Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

440results about How to "Shorten the track" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

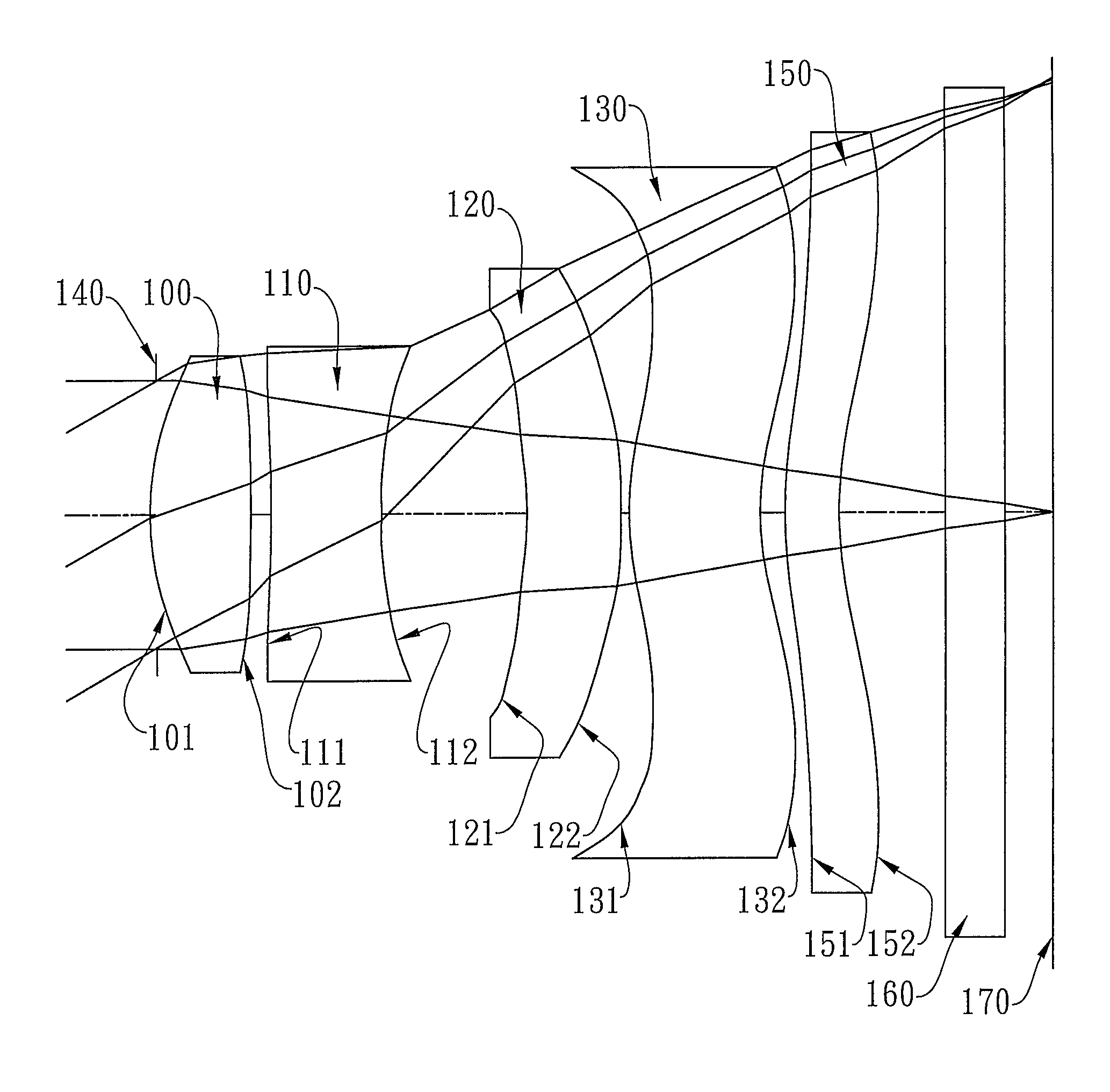

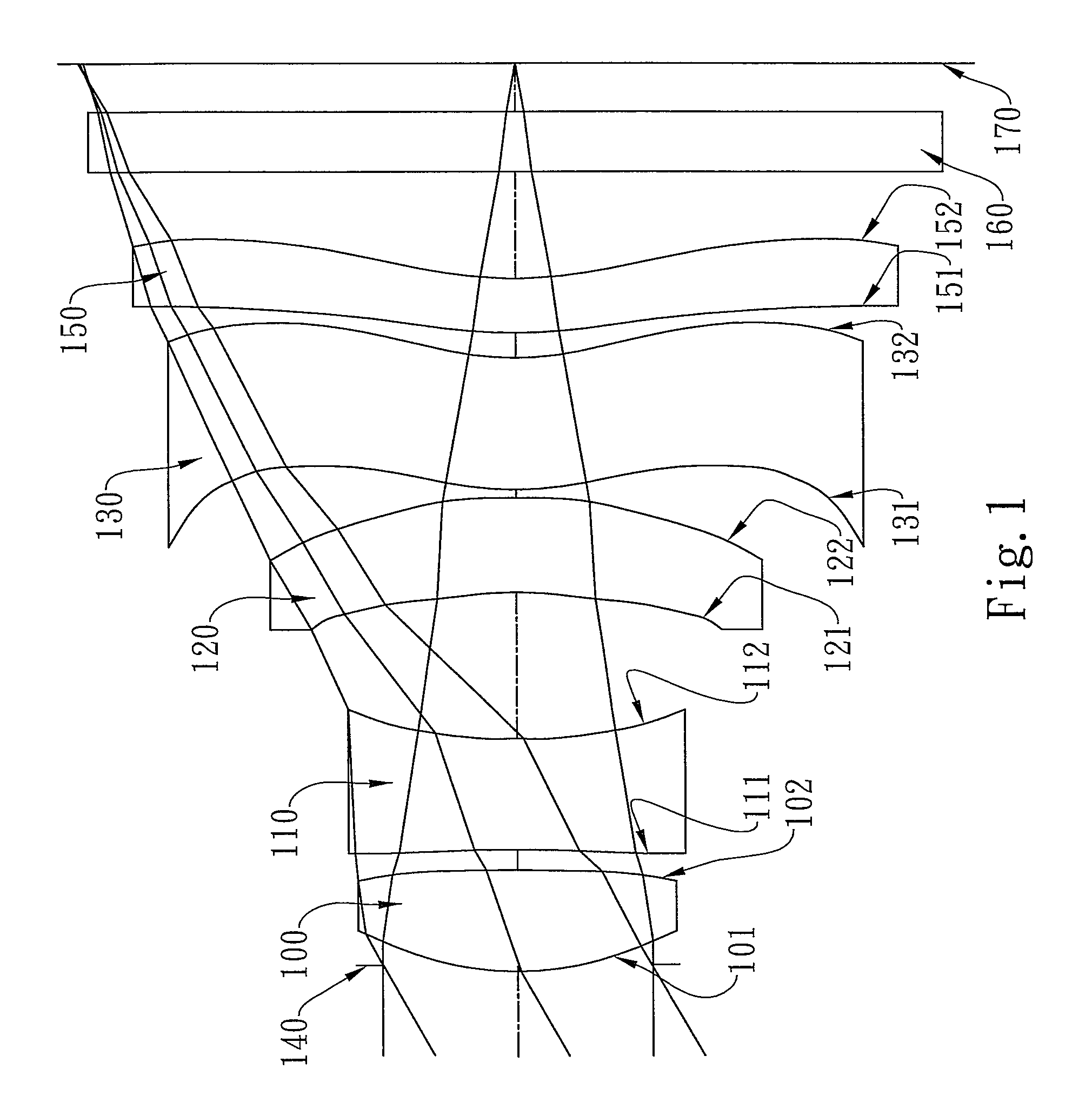

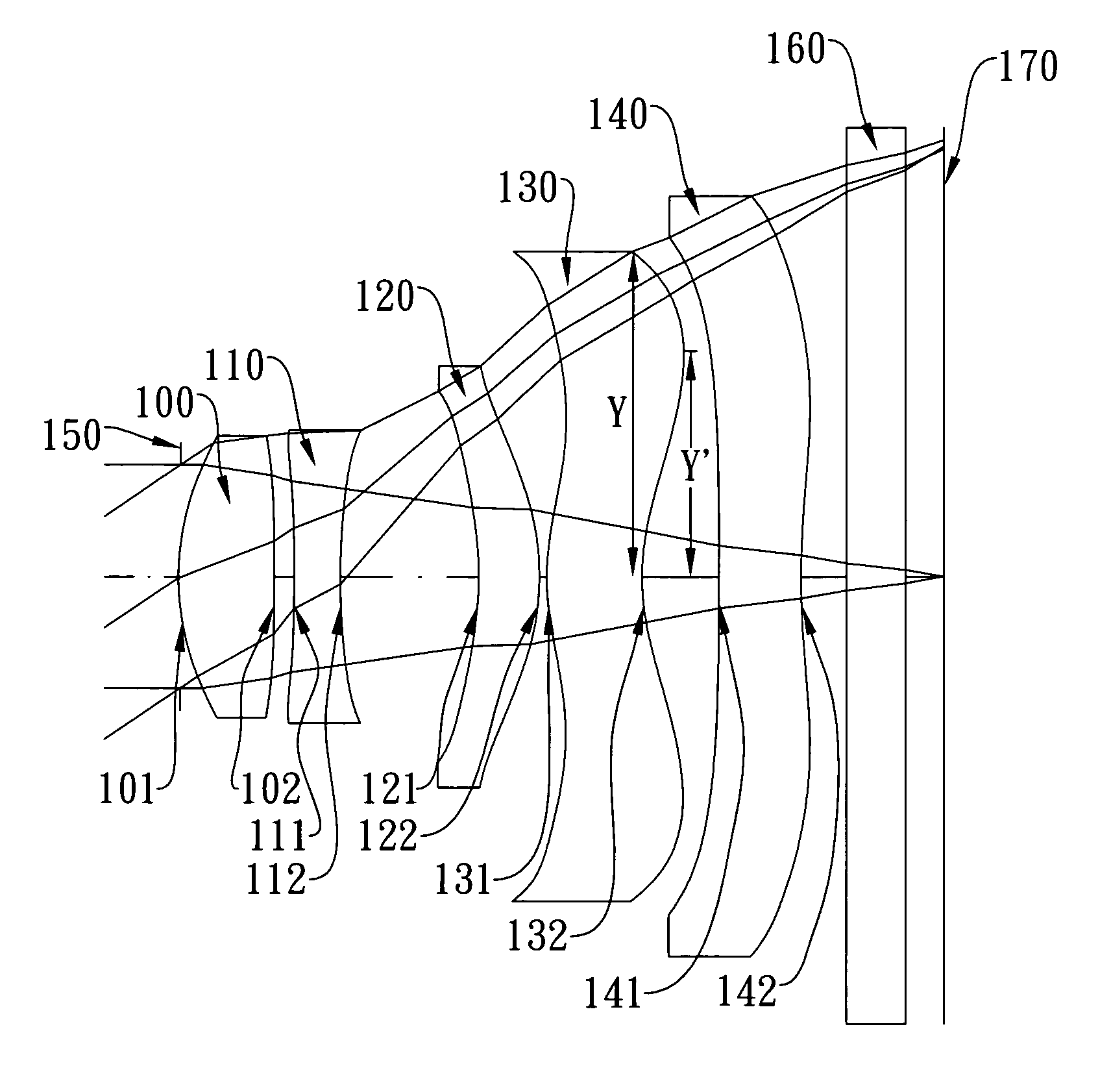

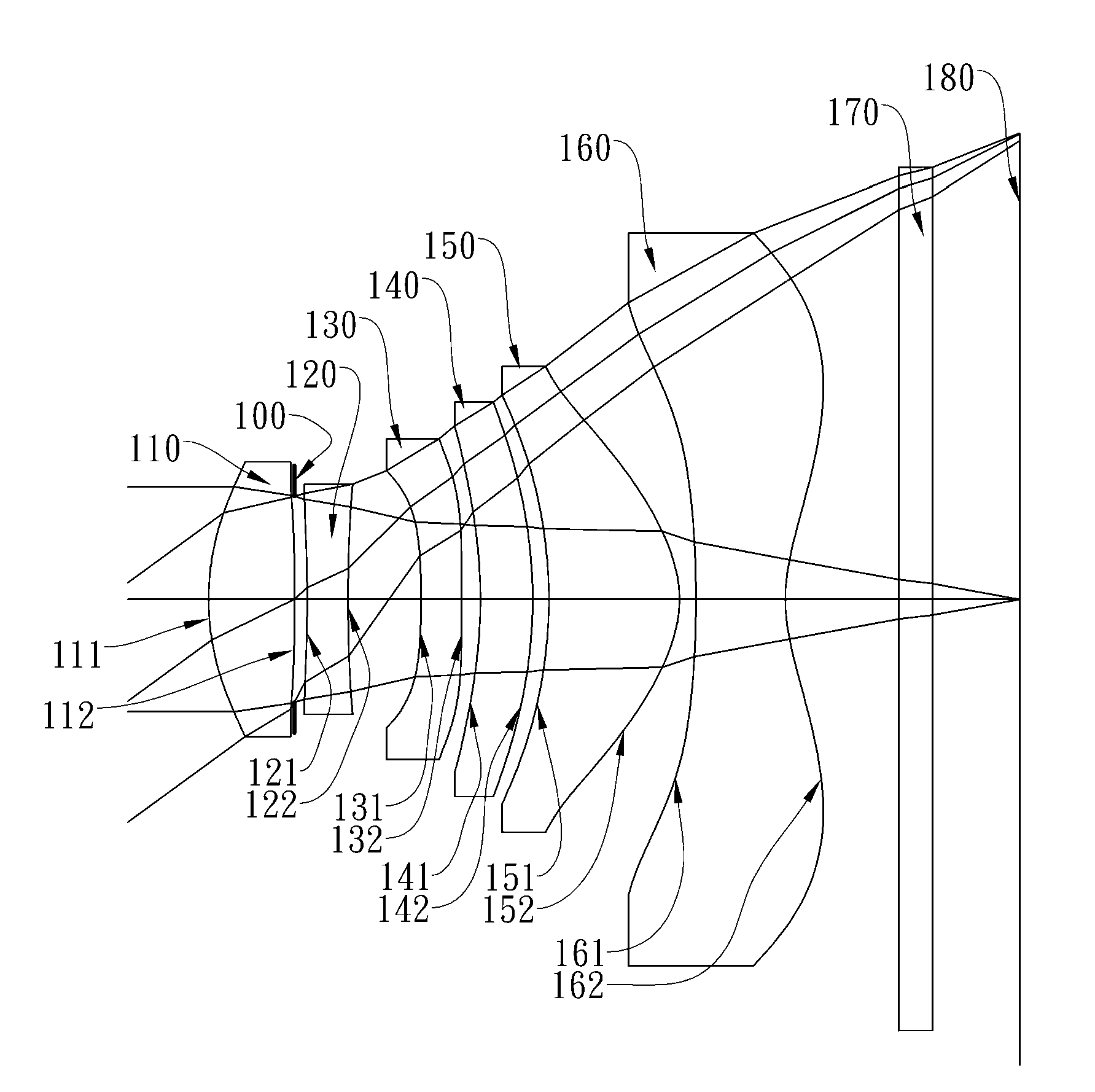

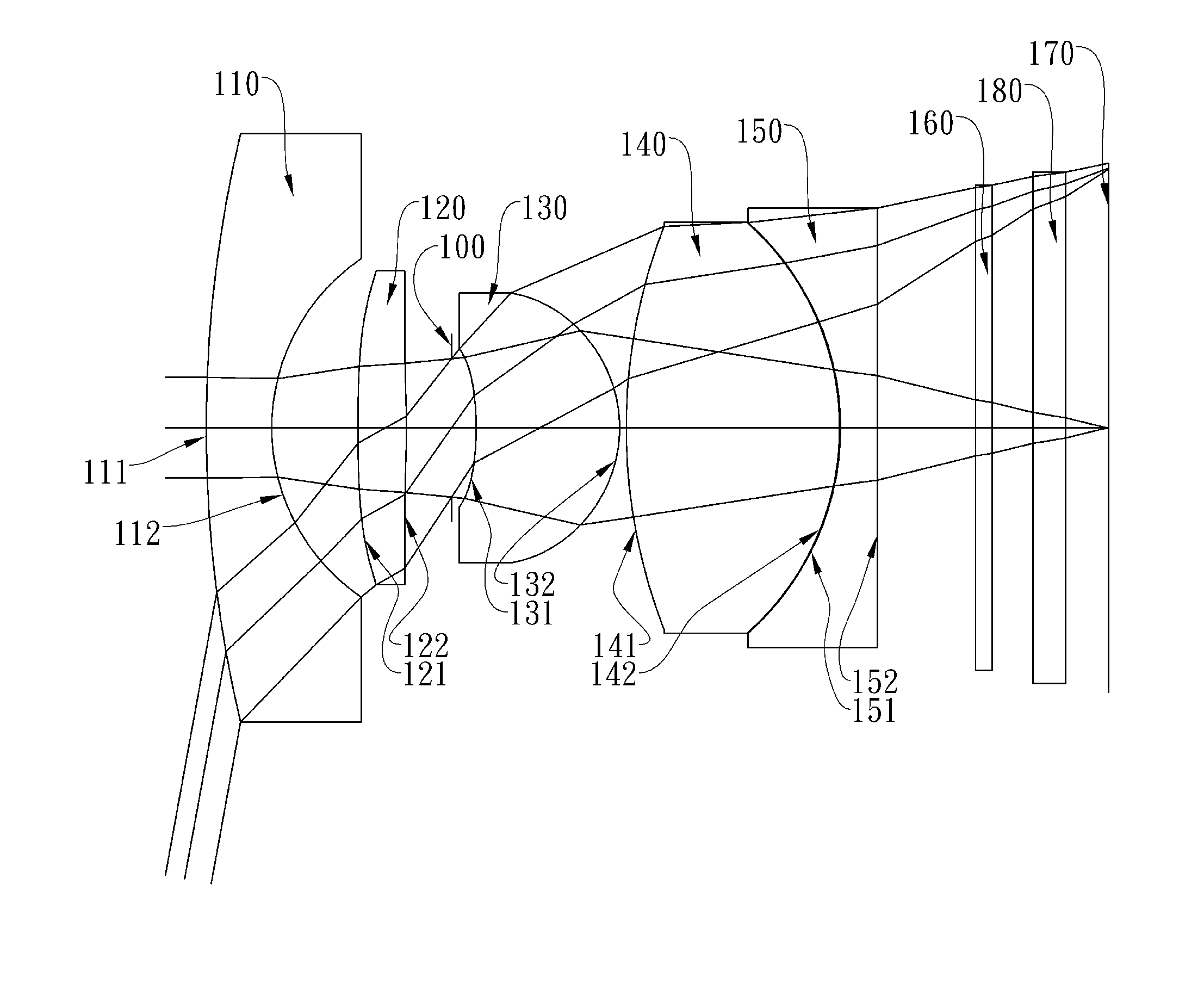

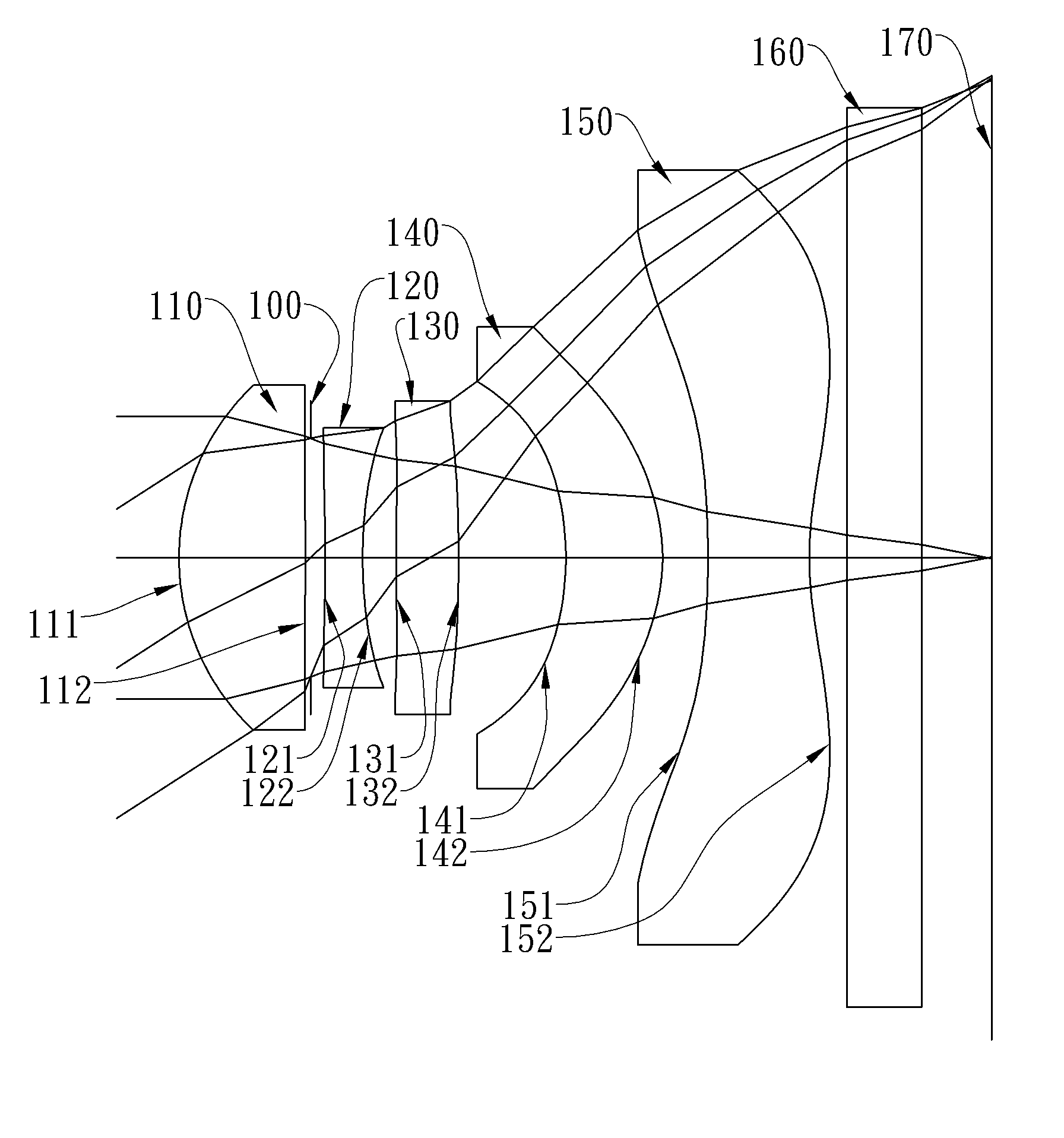

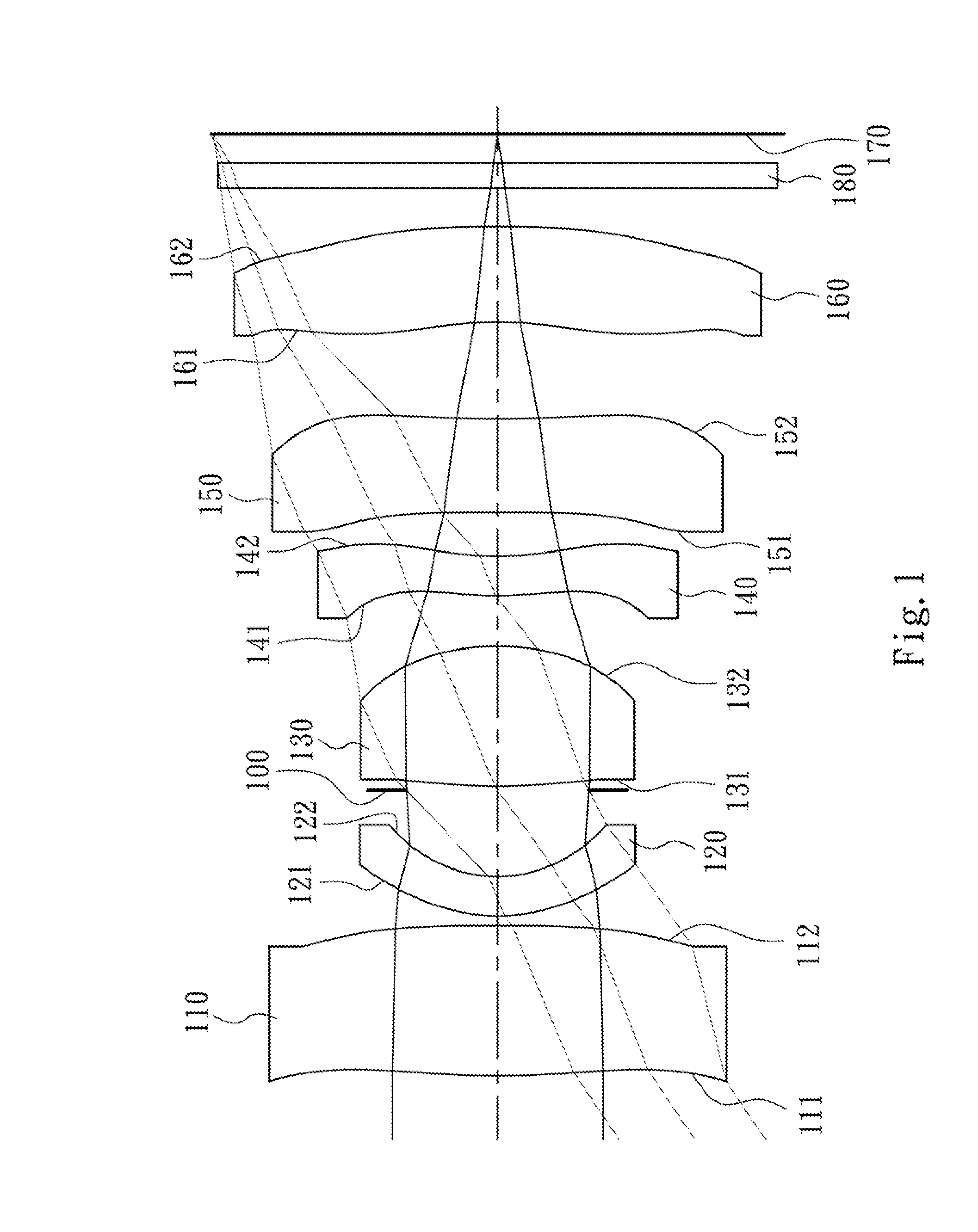

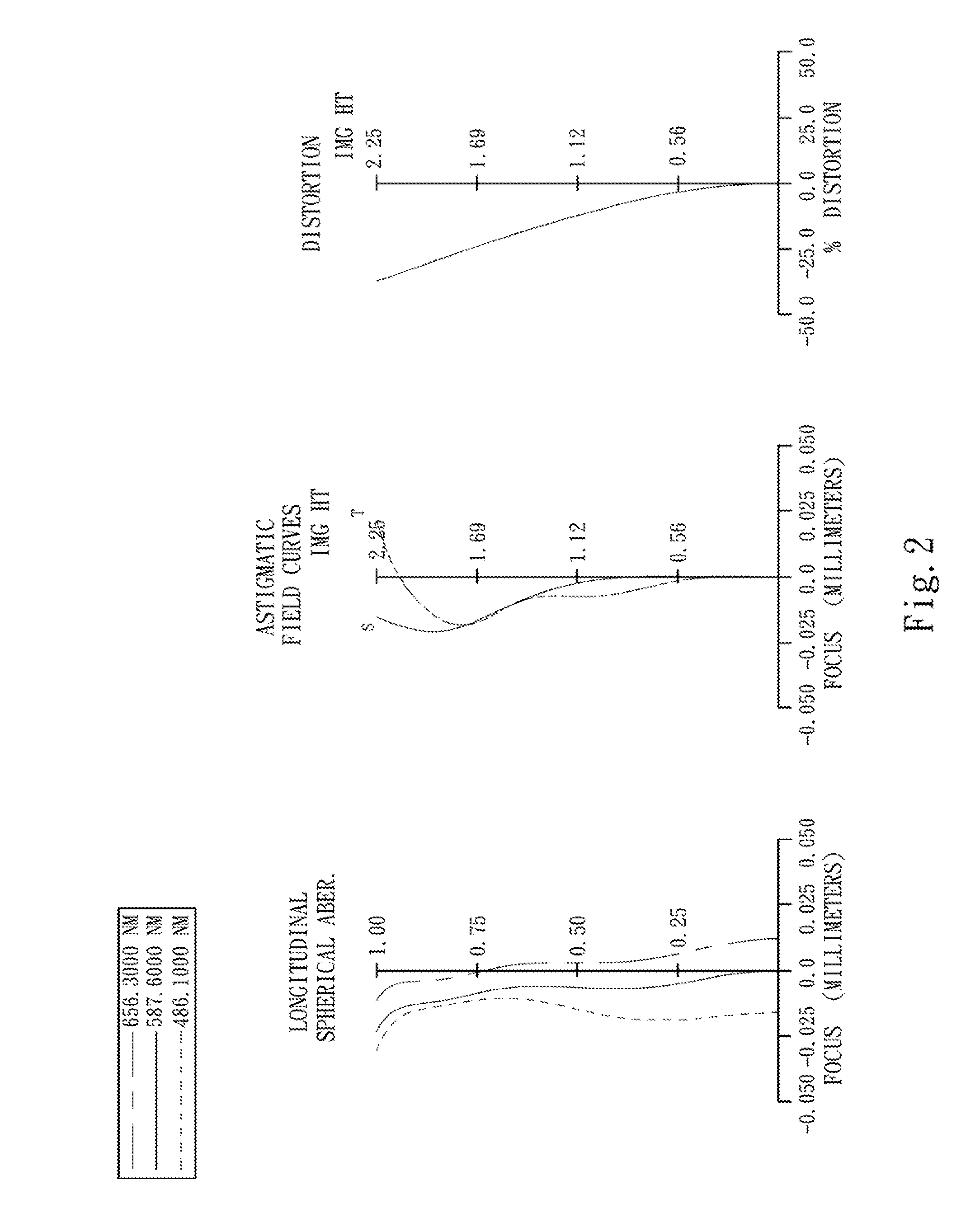

Imaging optical lens assembly

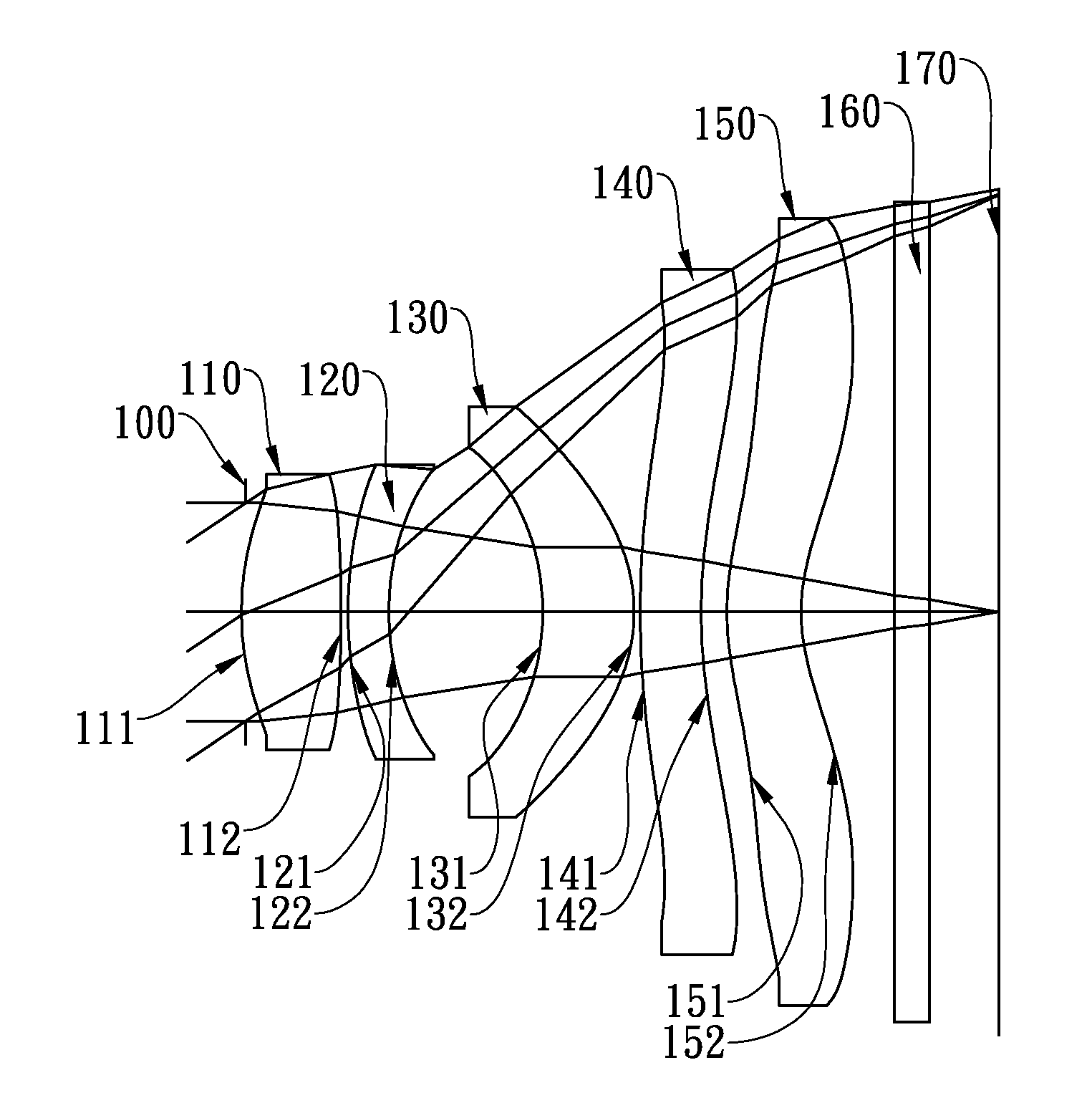

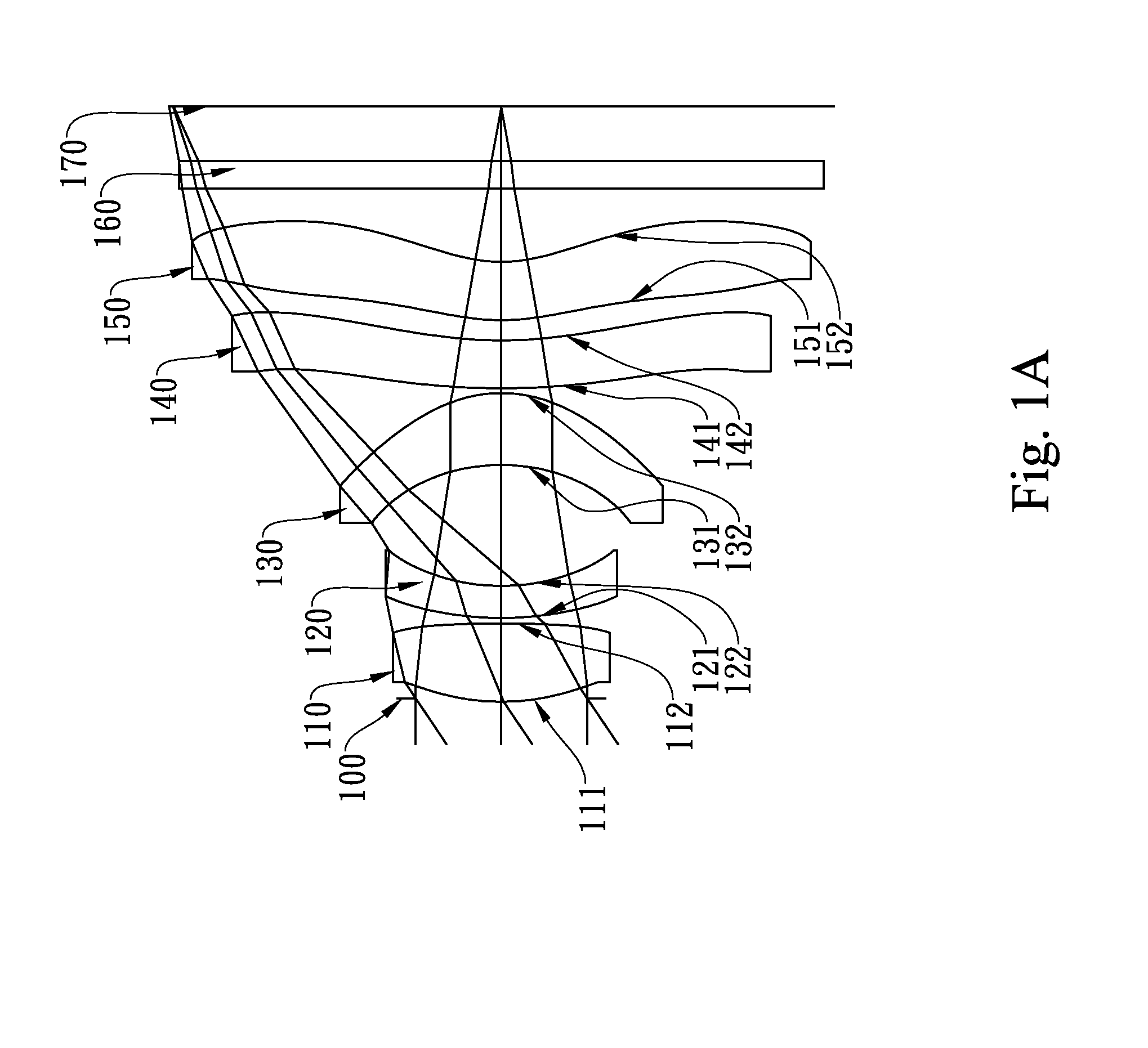

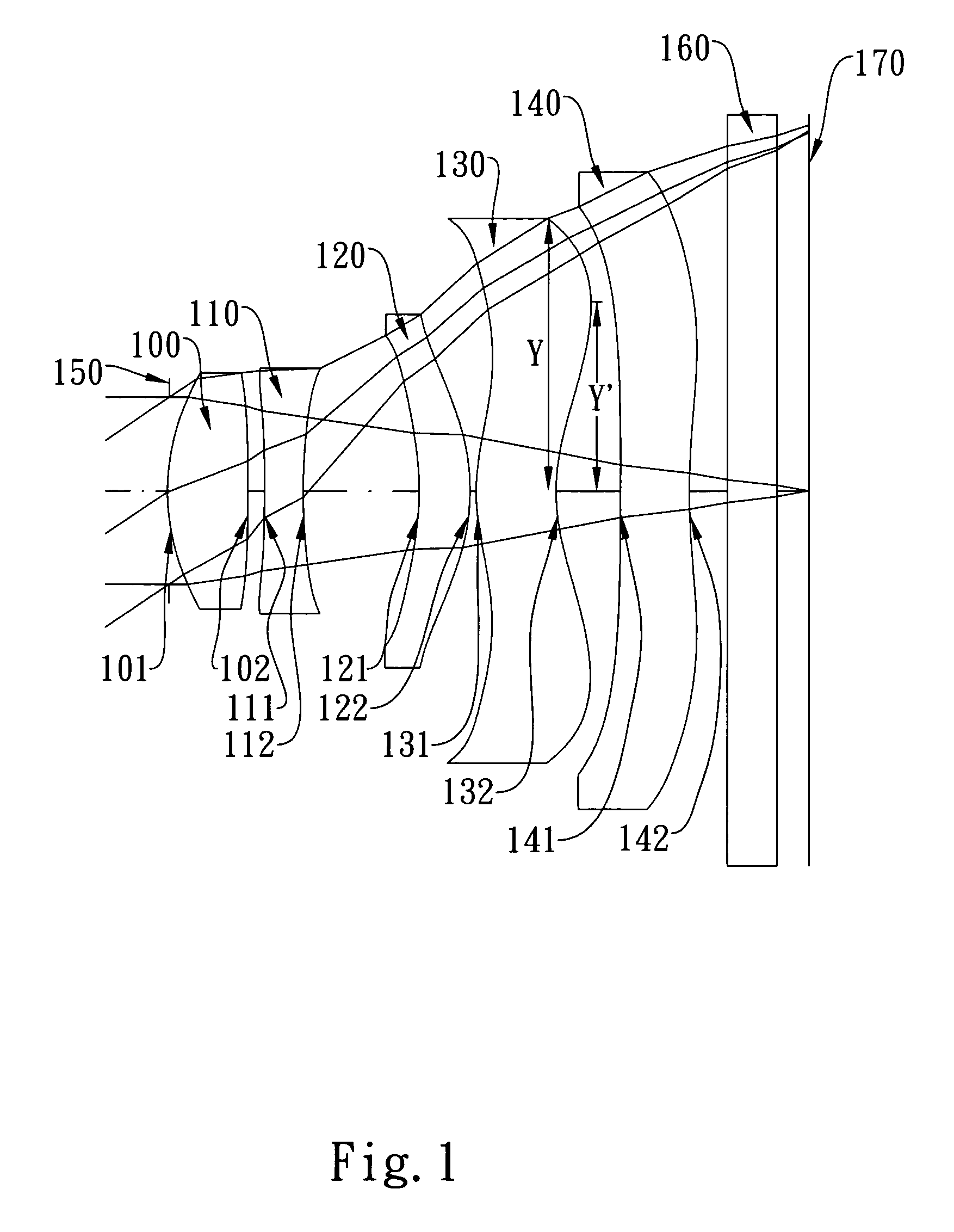

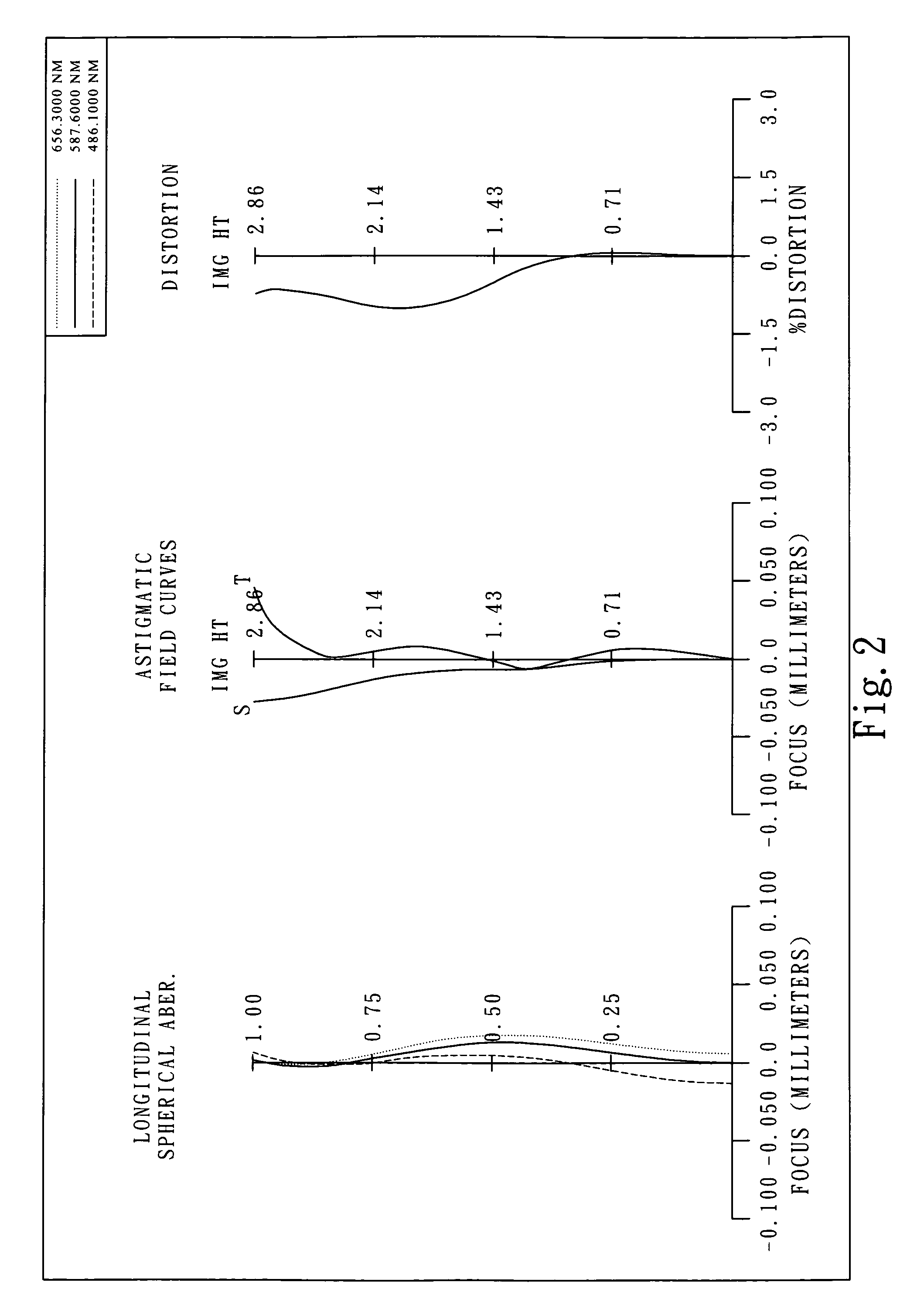

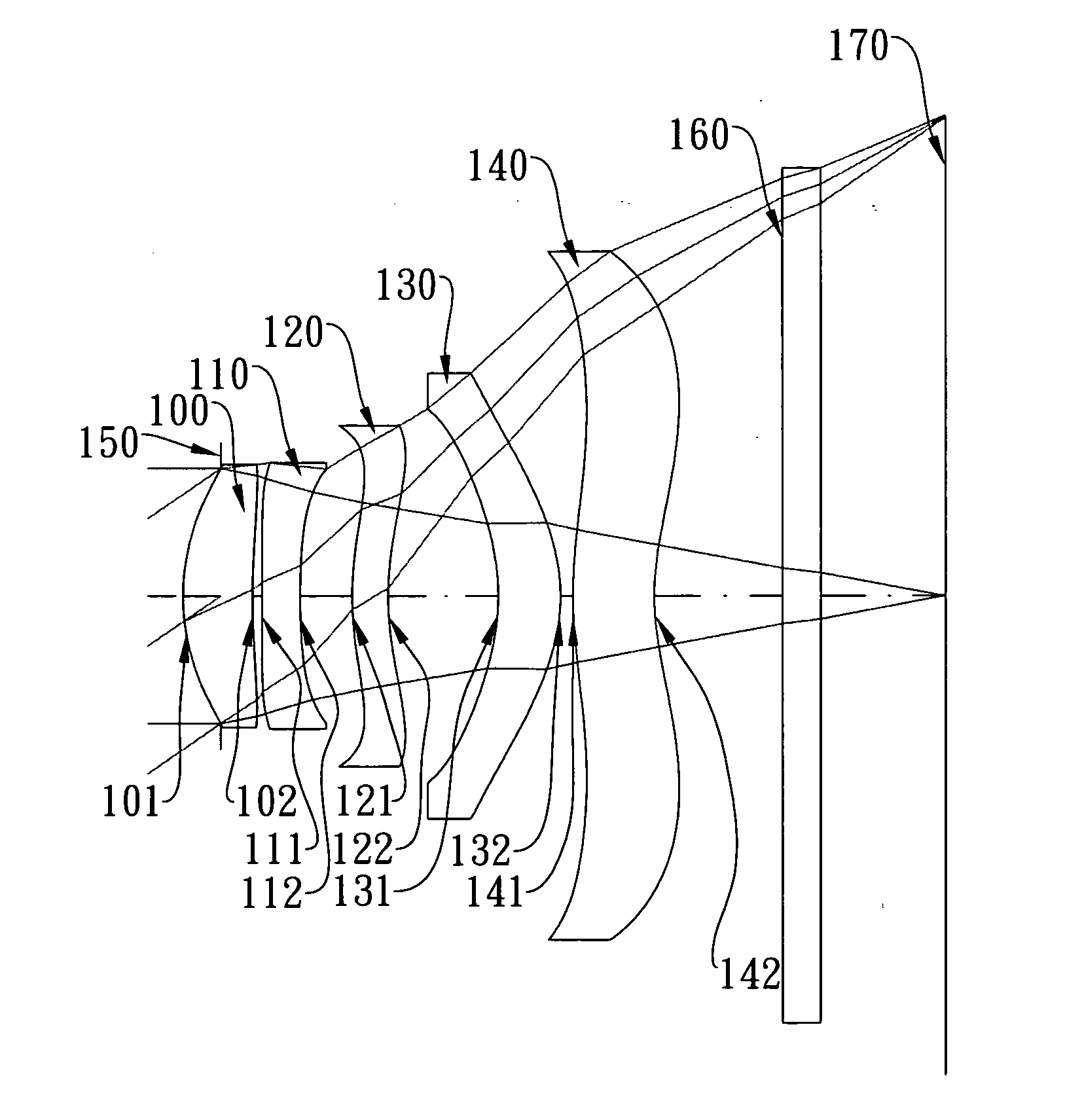

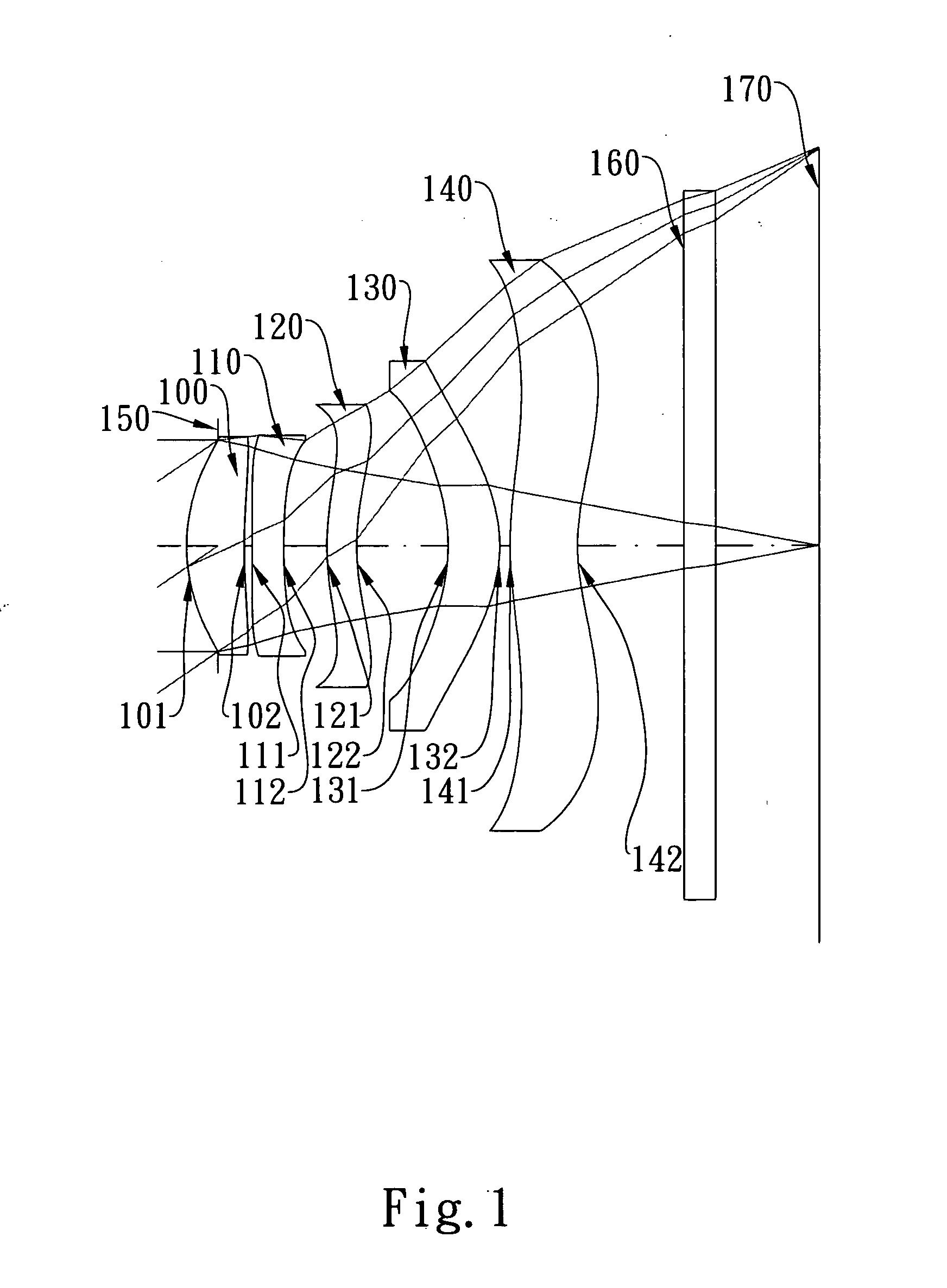

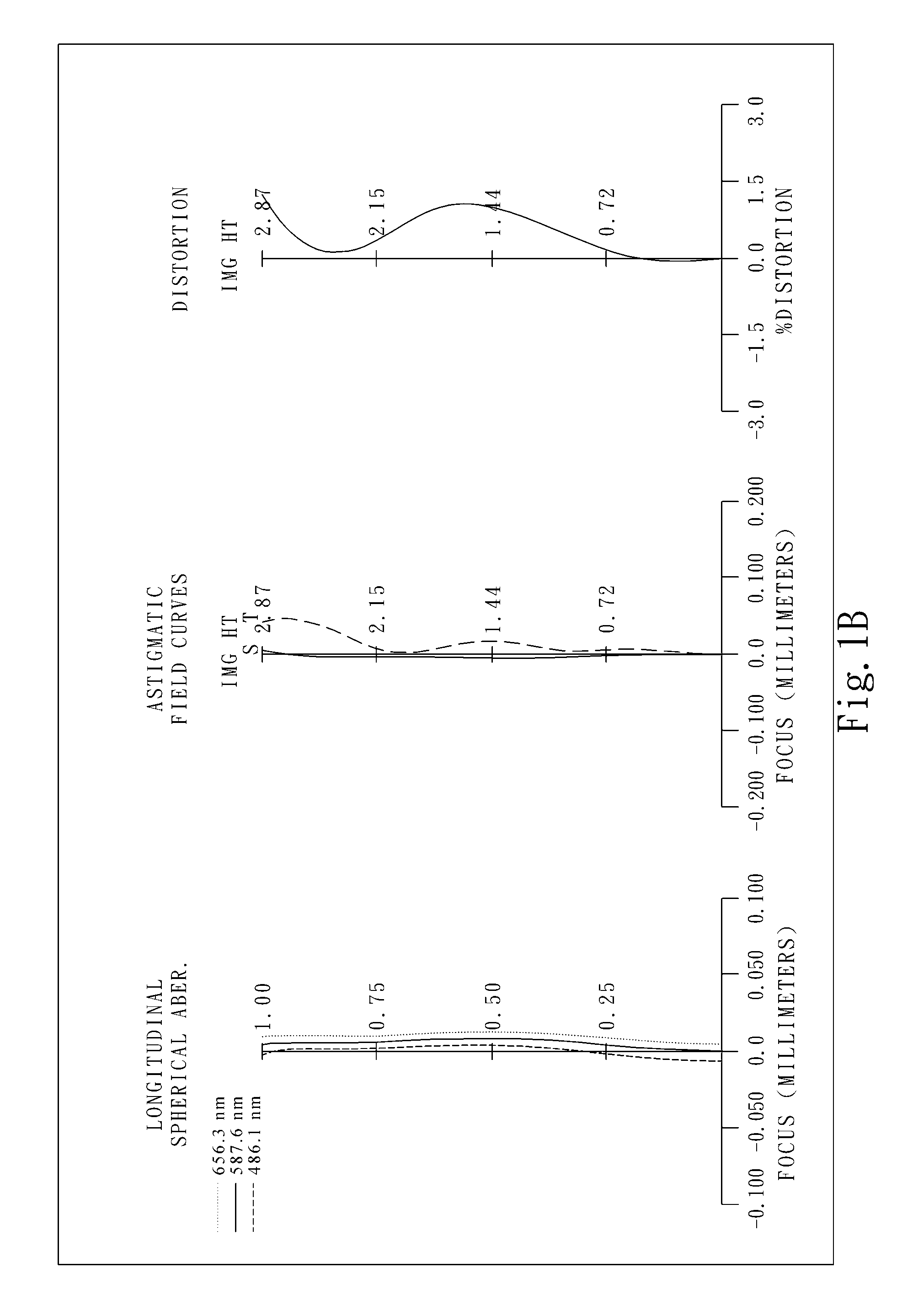

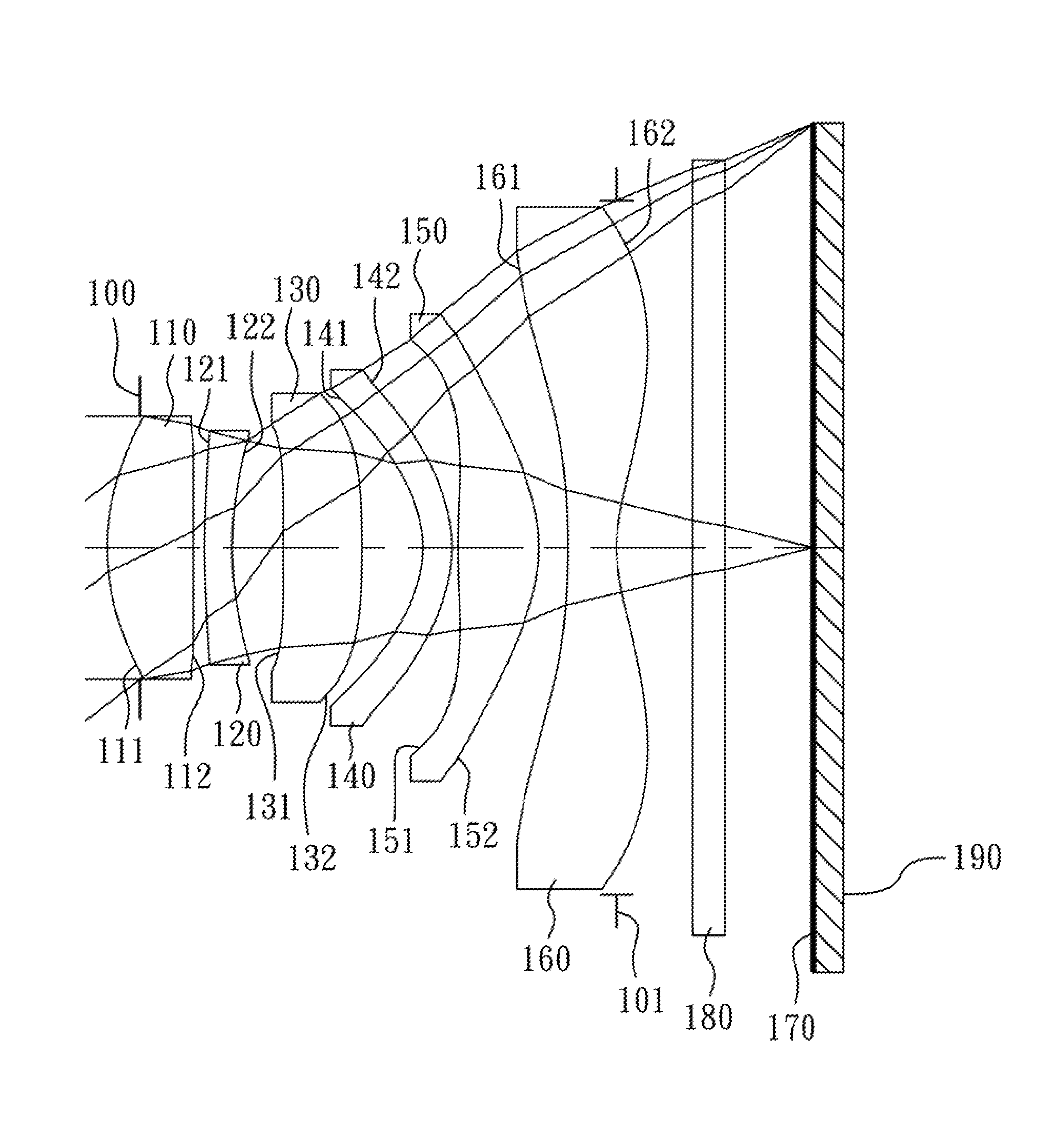

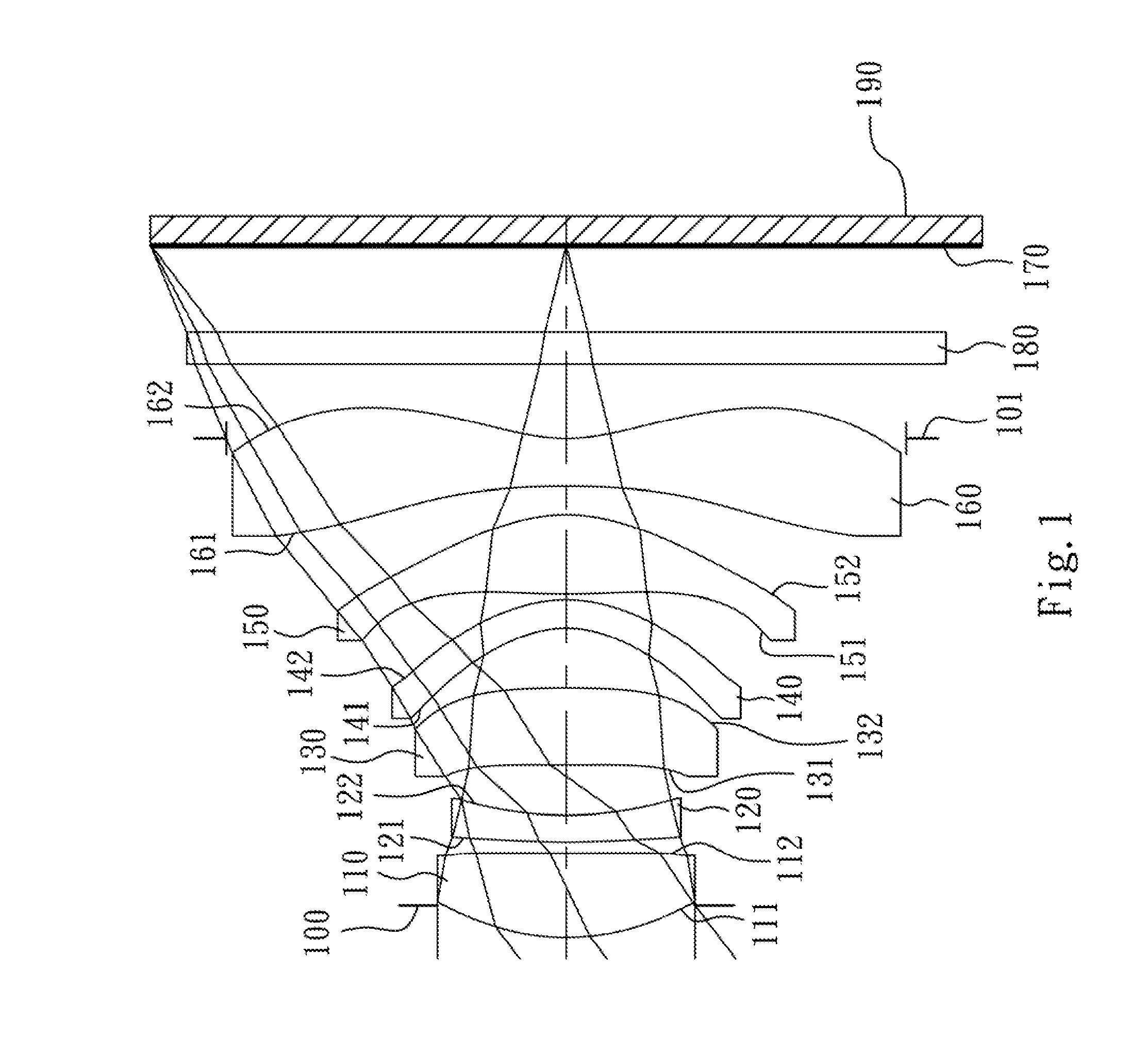

