Image-capturing lens assembly

a technology of image-capturing lens and assembly, which is applied in the field of image-capturing lens assembly, can solve the problems of reducing the total track length of the system, reducing the sensitivity of the optical system, and the three-element lens has become insufficient for a high-end imaging lens module, so as to improve the sensitivity of the optical system, and reduce the size of the lens assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

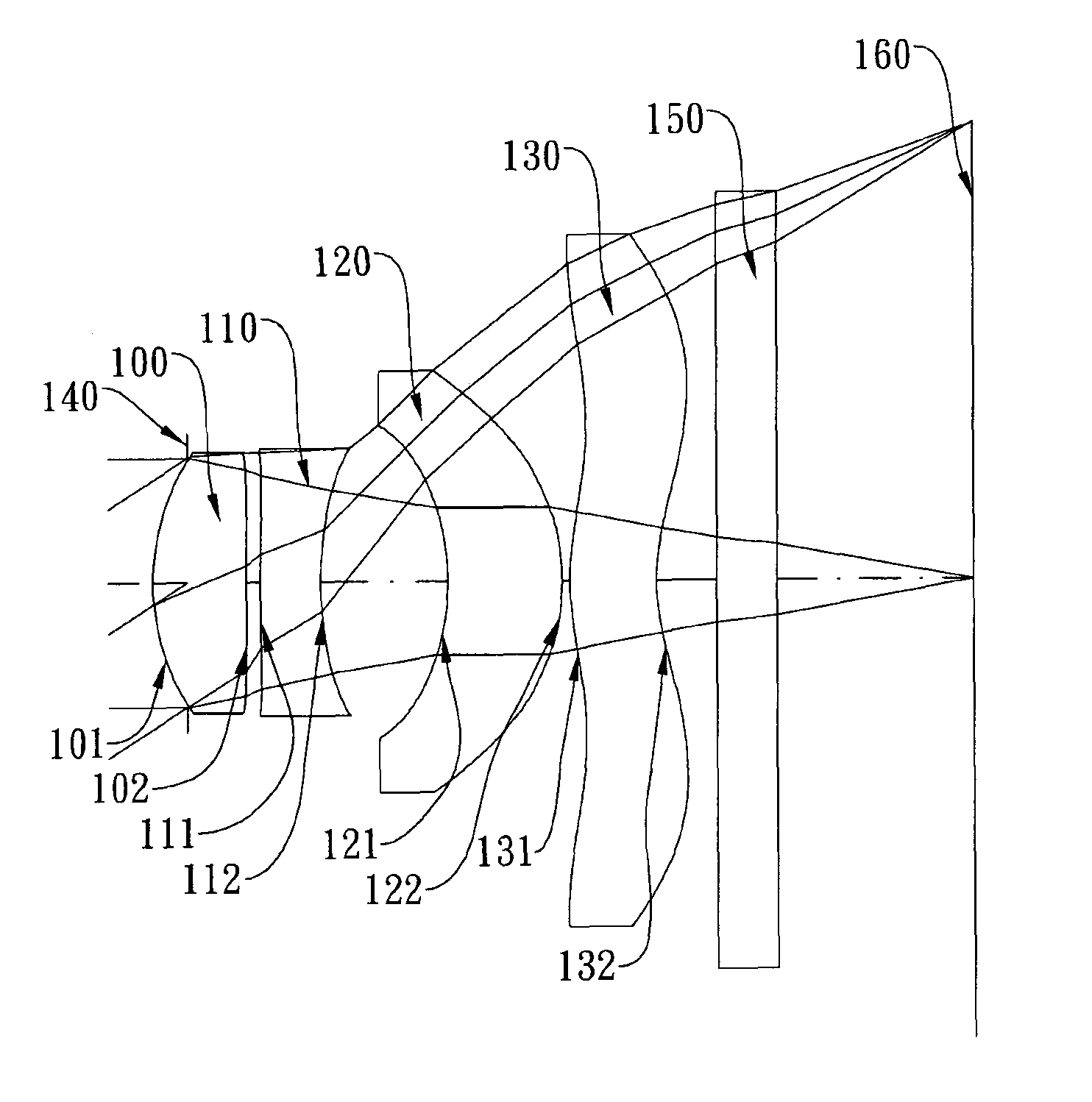

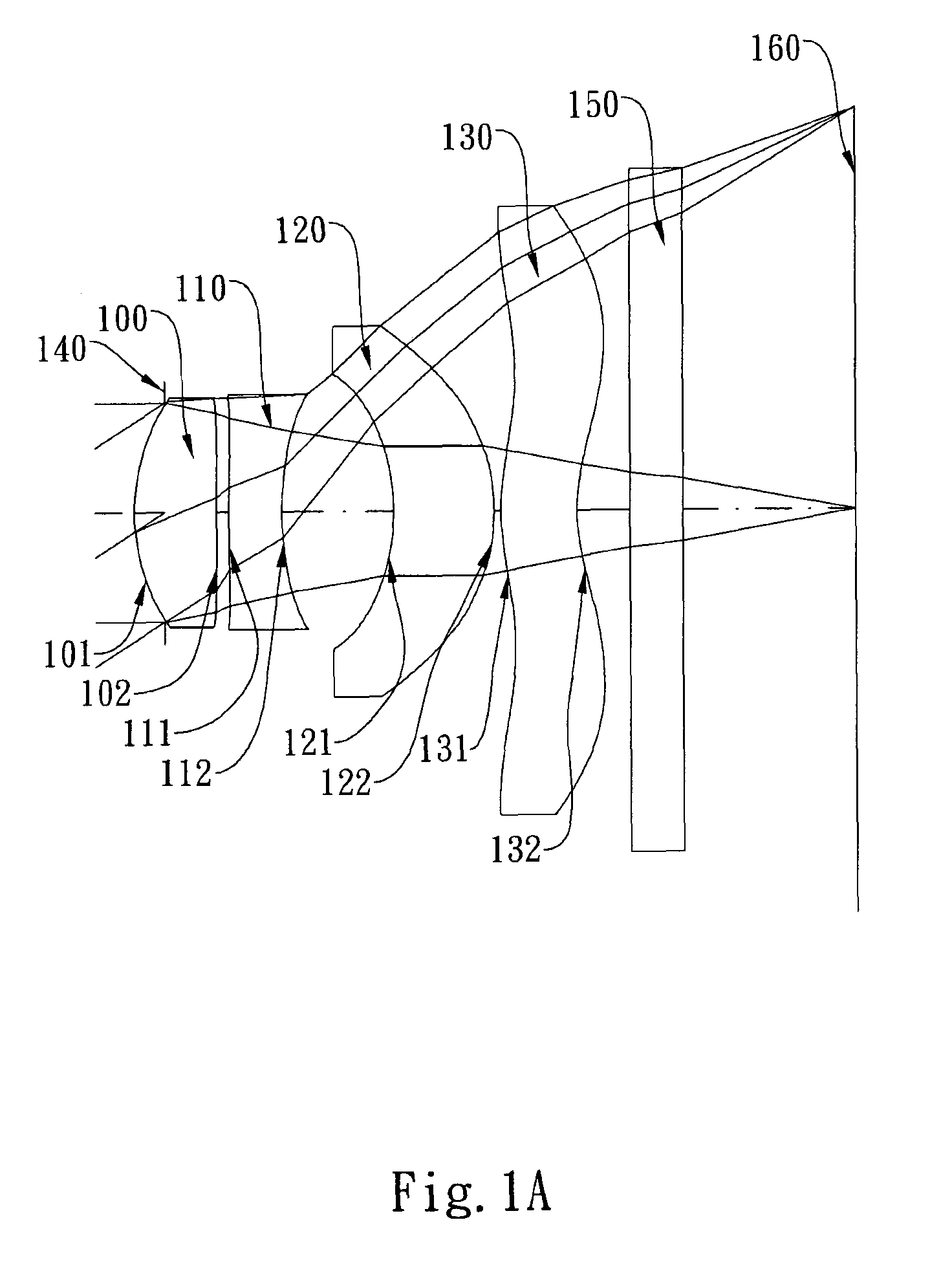

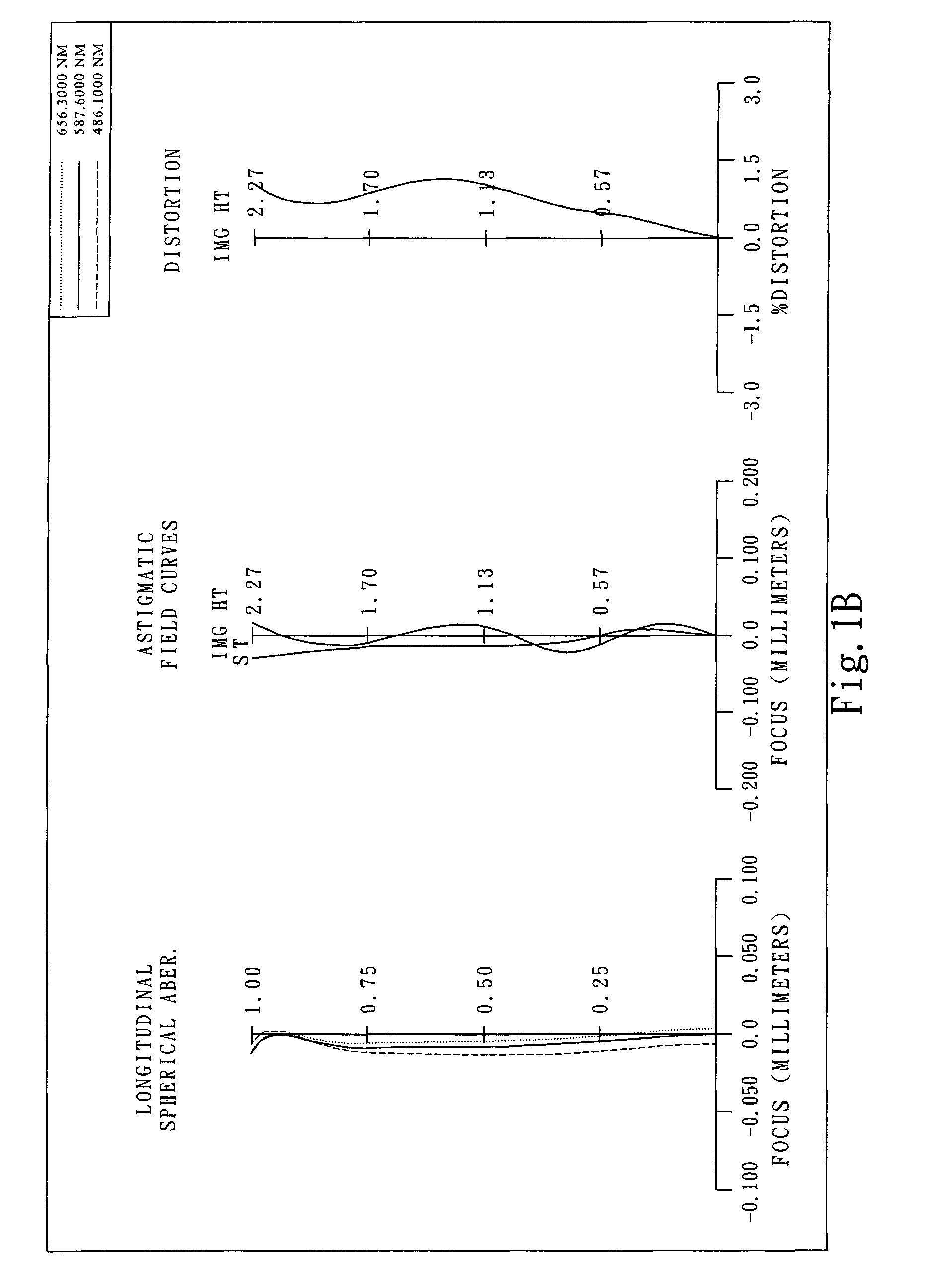

first embodiment

[0068]In the present image-capturing lens assembly, the focal length of the image-capturing lens assembly is f, and it satisfies the relation: f=3.53 (mm).

[0069]In the first embodiment of the present image-capturing lens assembly, the f-number of the image-capturing lens assembly is Fno, and it satisfies the relation: Fno=2.85.

[0070]In the first embodiment of the present image-capturing lens assembly, half of the maximal field of view of the image-capturing lens assembly is HFOV, and it satisfies the relation: HFOV=32.5 deg.

