Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1033results about How to "Increase photosensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photoresist cross-linker and photoresist composition comprising the same

InactiveUS6368773B1Enhance the imageAdequate resultOrganic chemistryPhotosensitive materialsCarboxylic acidKetone

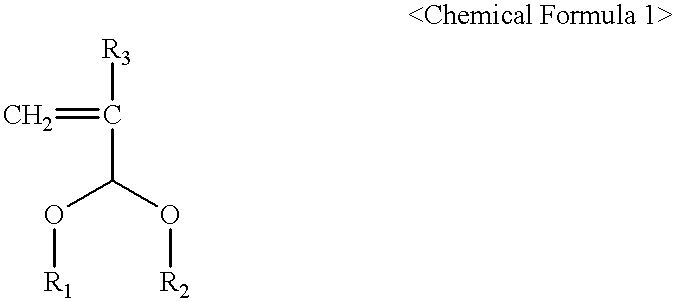

The present invention relates to a cross-linker for photoresist compositions which is suitable for a photolithography process using KrF (248 mn), ArF (193 mn), E-beam, ion beam or EUV light sources. Preferred cross-linkers, according to the present invention, comprise a copolymer of (i) a compound represented by following Chemical Formula 1 and / or (ii) one or more compound(s) selected from the group consisting of acrylic acid, methacrylic acid and maleic anhydride. ##STR1## wherein, R.sub.1 and R.sub.2 individually represent straight or branched C.sub.1-10 alkyl, straight or branched C.sub.1-10 ester, straight or branched C.sub.1-10 ketone, straight or branched C.sub.1-10 carboxylic acid, straight or branched C.sub.1-10 acetal, straight or branched C.sub.1-10 alkyl including at least one hydroxyl group, straight or branched C.sub.1-10 ester including at least one hydroxyl group, straight or branched C.sub.1-10 ketone including at least one hydroxyl group, straight or branched C.sub.1-10 carboxylic acid including at least one hydroxyl group, and straight or branched C.sub.1-10 acetal including at least one hydroxyl group; and R.sub.3 represents hydrogen or methyl.