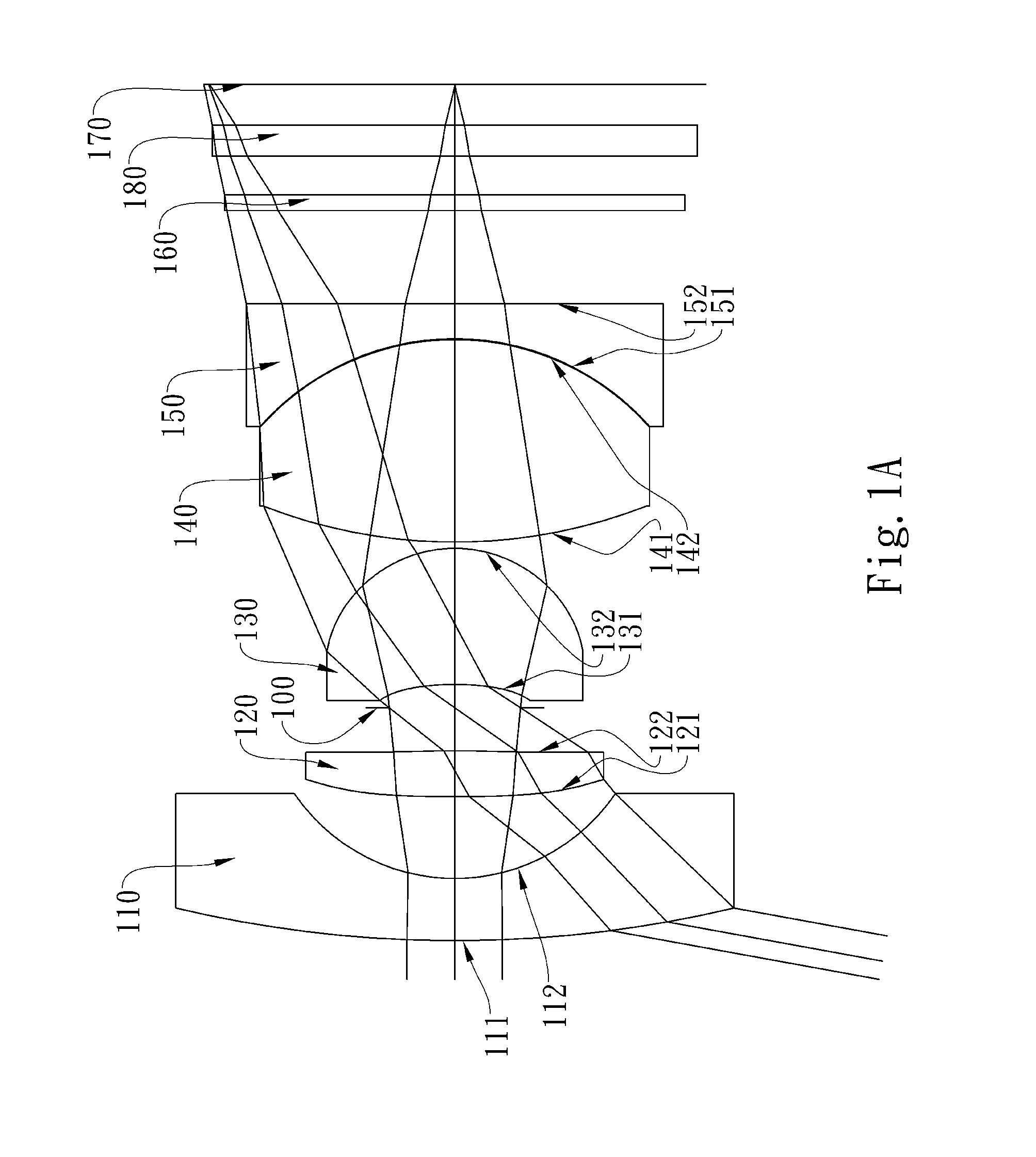

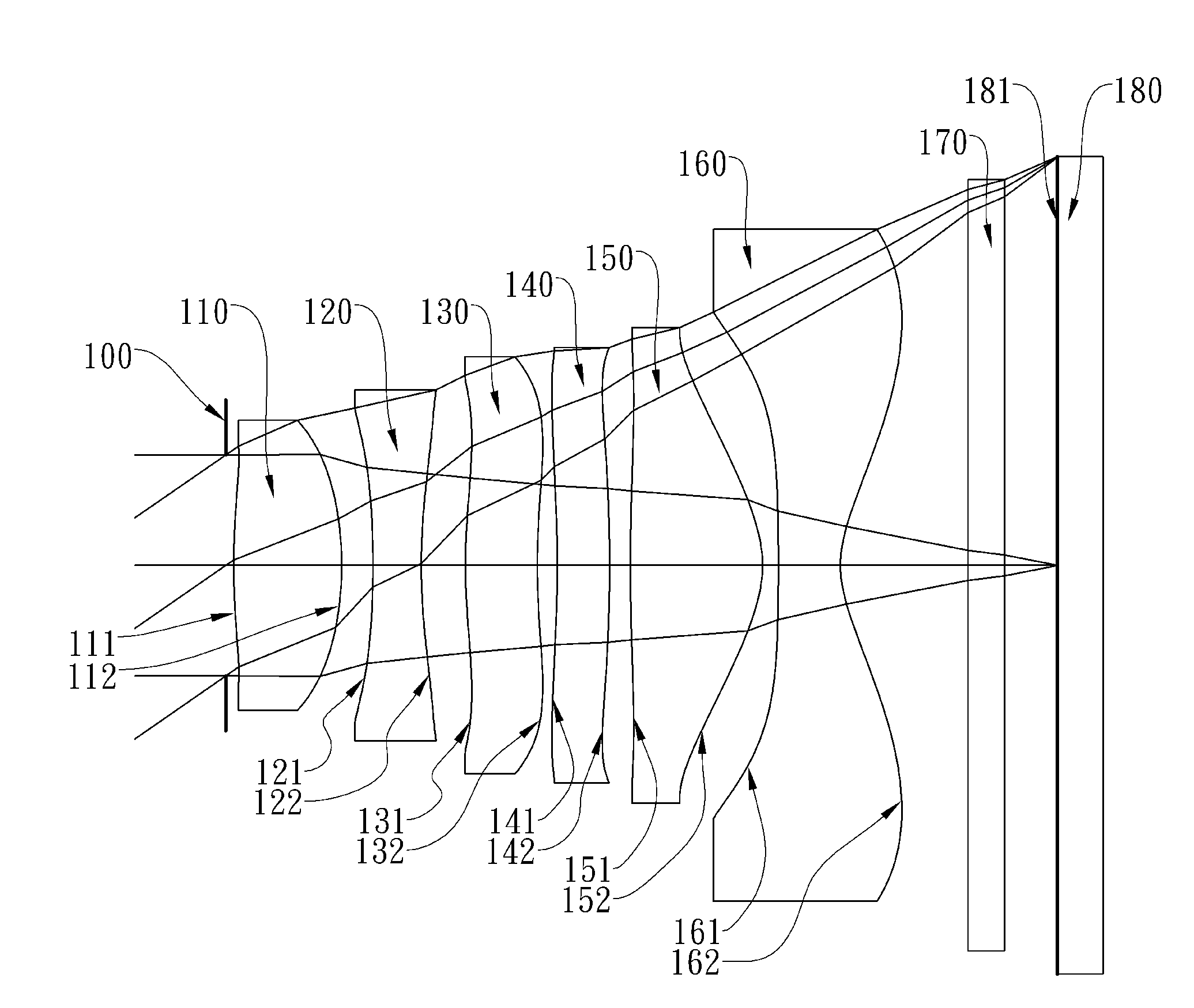

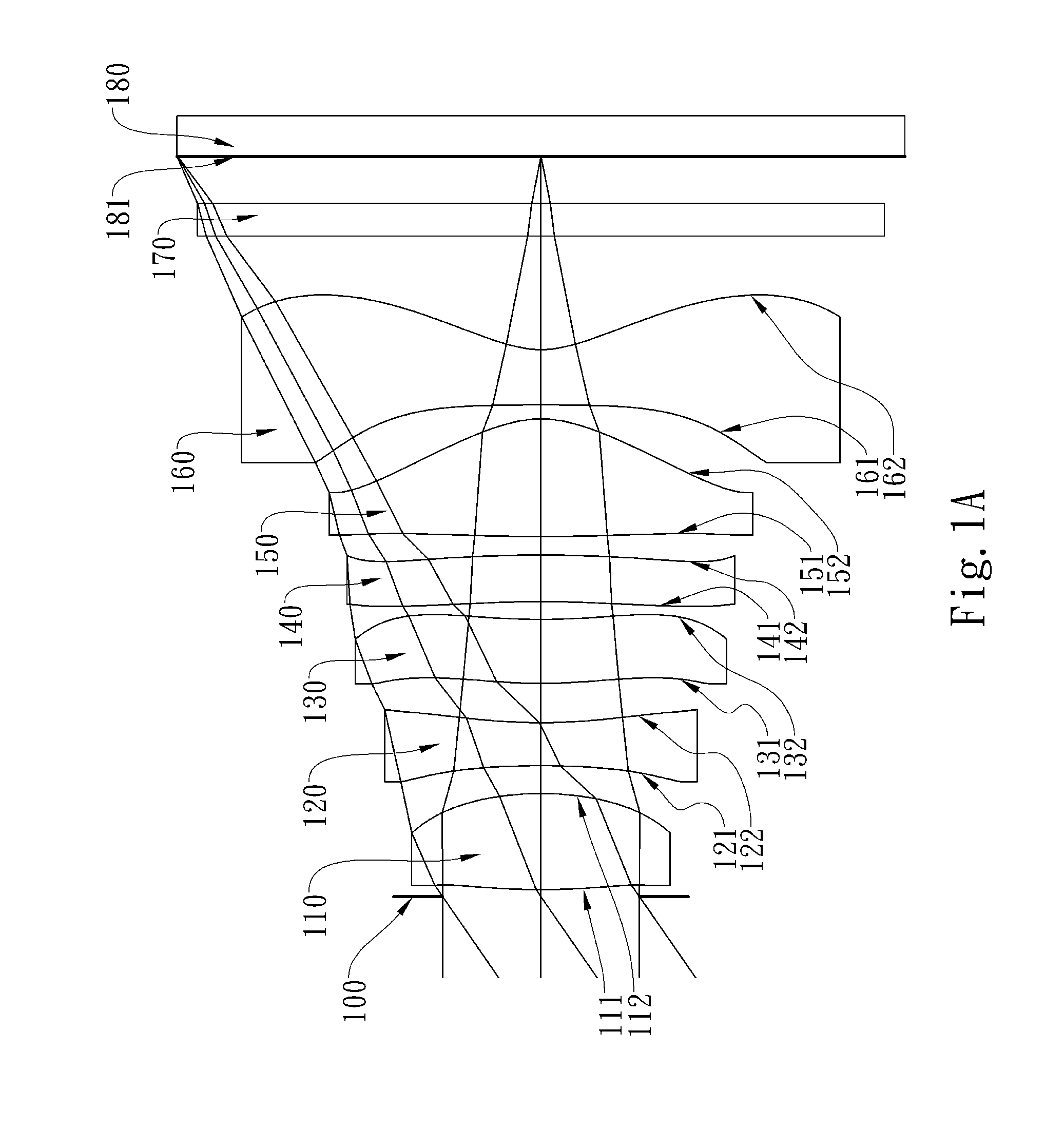

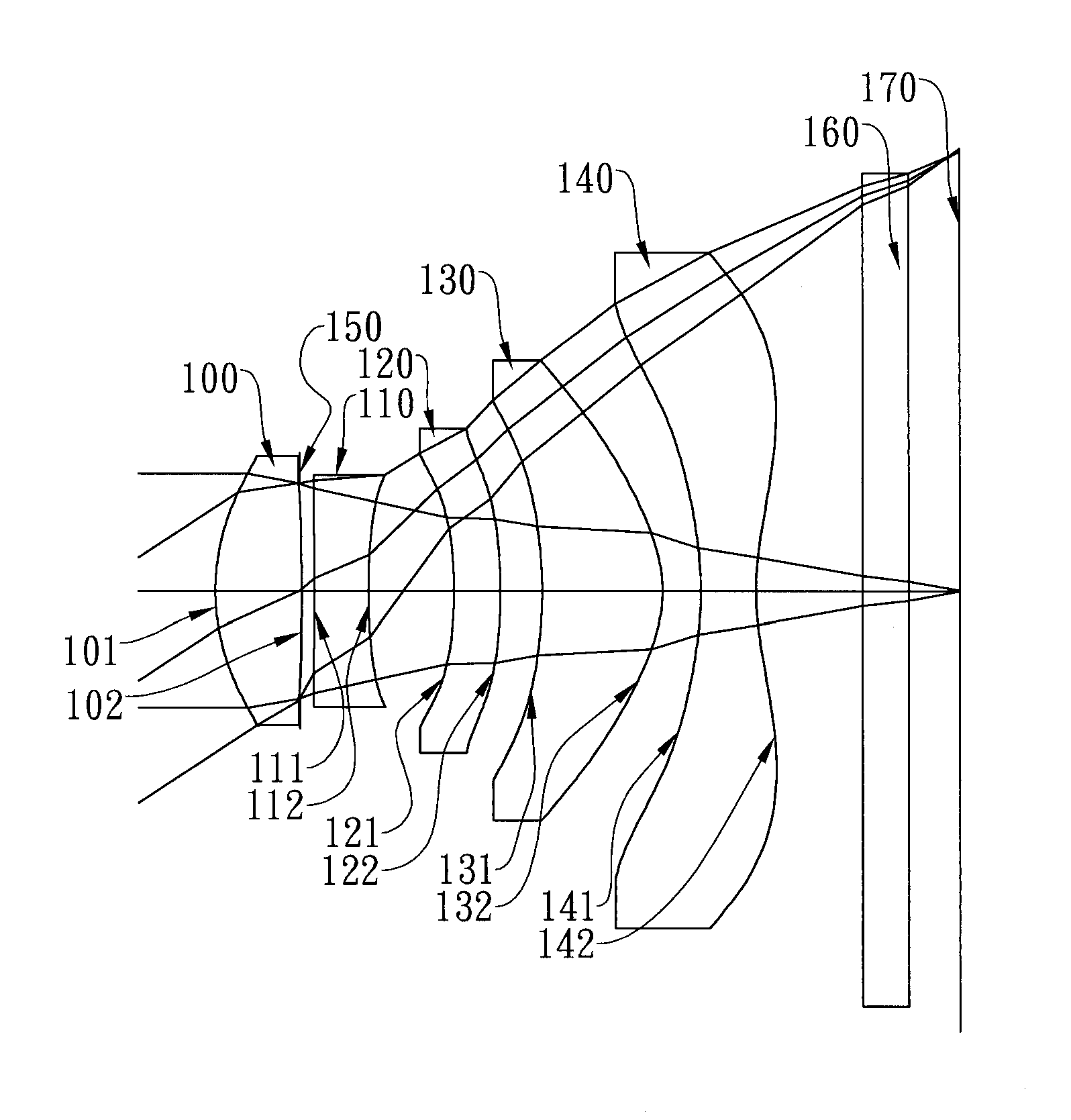

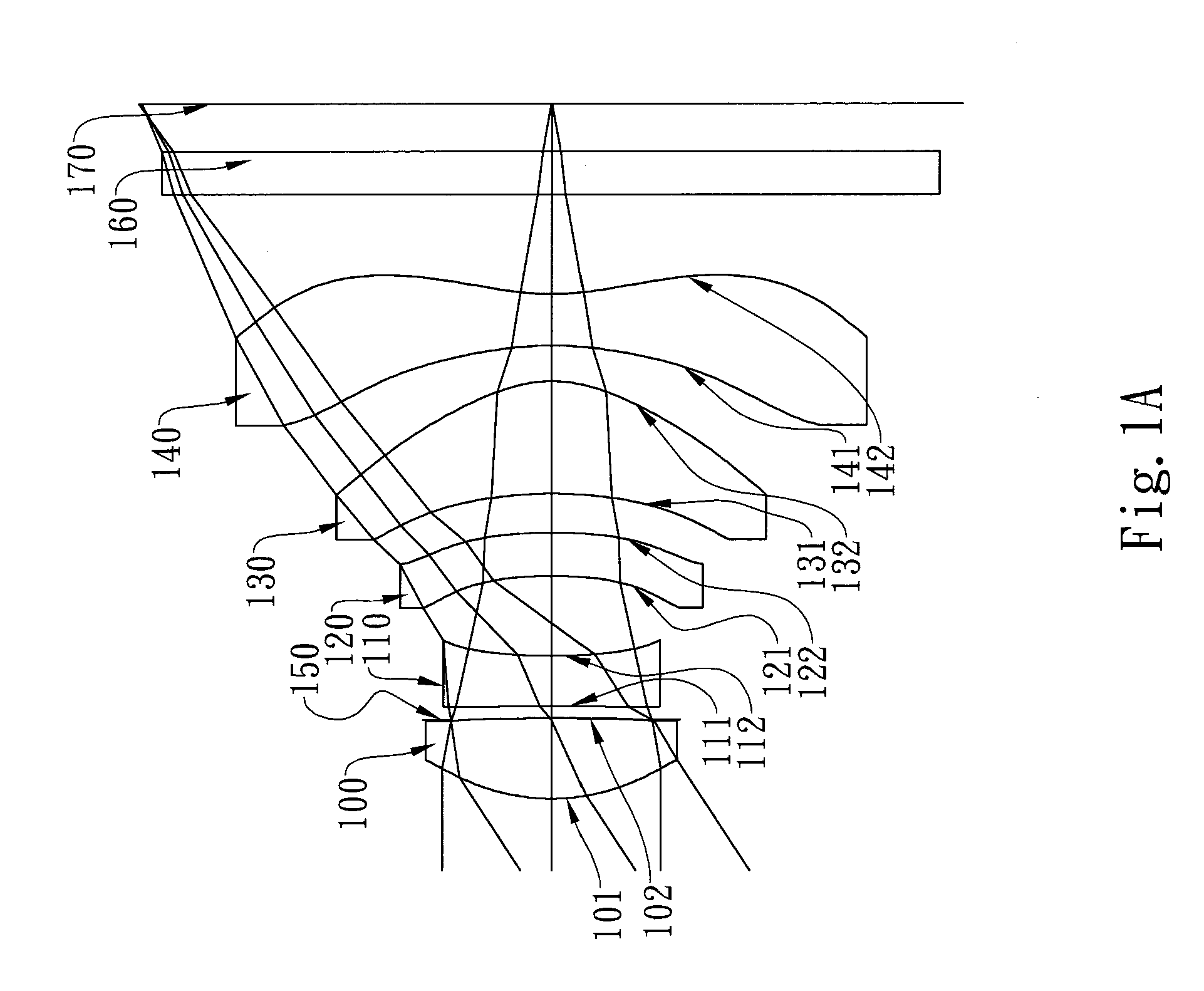

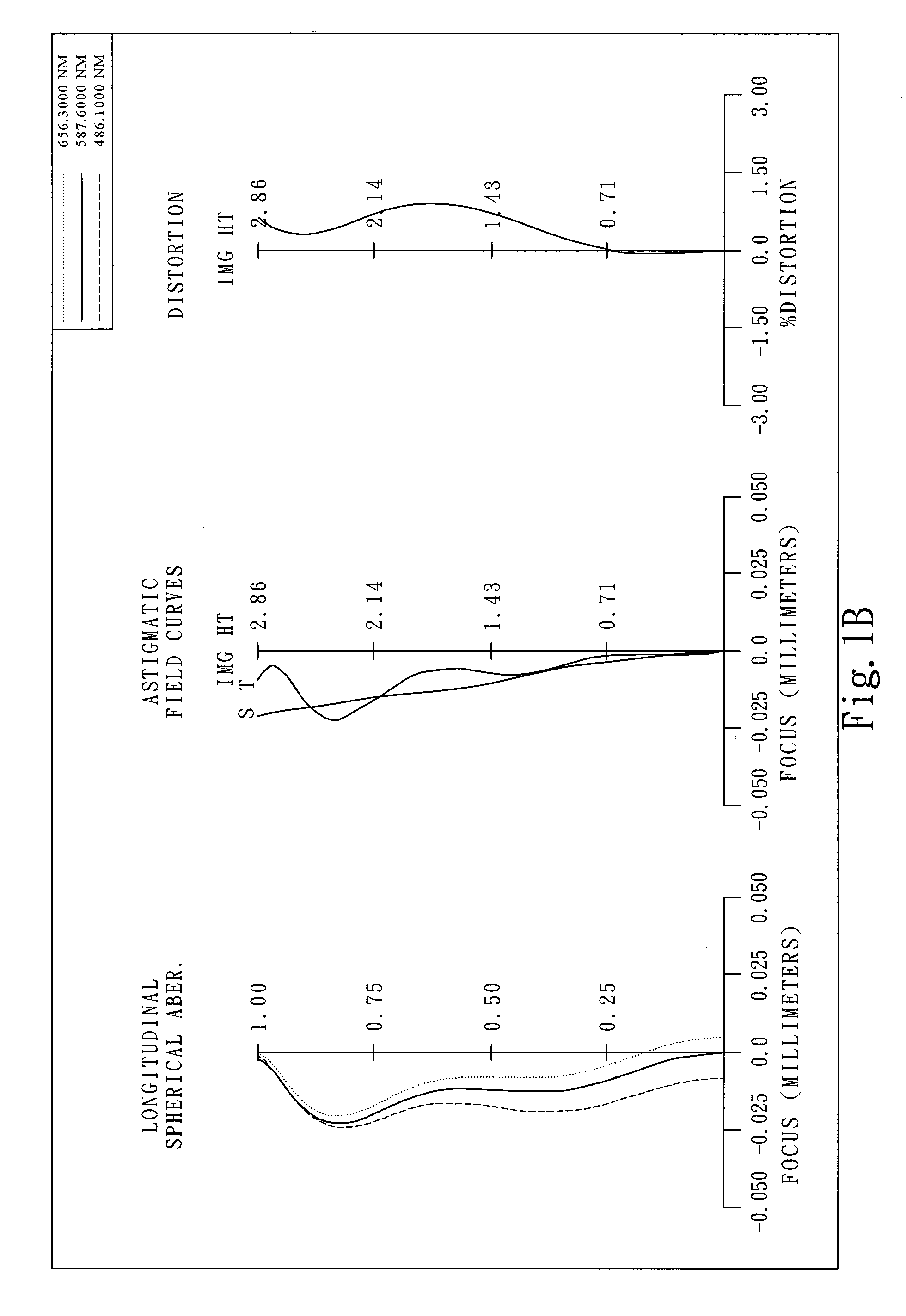

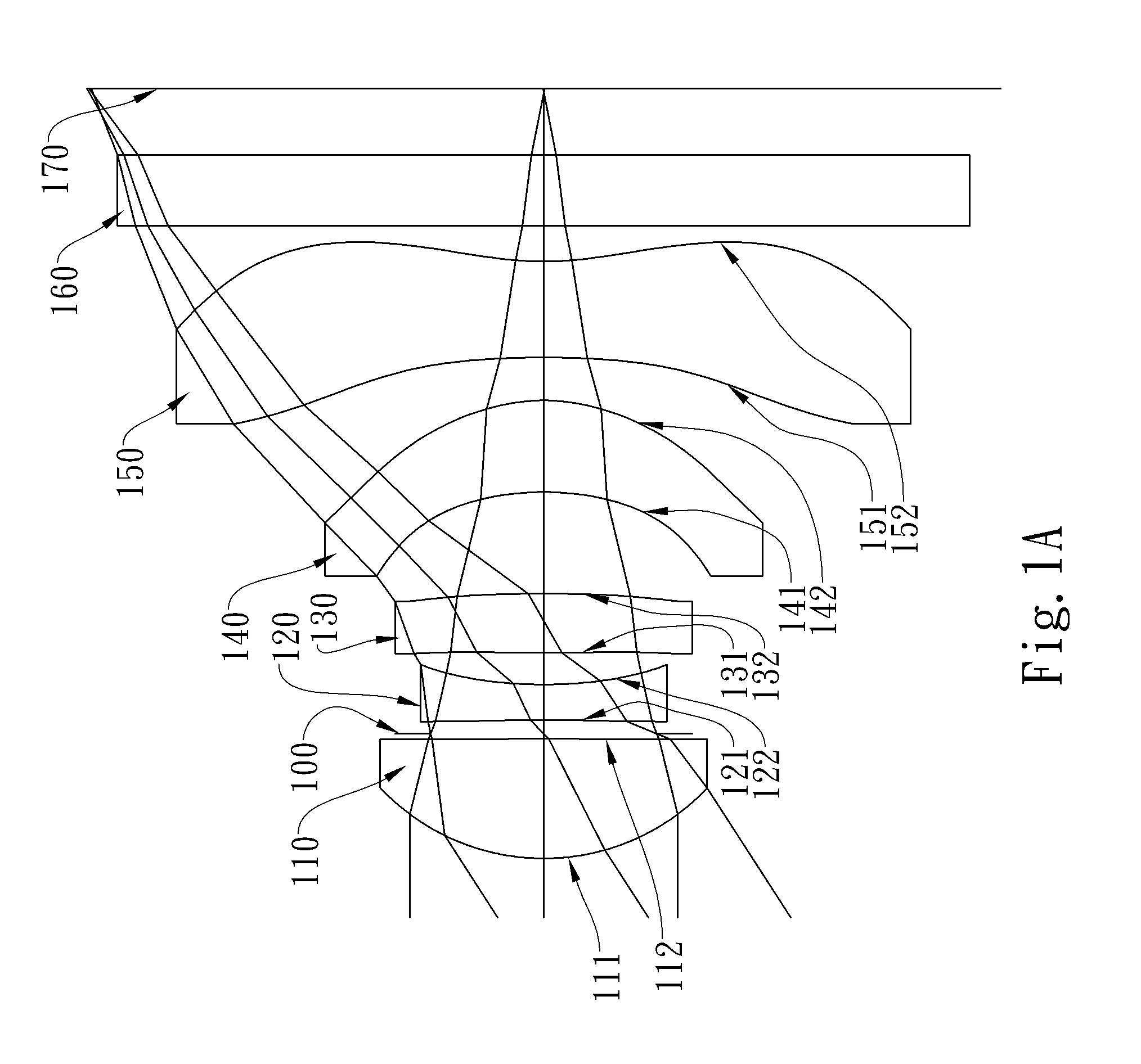

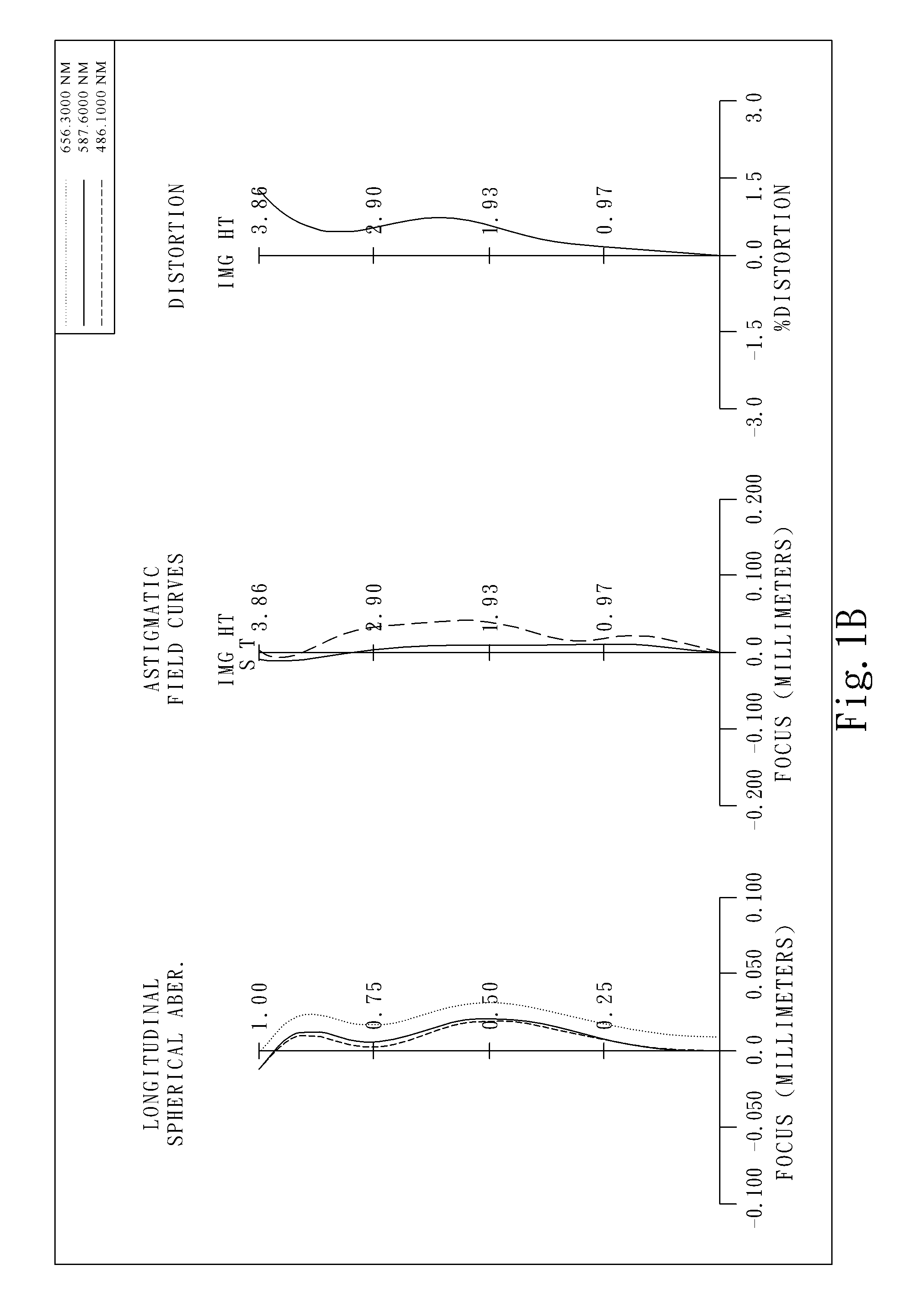

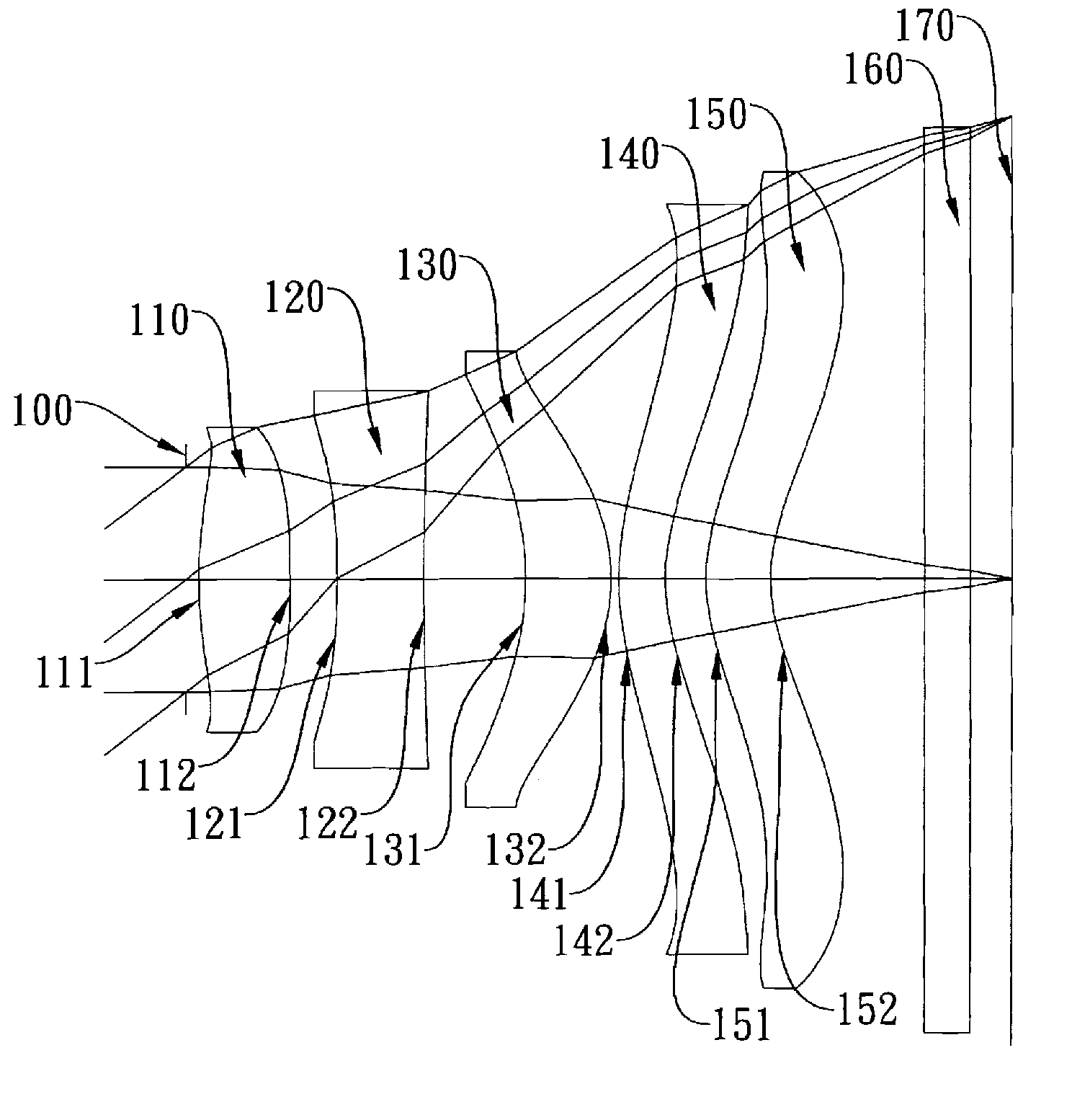

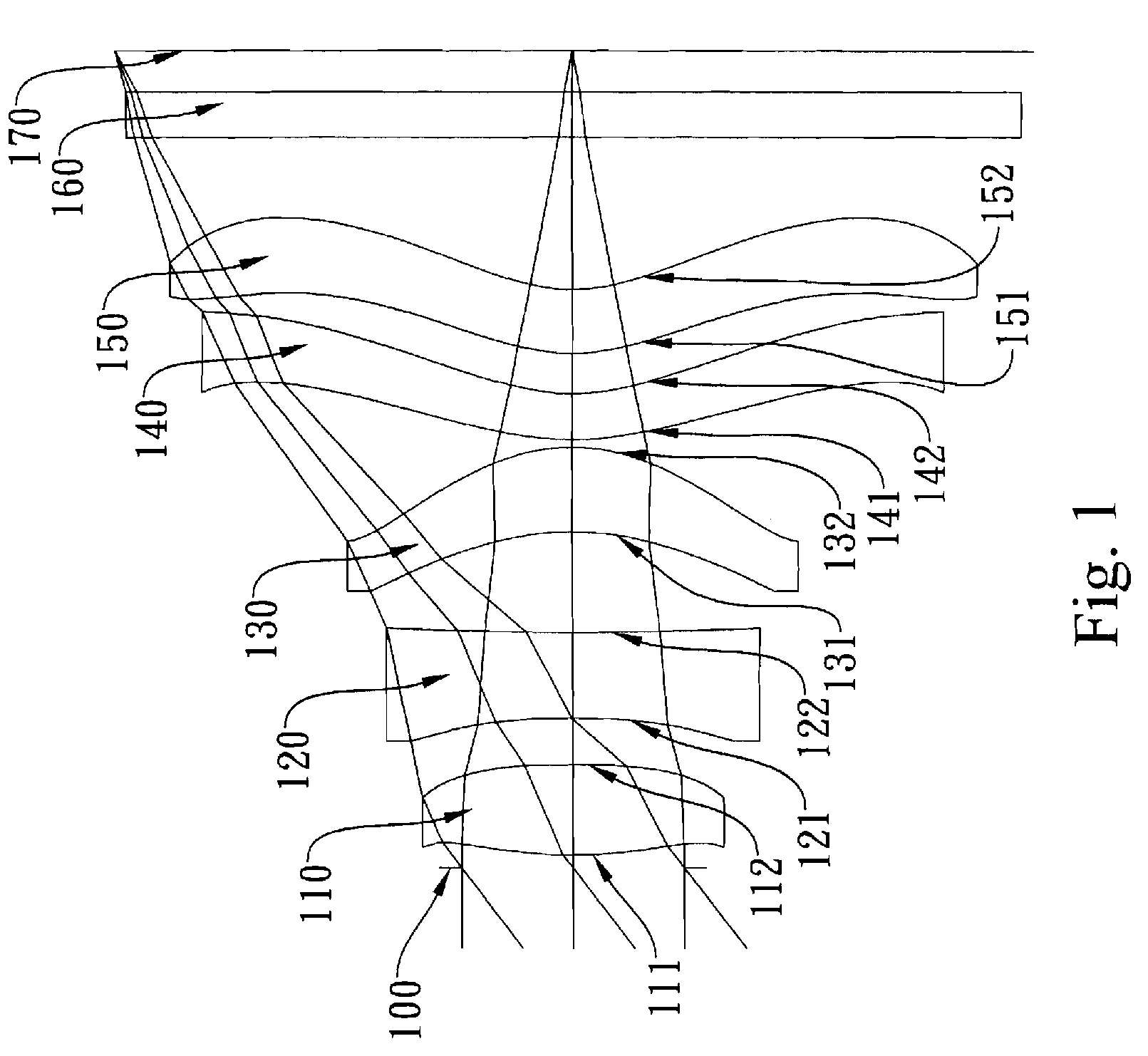

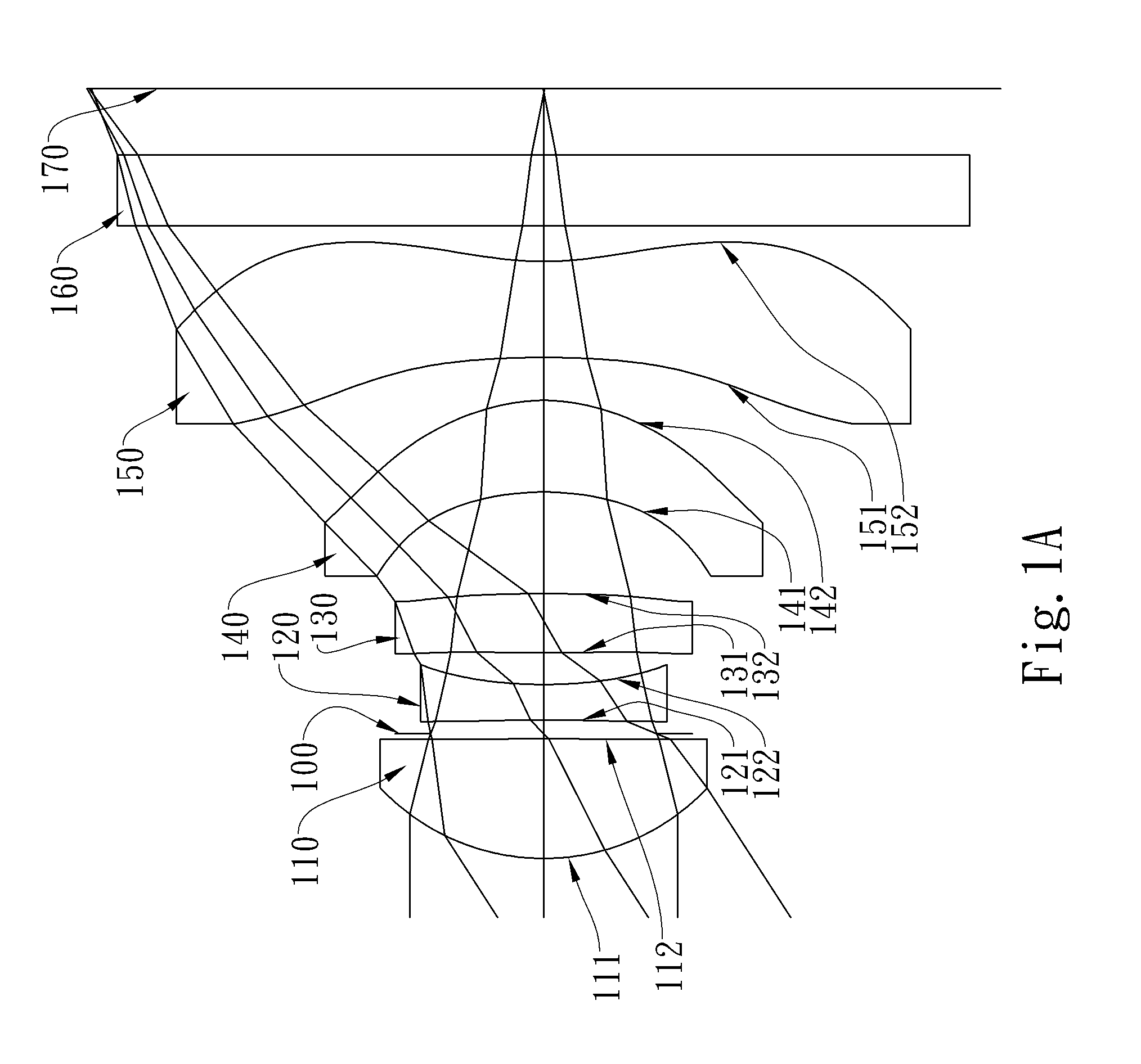

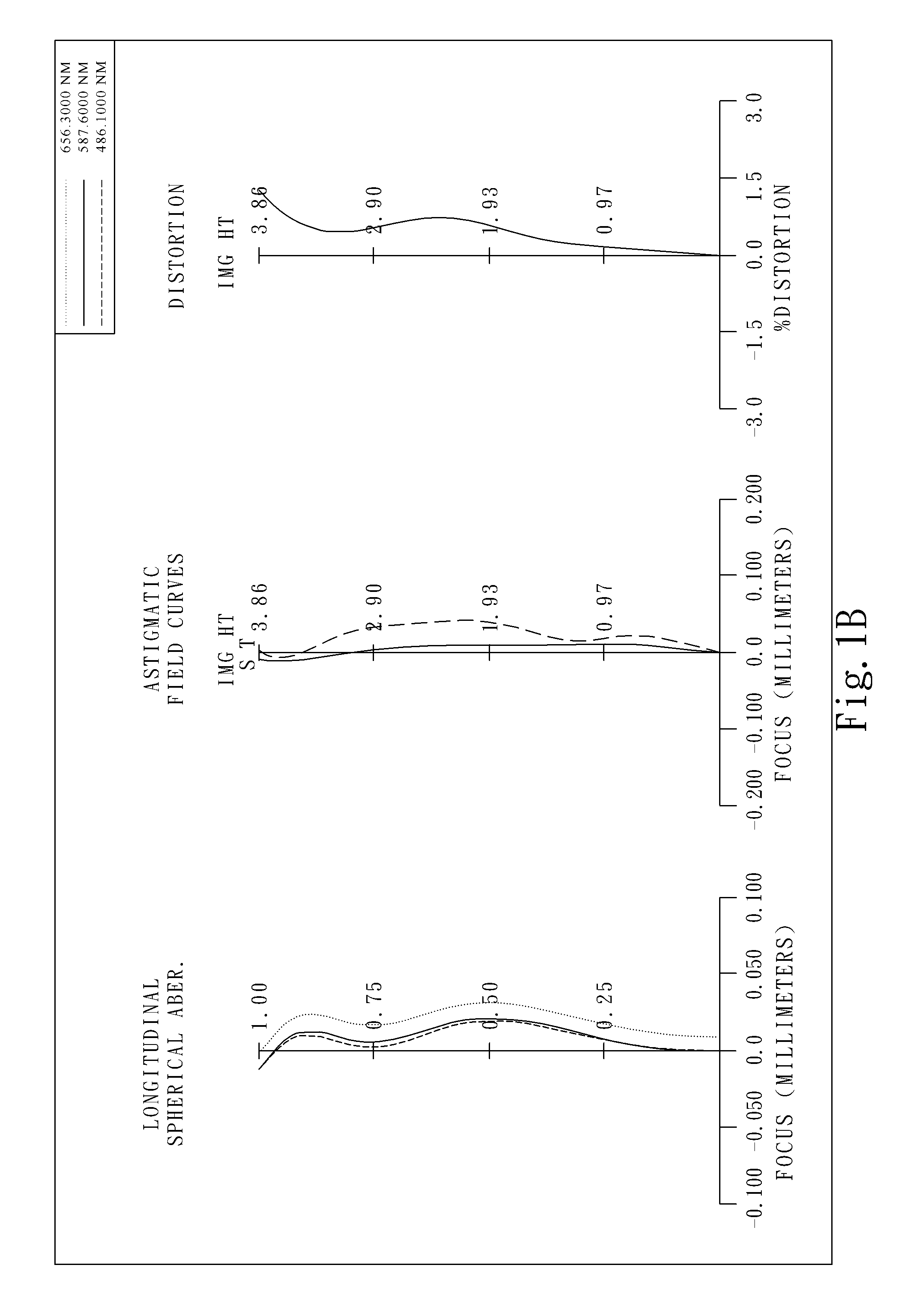

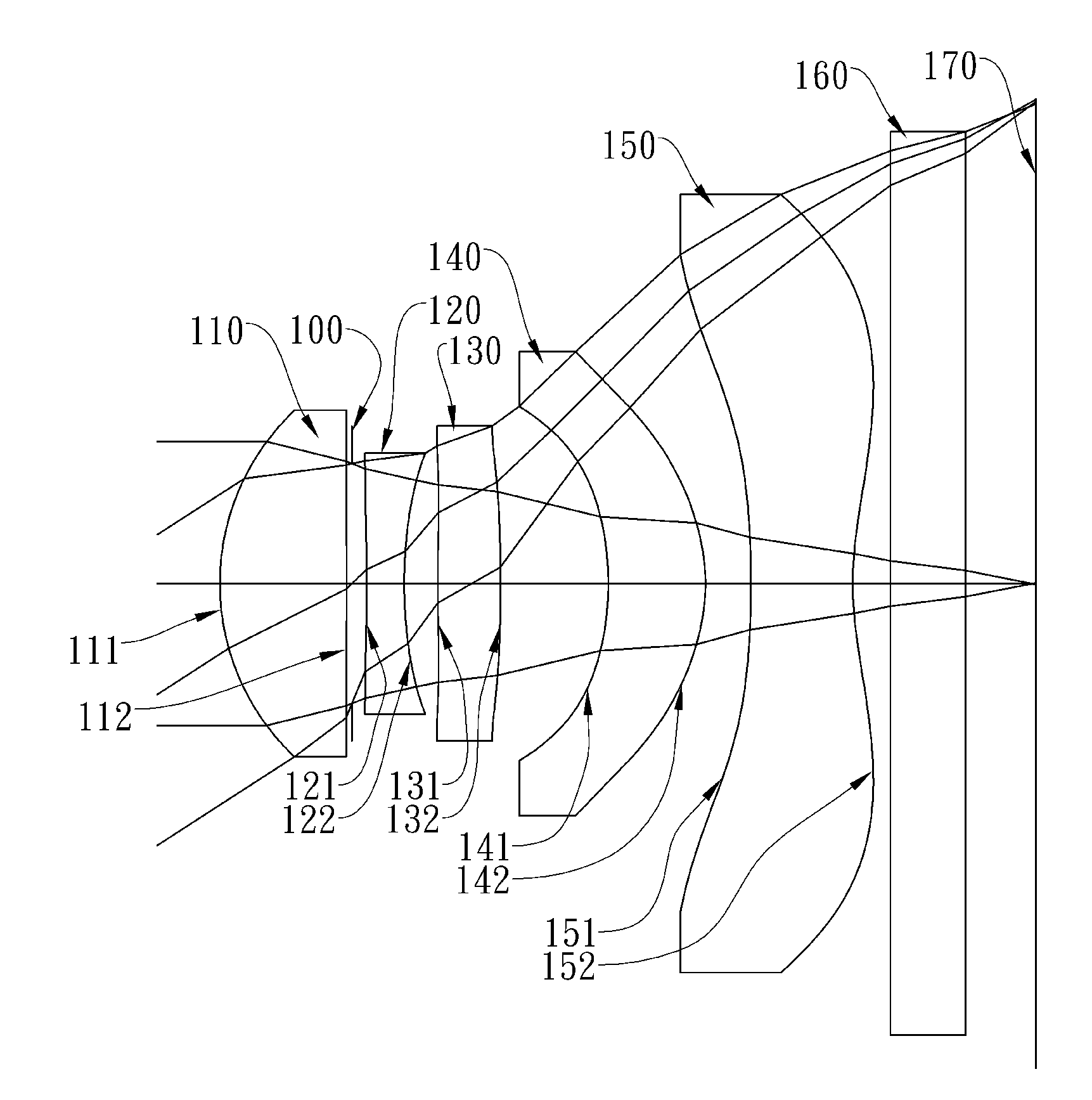

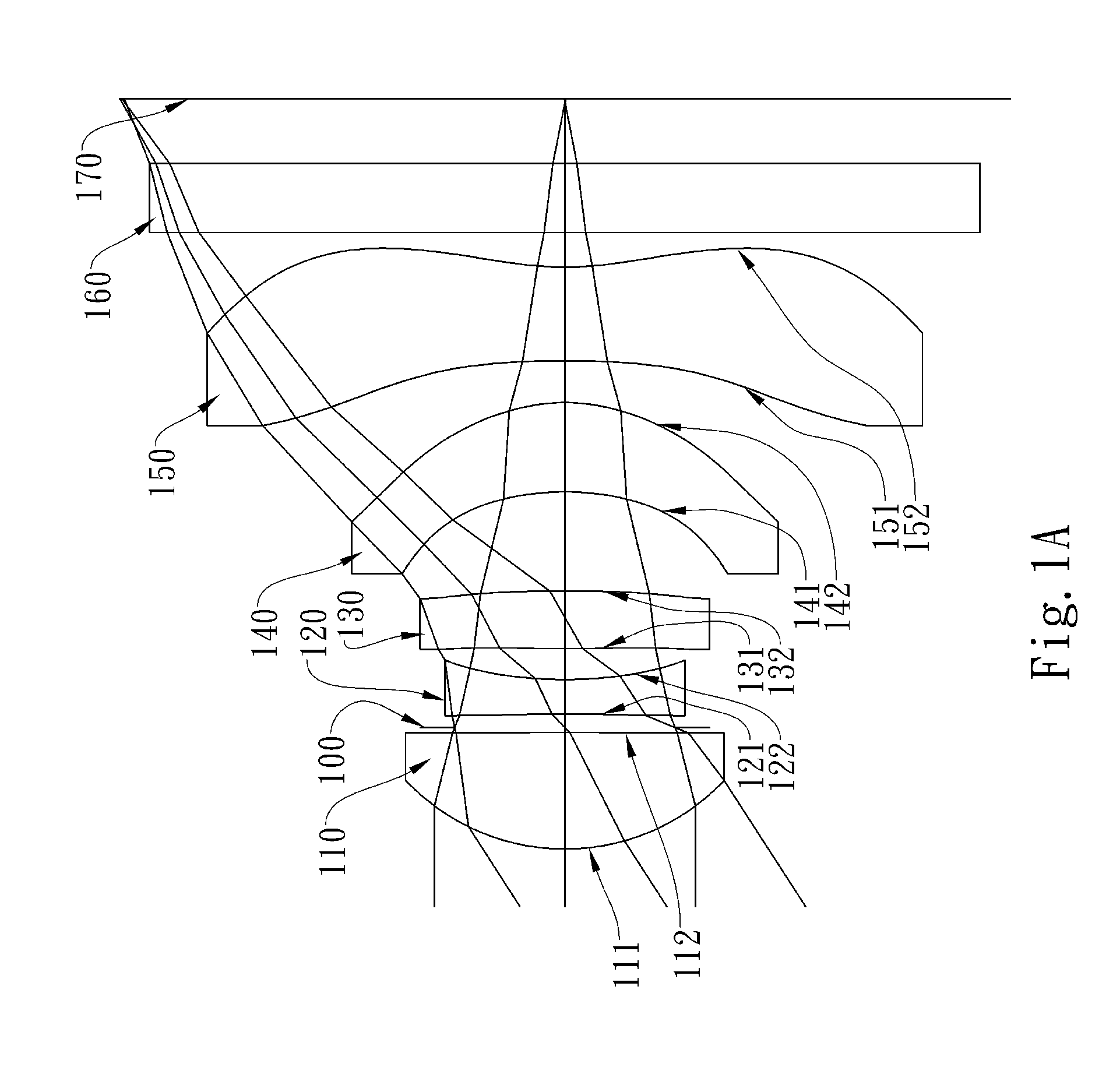

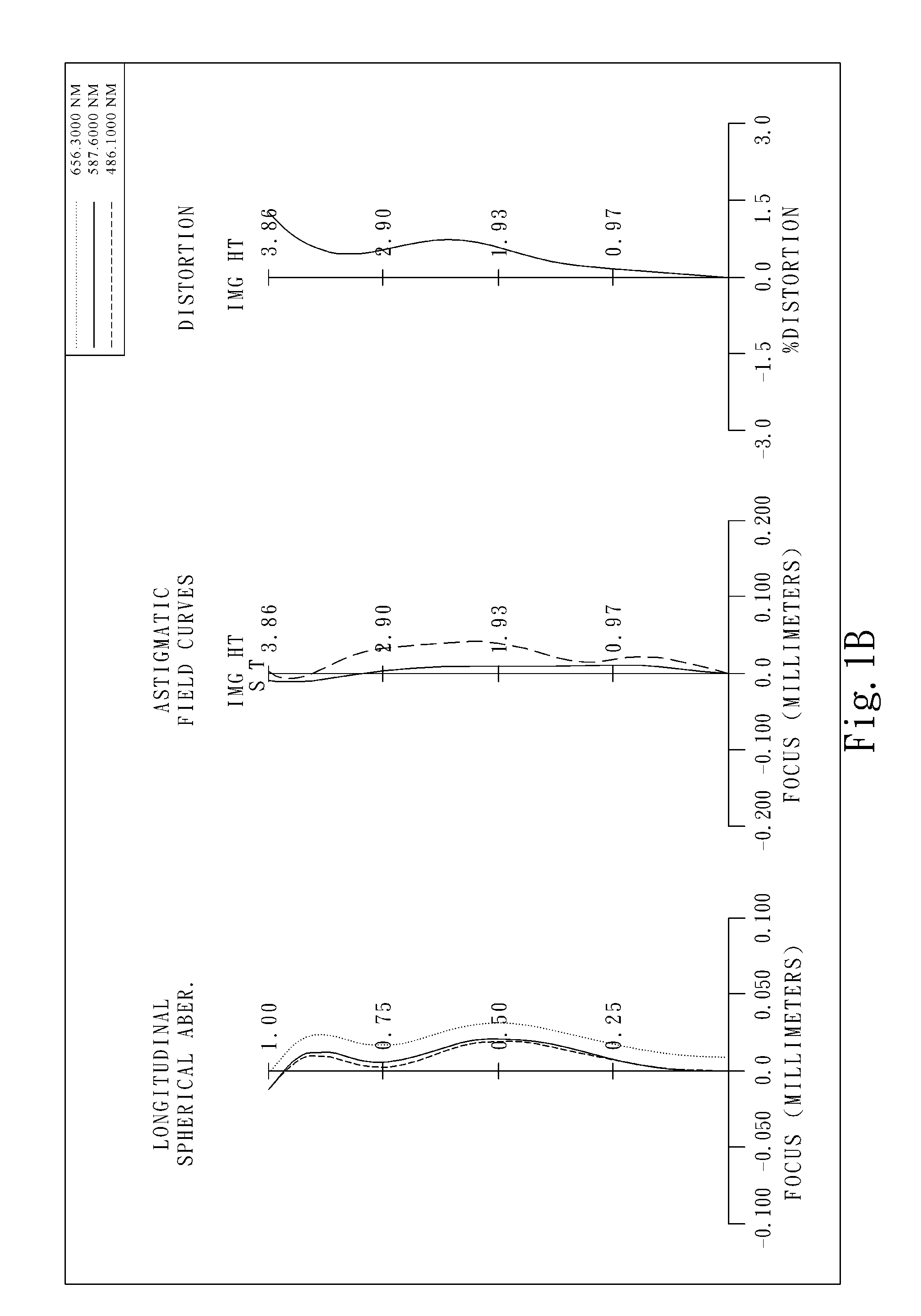

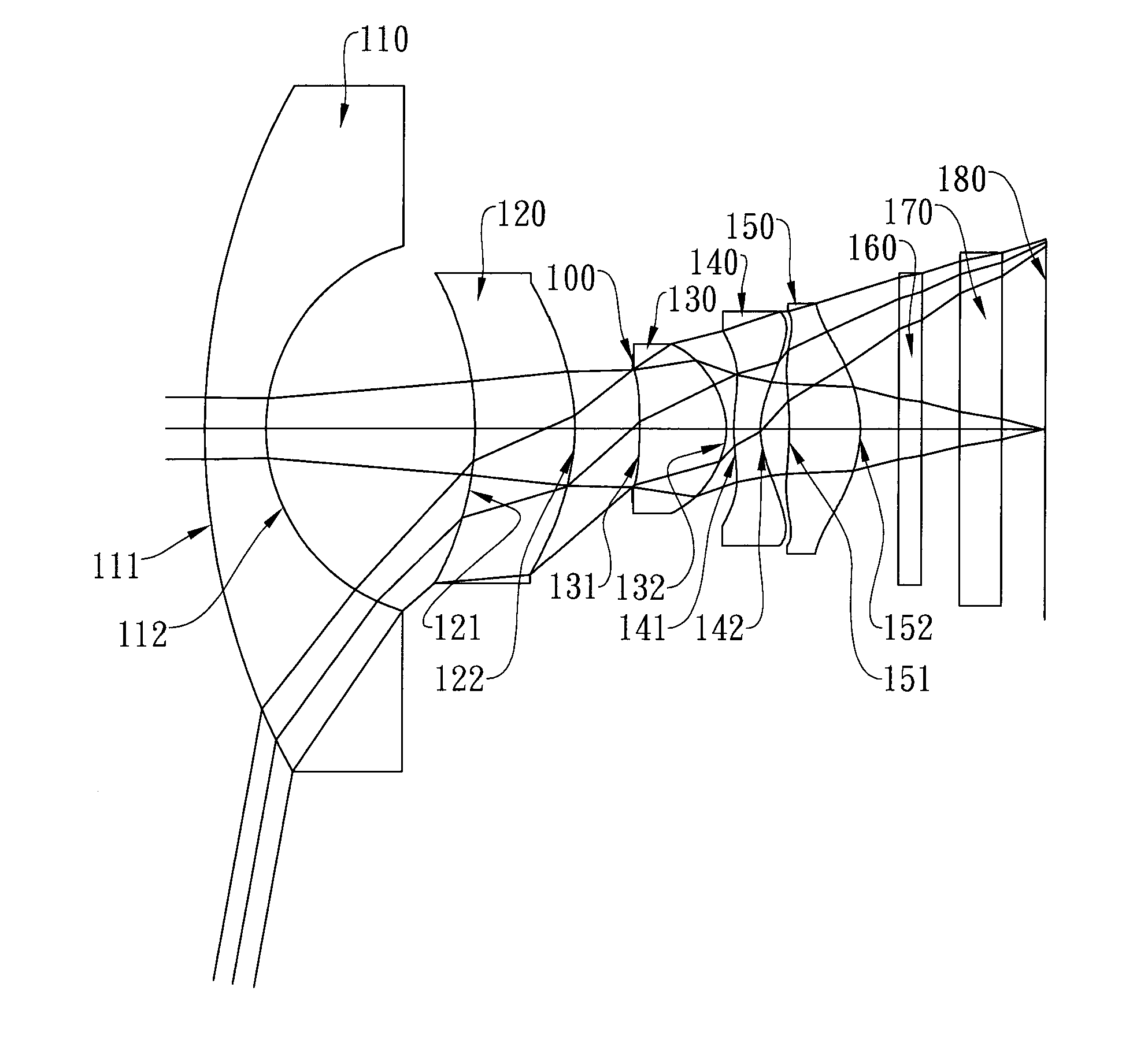

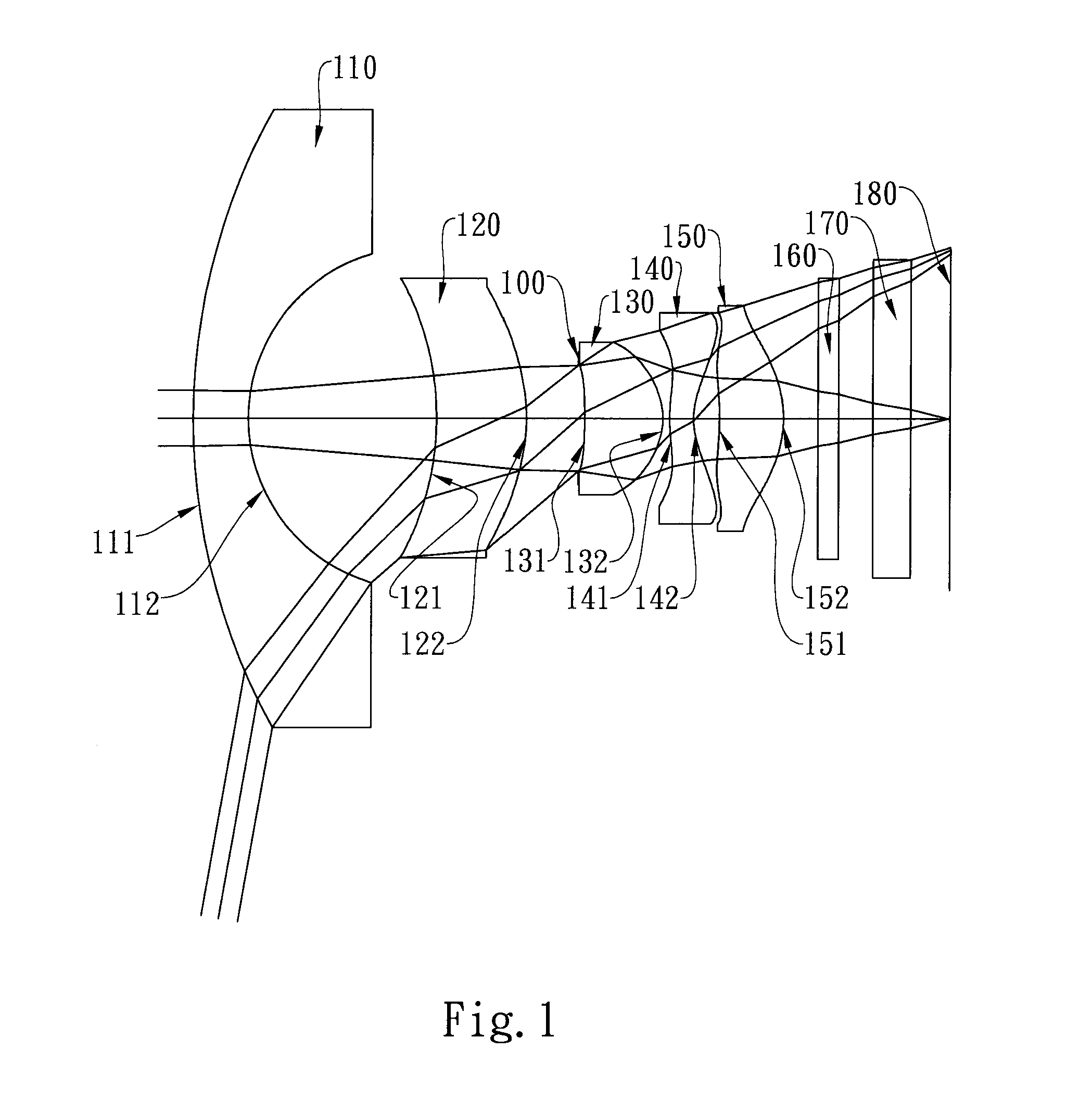

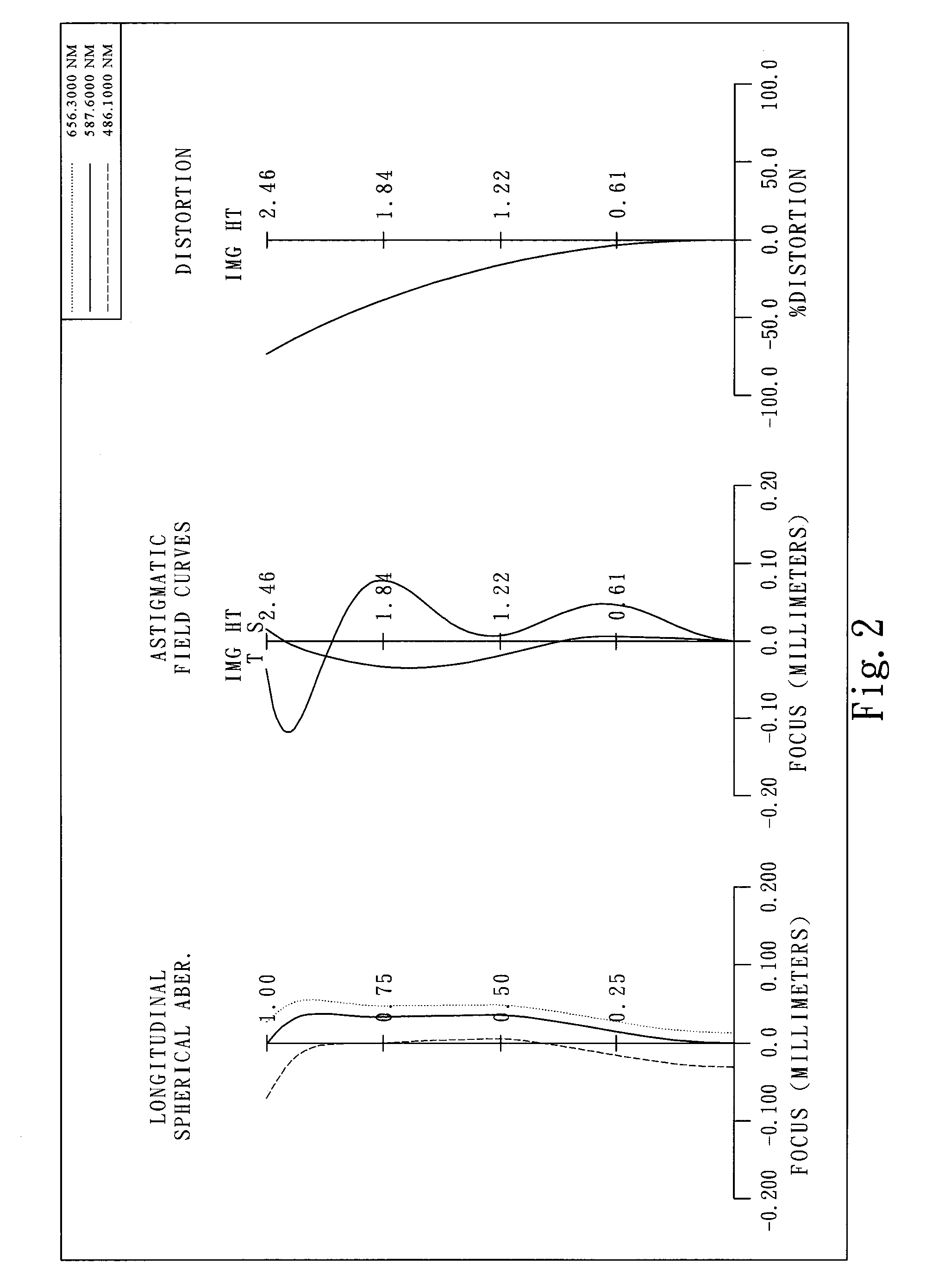

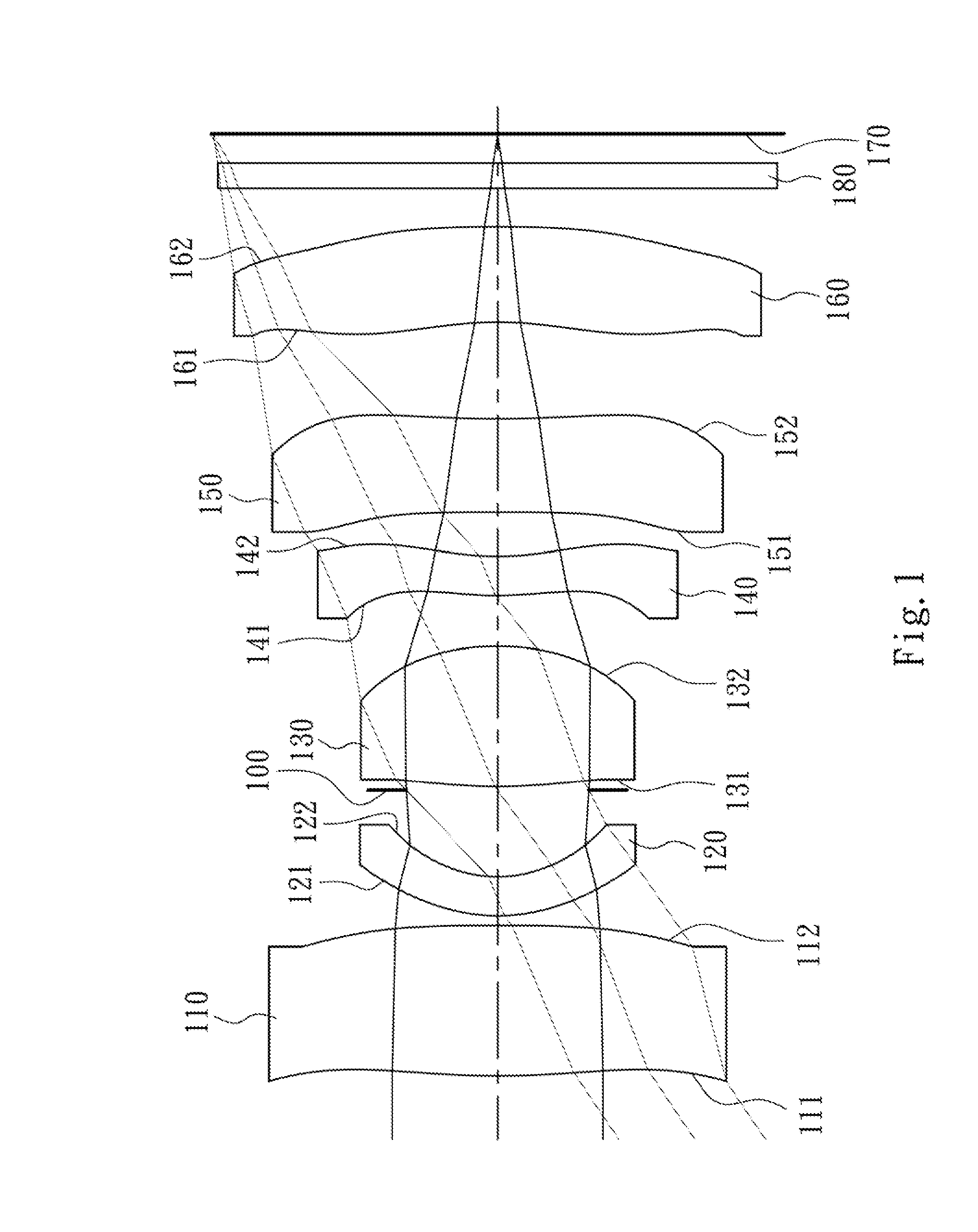

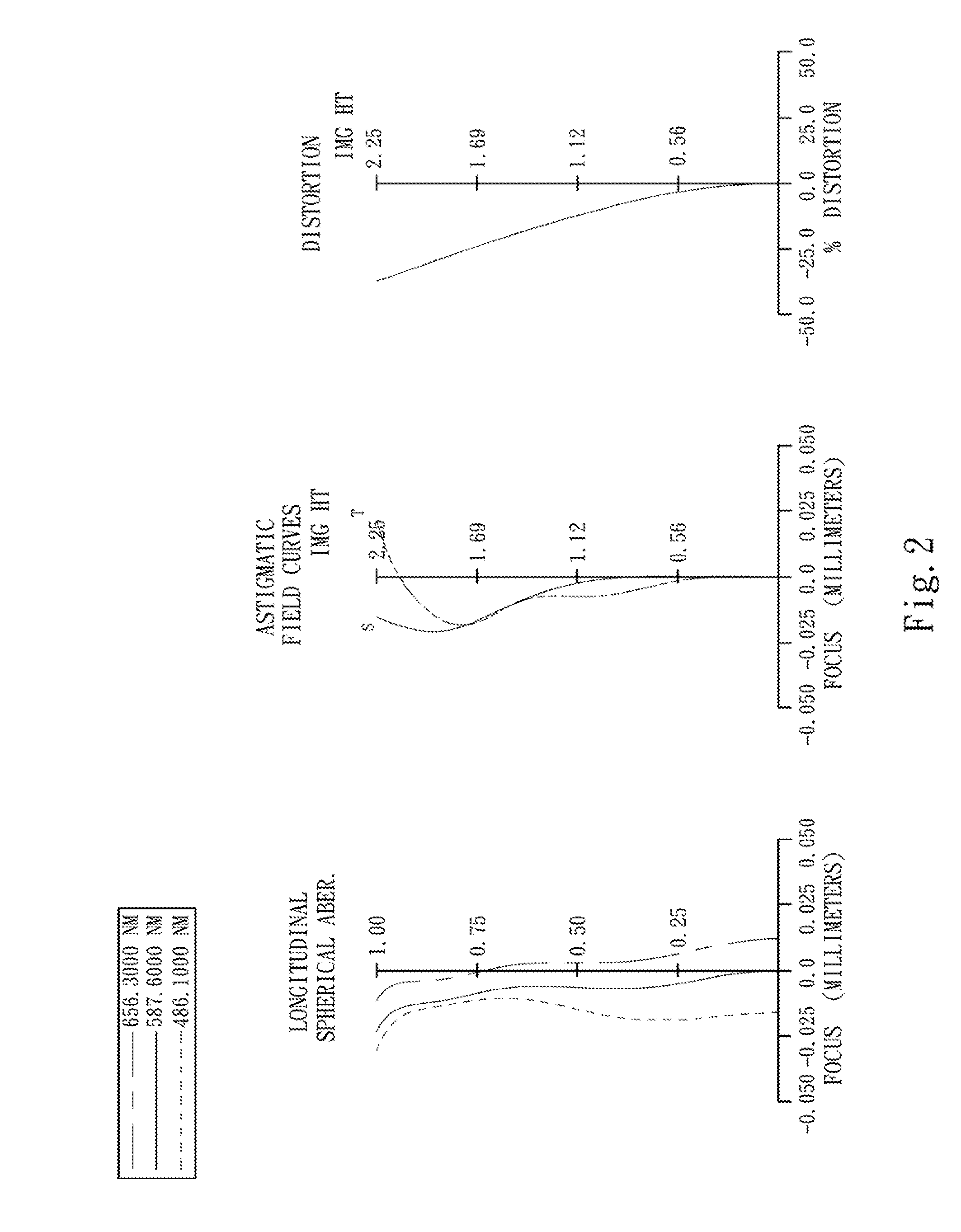

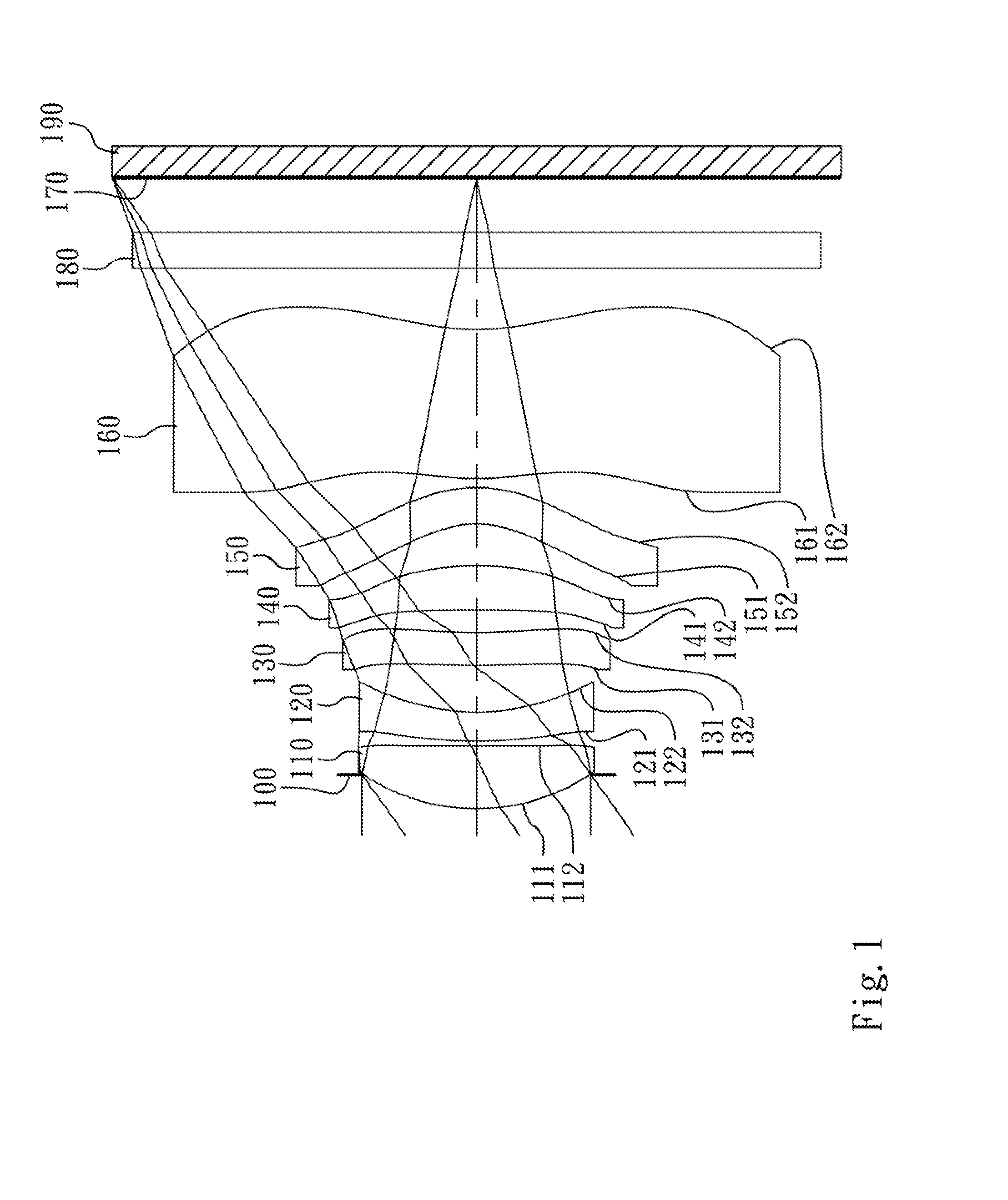

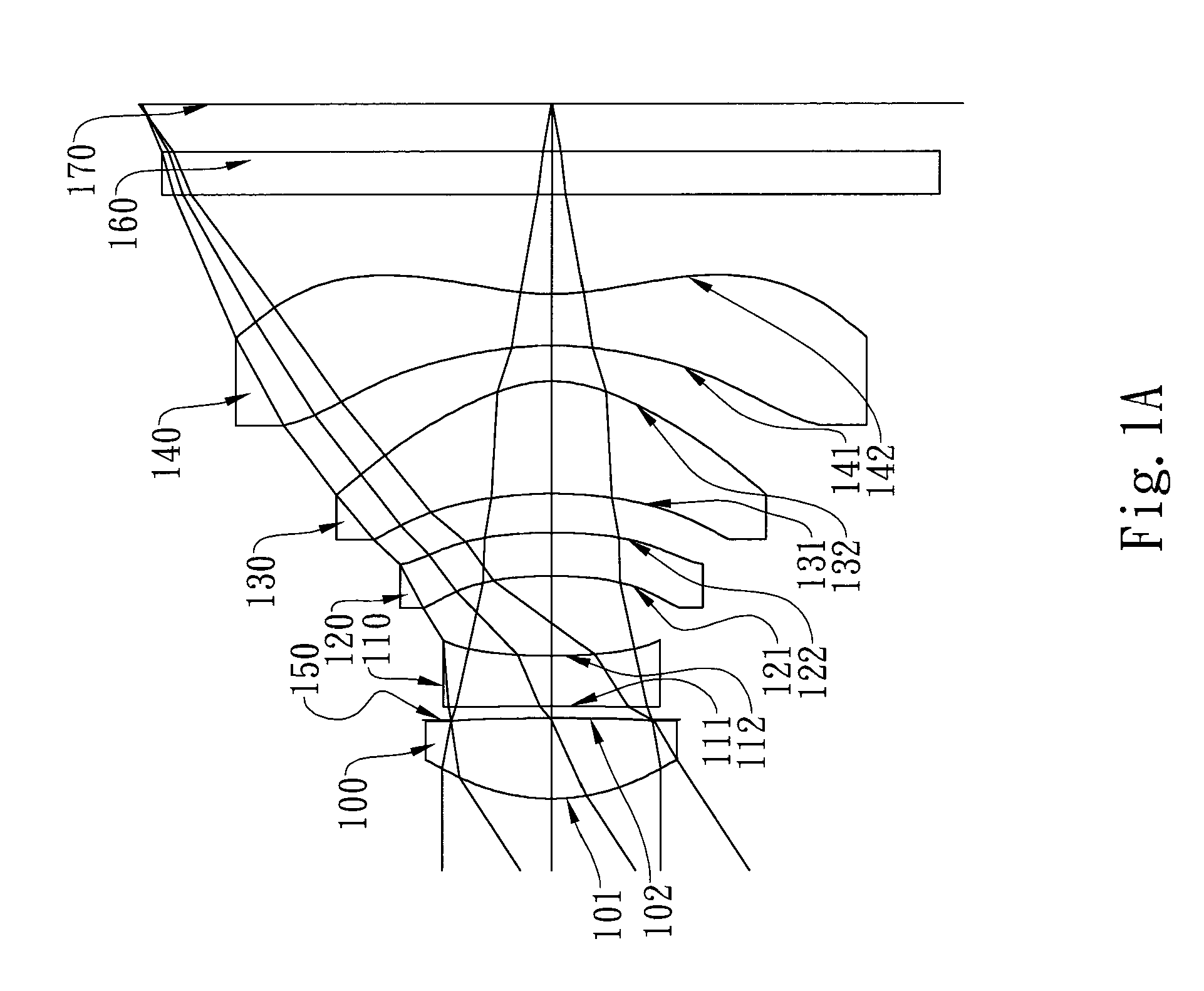

