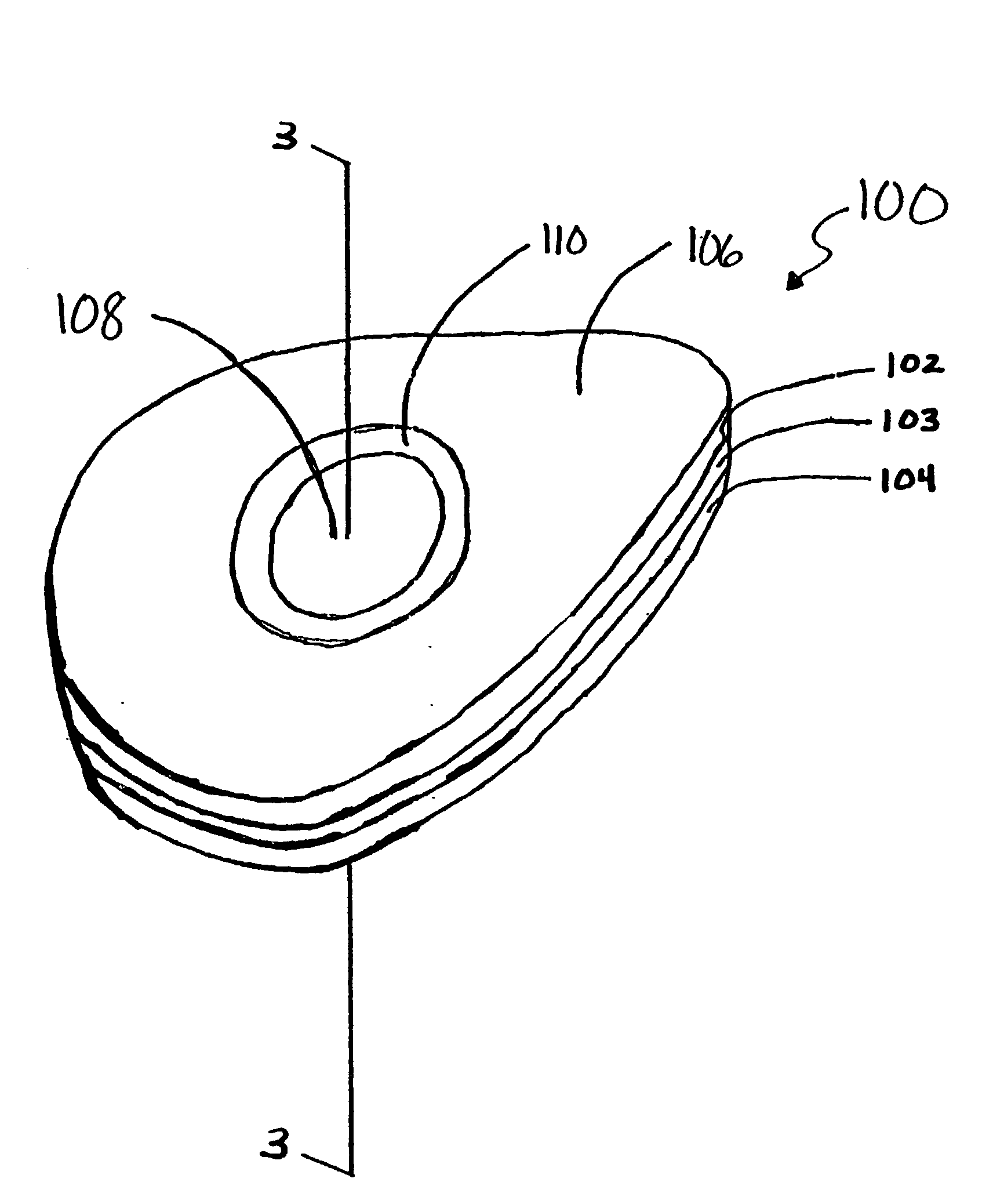

Automatic lens design and manufacturing system

InactiveUS7111938B2Easy to correctAberration correctionSpectales/gogglesEye surgeryCamera lensIntraocular lens

The present invention provides a method for designing and making a customized ophthalmic lens, such as a contact lens or an intraocular lens, capable of correcting high-order aberrations of an eye. The posterior surface of the customized contact lens is designed to accommodate the corneal topography of an eye. The design of the customized ophthalmic lens is evaluated and optimized in an optimizing routine using a computational model eye that reproduces the aberrations and corneal topography of an eye. The present invention also provides a system and method for characterizing the optical metrology of a customized ophthalmic lens that is designed to correct aberrations of an eye. Furthermore, the present invention provides a business model and method for placing an order for a pair of customized ophthalmic lenses.

Owner:ALCON INC

Eyeglass manufacturing method using variable index layer

An Eyeglass Manufacturing Method Using Epoxy Aberrator includes two lenses with a variable index material, such as epoxy, sandwiched in between. The epoxy is then cured to different indexes of refraction that provide precise corrections for the patient's wavefront aberrations. The present invention further provides a method to produce an eyeglass that corrects higher order aberrations, such as those that occur when retinal tissue is damaged due to glaucoma or macular degeneration. The manufacturing method allows for many different applications including, but not limited to, supervision and transition lenses.