Owner:HYUNDAI ELECTRONICS IND CO LTD

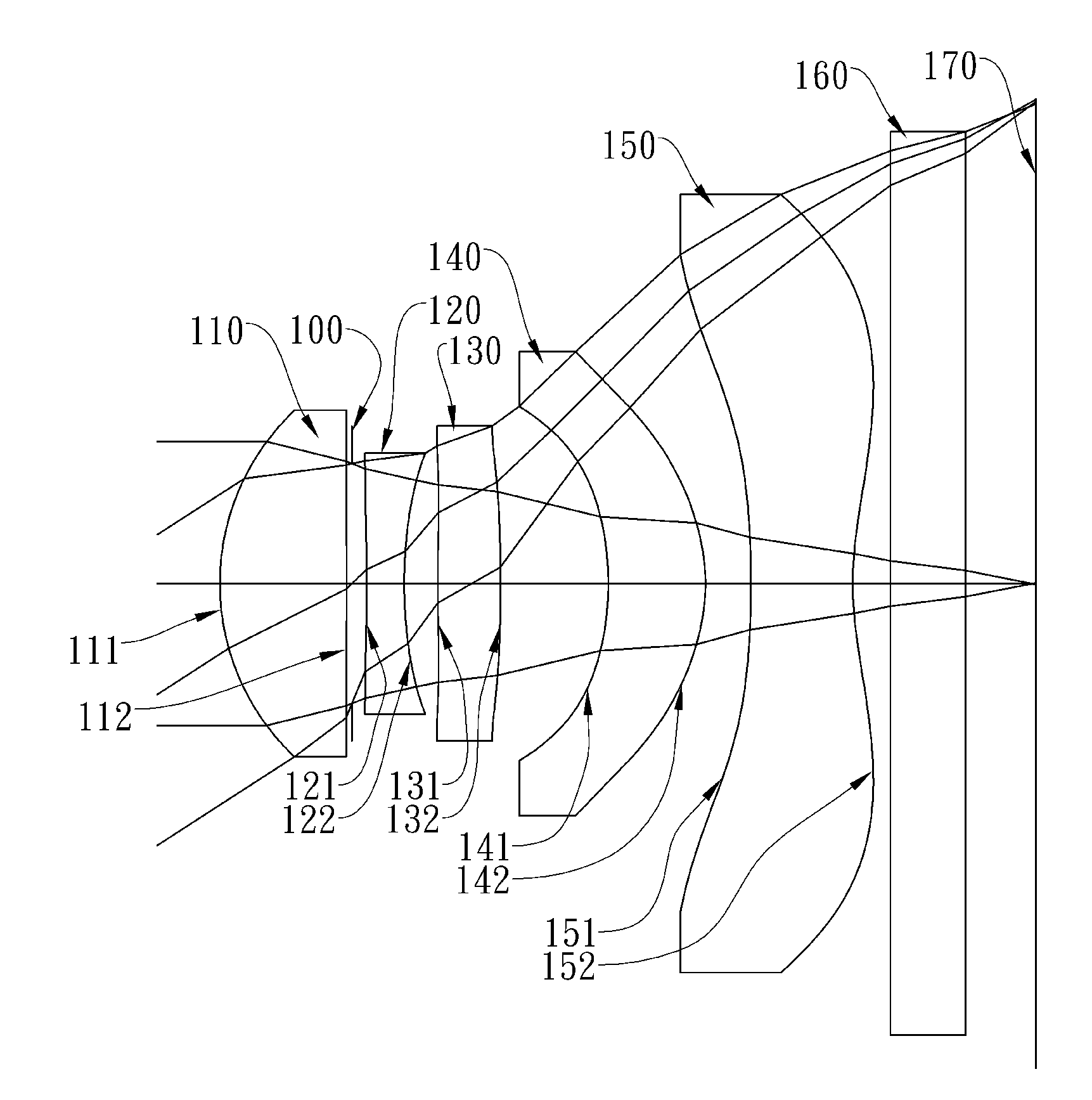

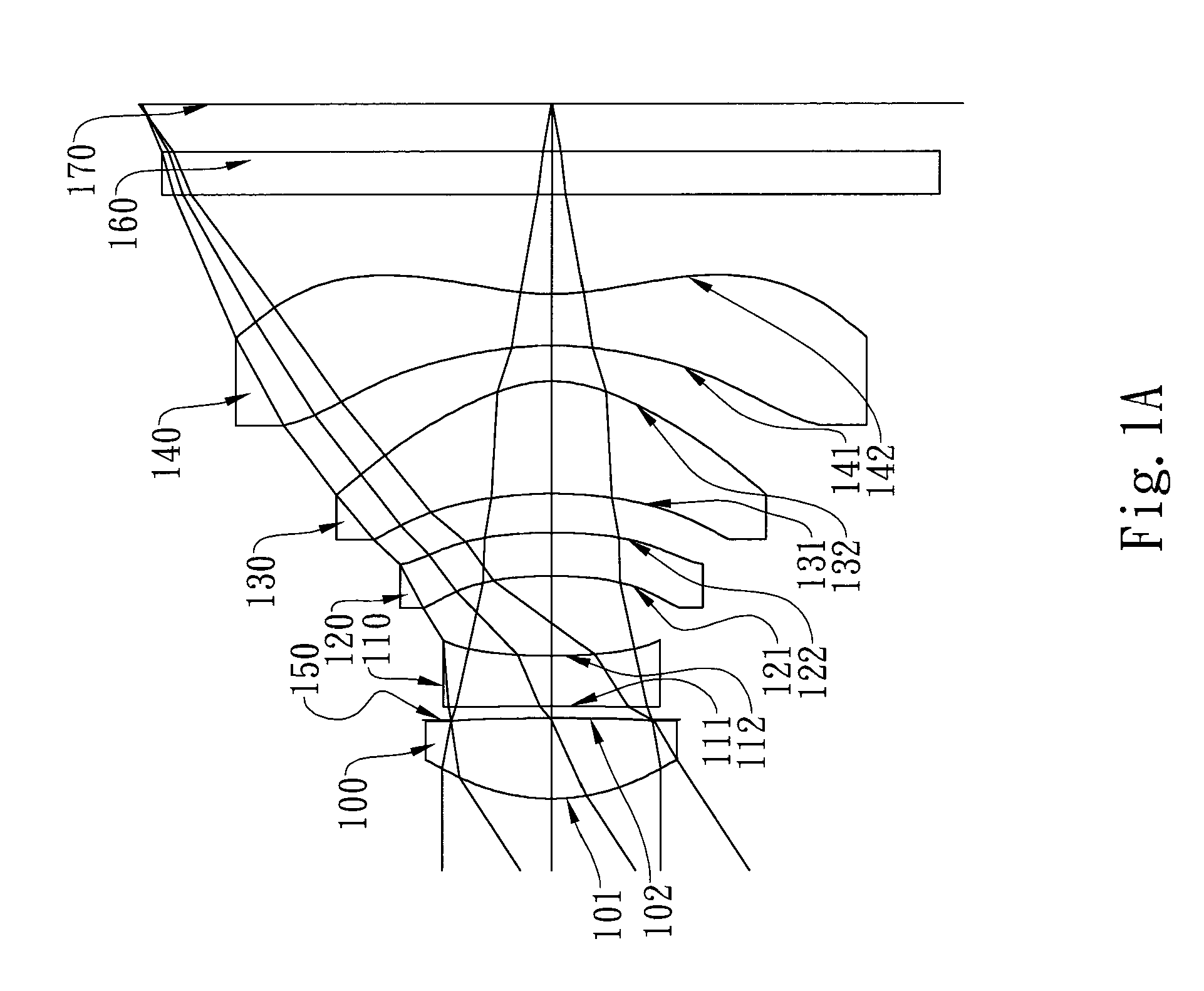

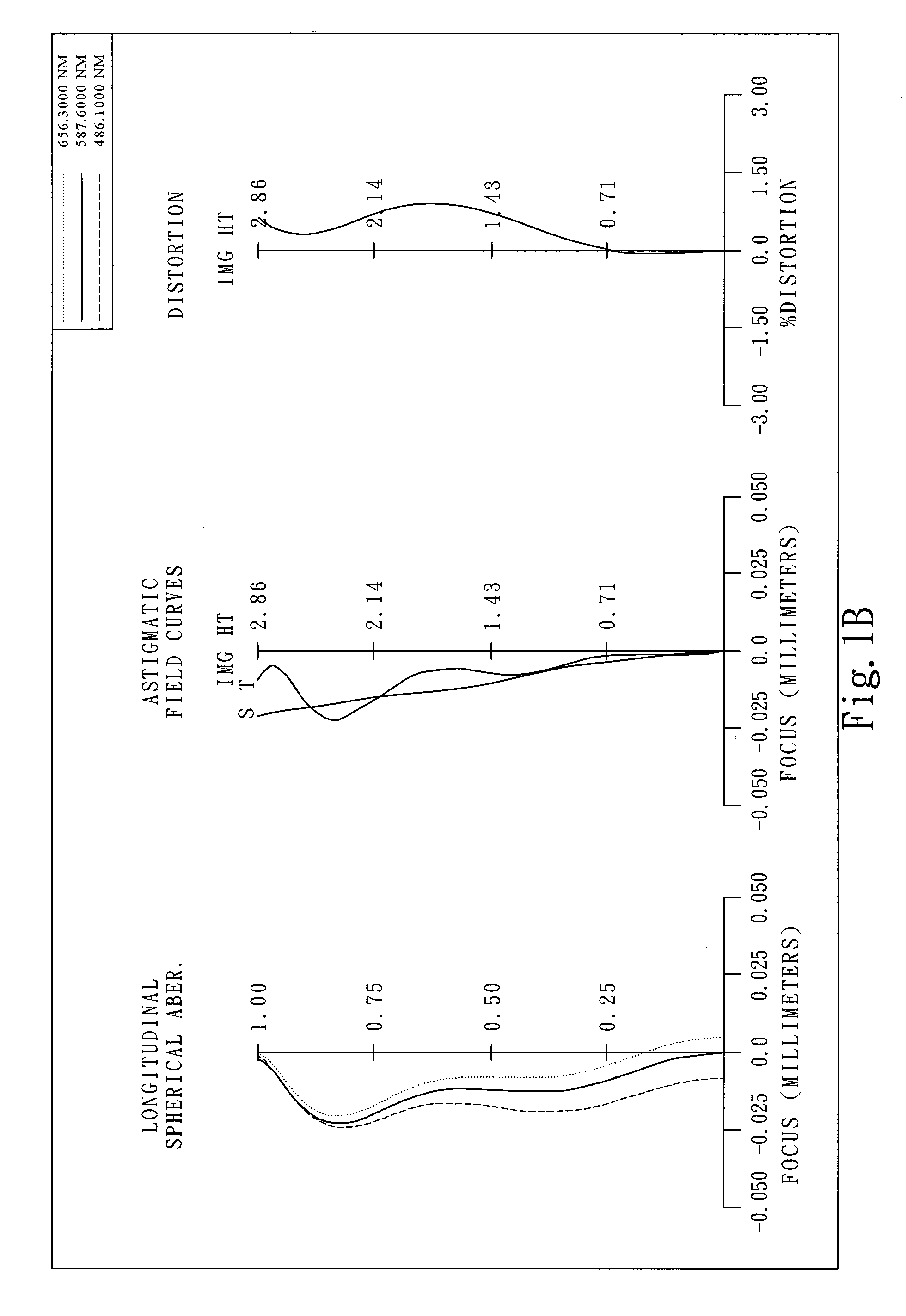

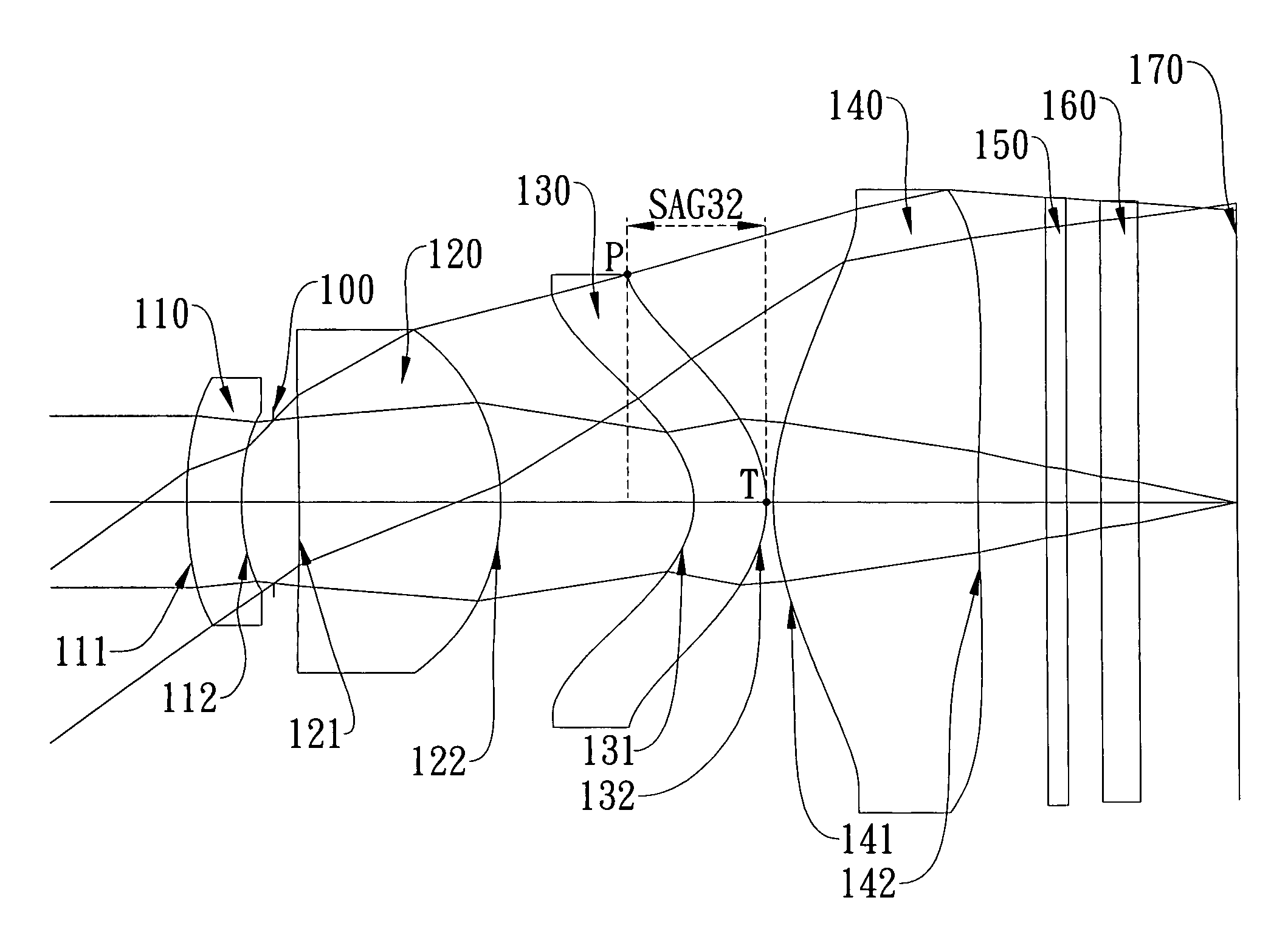

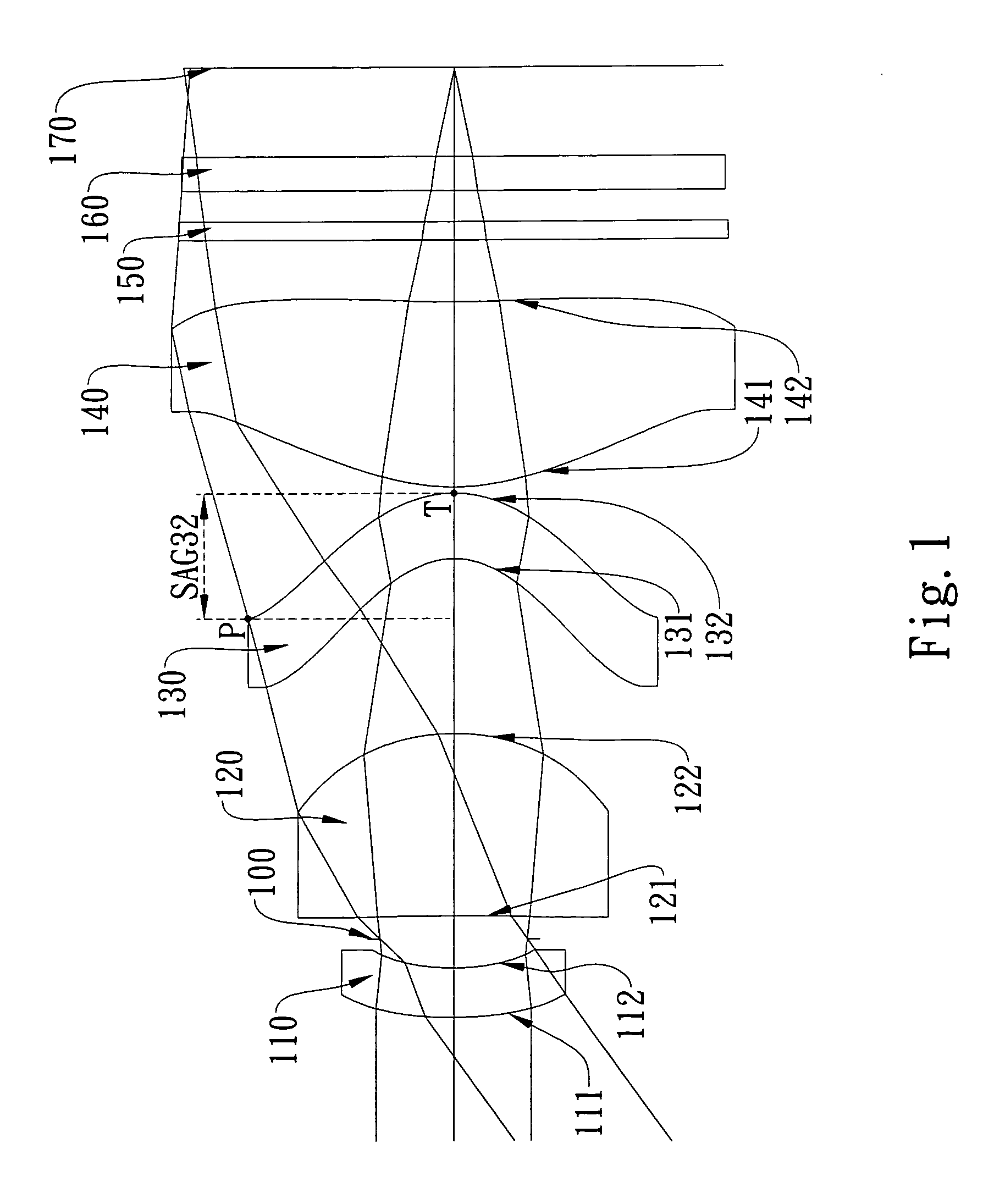

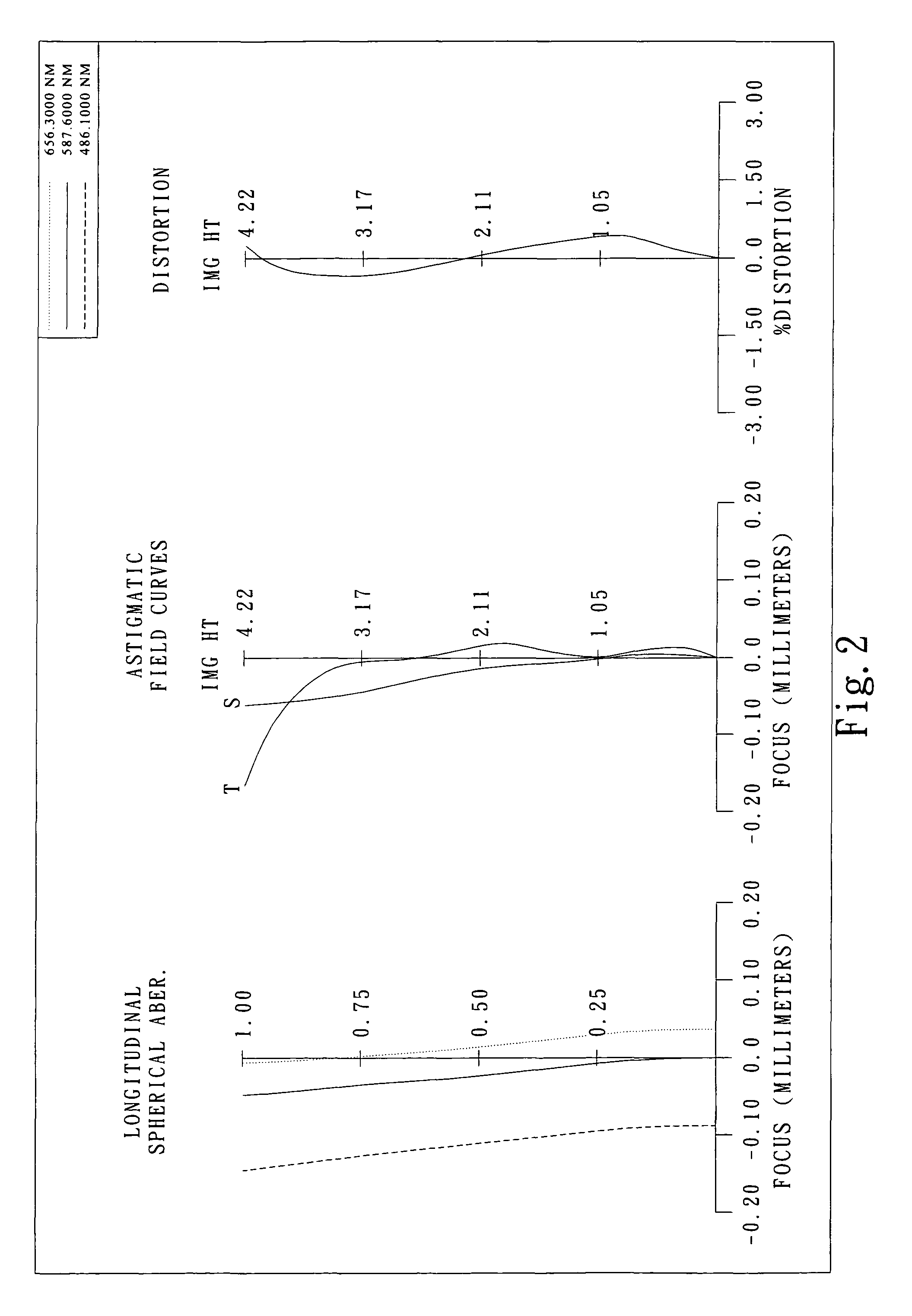

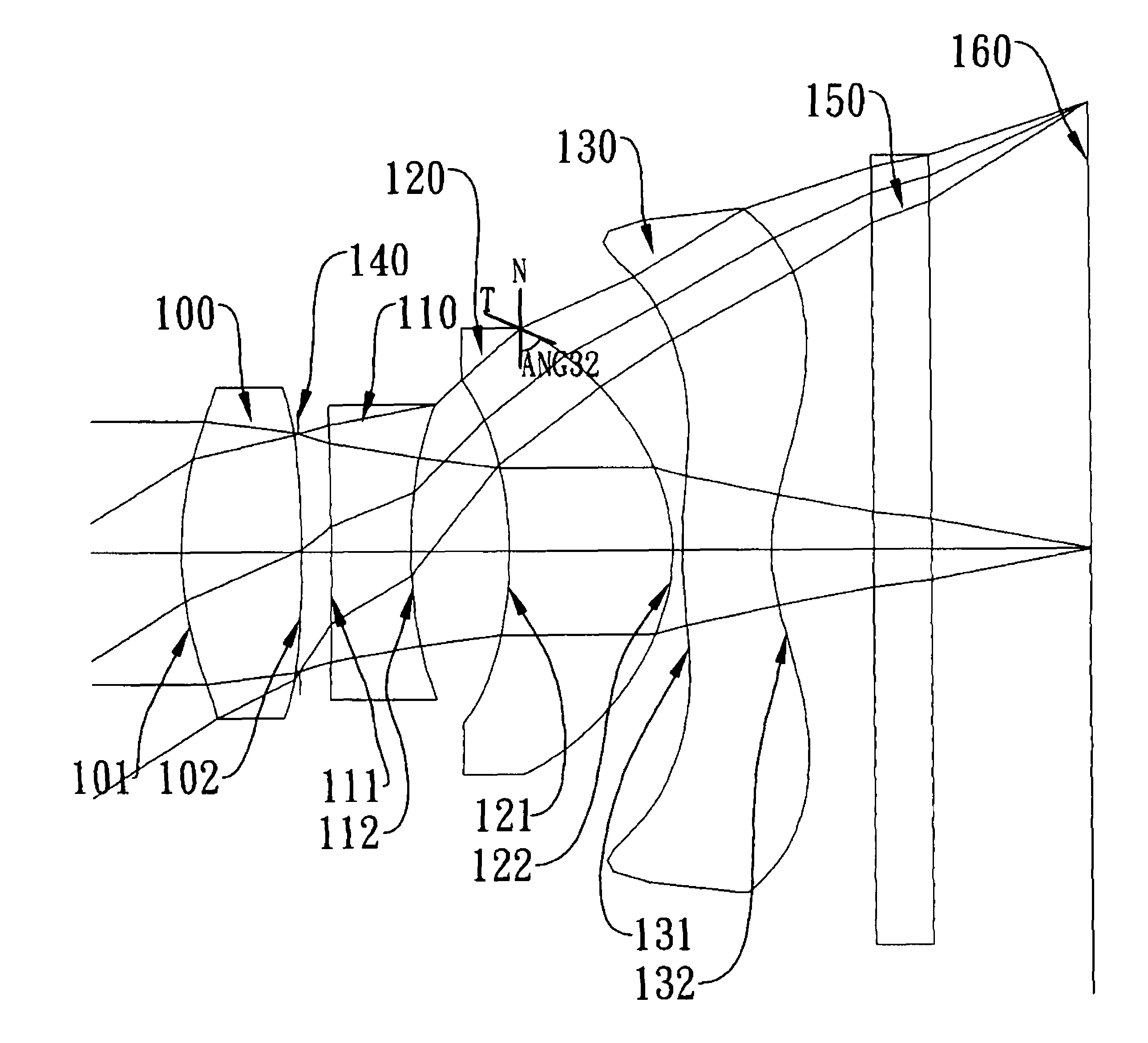

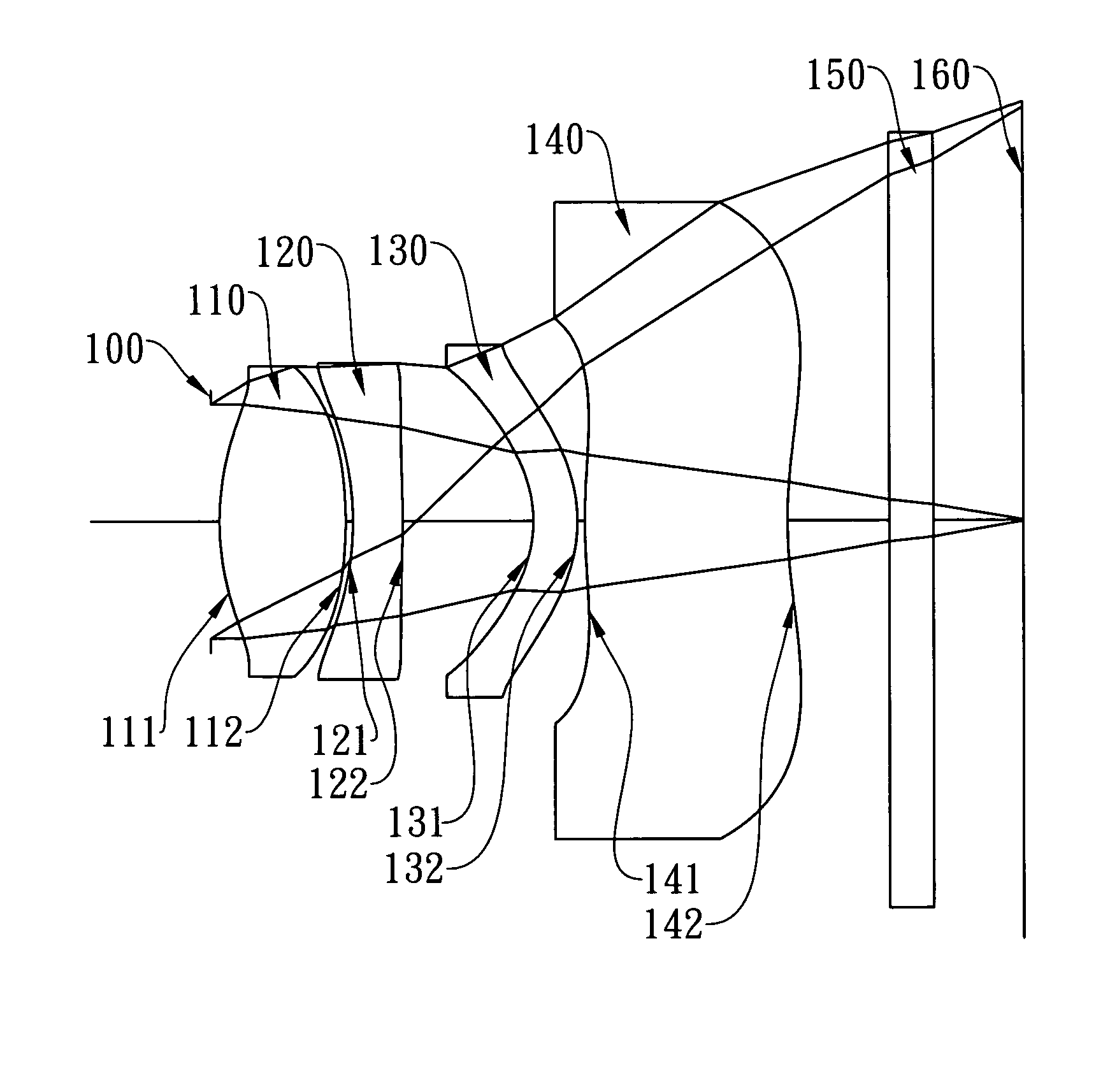

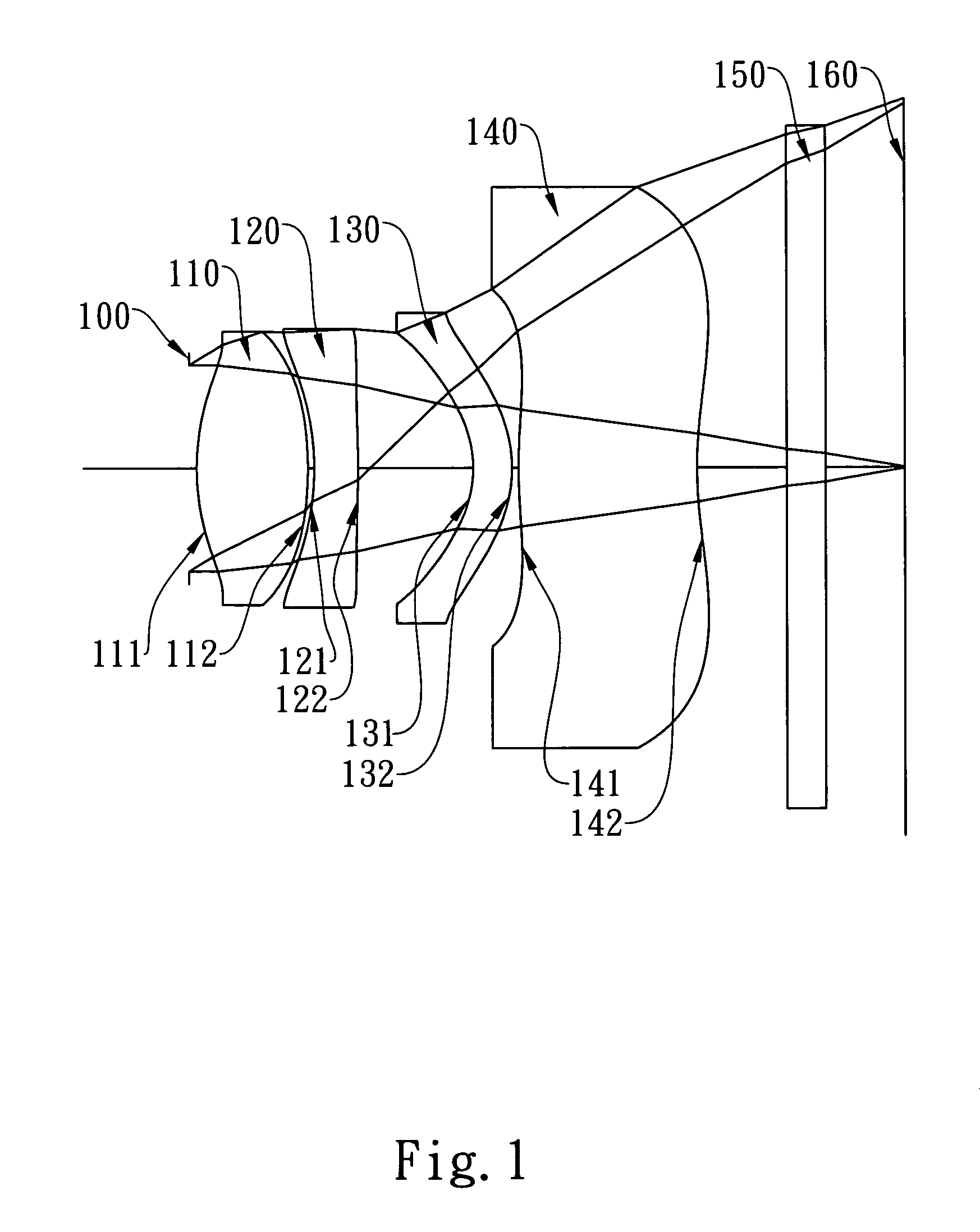

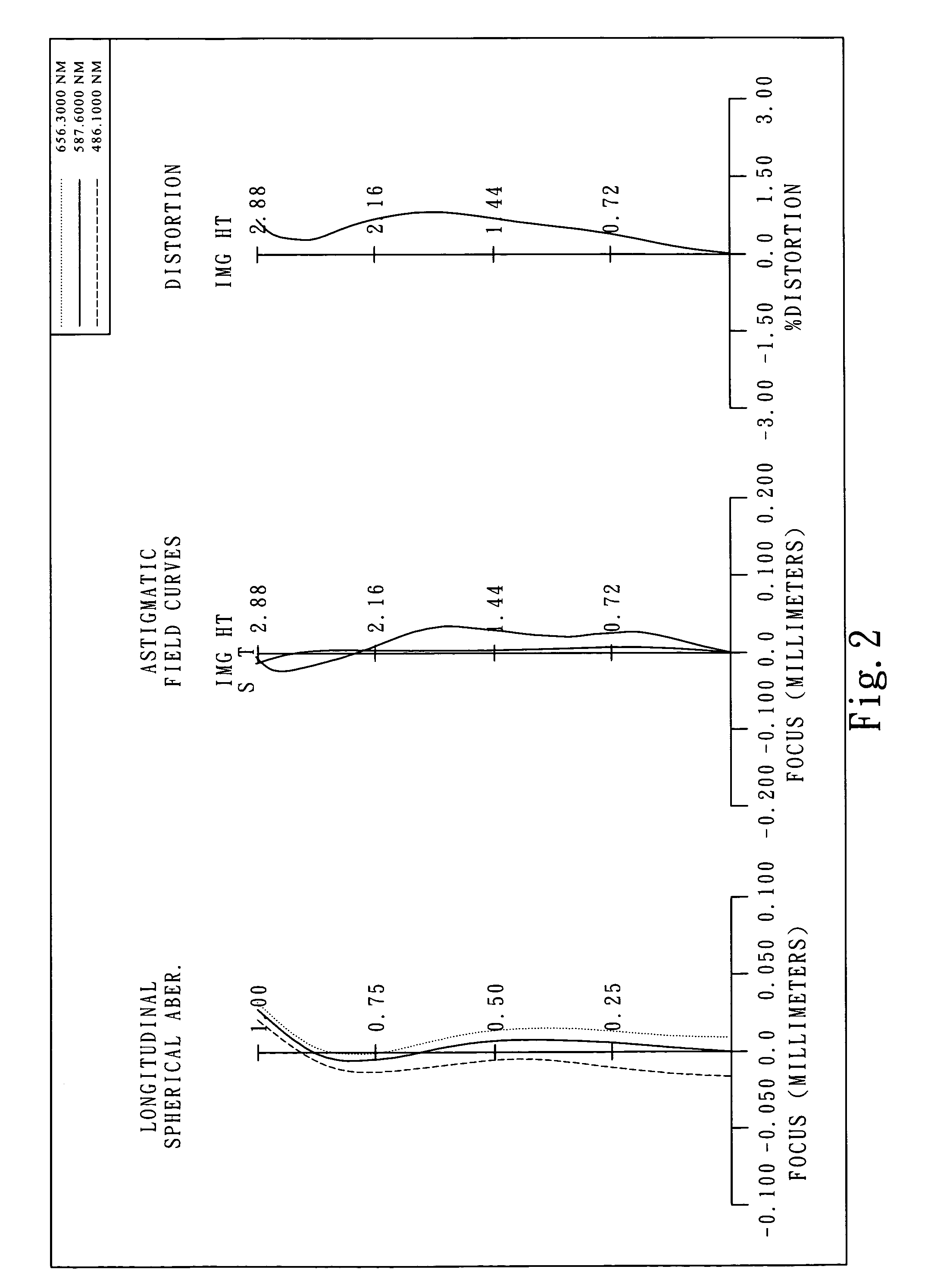

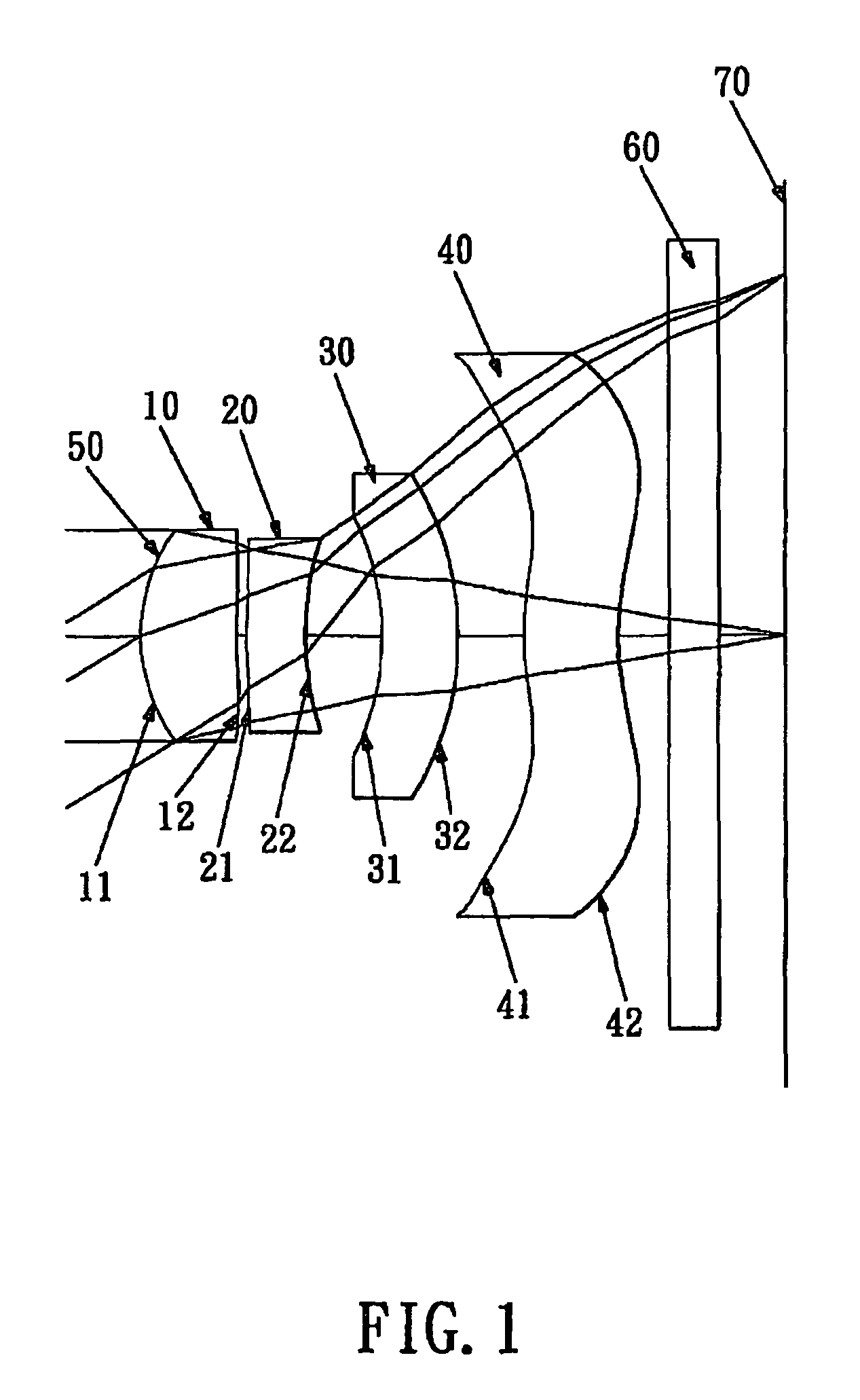

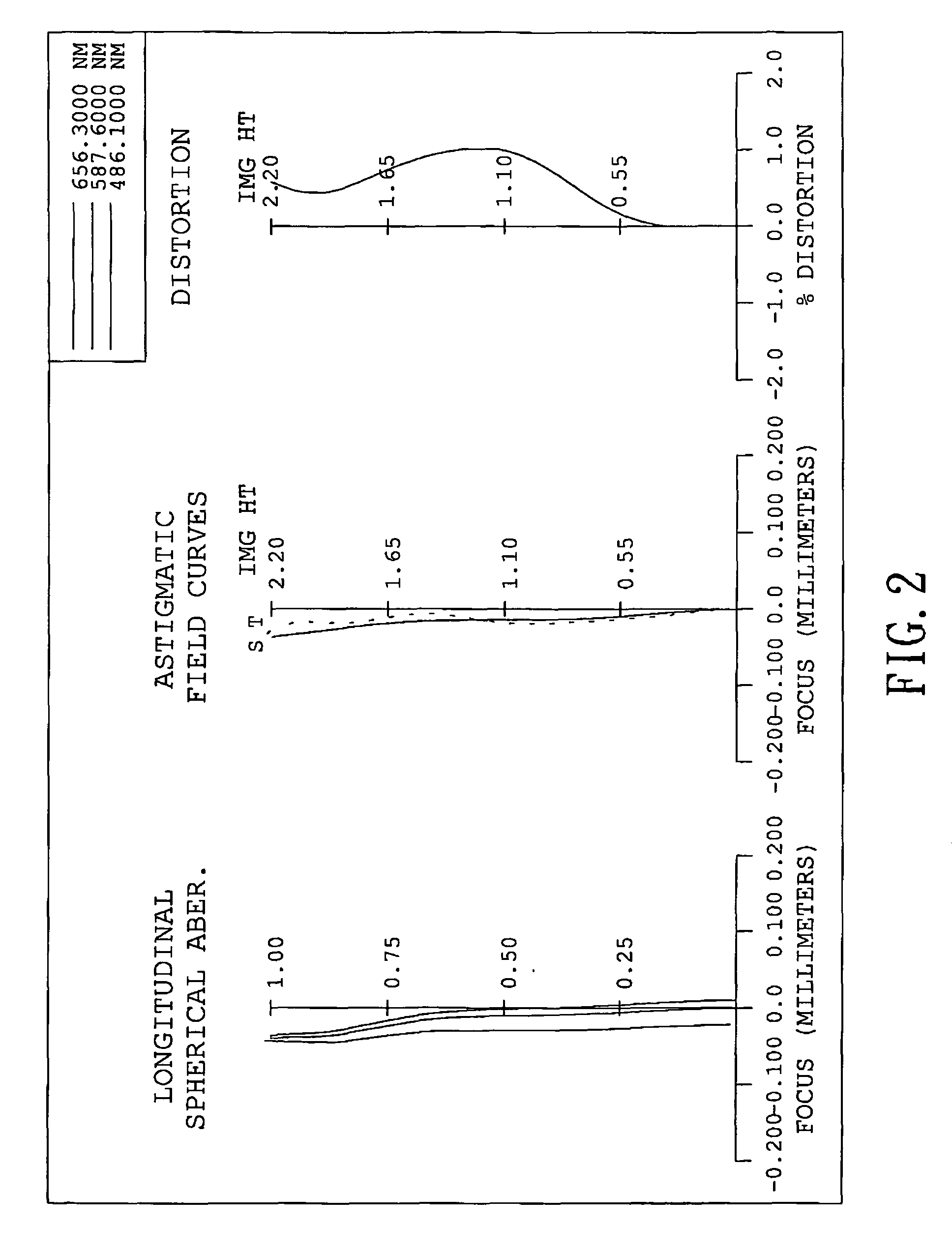

Imaging optical lens assembly

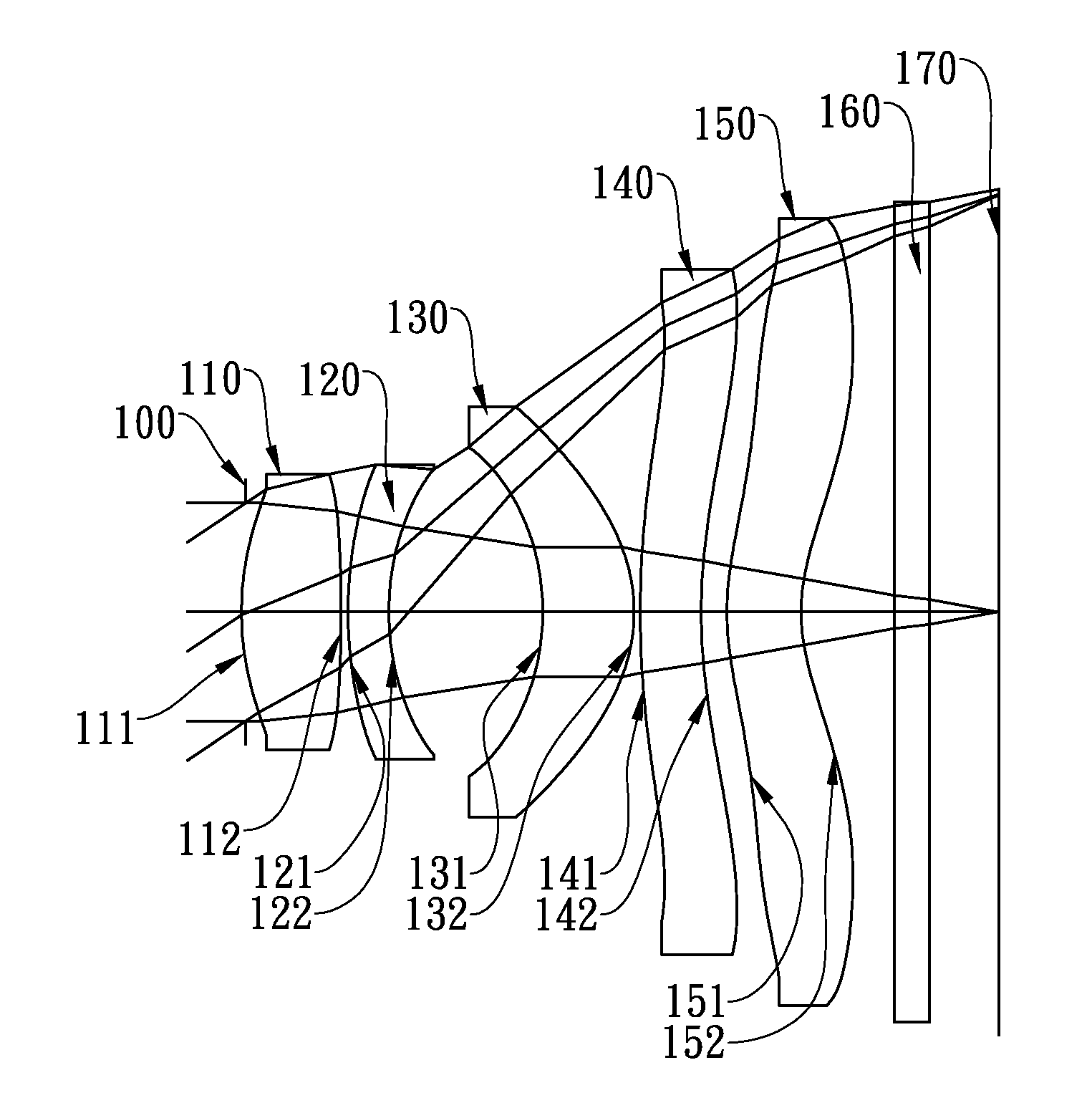

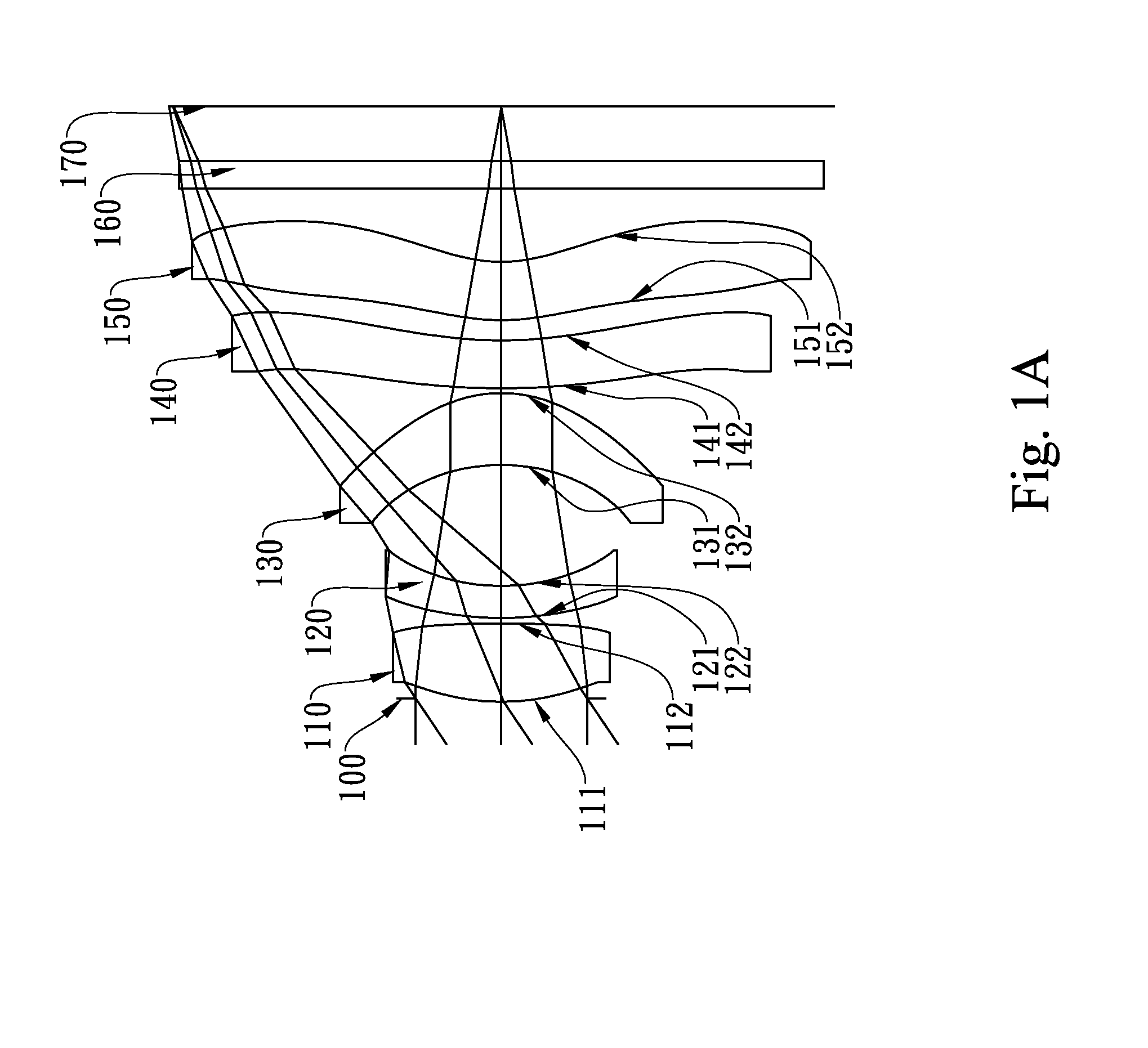

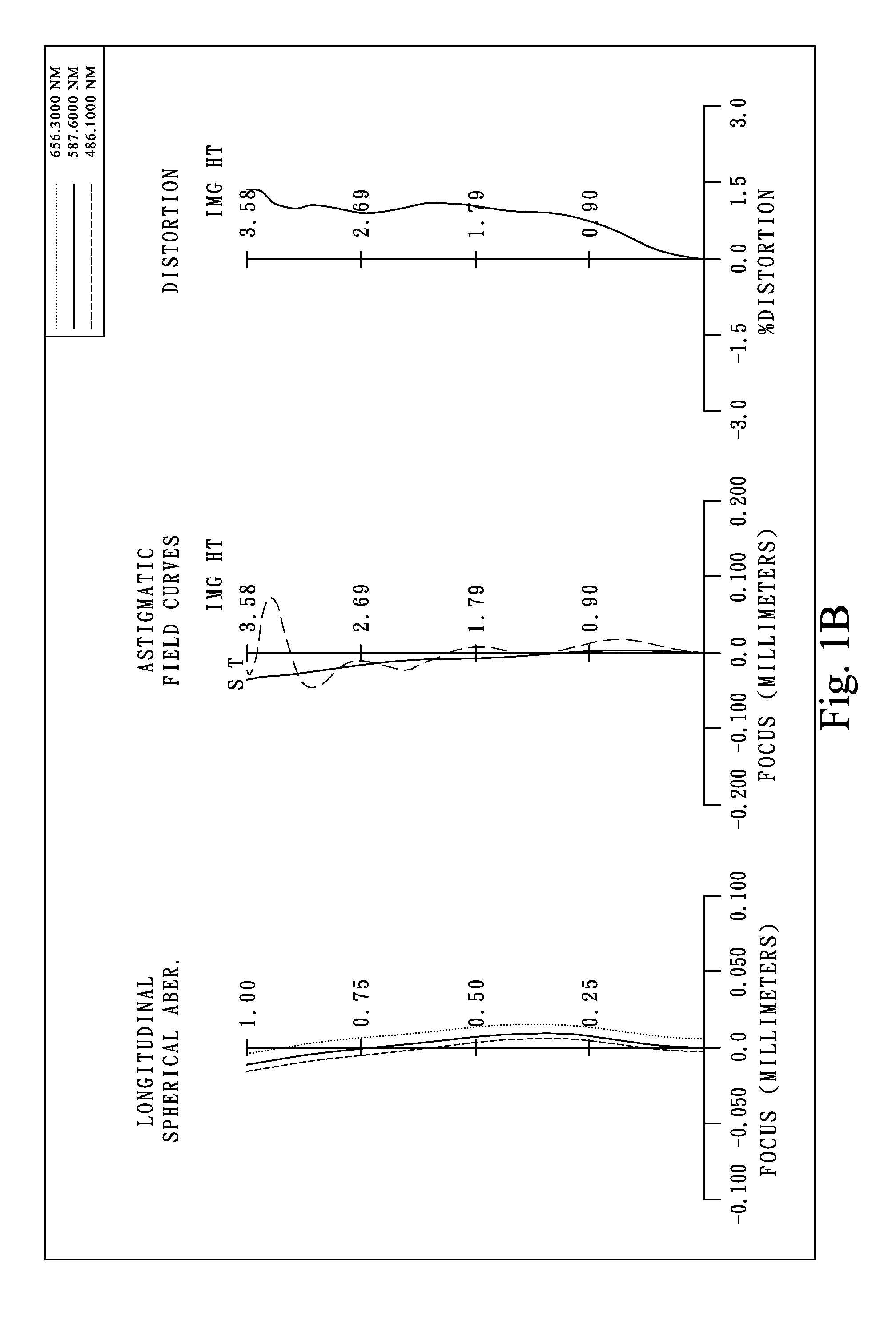

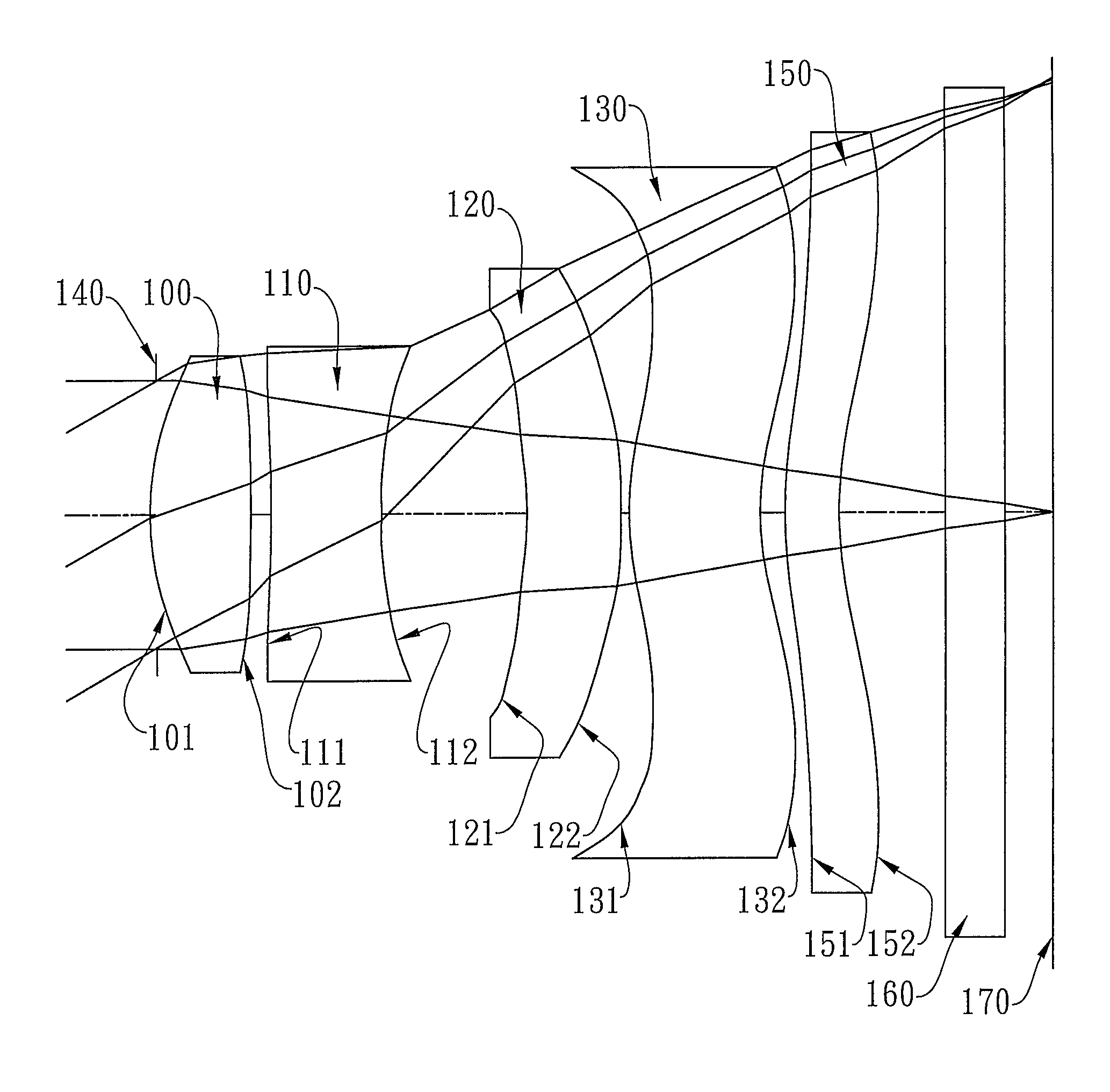

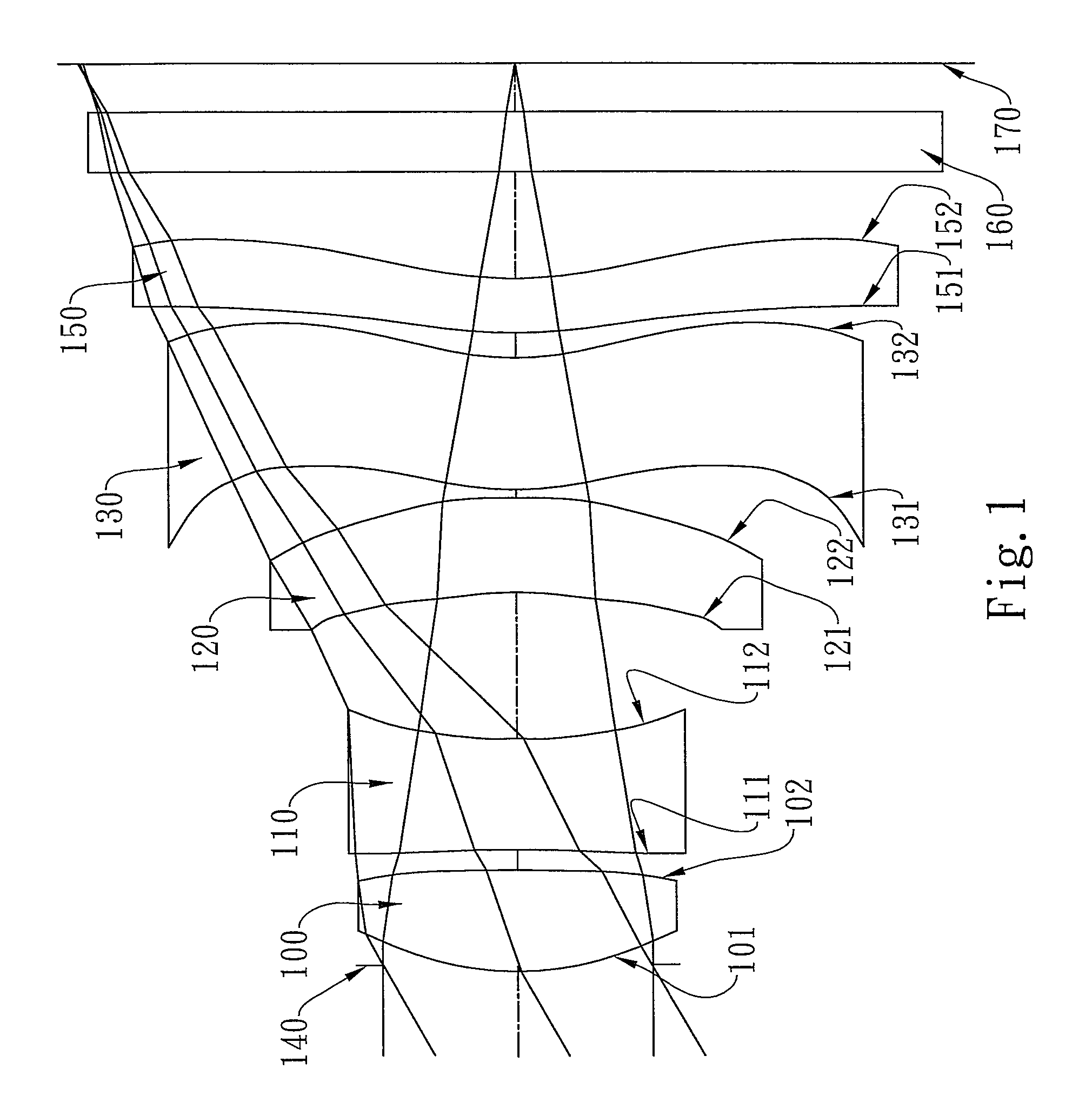