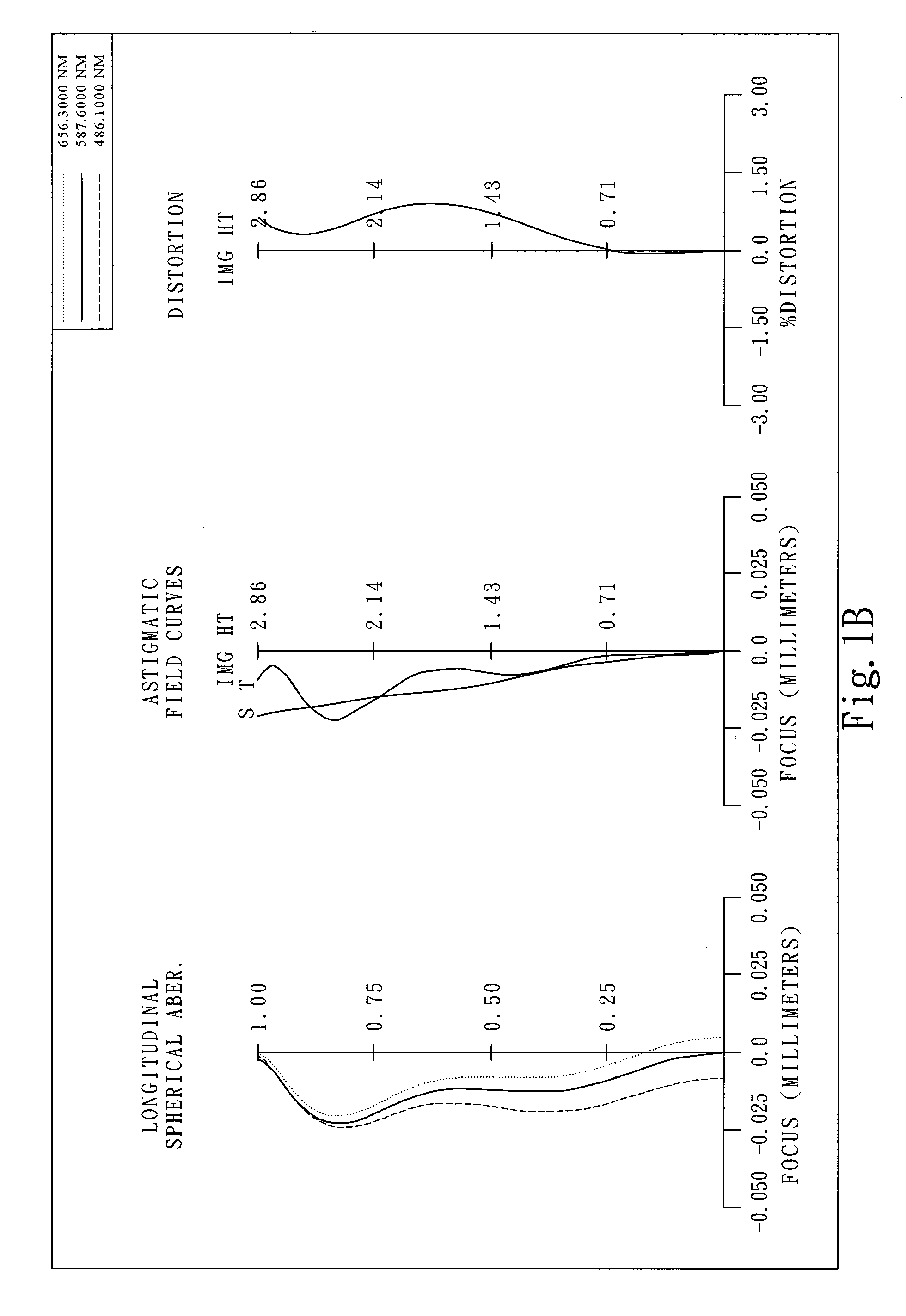

This invention provides an imaging optical lens assembly including: in order from an object side toward an image side: a first lens with positive refractive power and having a convex object-side surface, a second lens with negative refractive power and having a convex object-side surface and a concave image-side surface, a third lens with positive refractive power and having a concave object-side surface and a convex image-side surface, a fourth lens with negative refractive power and having a concave image-side surface, the object-side and image-side surfaces being aspheric, and a fifth lens having a concave image-side surface, the object-side and image-side surfaces being aspheric. The imaging optical lens assembly further comprises an aperture stop, disposed between an imaged object and the second lens, and an electronic sensor, disposed at the image plane for image formation.