Owner:ESSILOR INT CIE GEN DOPTIQUE +1

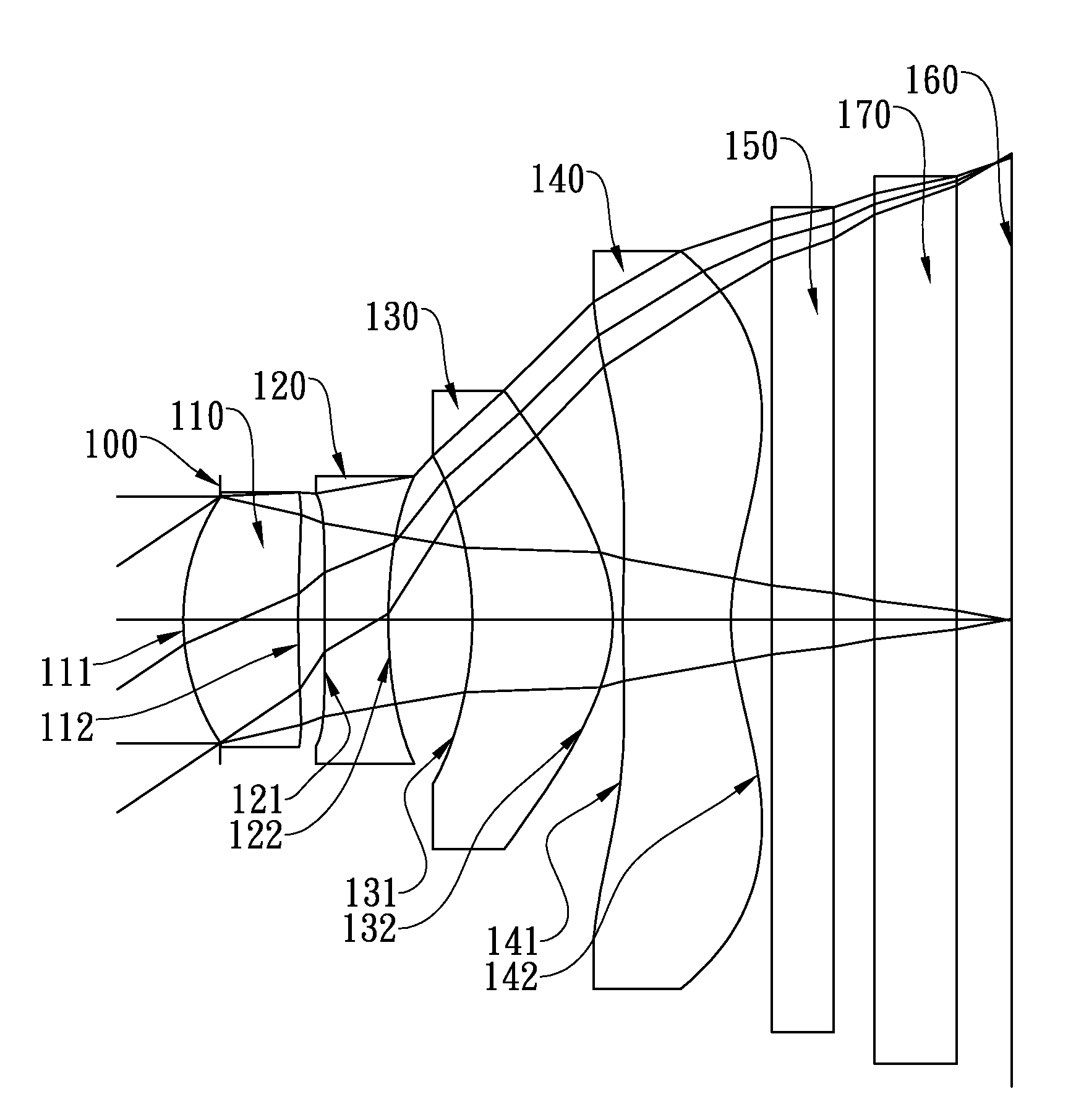

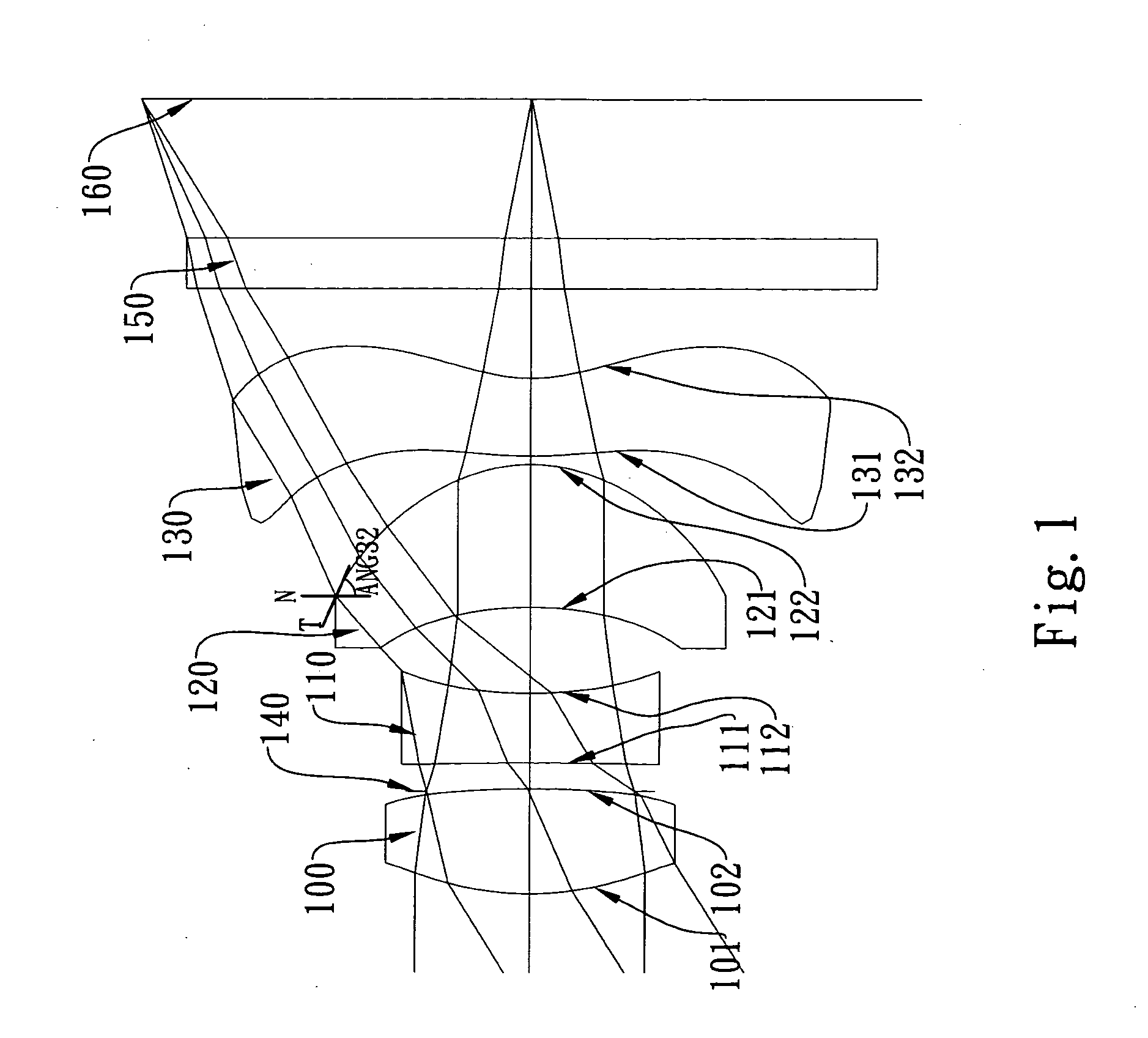

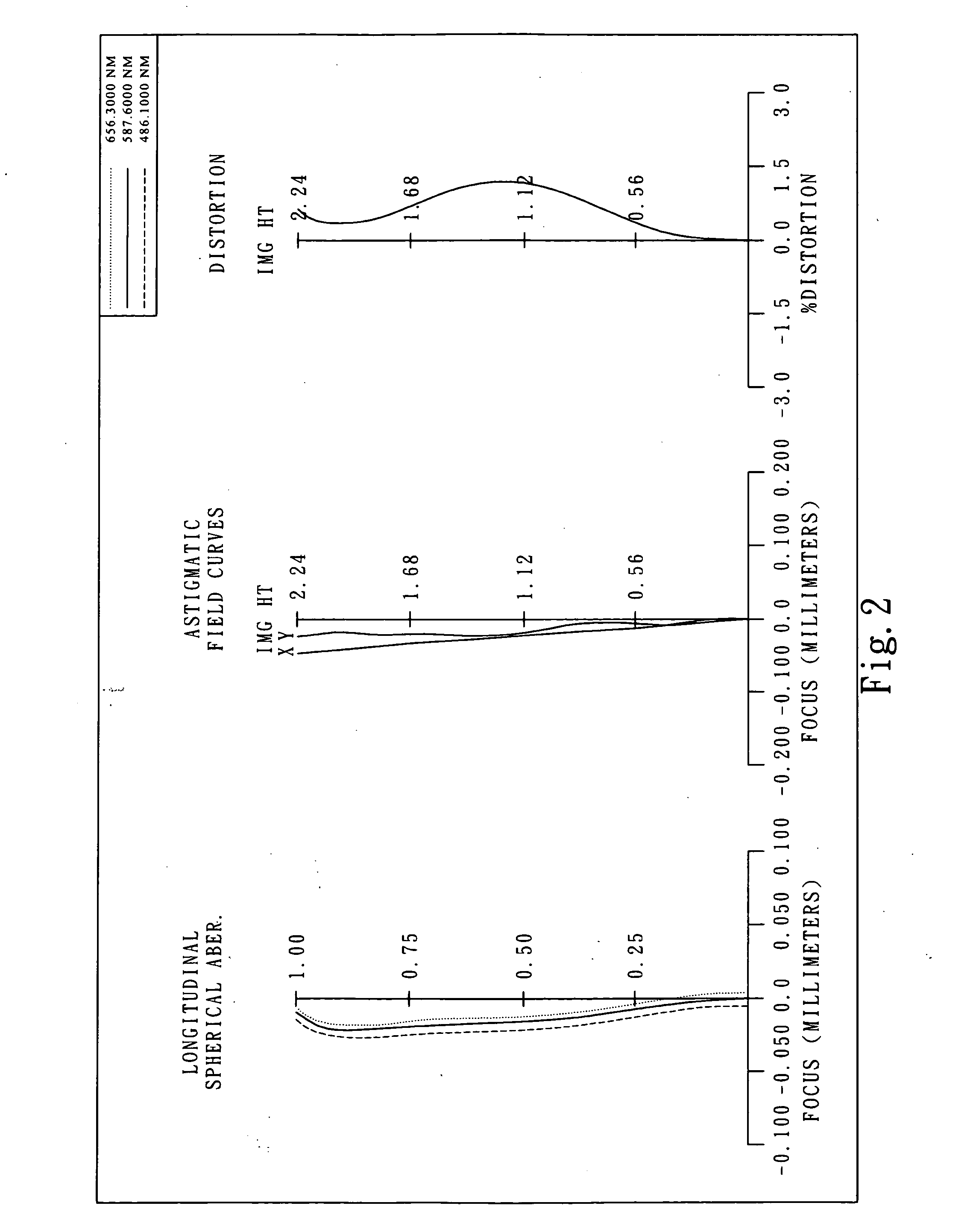

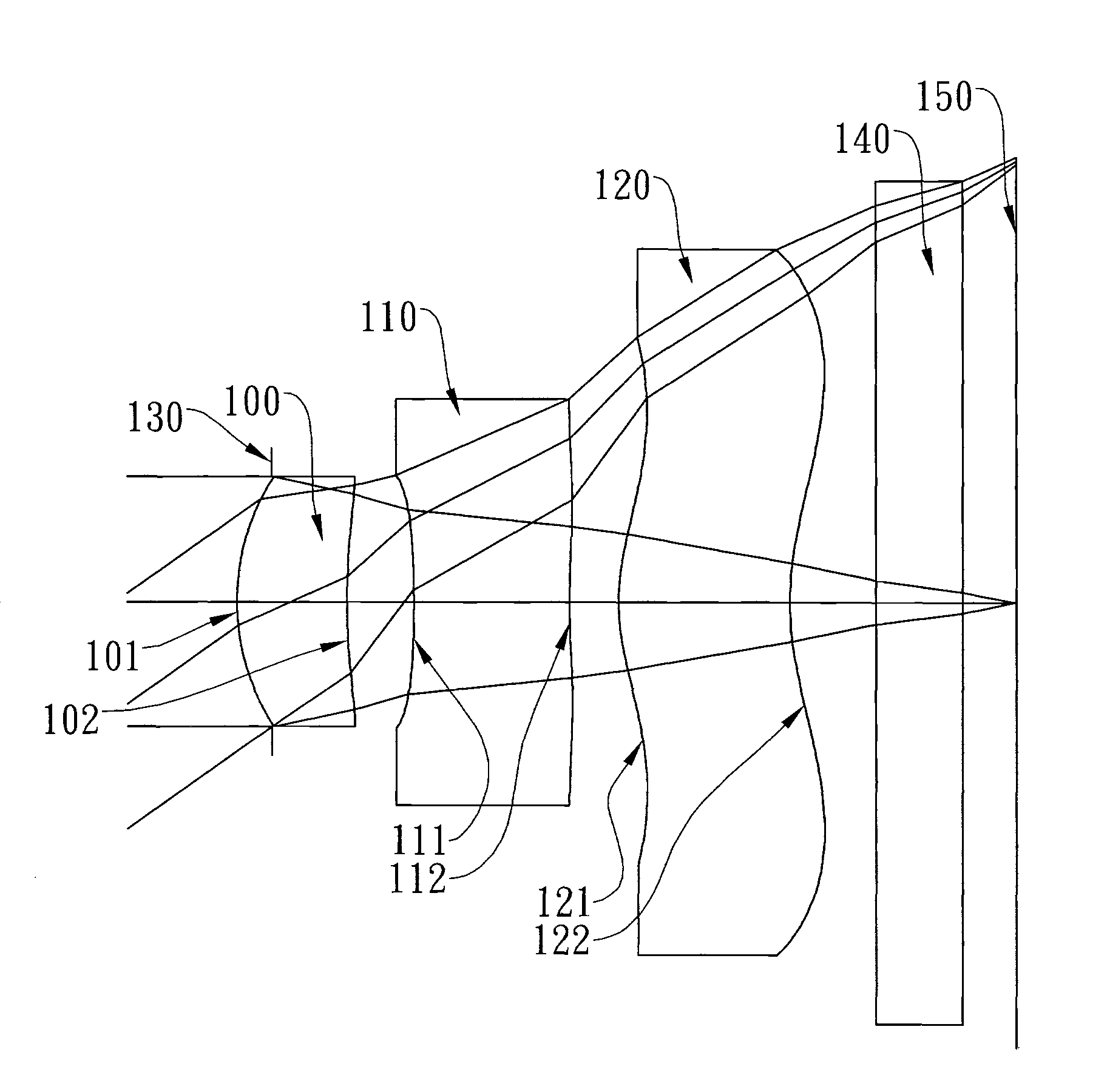

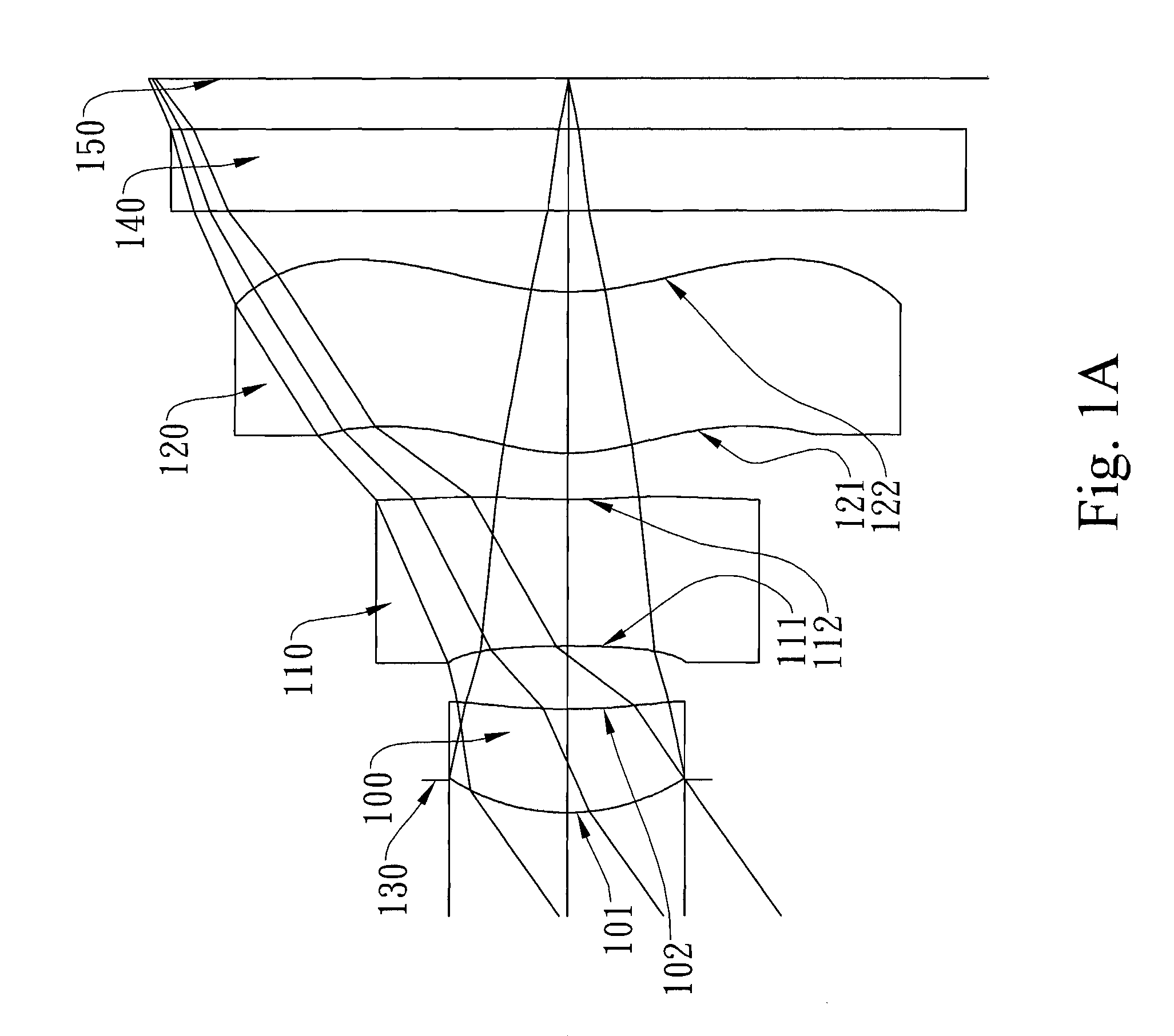

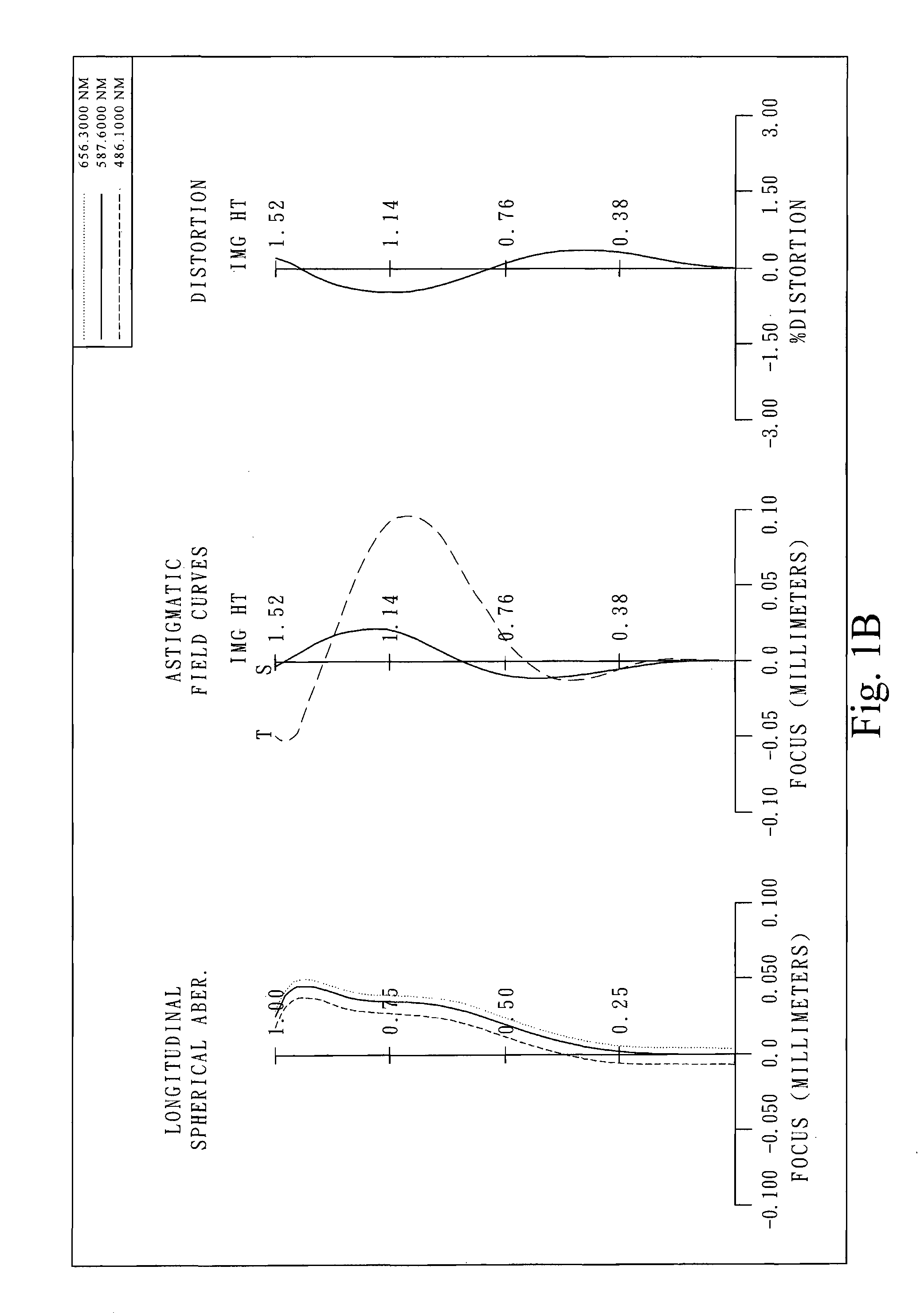

Imaging lens assembly

This invention provides an imaging lens assembly including five lens elements with refractive power, in order from an object side toward an image side: a first lens with positive refractive power having a convex object-side surface, a second lens with negative refractive power, a third lens having a concave object-side surface, a fourth lens with positive refractive power having an object-side surface and a convex image-side surface, and at least one of both surfaces thereof being aspheric, a fifth lens with negative refractive power having a concave image-side surface with at least one inflection point formed thereon. An aperture stop is positioned between an imaged object and the second lens. The imaging lens assembly further comprises an electronic sensor on which an object is imaged. With such arrangement, the size and the optical sensitivity of the lens assembly can be reduced. A high image resolution is also obtained.

Owner:LARGAN PRECISION

Method of manufacturing an optical lens

InactiveUS20050104240A1Convenient and economical methodHigh order aberrationSpectales/gogglesOptical surface grinding machinesCamera lensOptical correction

A method of manufacturing an optical lens that is configured to correct high order aberrations. One embodiment is a method of customizing optical correction in an optical system. The method includes measuring optical aberration data of the optical system. The method further includes calculating a lens definition based on the optical aberration data. Calculating the lens definition may include calculating a correction of at least one high order optical aberration. The method further includes fabricating a correcting lens based on the lens definition.

Owner:ENTERPRISE PARTNERS VI

Imaging lens assembly

ActiveUS7969664B2Reduce sensitivitySmall sizeTelevision system detailsColor television detailsConvex sideImaging lens

This invention provides an imaging lens assembly comprising: in order from an object side to an image side: a first lens with positive refractive power having a convex object-side surface and a convex image-side surface; a second lens with negative refractive power having a concave object-side surface; a third lens with positive refractive power having a convex image-side surface, at least one of both surfaces thereof being aspheric; and a fourth lens with negative refractive power having a convex object-side surface and a concave image-side surface on which at least one inflection point is formed; wherein there are four lenses with refractive power, an on-axis spacing between an aperture stop and an electronic sensor provided therein is SL, an on-axis spacing between the object-side surface of the first lens and the electronic sensor is TTL, they satisfy the relation: 0.75<SL / TTL<0.90.