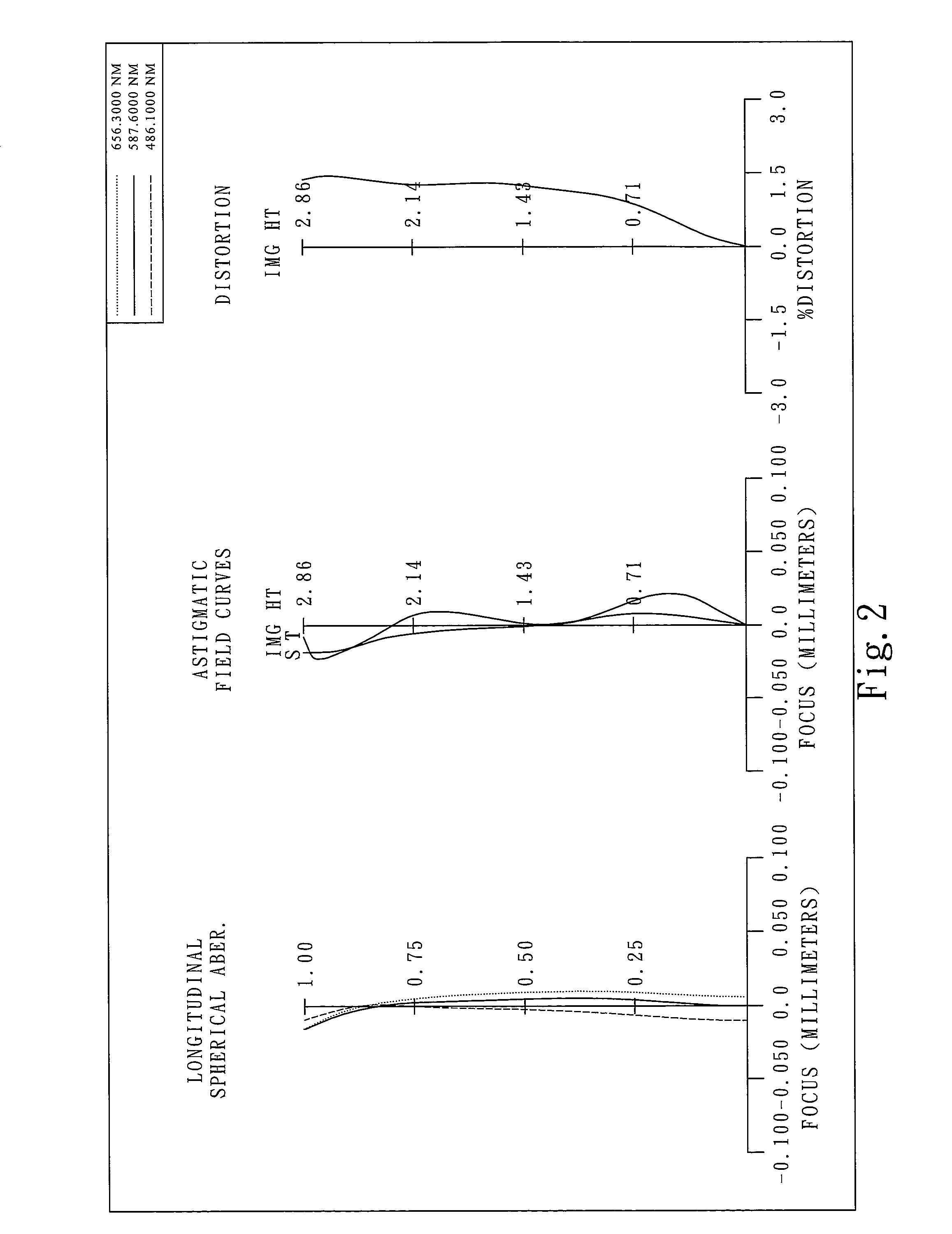

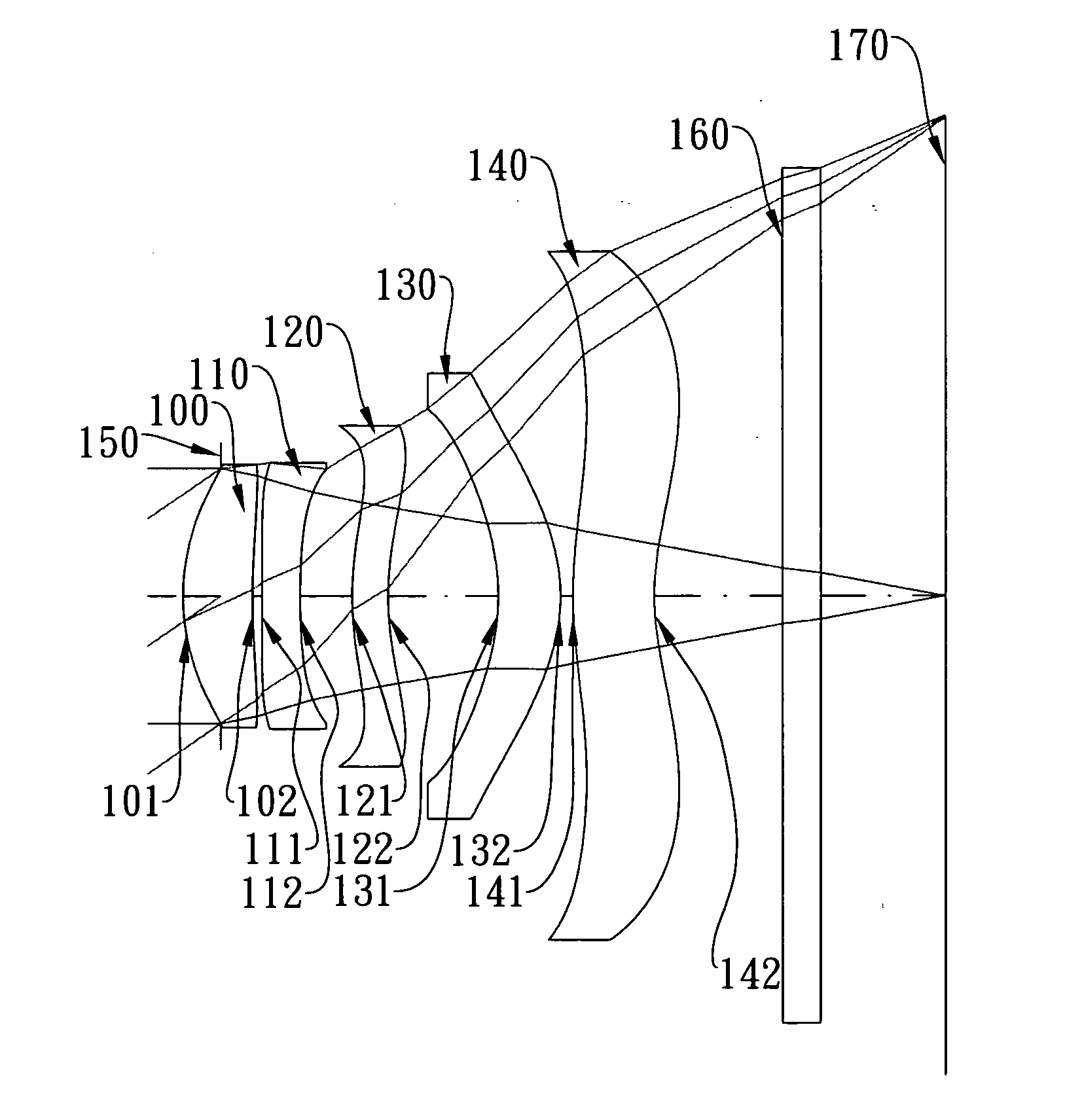

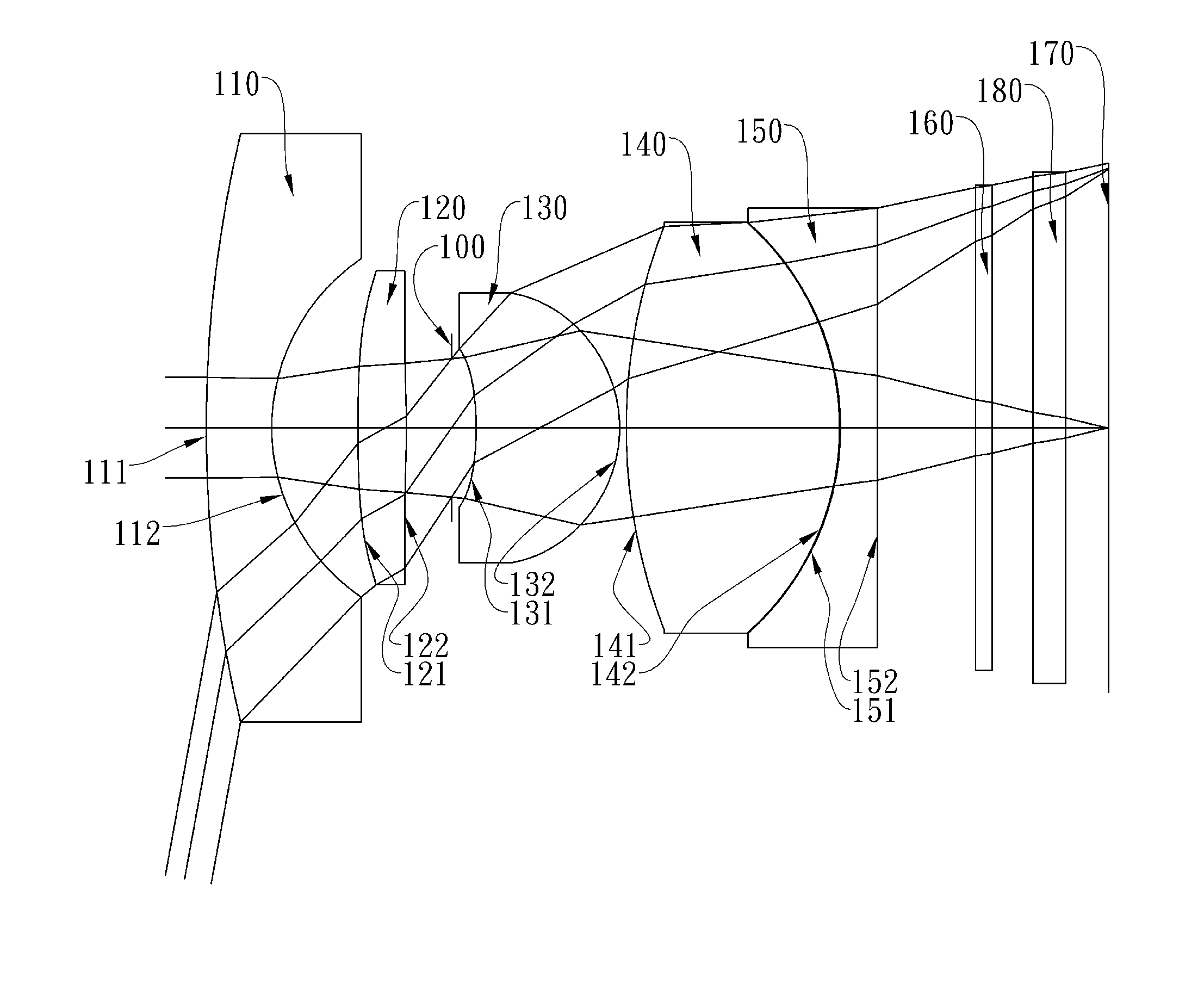

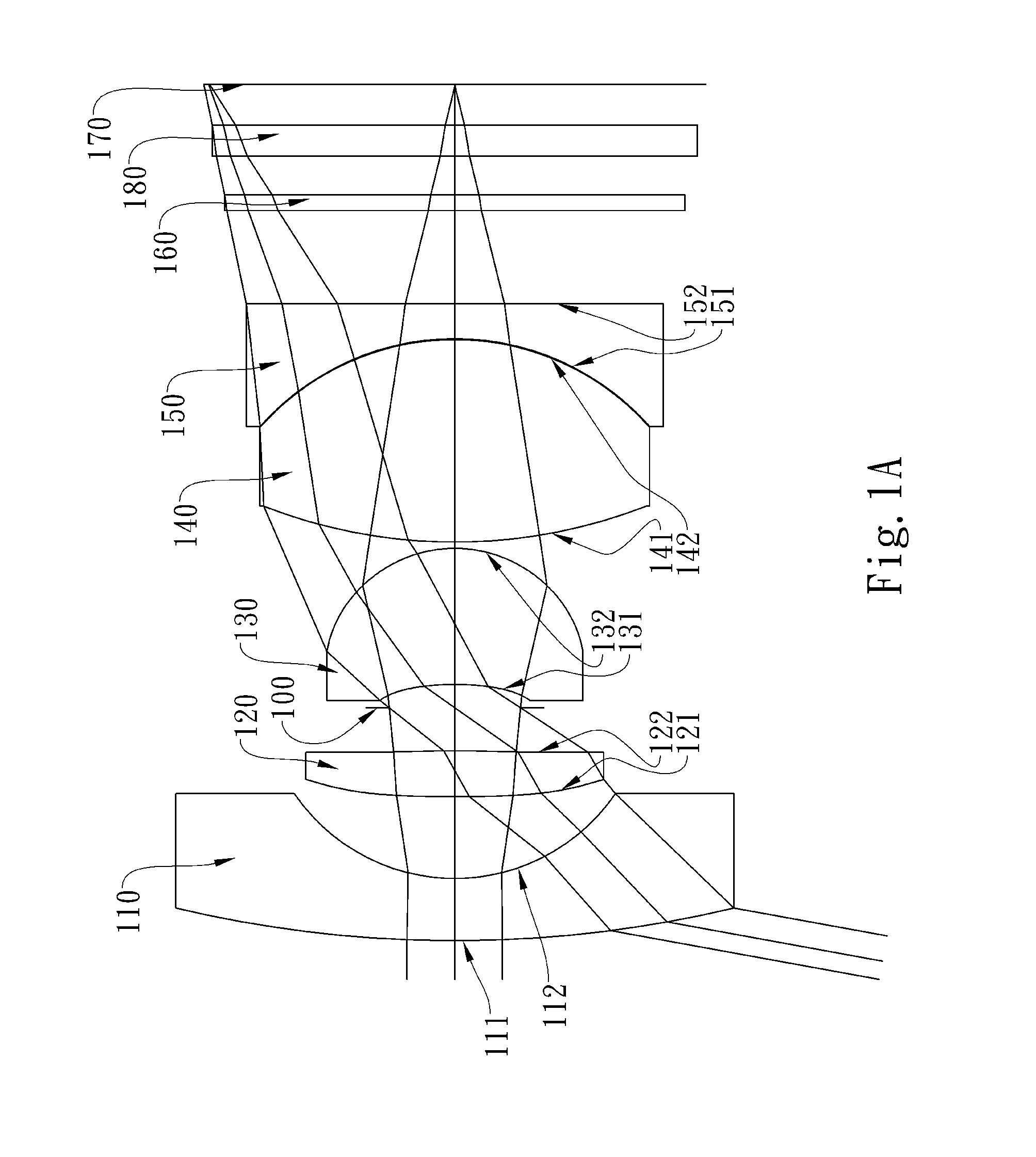

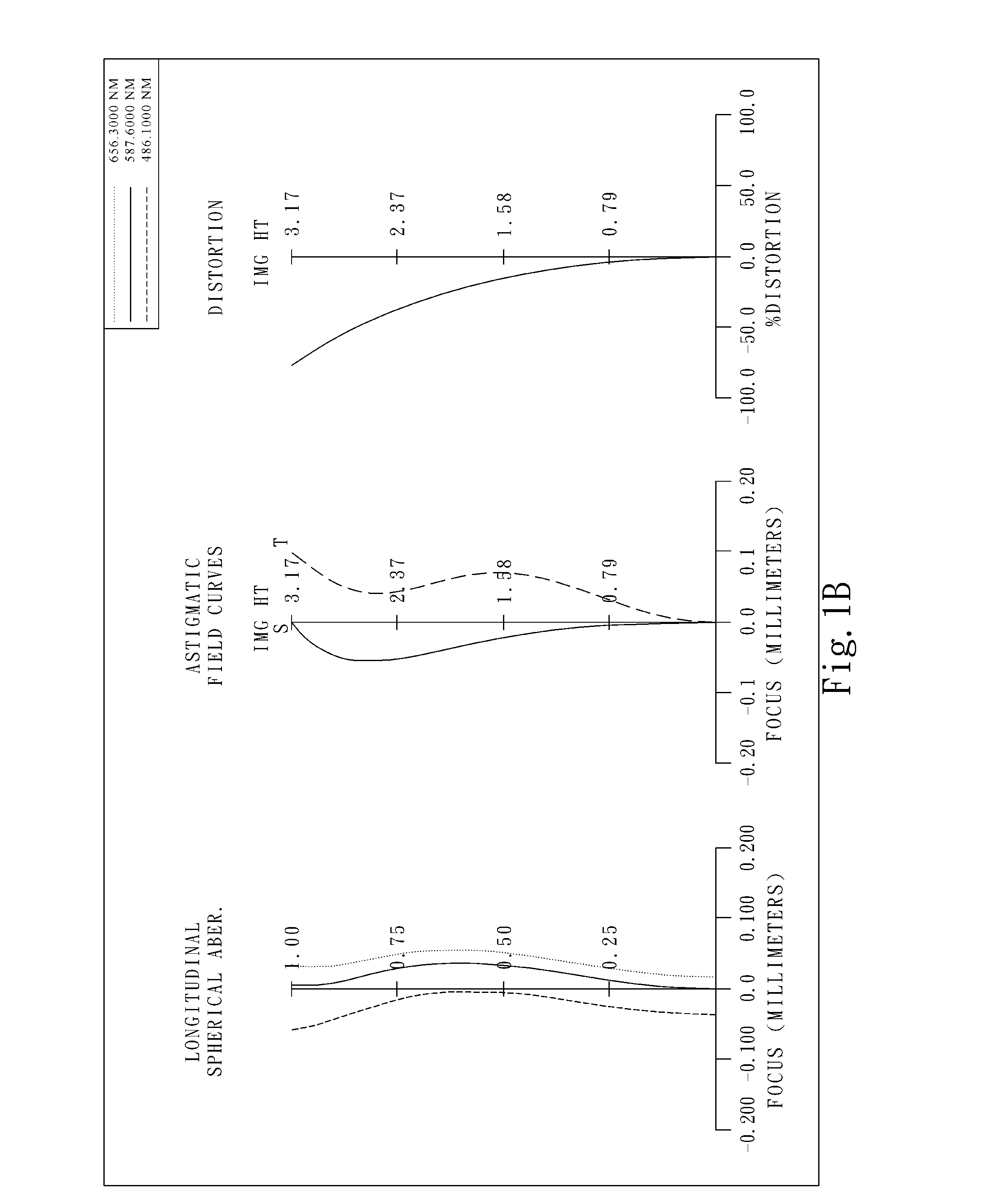

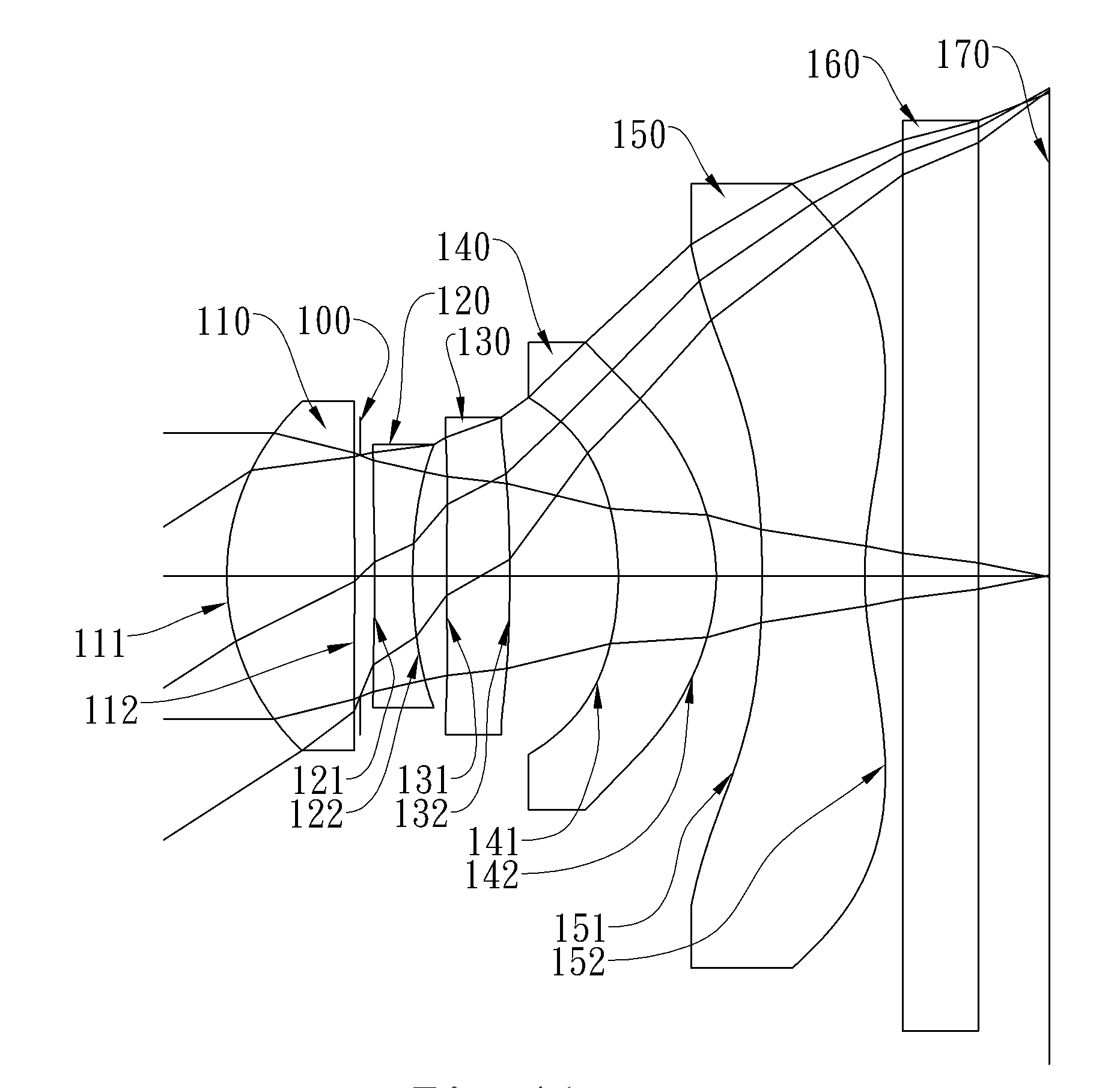

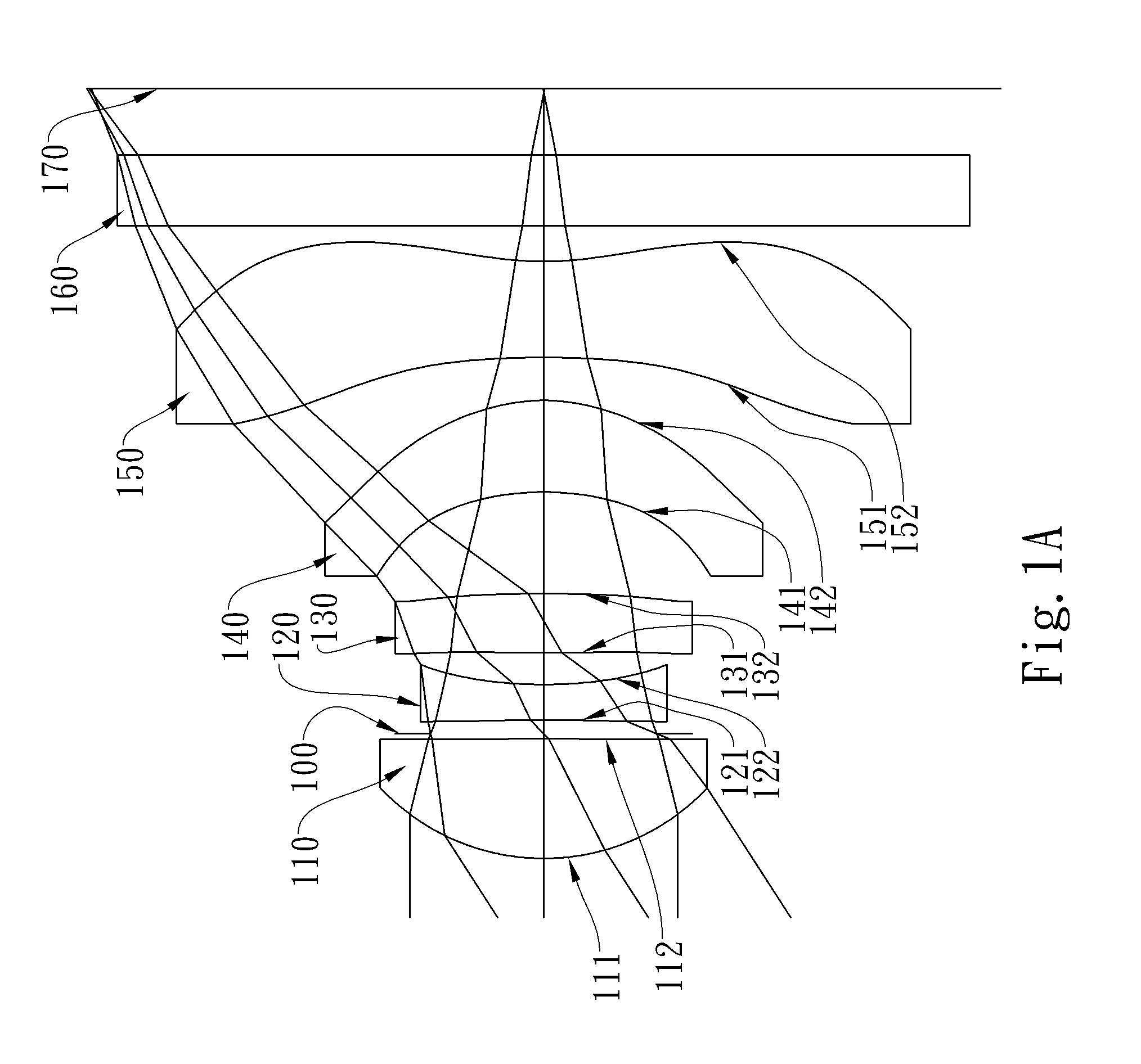

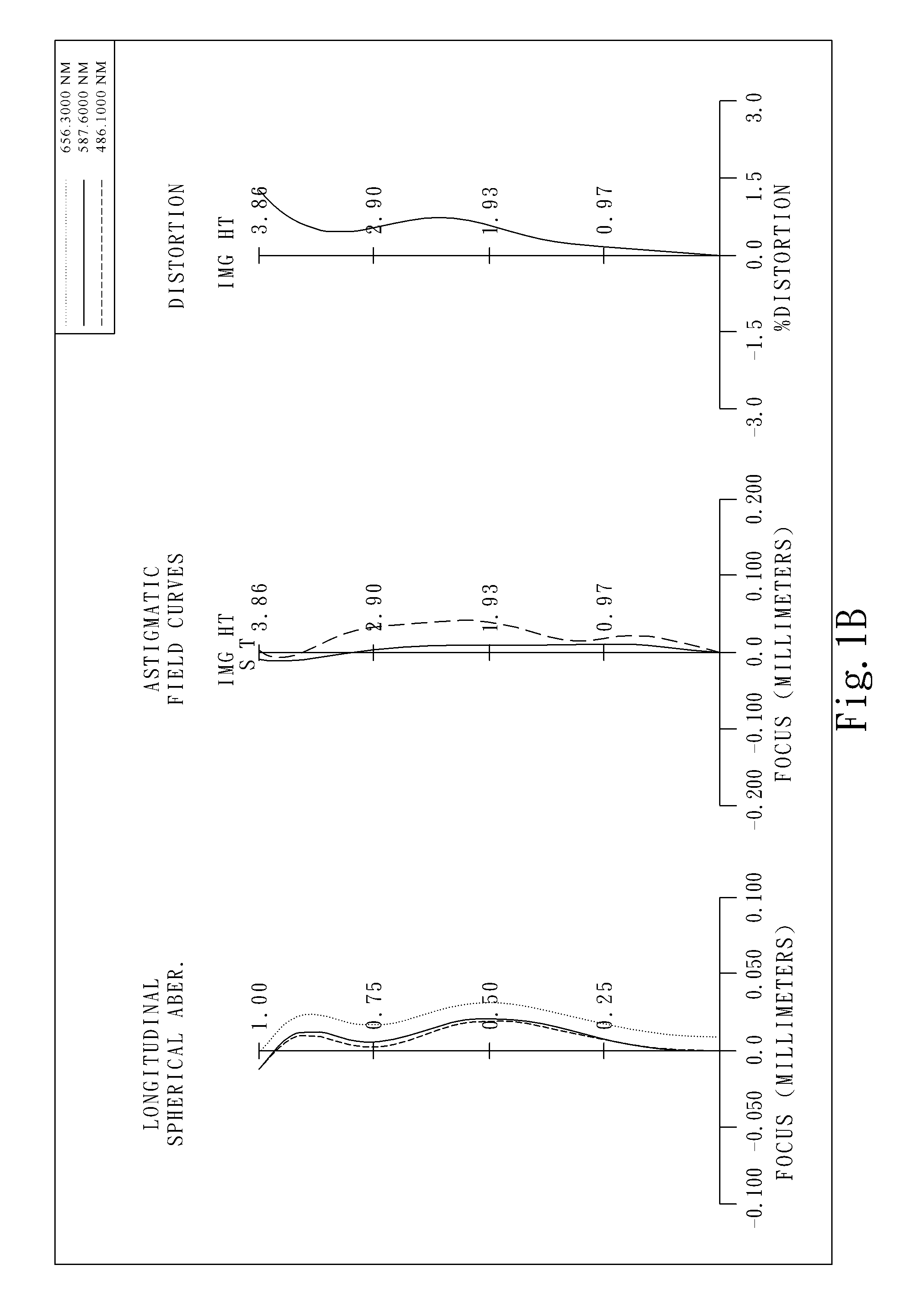

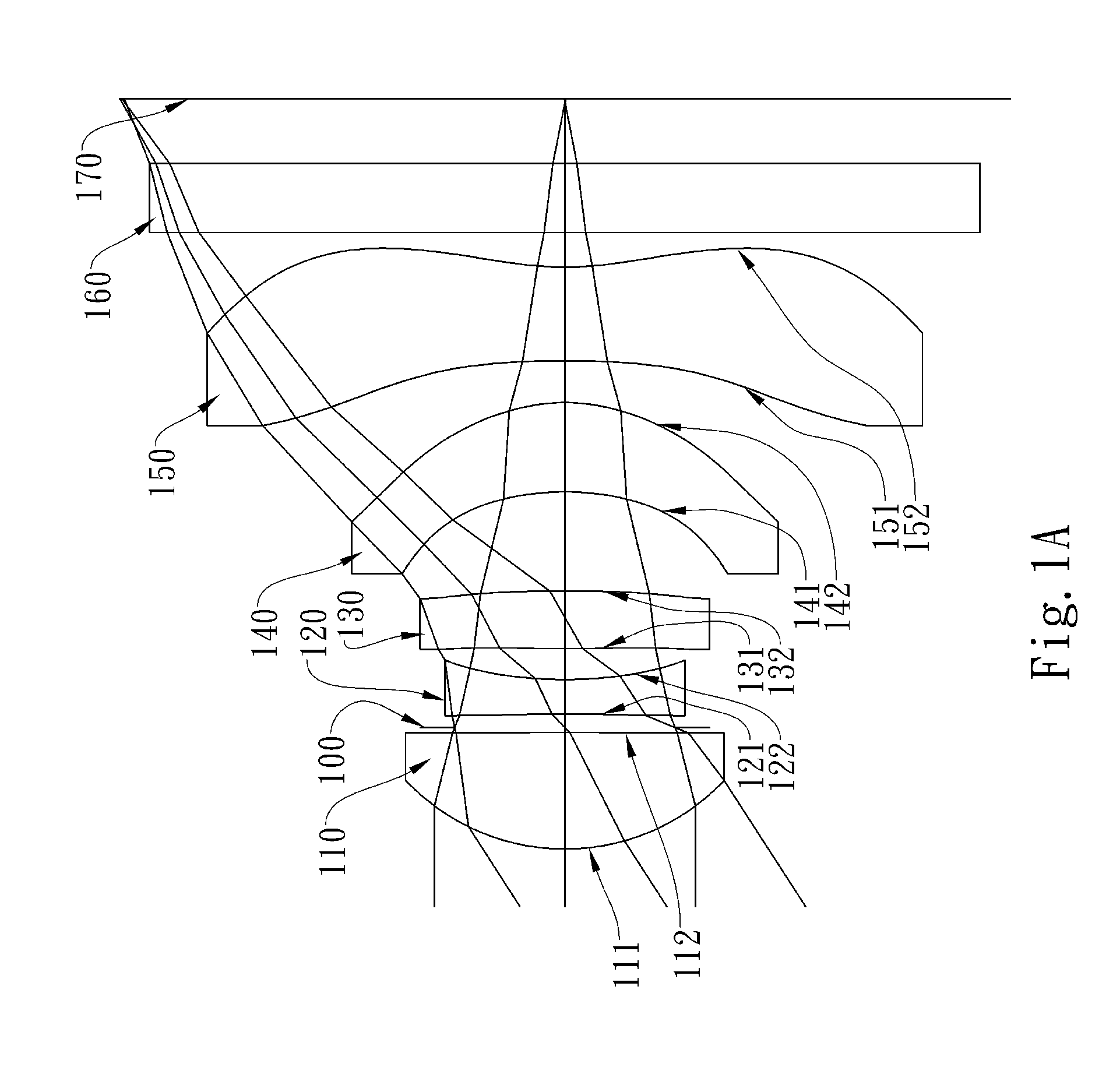

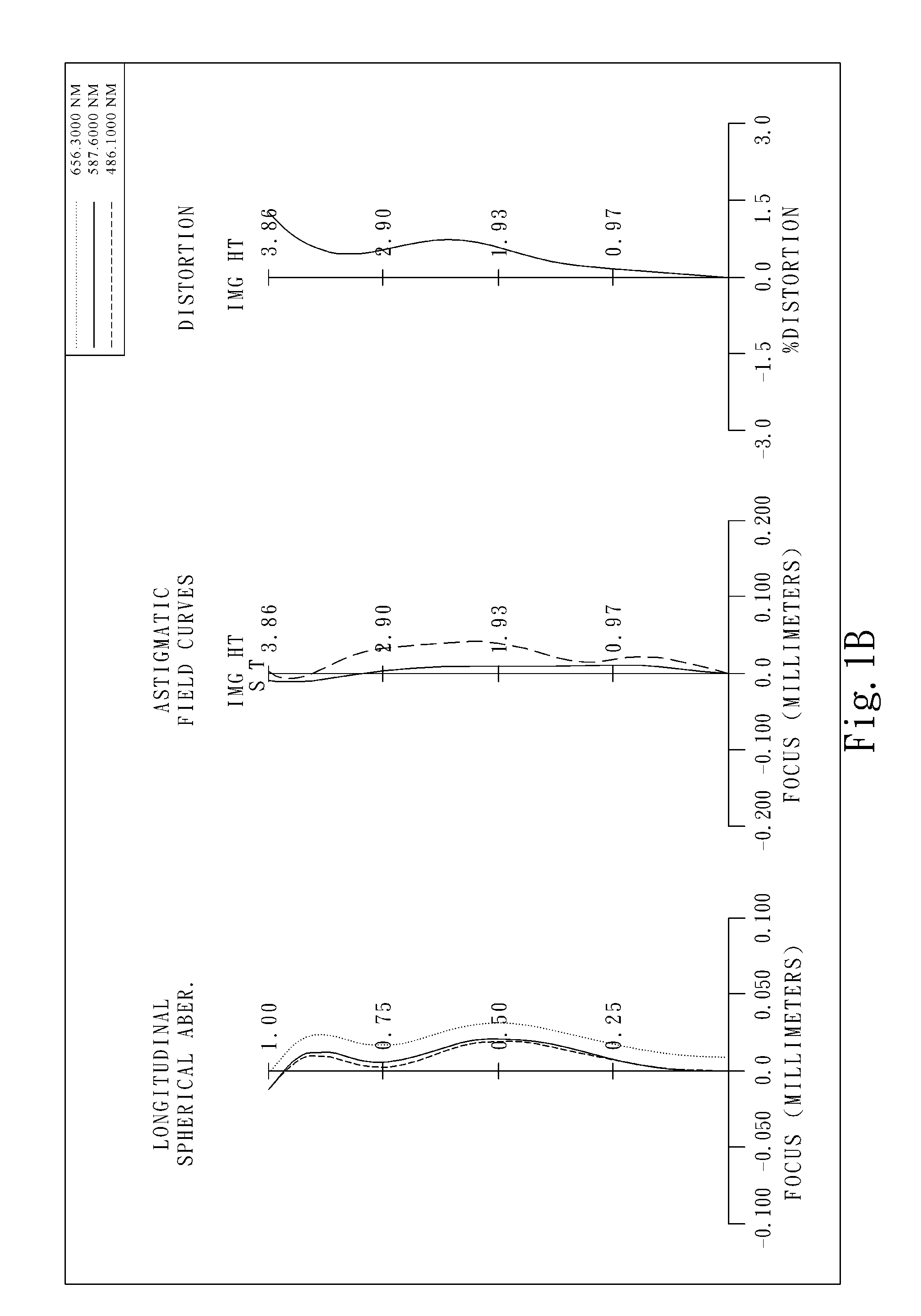

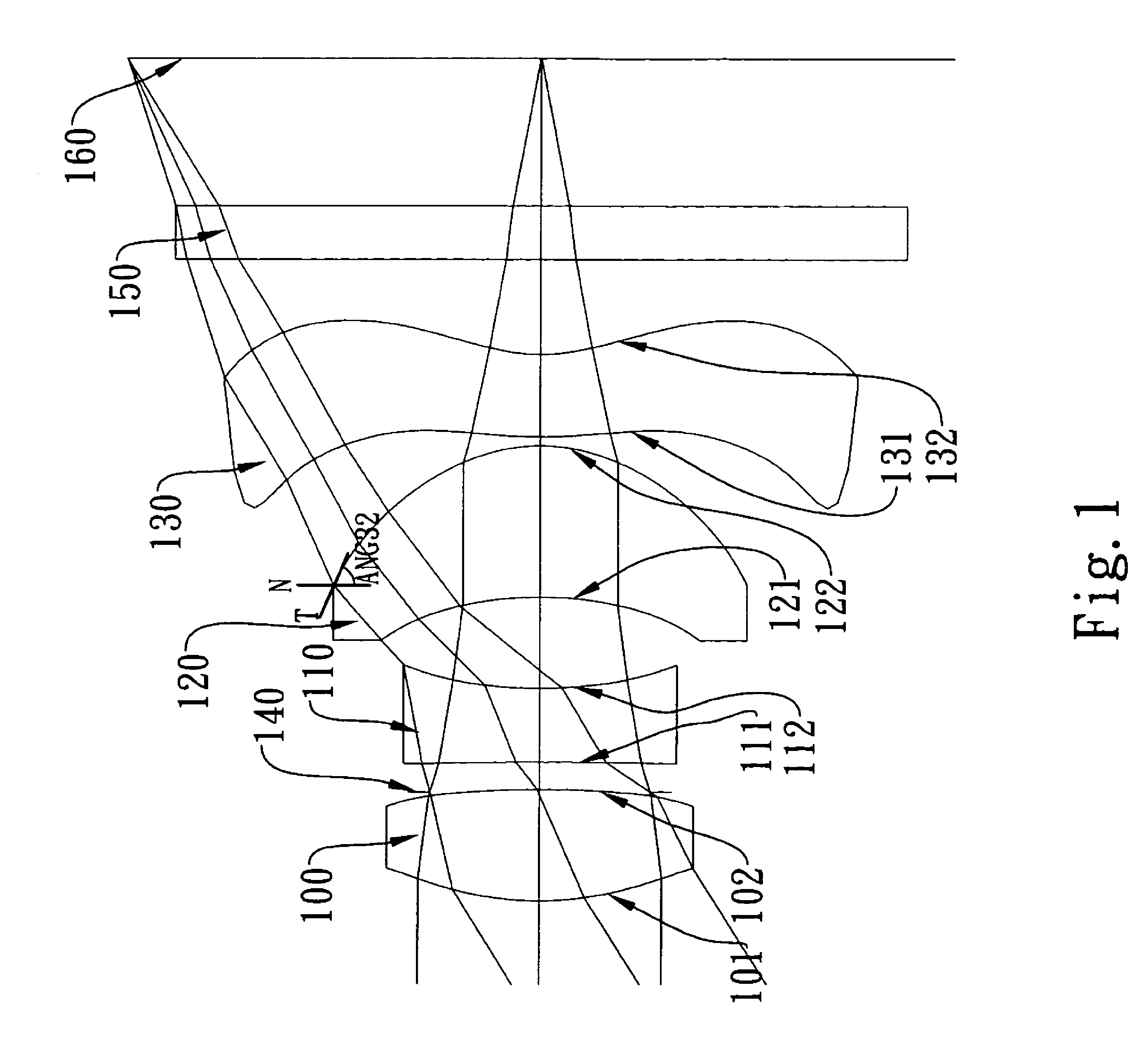

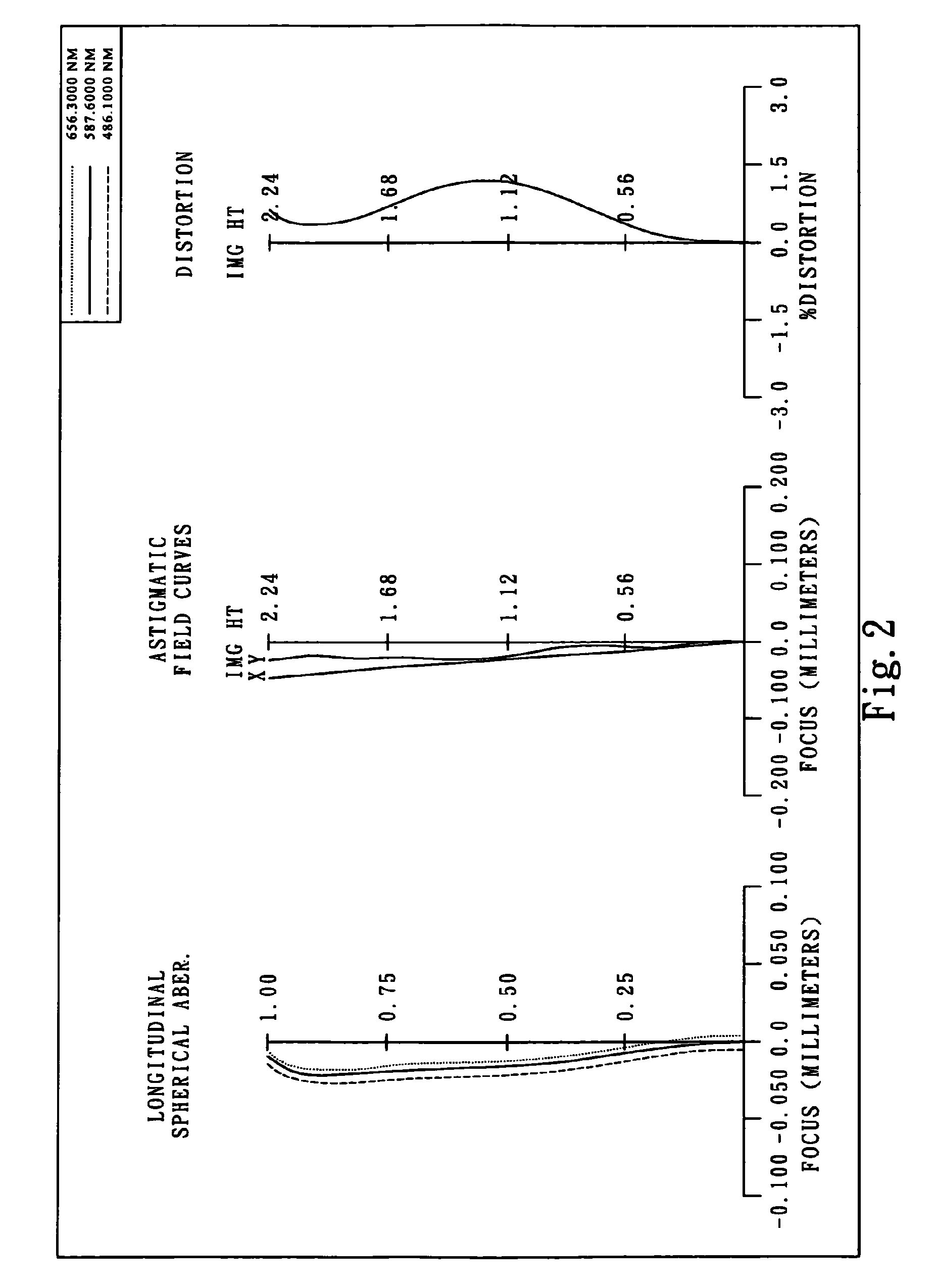

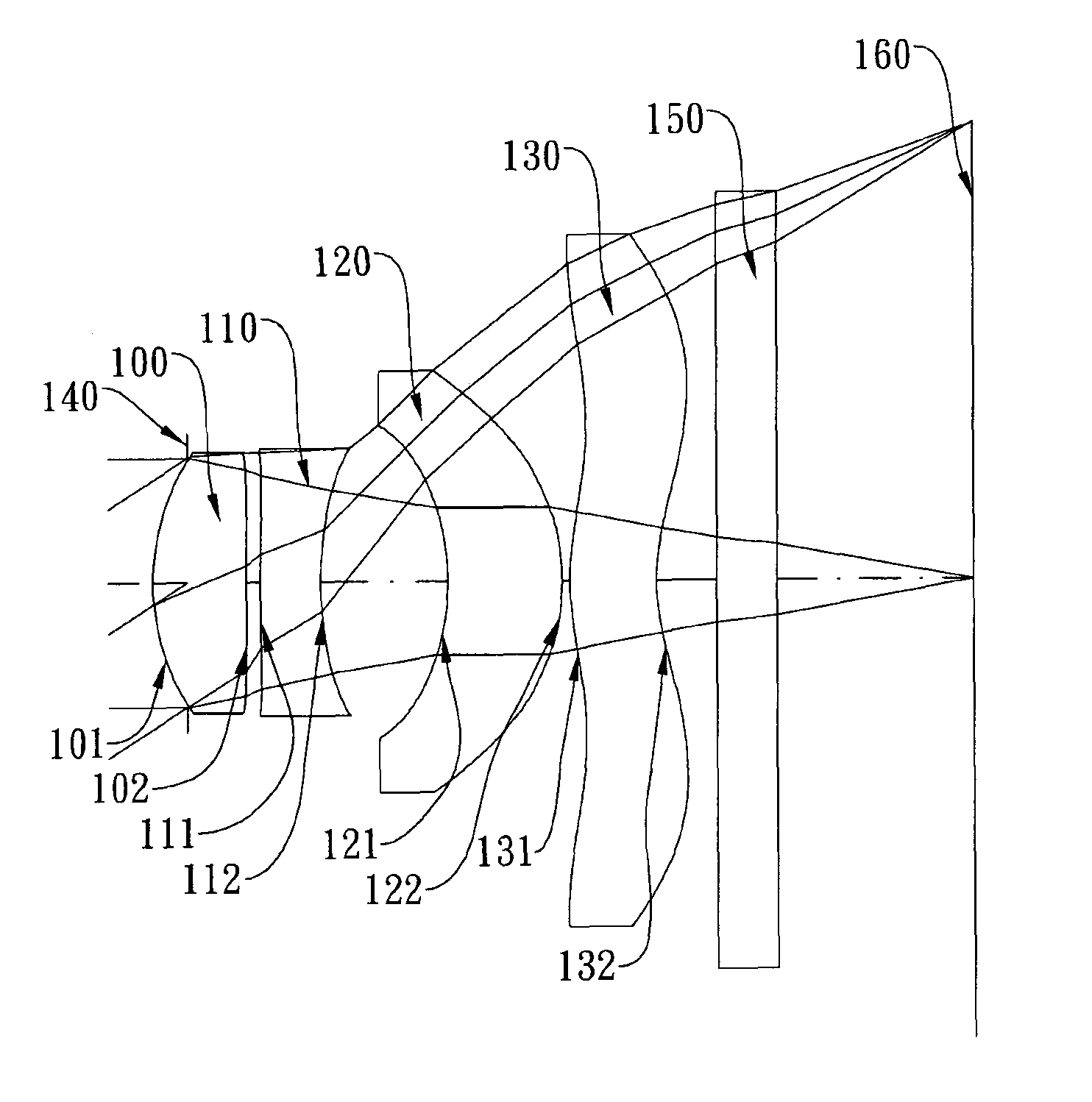

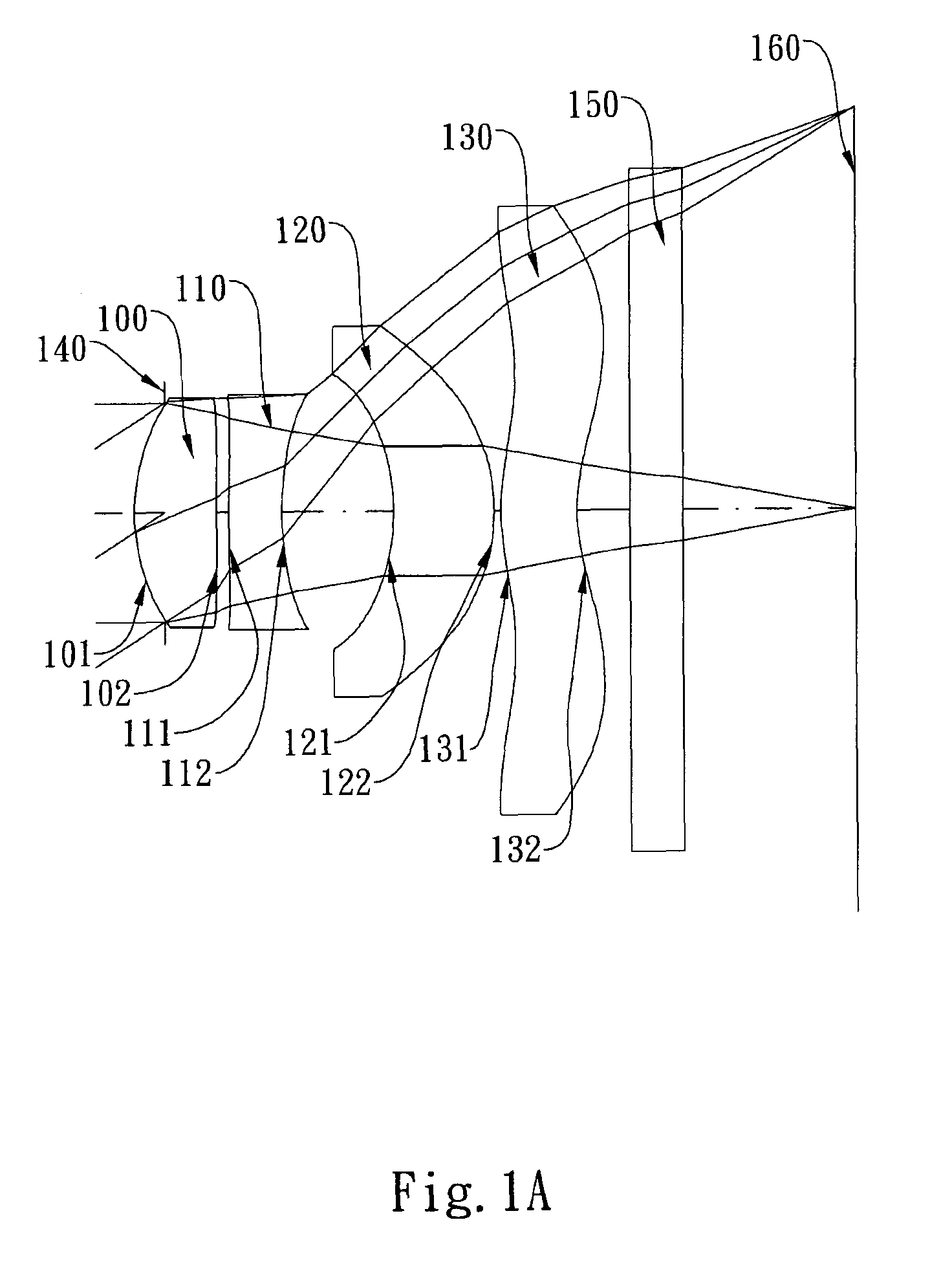

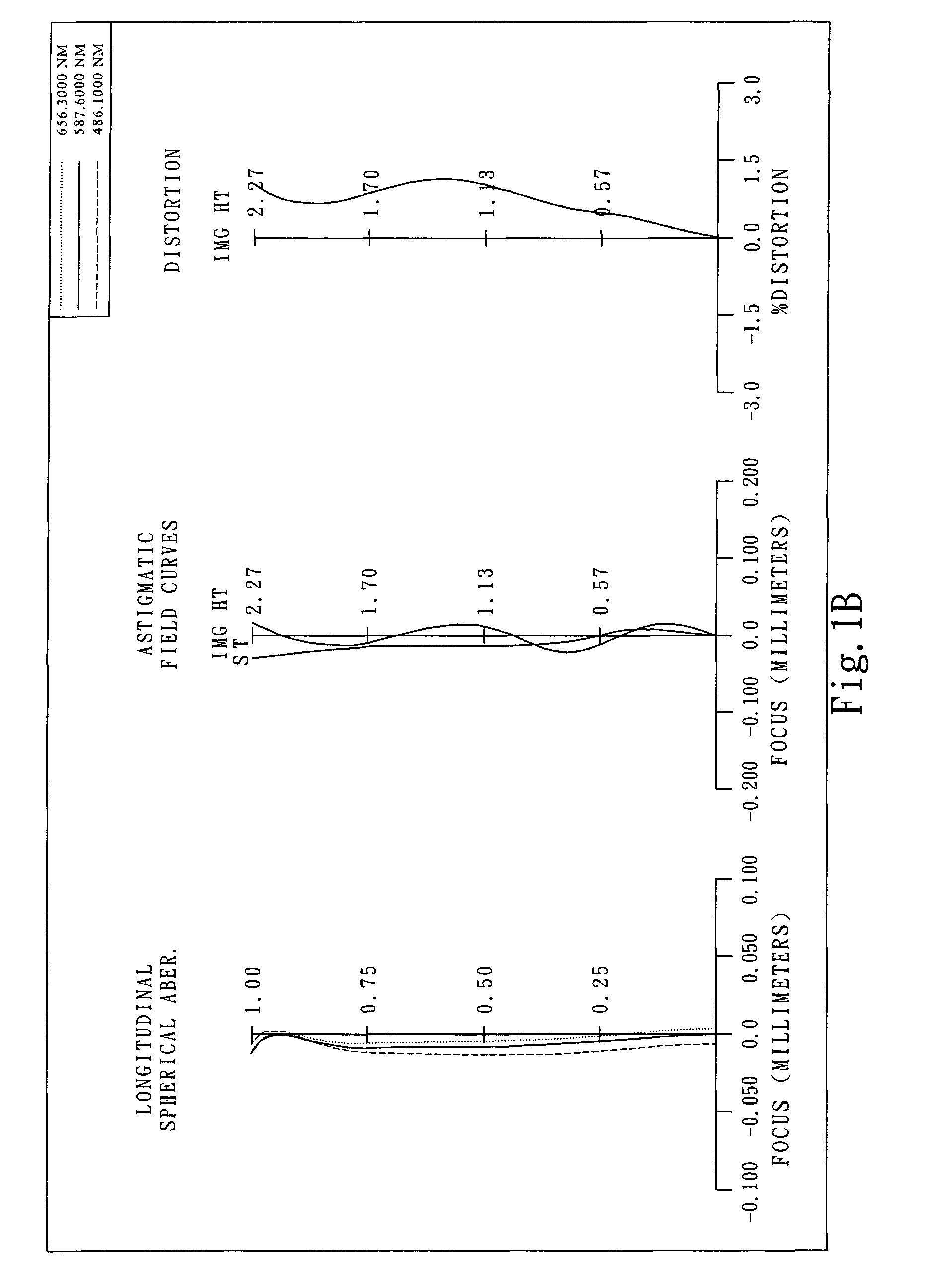

This invention provides an imaging optical lens assembly including: in order from an object side toward an image side: a first lens with positive refractive power and having a convex object-side surface, a second lens with negative refractive power and having a convex object-side surface and a concave image-side surface, a third lens with positive refractive power and having a concave object-side surface and a convex image-side surface, a fourth lens with negative refractive power and having a concave image-side surface, the object-side and image-side surfaces being aspheric, and a fifth lens having a concave image-side surface, the object-side and image-side surfaces being aspheric. The imaging optical lens assembly further comprises an aperture stop, disposed between an imaged object and the second lens, and an electronic sensor, disposed at the image plane for image formation.