Owner:LARGAN PRECISION

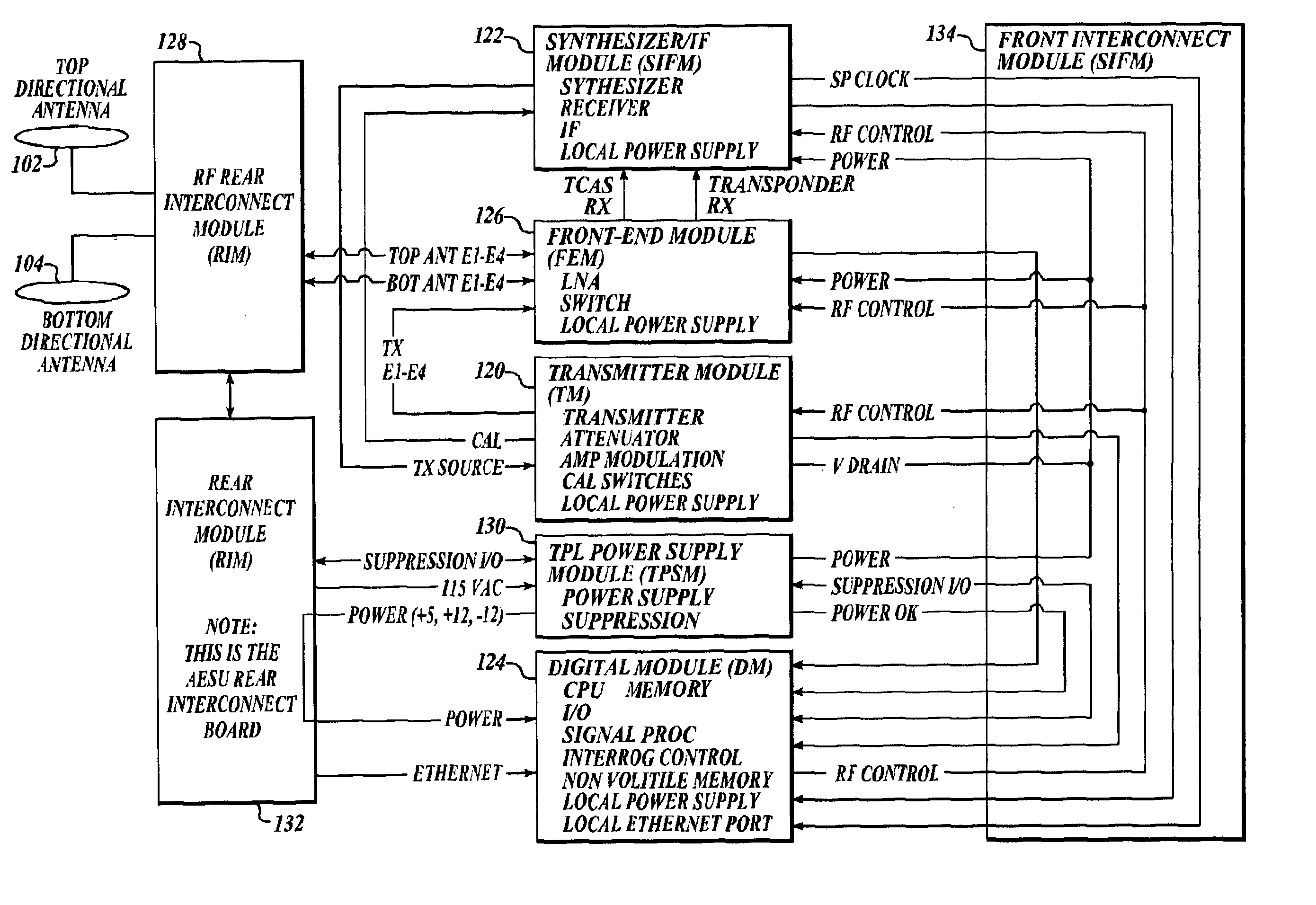

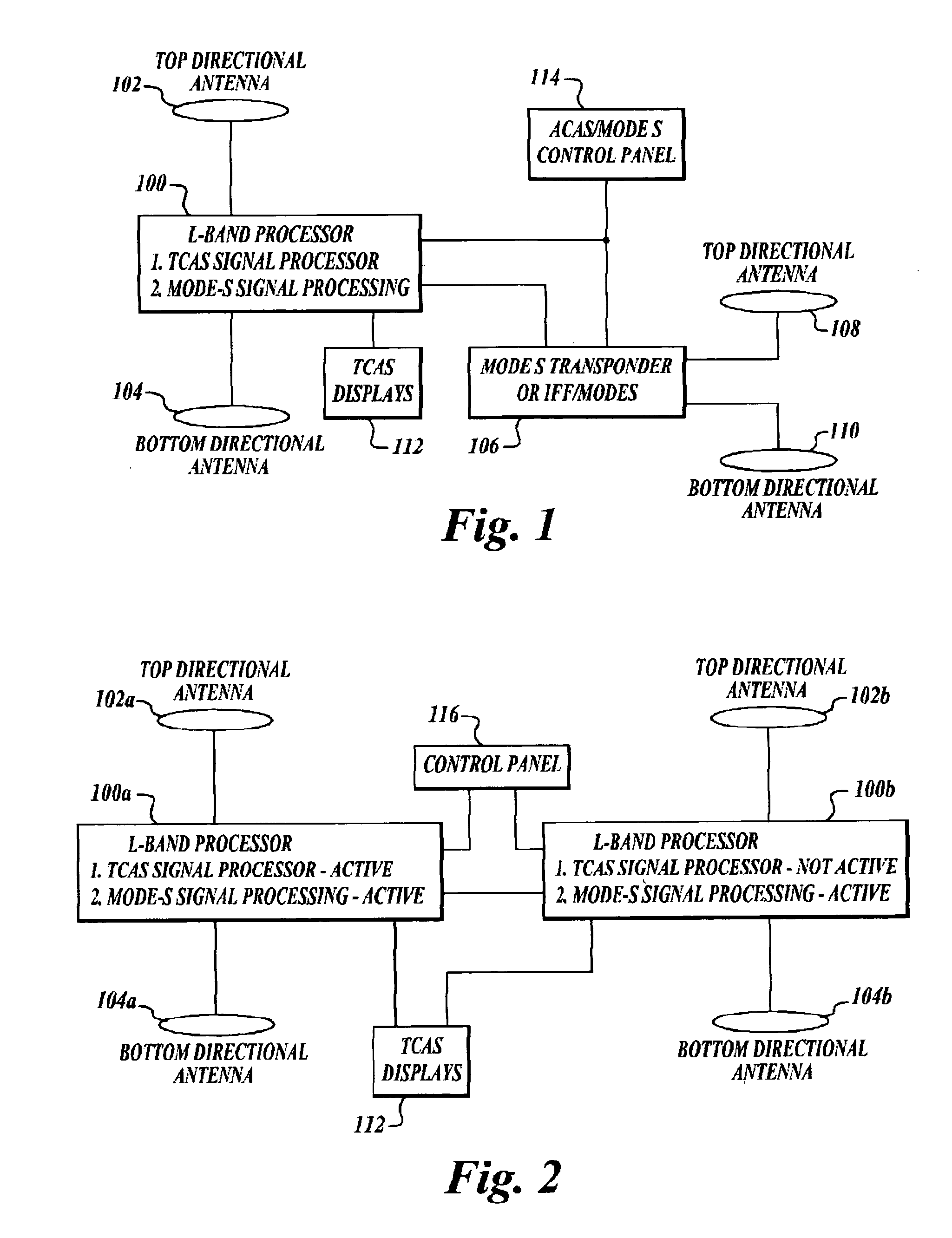

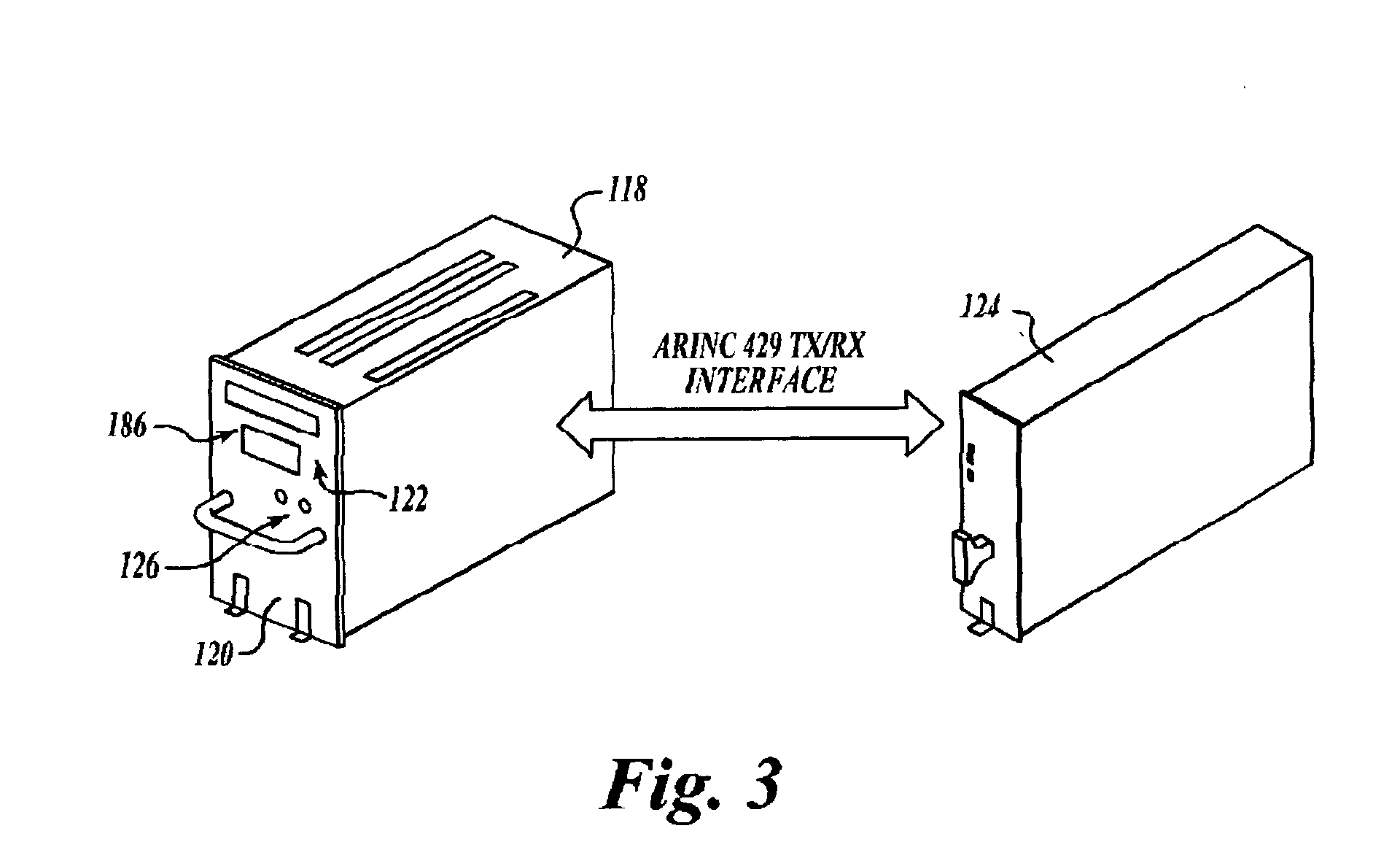

Integrated traffic surveillance apparatus

ActiveUS20050156777A1Improve reliabilityReduce weightRadio wave reradiation/reflectionRadio wave finder monitoring/testingMonitoring systemEngineering

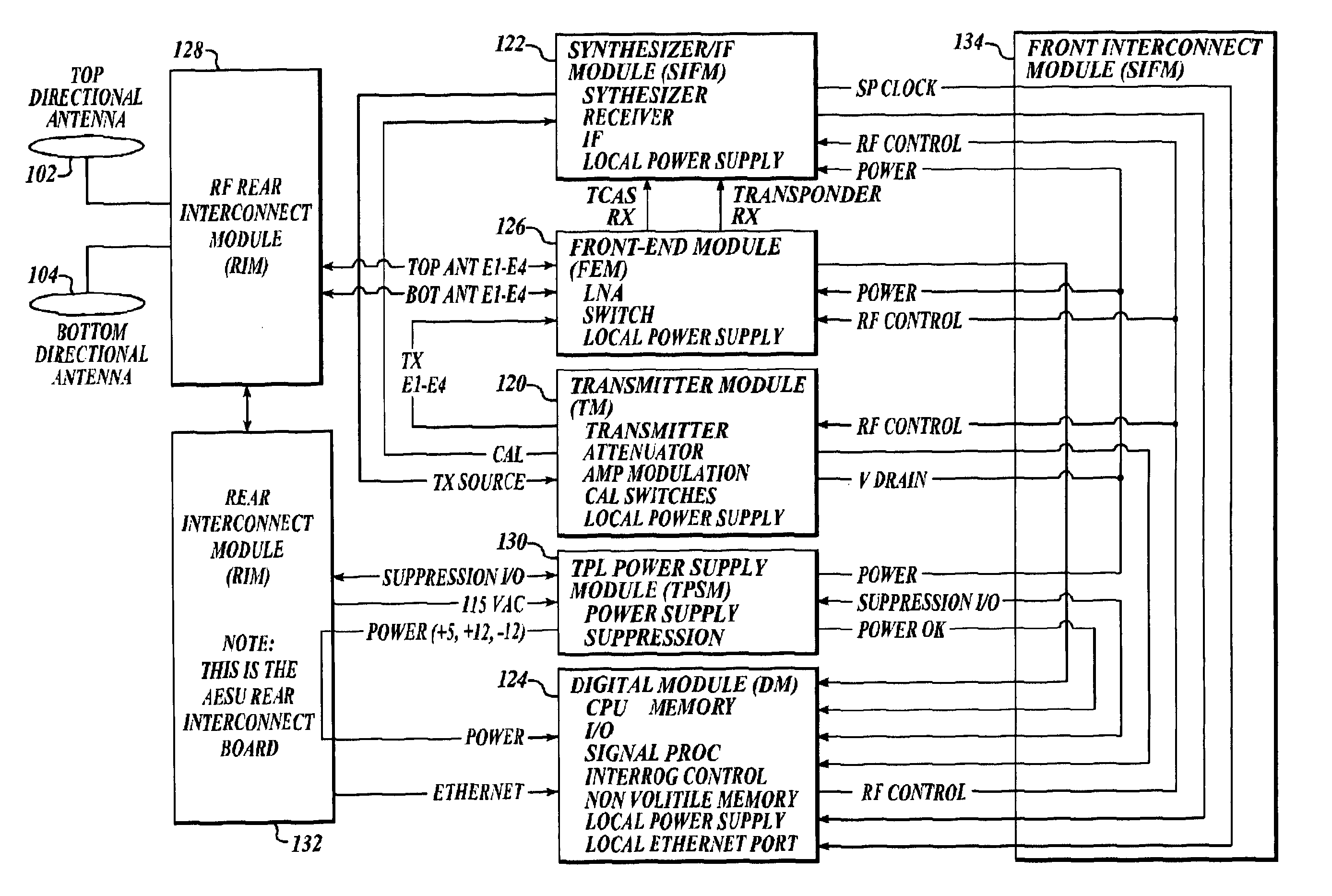

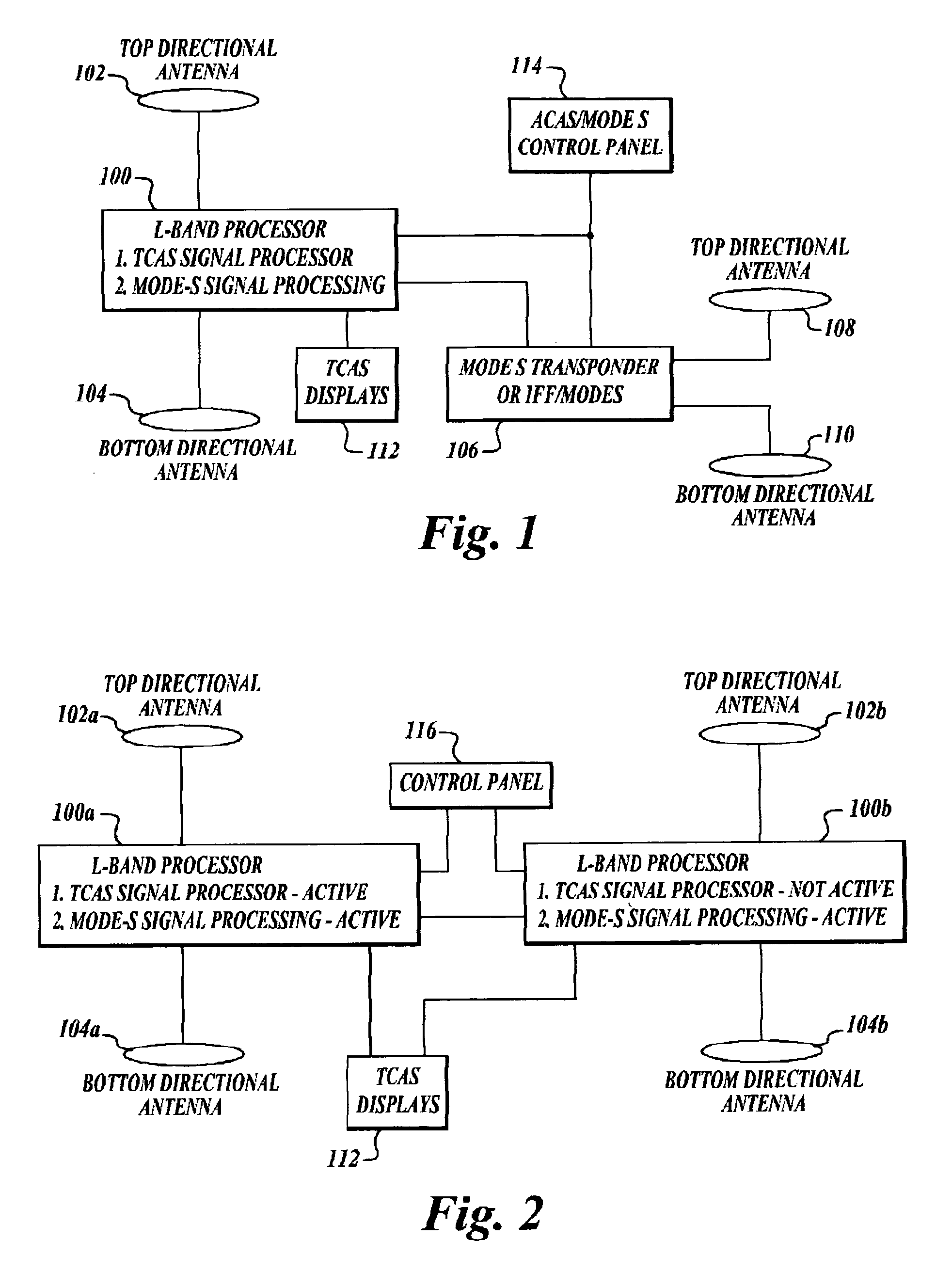

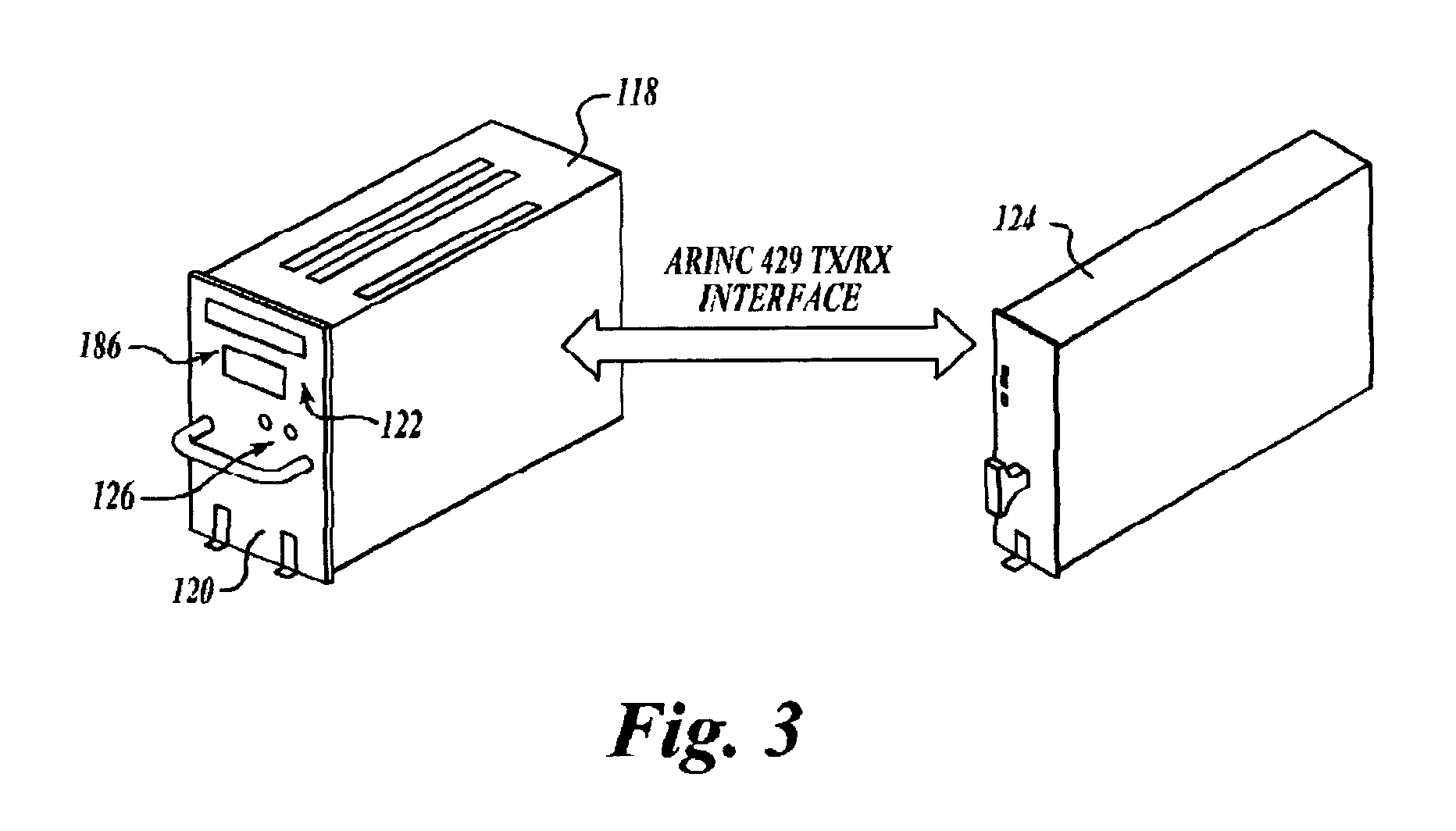

An apparatus and method for combining the functionality of multiple airborne traffic surveillance systems that operate in the L-band frequency range. The apparatus and method combine the functionality of both a Traffic Alert Collision Avoidance System (TCAS) and a Mode-Select (Mode-S) transponder in an integrated L-band traffic surveillance apparatus having a single processor that is embodied in a single Line Replaceable Unit.