Owner:LARGAN PRECISION

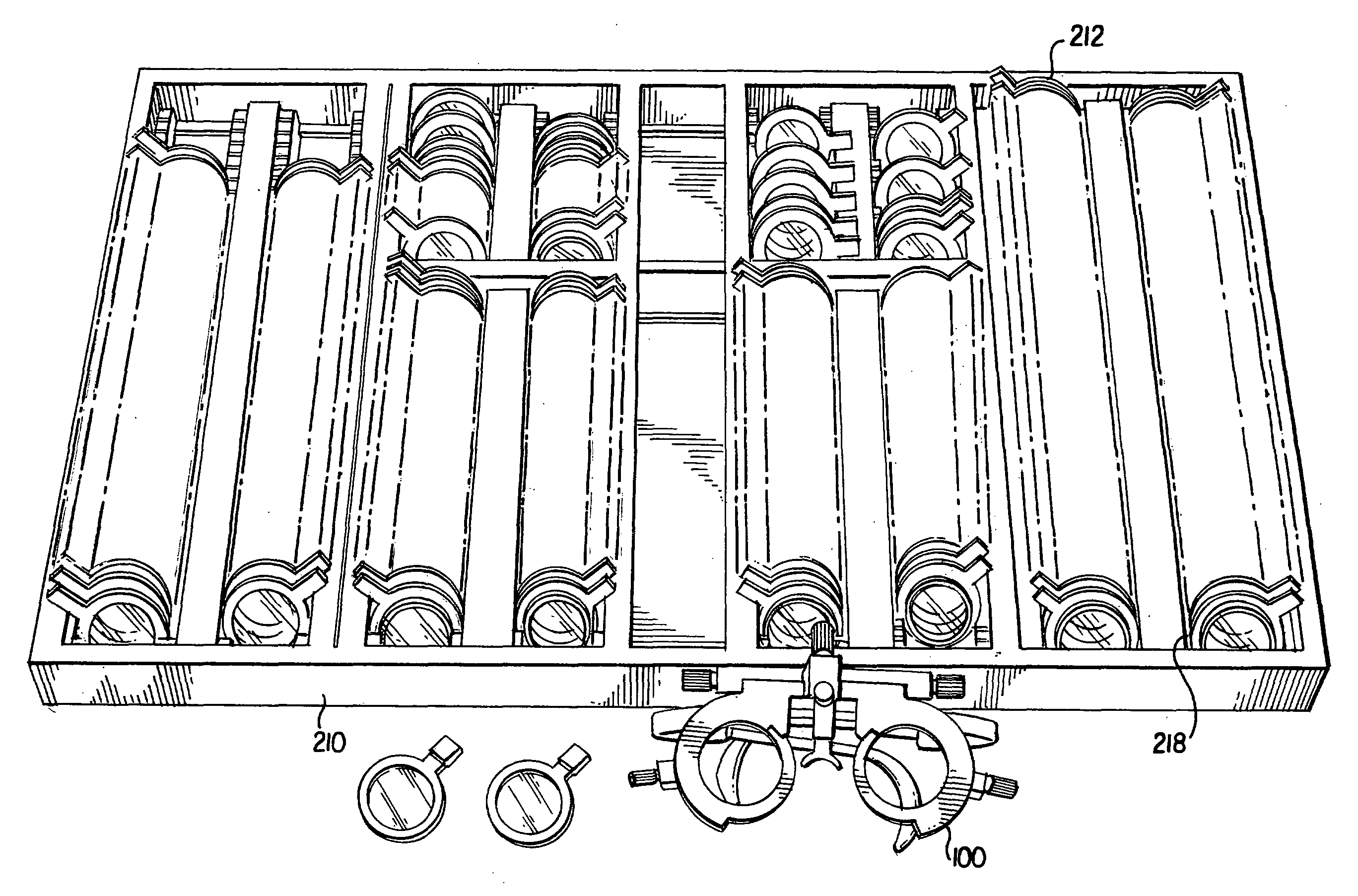

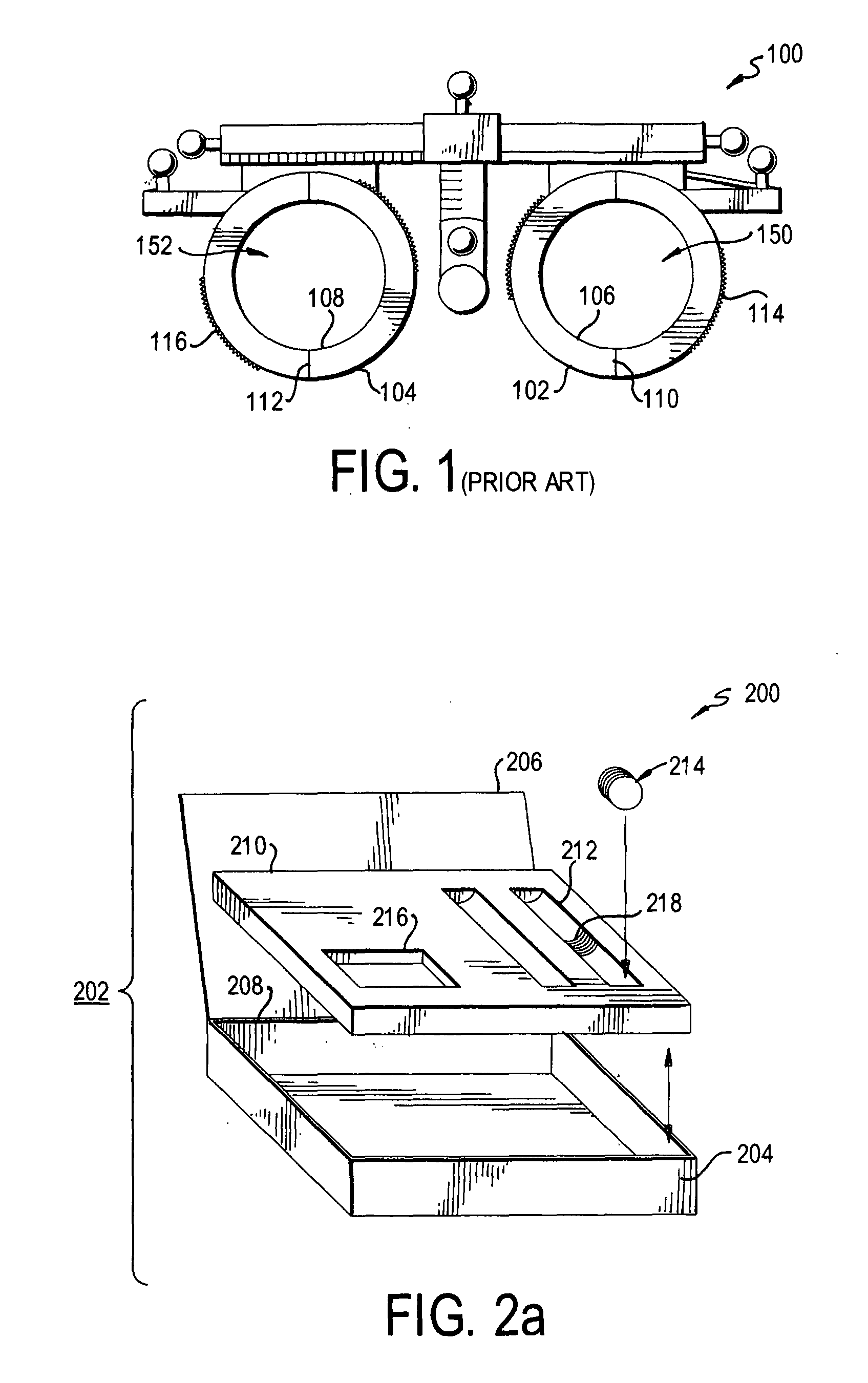

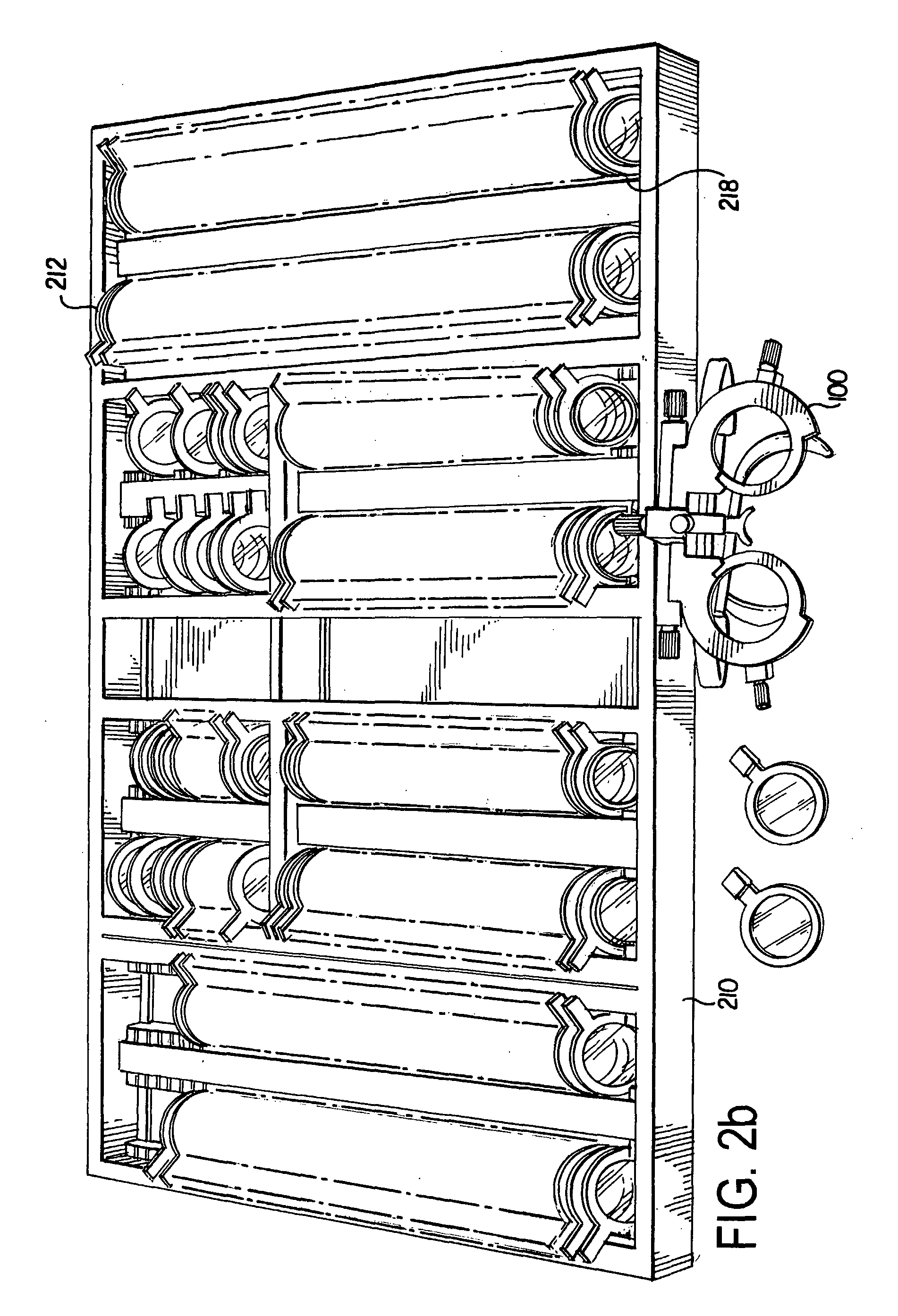

Apparatus And Method For Simulating Vision Correction

An ophthalmic diagnostic device is disclosed having a trial spectacle frame (100), phoropter (900), or other device adapted to be placed proximate a living eye of a patient, and having a set of trial lenses (300) adapted to be attached to the device. At least one of the trial lenses is adapted to correcting a higher order aberration associated with the living eye of the patient, including correcting a third, fourth and fifth higher order aberration or a combination of higher order aberrations as selected by the patient's healthcare practitioner.