Owner:LARGAN PRECISION

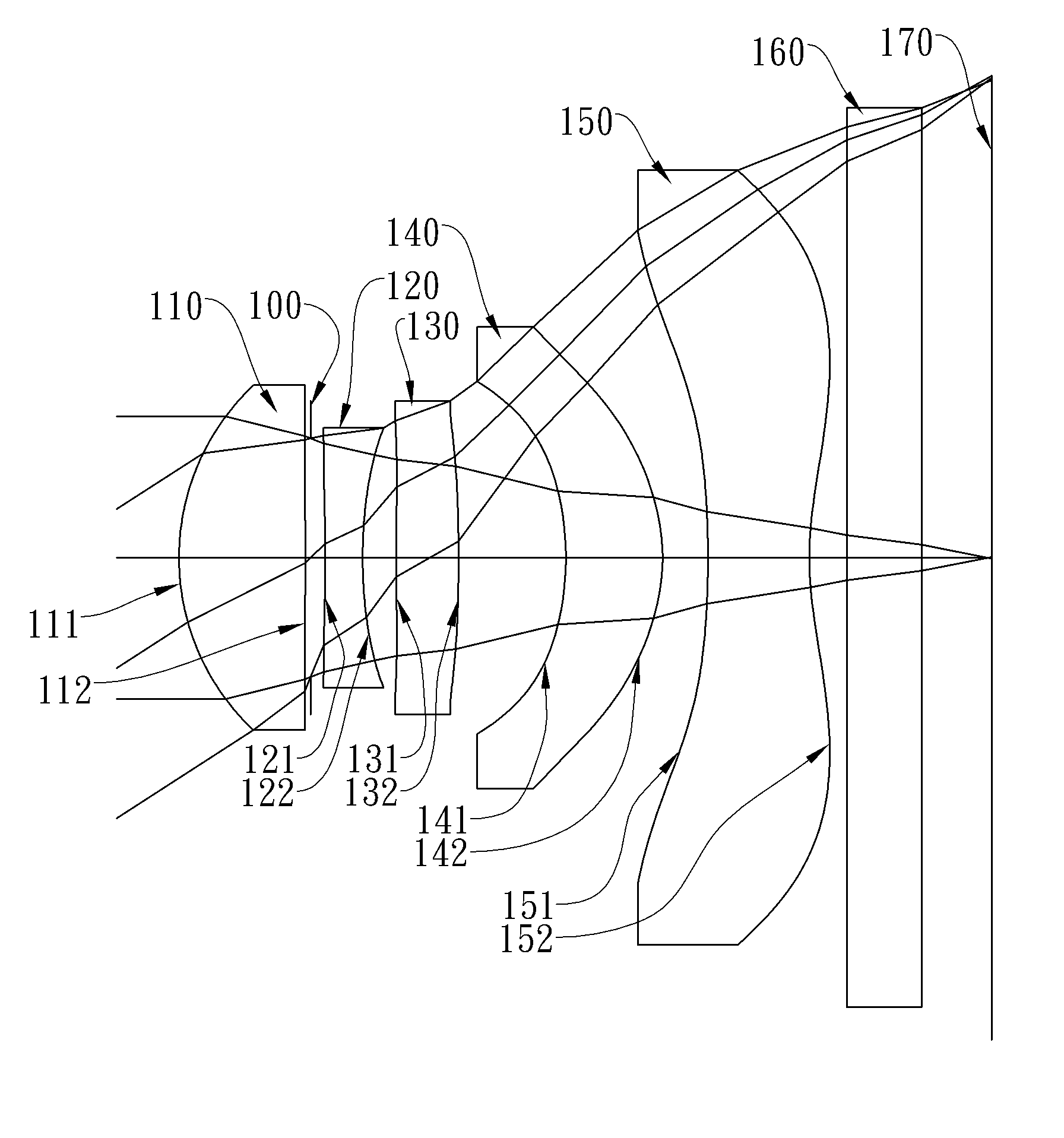

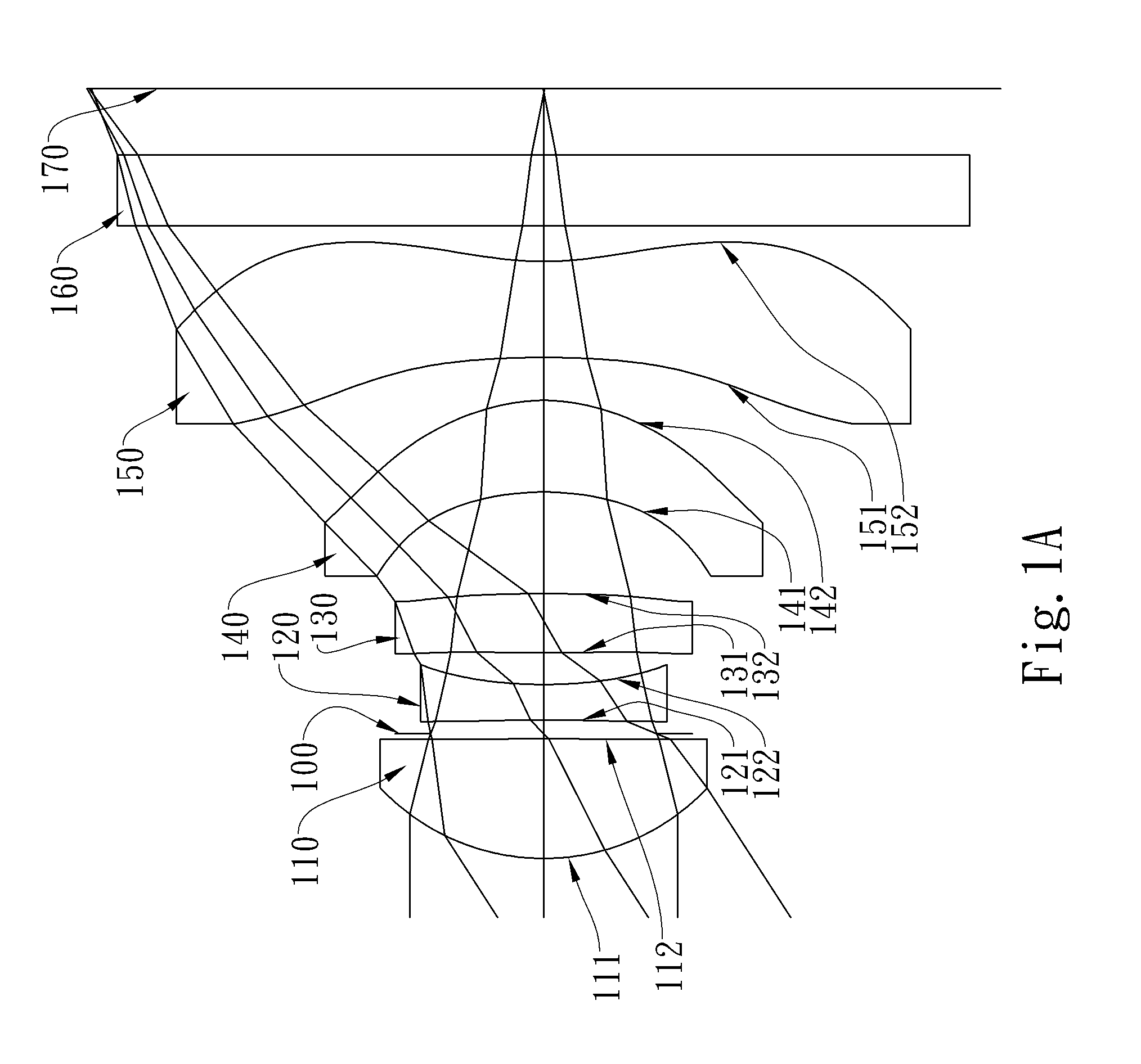

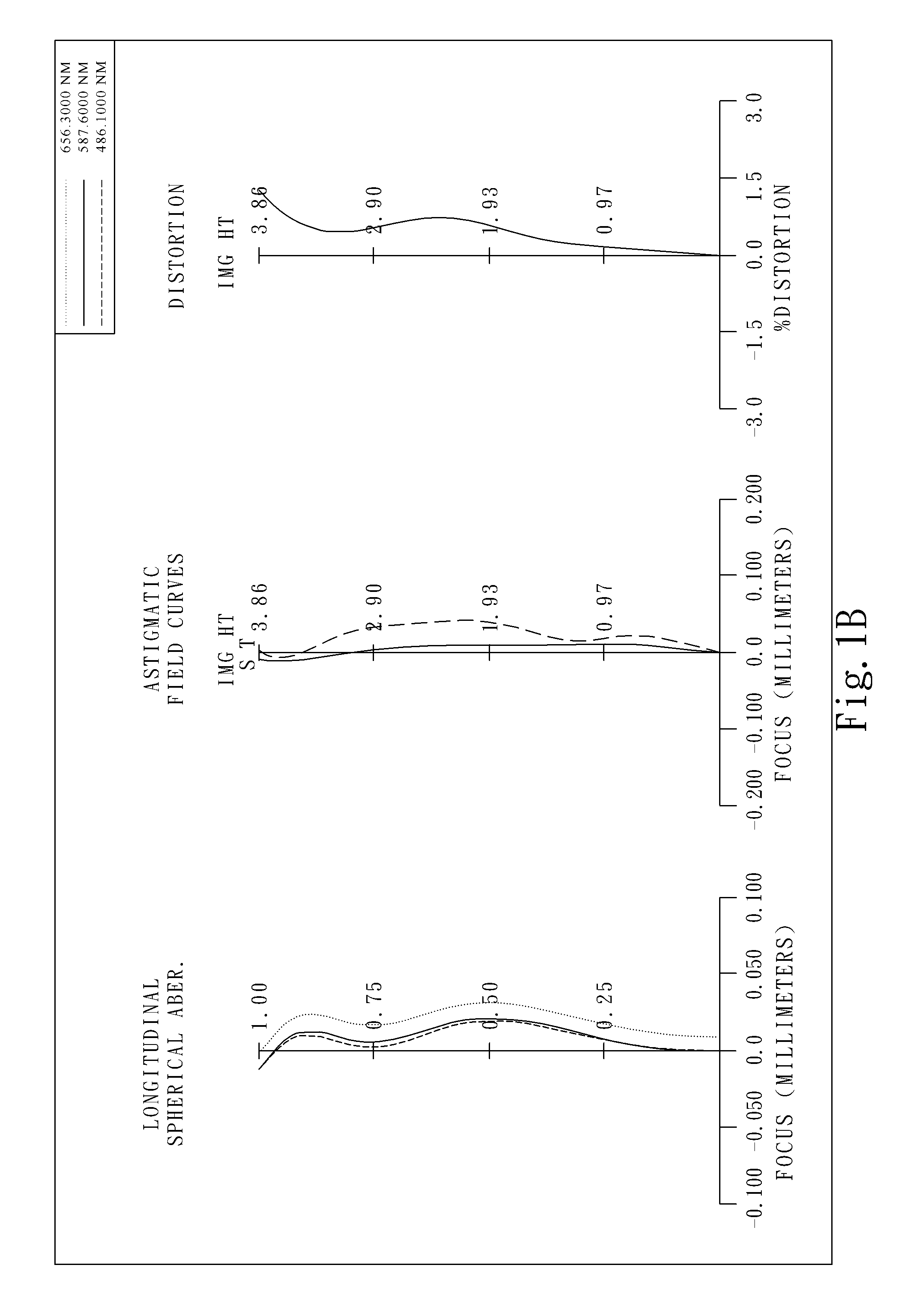

Imaging lens assembly

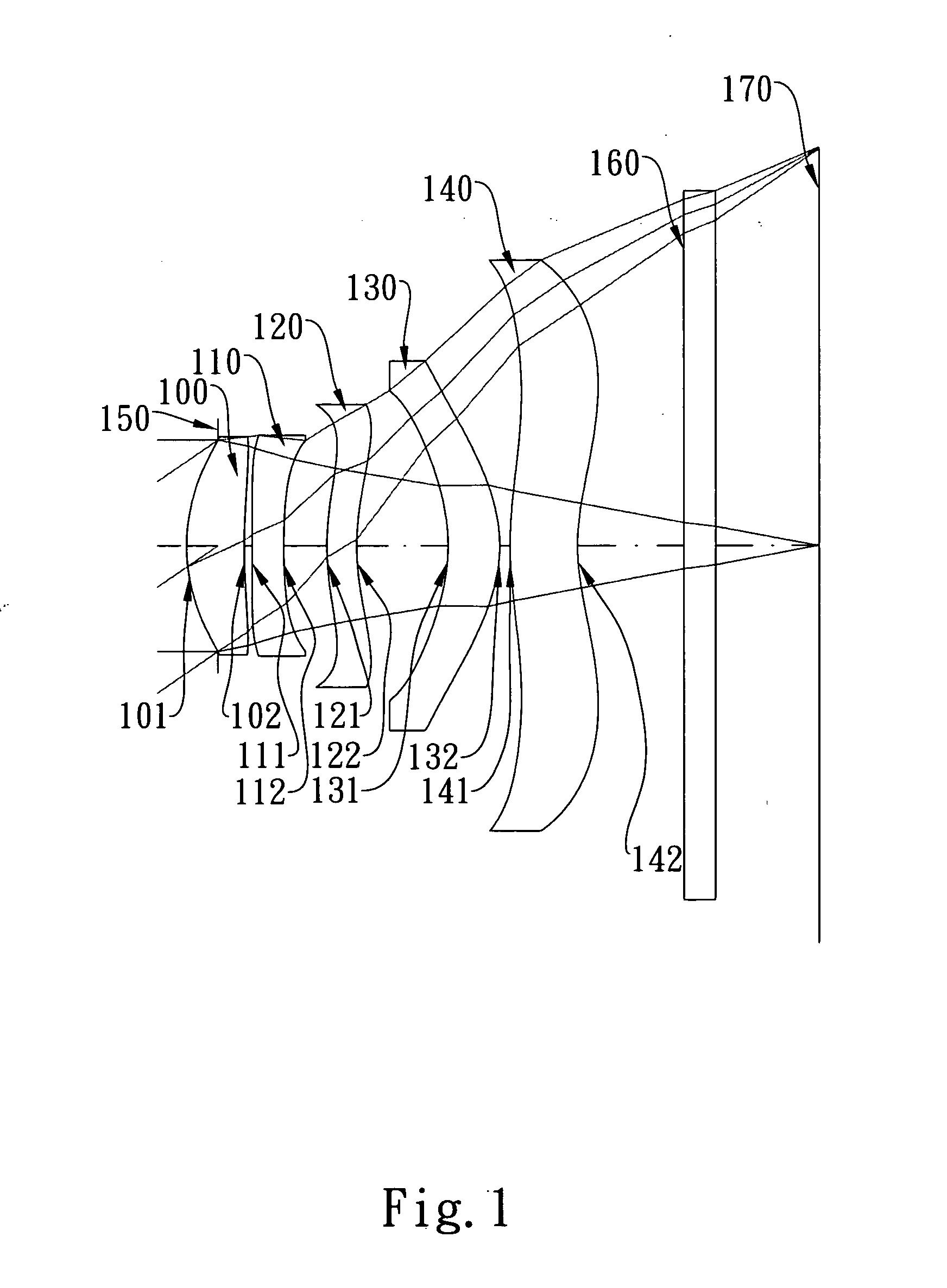

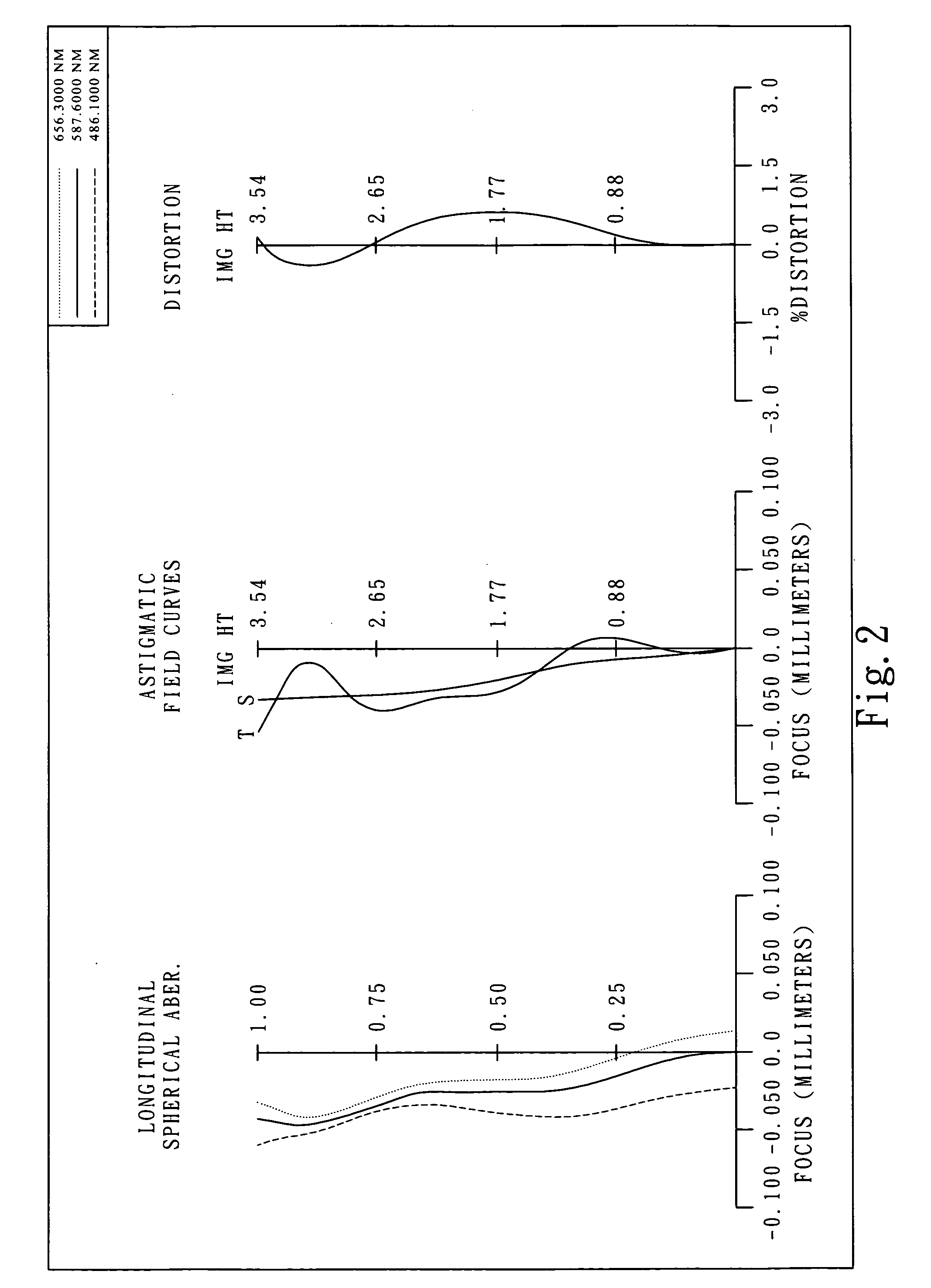

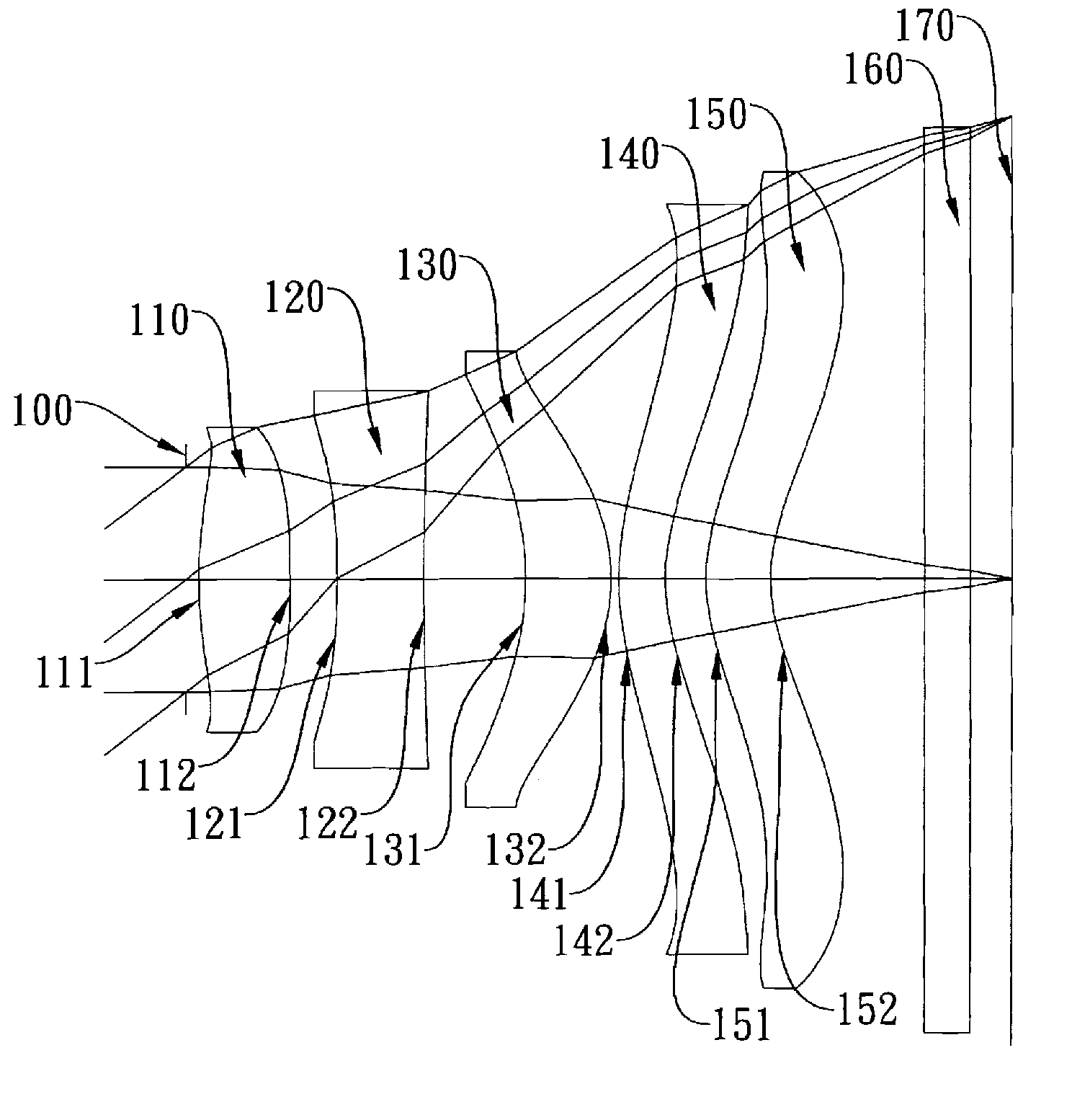

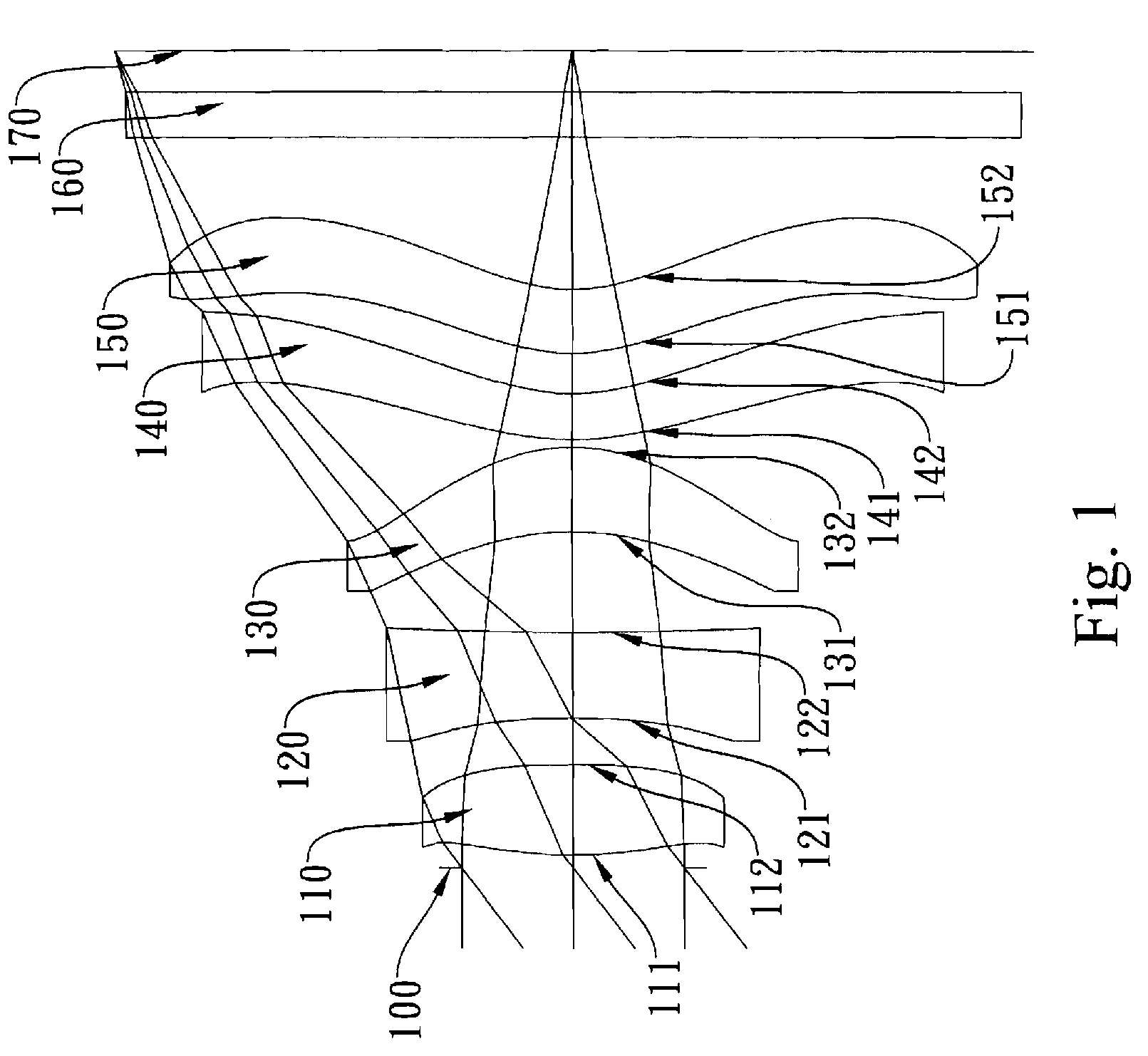

The present invention provides an imaging lens assembly including, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power; a third lens element with negative refractive power; a fourth lens element with positive refractive power having a convex object-side surface; a fifth lens element having a concave image-side surface, at least one inflection point being provided on the fifth lens element; and an aperture stop disposed between an imaged object and the third lens element. Such an arrangement of optical elements can effectively improve the image quality of the system and enable the imaging lens assembly to maintain a compact form. When the aperture stop is disposed near the object side, the telecentric feature is emphasized, resulting in a shorter total track length. When the aperture stop is disposed near the third lens element, the emphasis is on the wide field of view, and such an aperture stop placement helps to effectively reduce the sensitivity of the imaging lens assembly.

Owner:LARGAN PRECISION

Imaging lens system

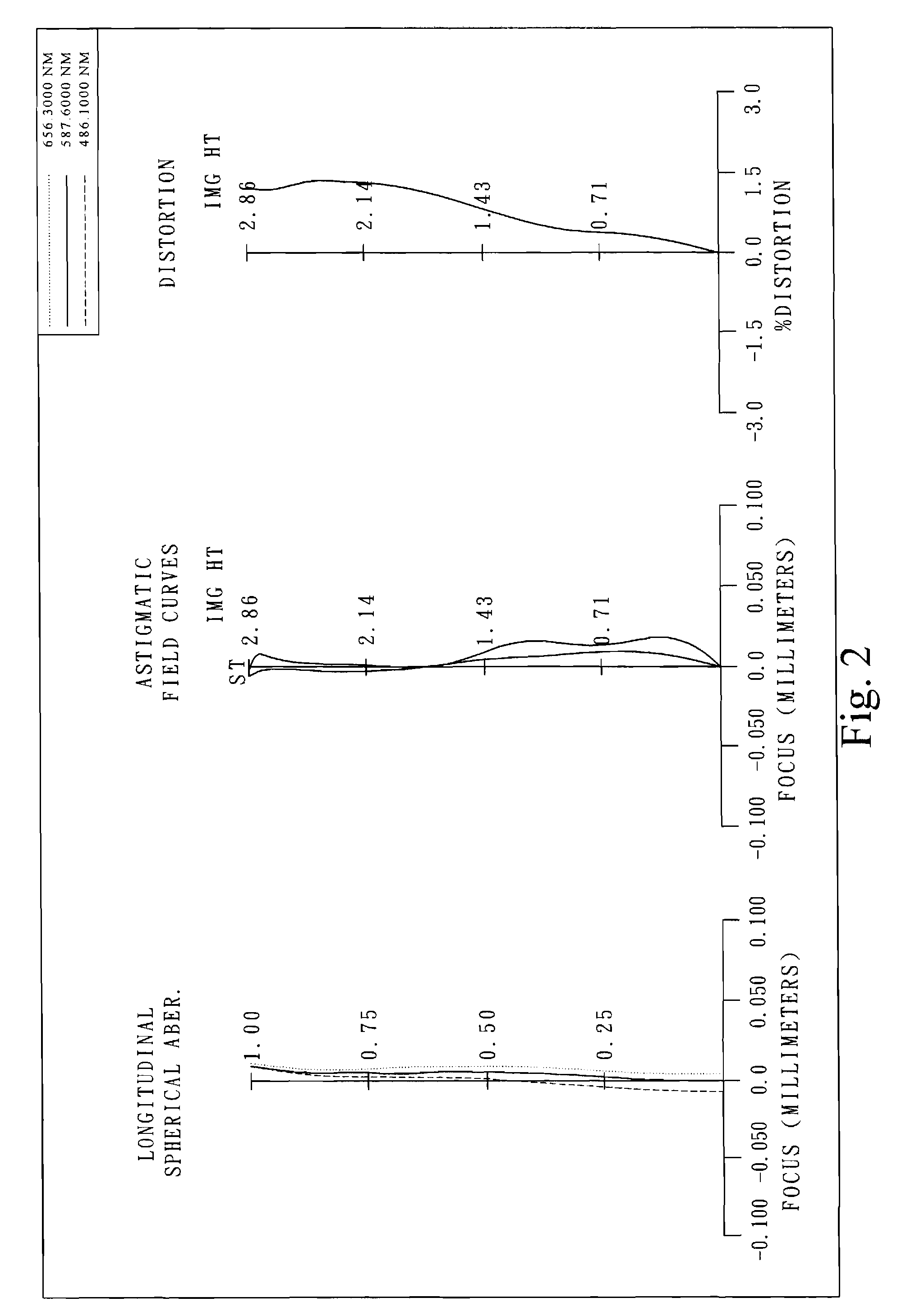

ActiveUS20110013069A1Short total track lengthImprove image qualityTelevision system detailsColor television detailsPhysicsCamera lens

This invention provides an imaging lens system including, in order from an object side to an image side: a first lens with positive refractive power having a convex object-side surface; a second lens with negative refractive power; a third lens having a concave image-side surface; a fourth lens with positive refractive power; a fifth lens with negative refractive power having a concave image-side surface, at least one surface thereof having at least one inflection point; and an aperture stop disposed between an imaged object and the third lens. The on-axis spacing between the first lens and second lens is T12, the focal length of the imaging lens system is f, and they satisfy the relation: 0.5<(T12 / f)×100<15.

Owner:LARGAN PRECISION

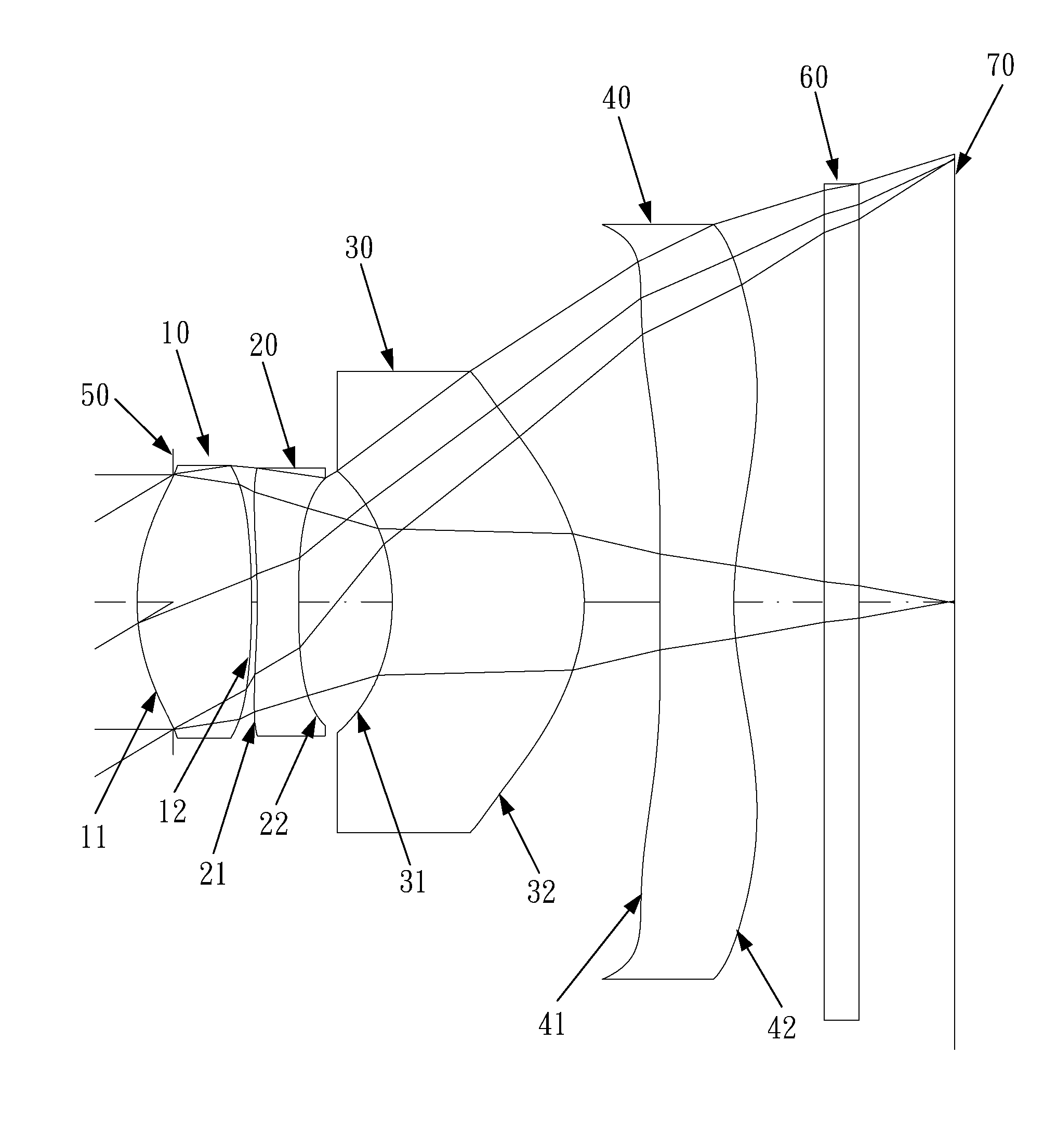

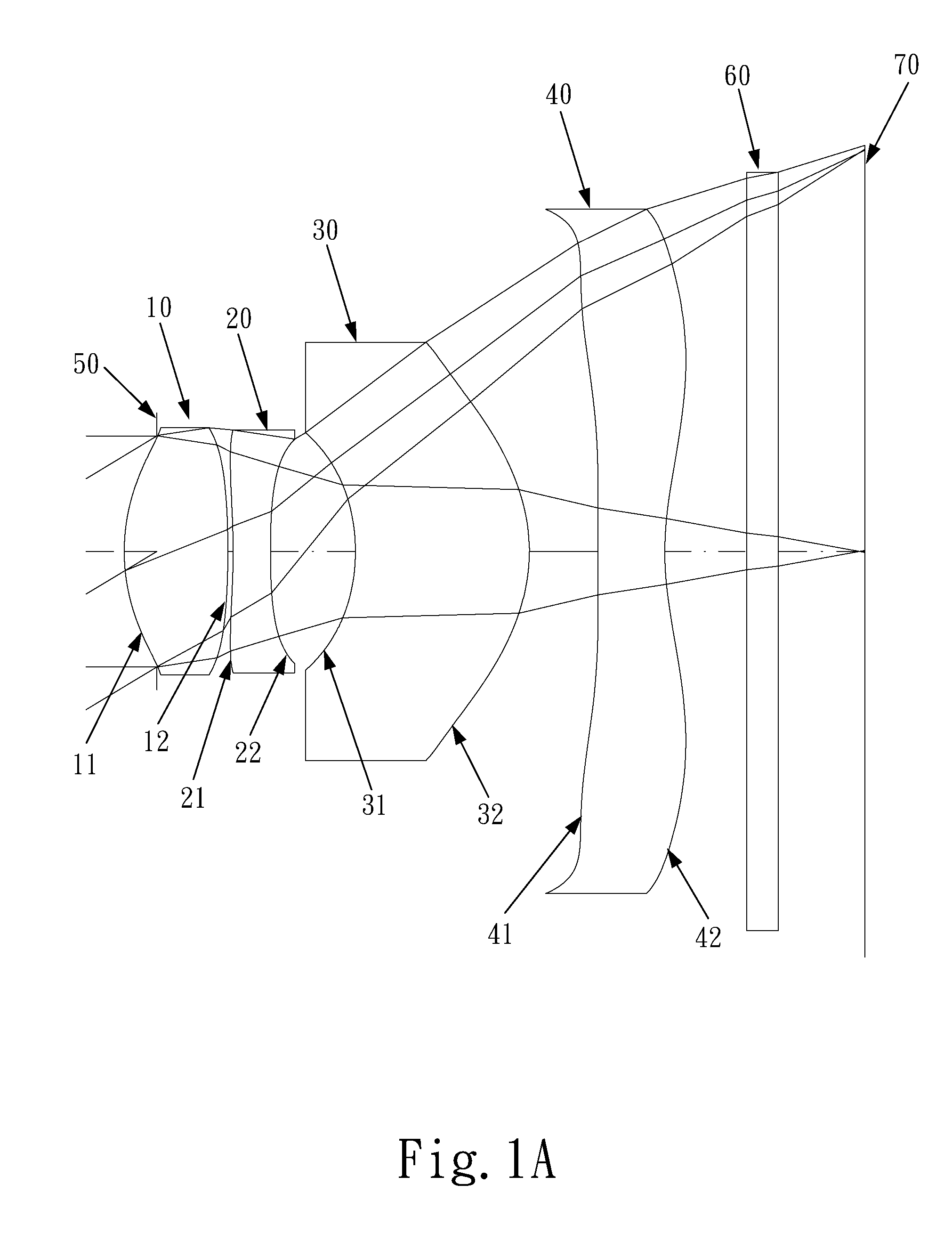

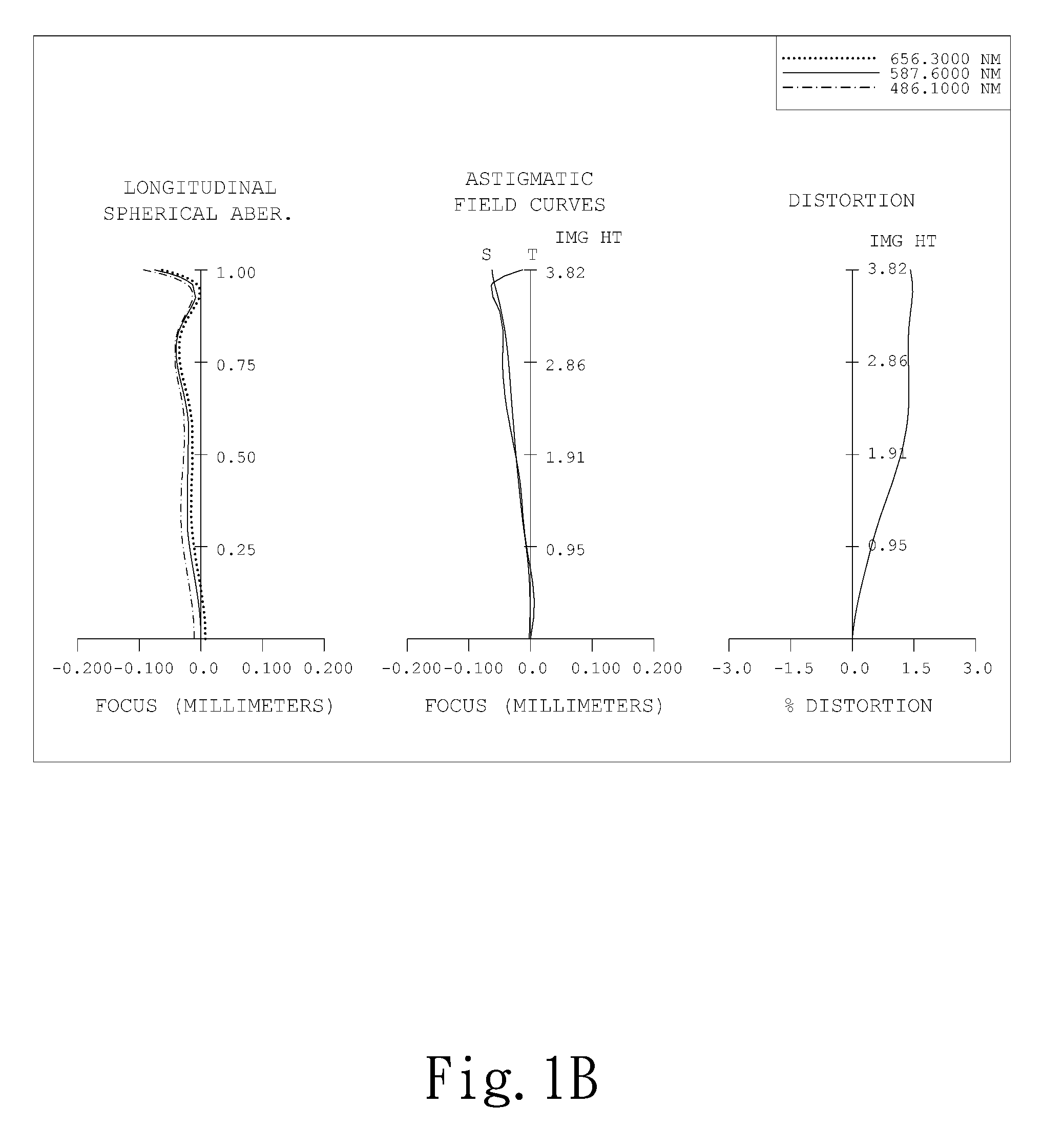

Wide-viewing-angle imaging lens assembly

ActiveUS20110316969A1Expand field of viewReduce sensitivityTelevision system detailsColor television detailsImaging lensField of view

The present invention provides a wide-viewing-angle imaging lens assembly comprising, in order from an object side to an image side: a front lens group, a stop, and a rear lens group. The front lens group comprises, in order from the object side to the image side: a first lens element with negative refractive power having a concave image-side surface and a second lens element. The rear lens group comprises, in order from the object side to the image side: a third lens element with positive refractive power having a concave object-side surface and a convex image-side surface, a fourth lens element with positive refractive power having a convex object-side surface and a convex image-side surface, and a fifth lens element with negative refractive power having a concave object-side surface. Such an arrangement of optical elements can effectively enlarge the field of view of the wide-viewing-angle imaging lens assembly, reduce the sensitivity of the optical system, and obtain good image quality.

Owner:LARGAN PRECISION

Optical lens system

The present invention provides an optical lens system comprising, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power; a third lens element with positive refractive power having a convex object-side surface and a convex image-side surface; a fourth lens element; and a fifth lens element having a concave image-side surface, the object-side and image-side surfaces thereof being aspheric and at least one inflection point being formed on the image-side surface. Such arrangement of optical elements can effectively minimize the size of the optical lens system, lower the sensitivity of the optical system, and obtain higher image resolution.

Owner:LARGAN PRECISION

Photographing optical lens assembly

This invention provides a photographing optical lens assembly including, in order from an object side toward an image side: a first lens element with positive refractive power having a convex object-side surface, a second lens element with negative refractive power having a concave object-side surface and a concave image-side surface, a third lens element with positive refractive power, a fourth lens element with negative refractive power having a convex object-side surface and a concave image-side surface, and at least one of surfaces thereof being aspheric, a plastic fifth lens element having a convex object-side surface and a concave image-side surface with at least one inflection point. An aperture stop is positioned between an imaged object and the third lens element. The photographing optical lens assembly further comprises an electronic sensor on which the object is imaged.

Owner:LARGAN PRECISION

Optical lens system

The present invention provides an optical lens system comprising, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power; a third lens element with positive refractive power having a convex object-side surface and a convex image-side surface; a fourth lens element; and a fifth lens element having a concave image-side surface, the object-side and image-side surfaces thereof being aspheric and at least one inflection point being formed on the image-side surface. Such arrangement of optical elements can effectively minimize the size of the optical lens system, lower the sensitivity of the optical system, and obtain higher image resolution.

Owner:LARGAN PRECISION

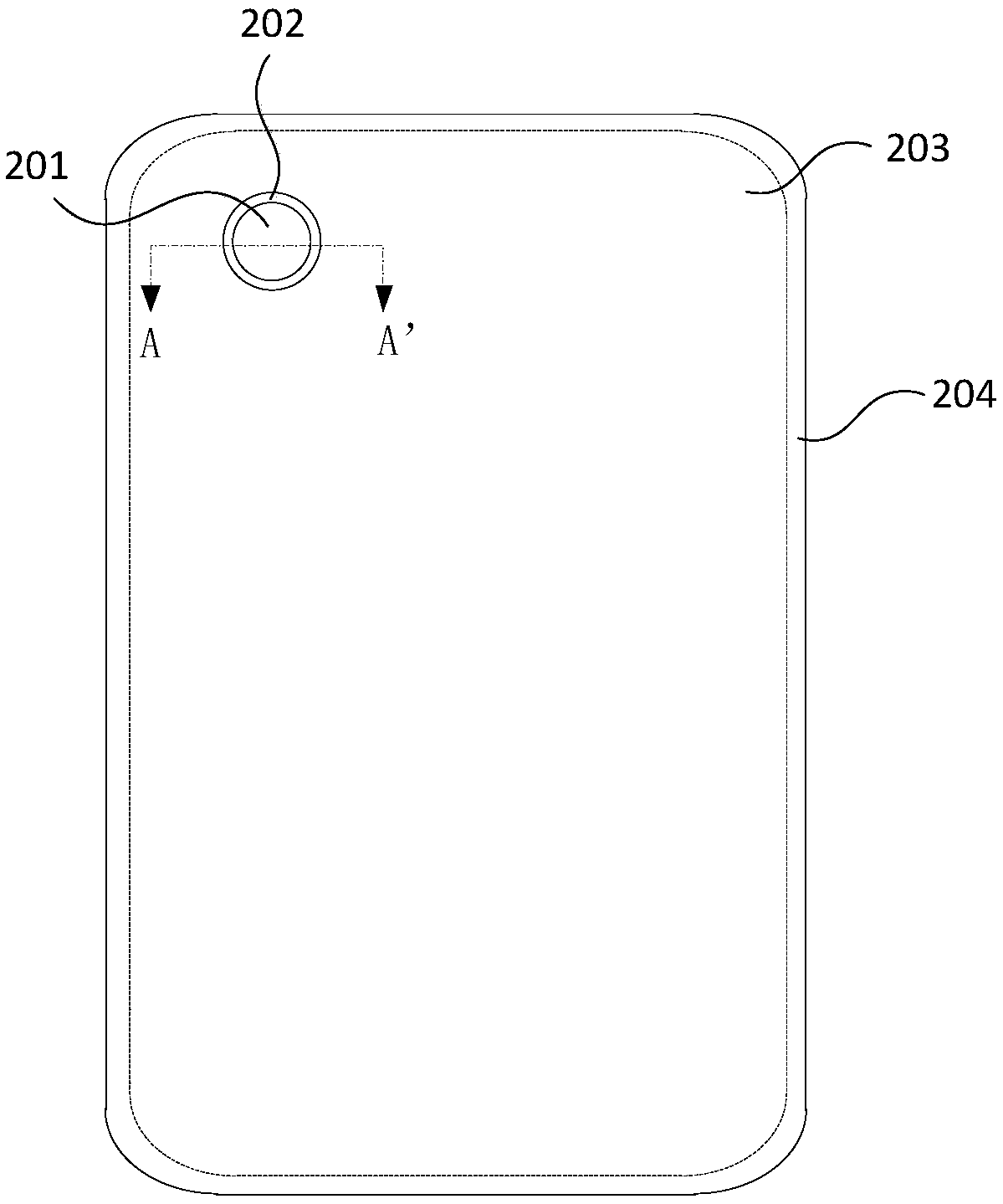

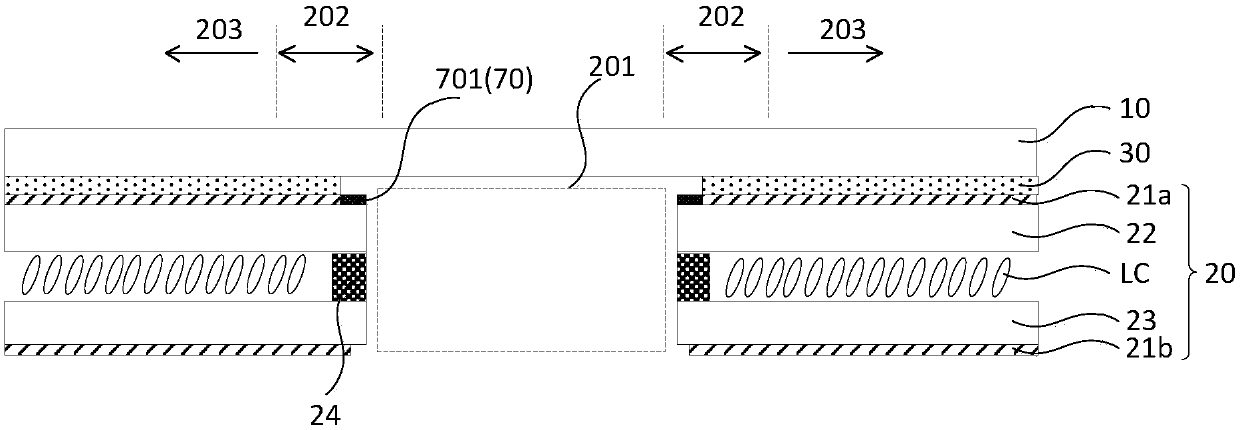

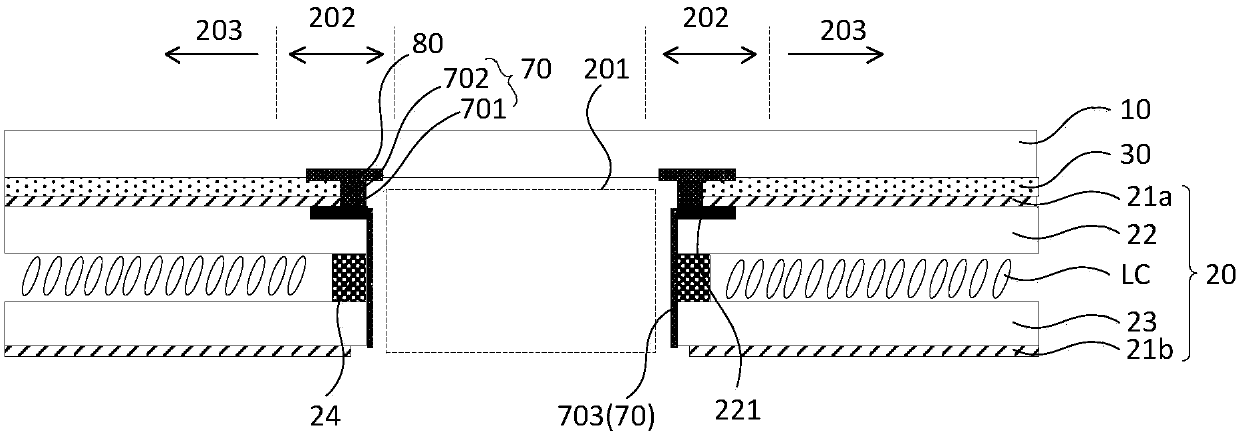

Display device

ActiveCN108681131AReduce thicknessIncrease visual rangeTelevision system detailsColor television detailsDisplay deviceComputer science

The invention relates to a display device. The display device comprises a cover plate and a display panel which are arranged oppositely; the display panel comprises a through hole, a first non-displayarea, a display area and a second non-display area; the through hole runs through the display panel along the thickness direction; the first non-display area surrounds the through hole; the display area surrounds the first non-display area; the second non-display area surrounds the display area; the positive projection of the cover plate on the plane on which the display area is covers the through hole; the display panel also comprises an upper polaroid; the upper polaroid is positioned on one side, near the cover plate, of the display panel; and a shading material is arranged on the surfaceof one side, near the through hole, of the upper polaroid. The display device provided by the invention can effectively improve the light leakage problem of the display panel and improve the shootingeffect of photosensitive devices such as a camera while increasing the screen-to-body ratio of the display panel.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Optical lens system

The present invention provides an optical lens system comprising, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power; a third lens element with positive refractive power having a convex object-side surface and a convex image-side surface; a fourth lens element; and a fifth lens element having a convex object-side surface and a concave image-side surface, the object-side and image-side surfaces thereof being aspheric and at least one inflection point being formed on the image-side surface. Such arrangement of optical elements can effectively minimize the size of the optical lens system, lower the sensitivity of the optical system, and obtain higher image resolution.