Owner:HONEYWELL INT INC

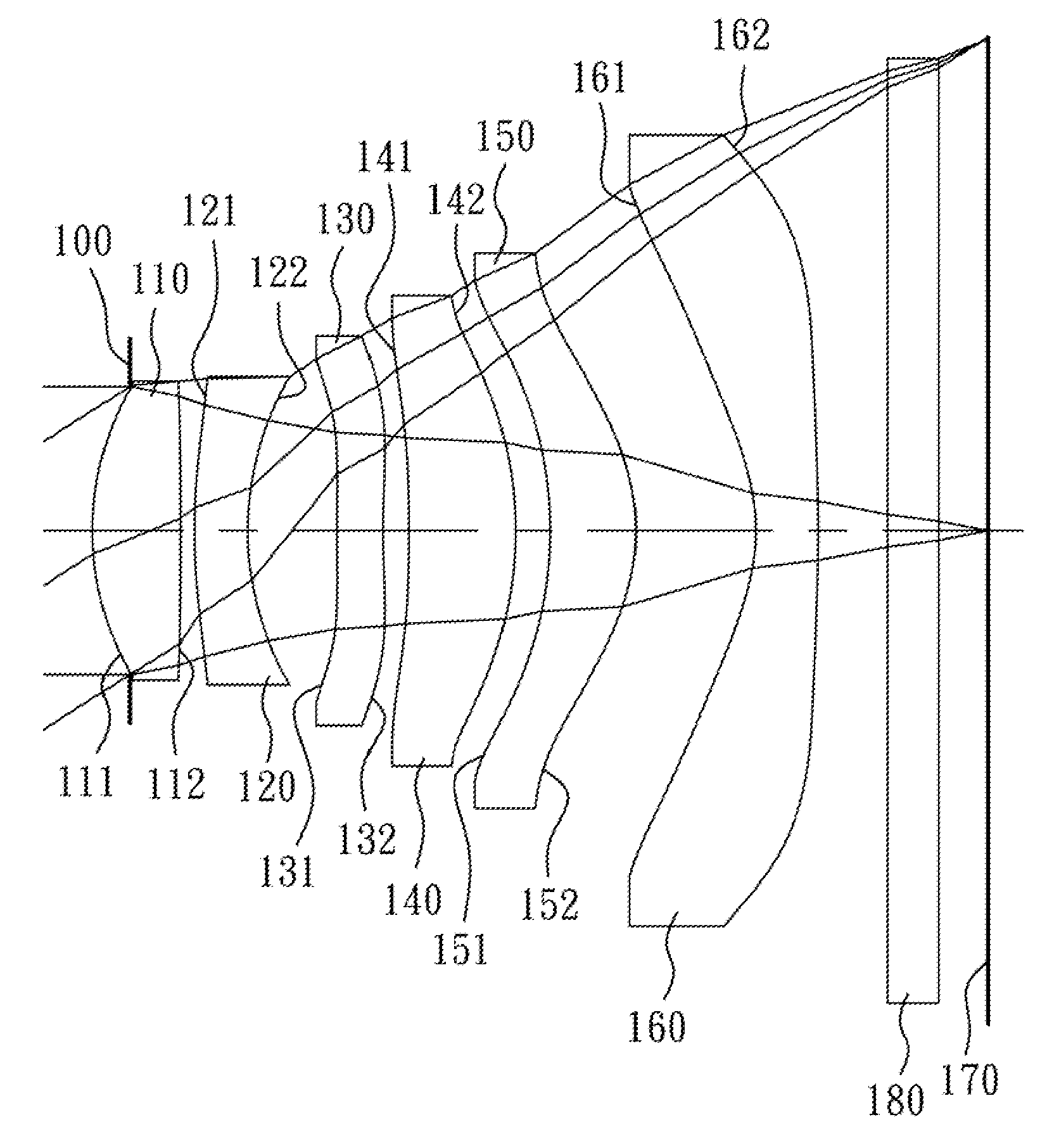

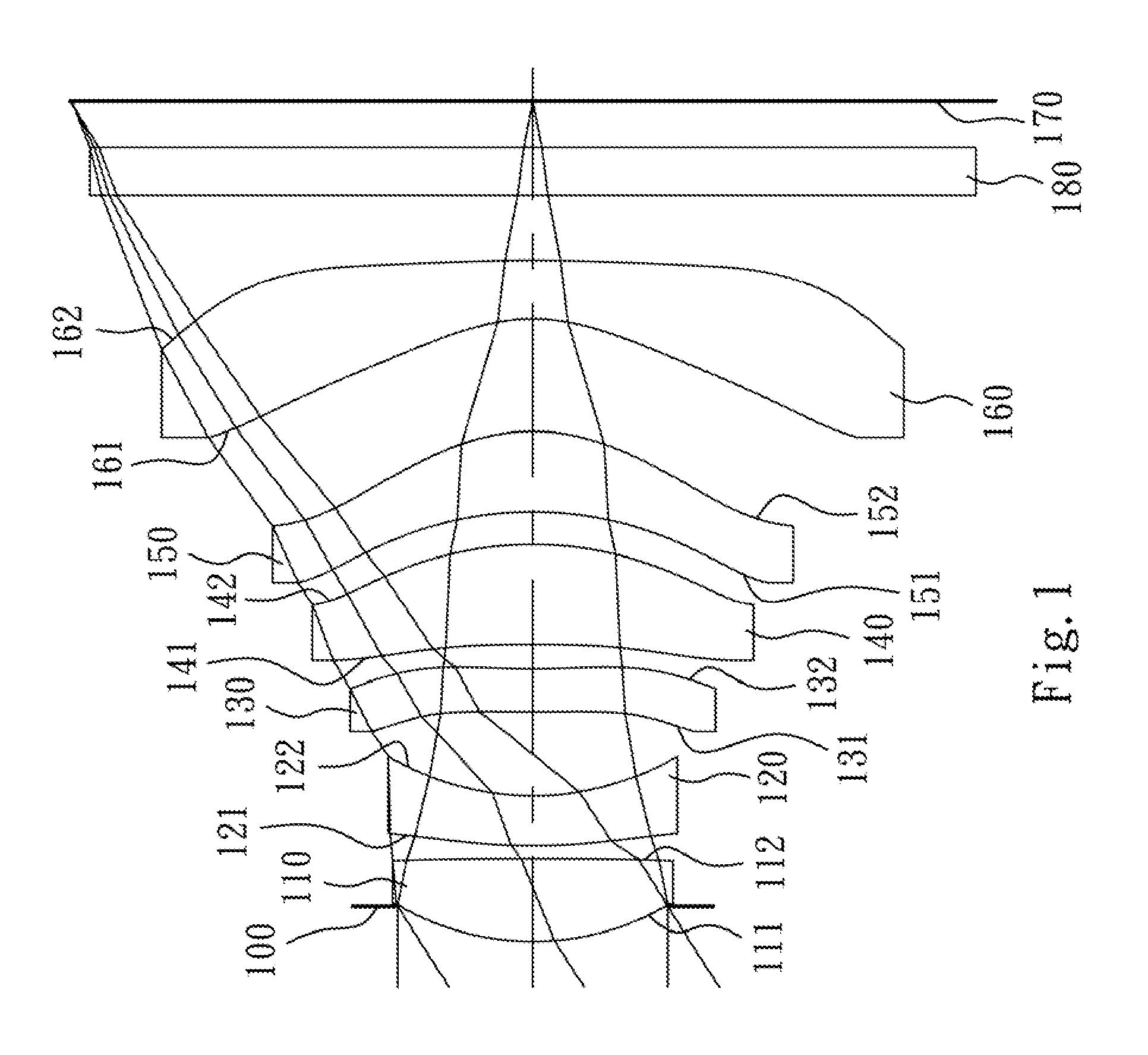

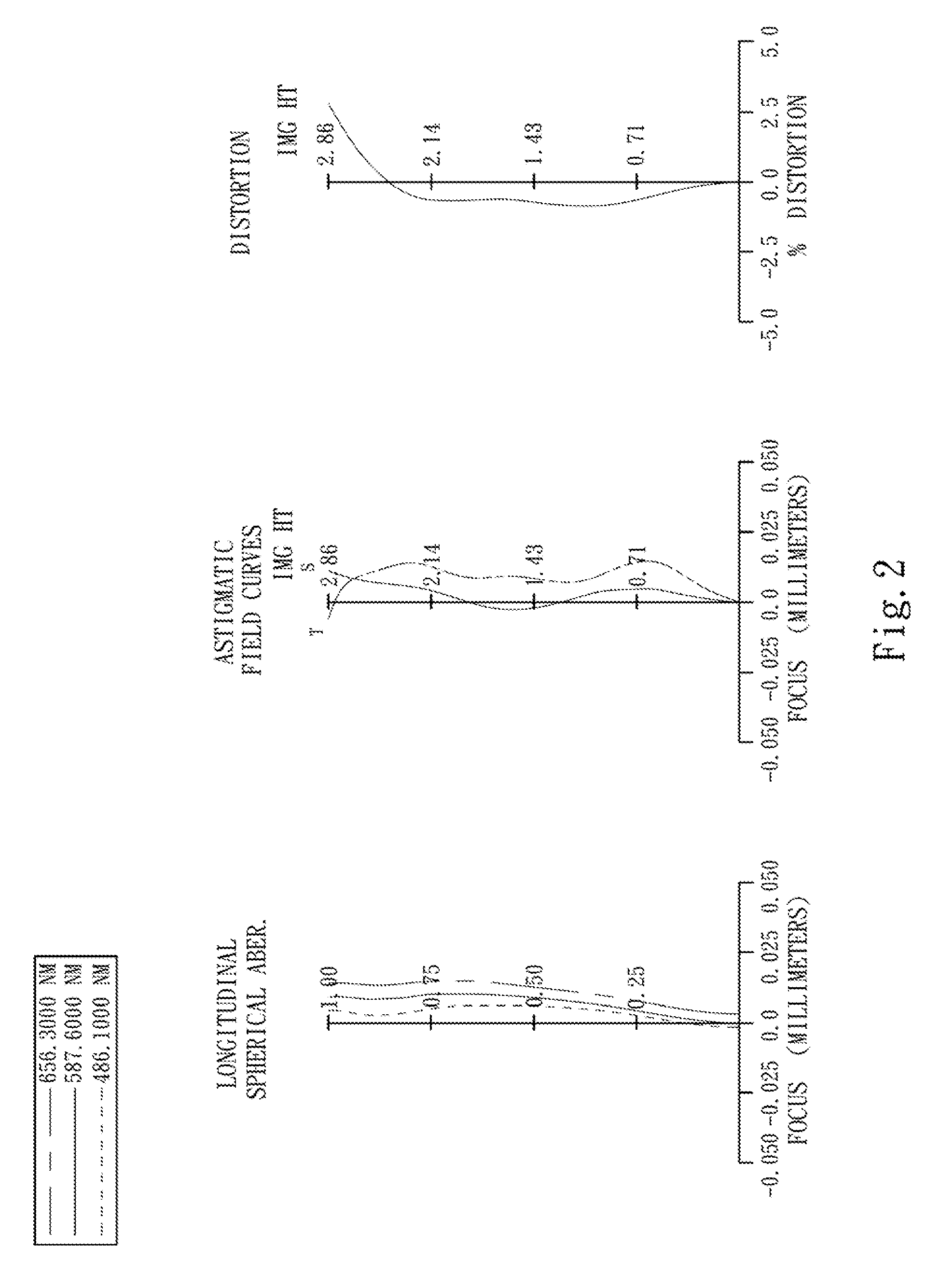

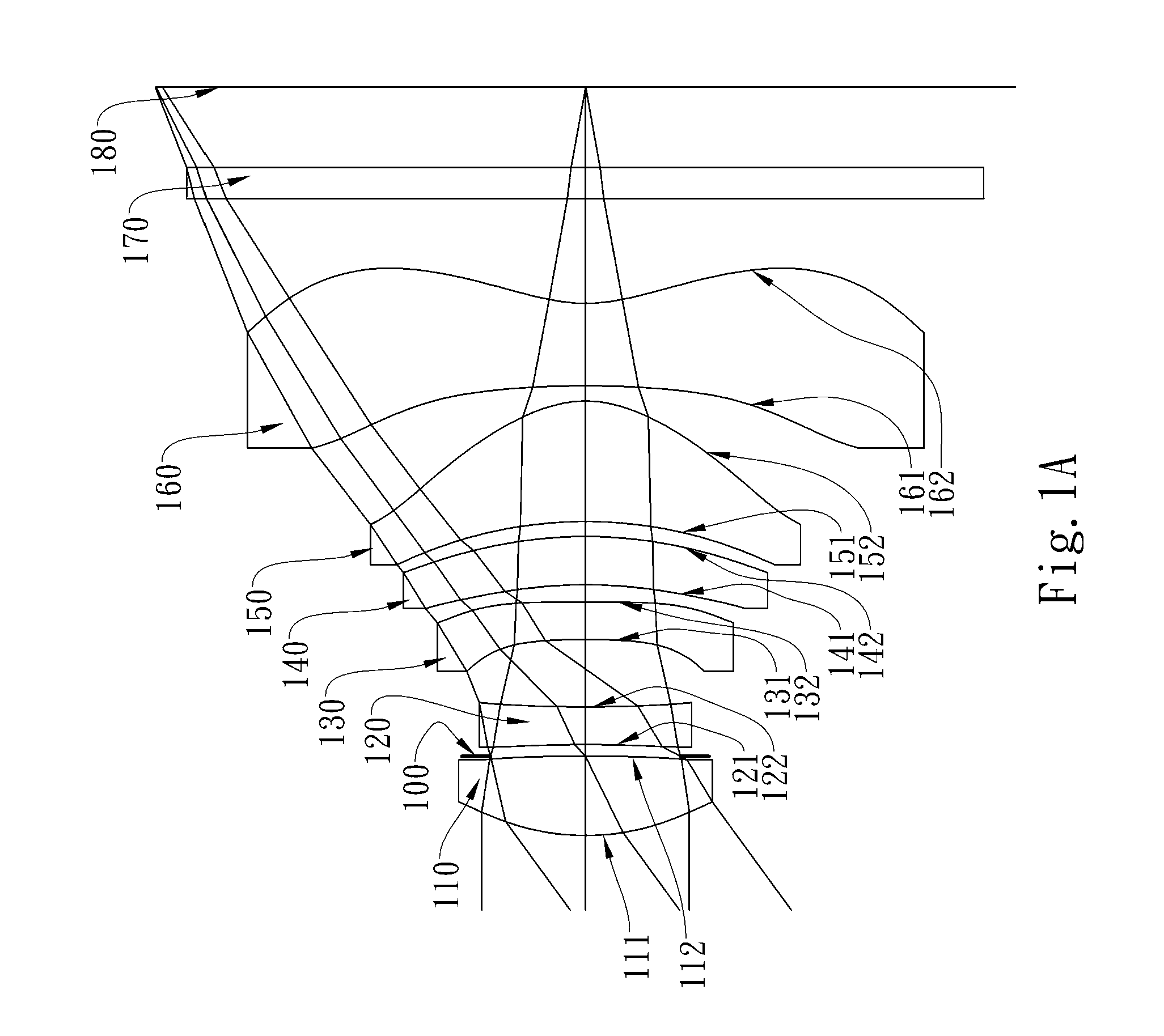

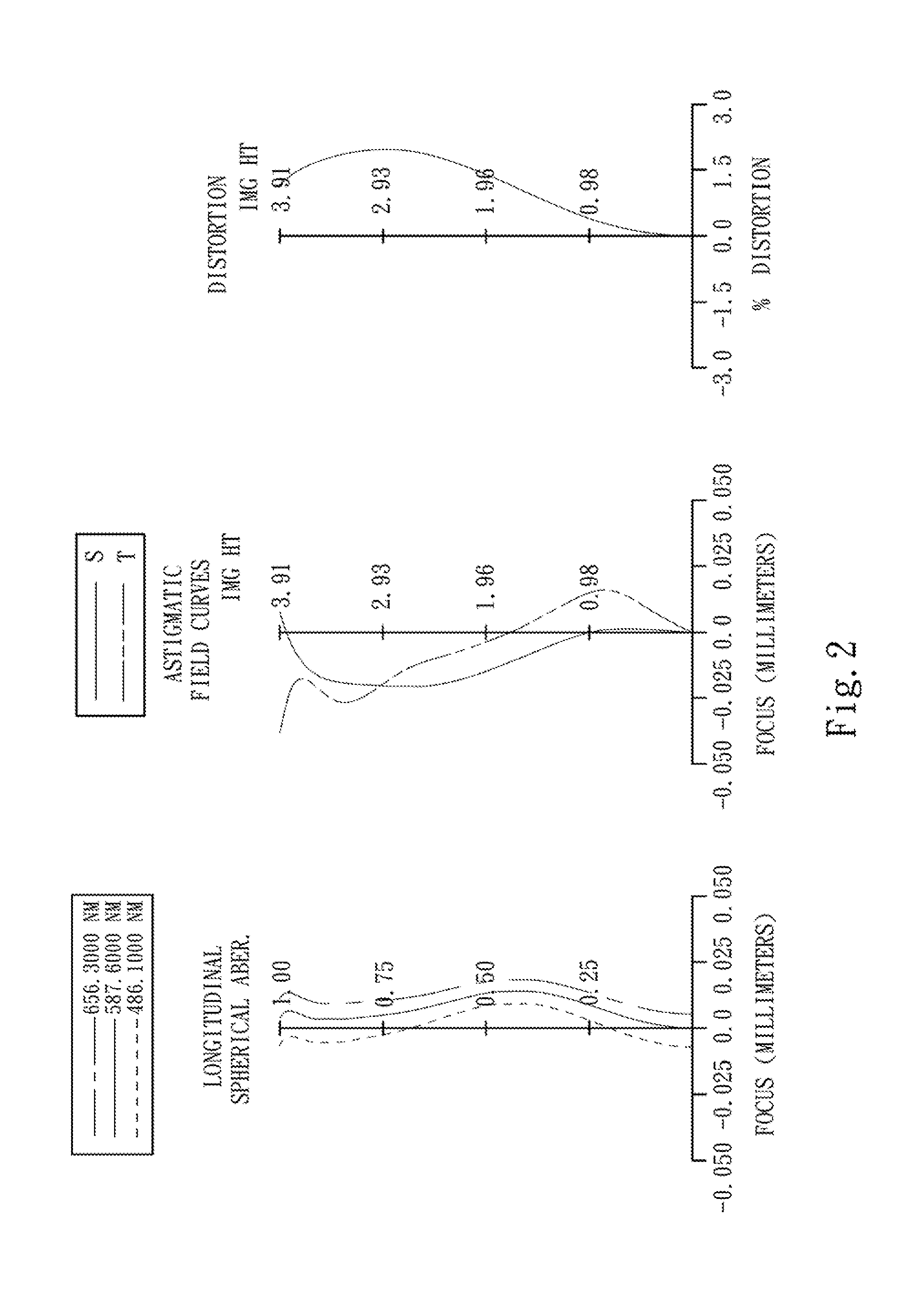

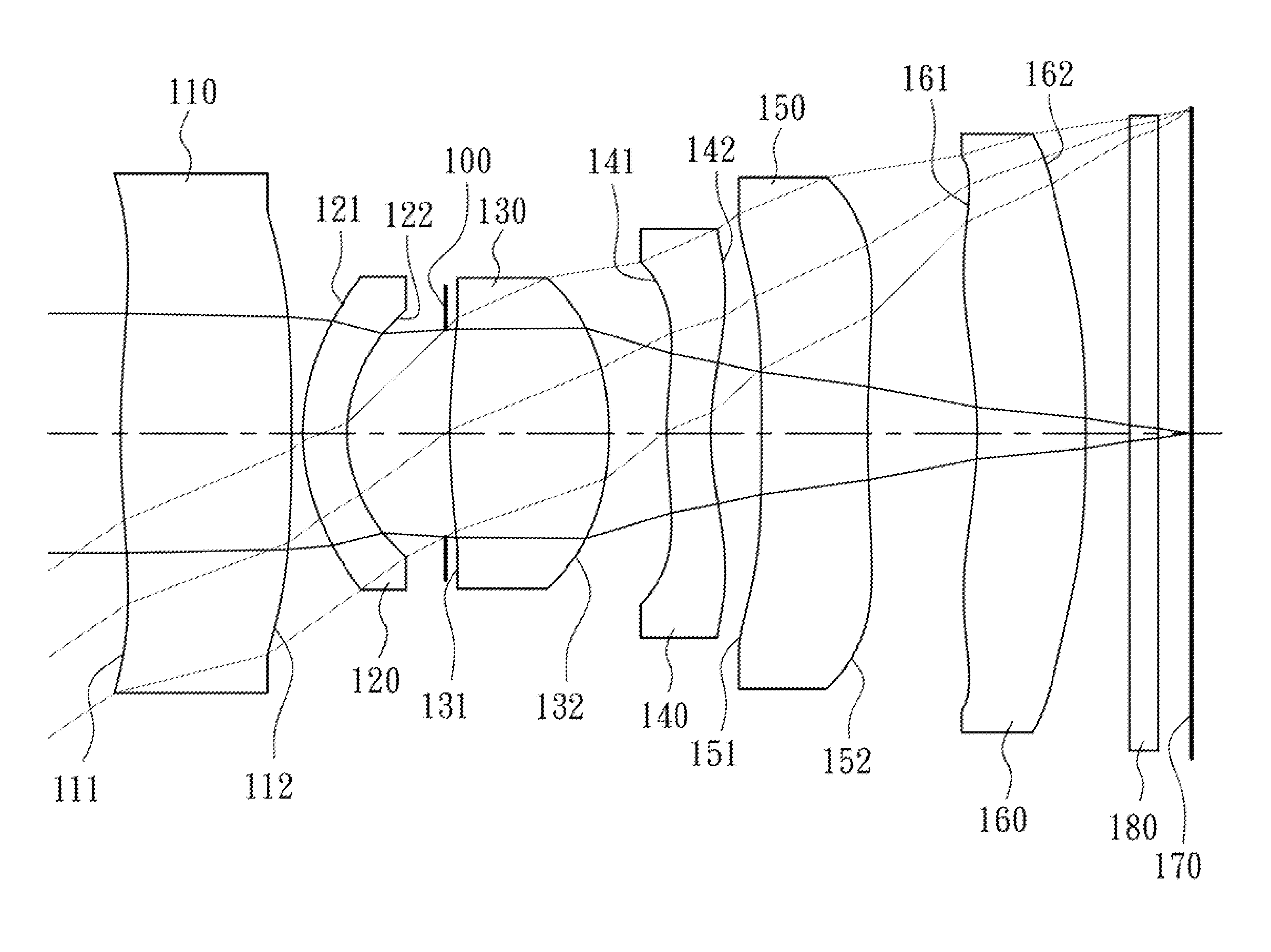

Imaging lens assembly

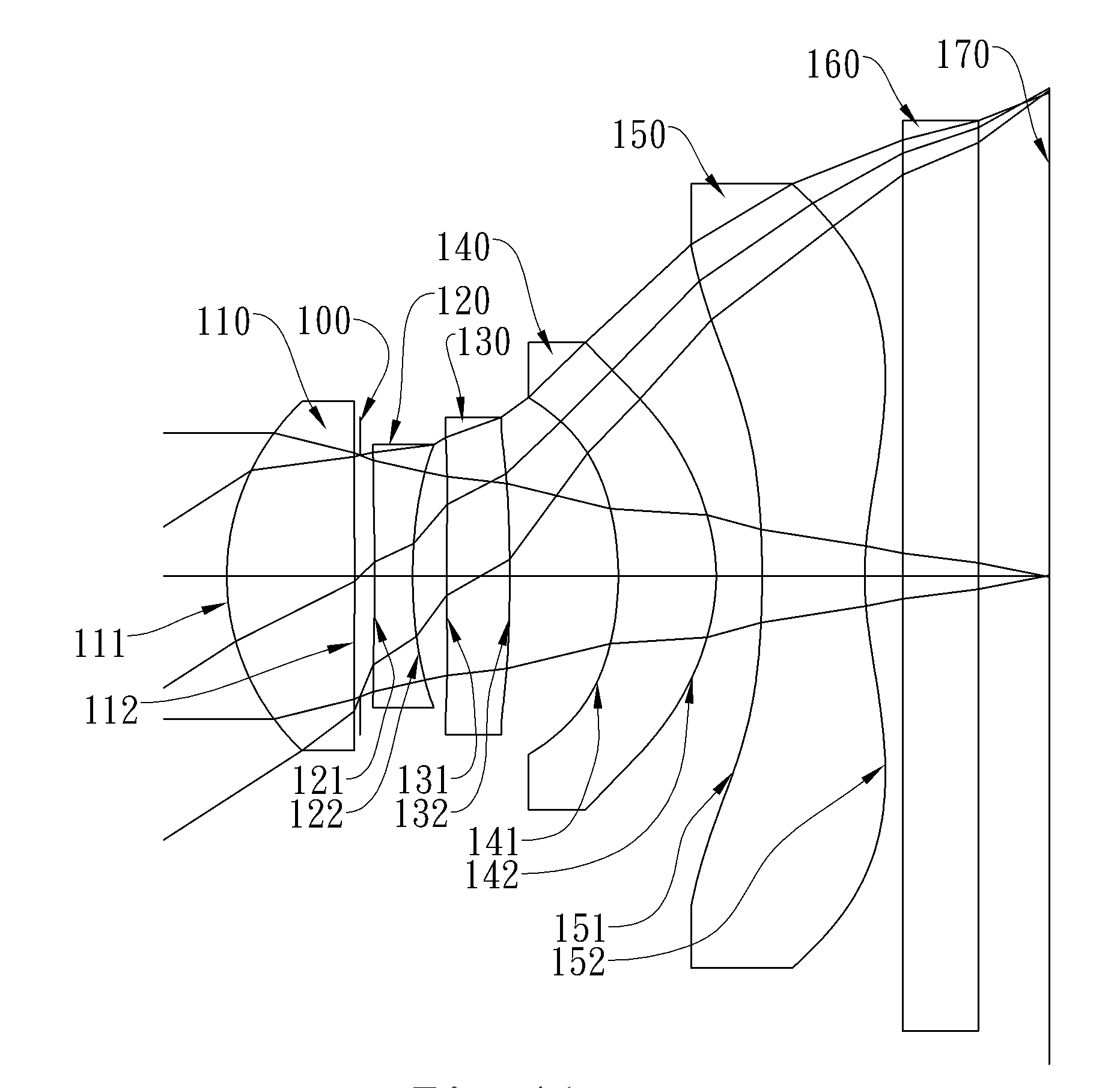

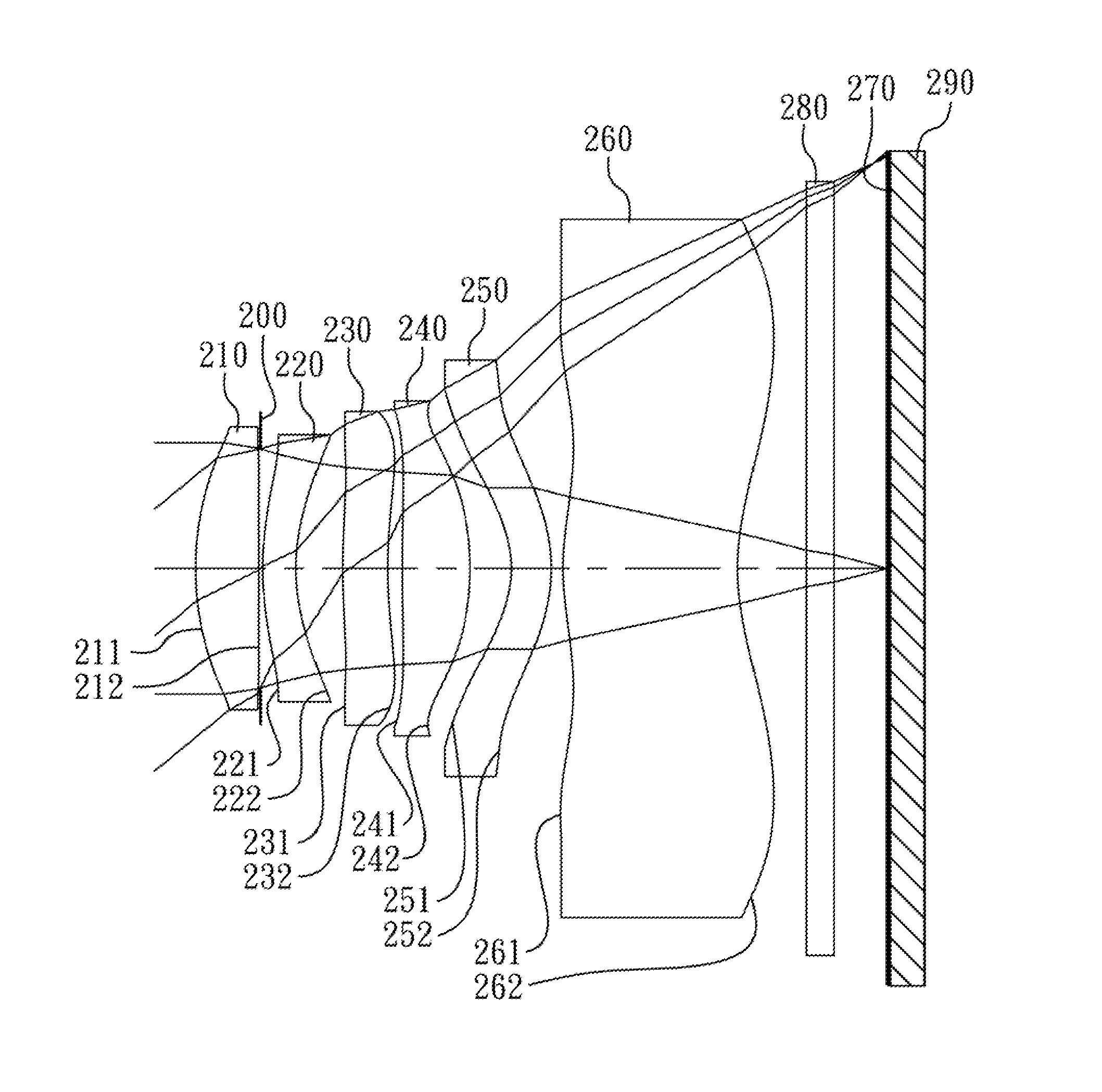

The present invention provides an imaging lens assembly including, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power; a third lens element with negative refractive power; a fourth lens element with positive refractive power having a convex object-side surface; a fifth lens element having a concave image-side surface, at least one inflection point being provided on the fifth lens element; and an aperture stop disposed between an imaged object and the third lens element. Such an arrangement of optical elements can effectively improve the image quality of the system and enable the imaging lens assembly to maintain a compact form. When the aperture stop is disposed near the object side, the telecentric feature is emphasized, resulting in a shorter total track length. When the aperture stop is disposed near the third lens element, the emphasis is on the wide field of view, and such an aperture stop placement helps to effectively reduce the sensitivity of the imaging lens assembly.

Owner:LARGAN PRECISION

Integrated traffic surveillance apparatus

ActiveUS7006032B2Improve reliabilityReduce weightRadio wave reradiation/reflectionRadio wave finder monitoring/testingMonitoring systemEngineering

An apparatus and method for combining the functionality of multiple airborne traffic surveillance systems that operate in the L-band frequency range. The apparatus and method combine the functionality of both a Traffic Alert Collision Avoidance System (TCAS) and a Mode-Select (Mode-S) transponder in an integrated L-band traffic surveillance apparatus having a single processor that is embodied in a single Line Replaceable Unit.