Owner:UNIVERSITY OF ROCHESTER

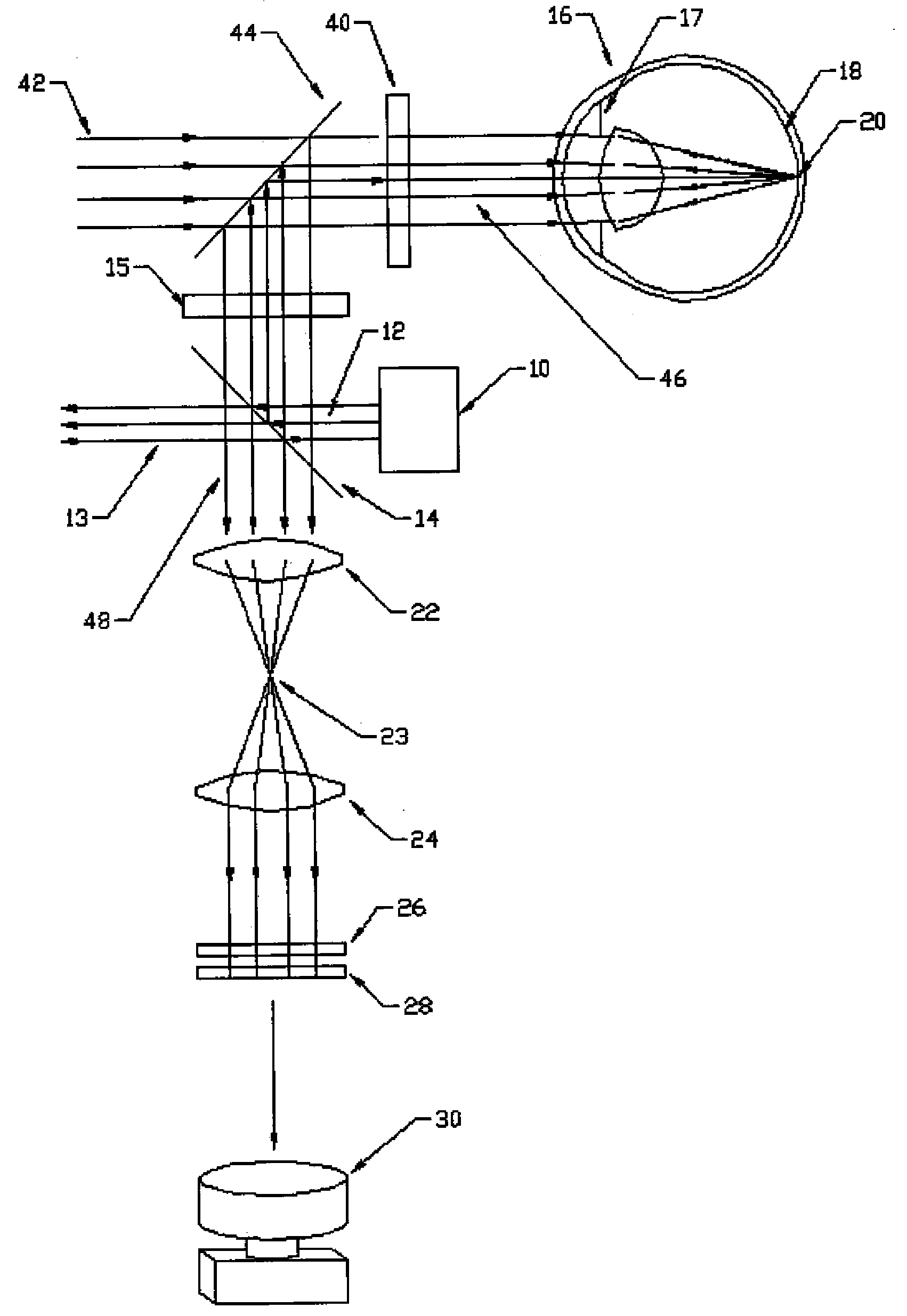

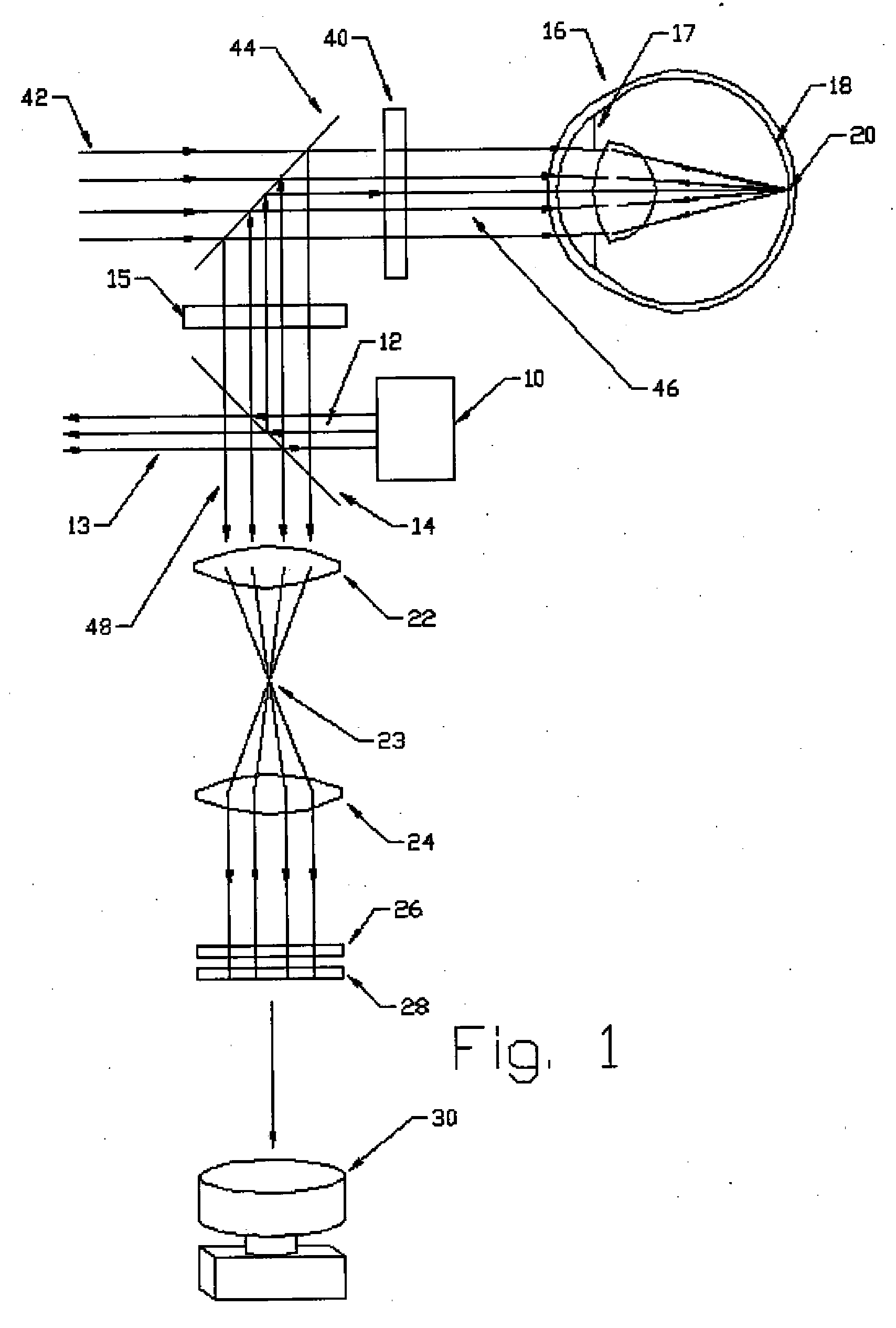

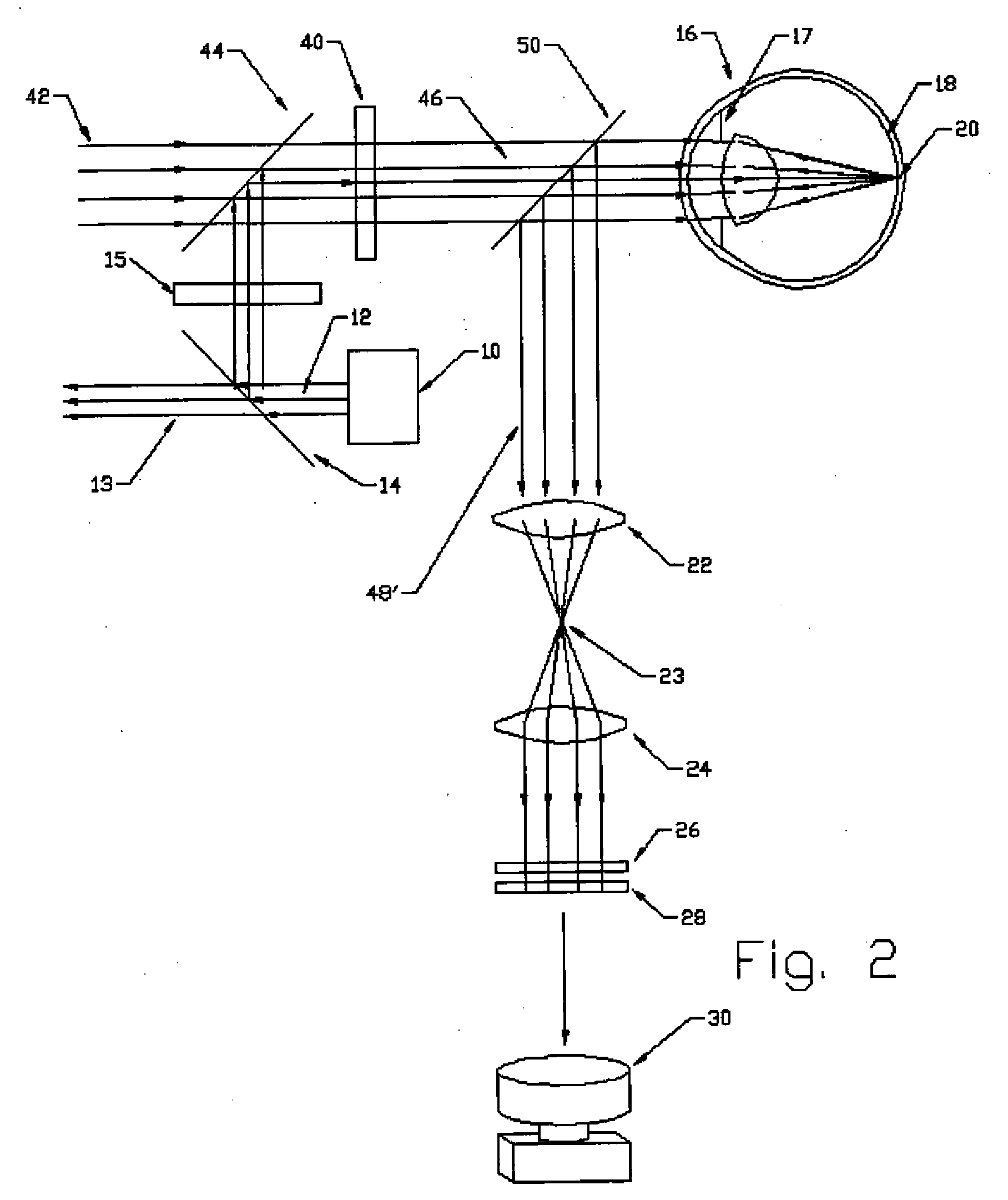

Interactive refractor incorporating wavefront sensing and adaptive optics

InactiveUS20060203196A1High order aberrationImprove visual effectsRefractometersSkiascopesPhysicsIntegrated systems

An integrated wavefront sensor and adaptive optic system includes an electroactive lens (40) positioned such that light from real world objects (42) being observed by a patient is combined, by a combiner optic (44), with a wavefront sensor illumination beam (12) into a single beam of light (46) that passes through or onto the electroactive lens (40). With this integrated system, the patient's vision may be measured and corrected, taking into account changes in the higher order aberrations that are influenced by the patient's accommodation, simultaneous to the patient observing, in real time, the refractive correction being proposed.

Owner:NOVARTIS AG

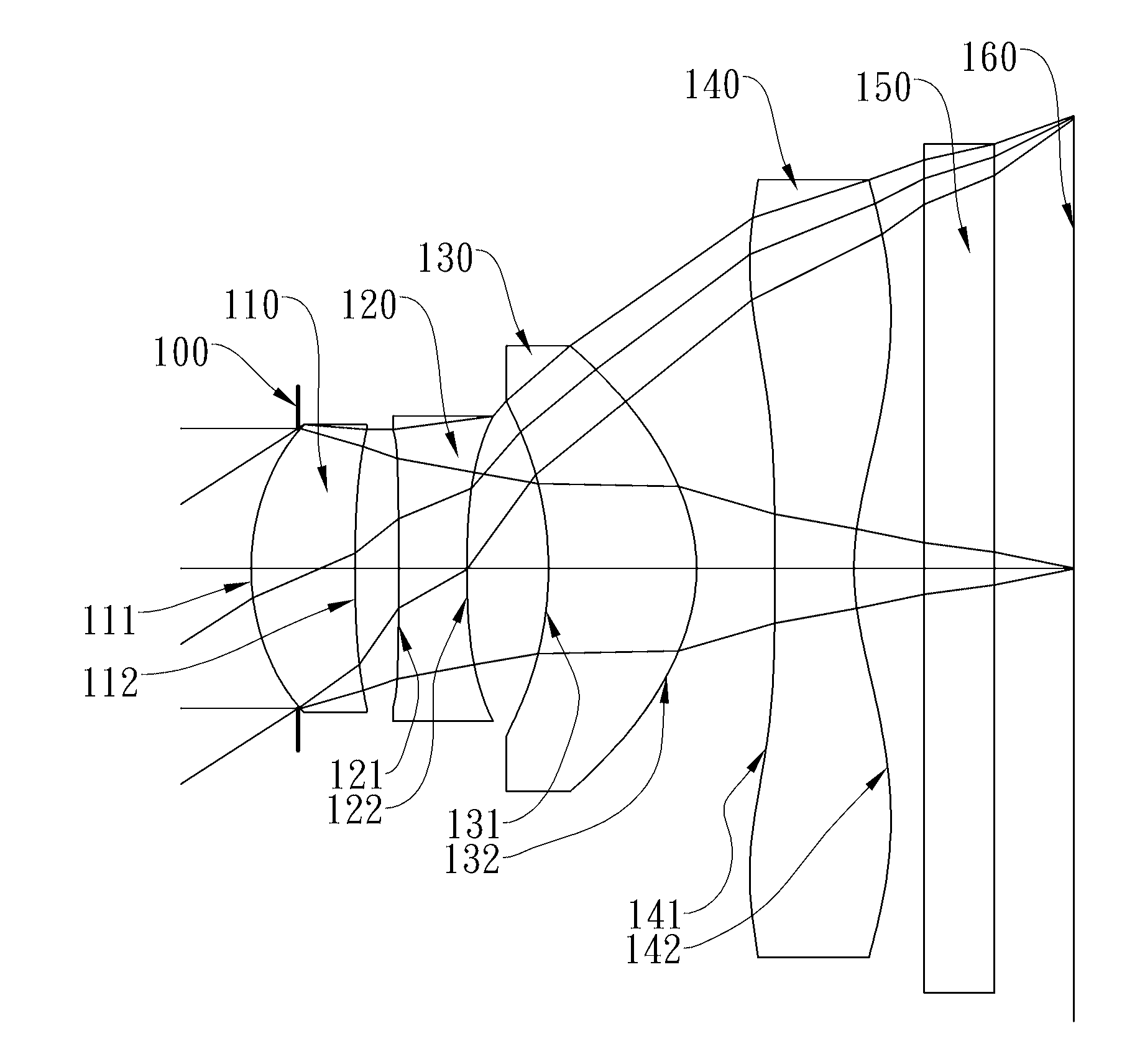

Optical imaging lens assembly

This invention provides an optical imaging lens assembly comprising five lens elements with refractive power, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power; a third lens element with negative refractive power; a fourth lens element with negative refractive power having at least one of the object-side and image-side surfaces thereof being aspheric; and a fifth lens element having a concave image-side surface, at least one of the object-side and image-side surfaces thereof being aspheric, and made of plastic. By such arrangement, photosensitivity and total track length of the optical imaging lens assembly can be reduced, and the aberration and astigmatism of the assembly can be effectively corrected. Moreover, high image resolution can be obtained.

Owner:LARGAN PRECISION

Image capturing lens assembly

ActiveUS8369029B2Improve image qualityLess powerTelevision system detailsColor television detailsOptical axisImage quality

Owner:LARGAN PRECISION

Optical imaging lens assembly

This invention provides an optical imaging lens assembly, in order from an object side toward an image side including: a first lens element with positive refractive power having a convex object-side surface, a second lens element with negative refractive power having a concave object-side surface and a concave image-side surface, a third lens element with positive refractive power having a concave object-side surface and a convex image-side surface, a fourth lens element with negative refractive power having a concave image-side surface, and the two surfaces being aspheric; wherein the optical imaging lens assembly further comprises an aperture stop disposed between an imaged object and the first lens element, and there are four lens elements with refractive power.