Owner:LARGAN PRECISION

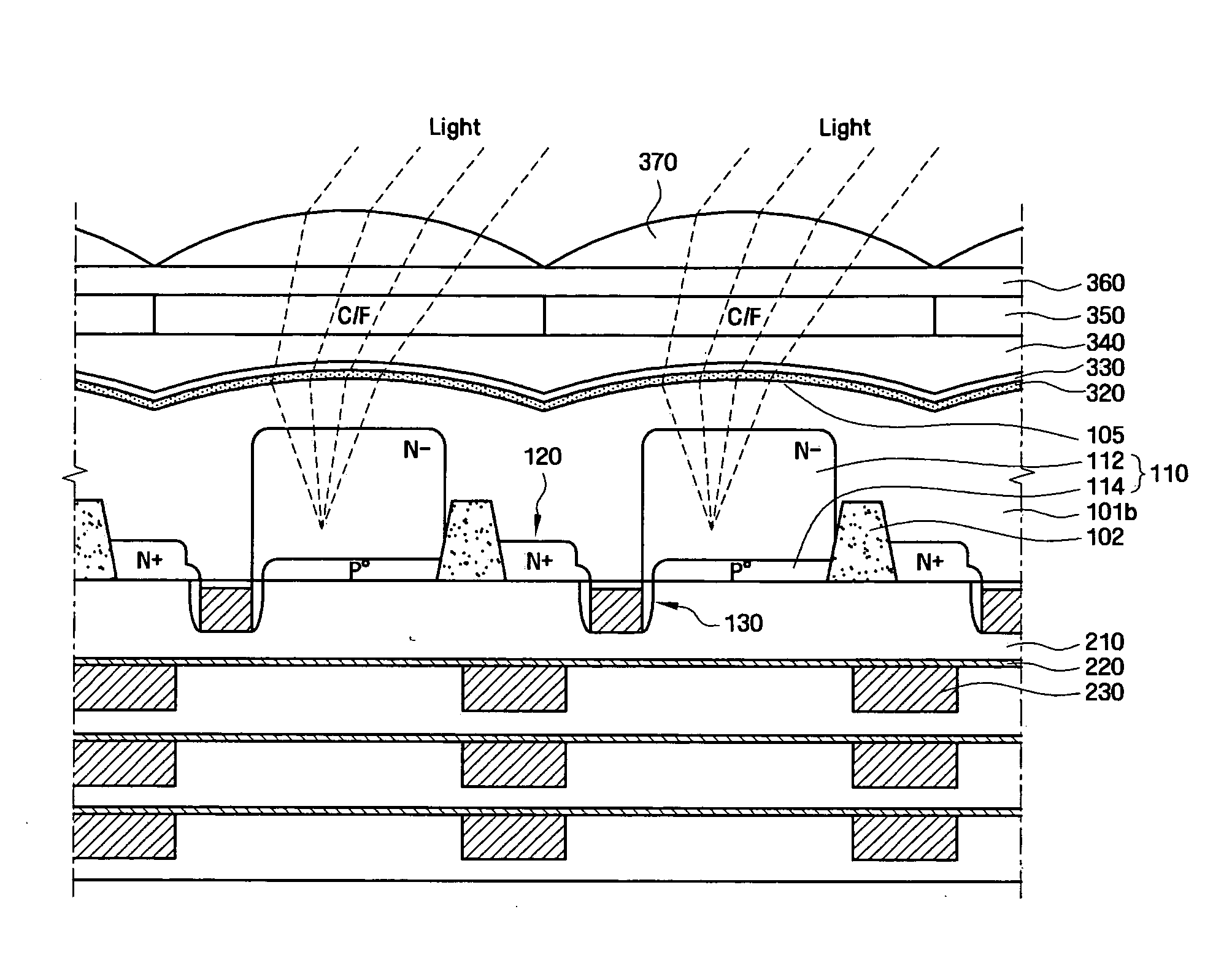

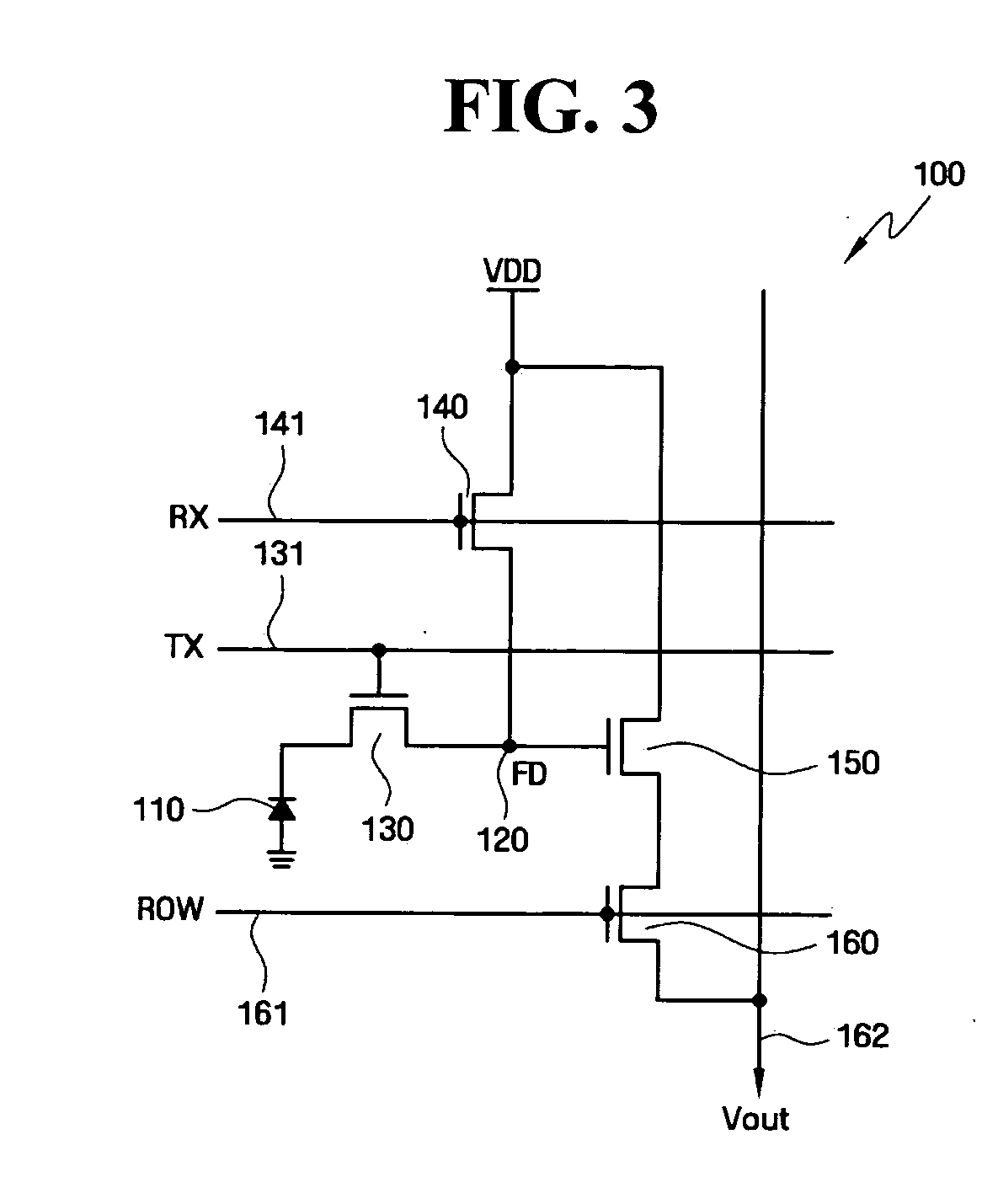

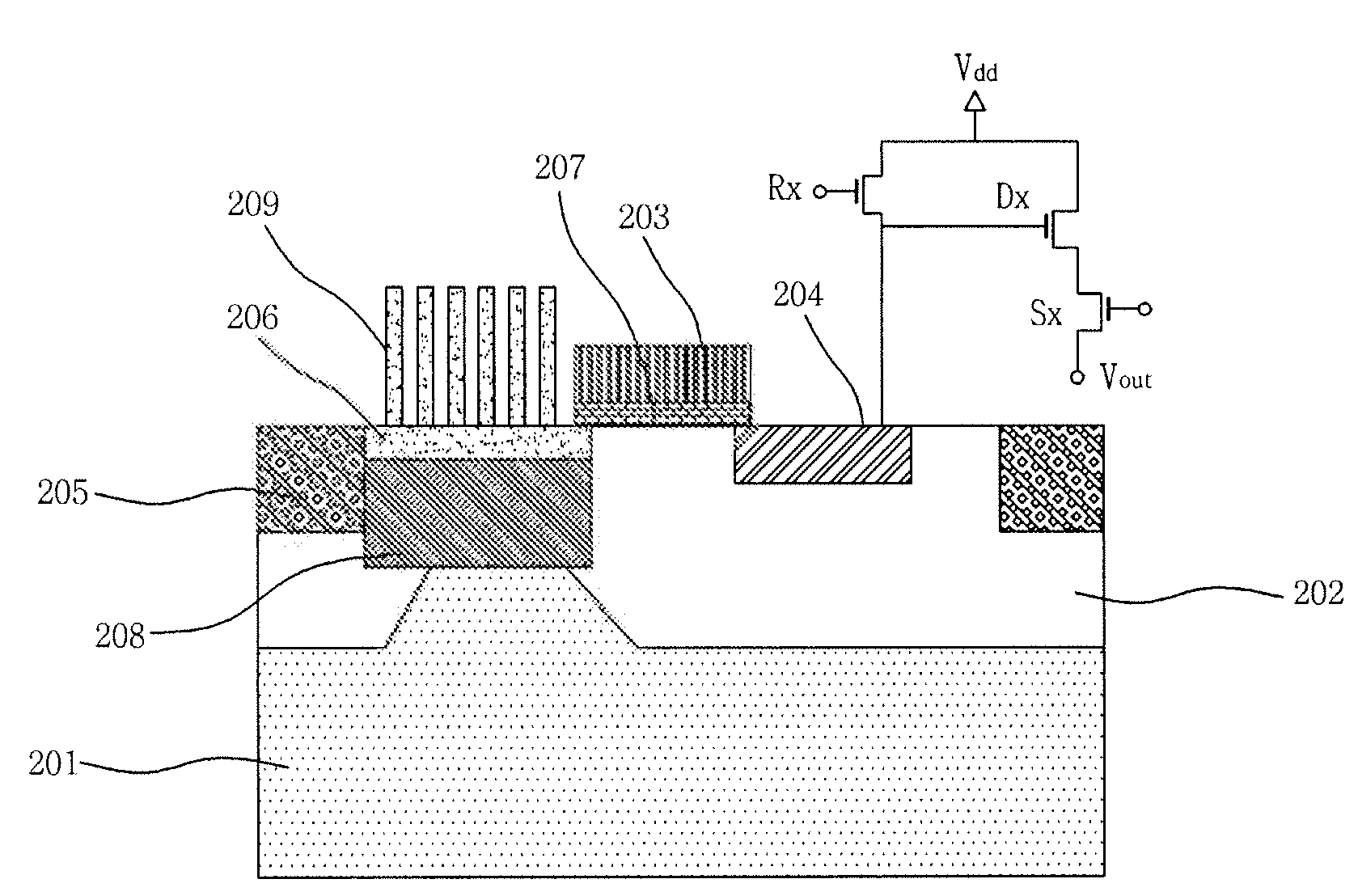

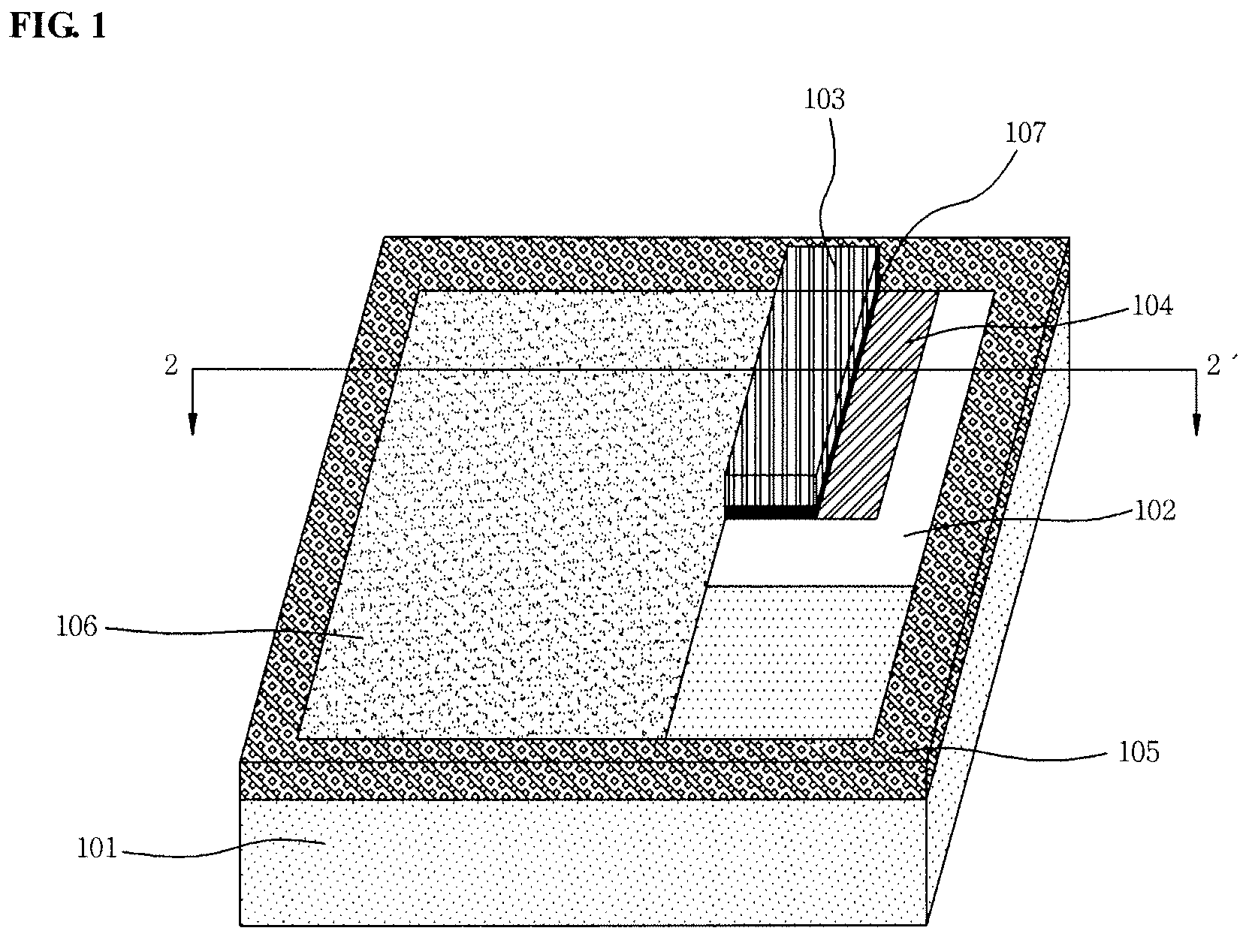

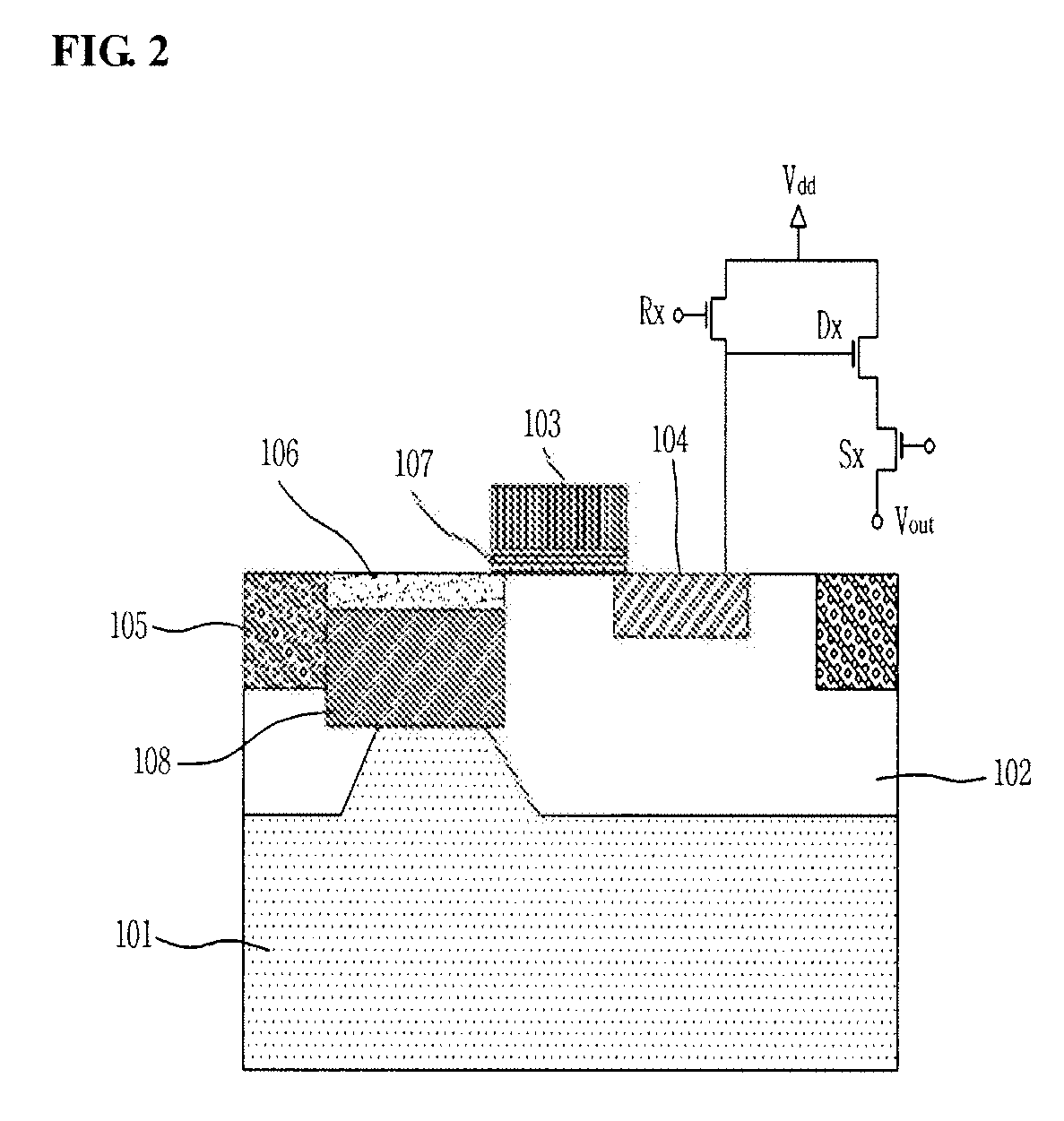

Unit pixels, image sensor containing unit pixels, and method of fabricating unit pixels

ActiveUS20090090937A1Increase photosensitivityReduce light lossSolid-state devicesSemiconductor/solid-state device manufacturingTransducerSemiconductor

Example embodiments provide a unit pixel, an image sensor containing unit pixels, and a method of fabricating unit pixels. The unit pixel may include a semiconductor substrate, photoelectric transducers formed within the semiconductor substrate, multi-layered wiring layers formed on a frontside of the semiconductor substrate, inner lenses formed on a backside of the semiconductor substrate corresponding to the photoelectric transducers, and microlenses formed above the inner lenses.

Owner:SAMSUNG ELECTRONICS CO LTD

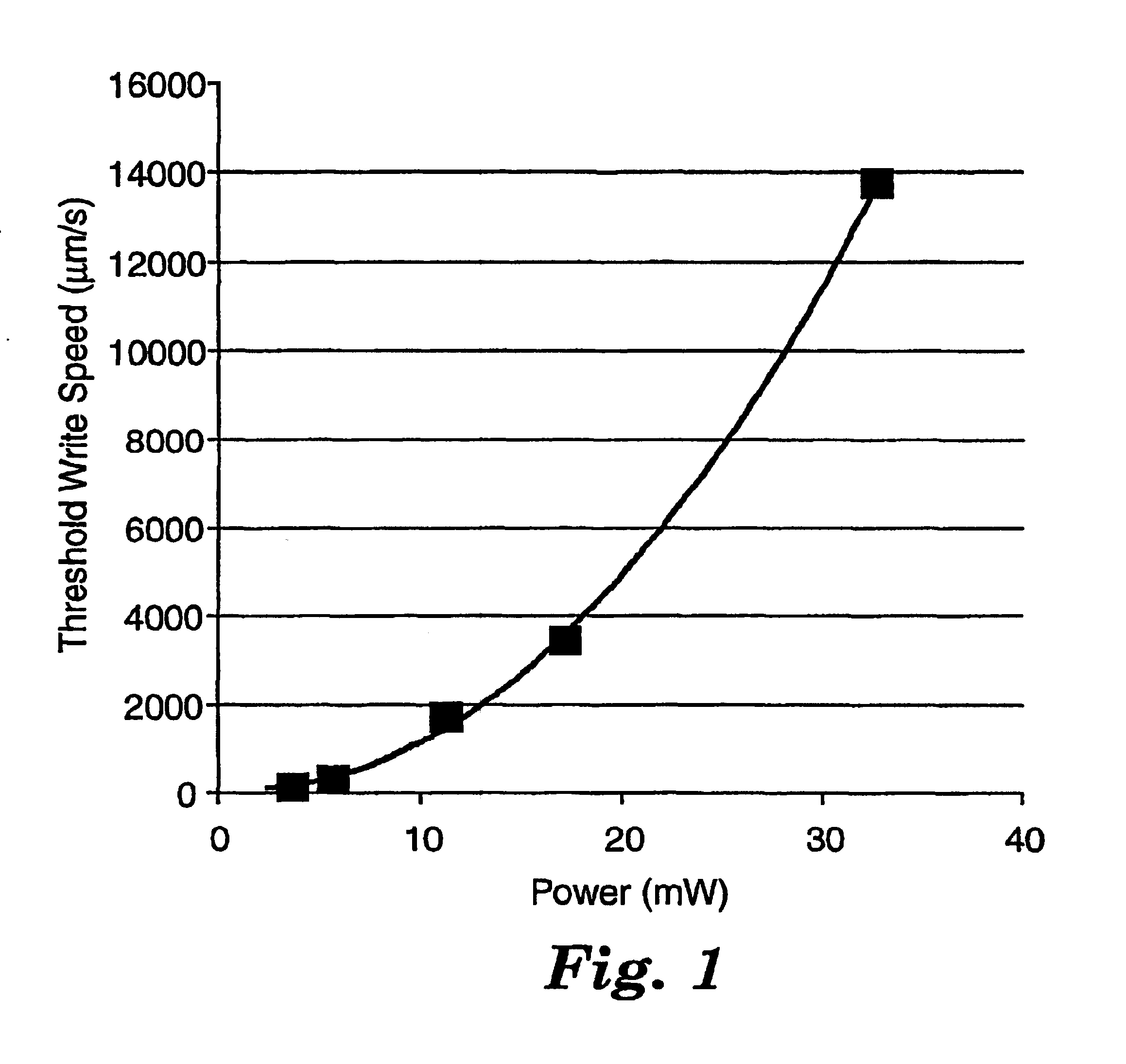

Multiphoton photosensitization system

InactiveUS6852766B1Efficiently formedHigh sensitivityOrganic chemistryPhotosensitive materialsChemical reactionPhotoinitiator

A method of multiphoton photosensitizing a photoreactive composition comprises irradiating the composition with light sufficient to cause simultaneous absorption of at least two photons, thereby inducing at least one acid- or radical-initiated chemical reaction where the composition is exposed to the light. The composition comprises: (a) at least one reactive species that is capable of undergoing such reaction; and (b) at least one multi-component, multiphoton photoinitiator system.

Owner:3M INNOVATIVE PROPERTIES CO

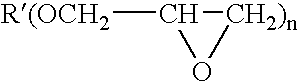

Photocurable Compositions

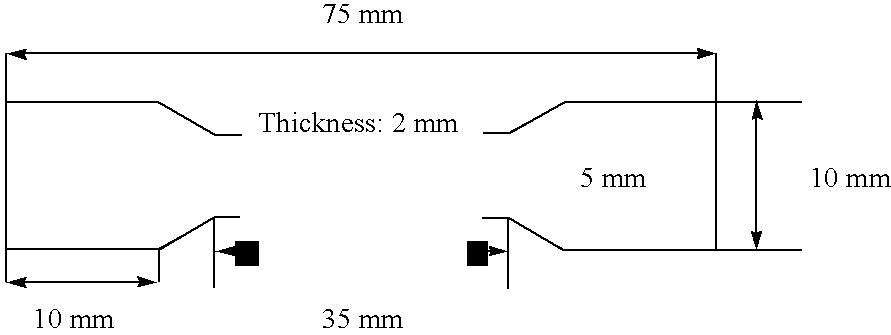

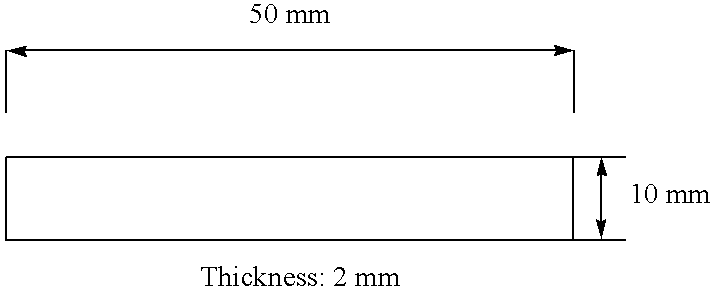

ActiveUS20070205528A1Reduce Shrinkage ProblemsHigh Tg cured propertyAdditive manufacturing apparatusNanostructure manufacturePhysicsRadiation exposure

An optical moulding process is disclosed comprising the sequential steps of: (a)(y) forming a layer of a photocurable composition; and (bXz) irradiating selected areas of the composition in the layer with radiation from a radiation source, thereby curing the composition in said selected areas and repeating the steps a) and b) on top of an earlier cured layer to form a three dimensional structure, wherein the radiation source used in step b) is a non-coherent source of radiation and wherein the photocurable composition comprises at least two curable components: (i) 45%-95% (and preferably at least 50%, more preferably at least 60%, e.g. at least 70%) by weight of the total curable components in the composition is a first component that is photocurable and that is such that, when cured in the presence of a photocuring initiator by exposure to UV radiation having an energy of 30 mJ / cm2, at least 90% of the component is cured within 50 milliseconds; and (ii) 5% to 55% (and preferably 10-40%, more preferably 15 to 30%, e.g. about 20%) by weight of the total curable components in the composition is a second component that results in the composition, on curing, shrinking, in a linear direction, by less than 3% and preferably that results in the composition having, after cure, a Tg of greater than 50° C., preferably at least 100° C. and more preferably at least 120° C.

Owner:3D SYST INC

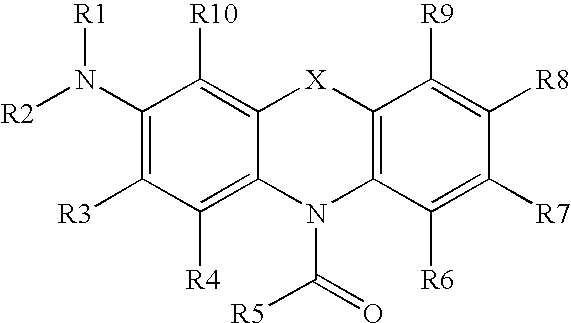

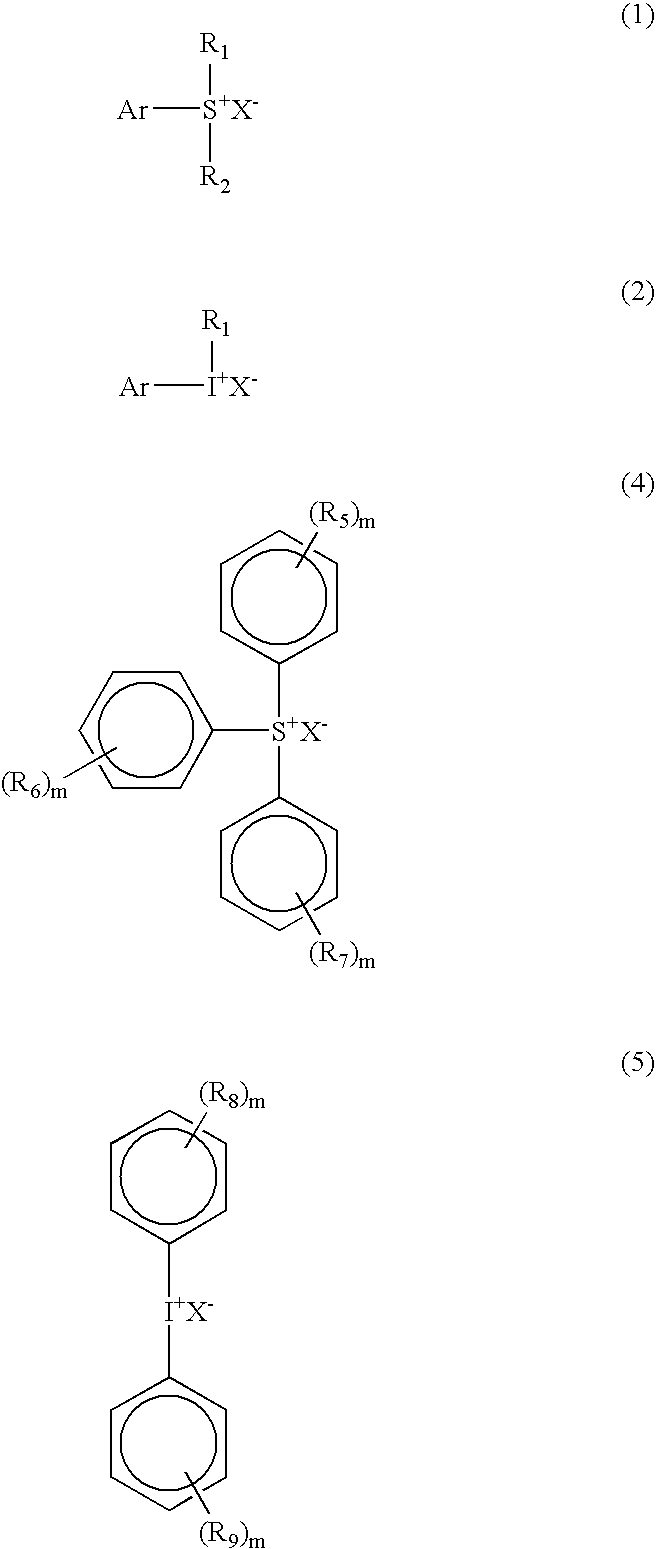

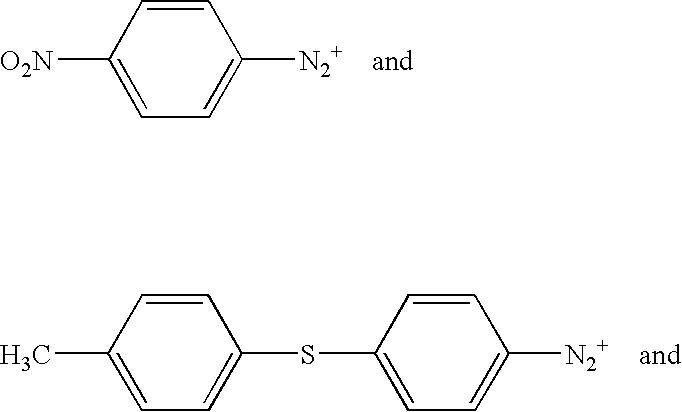

Photoresist composition for deep ultraviolet lithography comprising a mixture of photoactive compounds

InactiveUS6991888B2Reduce edge roughnessAcceptable photosensitivityOrganic chemistryOrganic compound preparationResistUltraviolet

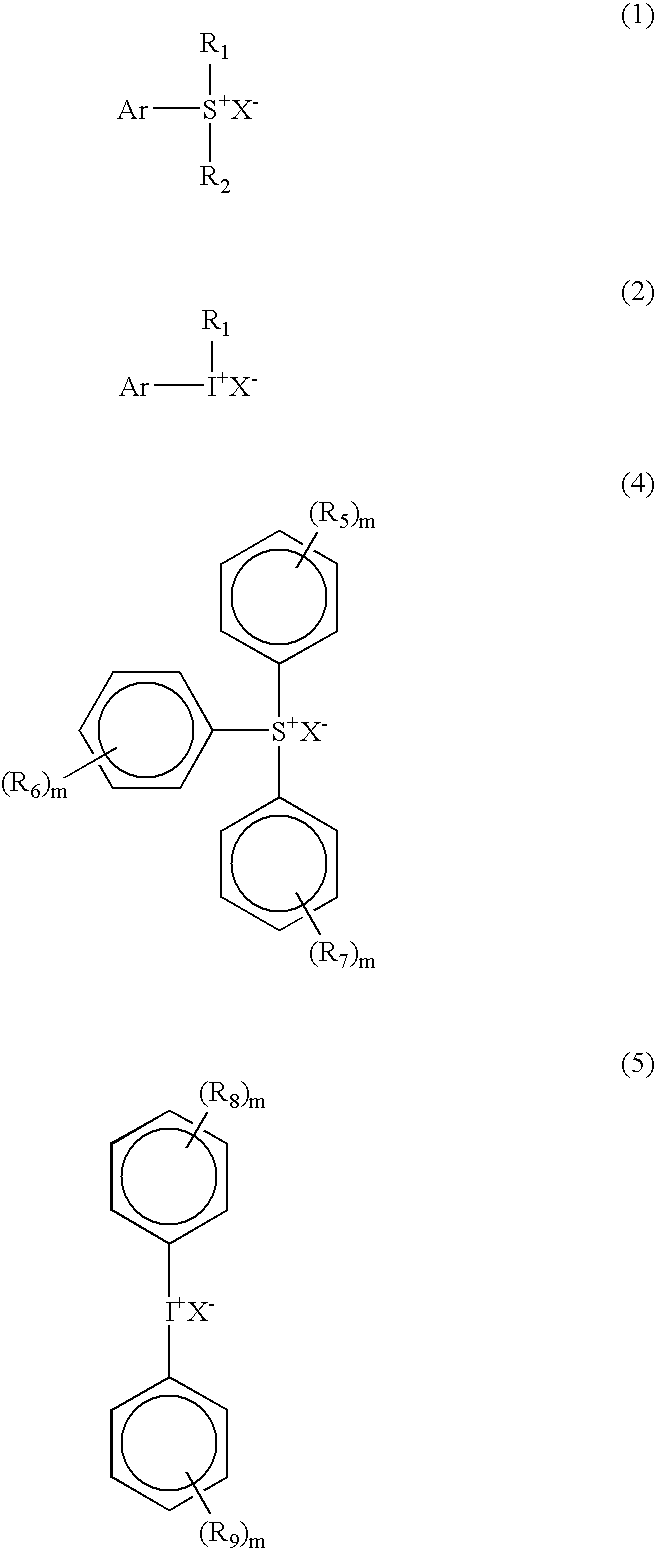

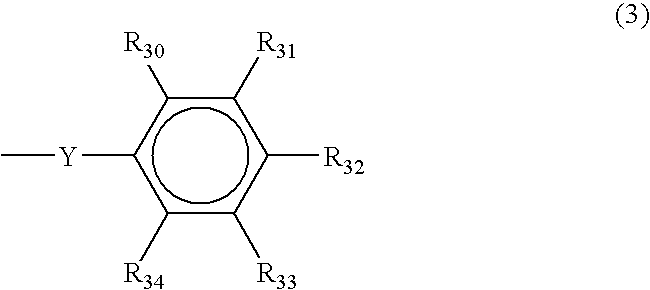

The present invention relates to a novel photoresist composition that can be developed with an aqueous alkaline solution, and is capable of being imaged at exposure wavelengths in the deep ultraviolet. The invention also relates to a process for imaging the novel photoresist as well as novel photoacid generators.The novel photoresist comprises a) a polymer containing an acid labile group, and b) a novel mixture of photoactive compounds, where the mixture comprises a lower absorbing compound selected from structure 1 and 2, and a higher absorbing compound selected from structure 4 and 5, where, R1 and R2 R5, R6, R7, R8, and R9 are defined herein; m=1–5; X− is an anion, and Ar is selected from naphthyl, anthracyl, and structure 3, where R30, R31, R32, R33, and R34 are defined herein.

Owner:MERCK PATENT GMBH

Imaging lens assembly

This invention provides an imaging lens assembly including five lens elements with refractive power, in order from an object side toward an image side: a first lens with positive refractive power having a convex object-side surface, a second lens with negative refractive power, a third lens having a concave object-side surface, a fourth lens with positive refractive power having an object-side surface and a convex image-side surface, and at least one of both surfaces thereof being aspheric, a fifth lens with negative refractive power having a concave image-side surface with at least one inflection point formed thereon. An aperture stop is positioned between an imaged object and the second lens. The imaging lens assembly further comprises an electronic sensor on which an object is imaged. With such arrangement, the size and the optical sensitivity of the lens assembly can be reduced. A high image resolution is also obtained.