Owner:HONEYWELL INT INC

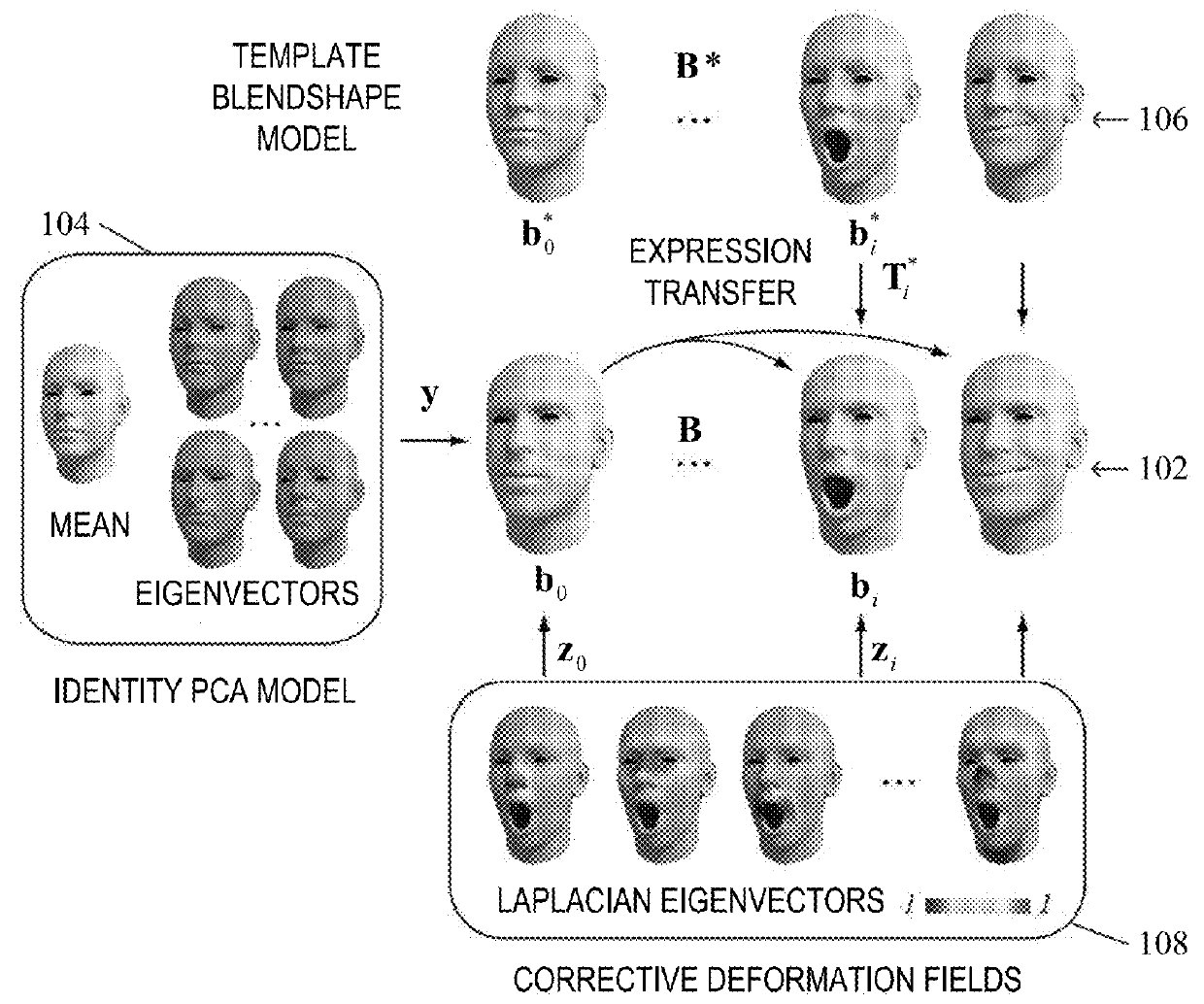

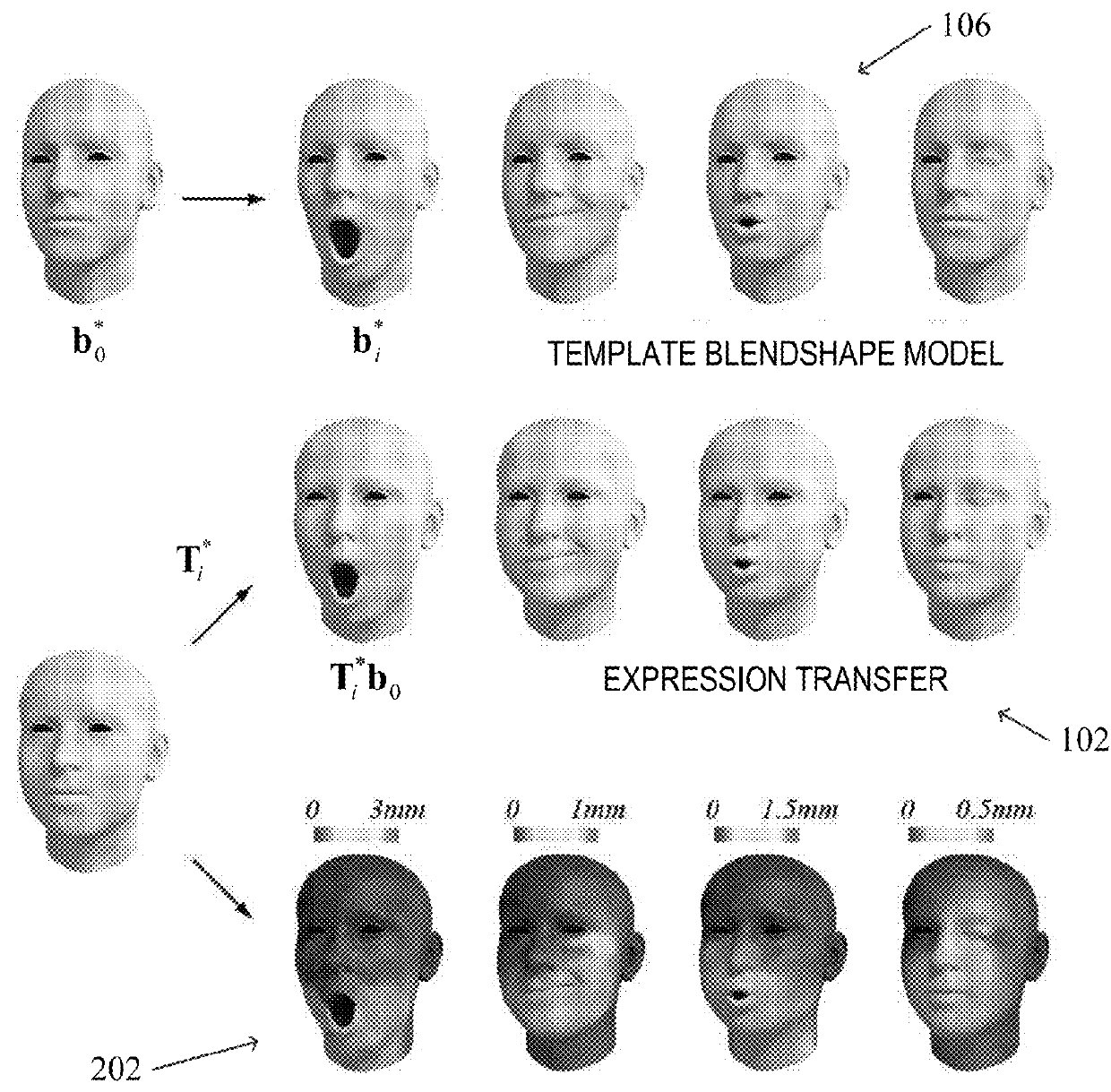

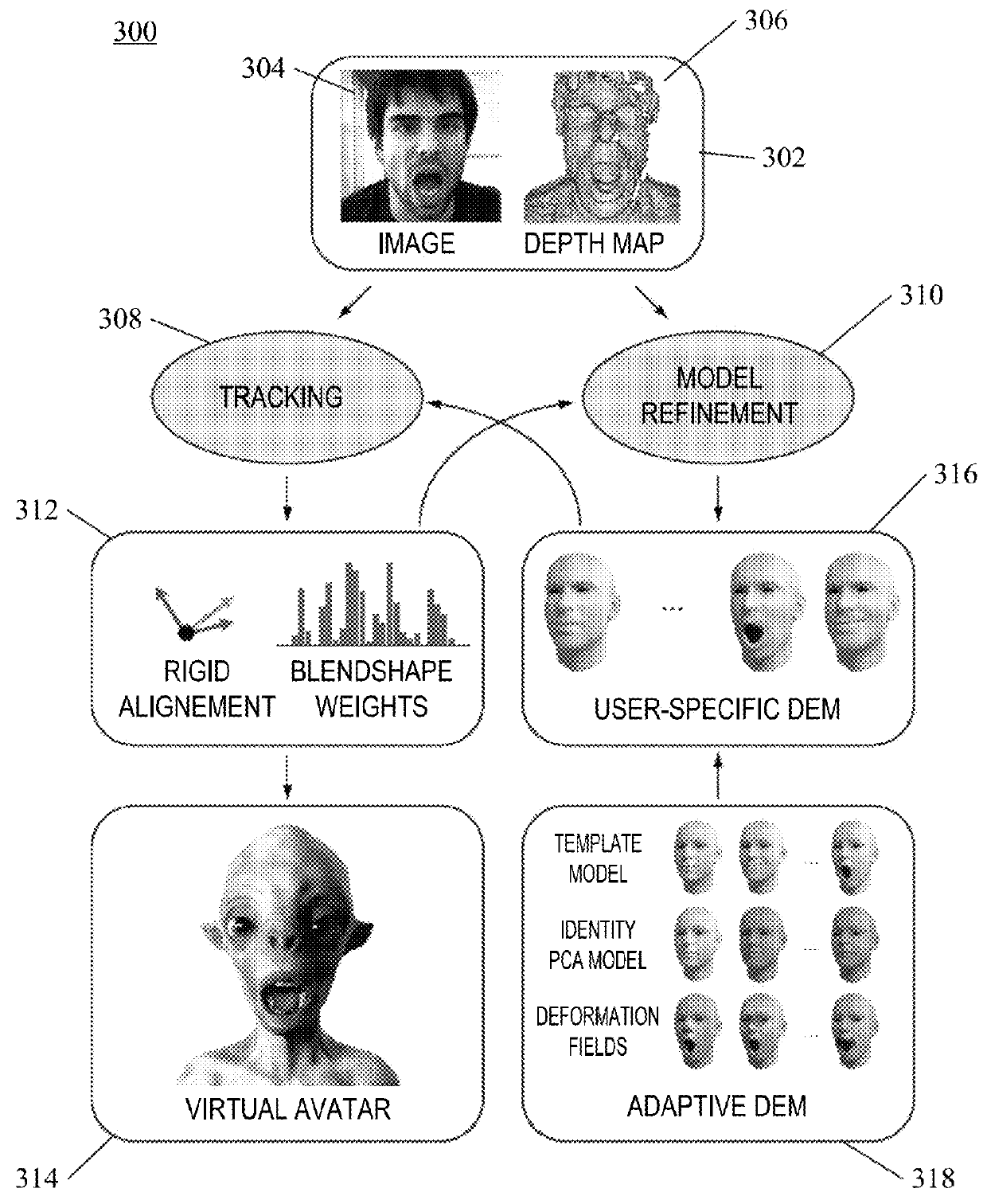

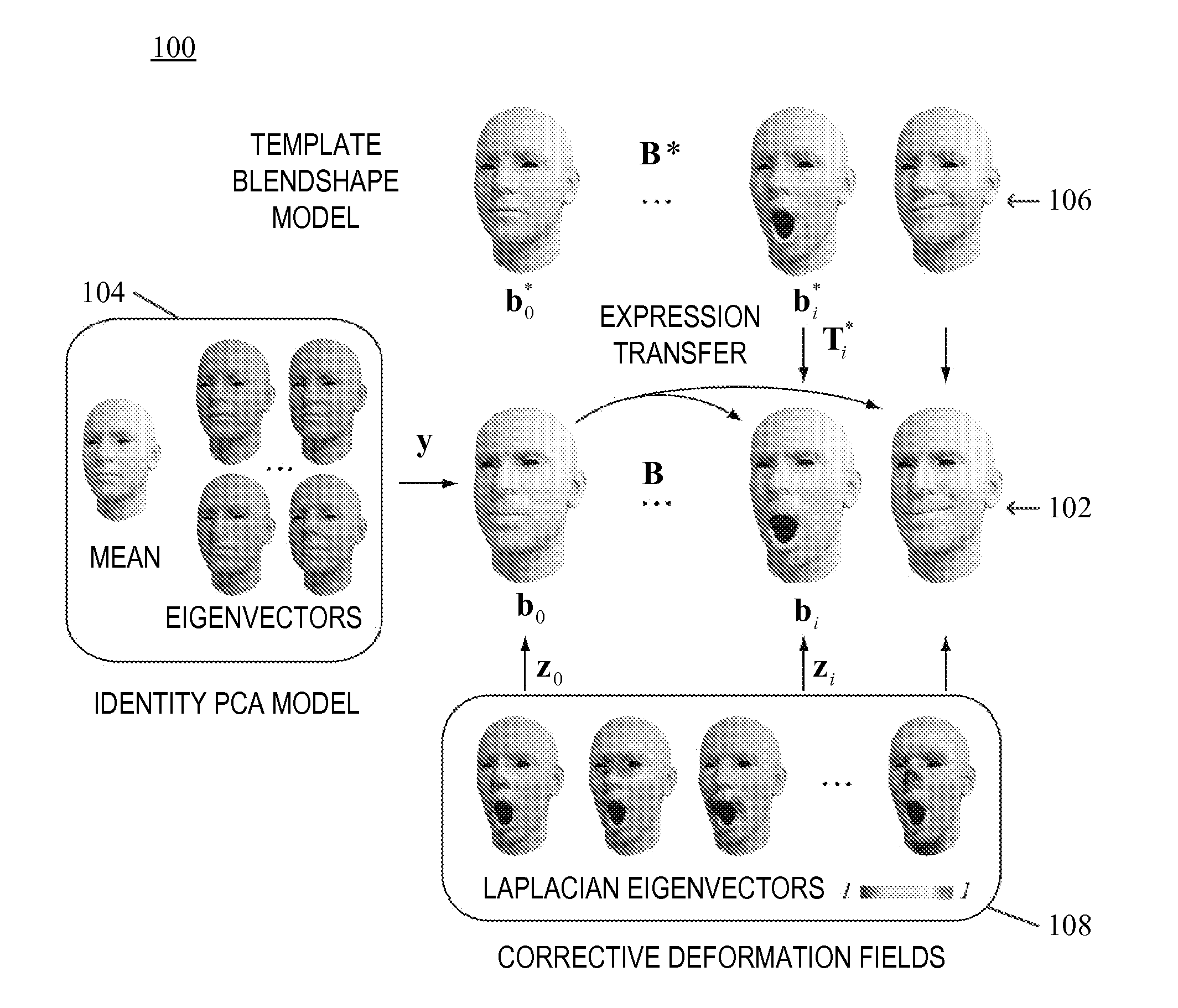

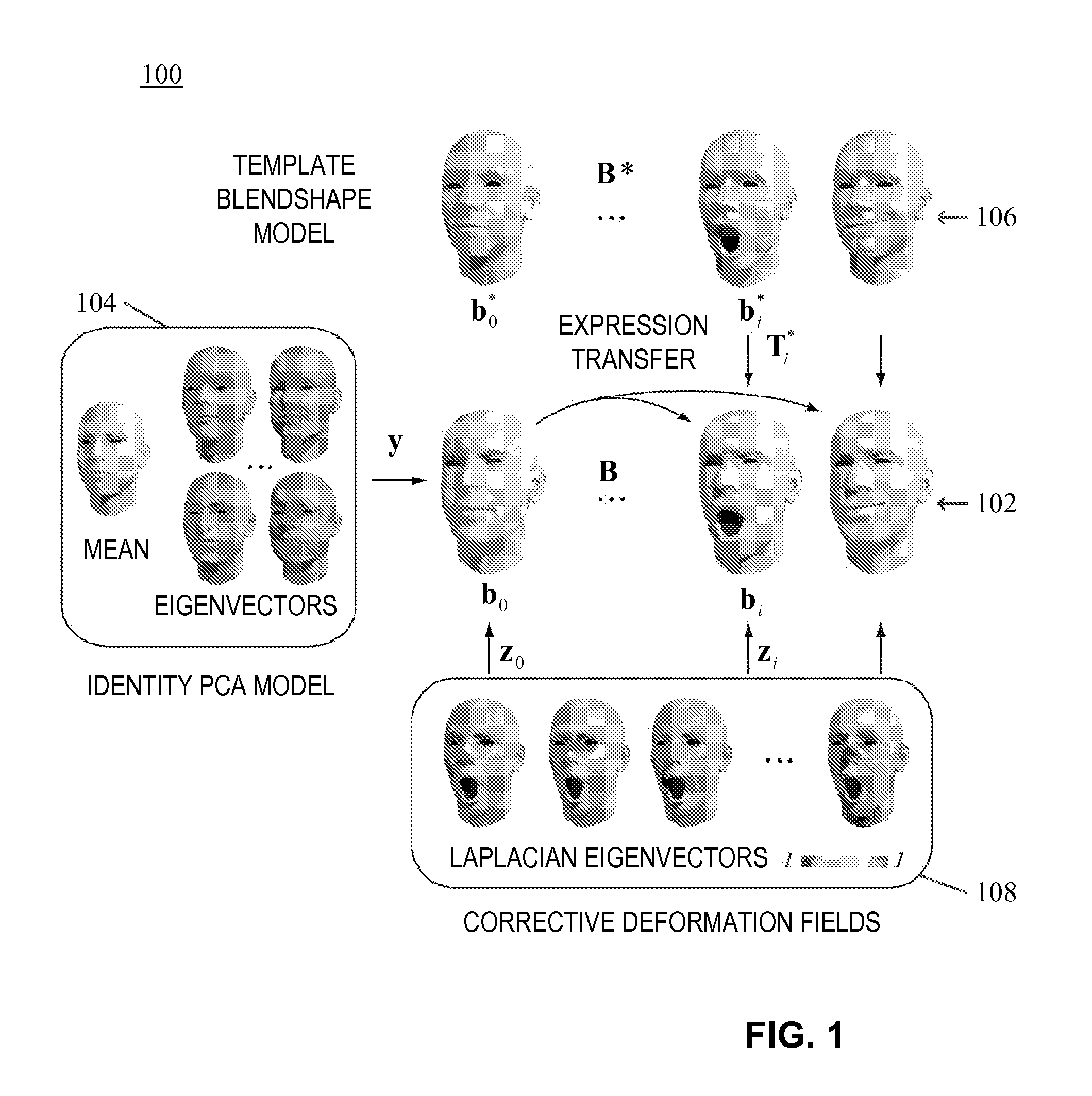

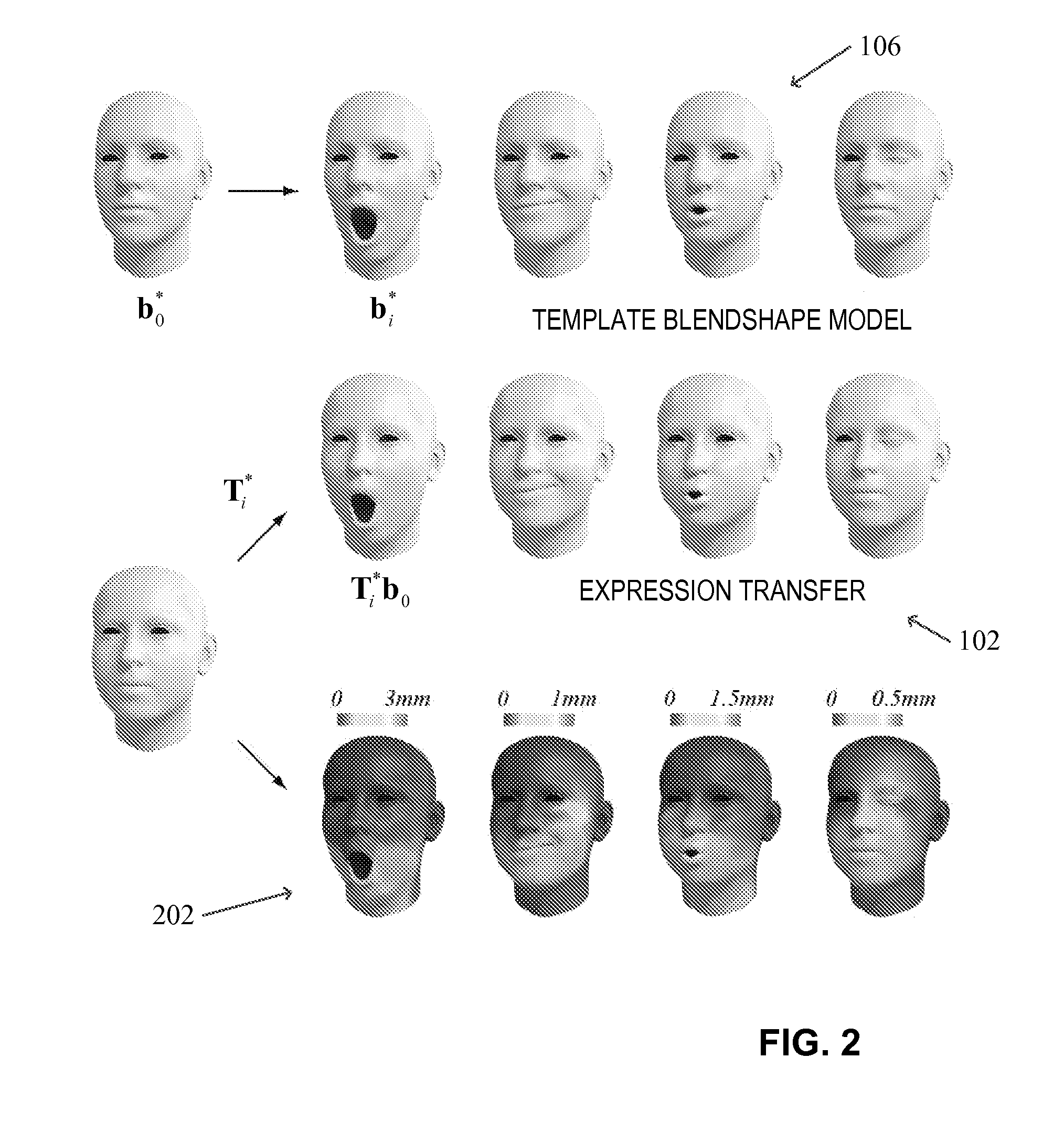

Online modeling for real-time facial animation

ActiveUS9378576B2Shorten the trackImprove tracking performanceImage analysisCharacter and pattern recognitionGraphicsPattern recognition

Embodiments relate to a method for real-time facial animation, and a processing device for real-time facial animation. The method includes providing a dynamic expression model, receiving tracking data corresponding to a facial expression of a user, estimating tracking parameters based on the dynamic expression model and the tracking data, and refining the dynamic expression model based on the tracking data and estimated tracking parameters. The method may further include generating a graphical representation corresponding to the facial expression of the user based on the tracking parameters. Embodiments pertain to a real-time facial animation system.

Owner:APPLE INC

Imaging lens system

The present invention provides an imaging lens system comprising, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power; a third lens element with positive refractive power, at least one of the object-side and image-side surfaces thereof being aspheric; a fourth lens element, the image-side surface thereof being aspheric and provided with at least one inflection point; a fifth lens element having a concave object-side surface, at least one of the object-side and image-side surfaces thereof being aspheric; and an aperture stop disposed between an imaged object and the second lens element. Such an arrangement of optical elements can effectively reduce the total track length and sensitivity of the optical system, and image quality can also be improved.

Owner:LARGAN PRECISION

Imaging lens system

ActiveUS20110013069A1Short total track lengthImprove image qualityTelevision system detailsColor television detailsPhysicsCamera lens

This invention provides an imaging lens system including, in order from an object side to an image side: a first lens with positive refractive power having a convex object-side surface; a second lens with negative refractive power; a third lens having a concave image-side surface; a fourth lens with positive refractive power; a fifth lens with negative refractive power having a concave image-side surface, at least one surface thereof having at least one inflection point; and an aperture stop disposed between an imaged object and the third lens. The on-axis spacing between the first lens and second lens is T12, the focal length of the imaging lens system is f, and they satisfy the relation: 0.5<(T12 / f)×100<15.

Owner:LARGAN PRECISION

Optical image capturing lens assembly

An optical image capturing lens assembly includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element, and a sixth lens element. The first lens element with positive refractive power has a convex object-side surface. The object-side surface and the image-side surface of the fifth lens element are aspheric and at least one of the object-side surface and the image-side surface has at least one inflection point formed thereon. The sixth lens element with negative refractive power has a concave object-side surface and a convex image-side surface, wherein the object-side surface and the image-side surface of the sixth lens element are aspheric.

Owner:LARGAN PRECISION

Online modeling for real-time facial animation

ActiveUS20140362091A1Improve tracking performanceShorten the trackImage analysisCharacter and pattern recognitionGraphicsPattern recognition

Embodiments relate to a method for real-time facial animation, and a processing device for real-time facial animation. The method includes providing a dynamic expression model, receiving tracking data corresponding to a facial expression of a user, estimating tracking parameters based on the dynamic expression model and the tracking data, and refining the dynamic expression model based on the tracking data and estimated tracking parameters. The method may further include generating a graphical representation corresponding to the facial expression of the user based on the tracking parameters. Embodiments pertain to a real-time facial animation system.

Owner:APPLE INC

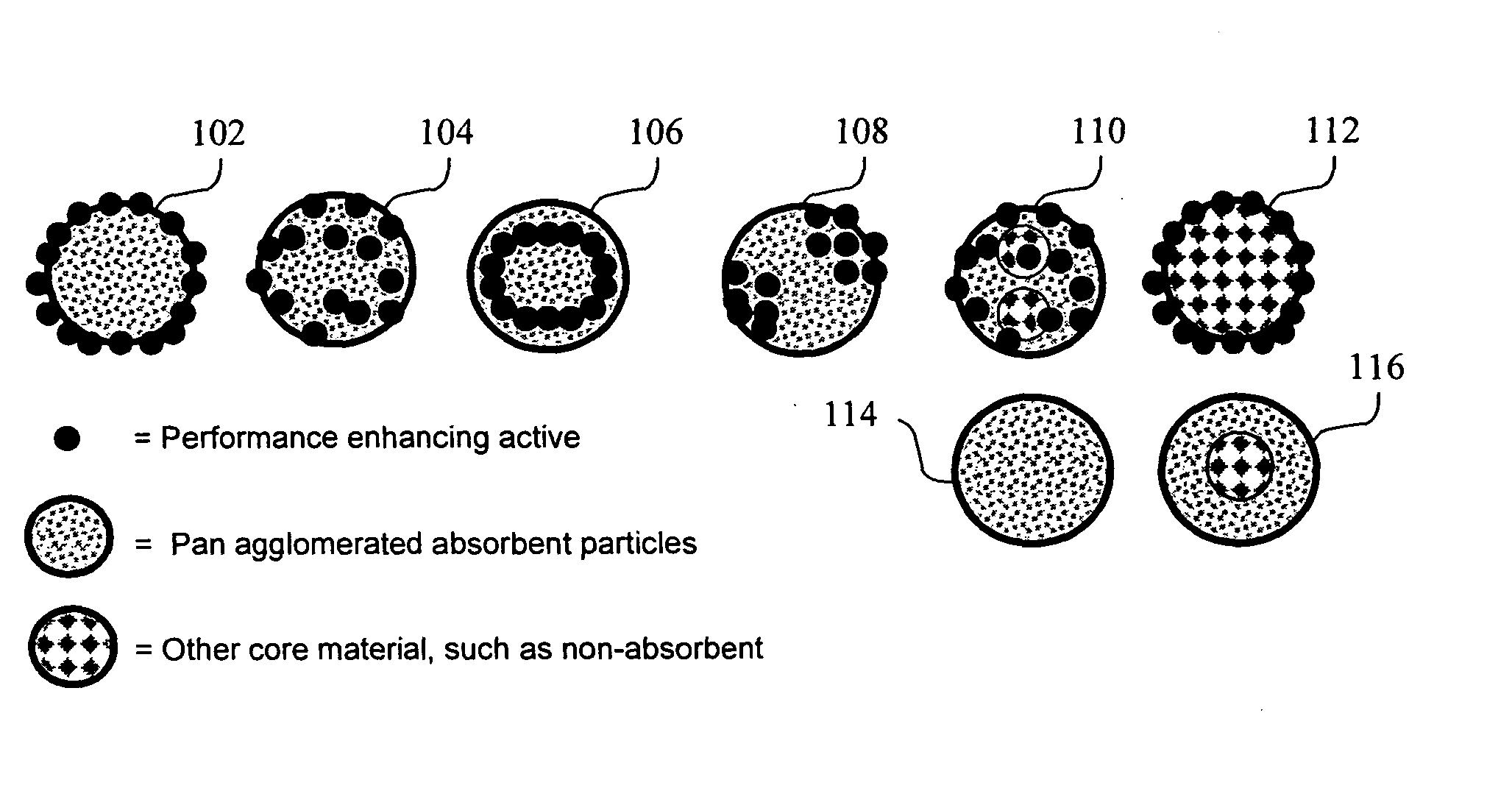

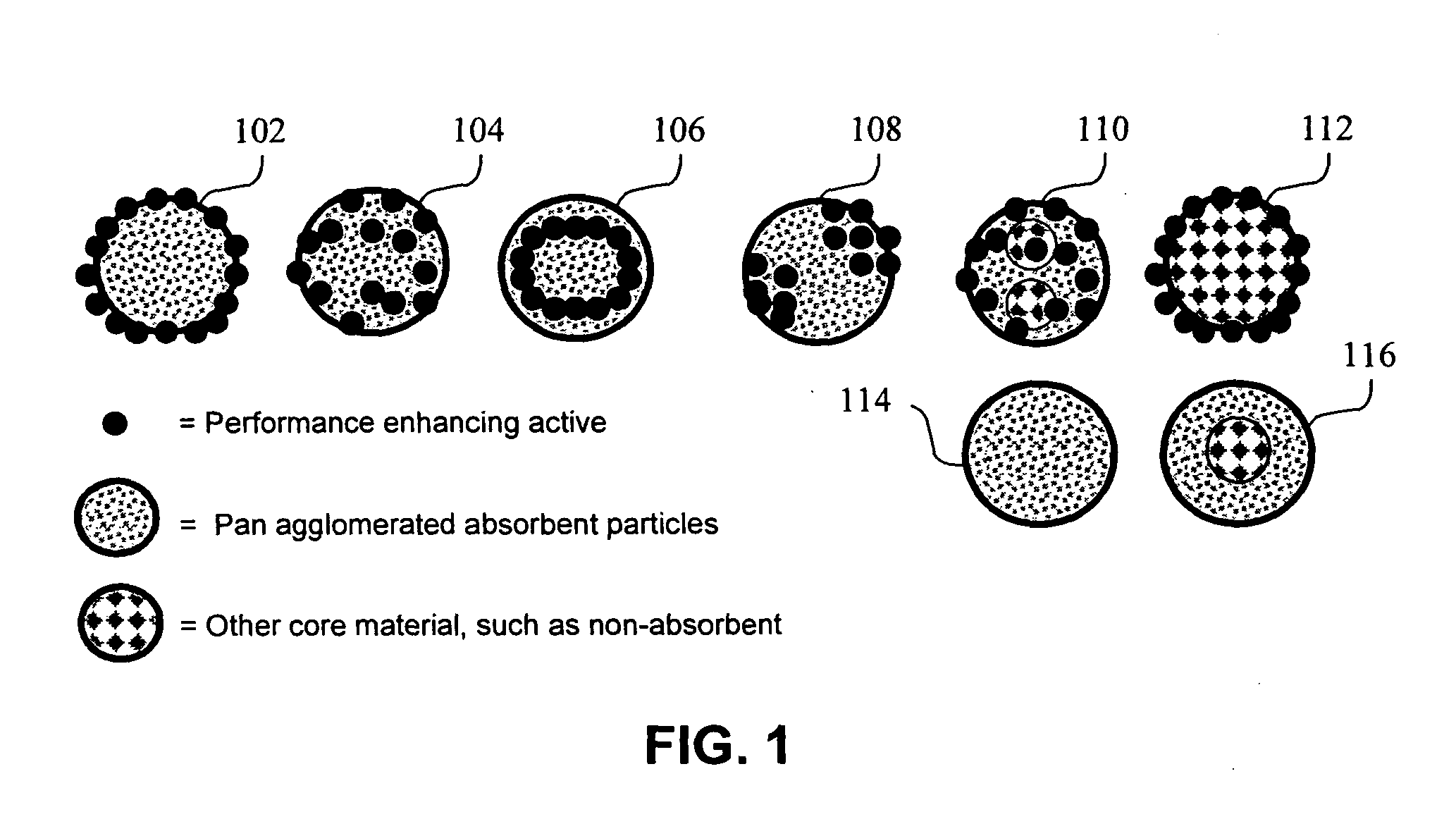

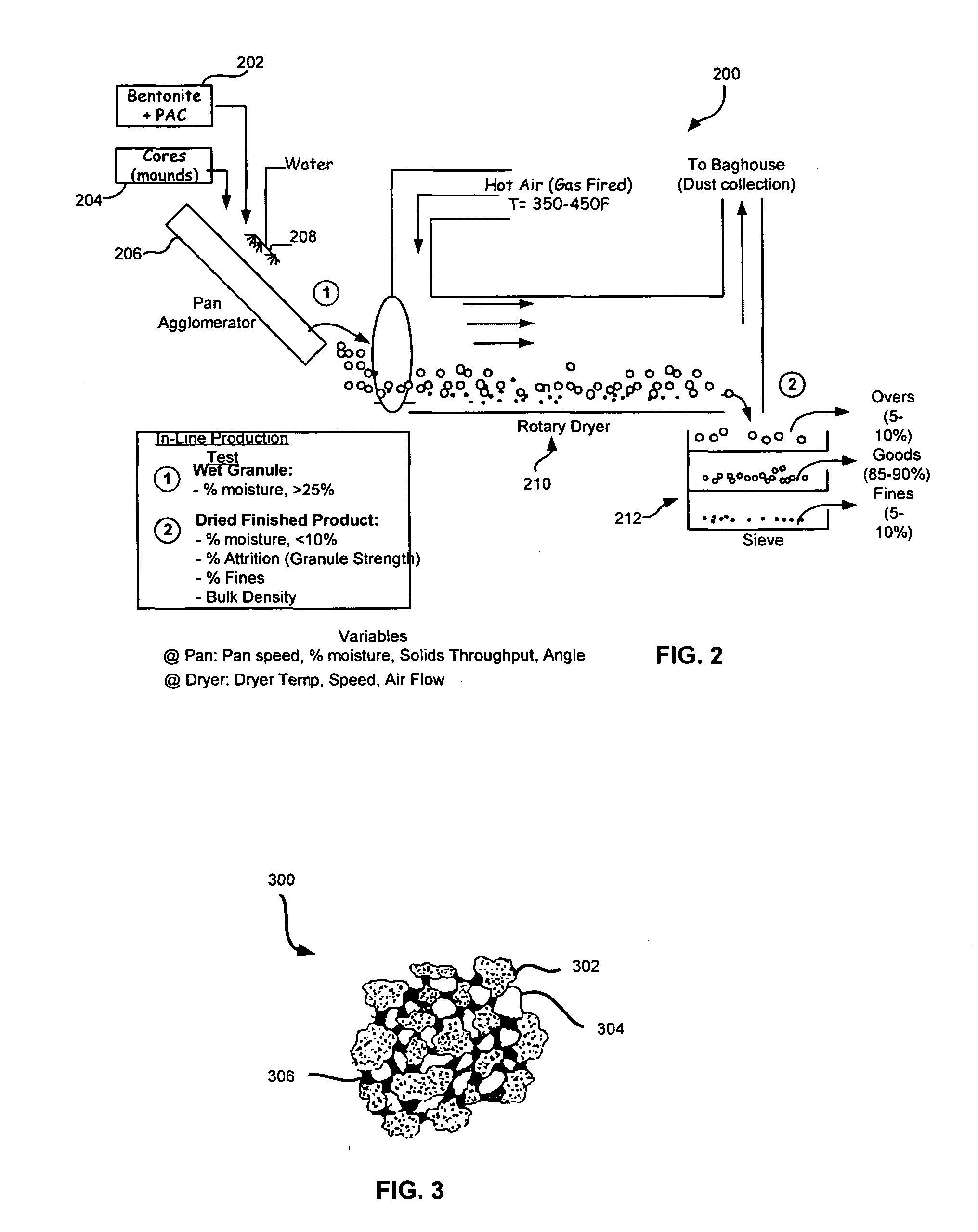

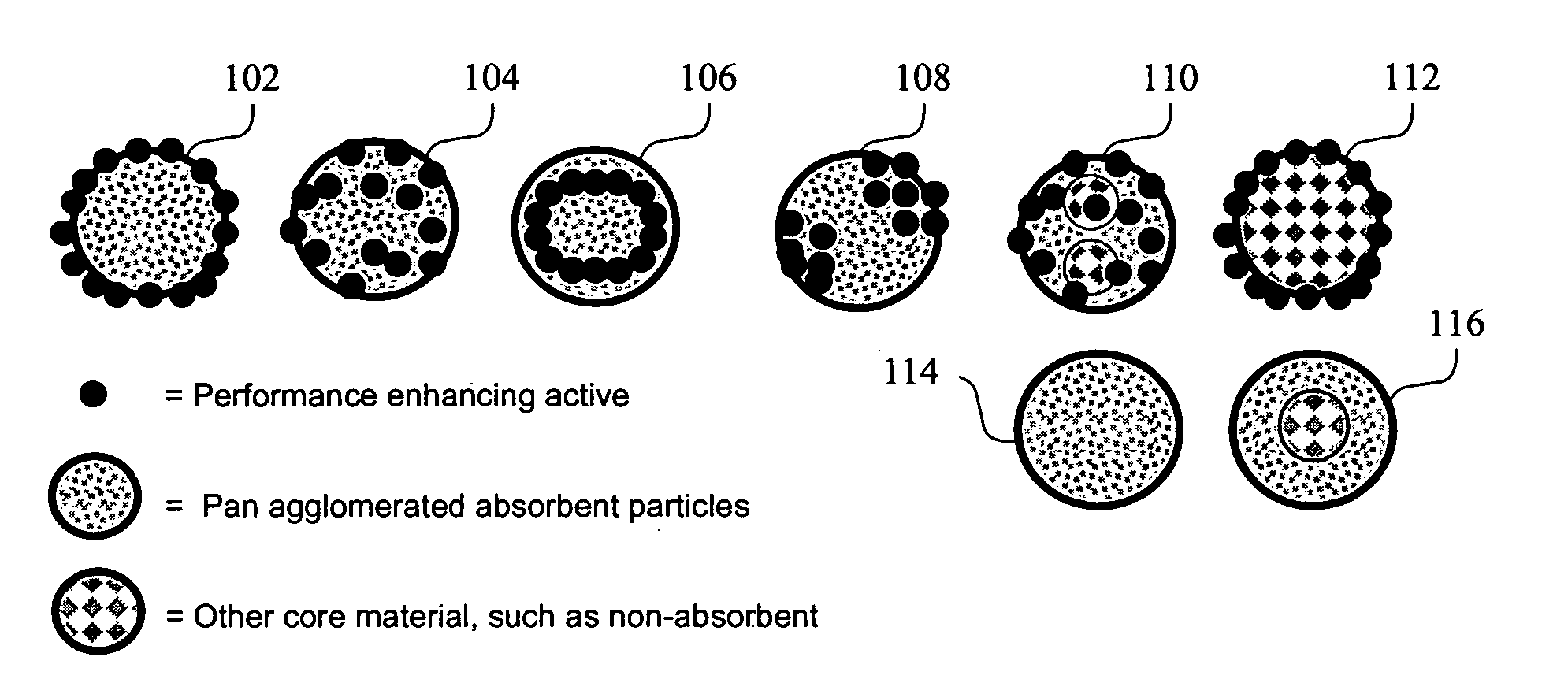

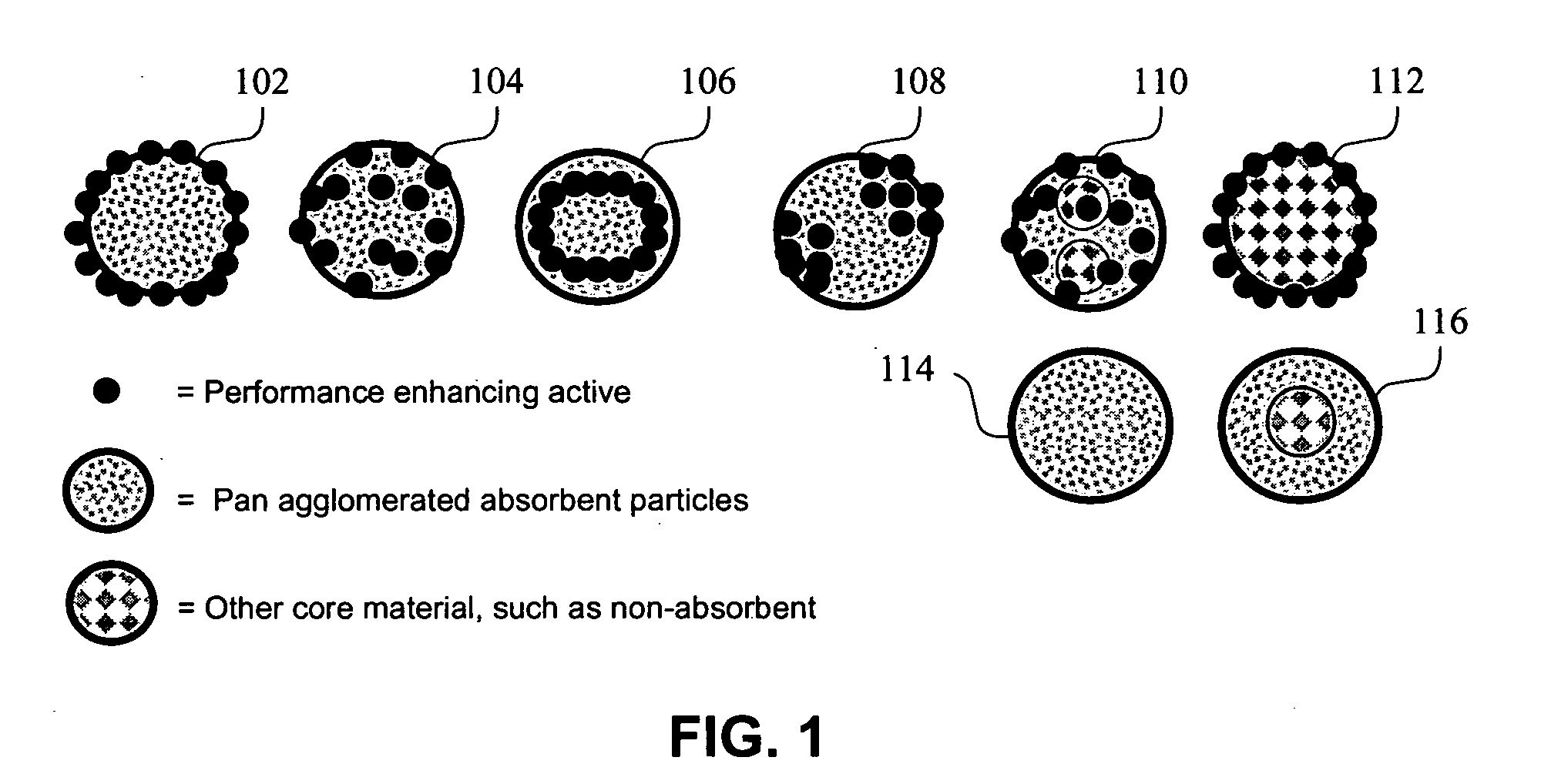

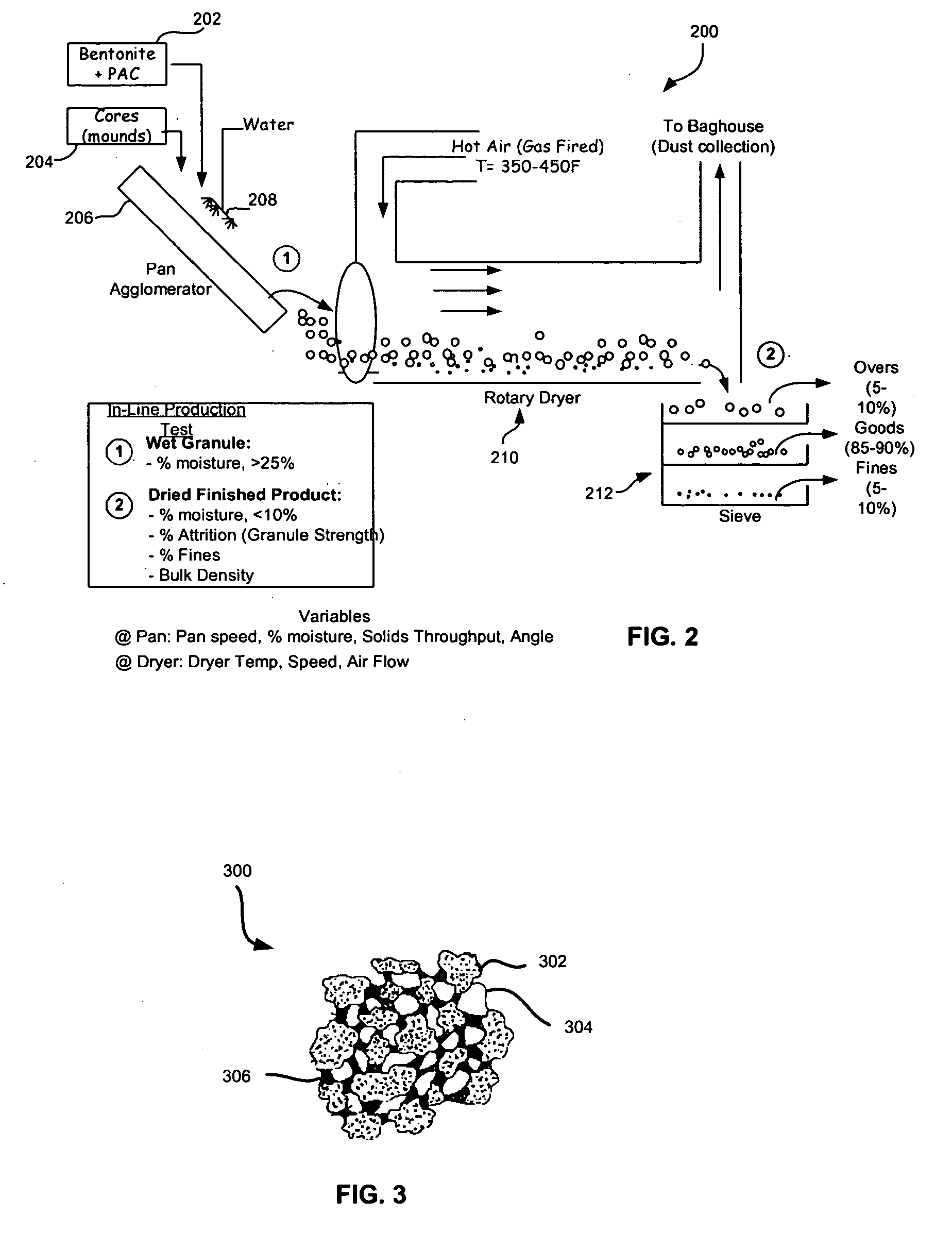

Composite absorbent particles

InactiveUS20050005869A1Low densityShorten the trackOther chemical processesAnimal housingFluidized bedEngineering

Composite particles and methods for making the same. An absorbent material is formed into a particle. An optional performance-enhancing active is coupled to the absorbent material before, during, or after the particle-forming process, homogeneously and / or in layers. Additionally, the composite absorbent particle may include a core material. Preferred methods for creating the absorbent particles include a pan agglomeration process, a high shear agglomeration process, a low shear agglomeration process, a high pressure agglomeration process, a low pressure agglomeration process, a rotary drum agglomeration process, a mix muller process, a roll press compaction process, a pin mixer process, a batch tumble blending mixer process, an extrusion process, and a fluid bed process.