Owner:LARGAN PRECISION

Image pick-up optical lens assembly

This invention provides an image pick-up optical lens assembly comprising, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface and a convex image-side surface; a second lens element with negative refractive power having a concave object-side surface and a convex image-side surface; a third lens element with positive refractive power having an object-side surface and a convex image-side surface, at least one of the surfaces thereof being aspheric; and a fourth lens element with negative refractive power having a convex object-side surface and a concave image-side surface, at least one of the surfaces thereof being aspheric. The image pick-up optical lens assembly further comprises an aperture stop disposed between an object and the first lens element. Such arrangement facilitates a significant reduction in size and sensitivity of the lens assembly while providing superb image quality with higher resolution.

Owner:LARGAN PRECISION

Optical lens assembly

ActiveUS8284502B2Improve image qualitySmall sizeTelevision system detailsTelevision system scanning detailsPhysics

This invention provides an optical lens assembly comprising, in order from an object side to an image side: a first lens element with positive refractive power; a second lens element with positive refractive power; a third lens element with negative refractive power having a concave object-side surface and a convex image-side surface, at least one of the object-side and image-side surfaces thereof being aspheric; and a fourth lens element with positive refractive power having an aspheric object-side surface and an aspheric image-side surface; wherein the number of lens elements with refractive power is four.

Owner:LARGAN PRECISION

Image lens assembly

An image lens assembly includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element and a sixth lens element. The first lens element with positive refractive power has a convex object-side surface. The second lens element has refractive power. The third lens element has positive refractive power. The fourth lens element has negative refractive power. The fifth lens element with positive refractive power has a convex object-side surface and a concave image-side surface. The sixth lens element with positive refractive power has a convex object-side surface and a concave image-side surface, wherein the image-side surface thereof changes from concave at a paraxial region to convex at a peripheral region. The fifth and sixth lens elements are made of plastic, and the surfaces thereof are aspheric.

Owner:LARGAN PRECISION

Image lens assembly

An image lens assembly includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element and a sixth lens element. The first lens element with positive refractive power has a convex object-side surface. The second lens element has refractive power. The third lens element has positive refractive power. The fourth lens element has negative refractive power. The fifth lens element with positive refractive power has a convex object-side surface and a concave image-side surface. The sixth lens element with positive refractive power has a convex object-side surface and a concave image-side surface, wherein the image-side surface thereof changes from concave at a paraxial region to convex at a peripheral region. The fifth and sixth lens elements are made of plastic, and the surfaces thereof are aspheric.