[0071]In the first embodiment of the present image-capturing lens assembly, the focal length of the image-capturing lens assembly is f, the focal length of the first lens element 100 is f1, and they satisfy the relation: f / f1=1.67.

[0072]In the first embodiment of the present image-capturing lens assembly, the focal length of the image-capturing lens assembly is f, the focal length of the third lens element 120 is f3, and they satisfy the relation: f / f3=0.33.

[0073...

second embodiment

[0087]In the present image-capturing lens assembly, the focal length of the image-capturing lens assembly is f, and it satisfies the relation: f=2.91 (mm).

[0088]In the second embodiment of the present image-capturing lens assembly, the f-number of the image-capturing lens assembly is Fno, and it satisfies the relation: Fno=2.40.

[0089]In the second embodiment of the present image-capturing lens assembly, half of the maximal field of view of the image-capturing lens assembly is HFOV, and it satisfies the relation: HFOV=31.6 deg.

[0090]In the second embodiment of the present image-capturing lens assembly, the focal length of the image-capturing lens assembly is f, the focal length of the first lens element 200 is f1, and they satisfy the relation: f / f1=1.66.

[0091]In the second embodiment of the present image-capturing lens assembly, the focal length of the image-capturing lens assembly is f, the focal length of the third lens element 220 is f3, and they satisfy the relation: f / f3=0.92.

[...

third embodiment

[0106]In the present image-capturing lens assembly, the focal length of the image-capturing lens assembly is f, and it satisfies the relation: f=6.14 (mm).

[0107]In the third embodiment of the present image-capturing lens assembly, the f-number of the image-capturing lens assembly is Fno, and it satisfies the relation: Fno=2.83.

[0108]In the third embodiment of the present image-capturing lens assembly, half of the maximal field of view of the image-capturing lens assembly is HFOV, and it satisfies the relation: HFOV=30.7 deg.

[0109]In the third embodiment of the present image-capturing lens assembly, the focal length of the image-capturing lens assembly is f, the focal length of the first lens element 300 is f1, and they satisfy the relation: f / f1=1.16.

[0110]In the third embodiment of the present image-capturing lens assembly, the focal length of the image-capturing lens assembly is f, the focal length of the third lens element 320 is f3, and they satisfy the relation: f / f3=0.72.

[0111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com