Owner:THE CLOROX CO

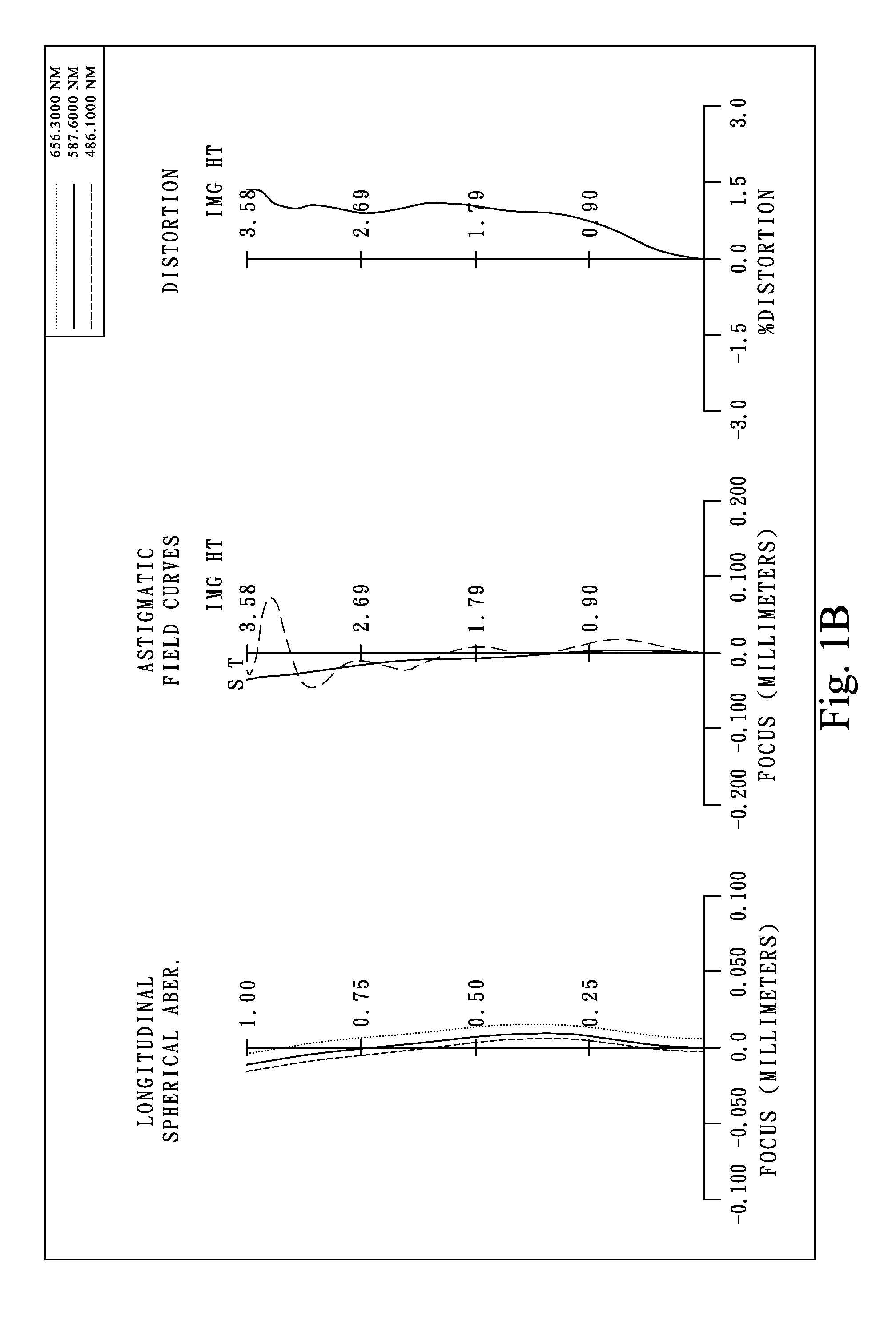

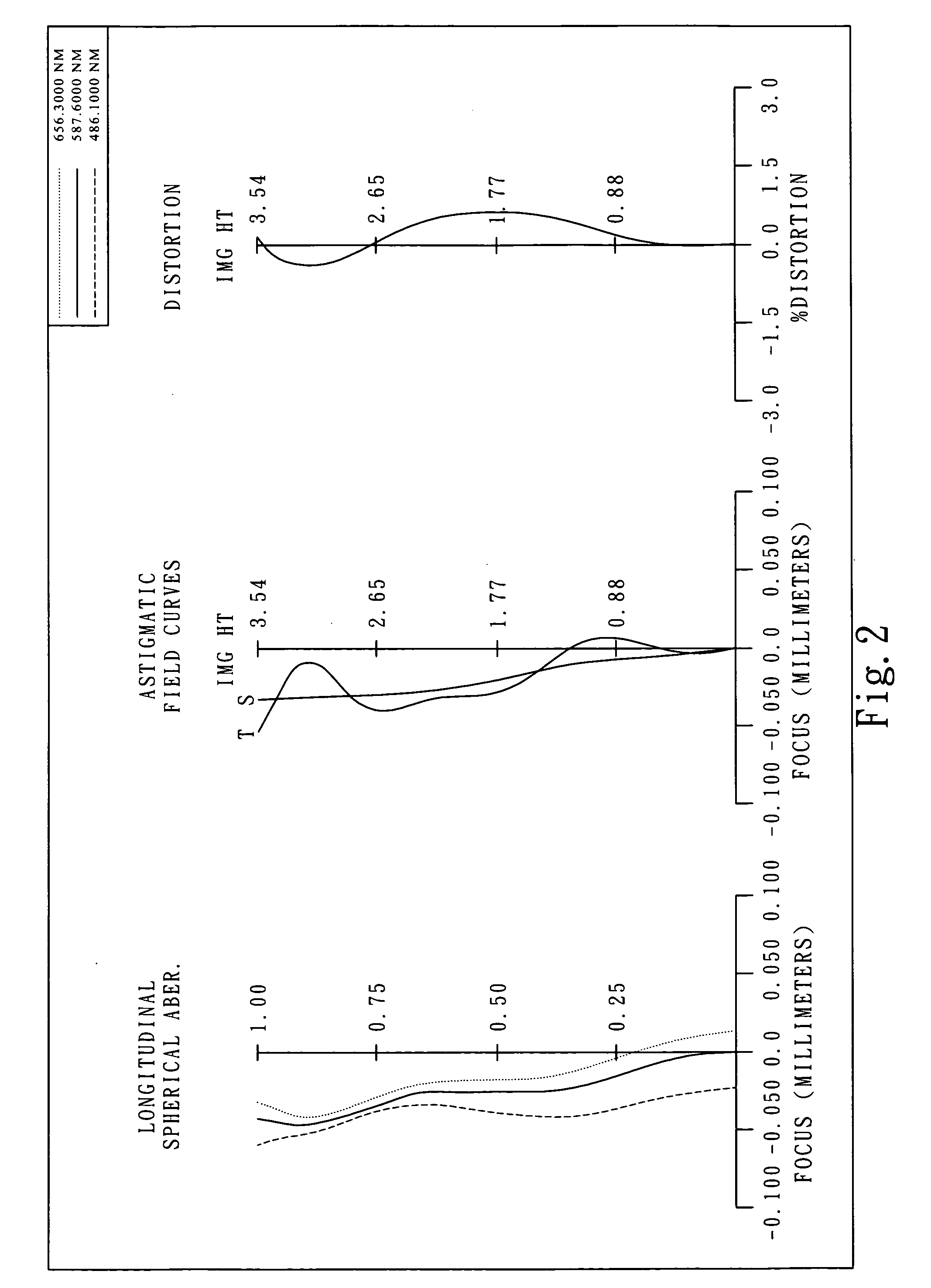

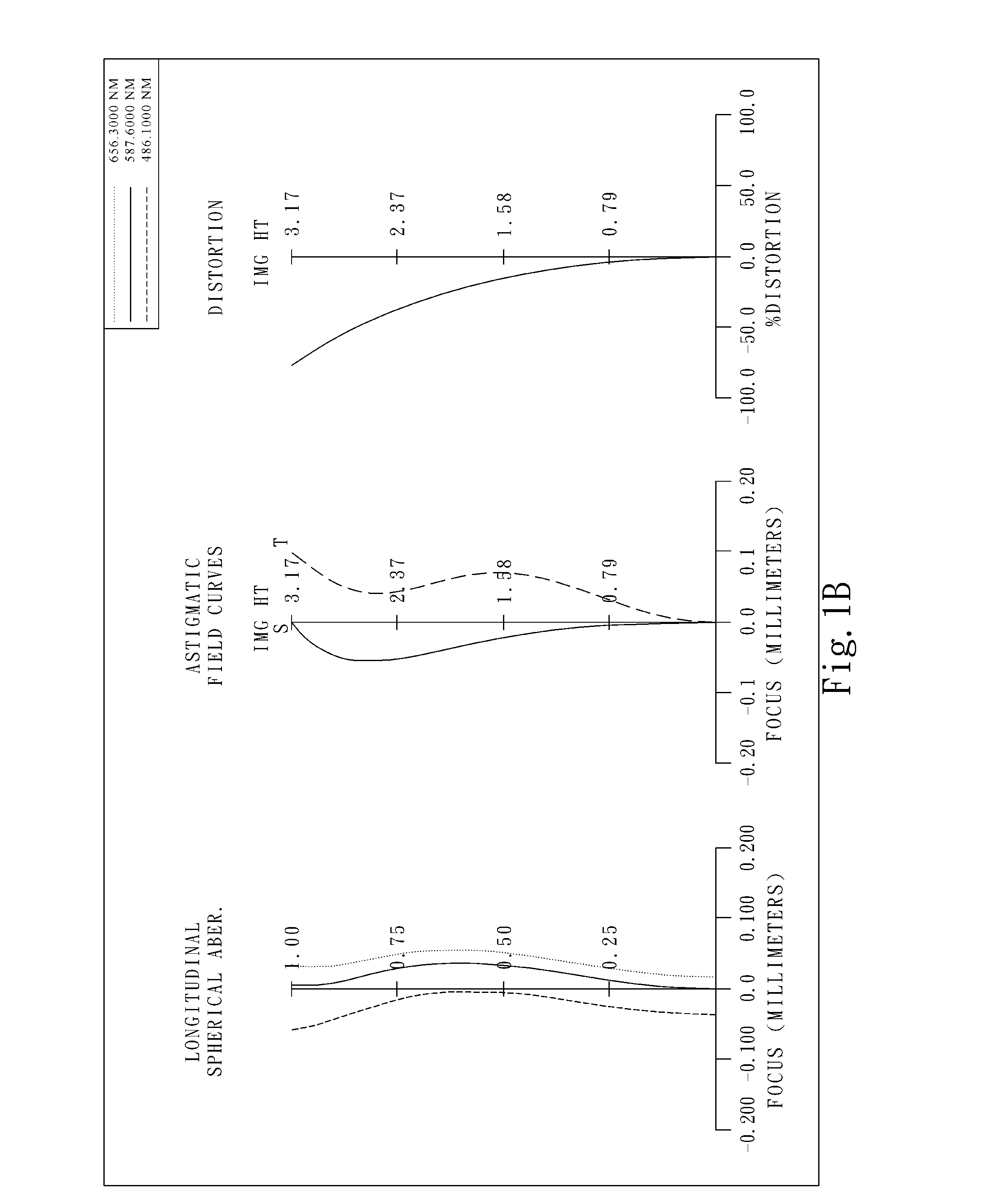

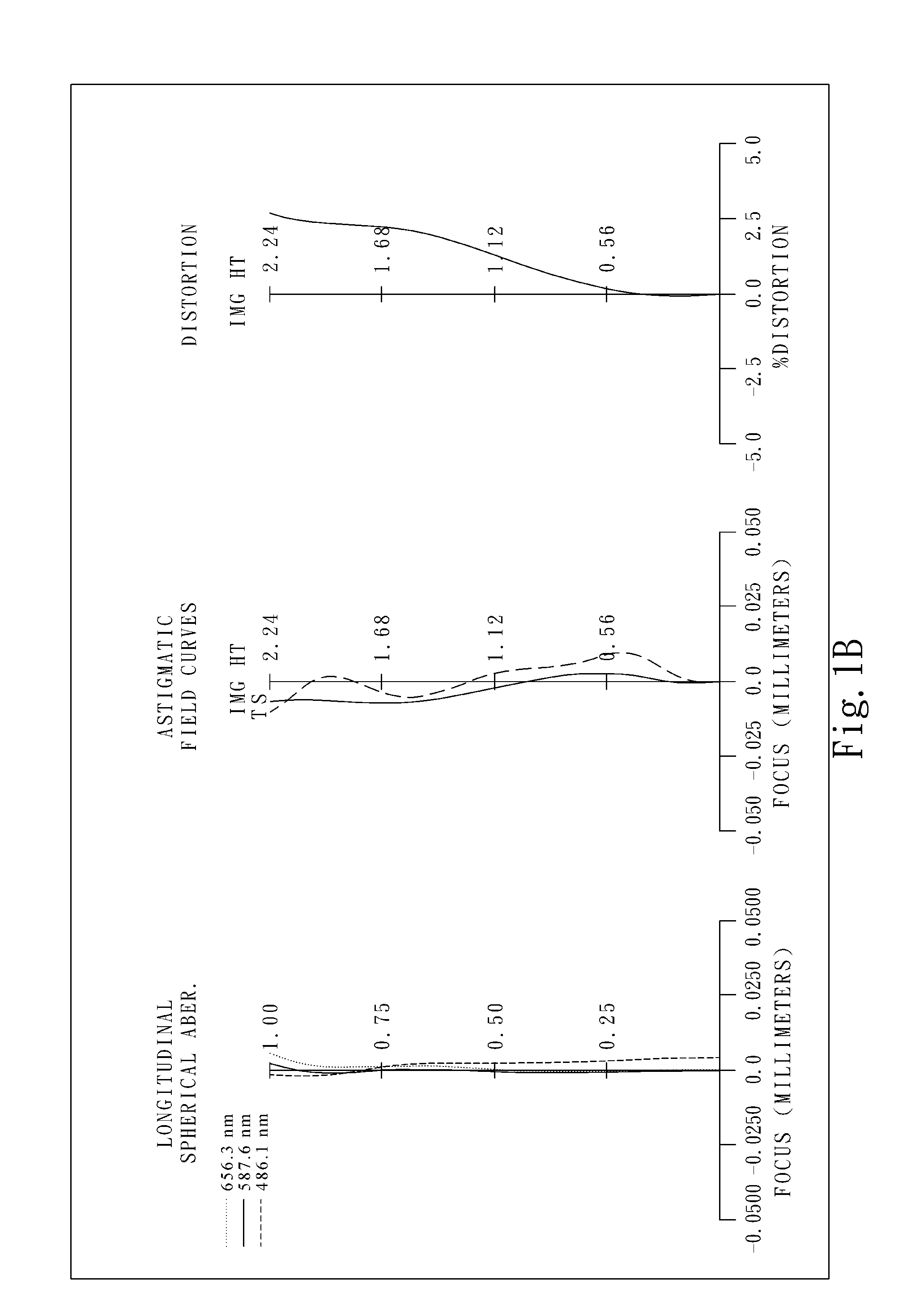

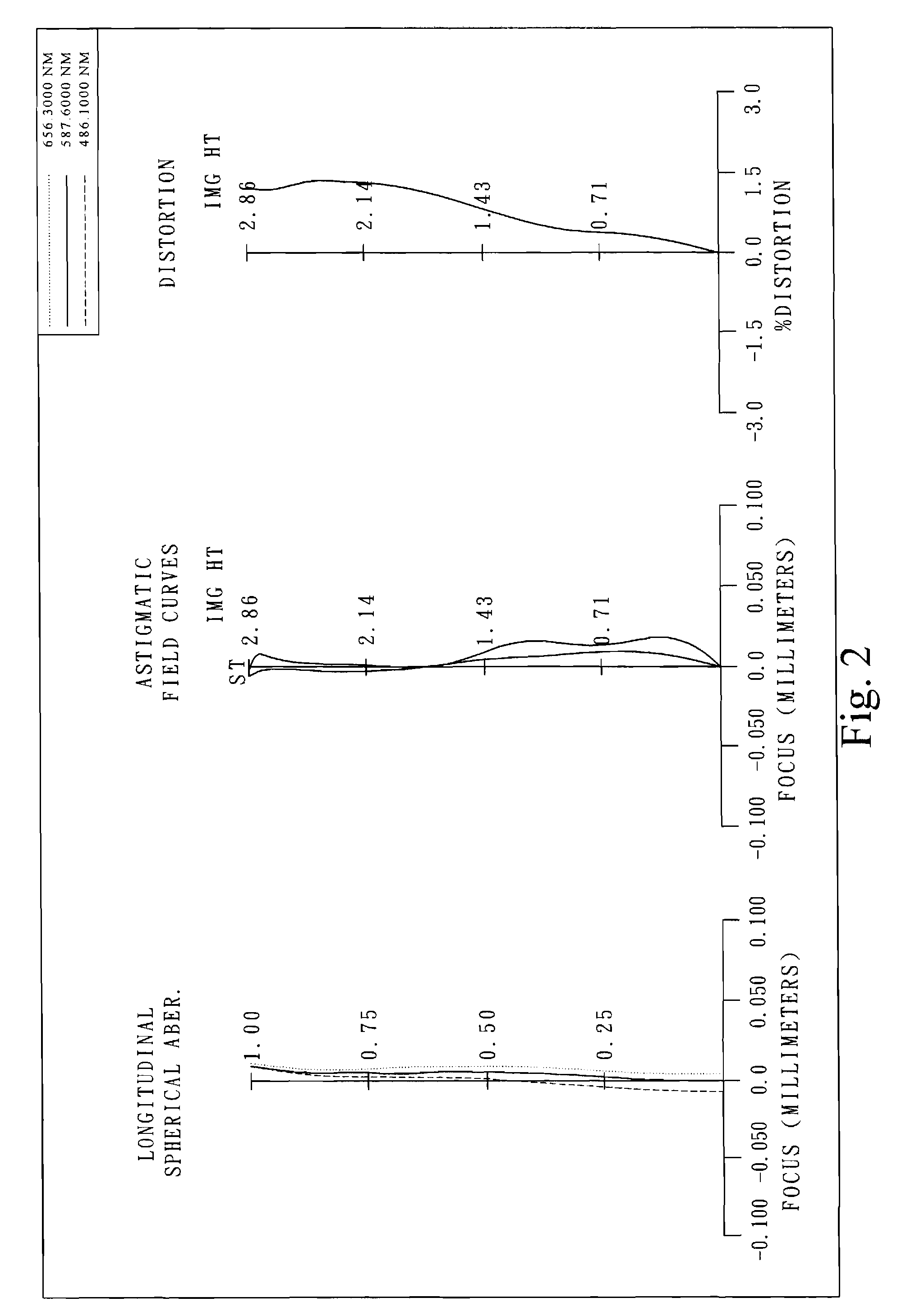

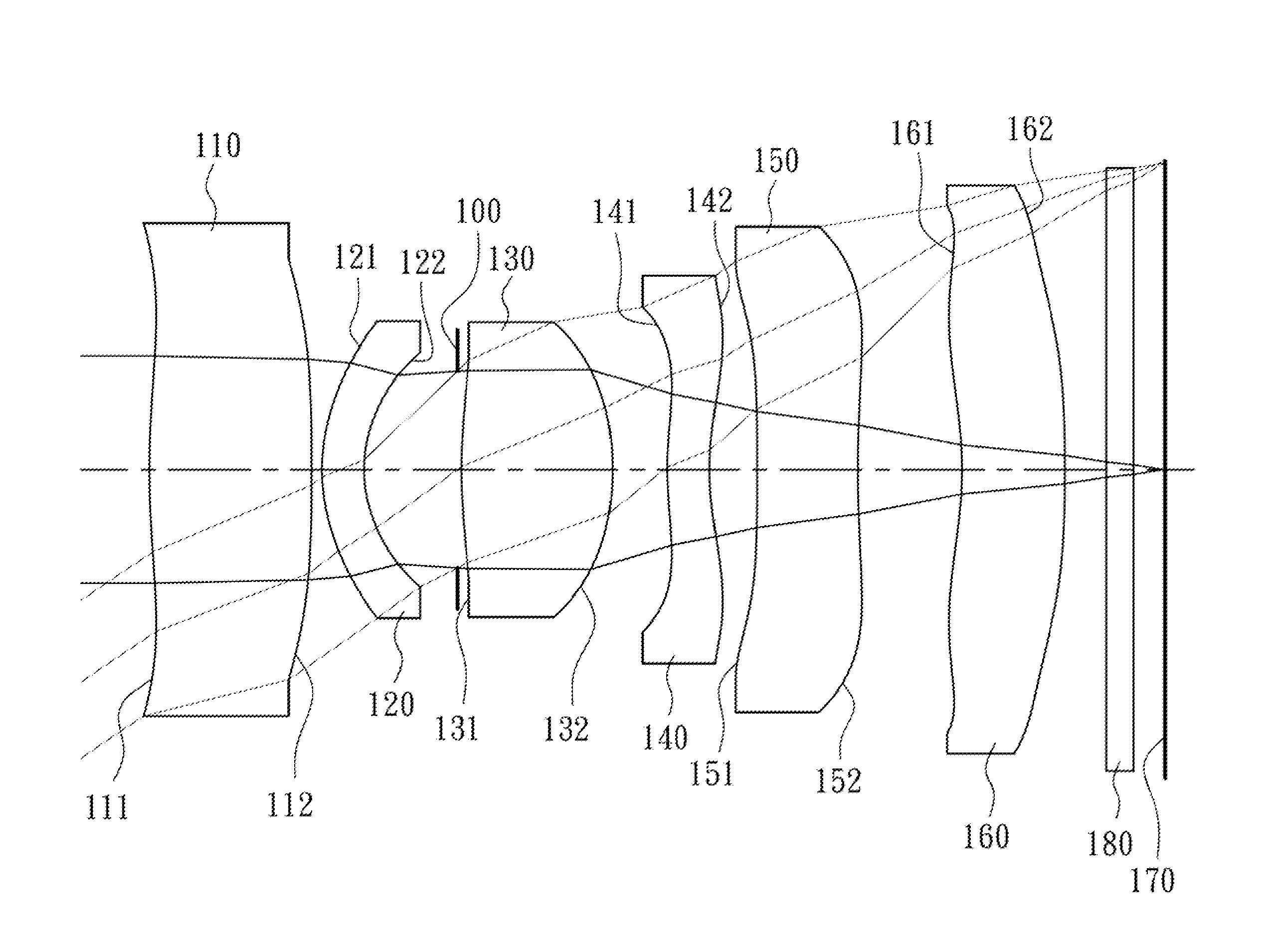

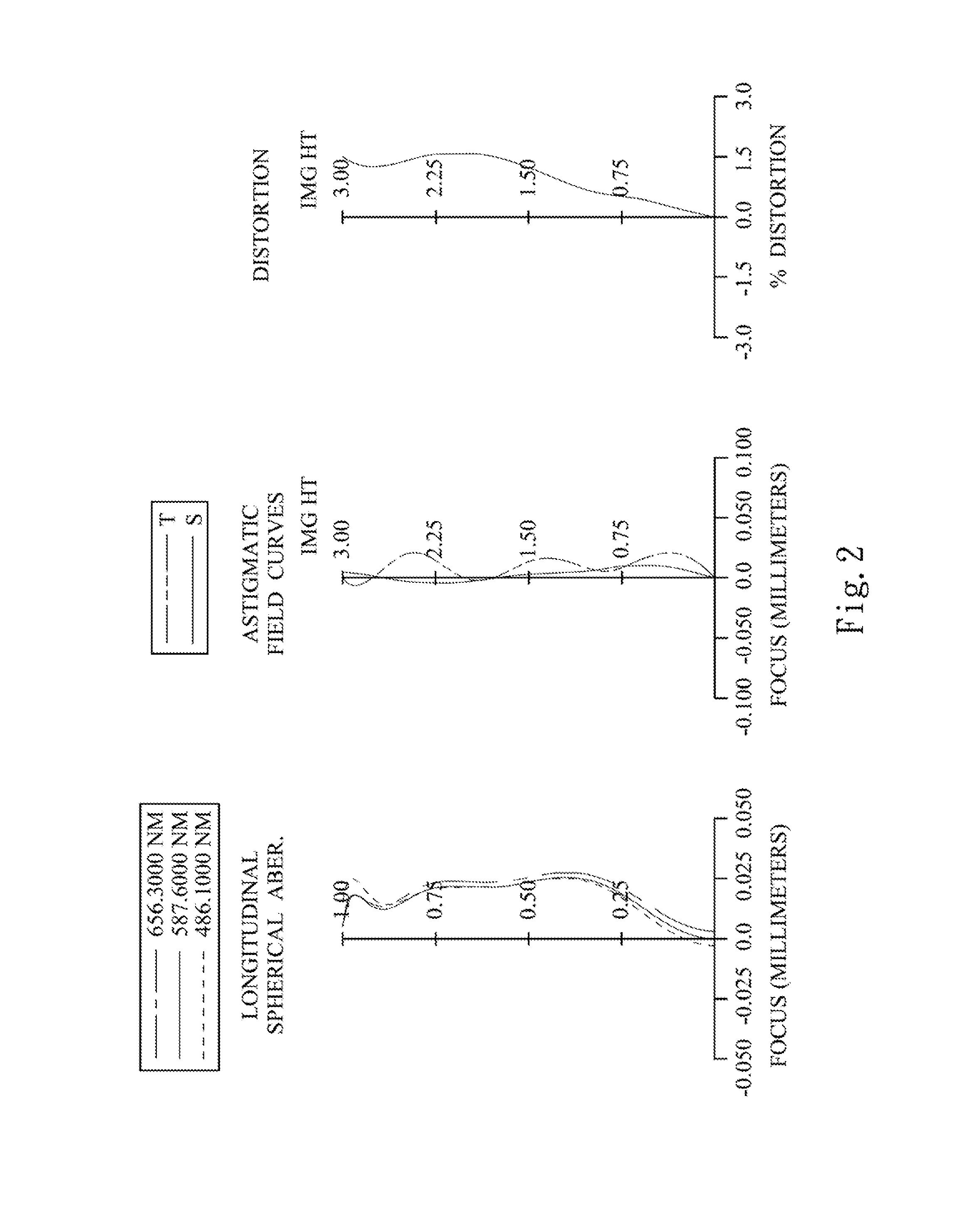

Image capturing lens assembly

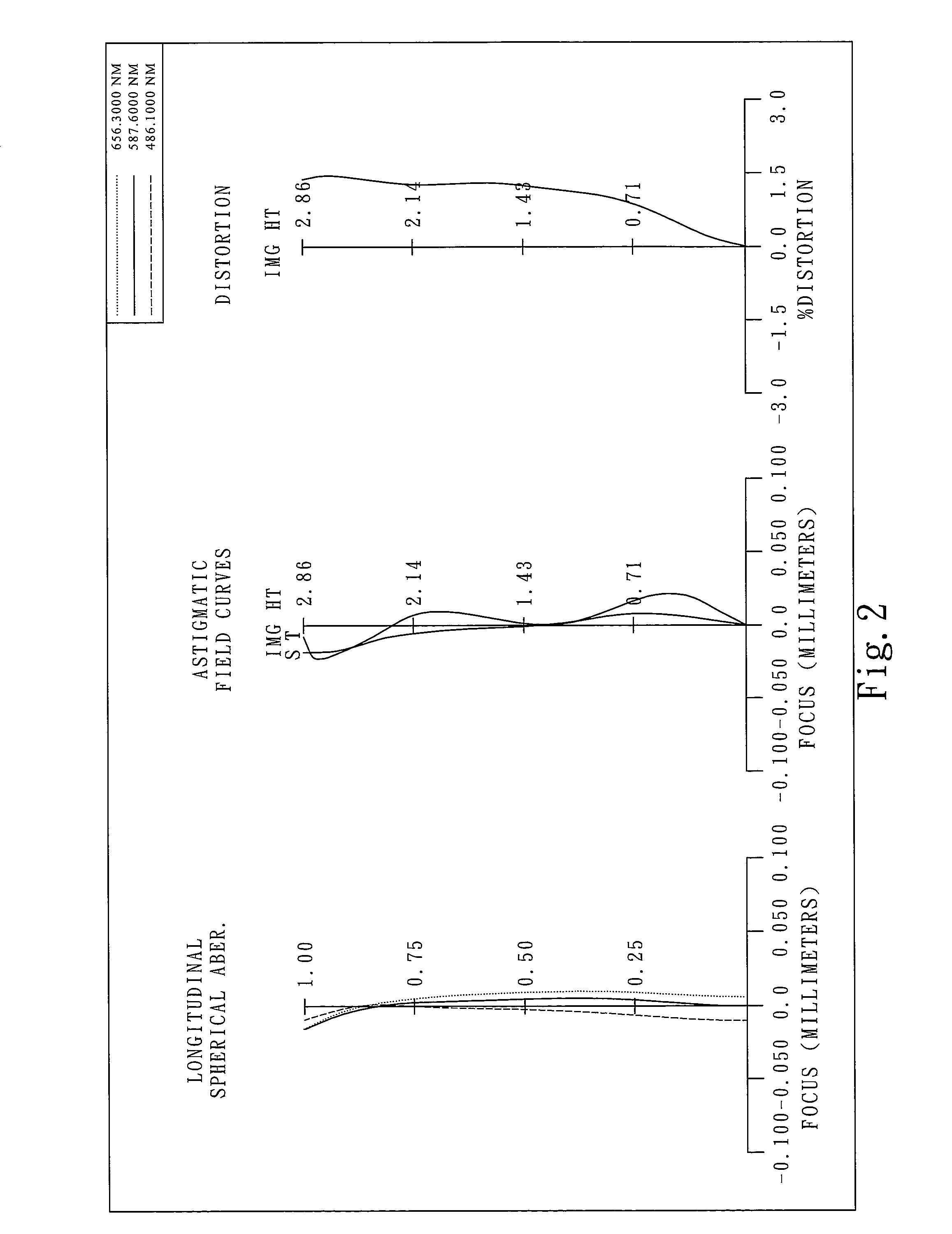

ActiveUS20120194726A1High image resolutionReduce track lengthTelevision system detailsColor television detailsImage resolutionAstigmatism

This invention provides an image capturing lens assembly, in order from an object side to an image side comprising: a first lens element with positive refractive power having a convex object-side surface; a second lens element; a third lens element; a fourth lens element having at least one of an object-side surface and an image-side surface thereof being aspheric; a fifth lens element with positive refractive power having a convex image-side surface, at least one of an object-side surface and the image-side surface thereof being aspheric, and the fifth lens element is made of plastic; and a sixth lens element with negative refractive power having a concave image-side surface, at least one of an object-side surface and the image-side surface thereof being aspheric, and the sixth lens element is made of plastic. By such arrangement, the photo-sensitivity and the total track length of the image capturing lens assembly can be reduced. Furthermore, the aberration and astigmatism of the assembly can be effectively corrected for obtaining higher image resolution.

Owner:LARGAN PRECISION

Optical image capturing lens assembly

An optical image capturing lens assembly includes, in order from an object side to an image side, the first lens element with positive refractive power having a convex object-side surface, the second lens element with refractive power, the third lens element with refractive power, the fourth lens element with refractive power having a concave object-side surface and a convex image-side surface, the fifth lens element with refractive power having a convex image-side surface, the object-side surface and the image side surface of the fifth lens element being aspheric, and the sixth lens element with negative refractive power made of plastic material and having a concave image-side surface. The object-side surface and the image-side surface of the sixth lens element are aspheric, and at least one surface thereof has at least one inflection point.

Owner:LARGAN PRECISION

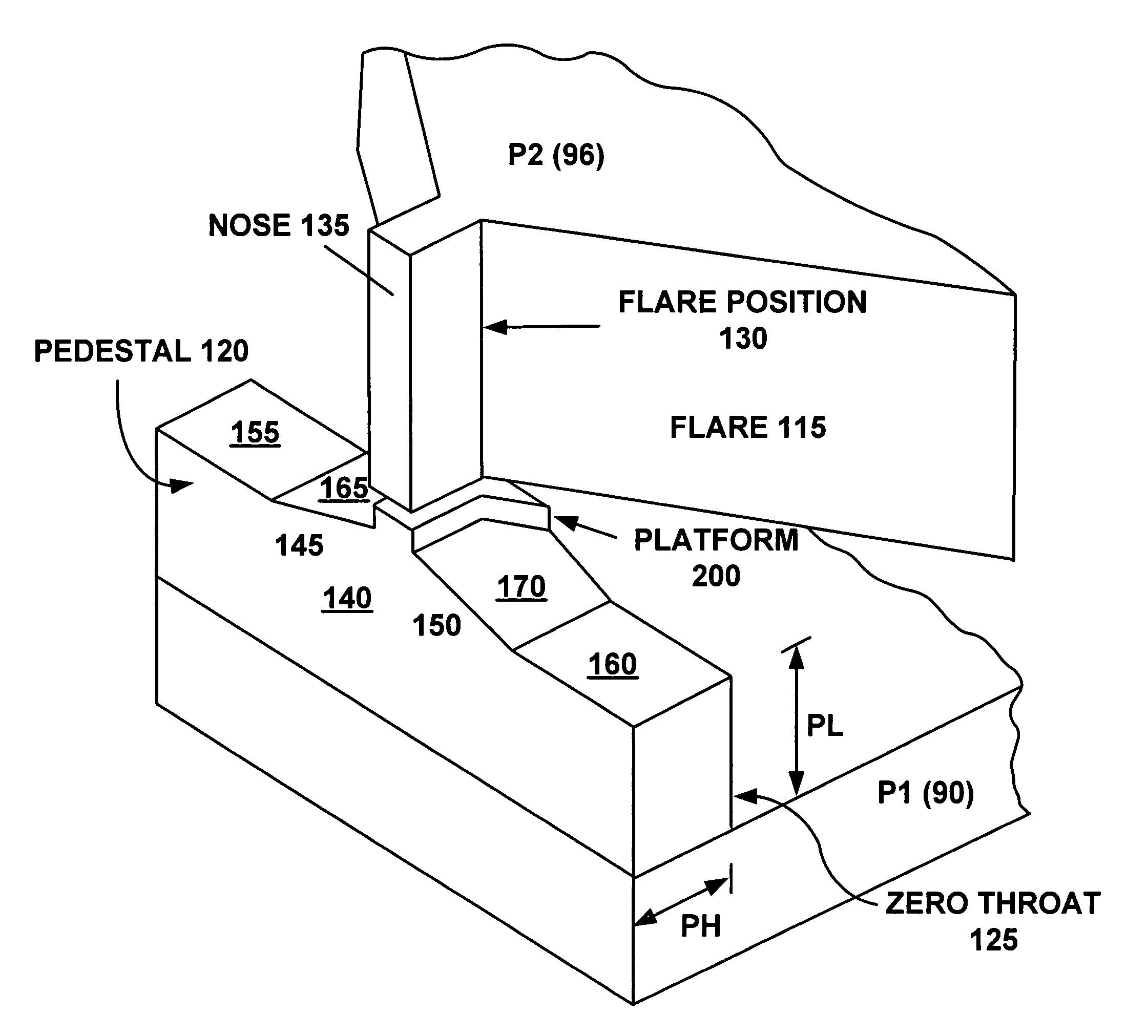

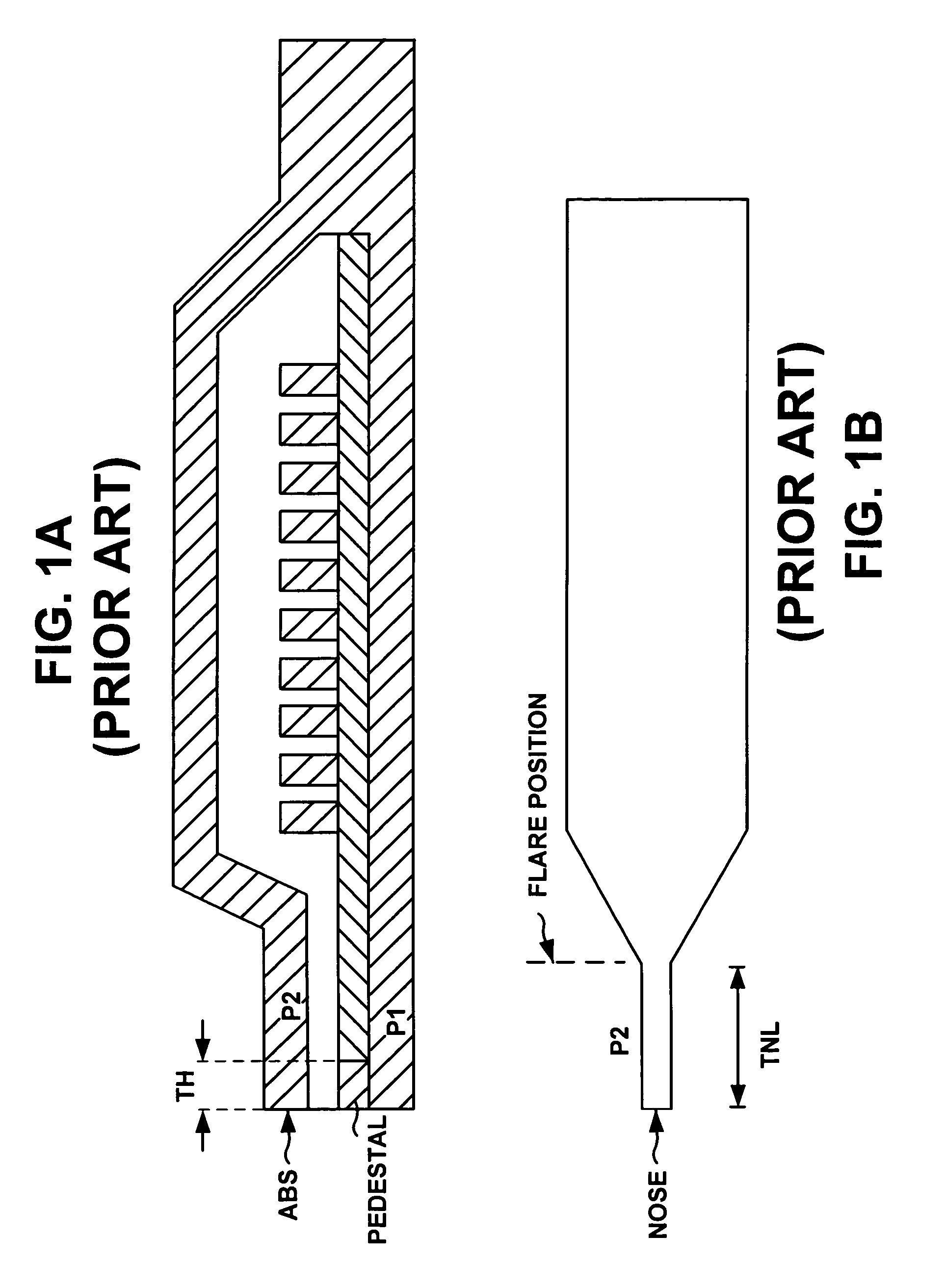

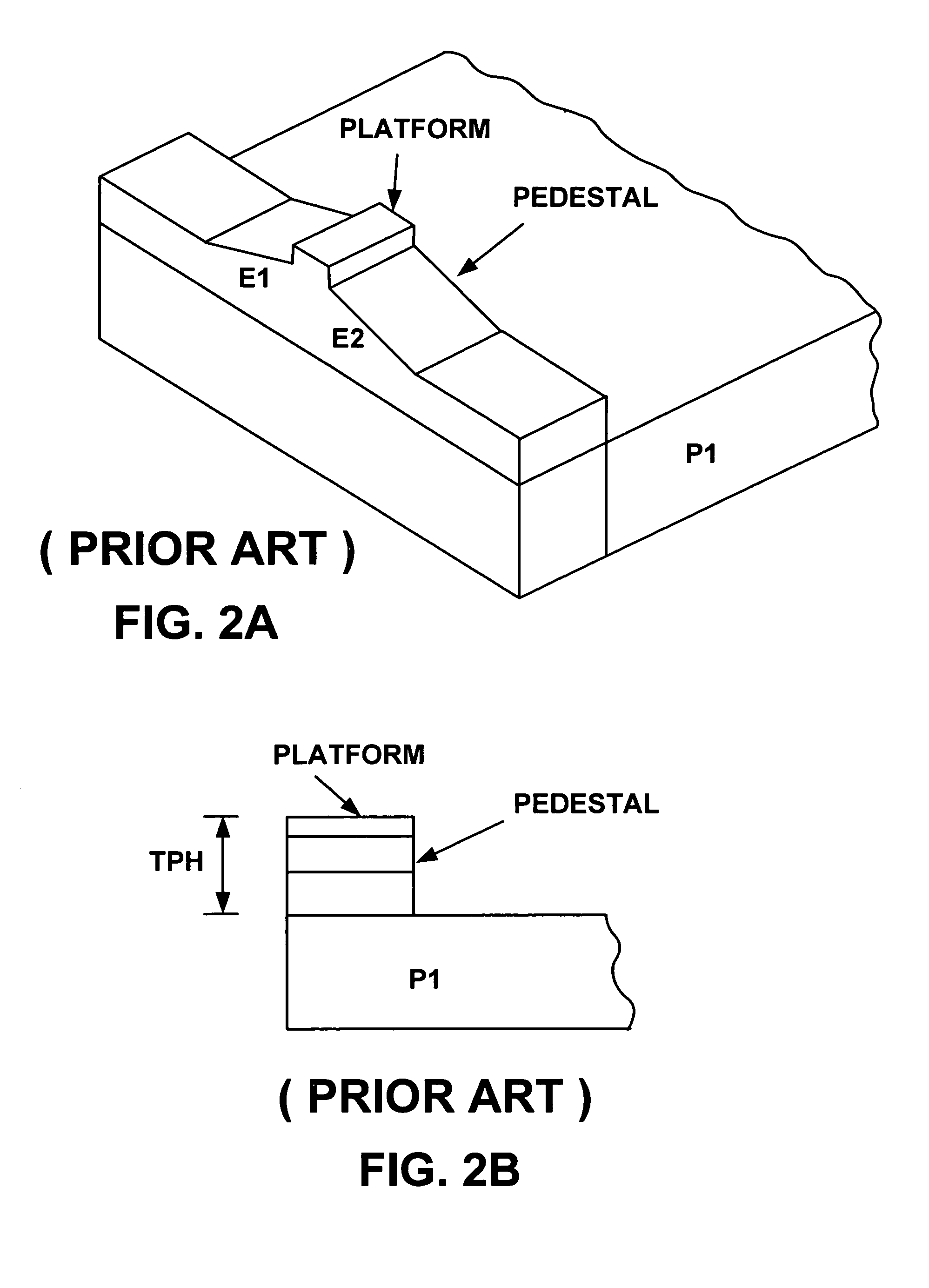

Write head for improved manufacturability larger write field and reduced adjacent track erasure

InactiveUS7349179B1Improve manufacturabilityReduce decreaseRecord information storageMagnetic recordingNoseMagnetic flux

A magnetic write head provides a significant write field and minimal adjacent track erasure, and lends itself to improved manufacturability. The write head includes a pedestal throat height that defines a bottom pole, P1, and that is substantially recessed from the air bearing surface. The write head further includes a top pole, P2, that defines a nose that is closer to the air bearing surface than the pedestal zero throat. This design achieves a relatively high ratio of the off-track to on-track field. As an example, a 1:4 ratio could be achieved to significantly mitigate the erasure problem of the adjacent tracks resulting from magnetic flux saturation.

Owner:WESTERN DIGITAL TECH INC

Wide-viewing-angle imaging lens assembly

ActiveUS20110316969A1Expand field of viewReduce sensitivityTelevision system detailsColor television detailsImaging lensField of view

The present invention provides a wide-viewing-angle imaging lens assembly comprising, in order from an object side to an image side: a front lens group, a stop, and a rear lens group. The front lens group comprises, in order from the object side to the image side: a first lens element with negative refractive power having a concave image-side surface and a second lens element. The rear lens group comprises, in order from the object side to the image side: a third lens element with positive refractive power having a concave object-side surface and a convex image-side surface, a fourth lens element with positive refractive power having a convex object-side surface and a convex image-side surface, and a fifth lens element with negative refractive power having a concave object-side surface. Such an arrangement of optical elements can effectively enlarge the field of view of the wide-viewing-angle imaging lens assembly, reduce the sensitivity of the optical system, and obtain good image quality.

Owner:LARGAN PRECISION

Magnetic tape

InactiveUS20070230054A1Shorten the trackSimple resultRecord information storageTape carriersMagnetic tapeNon magnetic

A magnetic tape including: a nonmagnetic support; a substantially nonmagnetic layer containing nonmagnetic powder and a binder; and a magnetic layer containing ferromagnetic powder and a binder, in this order, wherein the magnetic tape has a coefficient of temperature expansion of from 0 to 10×10−6 / ° C. and a coefficient of humidity expansion of 0 to 7×10−6 / % RH each in a transverse direction of the magnetic tape, and the magnetic tape has a dimensional deformation amount of from 0.01 to 0.06% in the transverse direction in case of applying a tensile stress of 1N to the magnetic tape at 60° C. for 50 hours in a longitudinal direction of the magnetic tape.

Owner:FUJIFILM CORP

Optical image capturing lens assembly

The present disclosure provides an optical image capturing lens assembly comprising, in order from an object side to an image side: a first lens element with positive refractive power having a convex image-side surface; a second lens element; a third lens element; a fourth lens element, at least one of an object-side surface and an image-side surface thereof being aspheric; a fifth lens element, at least one of an object-side surface and an image-side surface thereof being aspheric; and a sixth lens element with negative refractive power having a concave image-side surface, at least one of an object-side surface and the image-side surface thereof being aspheric, at least one inflection point being formed on at least one of the surfaces thereof. With the aforementioned arrangements, the sensitivity of the optical system can be attenuated while the aberration and astigmatism can be effectively corrected to improve the image quality.