Owner:LARGAN PRECISION

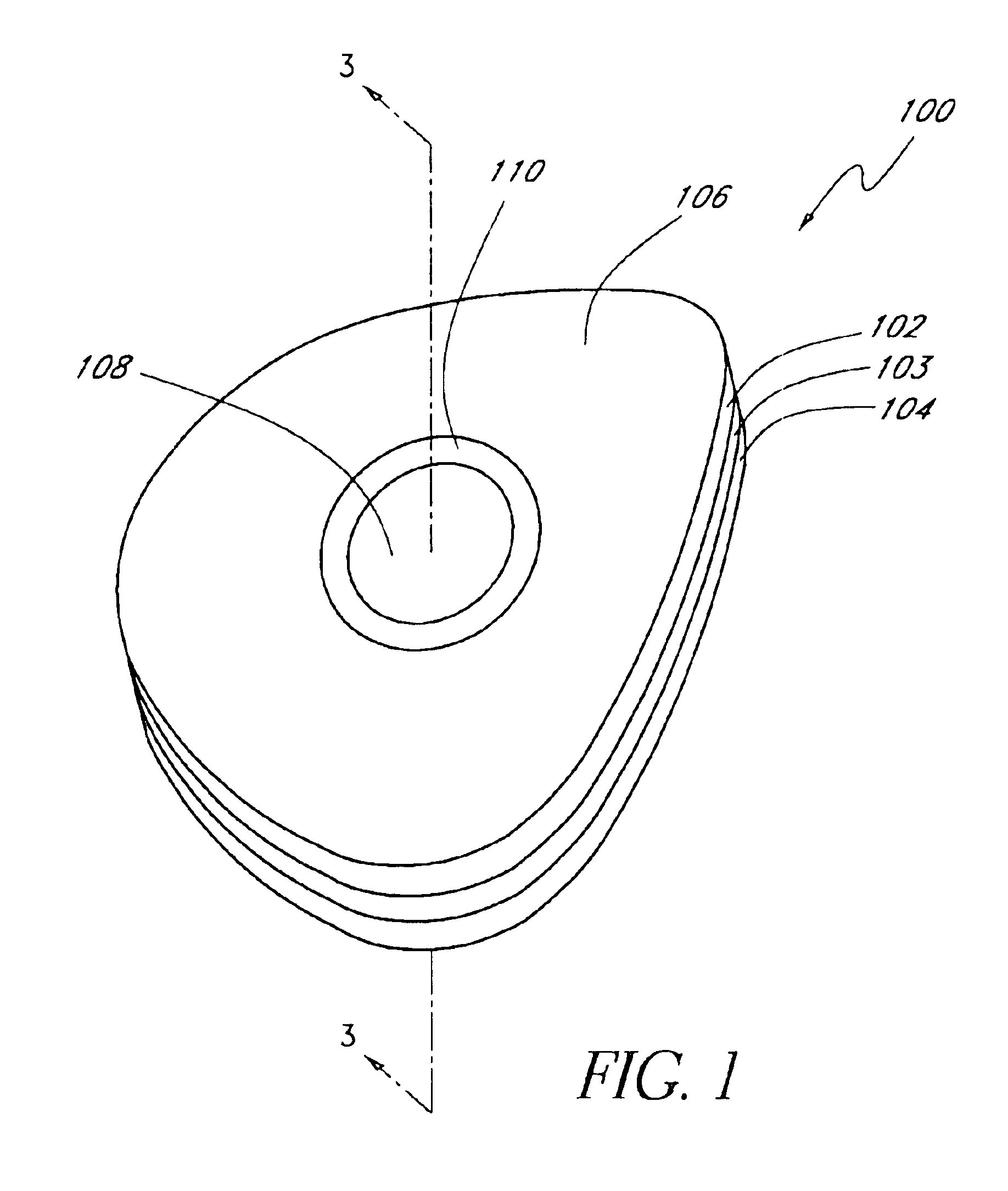

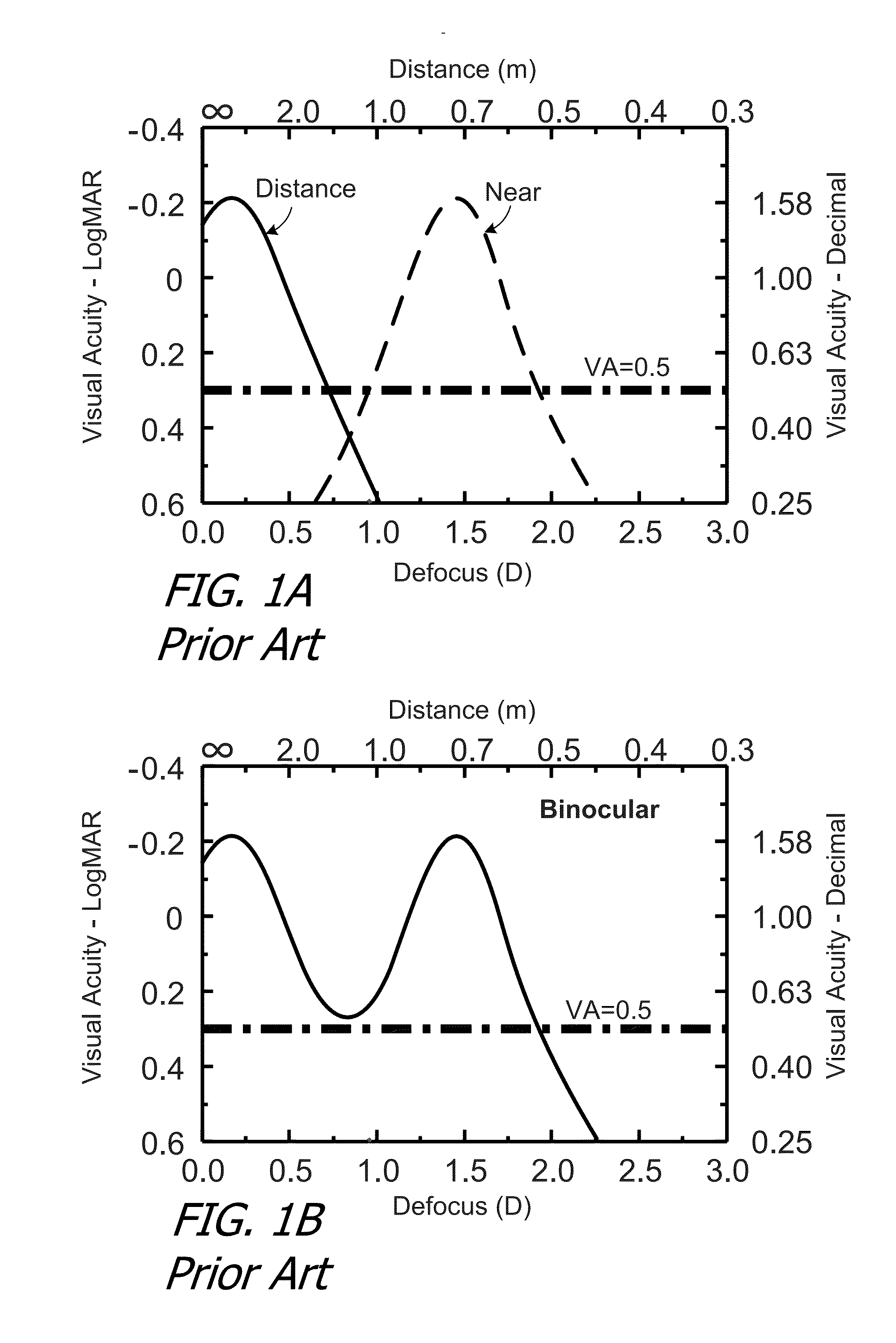

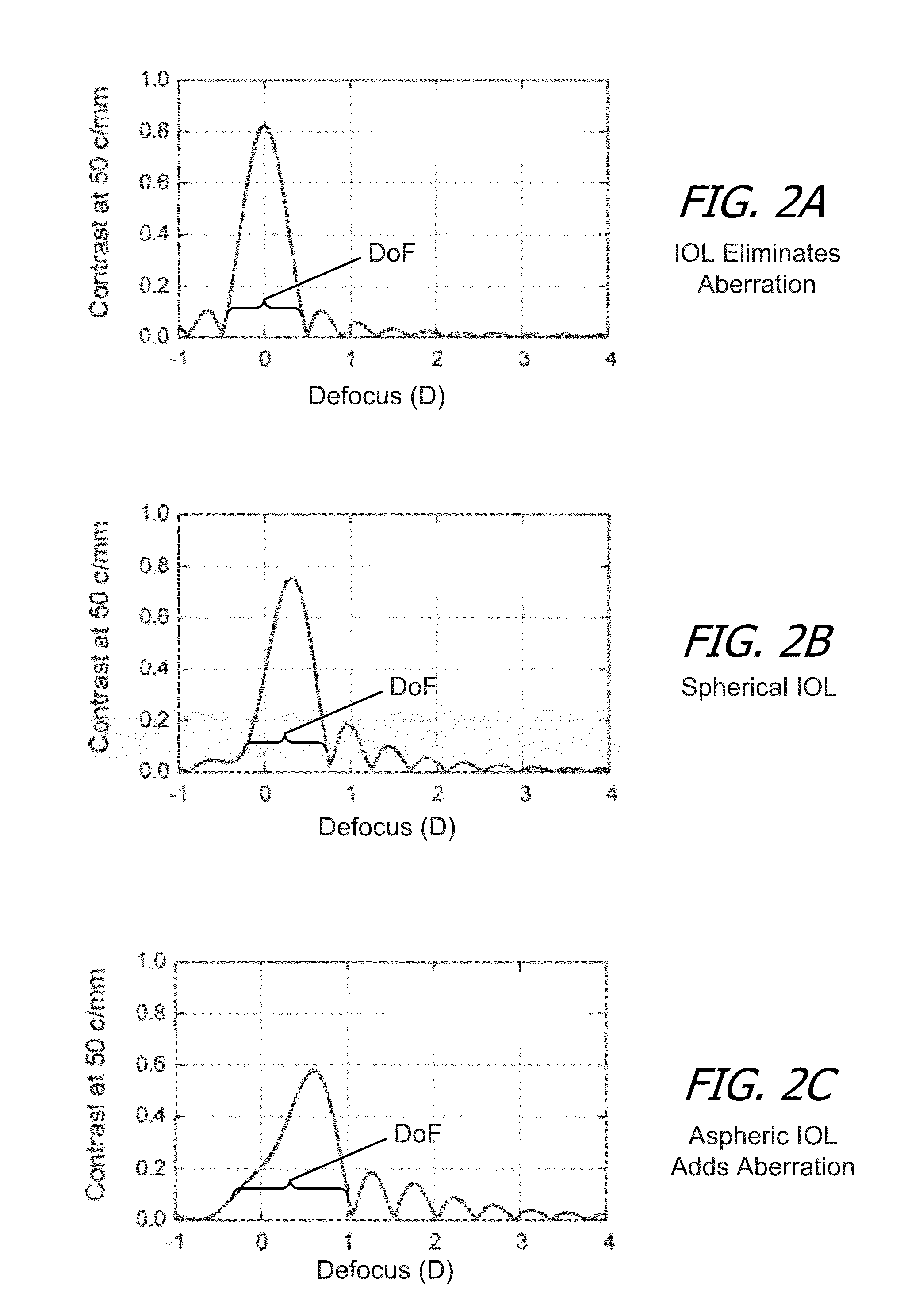

Extended Depth of Focus Intraocular Lens and Associated Methods

ActiveUS20140303725A1More spherical aberrationHigh order aberrationIntraocular lensMedicineExtended depth of focus

Owner:RAYNER INTRAOCULAR LENSES

Photographing optical lens assembly

This invention provides a photographing optical lens assembly, from an object side to an image side in order, comprising a first lens element with positive refractive power having a convex object-side surface, a second lens element with negative refractive power having a concave image-side surface, a third lens element with positive refractive power, a fourth lens element with negative refractive power having a concave image-side surface, both the two surfaces of the fourth lens thereof being aspheric. And an aperture stop is positioned between the first element and the second lens element. There are four lens elements with refractive power in the lens assembly.

Owner:LARGAN PRECISION

Image lens system

This invention provides an image lens system comprising: a first lens element with positive refractive power; a second lens element with negative refractive power having a concave object-side surface and a concave image-side surface, both the object-side and image-side surfaces thereof being aspheric and made of plastic; a third lens element with positive refractive power; and a fourth lens element with negative refractive power, and at least one inflection point is formed on at least one of the object-side and image-side surfaces thereof; wherein, the region of the image-side surface of the second lens element near the optical axis is concave, but the off-axis region thereof is convex. By such arrangement, not only the photosensitivity and total track length of the system can be reduced, but also better image quality can be obtained.

Owner:LARGAN PRECISION

Image capturing lens assembly

This invention provides an image capturing lens assembly in order from an object side to an image side comprising: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power; a third lens element with negative refractive power having a concave object-side surface; a fourth lens element having a concave object-side surface and a convex image-side surface; and a fifth lens element having a concave image-side surface, the object-side and image-side surfaces thereof being aspheric and at least one inflection point being formed on at least one of the object-side and image-side surfaces thereof. By such arrangement, it can effectively reduce the aberration as well as the total track length of the imaging lens system for obtaining higher image resolution.

Owner:LARGAN PRECISION

Imaging lens assembly

ActiveUS20110075271A1Reduce sensitivitySmall sizeTelevision system detailsColor television detailsConvex sideImaging lens

This invention provides an imaging lens assembly comprising: in order from an object side to an image side: a first lens with positive refractive power having a convex object-side surface and a convex image-side surface; a second lens with negative refractive power having a concave object-side surface; a third lens with positive refractive power having a convex image-side surface, at least one of both surfaces thereof being aspheric; and a fourth lens with negative refractive power having a convex object-side surface and a concave image-side surface on which at least one inflection point is formed; wherein there are four lenses with refractive power, an on-axis spacing between an aperture stop and an electronic sensor provided therein is SL, an on-axis spacing between the object-side surface of the first lens and the electronic sensor is TTL, they satisfy the relation: 0.75<SL / TTL<0.90.

Owner:LARGAN PRECISION

Photographing optical lens assembly

This invention provides a photographing optical lens assembly, from an object side to an image side in order, comprising a first lens element with positive refractive power having a convex object-side surface, a second lens element with negative refractive power having a concave image-side surface, a third lens element with positive refractive power, a fourth lens element with negative refractive power having a concave image-side surface, both the two surfaces of the fourth lens thereof being aspheric. And an aperture stop is positioned between the first element and the second lens element. There are four lens elements with refractive power in the lens assembly.