Owner:LARGAN PRECISION

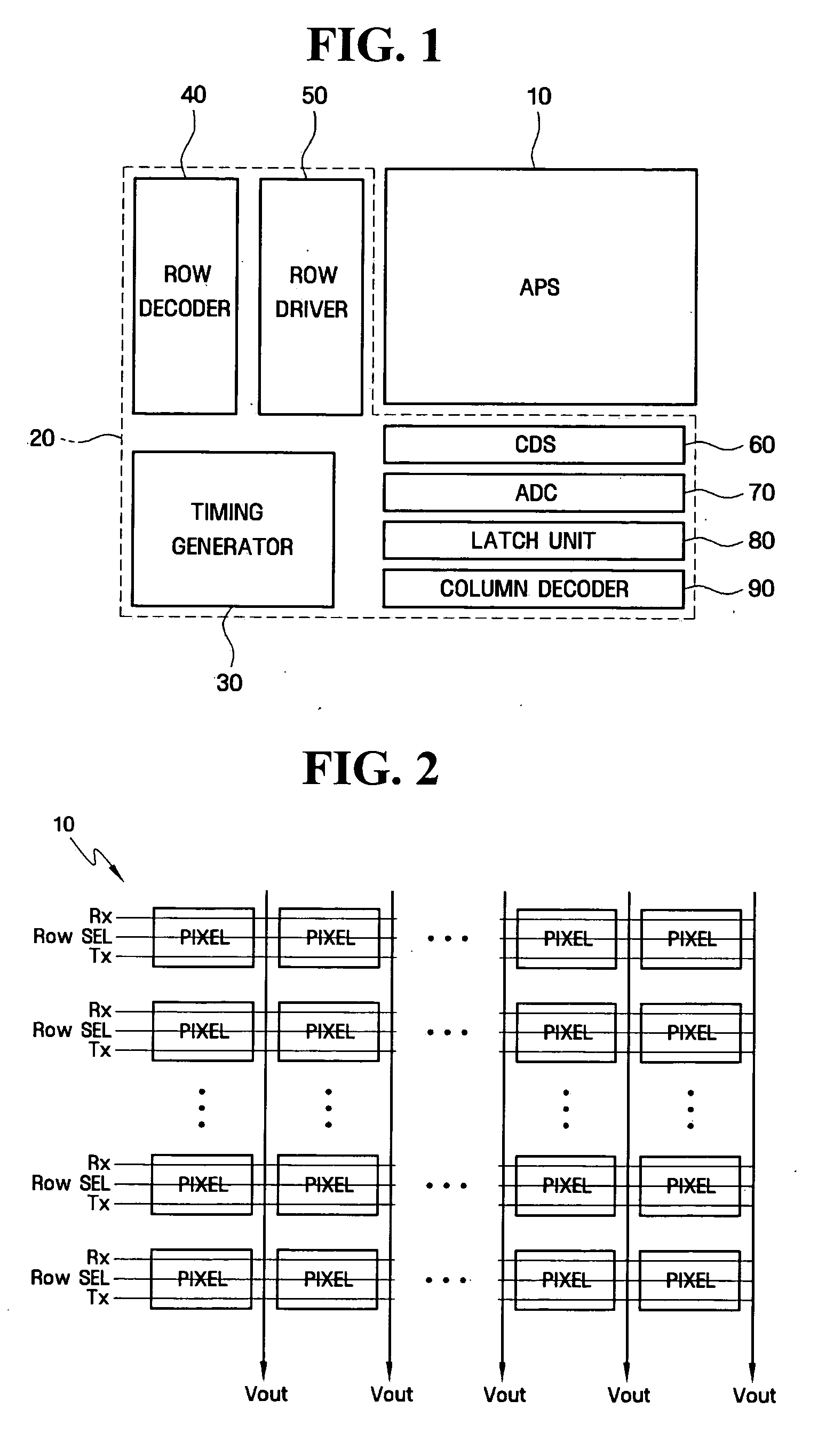

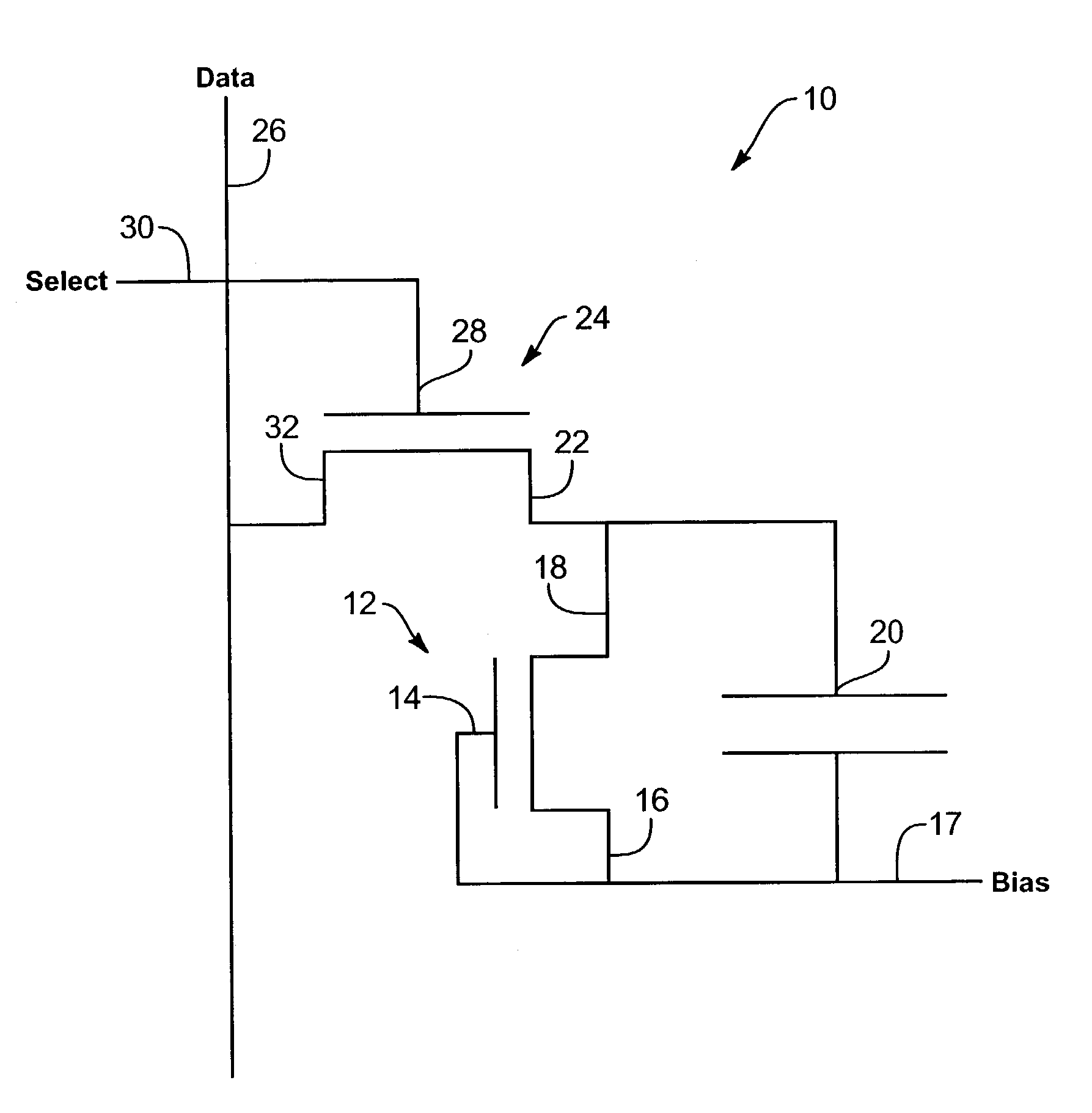

Image sensor with photosensitive thin film transistors

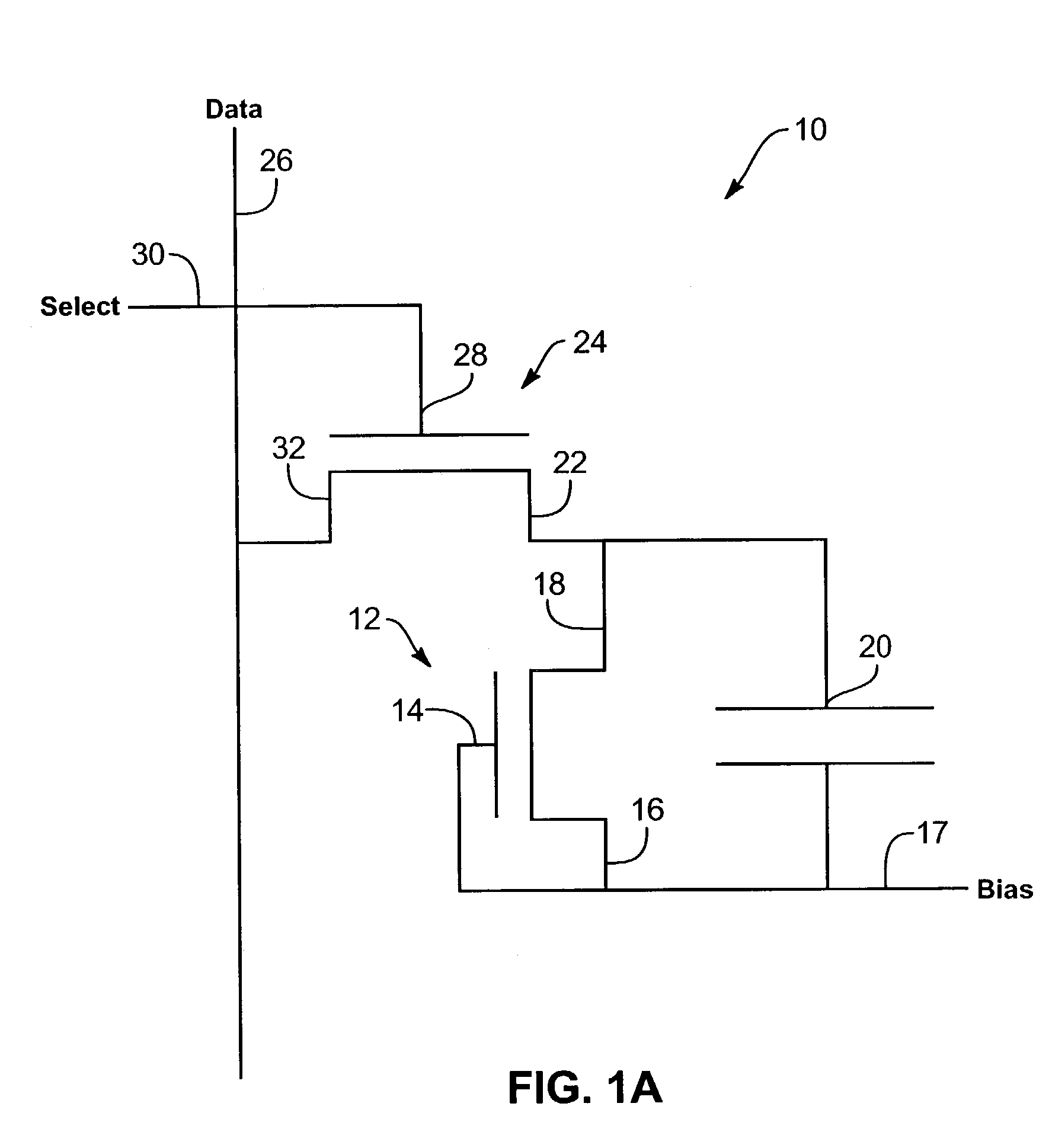

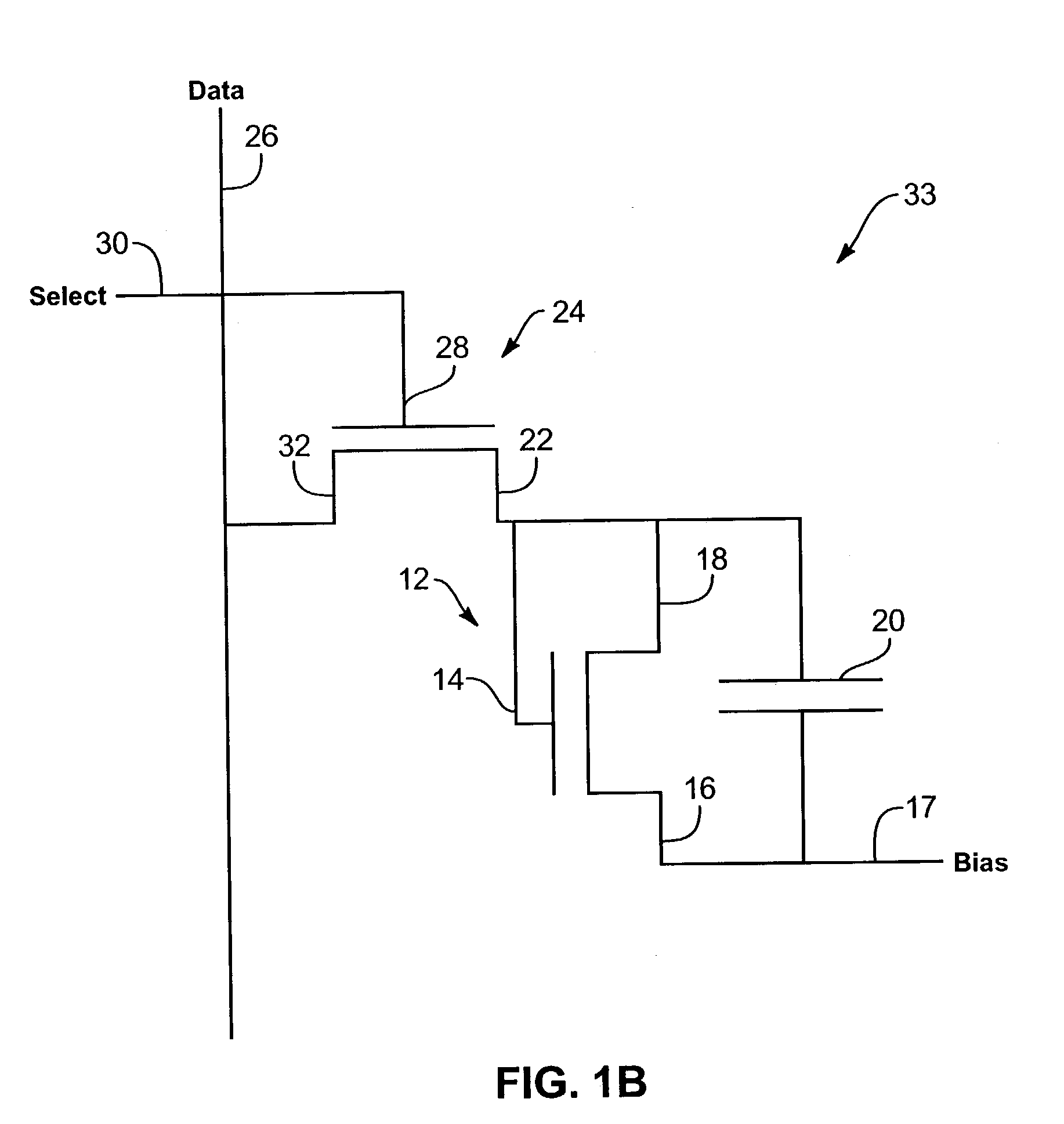

InactiveUS7023503B2Increase photosensitivityPrevent leakageStatic indicating devicesSolid-state devicesPhotocurrentCapacitor

An image sensor array includes image sensors having photo TFTs to generate photocurrent in response to received images. The photo TFTs each have their respective gate electrodes shorted to source electrodes to increase generated photocurrent. Storage capacitors are coupled to each photo TFT and discharged upon generation of a photocurrent. Each storage capacitor is coupled to a readout TFT that passes a current from the storage capacitor to a data line. Data lines indicate location of the received image on the image sensor array.

Owner:APPLE INC

Imaging lens assembly

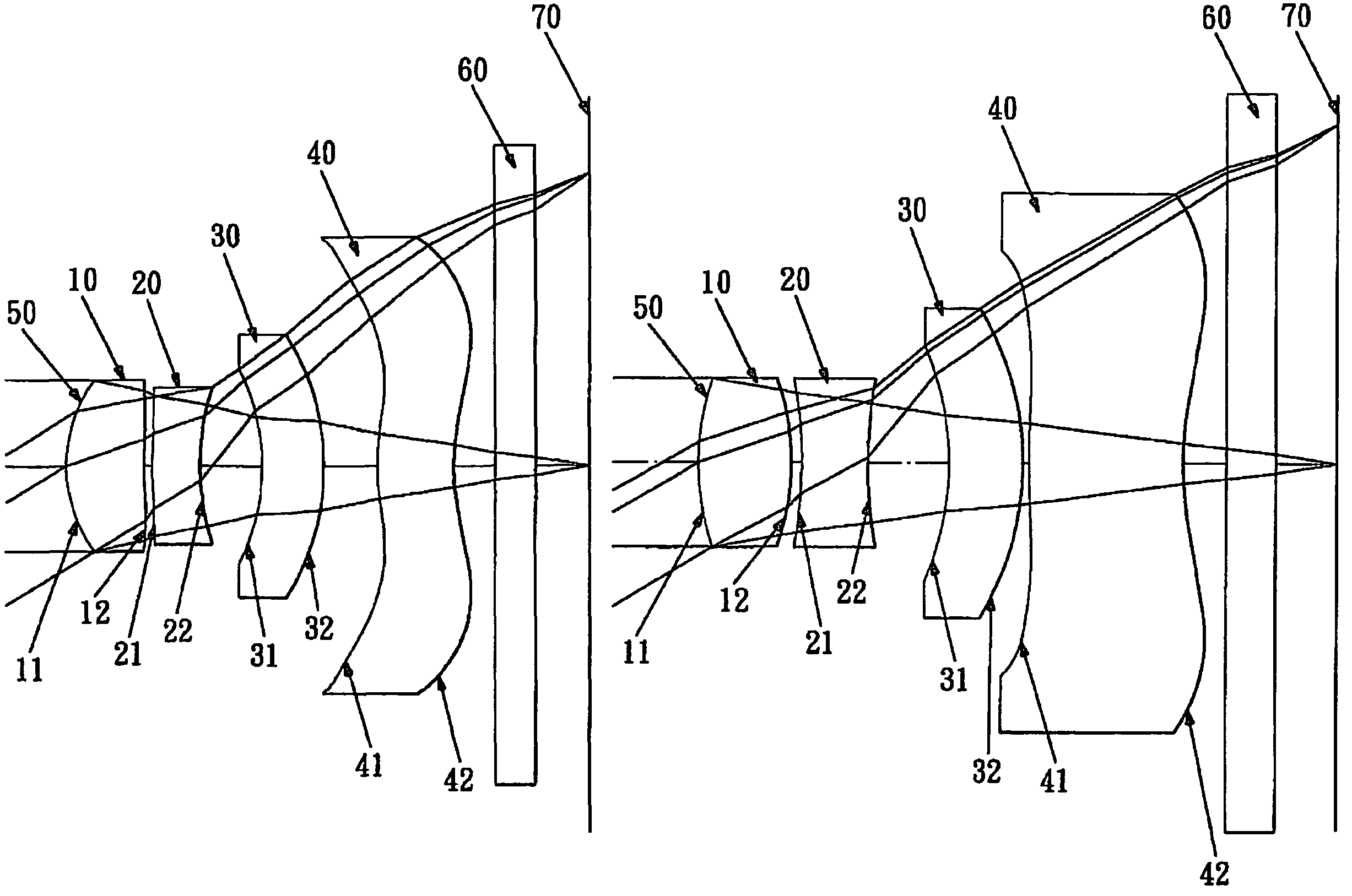

This invention provides an imaging lens assembly comprising, in order from an object side to an image side: a first lens element with negative refractive power having a convex object-side surface and a concave image-side surface; a second lens element with positive refractive power having a convex image-side surface; a third lens element with negative refractive power having a concave object-side surface and a convex image-side surface, both being aspheric; a fourth lens element with positive refractive power having a convex object-side surface, both its two surfaces being aspheric; and a stop disposed between the first and second lenses.

Owner:LARGAN PRECISION

Optical lens system for taking image

Owner:LARGAN PRECISION

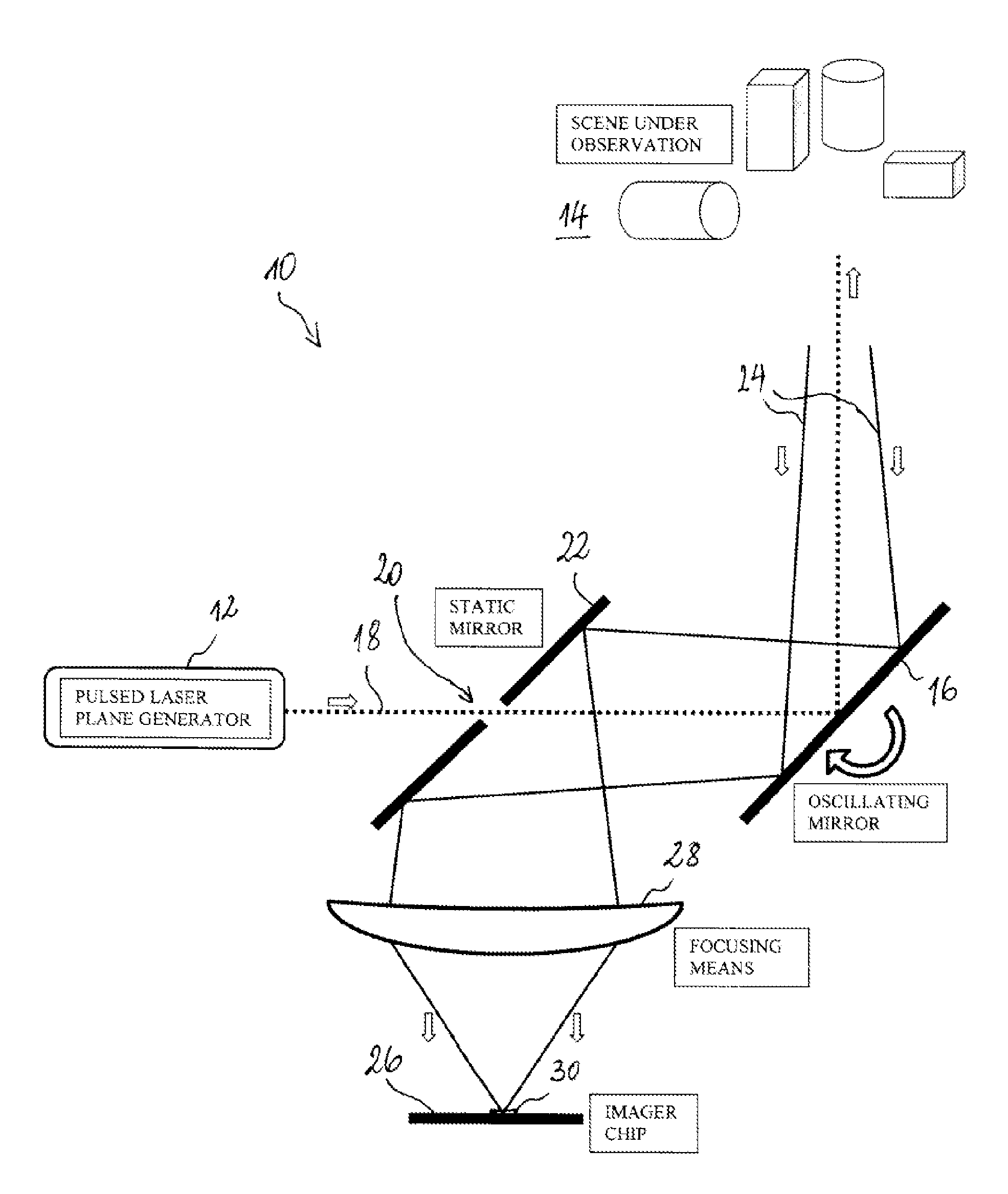

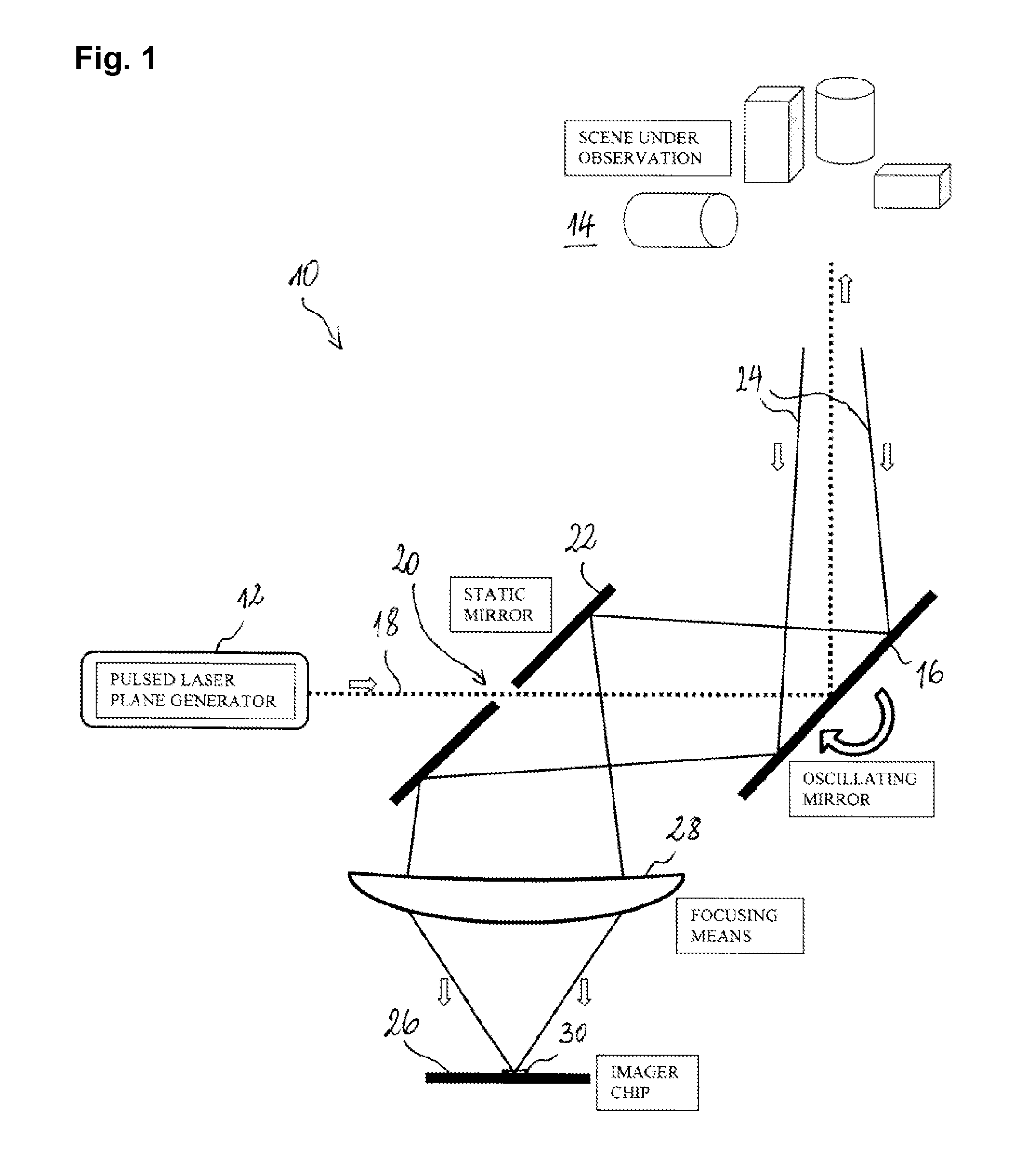

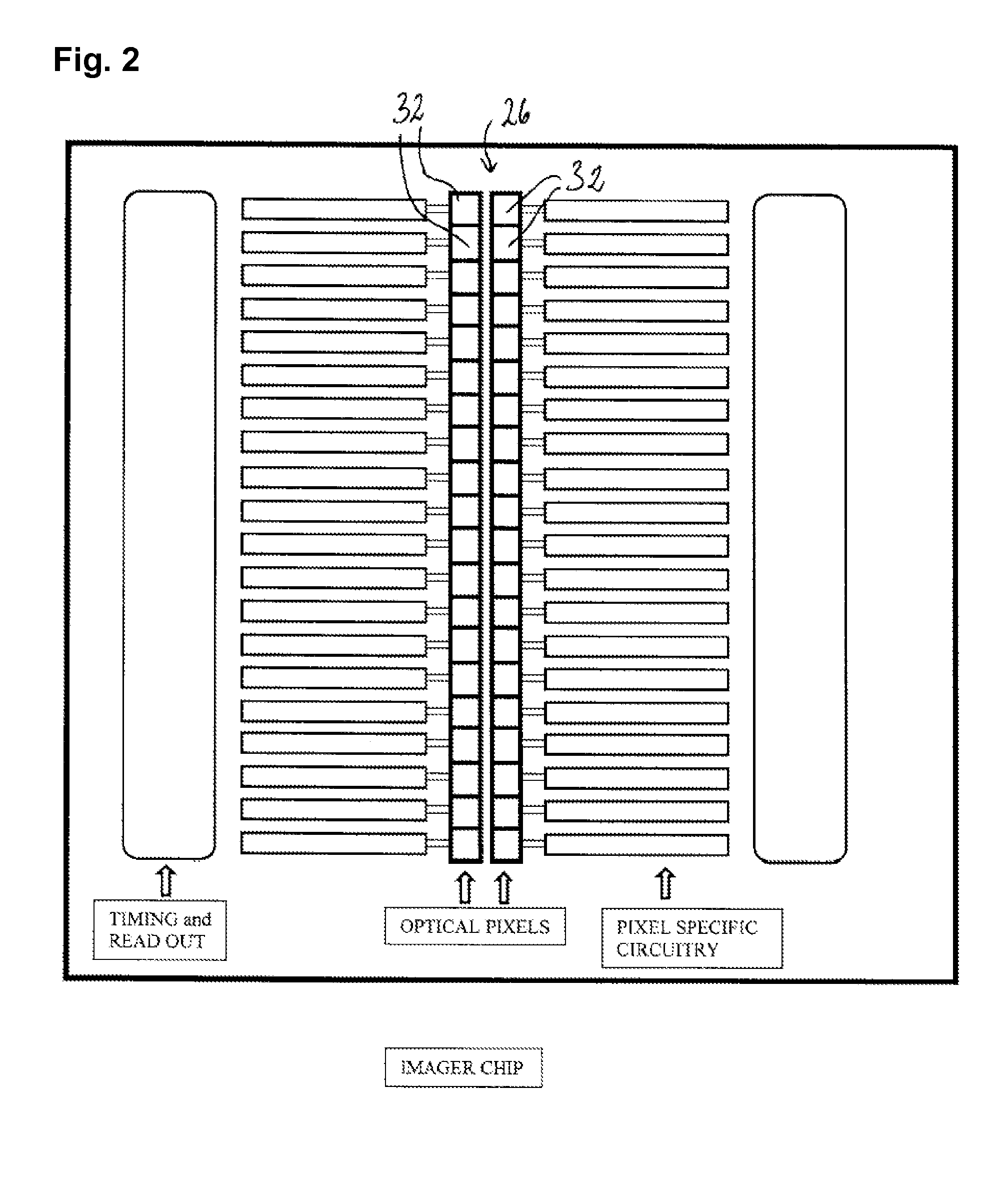

Scanning 3D imager

ActiveUS20130107016A1Improve performanceGood optical apertureElectromagnetic wave reradiationSteroscopic systemsSensor arrayLight beam

A scanning 3D imager for recording images of a scene comprises a light source configured to emit a fan-shaped pulsed light beam with linear cross section, a scanning mirror arranged in the light path of the light beam to guide the light beam into the scene and to successively illuminate slices of the scene by sweeping the light beam through the scene transversally to the linear cross section thereof, and an imager chip arranged to receive light from the scene via the scanning mirror, the imager chip comprising an photosensor array disposed in such a way that the illuminated slices of the scene are successively imaged thereon.

Owner:IEE INT ELECTRONICS & ENG SA

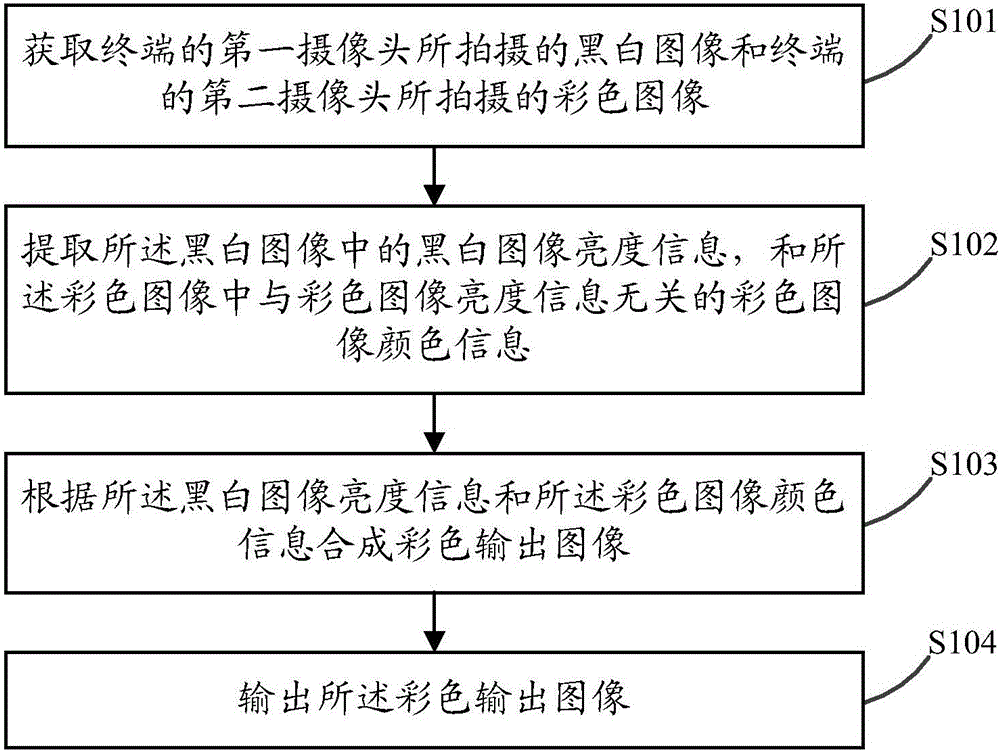

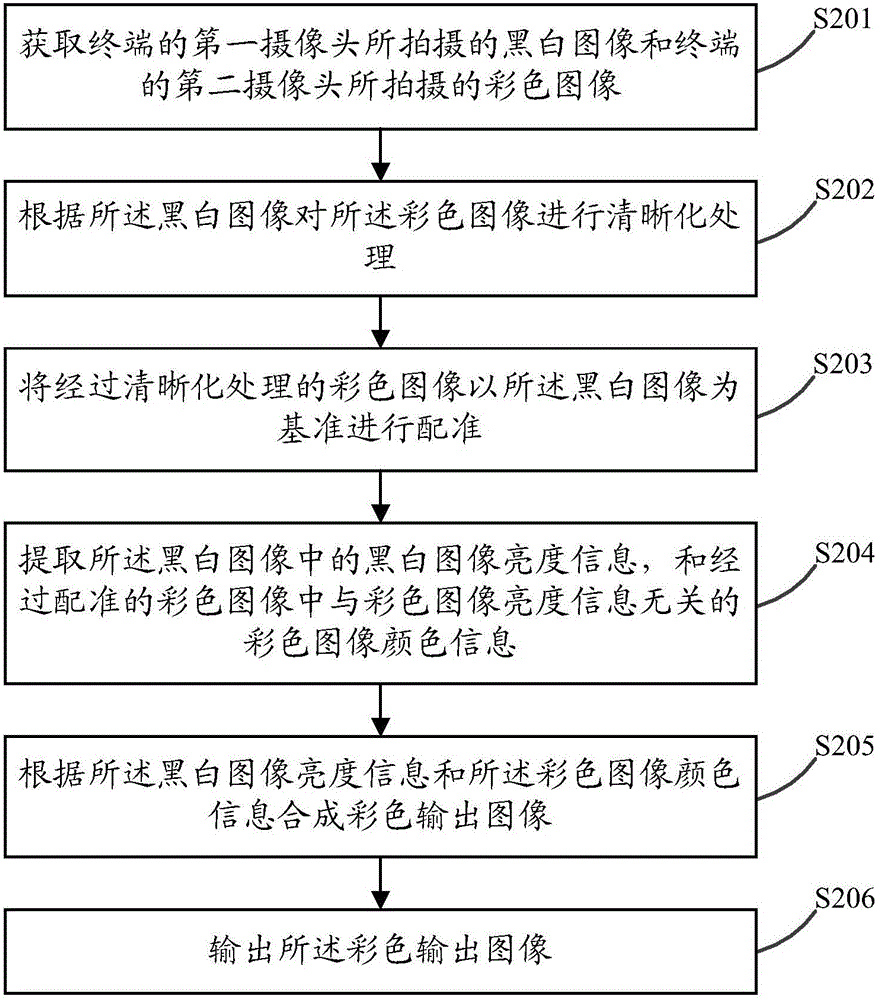

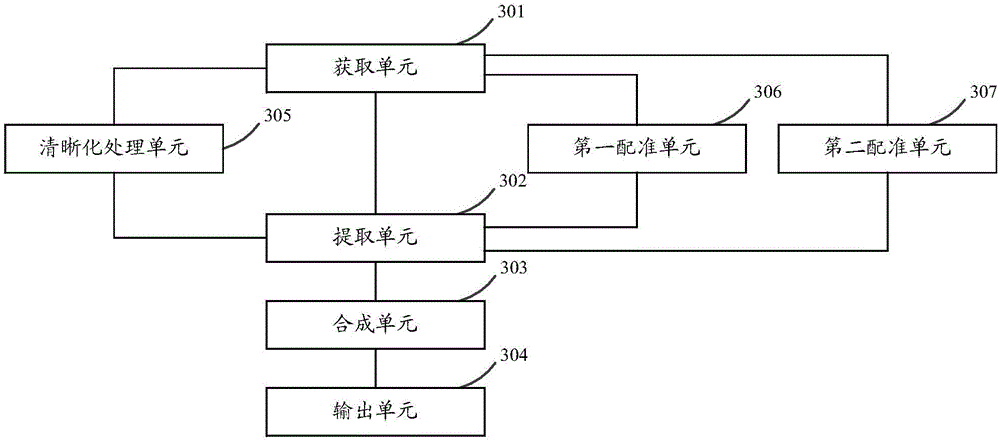

Image processing method and terminal

InactiveCN105049718AImprove qualityIncrease photosensitivityTelevision system detailsPicture signal generatorsBrightness perceptionImaging processing

The invention discloses an image processing method and a terminal. The method comprises steps: a black white image shot by a first camera of the terminal and a color image shot by a second camera of the terminal are obtained; sharp processing of the color image is carried out according to the black white image; black white image brightness information of the black white image and color image color information independent of the color image brightness information of the color image after sharp processing are extracted, synthesis of a color output image is carried out according to the black white image brightness information and the color image color information; the color output image is output. The picture shooting quality of the terminal can be raised.