Owner:LARGAN PRECISION

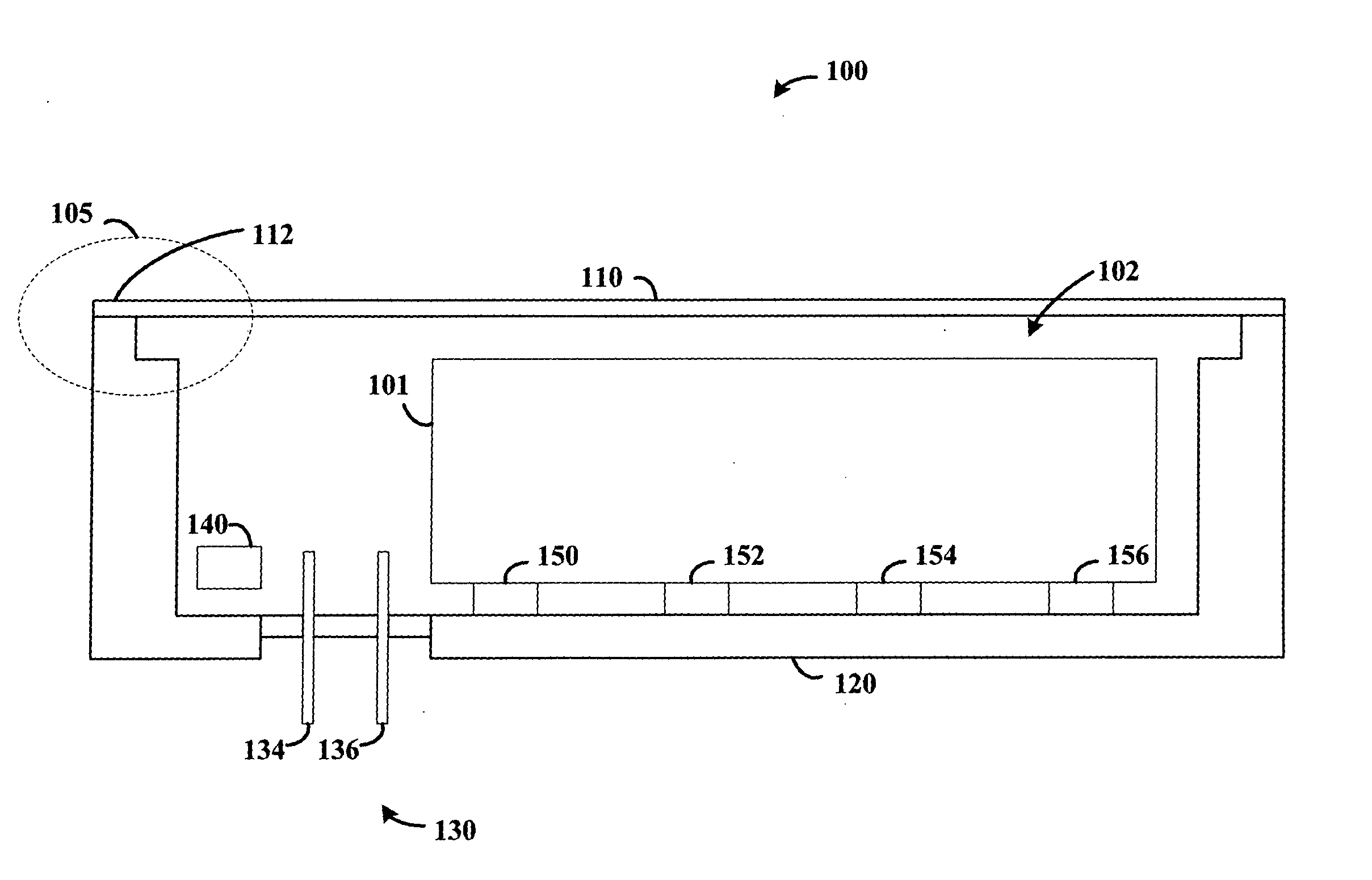

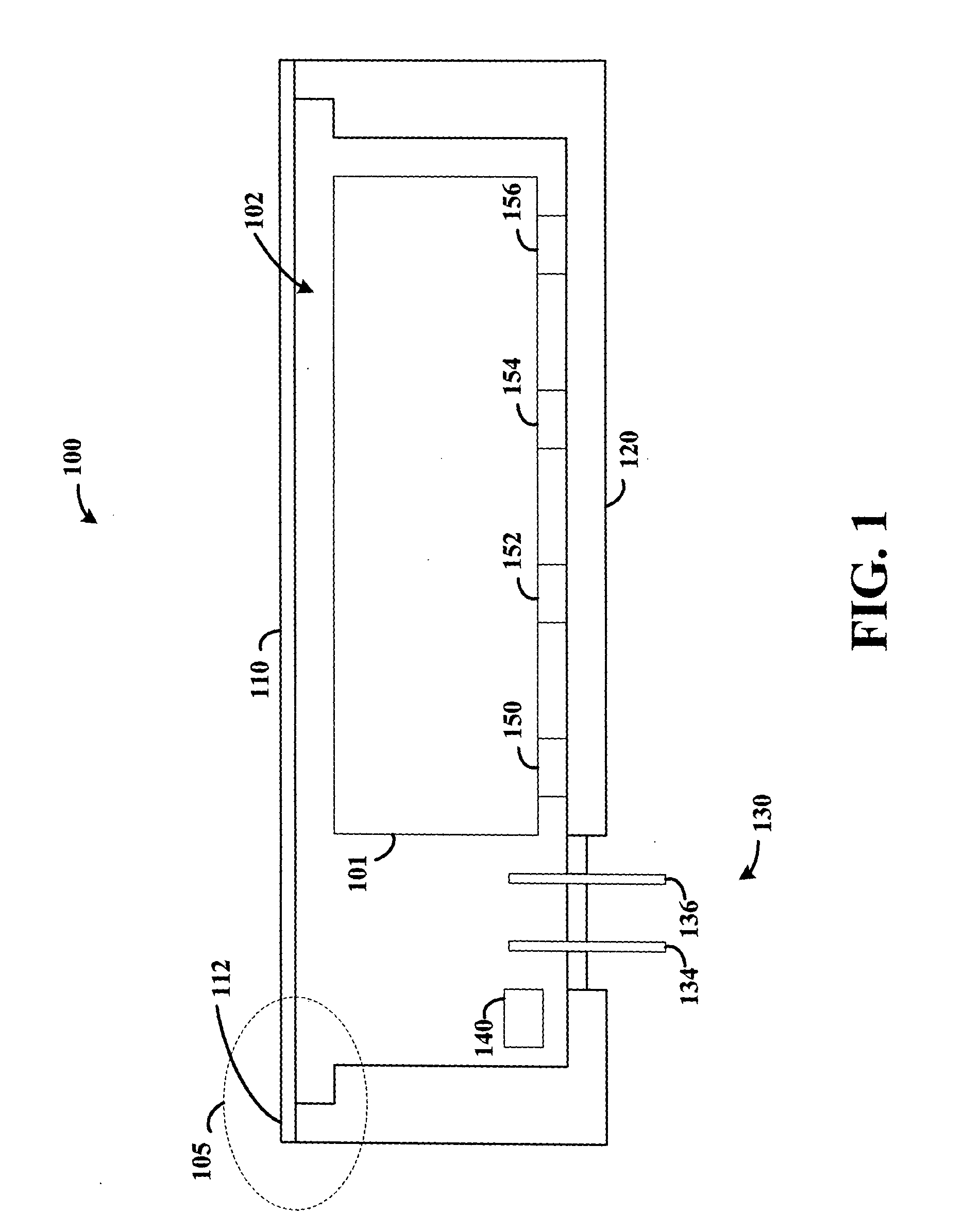

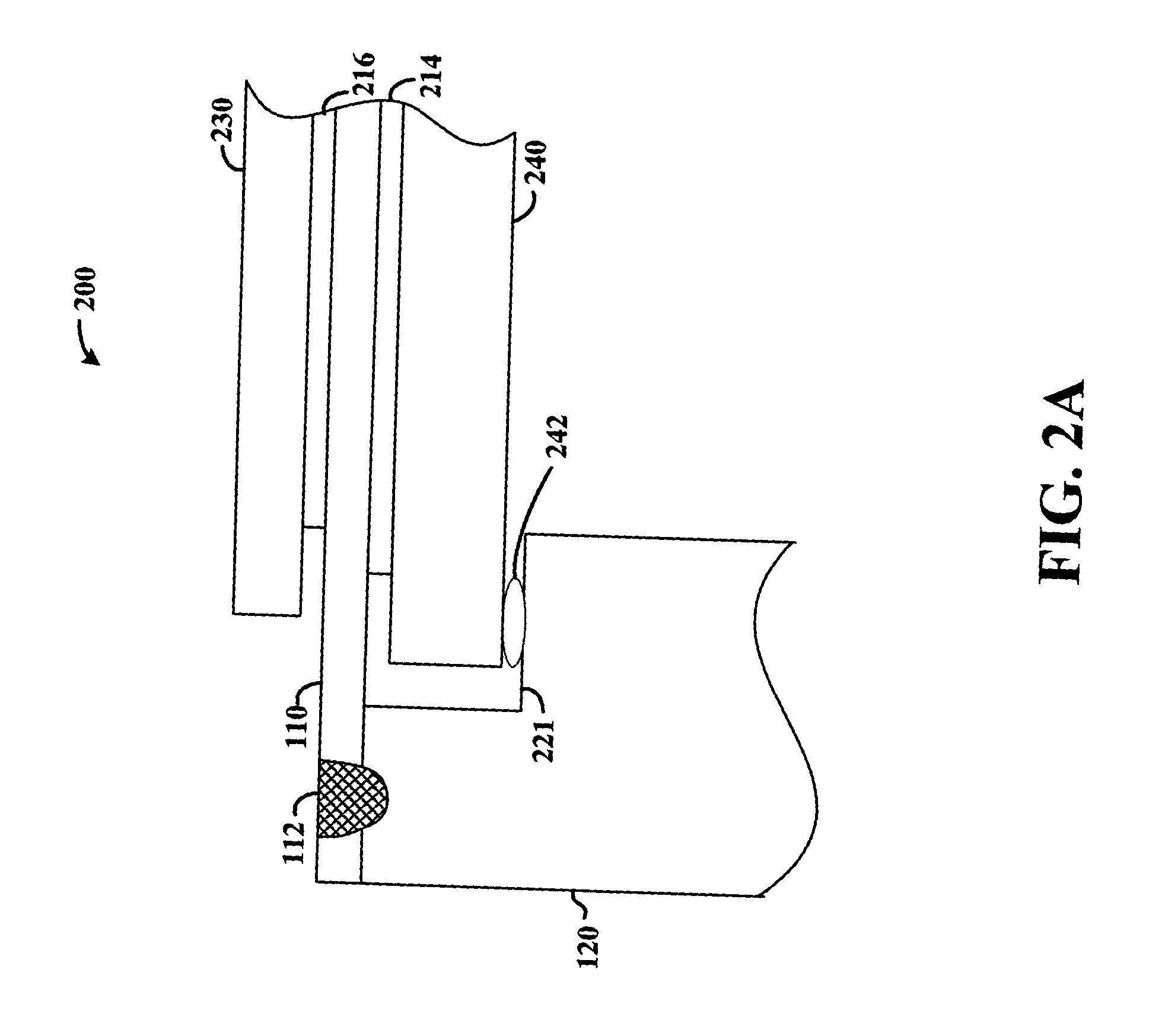

Hermetically sealed electronics arrangement and approach

InactiveUS20050068666A1Reduction of magnetic spacingImprove performanceApparatus modification to store record carriersUndesired vibrations/sounds insulation/absorptionMetallic enclosureCold formed

A hermetic sealing approach involves welding an Aluminum cover onto a low-cost Aluminum housing. According to an example embodiment of the present invention, a metal housing having a base and sidewalls extending upward therefrom is adapted to receive and couple to an HDD arrangement. The metal housing is formed using material and processing (e.g., cold formed or die cast Aluminum) that are relatively inexpensive. A feedthrough arrangement including a plurality of communication pins extends through an opening in the base and is coupled thereto, with the communication pins adapted to pass signals between the inside and the outside of the metal housing. A metal cover is welded to an upper portion of the sidewalls and, with the feedthrough arrangement, hermetically seals the metal housing.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Imaging lens assembly

This invention provides an imaging lens assembly including five lens elements with refractive power, in order from an object side toward an image side: a first lens with positive refractive power having a convex object-side surface, a second lens with negative refractive power, a third lens having a concave object-side surface, a fourth lens with positive refractive power having an object-side surface and a convex image-side surface, and at least one of both surfaces thereof being aspheric, a fifth lens with negative refractive power having a concave image-side surface with at least one inflection point formed thereon. An aperture stop is positioned between an imaged object and the second lens. The imaging lens assembly further comprises an electronic sensor on which an object is imaged. With such arrangement, the size and the optical sensitivity of the lens assembly can be reduced. A high image resolution is also obtained.

Owner:LARGAN PRECISION

Optical lens system

The present invention provides an optical lens system comprising, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power; a third lens element with positive refractive power having a convex object-side surface and a convex image-side surface; a fourth lens element; and a fifth lens element having a concave image-side surface, the object-side and image-side surfaces thereof being aspheric and at least one inflection point being formed on the image-side surface. Such arrangement of optical elements can effectively minimize the size of the optical lens system, lower the sensitivity of the optical system, and obtain higher image resolution.

Owner:LARGAN PRECISION

Photographing optical lens assembly

This invention provides a photographing optical lens assembly including, in order from an object side toward an image side: a first lens element with positive refractive power having a convex object-side surface, a second lens element with negative refractive power having a concave object-side surface and a concave image-side surface, a third lens element with positive refractive power, a fourth lens element with negative refractive power having a convex object-side surface and a concave image-side surface, and at least one of surfaces thereof being aspheric, a plastic fifth lens element having a convex object-side surface and a concave image-side surface with at least one inflection point. An aperture stop is positioned between an imaged object and the third lens element. The photographing optical lens assembly further comprises an electronic sensor on which the object is imaged.

Owner:LARGAN PRECISION

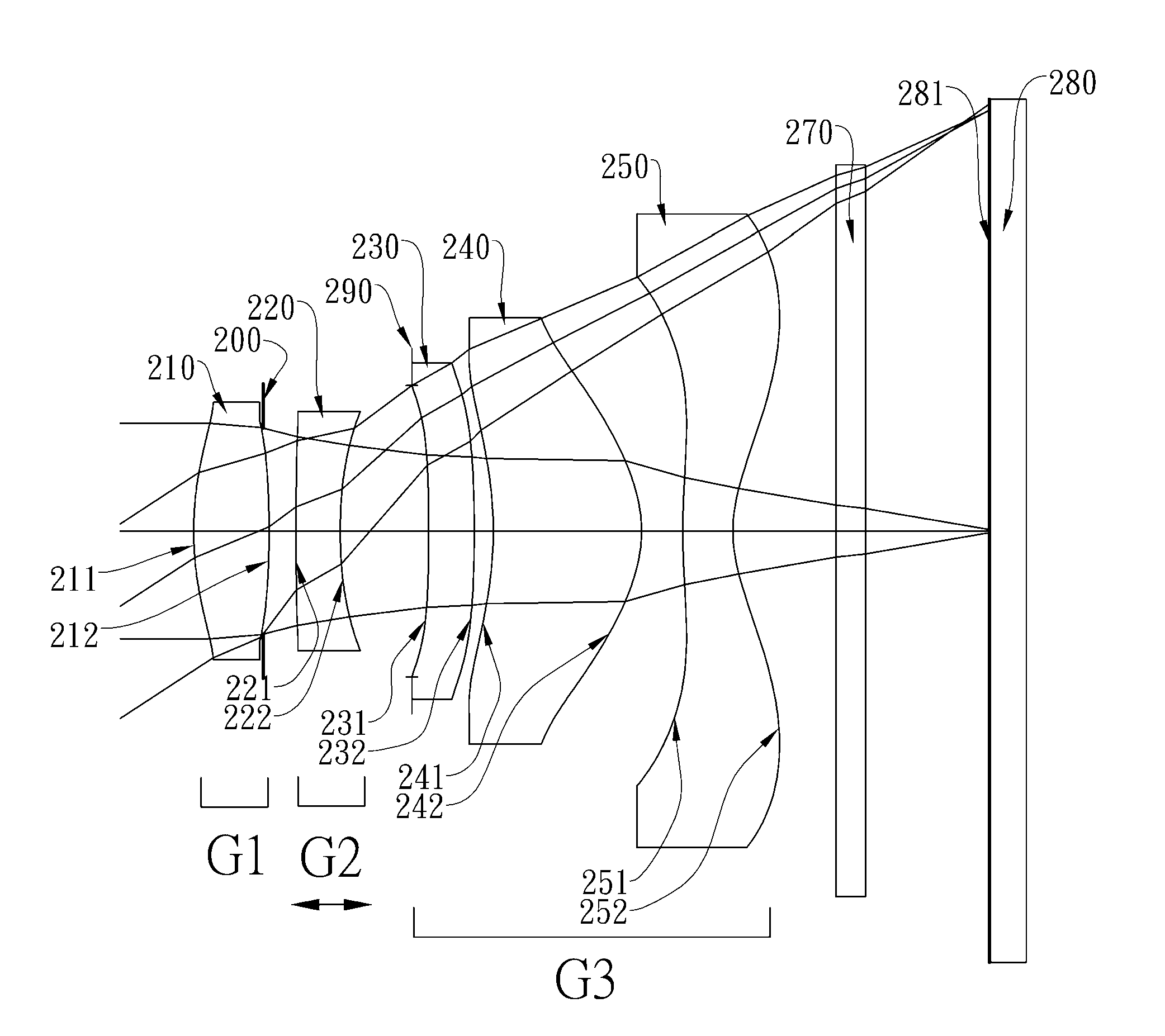

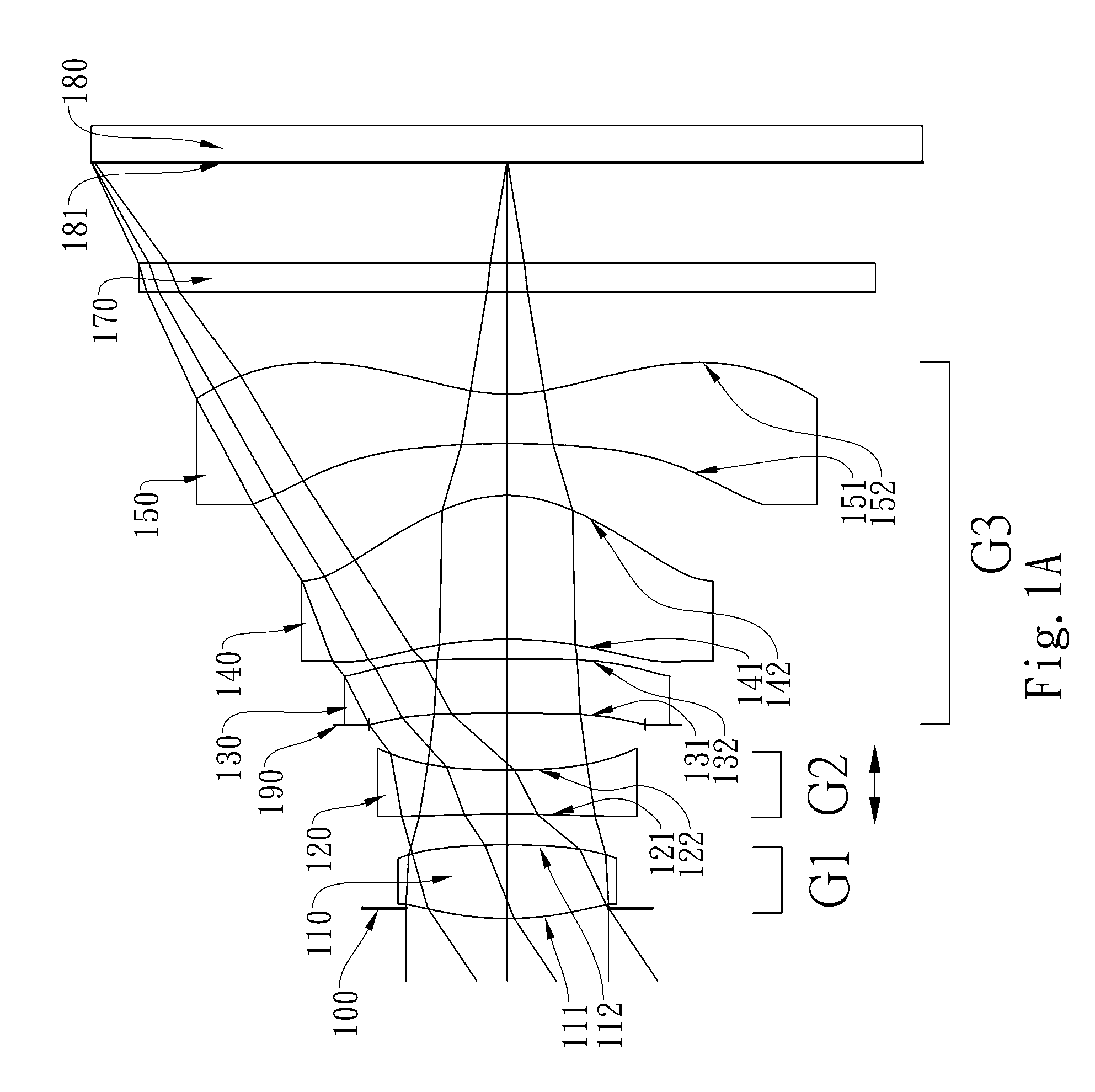

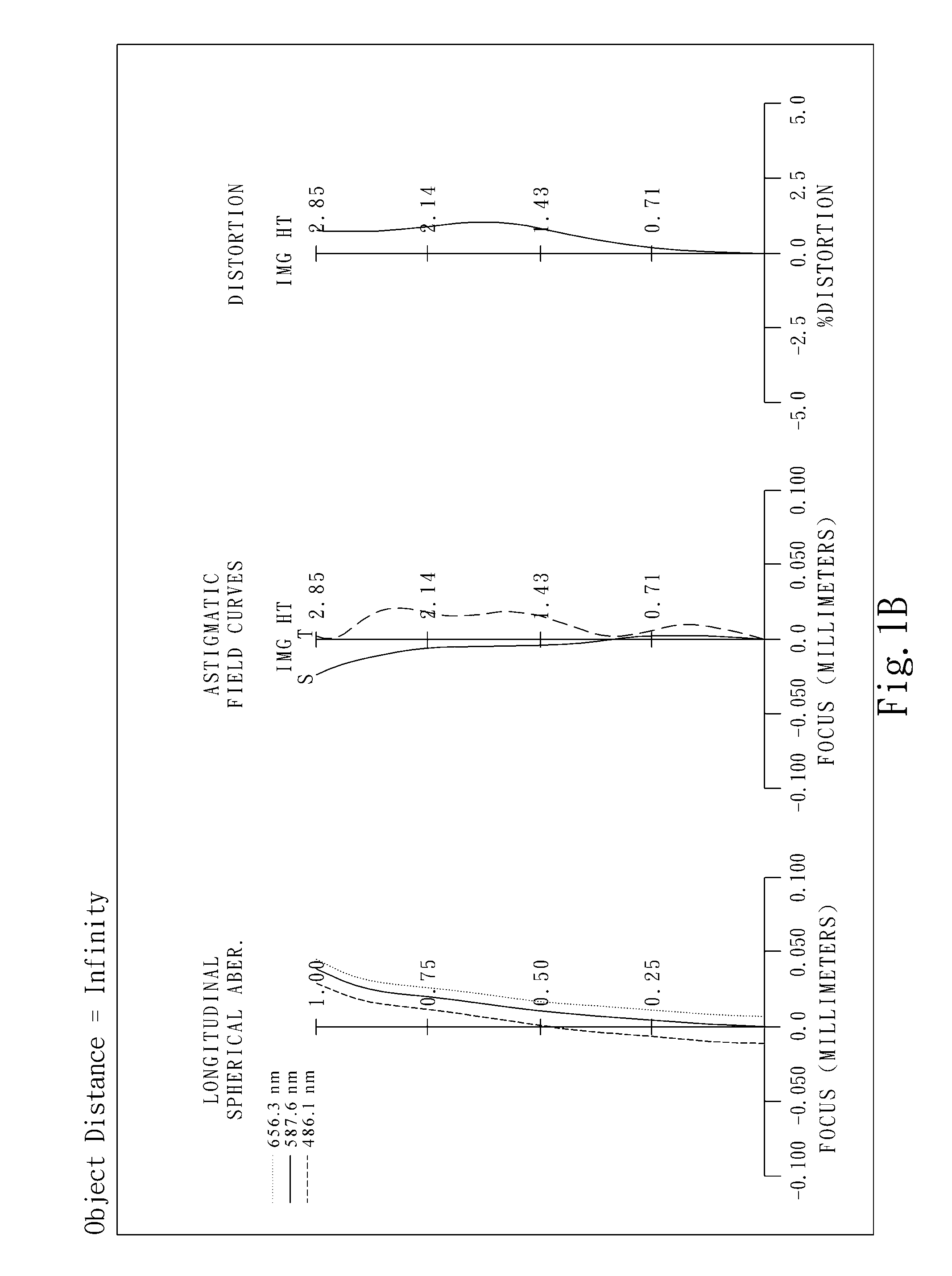

Optical image lens assembly

This invention provides an optical image lens assembly in order from an object side to an image side comprising: a first lens group has a first lens element with positive refractive power; a second lens group has a second lens element with negative refractive power; and a third lens group has at least three lens elements with refractive power; wherein a lens element in the third lens group closest to an image plane has negative refractive power and a concave image-side surface; wherein while a distance between an imaged object and the optical image lens assembly changes from far to near, focusing is performed by moving the second lens group along the optical axis toward the image plane. By such arrangement and focusing adjustment method, good image quality is achieved and less power is consumed.

Owner:LARGAN PRECISION

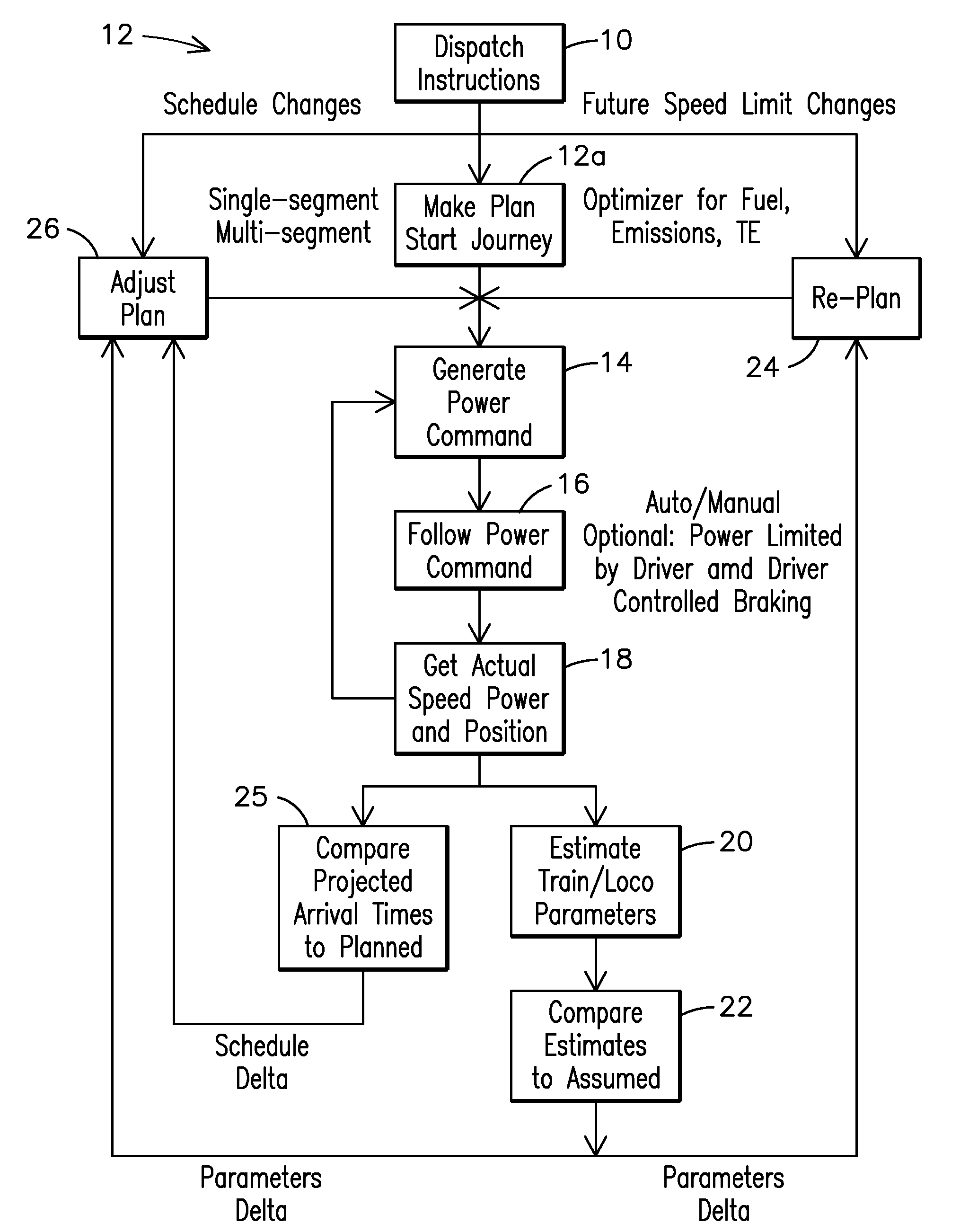

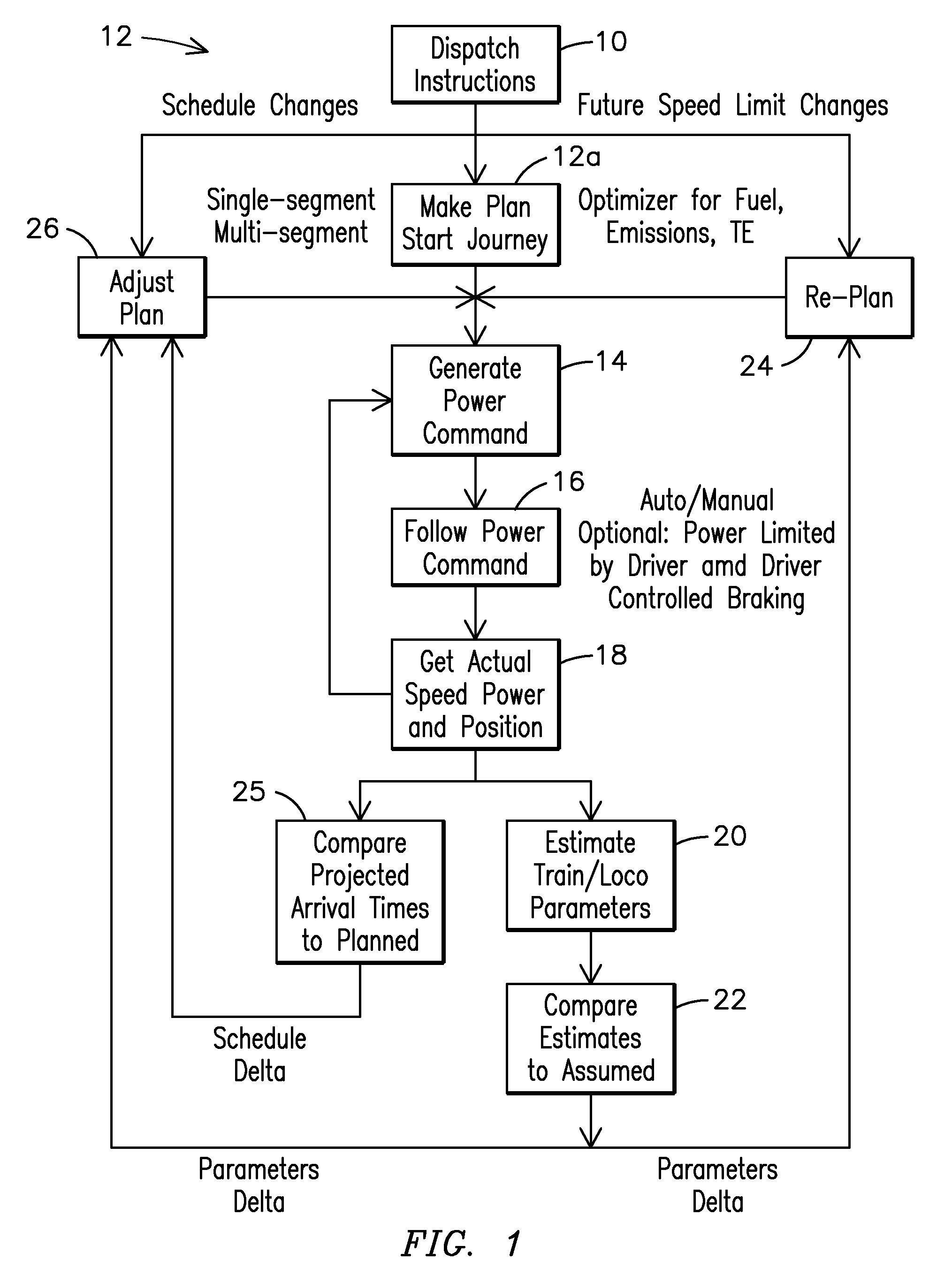

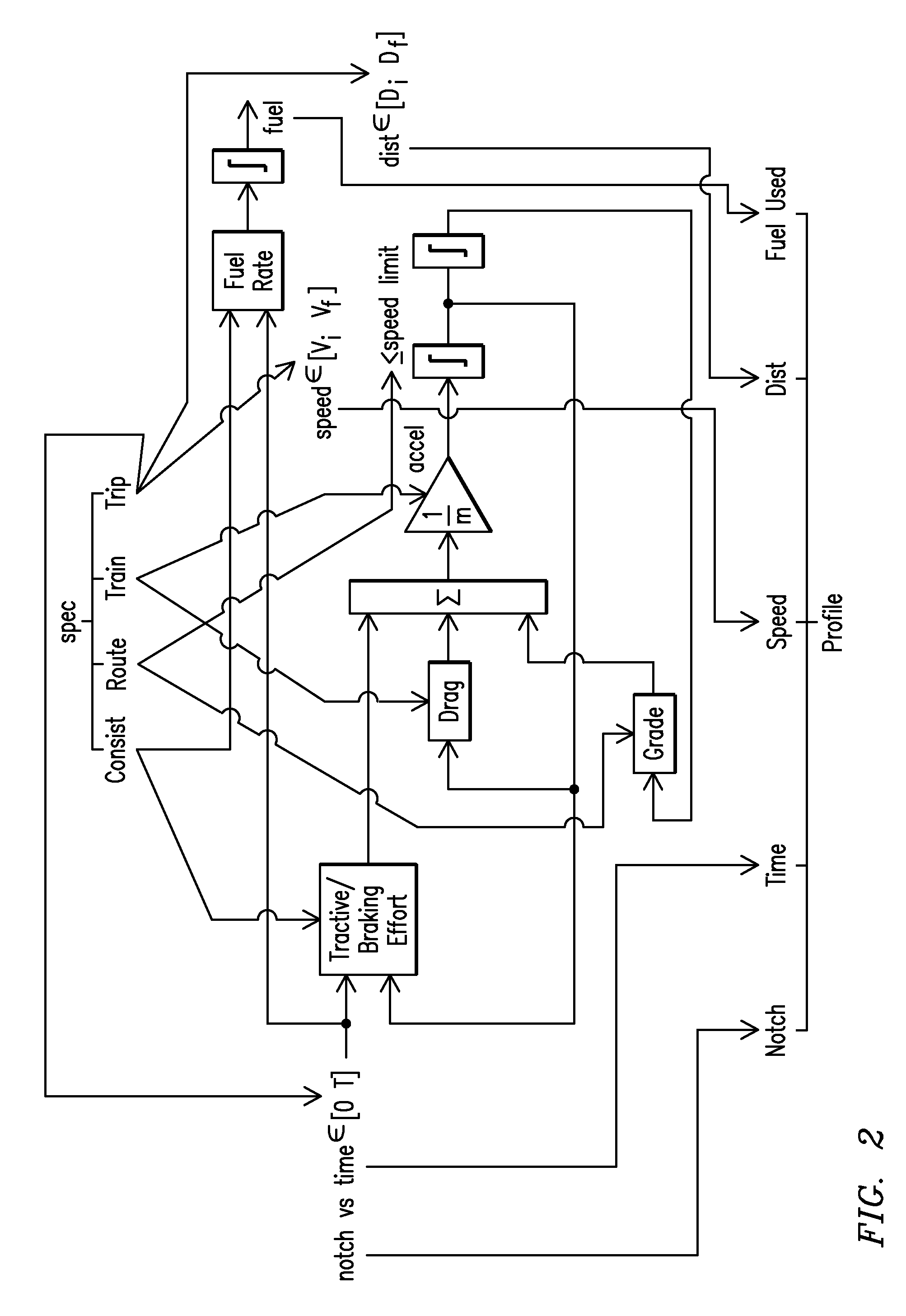

Trip optimizer method, system and computer software code for operating a railroad train to minimize wheel and track wear

ActiveUS20100023190A1Reduce the overall heightShorten speedDigital data processing detailsTrack side maintainanceWheel wearComputer software

A system for controlling a railroad train over a segment of track. The system comprises a first element for determining a location of the train on the segment of track; a second element for providing track characterization information for the segment of track; the track characterization information related to physical conditions of the segment of track; and a processor for controlling applied tractive forces and braking forces of the train responsive to the location of the train and the track characterization information to reduce at least one of wheel wear and / or track wear during operation of the train over the segment of track.

Owner:GE GLOBAL SOURCING LLC

Optical lens system

The present invention provides an optical lens system comprising, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power; a third lens element with positive refractive power having a convex object-side surface and a convex image-side surface; a fourth lens element; and a fifth lens element having a concave image-side surface, the object-side and image-side surfaces thereof being aspheric and at least one inflection point being formed on the image-side surface. Such arrangement of optical elements can effectively minimize the size of the optical lens system, lower the sensitivity of the optical system, and obtain higher image resolution.

Owner:LARGAN PRECISION

Optical lens system

The present invention provides an optical lens system comprising, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power; a third lens element with positive refractive power having a convex object-side surface and a convex image-side surface; a fourth lens element; and a fifth lens element having a convex object-side surface and a concave image-side surface, the object-side and image-side surfaces thereof being aspheric and at least one inflection point being formed on the image-side surface. Such arrangement of optical elements can effectively minimize the size of the optical lens system, lower the sensitivity of the optical system, and obtain higher image resolution.

Owner:LARGAN PRECISION

Composite absorbent particles

InactiveUS20050005870A1Low densityShorten the trackAnimal housingOther apparatusFluidized bedEngineering

Composite particles and methods for making the same. An absorbent material is formed into a particle. An optional performance-enhancing active is coupled to the absorbent material before, during, or after the particle-forming process, homogeneously and / or in layers. Additionally, the composite absorbent particle may include a core material. Preferred methods for creating the absorbent particles include a pan agglomeration process, a high shear agglomeration process, a low shear agglomeration process, a high pressure agglomeration process, a low pressure agglomeration process, a rotary drum agglomeration process, a mix muller process, a roll press compaction process, a pin mixer process, a batch tumble blending mixer process, an extrusion process, and a fluid bed process.

Owner:THE CLOROX CO

Optical photographing lens assembly

ActiveUS20110176049A1Expand field of viewReduce sensitivityTelevision system detailsColor television detailsOptical axisPhysics

This invention provides an optical photographing lens assembly comprising, in order from an object side to an image side: a first lens with negative refractive power having a concave image-side surface; a second lens with positive refractive power having a concave object-side surface and a convex image-side surface; a third lens with positive refractive power having a concave object-side surface and a convex image-side surface; a fourth lens with negative refractive power; and a fifth lens with positive refractive power; wherein the optical photographing lens assembly further comprises a stop disposed between the second and third lenses; and wherein the distance on the optical axis between the fourth and fifth lenses is T45, the focal length of the optical photographing lens assembly is f, the number of the lenses with refractive power is N, and they satisfy the relations: 0.10<(T45 / f)*10<6.00, 5≦N≦6.

Owner:LARGAN PRECISION

Image capturing lens assembly

An image capturing lens assembly includes, in order from an object side to an image side: the first lens element with positive refractive power, the second lens element with refractive power, the third lens element with positive refractive power, the fourth lens element with refractive power, the fifth lens element with refractive power, and the sixth lens element with refractive power, at least one surface of the sixth lens element thereof being aspheric and having at least one inflection point. By such arrangement, total track length and the photosensitivity of the image capturing lens assembly can also be effectively reduced while retaining high image quality.

Owner:LARGAN PRECISION

Image capturing optical lens system

An image capturing optical lens system includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element, and a sixth lens element. The first lens element with positive refractive power has a convex object-side surface. The second lens element has negative refractive power. The third lens element has refractive power. The fourth lens element has refractive power, wherein at least one surface of the fourth lens element is aspheric. The fifth lens element with negative refractive power has a concave object-side surface and a convex image-side surface, and the surfaces thereof are aspheric. The sixth lens element with refractive power has an image-side surface changing from concave at a paraxial region thereof to convex at a peripheral region thereof, and the surfaces thereof are aspheric.

Owner:LARGAN PRECISION

Image capturing lens assembly

An image capturing lens assembly includes, in order from an object side to an image side: the first lens element with positive refractive power, the second lens element with refractive power, the third lens element with positive refractive power, the fourth lens element with refractive power, the fifth lens element with refractive power, and the sixth lens element with refractive power, at least one surface of the sixth lens element thereof being aspheric and having at least one inflection point. By such arrangement, total track length and the photosensitivity of the image capturing lens assembly can also be effectively reduced while retaining high image quality.

Owner:LARGAN PRECISION

Imaging lens assembly

This invention provides an imaging lens assembly including five lens elements with refractive power, in order from an object side toward an image side: a first lens with positive refractive power having a convex object-side surface, a second lens with negative refractive power, a third lens having a concave object-side surface, a fourth lens with positive refractive power having an object-side surface and a convex image-side surface, and at least one of both surfaces thereof being aspheric, a fifth lens with negative refractive power having a concave image-side surface with at least one inflection point formed thereon. An aperture stop is positioned between an imaged object and the second lens. The imaging lens assembly further comprises an electronic sensor on which an object is imaged. With such arrangement, the size and the optical sensitivity of the lens assembly can be reduced. A high image resolution is also obtained.

Owner:LARGAN PRECISION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com