Owner:LARGAN PRECISION

Optical imaging lens assembly

ActiveUS8194172B2Shorten the trackReduce optical sensitivityTelevision system detailsColor television detailsImaging qualityImage quality

Owner:LARGAN PRECISION

Photographing optical lens assembly

This invention provides a photographing optical lens assembly from an object side toward an image side in order including a first lens element with negative refractive power having a concave image-side surface, a second lens element with positive refractive power having the object-side surface and the image-side surface being convex, a third lens element with negative refractive power having a concave image-side surface and both surfaces thereof being aspheric. An aperture stop is positioned between the first and the second lens elements. An electronic photo sensor is positioned at the image plane. There are three lens elements with refractive power in the photographing optical lens assembly.

Owner:LARGAN PRECISION

Optical imaging lens assembly

Owner:LARGAN PRECISION

Photographing optical lens assembly

Owner:LARGAN PRECISION

Photographing optical system

ActiveUS20120140105A1Shorten the lengthReduce photosensitivityTelevision system detailsColor television detailsImage resolutionOptic system

This invention provides a photographing optical system, in order from an object side to an image side comprising: a first lens element with positive refractive power having a convex object-side surface and concave image-side surface; a second lens element with negative refractive power; a third lens element with positive refractive power having a concave object-side surface and a convex image-side surface; and a fourth lens element with negative refractive power having a concave image-side surface and both the object-side and image-side surfaces thereof being aspheric; wherein the photographing optical system has four lens elements with refractive power. By such arrangement, the total track length and photosensitivity of the photographing optical system can be effectively reduced, and high image resolution can be obtained.

Owner:LARGAN PRECISION

Photographing optical system

ActiveUS8456766B2Shorten the lengthReduce photosensitivityTelevision system detailsColor television detailsImage resolutionOptic system

This invention provides a photographing optical system, in order from an object side to an image side comprising: a first lens element with positive refractive power having a convex object-side surface and concave image-side surface; a second lens element with negative refractive power; a third lens element with positive refractive power having a concave object-side surface and a convex image-side surface; and a fourth lens element with negative refractive power having a concave image-side surface and both the object-side and image-side surfaces thereof being aspheric; wherein the photographing optical system has four lens elements with refractive power. By such arrangement, the total track length and photosensitivity of the photographing optical system can be effectively reduced, and high image resolution can be obtained.

Owner:LARGAN PRECISION

Image lens system

This invention provides an image lens system comprising: a first lens element with positive refractive power; a second lens element with negative refractive power having a concave object-side surface and a concave image-side surface, both the object-side and image-side surfaces thereof being aspheric and made of plastic; a third lens element with positive refractive power; and a fourth lens element with negative refractive power, and at least one inflection point is formed on at least one of the object-side and image-side surfaces thereof; wherein, the region of the image-side surface of the second lens element near the optical axis is concave, but the off-axis region thereof is convex. By such arrangement, not only the photosensitivity and total track length of the system can be reduced, but also better image quality can be obtained.

Owner:LARGAN PRECISION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com