Owner:SHENZHEN GIONEE COMM EQUIP

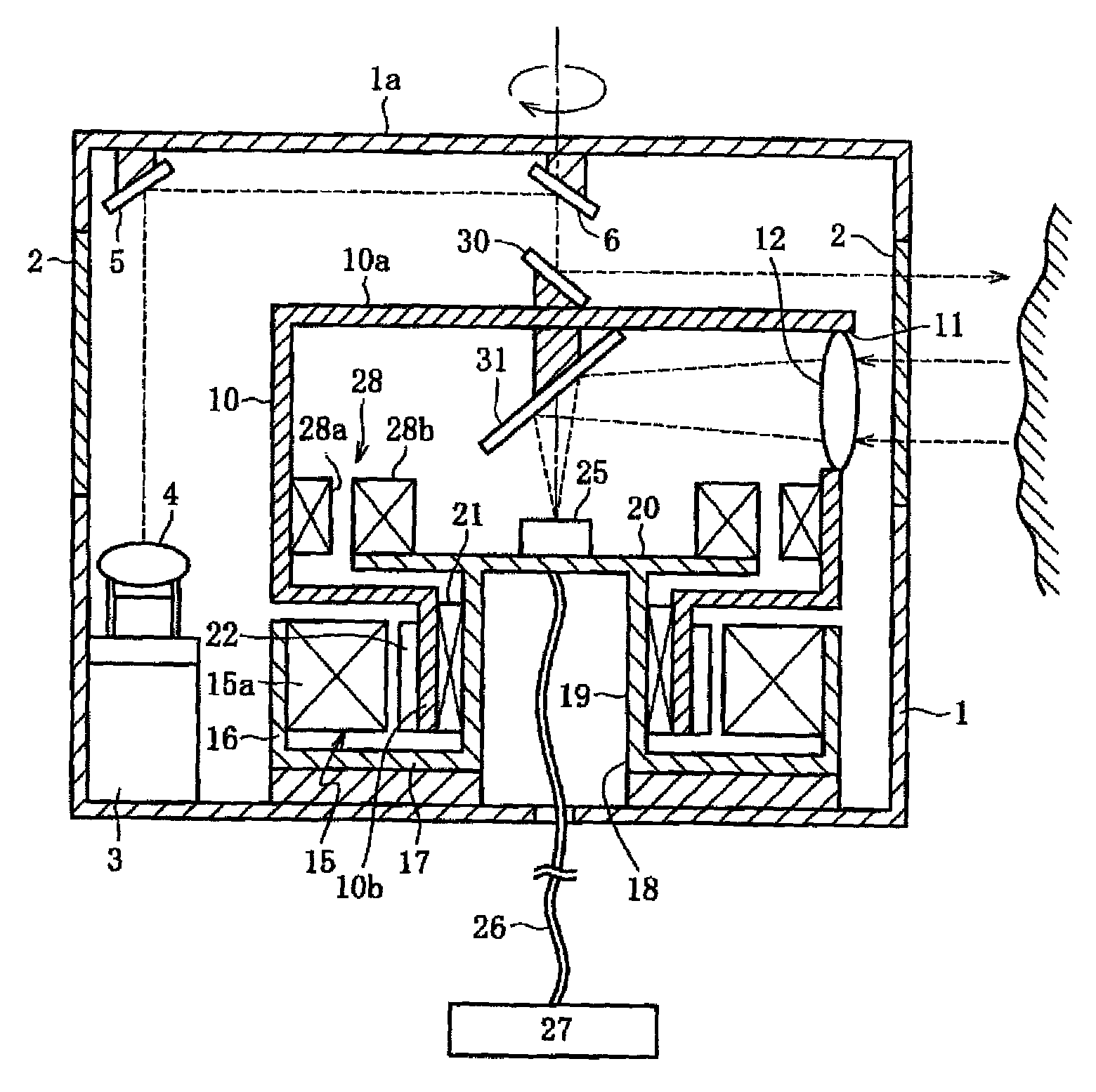

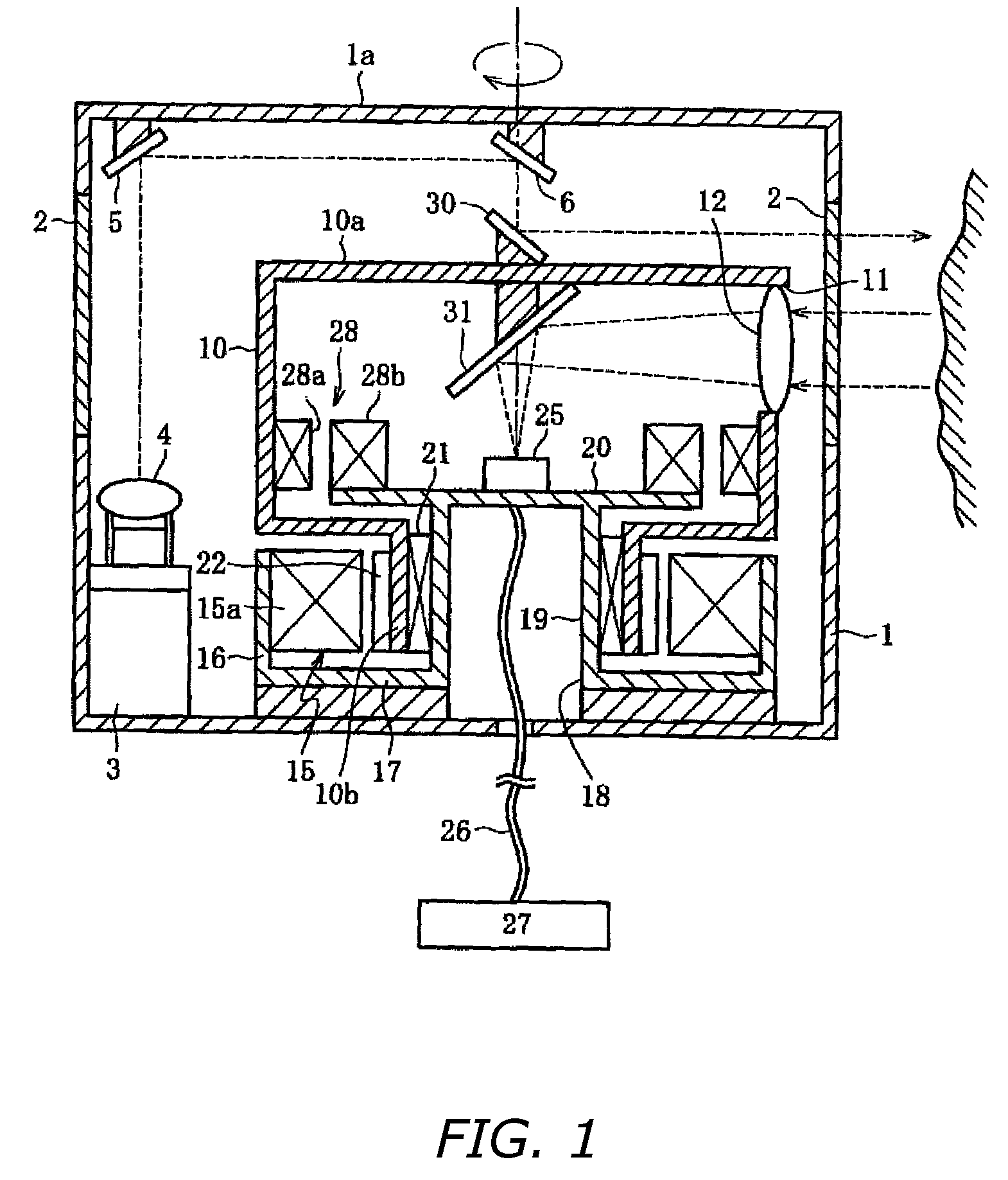

Scanning Range Sensor

ActiveUS20050024625A1Reduce distancePrevent from having blind spotOptical rangefindersActive open surveying meansRotational axisPhotodetector

A scanning range sensor includes an outer cover having a transparent window that is horizontally annular, a vertical type cylindrical rotary member inside the outer cover, a light receiving window with an optical lens of the cylindrical rotary member, a light projector between the outer cover and the cylindrical rotary member, an optical system for leading light from the light projector along the direction of the rotational axis of the cylindrical rotary member by the mirrors on the inner surface of the cylindrical rotary member, a photodetector that within the interior of the cylindrical rotary member is fixed and arranged separately from the cylindrical rotary member so as to coincide with the rotational axis of the cylindrical rotary member and is connected to a distance computation circuit, and a reflecting mirror and scanning mirror along the rotational axis of the cylindrical rotary member.

Owner:HOKUYO AUTOMATIC CO +1

Ionic photoacid generators with segmented hydrocarbon-fluorocarbon sulfonate anions

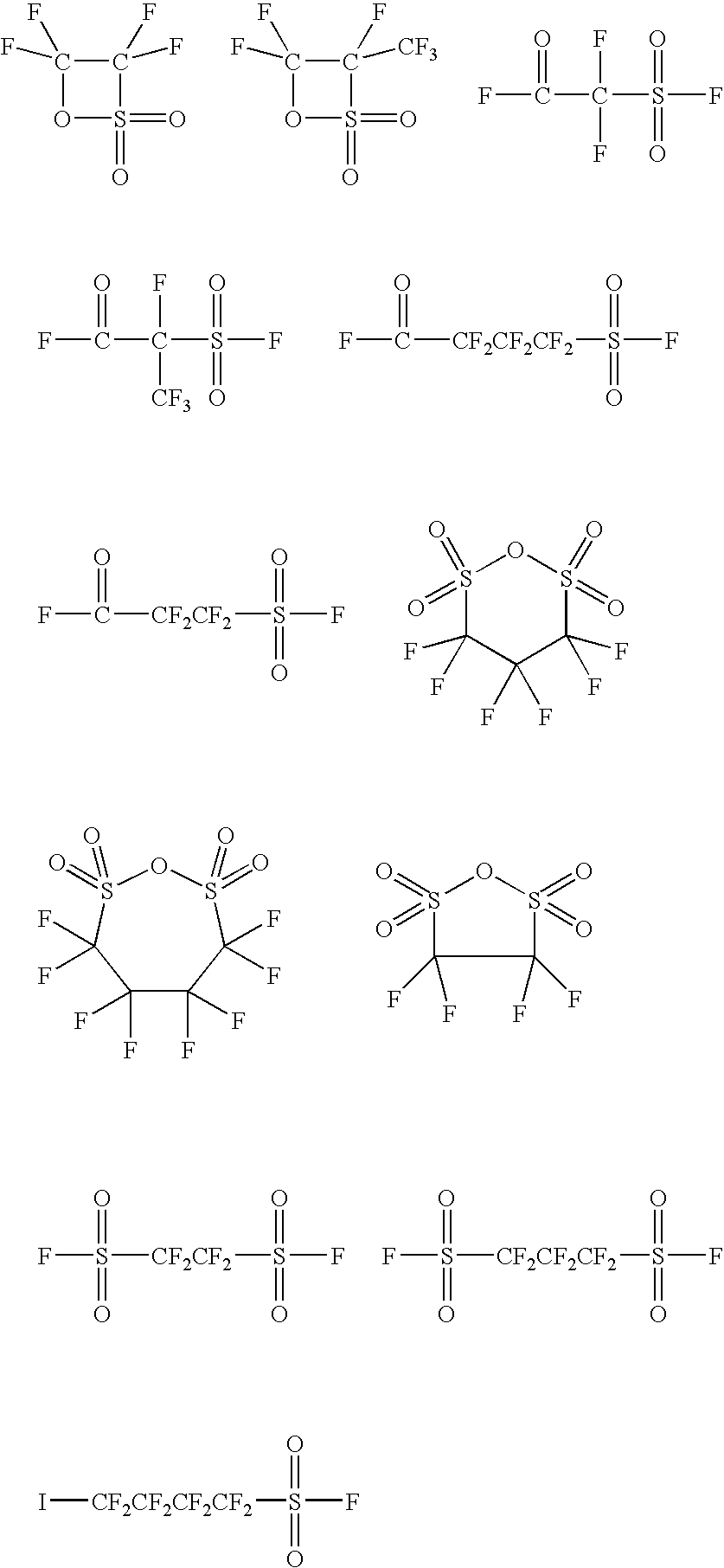

InactiveUS6841333B2Improve solubilitySolubility in organic compoundsOrganic compound preparationPhotosensitive materialsSolubilityAcid catalyzed

Photoacid generator salts comprising photoactive cationic moieties and segmented, highly fluorinated-hydrocarbon anionic moieties are disclosed which provide high photoacid strength and can be tailored for solubility and polarity. The present invention further relates to photoacid generators as they are used in photoinitiated acid-catalyzed processes for uses such as photoresists for microlithography and photopolymerization.

Owner:3M INNOVATIVE PROPERTIES CO

Polarisation asymmetric active optical waveguide, method of its production, and its uses

InactiveUS6151429AIncrease photosensitivityHigh refractive indexOptical fibre with multilayer core/claddingOptical resonator shape and constructionDopantWaveguide lasers

A method of producing an active optical waveguide having asymmetric polarization, said method comprising the steps of (a) providing an active optical waveguide (10) comprising: (i) a transverse refractive index profile (21) comprising a guiding region (11), an intermediate region (13), and a non-guiding region (12); (ii) a transverse photorefractive dopant profile (31) comprising a constant or graded photorefractive dopant concentration within at least one of the guiding, non-guiding and intermediate regions, except that the photorefractive dopant is not located solely in the guiding region; and (iii) exhibiting in said guiding region, intermediate region, or both, light guiding modes having different polarizations; and (b) exposing at least a part (10a, 10b) of the active optical waveguide to an effective transverse illumination of light (20) reacting with the photorefractive dopant and modifying said transverse refractive index profile; said part of the active optical waveguide being exposed to a fluence selectively suppressing the propagation of the light guiding modes having different polarizations so that the propagation of one mode is less suppressed than the propagation of the other mode(s). Such an active optical waveguide, single polarization mode optical waveguide lasers and multi-wavelength single polarization mode optical waveguide lasers comprising such an active optical waveguide, methods of their production, and their uses in telecommunications, in spectroscopy, in sensors and in absolute calibrated laser light sources.

Owner:KOHERAS +1

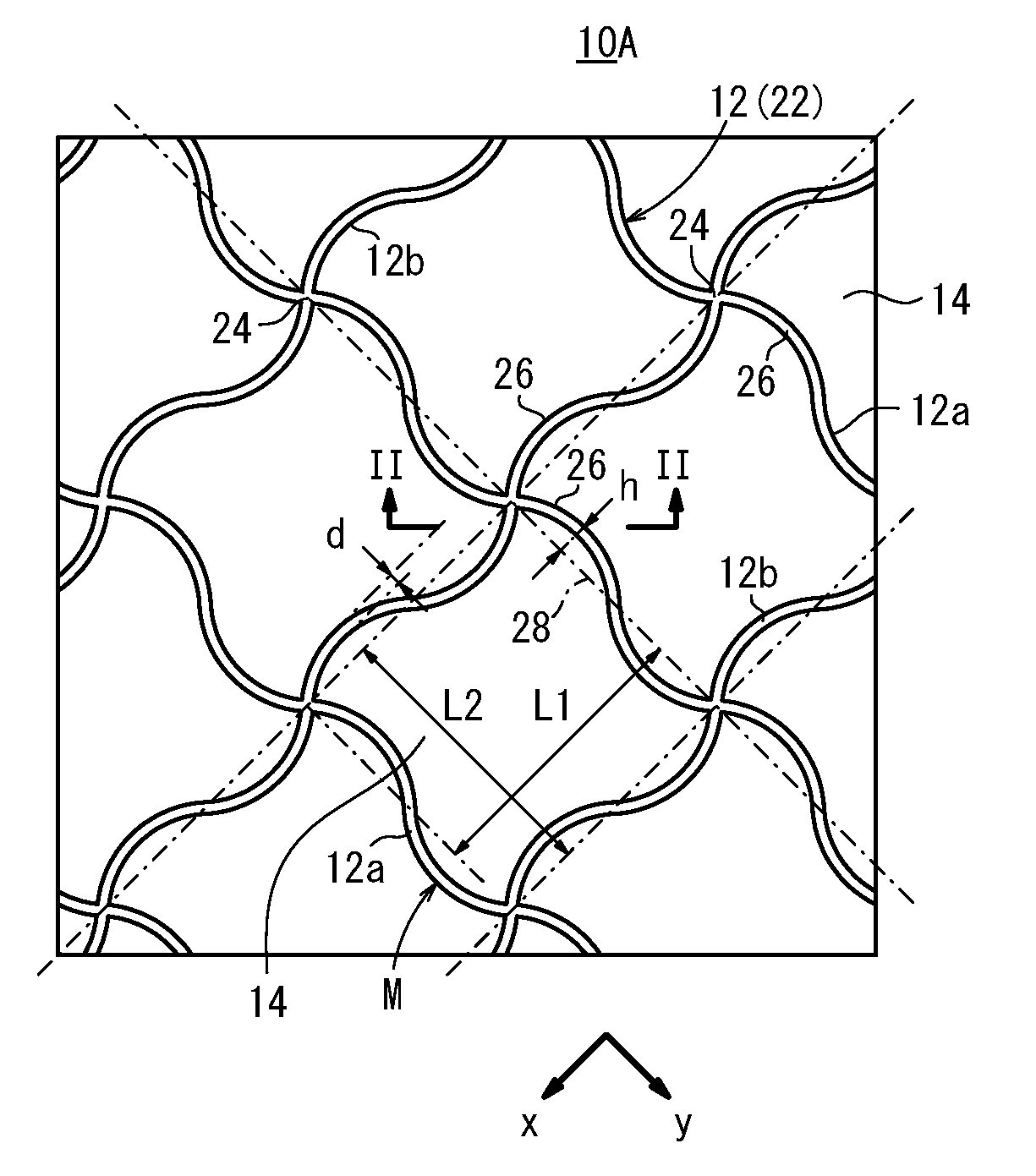

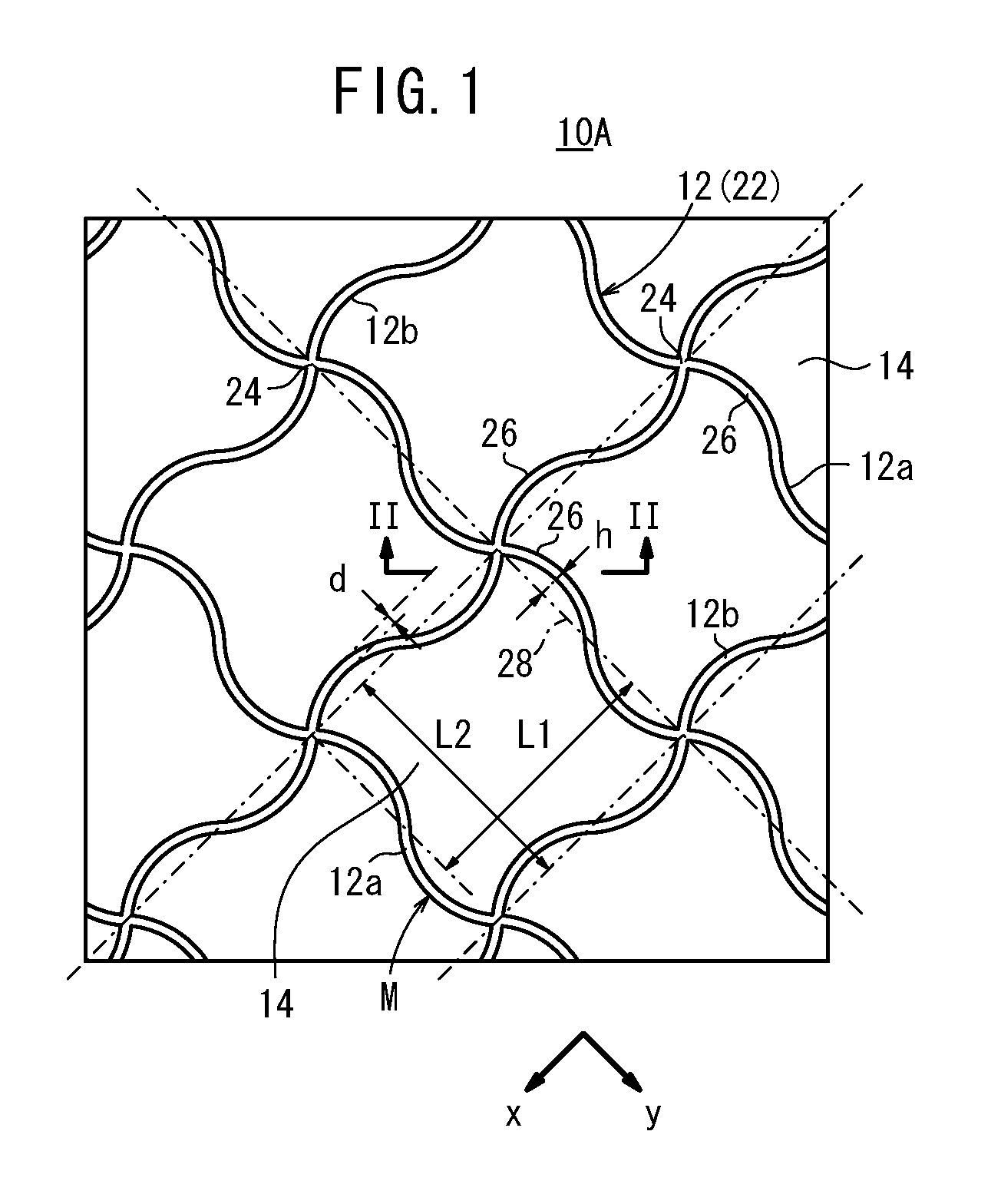

Conductive film, and transparent heating element

ActiveUS20110062146A1High light transmittanceIncrease blockingLayered productsTransparent/reflecting heating arrangementsVisibilityMetal filament

Provided is a conductive film, which is suitably used in a heating element of a transparent property (a transparent heating element) excellent in visibility and a heating power. The conductive portion of a first conductive film includes mesh patterns having multiple intersecting points (intersecting portions), which are constituted of a plurality of first metal filaments and a plurality of second metal filaments, and the conductive portion between the intersecting portions is formed into an undulating shape having at least one curve. The first conductive film is shaped such that the curves are arcuate and two arcs are formed continuously between the intersecting portions, wherein the protrusion-recess directions of the arcs are opposite to each other. Each arc has a center angle of about 90 degrees. Moreover, the conductive portion has a crossing angle of about 90 degrees.

Owner:FUJIFILM CORP

Coated optical fibers

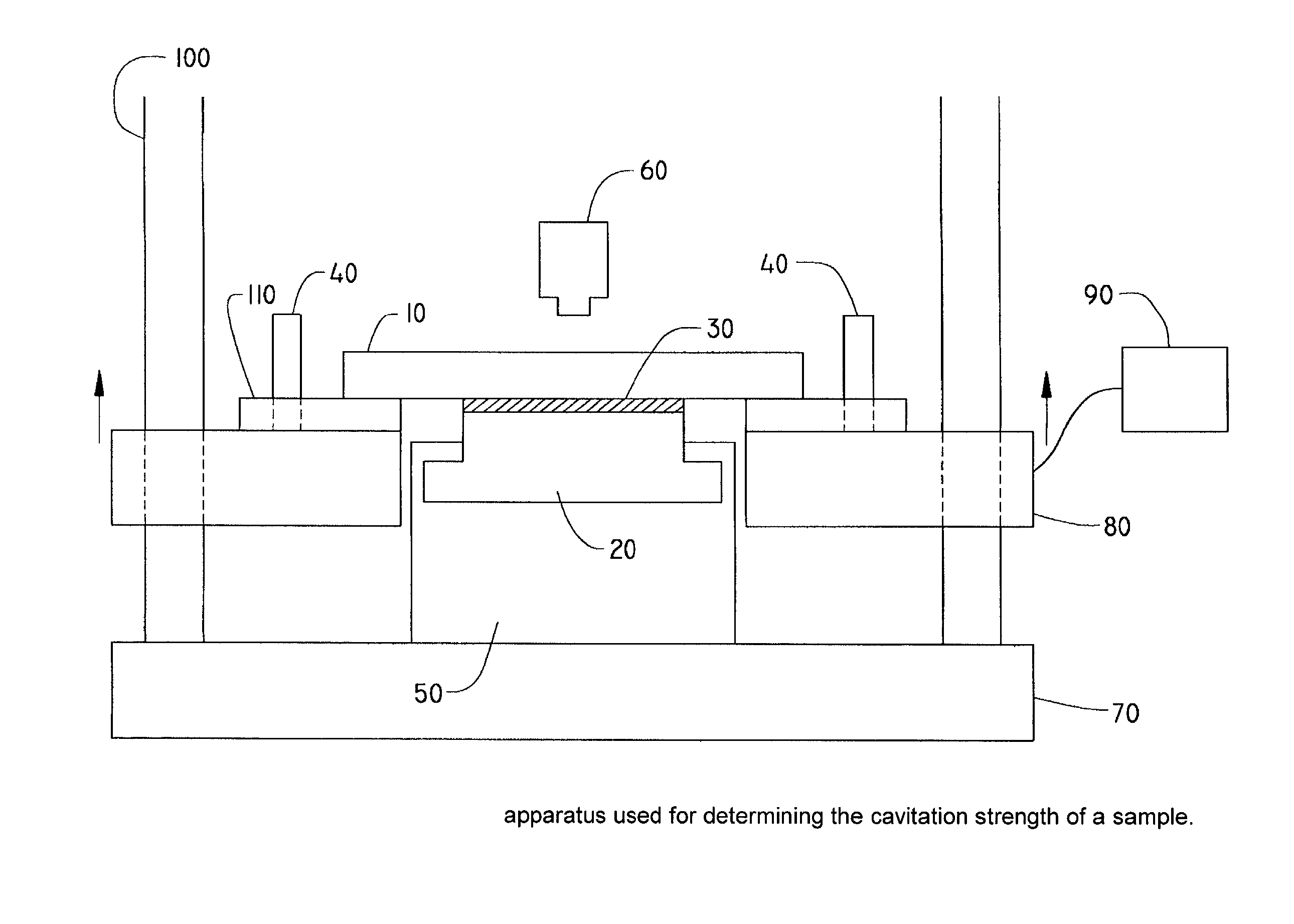

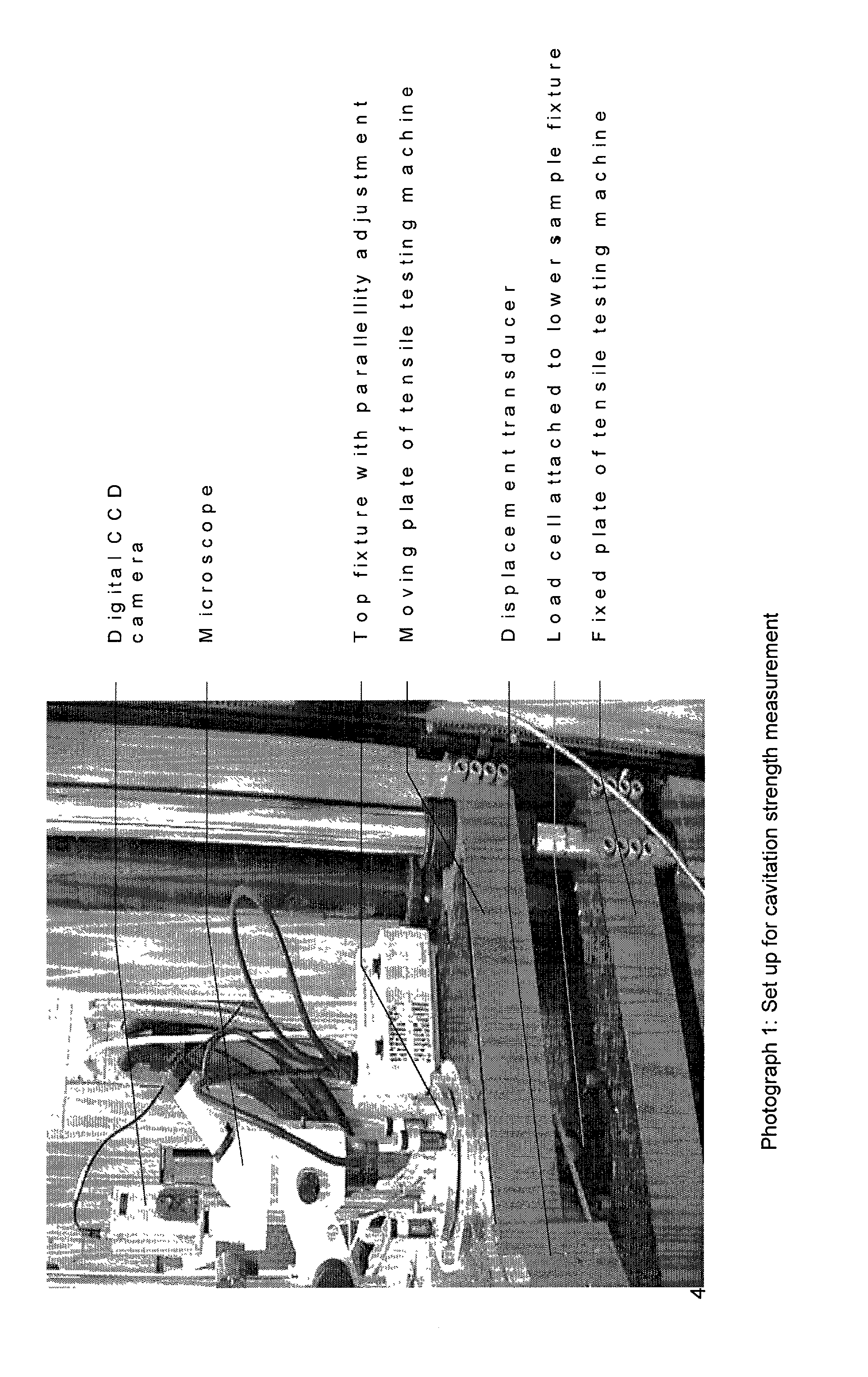

InactiveUS20020146225A1Sufficient high cavitation strengthLow modulusGlass optical fibreSynthetic resin layered productsHigh resistanceCavitation

The invention relates to coated optical fibers comprising soft primary coatings and to such primary coatings for protecting glass optical fibers having a sufficient high resistance against cavitation. In particular, the primary coatings have a cavitation strength at which a tenth cavitation appears (sigma10cav) of at least about 1.0 MPa as measured at a deformation rate of 0.20% min-1 and of at least about 1.4 times their storage modulus at 23° C. The coating preferably shows strain hardening in a relative Mooney plot, preferably has a strain energy release rate Go of about 20 J / m2 or more, and preferably has a low volumetric thermal expansion coefficient. The invention furthermore provides a method and apparatus for measuring the cavitation strength of a primary coating.

Owner:DSM IP ASSETS BV

Imaging lens assembly

ActiveUS7969664B2Reduce sensitivitySmall sizeTelevision system detailsColor television detailsConvex sideImaging lens

This invention provides an imaging lens assembly comprising: in order from an object side to an image side: a first lens with positive refractive power having a convex object-side surface and a convex image-side surface; a second lens with negative refractive power having a concave object-side surface; a third lens with positive refractive power having a convex image-side surface, at least one of both surfaces thereof being aspheric; and a fourth lens with negative refractive power having a convex object-side surface and a concave image-side surface on which at least one inflection point is formed; wherein there are four lenses with refractive power, an on-axis spacing between an aperture stop and an electronic sensor provided therein is SL, an on-axis spacing between the object-side surface of the first lens and the electronic sensor is TTL, they satisfy the relation: 0.75<SL / TTL<0.90.

Owner:LARGAN PRECISION

Complementary metal oxide semiconductor image sensor and method for fabricating the same

ActiveUS20070152248A1Increase photosensitivityEasy to integrateNanotechApparel holdersCMOSNanopillar

Provided are a CMOS image sensor and a method for fabricating the same. A nanopillar is plurally formed at an upper end of a light receiving element.

Owner:KOREA ADVANCED INST OF SCI & TECH

Imaging lens assembly

ActiveUS8089704B2Improve image qualityAberration correctionTelevision system detailsColor television detailsImaging lensPhysics

This invention provides an imaging lens assembly including, in order from an object side to an image side: a first lens with positive refractive power having a convex object-side surface; a second lens with negative refractive power having a convex image-side surface; a third lens having a concave object-side surface and a convex image-side surface, at least one of both surfaces thereof being aspheric; a fourth lens having a concave image-side surface, at least one of both surfaces thereof having at least one inflection point; and an aperture stop disposed between an imaged object and the second lens; the on-axis spacing between the first lens and second lens is T12, the focal length of the imaging lens assembly is f, the Abbe number of the first lens and third lens is, V1 and V3, respectively, they satisfy the relations: 0.5<(T12 / f)*100<20, 23<V1−V3.

Owner:LARGAN PRECISION

Image-capturing lens assembly

ActiveUS8179470B2Small sizeReduce sensitivityTelevision system detailsColor television detailsImage resolutionImage capture

This invention provides an image-capturing lens assembly comprising, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power; a third lens element with positive refractive power having a concave object-side surface and a convex image-side surface, the object-side and image-side surfaces thereof being aspheric; a fourth lens element with negative refractive power having a concave image-side surface on which at least one inflection point is formed, the object-side and image-side surfaces thereof being aspheric; and a stop disposed between an imaged object and the first lens element; wherein there are four lens elements with refractive power. Such an arrangement of optical elements can effectively reduce the size of the lens assembly, mitigate the sensitivity of the optical system and enable the lens assembly to obtain a higher resolution.

Owner:LARGAN PRECISION

Optical lens system for taking image

An optical lens system for taking image comprises, in order from the object side to the image side: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power having a concave image-side surface and at least one aspheric surface; a meniscus third lens element with negative refractive power having a convex image-side surface; and a fourth lens element with negative refractive power having a convex object-side surface and an aspheric image-side surface. The above configurations and arrangements of the lens elements can effectively reduce the size of the optical system while improving its resolution.

Owner:LARGAN PRECISION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com